Patents

Literature

241 results about "CHROMIC NITRATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium(III) nitrate describes several inorganic compounds consisting of chromium, nitrate and varying amounts of water. Most common is the dark violet hydrated solid, but an anhydrous green form is also known.

Sponge composite metallic organic framework material for adsorption separation

ActiveCN110038540AStrong loadHigh load rateGas treatmentOther chemical processesFragilityMetal-organic framework

The invention relates to a sponge composite metallic organic framework material for adsorption separation and belongs to the technical field of materials. According to the invention, a two-step in-situ growth method is adopted for loading MOFs (metallic organic framework material) into a duct in a sponge carrier. The MOFs is synthesized from following organic ligands and metal salts, wherein the organic ligands include pyrazine, trimesic acid, terephthalic acid, 2,5-dihydroxyterephthalic acid, and the metal salts include cupric fluosilicate, magnesium nitrate, zirconium chloride, cupric nitrate, chromic nitrate, ferric nitrate, aluminum nitrate and hydrates thereof. According to a preparation method provided by the invention, a large amount of MOFs loaded in the duct in the sponge carriercan be realized; MOFs load rate is high; load is stable; the defects of fragility and easiness in loss of MOFs powder can be overcome; a breakthrough experiment proves that the material provided by the invention has the characteristics of high CO2-absorbing capacity, high adsorption separation selectivity, stable adsorption separation property, and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method and application of solid acid catalyst

InactiveCN102814189AEfficient conversionHigh selectivityOrganic chemistryMolecular sieve catalystsTetramethylammonium hydroxideSolid acid

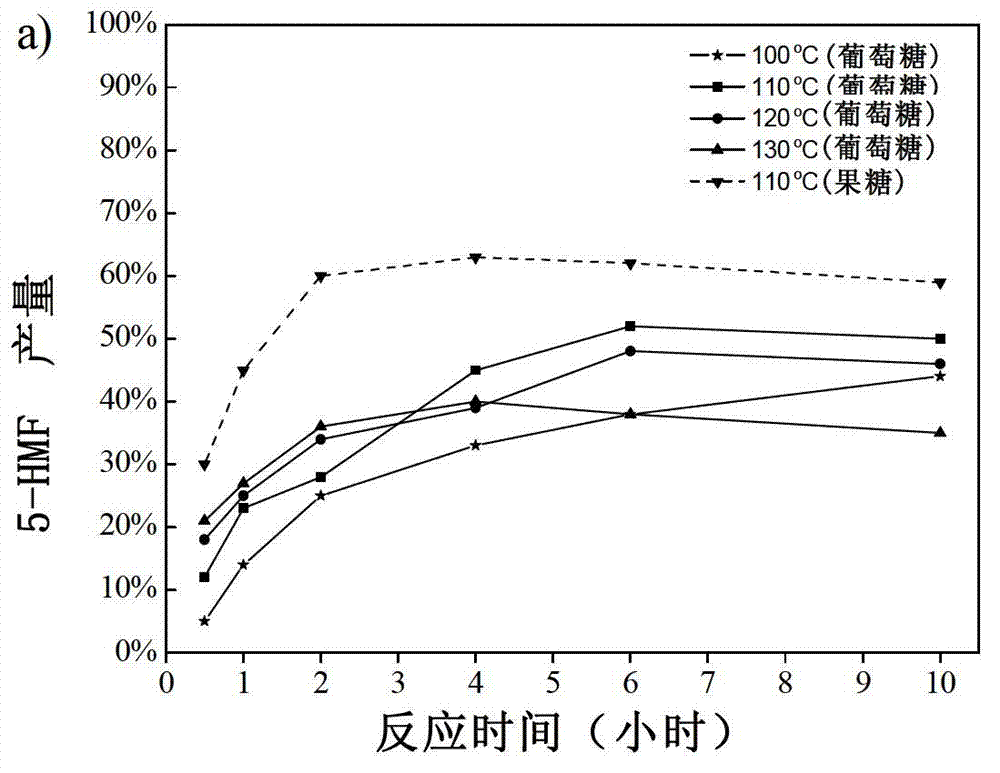

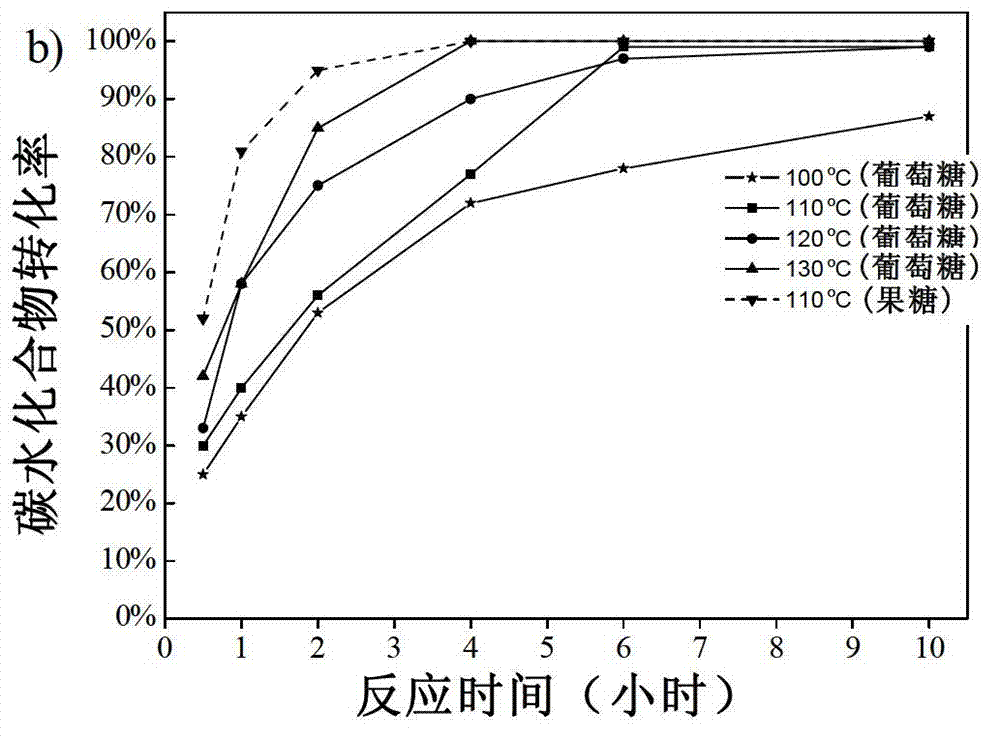

The invention discloses a preparation method and application of a solid acid catalyst. The preparation method of the solid acid catalyst comprises the following steps: (1) mixing a silicon source, an alkali source, a metallic compound and a template, and carrying out hydrothermal reaction to obtain a reaction product 1; (2) filtering the reaction product 1 to obtain a solid, and drying at 60-120 DEG C for 12-36 hours to obtain a reaction product 2; and (3) calcining the reaction product 2 at 500-600 DEG C for 3-10 hours to obtain the solid acid catalyst. The silicon source is selected from hydrophilic nano silicon oxide, sodium silicate and tetraethyl orthosilicate; the alkali source is selected from tetramethylammonium hydroxide, alkali metal hydroxide and ammonia water; the metallic compound is selected from tin tetrachloride, zirconium sulfate, sodium silicate, chromic nitrate, nickel nitrate and tetrabutyl titanate; and the template is cetyl trimethyl ammonium bromide. The solid acid catalyst disclosed by the invention can be used for preparing 5-hydroxymethylfurfural.

Owner:UNIV OF SCI & TECH OF CHINA

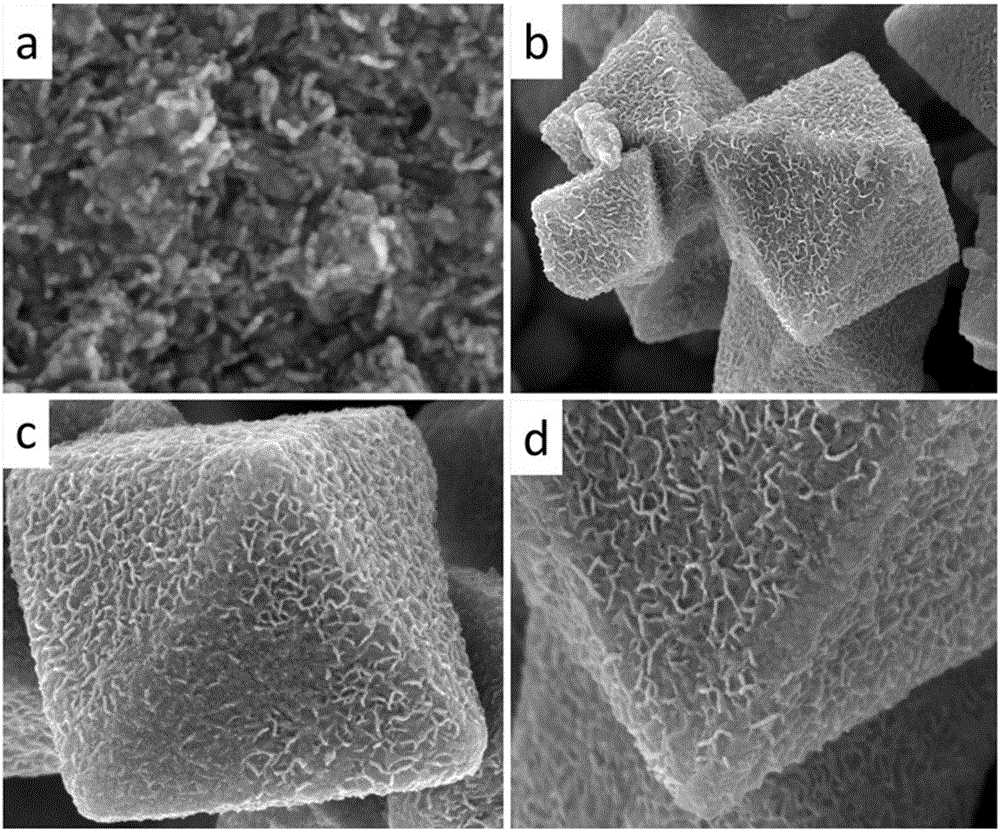

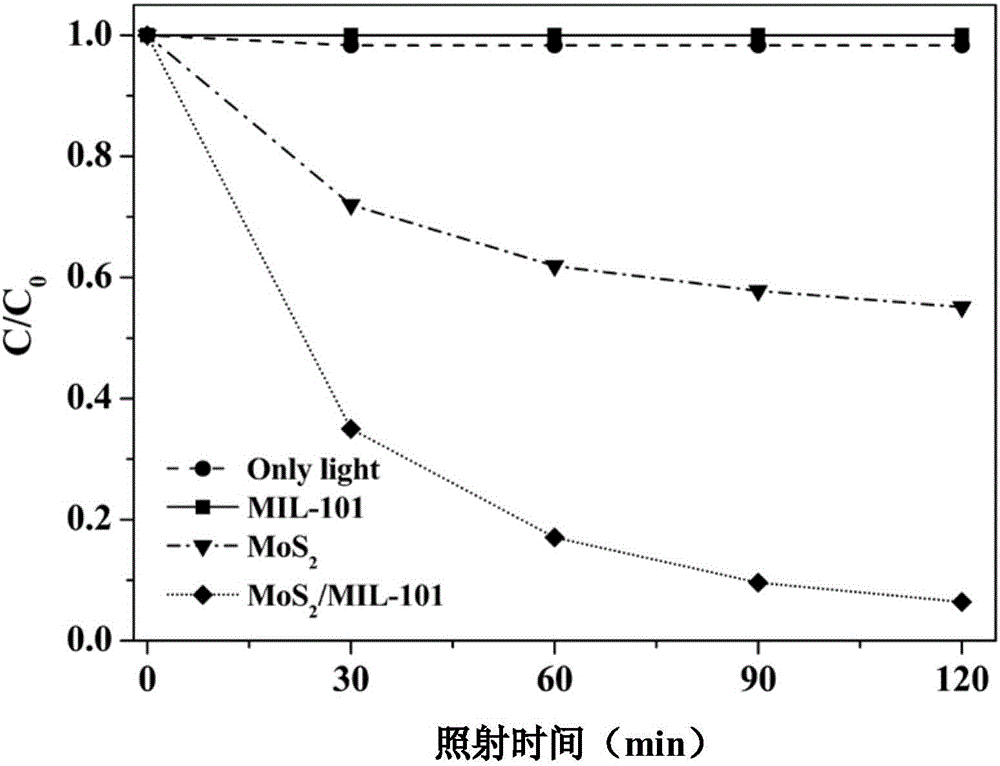

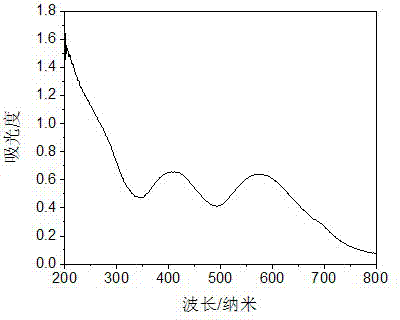

Molybdenum disulfide/MIL-101 composite photocatalyst material as well as preparation method and application thereof

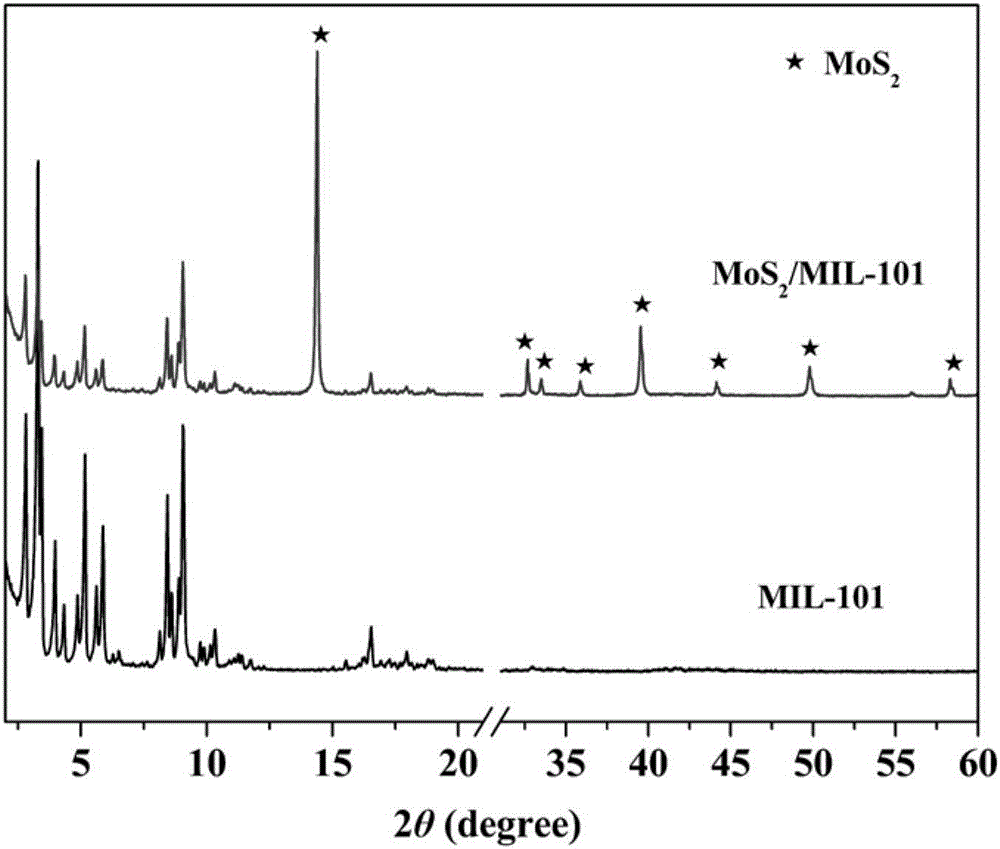

ActiveCN106582880AExcellent composite photocatalytic performanceEfficient degradation treatmentWater/sewage treatment by irradiationWater treatment compoundsActive edgeHydrofluoric acid

The invention belongs to the technical field of photocatalyst materials and discloses a molybdenum disulfide / MIL-101 composite photocatalyst material, a preparation method thereof and application in the field of antibiotic wastewater degradation treatment, in particular application in the field of degradation of antibiotic wastewater containing ciprofloxacin. The preparation method comprises the following steps: dissolving chromic nitrate, terephthalic acid and hydrofluoric acid into water, uniformly stirring, heating and reacting to obtain MIL-101; dissolving sodium molybdate and thioacetamide into water, uniformly stirring, then adding the MIL-101 obtained in the step (1), uniformly stirring, heating and reacting to obtain the MoS2 / MIL-101 composite photocatalyst material. The photocatalyst material disclosed by the invention contains highly dispersed MoS2 nanosheets and more exposed MoS2 active edges, has excellent composite photocatalytic performance and can be applied to antibiotic wastewater degradation treatment, especially realization of efficient degradation treatment on the antibiotic wastewater containing ciprofloxacin.

Owner:华工同创(东莞)环保技术有限公司

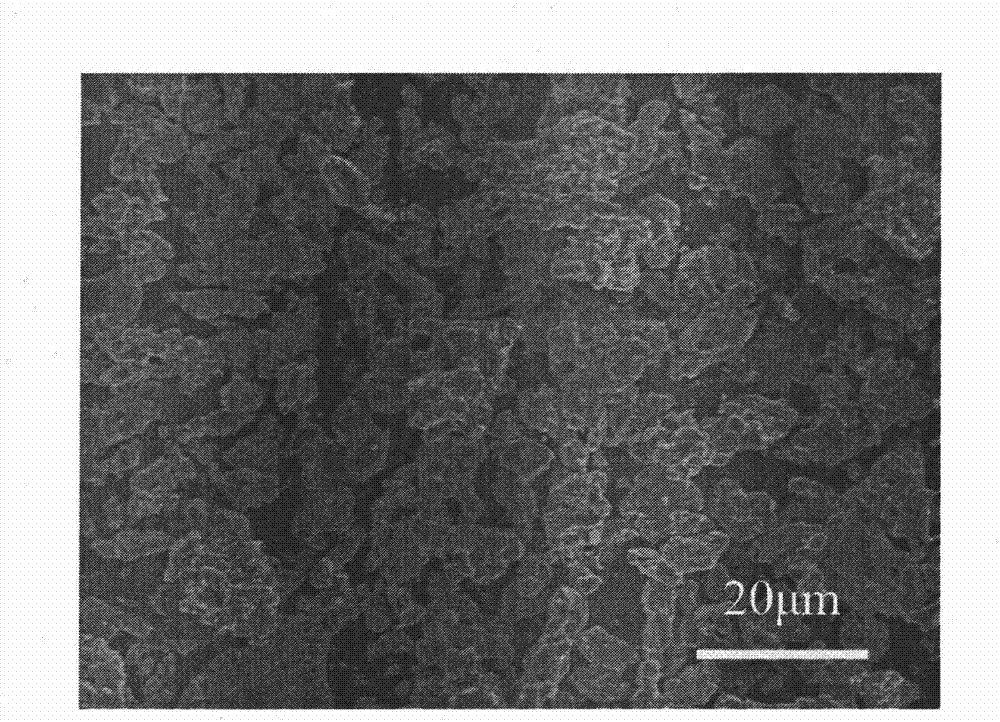

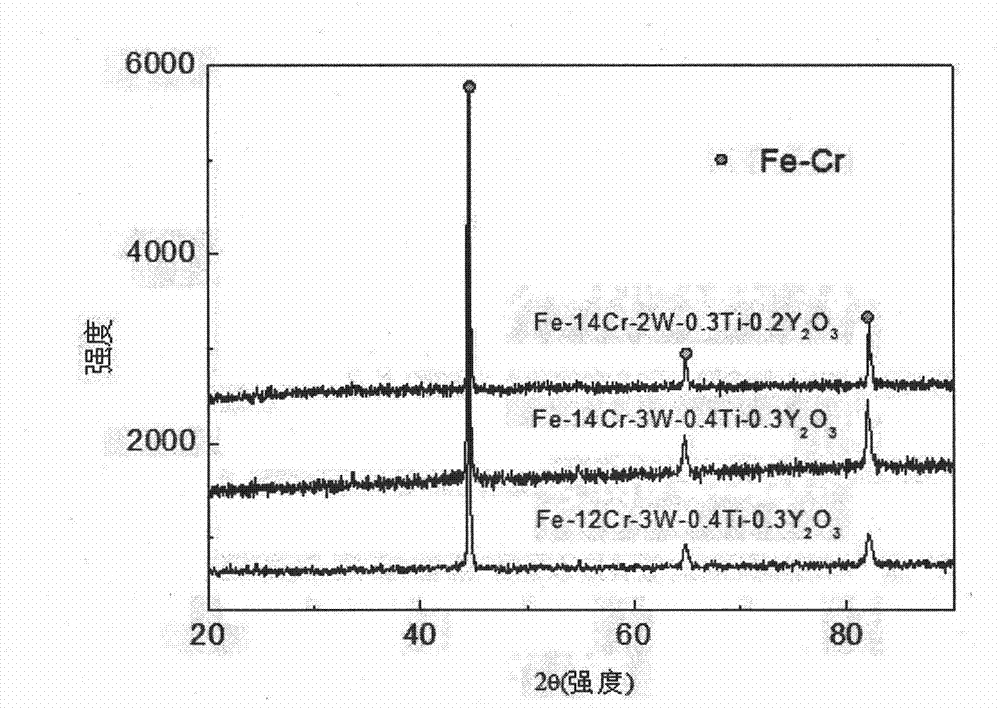

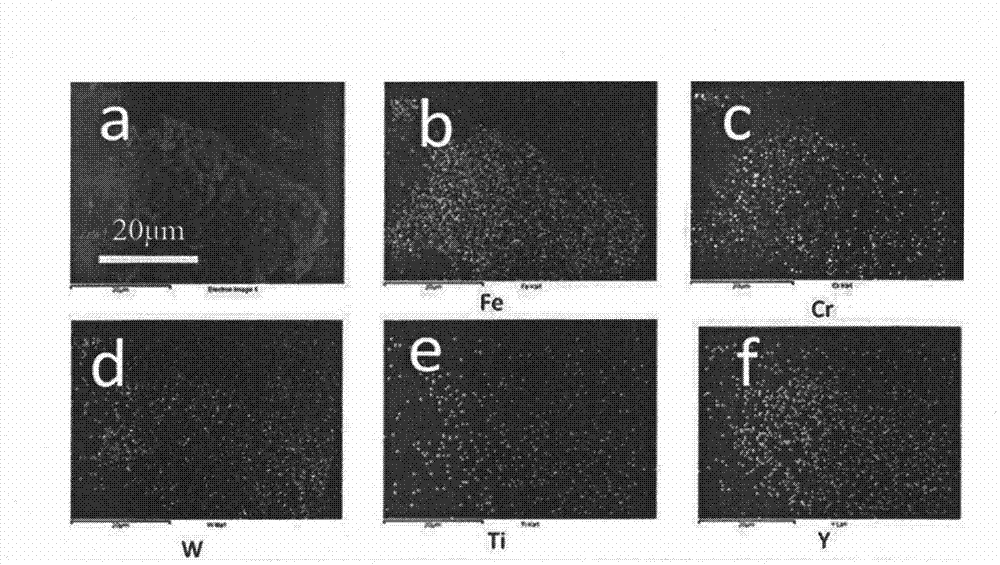

Method for preparing dispersion strengthening ferritic alloy steel powder of nanometer yttrium oxide particles

InactiveCN102814503AHigh purityEnergy-saving preparation methodMaterial nanotechnologyEthylenediamineAmmonium paratungstate

The invention discloses a method for preparing dispersion strengthening ferritic alloy steel powder of nanometer yttrium oxide particles. The method includes adding ethylene diamine tetraacetic acid and chromic nitrate into water, stirring the mixture at a temperature in a range from 50 DEG C to 60 DEG C for at least 12 hours, and obtaining a mixed liquid; adding citric acid, ferric nitrate, ammonium paratungstate, yttrium nitrate and tetrabutyl titanate into the mixed liquid, mixing the mixture at a temperature in a range in a range from 60 DEG C to 70 DEG C for at least 3 hours, and obtaining colloidal sol; adding polyethylene glycol into the colloidal sol, stirring the mixture at a temperature in a range in a range from 70 DEG C to 80 DEG C to form gel; and finally drying the gel at a temperature in a range from 100 DEG C to 120 DEG C for at least 12 hours and roasting the gel at a temperature in a range from 300 DEG C to 600 DEG C for 4 to 5 hours in sequence to obtain precursor oxide powder, placing the gel in a reducing atmosphere, roasting the gel at a temperature in a range from 1100 DEG C to 1300 DEG C for at least 3 hours to obtain object products which comprise, by weight, 12% to 14% of chromium, 2% to 3% of tungsten, 0.2% to 0.5% of titanium, 0.1% to 1% of yttrium oxide, and the balance iron. Yttrium oxide is evenly dispersed and distributed on matrixes composed of chromium, tungsten, titanium and iron, and the products can be used in fast breeder reactors and fusion reactors.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

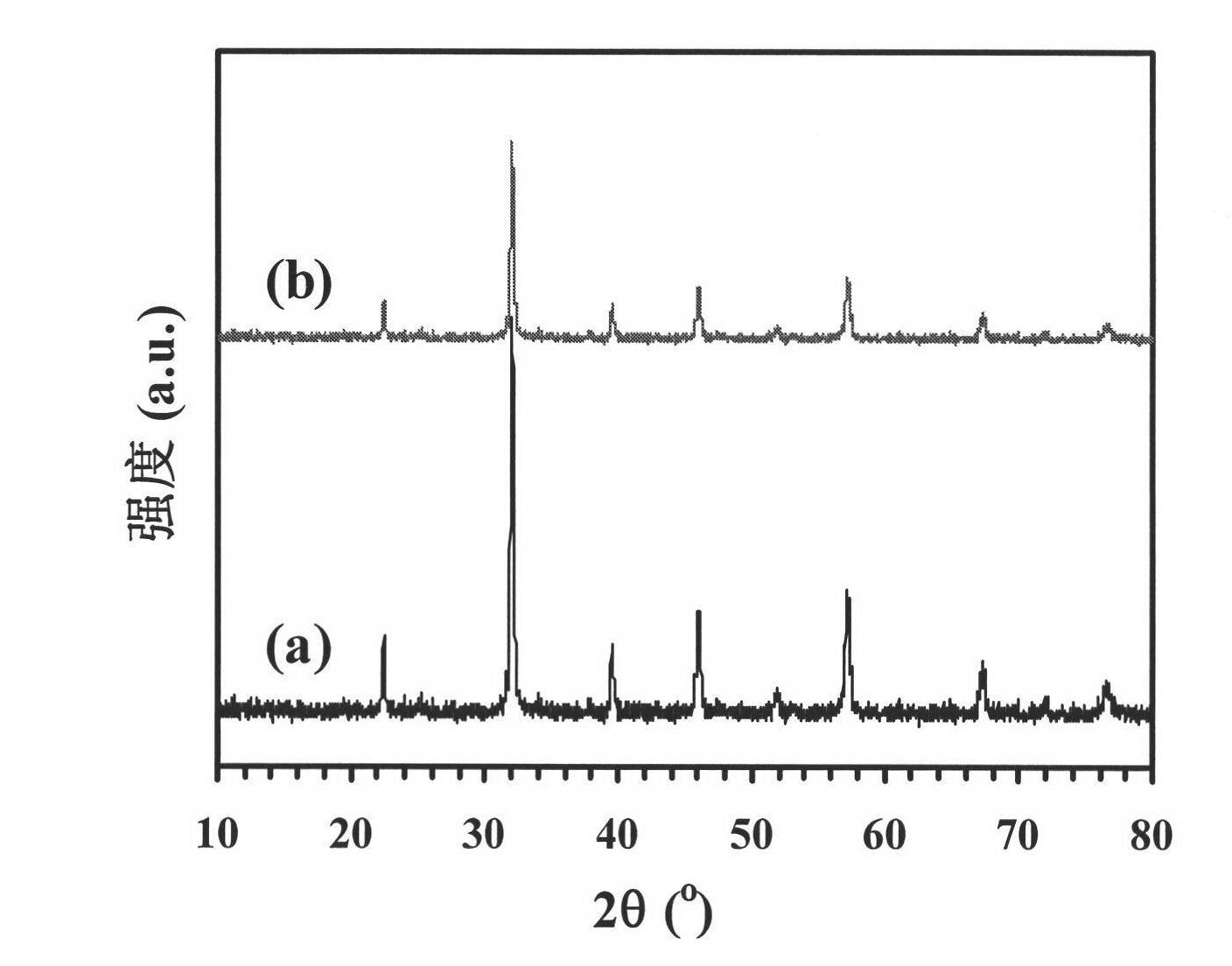

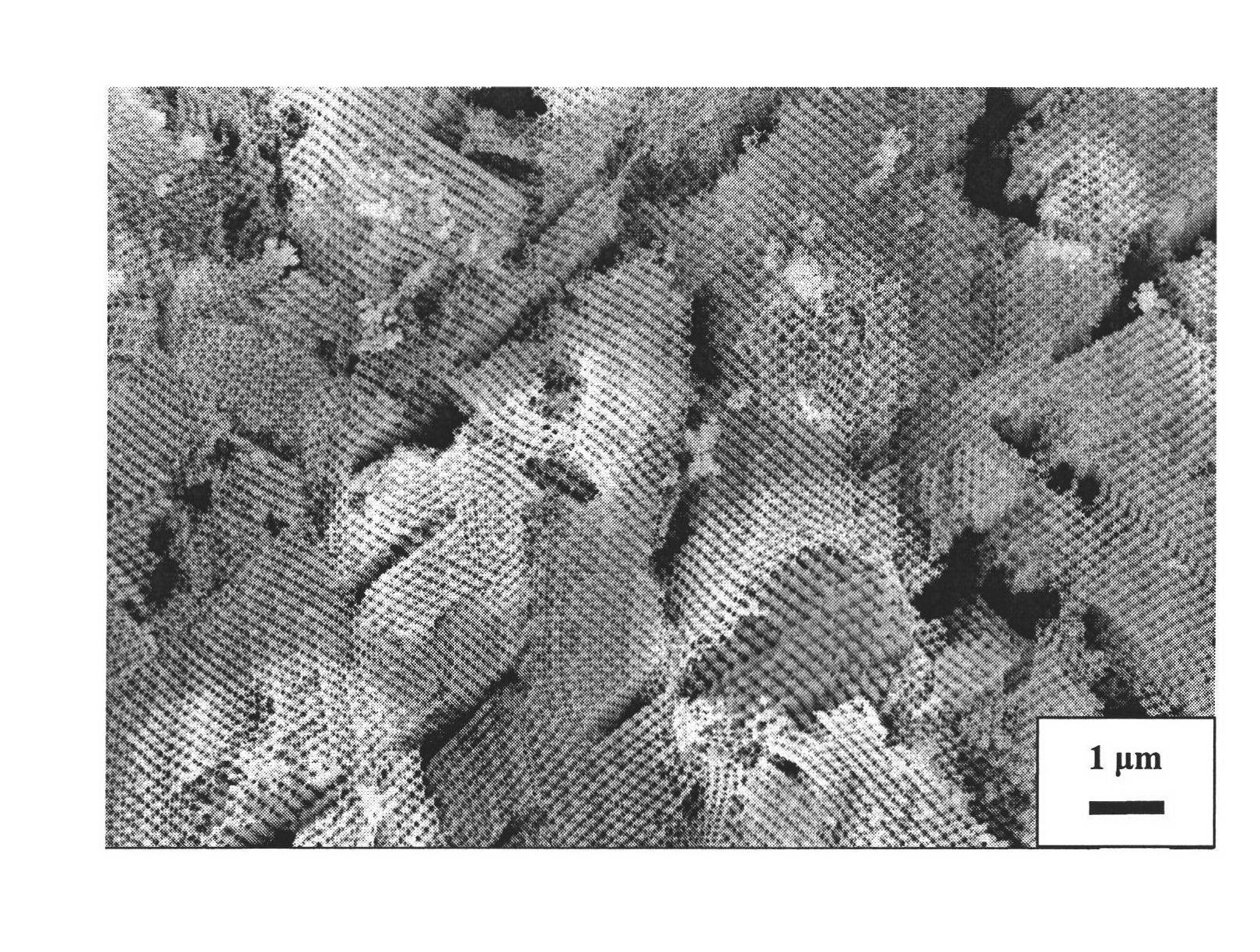

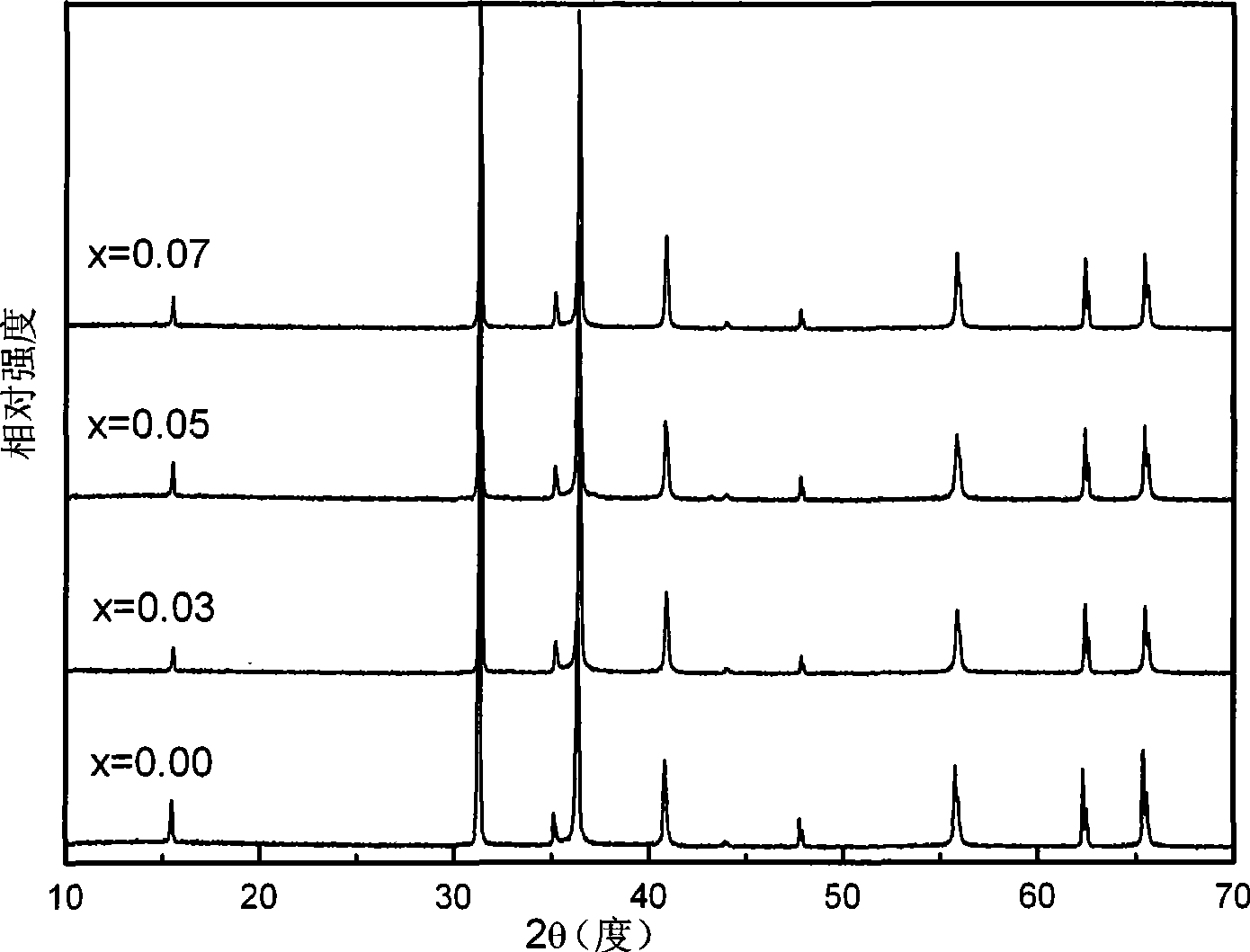

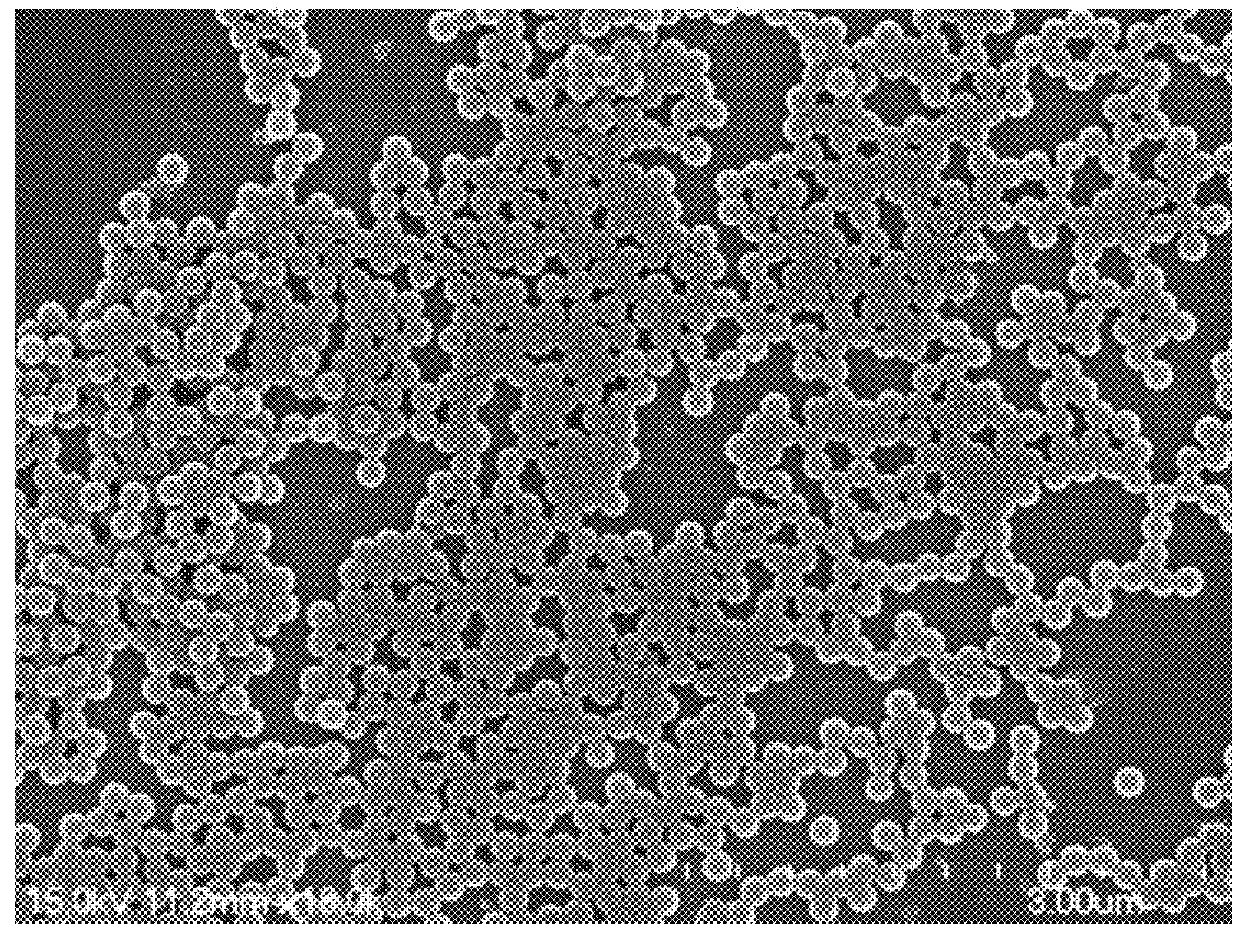

Preparation method of three-dimensional ordered macroporous La1-xSrxCrO3 with mesoporous pore wall

The invention discloses a preparation method of three-dimensional ordered macroporous La1-xSrxCrO3 (x=0, 0.4) with a mesoporous pore wall. The preparation method comprises the following steps of: dissolving lanthanum nitrate and chromium nitrate in mixed liquid of polyethylene glycol 400 and absolute methanol in the molar ratio of 1:1 or dissolving lanthanum nitrate, strontium nitrate and chromium nitrate in mixed liquid of polyethylene glycol 400, absolute methanol and deionized water in the molar ratio of 0.6:0.4:1; adding citric acid in the molar ratio of 1:1 of chromium nitrate to citric acid; performing ultrasonic treatment; adding absolute methanol solution of P123 and performing ultrasonic treatment so as to form homogeneous solution; adjusting metal ion concentration to be 2.0 mol / L; and pouring a polymethyl methacrylate (PMMA) microsphere template into the solution, soaking, performing suction filtration, drying and baking the obtained substance in two steps. The La1-xSrxCrO3prepared by the preparation method has high degree of crystallization, controllable particle shape and pore size, readily available raw materials, high product stability, high electrical conductivityand good application prospect.

Owner:BEIJING UNIV OF TECH

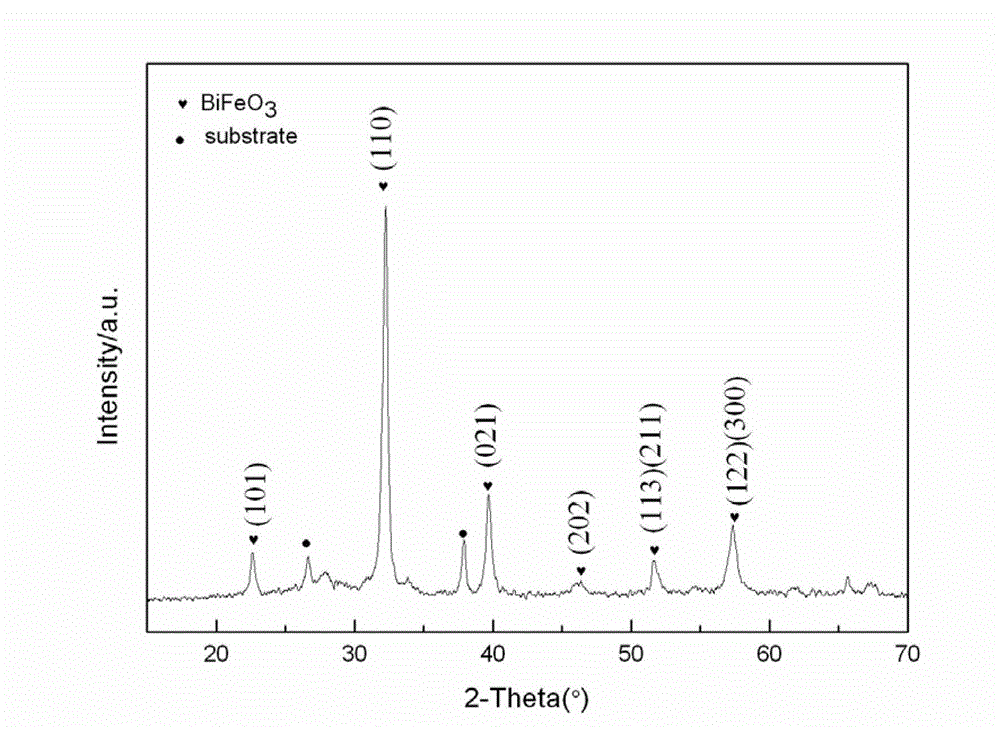

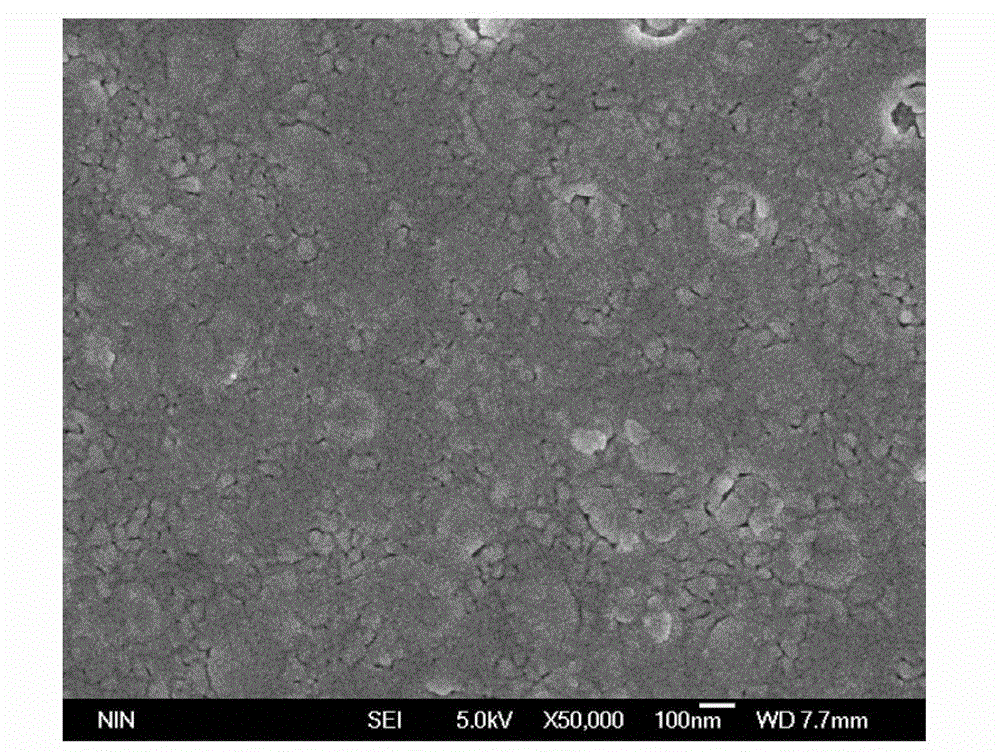

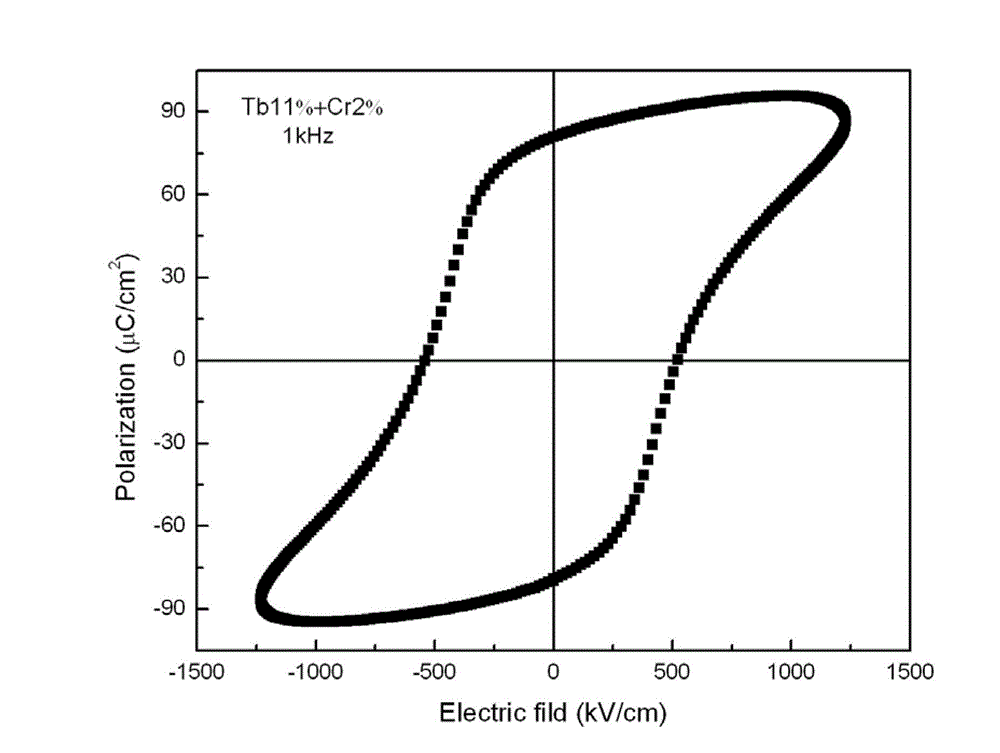

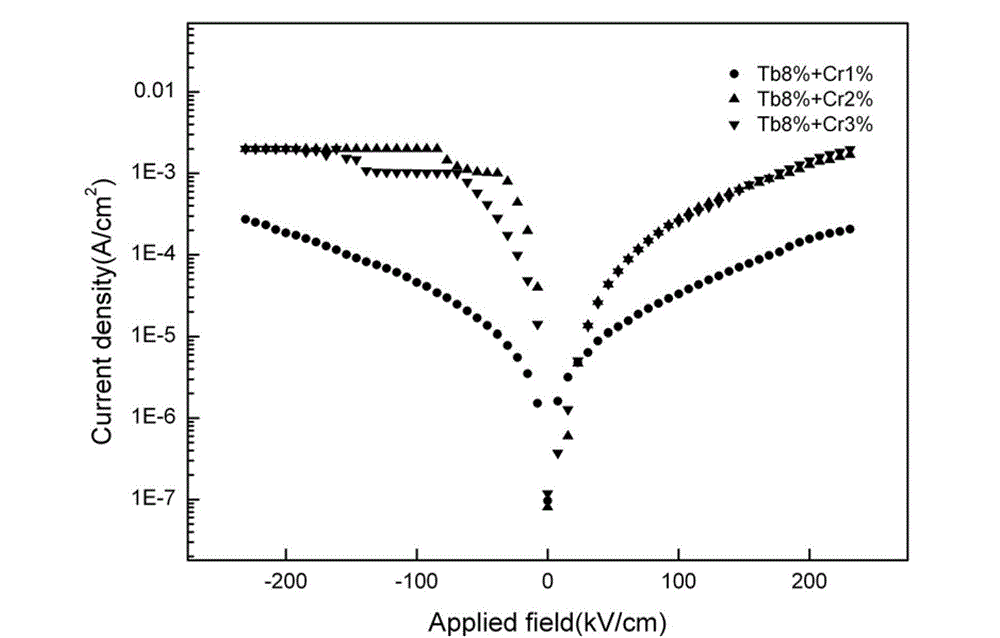

Method for preparing Tb/Cr-codoped high-remanent-polarization BiFeO3 film by sol-gel process

ActiveCN103058646AImprove ferroelectric propertiesChemical composition is easy to controlAcetic anhydrideCHROMIC NITRATE

The invention provides a method for preparing a Tb / Cr-codoped high-remanent-polarization BiFeO3 film by a sol-gel process, which comprises the following steps: dissolving bismuth nitrate, ferric nitrate, terbium nitrate and chromic nitrate in a mol ratio of 0.94:(1-x):0.11:x in a mixed solution of ethylene glycol monomethyl ether and acetic anhydride, and adding ethanolamine to obtain a stable BiFeO3 precursor solution, wherein the total metal ion concentration in the BiFeO3 precursor solution is 0.3 mol / L, and x=0.01-0.03; and carrying out spin coating and layer-by-layer annealing to obtain the Tb / Cr-codoped crystalline BiFeO3 film. The facility requests are simple, the experimental conditions are each to achieve, the film has favorable uniformity, the doping amounts of Tb and Cr can be accurately controlled, and the crystal structure can be adjusted by codoping to greatly enhance the ferroelectric properties of the film, so that the saturated remanent polarization of the film can reach 80.8 mu C / cm<2>.

Owner:盐城青墩津邦水务有限公司

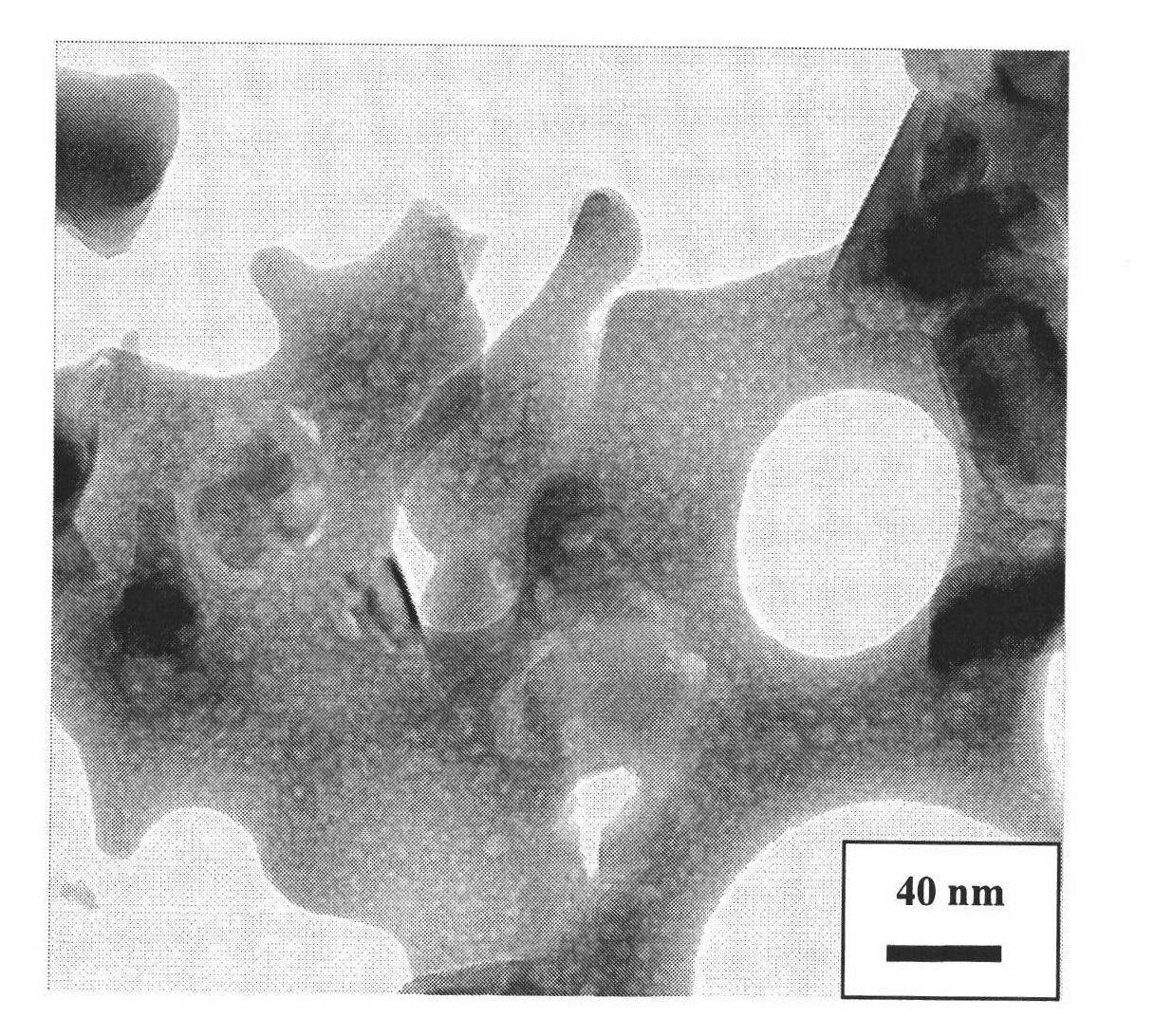

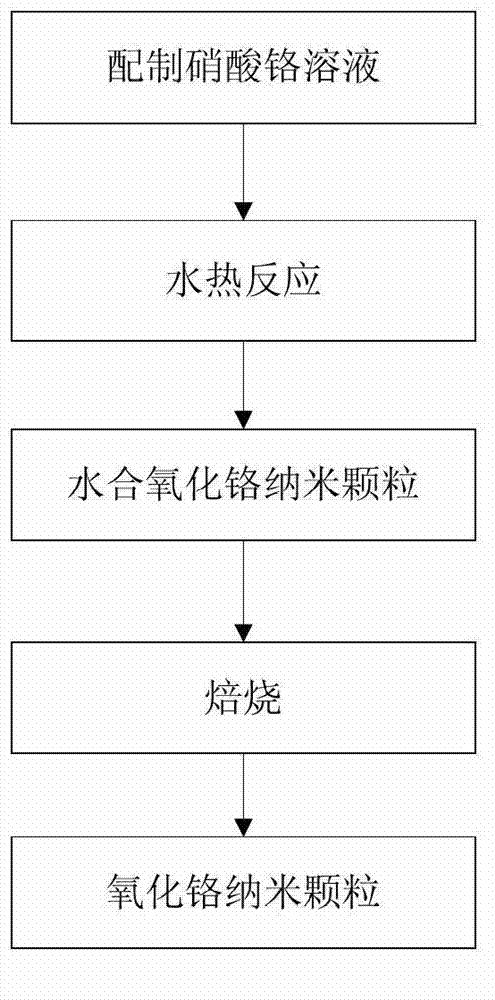

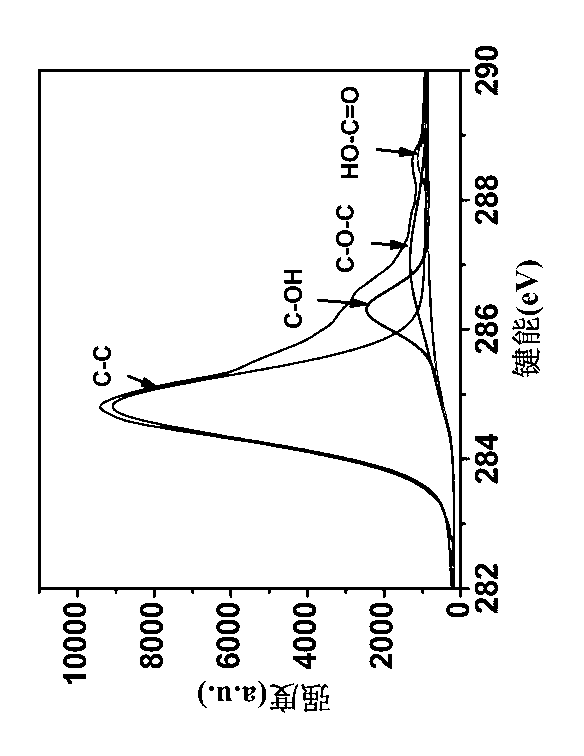

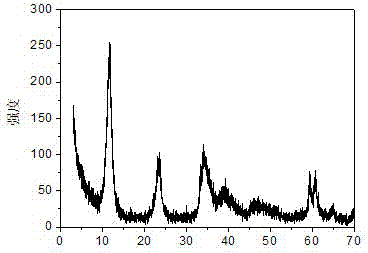

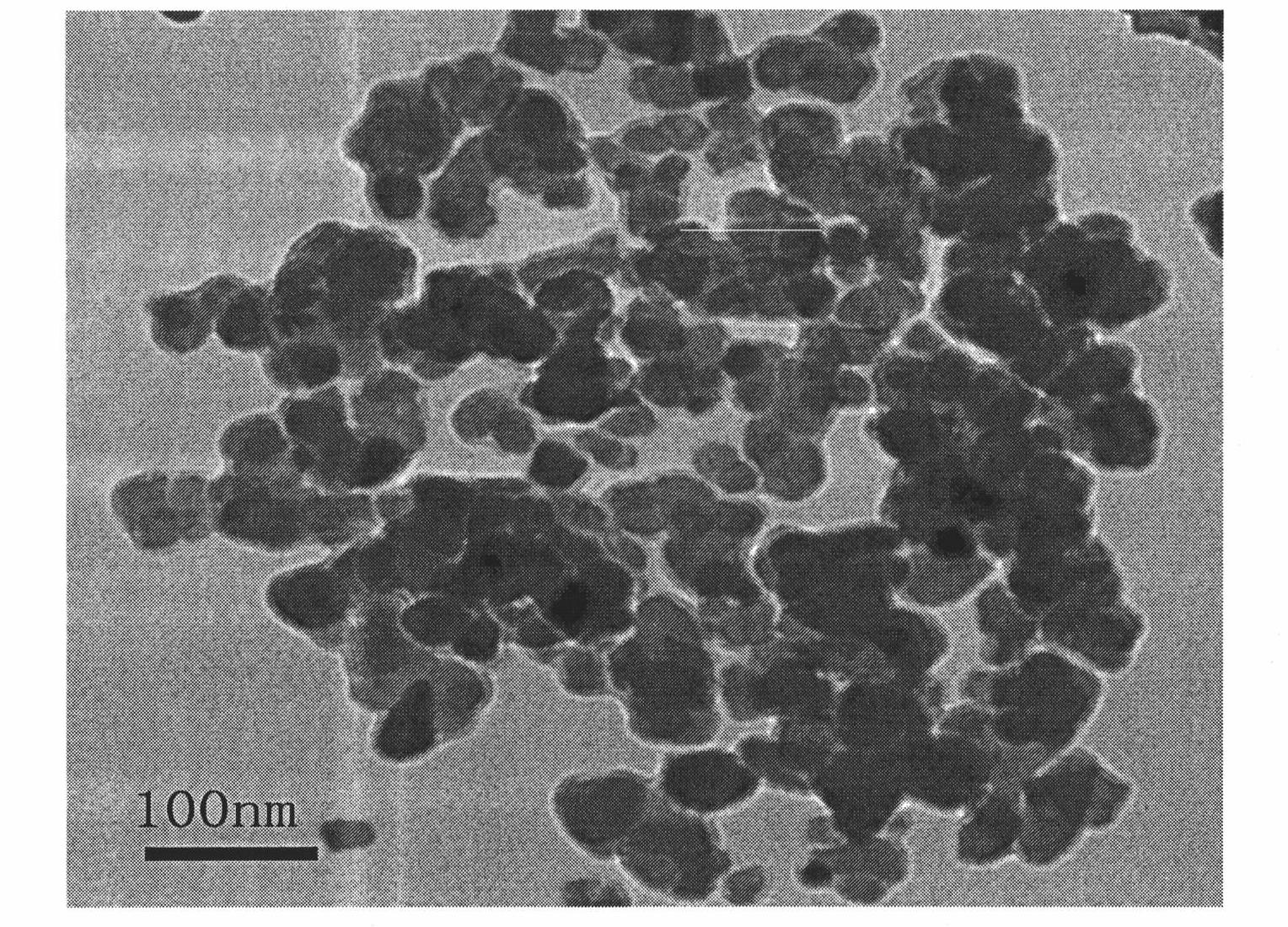

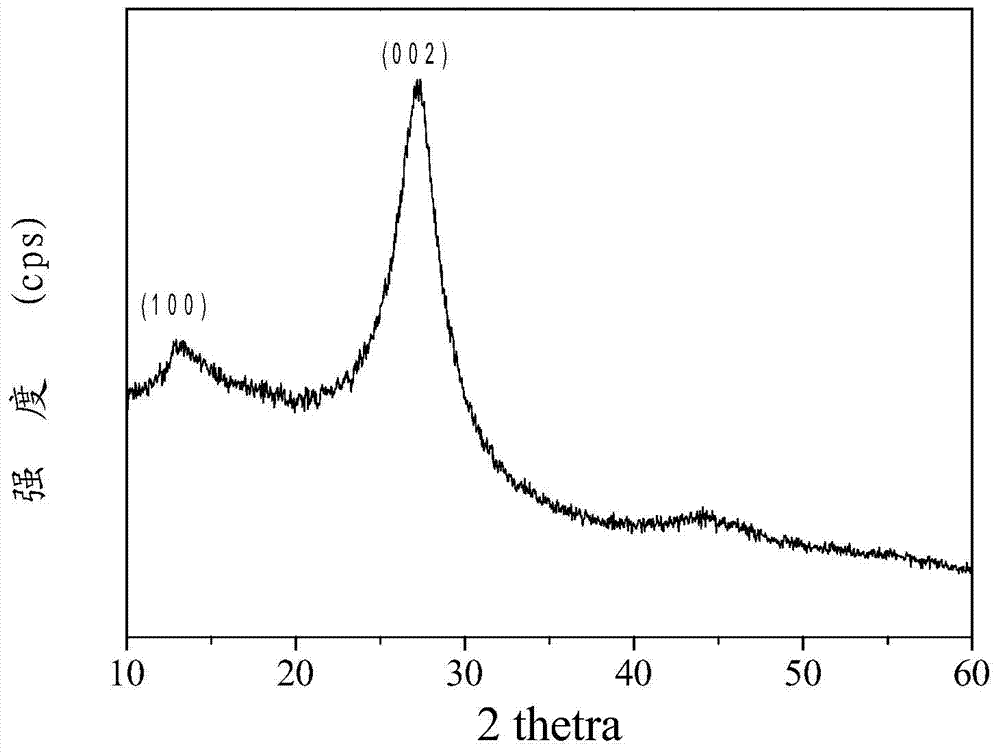

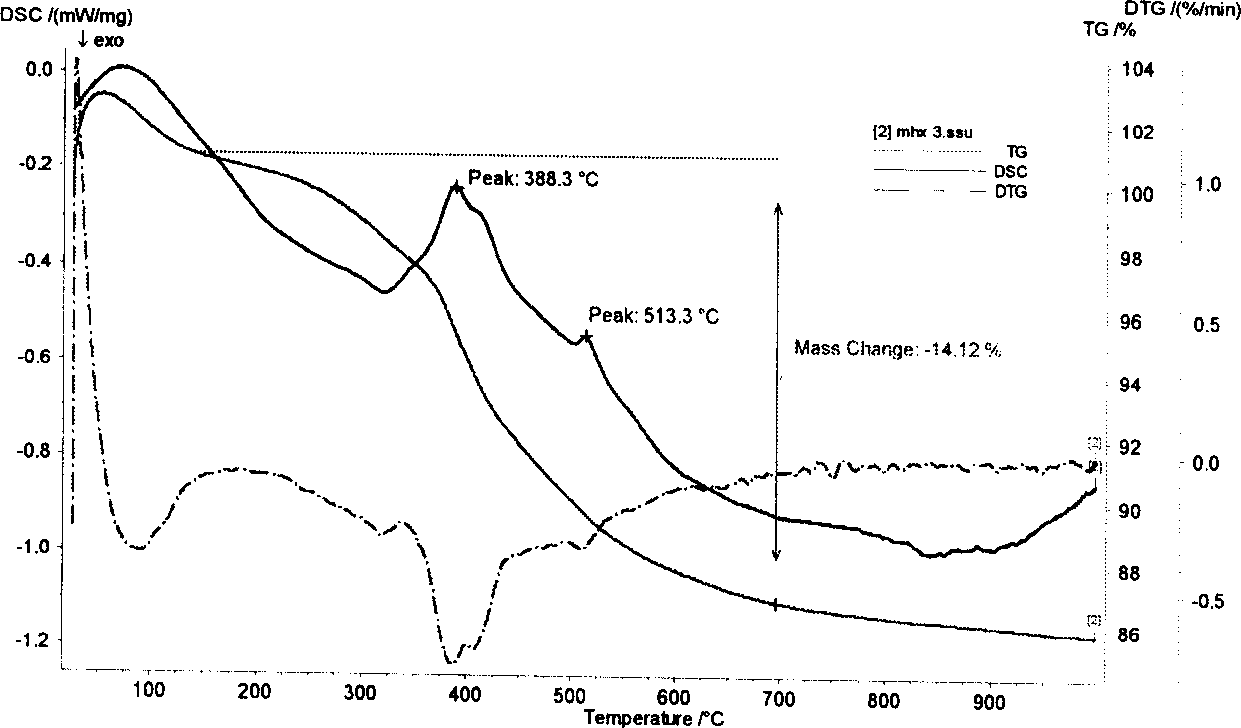

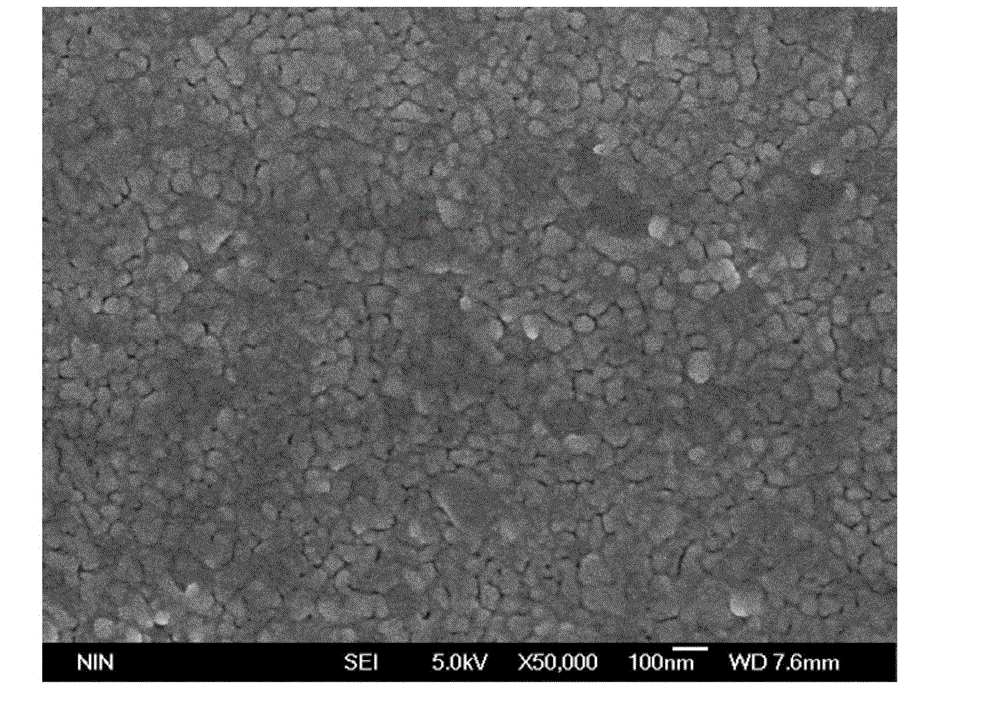

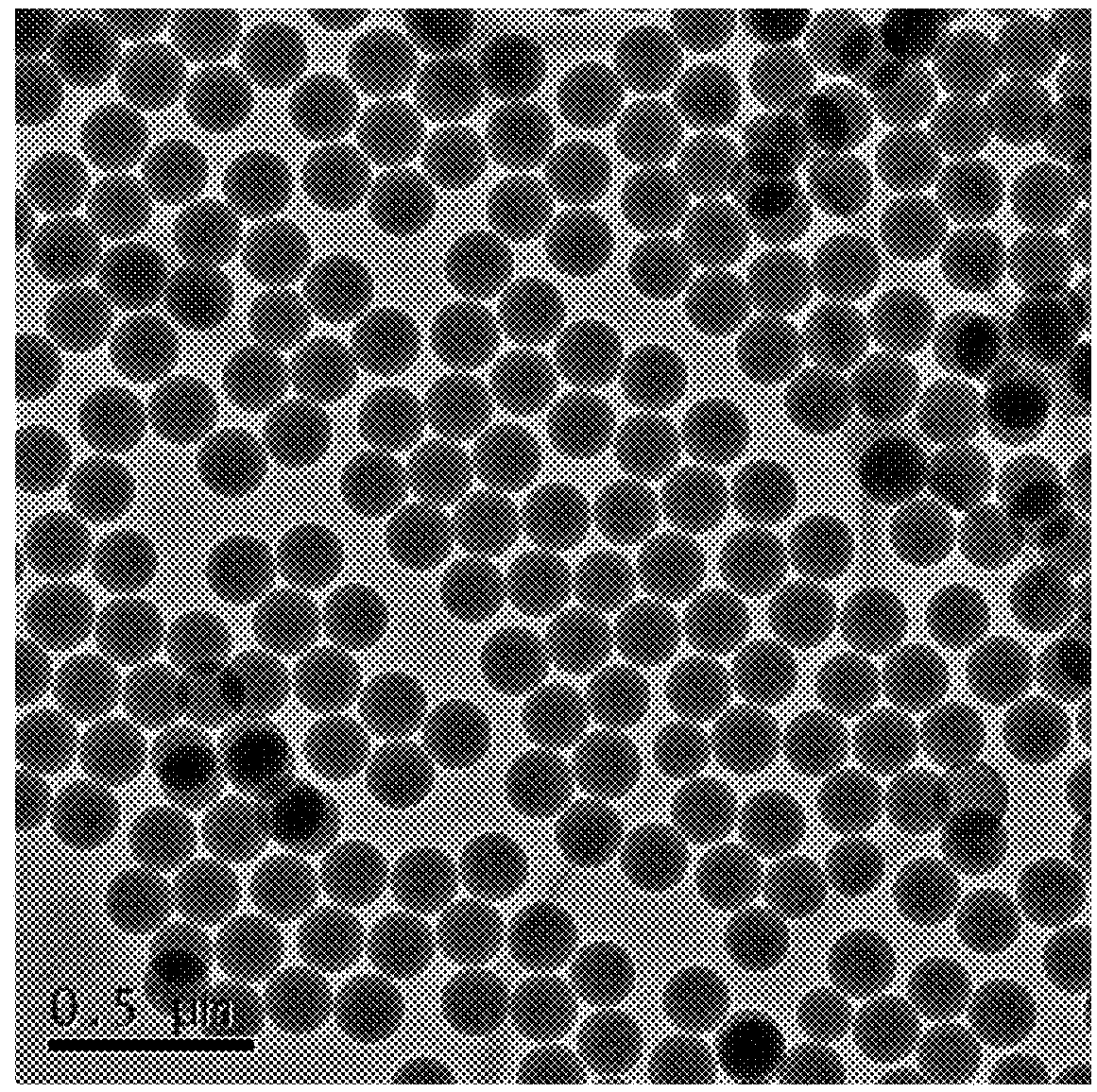

Preparation method for chromium oxide nanometer materials

InactiveCN102826605AHigh purityGood dispersionMaterial nanotechnologyChromium oxides/hydratesCleaning methodsSurface-active agents

The invention relates to a preparation method for chromium oxide (Cr2O3) nanometer materials, belonging to the technical field of inorganic material preparation. The preparation method comprises the steps: by taking chromic nitrate as raw materials, firstly carrying out hydrolysis to the chromic nitrate to generate hydrated chromium oxide nano particles through hydrothermal reaction under neutral or acidic conditions, and then the hydrated chromium oxide nano particles is performed with thermal calcination treatment so as to be crystallized into chromium oxide nanometer materials. According to the preparation method, the raw materials are non-toxic and harmless, no reducing agent, surface active agent or precipitating agent are needed, and the prepared nanometer chromium oxide has high purity, good specific surface area and excellent thermal stability. The particle size distribution is even, the chromium oxide nano particles with different particle sizes ranging from 20nm to 200nm can be obtained through simply regulating the acidity or calcination temperature of experiments. The method has low cost, is simple in production technique and easy for industrial large-scale production, and has no generation of chromium-containing wastes in the whole technique, thereby being an environment-friendly and clean method for preparing chromium oxide.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

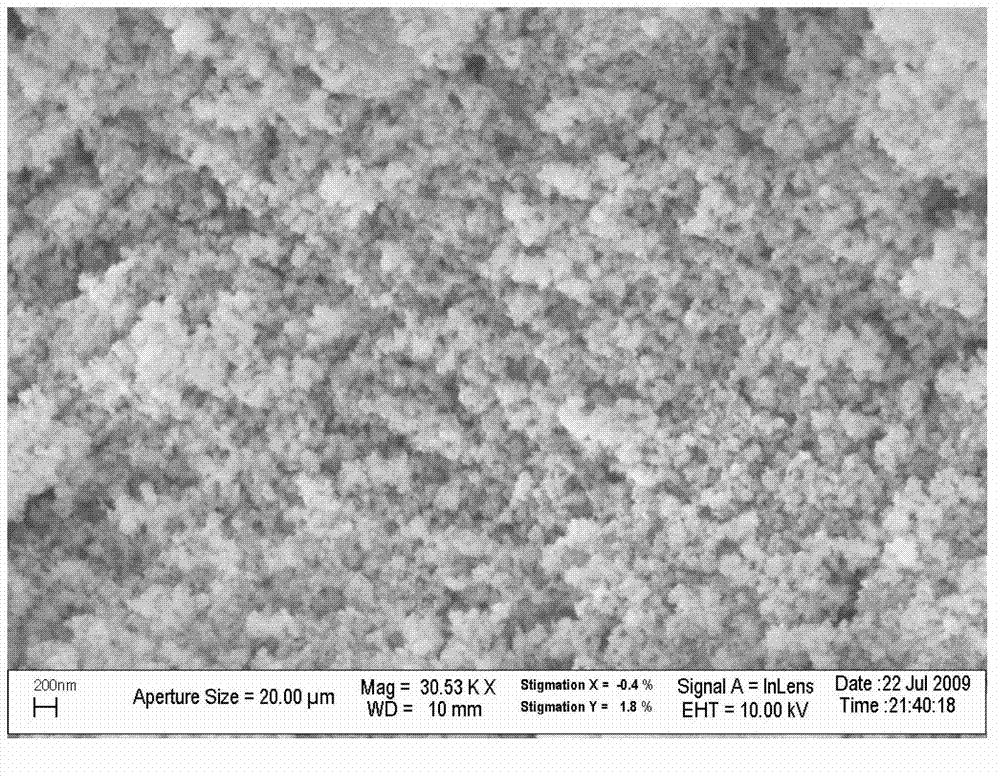

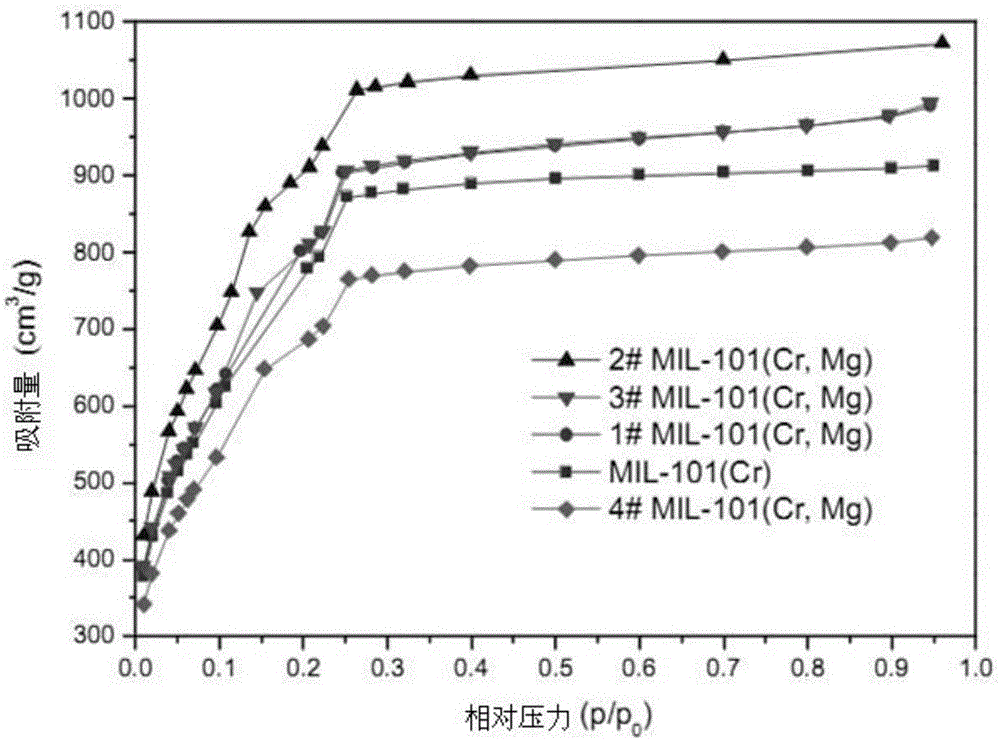

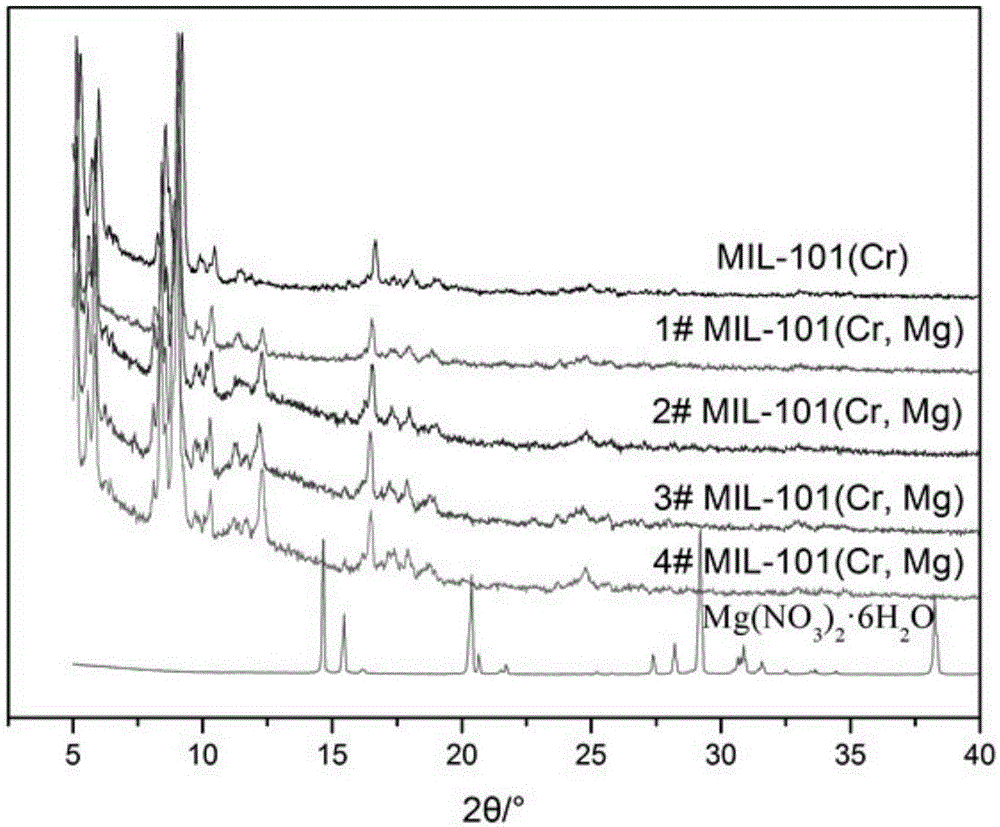

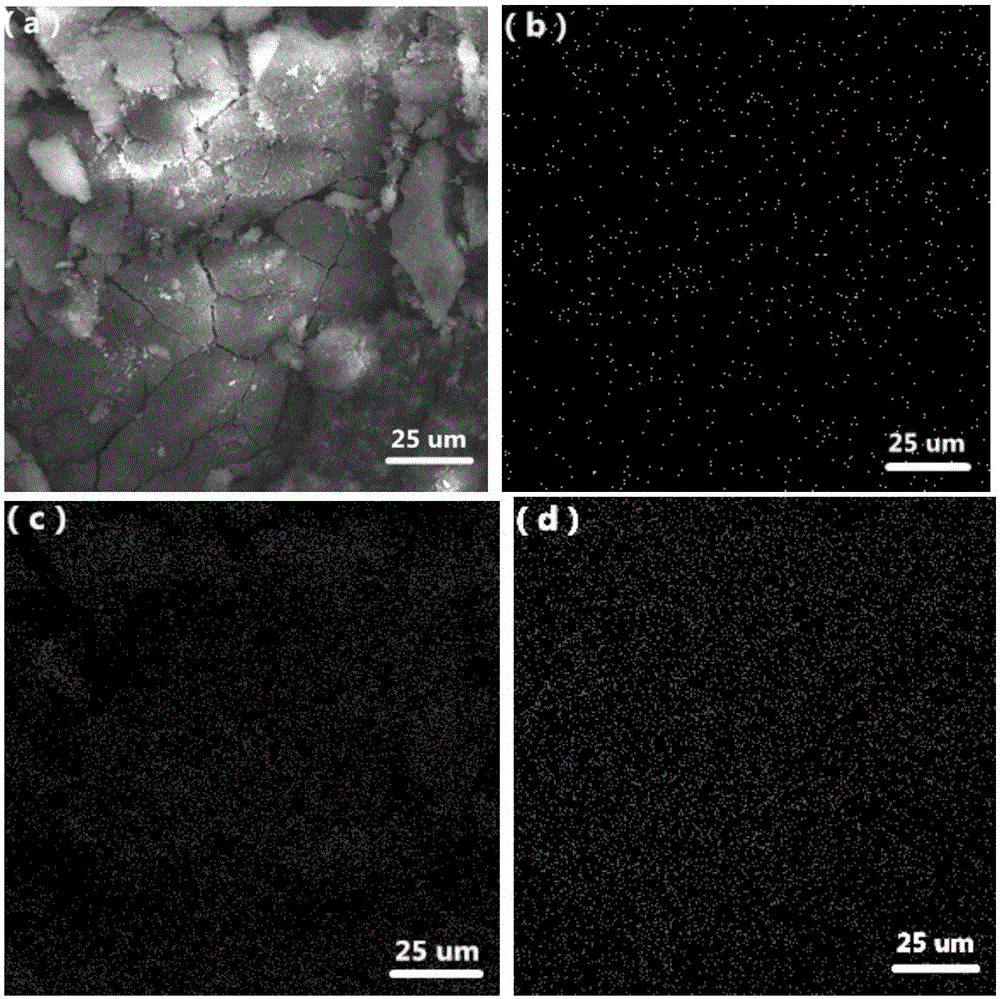

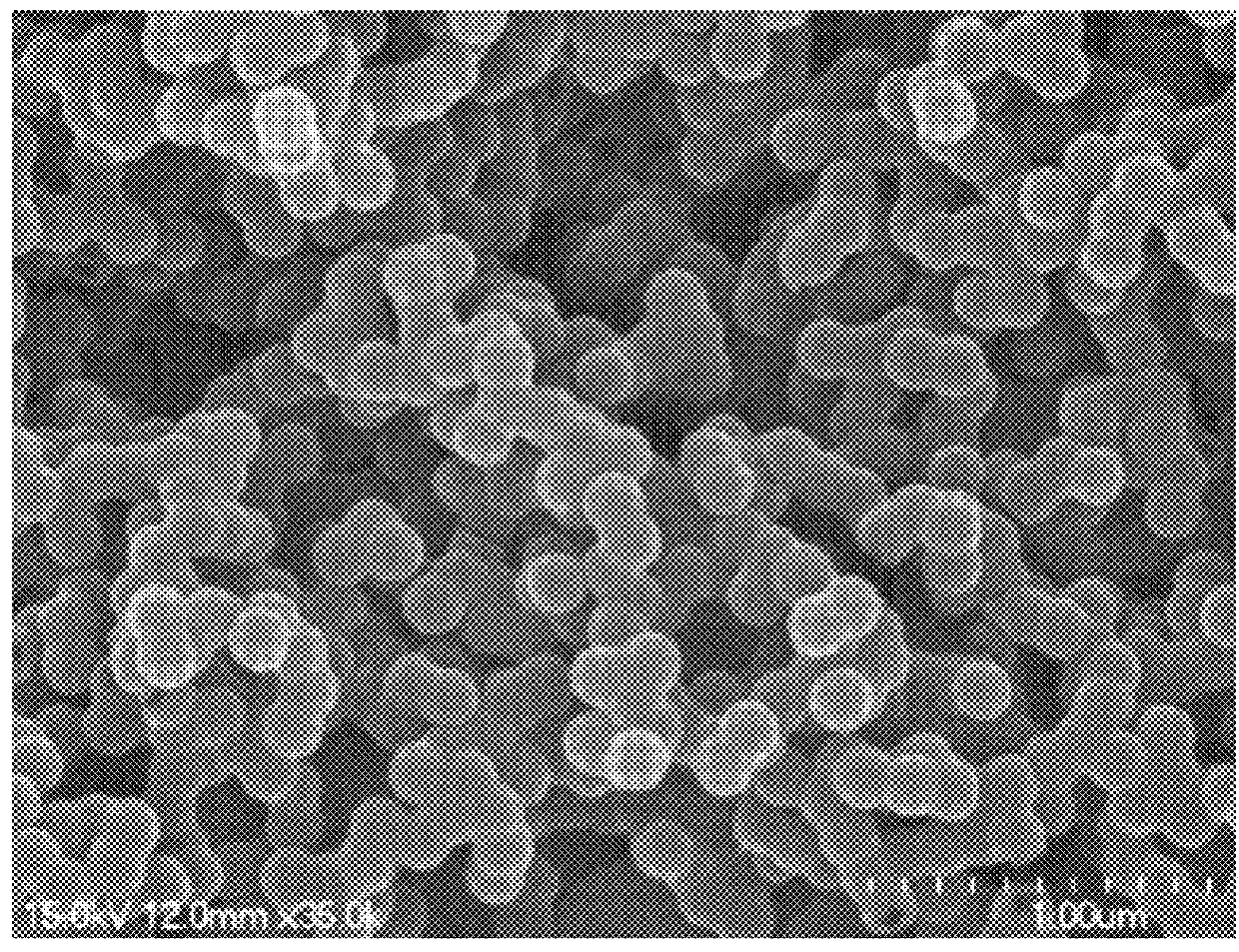

Magnesite-chrome bimetallic MOFs adsorbent MIL-101 (Cr, Mg) and preparation method thereof

ActiveCN105080490ARaw materials are easy to getReduce manufacturing costOther chemical processesDispersed particle separationSorbentWarm water

The invention belongs to the technical field of adsorbing materials, and discloses magnesite-chrome bimetallic MOFs adsorbent MIL-101 (Cr, Mg) and a preparation method thereof. The preparation method comprises the following preparation steps that 1, magnesium nitrate hexahydrate, chromic nitrate nonahydrate, terephthalic acid and hydrogen fluoride solution are added to distilled water, stirring and even mixing are carried out, and a heating reaction is carried out; 2, reaction liquid in the step 1 is filtered, unreacted solid ligand crystals are removed, organic solvent is added to filtrate for agitator treating, centrifugal separation is carried out to obtain sediment, the sediment is soaked in ethyl alcohol and is subjected to heat treatment, flushing is carried out with warm water, and solid particles are obtained; 3, drying and vacuum activation are carried out on the solid particles in the step 2, and MIL-101 (Cr, Mg) is obtained. Magnesium ions are introduced into the adsorbent, so that the adsorption capacity of CO2 is increased, and the adsorptive selectivity of the material to CO2 / N2 is enhanced.

Owner:SOUTH CHINA UNIV OF TECH

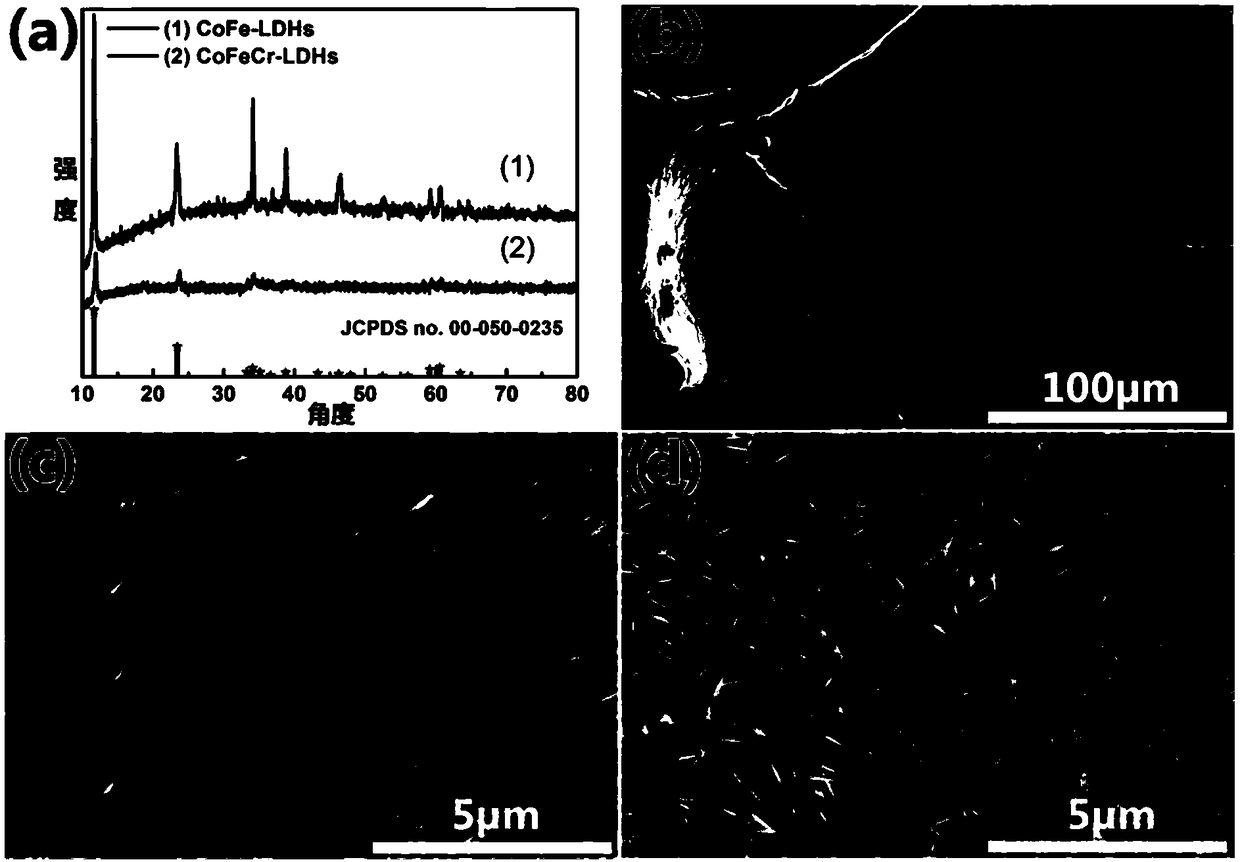

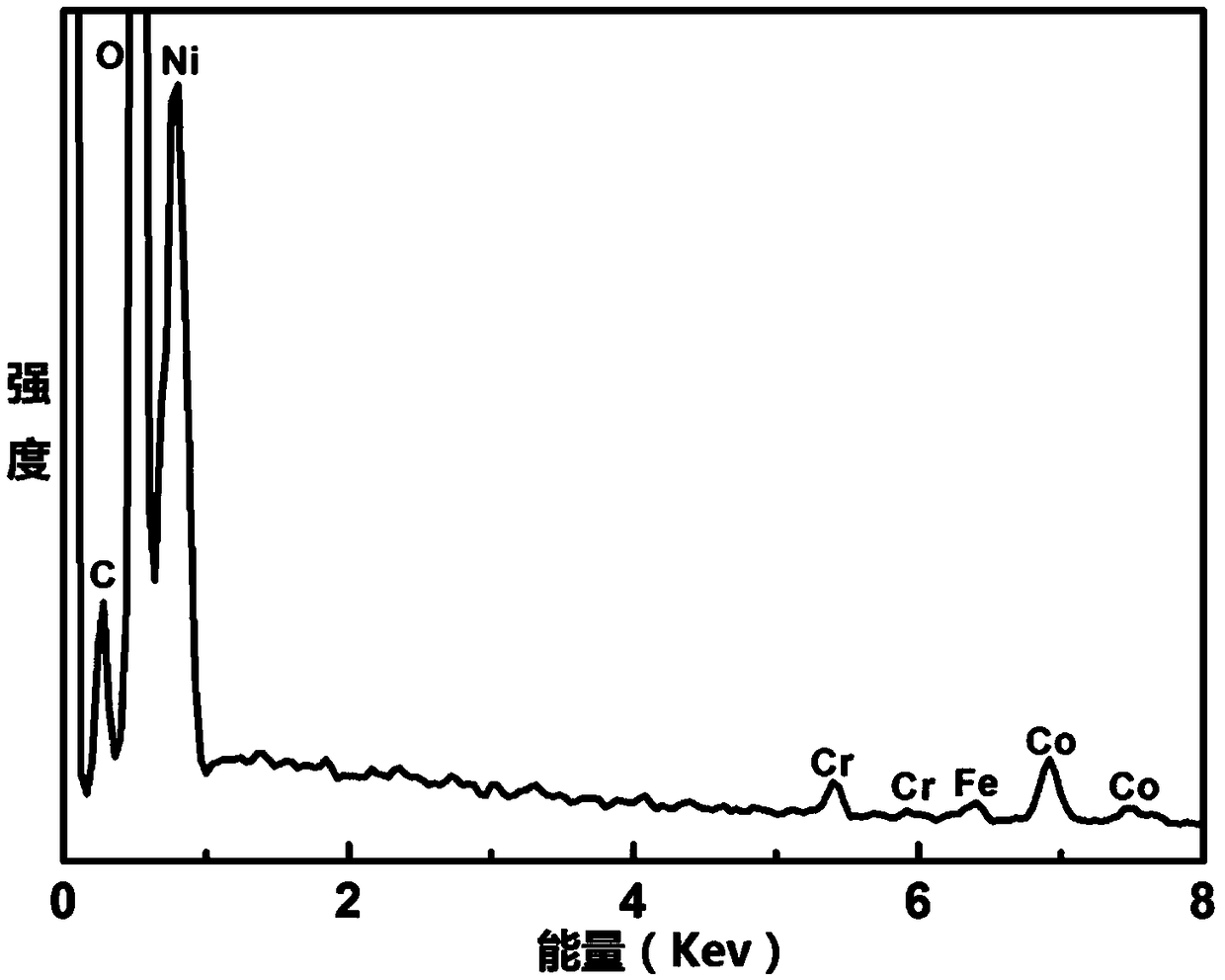

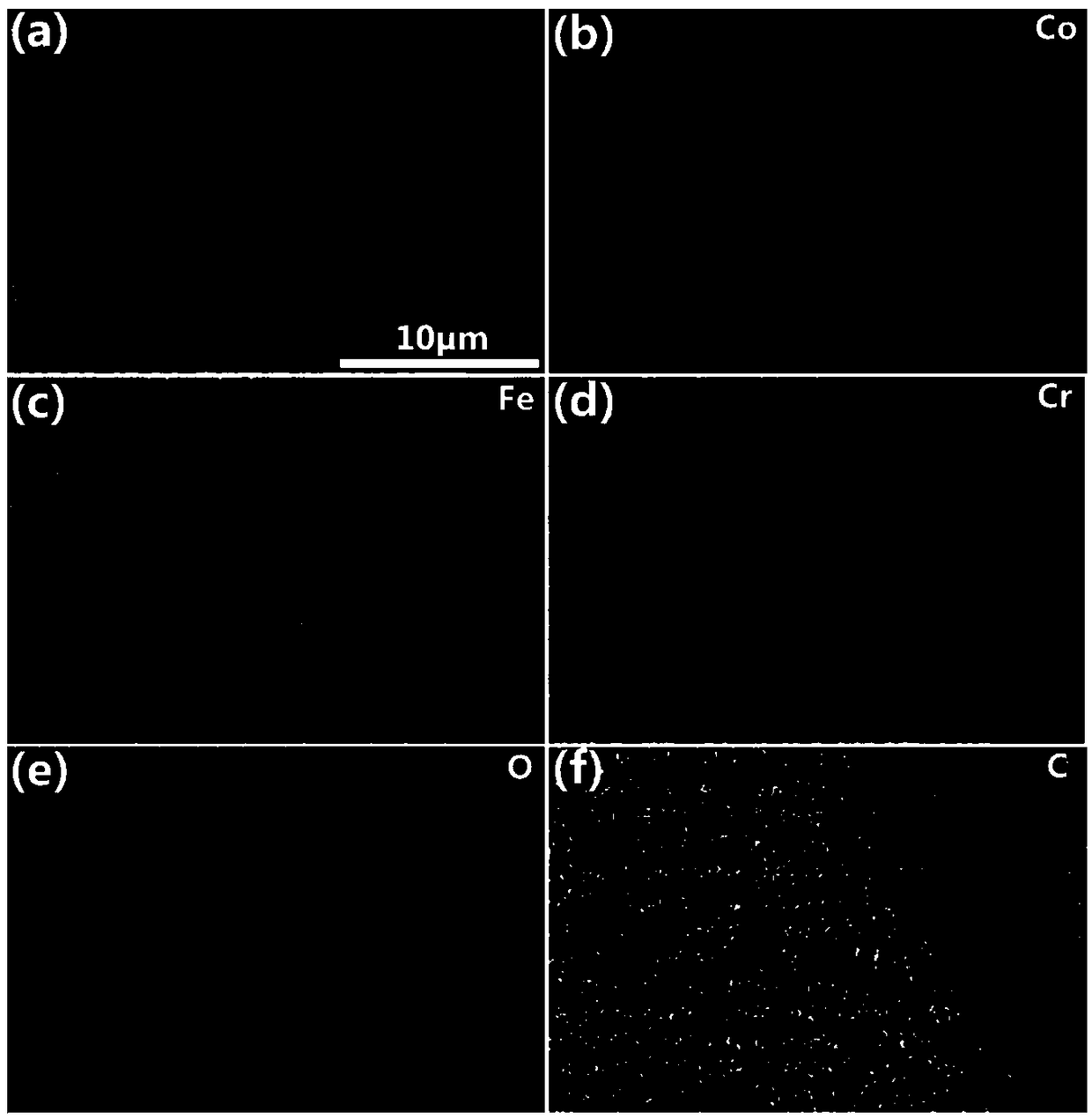

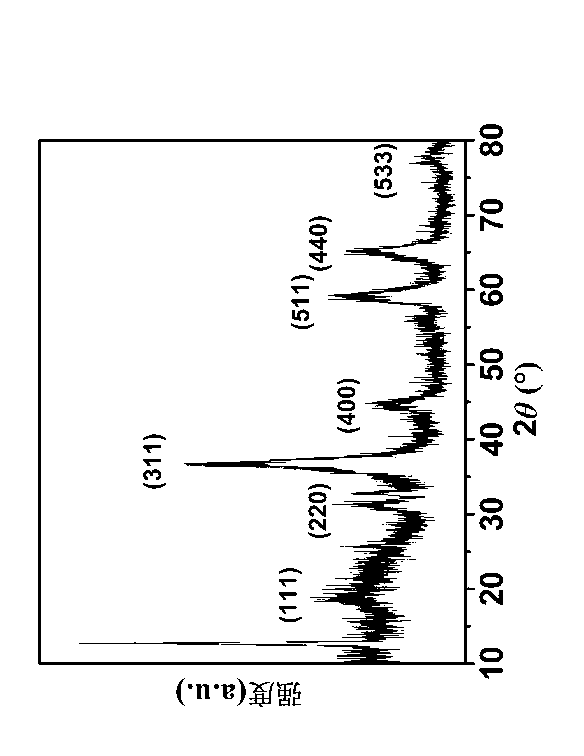

Ternary CoFeCr hydrotalcite nanorod and preparation method and application thereof

InactiveCN108910962ALower overpotentialLow costNanotechnologyCobalt compoundsElectrolysisElectrochemical decomposition

The invention discloses a ternary CoFeCr hydrotalcite nanorod and a preparation method and application thereof. The preparation method comprises the steps: mixing cobalt nitrate, iron nitrate, chromium nitrate, urea and ammonium fluoride in water so as to prepare a precursor mixed solution, placing a substrate in the precursor mixed solution, transferring the substrate together with the precursormixed solution to an autoclave, and then performing a reacting at 110-130 DEG C for 360-600 minutes so as to prepare the ternary CoFeCr hydrotalcite nanorod on the substrate. The ternary CoFeCr hydrotalcite nanorod together with the substrate is directly used as a working electrode for electrochemical decomposition of water. Not only the ternary CoFeCr hydrotalcite nanorod has better performance of water electrolysis and oxygen evolution than transition metal oxide in the prior art, but also the preparation process is simple, fast and efficient, has low production energy consumption, low production cost, environmental protection and no pollution, and is suitable for large-scale industrial production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Preparation method for nano metal oxide graphene composite material

InactiveCN103193225AEasy to makeThe preparation process is environmentally friendlyMaterial nanotechnologyOxide/hydroxide preparationCerium nitrateGraphene flake

The invention relates to a preparation method for a nano metal oxide graphene composite material. The preparation method comprises the following steps: preparing graphite oxide aqueous dispersion from graphite oxide and water; throwing the graphite oxide aqueous dispersion into a ball-milling tank of a ball mill; adding nitrate and performing ball milling, wherein the nitrate is selected from one of or a mixture of more of silver nitrate, cobalt nitrate, manganese nitrate, ferric nitrate, nickel nitrate, bismuth nitrate, copper nitrate, cerium nitrate, vanadium nitrate, chromium nitrate, titanium nitrate, beryllium nitrate and vanadium nitrate; and after ball milling, dispersing the mixed liquid obtained by ball milling by using a proper amount of deionized water, standing and layering, filtering out precipitate, washing and drying. The preparation process is simple; the yield is high; the scale is easy to enlarge so as to realize industrialized production; the preparation process is environment-friendly; and in the prepared composite material, the nano metal oxide has the particle size of less than 50 nm, is uniform in size and is dispersed on the surface of graphene uniformly, the thickness of the graphene sheet is between 1 and 10 carbon atoms, and a good crystal structure is obtained.

Owner:LIHAI CHEM IND CO LTD OF JIANGSU JINQIAO SALT & CHEM GRP

Co-precipitation preparation method of composite oxide denitration catalyst

InactiveCN103801325ALarge specific surface areaImprove denitrification activityDispersed particle separationCatalyst activation/preparationSodium metasilicatePtru catalyst

The invention discloses a co-precipitation preparation method of a composite oxide denitration catalyst and belongs to the technical field of preparation of nitric oxide reduction catalysts. The method comprises the following steps: in the presence of a solvent, mixing aluminum sulfate, titanium sulfate, ammonium vanadate and sodium metasilicate with at least one of ammonium tungstate, manganese chloride, nickel nitrate, cobalt nitrate and chromic nitrate; then placing an obtained precursor into a muffle furnace, and roasting the precursor to obtain the catalyst. According to the method, the use of TiO2 in a conventional V-W-Ti catalyst is reduced, and the cost is reduced; meanwhile, the specific surface area of the catalyst is increased. The formed catalyst contains two or more of components from Ti, Si, Al, V, W, Cr, Ni, Mn and Co; the denitration activity of the catalyst is favorably improved by the strong cooperative action of each active component and a carrier; the catalyst is applicable to SCR (selective catalytic reduction) denitration reaction at low temperature of 250-500 DEG C.

Owner:YANGZHOU UNIV

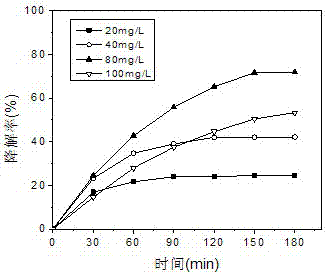

Method for preparing ZnFeCr hydrotalcite photocatalyst

InactiveCN103611543AEfficient Photocatalytic DegradationWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsSlurryZinc nitrate

The invention discloses a method for preparing a ZnFeCr hydrotalcite photocatalyst and relates to preparation methods of catalysts. The method comprises the following preparation steps of (1) preparing a salt solution of ferric nitrate, zinc nitrate and chromic nitrate, wherein the ratio of n(Zn) to n(Fe) to n(Cr) is 1: 1: 1, and the total concentration of metal ions is 1M; (2) preparing a 0.5M solution of sodium hydroxide (NaOH) and sodium carbonate (Na2CO3), wherein the ratio of NaOH to Na2CO3 is 2: 1; (3) simultaneously dropwise adding a metal salt solution and an alkali solution into the salt solution, and controlling the pH value to be 9-10; (4) carrying out hydrothermal crystallization on slurry, obtained after the dropwise adding is ended, for 24 hours at the temperature of 100 DEG C, then, filtrating, washing and drying, thereby obtaining the product. According to the method, the product has good performance in photocatalytic degradation of organic substances; the ZnFeCr hydrotalcite photocatalyst prepared by the method is low in cost, simple and convenient in operation and easy in large-scale production.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Black nanophase ceramics pigment and preparation method thereof

The invention discloses a black nanophase ceramics pigment and a preparation method thereof, the method comprises: dissolving ammonium oxalate, ammonium formate, ammonium acetate and ammonium propionate in water and then mixing evenly with chromic nitrate, manganous nitrate, ferric nitrate and cobalt nitrate, heating the mixture at the temperature of 400-500 DEG C, and combusting until no air gives out to obtain the black nanophase ceramics pigment. The invention has simple reaction conditions, and the raw materials such as the nitrates, the ammonium acetate and the like are medicaments with low price and abundant resource; and the invention is benefit to large-scale industrialized production. The prepared black nanophase ceramics pigment has black color, high temperature-resistance, stable performance and good dispersibility.

Owner:SOUTH CHINA UNIV OF TECH

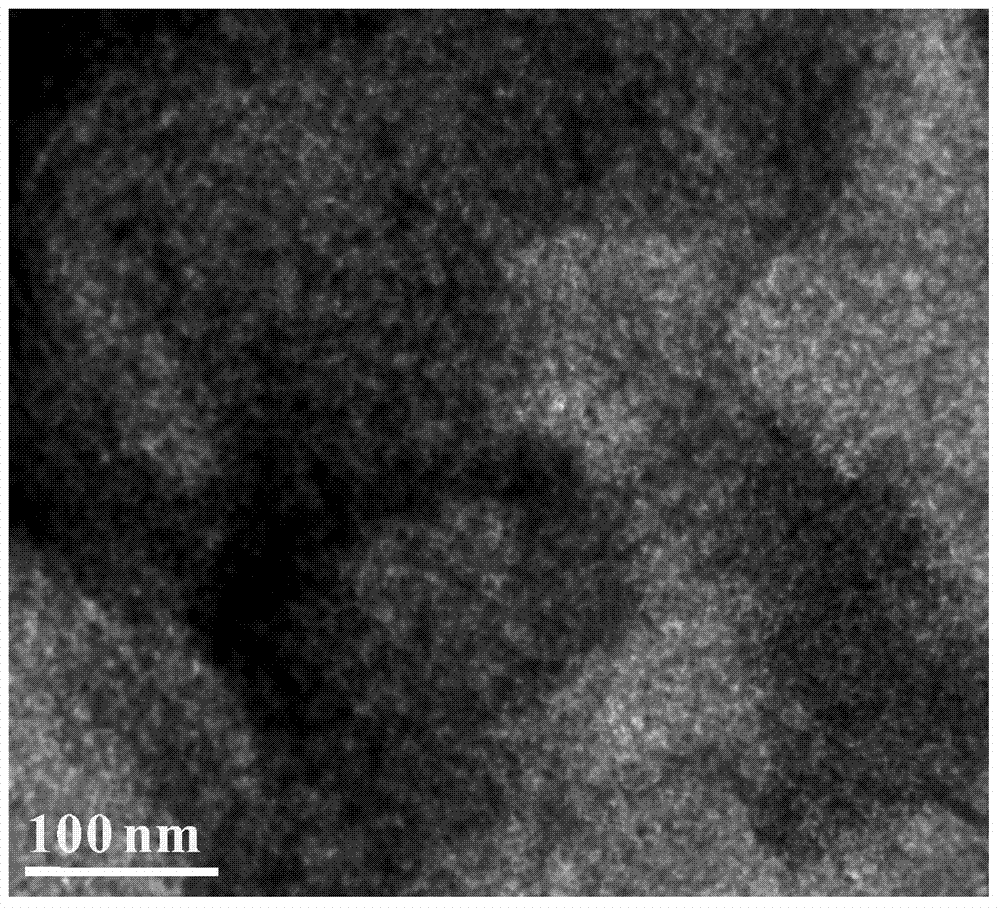

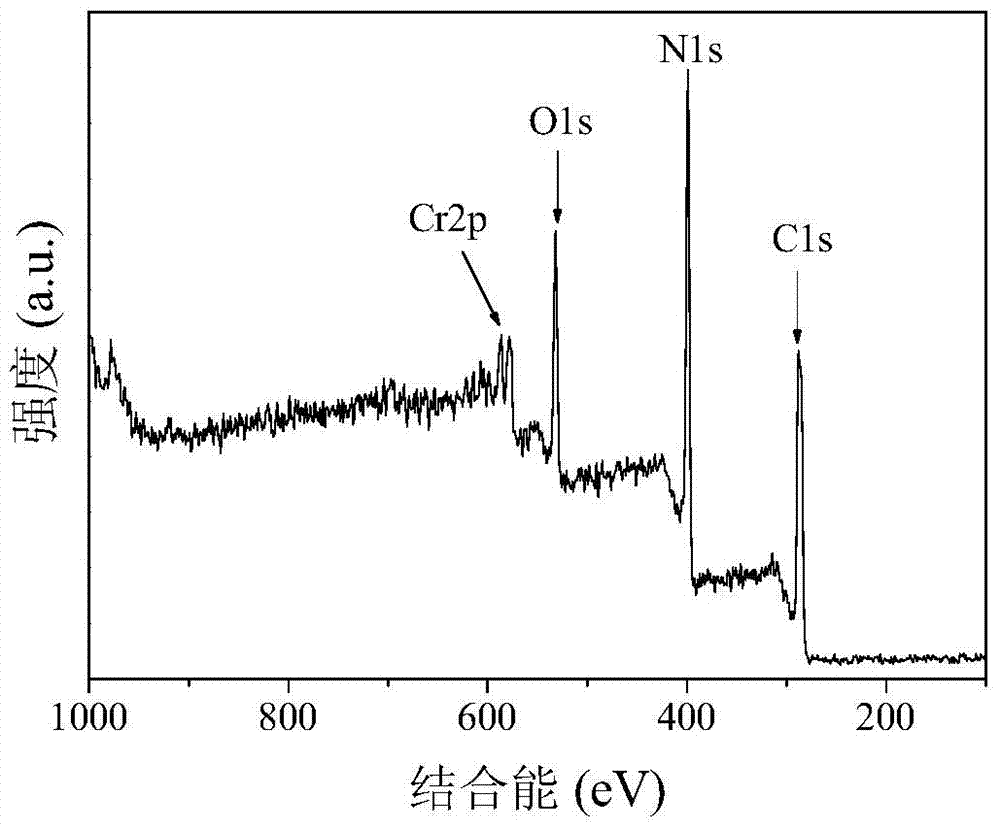

Chromic oxide-doped carbon nitride composite visible photocatalyst, and preparation method and application thereof

InactiveCN104707639AEfficient use ofInhibitory complexPhysical/chemical process catalystsWater/sewage treatment by irradiationEnvironmental resistancePhotocatalytic degradation

The invention discloses a method for preparing a chromic oxide-doped carbon nitride (Cr2O3@g-C3N4) composite visible photocatalysis material, and an application of the material. The method comprises the following steps: dissolving chromium nitrate and carbon and nitrogen sources, fully mixing, drying, and roasting the obtained dried mixture in inert atmosphere to obtain the Cr2O3@g-C3N4) composite visible photocatalyst. The catalyst has a good removal effect in visible photocatalysis degradation treatment of a rhodamine B solution, and still has high catalysis activity after the catalyst is reused five times. The composite visible photocatalyst overcomes the disadvantages of low phototransformation efficiency and low activity of a single material, and has the advantages of wide light response range, high visible photocatalytic activity, low cost, and simple and easily controlled preparation process. The photocatalyst can be used in the environmental protection field, and has wide application prospect in visible photocatalytic degradation of organic pollutants in water.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Heat-insulating ceramic fiber material and preparation method thereof

The invention relates to a heat-insulating ceramic fiber material and a preparation method thereof. The preparation method comprises the following steps: mixing ferric nitrate and chromium nitrate with deionized water, citric acid and ethylene glycol into sol, dipping ceramic fiber into the sol, and taking out and drying as well as carrying out heat treatment at the temperature of 250 to 600 DEG C to obtain the heat-insulating ceramic fiber material coated with high near infrared reflecting pigment layer. The heat-insulating ceramic fiber material and the preparation method have the advantages that the process is simple, the thermal conductivity of the materials manufactured is low and can reach 0.048W / (M.K), and the heat-insulating effect is good.

Owner:SHANDONG UNIV

Carried nanometer bi-metal catalyst, and prepn. method and application thereof

InactiveCN1868591ASimple preparation processShort reaction cycleOrganic compound preparationHydroxy group formation/introductionSupercritical dryingAlcohol

A nano-bimetal carried catalyst NiO-Cr2O3-SiO2 for preparing alcohol by catalytic hydrogenating reaction of aldehyde or ketone is prepared from nickel nitrate and chromium nitrate through adding them to alcohol-acetic acid solution, heating, hydrolyzing to obtain sol, supercritical drying in high-pressure reactor by using alcohol as medium to obtain aerogel, calcining to obtain NiO-CrO3-SiO2, and reducing in H2 to obtain NiO-Cr2O3-SiO2.

Owner:SHANXI UNIV

Densification formation type preparation method of nickel-based alloy powder

InactiveCN105921762AOvercome the problem of poor forming and densification abilityStrong forming abilityWater bathsTungstate

The invention discloses a densification formation type preparation method of nickel-based alloy powder. The method is characterized by comprising the following steps: weighting the following components in percentage by mass: 34.3 to 39.4% of nickelous nitrate hexahydrate, 23.9 to 26.9% of chromic nitrate nonahydrate, 1.7 to 2.2% of iron nitrate nonahydrate, 2.5 to 3.1% of ammonium tungstate monohydrate, and 30.7 to 35.4% of oxalic acid; preparing a 300mol solution through nickelous nitrate hexahydrate, chromic nitrate nonahydrate, and ammonium tungstate monohydrate, then heating to reach the temperature of 60 to 85 DEG C, and uniformly stirring; adding 2ml ammonium hydroxide, and stirring for a few minutes; adding iron nitrate nonahydrate and oxalic acid to the solution; maintaining the temperature in a water bath, and uniformly stirring; moving out the solution; naturally cooling to reach the room temperature; filtering and precipitating; drying, filtering and grinding the precipitate; placing the grinded powder into a corundum boat-shaped container; transferring the corundum boat-shaped container into a hydrogenation furnace to reduce at the temperature of 750 DEG C, so as to obtain high-temperature nickel-based alloy powder.

Owner:SHAANXI UNIV OF TECH

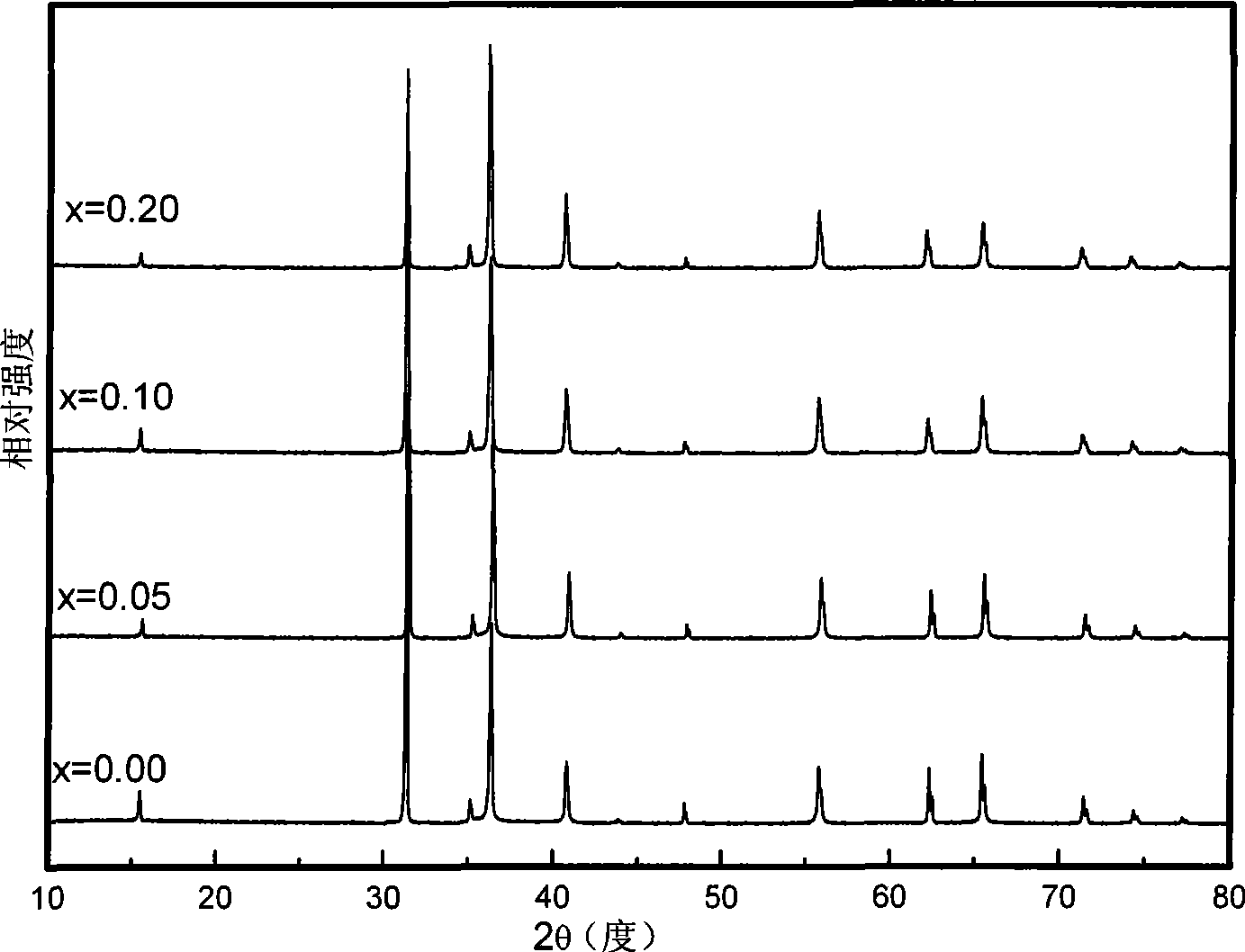

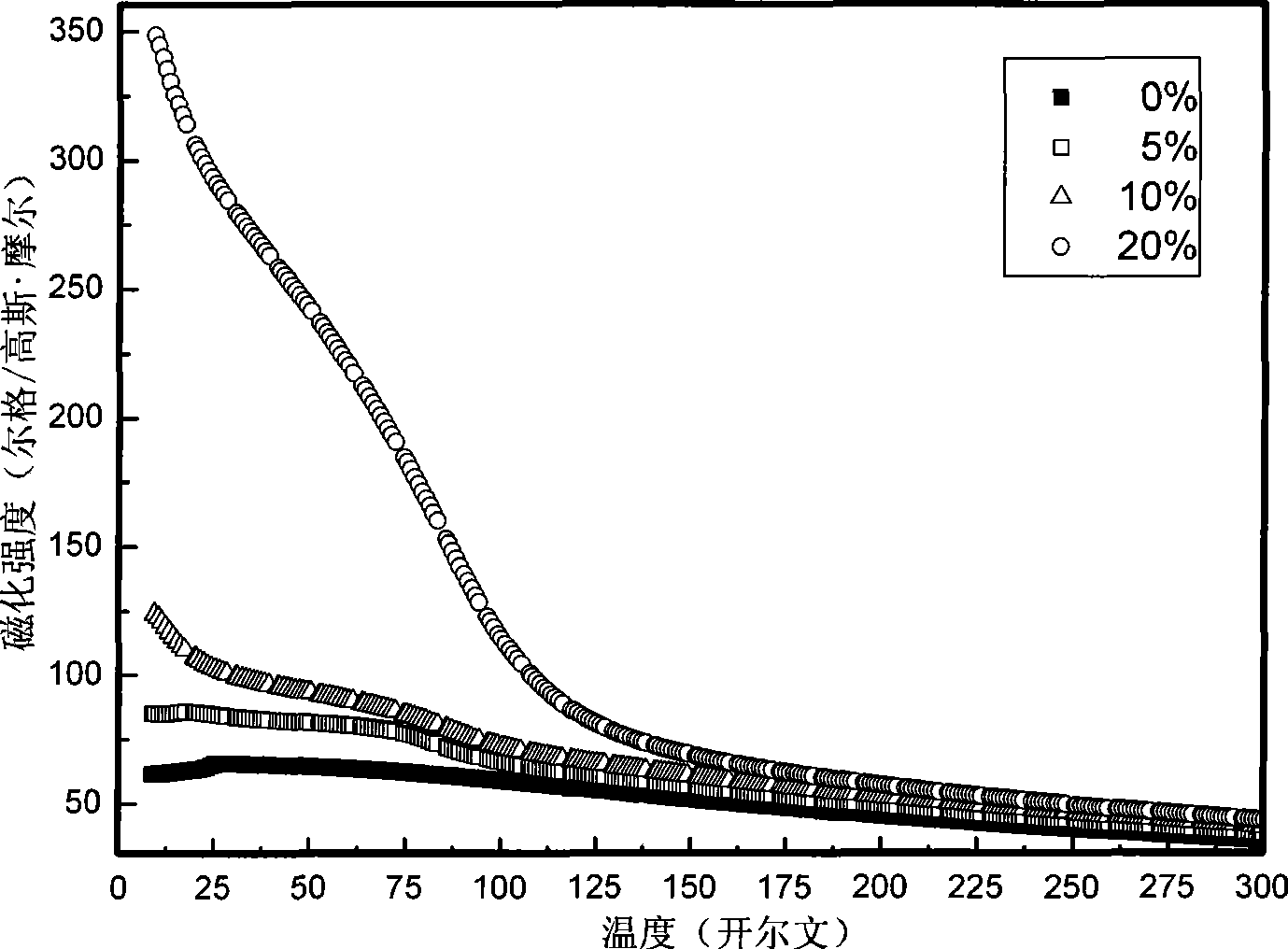

P type doping CuCrO2 based diluted magnetic semiconductor material and preparation thereof

InactiveCN101488387AWell mixedReproducibleInorganic material magnetismInductances/transformers/magnets manufactureMolecular levelStructural formula

The invention discloses a p type doped CuCro2-based dilute magnetic semiconductor material and a manufacturing method thereof. The CuCro2-based dilute magnetic semiconductor polycrystal block is manufactured, and has a molecular structural formula of CuCr(1-x)TMxO2, wherein, TM is transition metal elements which are Fe, Co, Ni, Mn, and the concentration thereof x is more than or equal to 0 and is less than or equal to 0.2. Cupric acetate, chromic nitrate and transition metal salt are measured according to a mole ratio of cupric, chromic to transition metal of 1: (0.80-1): (0-0.20), the powder is added into distilled water and added with adequate amount of citric acid, and then stirred at room temperature till fully dissolved, thereby obtaining a well mixed solution; then, after processes of parching, grinding, tablet compressing and heat treatment, dilute magnetic semiconductor block material of CuCr(1-x)TMxO2 is manufactured. The invention adopts a sol-gal method and has the advantages of low energy consumption, simple technique and the like. In the invention, all of the components in the solution are well mixed, and the uniformity degree can reach molecular level, so that multi-component homogenous dopant can be manufactured was well as products that are hard to be obtained by traditional solid phase methods. And experiment results have repeatability.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

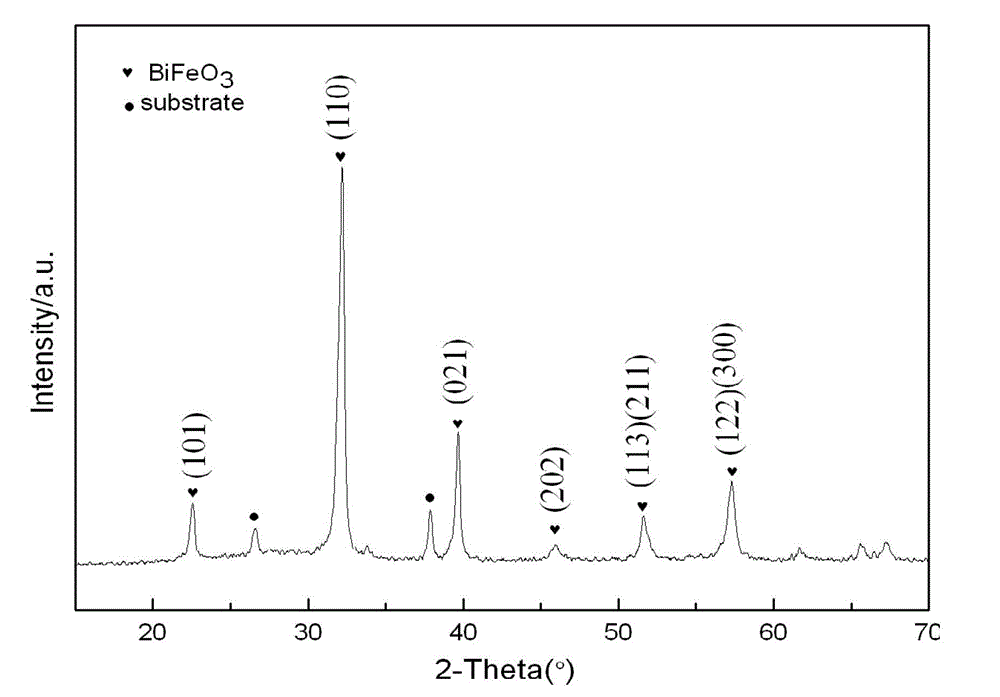

Preparation method of low-leakage current Bi0.92Tb0.08Fe(1-x)CrxO3 film

ActiveCN102976764AImprove multiferroic propertiesImprove electrical performanceAcetic anhydrideLow leakage

The invention provides a preparation method of a low-leakage current Bi0.92Tb0.08Fe(1-x)CrxO3 film. The method comprises the following steps of: dissolving bismuth nitrate, ferric nitrate, terbium nitrate and chromic nitrate at a molar ratio of 0.97:(1-x):0.08:x into the mixed solution of ethylene glycol monomethyl ether and acetic anhydride to form a mixed solution; adding ethanolamine into the mixed solution to adjust the viscosity and the complexing degree to obtain a stable BiFeO3 precursor liquid; and preparing a Tb and Cr co-doped crystalline BiFeO3 film by a spin-coating method and layer-by-layer annealing technology. The film is a crystalline Bi0.92Tb0.08Fe0.99Cr0.01O3 film, wherein the leakage current density is still kept below 10<-4>A / cm<2> in a 150kv / cm test electric field. According to the method provided by the invention, the requirements on equipment are simple, the experimental conditions are easy to realize, the prepared film has good uniformity, and the leakage current of the film is reduced through the co-doping of Tb and Cr.

Owner:SHAANXI UNIV OF SCI & TECH

Nanometer tungsten carbide powder preparing method

InactiveCN103658677ASimple preparation processEasy to controlNanotechnologyAmmonium metavanadateSlurry

The invention relates to a nanometer tungsten carbide powder preparing method. The method includes the following steps that chromic nitrate and ammonium metavanadate are dissolved into deionized water, APT is added, ball milling and slurry forming are carried out, water-soluble PF is then added to continue carrying out ball milling, and then spraying and drying are carried out to obtain composite powder; precursor powder is subjected to ball milling under low temperature with liquid nitrogen as the ball milling medium, and the ball milling product is dried under room temperature and is then placed into a carbon tube furnace and carbonized under hydrogen protection to obtain nanometer tungsten carbide powder. Chromium, vanadium and the PF are added at the beginning of processes, and sizes of WC powder particles can be easily and stably kept at the nanoscale through element internal inhibition in the production process, the external wrapping and isolation function of the PF and liquid nitrogen freezing and ball milling; furthermore, because the WC powder preparation process is simple and easy to control, industrialization production investment is small, production processes are simple and convenient to carry out, production cost is low, and industrial batch production is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

Titanium-dioxide-based double-layer hollow material, preparation method thereof, and application thereof in photocatalytic treatment of hydrogen sulfide

InactiveUS20180179079A1Easy to getLow costAdditive manufacturing apparatusLiquid surface applicatorsPolystyreneLayer by layer self assembly

A preparation method of a titanium-dioxide-based double-layer hollow material includes the following steps: (1) using polystyrene nanospheres with particle size of 180 nm as a template, tetrabutyl titanate as a precursor, to prepare hollow titanium dioxide by calcining; (2) subjecting said hollow titanium dioxide to carboxylation modification to prepare carboxylated titanium dioxide; and (3) dispersing said carboxylated titanium dioxide in ethanol, using chromic nitrate nonahydrate as an assembly agent and trimesic acid as a crosslinking agent to carry out layer-by-layer self-assembly so as to prepare the titanium-dioxide-based double-layer hollow material.

Owner:SUZHOU UNIV

Tempered glass

The invention relates to a tempered glass which is prepared from the following raw materials in parts by weight: 6-10 parts of waste glass, 5-10 parts of calcite, 5-7 parts of borax, 3-8 parts of clarifier, 7-10 parts of bauxite, 4-10 parts of titanium dioxide, 3-9 parts of chromic nitrate, 6-11 parts of potassium permanganate, 4-9 parts of chalcanthite, 3-6 parts of barium hydroxide, 4-11 parts of potassium silicate, 5-10 parts of silicon dioxide, 7-9 parts of aluminum oxide and 4-9 parts of bismuth oxide. The tempered glass has the advantages of favorable strength, favorable hardness and low possibility of spontaneous explosion, and can not hurt the human body.

Owner:QINGDAO ZHIGU INNOVATION TECH

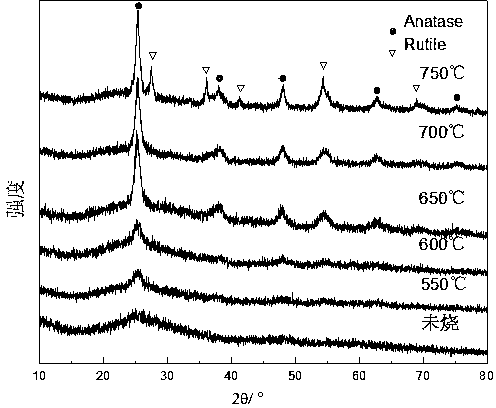

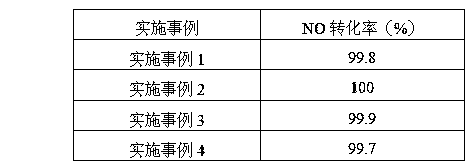

Coke oven flue gas denitration catalyst and preparation method thereof

ActiveCN106984349ALower surface energyGood dispersionPhysical/chemical process catalystsDispersed particle separationWater bathsPhosphate

The invention discloses a coke oven flue gas denitration catalyst and a preparation method thereof. The preparation method utilizes ammonium metavanadate as an active precursor, chromium nitrate as an auxiliary agent and oxalic acid and hydrochloric acid as reducing agents, and utilizes phosphoric acid to adjust and control the surface acidity of an active component. The preparation method comprises stirring, water bath heating, drying, calcining to obtain a Cr-doped oxyvanadium phosphate active component, adding the Cr-doped oxyvanadium phosphate active component and anatase TiO2 as a carrier with a specific surface area of greater than or equal to 250 m<2> / g into distilled water according to a ratio, carrying out stirring mixing, and carrying out water bath drying and calcining to obtain the catalyst. The catalyst utilizes phosphoric acid to adjust and control the surface acidity of the catalyst, and utilizes aid chromic nitrate to form an intercalation structure and promote formation of adjacent V<5+> and V<4+>. The catalyst has good low temperature denitration activity and strong SO2 and steam poisoning resistance and is suitable for industrial coke oven flue gas denitrification.

Owner:马鞍山方信环保科技有限公司

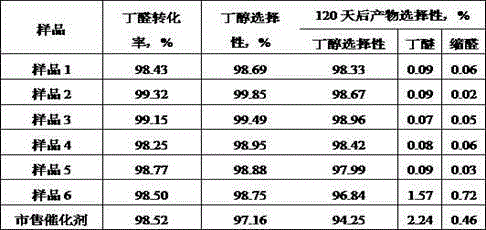

Method for improving selectivity and stability of nickel liquid phase hydrogenation catalyst

ActiveCN105080548AHigh activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsNickel saltPotassium

The invention belongs to the technical field of catalysts, and particularly relates to a method for improving the selectivity and the stability of a nickel liquid phase hydrogenation catalyst. The method is suitable for preparing the nickel liquid phase hydrogenation catalyst through co-precipitation. A soluble salt addition agent is supplied to nickel salt in a neutralizing process, soluble salt contains one or several kinds of magnesium nitrate, chromic nitrate, zirconium nitrate, calcium nitrate, lanthanum nitrate and cesium nitrate, and the supplying amount of the soluble salt is 0-0.95 time of the molar weight of the nickel salt. An alkali center adjusting addition agent of the catalyst is added to a filter cake, the alkali center adjusting addition agent and the filter cake are uniformly kneaded, the alkali center adjusting addition agent contains one or several kinds of oxide, hydroxide, metasilicate, carbonate and aluminosilicate of potassium, calcium, sodium, magnesium, zirconium and cesium, and the addition amount of the alkali center adjusting addition agent is 0-0.95 time of the molar weight of precipitated nickel. The method disclosed by the invention can obviously improve the selectivity and the stability of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process of plating diamond surface with composite film

ActiveCN104479423AImprove wettabilityFully coveredOther chemical processesInorganic pigment treatmentAcetic acidComposite film

The invention discloses a process of plating a diamond surface with a composite film. The process comprises the following steps: 1) performing surface treatment on a diamond grinding material; 2) mixing barium acetate with glacial acetic acid to prepare stable BaO sol, soaking the grinding material with the BaO sol, and drying and roasting the grinding material to obtain the diamond grinding material plated with a BaO film; 3) mixing chromic nitrate with glacial acetic acid to prepare stable Cr2O3 sol, soaking the grinding material with Cr2O3, drying and roasting the grinding materials to obtain the diamond grinding material coated with a BaO / Cr2O3 film. According to the process, the surface of the diamond grinding material can be plated with a layer of compact composite film, so that harmful chemical reaction on the diamond grinding material and ceramic bond in a sintering process can be avoided, the wettability of the diamond grinding material and the ceramic bond can also be improved, the holding force on the diamond grinding material by the ceramic bond is increased, and the service life of a grinding tool is prolonged.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

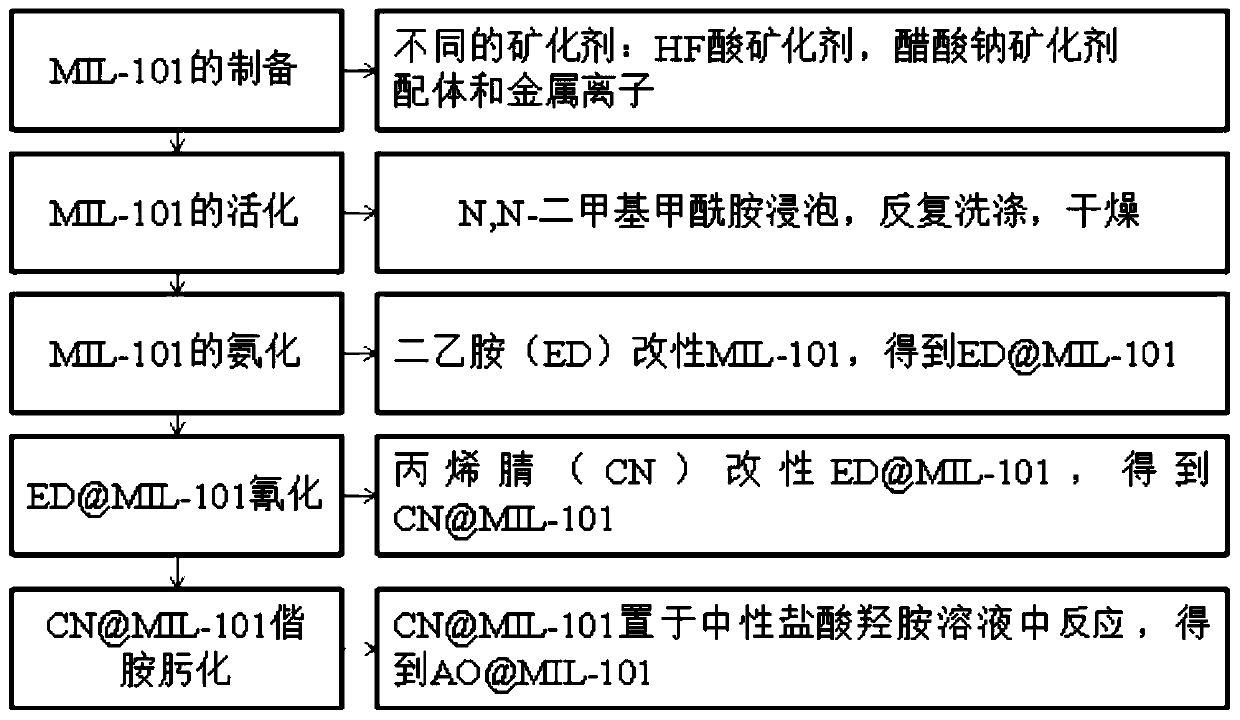

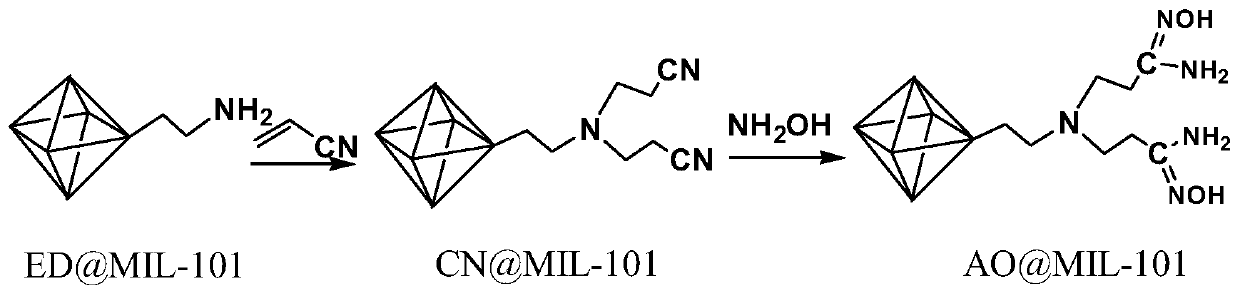

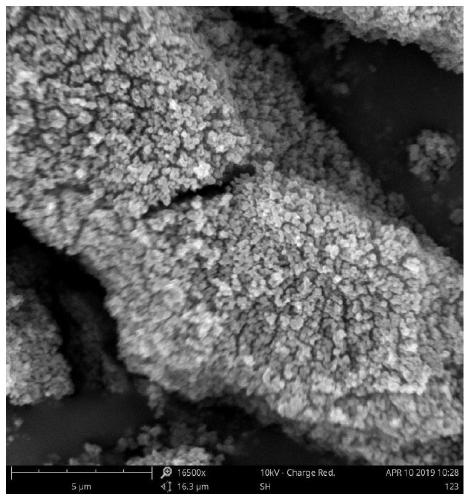

Amidoxime group modified MOF material and preparation method thereof

PendingCN110479213ALarge specific surface areaImprove water stabilityOther chemical processesRadioactive decontaminationWastewaterEnvironmental remediation

The invention relates to an amidoxime group modified MOF material and a preparation method thereof, and belongs to the technical field of materials. The amidoxime group modified MOF material is an MIL-101(Cr) material, and a central atom of the MIL-101(Cr) material which is subjected to coordination modification by amidoxime groups is Cr. The amidoxime group modified MOF material has the advantages of large specific surface area, good water stability, high adsorption efficiency and high adsorption rate; has good selective adsorption performance on uranium, and has good application prospects inthe fields of seawater uranium extraction, radioactive wastewater treatment, environmental remediation and the like. The preparation method is simple in process and good in separation effect, terephthalic acid and chromic nitrate nonahydrate which are relatively cheap reagents are adopted, and the synthesis steps are novel.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Mechanical zinc plating technique

InactiveCN103334100AReduce lossUniform thicknessLiquid/solution decomposition chemical coatingPressure inorganic powder coatingCopper platingWear resistance

The invention discloses a mechanical zinc plating technique which comprises the following steps of: 1) preplating: removing oil and rust and washing; 2) copper plating for priming: plating a thin copper layer on the surface of a workpiece by adopting a chemical copper dipping method, and washing after plating is finished; 3) zinc plating and excessive precipitation: adding zinc powder and dedicated initiator into a roller, rolling for 3-6 minutes; 4) zinc plating and precipitation: adding zinc powder, dedicated initiator, impact media and water into the roller, and rolling for 25-45 minutes; 5) surface passivation: placing the workpiece in passivation solution to form a passivation film; 6) aftertreatment: spin-drying, drying, detecting and accepting. The impact media refers to glass microbeads with the diameter of less than 0.5mm; the passivation solution is chromic nitrate. By adopting the process technology, the energy loss is low, the zinc-plating coating is uniform in thickness, and has good corrosion resistance, wear resistance and stability.

Owner:NANTONG TIANTIAN MACHINE TOOL

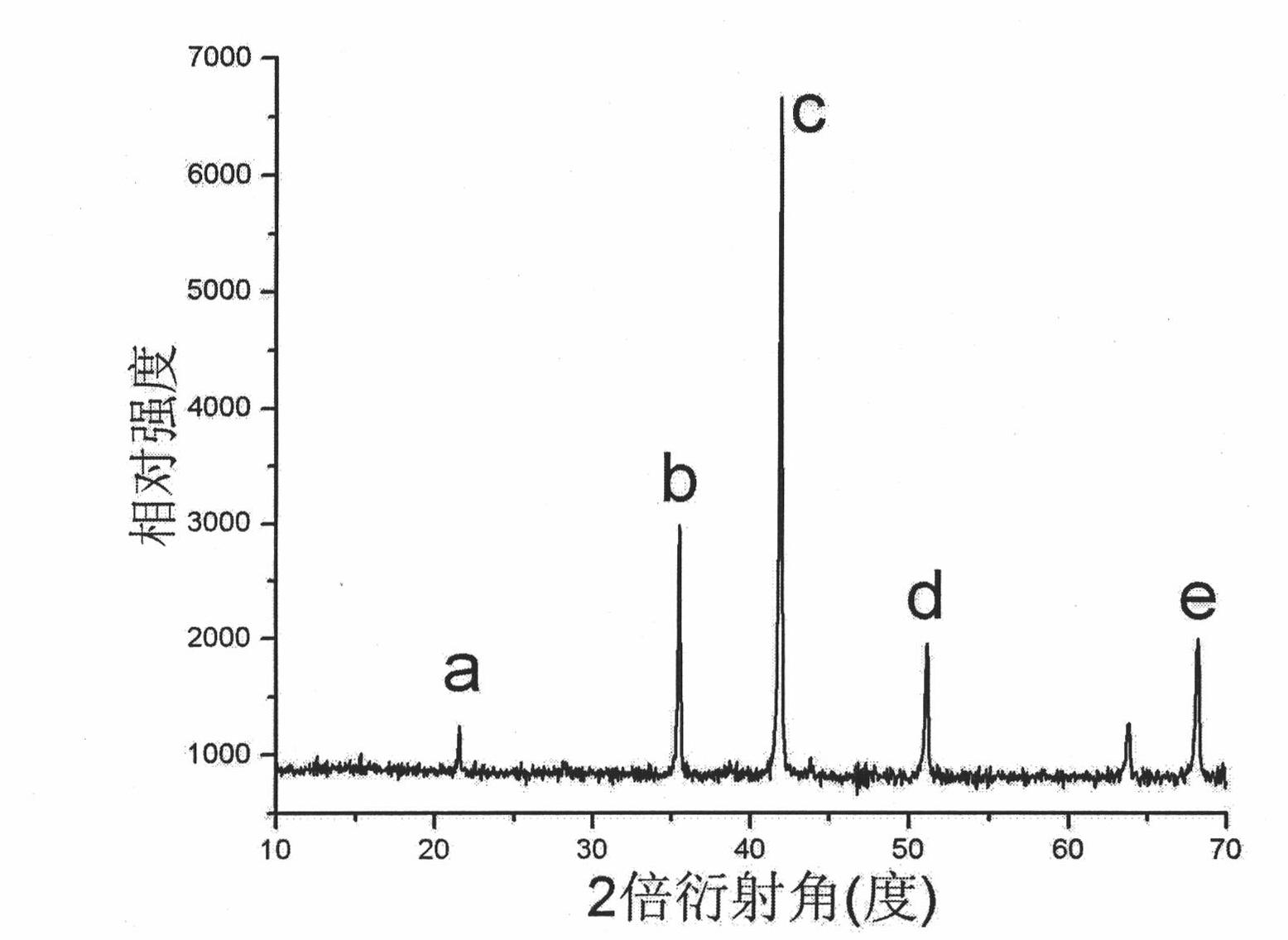

Preparation method and application of highly active bismuth chromate nano photocatalyst

ActiveCN107961785AWide light absorption rangeHigh Photocatalytic Quantum EfficiencyWater/sewage treatment by irradiationWater treatment compoundsOxygenCHROMIC NITRATE

The invention relates to a preparation method and application of a highly active bismuth chromate nano photocatalyst, and belongs to the technical field of nanomaterials. The preparation method comprises the steps: firstly, dissolving bismuth nitrate pentahydrate and chromic nitrate nonahydrate in a mannitol aqueous solution; dropwise adding a saturated sodium carbonate aqueous solution into the solution, and stirring evenly to obtain an emulsion; transferring the emulsion to a hydrothermal reaction kettle, carrying out a hydrothermal reaction, cooling to room temperature, centrifuging, washing and drying to obtain a precursor powder, and calcining the precursor powder, to obtain the bismuth chromate nano photocatalyst. The bismuth chromate nano photocatalyst prepared by the method has thesize in a range of 40-50 nm, and a light absorption band edge can be extended to a red light region; at the same time, the bismuth chromate nano photocatalyst has high-efficiency pollutant photocatalysis degradation and oxygen producing activity in a visible region, the oxygen producing quantum efficiency at 600 nm reaches 1.52%, and the bismuth chromate nano photocatalyst has quite good light stability. The preparation method provided by the method has cheap raw materials, has simple process, is suitable for industrialized mass production, and has good application prospects.

Owner:TSINGHUA UNIV

Galvanized steel sheet trivalent chromium passivator concentrated solution and preparation method

ActiveCN105586583ALong time corrosion resistanceUniform and stable film formationMetallic material coating processesSodium Hypophosphite MonohydrateNitrate

The invention discloses a galvanized steel sheet trivalent chromium passivator concentrated solution. The galvanized steel sheet trivalent chromium passivator concentrated solution is mainly prepared from 5-10 parts of chromic nitrate, 10-20 parts of chromium dihydrogen phosphate, 1-5 parts of inorganic acid, 5-10 parts of sealing agent acidic silica sol, 0.5-2 parts of sodium hypophosphite, 0.5-2 parts of cobalt nitrate, 0.1-2 parts of complexing agent organic acid and 50-65 parts of deionized water. A trivalent chromium passivator can achieve continuous passivation film formation on the surface of an automotive hot-dip galvanized steel sheet, the passivation reaction time is short, the salt spray resisting time of a film is long, and the galvanized steel sheet trivalent chromium passivator concentrated solution is suitable for workpiece treatment through automotive hot-dip galvanized steel sheet dipping and roller coating and especially suitable for the continuous passivation process.

Owner:宜昌鑫汇船舶修造有限公司

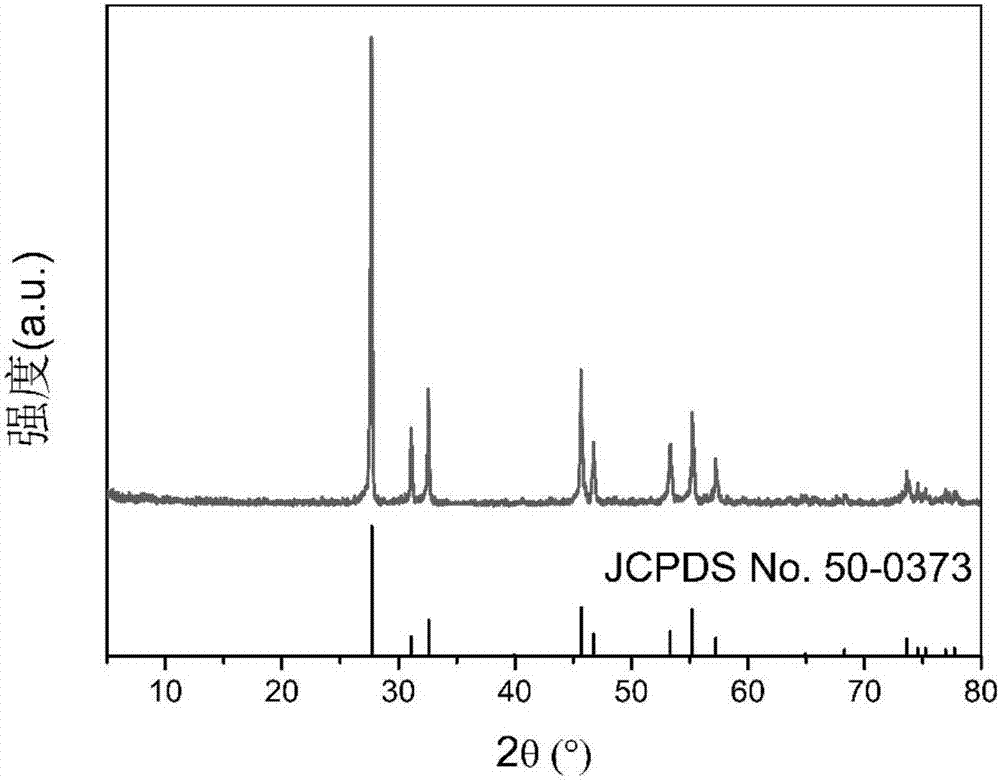

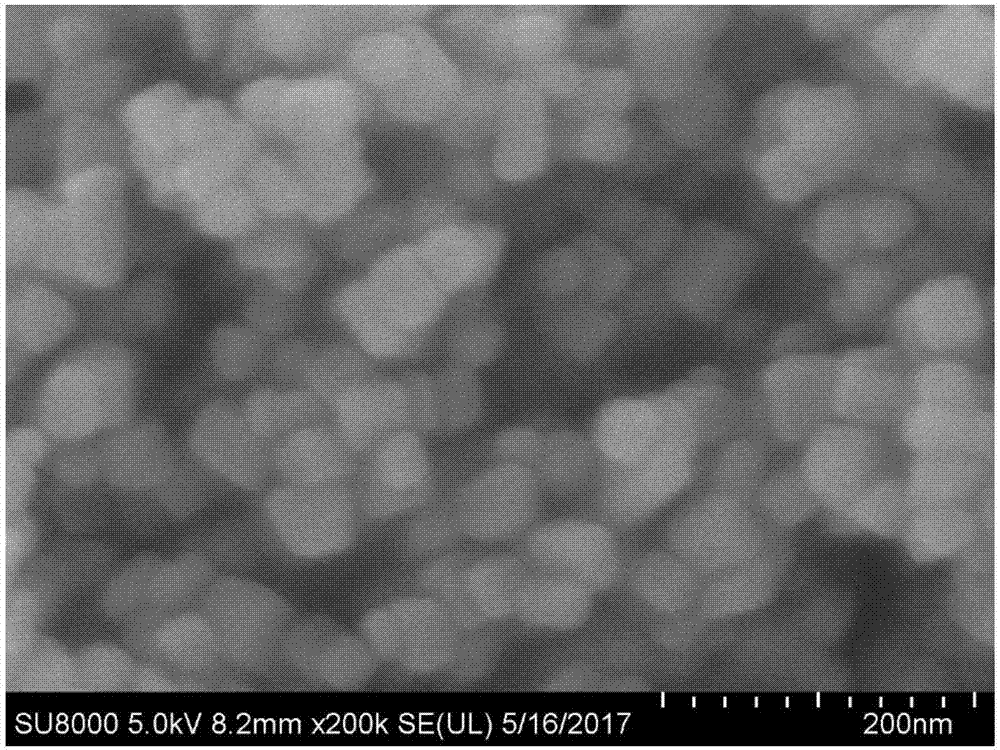

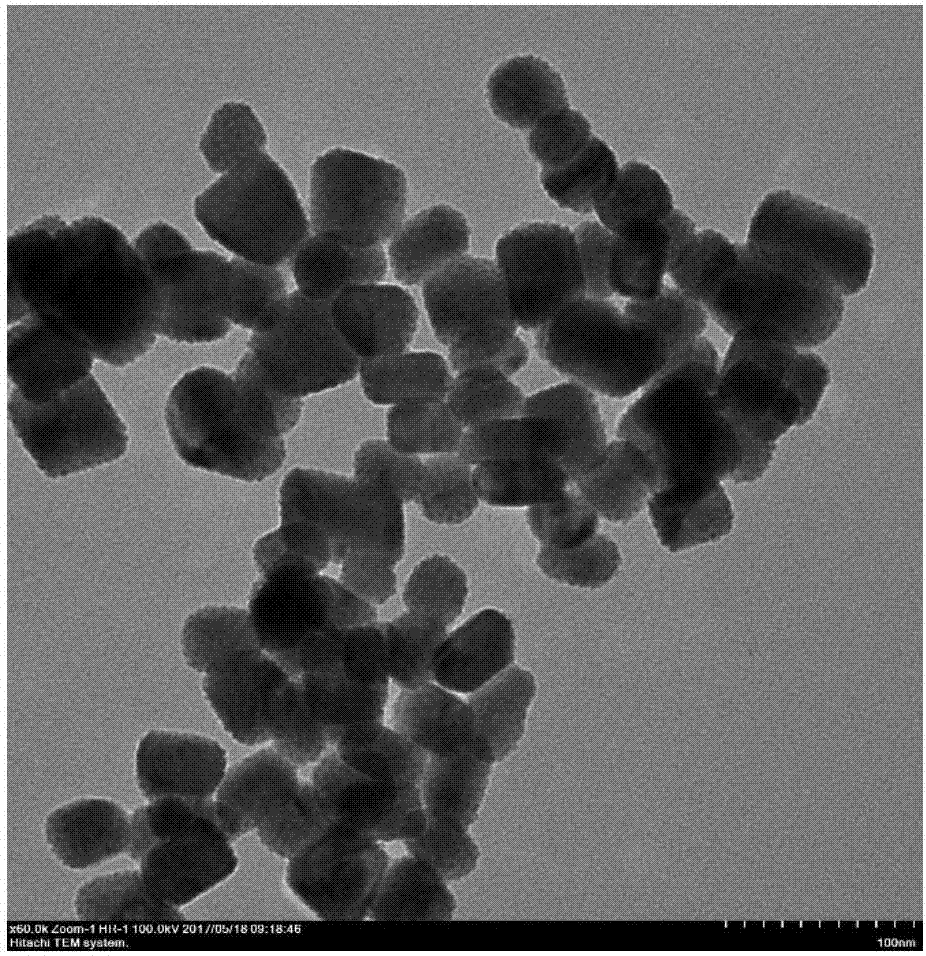

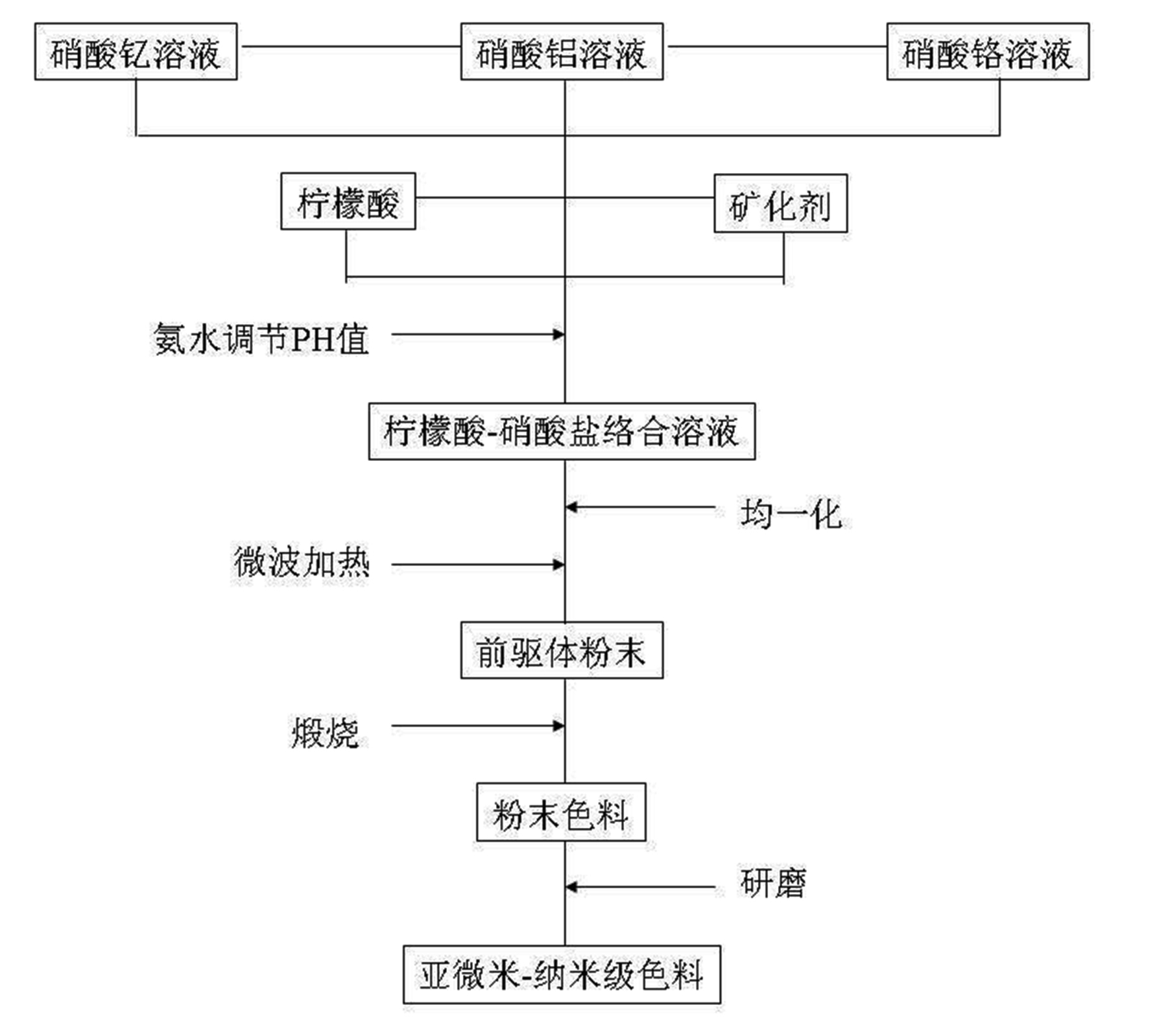

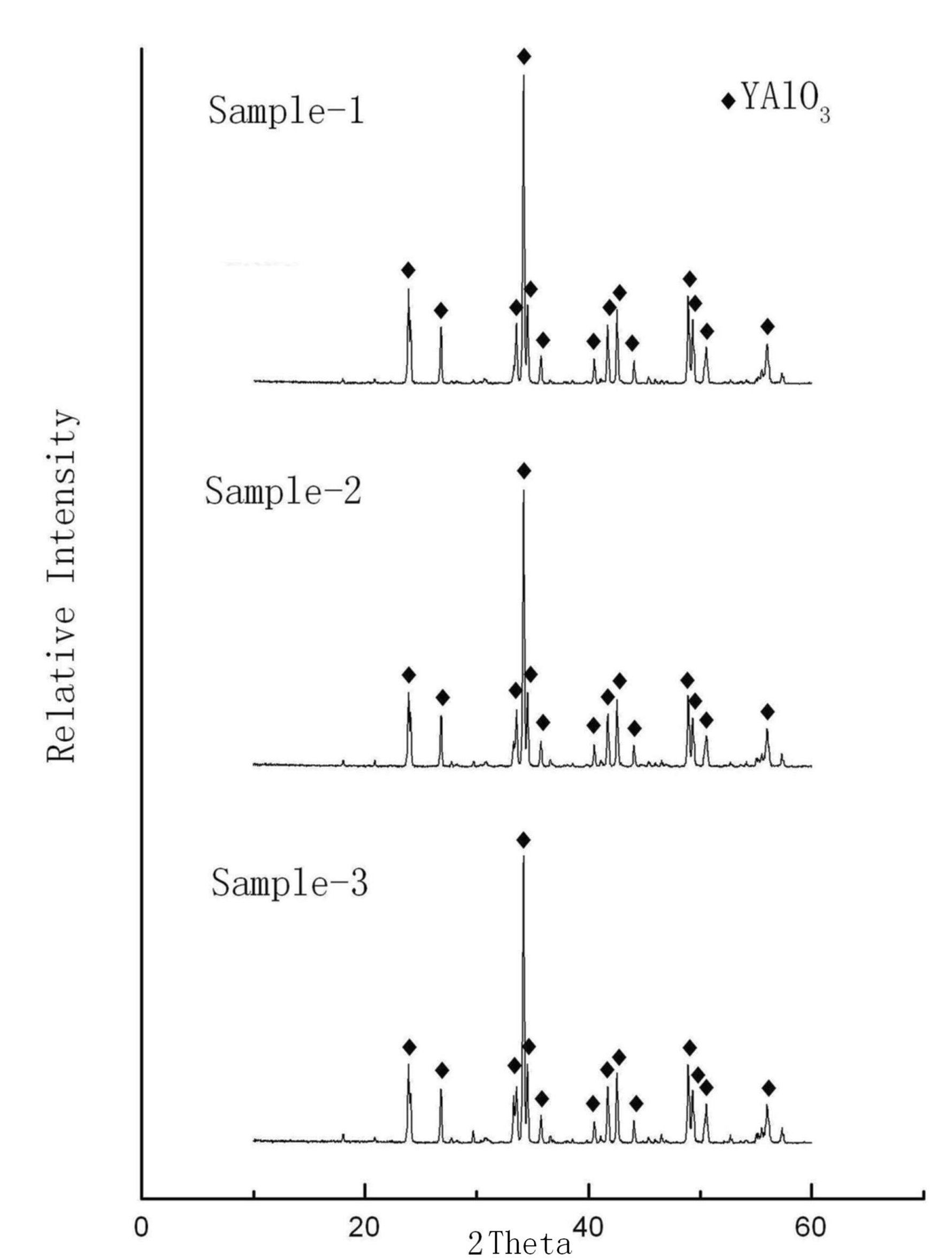

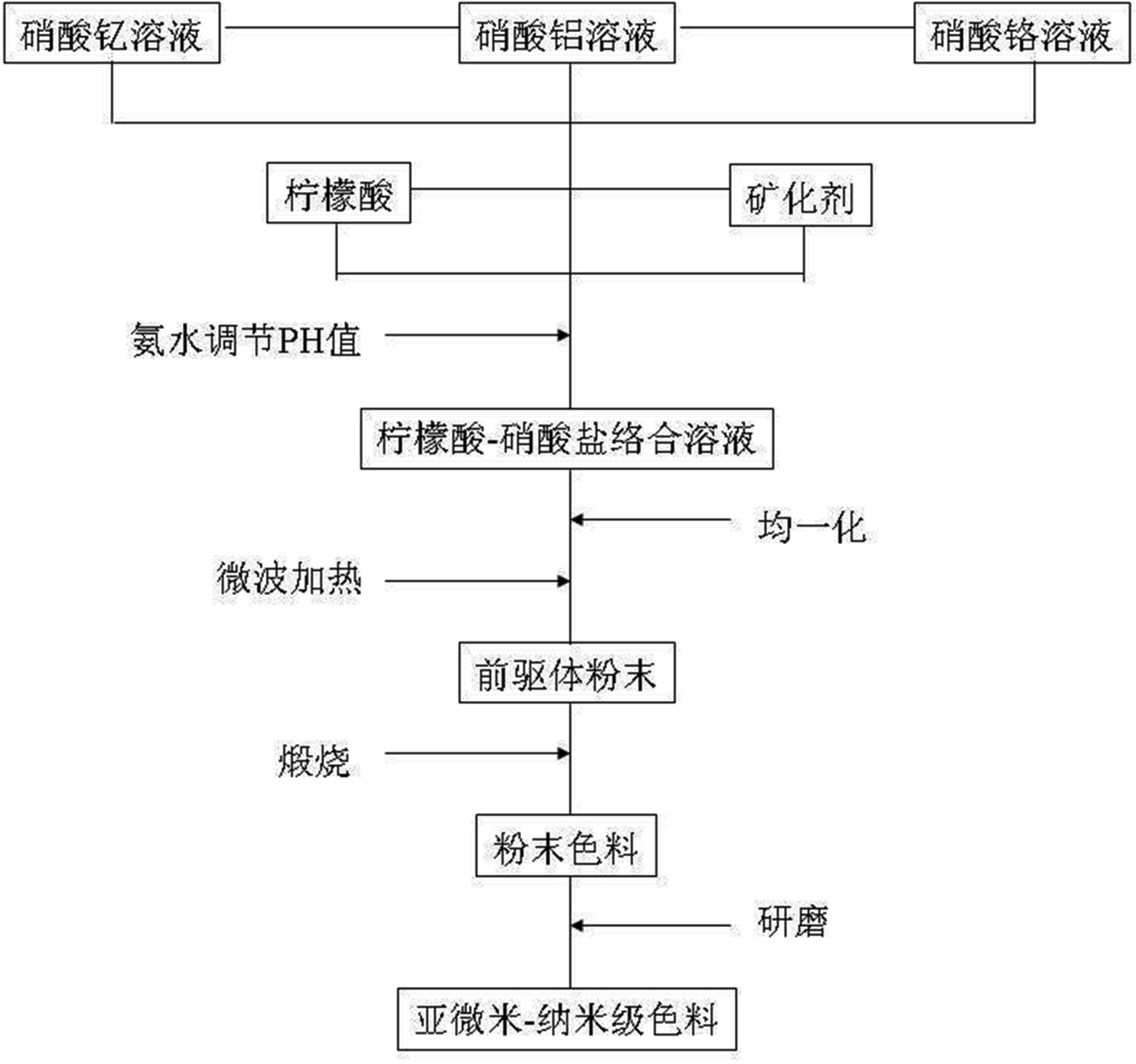

Submicron-nanometer level red ceramic pigment and manufacturing method thereof

InactiveCN102432341AImprove responseGood color strengthPigment physical treatmentPhysical chemistryBall mill

The invention relates to the technical field of ceramic pigment, in particular to a submicron-nanometer level red ceramic pigment and a manufacturing method thereof. The general form of the red ceramic pigment is YAL1-xCrxO3, wherein x=0.01-0.1, and the particle size distribution of the pigment is 90-900 nm. The manufacturing steps comprise: 1, burdening: using chromic nitrate, yttrium nitrate, aluminum nitrate and citric acid as starting raw materials; 2, mixing and heating: dissolving the starting raw materials into the deionized water, and adding a mineralizing agent into the solution and stirring the agent until the agent is fully dissolved, and regulating the pH value to 5-10 by ammonia water, and heating the solution by microwaves to lead the solution burn to form a precursor; 3, heat treatment: performing heat treatment on the precursor for 0.5-8 h at 700-1, 300 degrees centigrade to obtain chromium-doped yttrium aluminum red ceramic dye powder; 4, grinding: ball milling the powder for 0.3-2 h to obtain a submicron-nanometer level red ceramic pigment with a particle size distribution of 90-900 nm. The red ceramic pigment manufactured by the manufacturing method disclosed bythe invention has advantages of strong color development ability, small grain diameter and good dispersibility.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com