Patents

Literature

109 results about "Split-Hopkinson pressure bar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

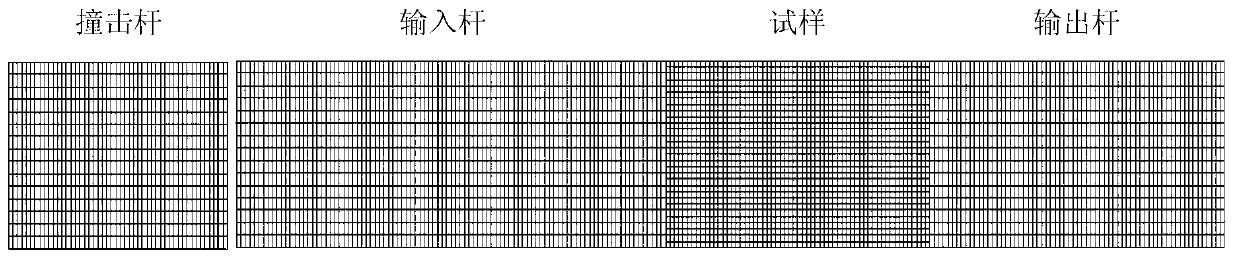

The Split-Hopkinson pressure bar, named after Bertram Hopkinson, sometimes also called a Kolsky bar, is an apparatus for testing the dynamic stress–strain response of materials.

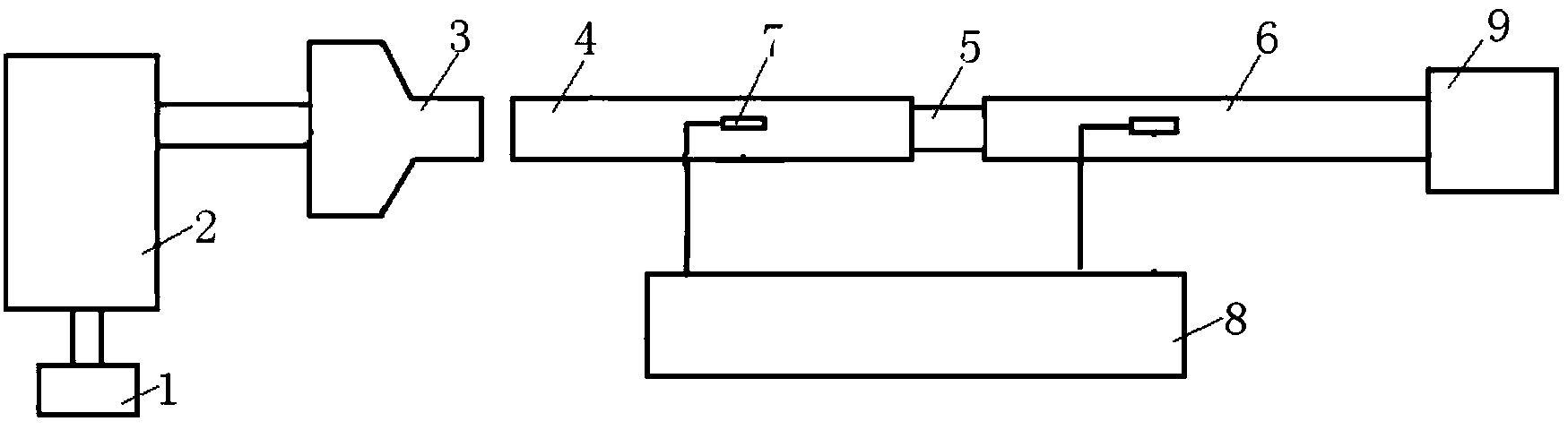

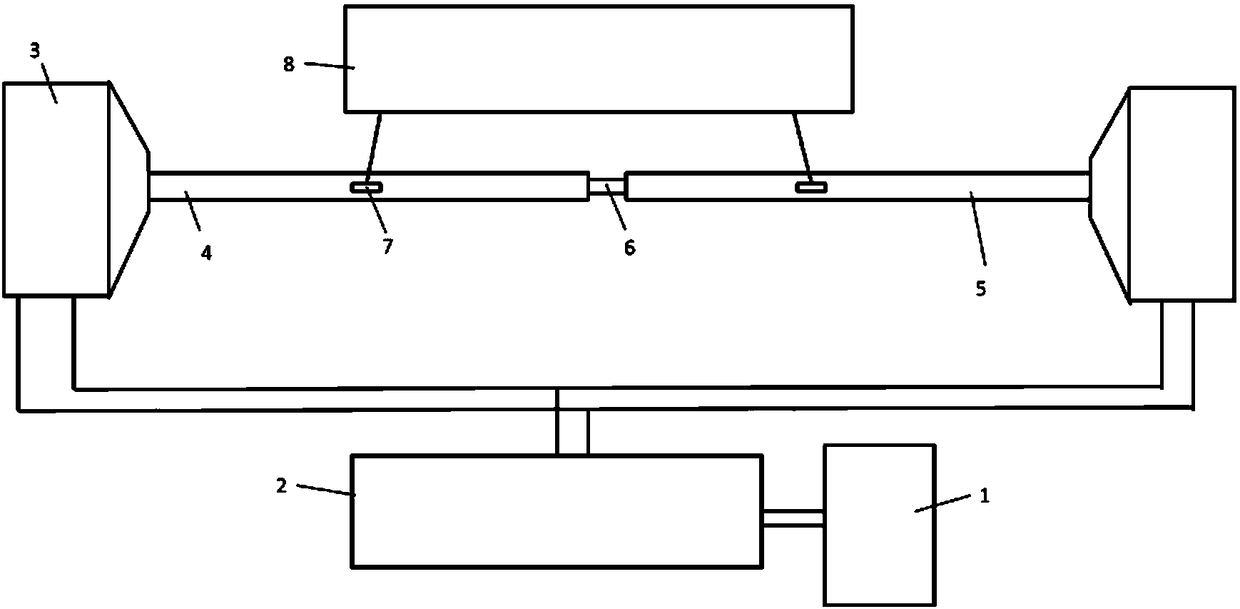

Experimental device of split hopkinson pressure bar based on electromagnetic force load

ActiveCN103913382AGood repeatabilityEasy to operateMaterial strength using tensile/compressive forcesElectromagnetic shieldingEngineering

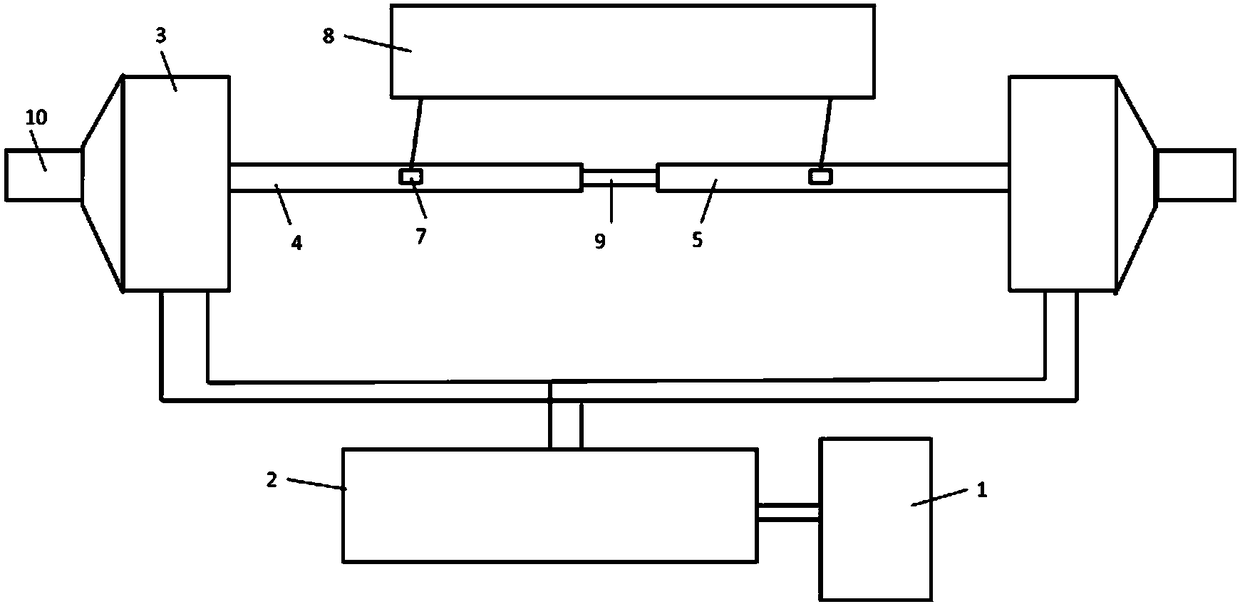

The invention discloses an experimental device of a split hopkinson pressure bar based on electromagnetic force load. The experimental device comprises an electromagnetic riveting device and a split hopkinson pressure bar experiment device, wherein the electromagnetic riveting device is arranged at one end of an incident bar of the split hopkinson pressure bar experiment device; the end face of an electromagnetic riveting gun on the electromagnetic riveting device is in full contact with the end face of the end of the incident bar, so that the electromagnetic riveting device can generate stress pulse which is directly input into the incident bar and generated pulse signals can be accurately controlled. By adopting the experimental device, the split hopkinson pressure bar is not greatly improved; the electromagnetic riveting device is only used for replacing an air gun in a conventional split hopkinson pressure bar system; accurate control of stress wave is achieved in an electromagnetic way; meanwhile, the width of the stress wave generated by the electromagnetic load is not limited by the length of an impacting bar, so that the width of the stress wave generated by the experimental device is large enough at a high strain rate, thereby achieving the normalization of experimental technologies of the split hopkinson pressure bar.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Experimental device for automatically loading impacts on SHPB (Split Hopkinson Pressure Bar) at high temperature

ActiveCN103674738AHeating evenlyImprove heating efficiencyPreparing sample for investigationMaterial strength using single impulsive forceEngineeringHigh pressure

The invention discloses an experimental device for automatically loading impacts on an SHPB (Split Hopkinson Pressure Bar) at a high temperature. The experimental device comprises a high-pressure air cylinder, an incident bar, a transmission bar, a base for the placement of the incident bar, the transmission bar and a test piece, and a test piece heater, wherein the test piece heater and the base are separately arranged; width-adjustable test piece guide rails for guiding the test piece from the test piece heater to the base are arranged between the test piece heater and the base; test piece baffle rods for limiting the test piece are arranged on one side of the test piece which is opposite to the base and the test piece guide rails; three-dimensional regulation of the base can be achieved. According to the adopted experimental device for automatically loading the impacts on SHPB at the high temperature, the test piece is uniformly heated, the experiment process is accurate, and the stability is high.

Owner:PLA UNIV OF SCI & TECH

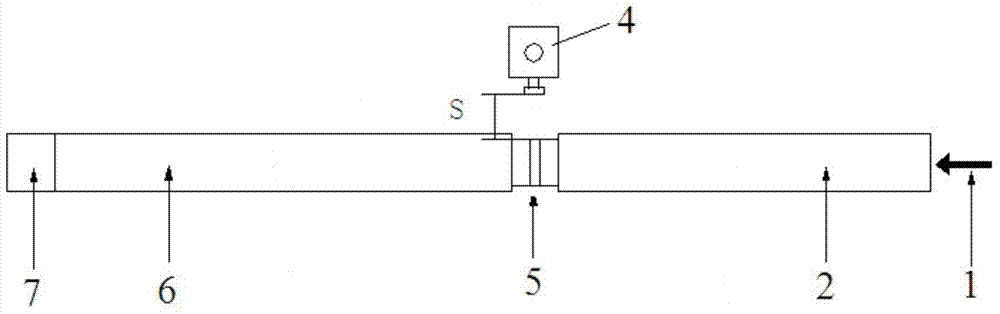

Measurement device and method for dynamic stretching crack propagation speed of fragile material

ActiveCN103792151AHigh measurement accuracyPrecisely determine when the extension startsMaterial strength using single impulsive forceMeasurement deviceStop time

The invention discloses a measurement device for the dynamic stretching crack propagation speed of a fragile material. The measurement device comprises an SHPB (split Hopkinson pressure bar) device, a specimen and a high-speed camera, wherein a round through hole is preformed in the center of the specimen, and the specimen is clamped between an incident rod and a transmission rod of the SHPB device; the high-speed camera is installed on an axis of the round through hole of the specimen. The measurement method comprises the following steps: applying impact load to the specimen by utilizing the SHPB device so as to enable a material to be cracked; meanwhile, shooting an image on the surface of the specimen in real time, confirming the crack starting and stopping time according to the record of the image, measuring the length of the crack actually, and calculating the dynamic stretching crack propagation speed. The measurement device and method provided by the invention can control the dynamic stretching crack propagation direction of the fragile material, and also can precisely confirm the crack propagation starting and stopping time, effectively improve the measurement precision of dynamic stretching crack propagation speed of the fragile material, and provide a novel conveniently operated, rapid, convenient, simple and effective method for confirming the dynamic stretching crack propagation speed of the rock-type fragile material under the impact load effect.

Owner:CENT SOUTH UNIV

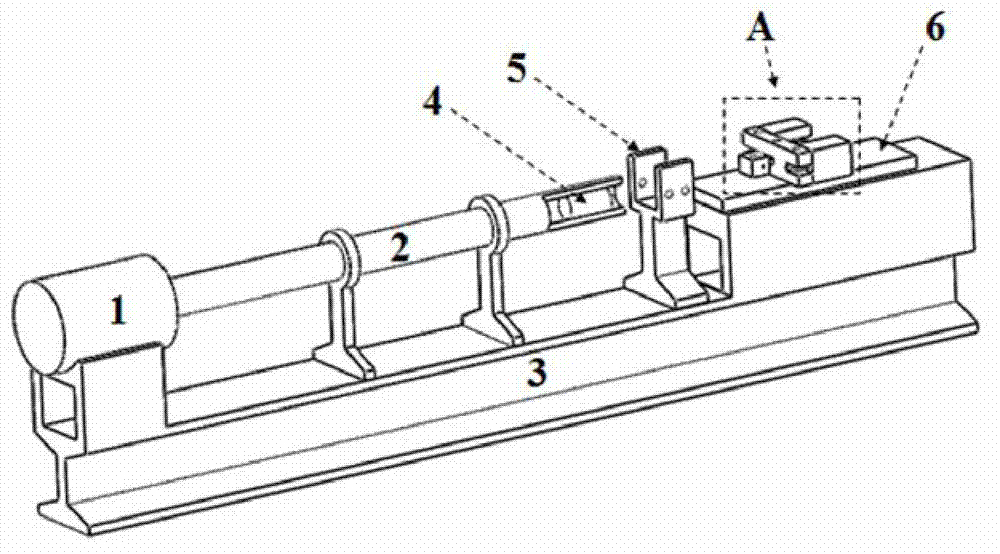

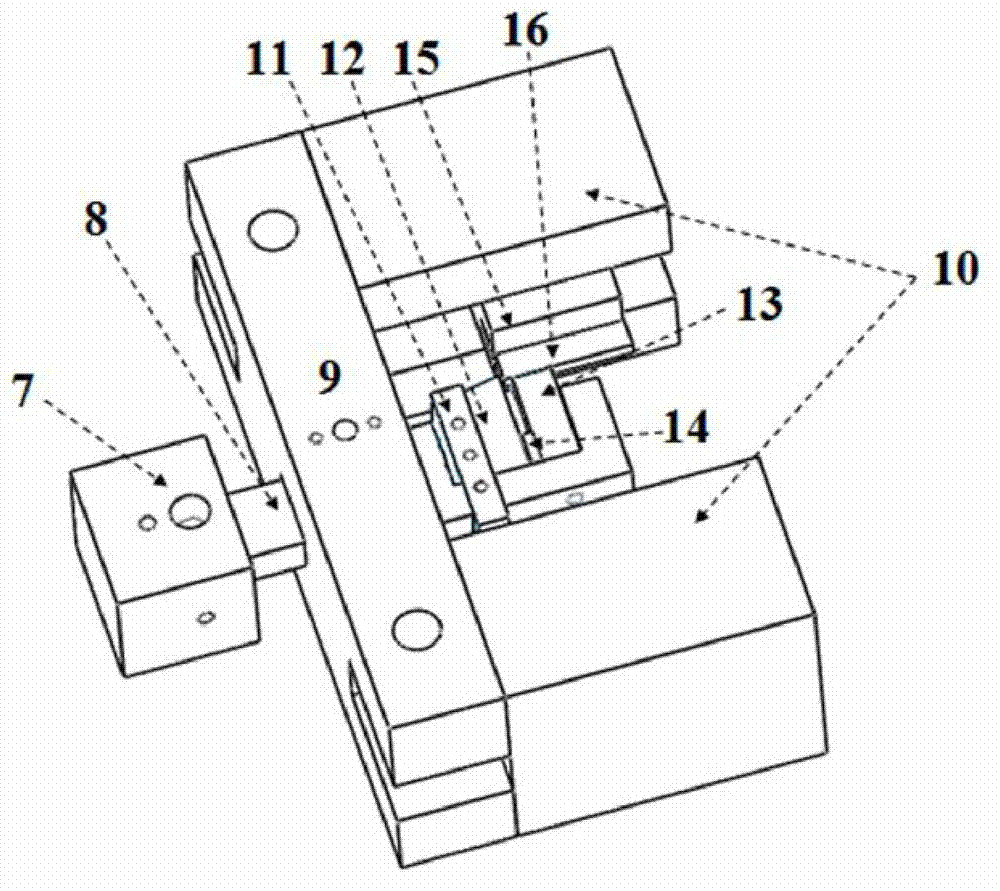

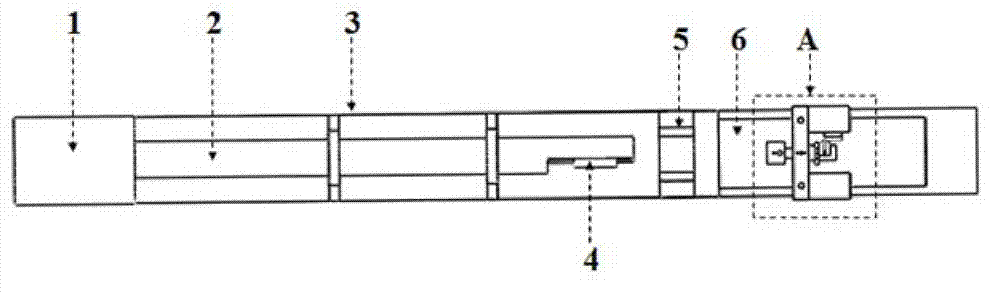

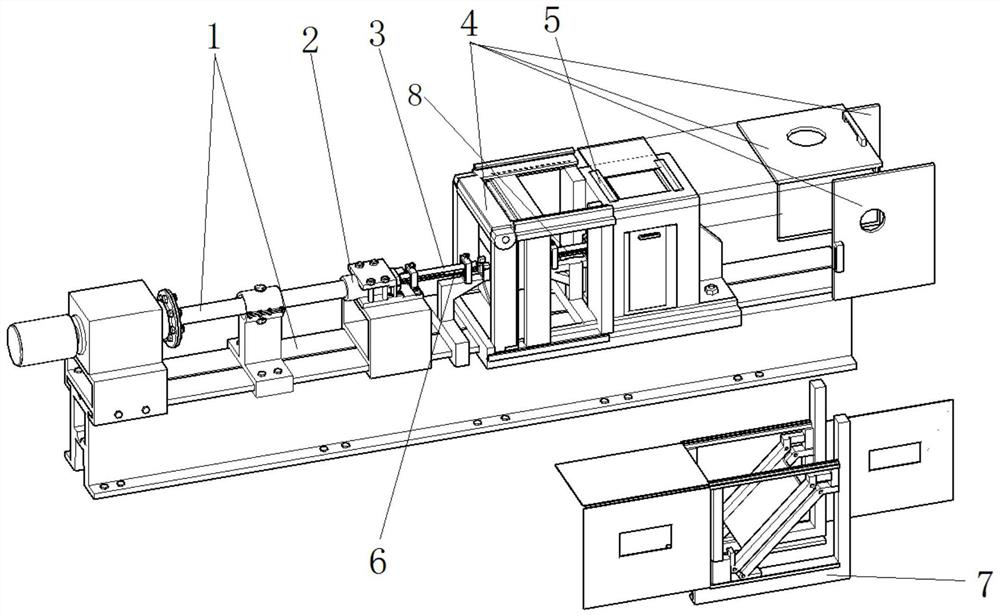

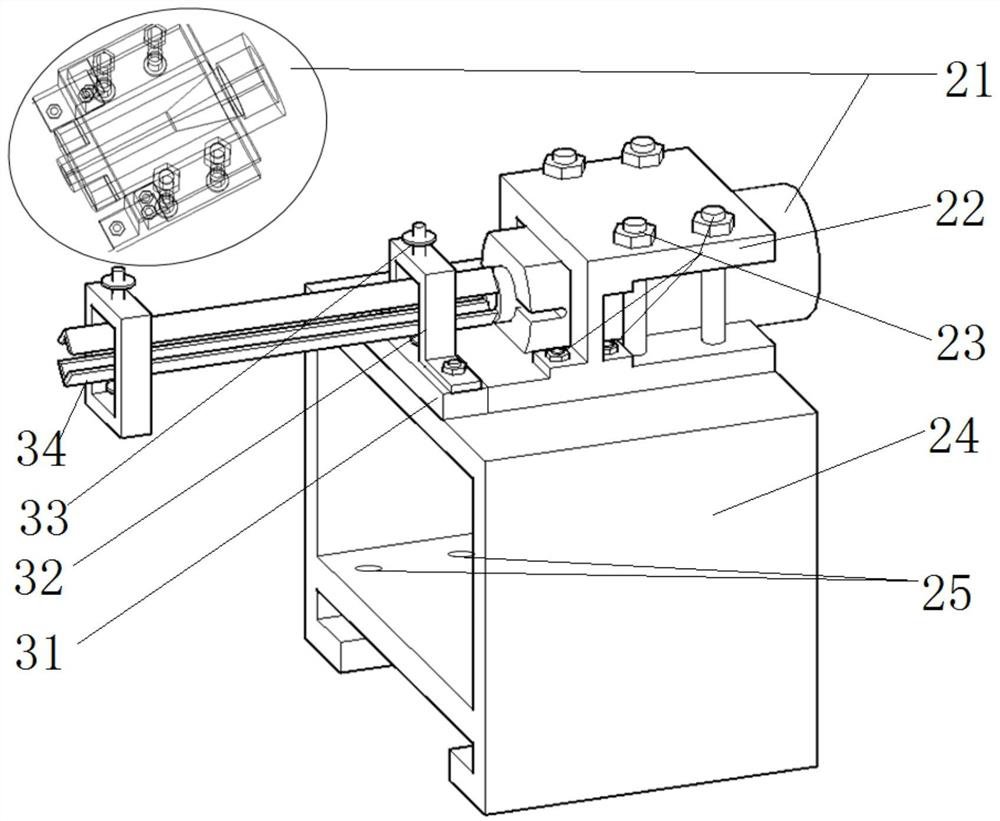

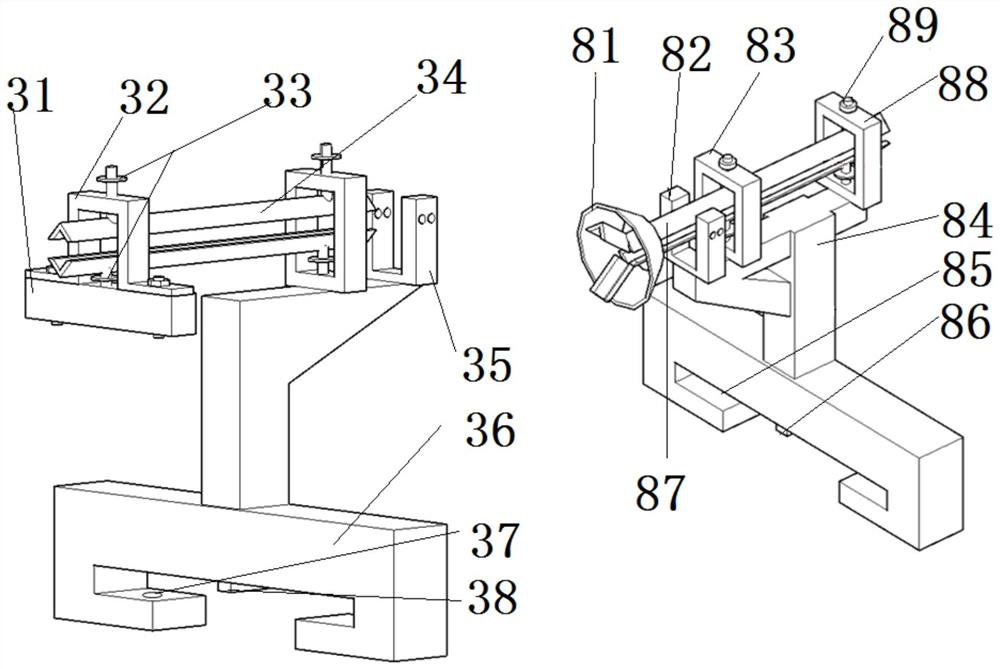

High-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology

ActiveCN103163037AHigh strain rateConstrained Cutting ExperimentInvestigating machinabilityGun barrelVelocity measurement

The invention discloses a high-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology. The high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology comprises a Hopkinson pressure bar loading mechanism which is used for pushing a bullet to move along a scheduled track at a scheduled speed, a laser velocity measurement mechanism which is used for measuring a movement speed before the bullet strikes a restrained cutting mechanism, the restrained cutting mechanism which is used for conducting restrained cutting of different plastic deformation degrees on a to-be-processed workpiece, a restrained cutting slideway mechanism which is used for giving a speed direction of restrained cutting, a fixing mechanism which is used for fixing the to-be-processed workpiece and a cutting stopping mechanism which is used for stopping a restrained cutting process. Different cutting speeds are obtained by adjusting pressure of air gun of the Hopkinson pressure bar and an initial position of the bullet in an acceleration gun barrel, different plastic deformation degrees can be obtained by adjusting the space between a tool of the restrained cutting mechanism and a restraining device, the high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology can be utilized to study a material interior microstructure evolution law when the material is with different strain rates and different plastic deformation degrees.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

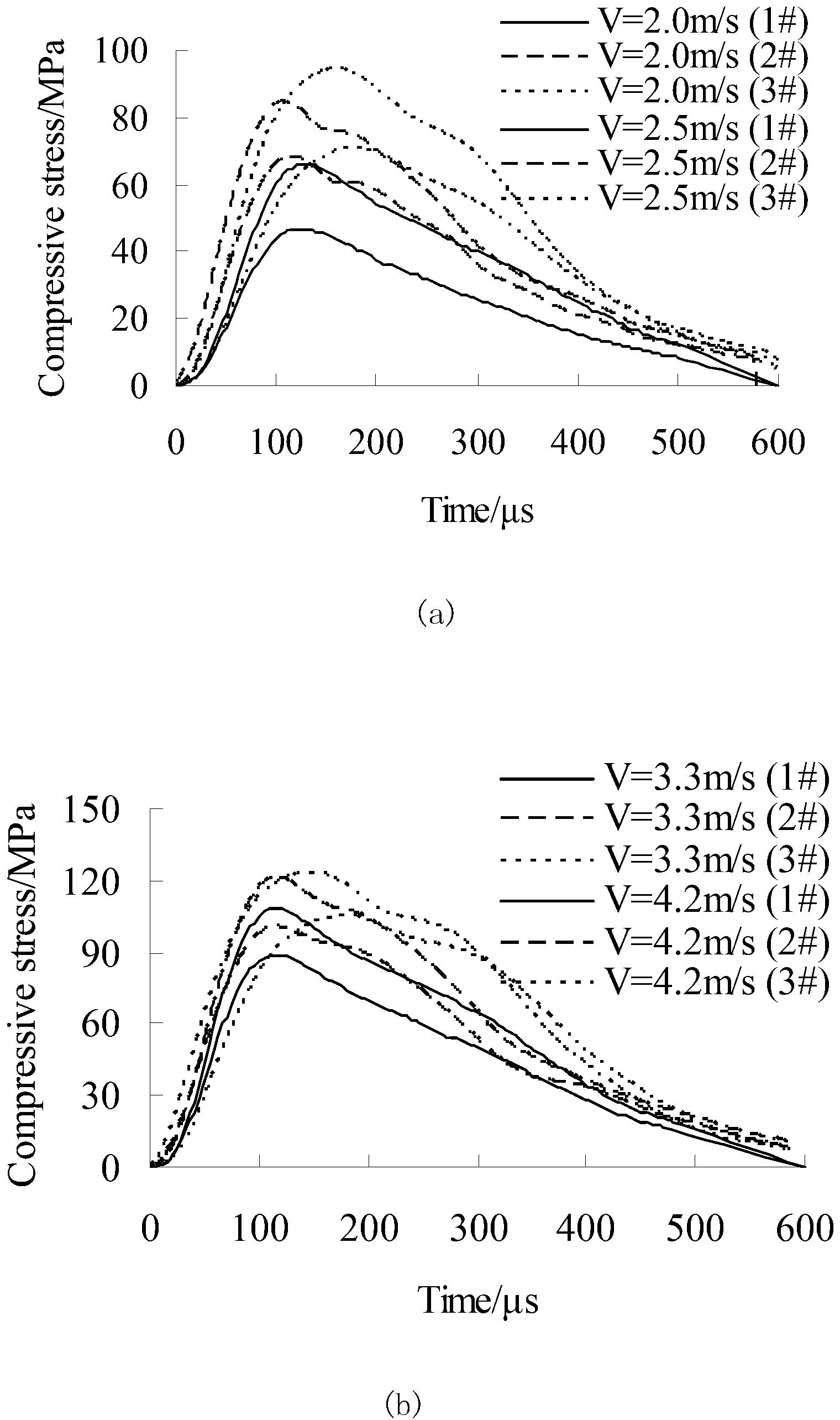

Pendulum load intermediate strain rate split Hopkinson pressure bar test device and method

ActiveCN103234844AGood waveform repeatabilityMaterial strength using repeated/pulsating forcesAudio power amplifierEngineering

Belongings to the technical field of rock dynamics, the invention relates to a pendulum load intermediate strain rate split Hopkinson pressure bar test device and a method. According to the invention, the hammerhead impact speed can be controlled by adjusting the pivot angle of a pendulum, thus realizing same dynamic stress wave loading under an intermediate strain rate loading condition. The device comprises a pendulum bracket that is provided with a pendulum; a calibration support is arranged on one side of the pendulum bracket, an incident bar and a transmission bar are disposed on the calibration support, and the incident bar, the transmission bar and the hammerhead axis are on one straight line; the incident bar and the transmission bar are provided with strain foils, which are in connection with the input end of an oscillographic recorder through pre-signal amplifiers, and the output end of the oscillographic recorder is connected to a computer. The method includes: adjusting the height and position of the calibration support, and ensuring alignment of the incident bar, the transmission bar and the pendulum hammerhead centere; making a sample clamped between the incident bar and the transmission bar; adjusting the pendulum pivot angle according to a required hammerhead impact speed; and releasing the pendulum to conduct an impact test, and recording and storing test data.

Owner:NORTHEASTERN UNIV

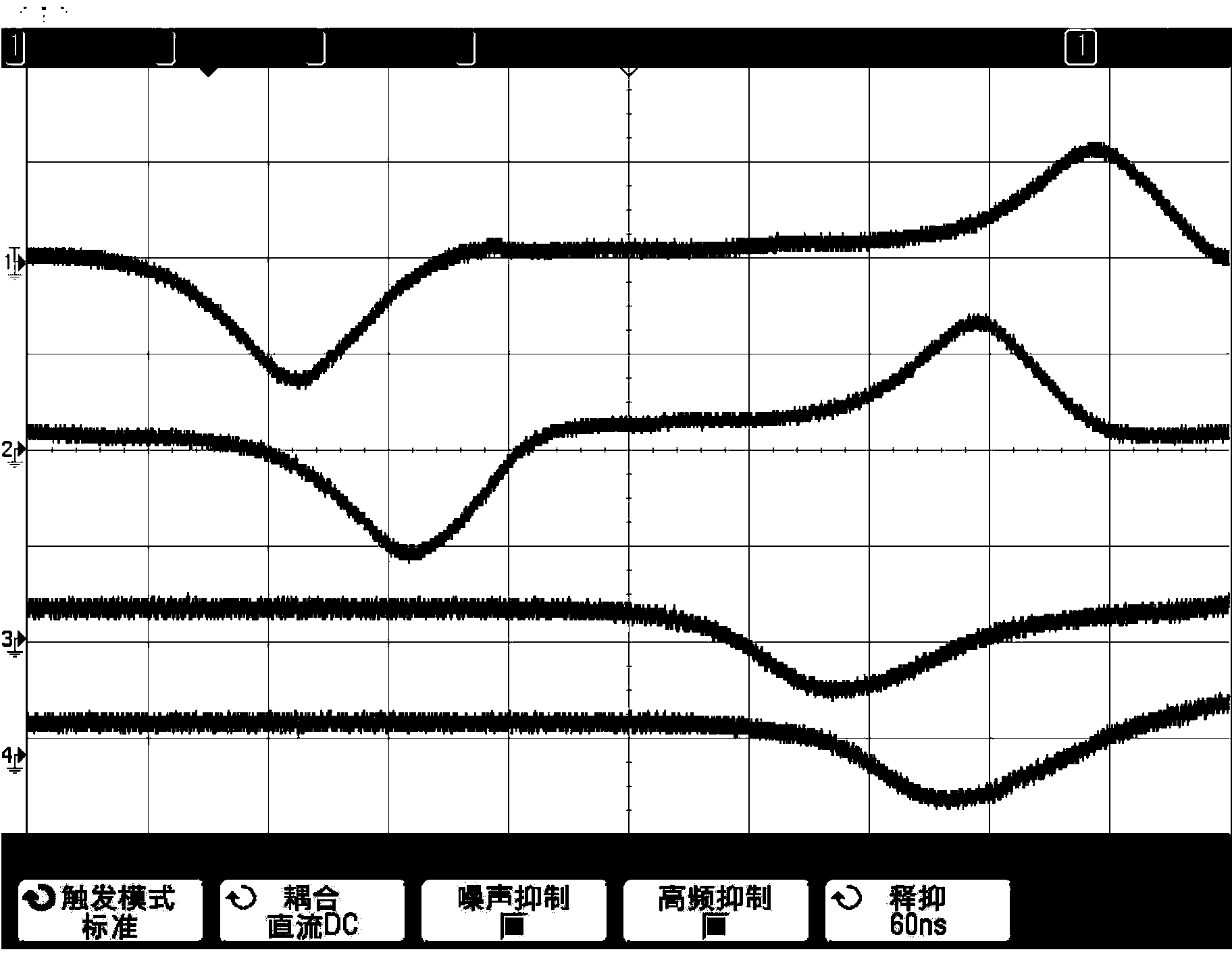

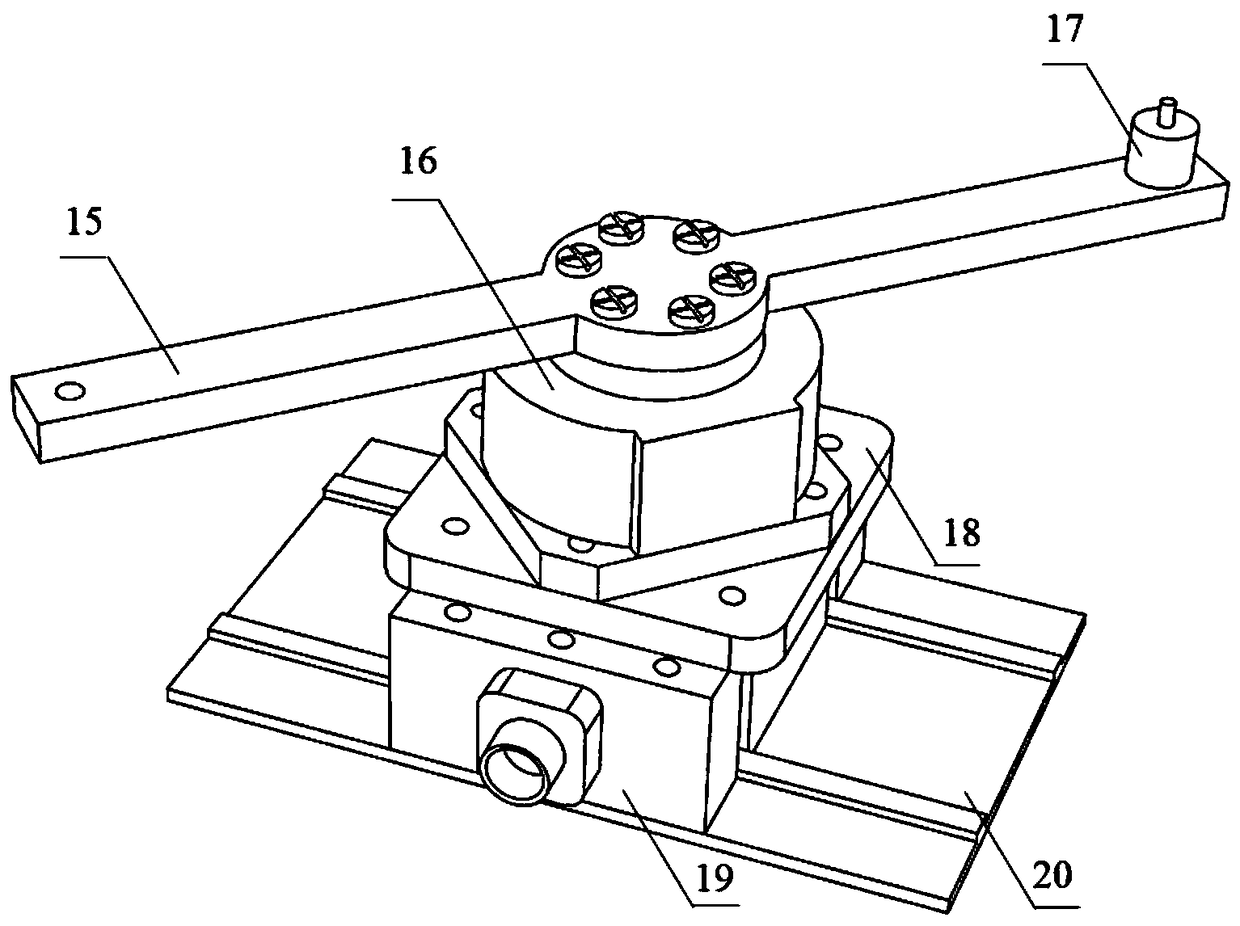

Single-axis two-way loading and split Hopkinson pressure bar and pull bar device and experimental method

ActiveCN108344648AAchieving Symmetrical LoadingHigh strain rateStrength propertiesCapacitanceExperimental methods

The invention relates to an experimental method of dynamic mechanics performance testing of materials, in particular to a single-axis two-way loading and split Hopkinson pressure bar and pull bar device and an experimental method. The device comprises a loading device and two incident bars, the loading device comprises a power source, a capacitor charger and loading guns, a power supply part of existing electromagnetic riveting equipment is adopted for the capacitor charger, and the loading guns with the same parameters are connected into the capacitor charger after being in parallel connection. By means of the single-axis two-way loading and split Hopkinson pressure bar and pull bar device and the experimental method, incident waves at the two sides simultaneously and symmetrically load aspecimen dynamically, symmetric loading of the specimen is achieved to shorten the balancing time of stress inside the specimen, the strain rate of the specimen is increased, and thus the defects ofexisting equipment of being low in strain rate and inaccurate in testing of elastic sections are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Device for rapid-heating quasi-static high-temperature Hopkinson pressure bar experiment

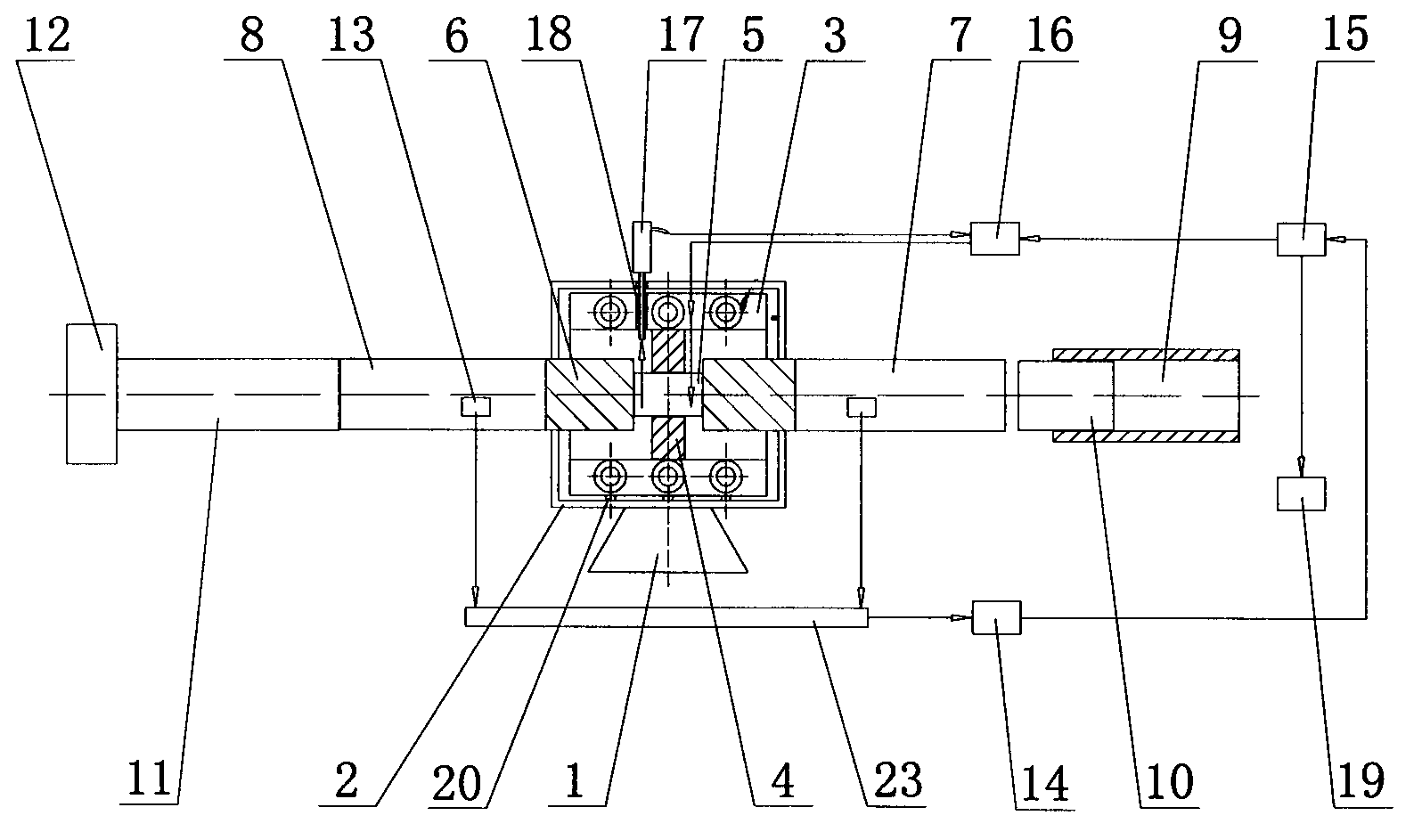

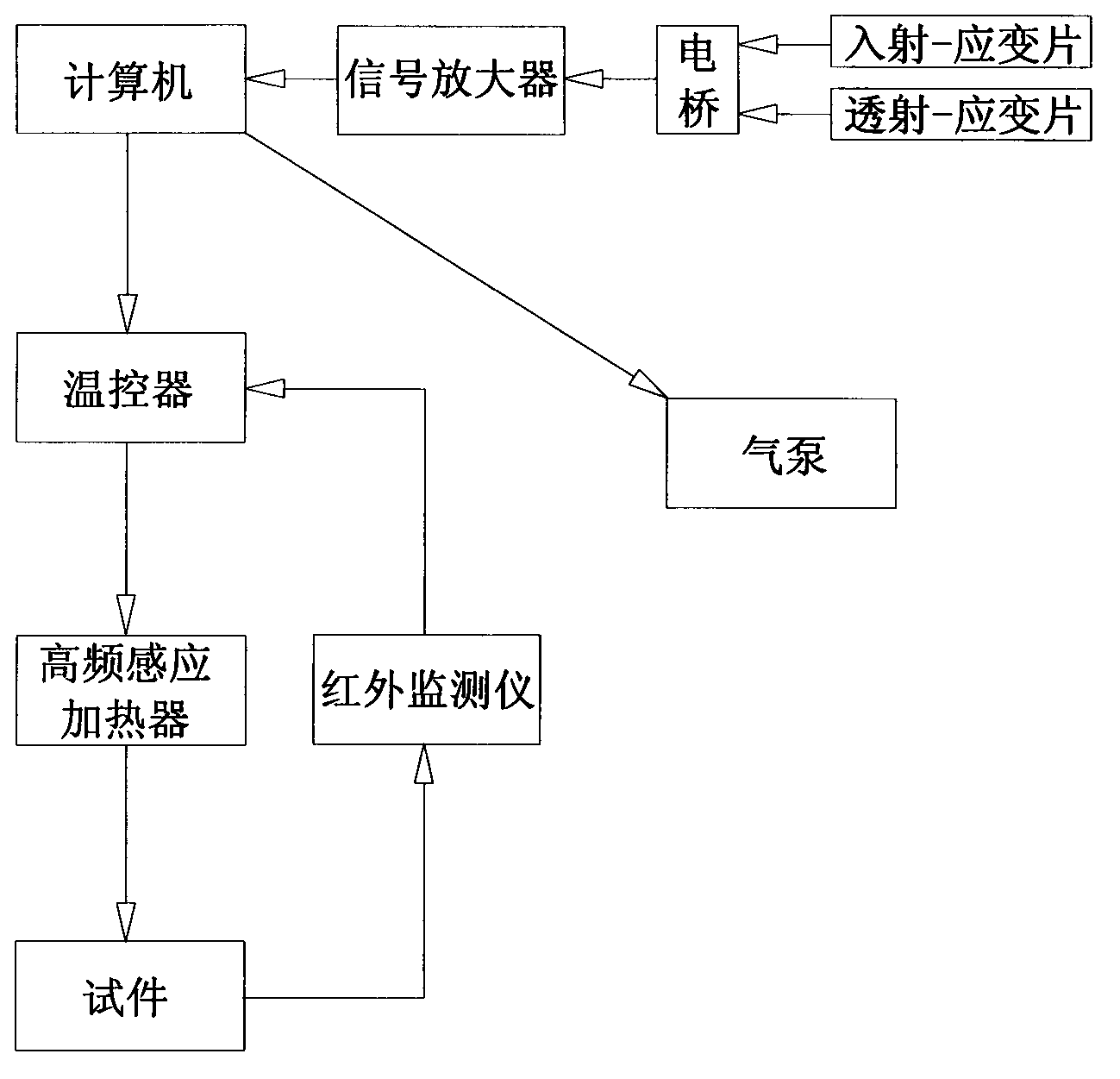

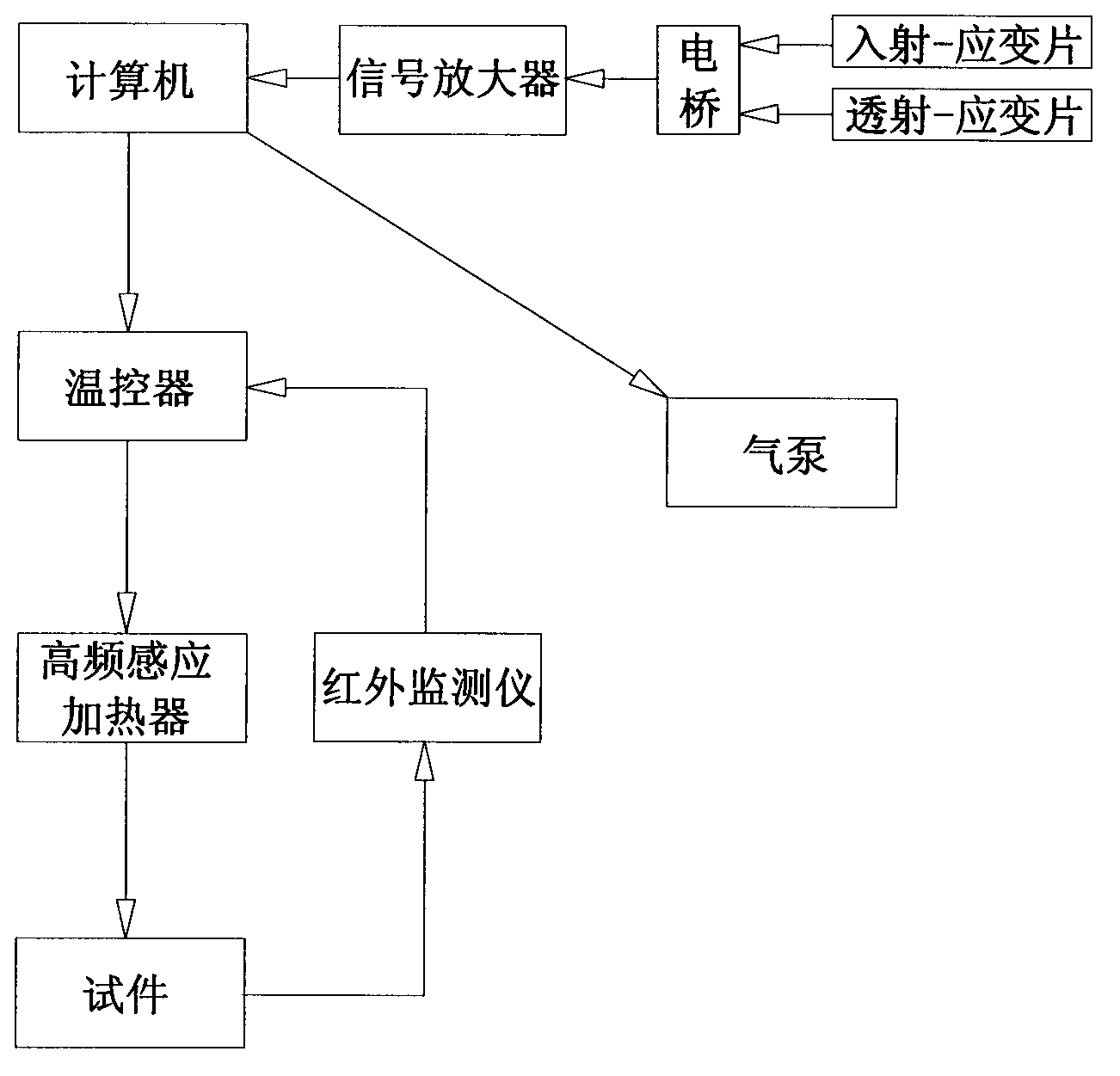

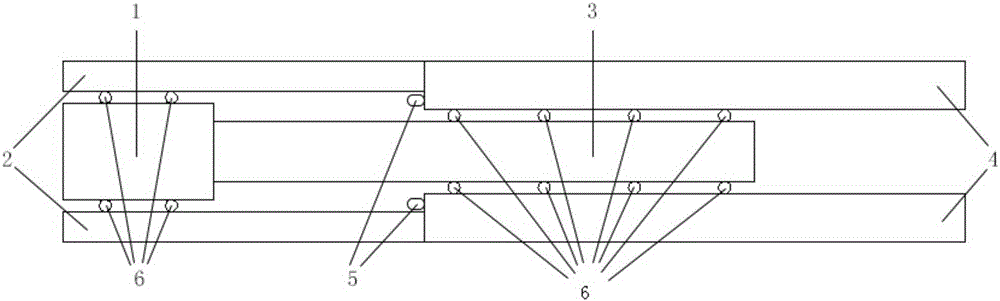

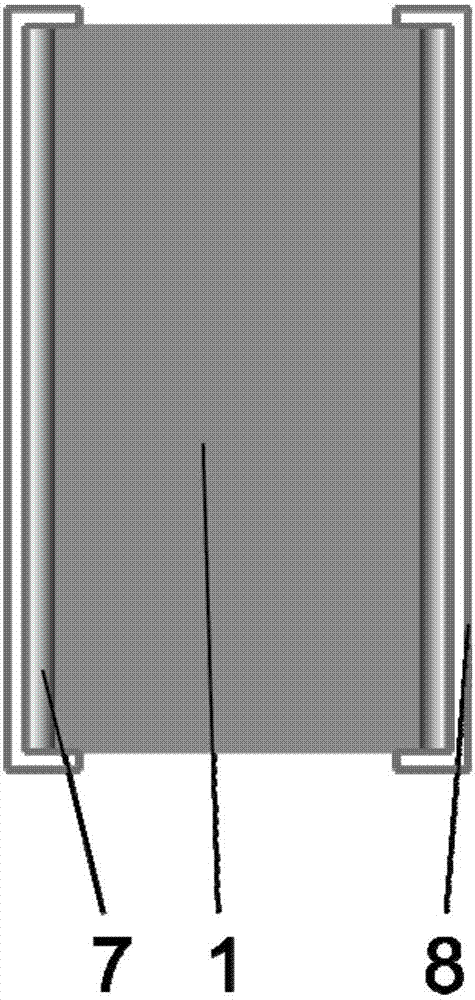

InactiveCN103018094AEliminate performance impactFast heatingPreparing sample for investigationStrength propertiesAudio power amplifierInduction heater

The invention discloses a device for a rapid-heating quasi-static high-temperature Hopkinson pressure bar experiment. The device adopts the technical scheme that a sample is mounted in the middle of a ceramic sleeve at the center of a high-frequency induction heater in a shielding cover; the both ends of the sample are connected with the inner ends of two short ceramic bars; the outer ends of the two short ceramic bars are connected with one end of an incidence bar and one end of a transmission bar respectively; stress wave signals of strain gages are measured from the incidence bar and the transmission bar respectively, and sent to a computer for data processing through an electric bridge and an amplifier; the computer controls the warming of the high-frequency induction heater and the sample through a temperature controller; and the sample temperature is fed back to the temperature controller by another infrared monitor. The device overcomes the defects that the available device for the split Hopkinson pressure bar experiment is complicated in structure, complicated to operate, low in working efficiency and difficult in data processing; and the quality of the experiment is influenced seriously. The device is suitable for the Hopkinson pressure bar experiments in different laboratories, in particular to the heating of the sample and the immediate processing of the information of the strain gages.

Owner:HUNAN UNIV OF SCI & TECH

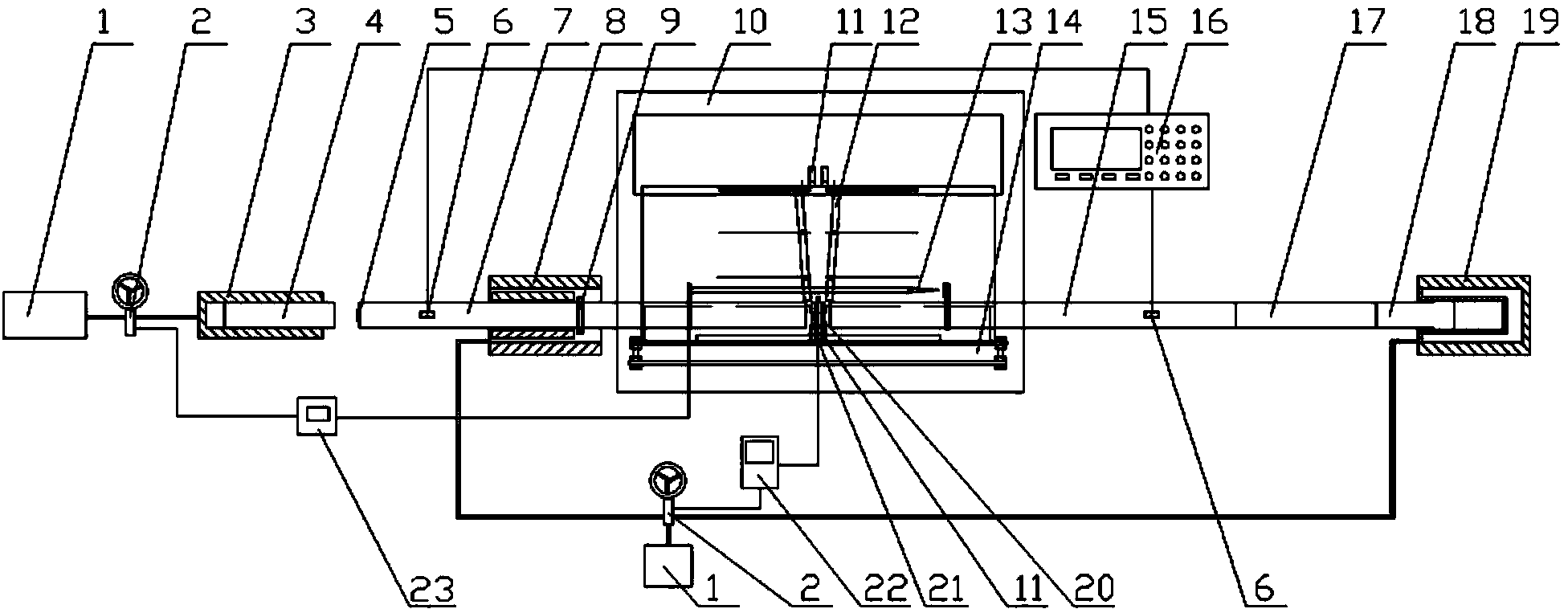

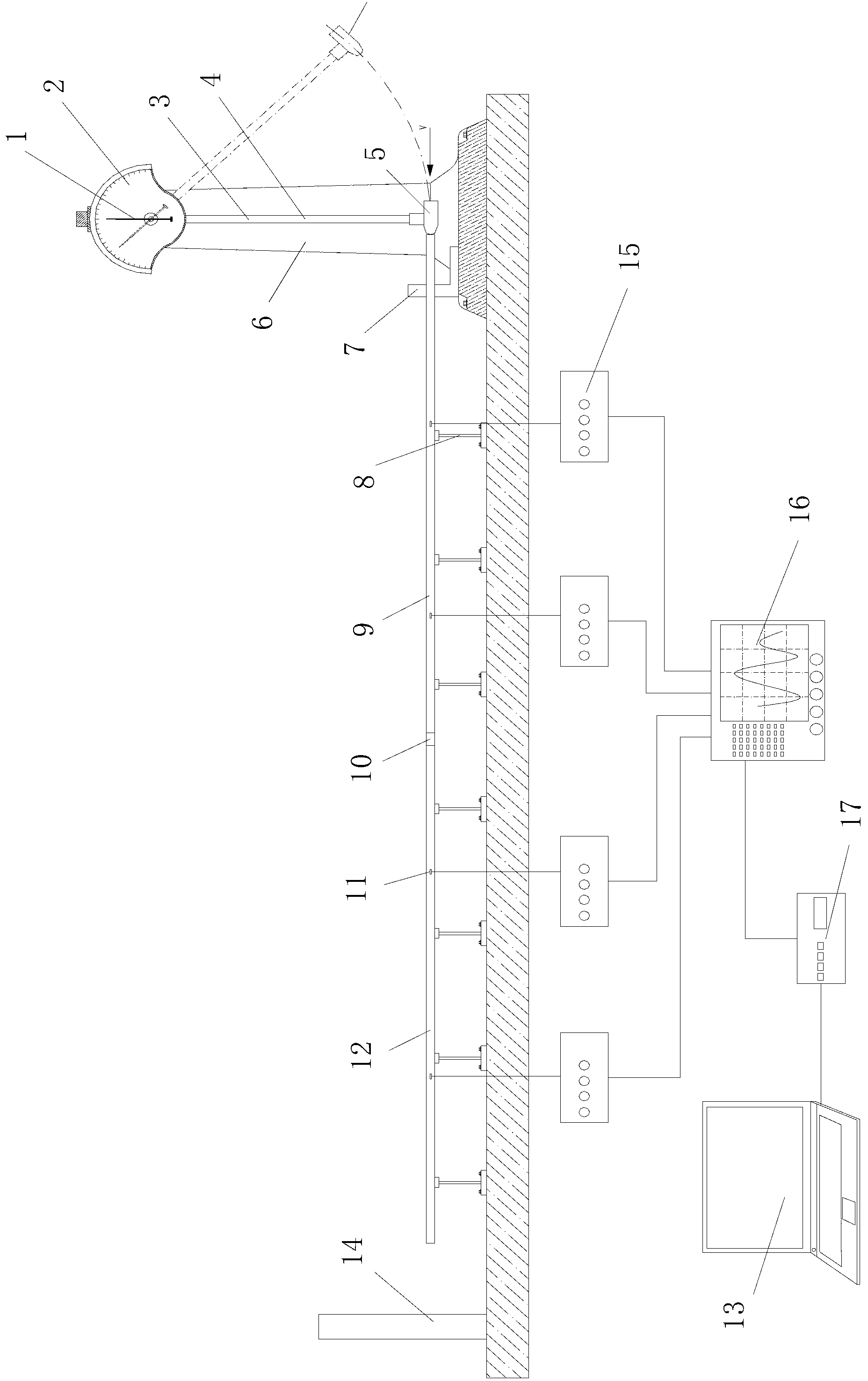

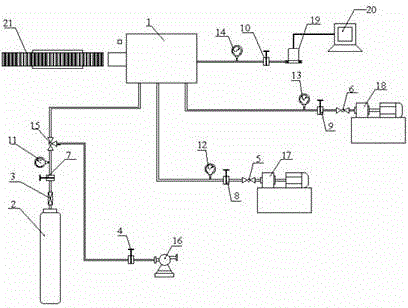

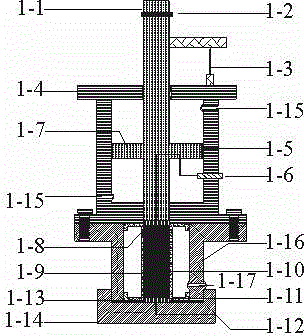

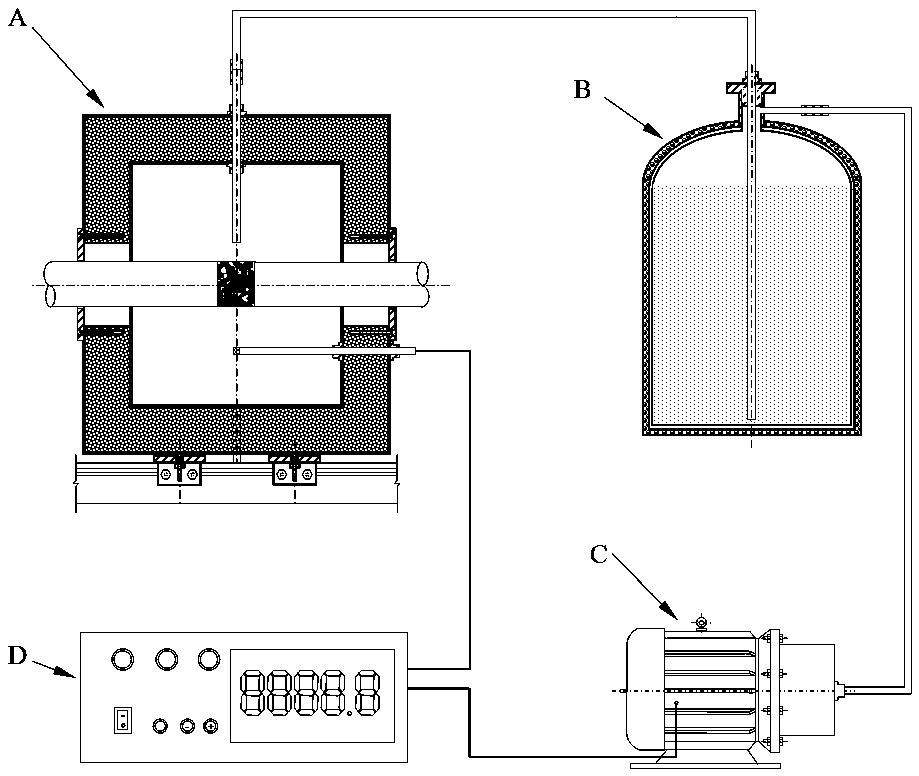

Seepage experiment system and method for gas-containing coal under action of impact load

InactiveCN104865176AReasonable structureSimple and fast operationPermeability/surface area analysisRadial stressAxial pressure

The invention discloses a seepage experiment system for gas-containing coal under the action of an impact load. The system comprises a coal sample fixing device, an impact load applying device as well as a high-pressure gas source device, an axial pressure loading device, a confining pressure loading device, a vacuumizing device and a metering and data acquisition device connected with the coal sample fixing device, wherein the impact load applying device is a split Hopkinson pressure bar device. The split Hopkinson pressure bar device is adopted to apply the impact load for simulating rock burst, three-dimensional loaded conditions of coal-rock masses in coal mine can be simulated by applying different axial stresses and radial stresses, and seepage experiment of a coal sample in a three-dimensional stress state under the action of the impact load is successfully carried out, so that the system has relatively important meaning in both theory and practice.

Owner:HENAN POLYTECHNIC UNIV

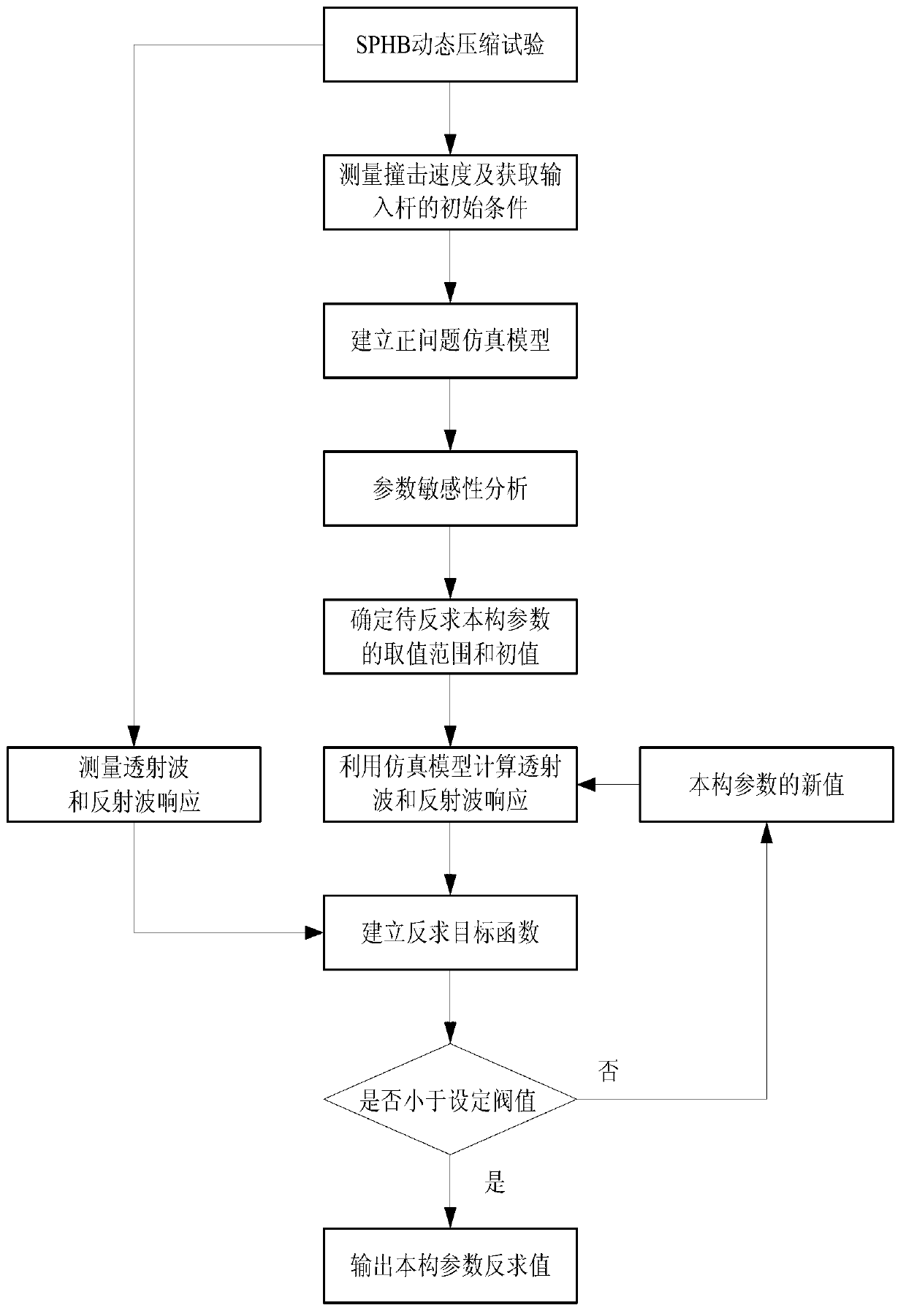

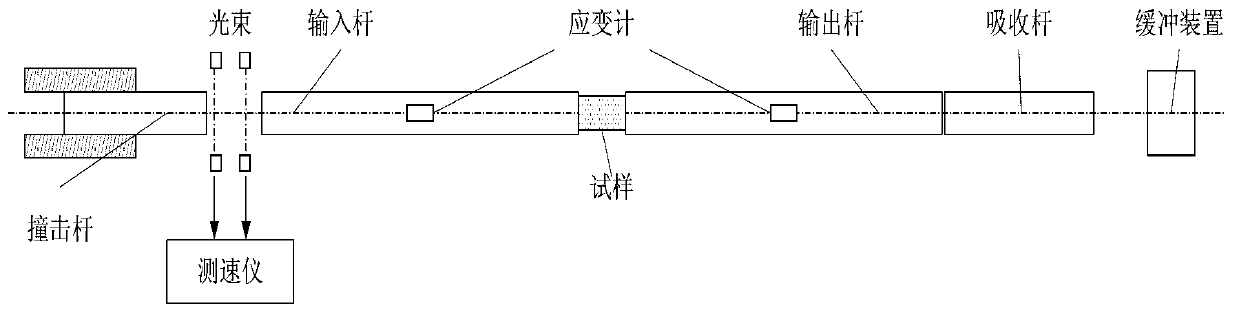

Identification method for dynamic constitutive parameters of concrete materials based on reverse calculation

ActiveCN103344482AAccurate identificationRealize identificationStrength propertiesReflected wavesTest measurement

The invention discloses an identification method for dynamic constitutive parameters of concrete materials based on reverse calculation. According to the identification method, a separating type Hopkinson pressure bar (SHPB (Split Hopkinson Pressure Bar)) test of concrete and a corresponding finite element analytical model are comprehensively utilized, a minimum error function corresponding to reflected waves and transmitted waves which are subjected to test measurement and numerical calculation is taken as a reverse calculation object function, and a group of dynamic constitutive parameters of the concrete materials are identified by carrying out searching and evaluation based on an optimized reverse calculation method; the constitutive parameters of the concrete materials can be fast acquired only by carrying out SHPB tests for several times, meanwhile, decoupling problems of an stress wave effect and a strain rate effect are avoided, and the structural response and the material response do not need to be separated; the parameters which are difficult to confirm in a conventional method can be accurately and effectively acquired, the number of times and the cost of physical tests are greatly reduced, and the practical value is relatively good.

Owner:HUNAN UNIV

Test piece dynamic lateral strain measurement device and method based on SHPB test system

ActiveCN110926936AThe experimental data is intuitiveAccurate lateral strain measurement dataMaterial strength using single impulsive forceData acquisitionClassical mechanics

The invention discloses a test piece dynamic lateral strain measuring device and method based on an SHPB test system, and belongs to the field of dynamic mechanical property testing of brittle materials such as coal rock by adopting the SHPB test system. The device comprises a fixing system, an oil pressure system and a data acquisition system; the fixing system is used for fixing the whole deviceon an SHPB test bed and adjusting the height of the device; the oil pressure system is used for applying required confining pressure to the test piece and converting a volume change signal of the test piece into an oil pressure change signal; the data acquisition system is used for capturing signals of oil pressure changes and obtaining a time-history change curve of lateral strain. The confiningpressure is applied to the test piece by utilizing the oil pressure system, comprehensive confining pressure loading of the test piece is simulated, and the comprehensive confining pressure loading and axial acting force caused by the split Hopkinson pressure bar device act together, so that simulation of a complex stress state of the test piece is realized; the relation between oil pressure andlateral strain is obtained through signals of oil pressure changes caused by the lateral strain so as to calculate the lateral strain.

Owner:SHANDONG UNIV OF SCI & TECH

Method of testing mechanical properties of coal in coal-rock composite under dynamic loading and combined static and dynamic loading

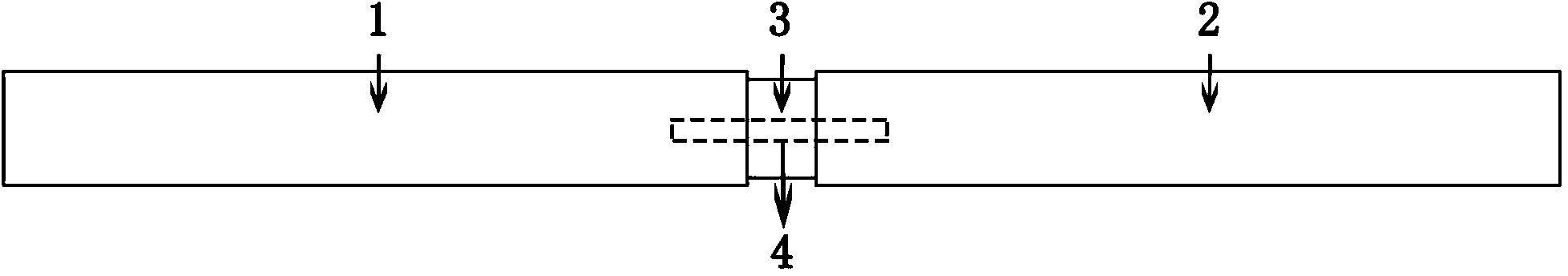

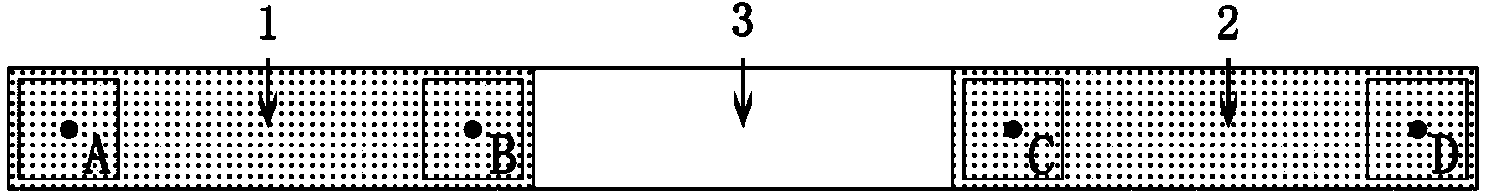

ActiveCN107314933AMeet the requirements of strain measurementOvercoming the conundrum of strainStrength propertiesStress variationStrain gauge

The invention discloses a method of testing mechanical properties of coal in coal-rock composite under dynamic loading and combined static and dynamic loading. An existing coal-rock composite test piece is used; starting from rock less prone to crushing, an SHPB (split Hopkinson pressure bar) test device is used, coal-rock composite loading test is performed by means of attaching a strain gauge, stress of coal is acquired according to stress at each end face of the coal test piece, and stress variation of the coal in the coal-rock composite under dynamic loading. Mechanical properties of coal in a certain surrounding rock environment are acquired, better guidance can be provided for field engineering practice, and the method has major guiding significance for disclosing true failure mechanism of engineering coal.

Owner:SHANDONG UNIV OF SCI & TECH

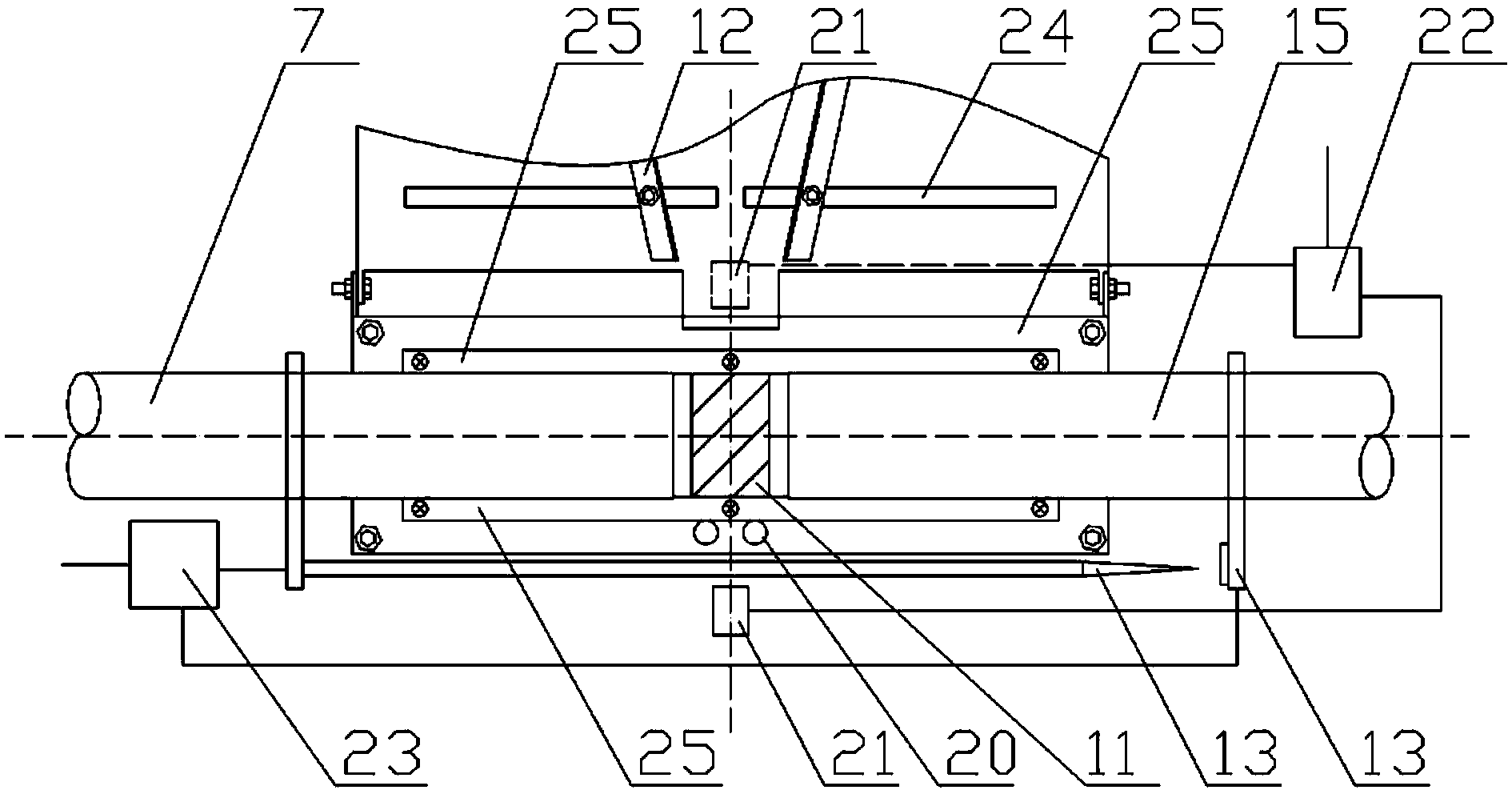

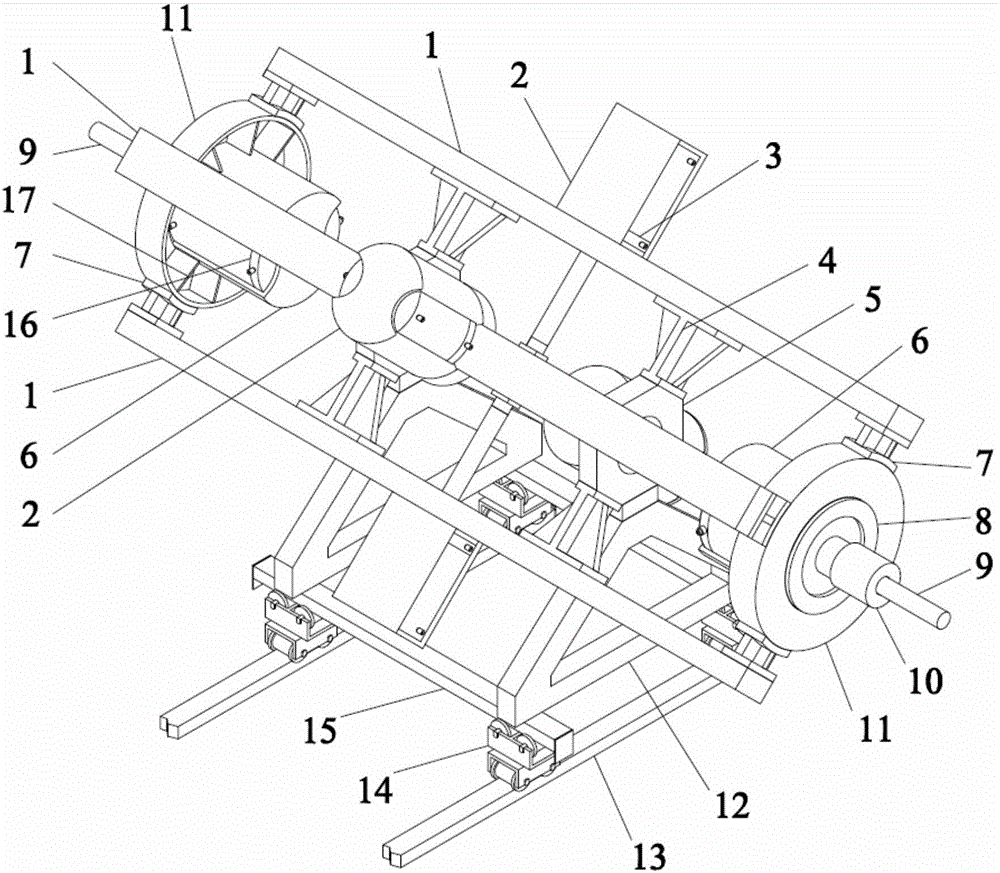

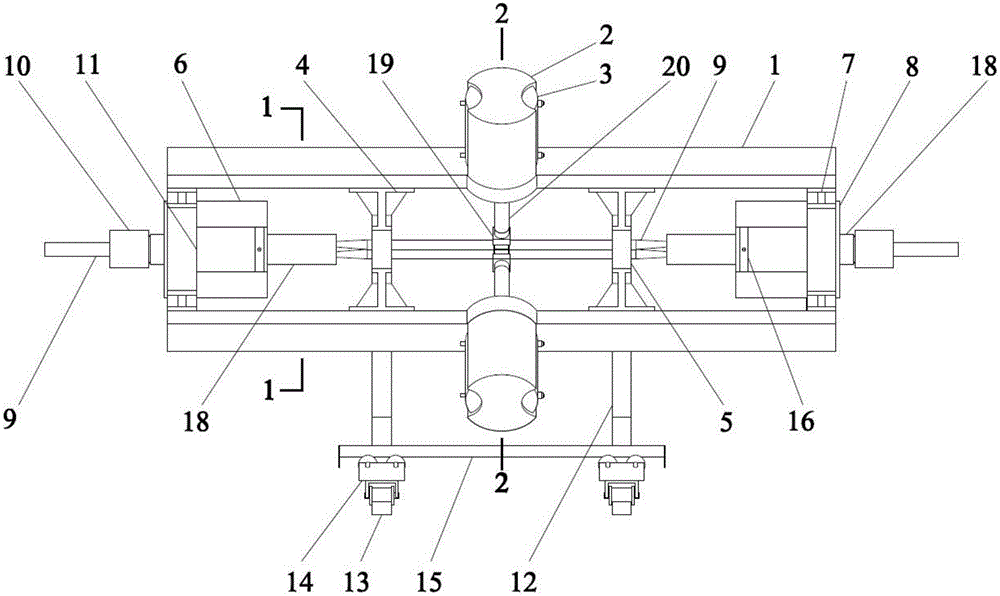

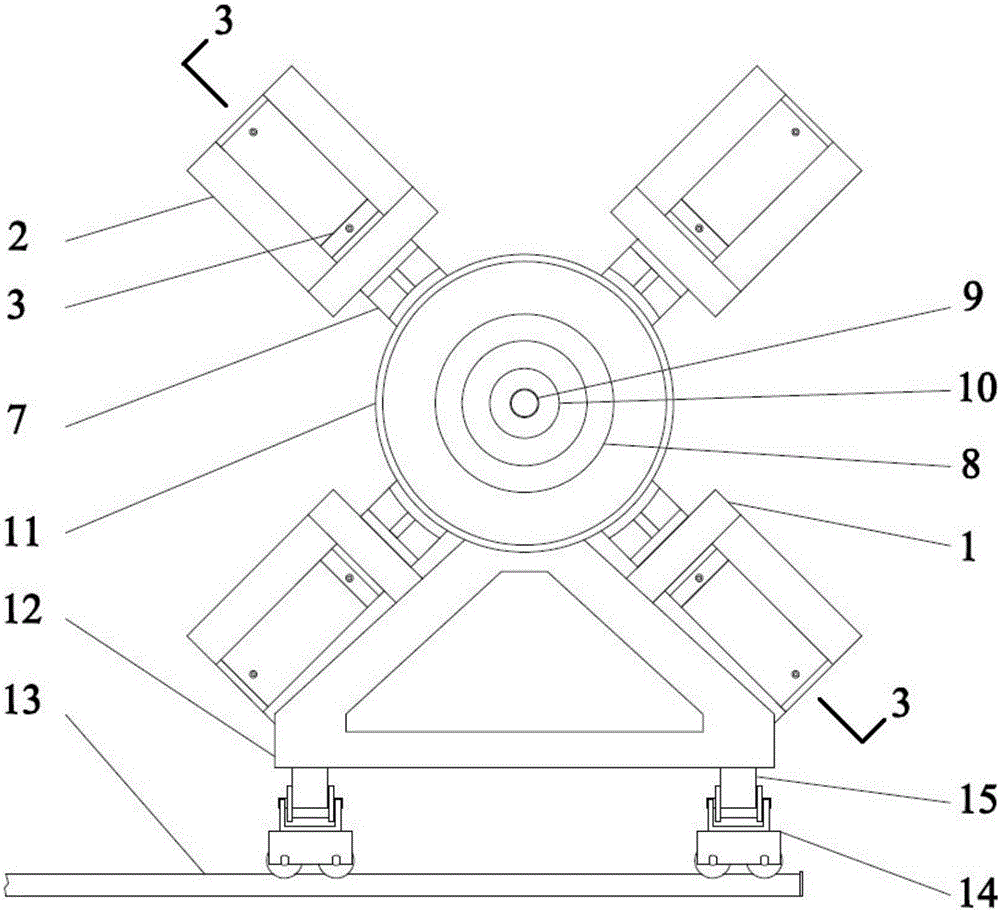

Universal type true-triaxial static load pre-loading system for split Hopkinson pressure bar

InactiveCN105716957ARealize dynamic and static combined loadingRealize true three-axis dynamic and static combined loadingMaterial strength using tensile/compressive forcesSteel frameRock sample

A general-purpose true triaxial static load preloading system for split Hopkinson compression bars, the main reaction force steel frame is the carrier of the axial preloading system and the radial preloading system. The main reaction force steel frame is installed on the bracket of the guide rail system. Two sets of axial preloading systems are respectively located at both ends of the main body reaction steel frame, and are installed on the axial reaction frame of the main body reaction steel frame. The four sets of radial preloading systems are all installed in the middle of the longitudinal direction of the assembly beam of the main reaction force steel frame; the centerlines of the radial jack cylinders in each radial preloading system are perpendicular to the axial preloading system Centerline of the axial preload rod in the loading system. The present invention is applicable to a large-diameter separated Hopkinson pressure rod device, and can realize a variable-size true three-axis static load preloading system for independent and controllable application of three-way static loads on rock samples, and has strong versatility and good economical efficiency features. The invention has the advantages of simple structure, convenient installation and operation, and high degree of automation.

Owner:AIR FORCE UNIV PLA

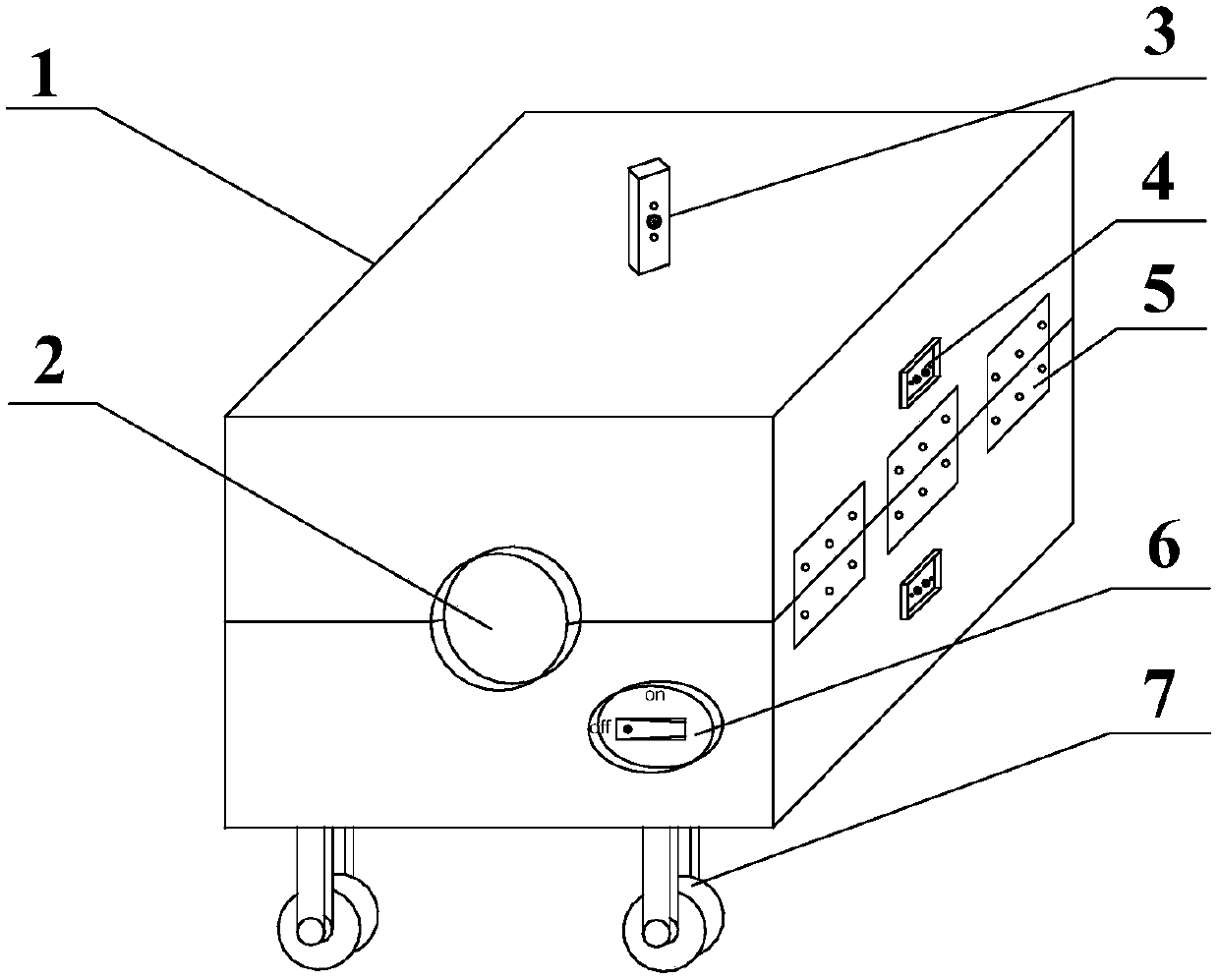

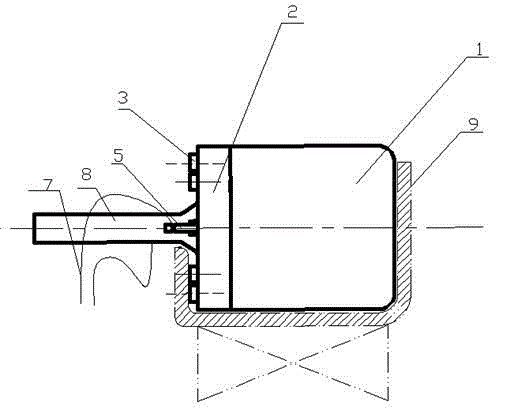

Fast heating device for high-temperature split Hopkinson pressure bar experiment

InactiveCN103024955APerformance impactFast heatingInduction heatingStrength propertiesQuality levelInduction heater

A fast heating device for a high-temperature split Hopkinson pressure bar experiment is characterized in that a support trolley is disposed outside a shielding cover, a high-frequency induction heater is disposed in the shielding cover, a ceramic sleeve is disposed at the center of the heater, a testing object is disposed at the center of the sleeve, two ends of the testing object are connected with inner ends of two short ceramic rods respectively, the outer ends of the two short ceramic rods connected with one of a incidence rod and one end of a transmission rod respectively, and strain foils are attached to the incidence rod and the transmission rod respectively to realize synchronous computer data processing. The defects that testing objects of the existing heating devices for the split Hopkinson pressure bar experiments are heated independently, heating and impacting are separated, system quasi-static butting and synchronous precision are difficult to meet the requirements, the existing heating devices are complex in structure, complicated to operate, low in work efficiency, and high in data processing difficulty, and quality and precision of the split Hopkinson pressure bar experiments are affected severely and the like are overcome. The fast heating device is applicable to split Hopkinson pressure bar experiments of various labs, and especially applicable to heating of metal testing objects and instant data processing of strain foil information in a split Hopkinson pressure bar experiment device.

Owner:HUNAN UNIV OF SCI & TECH

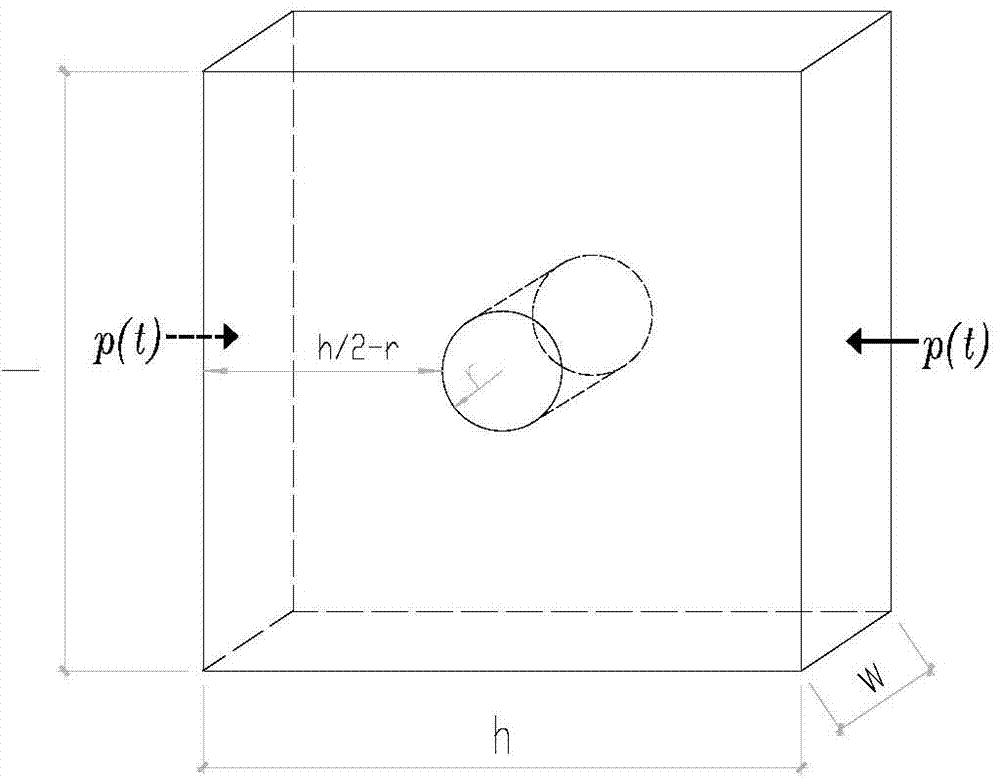

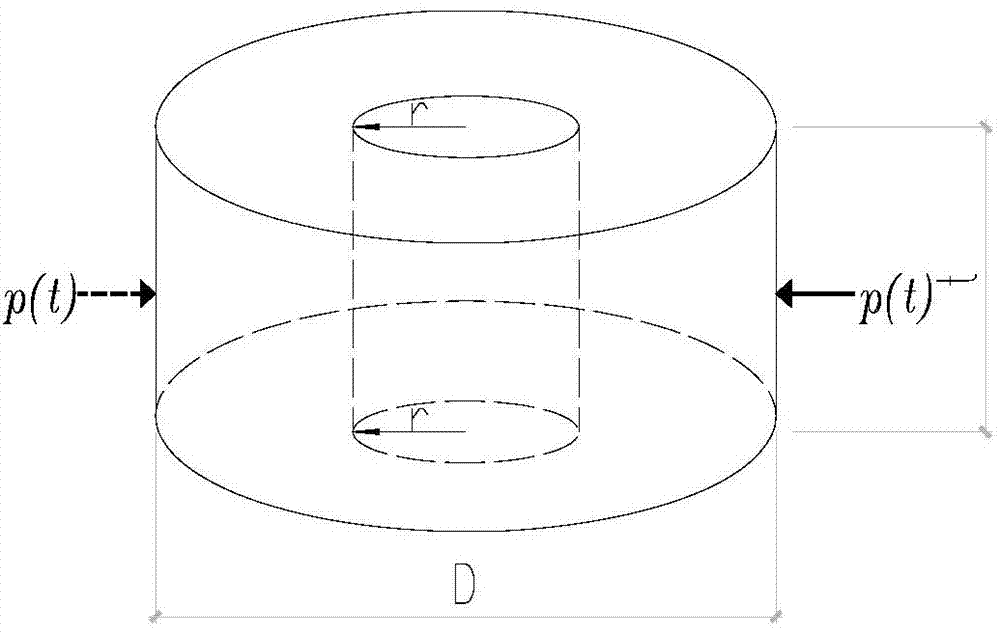

Method for determining tensile elasticity modulus of fragile material in SHPB (split Hopkinson pressure bar) split tension test

InactiveCN102128754AAccurate operationAvoid errorsMaterial strength using single impulsive forceEngineeringTensile testing

The invention discloses a method for determining the tensile elasticity modulus of a fragile material in an SHPB (split Hopkinson pressure bar) split tension test, which comprises the following steps: placing a cylindrical sample on an SHPB split tension test machine; exerting an impact load on the sample along the radial direction of the sample; measuring the displacement of the sample in a stress-loading process; and calculating the dynamic tensile elasticity modulus Edt of the material by utilizing the formula disclosed in the specification, wherein P(t)max is the maximum value of the dynamic load, L is the length of the sample, D is the diameter of the sample, mu is the Poisson ratio of the sample material, and Delta ut is the damage displacement of the central diameter length of the sample along the vertical loading direction when the sample is damaged. The method for determining the tensile elasticity modulus of a fragile material in an SHPB split tension test can be easily implemented and can acquire accurate measurement result.

Owner:CENT SOUTH UNIV +1

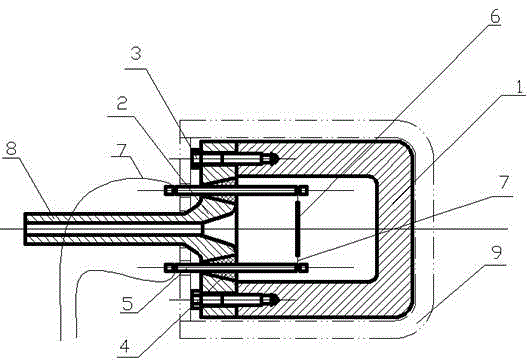

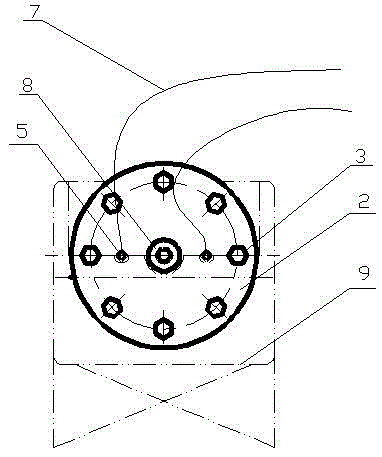

Double-cartridge electromagnetic drive device used for split Hopkinson pressure bar

ActiveCN105319124ARealize the loadAvoid introducingStrength propertiesMechanical engineeringElectromagnetic drive

The invention discloses a double-cartridge electromagnetic drive device used for a split Hopkinson pressure bar. The double-cartridge electromagnetic drive device comprises main guide rails, a main cartridge, an auxiliary guide rail, an auxiliary cartridge and buffering devices. The auxiliary guide rail is connected with the main guide rail. The inner diameter of the auxiliary guide rail is smaller than that of the main guide rails. The main cartridge is connected with the main guide rails. The auxiliary guide rail is connected with the main guide rails. The buffering devices are arranged at the joints of the main guide rails and the auxiliary guide rail. At the initial moment, the main cartridge is located at the front ends of the main guider rails and abuts against the auxiliary cartridge. By means of the double-cartridge electromagnetic drive device, difficulty and complexity of a conventional electromagnetic drive device for driving cartridges made from non-electromagnetic materials are lowered.

Owner:SOUTH CHINA UNIV OF TECH

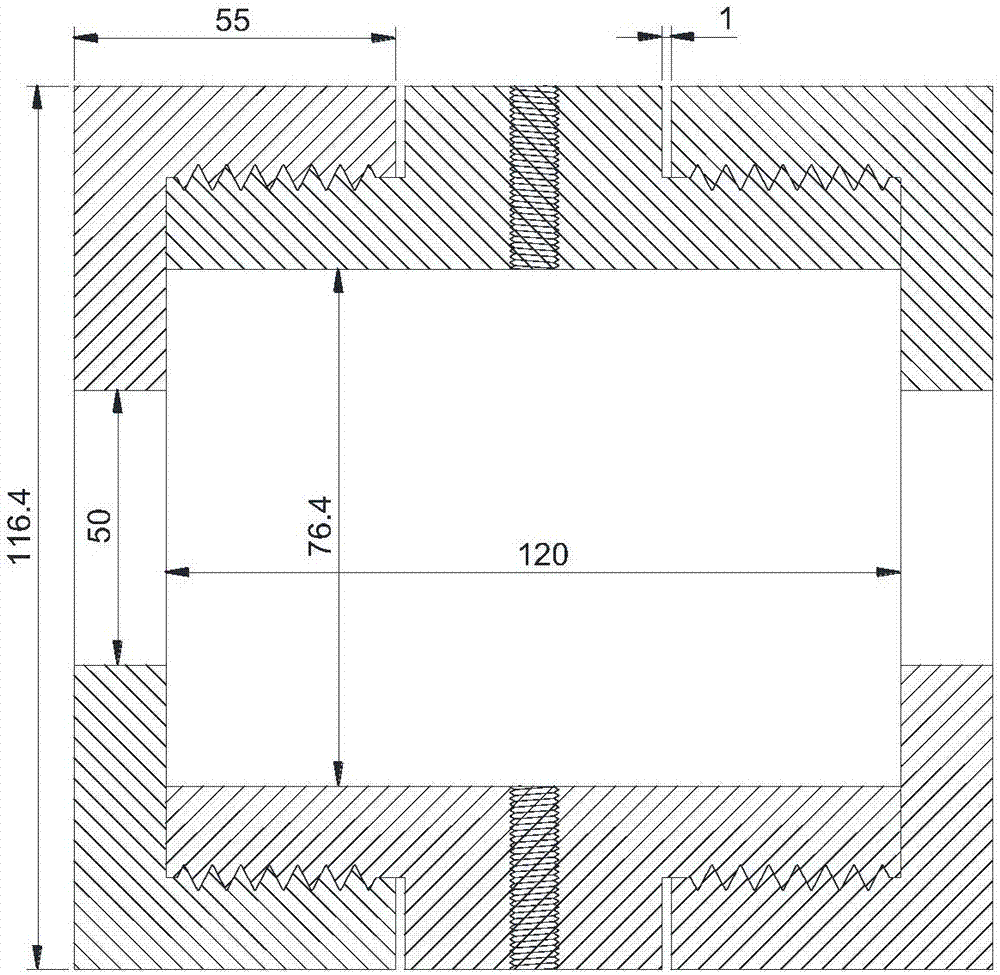

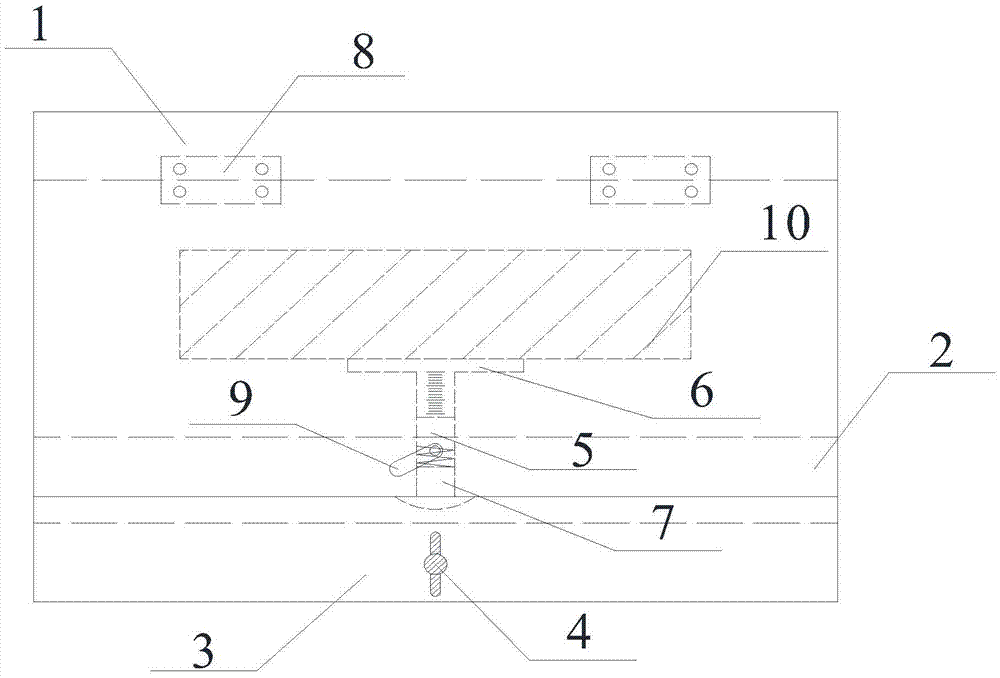

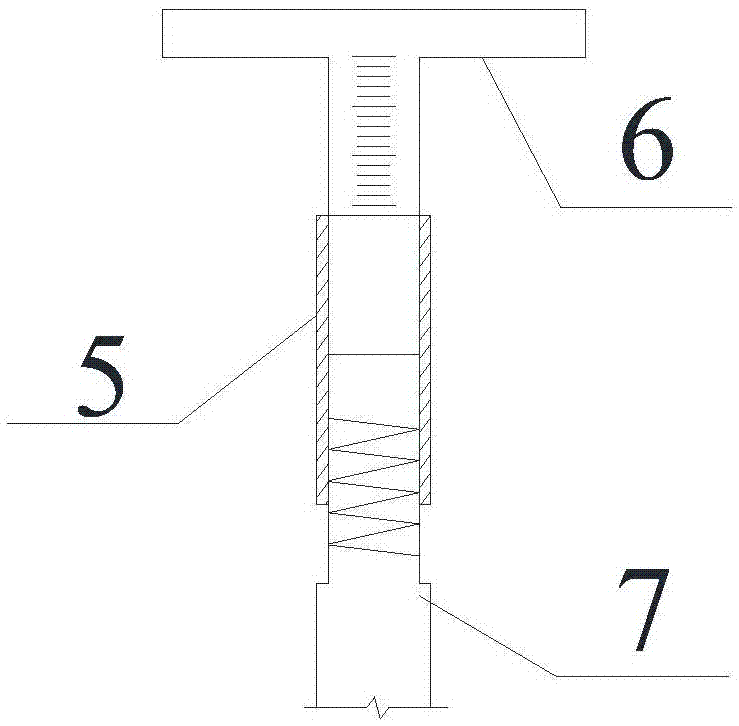

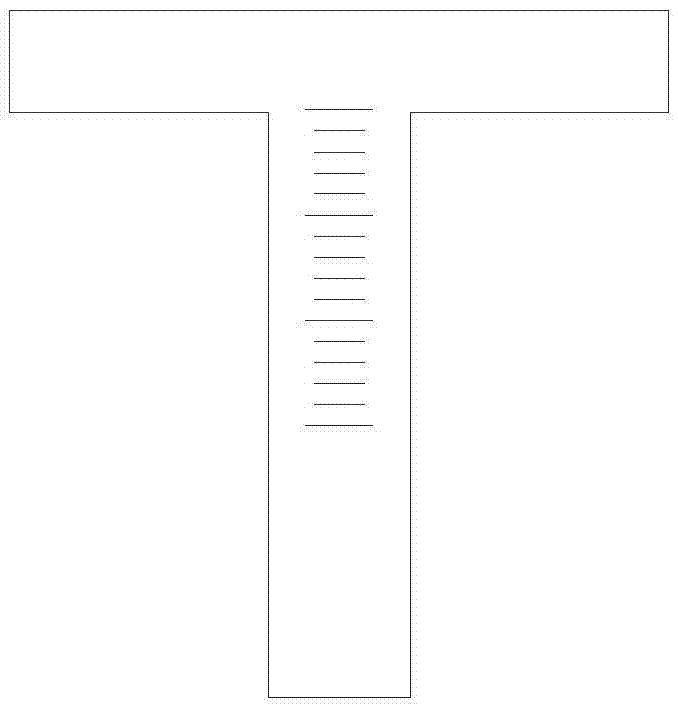

Novel support device of split Hopkinson pressure bar and adjustment method of support device

InactiveCN104198274ASimple structureEasy to adjustStrength propertiesEngineeringSplit-Hopkinson pressure bar

The invention relates to a novel support device of a split Hopkinson pressure bar and an adjustment method of the support device. The support device comprises a first support plate and a second support plate, wherein the second support plate is located above the first support plate and is parallel to the first support plate; a vertical screw rod is fixedly connected with the middle of the upper end face of the first support plate and sleeved with a rotatable adjustment block moving up and down; the second support plate is provided with adjustment bolts in a penetrating manner; the lower ends of the adjustment bolts push against the upper end face of the adjustment block to slightly adjust the height of the second support plate; and a groove for supporting a bar in a split Hopkinson pressure bar system is formed in the middle of the upper end face of the second support plate. The invention further relates to the adjustment method of the novel support device of the split Hopkinson pressure bar. The support device is simple in structure; the adjustment method is concise and easy to master; the adjustment time is saved; the split Hopkinson pressure bar can be effectively supported; when the split Hopkinson pressure bar is tested, collision faces are combined well; and obtained experimental data is high in accuracy, actual and reliable.

Owner:FUJIAN JIANGXIA UNIV

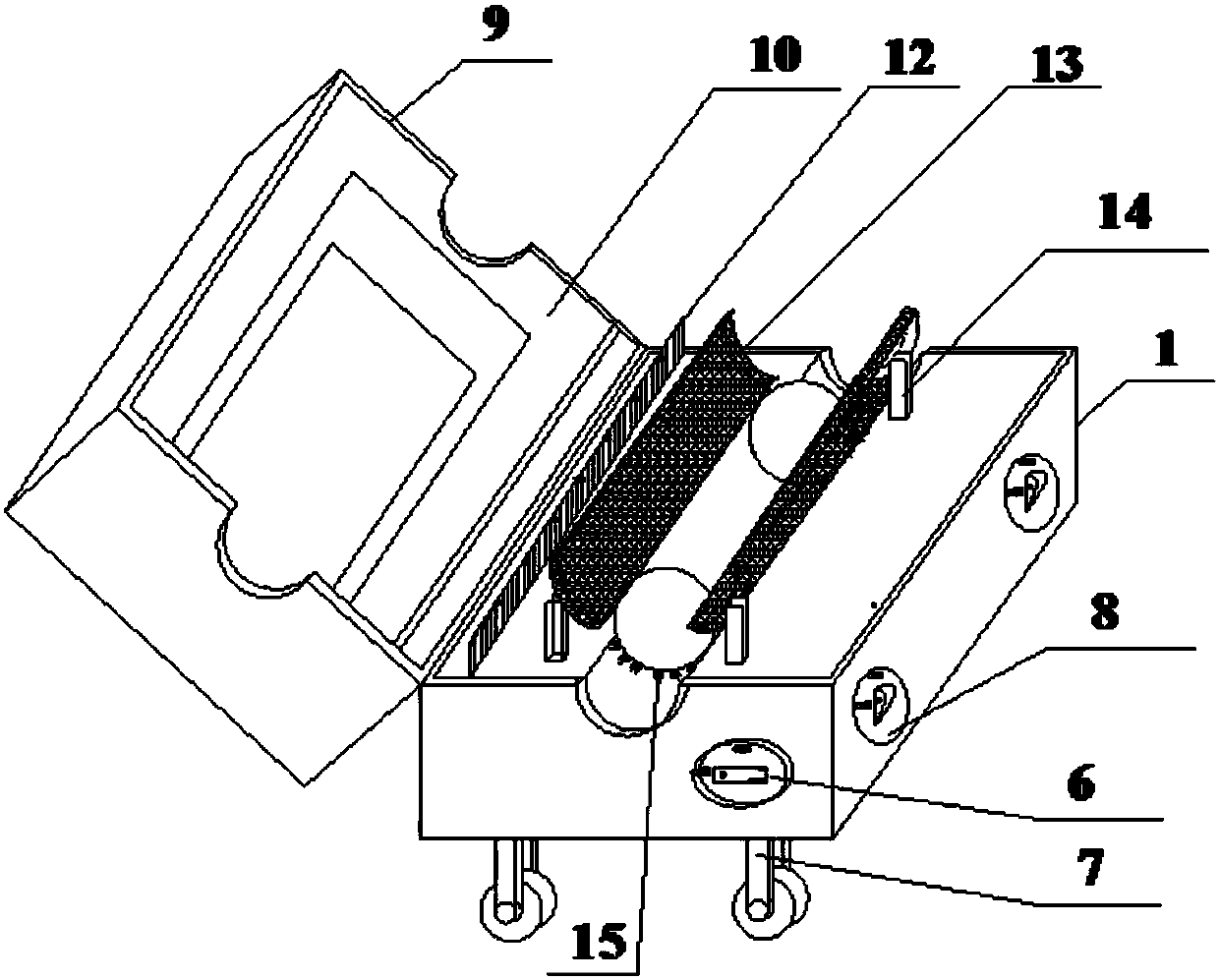

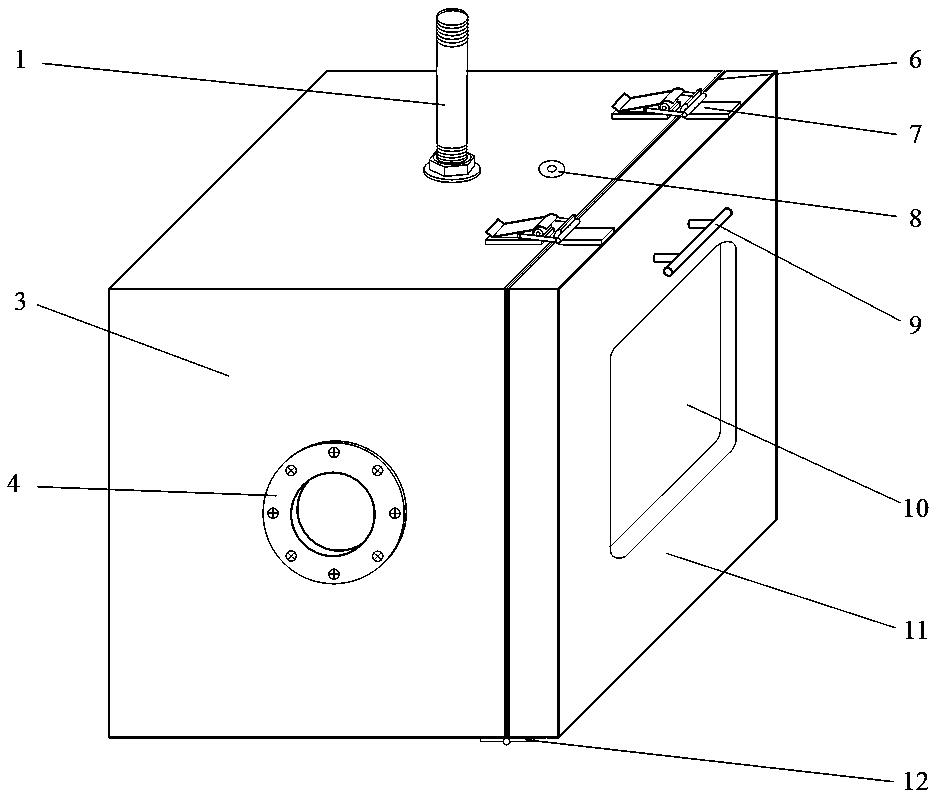

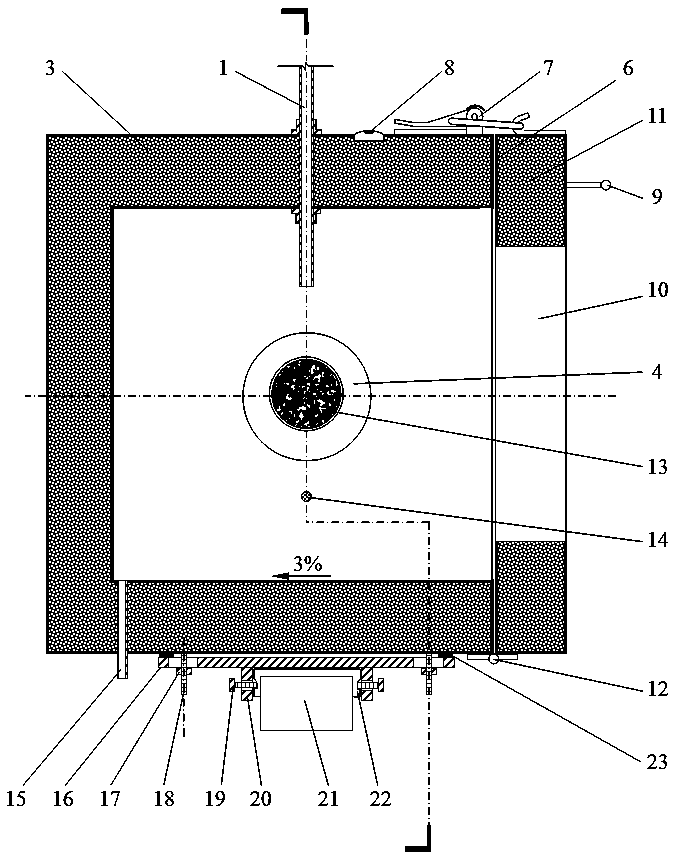

Multi-size rock test piece rapid heating device for SHPB (split Hopkinson pressure bar) impact test

InactiveCN108036996AReduce consumptionMeet the requirements of test pieces of different sizesPreparing sample for investigationTemperature control using electric meansSplit-Hopkinson pressure barProcess control

A multi-size rock test piece rapid heating device for SHPB (split Hopkinson pressure bar) impact test comprises a test box. The test box comprises a box body and a box body cover, one side of the boxbody is connected with the box body cover through hinges, the test box is provided with a through hollow channel, a wheel assembly is symmetrically arranged at the bottom of the hollow channel along acentral line, two sides of the hollow channel on the box body are connected with heating wire arc coils through heating wire fixing rods, a heating wire arc coil is arranged in the box body and corresponds to the bottom of the hollow channel, an insulation board switch and an insulation board matched with the hollow channel are arranged on the box body, and the insulation board switch is connected with the insulation board to control opening and closing of the insulation board. Rock test pieces are uniformly heated in the heating process, whole-process control and automated constant temperature management are performed, the device is wide in applicable range, efficient in heating and simple to operate and can meet the requirements of the test pieces with different sizes, and electric energy consumption is effectively reduced.

Owner:HOHAI UNIV

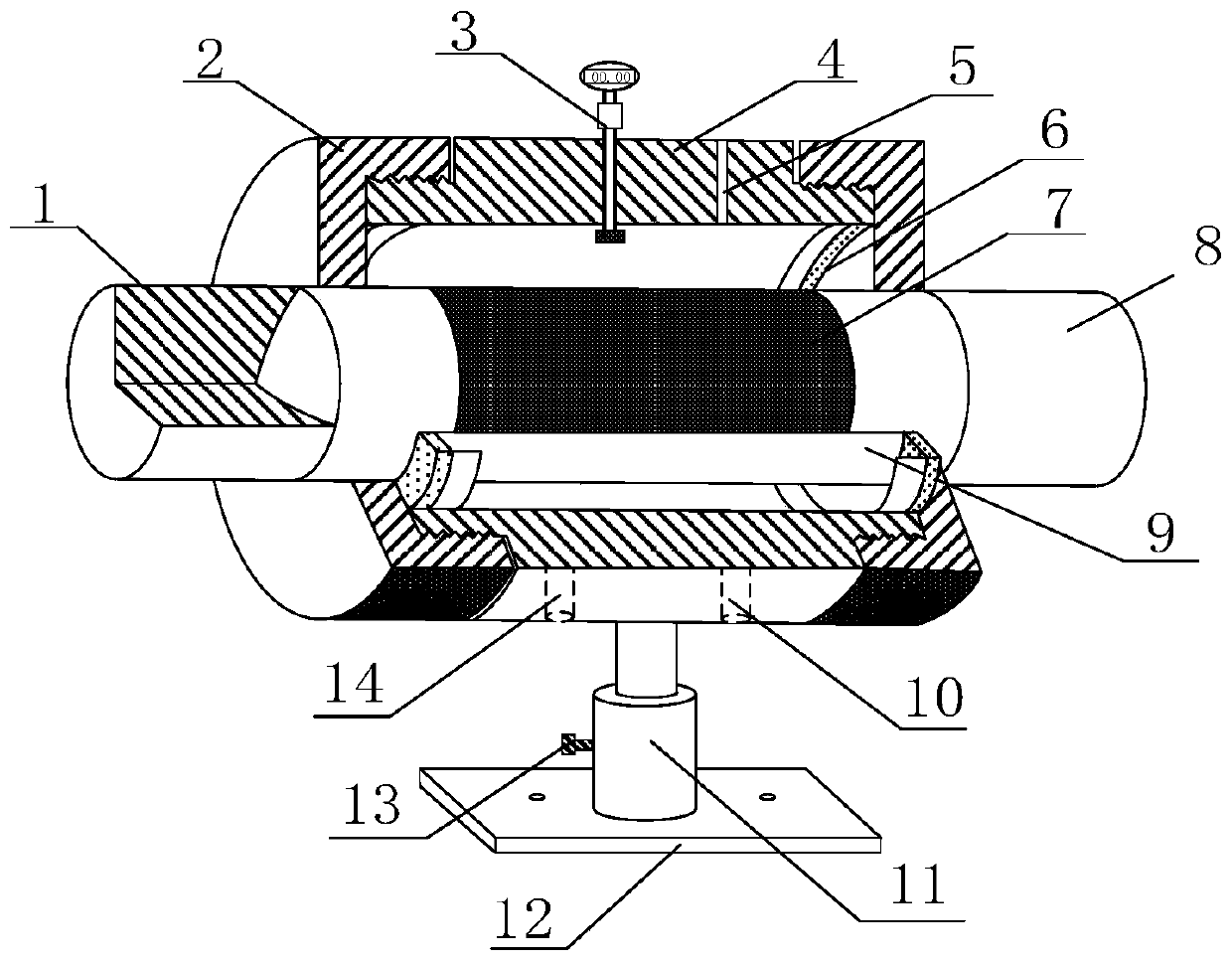

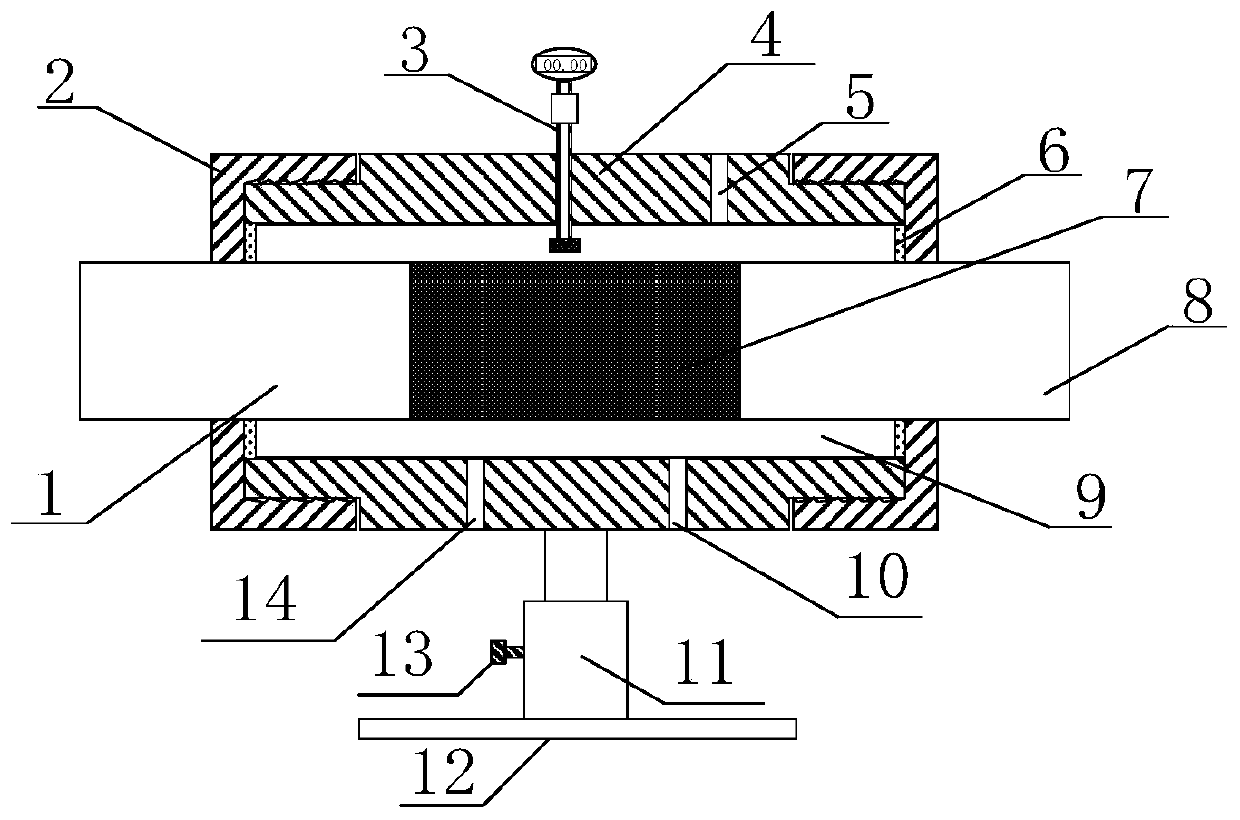

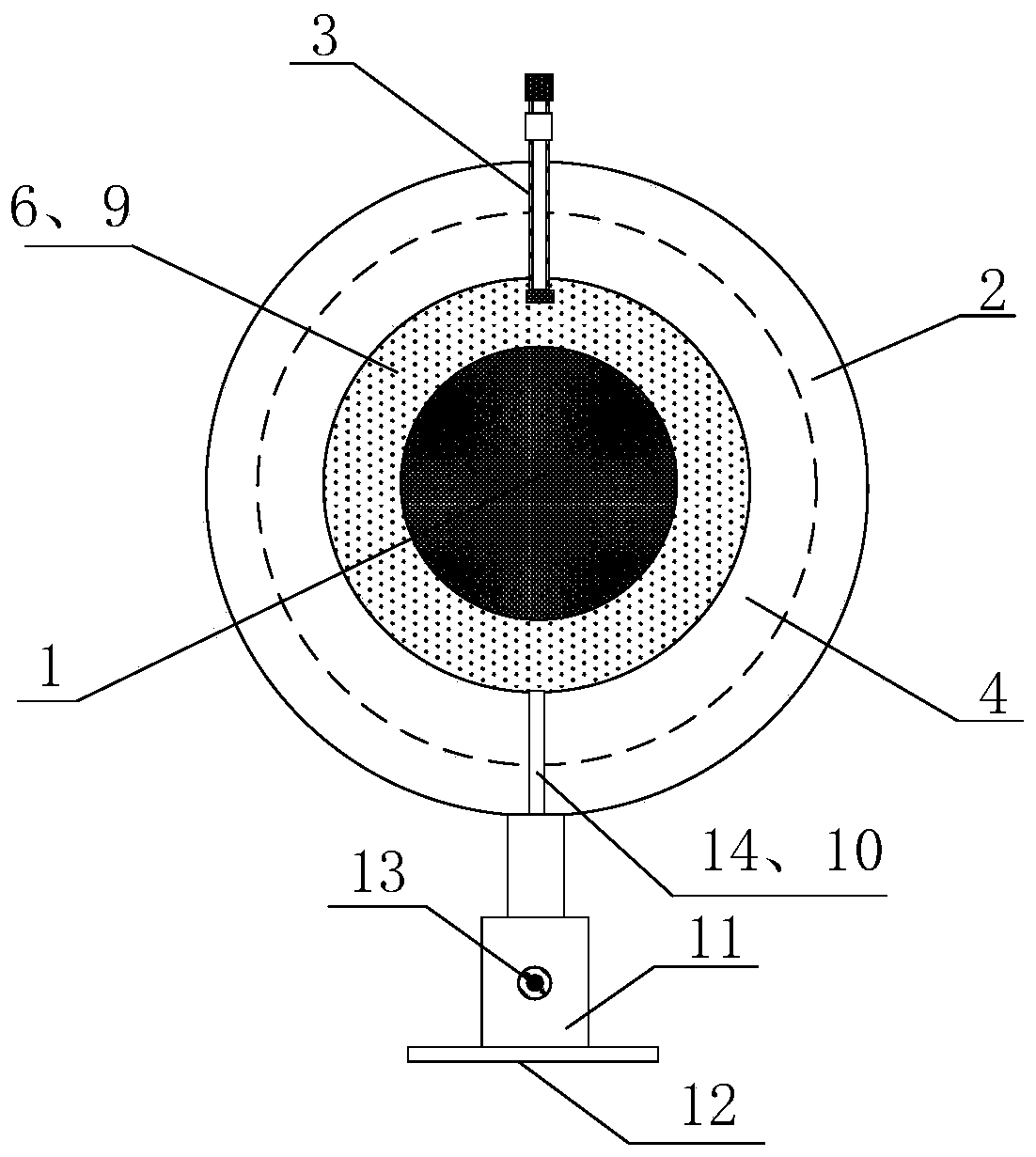

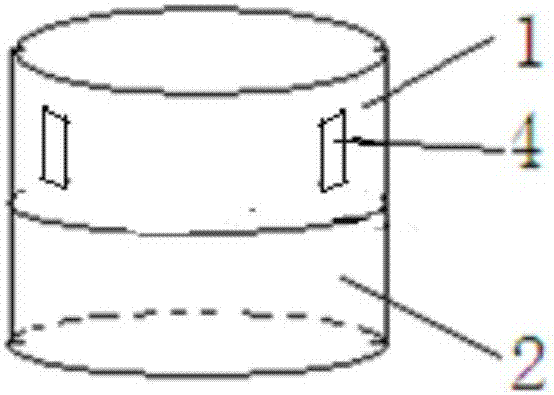

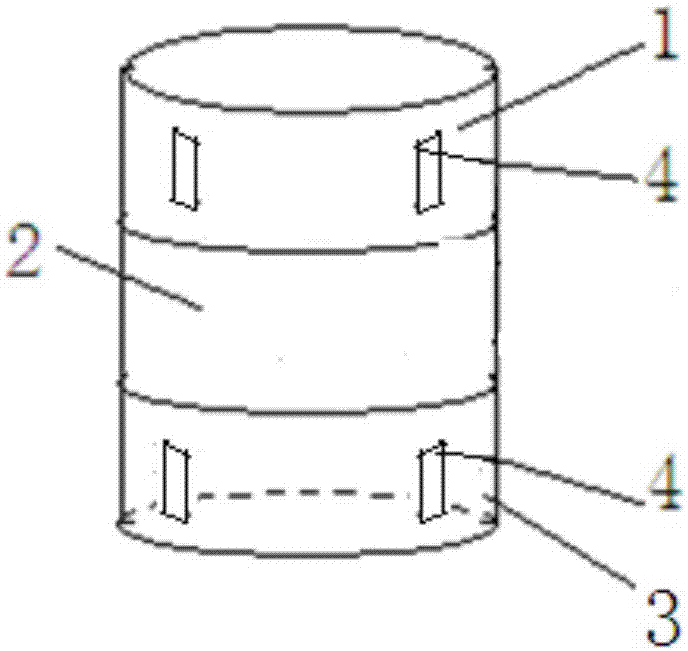

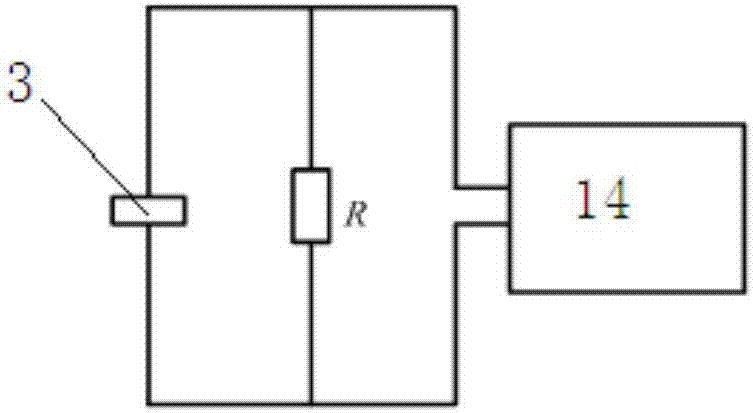

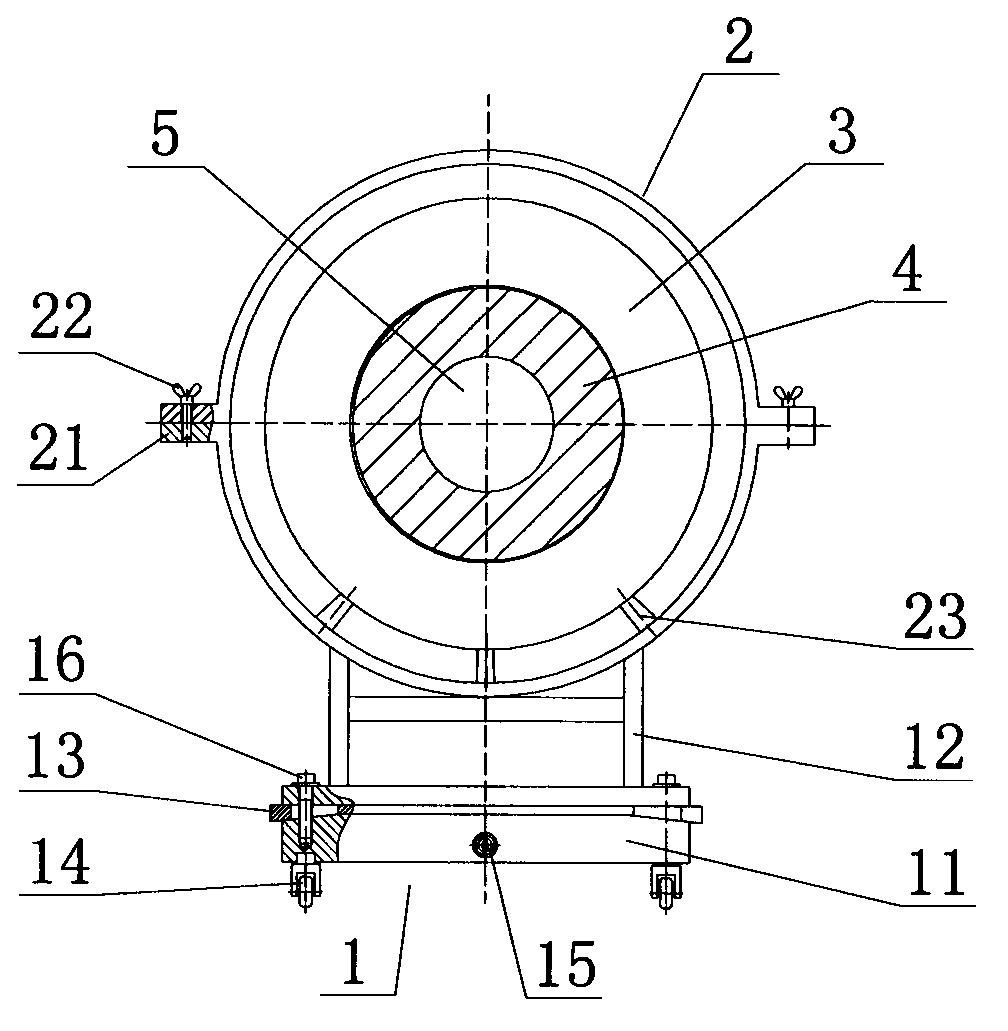

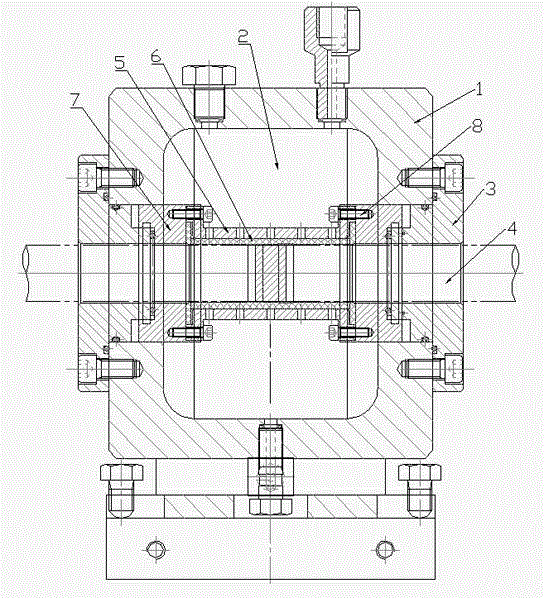

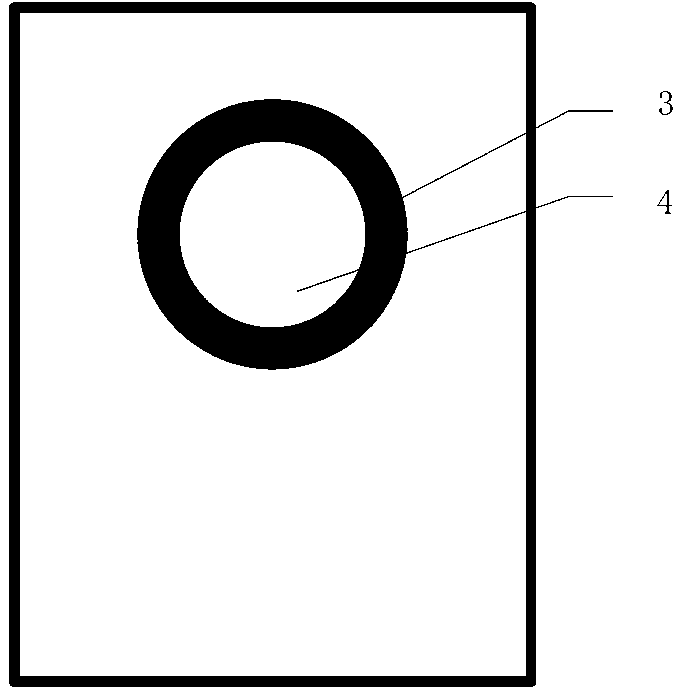

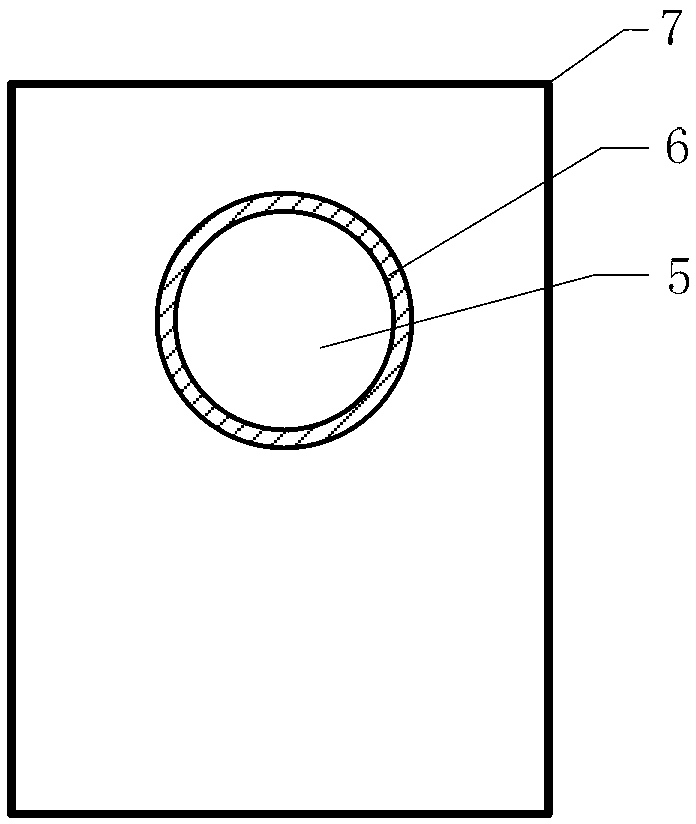

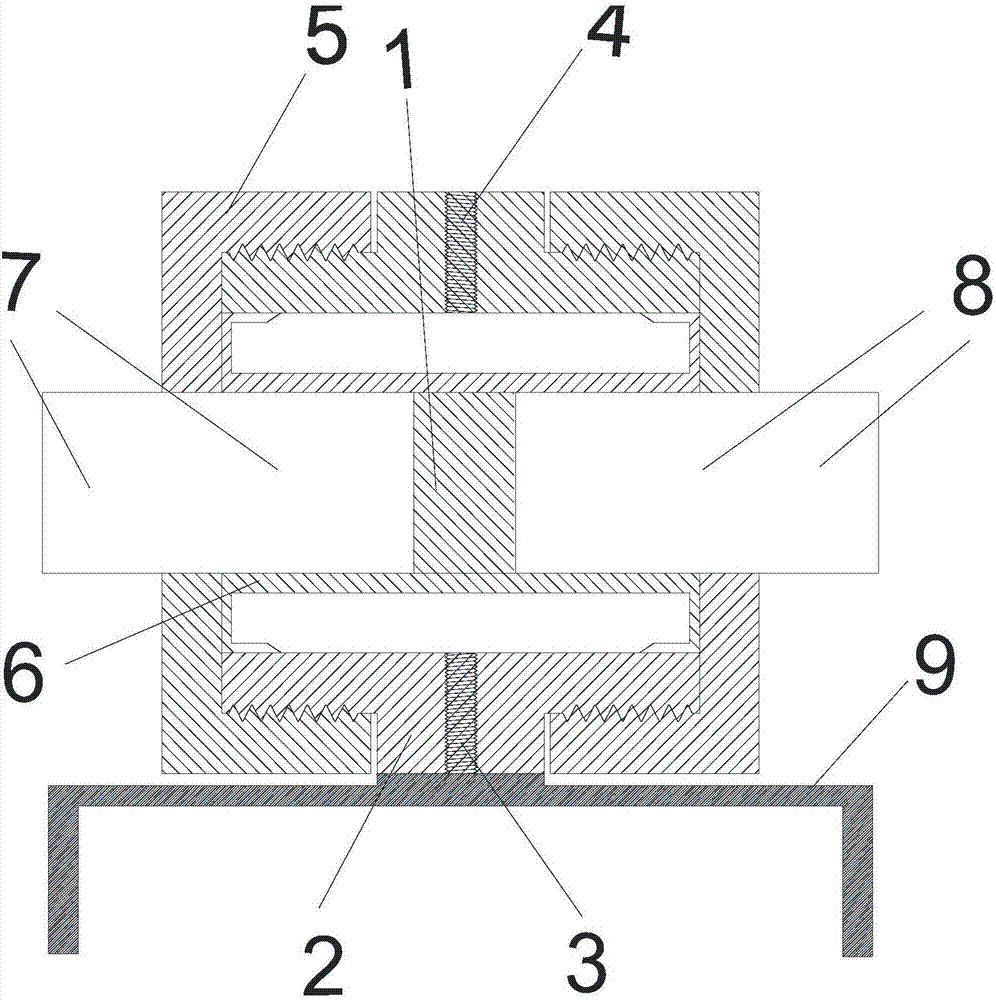

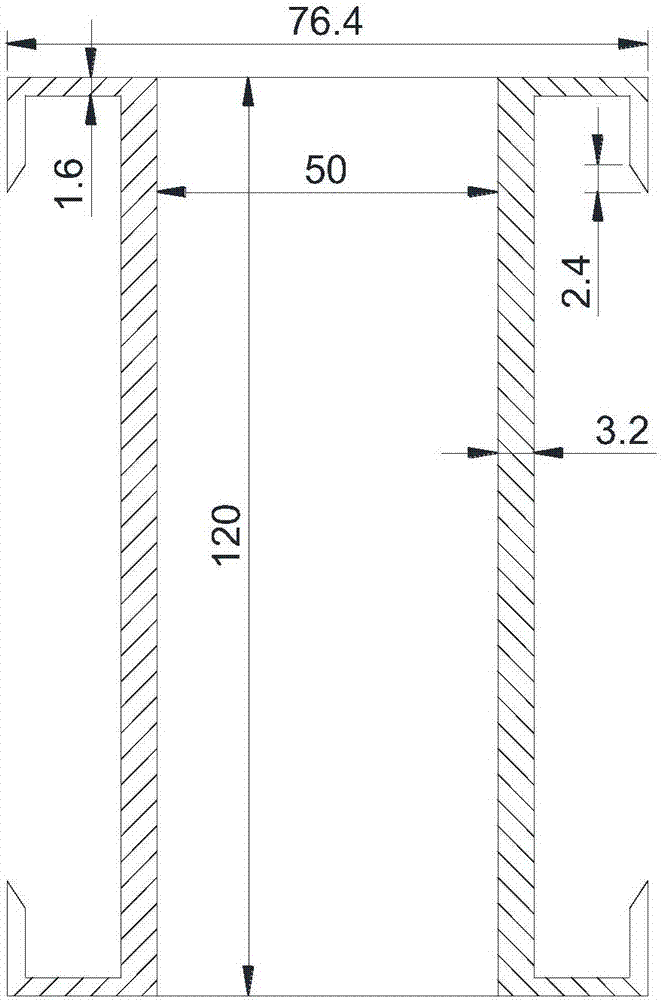

Confining pressure cylinder device for novel split Hopkinson pressure bar active confining pressure experiment

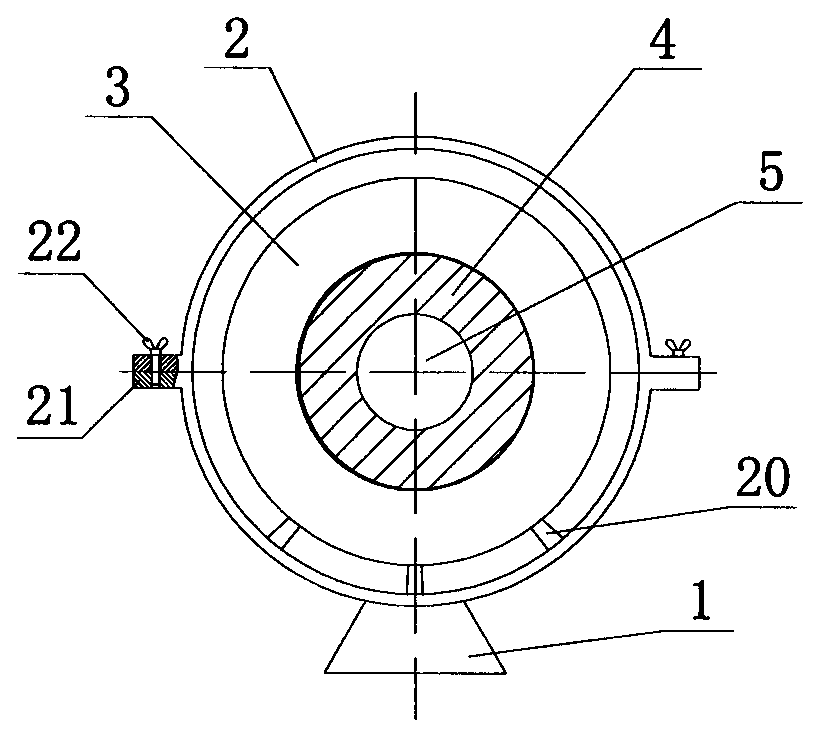

InactiveCN104677725APrevent outward movementSolve the problem of not pressing the test piece tightlyStrength propertiesPressure experimentHigh pressure

The invention relates to an impact loading experimental device for material dynamic mechanical property, and in particular relates to a confining pressure cylinder device for a novel split Hopkinson pressure bar active confining pressure experiment. The confining pressure cylinder device comprises a cylinder body, a pressure cavity in the cylinder body, cylinder covers, pressing blocks, a metal sleeve, a rubber sleeve and a shaft hole; the confining pressure cylinder device is characterized in that the cylinder covers are respectively arranged at two ends outside the cylinder body; corresponding to the cylinder covers, pressing blocks are respectively arranged at two ends of the pressure cavity, and one end of each pressing block extends into the cylinder body; the metal sleeve is arranged between the pressing blocks at two ends of the pressure cavity and is connected by virtue of a screw; the rubber sleeve is arranged on the inner side of the metal sleeve; and the rubber sleeve is arranged between the pressing blocks at two ends of the pressure cavity, so that the pressing blocks, the metal sleeve and the rubber sleeve are integrated. The device disclosed by the invention not only can prevent the rubber sleeve, in the case of deforming, from entering into a clearance formed between a sealing cover and a rod piece to drive the rod piece to move outwards, but also can solve a problem that a test piece cannot be tightly pressed by the rod piece since the rod piece is stressed to cause a trend of moving towards the outer side of the cavity body when the rod piece is closely held in the rubber sleeve under high pressure; and the confining pressure cylinder device is simple in structure.

Owner:LUOYANG LIWEI TECH

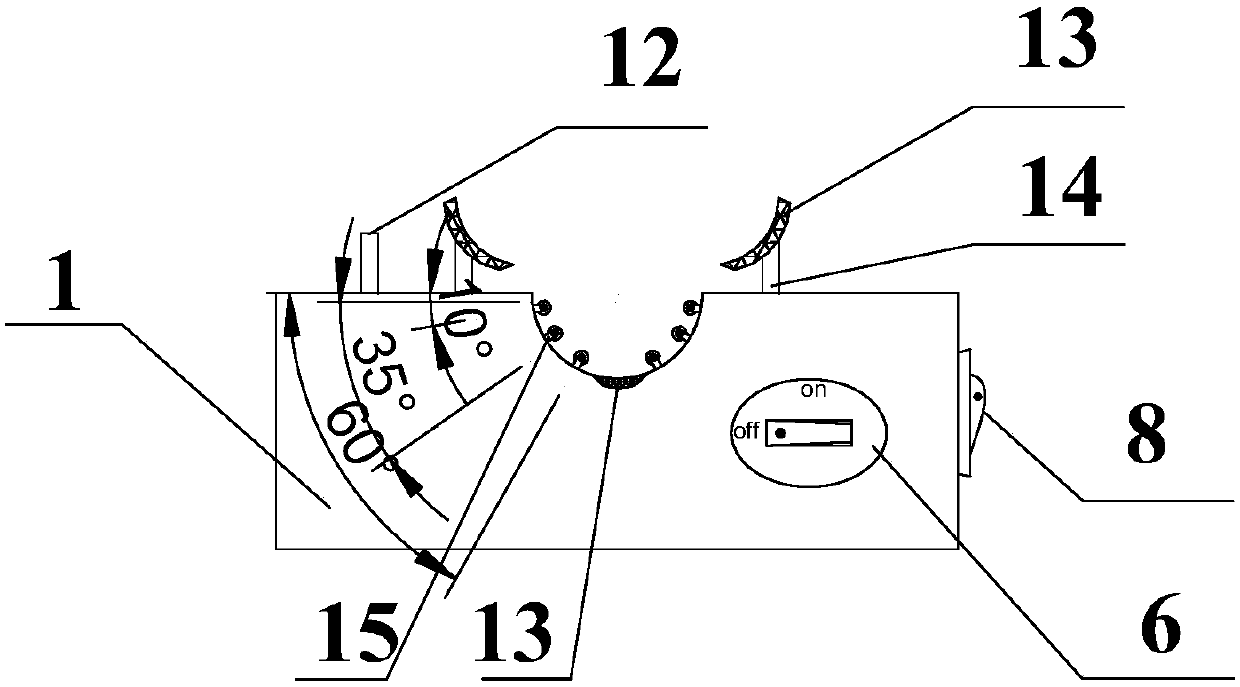

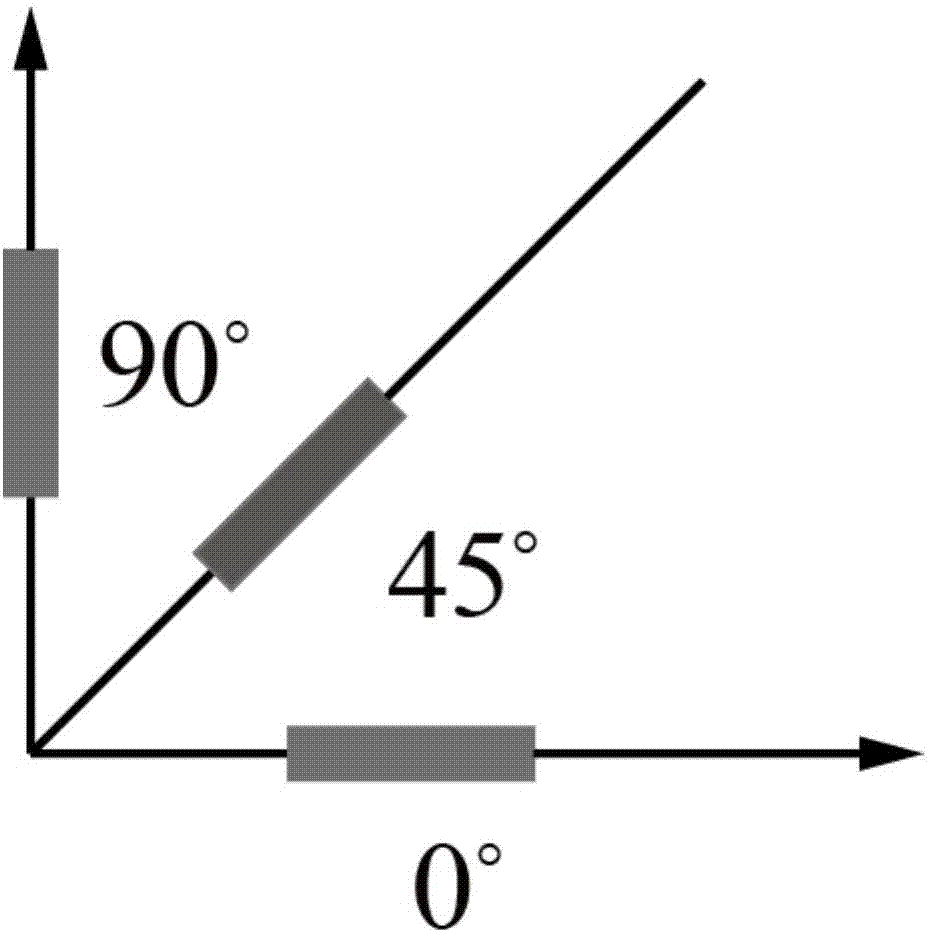

SHPB (Split Hopkinson Pressure Bar) experimental method for concrete material

InactiveCN107367427AImprove accuracyGuaranteed accuracyPreparing sample for investigationMaterial strength using single impulsive forceExperimental methodsRain gauge

The invention discloses an SHPB (Split Hopkinson Pressure Bar) experimental method for a concrete material. The experimental method is used for testing a Poisson's ratio of a concrete sample and reducing the error of a concrete SHPB experiment. The method comprises the following steps: preparing a cylindrical concrete sample of an SHPB experiment; pretreating the concrete sample, symmetrically attaching two 45-degree strain rosettes on side walls of the pretreated concrete sample, wherein the 45-degree strain rosettes are connected with an oscilloscope through a strain gage; fixing the concrete sample between an incident bar and a transmission bar through a clamp and a protective cover, and connecting the strain gauge with the oscilloscope through a strain gage; finally, shooting shots, and carrying out the SHPB experiment. According to the method disclosed by the invention, the Poisson's ratio of the concrete sample can be measured by adopting the 45-degree strain rosettes attached to the concrete sample, and compared with the past Poisson's ratio measurement method, the method disclosed by the invention is simple and easy to operate; due to pretreatment of the concrete sample, the error in the experimental process can be reduced, and the experimental accuracy is improved.

Owner:NANJING UNIV OF SCI & TECH

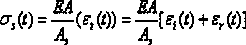

Synchronous measurement method of split Hopkinson pressure bar experiment based on digital images

The invention discloses a synchronous measurement method of a split Hopkinson pressure bar experiment based on digital images. The method comprises the steps as follows: before the experiment, mark areas are made on the outer surface of one end where an incident bar and a tested piece are contacted as well as the outer surface of one end where a transmission bar and the tested piece are contacted; in the experiment process, moving images of the tested piece and the mark areas in the impact experiment process are obtained by a high-speed camera; through trace analysis of deformation of the mark area, strain of the tested piece as well as the incident bar and the transmission bar at the two ends of the tested piece is further obtained; and according to the principle of the Hopkinson pressure bar experiment, , stress of the two ends of the tested piece is calculated based on strain of the two bars; and further, through the novel experimental technology based on the digital images, the strain of a test piece and the stress of two ends of the test piece can be obtained synchronously.

Owner:SOUTH CHINA UNIV OF TECH

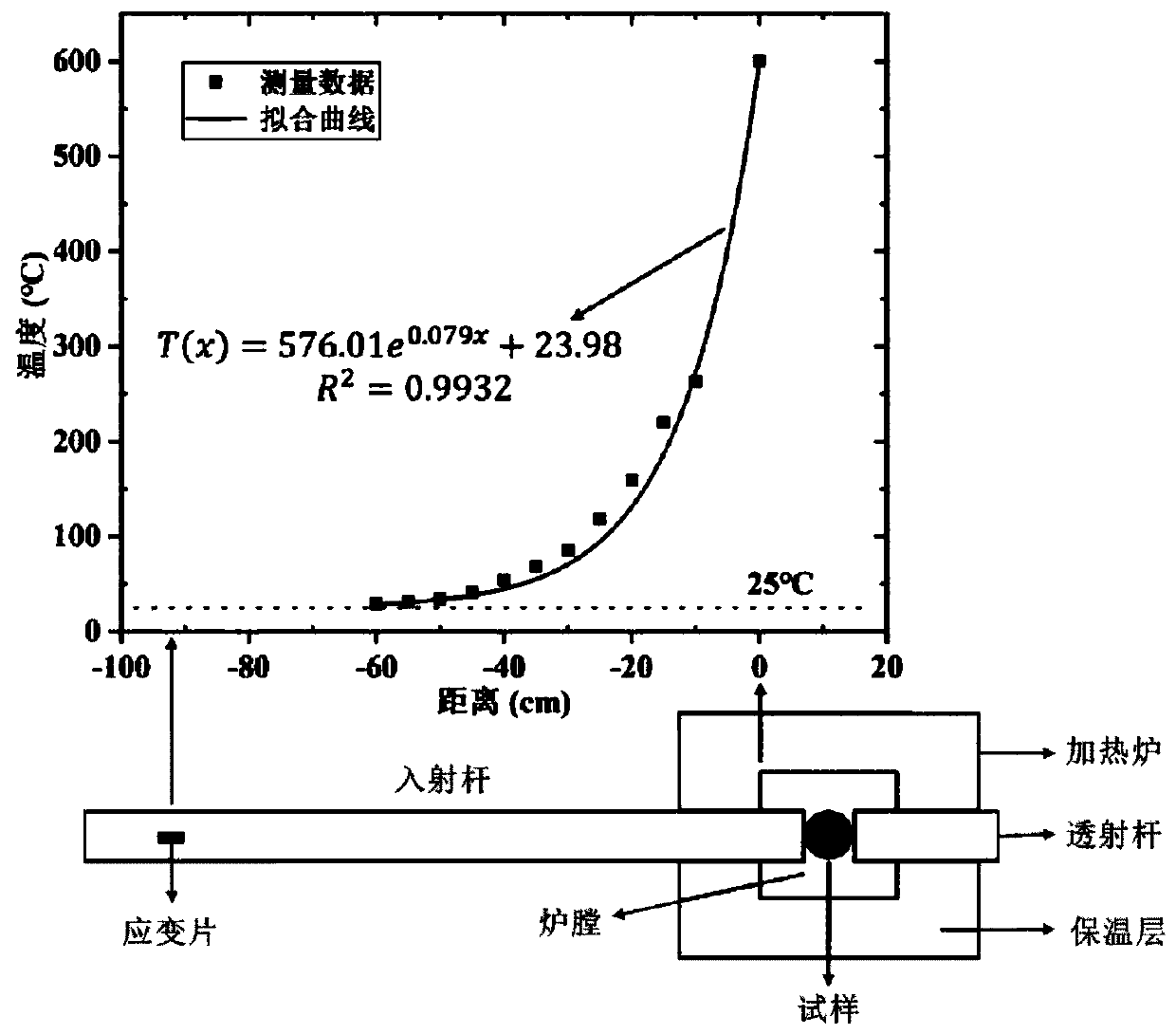

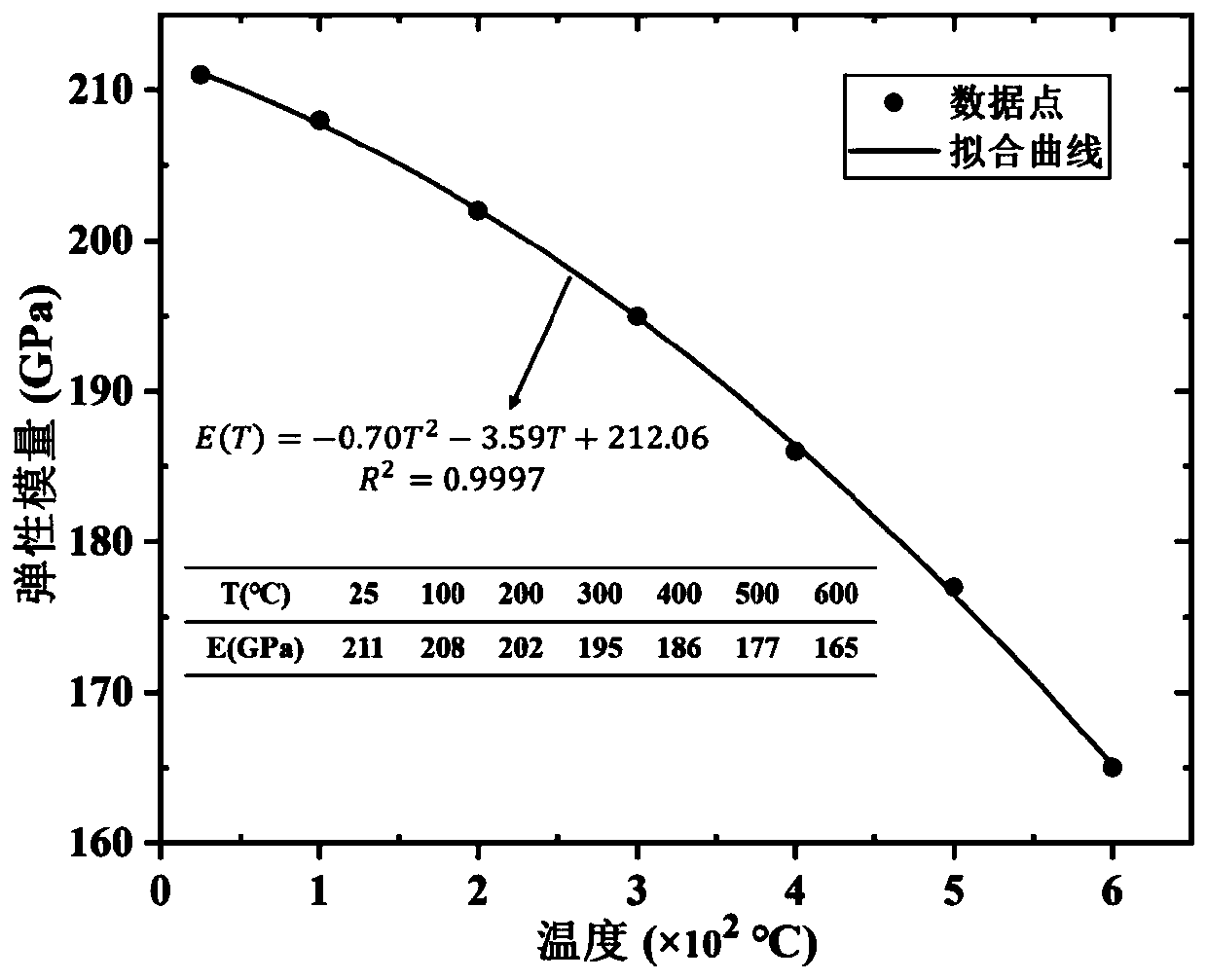

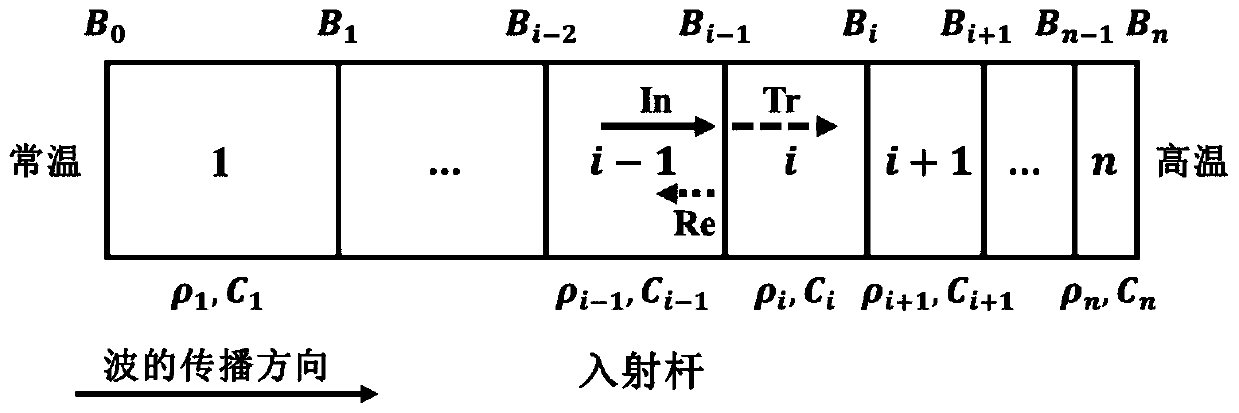

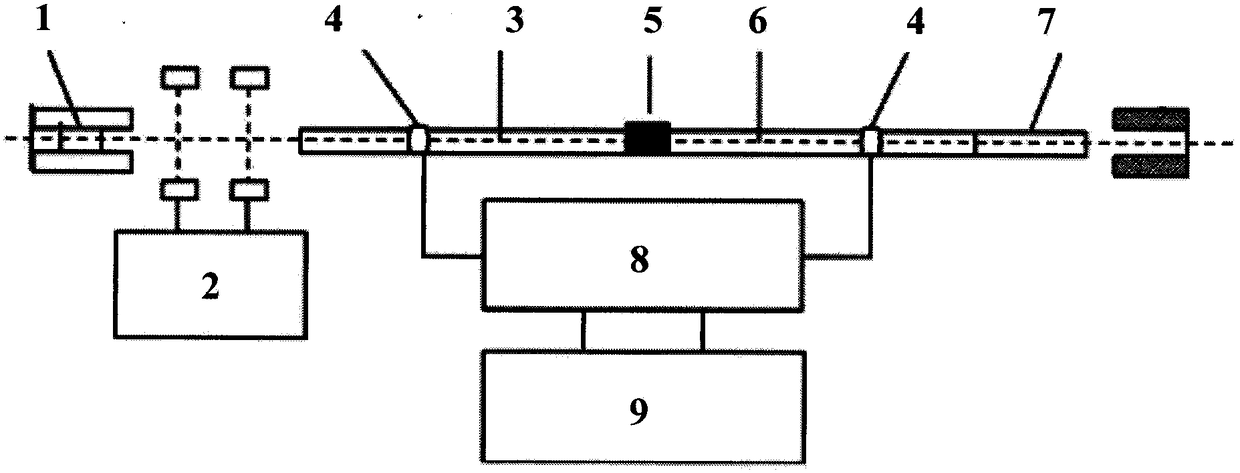

Method for testing dynamic mechanical property of rock at high temperature and matched heating furnace

ActiveCN111024529AOmit the search processGuaranteed accuracyMaterial strength using repeated/pulsating forcesThermodynamicsReflected waves

The invention discloses a method for testing the dynamic mechanical property of rock at high temperature, which comprises the following steps of coaxially mounting an incident bar and a transmission bar of an SHPB (split Hopkinson pressure bar) experimental system on through holes on two sides of a heating furnace respectively, and extending into the heating furnace to clamp a sample; adhering strain gauges to the incident bar and the transmission bar, wherein the strain gauges on the incident bar and the transmission bar are symmetrically arranged on two sides of the sample; starting a heating furnace, and heating the rock sample to a set temperature; launching a bullet, conducting an SHPB experiment, and measuring incident wave, reflected wave and transmitted wave data through a strain gauge; correcting the measured incident wave, reflected wave and transmitted wave data; and analyzing the deformation and damage conditions of the sample material by utilizing the corrected incident wave, reflected wave and transmitted wave to obtain accurate dynamic mechanical property data of the sample at high temperature.

Owner:CENT SOUTH UNIV

Method for testing stab sensitivity of mechanical initiating explosive devices

InactiveCN109387124ARealize metrological detectionSmall sample sizeAmmunition fuzesReflected wavesIncident wave

Owner:邢立平

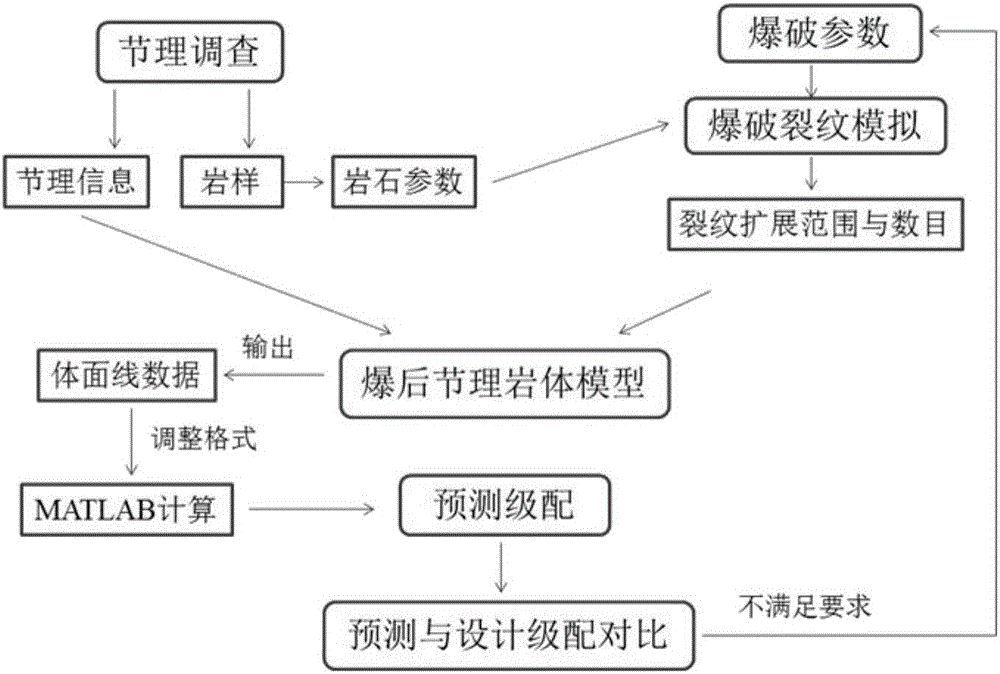

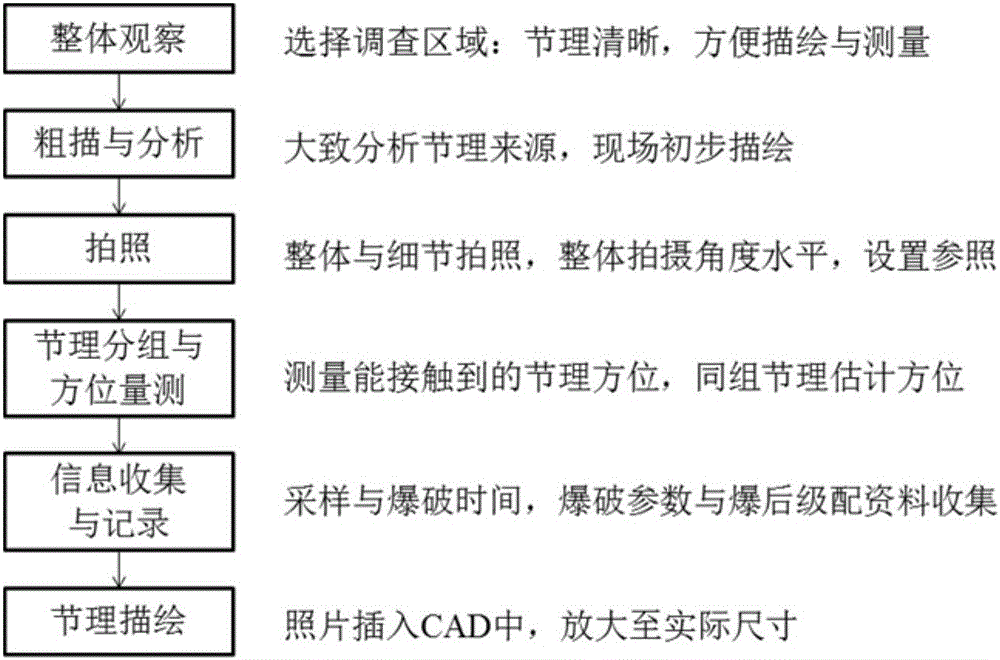

Rockfill material blasting grade prediction method for water-power engineering

ActiveCN106227913AEase of field applicationPractical Forecasting MethodsDesign optimisation/simulationSpecial data processing applicationsRockfill materialInvestigation methods

Owner:SICHUAN UNIV

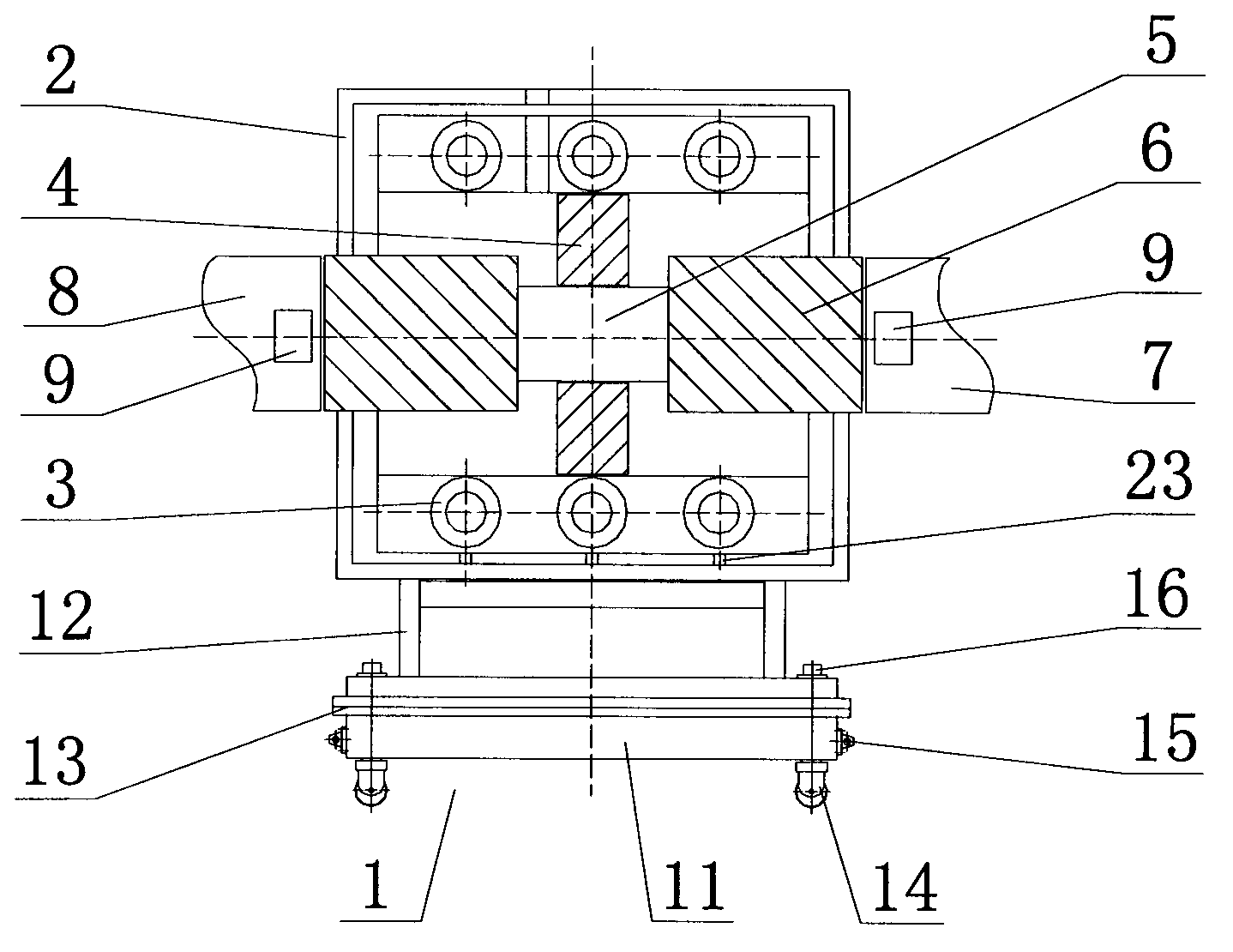

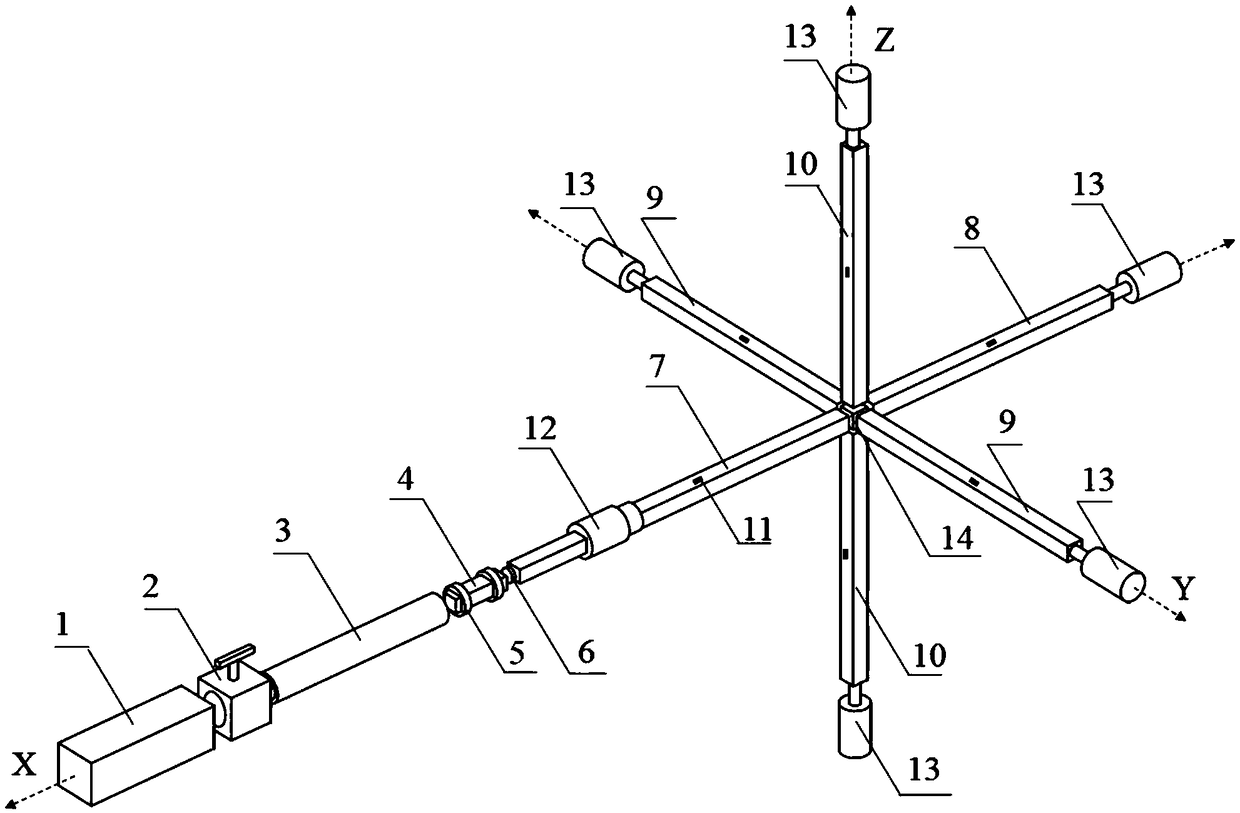

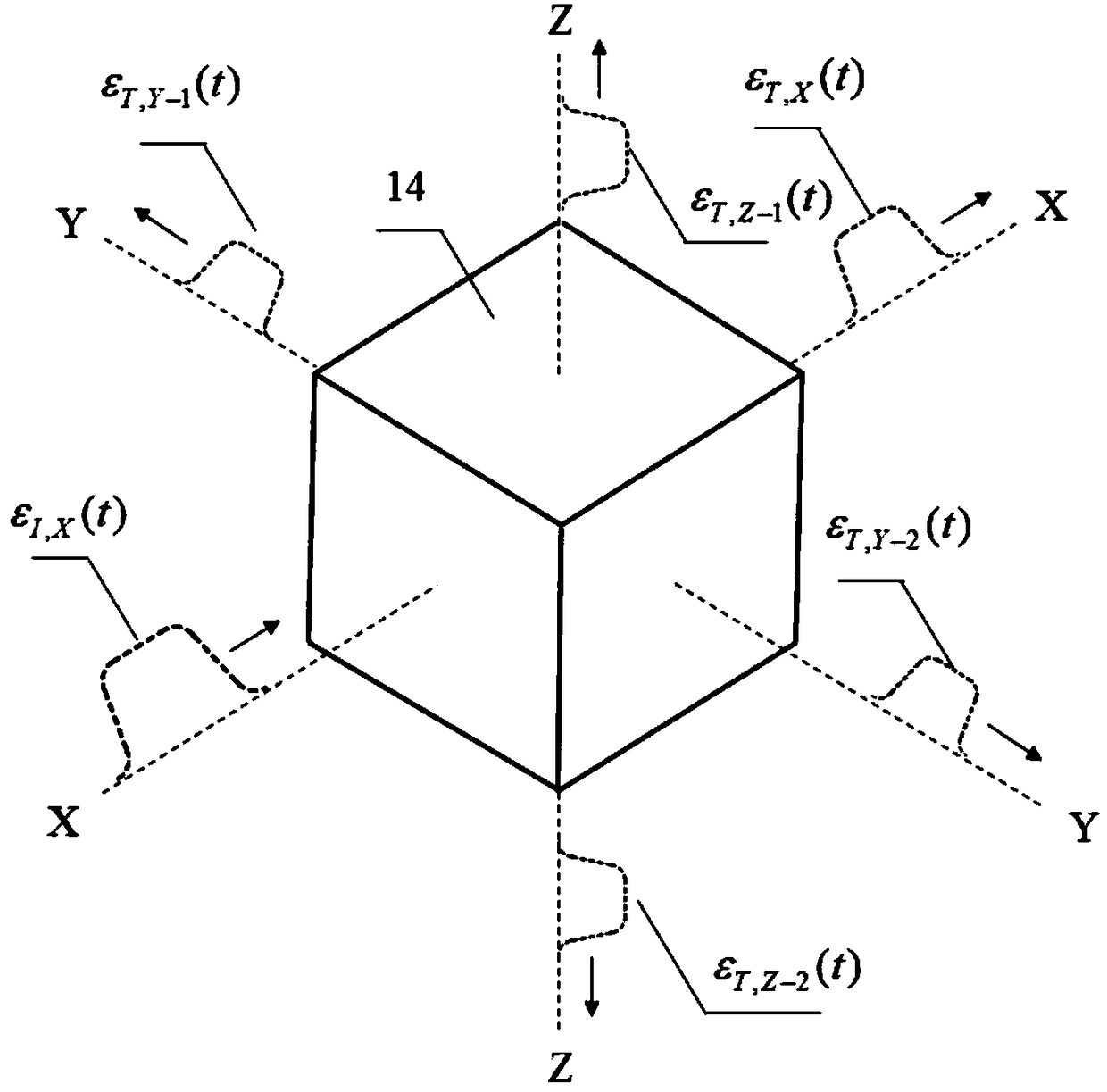

Triaxial Hopkinson rod synchronous dynamic calibrating apparatus and method of three-dimensional impact force sensor

ActiveCN108645562AAccurate dynamic calibration sensitivityAccurate dynamic calibration of linearityForce/torque/work measurement apparatus calibration/testingAccelerometerCoupling

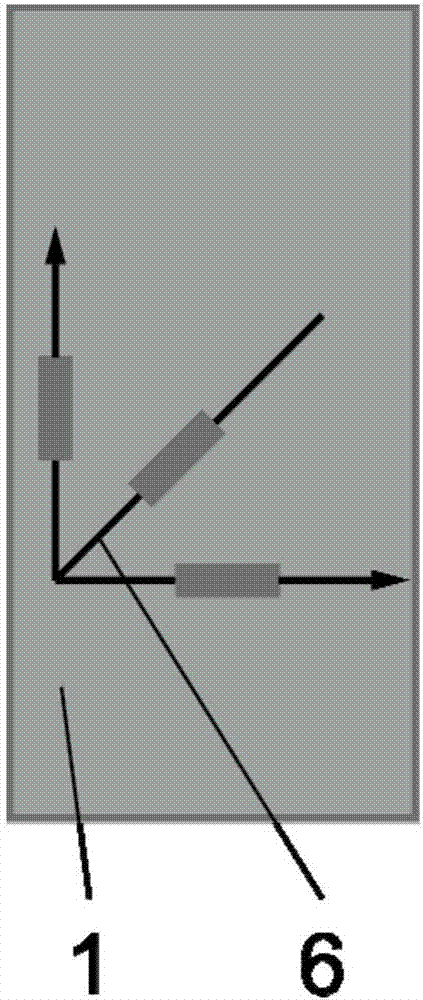

The invention relates to a triaxial Hopkinson rod synchronous dynamic calibrating apparatus and method of a three-dimensional impact force sensor. The triaxial Hopkinson rod synchronous dynamic calibrating apparatus and method of a three-dimensional impact force sensor are characterized in that a Y-axis transmission elastic rod and a Z-axis transmission elastic rod are respectively installed alongthe Y-axis and the Z-axis at the center of a one-dimensional split Hopkinson pressure bar system to form a true triaxial loading system. The triaxial Hopkinson rod synchronous dynamic calibrating apparatus and method of a three-dimensional impact force sensor has the advantages of generating dynamic loading in different direction at the same time, and performing triaxial calibration on the three-dimensional force sensor at the same time; avoiding the synchronism problem, of three-direction gas sources, too difficult to solve, ingeniously utilizing the transverse Poisson effect of the elasticplasmodium, performing dynamic sensitivity calibration under three-dimensional coupling of the three-dimensional force sensor; being able to perform high precision calibration on the dynamic linearityof the three-dimensional force sensor; and being able to perform single-axis or double-axis dynamic sensitivity calibration, being extensive in use, being simple in operation, being high in repeatability, and being high in accuracy and precision of measuring the dynamic linearity of an accelerometer.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A temperature compensating device used for a real-time low-temperature split Hopkinson pressure bar test

InactiveCN108776060AEvenly distributedNo sweatingMaterial strength using single impulsive forceRoom temperatureWorking temperature

The invention relates to a temperature compensating device used for a real-time low-temperature split Hopkinson pressure bar test. The device includes a low-temperature environment box, a low-temperature liquid nitrogen cylinder and a gas pressure pump. Liner walls of a box body and a door of the low-temperature environment box are provided with a heat insulation material. The top of the box bodyis provided with a liquid nitrogen feeding pipe, and symmetrical two side walls of the box body are provided with bar holes respectively. The door is provided with an observation window. The liquid nitrogen feeding pipe communicates with a liquid nitrogen discharging pipe extending into the inner bottom of the low-temperature liquid nitrogen cylinder. A gas outlet of the gas pressure pump communicates with an air feeding pipe of the low-temperature liquid nitrogen cylinder through a gas pipe. When in use, the low-temperature environment box is firstly mounted on a cross beam of a split Hopkinson pressure bar test device, then test piece clamping ends of an incident bar and a transmission bar of the split Hopkinson pressure bar test device are stuck into the box body through the bar holes at left and right sides of the box body respectively, and then a test piece is clamped between the clamping ends of the incident bar and the transmission bar. The working temperature range of the temperature compensating device ranges from room temperature to -100 DEG C, an outer shell of the box body is free of a sweating phenomenon, and test piece fragments are effectively prevented from flying out during impact in an SHPB test.

Owner:ANHUI UNIV OF SCI & TECH

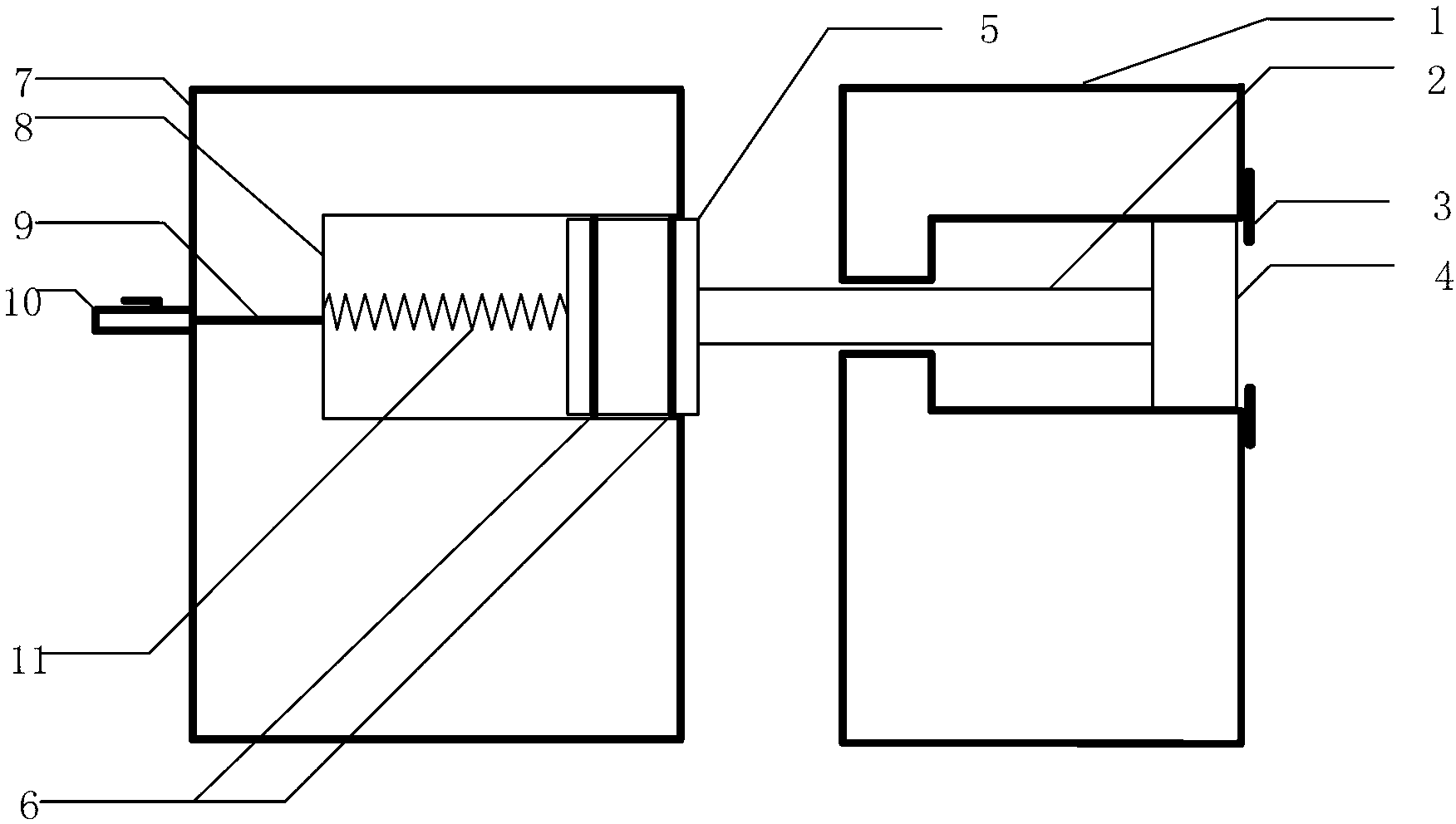

Adjustable air damper for split Hopkinson pressure bar

The invention aims to provide an adjustable air damper for a split Hopkinson pressure bar. The adjustable air damper for a split Hopkinson pressure bar comprises an impacted device and an energy absorption device, wherein the impacted device comprises an impacted base, a connecting rod and a rubber block, wherein the impacted base is provided with an impacted cavity therein; the rubber block is mounted in the impacted cavity; the connecting rod is connected to the rubber block, and penetrates the impacted cavity to reach the outside of the impacted base; the energy absorption device comprises an energy absorption base and an aluminum block; an energy absorption cavity is formed in the energy absorption base; the aluminum block is arranged at the right end of the energy absorption cavity and can move along the energy absorption cavity; a spring is arranged between the aluminum block and the left end of the energy absorption cavity; the connecting rod penetrates the impacted cavity to be connected to the aluminum block; an airflow channel is formed in the energy absorption base; the inlet of the airflow channel is communicated with the cavity; and a valve is arranged at the outlet of the airflow channel. According to the invention, the purpose of energy absorption is realized by using airtightness; the valve is utilized to adjust the capacity release rate of the air damper, which is simple and effective; and the metal block is used as an impacted carrier, so that the repeated utilization ratio is high, economy and environmental protection are realized.

Owner:HARBIN ENG UNIV

Portable self-seal rock SHPB (split Hopkinson pressure bar) test confining pressure loading device

PendingCN107966371AReal-time monitoring of deformation characteristicsEasy extractionMaterial strength using tensile/compressive forcesPressure systemTest measurement

The invention discloses a portable self-seal rock SHPB (split Hopkinson pressure bar) test confining pressure loading device, and belongs to the field of rock mechanics and dynamics indoor test measurement. The portable self-seal rock SHPB test confining pressure loading device is characterized in that an oil inlet and an exhaust opening are formed in a cylinder of a confining pressure device, cover plates are arranged at two ends of the cylinder, concentric circular holes with equal sizes are formed in the centers of the cover plates, the diameters of the concentric circular holes can be changed according to the sizes of test rock samples, double U-shaped synthetic rubber sleeves are arranged in the cylinder, spaces between the sleeves and the cylinder are filled with hydraulic oil, and the test rock samples are arranged in the double U-shaped synthetic rubber sleeves. The portable self-seal rock SHPB test confining pressure loading device has the advantages that hydraulic oil self-seal principles are adopted for integral systems, the oil inlet is connected with a loading system by a high-pressure oil pipe, and internal confining pressures of the cylinder can be monitored via theloading system in real time; radial stable confining pressures higher than 100 MPa can be applied by the portable self-seal rock SHPB test confining pressure loading device in a short time, strain gauges can be adhered with the rock samples, the rock samples can be led out from the circular holes in the cover plates by wires, deformation procedures of rock under impact load can be monitored in real time, the systems are easy to operate and convenient to carry, the confining pressures are stable, and the like.

Owner:UNIV OF SCI & TECH BEIJING

Gradienter for split-Hopkinson-pressure-bar splitting test piece

InactiveCN105445093AHigh precisionEasy to operateStrength propertiesSplit-Hopkinson pressure barFront cover

A disclosed gradienter for split-Hopkinson-pressure-bar splitting test piece mainly comprises a protective shield, a support, a half-thread bushing, a balancing tray and a fixed bar. The protective shield is formed by a protective-shield rear cover, a protective-shield front cover and two side baffle plates, and the center part of each side baffle plate is provided with a circular hole for passing of a split Hopkinson pressure bar; and the upper surface of the support is an oblique surface, the fixed bar is fixedly disposed on the upper surface, the upper part of the fixed bar is connected with the balancing tray through the half-thread bushing, the height of the balancing tray is adjusted by rotating the half-thread bushing, and the upper surface of the balancing tray is provided with scale. During experiment, the test piece is put at a corresponding scale, and by adjusting the vertical-direction height and the horizontal-direction scale, the fact is guaranteed that the diameter direction of a middle cross section along the height direction of the test piece is collinear with axes of an incidence bar and a transmission bar in the split Hopkinson pressure bar, and thus the precision of the splitting test is improved.

Owner:ANHUI UNIV OF SCI & TECH

Low-speed penetration experiment device based on split Hopkinson pressure bar

PendingCN112051166ASmall space requirementImprove securityStrength propertiesNuclear energy generationConvertersMuzzle

The invention discloses a low-speed penetration experiment device based on a split Hopkinson pressure bar. The low-speed penetration experiment device comprises a test platform, and a launching unit,a muzzle diameter converter, a target front slide rail speed measurement assembly, a target chamber unit, a bullet recycling box, a combined bullet and a target rear slide rail speed measurement assembly which are mounted on the test platform; the muzzle diameter converter is additionally arranged at the muzzle of the launching unit, and the combined bullet is pushed into the muzzle diameter converter and can be launched under the driving of the launching unit; the target chamber unit is arranged behind the muzzle diameter converter, a target plate is installed in the target chamber unit, andthe target front slide rail speed measurement assembly and the target rear slide rail speed measurement assembly are arranged in front of and behind the target plate respectively and used for limitingthe flight path of the combined bullet and detecting the speed of the combined bullet before and after target penetration; the bullet recycling box is arranged behind the target rear slide rail speedmeasurement assembly and the target chamber unit and used for recycling the combined bullets penetrating through the target.

Owner:QUANZHOU INST OF EQUIP MFG

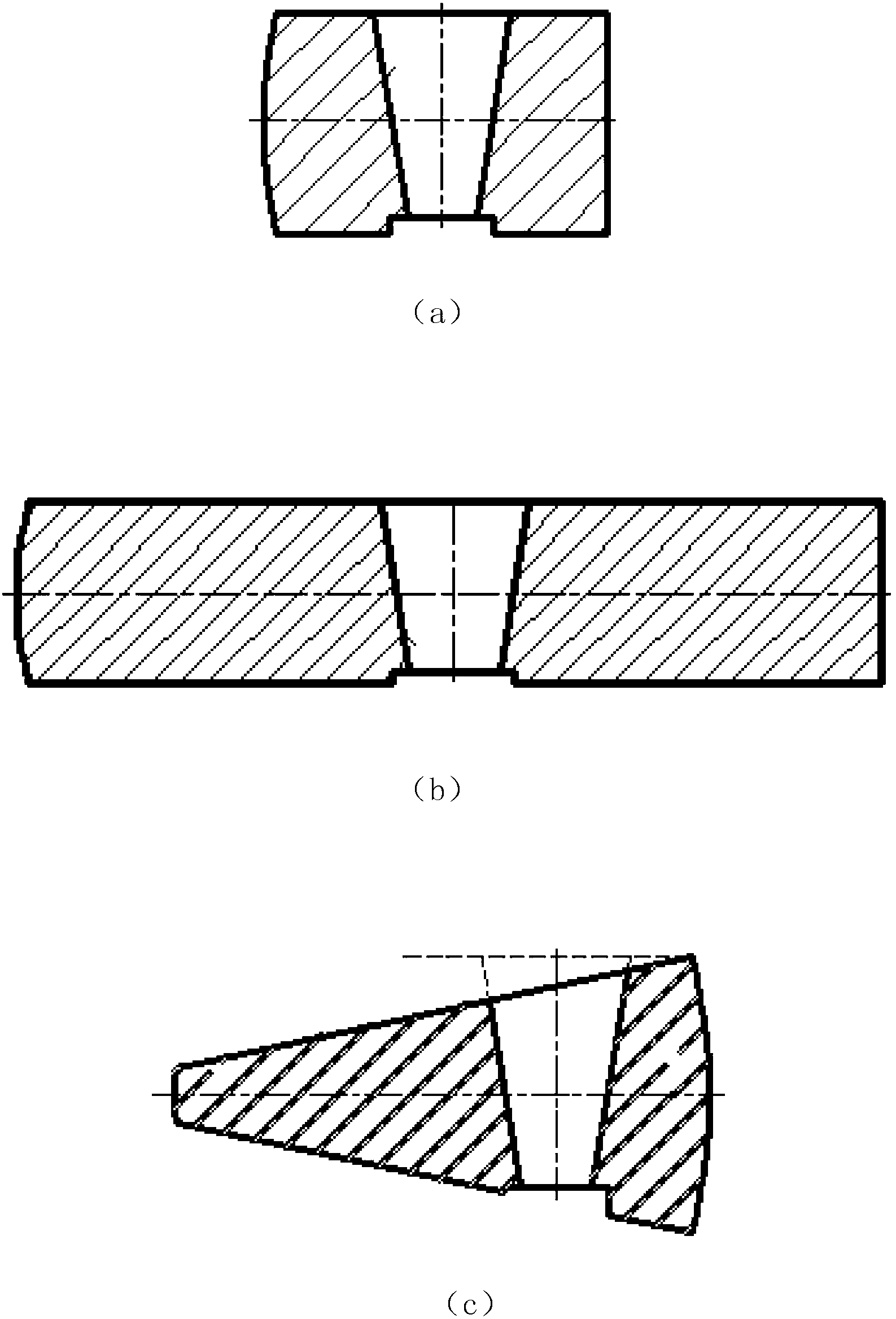

Novel SHPB (split Hopkinson pressure bar) explosive power source device

InactiveCN104483185AImpact speedImprove securityStrength propertiesControl systemPower control system

The invention relates to an SHPB (split Hopkinson pressure bar) explosive power source device which can accurately control impact speed / energy. The SHPB explosive power source device comprises a cylinder body, a cylinder cap, conducting rods and wires, and is characterized in that the cylinder cap is fixed on the cylinder body through bolts; a bullet launch bar is arranged at the center of the cylinder cap and is integrally designed with the cylinder cap; two conical through holes are symmetrically formed in two sides of the bullet launch bar on the cylinder cap, and rubber plugs are assembled in the conical through holes; the conducting rods are inserted on the rubber plugs; one end, located on the outer side of the cylinder body, of each conducting rod is connected with a power control system through the corresponding wire, and the other ends, located in the cylinder body, of the conducting rods are connected to an explosion fuse wire. During working, strong current is introduced to the explosion fuse wire through the wires to fuse and sublime the explosion fuse wire, high-pressure gas is generated to push a bullet to be ejected at a high speed, and explosion energy can be accurate by controlling parameters such as electric current, explosion fuse wire material and length and the like, so that the bullet impact speed is accurately controlled.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com