Patents

Literature

1127 results about "Tetrachloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrachloride may refer to: Carbon tetrachloride, CCl₄, also known as carbon tet Germanium tetrachloride, GeCl₄, a colourless liquid used as an intermediate in the production of purified germanium metal Molybdenum tetrachloride, MoCl₄ Selenium tetrachloride, SeCl₄ Silicon tetrachloride, SiCl₄ Tellurium tetrachloride, TeCl₄ Titanium tetrachloride, TiCl₄ Uranium tetrachloride, UCl₄, a dark green compound of uranium Vanadium tetrachloride, VCl₄, a bright red liquid and starting reagent in the preparation of vanadium compounds Zirconium tetrachloride, ZrCl₄, an intermediate in the conversion of zirconium minerals to metallic zirconium by the Kroll process. Lead tetrachloride, PbCl₄ Tin chloride, SnCl₄, also known as tin tetrachloride or stannic chloride.

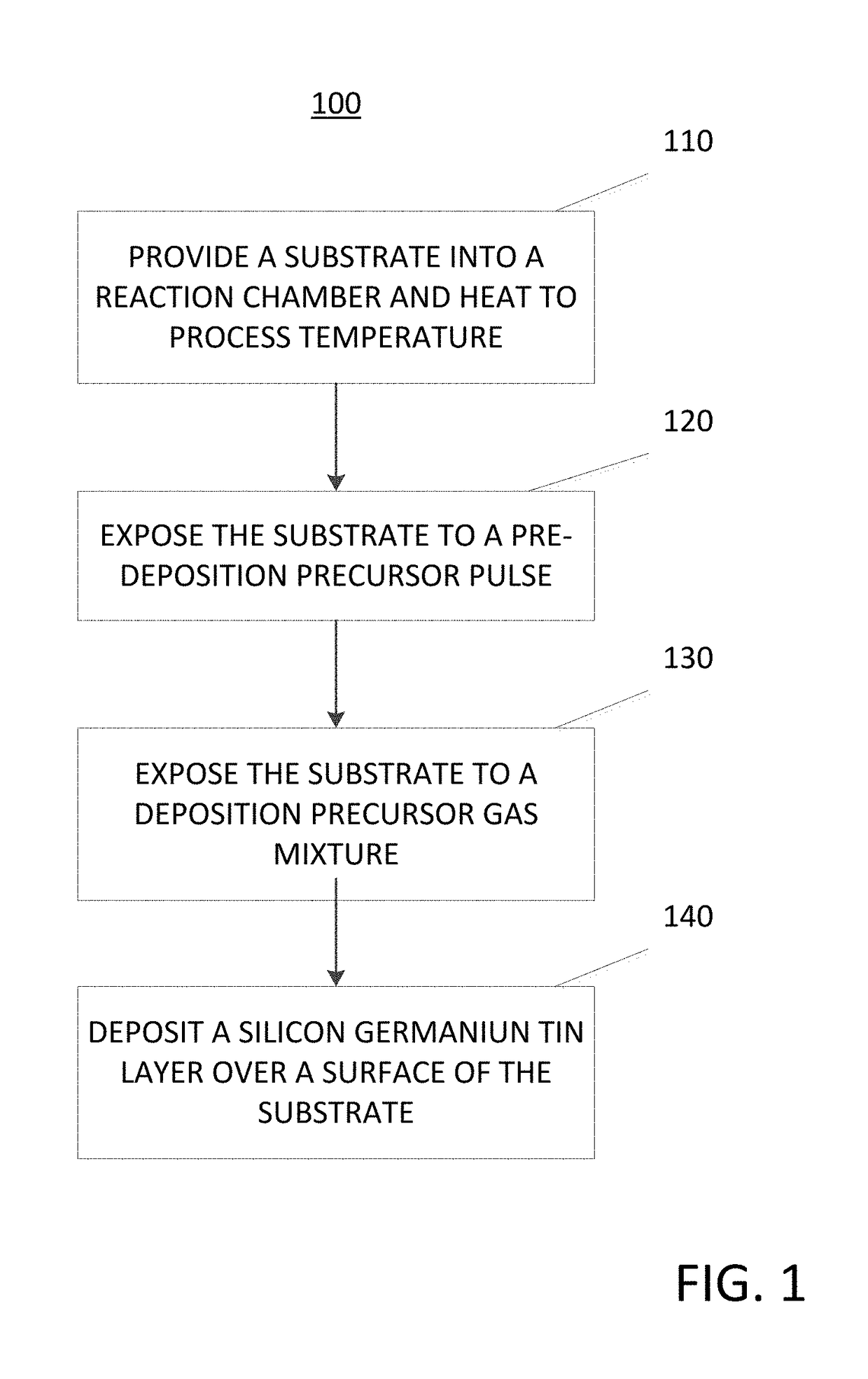

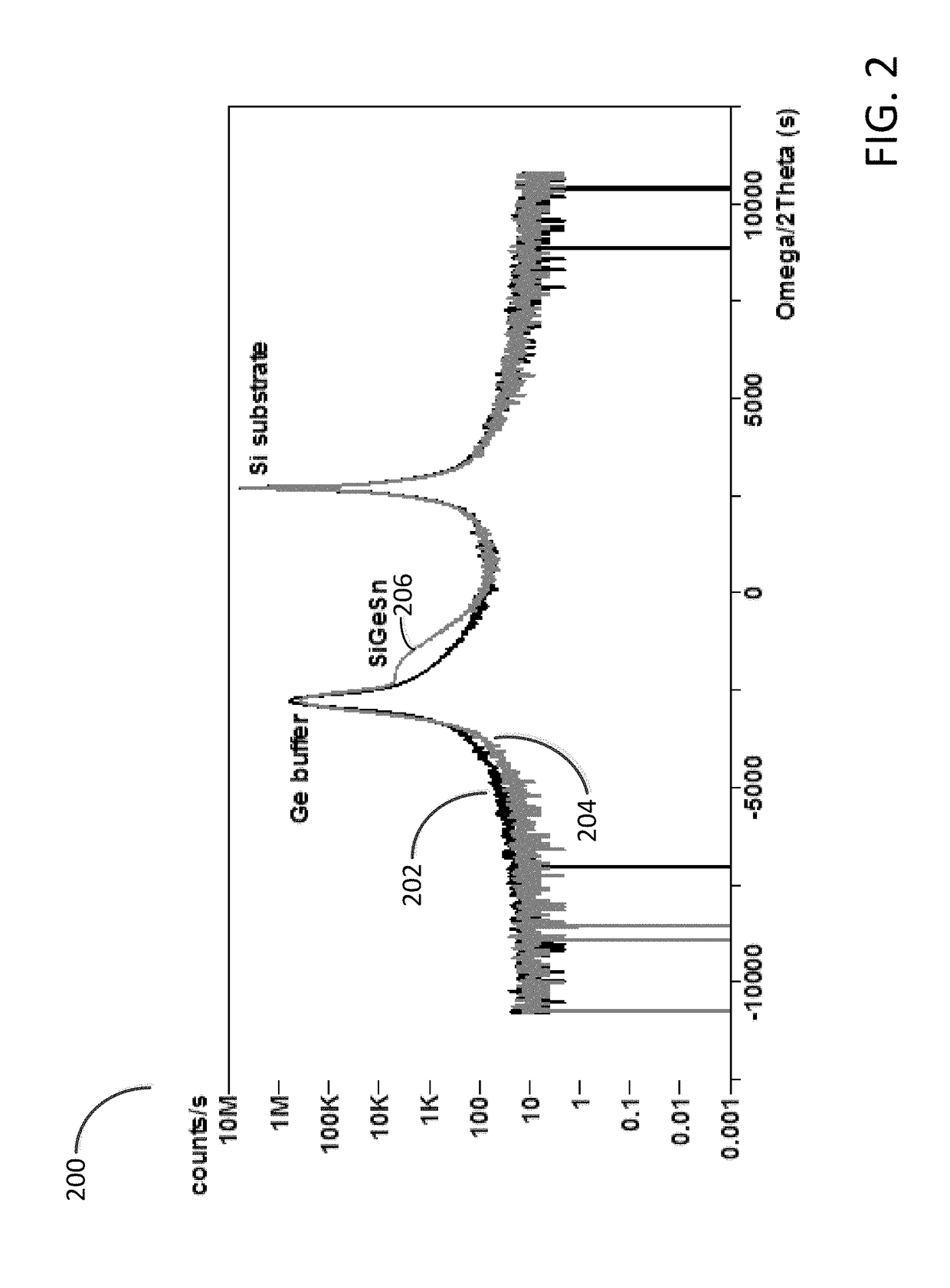

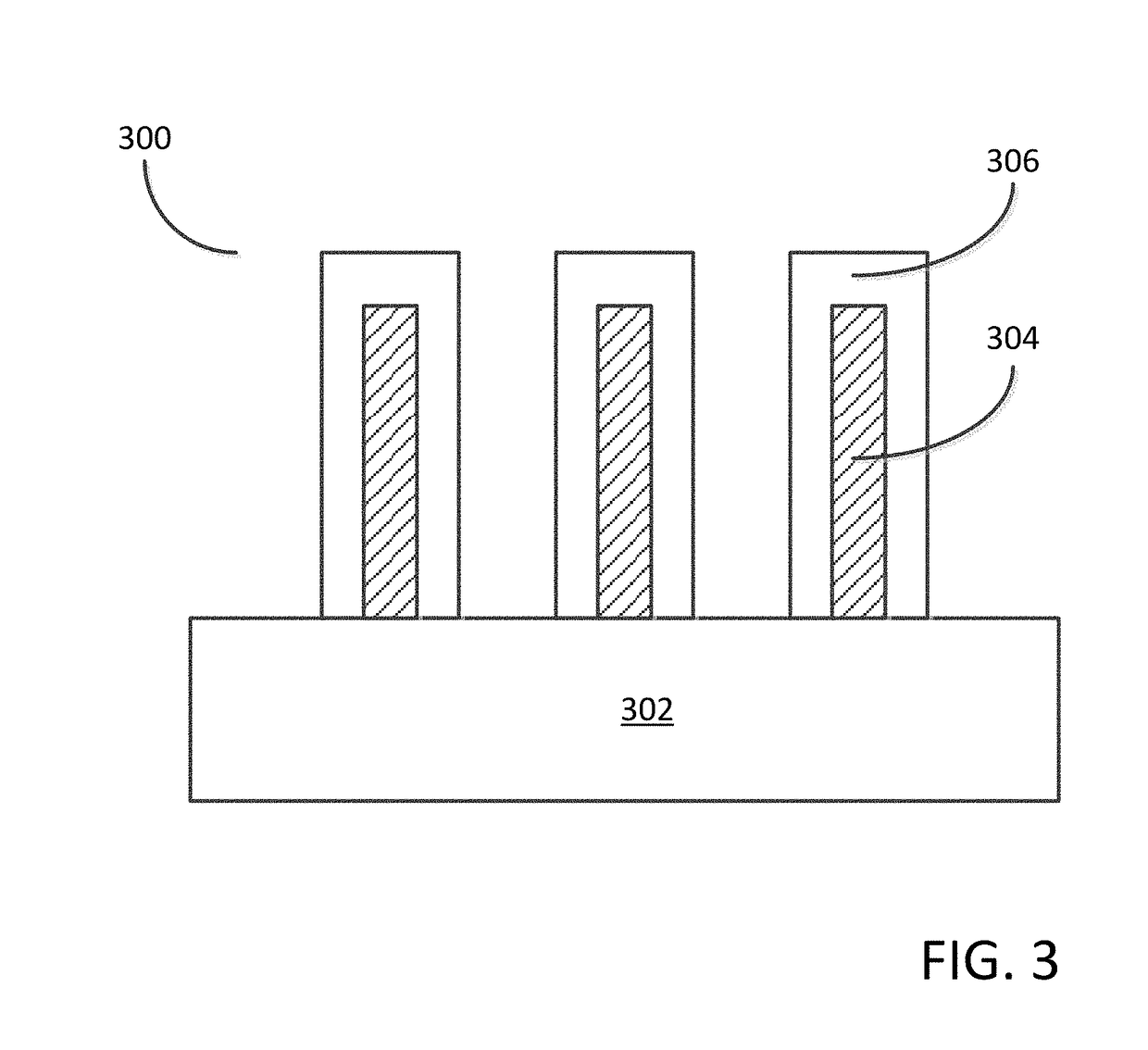

Methods for forming a silicon germanium tin layer and related semiconductor device structures

ActiveUS20190013199A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTetrachlorideGermane

A method for forming a forming a silicon germanium tin (SiGeSn) layer is disclosed. The method may include, providing a substrate within a reaction chamber, exposing the substrate to a pre-deposition precursor pulse, which comprises tin tetrachloride (SnCl4), exposing the substrate to a deposition precursor gas mixture comprising a hydrogenated silicon source, germane (GeH4), and tin tetrachloride (SnCl4), and depositing the silicon germanium tin (SiGeSn) layer over a surface of the substrate. Semiconductor device structures including a silicon germanium tin (SiGeSn) layer formed by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

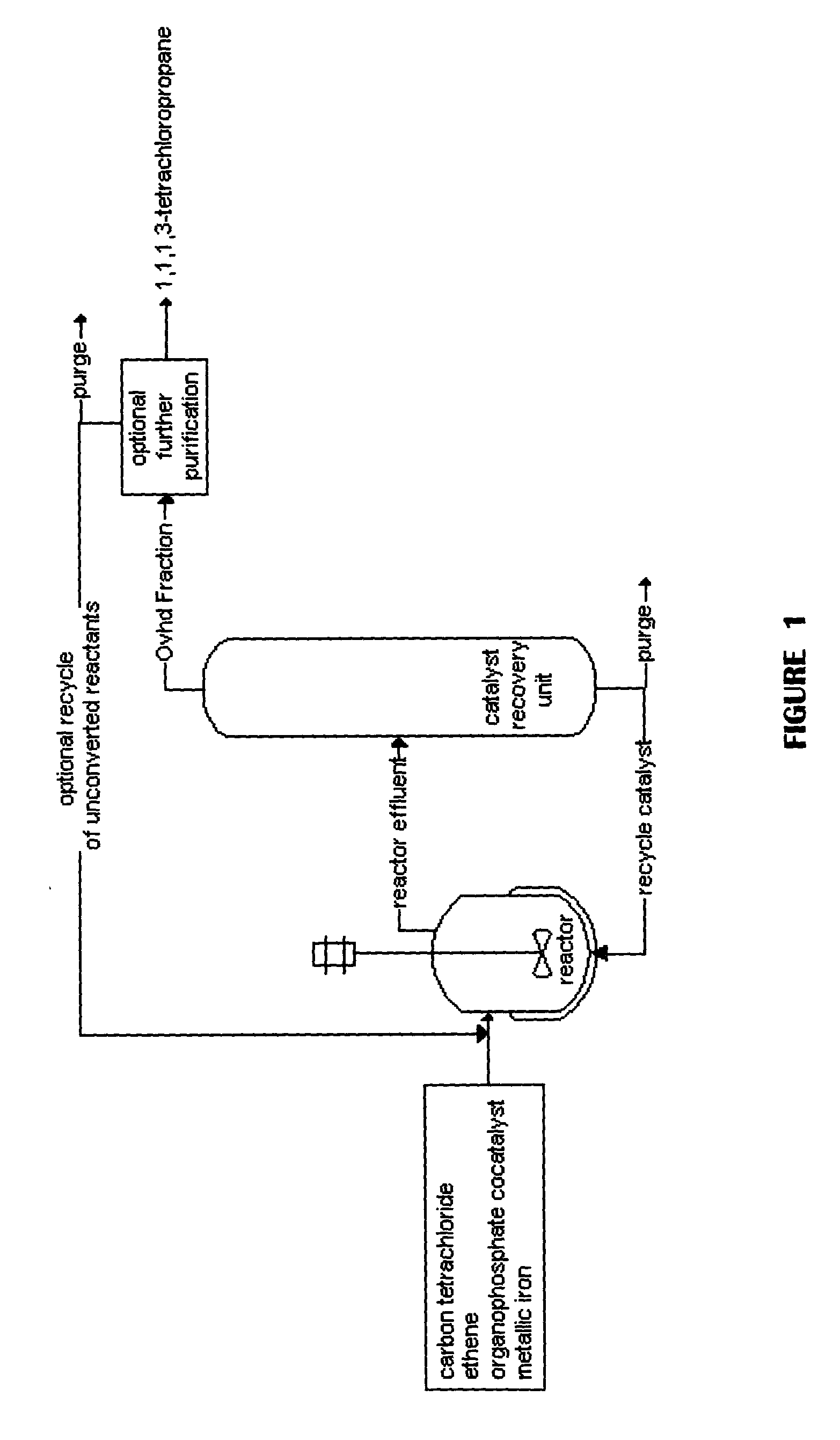

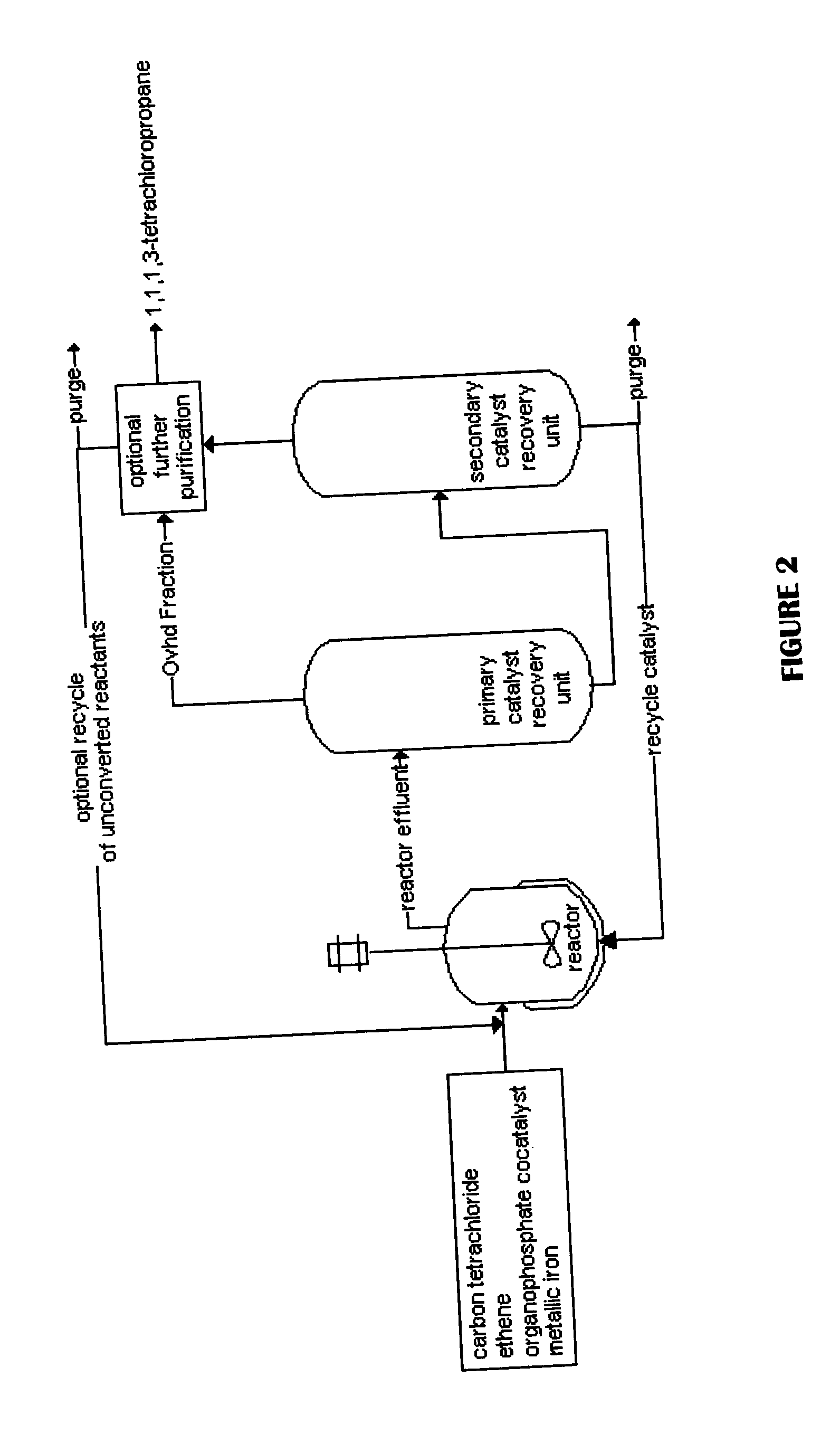

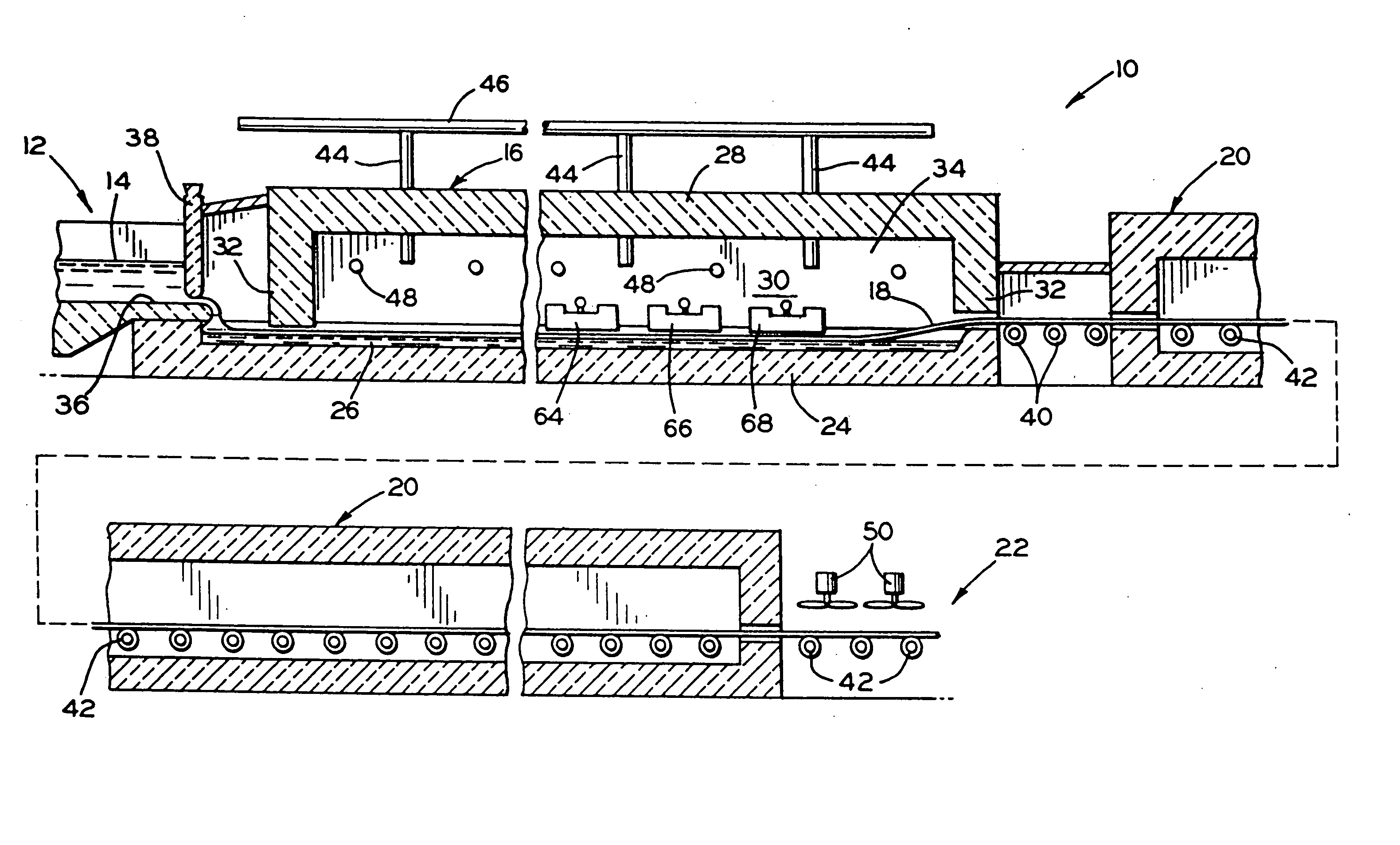

Method for producing 1,1,1,3-tetrachloropropane and other haloalkanes with iron catalyst

InactiveUS20040225166A1Efficient and economical to produceHalogenated hydrocarbon preparationTetrachlorideDistillation

A continuous process is provided for the manufacture of haloalkanes by the reaction of carbon tetrachloride with olefins in the presence of iron metal, trialkylphosphate, and ferric chloride. A fraction of the catalyst and co-catalyst are separated after the reaction and recycled. In a preferred application, the olefin is ethene, and the haloalkane product is 1,1,1,3-tetrachloropropane. Two distillation steps take place in order to enhance the production of 1,1,1,3-tetrachloropropane.

Owner:OCCIDENTAL CHEM CORP

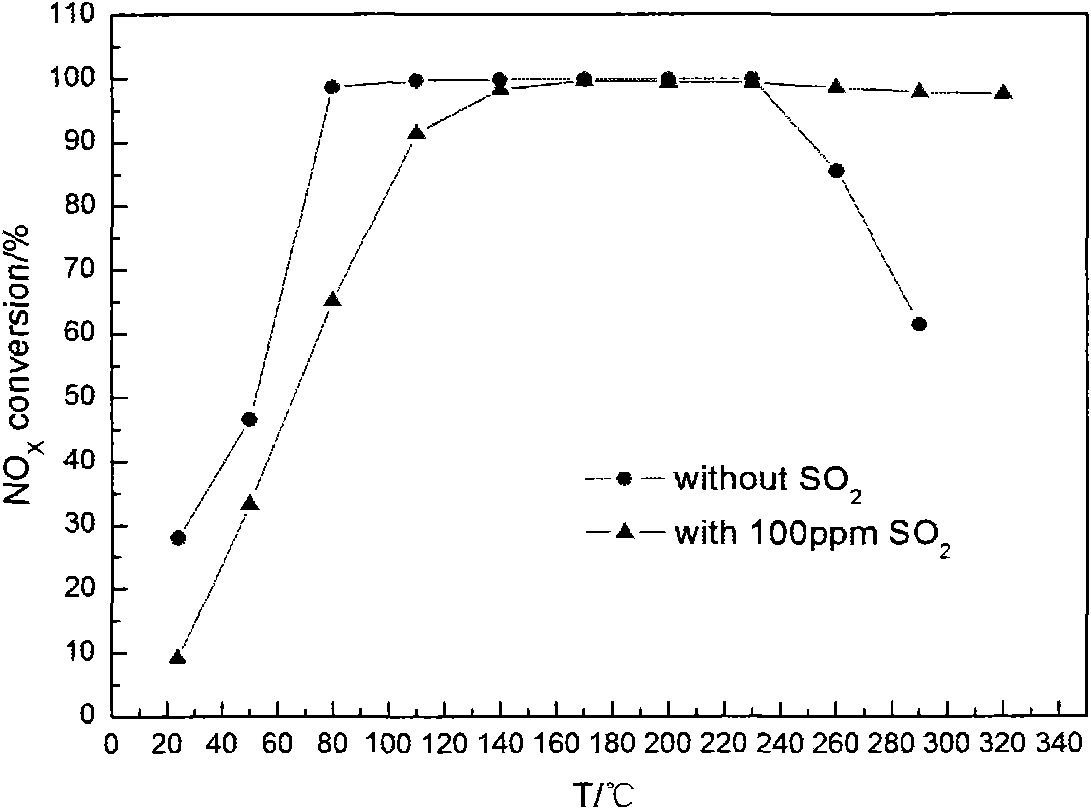

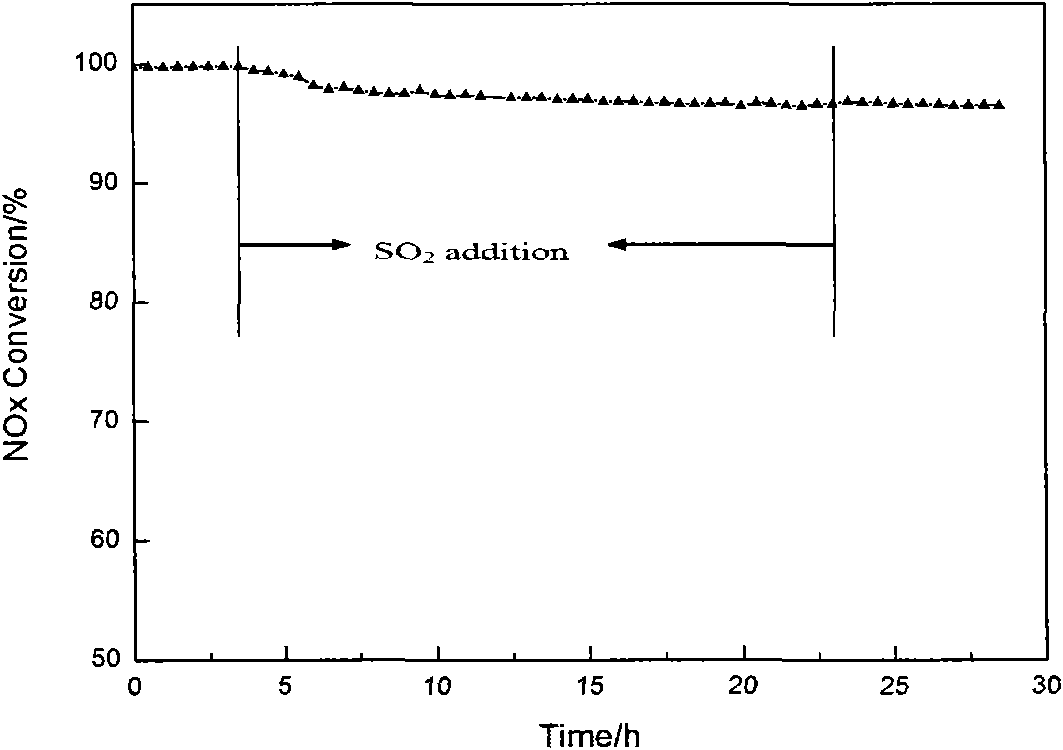

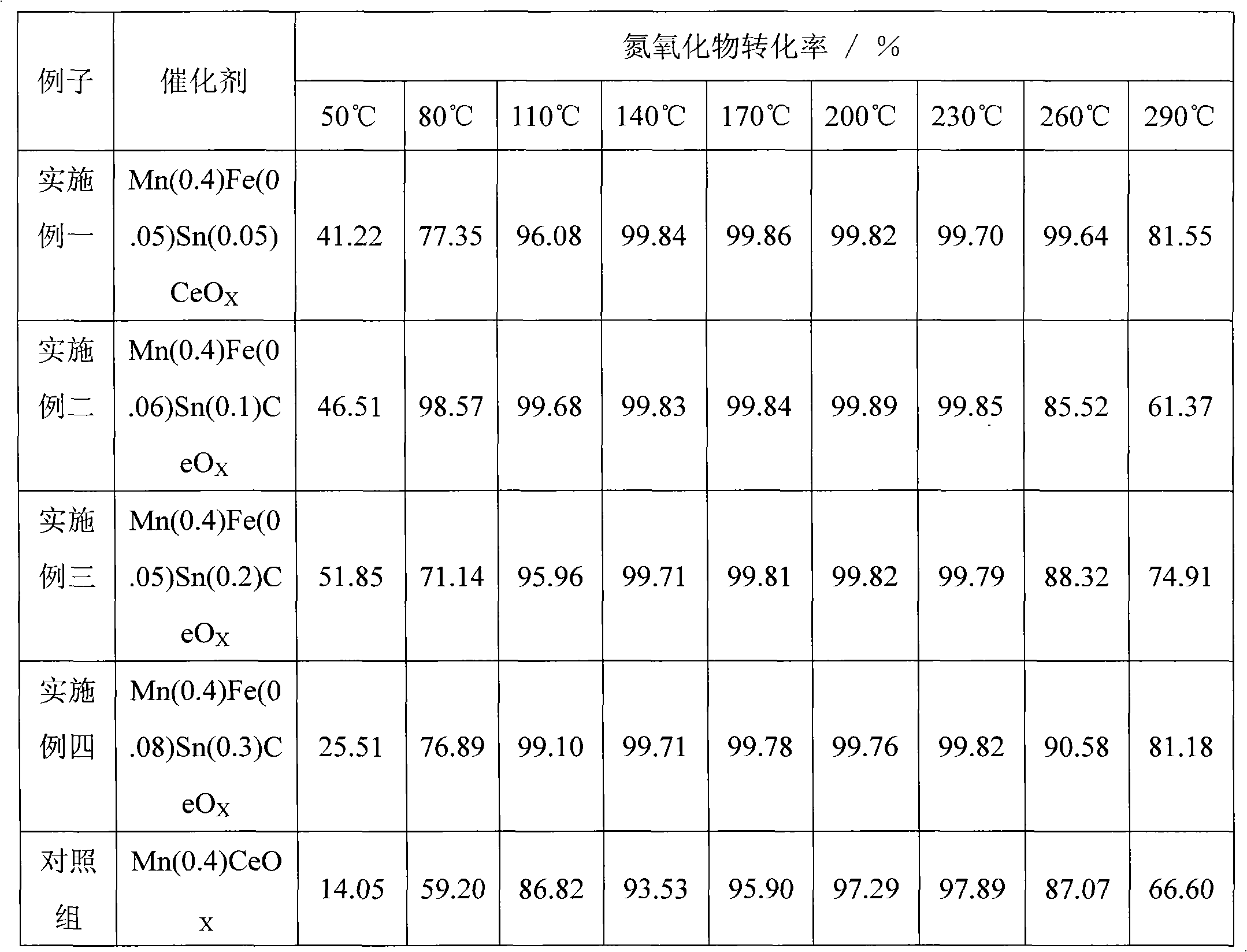

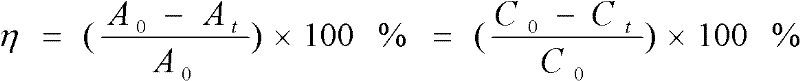

Manganese-based low-temperature denitration catalyst and preparation method thereof

ActiveCN101879452AImprove sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseSlurry

The invention relates to a manganese-based low-temperature denitration catalyst and a preparation method thereof. The preparation method comprises the following steps of: 1, dissolving manganous nitrate, ferric nitrate, crystal tin tetrachloride and cerous nitrate in water at normal temperature, and stirring the mixture to form transparent solution; 2, preparing solution of ammonium carbonate, dripping the solution of ammonium carbonate into the solution prepared by the step 1, and heating and stirring the mixture to obtain slurry; 3, ultrasonically immersing the slurry, leaching the slurry to obtain a filter cake, and then washing the filter cake with deionized water; and 4, drying and roasting the filter cake to obtain the manganese-based low-temperature denitration catalyst MnFeSnCeOx, wherein the molar ratio of Mn: Fe: Sn: Ce in the prepared catalyst is equal to (35-39):(2-5):(9-35):(54-21). The purification efficiency of nitric oxides reaches 71 to 100 percent when the metallic oxide catalyst is at the temperature of between 80 and 250 DEG C. The composite oxide catalyst has high sulfur resistance.

Owner:江苏中创清源科技有限公司

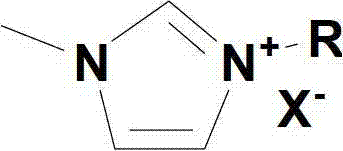

Process for the manufacture of halocarbons and selected compounds and azeotropes with HF

InactiveUS20050080302A1Preparation by hydrogen halide split-offPreparation by halogen halide additionAlkaneHalocarbon

A liquid phase process is disclosed for producing halogenated alkane adducts of the formula CAR1R2CBR3R4 (where A, B, R1, R2, R3, and R4 are as defined in the specification) which involves contacting a corresponding halogenated alkane, AB, with a corresponding olefin, CR1R2═CR3R4 in a dinitrile or cyclic carbonate ester solvent which divides the reaction mixture into two liquid phases and in the presence of a catalyst system containing (i) at least one catalyst selected from monovalent and divalent copper; and optionally (ii) a promoter selected from aromatic or aliphatic heterocyclic compounds which contain at least one carbon-nitrogen double bond in the heterocyclic ring. When hydrochlorofluorocarbons are formed, the chlorine content may be reduced by reacting the hydrochlorofluorocarbons with HF. New compounds disclosed include CF3CF2CCl2CH2CCl3, CF3CCl2CH2CH2Cl and CF3CCl2CH2CHClF. These compounds are useful as intermediates for producing hydrofluorocarbons. Azeotropes of CClF2CH2CF3 with HF and azeotropes of CF3CH2CHF2 with HF are also disclosed; as are process for producing such azeotropes. A process for purification of certain hydrofluorocarbons and / or chloro-precursors thereof from mixtures of such compounds with HF is also disclosed.

Owner:THE CHEMOURS CO FC LLC

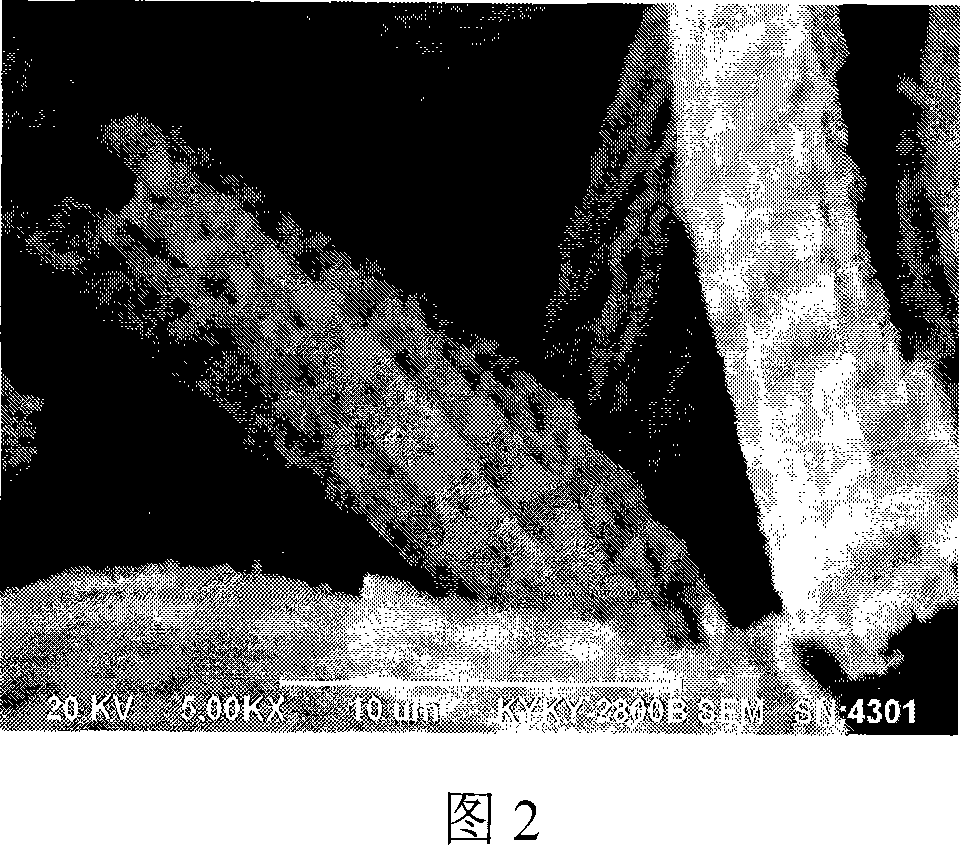

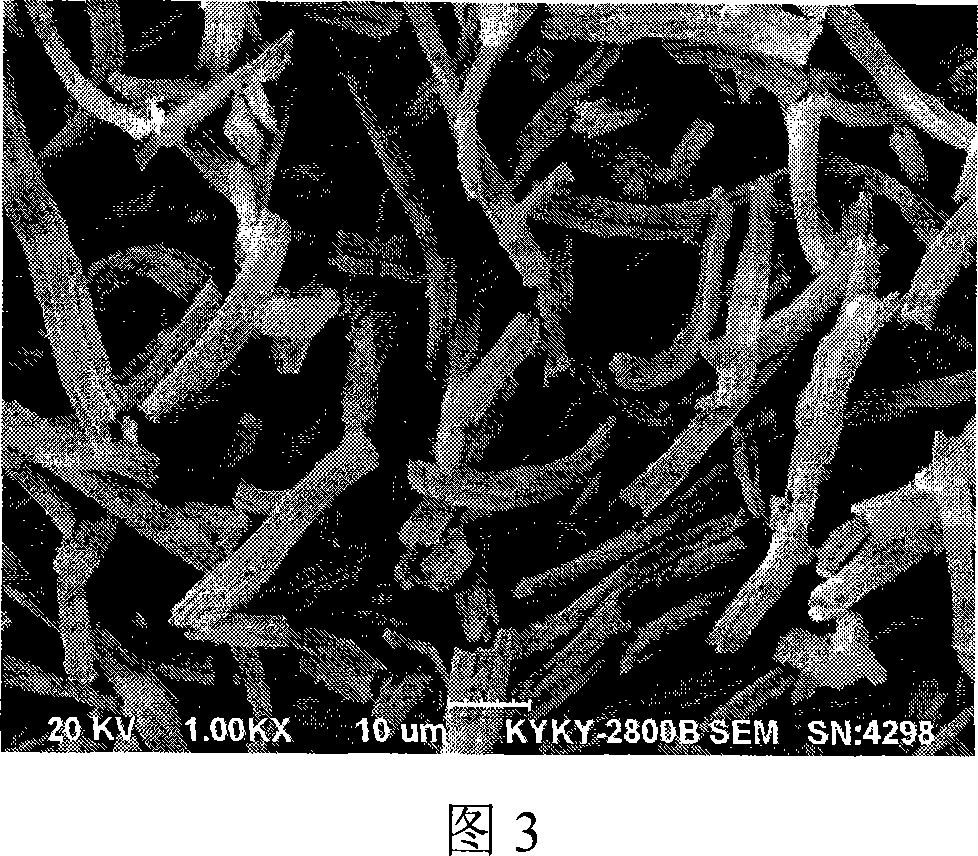

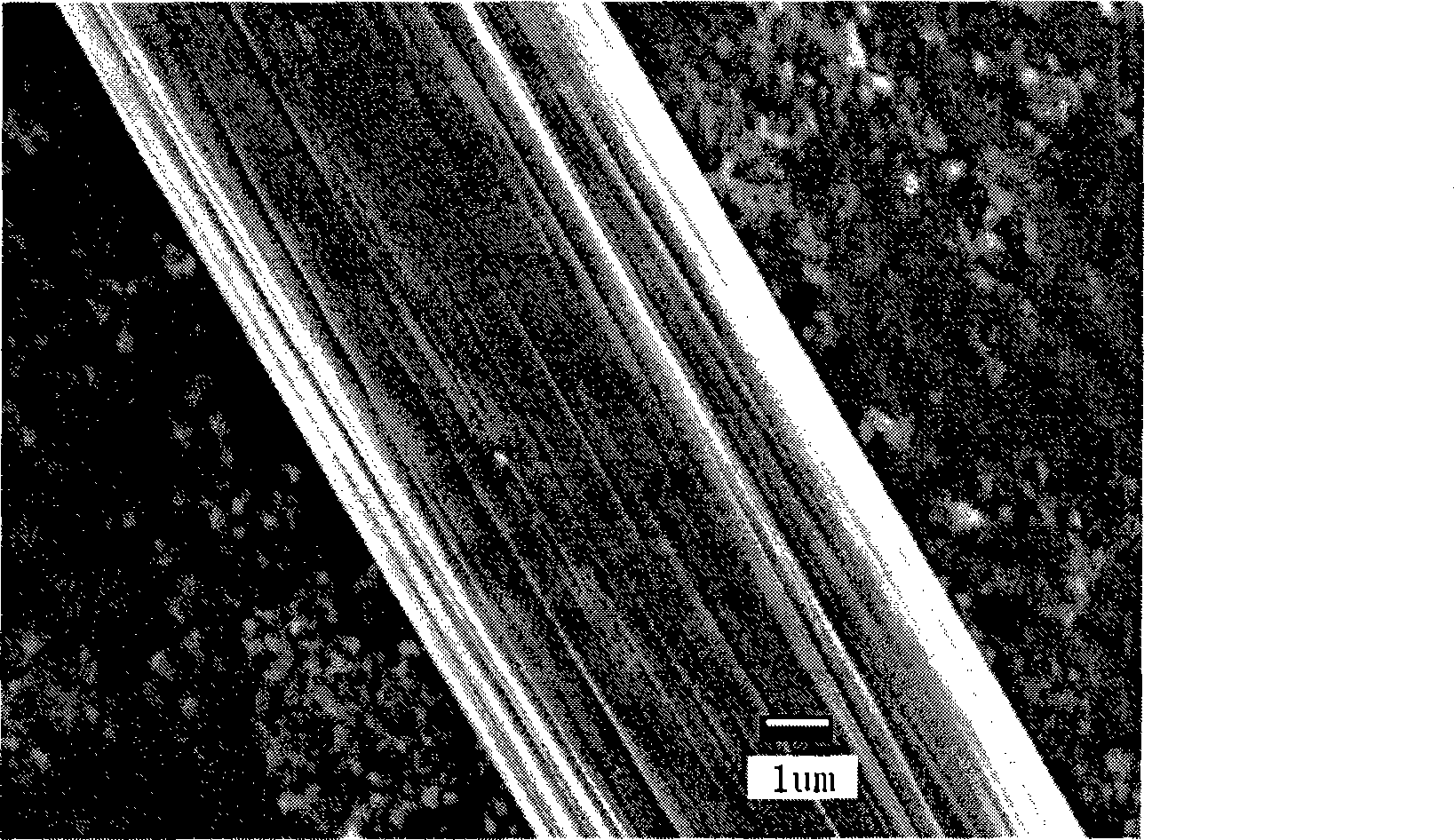

Preparing low density porous tin dioxide nano fiber laser target material by electro-static spinning method

InactiveCN1858308AHigh porosityChemical composition is easy to controlInorganic material artificial filamentsFilament/thread formingTin dioxideVolumetric Mass Density

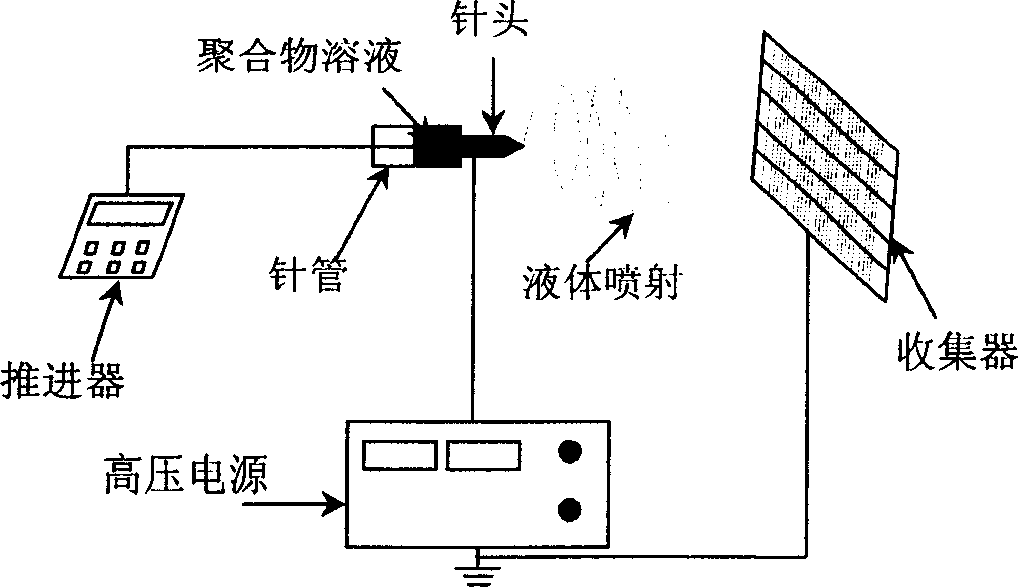

The electrostatic spinning process for preparing low density porous nanometer SnO2 fiber as laser target material is fast, efficient and simple. The electrostatic spinning process includes compound spinning solution with polyvinyl pyrrolidone, absolute ethyl alcohol, tin tetrachloride in certain weight proportion through mixing at room temperature; electrostatic spinning through spraying the spinning solution with spinning jet to an accepting screen 5-30 cm apart from the jet while applying electric field of 0.1-1 kv / cm, controlling the spraying time and the motion of the accepting screen to obtain fiber of different density and deposited in different areas; and roasting at 450-550 deg.c to obtain the nanometer SnO2 fiber.

Owner:SOUTHEAST UNIV

Synthesis of composite functional super high cross-linked adsorbing resin containing sulfo radical

The present invention discloses the synthesis of composite functional super high cross-linked adsorbing resin containing sulfo radical. The synthesis process of the present invention adopts styrene as monomer, divinyl benzene as cross-liking agent, liquid paraffin and other material as pore creating agent, magnesium sulfate and other material as dispersant, benzoyl peroxide as initiator, nitrobenzene and dichloro ethane or chloroben as sweller, and zinc chloride, ferric trichloride or tin tetrachloride and Lewis acid as catalyst, and prepares composite functional resin through preparing chloromethylated low cross-linked polystyrene resin, post-crosslinking reaction to obtain composite functional resin precursor of different crosslinking degree and final sulfonating with high concentration sulfuric acid to obtain composite functional resin with different specific surface area and different exchange capacity. The resin product has both adsorption and ion exchange function and thus wide application range.

Owner:NANJING UNIV +1

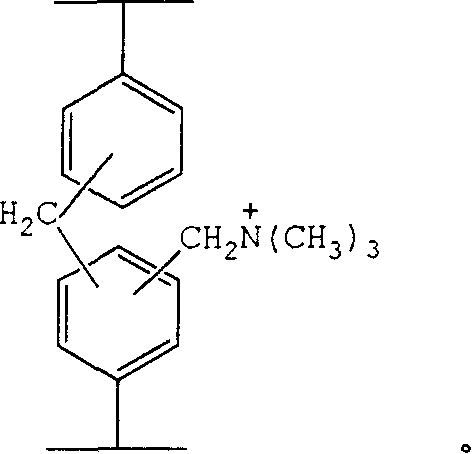

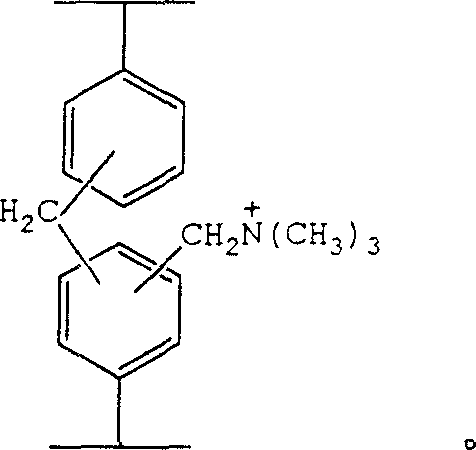

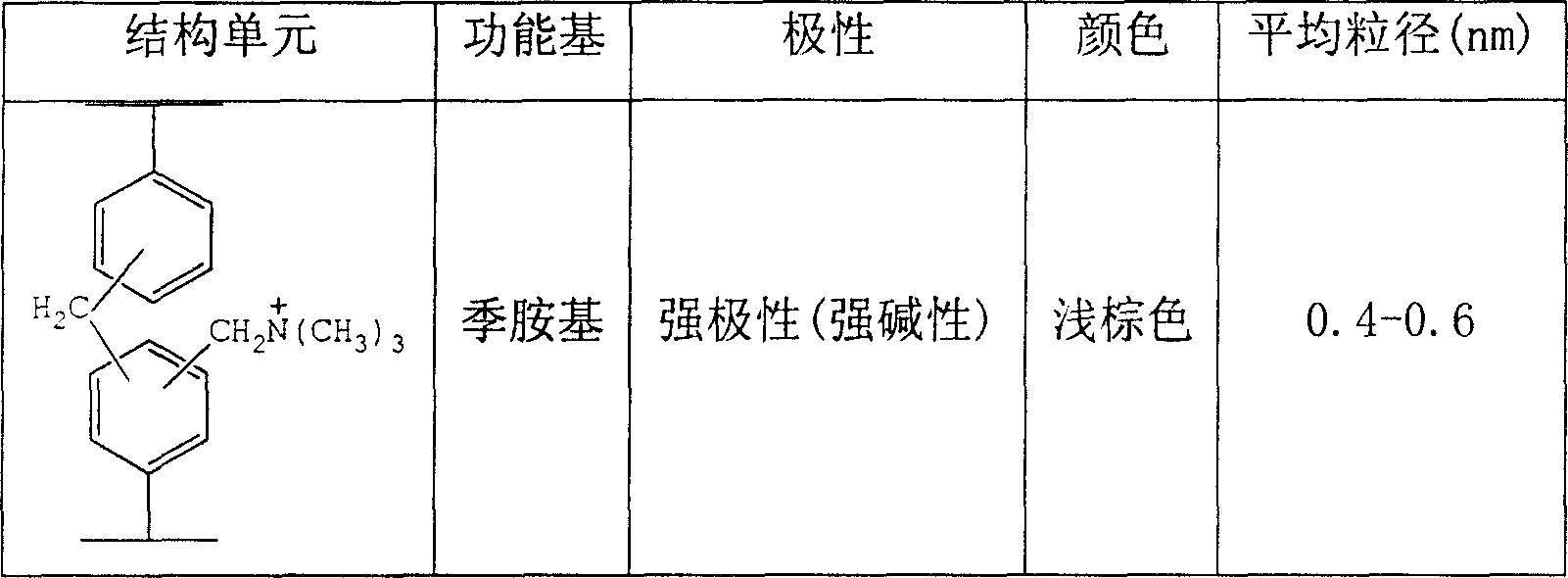

Composite functional super high cross-linked adsorption resin containing quaternary amine group, and its preparation method

ActiveCN1865302AHighlight hydrogen bondsProminent electrostatic effectOther chemical processesDibenzoyl PeroxideDisperser

The invention discloses a super high cross-linking adsorption resin with quaternary amines base composite function and making method, which comprises the following steps: utilizing phenylethene as monomer, diphenyl ethylene as cross linking agent, liquid wax as hole-sealing agent, magnesium carbonate as disperser, benzoyl peroxide as initiator; adopting nitrobenzene, substituted nitrobenzene, dichloroethanes or orthodichlorobenzene as swelling agent in the cross-linking reaction course of chloromethylation low cross-linking large-hole polyphenylacetylene; using zinc chloride, ferric chloride or tin tetrachloride as catalyst to produce different cross linking composite functional resin priority in the preset time and temperature condition; adding trimethylamine to aminate to produce the product. The resin possesses double functions of adsorption and ion exchanging, which can be applied in drug separation, little polluted water source and organic chemical waste water harnessing.

Owner:NANJING UNIV +1

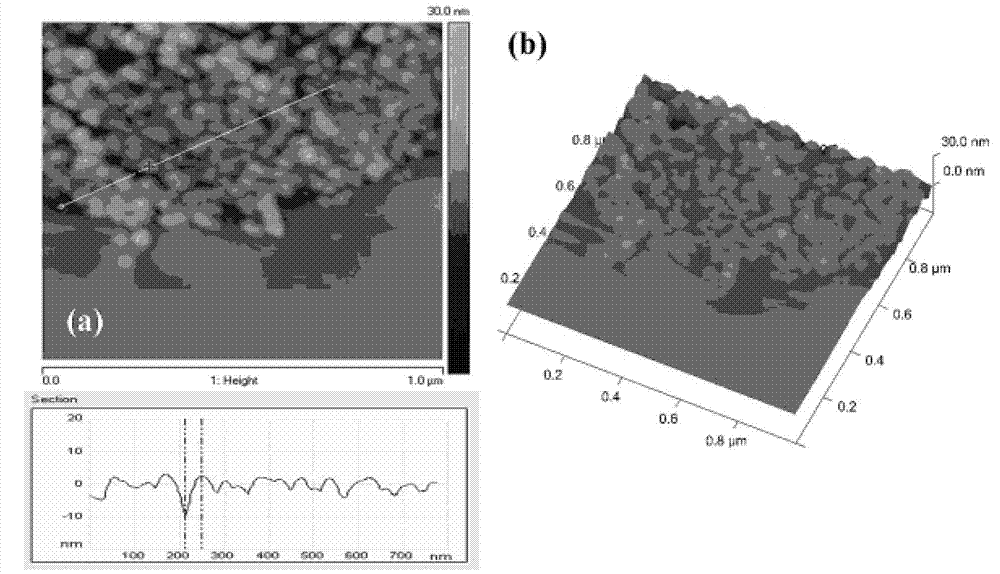

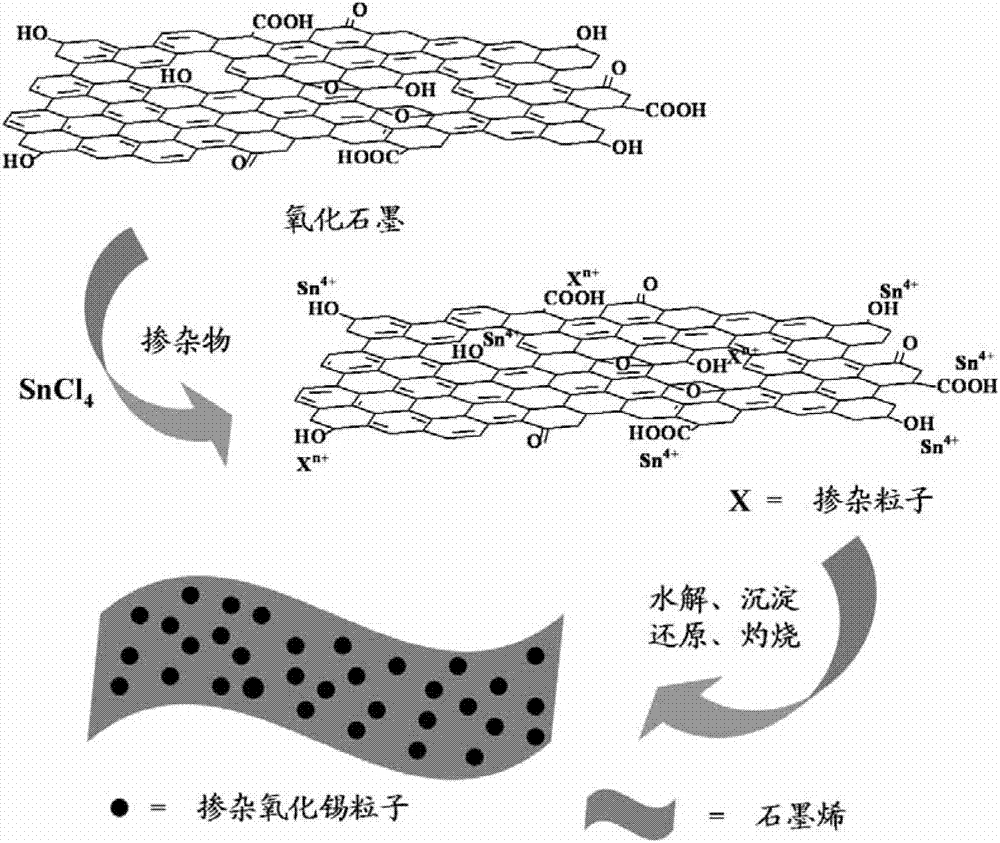

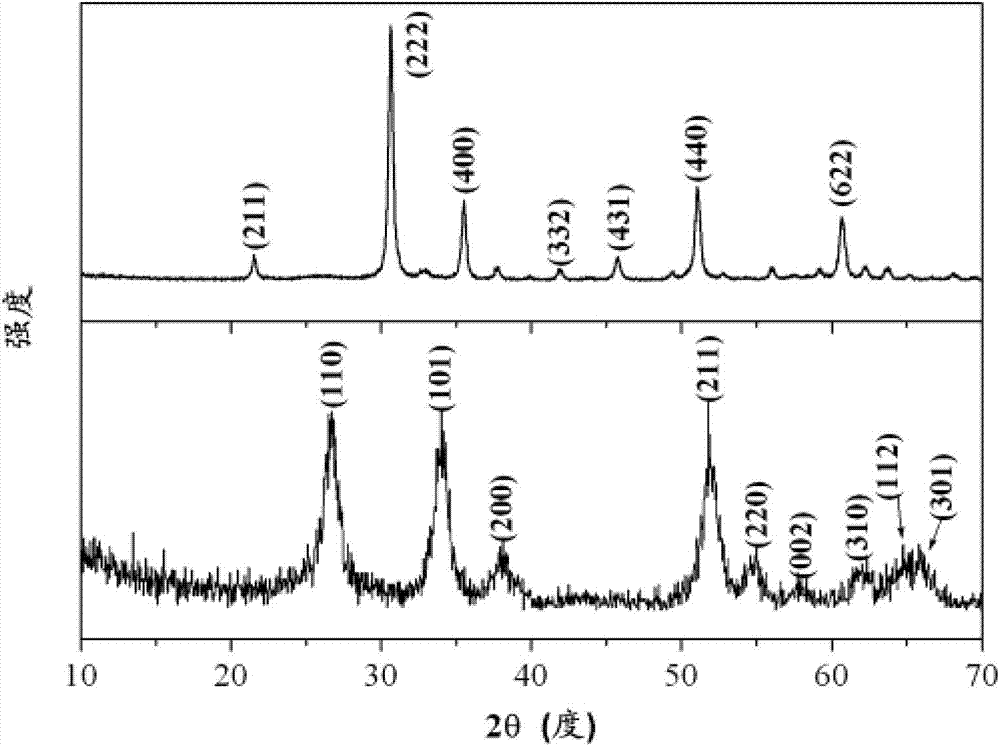

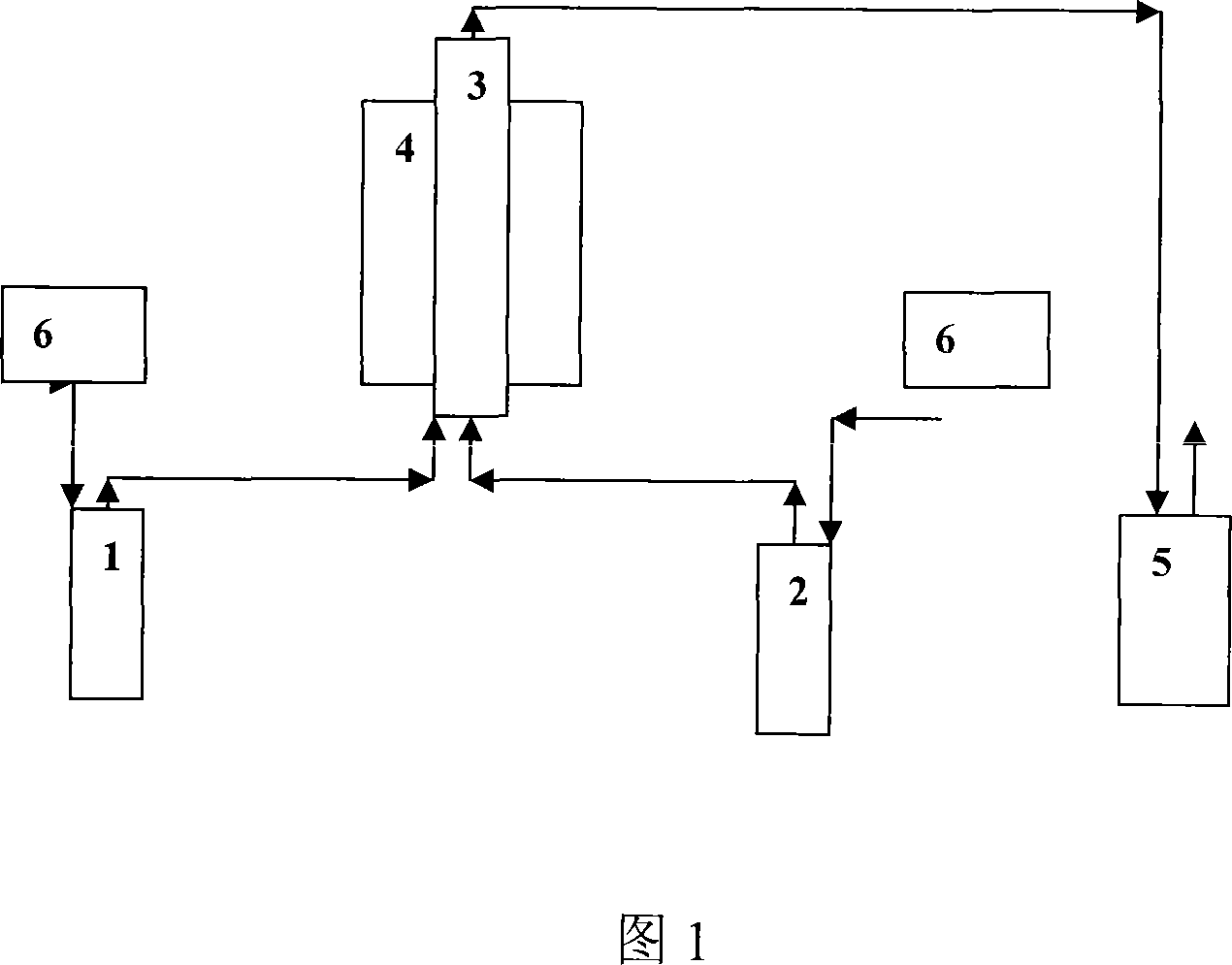

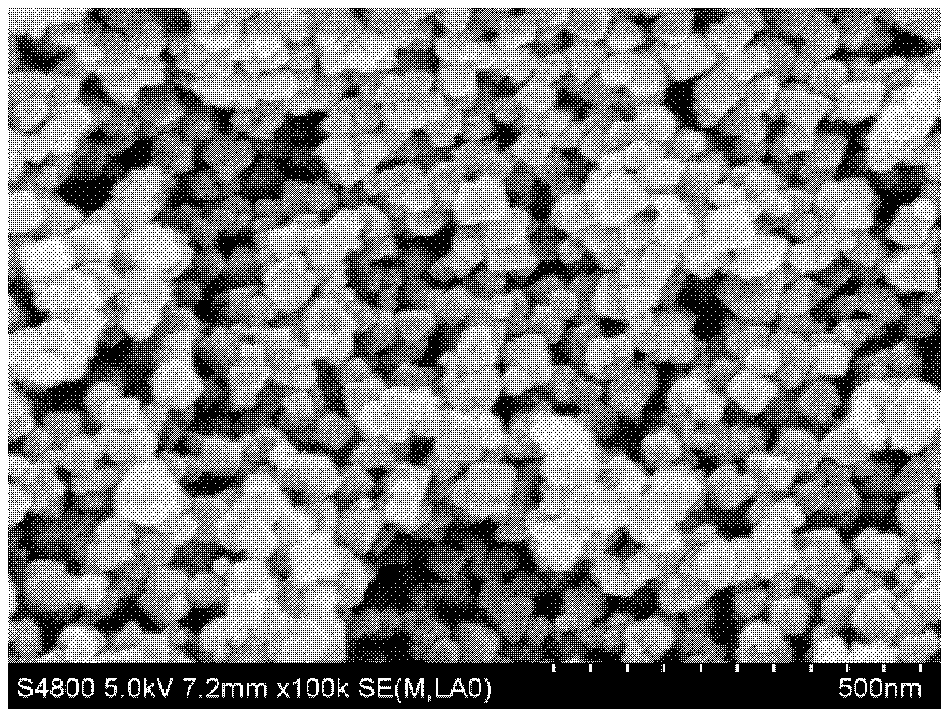

Graphene-modified doped tin oxide composite material and preparation method thereof

ActiveCN102778478ALarge specific surface areaUniform particle sizeMaterial analysis by electric/magnetic meansComing outEpoxy

The invention provides a preparation method of a graphene-modified doped tin oxide composite material, which comprises the following steps: a) dispersing graphite oxide containing hydroxy group, carboxyl group or epoxy group in water, adding tin tetrachloride or crystalline tin tetrachloride and an alcoholic solution of dopant, and adding ammonia water and a reducer to react until a precipitate comes out; and b) filtering out the precipitate, drying, and sintering under inert gas shielding to obtain the graphene-modified doped tin oxide composite material. The invention also provides a gas sensor prepared from the composite material. By introducing the graphene to modify the doped tin oxide, the graphene-modified doped tin oxide composite material has large specific area and uniform nano particle size, and the preparation method is simple and easy to implement; and compared with the doped tin oxide gas sensor, the gas sensor prepared from the composite material provided by the invention has high gas sensitivity, and is suitable for monitoring atmospheric environment and pit gas leakage.

Owner:UNIV OF SCI & TECH OF CHINA

Method of preparing titanium dioxide, stannum dioxide and doping composite fiber material thereof

InactiveCN101033082AGood lookingSimple structureNanostructure manufactureTitanium dioxideTin dioxideNitrogen gas

This invention relates to a method for preparing fiber TiO2, SnO2 and its doped compound material characterizing in utilizing a fiber material as a template, taking TBT, titanium tetrahalide, tin tetrachloride or a mixture as a precursor, which is carried by nitrogen or argon and enters into a reactor with a gas containing ammonia for chemical gaseous phase deposition, in which, the gas flow, deposition temperature and the sinter atmosphere and temperature are controlled, the inert gas is heated to get load-type fiber material to be sintered under the atmosphere of oxidation and reaction to remove the fiber template and form an oxide fiber material, and utilize the active carbon fiber template and ignition process to form porous fiber or tubular fiber material.

Owner:DALIAN UNIV OF TECH

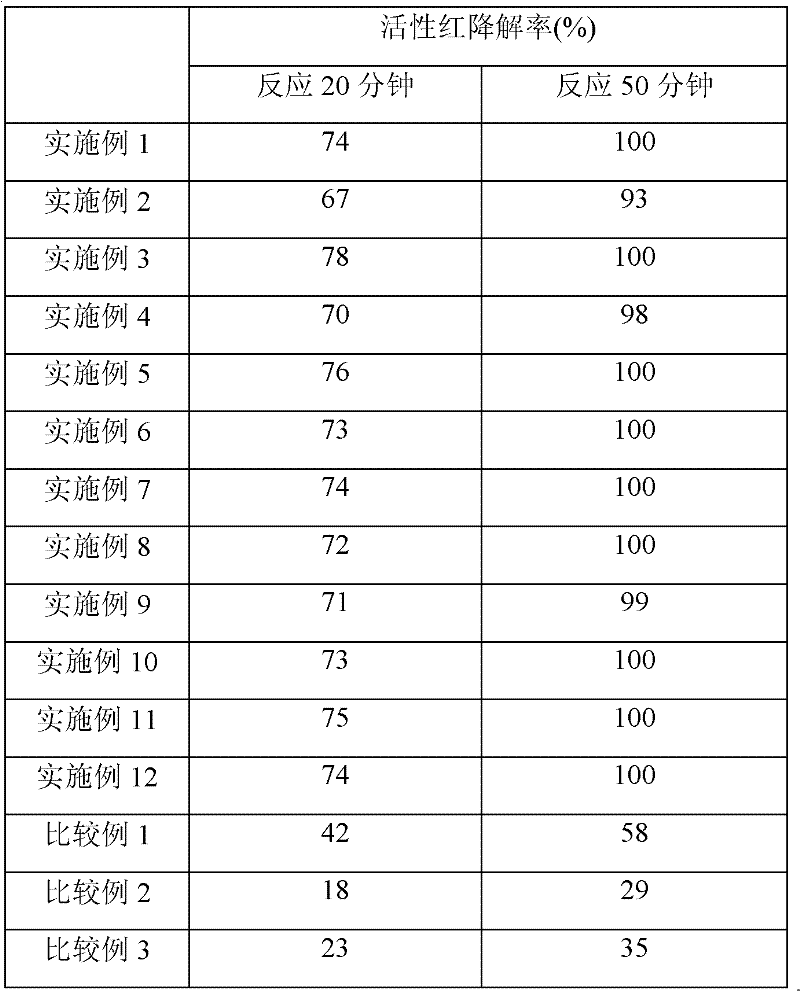

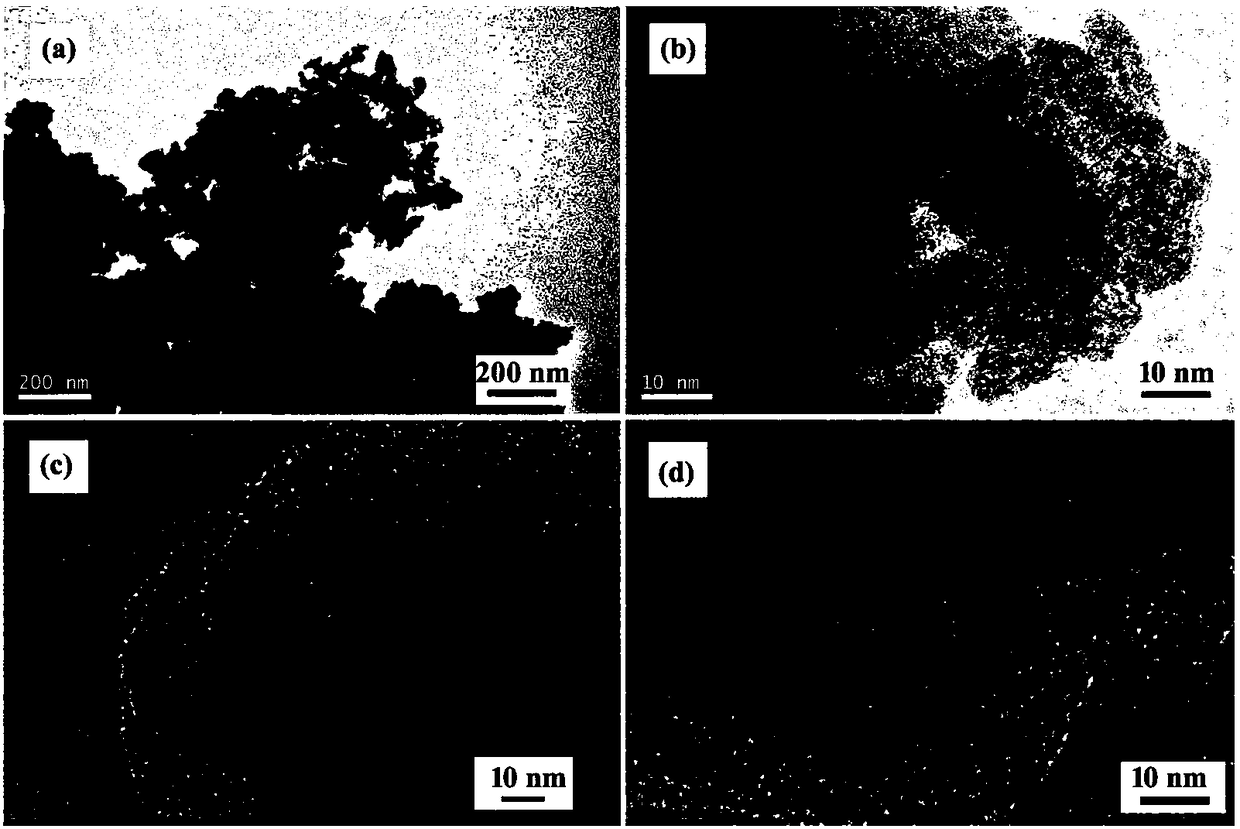

Adsorption-photocatalysis composite material synthesized on basis of in-situ synchronous assembly of UIO-66-NH2 and graphene

InactiveCN107029672AEasy to manufactureStrong controllability of reaction conditionsOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsMicrowaveTetrachloride

The invention discloses an adsorption-photocatalysis composite material synthesized on basis of in-situ synchronous assembly of UIO-66-NH2 and graphene (GR). The composite material is prepared by following steps: (1), weighing a certain amount of GR, dissolving the same in N, N-dimethyl formamide prepared in advance, and performing ultrasonic treatment to enable GR to be dissolved in a solution to obtain a solution A; (2), weighing a certain amount of 2-amino-terephthalic acid, dissolving the same in the solution A, ultrasonically treating, and stirring to obtain a solution B; (3), weighing a certain amount of a precursor, zirconium tetrachloride used for synthesizing MOF, dissolving the precursor in the solution B, ultrasonically treating, and stirring to obtain a solution C; (4), putting the solution C in microwaves for reaction for a period of time to obtain a product; (5), centrifuging and washing the product to obtain the composite material of UIO-66-NH2 and GR.

Owner:SHANGHAI NORMAL UNIVERSITY +1

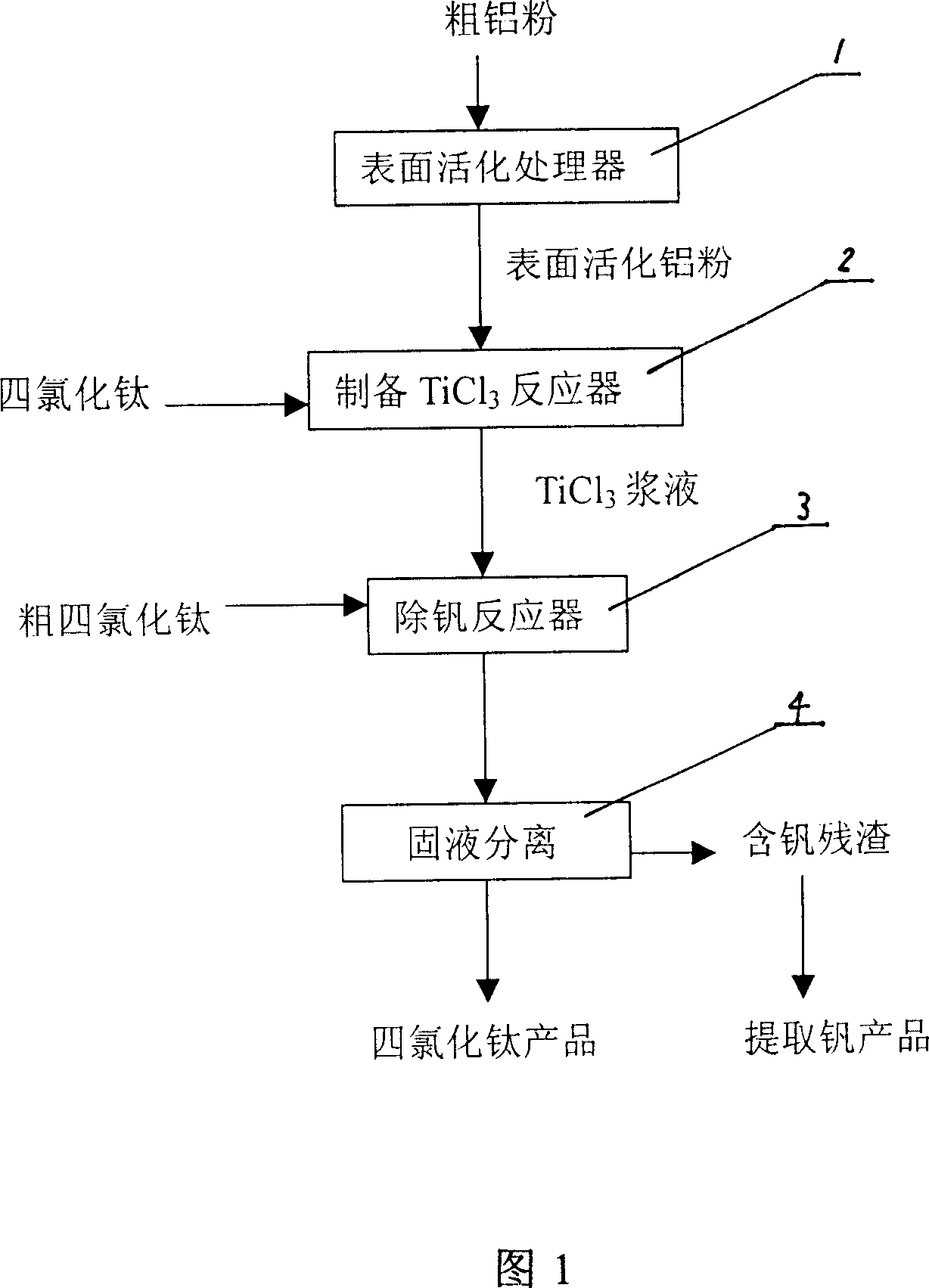

Method for removing vanadium in titanium tetrachloride

InactiveCN101054201ASimple processSimple waste treatmentTitanium halidesTetrachlorideBiological activation

The invention relates to a method for removing vanadium impurity from titanic tetrachloride. The invention prepares titanium trichloride serum by the reaction between the cost aluminum powders with the average grain size no bigger than 150mum after surface activation treatment. TiCl3 in the serum reduces VOCl3 in the titanic tetrachloride to be VOCl2 deposit so as to remove the vanadium. And the titanic tetrachloride after removing the vanadium contains no more than 0.0007% vanadium. The process of vanadium removal can be implemented together with rectification process in order to realize continuous operation. The invention has the advantages of simple in process, low in cost, safe in operation, high in product quality and recovery rate and simple in treating the ''three-waste'' pollution.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Method for preparing functionalization polyolefin resin

The preparation process of functional polyolefin resin includes electronic beam or gamma-ray pre-irradiation treatment of functional polyolefin resin; mechanical mixing of polyolefin resin after pre-treatment, functional monomer and electron donor reagent; and reacting extrusion for the polyolefin resin in molten state and functional monomer to produce grafting reaction. The polyolefin resin includes polyethylene, polypropylene, ethylene-propylene copolymer, ethylene-styrene copolymer, polystyrene, etc; the functional monomer is unsaturated organic acid or its derivative with amino group, isocyanate, hydroxyl group or other reactive functional group; and the electron donor reagent includes electron-rich compound with P, N, S or O element, p-benzoquinone, triphenyl phosphite, triphenyl phosphate, etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Method for recycling tin from waste tin-stripping solution based on tin-stripping solution of hydrochloric acid-tin salt system

ActiveCN103741142AAvoid the Cons of PollutionStrong oxidation abilityPhotography auxillary processesSolution treatmentTetrachloride

The invention discloses a method for efficiently recycling tin from a waste tin-stripping solution based on a tin-stripping solution of a hydrochloric acid-tin salt system. According to the tin-stripping solution, the components and the contents are as follows: 110-230g / L of tin tetrachloride, 70-220g / L of hydrochloric acid, 10-30g / L of iron chloride, 0.5-2.5g / L of a stabilizing agent, 5-30g / L of an accelerant and 2-5g / L of a brightener. The waste tin-stripping solution obtained by tin stripping is subjected to diaphragm electrodeposition treatment by using a cathode room and an anode room of an anion diaphragm electrolytic cell to recycle tin, the tin tetrachloride and ferric trichloride. According to the method for treating the waste tin-stripping solution, not only can the tin be effectively recycled from the waste tin-stripping solution, but also the tin tetrachloride and ferric trichloride can be regenerated and returned to prepare the waste tin-stripping solution to use; the problems of resource wastes, serious environment pollution and the like of a traditional waste tin-stripping solution treatment method are completely avoided.

Owner:CENT SOUTH UNIV

Composite rear earth pyrochlore-type oxide catalyst for catalyzing burning for removing soot of diesel vehicle and preparation method thereof

InactiveCN101879445AHigh selectivityThe synthesis process is simpleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthPyrochlore

The invention provides a composite rear earth pyrochlore-type oxide catalyst for catalyzing burning for removing soot of a diesel vehicle and a preparation method thereof, belonging to the technical field of a tail gas cleaning catalyst of the diesel vehicle. The expression formula of the composite metal oxide is A2B2-xMxO7, wherein A is La, B is Sn, M is Mn, Fe, Co, Ni or Cu. The invention adopts a coprecipitation method to prepare the catalyst, the preparation process is simple, and the cost is low. The preparation method comprises the following steps: mixing metal nitrate and tin tetrachloride solution; adjusting the pH value by ammonia solution; drying the obtained deposit; and roasting the deposit at the high temperature to obtain the composite rear earth pyrochlore-type oxide catalyst. Under the effect of the catalyst, a simulation diesel vehicle exhausts, the burning temperature of the soot particles is lowered to the exhaust range of the diesel vehicle, and the speed of the soot oxidation rate is improved. The catalyst is a useful catalyst for removing the pollution of soot particles of the diesel vehicle.

Owner:UNIV OF JINAN

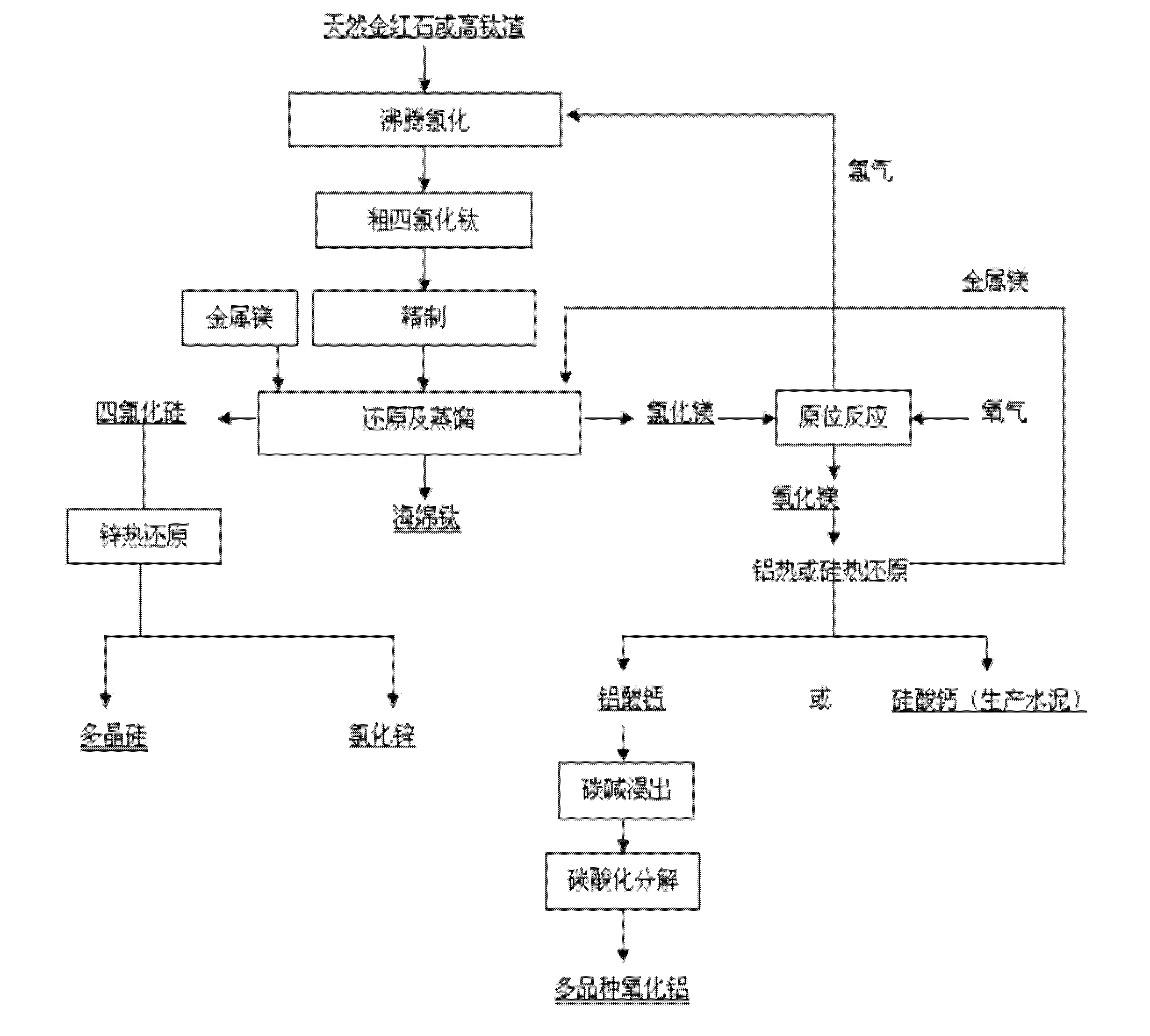

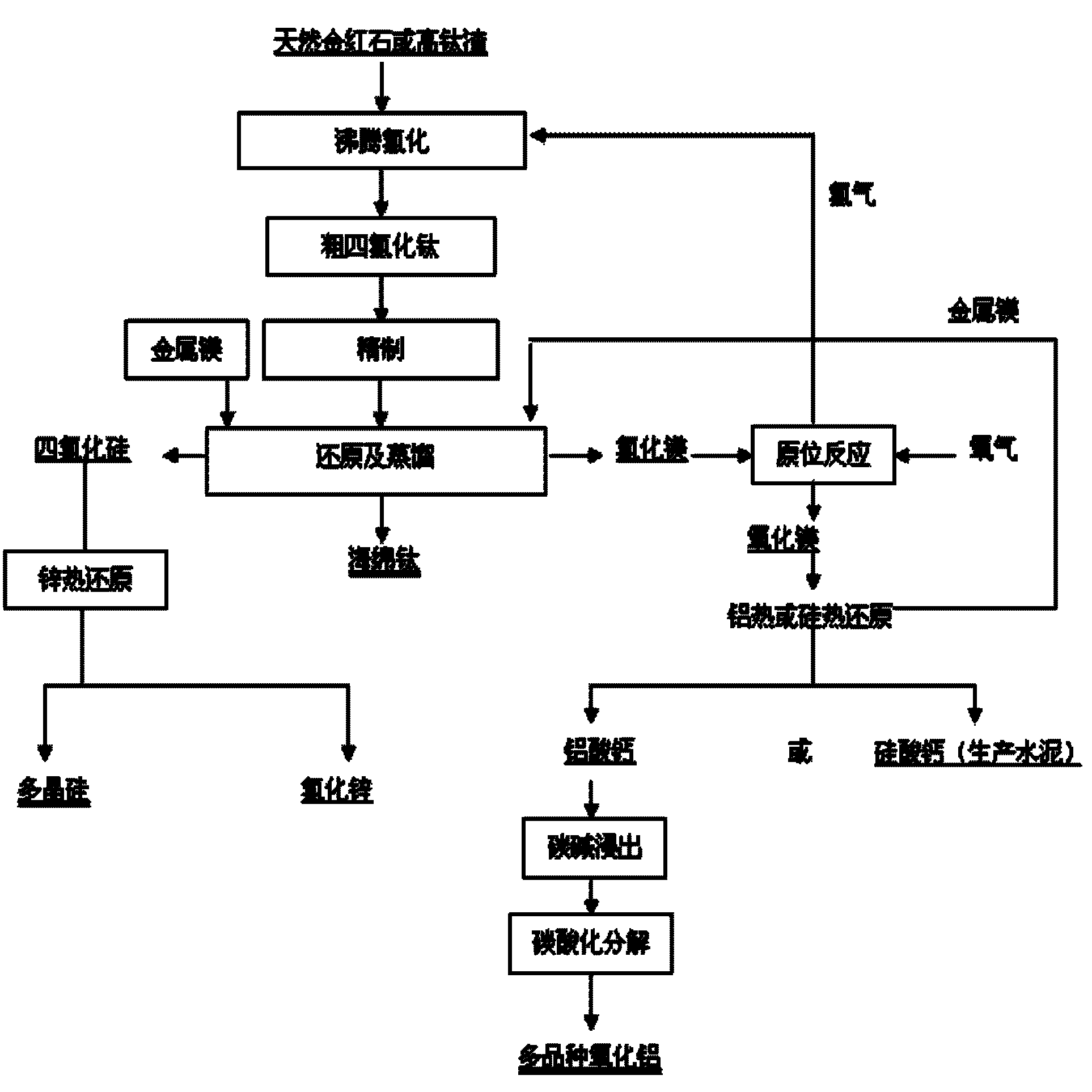

Method for preparing titanium sponge through magnesium and chlorine recycling

ActiveCN102181670ALess investmentReduce manufacturing costProcess efficiency improvementTitanium chlorideCopper wire

The invention relates to the technical field of preparation of nonferrous metal, in particular to a method for preparing titanium sponge through magnesium and chlorine recycling. The method comprises the following steps of: crushing natural rutile or titanium-rich slag, finely grinding to -0.25mm and chlorinating to obtain rough titanium tetrachloride; removing iron from the rough titanium tetrachloride by using a distillation tower with bottom temperature of between 140 DEG C and 145 DEG C and top temperature of 137 DEG C; removing silicon through a rectification tower with bottom temperature of 140 DEG C and top temperature of between 57 DEG C and 70 DEG C; removing vanadium by using copper wires to obtain a titanium tetrachloride product with purity of more than 99 percent; proportioning refined titanium tetrachloride and metal magnesium according to a mass ratio of magnesium to titanium as (1.3:1)-(1.8:1) and reacting at the temperature of between 700 DEG C and 1,000 DEG C to obtain mixture of the titanium sponge, the magnesium chloride and the silicon tetrachloride; and distilling the mixture of the titanium sponge, the magnesium chloride and the silicon tetrachloride for 30-35 hours under the conditions of temperature of between 880 DEG C and 1,000 DEG C and final vacuum degree of less than 0.1Pa to separate the titanium sponge and the magnesium chloride.

Owner:NORTHEASTERN UNIV

Catalyst used for preparing tetrachloroethylene and its preparation method and use

InactiveCN101143328AHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsGas phaseCobalt

The invention relates to novel catalyst to prepare tetrachloroethylene in carbon tetrachloride gas-phase catalysis. The invention is characterized in that the catalyst carrier is prepared from soluble salt solution or mixed solution with ammonia in coprecipitation method. And then one or two of the mixtures such as the compounds of platinum, palladium and nickel, etc, together with one or a plurality of the mixtures such as the compounds of silver, cobalt, tin, zinc, copper or iron is / are loaded on the catalyst carrier in conventional equivalent impregnation method or excessive impregnation method. One or two of the composite oxides of alumina, zirconia, silica and titania is / are used as the carrier or carriers of the catalyst. One or two of platinum, palladium or nickel and one or two of silver, cobalt, tin, zinc, copper and iron are used as the active components to form multi-metal catalyst. The catalyst prepared in the method of the invention maintains high transformation rate of carbon tetrachloride, at the same time reduces the production of by-products such as methane, maintains high selectivity of tetrachloroethylene, and maintains a long service life of the catalyst.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

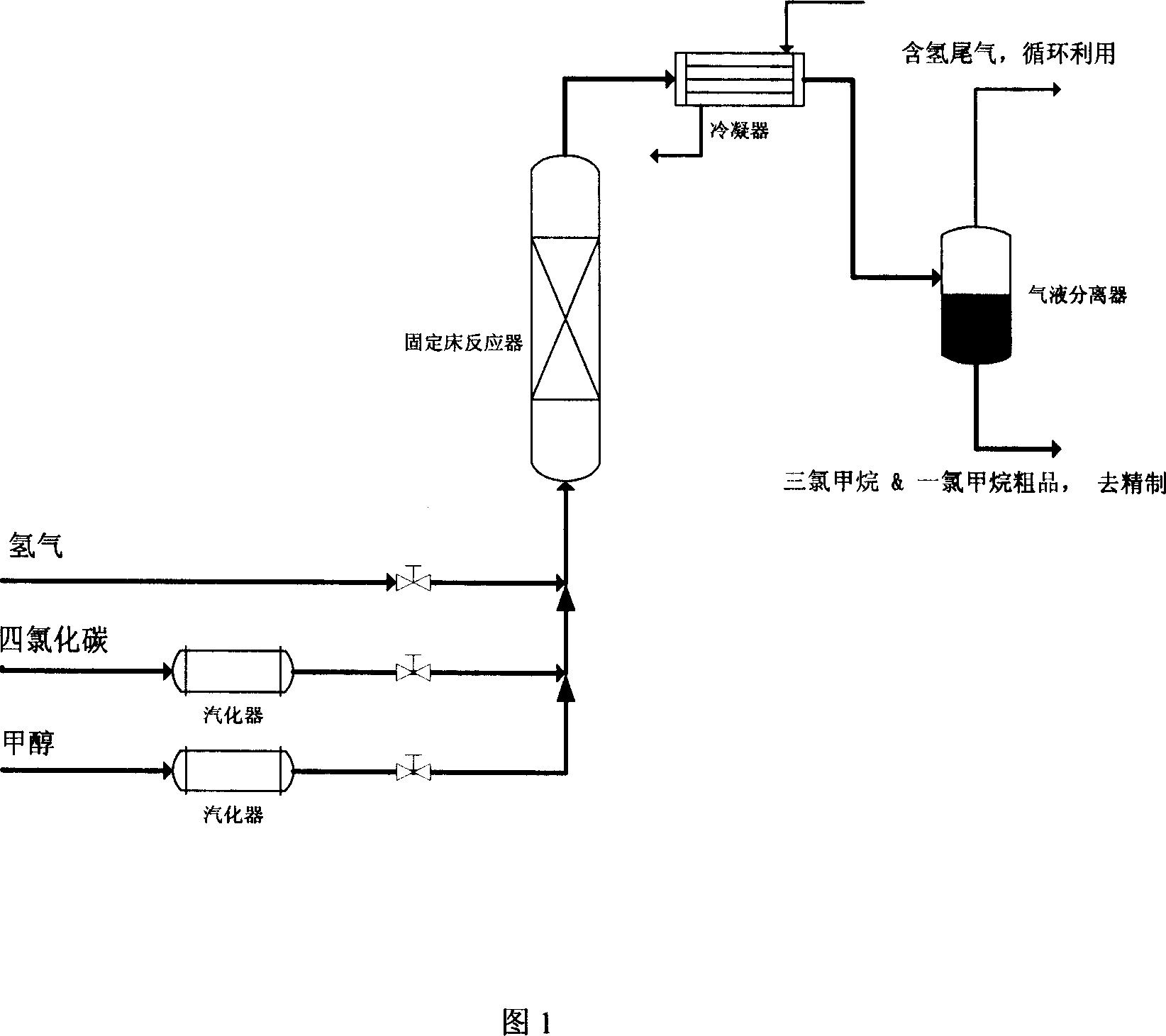

Catalyst and preparing method thereof, and use in hydrogenation-dechlorination of carbon tetrachloride

ActiveCN101015803AAchieving zero emissionsHigh activityHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsPt elementTitanium oxide

The invention relates to a novel catalyst for hydrotreating and dechlorinating high-level chloromethane as carbon tetrachloride to prepare low-level chloromethane. The catalyst uses one or several of palladium, platinum and nickel as active components, and uses at least two of zircite, titanium oxide and alumina as catalyst carrier. With said catalyst, the carbon tetrachloride is hydrotreated into chloroform which is mainly transferred into carrene, while the produced hydrochloride is reacted with carbinol to obtain methyl chloride.

Owner:溧阳常大技术转移中心有限公司

Carbon fiber reinforced friction material and its prepn

The present invention relates to new material, and is one kind of carbon fiber reinforced friction resistance material suitable for producing automobile and train brake disc and its preparation process. The carbon fiber reinforced friction resistance material is produced with reinforcing fiber, base resin and friction performance regulator, the reinforcing fiber is the mixture of carbon fiber, metal fiber and inorganic mineral fiber; the base resin is water latex modified phenolic resin; and the friction performance regulator consists of at least two of barium sulfate, ionic oxide, triiron tetrachloride, iron trichloride, magnesia and silica. The preparation process includes the steps of mixing material, pre-stoving, pressing and post-treatment. The carbon fiber reinforced friction resistance material has excellent friction resistance performance and the preparation process has no pollution.

Owner:SHANDONG UNIV

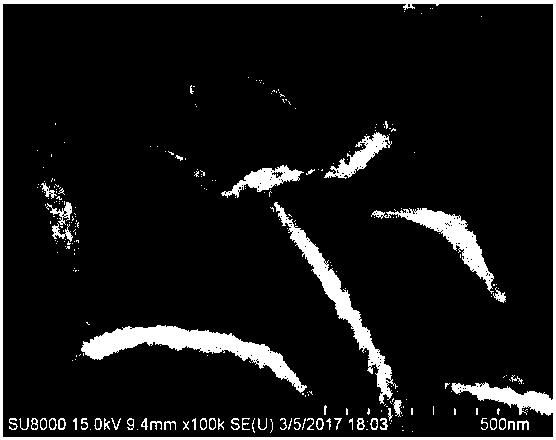

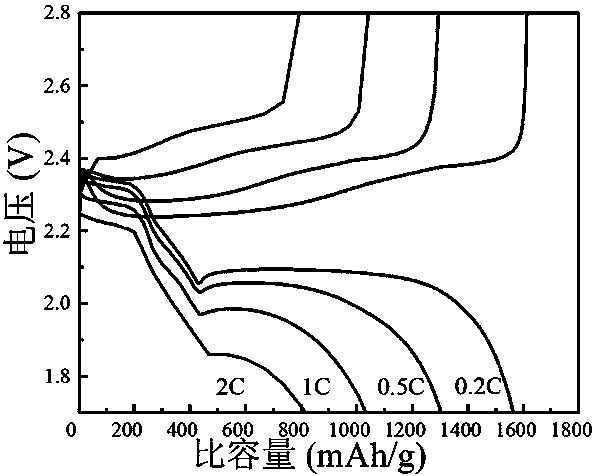

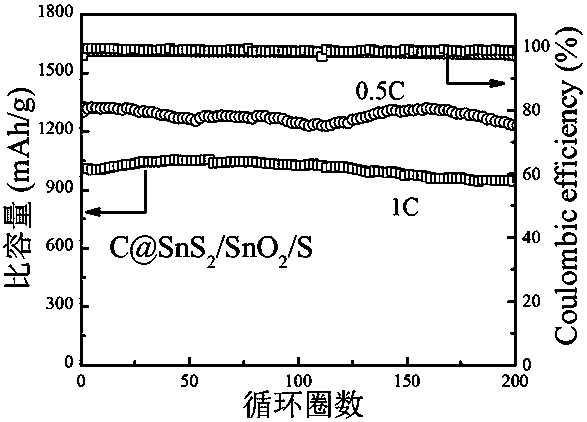

Preparation method and application of carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with heterojunction structure

ActiveCN107768620AGood adsorption capacity of lithium polysulfideImprove stabilityMaterial nanotechnologyLi-accumulatorsHeterojunctionTin dioxide

The invention relates to a preparation method and application of a carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with a heterojunction structure, and belongs to the technical field of an energy material. The method comprises the following steps: 1, dissolving tin tetrachloride, thioacetamide and carbon nanofiber into polypropyl alcohol and performing hydrothermal reaction to obtain a carbon nanofiber, tin disulfide and tin dioxide composite material with the heterojunction structure; 2, dipping the composite material obtained in the step 1 into a sulfur solution, taking out after 5 minutes, vacuum-drying and calcining at high temperature to obtain the carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with the heterojunction structure. The preparation method and the application of the carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with the heterojunction structure have the following advantages: the composite material has special interface effect, can effectively increase electrode surface electron and ion transmission speed and is favorable for realize efficient utilization of the sulfur and obtainingthe cyclic stable lithium sulfur battery. The composite material can be prepared by directly utilizing a one-step hydrothermal method, the preparation method is simple and practical, and the components are controllable.

Owner:HARBIN INST OF TECH

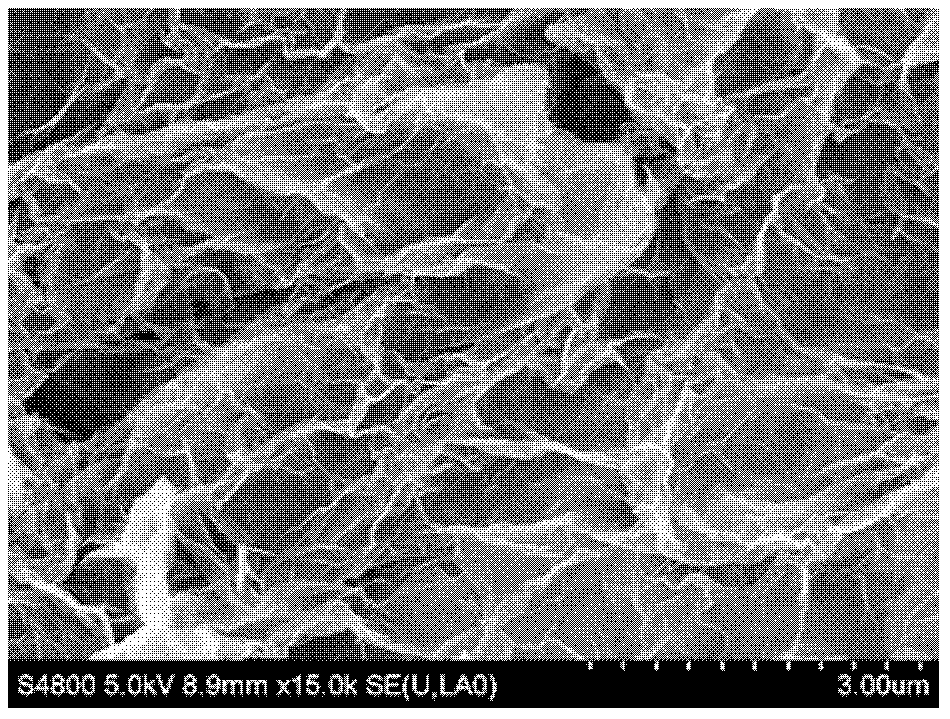

Composite material of stannic oxide and carbon, and preparation method thereof

InactiveCN101462045AReduce adverse effectsSmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsTin dioxideCarbon composites

The invention discloses a tin dioxide / carbon composite material, which contains nanometer tin dioxide and carbon, wherein the carbon is carbon fiber, and the nanometer tin dioxide is coated on the surface of the carbon fiber. A method for preparing the nanometer tin dioxide / carbon composite material comprises the following steps that: the carbon fiber with oxidized surface contacts an alkaline solution and then contacts tin tetrachloride under alkaline conditions. The method adopts a low-temperature condition to treat the tin dioxide / carbon fiber composite material, thereby effectively avoiding the adverse effect on carbon materials and tin dioxide nano-particles caused by high-temperature treatment. The method has the advantages of simple and convenient process, no pollution of solvents, convenient operation, and low cost. An effective constituent, namely the nanometer tin dioxide of photocatalysis is adhered to the carbon fiber with micron size, so the composite material is easy to recover.

Owner:JIANGSU HAIYU MACHINERY

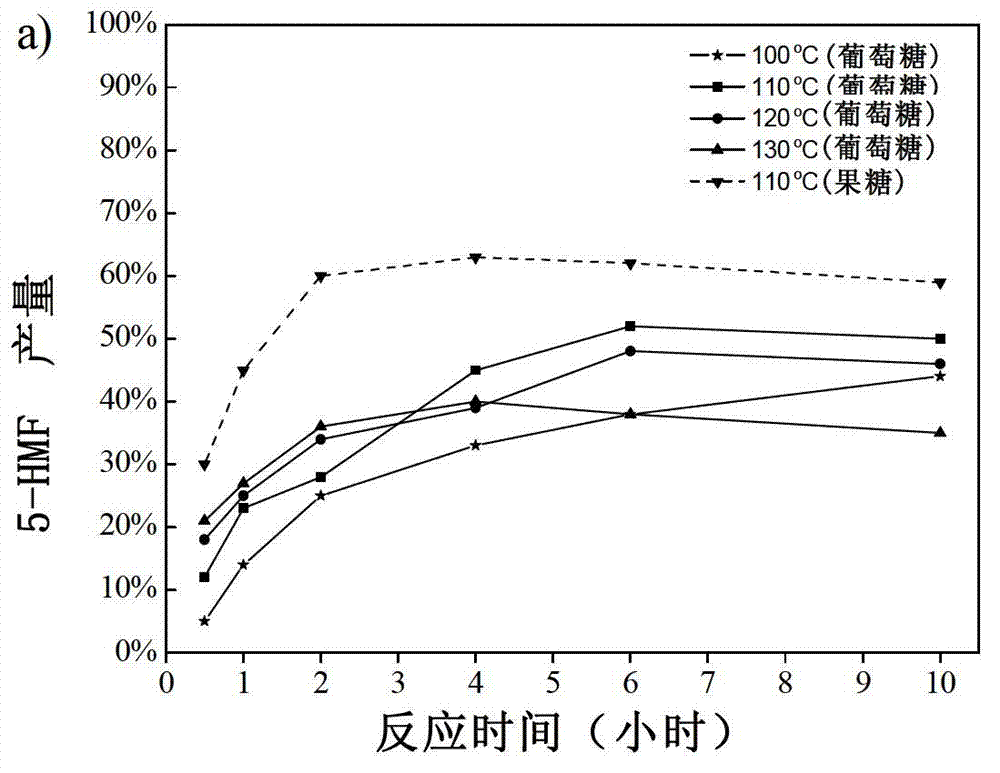

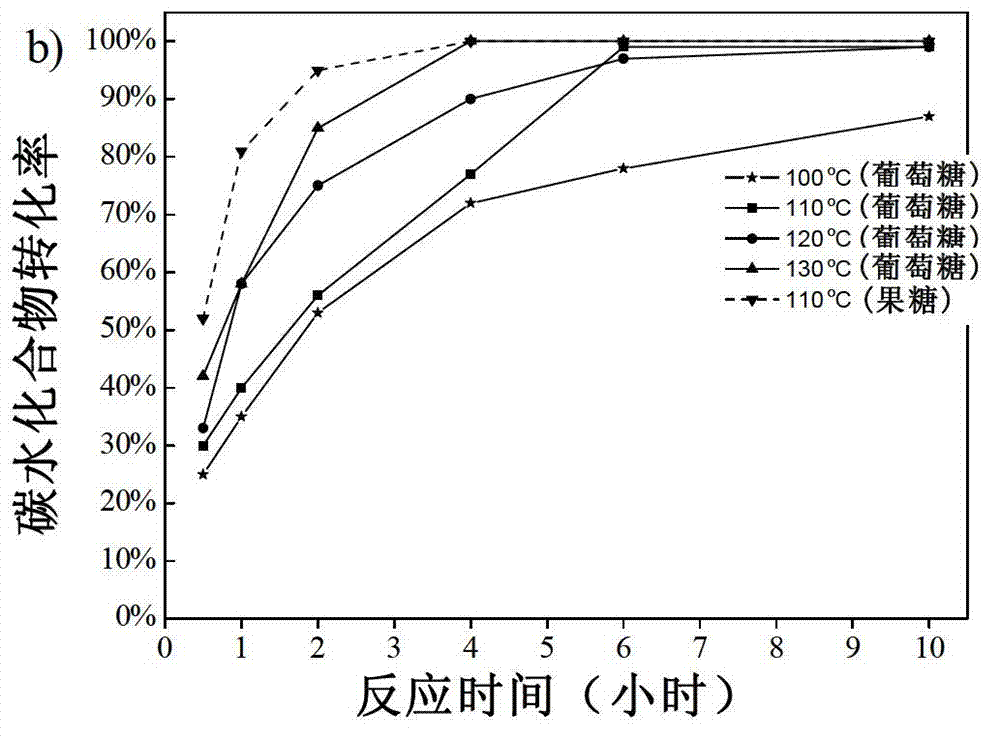

Preparation method and application of solid acid catalyst

InactiveCN102814189AEfficient conversionHigh selectivityOrganic chemistryMolecular sieve catalystsTetramethylammonium hydroxideSolid acid

The invention discloses a preparation method and application of a solid acid catalyst. The preparation method of the solid acid catalyst comprises the following steps: (1) mixing a silicon source, an alkali source, a metallic compound and a template, and carrying out hydrothermal reaction to obtain a reaction product 1; (2) filtering the reaction product 1 to obtain a solid, and drying at 60-120 DEG C for 12-36 hours to obtain a reaction product 2; and (3) calcining the reaction product 2 at 500-600 DEG C for 3-10 hours to obtain the solid acid catalyst. The silicon source is selected from hydrophilic nano silicon oxide, sodium silicate and tetraethyl orthosilicate; the alkali source is selected from tetramethylammonium hydroxide, alkali metal hydroxide and ammonia water; the metallic compound is selected from tin tetrachloride, zirconium sulfate, sodium silicate, chromic nitrate, nickel nitrate and tetrabutyl titanate; and the template is cetyl trimethyl ammonium bromide. The solid acid catalyst disclosed by the invention can be used for preparing 5-hydroxymethylfurfural.

Owner:UNIV OF SCI & TECH OF CHINA

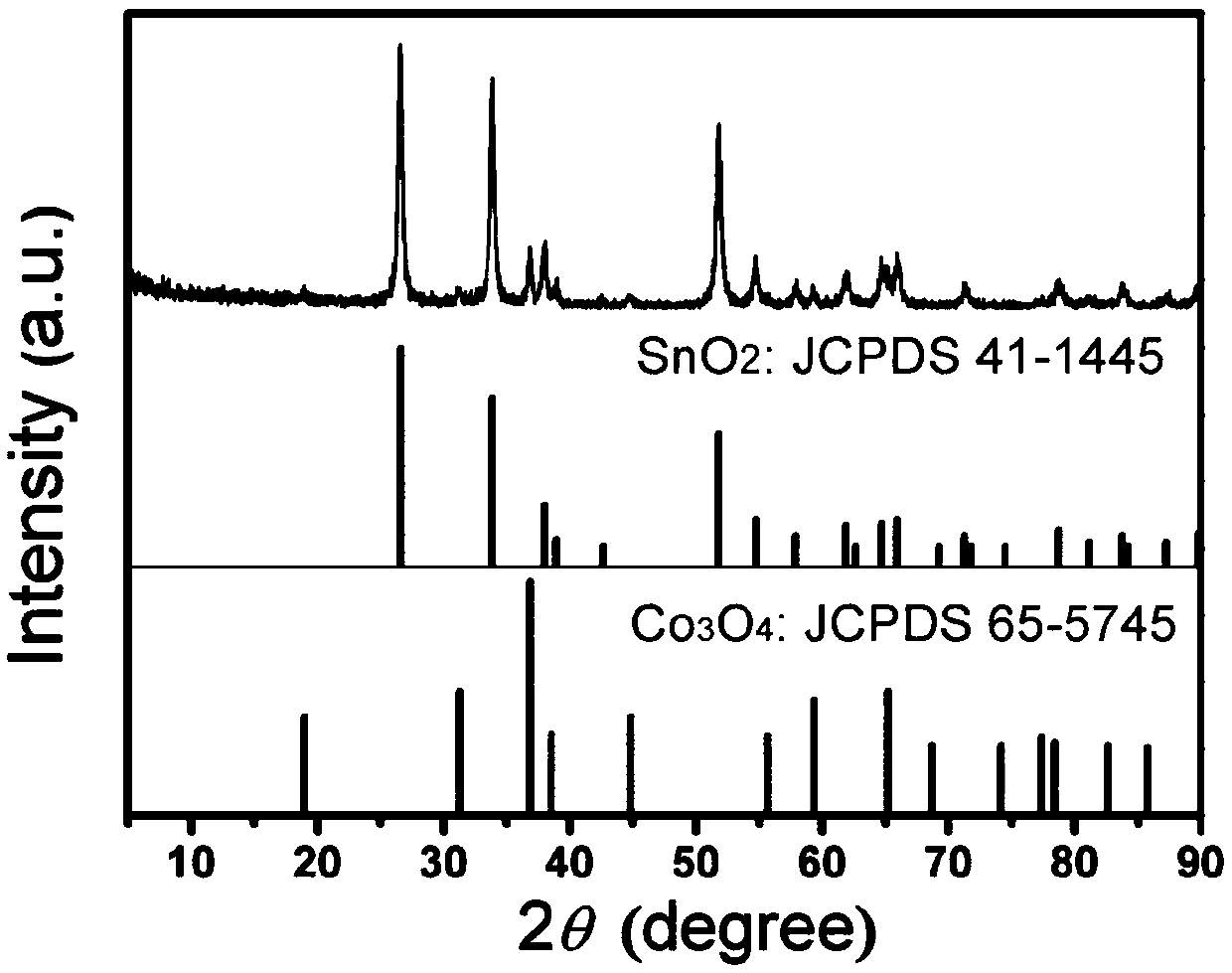

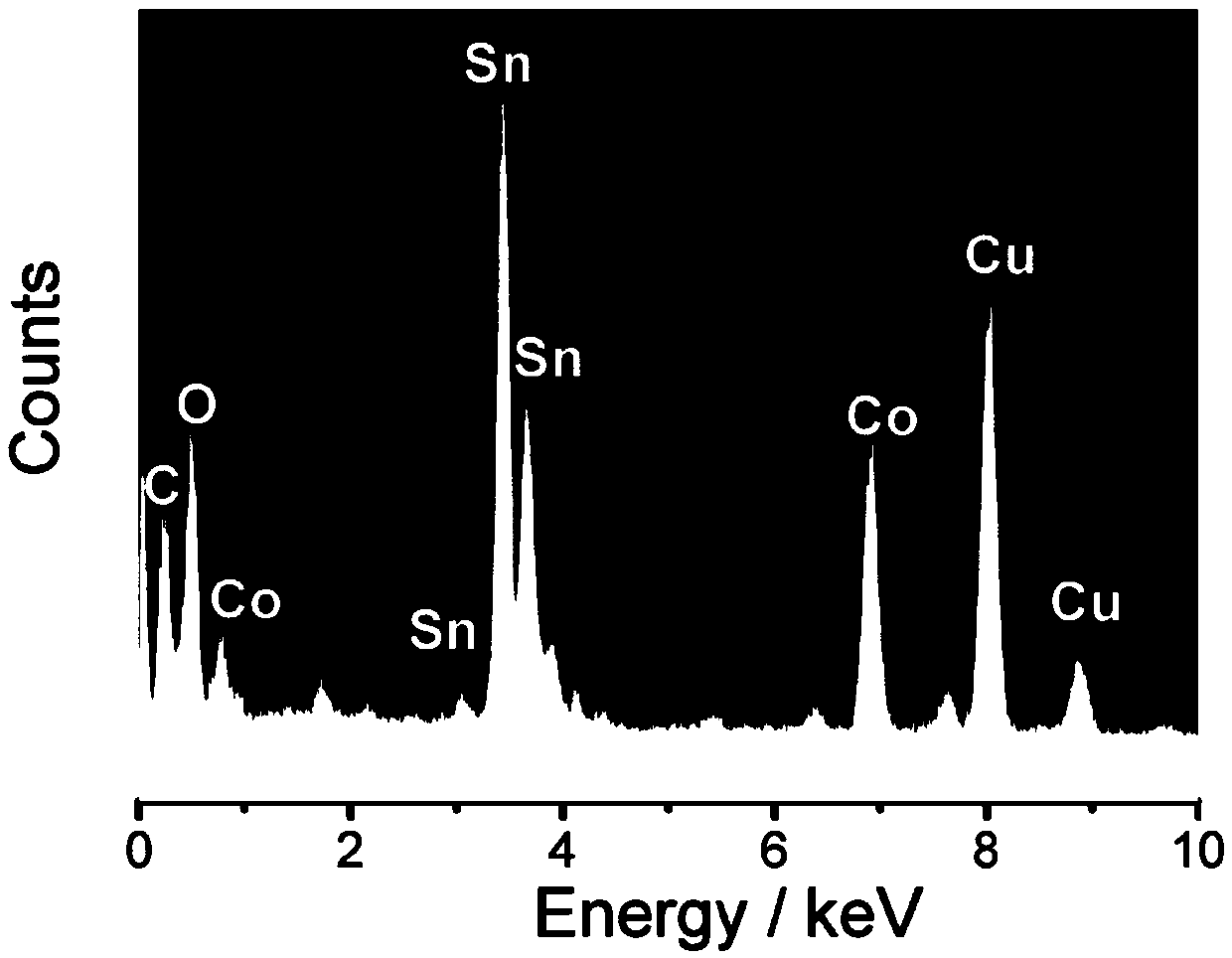

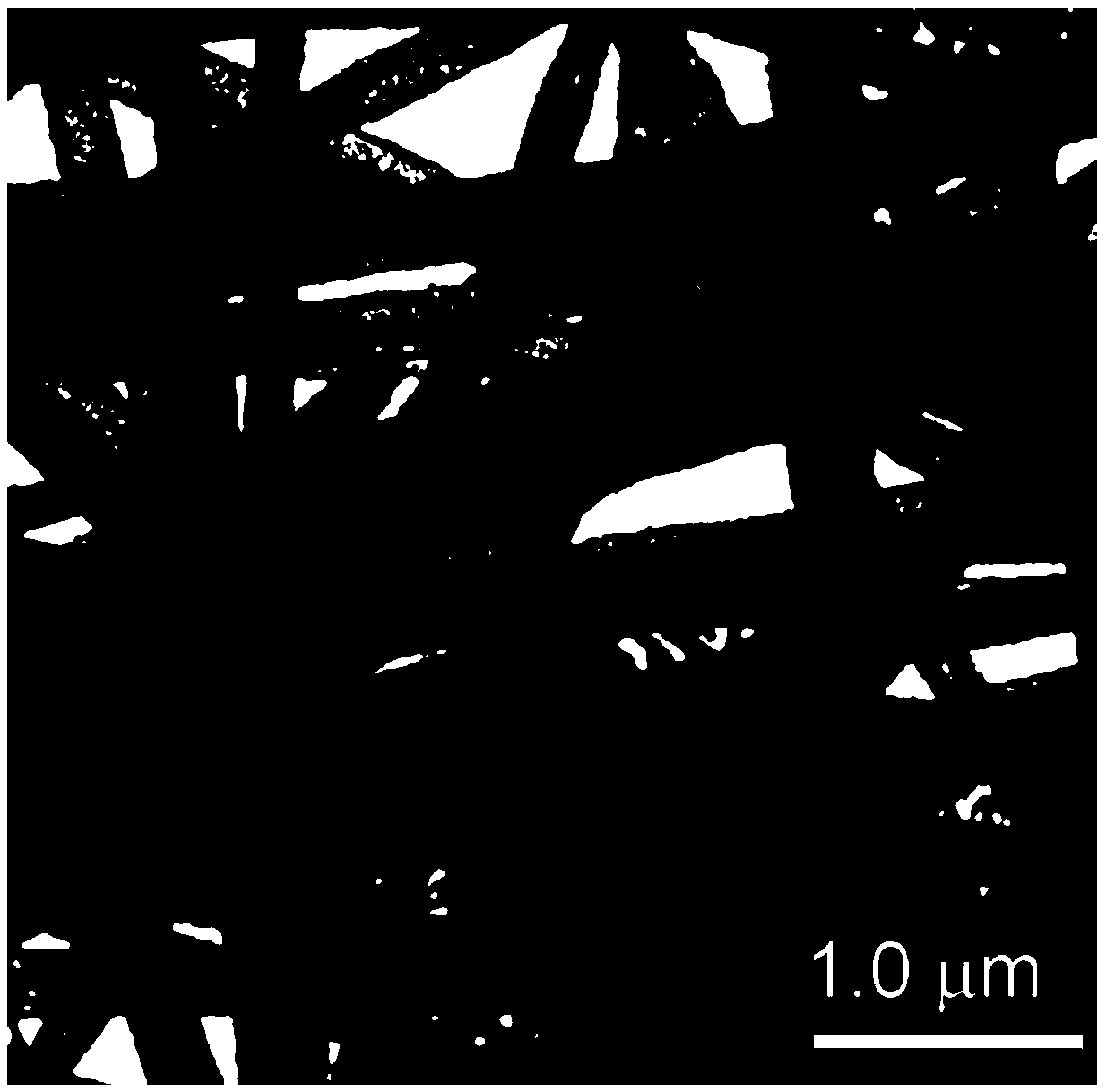

Hollow SnO2/Co3O4 hybrid nanotube as well as preparation method and application thereof

InactiveCN105514369AHigh specific capacityImprove stabilityMaterial nanotechnologyCell electrodesAir atmosphereSpinning

The invention discloses a hollow SnO2 / Co3O4 hybrid nanotube as well as a preparation method thereof. According to the method, an electrostatic spinning technique is adopted, a polymer is taken as a work medium, an organic solvent is taken as a dispersing agent, cobalt nitrate and tin tetrachloride are taken as precursors, polymer nanofibers containing uniformly distributed Co(II) and Sn(IV) are prepared, and then the hollow SnO2 / Co3O4 hybrid nanotube is prepared through sequential preoxidation and high-temperature calcination in an air atmosphere. Compared with preparation methods such as a template method, a coaxial electrostatic spinning method and the like, the method is simple and easy to implement and low in cost, the structure of the obtained hollow nanotube is controllable, and large-scale production can be realized. The hollow SnO2 / Co3O4 hybrid nanotube prepared with the method has the advantages of large specific surface area, multiple active sites, small density, high buffering capacity and the like; the hollow SnO2 / Co3O4 hybrid nanotube serving as a lithium ion battery anode material has excellent cycle performance and rate capability.

Owner:NANJING NORMAL UNIVERSITY

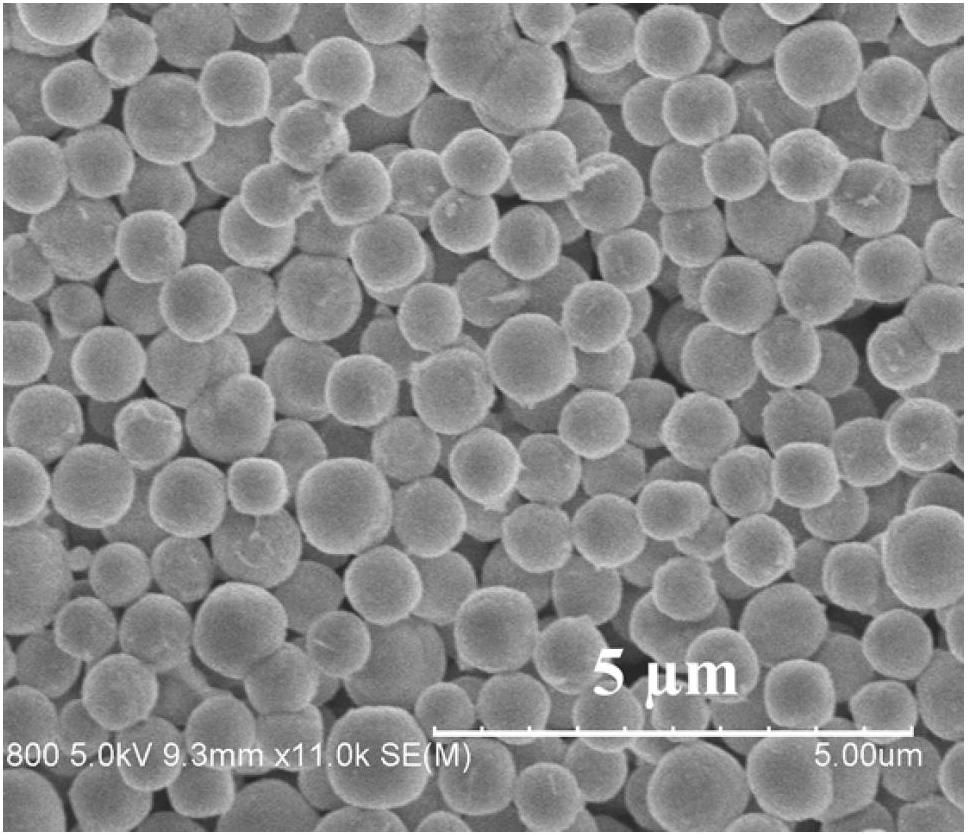

Preparation method of porous nickel oxide/tin dioxide micro/nano spheres

InactiveCN102680539AHigh purity powderPorous pore size distribution is uniformMaterial resistanceTin dioxideMicro nano

The invention discloses a preparation method of porous nickel oxide / tin dioxide micro / nano spheres, which comprises the following steps: stirring tin tetrachloride pentahydrate, nickel sulfate hexahydrate, sodium hydroxide and ammonia water which are used as raw materials, heating, separating, washing, drying and the like to obtain micro / nano spherical hydroxy nickel stannate; and roasting a micro / nano spherical NiSn(OH)6 precursor at high temperature, and cooling to respectively obtain porous micro / nano spherical NiO / SnO2 powder. The micro / nano spherical NiO / SnO2 product prepared by the method disclosed by the invention is light green powder, and has the advantages of large specific area and good product quality. The impedance gas sensing element prepared from the micro / nano spherical NiO / SnO2 powder has high sensitivity, and the sensitivity S value for 100ppm methylbenzene and formaldehyde gases is respectively up to 19.8 and 27.6.

Owner:ANHUI NORMAL UNIV

Manufacturing method of electrothermal film

ActiveCN104080208AImprove stabilityImprove temperature resistanceHeating element materialsNickel sesquioxideManganese

The invention discloses a manufacturing method of an electrothermal film. The manufacturing method comprises the following steps of A, preparing an electrothermal film treatment solution which comprises tin tetrachloride, titanium trichloride, antimony trichloride, calcium chloride, chromic oxide, manganese dioxide, nickel sesquioxide, isopropanol, alcohol and water, B, masking a substrate, C, heating the substrate to be 400-700 DEG C and then spraying the electrothermal film treatment solution on the substrate by a spray gun to form a semifinished electrothermal film, D, annealing the semifinished electrothermal film, and E, coating silver oxide paste on the surfaces of the two ends of the annealed semifinished electrothermal film, loading the semifinished electrothermal film into an electrode oven, baking and fusing the semifinished electrothermal film to form a whole, and obtaining the finished electrothermal film. The manufacturing method has the advantages that the stability of the electrothermal film is improved by adding antimony; the temperature resistance of the electrothermal film is improved by adding titanium; the infrared emitting ability of the electrothermal film is improved by adding nickel and manganese; and an adhesive force between the electrothermal film treatment solution and the substrate is increased by adding isopropanol.

Owner:成都世纪经尧科技有限公司

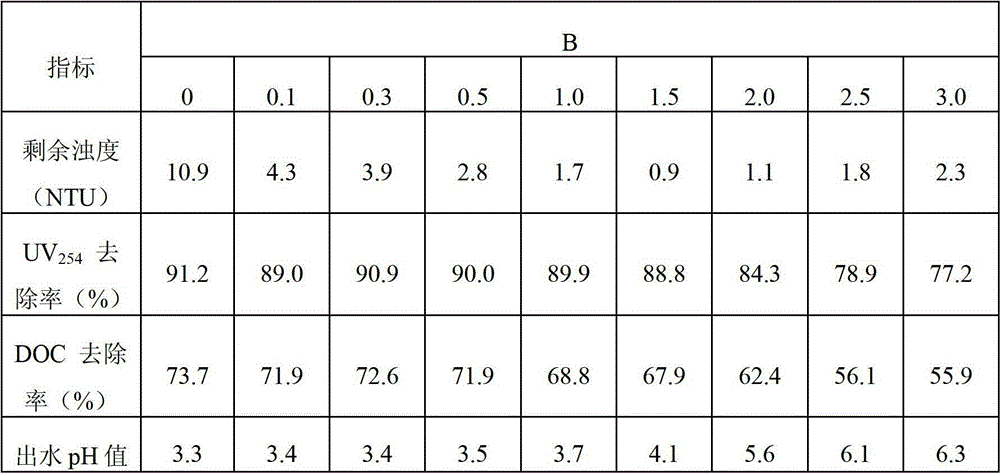

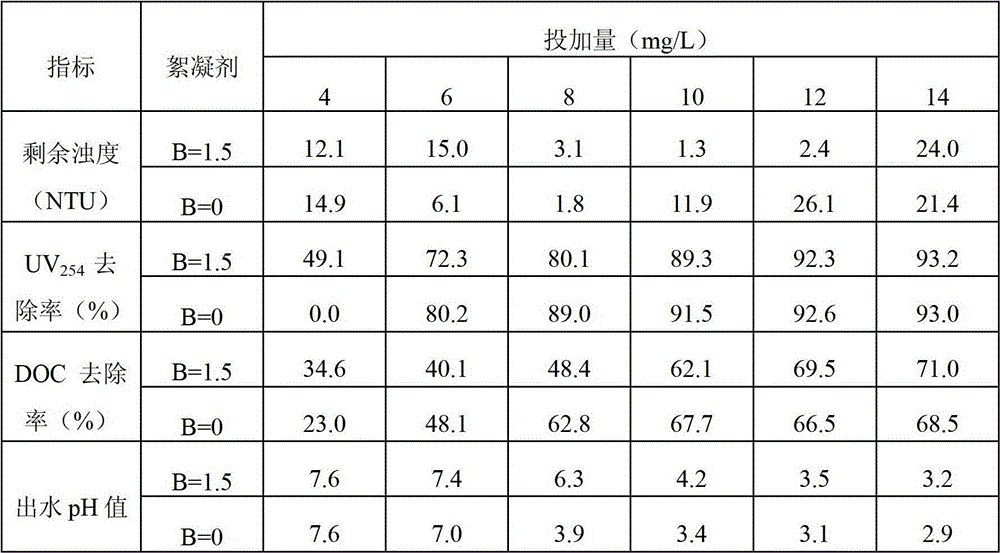

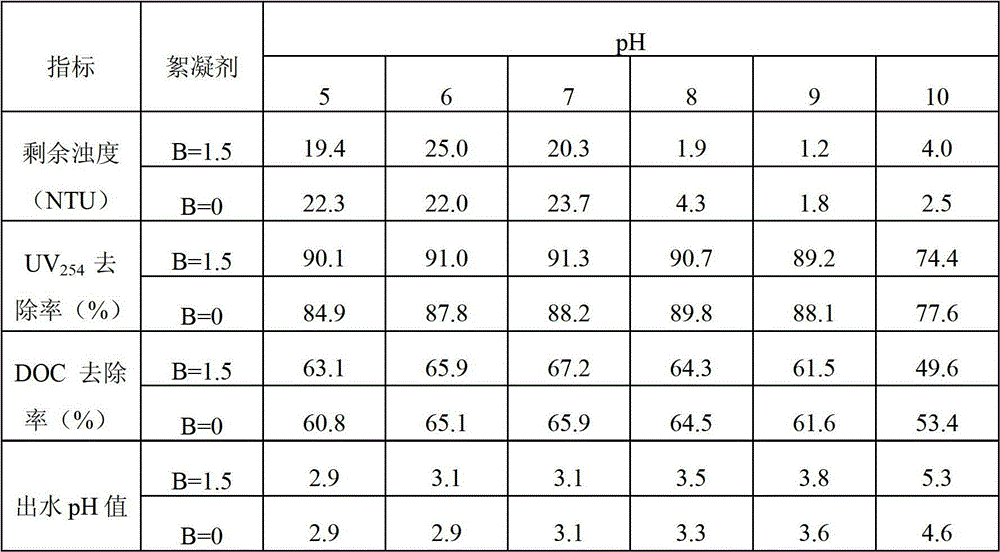

Polymerized titanium tetrachloride inorganic polymeric flocculant and preparation method of inorganic polymeric flocculant

ActiveCN102976462AGood flocculation effectSimple production processWater/sewage treatment by flocculation/precipitationChemical industrySludge

The invention relates to a preparation method of a polymerized titanium tetrachloride inorganic polymeric flocculant. The preparation method comprises the following steps: by using a titanium tetrachloride solution and sodium hydroxide as raw materials, adding sodium hydroxide into the titanium tetrachloride solution, wherein the alkalization degree is equal to 1.5-2, and the dropwise adding process of a sodium oxide solution is finished within 10-60 minutes; and then, further stirring for 1.5-5 hours until the solution becomes a colorless transparent liquid. The flocculant has the advantages of good product stability, strong colloidal substance adsorbing and bridging capabilities, good flocculation effect, wide application range, low sludge productivity and the like, can be widely applied to the fields of water supply, wastewater treatment, papermaking, textile dyeing and printing, daily chemical industry and the like and has a favorable water treatment effect. The method provided by the invention has the characteristics of simple and rapid process, economy, rapidness and the like.

Owner:SHANDONG UNIV

Method for preparing titanium dioxide/silicate mineral nano composites

ActiveCN102580713AIncrease the areaImprove adsorption capacityPhysical/chemical process catalystsWater/sewage treatment by irradiationNano compositesDissolution

The invention relates to a method for preparing titanium dioxide / silicate mineral nano composites. The method comprises the following steps of: firstly, adding silicate minerals to a titanium tetrachloride solution to activate the silicate minerals and dissolve foreign ions; secondly, adding a certain alkaline solution to convert titanium ions to titanium dioxide hydrate precipitates and washing off other foreign ions to obtain titanium dioxide hydrate / silicate mineral complex filter cakes; and thirdly, adding the filter cakes to the titanium tetrachloride solution, adopting the acid environment of the titanium tetrachloride solution to realize dissolution of the titanium dioxide hydrates, secondary activation of the silicate minerals and low temperature crystallization and growth of nanotitanium dioxide on the silicate minerals and carrying out filtering, washing, drying and grinding, thus finally preparing the titanium dioxide / silicate mineral nano composites. The method has the following advantages that the method is simple and practical in steps; the reaction conditions are mild; the raw materials are simple and have low cost; and the method is suitable for large-scale production and can be beneficial to effective improvement of the photocatalytic efficiency of titanium dioxide.

Owner:CHANGZHOU UNIV

Production of biological diesel oil by high-acid value grease

InactiveCN101074390AIncrease production speedHigh yieldFatty acid esterificationBiofuelsOil and greaseTetrachloride

Production of biological diesel-oil by peanut-oil offal and waste edible oil etc. high-acidity grease is carried out by pre- esterification reacting liquefied catalyst tin tetrachloride with free fatty acid from waste grease to decrease acidity, centrifugal removing catalyst and glycerol, trans-esterifying for residual grease by KOH to generate biological diesel-oil. It's convenient and efficient, has gentle reactive condition and better quality.

Owner:SHANDONG PEANUT RES INST

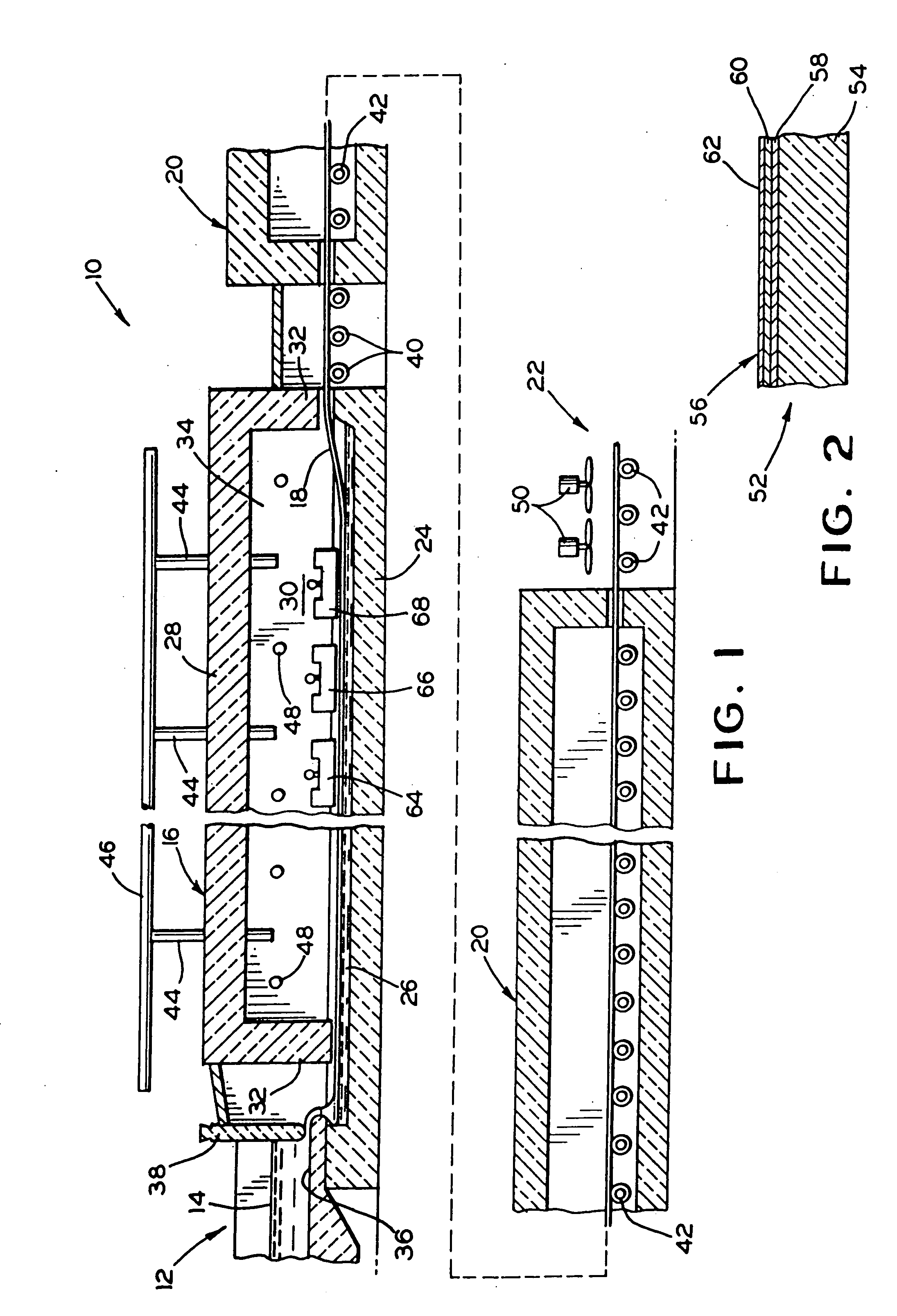

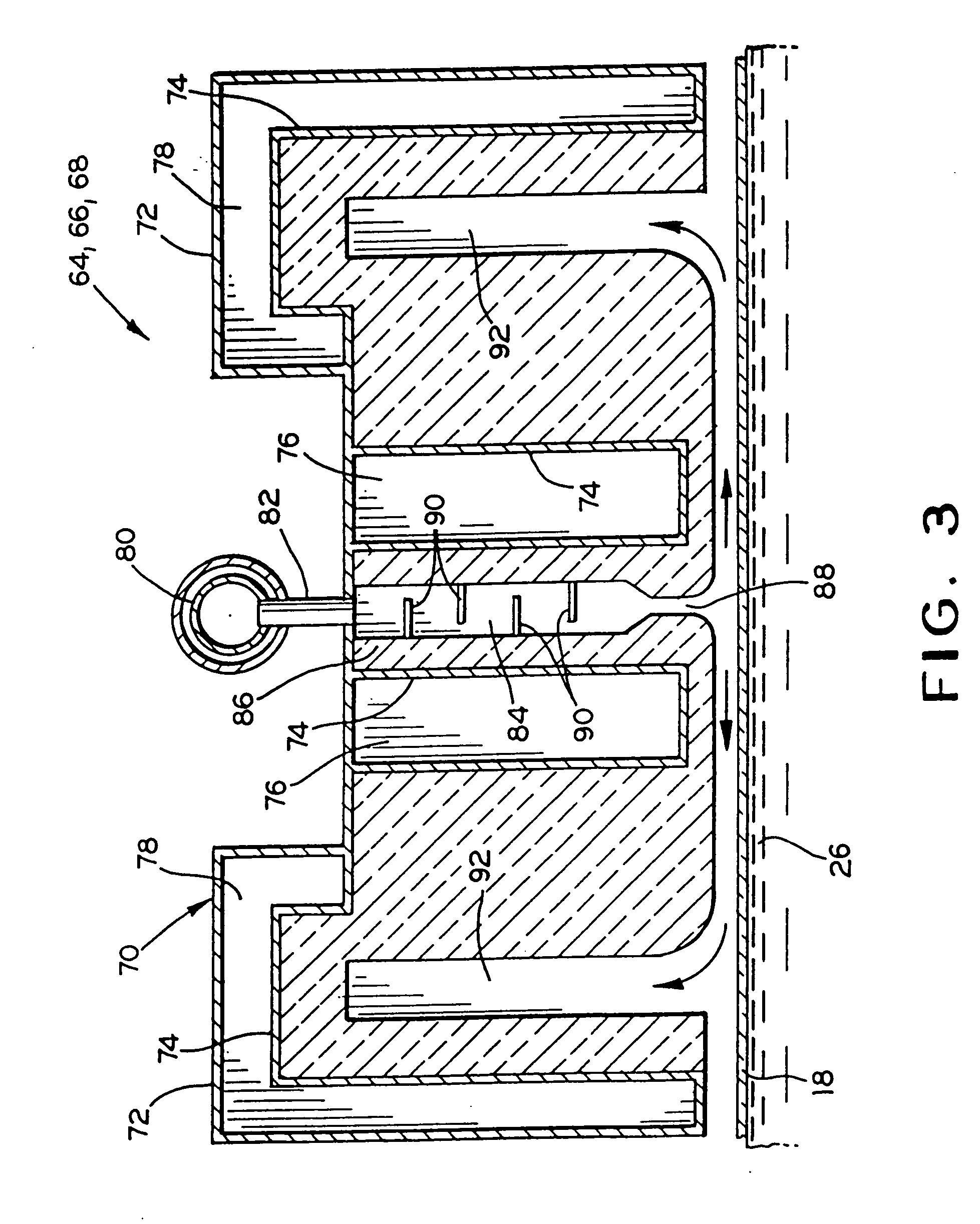

Method for depositing tin oxide and titanium oxide coatings on flat glass and the resulting coated glass

InactiveUS20060228476A1High mechanical strengthModify characteristicChemical vapor deposition coatingGas phaseRefractive index

A chemical vapor deposition process for laying down a tin or titanium oxide coating on a glass substrate through the use of an organic oxygen-containing compound and the corresponding metal tetrachloride. The organic oxygen compound is preferably an ester having an alkyl group with a β hydrogen in order to obtain a high deposition rate. The resulting article has a tin or titanium oxide coating which can be of substantial thickness because of the high deposition rates attainable with the novel process, and, in the case of titanium oxide coating possesses a desirable refractive index greater than 2.4. The coating growth rates resulting from the method of the present invention may be at least 130 Å per second.

Owner:PILKINGTON GROUP LTD

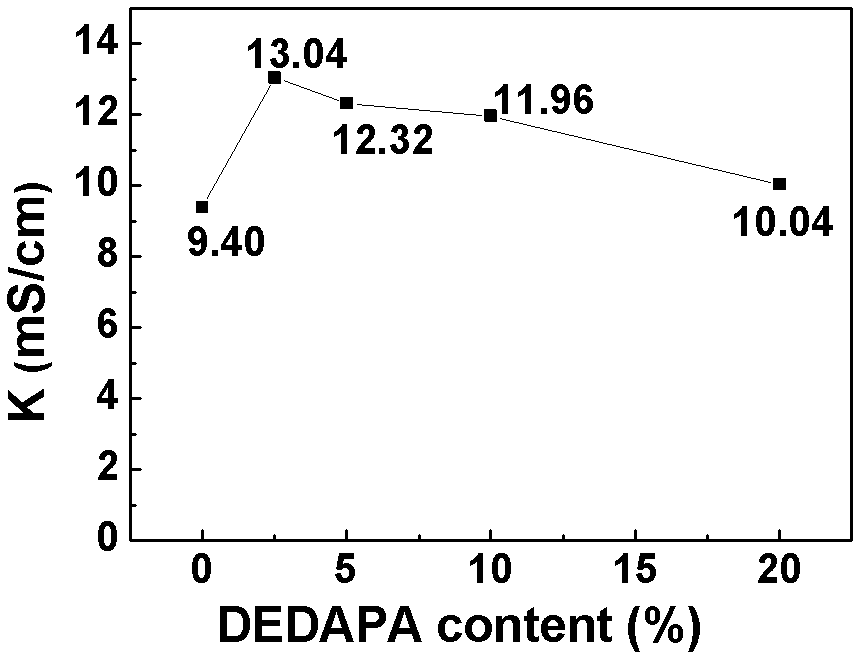

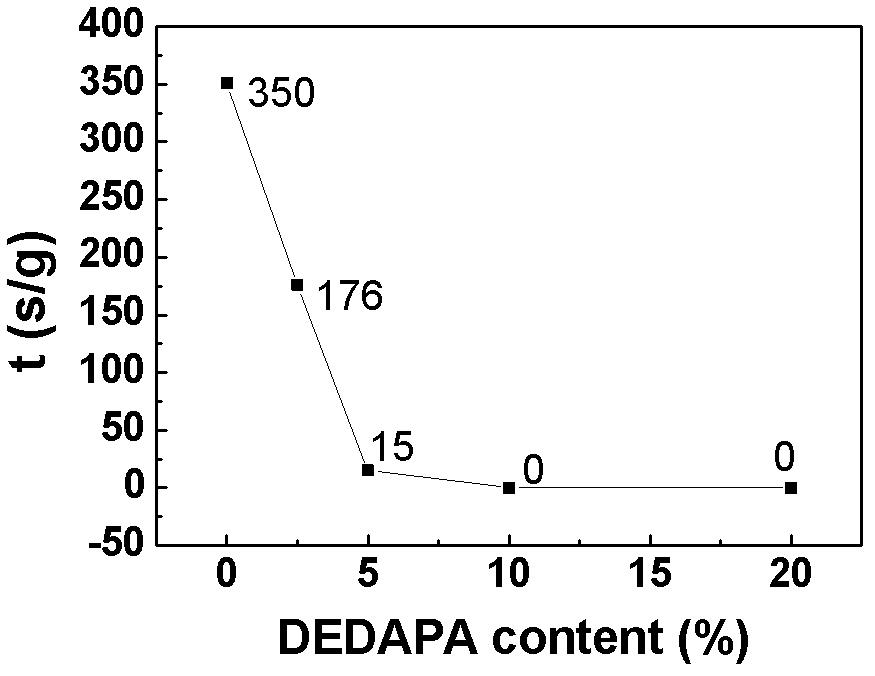

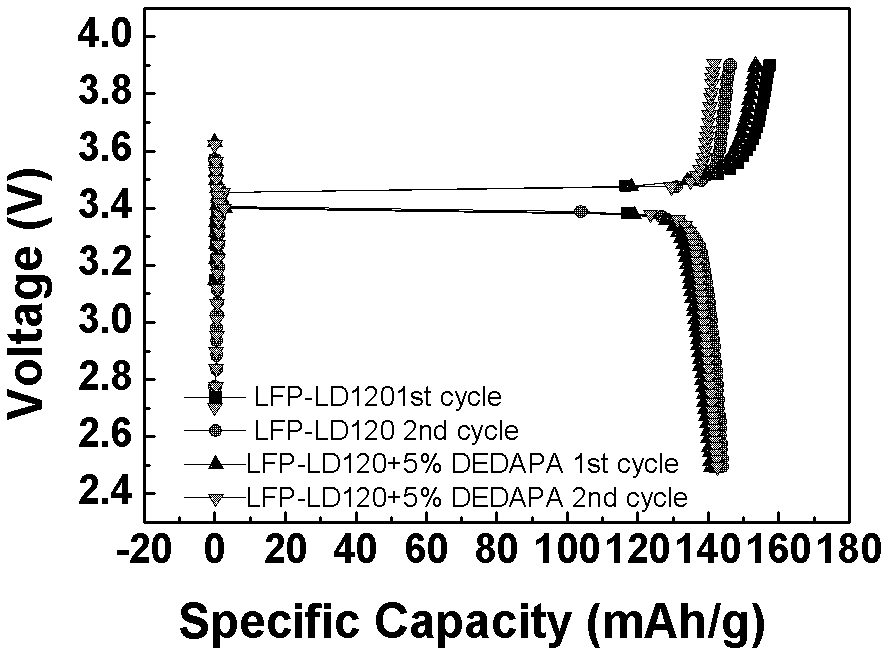

Flame-retardant lithium ion battery electrolyte and method for preparing same

The invention discloses a flame-retardant lithium ion battery electrolyte and a method for preparing the same and relates to a battery electrolyte. The electrolyte has the characteristic of flame retardance and complete non-combustion and is well compatible with an electrode material, and the wettability of a diaphragm can be improved. The flame-retardant lithium ion battery electrolyte comprises 5 to 20 percent of lithium salt, 60 to 90 percent of solvent and 1 to 20 percent of alkenyl phosphamide. The method comprises the following steps of: reacting dialkoxyl phosphoryl chloride and alkenyl-containing secondary amine, or hydro-diphosphite, the alkenyl-containing secondary amine, carbon tetrachloride and alkali, which are taken as raw materials, in an organic solvent to obtain an alkenyl phosphamide compound; and preparing the alkenyl phosphamide compound, the lithium salt and the solvent to obtain the flame-retardant lithium ion battery electrolyte.

Owner:XIAMEN UNIV

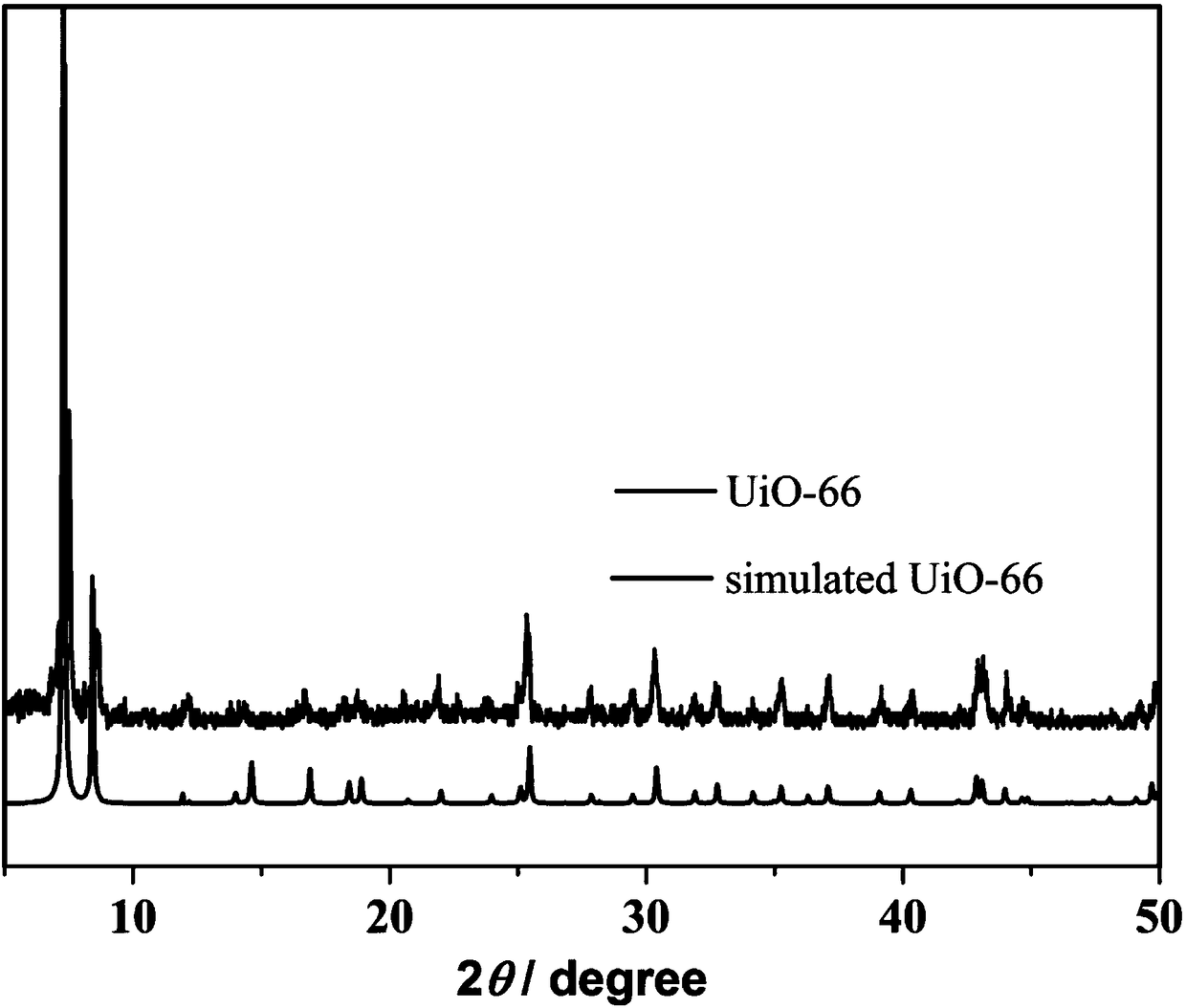

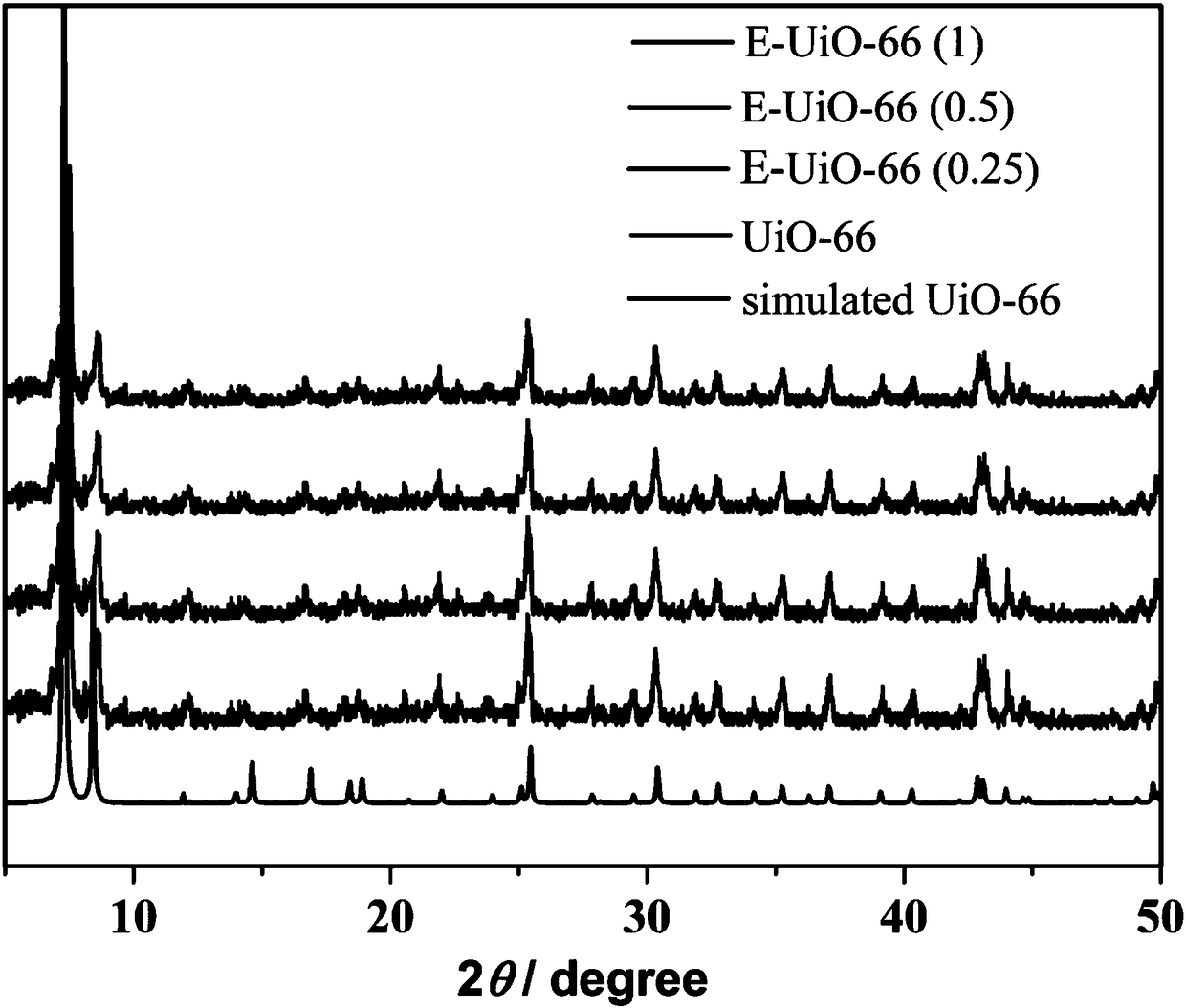

Pore-diameter extension method for UiO-66 metal organic framework material and application

ActiveCN108084453AEasy to makeEasy to operateOther chemical processesWater contaminantsOrganic dyeMetal-organic framework

The invention discloses a pore-diameter expanding method for a UiO-66 metal organic framework material. The pore-diameter expanding method comprises the following steps of: taking and mixing 2.47 parts by weight of zirconium tetrachloride, 1.47 parts by weight of terephthalic acid and 95 parts by weight of N, N-dimethyl formamide in a single-opening flask to carry out ultrasonic dissolving; putting in a microwave oven, condensing and refluxing for 15 minutes, and carrying out centrifugal separation; using alcohol and N, N-dimethyl formamide to wash a solid product, taking 1 part by weight of solid product, adding the solid product into 20 parts by weight N, N-dimethyl formamide solution with the concentration of dilute sulfuric acid being 0.25-1mol / L, stirring for 24 hours, then carrying out centrifugal separation, using N, N-dimethyl formamide and alcohol to wash, then drying in an environment with the temperature of 60-150 DEG C, then putting into a Soxhlet extractor, adopting acetone as a solvent to wash till siphoning for three times, after washing, drying for 6 hours in an environment with the temperature of 80 DEG C, and obtaining a mesoporous UiO-66 metal organic framework material. The UiO-66 metal organic framework material can be used as an absorbent to be applied to treatment of organic dyestuff wastewater.

Owner:BENGBU COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com