Patents

Literature

2203 results about "Epoxy acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light curing offset printing ink and preparation method thereof

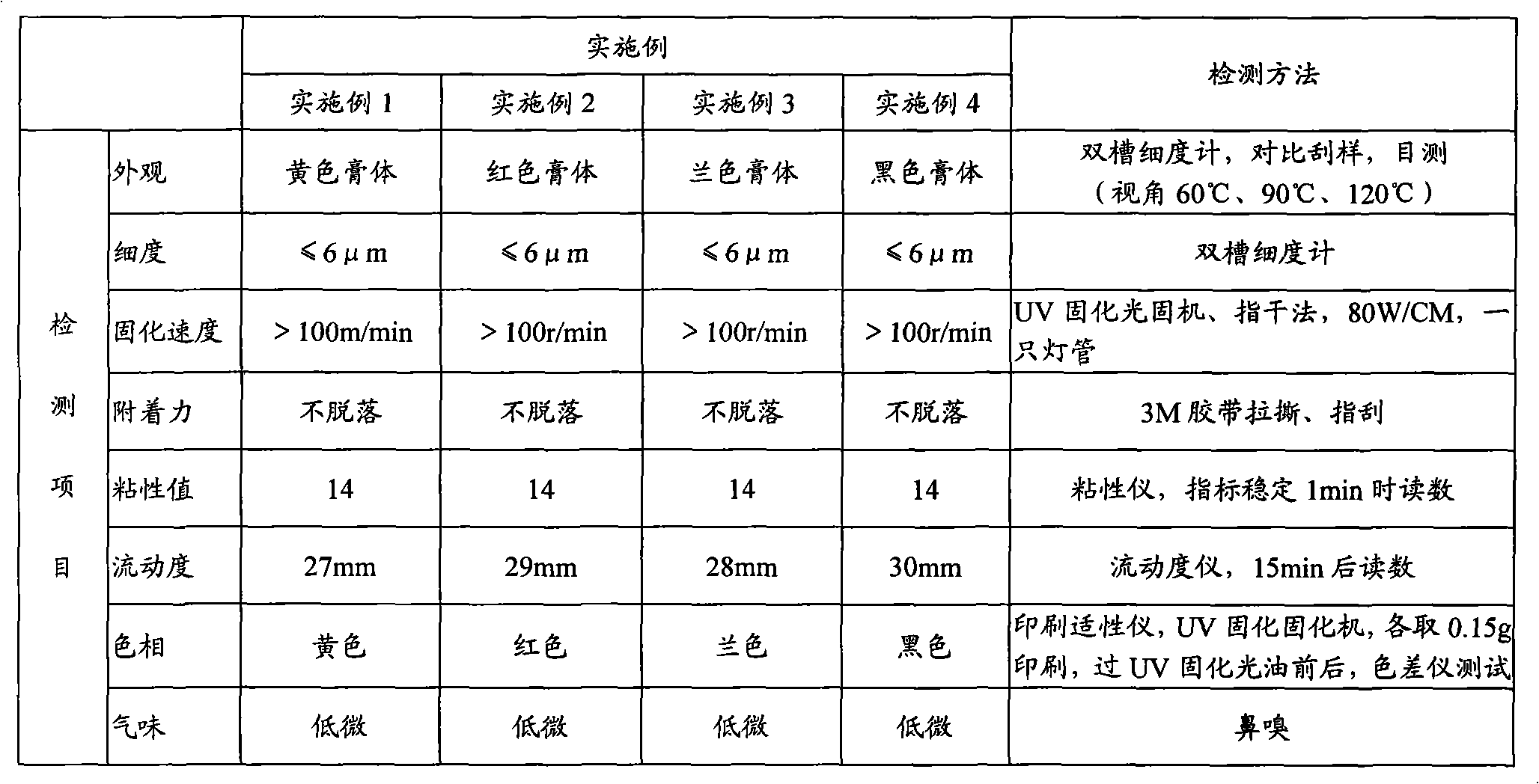

The invention relates to an ultraviolet light curing offset printing ink and a preparation method thereof. The ultraviolet light curing offset printing ink is made of 25.0-50.0% of polyfunctional polyester acrylic resin or polyfunctional chlorinated polyester acrylate, 0.0-15.0% of epoxy acrylate oligopolymer, 0.0-20.0% of polyfunctional urethane acrylate, 0.0-15.0% of difunctional or polyfunctional acrylic monomer, 0.0-20.0% of grinding-type resin, 2.0-10.0% of polyether acrylate modified by nano silicon dioxide, 0.0-5.0% of adhesion promoter, 3.0-5.0% of photoinitiator, 0.1-2.0% of polymerization inhibitor, 0.0-10.0% of filler, 16.0-55.0% of paint or dye and 0.2-5.0% of accessory ingredient. The prepared offset printing ink has high transparency as well as good adhesive attraction and flexility, and can be widely applied to packages printing industry and the printing of various transfer paper.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

UV curing color decorative coating

InactiveCN101407651ASolve the problem of deep curingAvoid pollutionMulticolor effect coatingsPolyesterUltraviolet

The invention relates to an ultraviolet curing color decorative coating, the components of the coating and the parts by weight thereof are as follows: 5 to 25 parts of epoxy acrylate prepolymer, 5 to 30 parts of polyurethane acrylate prepolymer, 2 to 10 parts of polyester acrylate prepolymer, 15 to 70 parts of acrylate monomer, 1 to 10 parts of photoinitiator, 1 to 35 parts of pigment, 0.5 to 10 parts of dispersant and 0.1 to 2 parts of auxiliary agent, the acrylate monomer is a mixture of the monomer with bifunctionality and the monomer with high functionality, wherein, the mixture ratio of the monomer with high bifunctionality to the monomer with bifunctionality is 1: 0.3 to 8. Compared with an ultraviolet curing transparent varnish, the ultraviolet curing color decorative coating has stronger decorative effect and almost the same curing speed, paint film hardness, adhesion, paint film gloss, and the like; and compared with a traditional solvent based colored paint, the ultraviolet curing color decorative coating does not contain volatile organic solvent, thereby avoiding the pollution and greatly improving the production efficiency. The ultraviolet curing color decorative coating is applicable to the decoration of plastics, wood materials, metals and other base materials.

Owner:BAODING LUCKY POLYMER MATERIAL TECH DEV +1

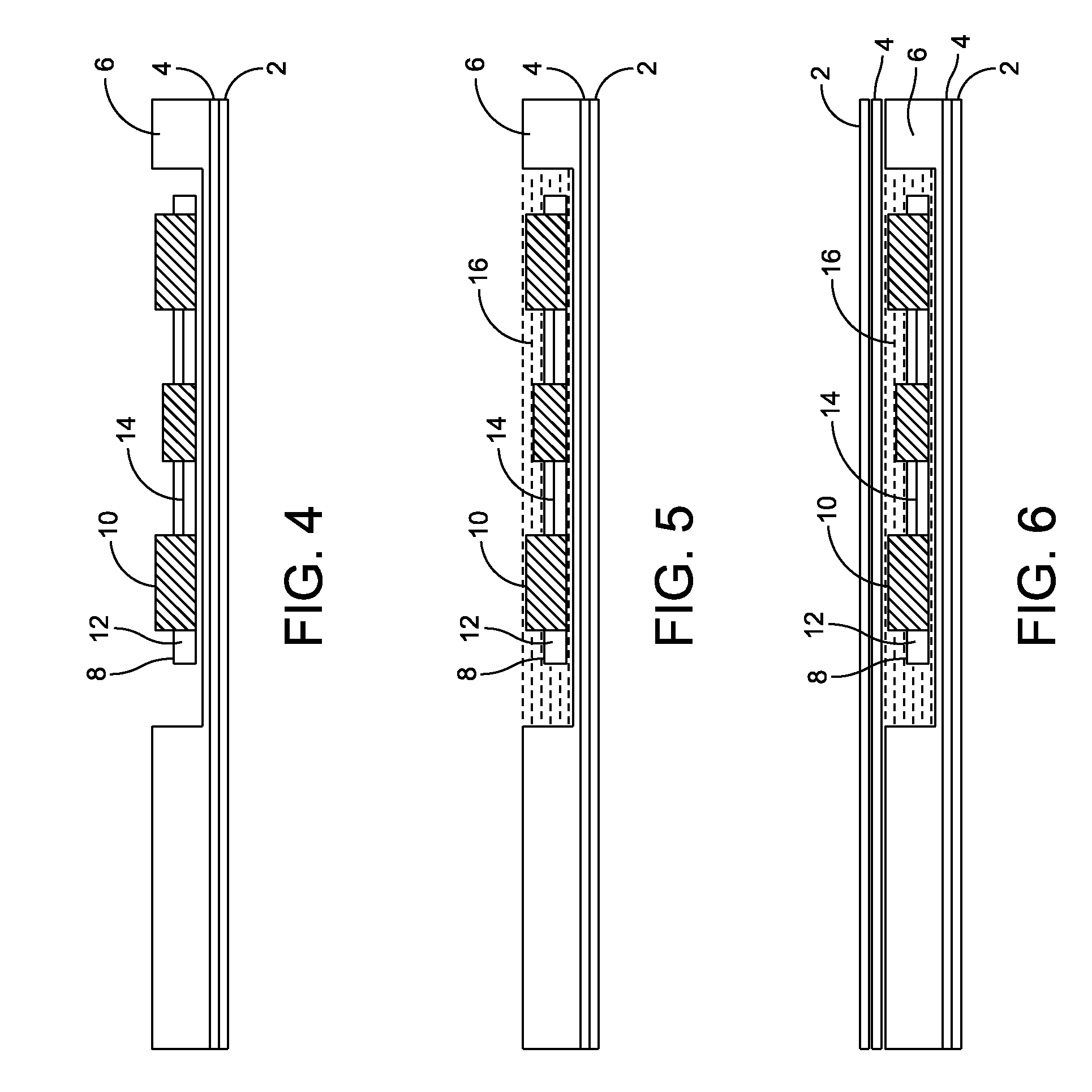

Information carrying card comprising a cross-linked polymer composition, and method of making the same

The disclosure provides a cross-linkable polymer composition, a core layer for an information carrying card comprising such cross-linked composition, resulting information carrying card, and methods of making the same. A crosslinkable polymer composition comprises a curable base polymer resin in a liquid or paste form, and a particulate thermoplastic filler. The base polymer resin is selected from the group consisting of urethane acrylate, silicone acrylate, epoxy acrylate, urethane, acrylate, silicone and epoxy. The particulate thermoplastic filler may be polyolefin, polyvinyl chloride (PVC), a copolymer of vinyl chloride and at least another monomer, or a polyester such as polyethylene terephthalate (PET), a compound or blend thereof.

Owner:X CARD HLDG

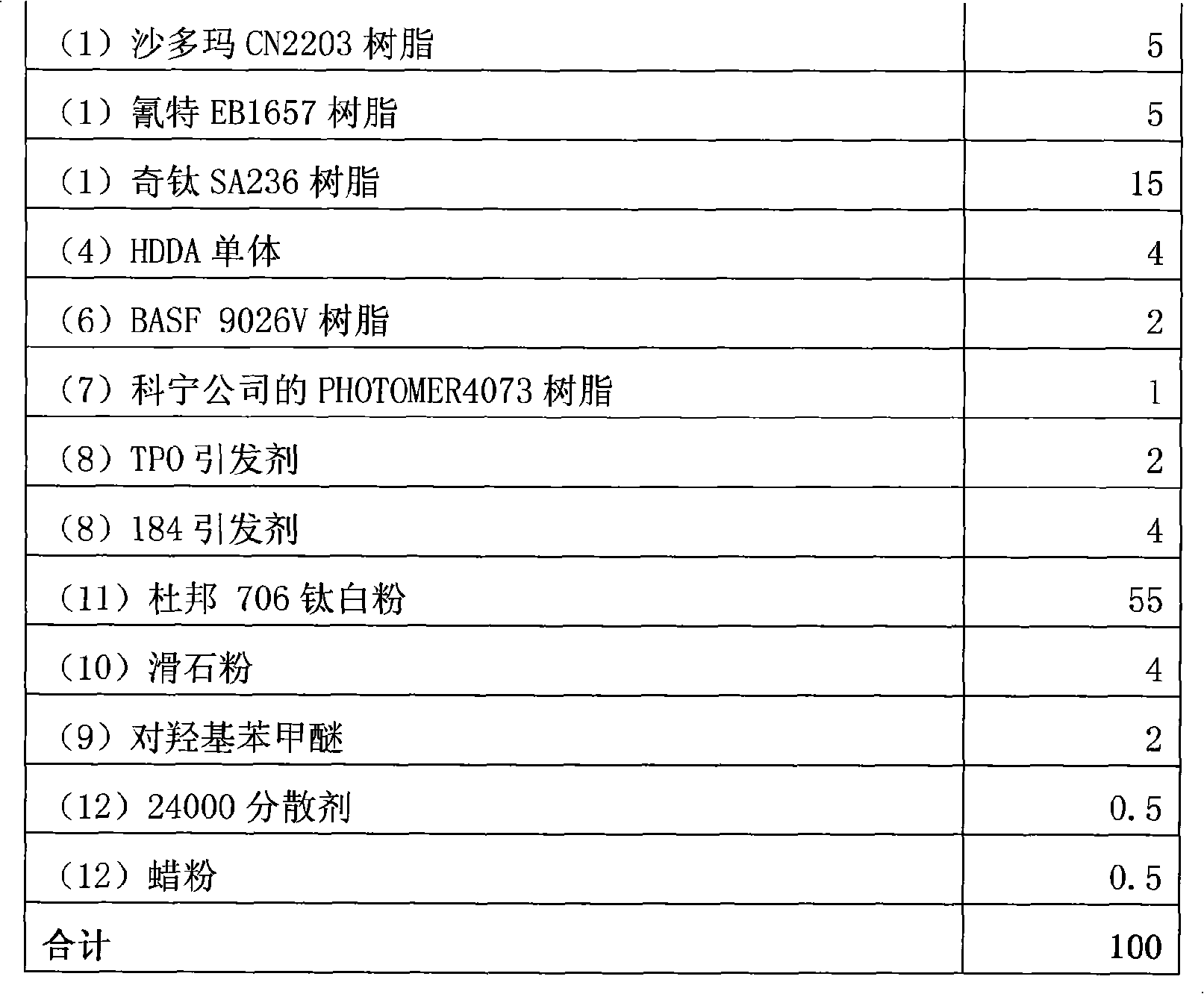

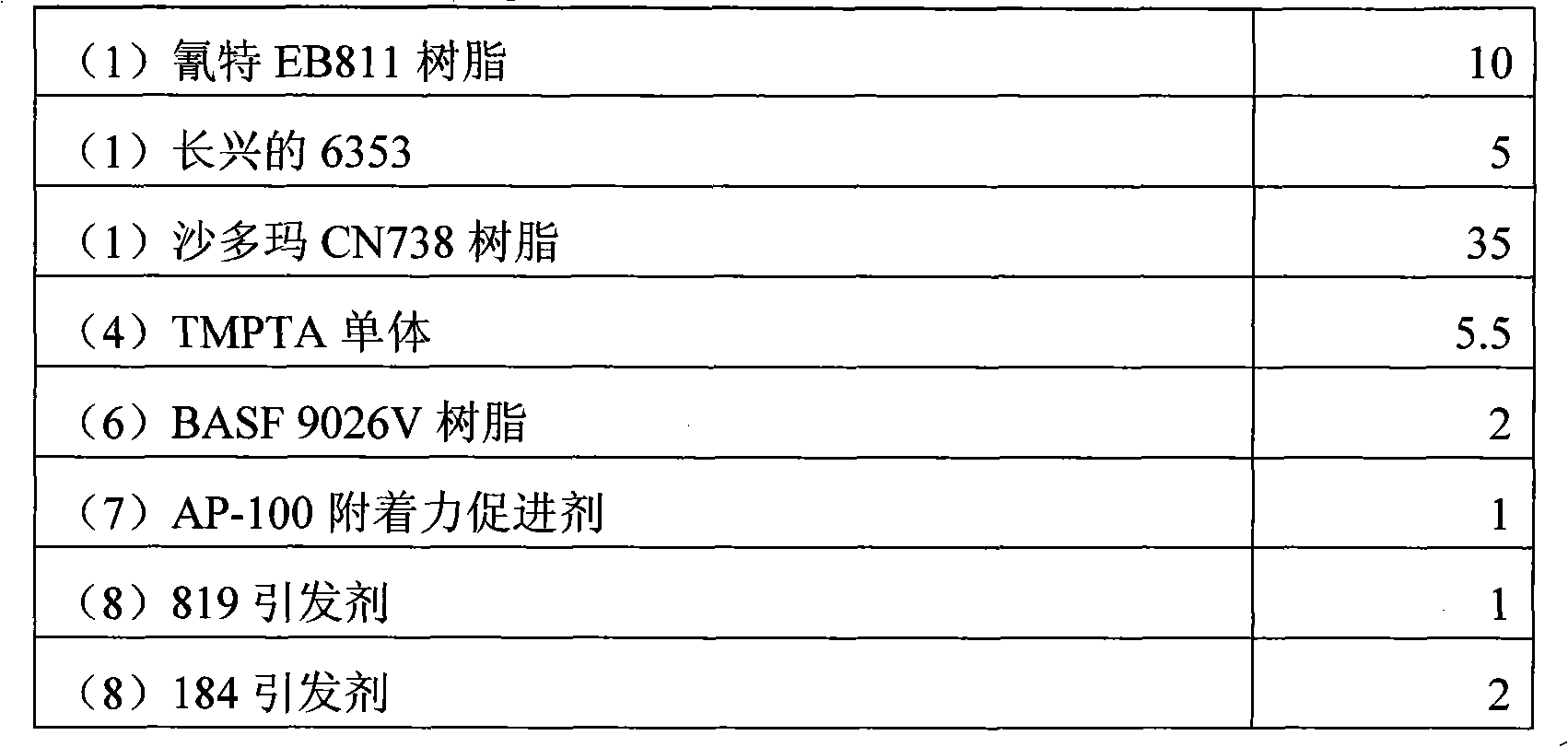

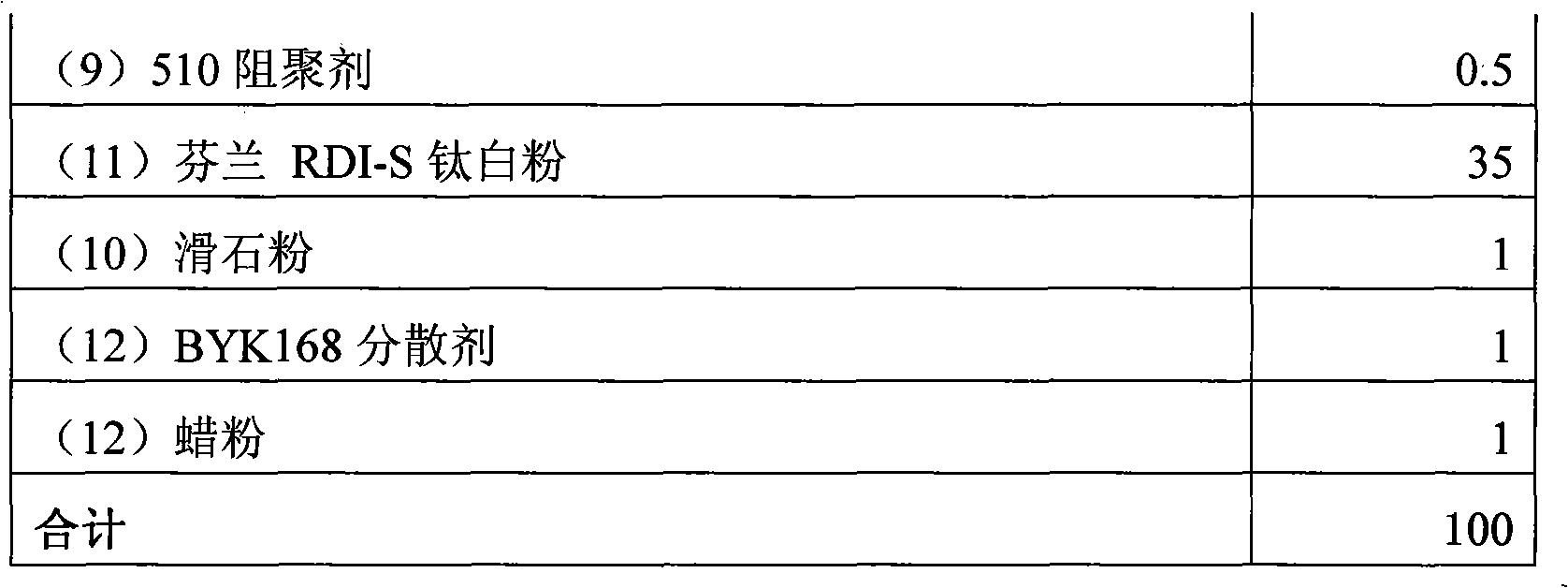

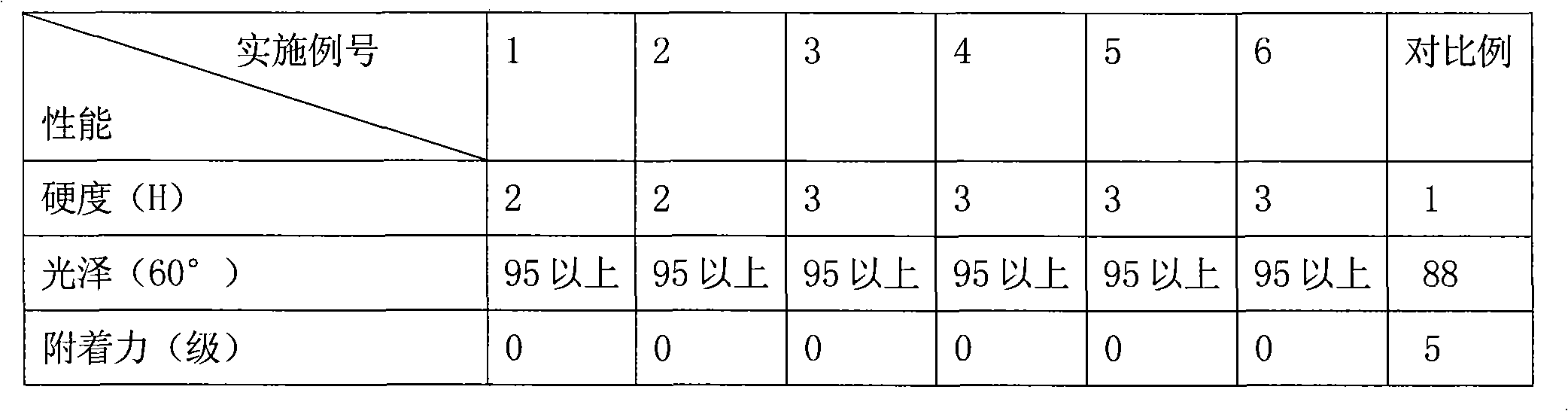

White composition capable of solidifying by ultraviolet light

InactiveCN101153127ASimple construction processImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterUltraviolet lights

The present invention discloses a white composition for ultraviolet solidification. The composition comprises the components of the weight percentages: (1) 10 percent to 40 percent of epoxy acrylate containing carboxyl; (2) 5 percent to 20 percent of polyurethane acrylic ester containing carboxyl; (3) 10 percent to 30 percent of super branching polyester acrylate; (4) 15 percent to 40 percent of acrylic monomer of single- or multi-functional degree; (5) 8 percent to 20 percent of titanium dioxide; (6) 1 percent to 8 percent of light initiator; (7) 0.5 percent to 3 percent of auxiliary aid; and (8) 0.5 percent to 10 percent of adhesive assistant agent. The construction process of the coating of the present invention is simple; the coating can be widely used (not limited) for various density boards, and solid plate materials. After the coating is solidified by ultraviolet irradiation, the coating film has good adhesive capability, high hardness, good covering capability and leveling performances.

Owner:湖南阳光新材料有限公司

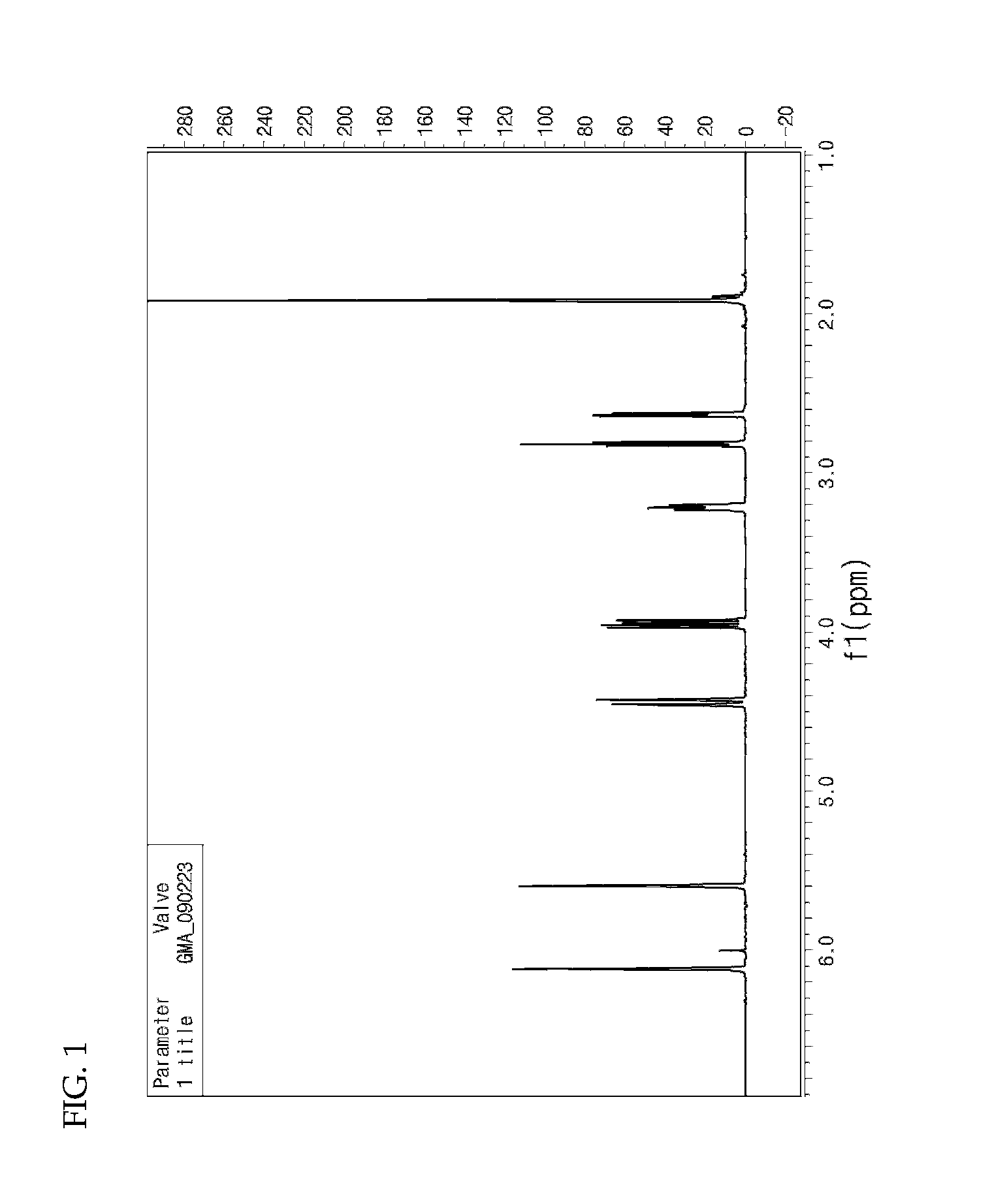

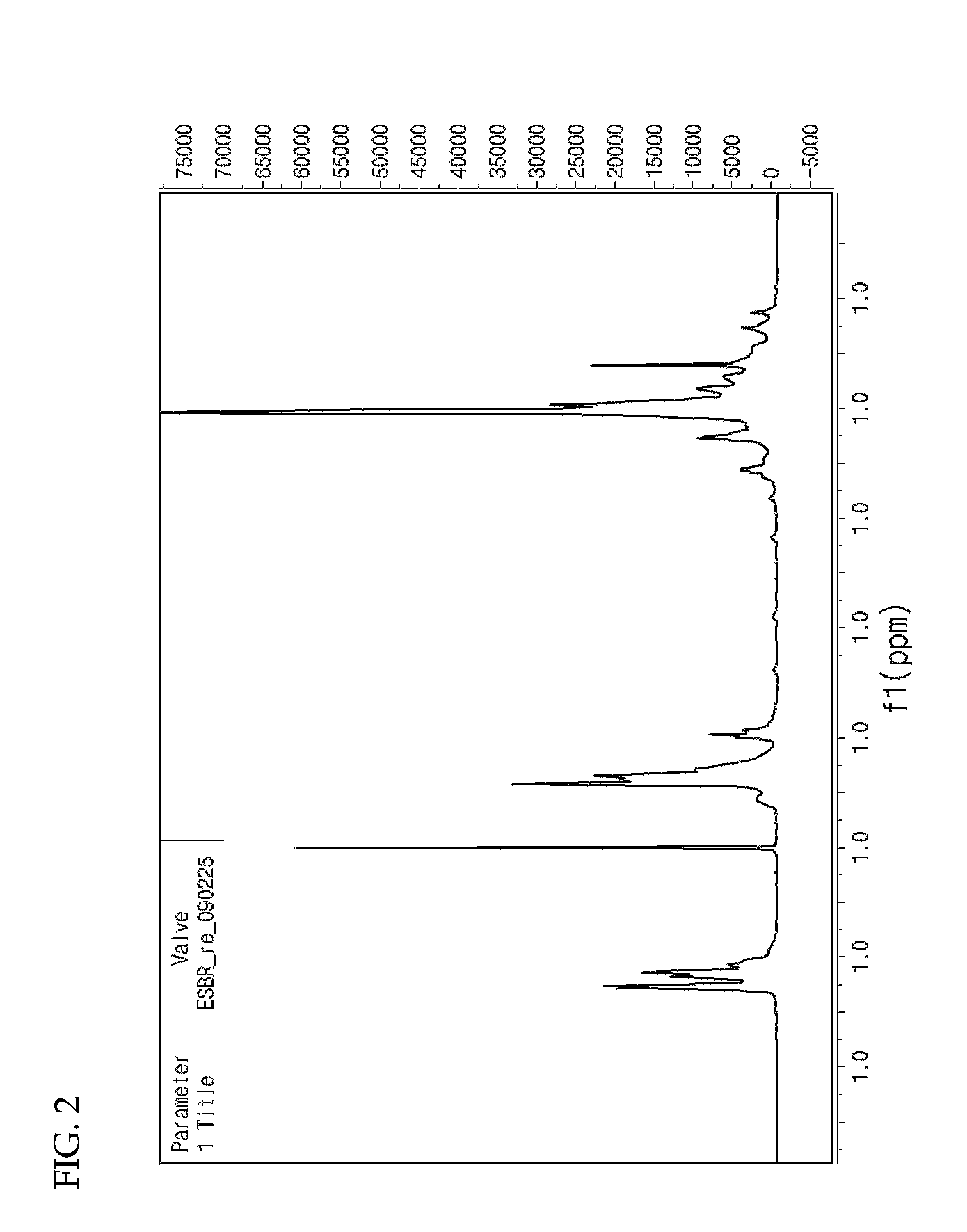

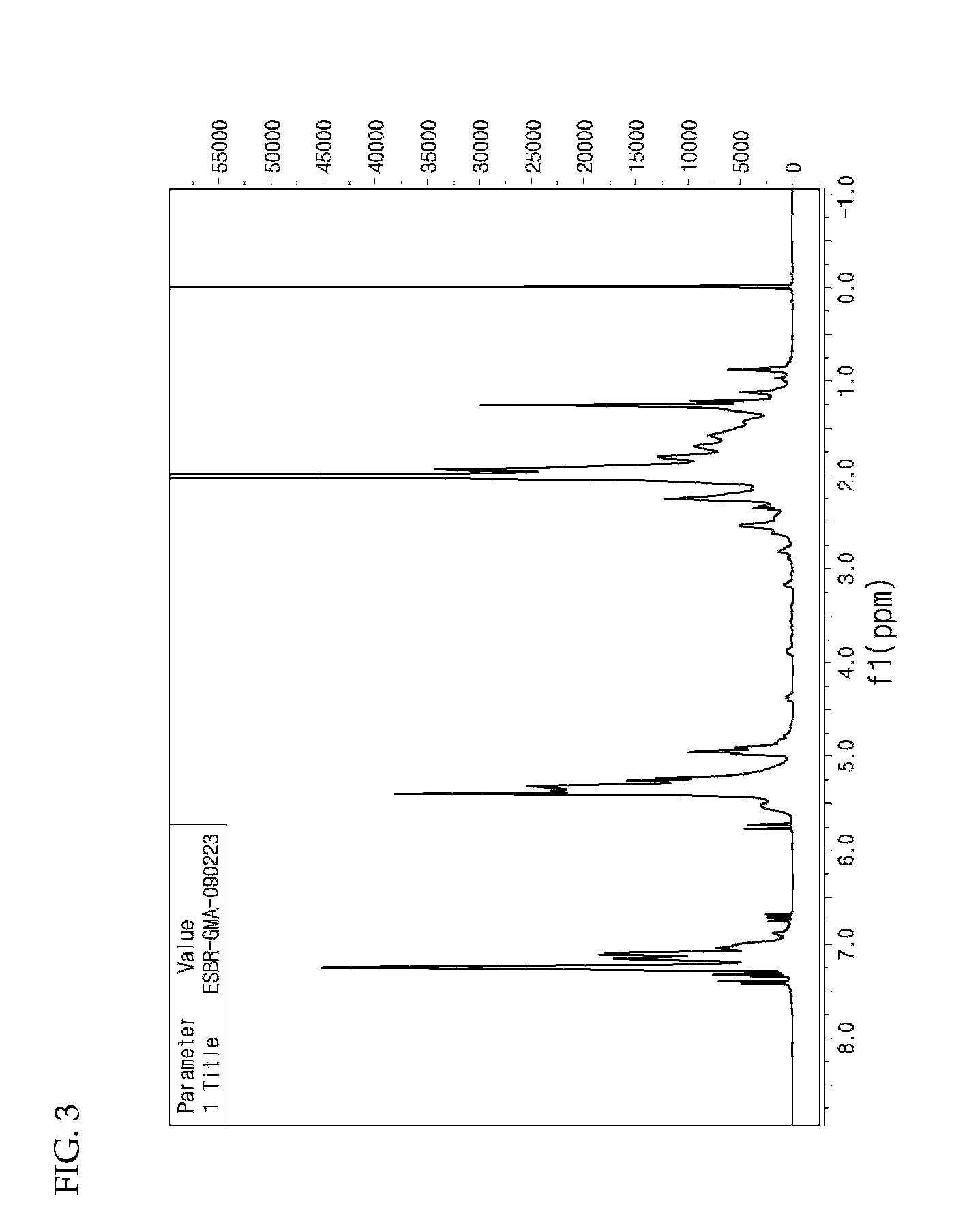

Functional styrene-butadiene copolymer

A functional styrene-butadiene copolymer is disclosed. More specifically, the copolymer is prepared by radical polymerization of a styrene monomer, a butadiene monomer and an epoxy acrylate monomer in an emulsion state and ring-opening of the resultant styrene-butadiene-epoxy acrylate copolymer. When blended with silica, the disclosed copolymer provides excellent wet stopping performance and superior wear resistance. Therefore, it can be usefully applied for industrial materials including fuel-efficient tires, snow tires, belts, hoses, etc.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

Golden blue ray-resistant protection film and preparation method thereof

InactiveCN103614089ASimple preparation processReduce manufacturing costFilm/foil adhesivesPolyurea/polyurethane coatingsPolyesterTectorial membrane

The invention relates to the technical field of protection films, and particularly relates to a golden blue ray-resistant protection film and a preparation method thereof. The golden blue ray-resistant protection film comprises a main film layer, a protection film layer and a release layer, wherein a blue ray-resistant layer is arranged on the upper surface of the main film layer; a first adhesive layer is arranged between the blue ray-resistant layer and the protection film layer; a second adhesive layer is arranged between the lower surface of the main film layer and the release layer; the blue ray-resistant layer is prepared from 2-10 parts by weight of nano CeO2:Er fluorescent powder and 100 parts by weight of acrylic ester; the acrylic ester is one or a mixture of more of urethane acrylate, epoxy acrylate, methacrylate and polyester acrylate. The preparation method is simple in preparation technology, and low in production cost; large-scale popularization and application are facilitated; the prepared protection film has an effect of resisting the blue ray, and has absorption and conversion functions on bluish violet high-energy short waves; the filtration rate at the blue ray wave band of 360-500nm can be up to over 90%. Therefore, the eye health is well protected.

Owner:NALI OPTICAL MATERIAL DONGGUAN +1

Water industrial paint based on organosilicon acrylic acid epoxy ester water dispersion and preparation method thereof

InactiveCN1927968AImprove corrosion resistanceGood physical propertiesEmulsion paintsEpoxyDefoaming Agents

The present invention provides one kind of water thinned industrial paint based on water dispersed organosilicon epoxy acrylate. The water thinned industrial paint is prepared with water dispersed organosilicon epoxy acrylate, inert antirust pigment, active antirust pigment, nanometer material modified antirust pigment, stuffing, dispersant, wetting agent, thickener, drying agent, mildew inhibitor, preservative, defoaming agent, deionized water and other materials. The water thinned industrial paint with water dispersed organosilicon epoxy acrylate as base material can form coating with the features of high mechanical strength and high anticorrosive performance similar to that of epoxy resin as well as the features of high weather resistance and good decoration performance like acrylate resin. The water thinned industrial paint has convenient use and wide application range.

Owner:广州市允升环保科技有限公司

Ultraviolet light curing nano antibacterial woodenware paint and preparation method thereof

InactiveCN1927971AEase of industrial productionNo harmAntifouling/underwater paintsPaints with biocidesLacquerUltraviolet lights

The present invention discloses one kind of ultraviolet ray cured nanometer antibiotic woodenware lacquer and its preparation process. The ultraviolet ray cured nanometer antibiotic woodenware lacquer includes epoxy acrylate, polyurethane acrylate, diluent, nanometer inorganic antiseptic, nanometer inorganic stuffing and photoinitiator. The preparation process includes adding nanometer inorganic antiseptic and nanometer inorganic stuffing into the diluent, stirring to disperse homogeneously, adding epoxy acrylate, polyurethane acrylate and photoinitiator and mixing homogeneously. The woodenware lacquer with nanometer inorganic antiseptic can inhibit the growth and propagation of bacteria and microbes to produce long term antibiotic effect.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

Ultraviolet curing coating for metal plating surface protection

ActiveCN1803942AHigh surface hardnessImprove water resistanceLiquid surface applicatorsCoatingsFiberCoated surface

The related UV solidifying paint for metal coated surface protection comprises: 10-30% epoxy acrylate and 5~20% urethane acrylate both as active oligomer, 10-30% composite adhesion reinforced resin as the mixture of thermalplastic acrylic resin with AA monomer modified by H3PO4 as one of synthetic monomer and fiber resin, 30~65% diluent, 5~20% active diluent, 1~10% light initiator, and 0.1~1% auxiliary agent. This invention solves the adhesion problem of UV paint on smooth metal surface very well, and contains other index up to protective and decorative requests.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

UV curable aqueous resin composition

The invention discloses a composition of vis-UV cured water resin, which consists of (A) 10-70 mass % of water epoxy acrylate solidified and modified by the ray; (B) 0 mass % -10 mass % of water acrylate monomer or water acrylate prepolymer; (C) 1 mass % -5 mass % of photochemical initiator; (D) 0.1 mass % -8 mass % of adjuvant; (E) 10 mass % -60 mass % of deionized water or alcoholic dissolvent; the composition can be used for water UV solidifying paint solidified by vis-UV, water UV solidified finishing and water UV solidified ink binding material; the external appearance of the vis-UV cured water composition is lacte or lacte liquid with blue rays; it can be diluted with water, the viscosity can be adjusted and the inducration speed is fast; it is nontoxic, ordorless, safety and environment-friendly; after the solidification by the ultraviolet, its film is neat and smooth, is of high glossiness, and is of good flexibility, scratch resistance, water resistance and solvent resistance.

Owner:GUANGDONG UNIV OF TECH

Ultraviolet curing coating

InactiveCN101638554AImprove anti-pollution performanceEasy to cleanPolyurea/polyurethane coatingsEpoxy resin coatingsUrethane acrylatePhotoinitiator

The invention relates to an ultraviolet curing coating which is characterized in that the ultraviolet curing coating comprises 1-35 wt% of epoxy acrylate, 1-35wt% of urethane acrylate, 20-50wt% of polyfunctional acrylate monomer, 1-15wt% of additive and 1-10wt% of photoinitiator. The coating formed by ultraviolet curing coating obtained by adopting the technical scheme has the advantages of good pollution resistibility, easy cleaning, high strength, strong adherence, high toughness and difficult stripping.

Owner:FOSHAN SHUNDE HEYGEY LIGHT CURING MATERIALS

UV curing offset printing ink and use

The invention relates to UV cured lithographic ink and purposes thereof. The ink is a compound which comprises the following components by the weight percent: 30 to 50 of polyester acrylic ester, 0 to 15 of epoxy acrylic ester, 2 to 22 of high-viscosity monofunctional polyurethane acrylic ester, 0 to 10 of acrylic monomer, 10 to 15 of photoinitiator, 2 to 5 of filler and 16 to 22 of pigment. The UV curing glue printing ink of the invention can be cured at high speed, can meet the requirements of high-speed packaging, printing and environment protection, does not contain VOC, has little irritation to the human skin, and can be used as lithographic ink for the high-speed printing, and paper and plastic printing of packaging and printing.

Owner:深圳市美丽华科技股份有限公司

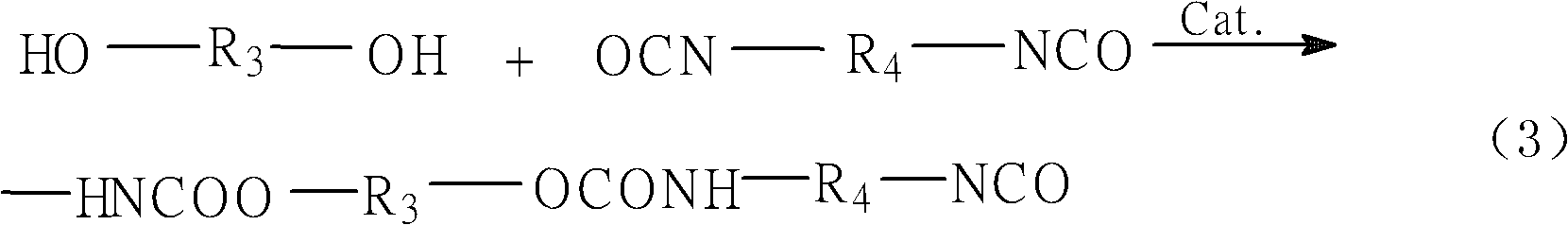

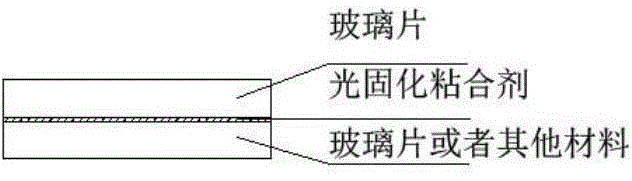

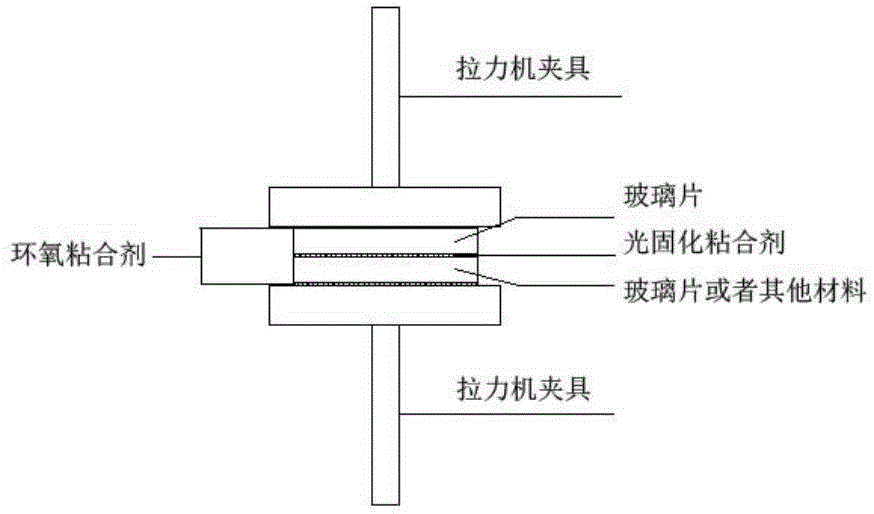

Synthesis and application of light-cured polyurethane-acrylic acid-epoxy resin adhesive

The invention relates to a novel polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer, a synthesis method of the pre-polymer, a high-performance ultraviolet (UV) cured polyurethane modified acrylic acid epoxy resin adhesive prepared from the pre-polymer and application of the UV cured adhesive to bonding of a nylon membrane material and a polyurethane or modified polyurethane elastic body. A method for preparing the photosensitive pre-polymer comprises the following steps of: 1, synthesizing a lower-viscosity epoxy acrylic ester pre-polymer; 2, preparing a pre-polymer of urethane acrylate resin; and 3, mixing or reacting the two pre-polymers in a certain ratio so as to obtain the polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer. A polyurethane-acrylic acid-epoxy resin UV cured adhesive is further prepared by adding a photoinitiator, a photosensitive diluent, a light curing crosslinking agent, other necessary aids and the like.

Owner:BEIHANG UNIV

Epoxy acrylate modified waterborne alkyd resin and preparation method and application thereof

The invention discloses an epoxy acrylate modified waterborne alkyd resin and a preparation method and an application thereof. The method comprises the steps: firstly, synthesizing a waterborne alkyd resin from a polyol, a polybasic acid and an oil monomer by adopting a dehydration condensation reaction; then carrying out an epoxy resin ring opening reaction to graft onto the waterborne alkyd resin so as to modify the waterborne alkyd resin; followed by carrying out free radical solution polymerization of acrylic soft and hard monomers with the modified alkyd resin, and modifying the alkyd resin by using acrylic ester; and finally pumping out a part of a polymerization solvent to neutralize the obtained waterborne alkyd resin, adding a cosolvent, and dispersing the alkyd resin to prepare an aqueous dispersion by adopting a high-speed disk dispersion machine and with water as a dispersion medium. In the addition to retaining own excellent characteristics, the modified alkyd resin also has good dryness, adhesive power and corrosion resistance of epoxy resin and the acrylic resin advantages of excellent drying, water resistance, chemical medicine resistance, high hardness, good weathering resistance and the like, and effectively improves the alkyd resin performance of water resistance, weather resistance and the like.

Owner:SOUTH CHINA UNIV OF TECH

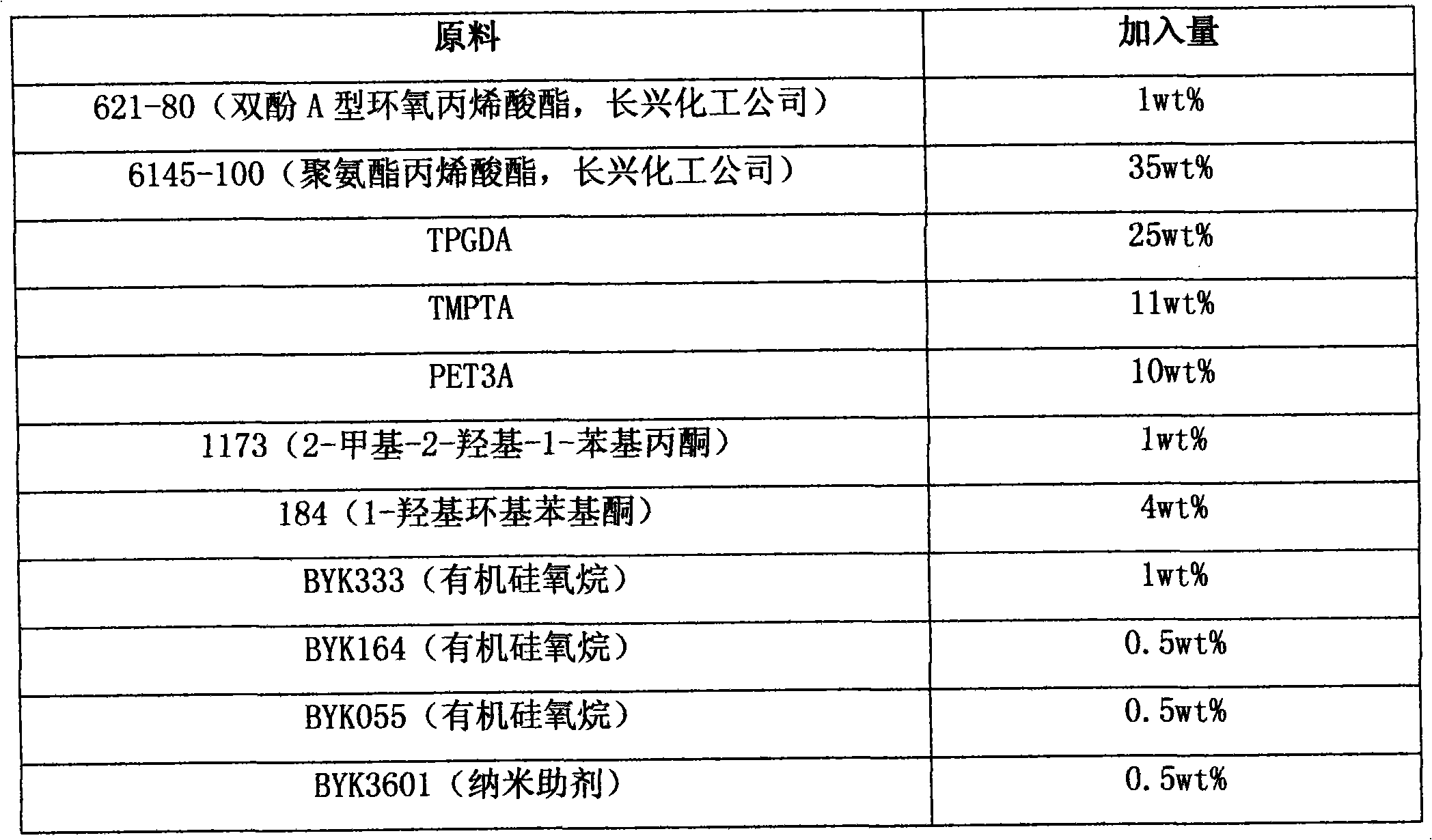

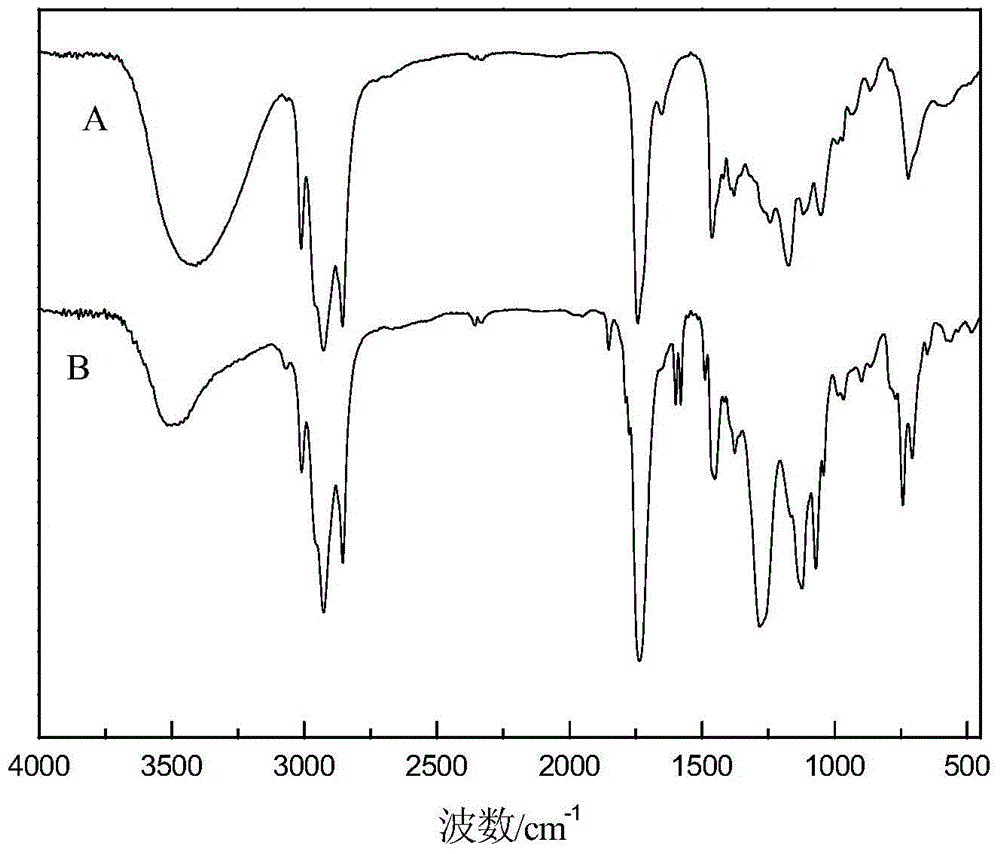

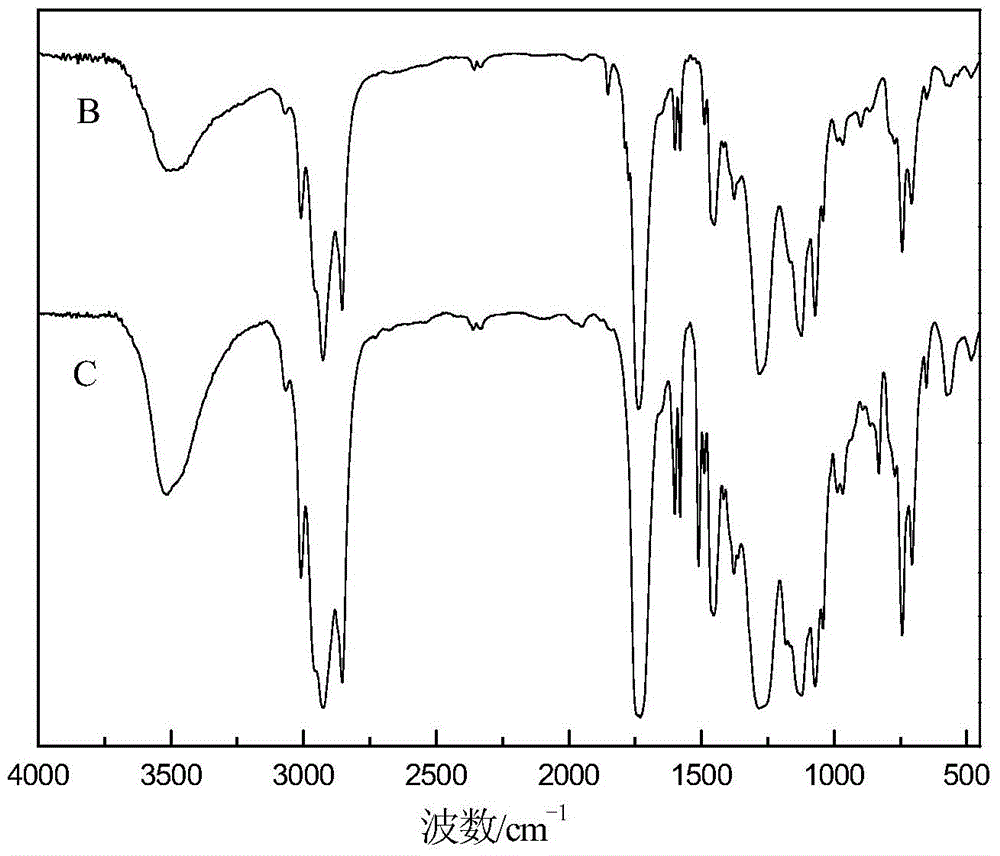

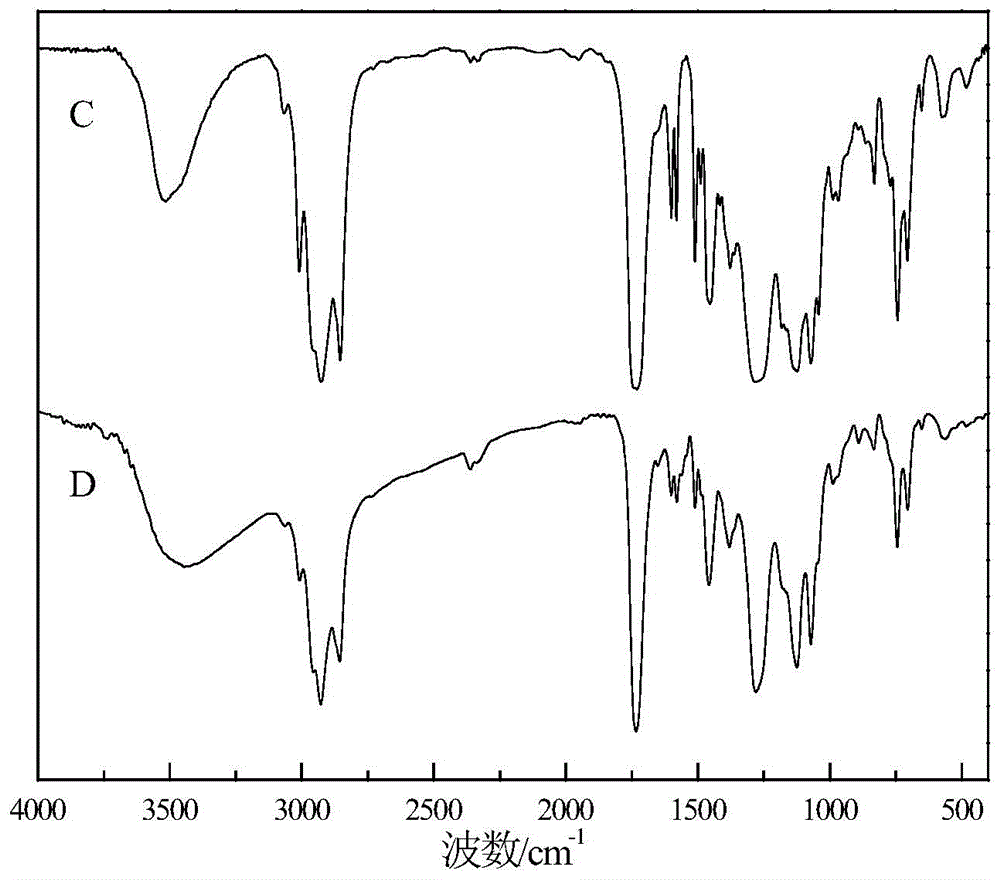

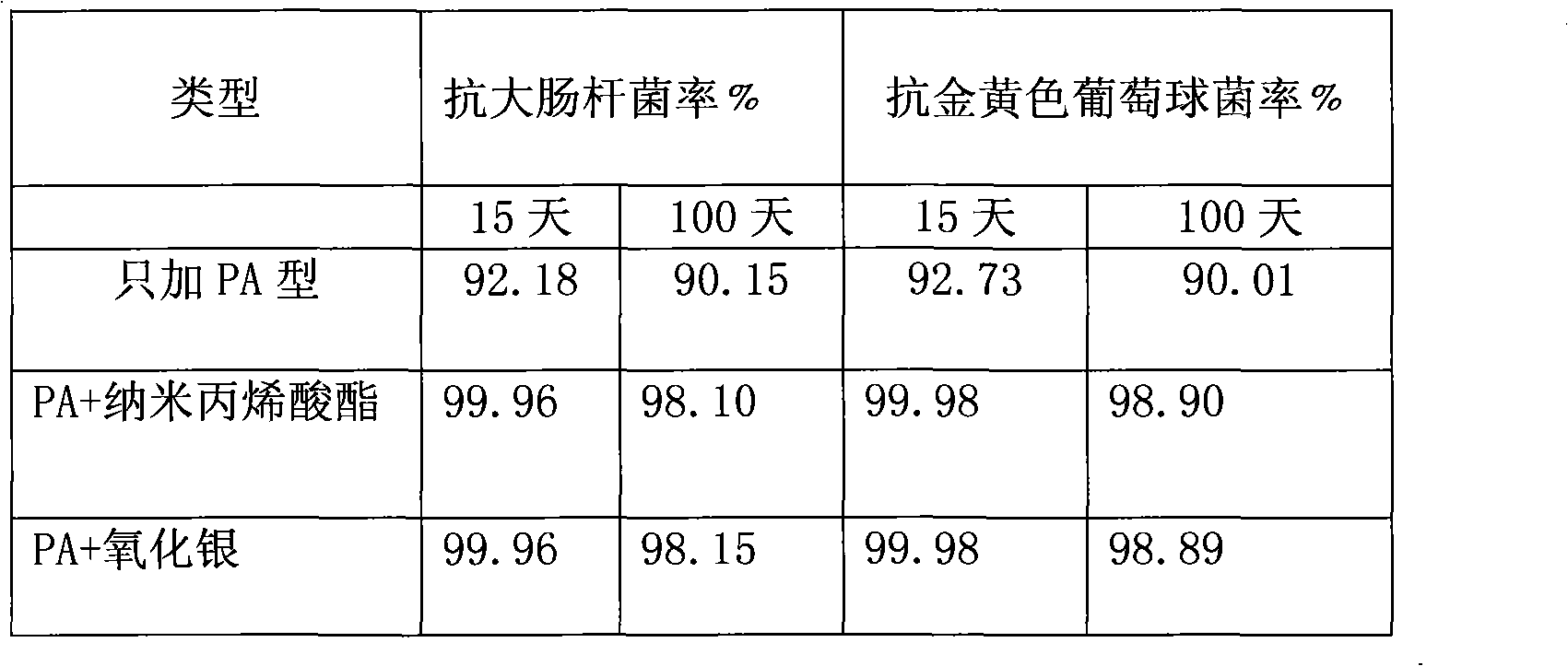

UV curing antibiotic coating and preparation thereof

InactiveCN101353545AImprove antibacterial propertiesSimple preparation processAntifouling/underwater paintsPaints with biocidesUV curingTMPTA

The invention discloses a UV-curable antimicrobial coating, the components of which are as follows: bisphenol A type epoxy acrylate EA; aliphatic PUA; special functional group acrylate PA; TPGDA; TMPTA; photoinitiators; nano acrylate; oxidized silver; and auxiliaries. The preparation method comprises the following steps of: step one, synthesizing special functional group heterocyclic compound PA and later adding phosphorus pentoxide to acrylic acid hydroxy esters so as to react with hydroxyl piperidine and then prepare special functional group heterocyclic compound PA; and step two, taking each component according to the formula, stirring and mixing each component so as to carry out dispersion at the speed of 900 to 1200r per min, then adding silver oxide and photoinitiators after being dispersed evenly, and finally obtaining UV-curable antimicrobial coating through dispersion. The UV-curable antimicrobial coating prepared by the invention has good anti-bacterial effect. As the self-prepared special functional group acrylate PA, the nano acrylate and the silver oxide are added, after UV-curable film-forming, the anti-coli rate can achieve over 99 percent and the anti-staphylococcal rate thereof achieves over 99 percent, and the effectiveness is long.

Owner:苏州市明大高分子科技材料有限公司

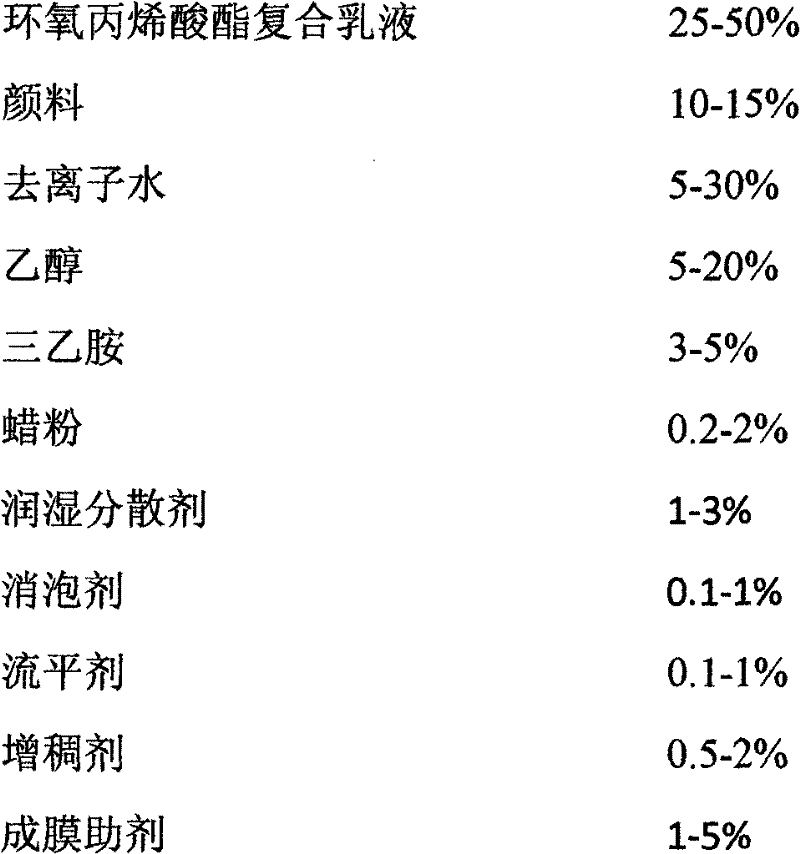

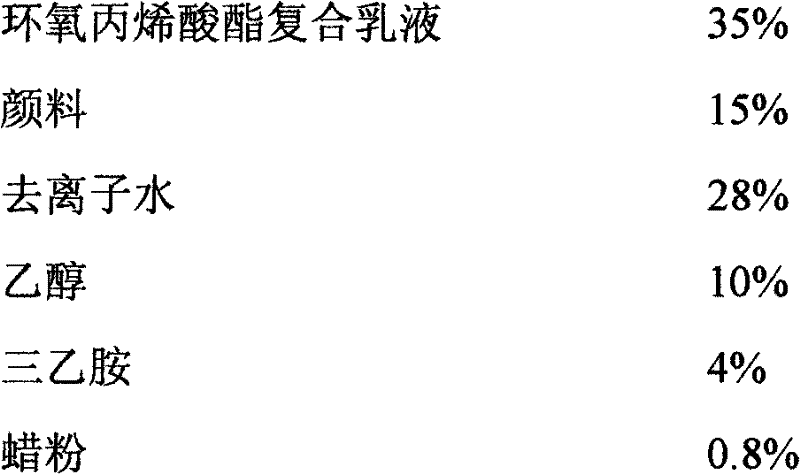

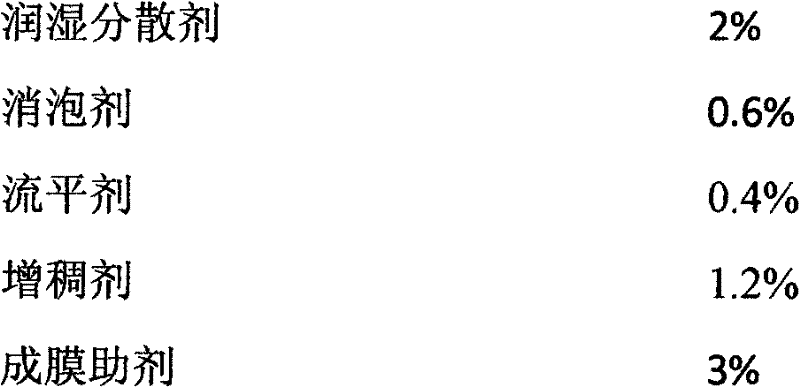

Environment-friendly type water-based intaglio ink used for package printing and preparation method thereof

The invention relates to a water-based ink and a preparation method thereof, especially to an environment-friendly type water-based intaglio ink used for package printing and a preparation method thereof. The ink is prepared by mixing epoxy acrylate composite emulsion, pigments, deionized water, ethanol, triethylamine, wax powder, a wetting dispersant, an anti-foaming agent, a levelling agent, a thickening agent and a film forming auxiliary agent according to a certain mass ratio, wherein, the epoxy acrylate composite emulsion is prepared by modifying acrylate emulsion with an epoxy resin and allowing the epoxy resin and acrylate to organically bind together, has the advantages of good adhesion, thermostability, good chemically-resistant properties and the like and has a certain application value when used as a binder for a water-based ink. The water-based intaglio ink in the invention is applicable to package printing in the field of flexible package which mainly relates to packaging of tobacco, liquor, foodstuffs, beverage, medicines, daily chemical articles and the like; the ink is nontoxic, non-combustible and non-explosible, has no pungent smell, accords with environmental protection requirements, and has a very promising prospect.

Owner:哈尔滨大东方新材料科技股份有限公司

Ultraviolet light curing vacuum coating foundation and finish

InactiveCN101250339AStrong adhesionExcellent environmental test performanceVacuum evaporation coatingSputtering coatingEpoxyUltraviolet lights

The invention discloses ultraviolet light curing vacuum plating primer and finish, wherein primer is formed by random proportion of double function aliphatic polyurethane acrylic ester, epoxy acrylic ester, trifunctional acrylic ester, double function acrylic ester, adhesion promoting resin, photo initiator, diluent, and auxiliary agent, finish is formed by random proportion of high function aliphatic polyurethane acrylic ester, large molecular resin, double functional aliphatic polyurethane acrylic ester, trifunctional aliphatic polyurethane acrylic ester, adhesion promoting resin, photo initiator, diluent, and auxiliary agent. The surface of substrate material is conducted with painting treatment of primer, which increases the plainness and adhesion fastness of the vacuum plating film, and vacuum plating film is conducted with the surface painting treatment of UV vacuum plating finish, which can prevent oxidization of metal film layer and endows vacuum plating film with excellent surface abrasion resistance and extreme wonderful hand feeling.

Owner:HUIZHOU CHANGRUNFA PAINT

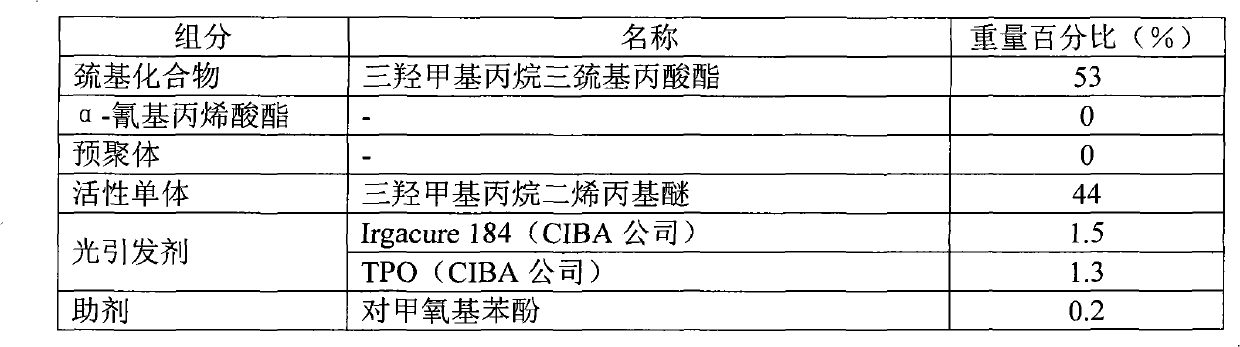

UV curable adhesive

ActiveCN101928541AHigh bonding strengthSuitable for continuous productionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPhotochemistry

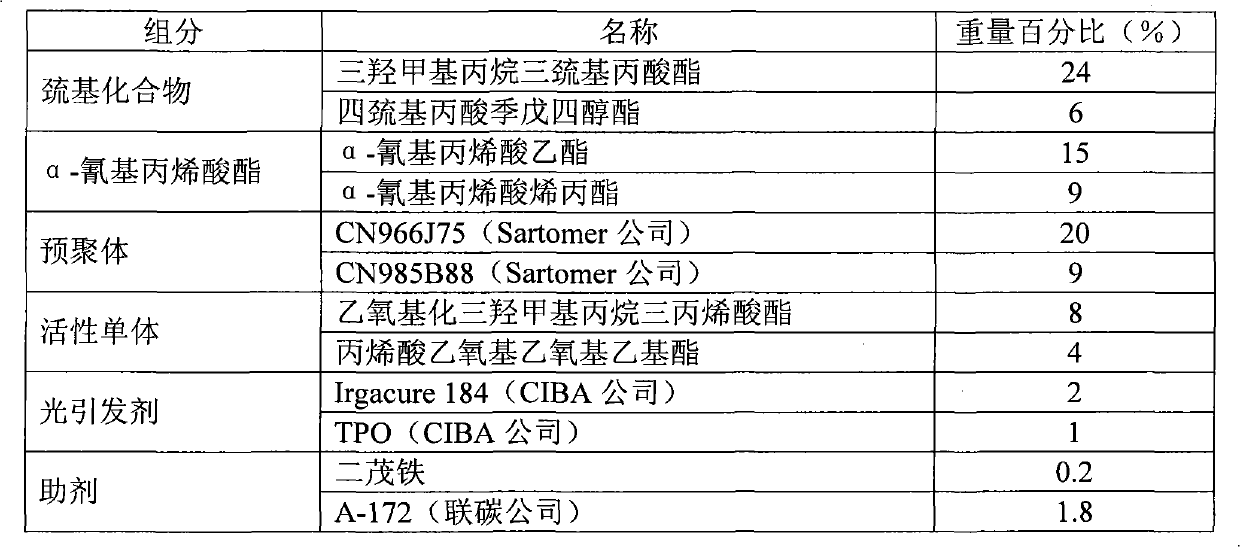

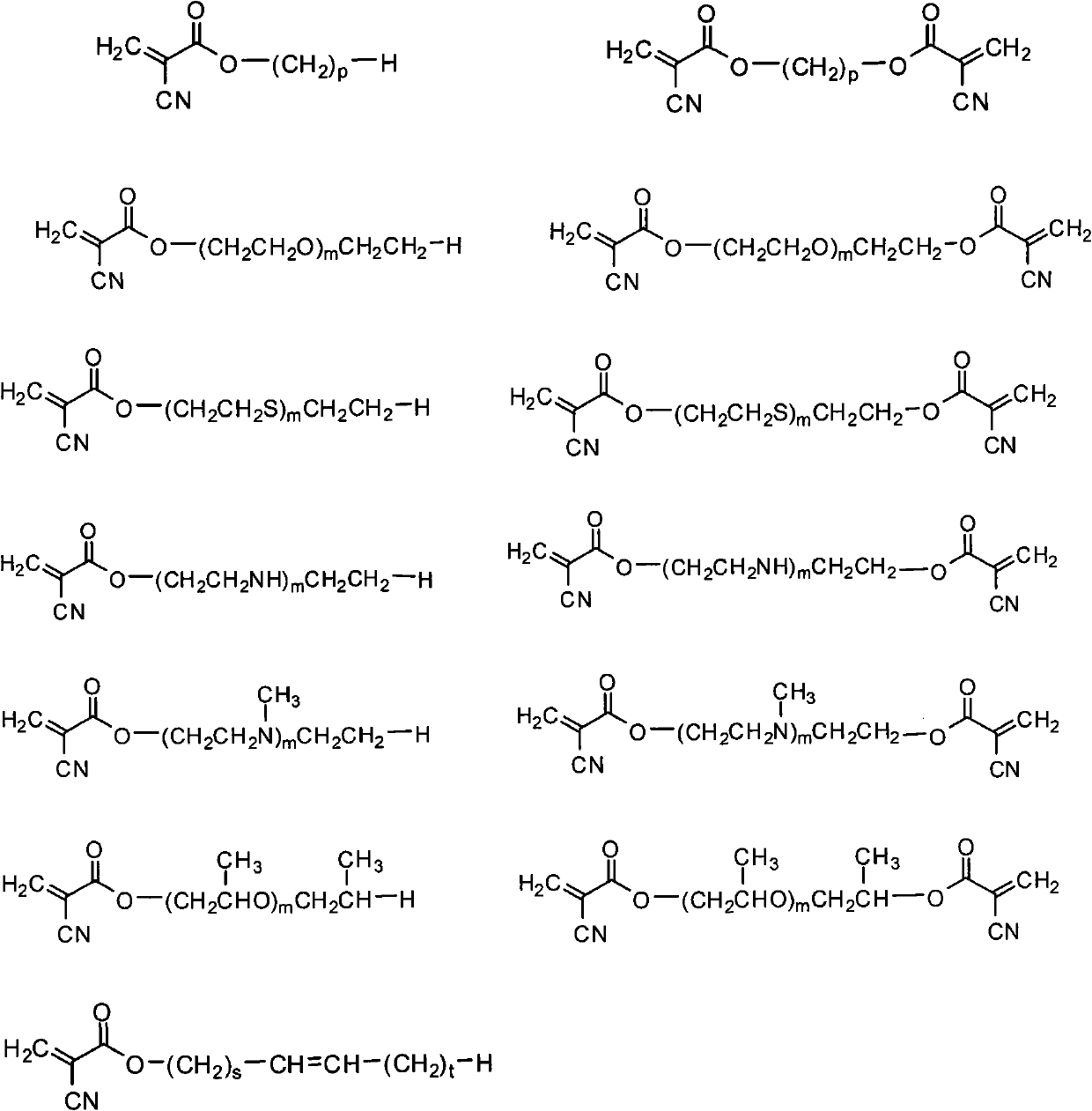

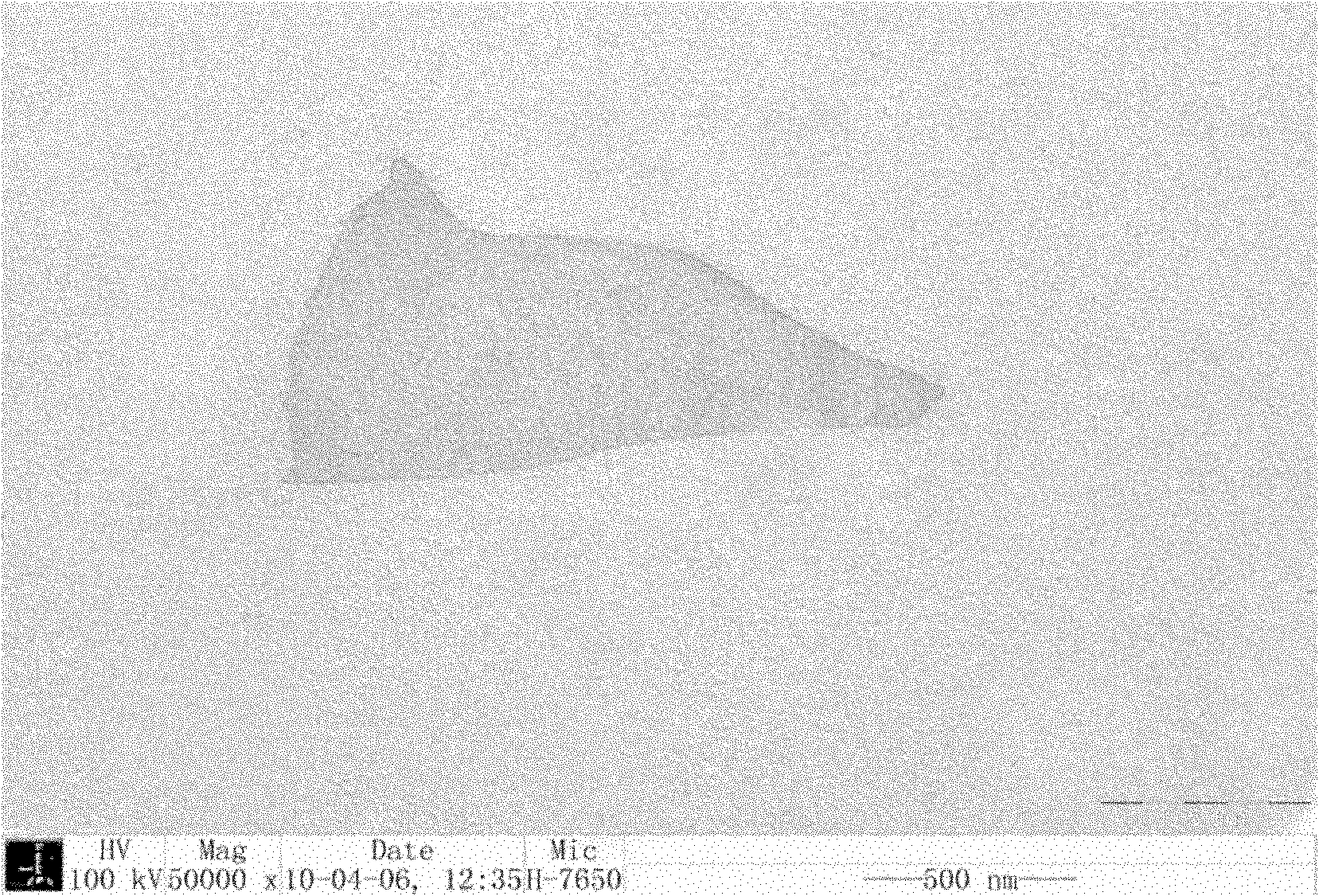

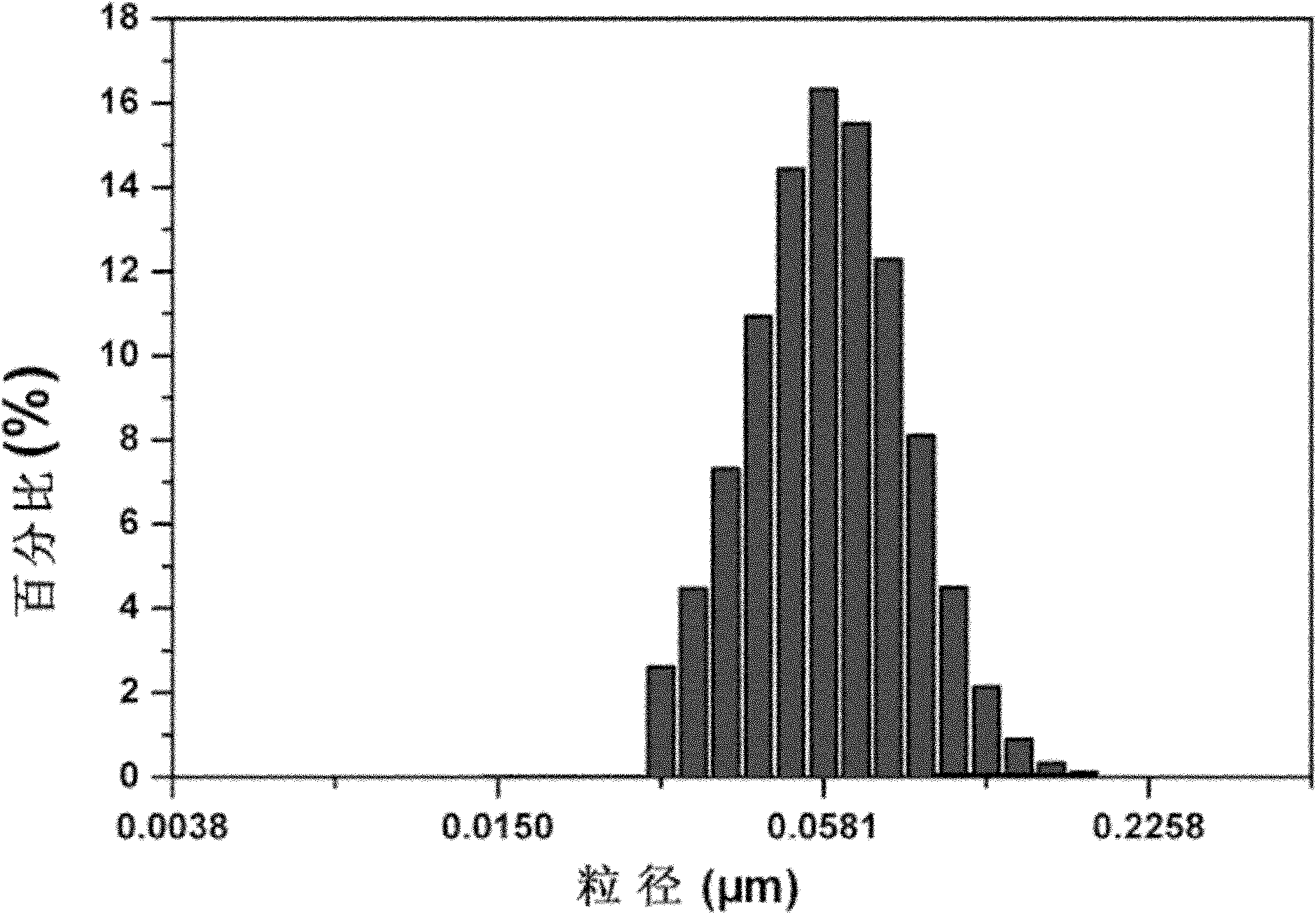

The invention discloses a sulfydryl / cyano acrylic ester UV curable adhesive composition, which comprises: 5 to 60 percent of sulfydryl compound which is selected from a sulfydryl alkyl acid ester and alkyl hydrosulfide; 5 to 60 percent of alpha-cyanoacrylate of a formula below; 0 to 60 percent of a prepolymer selected from polyester acrylate prepolymers, epoxy acrylate prepolymers and urethane acrylate prepolymers; 0 to 50 percent of active monomer which is selected from acrylic esters having a mono-functional group, double functional groups and multiple functional groups, allyl compounds and ethenyl compounds; 1 to 10 percent of photoinitiator; and 0 to 10 percent of assistant. The UV curable adhesive composition has a quick curing capability, high adhesive strength and low internal stress; and the obtained cured layer is flexible and can be widely to bond metal, metal oxides, plastics, rubber, glass, polyester and other substrate materials.

Owner:JIANGSU HECHENG ADVANCED MATERIALS

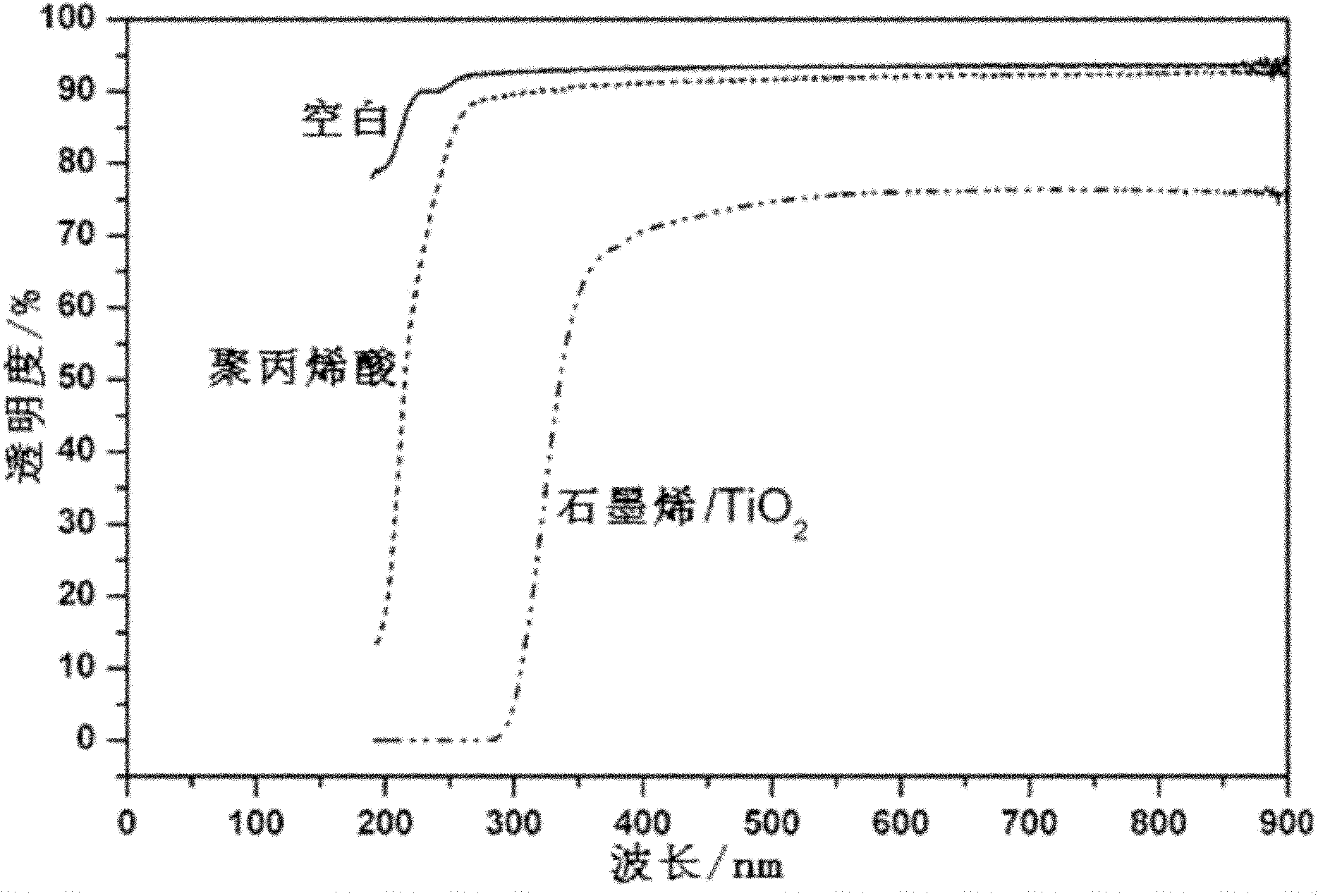

Graphene/TiO2-based near-infrared/ultraviolet radiation resistant polymer composite film and preparation method thereof

The invention relates to a graphene / TiO2-based near-infrared / ultraviolet radiation resistant polymer composite film and a preparation method thereof, relating to a near-infrared / ultraviolet radiation resistant composite film and a preparation method thereof. The invention aims to solve the problems of the existing heat reflecting material such as poor heat insulation effect, low transparency, serious light pollution and high production cost and the like. The composite film is prepared by adding the mixed liquid of graphene oxide dispersion and nano-TiO2 dispersion in the curing system of epoxy acrylate at a volume ratio of 1-10:50. The preparation method comprises the following steps: 1) preparing graphene oxide; 2) preparing TiO2 nanoparticles; 3) preparing nanometer graphene / TiO2 composite; and 4) preparing the graphene / TiO2-based near-infrared / ultraviolet radiation resistant polymer composite film. The composite film is mainly used for the glass coating of a building or means of transport for running an air-conditioning system.

Owner:HARBIN INST OF TECH

Radiation curable compositions

The present invention is directed to a composition curable by radiation having a wavelength of 300 nm or more, a method of producing a coated substrate using such composition and the coated product so-produced. More particularly, the composition of the present invention comprises A) from about 1 to about 99% by weight of an unsaturated polymer or oligomer, B) from about 1 to about 99% by weight of an unsaturated epoxy acrylate, C) one or more photoinitiators, and, optionally, D) one or more solvents.

Owner:ALLNEX NETHERLANDS BV

Double-solidification system fast-flowing underfill and preparation method thereof

InactiveCN102010686AGuaranteed reliabilityFast flowOther chemical processesEpoxynovolac adhesivesEpoxyPolyol

The invention discloses a double-solidification system fast-flowing underfill and a preparation method thereof. The underfill comprises the following raw materials in parts by weight: 30-80% of epoxy resin, 10-50% of epoxy acrylate, 5-30% of acrylate, 2-20% of polyol, 1-20% of silane coupling agent, 0.3-4% of cationic initiator, 0.1-3% of radical initiator and 0.1-0.5% of carbon black; and the preparation method comprises the following steps of: weighing the epoxy resin and the cationic initiator in the proportion, putting in a reaction kettle and stirring into a uniform solution; weighing the epoxy acrylate, the acrylate, the polyol, the silane coupling agent, the radical initiator and the carbon black in the proportion, putting in the reaction kettle in sequence, mixing and stirring to obtain the finished product of the double-solidification system fast-flowing underfill.

Owner:YANTAI DARBOND TECH

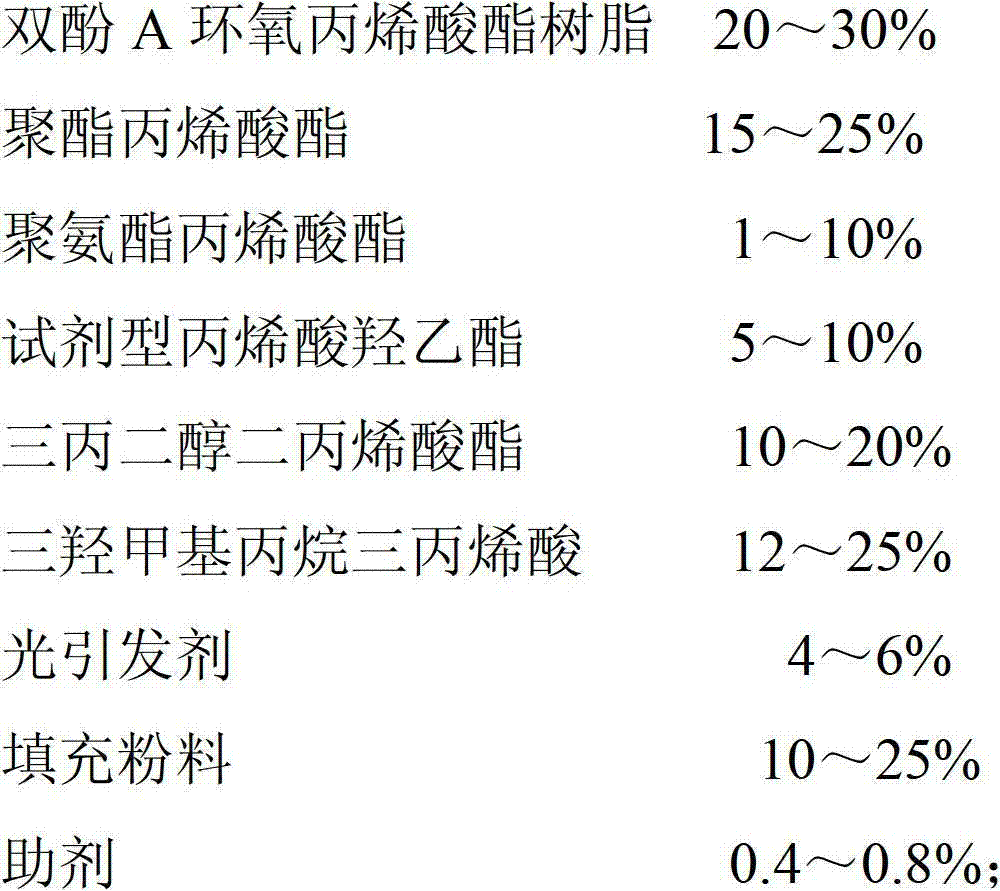

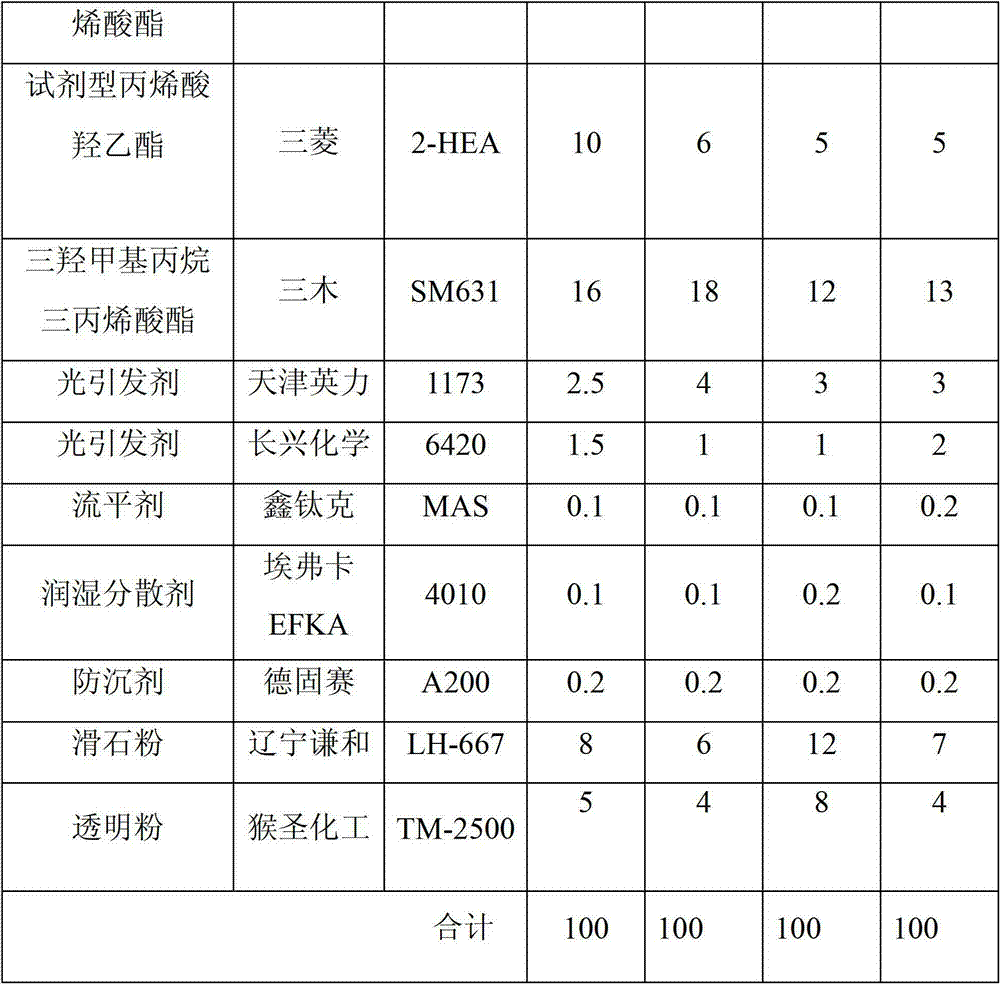

Ultraviolet light curing transparent priming paint and preparation method and use method thereof

ActiveCN102952455AReduce lossImprove product qualityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolyester

The invention discloses an ultraviolet light curing transparent priming paint and a preparation method and a use method thereof. The ultraviolet light curing transparent priming paint comprises the following components in percentage by weight: 20-30% of bisphenol A epoxy acrylate resin, 15-25% of polyester acrylate, 1-10% of urethane acrylate, 5-10% of reagent type hydroxyethyl acrylate, 10-20% of tripropylene glycol diacrylate, 12-25% of trimethylolpropane triacrylate, 4-6% of photoinitiator, 10-25% of filling powder and 0.4-0.8% of promotor. The ultraviolet light curing transparent priming paint is suitable for laser roller construction, has good grittiness and transparency, has the characteristics that sanding is not needed for semi-curing recoating between film layers and the like, and has thick coating performance and the performance that the surface is similar to a mirror surface, and compared with conventional roller coating, the coating weight is greatly increased, roller coating processes are saved, the priming paint is sanded by a sanding machine without large pressure and with a small number of sanded films, a workpiece has no bright spots, the fullness of a product is guaranteed, the product quality is improved, the loss of the machine is smallreduced, and the use amount of sanding belts is greatly reduced.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

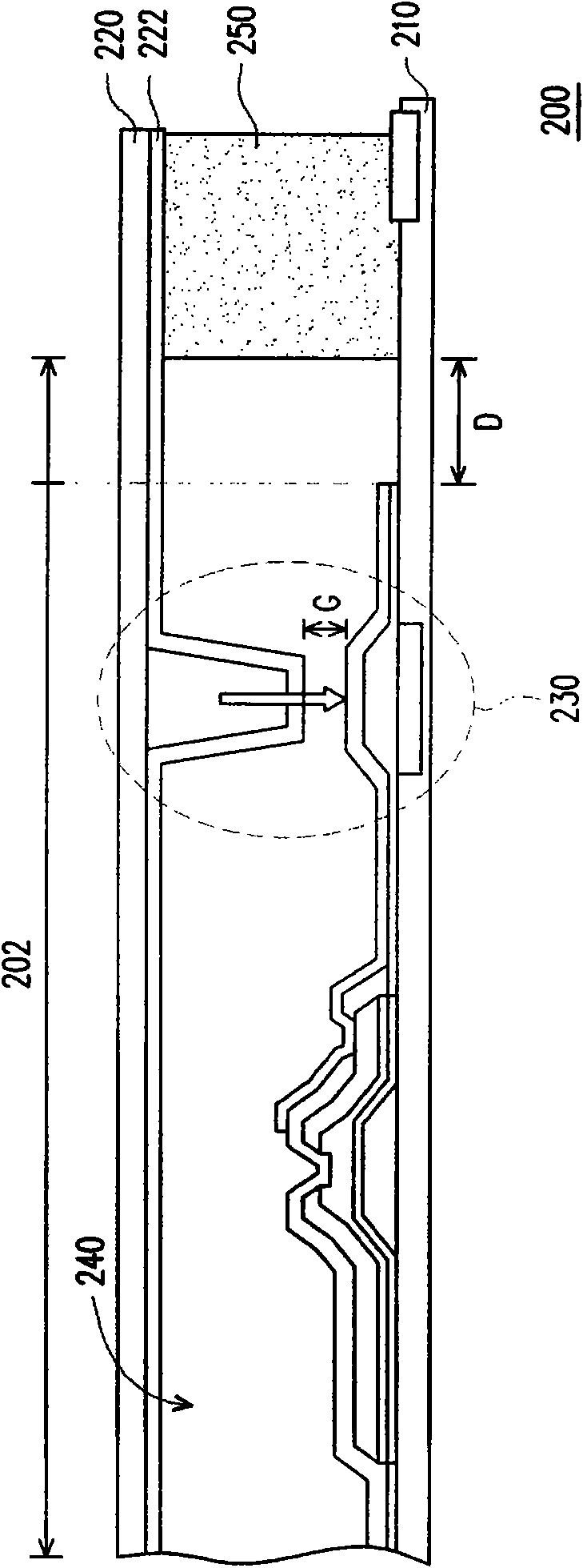

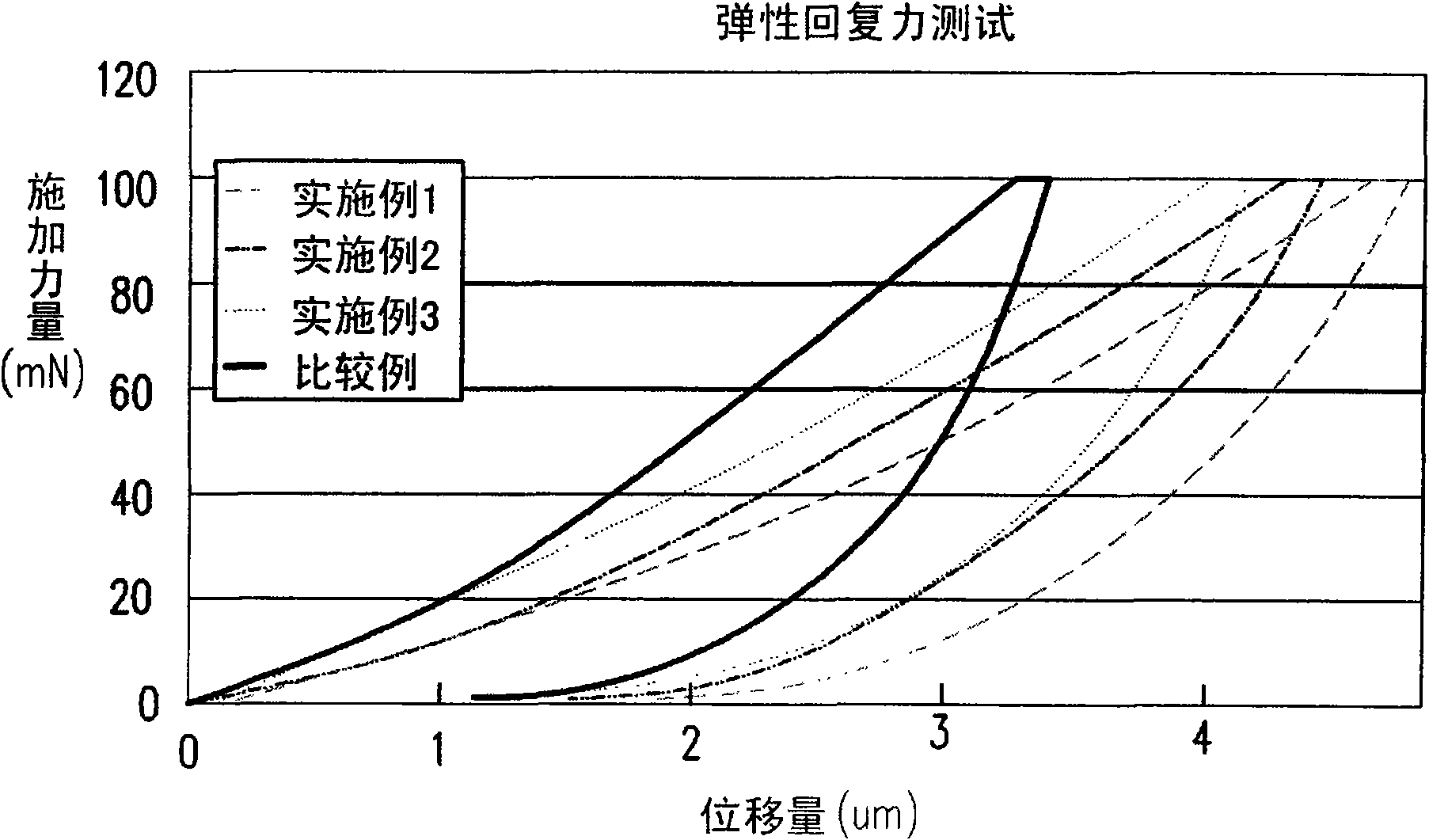

Touch-sensitive display panel, composition for forming sealant and sealant

InactiveCN101630210AElasticIncrease elasticityOrganic non-macromolecular adhesiveInput/output processes for data processingHydrogenEngineering

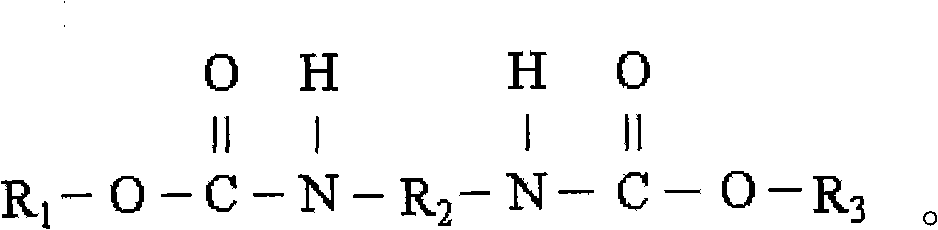

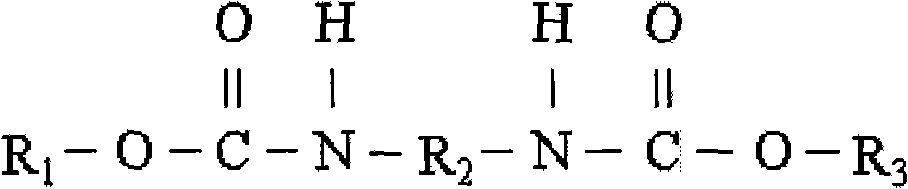

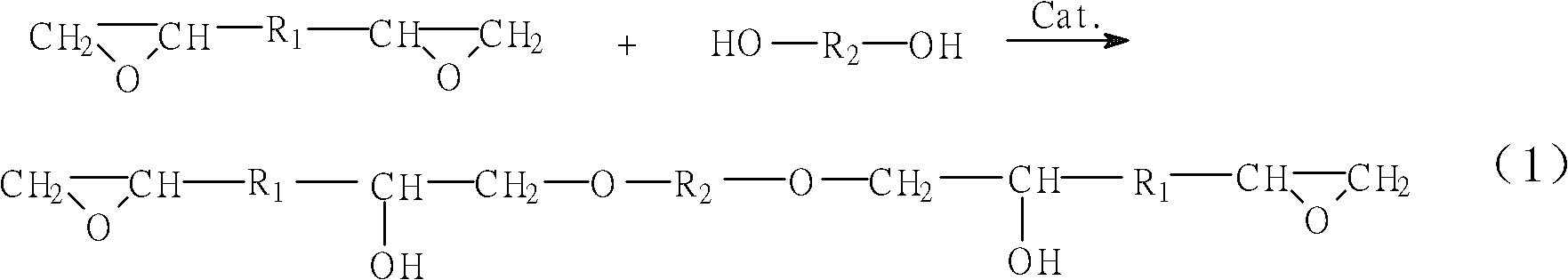

The invention discloses a touch-sensitive display panel, a composition for forming a sealant and the sealant. The touch-sensitive display panel comprises a first base panel, a second base plate, a touch-sensitive structure, a display medium and the sealant, wherein the touch-sensitive structure and the display medium are sealed between the first base panel and the second base panel by the sealant; and the sealant is formed by the polyreaction of the composition. The composition comprises the components by weight percent: 20 to 50% of bisphenol A epoxy acrylate monomer, 2 to 8% of acrylic acid monomer, 0.5 to 5% of light initiating agent and 1 to 5% of hardening agent. The chemical formula of the acrylic acid monomer is showed in the formula 1, wherein R1 is hydrogen or an alkyl radical with 1 to 3 carbon atoms and R2 is hydrogen or an alkyl radical with 1 to 20 carbon atoms.

Owner:AU OPTRONICS CORP

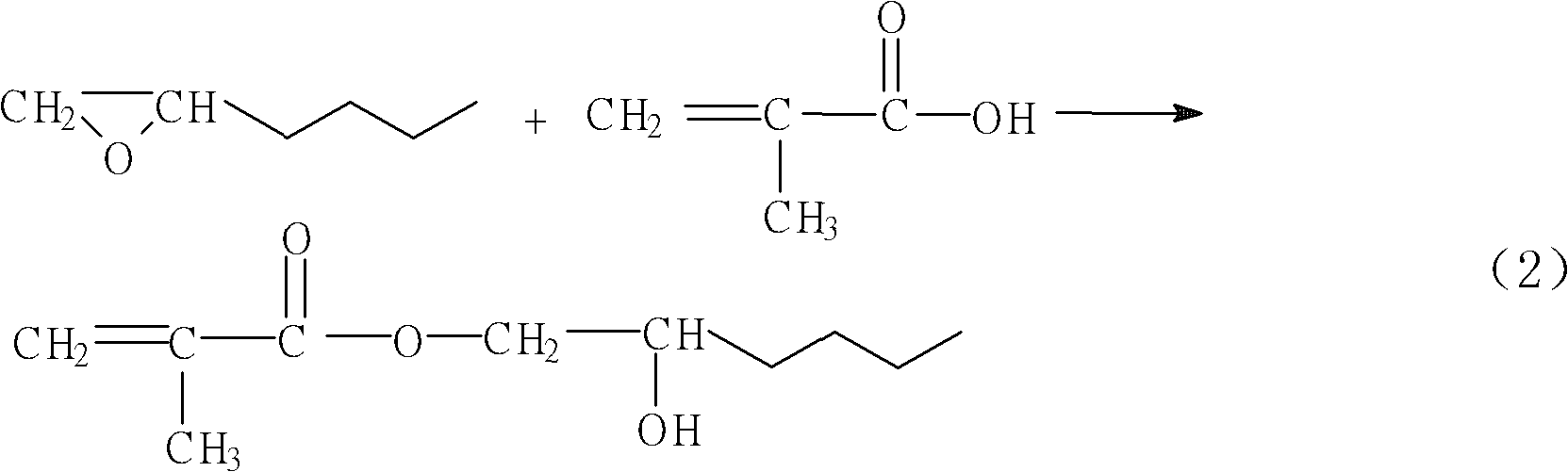

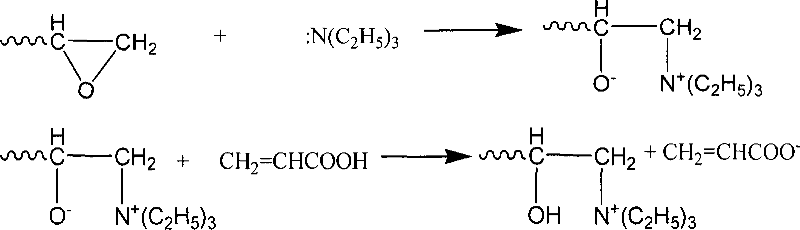

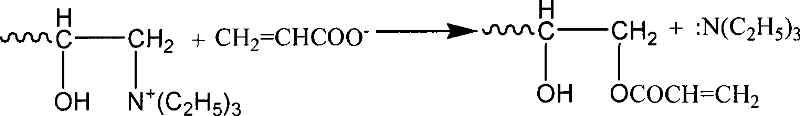

Preparation method of special epoxy resin for aqueous ultraviolet solidifying coating

A method of preparing special epoxy resin for water ultraviolet light curing coating includes steps: a) using bisphenol A type epoxy resin and acrylic acid as raw material, adding catalyst of triethylamine and inhibitor of p-hydroxyanisole, reacting at 70-100 DEG C, after mass concentration of acrylic acid lower than 40-50%, raising temperature to 110-120 DEG C until acid value of the system lower than 5mgKOH / 100g and generating epoxy acrylate; b) mixing the maleic anhydride and the epoxy acrylate according mole ratio of 0.8:1.05-0.8:1.05 and reacting water epoxy acrylate, adding catalyst triethylamine and inhibitor of p-hydroxyanisole under temperature of 60-100 DEG C and reacting for 1-3 h, adding dimethlyethanolamine to neutralizing, adding water and obtaining water epoxy acrylate with certain solid content.

Owner:CHINA PETROCHEMICAL CORP

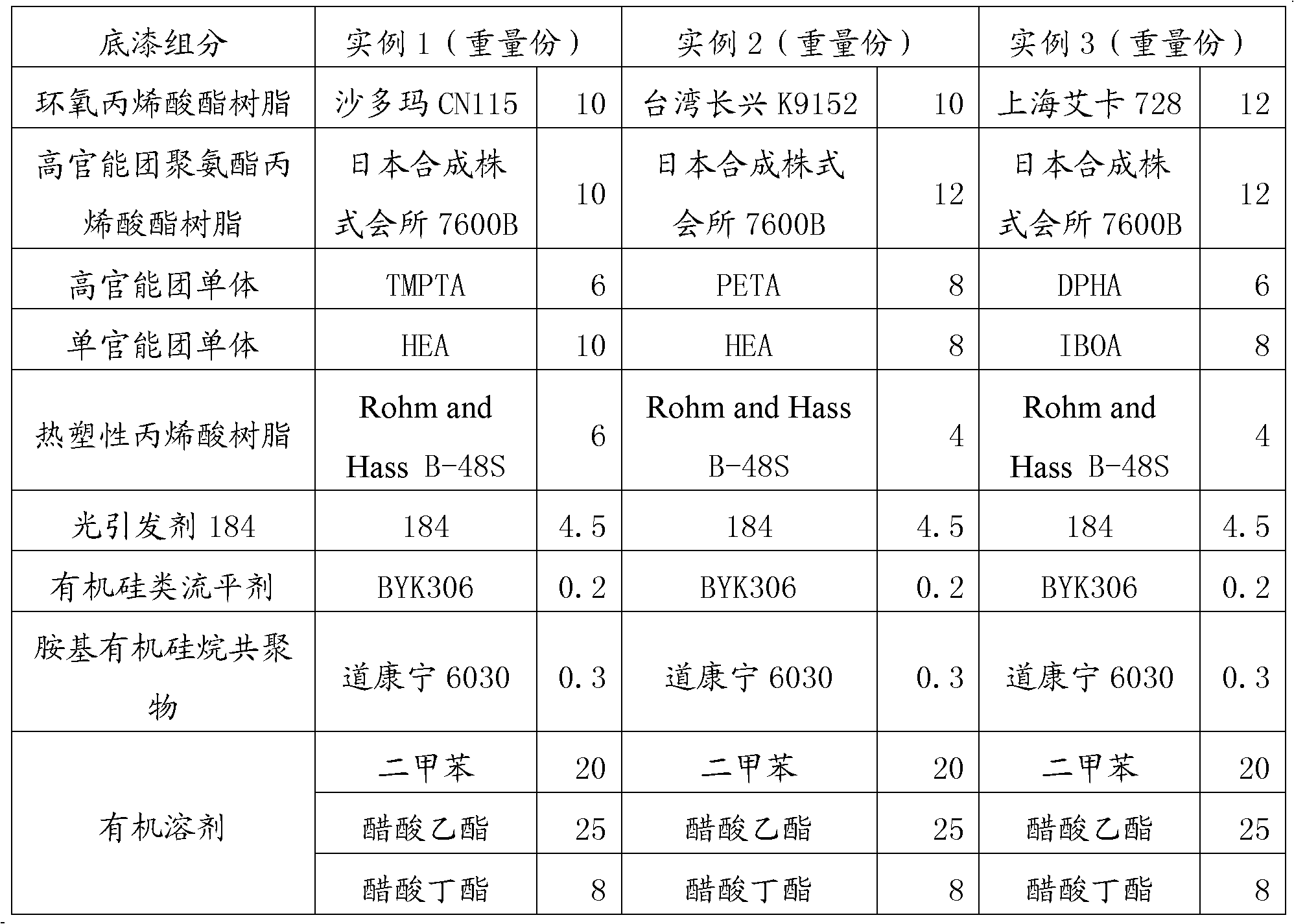

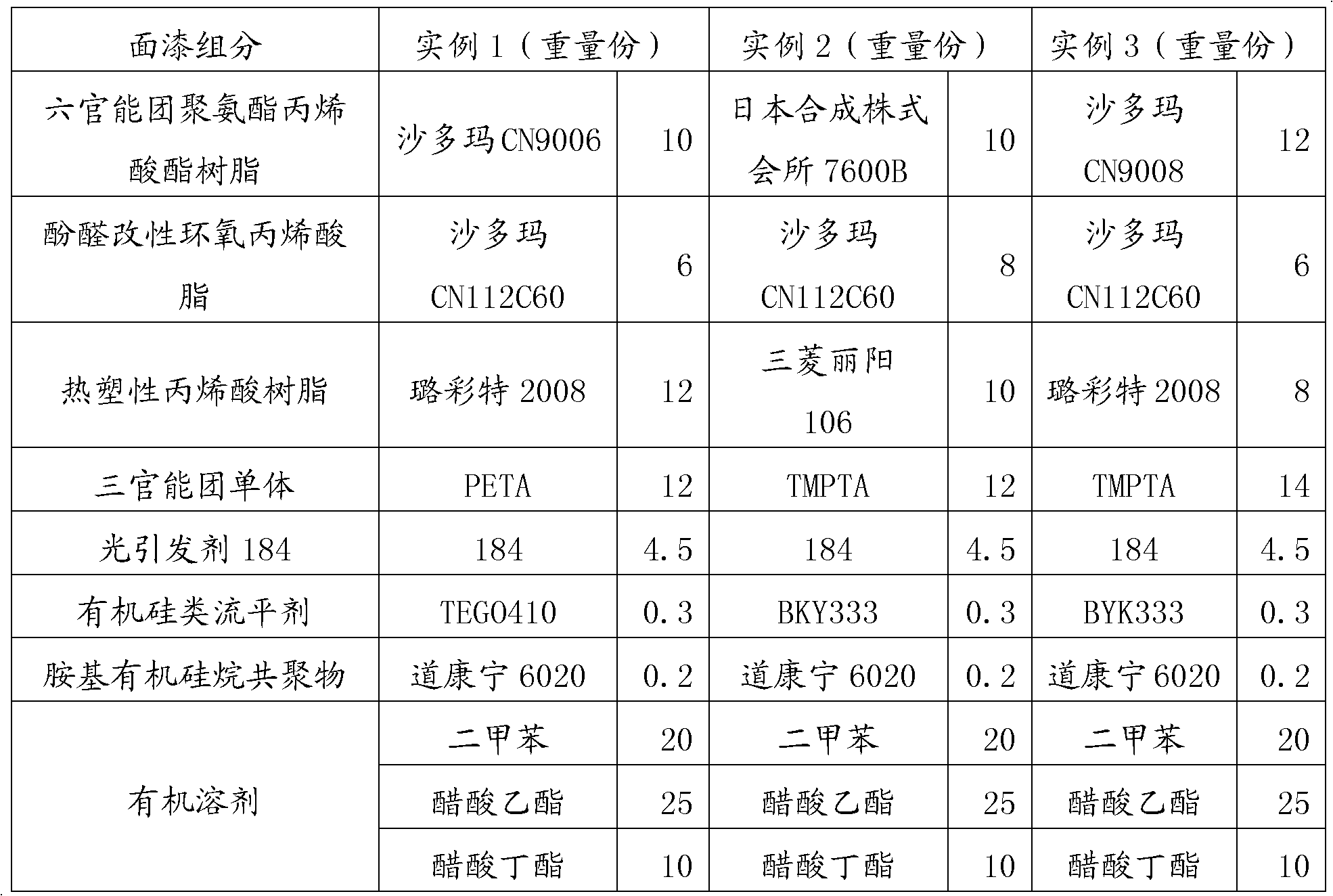

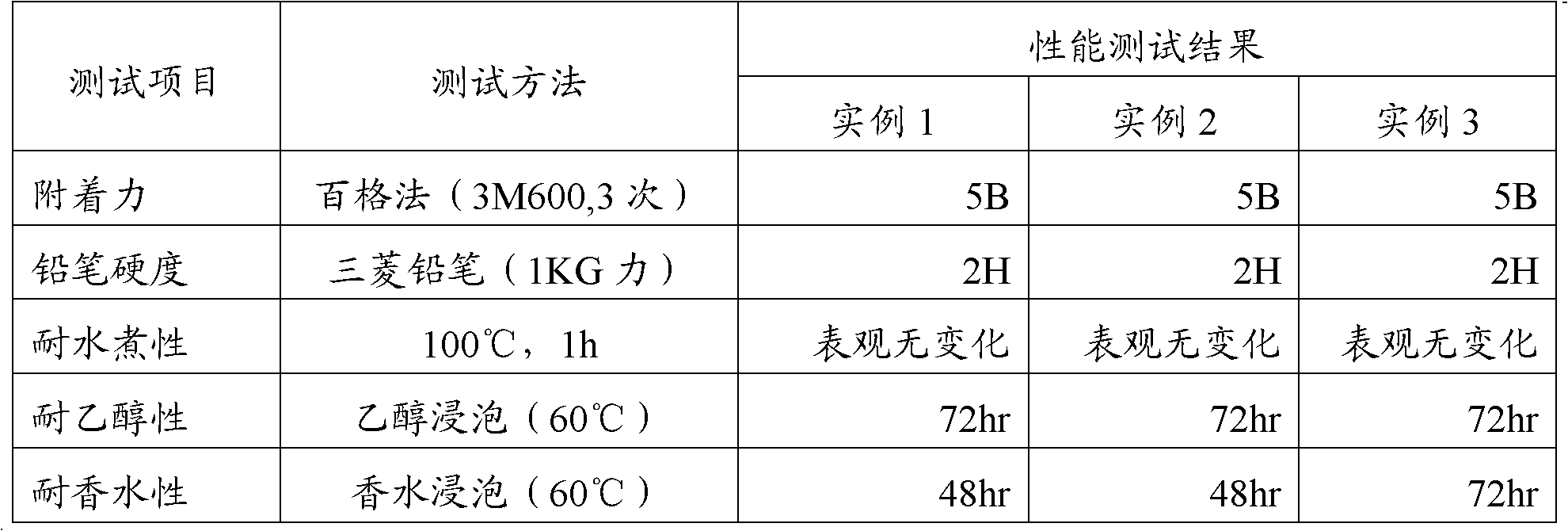

UV (ultraviolet)-curing glass coating paint

ActiveCN102134437AFast curingImprove boiling resistancePolyurea/polyurethane coatingsEpoxy resin coatingsOrganic solventAcrylic resin

The invention discloses a UV (ultraviolet)-curing glass coating paint which comprises a primer and a finish, wherein the primer comprises epoxy acrylate resin, high-functional-group polyurethane-acrylate resin, high-functional-group monomer, single-functional-group monomer, thermoplastic acrylic resin, photoinitiator 184, organosilicon leveling agent, amido-organosilane copolymer and organic solvent; and the finish comprises six-functional-group polyurethane-acrylate resin, phenolic modified epoxy acrylate, thermoplastic acrylic resin, three-functional-group monomer, photoinitiator 184, organosilicon leveling agent, amido-organosilane copolymer and organic solvent. The plating bottom surface coat of the paint has the advantages of high curing speed, higher crosslinking density during construction, high boiling resistance, high ethanol resistance and high perfume resistance.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

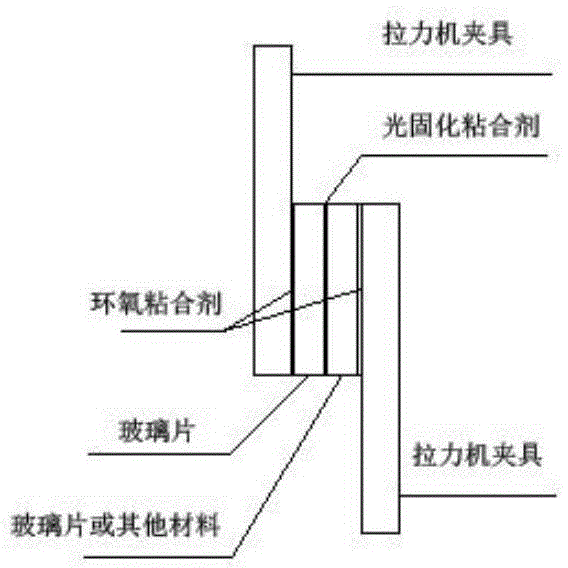

Preparation method of novel dual-cured UV curing binder

InactiveCN104449542AAdhesive processesNon-macromolecular adhesive additivesMetallic materialsDouble bond

The invention relates to a preparation method of a novel dual-cured UV curing binder, and belongs to the technical field of binder industry. The novel dual-cured UV curable binder is prepared by using radical polymerizable resins such as common urethane acrylate, epoxy acrylate and unsaturated polyester as main binding materials, using a double bond-containing reactive diluent as a solvent, and using a UV initiator and a thermal initiator as a compound initiator, supplemented by other binding agents. During curing, a certain initial binding power is firstly obtained by UV curing, and higher binding power is obtained by secondary curing through heating or oxygen isolation. The preparation method provided by the invention not only has the advantages of high curing speed of the traditional light curing binders, but also has the advantages of effectively avoiding the generation of internal stress in the curing process of the traditional light curing binder, and improving the binding strength of the binder; the binder has excellent solvent resistance, high binding strength, and low cost. The binder is widely used for binding glass and glass, glass and metal materials and other transparent materials.

Owner:JIANGNAN UNIV

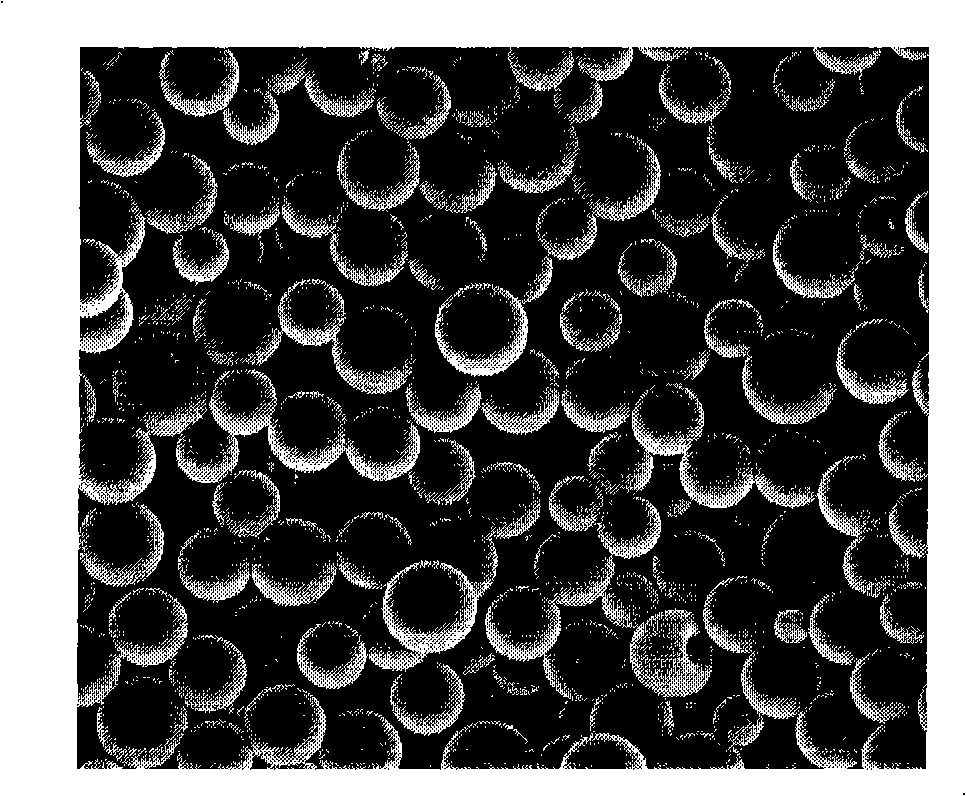

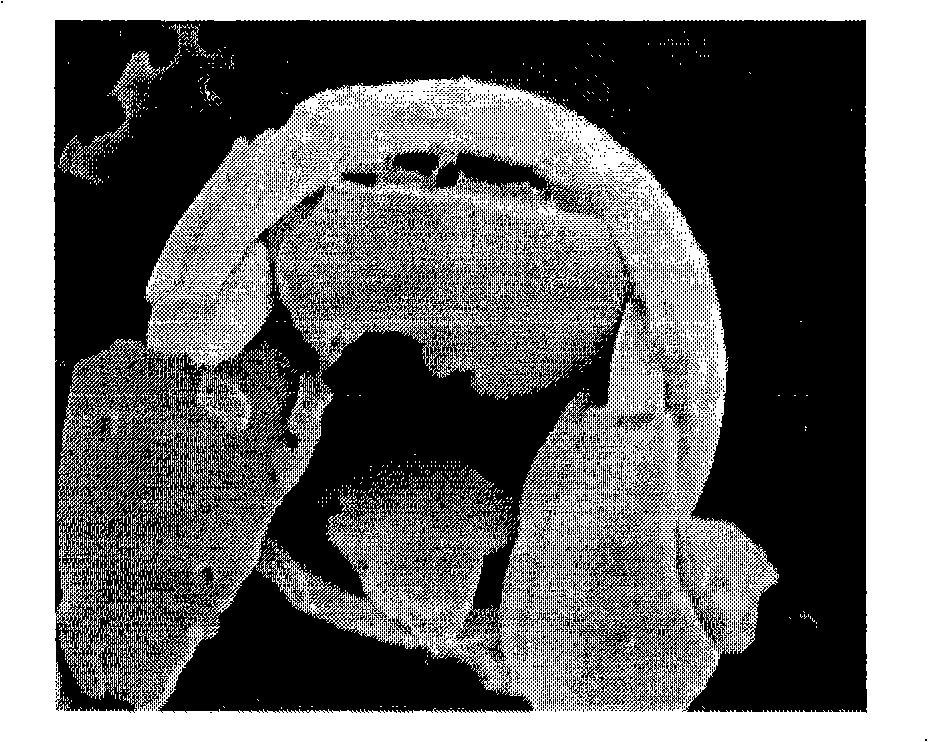

Epoxy resin micro-capsule and its preparation method

InactiveCN101319055AImprove sealingGood mechanical propertiesMicroballoon preparationMicrocapsule preparationEpoxyIn situ polymerization

The invention discloses an epoxy resin microcapsule and a preparation method thereof. The epoxy resin microcapsule comprises a capsule core and a capsule wall, wherein, the capsule core is an epoxy resin, and the capsule wall is a composition of an aepoxy acrylate resin, a polymerizable emulsifying agent, a crosslinking agent and an optical initiator; and the polymerization method of the capsule wall is ultraviolet irradiation and film forming through curing. The preparation method for the microcapsule comprises the following steps that: core materials, wall materials and an ultraviolet initiator are added into a water solution which is dissolved with a surfactant in turn under the condition of high-speed stirring; after an oil-in-water emulsion system is prepared by emulsification, ultraviolet light is immediately used for irradiating the emulsion, and the surface compositions of oil-in-water liquid droplets undergo in-situ polymerization and film forming through curing; a great dealof water is added for repeated sedimentation and water scrubbing; and microcapsule products are prepared through vacuum freeze drying of microcapsule deposits. The method has a simple technique, low energy consumption, quick speed and friendly environment. The capsule prepared takes the shape of a regular sphere, has good leak tightness and heat resistance, and can be widely applied to self-repairing of self-setting thread fasteners and thermosetting resin substrate composite materials.

Owner:SUN YAT SEN UNIV

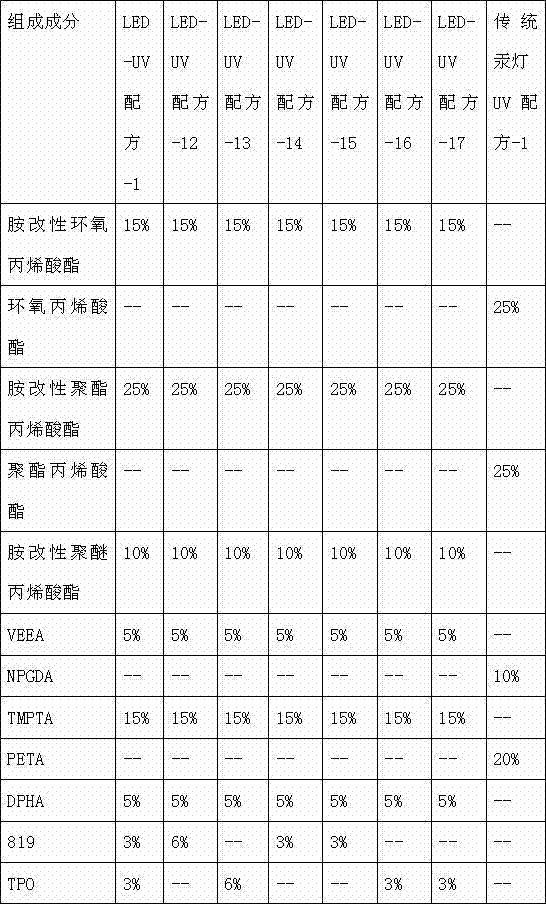

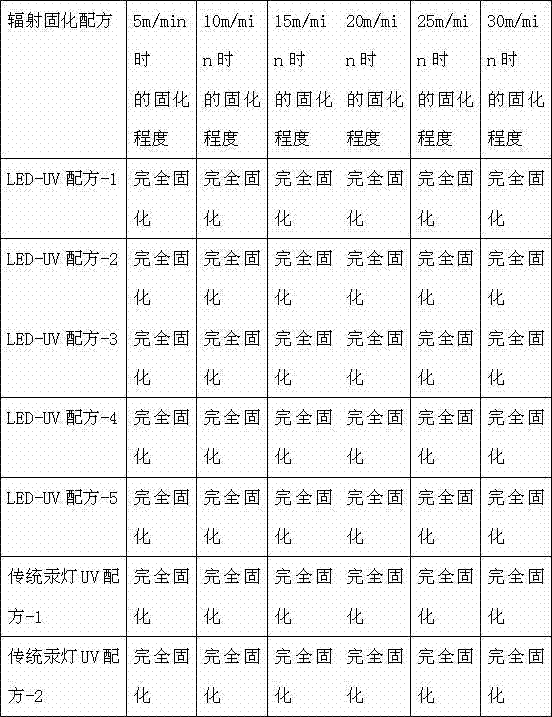

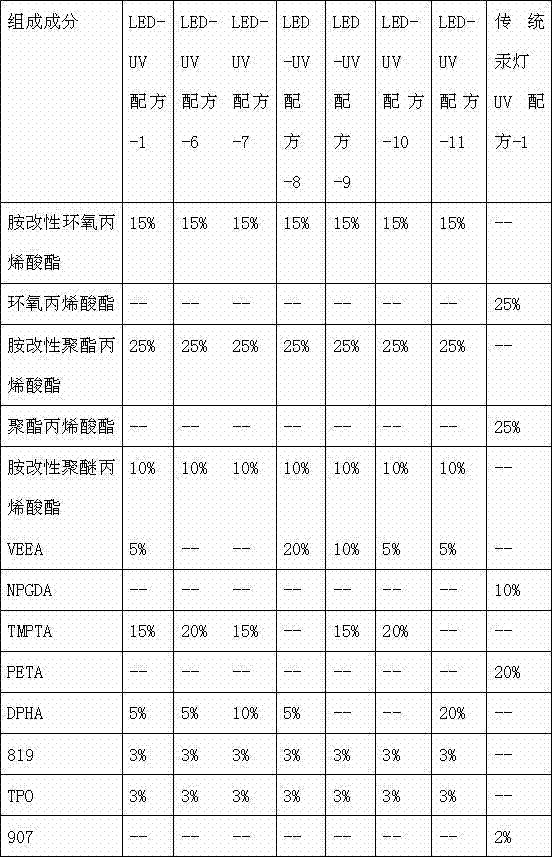

LED-UV surface light source light-curing silk-screen printing ink composition and preparation method thereof

The present invention relates to the field of ink and a preparation process thereof, and particularly to a LED-UV surface light source light-curing silk-screen printing ink composition and a preparation method thereof. The composition is characterized by comprising 25-55% by weight of an LED-UV resin and 10-25% by weight of an LED-UV monomer, wherein the LED-UV resin is a mixture comprising one or a plurality of materials selected from an amine-modified epoxy acrylate resin, an amine-modified polyester acrylate resin, and an amine-modified polyether acrylate resin, and the LED-UV monomer is a mixture comprising one or a plurality of materials selected from a 2-(vinylethoxy)ethyl diacrylate monomer, a trimethylolpropane triacrylate monomer, and a dipentaerythritol hexaacrylate monomer. The LED-UV surface light source light-curing silk-screen printing ink composition of the present invention has advantages of rapid curing speed, good film coating property, high glossiness, environment protection, energy saving, and the like.manufacturing process

Owner:东营华科新材料科技有限公司

Ultraviolet ray cured paint

An ultraviolet ray-cured paint consists of active oligomer, active diluent, light polymerization initiator and diluent; and the active oligomer is maleic anhydride-modified epoxy acrylic ester with acid value of 10-30 mg KOH / g. It has also adhesion strengthening resin containing epoxy group. It has the components includes maleic anhydride-modified epoxy acrylic ester 30-60 wt%, active diluent 15-45 wt%, adhesion strengthening resin containing epoxy group 2-5 wt%, light polymerization initiator 1.0-10 wt%, and diluent 0-20 wt%. It has high adhesion between the film and the metal substrate, high heat resistance, proper cost / performance ratio and lightened environment and human body harm, and is especially suitable for use in antirust decorative of metal surface.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com