Patents

Literature

260results about How to "Fully covered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

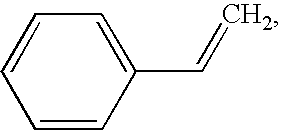

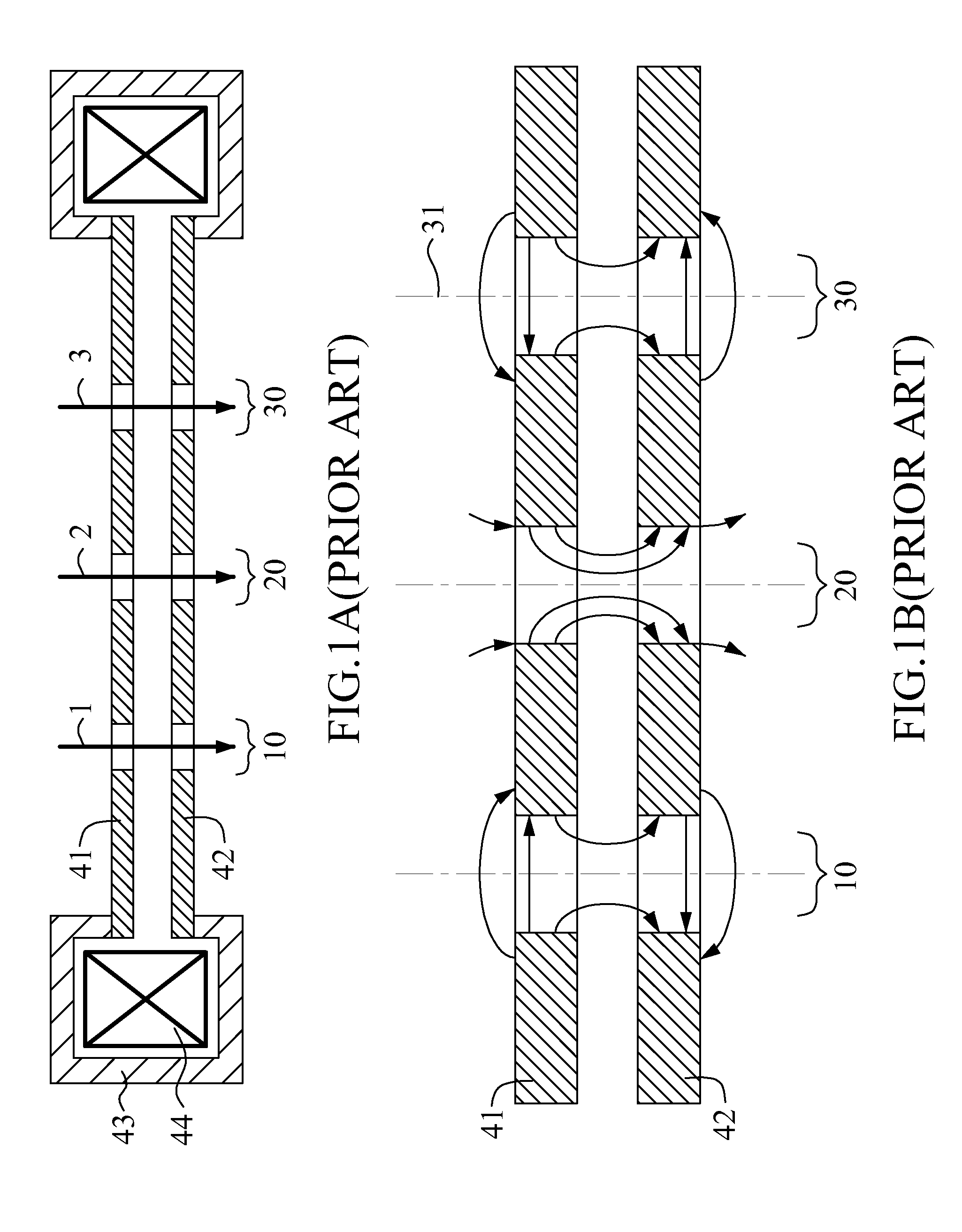

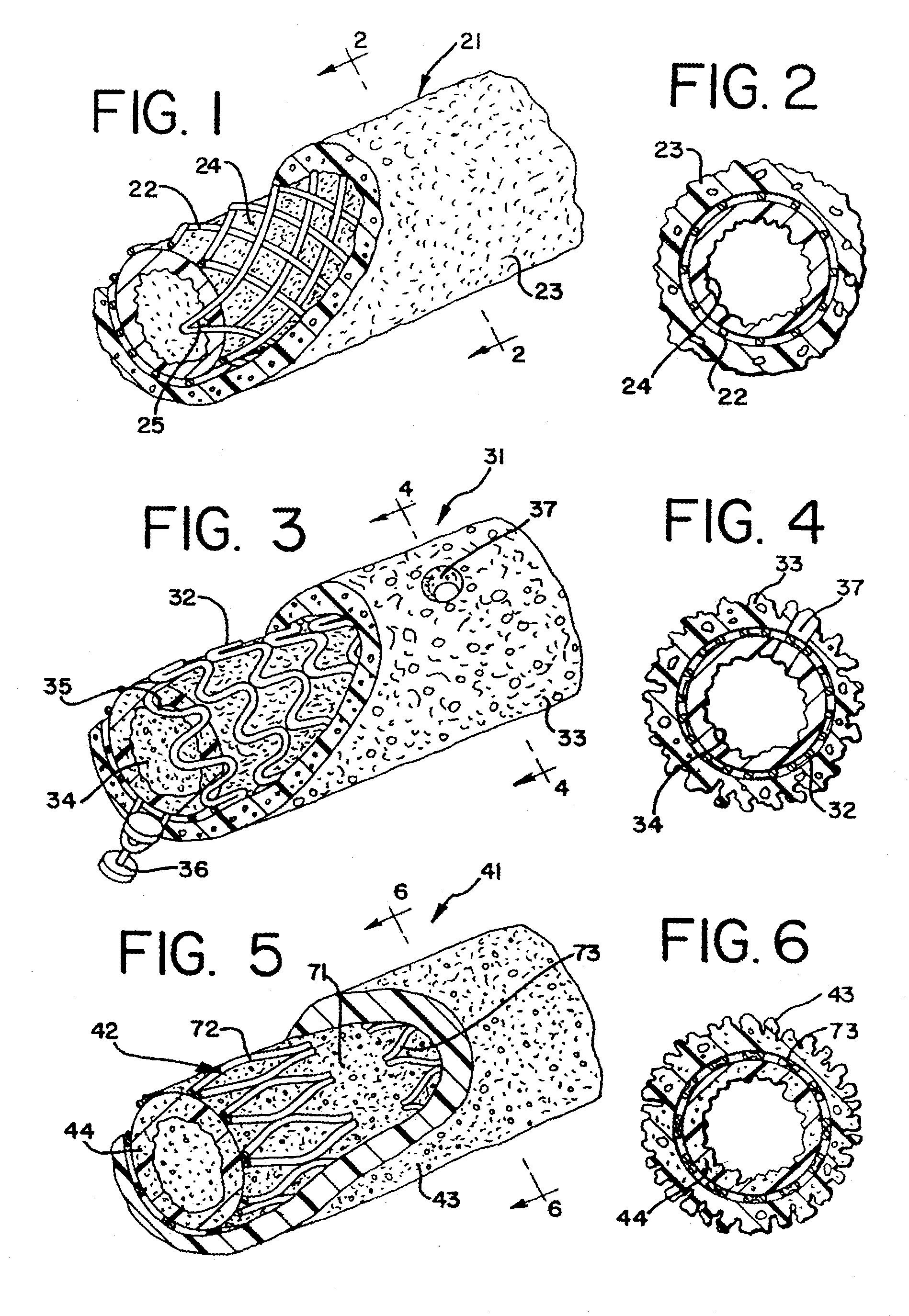

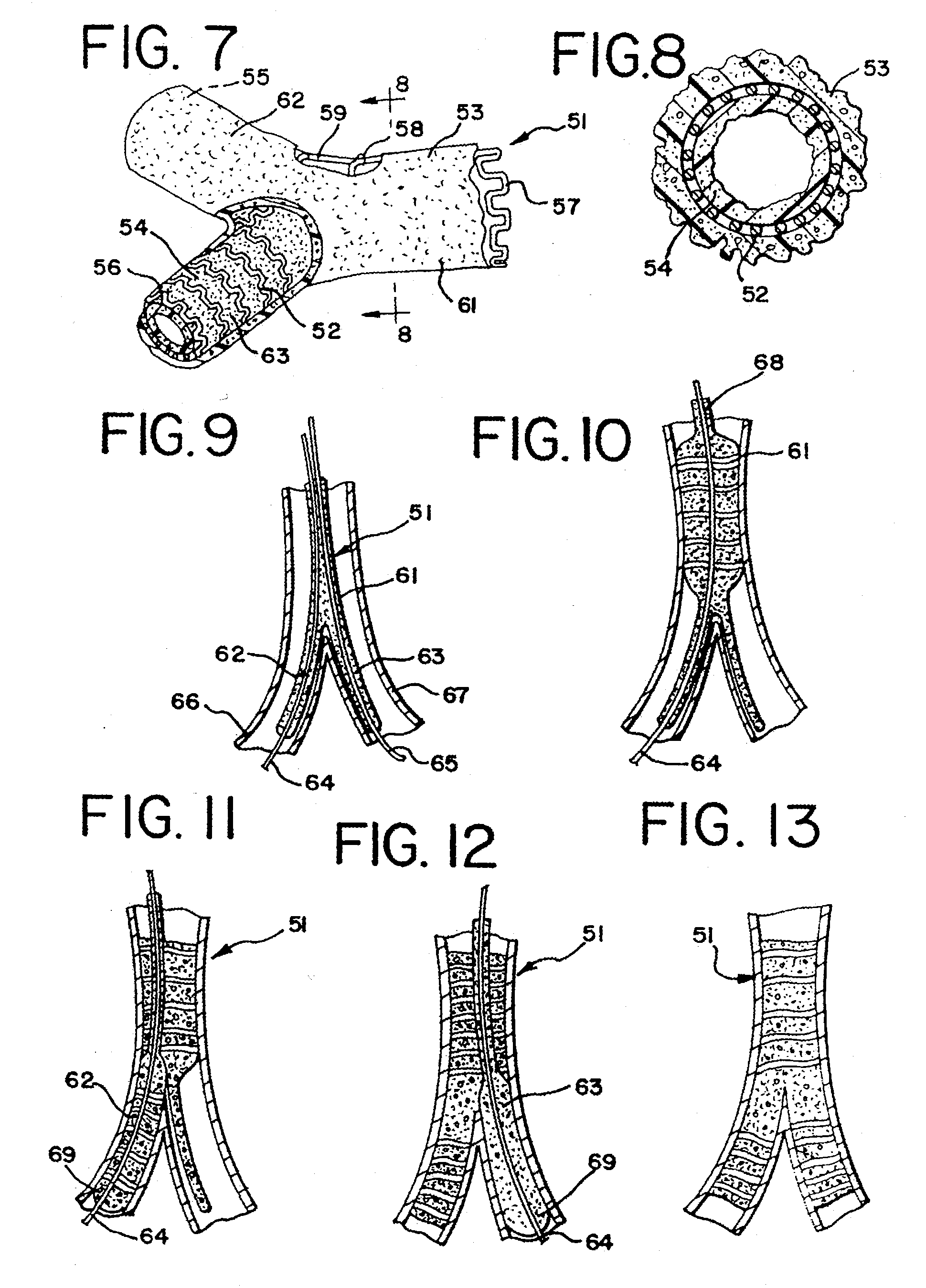

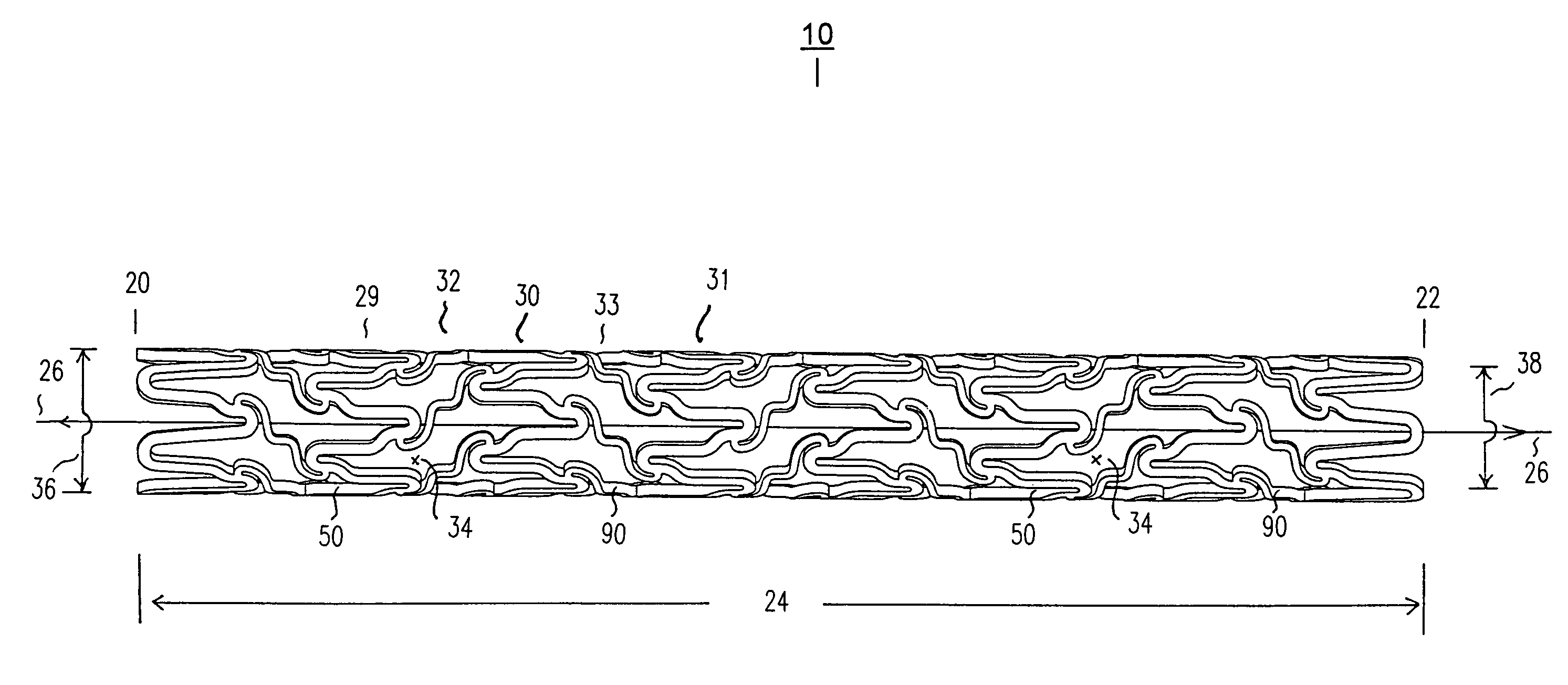

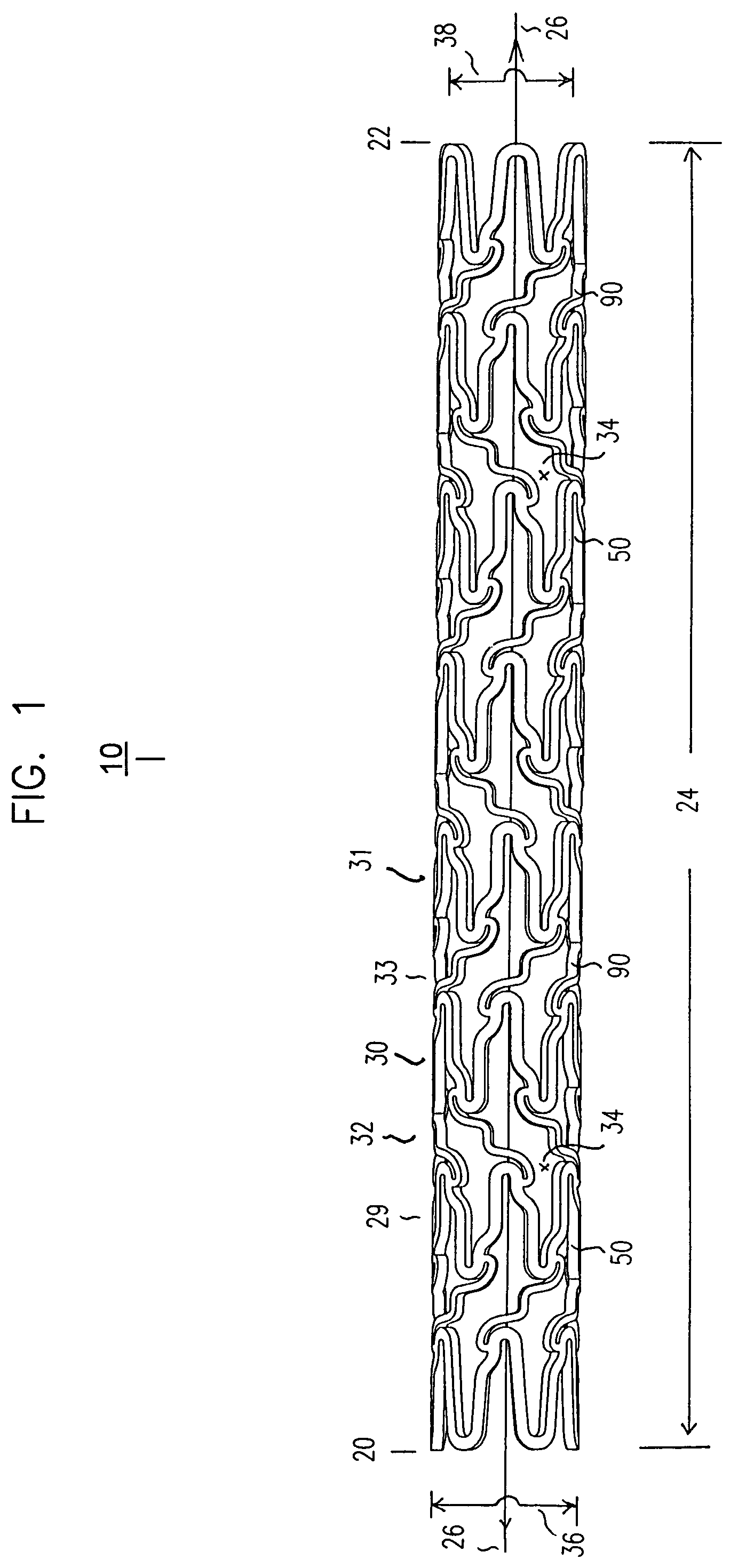

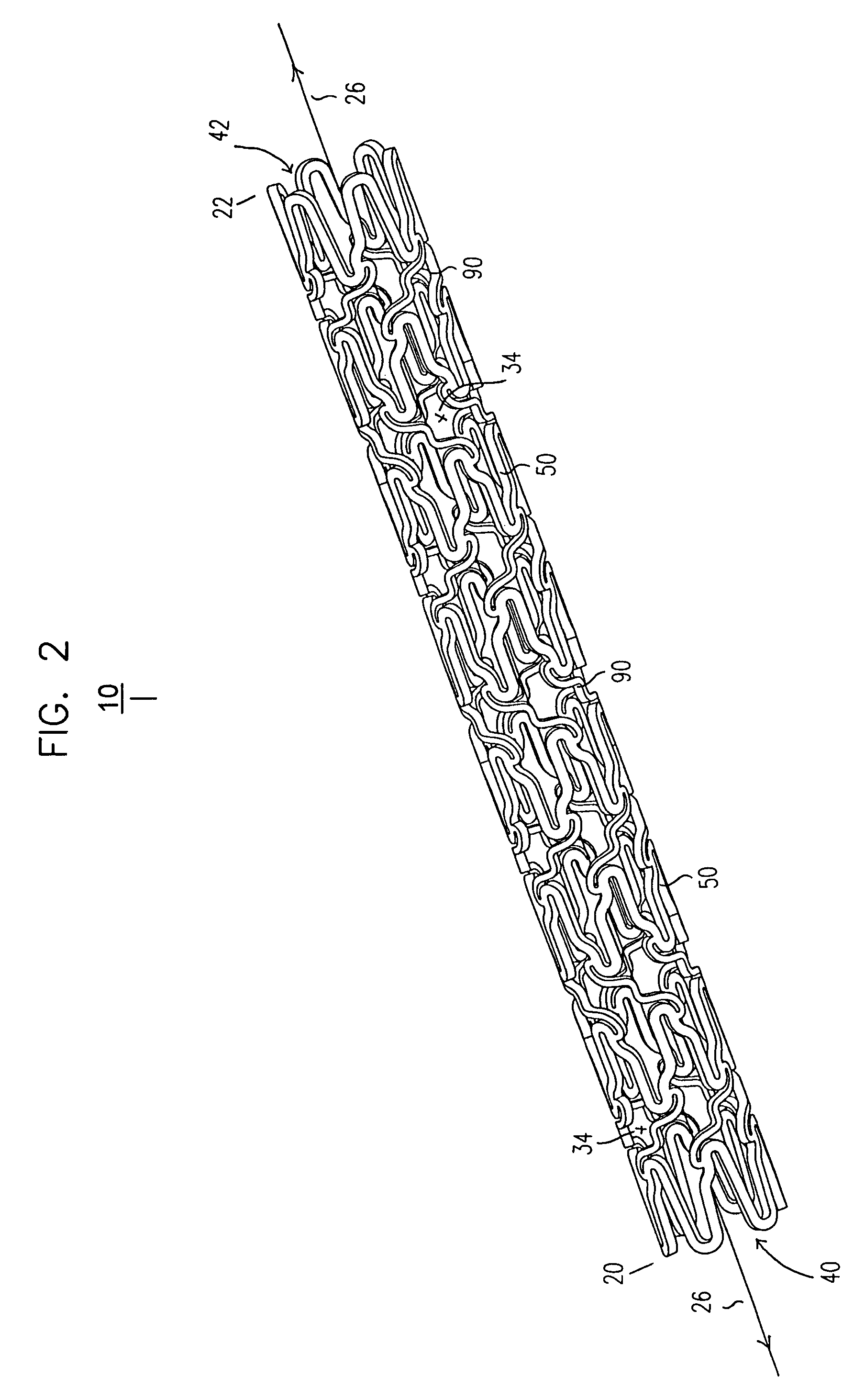

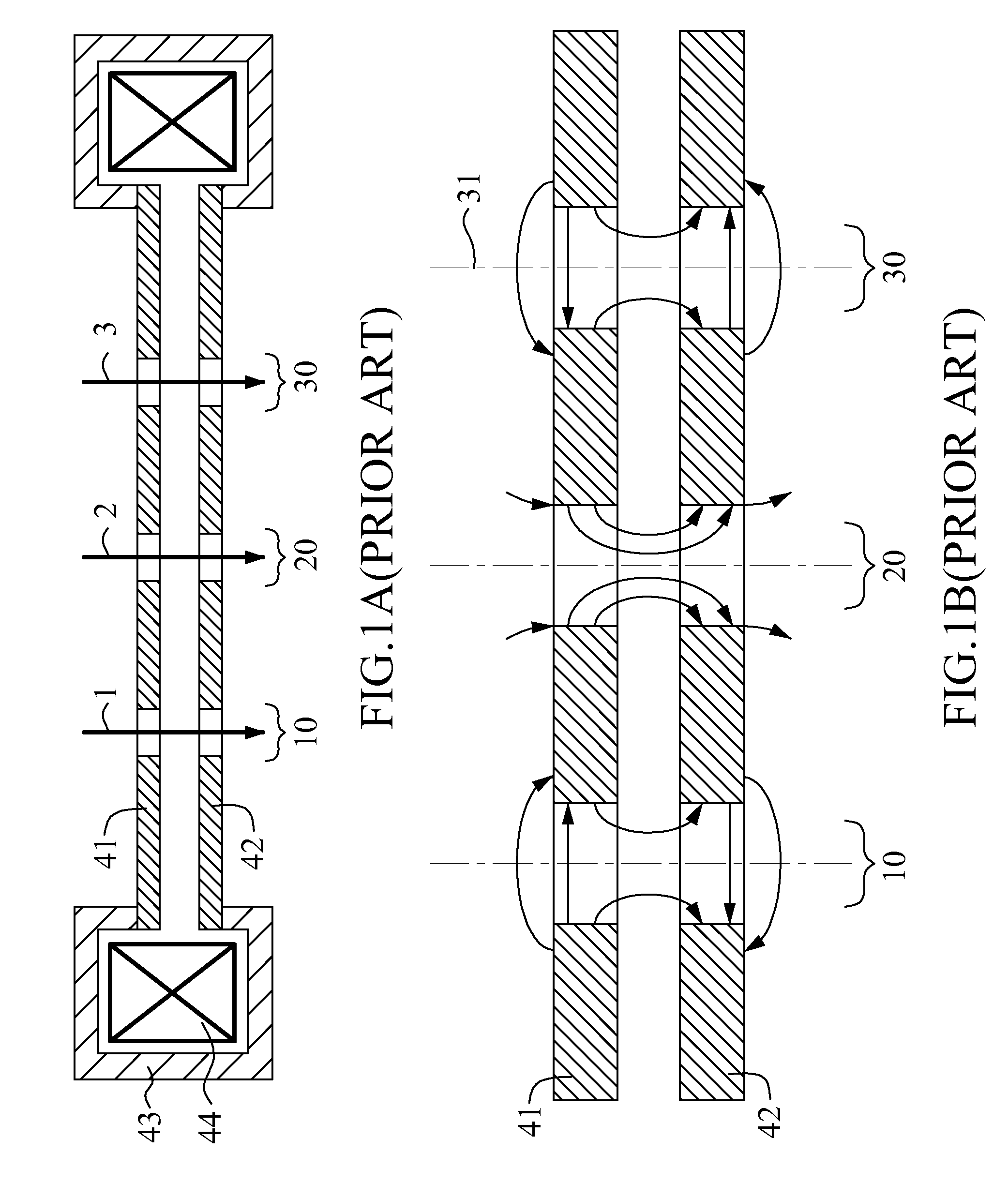

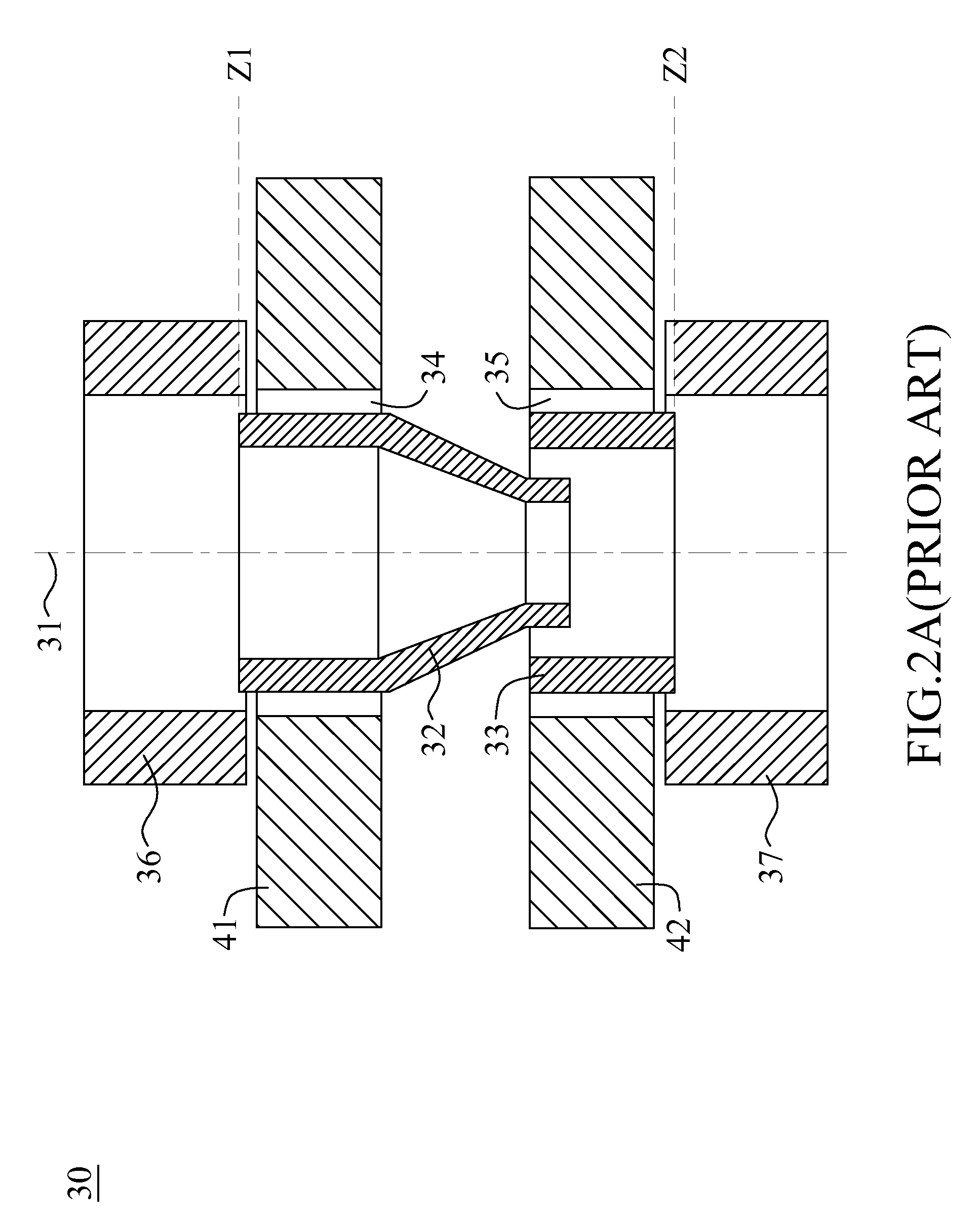

Intravascular stent and assembly

InactiveUS20040133271A1Maximum possible flexibility and conformabilityOptimal metal fractionStentsSurgeryVascular lumenIntravascular stent

Various intravascular stents, such as intracoronary stents, include improved expansion and connecting strut designs. Such stents can be both very flexible and fully cover vessel surface inside the vascular lumen, and be well designed for both the delivery phase and the deployed phase of the stent life cycle.

Owner:BOSTON SCI SCIMED INC

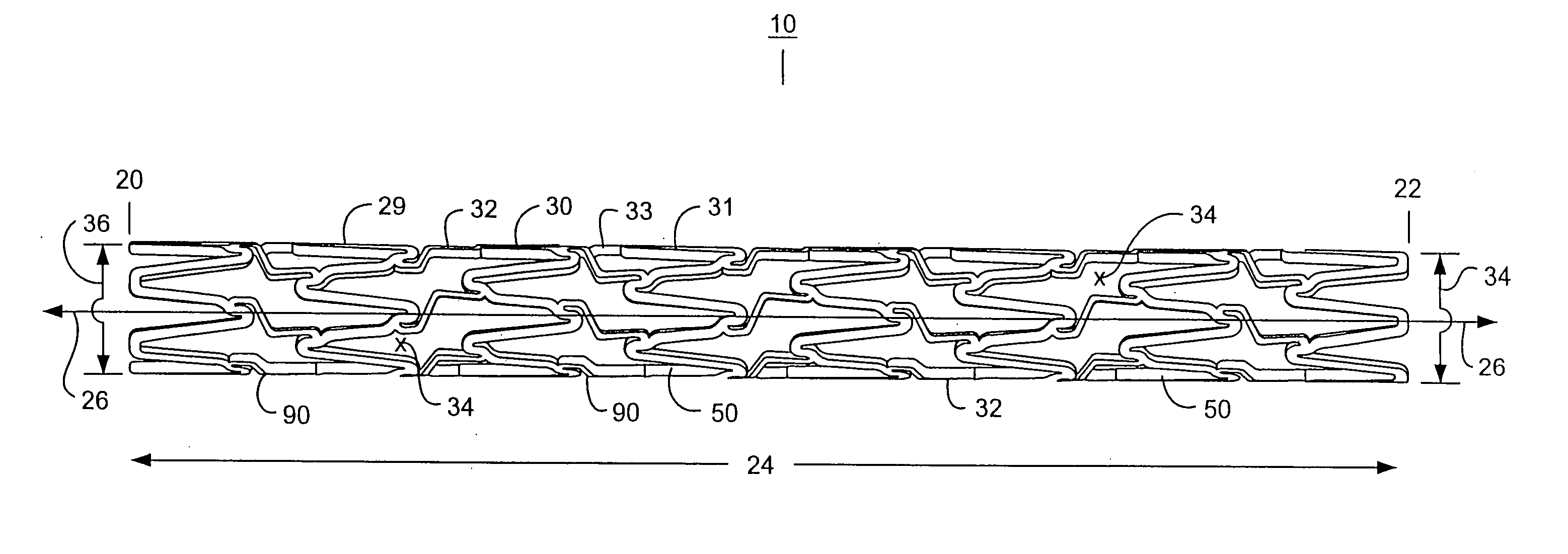

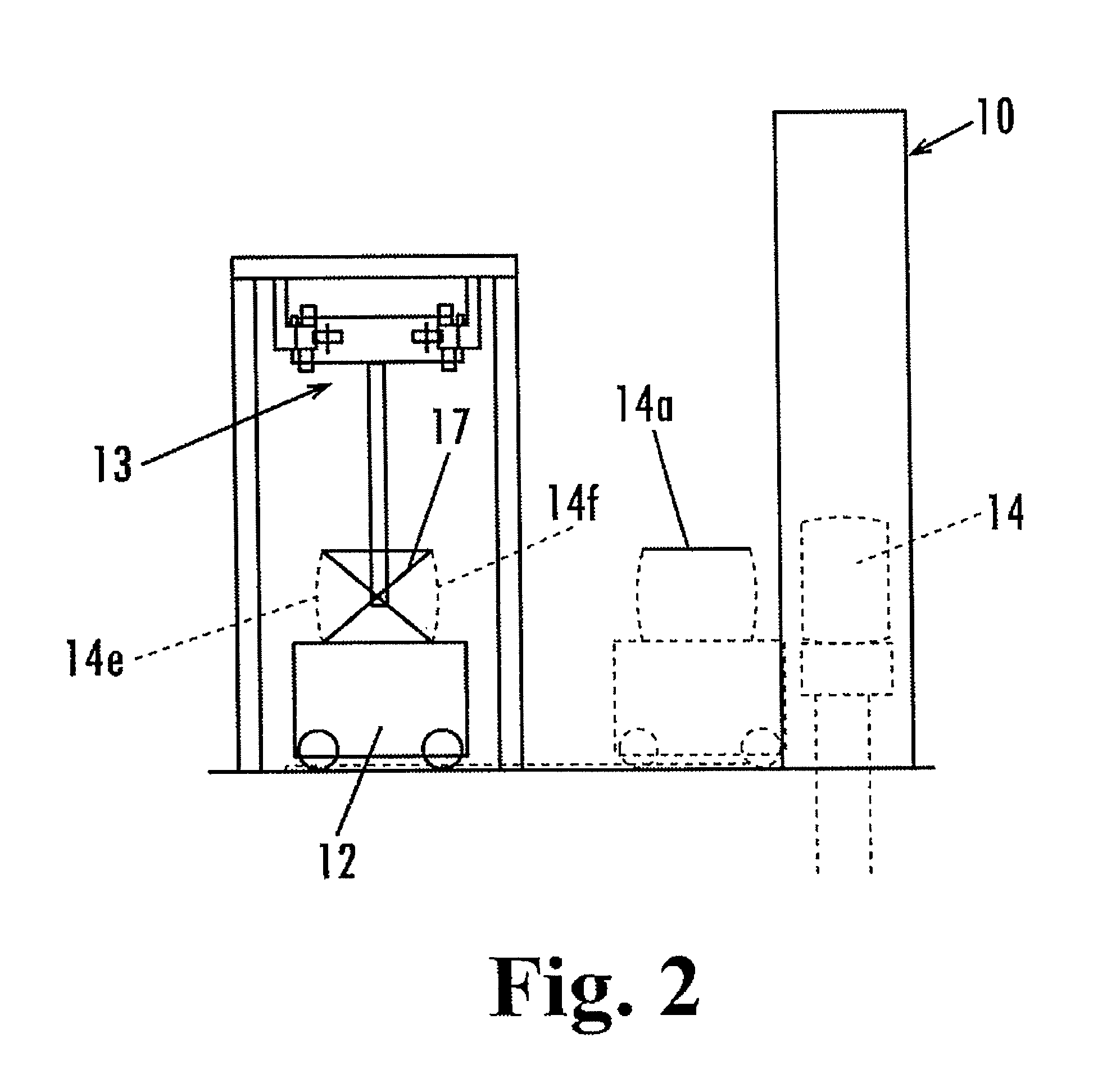

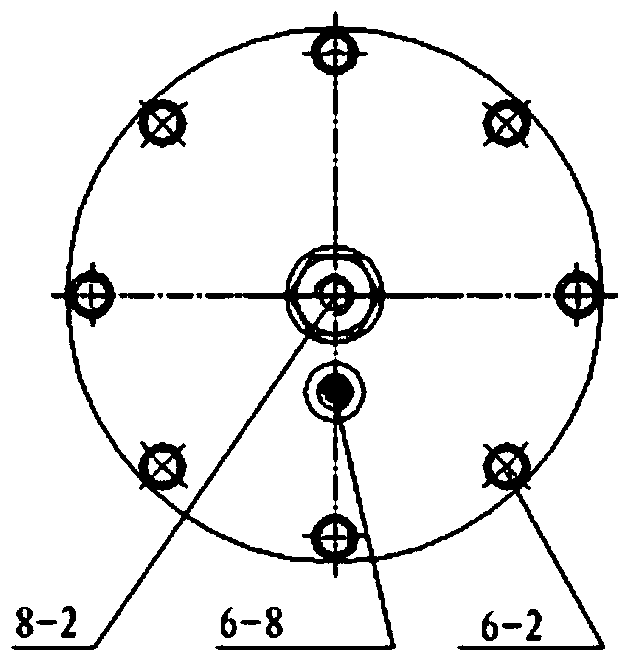

Apparatus of plural charged particle beams with multi-axis magnetic lens

ActiveUS8294095B2Low aberration lowAvoid damageMaterial analysis using wave/particle radiationElectrode and associated part arrangementsCouplingOptical axis

Owner:ASML NETHERLANDS BV

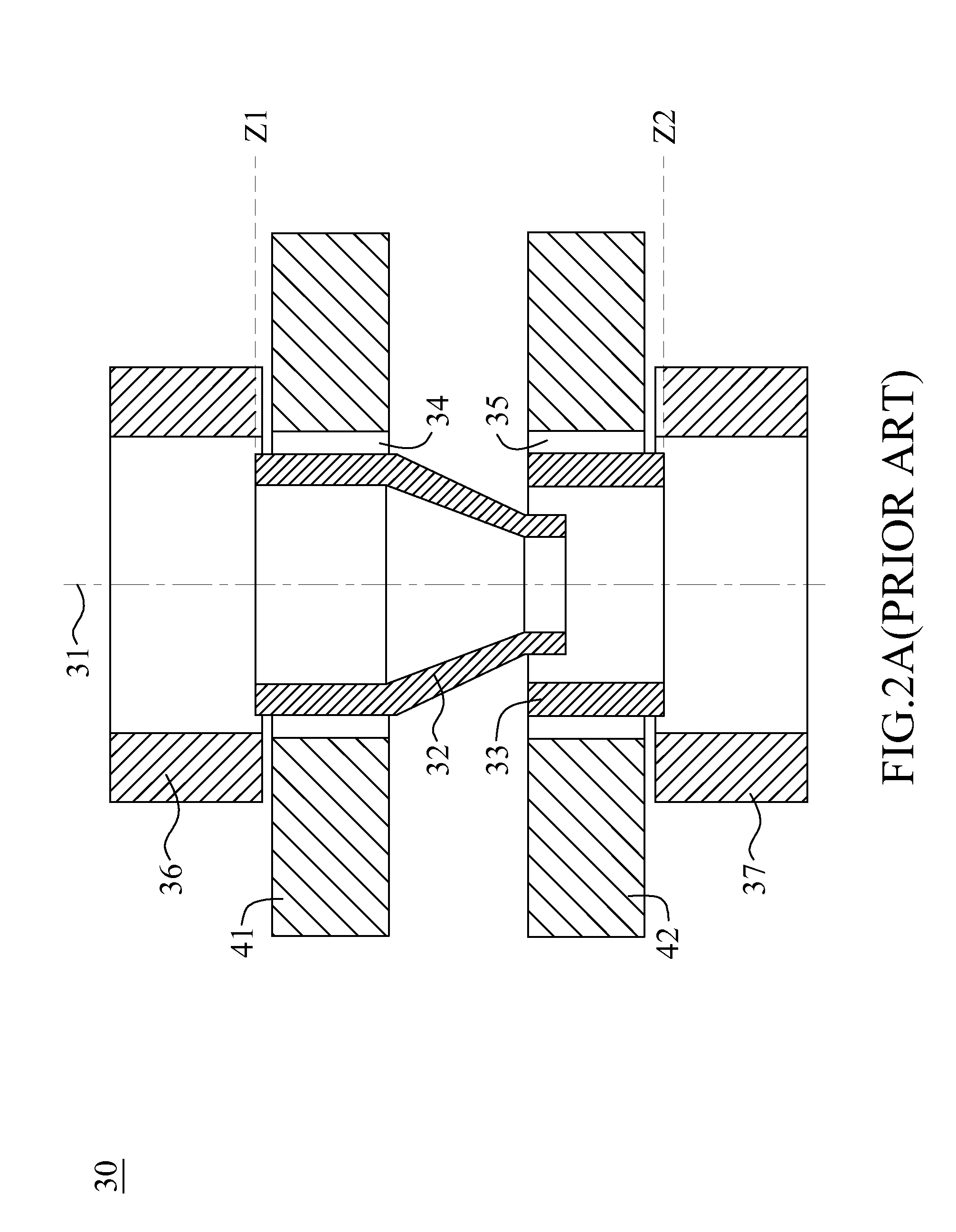

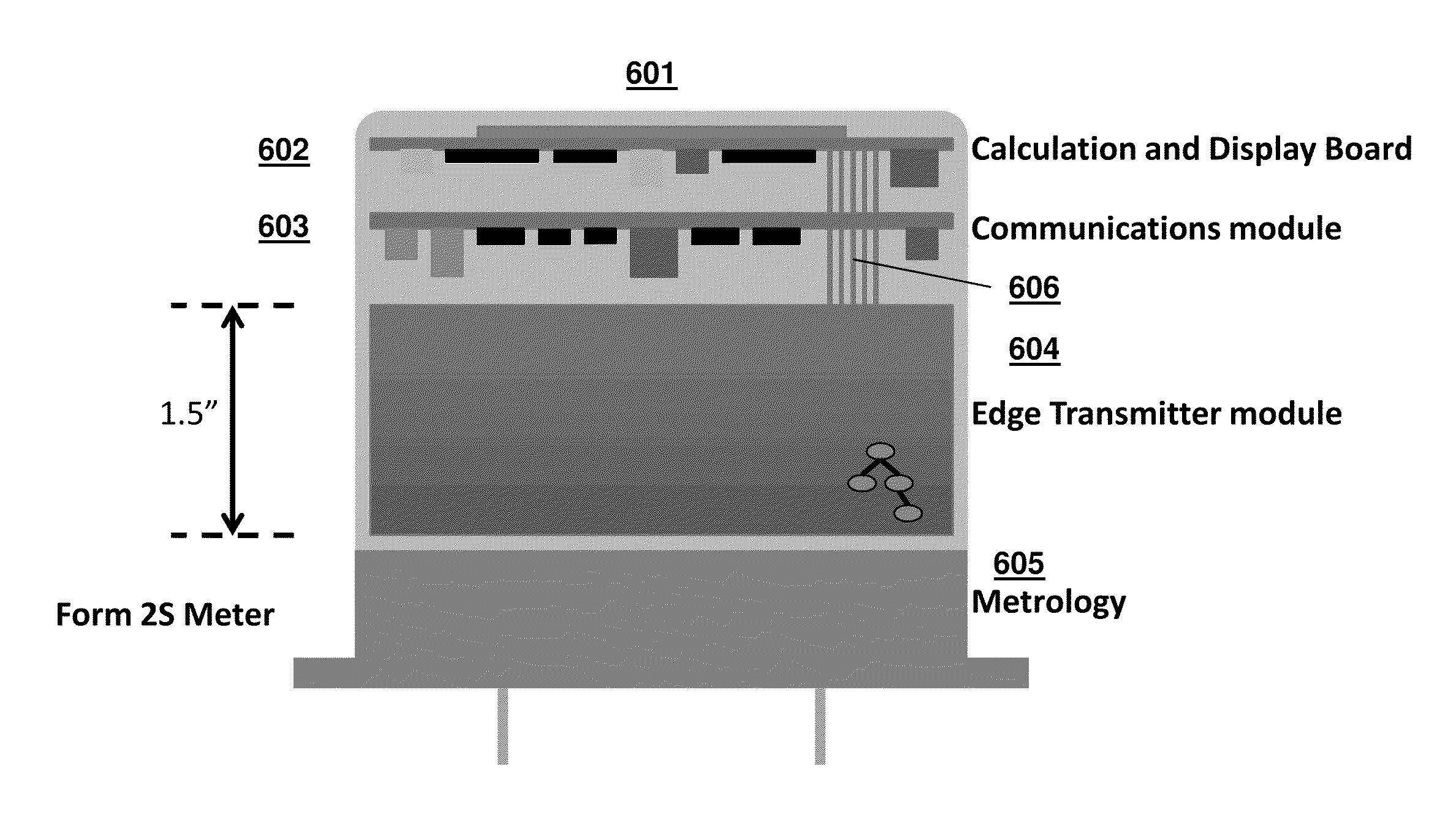

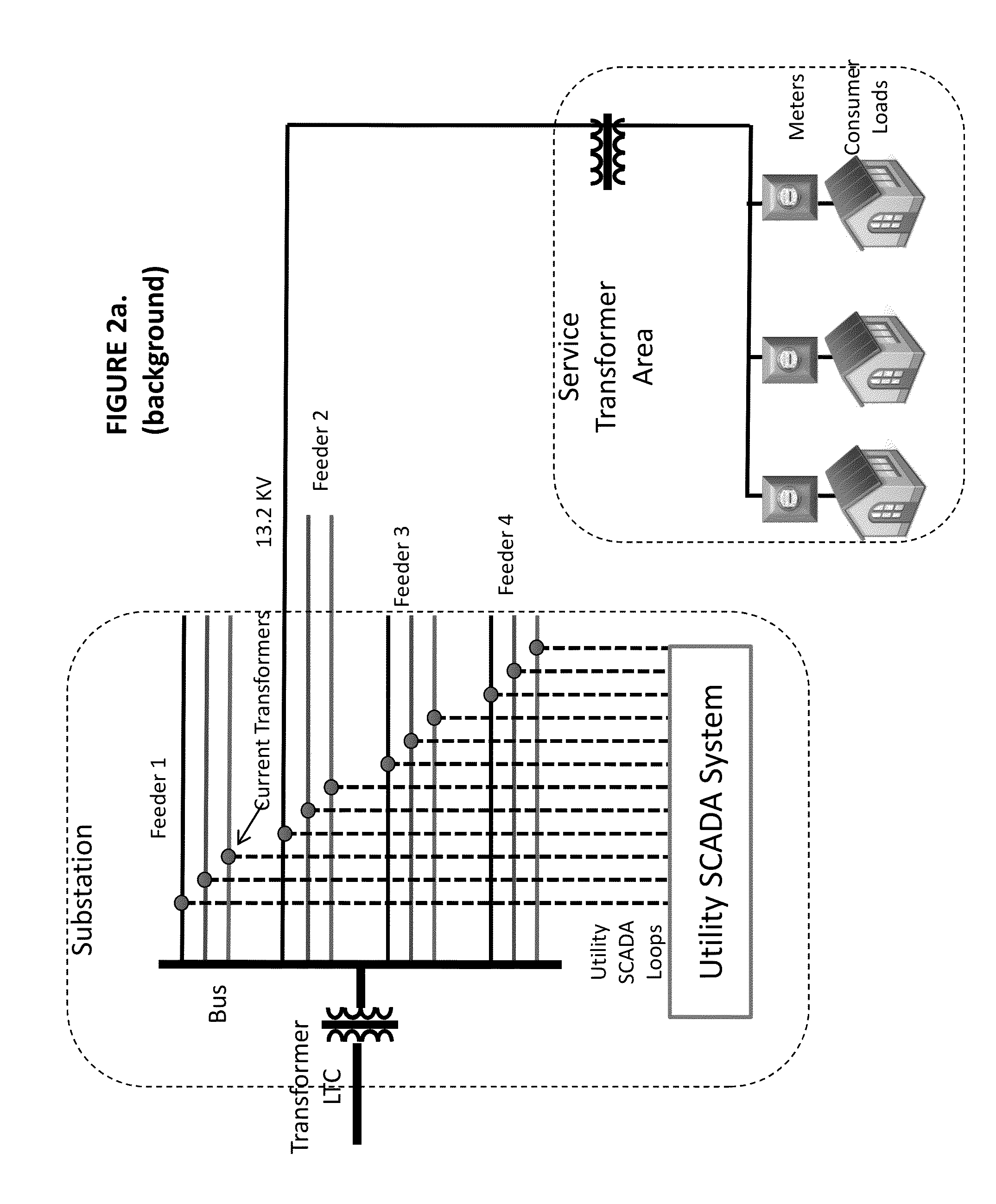

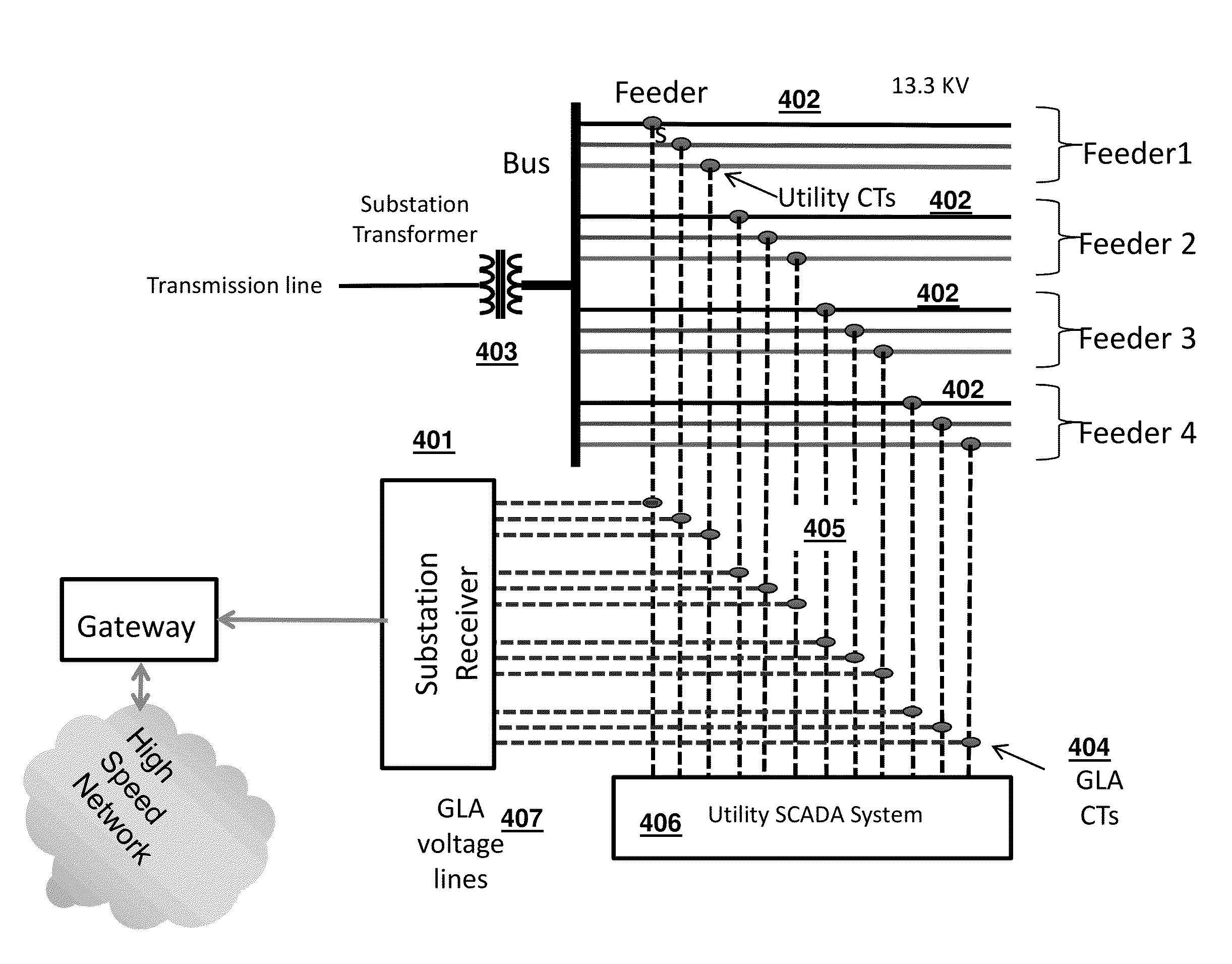

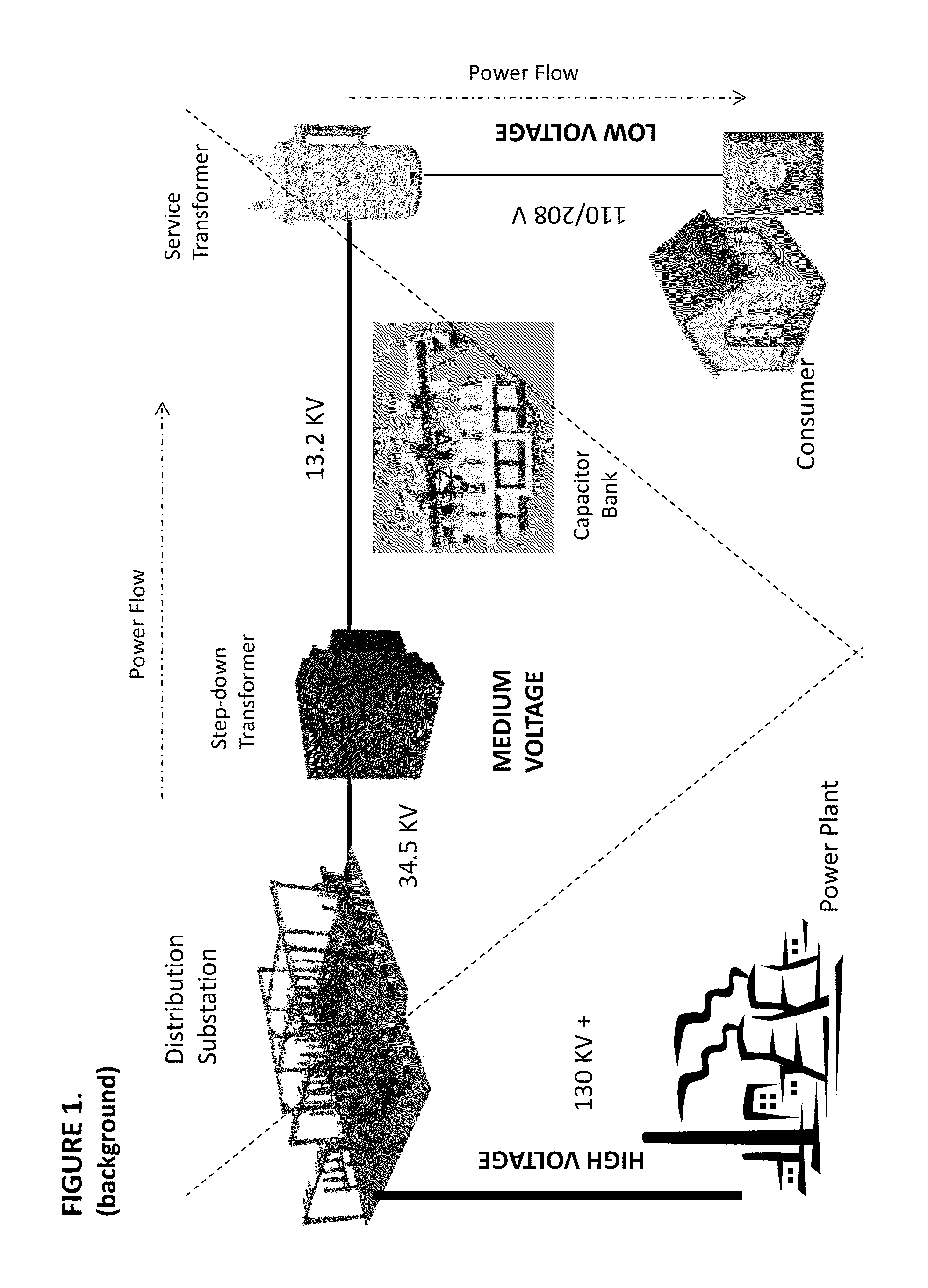

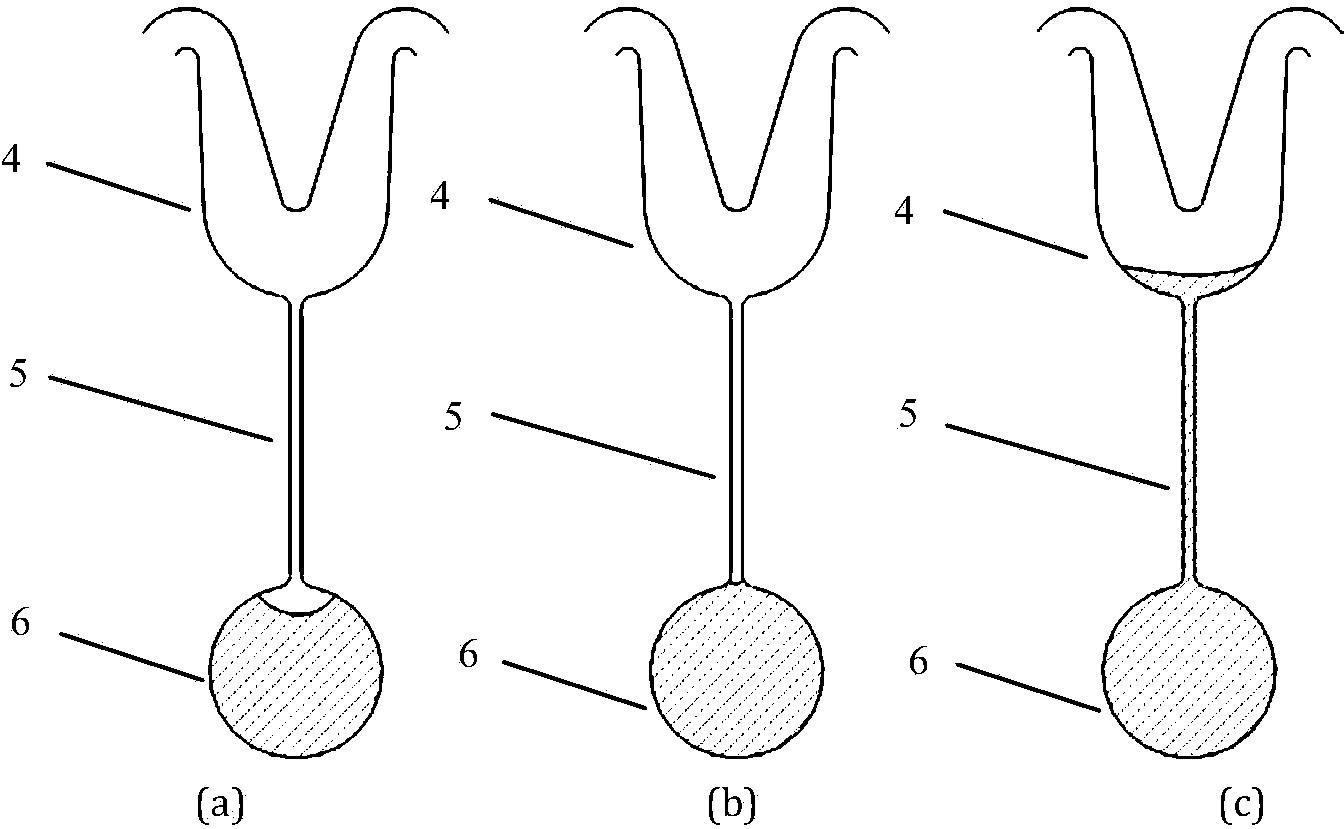

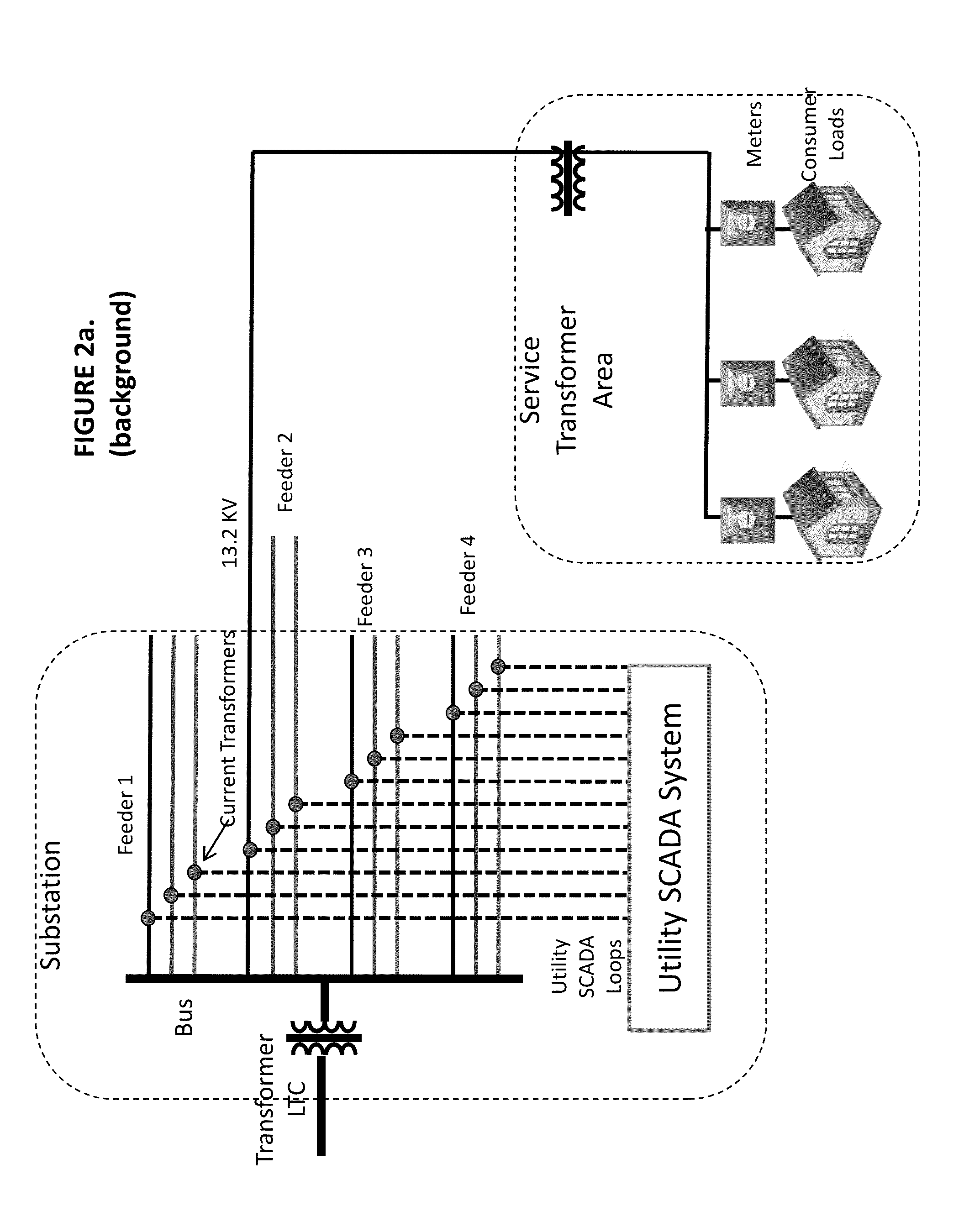

Methods for analyzing and optimizing the performance of a data collection network on an electrical distribution grid

InactiveUS20140233620A1Maximize probabilityReduce bitrateData processing applicationsCircuit arrangementsNetwork onComputer science

A system and methods for optimizing the performance of communication network utilizing an electrical distribution grid are disclosed. Optimization methods may include archiving historical message data and metrics from transmissions by Remote Hubs received on one or more Substation-to-Edge channels. Trends in the archived metrics over time are later analyzed to determine which combination of transmission variables such as frequency band, modulation method, drive voltage, and transmission time produce the highest message success rates overall. The results of such analysis may be used to provide feedback to the Remote Hubs or reveal necessary repairs to the network. Optimization may also be carried out locally by an individual Remote Hub by estimating the impedance of the transmission medium and adjusting either drive voltage or transmission band.

Owner:DOMINION ENERGY TECH +1

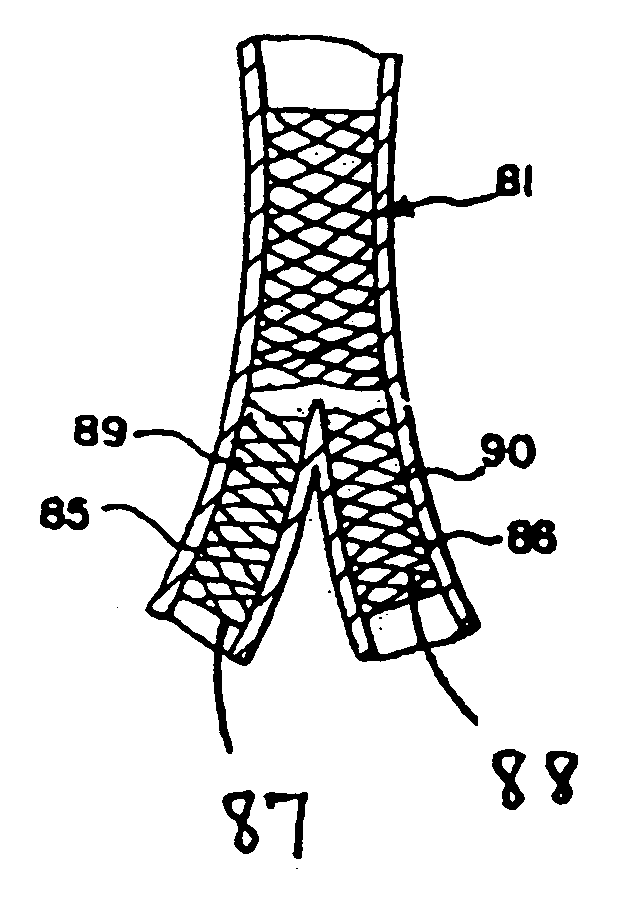

Expandable supportive branched endoluminal grafts

InactiveUS20090138067A1Facilitates good tissue ingrowthFully coveredStentsBlood vesselsProsthesisTubular stenosis

An endoluminal graft which is both expandable and supportive is provided in a form suitable for use in a branched body vessel location. The graft expands between a first diameter and a second, larger diameter. The support component is an expandable stent endoprosthesis. A liner is applied to the endoprosthesis in the form of a compliant wall material that is porous and biocompatible in order to allow normal cellular invasion upon implantation, without stenosis, when the expandable and supportive graft is at its second diameter. The supportive endoluminal graft is preferably provided as a plurality of components that are deployed separately at the branching body vessel location, one of which has a longitudinal seam defining leg portions within which the other components fit in a telescoping manner.

Owner:LIFEPORT SCI

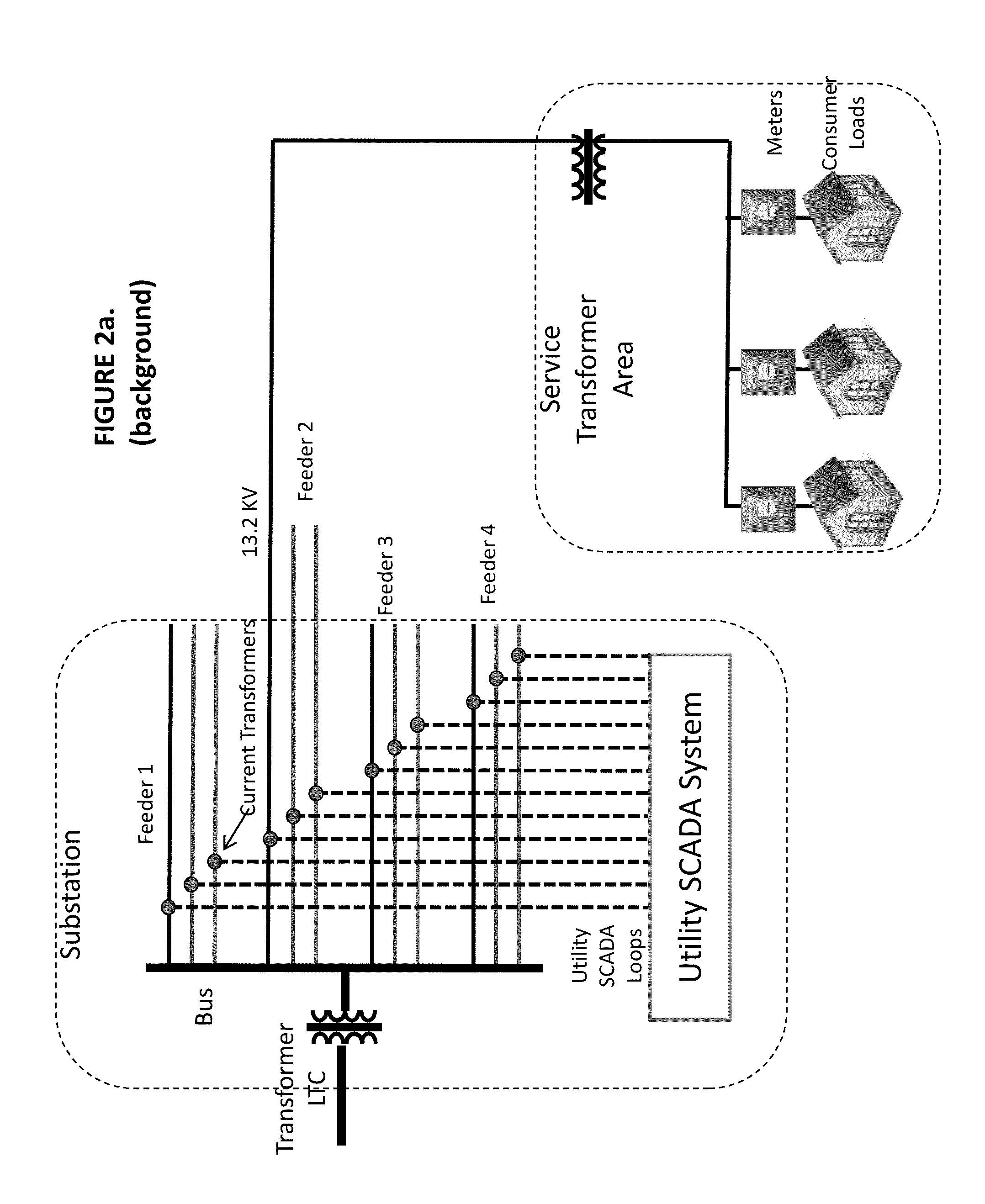

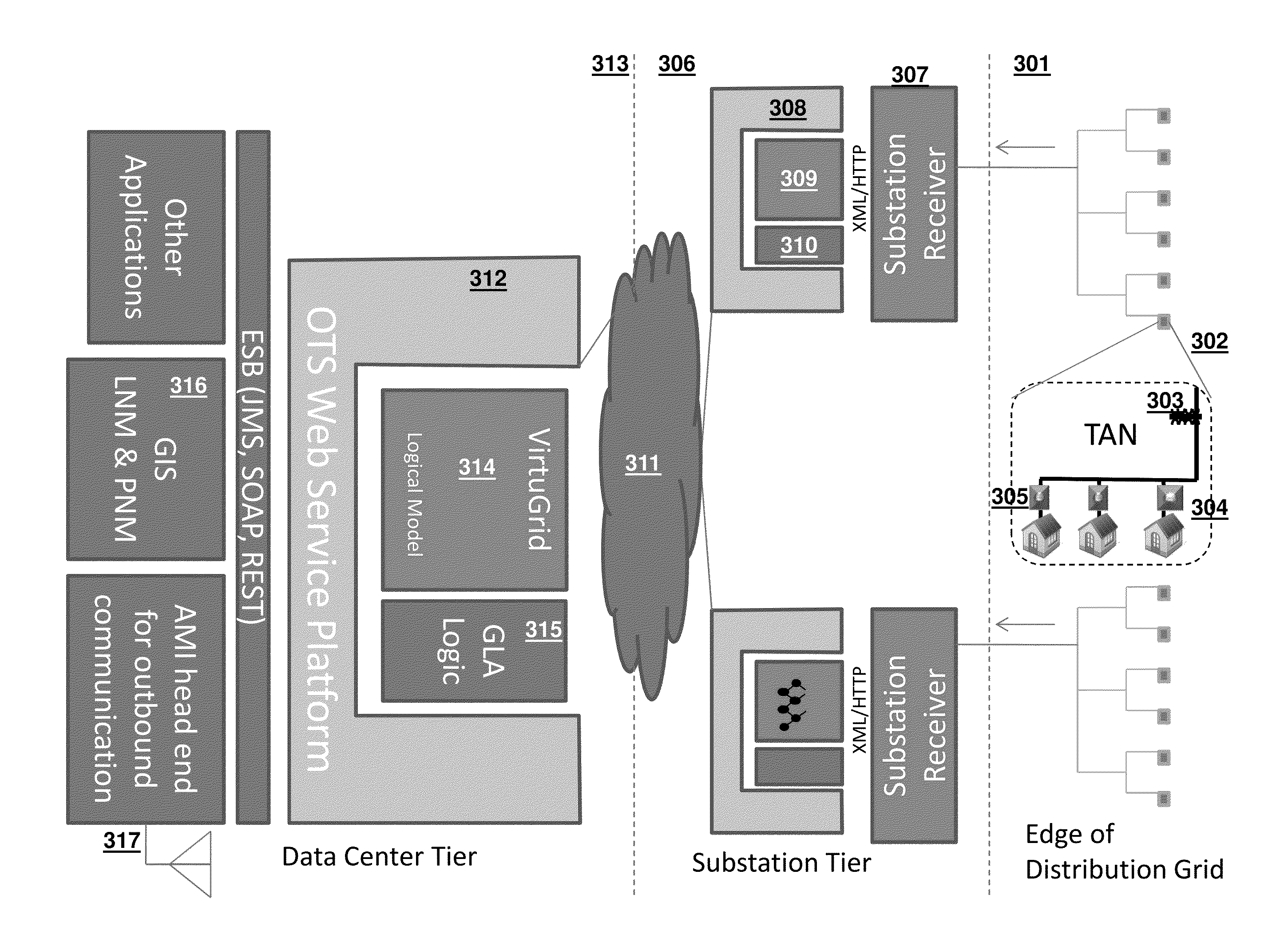

A system and method for inferring schematic and topological properties of an electrical distribution grid

InactiveUS20140233662A1Reduce bitrateLimited amountData processing applicationsCircuit arrangementsTopological orderGrid network

A system and method for inferring schematic and topological properties of an electrical distribution grid is provided. The system may include Remote Hubs, Subordinate Remotes, a Substation Receiver, and an associated Computing Platform and Concentrator. At least one intelligent edge transmitter, called a Remote Hub Edge Transmitter, may transmit messages on the electrical distribution grid by injecting a modulated current into a power main that supplies an electric meter. The Subordinate Remotes, Remote Hubs, the Substation Receiver, and the associated Computing Platform and Concentrator may contain processing units which execute stored instructions allowing each node in the network to implement methods for organizing the on-grid network and transmitting and receiving messages on the network. The Substation Receiver, Computing Platform and Concentrator may detect and infer schematic grid location attributes of the network and publish the detected and inferred attributes to other application systems including geospatial information systems maintaining the logical and physical network model.

Owner:TRC +1

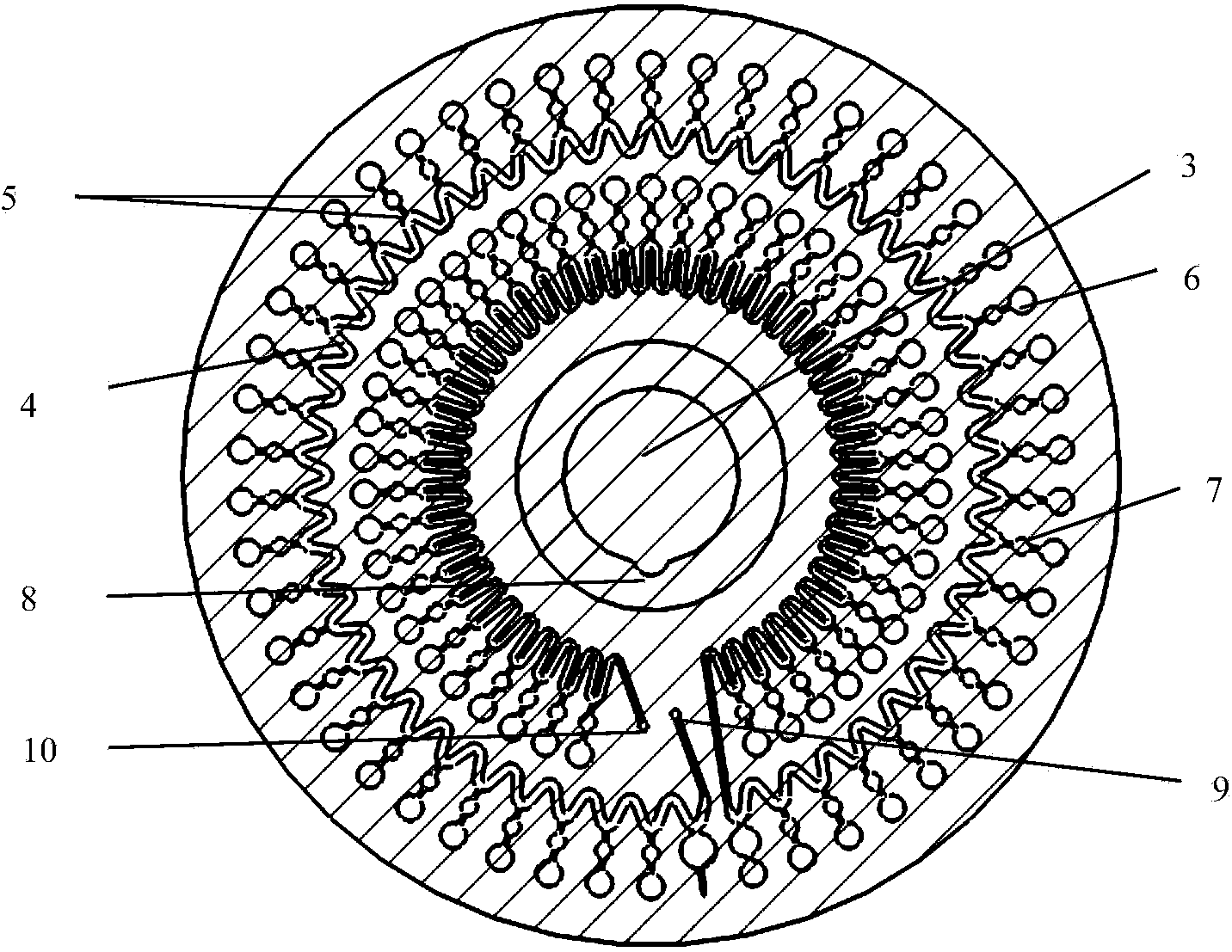

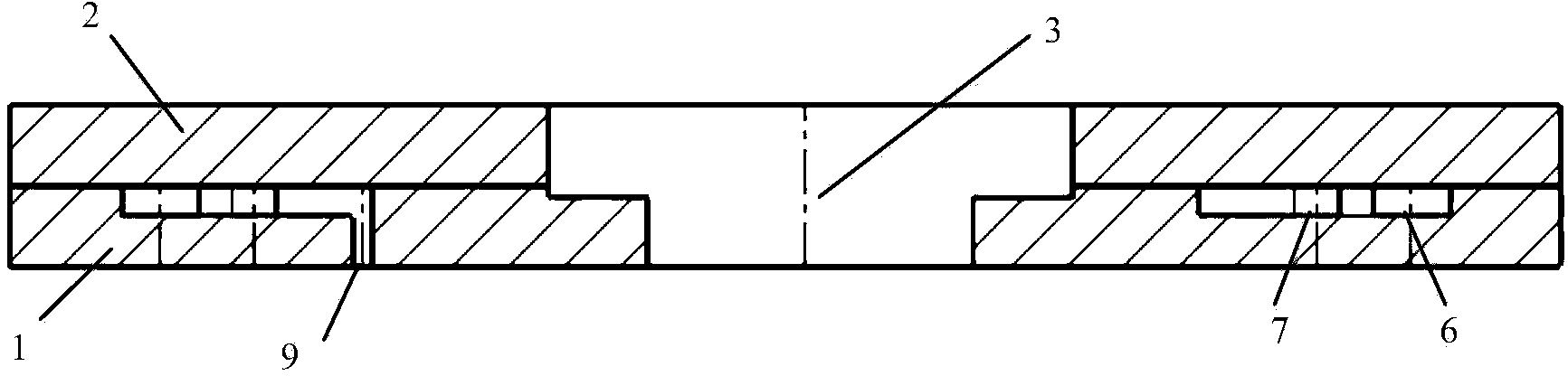

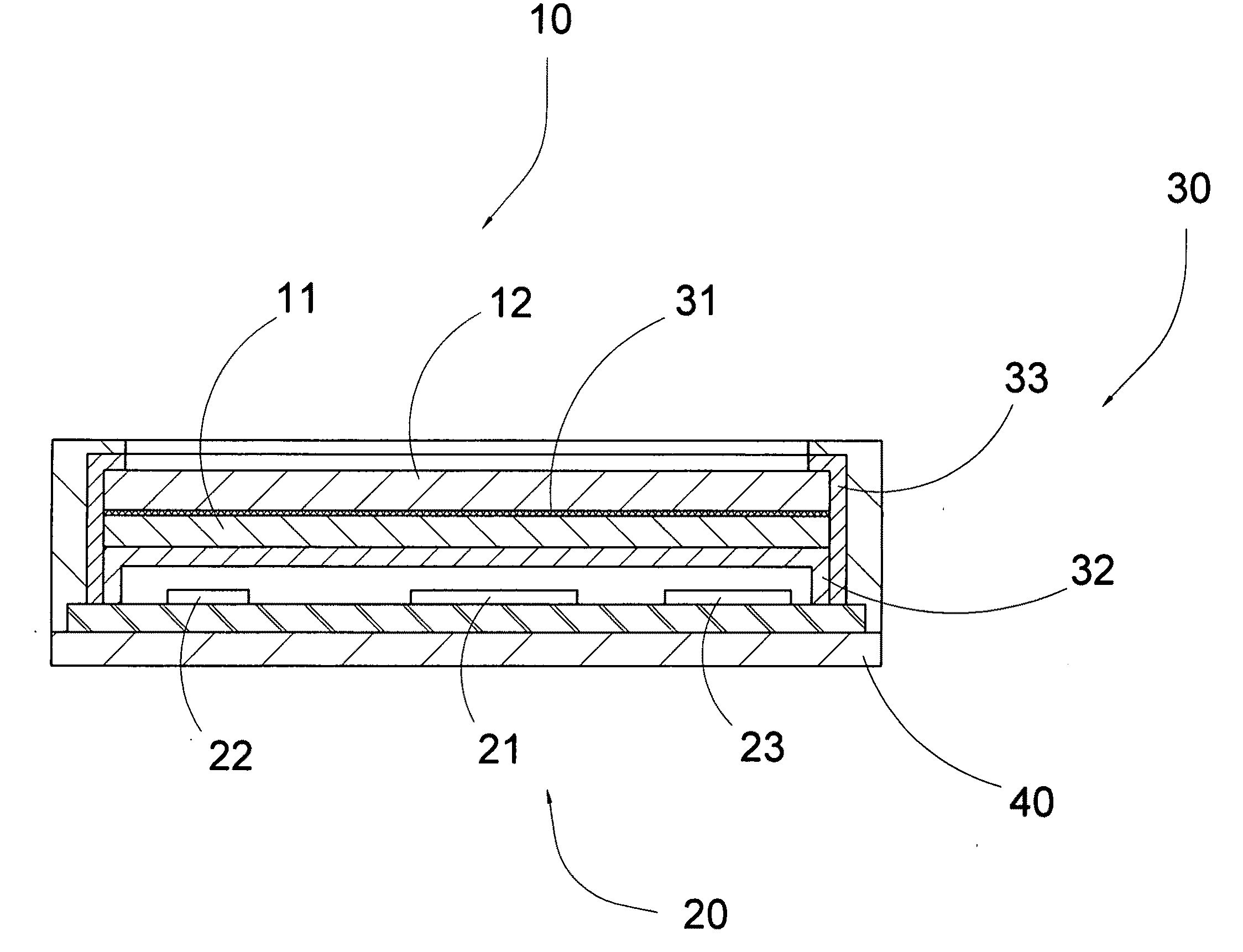

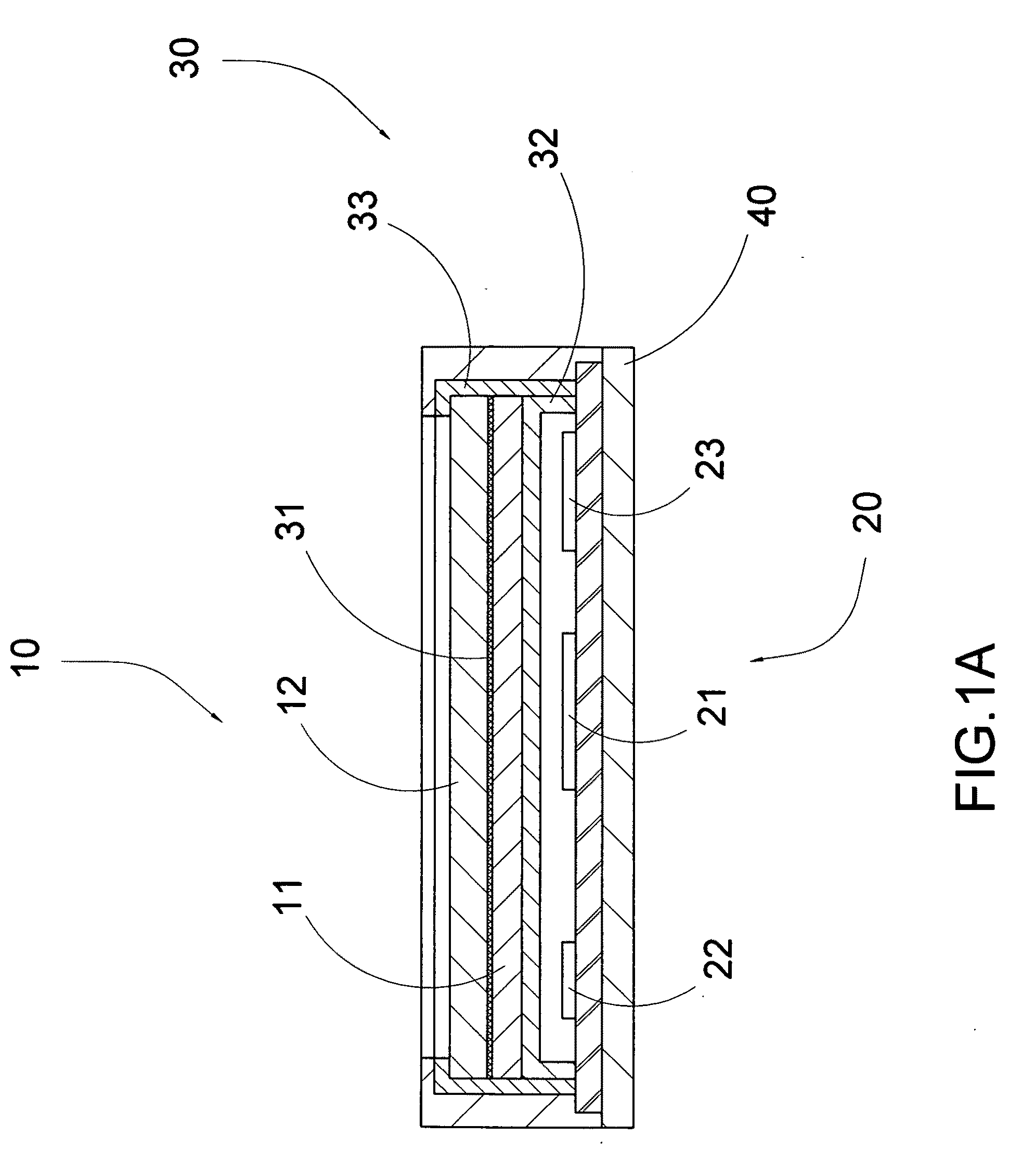

Micro-fluidic chip for multi-index detection

ActiveCN103831140AEvenly distributedFully coveredMicrobiological testing/measurementLaboratory glasswaresFluorescenceWave shape

The invention discloses a micro-fluidic chip for multi-index detection. The micro-fluidic chip comprises a substrate and a cover plate which is matched with the substrate in a sealed mode, wherein a through hole is formed in the center of the micro-fluidic chip; one or more wave-shaped main channels are formed in the substrate; one end of each main channel is communicated with a sample introduction hole formed in the substrate, and the other end of each main channel is communicated with an air outlet in the substrate; wave troughs of the main channels are arranged away from the direction of the through hole; wave crests of the main channels are arranged close to the direction of the through hole; any one wave trough of the main channel is communicated with a reaction pool through a connecting pipeline; a buffer pool is arranged on the connecting pipeline. The micro-fluidic chip can be detected by instruments through fluorescence, turbidity and development or is directly observed by naked eyes, can be detected in the reaction process in real time and also can be detected after the reaction is ended.

Owner:BOAO BIOLOGICAL CO LTD +1

Methods for discovering, partitioning, organizing, and administering communication devices in a transformer area network

InactiveUS20140236365A1Reduce bitrateLimited amountLevel controlCircuit arrangementsArea networkTransformer

A system and methods for managing a transformer area in an electrical distribution grid having at least one substation transformer and one service transformer are presented. At least one Remote Hub governed by a policy may be provided, which collects data about the transformer area. The Remote Hub may also execute a discovery procedure to inventory Remotes in the transformer area. The Remote Hub may use the collected data to detect events, such as exceptional conditions, configuration changes, or derived results, within the transformer area. Based on the collected data, the Remote Hub is able to transmit data about the transformer area via a Substation-to-Edge channel. A method and system for forming and establishing boundaries of Transformer Area Networks is also presented. Discovery procedures may be used to form Transformer Area Networks out of Remote Hubs and Remotes powered by the same phase of the service transformer.

Owner:DOMINION ENERGY TECH +1

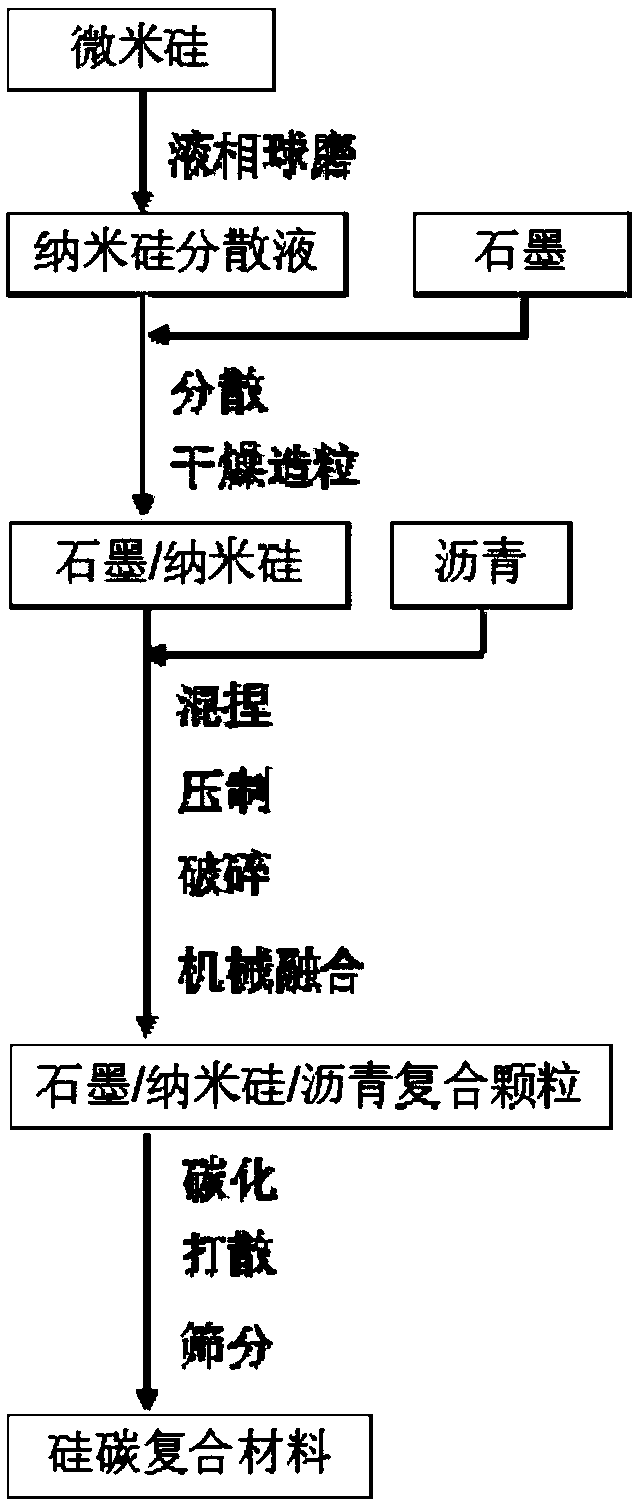

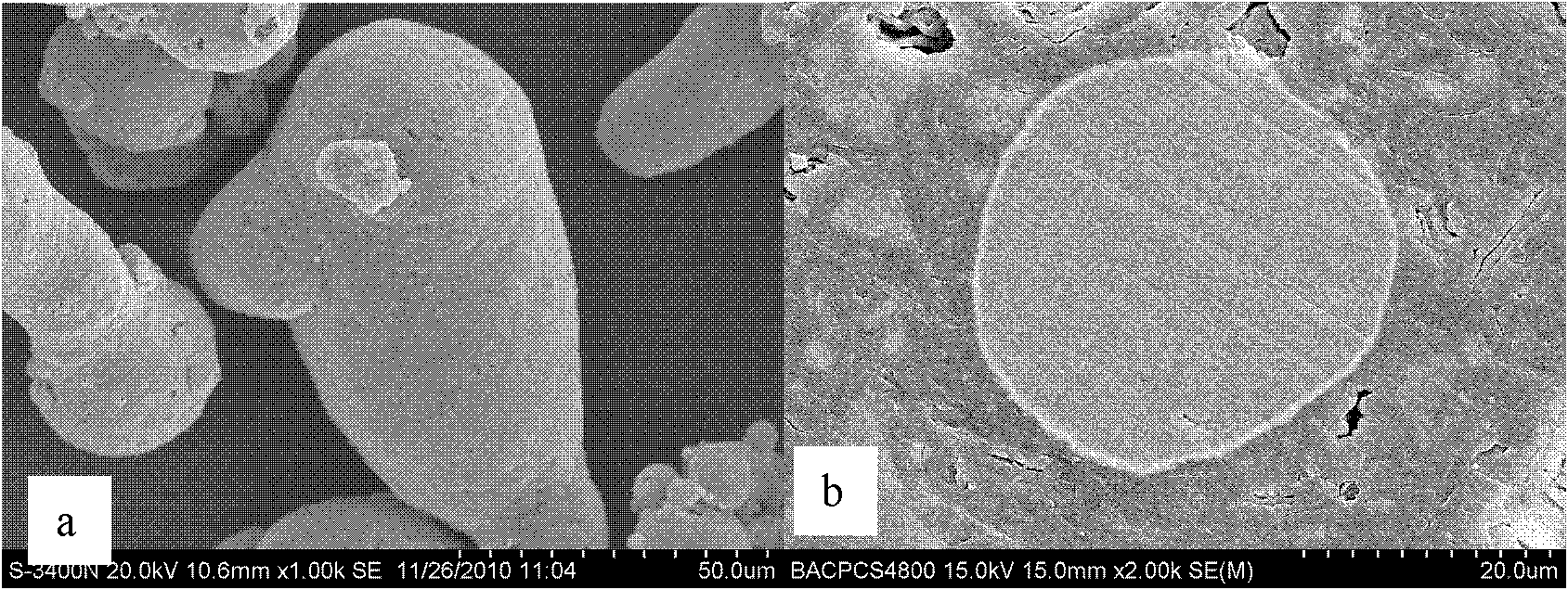

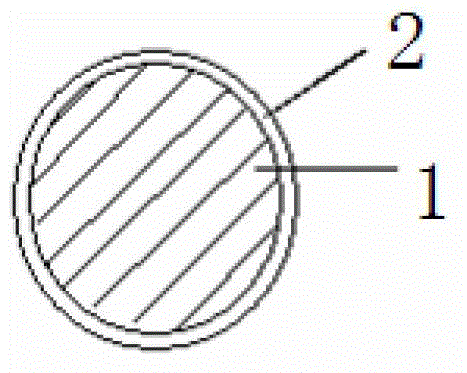

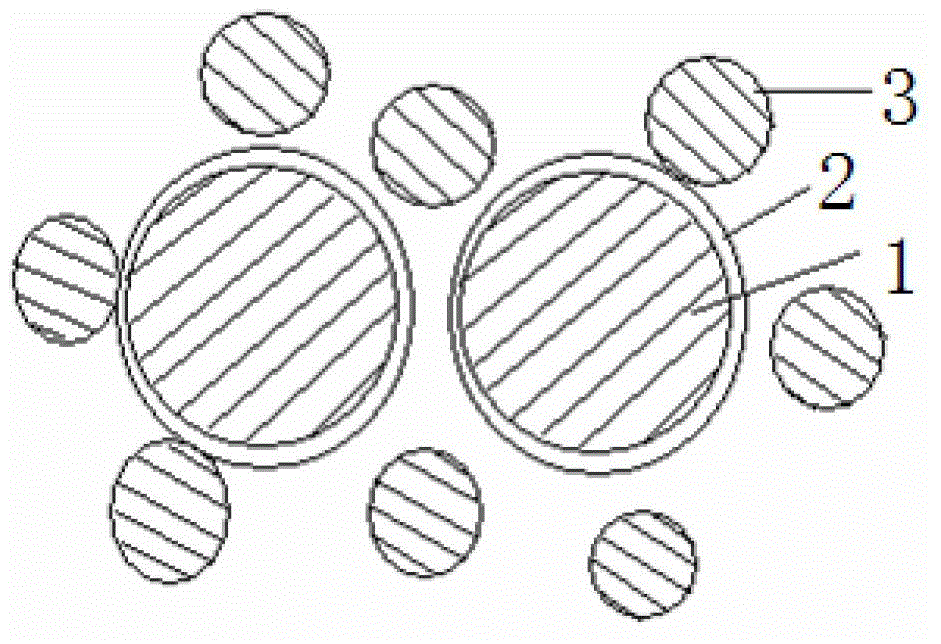

High-performance silicon-carbon cathode material and preparation method thereof

ActiveCN107785560ACover tightlyCoated evenlyNegative electrodesSecondary cellsNano siliconCarbonization

The invention relates to a high-performance silicon-carbon cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) dispersing silicon into a solvent, carrying out liquid-phase ball-milling, so as to obtain nano-silicon dispersion liquid, adding graphite, and carrying out liquid-phase ball milling so as to uniformly mix nano-silicon with graphite; (2) carrying out granulation on slurry obtained the step (1), so as to obtain graphite / nano-silicon composite particles; (3) carrying out granulation on the product of the step (2) and asphalt by virtue of a mixed kneading-pressing-crushing method, so as to obtain graphite / nano-silicon / asphalt composite particles, and carrying out mechanical fusion so as to realize spheroidization and uniform coating of the graphite / nano-silicon / asphalt composite particles in one step; and (4) carrying out carbonization, scattering and sieving, so as to obtain the high-performance silicon-carbon cathode material. The preparation method is simple and low in cost and can be used for easily producing the high-performance silicon-carbon cathode material in large scale.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

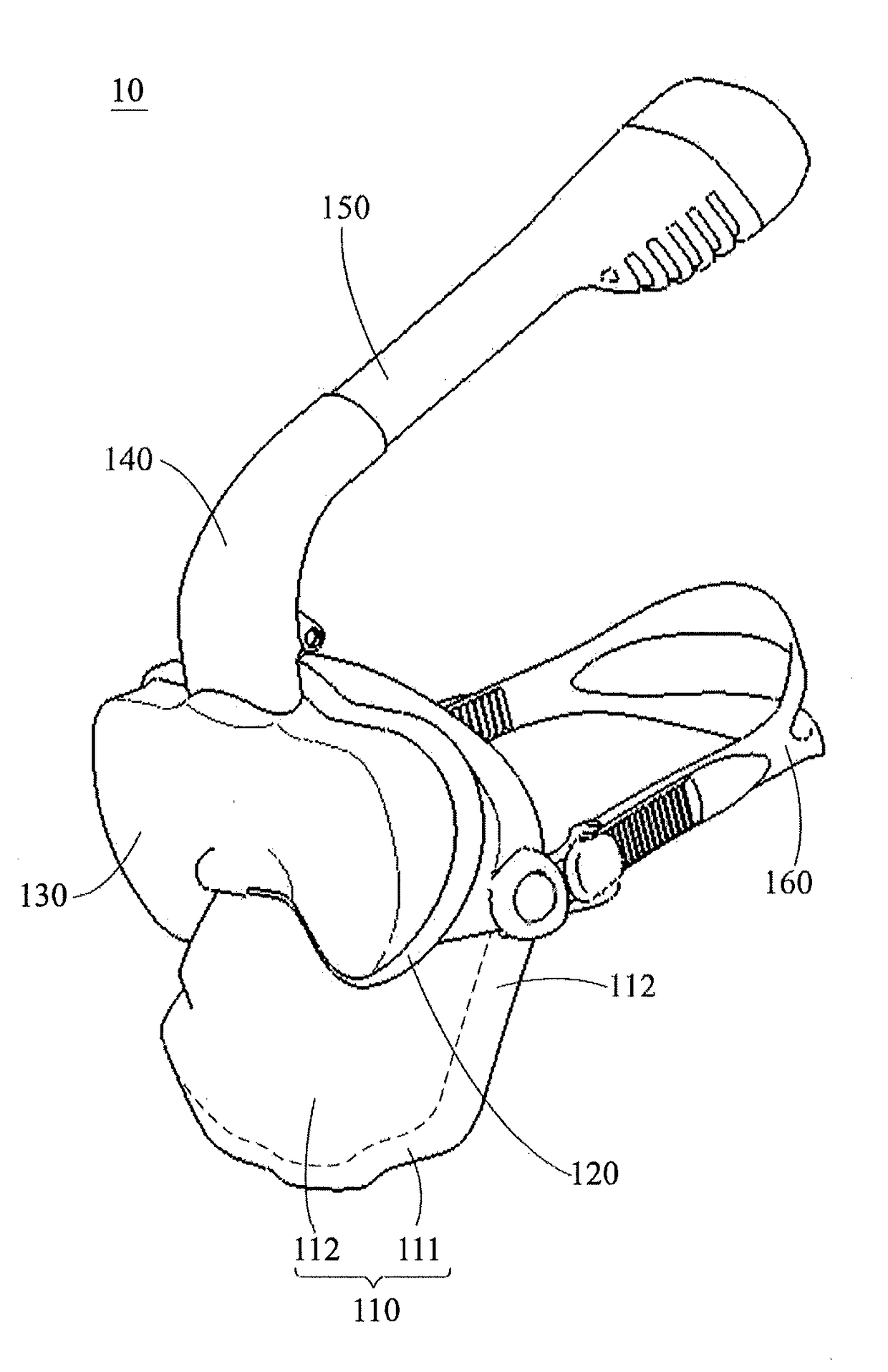

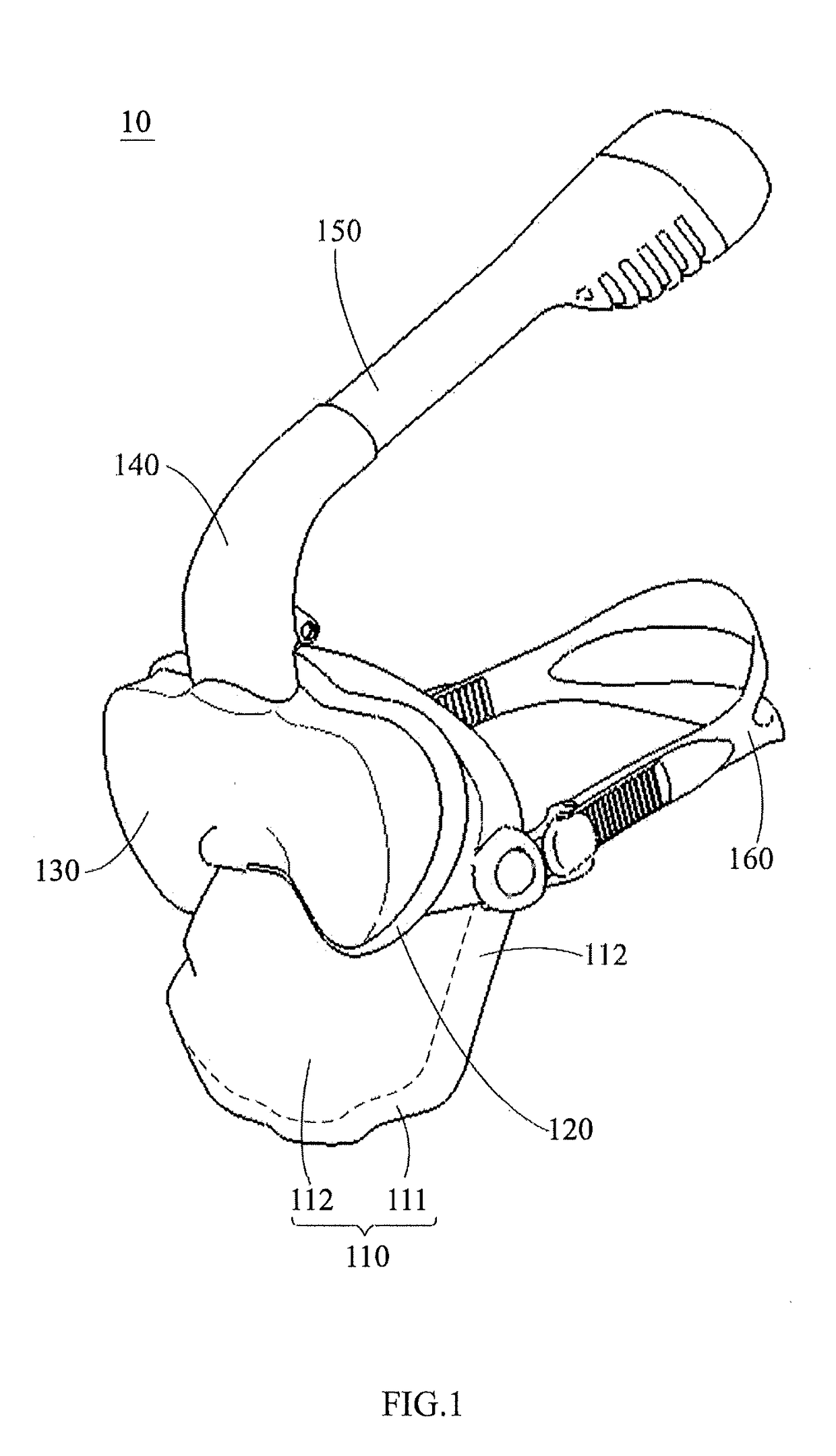

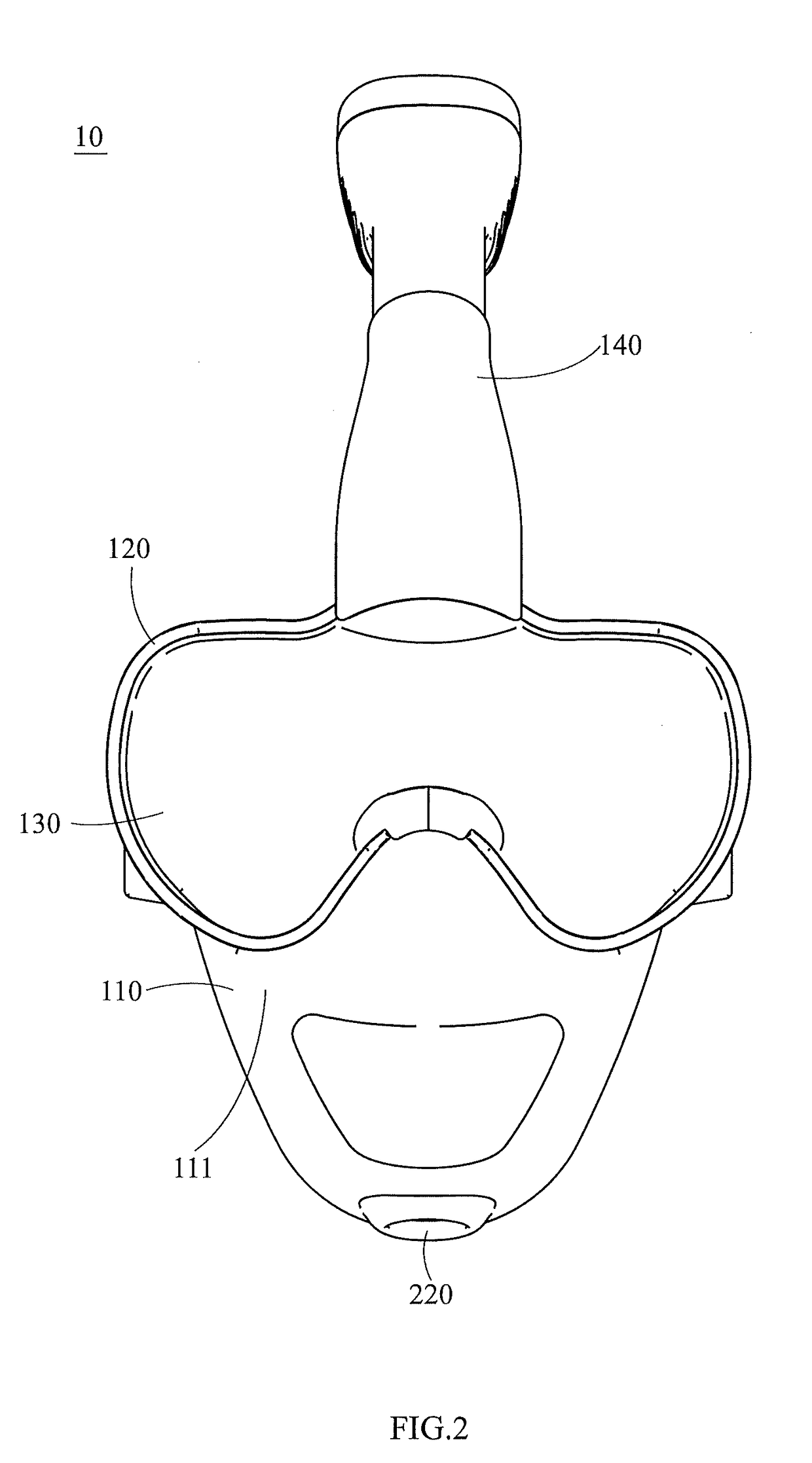

Diving and snorkeling mask structure

InactiveUS20170334531A1Easy to put on and take offImprove comfortTelevision system detailsColor television detailsEngineeringSacroiliac joint

A diving and snorkeling mask structure including a full face mask, a frame, at least one lens, a joint, a respiratory tube and at least one securing belt is disclosed. The full face mask includes a first soft material region connected with a second soft material region. The frame is combined with the second soft material region of the full face mask. The at least one lens is disposed in the frame. The joint is disposed on the full face mask, and adjacent to the upper side of the frame. The respiratory tube is disposed on the joint, and establishes the air communication with the full face mask via the joint. The at least one securing belt includes a side buckle element to snap fit the full face mask.

Owner:QBAS CO LTD

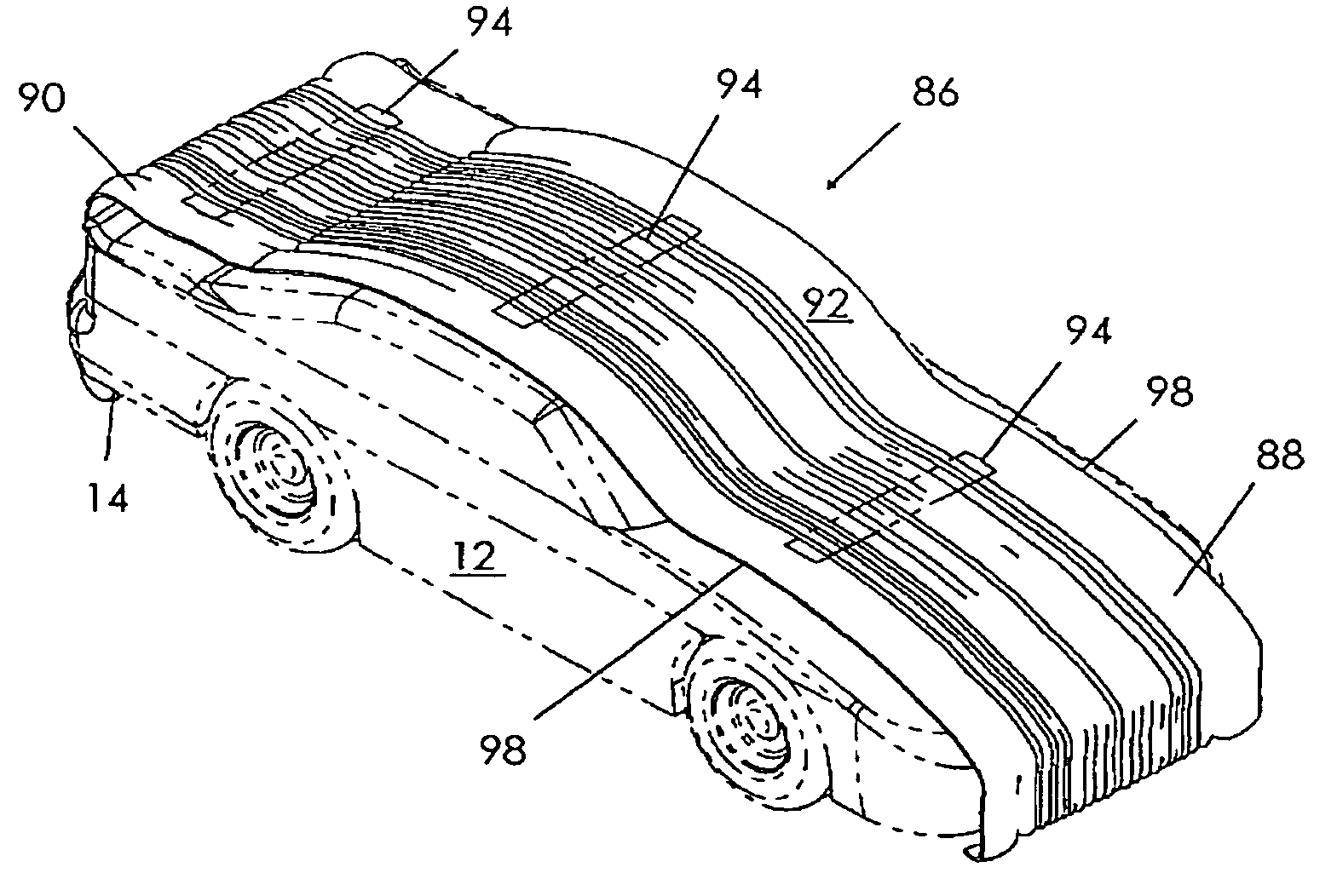

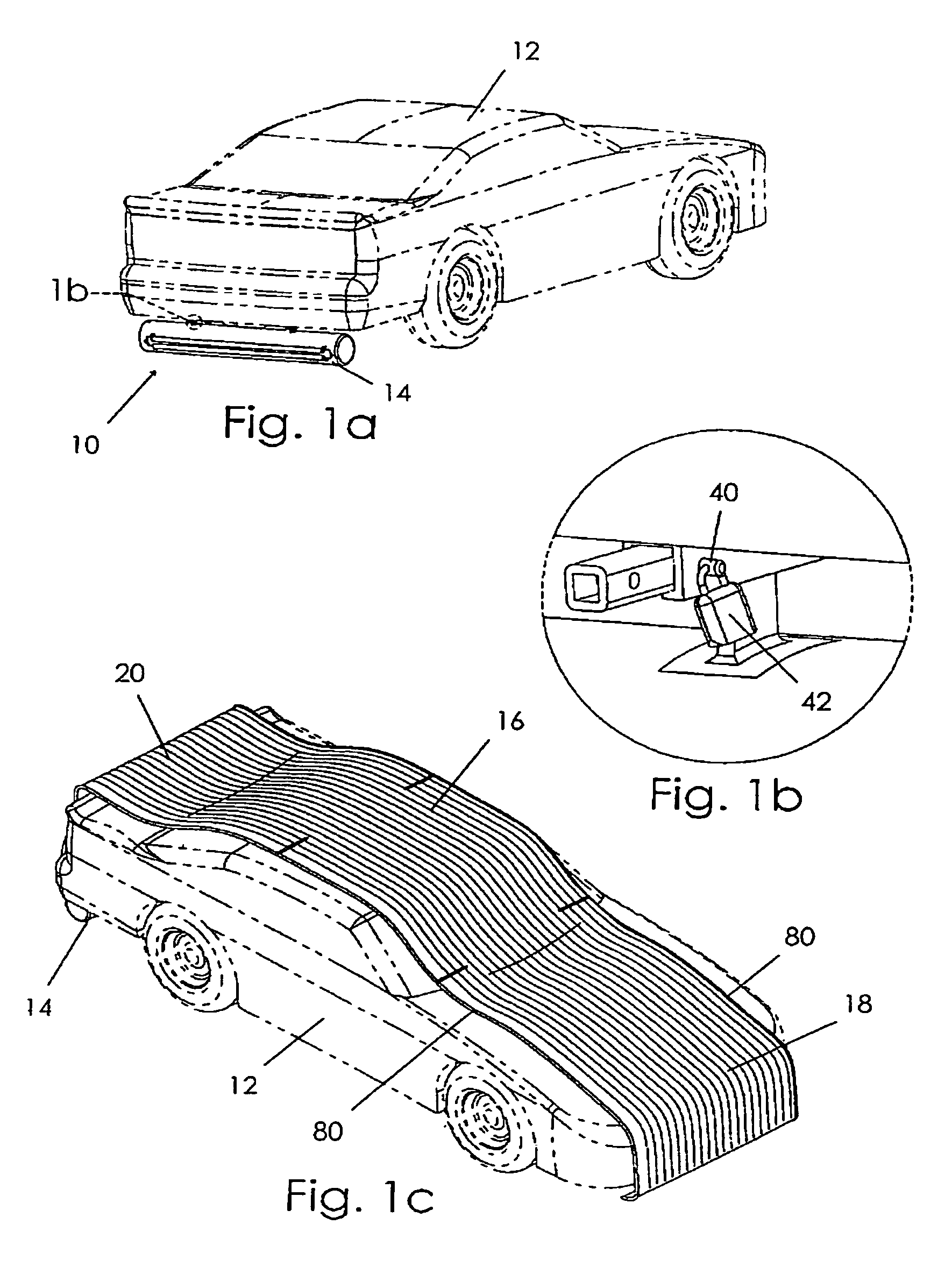

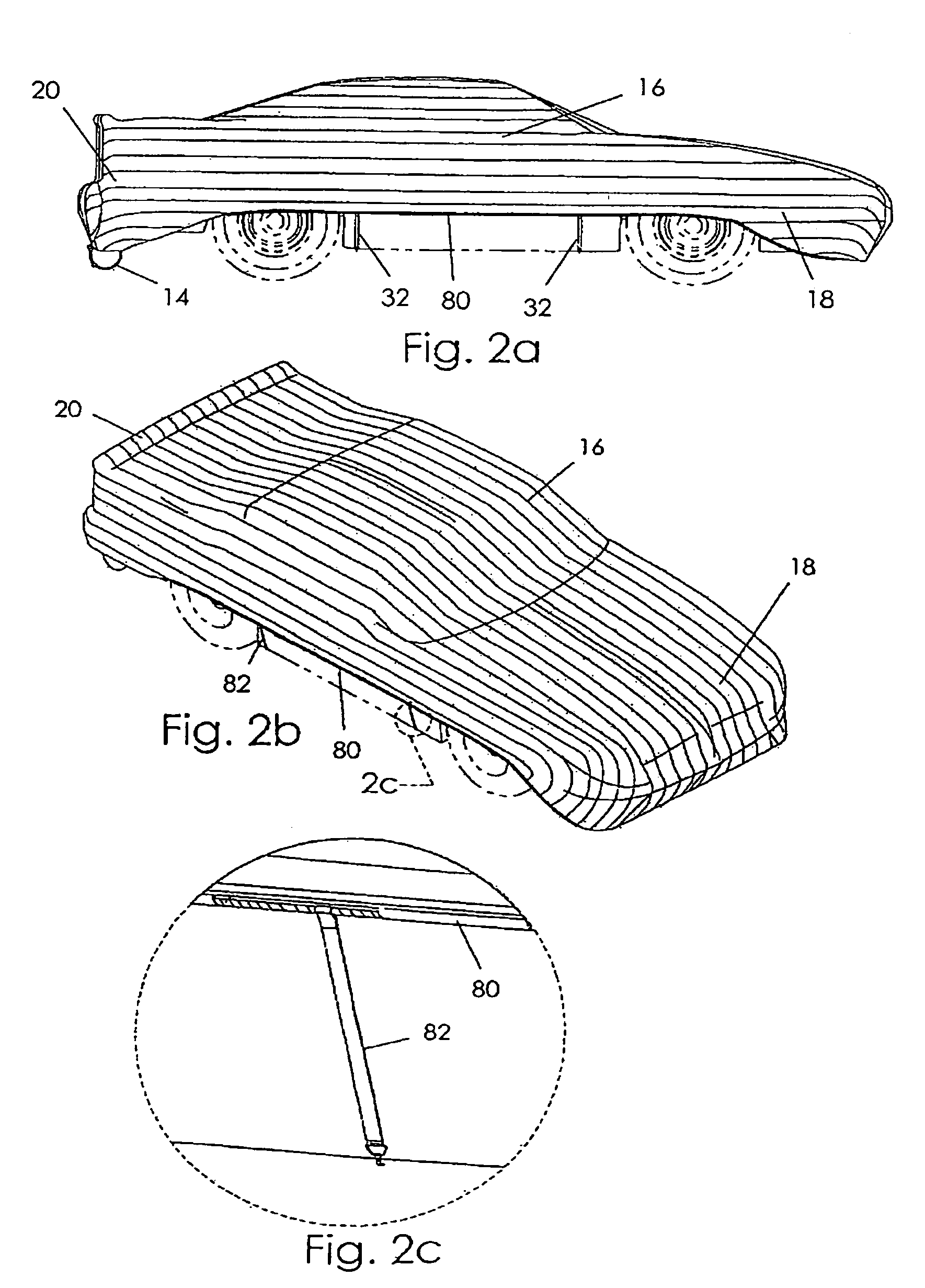

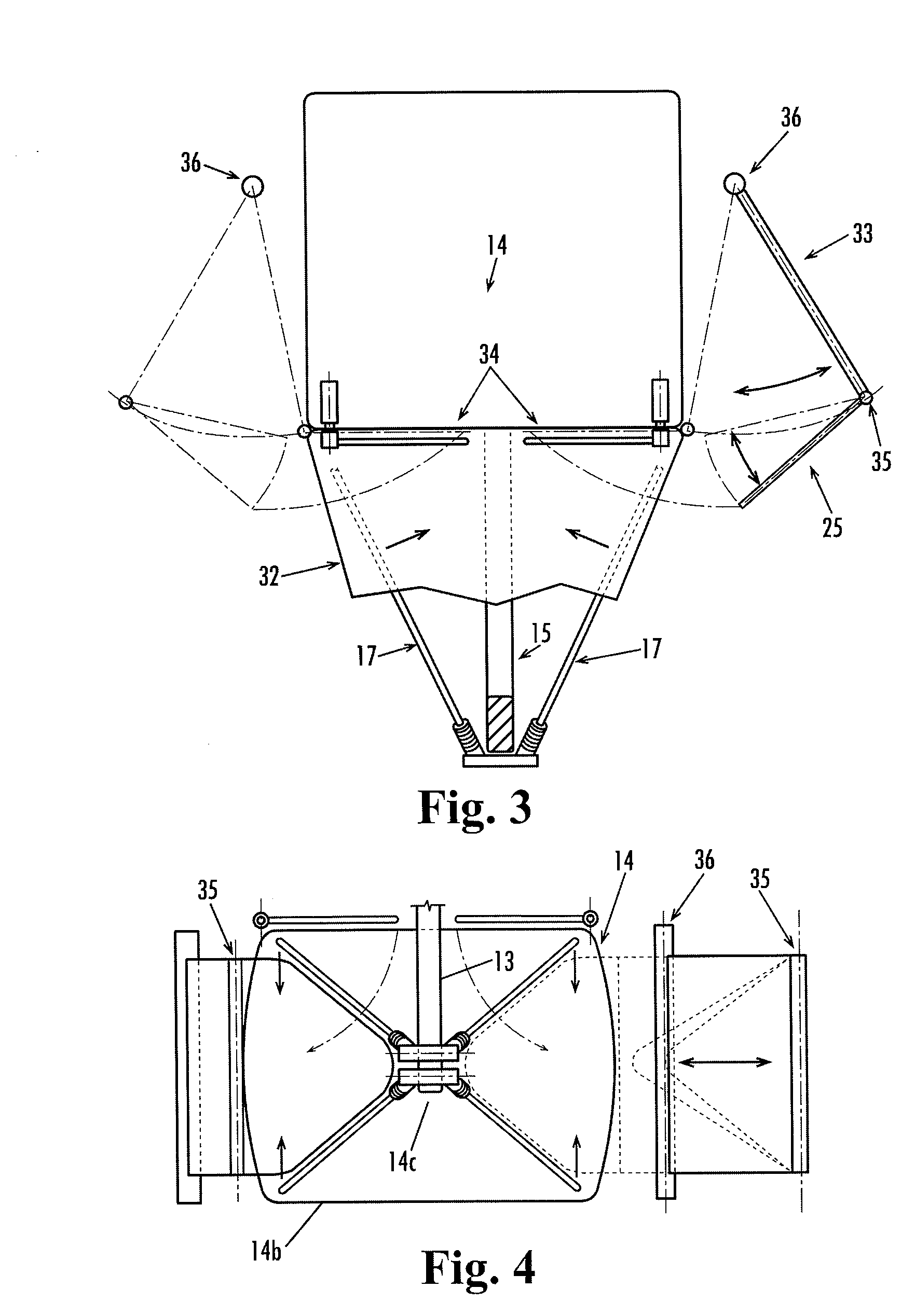

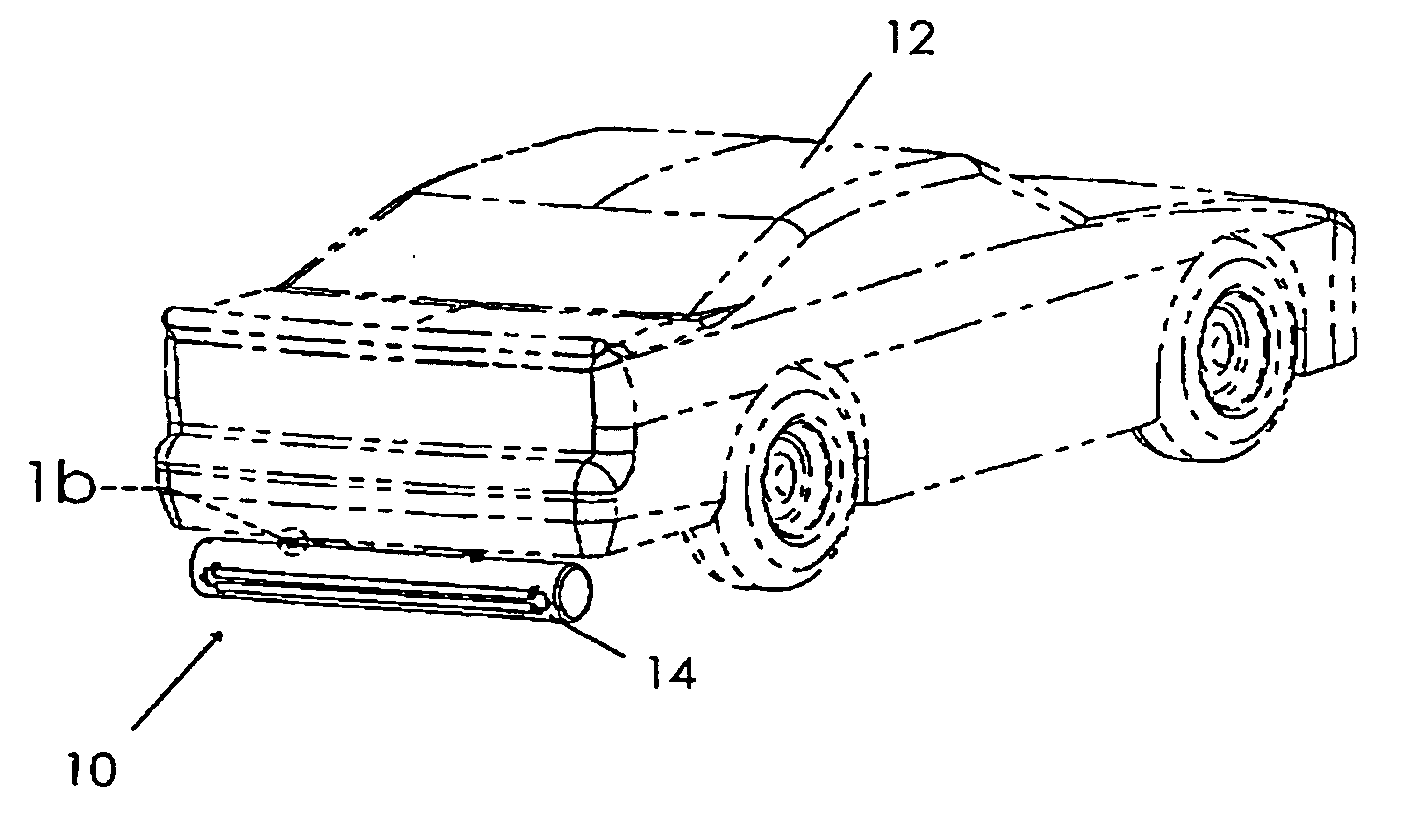

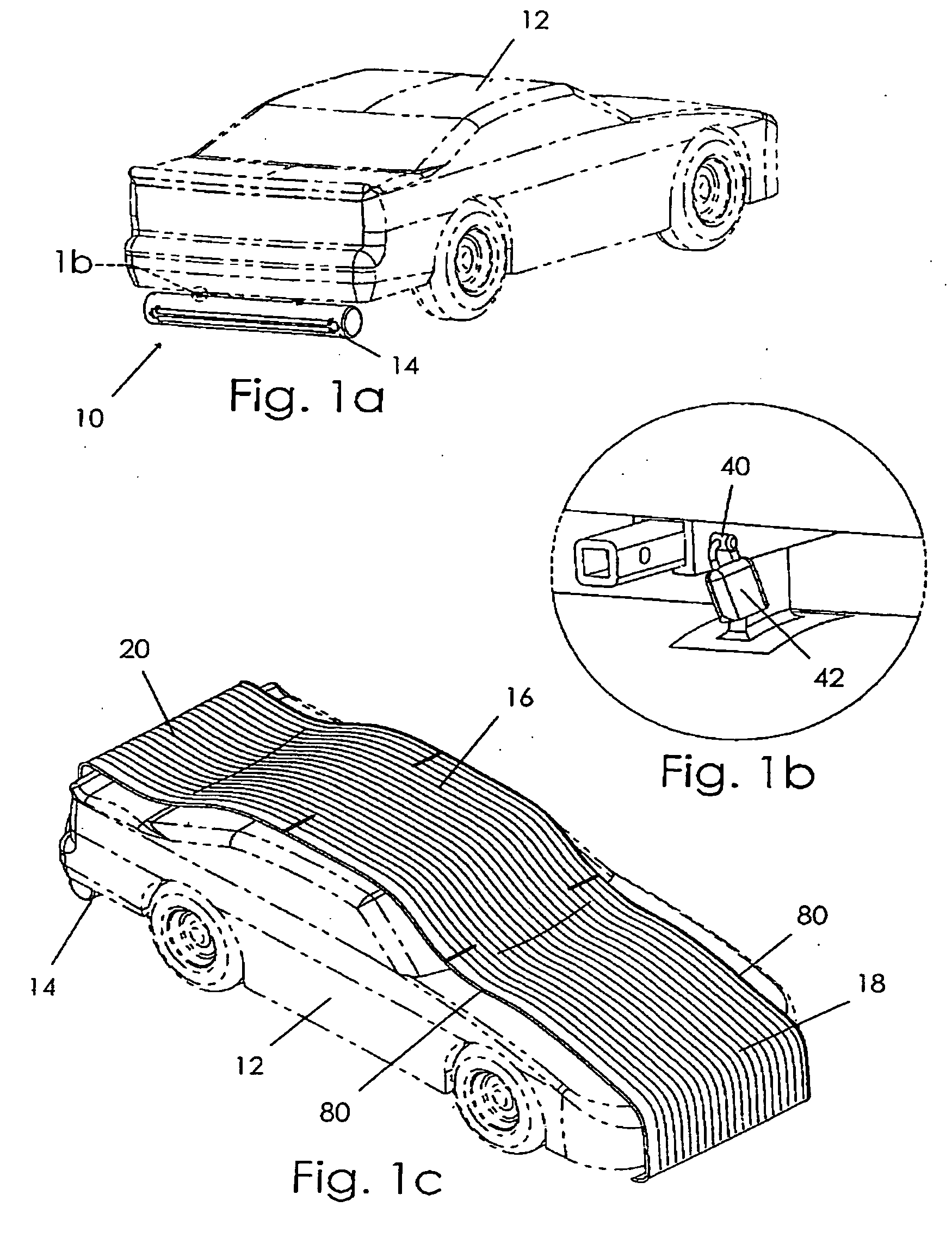

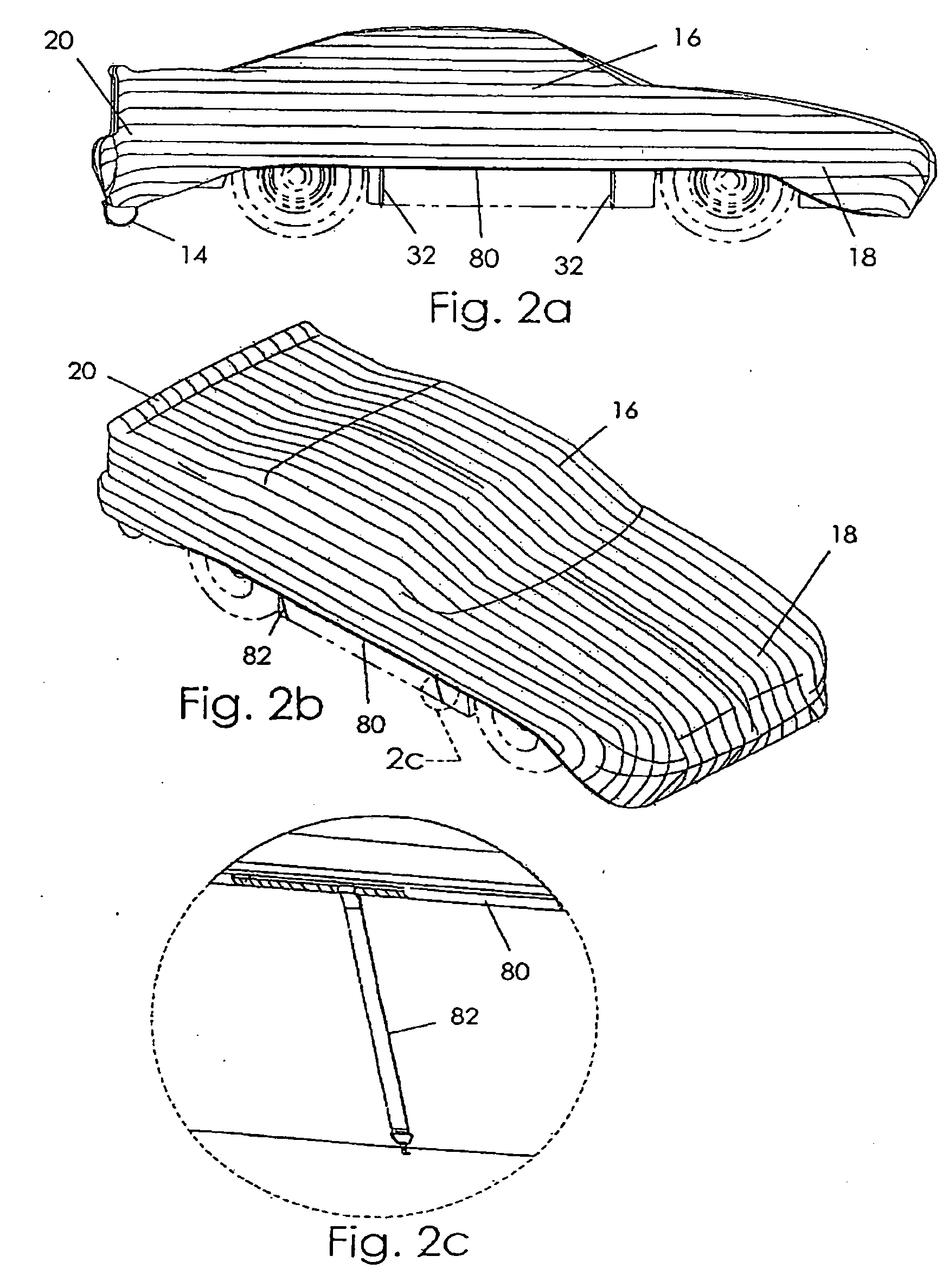

Retractable car cover

InactiveUS6964446B2Easy to stretchFully coveredWindowsFlexible coversMechanical engineeringWrap around

Owner:PORTER MATTHEW B

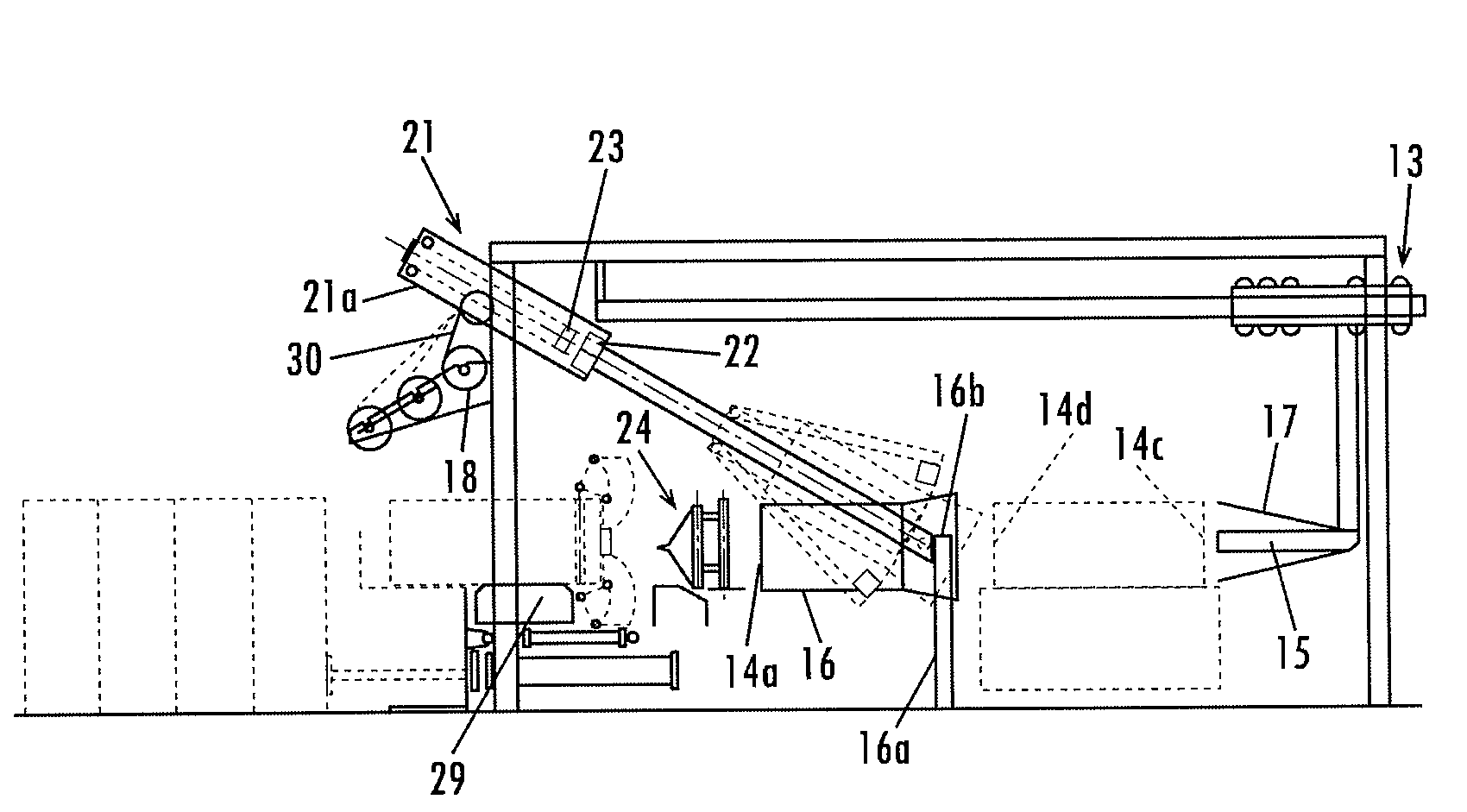

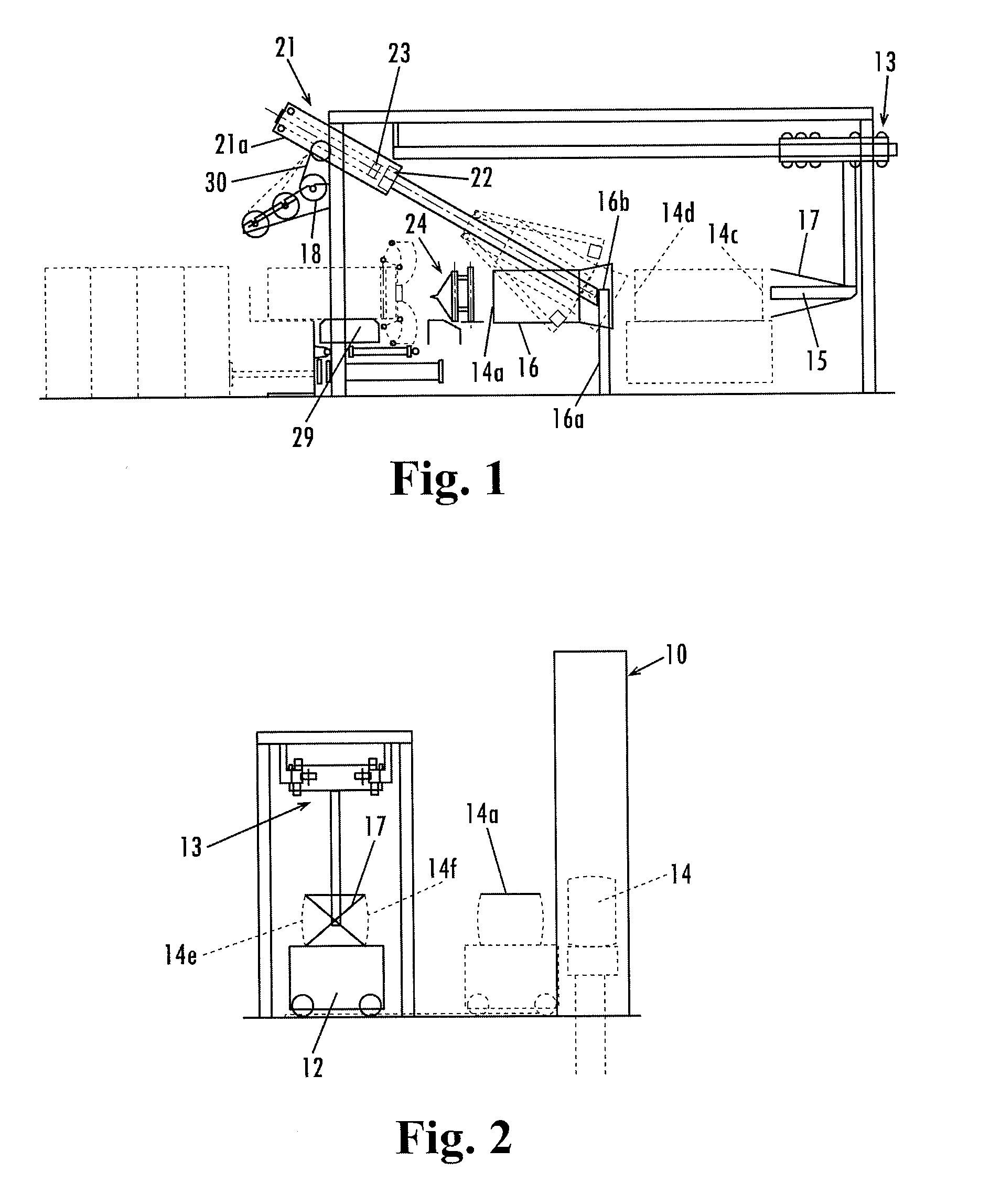

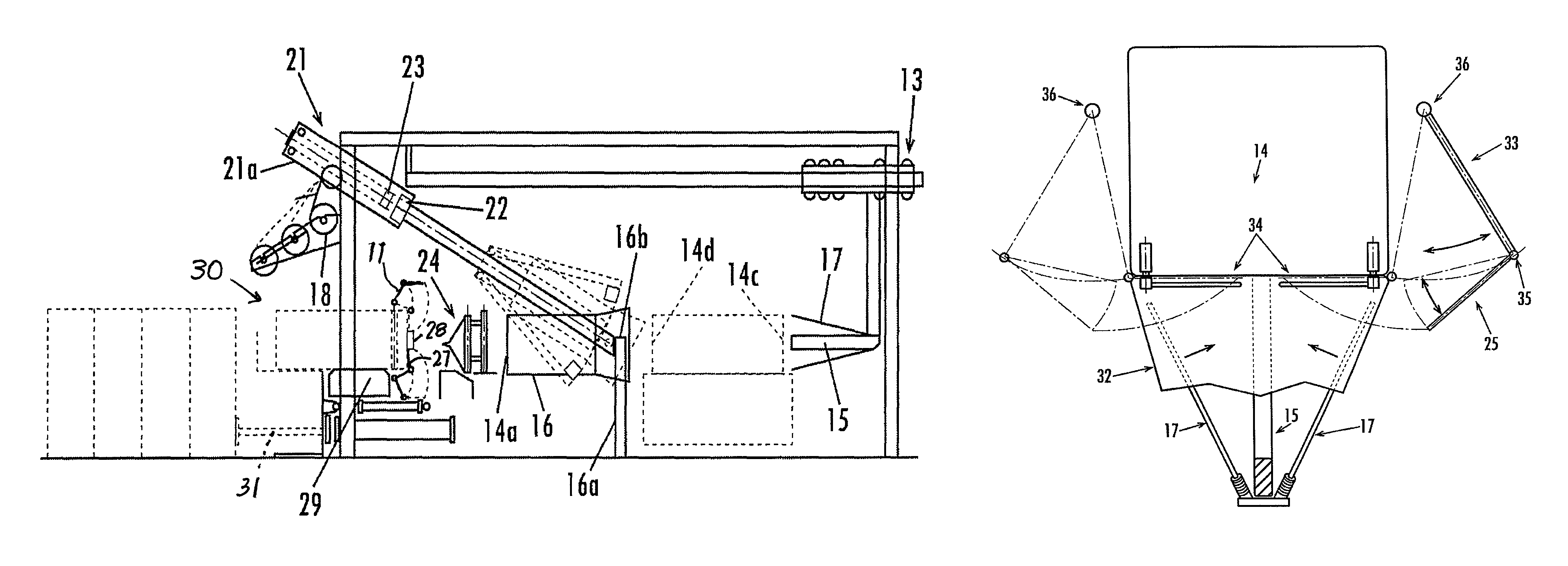

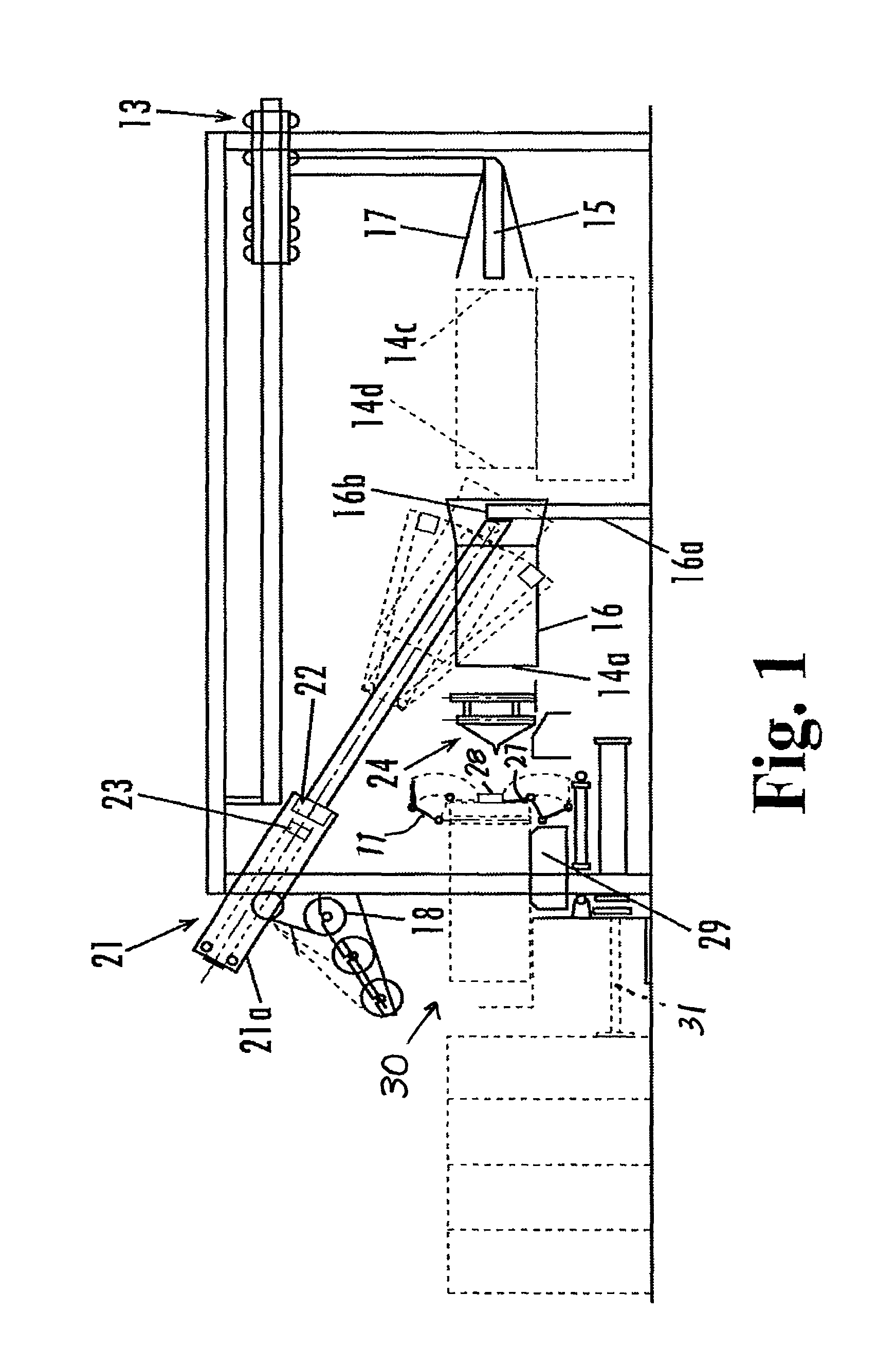

Automatic Bale Wrapping Apparatus

ActiveUS20090229226A1Effective movementReduce laborPaper-makingWrapper twisting/gatheringPleatSheet material

Apparatus is disclosed for enclosing bales of materials with at least four substantially rectilinear sides in flexible sheet material tubes having one open end into which the bales are inserted leaving the tube open end projecting loosely beyond the end of the bale utilizing structure temporarily placed inside the tube open end tending to resist inward movement of said tube such that the tube end may be formed into pleats at the four corners of the end of the bale and structure external of the tube cooperating to form and fold the pleats against the bale end surface where they are affixed.

Owner:LUMMUS INDS

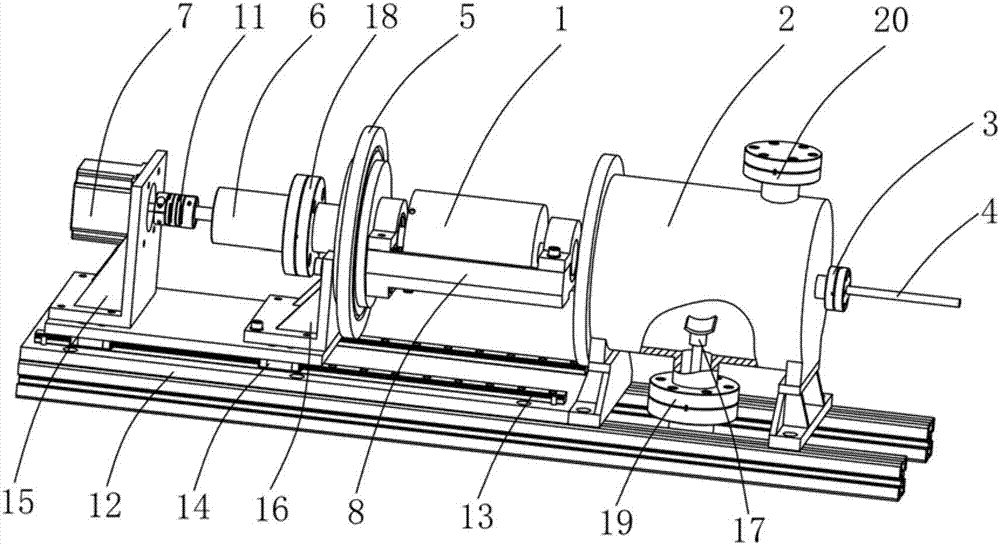

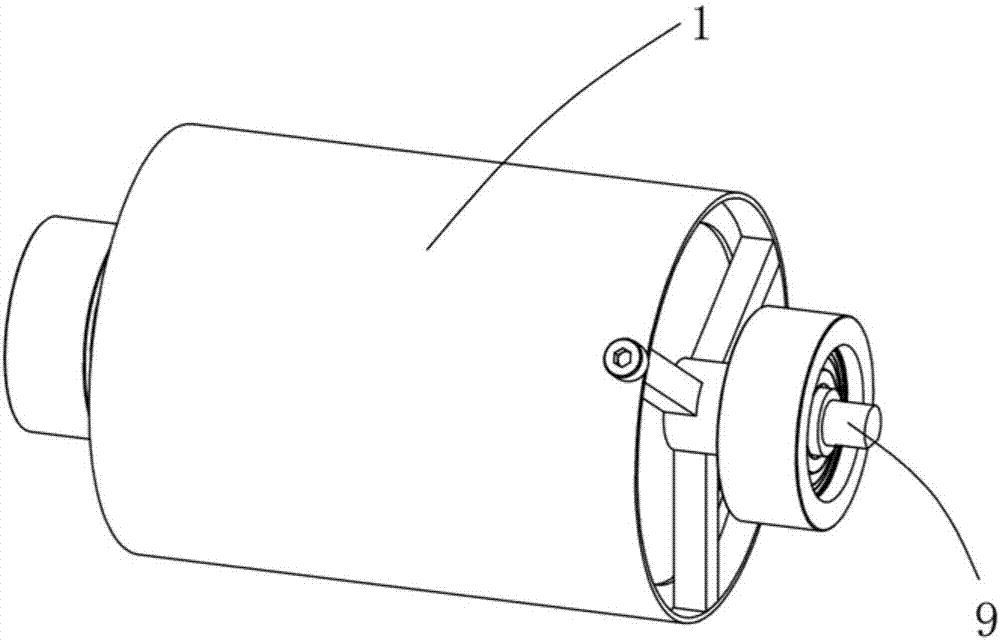

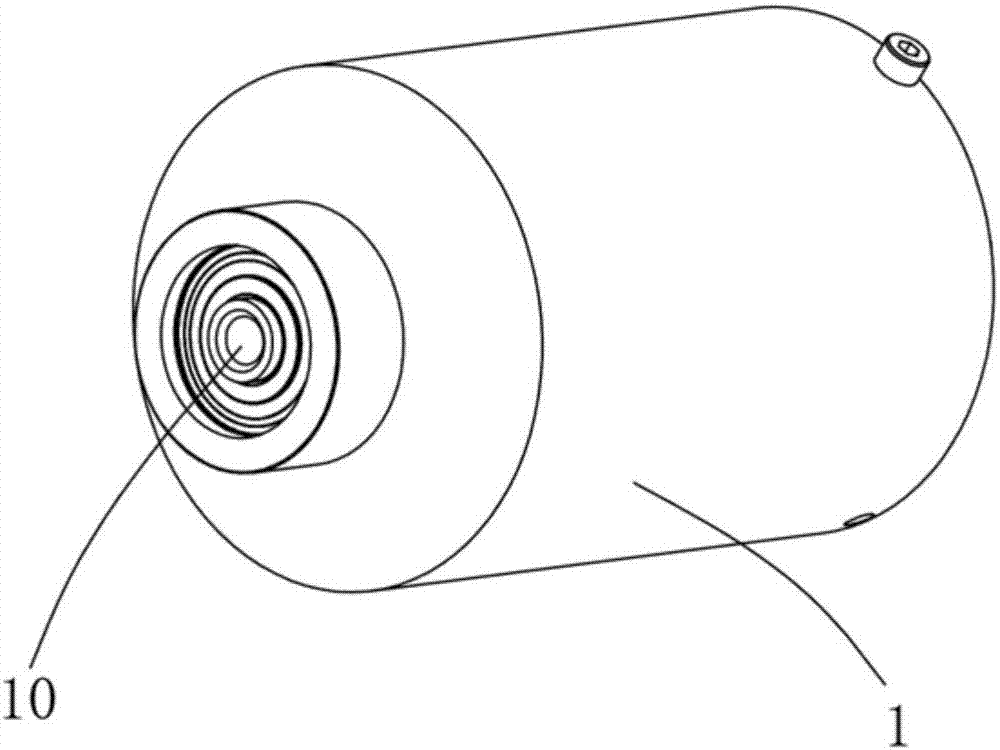

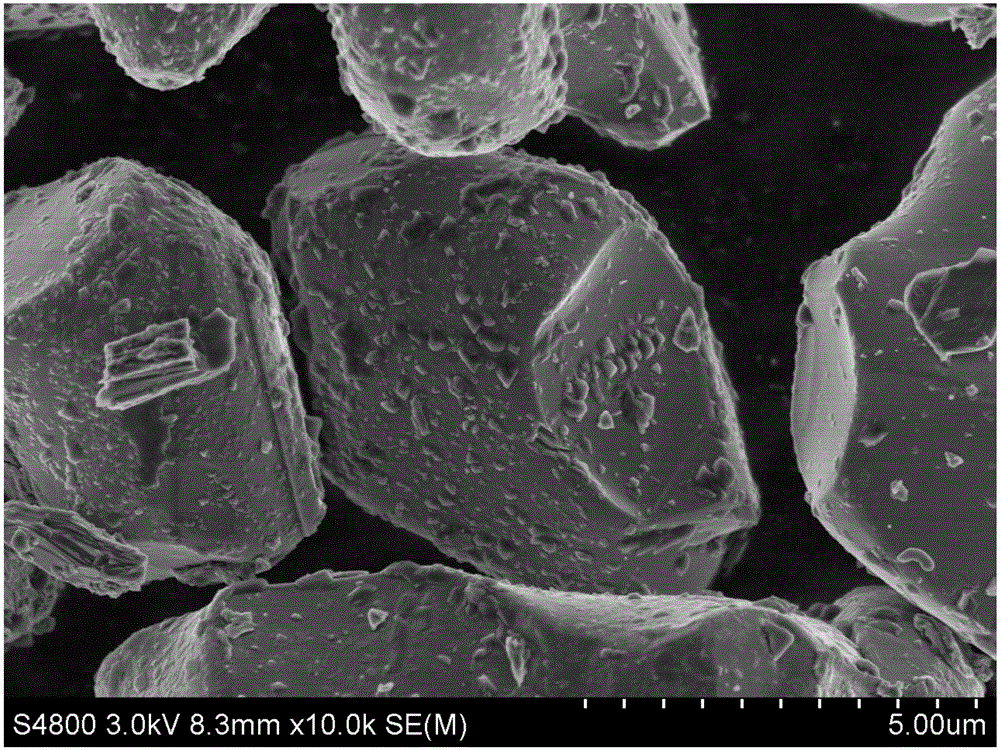

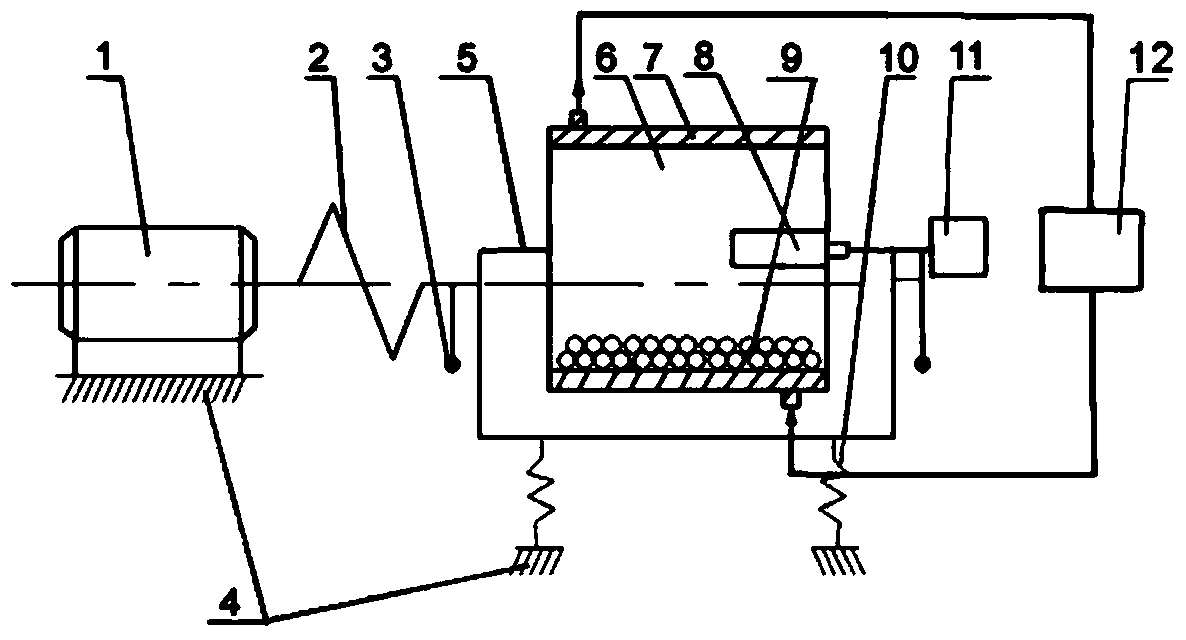

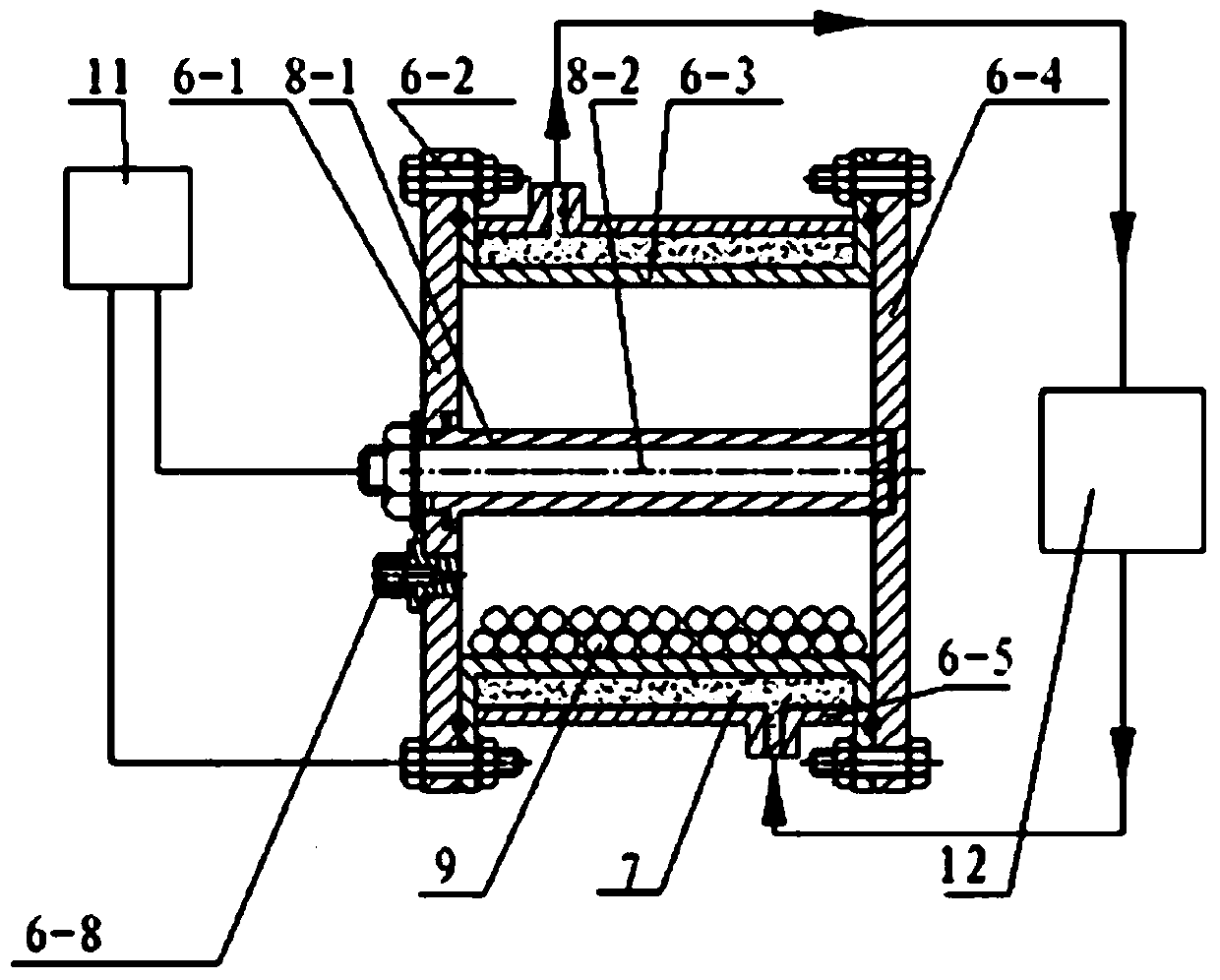

Powder-coated atomic layer deposition device

ActiveCN107502873AFully coveredCoated evenlyChemical vapor deposition coatingRotation methodEngineering

The invention discloses a powder-coated atomic layer deposition device. The powder-coated atomic layer deposition device comprises a powder container and a reaction cavity, wherein an inlet source hole is formed in one end of the reaction cavity; a gas inlet tube used for inputting reaction gas or carrier gas is arranged in the inlet source hole in a sealing mode; a cavity door is arranged at the other end of the reaction cavity; the powder container is arranged inside the cavity door; under driving of a power device, rotation can be realized; a gas inlet is formed in the powder container; the gas inlet tube enters an inner cavity of the powder container through the gas inlet; an ultrasonic vibrating rod is arranged inside the reaction cavity; and after the powder container enters the reaction cavity through a guide device, the outer side wall of the powder container is in contact with the ultrasonic vibrating rod. According to the powder-coated atomic layer deposition device disclosed by the invention, a rotary method is combined with an ultrasonic vibrating method, contact possibility of powder and reaction gas can be increased by rotation, and powder agglomeration can be relieved by energy generated by vibrations, so that powder is dispersed, and a uniform and compact film is finally coated on the surface of the powder.

Owner:HUST WUXI RES INST

Preparation method of silver-coated aluminum powder

InactiveCN102248159AFully coveredReduce dosageLiquid/solution decomposition chemical coatingAluminum IonCopper plating

The invention relates to a preparation method of silver-coated aluminum powder and belongs to the technical field of powder surface treatment. The preparation method comprises the steps of performing copper displacement plating and then performing silver displacement plating. In the step of performing copper displacement plating, fluoride serves as a complexing agent of aluminum ions, so that reaction of removing an oxide film from the surface of aluminum powder can be performed in a nearly neutral environment, dissolution of the aluminum powder is inhibited and deposition of the copper on the aluminum powder is promoted. In the step of performing silver displacement plating, ammonium sulfate solution serves as activating solution, potassium sodium tartrate serves as a complexing agent ofcopper, and a copper platting layer is removed by replacing silver by copper, so that the silver can be deposited on the aluminum powder. The final silver-coated aluminum powder does not contain interlayer copper and the aluminum powder is coated completely. The procedures of plating the interlayer copper and then plating the silver are adopted, so the difficulty of coating the silver on the aluminum powder is reduced.

Owner:BEIJING UNIV OF TECH

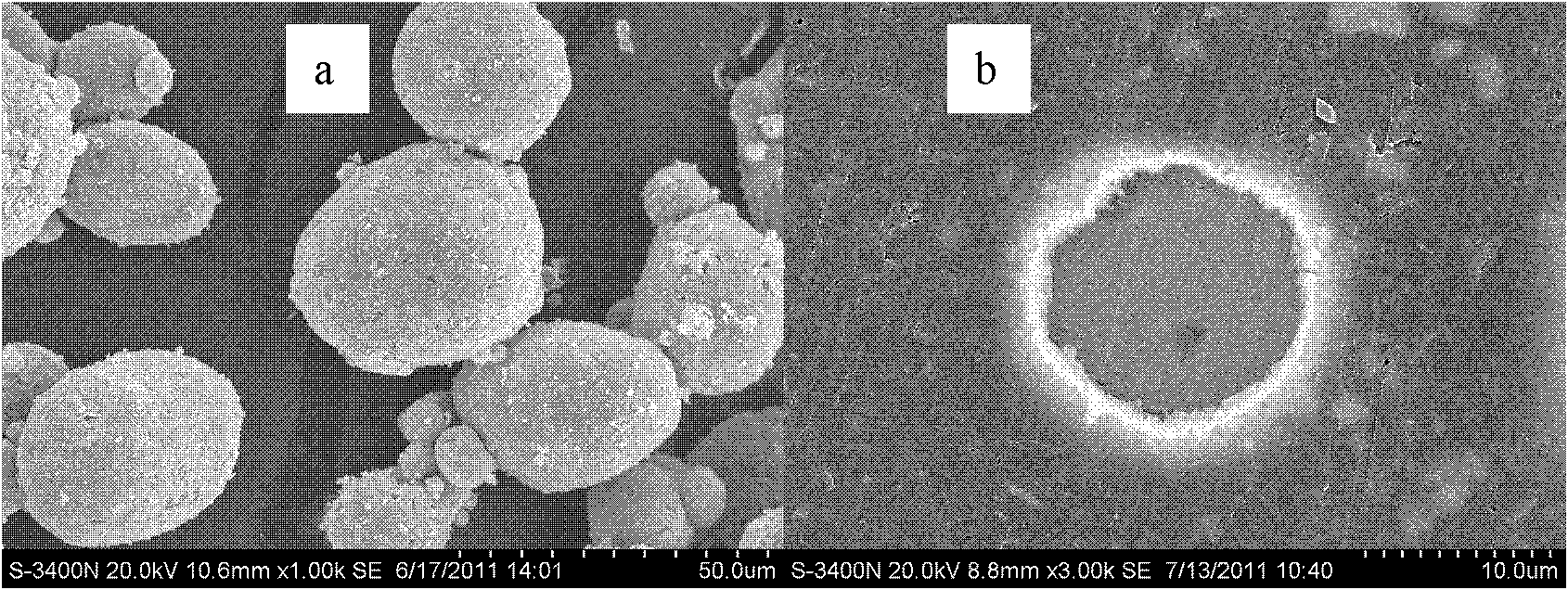

Metallic oxide-coated modified doped ternary anode material and preparation method thereof

ActiveCN105118967AIncrease capacityImprove diffusion abilityMaterial nanotechnologyCell electrodesSolid phasesOxide

The invention discloses a metallic oxide-coated modified doped ternary anode material and a preparation method thereof. The anode material is represented by Li (Ni0.5Mn0.3Co0.2)(1-x)SrxO2.mAl2O3, and comprises a substrate and a coating layer coating the outer part of the substrate, wherein the substrate is represented by Li(Ni0.5Mn0.3Co0.2)(1-x)SrxO2; the coating layer is Al2O3. The anode material is prepared through combining the solid phase method with the heterogeneous nucleation method. The metallic oxide-coated modified doped ternary anode material provided by the invention has higher electronic conductivity and cycling stability, the surface is uniformly and completely coated, and the preparation method is easy, controllable, low in cost and suitable for large-scale industrial production.

Owner:北京盟固利新材料科技有限公司

Double-wall sandwich structural microcapsule self-repairing rubber and preparation method thereof

ActiveCN103467791AImprove heat stabilityFully coveredMicroballoon preparationMicrocapsule preparationMolecular sieveCarbon black

The invention provides a double-wall sandwich structural microcapsule self-repairing rubber and a preparation method thereof, and relates to a rubber and a preparation method thereof. The preparation method comprises the step of sequentially mixing a rubber matrix, stearic acid, zinc oxide, an accelerant, an anti-aging agent, carbon black, paraffin, a double-wall sandwich structural self-repairing microcapsule and a nano mesoporous molecular sieve in proportion, wherein the double-wall sandwich microcapsule is utilized and adopts urea-formaldehyde resin as the wall material, so that the sealing performance is high, and the manufactured walls have moderate hardness; the nano mesoporous molecular sieve utilized as a synergist is naturally inorganic filler which can improve the mechanical performance of the rubber, and a double coating brings higher heat-resisting stability, therefore, the contact probability of a repairing agent and the catalyst is greatly increased, and the influence of excessively added repairing agents and catalysts to the mechanical performance of the rubber can be avoided. Once microcrack appears in the material, a plurality of pores act to improve the capillary siphon effect of the microcrack to the microcapsule, thus the probability of the repairing agent and the curing agent to enter the microcrack is greatly increased, and as a result, the repairing effect is greatly improved.

Owner:沈阳双骥橡塑科技有限公司

Production method of color carbon fibers

ActiveCN104862948AEasy to prepareThe deposition process is easyCarbon fibresTitanium dioxide thin filmMegasonic cleaning

The invention relates to a production method of color carbon fibers and belongs to the technical fields of inorganic non-metallic materials and surface treatment. The production method comprises the following steps of removing an adhesive layer and other attachment materials on the surface of the carbon fibers after ultrasonic cleaning through an organic solvent and depositing a layer of nanometer titanium dioxide thin film on the surface of the carbon fibers by an atomic layer deposition method so as to develop the carbon fibers. According to the production method of the color carbon fibers, the production process is simple and the deposition process is easy to control; the surface the nanometer titanium dioxide thin film deposited carbon fibers is rich in color, the color maintenance durability is good, and the oxidation resistance and the environmental erosion resistance of the carbon fibers are greatly improved; the cost is low, the pollution to the ecological environment is not produced, and the application prospect is broad.

Owner:WUHAN TEXTILE UNIV

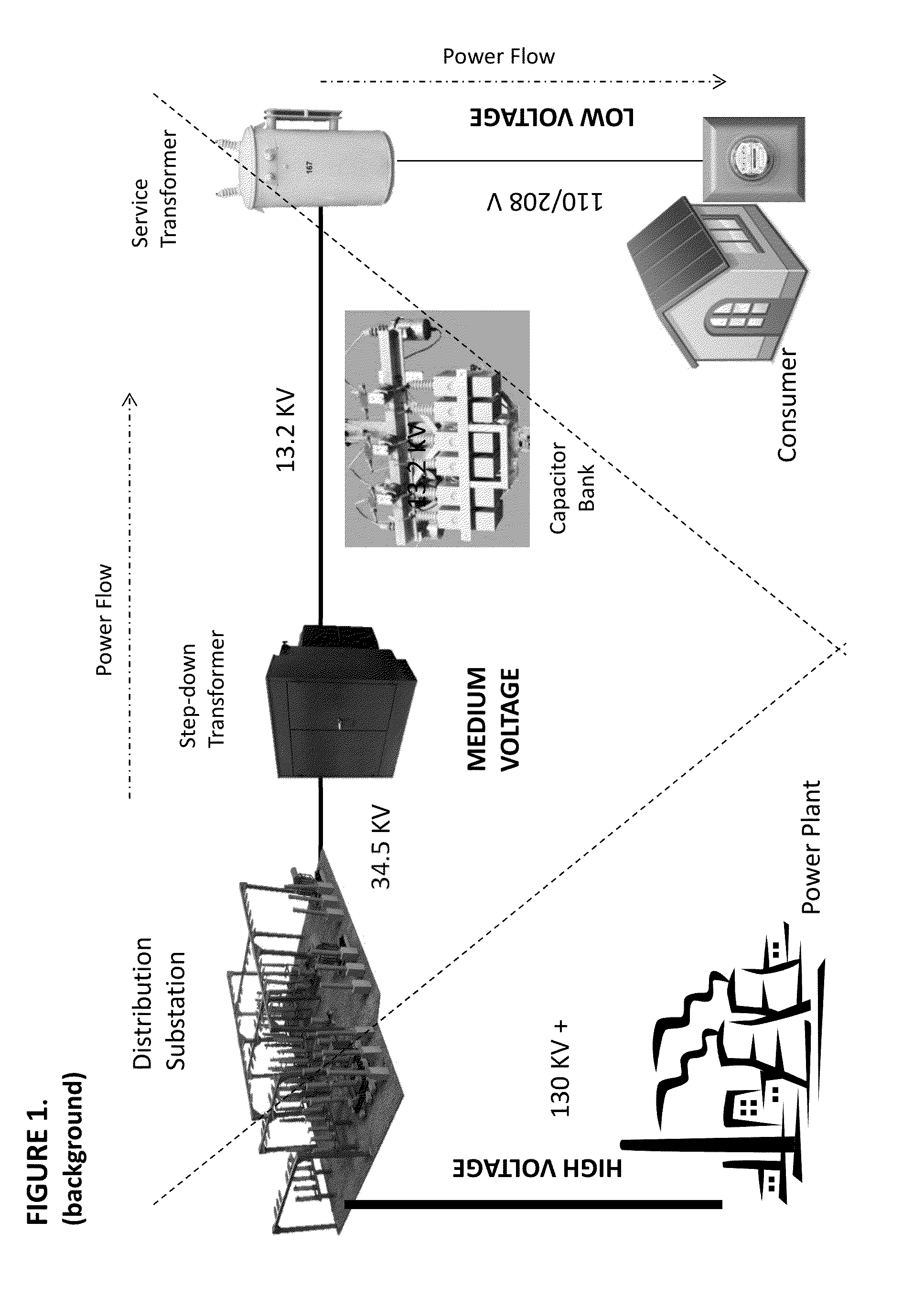

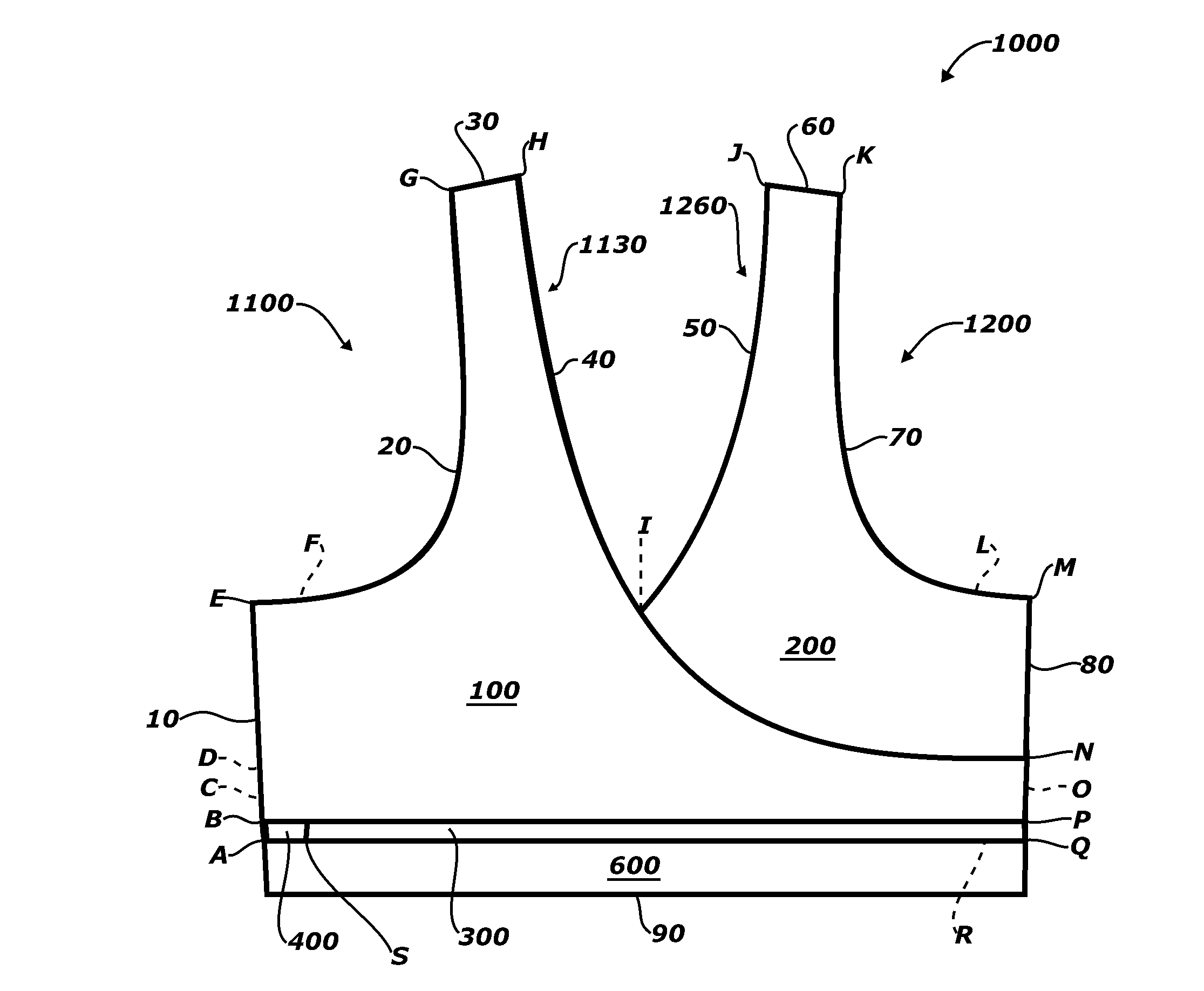

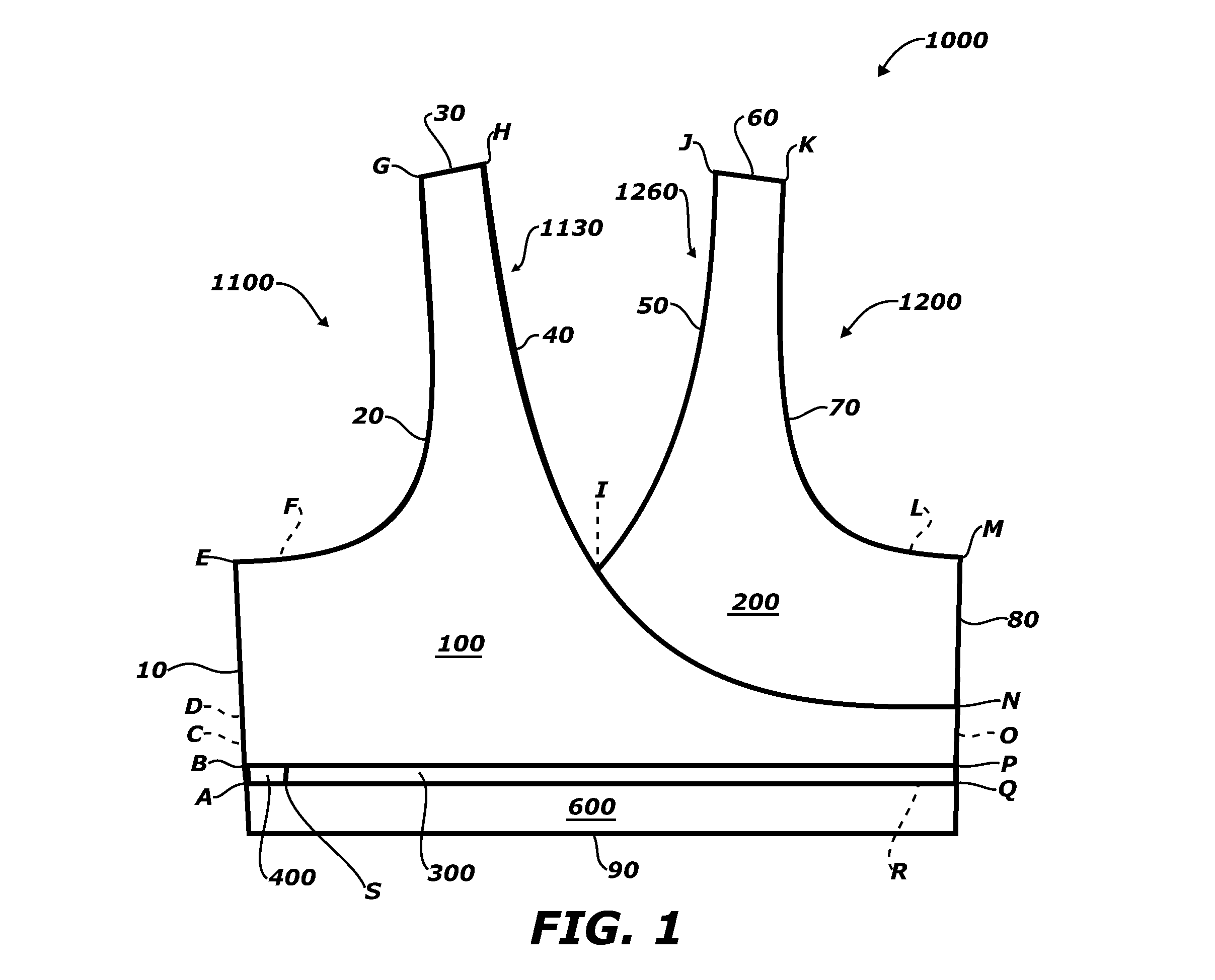

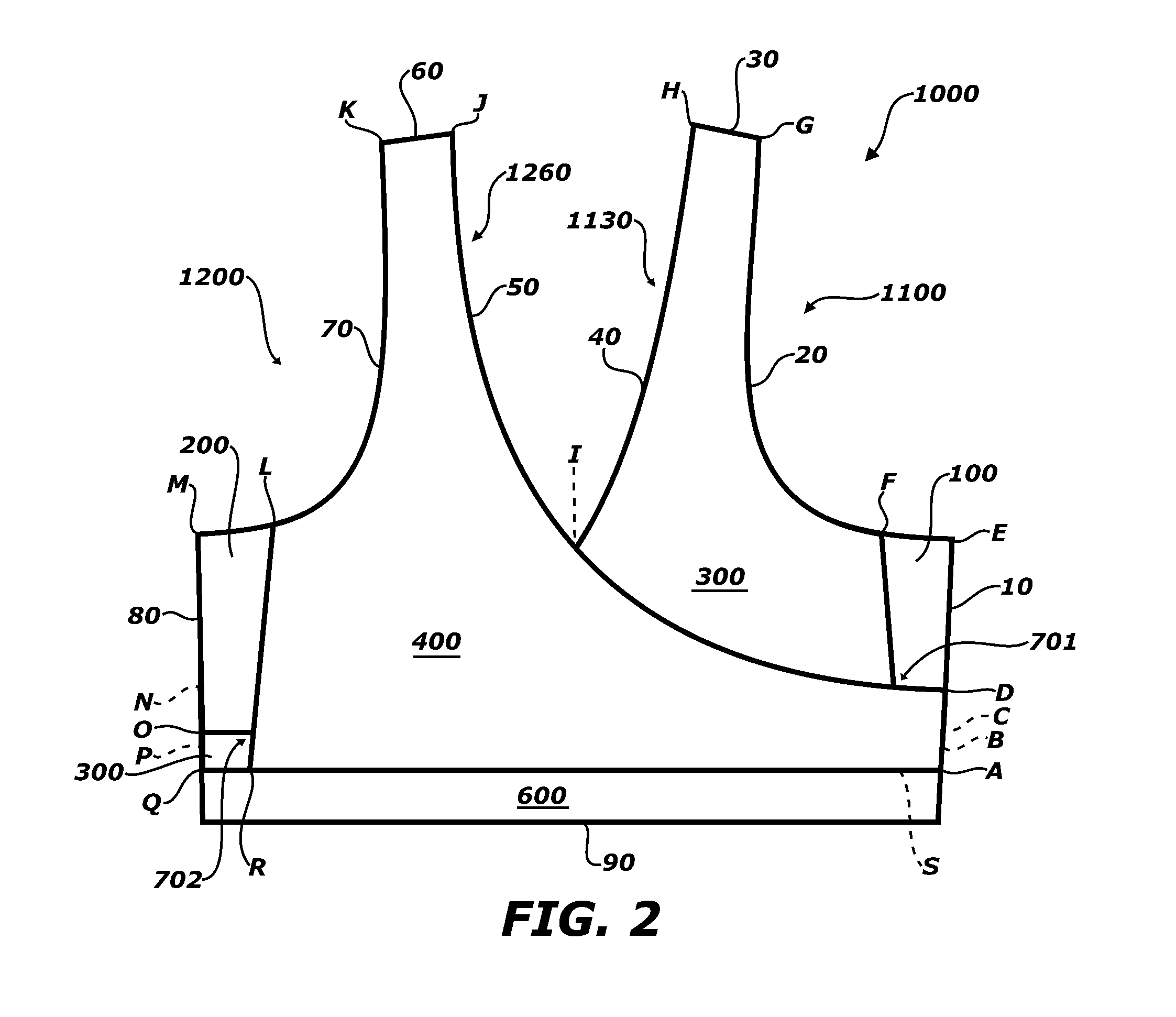

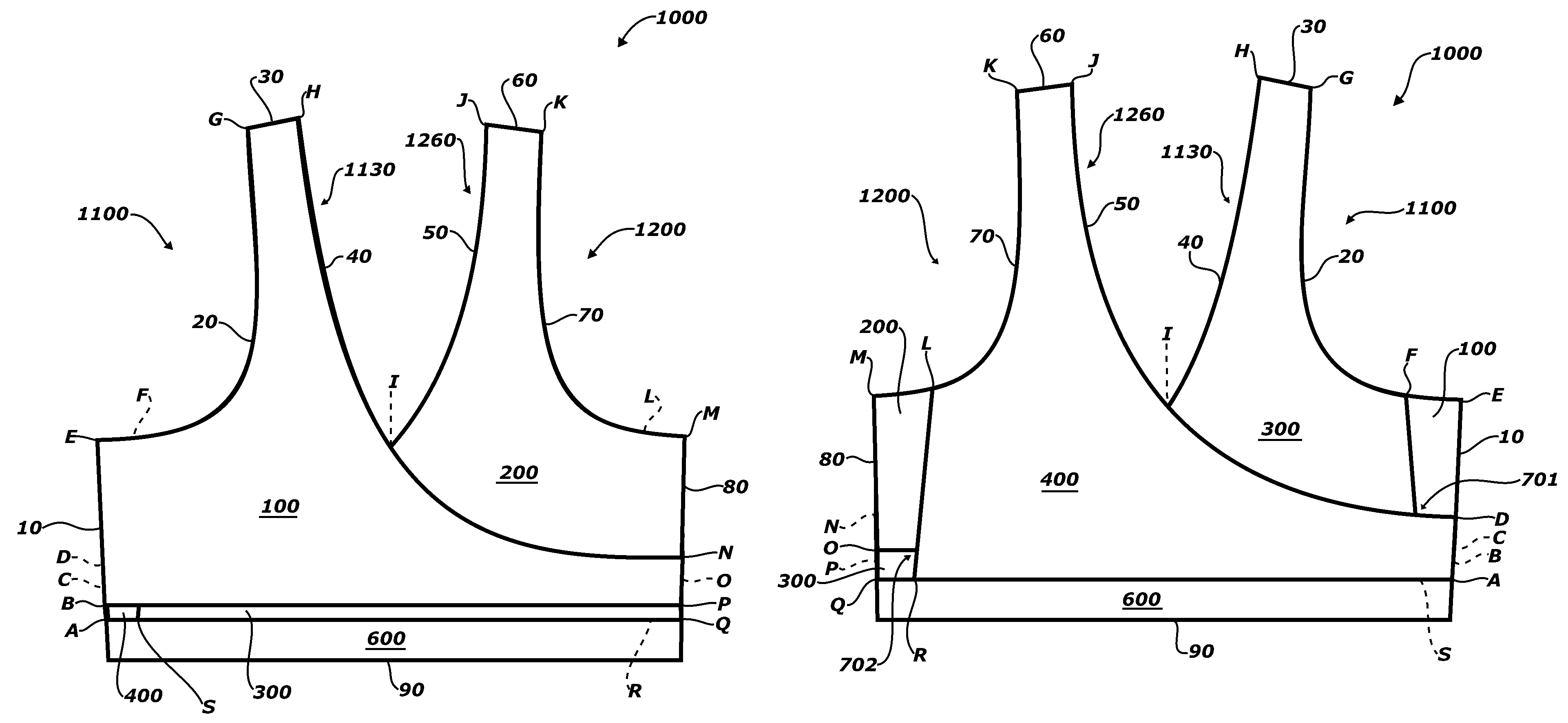

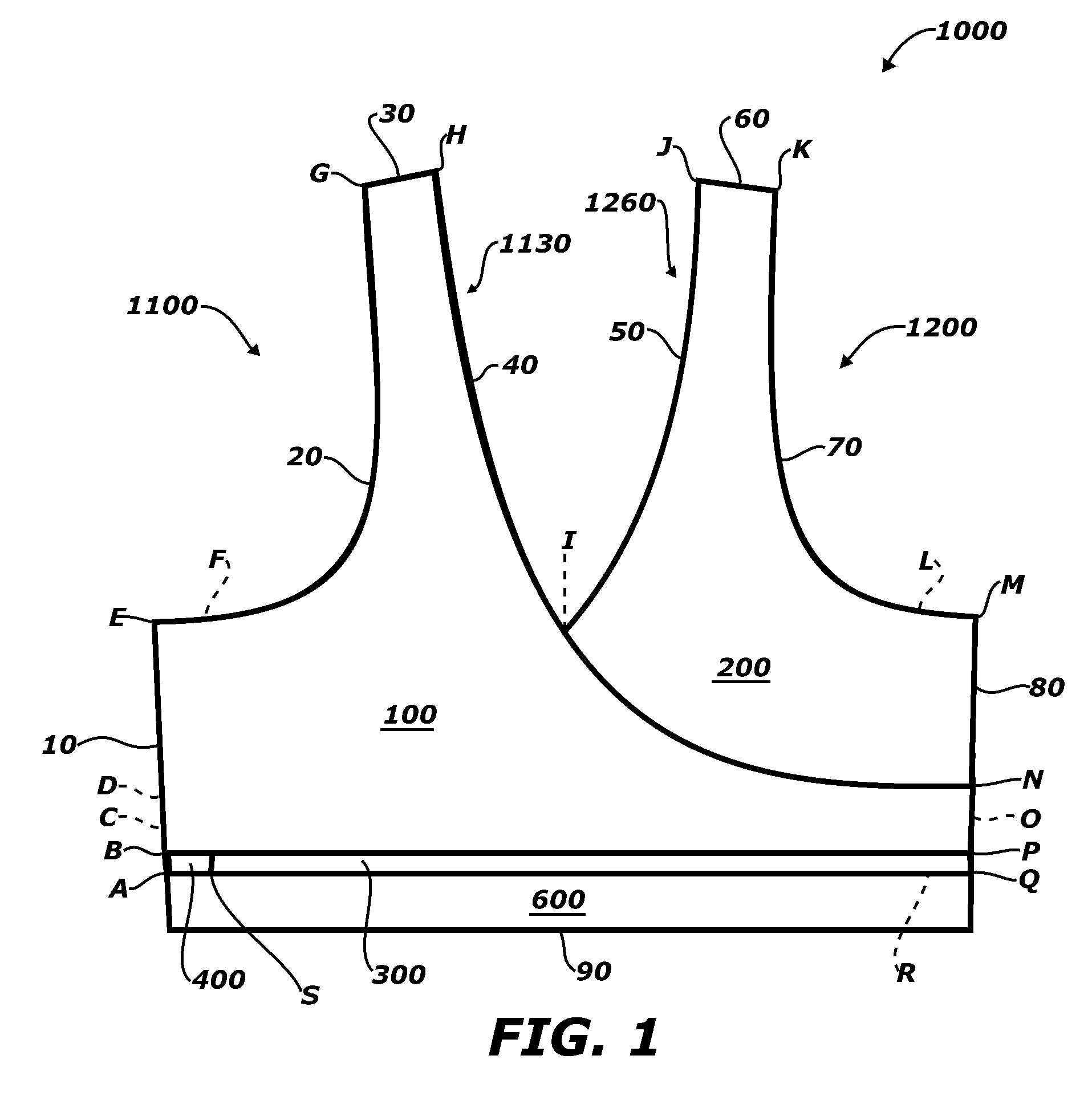

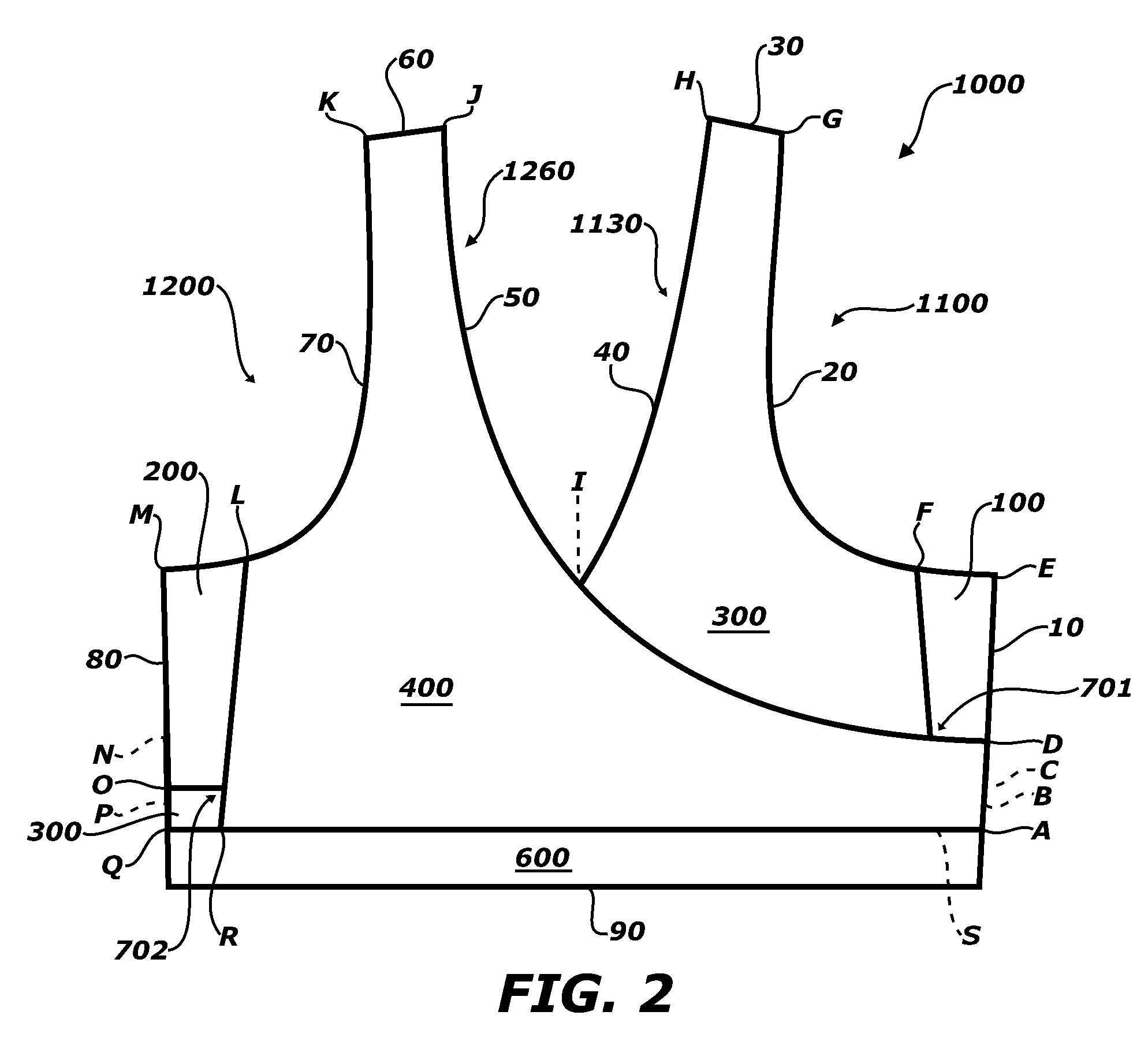

Garments for a nursing woman

A garment for a nursing woman includes at least partially overlapping layers of material. The layers extend between lateral sides of the garment. Some edges of the layers may be attached to edges of other layers or components, while at least one edge of each layer is a free edge. Free edges at least partially define nooks into which the funnels of breast pumps may be received. The free edges of the garment provide multi-directional support to the funnels to enable hands-free pumping. In some embodiments, medial edges of components of the garment cross one another and extend to contribute to the support of the funnels during use of the garment.

Owner:RUMINA NURSINGWEAR

Method of securely data protecting arrangement for electronic device

InactiveUS20100171202A1Erase informationFully coveredSemiconductor/solid-state device detailsSolid-state devicesData informationComputer module

A method of securely data protection for an electronic device includes the steps of: enclosing a core circuit module of the electronic within a protection element to form a protection circuit surrounding the core circuit module; operatively linking a detective circuit between the protection element and the core circuit module; and activating the detective circuit in case of a hack of the electronic device, such that when the electronic device is broken to access the core circuit module through the protection element, the detective circuit is activated to block data information saved in the core circuit module from being access.

Owner:ONBEST TECH HLDG

Automatic bale wrapping apparatus

ActiveUS7987651B2Effective movementReduce laborPaper-makingWrapper twisting/gatheringEngineeringPleat

Apparatus is disclosed for enclosing bales of materials with at least four substantially rectilinear sides in flexible sheet material tubes having one open end into which the bales are inserted leaving the tube open end projecting loosely beyond the end of the bale utilizing structure temporarily placed inside the tube open end tending to resist inward movement of said tube such that the tube end may be formed into pleats at the four corners of the end of the bale and structure external of the tube cooperating to form and fold the pleats against the bale end surface where they are affixed.

Owner:LUMMUS INDS

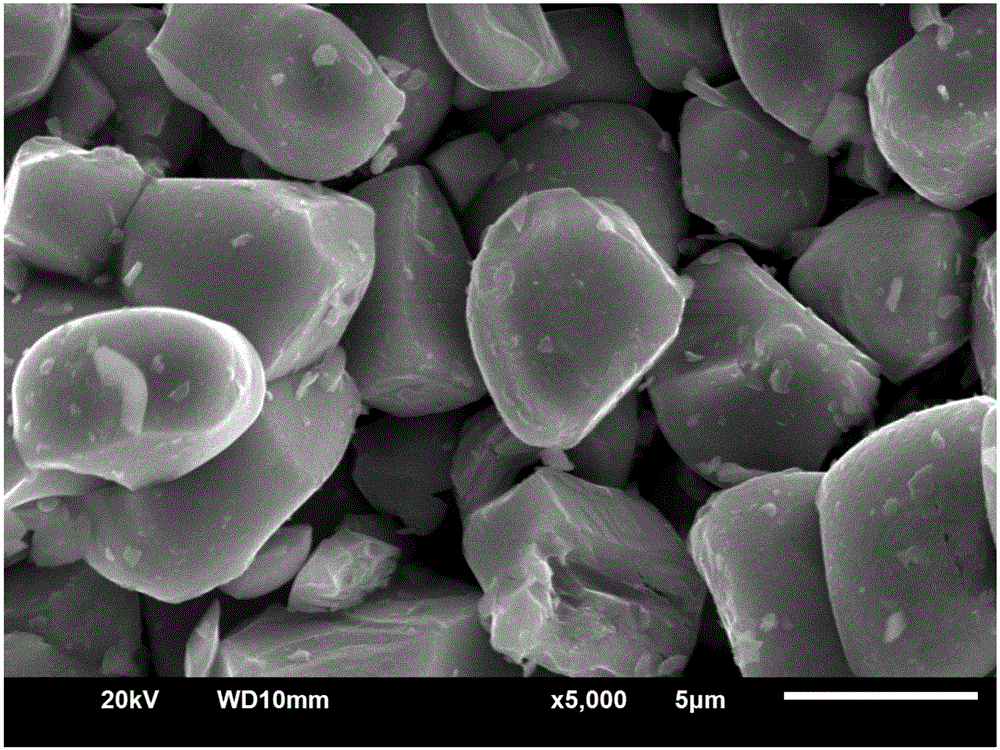

Preparation method of functionalized polyester fiber

ActiveCN102719931AGood dispersionInhibition of reagglomerationMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterPolytetramethylene terephthalate

The invention relates to a preparation method of a functionalized polyester fiber. The functionalized polyester fiber is prepared through blended spinning of functional powder coated by polyester chips and polybutylece terephthalate (PBT). A preparation method of the functional powder coated by the PBT includes that a layer of titanium catalysts is supported on the surface of the functional powder, added polybutylece terephthalate cyclic oligomer (CBT) polymerizes on the surface of the functional powder and generates PBT resin under the action of the catalysts, and the functional powder coated by the PBT is obtained after spray powdering. The catalysts for the polymerization of the CBT are supported on the surface of the functional powder through a supporting technology, the mass ratio of the PBT resin to the functional powder is (2-4):1, the mass ratio of the polyester chips to the functional powder coated by the PBT is (10-15):1, the functional powder coated by the PBT has a good compatibility with polyester, and the functionalized effects of the obtained functionalized polyester fiber are excellent.

Owner:DONGHUA UNIV

Garments for a nursing woman

A garment for a nursing woman includes at least partially overlapping layers of material. The layers extend between lateral sides of the garment. Some edges of the layers may be attached to edges of other layers or components, while at least one edge of each layer is a free edge. Free edges at least partially define nooks into which the funnels of breast pumps may be received. The free edges of the garment provide multi-directional support to the funnels to enable hands-free pumping. In some embodiments, medial edges of components of the garment cross one another and extend to contribute to the support of the funnels during use of the garment.

Owner:RUMINA NURSINGWEAR

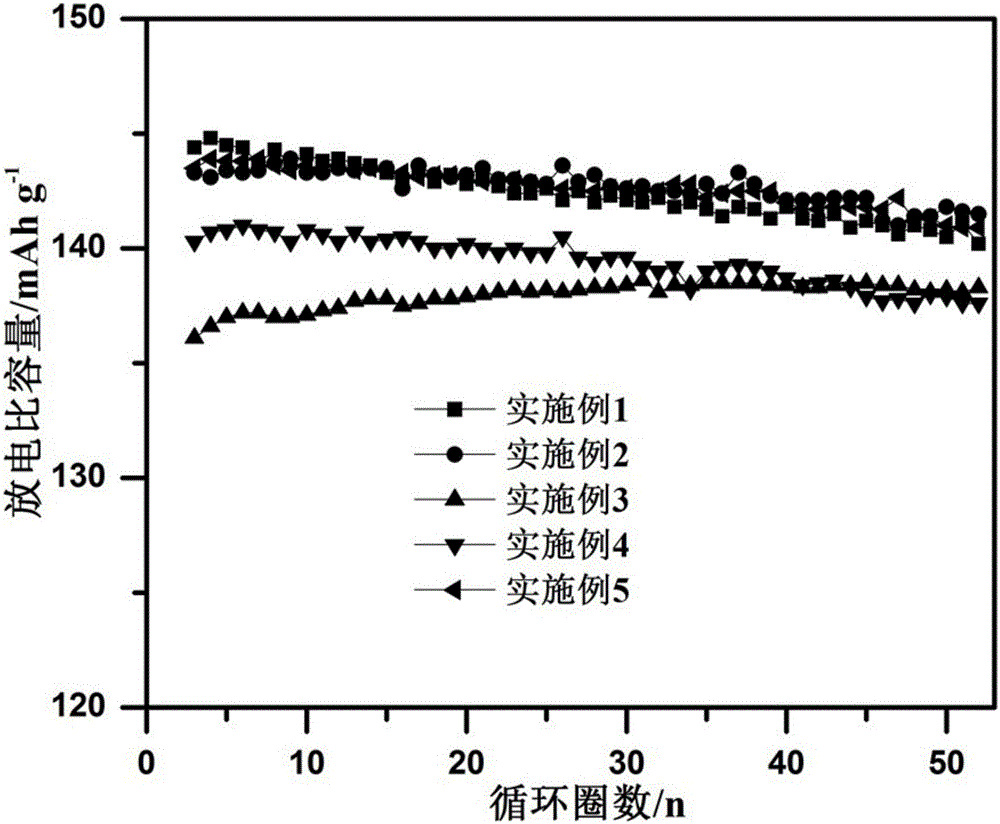

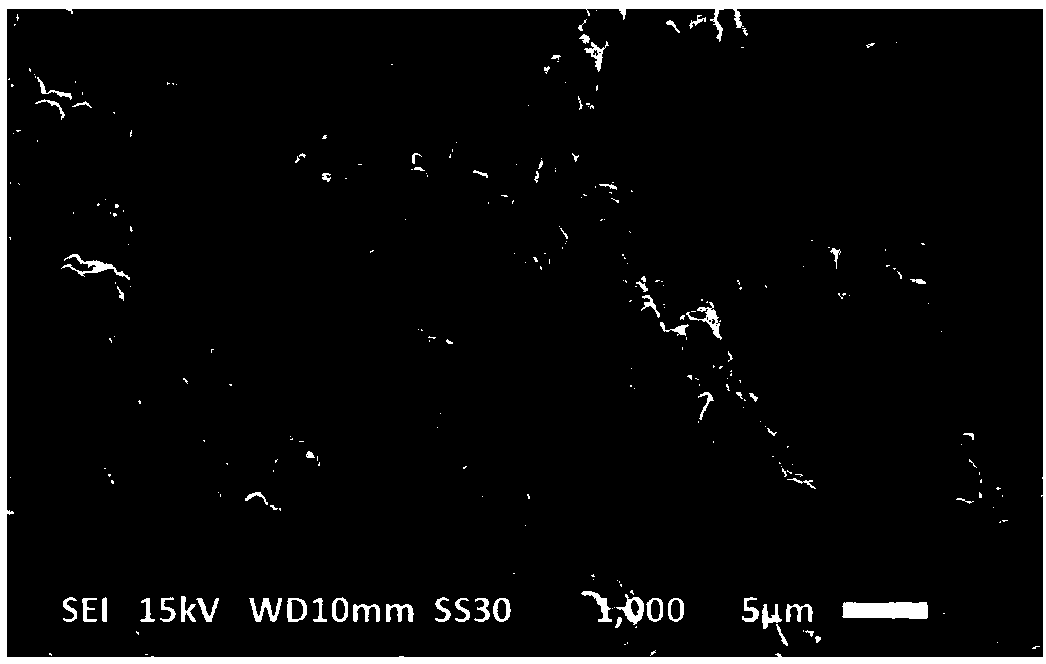

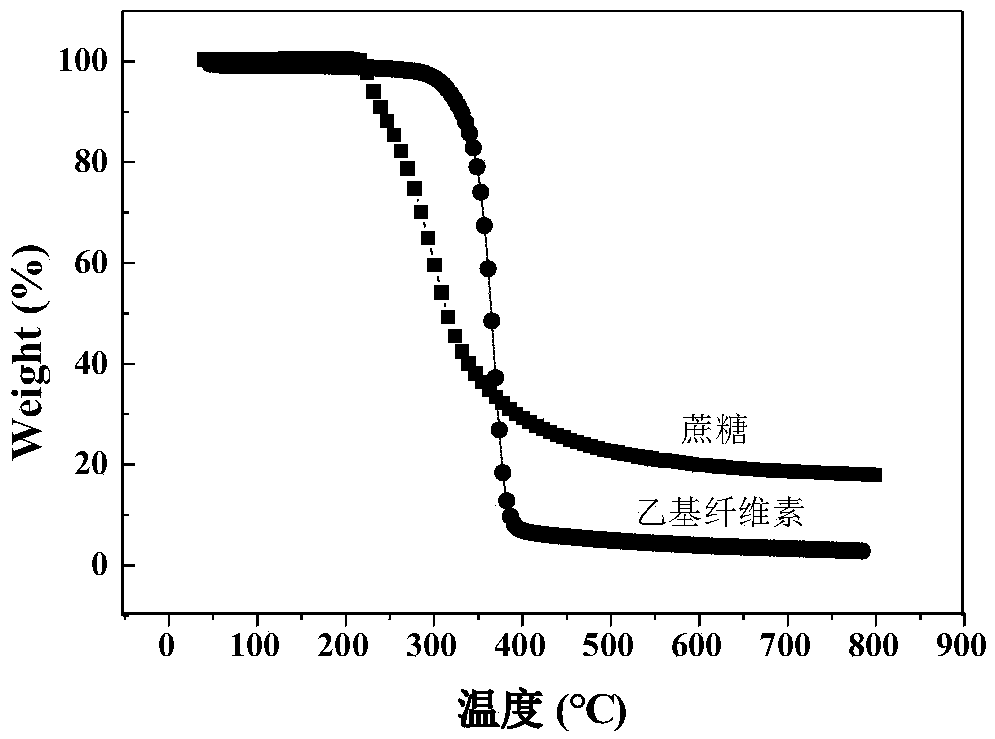

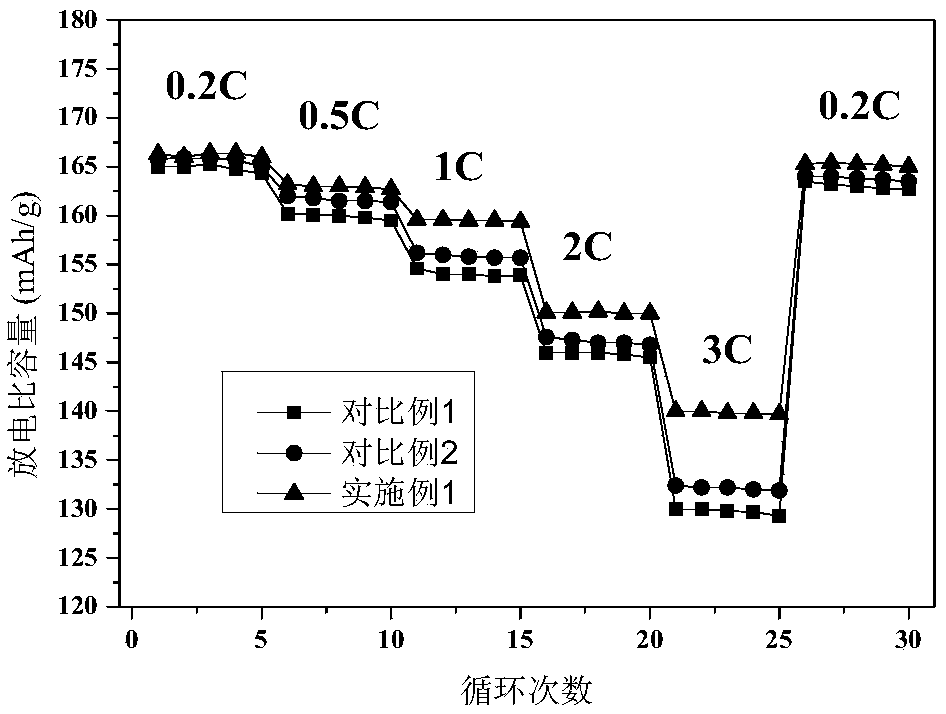

Preparation method of carbon-coated single crystal ternary cathode material

The invention discloses a preparation method of a carbon-coated single crystal ternary cathode material. The method includes: (S1) sintering a single crystal ternary cathode material precursor in oxygen atmosphere to prepare a precursor oxide; (S2) crushing the precursor oxide into primary granules; (S3) performing first sintering and secondary sintering to the dissociated precursor oxide and a lithium source to obtain a single crystal ternary cathode material substrate; (S4) preparing a mixed solution from the organic carbon source and a plasticizer, and adding the single crystal ternary cathode material substrate to the mixed solution, performing spray drying and collecting the product, organic-coated single crystal ternary cathode material; (S5) sintering the organic-coated single crystal ternary cathode material in an inert gas atmosphere, and crushing the product to obtain the carbon-coated single crystal ternary cathode material LixNi<1-y-z>CoyMnzO2 / C, 1 <= x <= 1.1, 0 < y <= 1 / 3and 0 < z <= 1 / 3. The single crystal ternary cathode material is coated with the carbon completely and uniformly, so that electronic conductivity and cyclic performance of the single crystal ternarycathode material are enhanced.

Owner:桑顿新能源科技(长沙)有限公司

Intravascular stent and assembly

InactiveUS7766956B2Maximum possible flexibility and conformabilityOptimal metal fractionStentsSurgeryVascular lumenIntravascular stent

Owner:BOSTON SCI SCIMED INC

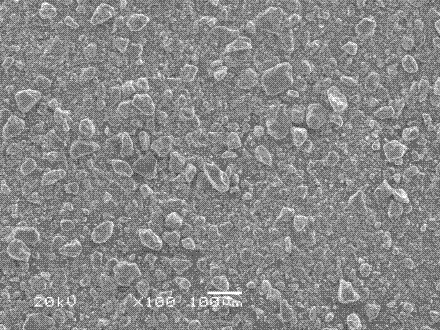

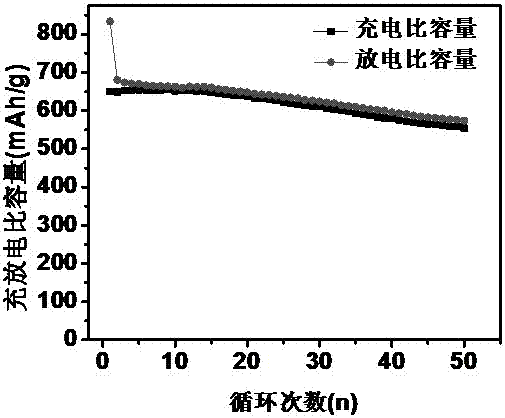

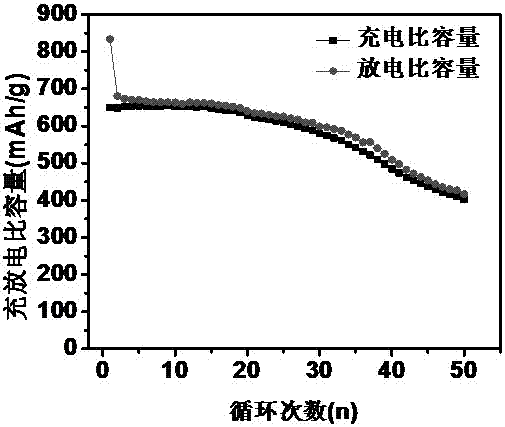

Preparation method for silicon-carbon composite negative electrode material

InactiveCN107017384AImprove liquidityCover tightlyCell electrodesSecondary cellsCarbon compositesCarbonization

The invention discloses a preparation method for a silicon-carbon composite negative electrode material. The preparation method comprises the steps of performing dispersing on nanometer silicon, graphite and an organic matter separately and mixing in proportion; next, performing heating and drying and heating until the temperature reaches an organic matter softening point temperature or above, and performing fusing and binding and low-temperature carbonization to obtain an organic matter cracked carbon-coated primary coating material; performing dispersing on the organic matter and the primary coating material separately and mixing in proportion; and next, performing heating and drying and heating until the temperature reaches an organic matter softening point temperature or above, and performing fusing and coating and high-temperature carbonization to obtain an organic matter cracked carbon-coated secondary coating material, namely the silicon-carbon composite negative electrode material provided by the invention. The initial reversible capacity of the negative electrode material prepared by the method can reach 649mAh / g, and the capacity retention ratio after 50 cycles can be maintained at 85.36%, and quite excellent cycling performance is shown; and in addition, the preparation method has a simple and environment-friendly process, low energy loss, rich silicon and graphite raw material resource, low cost and high safety, and is suitable for industrial production and use.

Owner:SHAANXI COAL & CHEM TECH INST +1

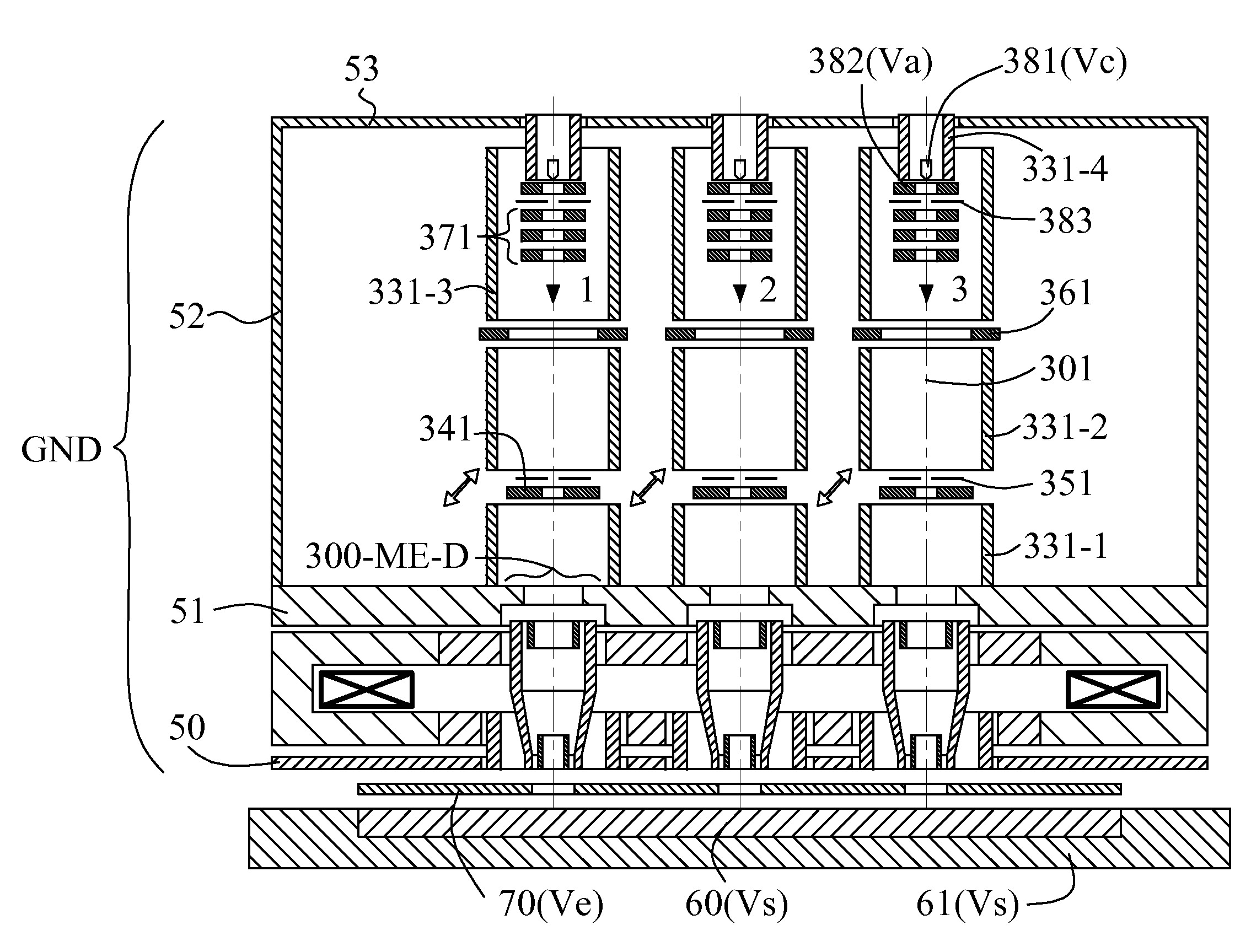

Apparatus of plural charged particle beams with multi-axis magnetic lens

ActiveUS8445862B2Low aberration lowAvoid damageElectric discharge tubesMaterial analysis by optical meansCouplingOptical axis

An apparatus basically uses a simple and compact multi-axis magnetic lens to focus each of a plurality of charged particle beams on sample surface at the same time. In each sub-lens module of the multi-axis magnetic lens, two magnetic rings are respectively inserted into upper and lower holes with non-magnetic radial gap. Each gap size is small enough to keep a sufficient magnetic coupling and large enough to get a sufficient axial symmetry of magnetic scale potential distribution in the space near to its optical axis. This method eliminates the non-axisymmetric transverse field in each sub-lens and the round lens field difference among all sub-lenses at the same time; both exist inherently in a conventional multi-axis magnetic lens. In the apparatus, some additional magnetic shielding measures such as magnetic shielding tubes, plates and house are used to eliminate the non-axisymmetric transverse field on the charged particle path from each charged particle source to the entrance of each sub-lens and from the exit of each sub-lens to the sample surface.

Owner:ASML NETHERLANDS BV

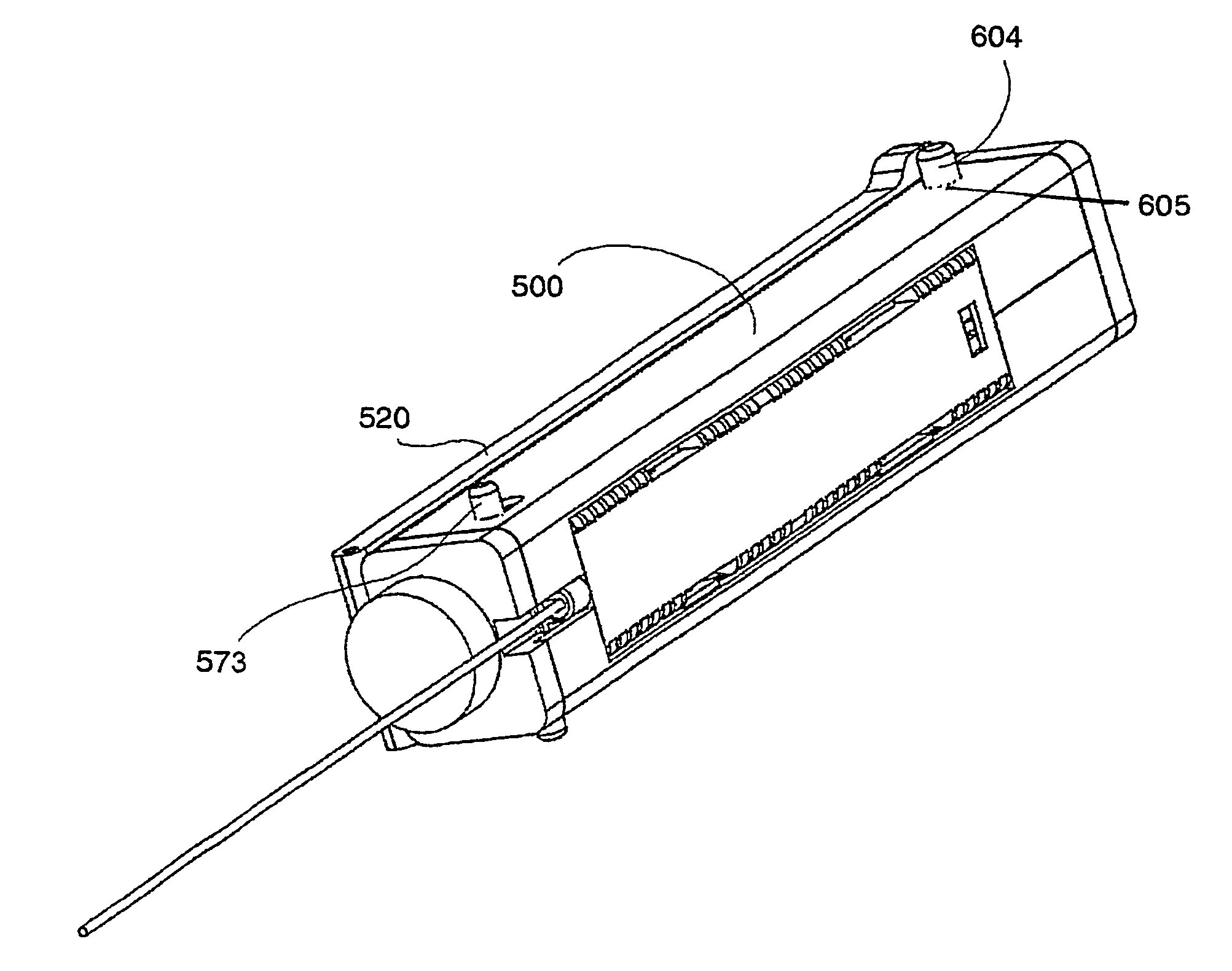

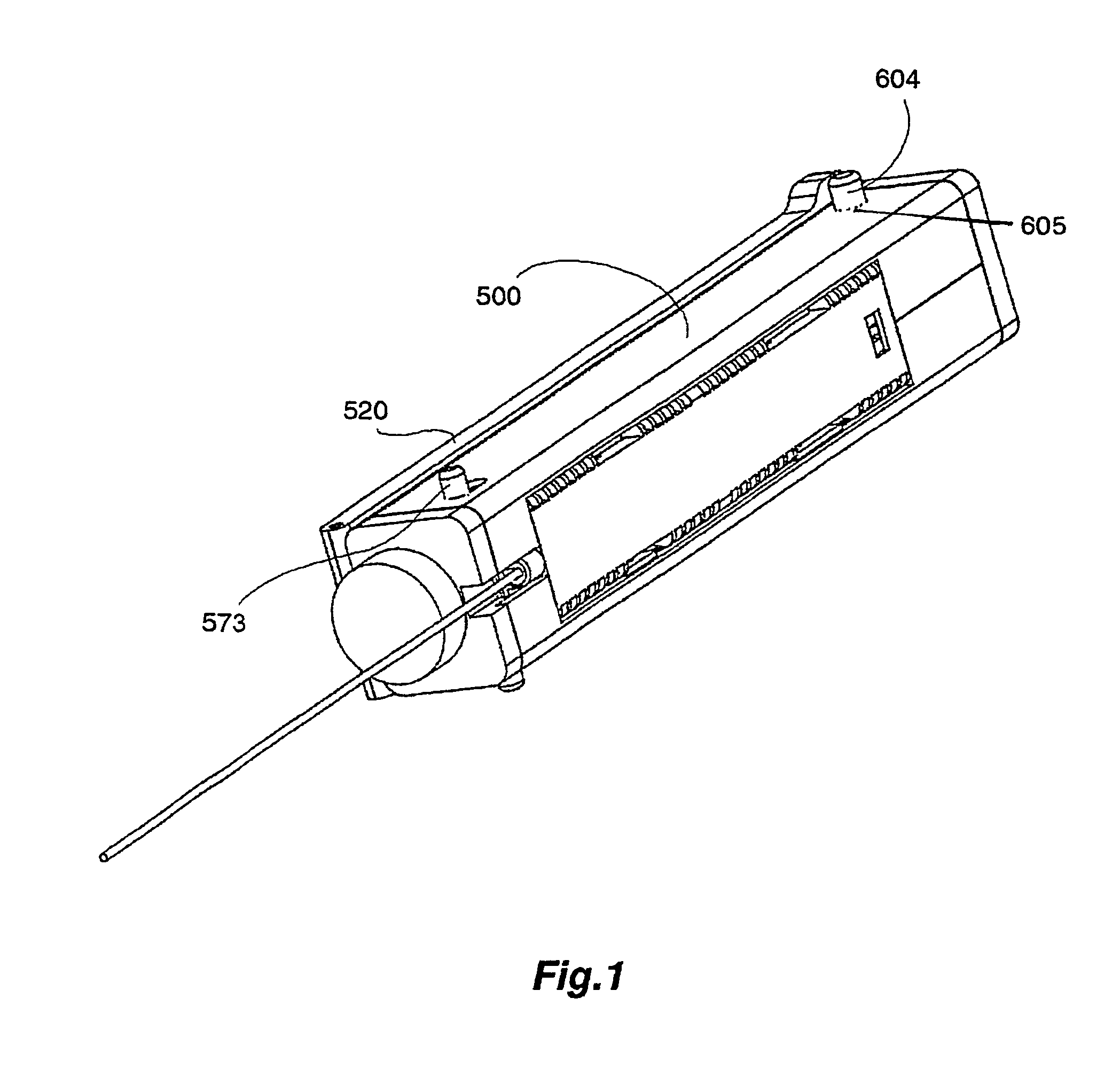

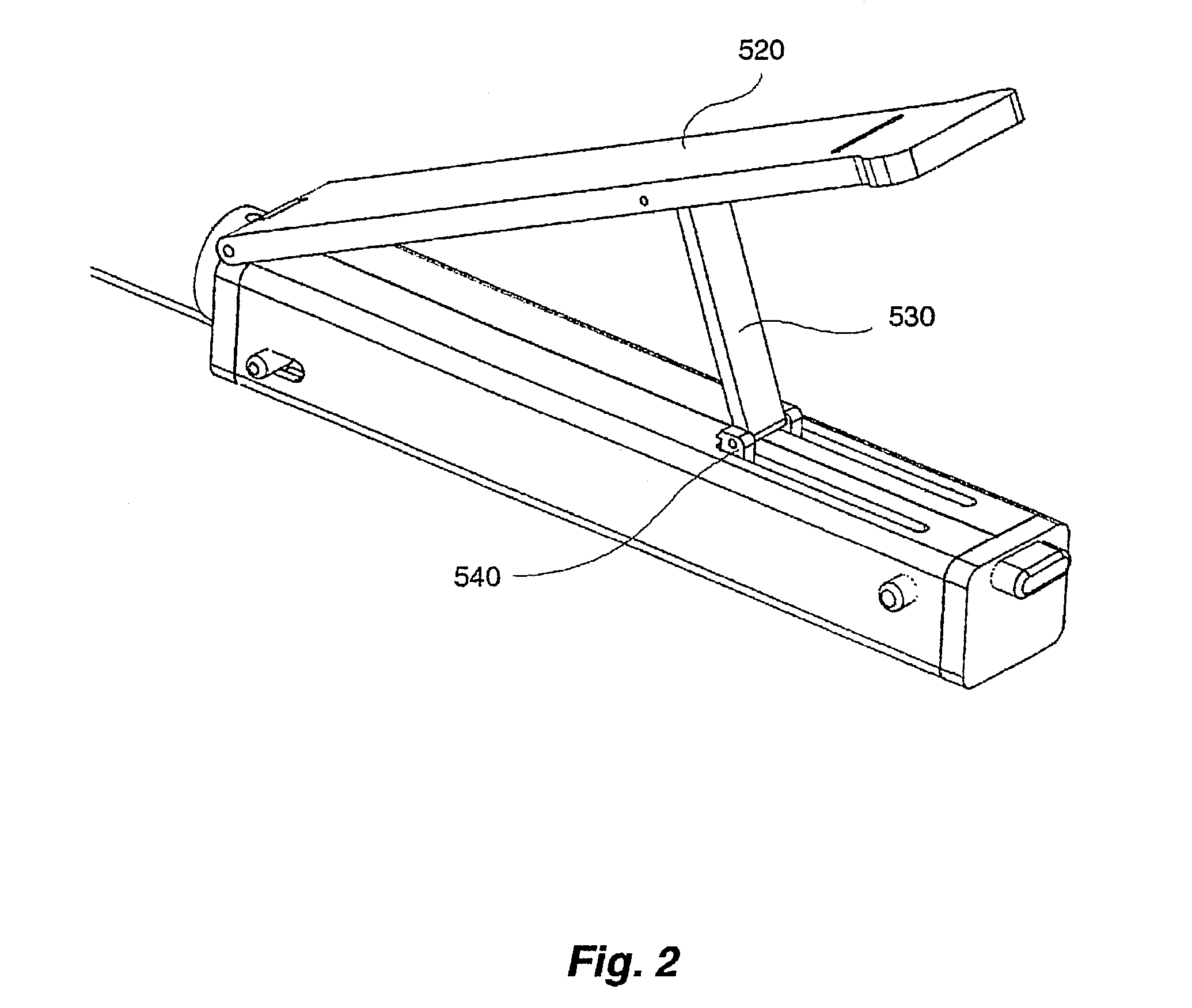

Multiple-use biopsy apparatus and corresponding single-use biopsy instrument

InactiveUS7041065B2Easily and safely mounted and dismountedFully coveredSurgical needlesVaccination/ovulation diagnosticsBiopsy instrumentsEngineering

A single-use biopsy instrument for mounting at a multiple-use biopsy apparatus, comprises a cartridge enclosing proximal end portions of a canula, a finger tube slidingly disposed on the canula, and a stylet slidingly disposed in the canula. The canula and the finger tube have proximal holding portions and are displaceable in regard of the cartridge by displacement means disposed in the biopsy apparatus engaging with the holding portions through one or several engagement openings in one wall of the cartridge. Also disclosed is a corresponding biopsy apparatus.

Owner:BIFOS

Retractable car cover

InactiveUS20050212322A1Smooth rotationEasy to stretchWindowsFlexible coversEngineeringMechanical engineering

Owner:PORTER MATTHEW B

Surface decorated lithium ion cell positive electrode material and its preparing method

InactiveCN1617371AFully contactedFully coveredElectrode manufacturing processesActive material electrodesLithiumPorosity

This invention relates to a material for decorating surface of the positive of Li ionic battery and its preparation method, first of all, putting a positive powder material Li-M1M2-O(M1M2=Co Mn Ni Cr into a solution with organic substance in the concentration of 0.05-2.00mol / 1 then to put the mixed substance into a heat water reactor with mixing for 0.1-4h under 150-200deg. to spray and dry the reacted solution, then a positive material is got covered uniform carbon microspheres having the advantage of high specific capacity, fine circulation performance, uniform porosity and no impurities.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Double-coated composite solid lithium manganate material and preparation method thereof

InactiveCN110880594AImprove conductivityPrevent polarizationSecondary cellsPositive electrodesGraphite oxideSingle crystal

The invention discloses a double-coated composite solid-state lithium manganate material and a preparation method thereof. The preparation method comprises the following steps of mixing and sinteringa lithium salt, a titanium salt, an aluminum salt and a phosphate raw material to obtain a solid-state electrolyte lithium titanium aluminum phosphate (Li <1+x> Al <x> Ti <2-x> (PO4) 3 (LATP); addingLATP, single crystal lithium manganate, a graphene oxide aqueous solution and zirconium oxide balls into a sand mill to be fully ground, nanocrystallizing the LATP and attaching the LATP to the surface of the lithium manganate, and meanwhile, coating the lithium manganate with graphene oxide; and after drying, reducing the graphene oxide into graphene at a high temperature in a hydrogen atmosphereto obtain the solid electrolyte and the graphene double-coated lithium manganate positive electrode material. According to the method, the consistency and repeatability of the material are ensured, the manufacturing cost is low, the solid electrolyte can inhibit the dissolution of manganese, the graphene blocks the reaction between the electrolyte and the positive electrode material, and the cycle performance and the high-temperature performance are improved.

Owner:SUZHOU PHYLION BATTERY

Surface modified nanometer material serving as lubricating oil additive as well as preparation method and application thereof

ActiveCN103804960AReduce the temperatureFast preparationAdditivesPigment treatment with macromolecular organic compoundsMechanical millingOil additive

The invention belongs to the technical fields of a nanometer material and lubricating oil, and discloses a surface modified nanometer material serving as a lubricating oil additive as well as a preparation method and an application thereof. The preparation method mainly comprises the following steps: putting a mixture of powder to be treated and a surface modification agent as well as grinding balls in a ball-milling tank of an improved dielectric barrier discharge plasma assisted mechanical milling device, feeding a discharge atmosphere medium, controlling the temperature of the ball-milling tank, adjusting discharge parameters, and starting the mechanical milling device so as to carry out dielectric barrier discharge plasma assisted mechanical milling, thus obtaining the surface modified nanometer material. The obtained powdery surface modified nanometer material can be added to the lubricating oil so as to improve the performance of the lubricating oil. The preparation method is simple to operate and good in controllability; the obtained surface modified nanometer material is small in particle size, high in activity, good in surface modification and extremely easy to deposit, flatly spread and diffuse on a mechanical friction surface and has excellent dispersion property in the lubricating oil, so that the friction of mechanical movement parts is reduced, and the worn surface is repaired.

Owner:麦卡伦(厦门)润滑油有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com