Patents

Literature

4652results about How to "No harm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plaster for promoting muscles and bones, and preparation and application thereof

InactiveCN102188673AImprove disease resistanceGood effectHeavy metal active ingredientsAnthropod material medical ingredientsPhellodendron amurenseLigusticum chuanxiong

The invention relates to a Chinese medicine plaster for treating diseases in muscles and bones, in particular to a plaster for promoting muscles and bones, and preparation and application thereof. The plaster is prepared by mixing pastes and powders; wherein the raw materials of the pastes by weight comprise: 25-60g of clematis root, 25-60g of heracleum, 25-60g of incised notopterygium rhizome, 25-60g of erycibe obtusifolia, 25-60g of garden balsam stem, 25-60g of gentiana macrophylla, 25-60g of prepared common monkshood daughter root, 25-60g of dried ginger, 25-60g of cinnamon, 25-60g of harlequin glorybower leaf and twig, 25-60g of rhizoma corydalis, 25-60g of ligusticum wallichii, 25-60g of frankincense, 25-60g of cowherb seed, 25-60g of lingzhi mushroom, 25-60g of gastrodia elata and 25-60g of astragalus, 25-60g of one or more of honeycomb, radix aconiti brachypodi and nux vomica, 0.1-3kg of minium and 0.5-5kg of vegetable oil; and the raw materials of the powders by weight comprise: 15-45g of clematis root, 15-45g of heracleum, 15-45g of incised notopterygium rhizome, 15-45g of phellodendron amurense, 15-45g of dragon's blood, 15-45g of gastrodia elata, 15-45g of nux vomica, 15-45g of rhizoma corydalis, 15-45g of borneol, 15-45g of harlequin glorybower leaf and twig and 15-45g of common monkshood mother root. The plaster for promoting muscles and bones has balanced effect, high medicine utilization ratio and good treatment effect.

Owner:赵贵凤

Alginate-base organic-inorganic composite hydrogel filtering membrane and preparation method thereof

ActiveCN103446898ASimple preparation processLow costSemi-permeable membranesCross linked hydrogelsPrecipitation

The invention discloses an alginate-base organic-inorganic composite hydrogel filtering membrane, which is designed and prepared aiming at the problems of low mechanical strength, high probability of deformation, low flux and the like of a pure ionic cross-linked hydrogel filtering membrane. According to the filtering membrane, sodium alginate is used as a membrane forming substrate, micro-nano inorganic particles are used as a reinforcing agent and a pore-enlarging agent, and the composite hydrogel membrane which is obtained after cross-linking of a cross-linking agent and elution of a pore-forming agent has better stability and mechanical performance than the pure ionic cross-linked alginate hydrogel membrane. The mechanical strength and the pore size of the membrane are adjusted by changing the type, the particle diameter size and the added amount of the micro-nano inorganic particles and the type and the concentration of the ionic cross-linking agent. The composite hydrogel filtering membrane is prepared through a simple preparation process and is low in cost; no organic waste liquid is produced; the obtained hydrogel flat membrane can resist the pressure of 0.1-0.6 MPa; the alginate hydrogel is dissolved after being subjected to soaking treatment of a sodium citrate solution; expensive micro-nano inorganic particles can be recovered through simple precipitation separation.

Owner:南通速润净水科技有限公司

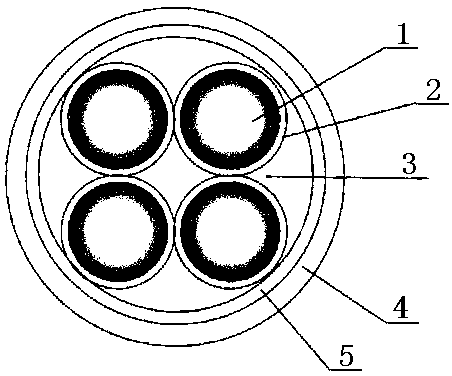

Fireproof and flame retardant mineral compound filling material and cable containing the same

ActiveCN103102134ANo harmImprove fire performanceInsulated cablesInsulated conductorsPolymer scienceFirming agent

The invention relates to a fireproof and flame retardant mineral compound filling material for cables. The filling material comprises a silicon-containing binder; an inorganic flame retardant compound; and a mineral compound. The filling material also can include a silicate modifier, a silicate curing agent and a pigment. Being free of any flammable substance, the fireproof and flame-retardant mineral compound filling material provided in the invention has an excellent fireproof effect, can lose moisture and absorb a lot of heat so as to achieve the flame retardant effect. With good flexibility, the fireproof and flame retardant mineral compound filling material has no hazard to the nature after it is abandoned.

Owner:上海宏胜电线电缆有限公司 +1

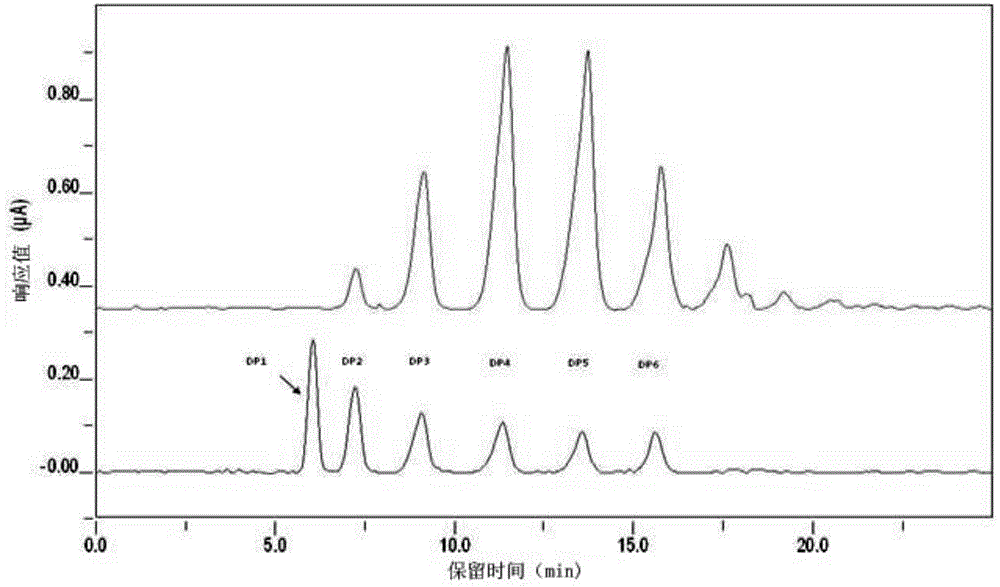

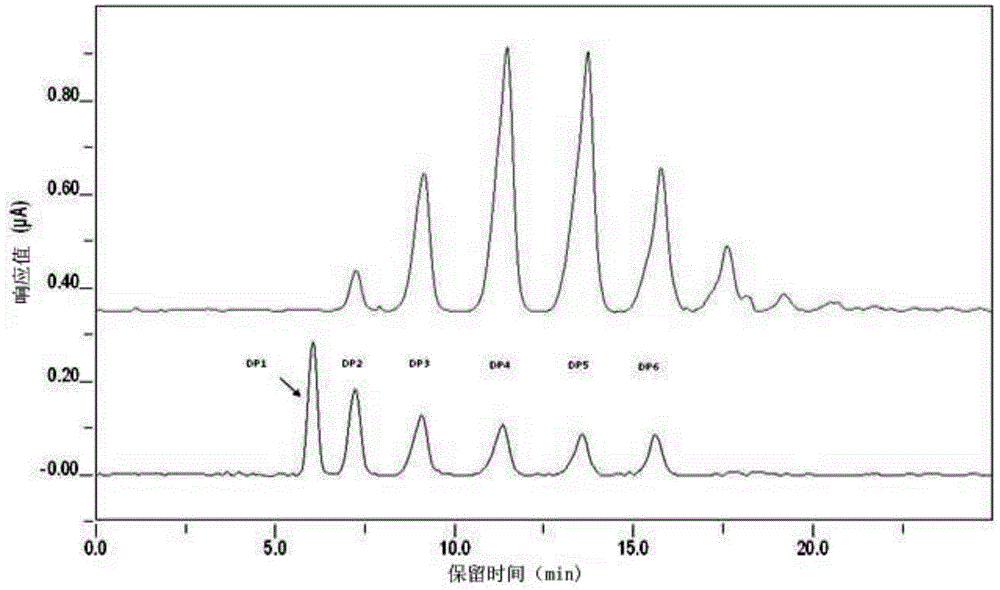

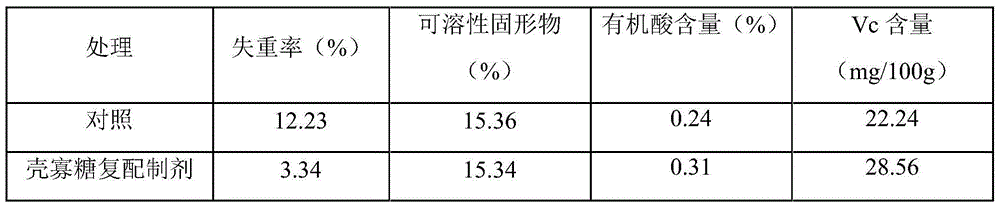

Chitosan oligosaccharide compounded preparation and application in prolonging shelf life of fruits

InactiveCN104642528AExtend fruit shelf lifeReduce usageFruit and vegetables preservationChemistryOrganic acid

A chitosan oligosaccharide compounded preparation for prolonging shelf life of fruits contains 0.3-5% of chitosan oligosaccharide with a fresh-keeping function, 0.1-2% of organic acid and 0.03-0.5% of a growth inhibitor. The compounded preparation is applied to fruits. By introducing chitosan oligosaccharide with the fresh-keeping function into a fruit preservative, the chitosan oligosaccharide compounded preparation has a double effect of sterilization and preservation. In addition, a medicament with chitosan oligosaccharide and organic acid as main components has advantages of safety, nontoxicity, low cost and low dosage, and is environmentally friendly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

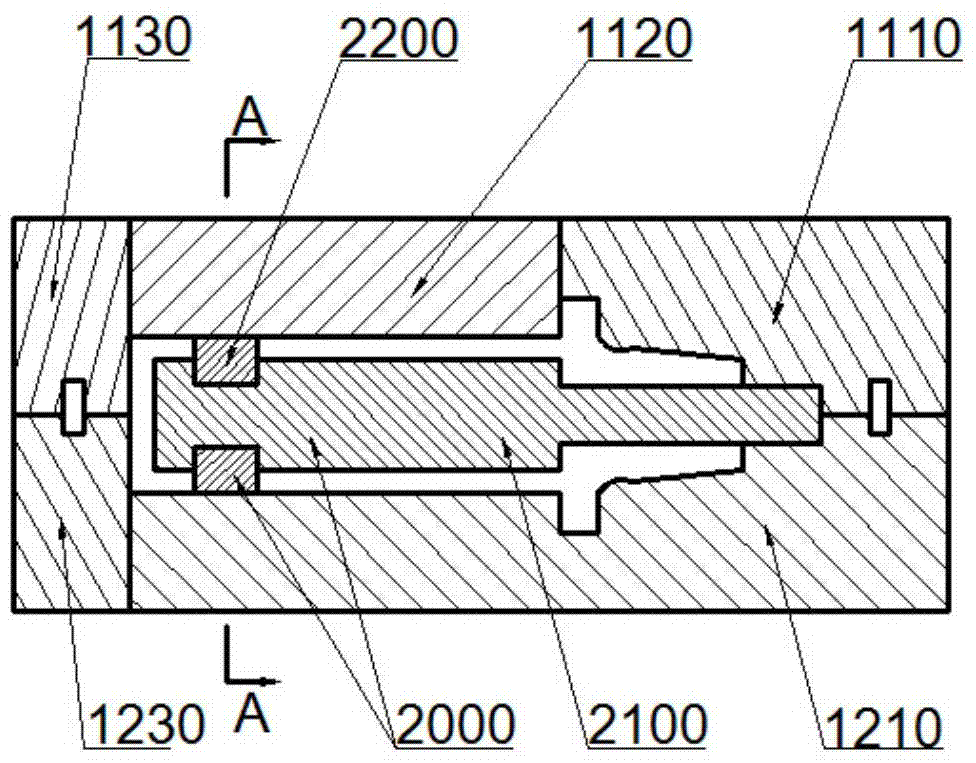

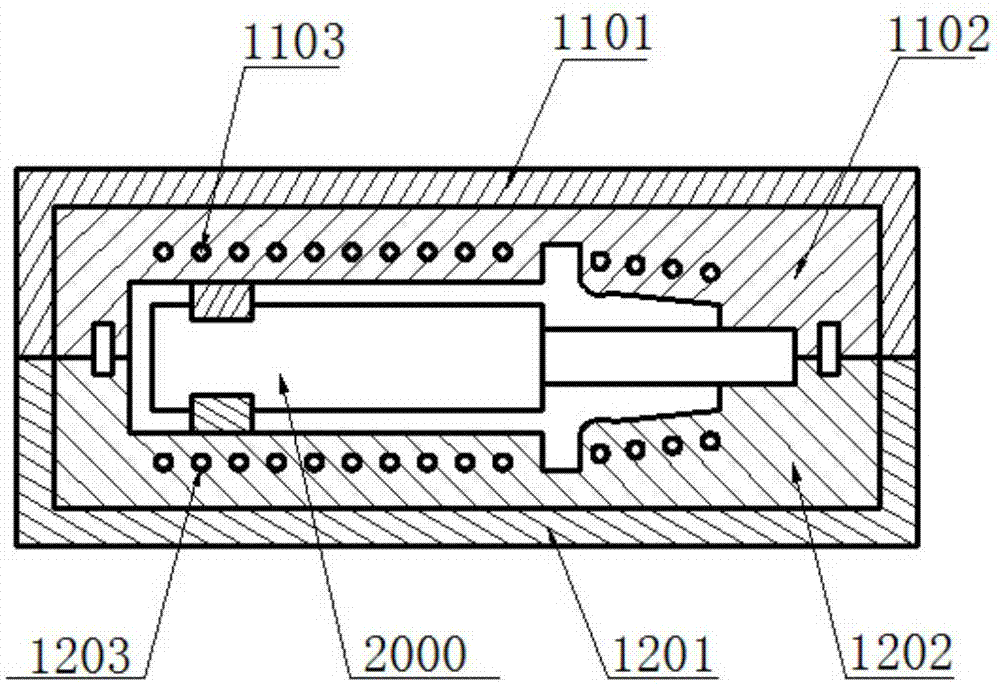

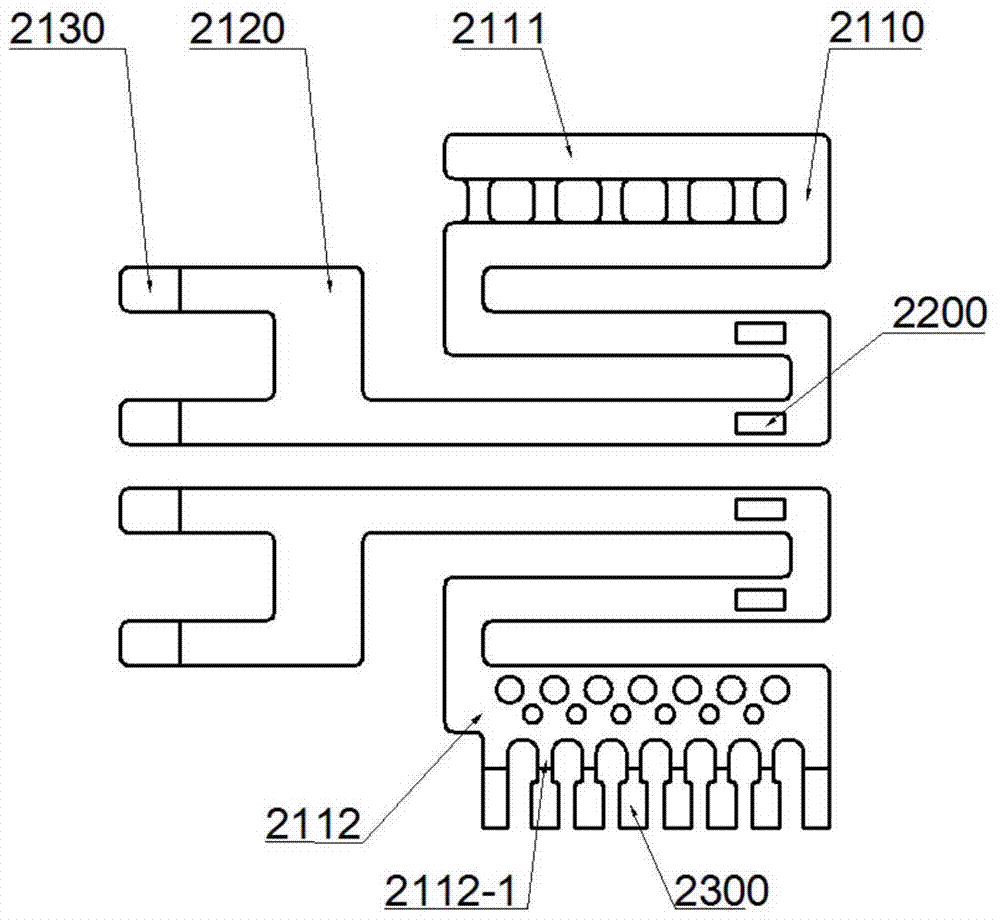

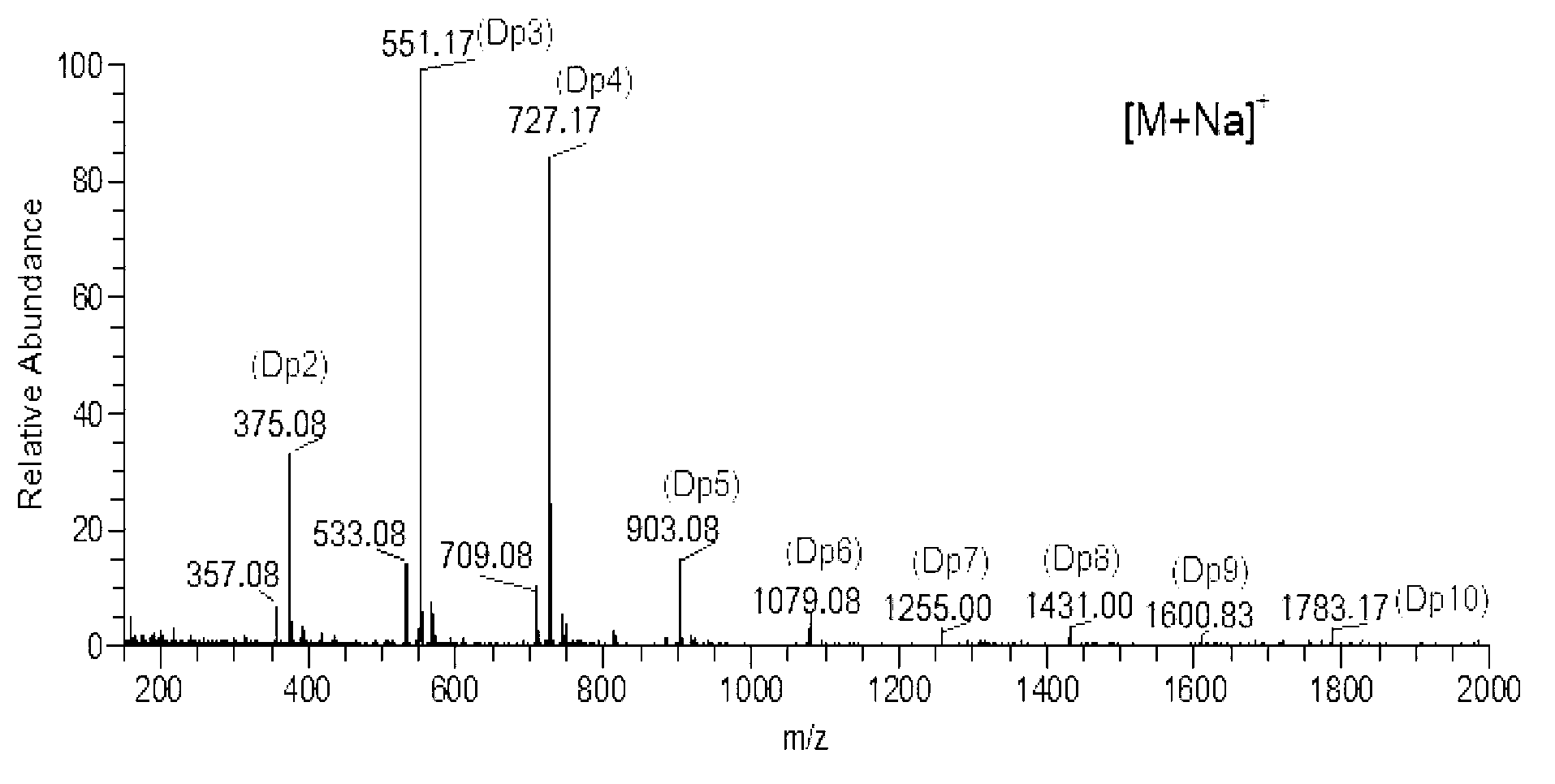

Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

The invention discloses a wax injection mold for investment casting of hollow turbine blades and a method for rapidly and accurately manufacturing the wax injection mold. The mold consists of a cavity mold, a mold core and an accessory structure, wherein the cavity mold comprises an upper mold and a lower mold of a combined structure; each mold block forming the cavity mold consists of an external aluminum mold frame, an internal cast zinc alloy inlay and a conformal cooling copper pipe embedded into the inlay; a mold core positioning piece which can be decomposed at a high temperature is arranged on a longitudinal rib of the mold core; and water-soluble core blocks used for forming exhaust openings in the rear edges of the turbine blades are arranged on rear edge ribs of the mold core. The matching precision of the mold core positioning piece and the cavity mold is guaranteed by adopting a cavity mold interior running-in method, and the matching precision of the water-soluble core blocks and the cavity mold is guaranteed by adopting a cavity mold interior adhesion method. The wax injection mold disclosed by the invention is low in manufacturing cost and short in period, and the high wax pattern precision and core positioning precision can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

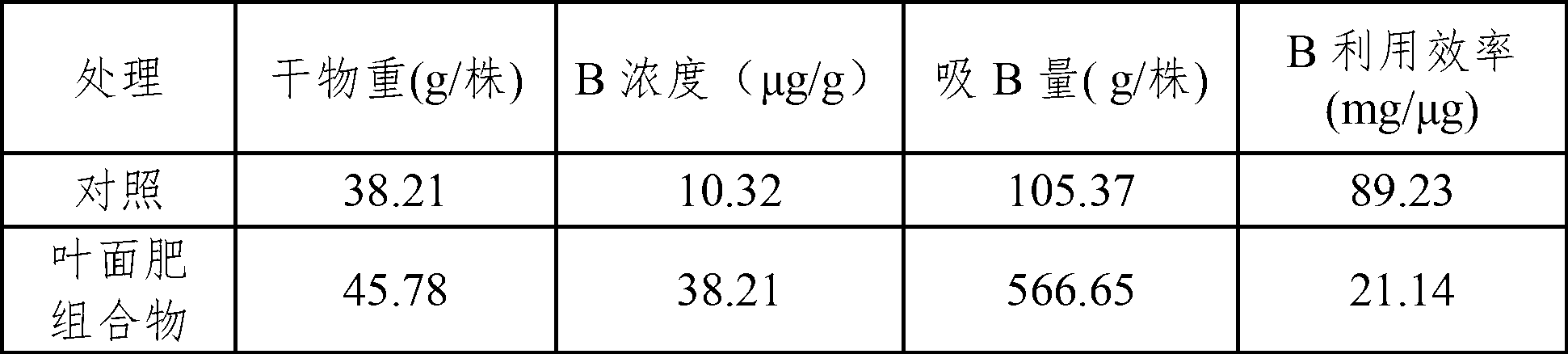

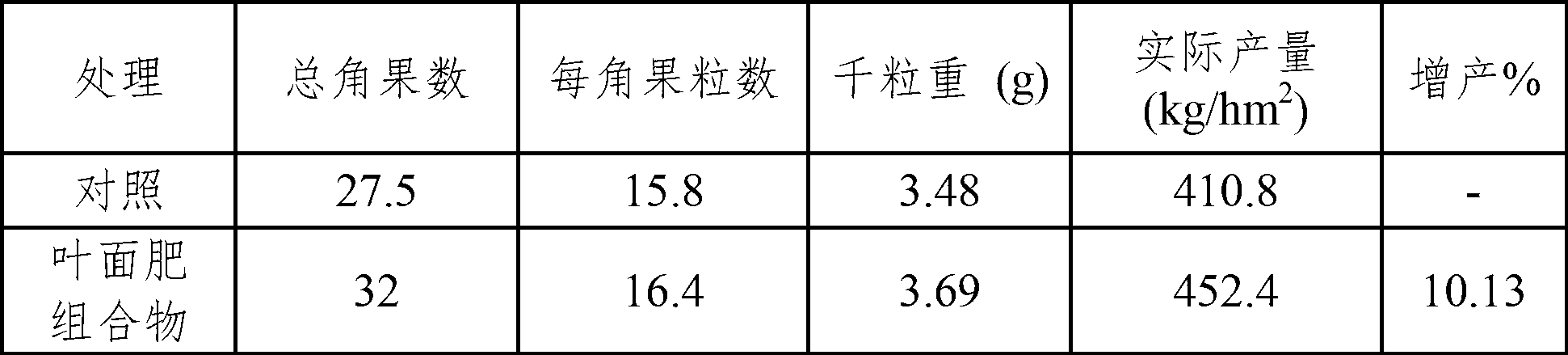

Leaf fertilizer composition comprising sodium alginate oligosaccharide and application of leaf fertilizer composition

ActiveCN103011968AWide variety of sourcesLow priceOrganic fertilisersLiquid fertilisersManganeseUronic acid

The invention discloses a leaf fertilizer composition comprising sodium alginate oligosaccharide, which is characterized in that the composition comprises sodium alginate oligosaccharide, amino acid and microelements that can promote plant growth significantly, wherein sodium alginate oligosaccharide is also known as sodium alginate, sea-tangle glue and algin, is natural polysaccharide carbohydrate extracted from sea tangle, and is a copolymer comprising a-L-mannuronic acid (M), b-D-guluronic acid (G) connected with a-L-mannuronic acid (M) by 1,4-glycosidic bond, and different GGGMMM fragments; a molecular formula is (C6H7O6Na)n; the degree of polymerization is 2-10; the uronic acid constitution M / G is equal to 7:3; the uronic acid content is greater than 90%, and is 2-3% of the total content; the content of a microelement leaf fertilizer is 2-20%; and the microelement leaf fertilizer comprises at least two of sulfur, boron, ferrum, manganese, copper, zinc and molybdenum. The composition is mainly applicable to industrial crops, fruit and vegetable crops, grain crops, economic trees, flowers, lawns and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

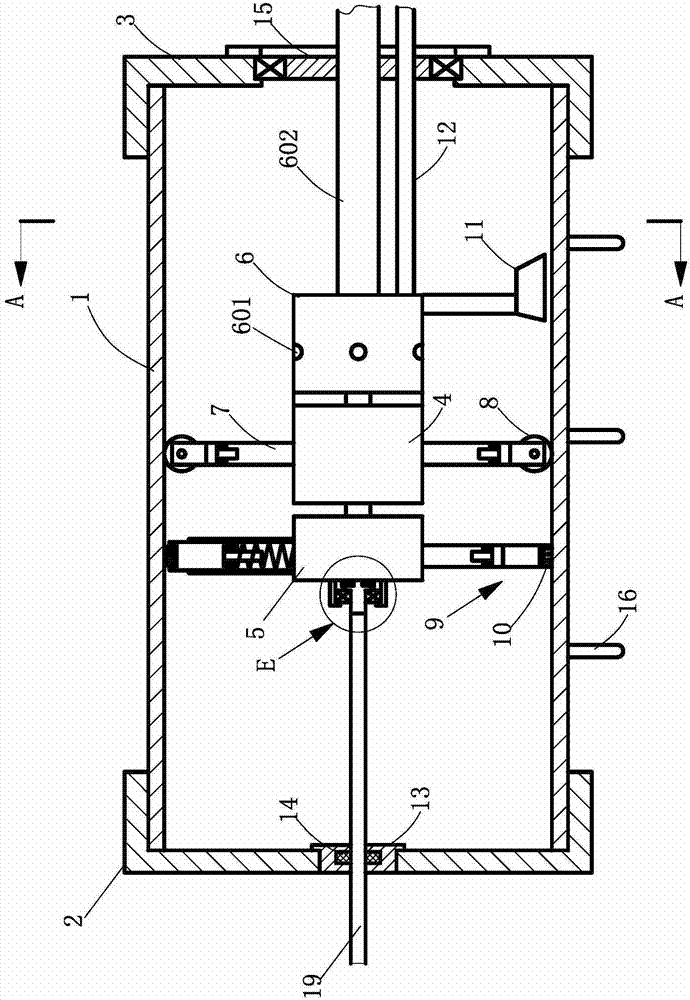

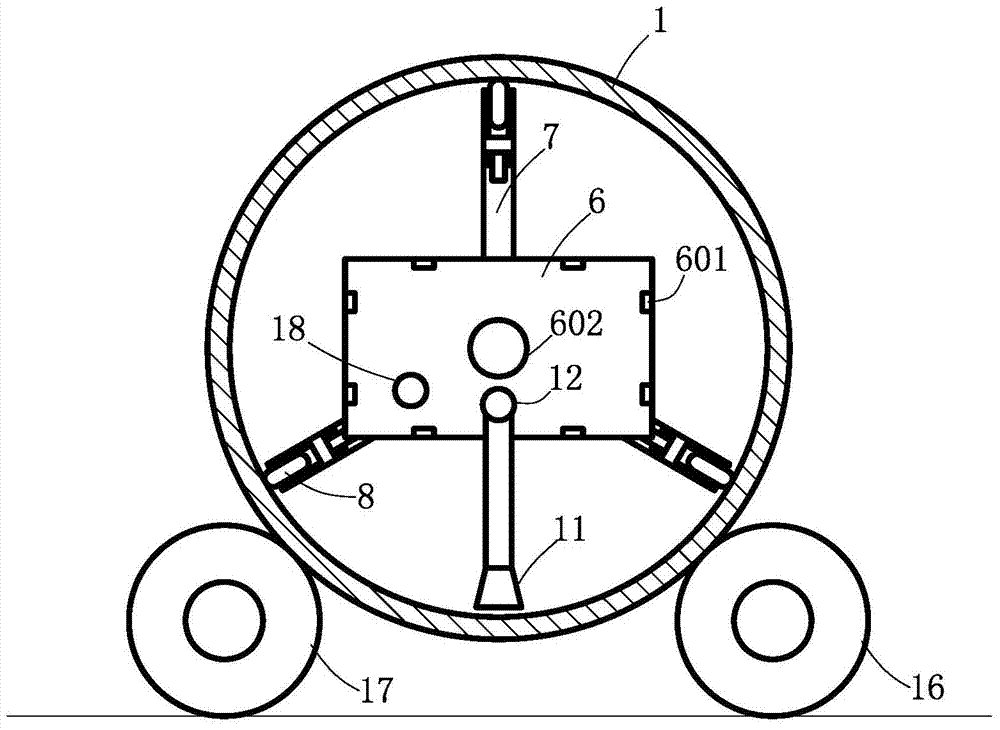

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

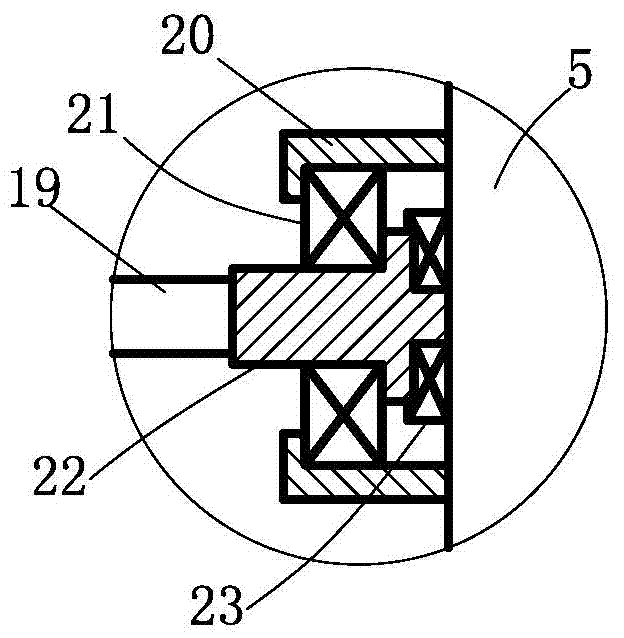

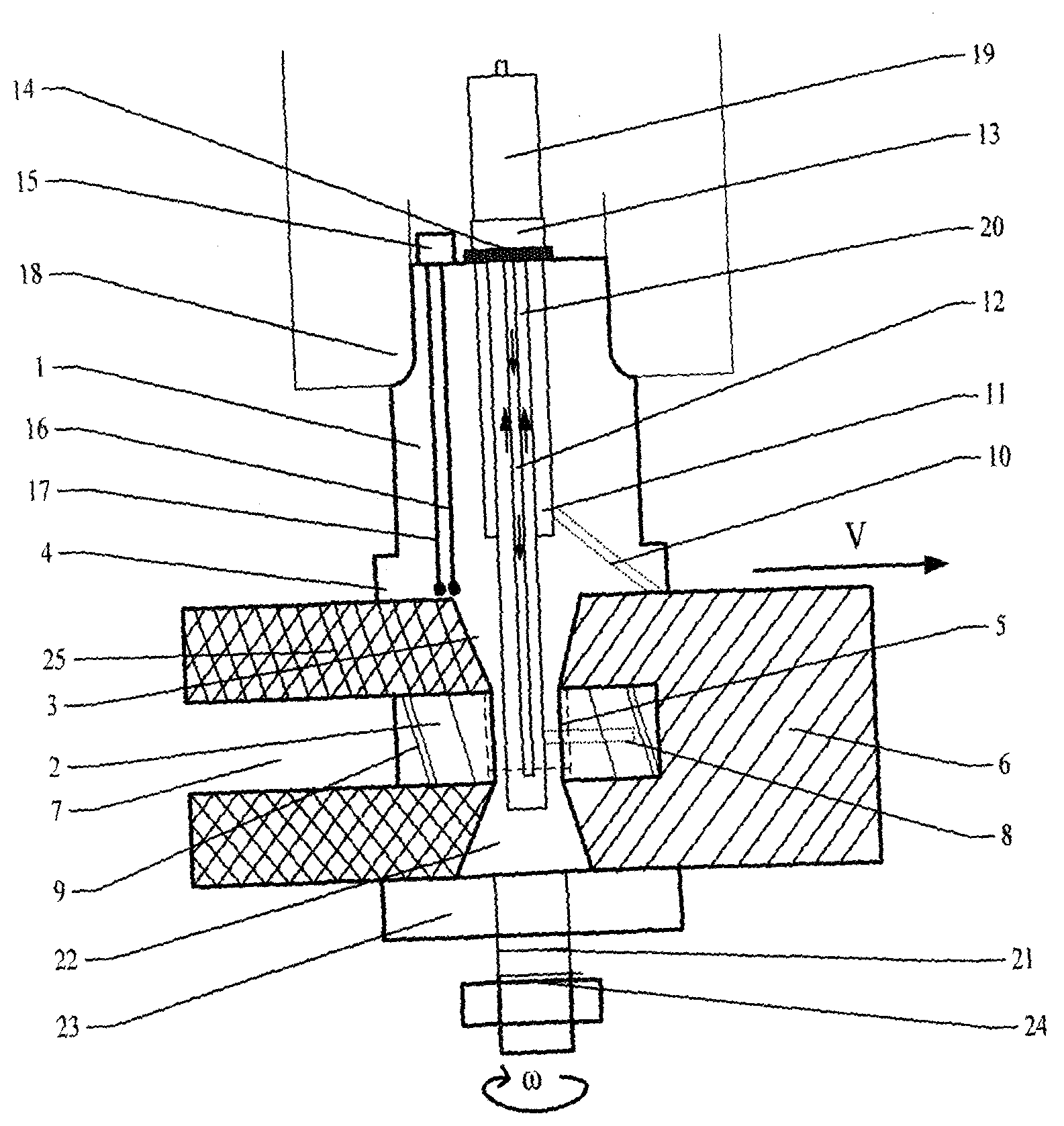

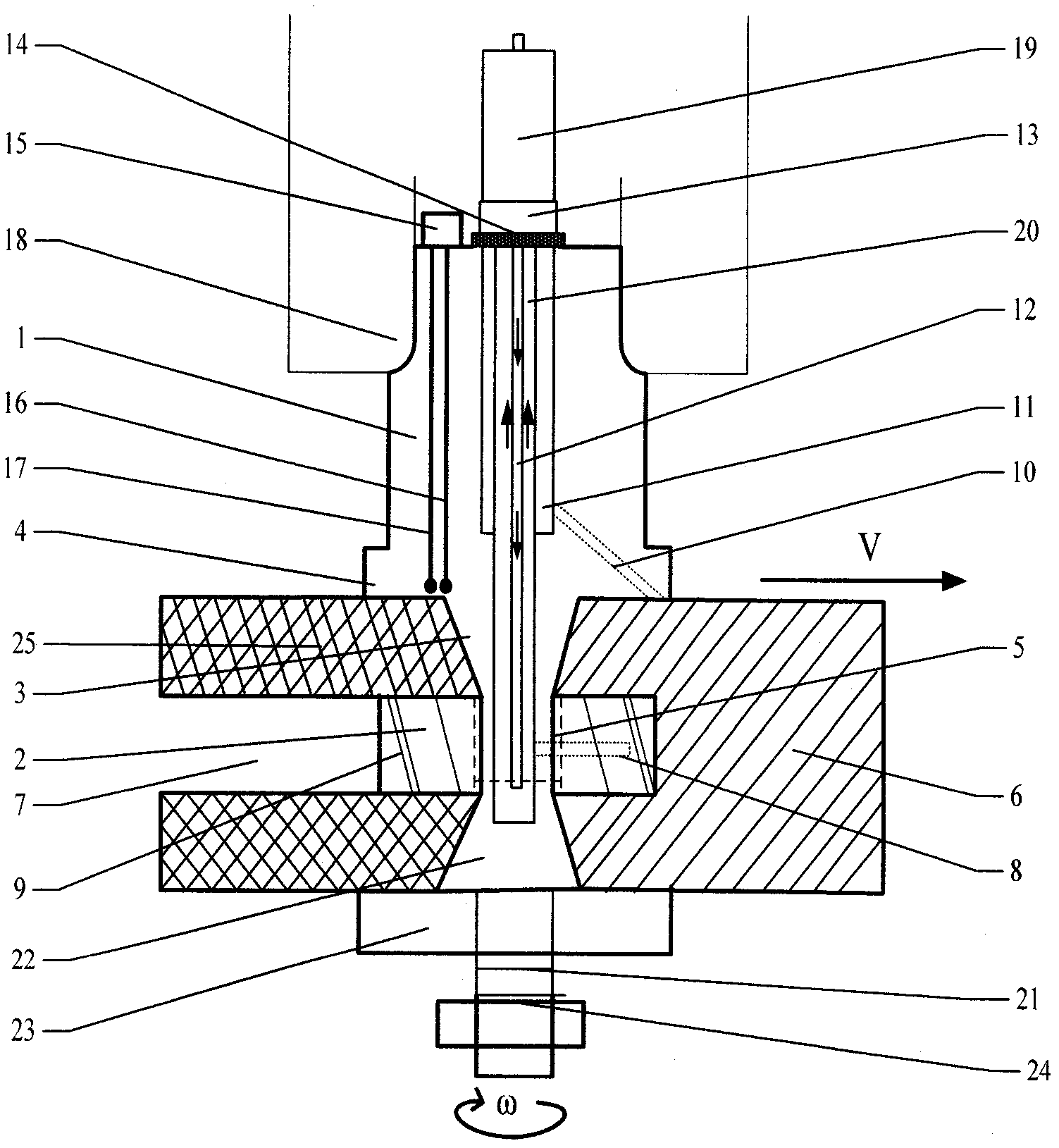

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

InactiveCN102490018AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsNon-electric welding apparatusInduction systemTemperature sensing

The invention discloses a cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and a manufacture method thereof, and particularly relates to a combined or composite processing device capable of simultaneously carrying out milling or cutting processing and stirring friction welding processing and a method thereof. The cutting-stirring friction welding composite processing device for the floating double-shaft-shoulder double-stirring needle integrates a cutting system or a milling system, a stirring friction welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure induction system, a milling liquid supply system and a sensing-free system. The cutting-stirring friction welding composite processing device has functions of temperature control, gas protection, pressure detection, cooling liquid protection, milling head replacing and floating double-shaft-shoulder self-supporting stirring friction welding. The method for carrying out cutting-stirring friction welding composite processing on workpieces can meet strength requirements of mechanical processing of ferrous light metal materials, carbon steel materials and alloy steel materials. The cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and the manufacture method of the cutting-stirring friction welding composite processing device reduce manufacture procedures, save processing cost, have the advantages of being high in efficiency, excellent in quality, high in stability and saving in energy, break through limitation of conventional machining technology, form a new method and a new thought for machinery processing, and have wide application prospects in industries of heating, air conditioners, ice manufacture, freshness keeping, medicine preparation, construction, aquatic products and foods.

Owner:CHONGQING UNIV

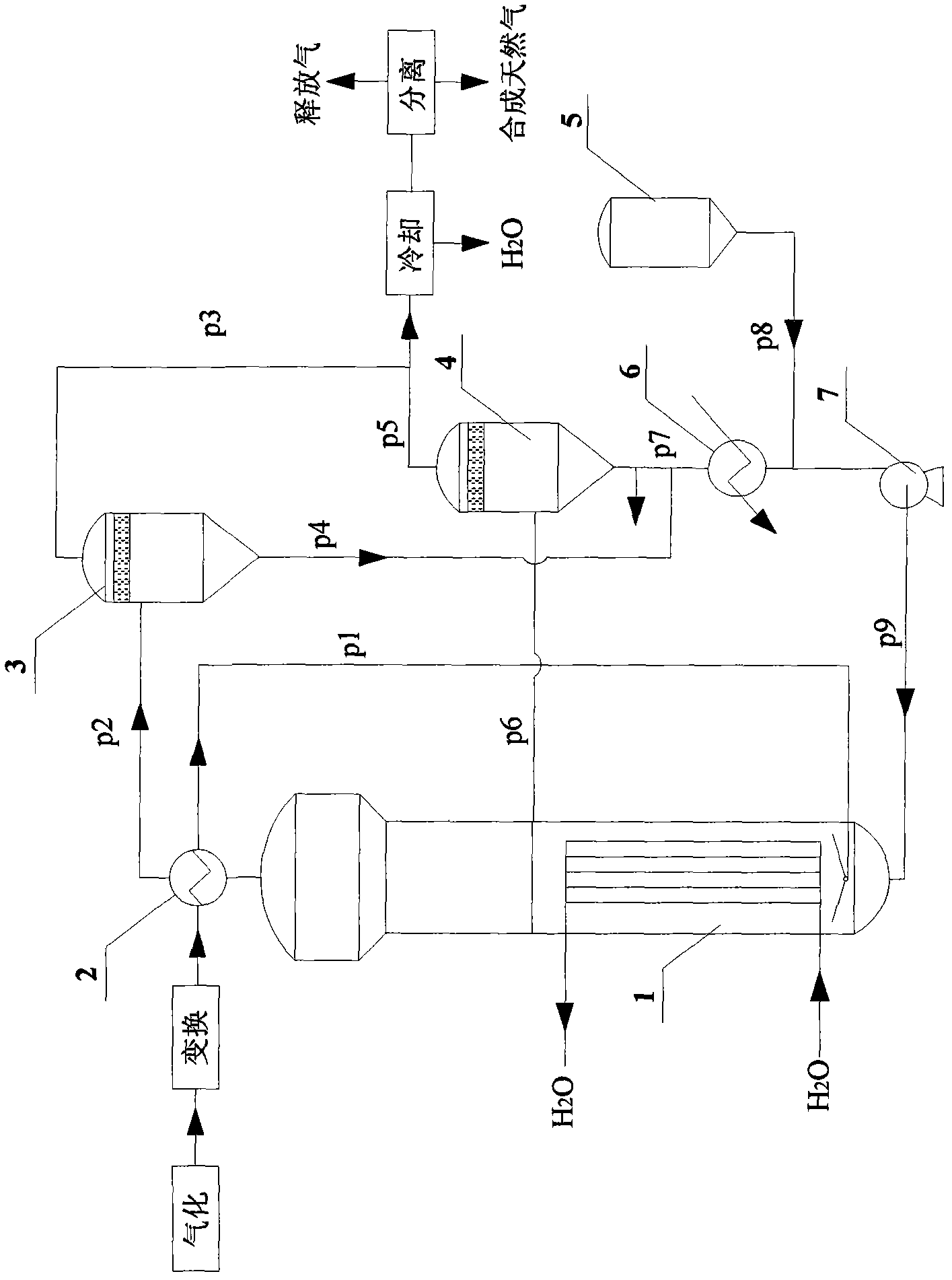

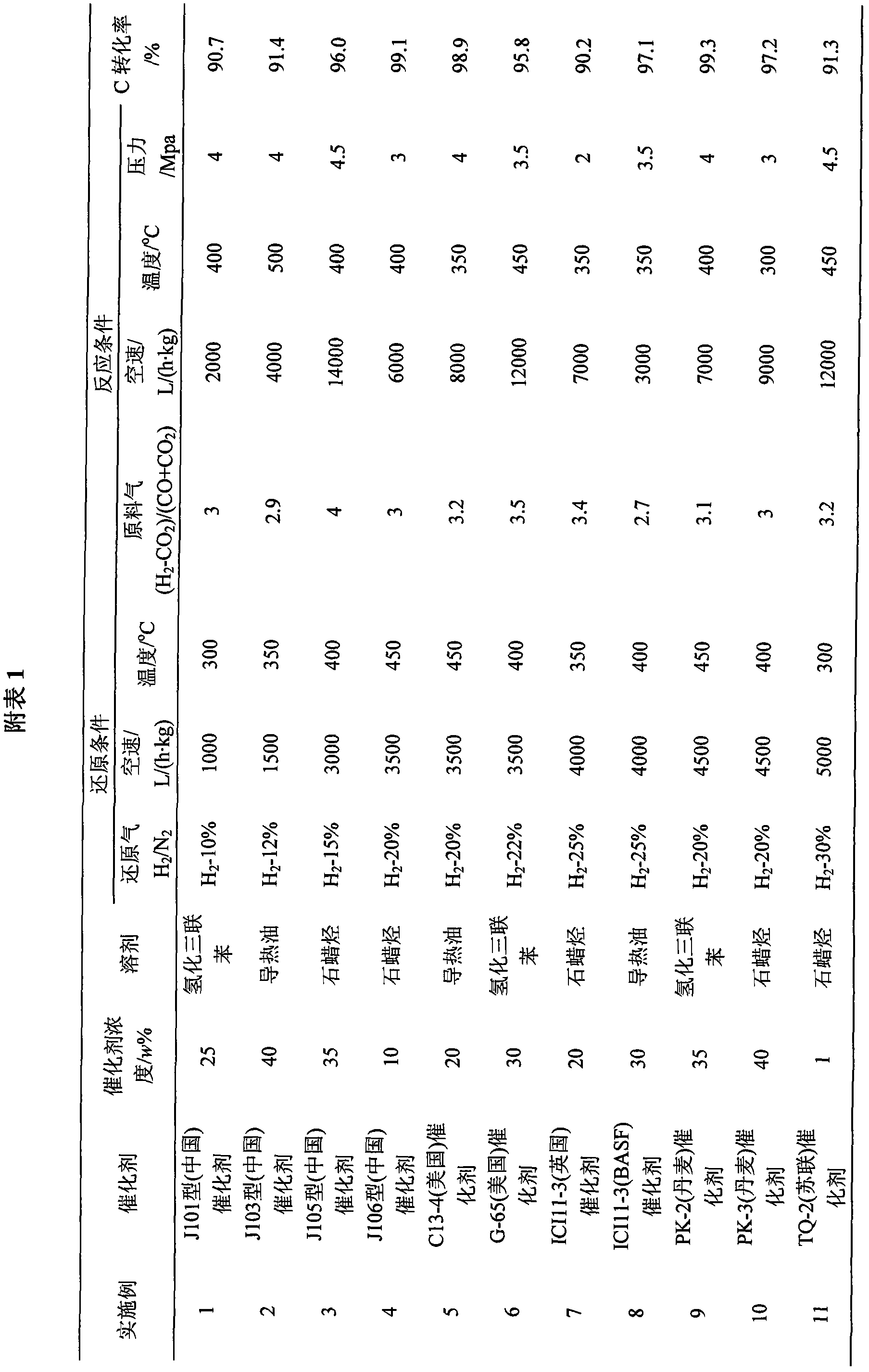

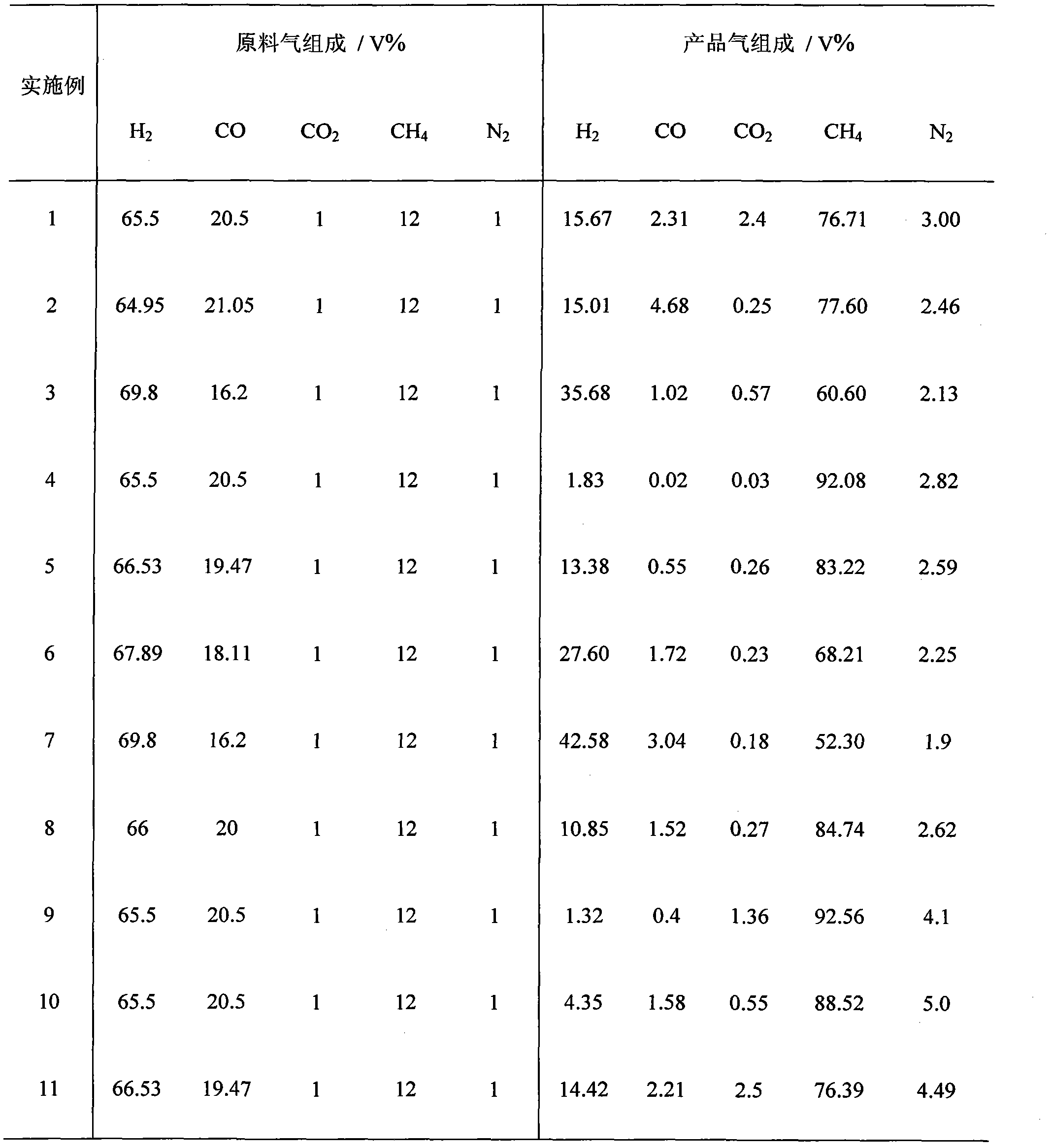

Process for synthesizing natural gas by methanation of coal synthesis gas

The invention discloses a process for synthesizing natural gas by methanation of coal synthesis gas, which comprises the following steps of: dispersing a fresh methanation catalyst into an inert liquid medium, delivering the medium into a slurry bed methanation reactor to perform reduction, performing methanation reaction on the transformed methanation raw gas after the reduction is finished, delivering the tail gas to a gas-liquid separator I, discharging the slurry liquid component and the catalyst in the tail gas from the bottom of the gas-liquid separator I, discharging the gas phase in the tail gas from the top of the gas-liquid separator I, delivering partial slurry liquid component containing the catalyst into a gas-liquid separator II, discharging the gas phase from the top of thegas-liquid separator II, merging the gas phases discharged from the tops of the gas-liquid separators I and II, cooling and purifying the gas phases to obtain synthesized natural gas, discharging theslurry liquid component containing the catalyst from the bottom of the gas-liquid separator II, merging the slurry liquid component discharged from the bottom of the gas-liquid separator II and the slurry liquid component and the catalyst discharged from the bottom of the gas-liquid separator I, discharging 1 to 5 percent of the weight sum of the slurry liquid component and the catalyst separatedfrom the two gas-liquid separators, and performing methanation reaction on the cooled rest slurry liquid component and catalyst and the fresh methanation catalyst dispersed into the insert liquid medium together. The process has the advantages of low power consumption and low equipment investment, and is easy to operate.

Owner:SEDIN ENG +1

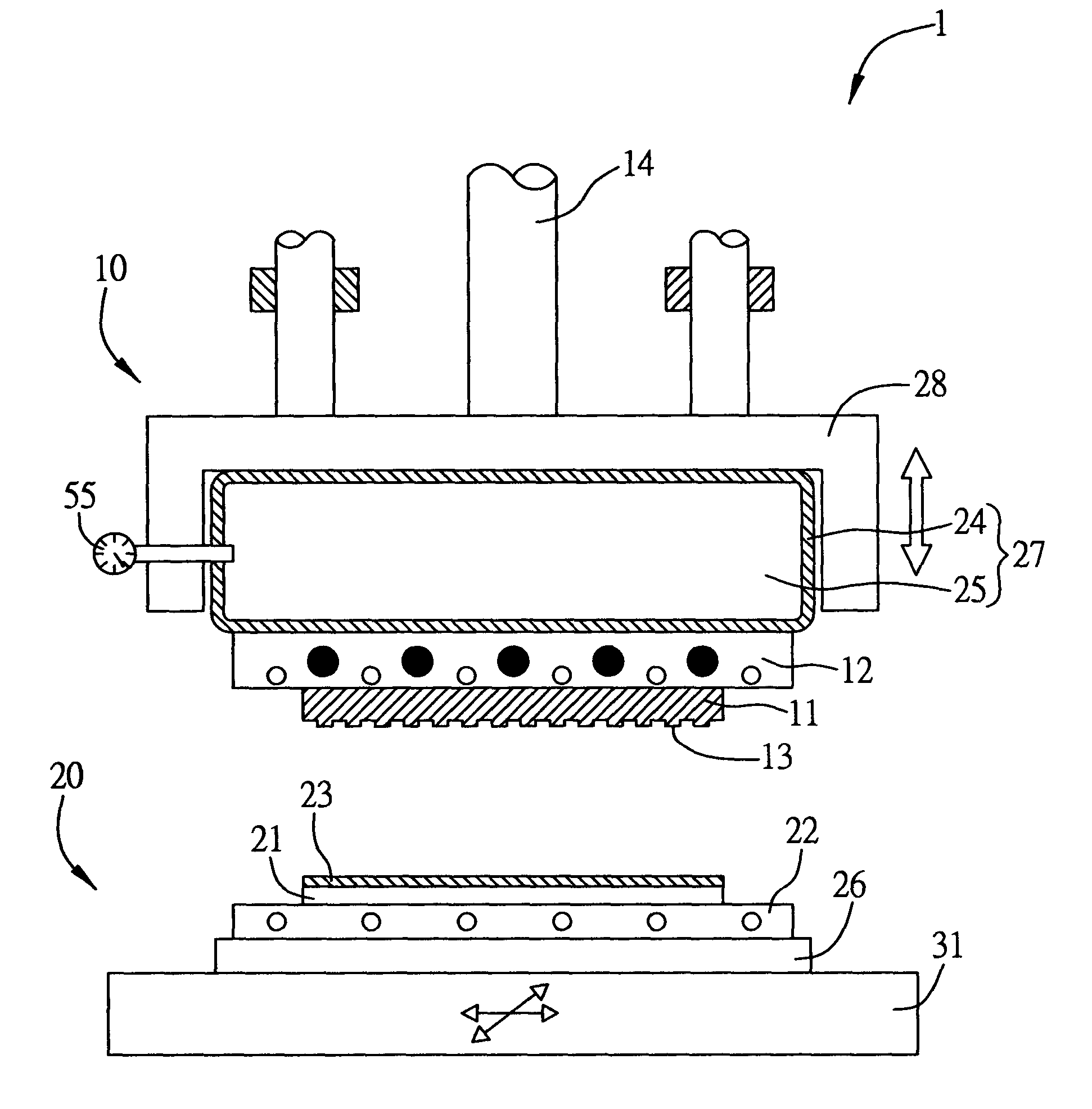

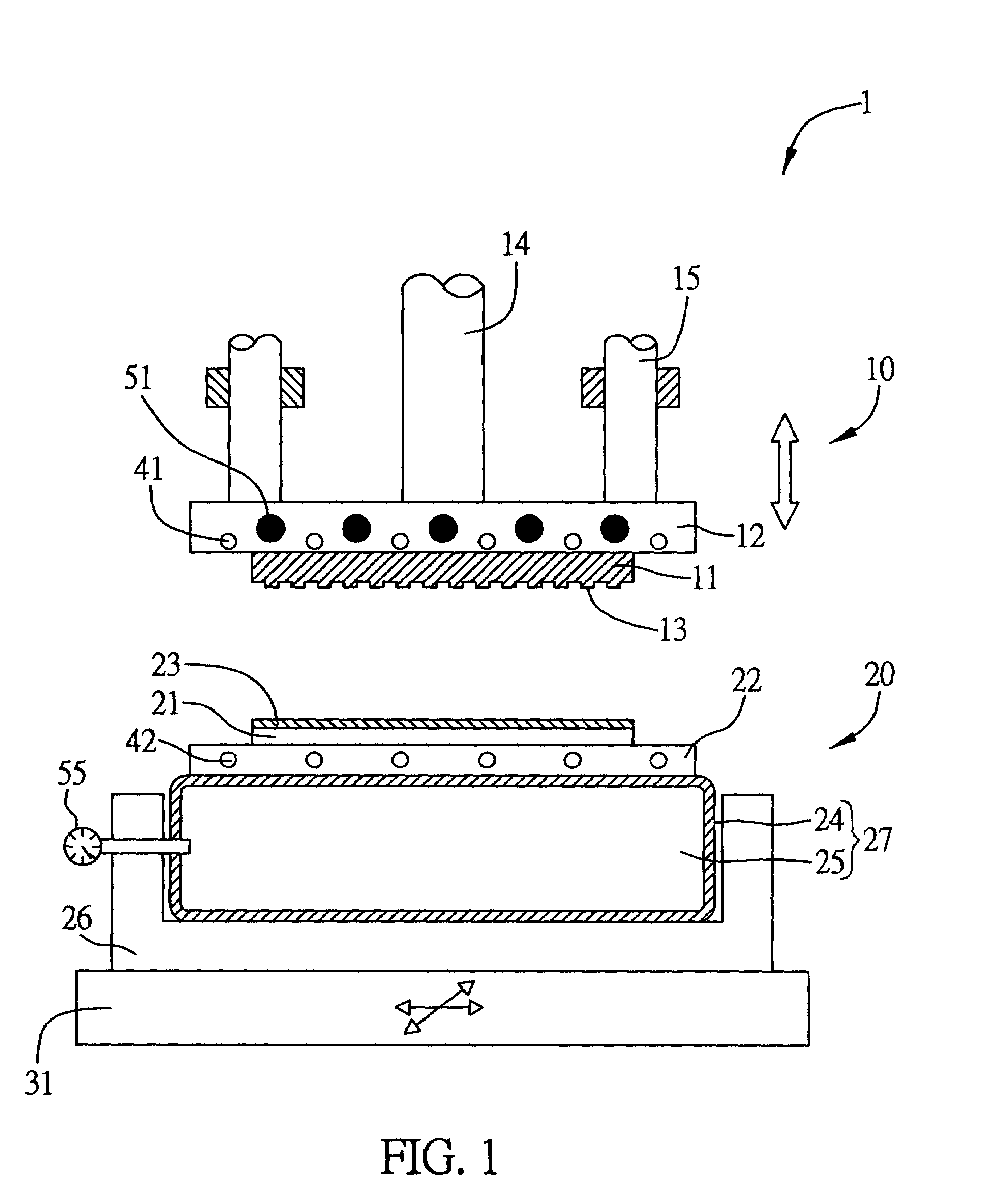

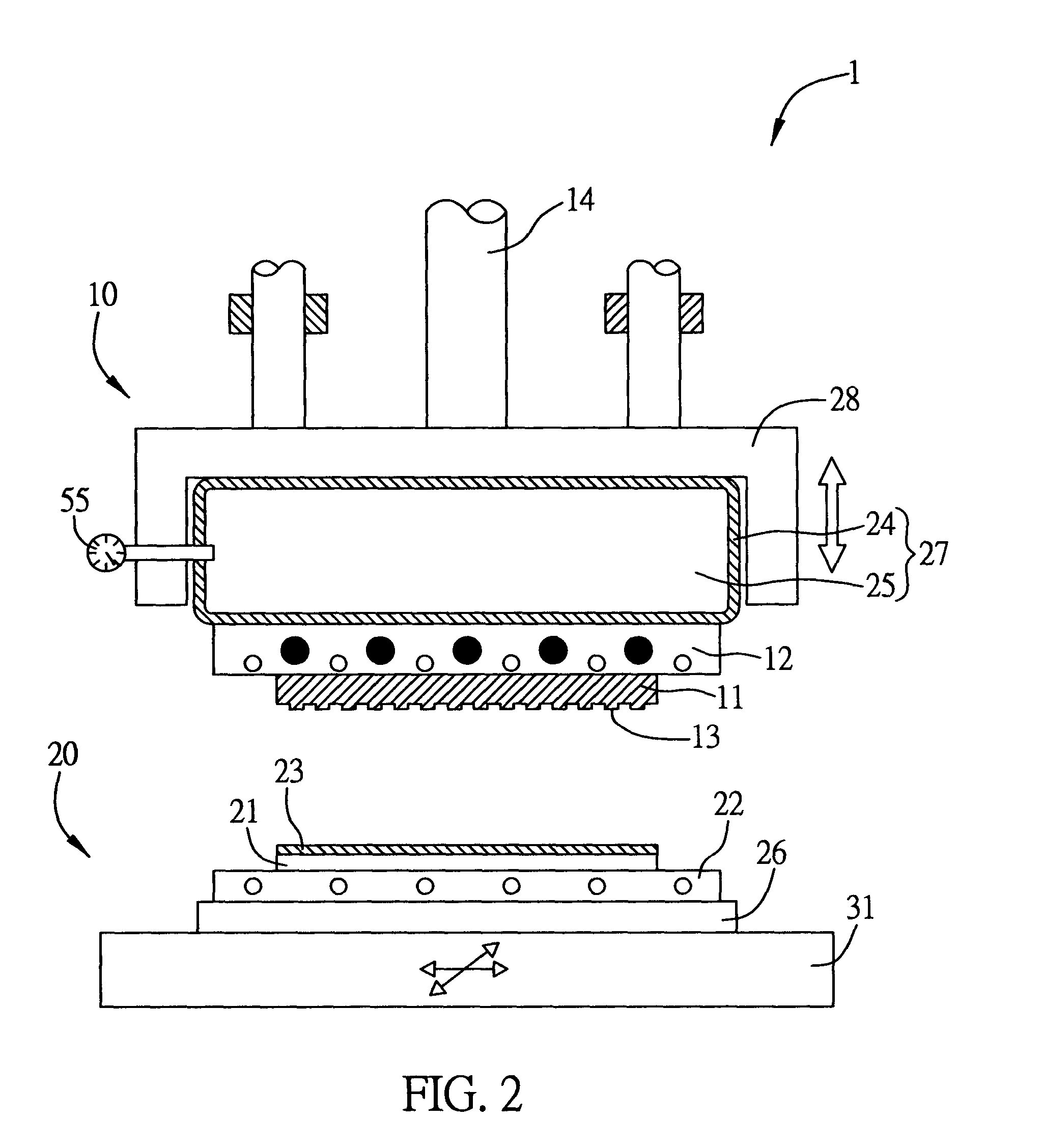

Parallelism adjustment device

InactiveUS7204686B2Enhance horizontal alignmentHigh level of freedomNanoinformaticsConfectioneryNanoimprint lithographyElectrical and Electronics engineering

A parallelism adjustment device applicable to nano-imprint lithography has an imprint unit, a carrier unit, a parallelism adjustment mechanism, and a driving source. The imprint unit has a first molding plate and an imprinting mold mounted on the first molding plate. The carrier unit has a second molding plate and a substrate mounted on the second molding plate. The parallelism adjustment mechanism has an enclosed resilient film and a fluid filled therein, and is coupled to at least one of the first and second molding plates. The driving source drives at least one of the imprint unit and the carrier unit to form contact between the mold and the moldable layer. The parallelism adjustment device is pressed via the contact to adjust parallelism for the imprint mold and the substrate and uniformly distributes the pressure between the mold and the substrate, making the molding quality of nano-imprint lithography significantly improved.

Owner:IND TECH RES INST

Natural cooling-making soap and low-temperature soap-making process

InactiveCN101649262AIncreased sensitivitySolve the problem of not moisturizingAlkali/ammonium soap compositionsAqueous sodium hydroxideDistilled water

The invention relates to a low-temperature soap-making process of natural cooling-making soap, which belongs to a washing article and a making process thereof. The cooling-making soap is made of the following raw materials in proportion by weight at low temperature: 20-28 distilled water, 60-71 base grease, 6-12 sodium hydroxide, essential oil accounting for 0.5-1.5 percent of the total weight ofthe distilled water, the base grease and the sodium hydroxide, and Chinese medicine accounting for 1.5-2.5 percent of the total weight of the distilled water, the base grease and the sodium hydroxide.The making process comprises the following steps: firstly, weighing the raw materials; secondly, adding the sodium hydroxide into the distilled water; thirdly, adding the base grease into a stainlesscontainer, heating by separating from water; fourthly, after reducing the temperature of the sodium hydroxide solution and the base grease solution, slowly pouring the sodium hydroxide solution intothe base grease solution, and completely stirring uniformly; fifthly, adding the essential oil and the powder of the Chinese medicine, and stirring uniformly; sixthly, pouring the liquid mixture intoa mould, demoulding, and standing thus obtaining the soap. The invention solves the problem of poor washing effect of the washing soap produced by the prior art.

Owner:王硕

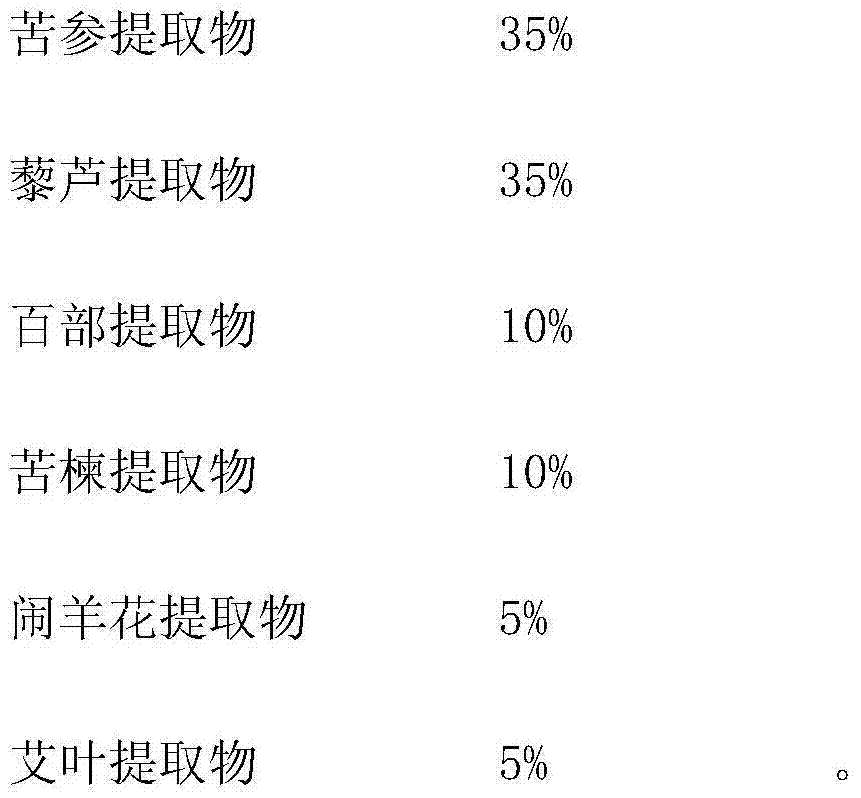

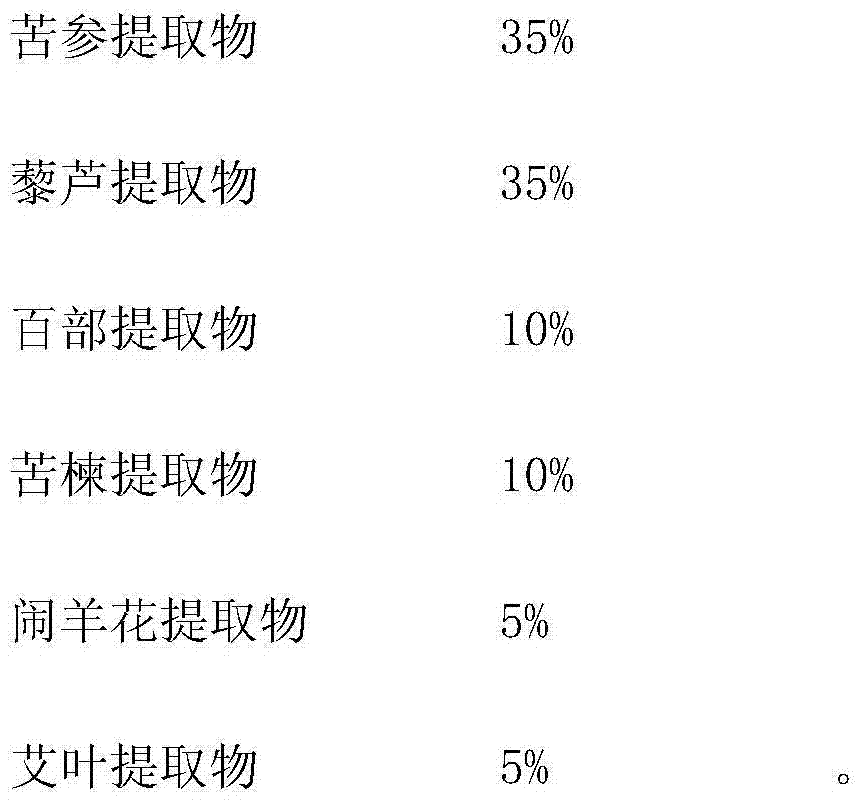

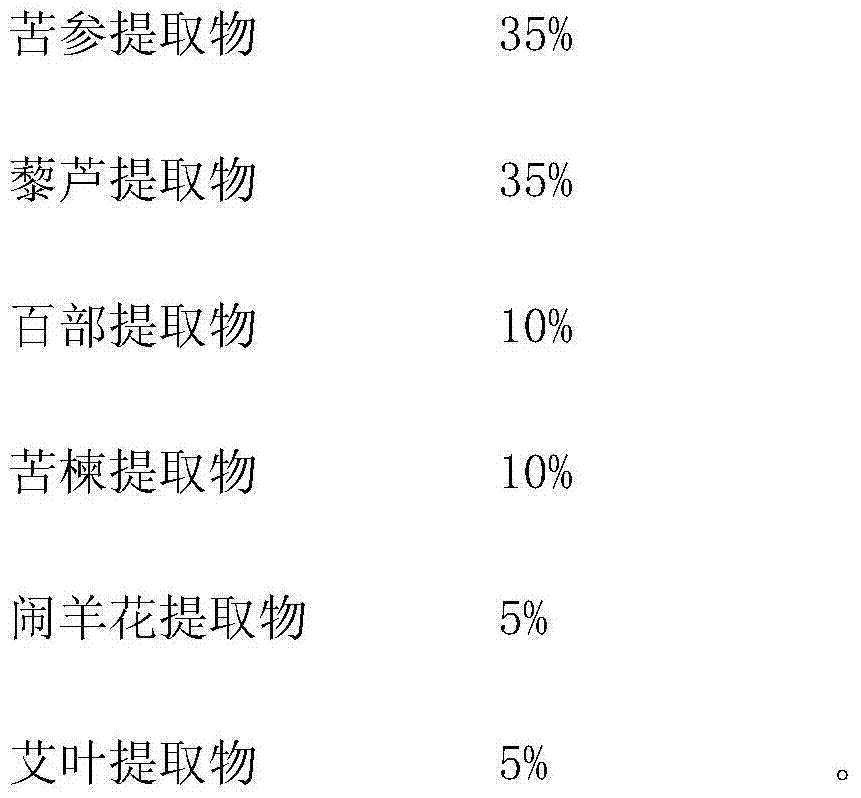

Composite plant source pesticide and preparation method thereof

The invention relates to a composite plant source pesticide, which is characterized by including a mother liquid and an additive. The mother liquor comprises the following raw materials by weight: 35% of a Sophora flavescens extract, 35% of a resveratrol extract, 10% of a radix stemonae extract, 10% of a Melia azedarach extract, 5% of a Chinese azalea flower extract and 5% of a folium artemisiae argyi extract. A preparation method provided by the invention comprises the steps of: weighing the Sophora flavescens, resveratrol, radix stemonae, tobacco, Melia azedarach and folium artemisiae argyi according to the proportion; conducting screening, boiling extraction and purification to prepare an extract containing active ingredients of each component; and then mixing the mother liquor and the additive to obtain the product. Through various tests, the product has no adverse excitant smell, no drug residue, no damage to human, livestock, agricultural products, air and soil, has insecticidal and antimicrobial effects, and is suitable for usage in field, greenhouse, nursery, golf course, tea garden and forestry greening.

Owner:天津市嘉禾兴农生物科技发展有限公司

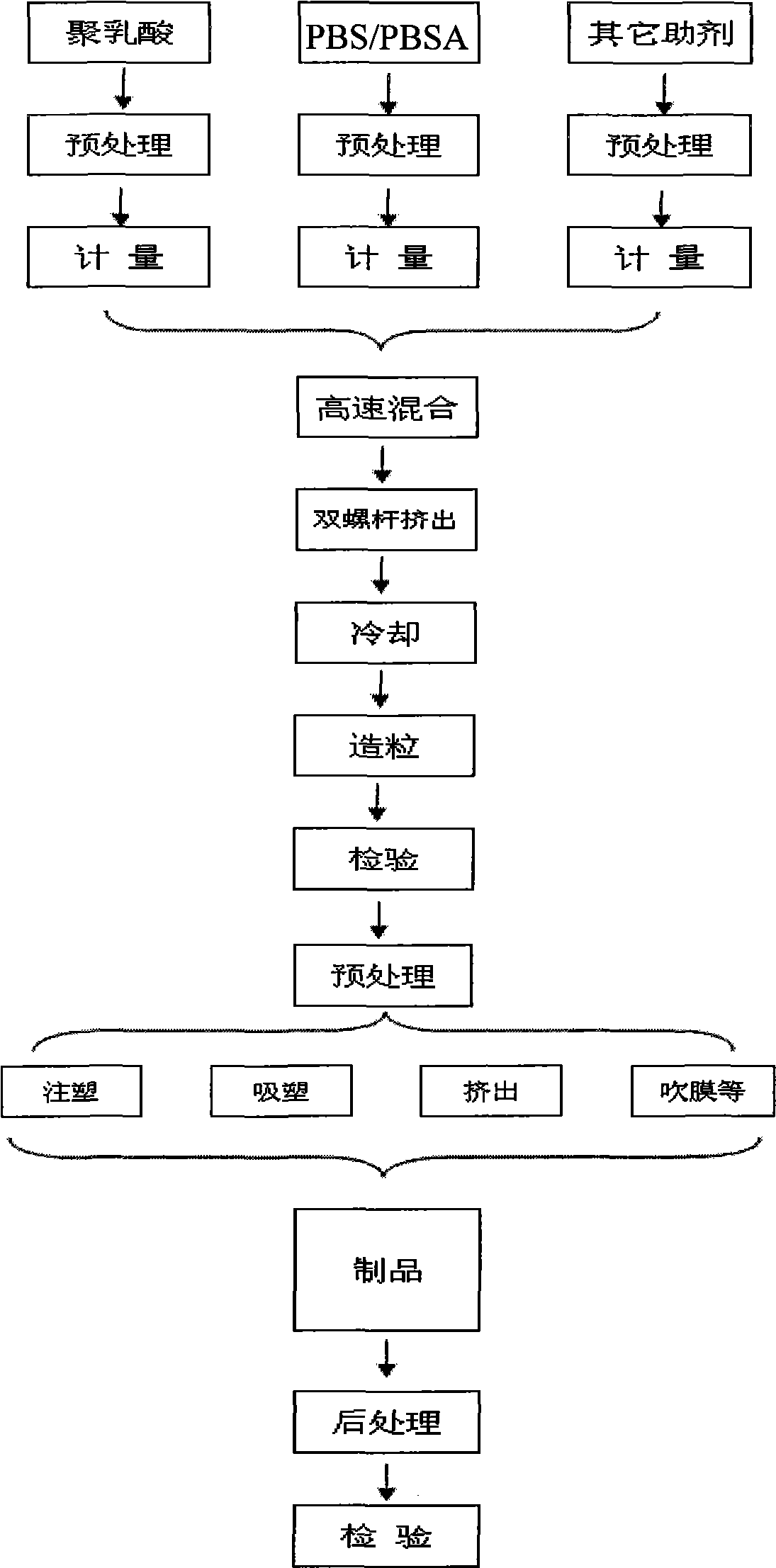

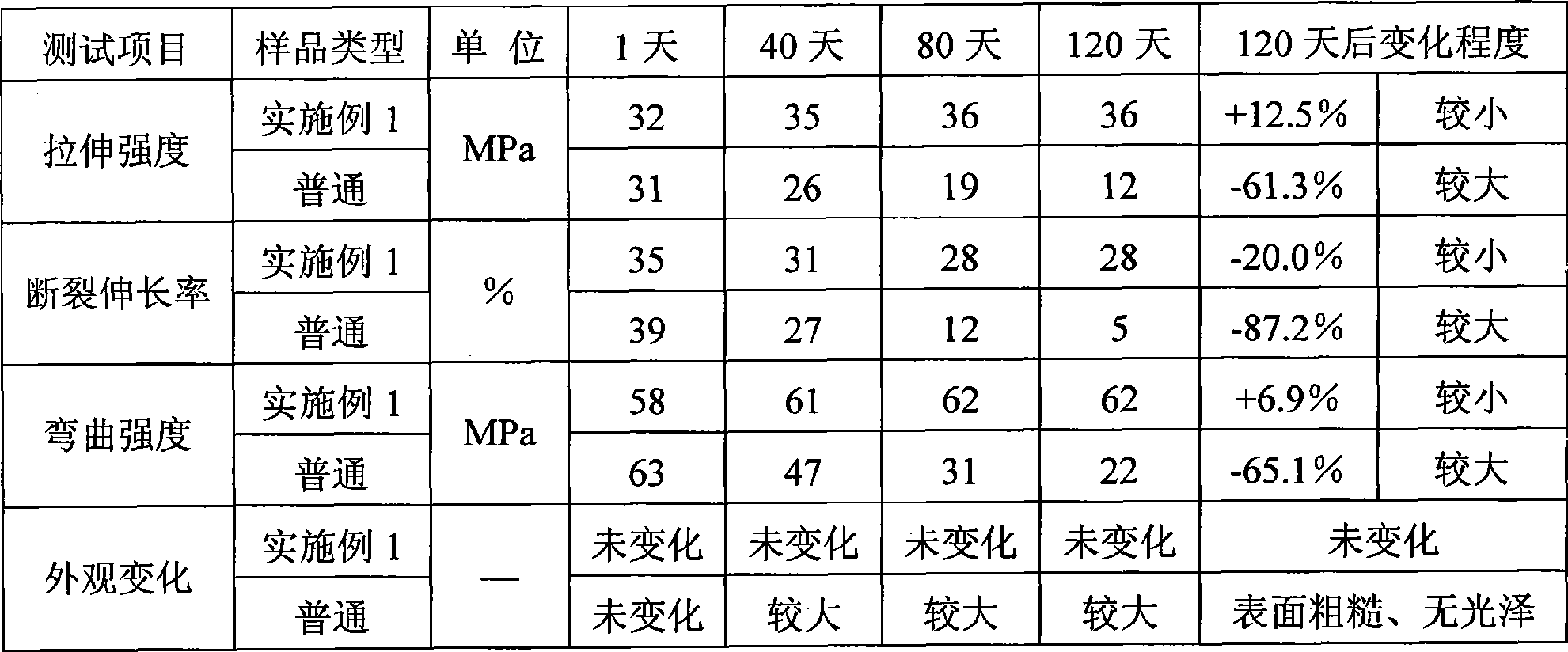

Material capable of completely biodegrading and preparation method thereof

The invention relates to a material capable of completely biodegrading, containing the following parts by weight:100 of polyester resin, 5-100 of polylactic resin and the multipolymer thereof, 10-80 of compounding converted starch, 10-60 of inorganic fillers and 0.1-0.9 of resin acceptor, wherein the polyester resin is at least one of polybutylene succinate resin, polybutylene adipate resin and the multipolymer thereof. The invention also provides a preparation method of the material. The material capable of completely biodegrading can combine the advantages of each component and has high intensity, modules, elongation at break and toughness, good heat resistance, and the like, thereby meeting the property requirements of a plurality of plastic products in the market and in particular products, such as non-returnable containers, mess kits, agricultural films, and the like, which cause serious white pollution, retaining the complete biodegradability of the material and reducing the production cost under the precondition of no influence on the property requirement.

Owner:深圳市未名北科环境材料有限公司 +1

Water high light wearable intaglio ink and preparing method thereof

The invention relates to a water-base printing ink and its producing method, especially water-base high light friction resistance gravure oil and the producing method thereof. The oil is suitable for packing print in the soft packing field such as food, drink, medicine, health products, chemicals and etc. The water-base high light friction resistance gravure oil is composed of acrylic resin, acrylic emulsion, dye, ethanol, built-up agent, dispersant, deionized water, water-base emulsifying wax, antifoamer, leveling agent. The inventive product completely meets the requirement of the gravure oil, has a reliable quality and can replace the solvent gravure oil, which can be dilute by the tap water of ethanol. The printing device can be washed directly by the tap water. The product has a high concentration, a low viscosity, a good printing adaptability has no harm to the environment and human body. The presswork has a clear pattern, a bright color, a powerful attached fastness, a good water resistance and friction resistance, has no harmful residue after drying and is not easy to fade and shed.

Owner:浙江永在油墨有限公司

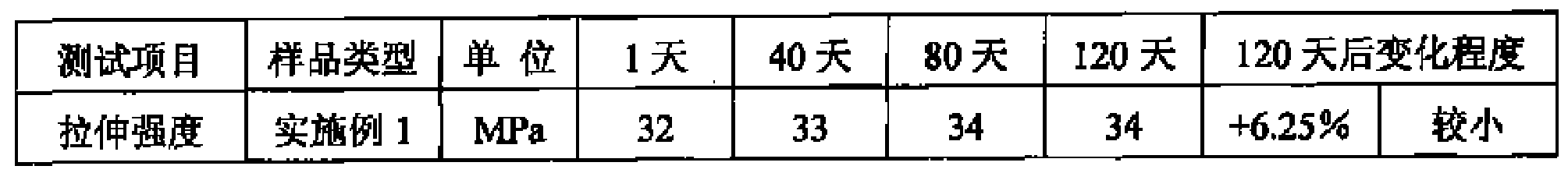

Medical mask

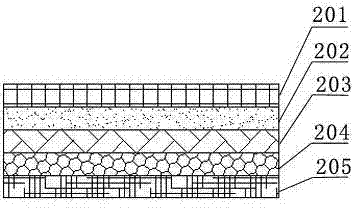

InactiveCN103393239AOvercome the problem of hurting the skinEasy to adjustProtective garmentFiberRespirator

The invention discloses a medical mask which comprises a mask body and ear hanging lines. The ear hanging lines are arranged at two opposite side edges of the mask body, the mask body sequentially comprises a gauze layer, a moisture absorption layer, an antibacterial fiber cloth layer, a filter layer and a cotton cloth layer from inside to outside, the gauze layer, the moisture absorption layer, the antibacterial fiber cloth layer, the filter layer and the cotton cloth layer are connected with one another, a flexible iron wire is penetratingly arranged at the upper edge of the middle of the mask body, and a cotton cloth strip is sleeved on each ear hanging line. The medical mask has the advantages that the mask body comprises five layer structures and is good in breathability and moisture absorption, and dust and bacteria in air can be filtered; the medical mask is comfortable to wear, injury to the skin of a human body or the soft tissues of the ears of the human body can be prevented, the medical mask can fit with the face of the human body in a seamless manner, and accordingly harmful substances in the air can be effectively prevented from being inhaled into the human body; the flexible iron wire can be folded to form a shape which is matched with the nose bridge of the human body, so that gas exhaled by the human body can be prevented from being upwardly sprayed to spectacle lenses to cause the problem of blurring of the spectacle lenses.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

High-temperature-resistant polymer thickening agent for oil field fracturing fluid as well as preparation method and application of thickening agent

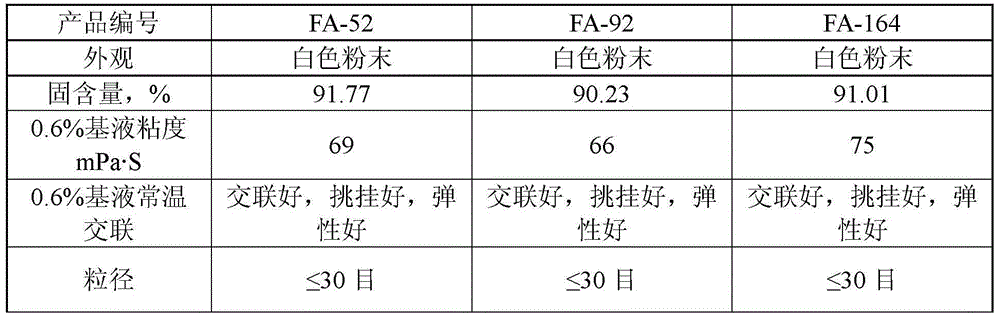

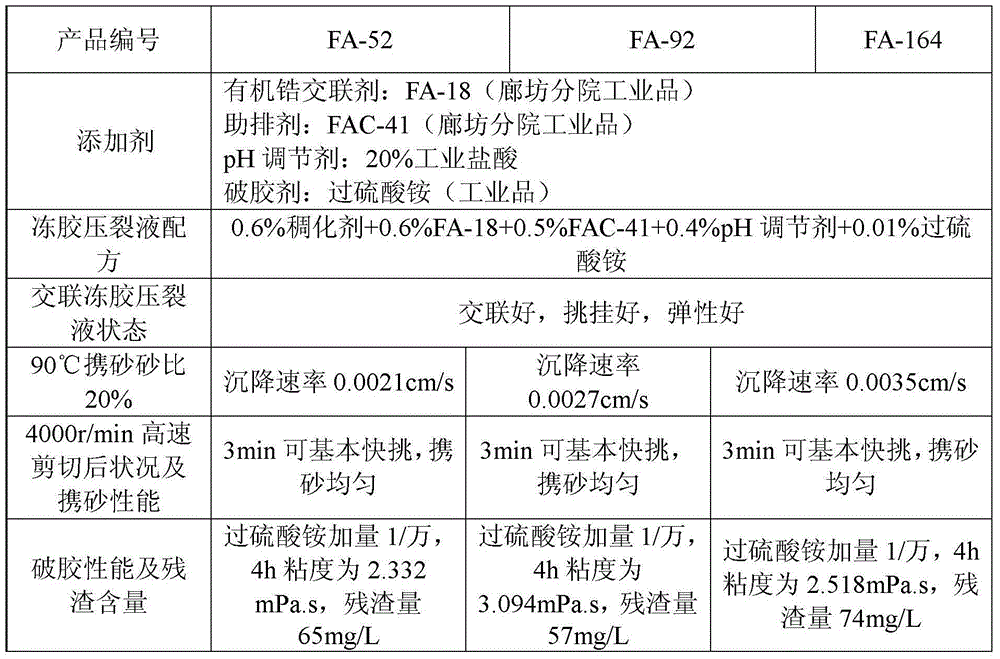

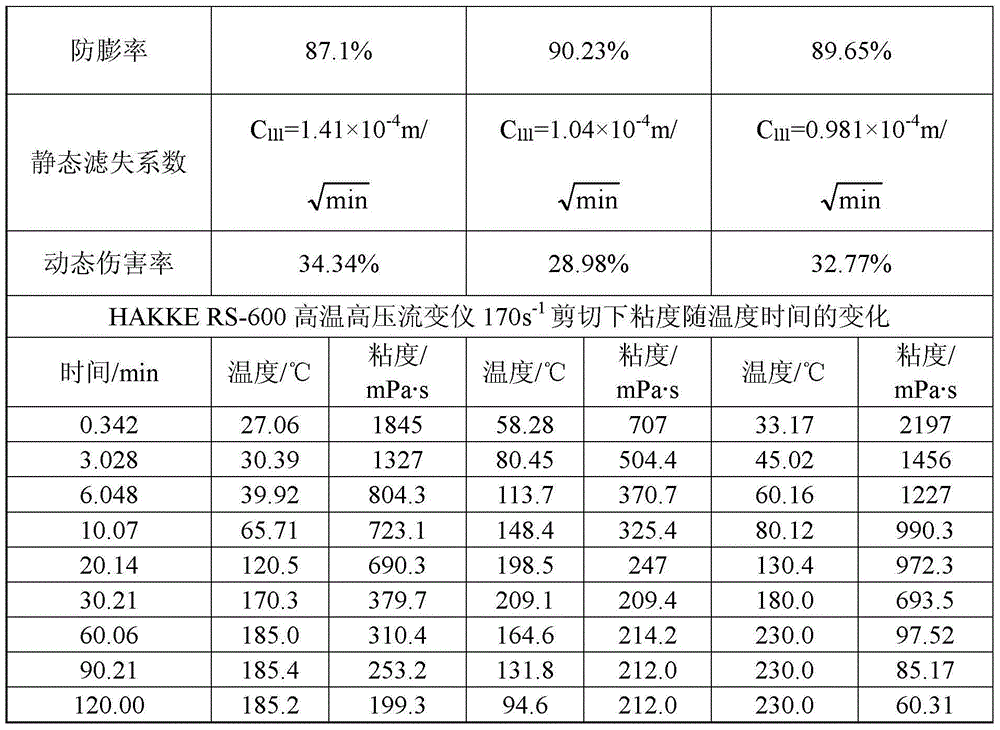

ActiveCN104449643AGood elasticityStrong ability to carry sandDrilling compositionSalt resistanceCarrying capacity

The invention discloses a high-temperature-resistant polymer thickening agent for an oil field fracturing fluid as well as a preparation method and application of the thickening agent. The preparation method of the thickening agent comprises the following step: polymerizing acrylamide, other olefin monomers, an initiating agent and a chain transfer agent in an aqueous solution by virtue of a solution process, wherein the weight ratio of acrylamide to the other olefin monomers to water is (10-20):(6-18):(62-84); and the other olefin monomers are selected from one or more, preferably two or three, of anionic olefin monomers, cationic olefin monomers or non-ionic olefin monomers. According to the high-temperature-resistant polymer thickening agent disclosed by the invention, free radicals are generated by using an aqueous solution catalyst process so as to ensure that the monomers are subjected to ternary polymerization or quaternary polymerization to form the anionic high molecular polyacrylamide polymer with the molecular weight of 4,000,000-8,500,000. After the thickening agent is crosslinked with a crosslinking agent, the thickening agent can be used for tolerating high temperature of more than 210 DEG C, and has the advantages of good crosslinked gel elasticity, strong sand carrying capacity, anti-shearing performance, salt resistance, no residues and the like.

Owner:PETROCHINA CO LTD

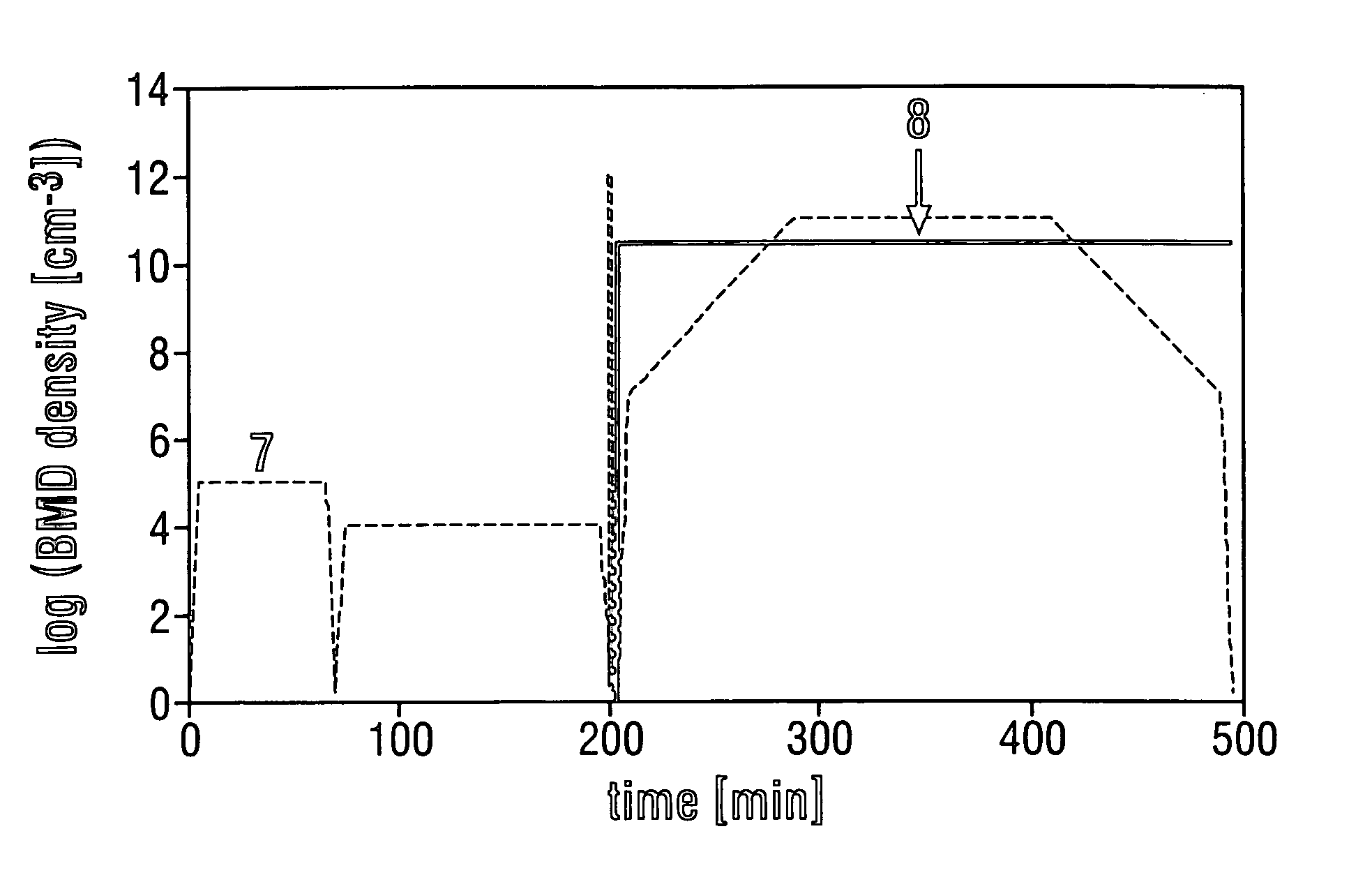

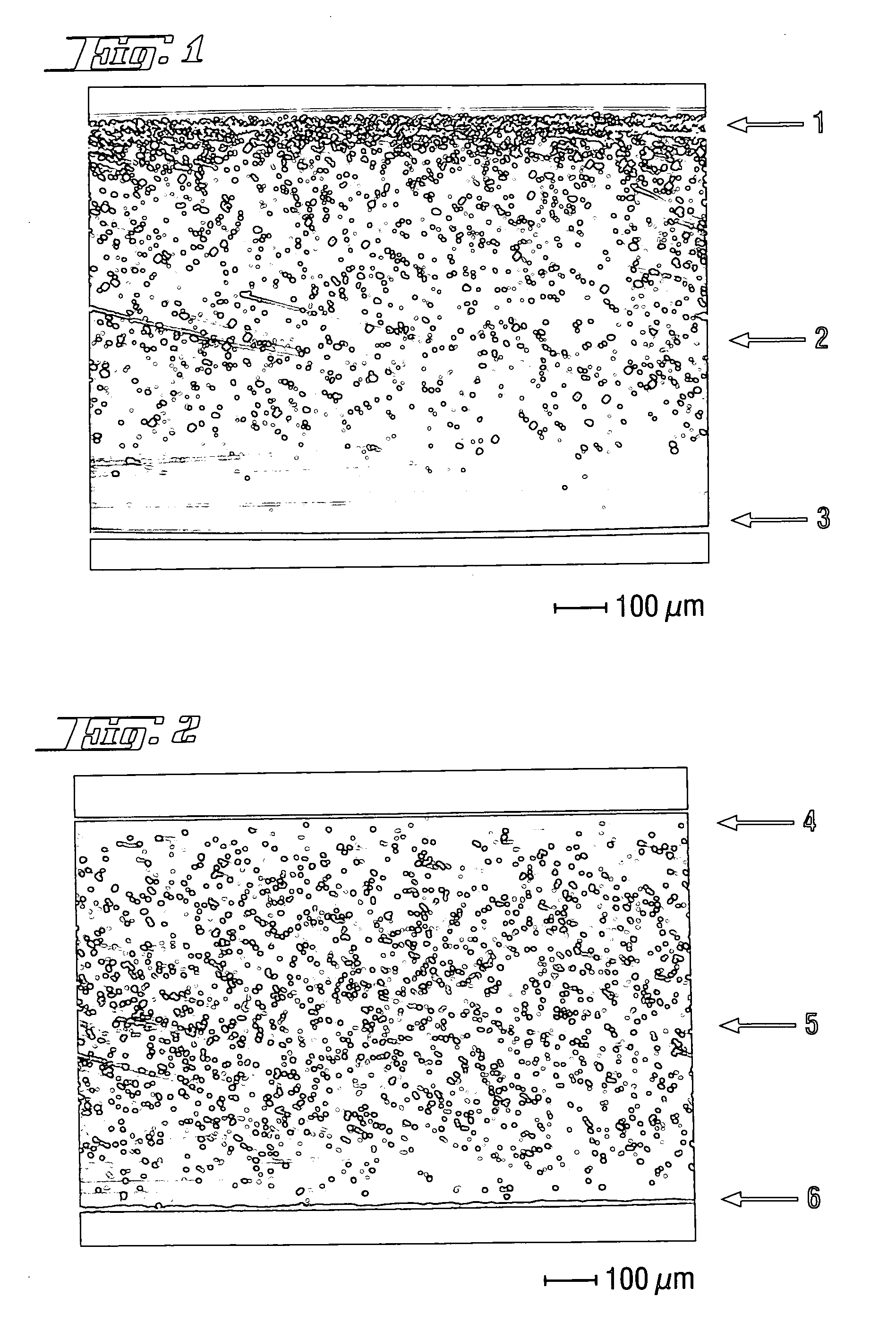

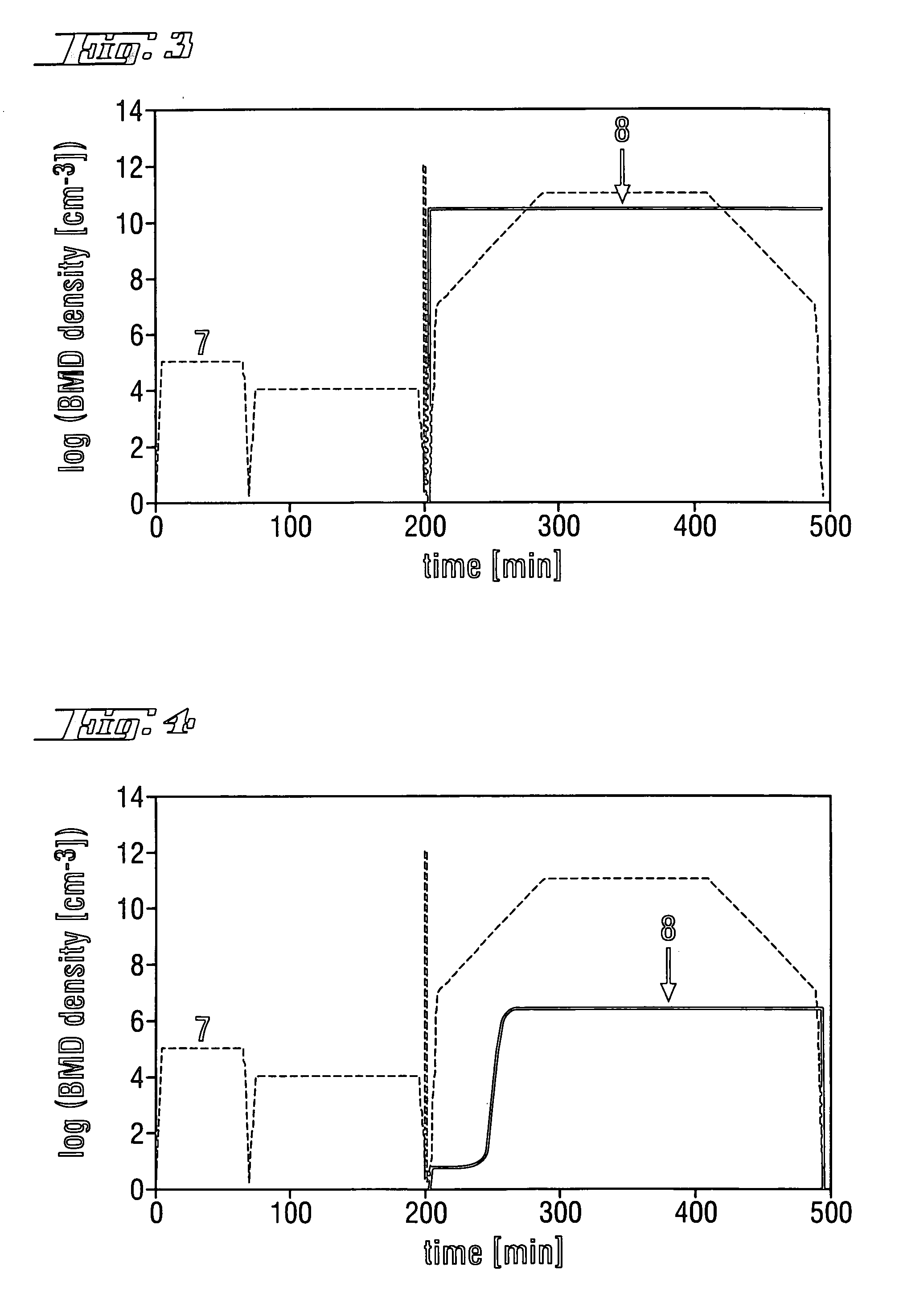

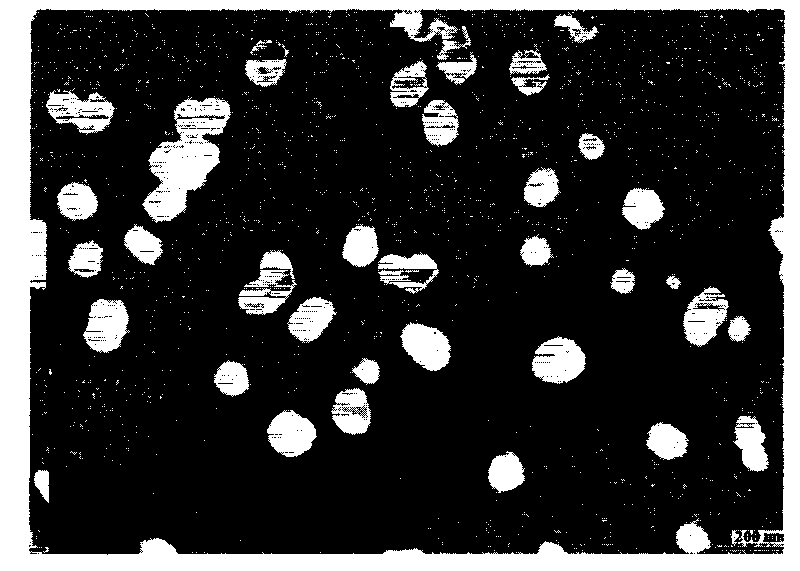

Layered semiconductor wafer with low warp and bow, and process for producing it

InactiveUS20060046431A1Easy to implementNo harmful side effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSilicon

Semiconductor wafers with a diameter of at least 200 mm comprise a silicon carrier wafer, an electrically insulating layer and a semiconductor layer located thereon, the semiconductor wafer having been produced by means of a layer transfer process comprising at least one RTA step, wherein the semiconductor wafer has a warp of less than 30 μm, a DeltaWarp of less than 30 μm, a bow of less than 10 μm and a DeltaBow of less than 10 μm. Processes for the production of a semiconductor wafer of this type require specific heat treatment regimens.

Owner:SILTRONIC AG

Method for preparing nano hydroxyapatite powder

InactiveCN101734635ANo pollution in the processNo harmNanostructure manufacturePhosphorus compoundsWater bathsPolyethylene glycol

The invention relates to a method for preparing nano hydroxyapatite powder, belonging to the field of the biomedical material. The method for preparing the nano hydroxyapatite powder comprises the following steps: adding the organic polymer of polyethylene glycol to the initial reactants of calcium nitrate and diammonium phosphate solution to adjust and control the morphologies of the products of reaction; adding aqueous ammonia to adjust the pH values of the products of reaction, and making the aqueous ammonia react with the products of reaction at different water bath temperature to synthesize nano hydroxyapatite precipitate, wherein the agglomeration of the synthesized nano hydroxyapatite precipitate can be inhibited by the polyethylene glycol functioning as the dispersant; freezing and drying synthesized nano hydroxyapatite precipitate slurry to obtain dry nano hydroxyapatite powder which contains by-products of reaction and polyethylene glycol, and calcinating the dry nano hydroxyapatite powder at high temperature to remove the by-products of reaction and the polyethylene glycol which are contained in the dry nano hydroxyapatite powder to obtain the nano hydroxyapatite powder which is in the shape of the ball or the rod and in the particle size of 10-100 nm and has high yield and good dispersion. The method for preparing the nano hydroxyapatite powder is simple, needs short preparing period, causes no poison and pollution and is suitable for industrial production.

Owner:SICHUAN UNIV

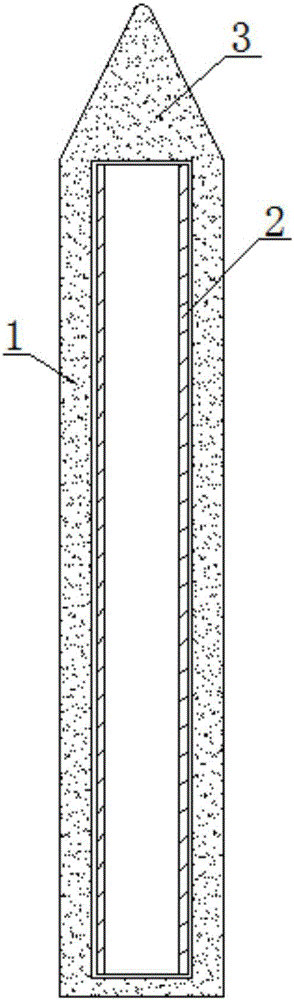

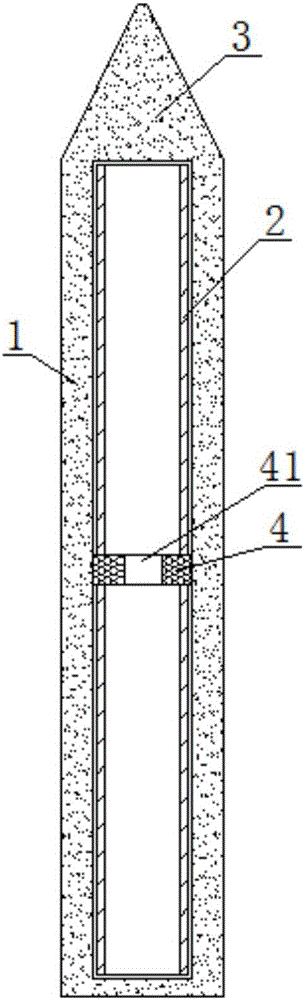

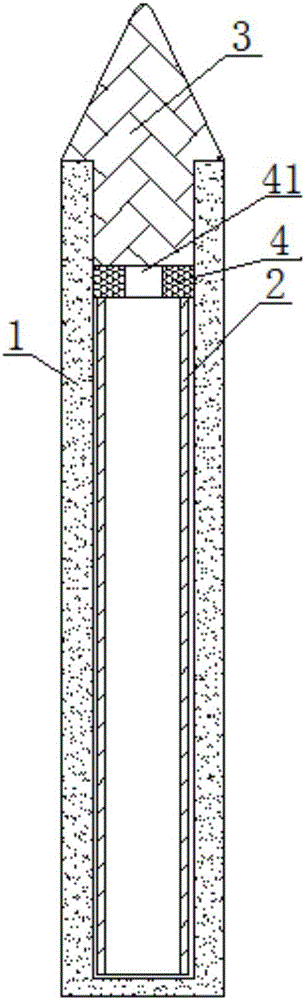

Heating body and curing object matched with heating body, electronic cigarette atomizer and electronic cigarette

PendingCN106617325AImprove yield rateAchieve atomizationTobacco devicesEngineeringAlternating current

The invention discloses a heating body and a curing object matched with the heating body, an electronic cigarette atomizer and an electronic cigarette. The heating body comprises a glass sleeve and multiple sections of metals which are embedded in the glass sleeve and are capable of generating magnetic induction intensity, a conical body in which the curing object is pierced is arranged at the front end of the glass sleeve; isolating layers for controlling various sections to generate heat independently are arranged between the adjacent metals; and pressure discharge holes are formed in the isolating layers. According to the invention, by conducting self-heating in a mode of electromagnetic induction heating and by generating high-frequency induction current for alternating current through DC conversion, the metals become heated to cure tobacco shreds, so that flavors and fragrances as well as fragrance compounds in the tobacco shreds are volatilized and atomized; by virtue of the glass sleeve, stuffing is prevented from getting oxidized or contaminated by the metals and staged heating is facilitated, so that a heating rate is uniform, curing is conducted fully, a heating rate is moderate and the cured tobacco shreds are pure in fragrance; and in addition, a sachet can be pierced to add relative aromatizing and atomizing aids.

Owner:湖南酷伯新晶电子科技有限公司

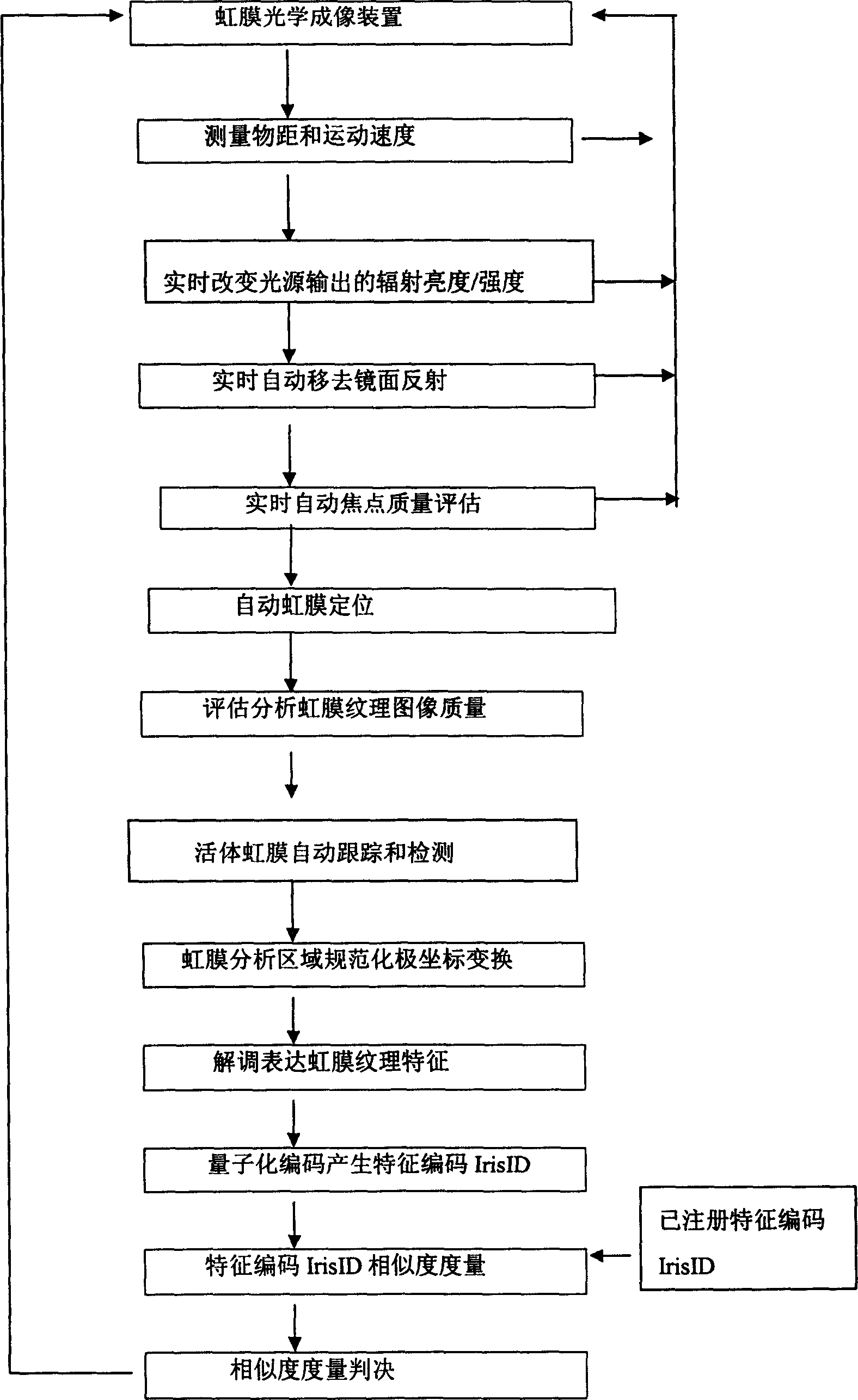

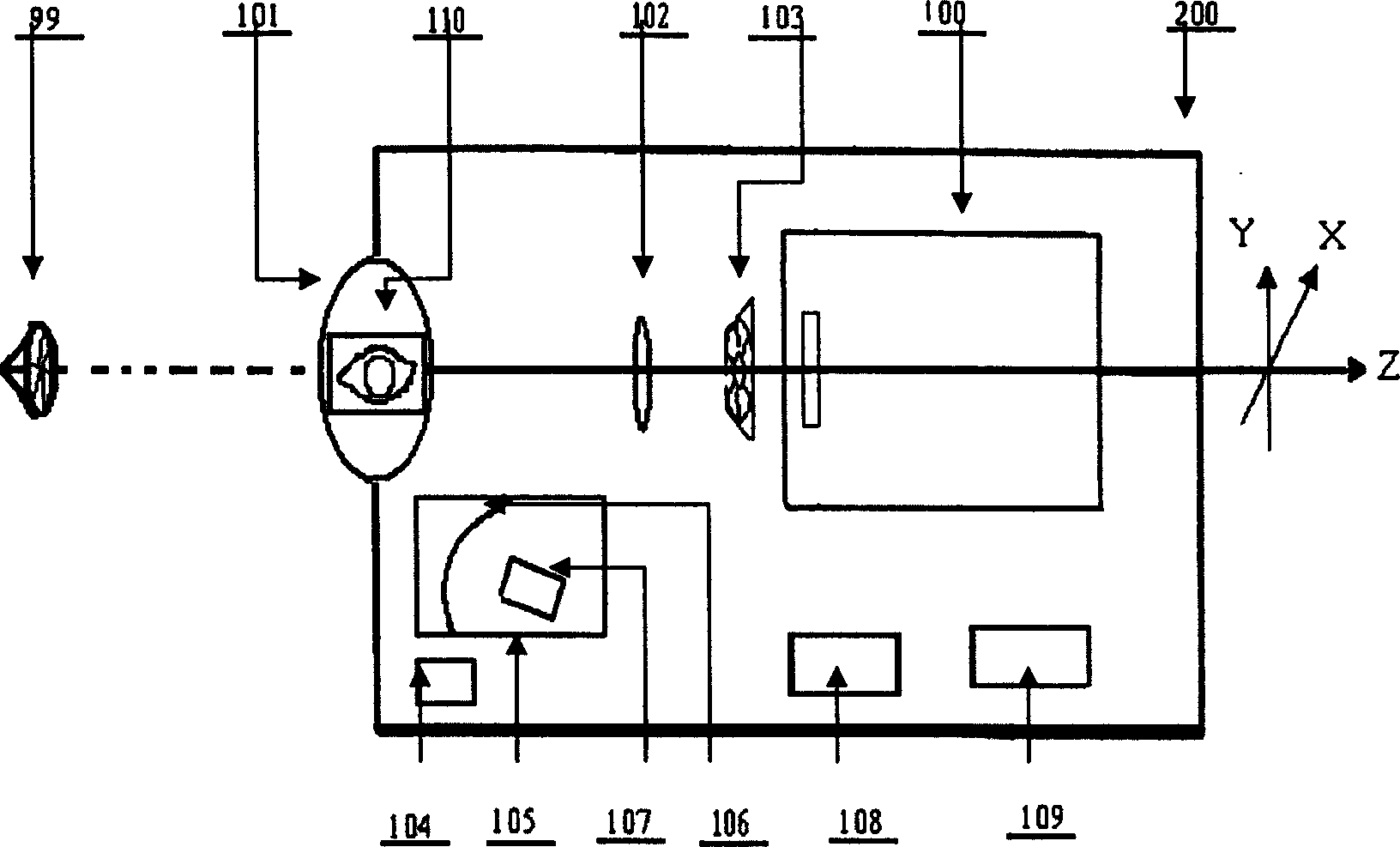

Bioassay system based on iris texture analysis

ActiveCN1623506AImprove qualityAvoid positioning failurePerson identificationCharacter and pattern recognitionImaging conditionNon invasive

The invention is a biometric system based on iris texture analysis, which overcomes the defects in the prior art that lack the support of iris image quality analysis mechanism and cannot complete the evaluation of iris texture image quality. The invention acquires iris texture images, automatically locates iris, evaluates and analyzes the quality of iris texture images, automatically tracks and detects living iris, standardizes polar coordinate transformation of iris analysis area, demodulates and expresses iris texture features, and generates feature code IrisID by quantization coding. Encoding IrisID similarity measurement, similarity measurement judgment and other steps are realized. The invention realizes the basic characteristic requirements of an ideal system: automaticity, non-invasiveness, friendly man-machine operation interface and high-quality imaging image; no correlation between geometric affine transformation and nonlinear affine deformation; no dependence on external imaging conditions ; Random probability distribution coding; High-precision false acceptance rate and false rejection rate performance.

Owner:SUZHOU SIYUAN KEAN INFORMATION TECH

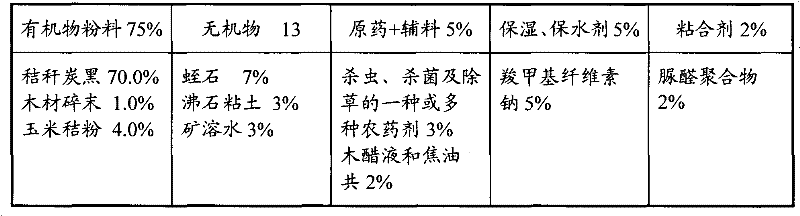

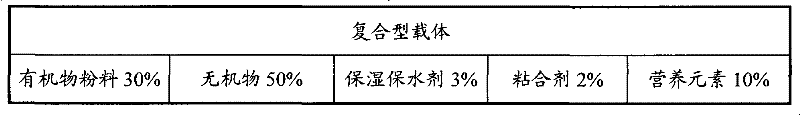

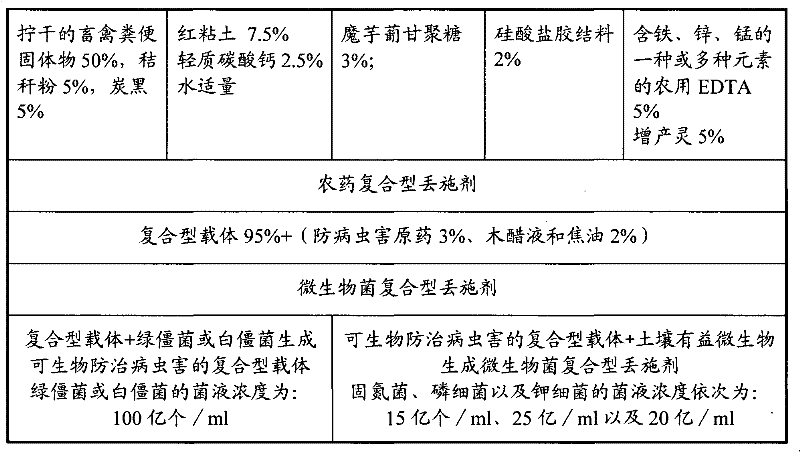

Throwing applying agent and preparation method thereof

ActiveCN102344309AEfficient use ofImprove utilization efficiencyBiocideAnimal repellantsDiseaseAdhesive

The invention discloses a composite throwing applying agent and a preparation method thereof, and the throwing applying agent comprises the following components by weight: 35-90% of composite carrier materials, 2-7% of disease and insect pest-resistant or herbicidal raw drugs, and 3-20% of wood vinegar and tar; wherein the composite carrier materials comprise the following components by weight: 30-80% of organic powder, 5-80% of inorganic powder, 1-10% of moisture-retaining water-retaining agents, 0.1-5.0% of adhesives, proper amounts of water, and 1-10% of plant nutrient elements and / or plant growth regulators; the disease and insect pest-resistant or herbicidal raw drugs comprise one or more than one of insecticidal, bactericidal or herbicidal pesticides or microbial reagents. The invention not only makes every effort to make the application of the throwing applying agent be simple, but also allows the carrier material to have several functions of adsorption, moisture retention, continuous play of the drug effect of the loaded pesticides, and supply of large and medium trace nutrients required by crops.

Owner:上海孚祥生态环保科技股份有限公司

Solid energy saving screw cleaning agent

The invention provides a solid energy saving screw cleaning agent which can prepare non-corrosive and non-abrasive energy saving screw cleaning material. The raw material formula of the cleaning agent is as follows by weight percentage: 40-60% of matrix resin, 30%-40% of modified powder and 10-20% of auxiliary agent, and the sum of the weight percentage of all the components is 100%; the auxiliary agent is a cleaning surface, a surface active agent, a lubricating agent, a forming agent and a blowing activator; the raw material formula of the modified powder is as follows by weight percentage: 83-97% of inorganic powder, 2.0-8.0% of dispersing agent and 1.0-5.0% of coupling agent. According to the proportion of the formula, the matrix resin, the prepared modified powder, the cleaning agent, the surface active agent, the lubricating agent, the forming agent and the blowing activator are added into a high-speed mixer, and then are extruded and formed by an extruder to obtain the solid screen cleaning agent.

Owner:彭超

Bactericidal antiviral incense and preparation method thereof

InactiveCN102793941AHighly effective antiviral effectAvoid blind spotsAntibacterial agentsBiocideBiotechnologyMicrobiology

The invention discloses bactericidal antiviral incense and a preparation method thereof, wherein the incense body comprises a substrate incense body which is prepared by mixing elm bark powder, an air freshening substance, and a bactericidal antiviral substance; the air freshening substance comprises one or more of clove, agilawood, agastache rugosus, sandalwood, and rhizoma cyperi; the bactericidal antiviral substance comprises one or more of radix angelicae, rhizoma atractylodis, and tarragon. The bactericidal antiviral incense comprises the following components by weight: 20-35 parts of elm bark powder, 10-30 parts of clove, 10-30 parts of agilawood, 10-30 parts of agastache rugosus, 10-30 parts of sandalwood, 10-30 parts of rhizoma cyperi, 10-35 parts of radix angelicae, 10-35 parts of rhizoma atractylodis, and 10-35 parts of tarragon. The incense has the characteristics of cold prevention, sterilization and disinfection, immunity improvement, pollution elimination, air purification, dehumidification and turbidity reduction, no western components, no harm to human body, and the like.

Owner:王申

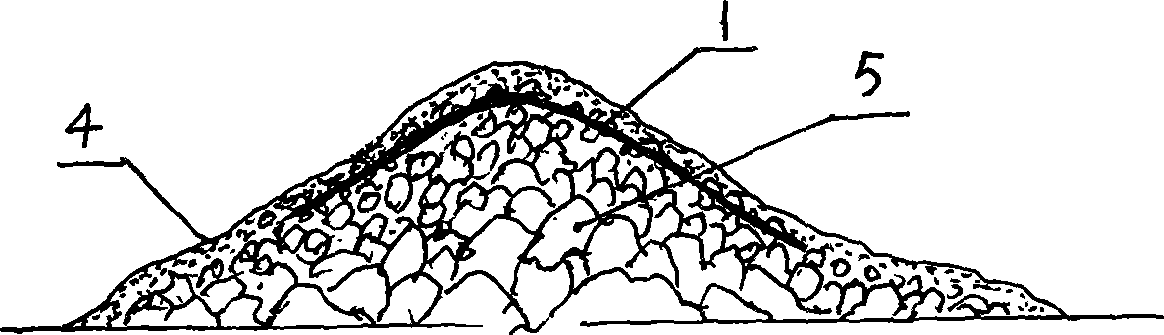

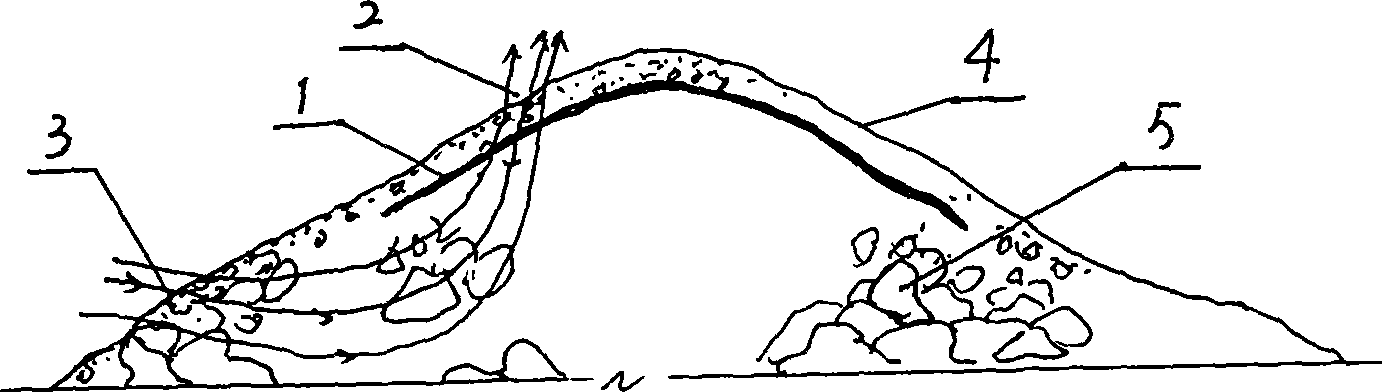

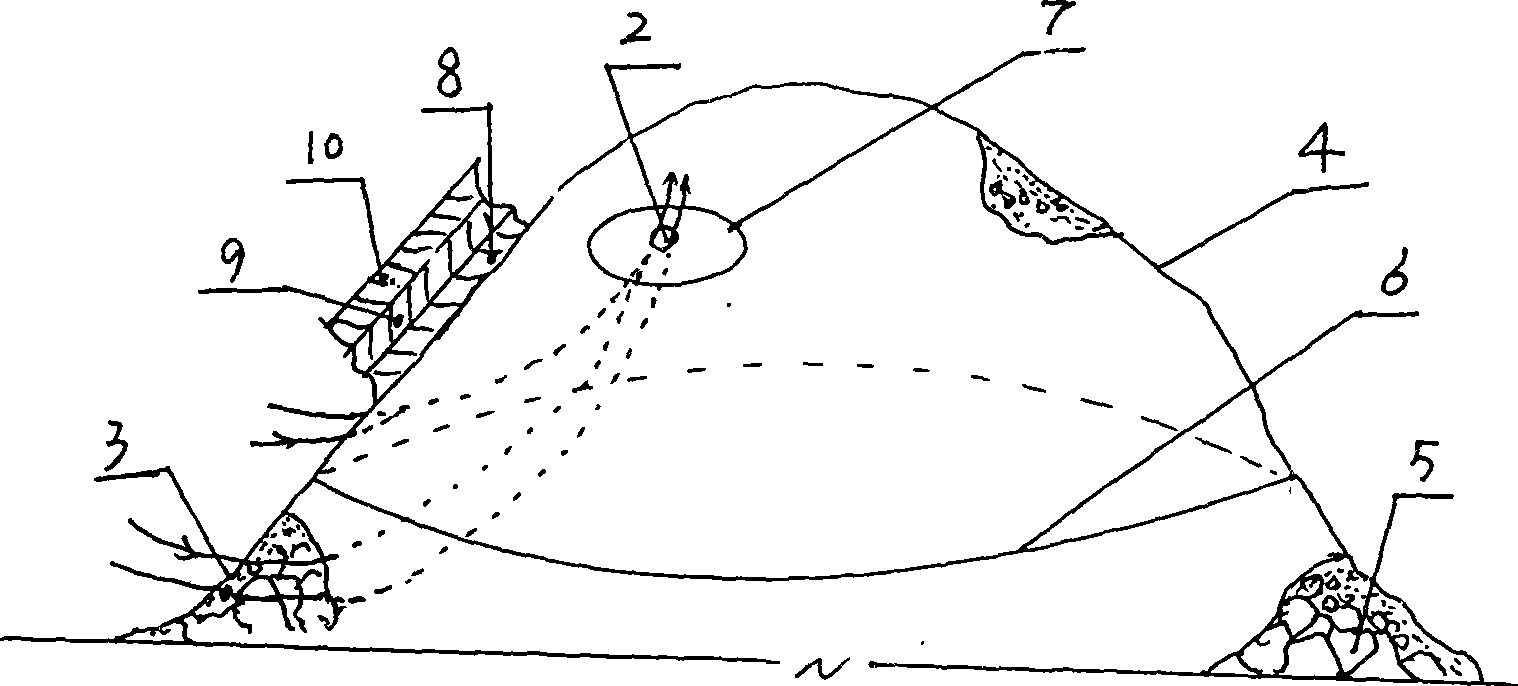

Method for comprehensively treating ecological environment of coal gangue hill

InactiveCN101519966AReduce flowAvoid formingUnderground miningSurface miningRevegetationEcological environment

The invention relates to a method for comprehensively treating the ecological environment of a coal gangue hill, which belongs to the field of mineral waste treatment and ecological environment restoration. The method mainly solves the problems of fire extinction, fire prevention and vegetation construction of the coal gangue hill. The method comprises the steps: the on-site reconnaissance of the coal gangue hill is carried out, and a construction operation plan is established; with fire prevention as principal and the combination of fire prevention and fire extinction, the fire prevention is crucial and is combined with the fire extinction, a thin layer of slurry is firstly sprayed on the coal gangue hill by a mechanical method to completely seal to form a sealing layer (8), transition slurry is sprayed on the sealing layer (8) to completely cover the sealing layer (8) to form a transition layer (9), slurry containing grass-shrub vegetation is spayed on the transition layer (9) to completely cover the transition layer (9) to form a planting layer (10); the contour line girdle band type operation in the spraying process is carried out from bottom to top to gradually and completely cover the hill, and different operating modes are selected according to practical conditions. The invention can not disturb the structure of the coal gangue hill, takes the fire prevention as the principal, combines the fire prevention with the fire extinction, has good and durable fire prevention effect, uses reliable and effective fire prevention and fire extinction measures as guarantee conditions to construct the planting layer, adopts grass-shrub plants, carries out hill sealing management and ensures vegetation restoration; in addition, the method uses the prior specialized mechanical devices to carry out construction operation, is easy to implement, has little difficulty, high efficiency and low investment and can ensure treatment effect.

Owner:赵平 +1

Mn-containing creep-resisting rolled zinc alloy belt material and preparation method thereof

InactiveCN101906555AOutstanding advantagesHighlight positive effectsRoll mill control devicesMetal rolling arrangementsRare-earth elementManganese

The invention relates to a Mn-containing creep-resisting rolled zinc alloy belt material. The material comprises the following components in percentage by weight: 0.5 to 3.0 percent of copper, 0.01 to 2.0 percent of manganese, 0.05 to 0.3 percent of titanium and the balance of zinc and less than 0.05 percent of impurities. An alloy component can also contain the following component in percentage by mass: 0.01 to 0.5 percent of X, wherein the X is at least one of aluminum and rare earth elements (Ce+La). A method for preparing the material comprises the following steps of: smelting by a protective covering method and adding alloy elements in the forms of pure zinc, Zn-Cu, Zn-Ti, Cu-Mn, pure aluminum and Ce+La composite rare earth, wherein a smelting temperature is between 650 and 740 DEG C; pouring at the temperature of between 420 and 480 DEG C; uniformly annealing cast ingots at the temperature of between 350 and 380 DEG C for 6 to 10 hours; performing hot rolling for multiple times at the temperature of between 220 and 280 DEG C, wherein total deformation is between 60 and 95 percent; performing cold rolling, wherein the total deformation is between 50 and 80 percent; and after rolling, annealing at the temperature of between 180 and 200 DEG C for 2 to 3 hours. The alloy of the invention has high creep resistance, hot processing performance and mechanical property and is suitable for the fields of building decoration, transportation, instruments, meters and the like.

Owner:CENT SOUTH UNIV

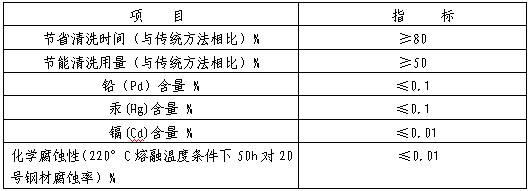

Glass cleaning agent composite for electronic industry

InactiveCN1482223AEasy to cleanRaw materials are easy to getInorganic non-surface-active detergent compositionsSodium bicarbonateSodium metasilicate

The electronic industrial glass cleaning agent composition belongs to the field of electronic industrial cleaning technology. The cleaning agent consists of sodium metasilicate, sodium hydroxide, sodium carbonate, sodium bicarbonate, Pluronic polyol, CMC, fluoric surfactant, complexing agent, defoaming agent and deionized water. It is used to clean substrate glass and coated conducting glass. During the cleaning, the cleaning agent in 1-5 % is compounded with deionized water in 95-99 % to compound the cleaning liquid for showering or ultrasonic cleaning to eliminate pollutant on glass fastcompletely. It is used to replace strong acid and strong alkali cleaning agent and has no damage to glass surface and no corrosion to ITO film. The cleaning agent has no bad smell, no toxicity and no corrosion, and is safe, reliable, environment friendly and low in cost.

Owner:SHANDONG UNIV

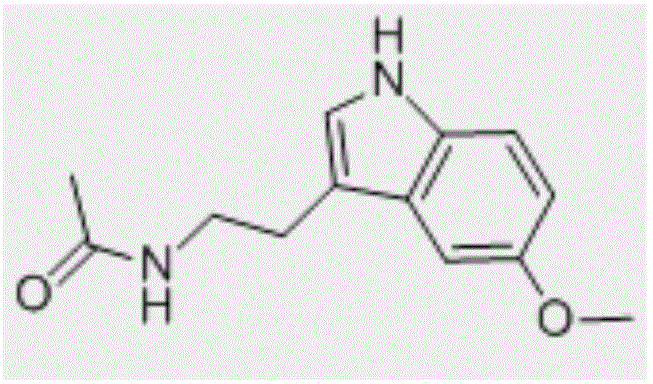

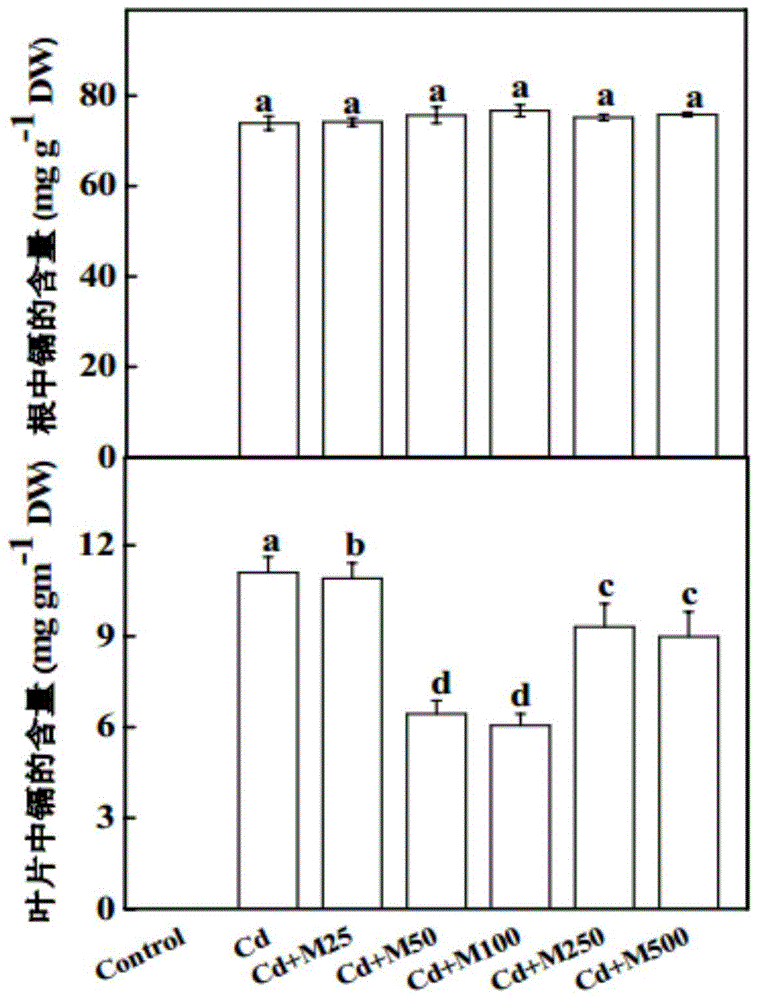

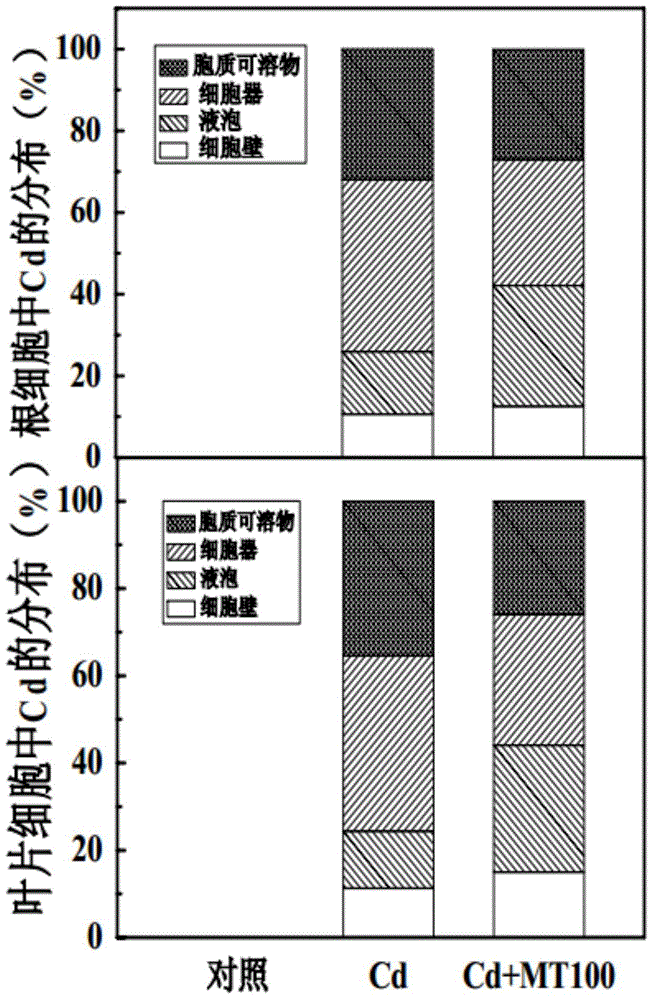

Application of melatonin in reducing cadmium accumulation in plants

ActiveCN104823738AReduce cadmium contentChange distributionPlant growth regulatorsBiocidePhytotoxicityLowering plants

The invention discloses an application of melatonin in reducing cadmium accumulation in plants. The application includes the following steps: (1) mixing melatonin and additives to form aqueous solution; (2) spraying the aqueous solution on plant leaf surfaces under cadmium stress or filling the aqueous solution in nutrient solution or soil where plants grow. The melatonin can quickly and efficiently reduce cadmium content in plant leaves, change distribution of cadmium ions in plant cells, and relieve damage of cadmium to cells; in addition, the melatonin is simple to prepare and convenient to use, does not cause product and environment pollution, does not generate phytotoxicity easily and has a wide application prospect.

Owner:ZHEJIANG UNIV

Polyester POY spinning finish and production method thereof

The invention discloses a polyester POY spinning finish, comprising 81-88% of lubricating agent, 3-5% of emulsifying agent, 4-7% of tow collecting agent, 3-5% of antistatic agent and 2-4% of additive by weight. The invention also discloses a production method of the polyester POY spinning finish. The product not only can endow the fibers with good processability but also is environment-friendly, overcomes the phenomenon that the finish corrodes equipment and can ideally solve the problem of easy cohesion on guide rolls during apparent cohesion and reduce fluff and broken yarns.

Owner:绍兴市上虞皇马化学有限公司

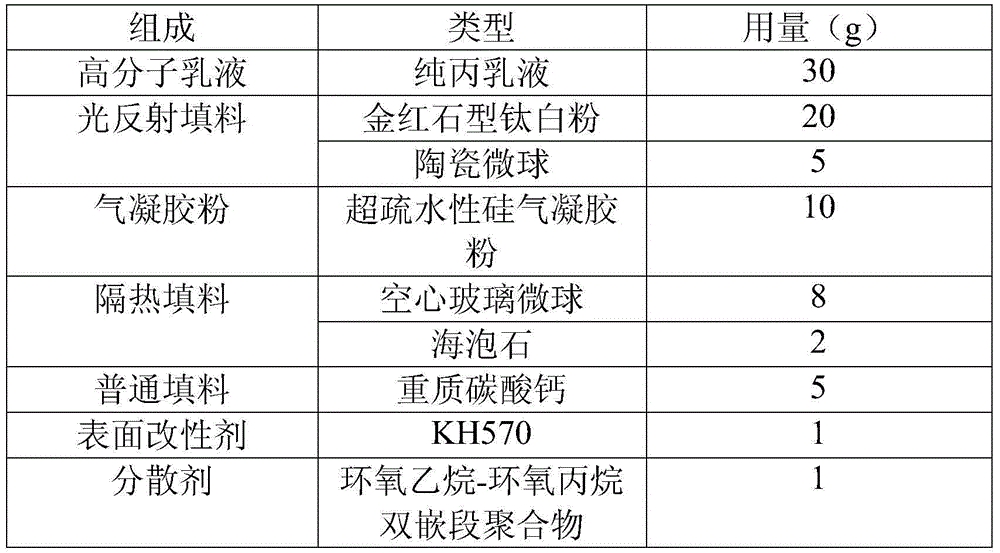

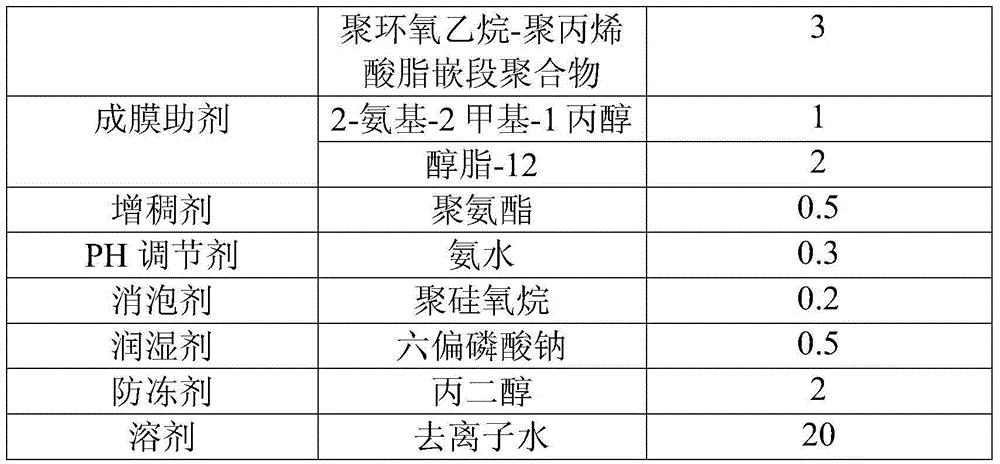

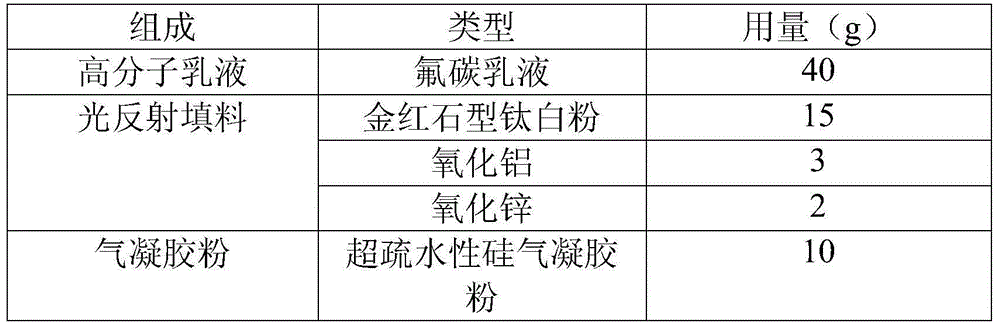

Waterborne energy-saving building coating and preparation method thereof

ActiveCN106700789AGet rid of the shortcomings of severely limited application fieldsIncreased hemispherical emissivityAntifouling/underwater paintsPaints with biocidesGreen environmentEmulsion

The invention specifically relates to a multifunctional green environment-friendly waterborne energy-saving building coating and a preparation method thereof, belonging to the technical field of energy-saving building coatings. The multifunctional high-efficiency energy-saving building coating comprises, by weight, 25 to 50% of a high polymer emulsion, 5 to 30% of a light-reflection filling material, 1 to 5% of aerogel powder, 5 to 10% of a heat-insulation filling material, 5 to 15% of a common filling material, 1 to 2% of a surface modifier, 1 to 5% of a dispersing agent, 0.1 to 4% of a film-forming aid, 0.1 to 2% of a thickening agent, 0 to 1% of an antifoaming agent, 0.01 to 0.5% of a pH regulating agent, 0.1 to 2% of a wetting agent and 0.5 to 2% of an antifreezing agent, with the balance being deionized water. The coating provided by the invention has heat-insulation and cooling effect in summer and heat preservation effect in winter, is applicable to energy-saving reconstruction of buildings in tropical zones and subtropical zones, and has the characteristics of safety, no toxicity, environment friendliness and no pollution; moreover, the coating has good weatherability, contamination resistance, flexibility and scrubbing resistance.

Owner:SHENYANG RES INST OF CHEM IND

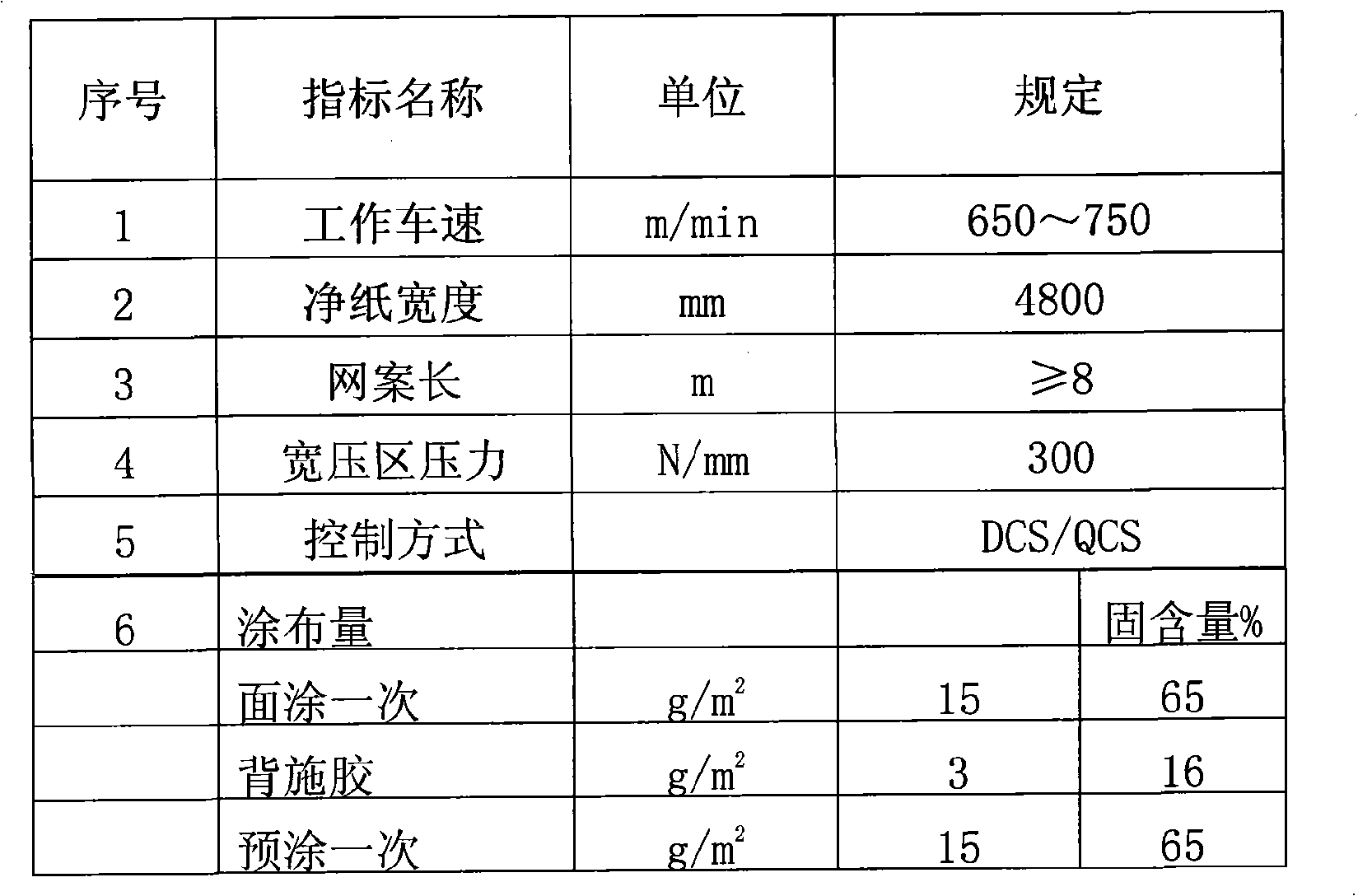

Method for producing coated kraft card board by home-made paper machine

The invention relates to technical field of coated kraft liner producing method. The producing method comprises feeding surface pulp, lining pulp, core pulp and bottom pulp pumped from machine chest of pulping workshop into respective machine chest; slushing and pressure screening the lining pulp, the core pulp and the bottom pulp by offline back water bank, then slushing and pressure screening the surface pulp by the offline back water bank after removing impurities in the surface pulp in a low concentration sand remover, finally all the pulp entering into a flow box to flow onto wire; after the pulp flowing onto wire, feeding the pulp into a coating system after forming by a four-long net forming machine, second shoe pressing, drying, glue blending, redrying, and press polishing by a two-roller hot pressing machine; feeding the coated paper into a state-regulating cylinder and a soft calendar to finish, then reeling by a horizontal paper reeling machine. The coated kraft liner producing method disclosed by the invention can greatly reduce use cost of the coated kraft liner to make the domestic market not dependent on import any longer.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com