Patents

Literature

9225results about How to "Uniform particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Encapsulated unsaturated fatty acid substance and method for producing the same

InactiveUS6531150B1Improve product qualityInhibit oxygen-permeabilityPowder deliveryGranular deliveryWater solubleGelatin

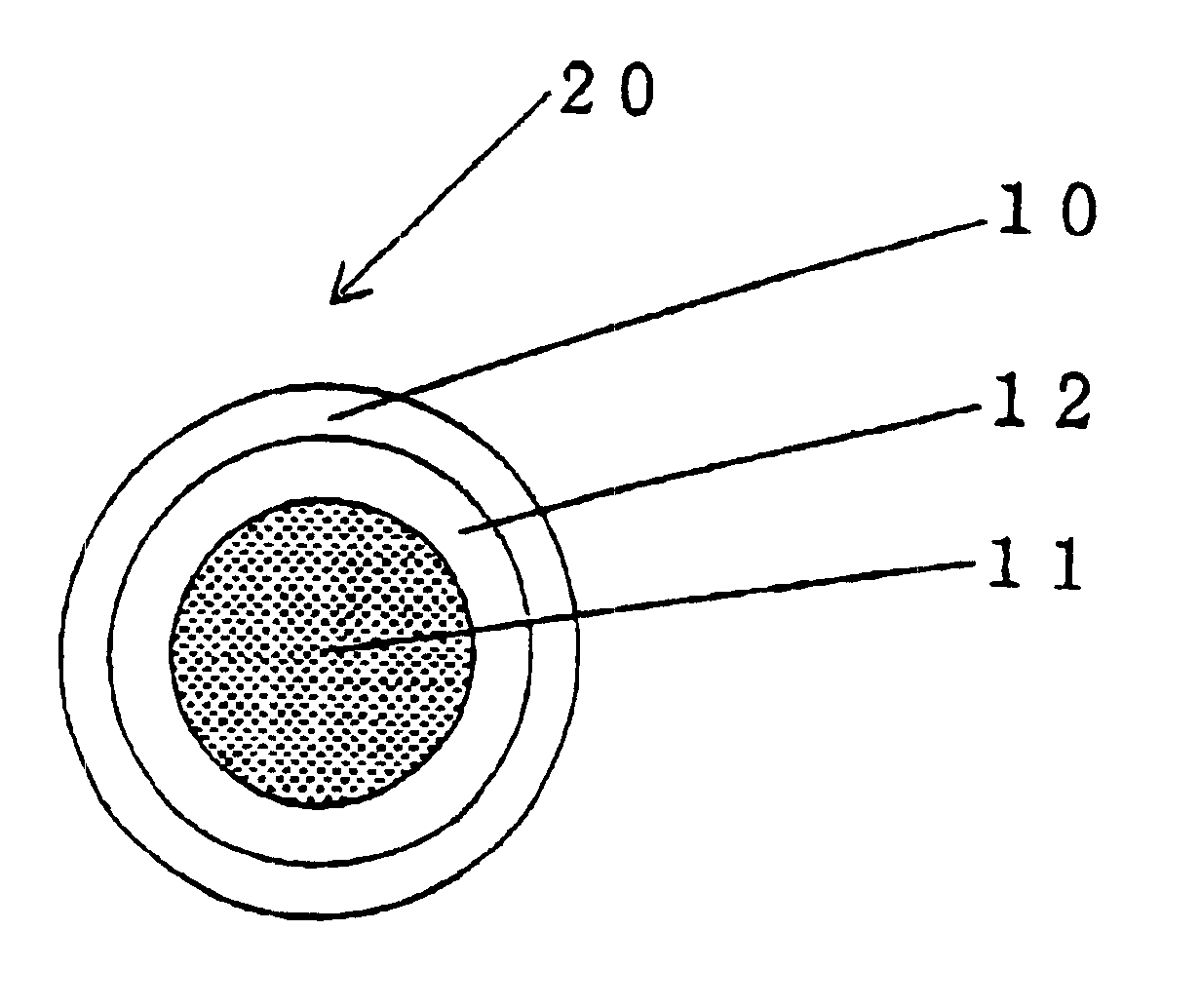

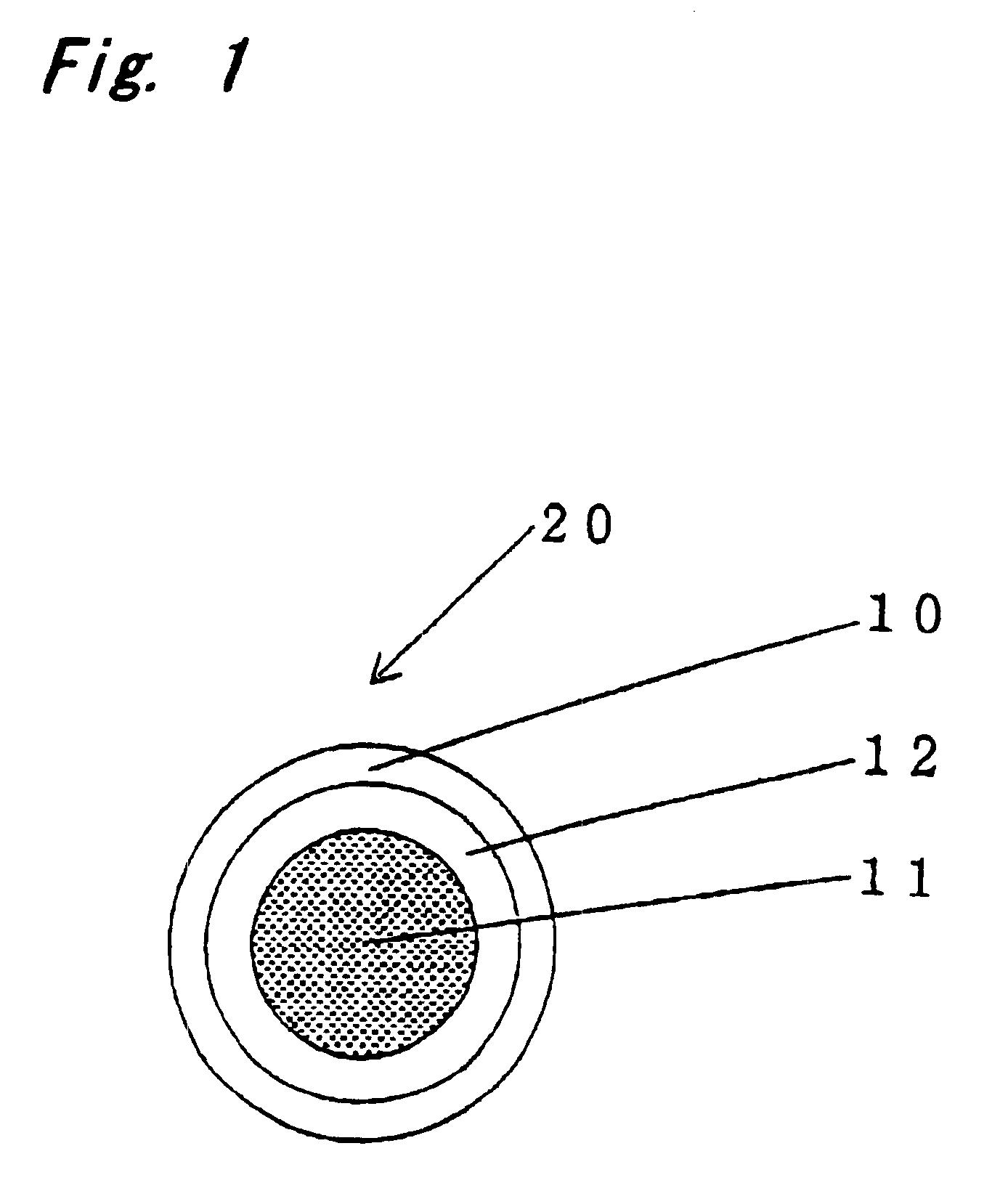

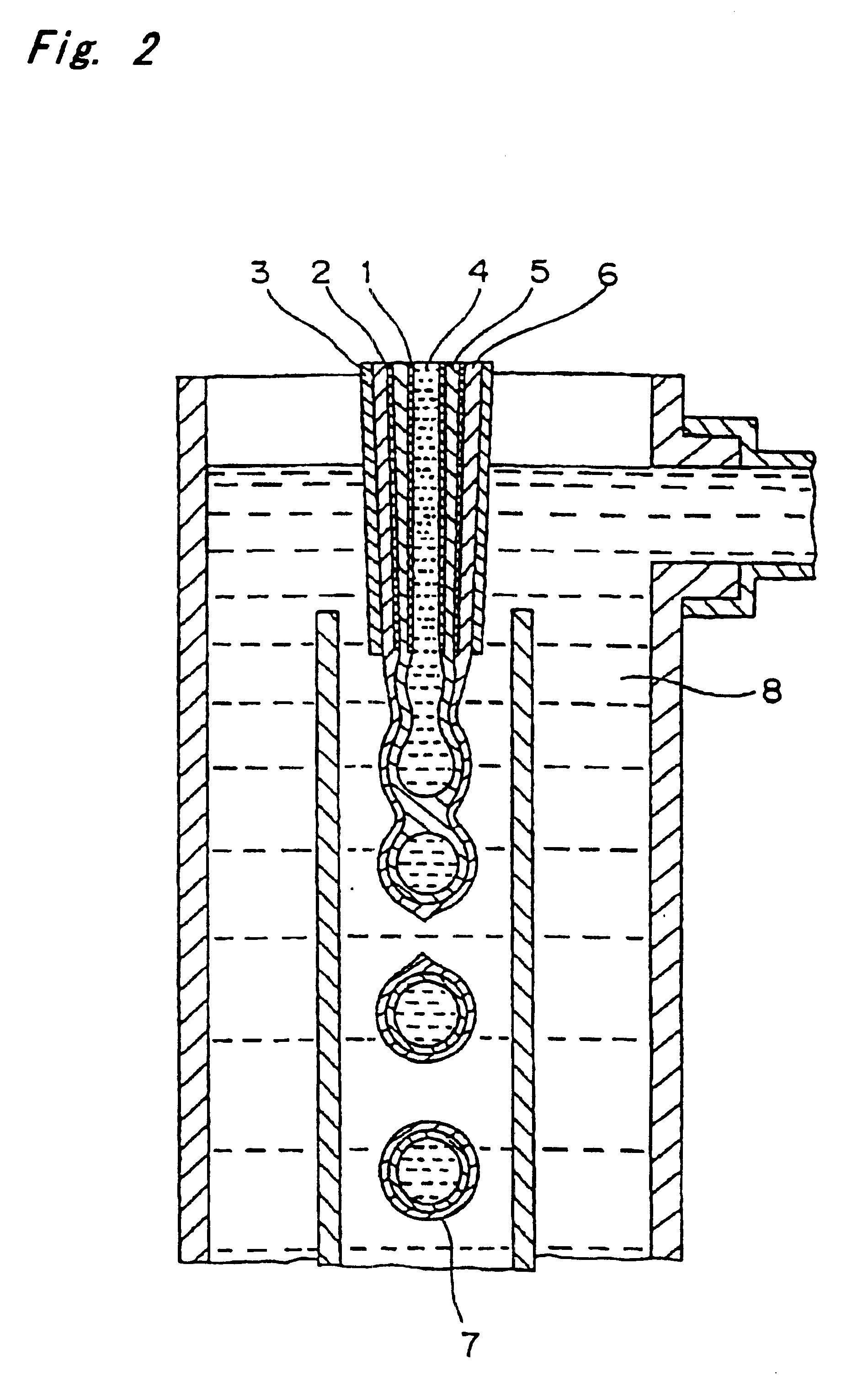

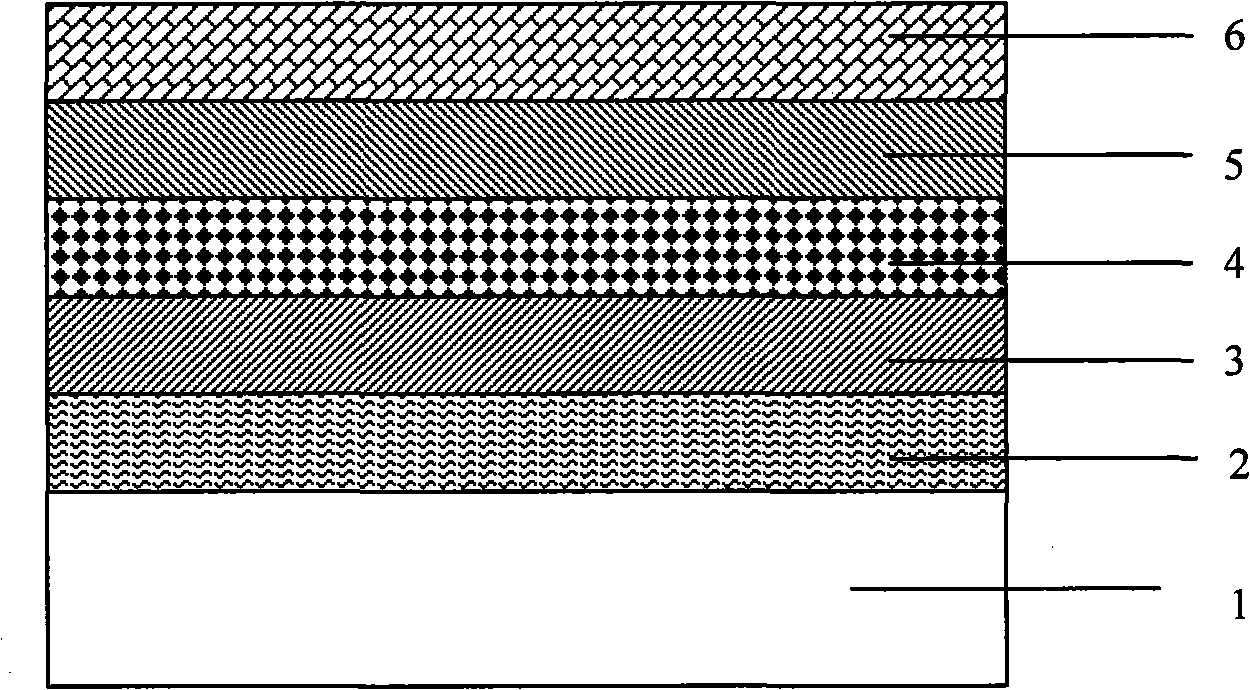

The present invention relates to an encapsulated unsaturated fatty acid substance in a form of a three-layered capsule, comprising an unsaturated fatty acid or a derivative thereof (11) as a content and a coating layer (10) mainly containing gelatin, encapsulating the content (11), wherein a water-soluble gel layer (12) containing an acid or an acid salt thereof is present between the coating layer (10) and the content (11). The encapsulated unsaturated fatty acid substance of the present invention is characterized by that it has neither insolubility nor deterioration with time, and that it is enteric.

Owner:MORISHITA JINTAN CO LTD

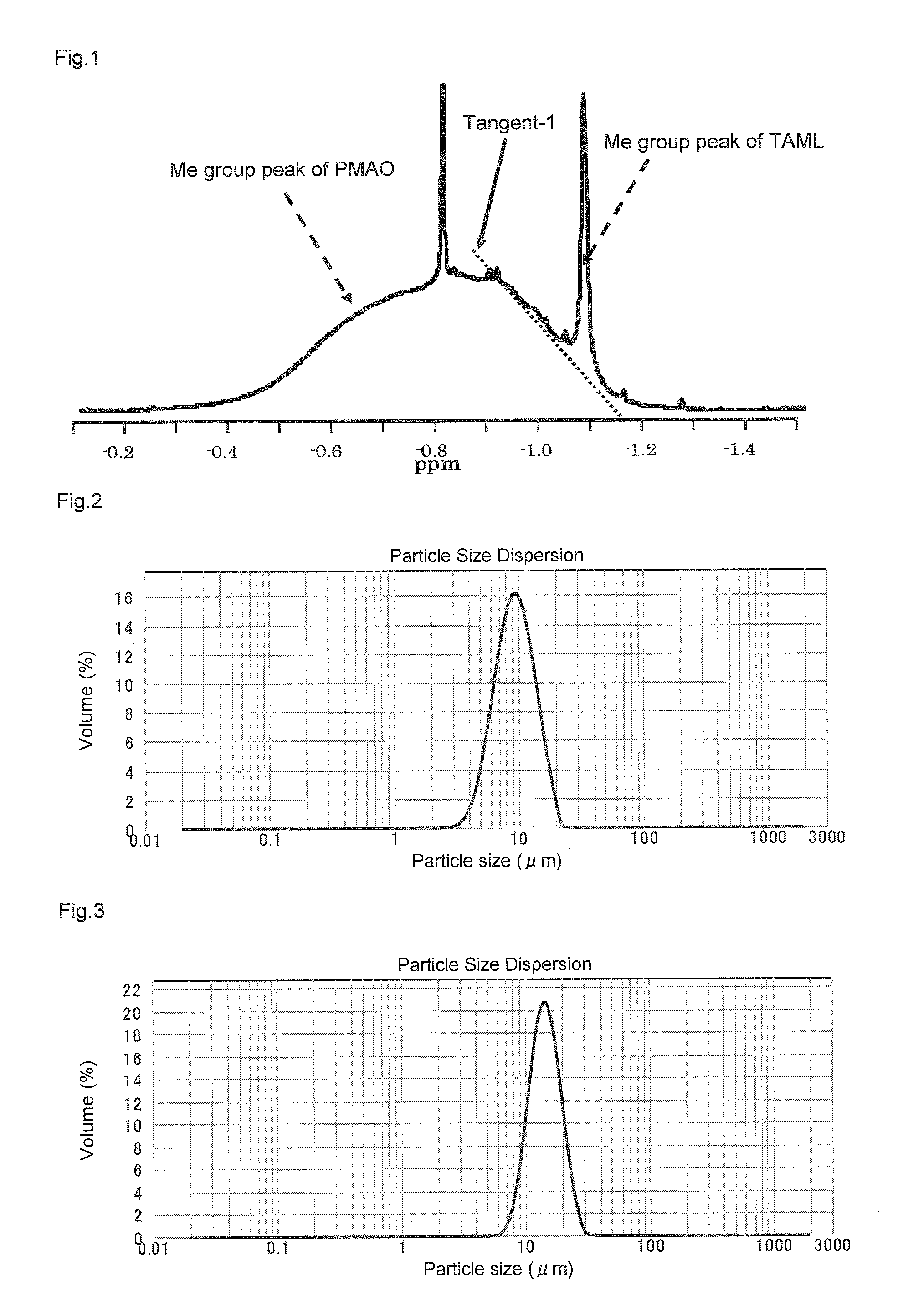

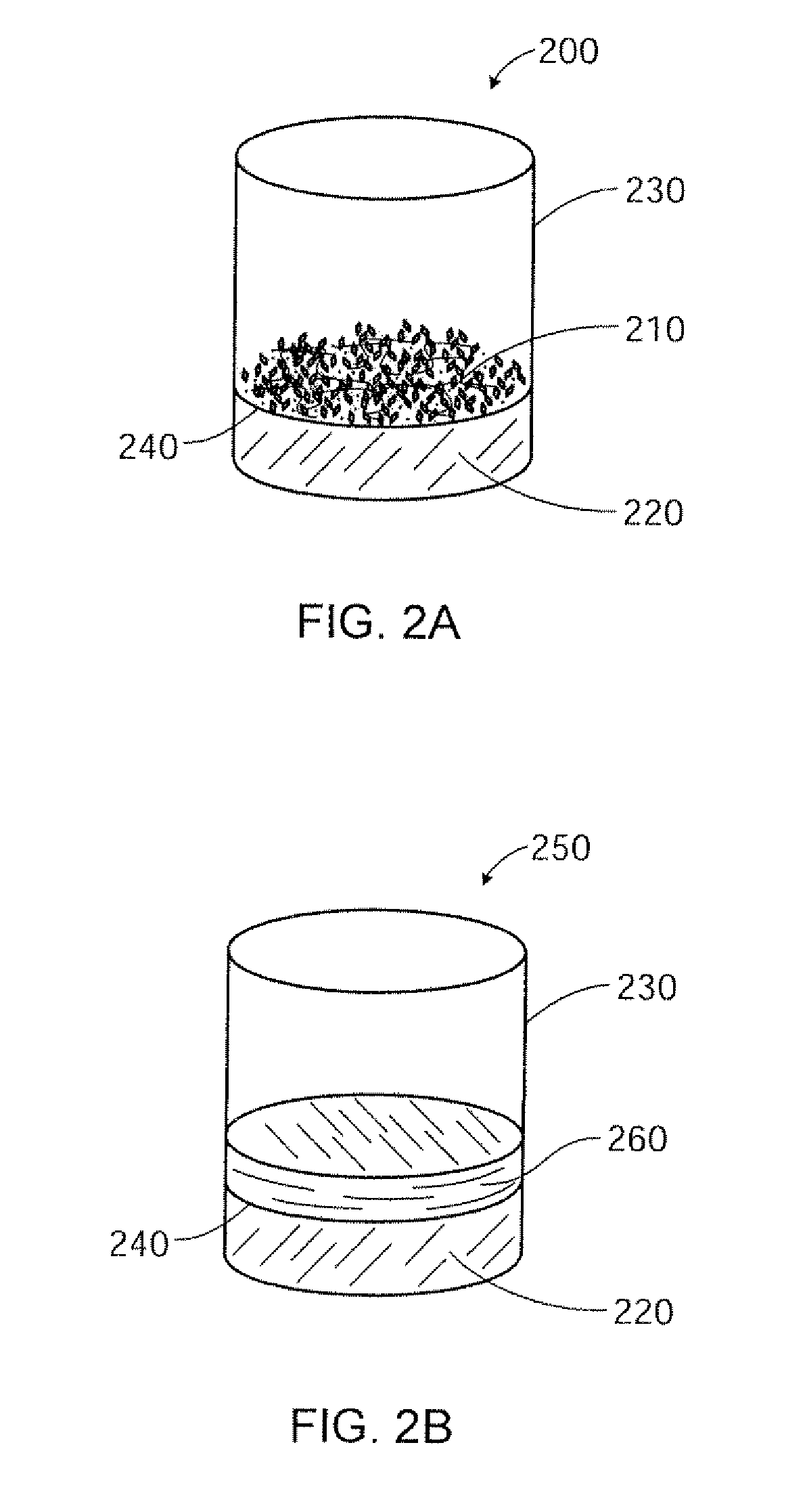

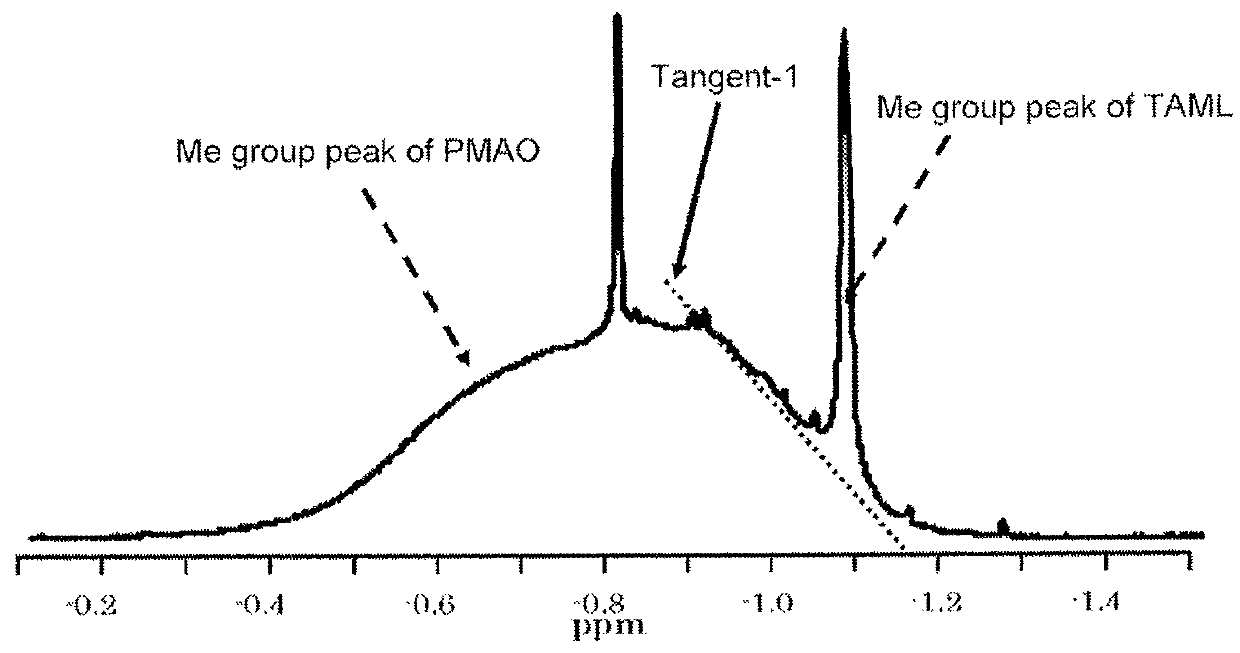

Solid polymethylaluminoxane composition and method for manufacturing same

ActiveUS8404880B2High polymerization activityReduce solubilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationMethyl group

Owner:TOSOH FINECHEM CORP

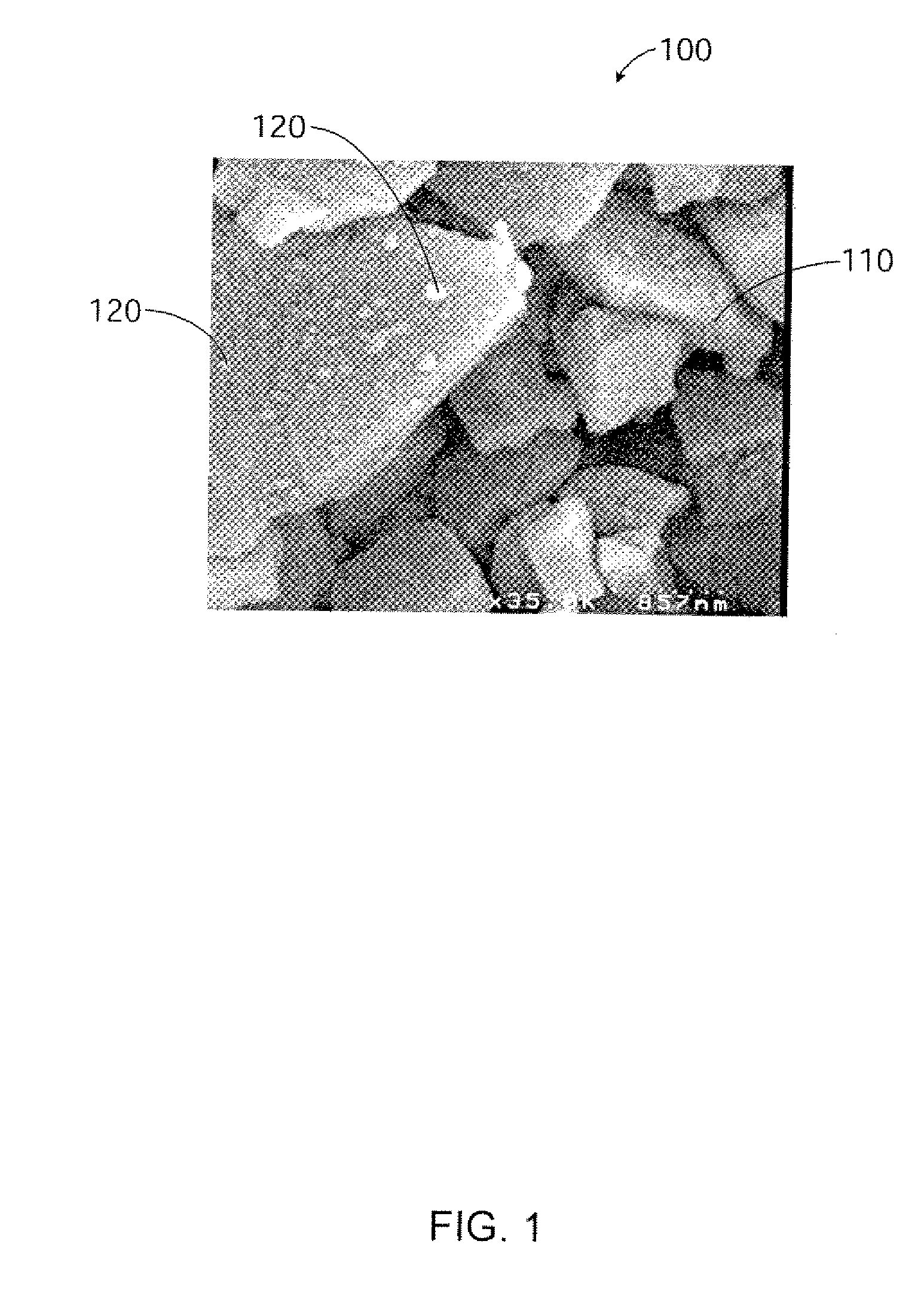

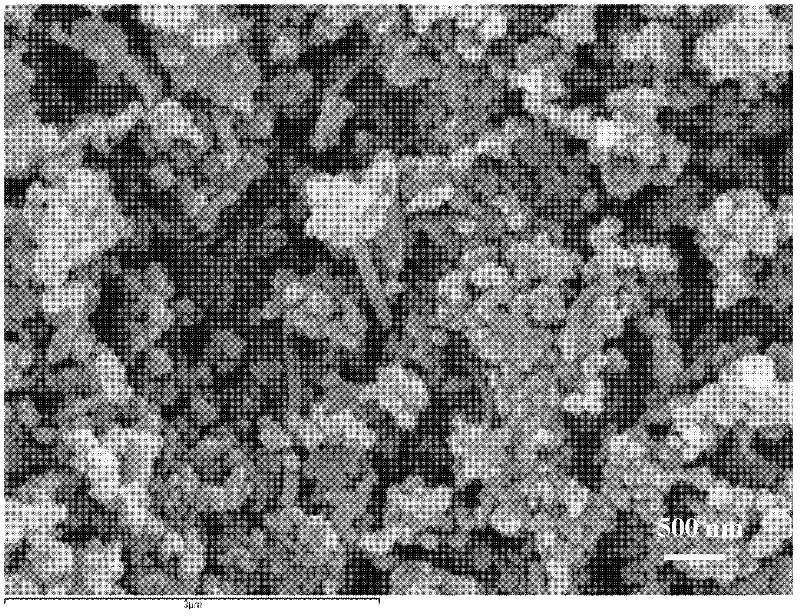

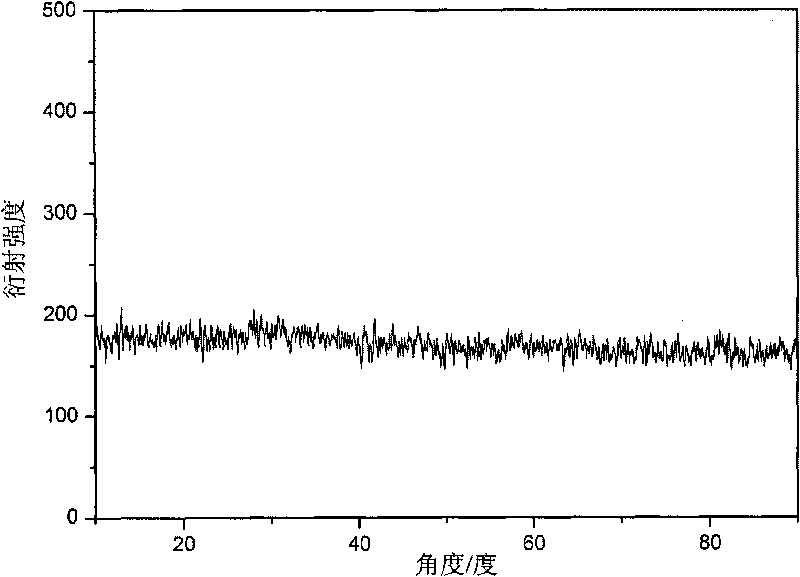

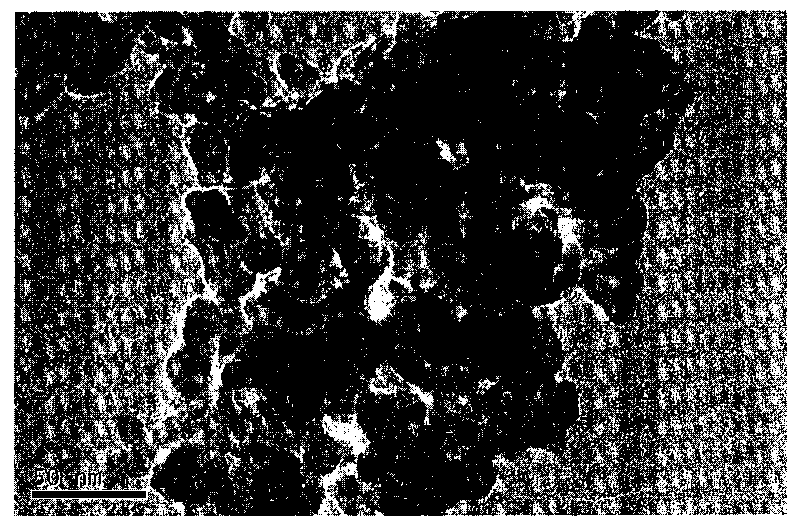

Sintered polycrystalline diamond material with extremely fine microstructures

InactiveUS20070056778A1Uniform particle sizePressurized chemical processDrill bitsPolycrystalline diamondHigh pressure

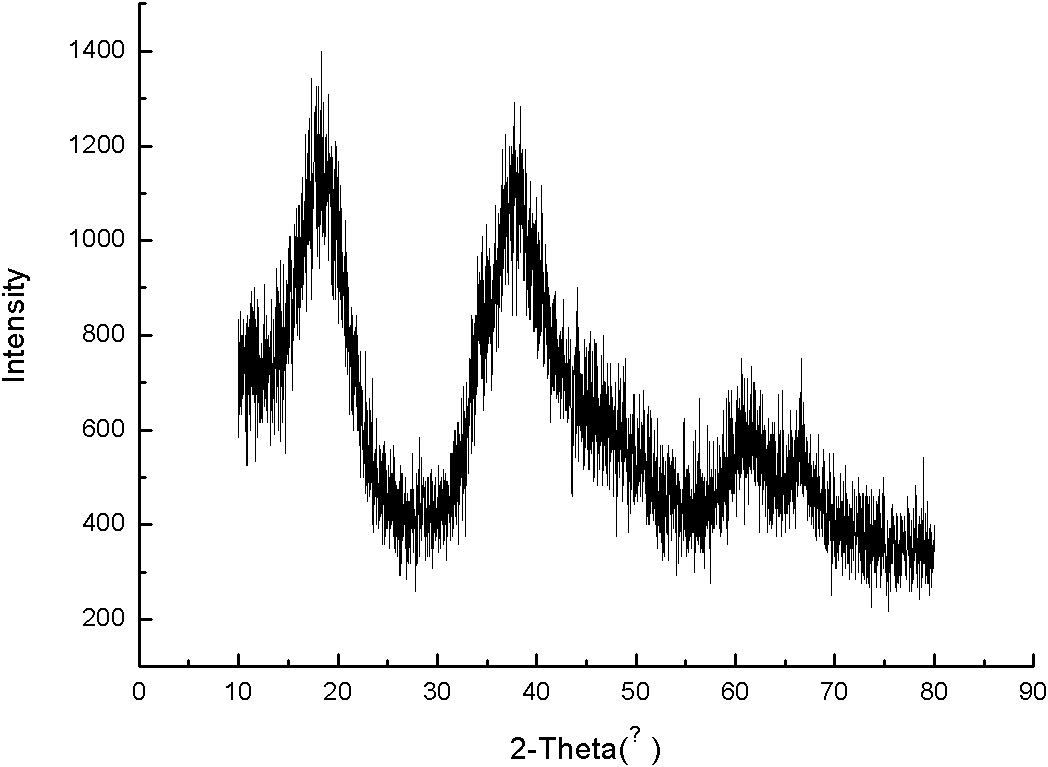

A sintered polycrystalline diamond material (PCD) of extremely fine grain size is manufactured by sintering a diamond powder with pre-blended catalyst metal under high pressure / high temperature (HP / HT) processing. The PCD material has an average sintered diamond grain structure of less than 1.0 μm.

Owner:DIAMOND INNOVATIONS INC

Method for manufacturing a small particle diameter product of solid polymethylaluminoxane composition

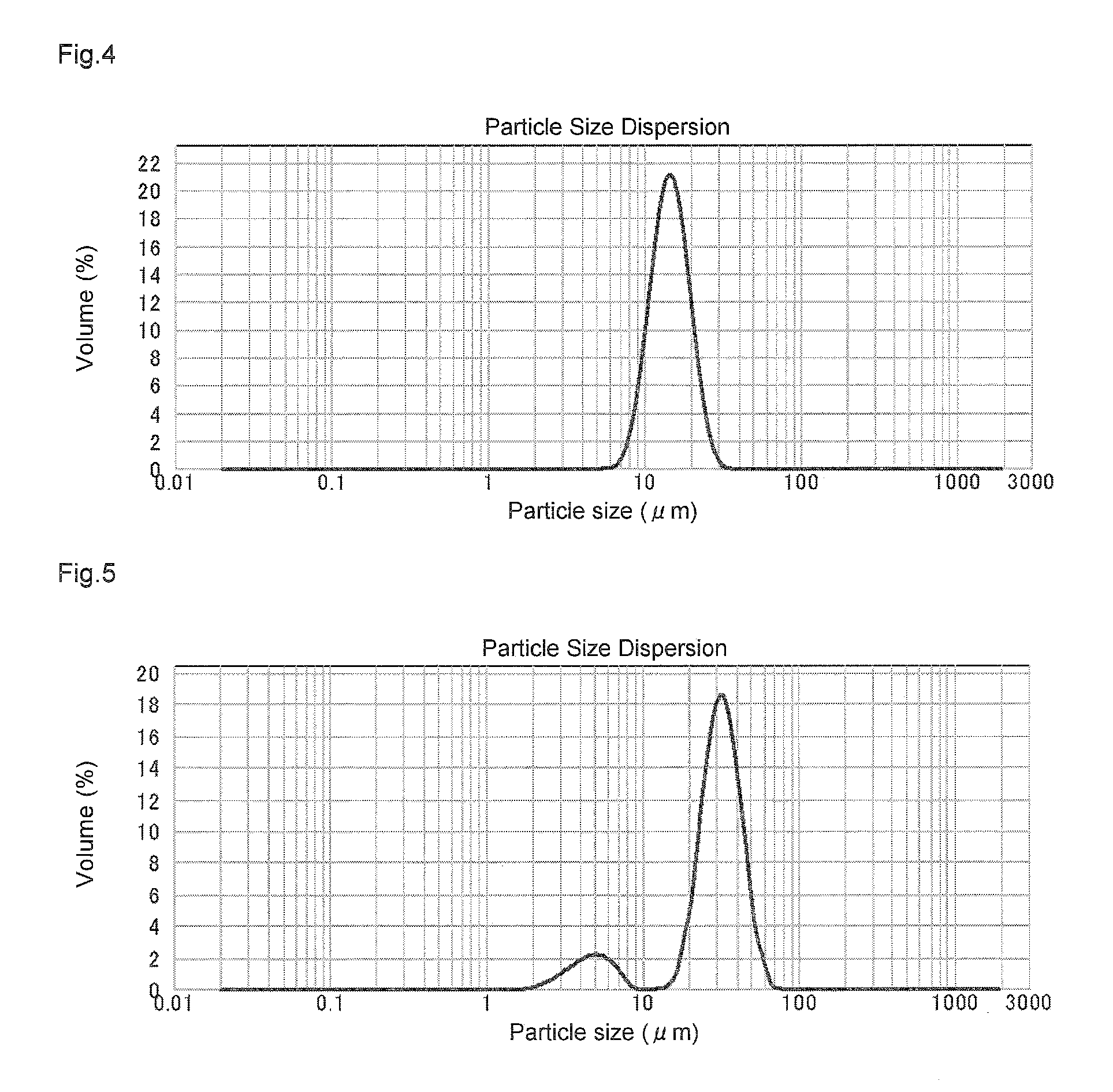

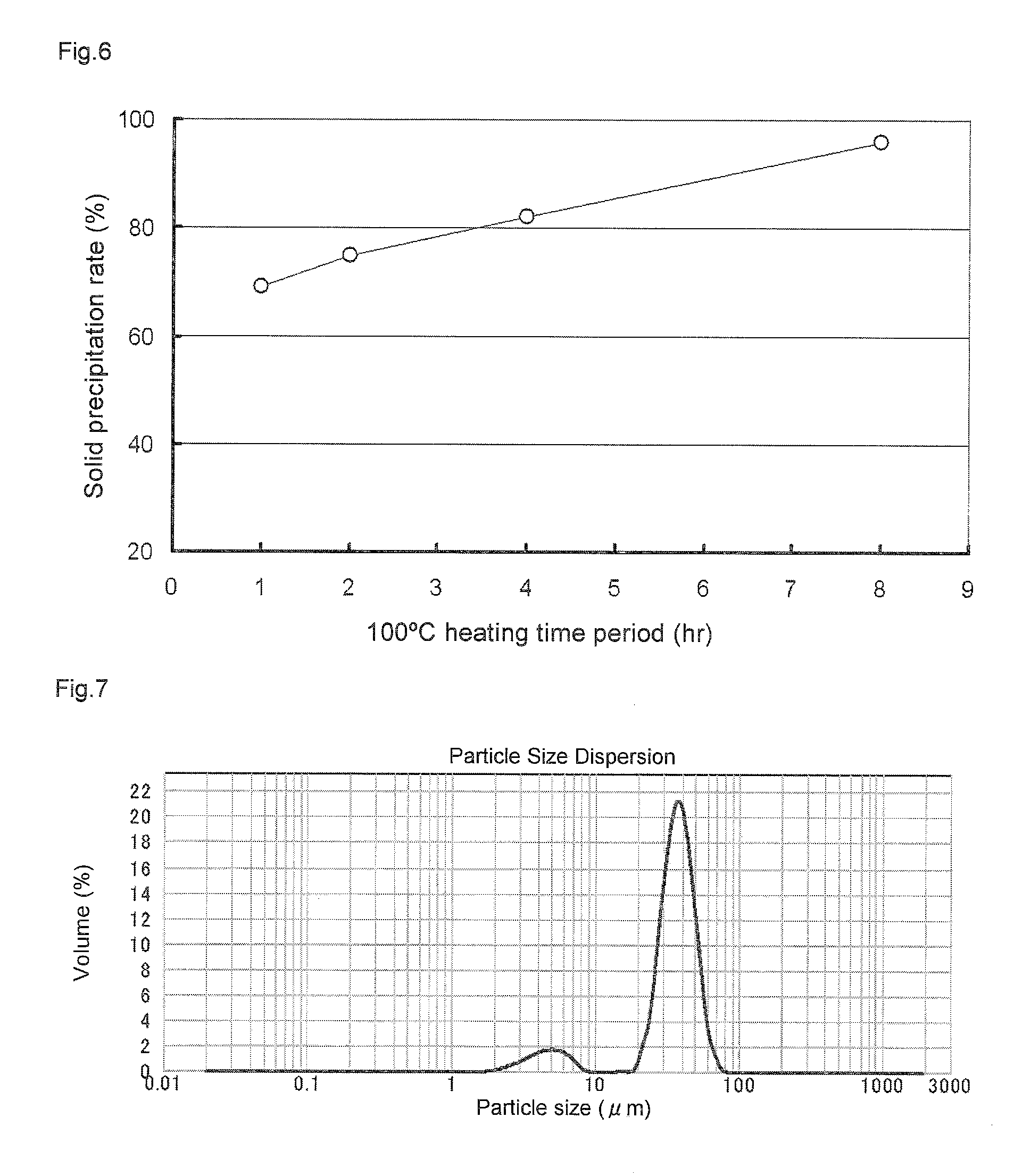

ActiveUS9340630B2Easy to optimizeHigh yieldGroup 3/13 element organic compoundsThin material handlingParticulatesDiameter product

A solid polymethylaluminoxane composition is provided having uniform particle diameter in the form of fine particles of less than 5 μm employed to polymerize olefins with high polymerization activity without silica. A method for manufacturing thereof, a polymerization catalyst, and a method for manufacturing a polyolefin are also provided. The solid polymethylaluminoxane composition: has an aluminum content within a range of 36 mass % to 43 mass %; has a mole fraction of methyl groups derived from trimethylaluminum moieties relative to the total number of mols of methyl groups of 12 mol % or less; and is particulate having a median diameter based on volume within a range of 0.1 μm to less than 5 μm. In a step of heating an aromatic hydrocarbon solution containing trimethylaluminum and the polymethylaluminoxane to cause solid polymethylaluminoxane composition to precipitate, prior to or during the heat treating step, a dry, inert gas is bubbled through.

Owner:TOSOH FINECHEM CORP

Synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio

InactiveCN1699173AUniform particle sizeHigh ratio of silicon to aluminumPentasil aluminosilicate zeoliteSynthesis methodsSurface-active agents

The invention relates to a synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio, which comprises using a surface active agent, charging it into acidified aluminium salt solution, then slowly dropping alkaline solution formed from sodium silicate, template agent and seed crystal into aluminium saline solution, the overall composition of the obtained reaction mixture being Na2O:Al2O3:SiO2:H2O=1.5-4.0:1:20-280:500-2000 by mol ratio, then subjecting the reaction mixture to thermal crystallization through the conventional method.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

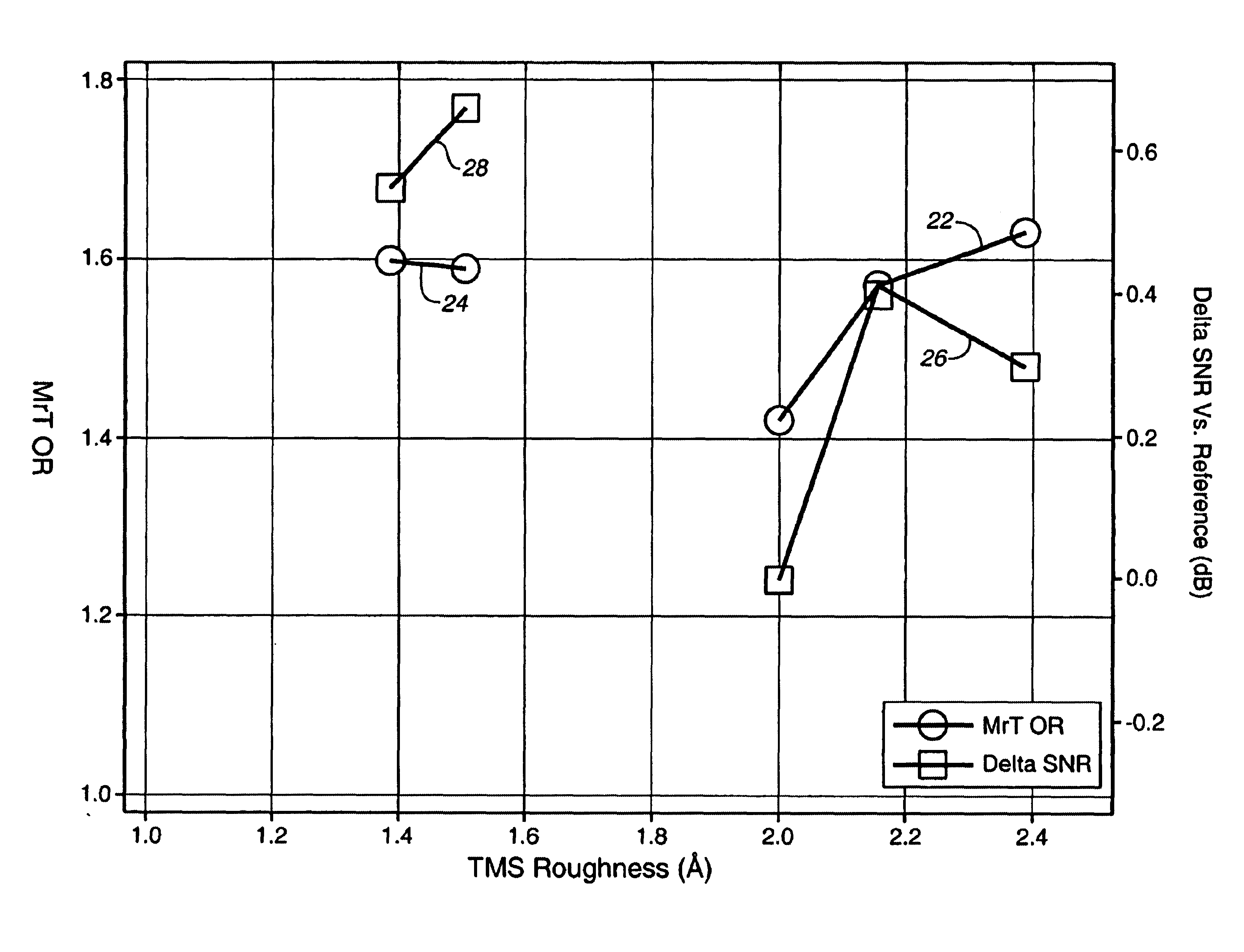

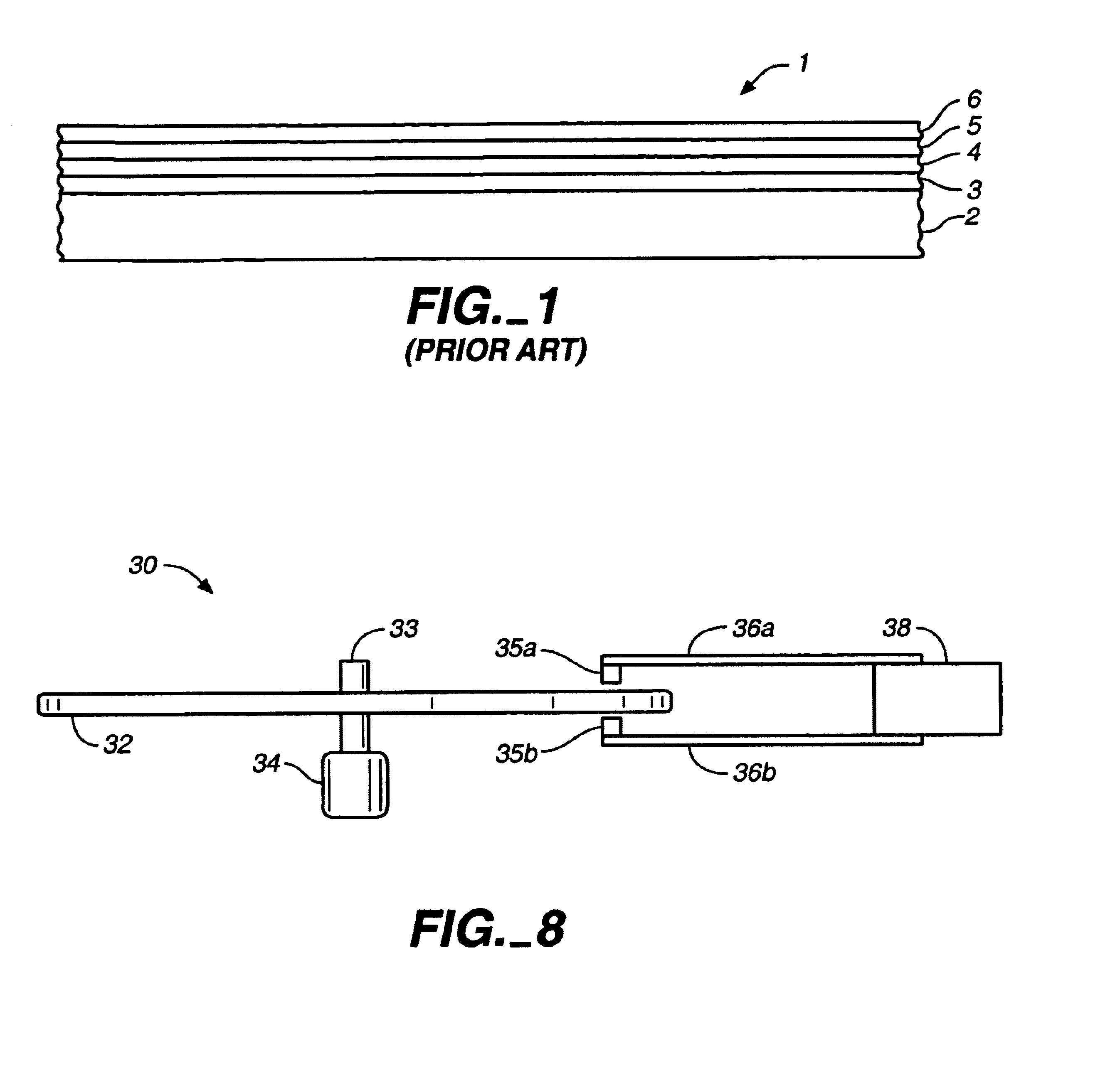

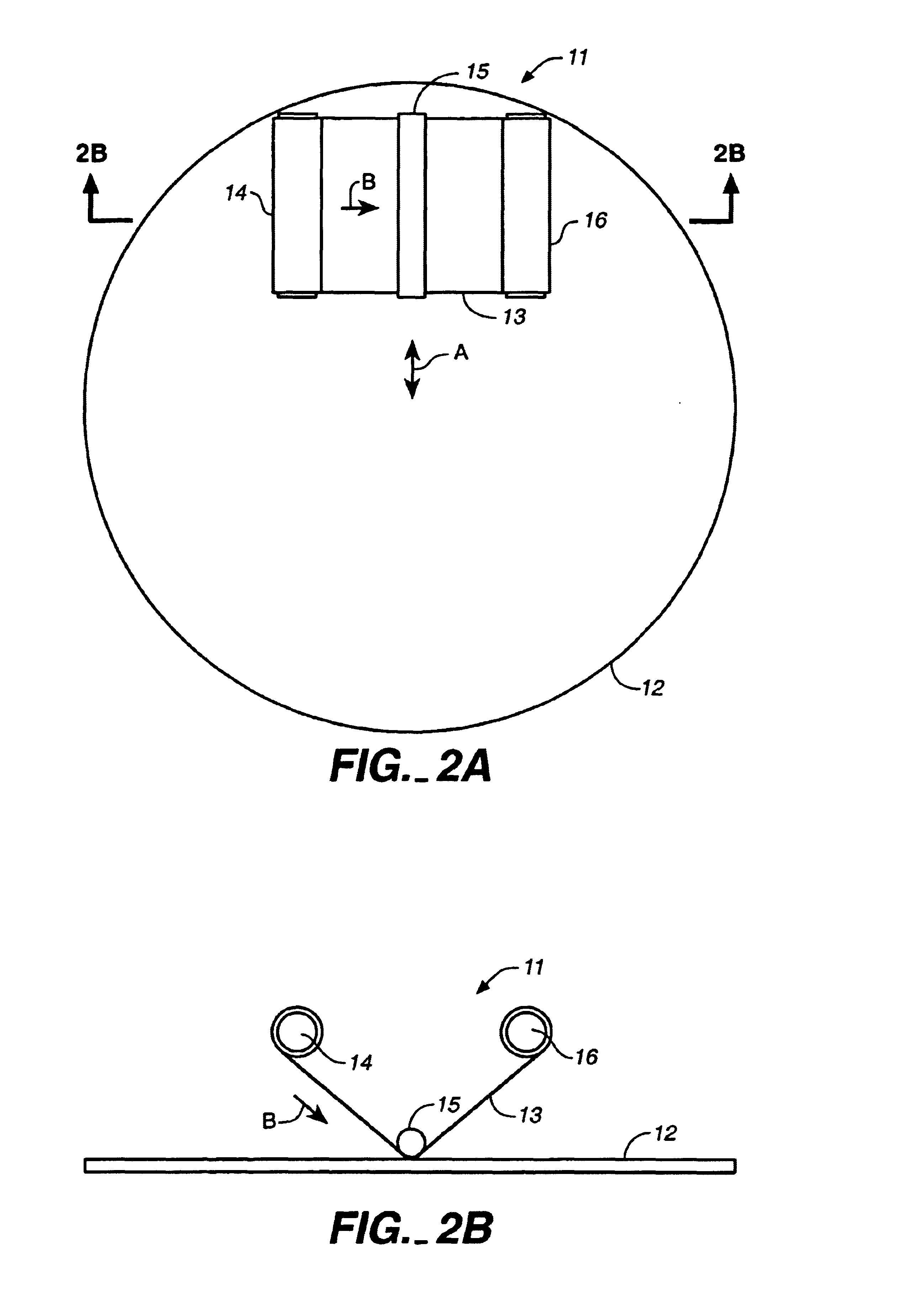

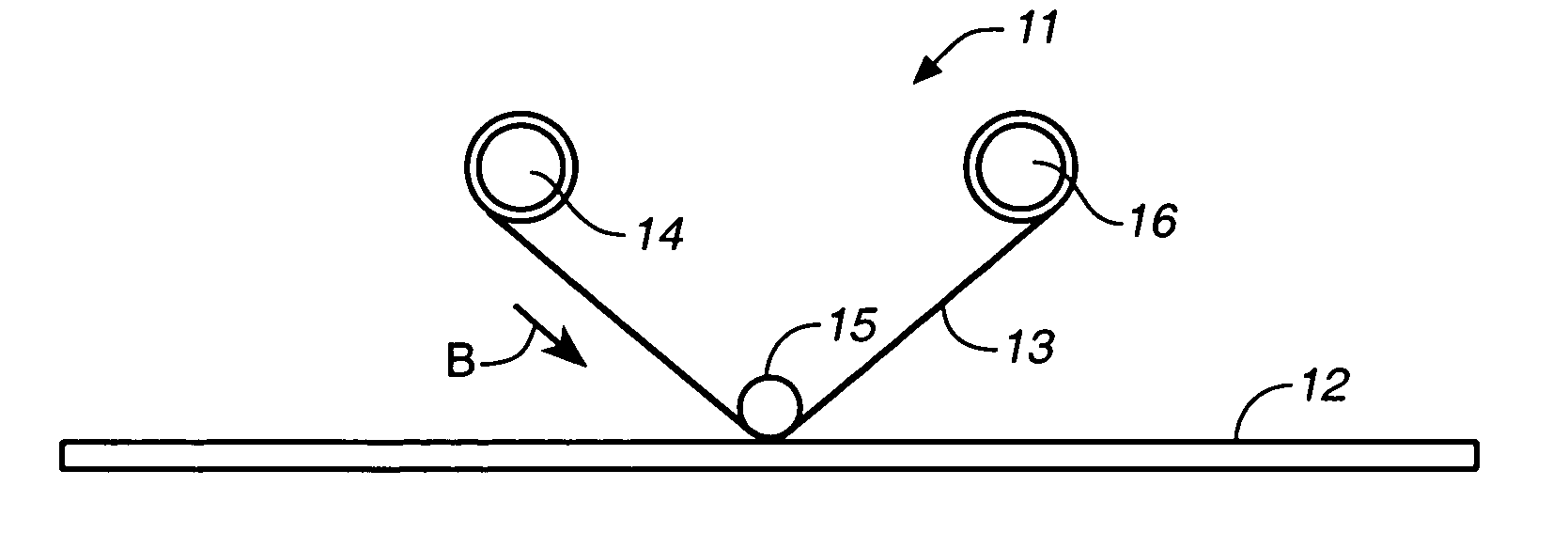

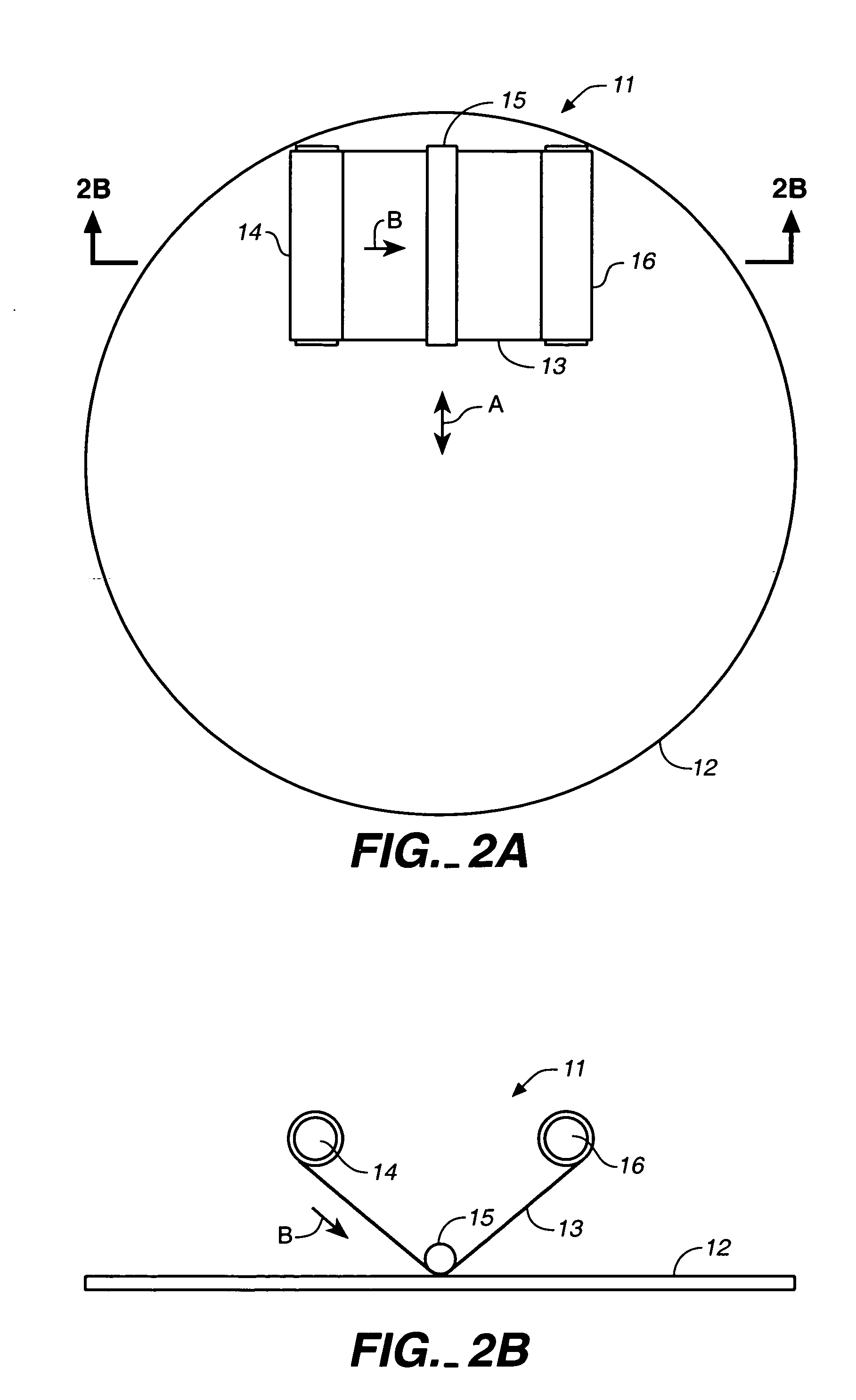

Texturing of magnetic disk substrates

InactiveUS6972135B2Uniform particle sizeLarge low-frequencyMagnetic materials for record carriersBase layers for recording layersNanometreMaterials science

A method for texturing a substrate for a magnetic disk comprises abrading the substrate using nano-sized diamond particles (e.g. having a diameter less than or equal to 20 nm). A magnetic layer is then deposited over the substrate. Even when the texture is extremely smooth (e.g. less than about 2.2 ÅRa), the disk still exhibits good Hc and MrT orientation ratios, SNR and PW50.

Owner:WD MEDIA

Texturing of magnetic disk substrates

InactiveUS20050142990A1Uniform particle sizeLarge low-frequencyBase layers for recording layersBelt grinding machinesNanometreMaterials science

A method for texturing a substrate for a magnetic disk comprises abrading the substrate using nano-sized diamond particles (e.g. having a diameter less than or equal to 20 nm). A magnetic layer is then deposited over the substrate. Even when the texture is extremely smooth (e.g. less than about 2.2 Å Ra), the disk still exhibits good Hc and MrT orientation ratios, SNR and PW50.

Owner:HOMOLA ANDREW

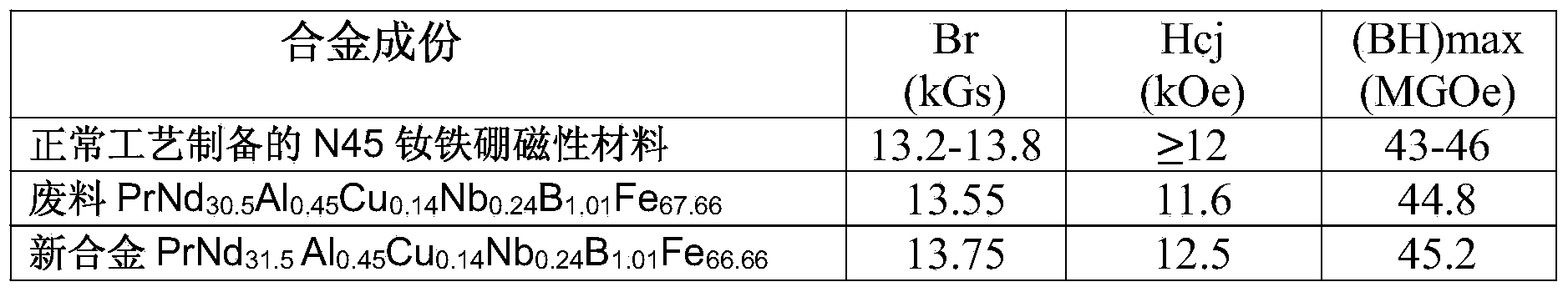

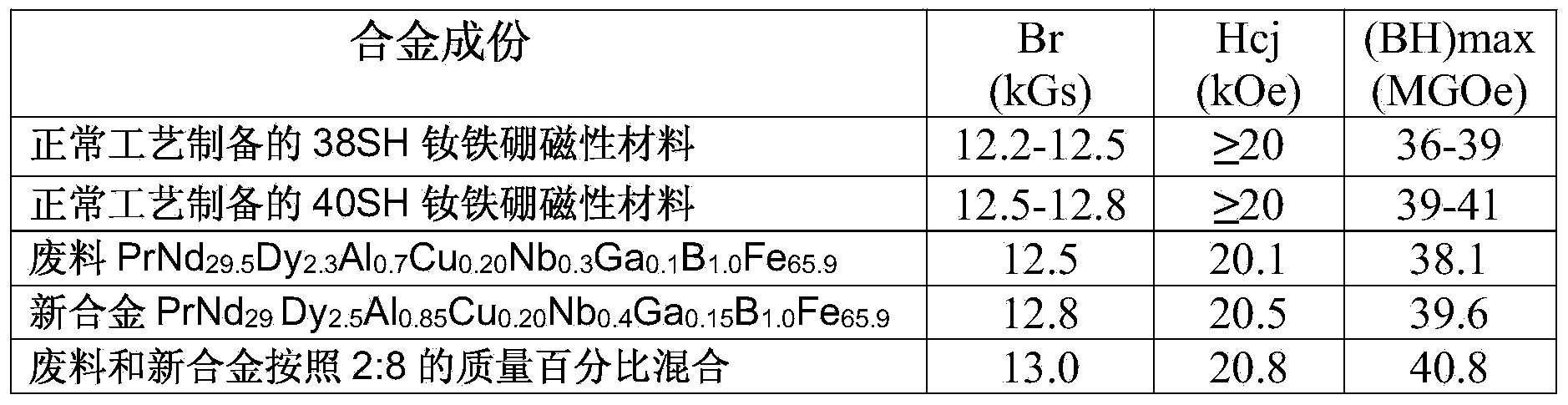

Method for preparing neodymium iron boron through regenerating waste material containing neodymium, iron and boron

ActiveCN103866127AFully absorb hydrogenImprove recycling ratesMagnetic materialsProcess efficiency improvementMetallurgyEconomic benefits

The invention provides a method for preparing neodymium iron boron through regenerating a waste material containing neodymium, iron and boron. The method comprises steps of (1) preprocessing the waste material; (2) correcting the components of the waste material; (3) crushing by hydrogen; (4) preparing into powder; (5) molding under a magnetic field; and (6) vacuum sintering. The method fully uses the waste material recycled in a production process, has high recovery rate of the waste material, can produce high performance product, has a simple and controllable flow, has high operability, uses no strong acid and strong base polluting the environment, is environment-friendly and energy-saving, and has high social and economic benefits.

Owner:CHINALCO JINYUAN RARE EARTH

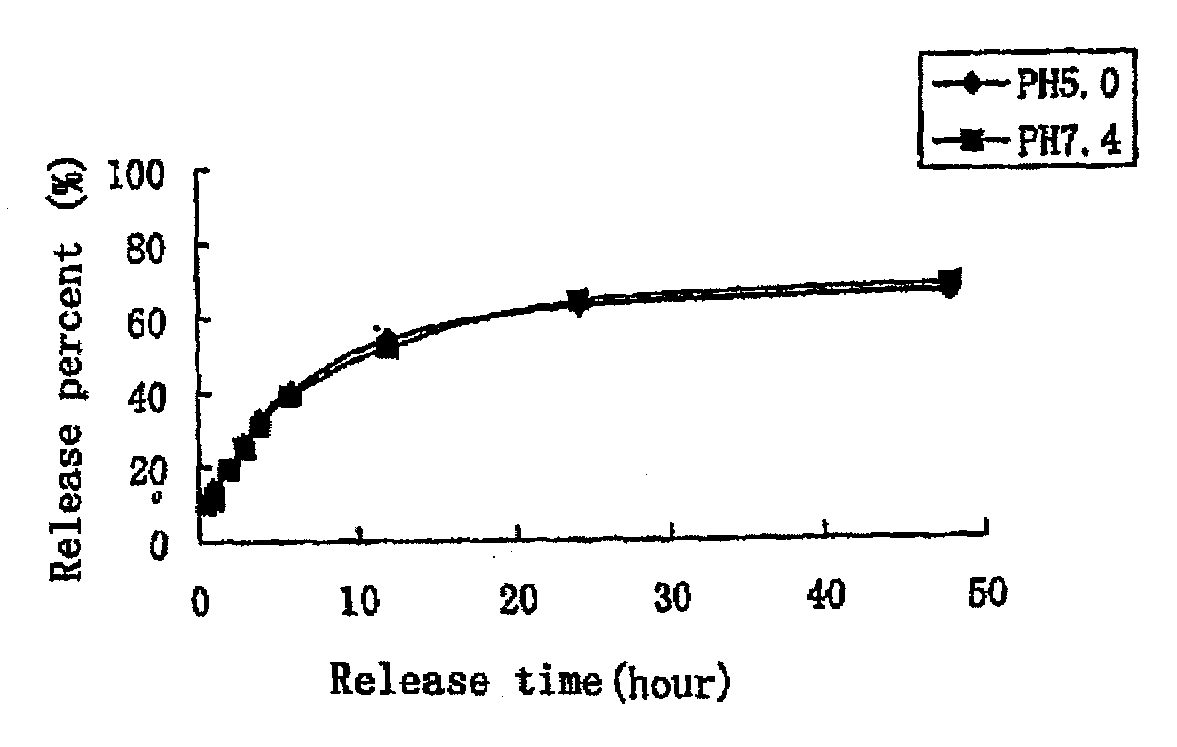

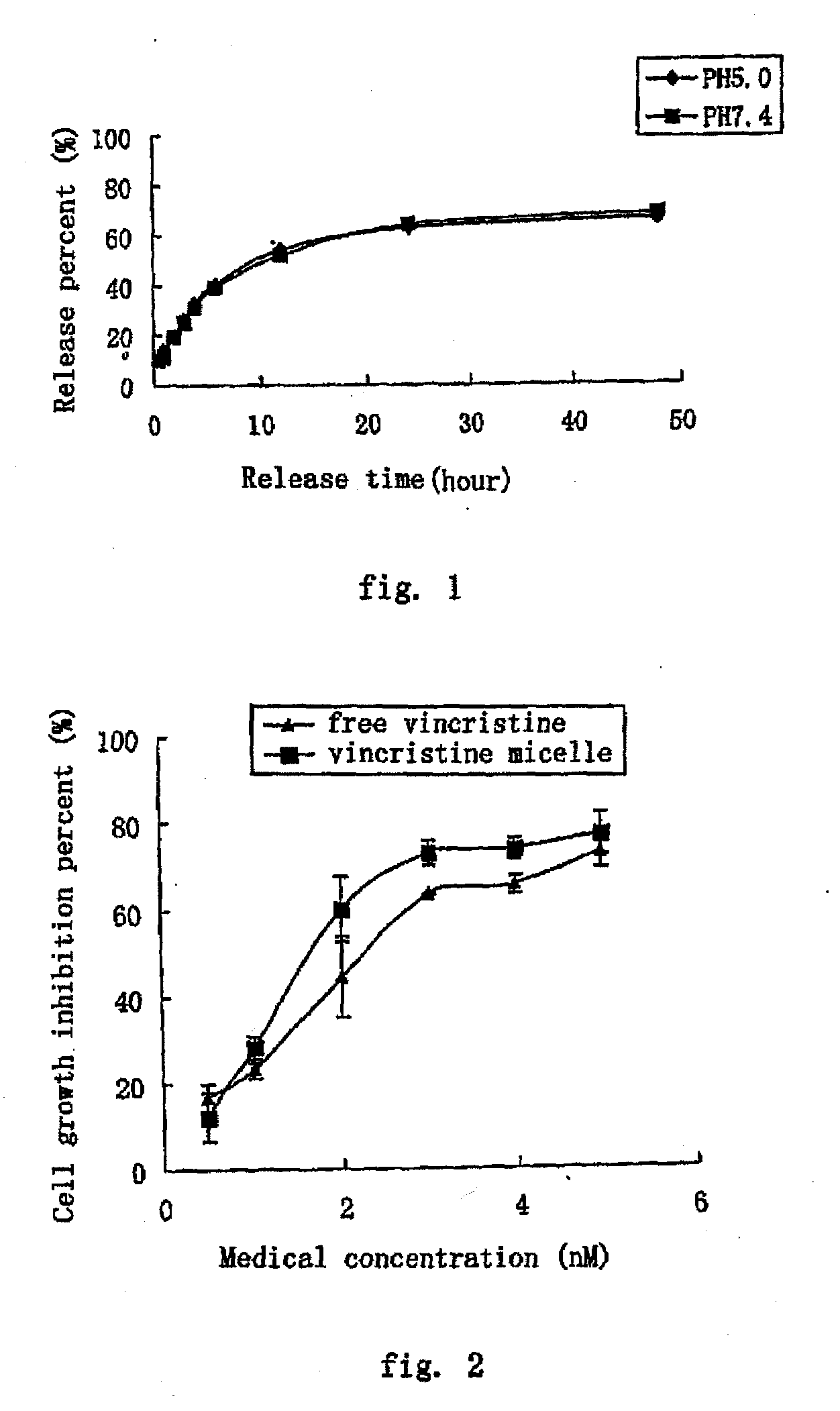

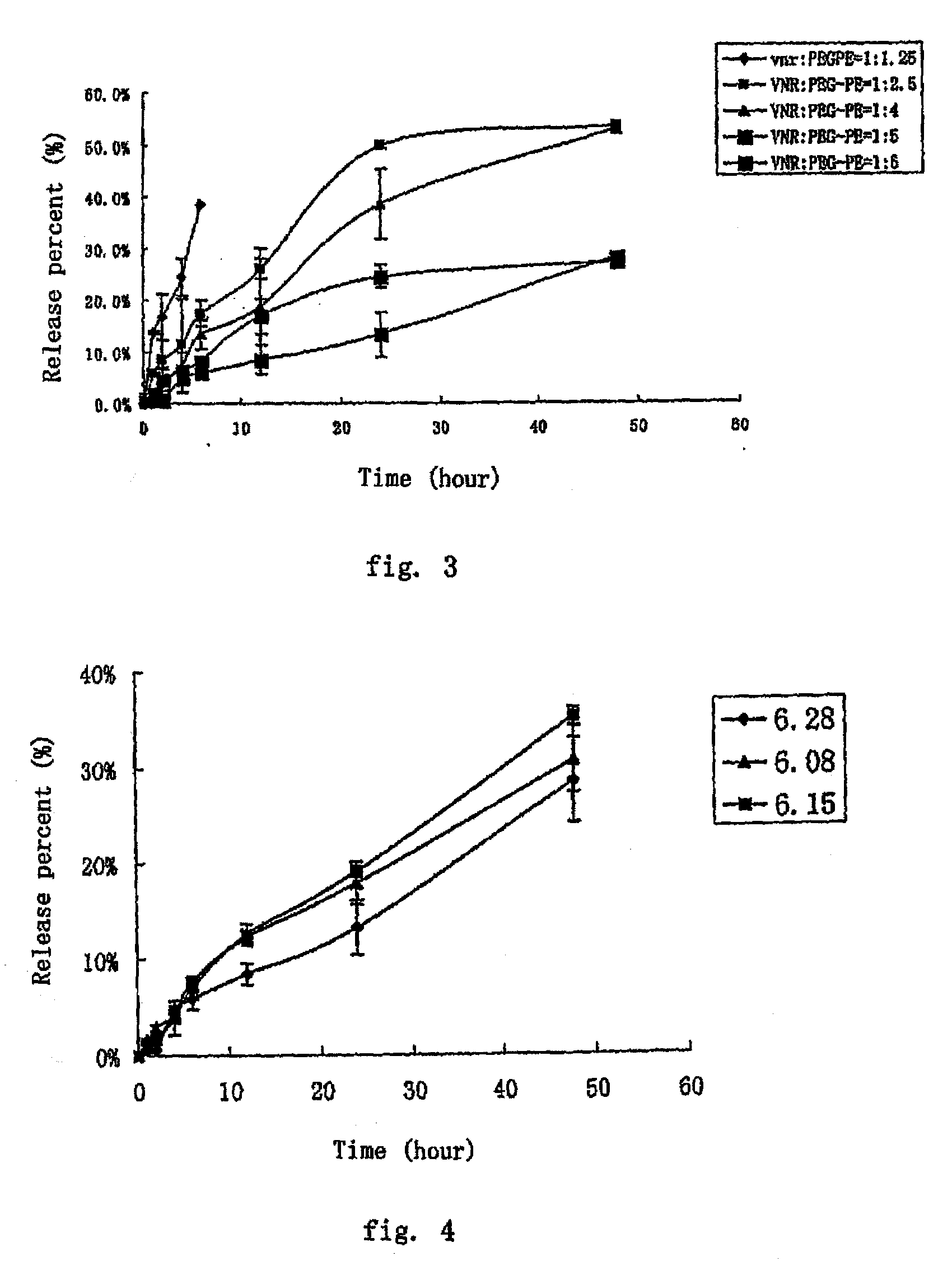

Nano Anticancer Micelles of Vinca Alkaloids Entrapped in Polyethylene Glycolylated Phospholipids

ActiveUS20090053293A1Good stabilityImprove drug distributionBiocidePharmaceutical non-active ingredientsVinorelbineAdjuvant

The present invention provides a nano-micellar preparation containing vinca alkaloids antitumor agent for intravenous injection, which cincludes a therapeutically effective amount of vinca alkaloids antitumor agent (vinblastine, vincristine, vindesine and vinorelbine), a phosphatide derivatized with polyethylene glycol, together with pharmaceutically acceptable adjuvants. The preparation is prepared by encapsulating the medicament with a nano-micelle to obtain the nano-micellar preparation containing vinca alkaloids antitumor agent for injection. The vinca alkaloids antitumor agent and the phosphatide derivatized with polyethylene glycol form a nano-micelle with a highly uniform particle size. In the micelle, the hydrophobic core of encapsulated medicament is surrounded by polyethylene glycol molecules to form a hydrophilic protective layer, so that the medicament is prevented from contacting with the enzymes and other protein molecules in blood and being recognized and phagocytozed by reticuloendothelial system in body, and the circulation time in vivo of the micelle is prolonged.

Owner:BEIJING DIACRID MEDICAL TECH

Method for forming electrode for flat panel display

InactiveUS20040043691A1Improve liquidityMaintain good propertiesTelevision system detailsMaterial nanotechnologyElectrical polarityDisplay device

The present invention provides a method for forming an electrode of a flat panel display device using ink for ink jet printing and an ink jet printer. The ink for ink jet printing is prepared by a method comprising the first step of contacting the vapor of a metal with the vapor of the first solvent, according to the vapor phase-evaporation technique, to thus give a dispersion of metal ultrafine particles; the second step of adding a low molecular weight polar solvent as the second solvent to the dispersion prepared in the first step to thus precipitate the metal ultrafine particles and removing the first solvent; and the third step of adding the third solvent to the precipitates thus prepared to carry out the solvent substitution and to give a dispersion of independently dispersed metal ultrafine particles, and prepared by adding a dispersant in or during the foregoing first and / or third steps, and the ink for ink jet printing consists of a dispersion excellent in ink characteristic properties. In the dispersion, metal ultrafine particles having a particle size of not more than 100 nm are independently and uniformly dispersed. The electrodes of FPD devices are formed using this ink for ink jet printing.

Owner:ULVAC INC

Polyacrylamide reversed-phase microemulsion and preparation method thereof

The invention relates to polyacrylamide reversed-phase microemulsion and a preparation method thereof. The polyacrylamide reversed-phase microemulsion is mainly used for solving the problem that product solid content is low and emulsion is unstable in the prior art. A semicontinuous polymerization method is adopted to add an aqueous phase containing monomers such as acrylamide into an oil phase containing an emulsifier, so that polymerization process control of the microemulsion is relatively stable, the microemulsion stability is good, and the content of solids capable of being separated out is high. By adopting a technical scheme that the polyacrylamide reversed-phase microemulsion comprises the following components in parts by weight: 20-70 parts of an oil-soluble solvent, 5-20 parts of an emulsifier and a co-emulsifier and 20-70 parts of an aqueous phase containing acrylamide polymer, the problem is solved well; the prepared polyacrylamide reversed-phase microemulsion is directly used or compounded with other oil-field chemicals so as to use for field application such as deep profile control, water shutoff and displacement of reservoir oil, which can be used for increasing recovery efficiency, for oil-field tertiary oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Material for rapid three dimensional printing forming and preparation method thereof

The invention discloses a material for rapid three dimensional printing forming and a preparation method thereof. The material comprises a modifying powder material A and bonding agent B, wherein preparation method of the modifying powder material A comprises the following steps: adding powder material and a first solvent into a ball mill or grinding mill, and milling to obtain a pretreated powder material; adding surfactant, lubricant and organic resin into a second solvent in sequence, and stirring and dispersing for 2-3 hours to obtain modifying solution; mixing the pretreated powder material and the modifying solution, adding into the grinding mill, mixing and milling at normal temperature, drying, grinding, and pulverizing to obtain the modifying powder material A. When in use, one weight part of the modifying powder material A and 0.01-0.07 weight parts of the bonding agent B are blended. The material provided by the invention is used as the raw material for a rapid three dimensional printing forming machine, and can be used for effective rapid forming on different types of three dimensional printing machines.

Owner:广州魁科机电科技有限公司

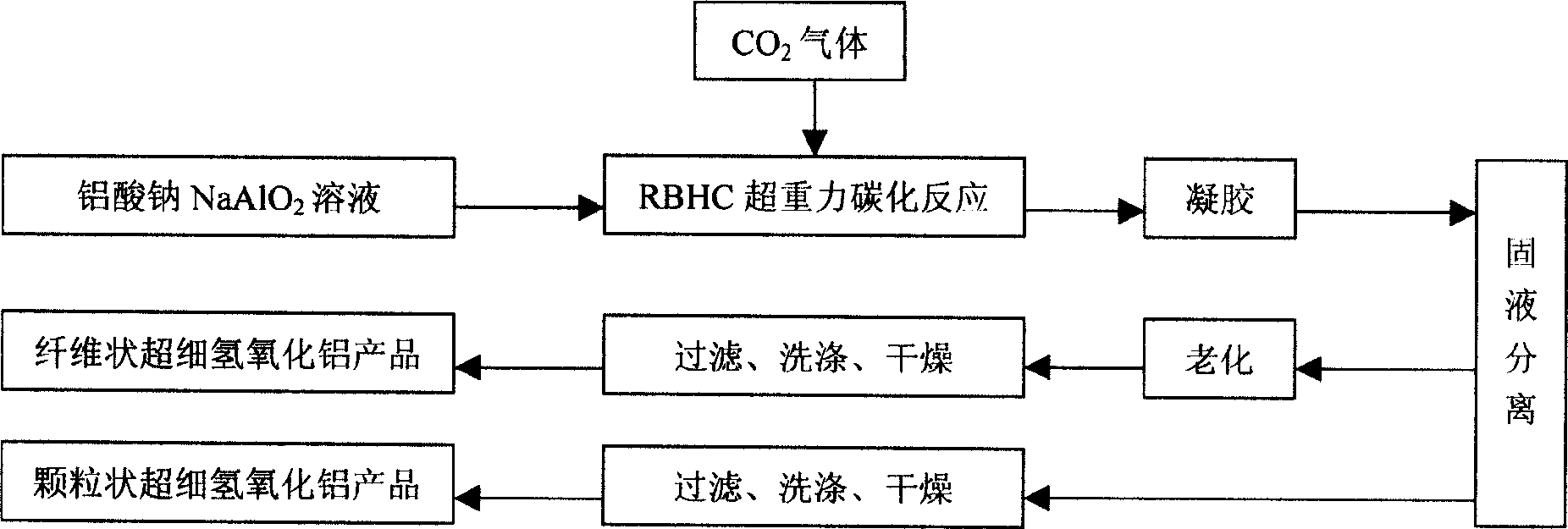

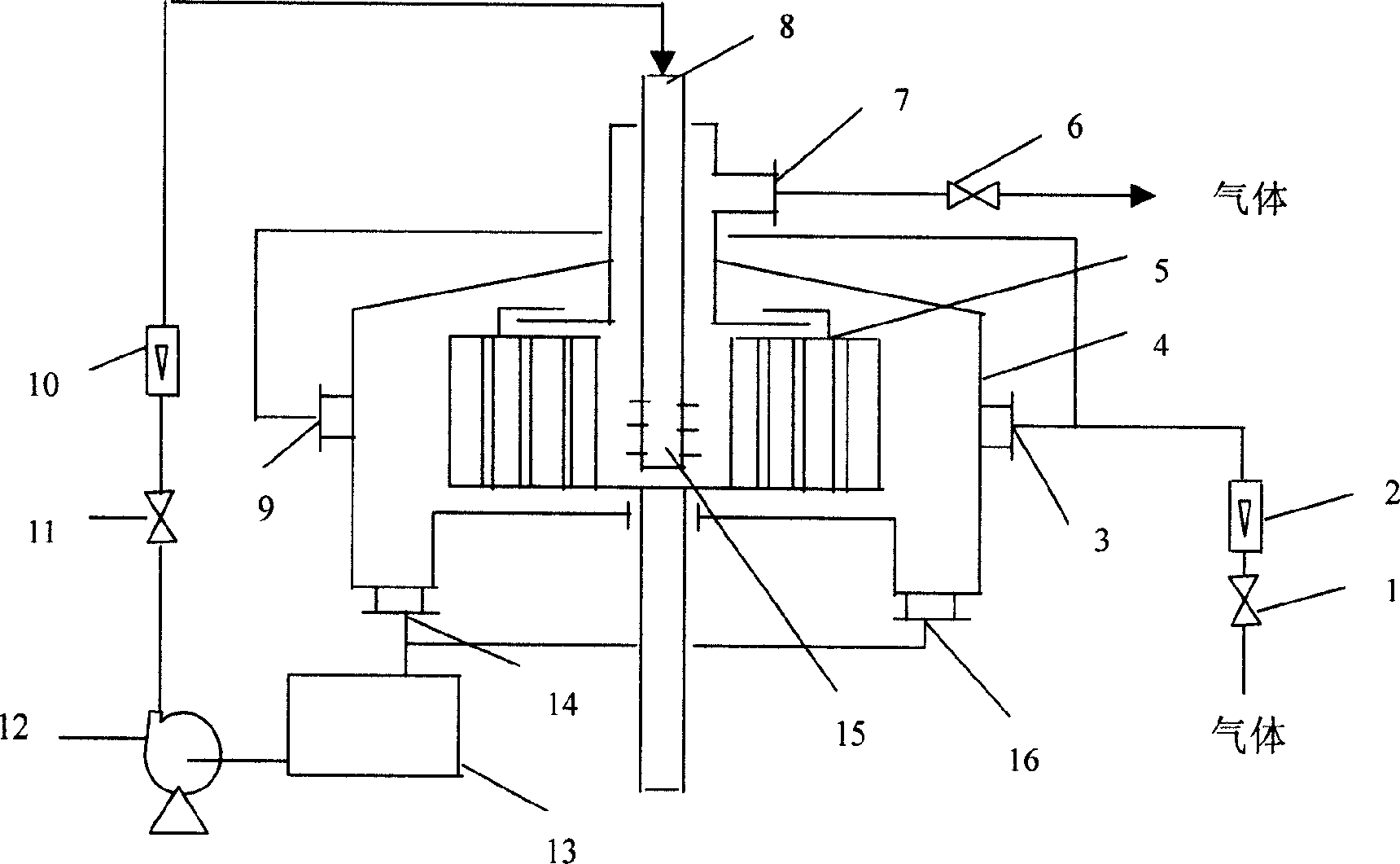

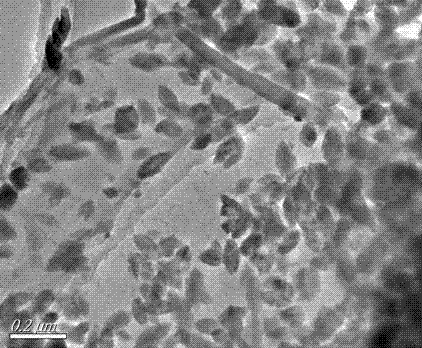

Preparation method of ultrafine aluminium hydroxide

InactiveCN1752006ASolve defects that are prone to clogging equipmentLow miscellaneous crystal contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationNanoparticleAluminium hydroxide

A process for preparing superfine aluminium hydroxide includes such steps as carbonifying reaction between NaAlO2 solution and the gas containing CO2 in gravitation condition to obtain aluminium hydroxide gel, preparing superfine aluminium hydroxide, filtering, washing, and drying. The product (nanofibers or nanoparticles of aluminium hydroxide) can be used as inorganic flame-retarding agent or for preparing catalyst.

Owner:XIANGTAN UNIV

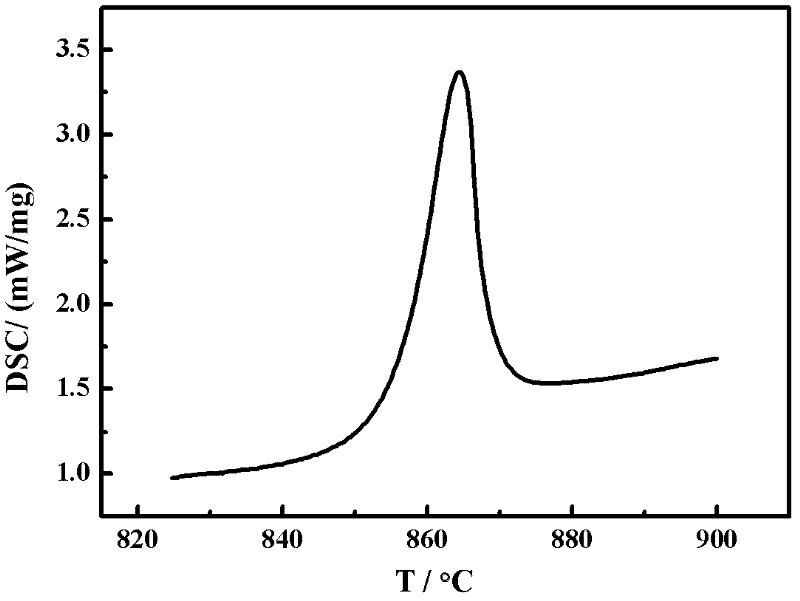

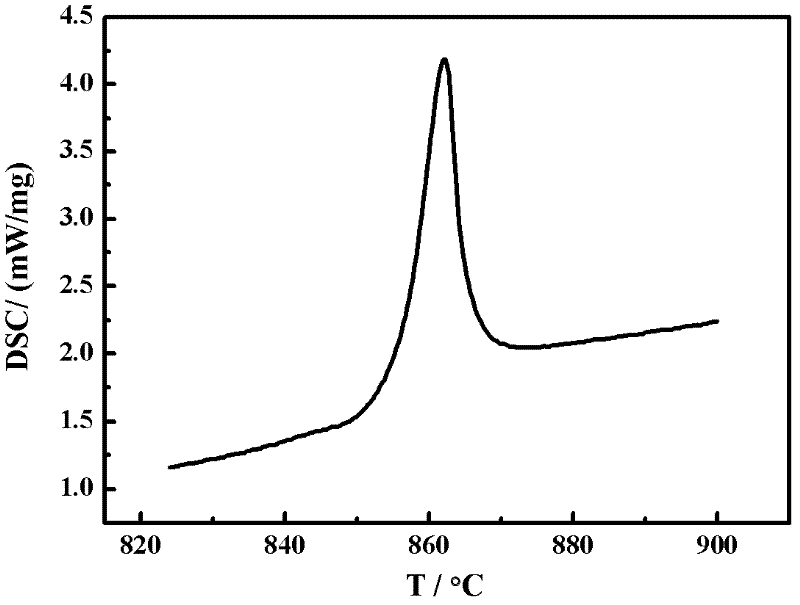

High-temperature composite phase change heat storage material and preparation method thereof

ActiveCN102585775ANo preprocessing requiredSimple manufacturing methodHeat-exchange elementsElectricityHeat conducting

The invention relates to a preparation method of a high-temperature composite phase change heat storage material, and relates to a high-temperature composite phase change heat storage material and a preparation method thereof. The method can be used for preparing high-temperature composite phase change heat storage material with high heat conductivity, so that the heat conductivity of the heat storage material is greatly improved, and the heat storage / release rate is greatly improved; and the preparation method is easy to control and simple to operate. The heat storage material can be directly obtained by sintering, without need of any bonding agent or other protectants, so that the heat-conducting property of the heat storage material is greatly improved, and the utilization ratio of the heat storage material is improved; the preparation method is simple to operate; and the prepared product can also be used for other intermediate-temperature low-temperature composite heat storage materials, as well as light heat utilization, heat-cold-electricity combined use, composite material synthesis and other many fields.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

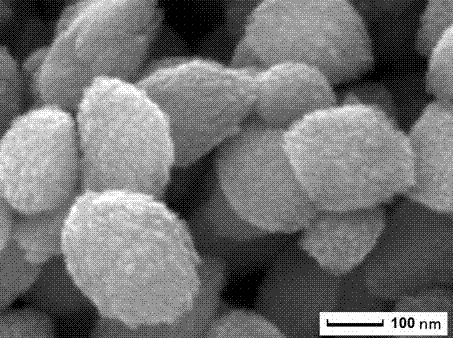

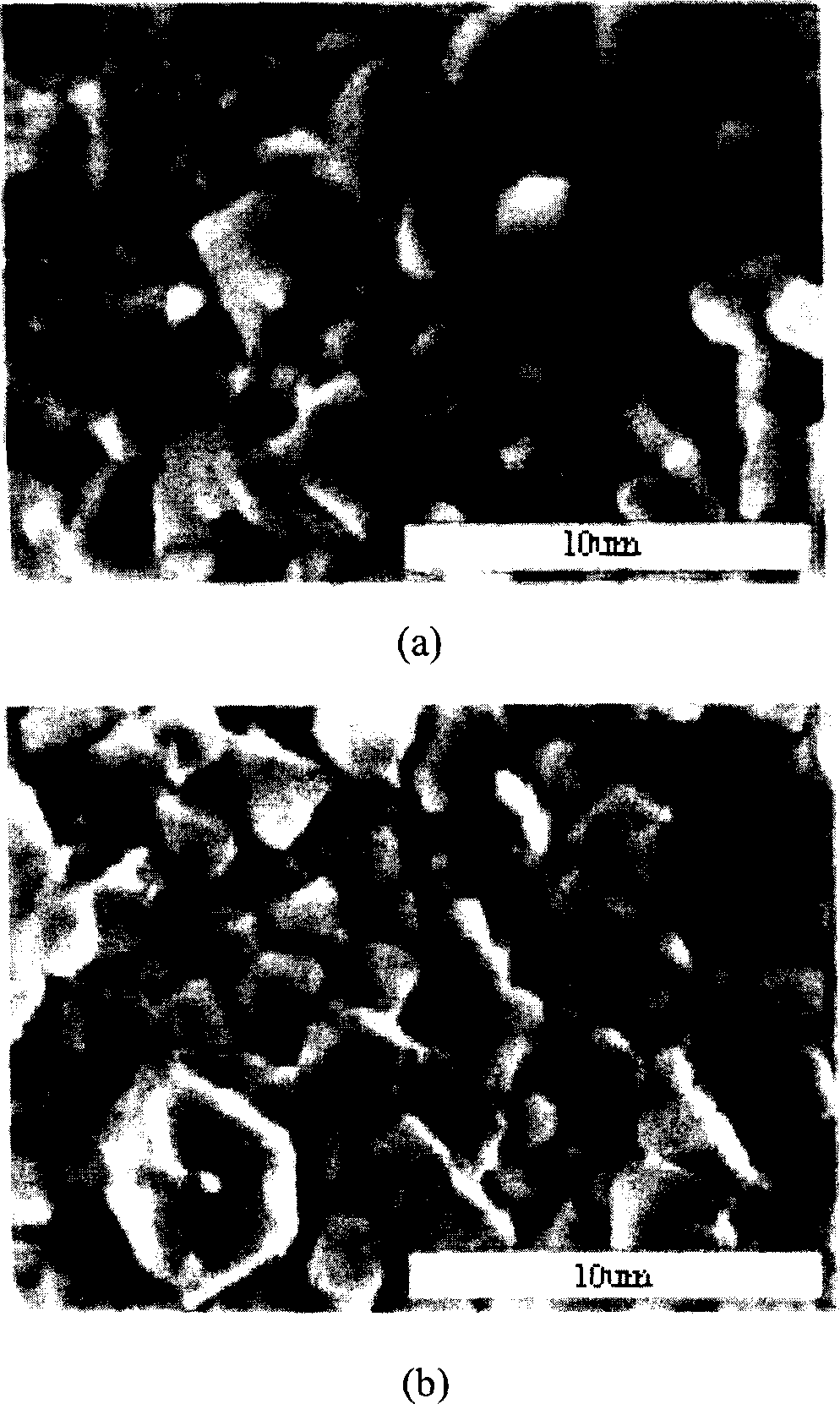

Preparation method of one-step hydrothermal synthesis of carbon/molybdenum disulfide composite microsphere

InactiveCN1994896AUniform particle sizeSimple methodVanadium oxidesMolybdenum sulfidesSucroseMicrosphere

The invention discloses a making method of carbon / molybdenum disulfide composite microball through water heat method, which comprises the following steps: dissolving molybdate in the deionized water to form 0.02-0.1m solution; adding thioacetamide or sulfourea as sulfur source with molar rate of thioacetamide or sulfourea and molybdate at 31-51; stirring evenly; adding glucose or sucrose as carbon source with the molar rate of glucose or sucrose and molybdate at 51-251; stirring completely; transmitting solution into water heat reacting autoclave to react under 200-240 deg. c for 20-24h; cooling naturally; separating; washing; drying to obtain the product.

Owner:ZHEJIANG UNIV

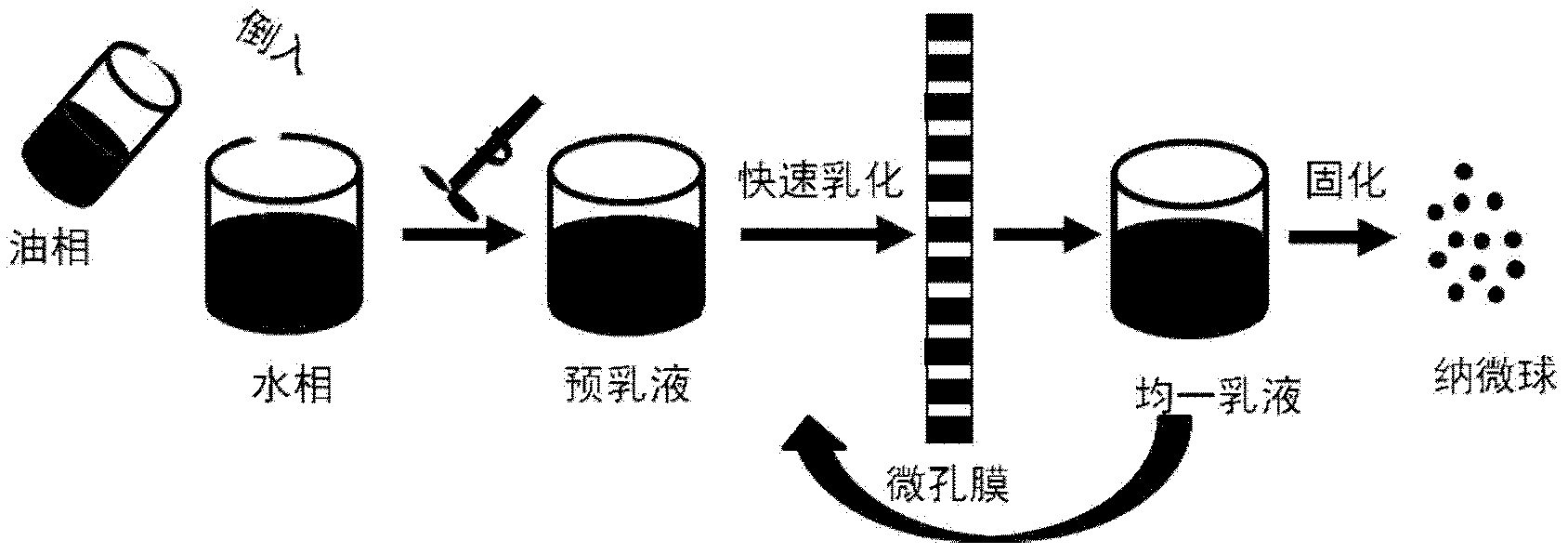

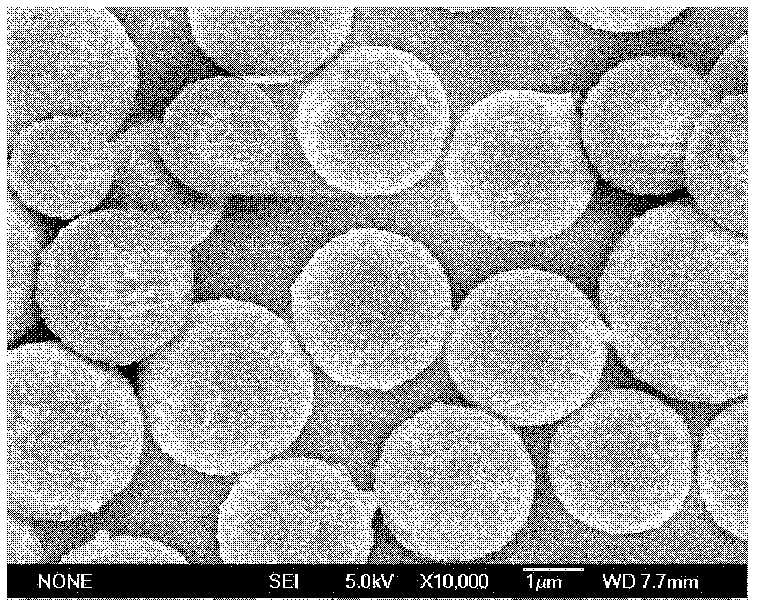

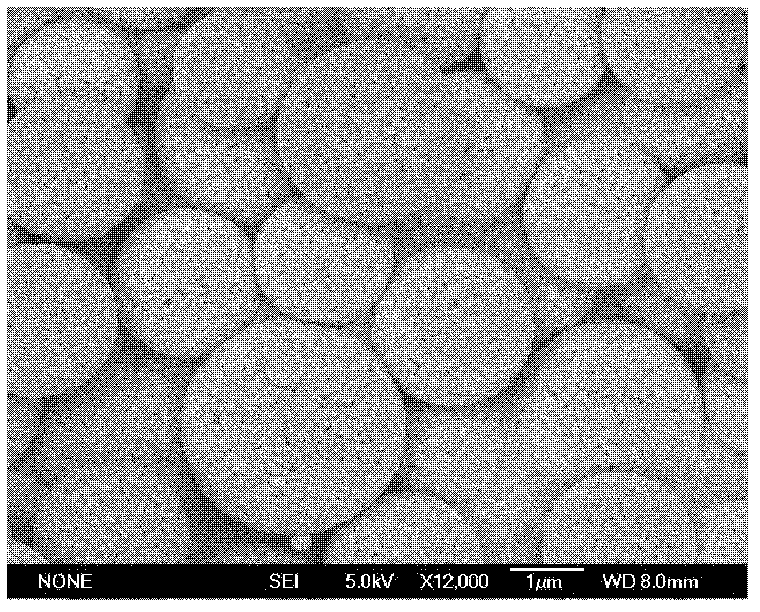

Polymer nanomicrosphere product with uniform and controllable size and preparation method thereof

The invention relates to a polymer nanomicrosphere product with uniform and controllable size and a preparation method thereof. The preparation method comprises the following steps: preparing polymerizable olefine monomers, an initiator, assistants and the like into an oil phase, and preparing water, a stabilizer, an emulsifier and the like into a water phase; and mixing the oil phase and water phase into an O / W pre-emulsion, quickly passing the pre-emulsion through a uniform-pore-size microporous membrane under pressure to form a uniform-particle-size O / W emulsion, and polymerizing and curing emulsion droplets in the emulsion into the uniform-particle-size polymer nanomicrospheres. The average particle size of the microspheres can be controlled within the range of tens of nanometers to 50 micrometers, and the particle size distribution coefficient C.V. is smaller than 20%. The method has the advantages of simple steps, favorable batch repetitiveness, uniform and controllable particle size, no need of subsequent screening and the like, is easy to control, can easily implement large-scale production, and therefore, has the characteristics of fewer emissions and low preparation cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

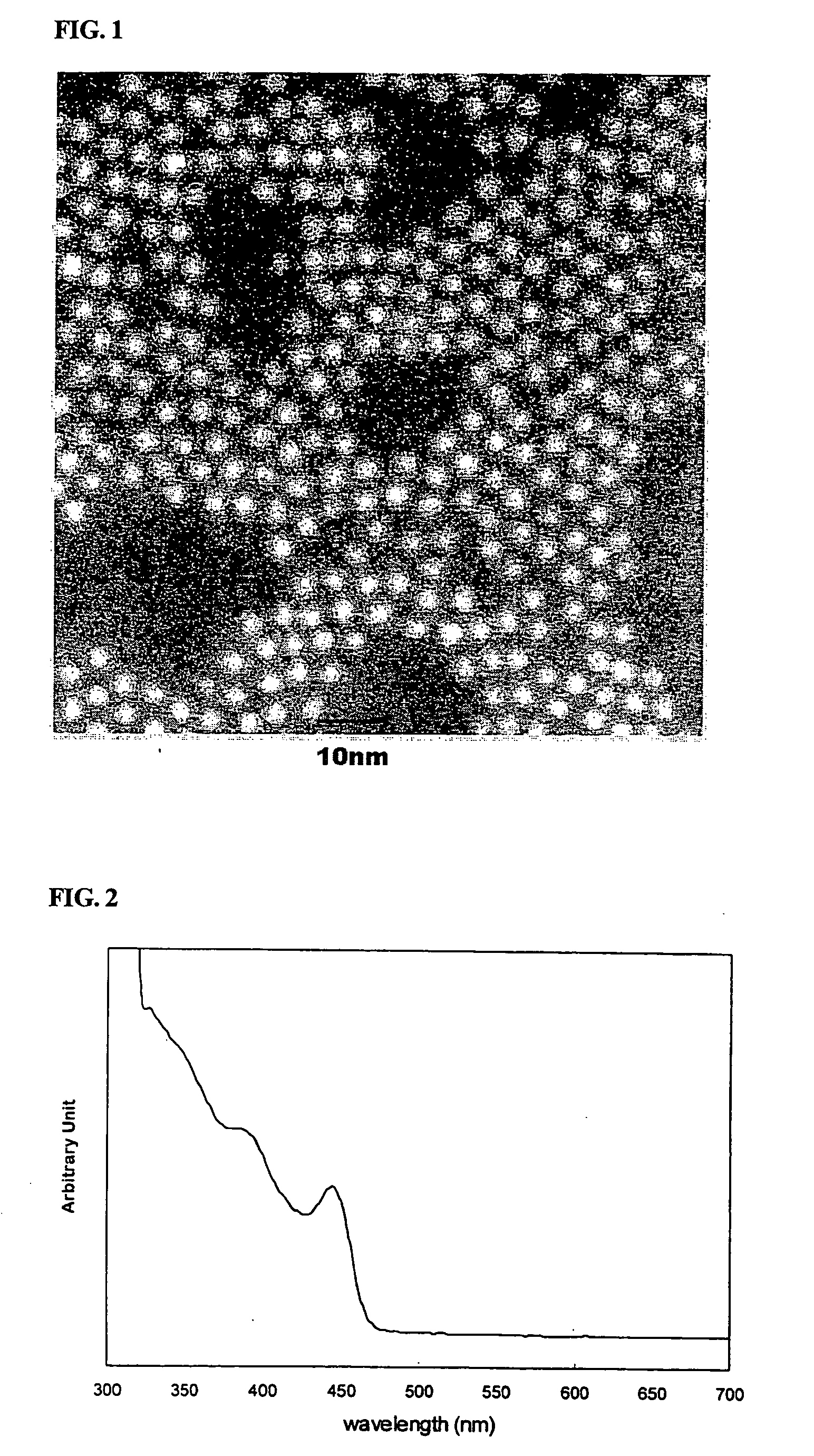

Method for manufacturing metal sulfide nanocrystals using thiol compound as sulfur precursor

ActiveUS20060039850A1Uniform size of particleUniform particle sizeTantalum compoundsCell electrodesSolventCompound (substance)

Disclosed herein is a method for manufacturing metal sulfide nanocrystals using a thiol compound as a sulfur precursor. The method comprises reacting the thiol compound and a metal precursor in a solvent to grow metal sulfide crystals to the nanometer-scale level. Further disclosed is a method for manufacturing metal sulfide nanocrystals with a core-shell structure by reacting a metal precursor and a thiol compound in a solvent to grow a metal sulfide layer on the surface of a core. The metal sulfide nanocrystals prepared by these methods can have a uniform particle size at the nanometer-scale level, selective and desired crystal structures, and various shapes.

Owner:SAMSUNG ELECTRONICS CO LTD

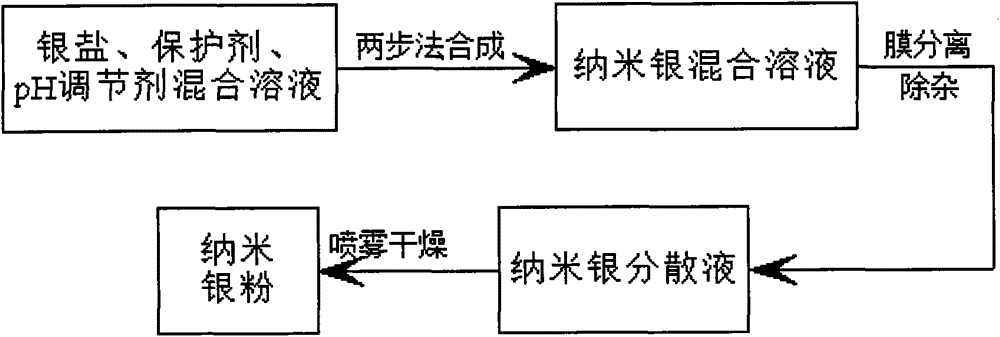

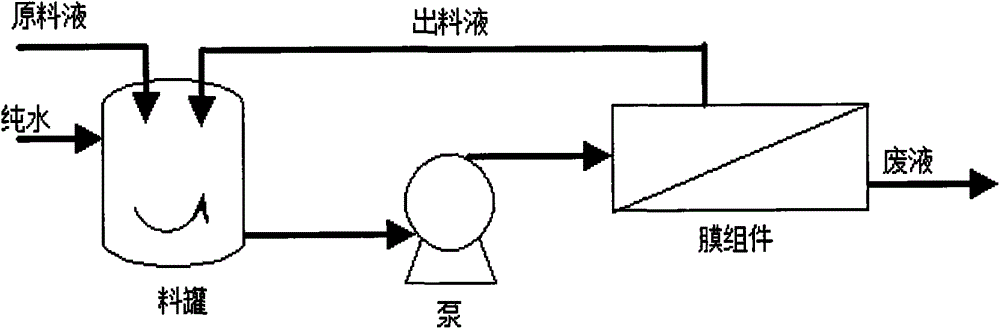

Method for preparing nanosilver powder in batches

ActiveCN104923801ASimple methodGuaranteed batch stabilityNanotechnologyBatch productionHigh concentration

The invention provides a method for preparing nanosilver powder in batches, belonging to the field of nano-material preparation. Nanosilver particles are synthetized in two steps, at first, a low-concentration reducing agent solution is slowly added into a solution mixed with silver salt, a protective agent, and a pH conditioning agent drop by drop, and then a high-concentration reducing agent solution is rapidly added drop by drop to obtain a nanosilver mixed solution; impurities in the nanosilver mixed solution are removed through a membrane separation device to obtain a nanosilver dispersion liquid; and at the end, absolute ethyl alcohol and a high-molecular dispersant are added into the nanosilver dispersion liquid, and spray drying is carried out by a spray drying device to obtain nanosilver powder in a certain particle size. The particle size of the prepared nanosilver powder is controllable, the batches are stable, the problems of non-uniform particle size during the synthesis of nanosilver, nanosilver separation, and agglomeration and acaking during powder preparation are solved, the preparation process and the operation are simple, and industrial and batches production is realized.

Owner:NANO TOP ELECTRONICS TECH

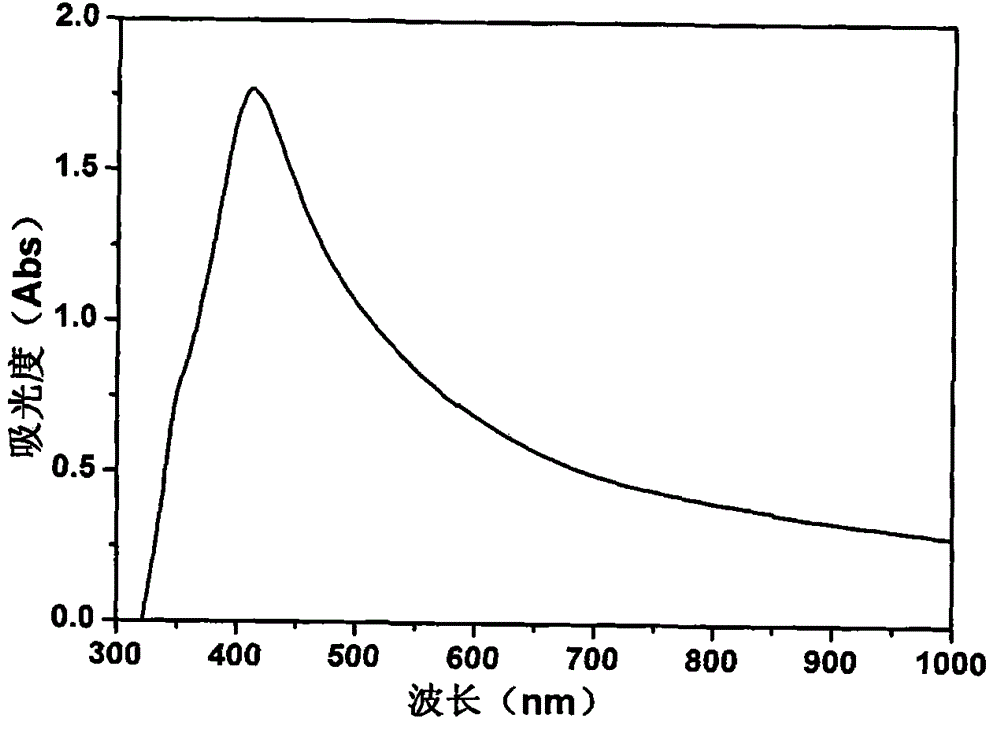

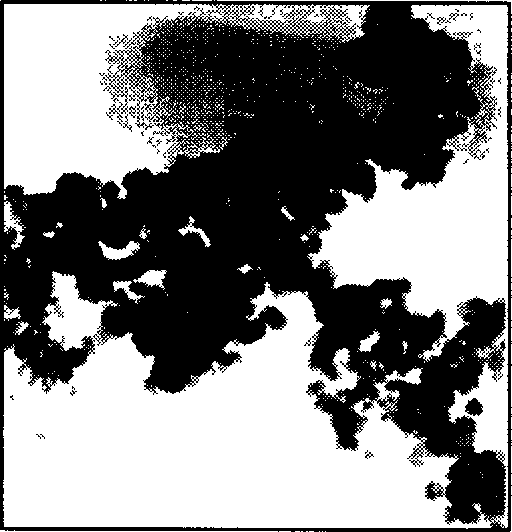

Graphene/mesoporous titanium dioxide visible light catalyst and preparation method

InactiveCN102350334AUniform particle sizeUniform sizePhysical/chemical process catalystsWater/sewage treatment by irradiationDispersityAcetic acid

The invention relates to a graphene / mesoporous titanium dioxide visible light catalyst and a preparation method, and belongs to the technical fields of nanometer composite materials and photocatalysis. The method comprises the following steps of: adding a graphene oxide into glacial acetic acid, and performing ultrasonic dispersion to obtain dispersion liquid of the graphene oxide; and adding a titanium source into the dispersion liquid of the graphene oxide, and preparing the graphene / mesoporous titanium dioxide nanometer composite visible light catalyst in a one-step in-situ form by a hydrothermal method. The graphene / mesoporous titanium dioxide visible light catalyst has the advantages of readily available raw materials and low cost, the preparation process is simple and convenient, and titanium dioxide in the obtained nanometer composite material has a nanometer poroid structure, a regular size and a special appearance; and titanium dioxide nanometer granules can be distributed onthe surface of graphene and are high in dispersity. Photocatalytic degradation experiments indicate that the graphene / mesoporous titanium dioxide nanometer composite light catalyst has a good photocatalytic degradation effect on rhodamine B under the irradiation of visible light, and is an ideal nanometer composite visible light catalyst.

Owner:JIANGSU UNIV

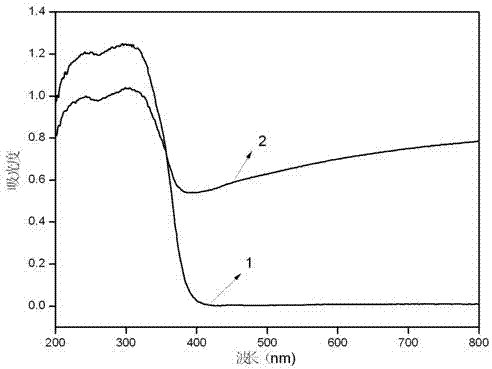

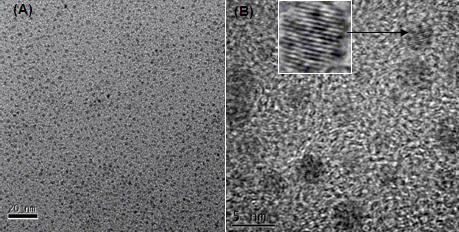

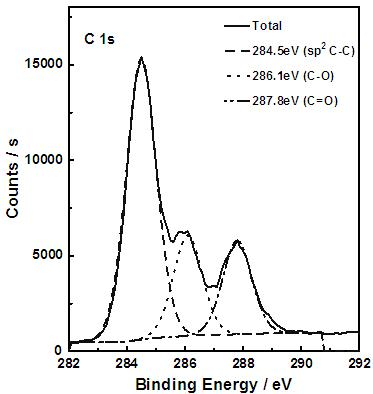

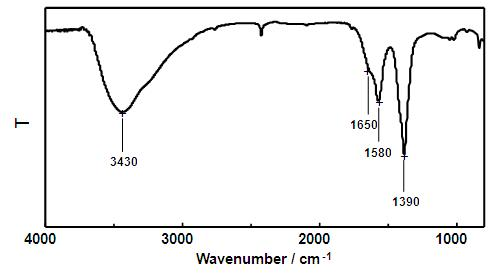

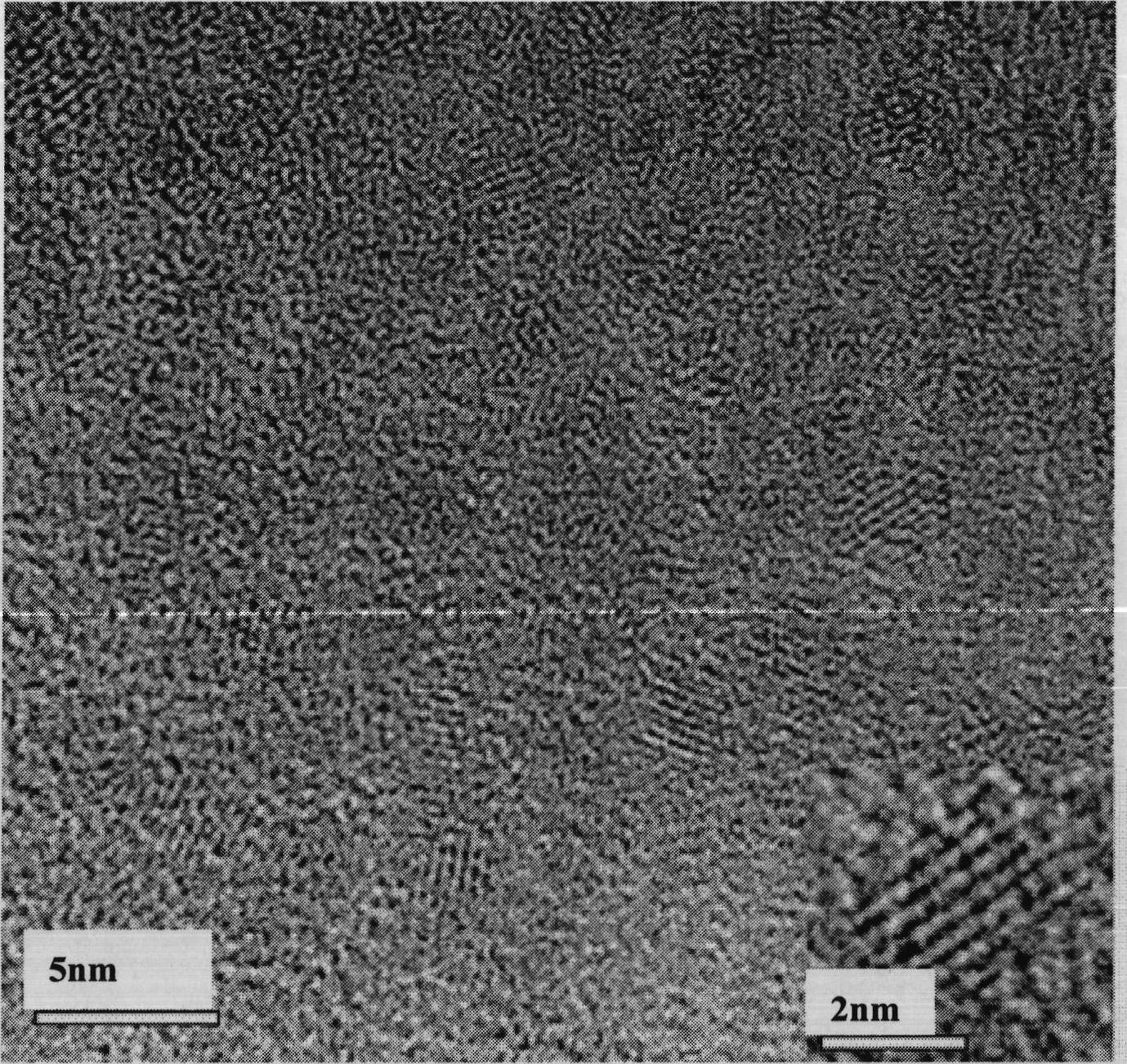

Method for extracting carbon quantum dots from activated carbon

ActiveCN101973541AUniform particle sizeImprove photoelectric performanceNanostructure manufactureLuminescent compositionsActivated charcoal powderCarboxyl radical

The invention provides a method for extracting carbon quantum dots from activated carbon, which comprises the following steps of: adding dry activated carbon powder to salpeter solution and stirring for backflow; performing reduced pressure distillation for evaporating suspension obtained by backflow to dryness; dispersing obtained black solids in water, and neutralizing obtained solution with sodium hydroxide; and finally, centrifugating neutralized black suspension for removing precipitation, separating supernatant fluid by using an ultrafiltration centrifugal tube or an ultrafiltration membrane, collecting filtrate, and drying the filtrate to obtain carbon quantum dots. The method uses cheap and available activated carbon as carbon sources, and can obtain a large number of carbon quantum dots by simple chemical oxidation process and simple subsequent processes of evaporation, saturation, centrifugation and ultrafiltration. The carbon quantum dots are graphite structure nanocrystals with the grain diameter of 3 to 5 nm, the surfaces of which have a large amount of hydroxide radicals. The carbon quantum dots have good fluorescence and electrochemiluminescence.

Owner:FUZHOU UNIV

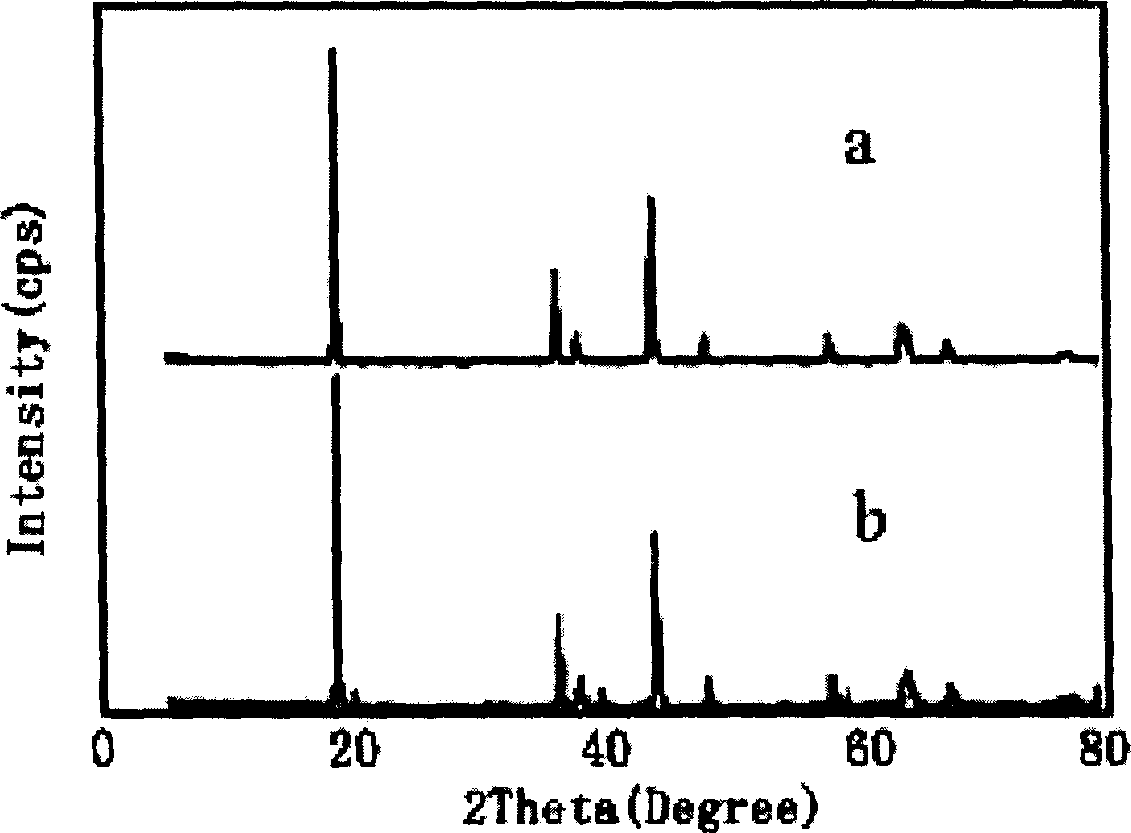

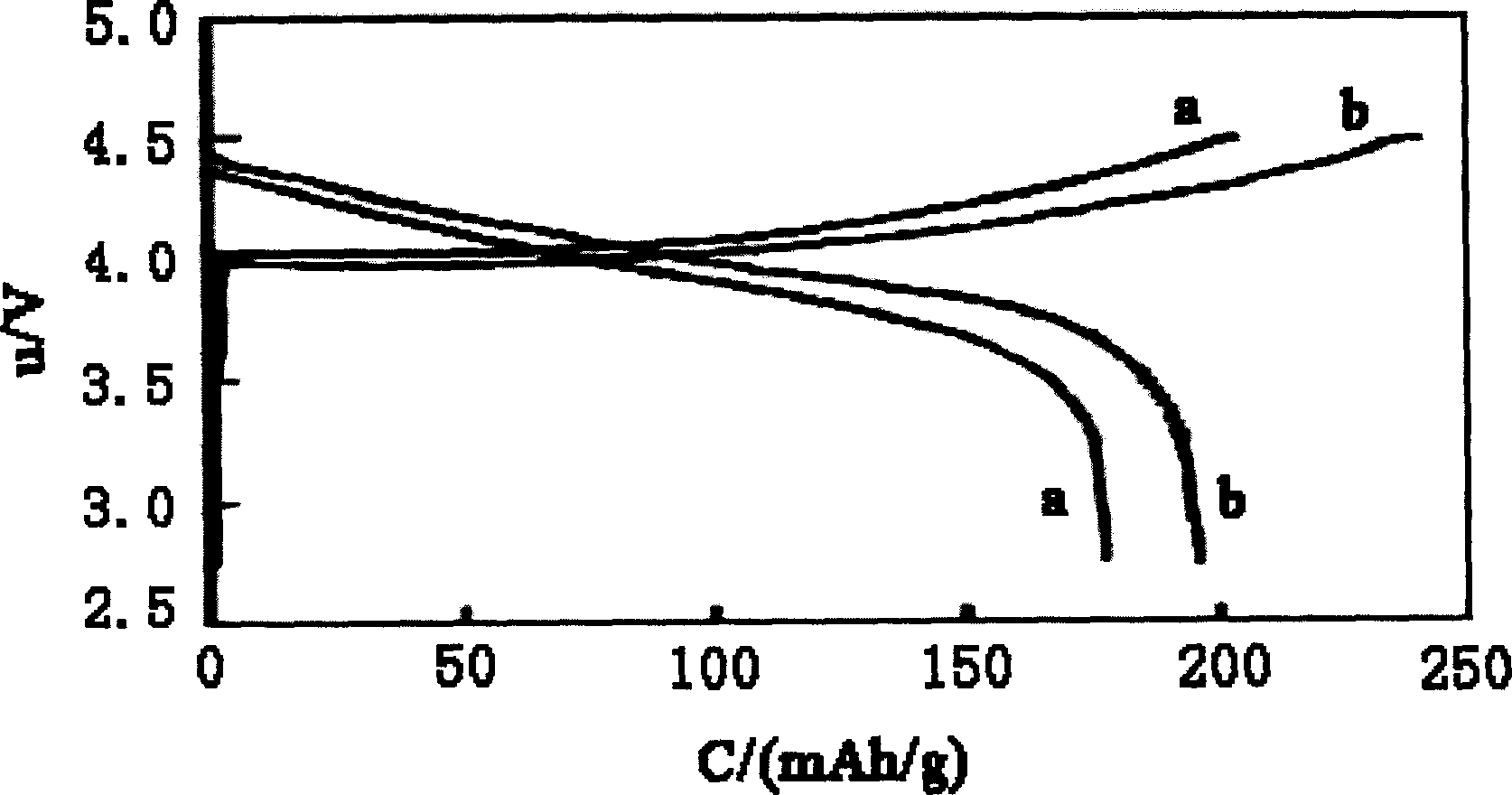

Manganese-included multi-element metal oxide, lithium ion secondary battery anode material and its preparing method

ActiveCN1770513AImprove cycle performanceUniform particle sizeCell electrodesSecondary cellsNickel saltLithium hydroxide

This invention relates to one multi-element metal oxidation and discloses The process method, which comprises the following steps: a, in nitrogen or inertance gas depositing the mixture of cobalt salt, nickel salt and maganism salt to generate Ni-Co-Mn compound hydrogen oxidation to process front drive after drying and grinding; b, adding lithium hydrate into the front drive grinding and processing mixture to remove absorbed water and structure water; c, processing products under degrees of 650 to 850 degrees; d, using high polymer as assistant agent to process surface covering on product; e, processing the product to remove solvent to process multi-metal oxidation.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

Process for producing iron phosphate for producing iron lithium phosphate material

The preparation method of iron phosphate used for preparing lithium iron phosphate material in the present invention relates to heavy metal phosphate, and the steps are: dissolving analytically pure soluble iron salt in distilled water to prepare a 0.05-5M aqueous solution, and the added mass is the iron salt mass 0.01~3% of anionic surfactant, then add analytically pure phosphoric acid according to the molar ratio of Fe3+:PO43-=1:0.8~1.2 and stir evenly, and slowly add alkaline solution with a concentration of 1~9M under stirring , the feeding time is more than 1 hour, until the pH value of the solution reaches 6-7, the iron phosphate precipitate is filtered, and the filtered iron phosphate is washed 3-5 times with distilled water 2-5 times its weight. Dry at ~90°C to obtain the product FePO4·2H2O powder. The iron phosphate product with two crystal waters prepared by the method of the invention has high reactivity, and the performance of the lithium iron phosphate material made by using it is better than that of the lithium iron phosphate material made by commercially available iron phosphate products.

Owner:HEBEI UNIV OF TECH

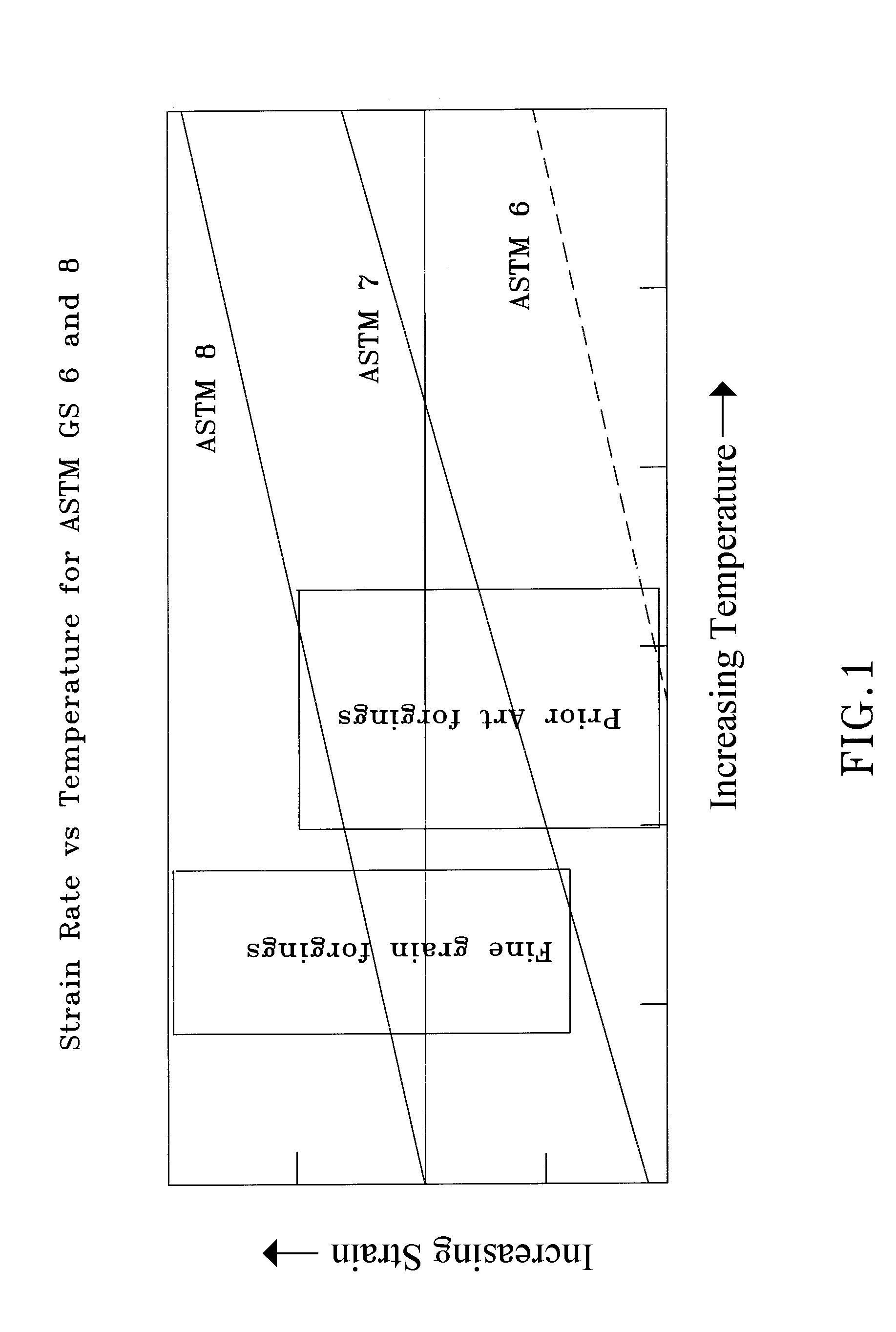

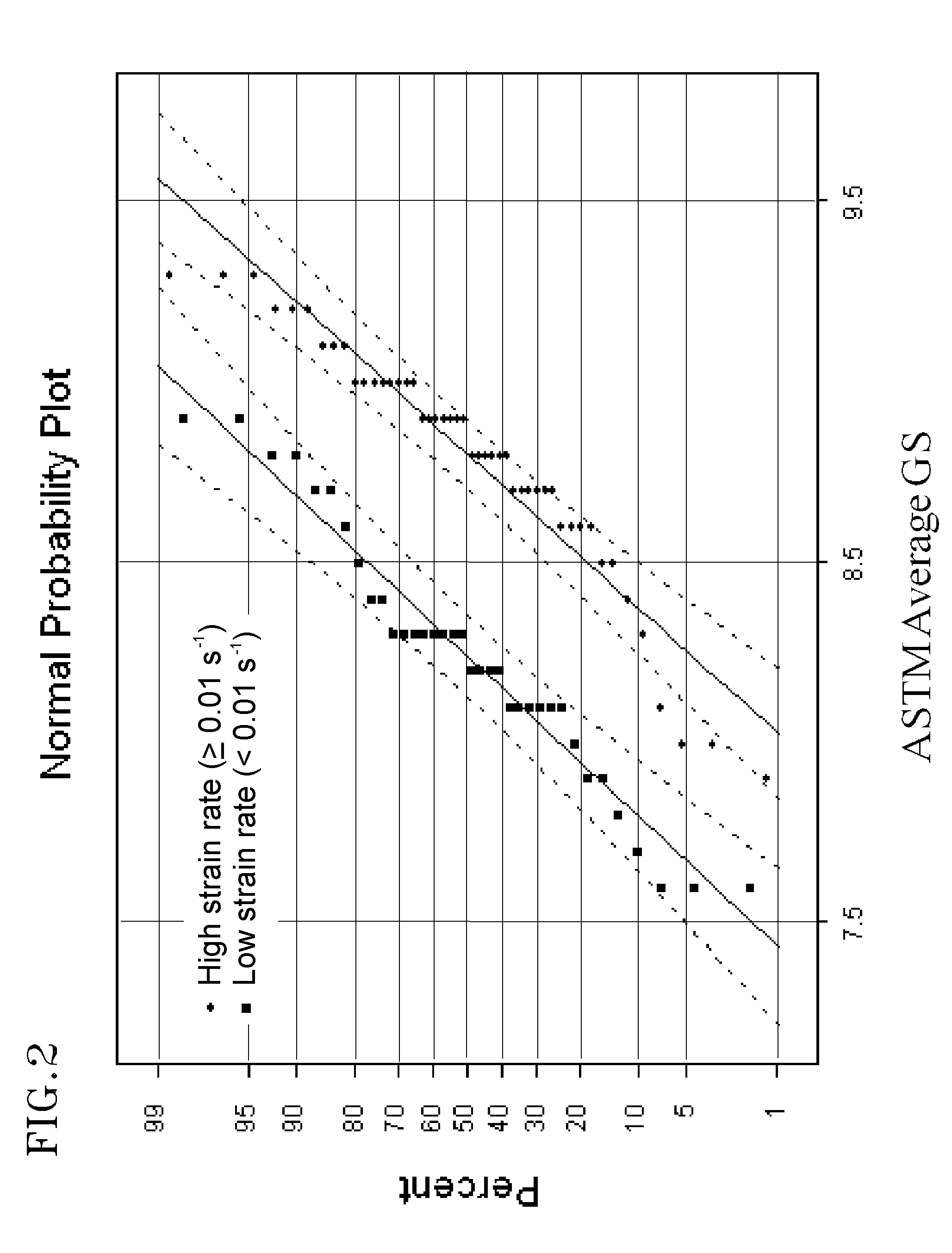

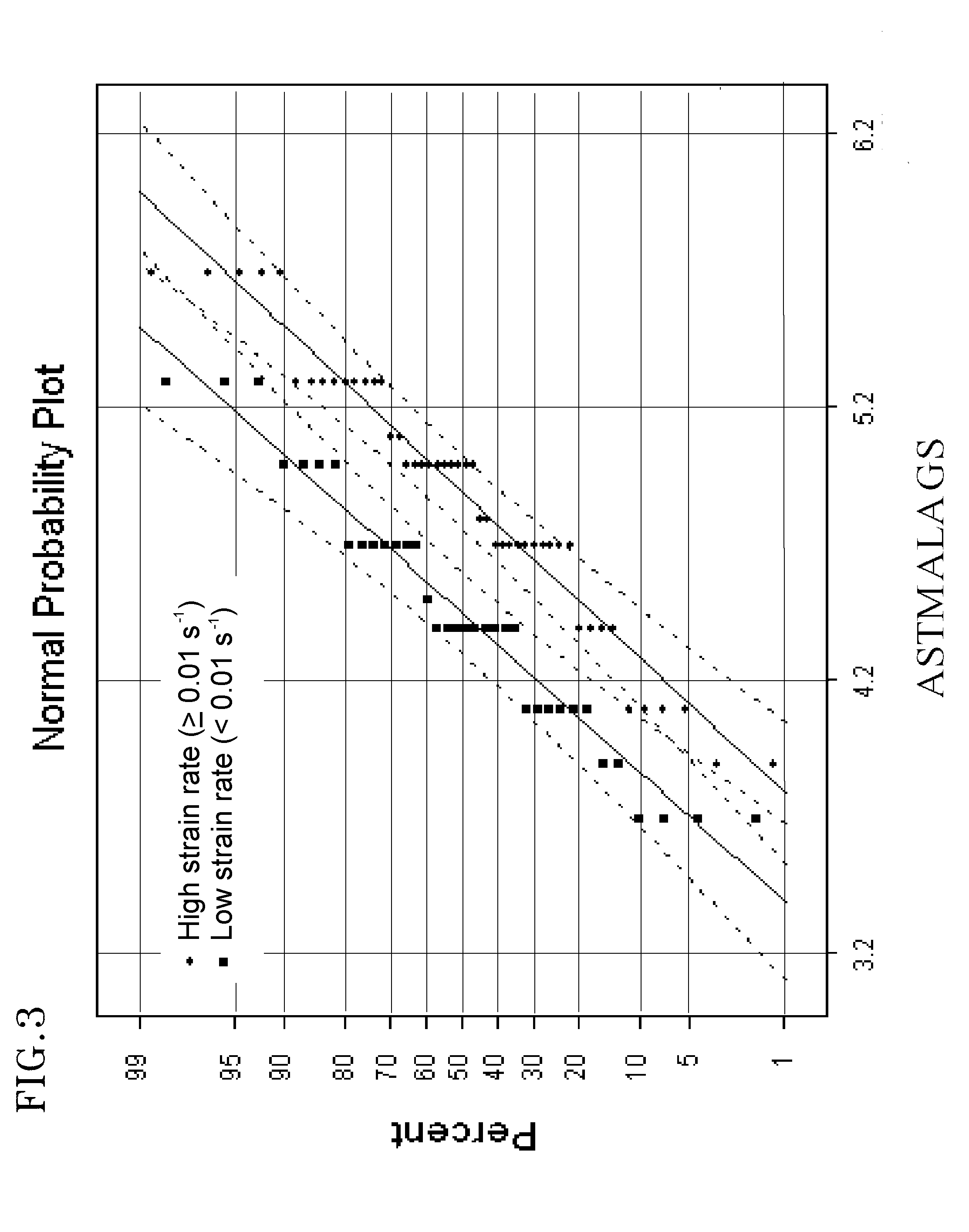

Method of controlling and refining final grain size in supersolvus heat treated nickel-base superalloys

InactiveUS20090000706A1High strain rateAvoiding necessity to forge superplasticallyHigh carbonHeat treated

A method of forming a component from a gamma prime precipitation-strengthened nickel-base superalloy. The method entails formulating the superalloy to have a sufficiently high carbon content and forging the superalloy at sufficiently high local strain rates so that, following a supersolvus heat treatment, the component is characterized by a fine and substantially uniform grain size distribution, preferably finer than ASTM 7 and more preferably in a range of about ASTM 8 to 10.

Owner:GENERAL ELECTRIC CO

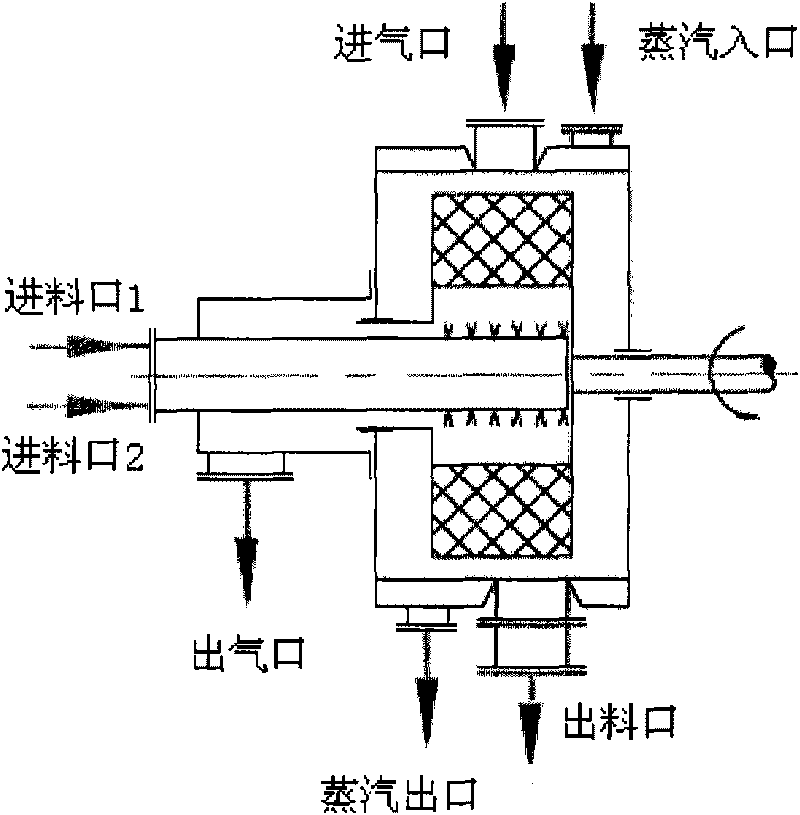

Method for preparing nano iron phosphate

InactiveCN101693531AReduce volumeReduce energy consumptionNanostructure manufacturePhosphorus compoundsPhosphateFerrous salts

The invention relates to a method for preparing nano iron phosphate, belonging to the technical field of the preparation of lithium ion battery cathode materials. The method is characterized by comprising the following steps: inputting an alkaline aqueous solution and a mixed solution formed by one of phosphoric acid or a soluble phosphate solution, one of a water-soluble ferrous salt solution and an oxidant or a ferric salt solution and a water-soluble dispersing agent into a rotating packed bed layer by a metering pump at a certain feeding speed; regulating the rotating speed of the rotating packed bed and controlling the pH value of the reaction system by an alkaline solution; discharging nano iron phosphate particles generated by reaction crystallization from a discharge hole of the rotating packed bed along with the mixed solution; and filtering, washing and drying the nano iron phosphate particles to obtain nano iron phosphate (FePO4.2H2O) powder. The method is simple and has easy operation and high efficiency, and the prepared iron phosphate reaches the nano grade, has uniform particle size and narrow distribution range and is suitable for industrialized production. The nano iron phosphate is a good precursor material for preparing lithium iron phosphate which is used as a cathode material of high-power type lithium ion batteries.

Owner:TSINGHUA UNIV

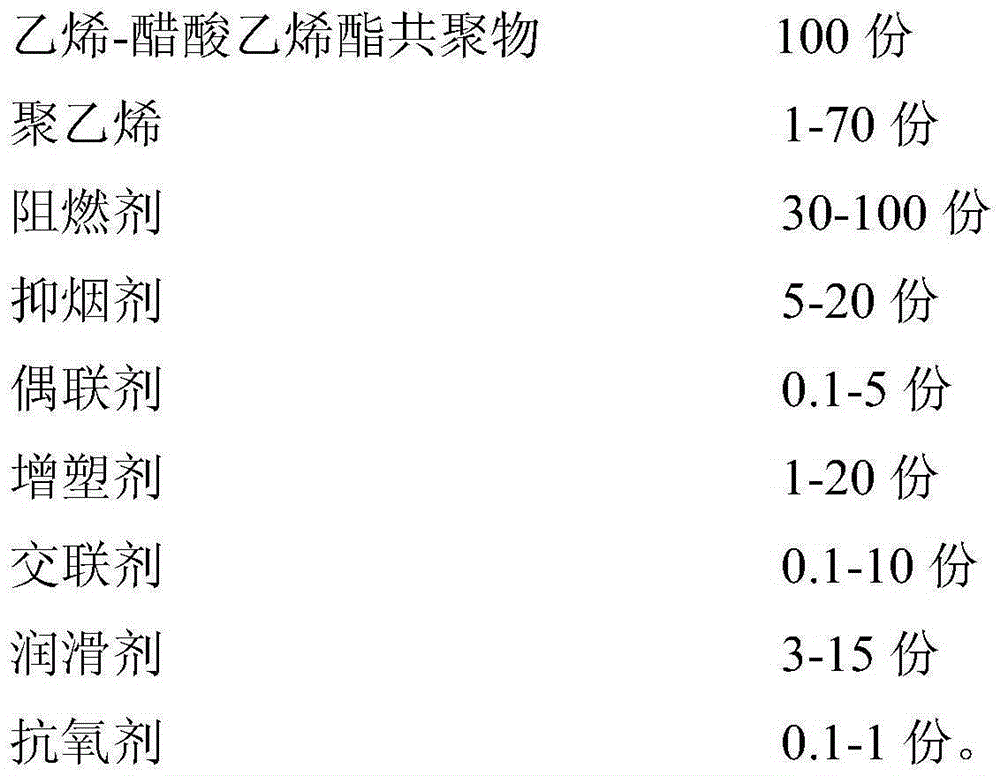

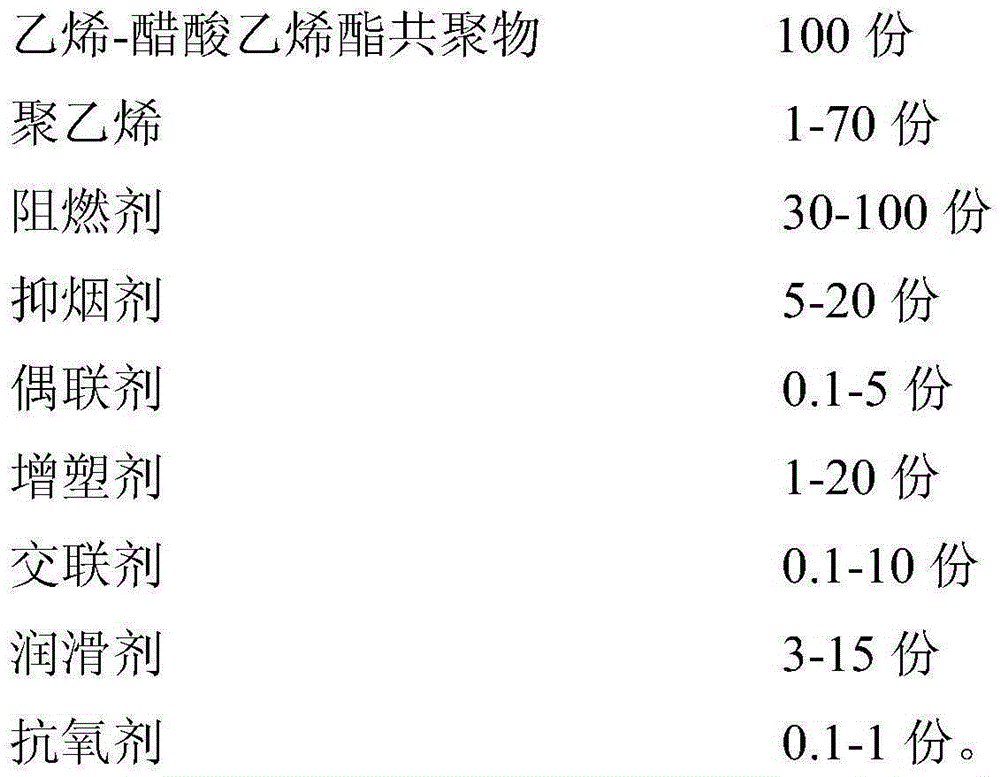

Flexible low-smoke halogen-free flame-retardant wire and cable material and preparation method thereof

InactiveCN105419072ASimple production processLow costPlastic/resin/waxes insulatorsInsulated cablesElastomerThermoplastic

The invention belongs to the technical field of materials and discloses a flexible low-smoke halogen-free flame-retardant wire and cable material and a preparation method thereof. The wire and cable material is prepared by using the following raw materials in parts by weight: 100 parts of ethylene-vinyl acetate copolymer, 1 to 70 parts of polyethylene, 30 to 100 parts of flame retardant, 5 to 20 parts of smoke suppressor, 0.1 to 5 parts of coupling agent, 1 to 20 parts of plasticizer, 0.1 to 10 parts of crosslinking agent, 3 to 15 parts of lubricant and 0.1 to 1 part of antioxidant. The wire and cable material disclosed by the invention is a thermoplastic sulfurized elastomer material, can be used for preparing insulating layers and sheath layers of wires and cables, and has the characteristics that no halogen is contained, the flame-retardant effect is good, the smoking amount is low, the surfaces of the insulating layers and sheath layers are smooth and do not stick with one another, the flexibility is good, the mechanical strength is high, the wear resistance is good, the processing fluidity is good, the process is simple and the material can be recycled.

Owner:SOUTH CHINA UNIV OF TECH

Ultra-fine highly effective anion powder material and its preparation method

The invention relates to an ultrafine high-effect negative ion powder material, which comprises: 60~95% natural negative ion releasing material, 2~30% activated material, and 3~25% energy transfer material. Wherein, using dry way and wet way to ultrafine break the material and obtain the product. This material increases the ion releasing ability more than twenty times to pure natural tourmalin and three times to the material theoretic value, and has high far-infrared radiation function without toxin.

Owner:深圳市金士吉康复用品科技有限公司

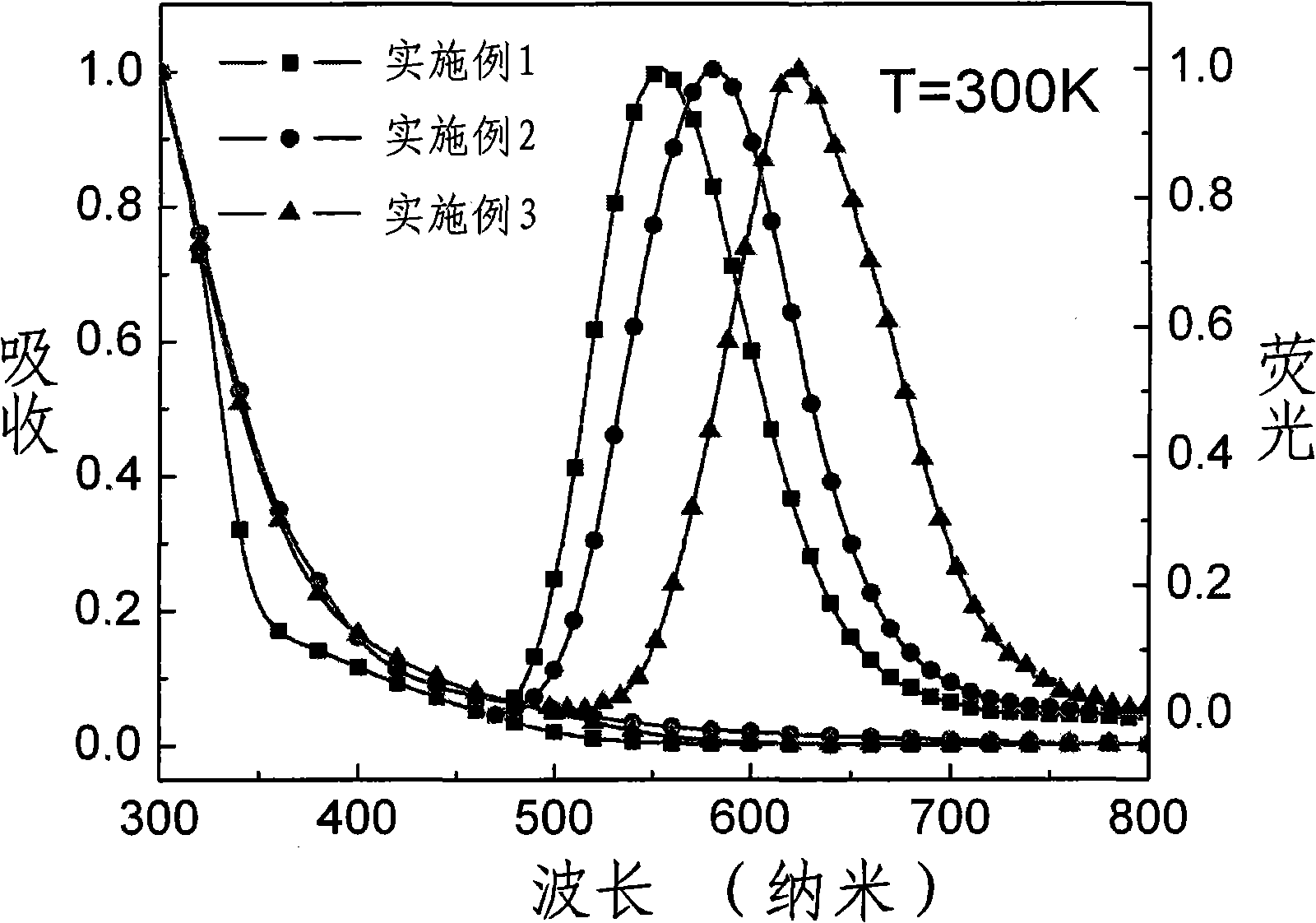

Preparation method and application in luminescent element thereof of CuInS2-ZnS/ZnSe/ZnS semiconductor quantum dots with core-shell structure

The invention discloses a preparation method and application in the luminescent element thereof of CuInS2-ZnS / ZnSe / ZnS semiconductor quantum dots with a core-shell structure, belonging to the technical field of the preparation method of the semiconductor quantum dot. The method comprises the following steps: dissolving the precursors of copper source, zinc source, indium source and sulfur source in nonpolar mixed solvent to perform nucleation and growth under a certain temperature and obtain a CuInS2-ZnS alloy core-ZCIS, then adding zinc source and selenium source alternately in the solution to perform epitaxial growth of ZnSe on the core, then perform epitaxial growth of ZnS to prepare the CuInS2-ZnS / ZnSe / ZnS quantum dots, finally adding polar solvent in the solution, settling, centrifuging, cleaning, and perform vacuum drying to obtain solid quantum dot powder. The prepared quantum dots are 2-8nm and have uniform particle size, controllable emission wavelength and high yield. The quantum dots are used as luminescent material to prepare red, yellow and green quantum dot luminescent elements and the luminescent elements have excellent luminescent property.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing spherical aluminum-doped nickel lithium carbonate for lithium ion battery positive electrode material

ActiveCN102074679AMorphology and particle size distribution controllableGood liquidityCell electrodesLoop stabilityLithium electrode

The invention relates to a method for preparing spherical aluminum-doped nickel lithium carbonate for a lithium ion battery positive electrode material by combining liquid phase oxidation and crystallization controlling. Through controlling of the preparation technique, firstly synthesizing a spherical hydroxyl oxygenized nickel cobalt aluminum precursor with high density, and then calcining at the temperature of 500-800 DEG C for 10-24 hours in a flow oxygen gas atmosphere after mixing the precursor with a lithium source, thus acquire the spherical aluminum-doped nickel lithium carbonate with high density. The synthesized aluminum-doped nickel lithium carbonate is in a single spherical shape, has good stacking density, and can be used for improving the volume ratio capacity of a battery.The aluminum-doped nickel lithium carbonate prepared by the method in the invention has the advantages of high specific capacity and good loop stability. The method provided by the invention has the advantages of simple technique, low cost, less pollution, good product performance and suitability for industrialized production.

Owner:深圳市费特森新能源有限责任公司

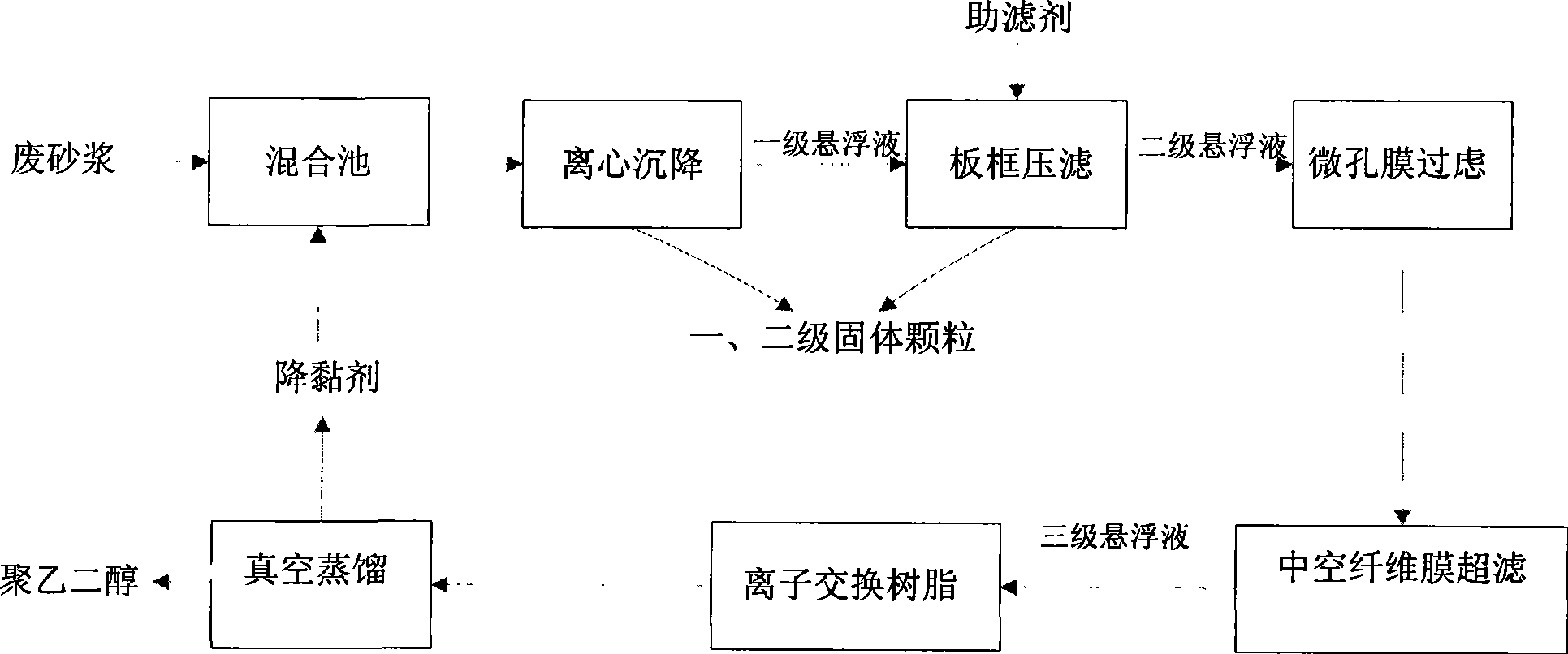

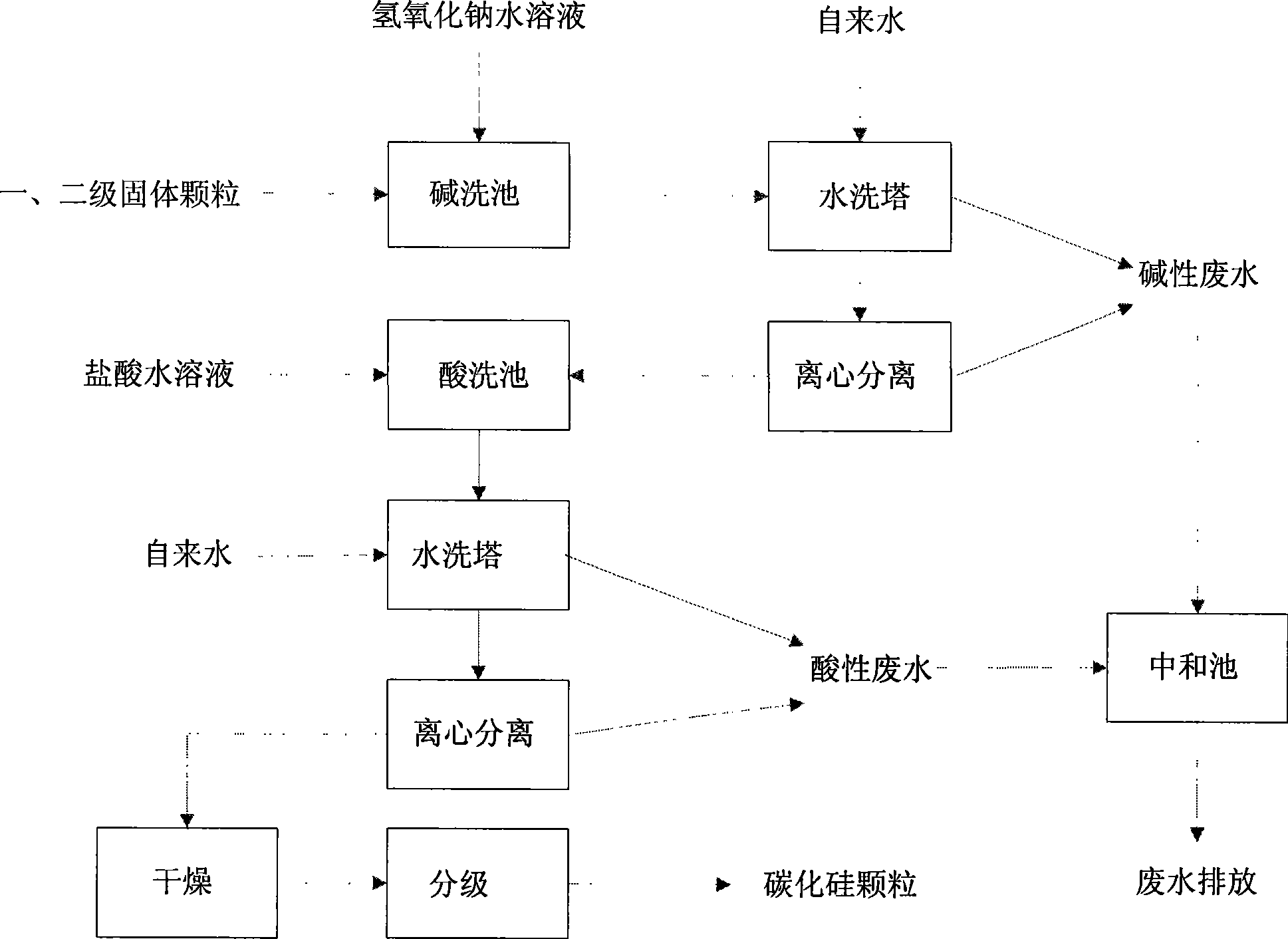

Process for recovering polyethylene glycol and silicon carbide in waste mortar from silicon wafer wire cutting

InactiveCN101474511AFacilitates flocculation and filtrationAvoid pollutionPlastic recyclingFiltration circuitsFiberHollow fibre

The invention relates to the field of silicon wafer wire-electrode cutting and discloses a method for recycling carborundum and cutting polyethyleneglycol in waste mortar by silicon wafer wire-electrode cutting. In monocrystalline silicon piece processing technique, a viscosity reduction agent is firstly added before waste mortar linear cutting, and then a suspending liquid part and a solid particles part are obtained by the solid-liquid separation; The suspending liquid part is added with a filter aid, then filter pressing with a plate frame, micro porous filtration, hyper filtration with hollow fiber and ion exchange are carried out sequentially, and finally, the suspending liquid is distillated in vacuum and polyethyleneglycol is recycled. Alkali reaction cleaning, water scrubber washing, centrifugalization, acid reaction cleaning, the second water scrubber washing, the second centrifugalization, the second acid reaction cleaning, drying and drying classification are carried out on the solid particles in sequence, and finally, recyclable silicon carbide particles are obtained.

Owner:西安通鑫半导体辅料有限公司

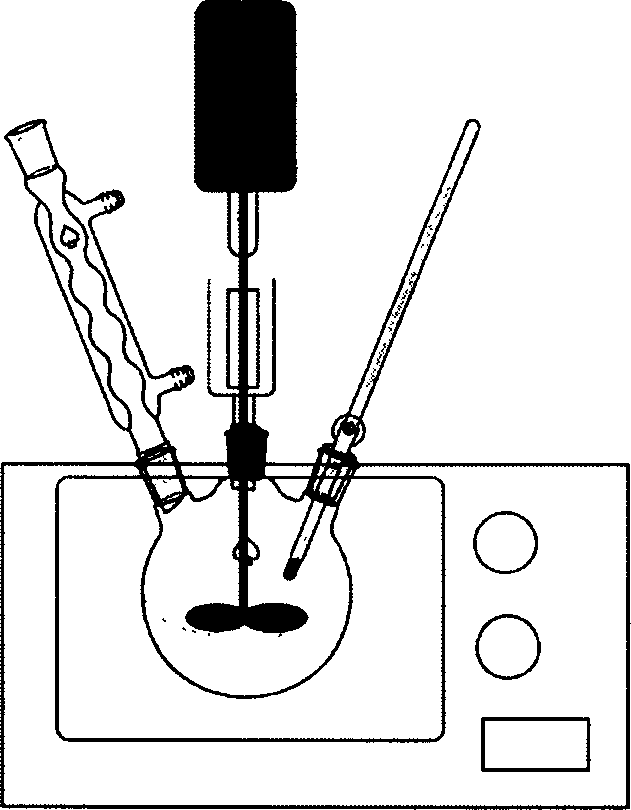

Preparation method of nanometer zinc oxide

A process for preparing nano-zinc oxide includes such steps as dissolving soluble Zn salt and urea in water, microwave radiating while reacting by homogenizing-depositing method to obtain the deposit of alkaline zinc carbonate, vacuum drying, ball grinding, calcining to obtain the crystal grains of nano-zinc oxide, mixing with surface modifier, organic solvent and disperser, ball grinding, and microwave radiating which surface modifying.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com