Patents

Literature

329 results about "Radial stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radial stress is stress towards or away from the central axis of a component.

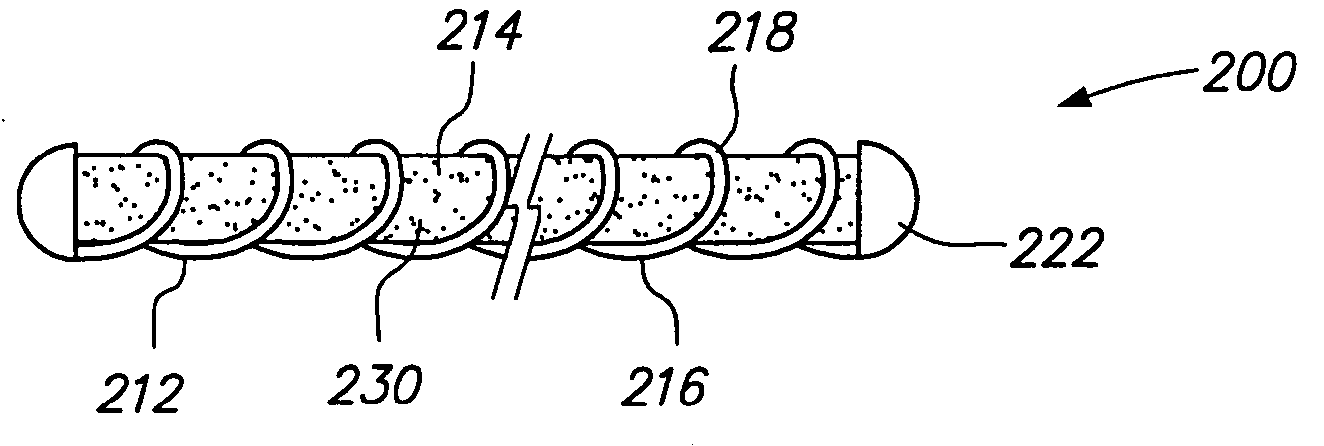

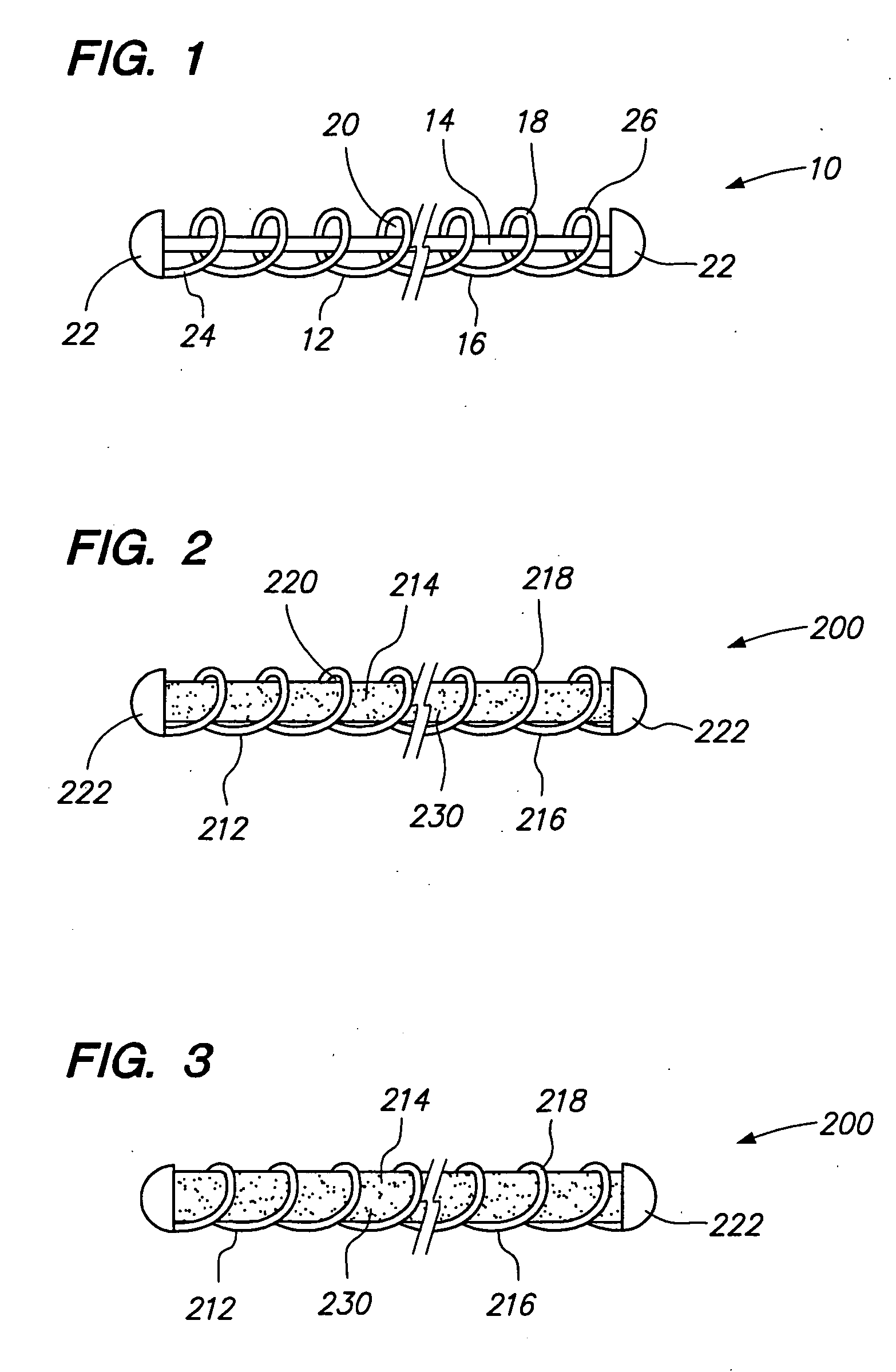

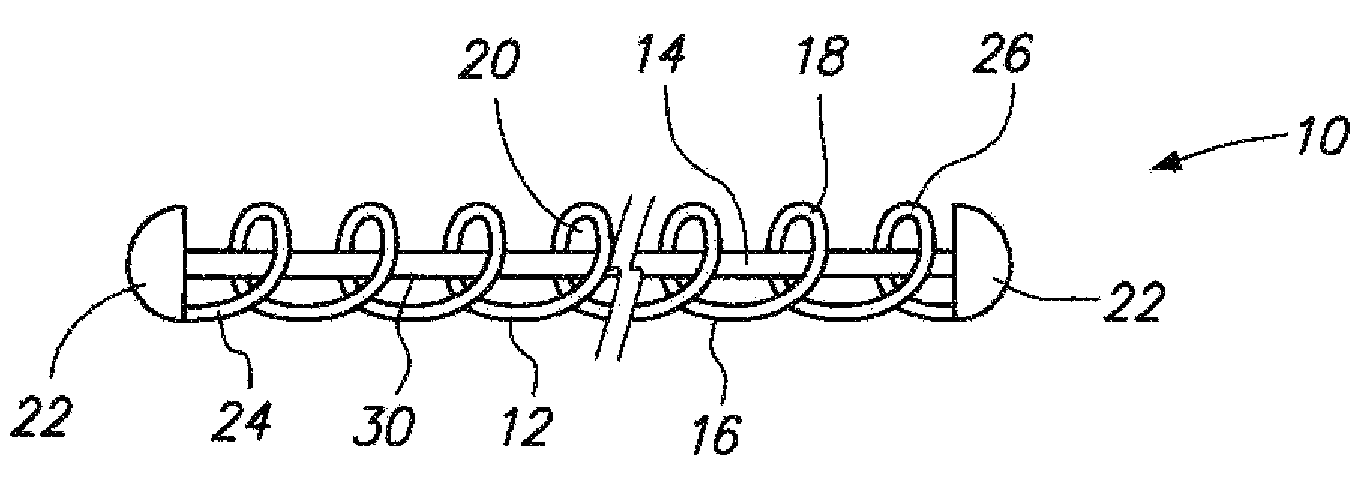

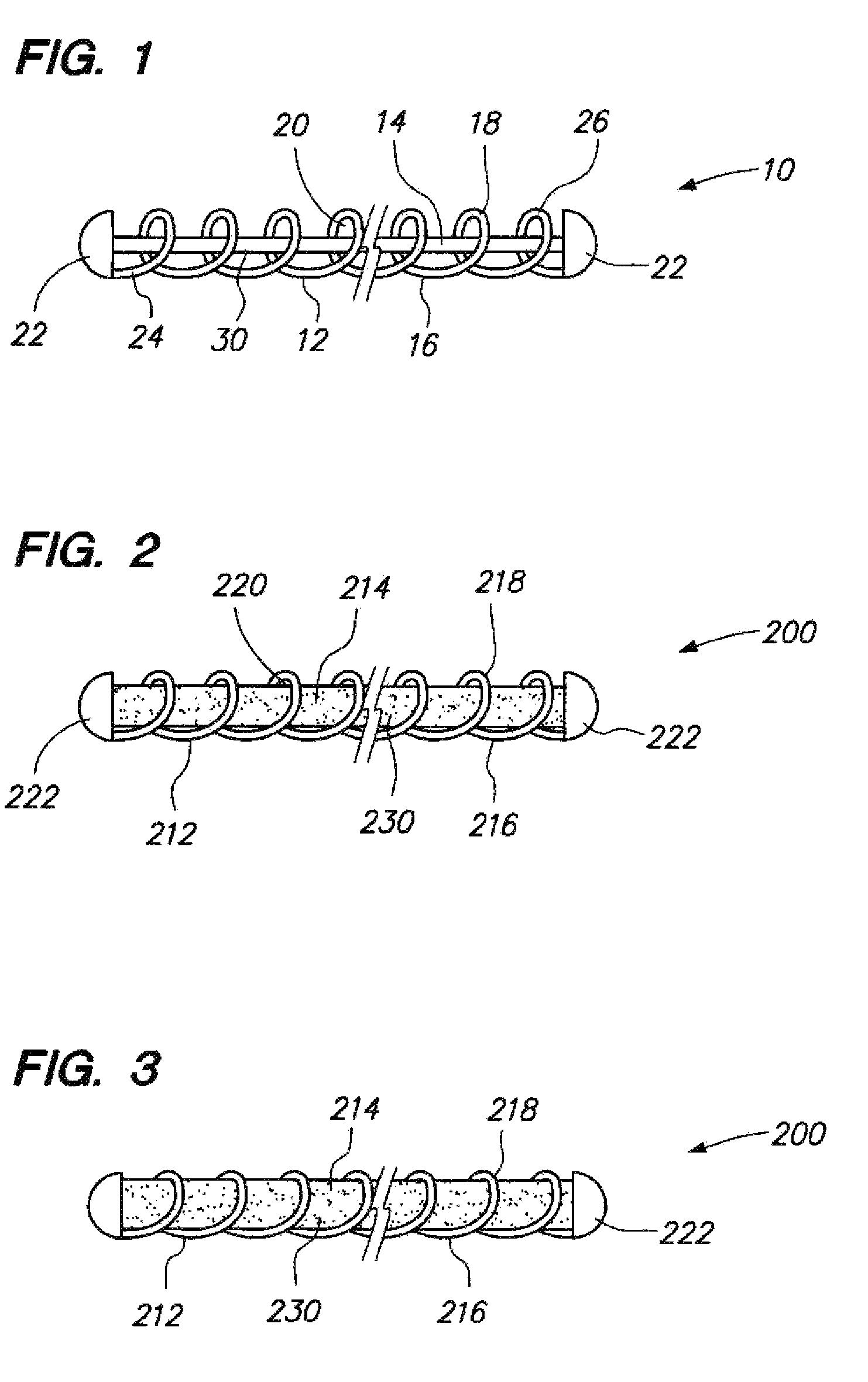

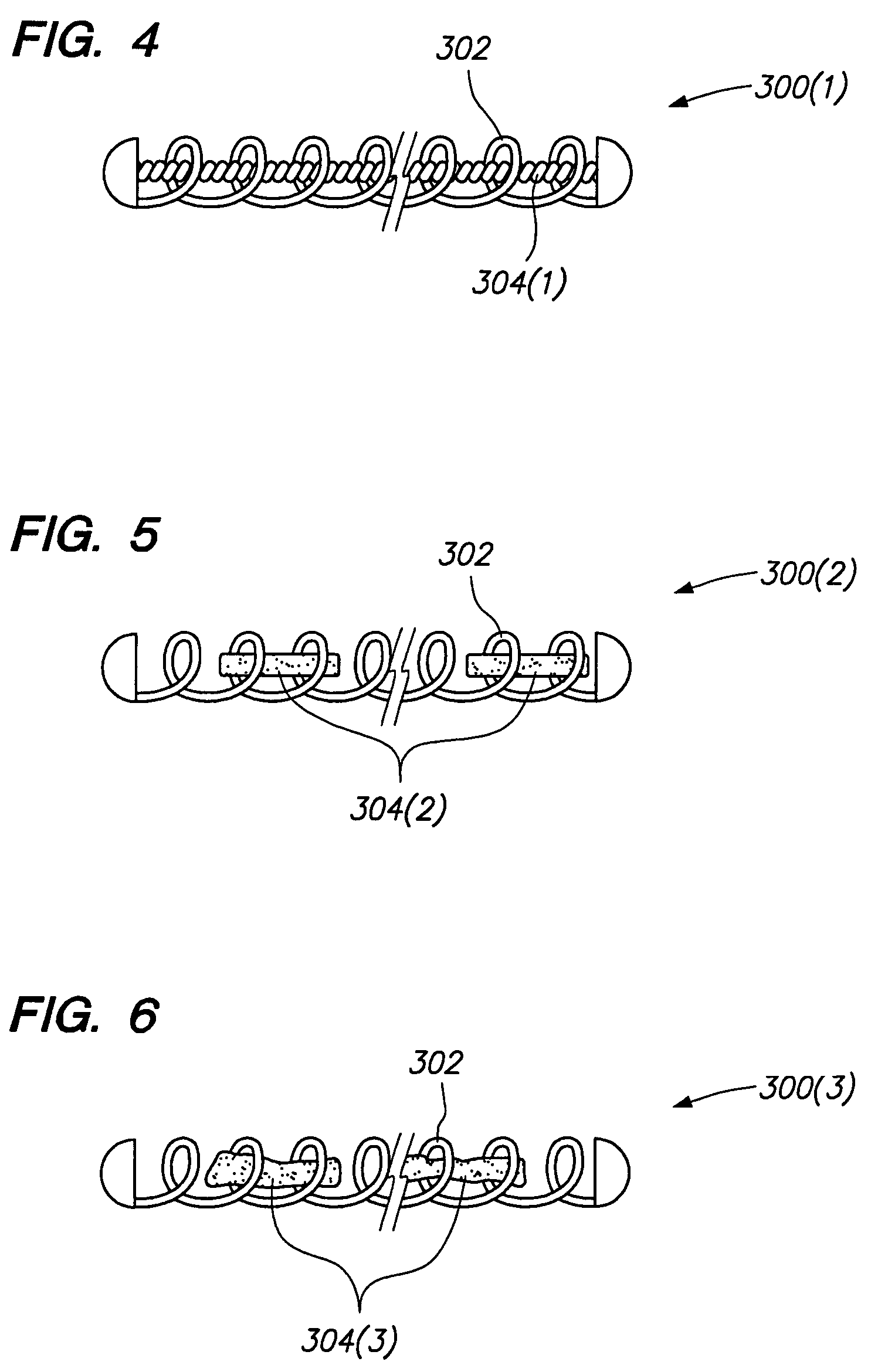

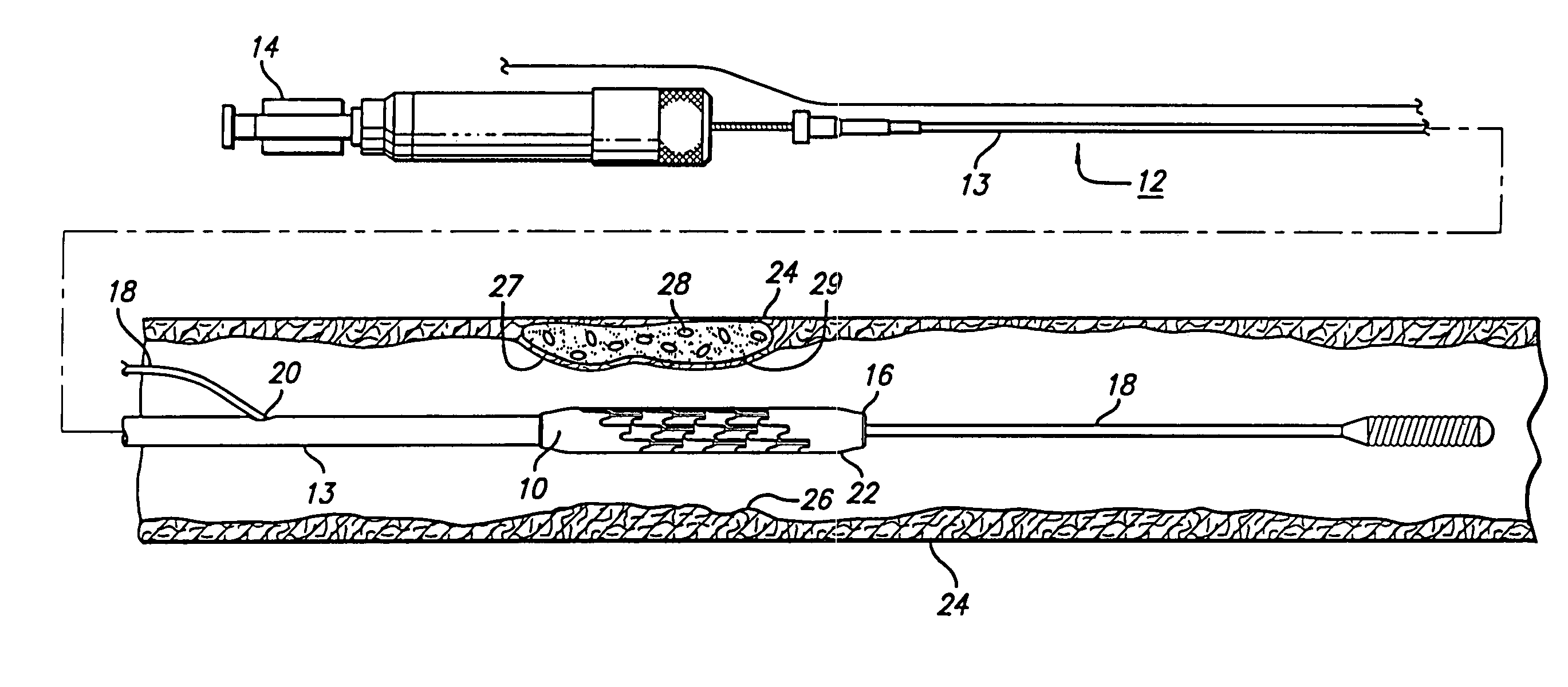

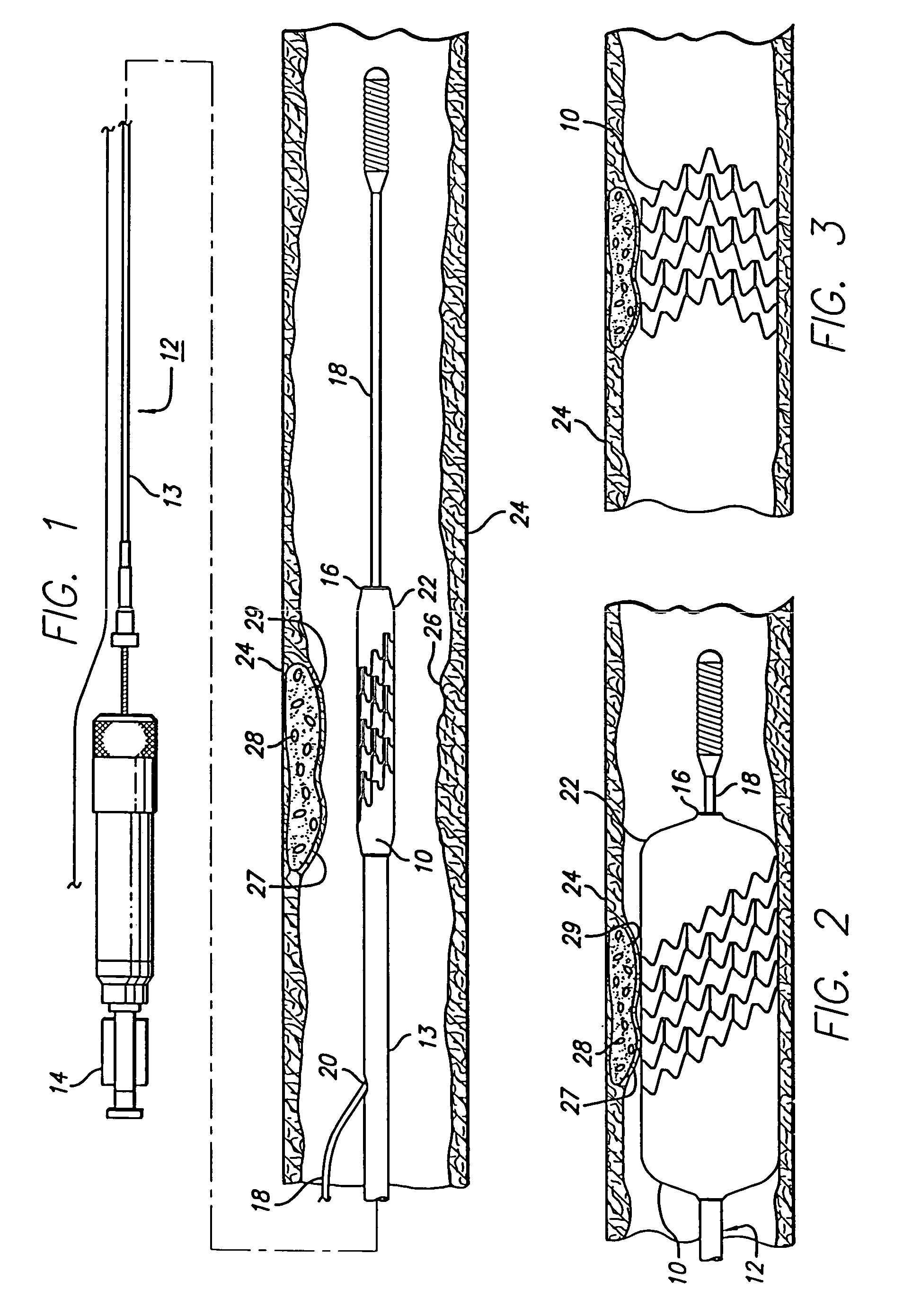

Vaso-occlusive devices with in-situ stiffening elements

Vaso-occlusive devices for occluding a body cavity include an internal element located within a lumen of the device. The internal element may include an active element configured to stiffen the coil in-situ made from a material that can expand to a desired size, thereby inducing a radial stress to the coil to stiffen the occlusive device. Alternatively, the active element is secured to two points on the occlusive device, and is made from a material that contracts, thereby inducing a compression to stiffen the device. The internal element may additionally include an agent carrier that comprises a bioactive material capable of eliciting a biological reaction after the device is placed in-situ. For example, the bioactive material can be a part of a composition of the agent carrier, absorbed by the agent carrier, or coated as a layer on the agent carrier.

Owner:BOSTON SCI SCIMED INC

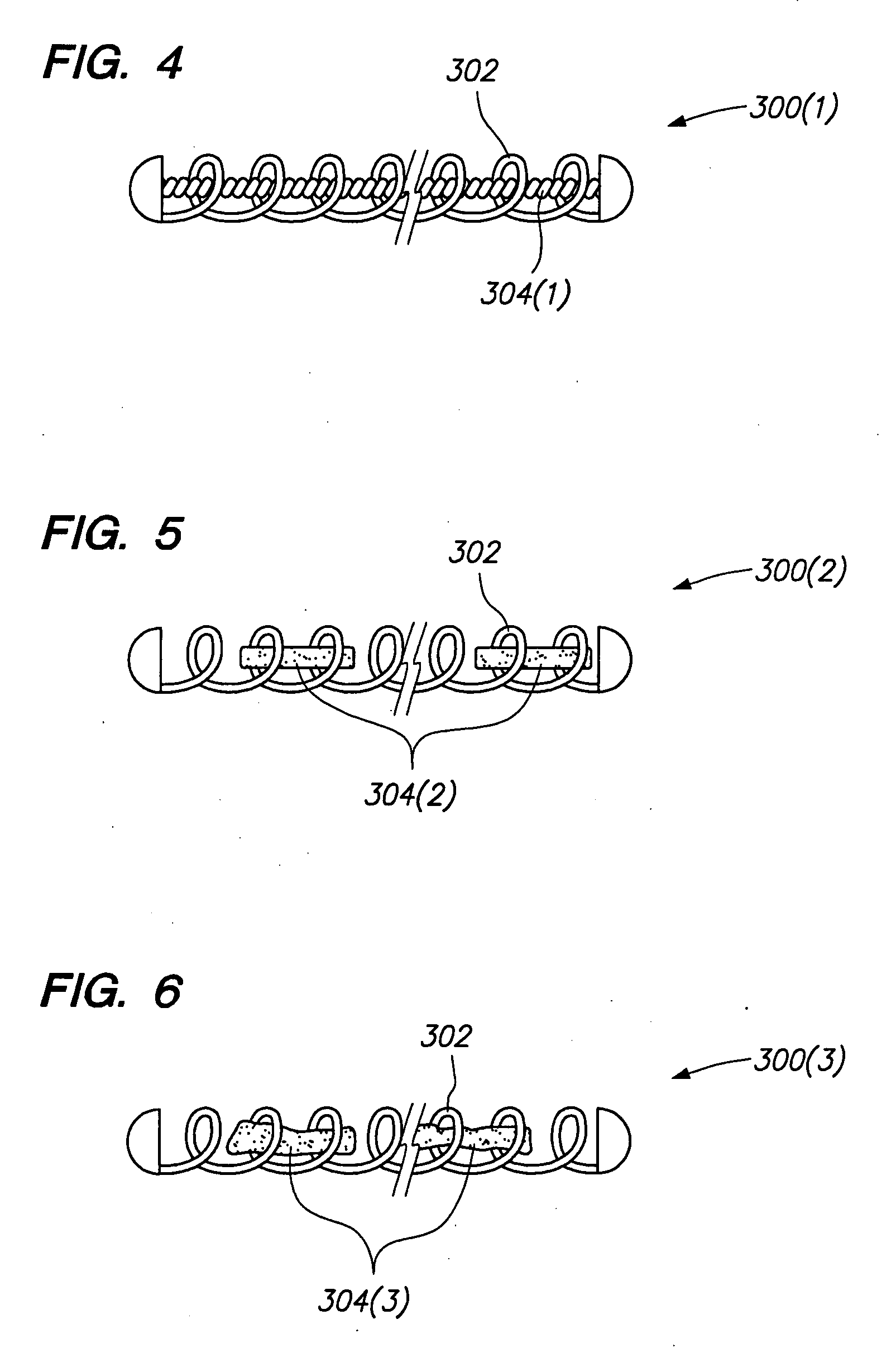

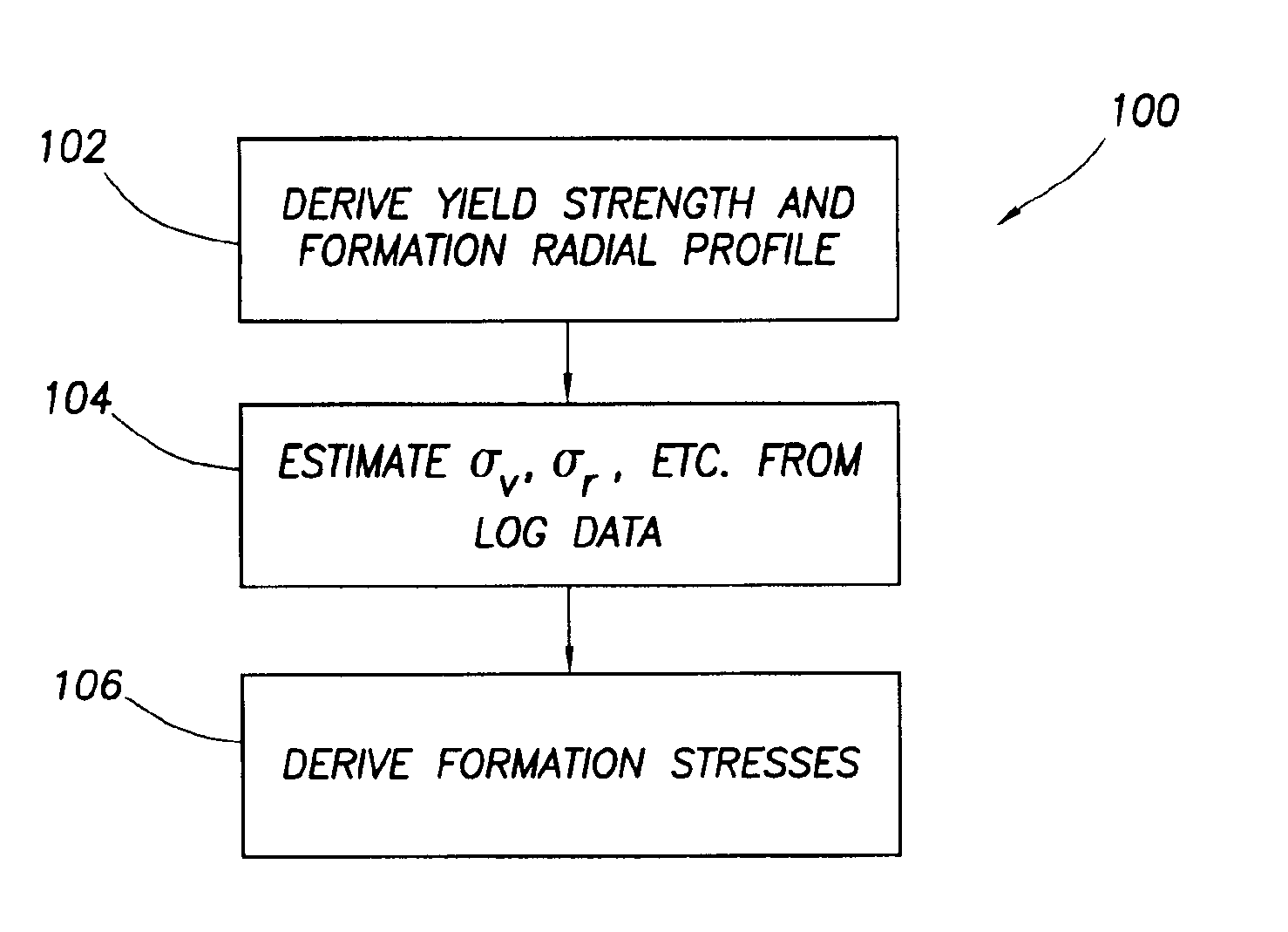

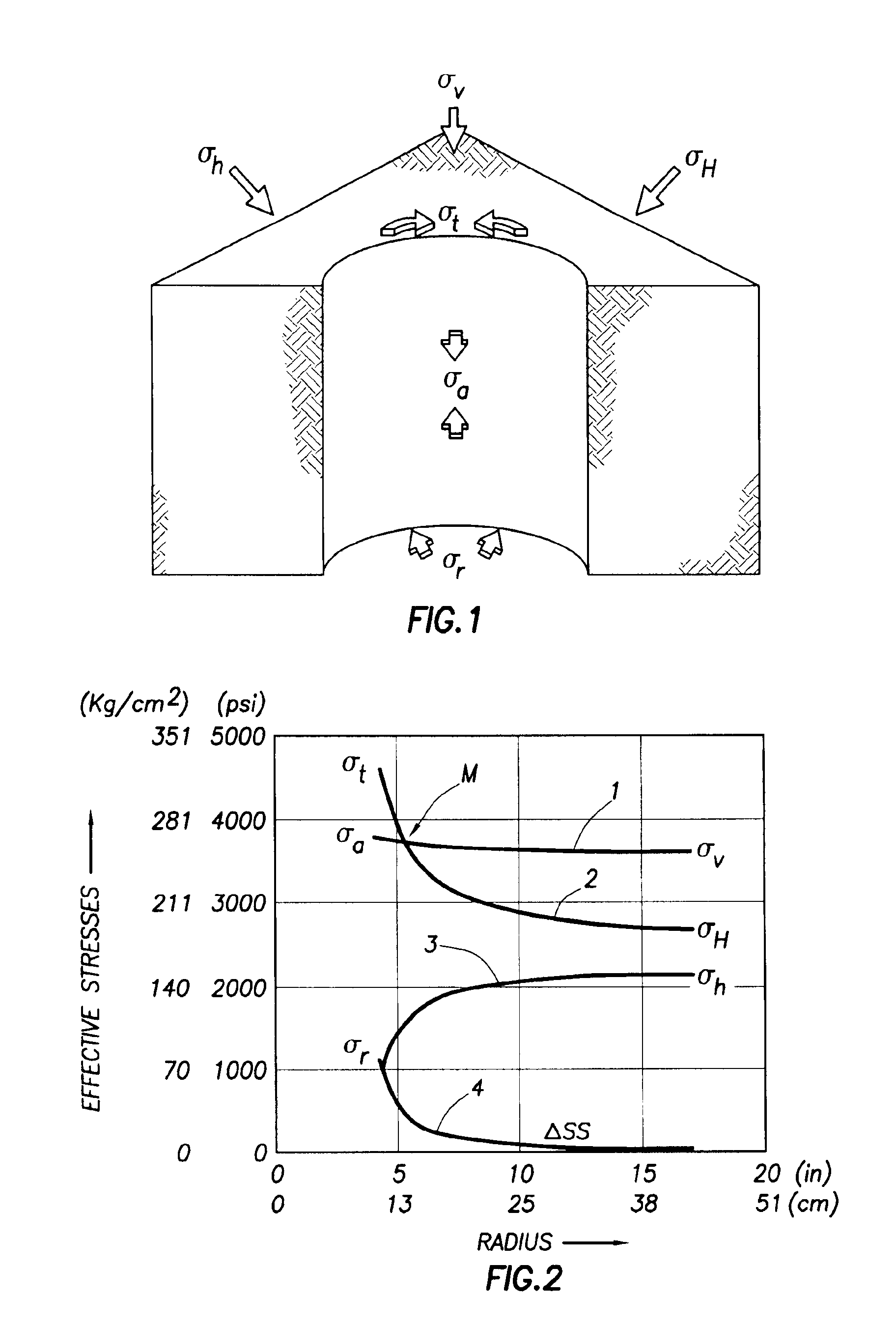

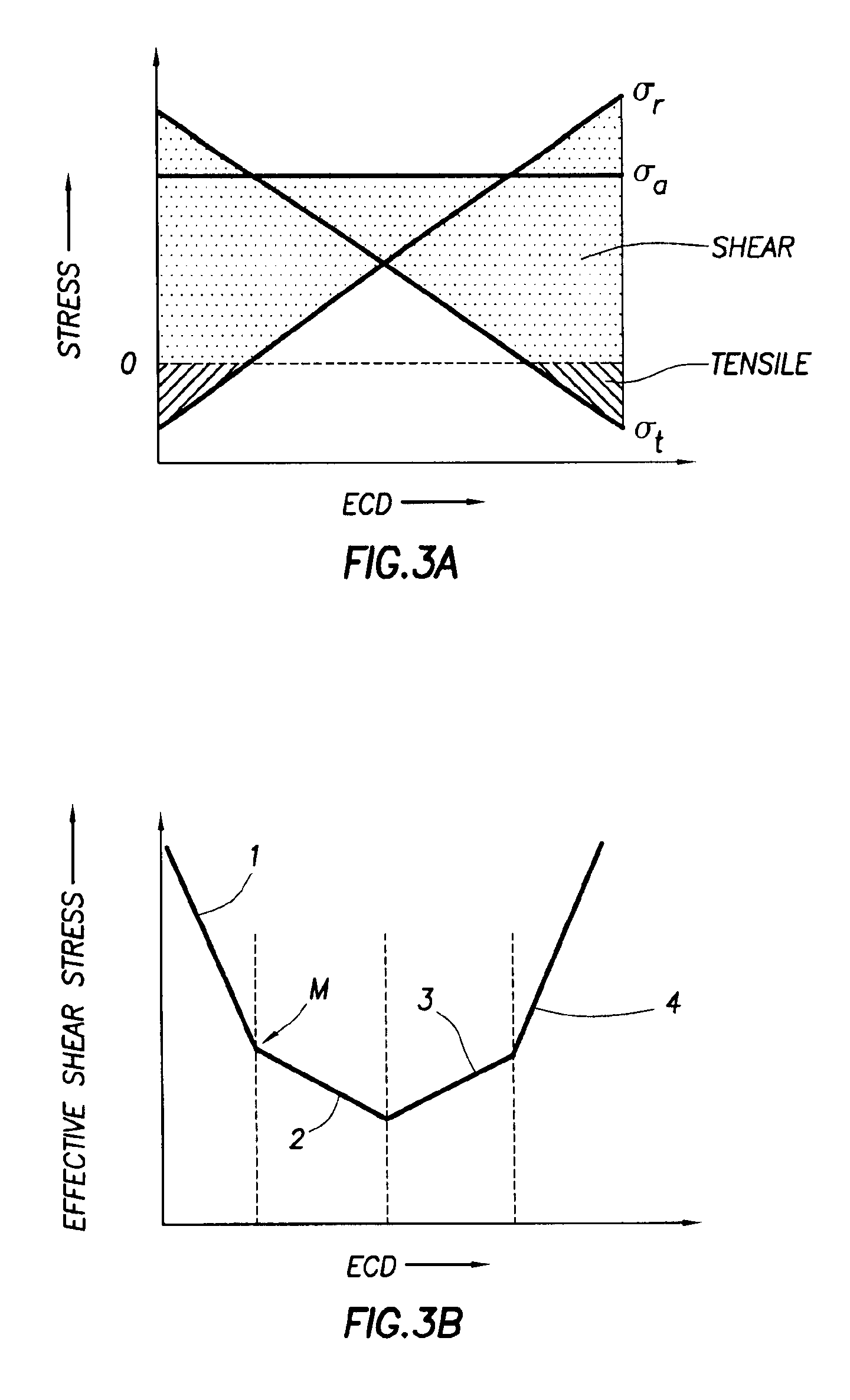

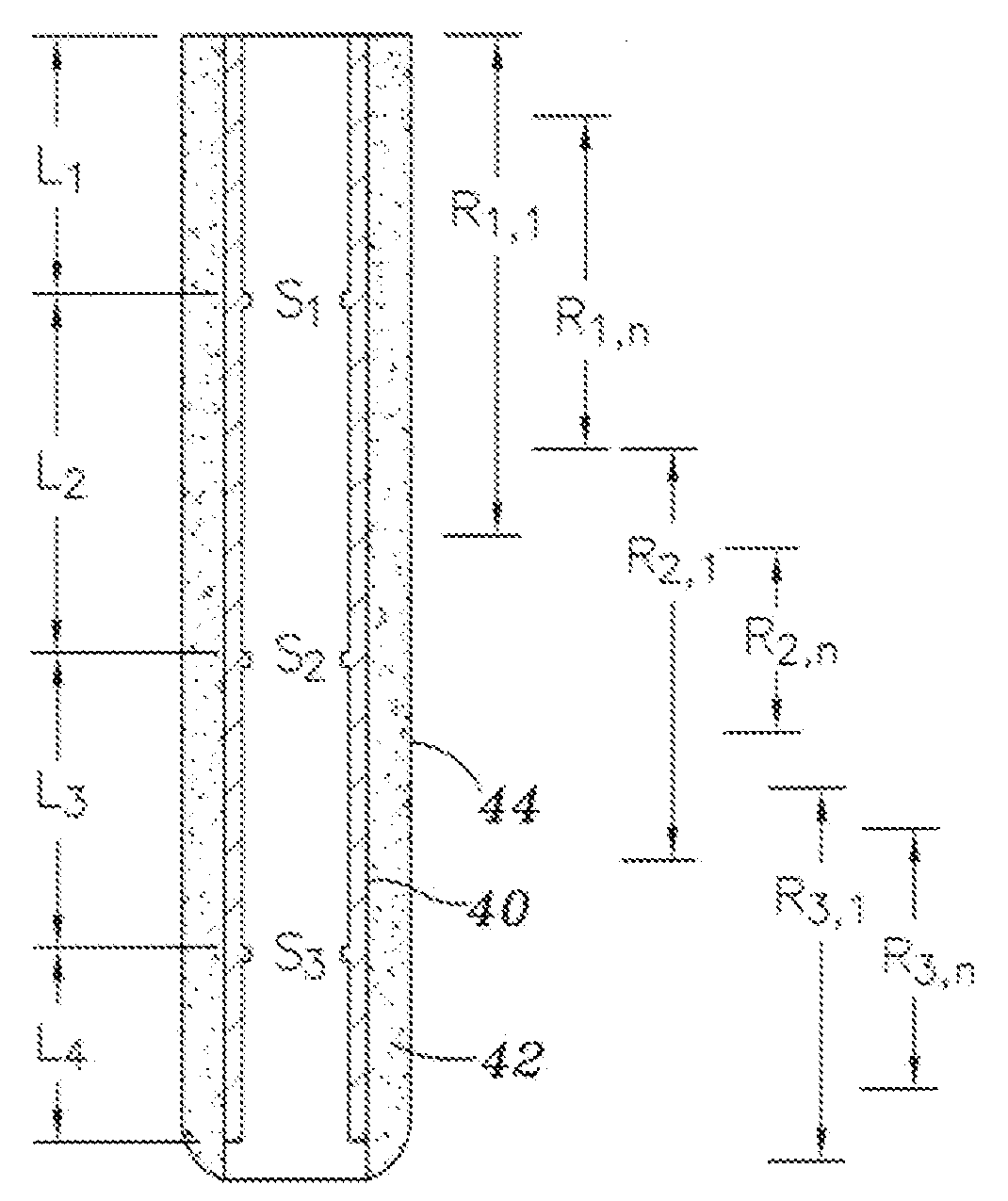

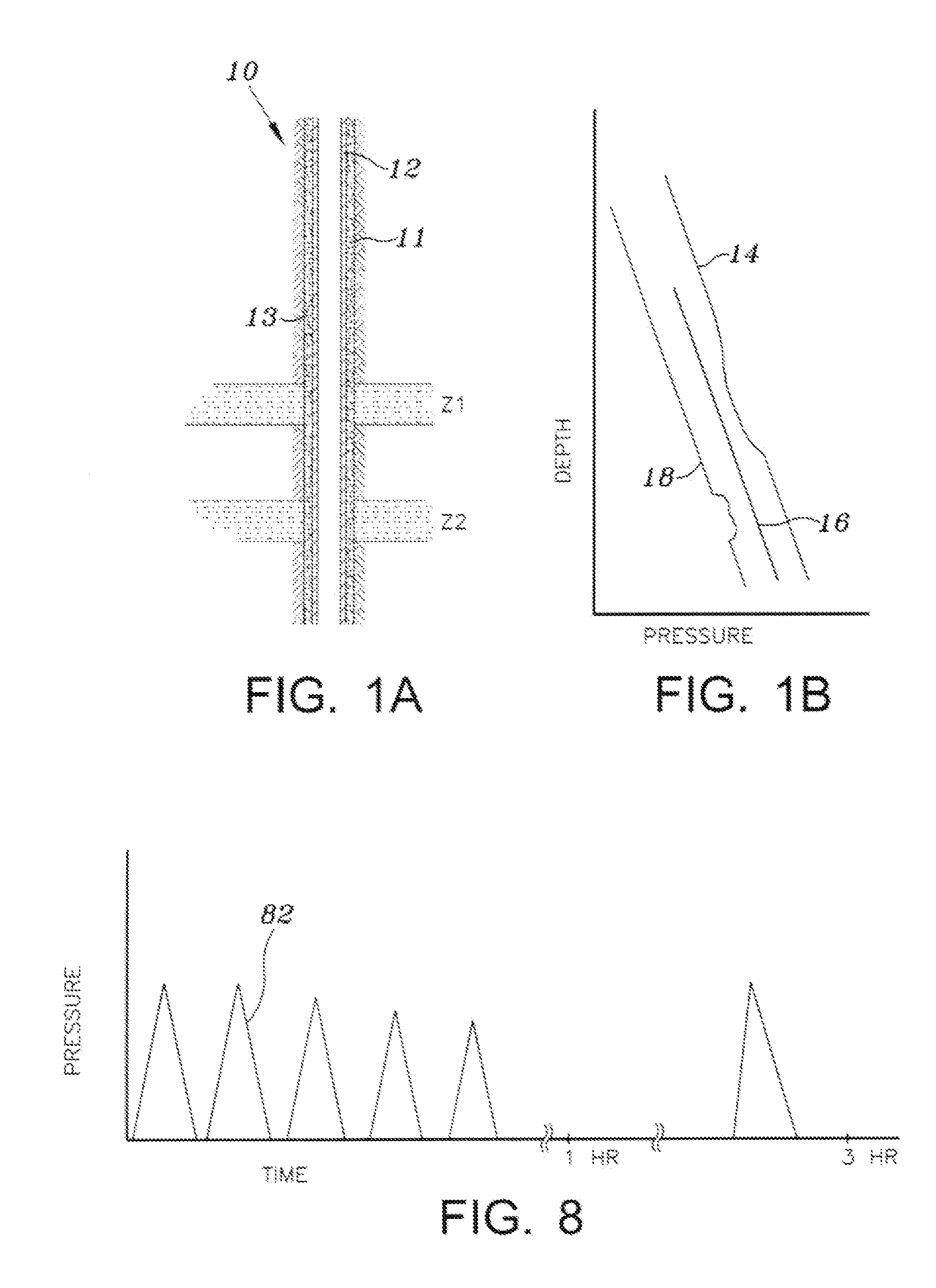

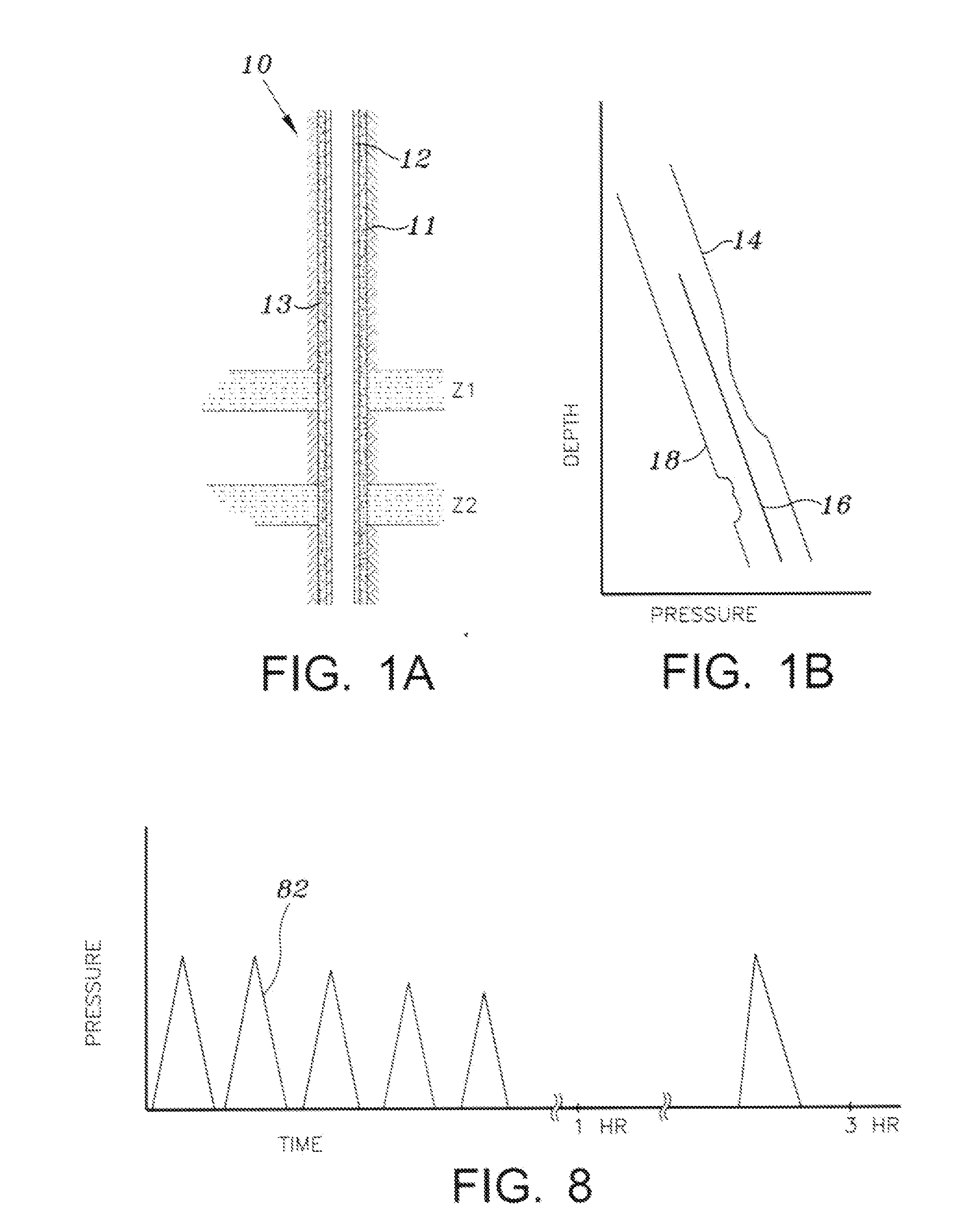

Methods and systems for determining formation properties and in-situ stresses

ActiveUS6904365B2Electric/magnetic detection for well-loggingSeismic signal processingRadial stressUltimate tensile strength

Systems and methods for determining a formation property related to formation strength and stresses are disclosed. A method for determining a formation strength includes obtaining radial formation property measurements at different wellbore pressures; generating a radial stress profile based on a formation model; generating a radial stress function from the radial stress profile; and comparing the radial formation property measurements with the radial stress function to determine the formation strength. A method for determining a formation stress profile includes deriving formation parameters from a formation radial profiling; obtaining formation log data that comprise formation density data; estimating formation stresses from the formation log data; and deriving a radial stress profile based on a formation model, the derived formation parameters, and the estimated formation stresses.

Owner:SCHLUMBERGER TECH CORP

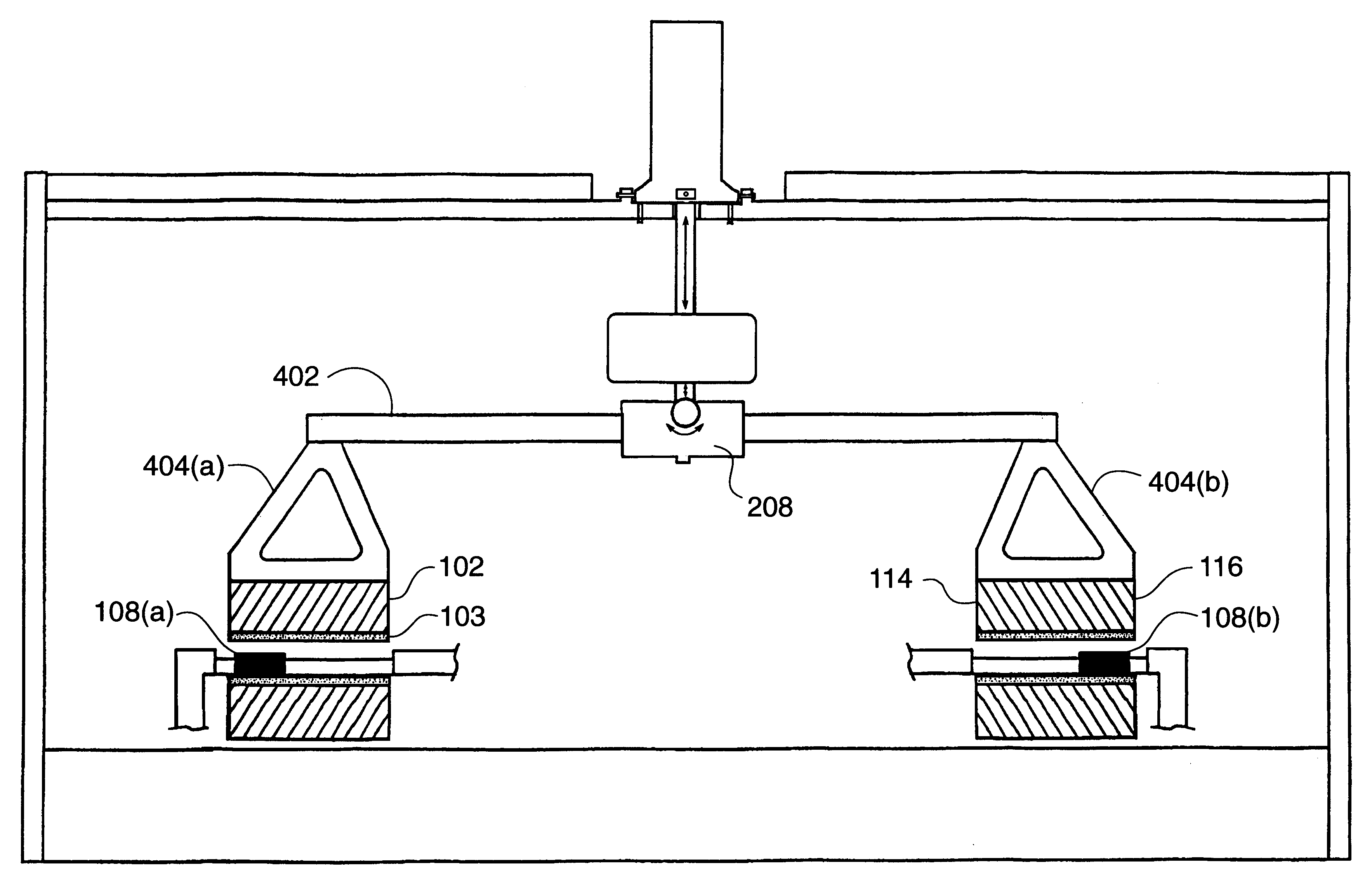

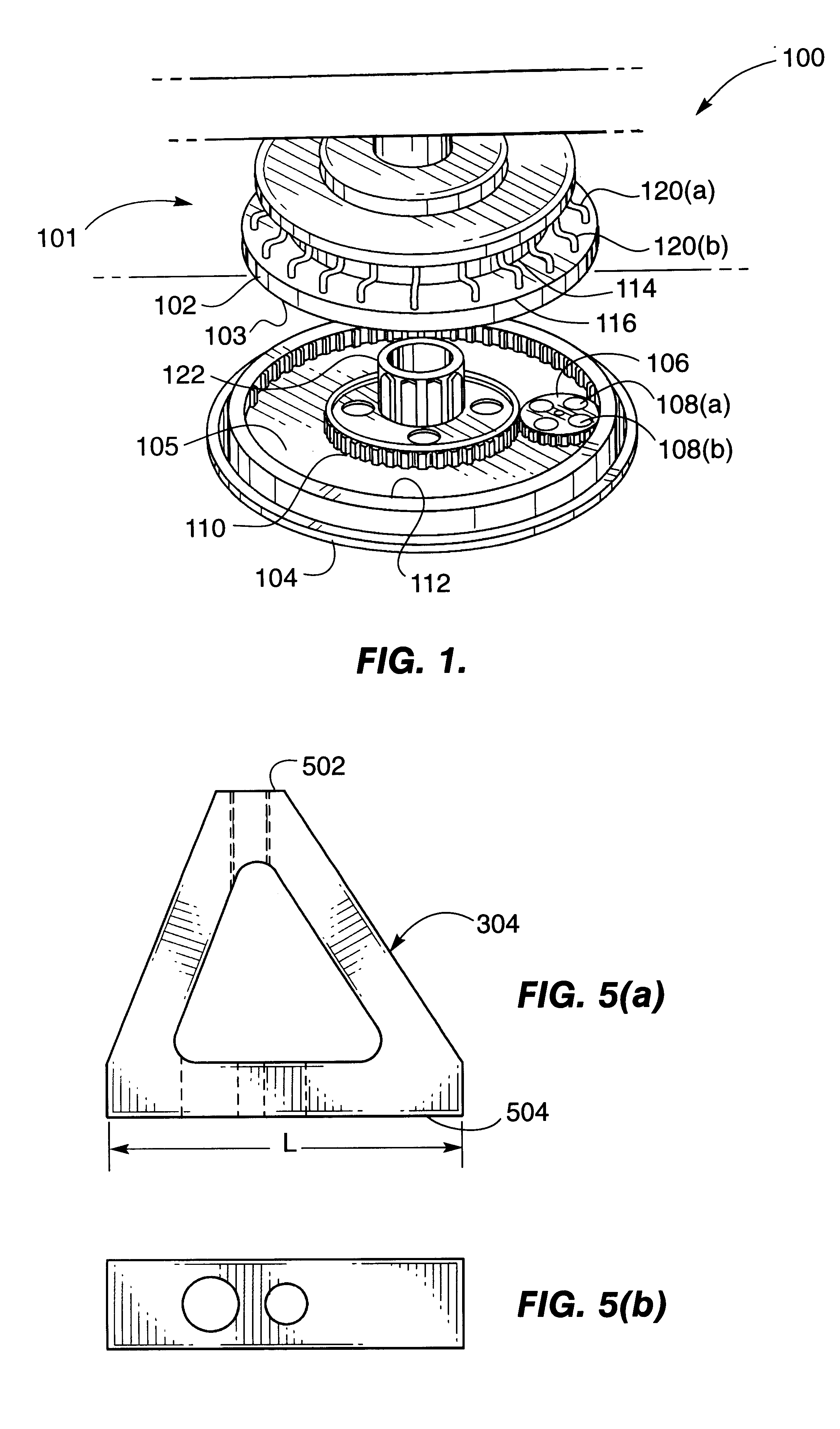

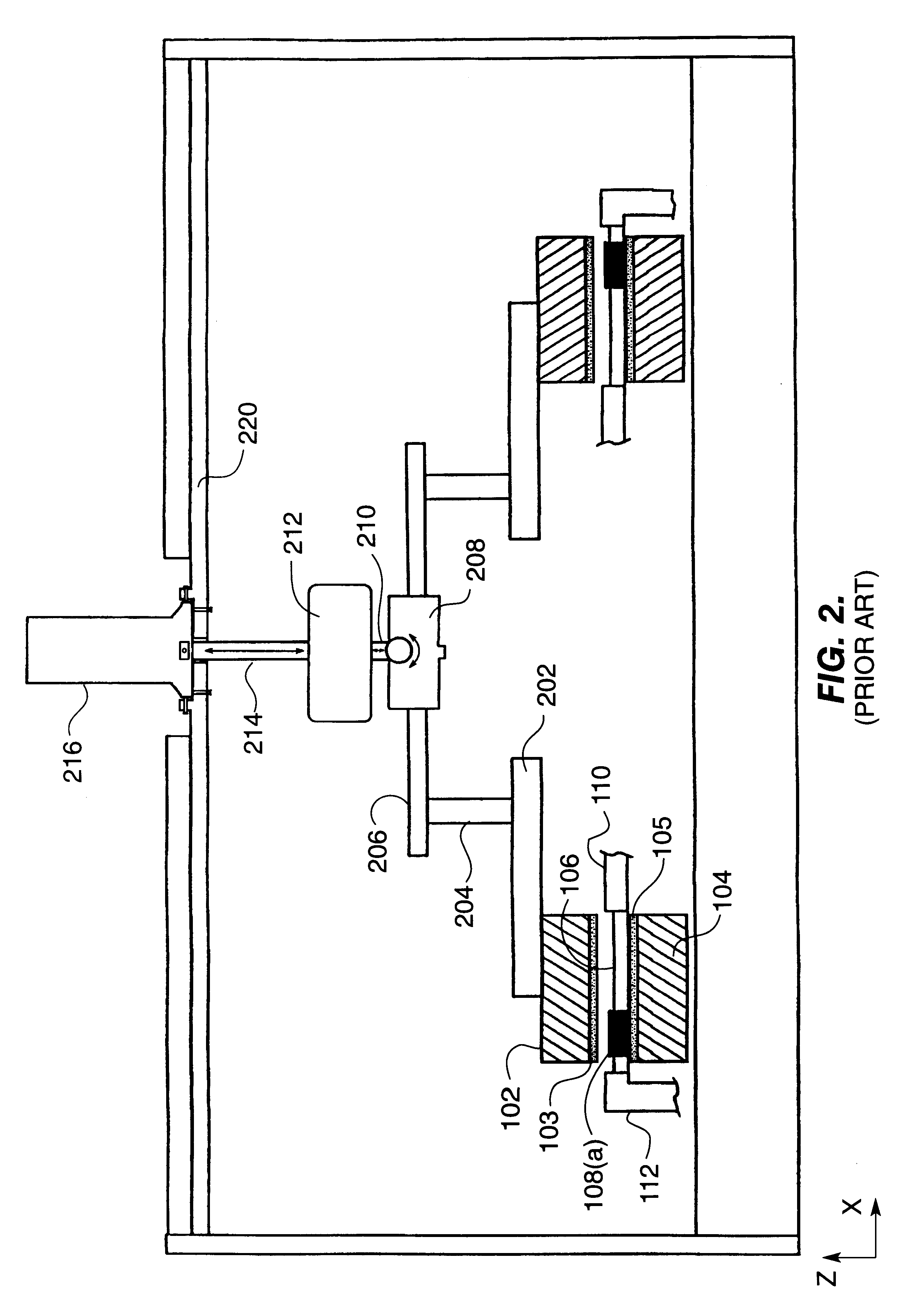

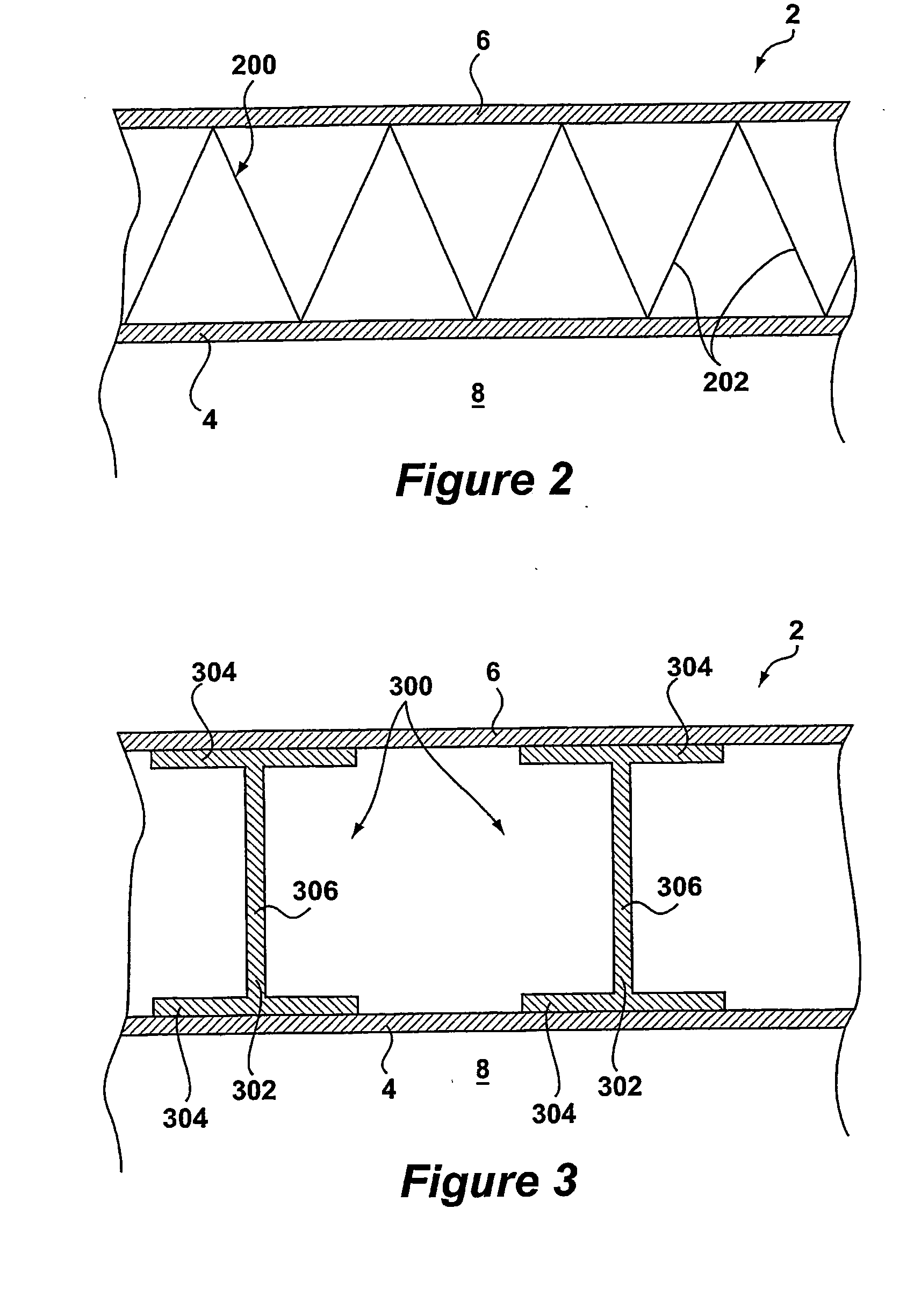

Apparatus for polishing using improved plate supports

InactiveUS6168506B1Reduce stress changesConstantEdge grinding machinesPolishing machinesRadial stressEngineering

A set of supports are advantageously disposed on a top plate having a polishing surface useful for polishing workpieces, thereby applying substantially uniform pressure to the top plate. In a preferred embodiment, the supports are non-isosceles triangular elements distributed evenly at 45 degree increments around a ring-shaped top plate. This structure effectively compensates for radial stress variations arising from non-optimum positioning of support points with respect to the inner and outer diameters of the polishing surface.

Owner:SPEEDFAM IPEC

Vaso-occlusive devices with in-situ stiffening elements

Vaso-occlusive devices for occluding a body cavity include an internal element located within a lumen of the device. The internal element may include an active element configured to stiffen the coil in-situ made from a material that can expand to a desired size, thereby inducing a radial stress to the coil to stiffen the occlusive device. Alternatively, the active element is secured to two points on the occlusive device, and is made from a material that contracts, thereby inducing a compression to stiffen the device. The internal element may additionally include an agent carrier that comprises a bioactive material capable of eliciting a biological reaction after the device is placed in-situ. For example, the bioactive material can be a part of a composition of the agent carrier, absorbed by the agent carrier, or coated as a layer on the agent carrier.

Owner:BOSTON SCI SCIMED INC

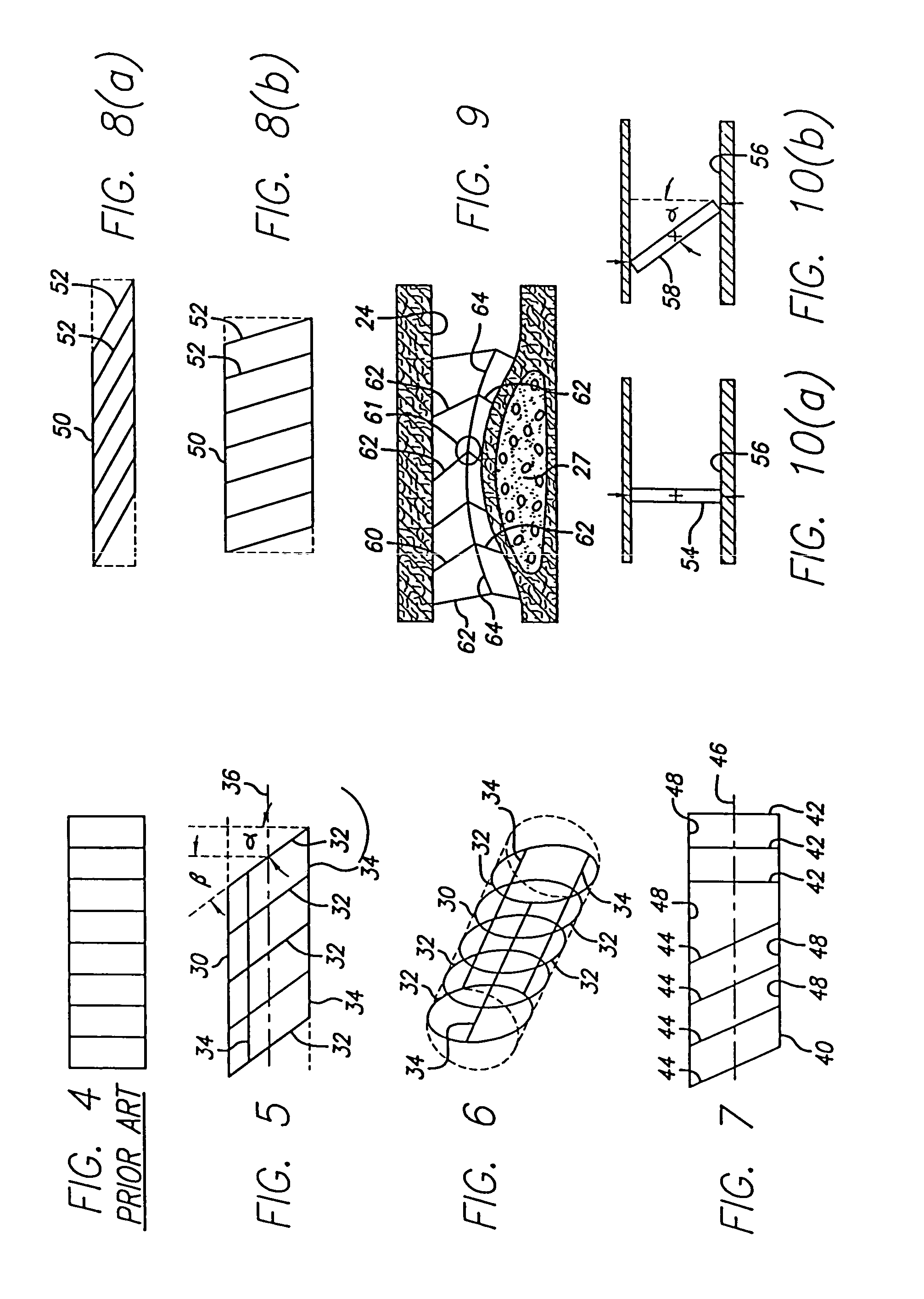

Inclined stent pattern for vulnerable plaque

InactiveUS7018403B1Reducing outward radial stressMinimize traumaStentsBlood vesselsVulnerable plaqueRadial stress

A stent for implantation in a body lumen for protecting from rupture a fibrous cap in order to treat vulnerable plaque. One embodiment of the stent includes inclined planar rings joined by interconnecting links. The planar rings are inclined relative to a plane perpendicular to a longitudinal axis extending the length of the stent. The inclined planar rings provide vessel support yet require lower balloon pressures to deploy and exert lower radial stresses so that when appositioned with vulnerable plaque are less likely to rupture the fibrous cap.

Owner:ABBOTT CARDIOVASCULAR

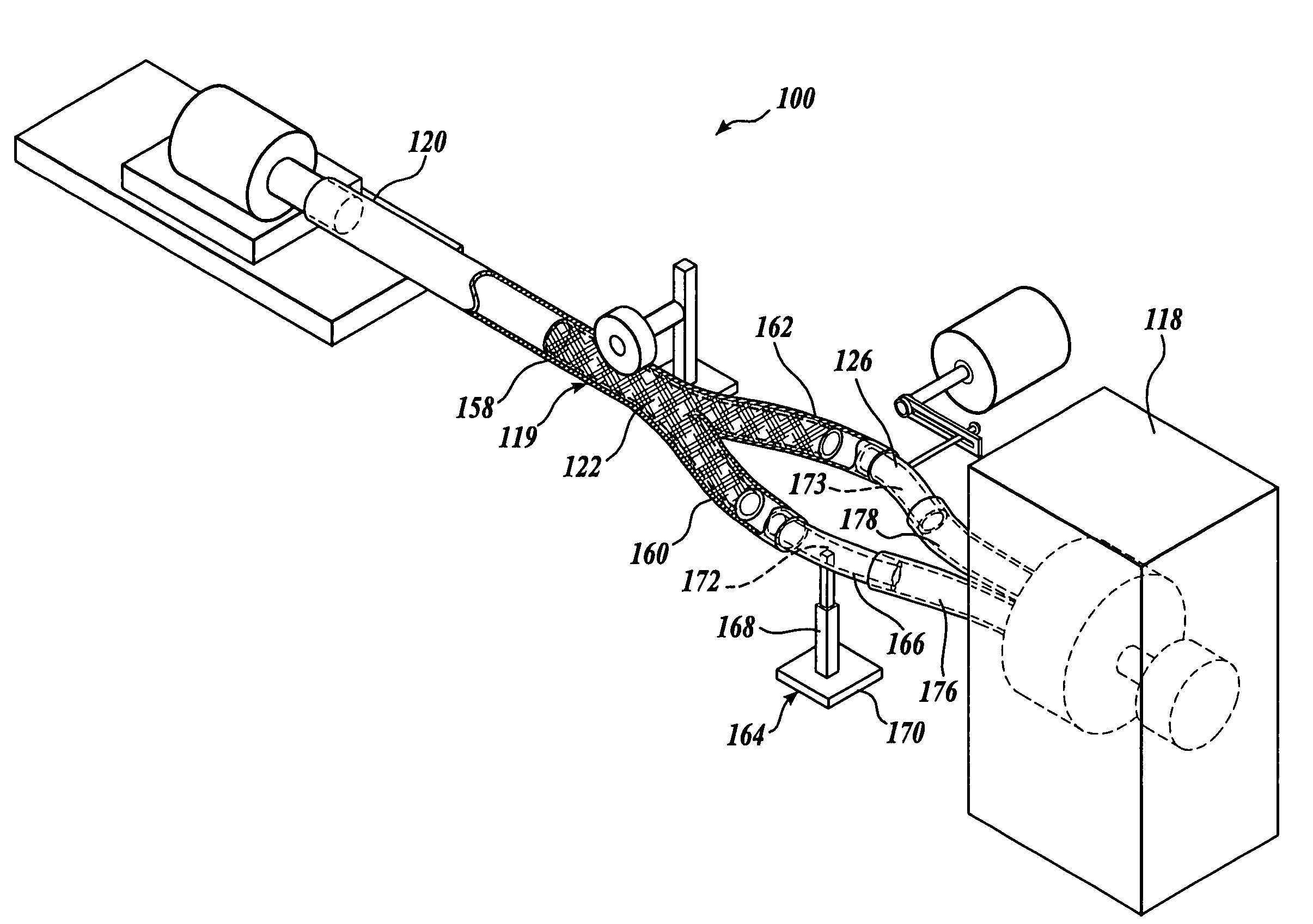

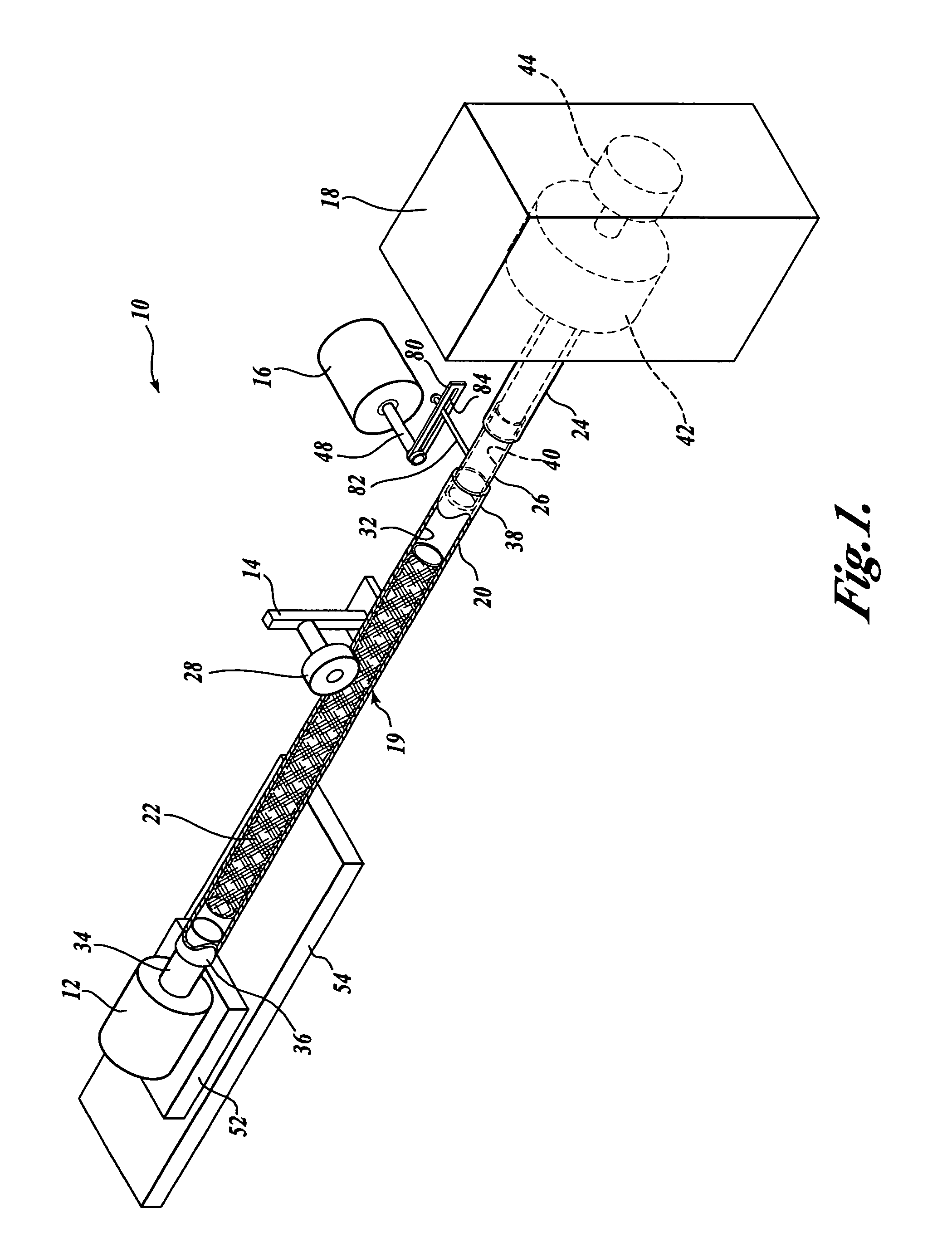

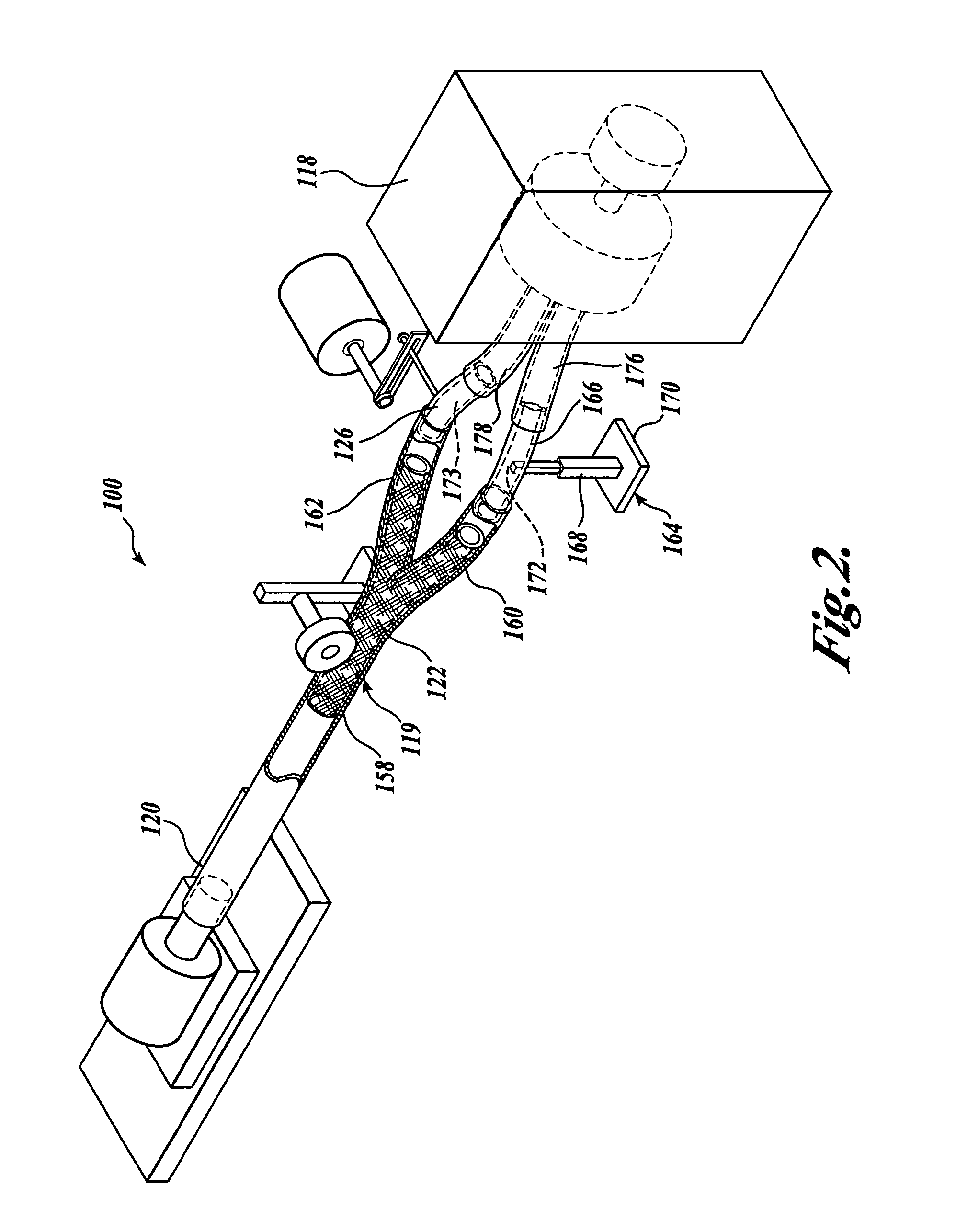

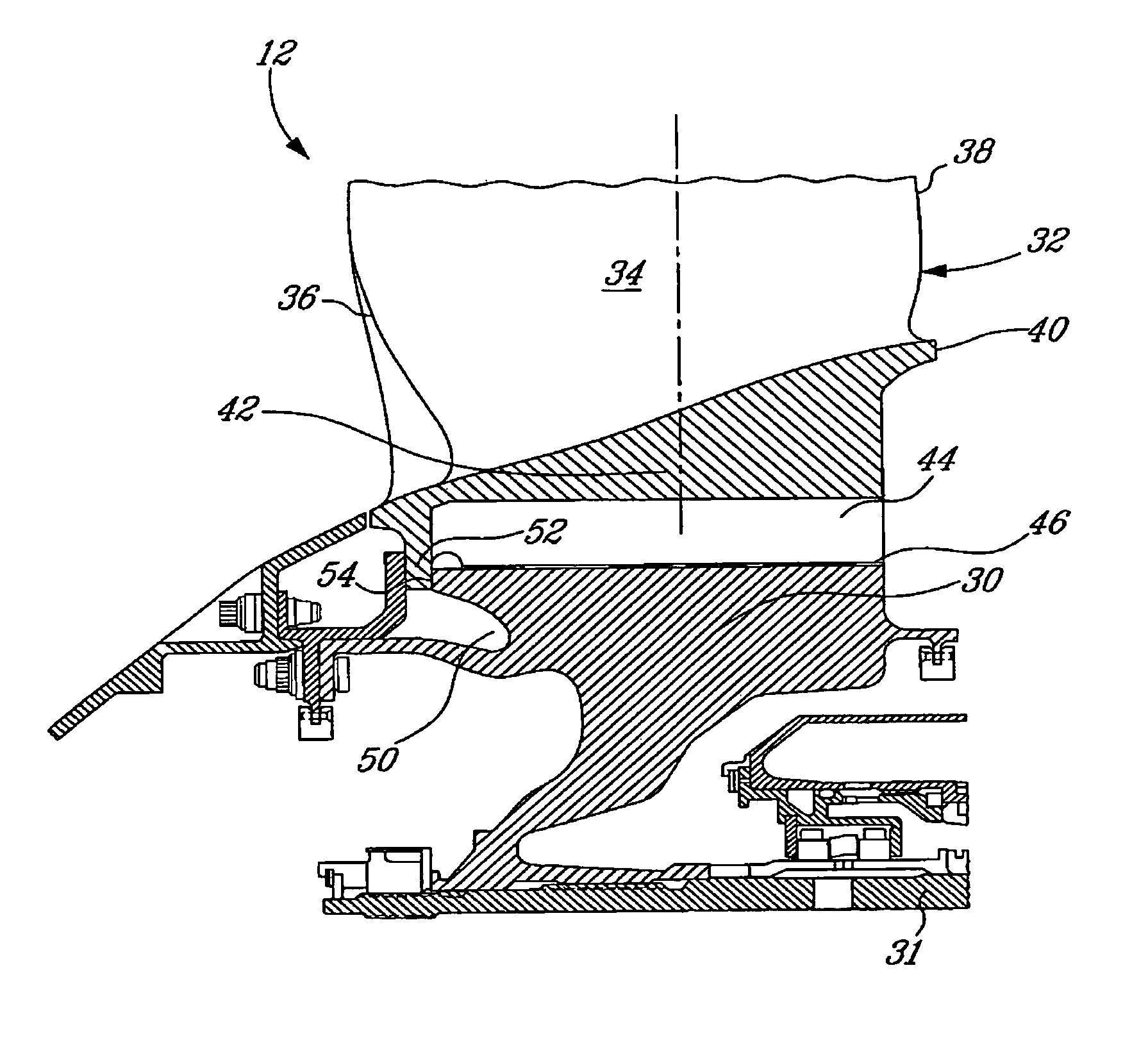

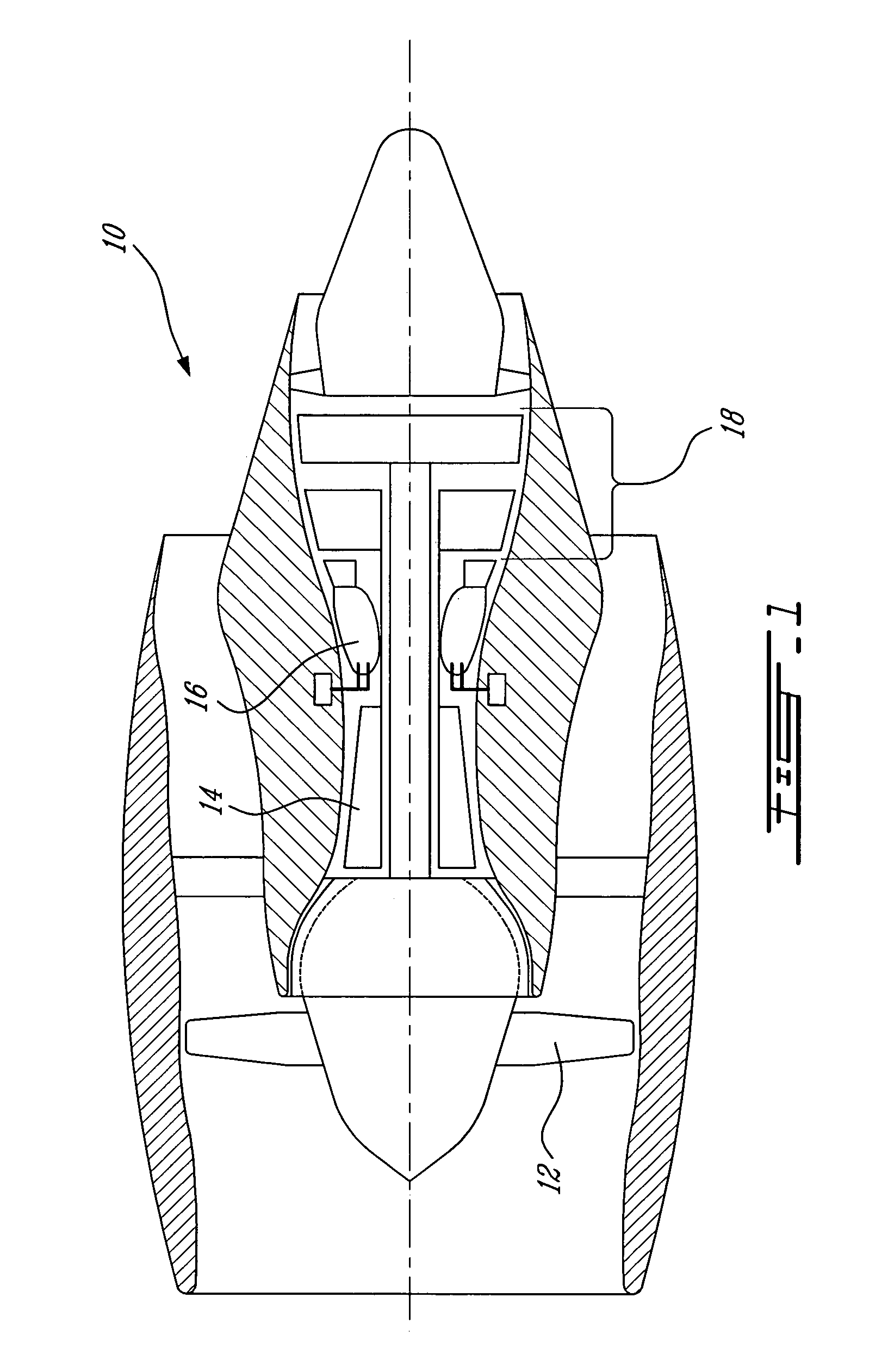

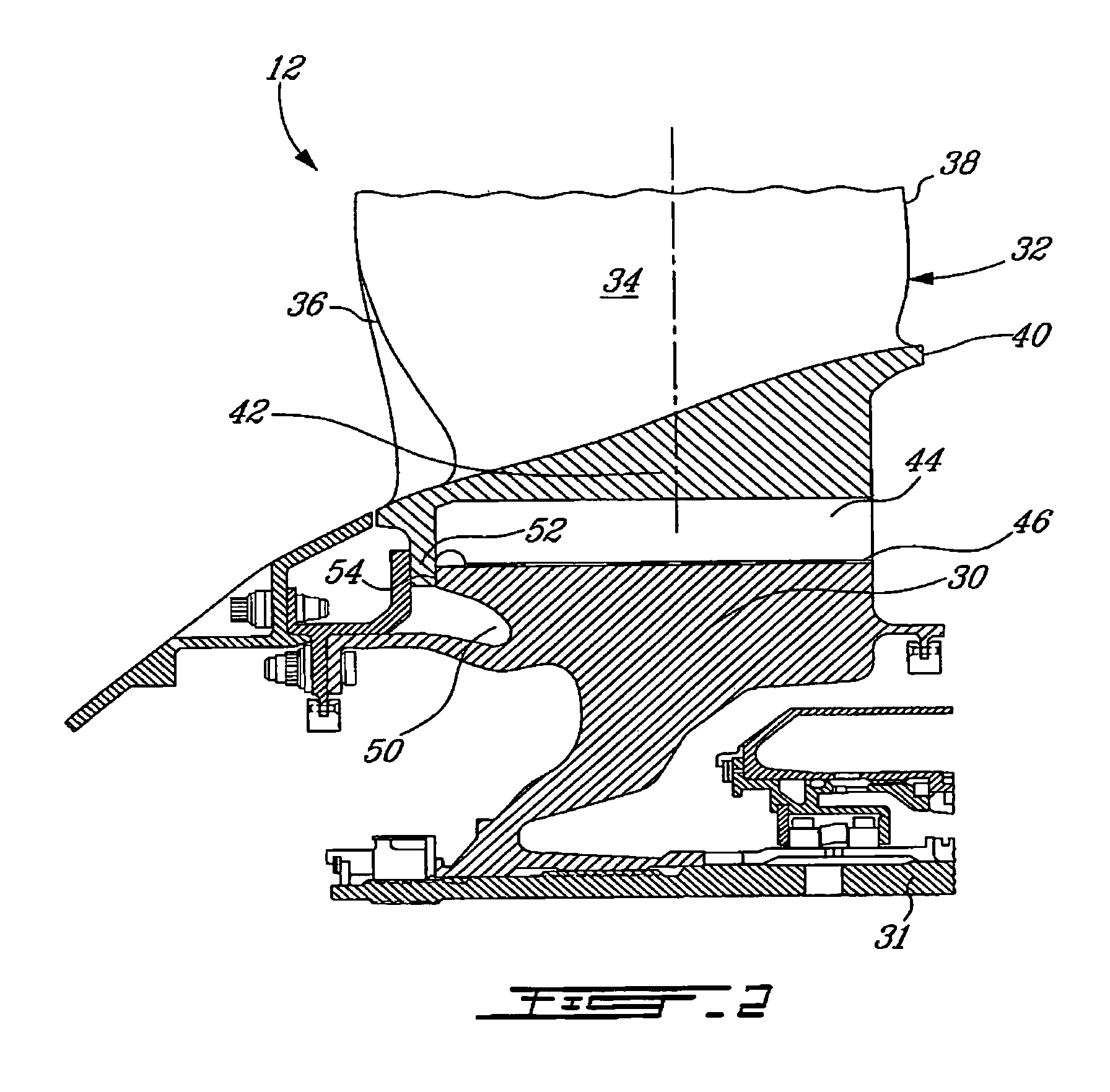

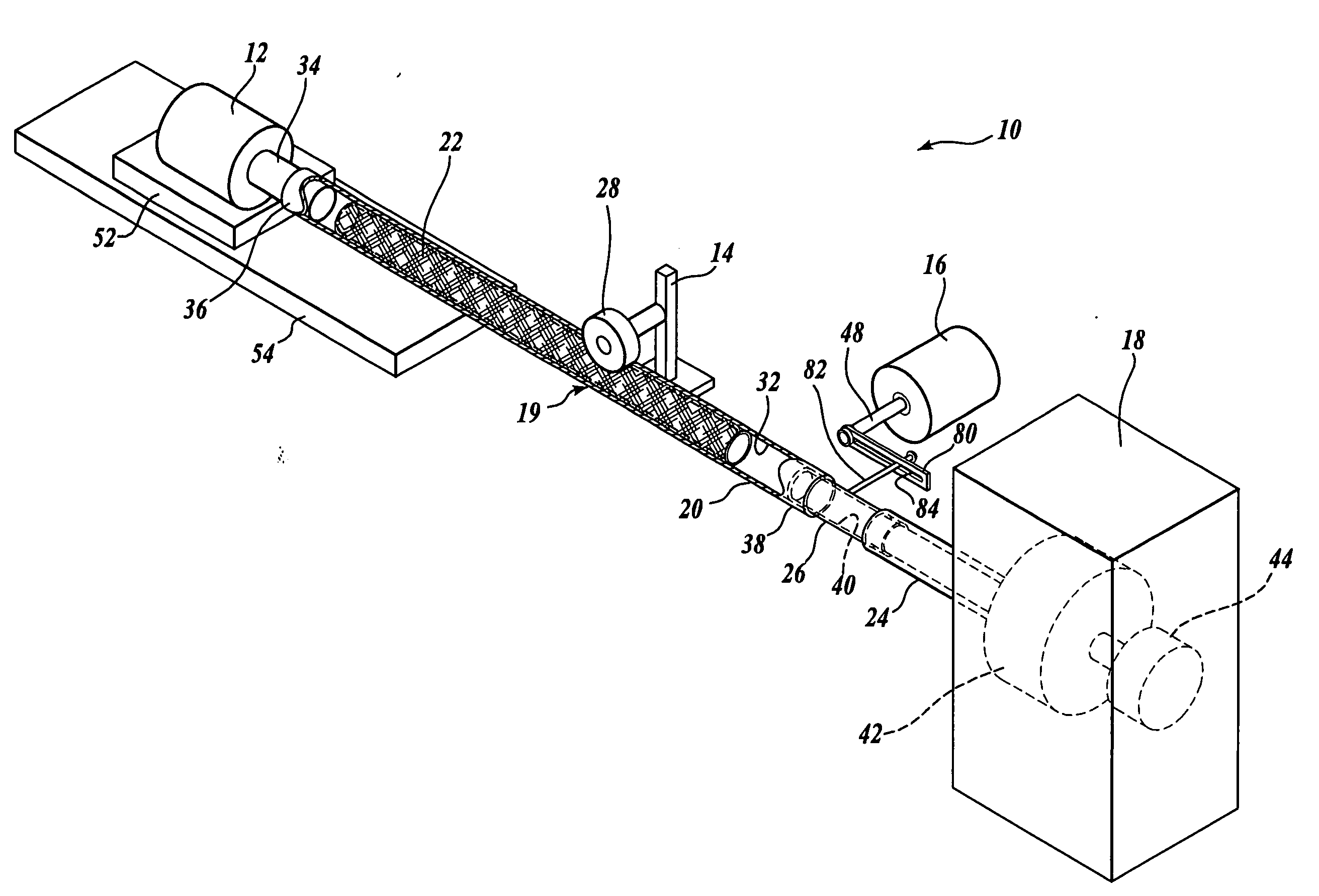

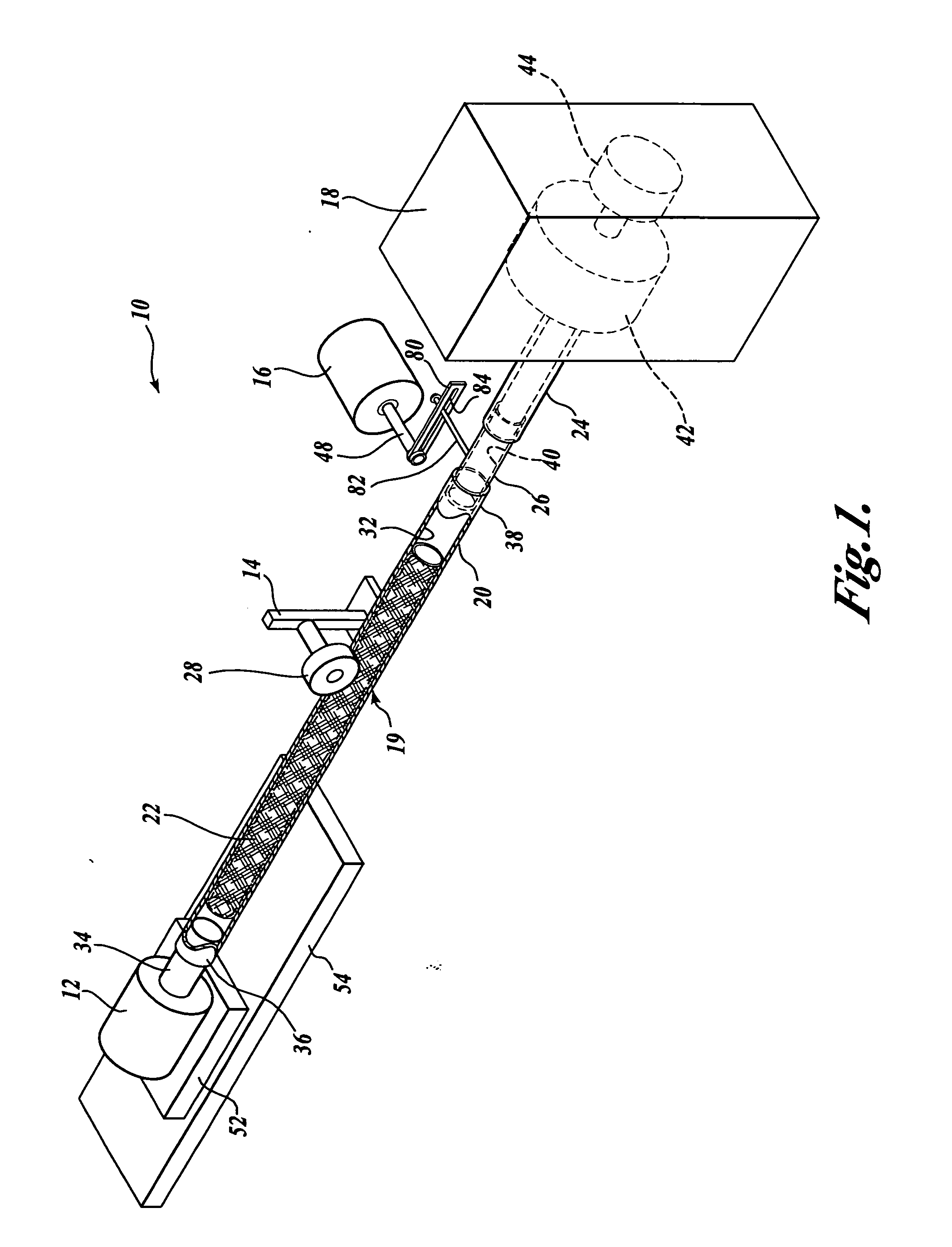

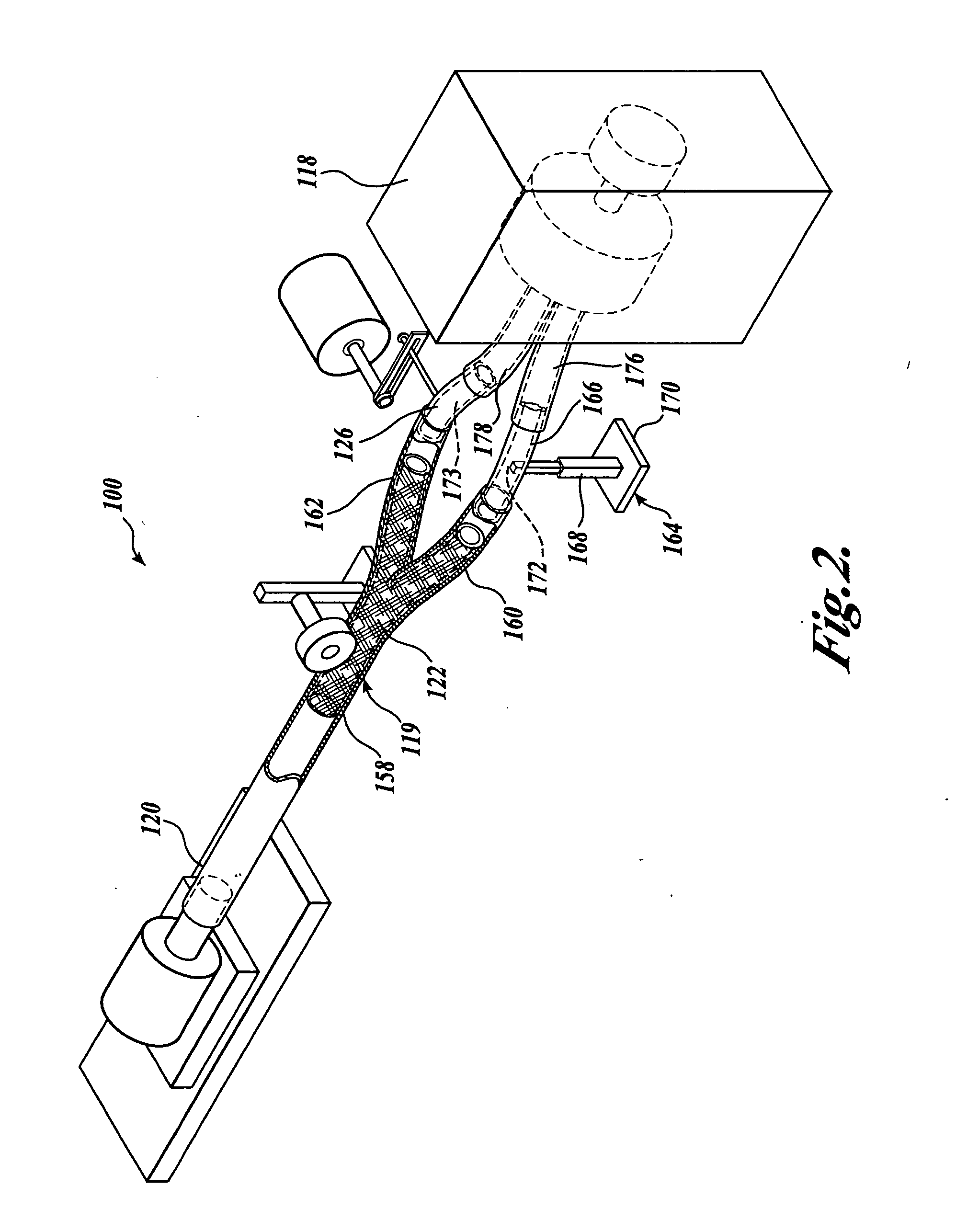

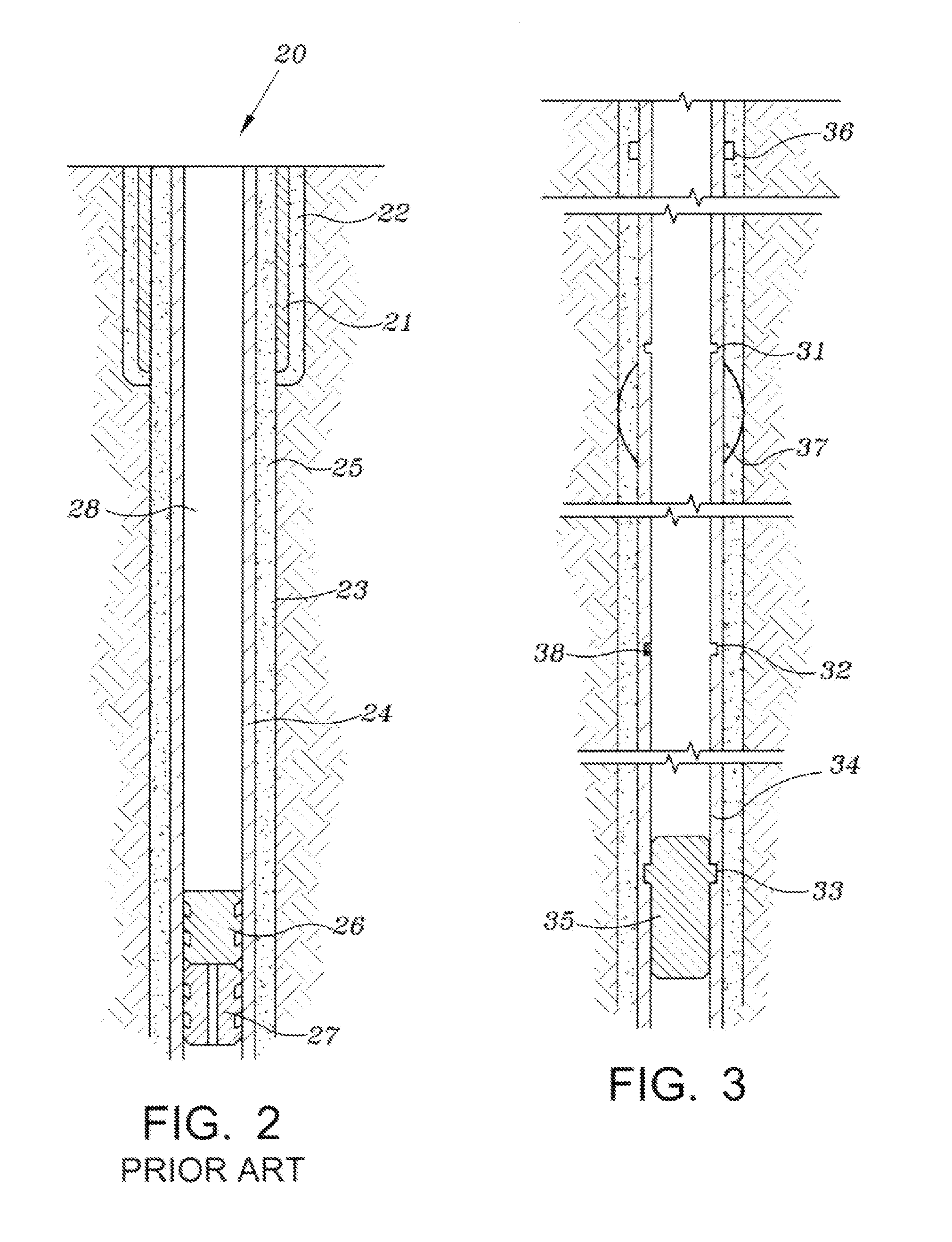

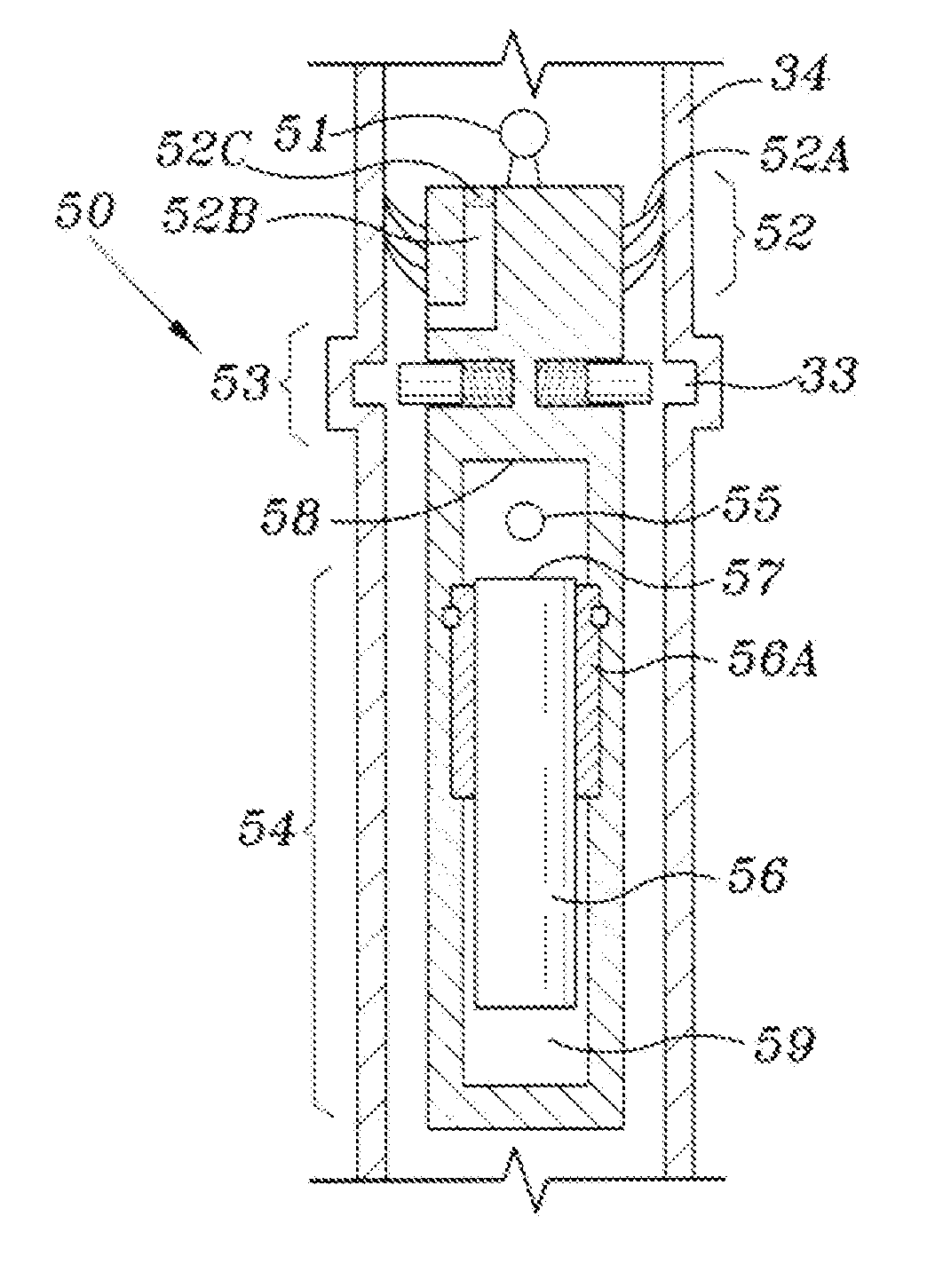

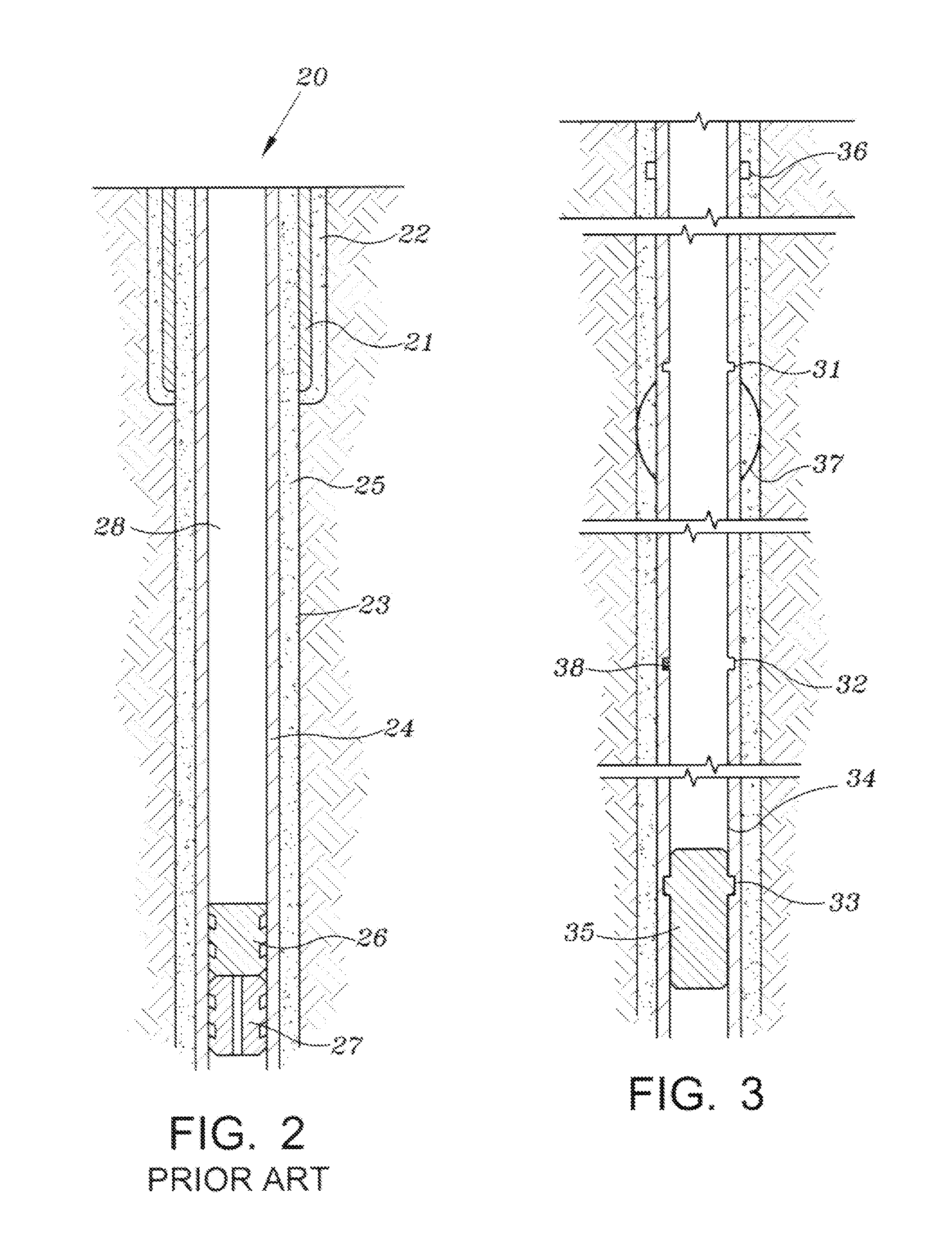

Method and apparatus for vascular durability and fatigue testing

A vascular prosthesis tester (10) for inducing stresses upon a vascular prosthesis (22) having a channel extending through the vascular prosthesis is disclosed. The tester includes a pump (18) adaptable to pressurize a fluid disposed within the channel to induce a radial stress upon the vascular prosthesis. The tester may further include a bend applicator (16) operable to induce a bending stress, a torque applicator (12) operable to induce a torque, a linear force applicator (52) operable to induce a linear force, and / or a stop (28) for inducing a lateral push stress upon the vascular prosthesis. A method of fatigue testing a vascular prosthesis contained within a fluid conduit is also disclosed. The method includes injecting a fluid within the inner channel and inducing a torque, bending stress, linear stress, and / or later push stress upon the vascular prosthesis.

Owner:TA INSTR WATERS LLC

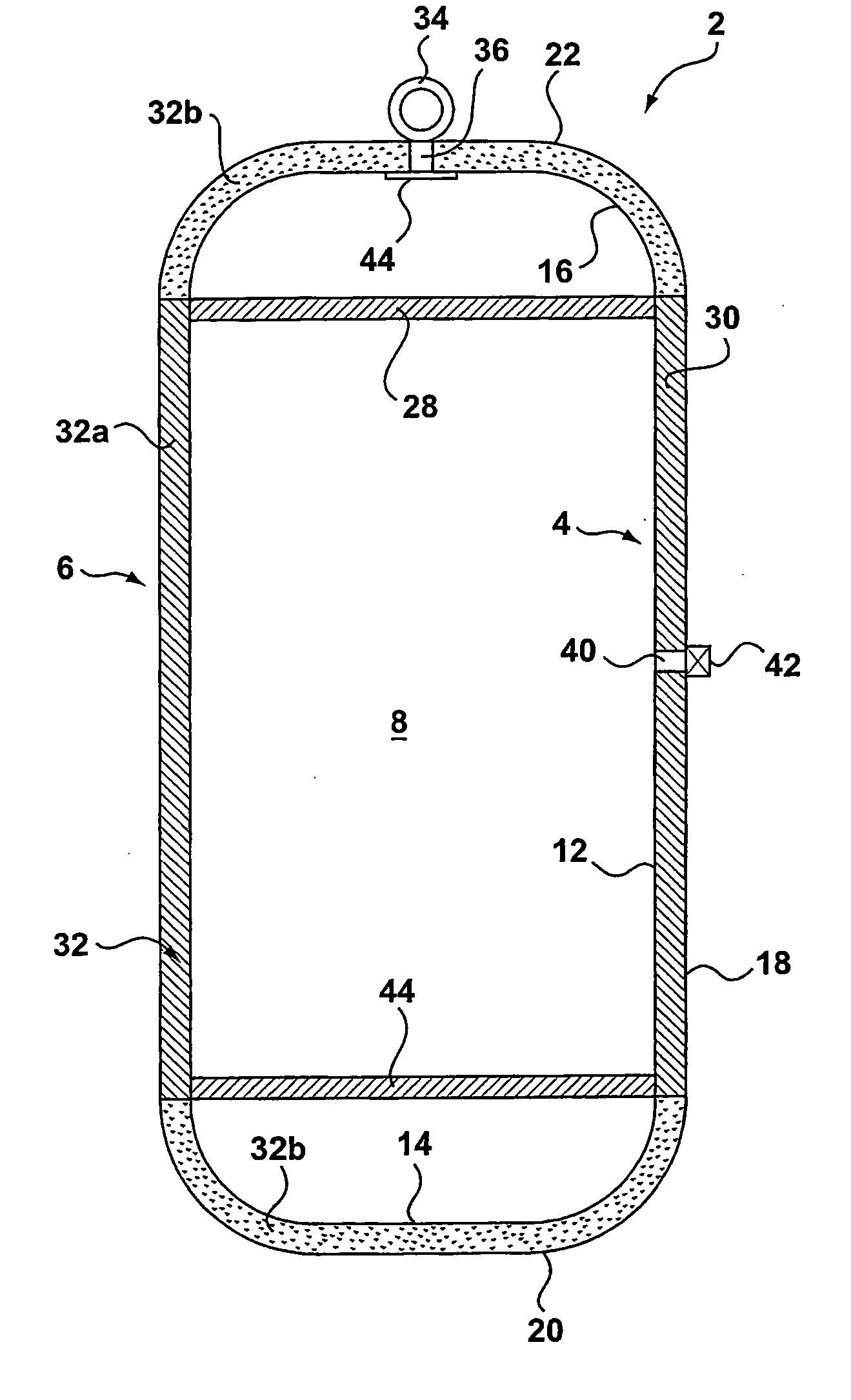

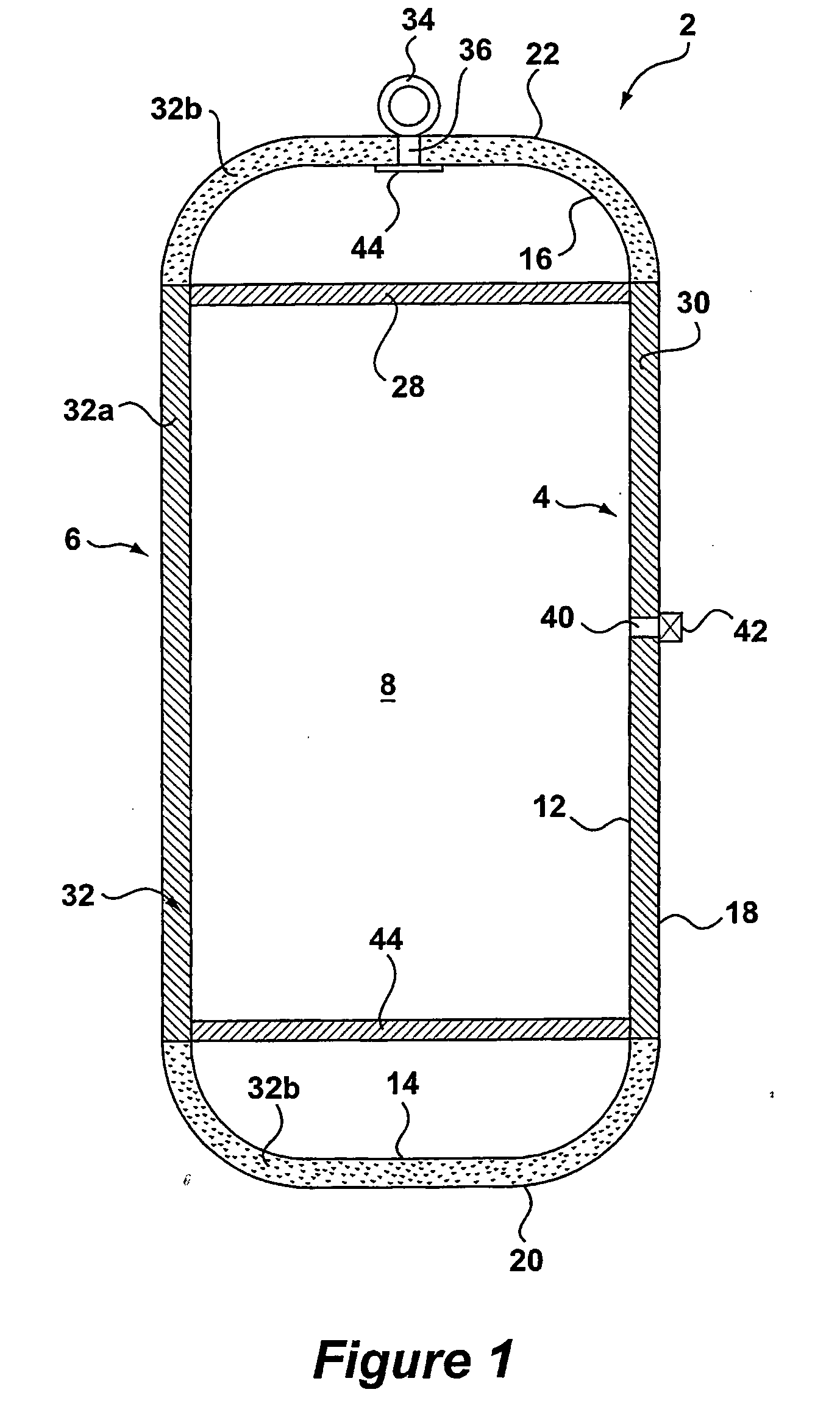

Underwater enclosure apparatus and method for constructing the same

InactiveUS20060159523A1Low curing temperatureMore temperaturePipe laying and repairNon-magnetic metal hullsRadial stressHydrostatic pressure

Apparatus for providing an enclosure, for example as a housing or to provide buoyancy, at underwater locations is disclosed comprising an inner shell and an outer shell, with a structural filler disposed between the two. The shells are prepared from fibre-reinforced plastic, with the fibres being oriented to provide resistance to both longitudinal and radial stresses induced in the apparatus by the hydrostatic pressure. The filler may be a structural filler comprising structural members extending between the inner and outer shells and occupying less than 60% of the volume of the cavity between the two shells. Alternatively, the filler may be a substantially void-free structural filler, such as a polyester resin. Methods of fabricating the apparatus are disclosed. In addition, a method of deballasting a buoyancy module is disclosed, in which the ballast, for example water, is withdrawn from the module by means of reduced pressure. Apparatus for deballasting is also disclosed.

Owner:COOPER CAMERON CORP

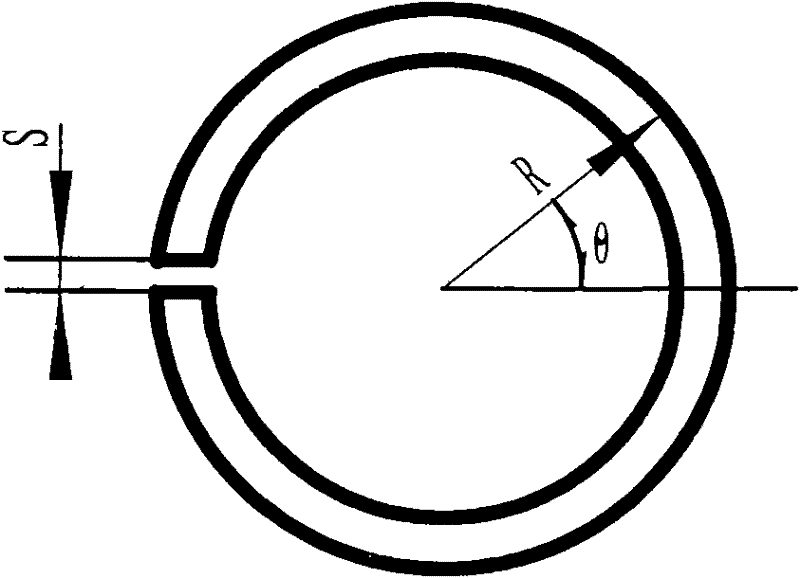

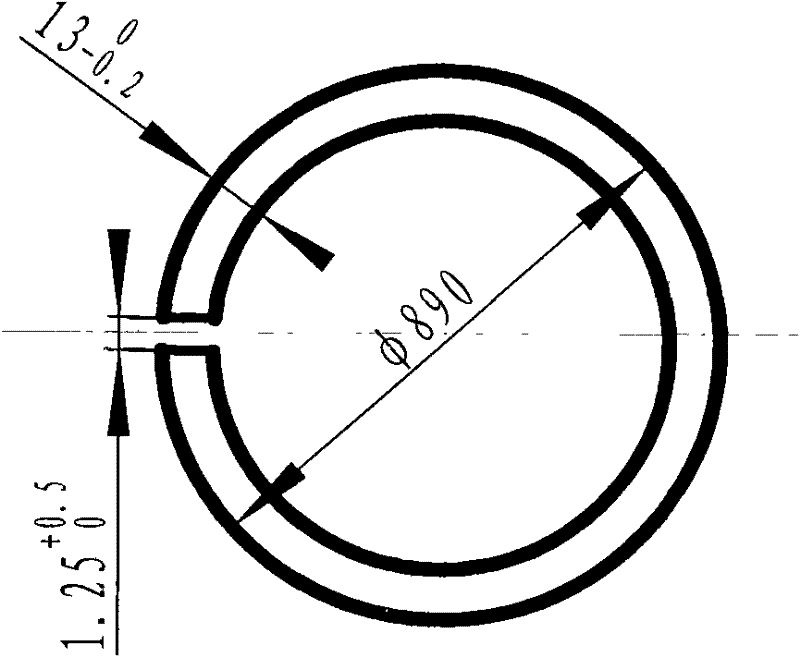

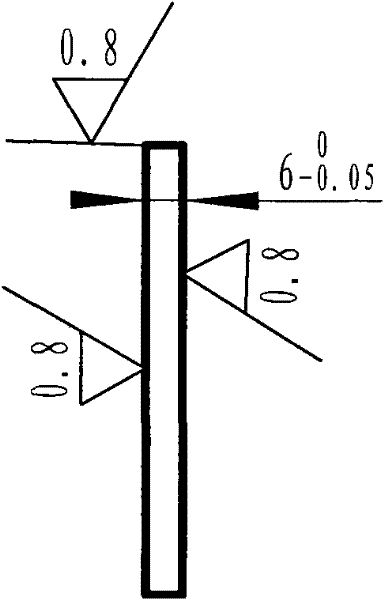

Method for manufacturing large elastic obturating piston ring

The invention belongs to the field of machining process and discloses a method for manufacturing a large elastic obturating piston ring. The method comprises the following steps: (1), turning the outer diameter, inner diameter and thickness of the product through a lathe; (2), drilling a process compression hole through a drilling machine; (3), performing semi-finish turning to the thickness through the lathe; (4), conducting heat treatment; (5), grinding the thickness plane through a grinding machine; (6), cutting an inner circle, an outer circle and an opening through a linear cutting machine; (7), performing external grinding through the grinding machine; and (8), grinding an inner hole through the grinding machine. The invention has the benefits that the method for manufacturing the large elastic obturating piston ring with the pressure-equalizing radial sealing ring structure is devised; the deformation law of roughly machining the contour under the state without radial stress and the influence to the profile tolerance and the opening dimension of the piston ring during the process of finely machining the inner circle and the outer circle under the radial stress state are discovered; the difficult process problems that the structure rigidity of parts is poor, the machining deformation is easily caused, and the machining accuracy of the parts is affected are solved; and the method fills the gap in China.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

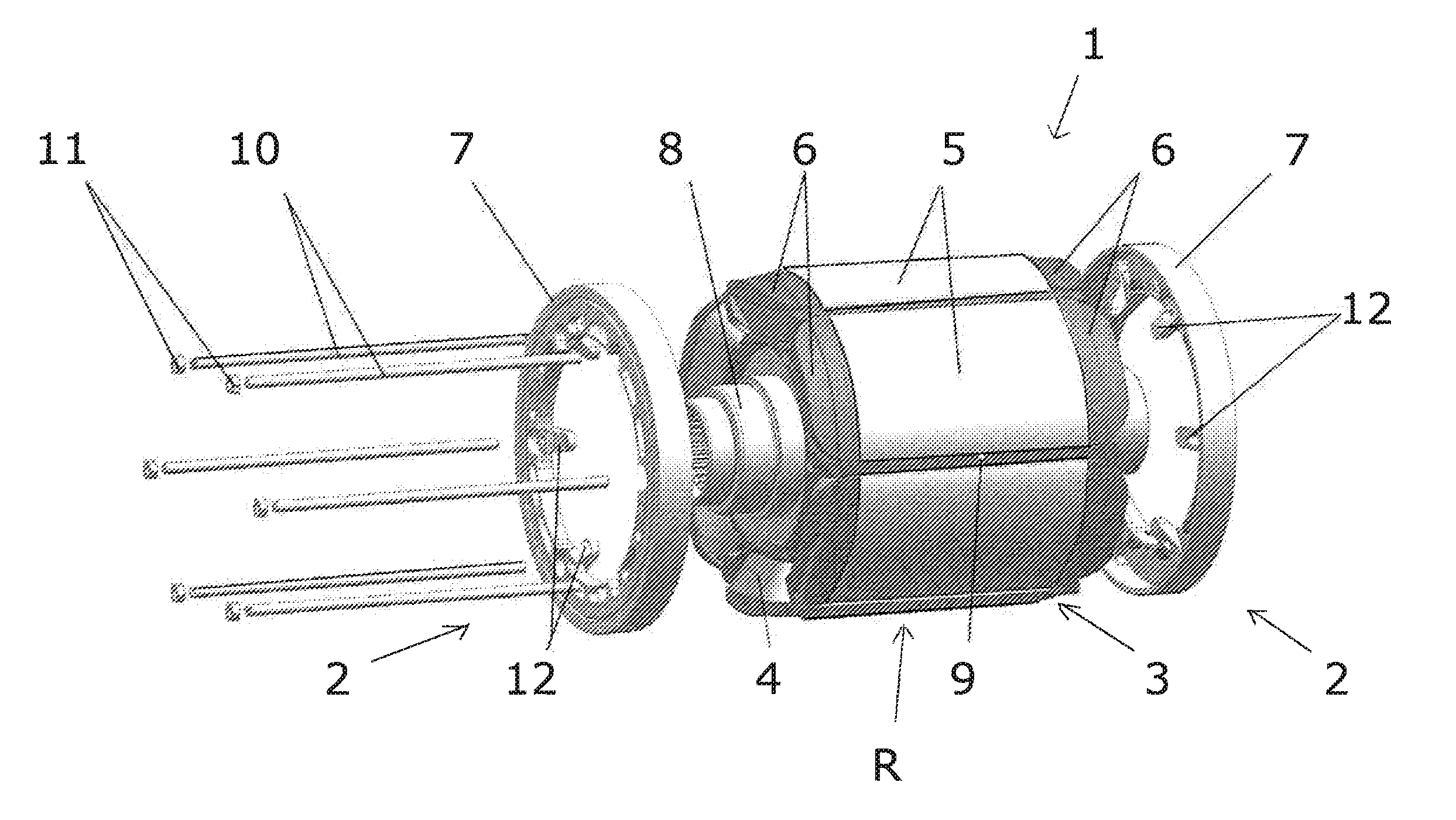

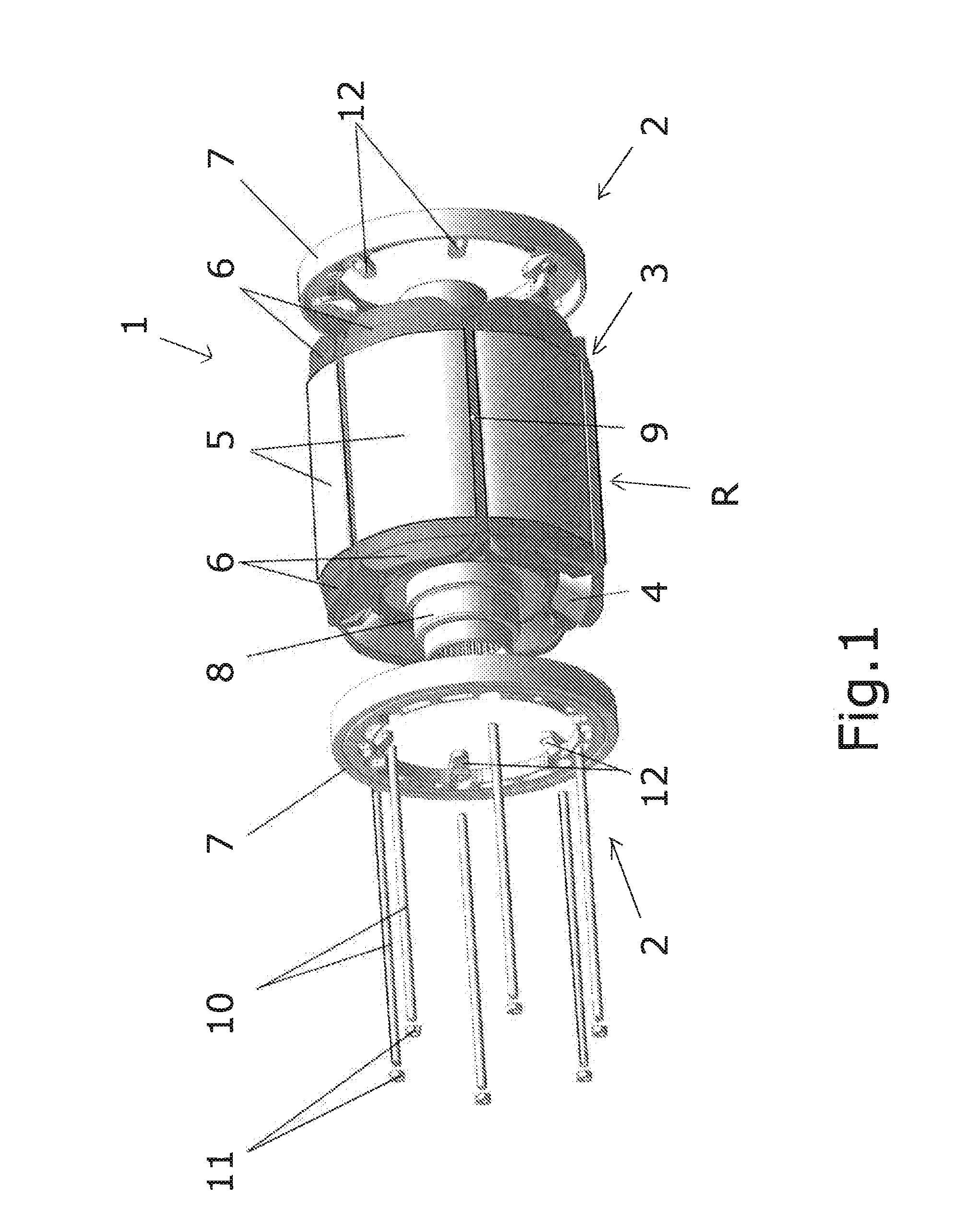

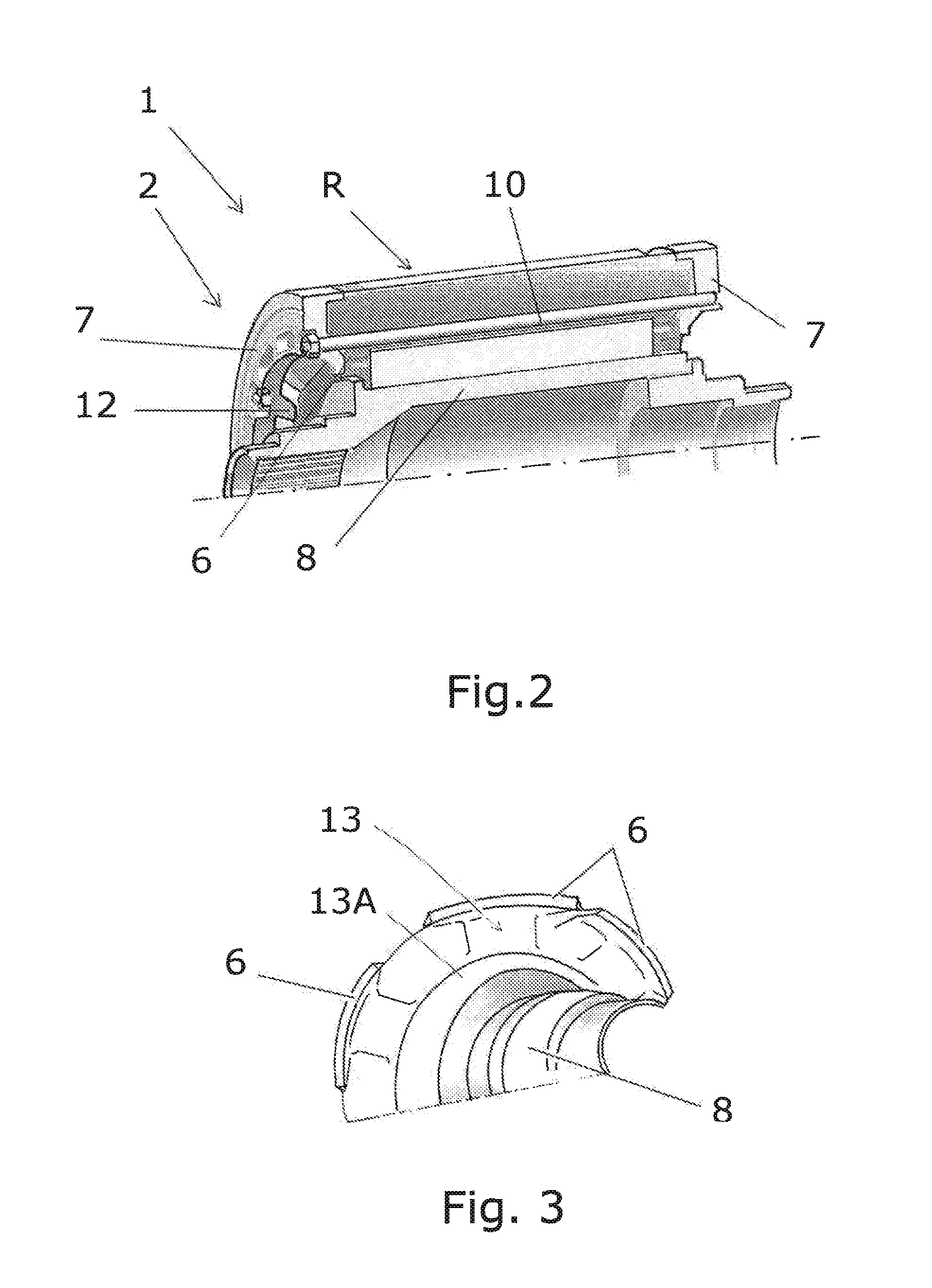

Rotor for electrical machine, in particular for a synchronous motor

InactiveUS20130106211A1Increase speedSynchronous generatorsWindings insulation shape/form/constructionRadial stressSynchronous motor

Electrical machine rotors (R) suited for synchronous motors of electric vehicle drives. A rotor (R) includes a rotor shaft (8), a sheet stack (3), windings, and a restraining system (2) with support elements. The support elements of the restraining system include support rings (7) to protect winding heads (4) projecting from the sheet stack (3) in the axial direction against radial stresses. The elements of the restraining system (2) protecting the winding heads (4) from stresses also include axially inner end caps (6) configured as supports for the finished winding heads (4) in the operating state, and as guides and supports during the winding of the pole windings of the rotor (R) about the axial edge of the sheet stack (3). The axially outer support rings (7) cooperate with the axially inner end caps (6) so that the support rings (7) may absorb centrifugal forces acting on winding heads (4) end caps (6).

Owner:BRUSA ELECTRONICS AG

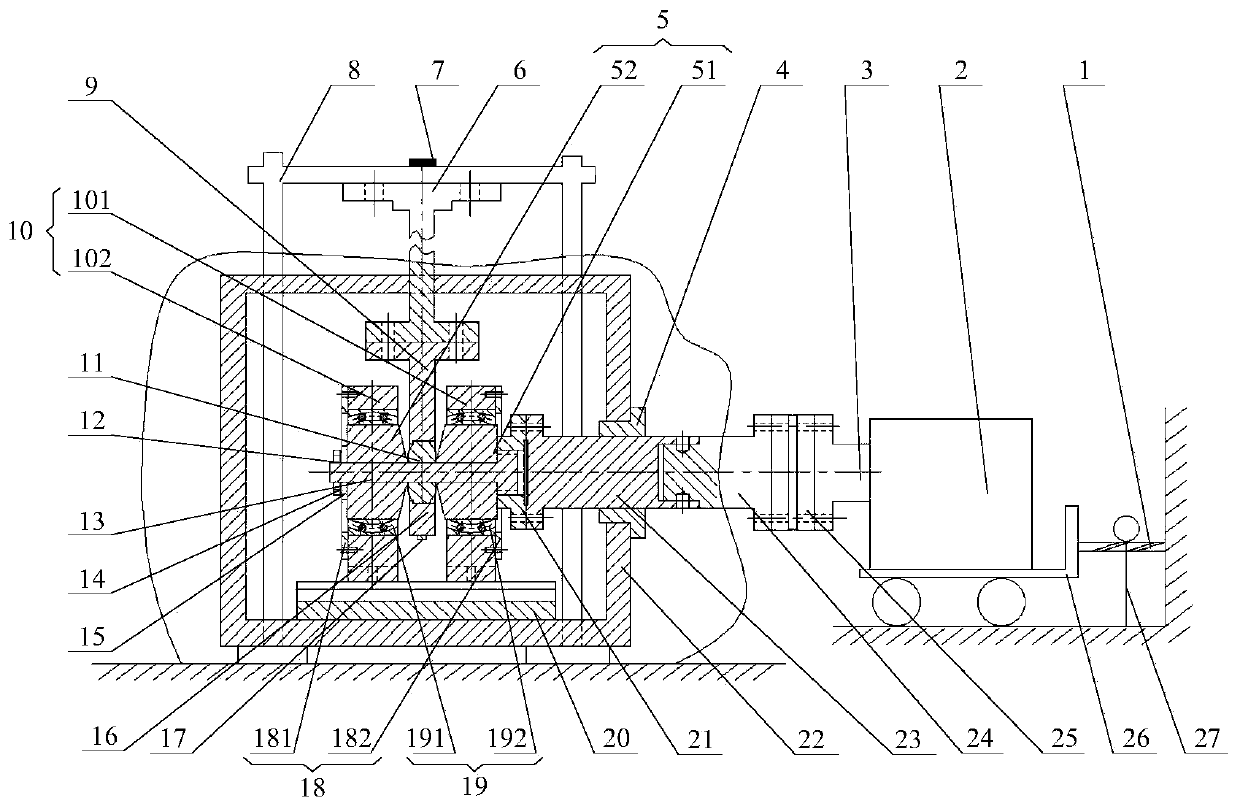

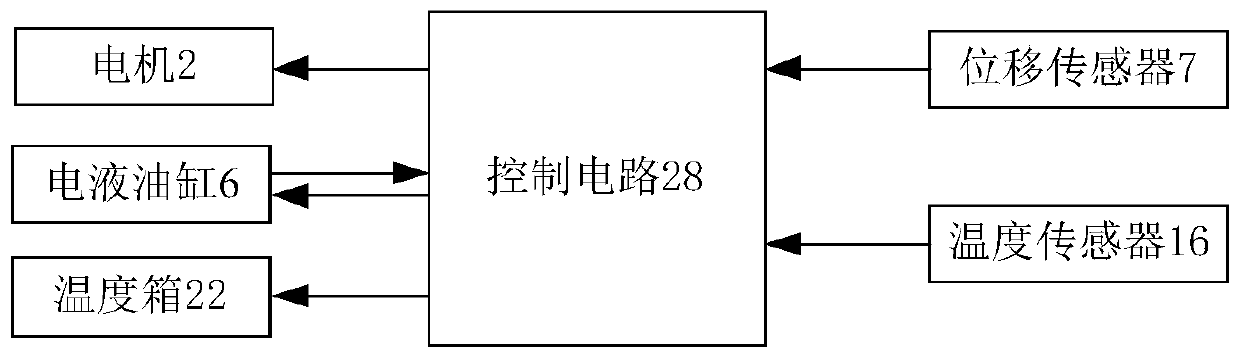

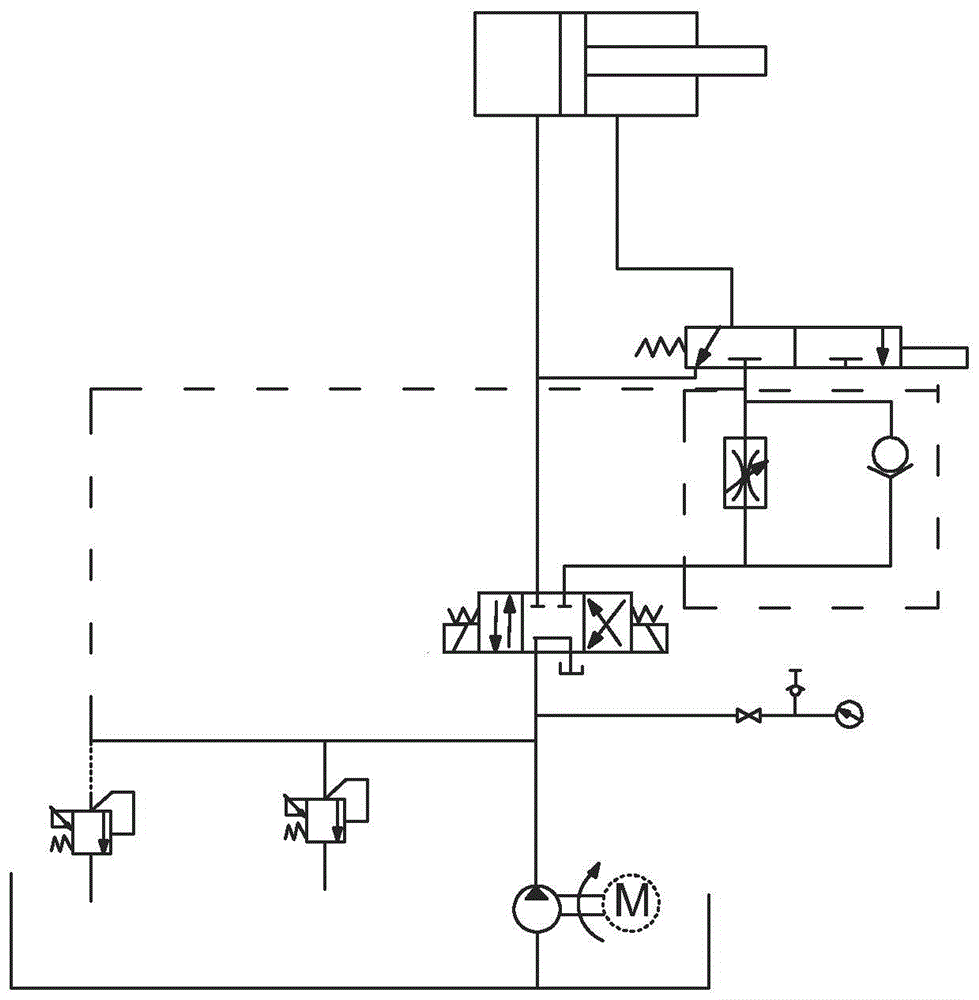

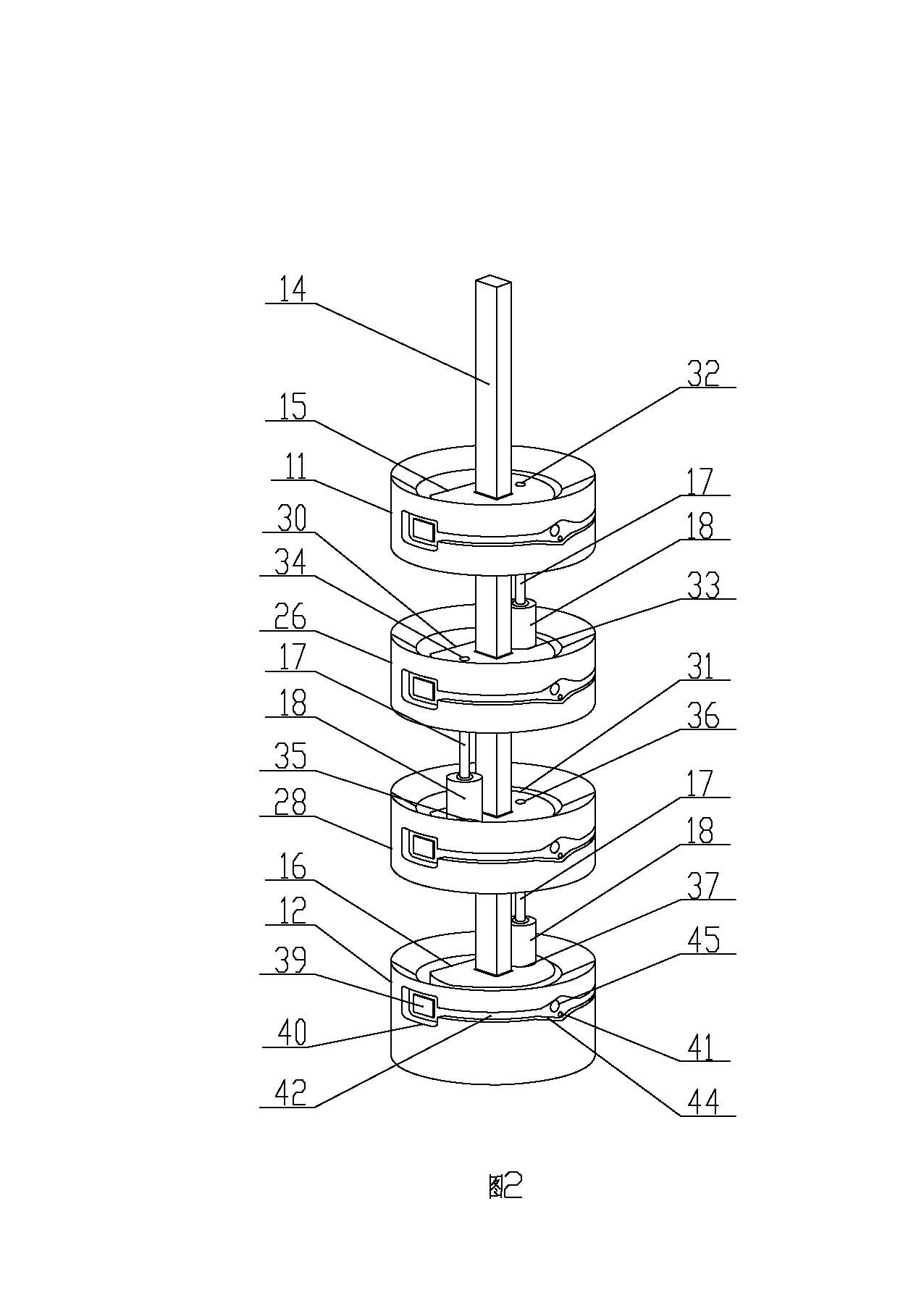

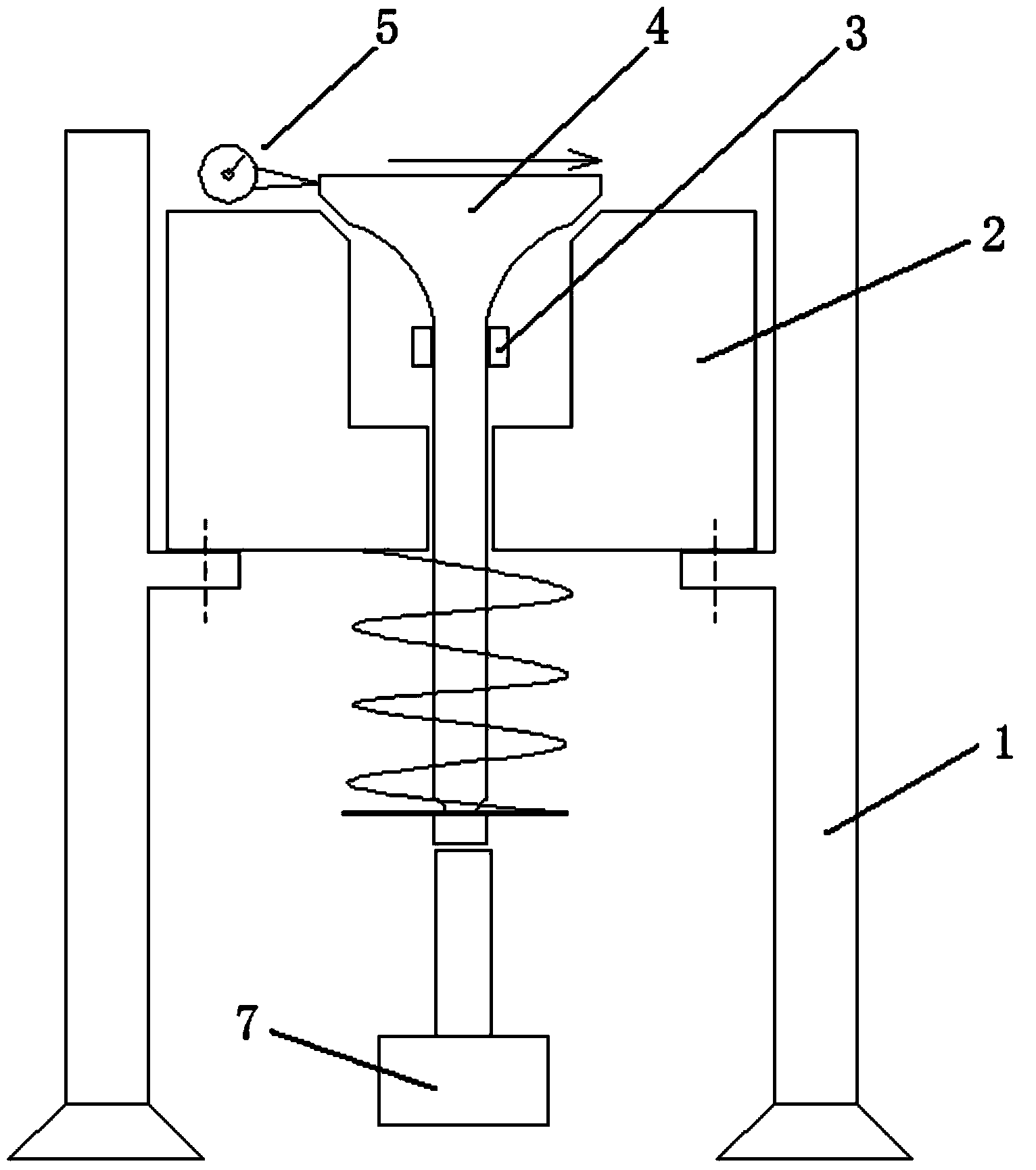

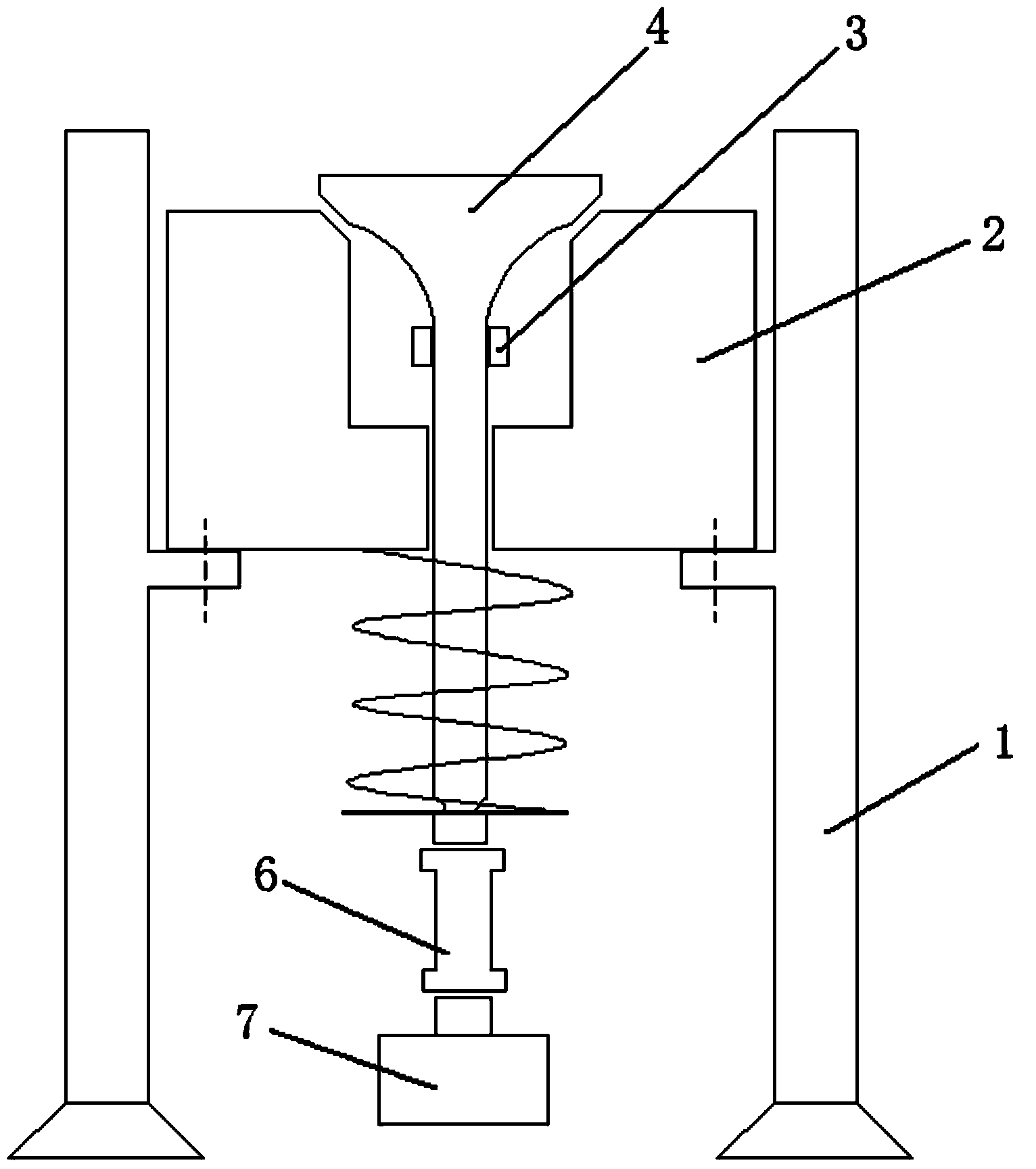

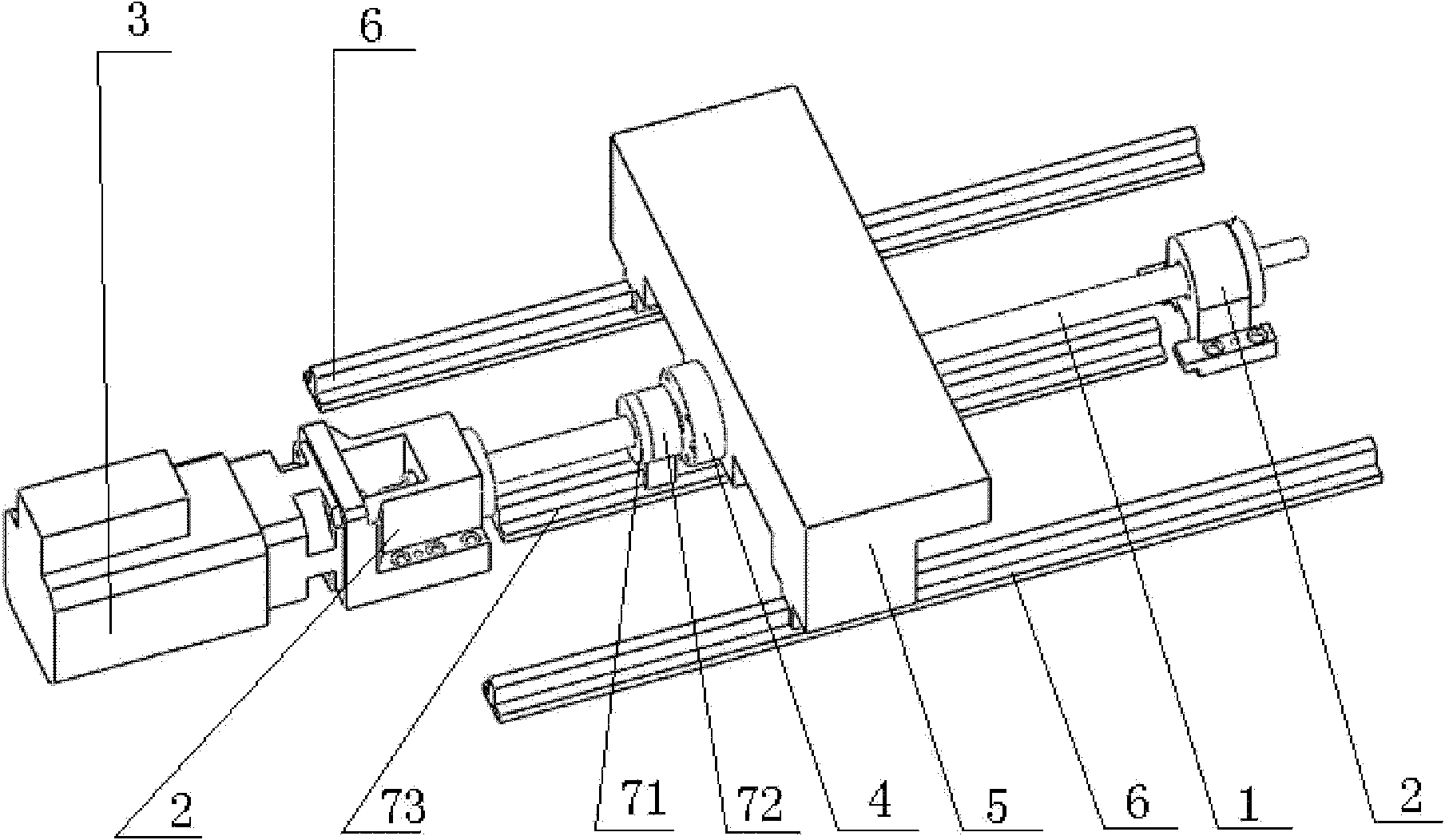

Joint bearing low-temperature wear test system and assembly method thereof

ActiveCN110243602AEasy to disassembleImprove general performanceMachine bearings testingInvestigating abrasion/wear resistanceTemperature controlRadial stress

The invention provides a joint bearing low-temperature wear test system. The system comprises a base, a temperature box, a radial stress subsystem, a power subsystem, a temperature control subsystem, a wear measurement subsystem and a clamp subsystem. The clamp subsystem comprises a pushing block, a loading plate, an accompanying test bearing seat, a mandrel, an accompanying test bearing, an end cover and a locking part, which are independent detachable parts; the mandrel, the pushing block or the loading plate can be replaced to realize clamping in a life test of joint bearings with different diameters, so that the utilization rate and the universality of a test clamp are improved; and in addition, the clamp subsystem adopts the structural design improvement that a single-side flange is added to an inner hole of the loading plate, the thickness of the pushing block is reduced, the flange and the end cover cooperatively fix the accompanying test bearing, and the like, so that the mandrel deformation or breakage easily caused in the joint bearing wear test process is effectively avoided.

Owner:CHINA AERO POLYTECH ESTAB

Bladed disk fixing undercut

An undercut is provided in a gas turbine engine disk to smooth out an uneven axial distribution of radial stress in the disk. The undercut is defined radially inwardly of the blade attachment slots provided at the periphery of the disk.

Owner:PRATT & WHITNEY CANADA CORP

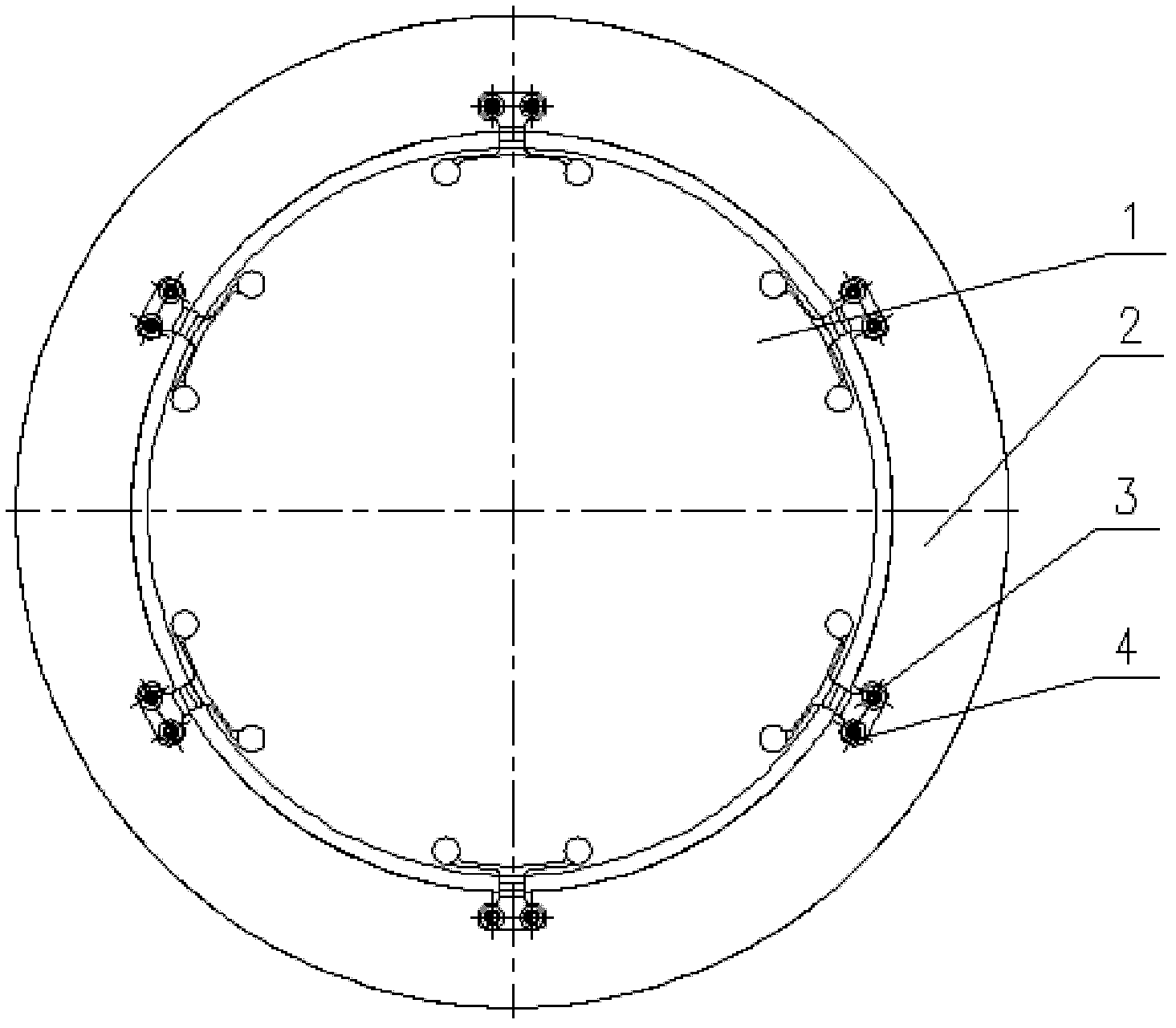

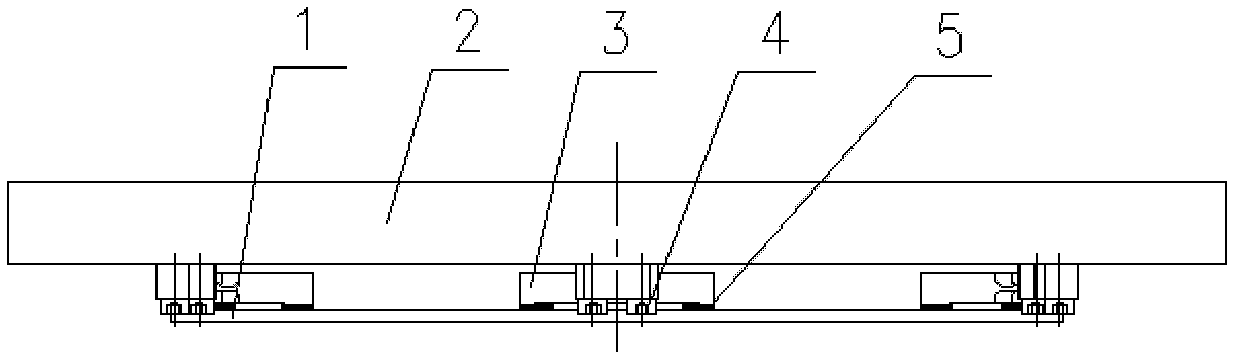

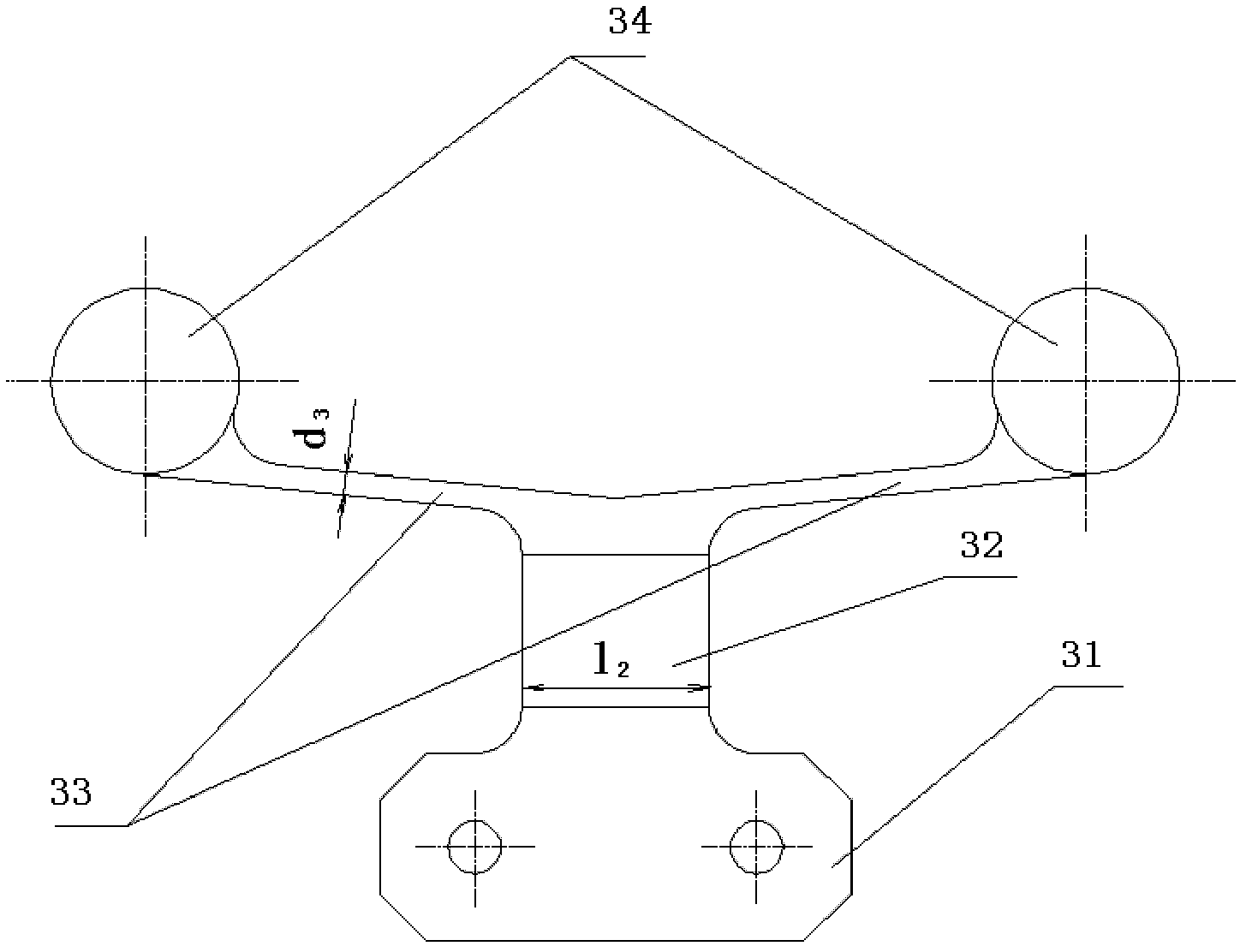

Spatial flexible filter supporting mechanism and method for mounting filter

The invention relates to a spatial flexible filter supporting mechanism, which comprises a mirror seat and at least three flexible supporting pieces, wherein each flexible supporting piece consists of a fixed end, an axial stress unloading part, a radial stress unloading part and an adhesive boss; the fixed ends are connected with the mirror seat through screws; the axial stress unloading parts are positioned between the fixed ends and the radial stress unloading parts; the adhesive bosses are arranged at the ends of the radial stress unloading parts; the part of the filter, which is close to the rim, is adhered with the adhesive bosses through adhesives; and the gravity of the filter is positioned in a polygon consisting of the adhesive bosses. The structural stress resistance and the thermal stress resistance of the filter supporting mechanism are improved; due to the flexible shock absorption function, the filter supporting structure can resist the impact shock at a rocket launch section, and can be used in the fields of designing aerospace and aviation filter supporting structures, designing structures of optical active supporting mirrors, designing structural shock absorption and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method and apparatus for vascular durability and fatigue testing

A vascular prosthesis tester (10) for inducing stresses upon a vascular prosthesis (22) having a channel extending through the vascular prosthesis is disclosed. The tester includes a pump (18) adaptable to pressurize a fluid disposed within the channel to induce a radial stress upon the vascular prosthesis. The tester may further include a bend applicator (16) operable to induce a bending stress, a torque applicator (12) operable to induce a torque, a linear force applicator (52) operable to induce a linear force, and / or a stop (28) for inducing a lateral push stress upon the vascular prosthesis. A method of fatigue testing a vascular prosthesis contained within a fluid conduit is also disclosed. The method includes injecting a fluid within the inner channel and inducing a torque, bending stress, linear stress, and / or later push stress upon the vascular prosthesis.

Owner:TA INSTR WATERS LLC

Method and Apparatus for Maintaining Pressure In Well Cementing During Curing

Method and apparatus are provided for cementing wells and preventing fluid entry into the wellbore before the cement cures and increasing radial stress in the cement. Impacts or vibrations are applied to the casing during the time that the cement is curing. The sources of the impacts or vibration are placed in the casing during displacement of the cement slurry and are mechanically coupled to the inside wall of the easing. The sources are later withdrawn from the casing.

Owner:COOKE JR CLAUDE E

Method and Apparatus for Maintaining Pressure In Well Cementing During Curing

InactiveUS20110290485A1Increased radial stressFluid removalVibration devicesRadial stressWell cementing

Method and apparatus are provided for cementing wells and preventing fluid entry into the wellbore before the cement cures and increasing radial stress in the cured cement. Impacts or vibrations are applied to the casing during the time that the cement is curing. The source or sources of the impacts or vibration are placed in the casing during displacement of the cement slurry or soon after placement and are mechanically coupled to the inside wall of the casing. The sources may later be withdrawn from the casing or expendable sources may be used.

Owner:COOKE JR CLAUDE E

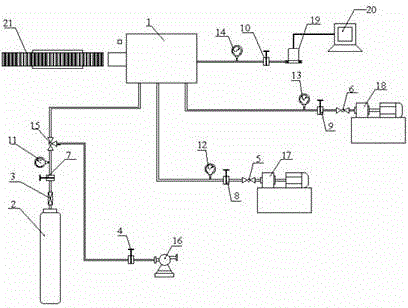

Seepage experiment system and method for gas-containing coal under action of impact load

InactiveCN104865176AReasonable structureSimple and fast operationPermeability/surface area analysisRadial stressAxial pressure

The invention discloses a seepage experiment system for gas-containing coal under the action of an impact load. The system comprises a coal sample fixing device, an impact load applying device as well as a high-pressure gas source device, an axial pressure loading device, a confining pressure loading device, a vacuumizing device and a metering and data acquisition device connected with the coal sample fixing device, wherein the impact load applying device is a split Hopkinson pressure bar device. The split Hopkinson pressure bar device is adopted to apply the impact load for simulating rock burst, three-dimensional loaded conditions of coal-rock masses in coal mine can be simulated by applying different axial stresses and radial stresses, and seepage experiment of a coal sample in a three-dimensional stress state under the action of the impact load is successfully carried out, so that the system has relatively important meaning in both theory and practice.

Owner:HENAN POLYTECHNIC UNIV

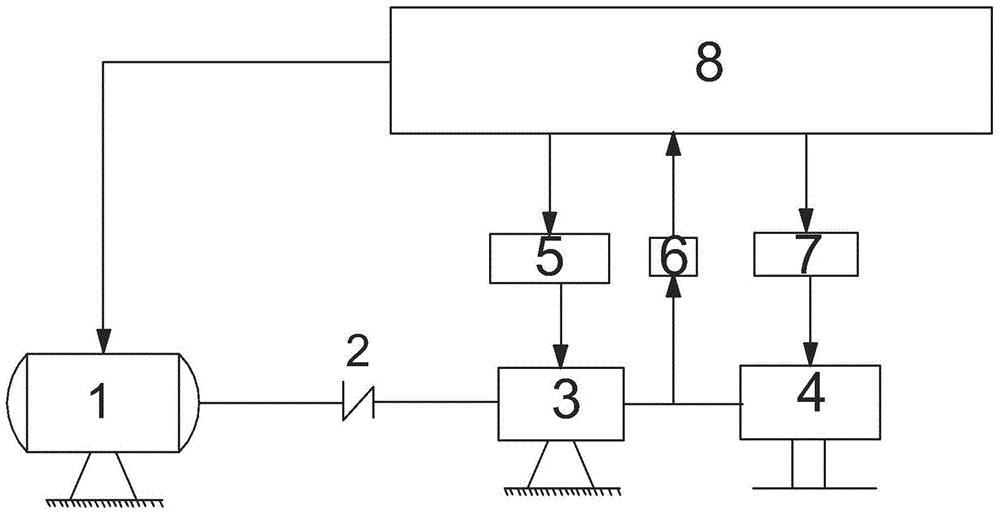

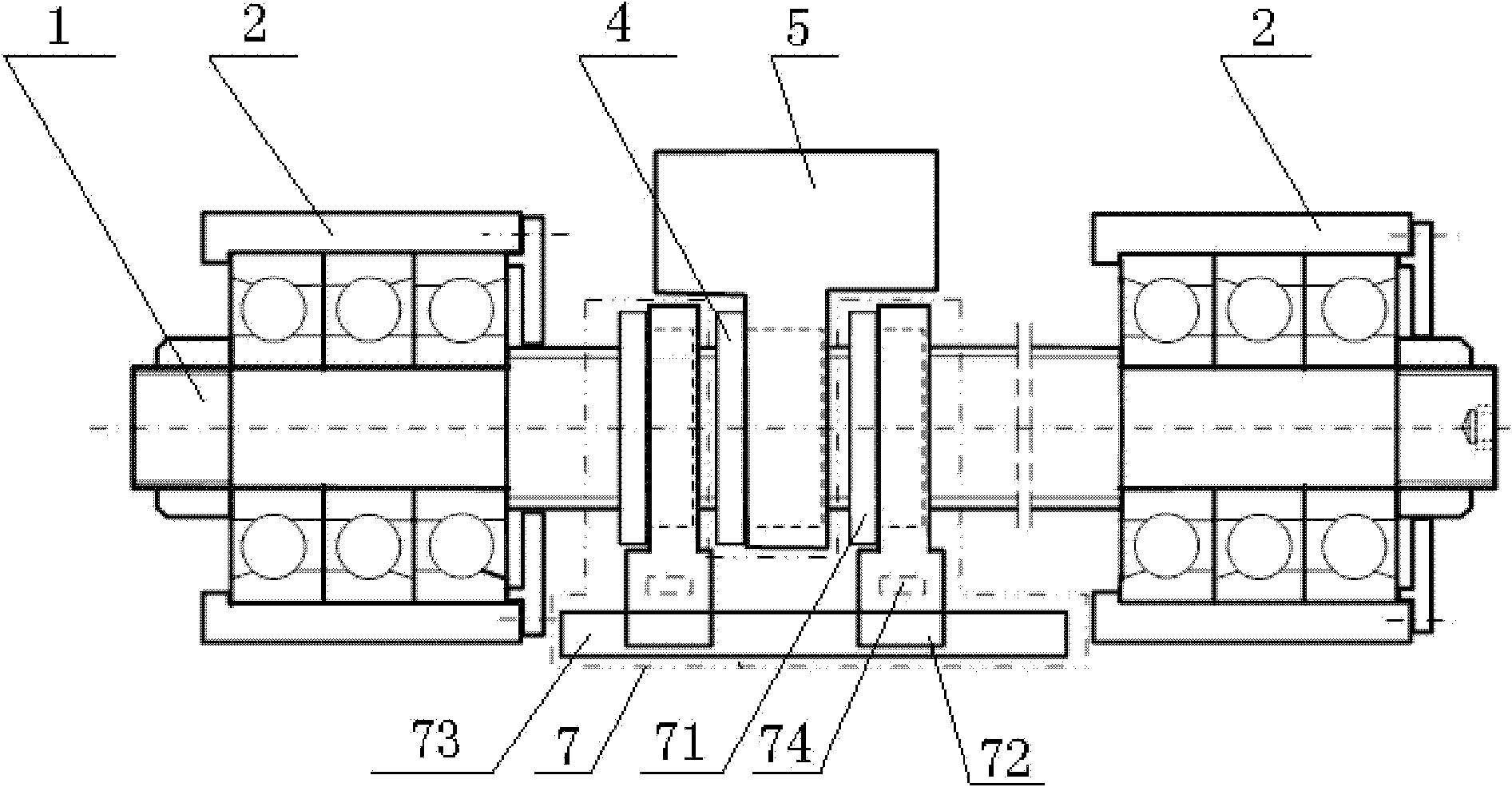

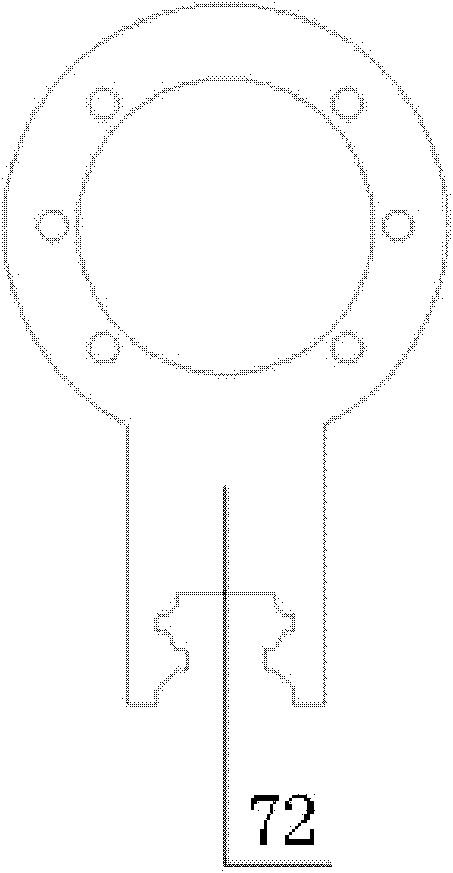

Electromagnetic hydraulic comprehensive simulation test loading device for shafting

InactiveCN104807629AThe magnetic field is stable and controllableSensitive load adjustmentMachine part testingHydraulic control unitRadial stress

The invention provides an electromagnetic hydraulic comprehensive simulation test loading device for a shafting. The electromagnetic hydraulic comprehensive simulation test loading device for the shafting comprises a prime motor and a master control unit, wherein the prime motor and the master control unit are connected with each other through a first coupling; the prime motor is used for supplying power to a test shaft to enable the test shaft to rotate; the rotation speed of the prime motor is controlled by the master control unit; the electromagnetic hydraulic comprehensive simulation test loading device for the shafting also comprises an electromagnetic torque loading device, a hydraulic force loading device, a sensor detection and feedback unit and a hydraulic control unit, wherein the electromagnetic torque loading device generates magnetic force through a direct current to supply torque to the moving test shaft, the hydraulic force loading device comprises a radial force loading device and an axial force loading device, and the sensor detection and feedback unit is used for collecting the torque applied by the electromagnetic torque loading device, force applied by the hydraulic force loading device, and the speed of the test shaft. By adopting the electromagnetic hydraulic comprehensive simulation test loading device for the shafting, which is provided by the invention, the torque, the axial stress status and the radial stress status of the test shaft in a running process can be simulated, so as to carry out the reliability test of the test shaft.

Owner:WUHAN UNIV OF TECH

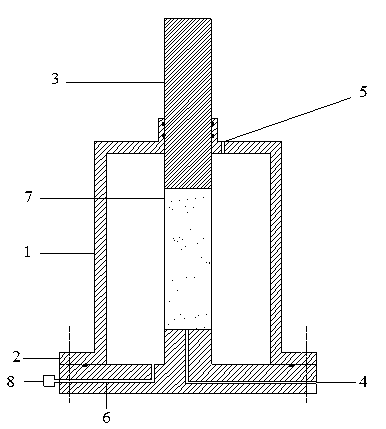

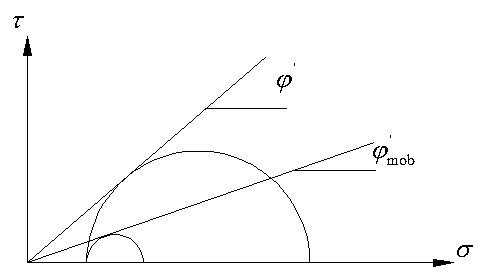

Determination method and apparatus for coefficient of earth pressure at rest

InactiveCN102830018AShorten the consolidation timeImprove test efficiencyMaterial strength using tensile/compressive forcesRadial stressFriction angle

The invention provides a determination method and a determination apparatus for the coefficient of earth pressure at rest, belonging to coefficient measuring methods and apparatuses for soil tests. In a conventional triaxial pressure chamber, an axial deformation constrained radial loading test is carried out on a soil sample so as to obtain a ratio of axial stress to radial stress; according to a two-dimensional asymptotic state criterion, relationship between a starting friction angle and a triaxial compression friction angle in the axial deformation constrained radial loading test satisfies equation I described in the specification, and relationship between the starting friction angle and the triaxial compression friction angle in a radial deformation constrained axial loading test satisfies equation II described in the specification. According to calculation results, the coefficient of earth pressure at rest in the axial deformation constraint radial loading test is 0.5 time of the ratio of axial stress to radial stress in the axial deformation constraint radial loading test. According to the method, errors generated when fixed section radial deformation control is used to substitute radial deformation control in a vertical direction of the soil sample in the radial deformation constrained axial loading test for the coefficient of earth pressure at rest can be avoided, and the method and the apparatus are suitable for accurate determination of coefficients of earth pressure at rest of saturated sand.

Owner:CHINA UNIV OF MINING & TECH

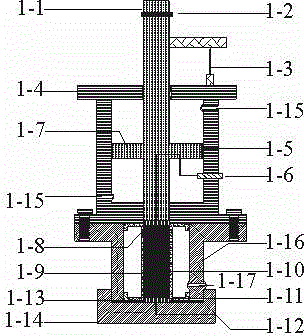

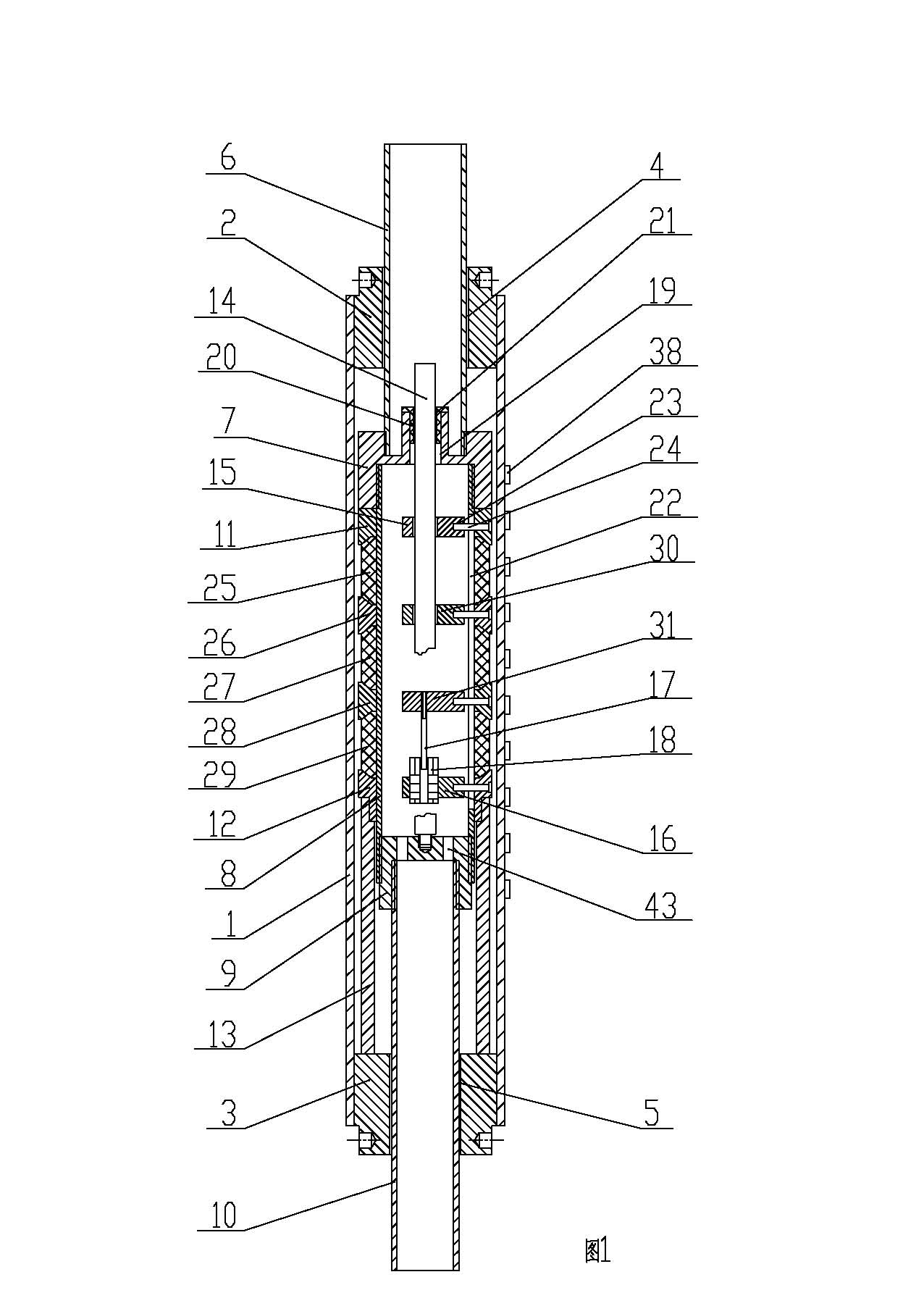

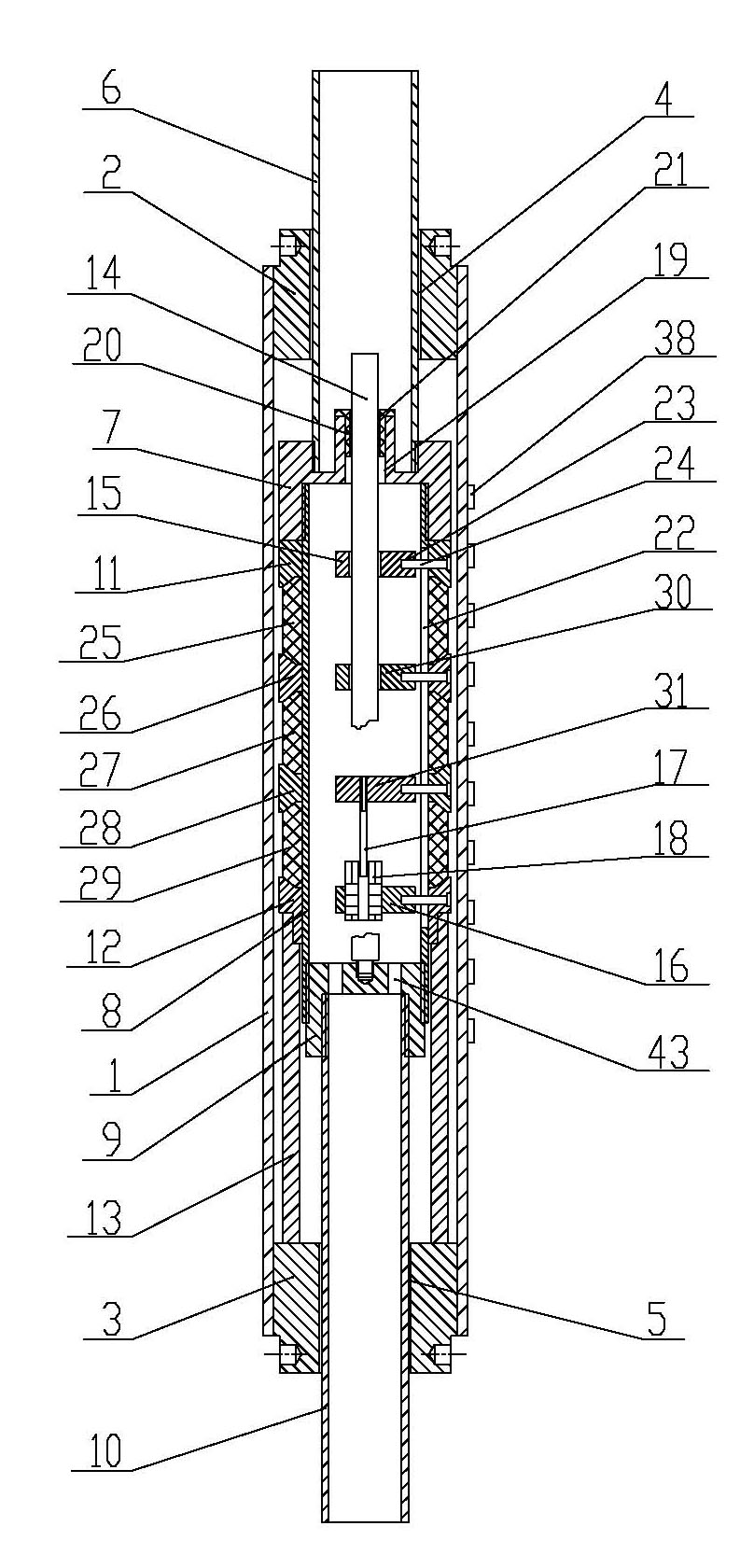

Mechanical parameter measuring device of underground compression type packer and using method thereof

ActiveCN102080514AGuaranteed not to be damagedCompact and reasonable structureMachine part testingSealing/packingRadial stressContact pressure

The invention relates to the technical field of a tool and method for mechanical parameter measuring of an underground packer rubber system for petroleum exploitation, in particular to a mechanical parameter measuring device of an underground compression type packer and a using method thereof. The mechanical parameter measuring device comprises a drivepipe, an upper head, a lower head, a packer, a radial stress sensor and an axial stress sensor; the packer with a seal element assembly is installed in the inner cavity of the drivepipe; and the exterior of the drivepipe is provided with the radial stress sensor, and the packer is provided with the axial stress sensor. The mechanical parameter measuring device provided by the invention has the advantages of reasonability and compactness, is convenient to use; and by utilizing the method provided by the invention, the parameters carried by each rubber, such as axial load, friction, compression deformation force and the contact pressure to the inner wall of the drivepipe can be measured effectively and accurately in real time in the operation of the packer, no damage to the signal output thread of each sensor can be ensured, the test cost is lowered greatly, and a reliable basis for improving the design of the packer can be provided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

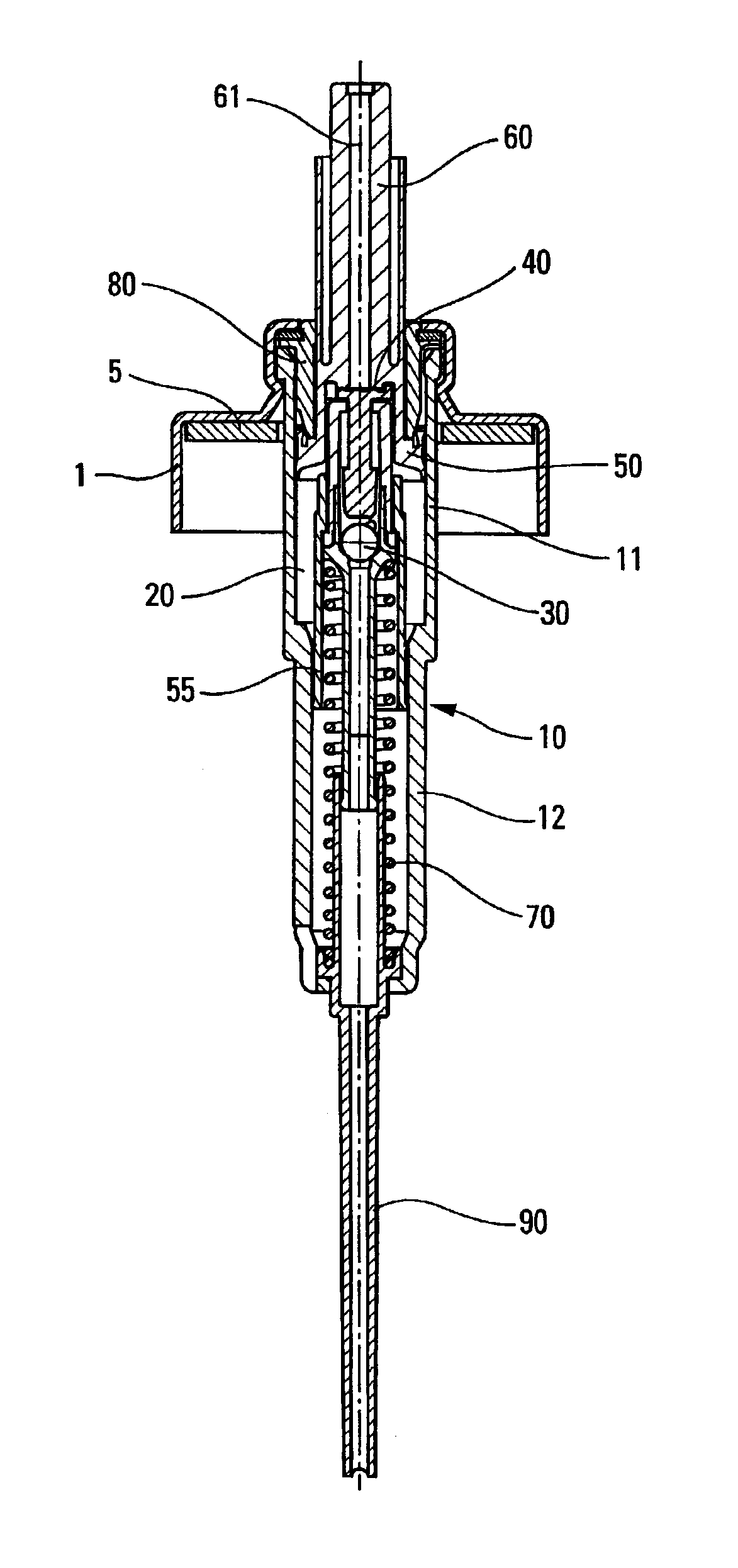

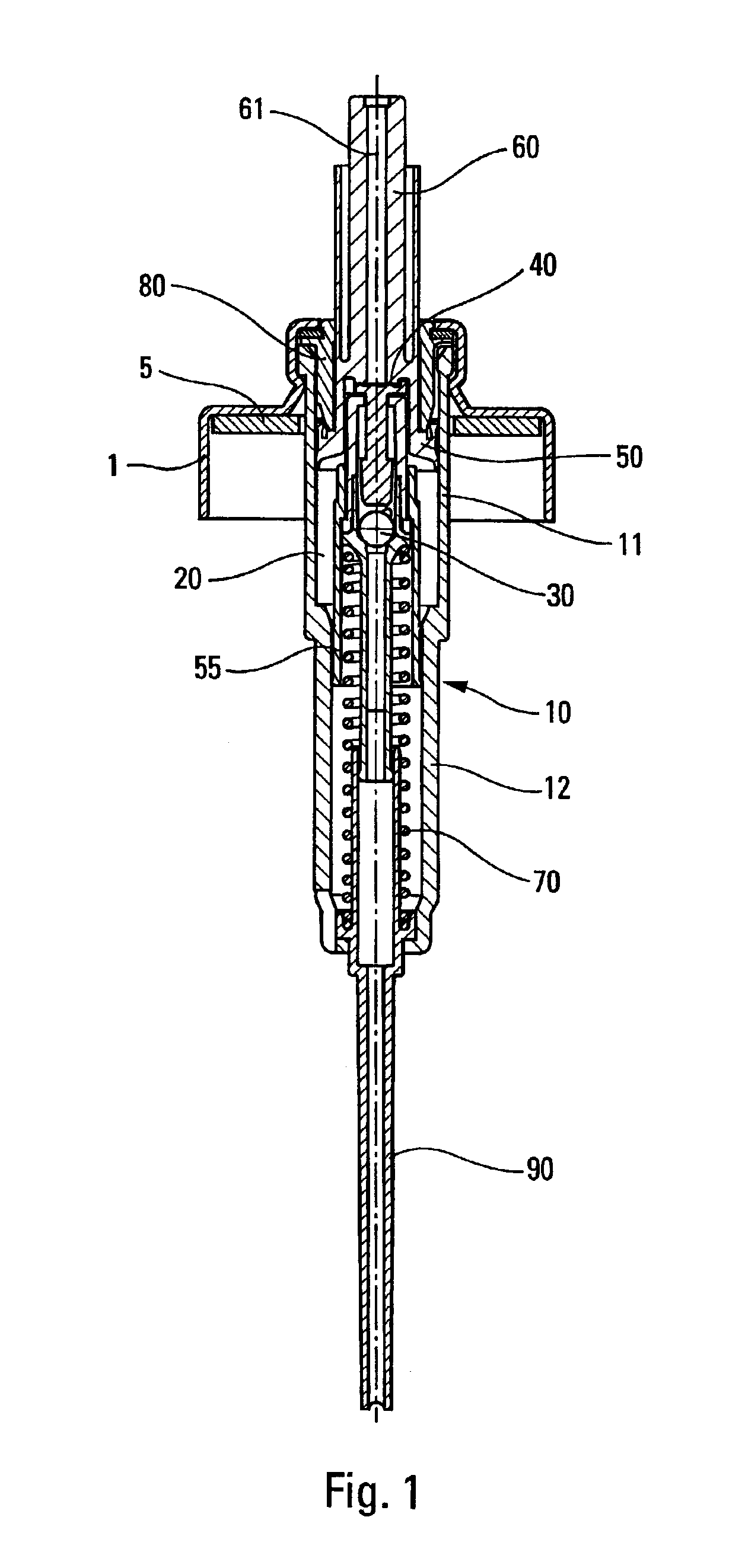

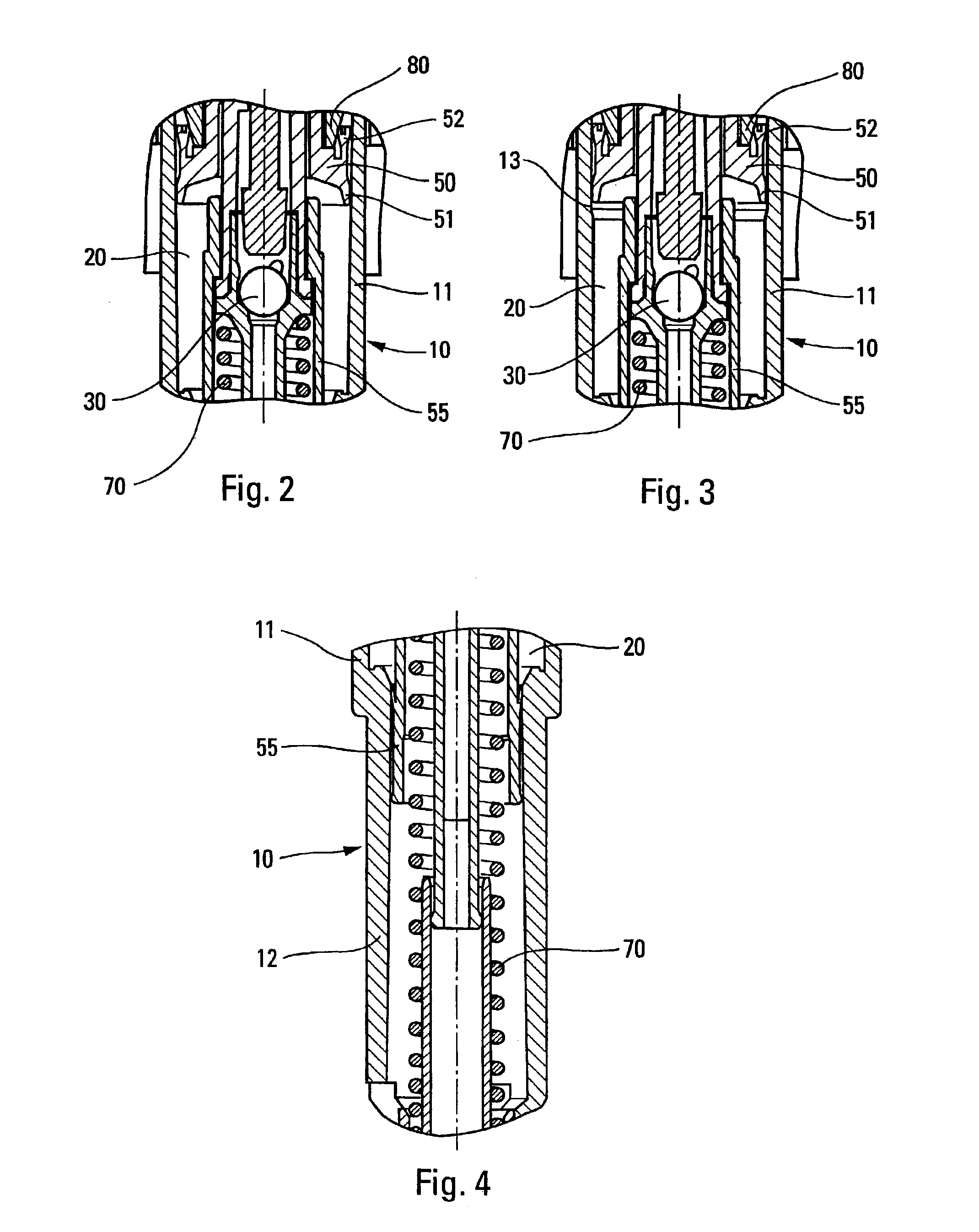

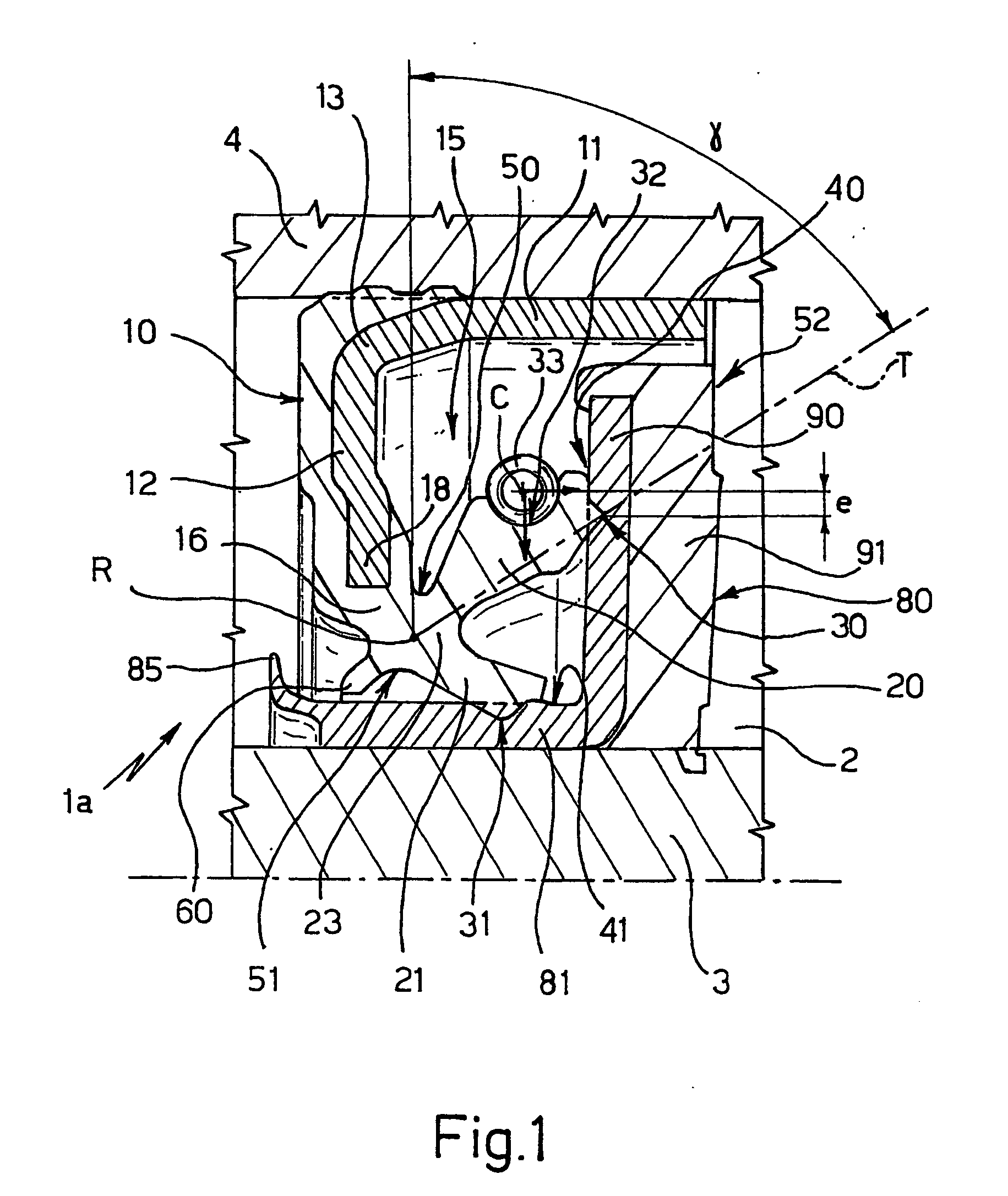

Fluid dispenser pump

InactiveUS6918514B2Simple and inexpensive to and assembleSimple and inexpensive to manufactureContracting/expanding measuring chambersLarge containersRadial stressRest position

A manually-actuated fluid dispenser pump including a pump body (10) and at least one piston (50, 55) mounted to slide in leaktight manner in said pump body (10) between a rest position and a dispensing position, said pump being characterized in that the pump body (10) is frustoconical at least in part so as to modify the radial stresses exerted on said at least one piston (50, 55) between said rest position and said dispensing position.

Owner:APTAR FRANCE SAS

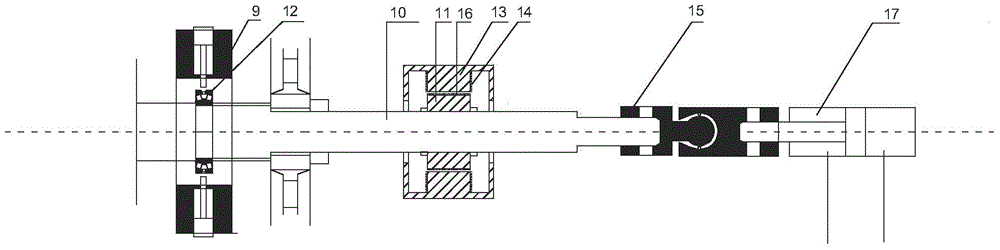

Device and method for measuring engine valve landing radial deflection

ActiveCN103759629AImprove test accuracyHigh data reliabilityUsing electrical meansRadial stressMeasurement device

The invention discloses a device and method for measuring engine valve landing radial deflection. The engine valve landing radial deflection is measured, static calibration is carried out firstly, and then landing of a valve is simulated to calculate the radial deflection of the valve. When a calibration test is carried out, strain foil is pasted on the neck of the valve, and a bridge box, a strain gage and an upper computer are connected. The valve and a valve spring are assembled on an air cylinder cover. Then, the air cylinder cover is fixed to a rack, and a lead screw lift abuts against the tail end of the valve to provide a stroke for the valve. Finally, a dial indicator abuts against the side end of the valve. Only the simple test device is needed, radial stress is exerted to the engine valve, the relation curve of voltages and the deflection is worked out according to data analysis, the voltage value of the strain foil is obtained at last through the valve free landing test, therefore, the deflection of the landing of the valve is calculated, the valve landing radial deflection is calculated, and test requirements are met.

Owner:HANGZHOU DIANZI UNIV

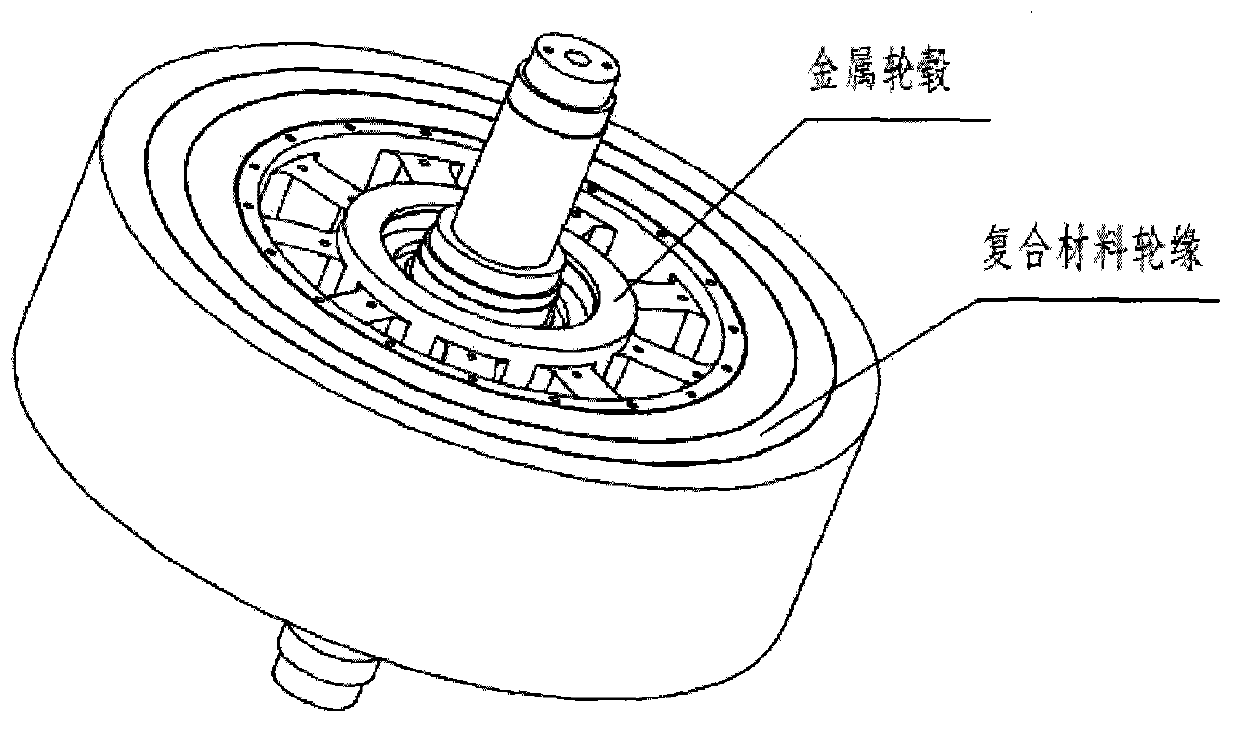

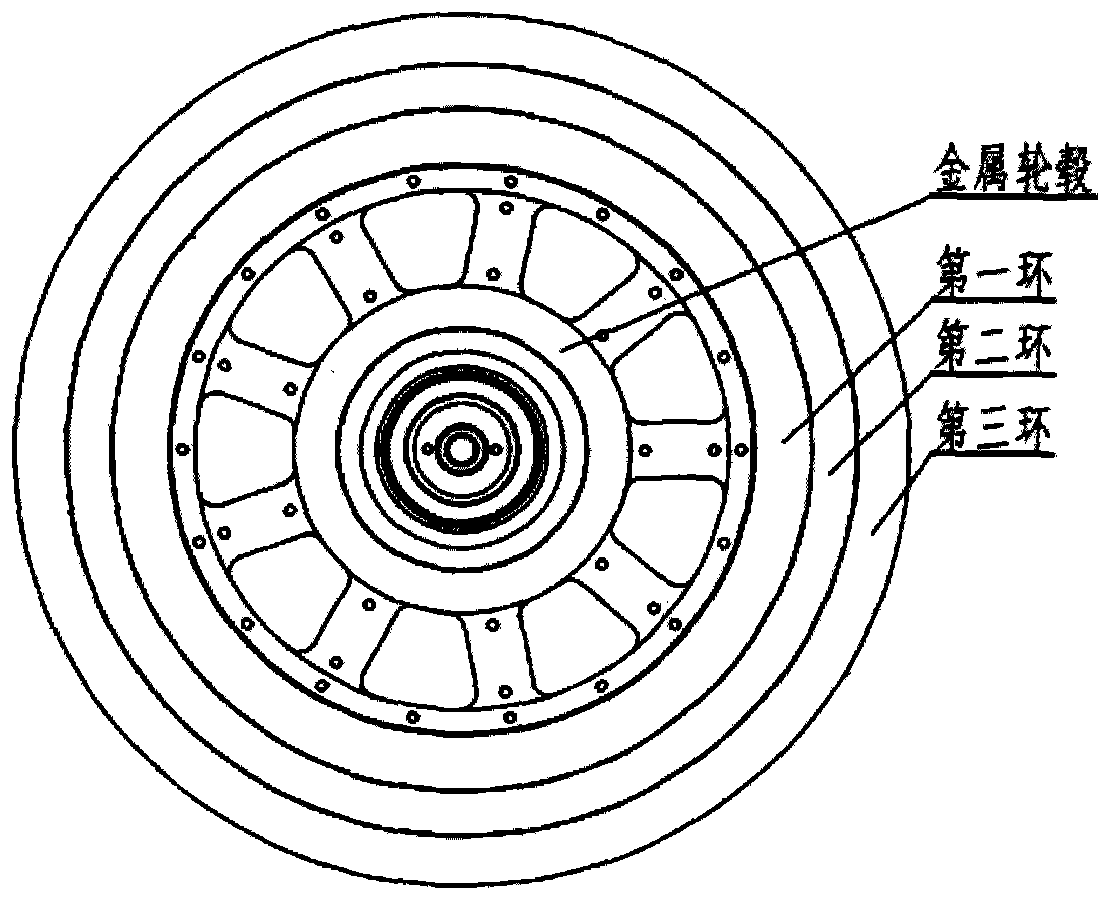

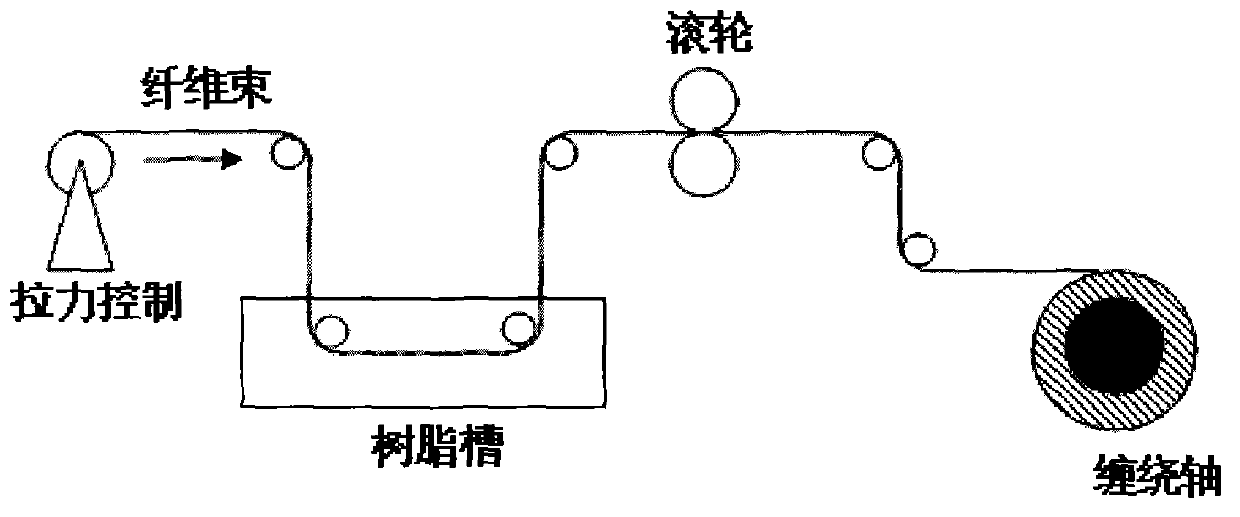

High-energy-storage flywheel rotor and manufacturing method thereof

The invention relates to a high-energy-storage flywheel rotor and a manufacturing method thereof. The flywheel rotor is composed of a metal hub and a composite material rim. The metal hub is made of a high strength alloy steel material and is formed in an inblock cast mode. The rim includes three fiber reinforced composite material rings which sequentially sleeve the hub in an interference assembly mode. The three fiber reinforced composite material rings are formed through a wet method winding process, and a gradation winding curing process and a tension decreasing winding process are adopted in the manufacturing process. By means of the three-layer structure obtained through tension winding and interference fit assembly, the radial stress distribution of a flywheel is changed, prestress is generated among the layers, and the flywheel is not delaminated or loosed even under high rotating speed. The problem that high rotating speed flywheel use cannot be met by metal flywheel strength, low energy storage efficiency and the like is solved, and the flywheel use safety and reliability are greatly improved.

Owner:北京奇峰聚能科技有限公司

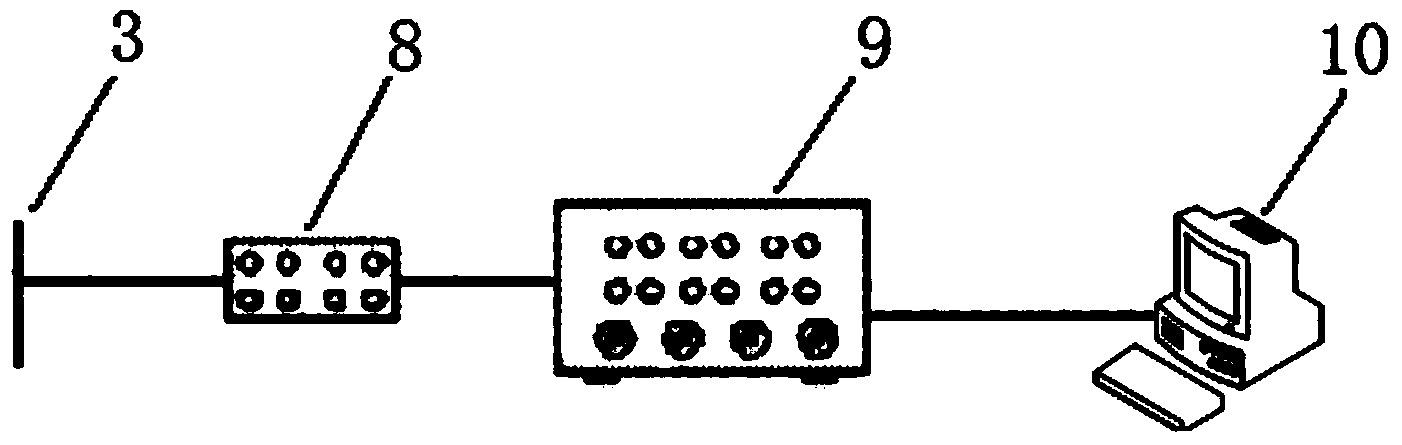

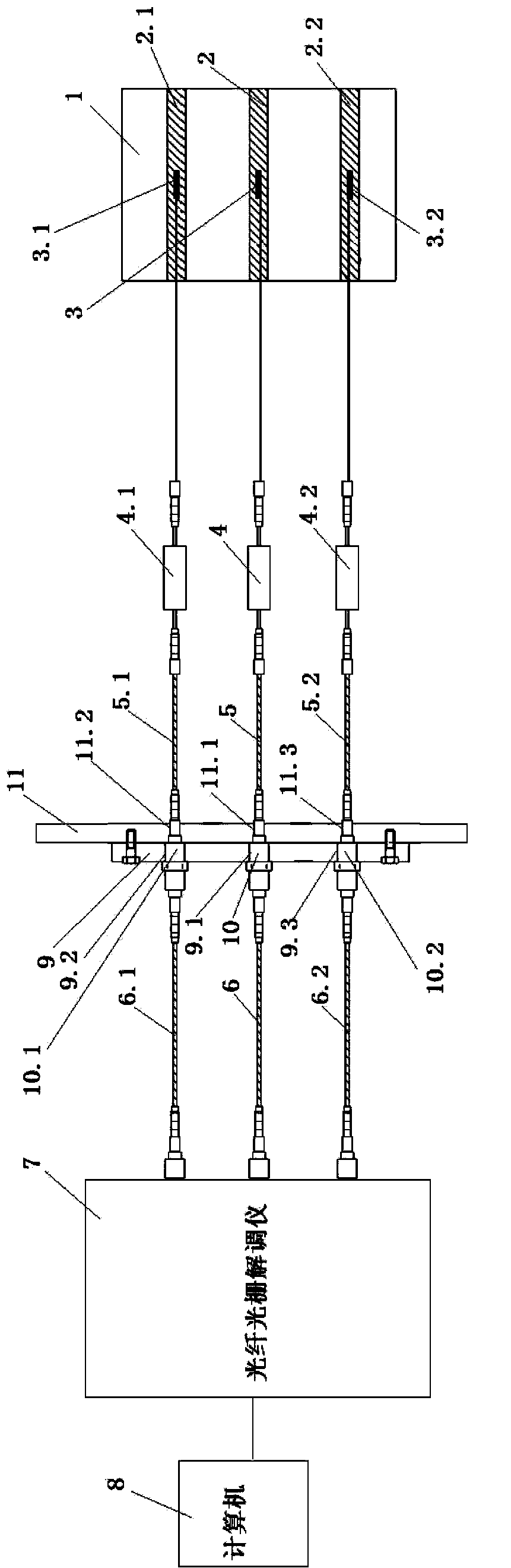

Device and method for measuring radial stress of transformer winding

ActiveCN103389176ASolve the problem of winding amplitude stress measurementAccurate and effective winding amplitude stress measurement dataForce measurement by measuring optical property variationFiberGrating

The invention discloses a device and a method for measuring radial stress of a transformer winding. The device comprises a first optical fiber splice, a first glass fiber tape, a first fiber bragg grating strain sensor, a first optical fiber coupler, a first internal connection optical fiber, a first external connection optical fiber, a fiber bragg grating interrogator and a computer, wherein the first glass fiber tape is glued on transformer coil winding surface insulation paper; the first fiber bragg grating strain sensor is fixed on the first glass fiber tape; an input end of the first optical fiber coupler is connected with an output end of the first fiber bragg grating strain sensor; one end of the first internal connection optical fiber is connected with an output end of the first optical fiber coupler; the first external connection optical fiber is connected with the other end of the first internal connecting optical fiber; the fiber bragg grating interrogator is connected with the first external connection optical fiber; the computer is connected with the fiber bragg grating interrogator; and the first internal connection optical fiber is connected with the first external connection optical fiber through the first optical fiber splice. According to the device and the method, accurate and effective winding radial stress measuring data are provided for research of anti-short-circuit capacity of a transformer and diagnosis of deformation of the transformer winding.

Owner:STATE GRID CORP OF CHINA +2

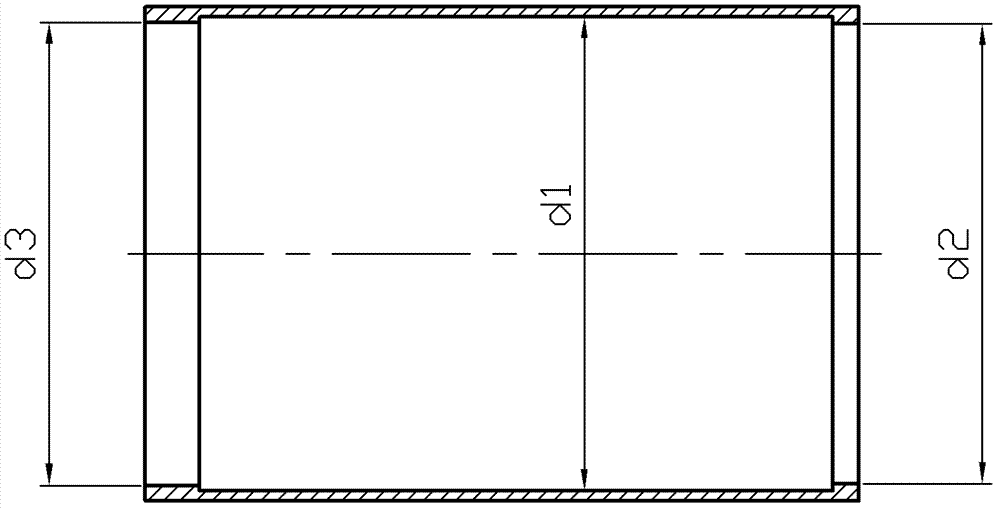

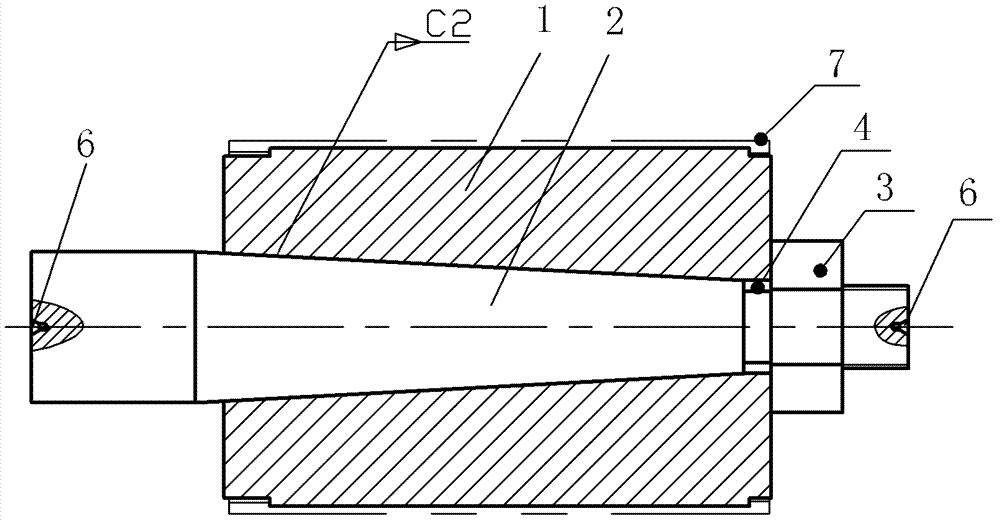

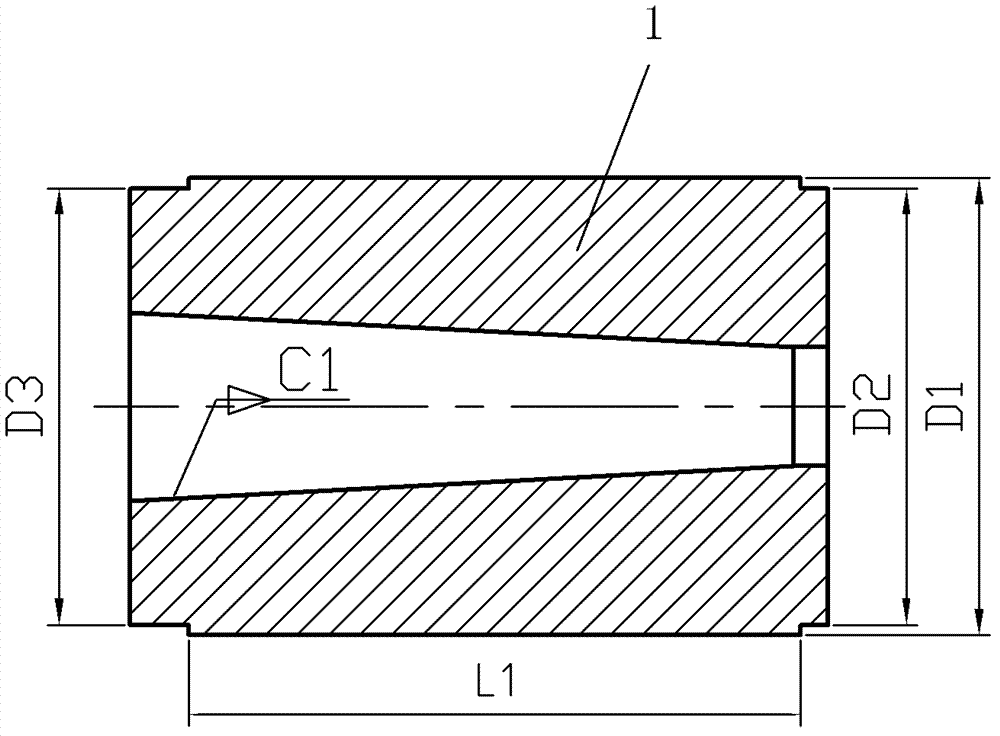

Internal expansion tool for mechanical processing

InactiveCN102814519AGuaranteed body inner holeGuaranteed verticalityExpansion mandrelsRadial stressMachine tool

The invention provides an internal expansion tool for mechanical processing, and belongs to the technical field of devices for mechanical processing. The internal expansion tool comprises an expansion tool main body, a mandrel and a nut, wherein the expansion tool main body comprises at least three blades which can be combined to form a cylindrical structure of which the periphery is matched with an internal circumference of a part to be processed; the mandrel is coaxial with the expansion tool main body and is arranged in the expansion tool main body, and the extending end of the mandrel is fixed through the nut; the axes at the two ends of the mandrel are top-arranged on a machine tool. The internal expansion tool is large in contact area on the internal wall, the clamping force is uniformly distributed, and the milling and grinding radial stress and deformation based on clamping stress are reduced, so that the roundness is ensured. An internal hole and an external circle of the expansion tool main body are ensured to achieve the coaxiality. The end surface of the part can be synchronously milled and grinded, so that the verticality of the end surfaces can be ensured. The internal expansion tool is applicable to processing thin-wall tubular parts and step-mouth tubular parts.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

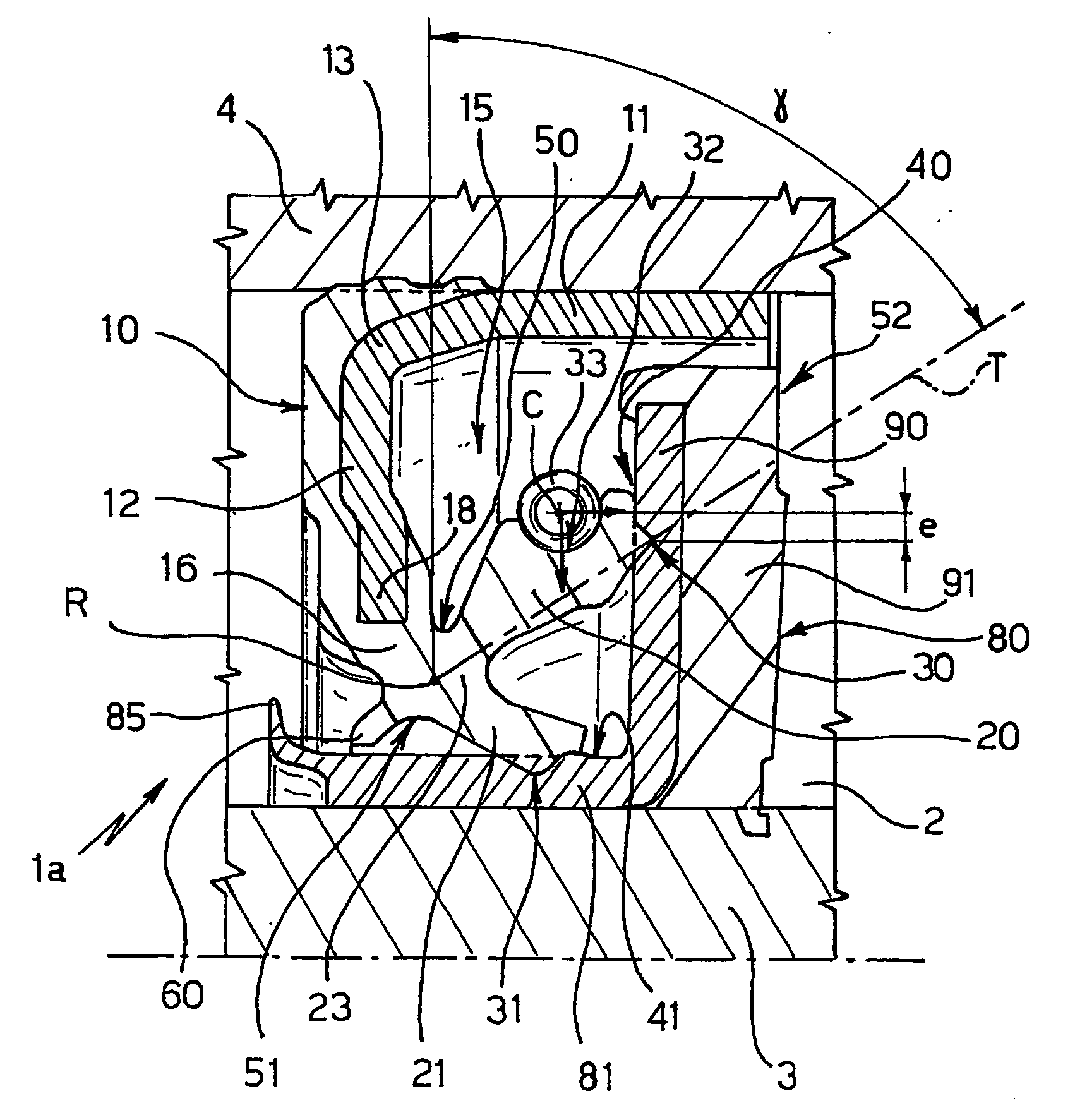

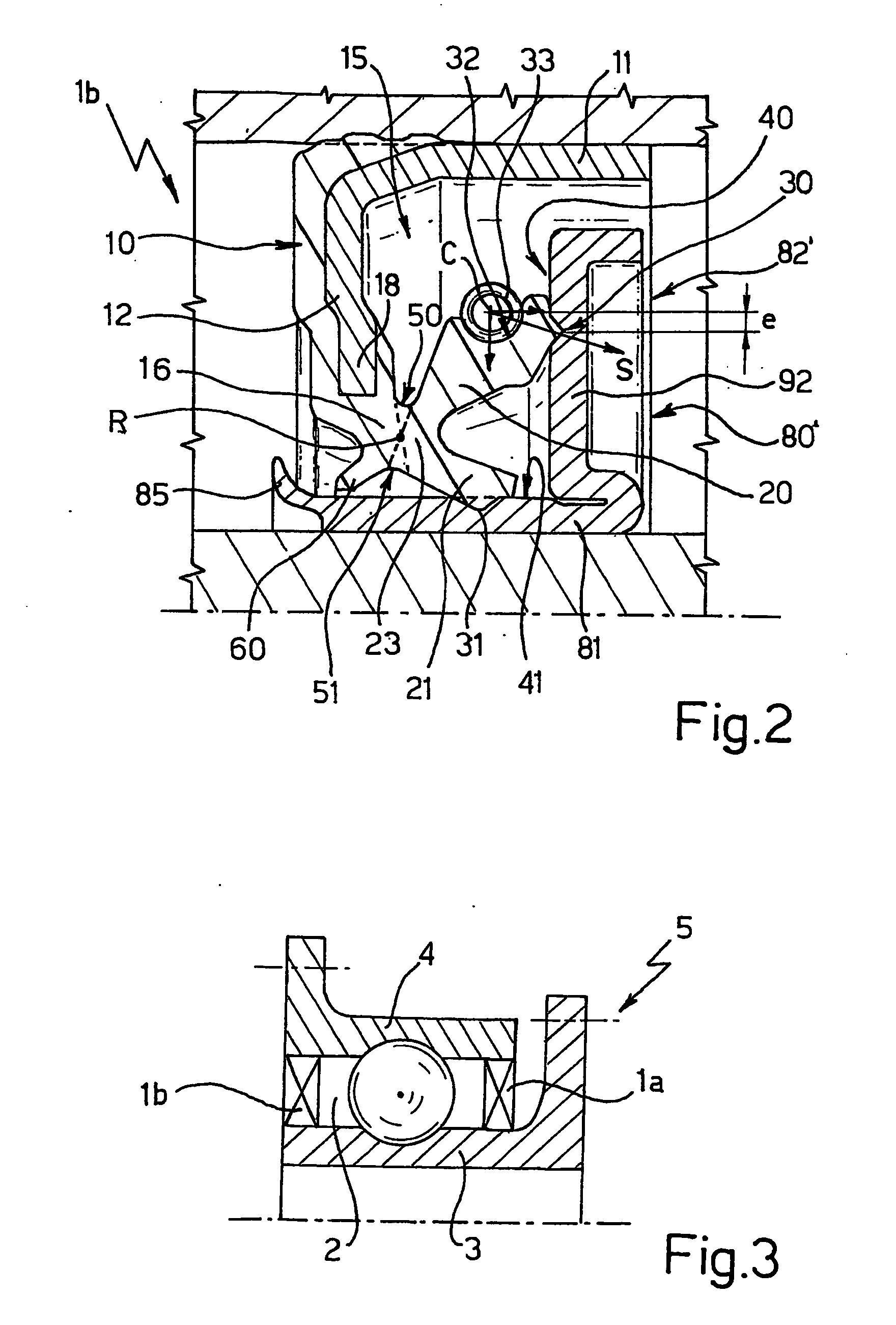

Annular Sealing Assembly, in Particular for Wheel Hubs

InactiveUS20090108539A1Low production costImprove sealing efficiencyEngine sealsBearing assemblyRadial stressEngineering

A sealing assembly (1a, 1b) including: a first annular shield (10) presenting a sleeve portion (11) and a flange portion (12) which extends radially from a first end (13) of the sleeve portion; and a sealing member (15) made of elastomeric material presenting an annular root portion (16) which extends radially and overhangingly from a peripheral edge (18) of the flange portion and a first axial annular sealing lip (20) in which the sealing member presents a second radial annular sealing lip (21), the lips (20, 21) axially and overhangingly extending from the opposite side of the first end of the sleeve portion, on a same side as a thinned end (23) of the root portion and being reciprocally spread to form a radial V-shaped section having vertex facing the root portion and axis parallel to the sleeve portion; the first lip presenting a radial seat (32) facing the opposite side of the second lip and accommodating a toroidal spring (33) applying an offset radial stress to an elastic hinge defined by the thinned end of the root portion, —the sealing lips may be coupled to a second and a third annular shields selectively arrangeable coaxial to the first shield (50,50′) and having similar dimensions.

Owner:AB SKF

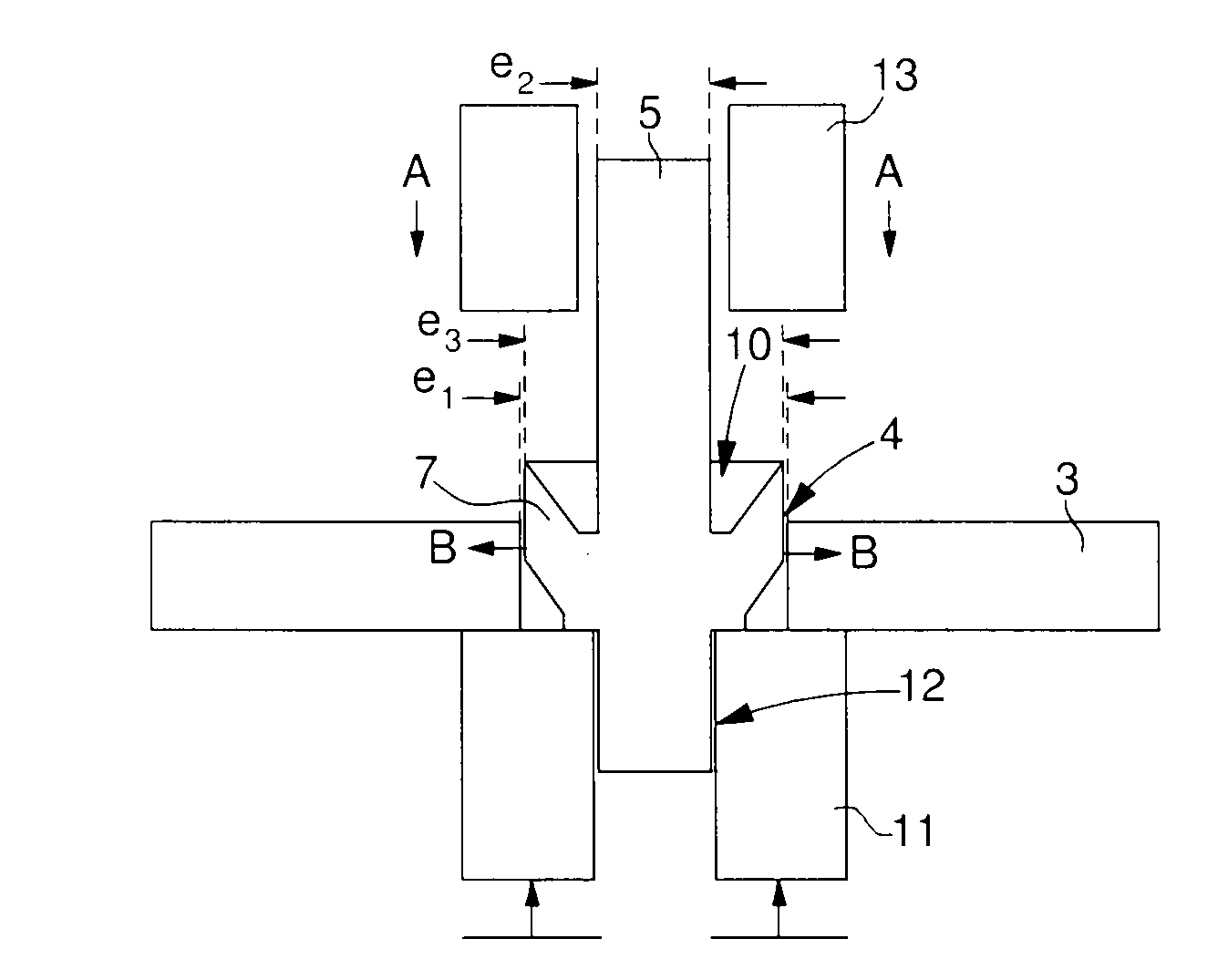

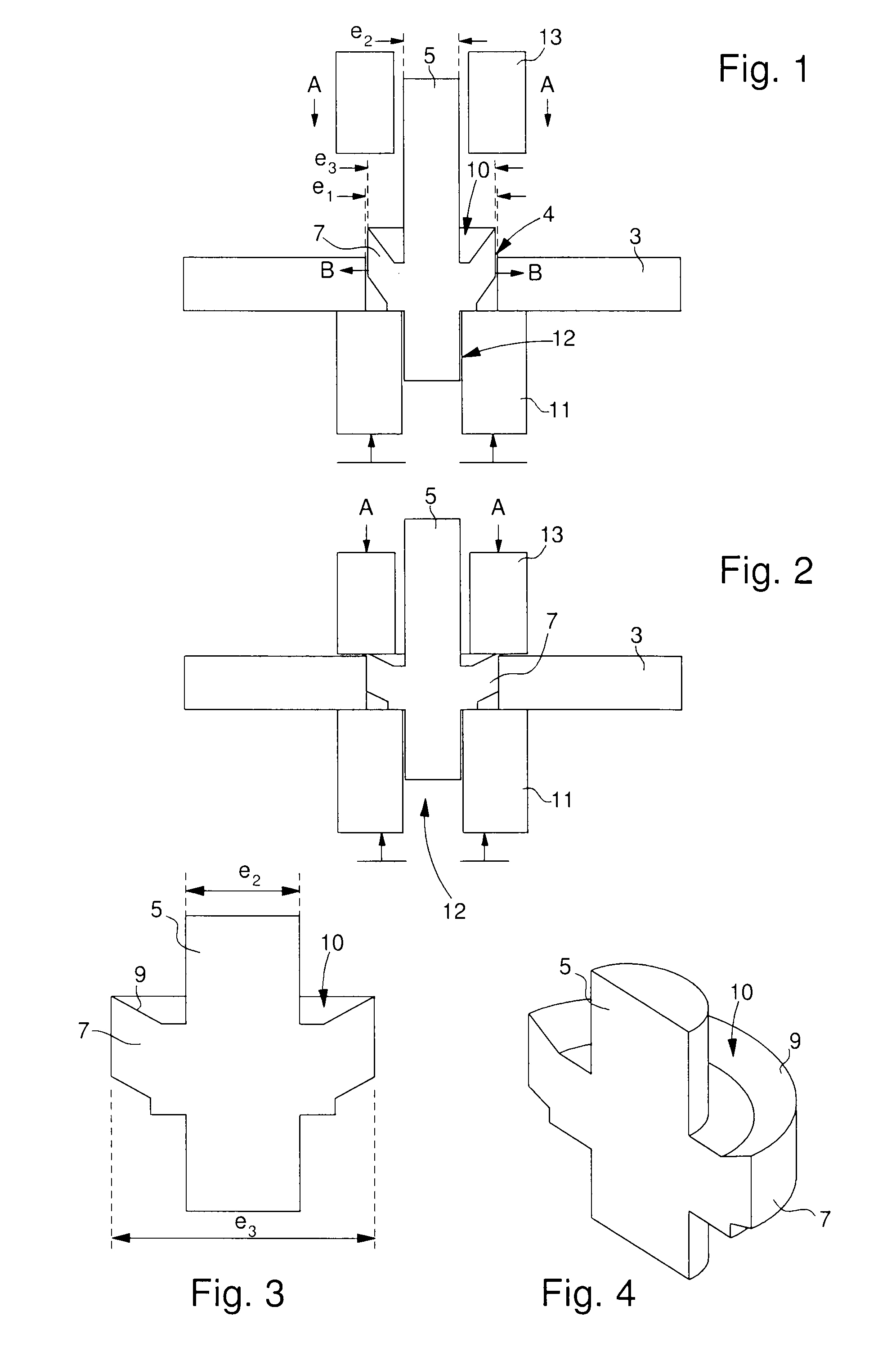

Assembly of a part that has no plastic domain

The invention relates to an assembly of a part that has no plastic domain. A method of assembling a member (5, 15) made of a first material in a part (3) made of a second material having no plastic domain, includes forming the part (3) with an aperture (4), inserting a radially flared portion of the member (5, 15) into the aperture (4), without any stress, and elastically and plastically deforming the flared portion of the member in the aperture (4) by moving two tools (11, 13, 21) towards each other axially, respectively on the top and bottom parts of the flared portion, so as to exert a radial stress (B) against the wall of the part (3) surrounding the aperture (4), causing the elastic deformation of the part, to secure the assembly in a manner that is not destructive for said part. The member can be a timepiece.

Owner:NIVAROX FAR SA

Assembly of a part that has no plastic domain

A method of assembling a member made of a first material in a part made of a second material having no plastic domain, includes forming the part with an aperture, inserting a radially flared portion of the member into the aperture, without any stress, and elastically and plastically deforming the flared portion of the member in the aperture by moving two tools towards each other axially, respectively on the top and bottom parts of the flared portion, so as to exert a radial stress against the wall of the part surrounding the aperture, causing the elastic deformation of the part, to secure the assembly in a manner that is not destructive for said part. The member can be a timepiece.

Owner:NIVAROX FAR

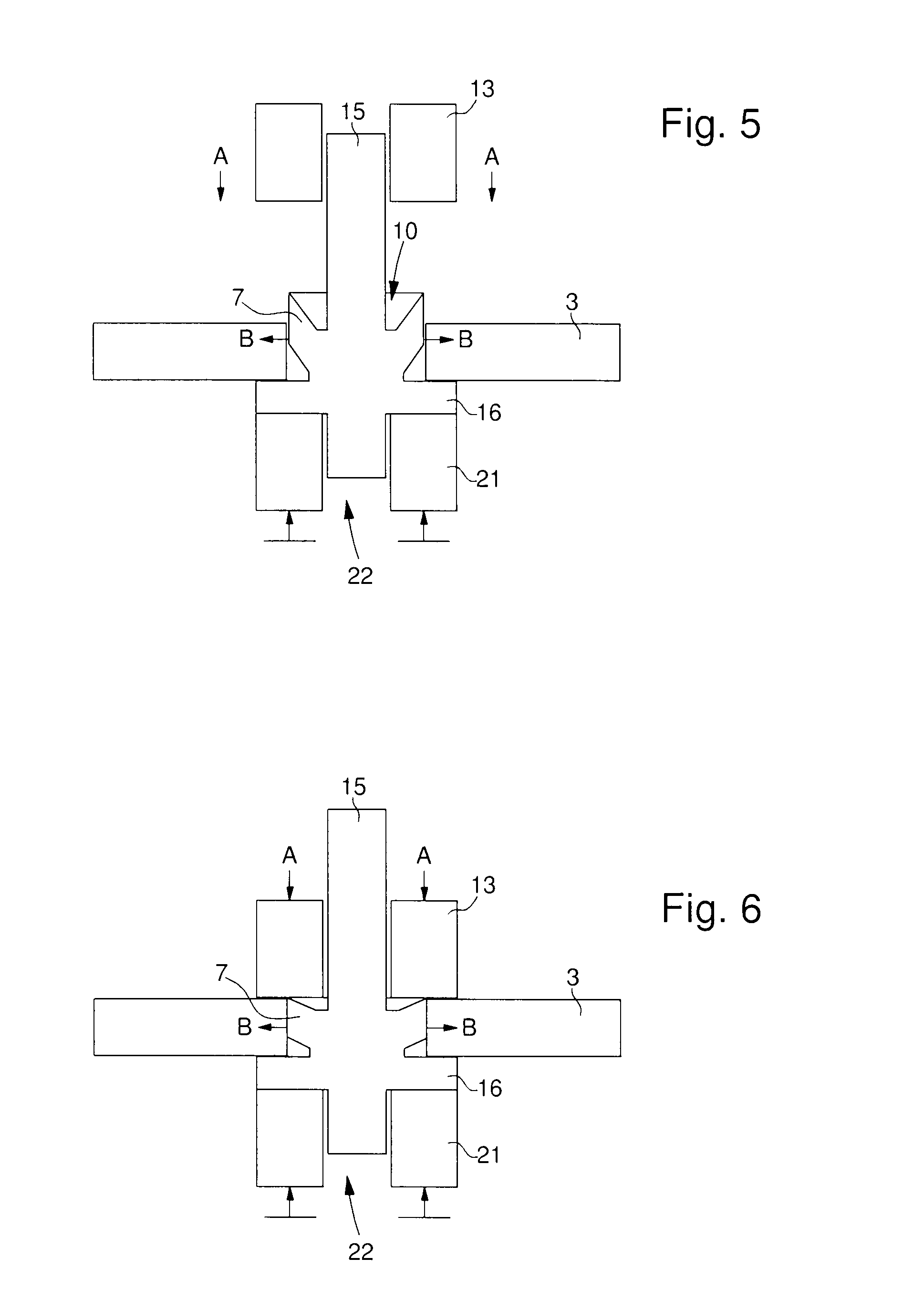

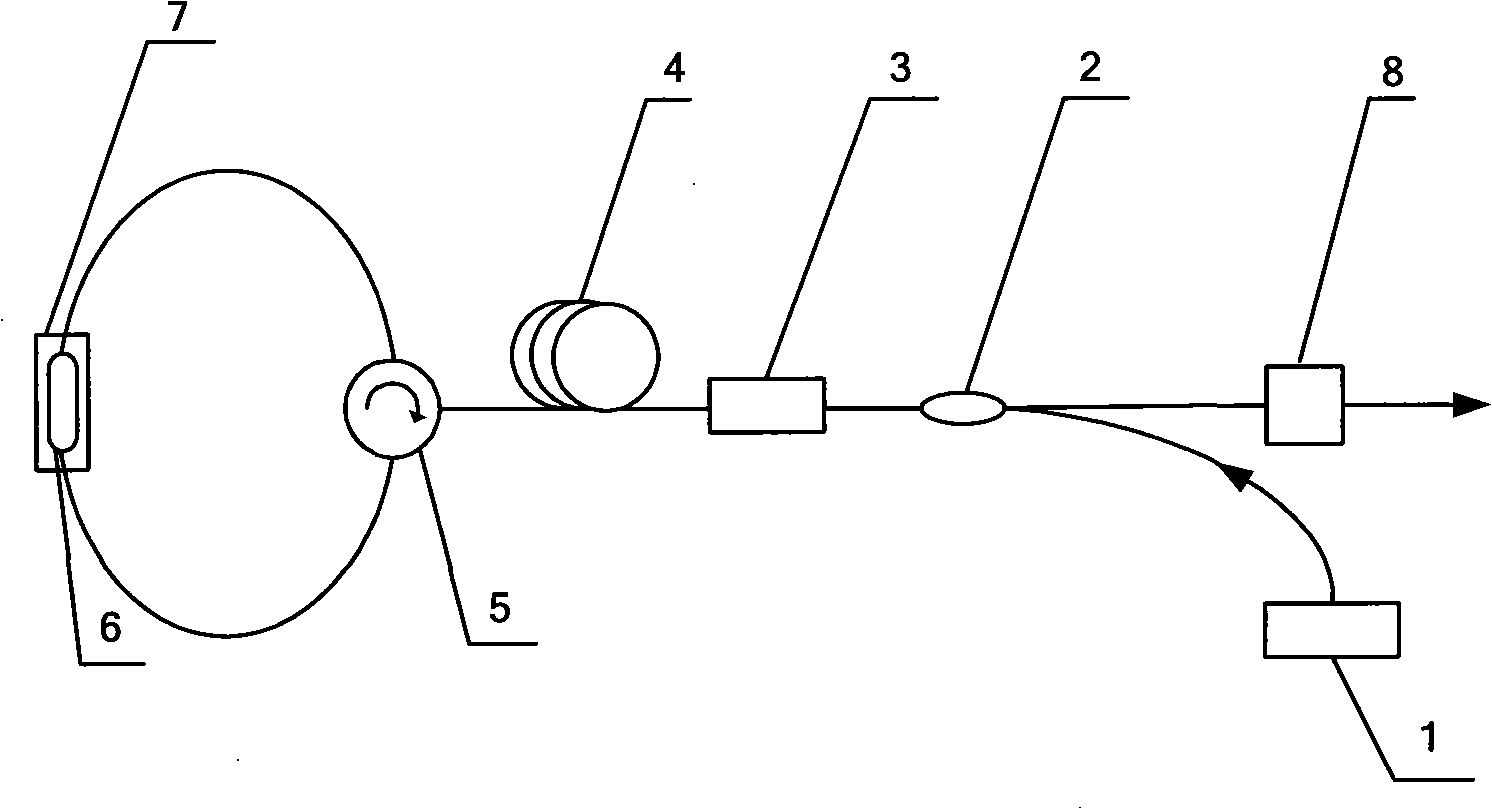

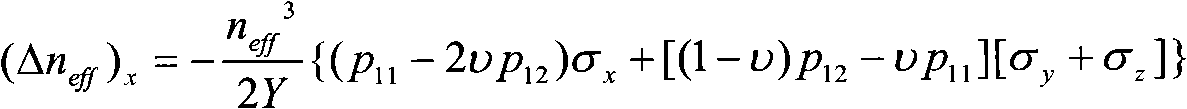

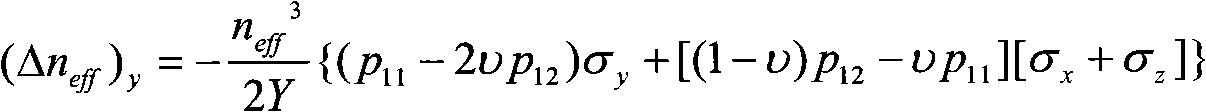

Optical generation method and devices of tunable high-frequency microwave signals

InactiveCN101540469AOptical resonator shape and constructionActive medium shape and constructionFiberGrating

The invention relates to an optical generation method and devices of tunable high-frequency microwave signals. The method utilizes radial stress to cause a narrowband transmission peak of a phaseshift Fiber Bragg Grating to be divided into two so as to realize a dual-wavelength laser and further generate the tunable high-frequency microwave signals by beat frequency. The devices for realizing the method comprise a pump light source with the wavelength of 980nm, a three-port 980nm / 1550nm optical wavelength-division multiplexer, a uniform Fiber Bragg Grating, a phaseshift Fiber Bragg Grating, a three-port optical circulator and an erbium-doped gain optical fiber as well as a photodetector, wherein the uniform Fiber Bragg Grating, the phaseshift Fiber Bragg Grating, the three-port optical circulator and the erbium-doped gain optical fiber form a laser resonator. All the gratings utilized by the method have the common grating structure, and compared with the generation method of electric microwave signals, the devices have simple structures and easy realization and are easy for generating the tunable microwave signals.

Owner:ZHEJIANG UNIV

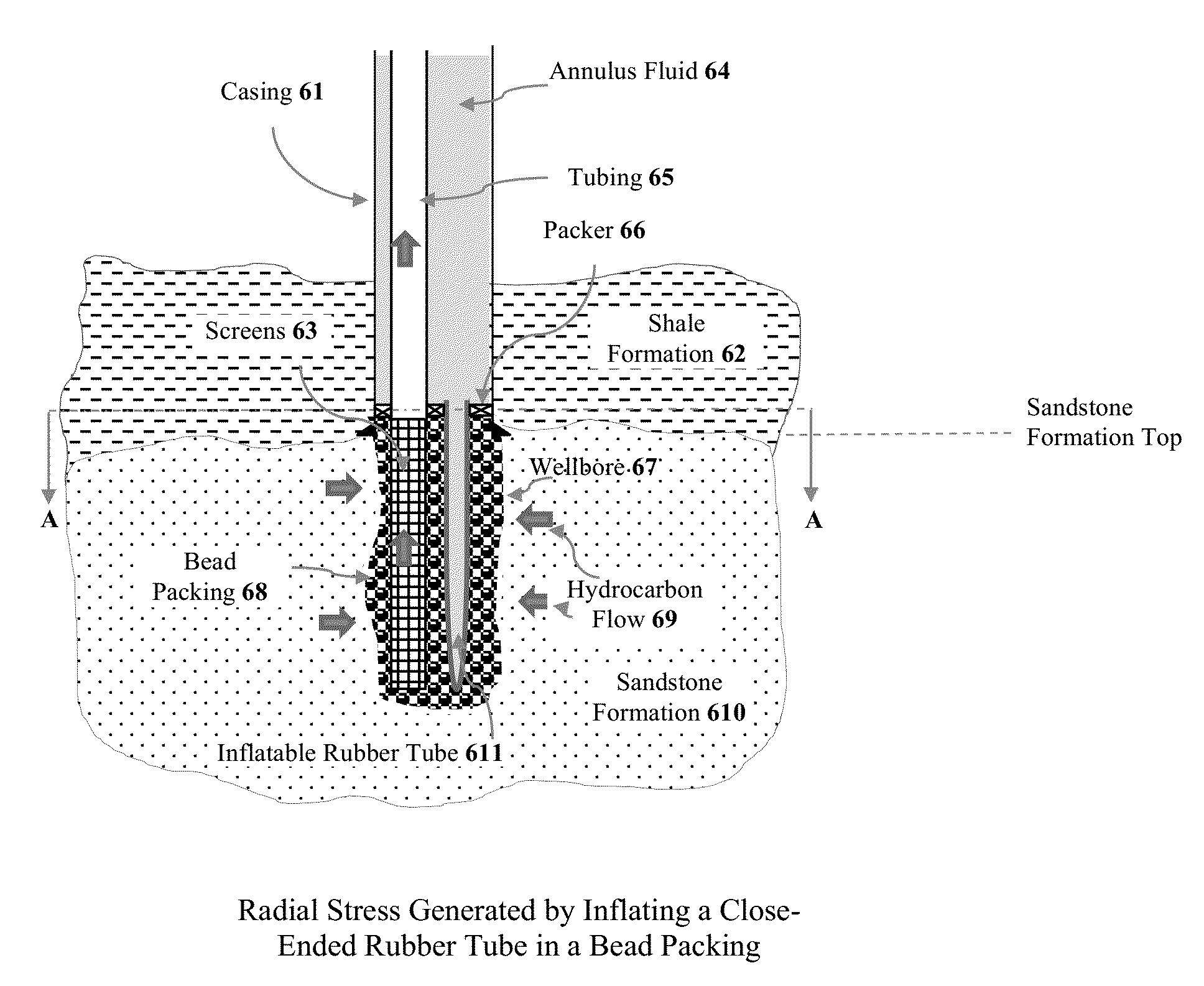

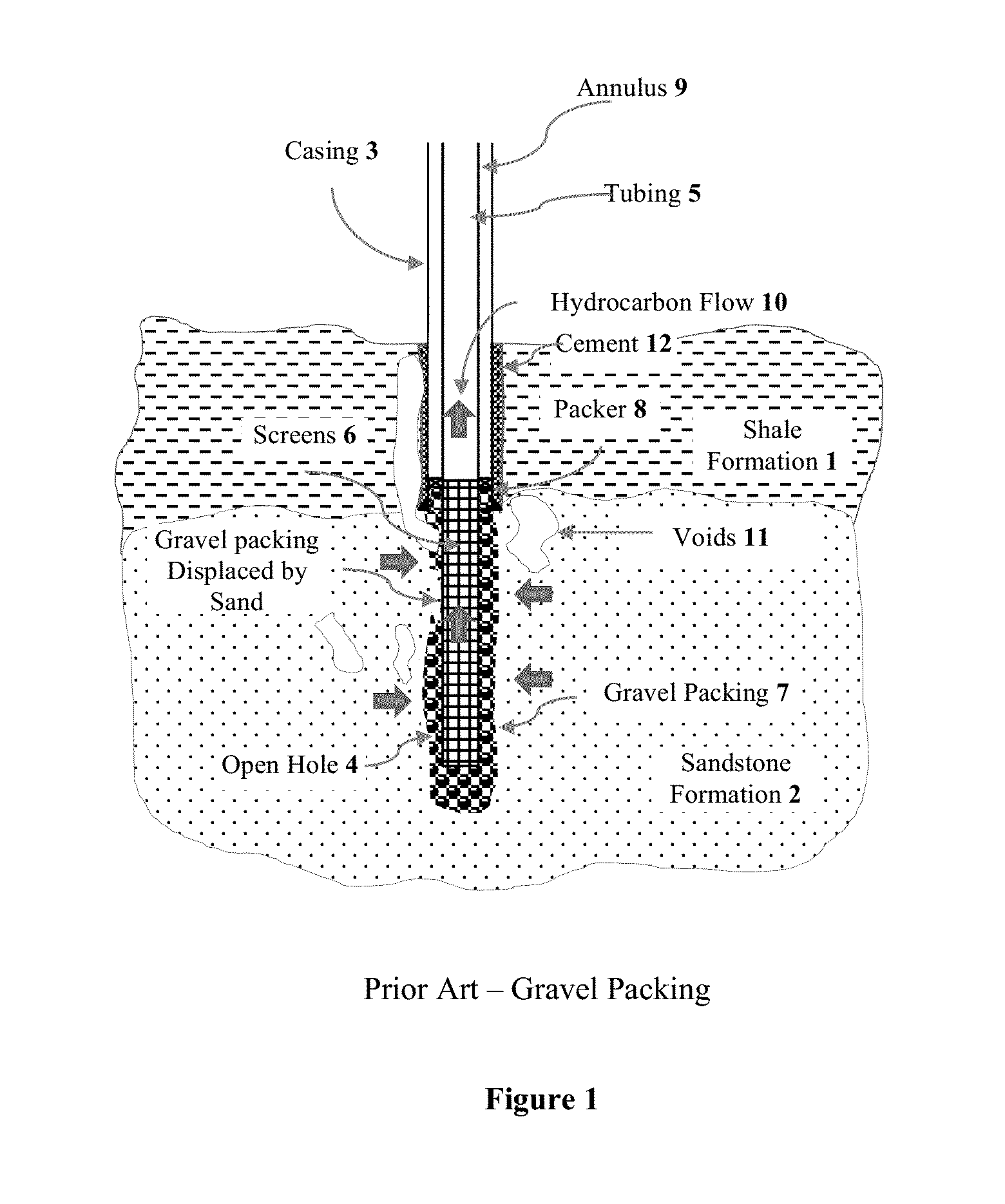

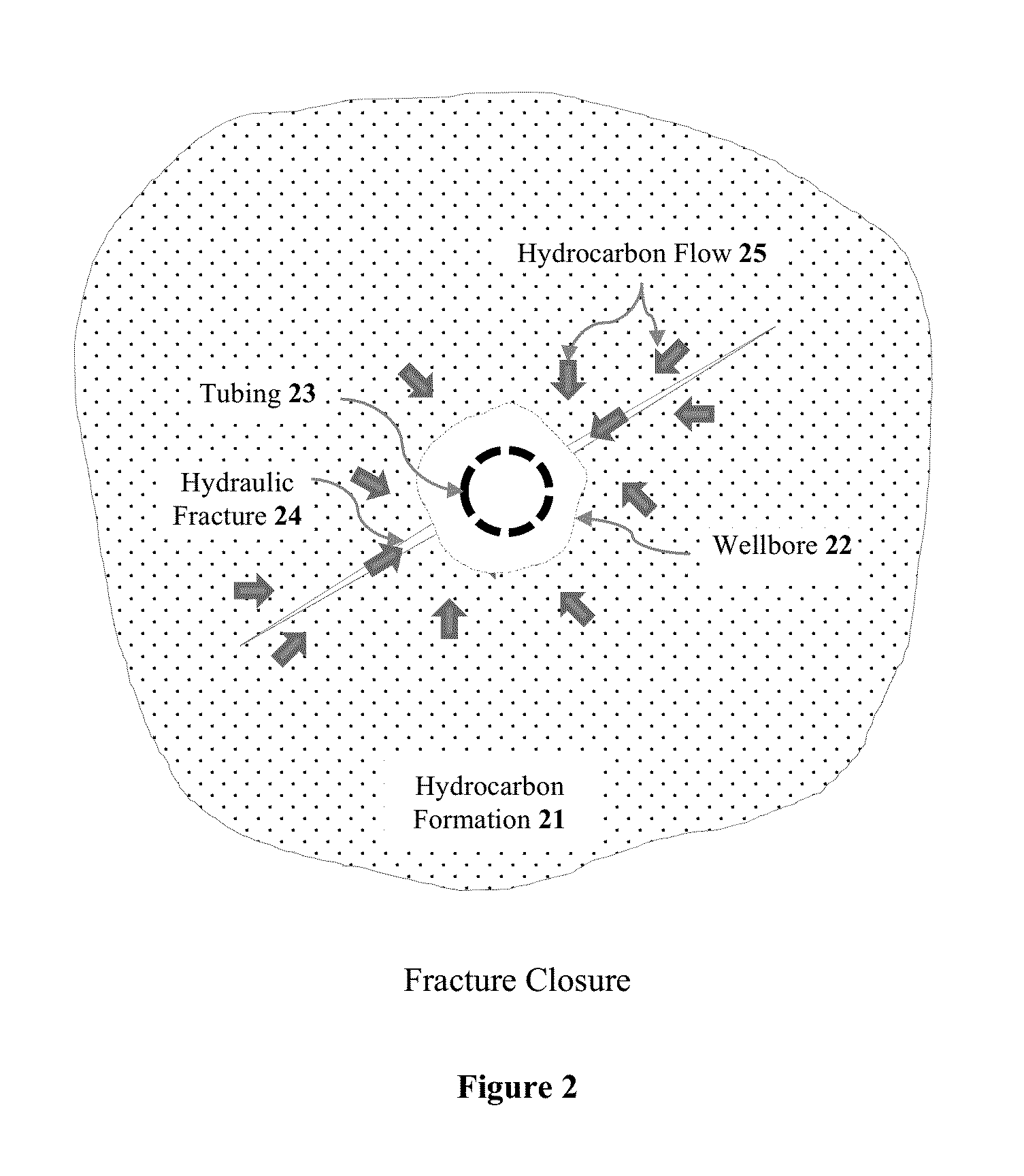

Method of Supporting a Subterranean Conduit

InactiveUS20160002998A1Small resistance to point loadingEasy to collapseFluid removalSealing/packingRadial stressEngineering

A method and apparatus for consolidating a formation penetrated by a wellbore utilize radial stress. The radial stress is created by loading the wellbore, wellbore casing or production pipe with preferably round, dense bead like materials. The shape and density of the bead like material transfers the axial direction of stress created by the vertical height of the bead like materials to a radial direction. The radial stress can also be generated by inflating an inflatable device. The radially directed stress can compact the geologic formation. This can include compaction of loose sand which otherwise may enter the production flow of hydrocarbon. The bead like materials can also support the wellbore casing or production piping from point loading. This can include point loading created by the movement of salt or other subterranean formations. The bead like materials can include barite, hematite, iron oxide, ilmenite, metal, alloy and combinations thereof.

Owner:SHARP ROCK TECH

Lead screw feeding platform with loading assistant support

ActiveCN102218665ASuppresses bending deformationSmall support distanceWork benchesLarge fixed membersRadial stressMotor drive

The invention relates to a lead screw feeding platform with a loading assistant support, which is characterized in that a motor drives a lead screw, two ends of the lead screw are fixedly supported by a bearing; the lead screw and a workbench driving nut form a rolling spiral kinematic pair; the workbench driving nut is provided with a workbench; the bottom end of the workbench is provided with aguide rail; a loading assistant support device is arranged between two bearing supporting devices; the loading assistant support device comprises assistant driving nuts respectively arranged on two sides of the workbench driving nut; two assistant driving nuts are connected with the lead screw; each assistant driving nut is respectively fixedly connected with a slide block; the lower parts of thetwo slide block form a moving pair with the assistant supporting guide rail; and two slide blocks are respectively provided with a pressure sensor. In the lead screw feeding platform, real-time loading can be realized by the loading assistant support, the radial stress situation of the lead screw can be detected to reflect the nonparallelism of the vertical direction of the guide rail to effectively inhibit the flexural deformation of the lead screw due to radial stress, thus, the lead screw feeding platform can be widely applied to the horizontal large-route high-speed feeding platform of a machine tool lead screw.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com