Patents

Literature

522 results about "Metasilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metasilicates are silicates containing ions of empirical formula SiO²⁻₃. Common stoichiometries include Mᴵ₂SiO₃ and MᴵᴵSiO₃.

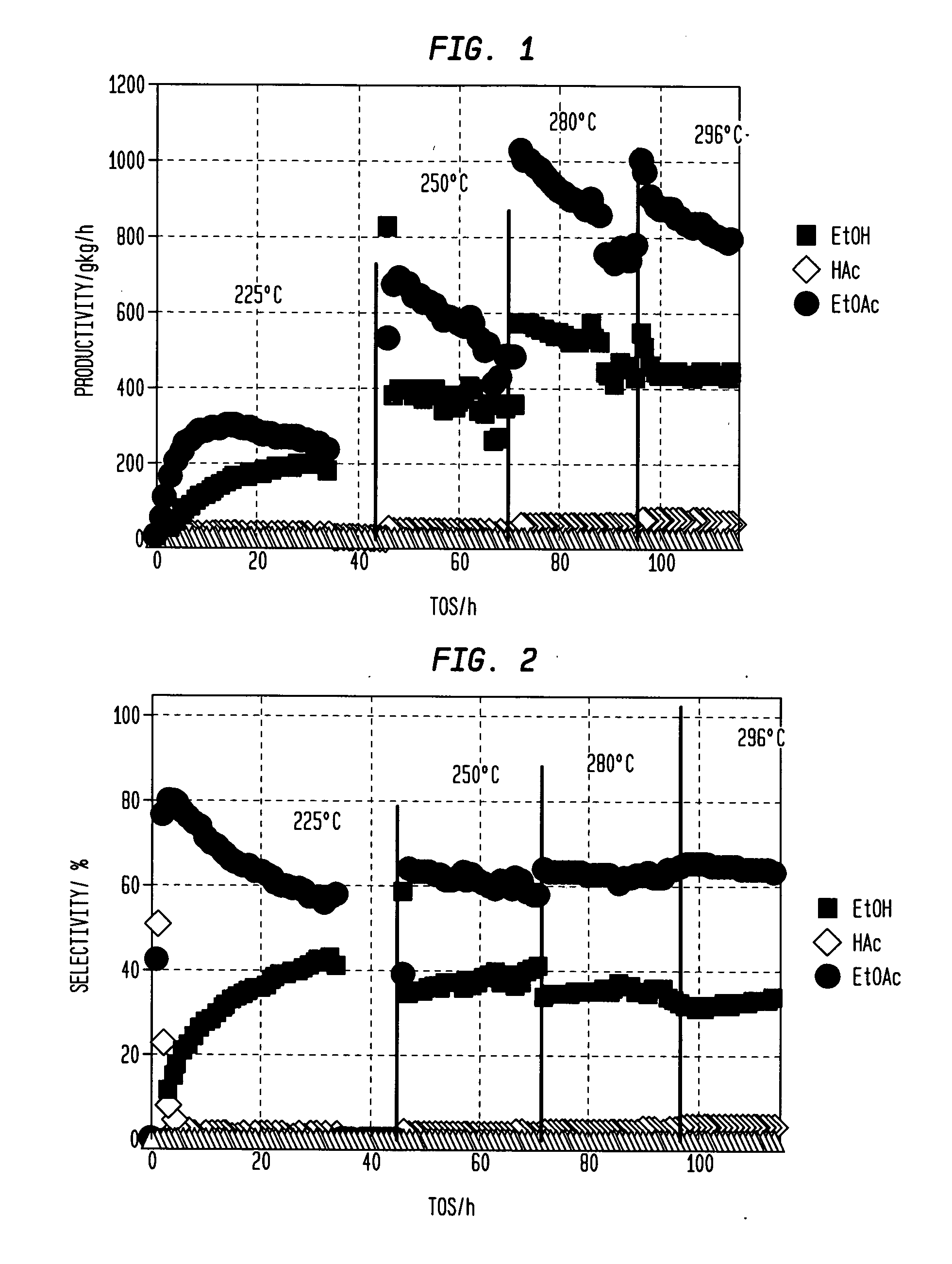

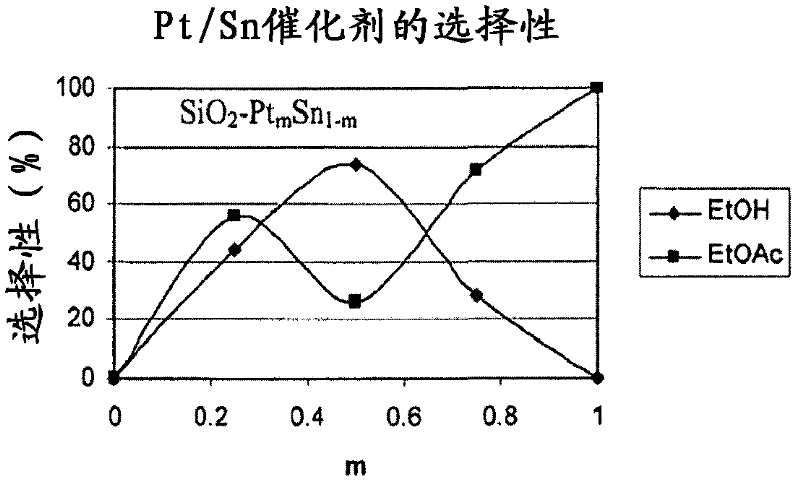

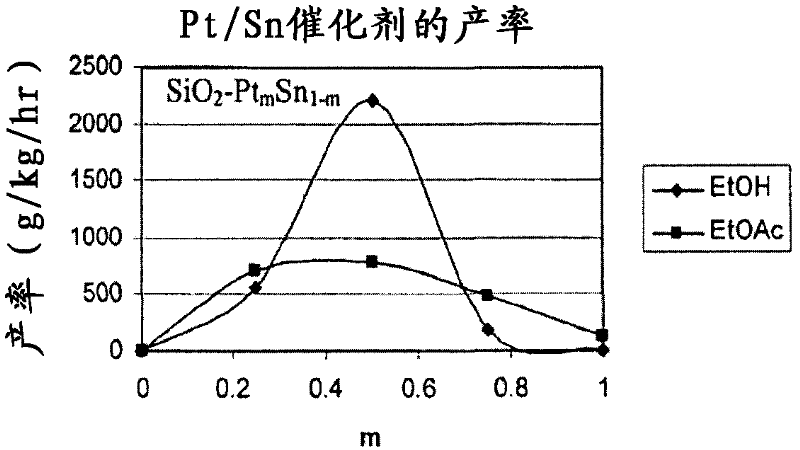

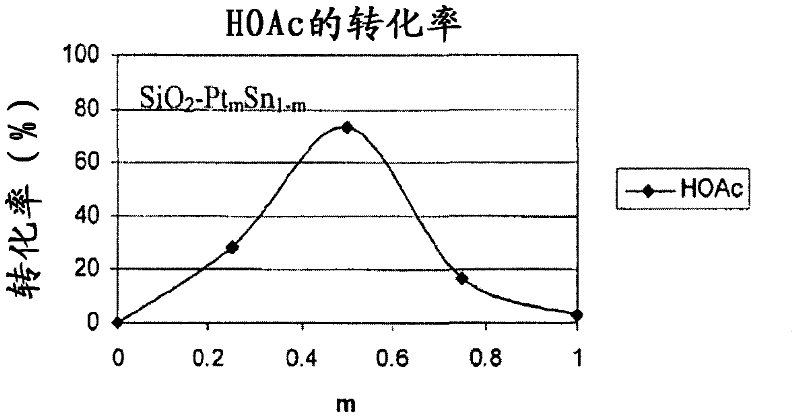

Tunable catalyst gas phase hydrogenation of carboxylic acids

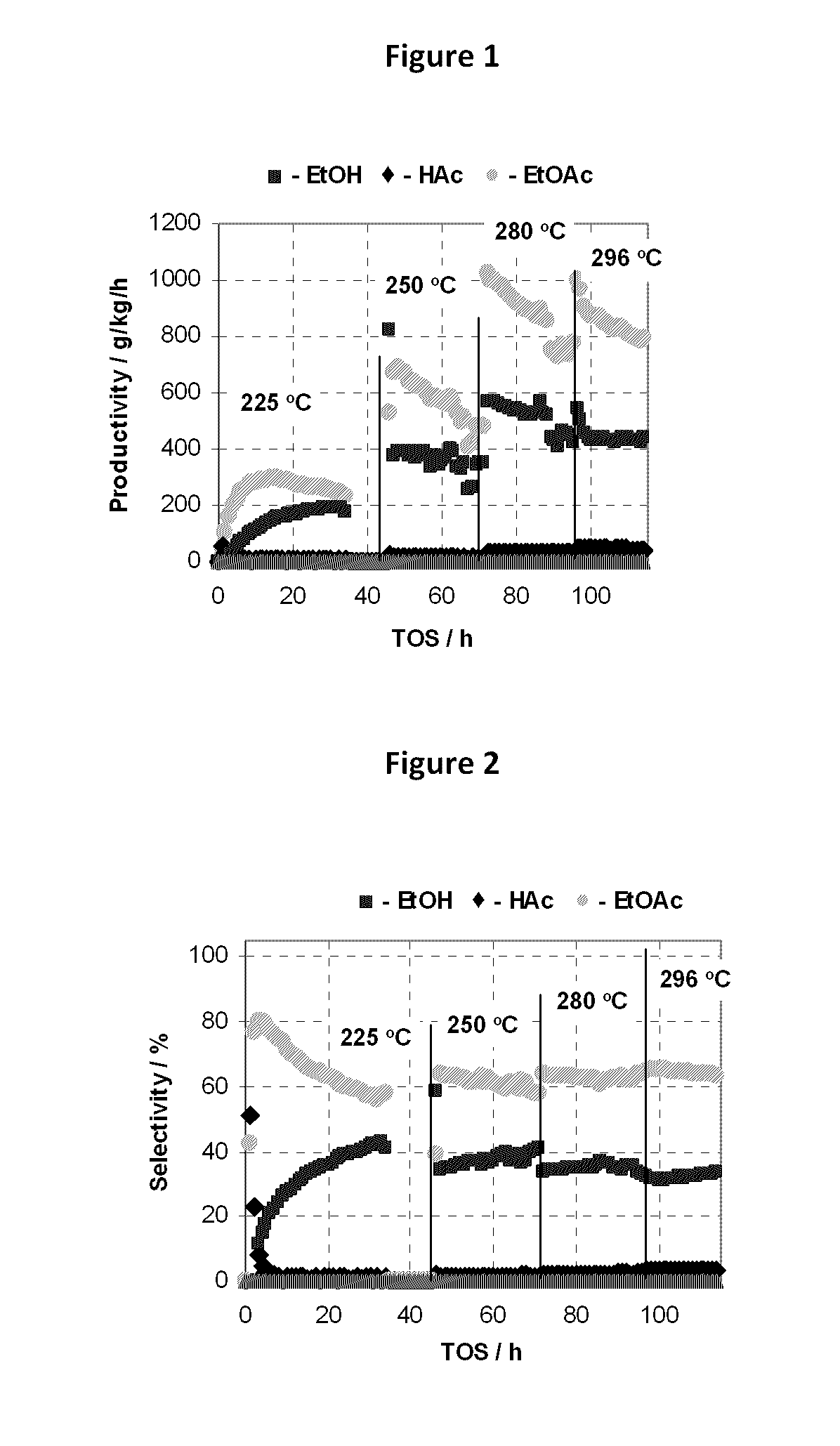

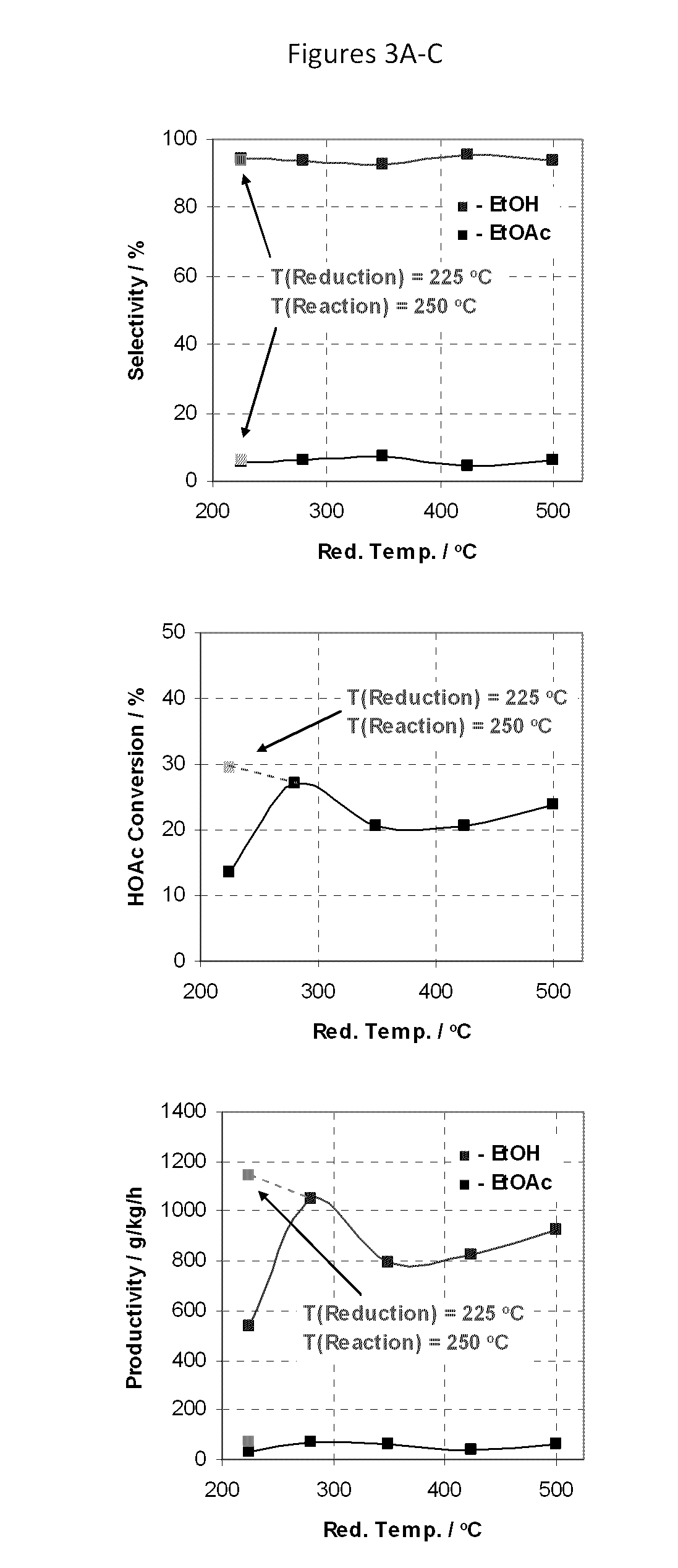

InactiveUS20100121114A1High selectivityExcessive loss of activityOrganic compound preparationHeterogenous catalyst chemical elementsPlatinumAcetic acid

A process for selective formation of ethanol from acetic acid includes contacting a feed stream containing acetic acid and hydrogen at an elevated temperature with catalyst comprising platinum and tin on a high surface area silica promoted with calcium metasilicate. Selectivities to ethanol of over 85% are achieved at 280° C. with catalyst life in the hundreds of hours.

Owner:CELANESE INT CORP

Low density cements for use in cementing operations

A cement mix suitable for blocking or plugging an abandoned pipeline or back filling a mine shaft, tunnel or excavations contains Portland cement or a cement blend of two components selected from Portland cement, fly ash, pozzolan, slag, silica fume and gypsum; diatomaceous earth; zeolite and an inorganic salt accelerator. The cement mix may further contain an alkali metasilicate and / or alkali silicate. A cementitious slurry, formulated from the cement mix, may have a density less than or equal to 1500 kg / m3, and exhibits good compressive strength.

Owner:BAKER HUGHES INC

Metal surface treating agent

InactiveCN102051611AReduce corrosion rateReduce surface tensionMetallic material coating processesMetasilicateChemical conversion

The invention relates to a metal surface treating agent which comprises the following components: silicate or metasilicate, chitosan, corrosion inhibitor, surfactant, antioxidant, wetting agent, film-forming additive, ethanol and water, wherein one or more of nanosized titanium dioxide, zirconium oxide or zirconium fluoride are evenly mixed with silicate or metasilicate and account for 3wt%-25wt% of silicate or metasilicate; the particle size of nanosized titanium dioxide, zirconium oxide or zirconium fluoride is less than 100nm; the degree of deacetylation of chitosan is 55%-100%; and the pH value of the composite is adjusted to 5.0-9.0. The invention provides the metal surface treating agent which uses environmentally friendly aqueous solution to form a metal chemical conversion film so as to inhibit the surface corrosion of metal; when the metal surface treating agent is used to treat the surface of the cold-rolled steel plate product, the rust-proof effect is especially good; and the metal surface treating agent can not cause environmental pollution and be green and environmentally friendly.

Owner:DALIAN POLYTECHNIC UNIVERSITY

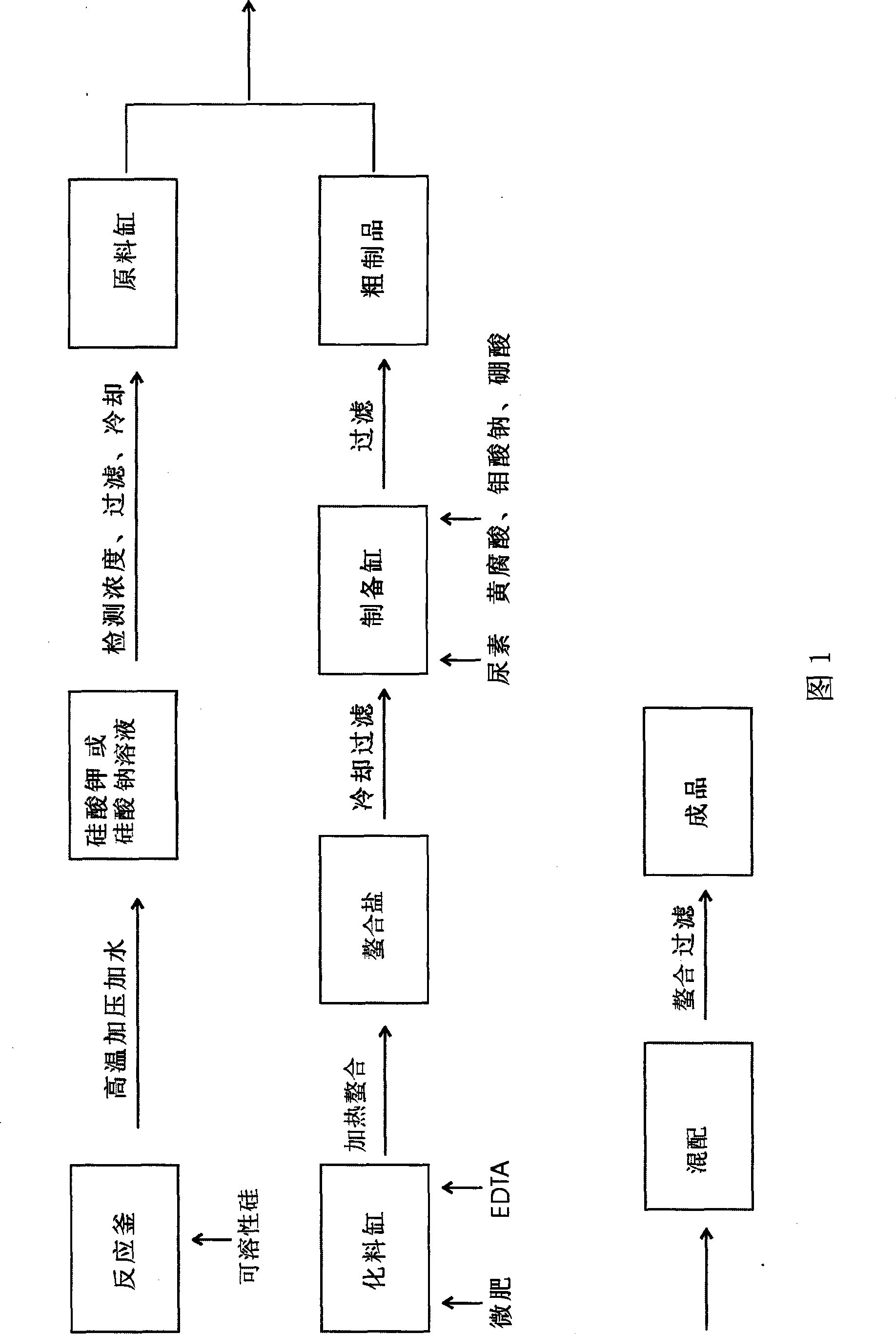

Liquid silicon fertilizer and technique for producing the same

InactiveCN101440001APromote growthIncrease resistanceOrganic fertilisersUrea compound fertilisersMetasilicateSilicic acid

The invention relates to a liquid silicon fertilizer and a production technique thereof, and belongs to the technical field of fertilizer. The liquid silicon fertilizer is characterized in that raw materials comprise soluble silicon, urea, trace elements, chelate and fulvic acid, which are prepared into the balanced compound fertilizer. The production technique comprises the following steps: 1, dissolving solid potassium metasilicate; 2, dissolving sulfate of the trace elements in water, and adding EDTA into the mixture to obtain the chelate of the EDTA trace elements; and adding boric acid, ammonium molybdate, the urea and the fulvic acid into the mixture after cooling and filtration; and 3, blending the chelate into the mixture to obtain the liquid silicon fertilizer. The production technique is characterized in that (1) the production technique uses water glass and the fulvic acid chelate, has better buffer action for alkali, and can effectively improve stability of SiO3; and (2) the trace elements are chelated twice by using the EDTA and the fulvic acid to form chelated metal ions, so as to prevent silicic acid radicals and the metal ions reacting to form silicate difficult to be dissolved in water, and influence utilization rate of silicon element. The production technique uses the liquid potassium metasilicate and large amount of elements, trace elements and organic substances to establish a balanced compound system, and can effectively improve utilization rate of the silicon element and various nutrient elements for the crops.

Owner:于春开

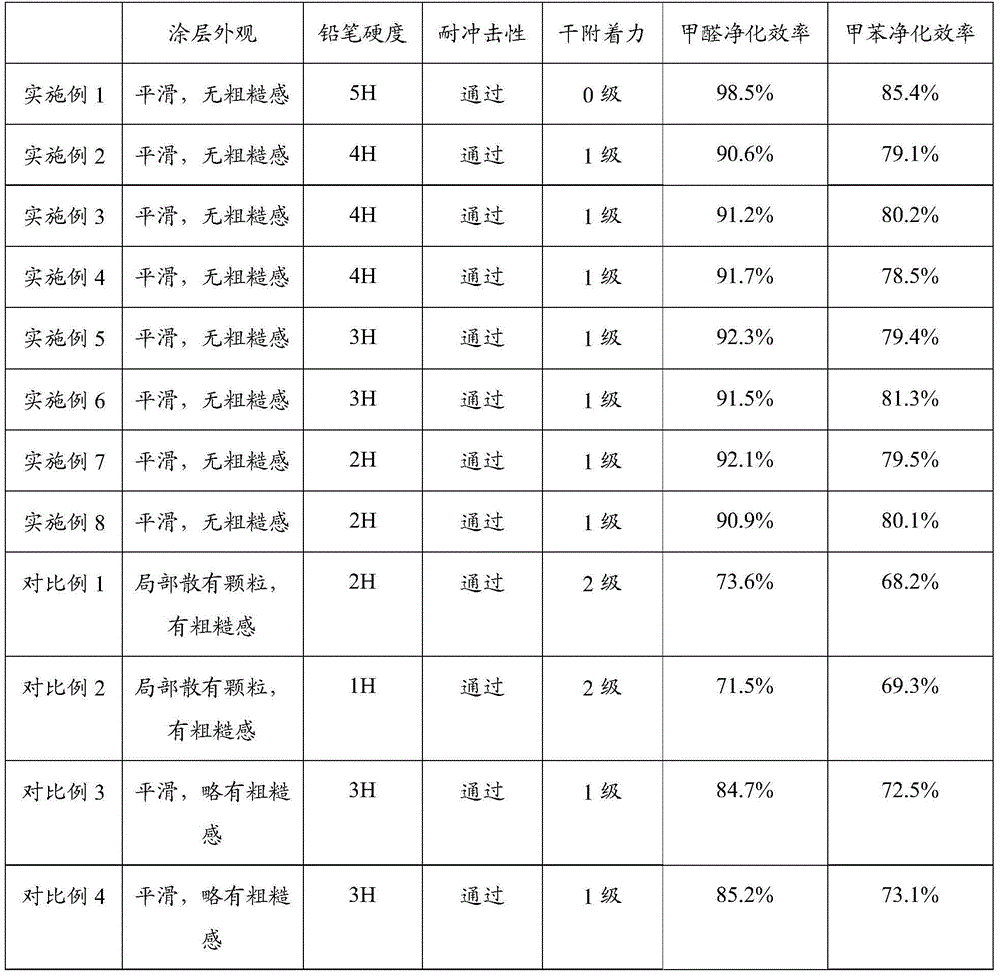

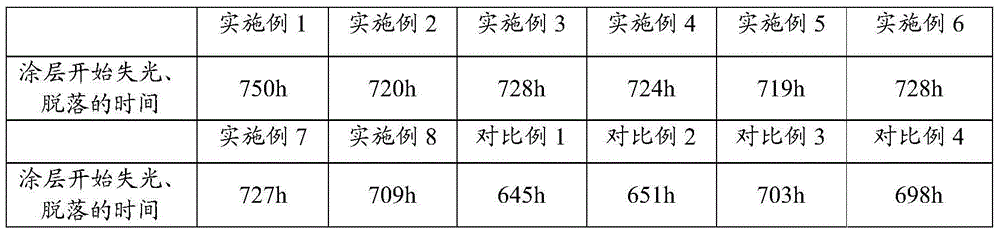

Multifunctional inorganic diatom ooze coating and preparation method thereof

InactiveCN104387816AStir wellNot easy to reuniteAntifouling/underwater paintsAlkali metal silicate coatingsCelluloseEmulsion

The invention relates to a multifunctional inorganic diatom ooze coating, which is prepared from the following components in percentage by mass: 10%-25% of water, 0.4%-0.8% of cellulose, 10-30% of a mixture of potassium metasilicate and silica sol, 0.2%-0.4% of a stabilizer, 0.1%-0.3% of a dispersing agent, 0.1%-0.3% of a silicon additive, 0.3%-0.5% of a defoaming agent, 0.1%-0.3% of an antibacterial agent, 0-20% of titanium dioxide, 5%-15% of nanometer kieselguhr, 10%-30% of coarse whiting, 2%-4% of talcum powder, 1%-3% of medical stone, 0-1.5% of anion, 0-2% of a nano-photocatalyst, 1%-2% of inorganic gel powder, 0-9% of an order-removing emulsion and 0-1.5% of pigment, wherein the sum of the components is 100%. The invention also provides a preparation method of the coating. The coating disclosed by the invention has the functions of sterilizing, preventing mold, purifying air and the like; and the preparation method disclosed by the invention is simple and easy to operate.

Owner:佛山市南海万磊建筑涂料有限公司

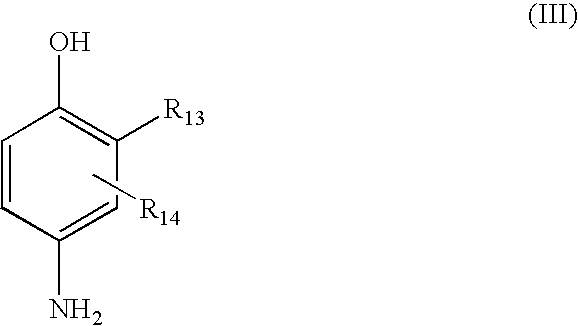

Composition useful for the oxidation dyeing of human keratinous fibres

A composition useful for the oxidation dyeing of human keratinous fibers and in particular hair containing, in a cosmetically acceptable medium based on water and at a basic pH, at least one oxidation dye and an alkalinizing agent containing at least one alkali metal, alkaline-earth metal or ammonium metasilicate and at least one alkanolamine, and the dyeing method using this composition.

Owner:LOREAL SA

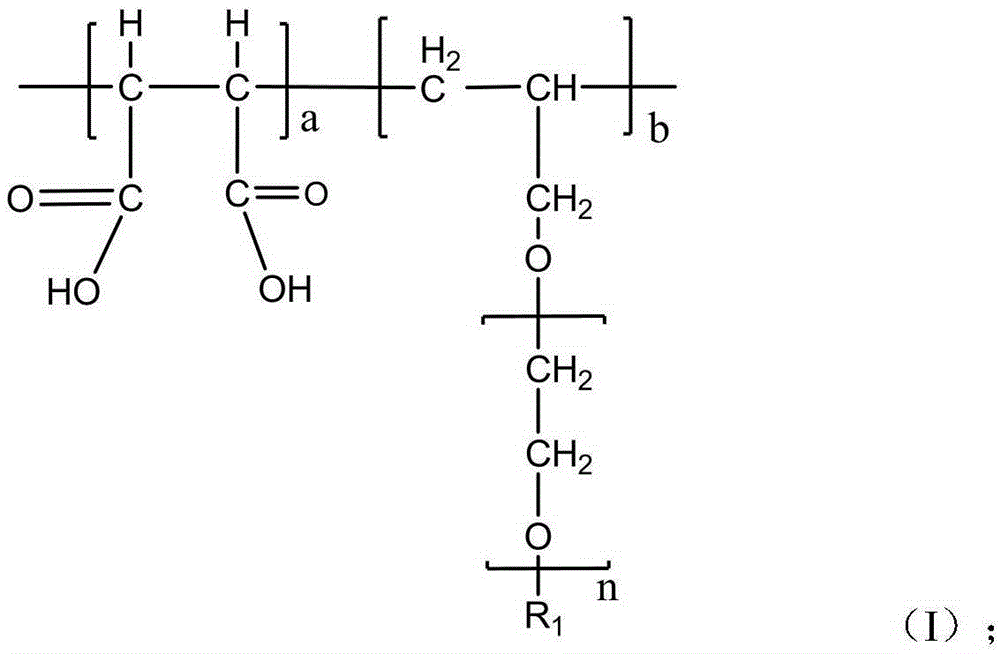

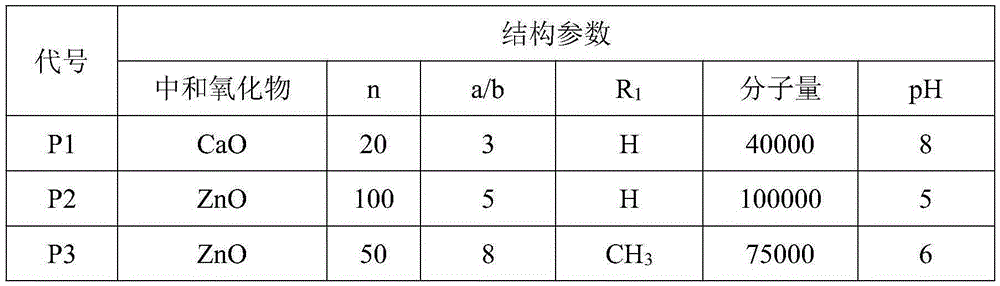

Nano suspension liquid concrete early strength agent and preparation method thereof

The invention provides a nano suspension liquid concrete early strength agent and a preparation method thereof. The nano suspension liquid concrete early strength agent is prepared from transition metal element doped nano calcium metasilicate suspension liquid, the suspension liquid is mainly composed of nanometer silicon particles, the chemical structure of the nanometer silicon particles is aCaO.bAl2O3.cZnO.SiO2.6H2O, 1<=a<=2, 0.50<=b<=1, and 0.25<=c<=0.50. The nanometer silicon particles are prepared from soluble calcium salt, soluble silicate, soluble aluminum salt, soluble zinc salt and a high polymer dispersing agent. On the one hand, the early strength agent contains no chlorine salt and has no corroding function on steel bars in concrete; on the other hand, an extremely stable suspension liquid system is achieved, adding is facilitated, and the early strength agent can be evenly dispersed easily in the concrete preparation process. The early strength of concrete can be remarkably improved, the early strength effect on concrete adopting highly-doped mineral admixtures is especially obvious, the early strength agent is especially suitable for production of precast concrete components, and a steam maintenance process can be effectively reduced and even omitted.

Owner:JIANGSU SOBUTE NEW MATERIALS

Novel negative ion additive

InactiveCN103805134ALow priceSimple preparation processOther chemical processesManufacturing technologyMetasilicate

The invention relates to a novel negative ion additive and belongs to the field of chemical engineering. The negative ion additive is characterized by comprising the following substances: a magnetic powder, rare earth, sodium carbonate, potassium metasilicate, tourmalinite and qicai stone. The invention has advantages of simple manufacture technology, cheap raw materials and suitability for large-scale production.

Owner:李雪娇

Multifunctional organic-inorganic composite polymeric microball and preparing method thereof

The present invention relates to an organic-inorganic composite high-molecular microsphere with multiple response property and its preparation method. Said method includes the following steps: using alkyl metasilicate as precursor, utilizing gel-sol process to prepare magnetic nano granules covered with silicon dioxide, and using silicane coupling agent to make surface modification, then adopting template polymerization process, using the above-mentioned magnetic nano granules as seed and using isopropyl acrylamide or its derivative as main monomer, and using acrylic acid or its salt as functional monomer and controlling the dose of main monomer, functional monomer and crosslinking agent to prepare the organic-inorganic composite high-molecular microsphere with different swelling ratios.

Owner:FUDAN UNIV

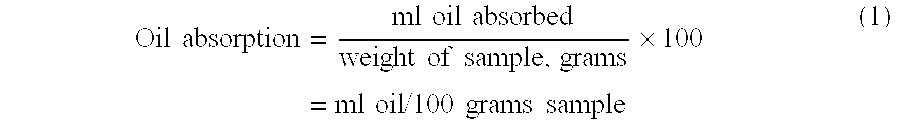

Oral care products comprising calcium metasilicates

Disclosed is an oral care composition comprising a calcium metasilicate having an aspect ratio (average major axial diameter / average minor axial diameter) of from about 1:1 to about 2.5:, and an oil absorption of from about 20 ml / 100 g to about 220 ml / 100 g. Also disclosed is an oral care composition comprising: a calcium metasilicate having an aspect ratio (average major axial diameter / average minor axial diameter) of from about 1:1 to about 2.5:, and an oil absorption of from about 20 ml / 100 g to about 220 ml / 100 g, a disintegration aid, an organoleptic enhancing agent, and an abrasive.

Owner:EVONIK OPERATIONS GMBH

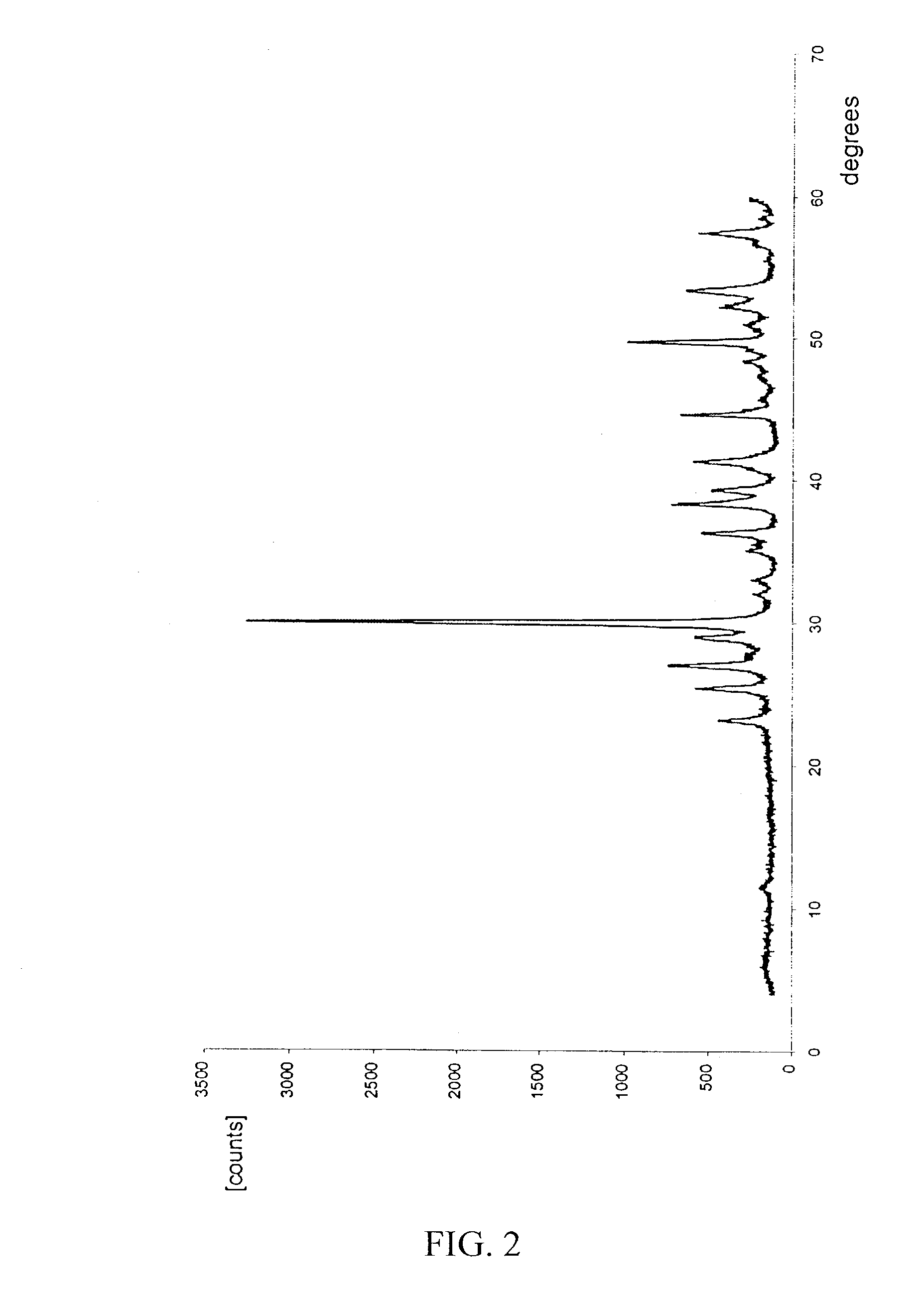

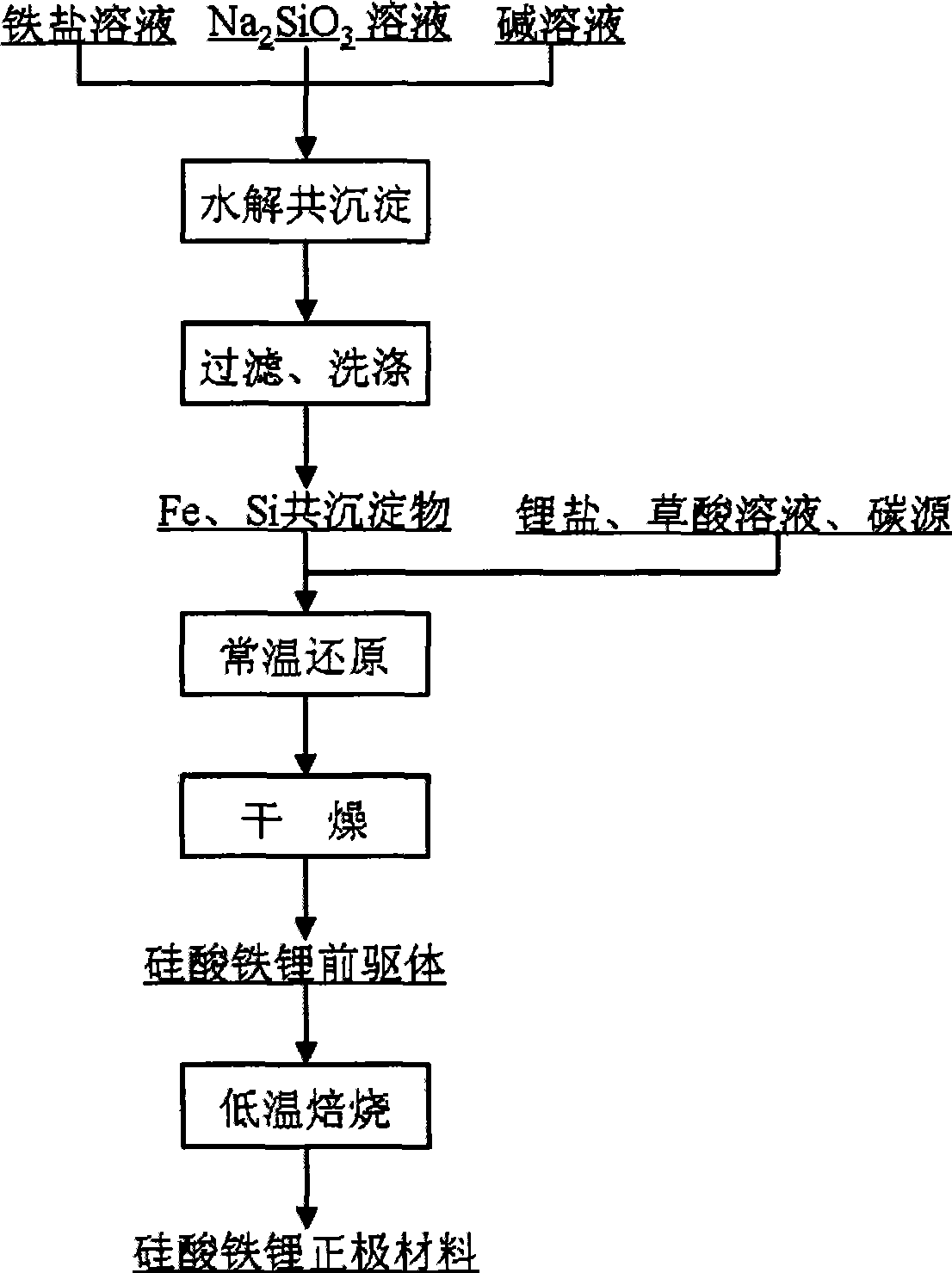

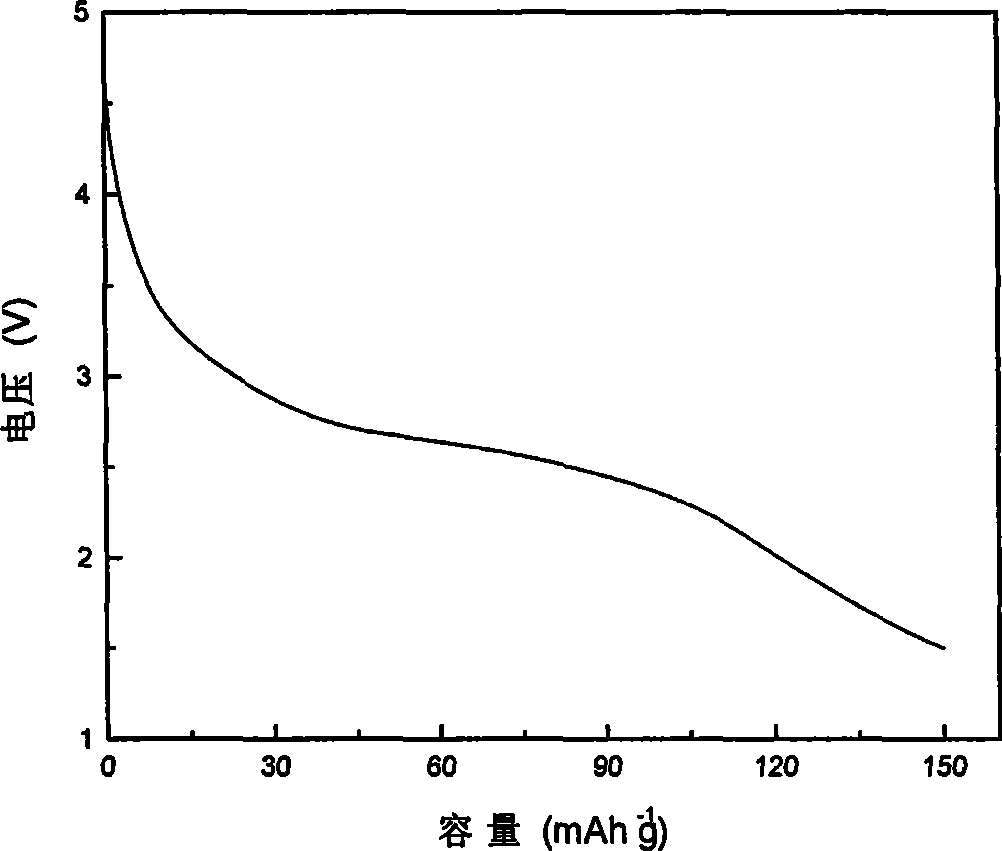

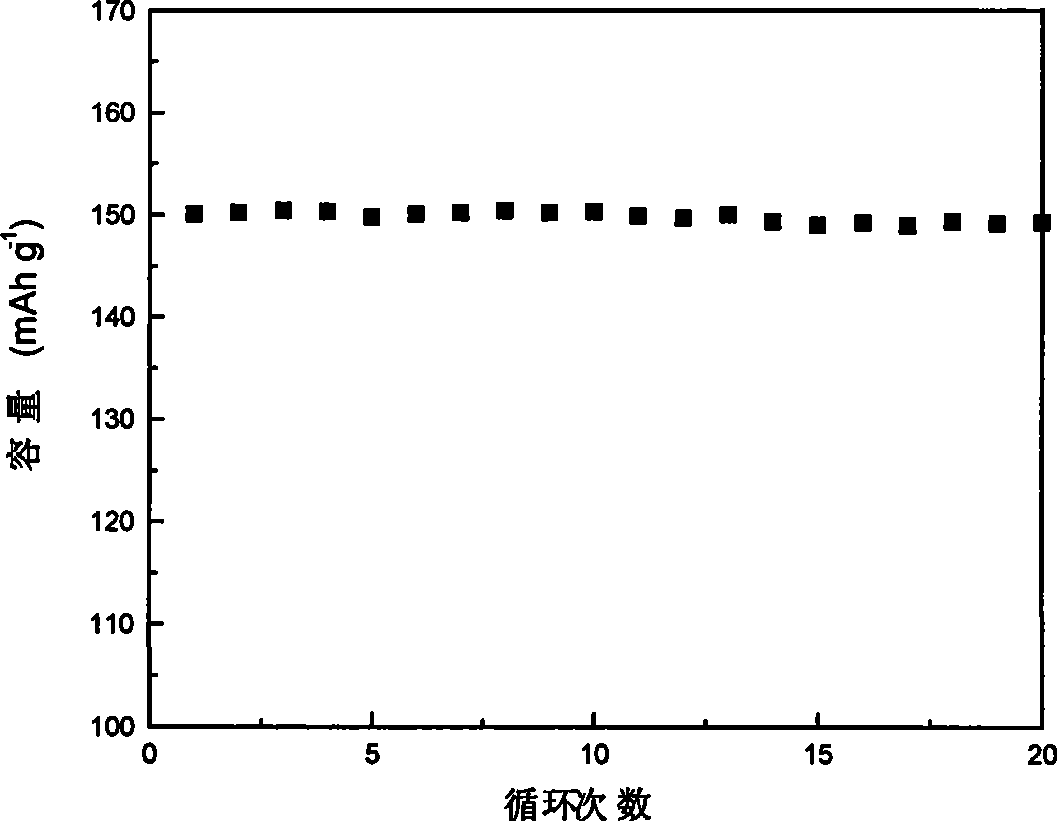

Production method of lithium ferric metasilicate anode material

InactiveCN101499527AWide variety of sourcesConvenient sourceElectrode manufacturing processesMetasilicateFERRIC IRON

The invention relates to a preparation method of lithium iron silicate cathode material. In the method, ferric saline, Na2SiO3 and lye are added into a reactor in a flowing way; the pH value of the reaction system is controlled, so that the hysrolysis reaction between the ferric iron and the SiO3 can occur; the common deposit of iron and silicon is prepared by filtering and washing; the common deposit of iron and silicon, the lithium source compound, the oxalic acid solution and the carbon source compound are mixedto become pulp state; the Fe is reduced to be Fe through ball milling; the precursor material of lithium iron silicate can be prepared by drying; the precursor material is calcinated under the conditions with the protective atmosphere and at the low temperature to form the agglomerated acidic lithium-iron anode material which is composed of nanoparticles. The method has the strong process adaptability; the industrial production can be easily realized; and the product has higher density and excellent electrochemical properties.

Owner:CENT SOUTH UNIV

Method for covering silicon dioxide film on aluminate series long afterglow fluorescent powder surface

InactiveCN1371957AImprove water resistanceHigh initial brightnessLuminescent compositionsWater bathsAluminate

The ethyl metasilicate is dissolved in ethyl alcohol and deionized water, heated in hot water bath with 50-90 deg.c to hydrolyze solution into transparent ethyl metasilicate sol; the long-persistencephosphor powder is immersed in the ethyl metasilicate sol, heated to 50-100 deg.c, the sol can be completely changed into gel; the covered mixture is placed in oven, oven-dried at 50-100 deg.c, and the over-dried covered powder is placed in sintering furnace, heat-insulated for 1-5 hr, at 300-500 deg.c and cooled so as to implement said invention which can obviously raise water-resisting propertyof long-persistence phosphor powder.

Owner:TSINGHUA UNIV

Preparation method of lithium ion battery positive material of ferric metasilicate lithium

The invention relates to a preparation method of a lithium ion battery positive material of ferric metasilicate lithium, which comprises the following steps: preparing precursors in a water solution of a compound surface active agent; Preparing the lithium ion battery positive material of the ferric metasilicate lithium in a mode of ultrasonic wave stirring and microwave oven calcination. The precursors prepared by the method of the invention have smaller granularity and more uniform grain diameter, in addition, the reaction raw materials are in sufficient contact because of the ultrasonic wave stirring, and the reaction process can be carried out more easily and faster. The preparation method of the lithium ion battery positive material of the ferric metasilicate lithium of the invention solves the problem of diffusion of lithium ions in the materials in the prior art, and is favorable for improving the high-rate electric discharge capability of the ferric metasilicate lithium positive material.

Owner:湖南格林新能源有限公司

Low density cements for use in cementing operations

A cement mix suitable for blocking or plugging an abandoned pipeline or back filling a mine shaft, tunnel or excavations contains (i) Portland cement or a mixture of at least two components selected from Portland cement, fly ash, slag, silica fume, gypsum, bentonite and limestone; (ii) diatomaceous earth; (iii) zeolite, (iv) an aluminum silicate and (v) an inorganic salt accelerator. The cement mix may further contain an alkali metasilicate and / or alkali silicate. A cementitious slurry, formulated from the cement mix, may have a density less than or equal to 1500 kg / m3, and exhibits good compressive strength.

Owner:BAKER HUGHES INC

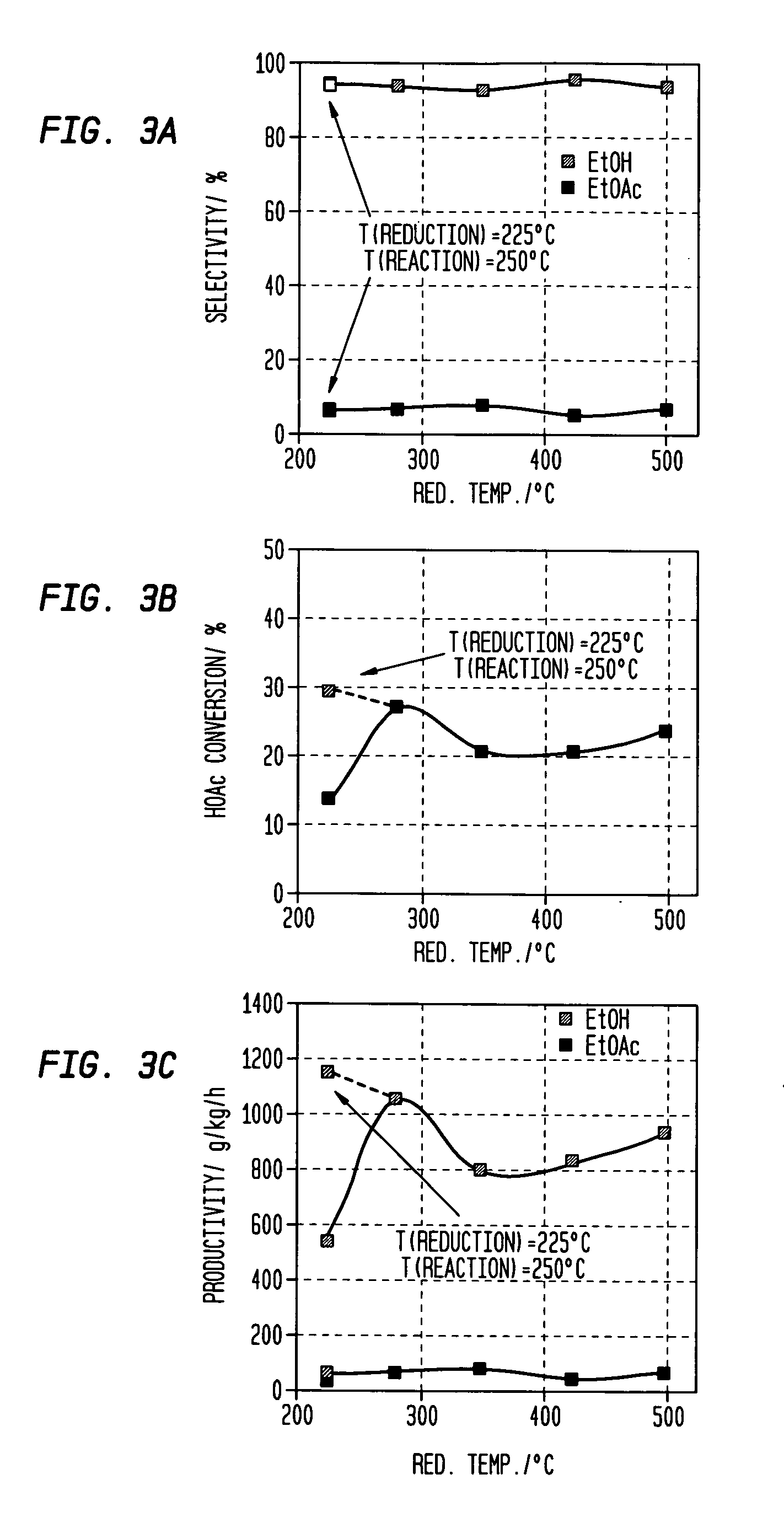

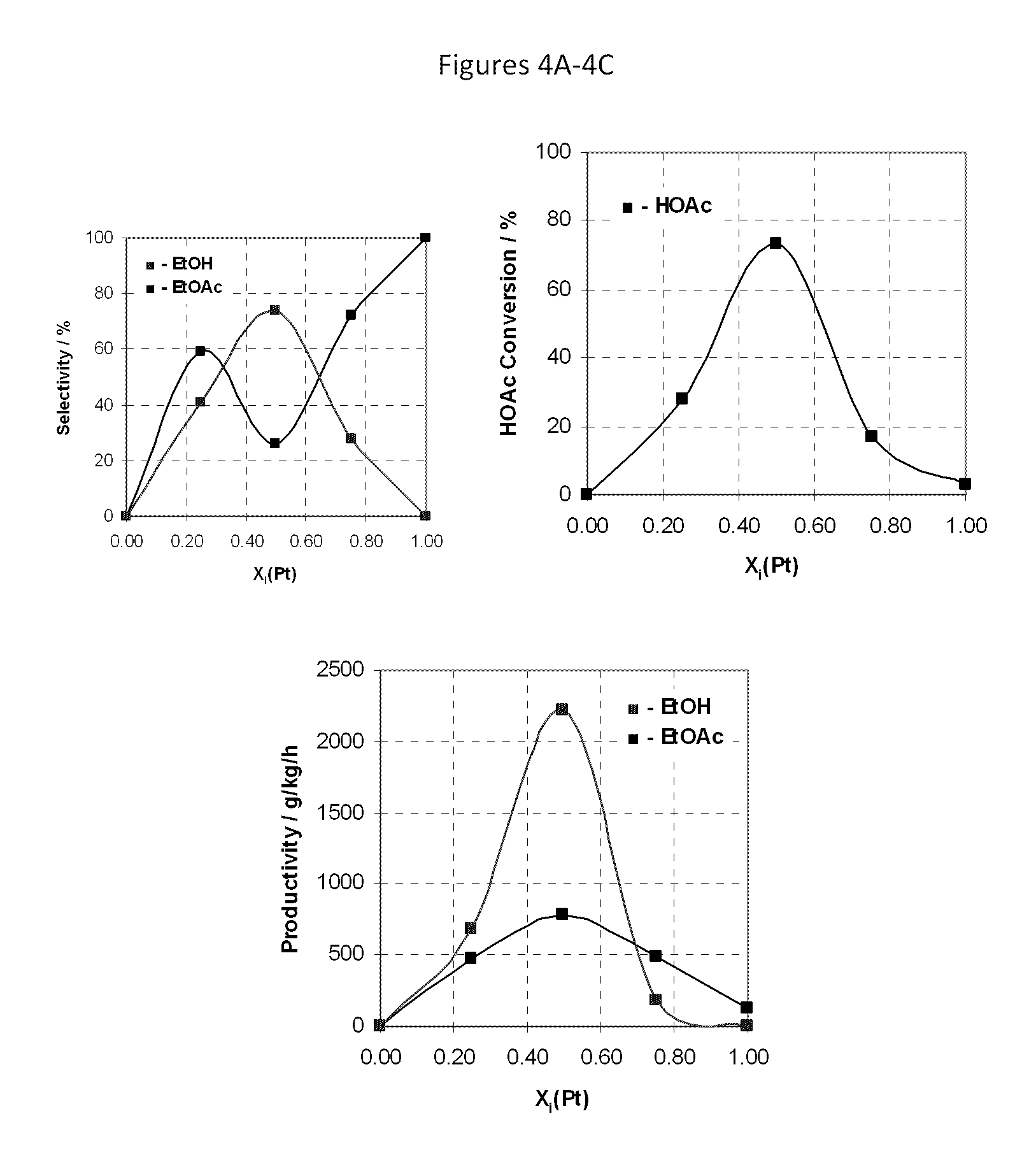

Catalyst for gas phase hydrogenation of carboxylic acids having a support modified with a reducible metal oxide

InactiveUS8080694B2High selectivityControl of the acidity of the support can be quite beneficialOrganic compound preparationHeterogenous catalyst chemical elementsGas phaseMetasilicate

Owner:CELANESE INT CORP

Nano silicon dioxide preparation method

This invention discloses a method for producing nanometer silica dioxide particle. The procedures comprise: add the alkali metal metasilicate into the mixture of hydrocarbons component, surfactant and cosurfactant to form the nanometer super solubilizing colloidal group system of oil-coated high concentration alkali metal metasilicate, which limits the produced nanometer silica dioxide in the nanometer colloidal group for precipitation reaction, and then the invented nanometer silica dioxide can be obtained by washing and drying. By using the characteristic of the highly internal phase dispersed system of oil-coated high concentration alkali metal metasilicate which can in-situ synthesize nanometer particles, the particle diameter of the produced silica dioxide can be 1-100nm, with a narrow range and single distribution state. This invention is characterized of low consumption of surfactant and hydrocarbon component, and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

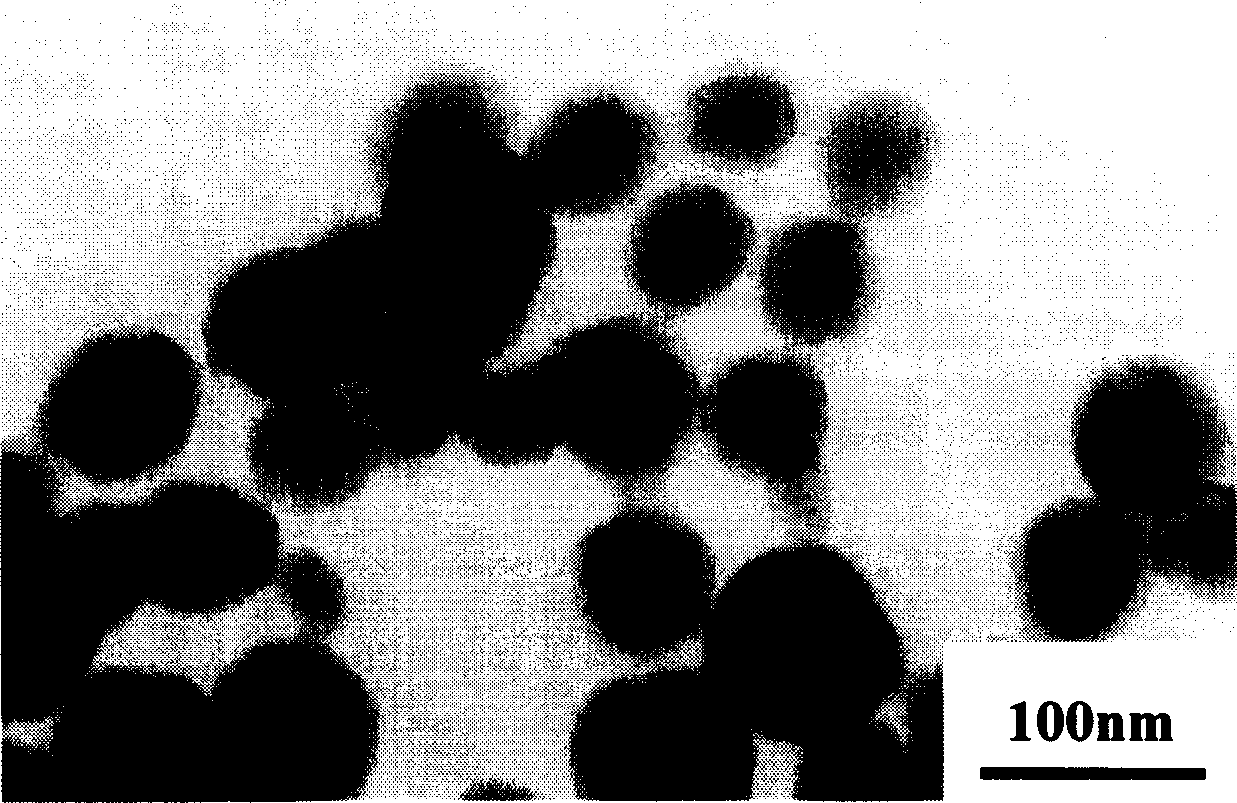

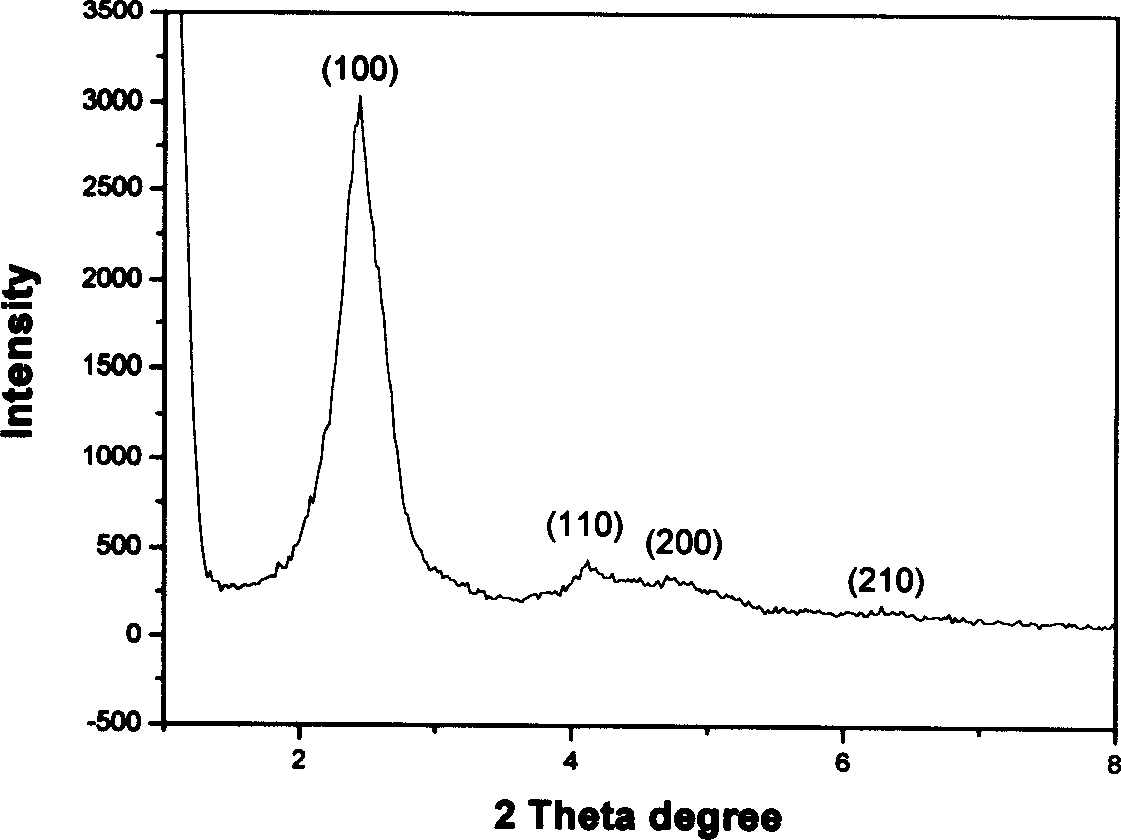

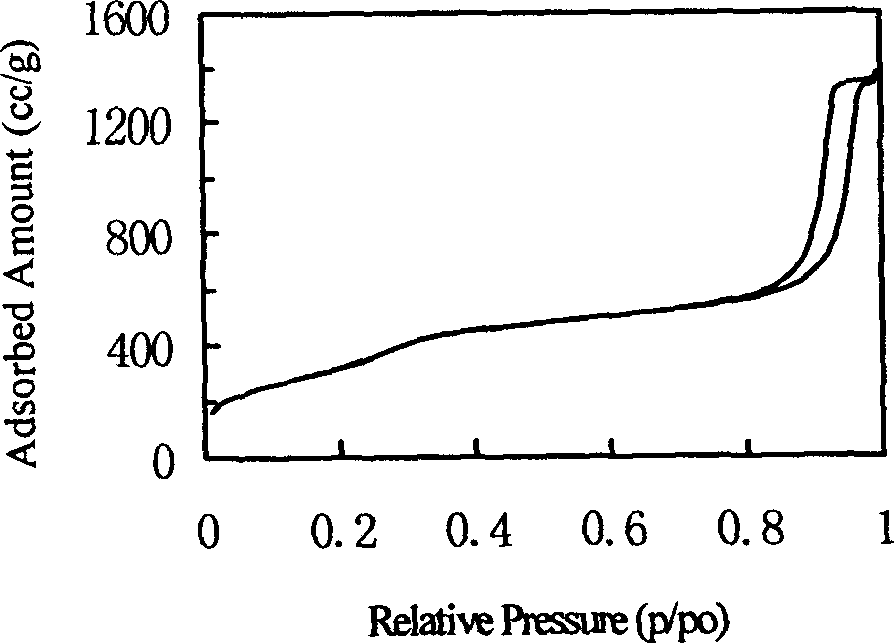

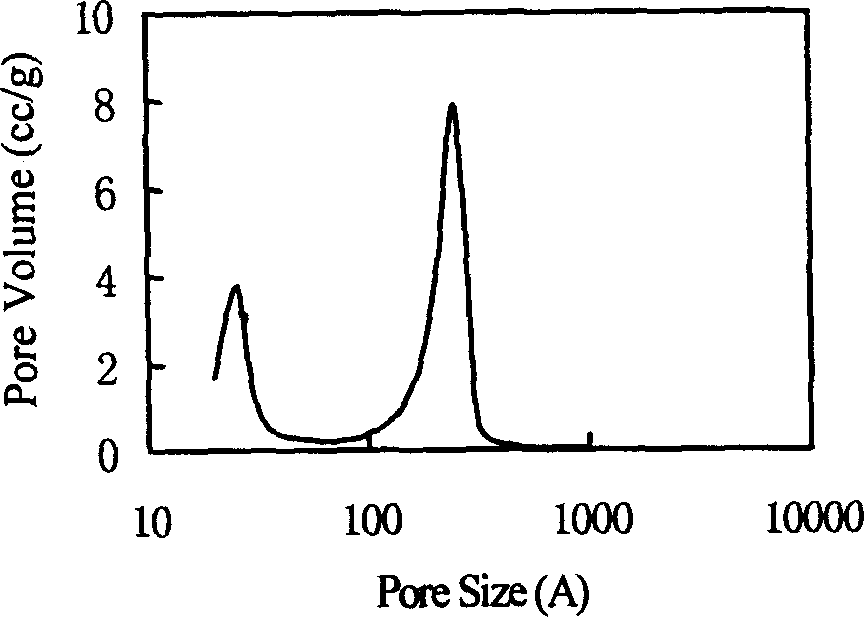

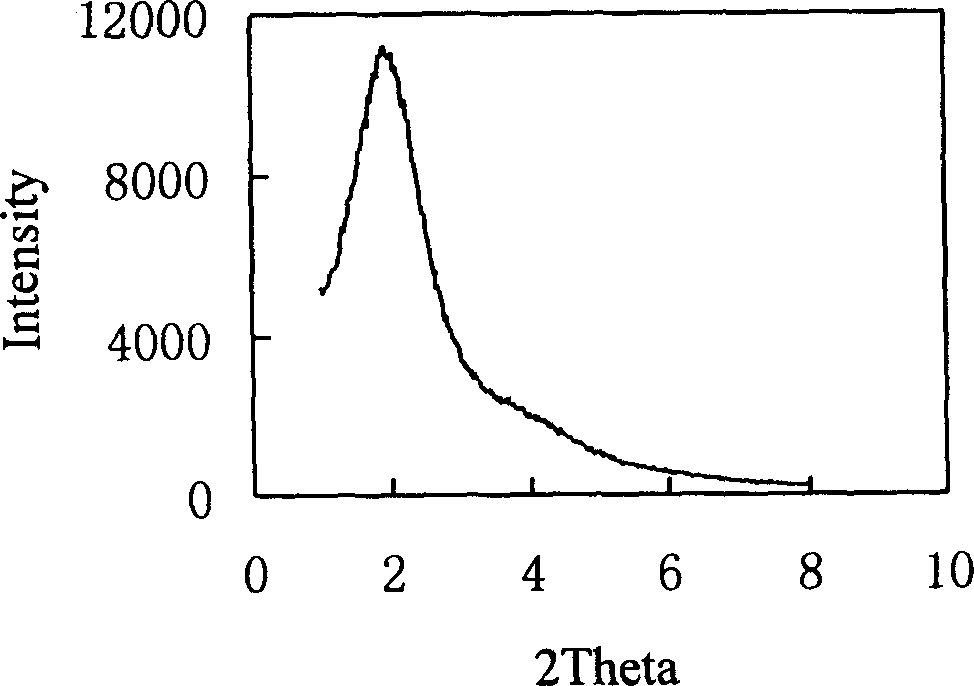

Prepn of mesoporous spherical nano Sio2 particle

The preparation process of mesoporous spherical nano SiO2 particle includes mixing deionized water, CTAB, tetraethyl metasilicate, water solution or ammonia water solution of sodium hydroxide and alcohol solvent in certain proportion; heating reaction of the mixture inside PTFE reactor with protecting stainless steel casing and set in stove with blower; filtering of the reacted solution; washing and high temperature roasting to obtain mesoporous spherical nano SiO2 particle with homogeneous size. The process of the present invention is simple, low in cost and short in production period, and the prepared mesoporous spherical nano SiO2 particle is homogeneous in size, regular in appearance and ordered in pore channel.

Owner:SHANGHAI JIAO TONG UNIV

Catalyst for hydrogenating cis-butenedioic anhydride to prepare butanedioic anhydride and its prepn and application

InactiveCN1453066AHigh surface areaImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCarboxylic acid anhydrides preparationButanedioic acidPtru catalyst

The catalyst has active component Ni and carrier SiO2 and Al2O3 in the molar ratio of 1 to 1.47-5.98 to 0-3.3. The catalyst is prepared with Ni(NO3)2, ethyl metasilicate with or without aluminum nitrate and ethanol, and through pH regulation to 3-5 or 7-9 with acetic acid, ammonia water or urea, heating at 80-120 deg.c to form gel, roasting at 400-550 deg.c and reduction at 400-580 deg.c. One technological process of catalytically hydrogenating cis-butenedioic anhydride to prepare butasnedioic anhydride in the state with or without solvent is provided. The catalyst has the features of highspecific surface area, high dispersion of metal in carrier, high heat stability, high catalytic activity, high selectivity, capacity of being reused, easy separation from the product, low cost, low consumption and mild reaction condition.

Owner:SHANXI UNIV

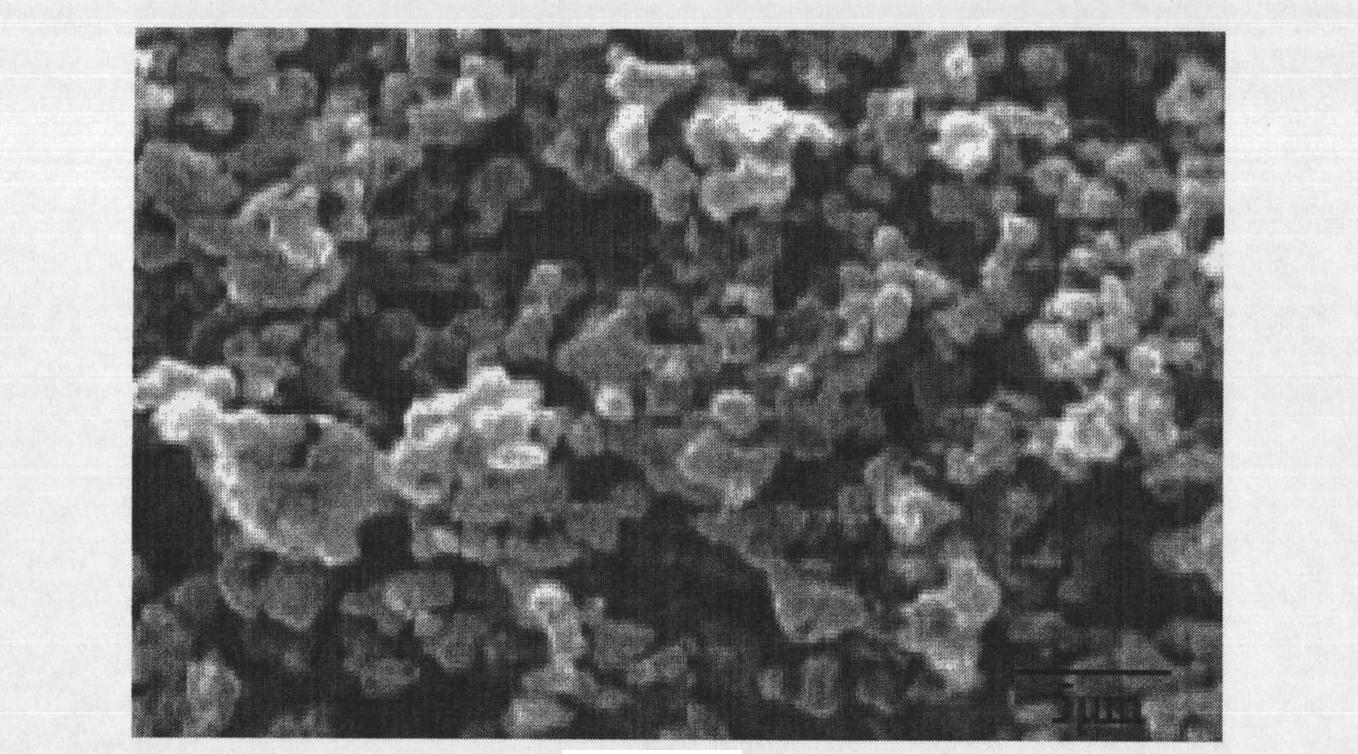

Treatment method of magnesium alloy material capable of being absorbed by human body and magnesium alloy composite layer

ActiveCN101560686AProlong degradation timeNot easy to fall offAnodisationProsthesisMicro arc oxidationMetasilicate

The invention provides a treatment method of a magnesium alloy material capable of being absorbed by a human body and a magnesium alloy composite layer. The treatment method comprises the following steps: (1) the magnesium alloy material capable of being absorbed by the human body is washed to remove surface pollutants; (2) the magnesium alloy material capable of being absorbed by the human body is put in electrolyte solution containing silicon, micro-arc oxidation treatment is carried out under the condition that the voltage is larger than 200 to 600V, so as to lead the surface of the magnesium alloy material capable of being absorbed by living creature to form a micro-arc oxidation film layer; and (3) the magnesium alloy material capable of being absorbed by the human body after micro-arc oxidation treatment is washed and then dried. The magnesium alloy composite layer comprises the magnesium alloy material capable of being absorbed by the human body as matrix and the micro-arc oxidation film layer which covers the surface of the matrix and has the thickness of 0.5 to 50 microns; the micro-arc oxidation film layer comprises an inner layer and an outer layer, wherein the inner layer is an magnesium oxide layer and the outer layer is a crystalline compound layer of magnesium silicate or / and magnesium metasilicate. The magnesium alloy composite layer achieves the purpose of prolonging the degradation time of magnesium alloy.

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

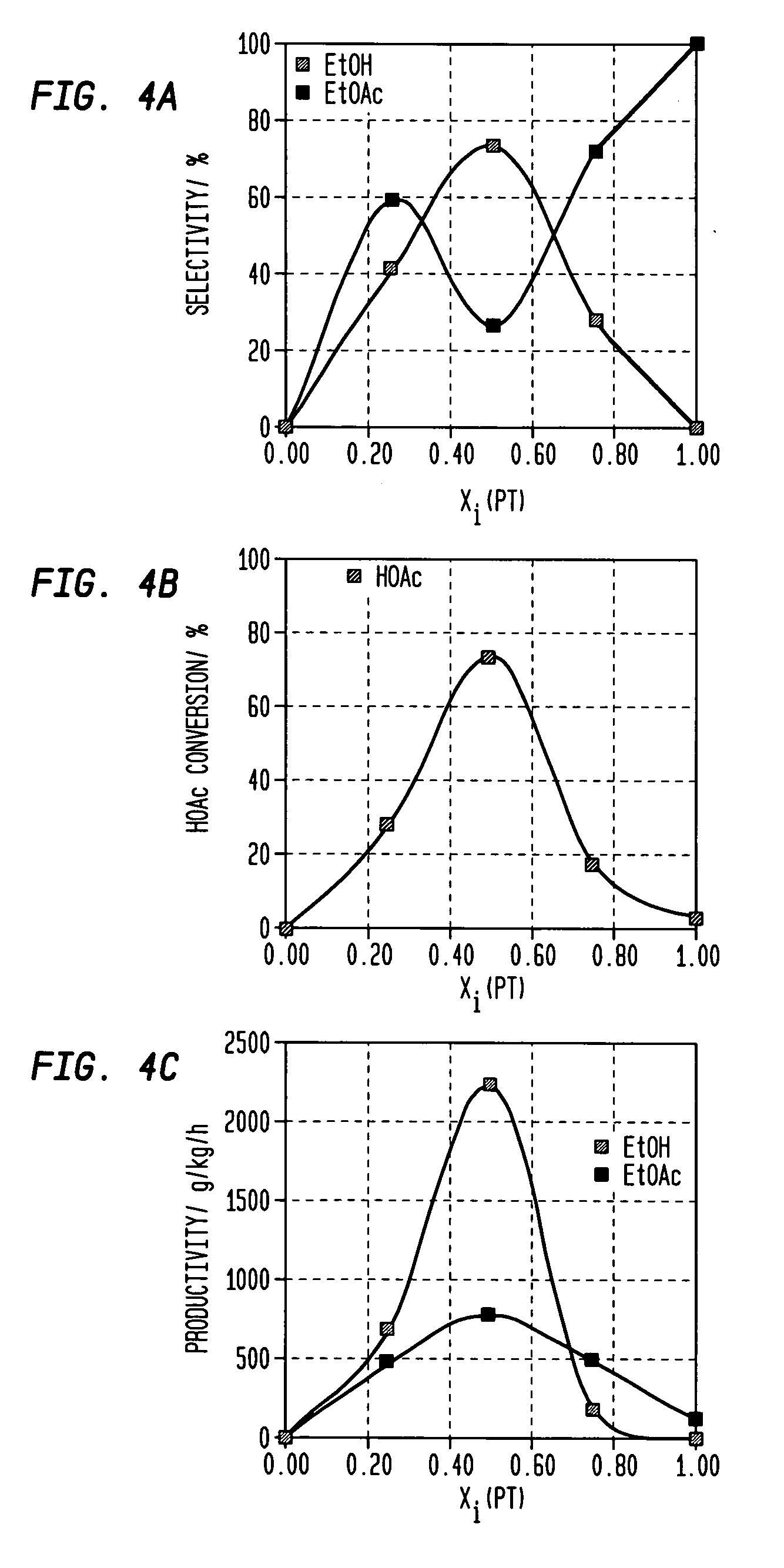

Catalysts for making ethanol from acetic acid

Catalysts and processes for forming catalysts for use in hydrogenating acetic acid to form ethanol. In one embodiment, the catalyst comprises a first metal, a silicaceous support, and at least one metasilicate support modifier. Preferably, the first metal is selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, molybdenum, and tungsten. In addition the catalyst may comprise a second metal preferably selected from the group consisting of copper, molybdenum, tin, chromium, iron, cobalt, vanadium, tungsten, palladium, platinum, lanthanum, cerium, manganese, ruthenium, rhenium, gold, and nickel.

Owner:CELANESE INT CORP

Method of preparing alkali resistance ultra-pure silicasol

The invention discloses a making method of alkaline-resistance hyperhigh pure silicasol, which comprises the following steps: 1. adopting distilled pure organic silicane as raw material; dissolving in the inorganic acid or organic acid to obtain acid metasilicate acid solution; 2. dissolving rectified organic silicane in the inorganic alkaline or organic alkaline solution to obtain the alkaline silicon solution; or diluting inorganic alkaline or organic alkaline solution to obtain alkaline solution without silicon; 3. reacting acid metasilicate acid solution and alkaline solution without silicon under 105 deg.c; obtaining the silicasol; 4. heating silicasol under normal pressure or decompressing condition to boil to remove carbinol or alcohol and partial water; obtaining the product with density over 20%.

Owner:苏州西丽卡电子材料有限公司

Nano hydroxyl magnesium silicate powder and preparation method thereof

InactiveCN101386713AImprove anti-wear and anti-friction performanceExtends service life of moving friction websInorganic pigment treatmentAdditivesMetasilicateMechanical equipment

The invention discloses a nanometer hydroxy magnesium metasilicate powder body which is prepared from the following raw materials: 5 to 20 percent of diatomite, 15 to 25 percent of magnesium sulfate, 10 to 20 percent of sodium hydroxide and 45 to 70 percent of sodium dioxide. The particle diameter of the nanometer hydroxy magnesium metasilicate powder body is less than or equal to 100 nanometers,thereby really reaching the nanometer level. The nanometer hydroxy magnesium metasilicate powder body is used as an additive of a lubricating oil product, can substantially improve the antiwear and antifriction performances, the lubricating oil product has self-repairing function, and the nanometer hydroxy magnesium metasilicate powder body remarkably prolongs the service life of motion friction of mechanical equipment.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Method for synthesizing high-crystallinity ZSM-5 molecular sieve without organic template

InactiveCN101177282AHigh crystallinityHigh solid contentPentasil aluminosilicate zeoliteAluminateMetasilicate

The invention discloses a synthesizing method of high crystallinity ZSM-5 molecular sieve without using organic template, comprising the following steps: mixing silicon source and aluminum source with de-ionized water and inorganic base (needless if two silicon source is used) according to a certain proportion, wherein, the silicon source is unbodied solid of silicon dioxide or the mixture of the unbodied solid of silicon dioxide and solid metasilicate, and the aluminum source is aluminate or aluminum compounds; placing the mixture in a stainless steel reaction kettle provided with a teflon lining and performing hydrothermal crystallization under certain condition. The invention is characterized in that the high crystallinity ZSM-5 molecular sieve can be obtained without adding crystal seed into the mixture; and the ratio of water to silicon is small and the solid content is high; the expensive and environment-unfriendly organic template and the corrosive inorganic acid are not used. The invention has the advantages of low production cost, high productivity of single kettle, simple technology and environmental protection.

Owner:ZHEJIANG UNIV

Environment-friendly composite calcium metasilicate plate and preparation method thereof

The invention discloses an environment-friendly composite calcium metasilicate plate and a preparation method thereof. The preparation method comprises the following step: coating a nanometer titania photocatalyst aqueous suspension on a base plate of the calcium metasilicate plate in a rolling coating or spraying coating manner to obtain the environment-friendly composite calcium metasilicate plate, wherein the base plate of the calcium metasilicate plate is prepared from a silicon material, a calcium material, reinforced fibers and assistants; the nanometer titania photocatalyst aqueous suspension comprises titanium dioxide powder with the fineness of not greater than 50nm, a surface active agent, an adhesive and water. According to the preparation method, the nanometer titania photocatalyst aqueous suspension is coated on the base plate of the calcium metasilicate plate to form a water-based film; the water-based film is coated on the surface of a base material and then dried to form a membrane which can be used for highly catalyzing and degrading under the effect of light, so that indoor formaldehyde can be absorbed and degraded, and the antibacterial effect is also improved.

Owner:白山市东北亚新型建筑材料有限公司

Solidification matrix

ActiveUS7893012B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsMethacrylateMetasilicate

A solid cleaning composition includes methacrylate, water, defoamer, carboxylate, sodium carbonate, metasilicate, and surfactant. The solid cleaning composition includes between about 1% and about 10% methacrylate by weight, less than about 5% water by weight, between about 1% and about 5% defoamer by weight, between about 10% and about 30% carboxylate by weight, between about 15% and about 80% sodium carbonate by weight, between about 1% and about 5% metasilicate by weight, and between about 1% and about 5% surfactant by weight. The solidification system may be used, for example, in a solid detergent composition.

Owner:ECOLAB USA INC

Water-based paint remover as well as preparation method and using method thereof

InactiveCN101747677AEasy to useNo input requiredChemical paints/ink removersWater basedCITRATE ESTER

The invention relates to a water-based paint remover as well as a preparation method and a using method thereof, belonging to the technical field of paint removers. The paint remover comprises water and the following components in percentage by weight: 4 percent-10 percent of sodium hydroxide, 8 percent-12 percent of alkali auxiliary agents, 2.5 percent-4 percent of oxidants, 0.5 percent-1.5 percent of complex additives, 0.01 percent-0.1 percent of builders, wherein the alkali auxiliary agents are sodium carbonates and / or trisodium phosphates; the oxidants are potassium permanganates or chromic anhydrides; the complex additives are silicates or compounds of the metasilicates and corrosion inhibitors; and the builders are citrates. The water-based paint remover has the advantages of high paint removing capacity, low cost, environmental protection without pollution and simple and convenient preparation method and using method without a large quantity of equipment investment.

Owner:ANHUI JIANGNAN MACHINERY

Planting method for high-quality selenium-rich rice

InactiveCN105309256AHigh nitrogen contentImprove fertilityCalcareous fertilisersMagnesium fertilisersMetasilicatePotassium

The invention discloses a planting method for high-quality selenium-rich rice. The method includes the following steps of firstly, preprocessing a rice field, wherein a field where broad beans are planted is selected, and green manuring, irrigation, wet compositing, rotary tillage and harrowing and ridging are conducted after broad beans are picked; secondly, transplanting rice seedlings; thirdly, conducting tillering and fertilizer applying; fourthly, stocking ducks; fifthly, conducting full heading and fertilizer applying, wherein ducks are driven out after full heading is conducted on the seedlings, the water depth of the rice field is kept at 9-11 cm, 1-3 kg of urea, 1-2 kg of potassium metasilicate and 100-280 kg of organic selenium fertilizer aqueous solution are applied in a dressing mode in each mu of field, the weight ratio of organic selenium fertilizer to water is 1 to 500-700, and the selenium content in organic selenium fertilizer is 0.1-0.3 mg / kg; sixthly, conducting harvesting. Planted rice is high in selenium element content, good in quality and high in yield.

Owner:ANHUI MUMAHU AGRI DEV GRP

Nano waterproof paint

ActiveCN103555090AImprove waterproof performanceStrong scrub resistanceCoatingsAcrylic resinMetasilicate

The invention discloses a nano waterproof paint, which is prepared by the raw materials by weight: 70-80 parts of polyvinyl acetate emulsion, 3-5 parts of potassium metasilicate, 2-4 parts of lithium silicate, 8-10 parts of potassium titanate whisker, 5-7 parts of aqueous self-drying organosilicon modified acrylic resin HA88405, 15-20 parts of nanometer powdered carbon, 2-3 parts of nano zinc oxide, 3-5 parts of oxidation starch, 1-2 parts of urea, 1-2 parts of actinolite powder, 2-3 parts of ethylene dimethacrylate, 7-10 parts of bonding auxiliary agent, and 10-20 parts of deionized water. The waterproof paint has good waterproof paint, strong scrub resistance, and good stain resistance, and also has certain anticorrosion and sterilization efficacies, and good comprehensive properties.

Owner:湖南亚仕龙建材商贸有限公司

Preparation method of quartz crucible coating

InactiveCN102260902APlay a protective effectExtended service lifeBy pulling from meltCoatingsMetasilicateBarium hydroxide

The invention provides a method for preparing a quartz crucible coating. The method comprises the following steps of: (a) preparing a barium hydroxide solution, wherein the weight ratio of barium hydroxide to water in the barium hydroxide solution is 1:(46-52); and (b) heating a quartz crucible till the temperature is above 200 DEG C, uniformly spraying the barium hydroxide solution on the inner wall and the upper opening of the quartz crucible, and forming a barium hydroxide coating on the inner wall and the upper opening of the quartz crucible after spraying. According to the method, the barium hydroxide formed on the surface of the crucible is reacted with carbon dioxide in air to form barium carbonate; when the quartz crucible is heated on a mono-crystal furnace, the barium carbonate is decomposed into barium oxide; the barium oxide is reacted with the quartz crucible to form barium metasilicate; a barium metasilicate layer can be used for protecting the quartz crucible; mono-crystal silicon can be prevented from reacting with the quartz crucible in a high-temperature drawing process; the service life and the long crystal yield of the quartz crucible are improved; furthermore,the intensity of the quartz crucible can also be increased; and the high-temperature softening phenomenon is reduced.

Owner:JIANGSU JINGDING ELECTRONICS MATERIAL

Double mesopore molecular sieve and its preparation method

InactiveCN1380250ARich varietyIncreased diffusion sitesSilicaMolecular-sieve silica-polymorphsChemical synthesisMolecular sieve

The present invention relates to a double-mesopore molecular sieve and its preparation method, belonging to the field of chemical synthesis technology, and is characterized by that the double-pore pore size distributions of said material are being in the mesopore zone, so that said material can effectively meet the requirements to the catalyst pore size distribution for macromolecualr shape selection and diffusion effect, and is a potential industrial catalyst and catalyst carrier. Its preparation method uses quaternary ammonium salt cationic surfactant as template agent, and in the weak alkaline system utilizes the room-temp. hydrolysis and condensation polymerization of ethyl metasilicate to synthesize the invented double-mesopore distribution molecular sieve.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com