Patents

Literature

2127 results about "Magnesium silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium silicate is a chemical compound consisting of magnesium, silicon, and oxygen. It exists in several forms, both natural and manufactured. ... It is produced from the reaction of sodium silicate and a magnesium compound, such as magnesium sulfate. When produced in this way, the particles of the compound are porous, meaning that they consist of spaces through which liquid or gas can pass.

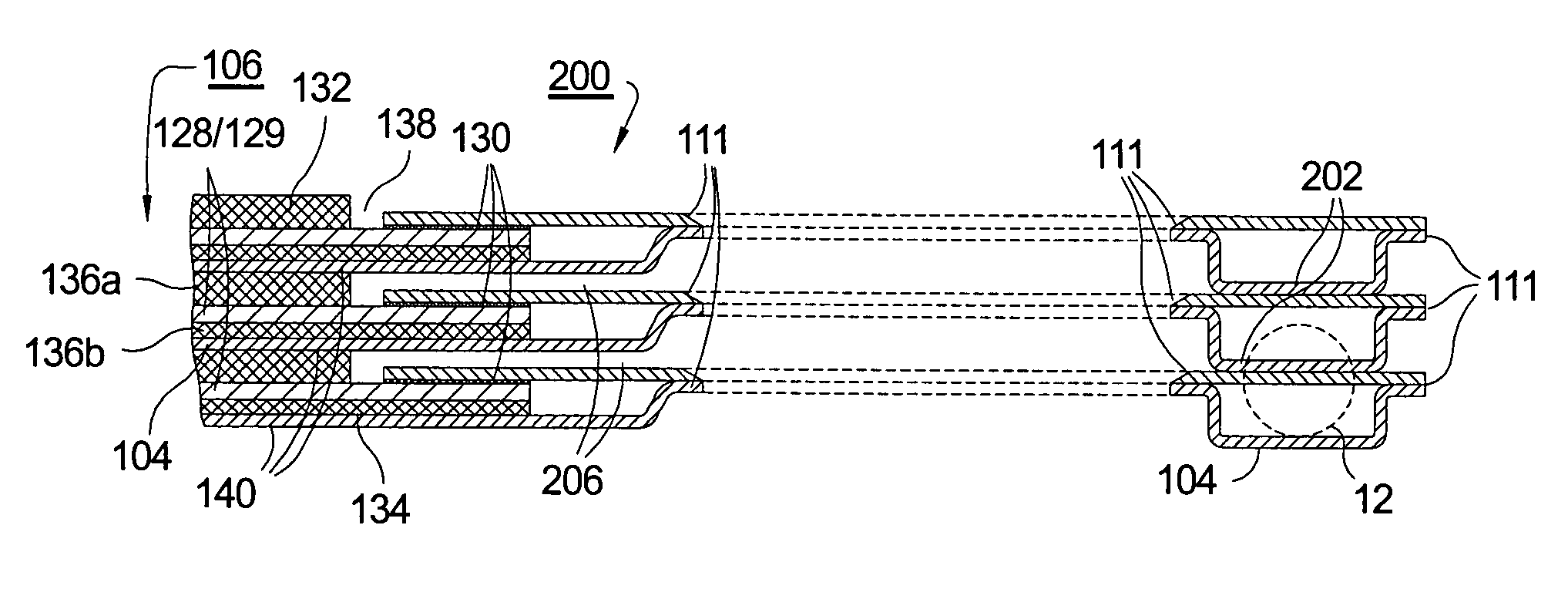

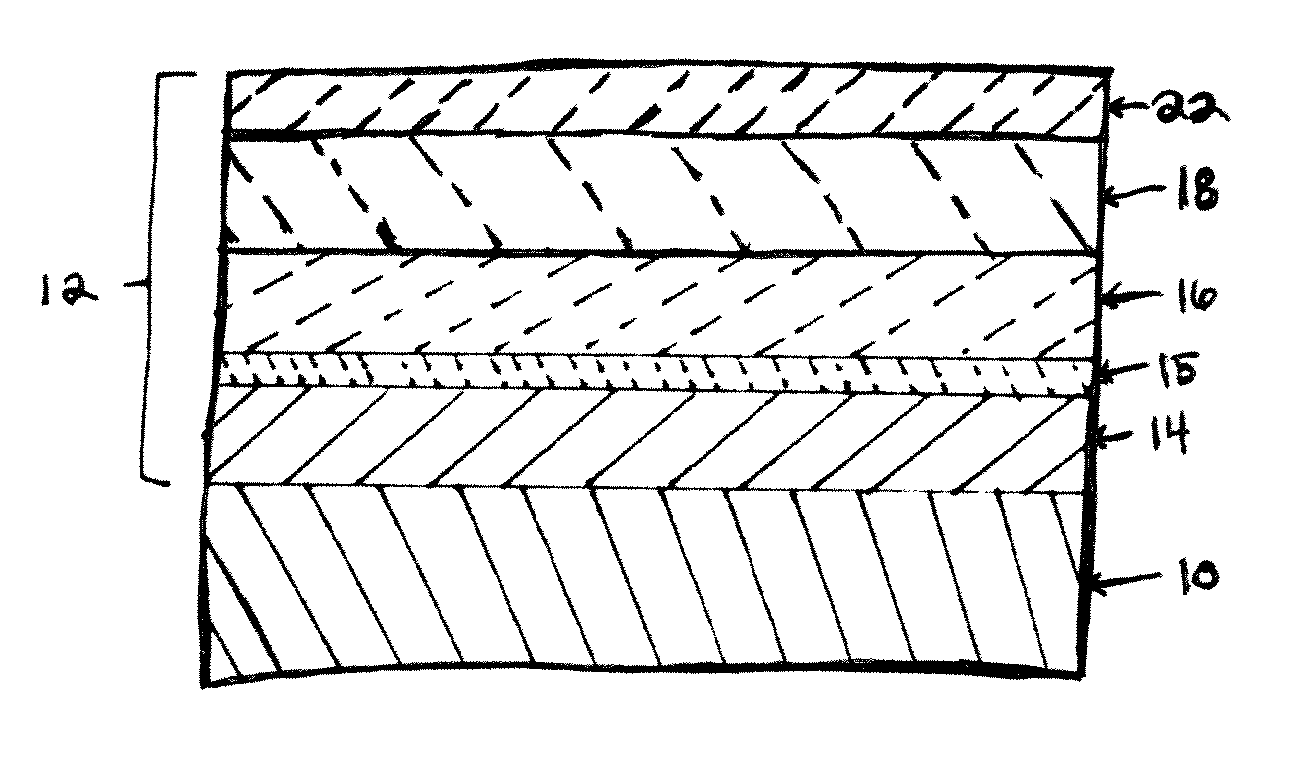

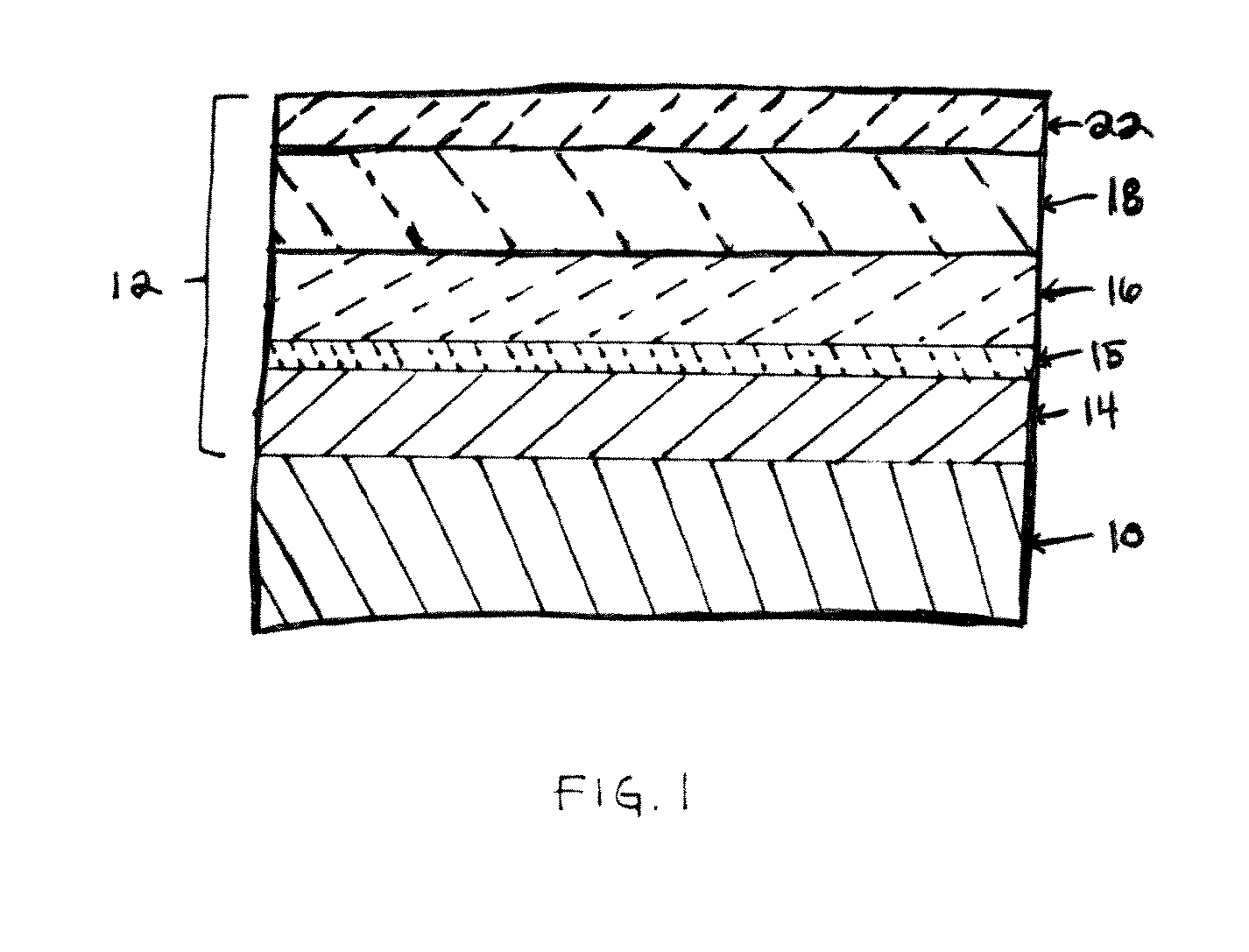

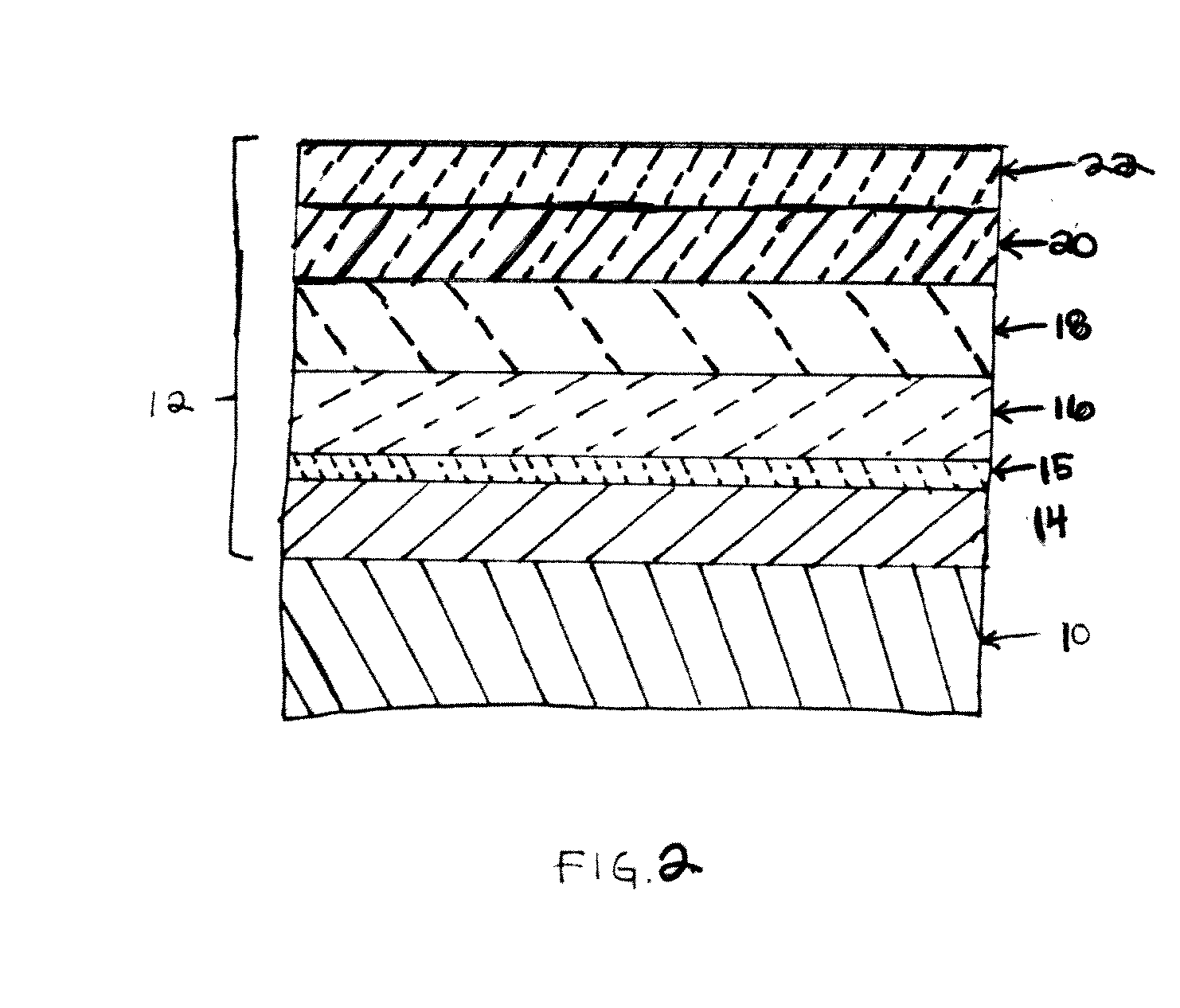

Toner and image forming method

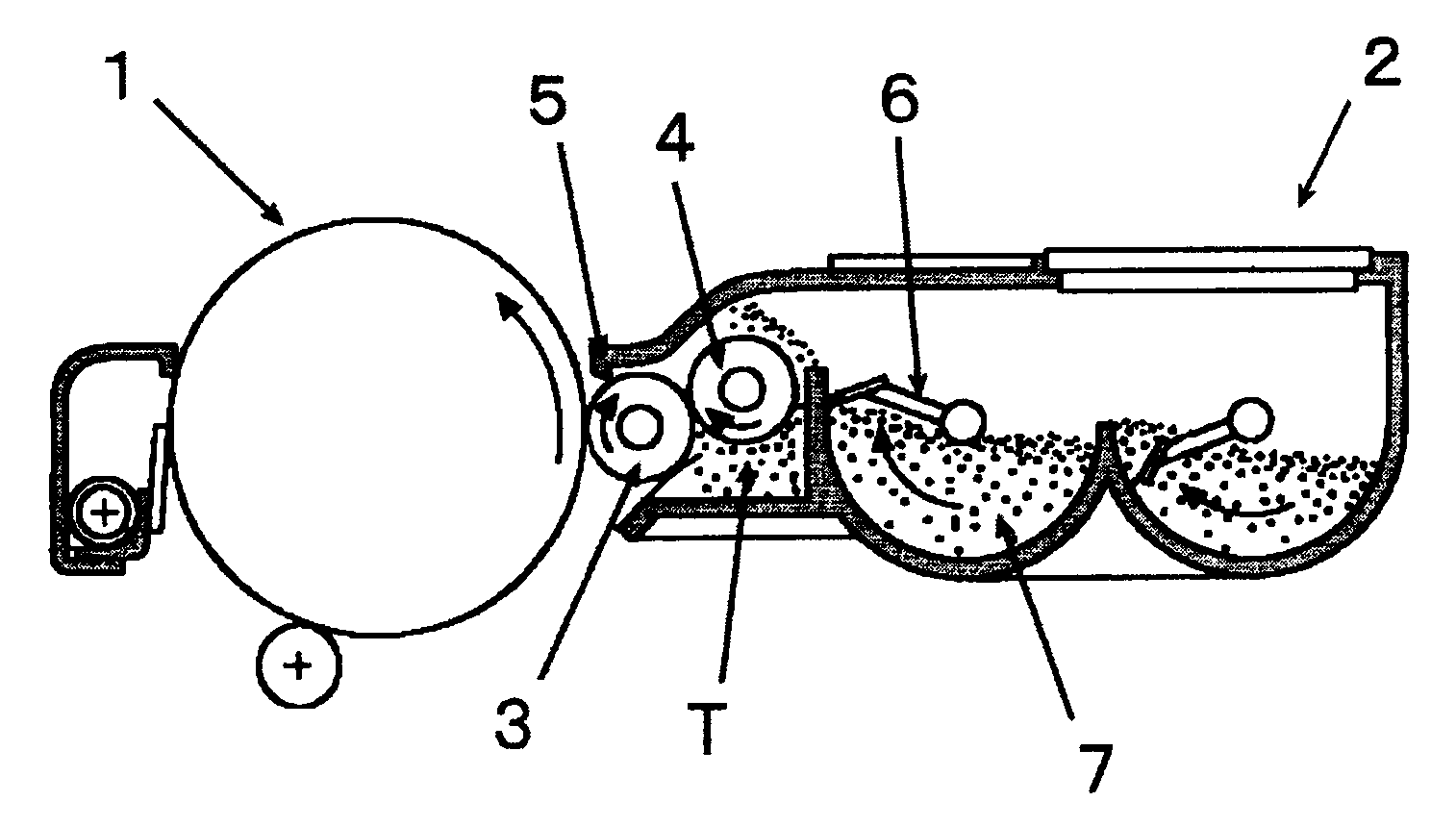

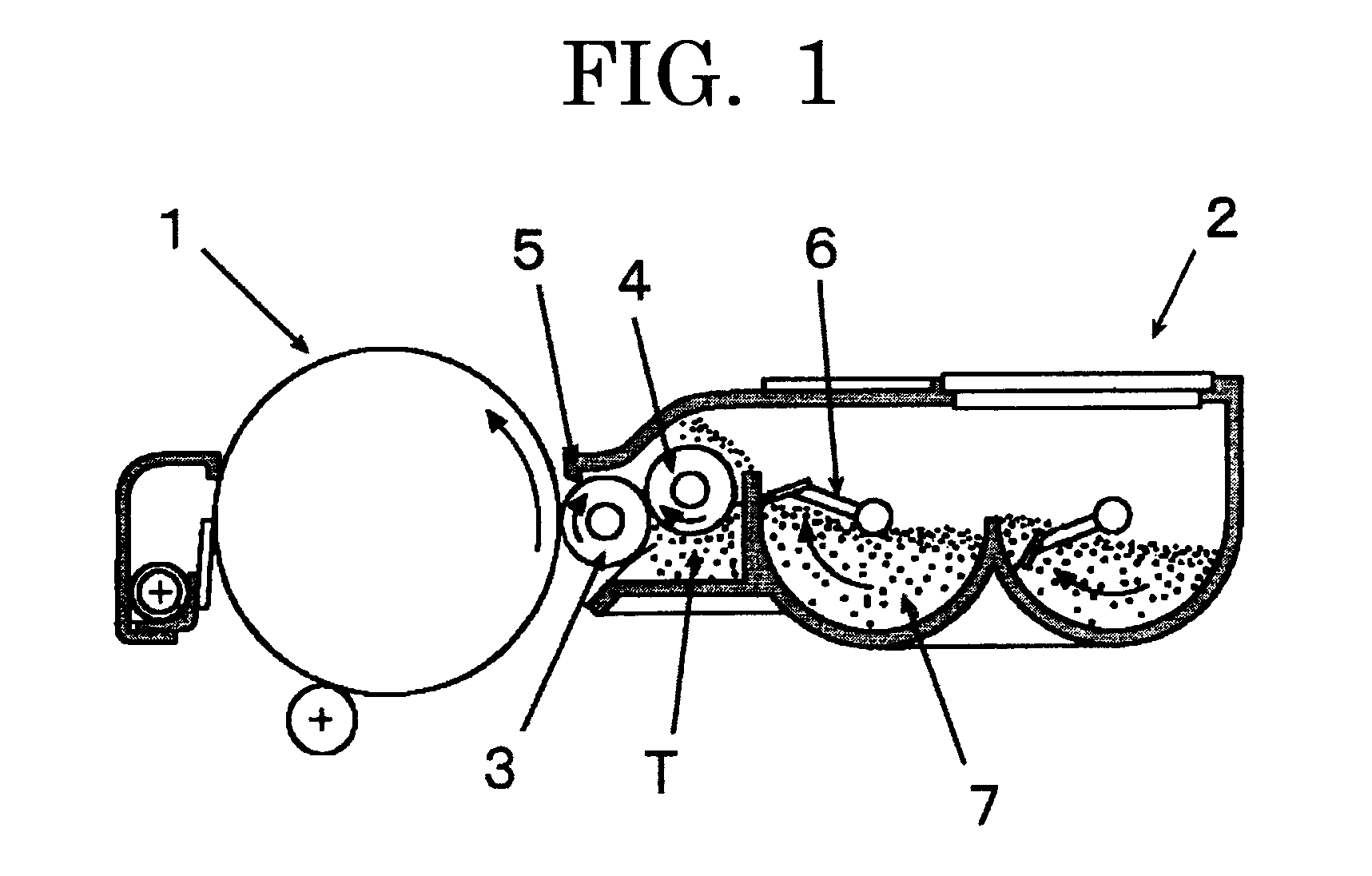

InactiveUS20070207399A1Improve stabilityUniformly and efficiently chargingElectrographic process apparatusDevelopersImage transferLatent image

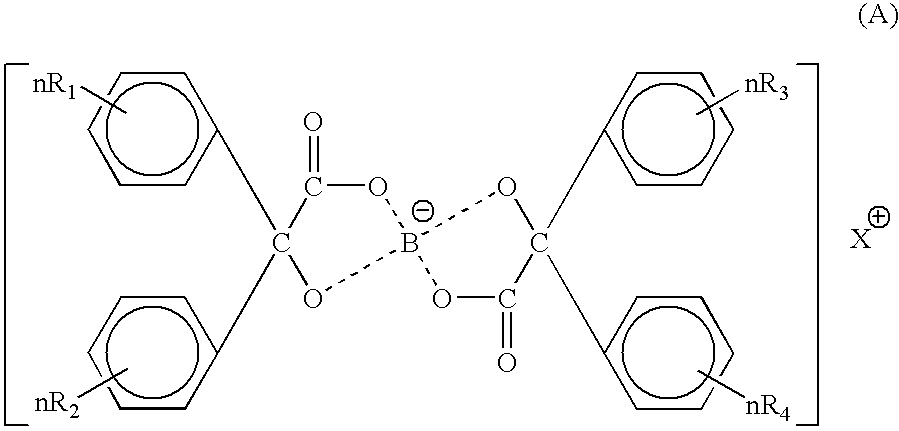

Toner for electrostatic charge development wherein no scumming occurs, and toner leakage caused by charge defect of the toner on a developing roller can be inhibited, and an excellent image stability is obtained is provided.The toner used for an image forming method having a latent electrostatic image forming step of forming a latent electrostatic image on a latent electrostatic image bearing member primarily charged, a developing step of developing the latent electrostatic image by each toner which multiple developing devices have to form a toner image on the latent electrostatic image bearing member, a transferring step of transferring the toner image with respective colors formed on the latent electrostatic image bearing member onto a recording material and a fixing step of fixing the toner image transferred onto the recording material, wherein the toner comprises a colorant and a resin and contains an organic boron compound represented by a following chemical formula (A) as a charge controlling agent, further the toner is treated with an inorganic fine particle and at least one of the inorganic particles is a magnesium silicate compound represented by a following general formula [2] is provided.wherein X is an alkali metal, R1, R2, R3 or R4 each represents a hydrogen atom, an alkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, or a halogen atom.MgxSiyO(x+2y) [2]wherein x and y are integers.

Owner:RICOH KK

Light source comprising a light-emitting element

InactiveUS20040090174A1High luminous efficiencyHigh degreePlanar light sourcesPoint-like light sourceAlkaline earth metalLuminophore

The invention relates to a light source comprising a light-emitting element, which emits light in a first spectral region, and comprising a luminophore, which comes from the group of alkaline-earth orthosilicates and which absorbs a portion of the light emitted by the light source and emits light in another spectral region. According to the invention, the luminophore is an alkaline-earth orthosilicate, which is activated with bivalent europium and whose composition consists of: (2-x-y)SrOx(Ba, Ca)O(1-a-b-c-d)SiO2aP2O5bAl2O3cB2O3dGeO2:yEu<2+> and / or (2-x-y)BaOx((Sr, Ca)O(1-a-b-c-d)SiO2aP2O5bAl2O3cB2O3dGeO2:yEu<2+>. The desired color (color temperature) can be easily adjusted by using a luminophore of the aforementioned type. The light source can contain an additional luminophore selected from the group of alkaline-earth aluminates, activated with bivalent europium and / or manganese, and / or can contain an additional red-emitting luminophore selected from the group Y(V, P, Si)O4:Eu or can contain alkaline-earth magnesium disilicate.

Owner:TOYODA GOSEI CO LTD

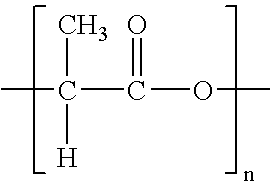

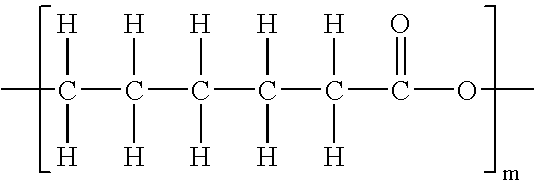

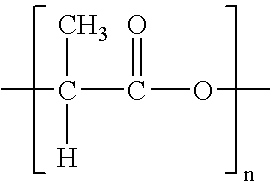

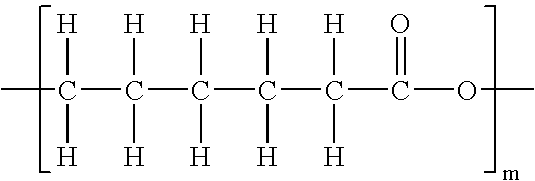

Biodegradable poly(lactic acid) polymer composition and films, coatings and products comprising Biodegradable poly(lactic acid) polymer compositions

InactiveUS7393590B2Improve ductilityIncrease flexibilitySynthetic resin layered productsThin material handlingPolyesterPolymer science

The present invention relates to biodegradable polymer compositions comprising poly(lactic acid) and poly(epsilon caprolactone) and co-polyester polymer with adipic acid mixed with organic peroxide and magnesium silicate minerals. In addition, the present invention relates to films, coatings and products made on the basis of said compositions and to a method for their preparation.

Owner:CEREPLAST INC

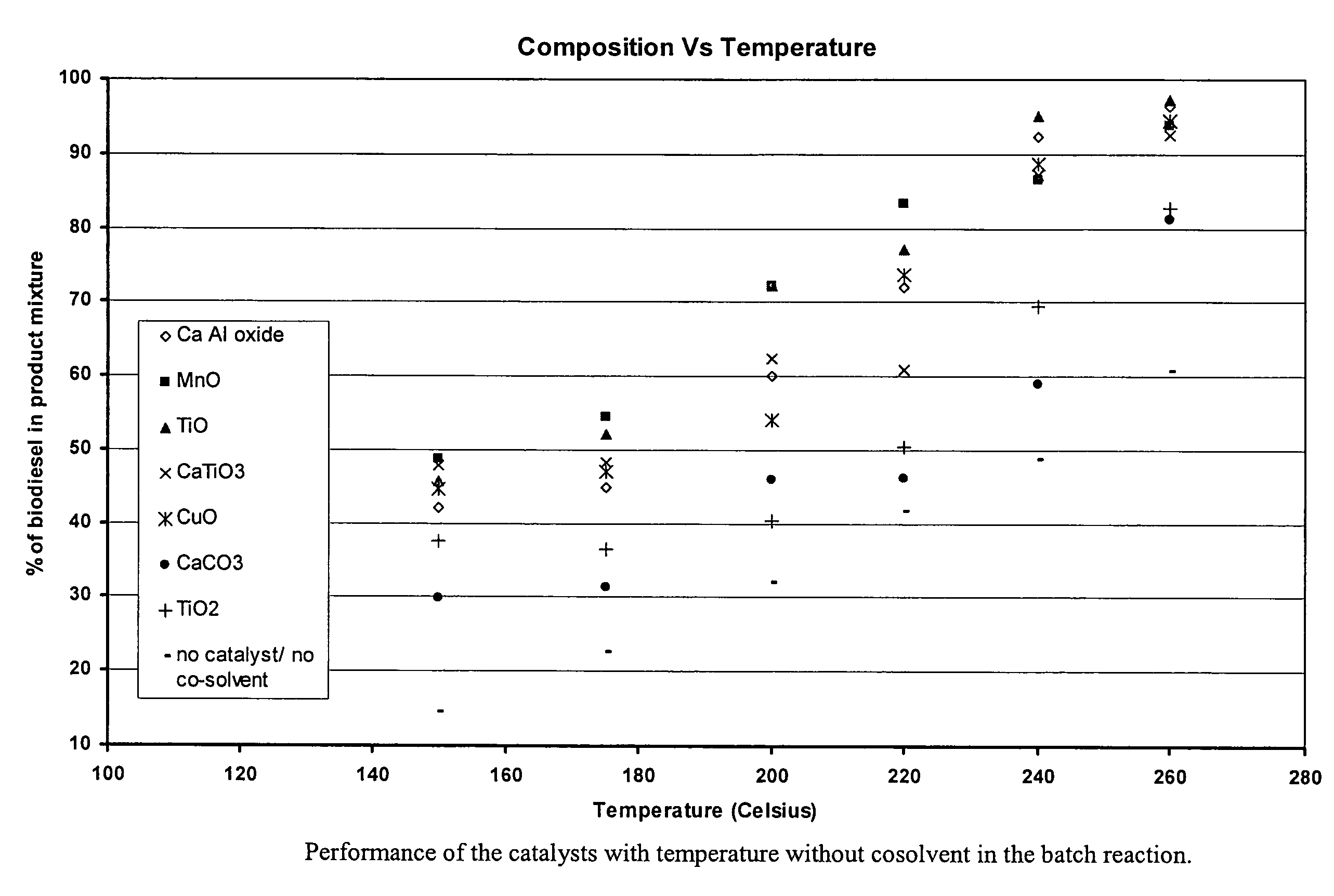

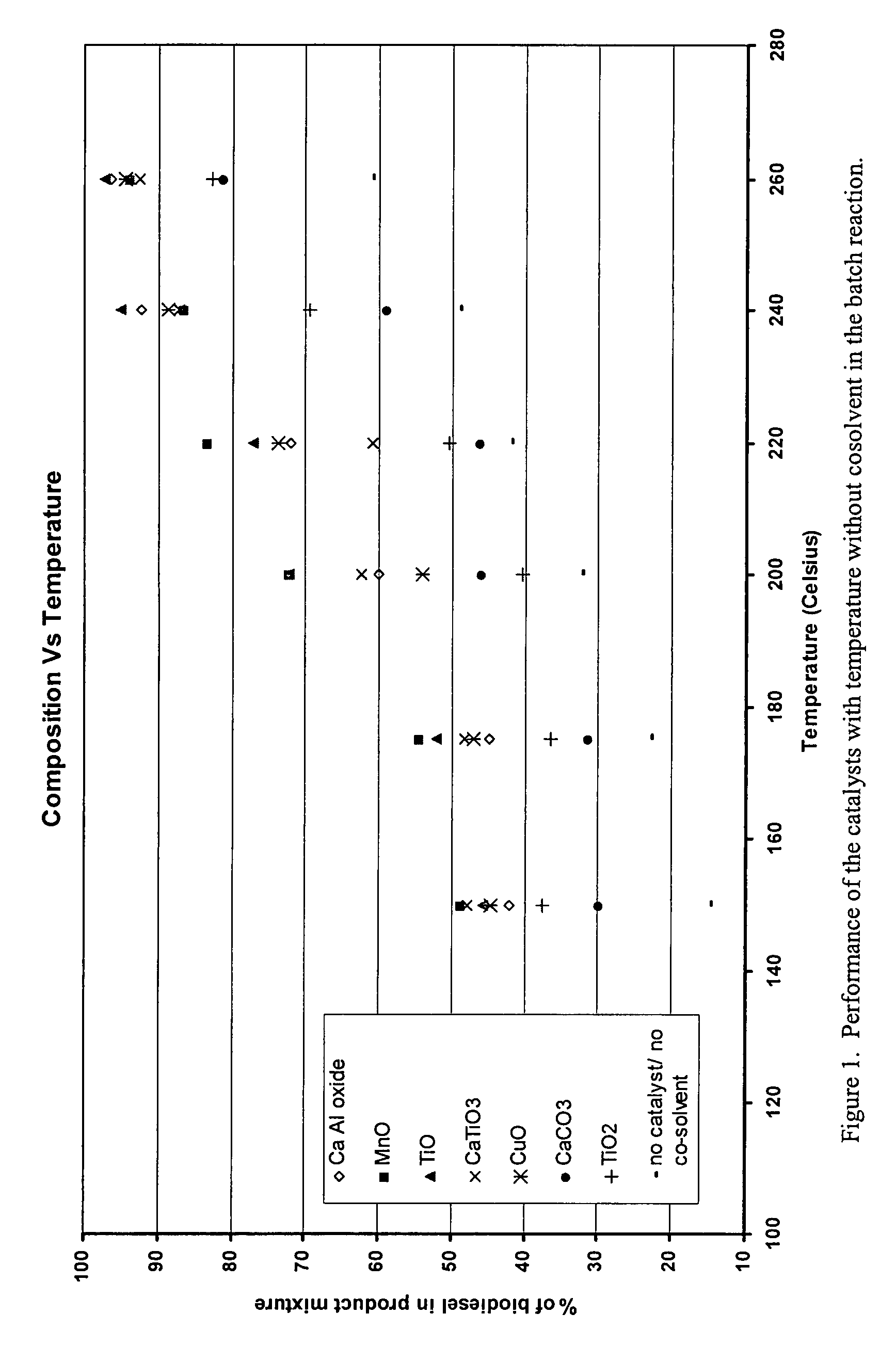

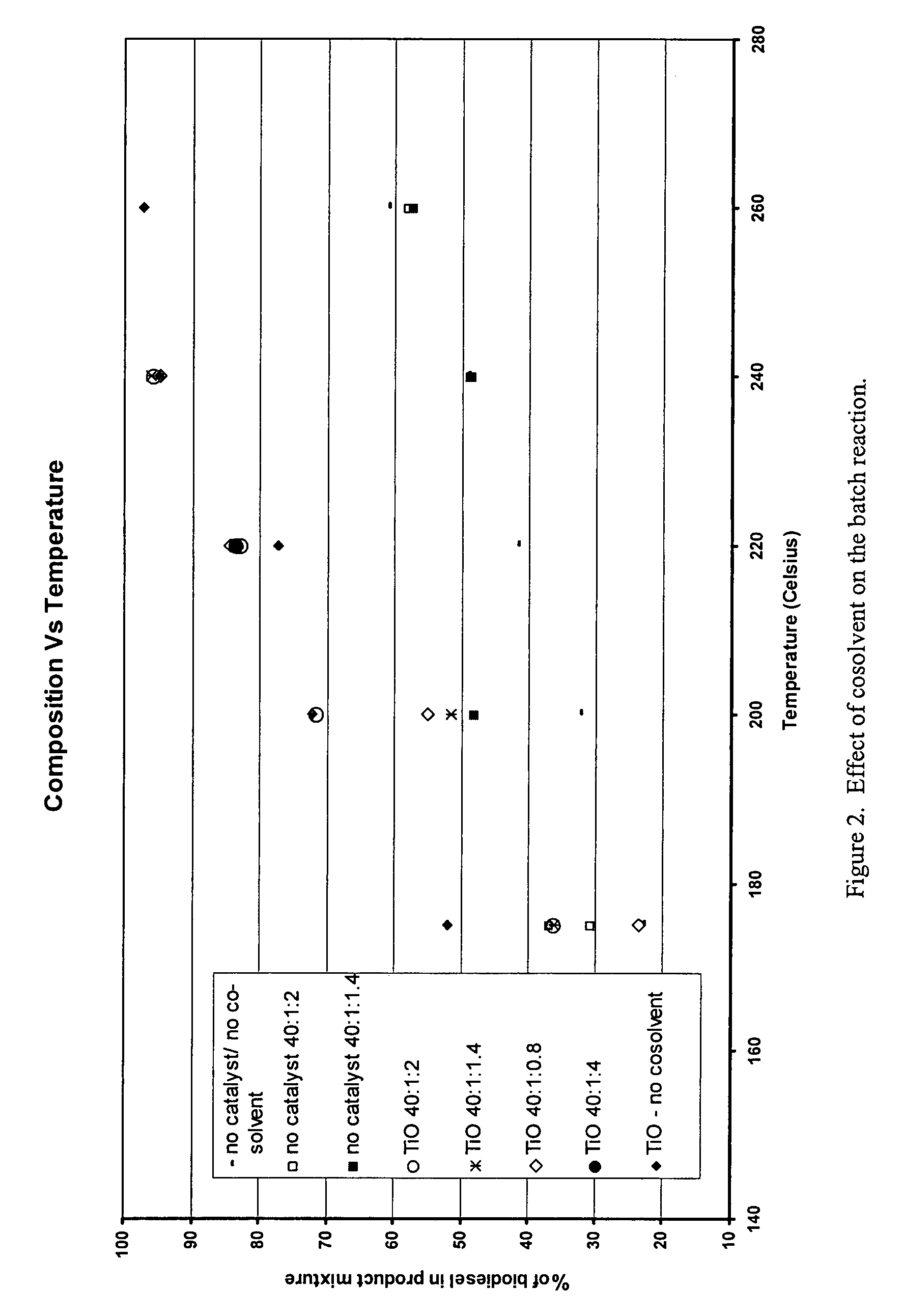

Green biodiesel

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

Process for removal of catalyst residues from poly-alpha-olefins

ActiveUS20050101761A1Reduce raw material usageOperation efficiency can be improvedHydrocarbonsAdsorption purification/separationCalcium silicateHalogen

A method is disclosed for reducing levels of residual halogen and Group IIIb metals in a crude poly(α-olefin) polymerized in the presence of a catalyst comprising the halogen and Group IIIb metals, wherein the method comprises: A) washing the crude poly(α-olefin) with water; B) separating the aqueous and organic phases; C) then adding an adsorbent selected from the group consisting of magnesium silicates, calcium silicates, aluminum silicates, aluminum oxides, and clays to the organic phase to form a slurry; D) heating the slurry under reduced pressure at a temperature of at least about 180° C. for at least about thirty minutes; and then E) separating the adsorbent from the slurry.

Owner:CHEMTURA CORP

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

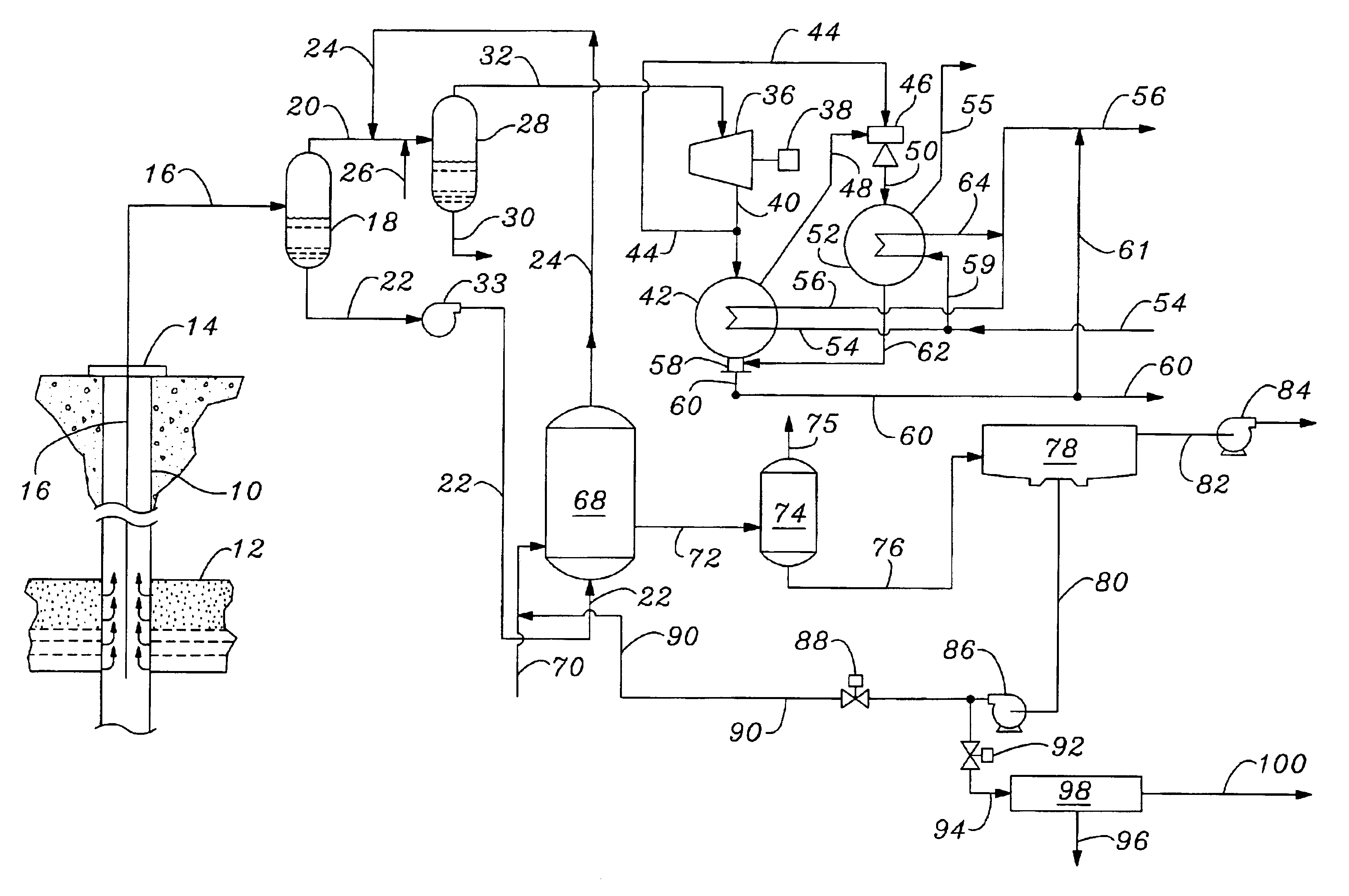

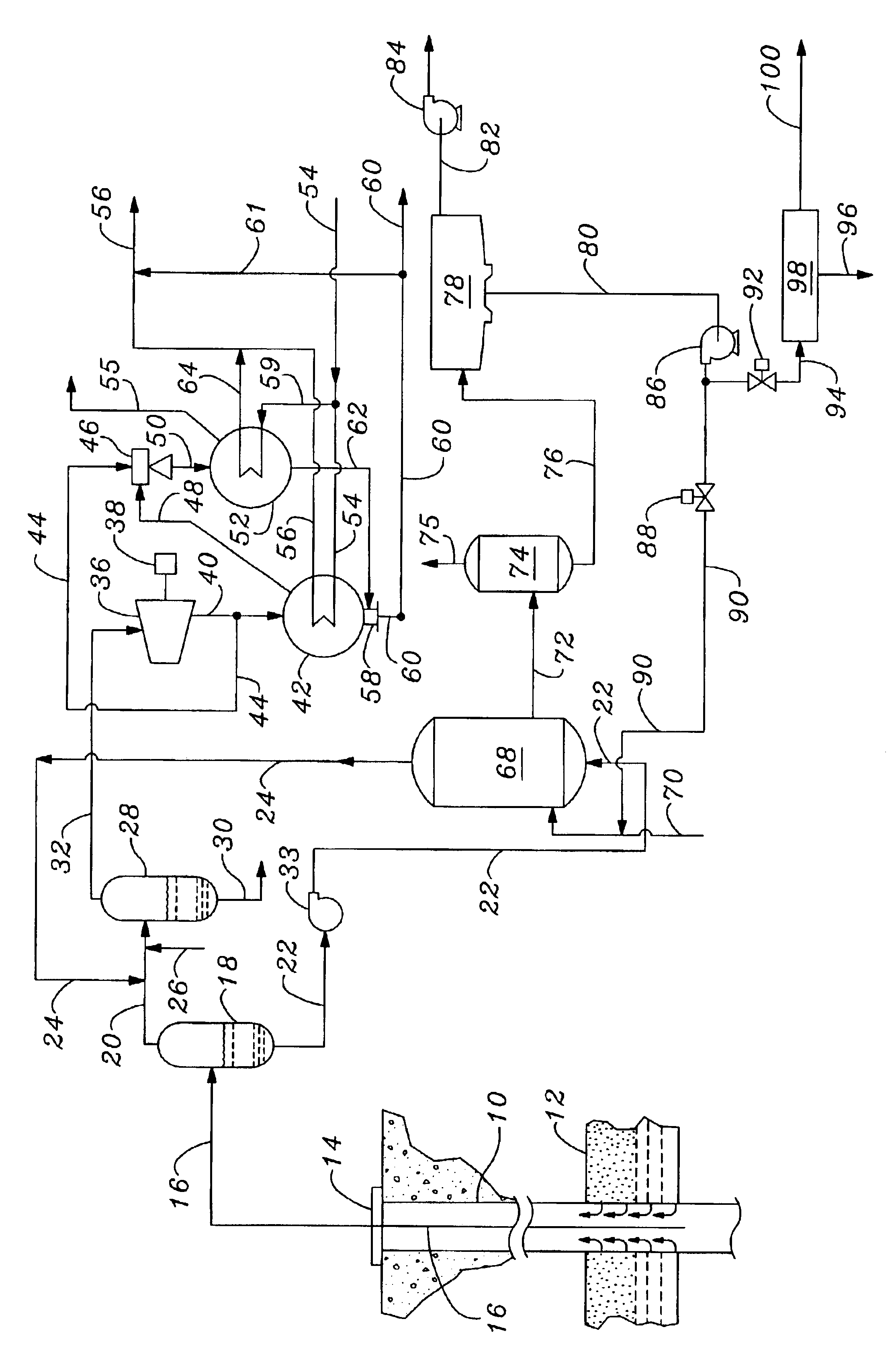

Method for synthesizing crystalline magnesium silicates from geothermal brine

Crystalline magnesium silicates are synthesized from silica-containing brines, preferably spent geothermal brines, by mixing the brine with a magnesium-containing compound, adjusting the pH of the resultant mixture between 8.0 and 14, and crystallizing the magnesium silicate from the mixture at a temperature between 50° C. and 200° C. Kerolite is preferably synthesized from brine by adjusting the pH in a range between 9.5 and 10.5 and heating the mixture to between 100° C. and 170° C. to precipitate the crystalline kerolite. The brine remaining after the crystallization step is depleted in silica and can be further processed without significant problems caused by silica scaling.

Owner:UNION OIL OF CALIFORNIA

Ceramic proppant with low specific weight

InactiveUS20080070774A1Avoid product qualitySintering range is again narrowedFluid removalCeramic shaping apparatusMagnesium orthosilicateUltimate tensile strength

A precursor composition for the production of granulated ceramic material, particularly for ceramic proppants, comprises 20 to 55% by weight of magnesium orthosilicate, 20 to 35% by weight of MgO, and 2.5 to 11% by weight of Fe2O3. The resulting lightweight proppant material shows high mechanical strength. To further decrease the specific density of the proppant, the formation of small pores can be increased by adding 0.3 to 2.4% carbon as a gas-forming agent.

Owner:OBSCHESTVO S OGRANICHENNOY OTVETSTVENNOSTYU FORES

Biodegradable poly(lactic acid) polymer composition and films, coatings and products comprising Biodegradable poly(lactic acid) polymer compositions

InactiveUS20050192410A1Increase flexibilityImprove ductilitySynthetic resin layered productsThin material handlingPolymer scienceBiodegradable polymer

The present invention relates to biodegradable polymer compositions comprising poly(lactic acid) and poly(epsilon caprolactone) mixed with organic peroxide and magnesium silicate minerals. In addition, the present invention relates to films, coatings and products made on the basis of said compositions and to a method for their preparation.

Owner:CEREPLAST INC

Methods for making environmental barrier coatings and ceramic components having cmas mitigation capability

ActiveUS20100159150A1Liquid surface applicatorsMolten spray coatingRare-earth elementALUMINUM PHOSPHATE

Methods of making components having calcium magnesium aluminosilicate (CMAS) mitigation capability involving providing a component; applying an environmental barrier coating to the component, the environmental barrier coating having a separate CMAS mitigation layer including a CMAS mitigation composition selected from rare earth elements, rare earth oxides, zirconia, hafnia partially or fully stabilized with alkaline earth or rare earth elements, zirconia partially or fully stabilized with alkaline earth or rare earth elements, magnesium oxide, cordierite, aluminum phosphate, magnesium silicate, and combinations thereof.

Owner:GENERAL ELECTRIC CO

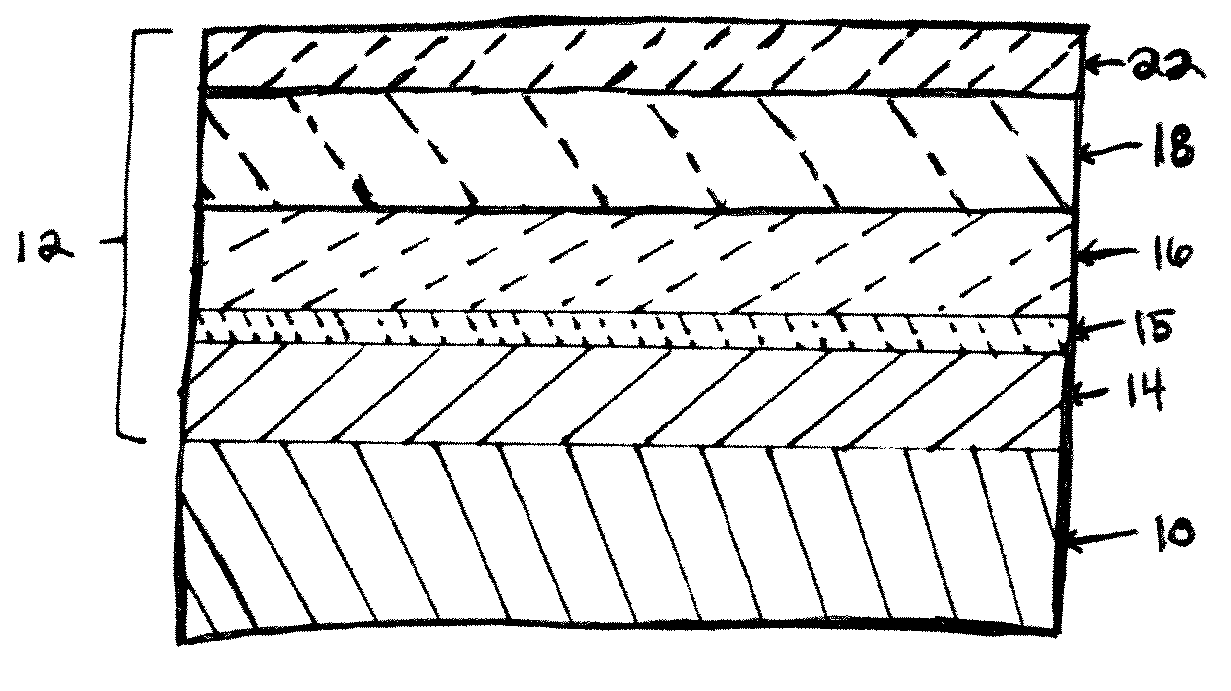

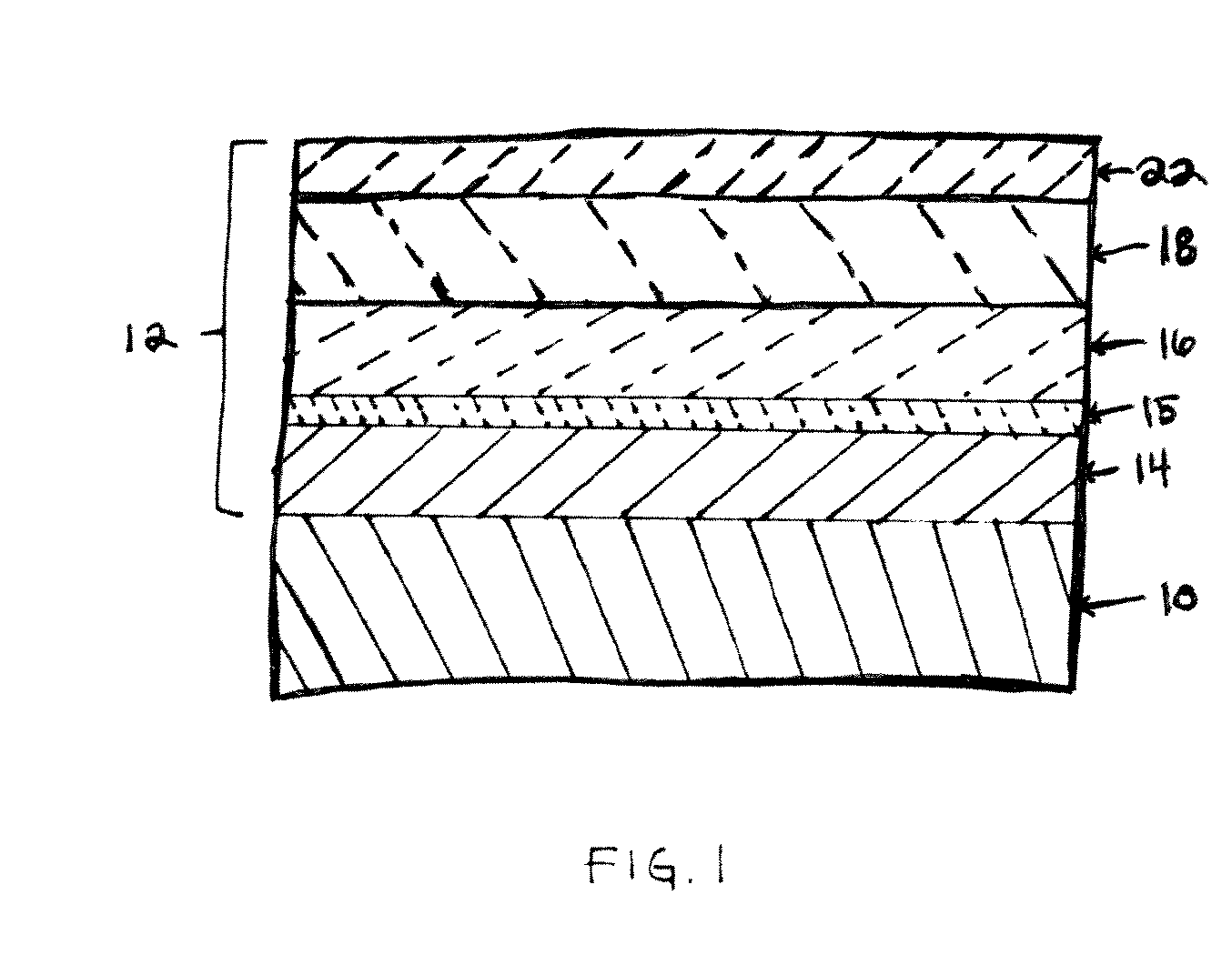

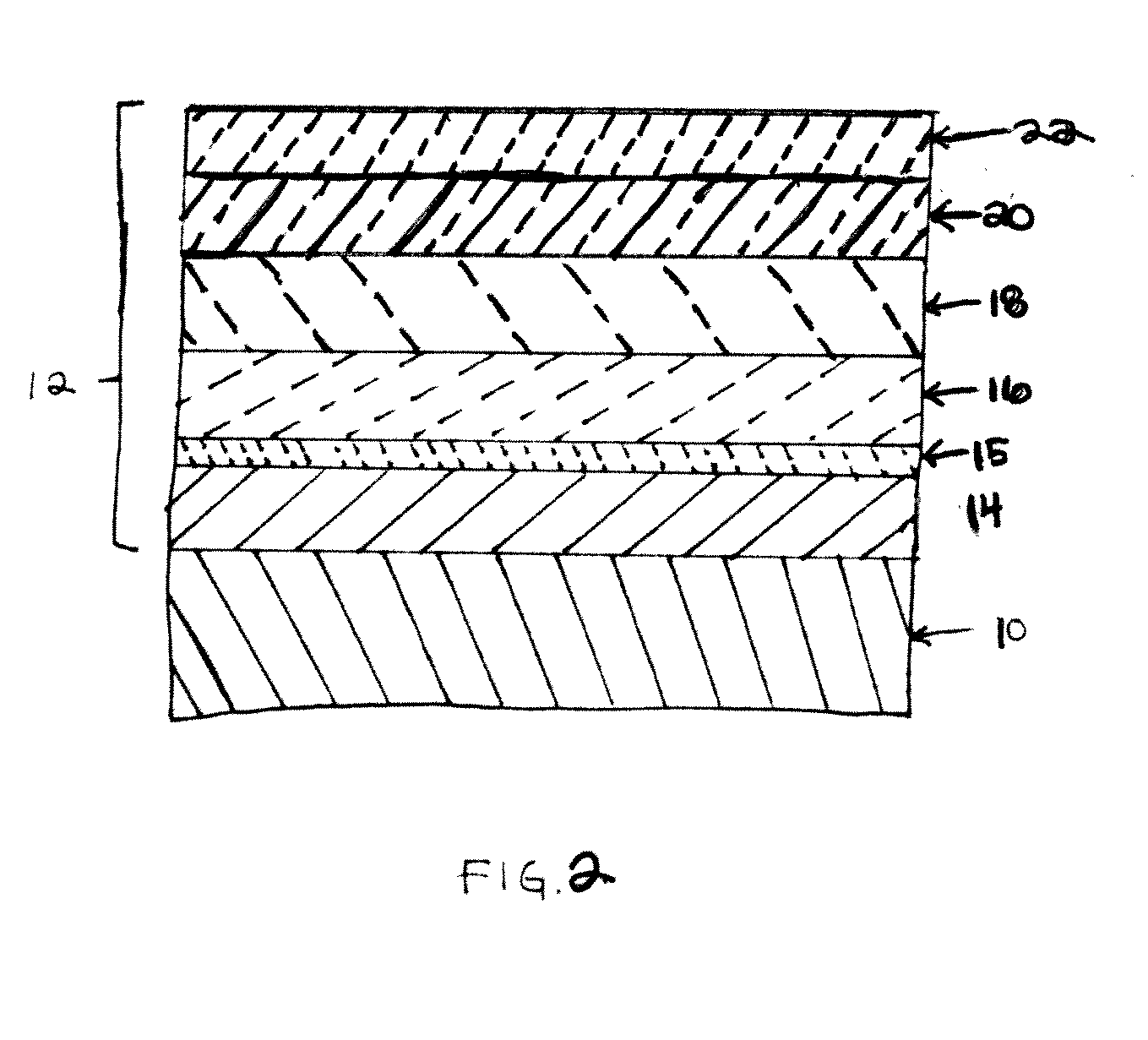

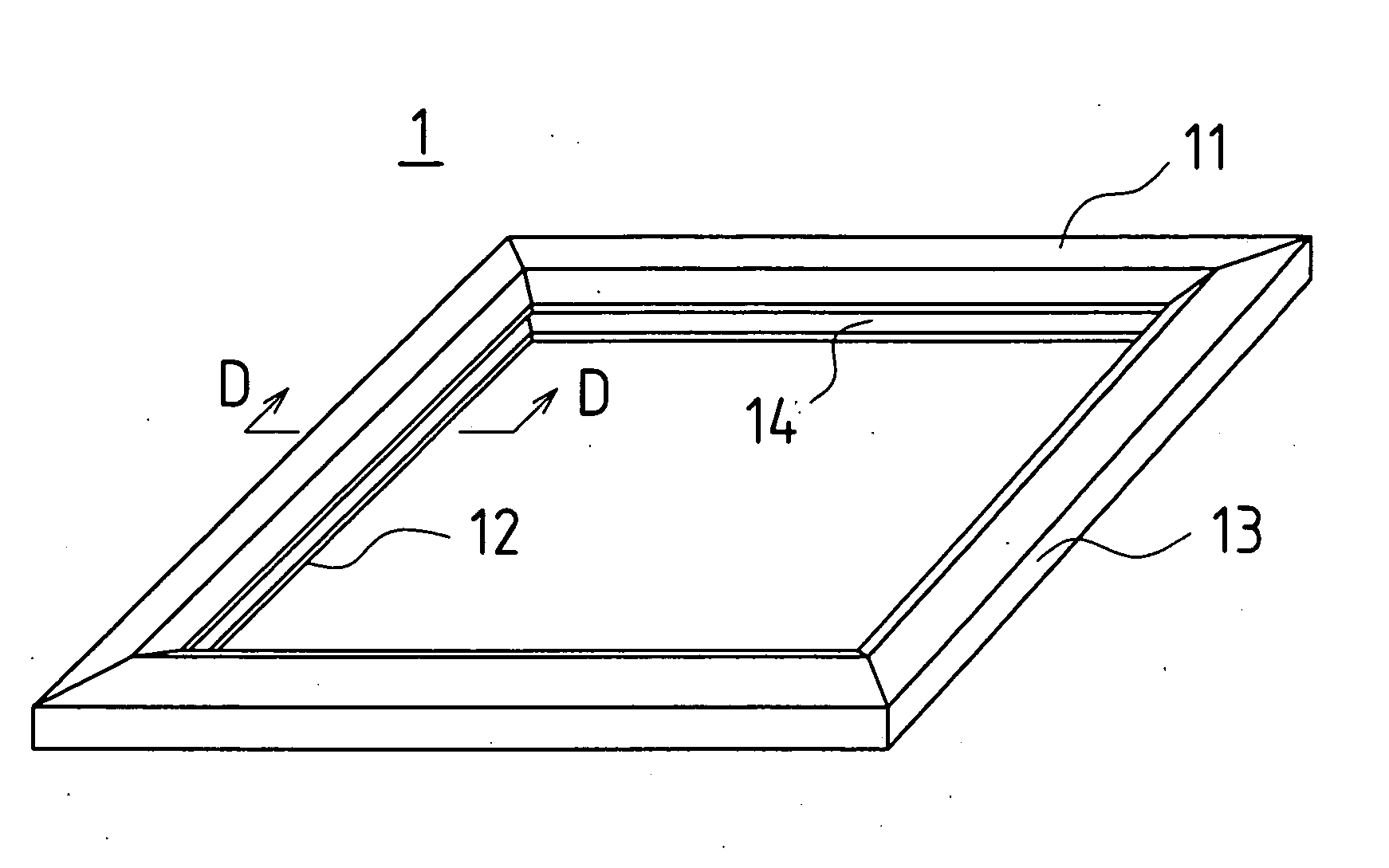

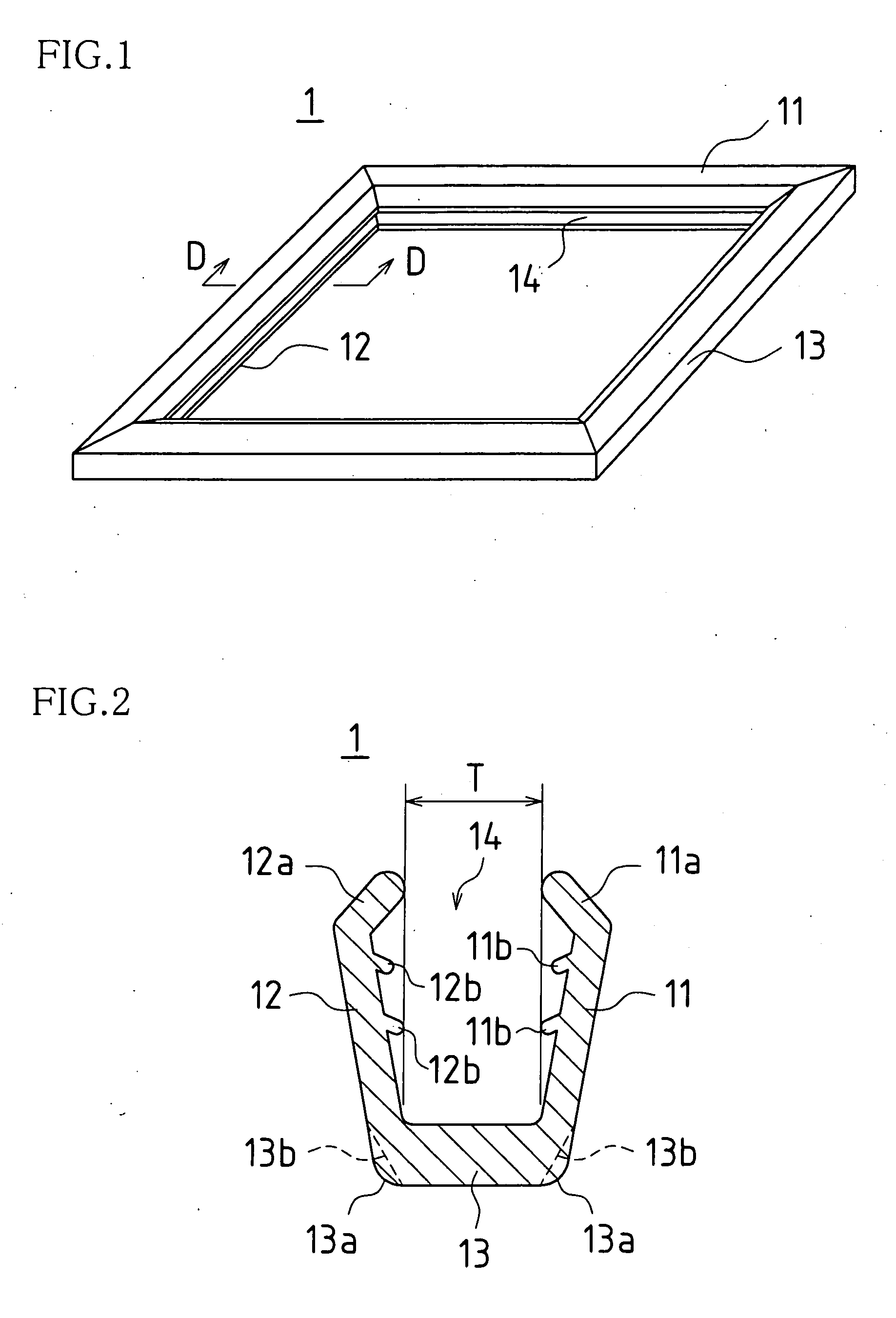

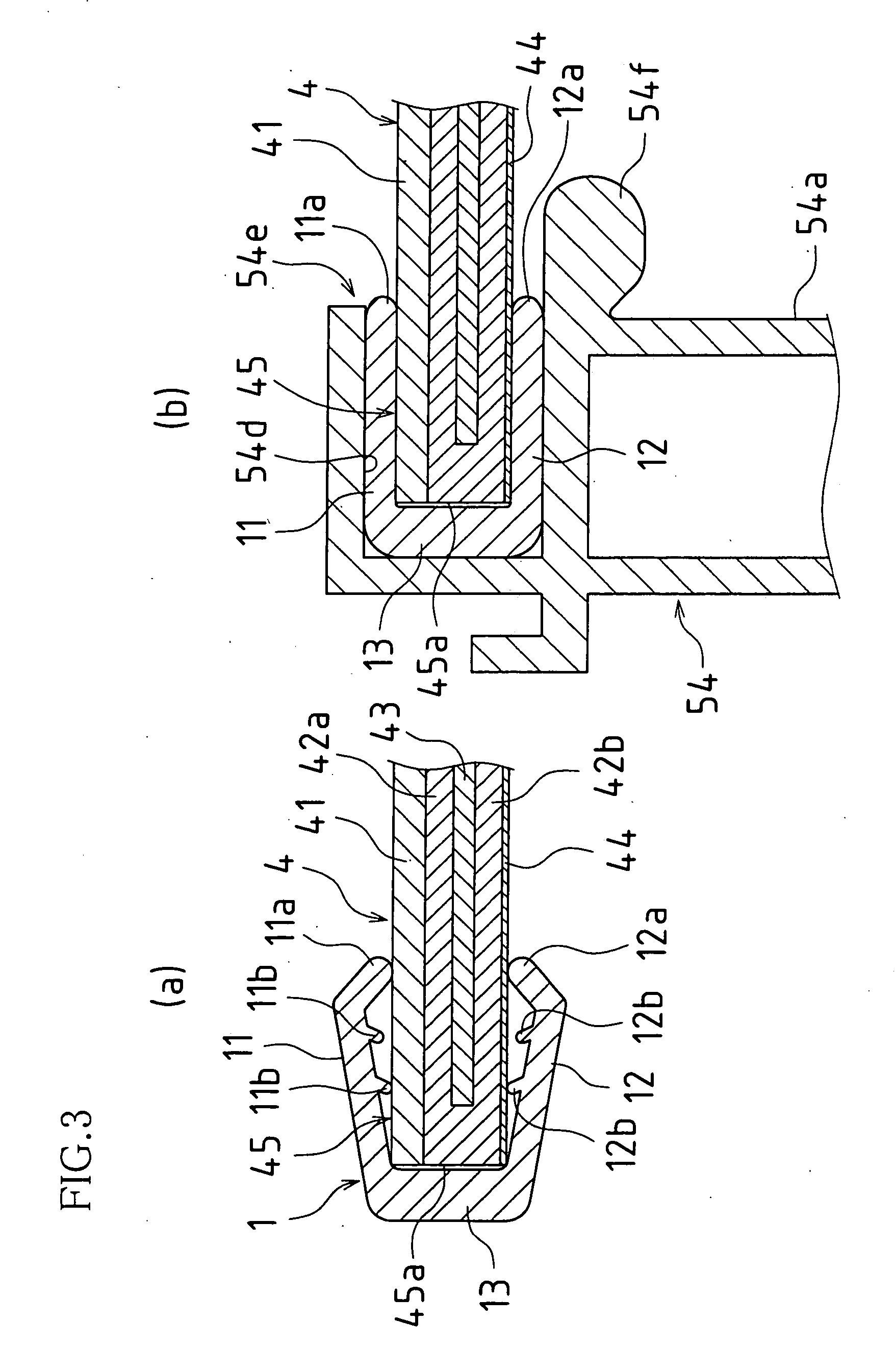

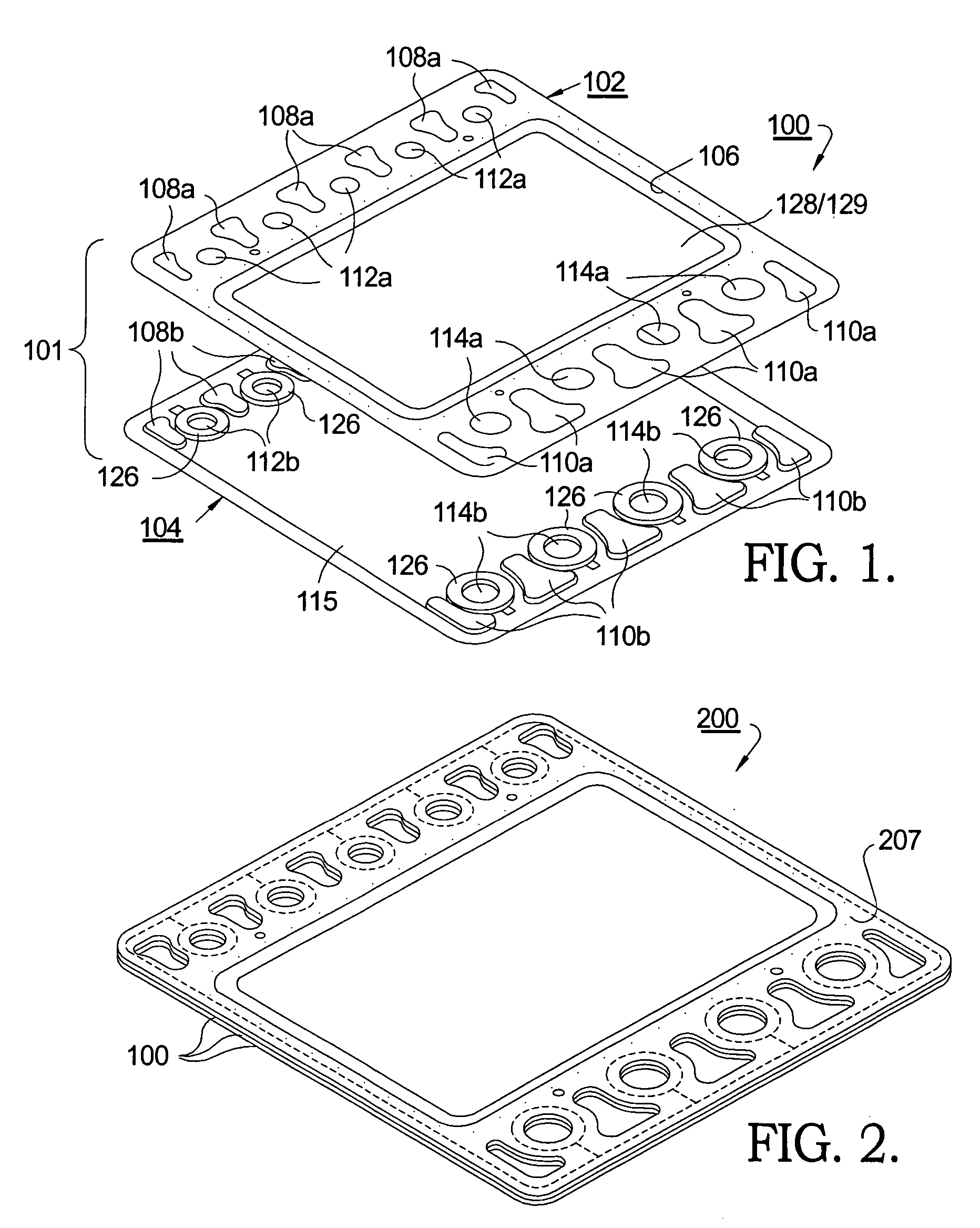

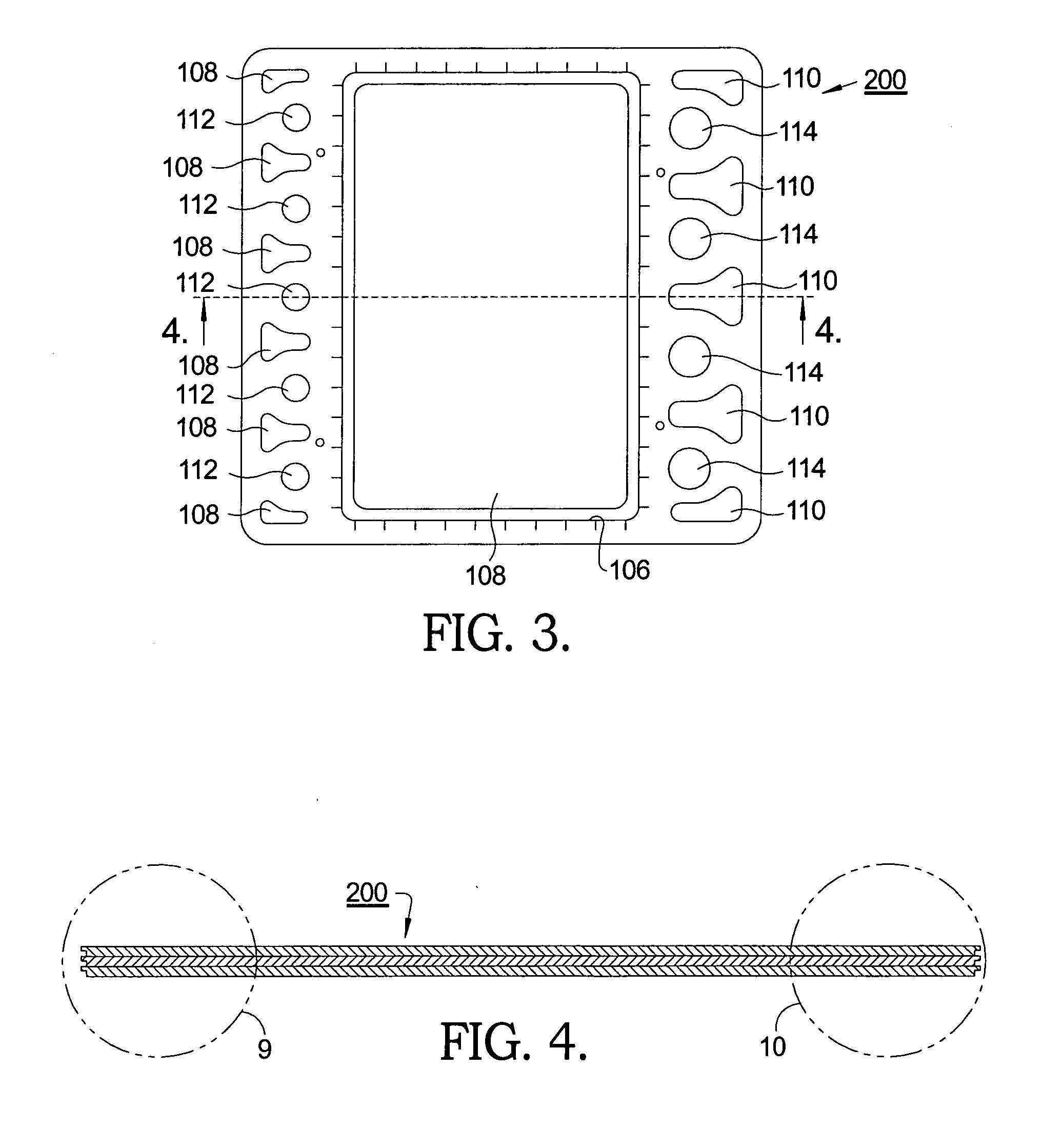

Solar cell module and edge face sealing member for same

InactiveUS20040084078A1Avoid yellowingPrevent degradationPhotovoltaic supportsRoof covering using slabs/sheetsElastomerPolystyrene

Edge face sealing member(s) 1 may be roughly c-shaped in cross-section, may be frame-like in shape and formed in more or less parallel fashion with respect to outer shape(s) of solar cell module body or bodies, may comprise upper sealing region(s) 11 abutting front surface(s) of solar cell module(s), may further comprise lower sealing region(s) 12 abutting back surface(s) of solar cell module(s), and may further comprise side sealing region(s) 13 abutting edge face(s) of solar cell module(s). Furthermore, respectively formed on facing surfaces of upper sealing region(s) 11 and lower sealing region(s) 12 there may be projections 11b, 12b. Furthermore, polypropylenic and / or polystyrenic elastomer resin(s) may be used as material(s) making up edge face sealing member(s) 1, and magnesium silicate may be present as additive(s) for prevention of yellowing of sealing resin layer(s) at solar cell module body or bodies.

Owner:SHARP KK

Bi-component high-strength polyurethane waterproofing paint

ActiveCN101100582AImprove performanceQuality improvementAntifouling/underwater paintsPaints with biocidesExtensibilityToluene diisocyanate

A dual-component high-strength polyurethane water proof coating contains A and B components; A component consists of polyether dibasic alcohol 120-200 proportion, polyether trivalent alcohol 40-180 proportion, toluene diisocyanate 47-80 proportion, dibutyl ester 1.5-3 proportion, and tartaric acid 0.1-1 proportion. B component consists of filling oil 50-90 proportion, paraffin chloride 20-50 proportion, dibutyl ester 10-30 proportion, 3,3-dichloro-4,4-diphenyl-methane-diamine 45-70 proportion, poly-ether trivalent alcohol 60-360 proportion, hydrated magnesium silicate 50-60 proportion, kaolin 10-50 proportion, heavy calcium carbonate 50-60 proportion, iron oxide brown or carbon black 3.5-4.5 proportion, de-foaming agent 0.2-0.5 proportion, and dibutyltin dilaurate 0.2-0.5 proportion. It's convenient and cheap, has excellent adhesion, strength and extensibility and more solid content and no environmental pollution. It can be used for foundation construction and municipal traffic engineering.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Anticorrosive pigment composition and coating compositions containing the same

A nontoxic anticorrosive pigment composition free from toxic heavy metals comprises a condensed phosphoric acid aluminum salt, typically aluminum dihydrogen tripolyphosphate, and magnesium silicate, typically magnesium hexasilicate. The anticorrosive pigment composition enhances the thermal resistance of paint films when formulated in a coating composition containing a chlorine-containing vinyl polymer such as vinyl chloride-vinylidene chloride copolymer emulsion paints.

Owner:TAYCA CORP

Ceramic coatings for insulating modular fuel cell cassettes in a solid-oxide fuel cell stack

ActiveUS20070134537A1Improve adhesionEngine sealsFuel cells groupingCeramic coatingSurface oxidation

In assembling an SOFC fuel cell stack from a plurality of cassettes, the mounting plate of one cassette is attached to, and insulated from, the separator plate of the next-adjacent cassette by a peripheral dielectric seal consisting of a ceramic coating and a metal braze. Materials suitable for the ceramic coating include yttrium stabilized zirconia (YSZ), zirconia toughened alumina, magnesium silicates such as the mineral forsterite, magnesium aluminates, magnesium aluminosilicates and lanthanum zirconate. The ceramic coating may be applied to the cassette's outer surface in known fashion as by physical vapor deposition, chemical vapor deposition, sputtering, and various methods of plasma spray. An underlayer of alumina may also be used to provide a redundant layer of electrical insulation.

Owner:BATTELLE MEMORIAL INST +1

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

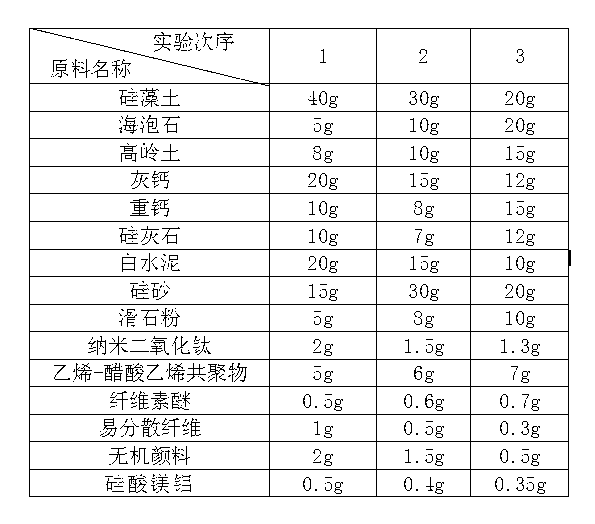

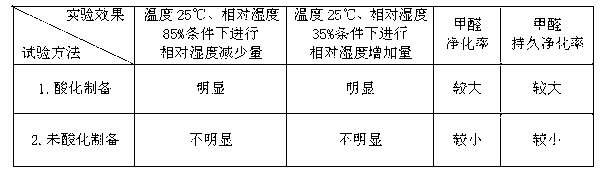

Silicic acid mud interior wall decorating material and preparation method thereof

The invention relates to a silicic acid mud interior wall decorating material and a preparation method thereof. The silicic acid mud interior wall decorating material mainly comprises diatomite, sepiolite, kaolin, sierozem, coarse whiting, wollastonite, white cement, silica sand, talcum powder, nanometer titanium dioxide, ethylene-vinyl acetate copolymer, cellulose ether, aluminium-magnesium silicate, easily dispersed fiber, inorganic pigments and has the functions of humidity control and air purification. The preparation method comprises the following steps of: firstly acidizing the diatomite, the sepiolite and the kaolin, removing harmful ingredients in the diatomite, the sepiolite and the kaolin, improving the activation property of the material, then filtering, washing, drying and crushing, and finally adding the diatomite, the sepiolite and the kaolin and the other components to a dry powder blender for uniformly stirring. When being used, water is added to powder, so that the powder is prepared into paste or emulsion; the silicic acid mud interior wall decorating material is suitable for roll coating, spray finishing, blade coating and the like in interior wall decoration and has the functions of indoor humidity adjustment, peculiar smell elimination, removal of harmful gases such as formaldehyde and toluene in air and lasting environmental protection and simultaneously has the characteristics of rich color, strong sense of texture and environmental friendliness.

Owner:商志民

Cmas mitigation compositions, environmental barrier coatings comprising the same, and ceramic components comprising the same

Calcium magnesium aluminosilicate (CMAS) mitigation compositions selected from rare earth elements, rare earth oxides, zirconia, hafnia partially or fully stabilized with alkaline earth or rare earth elements, zirconia partially or fully stabilized with alkaline earth or rare earth elements, magnesium oxide, cordierite, aluminum phosphate, magnesium silicate, and combinations thereof when the CMAS mitigation composition is included as a separate CMAS mitigation layer in an environmental barrier coating for a high temperature substrate component.

Owner:GENERAL ELECTRIC CO

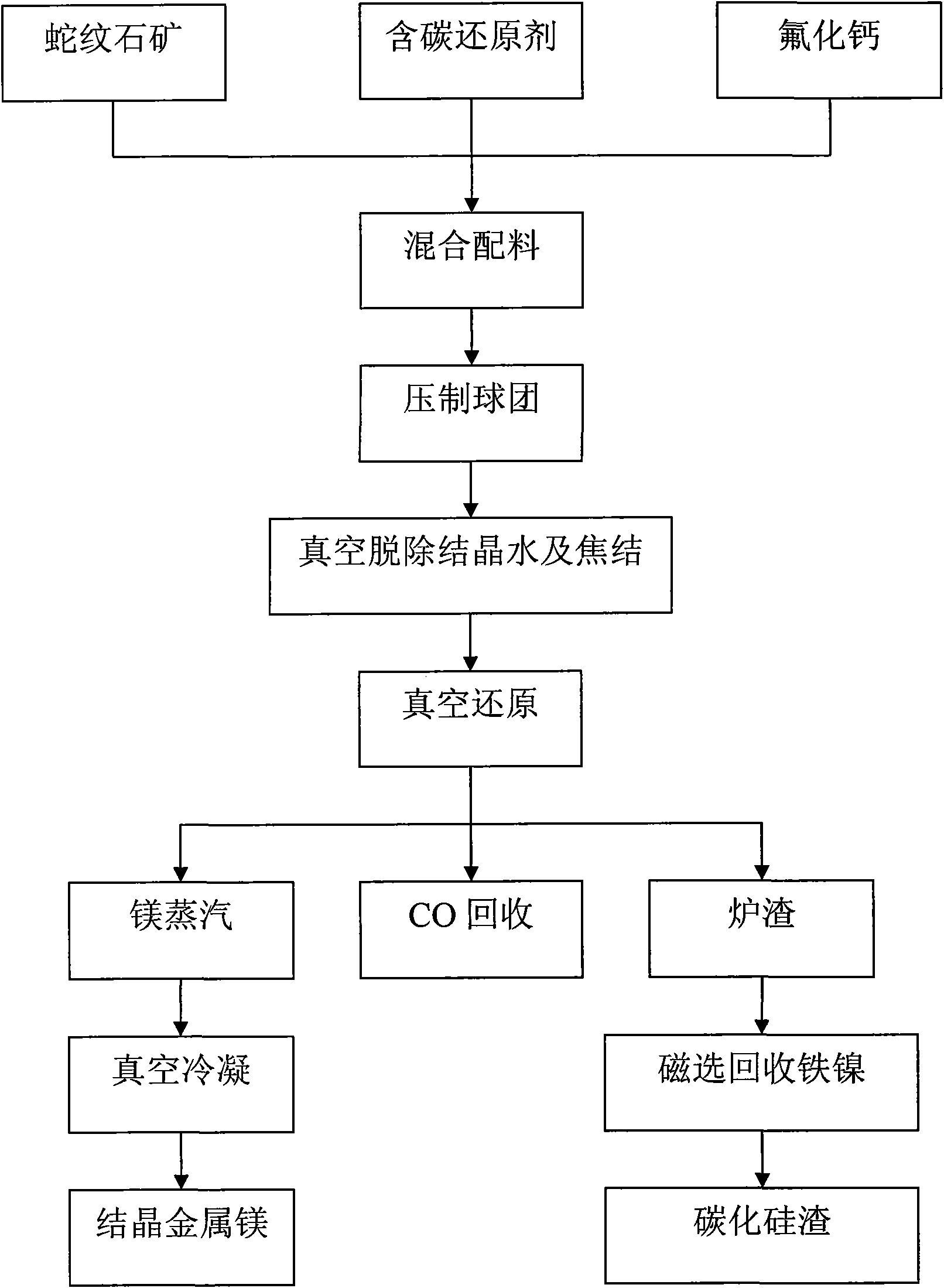

Method for preparing magnesium metal and by-product by vacuum carbothermic reduction with serpentine minerals

InactiveCN101560603AHigh in magnesiumNo need for calcination to remove carbonProcess efficiency improvementMagnetic separationSlagMassicot

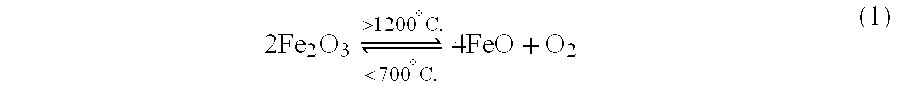

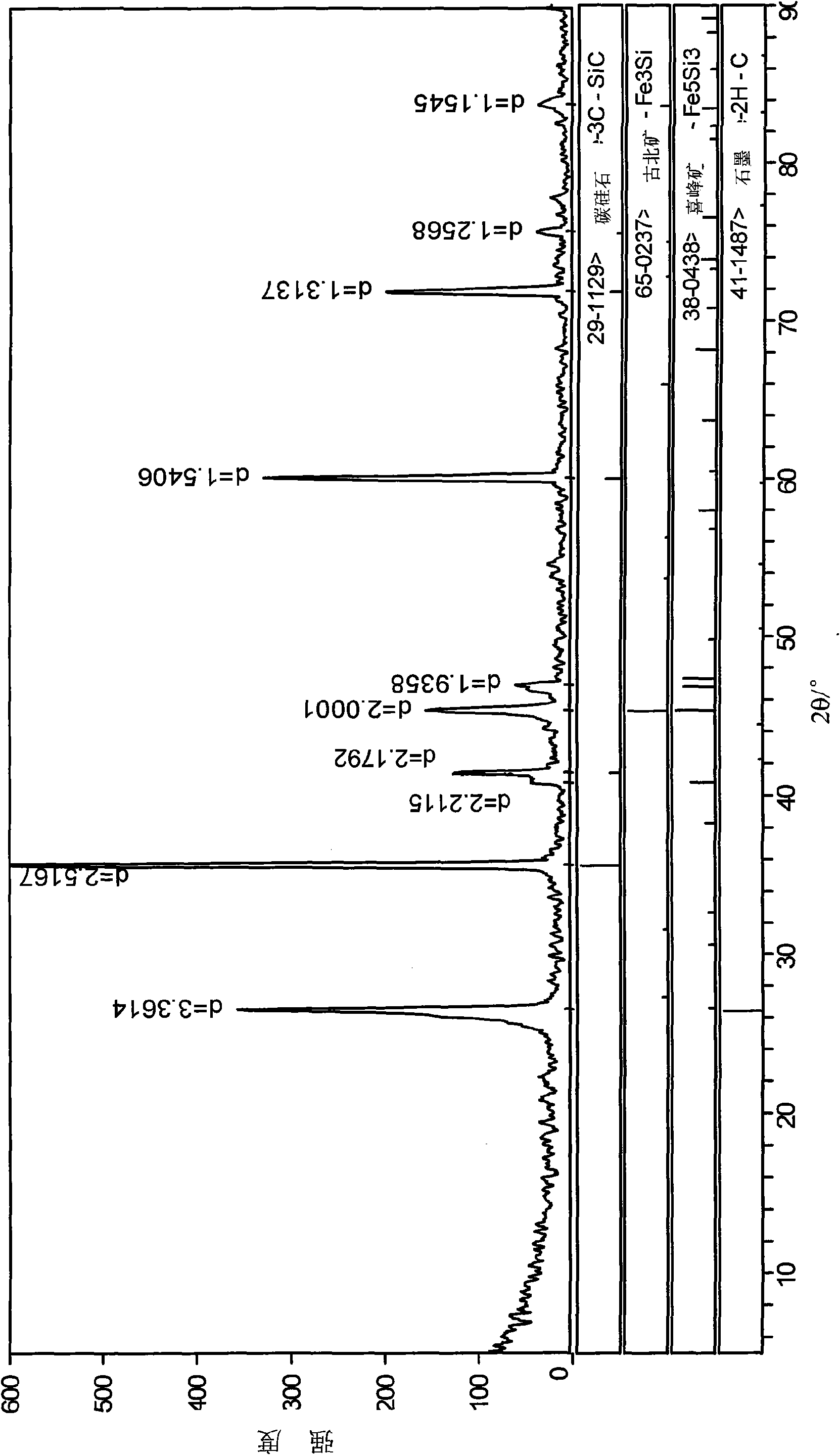

The invention discloses a method for preparing a magnesium metal and a by-product by vacuum carbothermic reduction with serpentine minerals. The method comprises the following steps: using serpentine mineral powder as a raw material; adding a carbonaceous reducing agent which is 1 to 2 times of the theoretical quantity of carbon required for completely reducing magnesium silicate in the serpentine; adding a catalyst, and mixing the materials evenly to obtain a mixed raw material; pressing the mixed raw material into spherical or blocky ball agglomerations and drying the ball agglomerations; putting the dried ball agglomerations into a vacuum furnace, controlling the vacuum degree in the furnace to between 10 and 500 Pa, raising the temperature to between 500 and 700 DEG C, and keeping the temperature for 20 to 60 minutes to remove crystal water and clinker the materials; keeping the vacuum degree in the furnace, raising the temperature to between 1,200 and 1,500 DEG C, and reducing the magnesium silicate and oxides of metallic iron and nickel at a constant temperature for 30 to 60 minutes; and condensing magnesium vapor obtained from the reduction on a magnesium condenser into crystallized magnesium, recycling the metallic iron and the metallic nickel in the slag through magnetic separation, and preparing the slag after the magnetic separation into industrial silicon carbide through decarburization and purification.

Owner:北京华夏建龙矿业科技有限公司

Thermal protective coating

ActiveUS20060156958A1Extended shelf lifeExcellent optical propertiesAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Water-based interior wall thermal insulation nano coating

InactiveCN101948652ALow toxicitySimple preparation processRadiation-absorbing paintsWater basedThermal insulation

The invention provides a water-based interior wall thermal insulation nano coating, belonging to the technical field of environment-friendly water-based building energy conservation coating. The coating comprises the following components by weight percentage: 20-40% of emulsion, 20-35% of pigment filler, 5-15% of thermal insulation function material, 0.1-1% of thickening agent, 0.5-2.5% of wetting and dispersing agent, 0.1-0.6% of defoaming agent, 0.4-2.5% of anti-creaming agent, and the balance water. Due to containing no organic matters with large volatility, the coating in the invention has little toxicity and is favor to environment protection. The adopted pigment filler in the invention is nano-level or superfine magnesium carbonate or magnesium silicate, thus greatly improving the surface area of the pigment, and increasing gaps among coating particles by a large margin, thereby enhancing the thermal separation property of the coating. The water-based interior wall thermal insulation nano coating provided in the invention has obvious radiative thermal insulation and separation type thermal insulation effects, and has simple preparation process and wide application.

Owner:CHINA MCC17 GRP

Sulfur-tolerance deoxidation catalyst and preparation and use thereof

InactiveCN101301611ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsAluminum silicateMordenite

The invention discloses a sulfur-tolerant deoxidizing catalyst, preparation method and application thereof. The catalyst of the invention is composed of active components and porous carriers, the active components are one or more of compound of iron and / or copper, the porous carriers are selected from one or more of aluminium oxide, titanium oxide, zirconium oxide, zinc oxide, magnesium oxide, calcium oxide, silicon dioxide, aluminophosphate molecular sieves, A type molecular sieves, X type molecular sieves, Y type molecular sieves, mordenite, ZSM-5 zeolite, kieselguhr, kaoline, natural clay, aluminum silicate and magnesium silicate. Based on the oxide content, the active components loading amount is 1-95% by weight, the rest are porous carriers. The catalyst of the invention has definite sulfur-tolerant performance, is suitable for deoxidation treatment of coal seam gas with oxygen content of 3-6% (V / V), and can deoxidize the coal seam gas to make the oxygen content less than 0.5%.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for producing oriented silicon steel with good bottom by low-temperature heating

ActiveCN1978707AGuarantee normal implementationEfficient formationSolid state diffusion coatingFurnace typesHot TemperatureSilicon

The invention supplies a method used to produce orientation silicon steel by low temperature heating. It includes the following steps: heating the plate blank under 1280 degree centigrade; hot rolling; once or double cold rolling to gain finished product sheet thickness; nitriding treatment; decarburizing annealing; coating insulator; high temperature annealing. In the nitriding technology, heating area dew point is controlled at -15-40 degree centigrade. The invention has the advantages of high nitriding efficiency, no influence from the surface oxide film, excellent MgO coat formula which makes the magnesium silicate substrate have good magnetic property, ensure the implementation for the next hot leveling annealing and insulating coating.

Owner:BAOSHAN IRON & STEEL CO LTD

Intimate physical mixtures containing macrocyclic polyester oligomer and filler

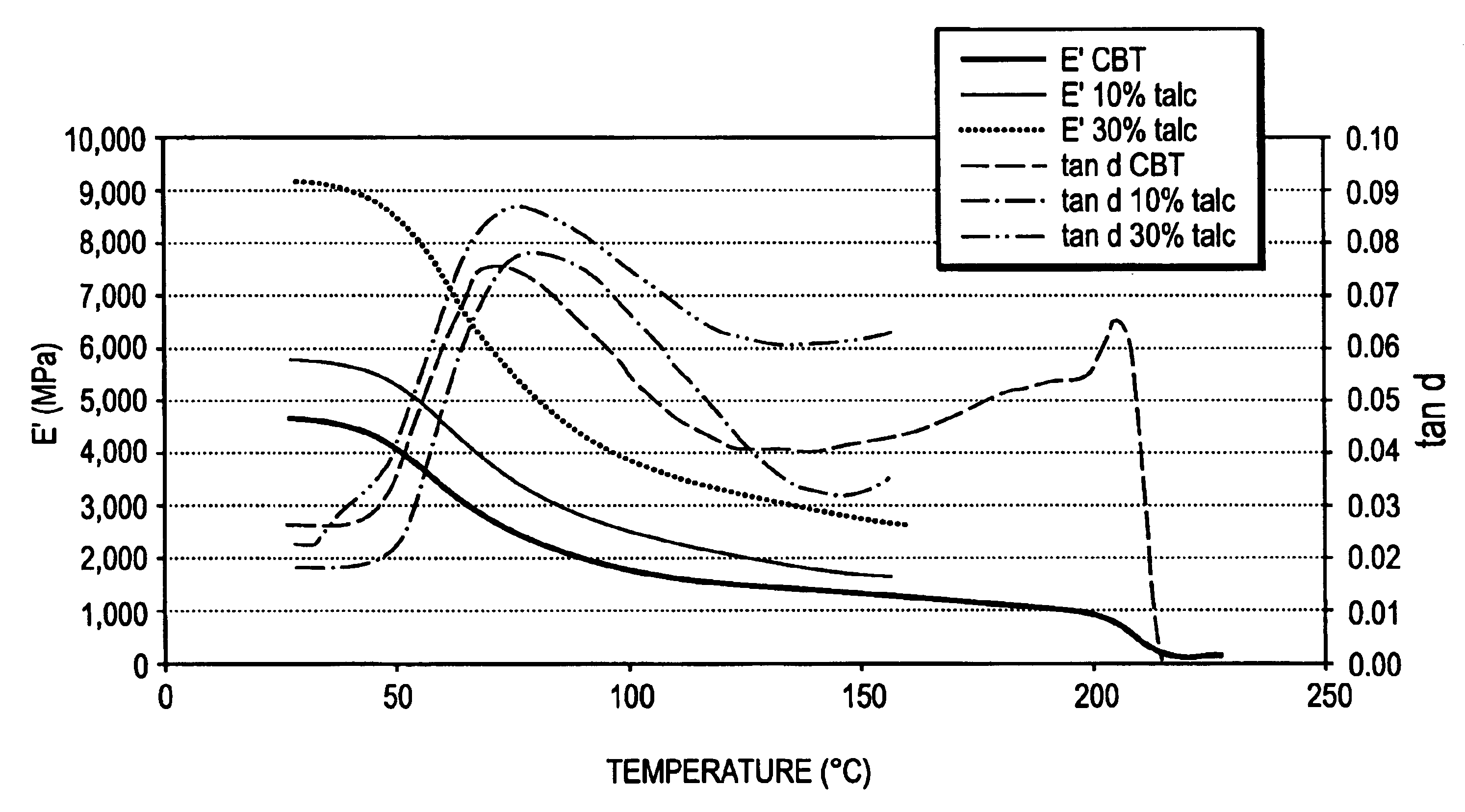

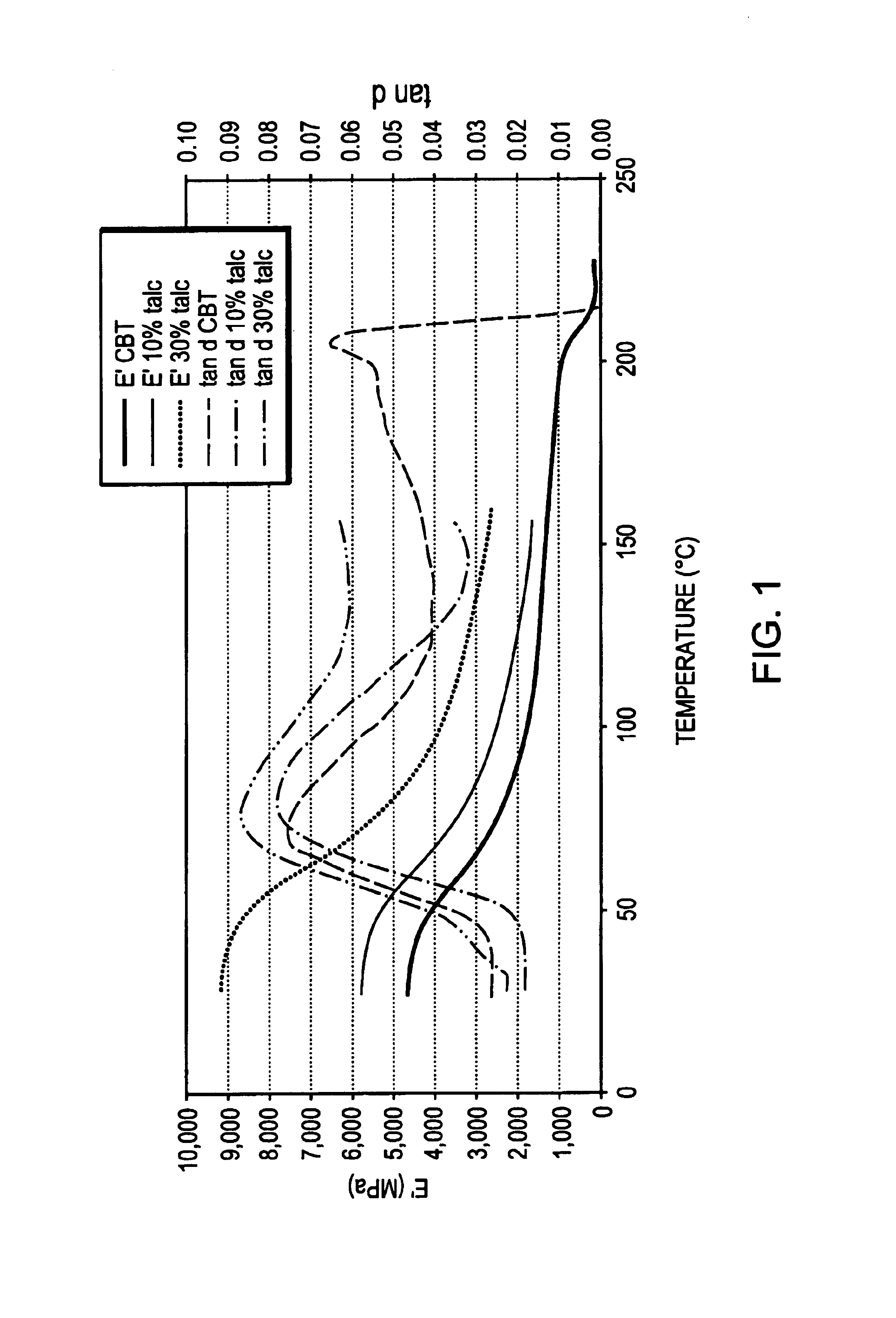

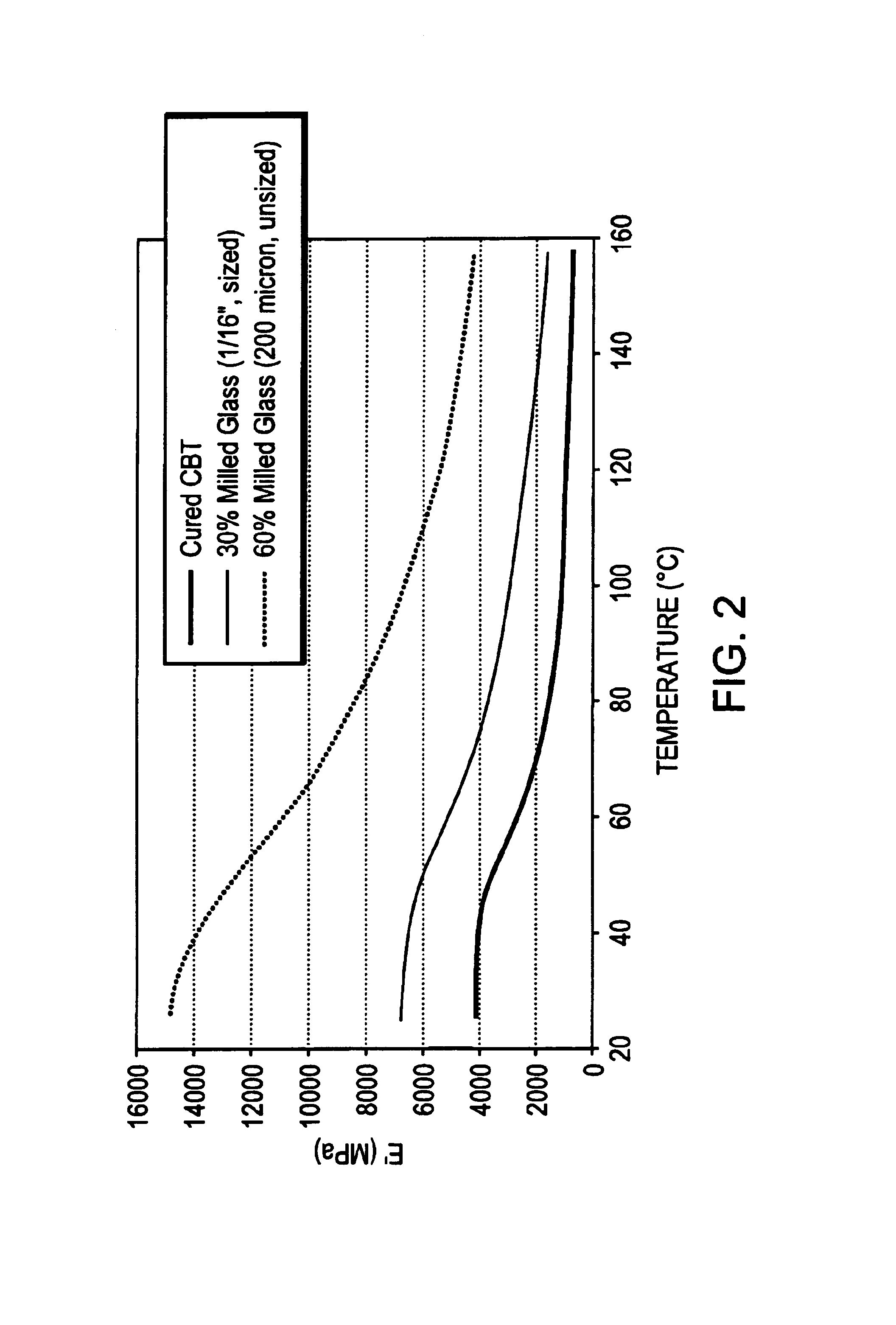

InactiveUS6960626B2Improve filler dispersionImprove compatibilityTin organic compoundsSynthetic resin layered productsPolyesterOligomer

The invention provides intimate physical mixtures of macrocyclic polyester oligomer (MPO) and filler, as well as methods for their preparation and use. Improved dispersion of filler in a polymer matrix is achieved upon polymerization, and larger amounts of filler with high aspect ratio can be used. In one aspect, the invention provides mixtures of MPO with magnesium silicate. In another aspect, the invention provides a mixture of MPO, filler, and polymerization catalyst as a one-part, ready-to-polymerize material with a long shelf life. The one-part material can be used, for example, in the manufacture of parts without modification of existing processing equipment.

Owner:CYCLICS CORP

Light and color glazed tile for building

The invention discloses a light and color glazed tile for a building, which is obtained by the following steps: adding 0.4 to 0.6 kg of magnesium oxide to each kilo of a magnesium chloride solution; agitating the mixture for 6 to 8 minutes; successively adding 0.05 to 0.1 kg of magnesium silicate, 0.02 to 0.03 kg of urea-formaldehyde resin, 0.06 to 0.1 g of ammonium carbonate, 2 to 3 g of trisodium phosphate and 2 to 3 g of pigment; agitating the obtained mixture for 20 to 30 minutes; pouring the agitated mixture to a glass fiber cloth; scraping and compacting the poured mixture; and performing natural cure and drying to obtain the light and color glazed tile for the building. In the way above, the light and color glazed tile for the building has the advantages of smooth and clean surface, bright color, color retention, fracture resistance, compression resistance, thermal and cooling shock resistance, acid and alkali resistance, freezing resistance, light weight, low water absorption, good thermal insulation, good sound insulation and low cost.

Owner:CHINA CHANGSHU CONSTR GRP

Foldable polyolefin films

InactiveUS20060167169A1Special tyresTreatment with hydrotreatment processesLow-density polyethyleneLinear low-density polyethylene

The present invention relates to foldable polyolefin film compositions, comprising a blend of high density polyethylene, linear low density polyethylene, a magnesium silicate and an alkaline or alkaline earth metal carbonate, to foldable polyolefin films made from such compositions and to a method for producing such.

Owner:PLASTICOS FLEXIBLES

AC wet capacitor impregnating agent

InactiveCN102290234AImpact on life performanceExtended service lifeFixed capacitorsSilicone oilCapacitor

The invention discloses an impregnating agent for an AC wet capacitor, which comprises castor oil, salad oil and other vegetable oils or methyl silicone oil, benzyl silicone oil, PO oil and other mineral oils and hydrated magnesium silicate superfine powder. The content of the hydrated magnesium silicate superfine powder is preferably 3-8% (by weight). The hydrated magnesium silicate superfine powder is mixed with vegetable oil or mineral oil to form a suspension after stirring. The invention absorbs the moisture in the impregnating agent by adding hydrated magnesium silicate superfine powder in the impregnating agent. In this way, the moisture contained in the impregnating agent is absorbed, which cannot affect the service life of the capacitor, and can effectively improve the service life of the capacitor.

Owner:ANHUI SAFE ELECTRONICS

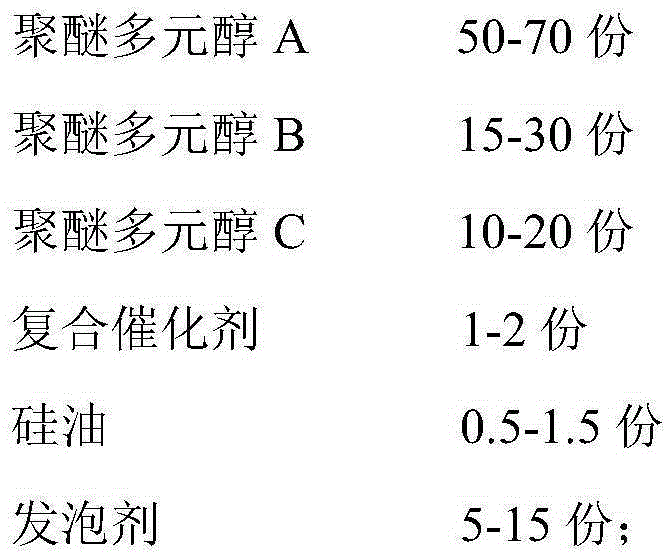

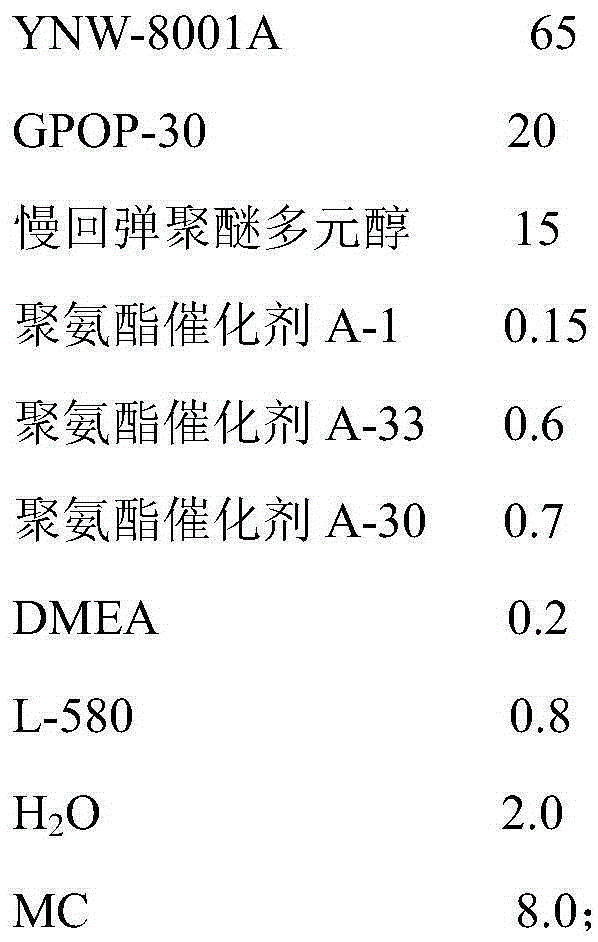

Slow-recovery polyether polyol and preparation method thereof and slow-recovery foam and preparation method thereof

The invention relates slow-recovery polyether polyol and a preparation method thereof and slow-recovery foam and a preparation method thereof, and belongs to the technical field of organic polymer synthesis. The slow-recovery polyether polyol is a copolymer of propylene epoxide and ethylene oxide, and the copolymer takes a composite small-molecular-weight polyhydric alcohol compound as initiator. The preparation method of the slow-recovery polyether polyol comprises the steps that the composite small-molecular-weight polyhydric alcohol compound and a catalyst are reacted in a pressure-proof reaction kettle, a polymeric monomer, water, phosphoric acid and magnesium silicate are sequentially added for reaction, and the slow-recovery polyether polyol is obtained; the slow-recovery foam is prepared from a component A and a component B, wherein the component A is prepared from polyether polyol, a composite catalyst, silicone oil and a foaming agent, and the component B adopts modified DMI; the preparation method of the slow-recovery foam comprises the steps that the component A and the component B are evenly mixed and poured into a mold for curing, and the slow-recovery foam is obtained. The slow-recovery foam material has the advantages of being extremely low in depression residue, good in tensile property and capable of reducing the usage amount of an opening agent.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

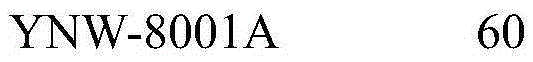

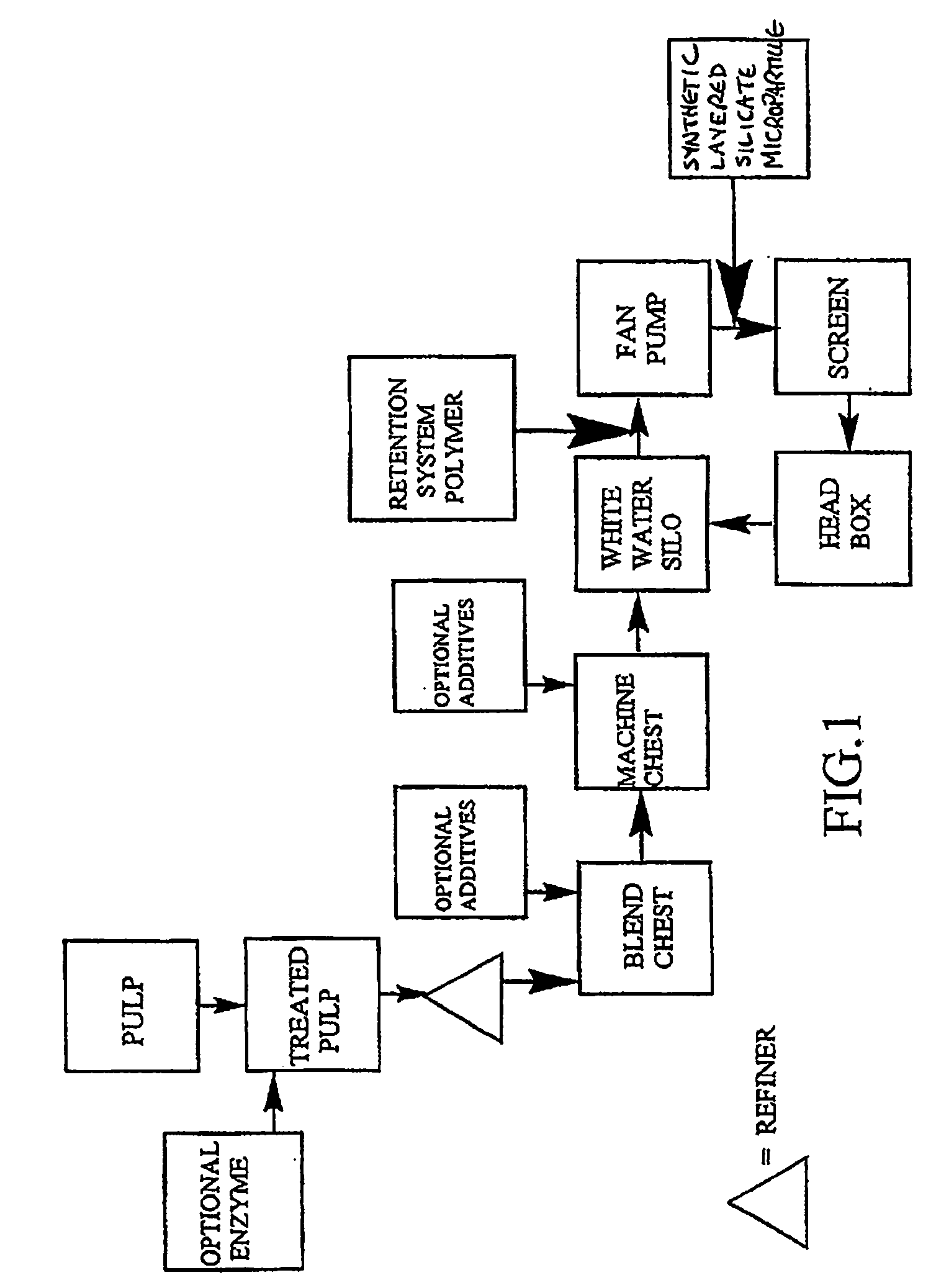

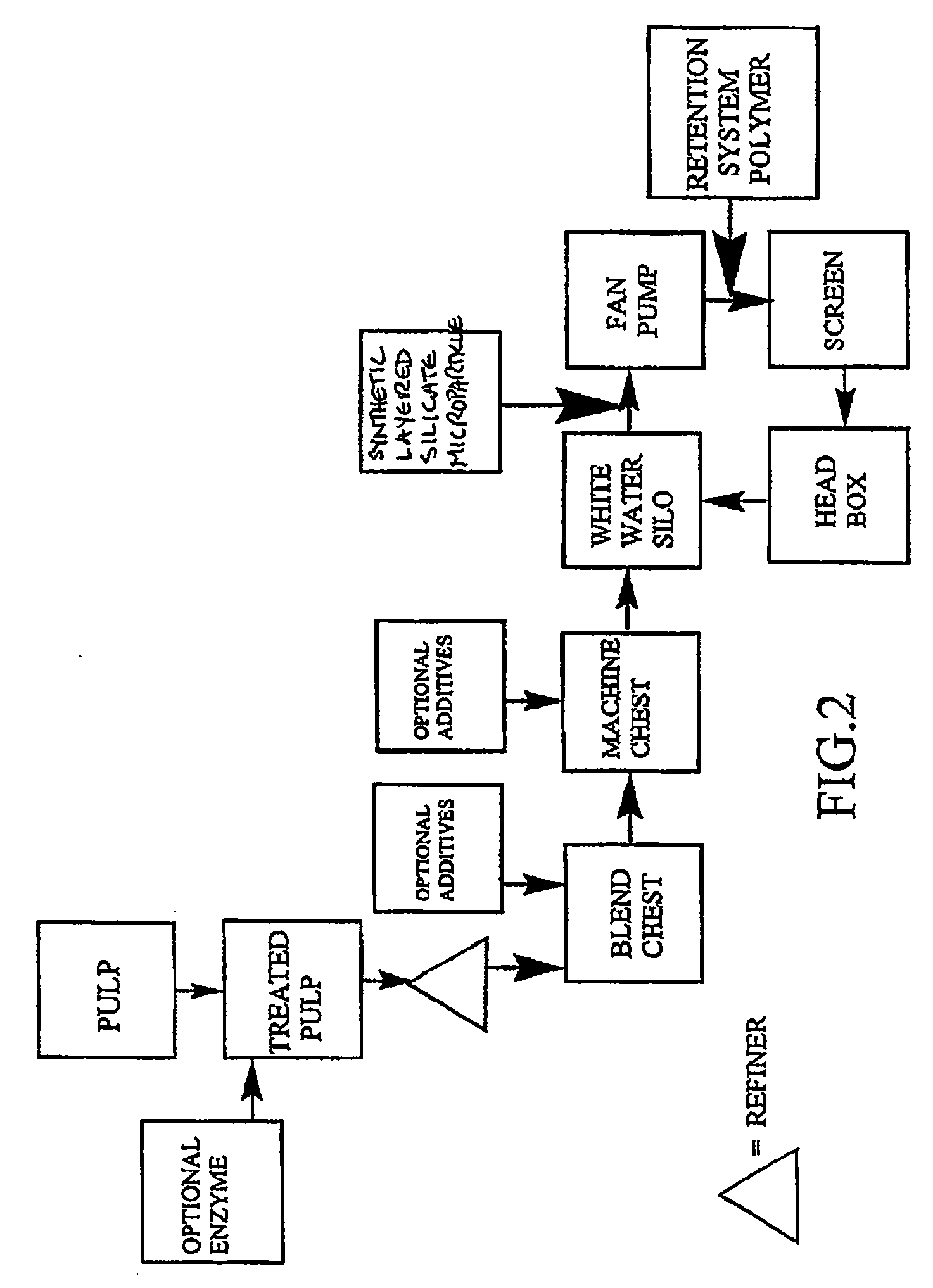

Process for making paper

InactiveUS20050161183A1Extended shelf lifeSignificant improvementNatural cellulose pulp/paperSpecial paperLithiumPapermaking

Methods for making paper or paperboard are described. One preferred method comprises forming a treated pulp by added to a papermaking pulp a synthetic layered silicate, a peptizer and at least one polymer. The synthetic layered silicate preferably comprises a synthetic hydrous sodium lithium magnesium silicate and the polymer is selected from cationic, nonionic and amphoteric polymers. The peptizer is preferably an inorganic polyphosphate peptizer and is contained in certain commercial synthetic layered silicate products. The inventor has surprisingly found that the peptizer provides significant improvements in drainage, retention and turbidity, thereby improving the papermaking process and the paper or paperboard product.

Owner:BUCKMAN LAB INT INC

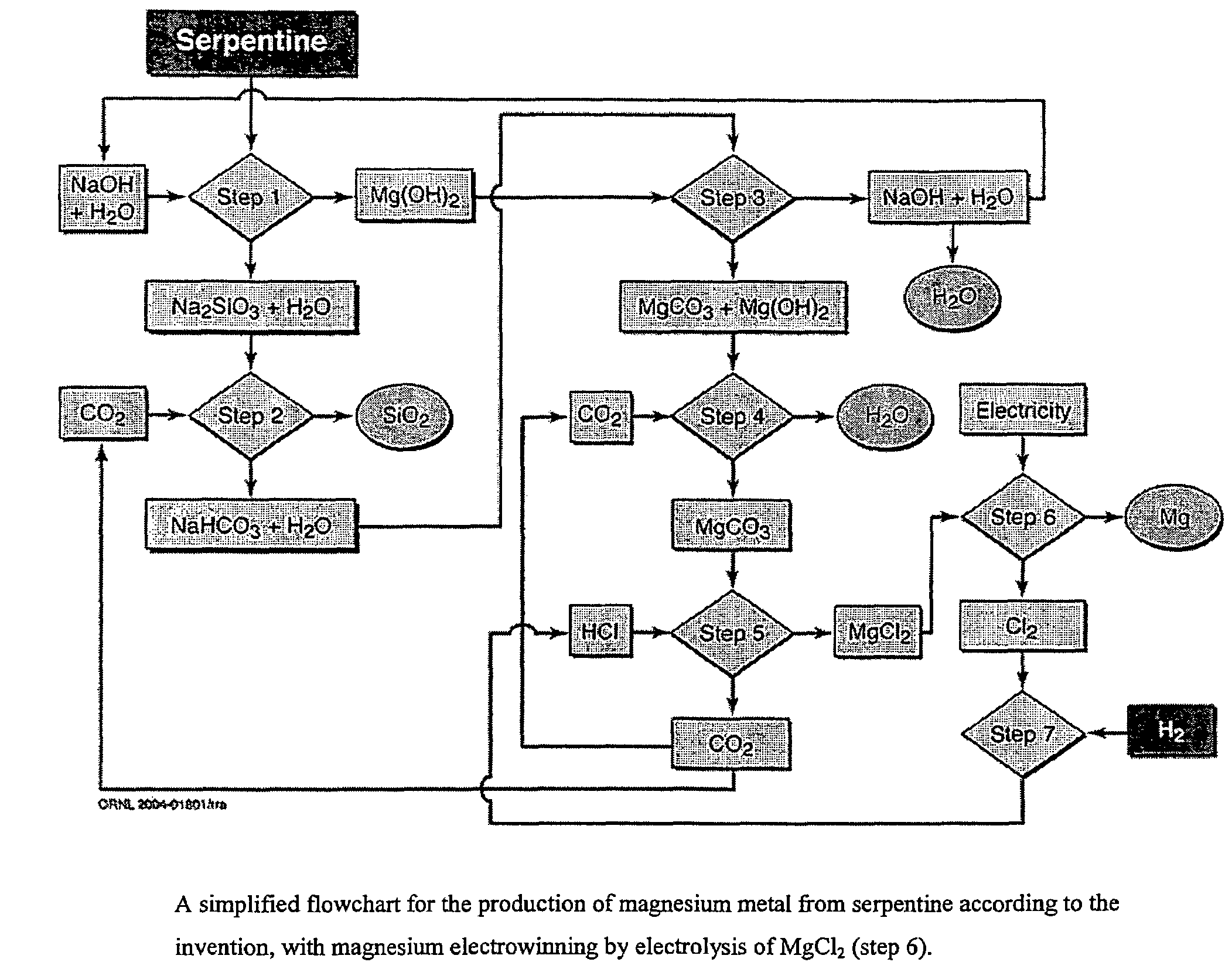

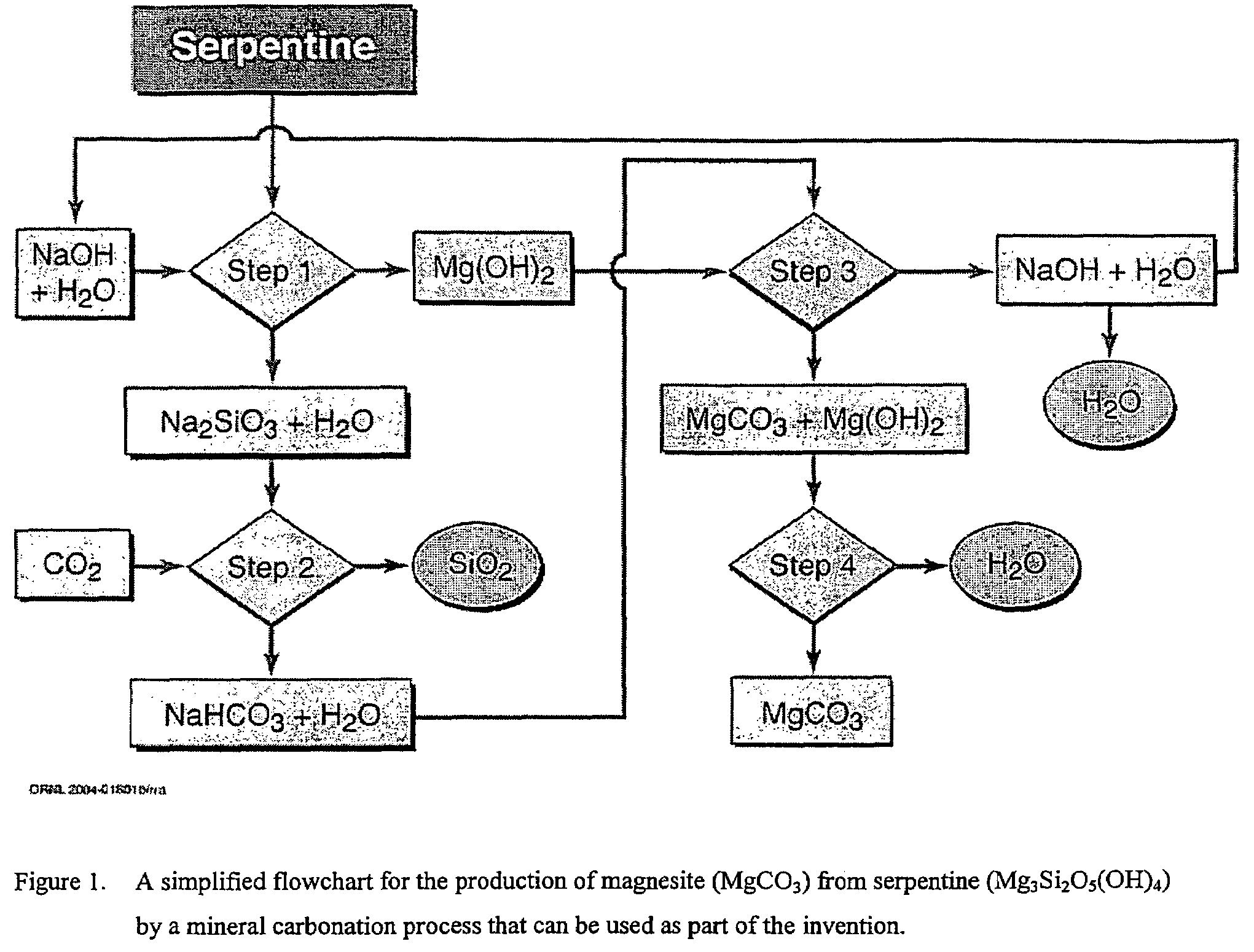

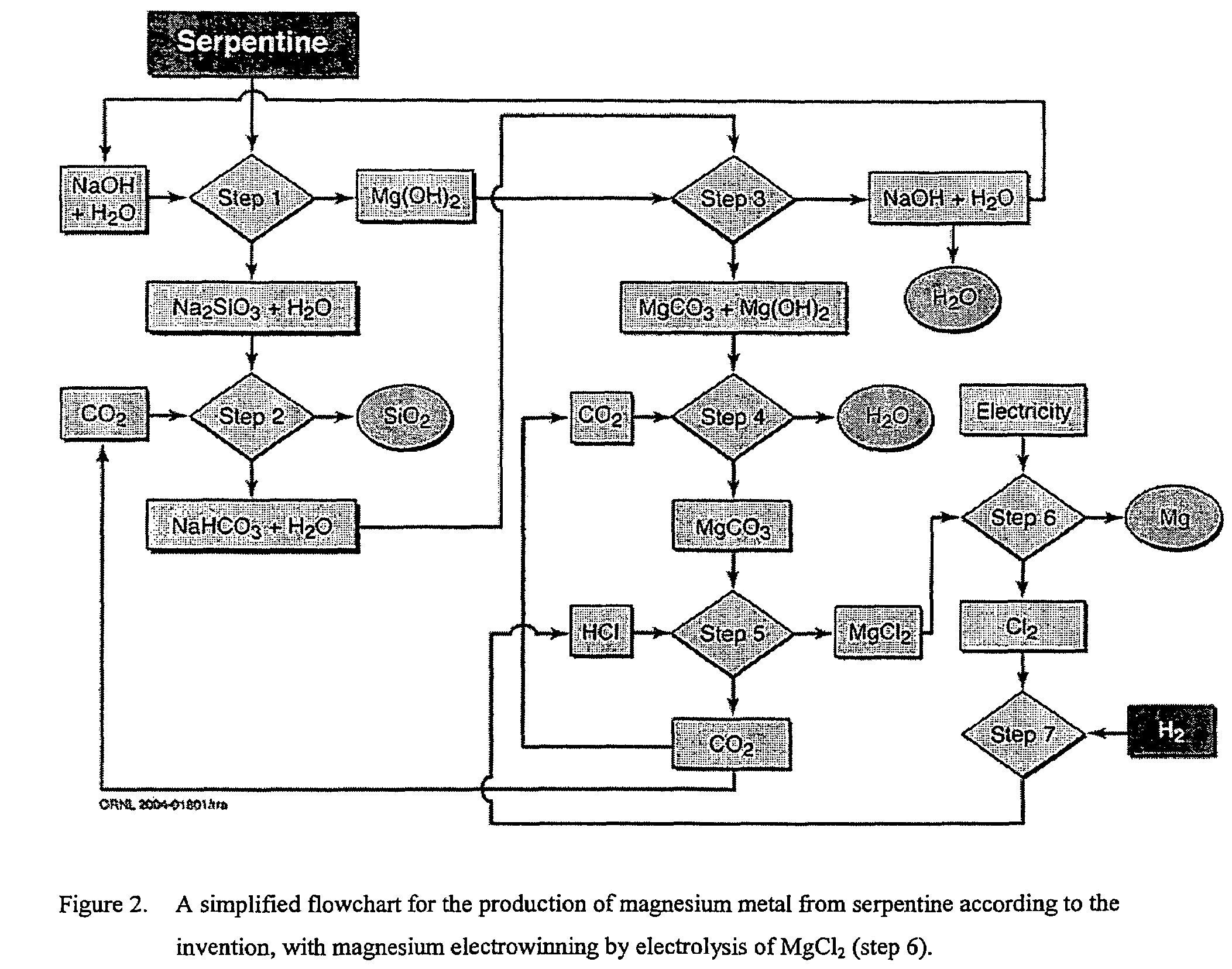

Production of magnesium metal

A process of producing magnesium metal includes providing magnesium carbonate, and reacting the magnesium carbonate to produce a magnesium-containing compound and carbon dioxide. The magnesium-containing compound is reacted to produce magnesium metal. The carbon dioxide is used as a reactant in a second process. In another embodiment of the process, a magnesium silicate is reacted with a caustic material to produce magnesium hydroxide. The magnesium hydroxide is reacted with a source of carbon dioxide to produce magnesium carbonate. The magnesium carbonate is reacted to produce a magnesium-containing compound and carbon dioxide. The magnesium-containing compound is reacted to produce magnesium metal. The invention further relates to a process for production of magnesium metal or a magnesium compound where an external source of carbon dioxide is not used in any of the reactions of the process. The invention also relates to the magnesium metal produced by the processes described herein.

Owner:UNIV OF TENNESSEE RES FOUND +2

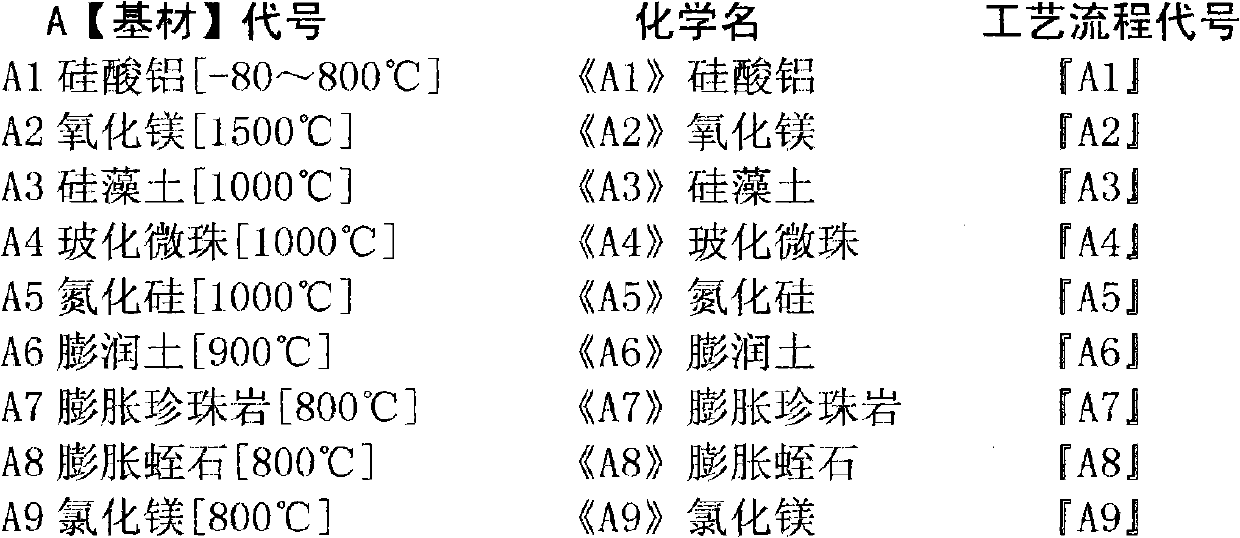

Innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product

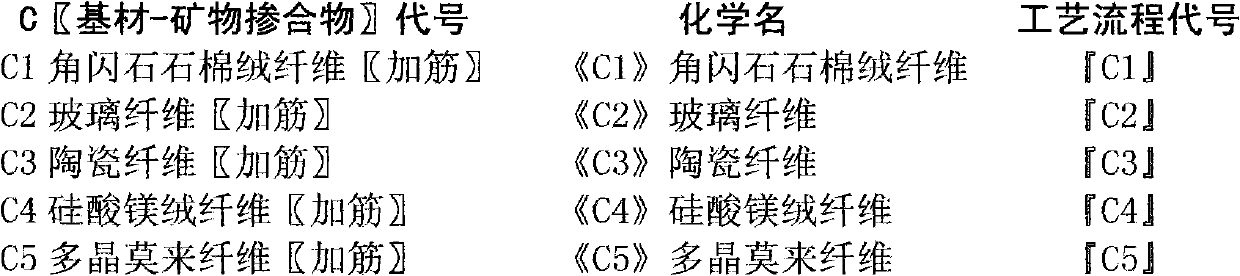

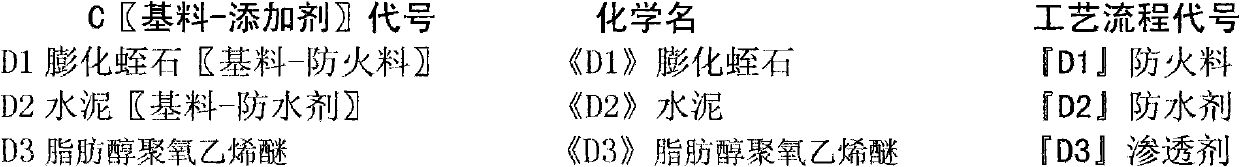

The invention discloses innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and products, which comprise nine base materials resisting the temperature of 80 DEG C below zero to 1,000 DEG C, i.e., aluminum silicate, magnesium oxide [1,500 DEG C], diatomite [1,000 DEG C], vitrified micro bubbles [1,000 DEG C], silicon nitride [1,000 DEG C], bentonite [900 DEG C], expanded perlite [800 DEG C], expanded vermiculite [800 DEG C] and magnesium chloride [800 DEG C], two mineral admixtures, five reinforcements, i.e., amphibole asbestos wool fiber, glass fiber, ceramic fiber, magnesium silicate wool fiber and polycrystalline mullite fiber and 14 base material-additives of different functions, i.e., a fire-proof material, a water-proof agent, an anti-radiation agent, an anti-mildew agent, an adhesive, an anti-freezing agent, a thixotropic agent, a curing agent, a brightening agent, an early strength agent, a foaming agent, an expanding agent and a masking agent, wherein nine kinds of low-carbon fire-proof insulating mortar which are used in different environments are developed through an innovative technical formula and are used for coating interior and exterior walls and manufacturing an insulating material for various plates, pipes and irregularly-shaped products; and the innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product are national initiative environment-friendly low-carbon and fire-proof insulating mortar and product.

Owner:于斌 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com