Patents

Literature

90 results about "Organic Boron Compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organoborane or organoboron compounds are chemical compounds of boron and carbon that are organic derivatives of BH3, for example trialkyl boranes.

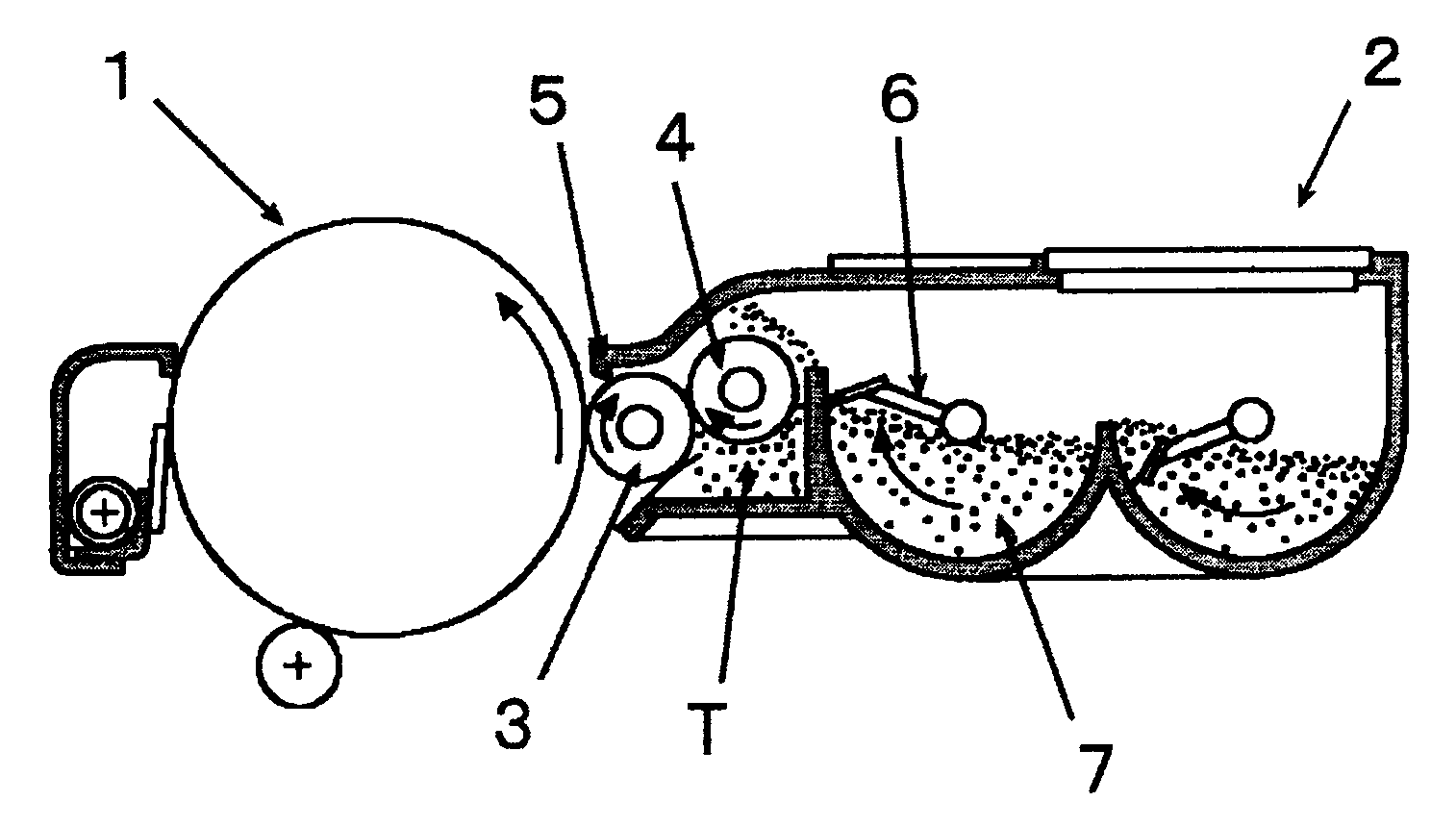

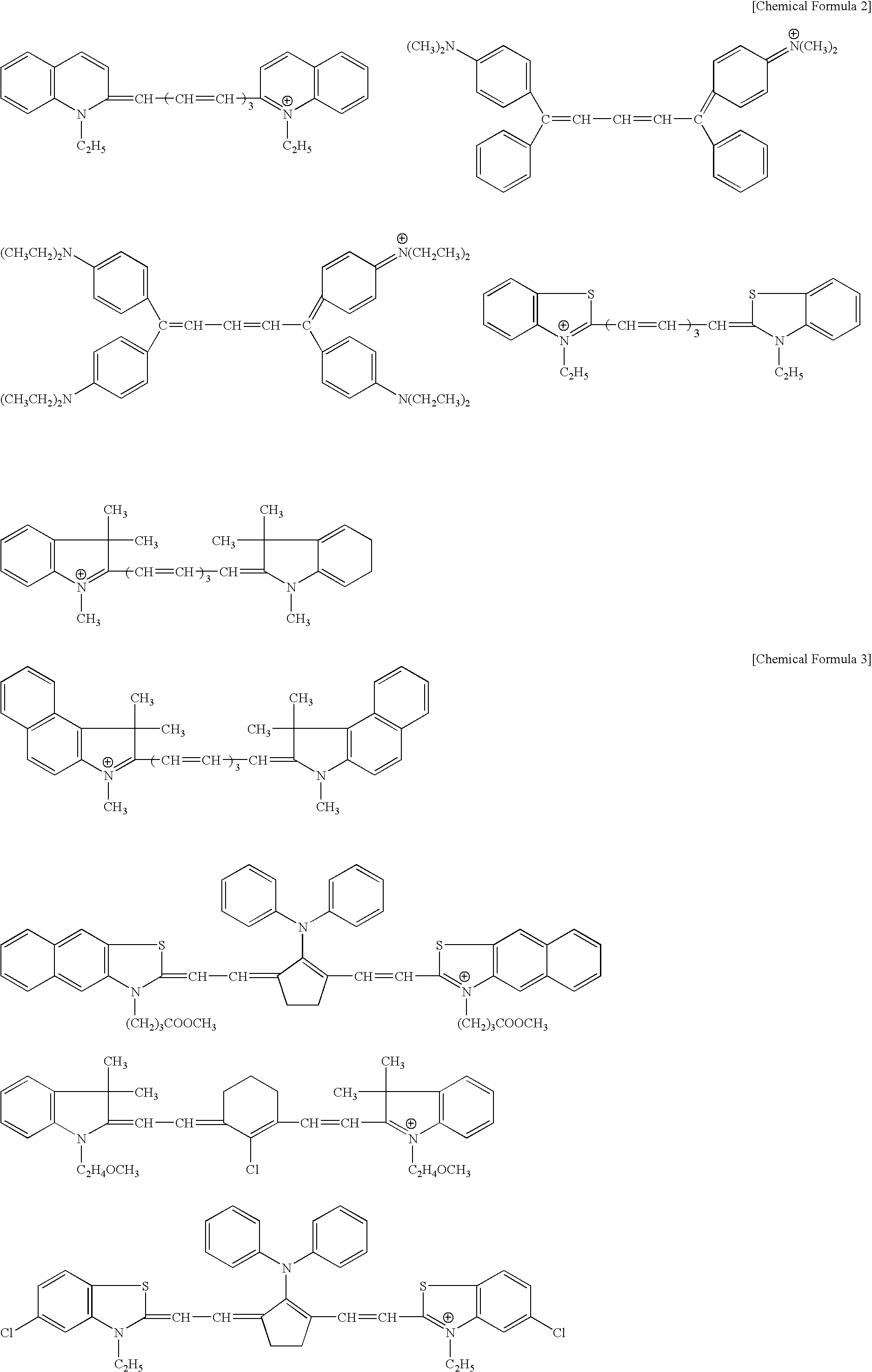

Toner and image forming method

InactiveUS20070207399A1Improve stabilityUniformly and efficiently chargingElectrographic process apparatusDevelopersImage transferLatent image

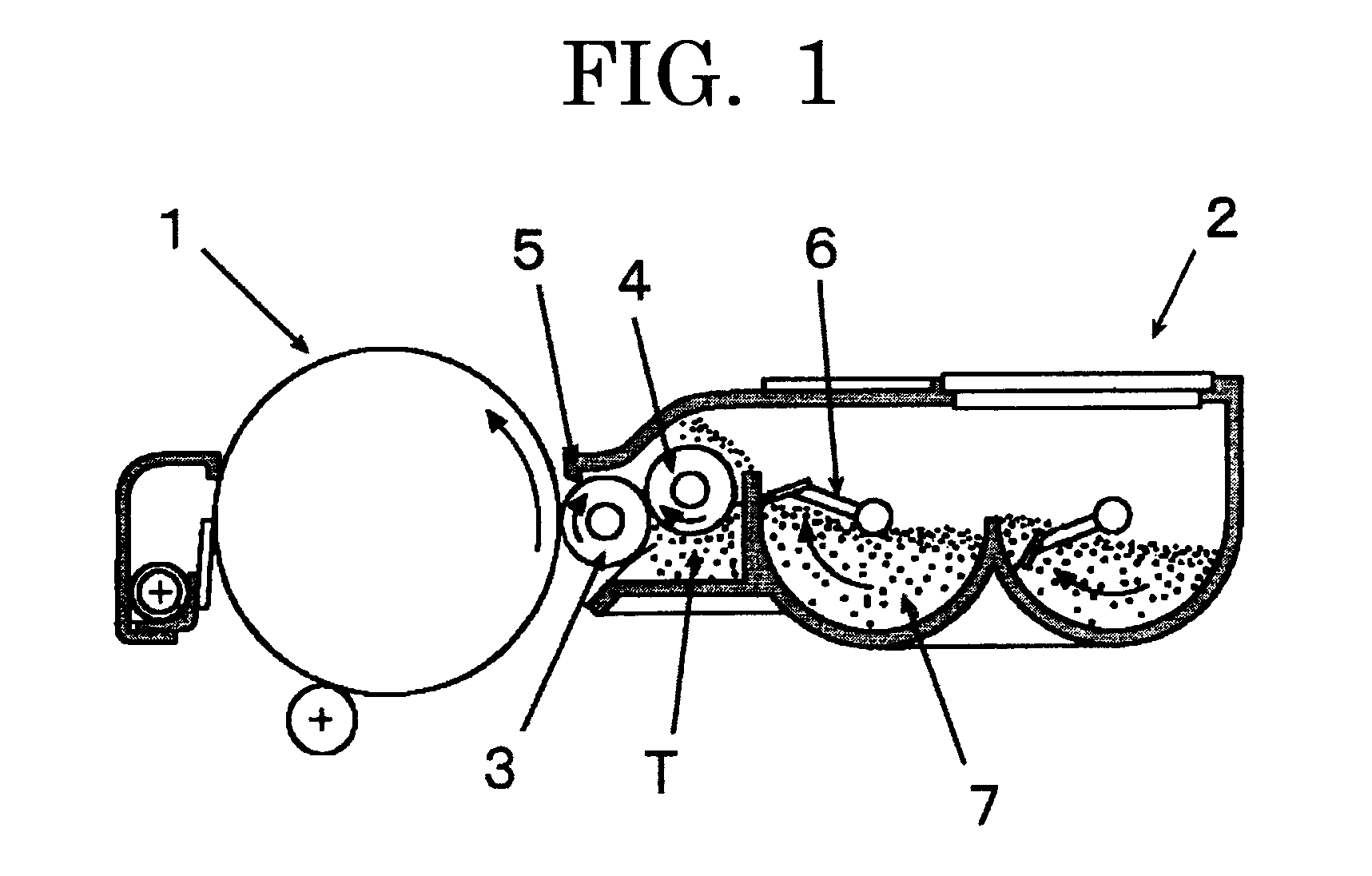

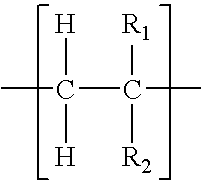

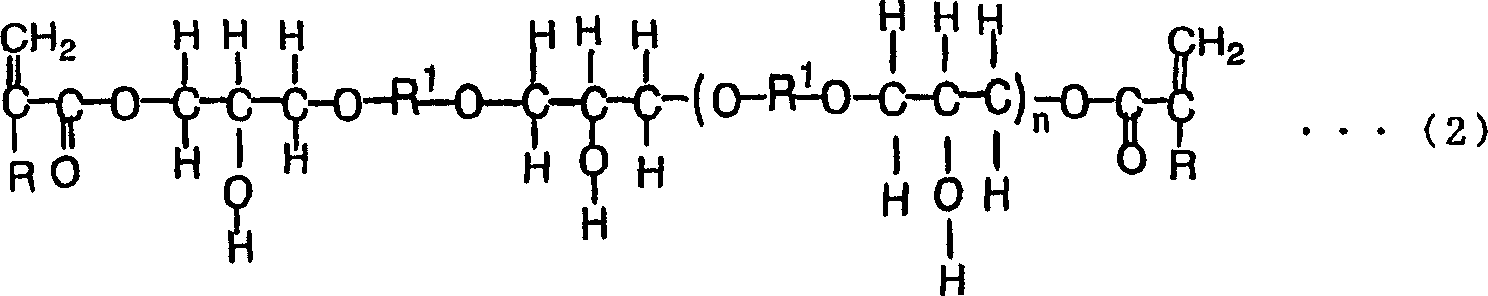

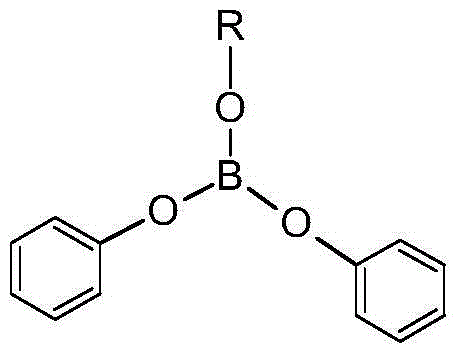

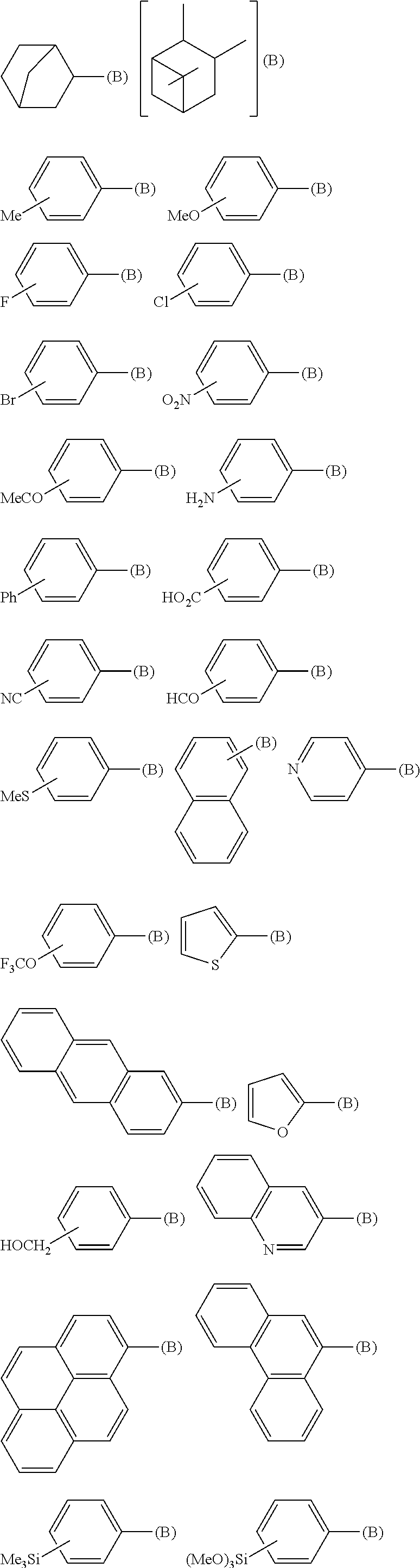

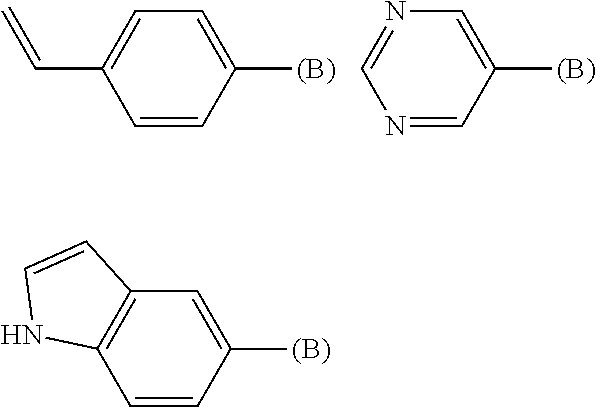

Toner for electrostatic charge development wherein no scumming occurs, and toner leakage caused by charge defect of the toner on a developing roller can be inhibited, and an excellent image stability is obtained is provided.The toner used for an image forming method having a latent electrostatic image forming step of forming a latent electrostatic image on a latent electrostatic image bearing member primarily charged, a developing step of developing the latent electrostatic image by each toner which multiple developing devices have to form a toner image on the latent electrostatic image bearing member, a transferring step of transferring the toner image with respective colors formed on the latent electrostatic image bearing member onto a recording material and a fixing step of fixing the toner image transferred onto the recording material, wherein the toner comprises a colorant and a resin and contains an organic boron compound represented by a following chemical formula (A) as a charge controlling agent, further the toner is treated with an inorganic fine particle and at least one of the inorganic particles is a magnesium silicate compound represented by a following general formula [2] is provided.wherein X is an alkali metal, R1, R2, R3 or R4 each represents a hydrogen atom, an alkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, or a halogen atom.MgxSiyO(x+2y) [2]wherein x and y are integers.

Owner:RICOH KK

Intumescent Seal

InactiveUS20090326117A1Reduce riskHigh mechanical elasticity and resistanceOther chemical processesEngine diaphragmsOrganic Boron CompoundsPassive fire protection

A flexible intumescent seal for passive fire protection has a base material that consists of a blend comprising at least one thermoplastic polymer, expandable graphite and at least one acid generating compound. The acid generating compound is an organic boron compound and the at least one thermoplastic polymer is a vinyl polymer and / or copolymer. The seal may be formed by extrusion, drawing, molding or injection of the blend.

Owner:BENUSSI GIAMPAOLO +2

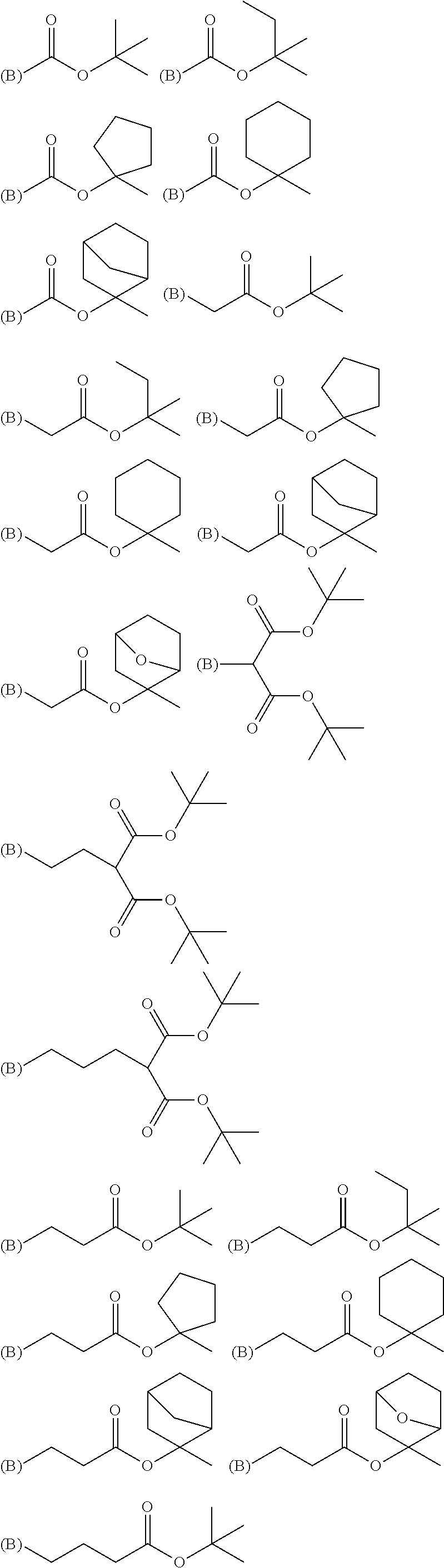

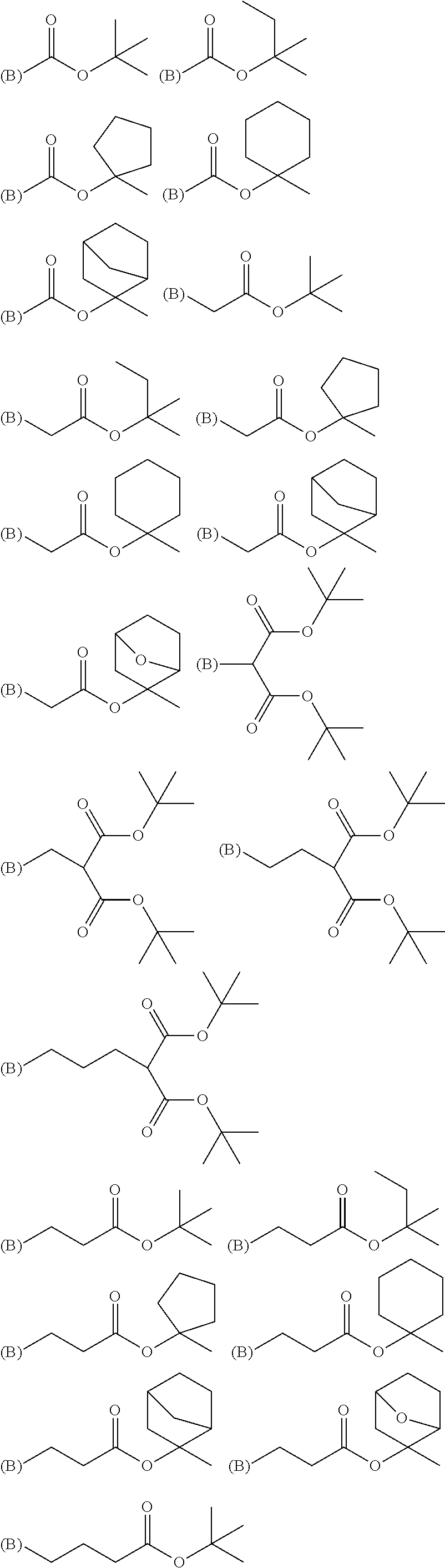

Dental or surgical adhesive and polymerization initiator composition therefor

A polymerization initiator composition which does not burn or ignite even when it contacts paper or the like in air and can provide high polymerization activity to a polymerizable composition to cure it in a short period of time, and an adhesive composition comprising the same. The above polymerization initiator composition comprises 100 parts by weight of (A) an organic boron compound such as a trialkyl boron, alkoxyalkyl boron, dialkyl borane, monocyclo or bicyclo compound having a boron atom as a hetero atom or partially oxidated trialkyl boron, 5 to 40 parts by weight of (B) an aprotic solvent having a boiling point of 50 to 120 DEG C, and 0.2 to 5 parts by weight of (C) an alcohol having a boiling point of 60 to 180 DEG C.

Owner:SUN MEDICAL

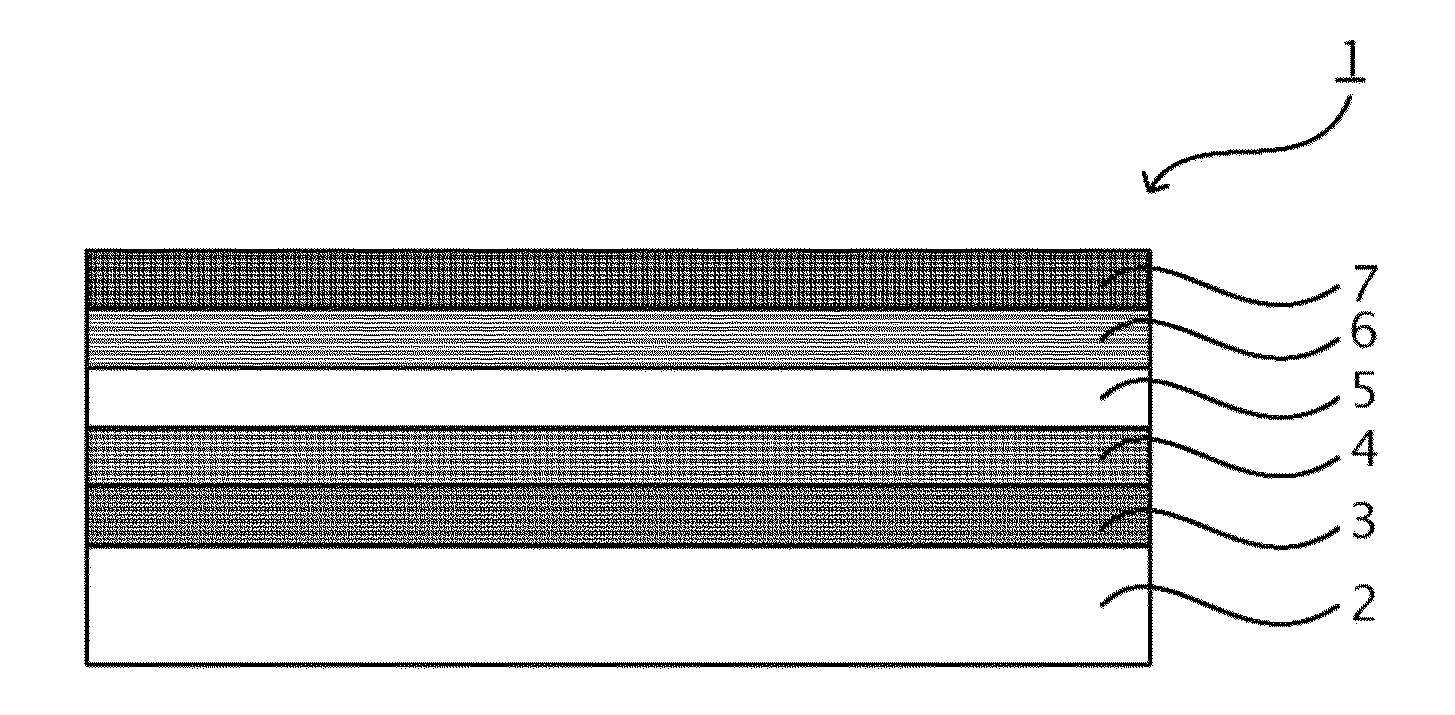

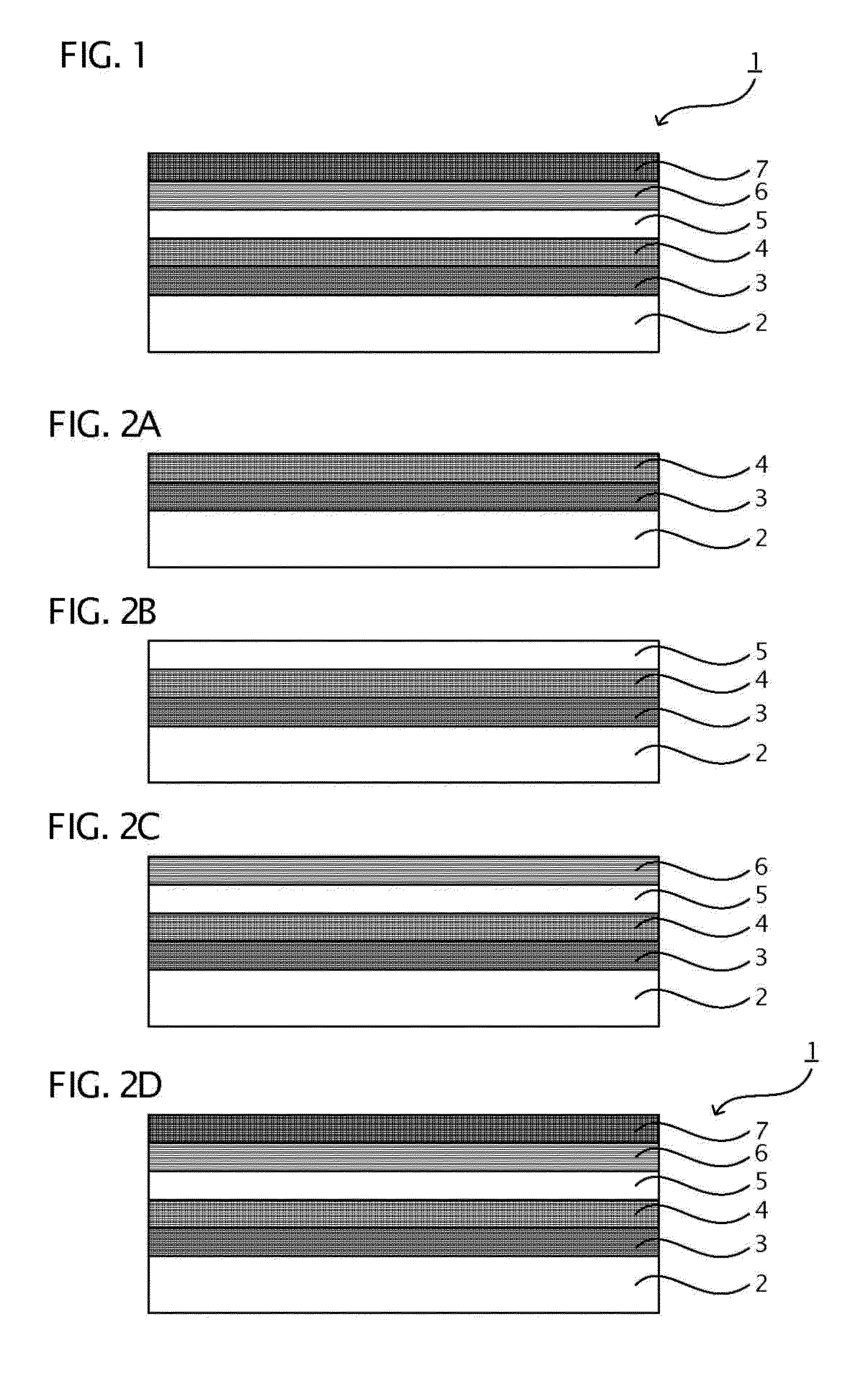

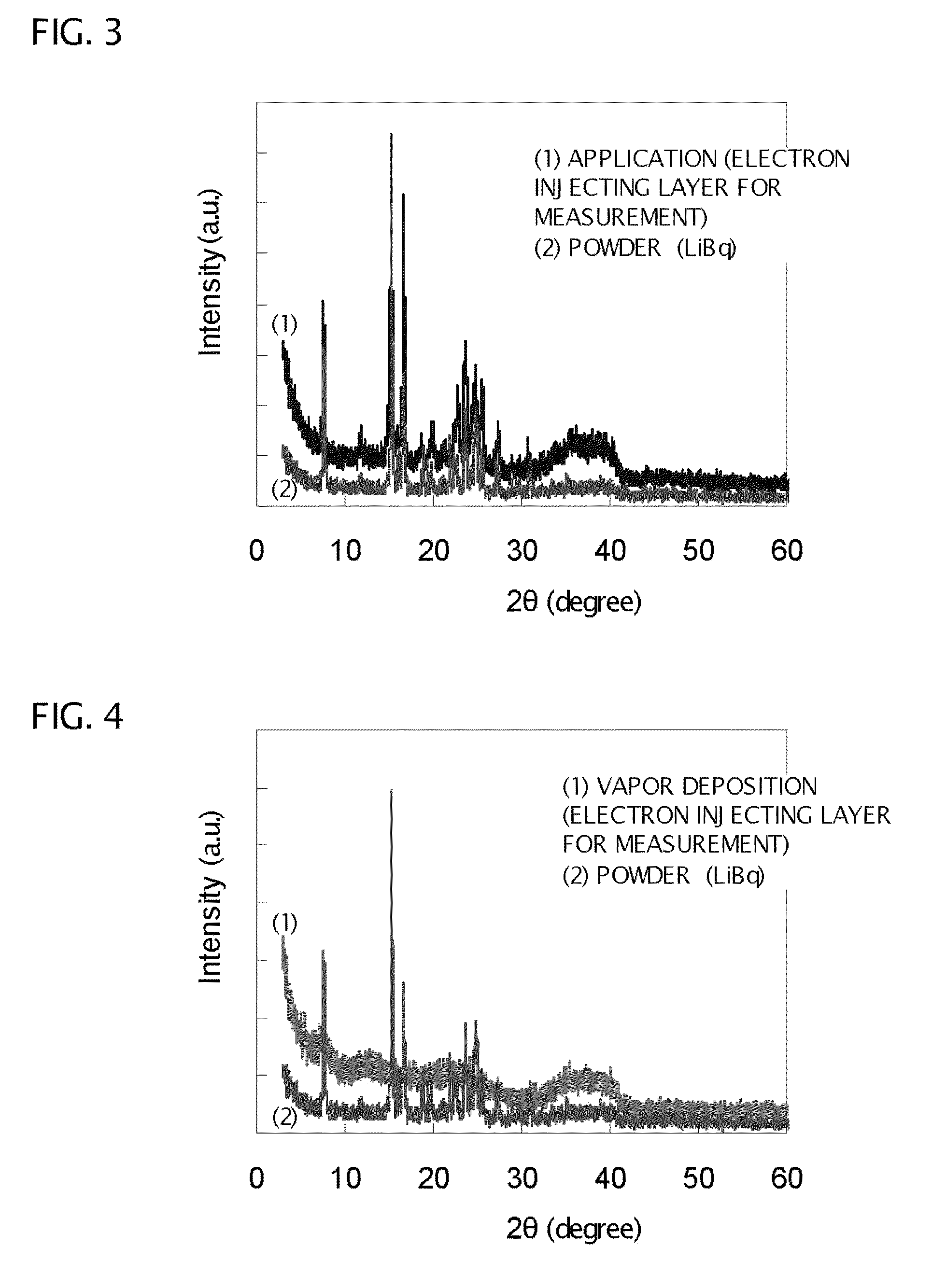

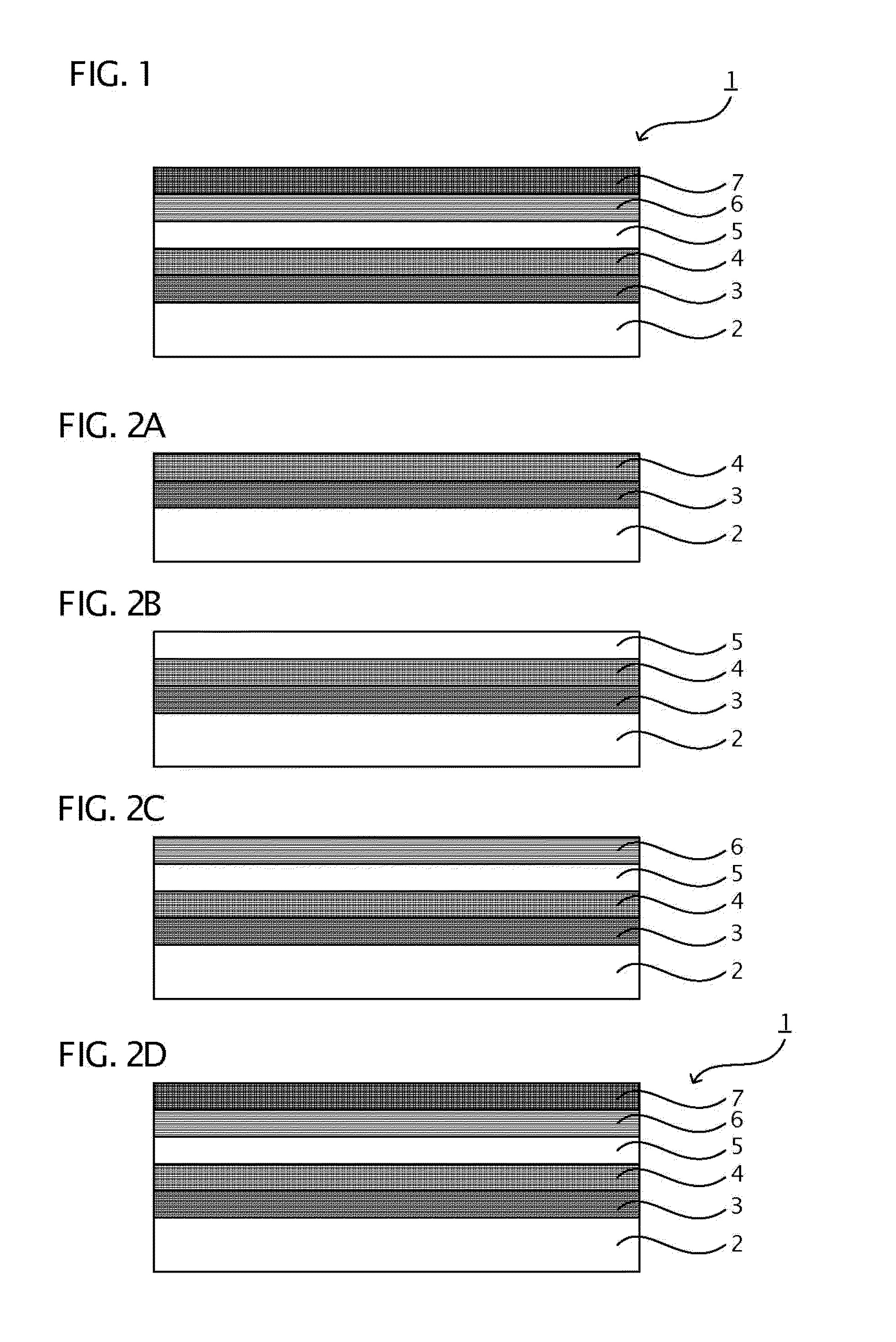

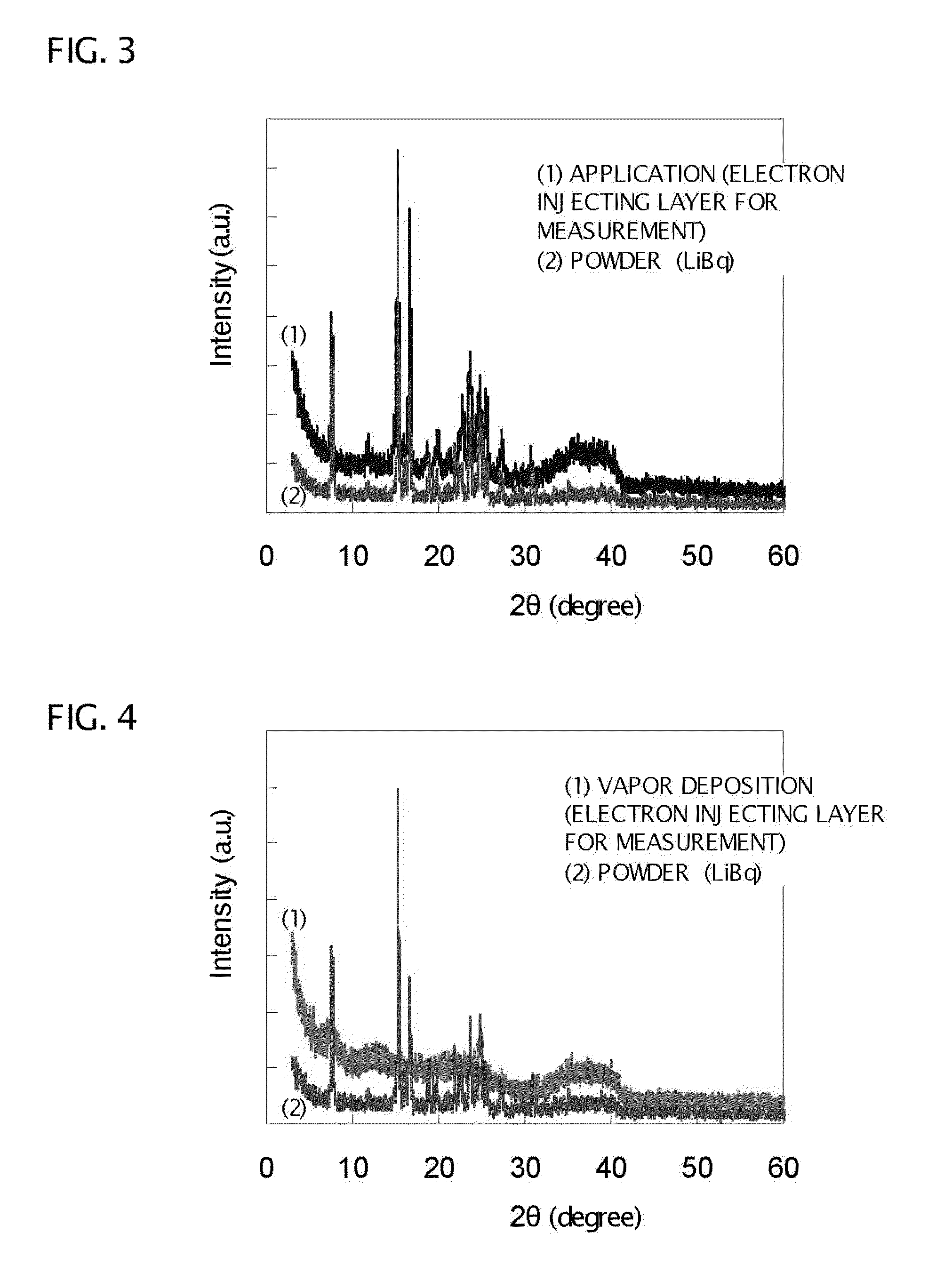

Organic electroluminescent element, method for manufacturing organic electroluminescent element, and coating liquid for electron injection and transport layer

InactiveUS8969862B2Improve efficiencyEasy to useConductive materialSolid-state devicesElectron injectionTransport layer

Owner:DAI NIPPON PRINTING CO LTD

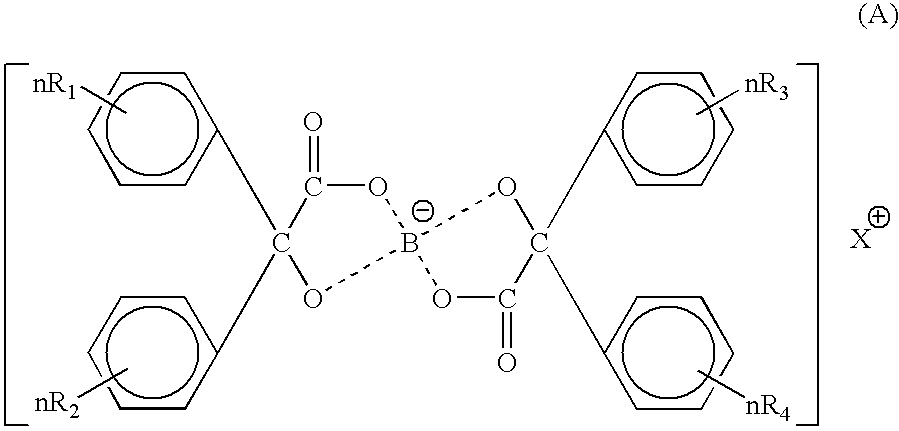

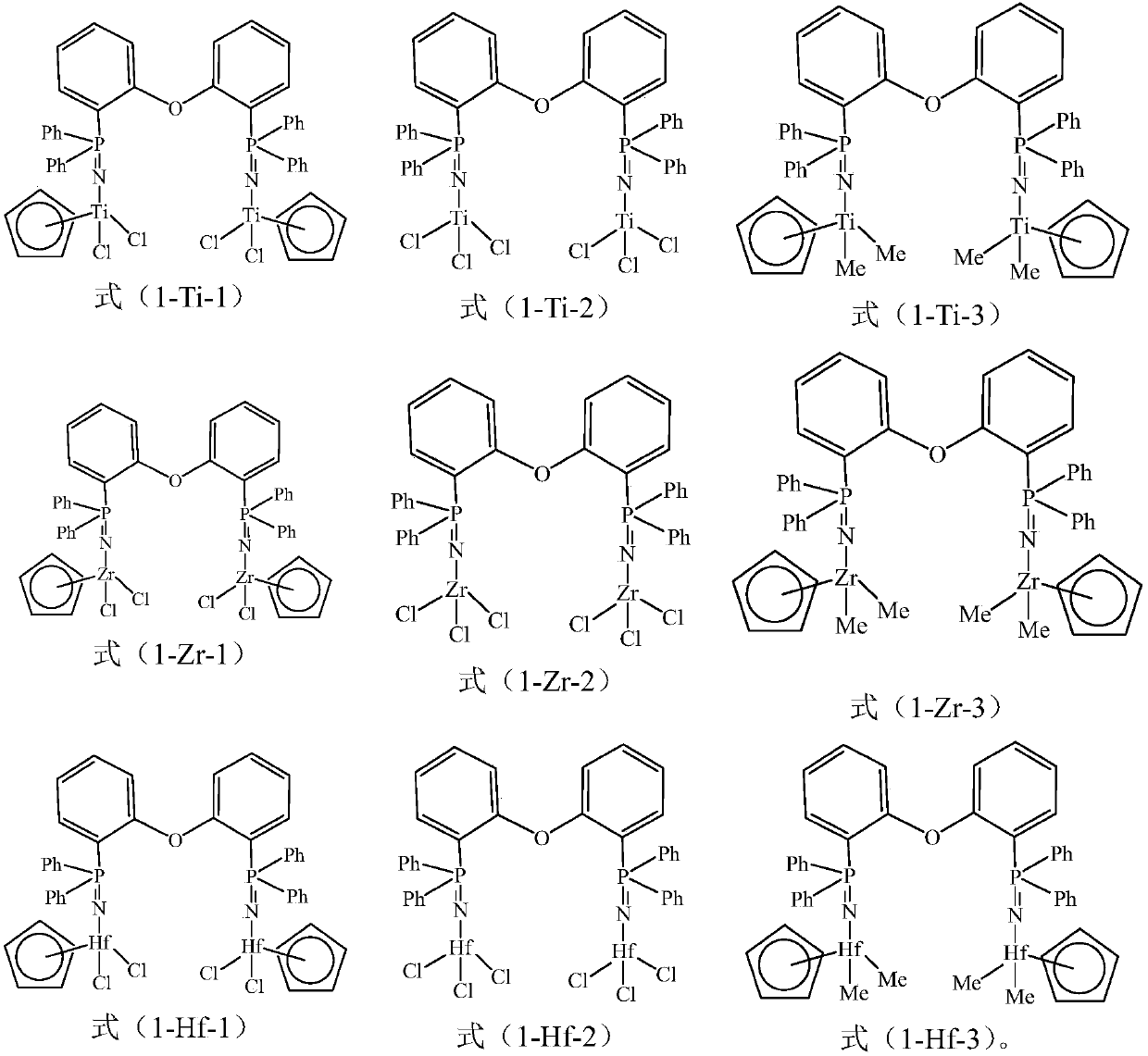

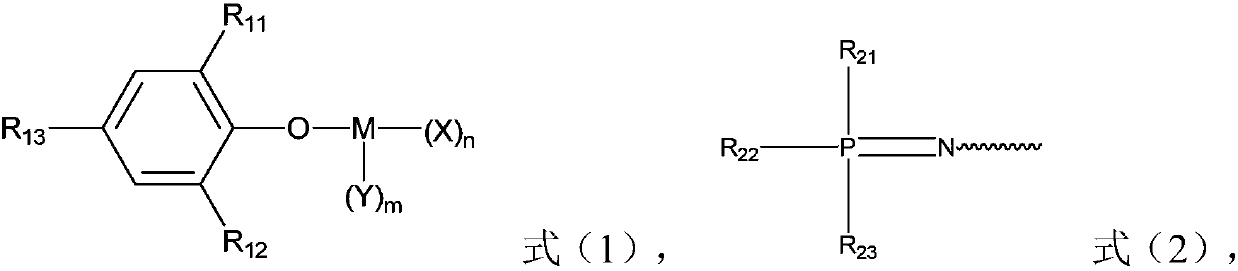

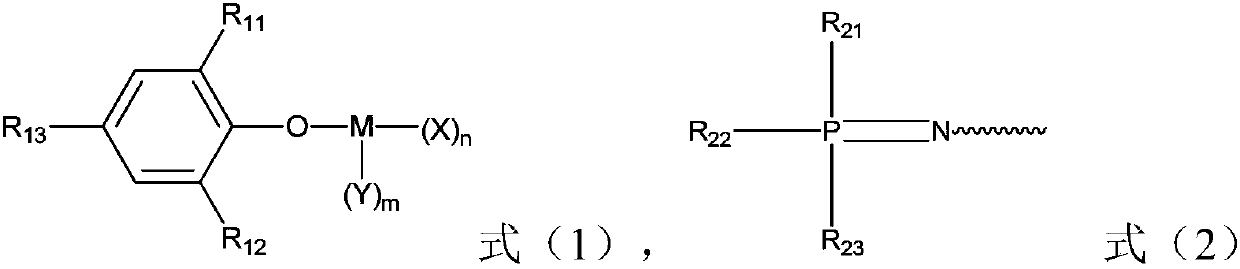

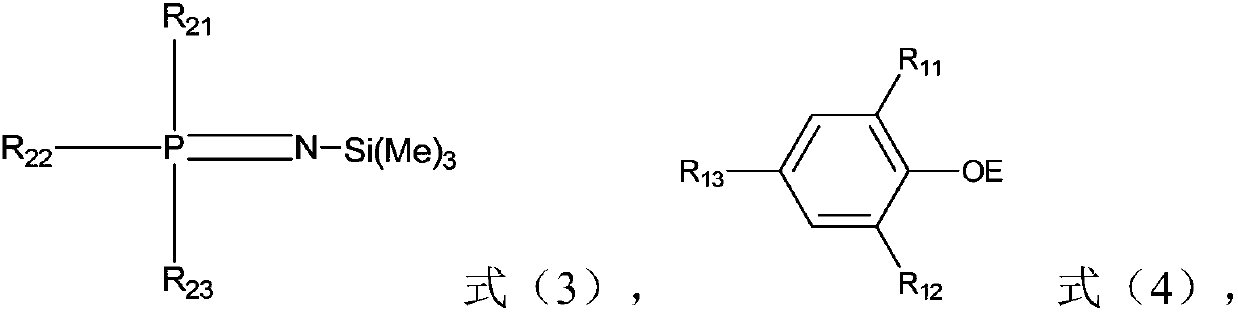

Polyolefin elastomer and preparation method thereof

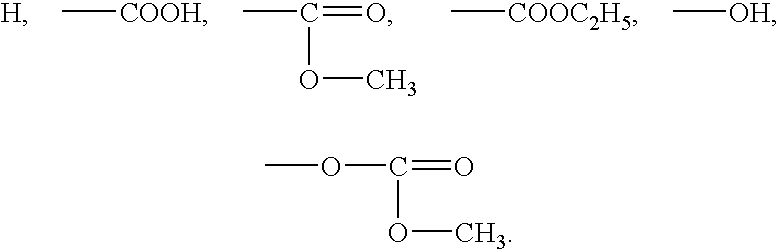

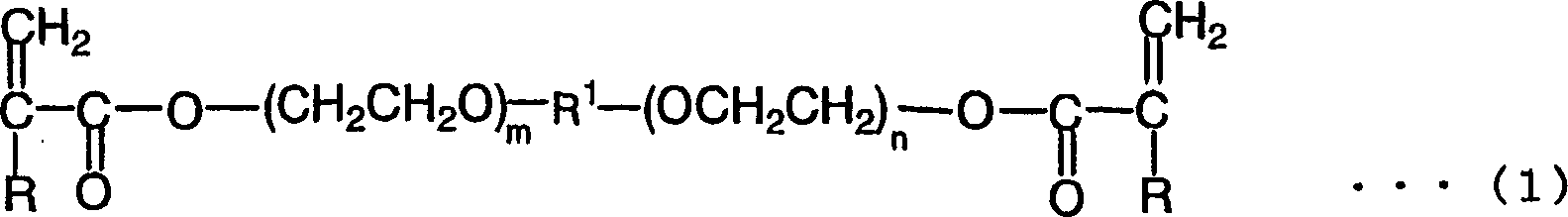

The invention relates to the field of olefin polymerization, in particular to a polyolefin elastomer and a preparation method thereof. The molecular weight of the polyolefin elastomer is distributed as a bimodal structure, and the preparation method includes the following steps that in an organic solvent, in the presence of a catalyst and hydrogen, the polymerization reaction of ethylene, [alpha]olefin and optional cycloolefin is conducted; the catalyst contains a main catalyst and an activator, and the activator includes one or more optional compounds containing organic boron; and the main catalyst is one or more pre-transition metal compounds or crystals thereof shown in a formula (1). According to the polyolefin elastomer and the preparation method thereof, the pre-transition metal compounds or the crystals thereof are adopted to be the main catalyst for polymerization, and the polyolefin elastomer with obvious bimodal distribution is prepared by using a catalyst system in a singlereactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

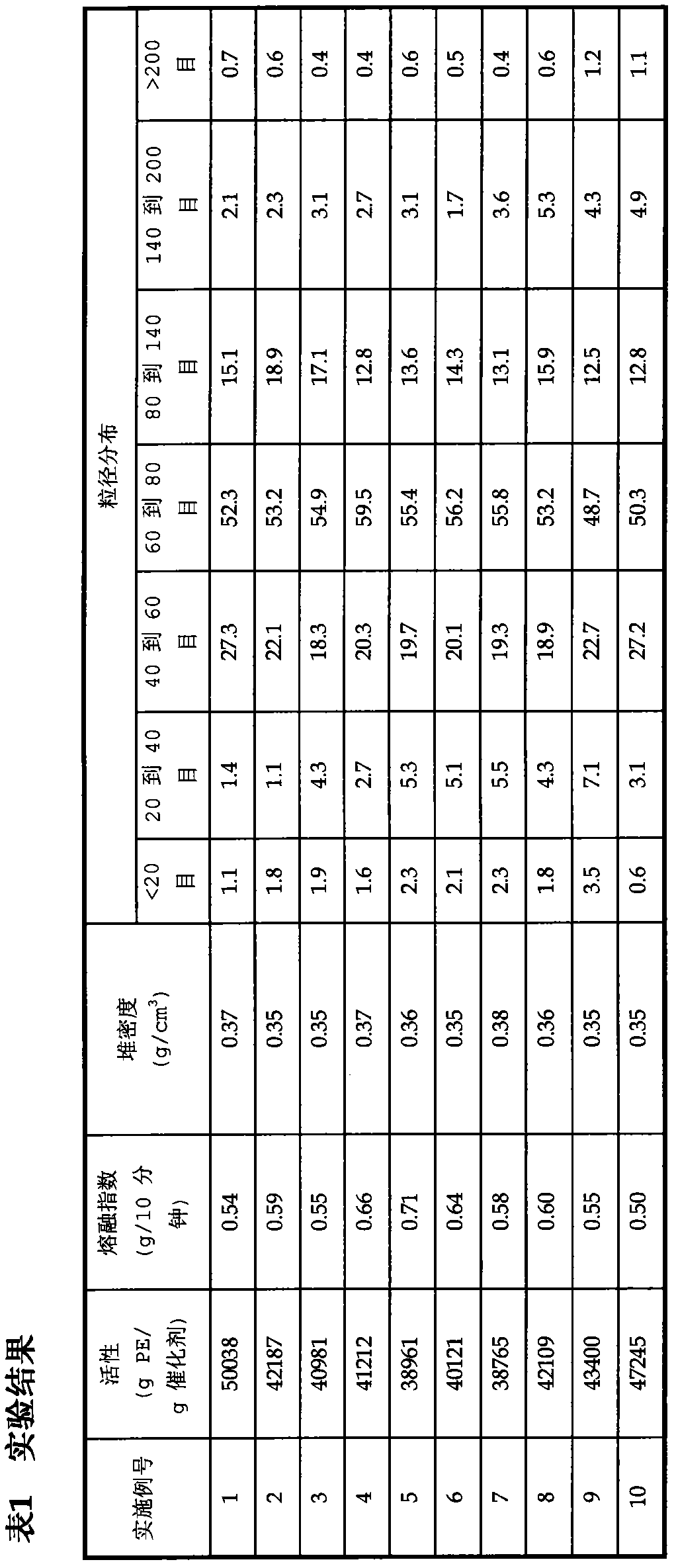

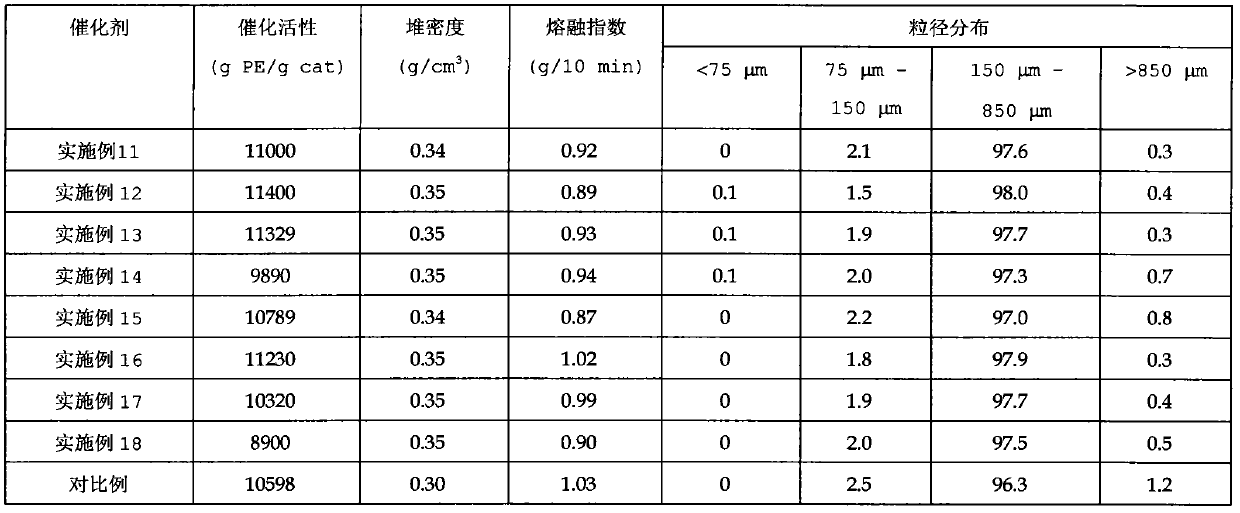

Catalyst components and catalysts for ethylene polymerization

Owner:CHINA PETROLEUM & CHEM CORP +1

Negative photosensitive composition and negative photosensitve lithographic printing plate

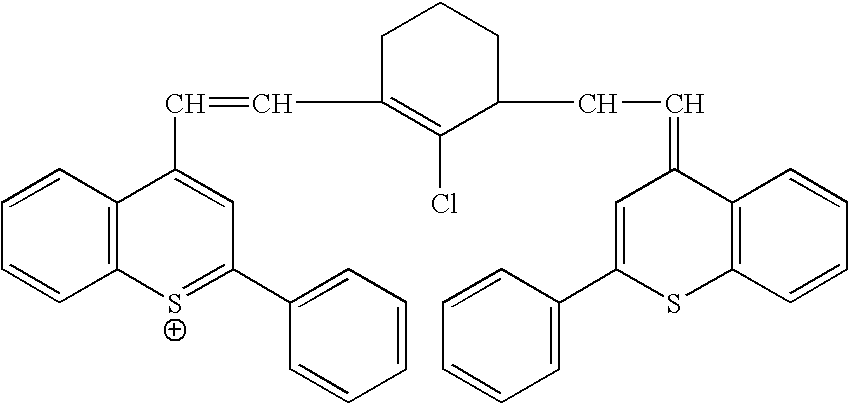

InactiveUS20070148582A1Good storage stabilityHigh sensitivityPhotosensitive materialsThermographyInfraredOrganic Boron Compounds

The present invention relates to a negative photosensitive composition comprising: (A) an infrared absorber, (B) an organic boron compound which has a function as a polymerization initiator when used in combination with the infrared absorber (A), (C) an onium salt, and (D) a compound having a polymerizable unsaturated group. The use of the negative photosensitive composition of the present invention makes it possible to provide a negative photosensitive composition which is curable by infrared light and is less likely to cause polymerization inhibition due to oxygen during radical polymerization, and is also excellent in storage stability, and to provide a negative photosensitive lithographic printing plate which can directly form images by irradiation with infrared light from a solid laser or a semiconductor laser based on digital signals without preheating and shows high sensitivity, and is also excellent in printing durability and storage stability.

Owner:KODAK POLYCHROME GRAPHICS +1

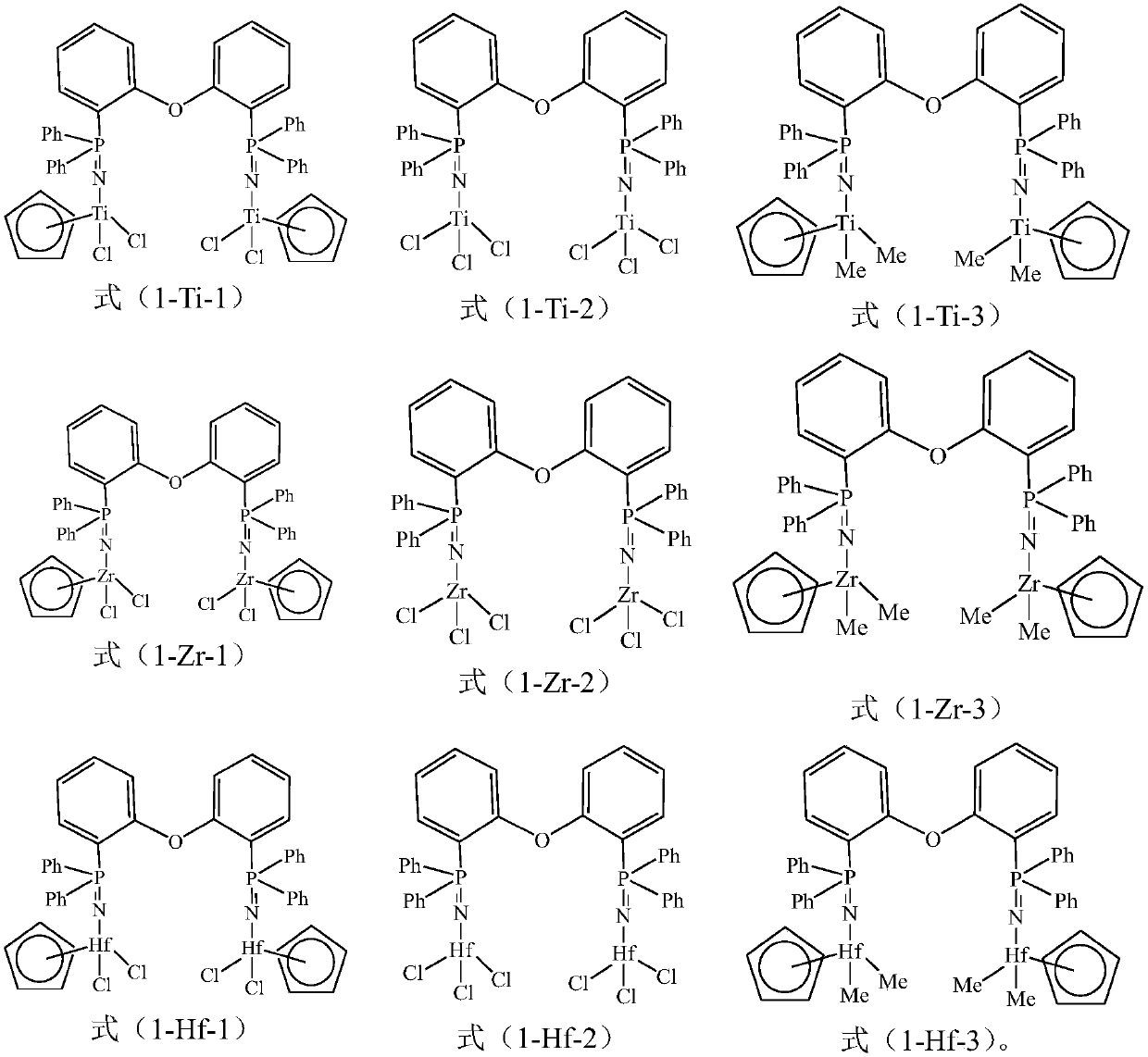

Non-metallocene compound and ethylene-styrene copolymer, preparation method of non-metallocene compound and ethylene-styrene copolymer, catalyst composition for olefin polymerization and application of catalyst composition

ActiveCN107793510AHigh catalytic activityHigh ethylene structural unit contentOrganoboron compoundsOlefin polymerization

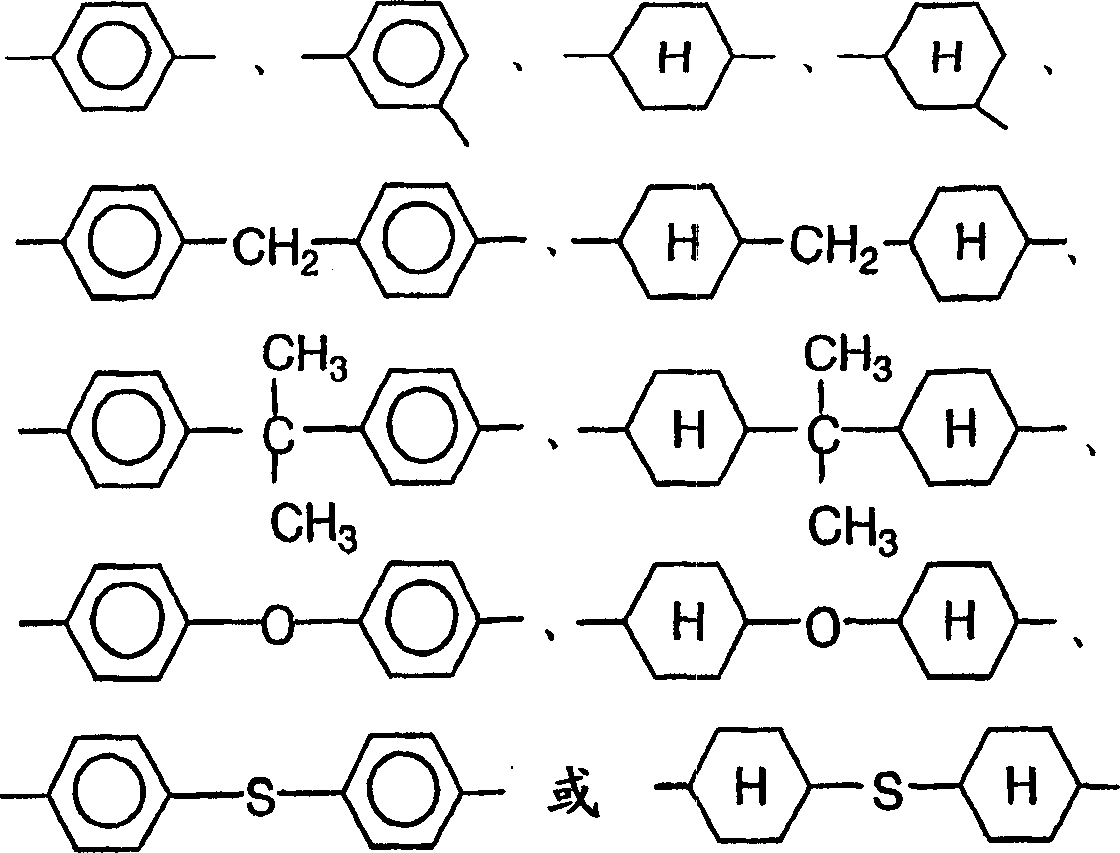

The invention relates to the field of catalysts, and discloses a non-metallocene compound and an ethylene-styrene copolymer, a preparation method of the non-metallocene compound and the ethylene-styrene copolymer, a catalyst composition for olefin polymerization and an application of the catalyst composition. The non-metallocene compound has the structure shown in a formula (I). The catalyst composition for olefin polymerization provided by the invention comprises a main catalyst and a cocatalyst, wherein the main catalyst is the non-metallocene compound provided by the invention, and the co-catalyst contains an aluminum-containing compound and an optional organic boron compound. The catalyst composition for olefin polymerization provided by the invention has the advantage of high catalytic activity. The catalyst composition provided by the invention can be used to catalyze the olefin polymerization of an ethylene monomer and a vinyl aromatic monomer, so that the single ethylene-styrene copolymer with relatively high content of ethylene structure units and can be obtained, and therefore, the toughness of the obtained copolymer is obviously better than the toughness of polymers in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

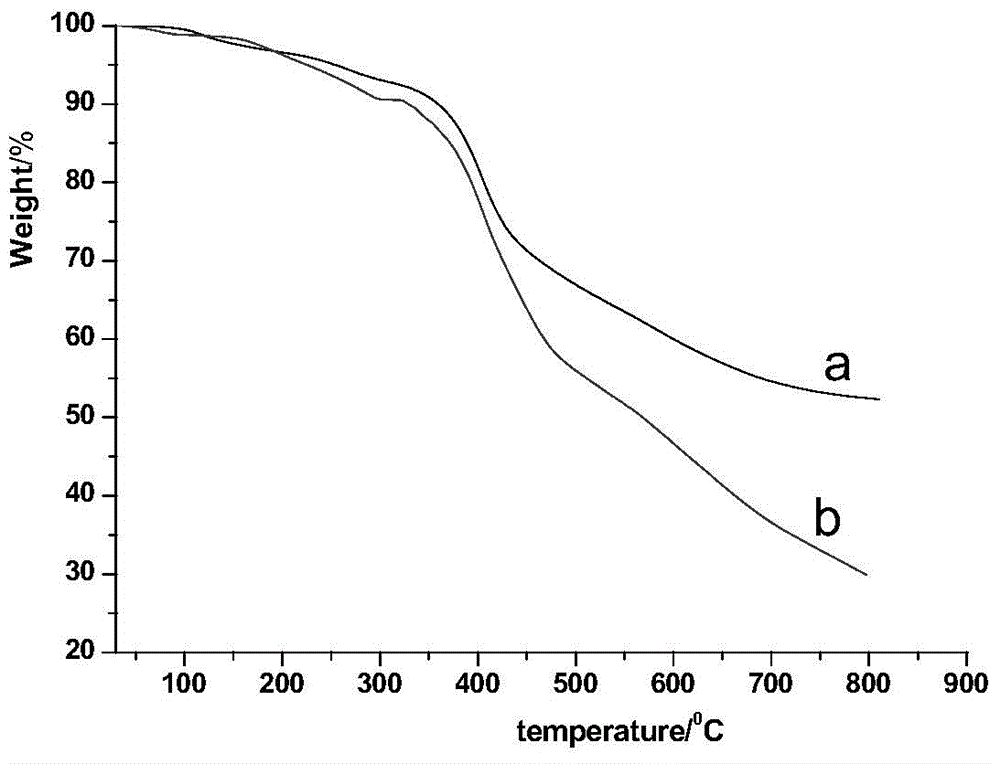

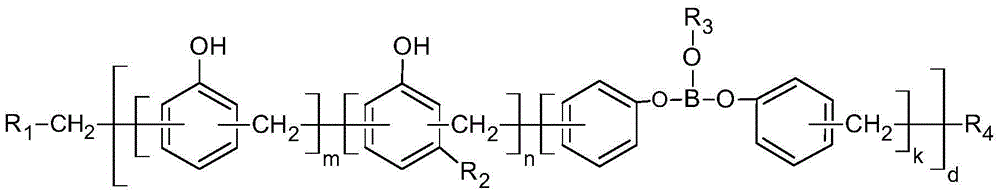

Preparation method of modified phenolic resin and modified phenolic resin prepared by preparation method

The invention provides a preparation method of modified phenolic resin and modified phenolic resin prepared by the preparation method. By adopting organic boron and anacardol for double modification of phenolic resin, the preparation method comprises the following steps: firstly, carrying out reaction on an organic boron compound and excessive aldehyde under an alkaline condition to generate hydroxymethylated organic boron; then adding phenol, anacardol and an acidic catalyst; carrying out reaction under an acidic condition at 90-120 DEG C for 1-6 hours; and dehydrating to obtain the modified phenolic resin. The modified phenolic resin prepared by the method has good heat resistance and toughness and low cost and further has a good environmental benefit.

Owner:沙县宏盛塑料有限公司

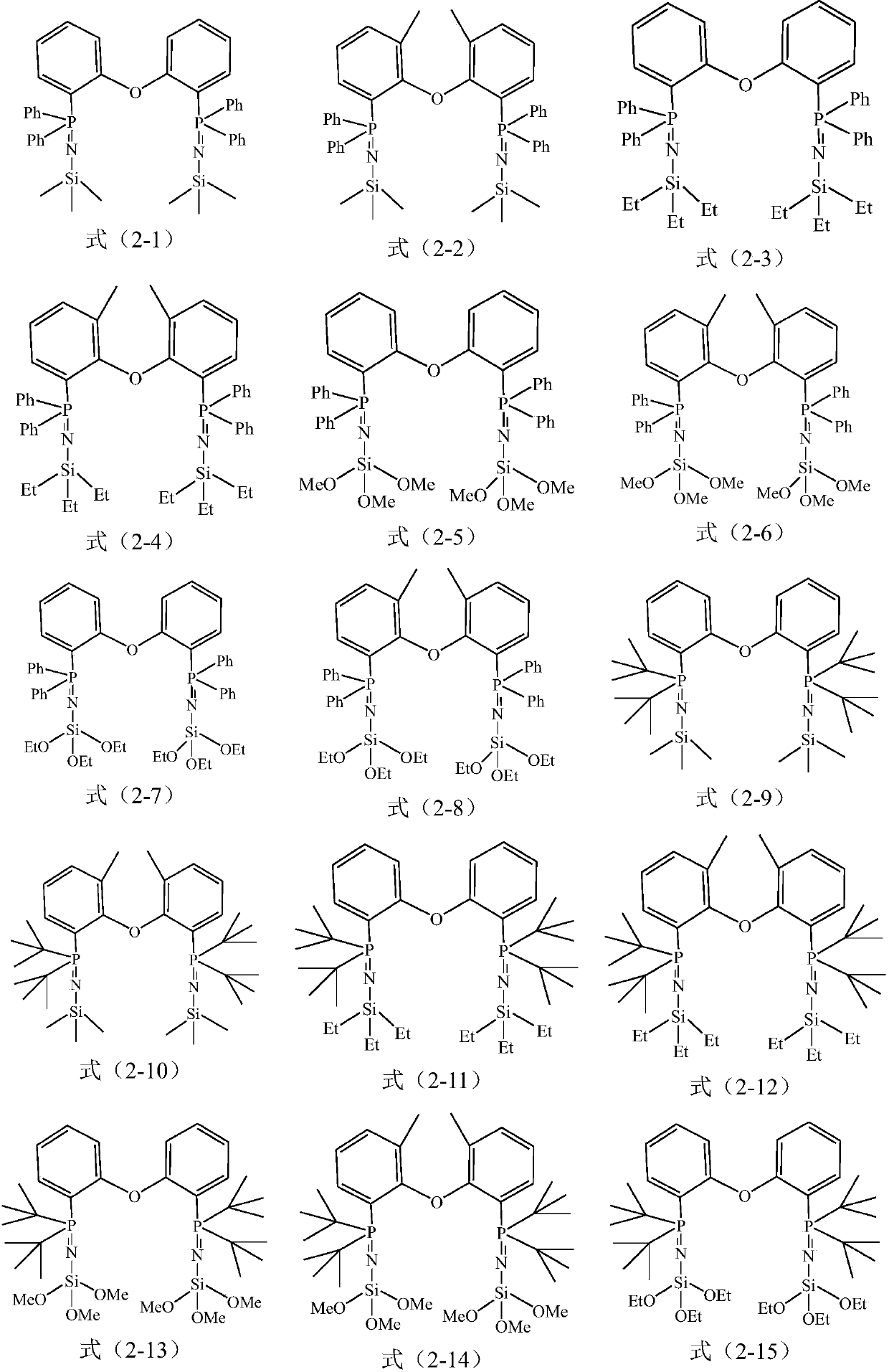

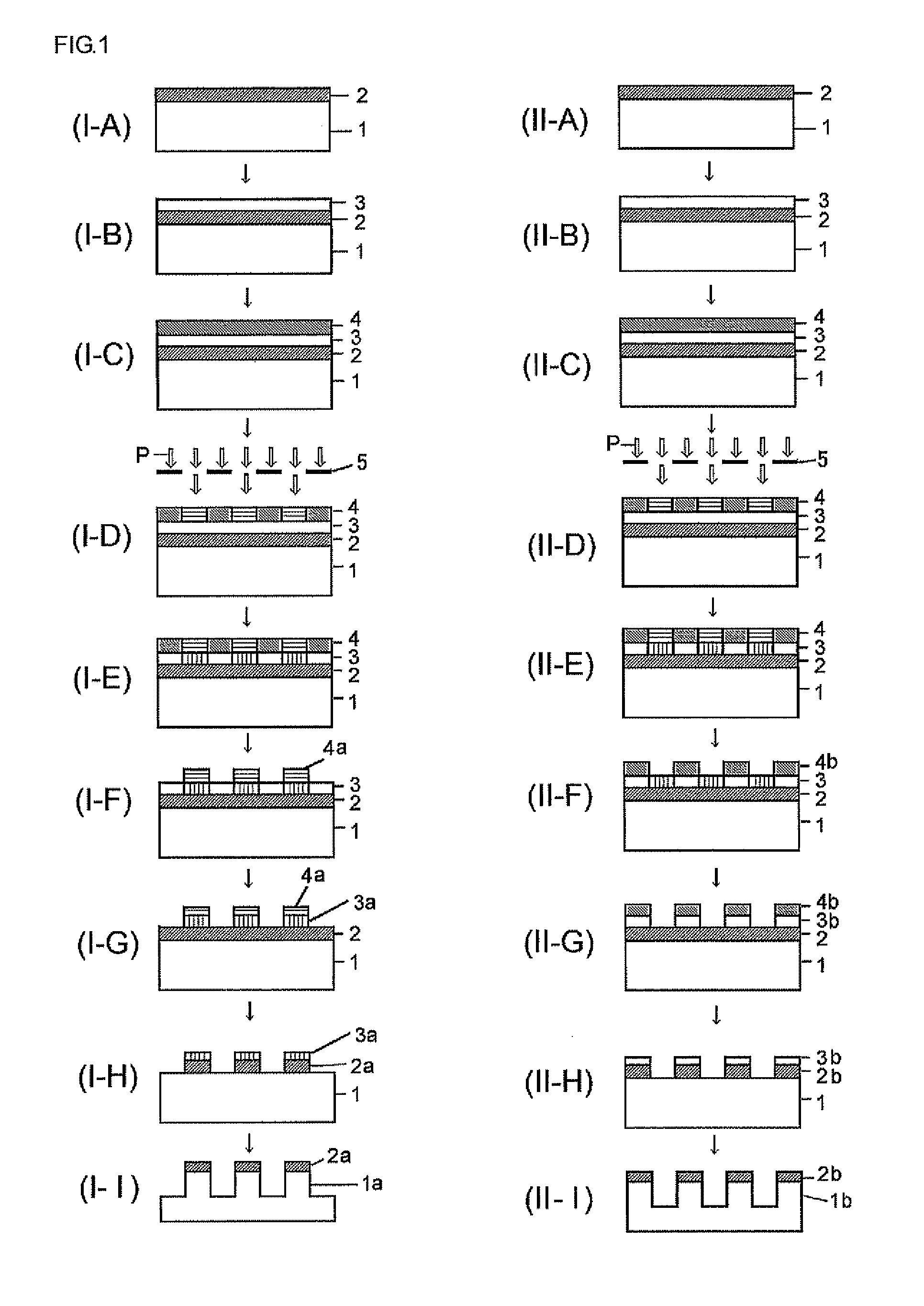

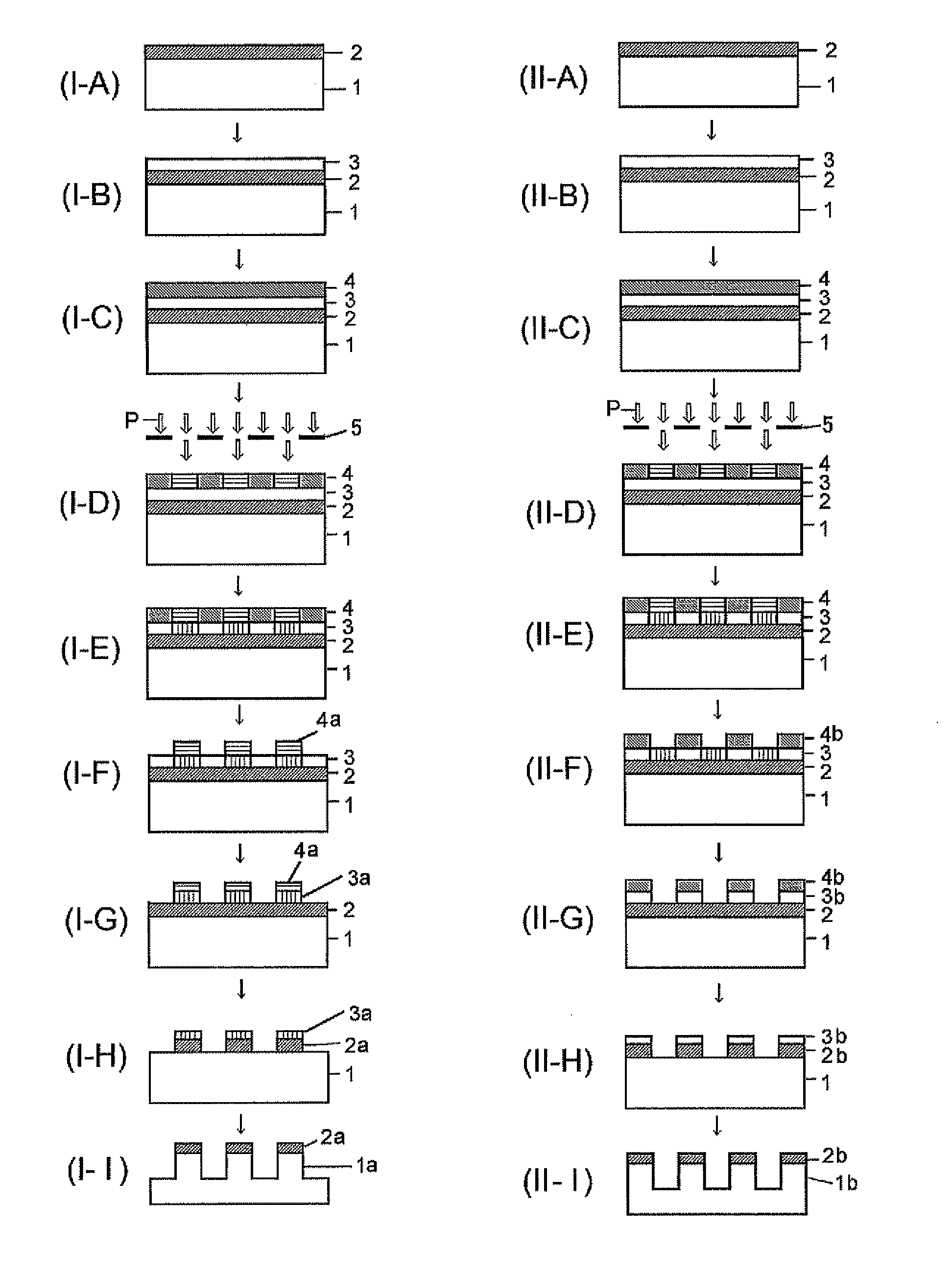

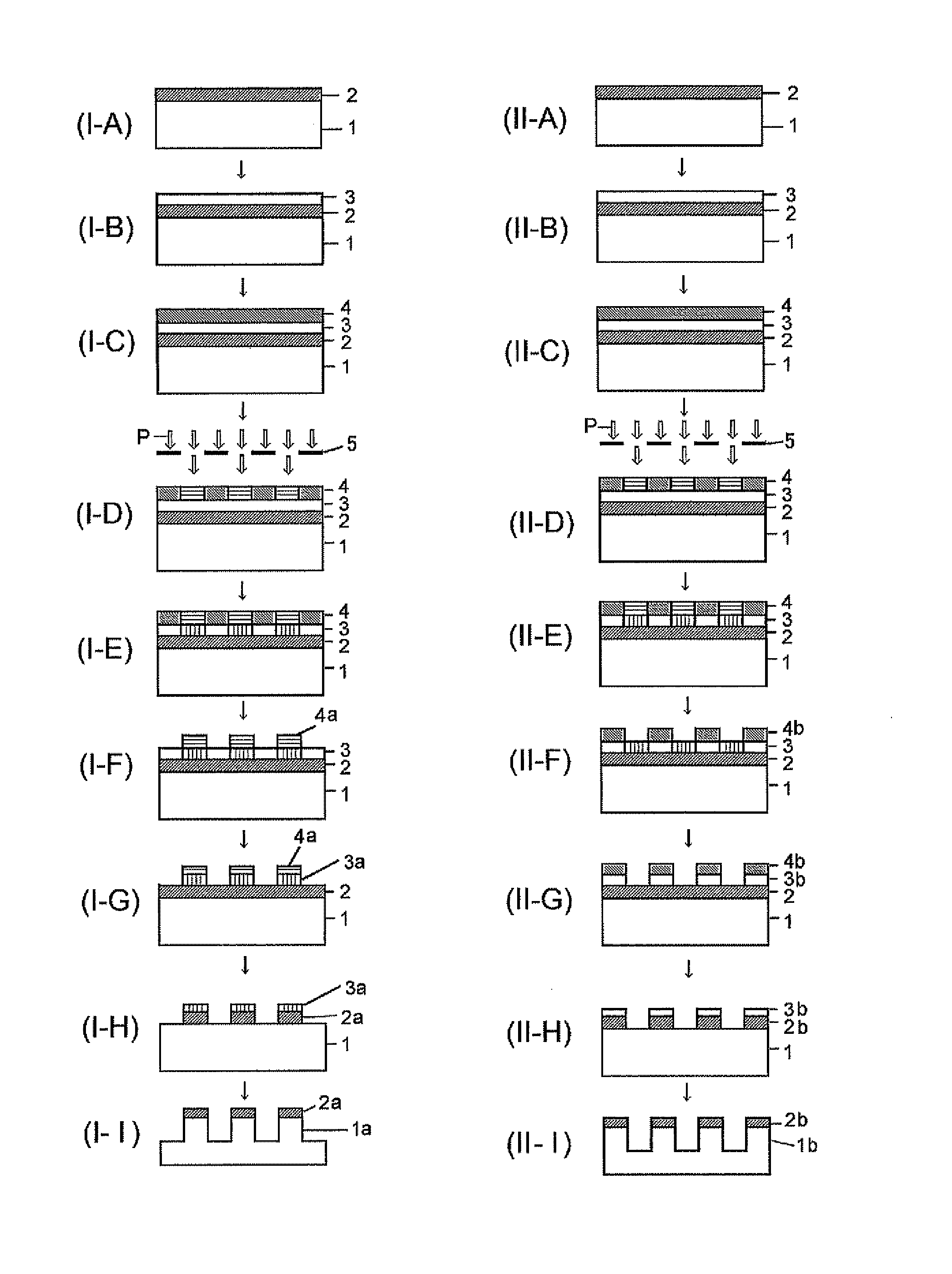

Silicon-containing resist underlayer film-forming composition and patterning process

ActiveUS20130137271A1Improve adhesionExcellent resist patternPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistOrganic film

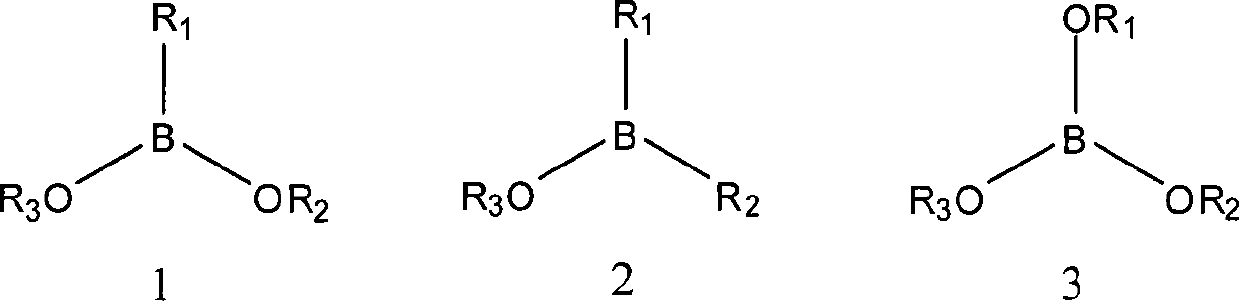

The present invention is a silicon-containing resist underlayer film-forming composition containing a condensation product and / or a hydrolysis condensation product of a mixture comprising: one or more kinds of a compound (A) selected from the group consisting of an organic boron compound shown by the general formula (1) and a condensation product thereof and one or more kinds of a silicon compound (B) shown by the general formula (2). Thereby, there can be provided a silicon-containing resist underlayer film-forming composition being capable of forming a pattern having a good adhesion, forming a silicon-containing film which can be used as a dry-etching mask between a photoresist film which is the upperlayer film of the silicon-containing film and an organic film which is the underlayer film thereof, and suppressing deformation of the upperlayer resist during the time of dry etching of the silicon-containing film; and a patterning process.R1m0B(OH)m1(OR)(3-m0-m1) (1)R10m10R11m11R12m12Si(OR13)(4-m10-m11-m12) (2)

Owner:SHIN ETSU CHEM IND CO LTD

A kind of preparation method of titanium catalyst component and its titanium catalyst component, and a kind of preparation method of titanium catalyst and its titanium catalyst

The present invention relates to a method for preparing a titanium catalyst component, comprising the steps: reacting a magnesium halide in a solvent including an alcohol to obtain a homogeneous solution, reacting at least one organic boron compound with the homogeneous solution, reacting a titanium compound with the homogeneous solution, a titanium catalyst component obtainable by said method, a method for preparing a titanium catalyst and a titanium catalyst obtainable by said method.

Owner:SUD CHEM IP GMBH & CO KG

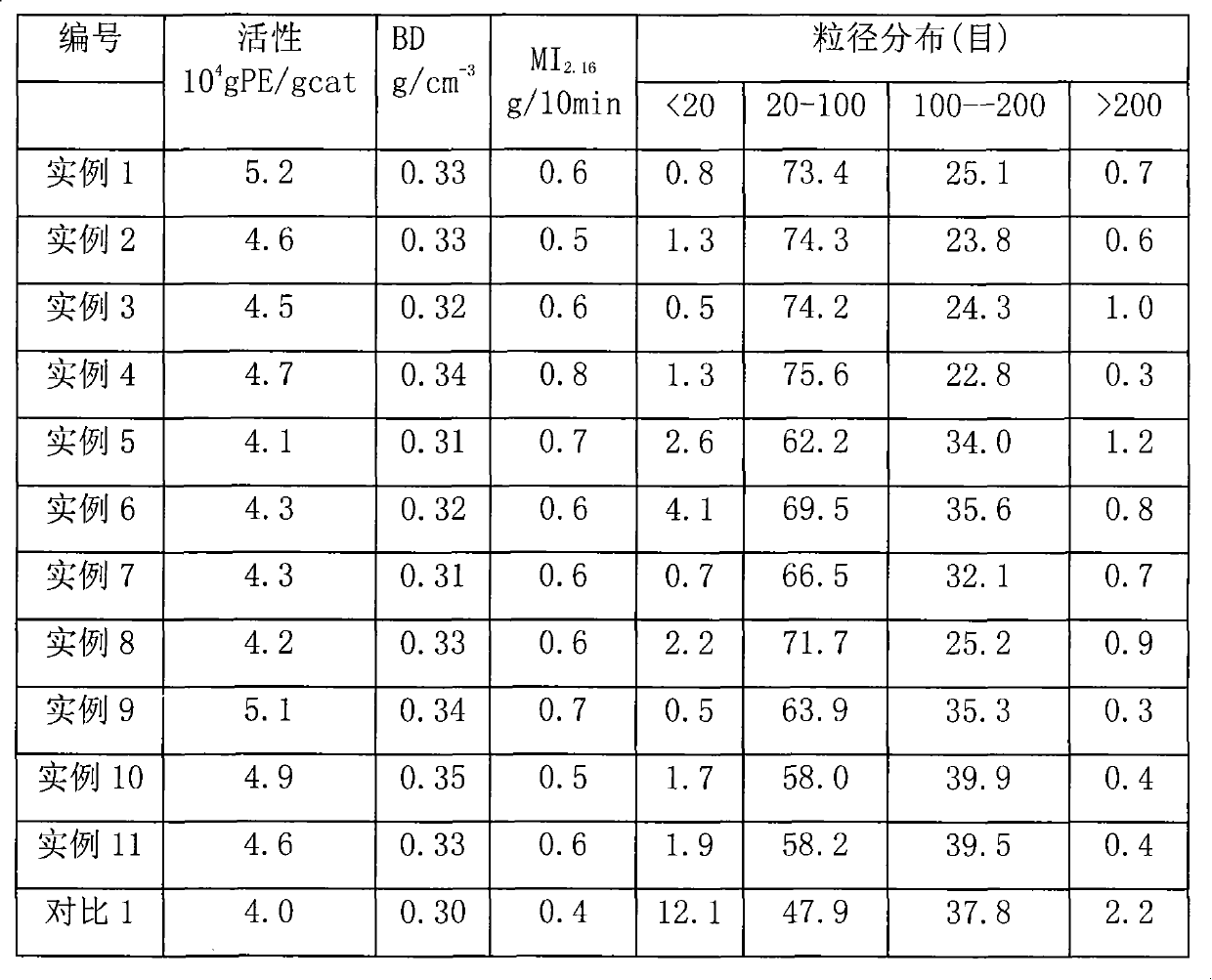

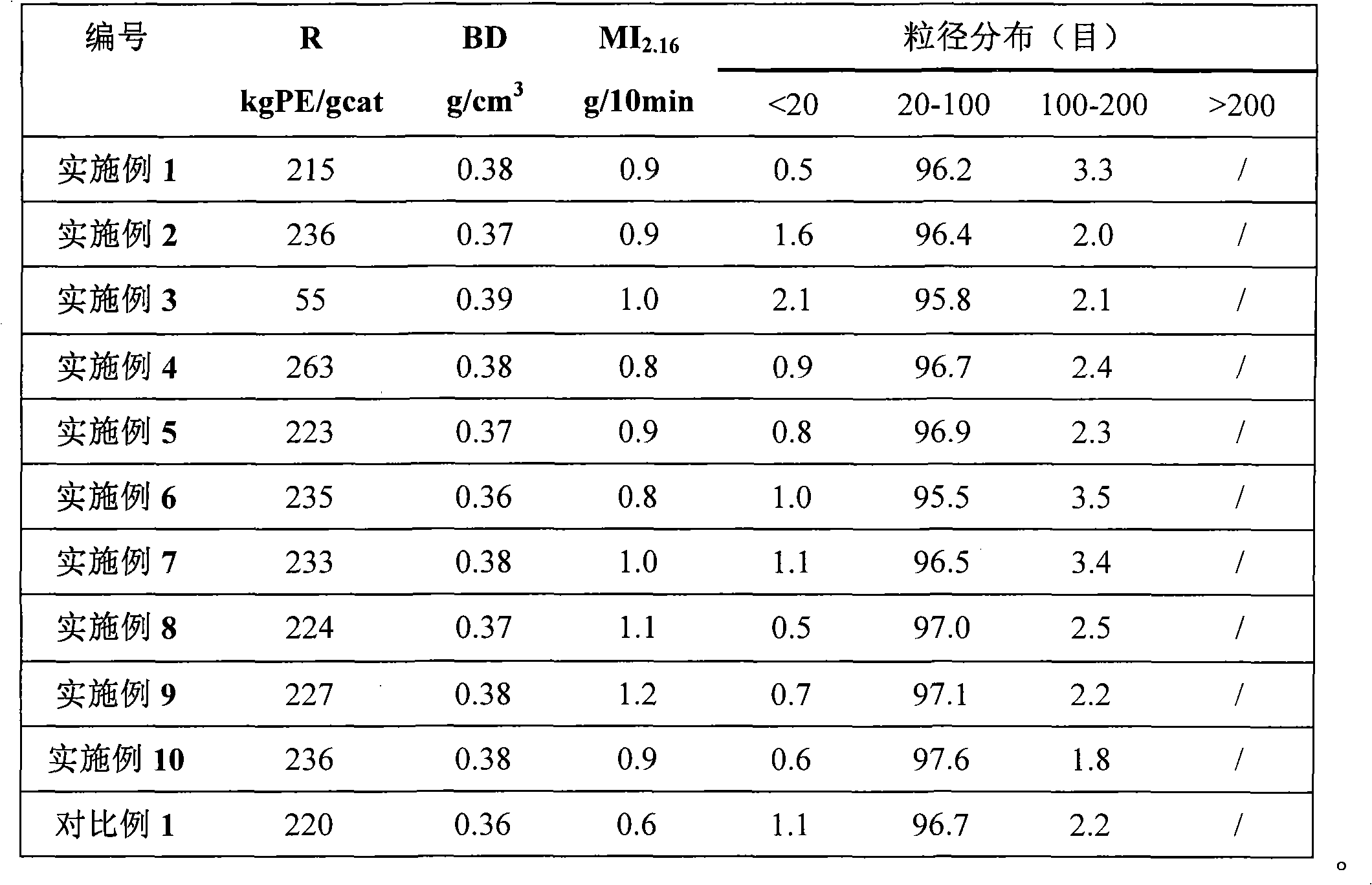

Catalyst component for vinyl polymerization or copolymerization and catalyst thereof

The invention provides a catalyst component for vinyl polymerization or copolymerization. The catalyst component comprises a magnesium complex, at least one titanium compound, at least one organic alcoholic compound, at least one organic boron compound and an optional organic aluminum reaction product which are loaded on an inorganic oxide carrier. The catalyst has the advantages of high catalytic activity, high hydrogen regulation sensitivity, narrow polymer particle size distribution and the like, and is very suitable for the slurry polymerization process of ethylene and a combination polymerization process needing a catalyst with high activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

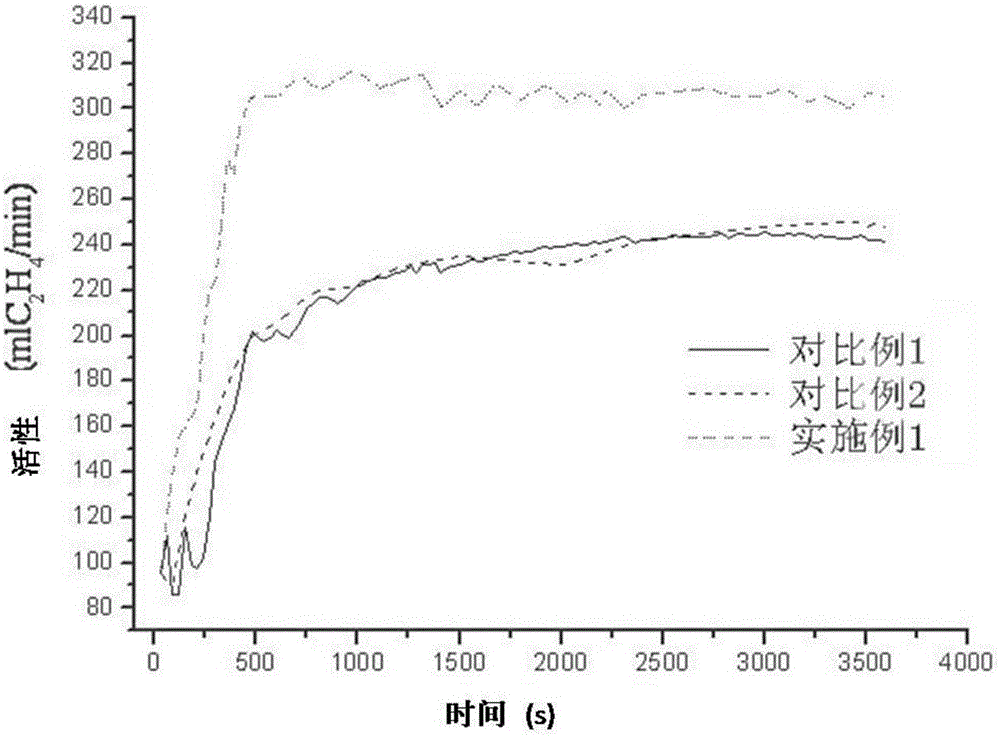

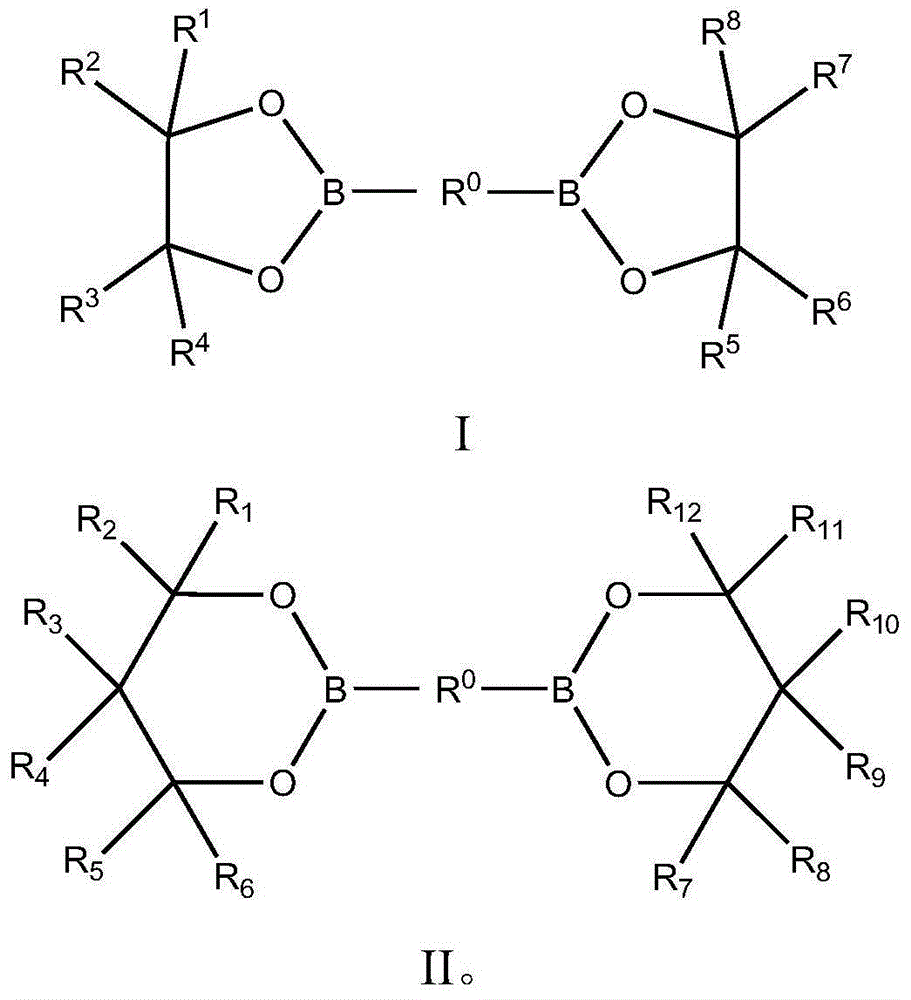

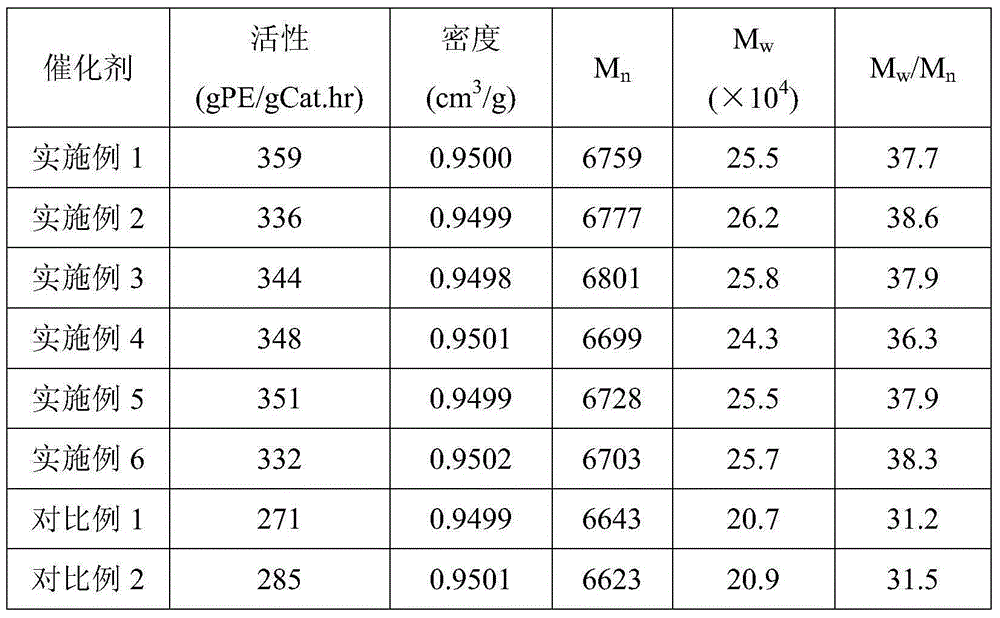

Catalyst component used for ethylene polymerization, preparation method and application thereof

ActiveCN106467583AShorten the polymerization induction periodHigh activityChromium CompoundsOrganic Boron Compounds

The invention provides a catalyst component used for ethylene polymerization, which comprises a chromium compound, an organic aluminum compound and an organic boron compound loaded on a carrier, and the organic boron compound contains a B-R0-B structure. The invention also provides a preparation method of the catalyst component, and an ethylene polymerization catalyst based on the catalyst component, the catalyst has good polymerization activity when used for ethylene homopolymerization or ethylene and alpha-alkene copolymerization, and can obtain the polyethylene with wide molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silicon-containing resist underlayer film-forming composition and patterning process

ActiveUS20130137041A1Improve accuracyImprove etch selectivityPhotosensitive materialsSemiconductor/solid-state device manufacturingSimple Organic CompoundsOrganic Boron Compounds

The present invention is a silicon-containing resist underlayer film-forming composition containing at least any one of a condensation product and a hydrolysis condensation product or both of a mixture comprising: one or more kinds of a compound (A) selected from the group consisting of an organic boron compound shown by the following general formula (1) and a condensation product thereof and one or more kinds of a silicon compound (B) shown by the following general formula (2). Thereby, there can be provided a resist underlayer film applicable not only to the resist pattern formed of a hydrophilic organic compound obtained by the negative development but also to the resist pattern formed of a hydrophobic compound obtained by the conventional positive development.R1m0B(OH)m1(OR)(3-m0-m1) (1)R10m10R11m11R12m12Si(OR13)(4-m10-m11-m12) (2)

Owner:SHIN ETSU CHEM IND CO LTD

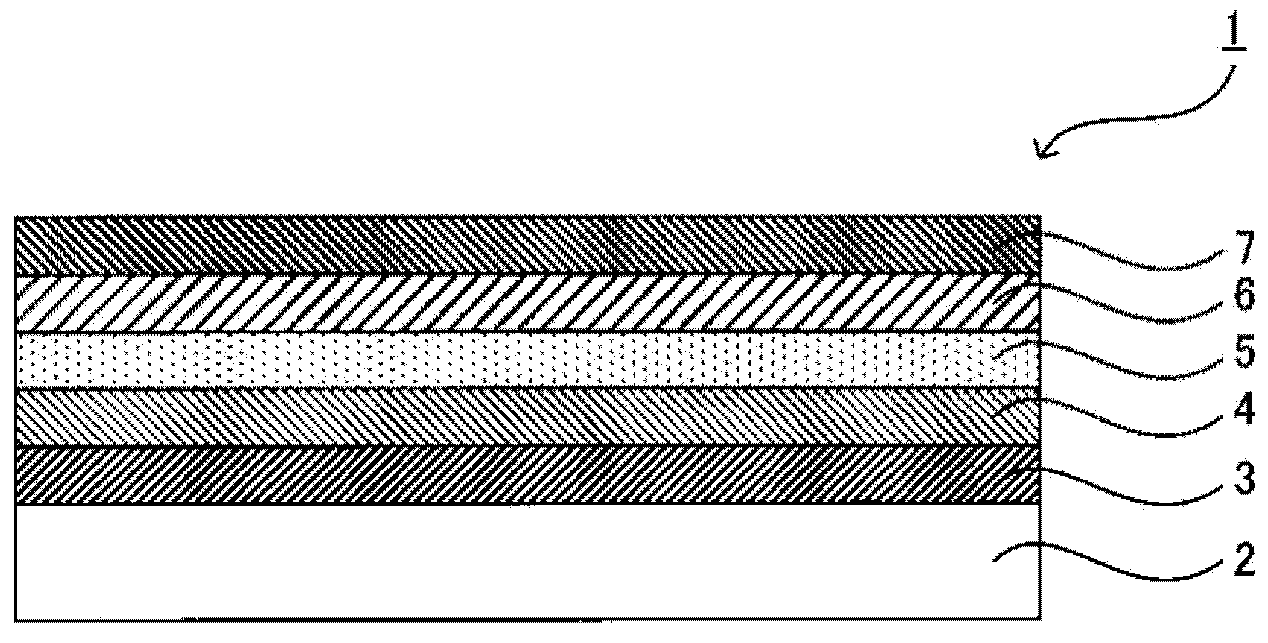

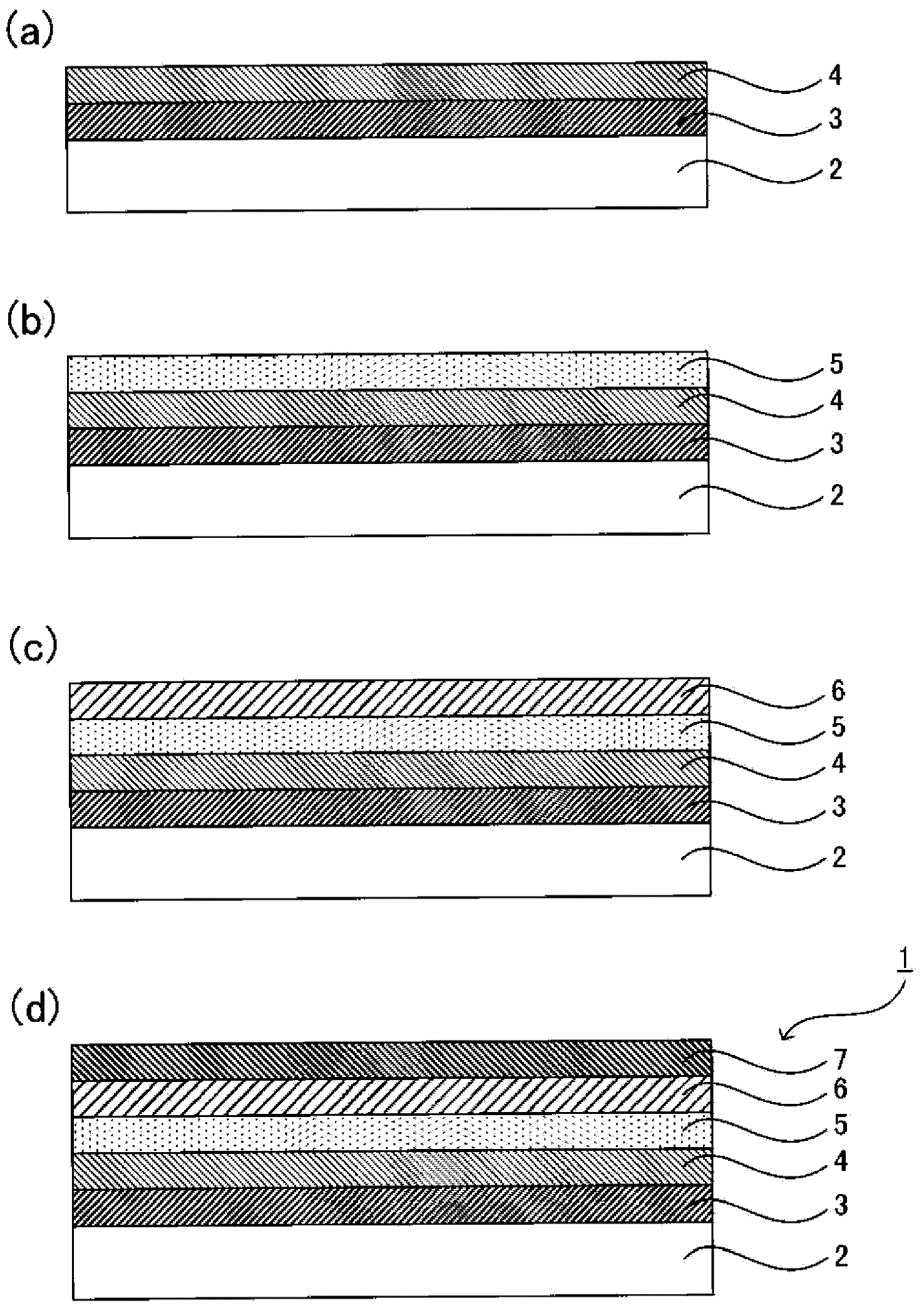

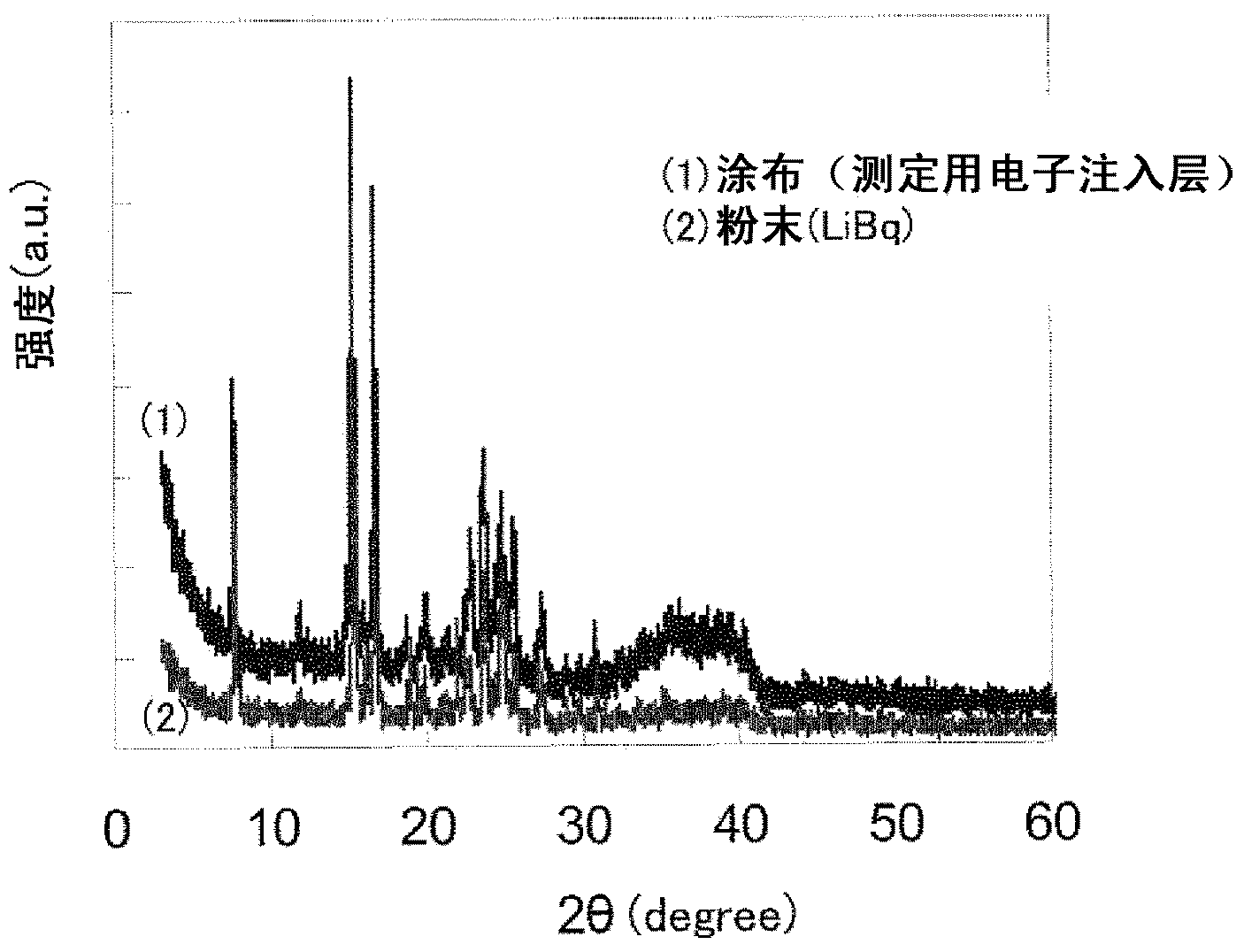

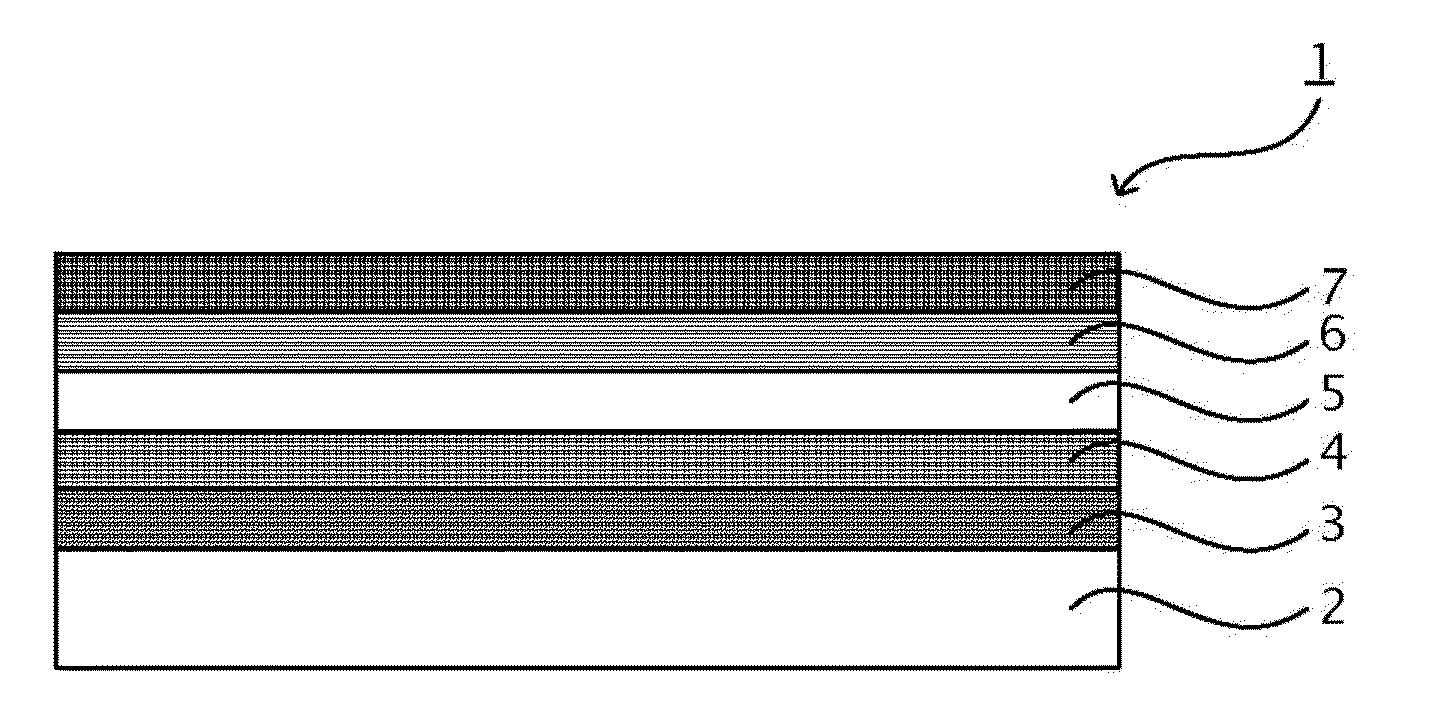

Organic electroluminescent element, method for manufacturing organic electroluminescent element, and coating liquid for electron injection/transport layer

InactiveCN103460427AElectroluminescent light sourcesSolid-state devicesElectron injectionTransport layer

The main purpose of the present invention is to provide an organic EL element, which has an electron injection / transport layer containing an organic boron compound, and has excellent characteristics, such as efficiency and service-life. The present invention achieves the above-mentioned purpose by providing an organic EL element characterized in having: an anode; a light emitting layer, which is formed on the anode; an electron injection / transport layer, which is formed on the light emitting layer, contains an organic boron compound, and has a crystal structure; and a cathode, which is formed on the electron injection / transport layer.

Owner:DAI NIPPON PRINTING CO LTD

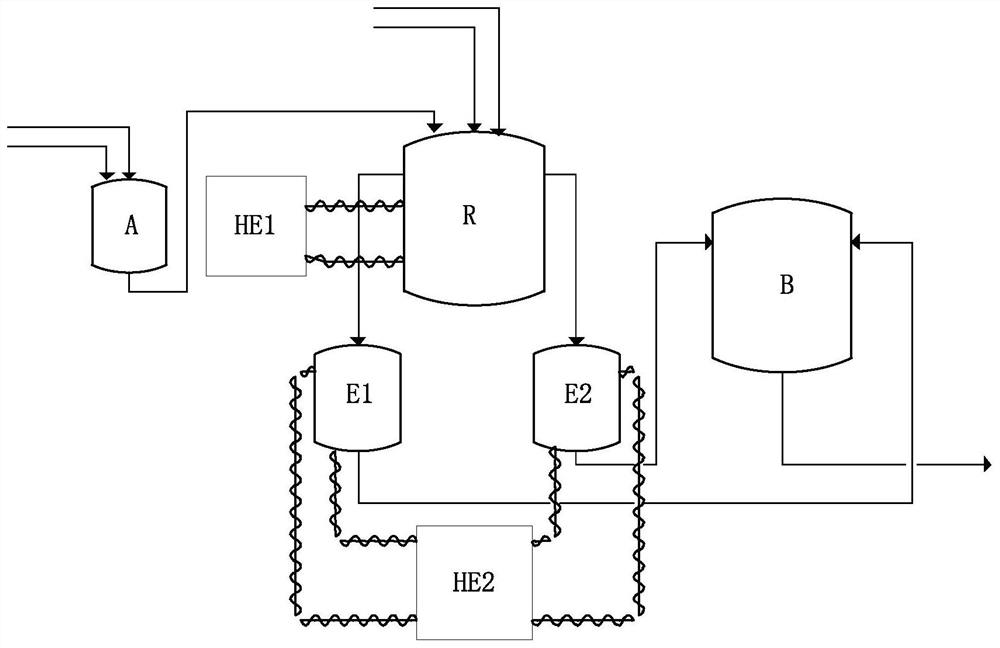

Ethylene oligomerization catalyst and method for continuously producing 1-hexene and 1-octene

ActiveCN113441185AReduce the amount addedReduce generationOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsChromium CompoundsPtru catalyst

The invention discloses a method for continuously producing 1-hexene and 1-octene, the method comprises the following steps: (1) mixing a solvent and an aluminum alkyl compound through a mixing tank, continuously introducing the mixture into a reaction kettle, introducing ethylene, and carrying out ethylene oligomerization reaction under the action of a continuously introduced catalyst to obtain a reaction solution containing 1-hexene and 1-octene; (2) a reaction solution containing 1-hexene and 1-octene enters an overflow tank reactor through an overflow pipeline; and (3) enabling the reaction liquid obtained in the overflow tank reactor to enter a quenching reactor, and quenching the reaction by using an alcohol substance as a quenching agent to obtain 1-hexene and 1-octene. The used catalyst is a solution formed by a metal chromium compound, a PNSiNP ligand and an organic boron compound. Under the condition that the reaction temperature is not changed, the overflow tank adopts a higher temperature, and a polymer from the reaction kettle can be dissolved in a reaction solution, so that the possibility of pipeline blockage is reduced, and the continuous operation time of the device is prolonged.

Owner:WANHUA CHEM GRP CO LTD

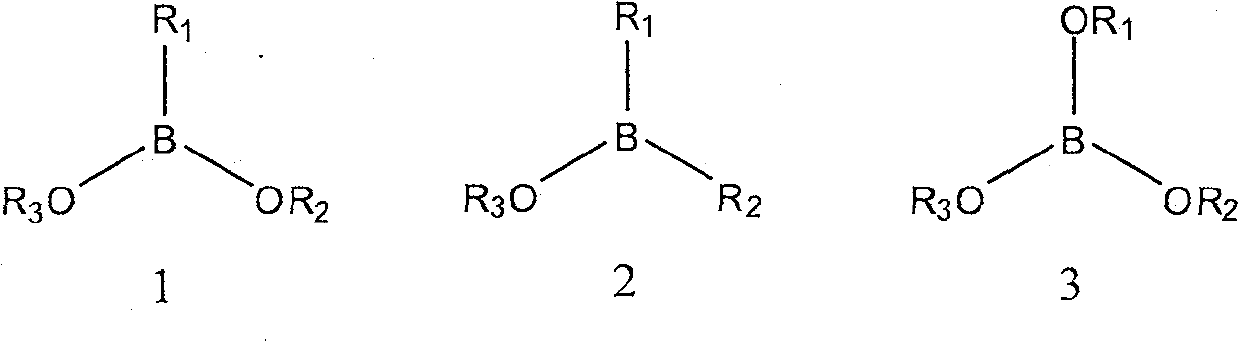

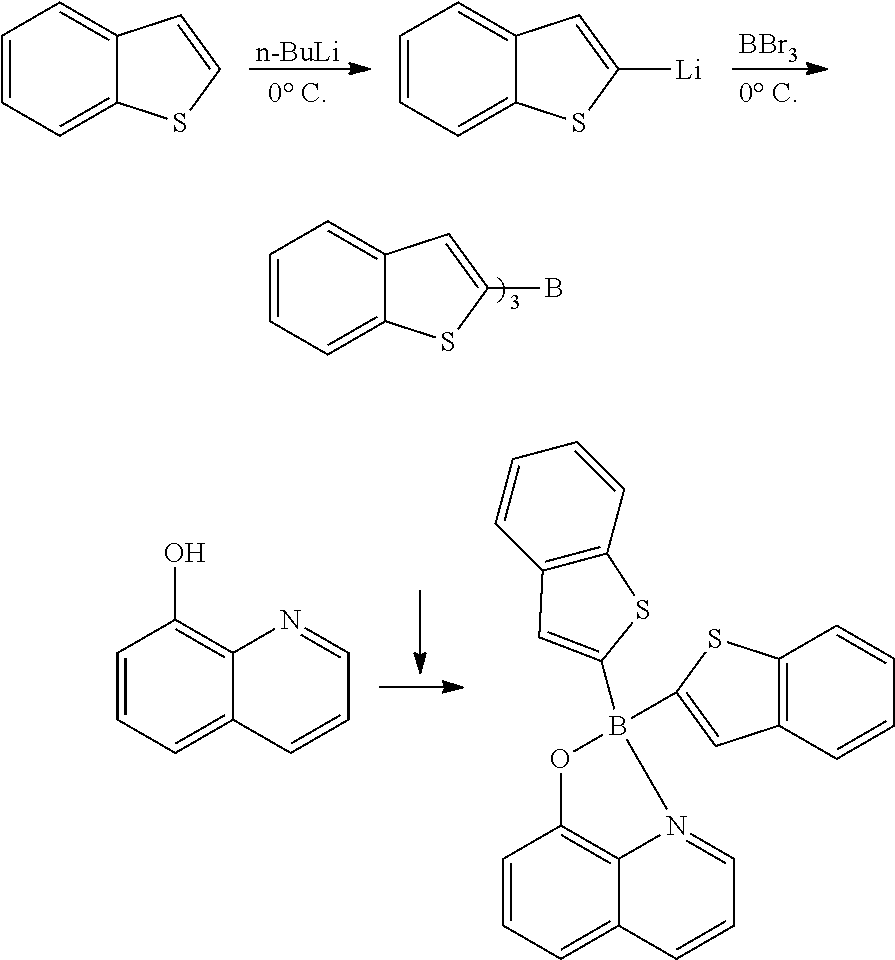

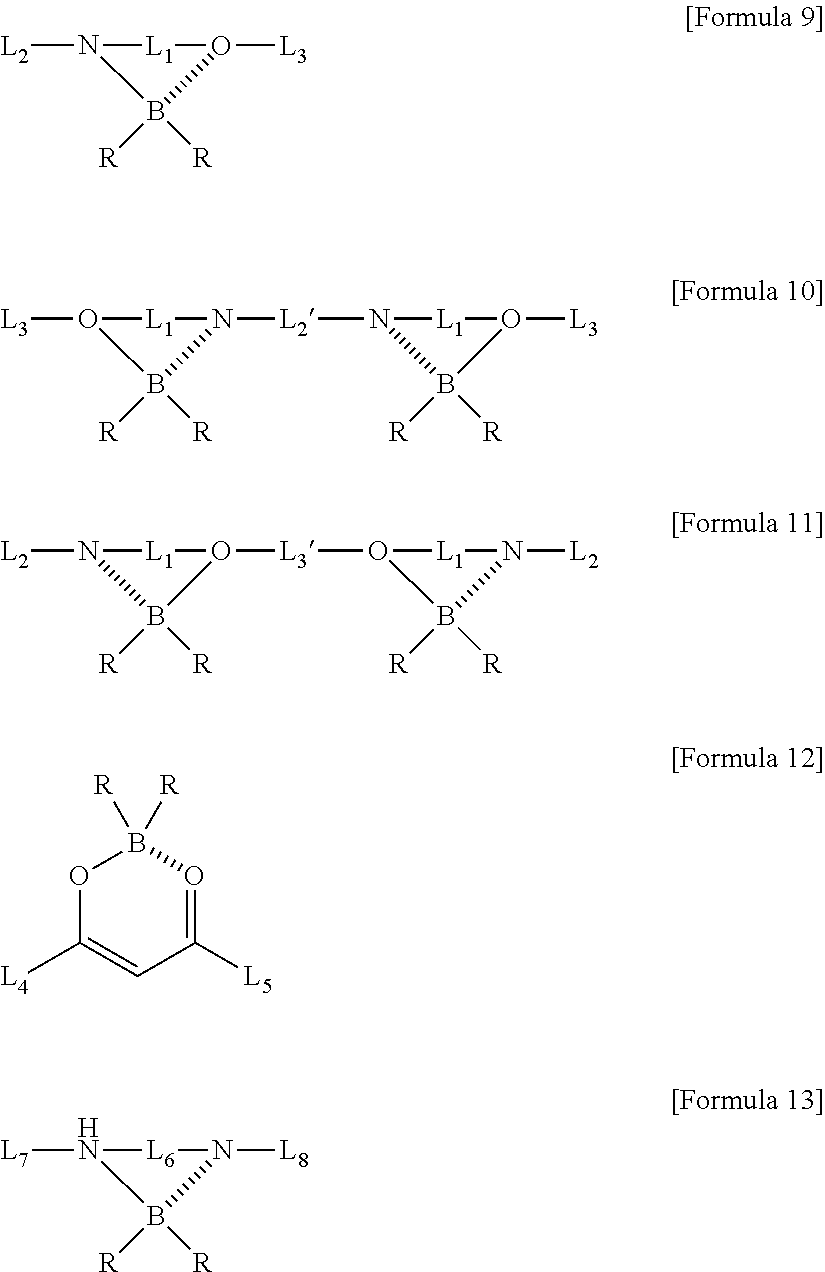

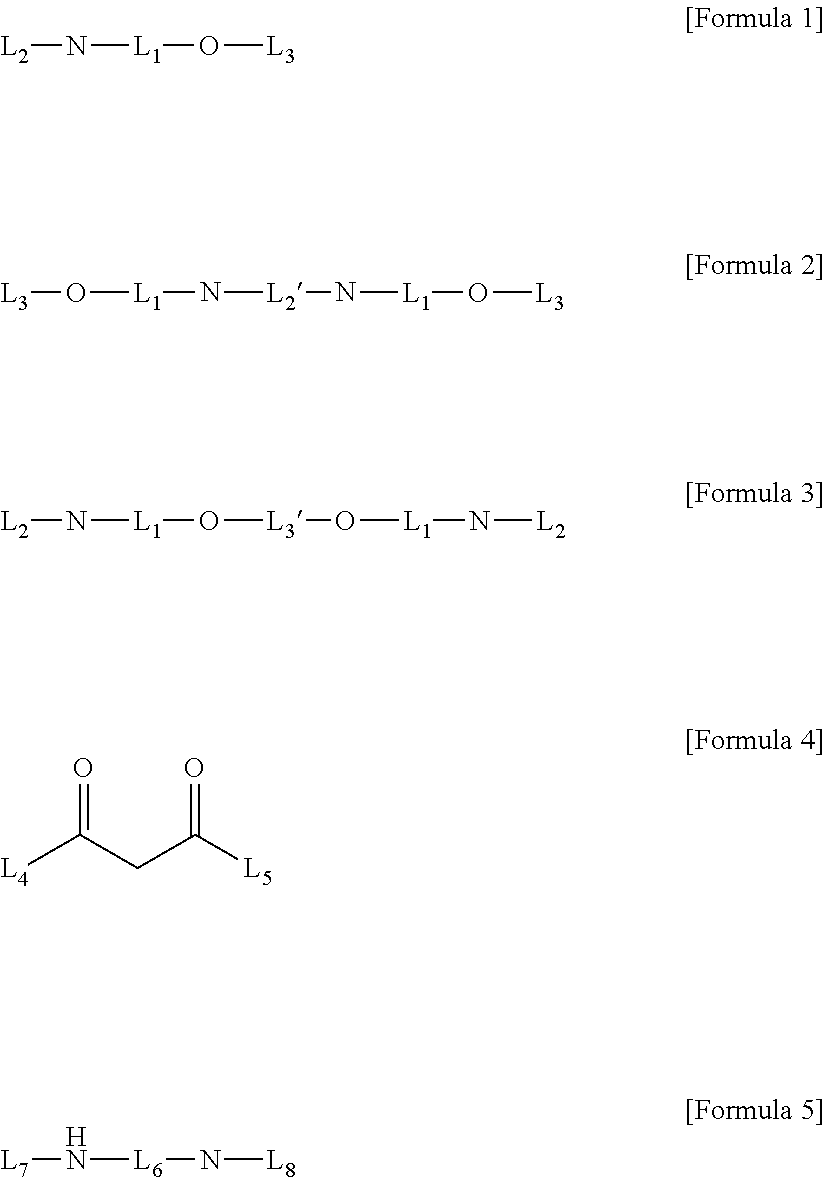

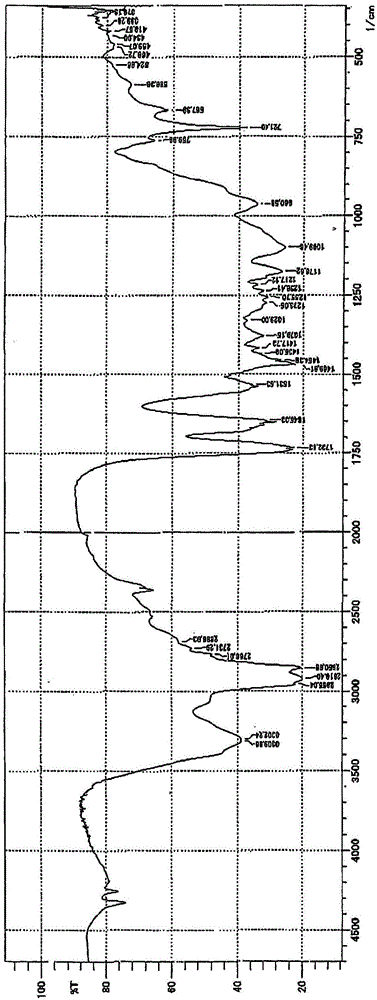

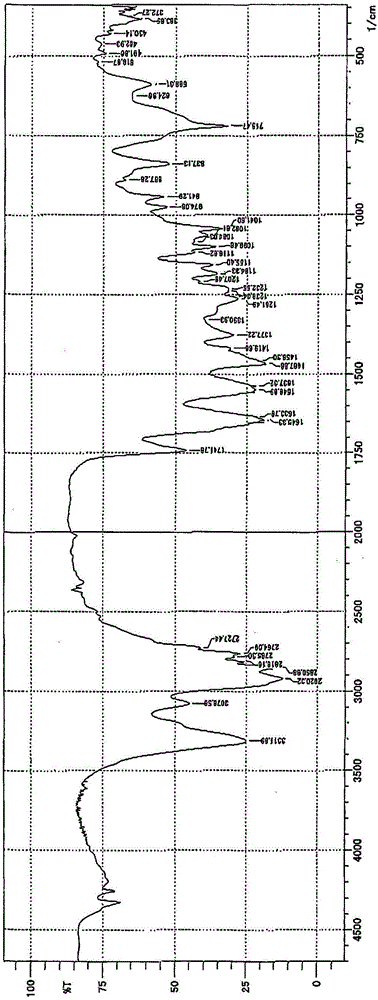

Method for Preparing Four-Coordinated Organic Boron Compound

ActiveUS20180298034A1Increase productionGood yieldSolid-state devicesSemiconductor/solid-state device manufacturingArylOrganic Boron Compounds

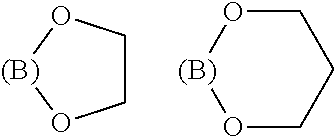

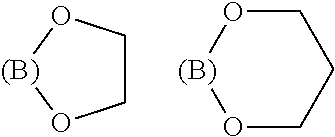

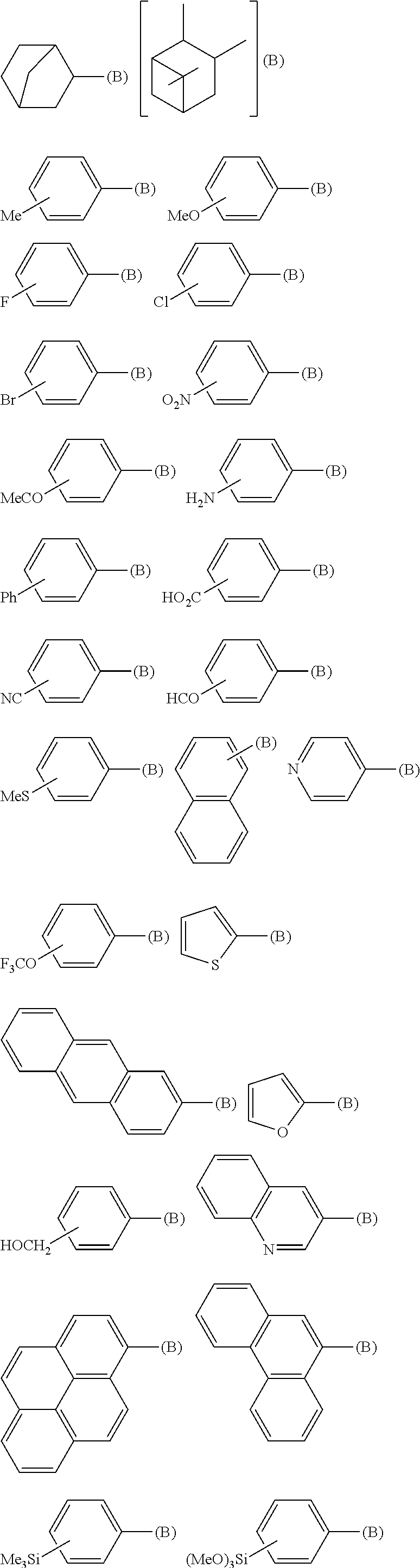

The present invention relates to a method for preparing a four-coordinated organic boron compound, and more specifically, to a method for preparing various and widespread four-coordinated organic boron compounds by directly using an aryl, heteroaryl, or vinyl-functional boronic acid, boroxine, or borate compound as a starting material and adding the compound to any bidentate N,O-ligand, O,O-ligand, or N,N-ligand.

Owner:KOREA RES INST OF CHEM TECH

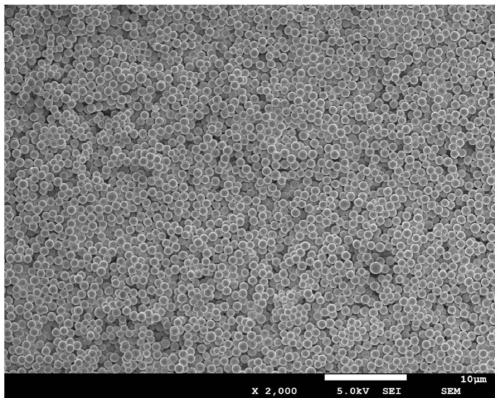

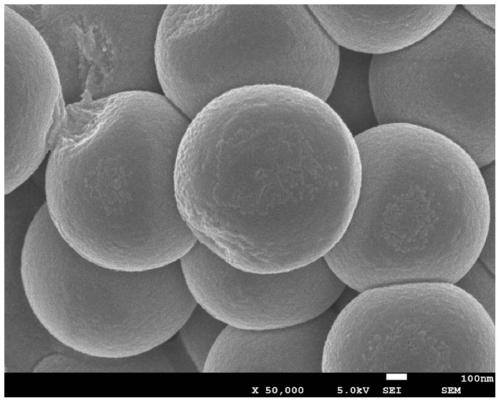

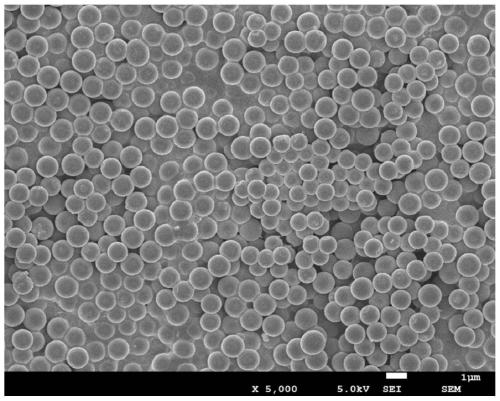

Preparation method for boron-containing phenolic resin microsphere and carbon microsphere

ActiveCN110144046ASmall particle sizeImprove carbonization yieldCarbon preparation/purificationResin microsphereOrganic Boron Compounds

The invention specifically relates to a preparation method for a boron-containing phenolic resin microsphere and a carbon microsphere, belonging to the field of chemical synthetic resin microspheres.The preparation method for the boron-containing phenolic resin microsphere comprises the following steps: firstly, subjecting an organoboron compound and aldehyde to prepolymerization under acidic conditions; then subjecting a product of the previous step to a polycondensation reaction with aldehyde and a curing agent under the conditions of a basic catalyst and a solvent; and finally putting a product of the previous step in an autoclave for further polycondensation and crosslinking to obtain the boron-containing phenolic resin microsphere. The invention has the beneficial effects that the preparation method for the boron-containing phenolic resin microsphere and the carbon microspheres in the invention employs the organic boron compound as a phenol source and prepares the boron-containing phenolic resin microsphere through four steps, so the reactivity of the organic boron compound is effectively increased, the dispersibility and particle size of the microsphere are well controlled,and the carbonization yield of the microspheres is significantly improved. According to testing results, the particle size of the microsphere prepared in the invention can be controlled to a range of1-1000 nm, and the yield of the carbonization product of the microsphere is 75% or more.

Owner:沙县宏盛塑料有限公司 +1

Adhesive For Dental or Surgical Use and Polymerization Initiator Composition For the Same

InactiveUS20080171841A1High polymerization activityShort timeCosmetic preparationsImpression capsAlcoholOrganic Boron Compounds

A polymerization initiator composition which does not burn or ignite even when it contacts paper or the like in air and can provide high polymerization activity to a polymerizable composition to cure it in a short period of time, and an adhesive composition comprising the same. The above polymerization initiator composition comprises 100 parts by weight of (A) an organic boron compound such as a trialkyl boron, alkoxyalkyl boron, dialkylborane, monocyclo or bicyclo compound having a boron atom as a hetero atom or partially oxidated trialkyl boron, 5 to 40 parts by weight of (B) an aprotic solvent having a boiling point of 50 to 120° C., and 0.2 to 5 parts by weight of (C) an alcohol having a boiling point of 60 to 180° C.

Owner:SUN MEDICAL

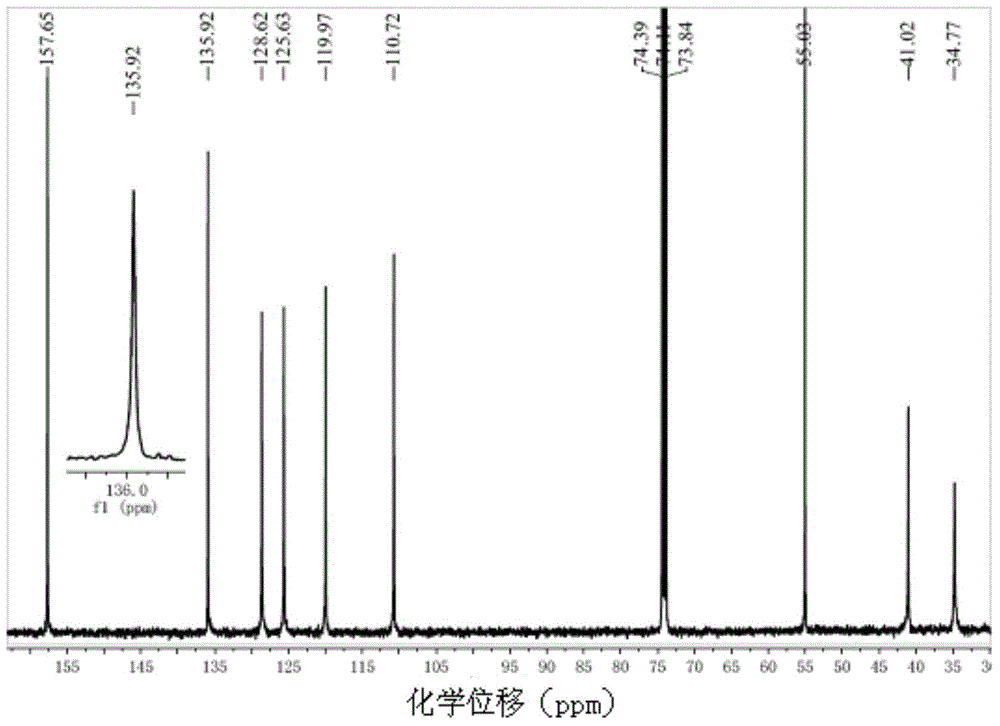

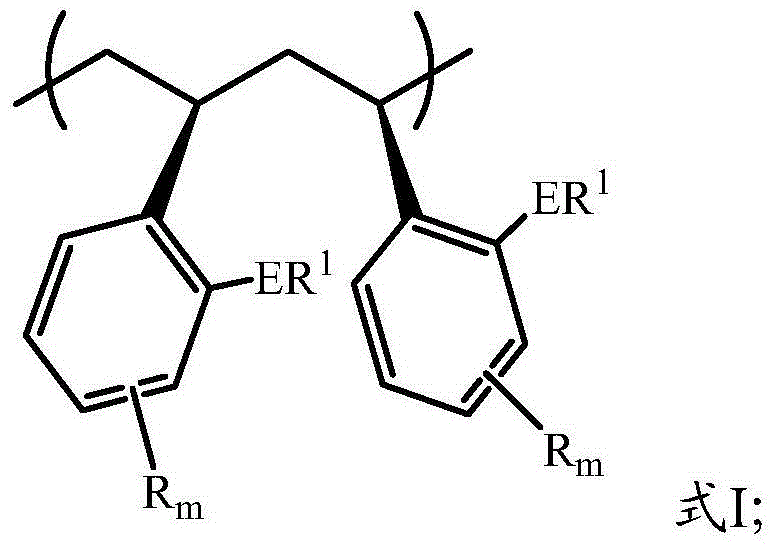

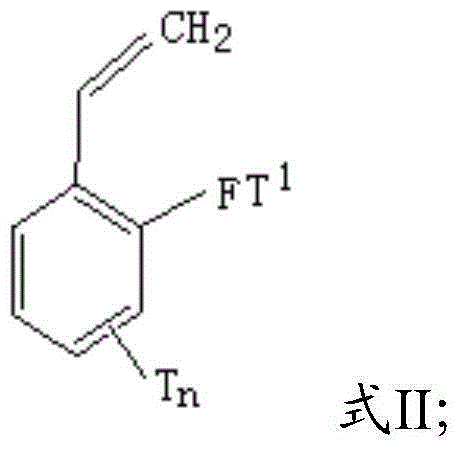

Functional highly-isotactic polystyrene and preparation method thereof

The present invention provides functional highly-isotactic polystyrene comprising repeating units having the structure of formula I, in the formula I, E is sulfur or oxygen, R1 is an alkyl group having 1-10 carbon atoms or an aryl group having 6-10 carbon atoms, R is an alkoxy group having 1-20 carbon atoms or an aryloxy having 6-20 carbon atoms, the R can substitute arbitrary position on a benzene ring; m represents the number of substituent groups R, and the m is greater than or equal to 0 and less than or equal to 4. The present invention provides a preparation method of the functional highly-isotactic polystyrene comprising the repeating units having the structure of the formula I, the method comprises polymerization of functionalized styrene to obtain the functional highly-isotactic polystyrene under the role of a catalyst, the functionalized styrene has a structure of formula II, and the catalyst comprises a rare earth complex, an organic boron compound and an organic aluminum compound. The functional highly-isotactic polystyrene has high isotactic selectivity.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-performance calcium-series drawing powder and preparation method thereof

InactiveCN104017626AReduce consumptionQuality improvementBase-materialsOrganic Boron CompoundsStearic acid

The invention discloses high-performance calcium-series drawing powder comprising the following components in percentage by weight: 40-60% of stearic acid, 2-3% of organic molybdenum compound, 1-3% of melamine complex, 1.5-2.5% of organic boron compound, a proper amount of chemical additive and the balance of lime. A preparation method comprises the following steps: melting the stearic acid, then adding the lime, melamine complex, an organic molybdenum compound, an organic boron compound and the proper amount of chemical additive, continuously heating to 150-200 DEG C while stirring continuously, and reacting completely to obtain the high-performance calcium-series drawing powder. The high-performance calcium-series drawing powder is insoluble in water, good in lubricating effect and low in consumption.

Owner:GUIZHOU WIRE ROPE

Organic electroluminescent element, method for manufacturing organic electroluminescent element, and coating liquid for electron injection and transport layer

InactiveUS20140008638A1Improve efficiencyEasy to useConductive materialSolid-state devicesElectron injectionOrganic Boron Compounds

A main object of the present invention is to provide an organic EL element including an electron injection and transport layer containing an organic boron compound, which has excellent characteristics such as efficiency and service life. The present invention achieves the object mentioned above by providing an organic EL element including: an anode; a light emitting layer formed on the anode; an electron injection and transport layer that is formed on the light emitting layer, contains an organic boron compound, and has a crystalline structure; and a cathode formed on the electron injection and transport layer.

Owner:DAI NIPPON PRINTING CO LTD

Negative photosensitive composition and negative photosensitive lithographic printing plate

ActiveCN1898604AInhibition of polymerizationImprove stabilityThermographyPhotosensitive materials for photomechanical apparatusInfraredOrganic Boron Compounds

The present invention relates to a negative photosensitive composition comprising (A) an infrared absorber, (B) an organoboron compound that functions as a polymerization initiator by using in combination with (A) the infrared absorber, (C) an onium salt , and (D) a compound having a polymerizable unsaturated group. By using the negative photosensitive composition of the present invention, it is possible to provide a negative photosensitive composition that can be cured by infrared rays, is less likely to be inhibited by oxygen during radical polymerization, and has excellent storage stability, and provides a The negative photosensitive lithographic printing plate directly forms an image by irradiating infrared rays irradiated from a solid-state laser or a semiconductor laser based on a digital signal without preheating, has high sensitivity, and has excellent printing resistance and storage stability.

Owner:柯达彩色绘图日本株式会社

Silicon-containing resist underlayer film-forming composition and patterning process

ActiveUS8945820B2Improve adhesionExcellent resist patternPhotosensitive materialsSemiconductor/solid-state device manufacturingOrganic filmResist

Owner:SHIN ETSU CHEM IND CO LTD

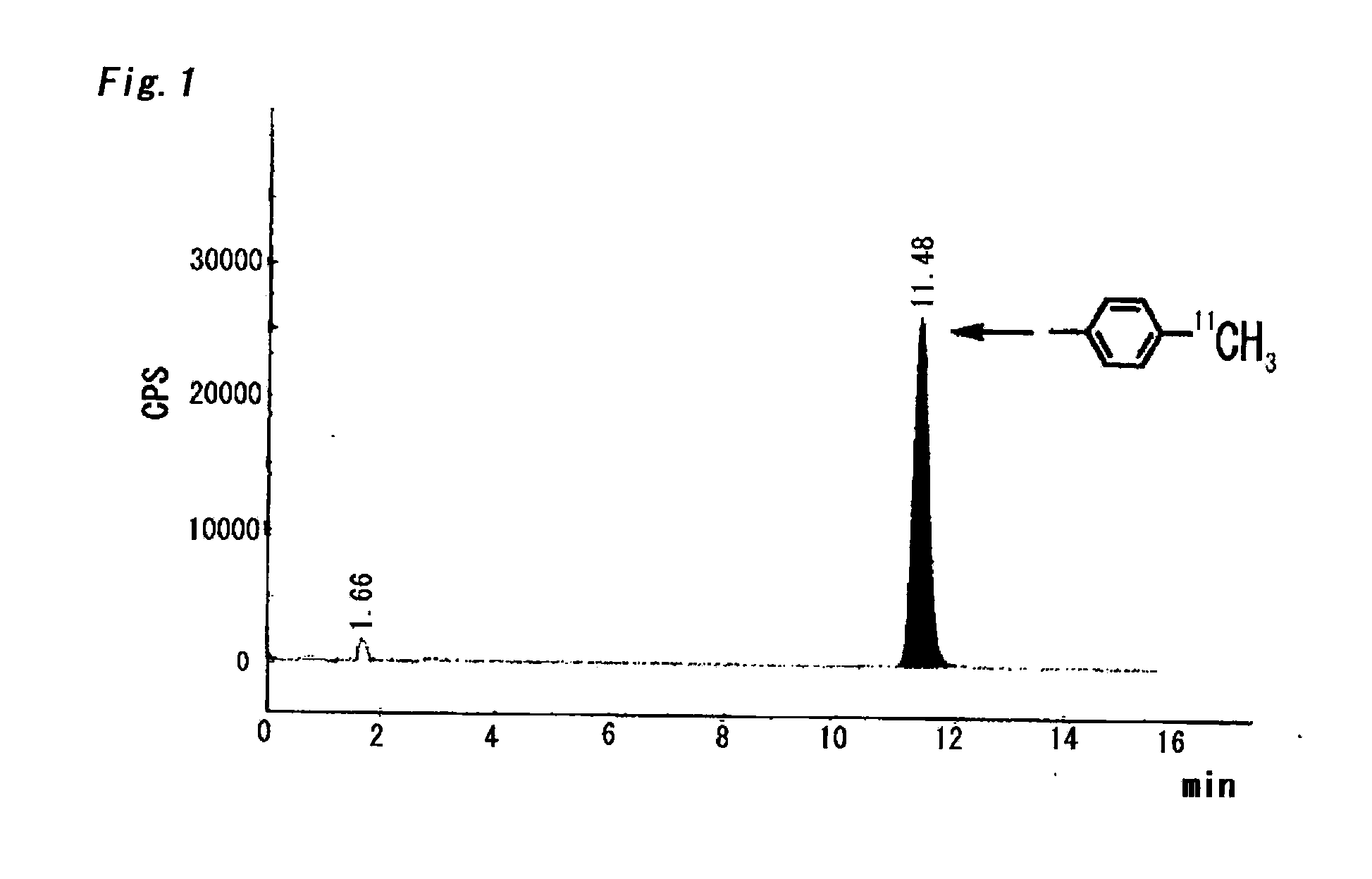

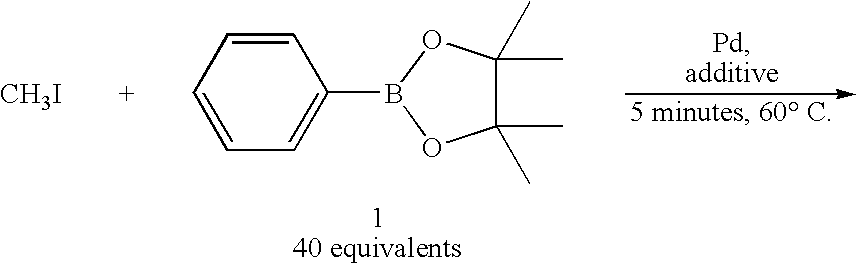

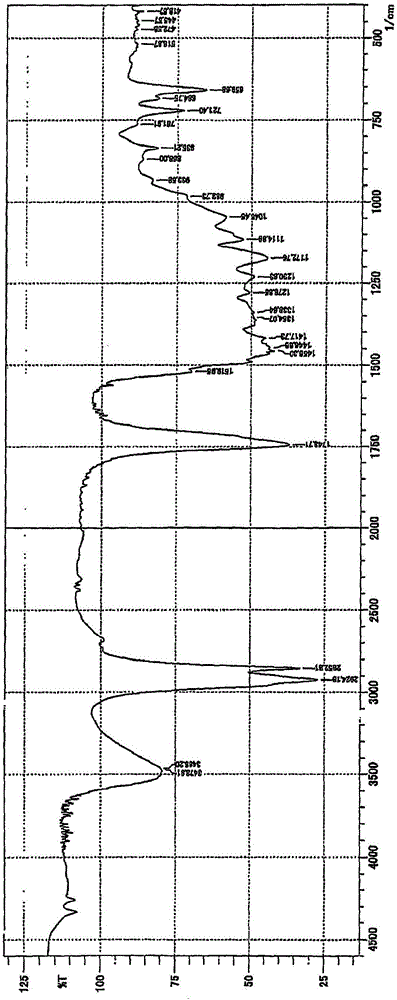

Method of Rapid Methylation, Kit for Preparing PET Tracer and Method of Producing PET Tracer

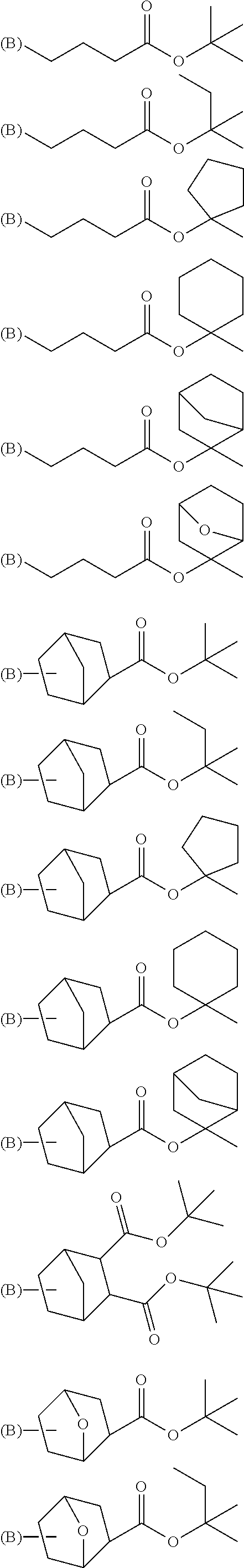

ActiveUS20100249477A1High yieldEasy accessHydrocarbon by isomerisationCarboxylic acid esters preparationOrganic Boron CompoundsSolvent

It is intended to provide a method of rapid methylation of an aromatic compound or an alkenyl compound, which is capable of obtaining an aromatic compound or an alkenyl compound labeled with a methyl group or a fluoromethyl group under a mild condition rapidly in high yield using an organic boron compound whose toxicity is not so high as a substrate; a kit for preparing a PET tracer to be used in the same, and a method of producing a PET tracer using the same. In an aprotic polar solvent, methyl iodide or X—CH2F (wherein X is a functional group which can be easily released as an anion), an organic boron compound in which an aromatic ring or an alkenyl group is attached to boron are subjected to cross-coupling in the presence of a palladium(0) complex, a phosphine ligand, and a base.

Owner:RIKEN +1

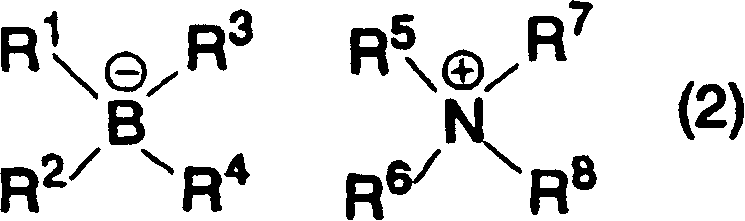

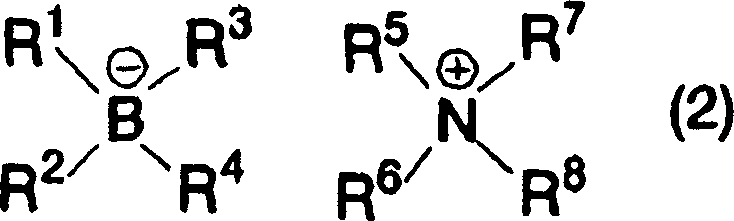

Antistatic agent, molded article comprising insulator polymer material, and method for producing same

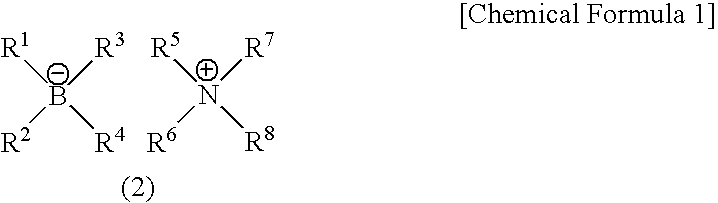

ActiveCN105164224AGood reproducibilityAvoid electrificationOther chemical processesGroup 3/13 element organic compoundsAntistatic agentPolymer science

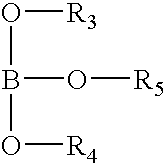

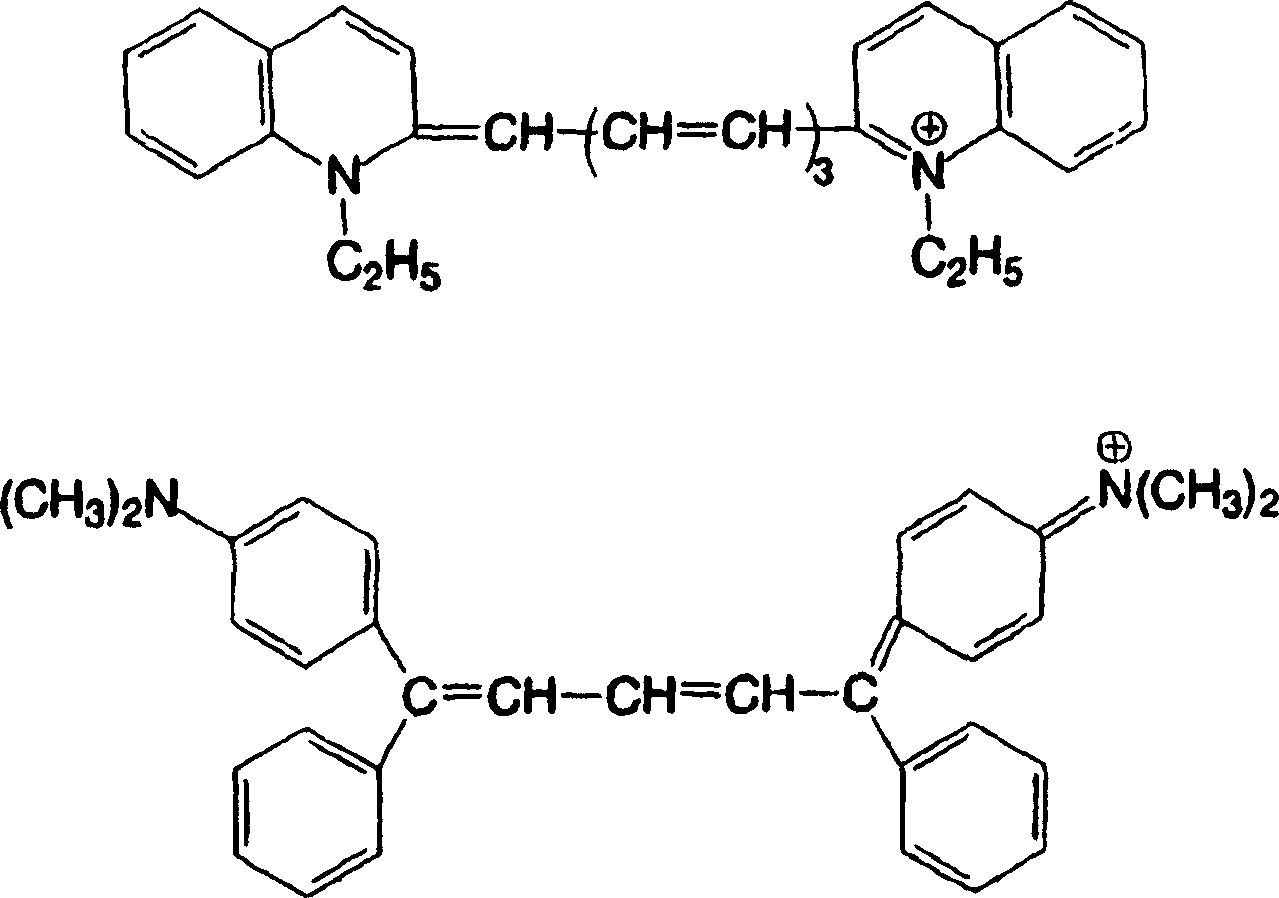

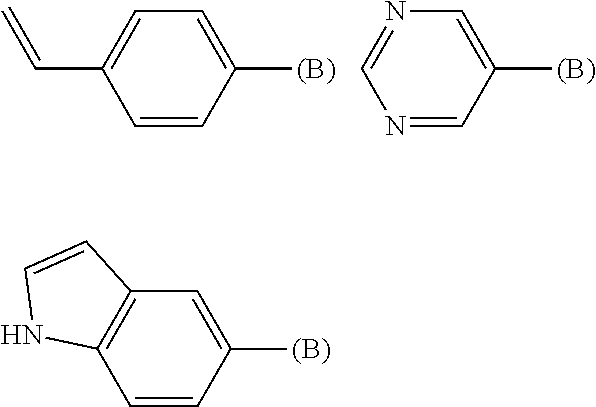

The purpose of the present invention is to provide a donor-acceptor antistatic agent capable of more reliably preventing charging of an insulator polymer material that has good reproducibility and persistence. This antistatic agent is an antistatic agent for an insulator polymer material, the antistatic agent comprising a donor-acceptor molecule compound represented by general formula (1), and being obtained by mixing, melting, and reacting a semi-polar organic boron compound (donor component) shown in the upper part of general formula (1) and a basic nitrogen compound (acceptor component) shown in the lower part of formula (1). In the formula, R1 and R2 are each independently CH3(CH2)16-CO-OCH2 or HOCH2, and at least one is CH3(CH2)16-CO-OCH2; R3 and R4 are each independently CH3, C2H5, HOCH2, HOC2H4, or HOCH2CH(CH3); and R5 is C2H4 or C3H6.

Owner:BORON LAB

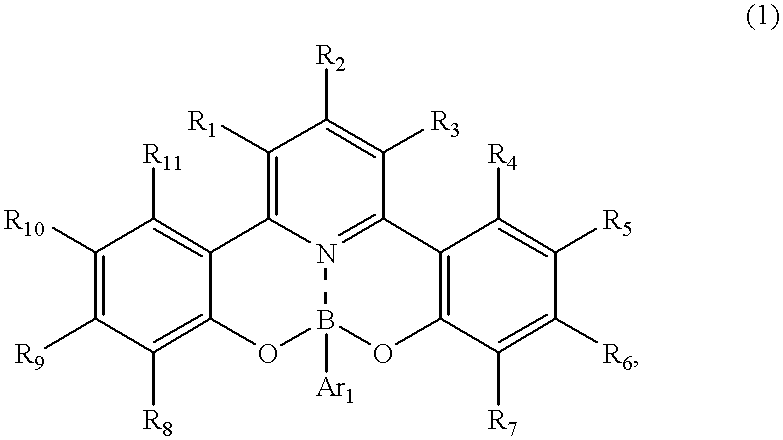

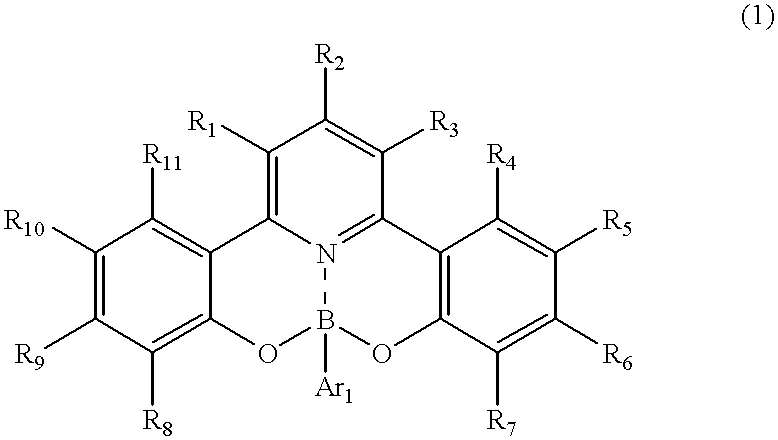

Novel organic boron compound, process for producing the compound and organic luminescnece device using the compound

InactiveUS20020008465A1Enhanced glowImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesArylHydrogen

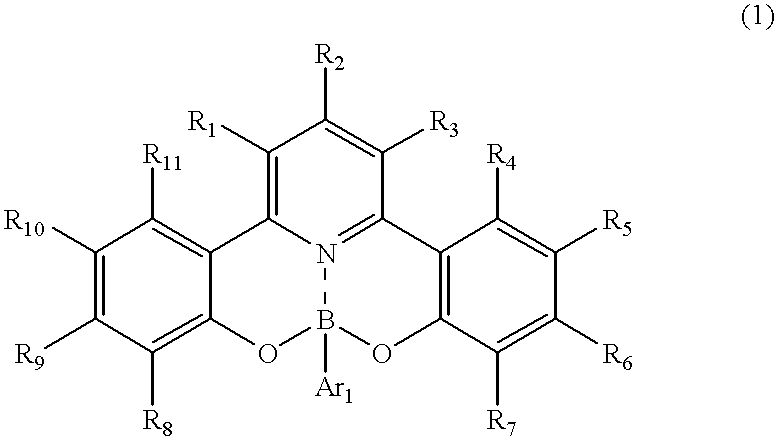

An organic boron compound effective for constituting a functional layer in an organic luminescence device is represented by formula (1) below: wherein Ar1 denotes an optionally substituted aryl group or heterocyclic group; R1-R11 independently denote hydrogen, halogen, alkyl, alkenyl, amino, alkoxy, formyl, nitrile, aroyl, alkyloyl, aryl, aralkyl or heterocyclic group, each optionally substituted with the proviso that an adjacent one or more pairs of R1-R11 can form a condensed ring. The organic boron compound can be produced through a process including (A) a step of reacting an aromatic ketone compound X with an aromatic ketone compound or an aromatic aldehyde compound in the presence of ammonium chloride, and (B) a step of reacting a product of the step (A) with an aromatic boric acid compound.

Owner:CANON KK

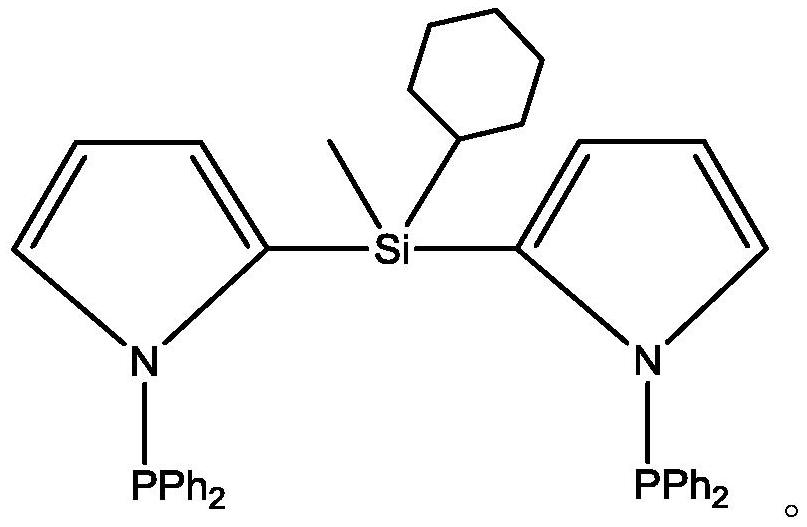

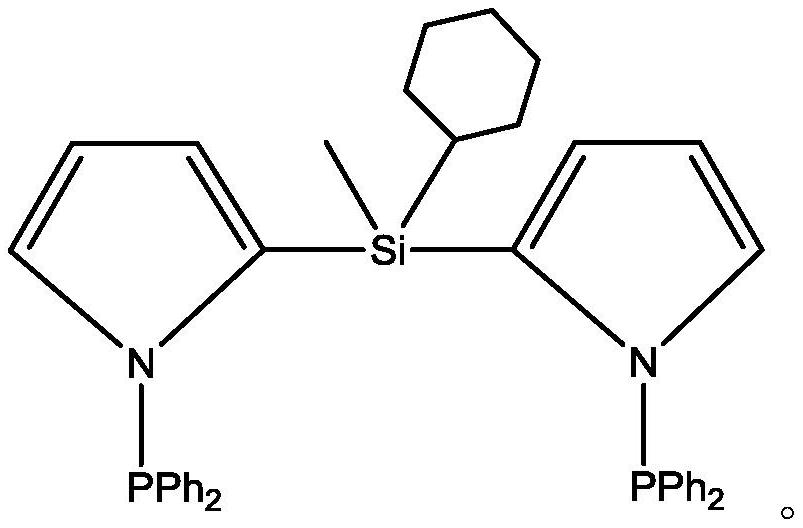

Catalyst system for preparing 1-octene through ethylene selective oligomerization and preparation method and application thereof

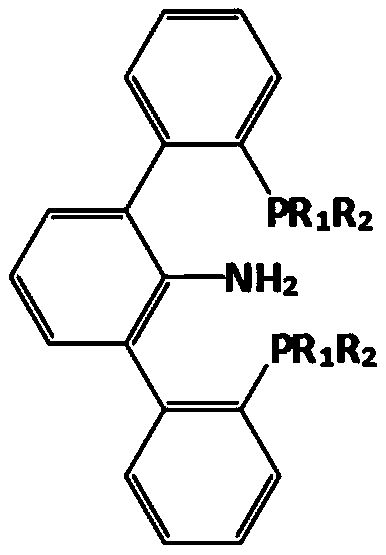

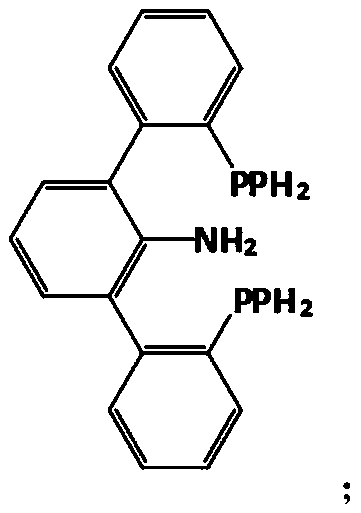

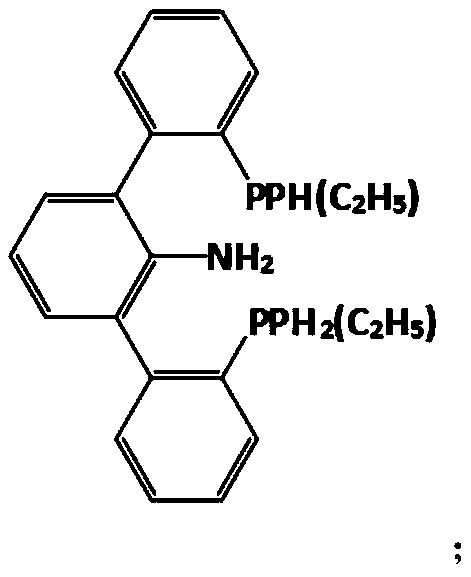

ActiveCN110479382AHigh selectivityOligomer contentGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsOligomer1-Octene

The invention provides a catalyst system for preparing 1-octene from ethylene, which comprises three components: a ligand A, a transition metal compound B and an activating agent C, wherein the structural formula of the ligand A is shown in the specification, and the transition metal compound B is a group IVB-VIII metal compound; and the activating agent C is selected from an organic aluminum compound or an organic boron compound. When the catalyst system is used for ethylene oligomerization, the catalyst system has excellent selectivity for preparing 1-octene through ethylene tetramerizationand relatively low oligomer generation amount, and has relatively clear application prospect in the technical field of preparation of 1-octene through ethylene oligomerization.

Owner:迈瑞尔实验设备(上海)有限公司

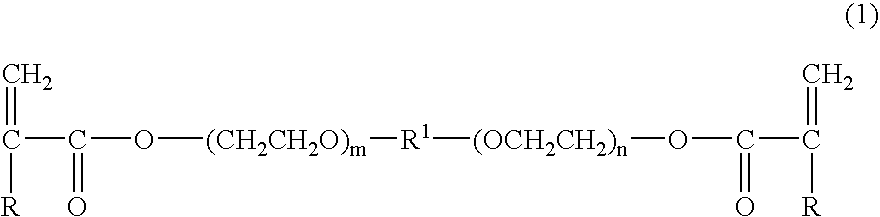

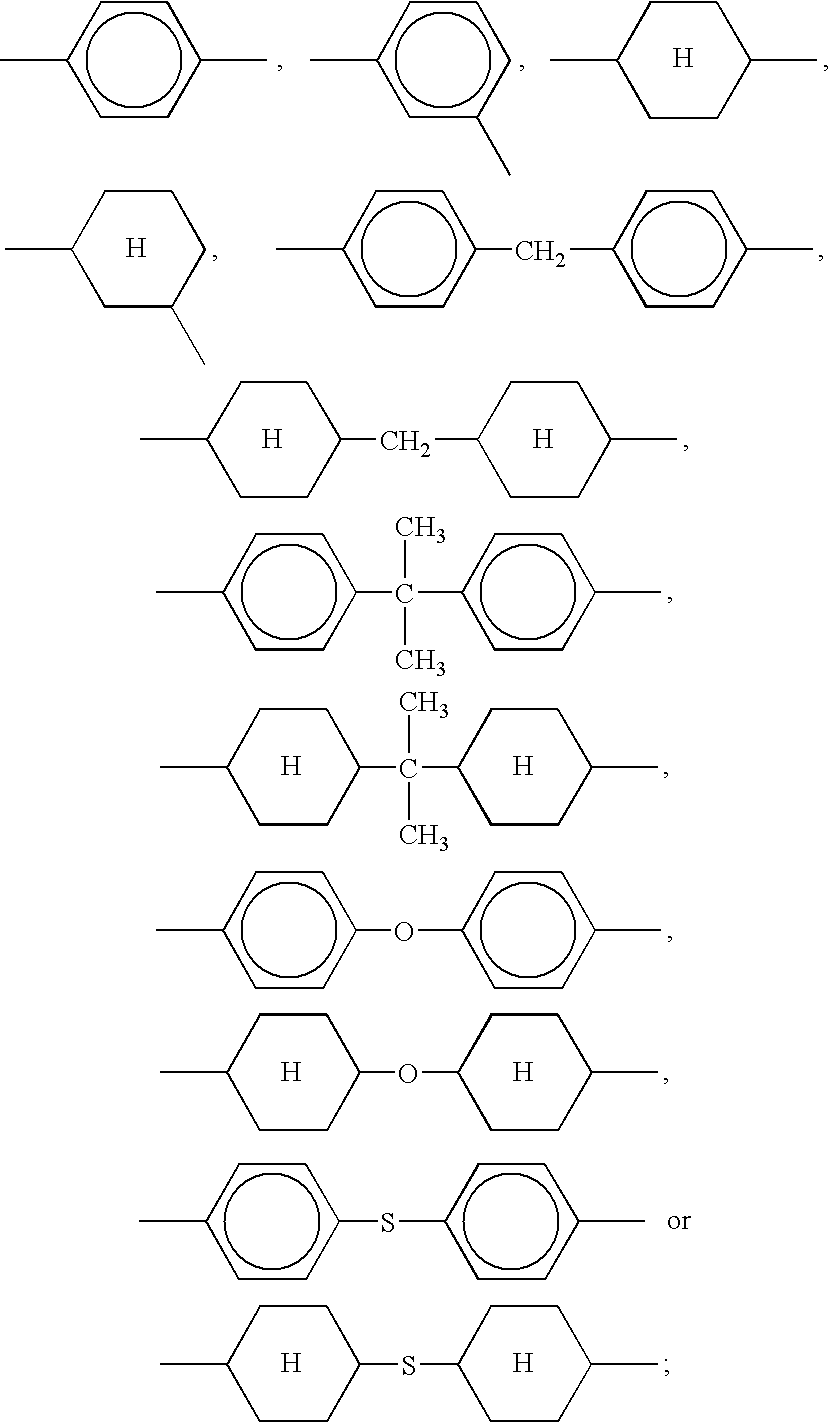

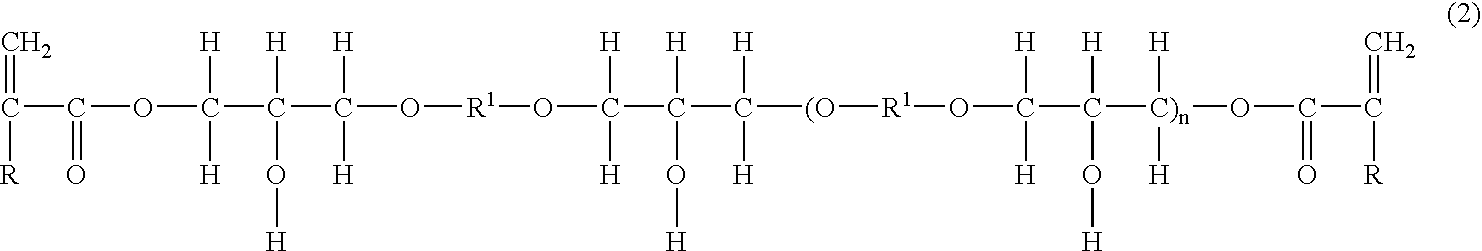

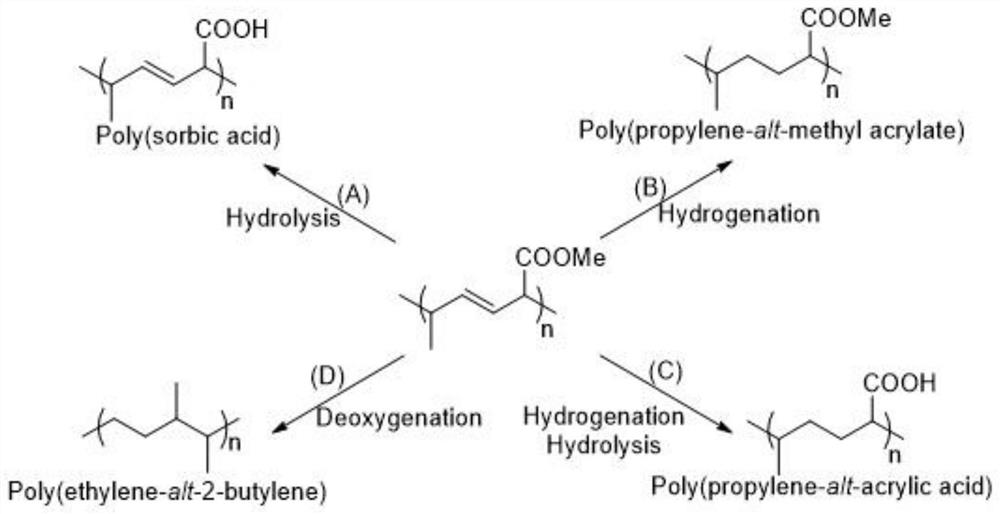

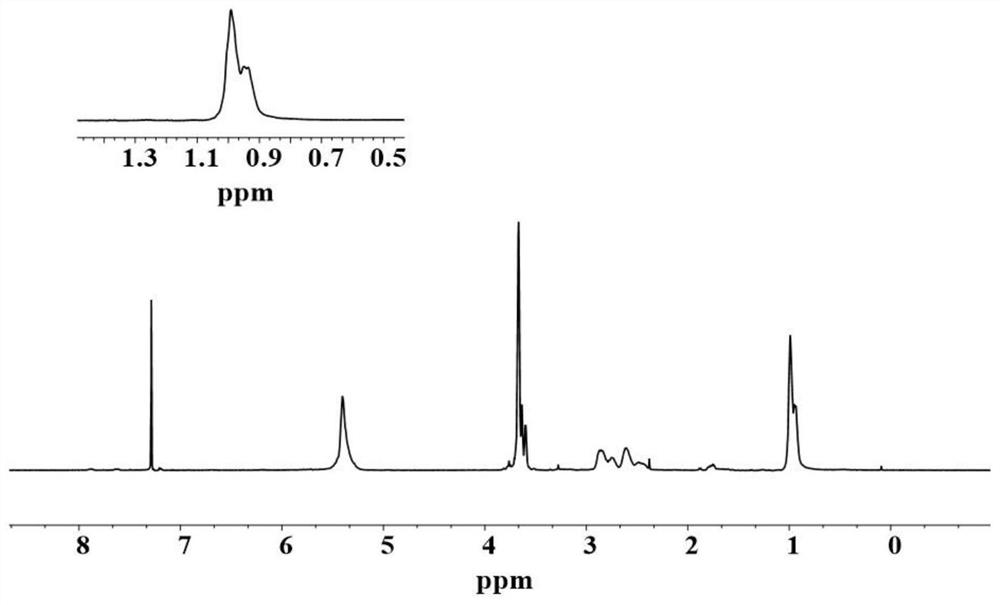

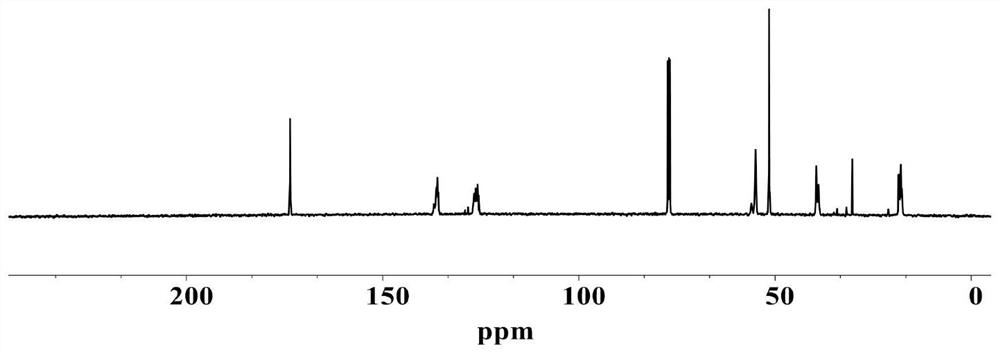

Application of Lewis base, sorbate polymer and derivative of sorbate polymer

ActiveCN113736001AEasy to operateSuitable for industrial productionAdhesivesPolymer scienceOrganic Boron Compounds

The invention provides application of Lewis base, a sorbate polymer and a derivative of the sorbate polymer, belonging to the technical field of catalysts. According to the invention, azacyclo-olefin with a structure as shown in a formula I or a formula II is high in nucleophilicity, and the initiation efficiency and the polymerization activity of polymerization of an (E,E)-sorbate monomer can be improved; the steric hindrance and acidity of an organic aluminum compound are appropriate, back biting and inactivation of chains in the polymerization process of the (E,E)-sorbate monomer are avoided, the lewis base and lewis acid (the organic aluminum compound and / or an organic boron compound) are used in cooperation to serve as a polymerization catalyst of the (E,E)-sorbate, 1,4-selective addition polymerization reaction can be achieved 100% at a room temperature, and initiation efficiency is high.

Owner:JILIN UNIV

Silicon-containing resist underlayer film-forming composition and patterning process

ActiveUS8715913B2Improve etch selectivityImprove responsePhotosensitive materialsSemiconductor/solid-state device manufacturingSimple Organic CompoundsOrganic Boron Compounds

The present invention is a silicon-containing resist underlayer film-forming composition containing at least any one of a condensation product and a hydrolysis condensation product or both of a mixture comprising: one or more kinds of a compound (A) selected from the group consisting of an organic boron compound shown by the following general formula (1) and a condensation product thereof and one or more kinds of a silicon compound (B) shown by the following general formula (2). Thereby, there can be provided a resist underlayer film applicable not only to the resist pattern formed of a hydrophilic organic compound obtained by the negative development but also to the resist pattern formed of a hydrophobic compound obtained by the conventional positive development.R1m0B(OH)m1(OR)(3-m0-m1) (1)R10m10R11m11R12m12Si(OR13)(4-m10-m11-m12) (2)

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com