Non-metallocene compound and ethylene-styrene copolymer, preparation method of non-metallocene compound and ethylene-styrene copolymer, catalyst composition for olefin polymerization and application of catalyst composition

A non-metallocene and compound technology, applied in the field of catalysts, can solve the problems of low content of ethylene structural units, inability to obtain toughness, insufficient activity of olefin polymerization catalysts, etc., and achieve the effects of good toughness and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

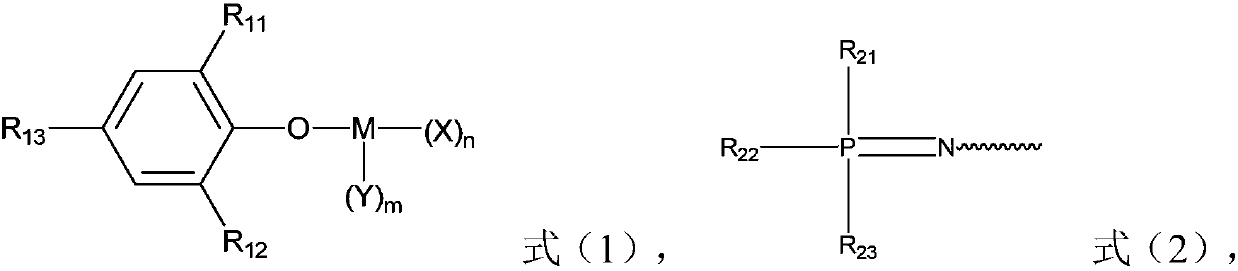

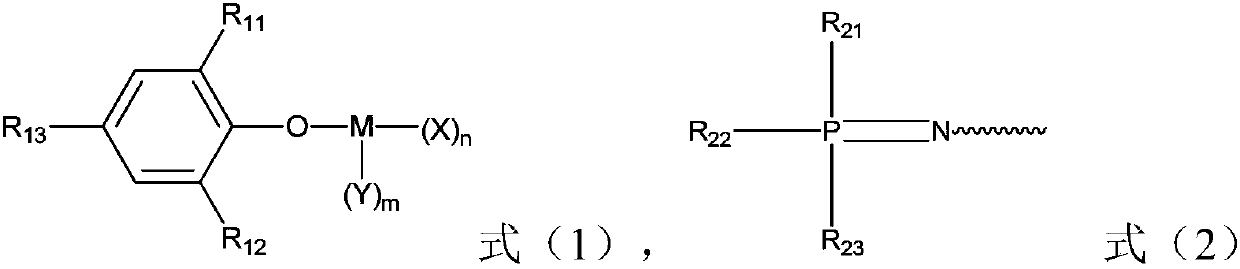

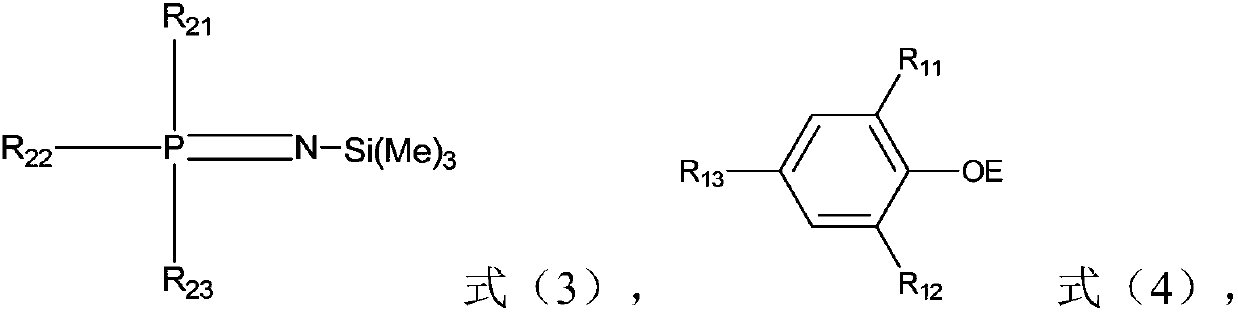

[0091] The non-metallocene compound shown in preparation formula (1), wherein, R 11 and R 12 is methyl, R 13 is H, M is titanium, Y is a phosphinimine group shown in formula (2), and R 21 , R 22 and R 23 Both are tert-butyl, X is Cl, m is 1, and n is 2, which is (2,6-dimethylphenoxy)tri-tert-butylphosphinimine titanium dichloride.

[0092] At -78°C, in 100 mL of toluene, 5 mL of toluene solution dissolved with 10 mmol of titanium tetrachloride was slowly added dropwise to 10 mmol of tri-tert-butylphosphinoimidetrimethylsilane in toluene (10 mL) to react for 12 h, The excess toluene was removed under reduced pressure to obtain tri-tert-butylphosphinimine titanium trichloride.

[0093] At -78°C, 2,6-dimethylphenol (10 mmol) was dissolved in 50 mL of toluene, and 20 mL of the aforementioned tri-tert-butylphosphinimine titanium trichloride solution in toluene was slowly added dropwise. After the dropwise addition, the temperature was slowly raised to reflux for 12 h, and exc...

Embodiment 2

[0097] The non-metallocene compound shown in preparation formula (1), wherein, R 11 and R 12 is methyl, R 13 is H, M is titanium, Y is a phosphinimine group shown in formula (2), and R 21 , R 22 and R 23 Both are tert-butyl, X is methyl, m is 1, and n is 2, that is, (2,6-dimethylphenoxy) tri-tert-butylphosphinoimide dimethyltitanium.

[0098] (2,6-dimethylphenoxy)tri-tert-butylphosphinimine titanium dichloride was prepared by the same method as in Example 1.

[0099] Dissolve 10mmol of (2,6-dimethylphenoxy)tri-tert-butylphosphinimine titanium dichloride in 10mL of ether, add 50mL of ether solution containing 30mmol of MeMgBr under stirring, and react at 25°C for 12h , The solvent was removed under reduced pressure, the product was washed 3 times with pentane, and dried under vacuum to obtain the target product with a yield of 89% (calculated using tri-tert-butylphosphinimidotrimethylsilane as the starting material).

[0100] The characterization data of gained (2,6-dimet...

Embodiment 3

[0103] The non-metallocene compound shown in preparation formula (1), wherein, R 11 and R 12 is tert-butyl, R 13 is H, M is zirconium, Y is a phosphinimine group shown in formula (2), and R 21 , R 22 and R 23 Both are tert-butyl, X is Cl, m is 1, and n is 2, which is (2,6-di-tert-butylphenoxy) tri-tert-butylphosphinoimide zirconium dichloride.

[0104] At -78°C, in 100 mL of toluene, 5 mL of toluene solution dissolved with 14 mmol of zirconium tetrachloride was slowly added dropwise to 10 mmol of tri-tert-butylphosphinoimidetrimethylsilane in toluene solution (10 mL) to react for 12 h, The excess toluene was removed under reduced pressure to obtain tri-tert-butylphosphinimine zirconium trichloride.

[0105]At -78°C, 2,6-di-tert-butylphenol (12 mmol) was dissolved in 50 mL of toluene, and 20 mL of the aforementioned toluene solution of tri-tert-butylphosphinimine zirconium trichloride was slowly added dropwise. After the dropwise addition, the temperature was slowly raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com