Patents

Literature

156results about How to "High strain rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

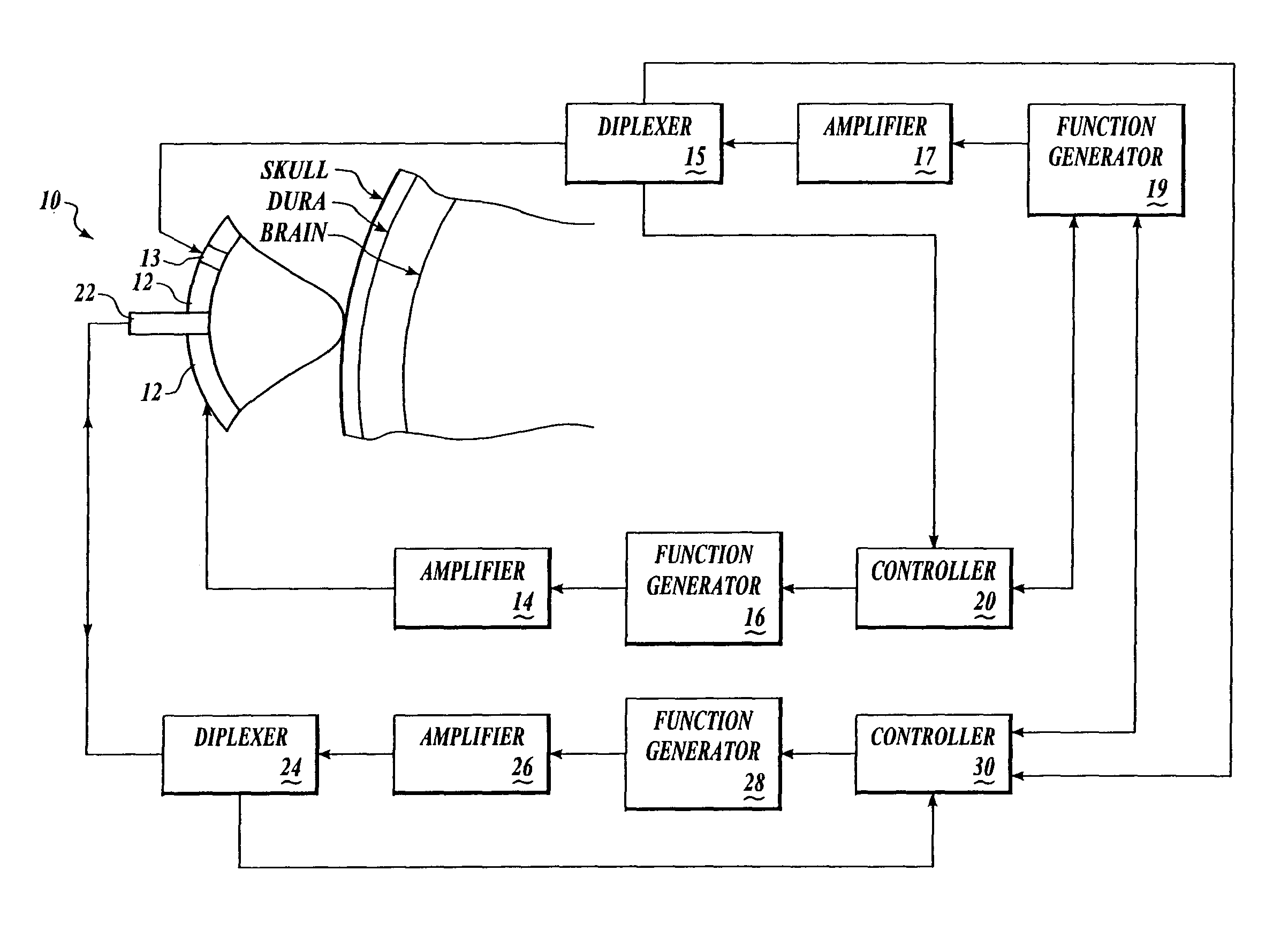

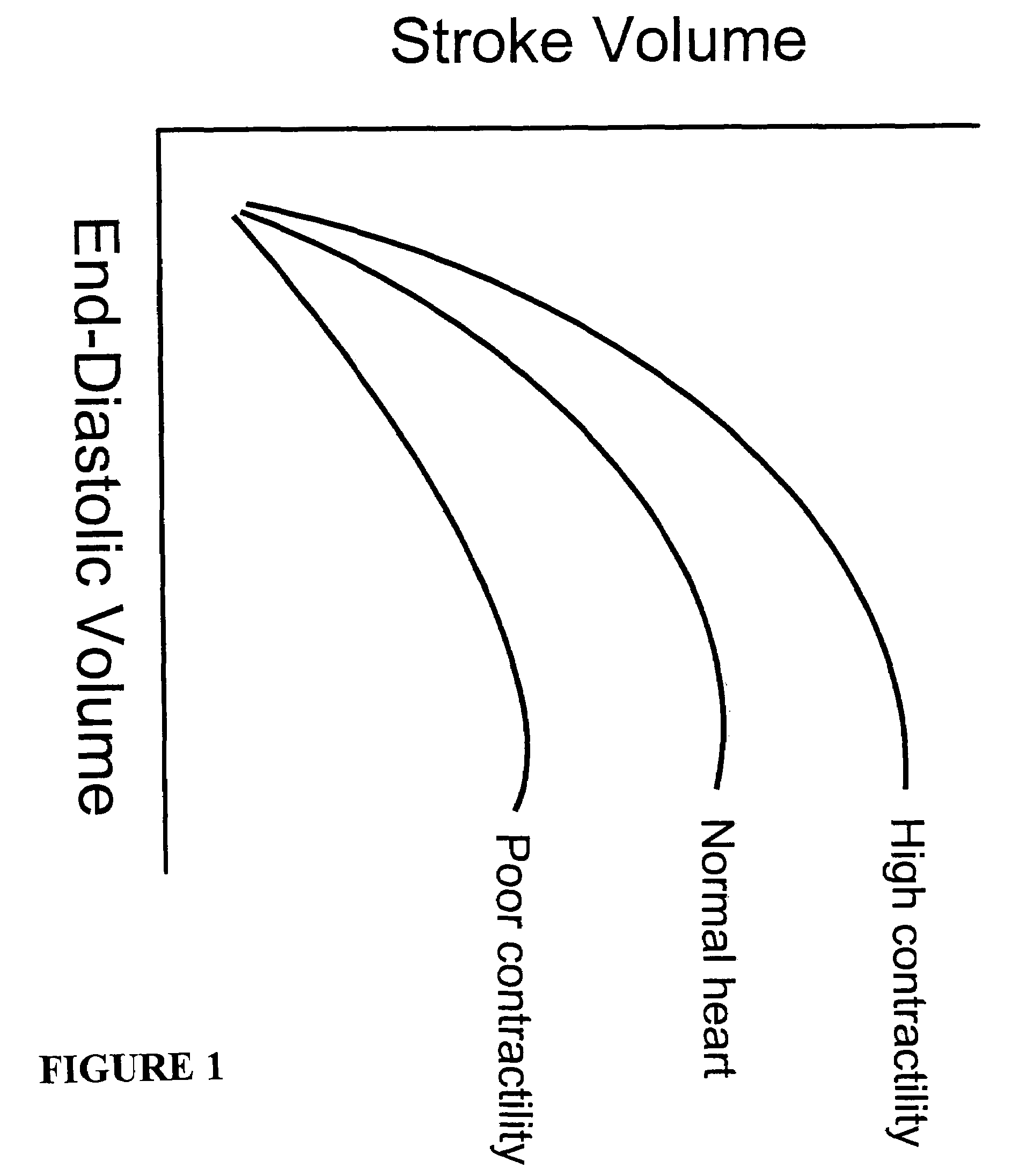

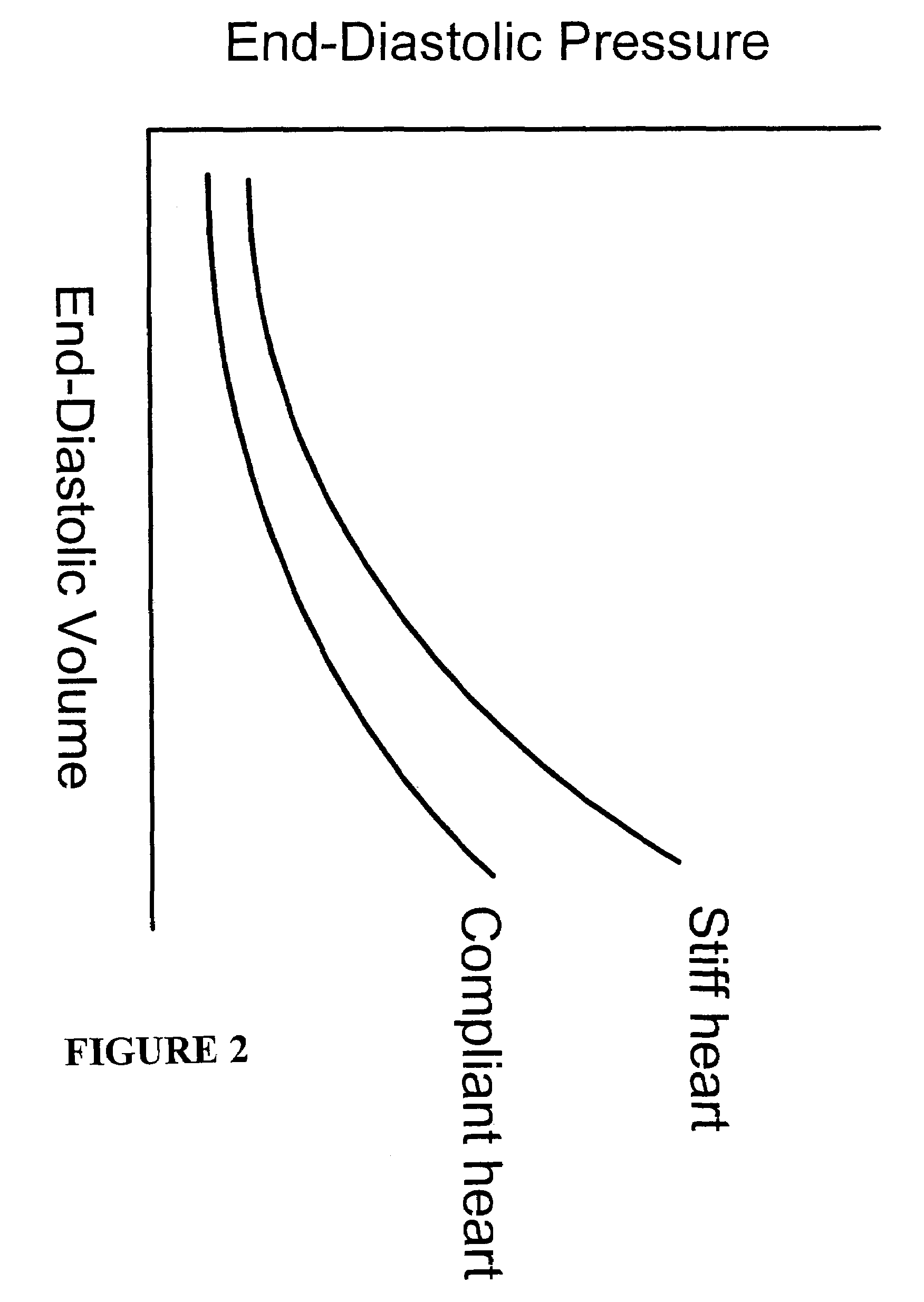

Systems and methods for making noninvasive assessments of cardiac tissue and parameters

InactiveUS7022077B2Maximize tissue displacementEasy diagnosisBlood flow measurement devicesOrgan movement/changes detectionSonificationUltrasound techniques

Systems and methods for noninvasive assessment of cardiac tissue properties and cardiac parameters using ultrasound techniques are disclosed. Determinations of myocardial tissue stiffness, tension, strain, strain rate, and the like, may be used to assess myocardial contractility, myocardial ischemia and infarction, ventricular filling and atrial pressures, and diastolic functions. Non-invasive systems in which acoustic techniques, such as ultrasound, are employed to acquire data relating to intrinsic tissue displacements are disclosed. Non-invasive systems in which ultrasound techniques are used to acoustically stimulate or palpate target cardiac tissue, or induce a response at a cardiac tissue site that relates to cardiac tissue properties and / or cardiac parameters are also disclosed.

Owner:PHYSIOSONICS +1

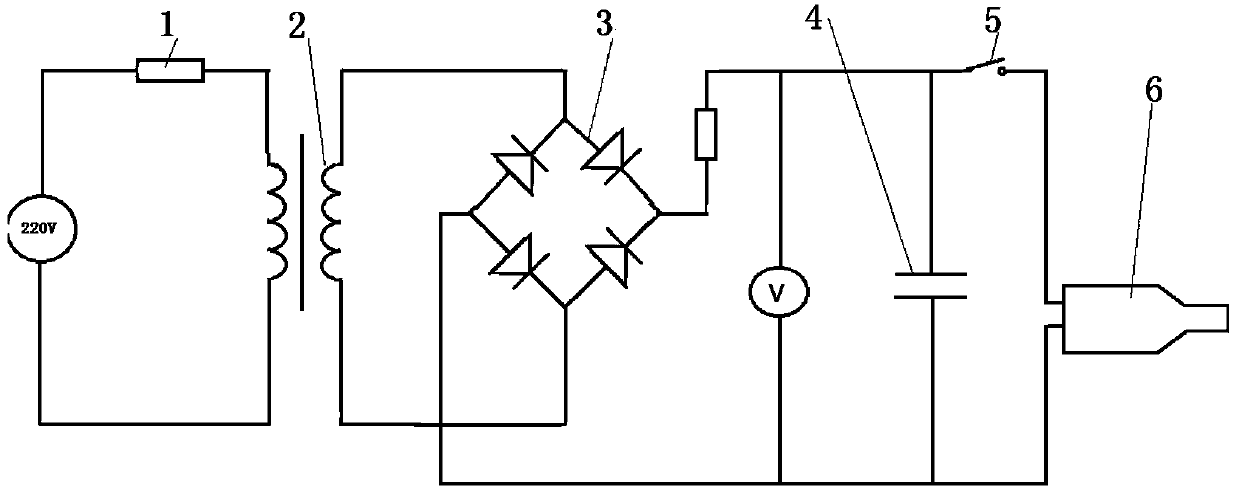

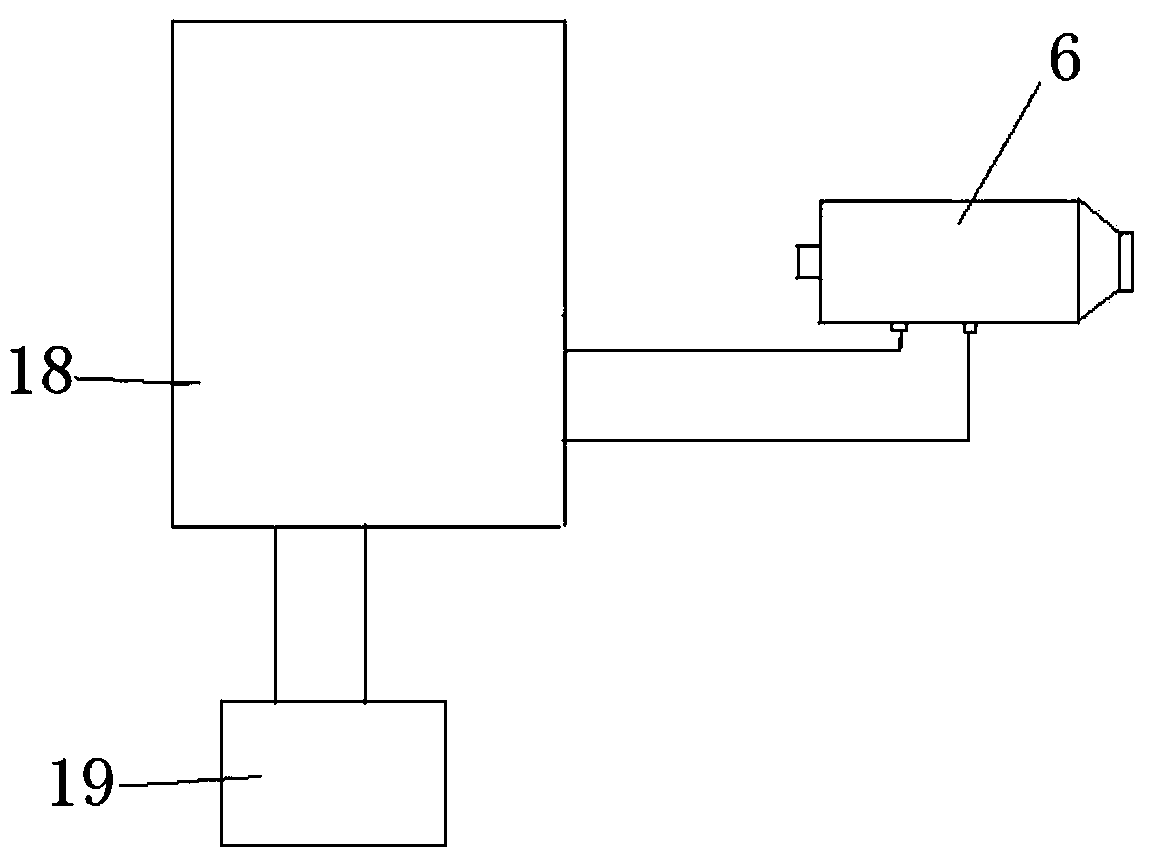

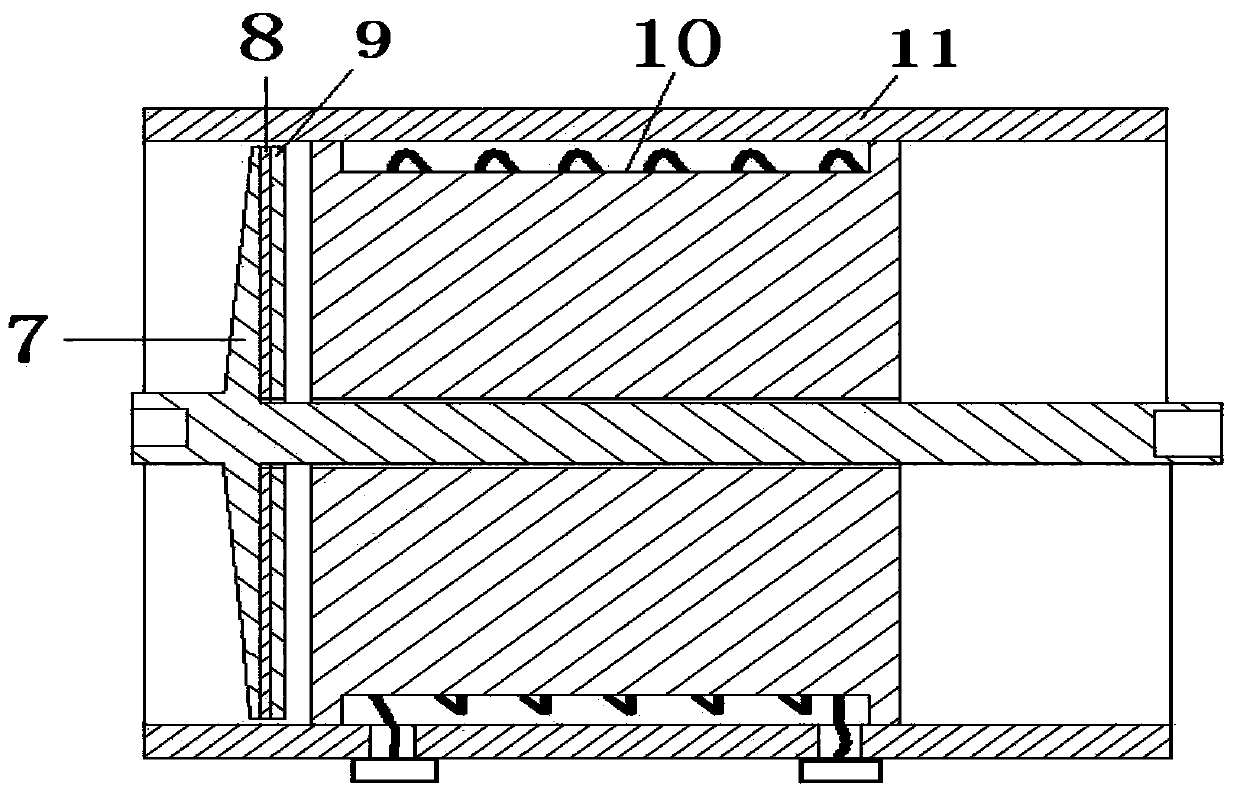

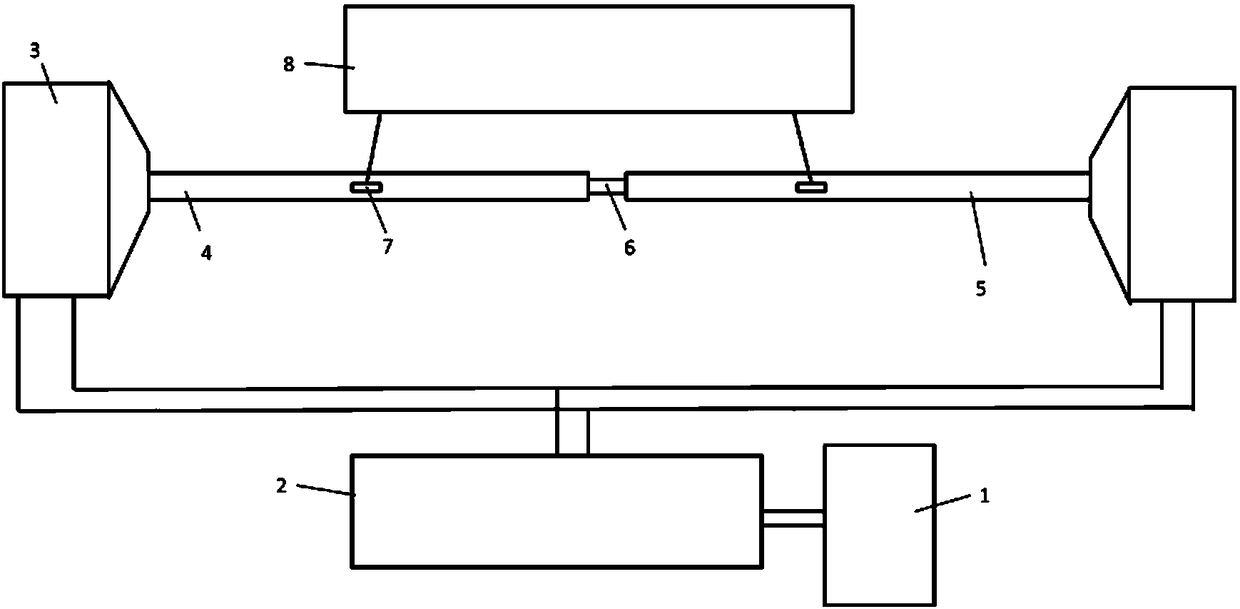

Stretching and compression stress wave generator based on electromagnetic force and experimental method

ActiveCN103994922AEasy to controlGood repeatabilityMaterial strength using tensile/compressive forcesAudio power amplifierExperimental methods

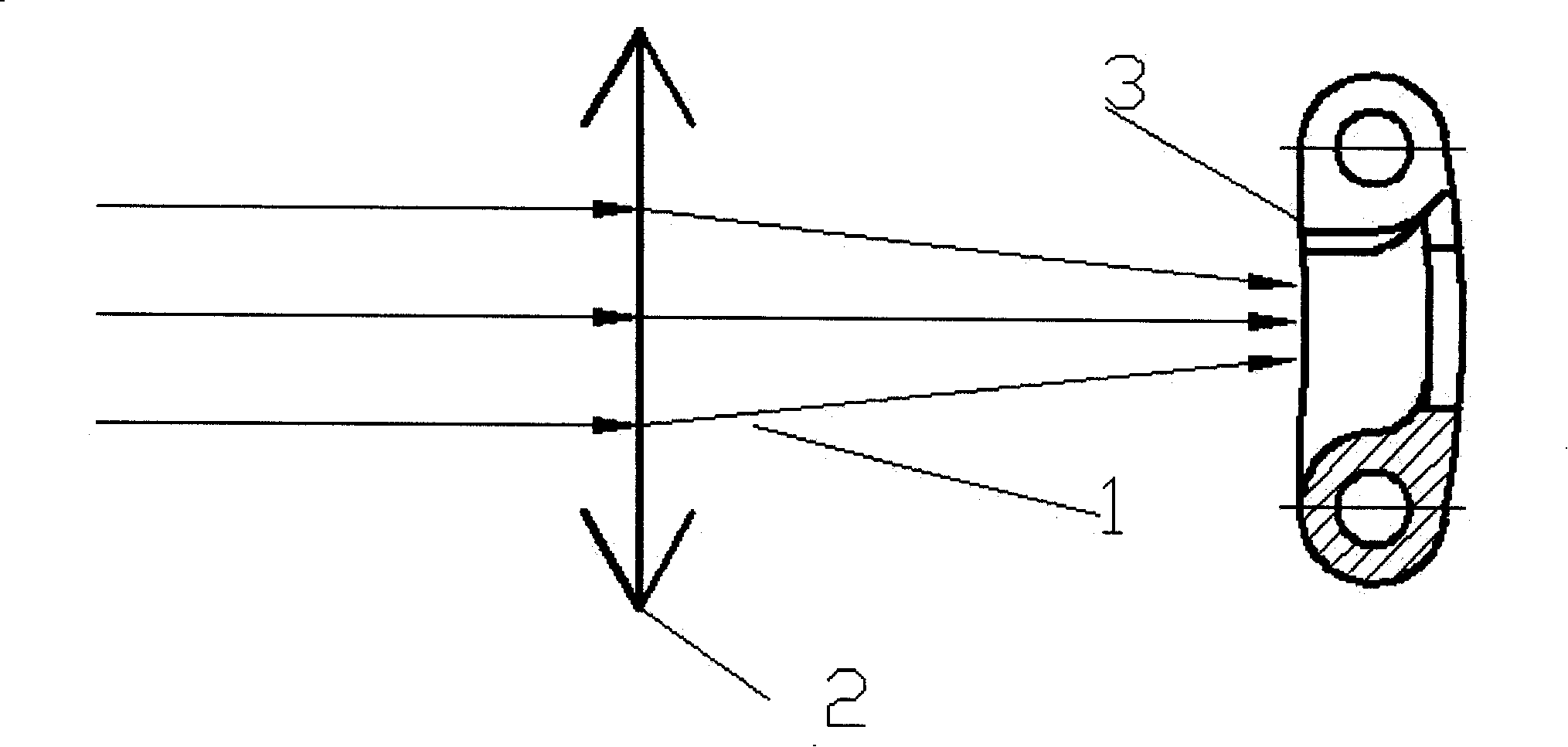

The invention provides a stretching and compression stress wave generator based on electromagnetic force and an experimental method. The stress wave generator is such structured that a capacitor charger is connected with a loading gun. A main coil, an insulating layer and a secondary coil all sleeve the locating shaft of a tapered amplifier. A power supply system is employed to provide the main coil of the loading gun with instant strong current, so strong eletromagnetic repulsion is generated between the main coil and the secondary coil; and the eletromagnetic repulsion is converted into stress waves which are amplified by the tapered amplifier and then output to a Hopkinson bar. The stretching and compression stress wave generator has a simple structure and strong controllability, can realize a strain rate and a strain scope which cannot be reached by a traditional disconnect-type Hopkinson bar, allows Hopkinson bar experimental techniques to be standardized, realizes integration of experimental apparatuses of a pull bar and a pressure bar and reduces complexity and occupied space of equipment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

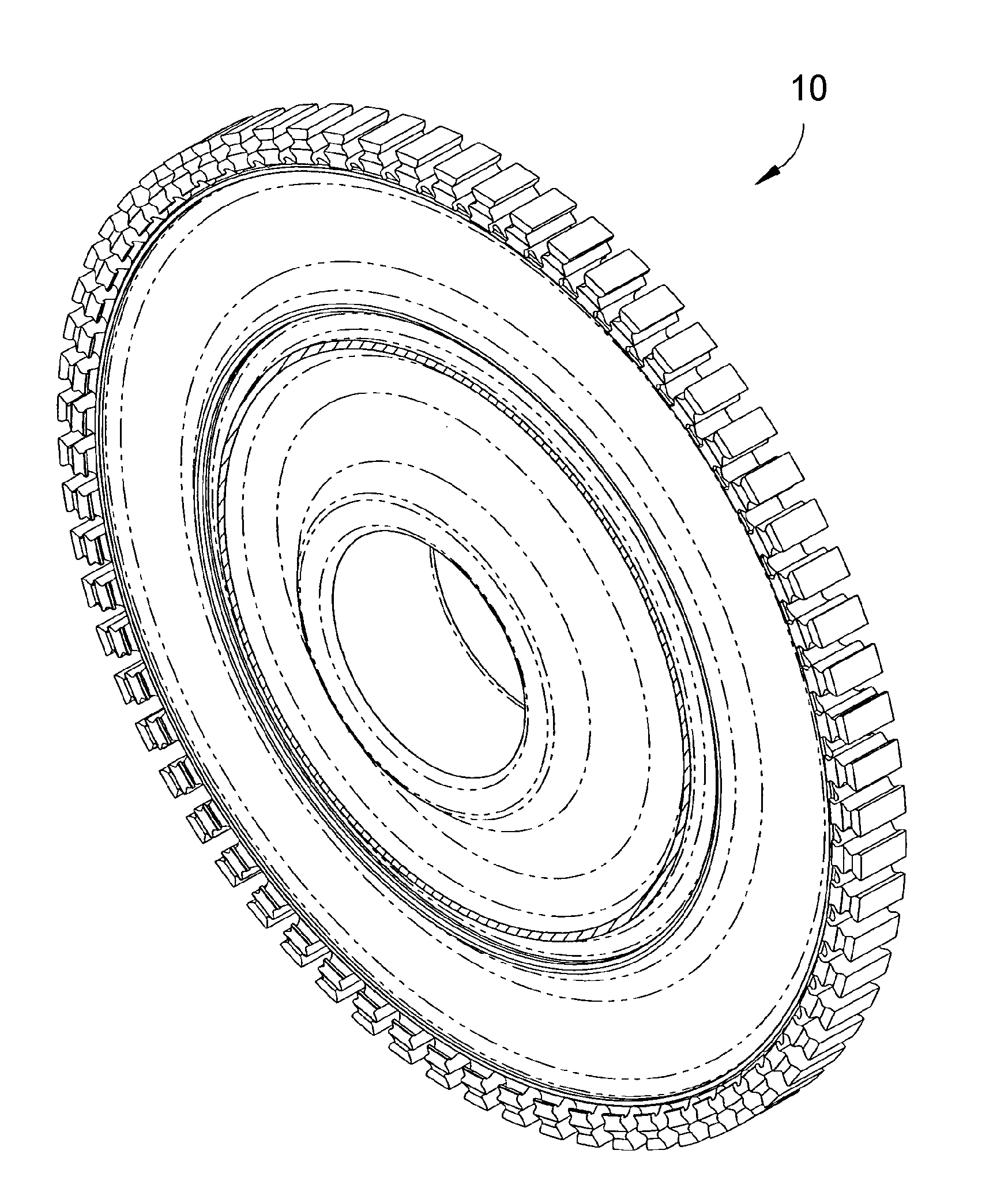

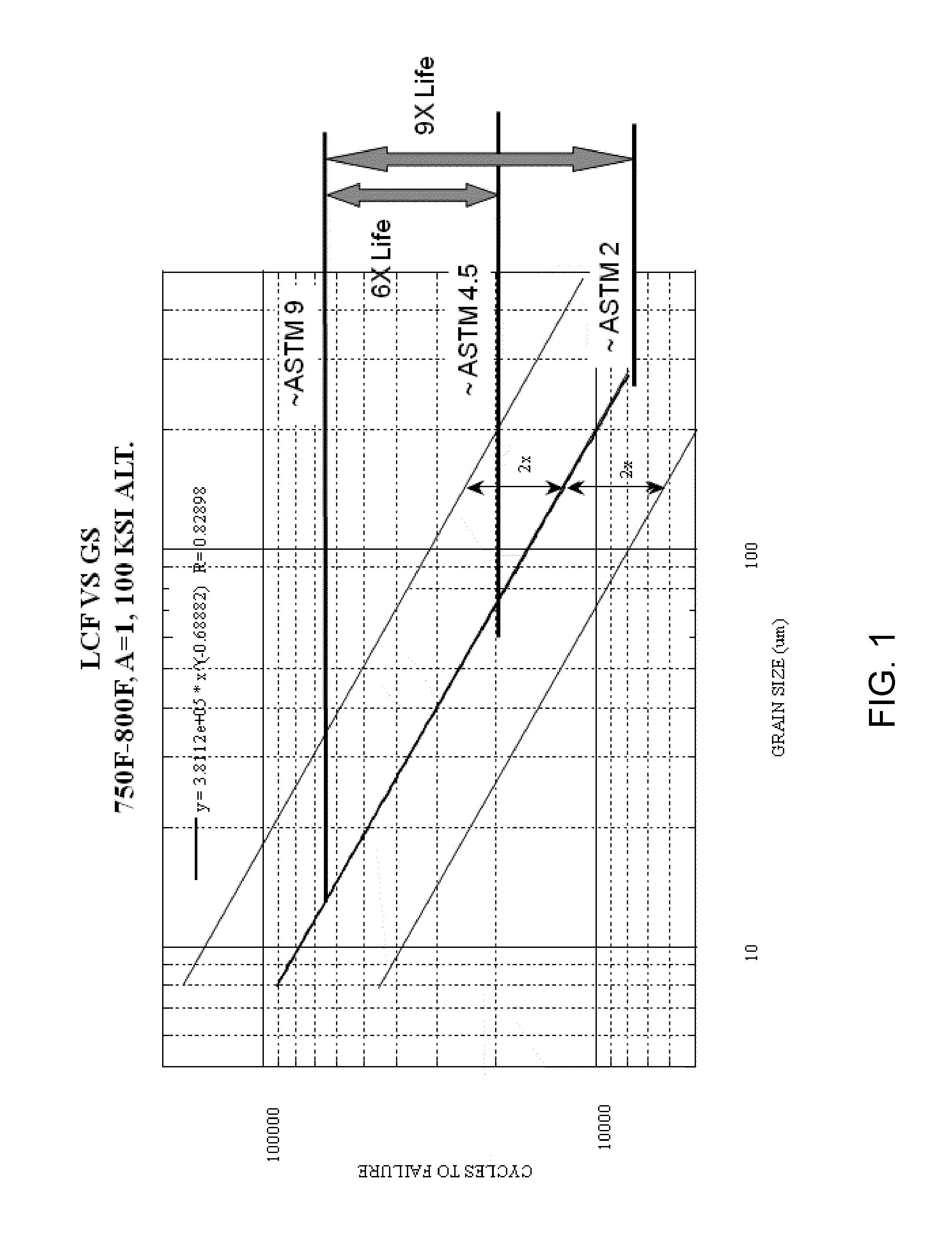

Method of controlling and refining final grain size in supersolvus heat treated nickel-base superalloys

InactiveUS20100329883A1Finer uniform grain sizeImproved low cycle fatigue behaviorPropellersEngine manufactureRheniumNiobium

A gamma prime precipitation-strengthened nickel-base superalloy and method of forging an article from the superalloy to promote a low cycle fatigue resistance and high temperature dwell behavior of the article. The superalloy has a composition of, by weight, 16.0-22.4% cobalt, 6.6-14.3% chromium, 2.6-4.8% aluminum, 2.4-4.6% titanium, 1.4-3.5% tantalum, 0.9-3.0% niobium, 1.9-4.0% tungsten, 1.9-3.9% molybdenum, 0.0-2.5% rhenium, greater than 0.05% carbon, at least 0.1% hafnium, 0.02-0.10% boron, 0.03-0.10% zirconium, the balance nickel and incidental impurities. A billet is formed of the superalloy and worked at a temperature below the gamma prime solvus temperature of the superalloy so as to form a worked article, which is then heat treated above the gamma prime solvus temperature of the superalloy to uniformly coarsen the grains of the article, after which the article is cooled to reprecipitate gamma prime. The article has an average grain size of not coarser than ASTM 7 and is substantially free of critical grain growth.

Owner:GENERAL ELECTRIC CO

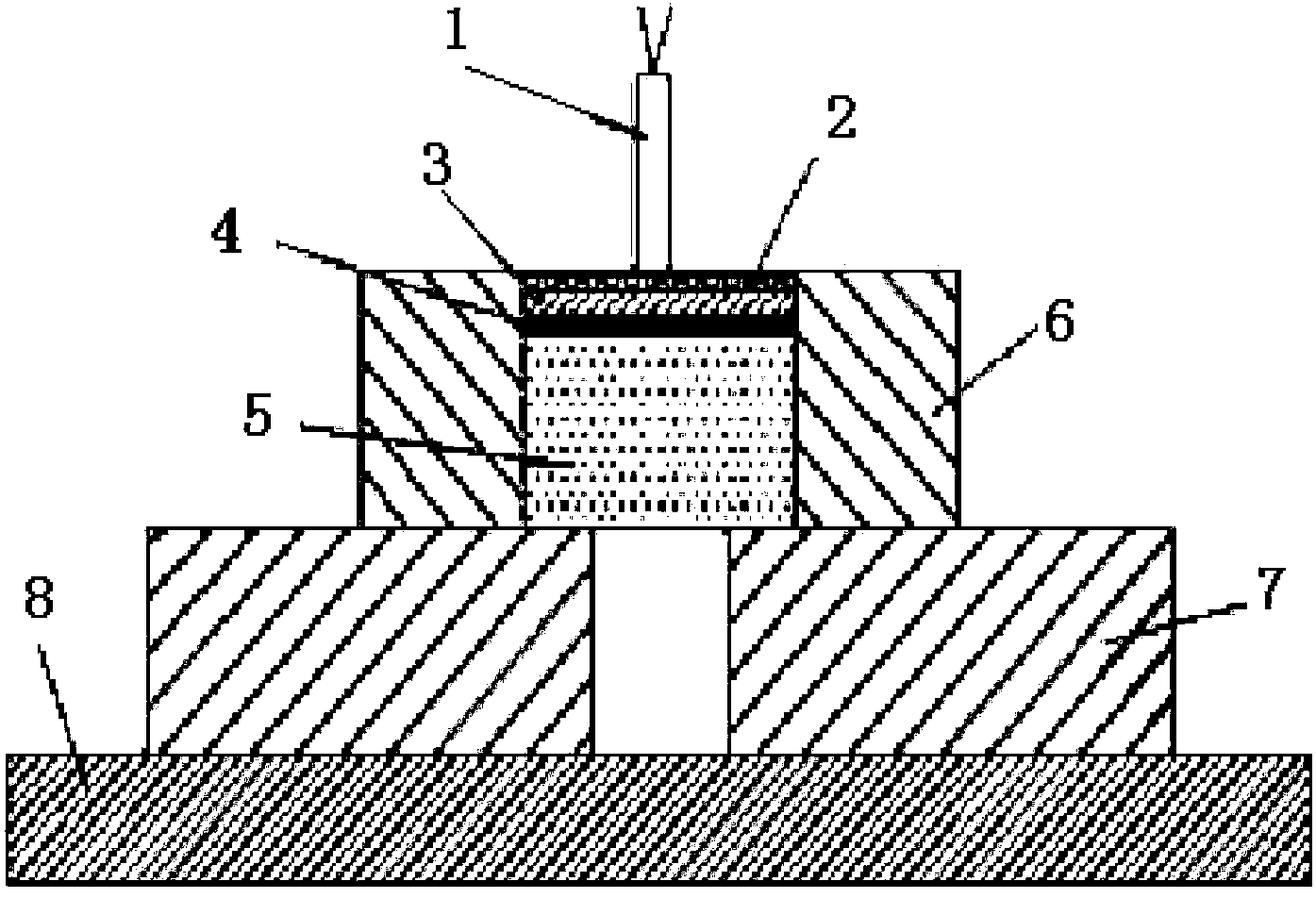

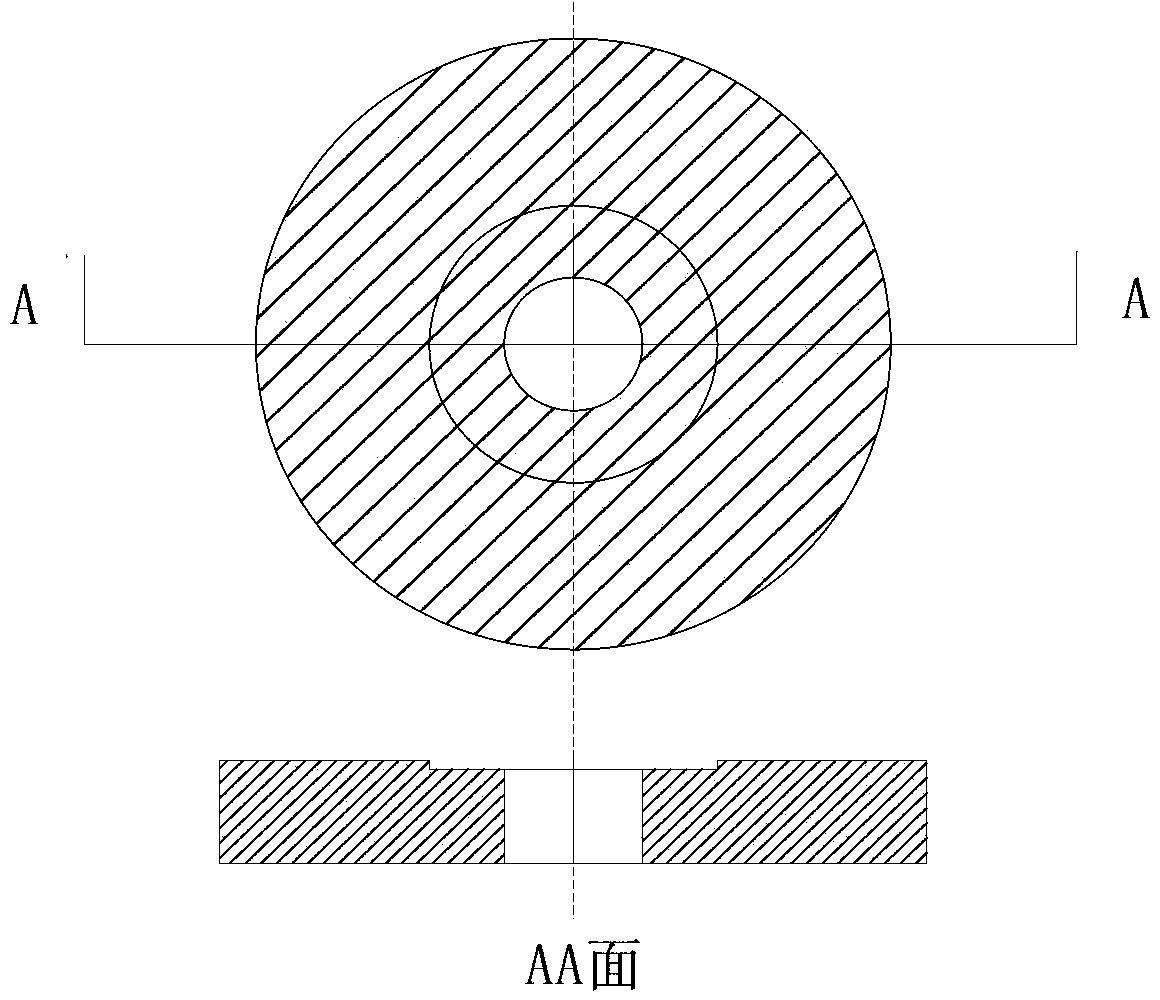

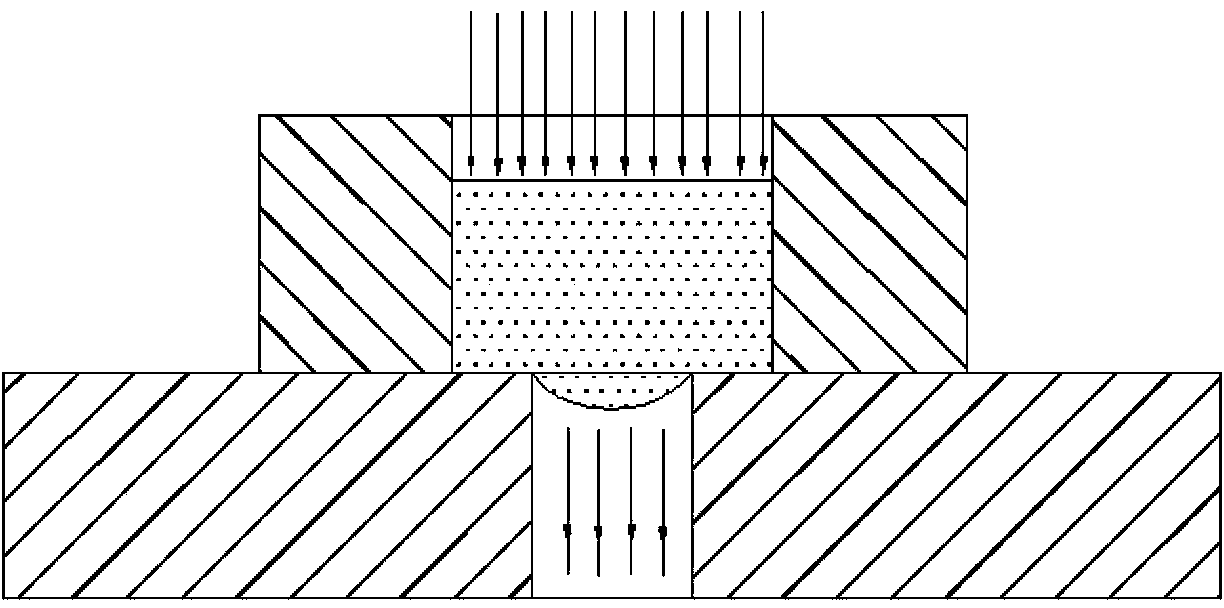

Composite loading test device for explosive blasting impact and shearing

InactiveCN103487337AThe test result is accurateHigh strain rateMaterial strength using steady shearing forcesMaterial strength using single impulsive forceDetonatorEngineering

The invention discloses a composite loading test device for explosive blasting impact and shearing. The composite loading test device comprises a loading source assembly, a shearing implementation assembly and a witness plate, wherein the loading source assembly comprises a detonator, a driving explosive, a buffer layer and a driving steel plate; the driving explosive, the buffer layer and the driving steel plate are circular sheets; the detonator is fixed on the circular driving explosive; the shearing implementation assembly comprises a main explosive, a limiting body and a base; the driving explosive, the buffer layer, the driving steel plate and the main explosive are sequentially arranged in the limiting body from top to bottom; the inner diameter of the base is smaller than the section diameter of the main explosive; the limiting body is arranged on the base; the witness plate is a cylinder; the base is fixed on the witness plate. The composite loading test device has an integrated impact and shearing action, has high strain rate, is used for performing an explosive blasting test caused by the impact and shearing action, and can meet requirements on research and investigation of influence of the integrated impact and shearing action on explosive loading and ignition.

Owner:XIAN MODERN CHEM RES INST

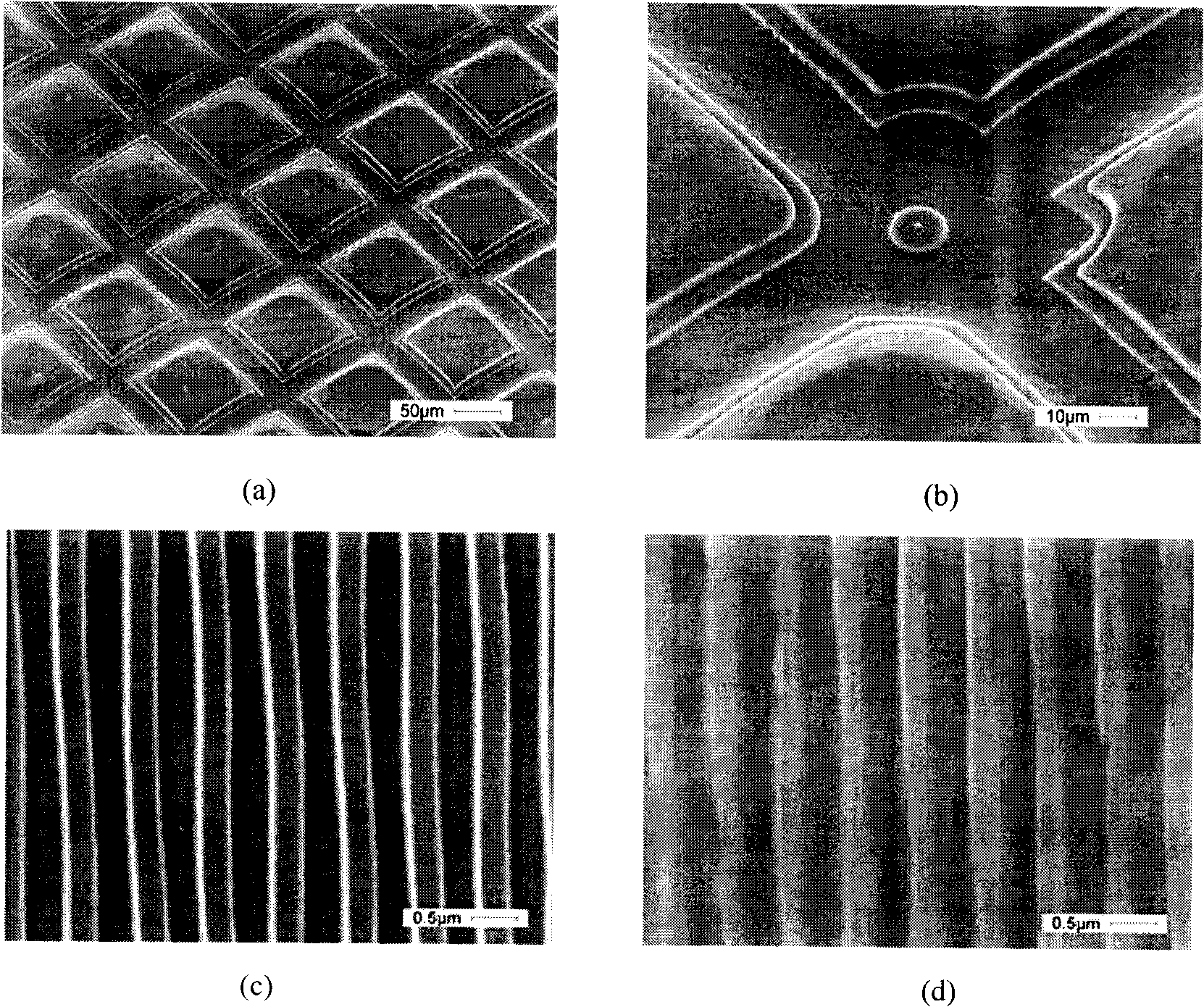

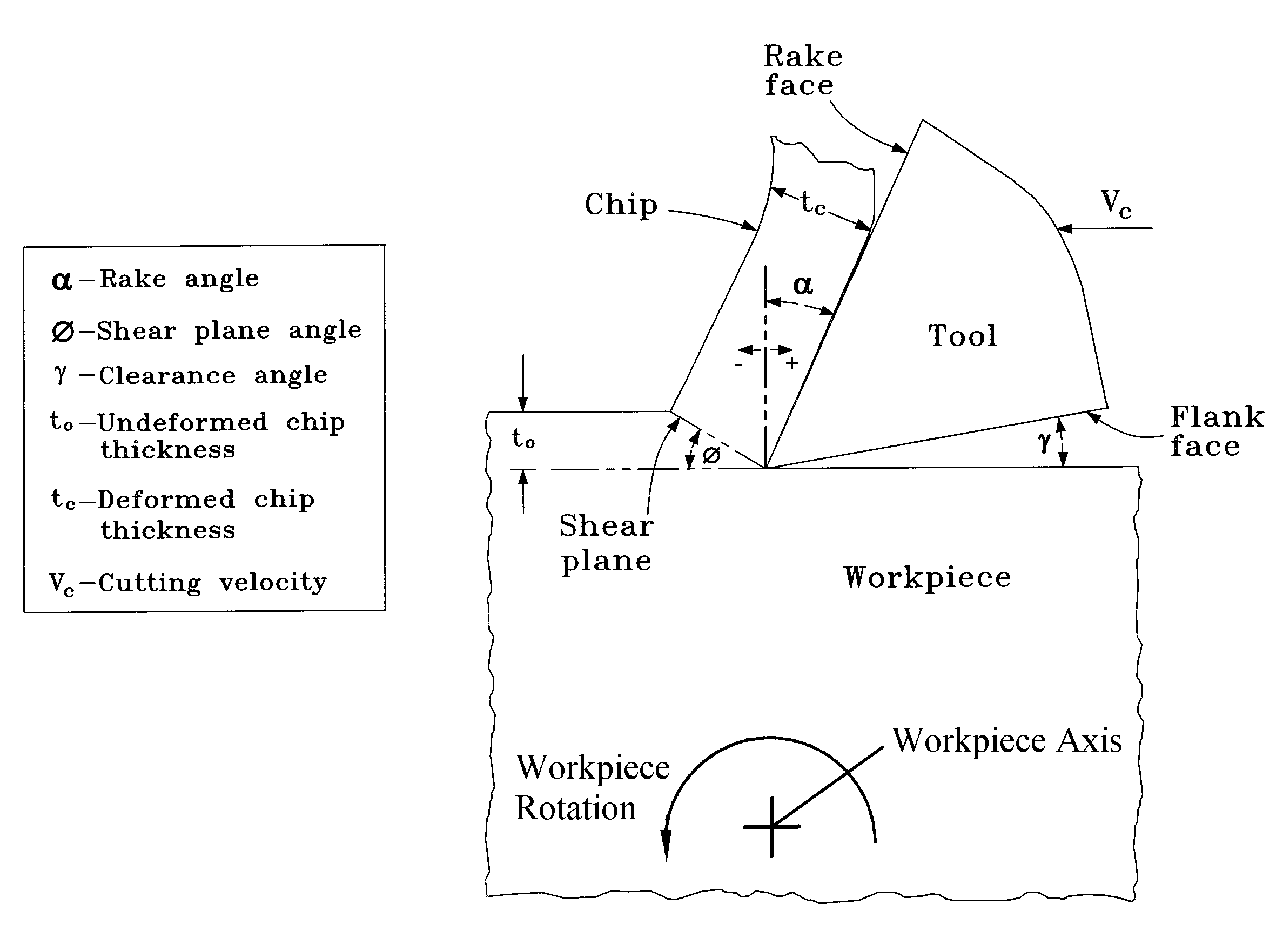

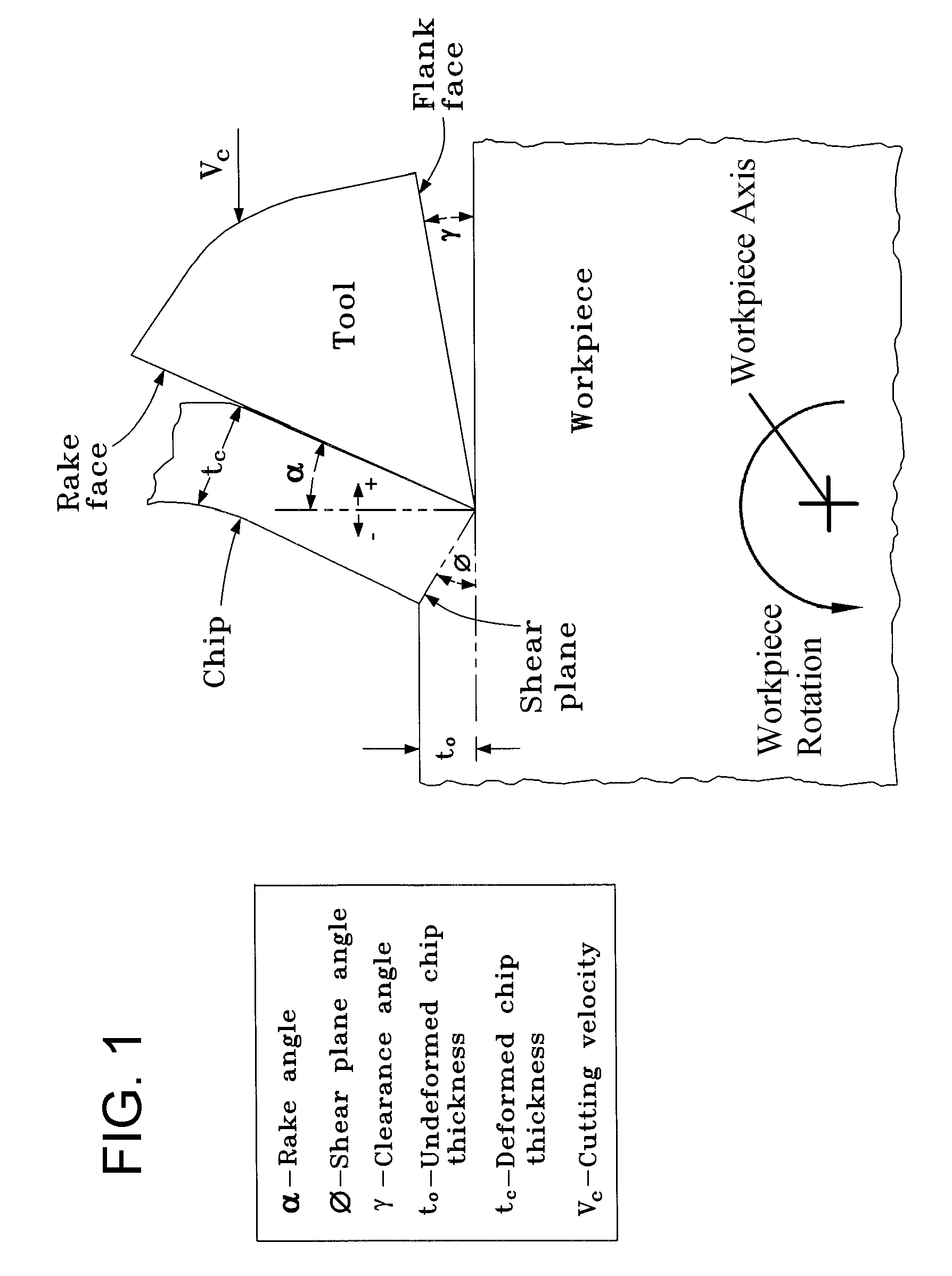

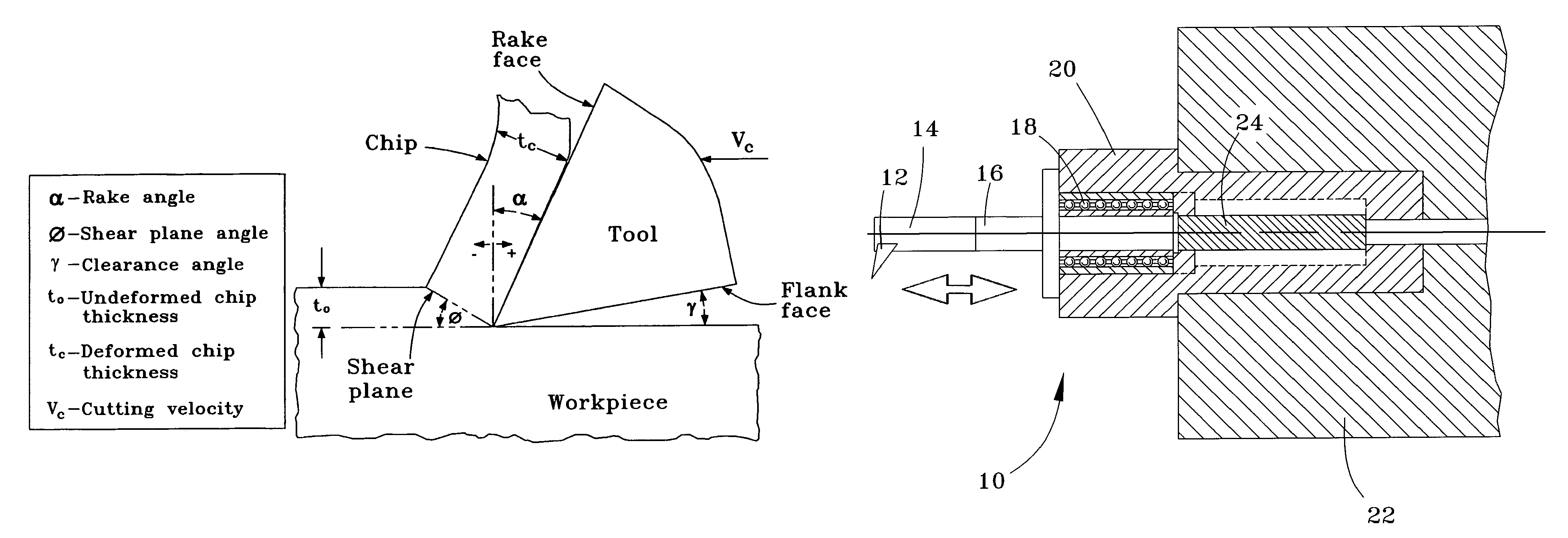

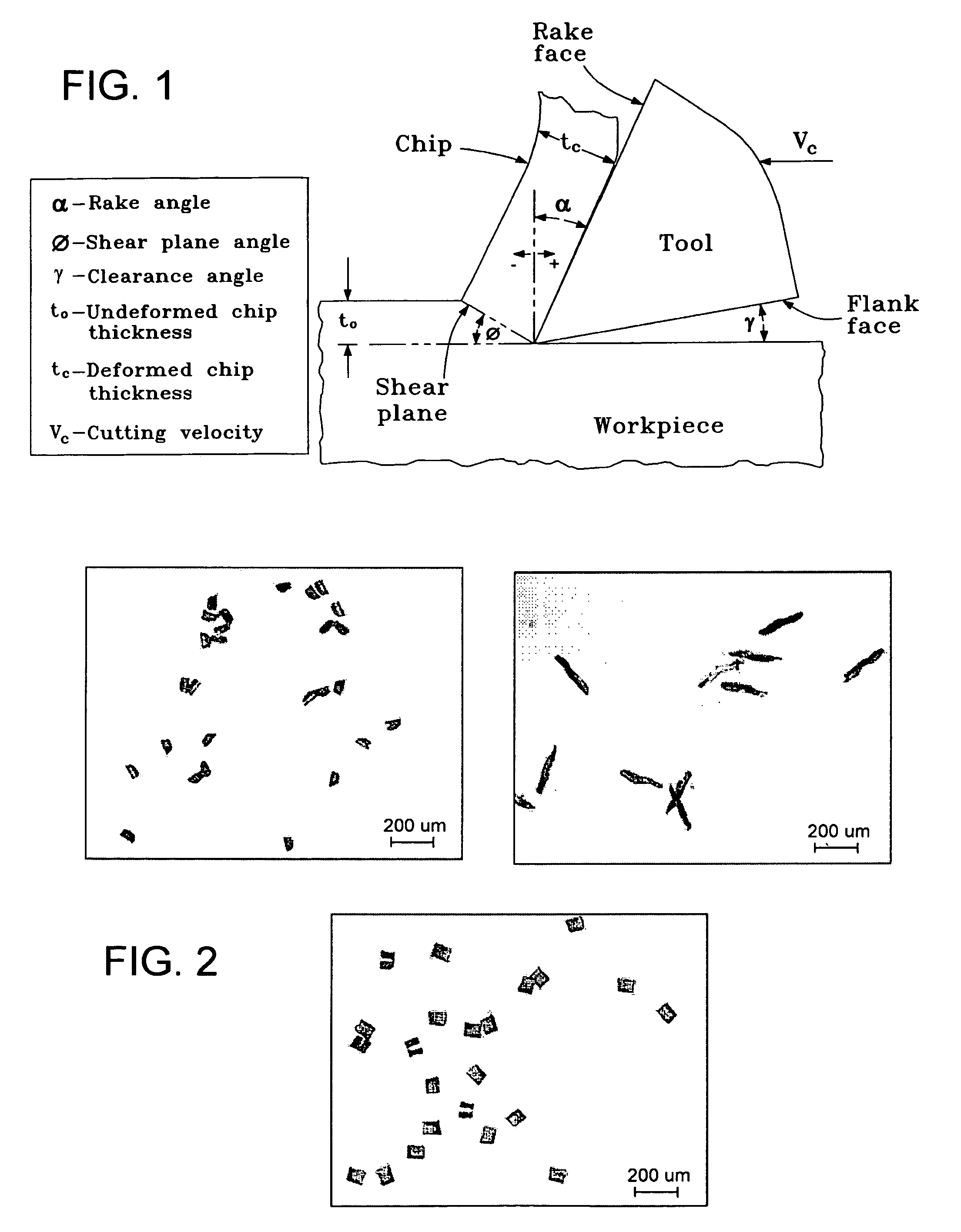

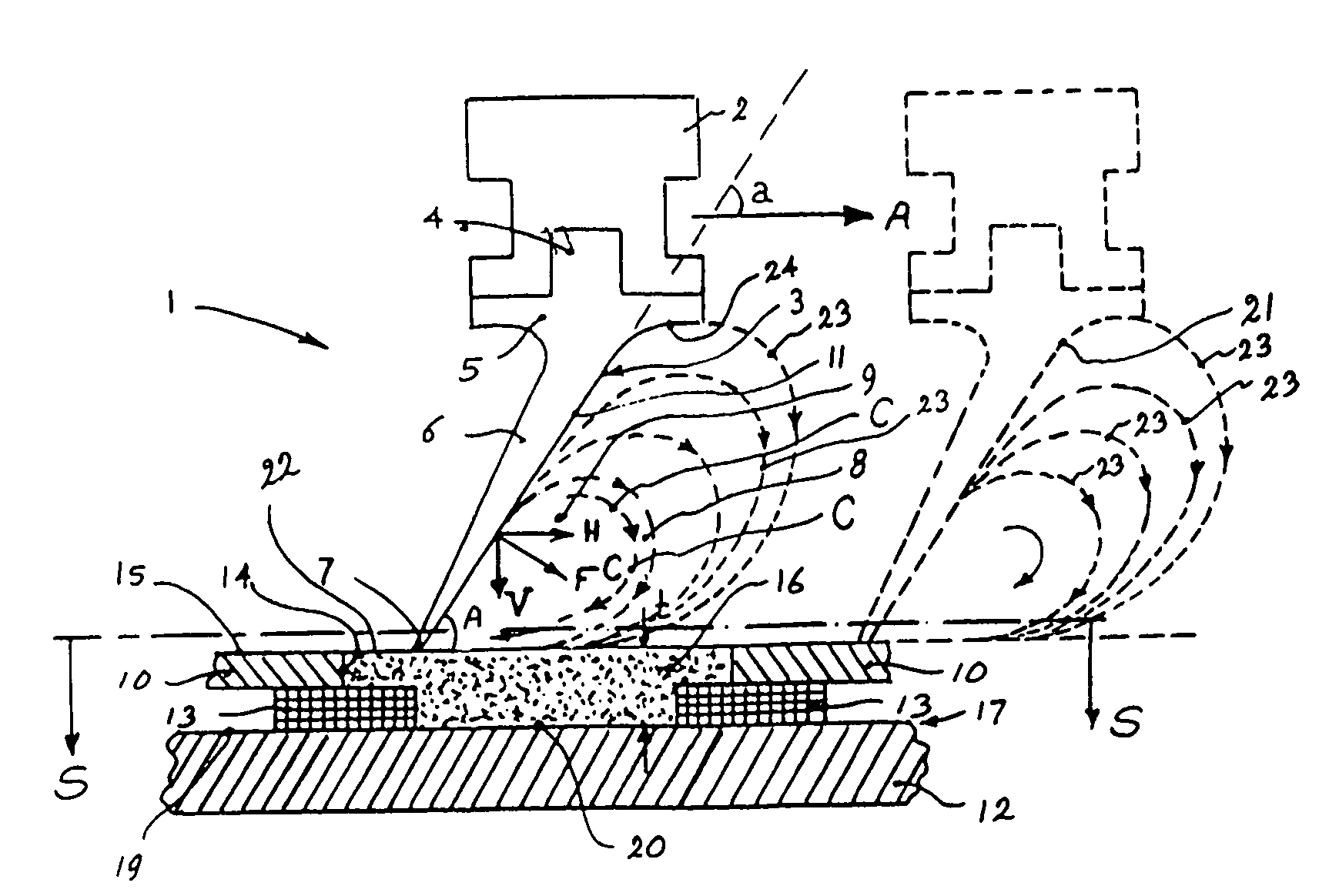

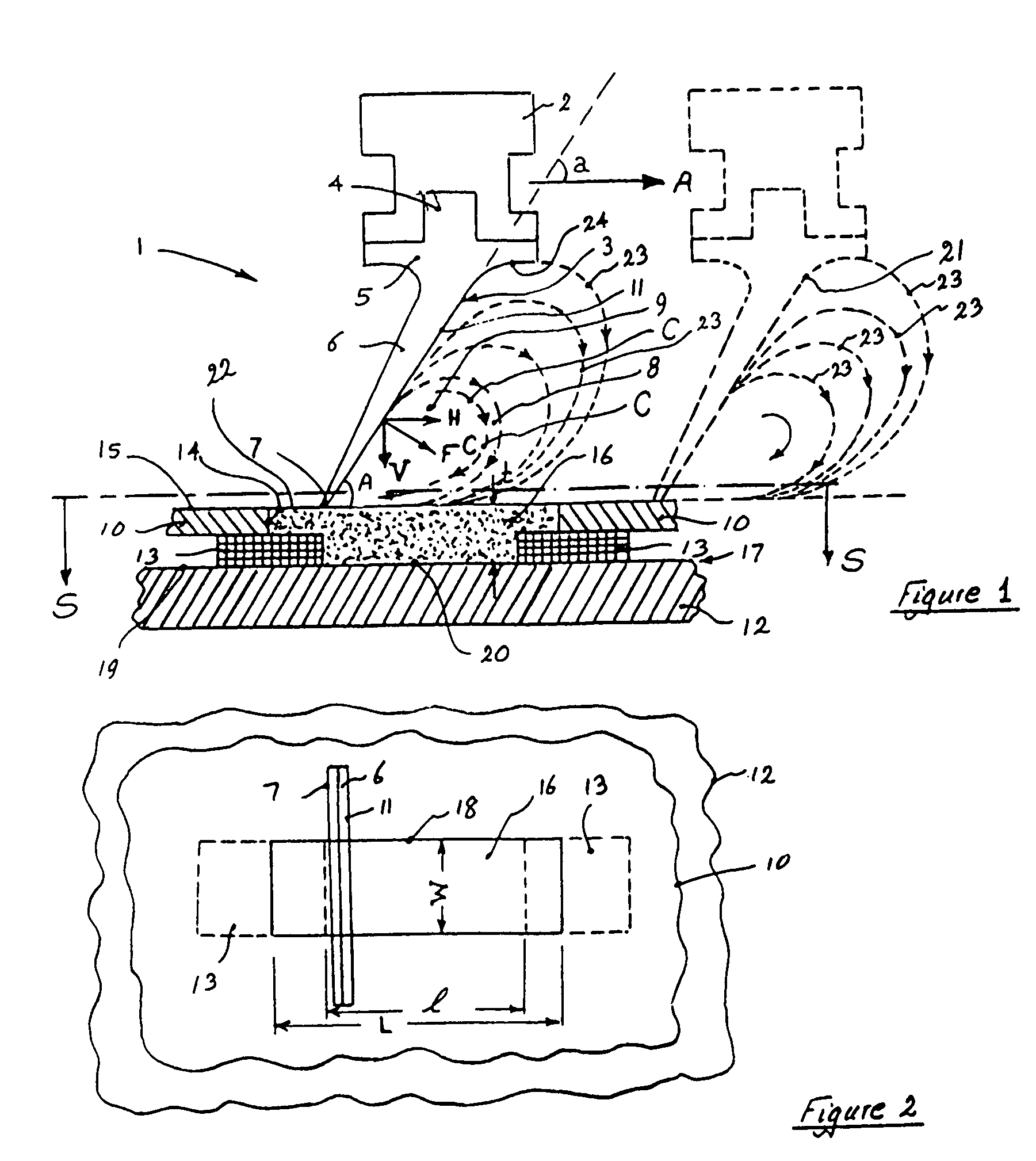

Tool holder assembly and method for modulation-assisted machining

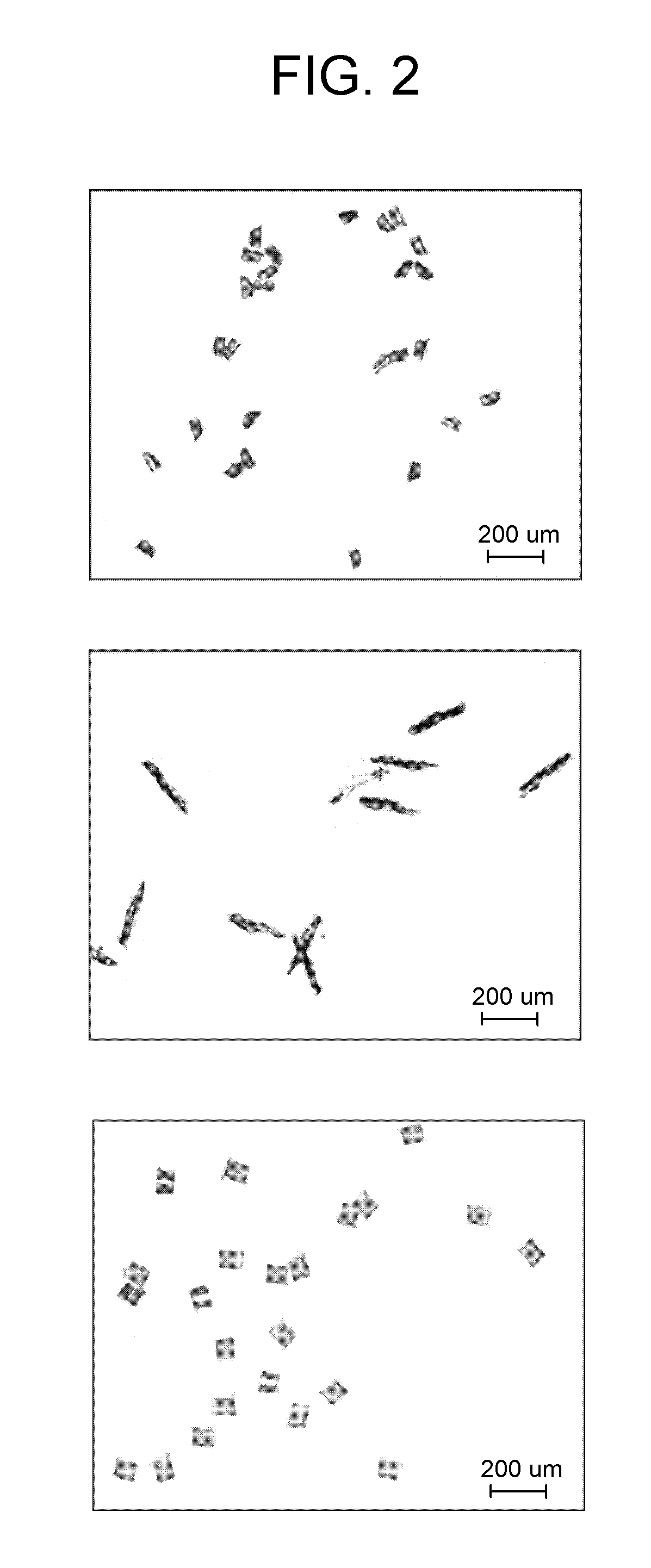

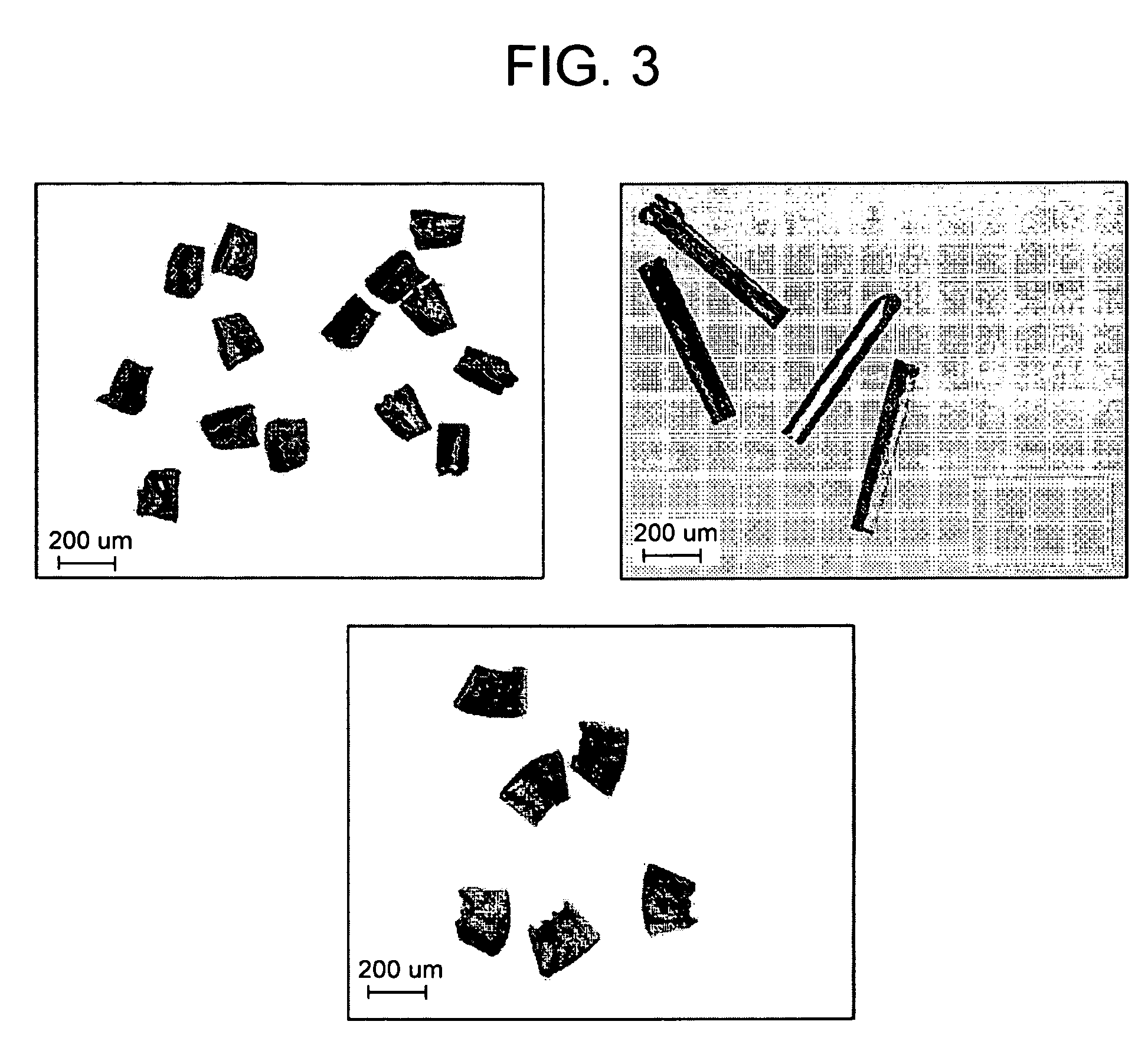

ActiveUS20060251480A1Accurately and repeatably obtainedLarge deformationTransportation and packagingAuxillary equipmentMachining processTool holder

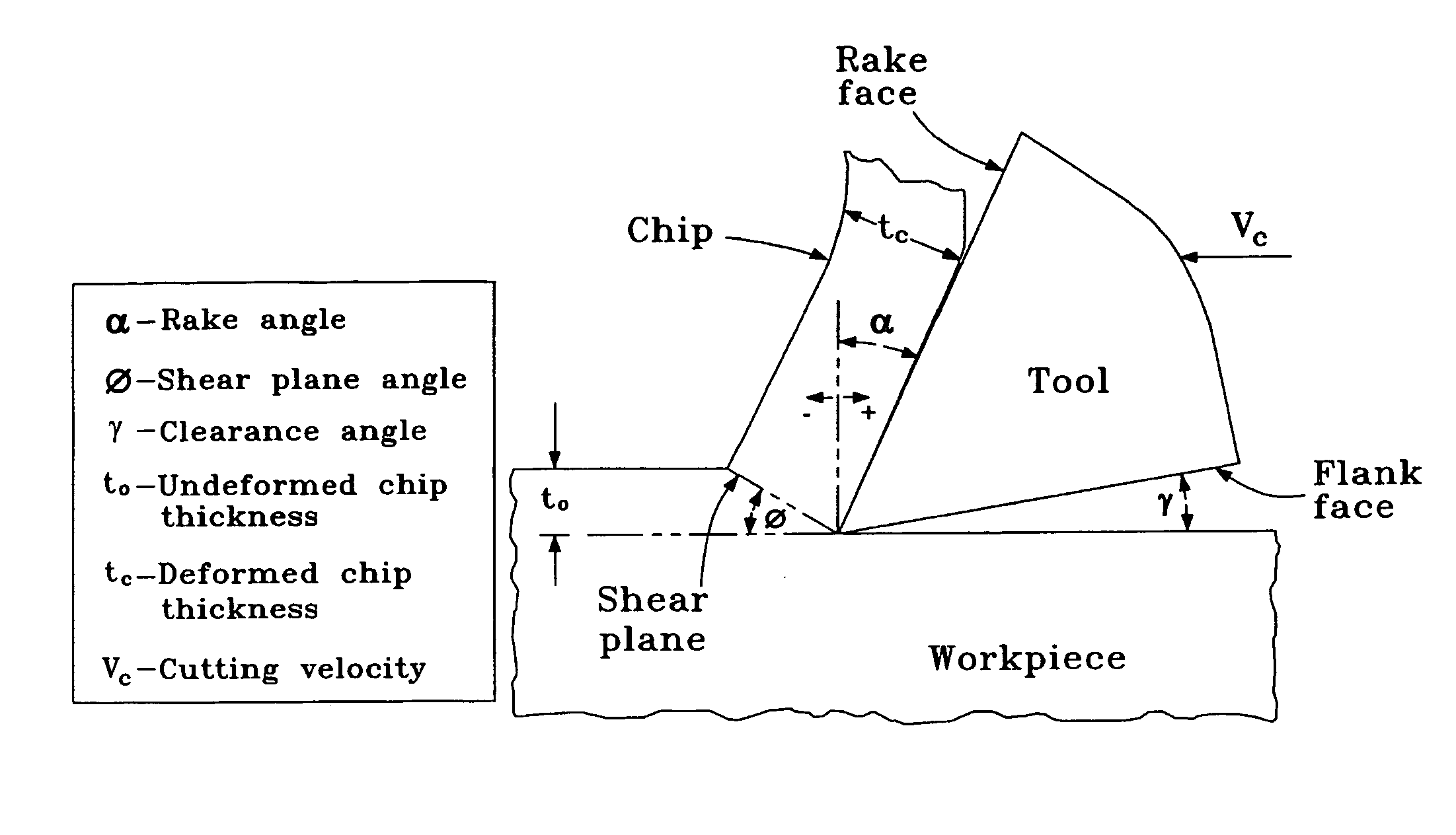

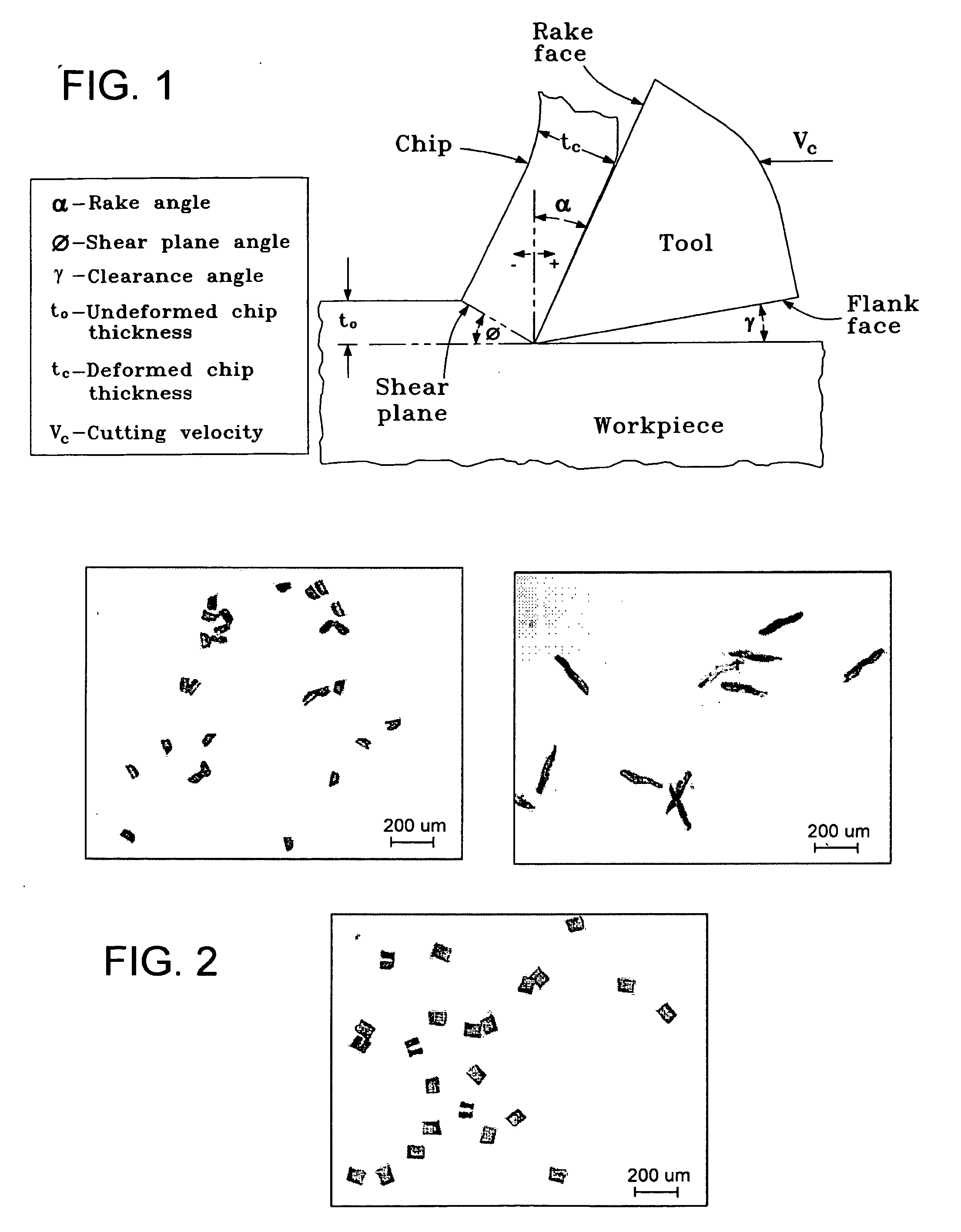

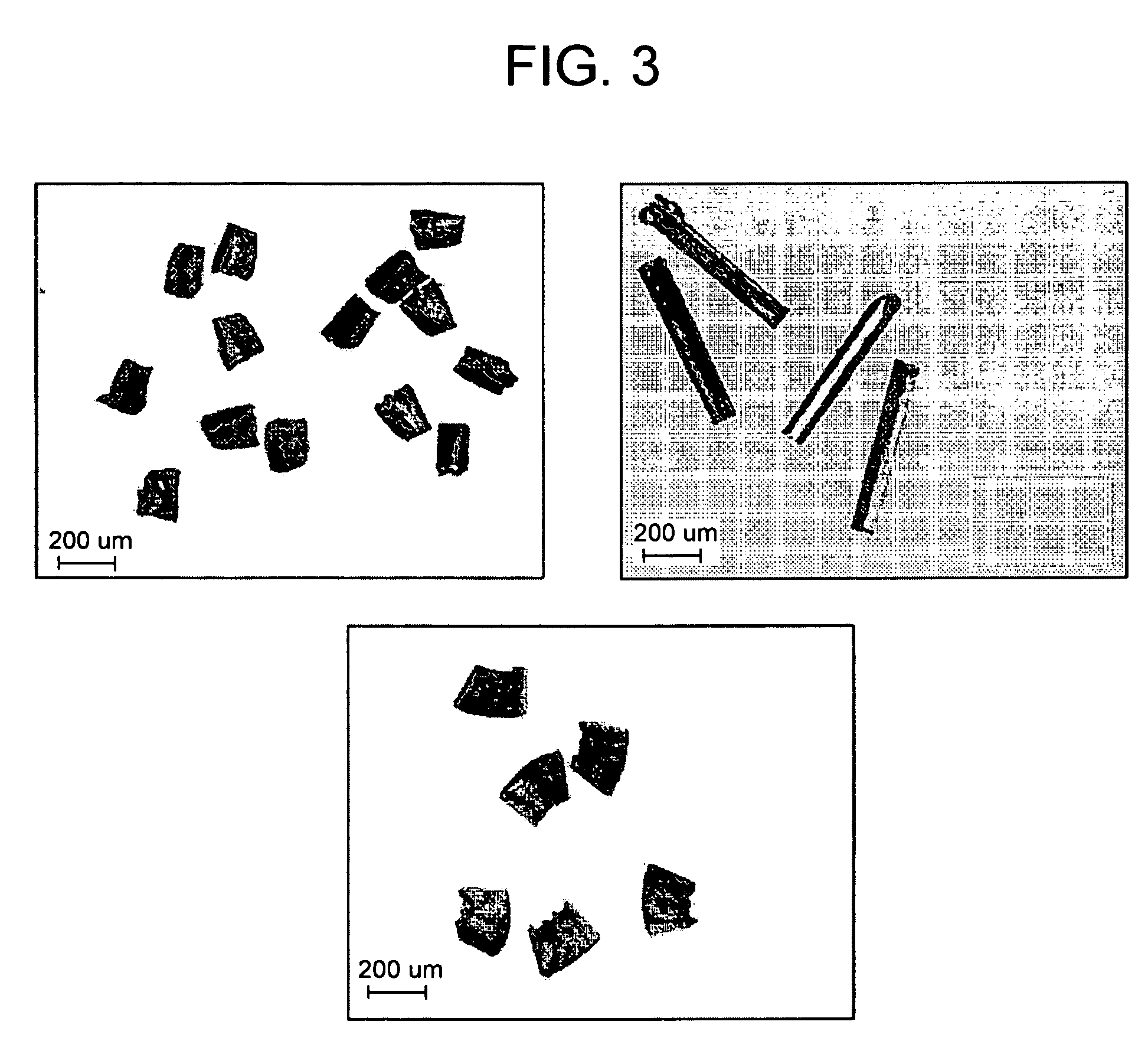

A tool holder assembly and method for intentionally inducing modulation in a machining process. The tool holder assembly is configured for mounting in a tool block on a machining apparatus and includes a tool holder body configured to be secured to the tool block of the machining apparatus, a tool holder mounted on the tool holder body and configured for securing a cutting tool thereto, and a device for imposing a superimposed modulation on the tool holder so as to move the cutting tool relative to the tool holder body and thereby relative to the tool. The tool holder assembly is useful in a process for producing chips having a desired shape and size, and particularly to a method of controllably producing nanocrystalline chips.

Owner:PURDUE RES FOUND INC

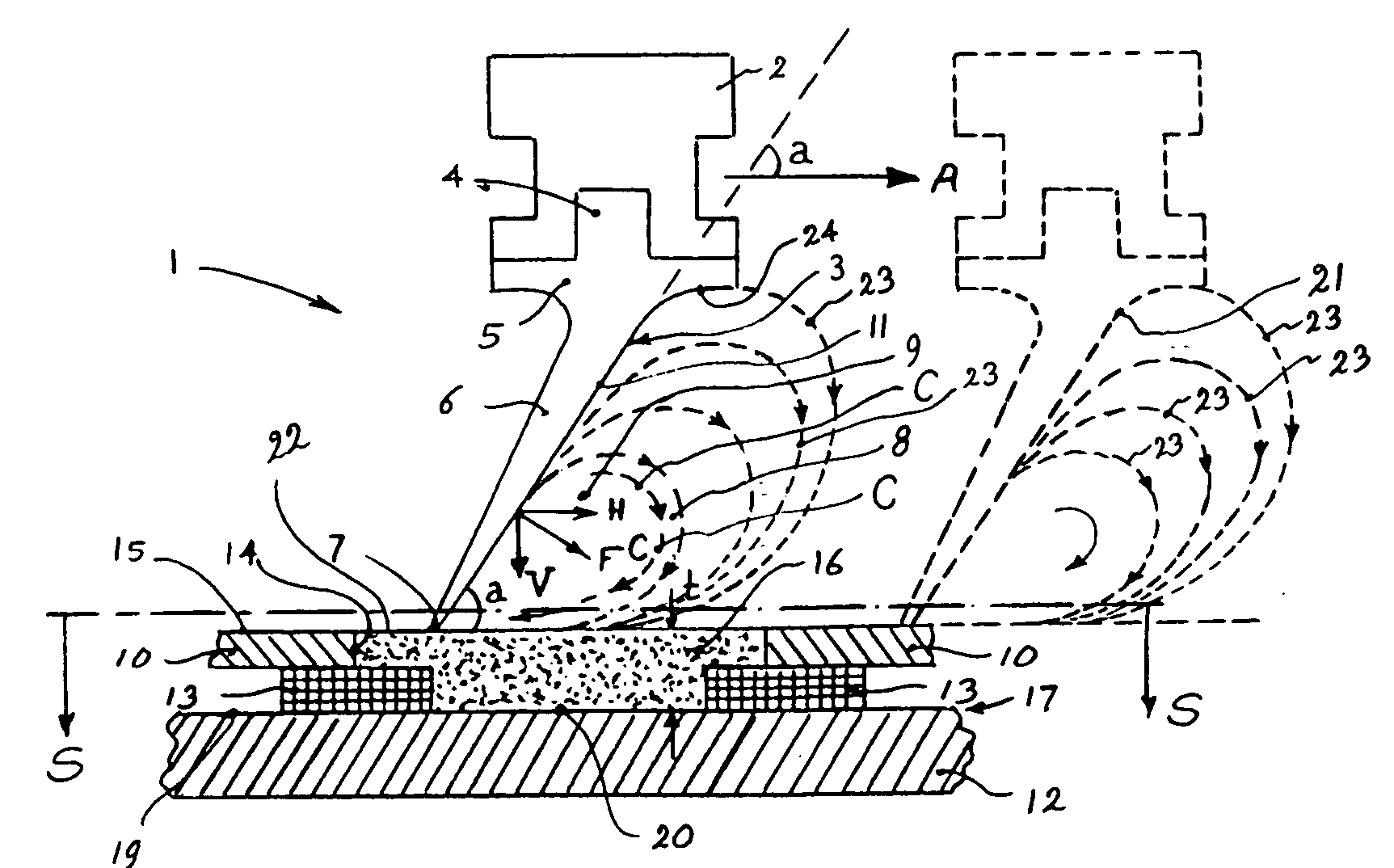

Polymer thick-film resistive paste, a polymer thick-film resistor and a method and an apparatus for the manufacture thereof

InactiveUS20050051360A1Low/insignificant dimensional and shape changeHigh solid contentPretreated surfacesLiquid/solution decomposition chemical coatingPolymer sciencePrinted circuit board

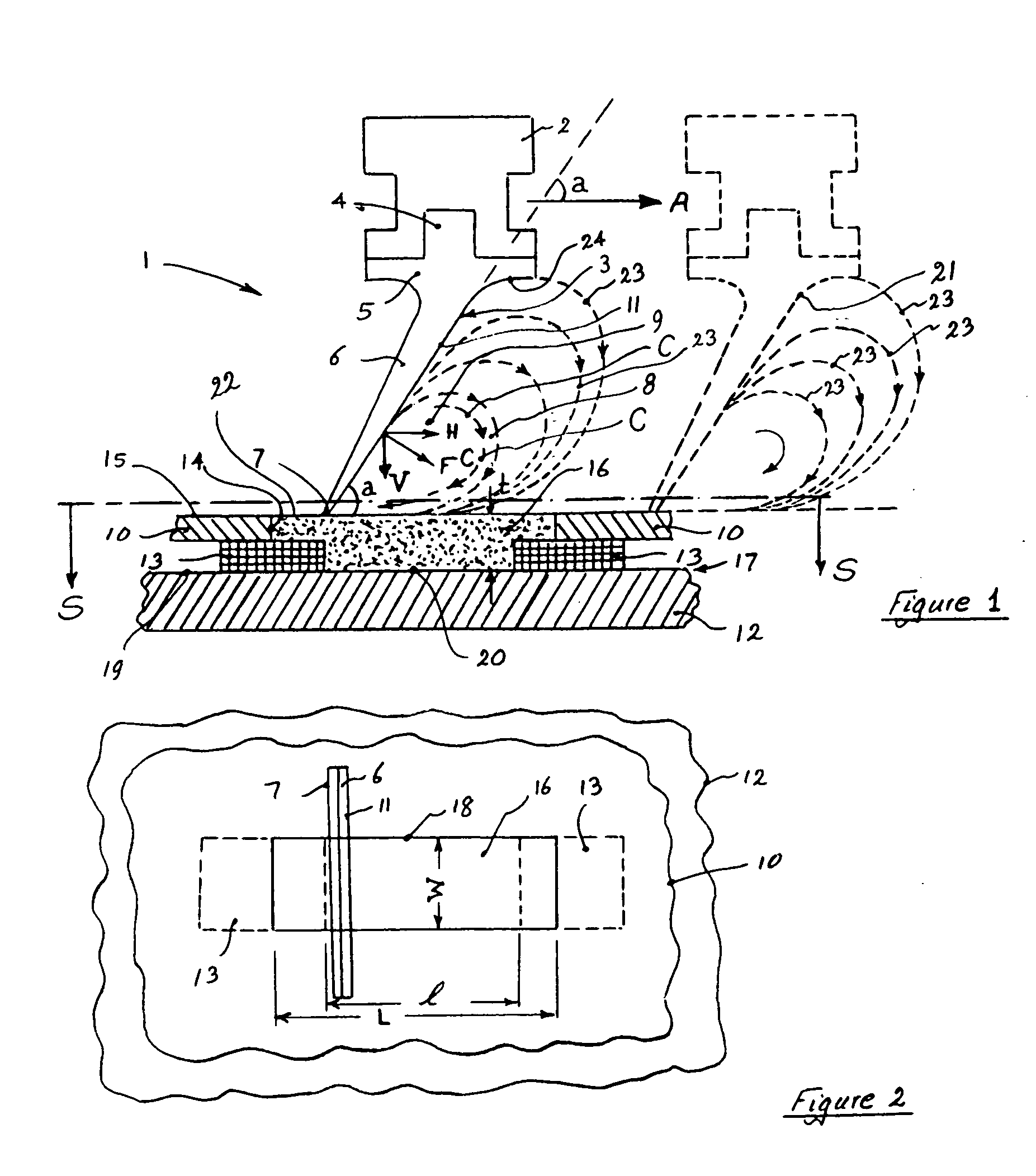

The present invention teaches formulations, apparatus and a method of applying high thixotropic index polymer thick-film resistive pastes for making polymer thick-film resistors with improved tolerances by providing a squeegee with a blade tilted at an angle of 10 to 85 to the surface of the printed circuit board thus causing a fluid rotational motion within the bead of the polymer thick-film resistive paste as the squeegee blade moves relative to the printed circuit board. This rotational motion increases the shear strain rate experienced by the paste within the bead and results in a more effective filling of the resistor-shaped cavity without including air bubbles, experiencing elastic recovery of the paste and, without surface fractures of the paste.

Owner:EMBED TECH

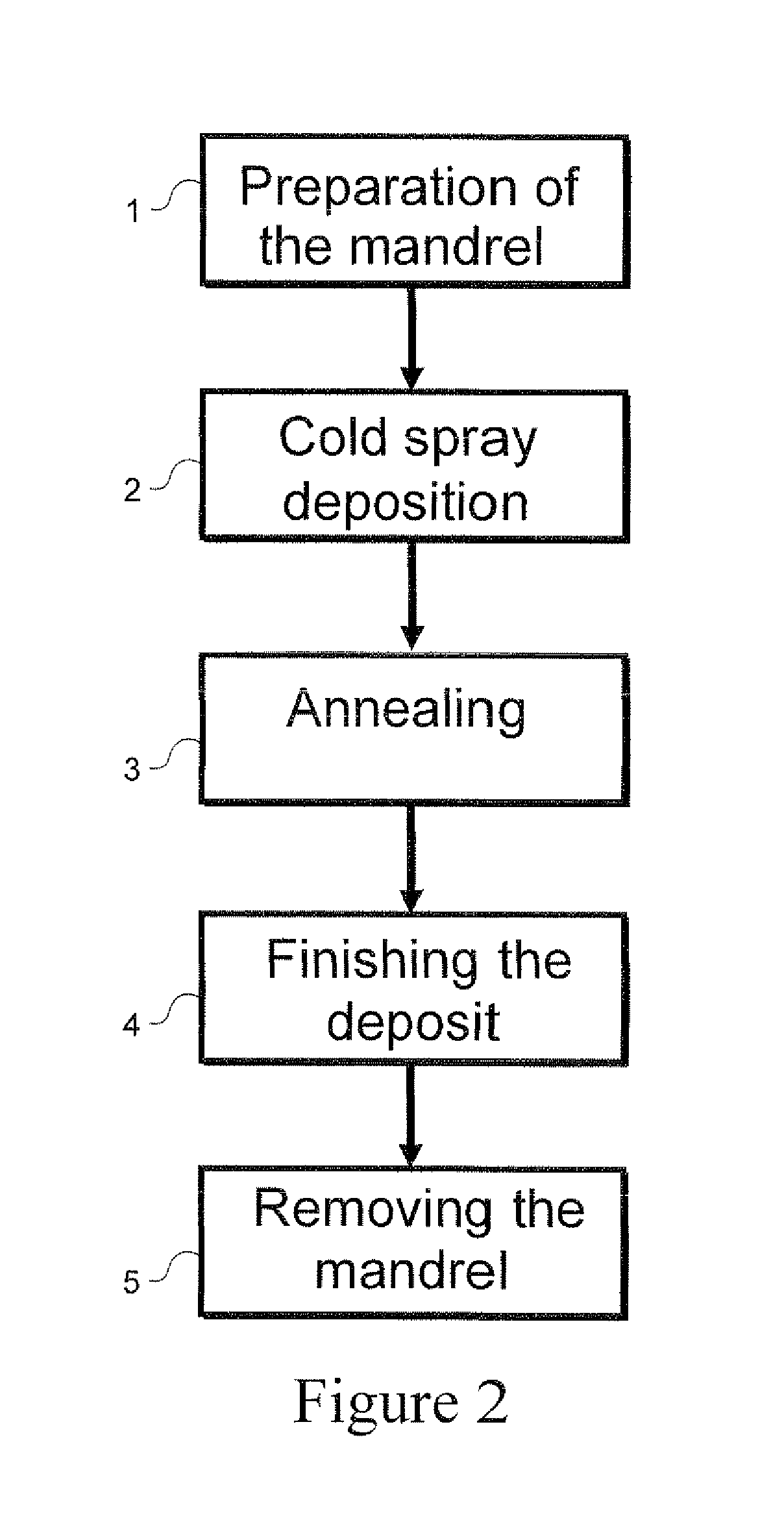

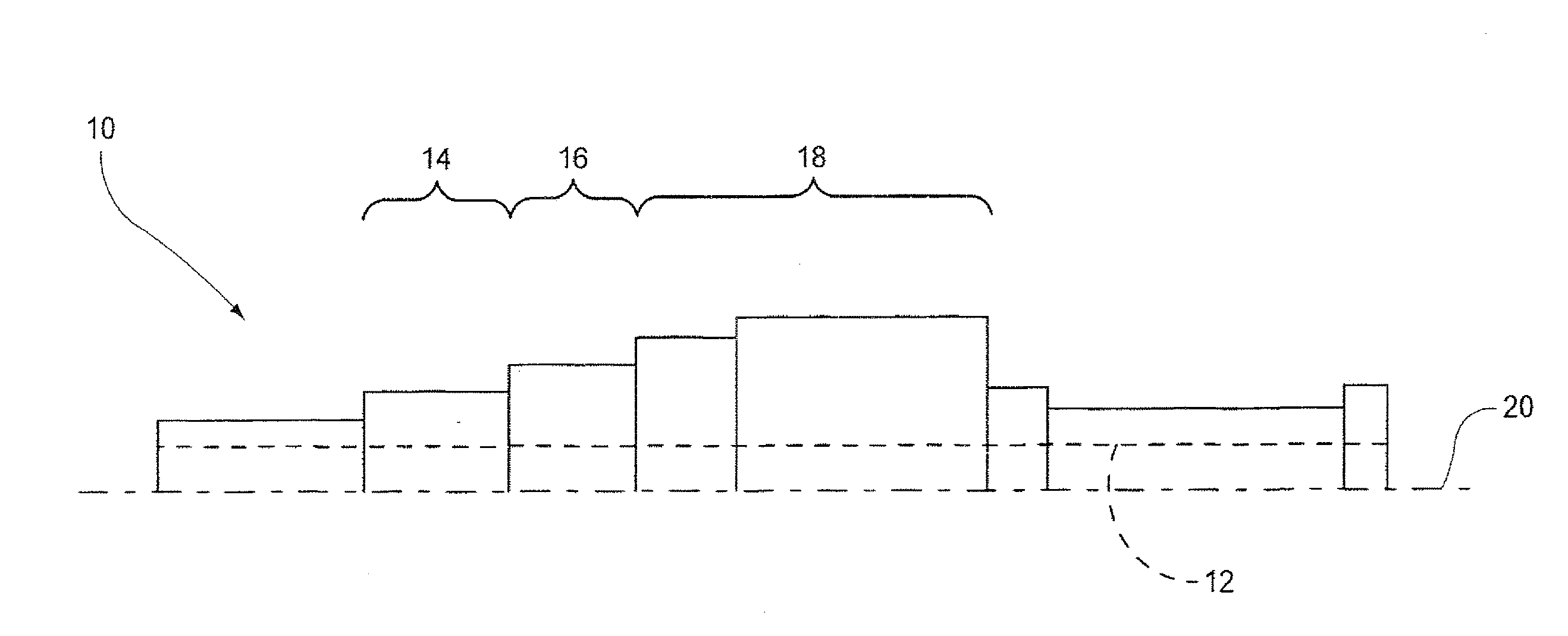

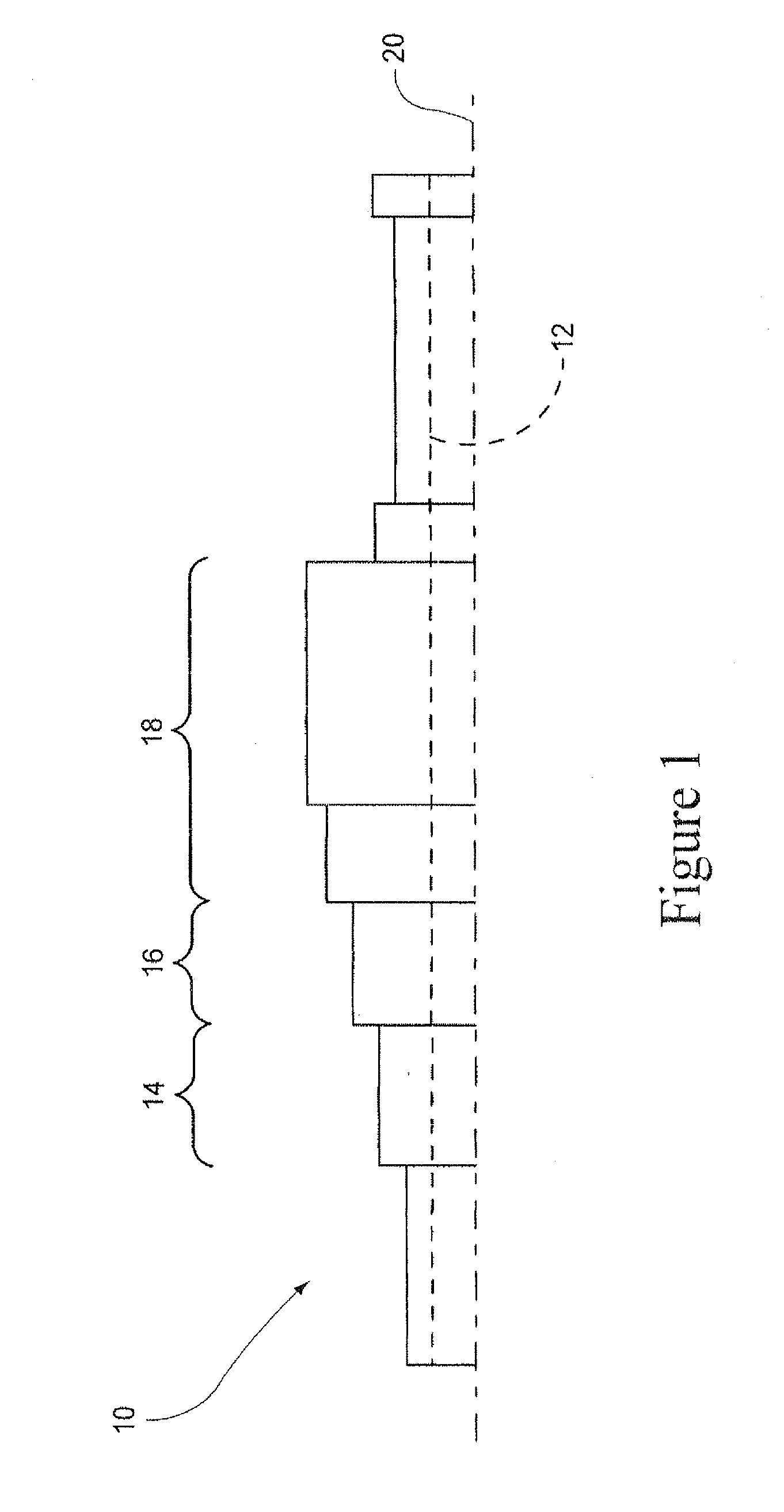

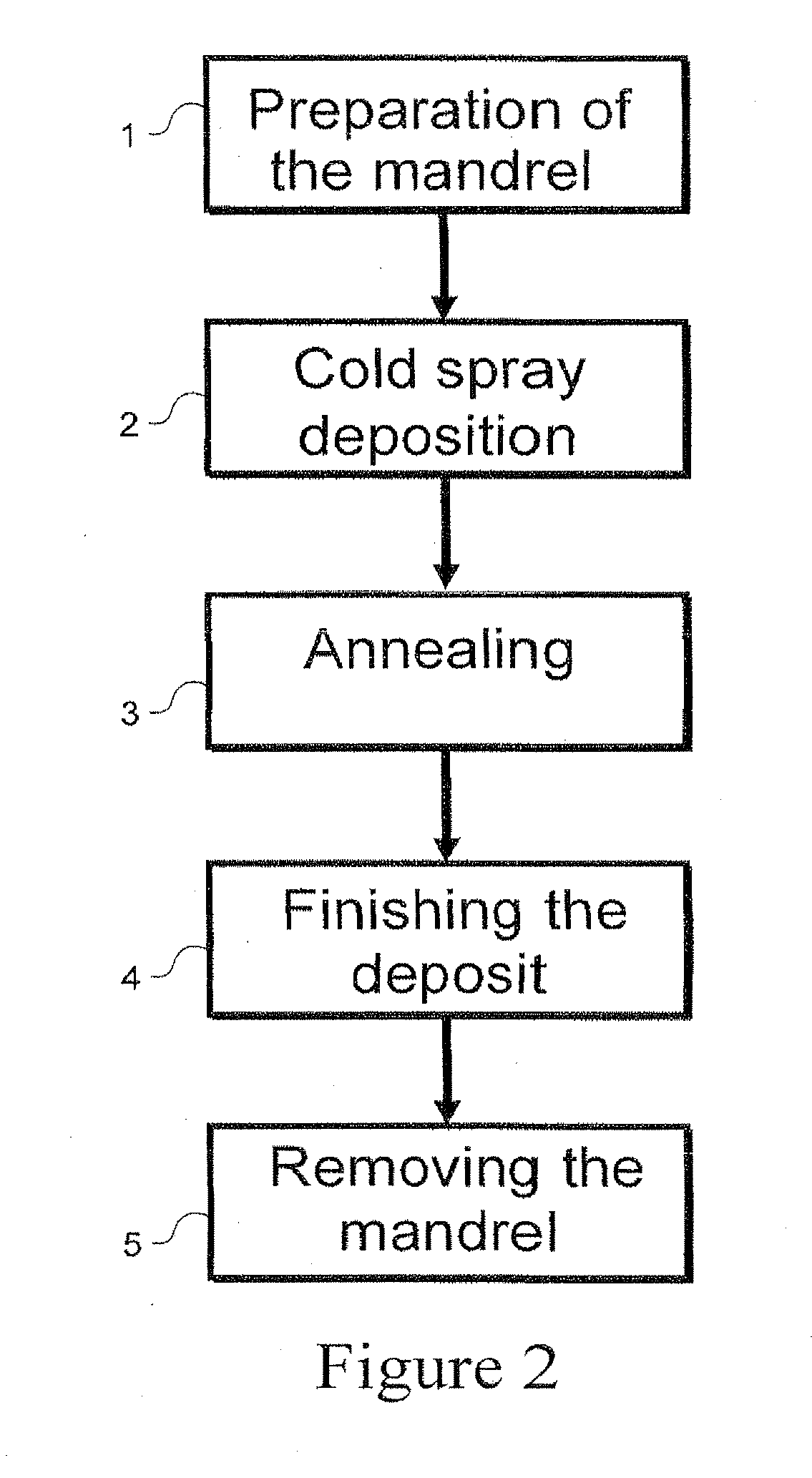

Turbine rotor fabrication using cold spraying

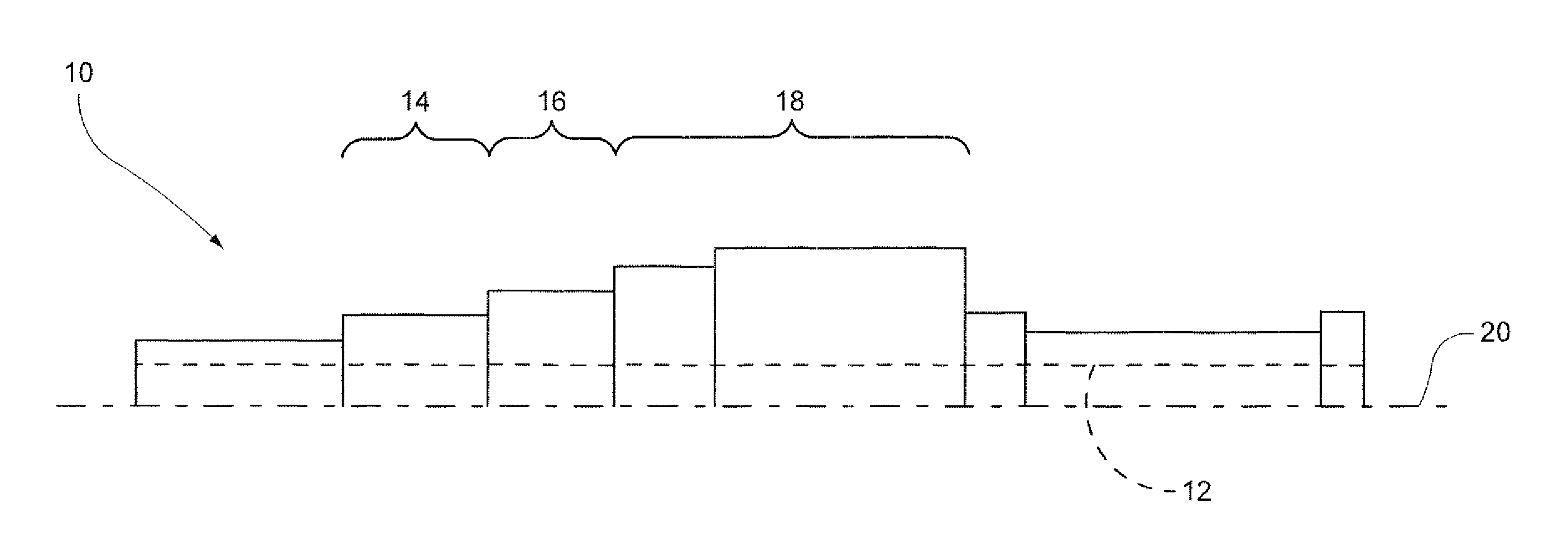

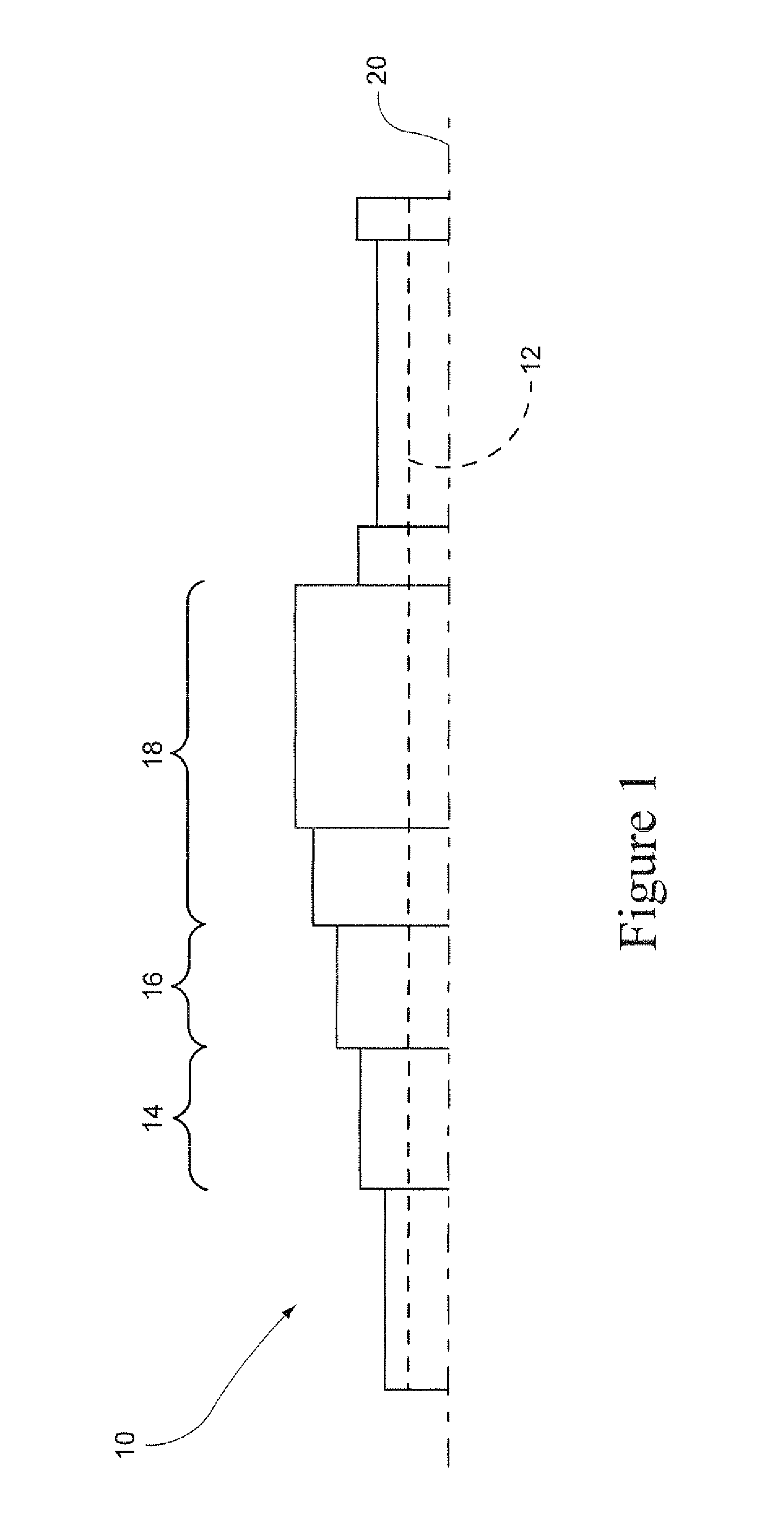

ActiveUS20110078896A1High strengthIncrease strainMetal rolling stand detailsPretreated surfacesEngineeringNet shape

A method of manufacturing a rotor includes: (a) providing a core shaft; (b) cold spraying alloy powder particles onto the core shaft; (c) controlling the cold spraying to form sections at least of different shape along the core shaft to thereby form a near-net shape rotor; and (d) heat treating the near-net shape rotor to relieve stresses and to form diffusion bonding across interfaces between individual powder particles and the core shaft, and finish-shaping said near-net shape rotor.

Owner:GENERAL ELECTRIC CO

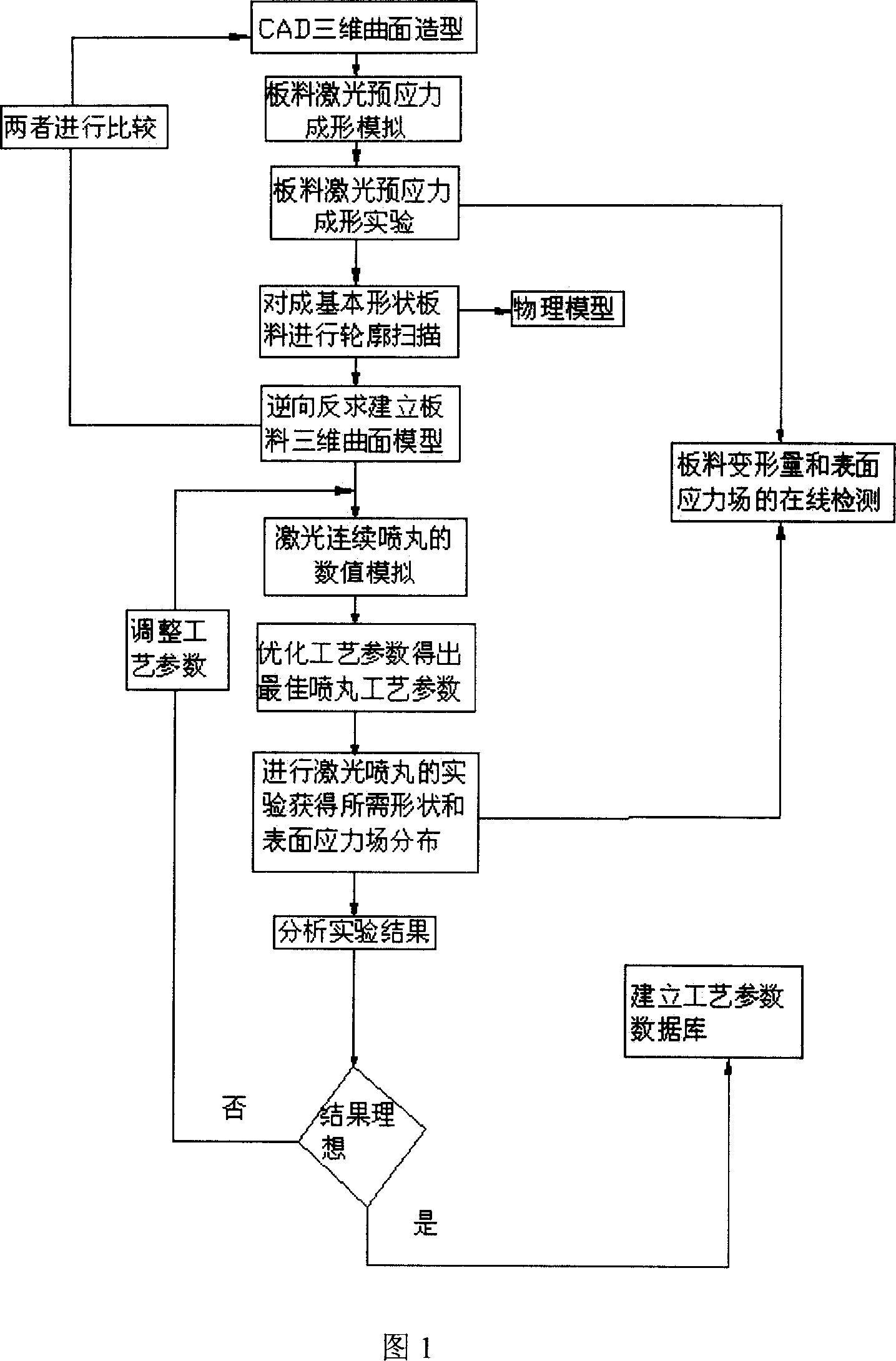

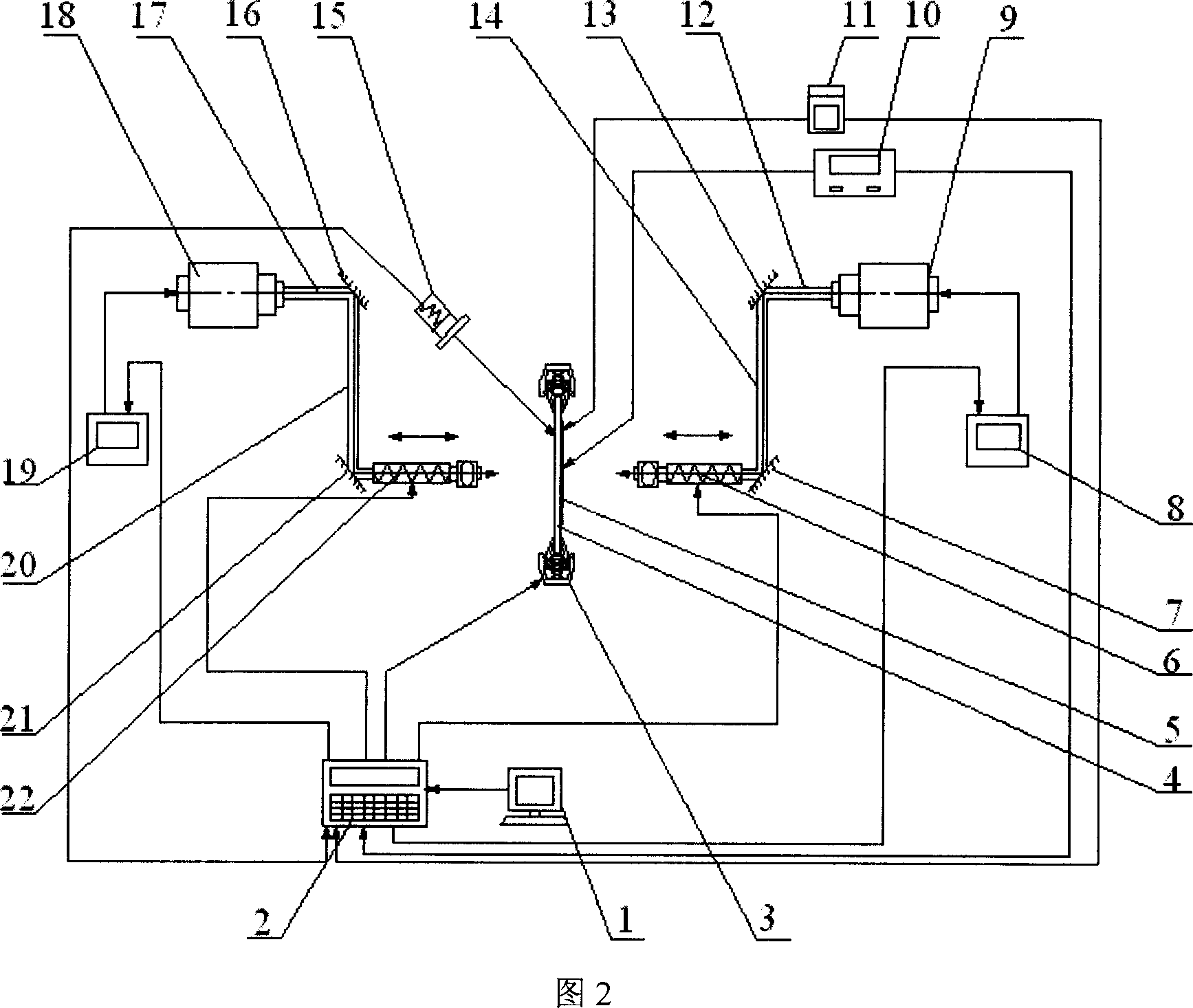

Method and apparatus of forming cut deal laser prestress composite shot blasting

InactiveCN101011777AImprove surface qualityImprove fatigue resistanceNumerical controlLaser beam welding apparatusSurface stressLaser light

A cut deal laser inherent stress composite peen forming features in the clipper using robot, using carbon dioxide to realize the basic formation, profile measuring feedback system controlling the deformation quantity, left stress meter measuring the surface stress of the board, optical scanning the pre formation, realizing board through model analog software, getting optimized process parameter instructing laser consecutive peen formation, using neodymium glass laser providing short pulse strong laser light, laser impact wave as the force source of precise forming, using the profile feedback device and on line measuring board surface stress left stress to control the deformation quantity to realize precision forming with complex shapes.

Owner:JIANGSU UNIV

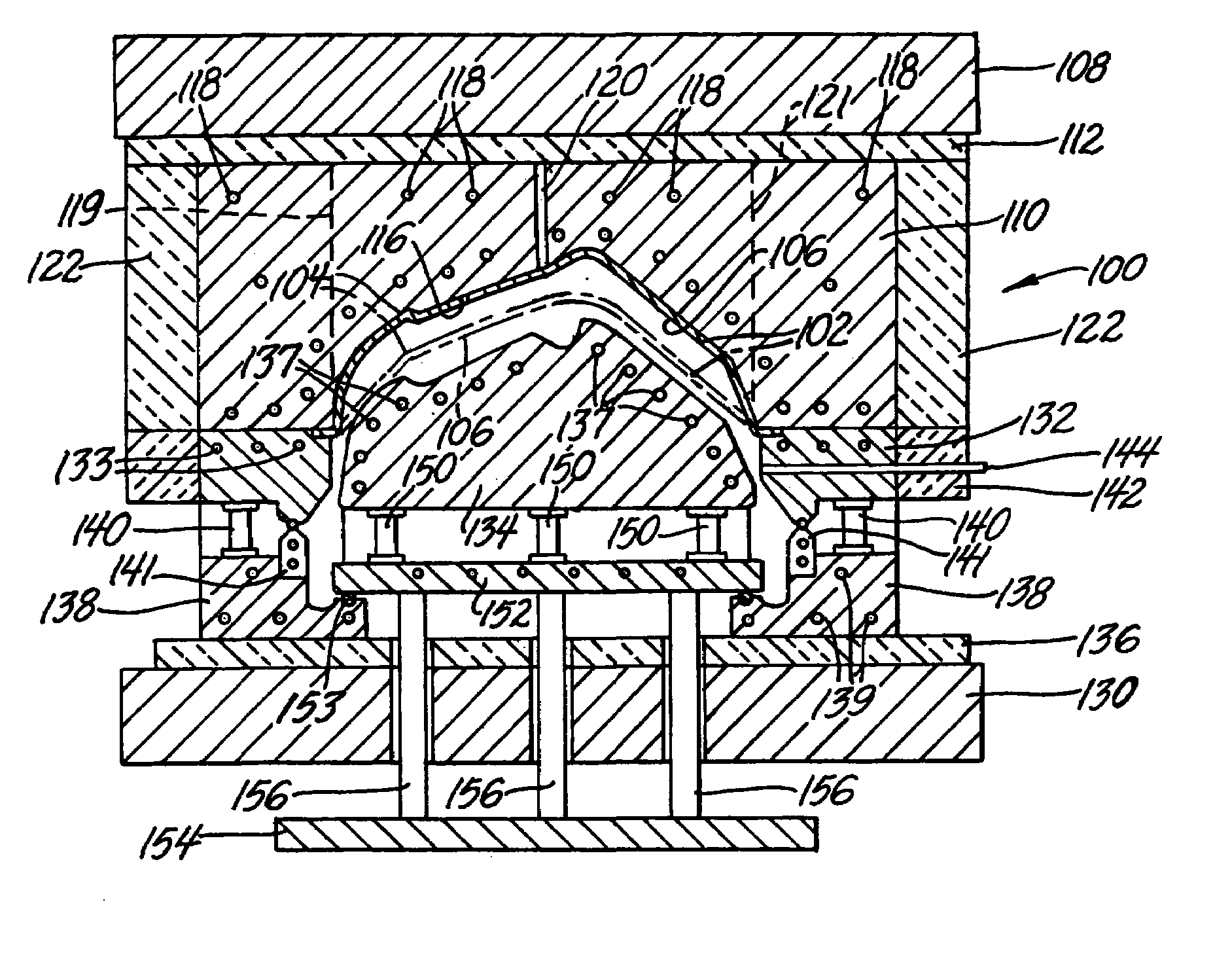

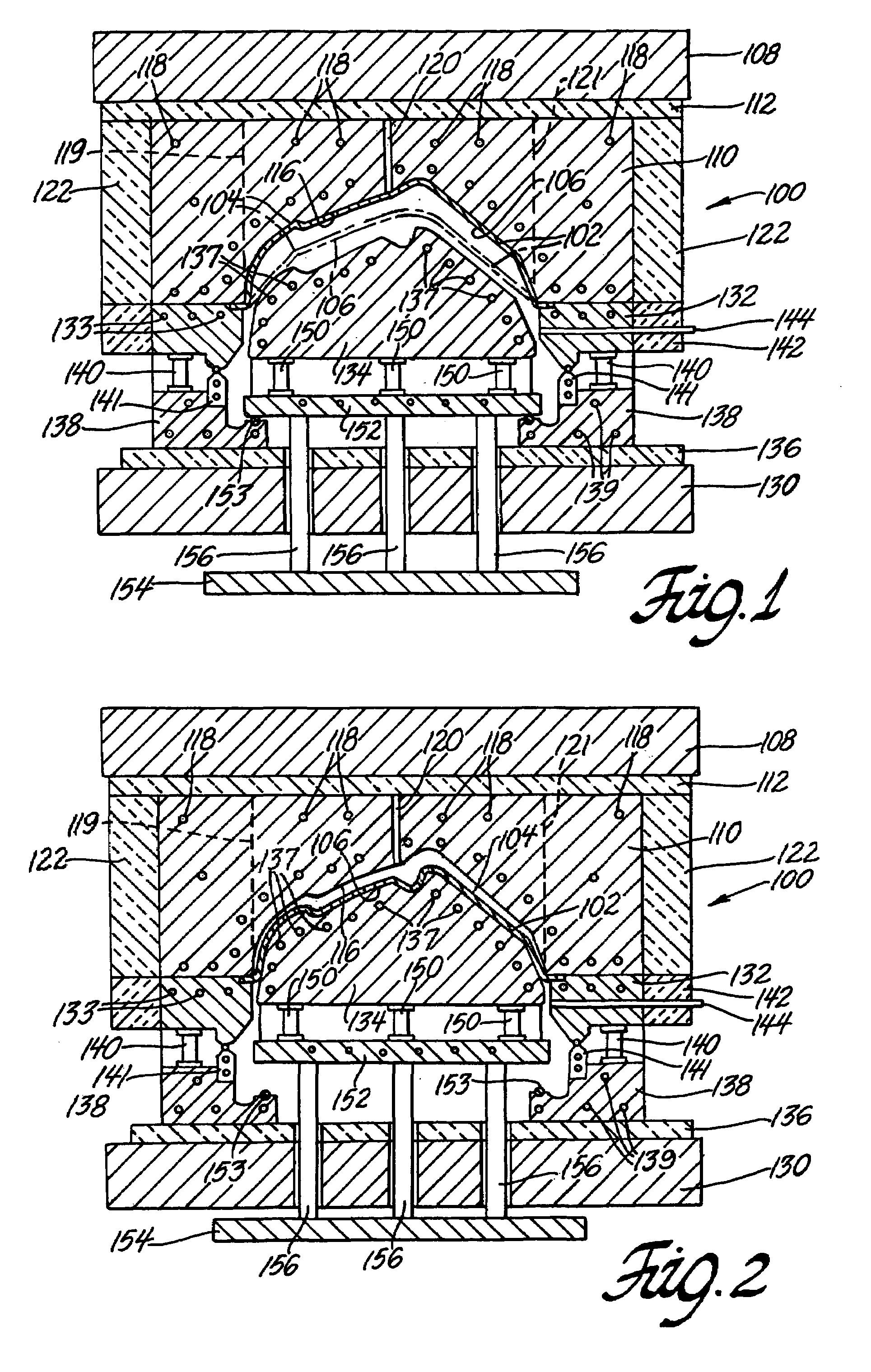

Two temperature two stage forming

InactiveUS6910358B2Facilitate rapid plastic elongation of sheet materialExhaust fastShaping toolsTwo temperatureMaterials science

Owner:GM GLOBAL TECH OPERATIONS LLC

Impact tensile test machine

InactiveUS7533557B1High strain rateHigh elongationForce measurementUsing electrical meansAerospace engineeringEngineering

A high-speed tensile test device is disclosed, which measures the stress-strain behavior, up to failure, of polymeric materials, at high strains (as much as 1000%), and high strain rates (up to 104 / s). A weight, when dropped down a vertical track, impacts two L-levers positioned below and on each side of the weight, pushing the horizontal arms of the L-levers. The L-levers have cable connected to the vertical arms of the L-levers and are looped around pulleys, then connected to shuttles located on a horizontal track. The shuttles are attached to load cells, which are connected to grips that hold a sample to be tested. When the horizontal arms of the L-levers are pushed by the weight, they pivot, causing the cables to pull on the shuttles, load cell, and grip, which move in an outward direction, stretching the sample.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Stirring-friction-based crack repair method

InactiveCN103212778AReduce distortionReduce stressNon-electric welding apparatusUltimate tensile strengthAstronautics

The invention relates to a stirring-friction-based crack repair method which mainly is used for solving the problems in the prior art that the repair cost is high, the repair quality is poor and cracks appear repeatedly. The method is applied to the repair of surface cracks and through cracks of plate-shell metal structures, so as to enable cracked workpieces to meet reuse requirements. The method comprises the following specific steps of designing and manufacturing a friction repair tool according to the position and size of a crack, a material to be repaired, structural characteristics and the like; and realizing the friction between a shaft shoulder and the surface of the material to be repaired through the rotation of the repair tool so as to enable metal of a repair area to reach a thermoplastic state under the action of frictional heat, and realizing the flowing transfer and dynamic recrystallization of thermoplastic metal around the crack by using the rotating and upsetting action of the shaft shoulder of the repair tool, thereby realizing the filling repair of the crack. The method has the advantages that the method is simple, the damage to base metal is little, the quick, equal-strength and in-situ repair of engineering cracks can be realized, and the repair process is economical and environment-friendly. The method can be applied to the crack repair in fields, such as aeronautics and astronautics, shipbuilding, automobiles and rail transportation and has broad application prospects.

Owner:SHENYANG AEROSPACE UNIVERSITY

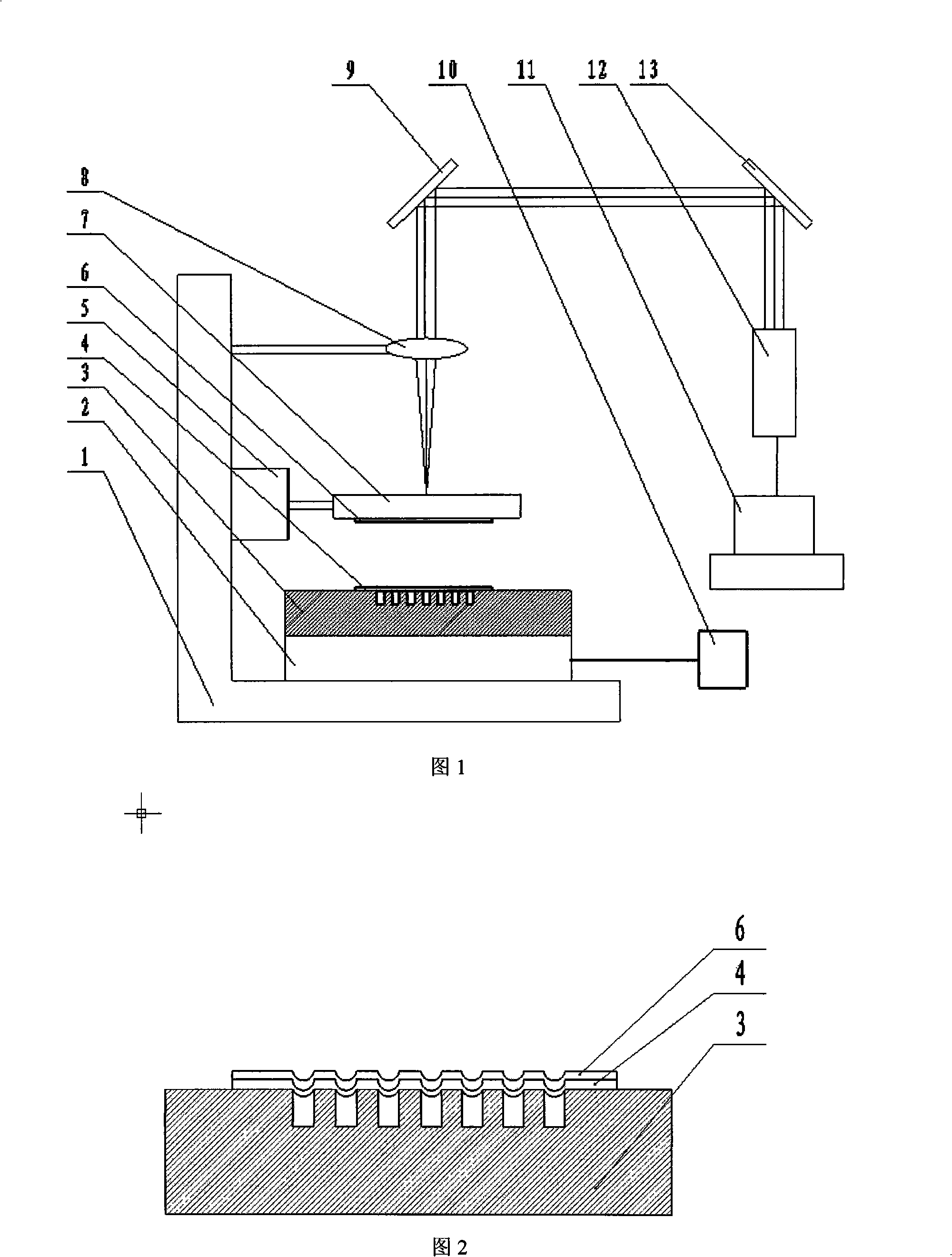

Method for impacting micro-plasticity forming with strong laser and device thereof

InactiveCN101254574AHigh surface hardnessHigh sensitivitySemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesShock waveElectrolysis

A plastic micro-forming method by using strong laser shock and a device thereof belong to the field of micro-electro-mechanical system (MEMS) processing and laser micro-processing technology. The method is characterized in that the method comprises the following steps: polishing both sides of a target for experiment by electrolysis; pressing a transparent optical medium with a thickness of micrometer level on a press plate as a constrained layer; tightly pressing a metal flying plate on the optical medium; fastening the optical medium, the metal flying plate, the target and a template on a special target clamping machine through the press plate; turning on a nano-second pulsed laser; adjusting the optical path to focus the laser outputted from the nano-second pulse laser on the target surface; subjecting the nano-second pulsed laser to single emission to achieve single pulse laser shock on the target. The method can generate ultrahigh pressure and strain rate during production of a sample, and the application of pressure of the generated shock wave has higher planarity, completeness and repeatability, thus improving surface rigidity of micro-metal parts and improving micro-sensing sensitivity. Accordingly, a micro-driving device can provide higher drive force, torsional moment and energy.

Owner:JIANGSU UNIV

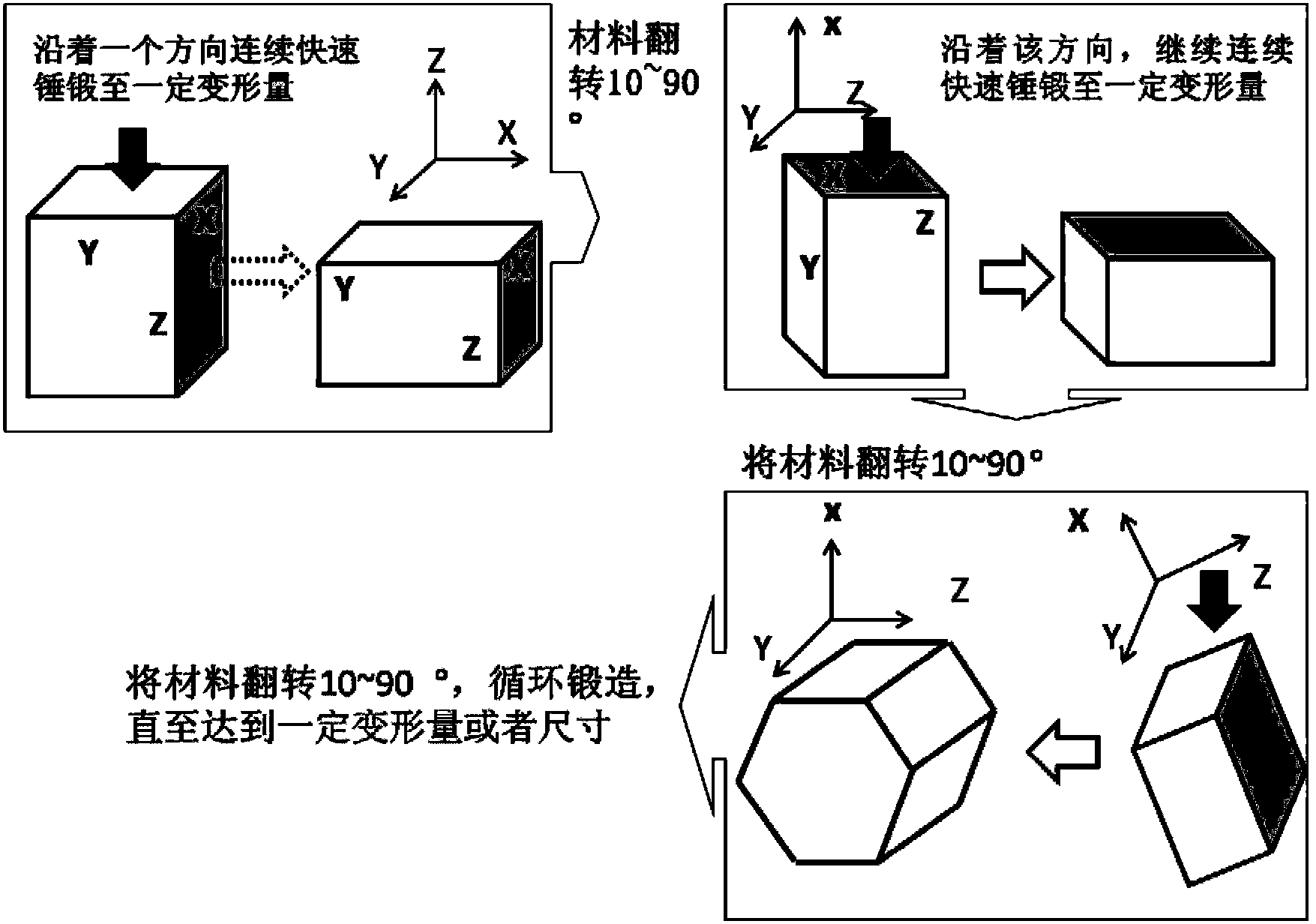

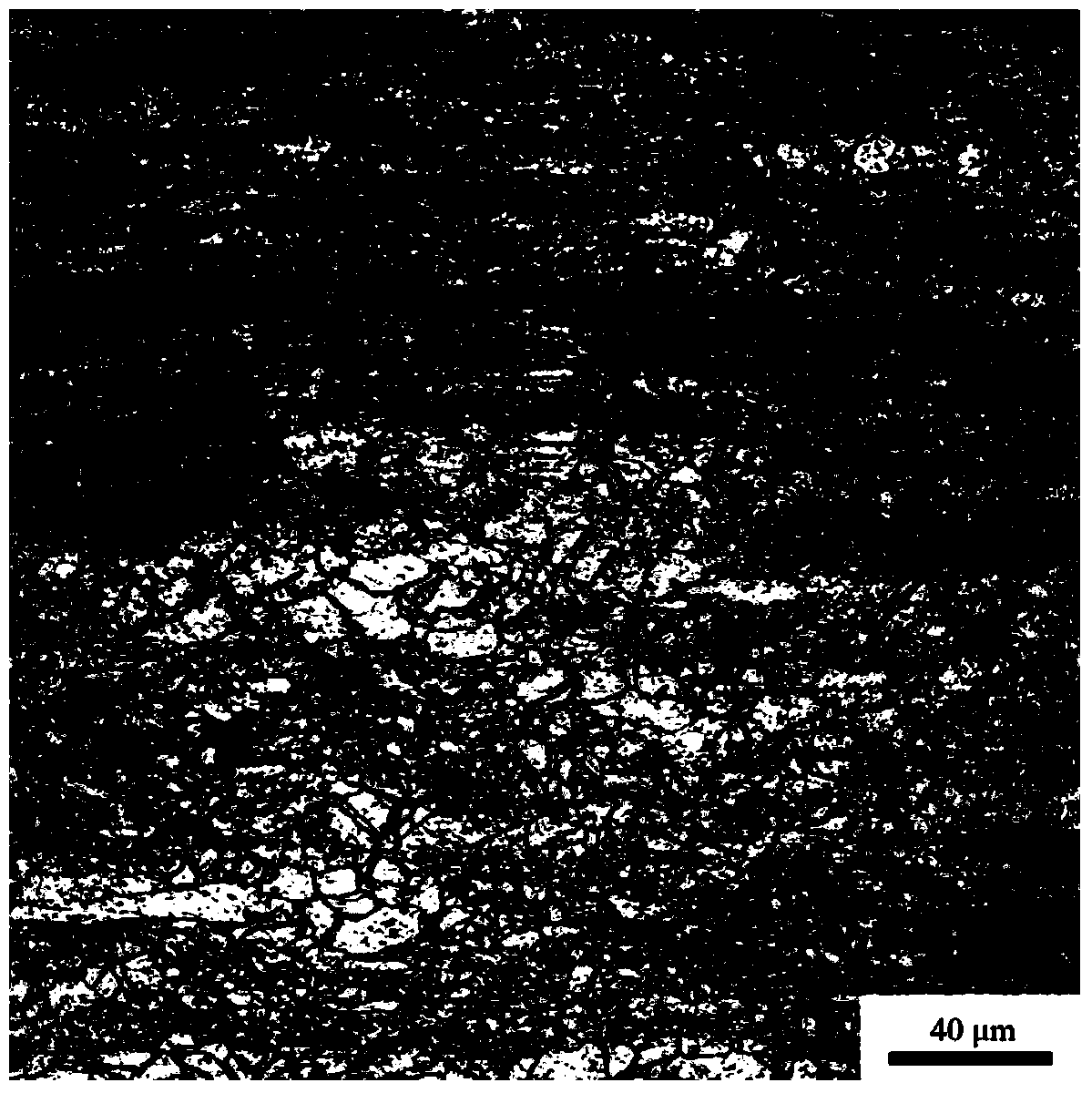

Forging method for multi-direction, circulatory and high-speed hammer forging of magnesium alloy

ActiveCN103805923AOvercome the shortcomings of poor plastic processing performanceLess slipHigh velocityHeat treated

The invention relates to a magnesium alloy plastic processing technology, and relates to a forging method for multi-direction, circulatory and high-speed hammer forging of a magnesium alloy. The method comprises the specific steps: after carrying out homogenization annealing of a casting-state or deformation-state magnesium alloy, carrying out continuous high-speed hammer forging along one direction of the bulk material at a certain temperature; after a certain deformation amount is reached, overturning the material, and continuing to carry out continuous high-speed hammer forging along another direction to reach a certain deformation amount; then overturning the material to another direction, and carrying out such circulatory hammer forging until the material reaches a predetermined deformation amount and size; and finally, carrying out heat treatment on the material. The method utilizes the textured micostructure formed during the processes of high-speed hammer forging of the magnesium alloy to be combined to change the hammer forging direction, thereby improving the ultimate deformation amount that the magnesium alloy can withstand and is not cracked during forging, and improving the plastic processing performance of the magnesium alloy. The method is suitable for magnesium and the alloy material thereof, and improves the forging processing production efficiency of magnesium and the alloy material thereof.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

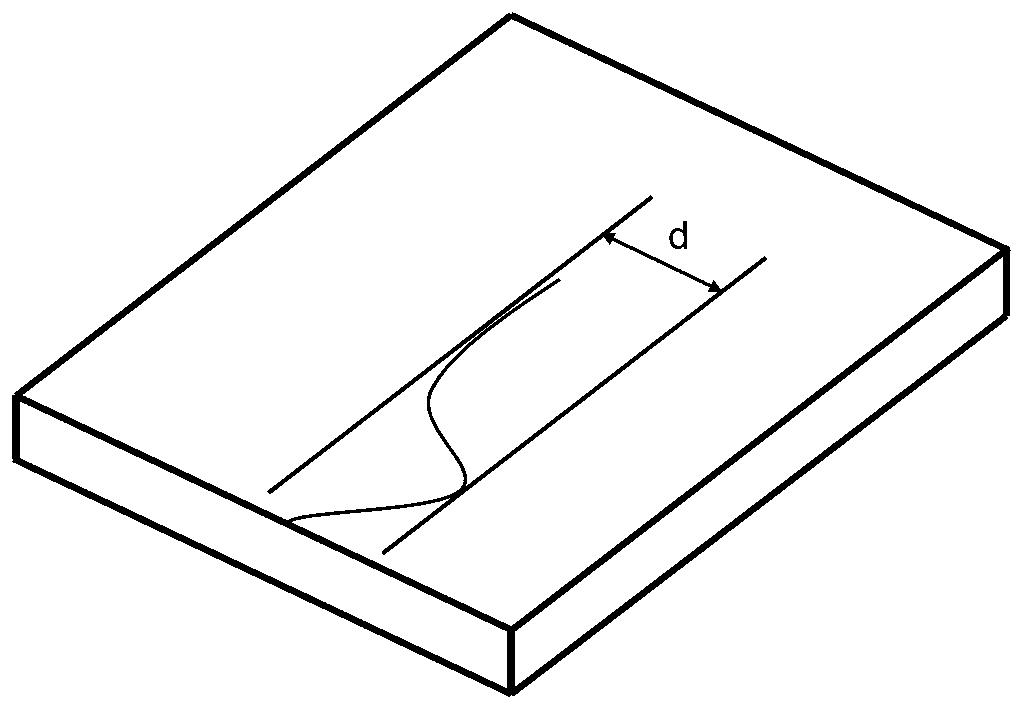

Machining method to controllably produce chips with determinable shapes and sizes

InactiveUS7628099B2Accurately and repeatably obtainedLarge deformationProgramme controlTransportation and packagingEngineeringSwarf

A method of controllably producing chips with a desired shape and size. The method generally entails machining a body with a cutting tool while superimposing modulation on the cutting tool so as to move the cutting tool relative to the body being machined and cause instantaneous and periodic separation between the cutting tool and the body at a point of contact between the cutting tool and the body, wherein each separation between the cutting tool and the body yields a chip. In this manner, the shapes and sizes of the chips are determined at least in part by the modulation cycle, and particularly the length of time the cutting tool is engaged with the body being machined.

Owner:PURDUE RES FOUND INC

Tool holder assembly and method for modulation-assisted machining

ActiveUS7587965B2Accurately and repeatably obtainedLarge deformationTransportation and packagingAuxillary equipmentMachining processTool holder

Owner:PURDUE RES FOUND INC

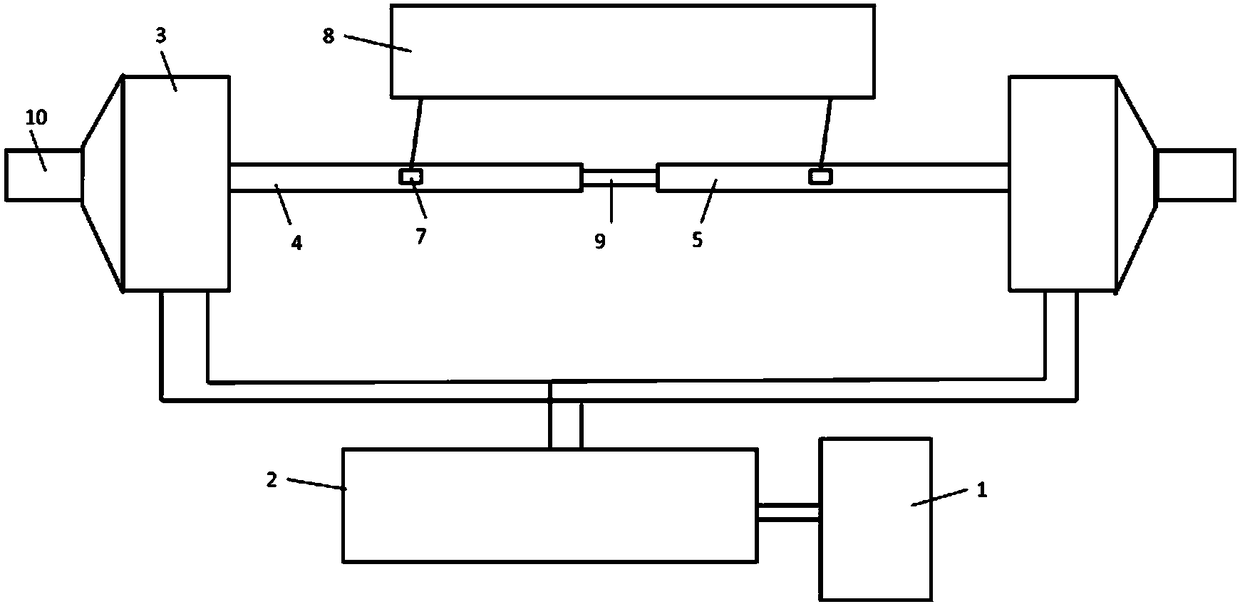

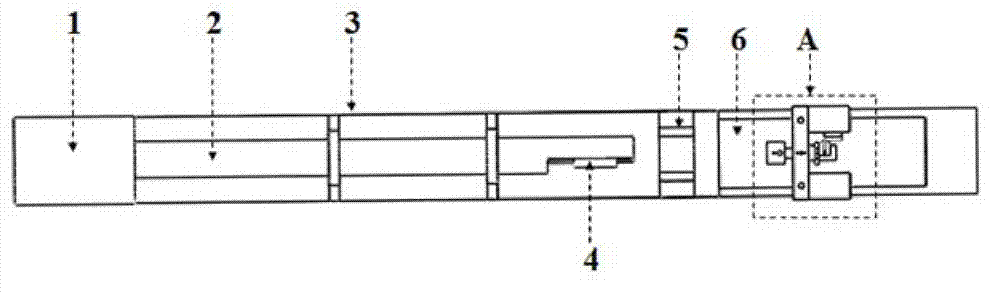

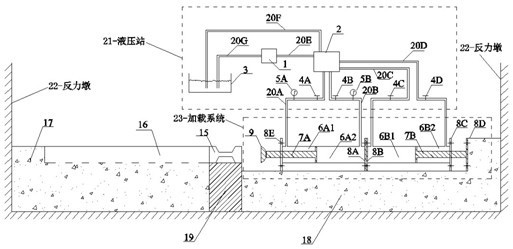

Single-axis two-way loading and split Hopkinson pressure bar and pull bar device and experimental method

ActiveCN108344648AAchieving Symmetrical LoadingHigh strain rateStrength propertiesCapacitanceExperimental methods

The invention relates to an experimental method of dynamic mechanics performance testing of materials, in particular to a single-axis two-way loading and split Hopkinson pressure bar and pull bar device and an experimental method. The device comprises a loading device and two incident bars, the loading device comprises a power source, a capacitor charger and loading guns, a power supply part of existing electromagnetic riveting equipment is adopted for the capacitor charger, and the loading guns with the same parameters are connected into the capacitor charger after being in parallel connection. By means of the single-axis two-way loading and split Hopkinson pressure bar and pull bar device and the experimental method, incident waves at the two sides simultaneously and symmetrically load aspecimen dynamically, symmetric loading of the specimen is achieved to shorten the balancing time of stress inside the specimen, the strain rate of the specimen is increased, and thus the defects ofexisting equipment of being low in strain rate and inaccurate in testing of elastic sections are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

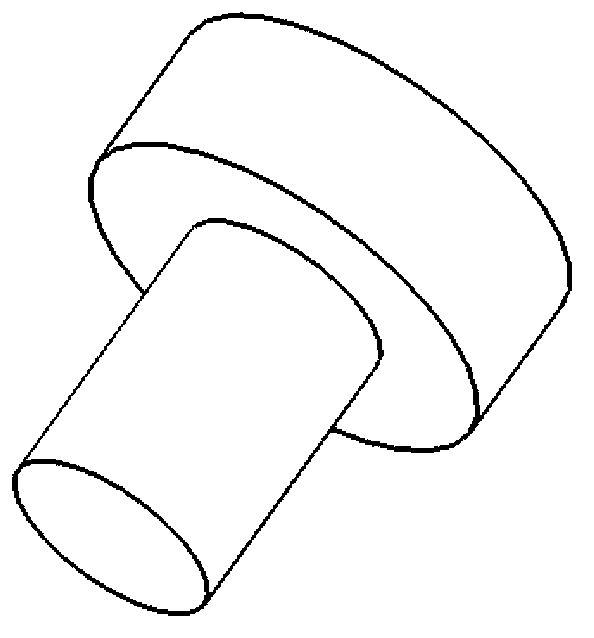

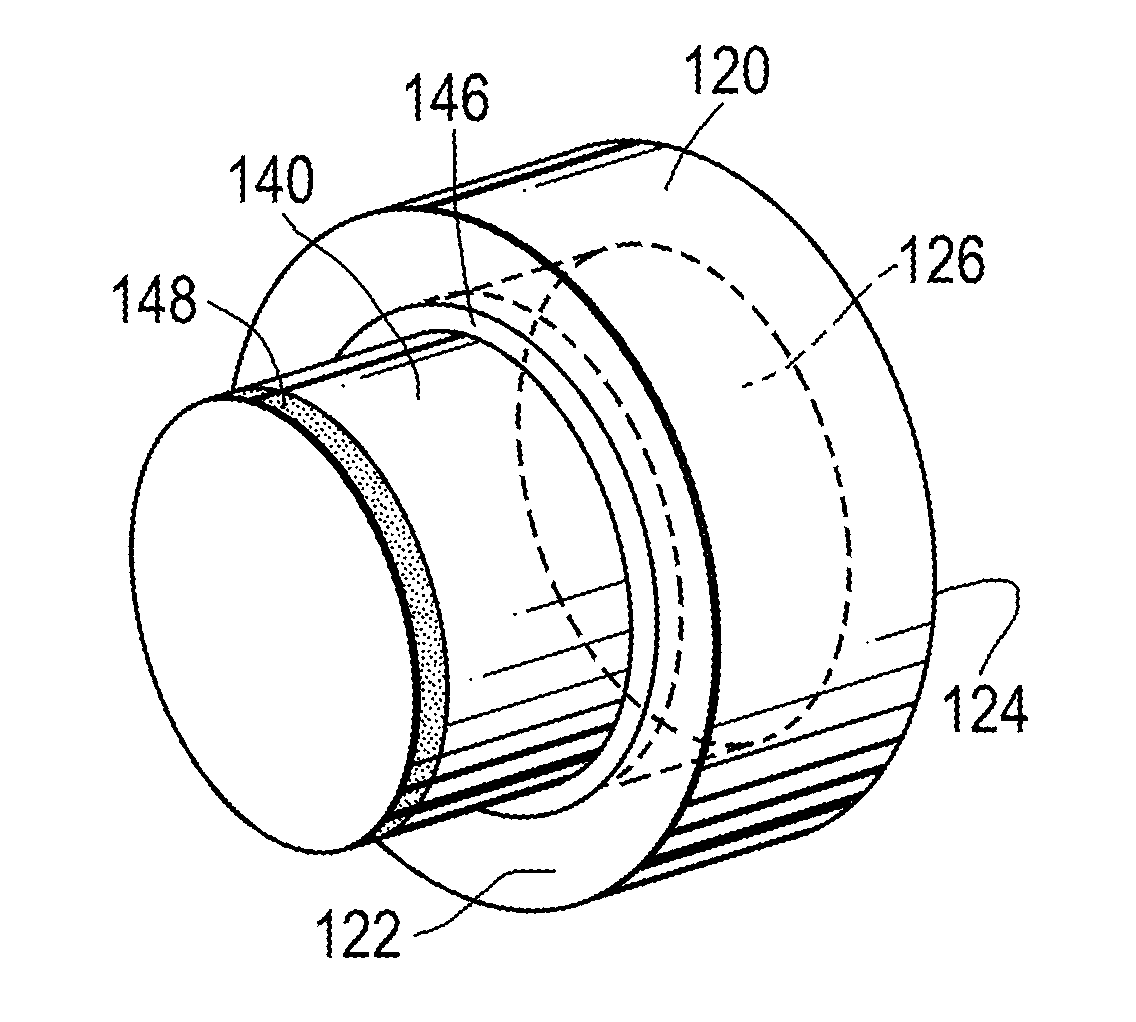

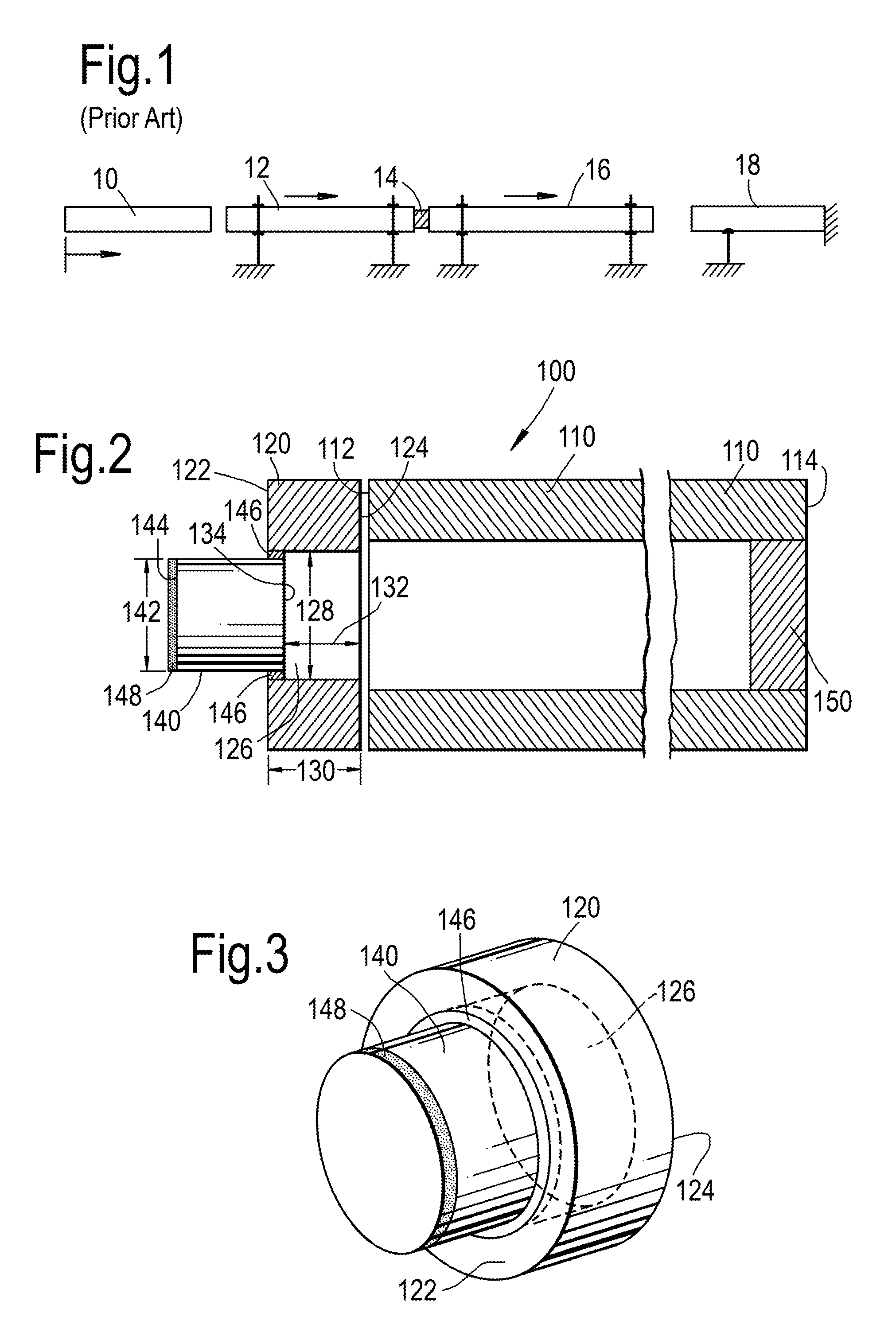

Output member

InactiveUS20160178496A1High strain rateProtection from damageAcceleration measurementApparatus for force/torque/work measurementCircular cavityBiomedical engineering

An output member for a Direct Impact Hopkinson pressure bar includes an elongate tube portion and a disc-shaped cap portion. The tube portion has a first end and an opposite second end, while the cap portion includes a first face and an opposite second face. A circular stub protrudes from a centre of the first face, and a circular cavity is formed in the second face. Each of the stub and the cavity is concentric with the cap portion, with a diameter of the cavity being greater than a diameter of the stub. The second face of the cap portion is positioned in intimate contact with the first end of the tube portion, with the cap portion being concentric with the tube portion.

Owner:ROLLS ROYCE PLC

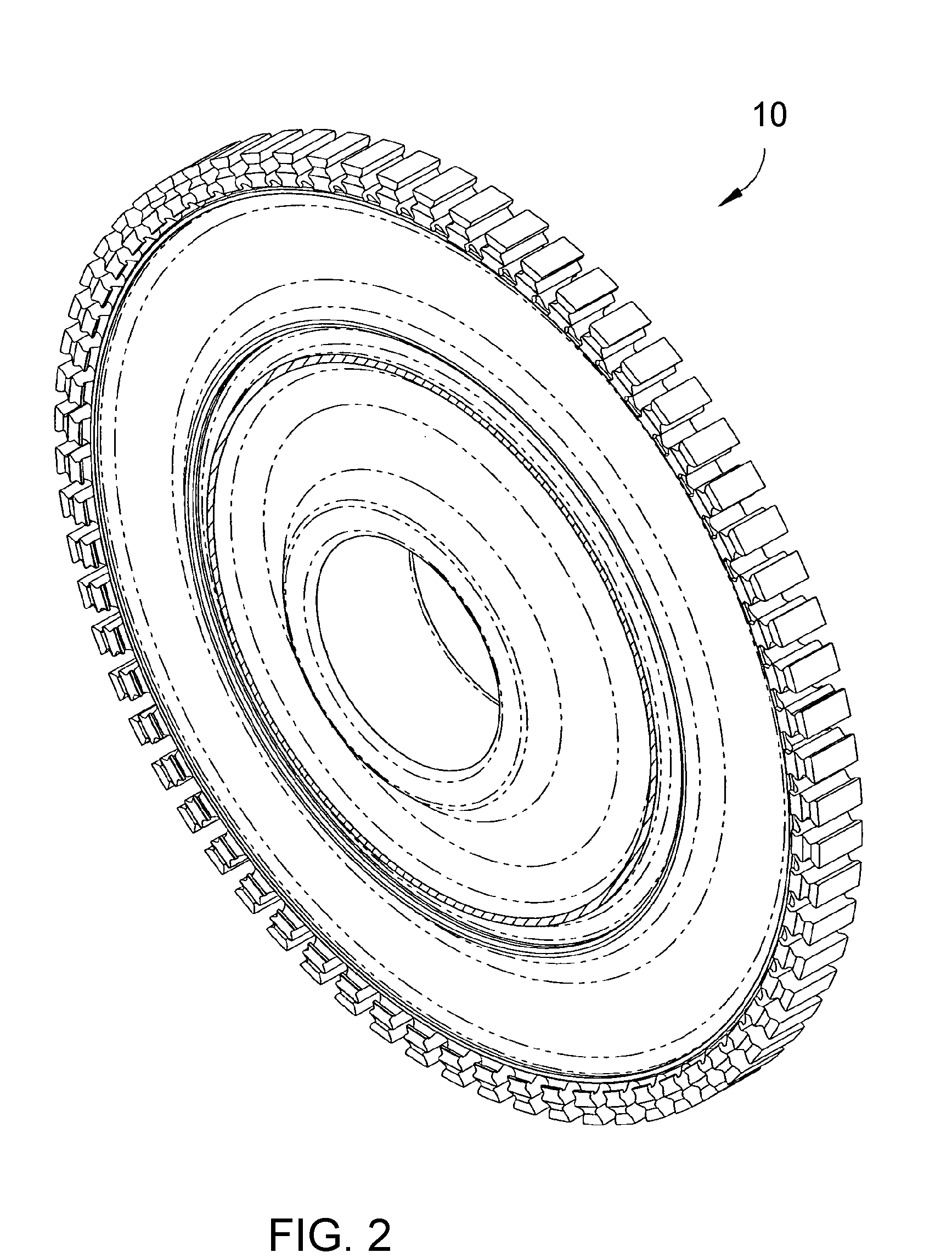

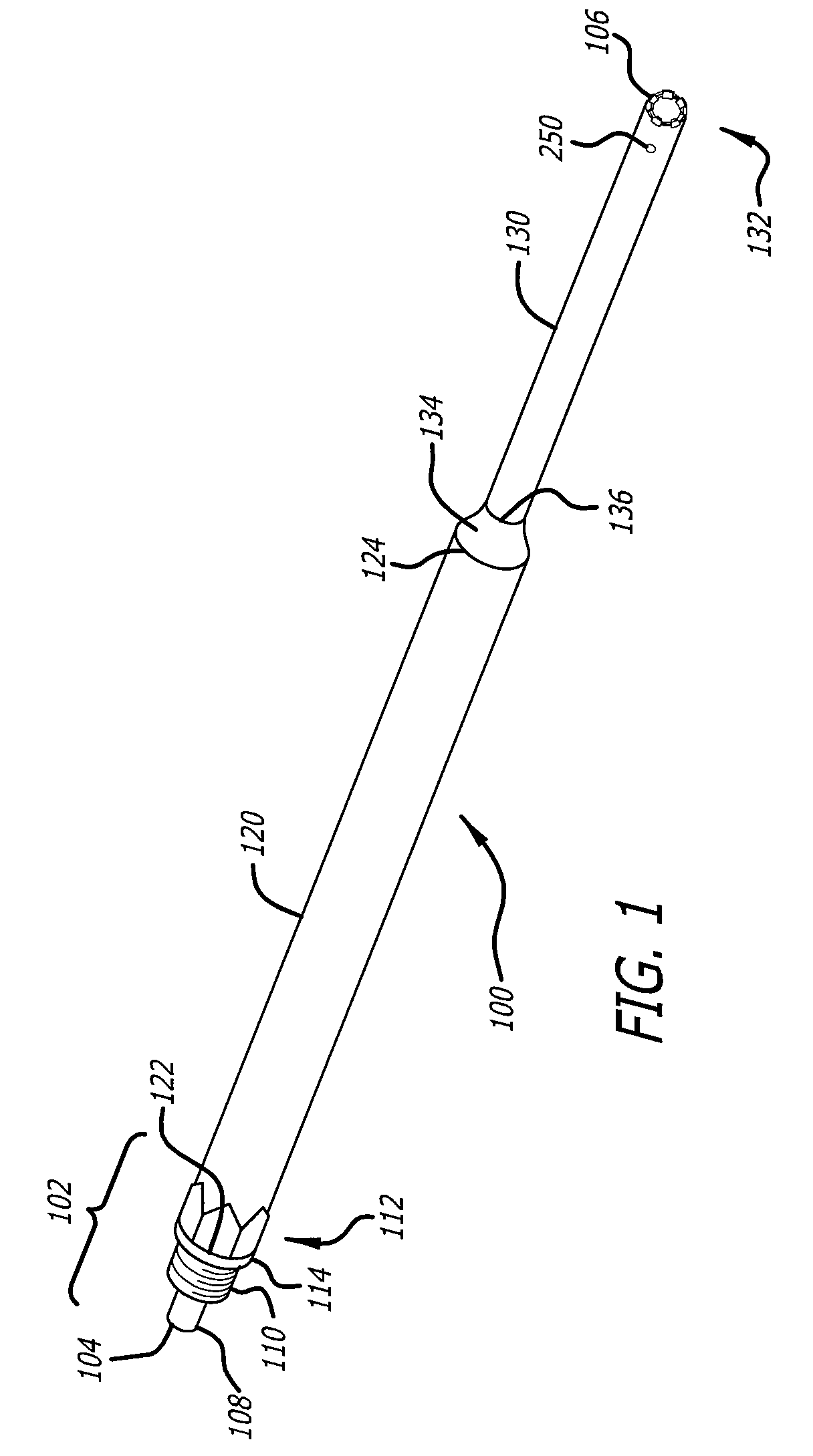

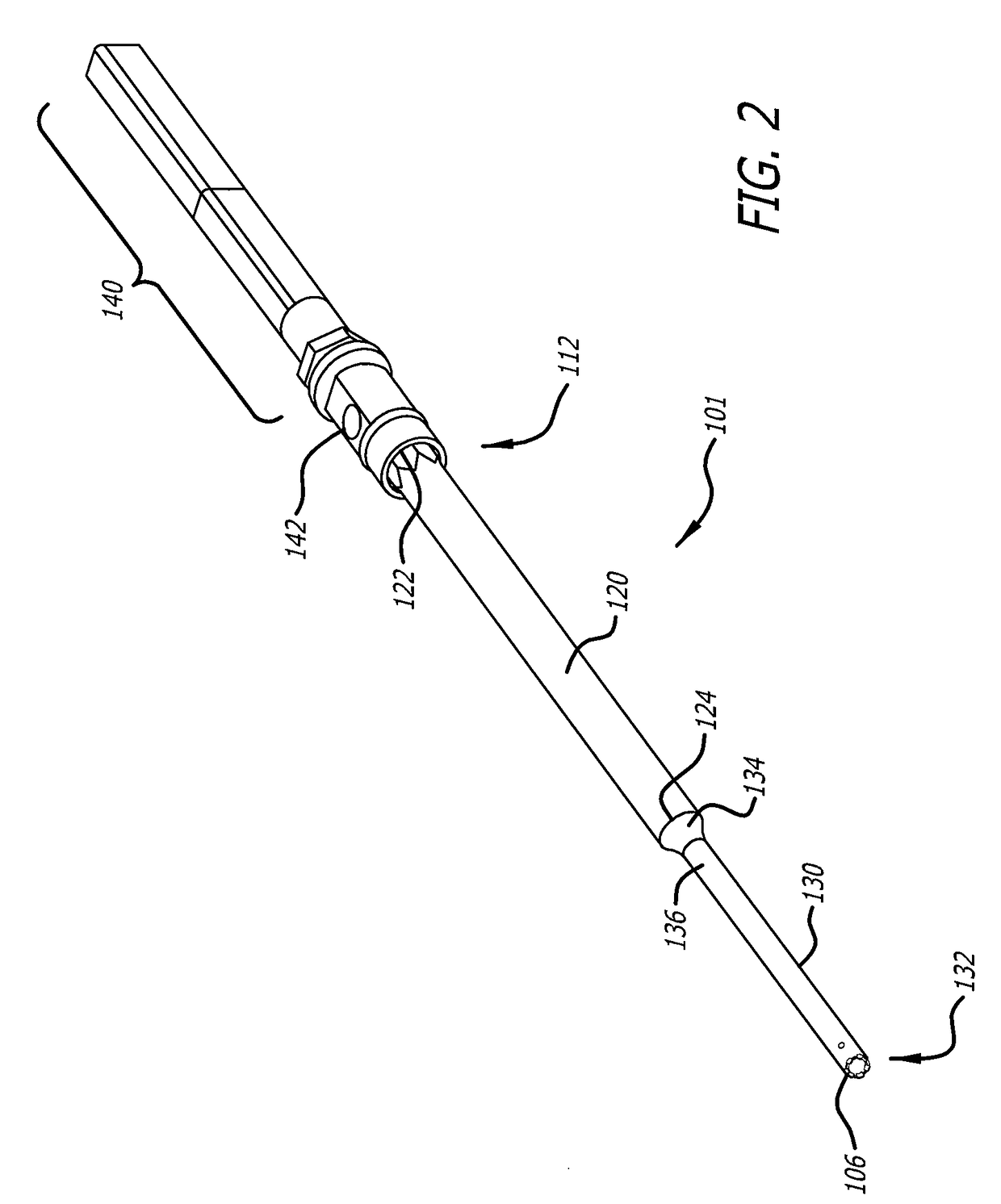

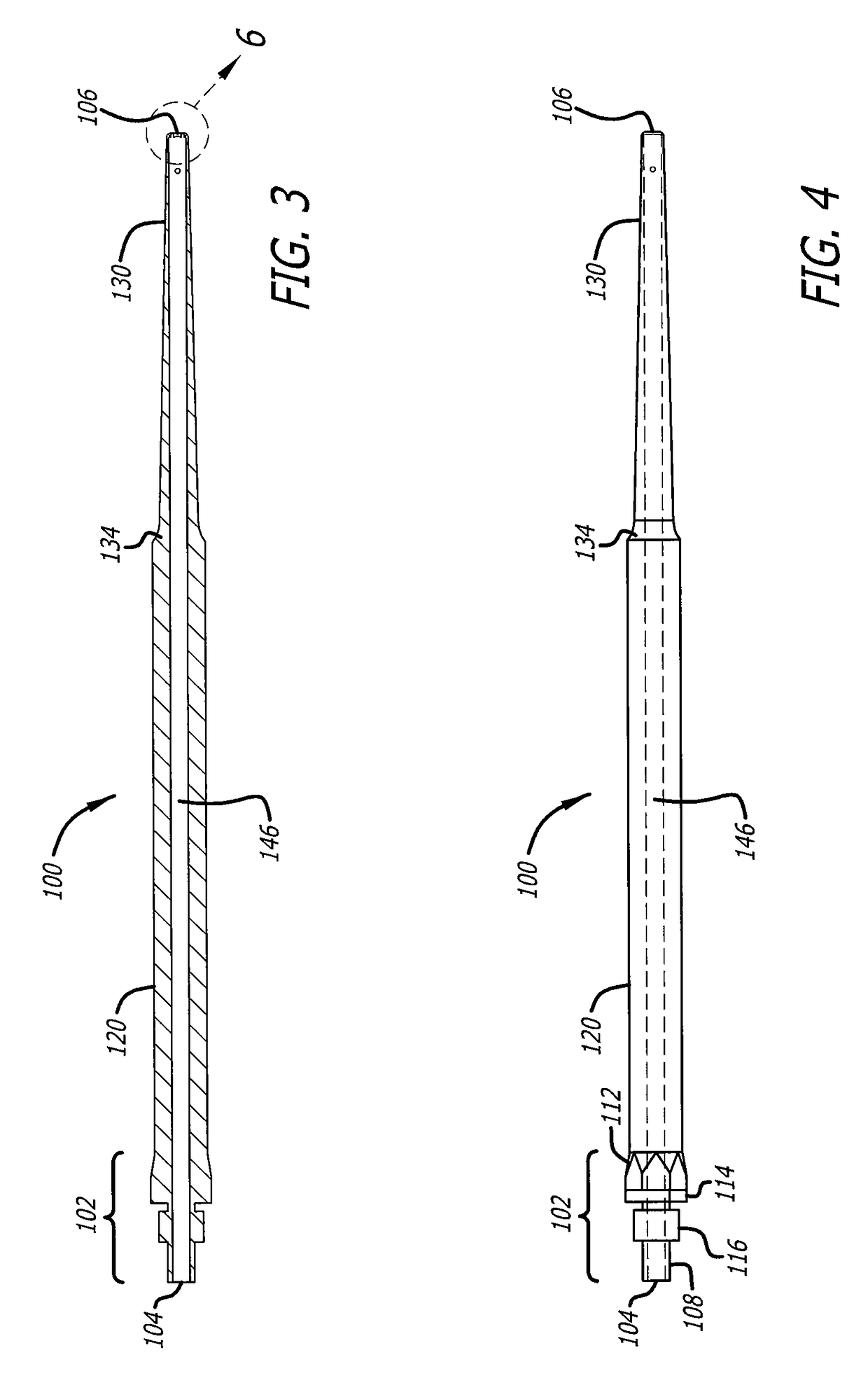

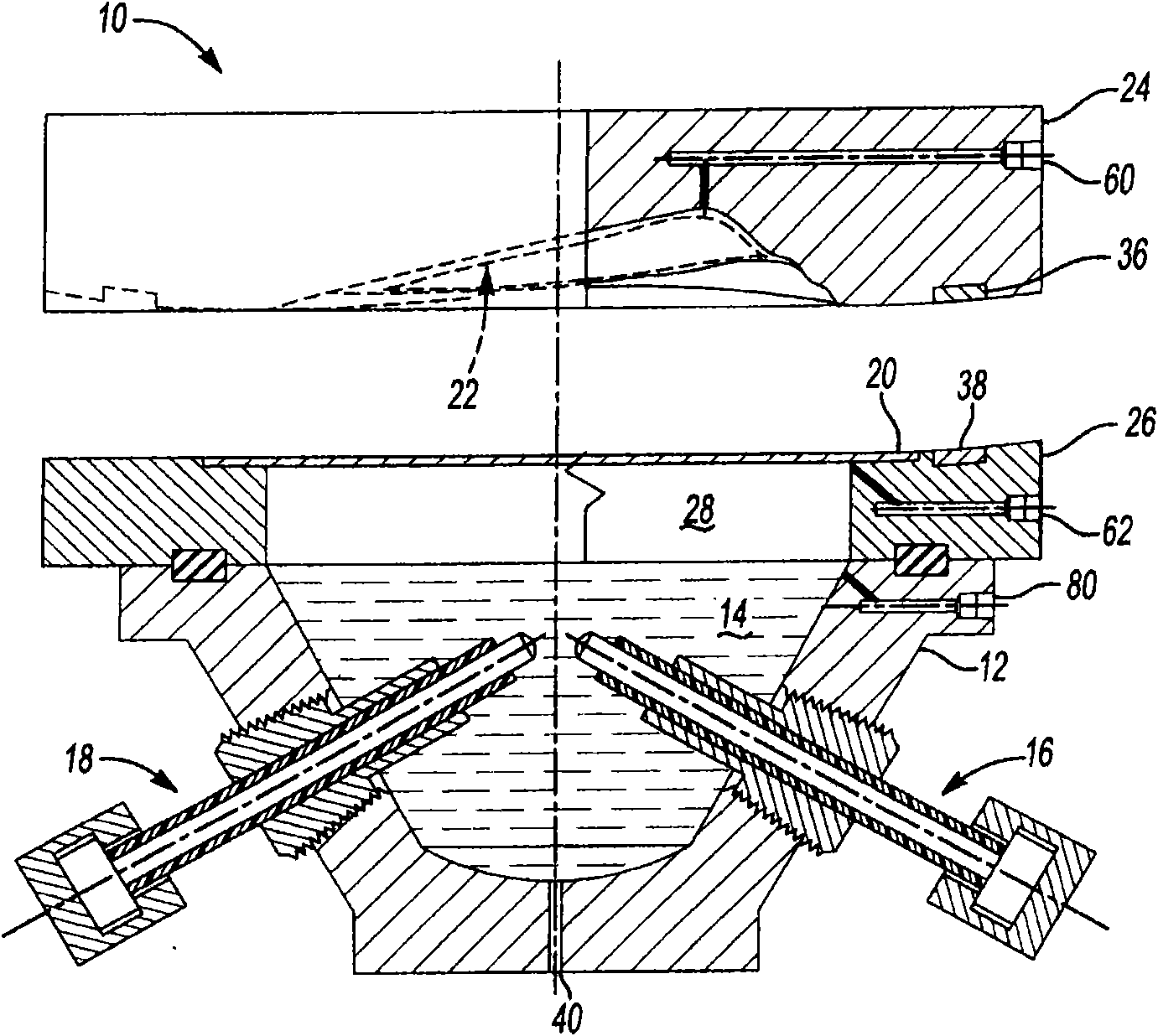

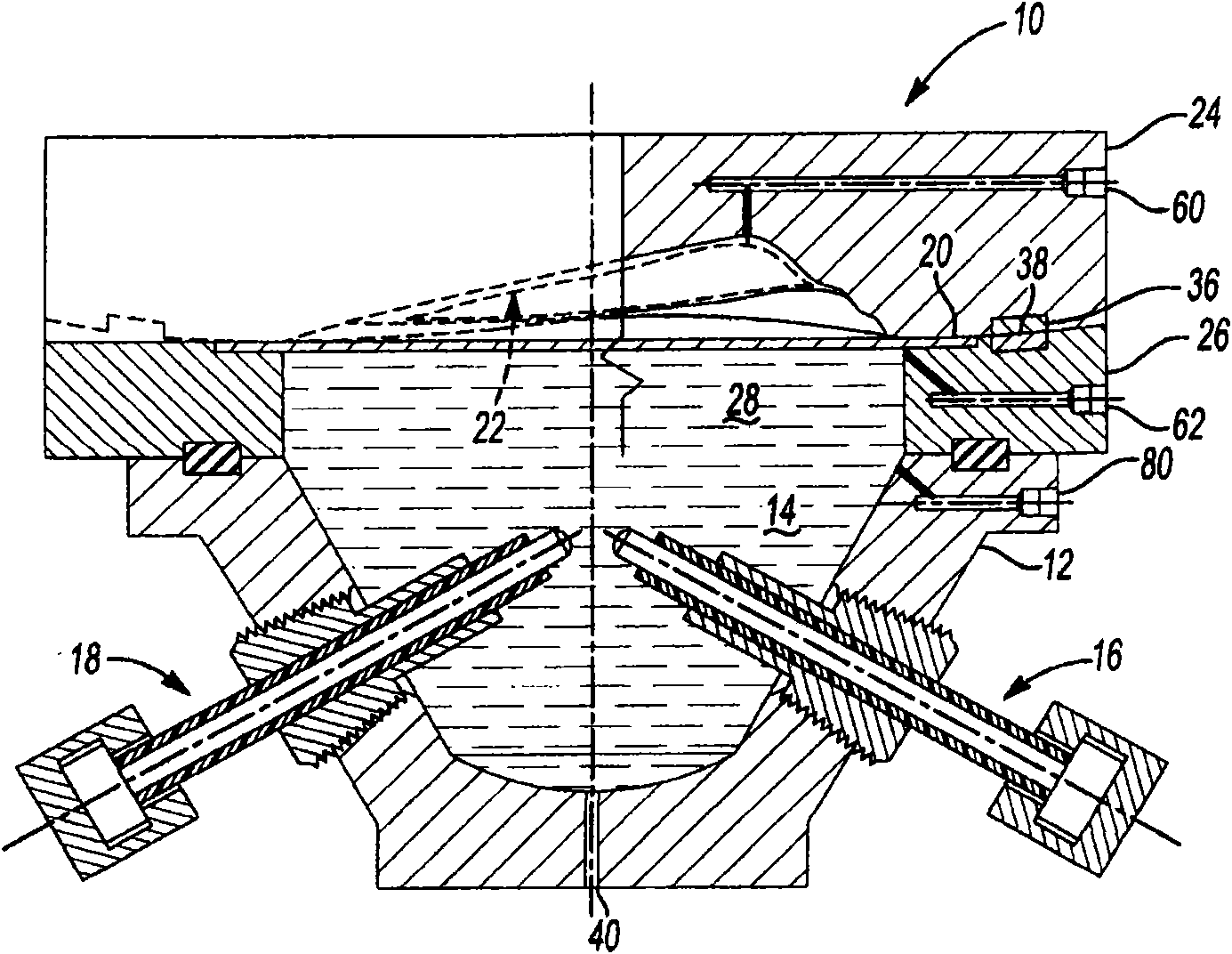

Shear stress ultrasonic horn for ultrasonic surgical aspiration

An ultrasonic horn for use with an ultrasonic surgical hand piece including a resonator comprises a contacting annulus having a plurality of angled lands. The lands are alternated around the annulus such that adjacent lands have opposite angles. As a result of the adjacent angled lands, a shear stress field is developed in contacted tissue due to the promotion of refracted longitudinal ultrasonic waves propagating in different directions at the interface to the coupled tissue. The shear stress field enhances the fragmentation and removal rate of fibrous, elastic, and tenacious tissue. The horn is hollow permitting suction to be applied to the tissue for controlling tissue contact with the lands.

Owner:INTEGRA LIFESCI IRELAND

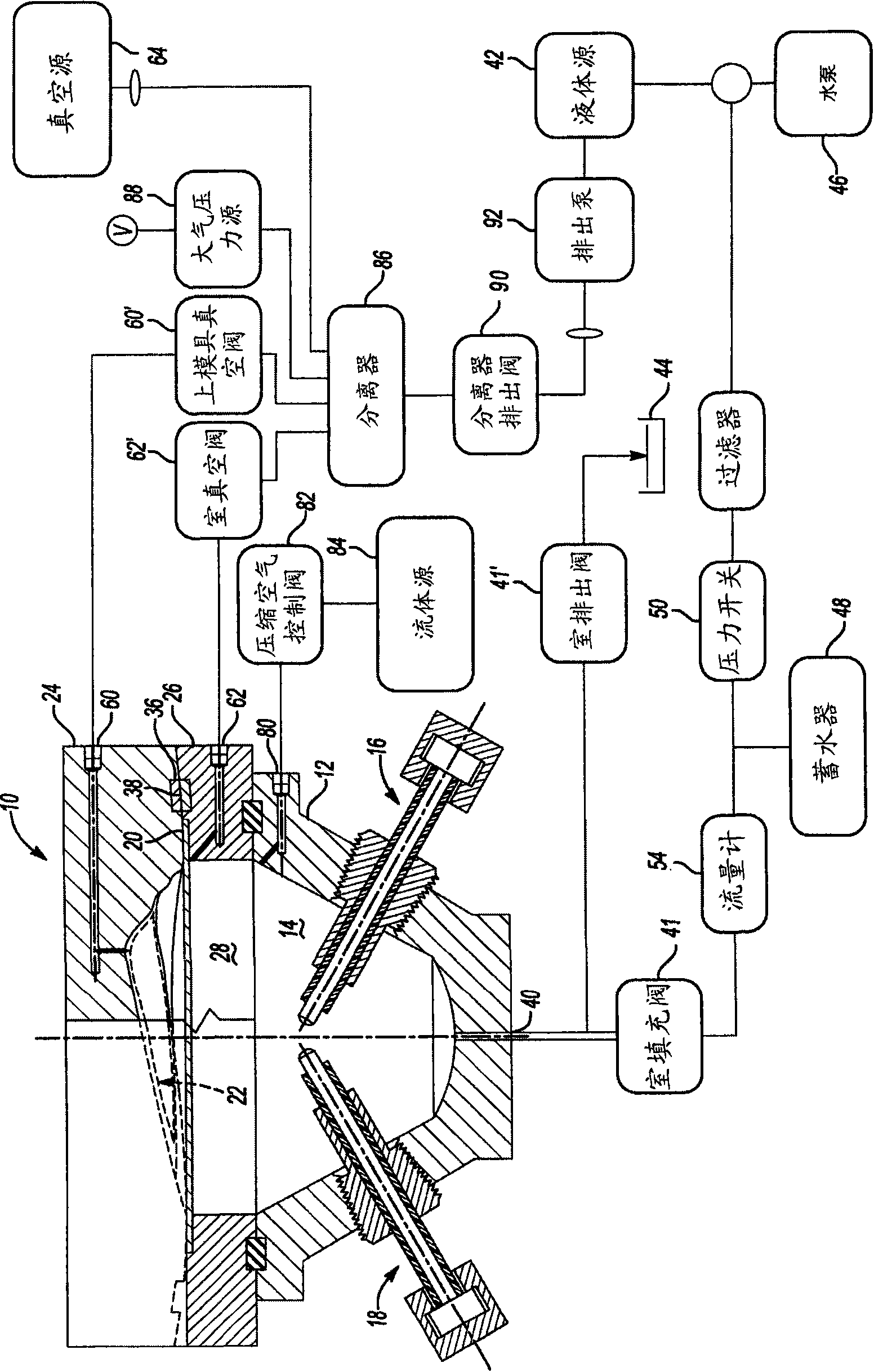

Electrohydraulic forming method for formed sheet metal blank

The invention discloses an electrohydraulic forming method for formed sheet metal blank. The method includes pressing against the die blank by pressure generated from the liquid filled container; eliminating the pressure from the tool; generating a shockwave within the fluid for force generation so that the blank abuts against the die.

Owner:FORD GLOBAL TECH LLC

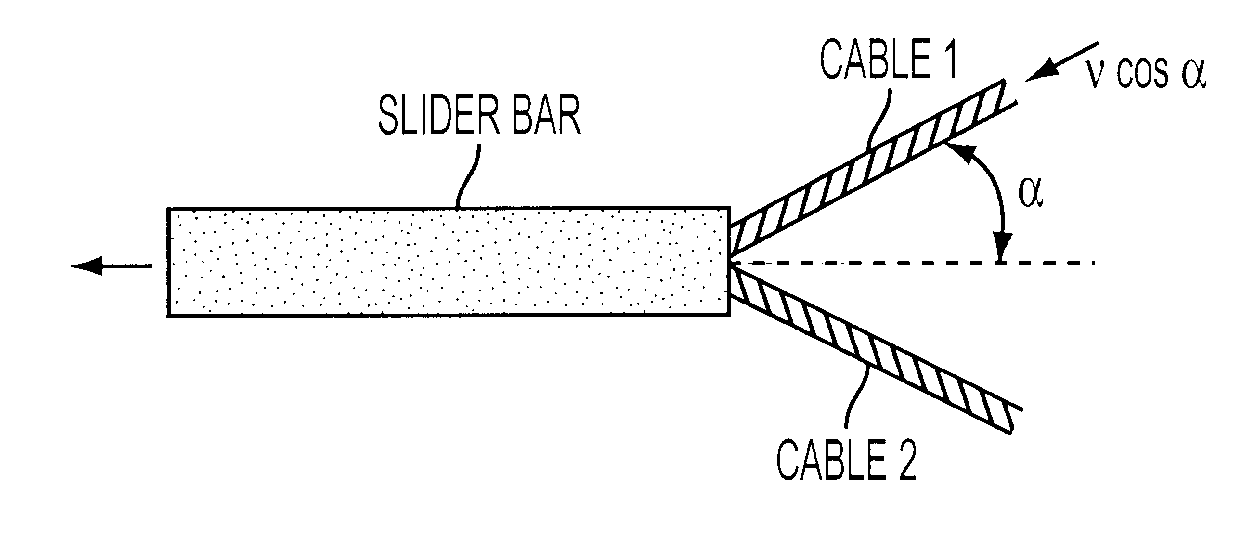

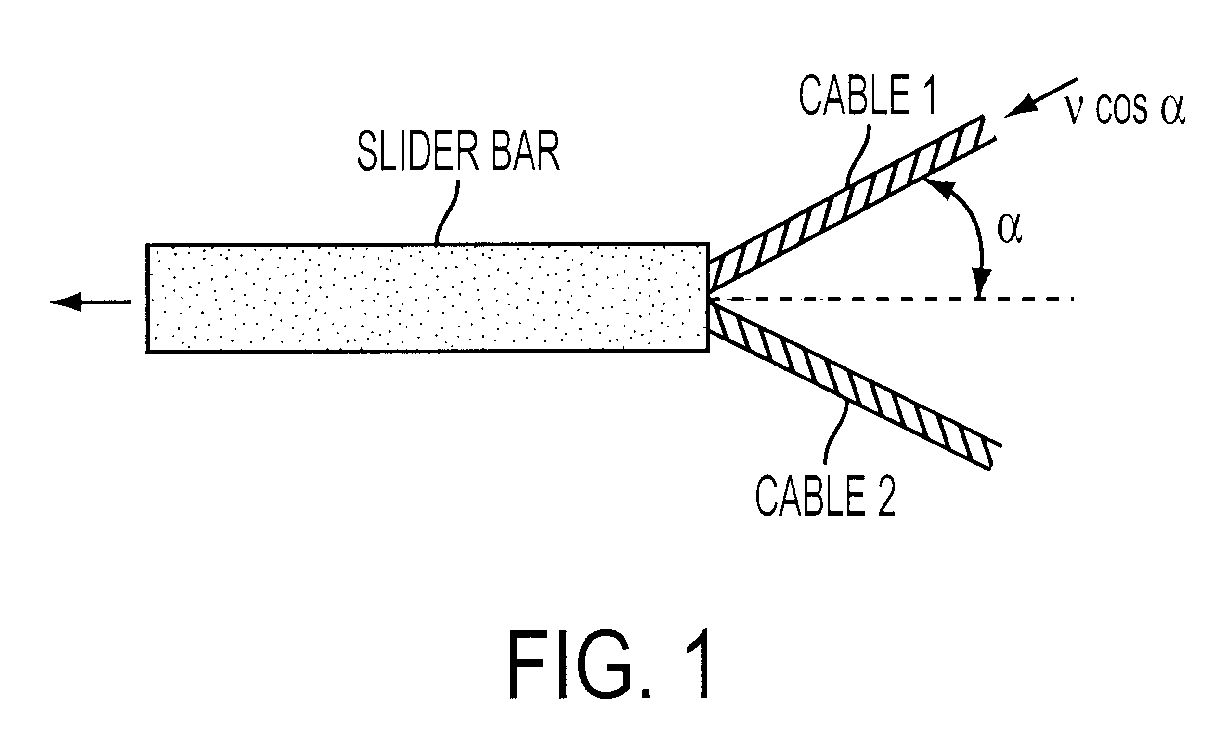

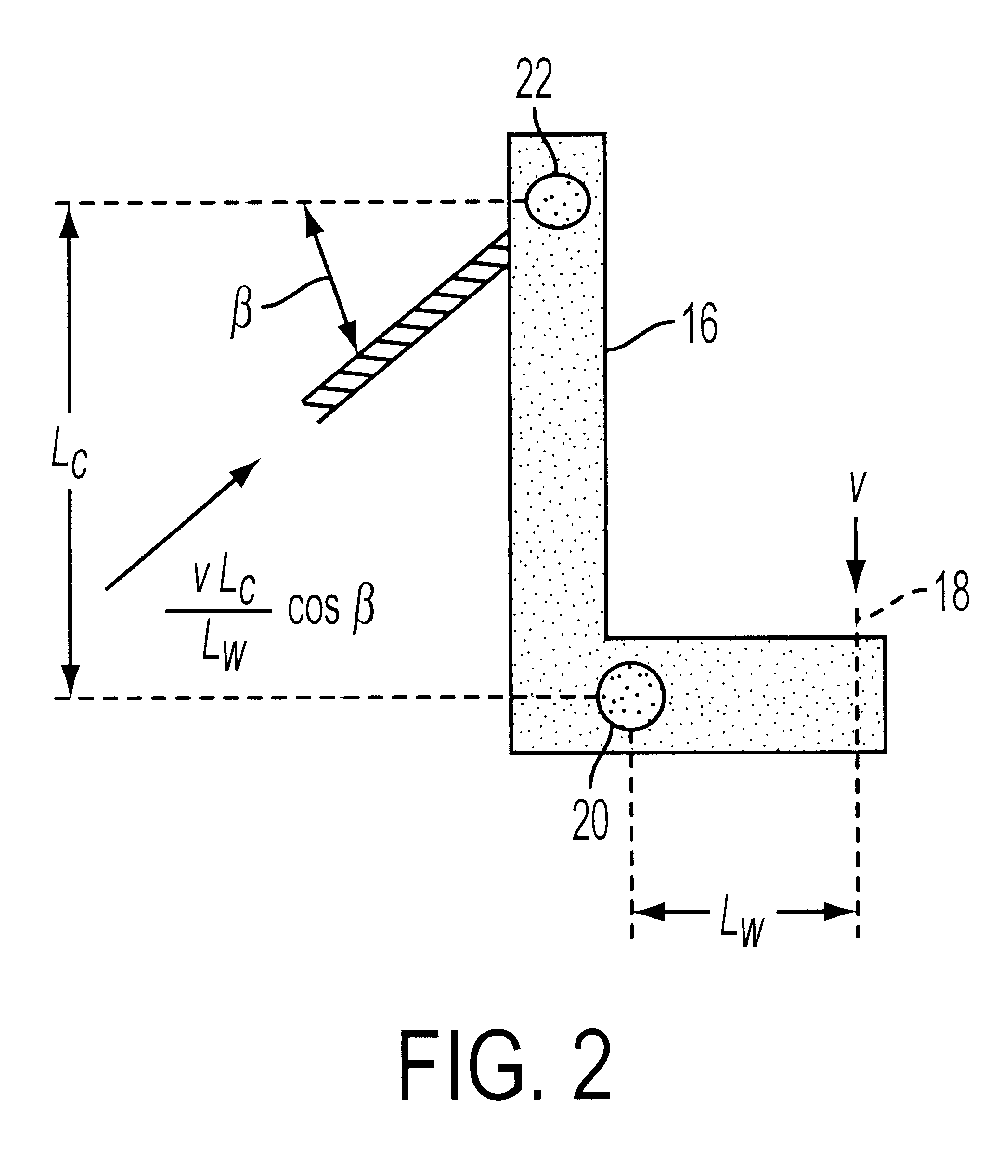

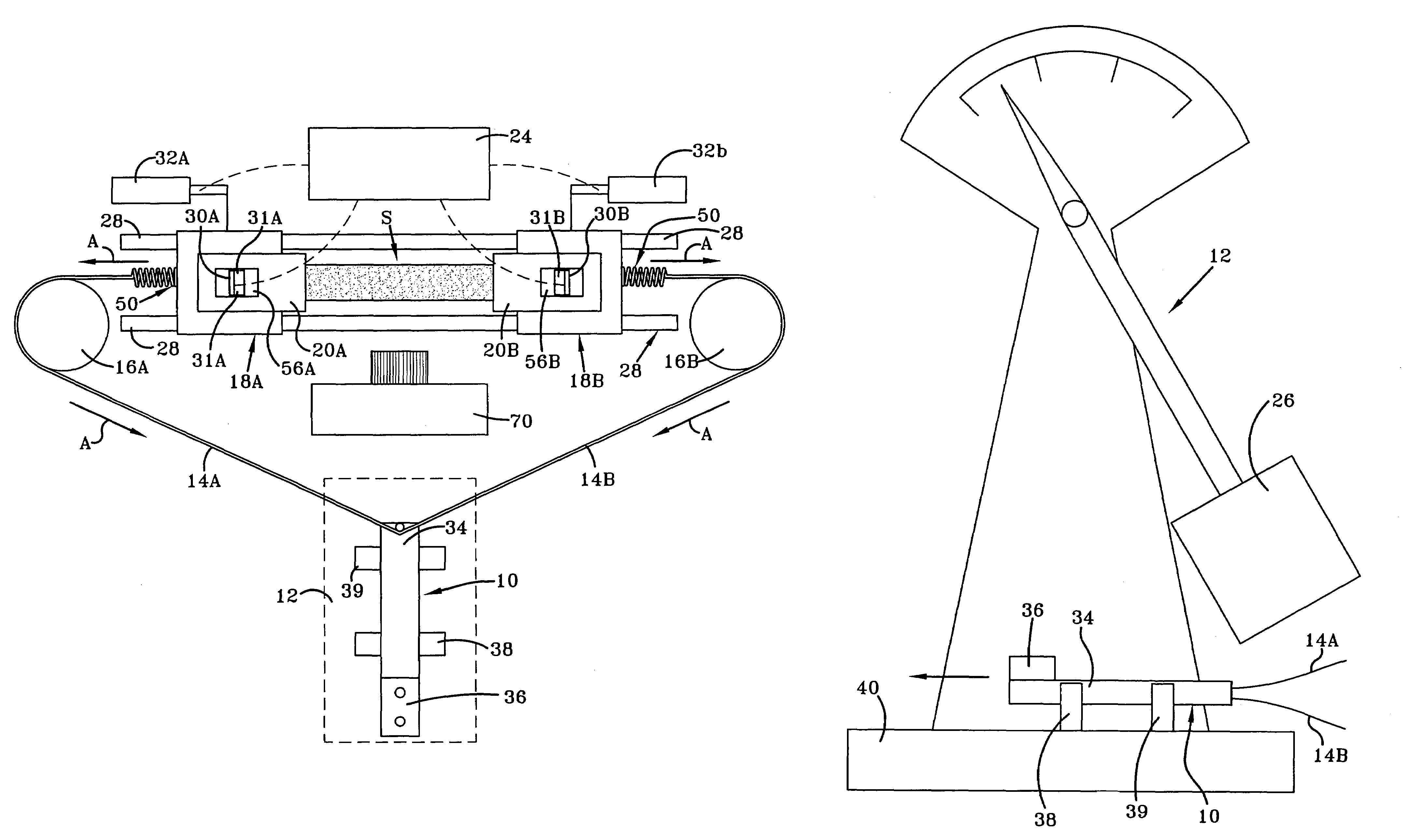

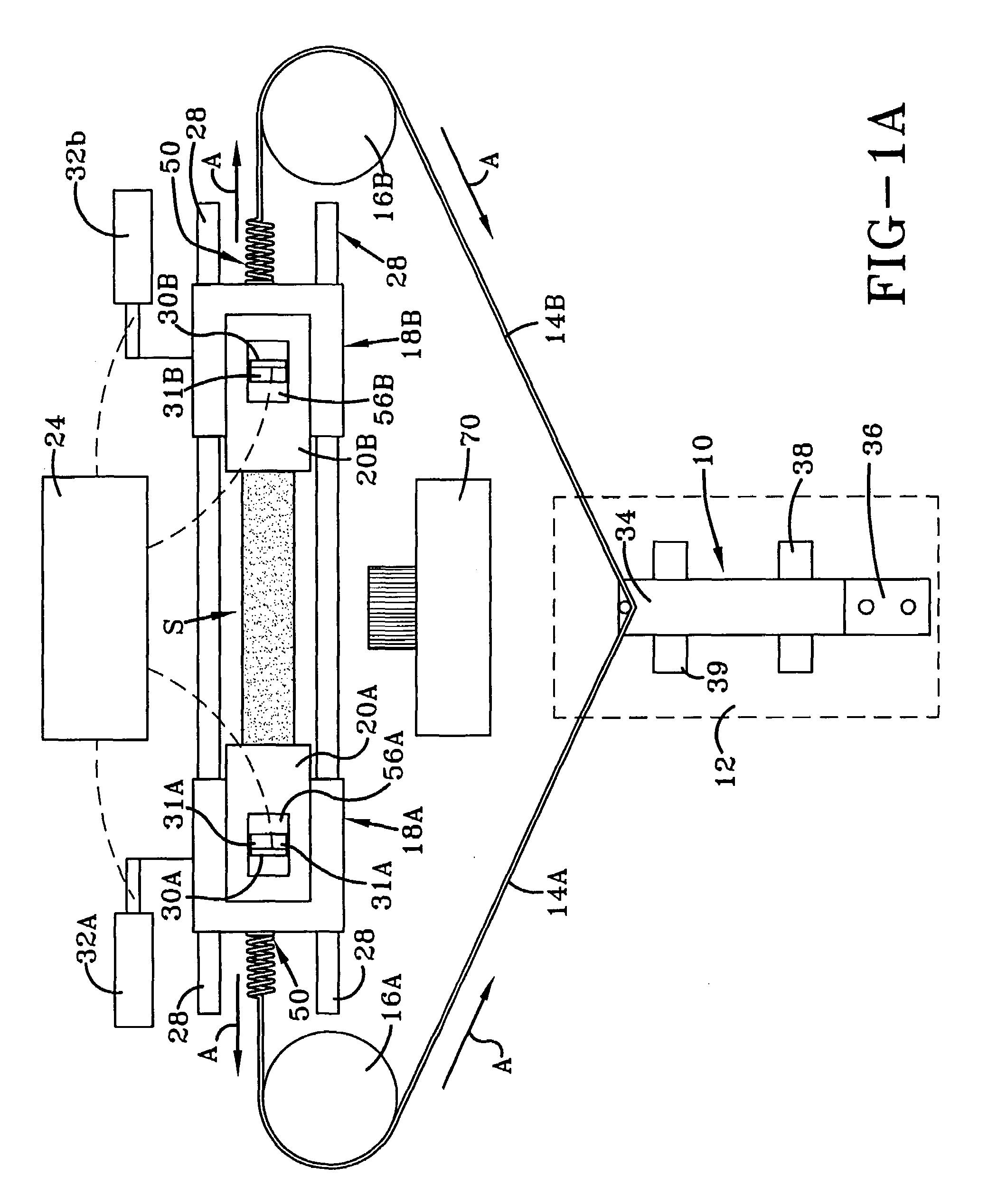

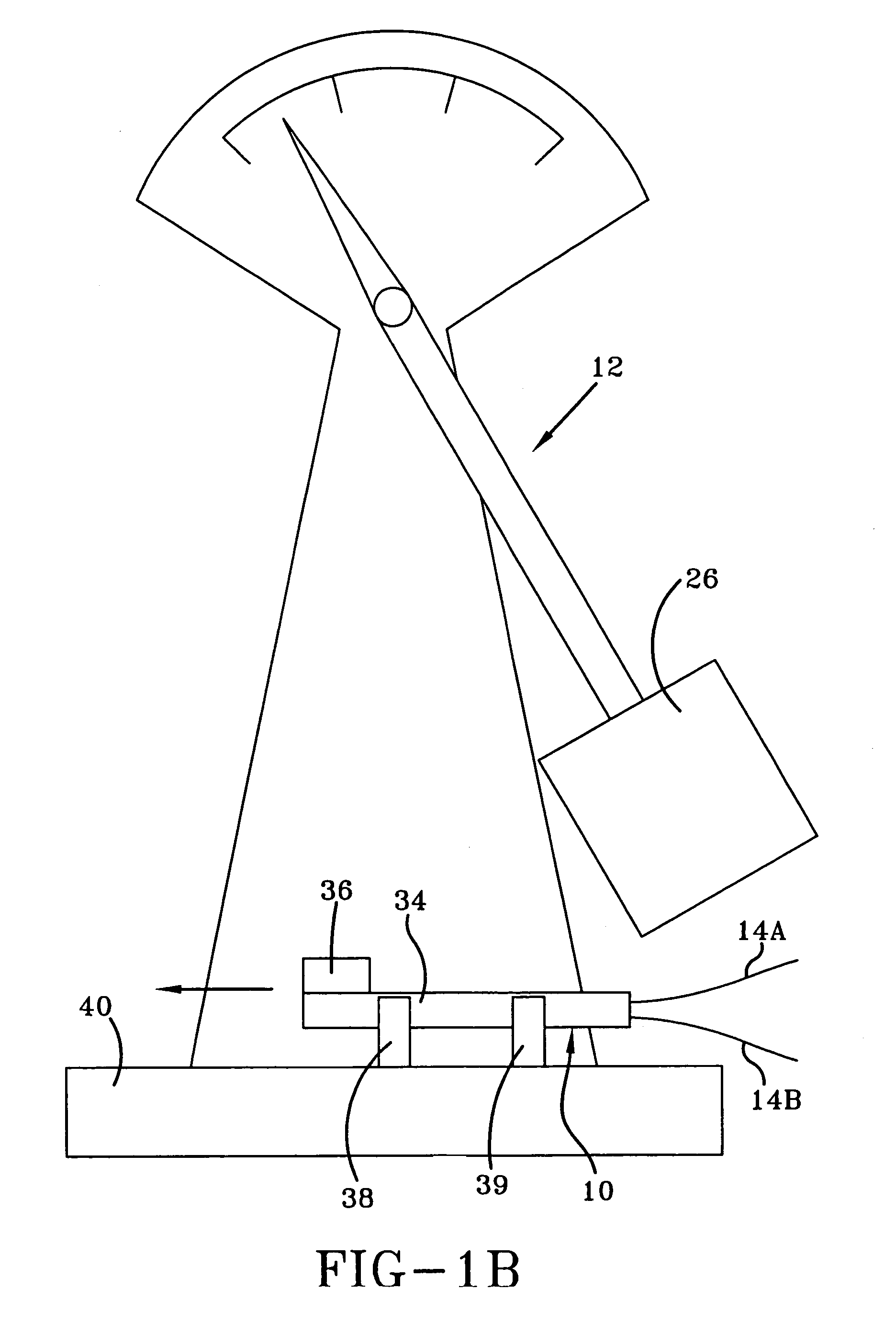

Tensile impact apparatus

InactiveUS7320242B2Increase ratingsHigh strain rateAcceleration measurementMaterial testing goodsEngineeringImpact loading

The present invention generally relates to a tensile impact apparatus that is designed to give dynamic stress-strain curves and fracture characteristics for a rubber specimen undergoing tensile impact loading. More particularly, this invention relates to a tensile impact apparatus that is capable of achieving strains of up to fracture. The apparatus is also capable of visually recording fracture phenomena.

Owner:THE UNIVERSITY OF AKRON

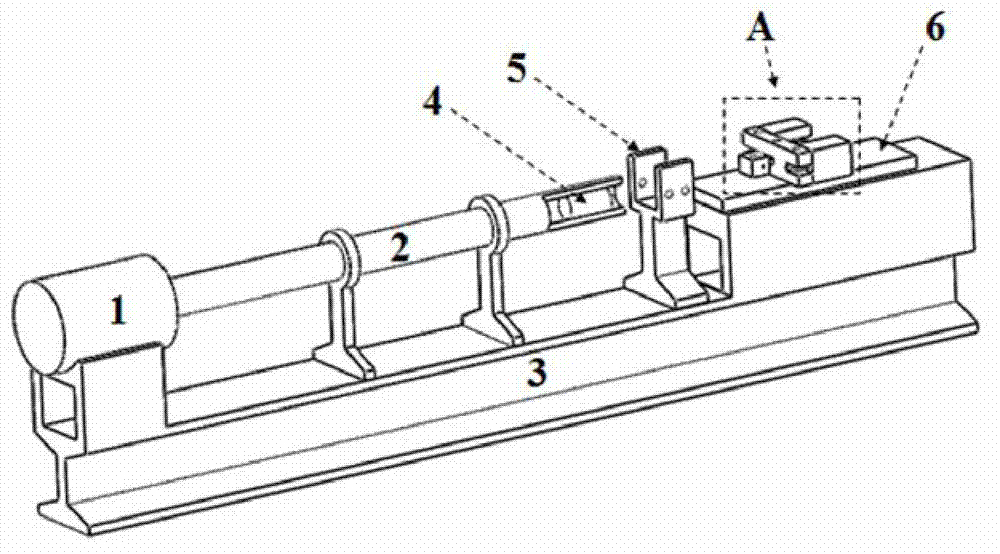

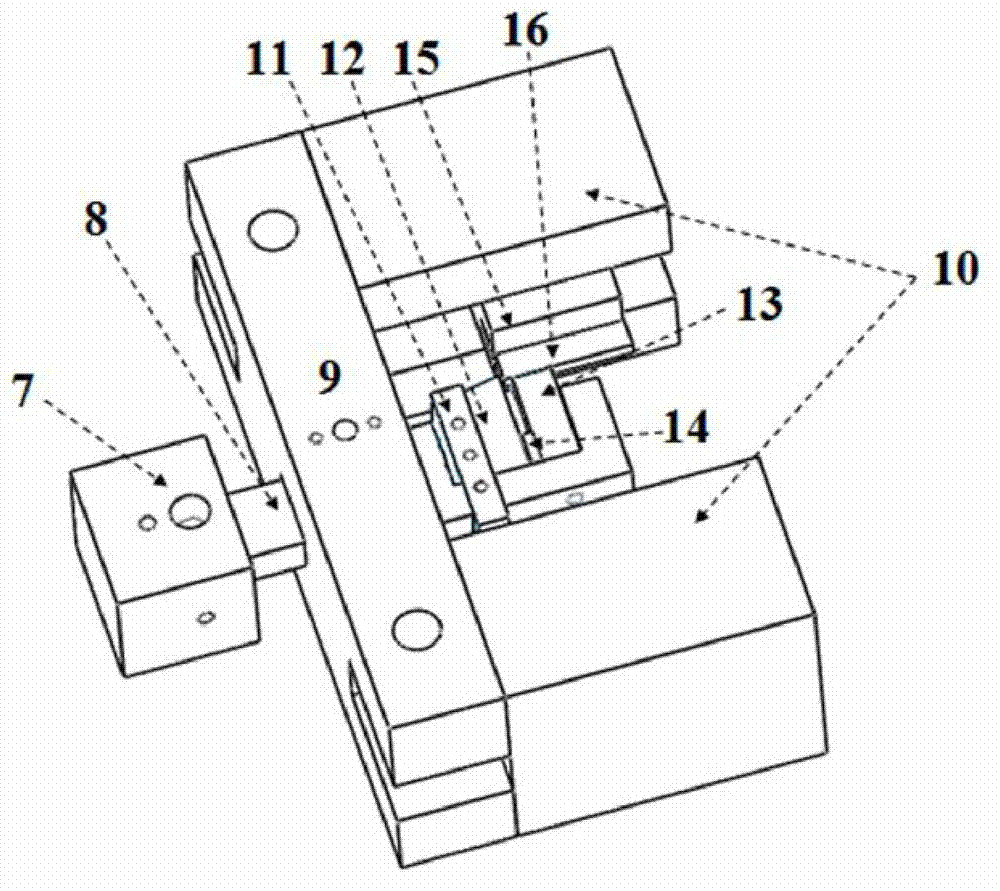

High-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology

ActiveCN103163037AHigh strain rateConstrained Cutting ExperimentInvestigating machinabilityGun barrelVelocity measurement

The invention discloses a high-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology. The high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology comprises a Hopkinson pressure bar loading mechanism which is used for pushing a bullet to move along a scheduled track at a scheduled speed, a laser velocity measurement mechanism which is used for measuring a movement speed before the bullet strikes a restrained cutting mechanism, the restrained cutting mechanism which is used for conducting restrained cutting of different plastic deformation degrees on a to-be-processed workpiece, a restrained cutting slideway mechanism which is used for giving a speed direction of restrained cutting, a fixing mechanism which is used for fixing the to-be-processed workpiece and a cutting stopping mechanism which is used for stopping a restrained cutting process. Different cutting speeds are obtained by adjusting pressure of air gun of the Hopkinson pressure bar and an initial position of the bullet in an acceleration gun barrel, different plastic deformation degrees can be obtained by adjusting the space between a tool of the restrained cutting mechanism and a restraining device, the high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology can be utilized to study a material interior microstructure evolution law when the material is with different strain rates and different plastic deformation degrees.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

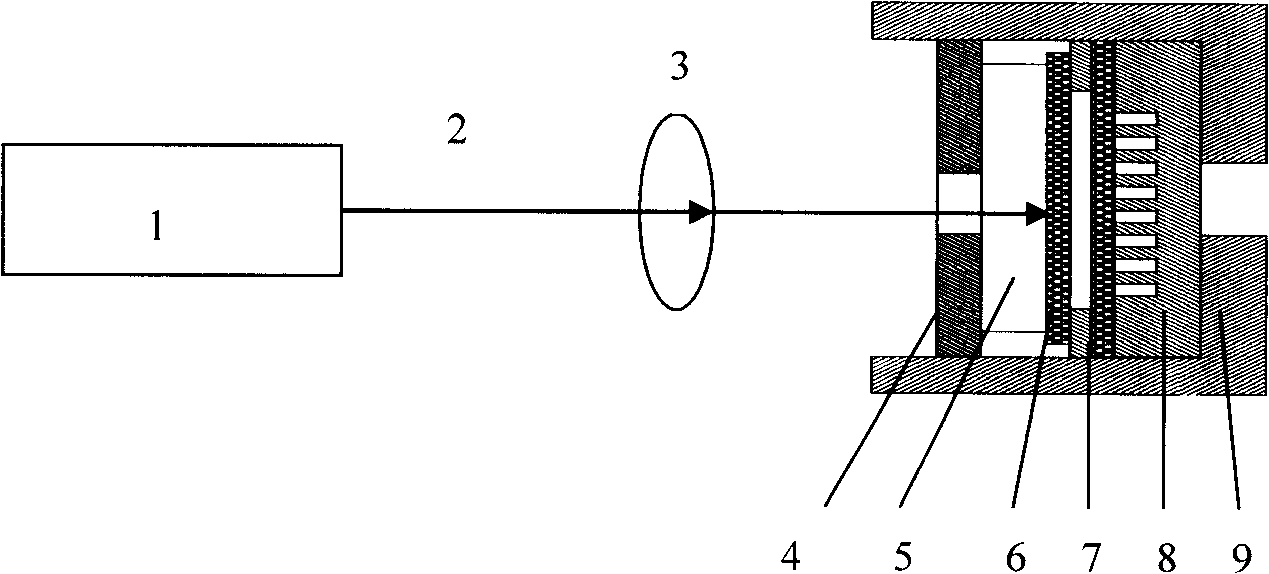

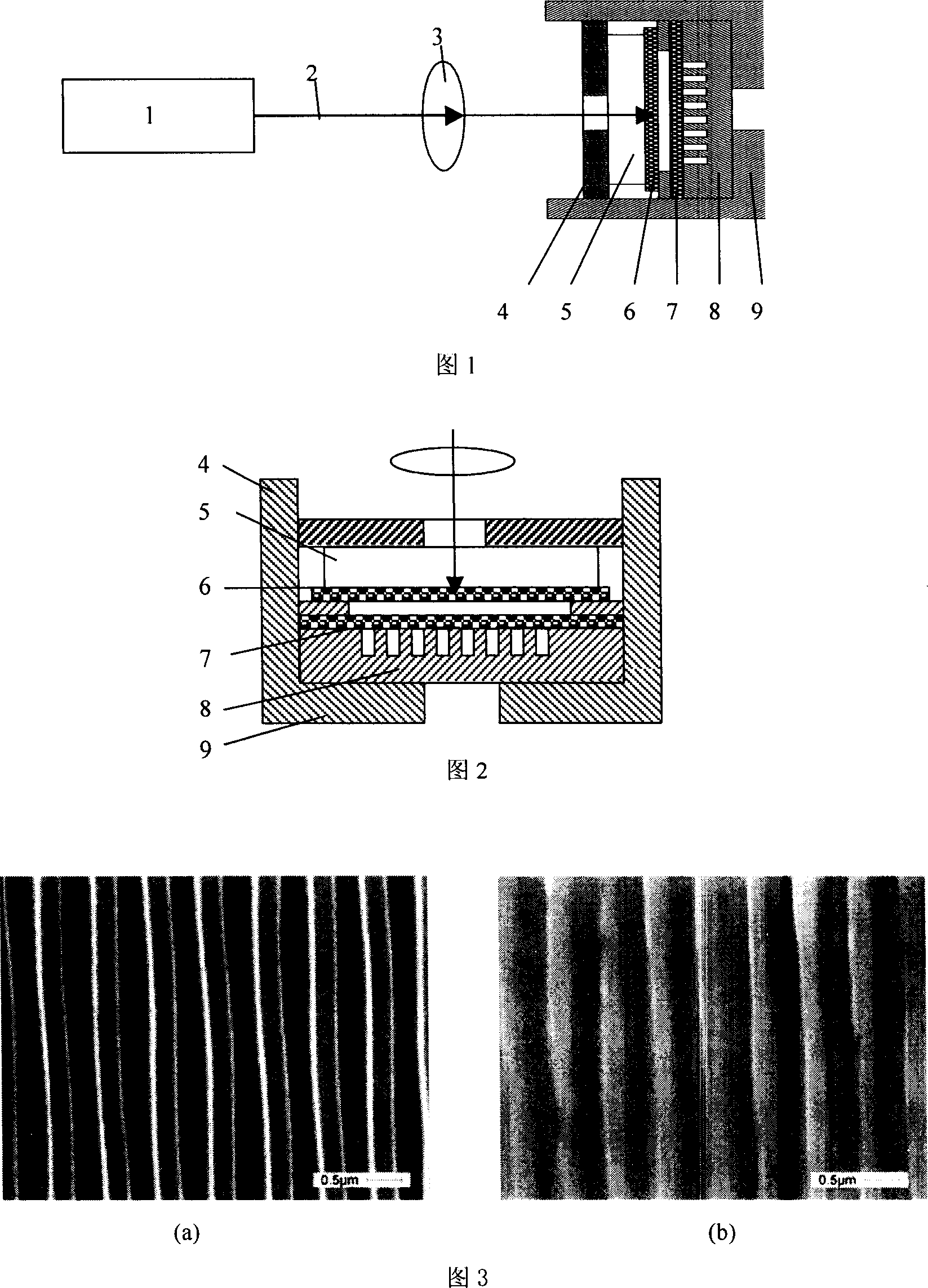

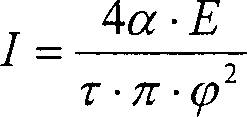

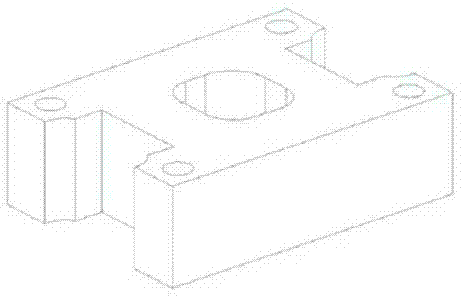

Method and apparatus for preparing and forming minitype compound material

InactiveCN101323051AFast strain rateHigh strain rateLaser beam welding apparatusMetallurgyNd:YAG laser

The invention relates to a method and a device for preparing and forming a micro composite material. The device consists of an Nd:YAG laser, a reflector, a lens, a restraint layer, a single-dimension mobile platform, a micro die, a three-dimension mobile worktable, a three-dimension mobile platform controller, an L-shaped base and a computer. The method for the synchronous realization of material composite and micro forming comprises: pulsed laser is used for driving a metal foil plate to move at high speed; the metal foil plate impacts a base foil plate in the micro die at high speed after moving a certain distance; the high temperature and high pressure generated in the impact surface can realize the composite connection between the metal foil plate and the base foil plate; the connected metal foil plate and base foil plate have certain impulse and compress to the direction of the die; owing to the limitation of the die, the shape of the micro die can be duplicated, thus realizing the synchronization of composite material production and micro forming. The method and the device have the advantages of reasonable design, simple process, good consistency, and being applicable to mass production.

Owner:JIANGSU UNIV

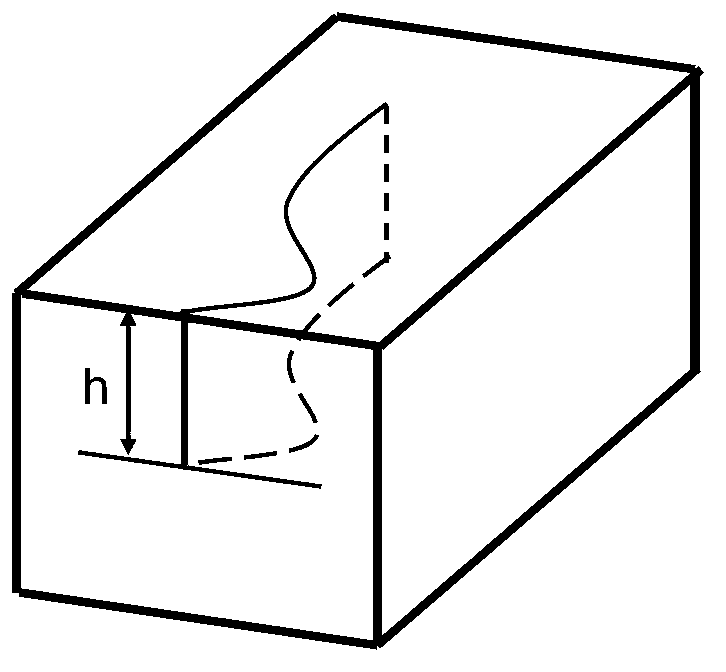

Transient unloading loose simulating system for excavating jointed rock mass

The invention discloses a transient unloading loose simulating system for excavating a jointed rock mass. The transient unloading loose simulating system for excavating the jointed rock mass comprises counterforce piers, a jointed rock mass model, an experimental table provided with displacement scale marks, a transitional block cushioning box, a transitional block arranged on the transitional block cushioning box, a hydraulic station, a loading device, a loading device supporting table and a monitoring system, wherein the counterforce piers are fixed on the outer sides of the loading device supporting table and the experimental table; the transitional block cushioning box is arranged on the other side of the experimental table; a slot for accommodating the jointed rock mass model is formed on the upper surface of the experimental table; the transitional block (15) is a square column with a variable cross section, and the section areas of the two ends of the transitional block are larger than the section area of the middle section; the width and height of the jointed rock mass model are matched with those of the transitional block (15); the loading device is horizontally arranged on the loading device supporting table; and the monitoring system is used for monitoring the simulating process. By the system, the load on the jointed rock mass model is quickly unloaded, and the actual unloading condition in an engineering is met well.

Owner:WUHAN UNIV

Method of applying a polymer thick-film resistive paste for making polymer thick-film resistor having improved tolerances

InactiveUS7575778B2Low/insignificant dimensional and shape changeHigh solid contentPretreated surfacesLiquid/solution decomposition chemical coatingElectrical resistance and conductanceEngineering

The present invention teaches formulations, apparatus and a method of applying high thixotropic index polymer thick-film resistive pastes for making polymer thick-film resistors with improved tolerances by providing a squeegee with a blade tilted at an angle of 10° to 85° to the surface of the printed circuit board thus causing a fluid rotational motion within the bead of the polymer thick-film resistive paste as the squeegee blade moves relative to the printed circuit board. This rotational motion increases the shear strain rate experienced by the paste within the bead and results in a more effective filling of the resistor-shaped cavity without including air bubbles, experiencing elastic recovery of the paste and, without surface fractures of the paste.

Owner:EMBED TECH

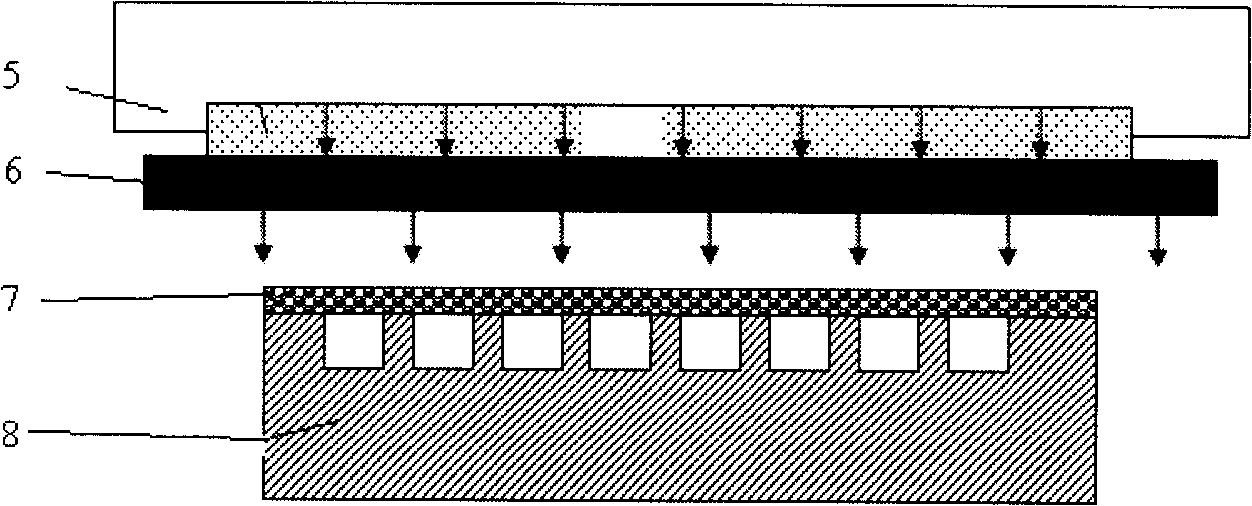

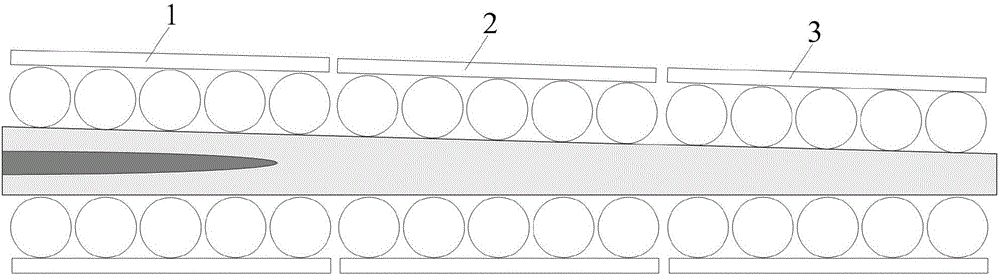

Laser loaded 3D micron and nano size forming process and equipment

InactiveCN1986387AHigh strain rateHigh processing flexibilityNanostructure manufactureLaser beam welding apparatusOptical mediumAbsorption layer

The laser loaded 3D micron and nanometer size forming process and equipment belongs to the field of MEMS processing technology and laser micro processing technology. The 3D forming process includes the following steps: grinding and polishing the two sides of target, and pressing one micron level thick aluminum film as the absorption layer and one transparent optical medium as the restraint layer onto the target; regulating ns pulse laser and optical path for focusing the laser onto the target surface and emitting single ns laser pulse to impact the target for adhesion between the target and the template. The present invention can form impacted surface with greatly raised hardness, corrosion resistance, wear resistance and fatigue strength, and may be used widely in machining key parts in MEMS. The machining process has the advantages of easy control, high machining flexibility and no pollution.

Owner:JIANGSU UNIV

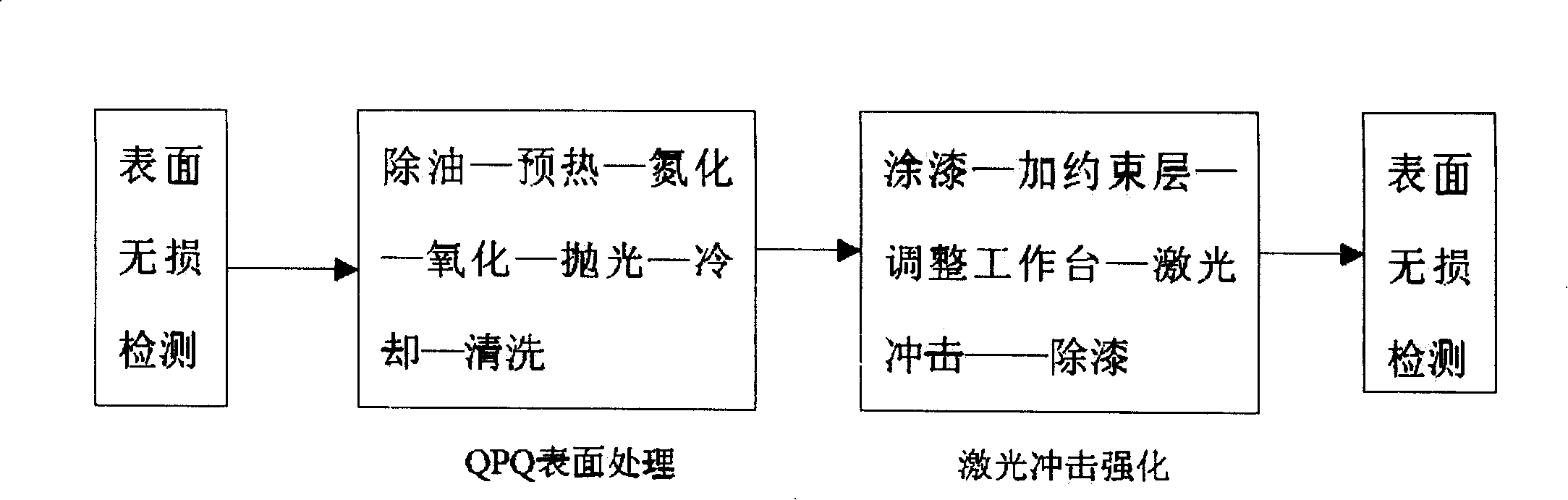

Composite treating method for prolonging life of grating machine key components

ActiveCN101225456APrecise positioningSave resourcesSolid state diffusion coatingHeat treatment process controlStress concentrationMolten salt

The invention relates to a complex processing method for prolonging the service lift of chain grate key parts, belonging to mechanical manufacturing and material processing and application technical field, which comprises: firstly, surface nondestructive testing is carried out on the key parts of the chain grate of process; molten salt complex processing are carried out in parts of the surface according to the surface drawbacks tested by surface nondestructive testing; before the laser shocks, the workpiece surface is coated with black coating layer and use water as protective layer, and the laser shock processes the area which is easy to fatigue and fracture and has concentrated stress. The molten iron pretreatment spray-feeding device before iron-making blast furnace has the advantages of simple shortcut, high efficiency, low maintenance cost, short processing time (30 minutes to 5 hours), and the continuous operation can be realized, thus, high efficiency of production is ensured.

Owner:江苏宏大特种钢机械厂有限公司

Method of repairing a turbine rotor using cold spraying

InactiveUS20120272523A1High strengthIncrease strainPressure inorganic powder coatingEngineeringMechanical engineering

A method of repairing a damaged rotor comprising: (a) preparing a locally damaged portion of the rotor; (b) cold spraying alloy powder particles onto the locally damaged portion; (c) controlling the cold spraying in step (b) to restore the locally damaged portion to form a repaired portion having substantially the same properties and shape as originally manufactured; and (d) heat treating at least the repaired portion.

Owner:GENERAL ELECTRIC CO

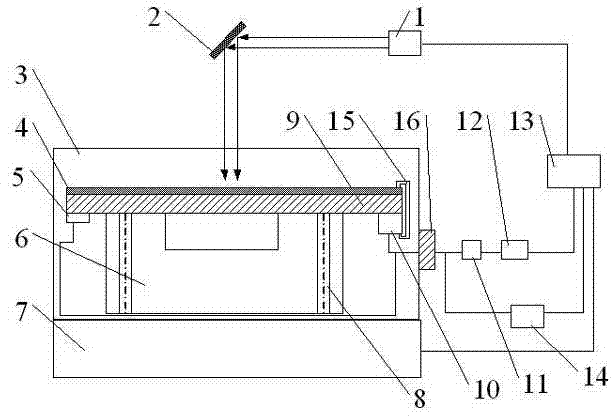

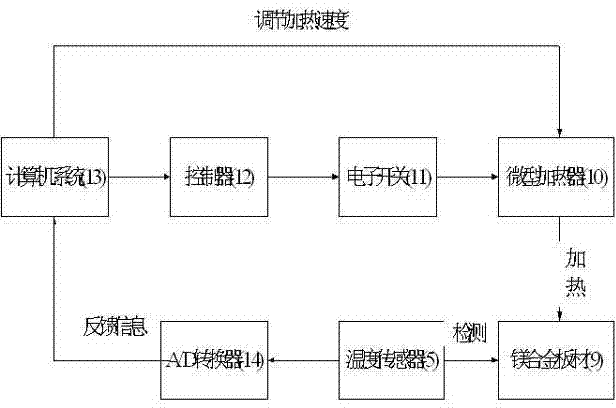

Method and device for forming magnesium alloy formed parts with excellent high-temperature mechanical property

ActiveCN102513440AImprove plasticityActivate other slip coefficientsLaser beam welding apparatusConvertersLaser peening

The invention discloses a method and a device for forming magnesium alloy formed parts with excellent high-temperature mechanical property. The device mainly comprises a die, a laser, a thermal sensor, a miniature heater and the like. The method includes: heating magnesium alloy to 120-150 DEG C to realize high-speed contact molding according to the laser peening quick-forming technology which utilizes dynamic strain ageing reinforcement, heat forming and high-pressure strain rate of thermal laser peening, placing magnesium alloy plates on a die in a work cavity, attaching energy converters on the magnesium alloy plates, vacuumizing the work cavity, and realizing high-speed contact molding of the magnesium alloy plates by the thermal laser peening process through the miniature heater and the laser. Dislocation anchoring effect and nano precipitates are formed in formed parts by the thermal laser peening technology, so that the magnesium alloy formed parts have excellent high-temperature mechanical property such as high-temperature creep resistance, high-temperature strength and the like, thermal high-strain-rate forming of the magnesium alloy plates is realized, and forming performance and efficiency of the magnesium alloy are improved.

Owner:JIANGSU UNIV

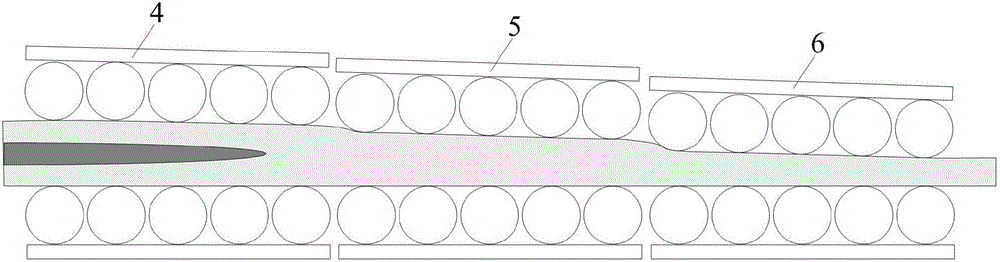

Continuous casting billet solidification end single-point and continuous heavy reduction technology

The invention provides a continuous casting billet solidification end single-point and continuous heavy reduction technology and belongs to the field of continuous casting production. The heavy reduction technology is completed through 1-3 fan-shaped sections. Each fan-shaped section comprises 5-7 pairs of pinch rolls, wherein each pair of pinch rolls comprises an upper supporting roll and a lower supporting roll. The single-point reduction of 3-20 mm is exerted on the upper supporting roller at an inlet of each fan-shaped section, so that the single roll reduction effect is achieved; and in this way, the strain rate of the heart portion of a casting billet can be effectively improved, and welding of a central pipe and the improvement on the density of the heart portion of the casting billet are facilitated. Meanwhile, the billet is continuously rolled by the follow-up upper supporting rolls of each fan-shaped section at the reduction rate of 1.5-5.0 mm / m, and it is guaranteed that the casting billet cannot rebound after rolling is conducted. Besides, a billet shell of the casting billet is forced to continuously shrink, and therefore the looseness caused by the difference between the inner shrinkage rate and the outer shrinkage rate of the casting billet is relieved.

Owner:NORTHEASTERN UNIV LIAONING

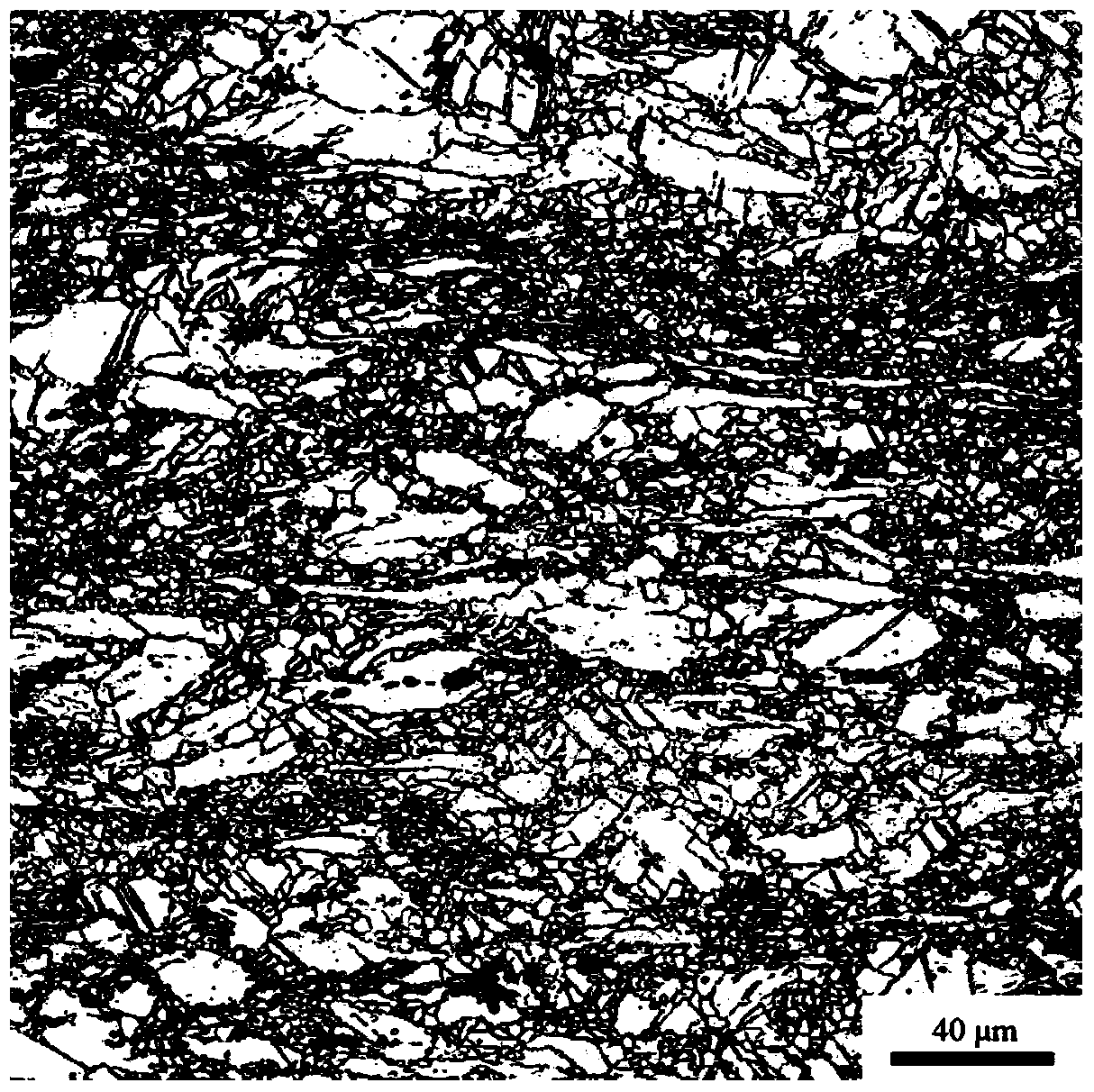

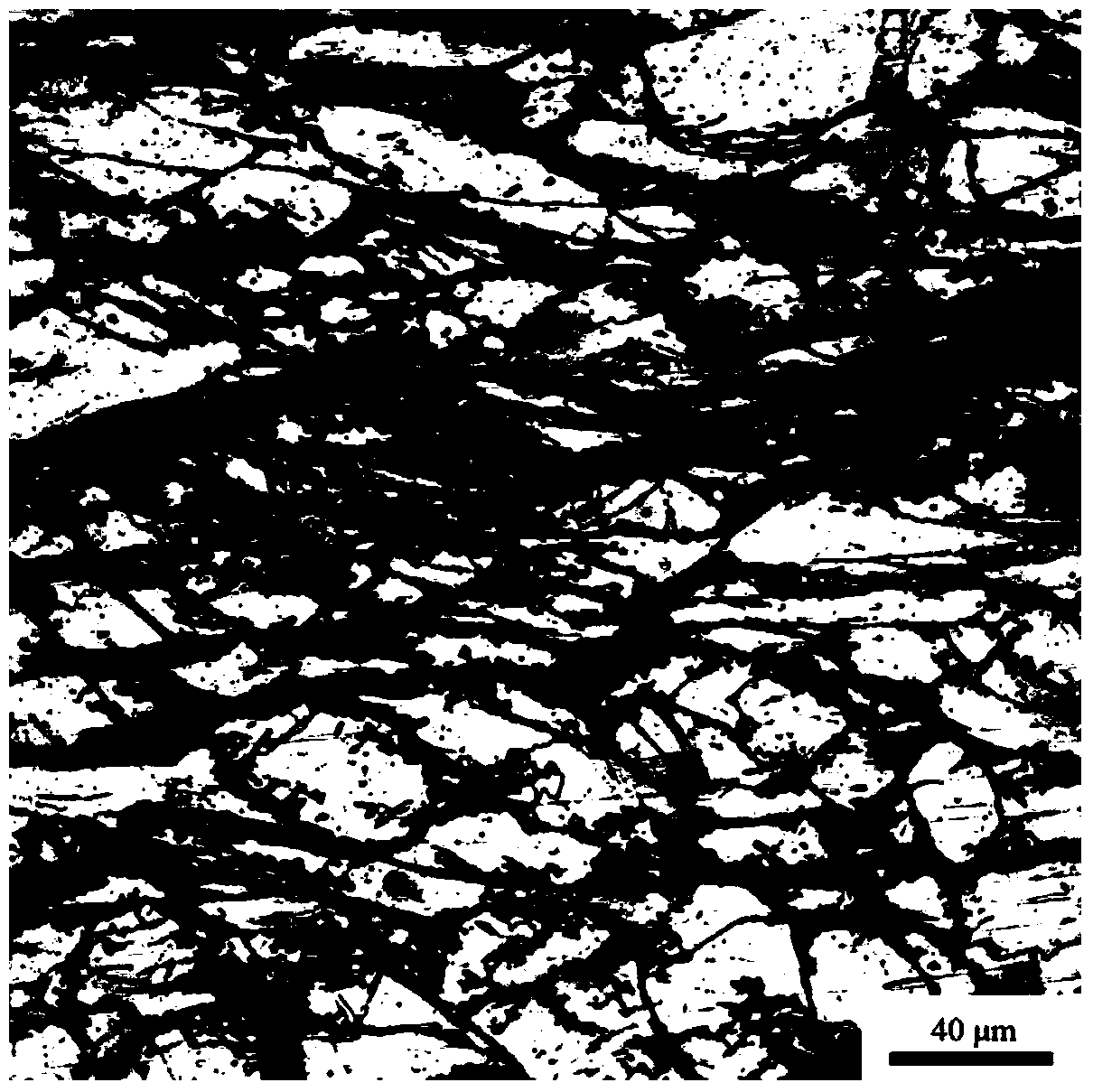

Method for rolling high-ductility and high-scalability Mg-Al series magnesium alloy plates

InactiveCN104259201AEnhanced ability to recover and recrystallizeImprove plasticityTemperature control deviceTension/compression control deviceDynamic recrystallizationSingle pass

The invention relates to a magnesium alloy processing method, in particular to a method for rolling high-ductility and high-scalability Mg-Al series magnesium alloy plates. The method comprises the steps of milling, heating and heat preservation of a plate, heating and heat preservation of a roller, rolling and cooling, wherein the rolling speed is 10-100 m / min; the rolling reduction of each time of rolling is 45%-80%. As the high-speed single-pass big-dependent-variable rolling is adopted for inducing obvious dynamic recrystallization, fully fine equiaxed grains are generated, and accordingly, the magnesium alloy plates of which the ductility and the scalability are greatly improved are acquired. Besides, as the annealing process is omitted, the manufacturing cost is greatly lowered, and the method is more suitable for large-scale industrial production.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com