Preparation method of silver-coated aluminum powder

A technology of silver-coated aluminum and aluminum powder, which is applied in the direction of liquid chemical plating, coating, metal material coating technology, etc., and can solve problems such as cumbersome process, poor coating effect, and complicated treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Electroless copper plating:

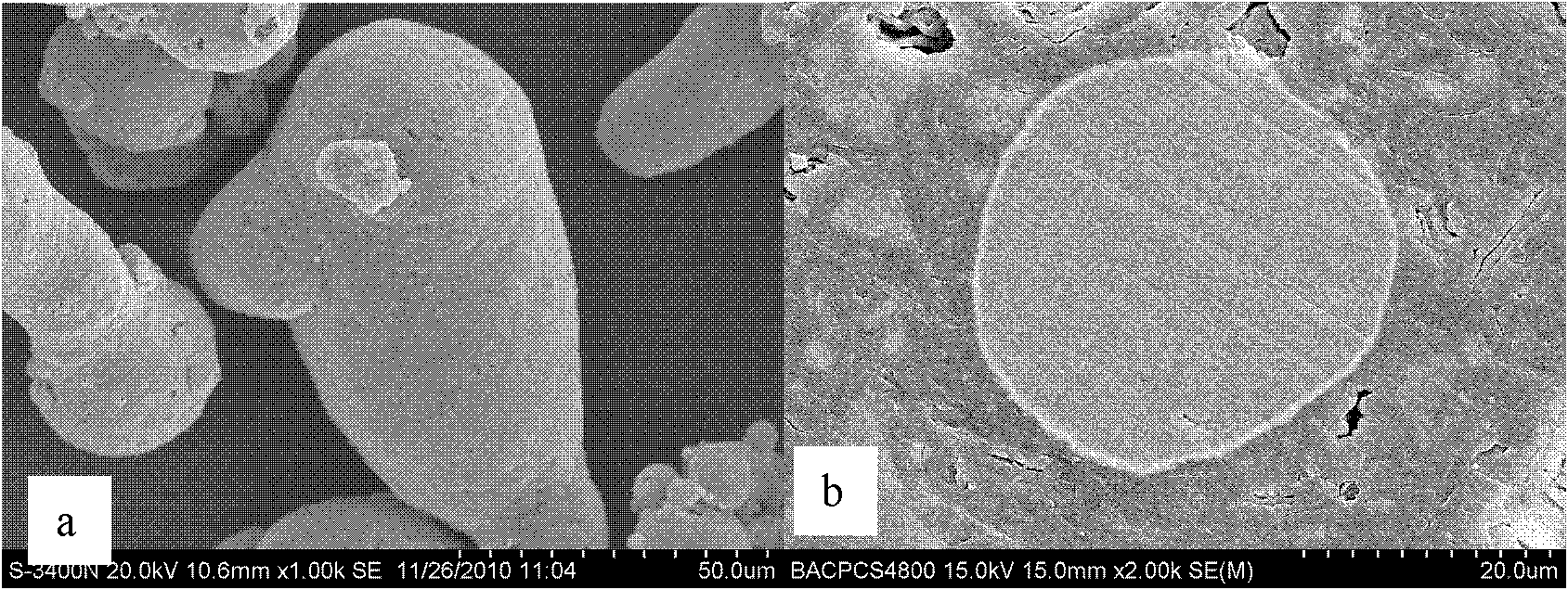

[0037] Take 5g of 100μm spherical aluminum powder, add it to 10ml of acetone solution, ultrasonically clean it for 5 minutes to remove the grease on the surface, wash it with deionized water for 3 times, and filter it for later use. Take by weighing 1.2g anhydrous copper sulfate (at this moment aluminum powder and CuSO 4 The mass ratio is 5:1.2), disodium edetate 5.6g (CuSO 4 , EDTA-2Na molar ratio is 0.5), after dissolving with deionized water respectively, mix and place for 10 minutes to make it fully complexed. Add the pretreated aluminum powder to the above mixed solution, add 2 g of polyethylene glycol, adjust the pH value of the solution to 6 with hexamethylenetetramine-hydrochloric acid (pH=5.4), adjust the volume of the plating solution to 350 ml and raise the temperature to 30°C. Add 0.25g of solid sodium fluoride (the mass of sodium fluoride accounts for 5% of the mass of the powder), replace and plate for 30 minutes, stop stir...

example 2

[0041] Electroless copper plating:

[0042] Take 5g of 50μm aluminum powder, add it to 20ml of acetone solution, ultrasonically clean it for 10 minutes, remove the grease on the surface, wash it with deionized water for 3 times, and filter it for later use. Take by weighing 2.4g anhydrous copper sulfate (aluminum powder and CuSO 4 The mass ratio is 5:2.4), disodium edetate 5.6g (CuSO 4 , EDTA-2Na molar ratio is 1.0), after dissolving with deionized water respectively, mix and place for 10 minutes to make it fully complexed. Add the pretreated aluminum powder to the above mixed solution, add 2 g of gelatin, adjust the pH value of the solution to 4 with potassium hydrogen phthalate-hydrochloric acid buffer solution (pH=4), adjust the volume of the plating solution to 350 ml and heat up to 40°C, add 0.5g of solid sodium fluoride (the mass of sodium fluoride accounts for 10% of the mass of the powder), replace and plate for 30 minutes, stop stirring when the solution is clear, f...

example 3

[0046] Electroless copper plating:

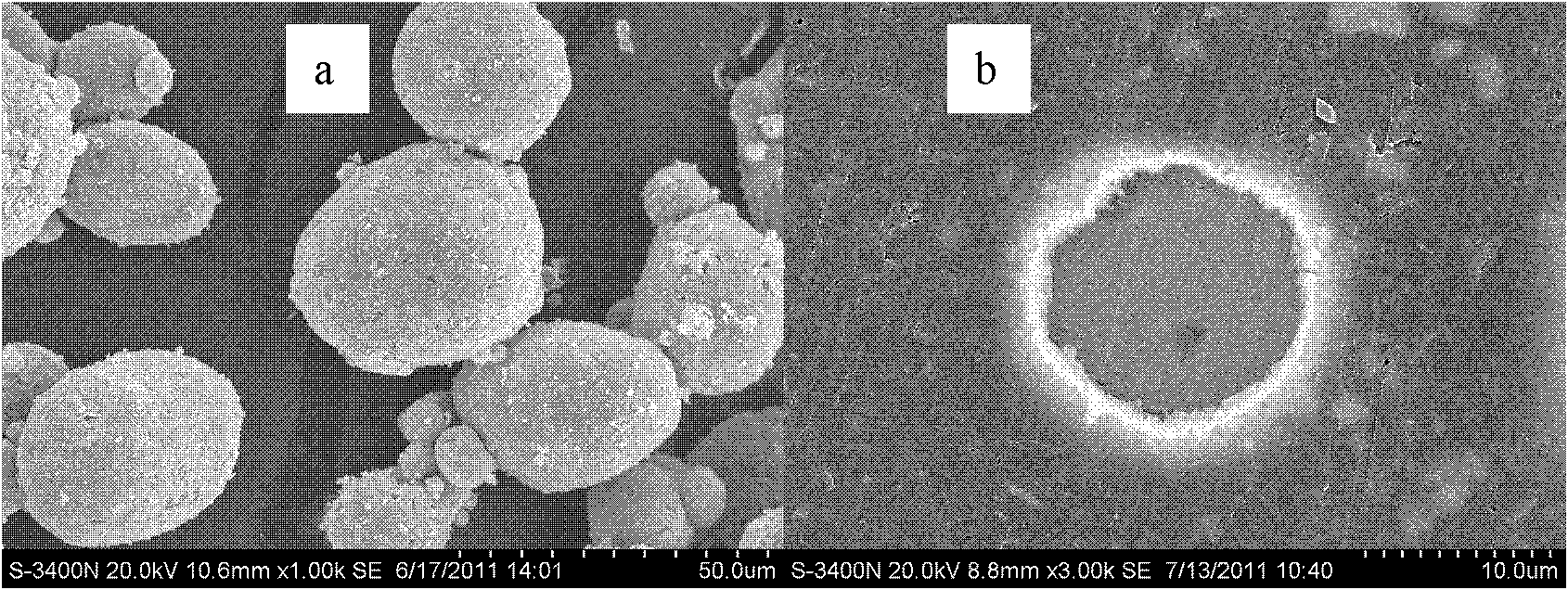

[0047] Take 5g of 20μm aluminum powder, add it to 30ml of acetone solution, ultrasonically clean it for 10 minutes to remove the grease on the surface, wash it with deionized water for 3 times, and filter it for later use. Weigh 4.8g anhydrous copper sulfate aluminum powder and CuSO 4 The mass ratio is 5:4.8), disodium edetate 5.6g (CuSO 4 , EDTA-2Na molar ratio is 2.0), after dissolving with deionized water respectively, mix and place for 10 minutes to make it fully complexed. Add the pretreated aluminum powder to the above mixed solution, add 3g of gelatin, adjust the pH value of the solution to 7 with potassium hydrogen phosphate diformate-sodium hydroxide (pH=6.8), adjust the volume of the plating solution to 350ml and raise the temperature to 40 ℃, add 0.75g of solid sodium fluoride (the mass of sodium fluoride accounts for 15% of the mass of the powder), replace and plate for 30 minutes, stop stirring when the solution is clarified,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com