Patents

Literature

3128 results about "Chemical plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plating chemicals and anodizing chemicals include metal salts, formula additives, and other consumables for the electrodeposition, electroless plating, electroplating, or anodized layer formation. Electrodeposition is a process which deposits a metal at the cathode from a solution of its ions.

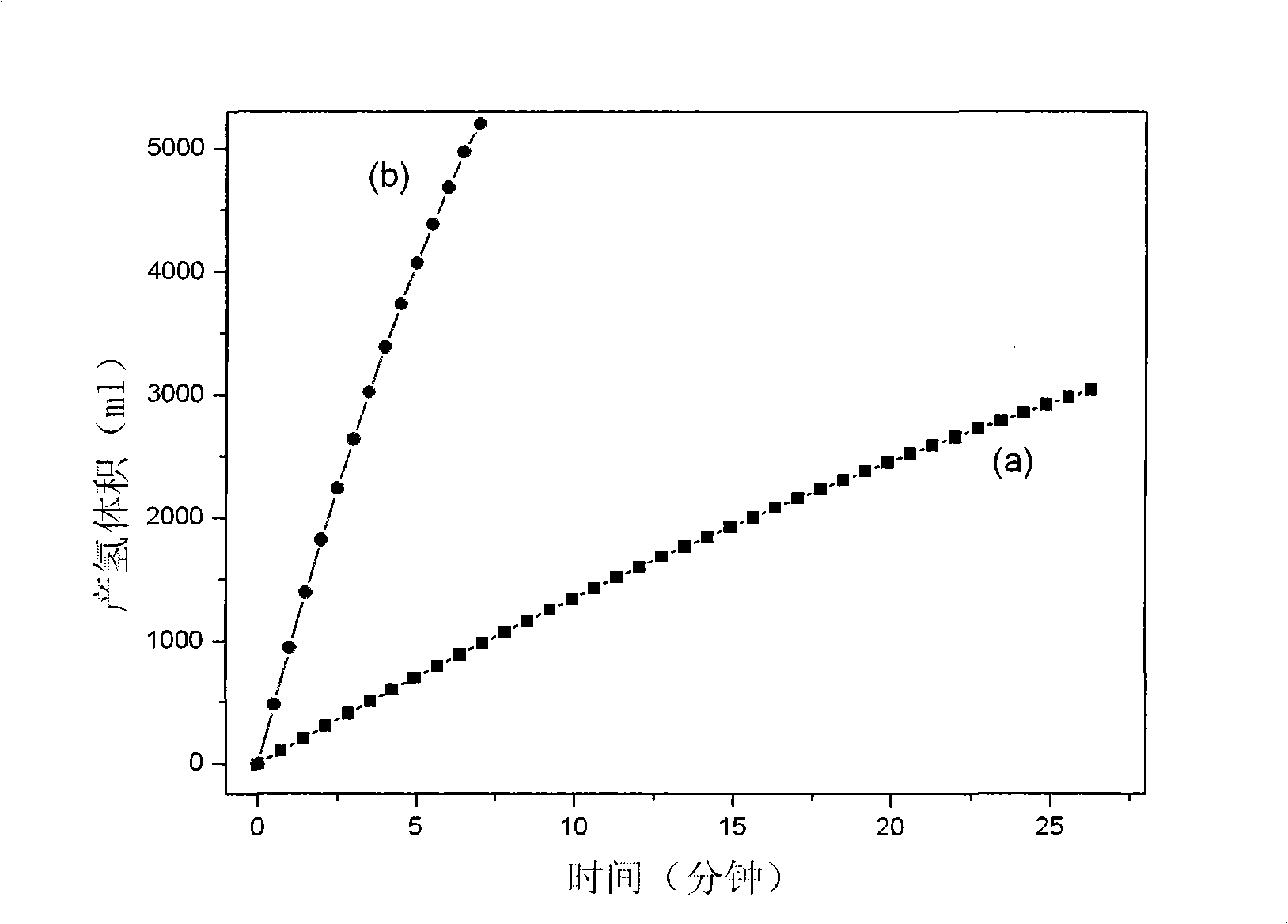

Catalyst for hydrogen production by catalyzing and hydrolyzing borohydride and preparation method thereof

InactiveCN101347736AFast deposition rateIncrease concentrationMetal/metal-oxides/metal-hydroxide catalystsMetal hydridesChemical platingRare earth

The invention relates to hydrogen production and hydrogen storage technologies and materials, in particular to a catalyst for catalytic hydrolysis of borane for the hydrogen production and a preparation method thereof, thereby solving the problems that the direct application of powder catalyst in a catalytic hydrolysis solid-liquid reaction system can cause the loss of the catalyst, the catalytic hydrolysis reaction is difficult to control and the hydrolysis by-products are difficult to be recovered, etc. The catalyst is composed of an active component and a carrier; the active component is a binary, ternary or multinary alloy or a single precious metal or the combination thereof which is composed of one or more transition metals, rare earth metals or precious metals and metalloids; the active component is deposited on the carrier through the improved chemical plating technology, the surface thereof is rough and porous, and the structure of the prepared catalyst is the amorphous or the nanocrystalline structure. The preparation method has simple preparation process, high preparation efficiency and convenient large-scale preparation; the sources of the used raw materials are rich; the catalytic activity of the prepared supported catalyst is high, the real-time control of the catalytic hydrolysis reaction of the borane can be realized, the catalytic performance is stable, and the catalyst can be repeatedly used for a plurality of times.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

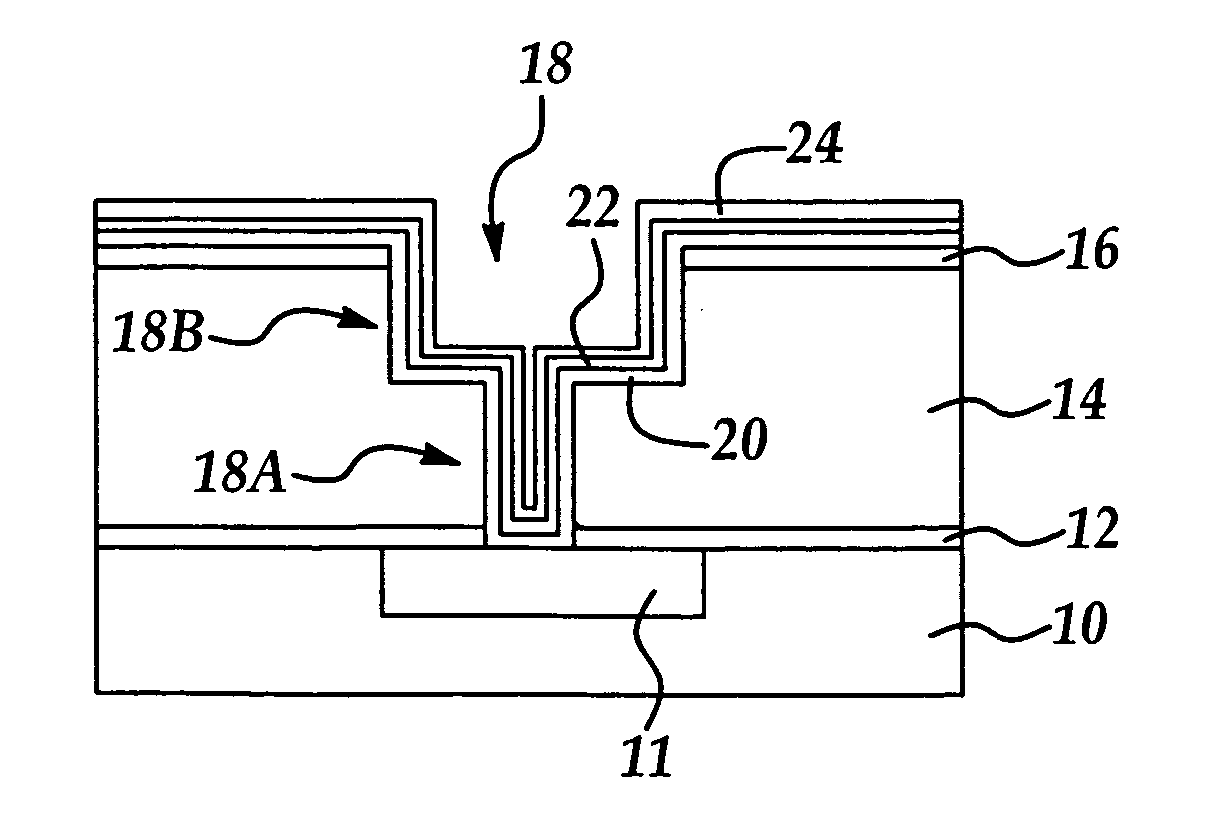

Method for forming a multi-layer seed layer for improved Cu ECP

InactiveUS20050110147A1Semiconductor/solid-state device detailsSolid-state devicesChemical platingHydrogen

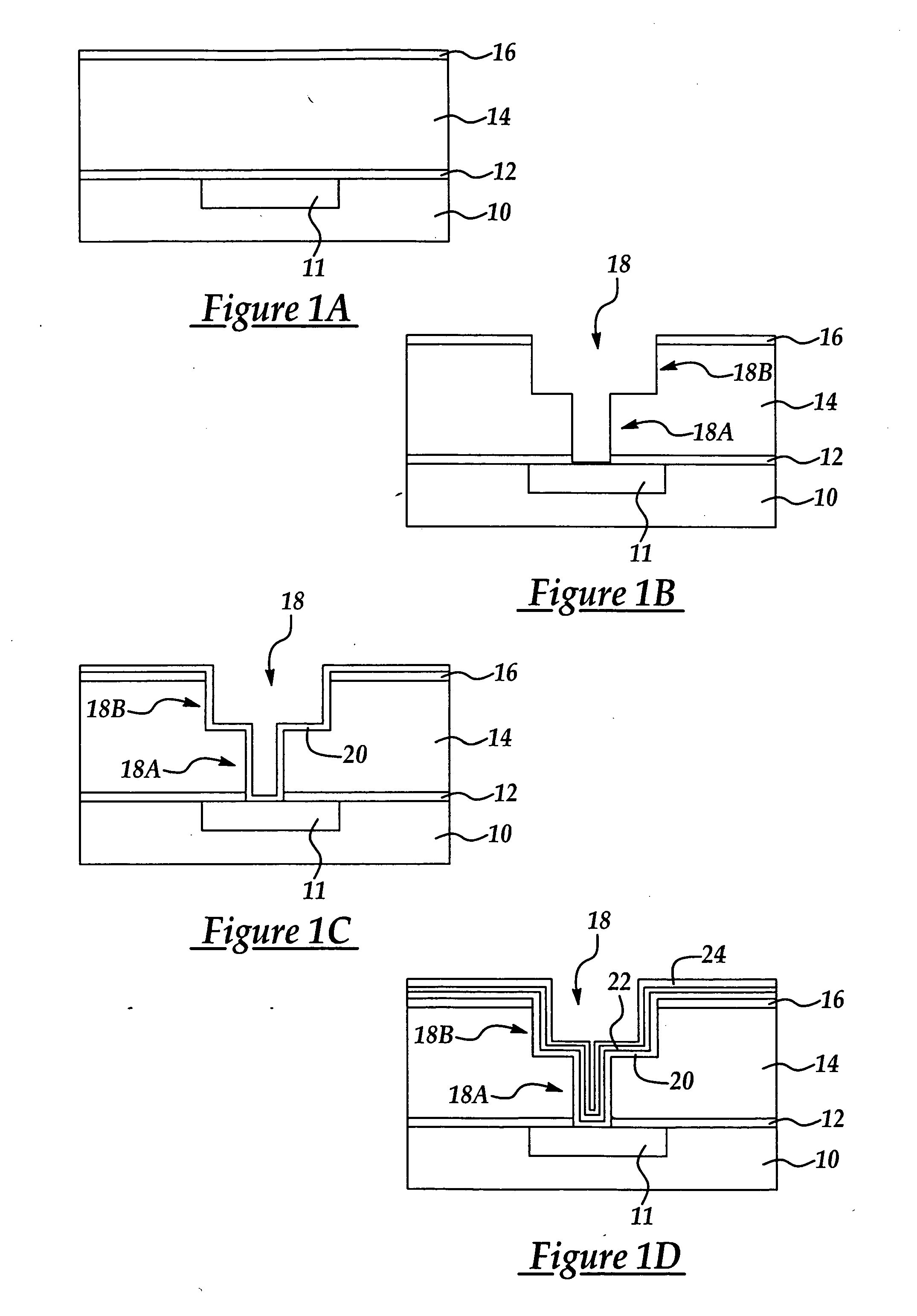

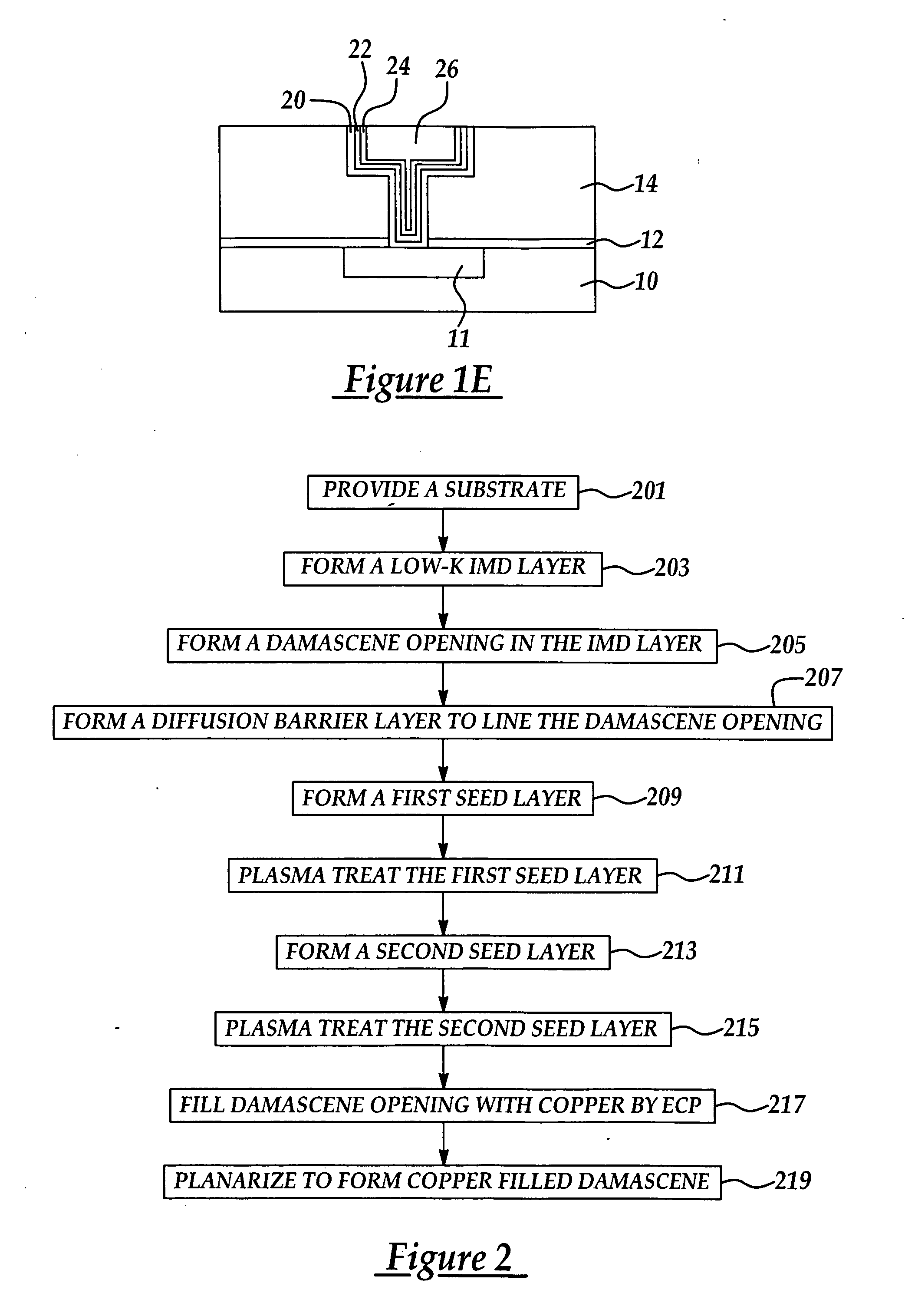

A copper filled damascene structure and method for forming the same the method including providing a substrate comprising a semiconductor substrate; forming an insulator layer on the substrate; forming a damascene opening through a thickness portion of the insulator layer; forming a diffusion barrier layer to line the damascene opening; forming a first seed layer overlying the diffusion barrier; plasma treating the first seed layer in-situ with a first treatment plasma comprising plasma source gases selected from the group consisting of argon, nitrogen, hydrogen, and NH3; forming a second seed layer overlying the first seed layer; forming a copper layer overlying the second seed layer according to an electro-chemical plating (ECP) process to fill the damascene opening; and, planarizing the copper layer to form a metal interconnect structure.

Owner:TAIWAN SEMICON MFG CO LTD

Plastic composition and surface selective metallization process thereof

ActiveCN101654564AImprove bindingHigh precisionCatalyst activation/preparationLiquid/solution decomposition chemical coatingLaser etchingChemical plating

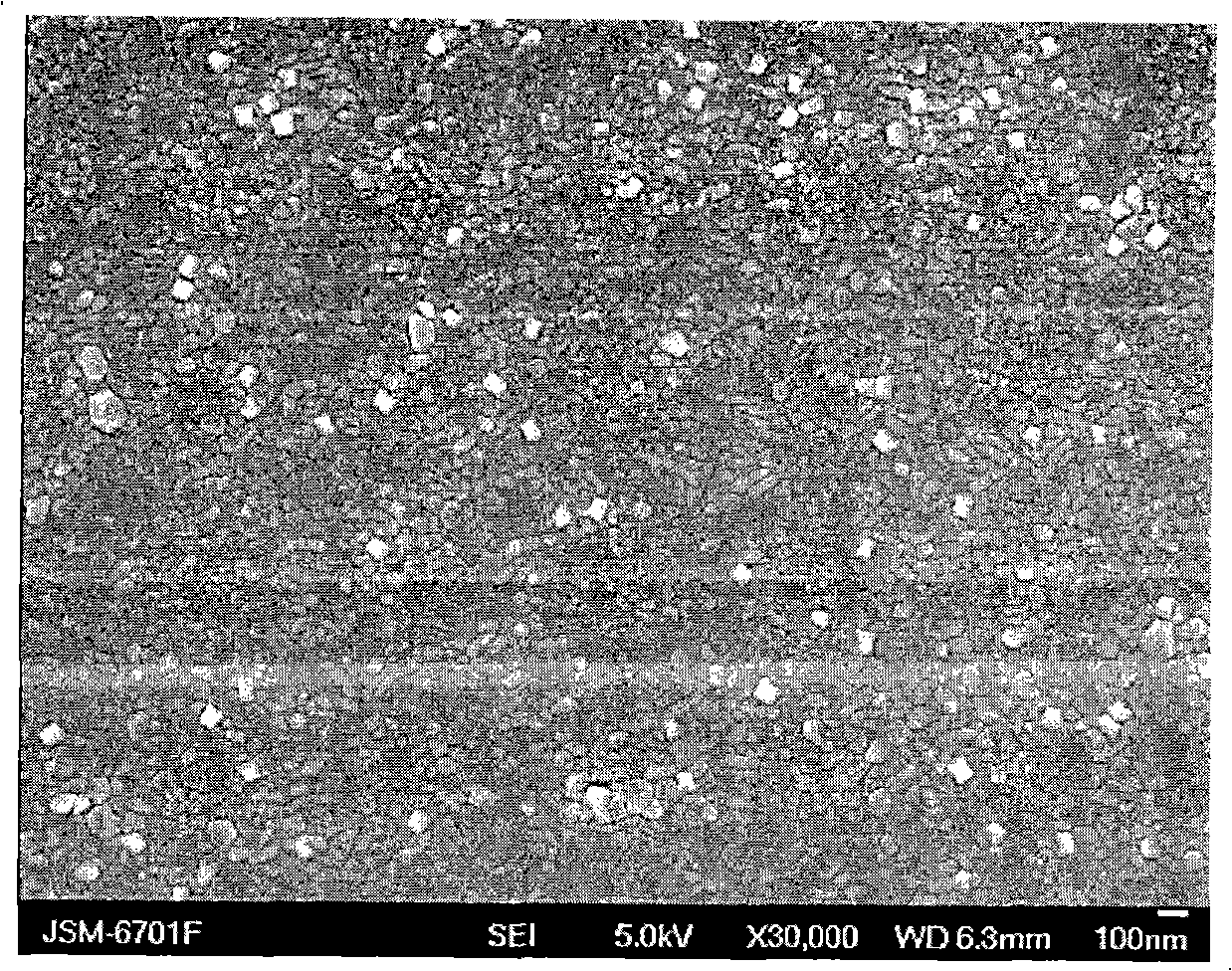

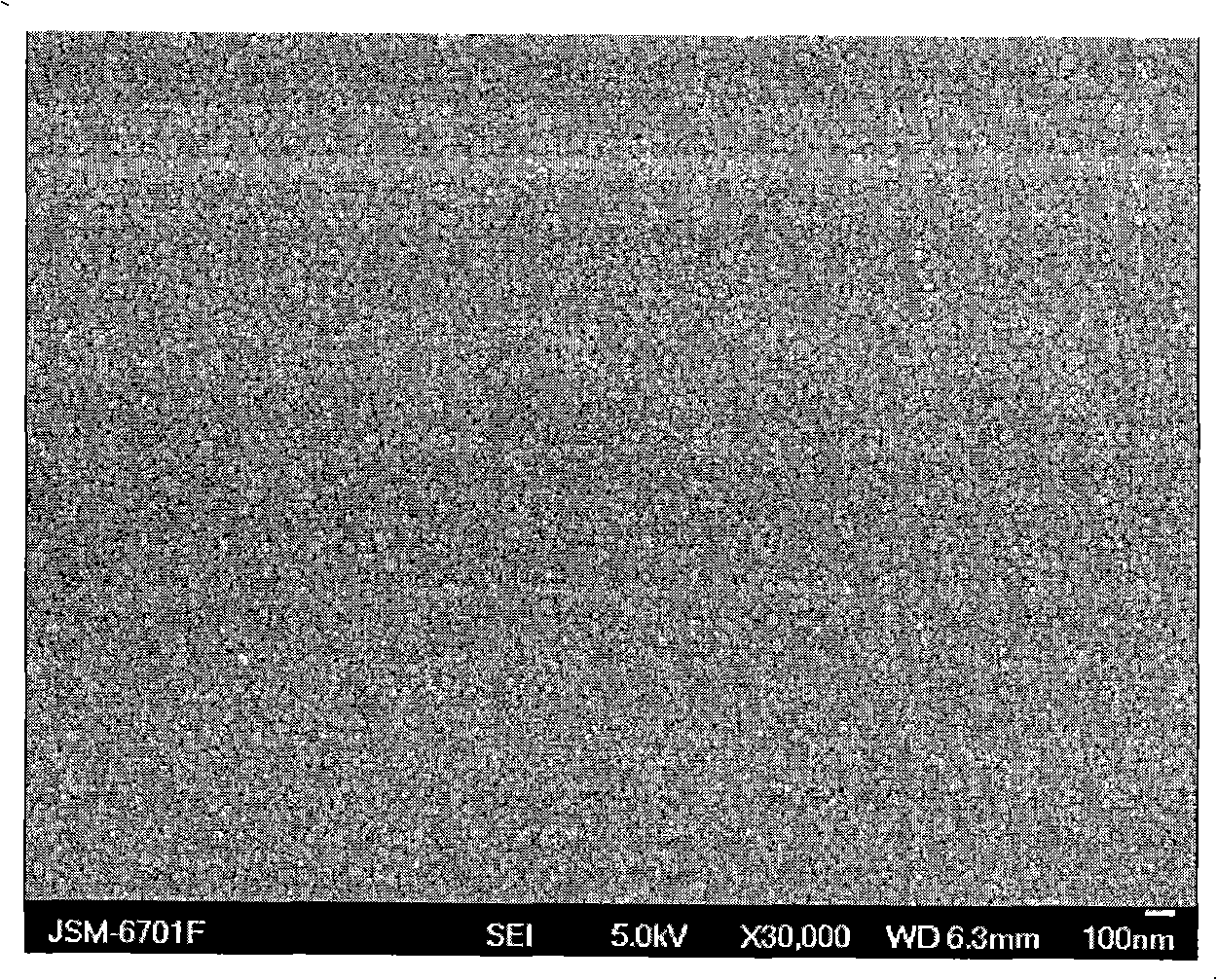

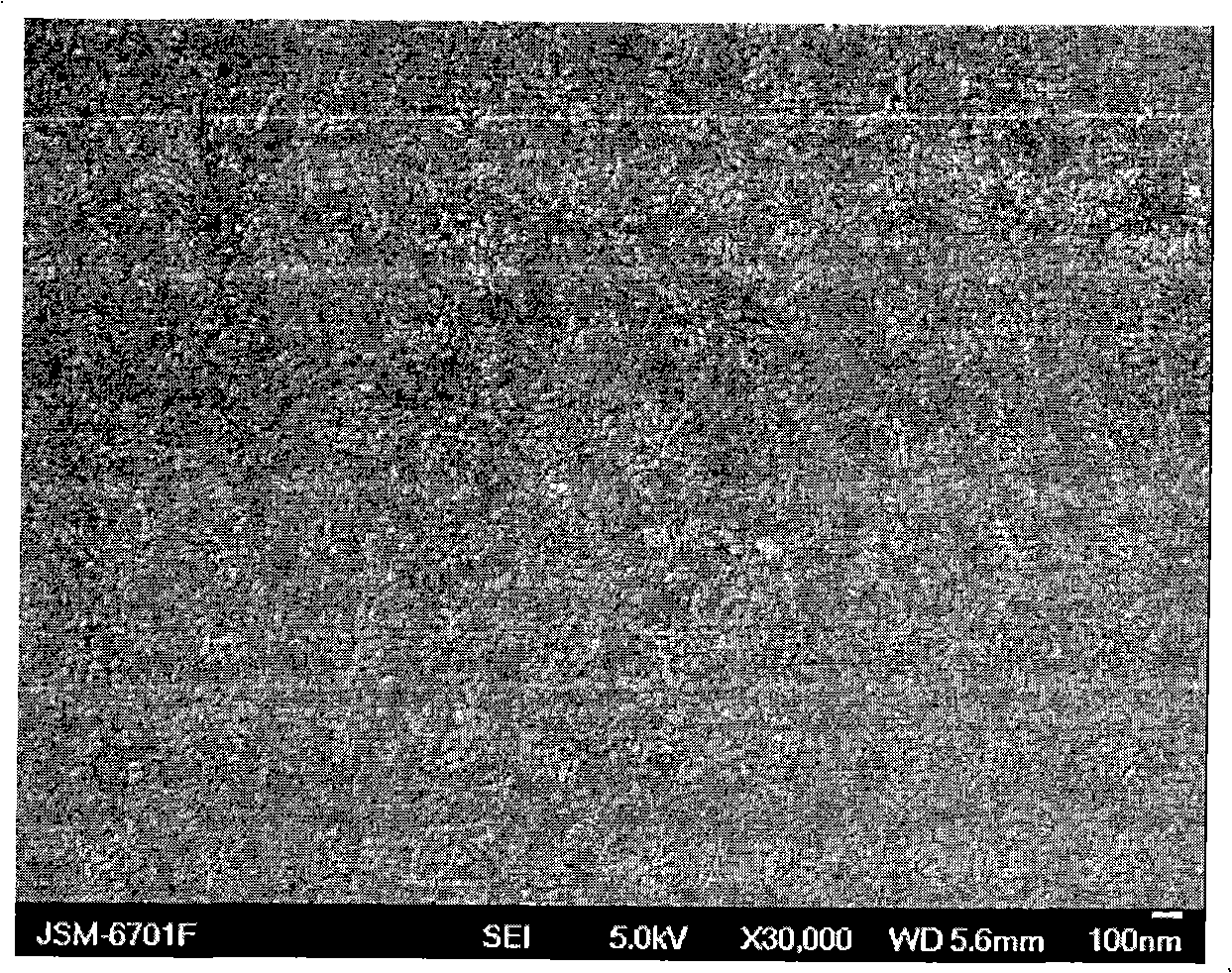

The invention provides a plastic composition and a surface selective metallization process thereof. The plastic composition comprises a high molecular polymer and a photocatalyst, wherein the mass ratio of the polymer to the photocatalyst is 1 to 100. The surface selective metallization process of the plastic composition comprises the following steps: performing laser etching on the surface of theplastic composition; putting the plastic composition after the laser etching into an aqueous solution containing a metal ion salt and a cavity sacrificial agent to perform photocatalysis reduction reaction so as to obtain a plastic composition with nanometer metal particles on the surface; and finally performing metal chemical plating. By adopting the plastic composition and the surface selectivemetallization process of the plastic composition, the bonding force of a plating layer and the chemical plating precision are very high.

Owner:BYD CO LTD

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

Ruthenium layer formation for copper film deposition

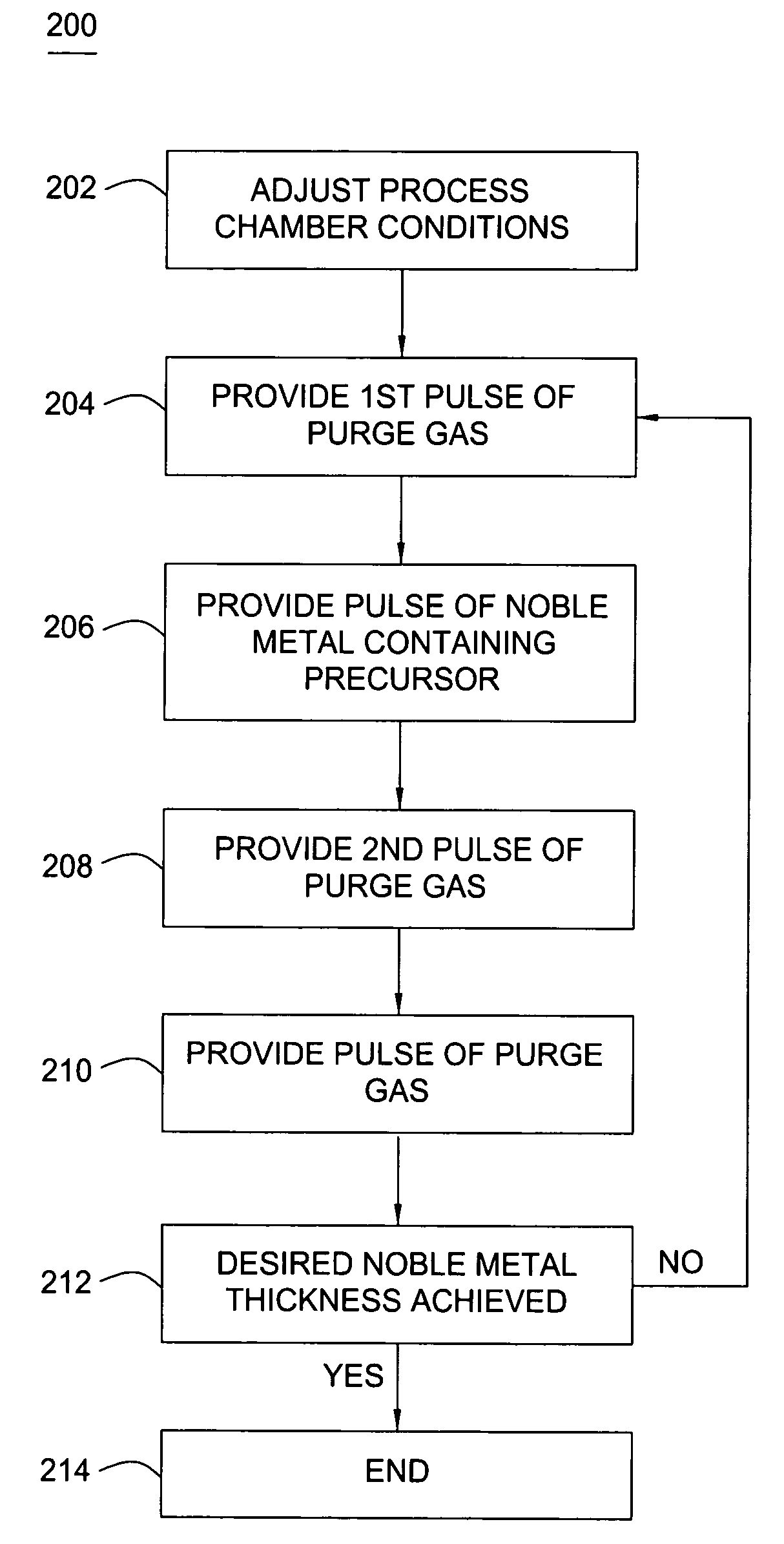

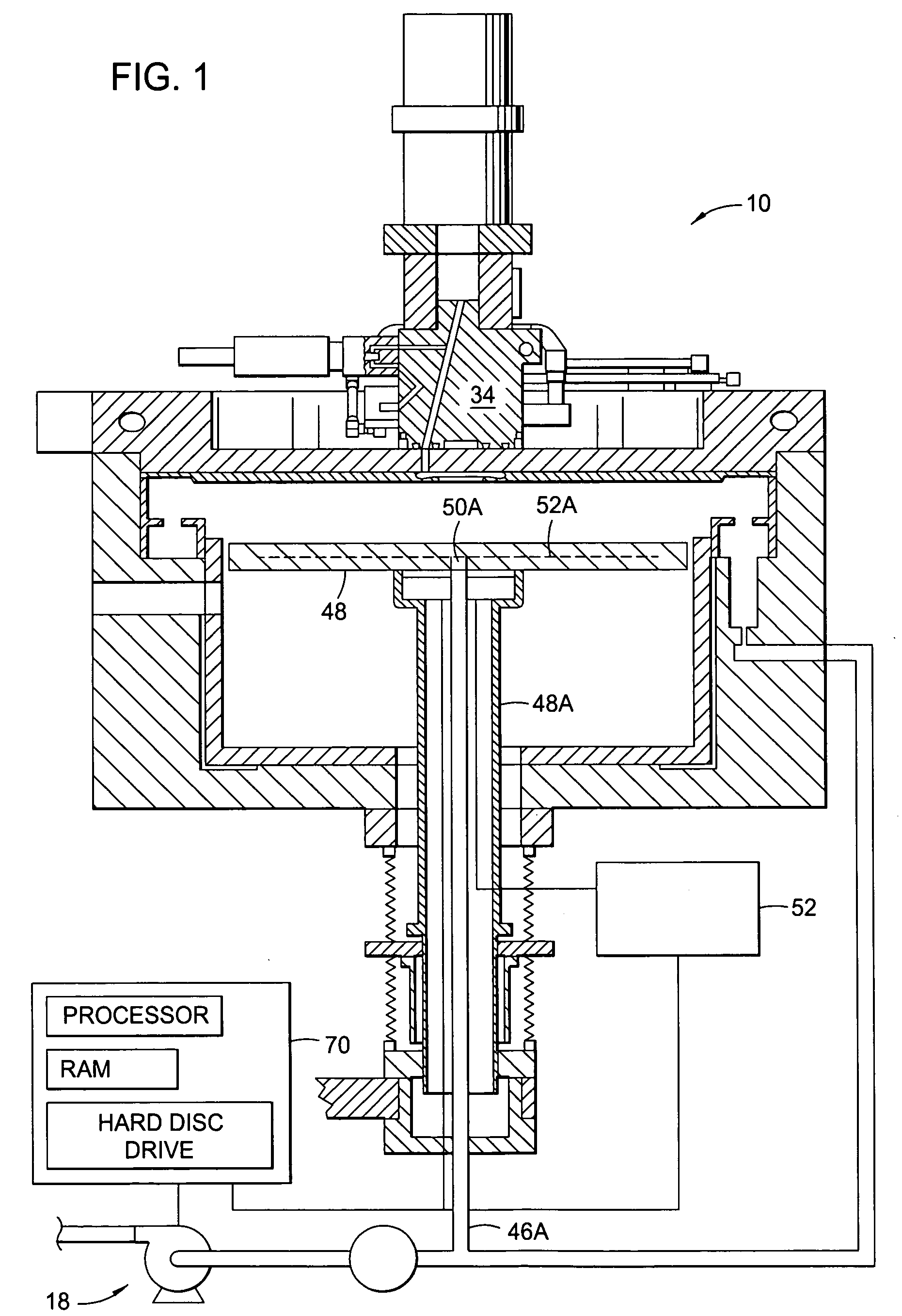

In one embodiment, a method for forming a material on a substrate is provided which includes positioning a substrate containing a dielectric material having vias formed therein within a process chamber, forming a barrier layer within the vias and on the dielectric material during a barrier deposition process, forming a ruthenium layer on the barrier layer during a ruthenium deposition process, and filling the vias with a copper material during a copper deposition process. The copper material may be formed by depositing a copper bulk layer over a copper seed layer. The method further provides that the ruthenium layer may be formed by an atomic layer deposition process (ALD) or a physical vapor deposition (PVD) process and the copper material may be formed by an electroless chemical plating process, an electroplating process, a chemical vapor deposition process, an ALD process and / or a PVD process.

Owner:APPLIED MATERIALS INC

Method for preparing conductive ultrahigh molecular weight polyethylene fiber

The invention relates to a method for preparing a conductive ultrahigh molecular weight polyethylene fiber. The conventional method is complicated in process and causes environmental pollution. The method comprises the following steps of: firstly, immersing the ultrahigh molecular weight polyethylene fiber into acetone, ethanol or a tetrahydrofuran solution, performing ultrasonic washing on the fiber and airing; secondly, dissolving a dopamine substance into a buffer solution to prepare an activation solution, placing the ultrahigh molecular weight polyethylene fiber into the activation solution and activating the ultrahigh molecular weight polyethylene fiber under stirring; and finally, immersing the activated ultrahigh molecular weight polyethylene fiber in a plating solution at temperature of 10 to 60 DEG C for 0.5 to 10 hours so as to finish silver plating. By the method, the surface of the ultrahigh molecular weight polyethylene fiber is activated by using dopamine polymer and metallized by using chemical plating, so that the ultrahigh molecular weight polyethylene fiber with extremely high conductivity can be obtained; and the whole process is environment-friendly and pollution-free.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method of preparing electric conductive adhesive by chemical plating silver on graphite powder surface

InactiveCN1919933AEase of mass productionLow resistivityInorganic pigment treatmentSemiconductor/solid-state device manufacturingChemical platingSilver plate

The invention discloses a chemical silver plating preparing conducting resin method on the graphite powder surface in the chemical silver plating and micro-electronics connection material technique domain, which comprises the following steps: oxidizing the graphite powder in the air at 600-650DEG C; putting the dispersant, reducer and stabilizing agent in de-ionized water for reduced liquid; adding in graphite powder to stir; putting the silver nitrate in the de-ionized water; adding in ammonia and sodium hydroxide to get argentamine; putting the reduced liquid in the argentamine liquid to finish chemical silver plating on the graphite powder surface; filtering; separating and washing; drying in vacuum to get silver coated graphite powder.

Owner:TSINGHUA UNIV

Flexible land grid array connector

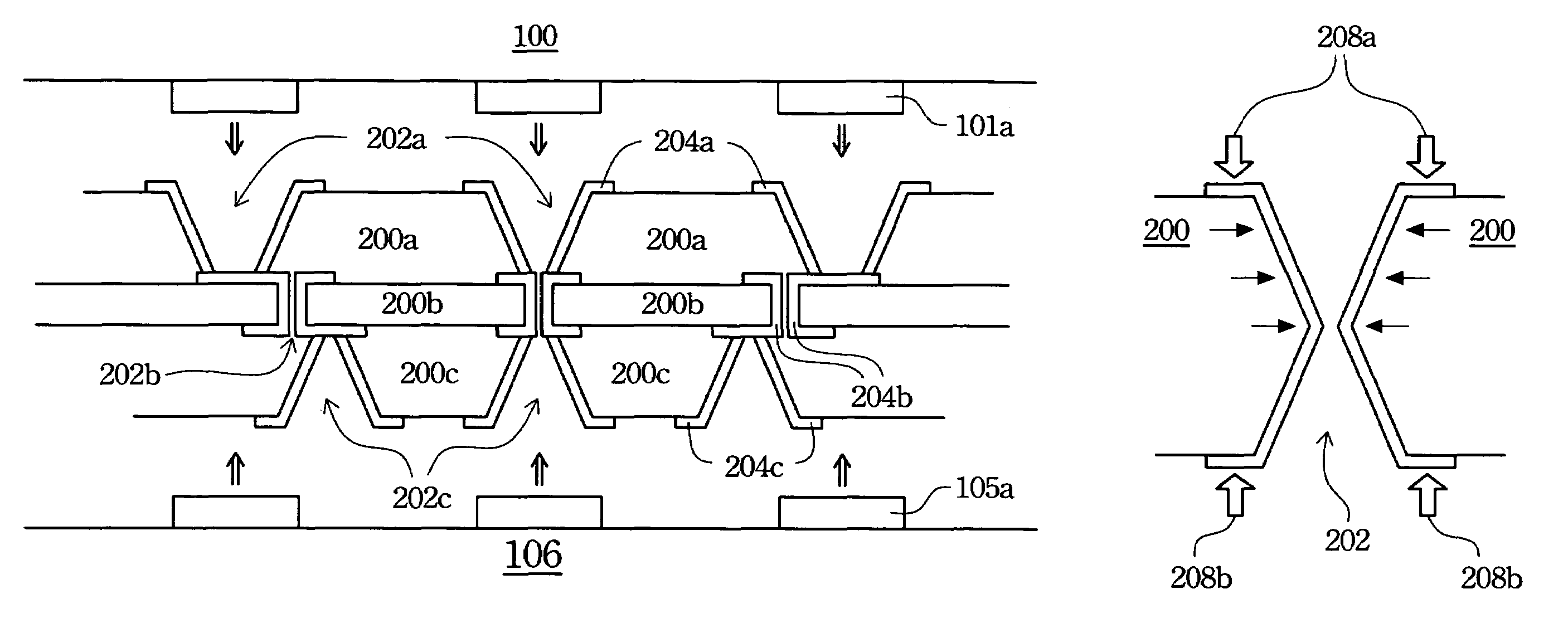

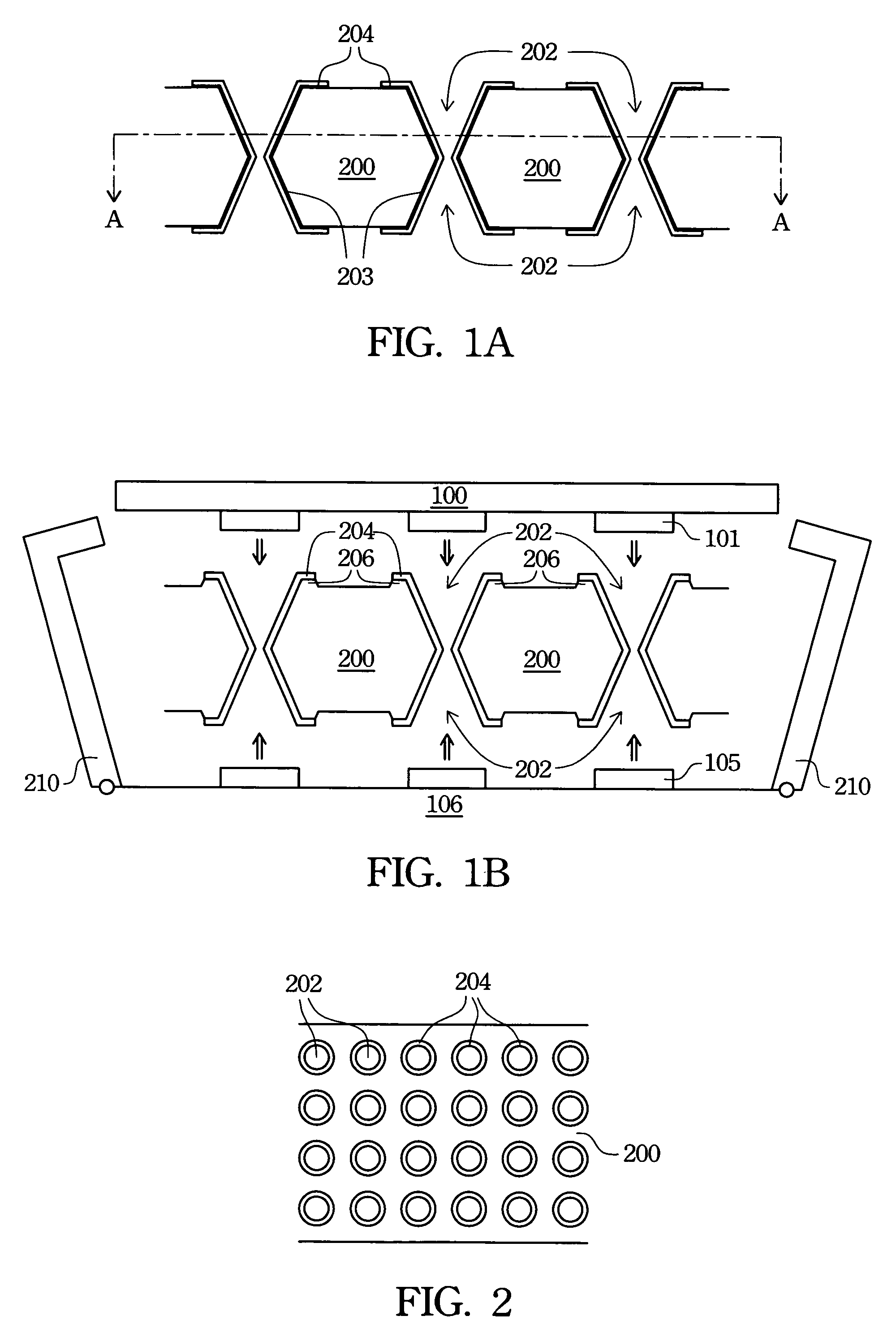

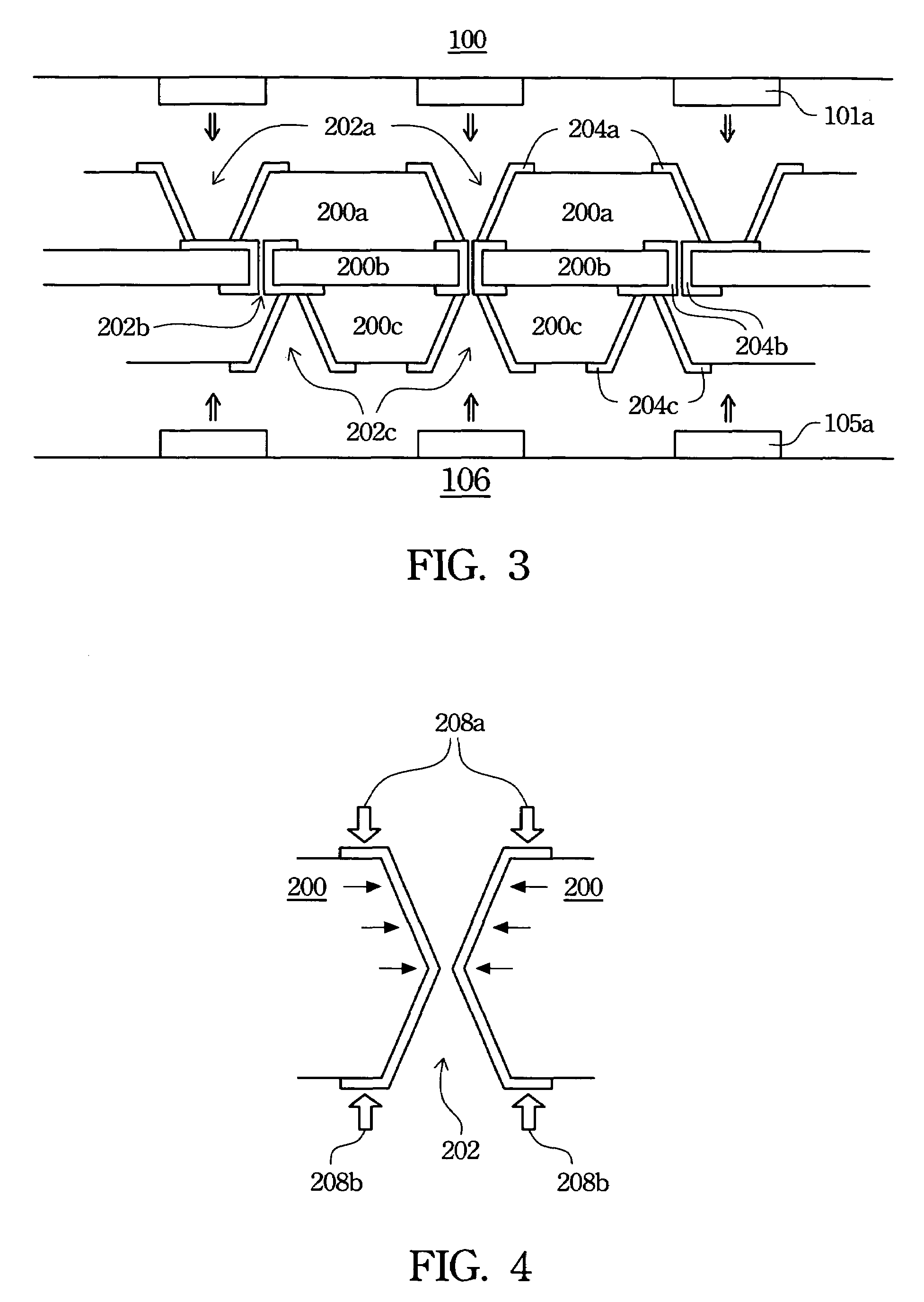

InactiveUS7021941B1Ensure electrical connection reliabilityIncreased durabilityElectrically conductive connectionsCoupling device detailsElastomerChemical plating

An LGA connector is used to interconnect an LGA package and a printed circuit board. The LGA connector includes an elastomeric body with a plurality of through-holes. Metal films are formed on inner walls of through-holes and splay out around the mouths of their upper and lower openings. The metal films are formed by vacuum metallization, sputtering, chemical plating, electrical plating or PVD. The through-holes have a funnel-like shape to absorb external stresses and redirect the stress to shrink the through-hole diameters. Moreover, the metal films' elastic deformation is larger than conventional metal conductive fillers so as to improve reliability.

Owner:SPEED TECH

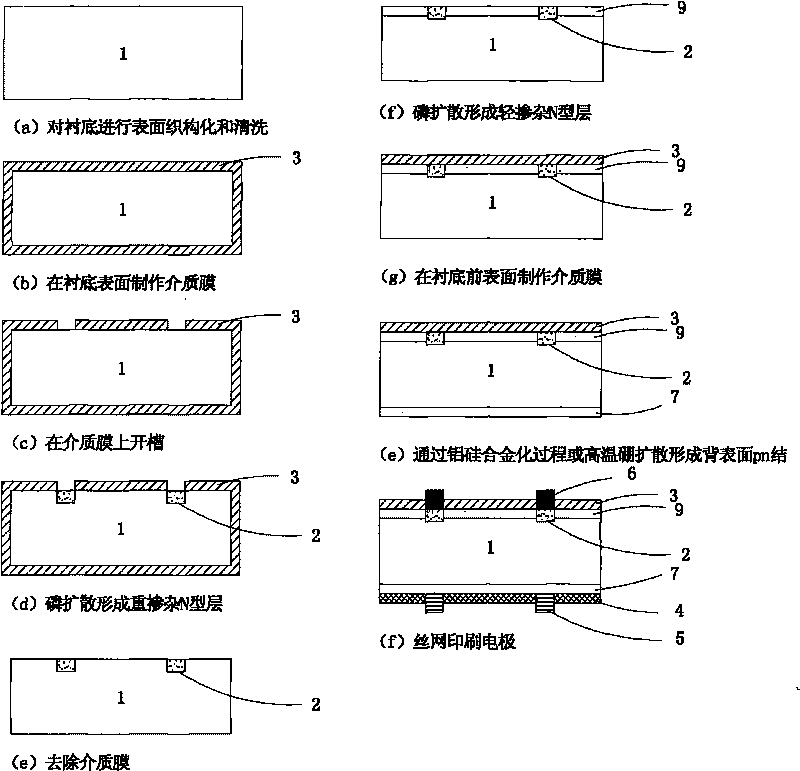

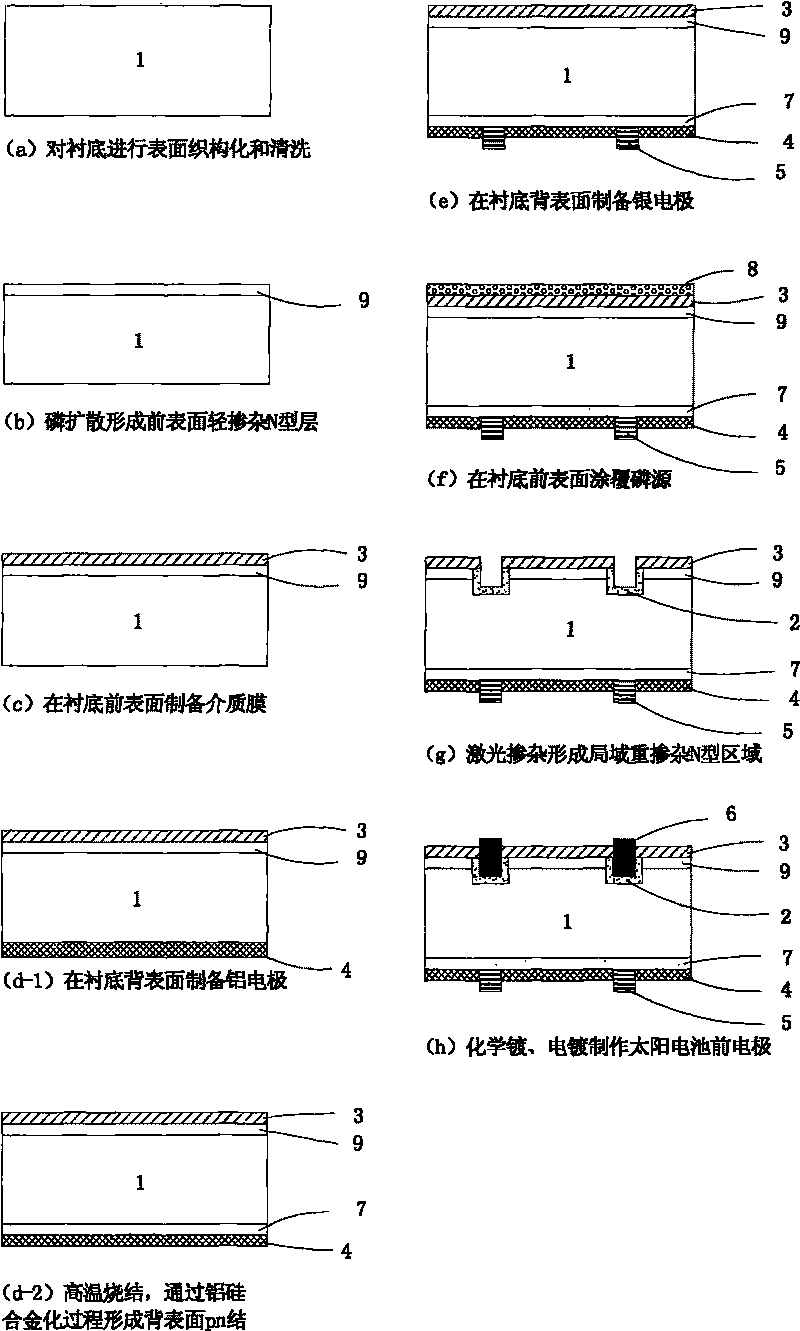

Manufacture method of selective front surface field N-type solar cell

InactiveCN101764179ASimple processLow costFinal product manufactureSemiconductor devicesChemical platingSilicon alloy

The invention discloses a manufacture method of a selective front surface field N-type solar cell, which is characterized in that a back surface p-n junction is formed by utilizing an aluminum-silicon alloying process and a high-temperature boron diffusion process, a front surface lightly doped N-type layer is formed by high-temperature phosphorous diffusion, a front surface local heavily doped N-type region is formed by laser doping, and a front electrode is manufactured on the heavily doped N-type region by utilizing a chemical plating method or an electroplating method. Compared with the traditional manufacture process, the invention has the advantages of simple process and low cost and does not need secondary contraposition.

Owner:SUN YAT SEN UNIV

Quick high-flexibility manufacturing method for ceramic circuit board

ActiveCN103188877AImprove bindingImprove thermal conductivityPrinted circuit manufactureLaser beam welding apparatusChemical platingChemical reaction

A quick high-flexibility manufacturing method for a ceramic circuit board comprises the following steps: irradiating laser on the surface of a ceramic matrix, and controlling the energy density of the laser to reach above the fracture threshold of the chemical bond of the compound containing active ions, so that chemical reaction occurs on the surface of the ceramic matrix, an active substance is separated out to serve as a chemical plating catalytic source, and the active substrate generated by the reaction and the matrix form chemical metallurgical bonding, wherein different laser sources are selected aiming at different ceramic materials according to the chemical bond energy of the ceramic material components, and the laser energy is controlled to reach the ceramic modified threshold by controlling the average power of laser output, pulse repetition frequency, scanning speed, defocusing amount, space between scanning line and scanning times; and the ceramic matrix modified by the laser is placed into a chemical plating solution to perform plating to form a metal coating. The surface of the ceramic is modified by the laser, so that a metal conductive layer and the matrix form chemical metallurgical bonding, the bonding force of the circuit board is greatly increased, and the heat-conducting property and the electric property are improved.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

Method for processing surface of magnesium alloy

InactiveCN101092694AReduced insulationPrevent breakdownAnodisationLiquid/solution decomposition chemical coatingMicro arc oxidationChemical plating

This invention discloses a surface treatment method for Mg-based material. The method comprises: (1) performing micro-arc oxidation treatment on Mg or Mg alloy work piece as the anode in a Cl--free alkaline micro-arc oxidation electrolyte; (2) activating; (3) performing preliminary chemical plating of Ni; (4) performing chemical plating of Ni; (5) performing thermal treatment. The micro-arc oxidation treatment comprises: (1) applying a positive pulse with an average current density of 5-20 A / dm2 until the voltage is automatically elevated to a critical value, and applying a constant working voltage of 50-80 V (total time = 5-30 min); (2) applying a positive pulse of 30-300 V and a negative pulse of 0-200 V with an average current density of 0.5-15 A / dm2 (total time = 10-60 min). The activation comprises: (1) performing anode alkaline coarsening treatment for 3-10 min; (2) performing surface activation treatment; (3) performing cathode alkaline electrification reduction activation treatment; (4) performing cathode acidic electrification dispergation activation treatment. The treated Mg alloy work piece has high corrosion resistance of ceramic materials and the properties and touch sense of metal materials.

Owner:李克清 +1

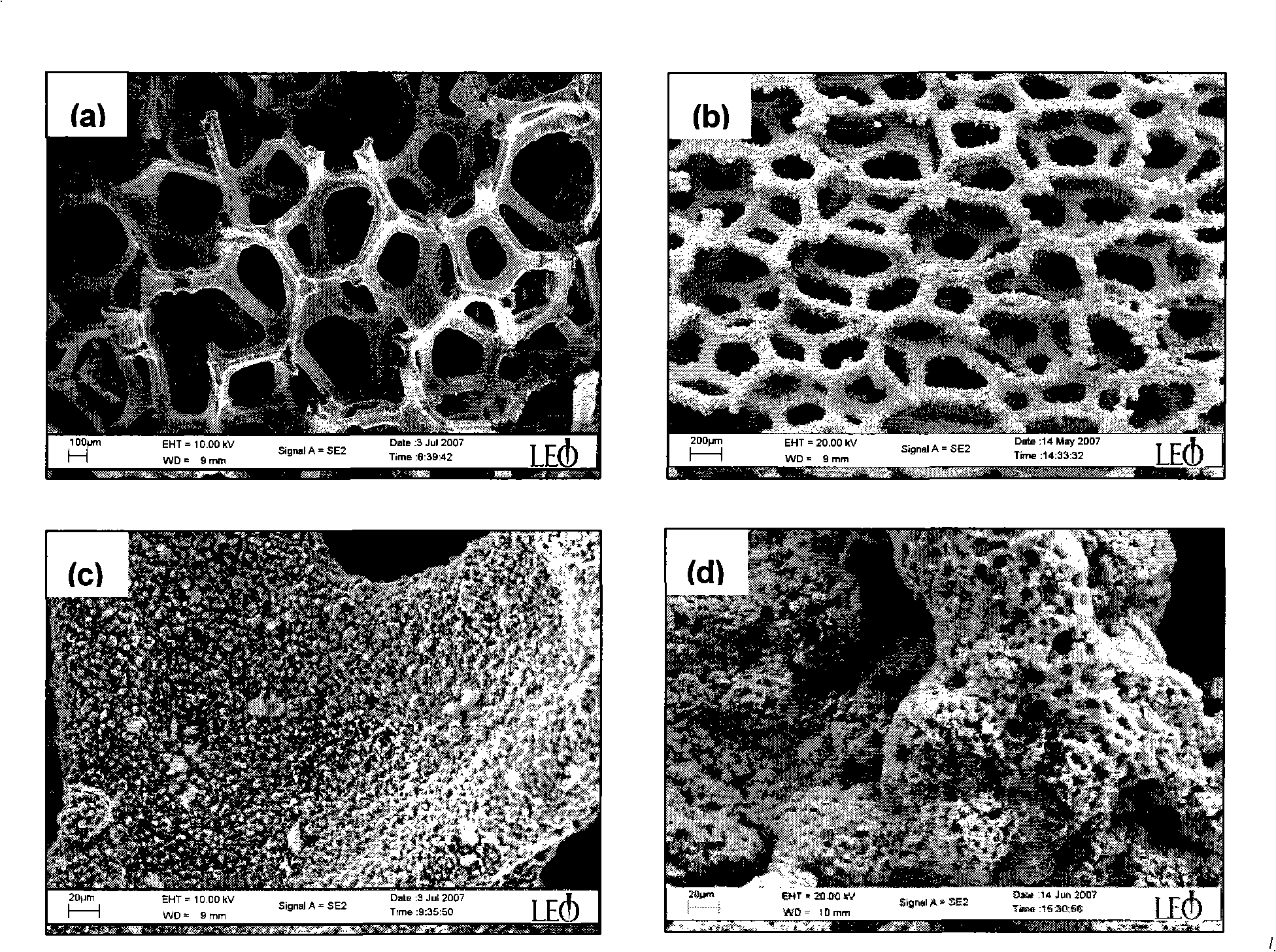

Foam metal hydrogenating catalyst and its preparing method and use

ActiveCN1781595ALow densityHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPorosityChemical plating

The present invention discloses hydrogenating catalyst of foam metal and its preparation process and application. The hydrogenating catalyst includes foamed metal carrier and active noble metal component in effective amount supported onto the carrier, the carrier is prepared through powder metallurgical process, and the active component is supported via chemical plating process and distributed homogeneously on the port surfaces of the foamed carrier. The catalyst has the advantages of high catalytic activity, firm combination between the active component and the carrier, high stability, simple preparation process, high porosity of the carrier, great specific surface area, etc. in addition, the catalyst provides sufficient gas-liquid contact area, is favorable to mass transfer between gas phase and liquid phase, may be used in catalytic rectification and possesses both reaction and separation effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

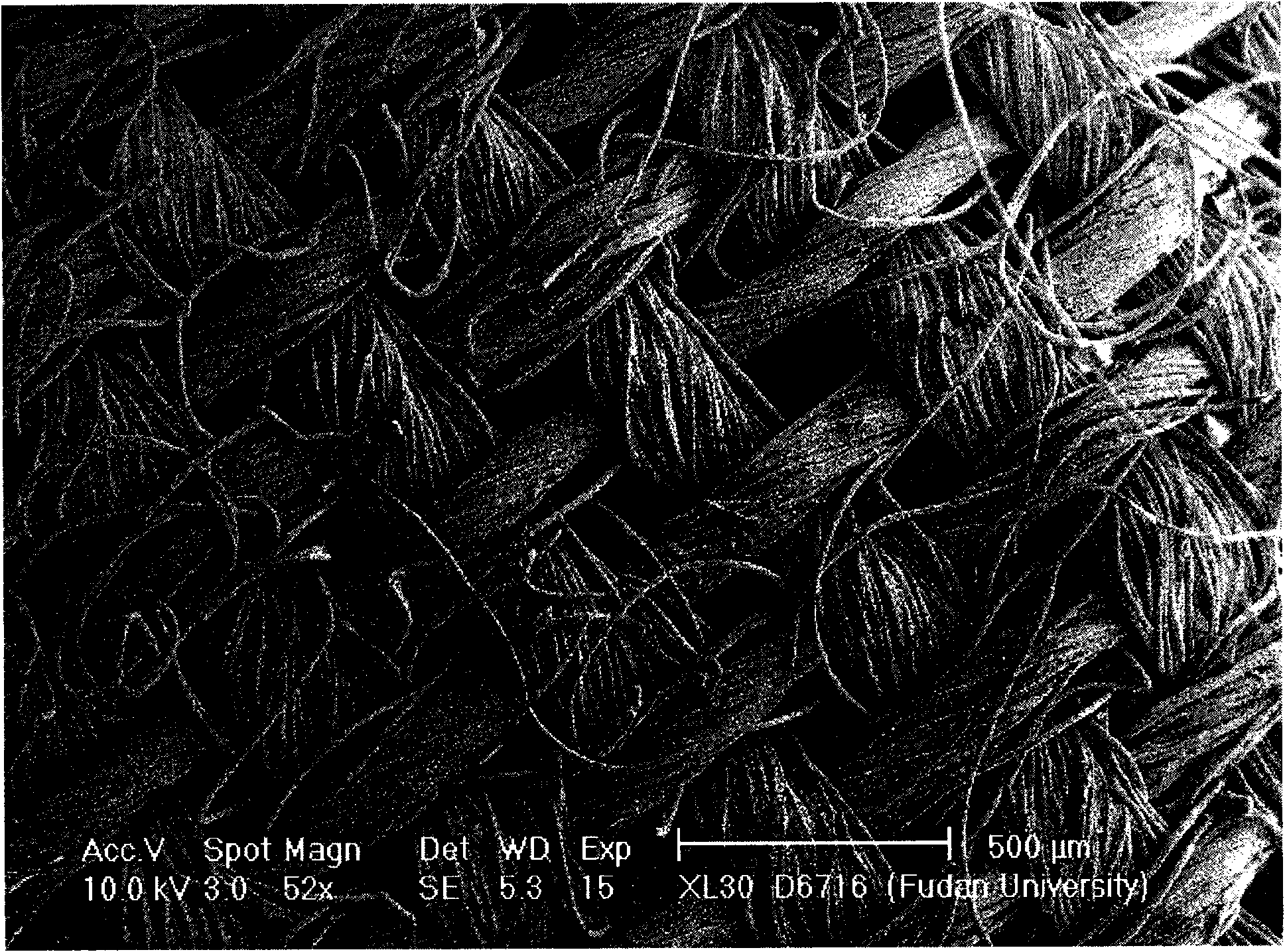

Low-silver-loaded electromagnetic wave shielding fabric preparation method

InactiveCN101613931AHigh bonding strengthImprove conductivityMagnetic/electric field screeningFibre typesPolyesterUltrasound - action

The invention belongs to the technical field of electromagnetic wave shielding material and relates to a low-silver-loaded electromagnetic wave shielding fabric preparation method, comprising the following specific steps: modifying the surface of polyester fabric, introducing an active group--sulphydryl under the premise of not increasing the surface area of the fabric, and then plating silver with ultrasonic wave; wherein, Ag-S chemical bond is formed between sulphydryl and silver so that the compactness of the silver coating and the adhesion force of the fabric substrate are increased; in the process of chemical plating, fresh plating solution is always on the surface of the fabric and the materials which are absorbed on the surface of the fabric through physical adsorption are removed timely owning to the action of ultrasonic wave so that the continuity and compactness of the silver coating can be improved further; the silver loading content of the prepared silver-loaded electromagnetic wave shielding fabric is 6.7-7.0% by weight; the fabric is more resistant to the corrosion of the air and water, the electromagnetic shielding effectiveness is more than 32dB in the range of 0.01-18GHz, namely the anti-electromagnetic radiation rate is more than 99.9%; the fabric can be widely used in electromagnetic wave antiradiation clothes and in the field of electromagnetic wave shielding for special departments such as military, national defense and the like.

Owner:FUDAN UNIV

Aluminum alloy surface treatment method

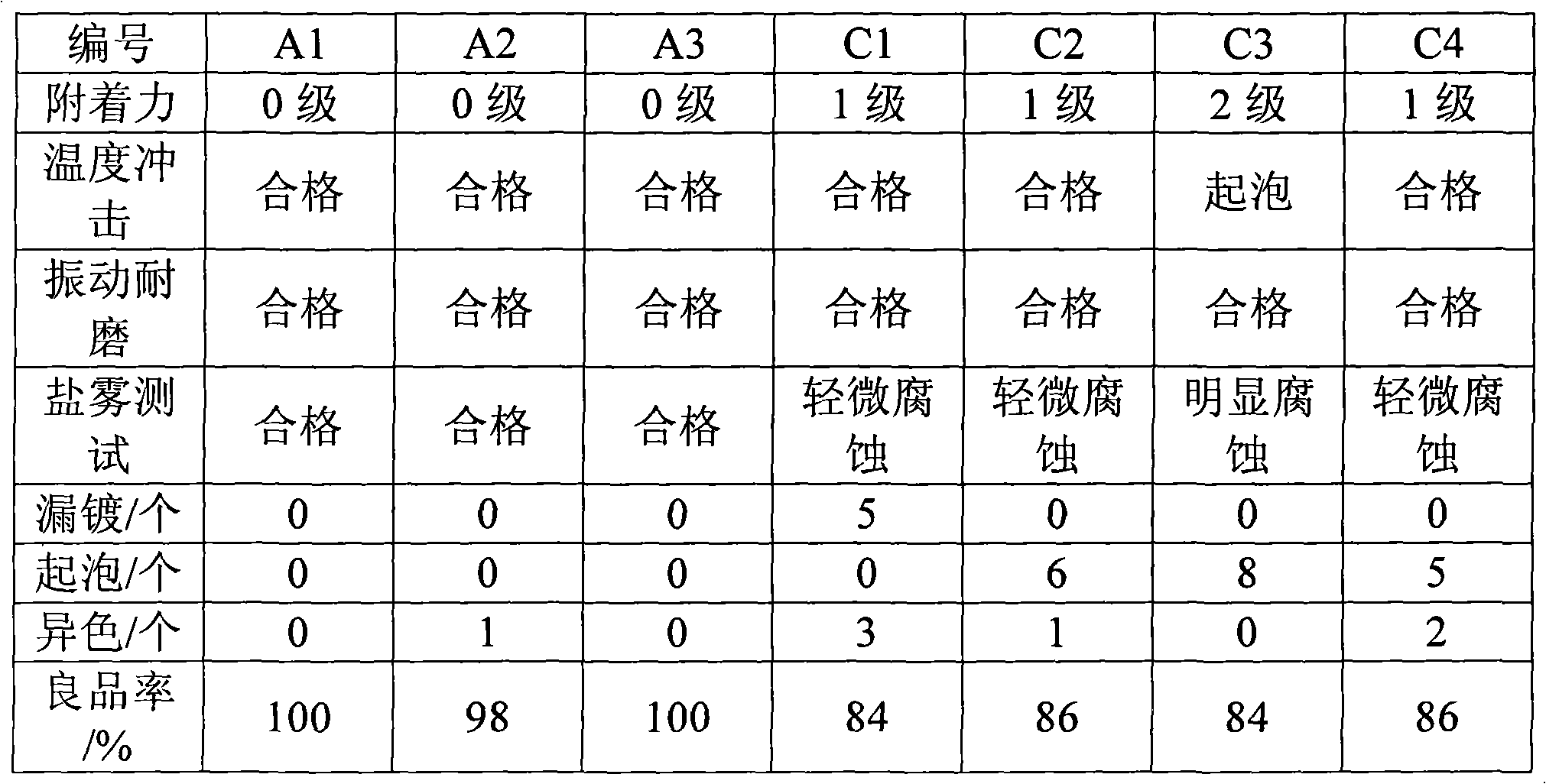

InactiveCN101922010ALess prone to missing platingNot prone to foamingHot-dipping/immersion processesAnodisationAcid etchingLaser etching

The invention provides an aluminum alloy surface treatment method which comprises the steps of sequentially carrying out pretreatment, chemical plating and electroplating on an aluminum alloy matrix, wherein the pretreatment comprises the steps of sequentially carrying out anode oxidation, laser etching, erosion and acid etching on the aluminum alloy matrix. By using the method for forming electroplating texture on the surface of an aluminum alloy, the obtained product has natural texture, is not subject to skip plating, bubbling and discoloration phenomena and has a good decorative effect. Besides, the method has the advantage of simple operation, realizes the unshaded treatment and the convenient maintenance by using the technology of anode oxidation plus electroplating, and facilitates the mass production.

Owner:BYD CO LTD

Surface treatment method of aluminum alloy and treatment liquid

InactiveCN101709459AImprove anti-corrosion performanceUniform thicknessLiquid/solution decomposition chemical coatingSalt resistanceChemical plating

The invention relates to a surface treatment method of aluminum alloy, which comprises the following steps of: pre-treating: removing oil stains on the aluminum alloy surface by adopting an alkali degreasing solution; alkali washing: purifying the aluminum alloy surface at 50-60 DEG C by adopting alkali wash to remove a natural oxide film on the aluminum alloy surface; acid pickling: treating the aluminum alloy surface at room temperature for 1-5 minutes by adopting a pickling solution to further remove residual spots left on the aluminum alloy surface after alkali washing; and chemically plating Ni-P: forming a Ni-P plating layer on the aluminum alloy surface by adopting a pre-prepared chemical plating Ni solution with pH value of 5-6.5 at 85-90 DEG C for 90-240 minutes. By adopting a chemical plating Ni-P layer process to form a uniform favorable plating layer with good acid resistance, alkali resistance and salt resistance outside an aluminum alloy shell, the invention avoids the phenomena of uneven thickness of a protective layer and spraying missing on a complex structure part, and remarkably improves the anticorrosion performance of the aluminum alloy.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Method for chemical plating metal for non-metal substrate surface and pretreatment system used thereof

InactiveCN1641070ASave resourcesReduce manufacturing costLiquid/solution decomposition chemical coatingAlkaneCopper plating

The present invention discloses new activating process and activating solution with non-noble metal for chemical plating of metal onto the surface of non-metal base material. The activating solution is alkaline organic metal complex solution comprising water soluble salt of bivalent Ni, Cu or Co ion, organic alkane complexing agent and pH regulator. The new activating process and activating solution of the present invention may be used to replace available process and solution with noble metal for wide use in the chemical plating of metal material onto the surface of non-metal base material, such as chemically plating nickel, chemically plating copper, chemically plating cobalt, etc. The activating solution of the present invention is stable, simple in technological process and low in cost, and the present invention makes it possible to save noble metal resource effectively and is ideal technology to replace available one.

Owner:HUNAN CORUN NEW ENERGY CO LTD

Method for preparing front electrodes of solar cells

InactiveCN101562217AReduce surface recombinationHigh aspect ratioFinal product manufactureSemiconductor devicesStencil printingChemical plating

The invention relates to a method for preparing front electrodes of solar cells, which comprises the following steps: firstly preparing discontinuous dot electrodes; and then connecting the dot electrodes by electroplating technology to realize that the electrodes collect and transport current but dielectric films still exist between the dot electrodes to have the function of passivation. The discontinuous dot electrodes are prepared by photoetching, evaporation and dissection methods, or firstly printed by silkprint, stencil printing or ink jet printing and then prepared by a sintering method. The electroplating is photoinductive electroplating or chemical plating. The dot electrodes effectively reduce surface recombination; and the adopted electroplating technology not only simply and accurately realizes the connection of the dot electrodes, but also effectively reduces the width of grid lines, namely reduces electrode shading areas and further reduces the surface recombination so as to contribute to improving battery efficiency.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

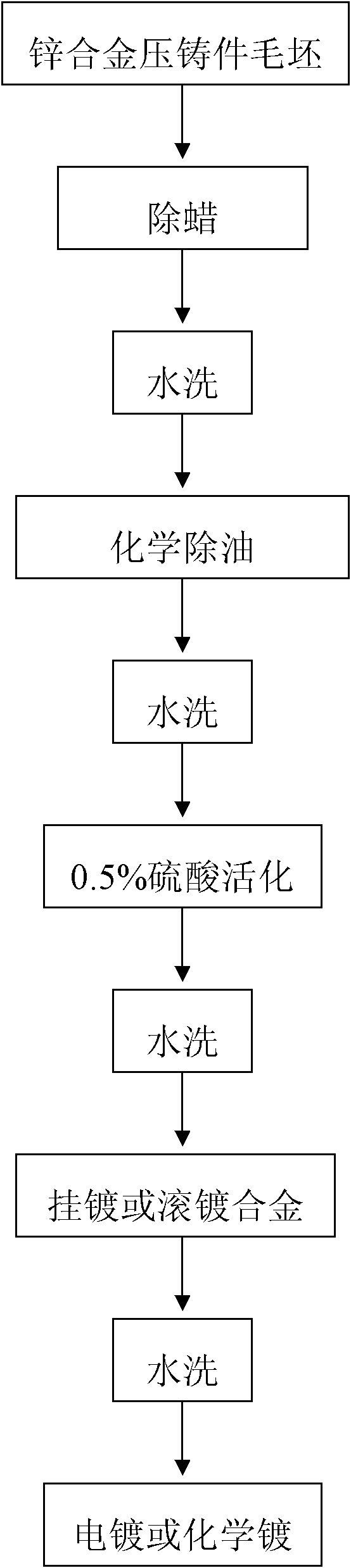

Cyanogen-free plating method of zinc alloy die casting

The invention discloses a cyanogen-free plating method of a zinc alloy die casting. The method is a plating method in which cyanogen-free copper-zinc alloy, copper-stannum alloy or ormolu is subjected to barrel plating or rack plating in a cyanogen-free copper-zinc alloy solution, copper-stannum alloy solution or ormolu solution as grounding layers so as to provide a pre-plating layer with good bonding force for subsequent plating or chemical plating. The method comprises the following steps: (1) carrying out ultrasonic wax removal or tumbling wax removal on a zinc alloy die casting blank; (2) washing; (3) chemically removing oil; (4) washing; (5) activating with 0.5% sulfuric acid; (6) washing; (7) carrying out barrel plating or rack plating on the alloys in the cyanogen-free copper-zinc alloy solution, copper-stannum alloy solution or ormolu solution; (8) washing; and (9) carrying out the subsequent plating or chemical plating. By using the method provided by the invention, cyanogen-free barrel plating or rack plating alloy is carried out on the zinc alloy die casting so that the obtained plating layer is semi-bright and has good bonding force.

Owner:广州市二轻研究所股份有限公司

Metal oxide blended silver-tin dioxide electric contactor material and its preparing method

The present invention belongs to the preparation techonlogy of electric alloy material. The electric contactor material consists of Ag 85-90 wt%, SnO2 5-20 wt% and blended metal oxide 0.5-8 wt%. The blended metal oxide is ZrO2, ZnO, TiO2, MnO2, WO3 or Sb2O3. The electric contactor material is prepared through coating oxide through chemical plating with plating liquid with dispersant, mixing the coated pwoder and silver powder, pressing, sintering, hot extruding, cold drawing or cold rolling, and making rivet or punched product. The present invention has the features of homogeneous oxide dispersion, good fusion welding resistance, high arc corrosion resistance and less electric transfer. The production process is simple, practical, low in cost and suitable for large scale production.

Owner:TIANJIN UNIV

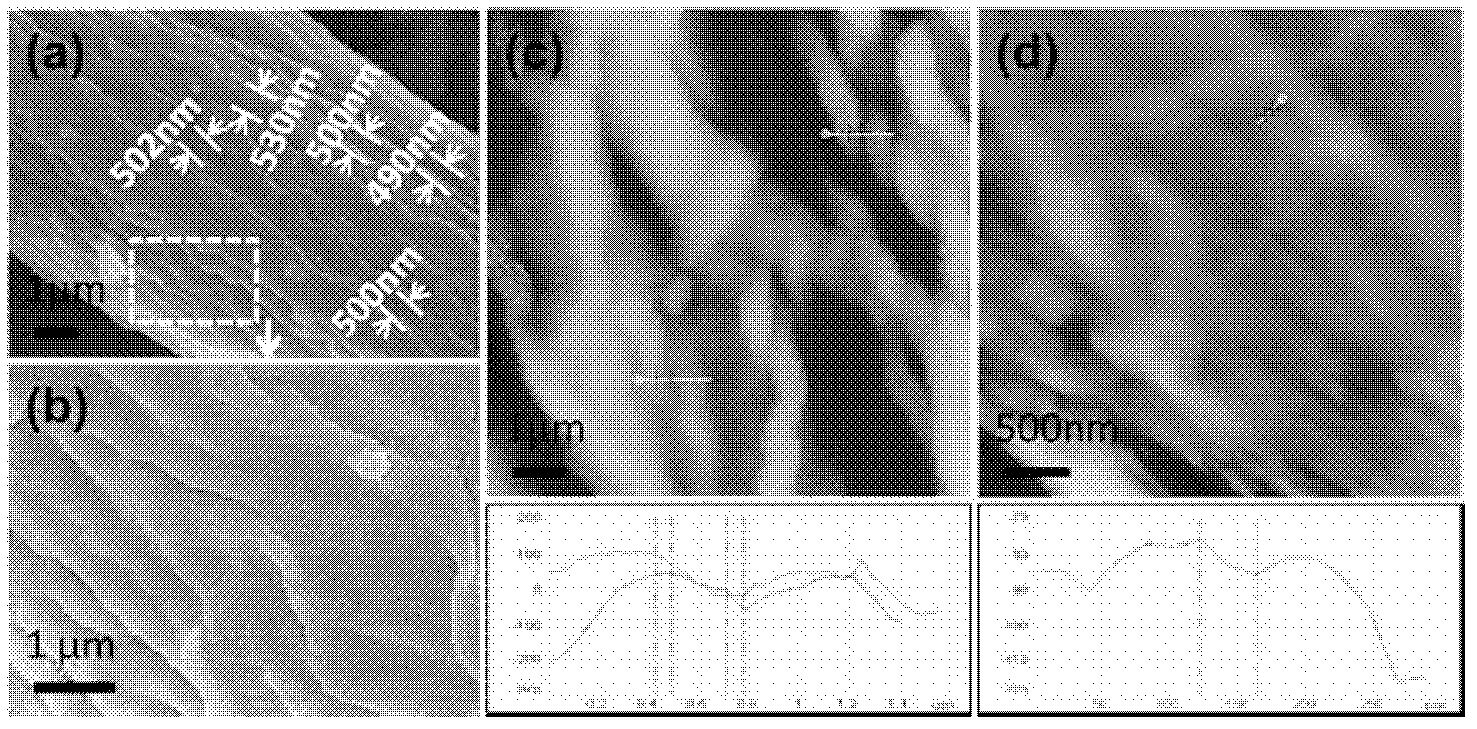

Surface enhanced raman detection test paper and application thereof

The invention relates to a piece of surface enhanced raman detection test paper and the application thereof, which belong to the technical field of ultra-sensitive test analysis, in particular to the piece of surface enhanced raman detection test paper and the application of the paper to detection of biological or chemical probe molecules with raman signals. The surface enhanced raman detection test paper is obtained by covering a precious metal layer on the surface of paper with a natural fiber micro nano multi-grade structure through the physical vapor deposition or chemical plating technology, the paper can be filter paper, parchment paper, napkin, newspaper or printing paper and the like, the precious metal film is gold or silver and the like, and the thickness of the precious metal film is 5 nanometers to 90 nanometers. Combined action of size, period and roughness enables incident light to generate a local electric field on the surface of a multi-stage structure and enables the electric field to be enhanced, and the detection limit can reach 10-10mol / L. The test paper has the advantages of being good in flexibility, low in cost, free of environment pollution, capable of being prepared in batch and the like, thereby being capable of being used in detection of probe molecules such as rhodamine 6G, p-aminothiophenol, riboflavin or ethanol and the like.

Owner:JILIN UNIV

Method for performing electroless nickel plating on surface of aluminum nitride ceramic

ActiveCN101962760AHigh bonding strengthImprove high temperature resistanceLiquid/solution decomposition chemical coatingElectroless nickelSodium acetate

The invention provides a method for performing electroless nickel plating on the surface of aluminum nitride ceramic, belonging to the ceramic thin-film metallization field. The method comprises the following specific steps: 1) polishing the surface of aluminum nitride with a machinery; coarsening the aluminum nitride substrate with mixed acid or alkali, completely cleaning away the residual acid or alkali; 3) sensitizing the coarsened substrate in stannous chloride solution, activating in palladium chloride solution or performing activation without palladium; 4) weighting a certain amount of nickel sulphate, sodium hypophosphite, sodium citrate, sodium acetate, lactic acid, thiourea and sodium dodecyl sulfate in sequence to prepare a chemical plating solution; and 5) adjusting the pH value of the solution to 4.0-6.0 with acid or alkali, heating the solution to 70-95 DEG C, and placing the prepared substrate in the solution to perform electroless nickel plating. The invention is characterized in that the electroless nickel plating can be performed on the surface of the aluminum nitride ceramic substrate which is difficult to plate; and a certain amount of surfactant is added so that the plating becomes denser and smoother, the binding force between the plating and the substrate is increased, and the solderability of the plating is better.

Owner:UNIV OF SCI & TECH BEIJING

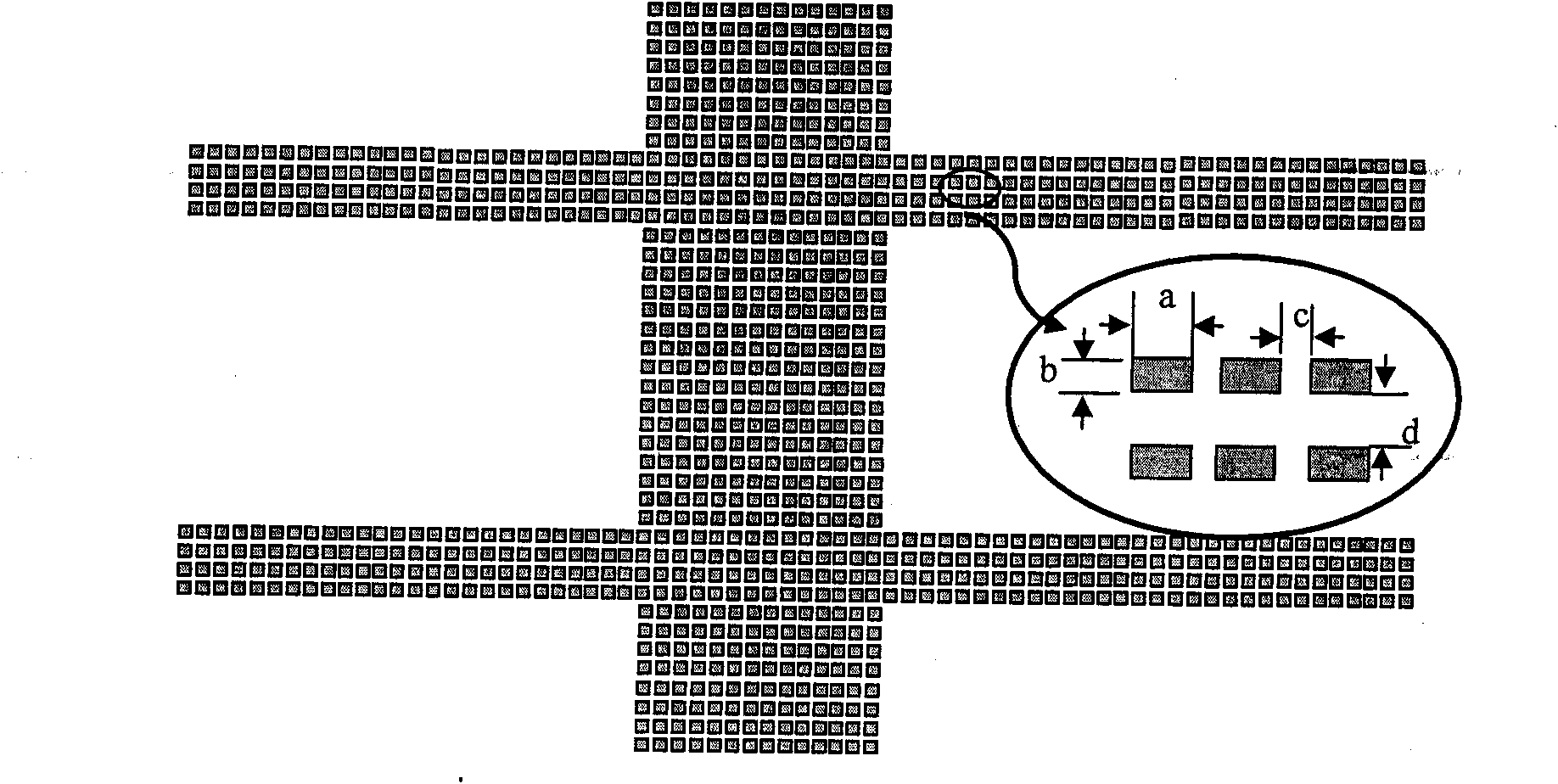

Manufacturing and repairing method for conductive circuit of three dimensional mold interconnecting device

ActiveCN101394710AReduce material costsNo etchant requiredConductive pattern formationChemical platingOrganic solvent

The invention discloses a method for manufacturing and repairing a three-dimensional molding interconnection device conductive line. The method comprises the following steps: (1) depositing a 0.1-50 micrometer thick prearranged sizing agent layer of a conductive sizing agent on the surface of a molding structural element according to the design configuration of a conductive line; (2) baking or airing the prearranged layer of the conductive sizing agent, and removing an organic solvent thereof; (3) utilizing a laser beam to irradiate the prearranged sizing agent layer so as to enable metal conductive particles in the sizing agent to be melted and mixed with a 5-500mum thin layer of the surface of a plastic matrix, and the metal conductive particles in the sizing agent to be embedded in the surface of the matrix, thereby obtaining a conductive pattern; and (4) conducting chemical plating of 2-10mum copper on the surface of the conductive pattern, and then conducting chemical plating of 1-3mum anticorrosion metal. By the method, various complex conductive lines can be quickly and directly manufactured or repaired on the surface of three-dimensional molding structural member of various plastic matrix. No platability is required for base materials or no special requirement is needed for the molding technical. The invention has the advantages of simple process, environment-friendliness, low cost and high flexibility.

Owner:WUHAN XINRUIDA LASER ENG

Chemical copper-plating solution and chemical copper-plating method

InactiveCN102191491AImprove stabilityImprove yieldLiquid/solution decomposition chemical coatingChemical platingCopper plating

The invention provides chemical copper-plating solution. The chemical copper-plating solution is the aqueous solution containing copper salt, N-methylmorpholine, formaldehyde, complexing agent, stabilizer and pH regulator and the pH value of the chemical copper-plating solution is 12-13. The invention also provides a chemical copper-plating method. The method comprises the following steps: directly contacting a part to perform chemical copper plating with the chemical copper-plating solution, cleaning and drying to obtain the plated part. By adopting the chemical copper-plating solution, the stability of the copper-plating solution can be greatly increased and the plating speed can be increased. By adopting the chemical copper-plating method provided by the invention to plate copper on the part to be plated, the yield of the copper-plating product can be increased largely and the work efficiency of chemical plating can be increased, thus the method is good for industrialized mass production.

Owner:BYD CO LTD

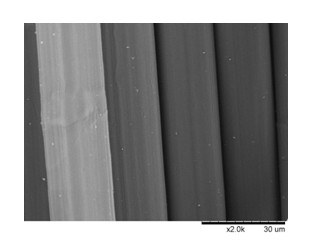

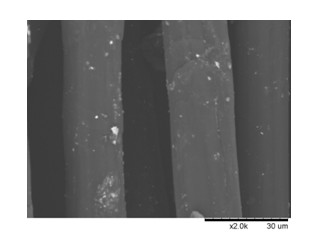

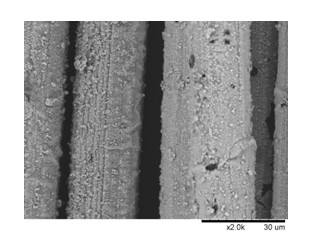

Chemical nickel-plating method for carbon fiber

InactiveCN102086517ALow costEasy to operateLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a chemical nickel-plating method for carbon fiber, which is designed for overcoming the disadvantages of high cost, a large number of process steps and poor operability existing in the prior art. In the method, a chemical plating process is adopted; and a pre-treatment is performed on a raw material and chemical plating solution is prepared before the chemical plating. The pre-treatment process comprises the steps of: calcining by using a muffle furnace to remove glue; soaking in solution of absolute ethanol to remove oil; performing surface roughening and activating treatment by using solution of sodium hydroxide and solution of silver ammonia; sensitizing by using a sensitizer, namely stannous chloride; and performing surface reduction by using solution of sodium hypophosphite. The chemical plating solution consists of nickel sulfate hexahydrate, sodium hypophosphite, sodium pyrophosphate and sodium citrate. The chemical nickel-plating on the carbon fiber is finished by placing a pre-treatment product of the chemical plating into the chemical plating solution, and reacting, standing, filtering and drying under a chemical plating condition. The method has the characteristics that: the product has a uniform surface, a compact plating layer and uniform particles.

Owner:沈阳临德陶瓷研发有限公司

Carbon fiber surface modification method

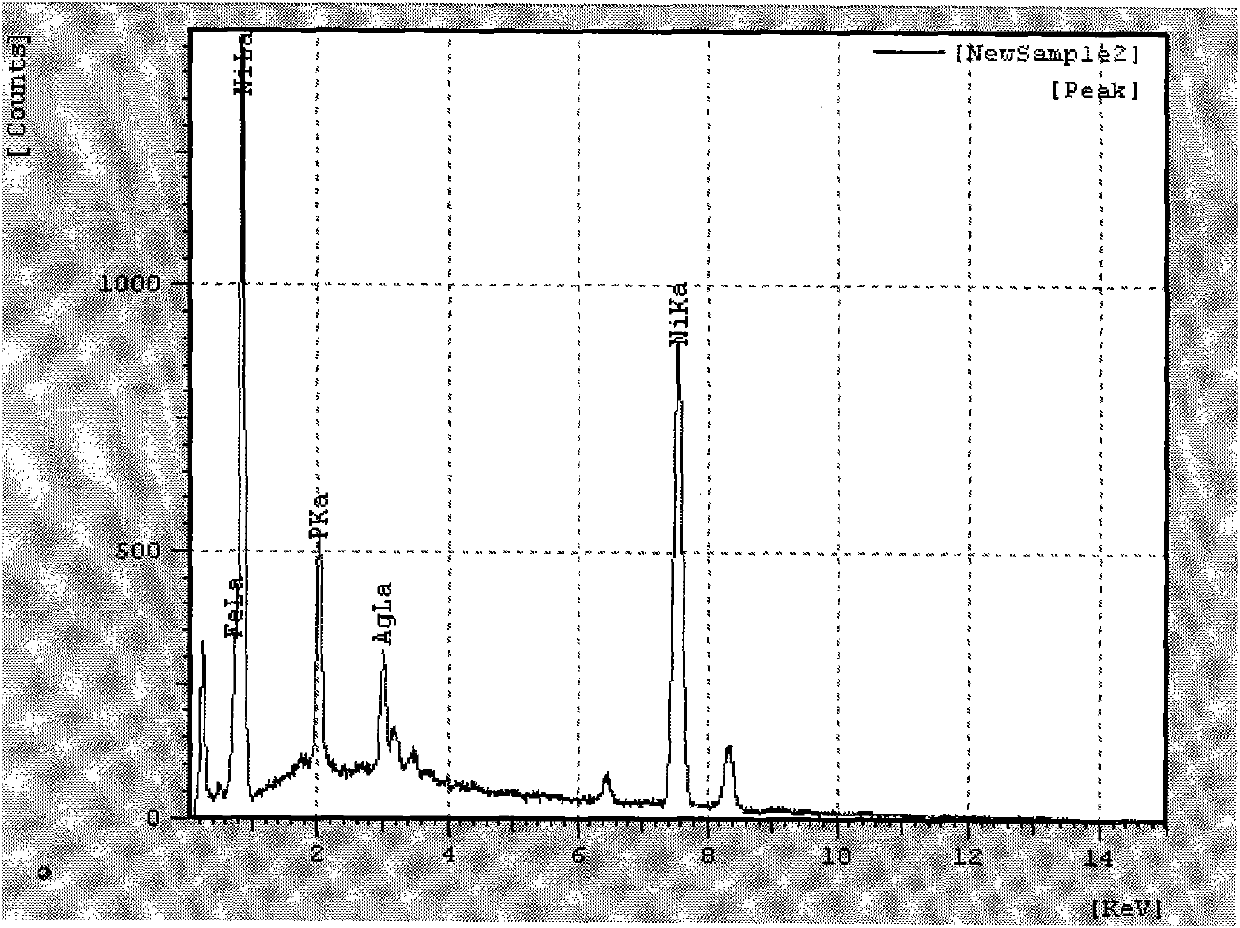

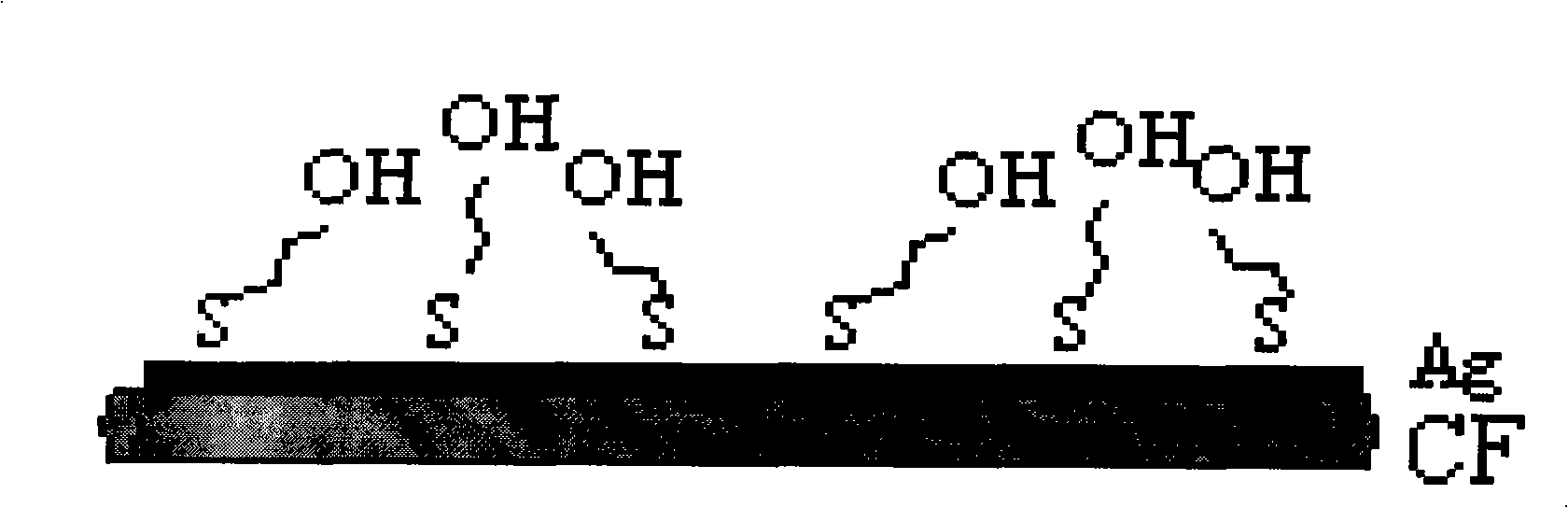

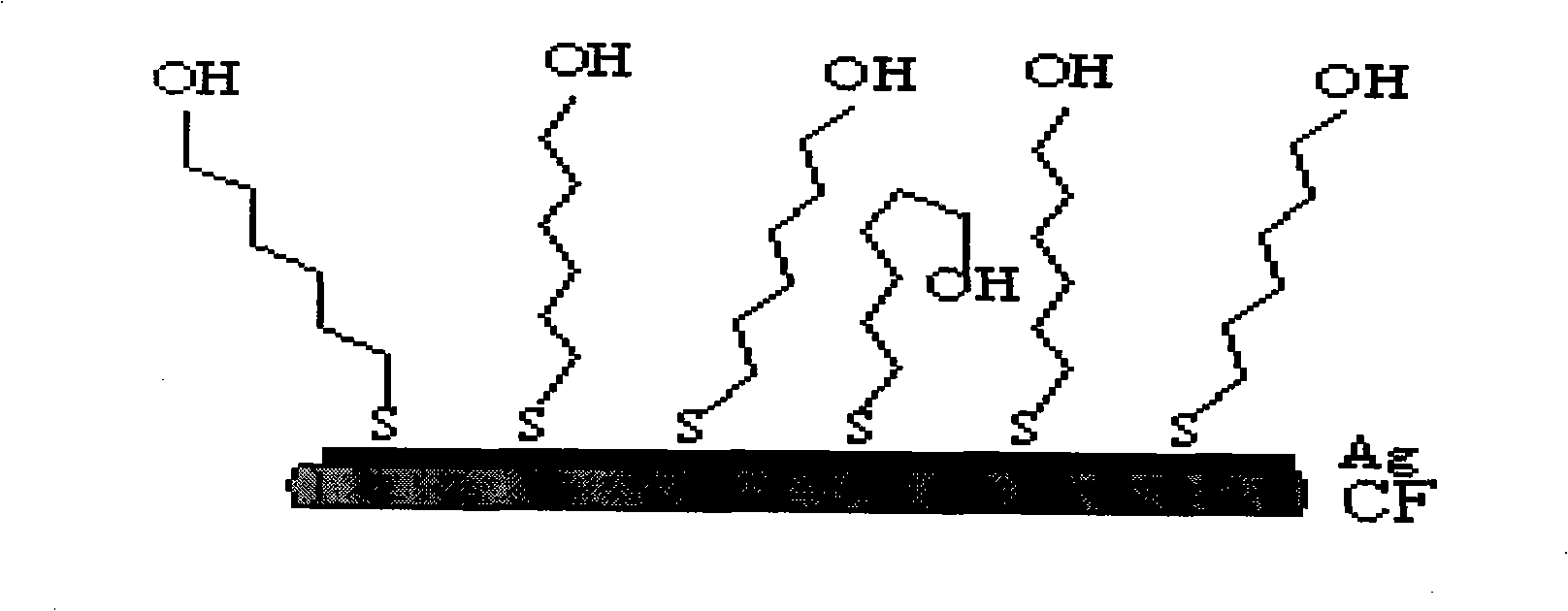

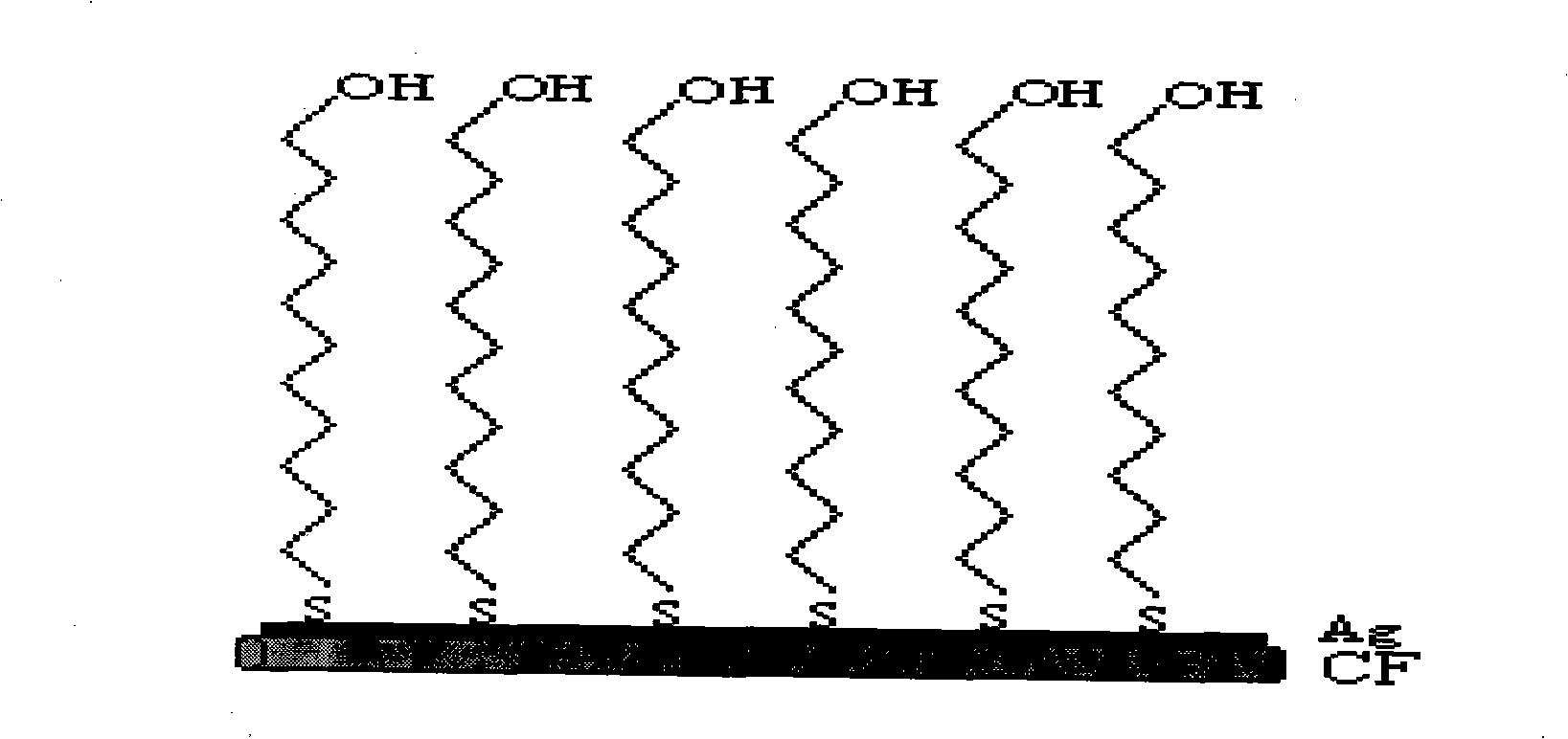

The invention discloses a carbon fiber surface modification method, and relates to a carbon fiber modification method. The invention solves the problem of the uncontrollability of the distribution and arrangement of a carbon fiber surface functional group, which is not propitious to the study of the mechanism of a carbon fiber interface. The carbon fiber is plated with silver after surface pre-processing, then the carbon fiber with the silver-plated surface is infused in the dilute solution of thiol molecule containing sulfur element; depending on the coactions of the bonding reaction of sulfur atoms and metb and the force among self-assembly molecules, the thiol molecule has chemical absorption on the fiber surface and forms a closely arranged and ordered two-dimensional self-assembly single molecule membrane; two procedures are as follows: 1. the chemical plating of silver on the carbon fiber surface; and 2. the self assembly of molecules of organic sulfide on the silver-plating carbon fiber. The carbon fiber surface modification method has the advantages of realizing controllable, directional and ordered arrangement on the carbon fiber surface functional group from the molecule level, thus being beneficial to the study of the mechanism of the carbon fiber composite material interface.

Owner:HARBIN INST OF TECH

Non-ammonia type plating solution for chemical nickel plating

InactiveCN101314848ANo pollution in the processNo pollutionLiquid/solution decomposition chemical coatingChemical platingNickel salt

The invention discloses an ammonia-free chemical nickel plating bath which adopts an ammonia-free pH modifying agent to regulate the pH value of the bath. Each liter of the bath contains the components that nickel salt is 24 to 30g, reducing agent is 24 to 33g, buffering agent is 10 to 18g, complexing agent is 20 to 30g, stabilizing agent is 0.5 to 1.5mL, brightener is 1.5 to 3.0mL, and others are water. In the ammonia-free chemical nickel plating bath, the ammonia-free pH modifying agent is selected from one or the mixture of sodium hydroxide, and potassium hydroxide or potassium carbonate. All materials in the ammonia-free chemical nickel plating bath do not contain heavy metal, ammonia water is not utilized to regulate the pH value, the problems of environment pollution, invalidation caused by overlong storing time of the bath, etc. are not caused, and the obtained chemical plating bath is friendly to the environment, in addition, the luminance brightness of the made plating layer can be full-bright. The bath has wide application prospect.

Owner:SUN YAT SEN UNIV

Surface chemical metal plating carbon nanotube field-emission cathode preparation method

ActiveCN101661858AImprove stabilityFacilitates electron conductionCold cathode manufactureState of artChemical plating

The invention provides a surface chemical metal plating carbon nanotube field-emission cathode preparation method, which belongs to a carbon nanotube field emission cathode technology, solves the shortcomings of the existing technology, improves the electronic conduction and emission capabilities of the carbon nanotube and enhances the contact between a carbon nanotube film and a substrate electrode. The preparation method comprises the following steps: the carbon nanotube is processed through purification, cutting, scattering, and then through sensitization and activation, the carbon nanotubesurface forms a noble metal catalytic center; then the carbon nanotube surface forms a metal layer through a chemical plating method, the surface chemical metal plating carbon nanotube is prepared into evenly and stably dispersed carbon nanotube electrophoresis liquid, and finally pulse electrophoresis deposition is used for preparing the cathode of the carbon nanotube. The surface chemical metalplating carbon nanotube has good electronic conduction and emission capabilities, the carbon nanotube field-emission cathode and a substrate electrode can form good attachment, and the invention canrealize large-area, imaging and uniform preparation for the carbon nanotube field-emission cathode.

Owner:FUZHOU UNIV

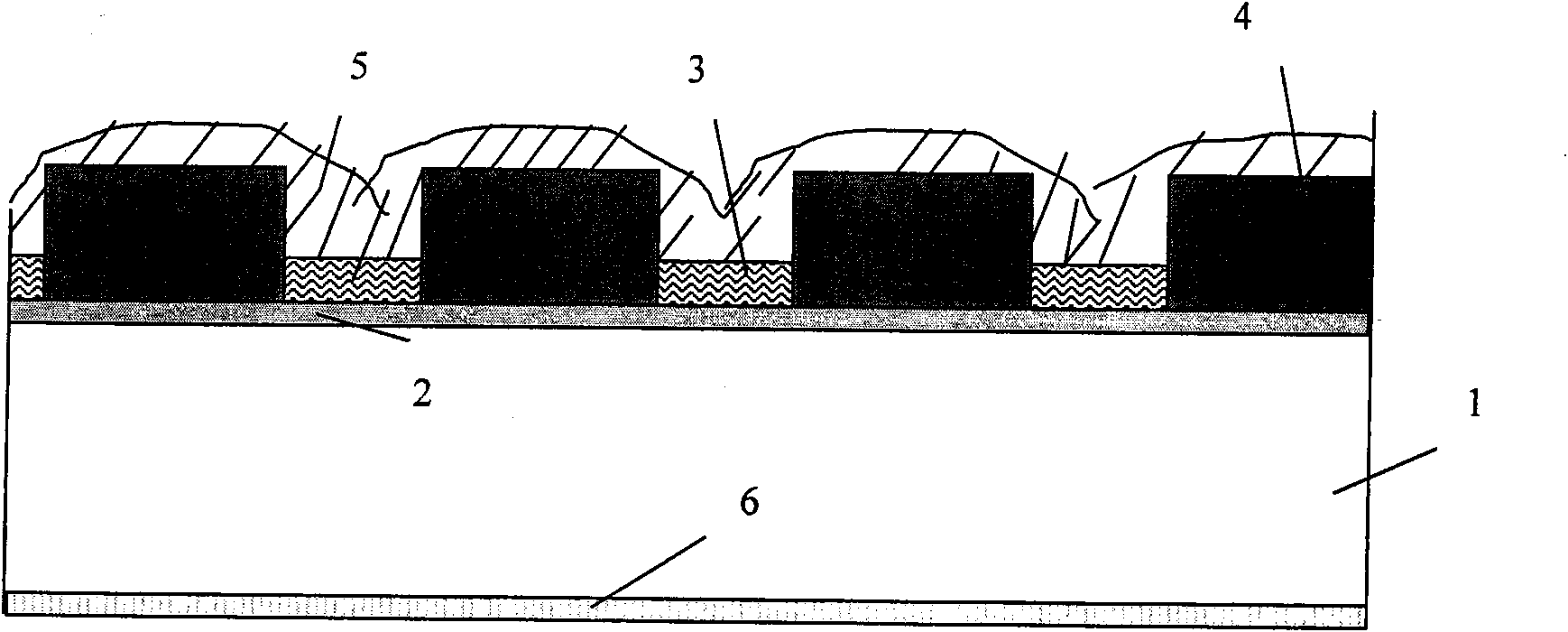

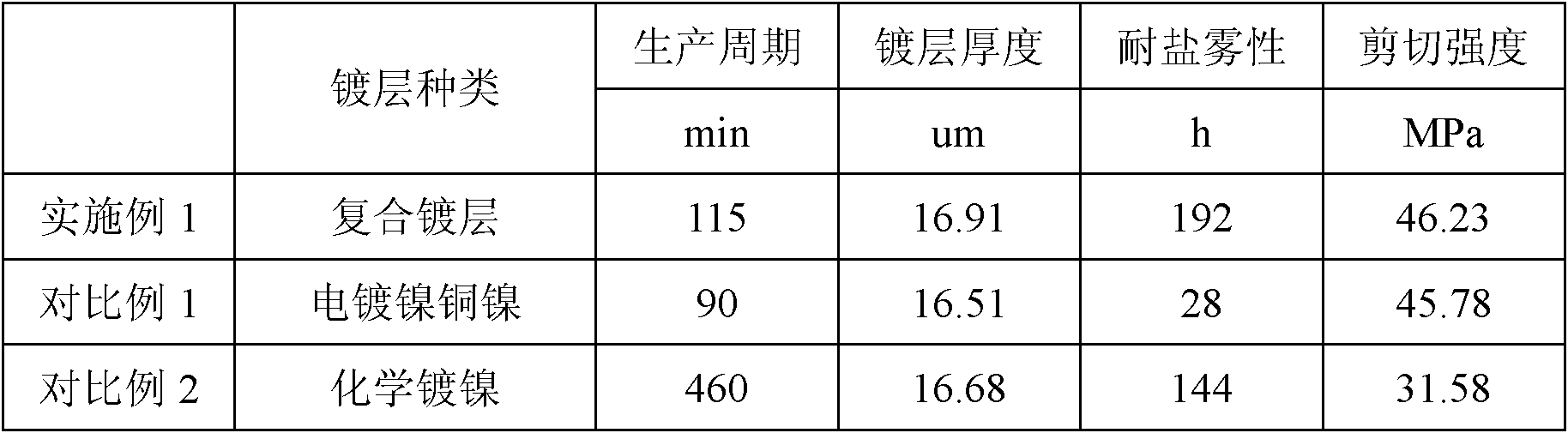

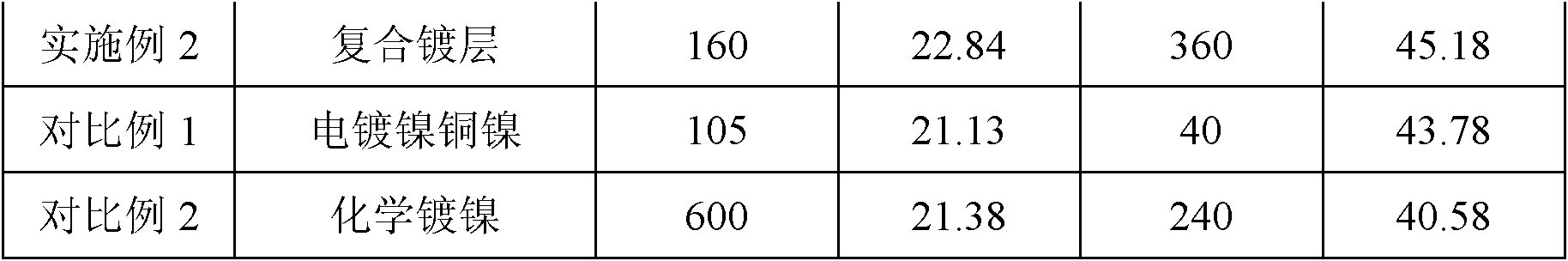

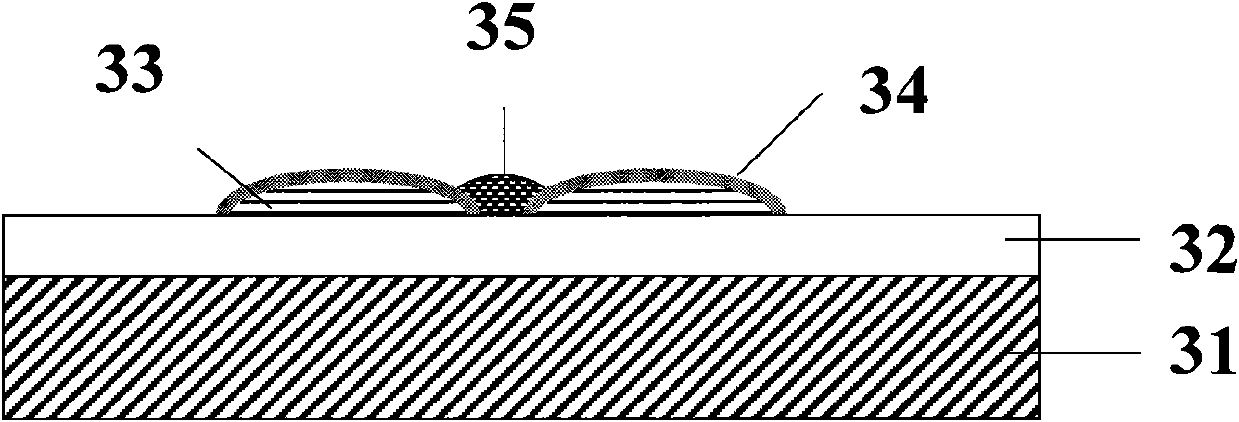

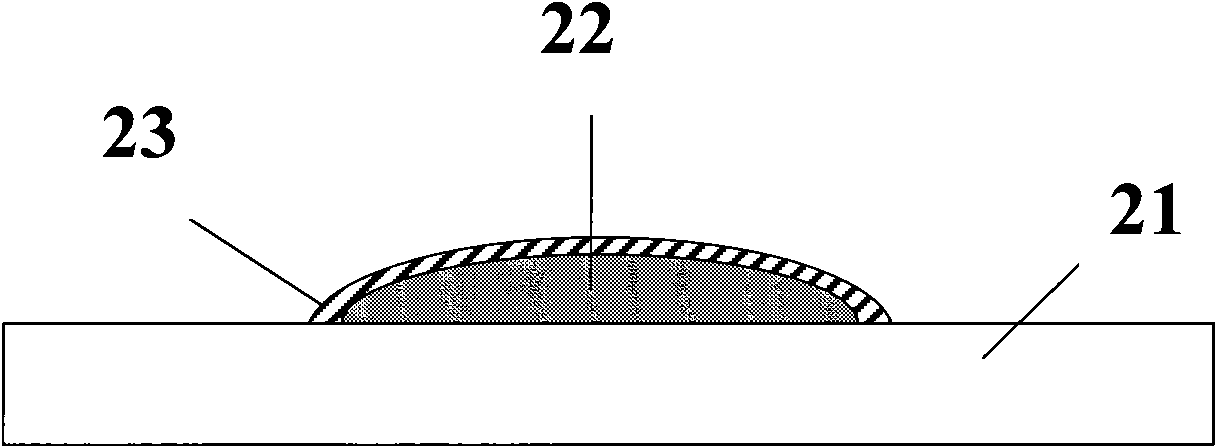

Electroplating and chemical plating composite protecting process for NdFeB permanent magnet and NdFeB permanent magnet with composite protective layer

InactiveCN102108511AImprove corrosion resistanceReduce porosityPermanent magnetsLiquid/solution decomposition chemical coatingChemical platingPre treatment

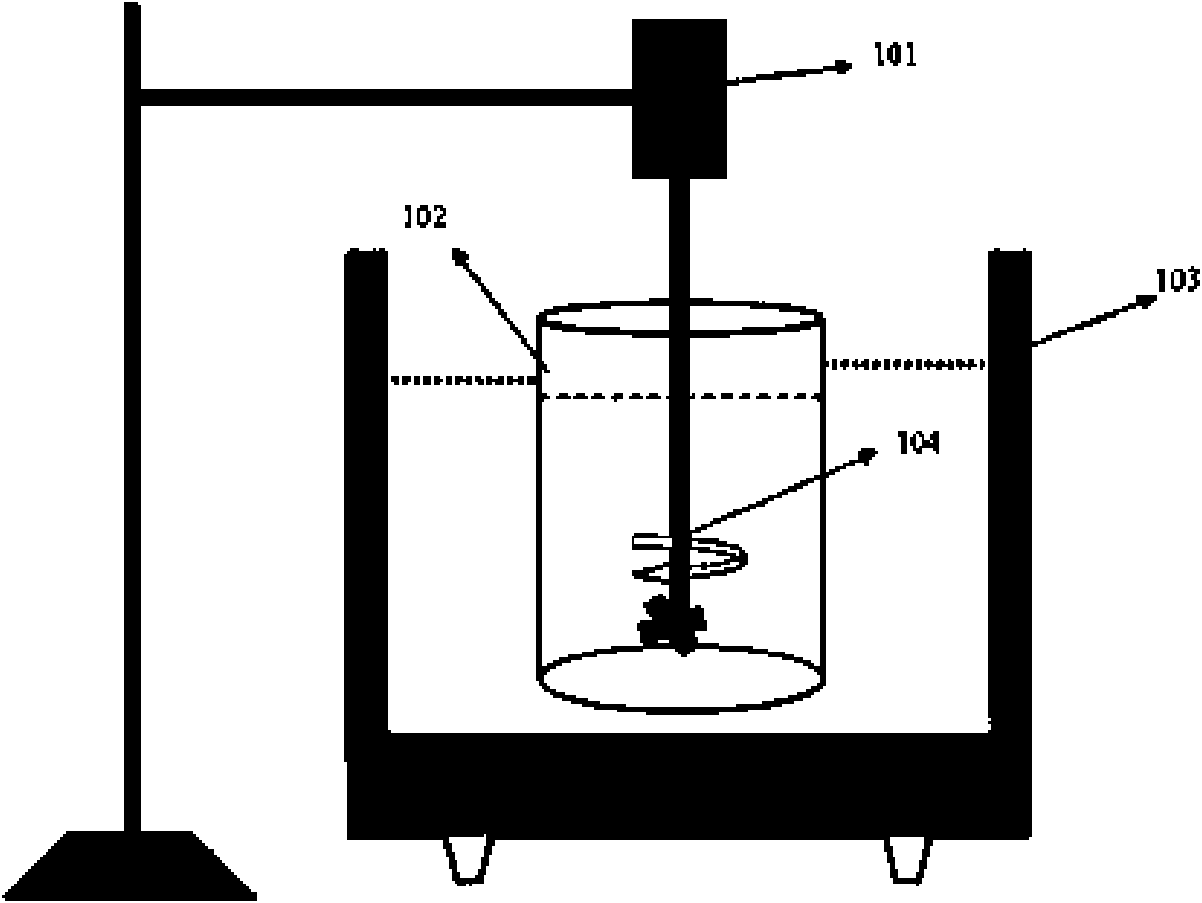

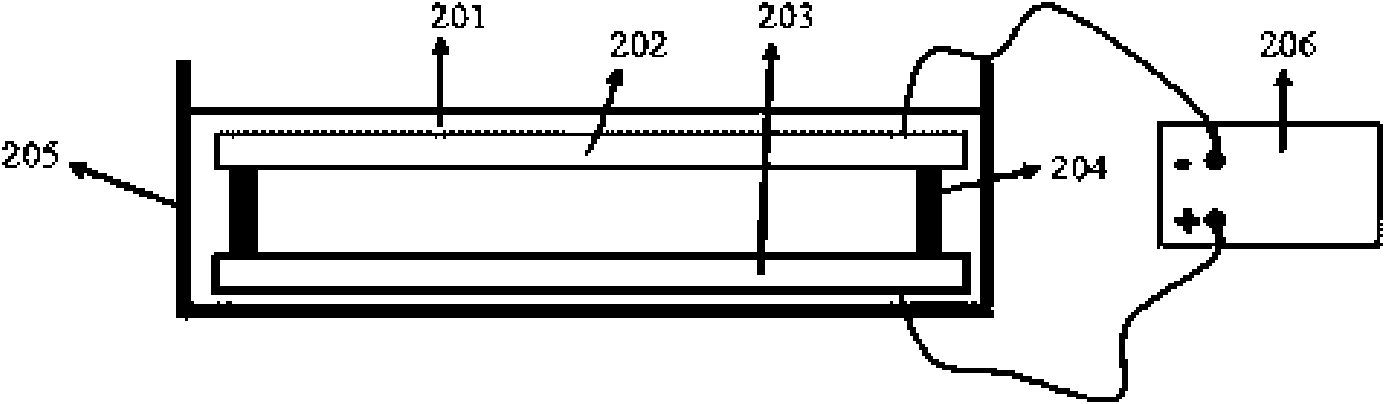

The invention provides an electroplating and chemical plating composite protecting process for an NdFeB permanent magnet and the NdFeB permanent magnet with a composite protective layer, relating to the surface treatment protecting process for the NdFeB permanent magnet. The invention aims at providing the NdFeB permanent magnet electroplating and chemical plating composite protecting process and the NdFeB permanent magnet with the composite protective layer with high production efficiency and good corrosion resistance. The electroplating and chemical plating composite protecting process for the NdFeB permanent magnet comprises the following steps: (1) pre-treatment: the NdFeB permanent magnet is subjected to oil removal, dust removal and surface activation; (2) electroplating: the surface of the NdFeB permanent magnet is electroplated; (3) transitional treatment: the electroplated NdFeB permanent magnet is subjected to water cleaning and surface activation; (4) chemical plating: nickel is plated chemically outside the electroplating layer of the NdFeB permanent magnet; and (5) post-treatment: the chemically plated NdFeB permanent magnet is subjected to water cleaning, surface adjustment and drying.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

Method for preparing compound electrode

InactiveCN101950771AGood value for moneyBroaden your optionsFinal product manufactureSolid-state devicesChemical platingConductive materials

The invention relates to a method for preparing a compound electrode, which aims to widen the selection range of electrode materials and simplify a production process so as to obtain the electrode with the best cost performance and reduce the using amount of noble metal. The method comprises the following steps of: selecting a semiconductor or insulated material as a substrate of the compound electrode; obtaining a printing electrode layer on the first layer of the bottom part of the compound electrode on the substrate by a printing process, and solidifying the printing electrode layer; and finally, obtaining electrode parts on the second layer or above the second layer of the compound electrode on the printing electrode layer by a plating process, wherein the plating process comprises electronic plating and chemical plating. The compound electrode prepared by the method is made of two or more layers of different conducting materials, and the preparation method combines the advantages of preparing electrodes by an electronic plating method and a printing method and can be widely applied to the field of printing electronics.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method of manufacturing vacuum composite film coating on surface of neodymium iron boron magnet

InactiveCN101403093AAvoid the disadvantages of brittlenessImprove anti-corrosion performanceVacuum evaporation coatingSputtering coatingComposite filmChemical plating

The invention relates to the technical filed of vacuum plating, in particular to a preparation method for conducting vacuum compound plating on the surface of a neodymium iron boron magnet, which is characterized in that the preparation method comprises the following steps: A. pre-treatment, the mixed liquor of washing liquid and purified water is used for conducting oil removal and parting medium washing to the magnet surface in an ultrasonic wave cleaner; B. ion cleaning and activation, the pre-treated neodymium iron boron magnet which is dried at 80-100 DEG C for 5-10 minutes undergoes bombardment activation of a glow plasma in vacuum environment, so as to increase surface activation energy; and C. vacuum plating, vacuum plating treatment is conducted to the neodymium iron boron magnet washed by ions in a vacuum chamber, and a metal plating is prepared on the surface. The deposited metal film on the surface of the neodymium iron boron magnet has the advantages of good stability, high bonding force and tightness, stronger anti-corrosion performance in cold and hot alternation environment. Furthermore, in the physical vapor deposition plating process, the plating thickness is affected much less by the magnet workpiece corner than in electroplating and chemical plating, and the pollution problem is avoided in the preparation process.

Owner:兰州大成科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com