Patents

Literature

59results about How to "Suppresses bending deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

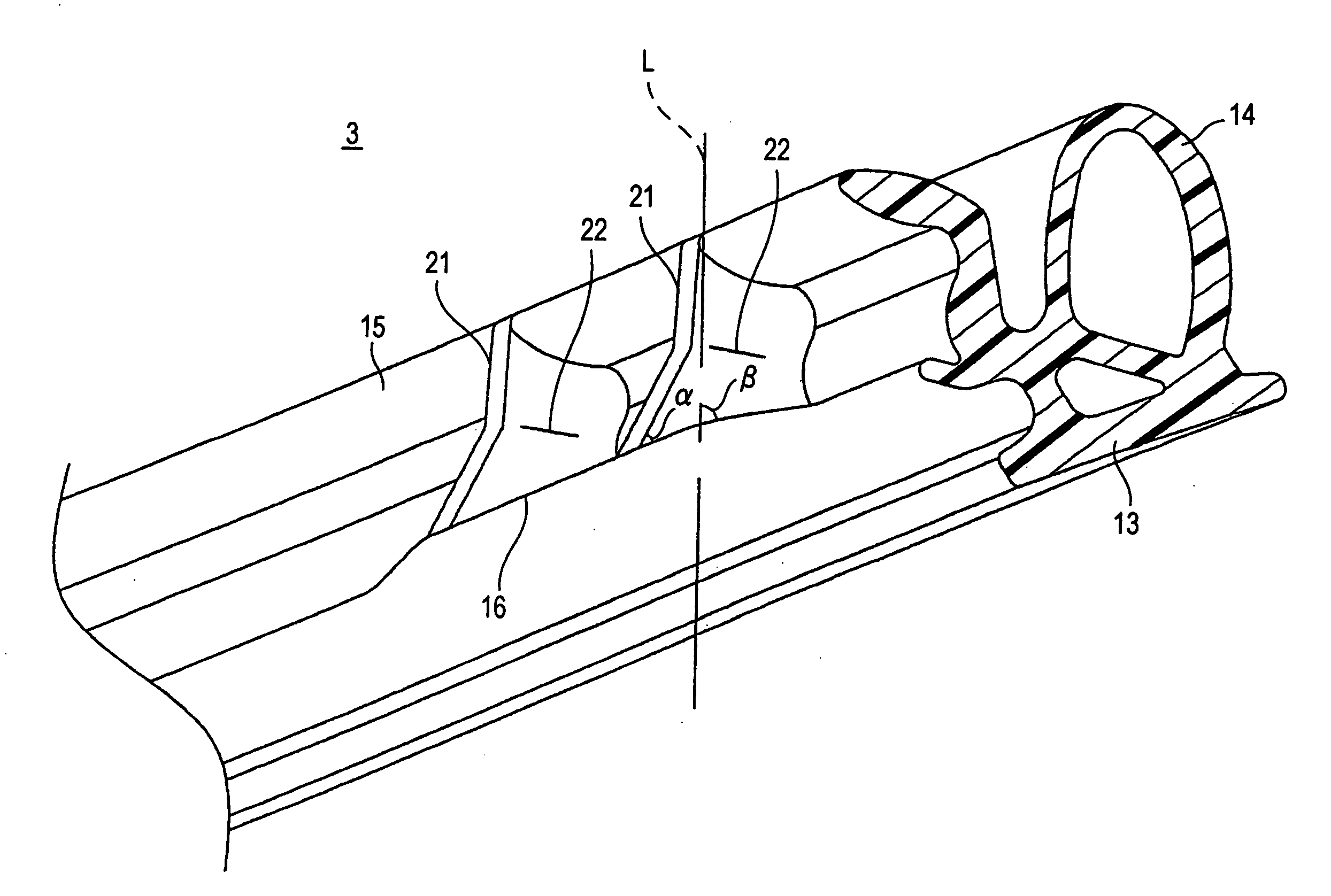

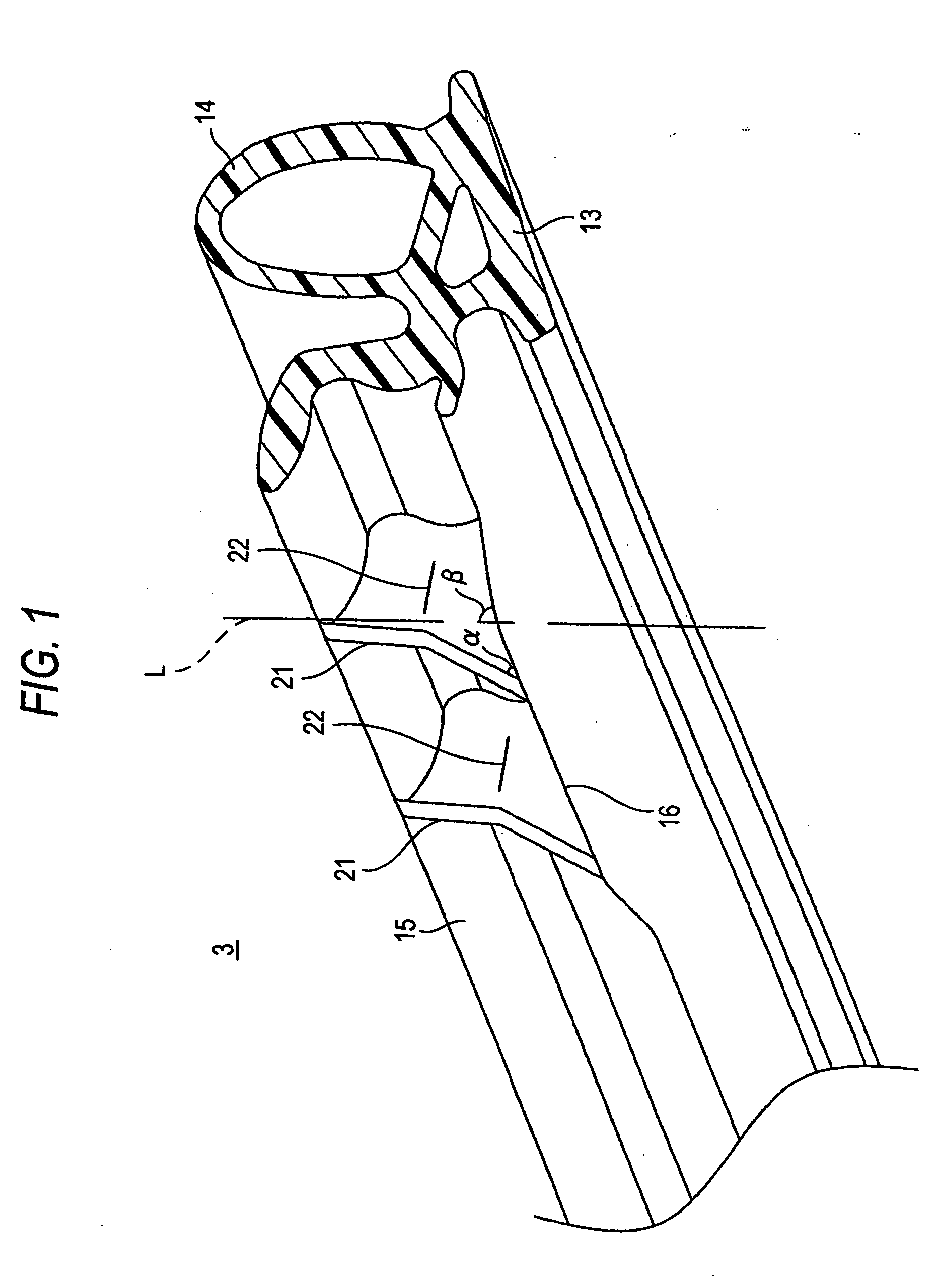

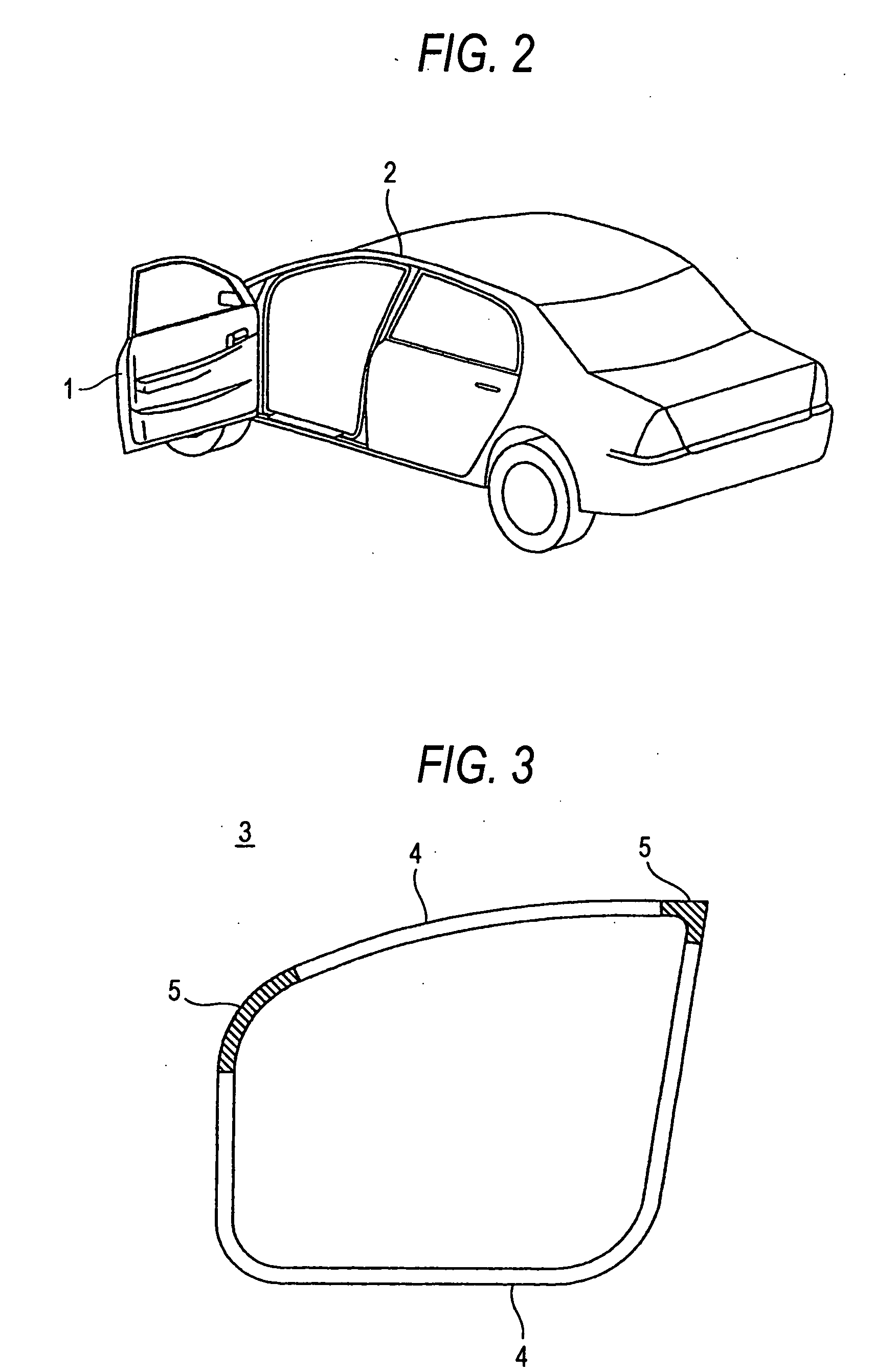

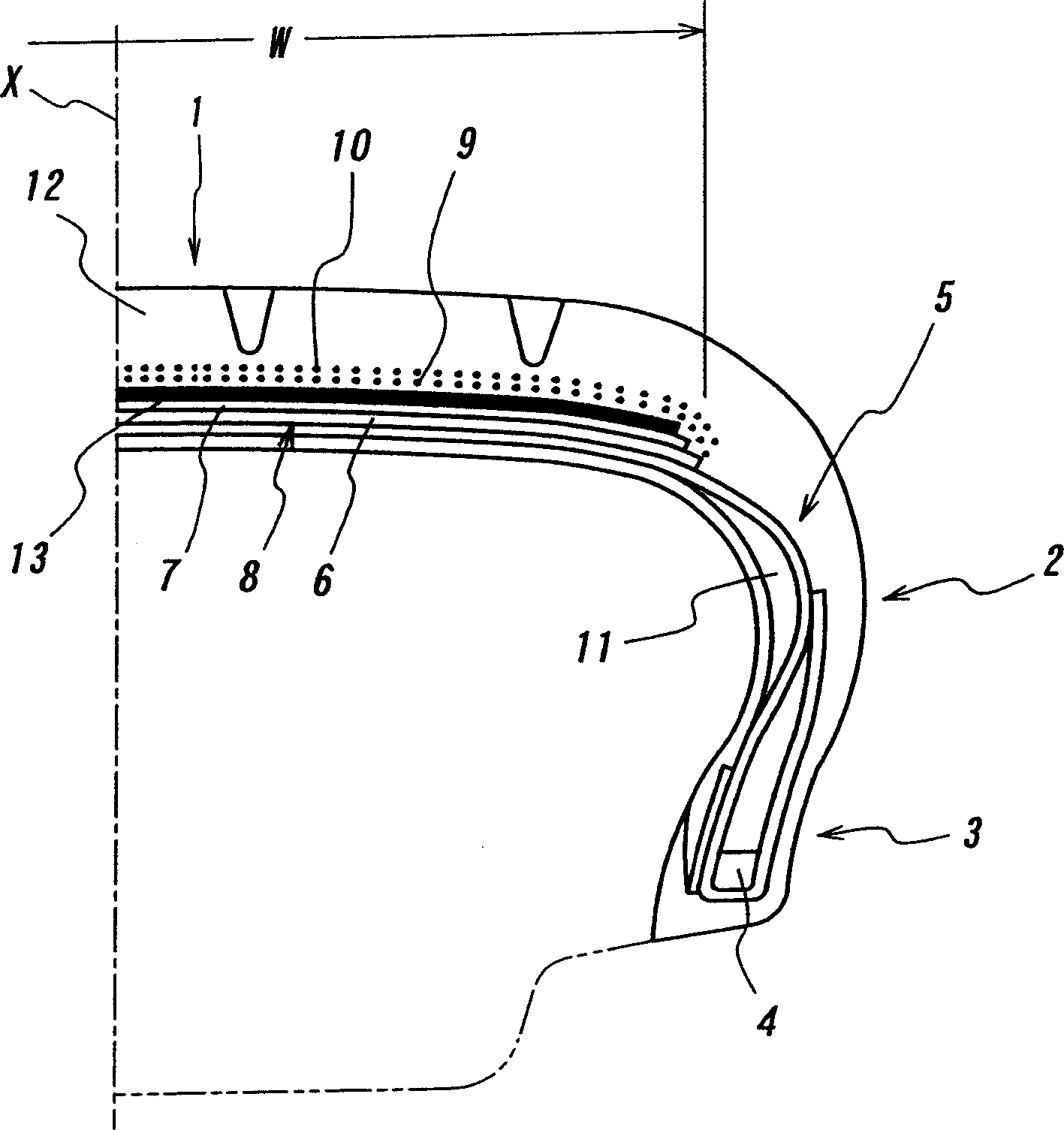

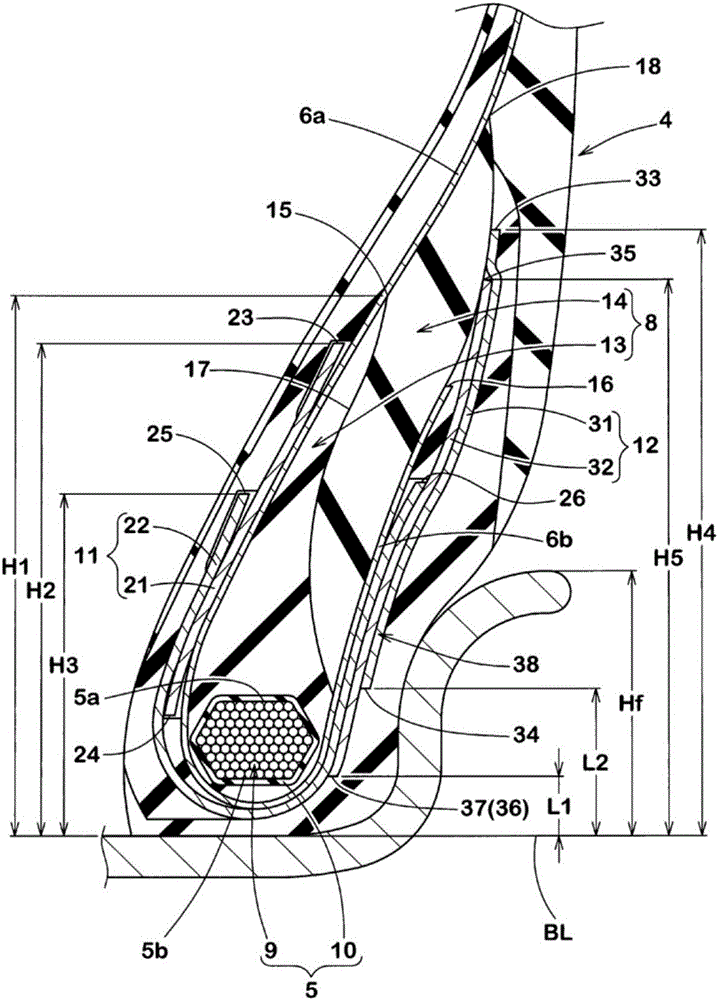

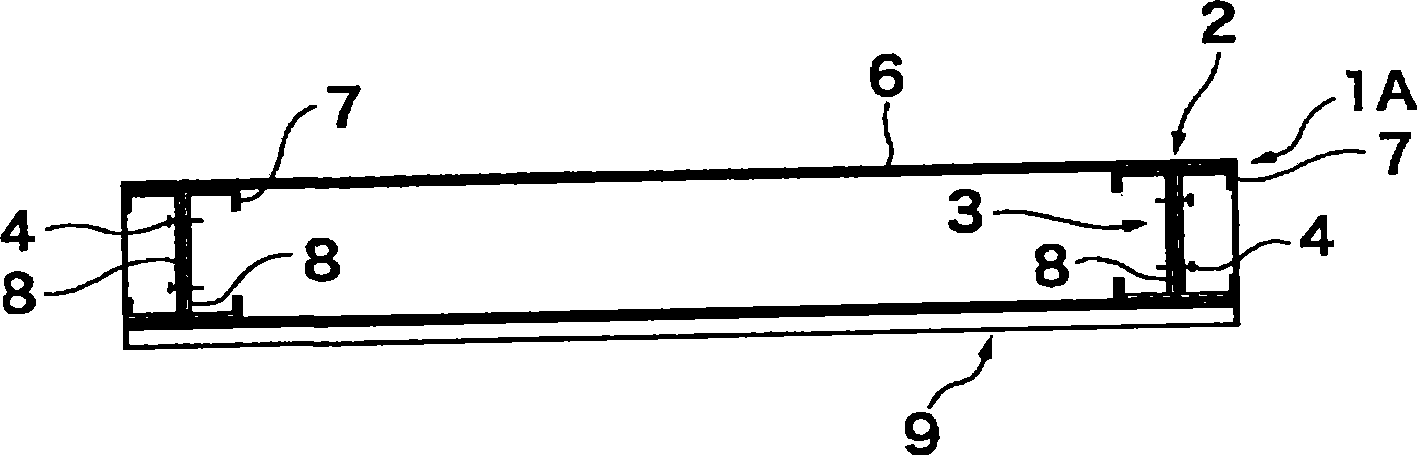

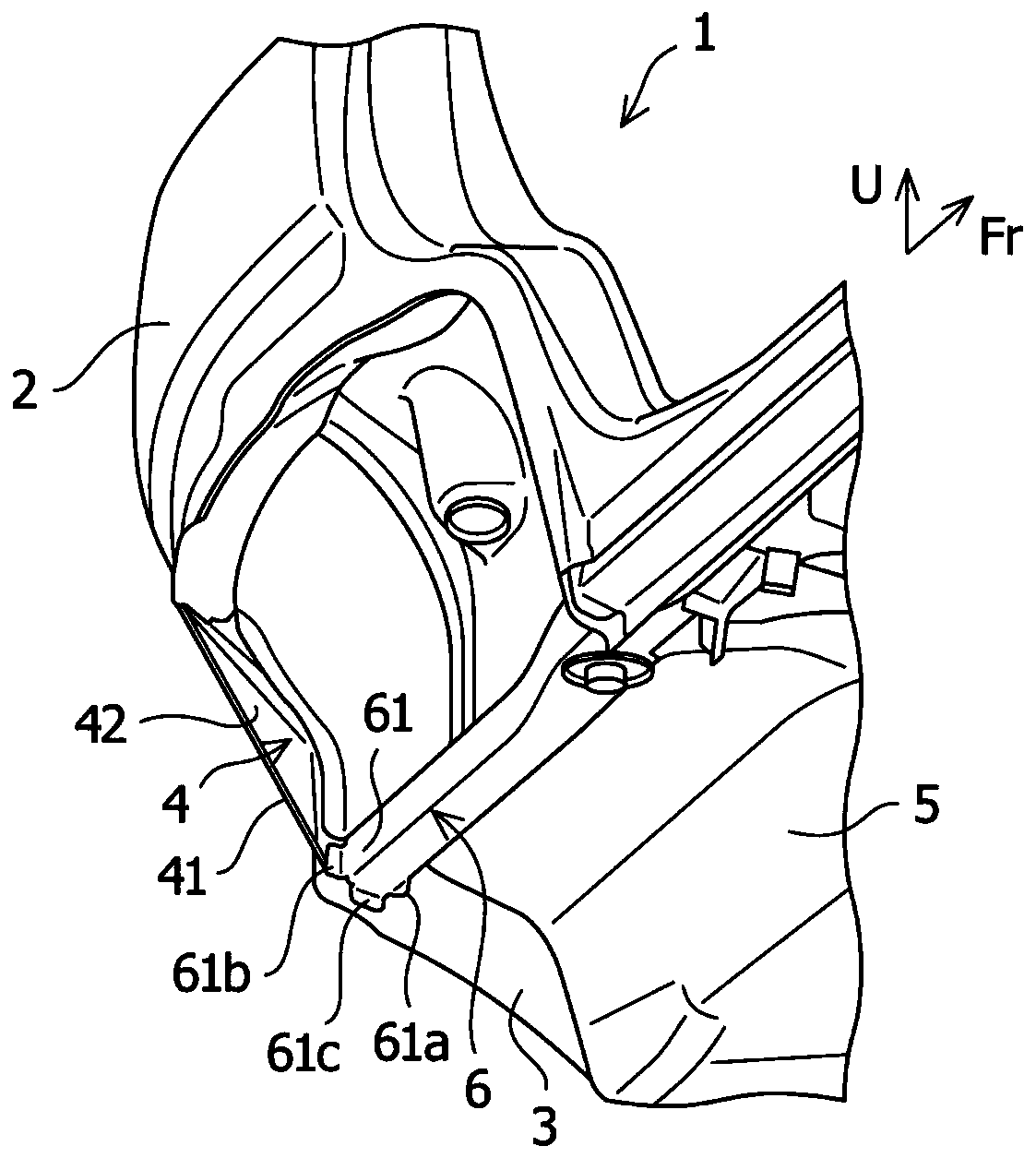

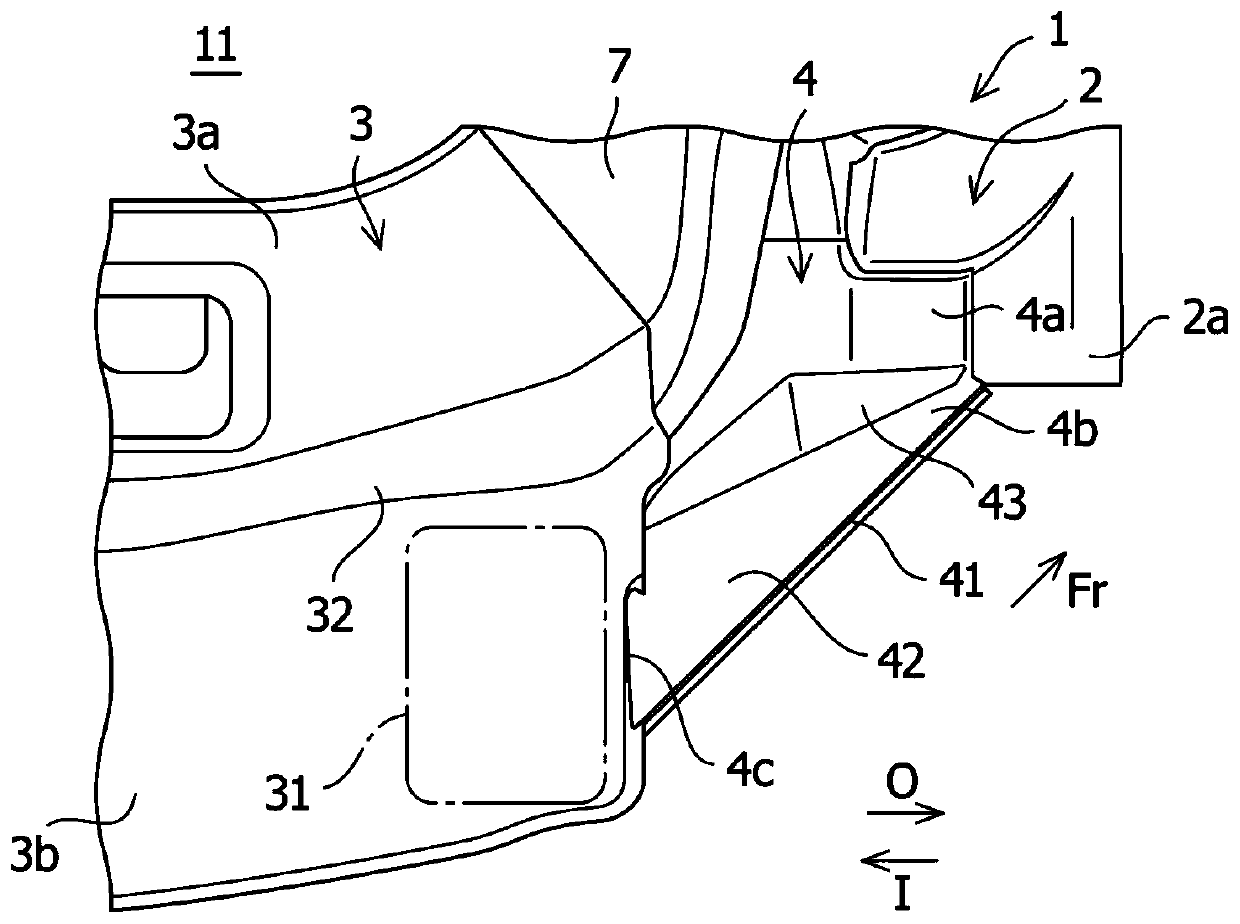

Door weather strip

InactiveUS7197850B2Suppresses bending deformationReliable preventionCondensed water drain-offVehicle sealing arrangementsAcute angleEngineering

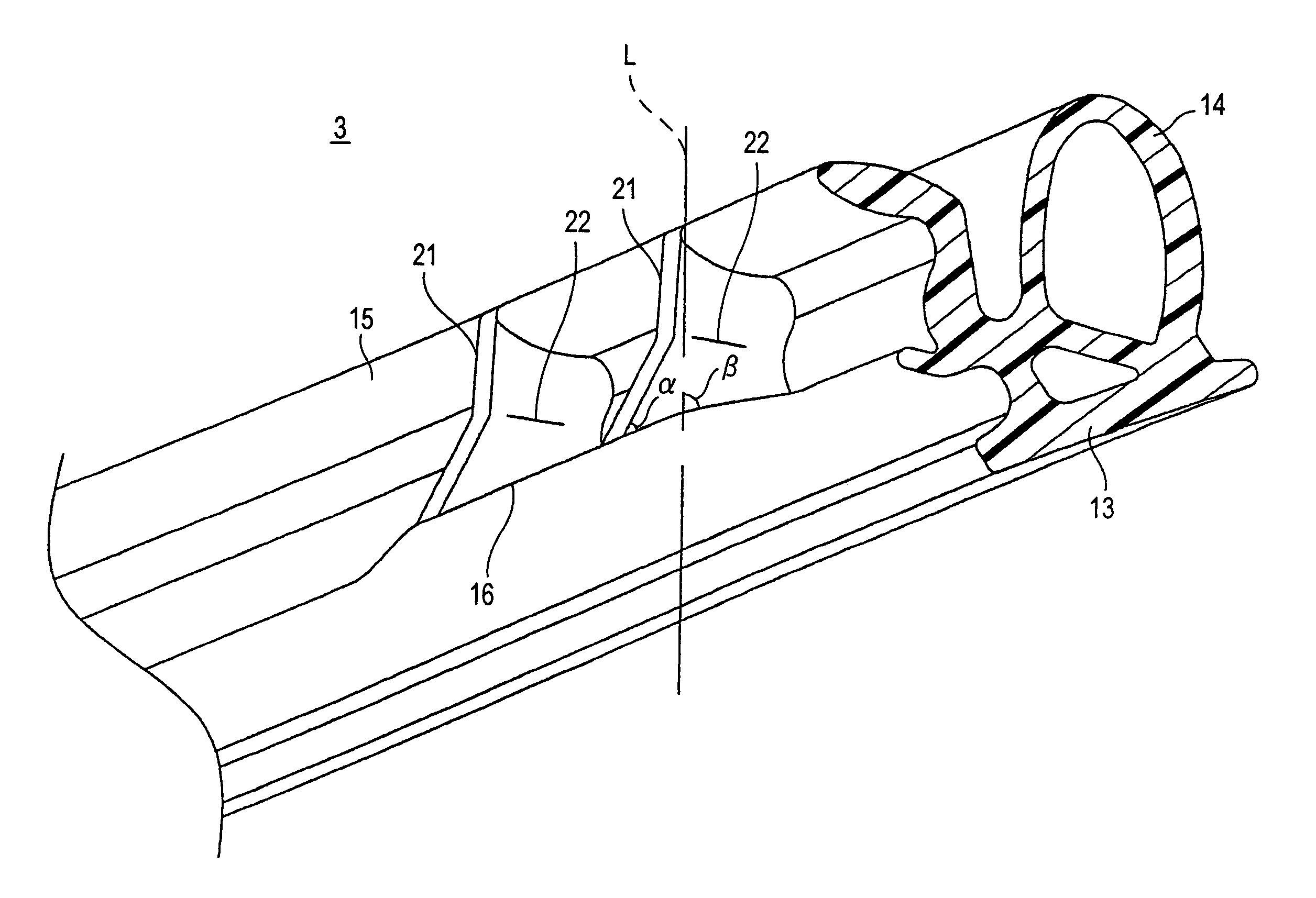

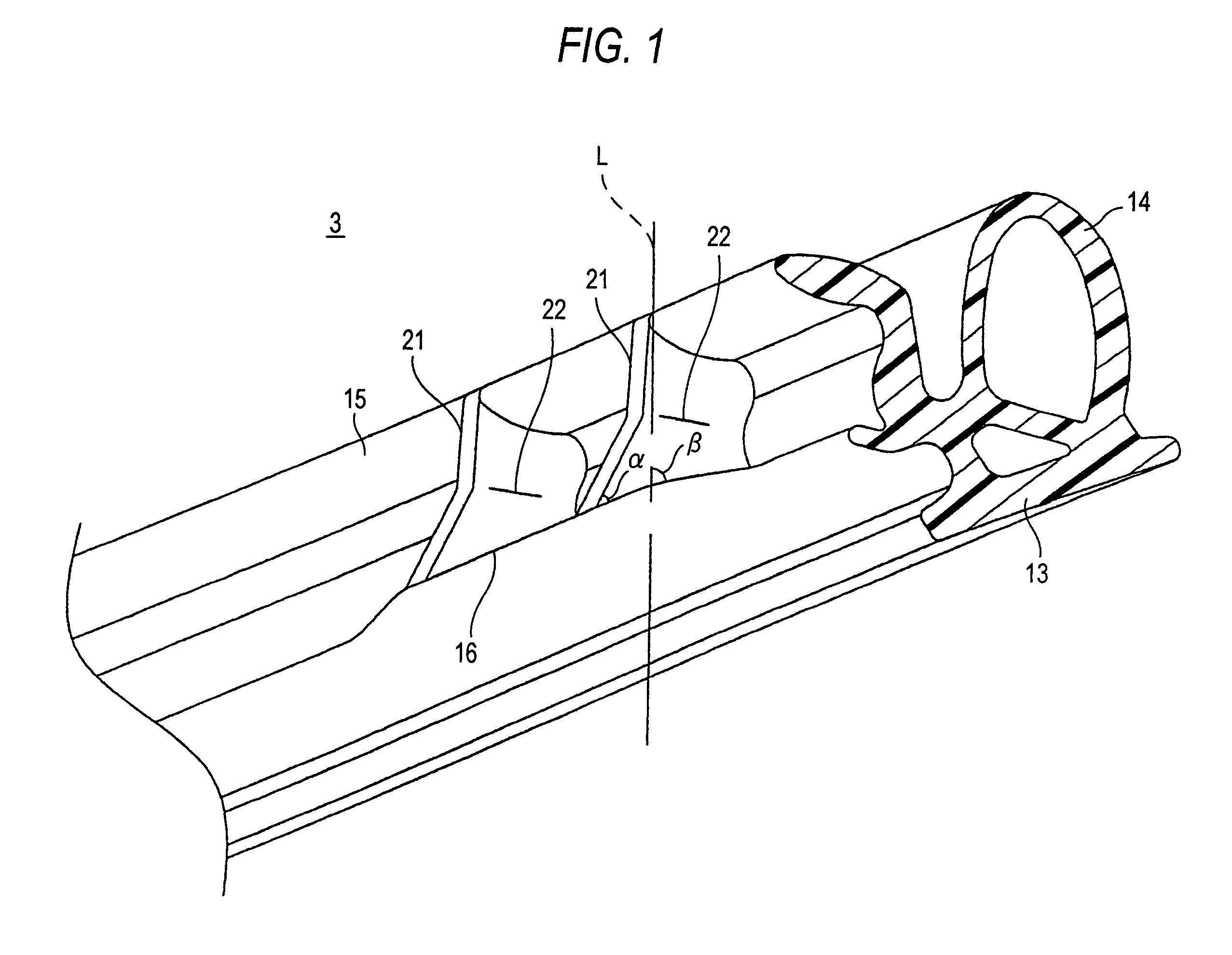

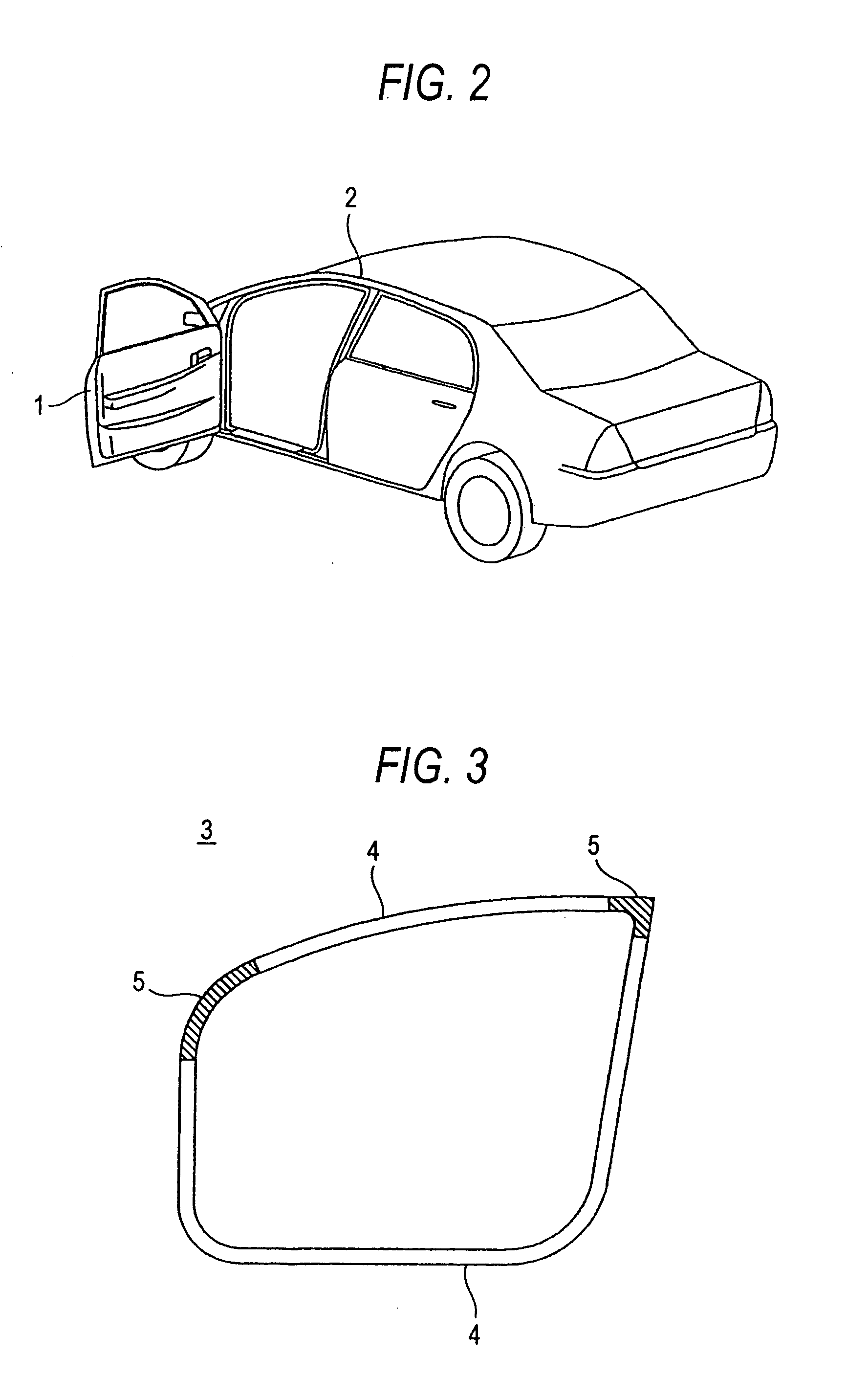

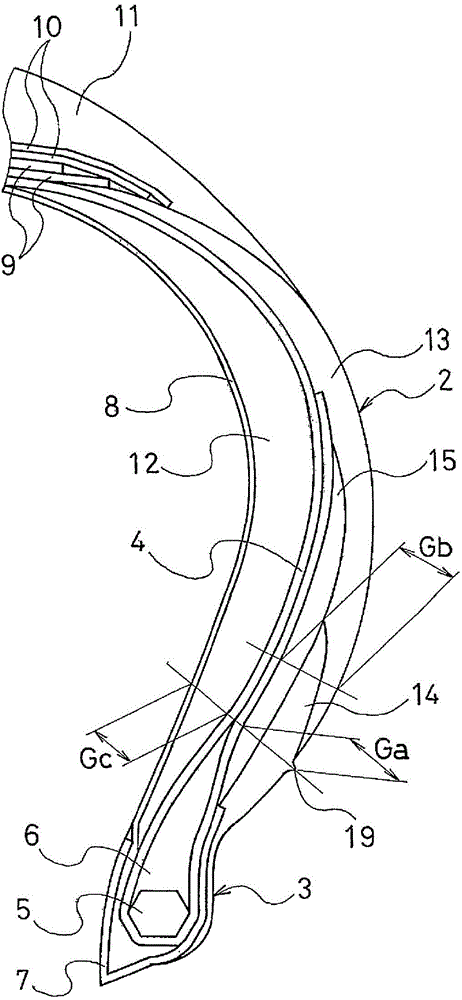

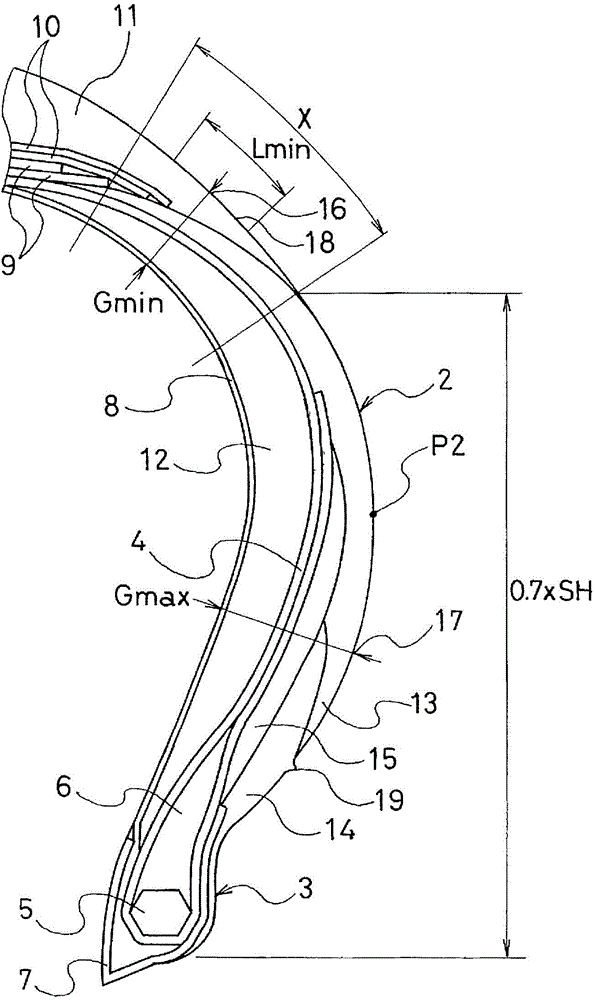

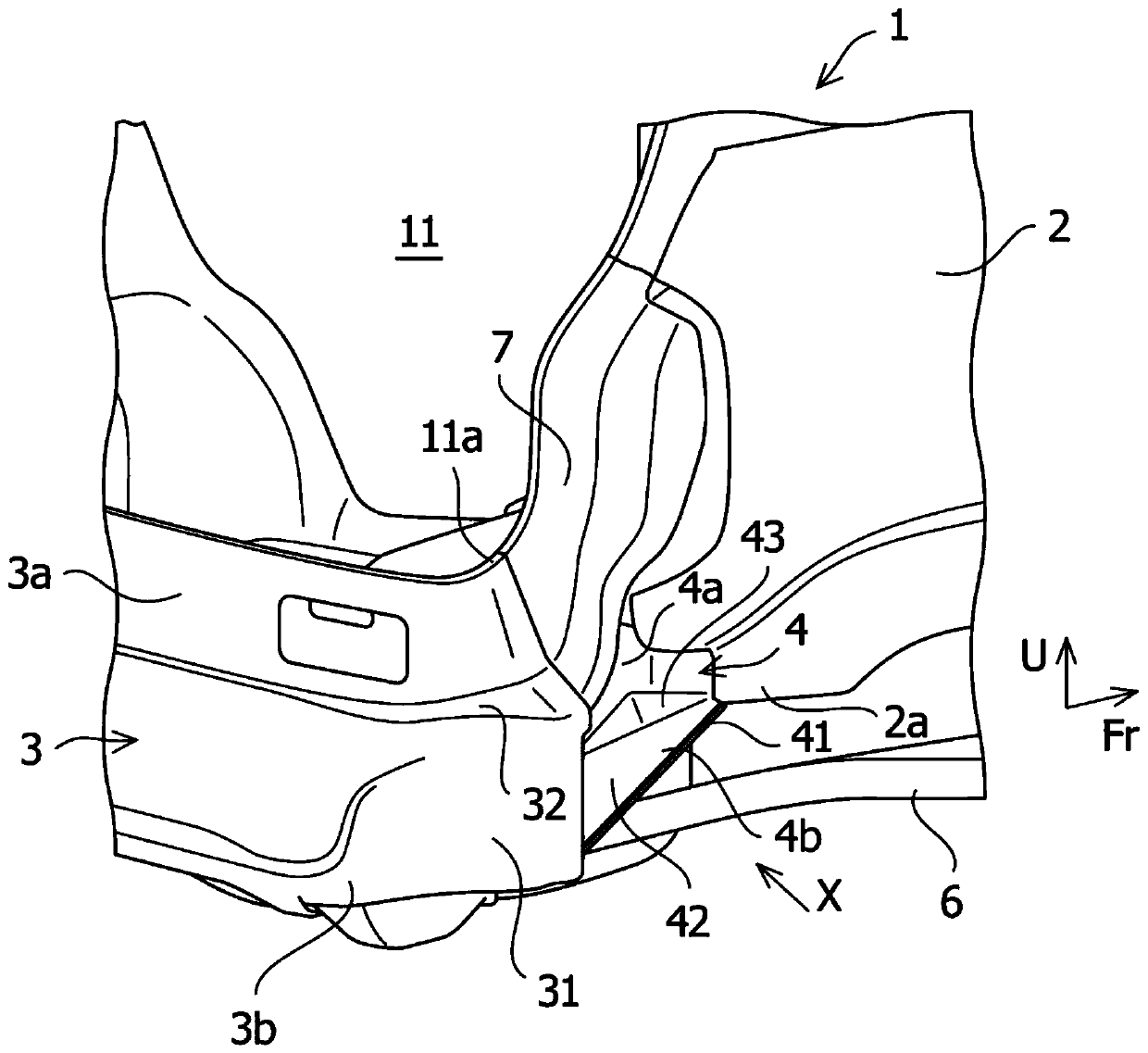

A door weather strip has a mounting base portion, a hollow seal portion, a sub-seal lip, and a backside seal lip. Leading lips are provided in the middle of a front pillar part in such a way as to connect the backside seal lip to the sub-seal lip. Each of the leading lips forms an acute angle with respect to an extending direction of the backside seal lip. Especially, in an attached state, an intersection angle α formed between the backside seal slip and each of the leading lips is set to be smaller than an angle β formed between the extending direction of the backside seal lip, and a vertical line.

Owner:TOYODA GOSEI CO LTD

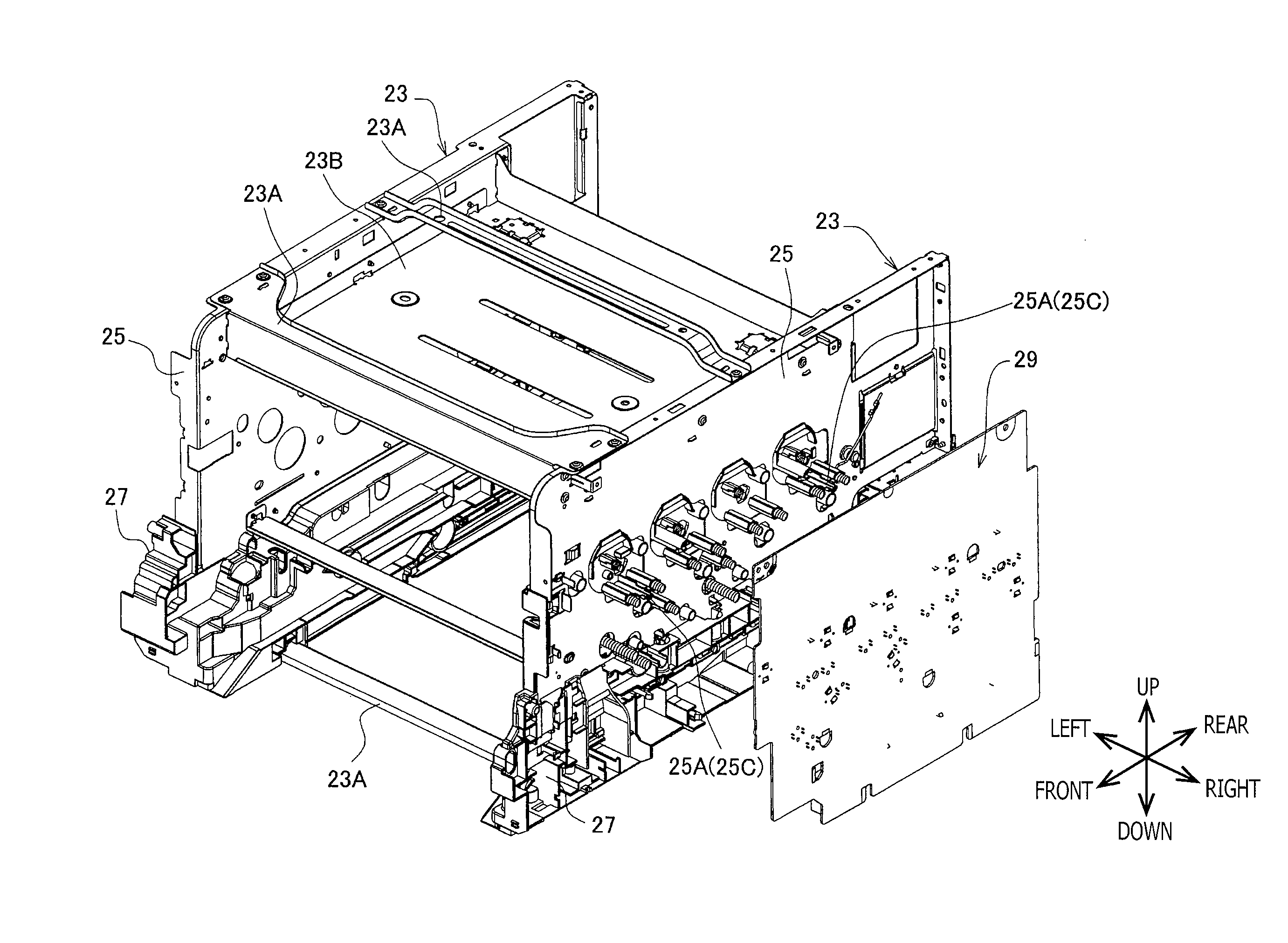

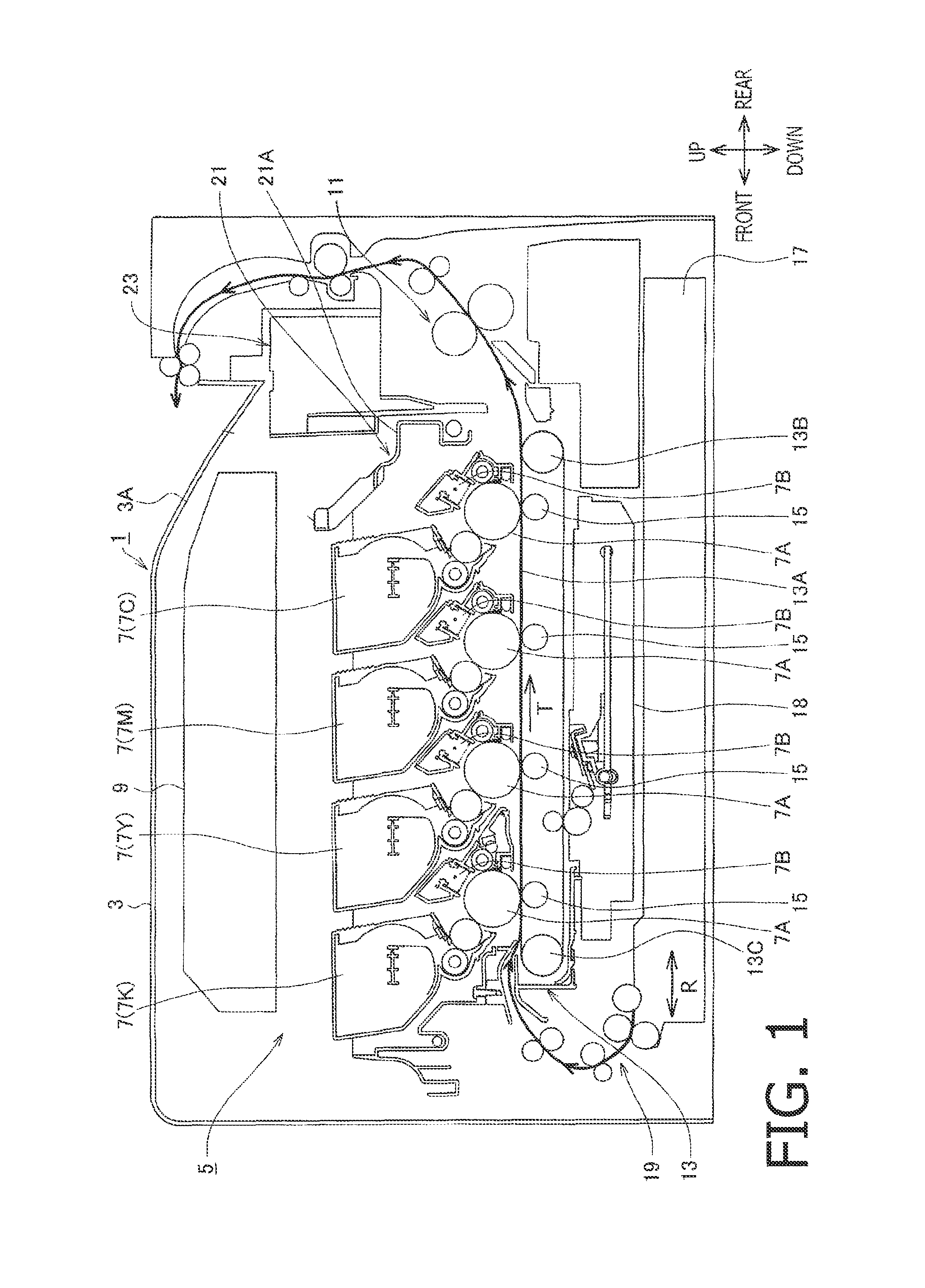

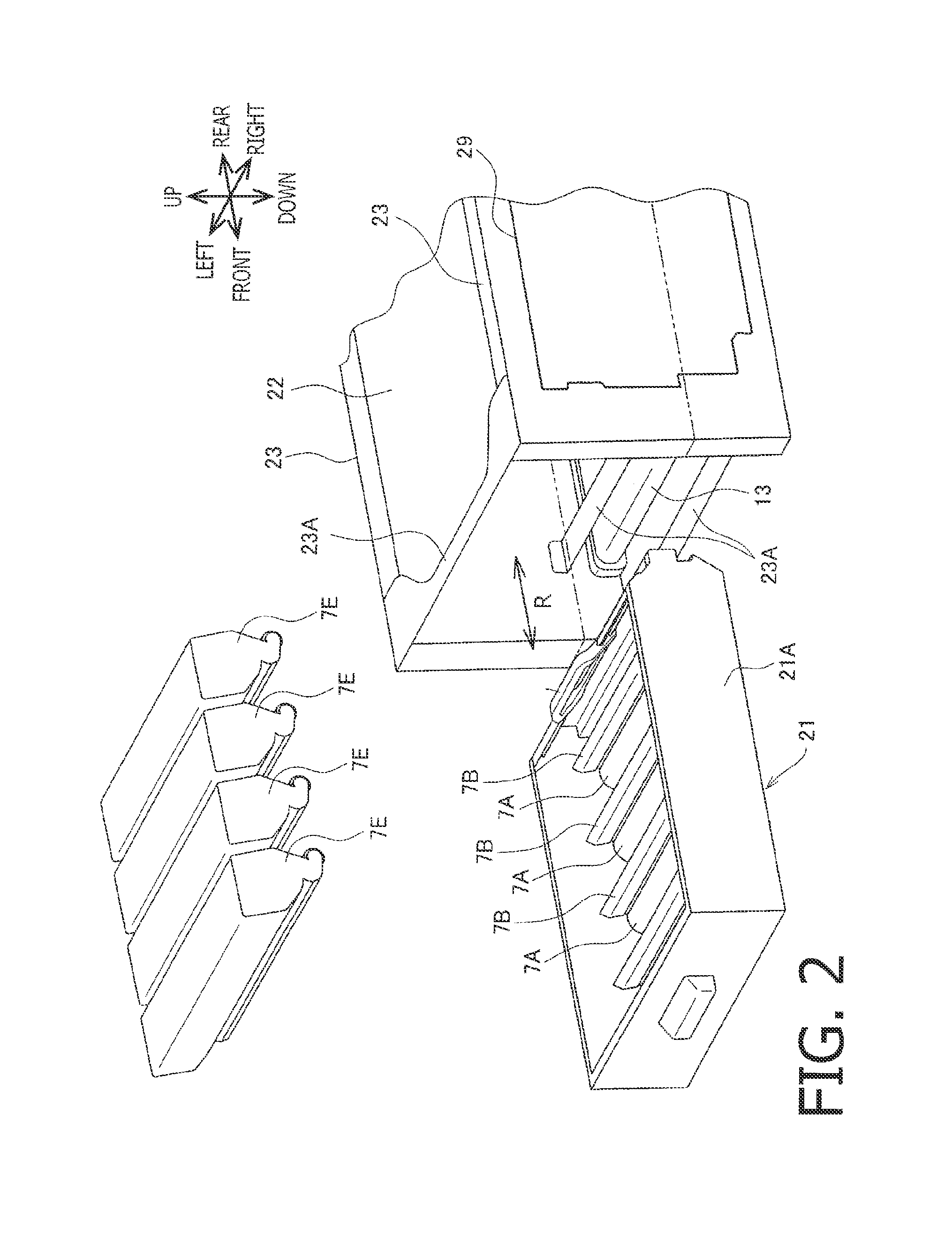

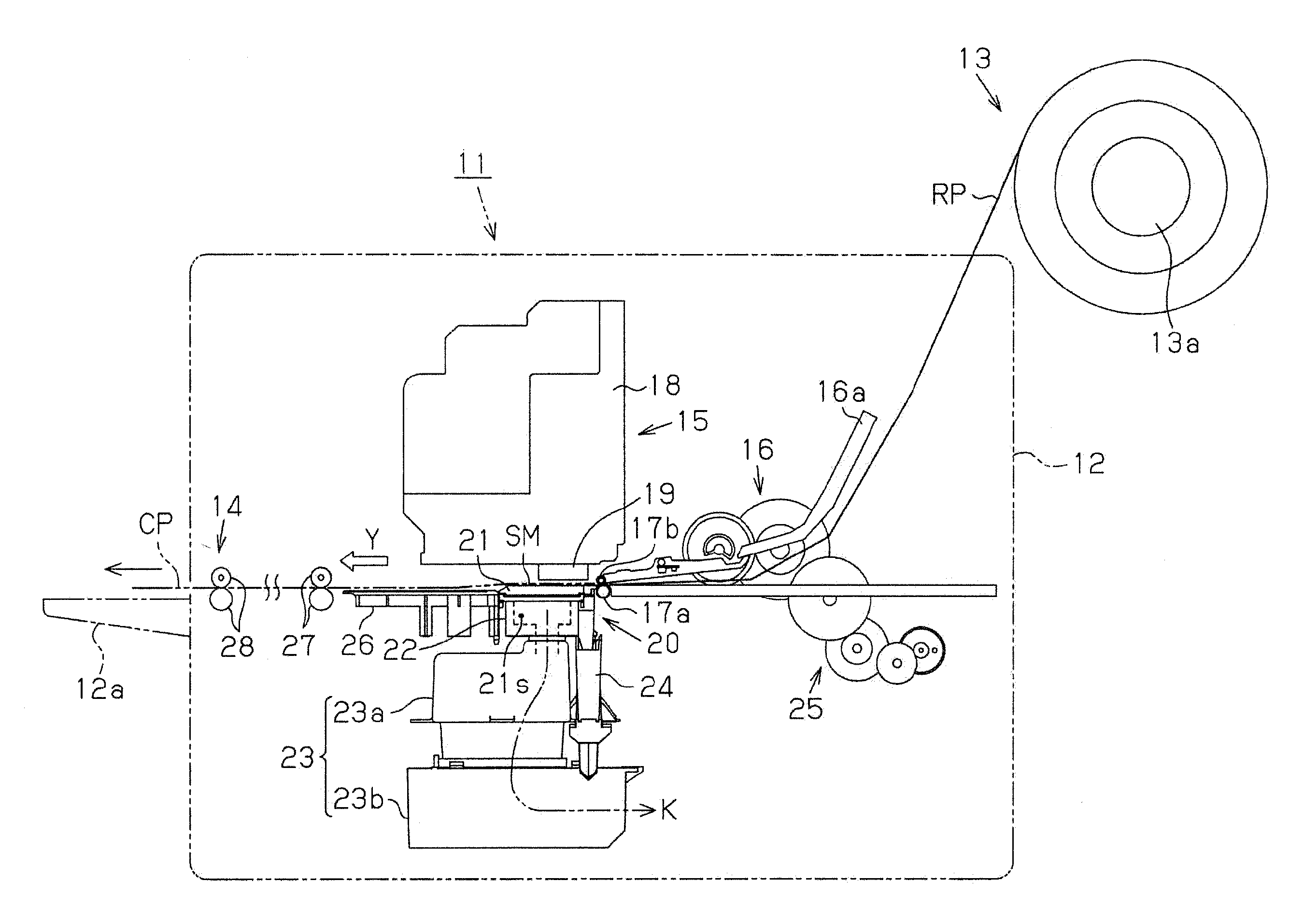

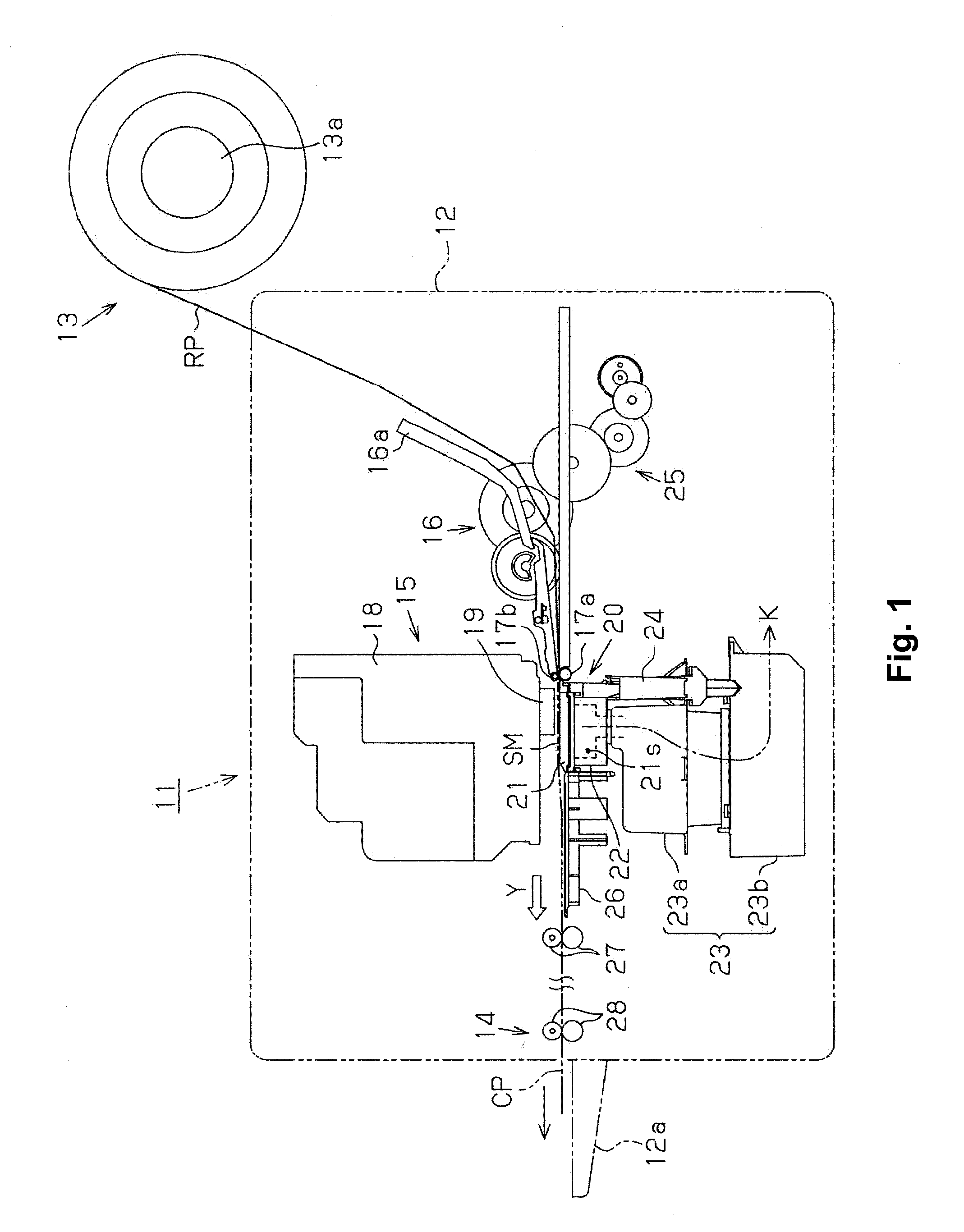

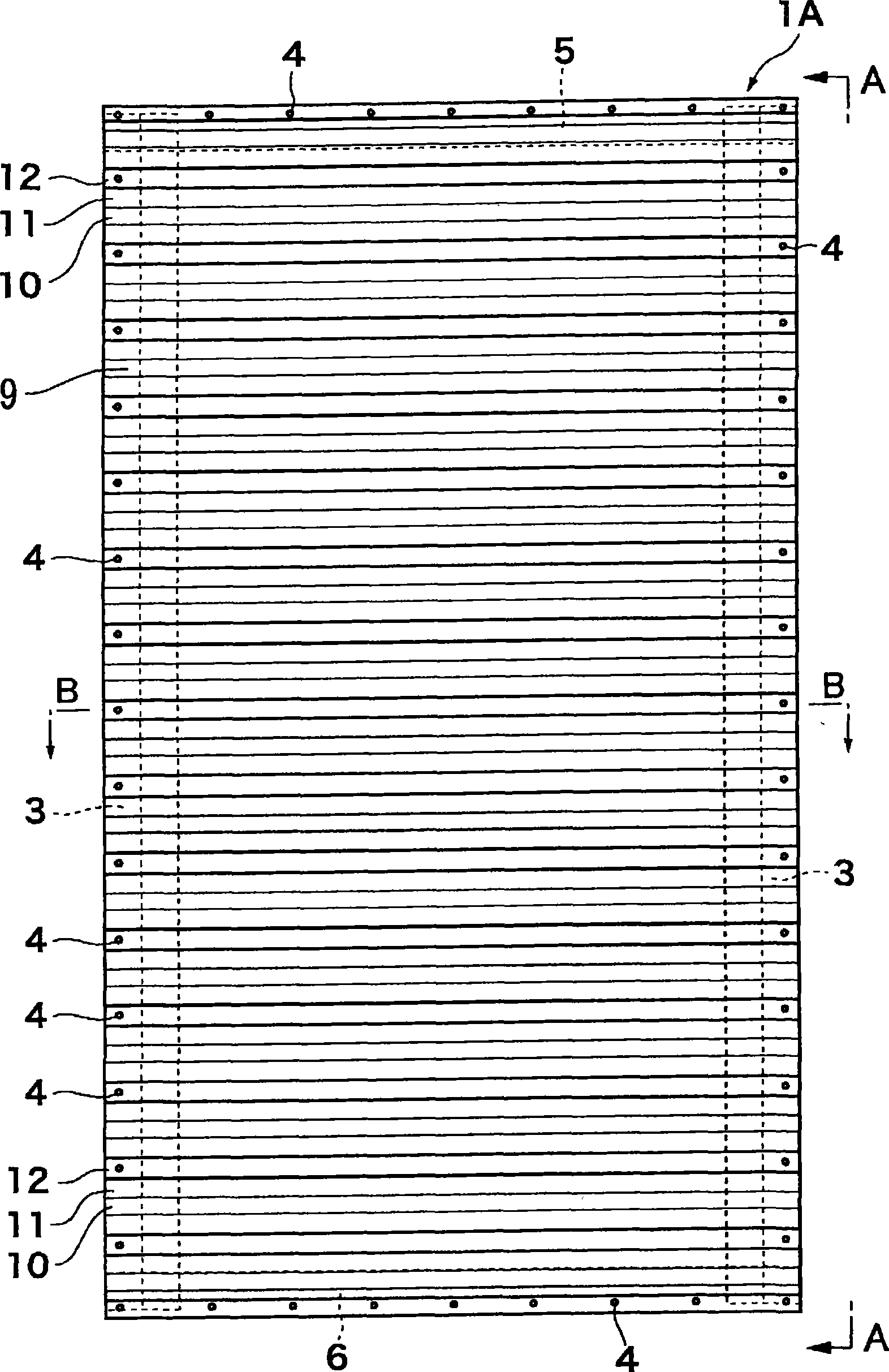

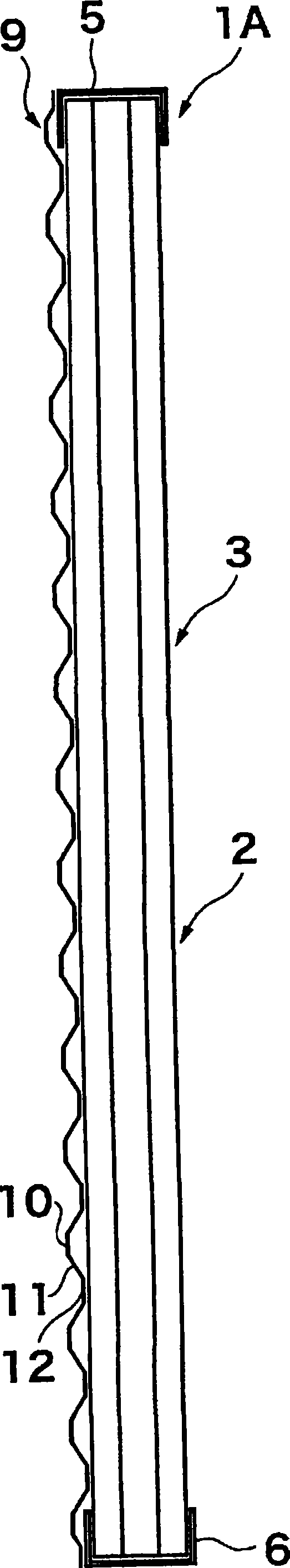

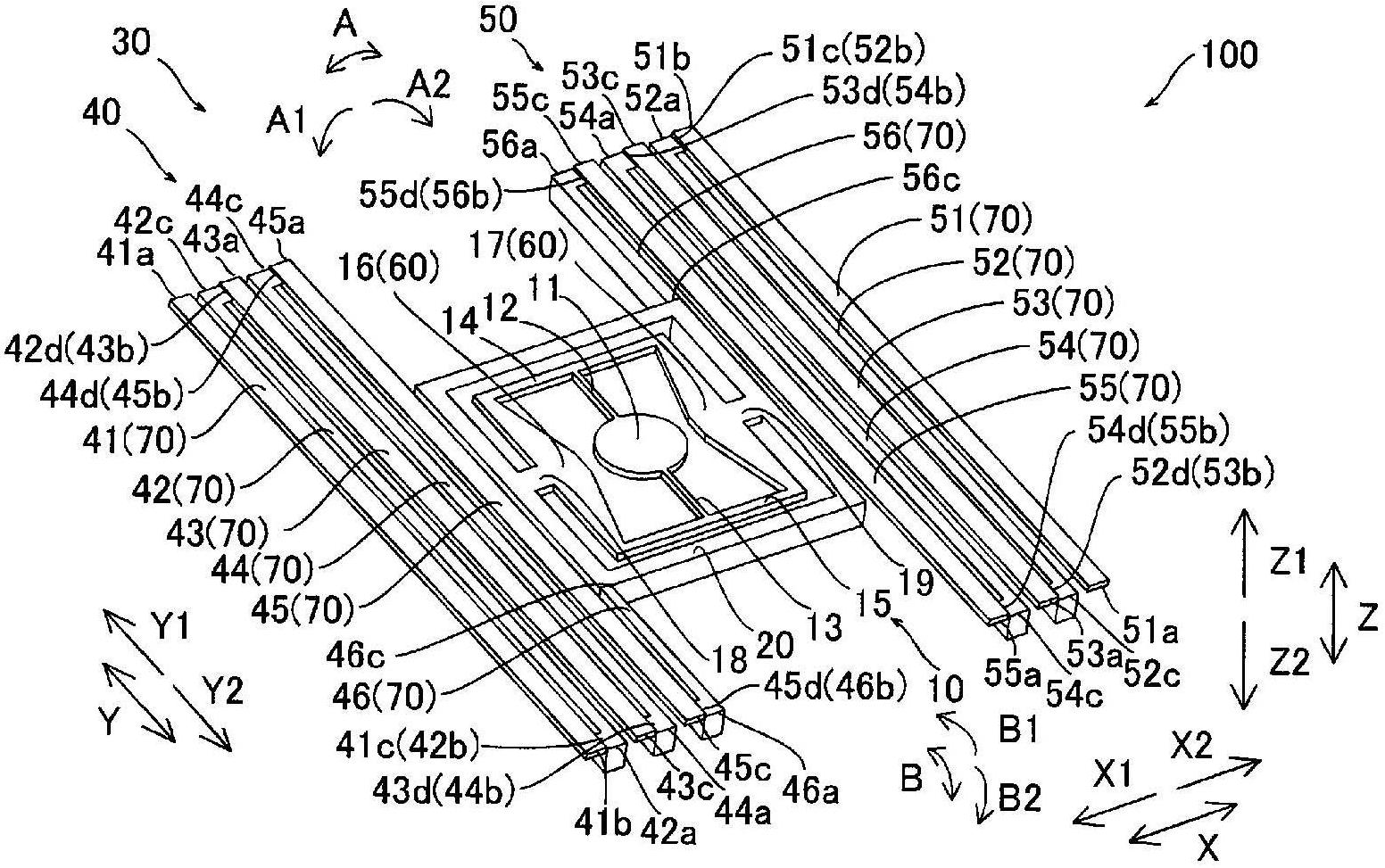

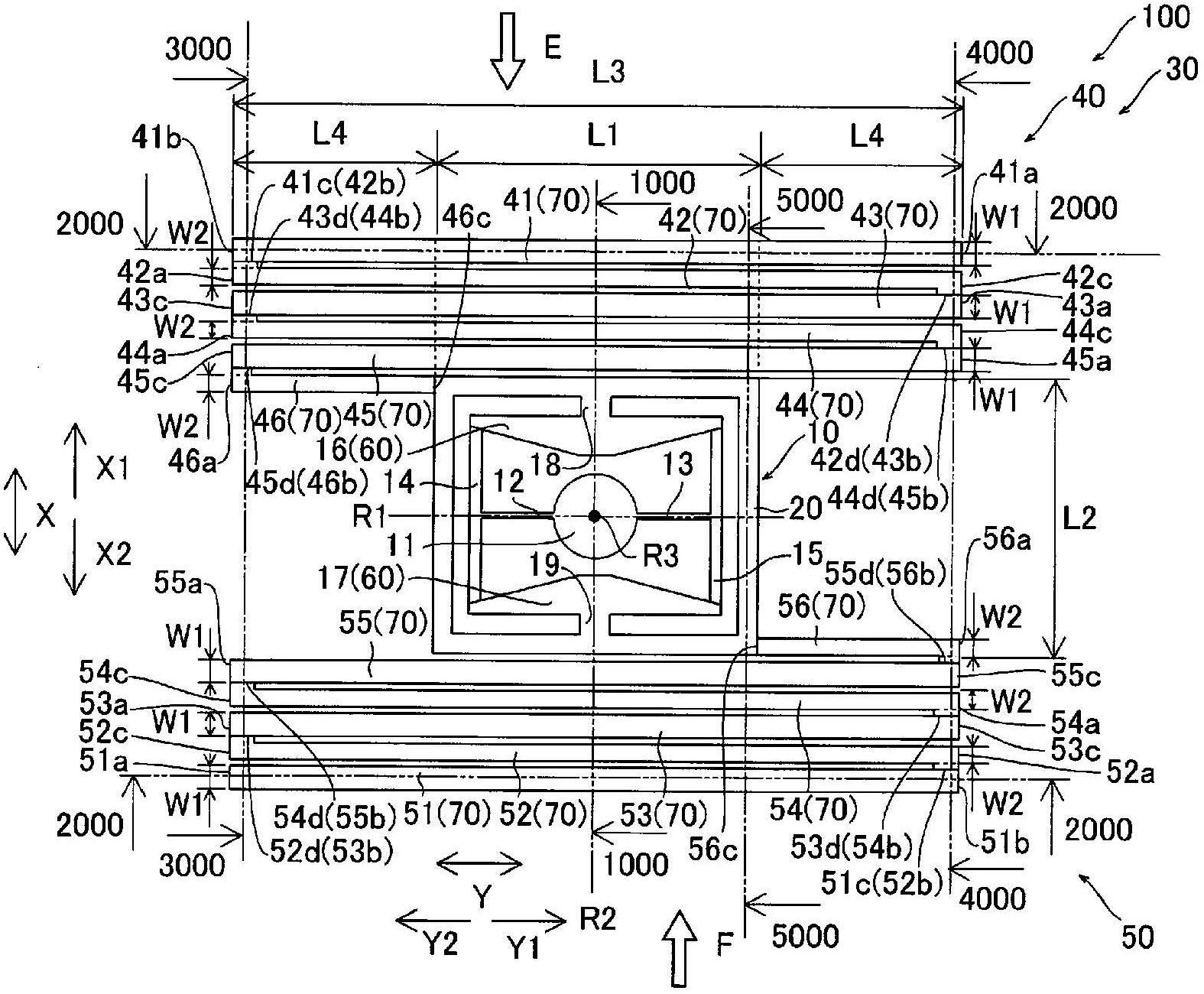

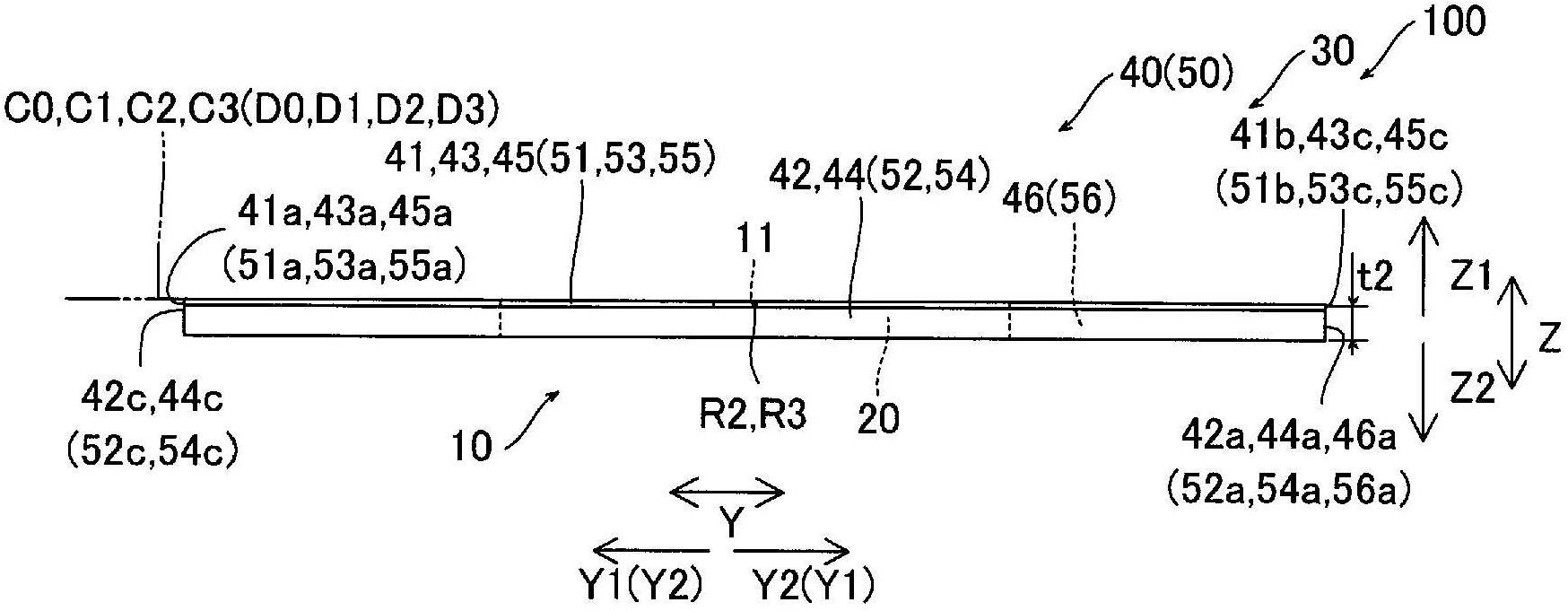

Image formation device having first frame for supporting image formation unit and second frame of lower flexure rigidity

ActiveUS8532524B2Suppresses bending deformationElectrographic process apparatusImage formationEngineering

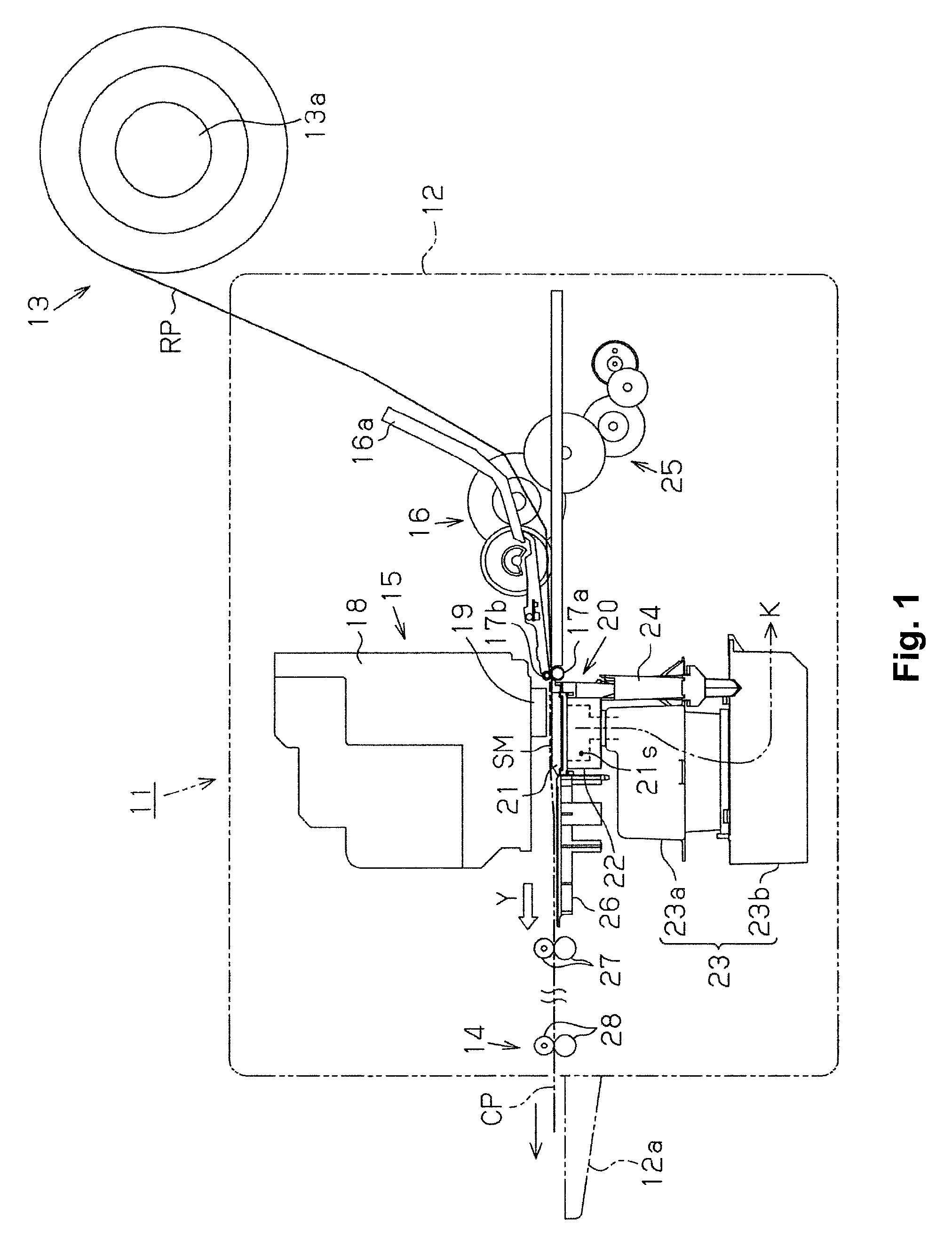

An image formation device is provided with an image formation unit configured to form an image on a recording sheet, a first frame arranged to support the image formation unit, a second frame connected to the first frame, flexure rigidity of the second frame being smaller than flexure rigidity of the first frame, an electric substrate electrically connected with the image formation unit. With the above configuration, the electric substrate is arranged to extend from the first frame to the second frame and is secured onto the first frame with the position on the first frame being adjusted.

Owner:BROTHER KOGYO KK

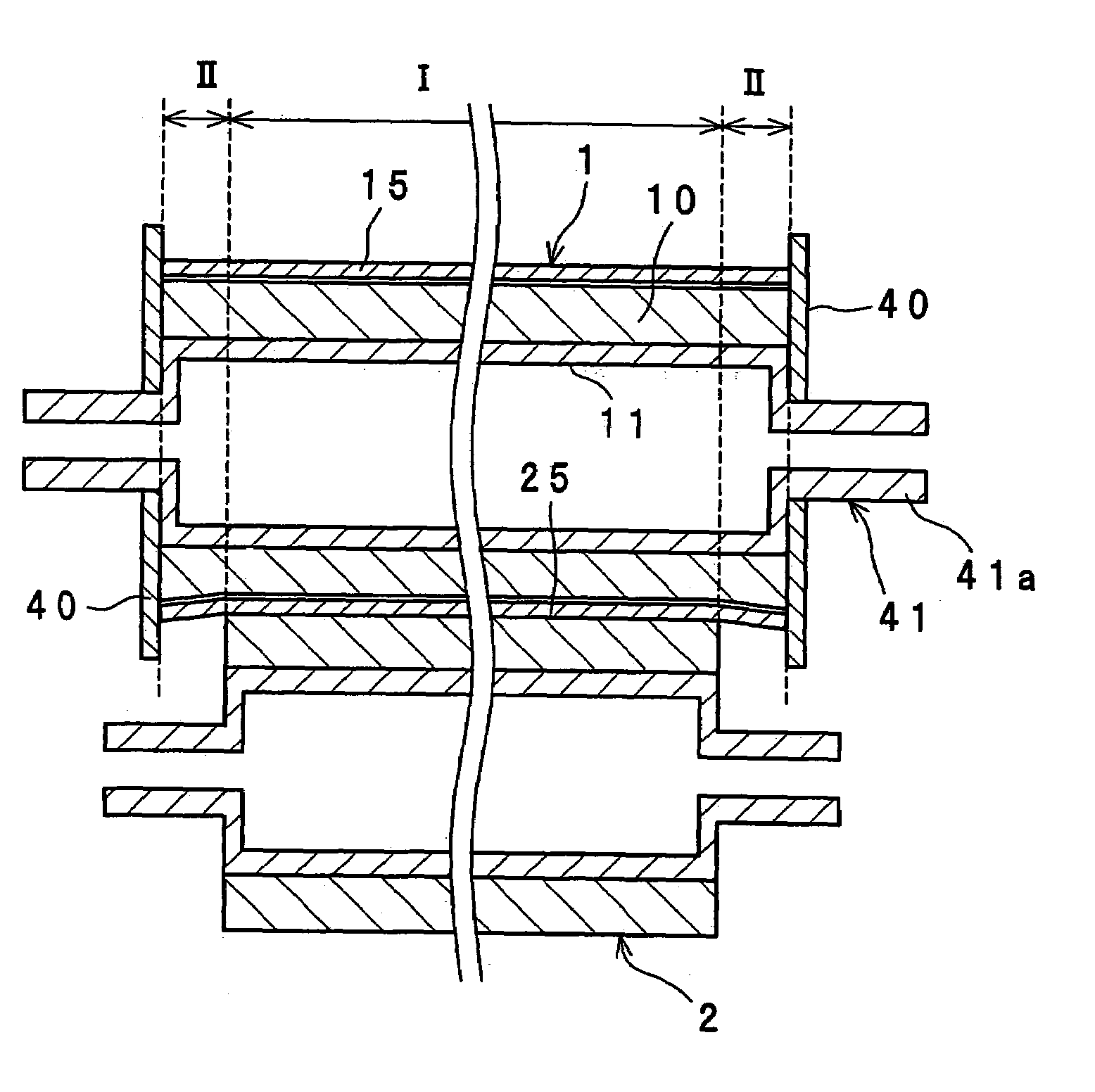

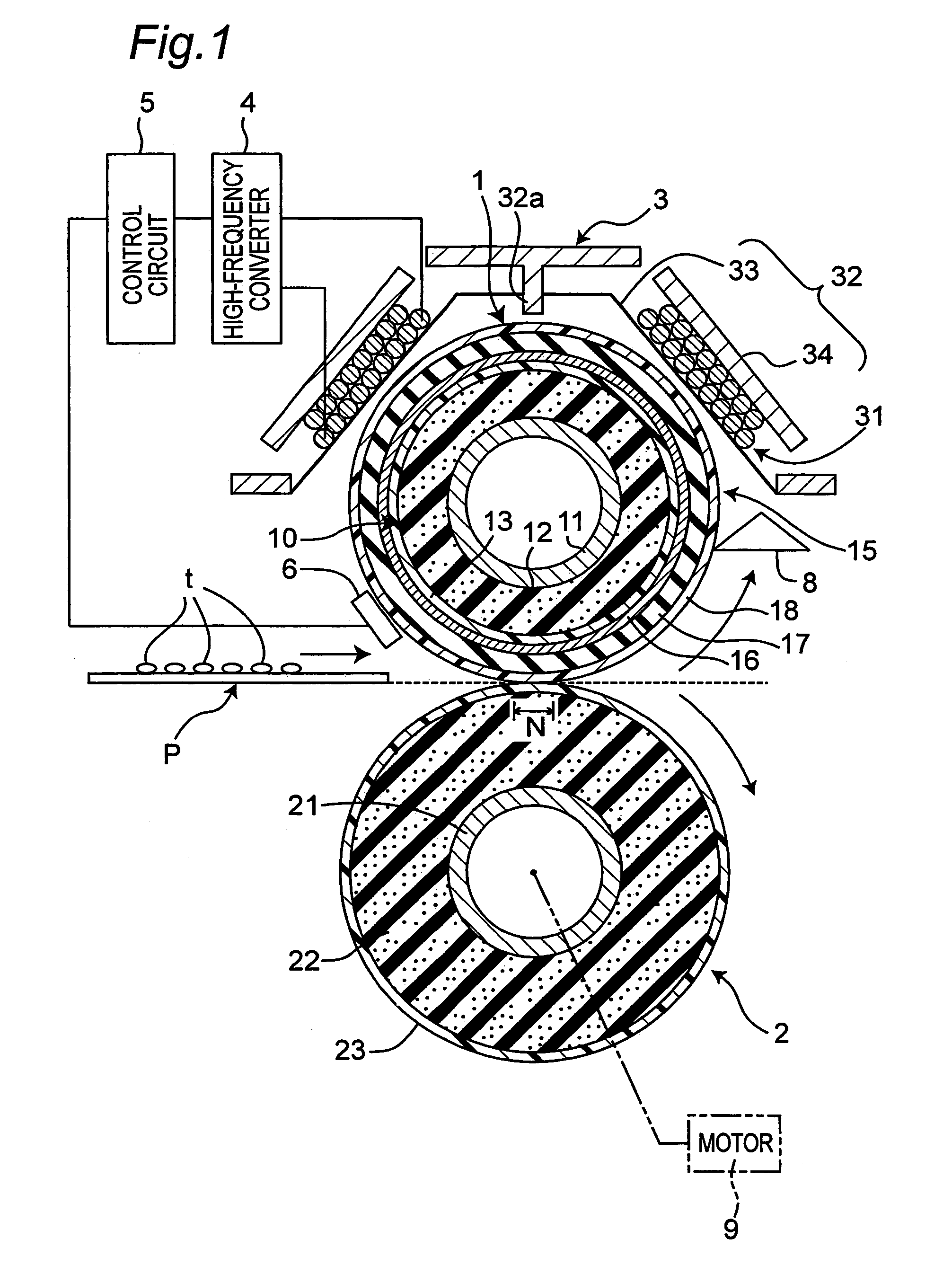

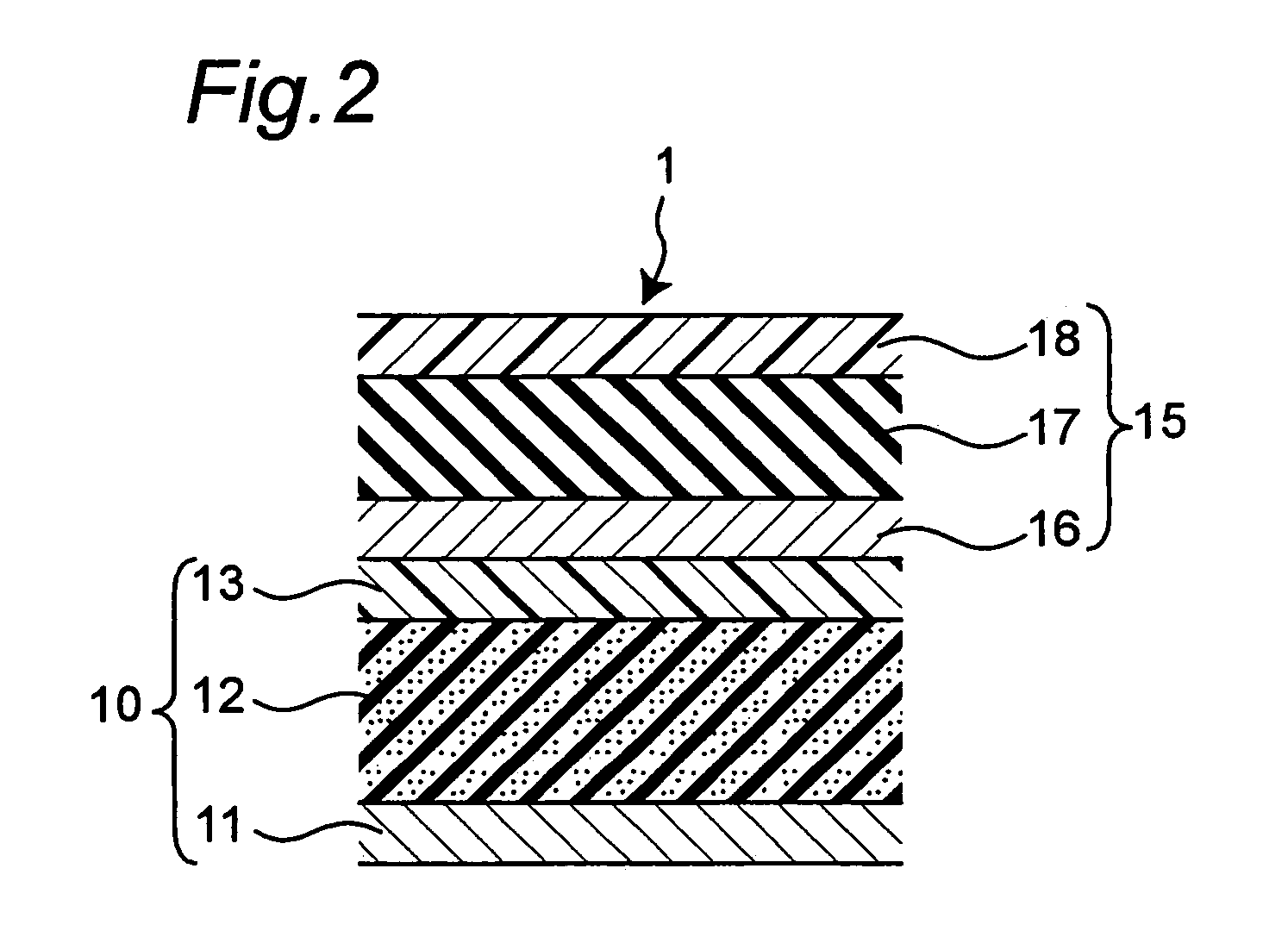

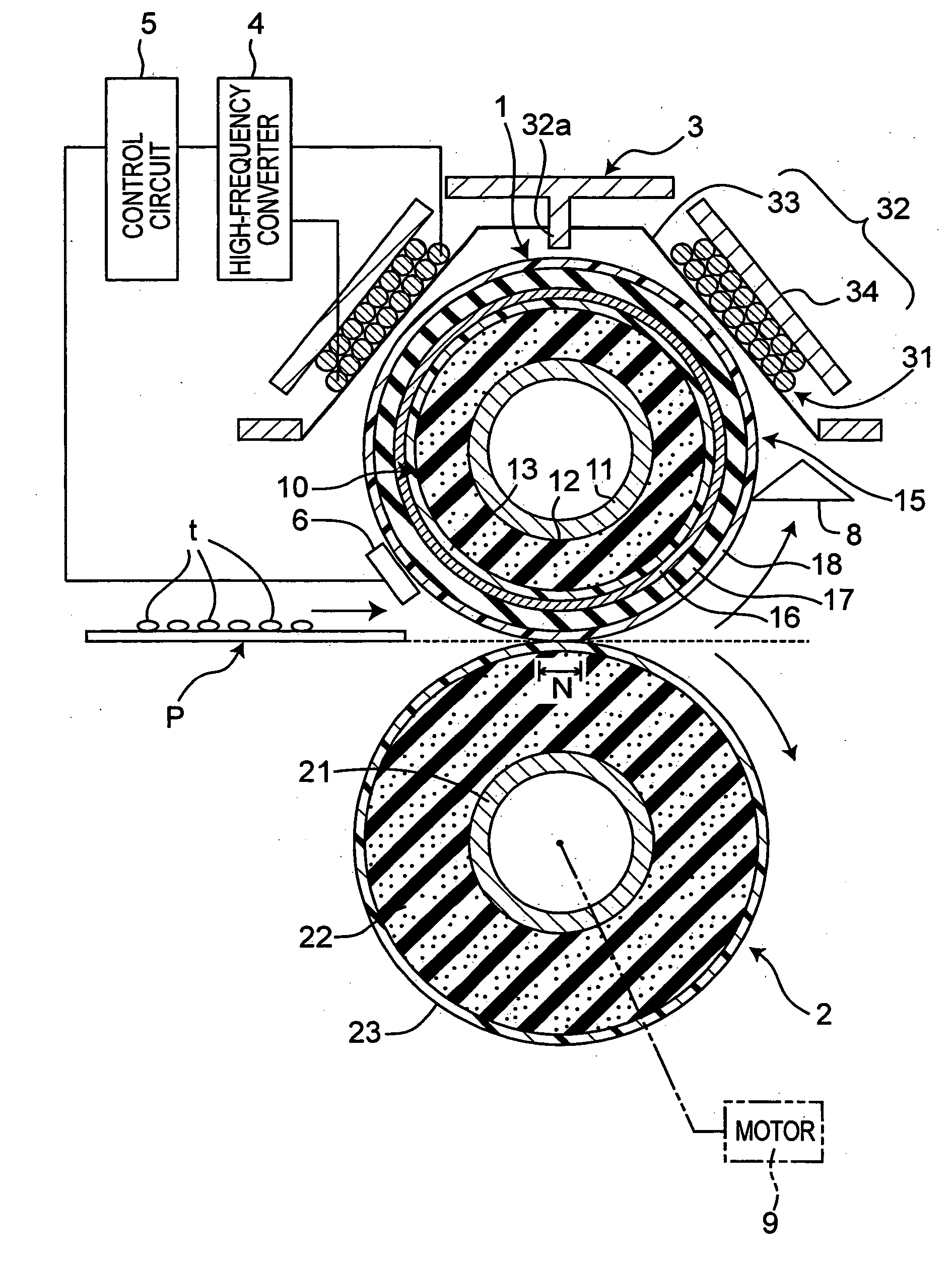

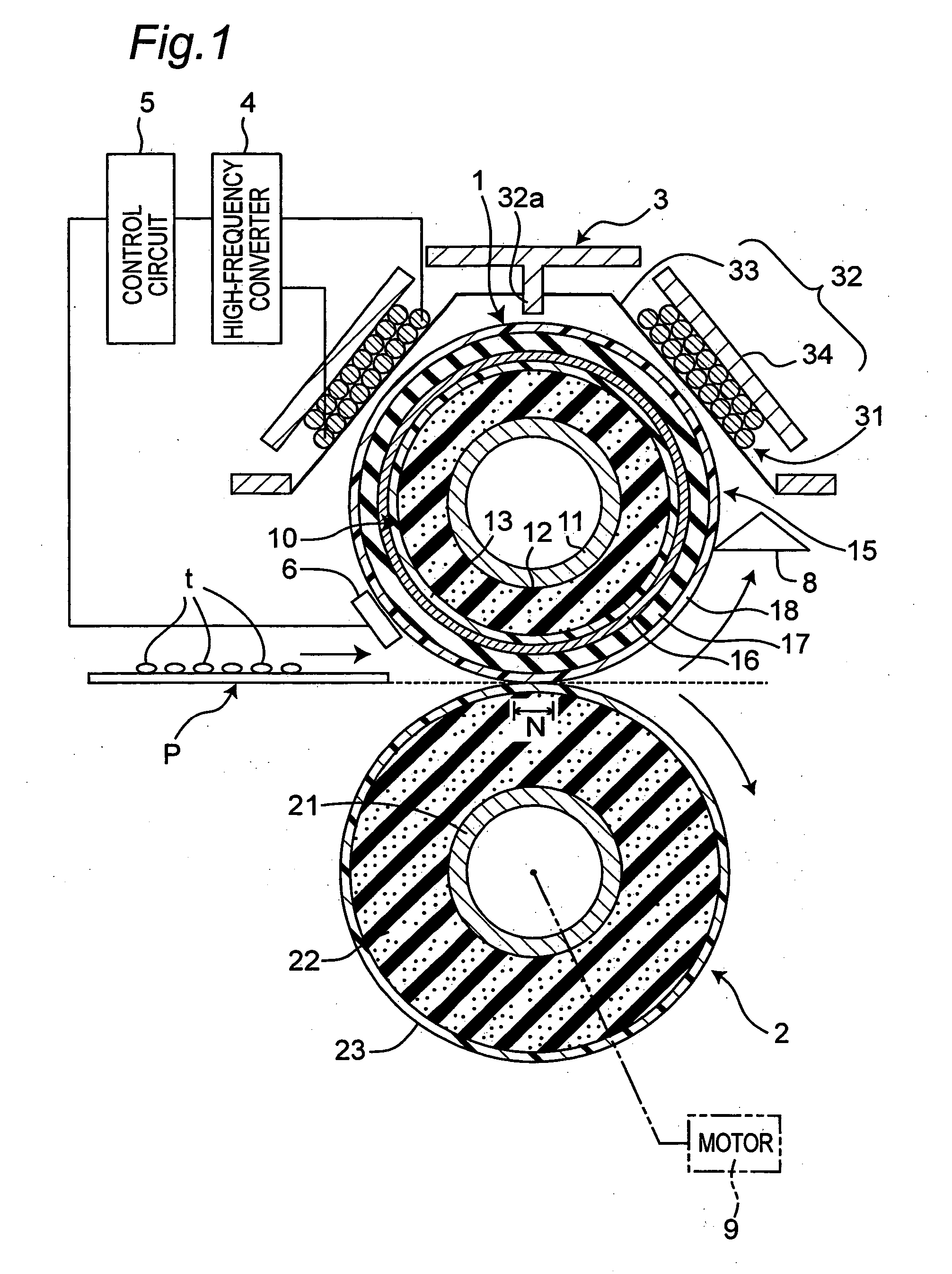

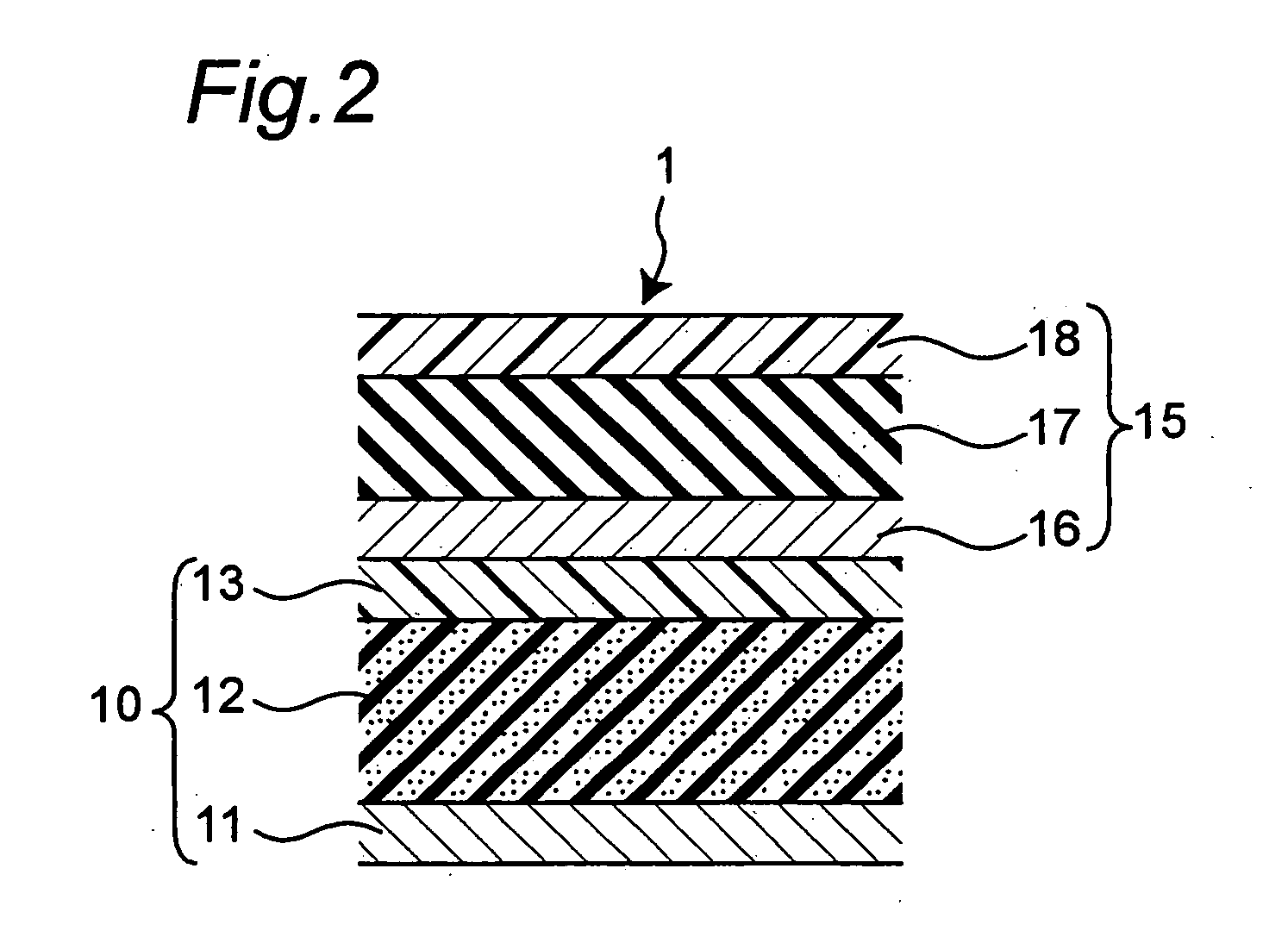

Fixing device

ActiveUS7218884B2Suppresses bending deformationIncreased durabilityOhmic-resistance heatingElectrographic process apparatusEngineeringMechanical engineering

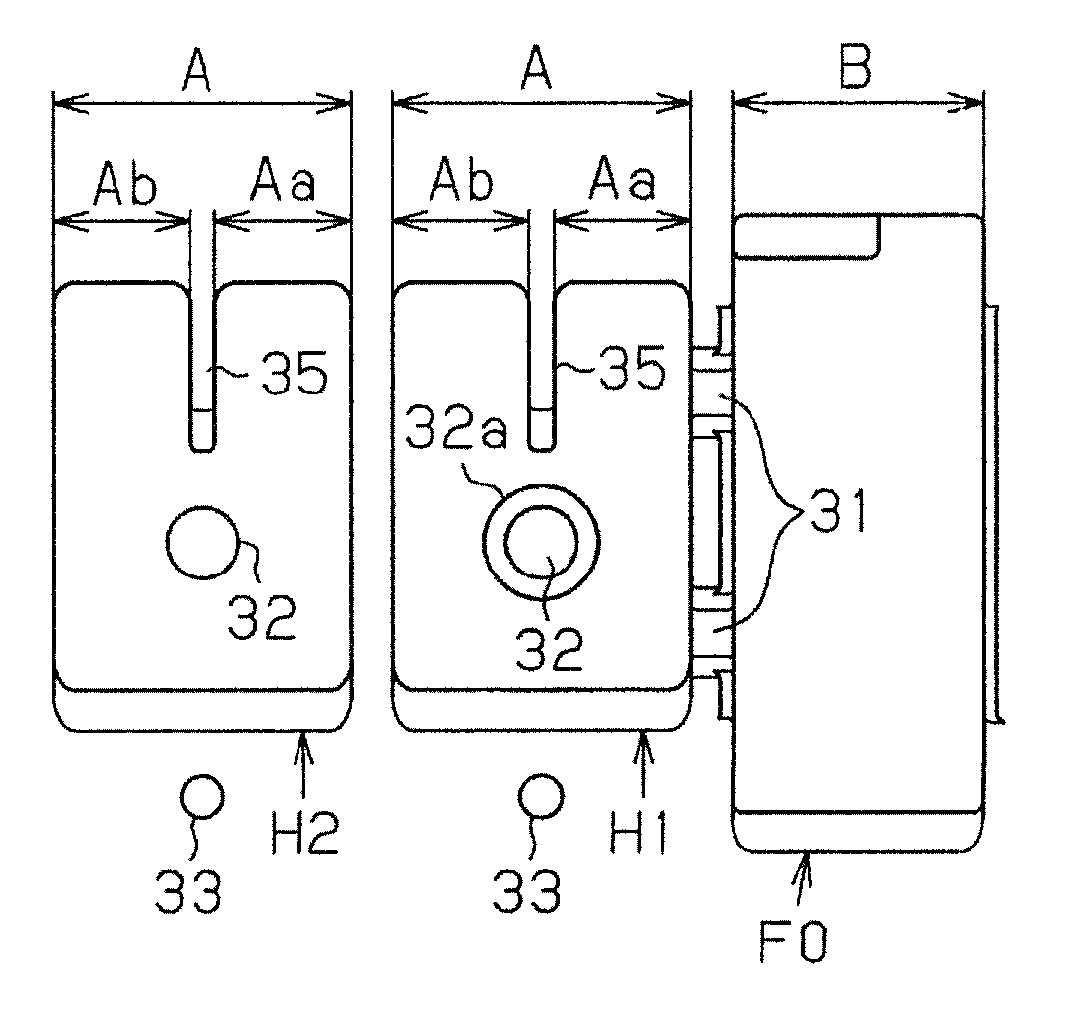

A fixing device has a fixing roller including an inside roller, an outside roller and a regulation member. The regulation member is disposed outside of both ends of the outside roller in the axial direction to regulate axial movement of the outside roller. An axial length of the contact face, where the pressure roller contacts with the outside roller, is smaller than an axial length of the outside roller. Thereby, both ends of the outside roller hardly receive bending deformation caused by pressure of the pressure roller. This makes it possible to reduce stress exerted to both ends of the outside roller, and therefore, the ends of the fixing roller are prevented from being damaged to enhance durability of the fixing roller.

Owner:KONICA MINOLTA BUSINESS TECH INC

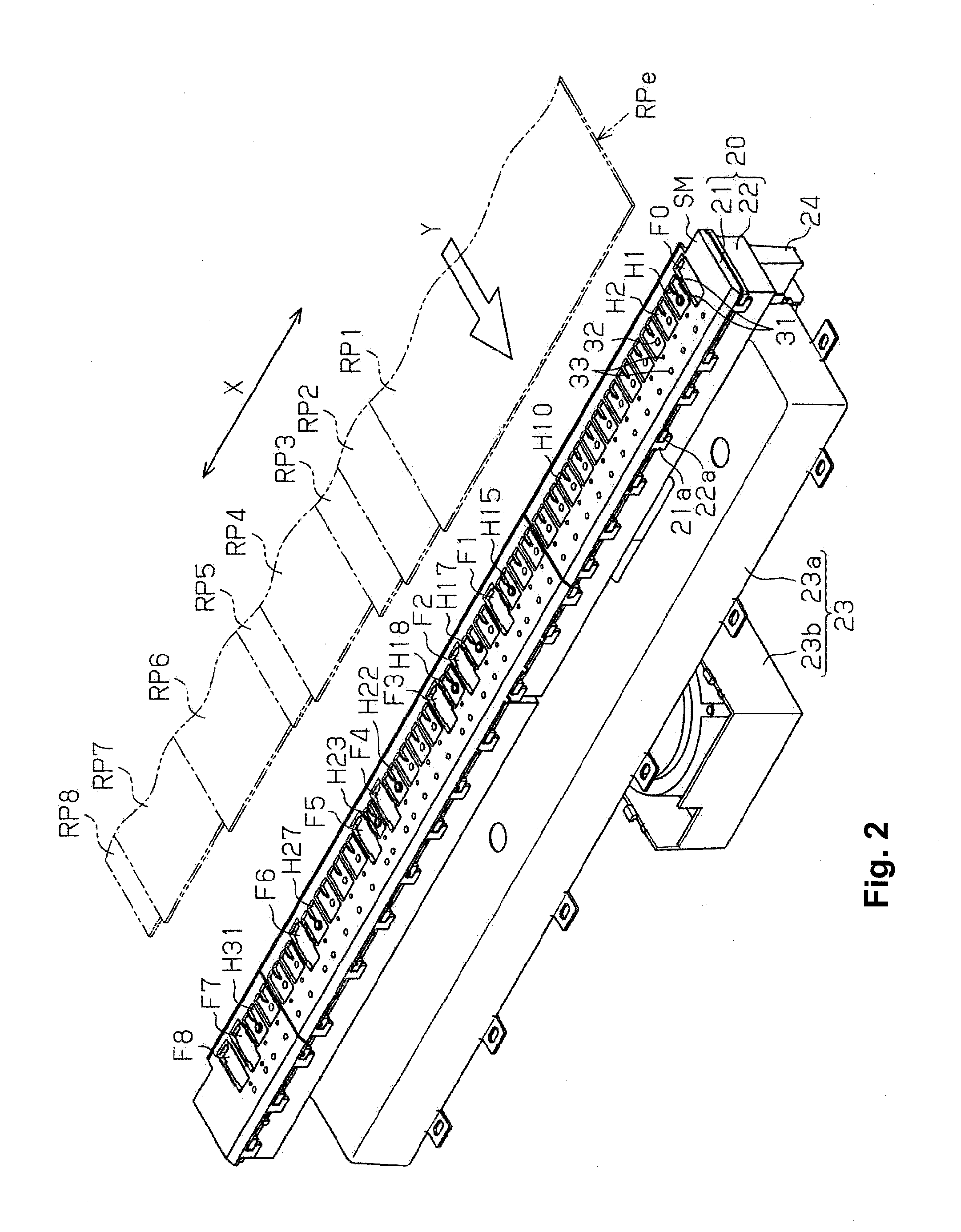

Liquid ejection device

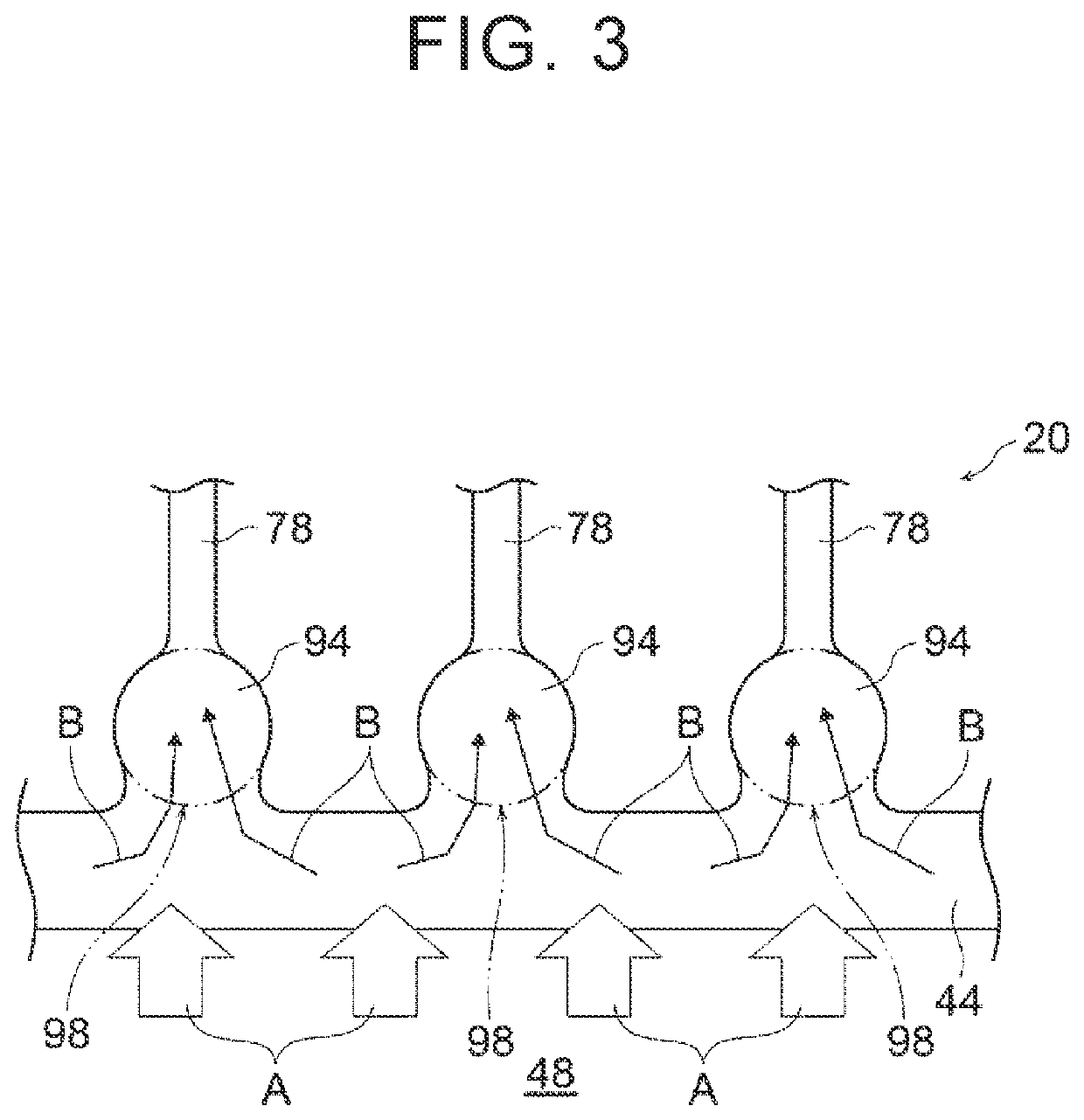

InactiveUS20130208065A1Deformation is generatedLarge easilyOther printing apparatusSupport surfaceElectrical and Electronics engineering

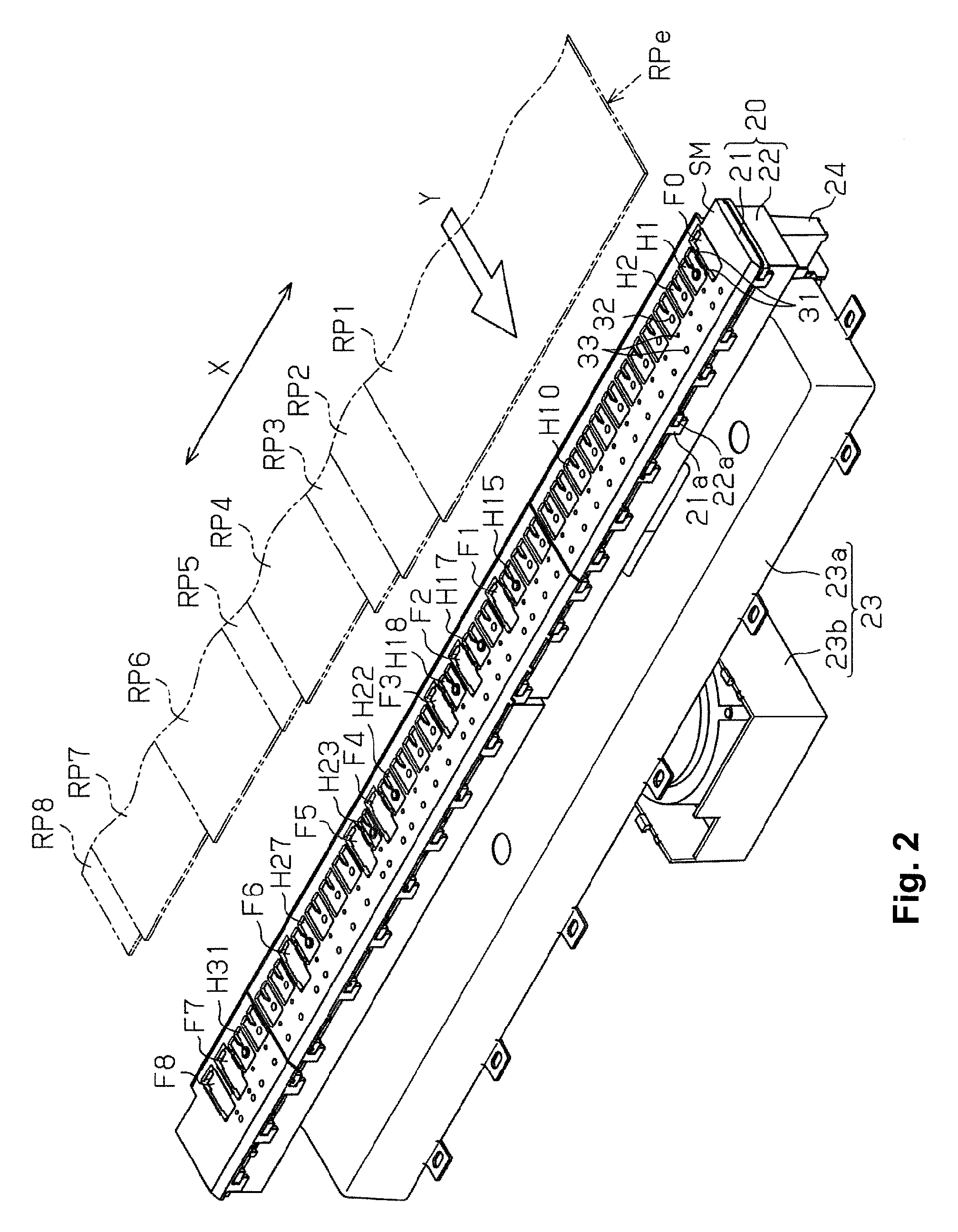

A liquid ejection device includes a transport unit, a medium support unit and a liquid ejection head. The medium support unit includes a plurality of first recesses and a plurality of second recesses arranged on a medium support surface along a width direction orthogonal to a transport direction. The first and second recesses are configured and arranged to be imparted with negative pressure. A width dimension of an opening of the first recess in the width direction is larger on the downstream side than on an upstream side. A width dimension of an opening of the second recess in the width direction is smaller than the width dimension of the opening of the first recess in the width direction on the downstream side with respect to the transport direction. The second recesses are configured and arranged to accept the liquid ejected toward the ejection medium from the liquid ejection head.

Owner:SEIKO EPSON CORP

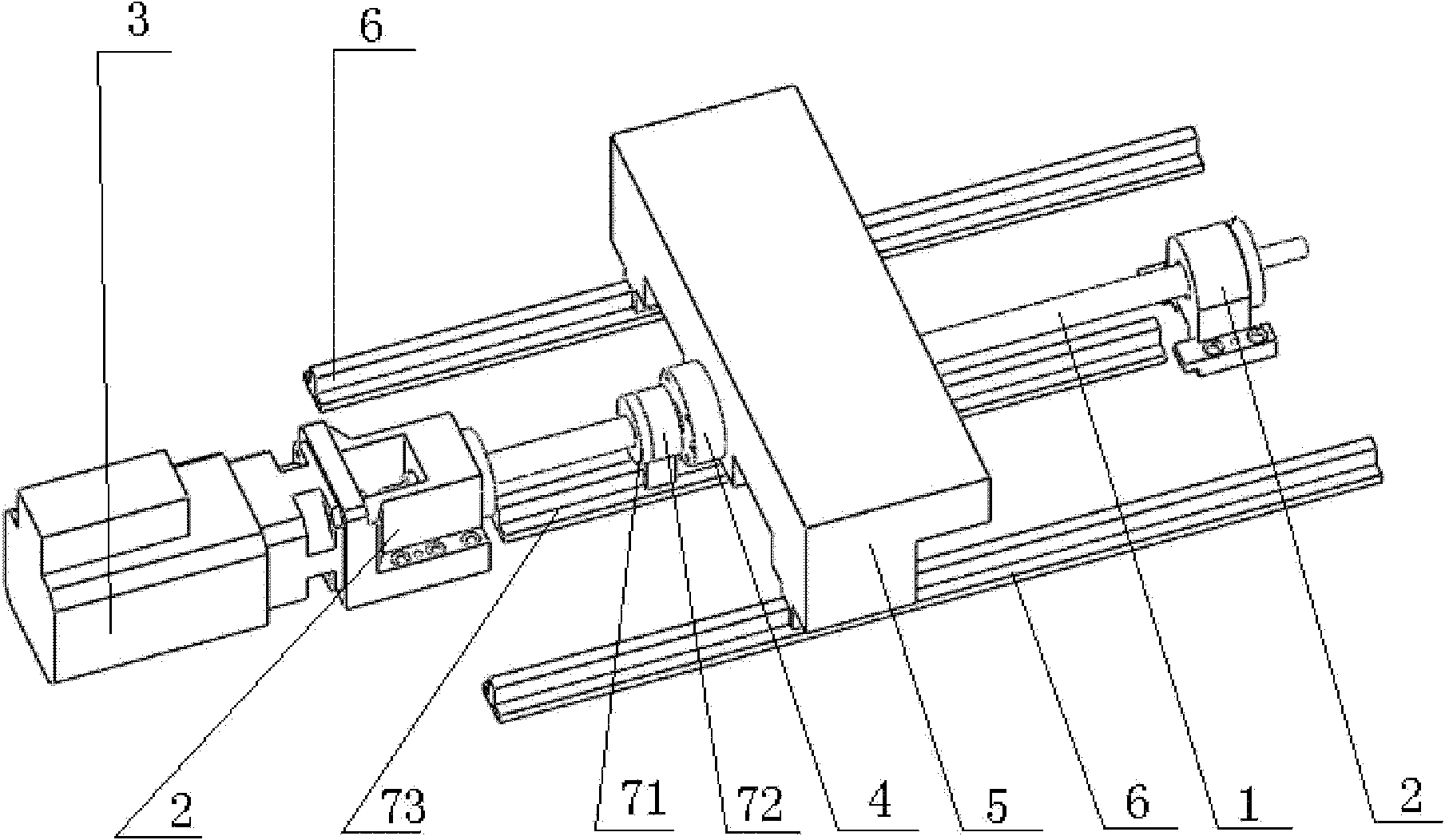

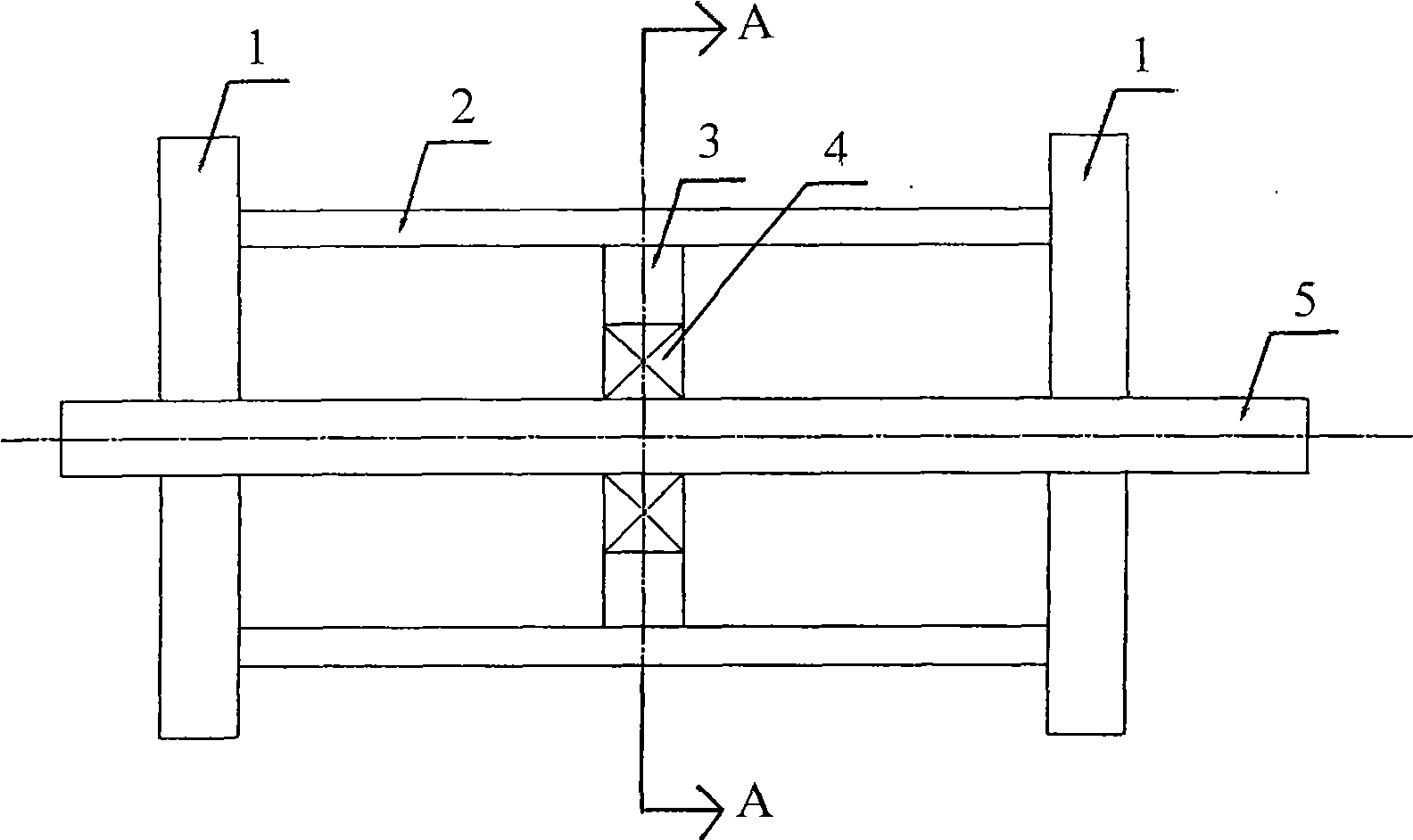

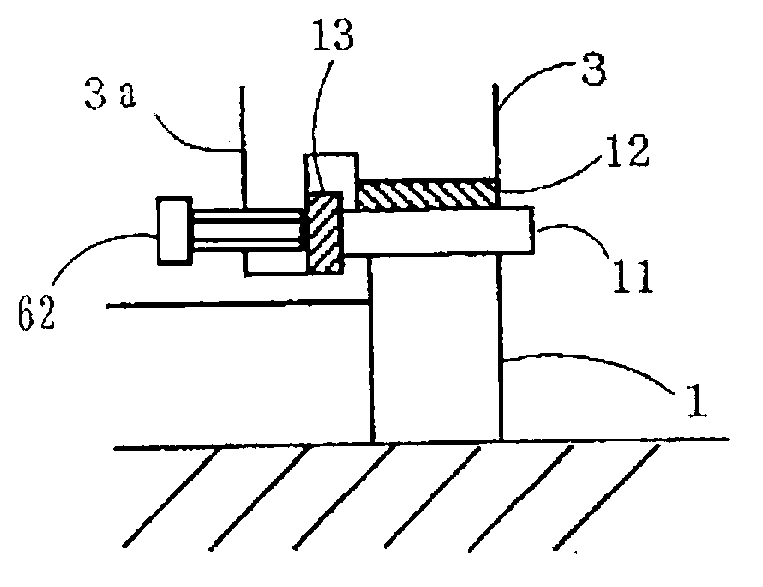

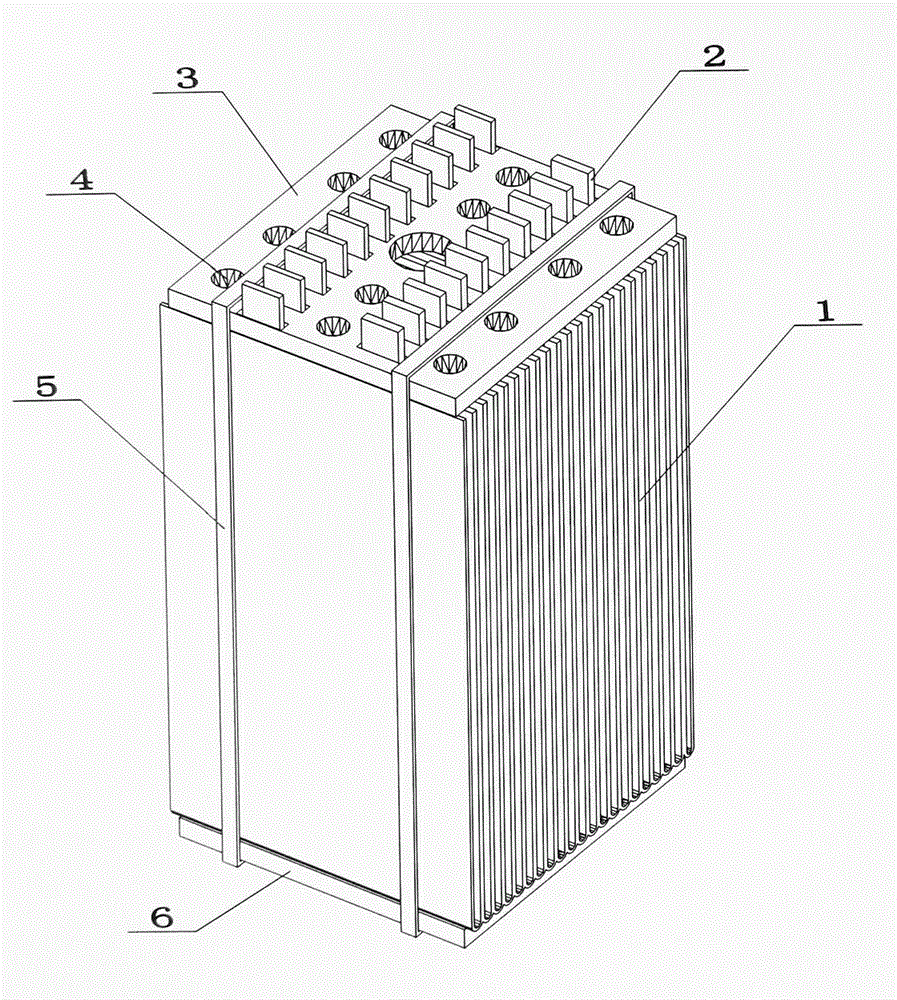

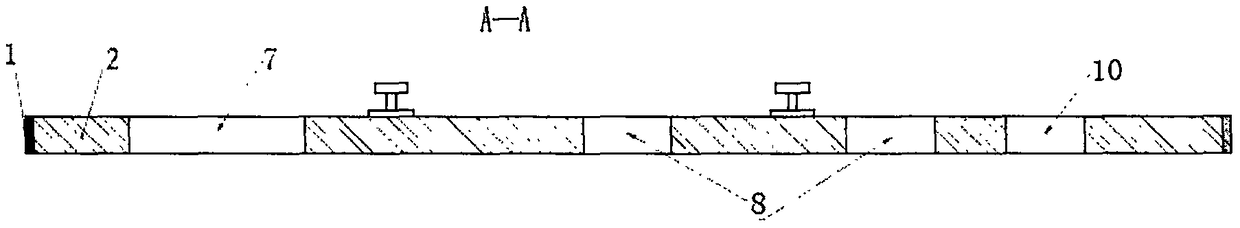

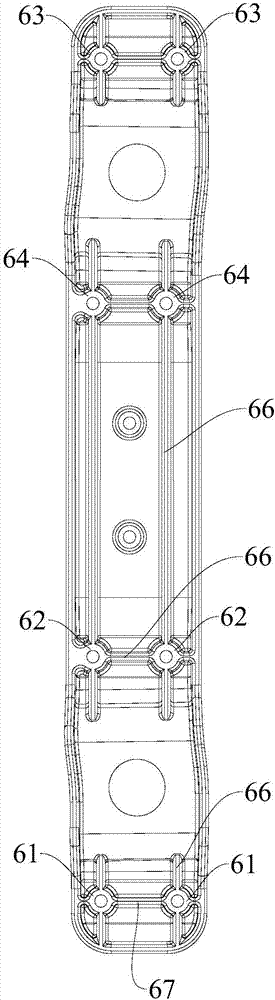

Lead screw feeding platform with loading assistant support

ActiveCN102218665ASuppresses bending deformationSmall support distanceWork benchesLarge fixed membersRadial stressMotor drive

The invention relates to a lead screw feeding platform with a loading assistant support, which is characterized in that a motor drives a lead screw, two ends of the lead screw are fixedly supported by a bearing; the lead screw and a workbench driving nut form a rolling spiral kinematic pair; the workbench driving nut is provided with a workbench; the bottom end of the workbench is provided with aguide rail; a loading assistant support device is arranged between two bearing supporting devices; the loading assistant support device comprises assistant driving nuts respectively arranged on two sides of the workbench driving nut; two assistant driving nuts are connected with the lead screw; each assistant driving nut is respectively fixedly connected with a slide block; the lower parts of thetwo slide block form a moving pair with the assistant supporting guide rail; and two slide blocks are respectively provided with a pressure sensor. In the lead screw feeding platform, real-time loading can be realized by the loading assistant support, the radial stress situation of the lead screw can be detected to reflect the nonparallelism of the vertical direction of the guide rail to effectively inhibit the flexural deformation of the lead screw due to radial stress, thus, the lead screw feeding platform can be widely applied to the horizontal large-route high-speed feeding platform of a machine tool lead screw.

Owner:TSINGHUA UNIV

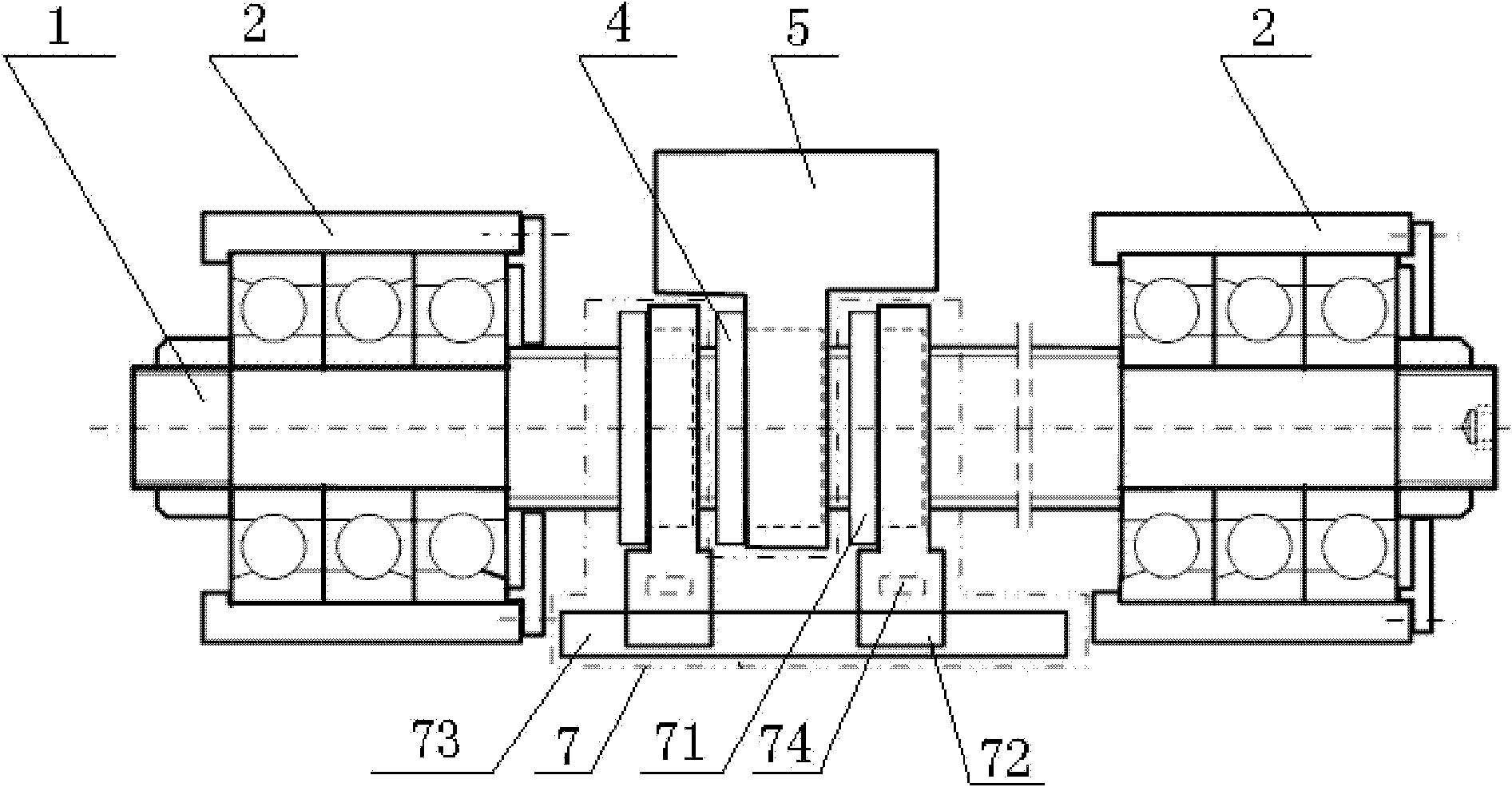

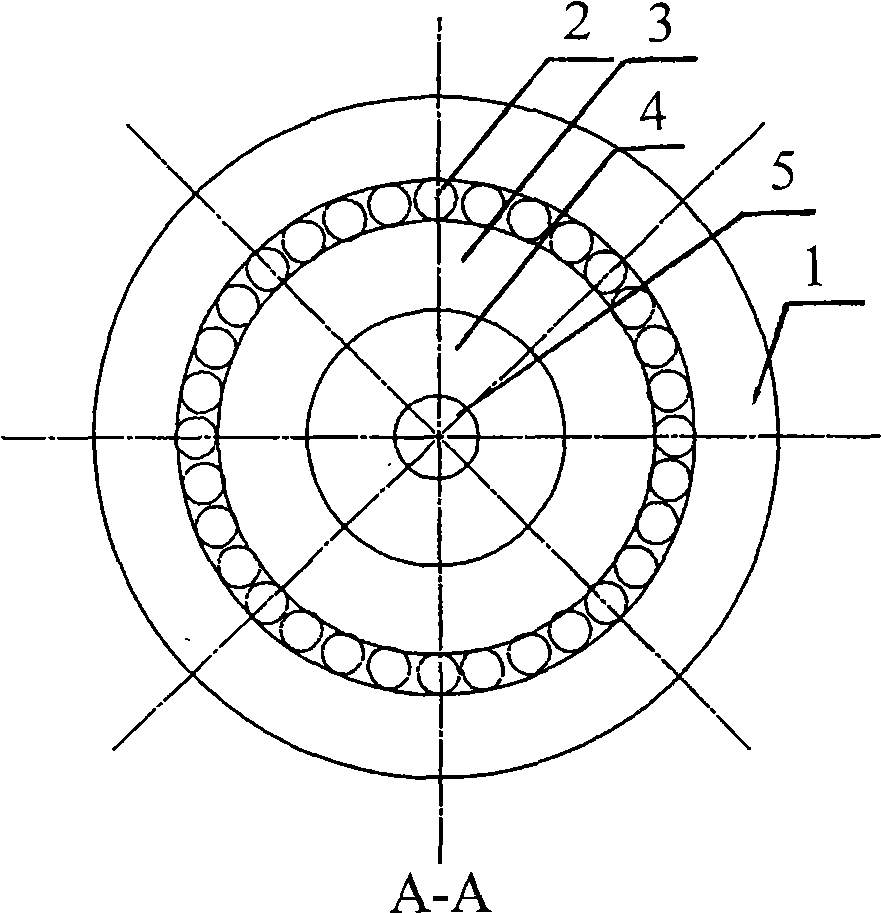

Rotor cage type elastic support

InactiveCN101504038ASuppresses bending deformationReduce vibrationRolling contact bearingsBearing unit rigid supportEngineeringRotor cage

The invention discloses a squirrel-cage elastic support. The support comprises two fixing rings, a plurality of elastic strips and a bearing, wherein the plurality of the elastic strips on the same circumference are equationally fixed between the end surfaces of the two fixing rings to form a squirrel cage, a shaft inside the squirrel-cage is fixedly connected with a bearing inner race, a rolling outer ring is contacted with the elastic strips to form the squirrel-cage elastic support; or a bearing outer ring is fixedly connected with a bearing support, and the bearing support is contacted with the elastic strips to form the squirrel-cage elastic support. In the condition of permission and fitness of a mechanical structure, the squirrel-cage elastic support can inhibit bend and deformation of the shaft, reduce vibration of a machine, reduce the damage to the structure or parts, improve the operation stability of the machine, prolong the service life of the machine, reduce noise generated by vibration and the like. The squirrel-cage elastic support can be applied to various rotary machines.

Owner:ZHEJIANG UNIV

Door weather strip

InactiveUS20050028448A1Affect seal performanceSuppresses bending deformationSealing arrangementsVehicle sealing arrangements

A door weather strip has a mounting base portion, a hollow seal portion, a sub-seal lip, and a backside seal lip. Leading lips are provided in the middle of a front pillar part in such a way as to connect the backside seal lip to the sub-seal lip. Each of the leading lips forms an acute angle with respect to an extending direction of the backside seal lip. Especially, in an attached state, an intersection angle α formed between the backside seal slip and each of the leading lips is set to be smaller than an angle β formed between the extending direction of the backside seal lip, and a vertical line. A large amount of water flowing down a groove like dribbles does not accumulate on the leading lips. Even just a small amount of the water is positively led to the exterior side of an automobile.

Owner:TOYODA GOSEI CO LTD

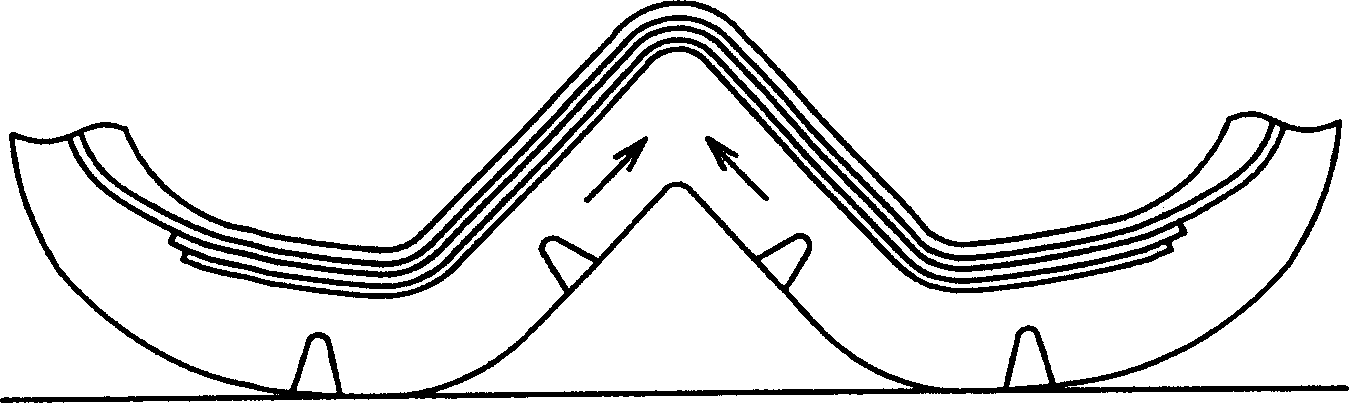

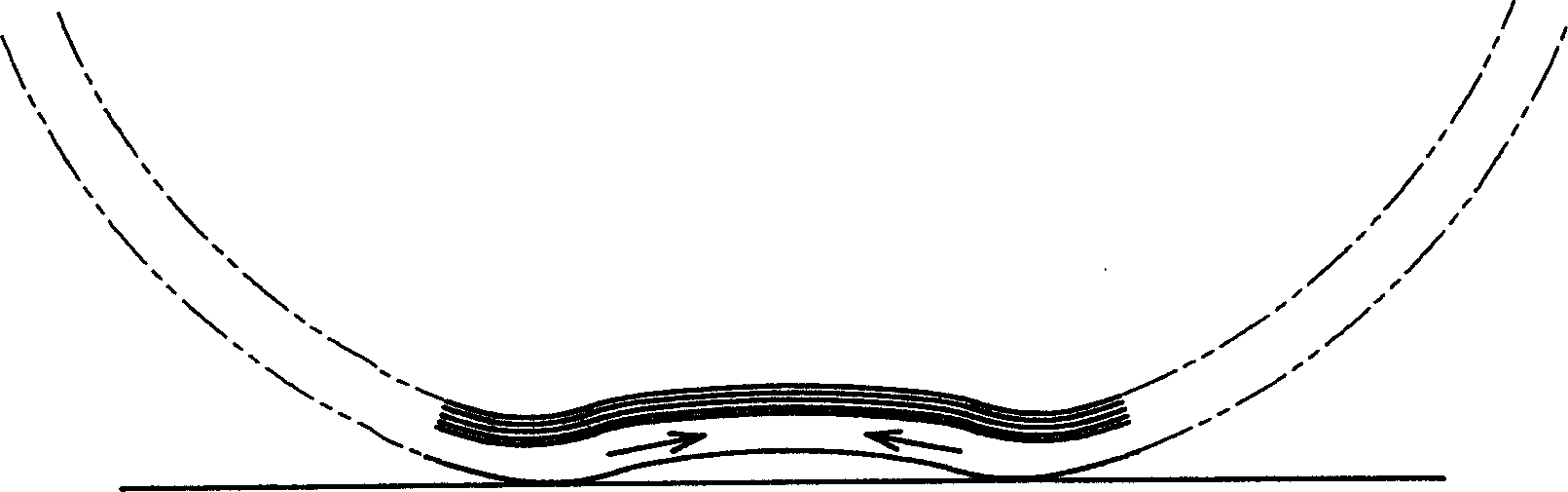

Pneumatic tire

InactiveCN1514776AHigh compression rigidityTaxiing displacement limitPneumatic tyre reinforcementsTyre tread bands/patternsGround contactEngineering

It is to provide a pneumatic tire in which a bulk modulus of elasticity of a tread rubber is small and an inverse V-shaped bending in a tread portion is suppressed to effectively prevent separation failure, breakage and the like of a belt layer, which comprises a radial carcass, a belt of two belt layers with a cross cord arrangement reinforcing a tread portion at an outer peripheral side of a crown portion of the radial carcass and a rubber reinforcing layer having a crescent-shaped form at a cross section, wherein the tread rubber forming a ground contact face of the tread is made of rubber having a bulk modulus of elasticity of not more than 4 GPa and an additional belt layer of cords having a cord angle with respect to an equatorial plane of the tire larger than that of cords in each of belt layers is arranged on an outer peripheral side of the belt and a compression rigidity of the additional belt layer in a widthwise direction of the tread is made 2 times or more larger than that of the belt layer.

Owner:BRIDGESTONE CORP

Fixing device

ActiveUS20060099015A1Maintain durabilitySuppresses bending deformationOhmic-resistance heatingElectrographic process apparatusEngineeringMechanical engineering

A fixing device has a fixing roller including an inside roller, an outside roller and a regulation member. The regulation member is disposed outside of both ends of the outside roller in the axial direction to regulate axial movement of the outside roller. An axial length of the contact face, where the pressure roller contacts with the outside roller, is smaller than an axial length of the outside roller. Thereby, both ends of the outside roller hardly receive bending deformation caused by pressure of the pressure roller. This makes it possible to reduce stress exerted to both ends of the outside roller, and therefore, the ends of the fixing roller are prevented from being damaged to enhance durability of the fixing roller.

Owner:KONICA MINOLTA BUSINESS TECH INC

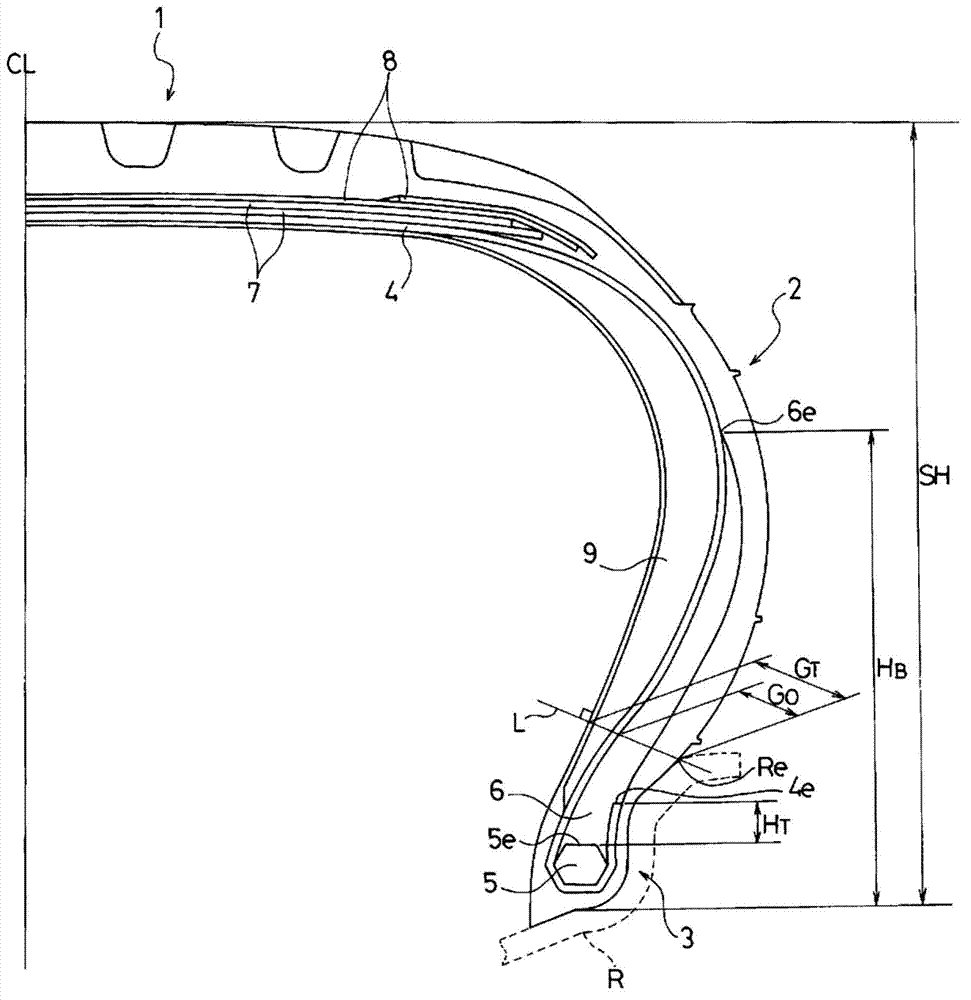

Pneumatic tire

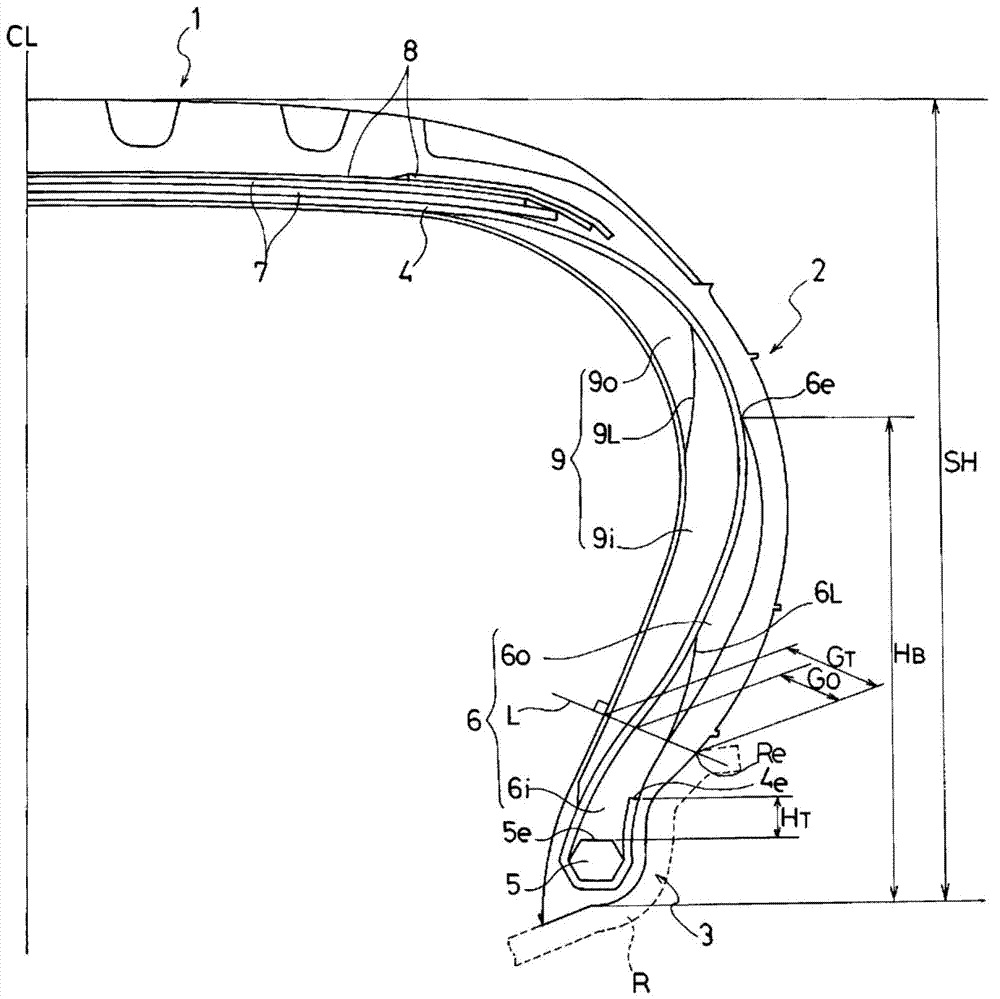

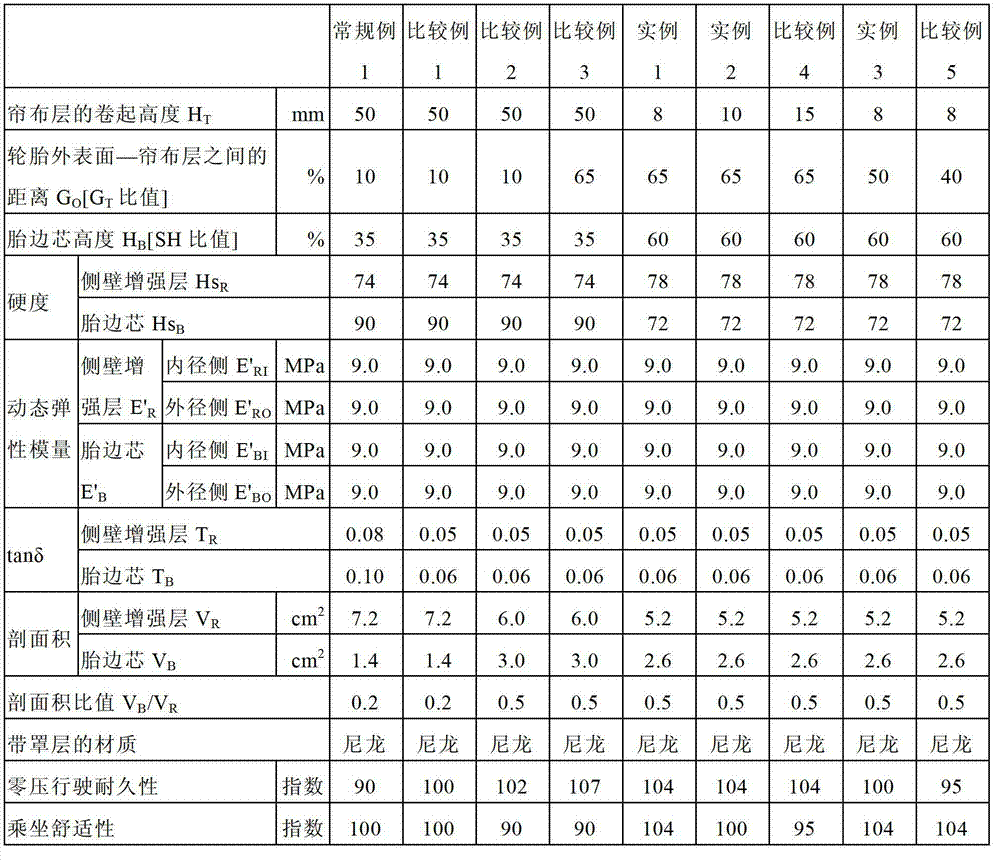

InactiveCN103317971AReduce rigidityGuaranteed rigidityTyre beadsTyre sidewallsEngineeringDynamic elastic modulus

In a pneumatic tire, a height from a turned-up edge of a carcass layer (4) is not more than 10 mm, a distance GO from a tire outer surface to the carcass layer (4) is not less than 50% of the total gauge, a height HB of the bead filler (6) is from 50% to 80% of a tire cross-section height SH, a cross-sectional area ratio VB / VR of the bead filler (6) to a side reinforcing layer (9) is not less than 0.4 and not more than 0.6, a hardness HsB of the bead filler (6) is not less than 65 and not more than 80, and the hardness HsR of the side reinforcing layer (9) is not less than 75 and not more than 85, a size relationship between the hardness HsB and the hardness HsR is HsB<=HsR, a dynamic elastic modulus E'B is not less than 7.0 MPa and not more than 15.0 MPa, and a dynamic elastic modulus E'R is not less than 7.0 MPa and not more than 15.0 MPa, a value TB of tan delta is not more than 0.06, and a value TR of tan delta is not more than 0.05. The invention provides a pneumatic tire by which both riding comfort when regular traveling and run-flat durability can be achieved at high levels.

Owner:THE YOKOHAMA RUBBER CO LTD

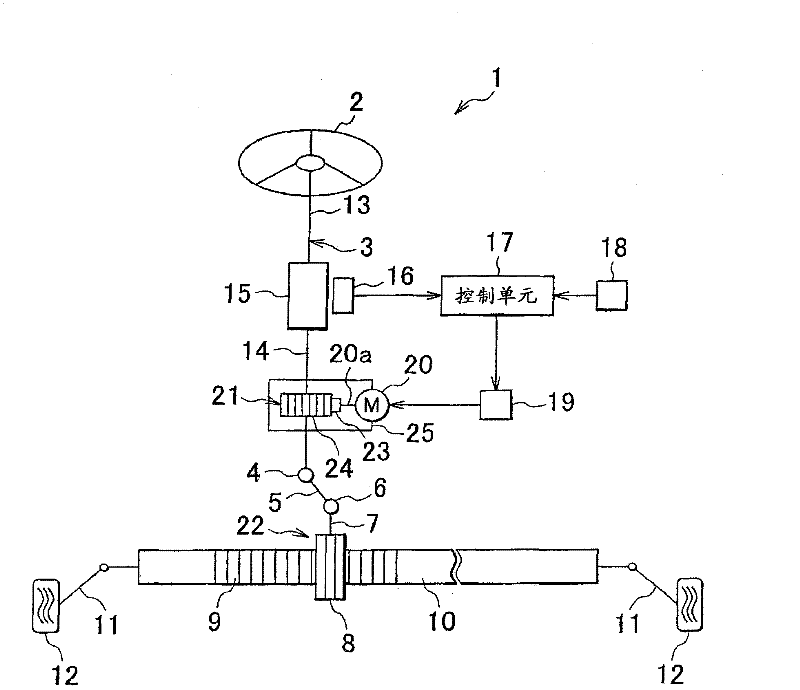

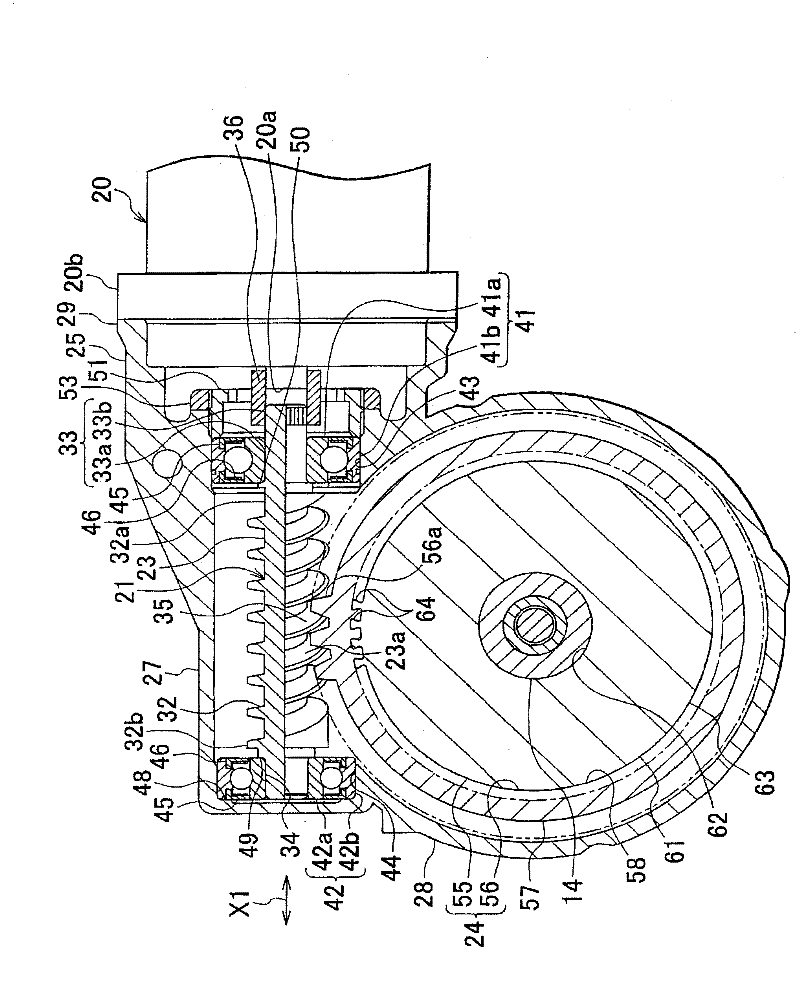

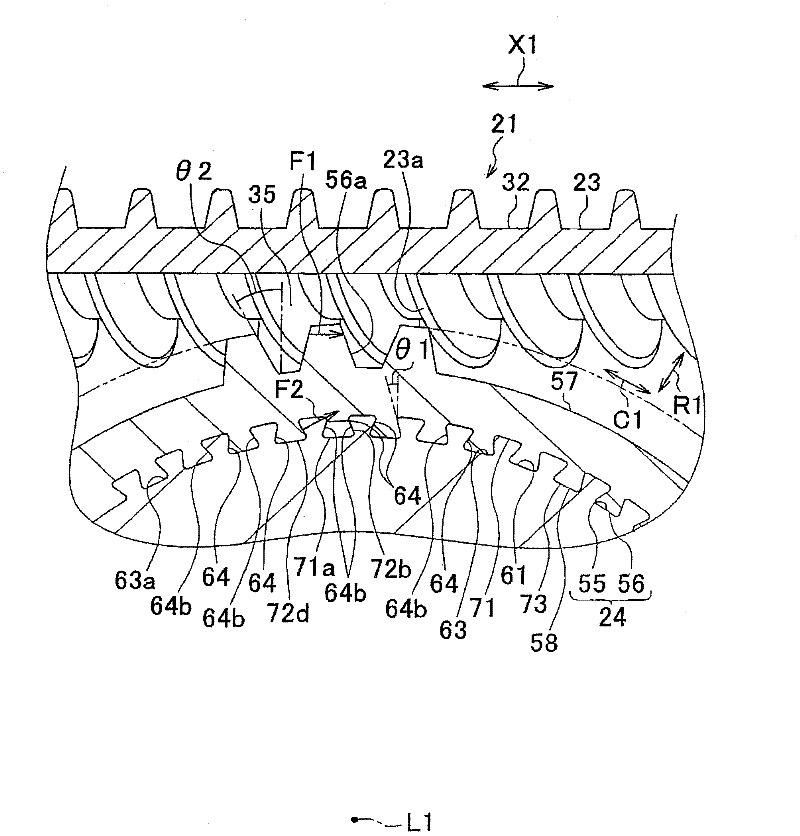

Worm drive

InactiveCN102410356ASuppresses bending deformationWalking smoothlyPortable liftingGearing elementsJoined teethSynthetic resin

A worm wheel (24) of a worm drive (21) includes an annular synthetic resin member (56) having tooth portions (56a) meshing with a worm shaft (23) and a core (55) having an outside diameter portion (61) joined to an inside diameter portion (58) of the synthetic resin member (56). The outside diameter portion (61) of the core (55) has first joining tooth portions (64) that protrude outward in a radial direction (R1) and are joined to the inside diameter portion (58) of the synthetic resin member (56). Each of the first joining tooth portions (64) includes a widening portion (64b) whose width in a circumferential direction (C1) increases toward the outside in the radial direction (R1).

Owner:JTEKT CORP

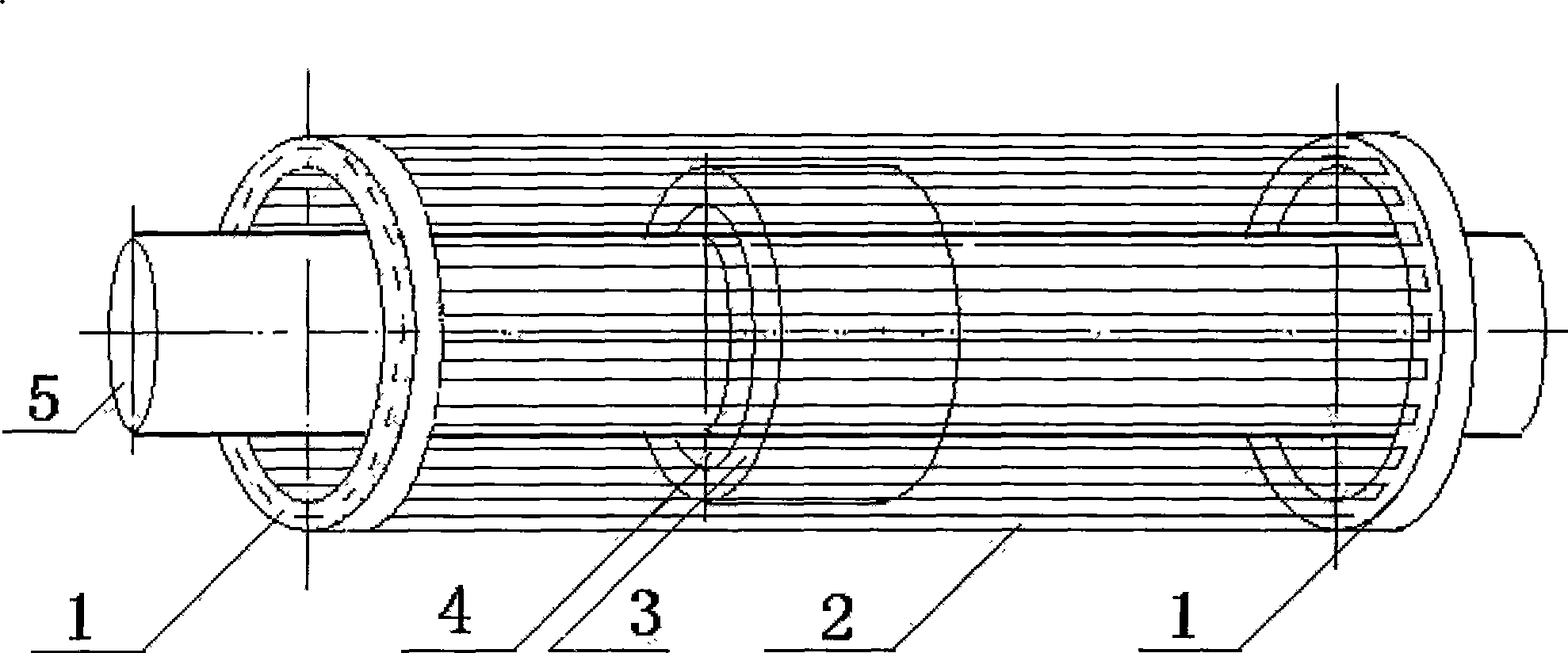

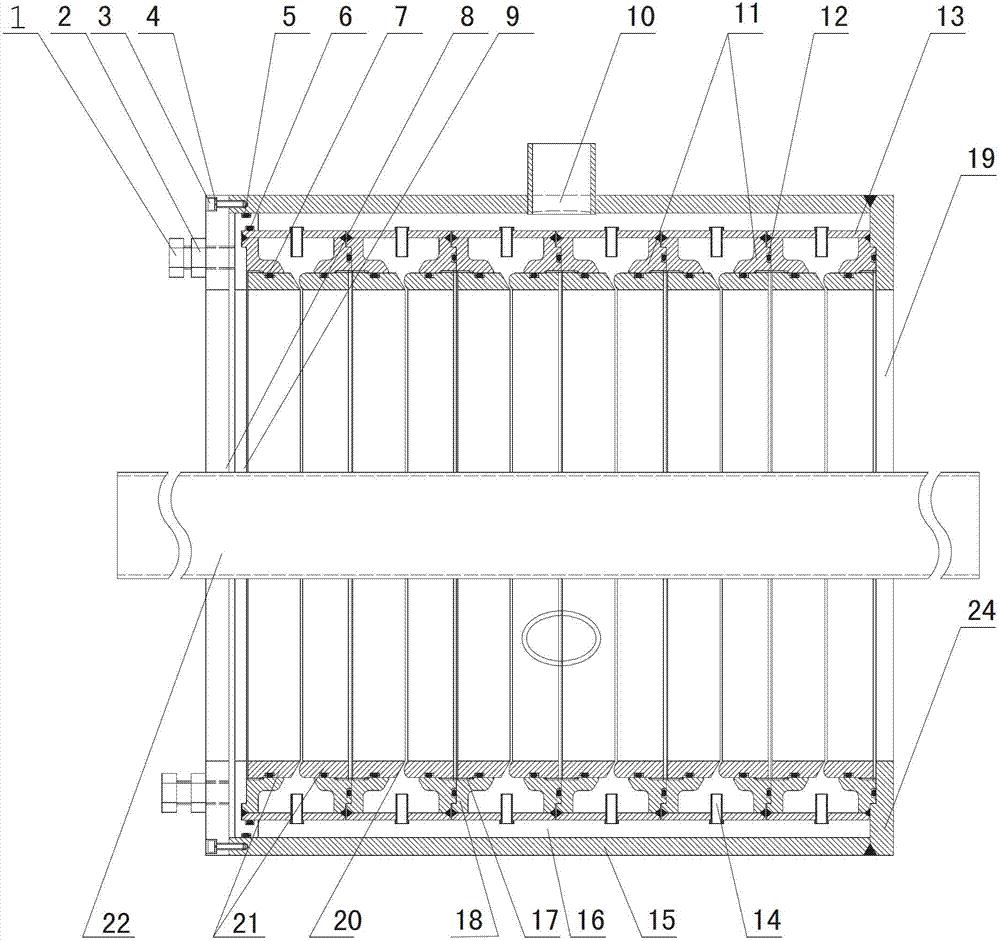

Super high-speed quenching device for steel tube

ActiveCN102876874ASuppresses bending deformationSpeed up heat exchangeFurnace typesHeat treatment furnacesSpray nozzleWater spray

The invention discloses a super high-speed quenching device for a steel tube and relates to a cooling device. The quenching device comprises a shell with water inlets; a plurality of inclined seam nozzle units are arranged in the shell and are pressed against each other in parallel; gaps are reserved between the shell and the inclined seam nozzle units and are cooling water layers; each inclined seam nozzle unit has an annular structure, and sequentially consists of a water guide plate, a flow stabilization layer wall plate and a nozzle adjustment sleeve plate from exterior to interior; a plurality of water guide columns are uniformly distributed on the circumference of each water guide plate; the extension lines of the water spraying directions of all the water guide columns are intersected to form an inscribed circle, and the diameter of the inscribed circle is less than or equal to that of the steel tube to be cooled; the water guide columns of the adjacent inclined seam nozzle units are staggered; an inner cavity which is formed by the flow stabilization layer wall plates has a shape of a funnel with a wide exterior and a narrow interior; each nozzle adjustment sleeve plate is annular; gaps between the nozzle adjustment sleeves plates are inclined seam nozzles; the inclined seam nozzles are inclined seams of which the width is gradually reduced from exterior to interior.

Owner:沈阳科安捷材料技术有限公司

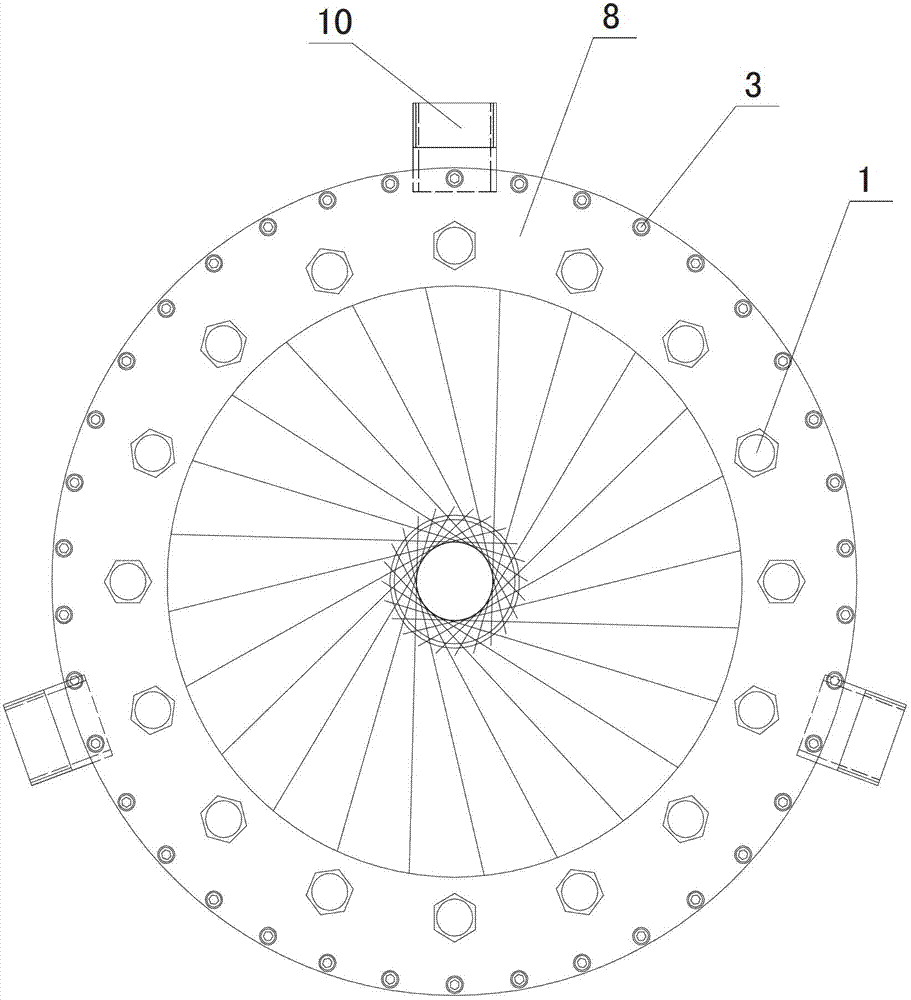

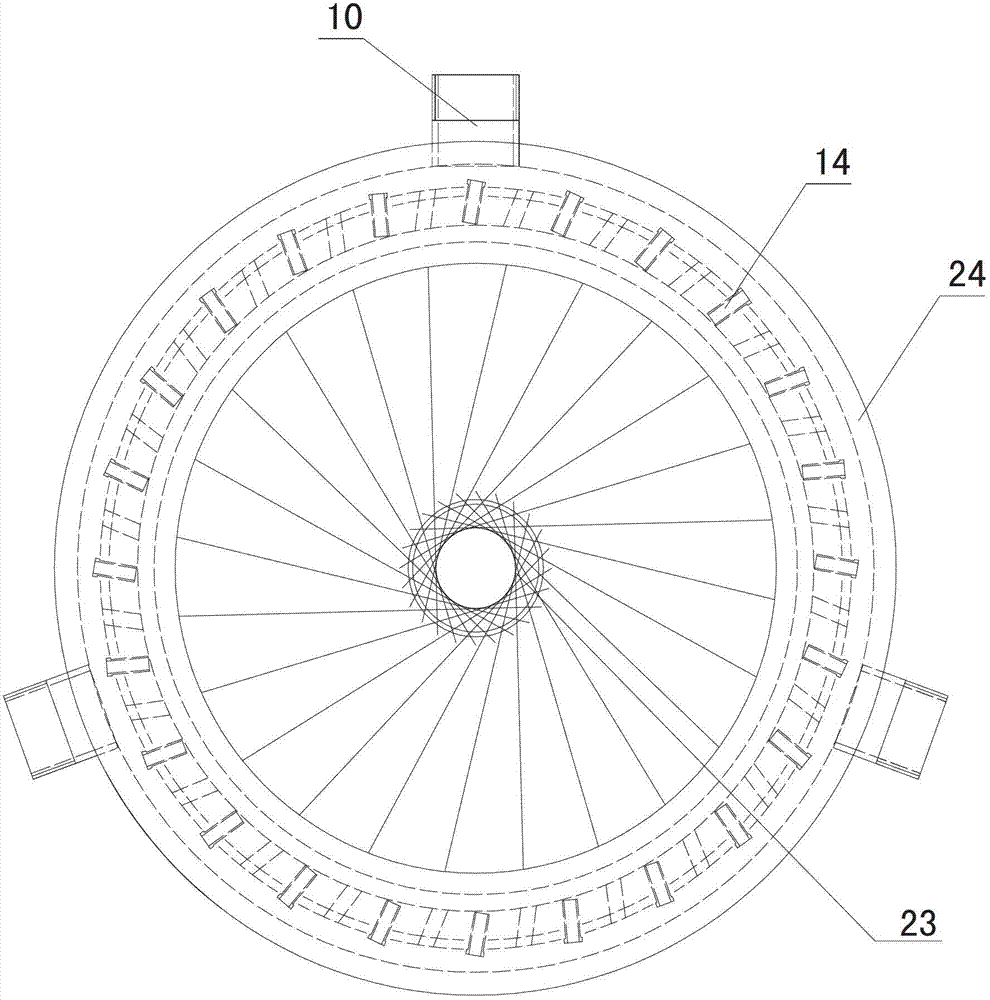

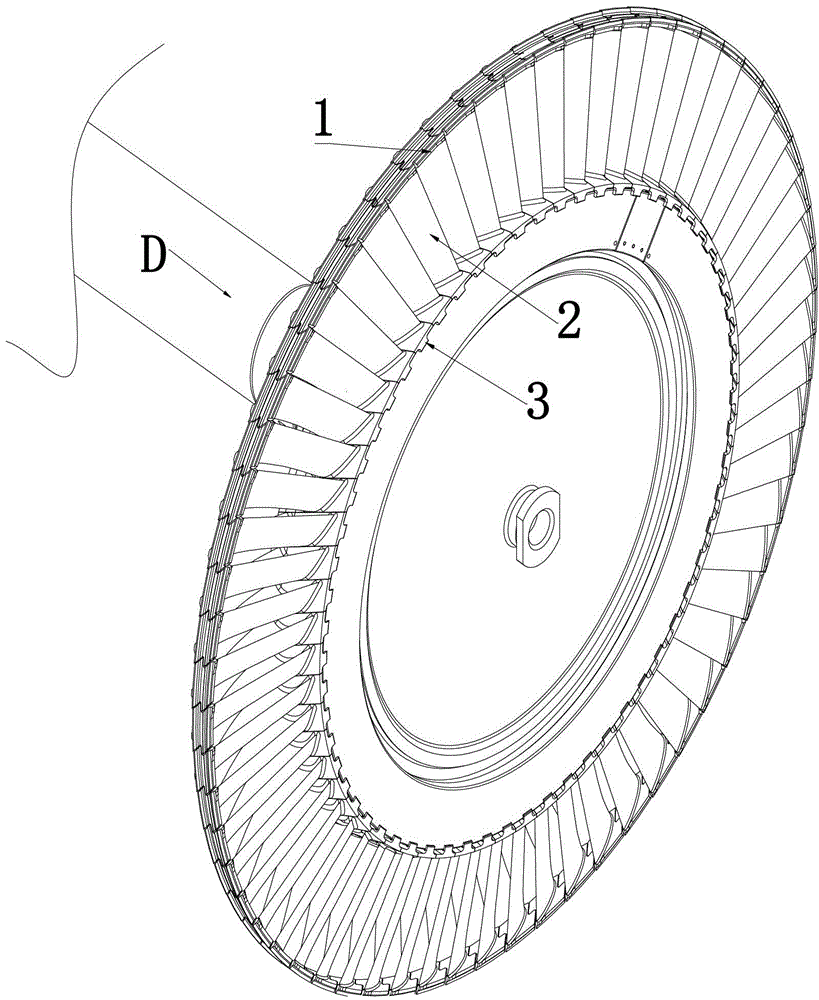

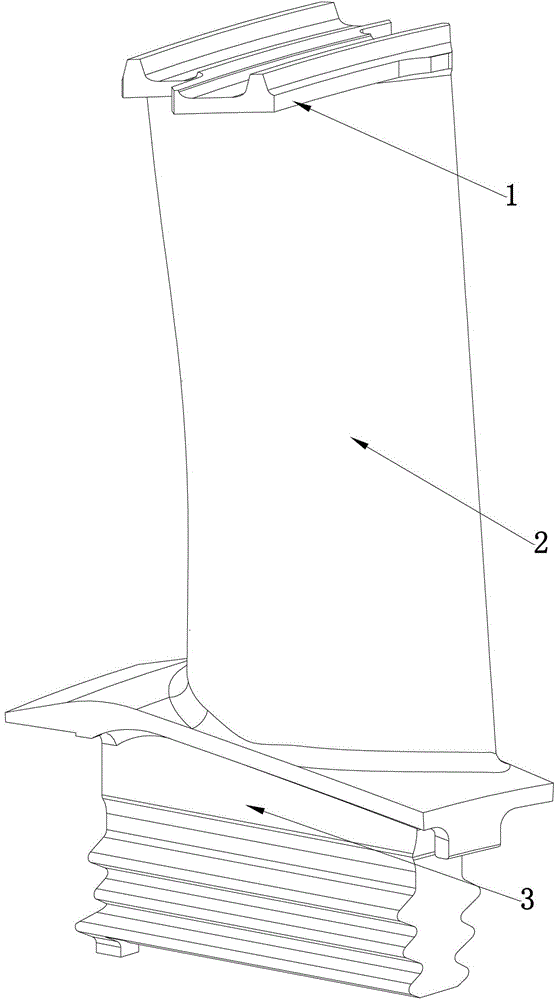

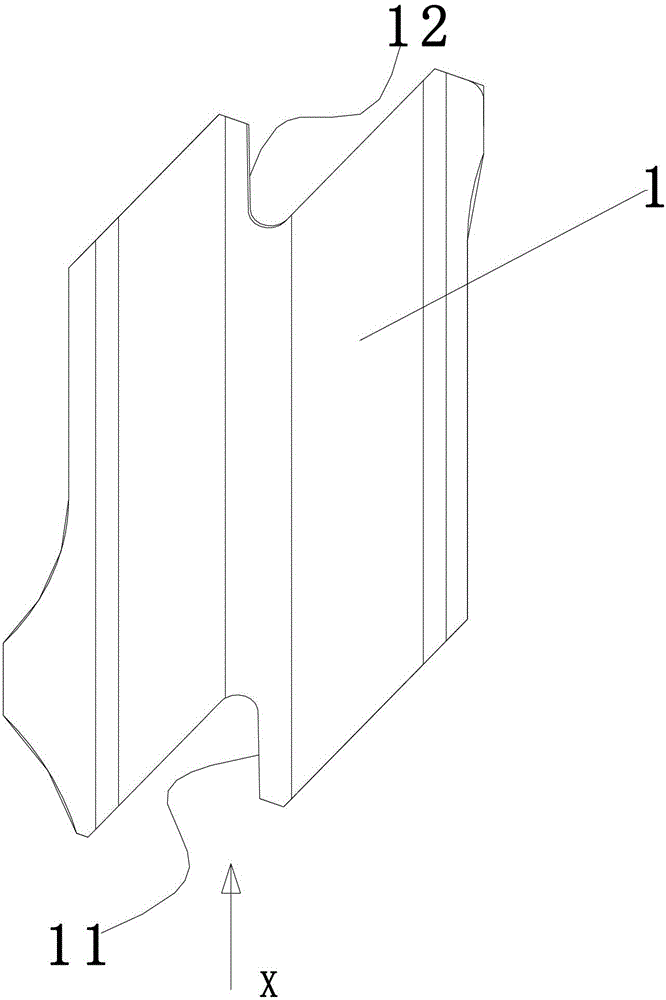

Turbine rotor blade and gas turbine with same

ActiveCN102877892AImprove efficiencySuppression of radial deformationBlade accessoriesMachines/enginesTurbine bladeGas turbines

The invention provides a turbine rotor blade and a gas turbine with the same. The turbine rotor blade comprises a shroud, a blade body and a tenon, the shroud comprises a first pre-twist contact surface and a second pre-twist contact surface, wherein the first pre-twist contact surface is peripherally arranged at a first peripheral end of the shroud, and the second second pre-twist contact surface is peripherally arranged at a second peripheral end of the shroud. Arrangement of the first pre-twist contact surface and the second pre-twist contact surface includes that after a plurality of turbine rotor blades are assembled, the second pre-twist contact surface of each turbine rotor blade is matched with the first pre-twist contact surface of each adjacent turbine rotor blade in an extrusion manner, so that the shrouds of each two adjacent turbine rotor blades jointly generate a pre-twist angle by using a blade stacking shaft as the axis. According to the technical scheme, the shrouds of each two adjacent turbine rotor blades have the pre-twist moment with the direction opposite to that of the moment generated by gas impact force, so that twist and bending deformation of the blades in work can be effectively inhibited, and flow blade profile loss is reduced.

Owner:HUNAN HANGXIANG GAS TURBINE

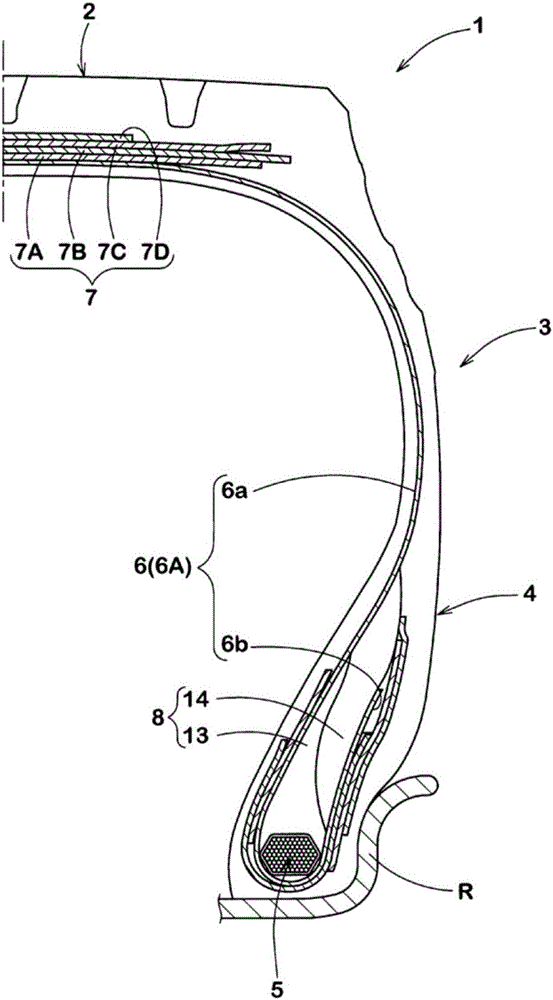

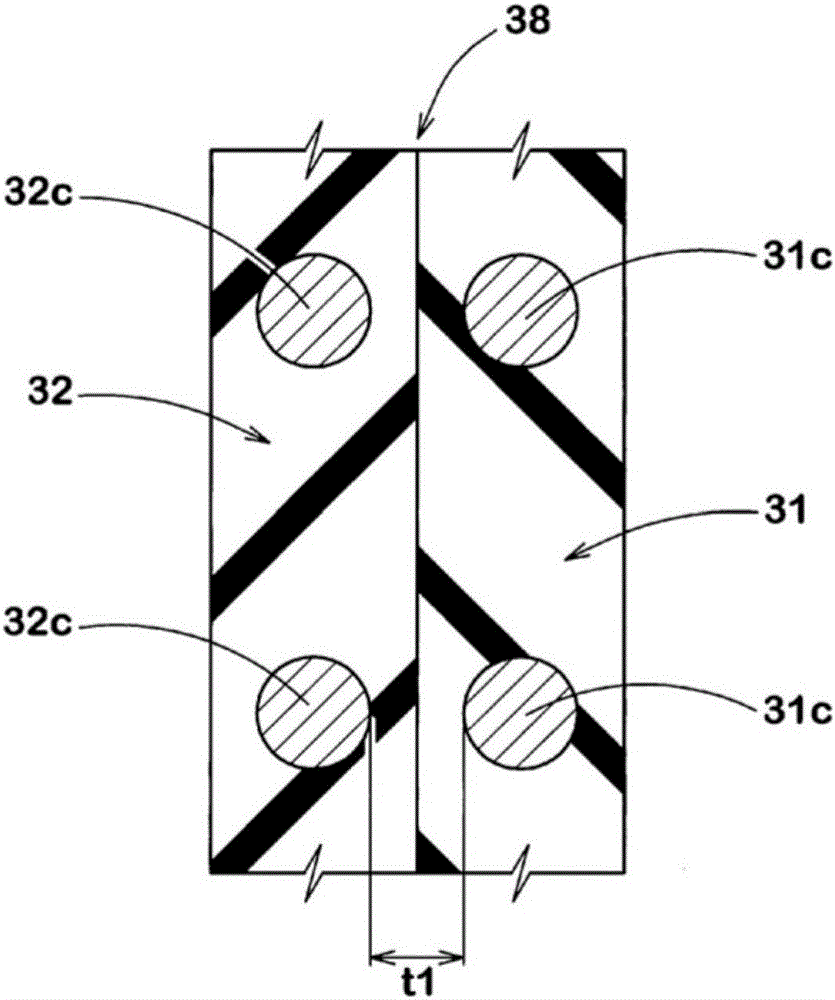

Heavy Load Tyre

The present invention provides a heavy load tyre capable of improving the durability of a tyre bead part. The heavy load tyre is equipped with a tyre 6 made of a tyre body cord fabric 6A, and the tyre body cord fabric 6A comprises a main body part 6a and a return part 6b. The tyre bead part 4 is equipped with a first reinforcing part 11 located at the side of the main body part 6a and a second reinforcing part 12 located at the side of the return part 6b, the first reinforcing part 11 comprises a first steel wire cord fabric layer 21 and a second first steel wire cord fabric layer 22 of which the cross-section is roughly U-shaped, and the second reinforcing part 12 comprises a first organic fiber cord fabric layer 31 covering the outer end at the side of the return part 6b of the second steel wire cord fabric layer from the axial outer side of the tyre and a second organic fiber cord fabric layer 32.

Owner:SUMITOMO RUBBER IND LTD

Wall panel

Owner:NIPPON STEEL CORP

Vibrating mirror element and manufacturing method for same

InactiveCN102695978AIncreasing the thicknessSmall sizeDecorative surface effectsChemical vapor deposition coatingElectrical and Electronics engineering

Owner:FUNAI ELECTRIC CO LTD

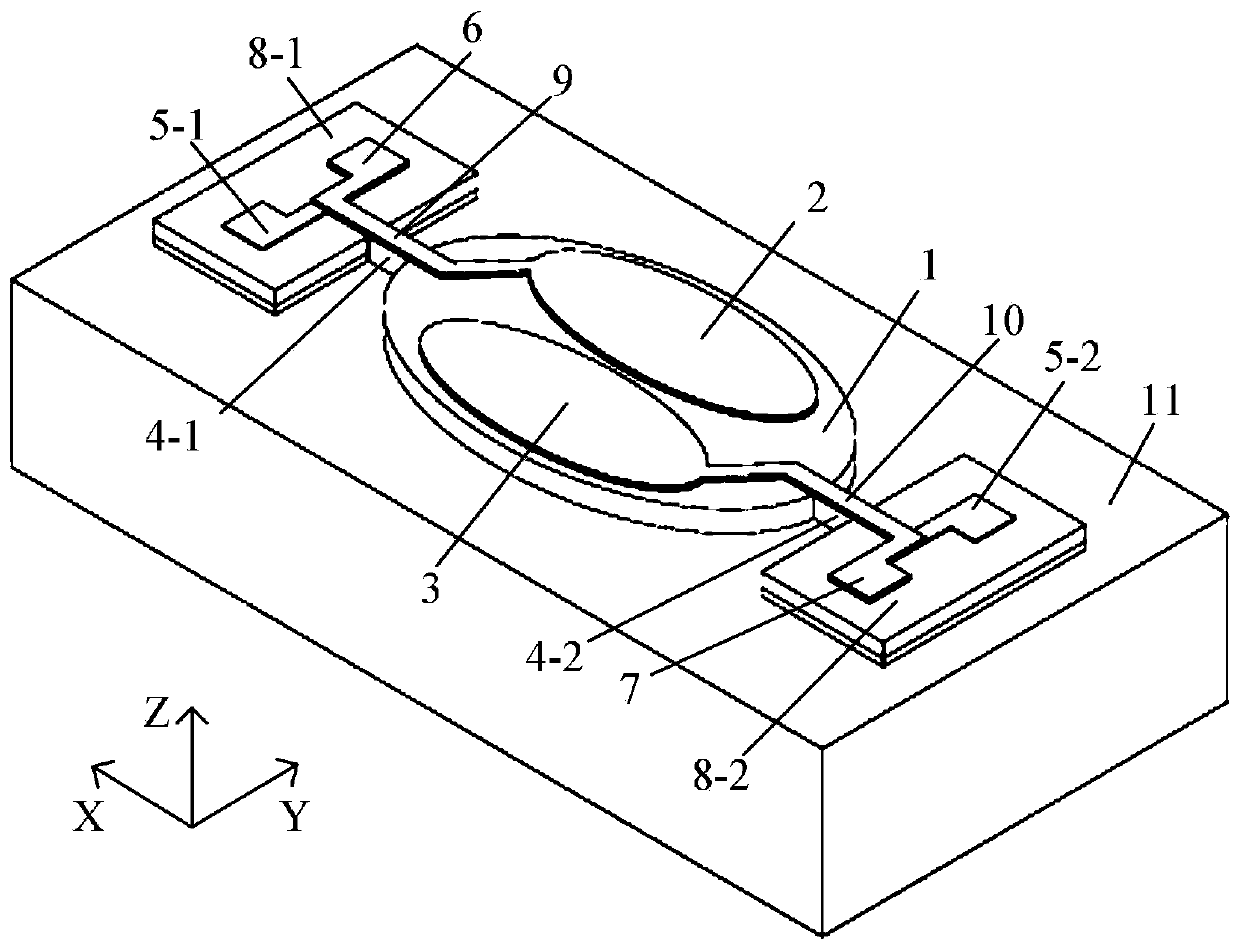

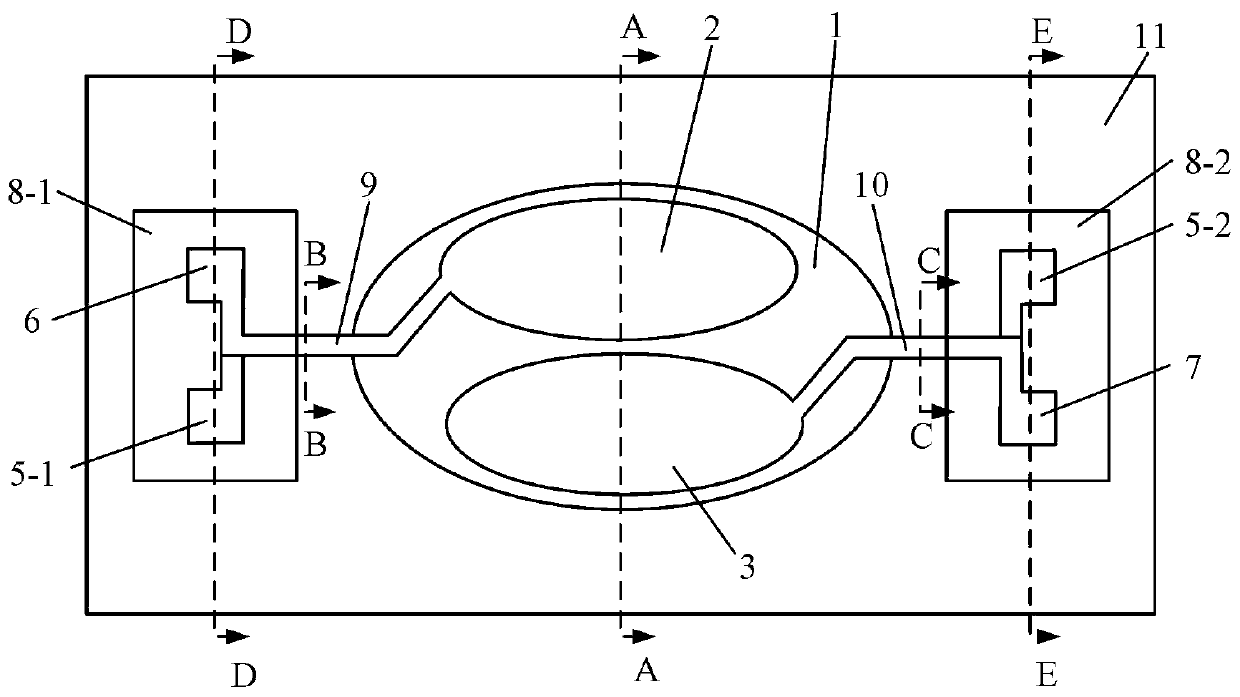

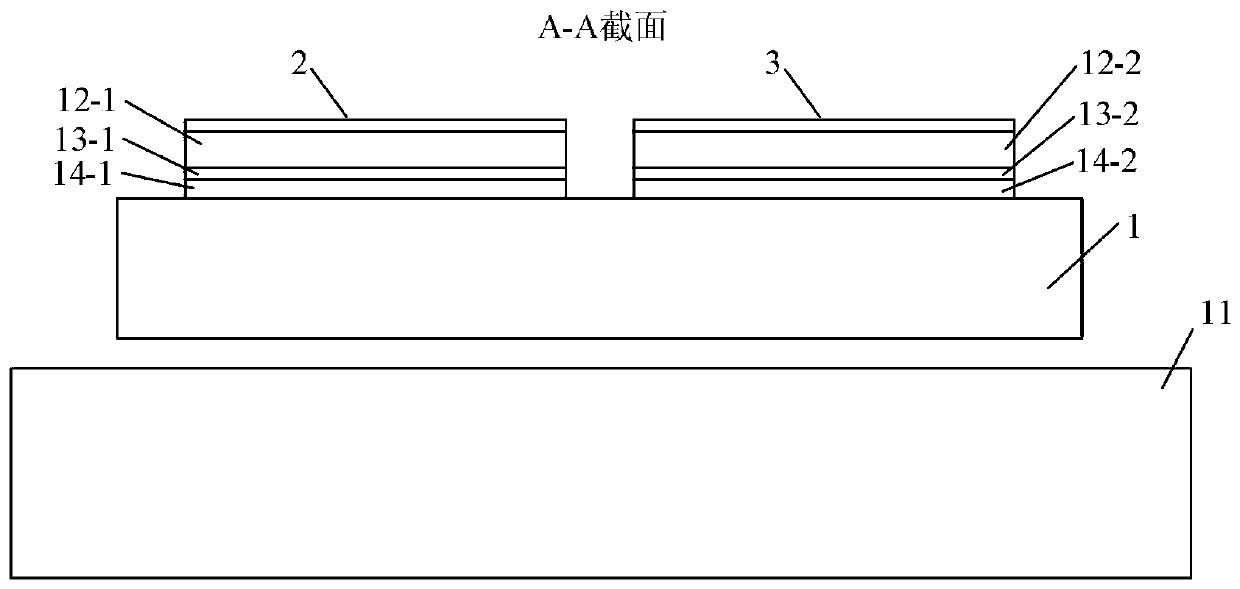

High-quality factor elliptical resonator

ActiveCN110120795AHigh quality factorSuppress stretch deformationImpedence networksLong axisEngineering

The invention discloses a high-quality factor elliptical resonator, which comprises an elliptical harmonic oscillator, a piezoelectric driver, a piezoelectric detector, a supporting beams, anchor points, pins, wires and a substrate; the supporting beams comprise the first supporting beam and the second supporting beam. The wires comprise a driving signal wire, a detection signal wire, a first grounding signal wire and a second grounding signal wire; the anchor points comprise a first anchor point and a second anchor point; the pins comprise a first grounding signal pin, a second grounding signal pin, a detection signal pin and a driving signal pin; a suspended elliptical harmonic oscillator is arranged on the top surface of the substrate, one end of a long axis of the elliptical harmonic oscillator is connected with the first anchor point through the first supporting beam, and the other end of the long axis of the elliptical harmonic oscillator is connected with the second anchor pointthrough the second supporting beam; the problem of loss caused by torsional deformation of the supporting beam in the prior art is solved.

Owner:XIHUA UNIV

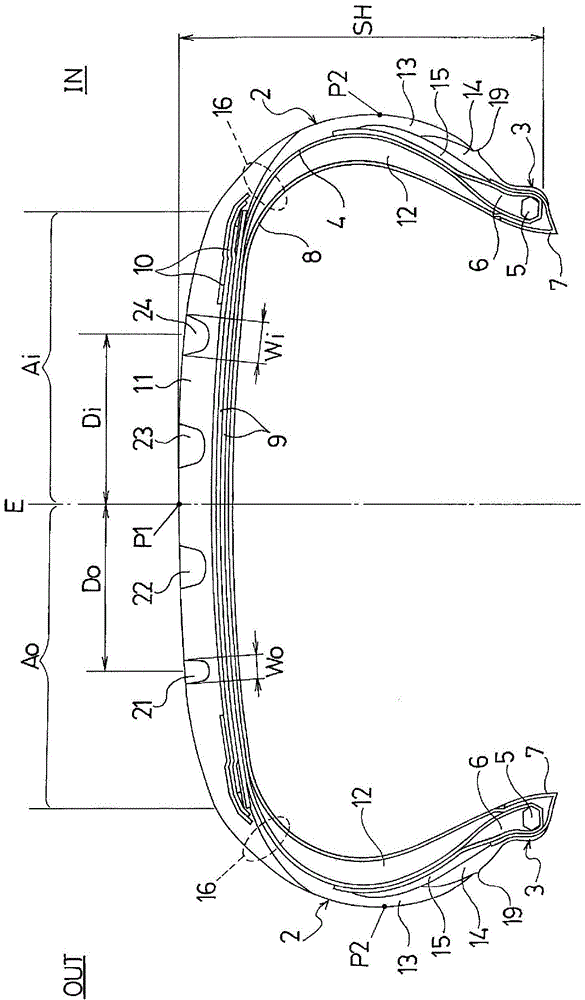

Run-flat tire

ActiveCN104936796AAvoid local stress concentrationsAvoid breakingSpecial tyresPneumatic tyre reinforcementsGroove widthEngineering

Provided is a run-flat tire that achieves a high dimension of both run-flat durability and riding comfort, and enables the improvement of steering stability during normal traveling. In the side-reinforced run-flat tire, the relationship between the rim width (Wr) and the distance (Do) to the tire equator plane from the center position of a peripheral-direction primary groove positioned to the outermost side in the widthwise direction of the tire in the outside region of the vehicle is 0.20 ≤ Do / Wr ≤ 0.30, the relationship between the rim width (Wr) and the distance (Di) to the tire equatorial plane from the center position of a peripheral-direction primary groove positioned to the outermost side in the widthwise direction of the tire in the inside region of the vehicle is 0.25 ≤ Di / Wr ≤ 0.35, the relationship between the groove width (Wi) of the peripheral-direction primary groove positioned at the outermost side in the widthwise direction of the tire at the inside region of the vehicle and the groove width (Wo) of the peripheral-direction primary groove positioned at the outermost side in the widthwise direction of the tire at the outside region of the vehicle is 0.80 ≤ Wo / Wi ≤ 0.90, the relationship between the thickness (Ga) at a rim check line position of an outside rubber portion at the outside of a carcass layer and the greatest thickness (Gb) of same is 0.8×Gb ≤ Ga ≤ 1.0×Gb, and the relationship between the thickness (Gc) at the rim check line position of an inside rubber portion at the inside of the carcass layer and the thickness (Ga) is 0.7×Ga ≤ Gc ≤1.0×Ga.

Owner:YOKOHAMA RUBBER CO LTD

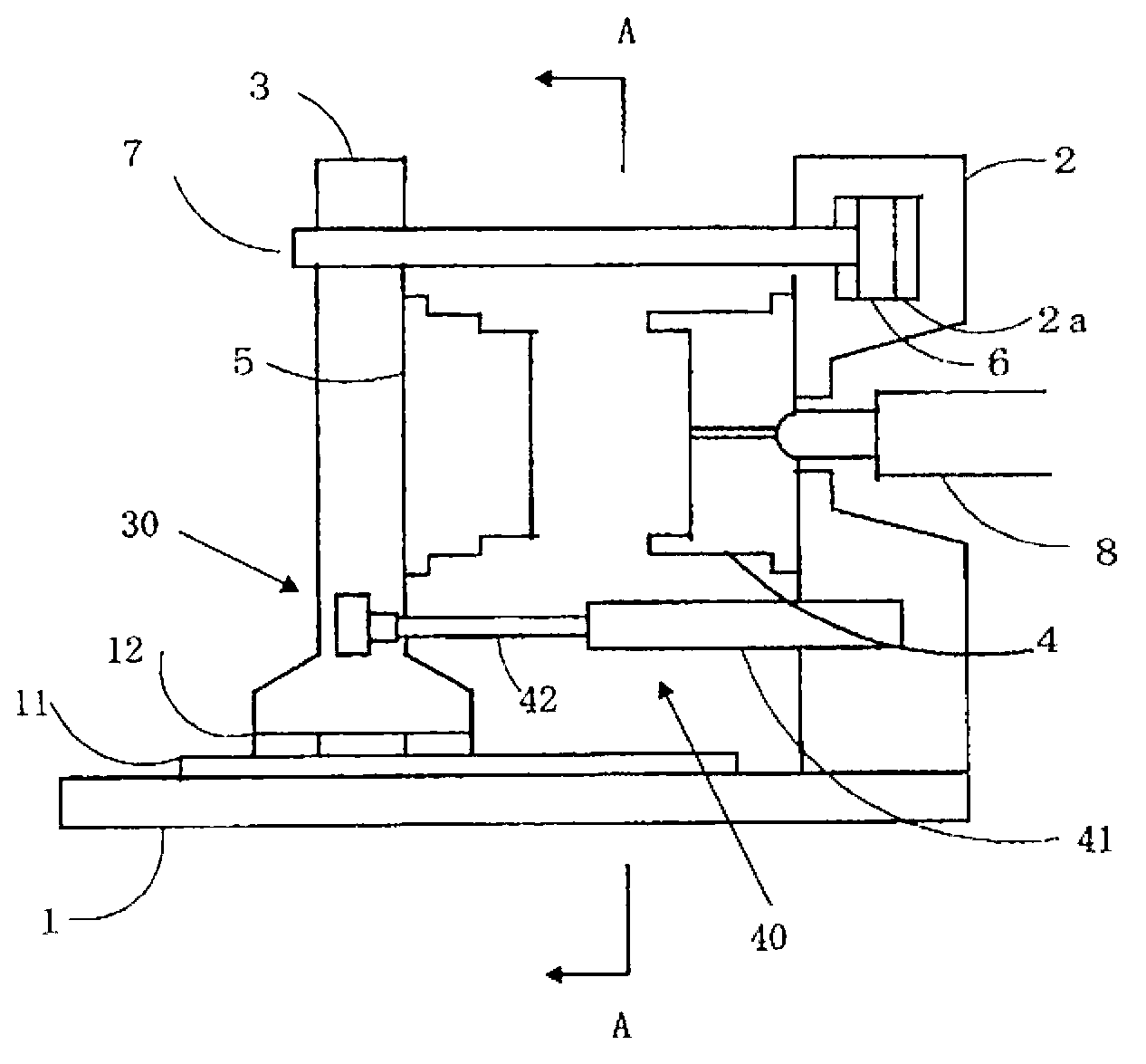

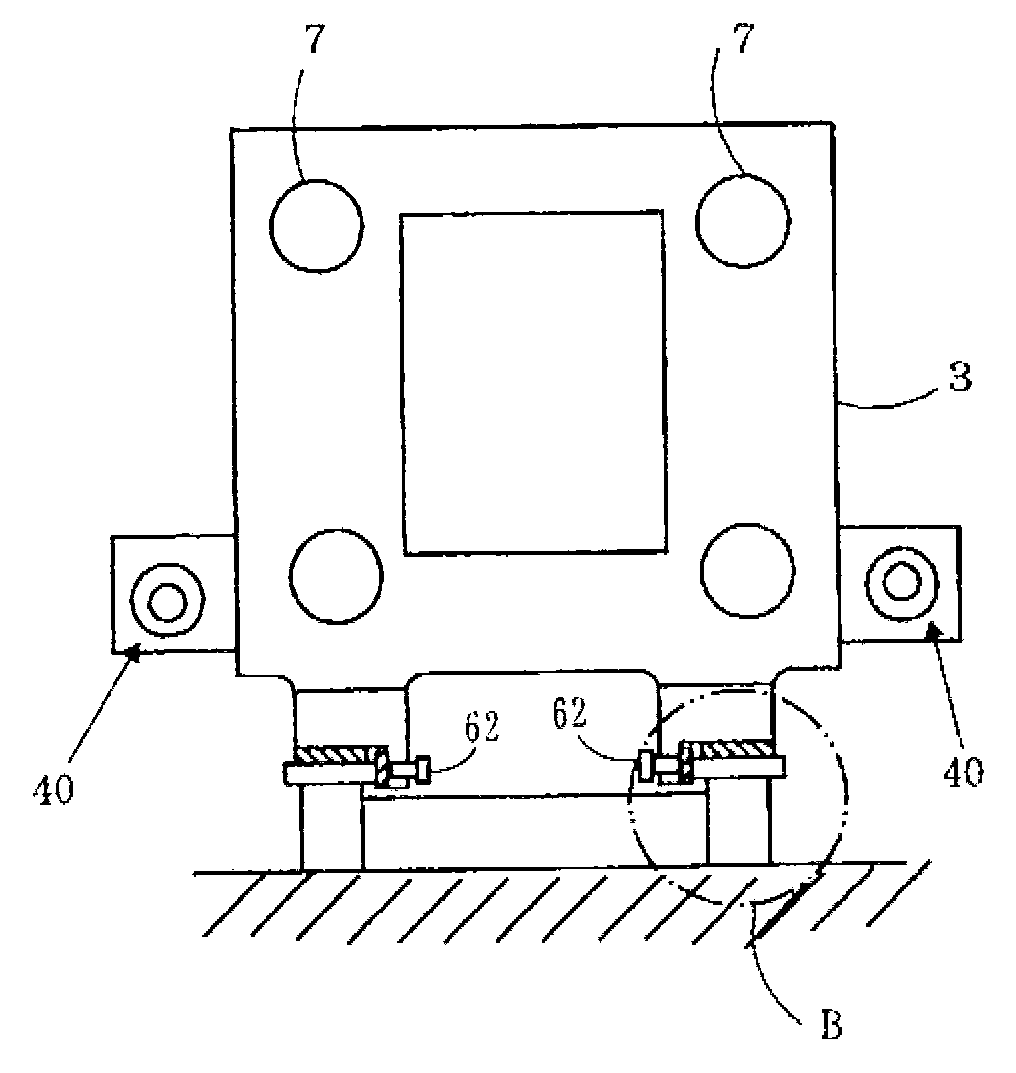

Die clamping device for injection molding machine

Breakage of the actuator moving the movable platen in the clamping device of an injection moulder is prevented. The clamping device includes a movable platen shifting device increasing and decreasing a horizontal distance between the movable platen (3) and the fixed platen (2). It includes an actuator (41), a clevis pin connecting the actuator (41) and the movable platen (3), a clevis pin holding part holding a central axis of the clevis pin perpendicular to a moving direction of the movable platen (3), and a clevis pin connecting part that connects the actuator (41) and the clevis in. The clevis pin connecting part is a supporting structure rotating with the clevis pin. The clevis pin connecting part is supported by the movable platen (3). The clevis pin, the clevis pin connecting part, and the front end of the actuator are aligned in a straight line.

Owner:MITSUBISHI HEAVY INDS PLASTIC TECH

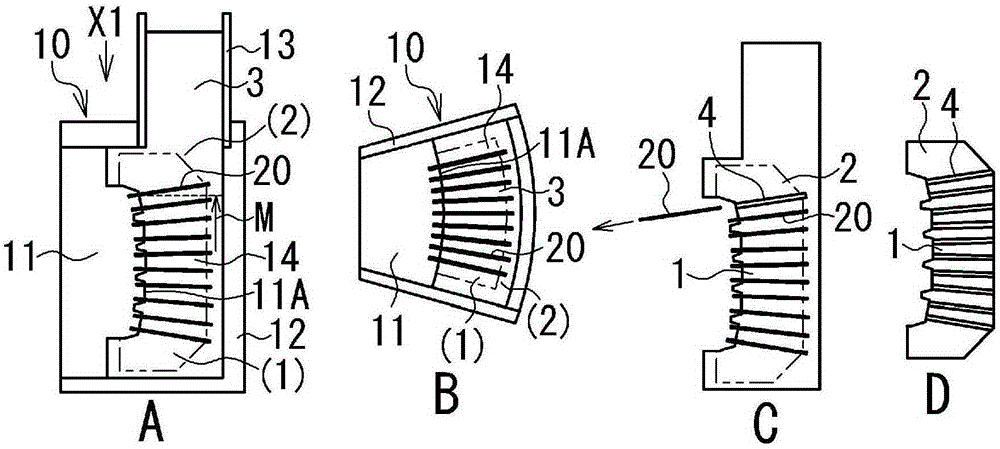

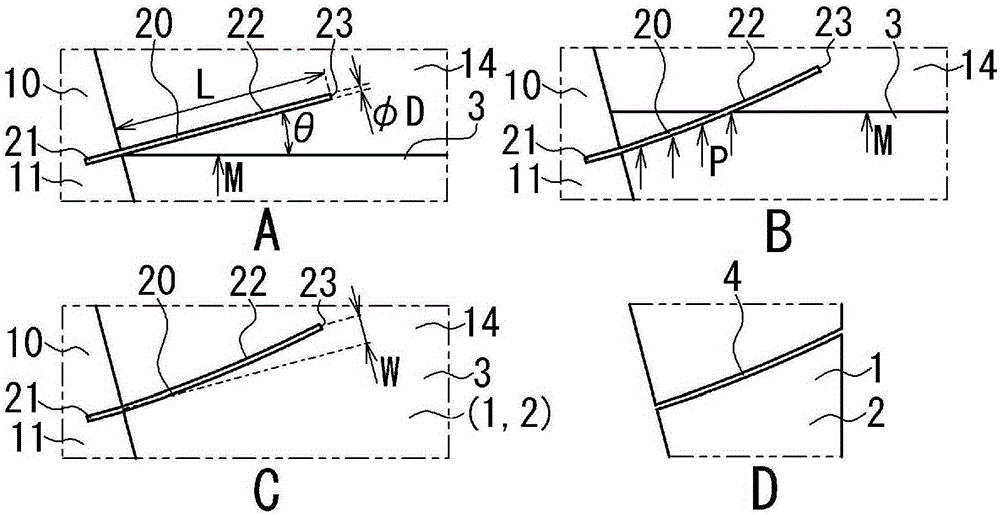

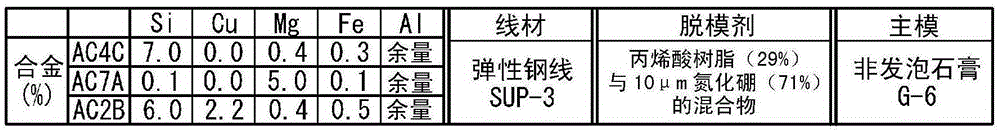

Method for manufacturing tire molding die and tire molding die

The present invention limits bending deformation of wires disposed inside the mold during casting of the tire molding die and forms die vent holes with good precision. Using a relational formula representing the relationship between the length (L) of wires (20) inside a casting space (14), the diameter (D) of the wires (20), the contact angle (theta) of the wires (20) with respect to the molten metal (3), and the flexure (W) of the wires (20) due to the casting that have been determined previously by experimentation, the contact angle (theta) for the wires (20) such that the flexure (W) of the wires (20) will be within a permissible range is calculated from the actual length (L) and diameter (D) of the wires (20). On the basis of the calculated contact angle (theta) for the wires (20), the wires (20) are disposed inside the casting space (14). Molten metal (3) is injected into the casting space (14) in which the wires (20) are disposed to cast a casting (2) in which the wires (20) are cast-in inside the casting space (14). The wires (20) are withdrawn from the casting (2) to form the vent holes (4).

Owner:BRIDGESTONE CORP

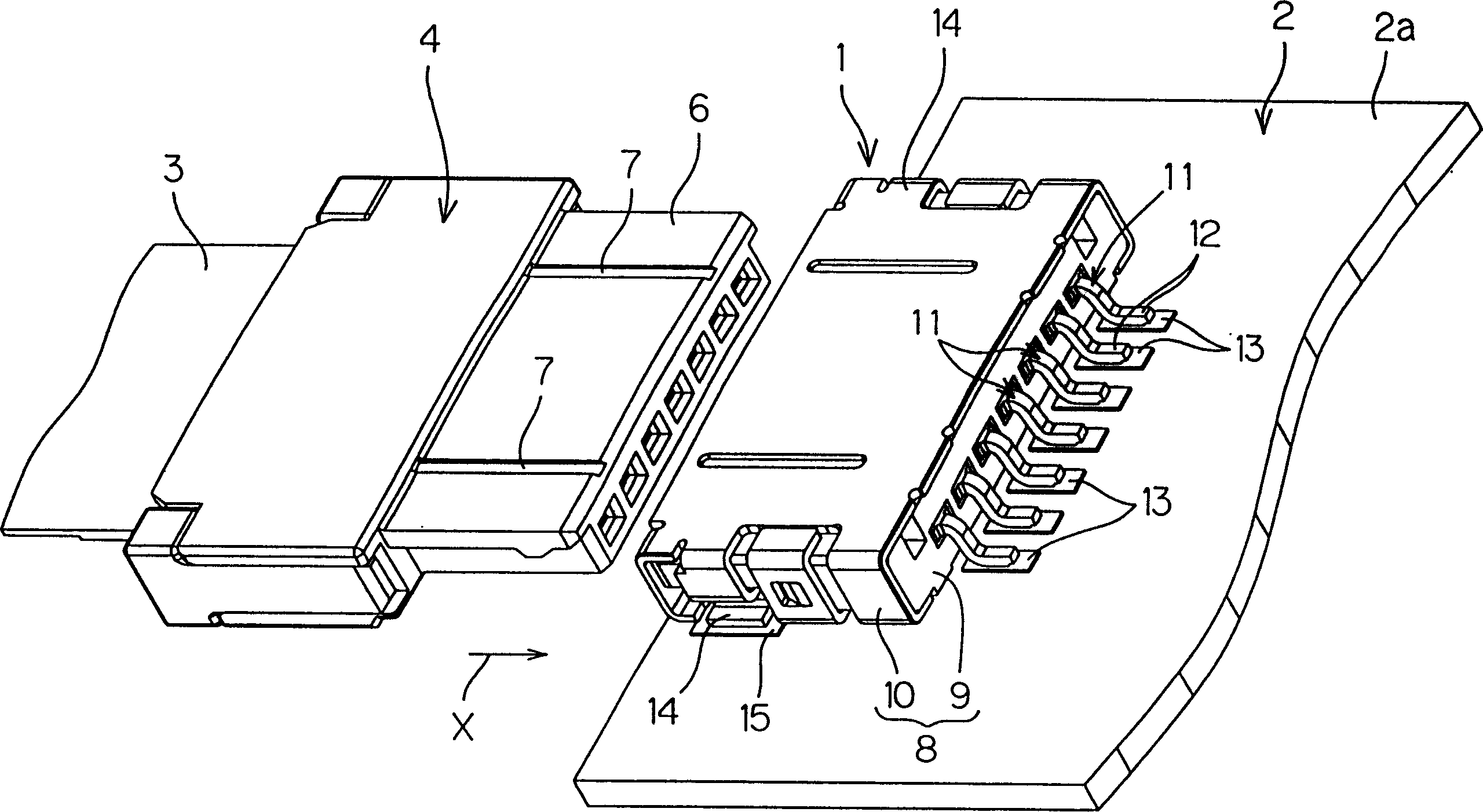

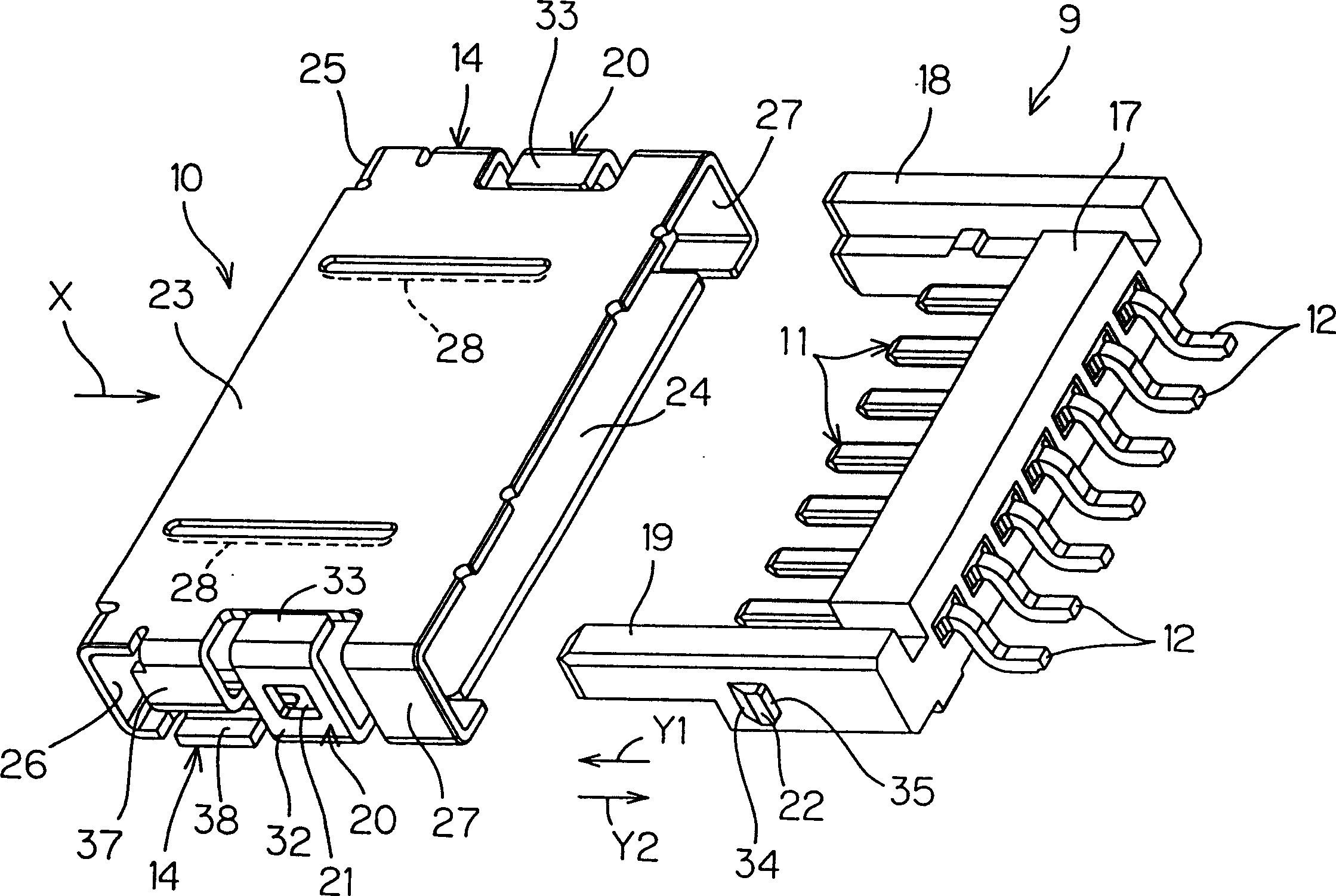

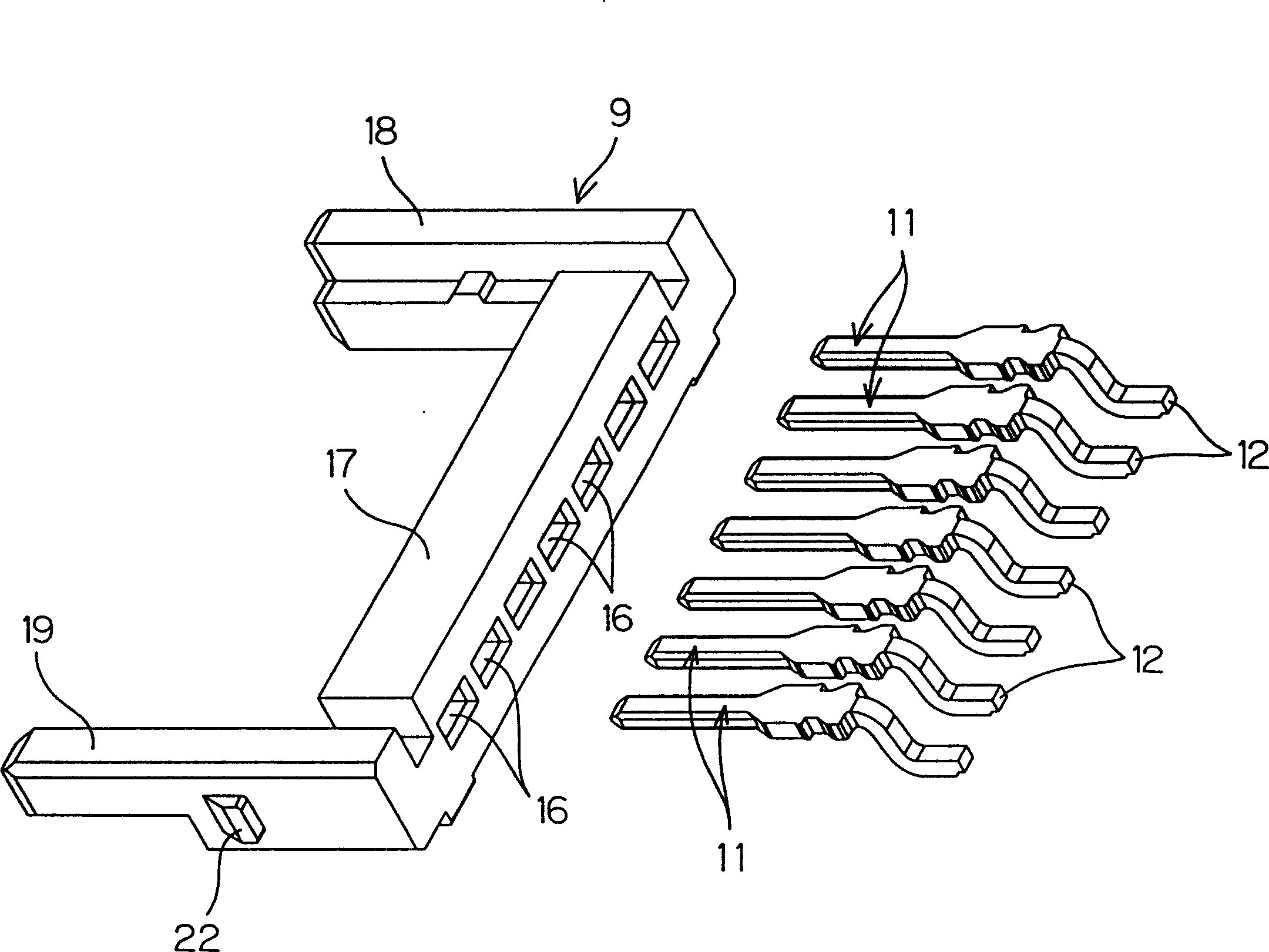

Connector for printed wiring board

InactiveCN1192463CSuppresses bending deformationSuppression of warpingPrinted circuit assemblingElectrically conductive connectionsEngineeringSynthetic resin

A connector includes a connector body having an insertion space for receiving its counterpart connector. The connector body includes a synthetic-resin housing for retaining contacts, and a metallic shell. A part of the insertion space is defined by an upper plate of the shell. The upper plate of the shell has extensions extended therefrom along corresponding side walls of the housing. The extensions include legs soldered to a conductive portion on a printed wiring board surface. The legs are outwardly extended and confined in an outline of the connector body as viewed in plan.

Owner:JST MFG CO LTD

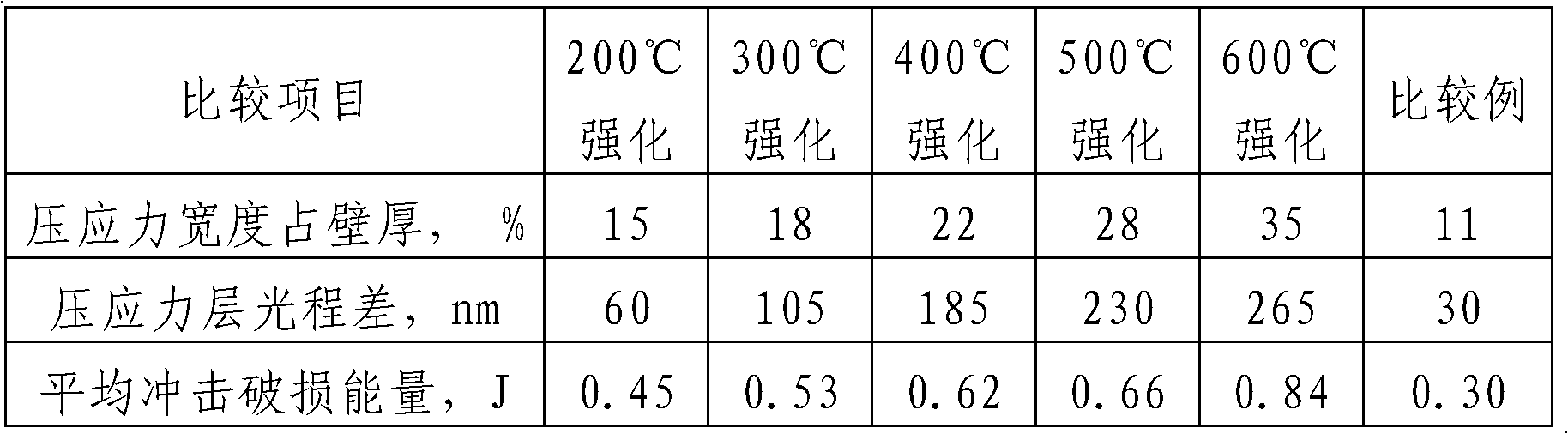

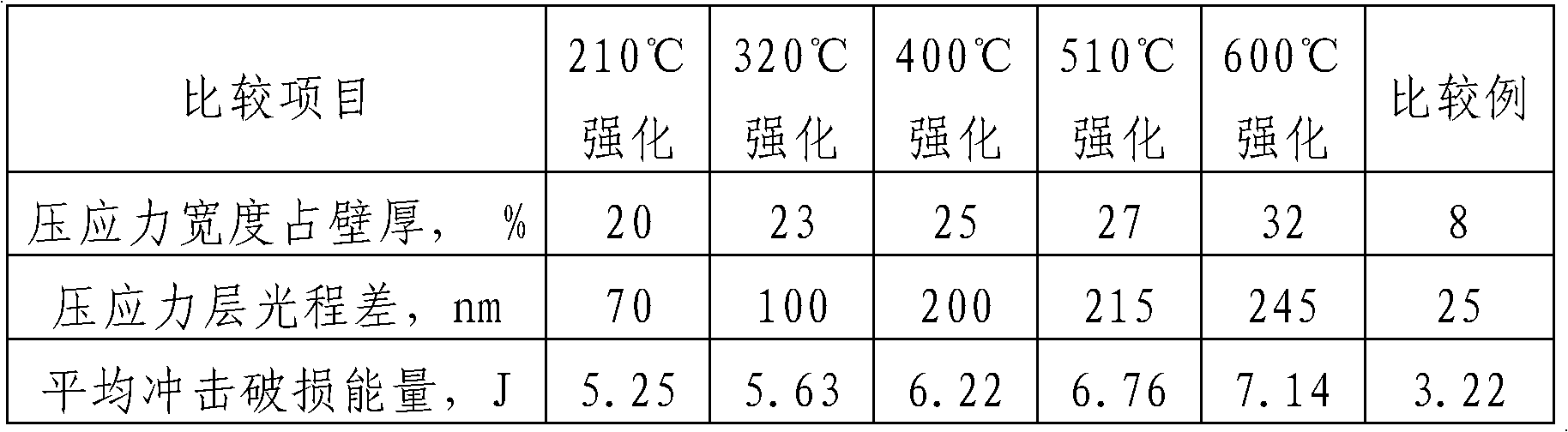

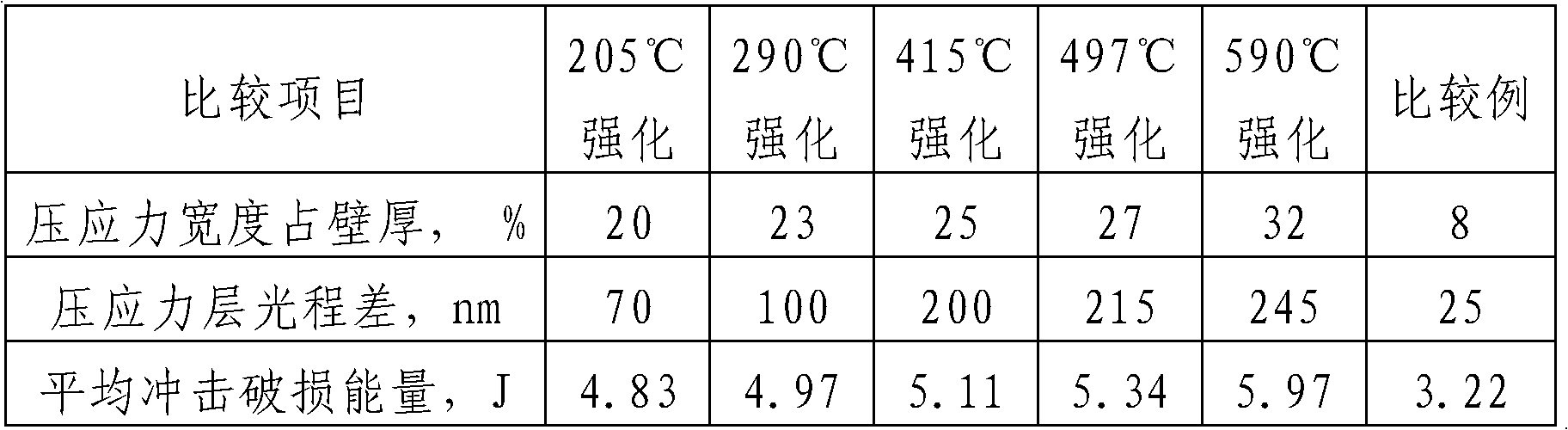

Strengthening treatment method for glass tube in on-line production process

The invention relates to a strengthening treatment method for a glass tube in the on-line production process and belongs to the field of manufacturing of glass materials. In the method, when the temperature of the glass tube is below the annealing temperature point and the surface temperature of the glass tube is between 200 and 600 DEG C, a liquid strengthening medium is sprayed on the outer side of the glass tube by an annular ultramicro atomizer, wherein the strengthening medium is pure water, aqueous solution of pure water and vinyltriethoxysilane, aqueous solution of diethyl dichlorosilane or aqueous solution of isobutyl trimethoxysilane; the solid content of the aqueous solution is 15 to 35 weight percent; and the solvent is pure water. The invention aims to provide the strengthening treatment method for the glass tube in the on-line production process. By the method, mechanical strength of the glass tube is improved and the application safety of the glass tube is improved. The strengthening treatment process belongs to an on-line process, so energy is saved to the maximum extent, labor cost is reduced, the production process is simplified, and occupied area is reduced.

Owner:BEIJING UNIV OF TECH

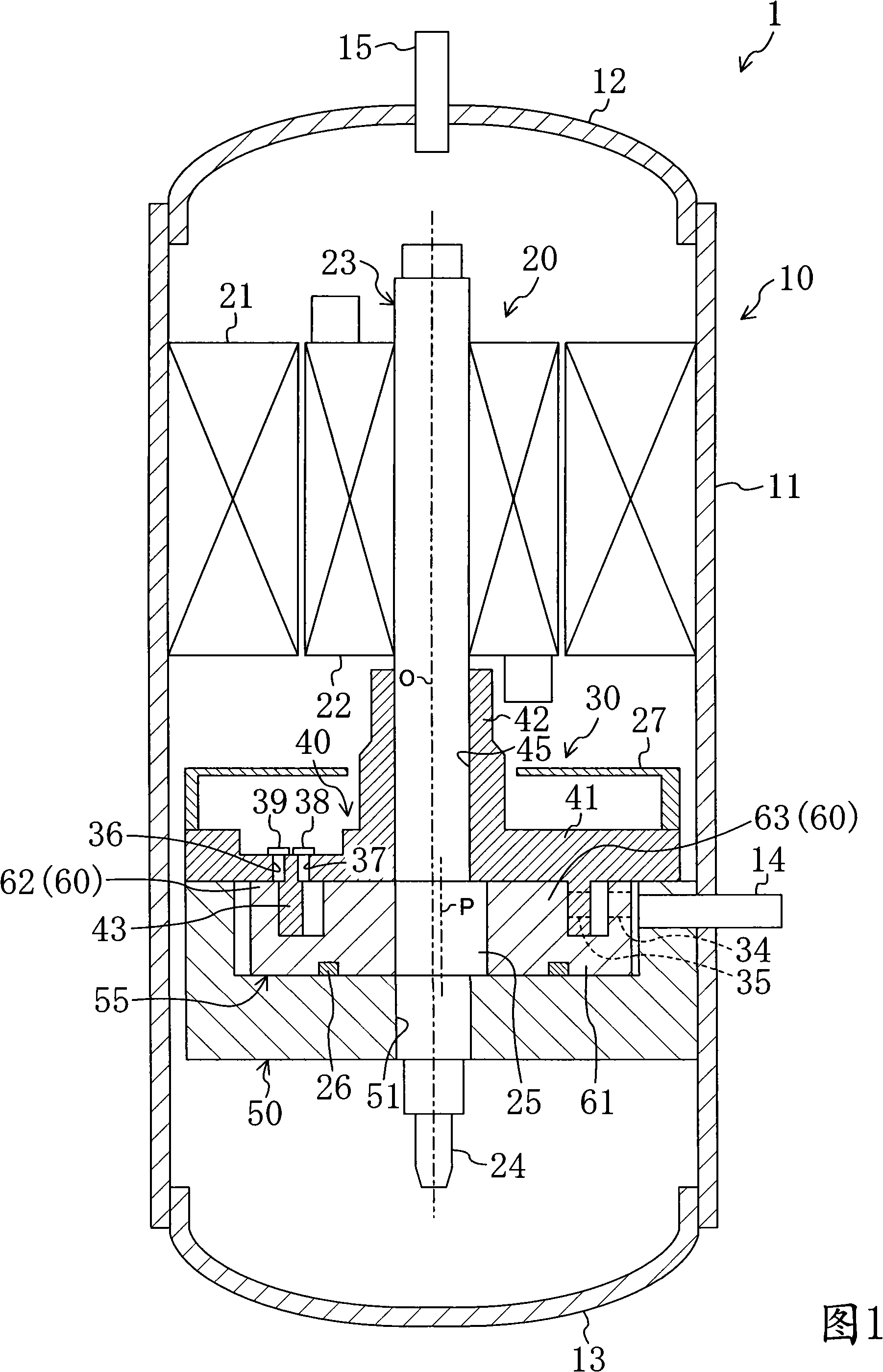

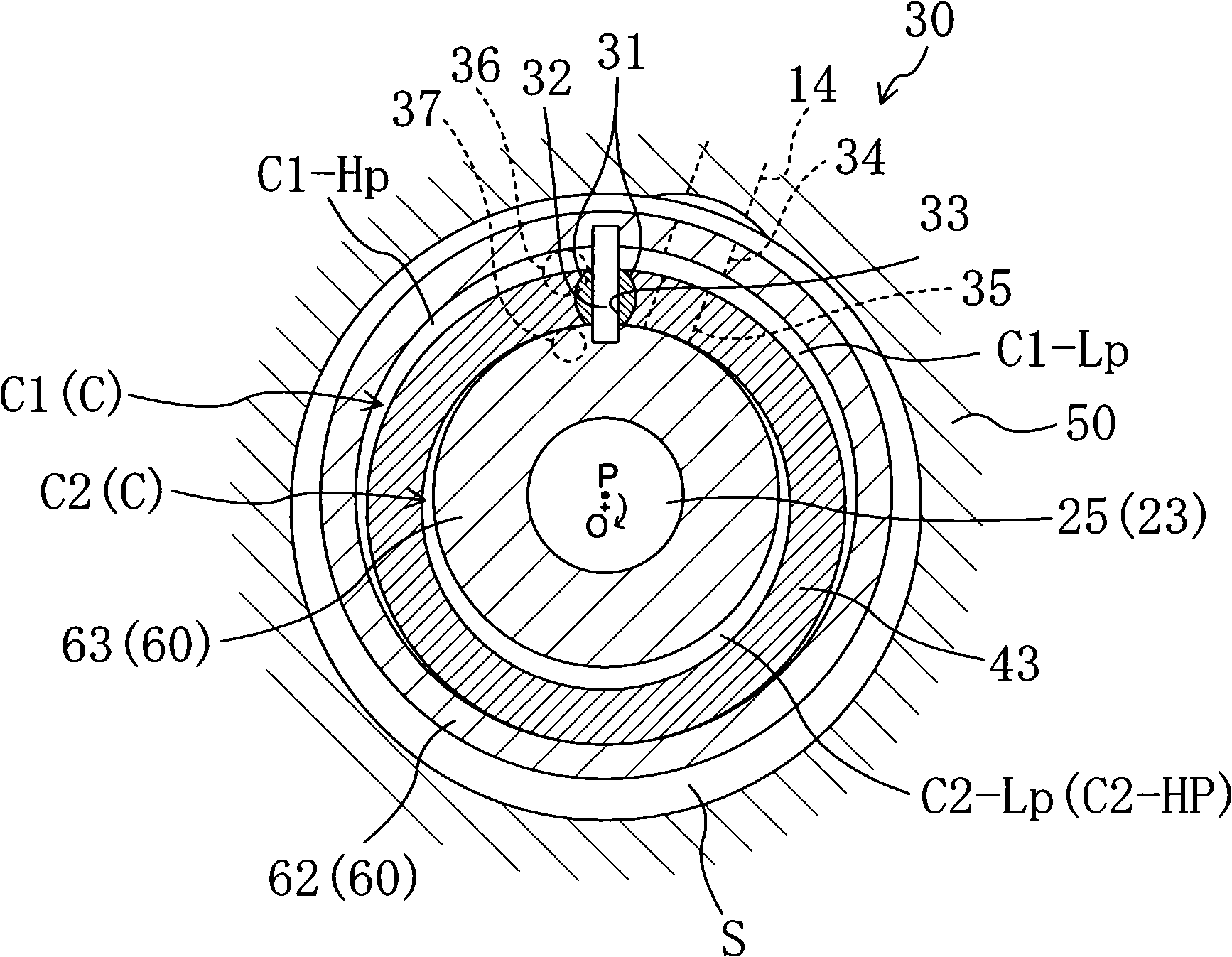

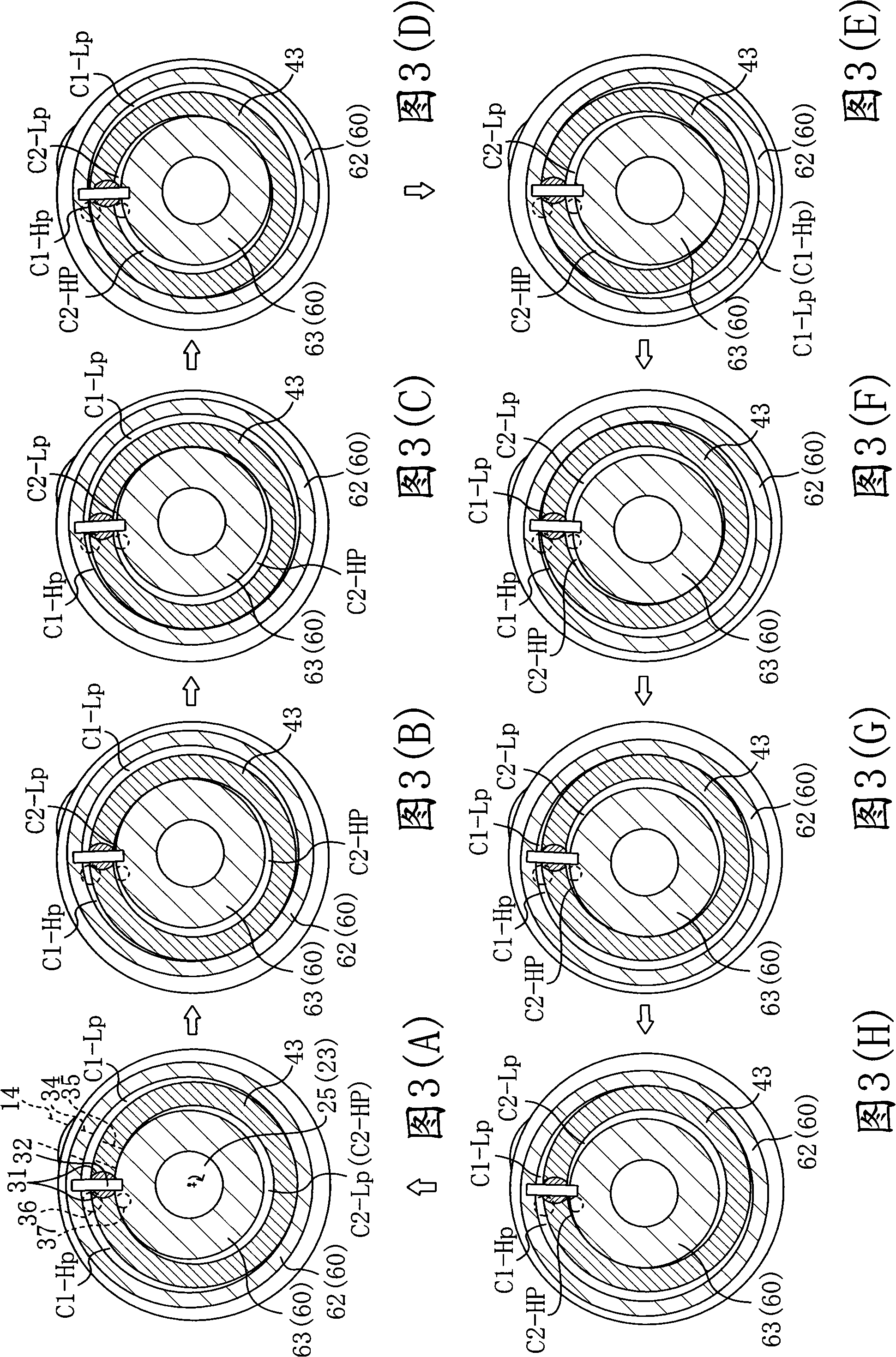

Rotary compressor

ActiveCN101283183APrevent leakageAvoid wear and scorchingRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsDrive shaftPiston

A cylinder (60) on the moving side is connected via an eccentric section (25) to a drive shaft (23) supported by a main bearing (45). On the other hand, an annular piston (43) on the stationary side is formed at a front head (40) integrally with the main bearing (45).

Owner:DAIKIN IND LTD

Polar group fastening structure for lead-acid storage battery

InactiveCN104538683AInhibition of longitudinal elongationInhibition of lateral elongationFinal product manufactureLead-acid accumulators constructionInternal resistanceEngineering

The invention provides a polar group fastening structure for a lead-acid storage battery. An upper clamp plate and a lower clamp plate are respectively arranged on the top and the bottom of a polar group and are tightened by a packing belt, and a lug hole and an acid penetrating hole are formed in the upper clamp plate. The polar group fastening structure provided by the invention is used for assembling the polar group of the lead-acid storage battery, and can be used for effectively inhibiting longitudinal extension of a grid and maintaining the stability of the grid structure in a charge and discharge process of the battery particularly for the battery with the anode which is lead-calcium alloy, and meanwhile, the influence caused by longitudinal extension of the grid on internal resistance is reduced and the service life of the battery is prolonged.

Owner:SHUANGDENG GRP

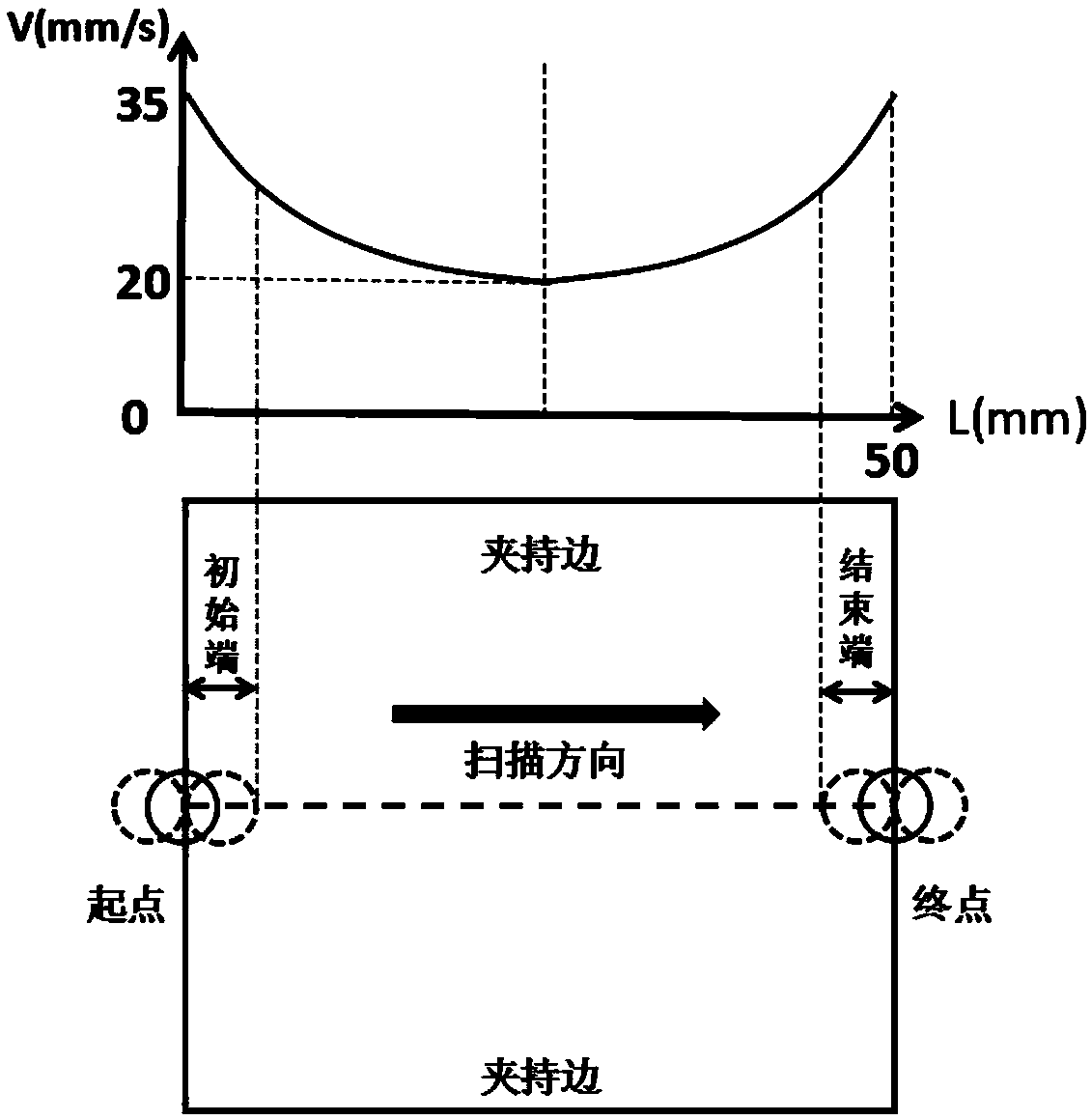

Scanning method for restraining bending deformation of laser-welded thin plate

ActiveCN109048052ARestricted movementReduce collapseLaser beam welding apparatusLaser scanningEngineering

The invention provides a scanning method for restraining bending deformation of a laser-welded thin plate. The scanning method comprises the steps: step S1, before welding, preprocessing the surface of a thin plate sample to be welded, and preheating the preprocessed sample; step S2, fixing the face to be processed of the preheated thin plate sample on a welding workbench upwards; step S3, settinglaser welding process parameters; and step S4, controlling the scanning speed for laser scanning welding for the sample by adopting a symmetric parabola type variable-speed scanning method accordingto the change law of a quadratic parabola. Under the premise of ensuring reasonable laser heat input, the conventional constant scanning speed is changed to the symmetric parabola type scanning speed,so that the scanning method improves the uneven distribution of temperature and stress on a scanning line and reduces pit collapse in the initiating end and the tail end of a welding bead. Meanwhile,the scanning method can also restrain the undesired bending deformation of the thin plate during welding.

Owner:JIANGSU UNIV

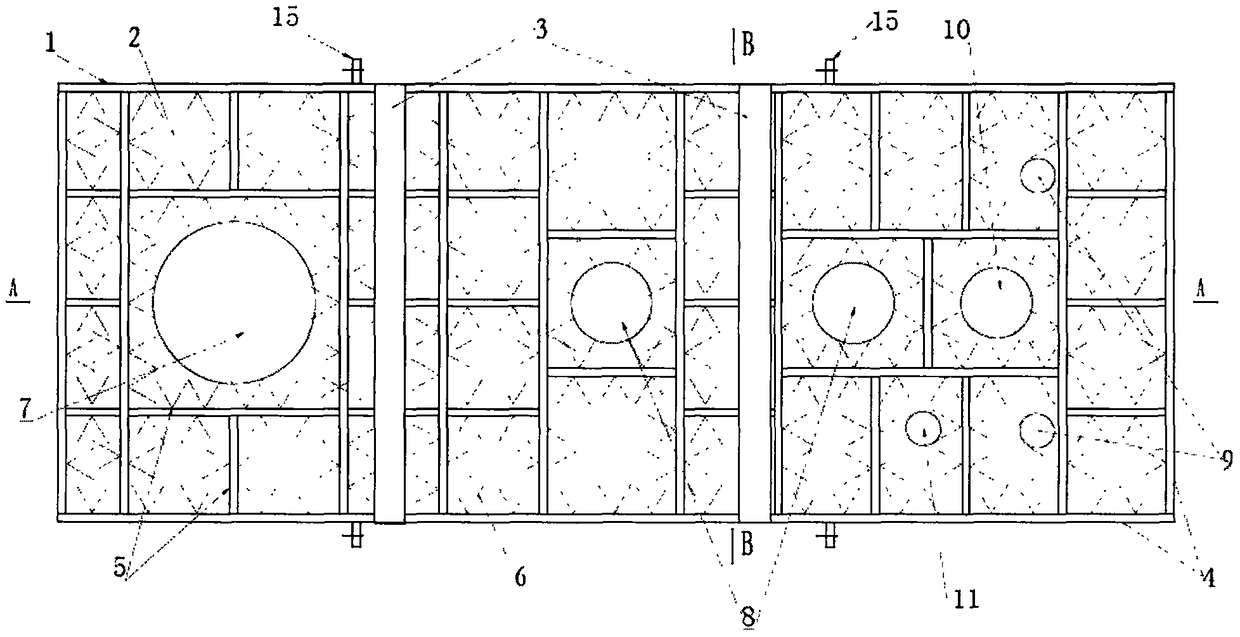

Composite frame cladding cover for long-life tundish

PendingCN108247028ASmall amount of deformationStrong ability to bend and deformMelt-holding vesselsTundishTemperature measurement

The invention relates to a composite frame cladding cover for long-life tundish. The composite frame cladding cover comprises a composite frame structure, a refractory material and triangular anchoring parts, wherein the composite frame structure comprises an outer beam, rectangular frames and rib plates, the rectangular frames are welded and connected by transverse side plates and longitudinal side plates, the rib plates are arranged in the rectangular frames, the rib plates are connected by transverse rid plates and longitudinal rid plates, the triangular anchoring parts are uniformly fixedto the rectangular frames and the rib plates, the composite frame structure and the refractory material are integrally poured and formed, a large steel flowing hole, two baking holes, a small steel flowing hole, two small exhaust holes and a temperature measurement hole are formed in a steel structure poured by the refractory material, the shape of the composite frame structure is consistent withthat of the opening of the tundish, and the thickness of the rectangular frames of the composite frame structure is consistent with that of the cladding cover of the tundish. The cladding cover for the tundish has the advantage of long service life, thereby reducing the enterprise cost.

Owner:SHANGHAI LIER REFRACTORY MATERIAL

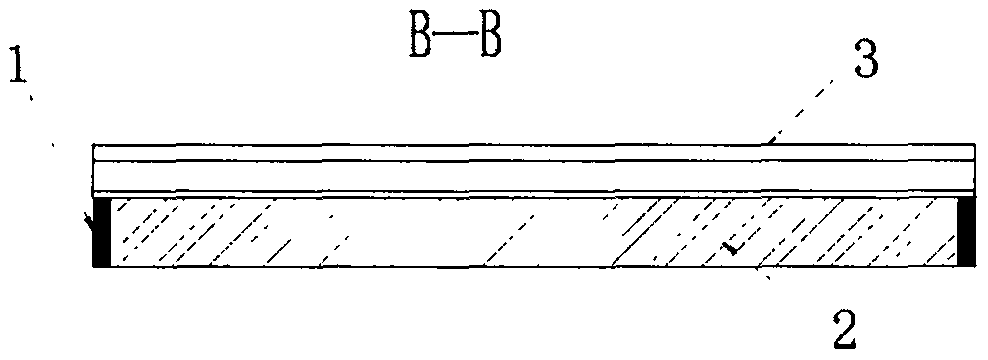

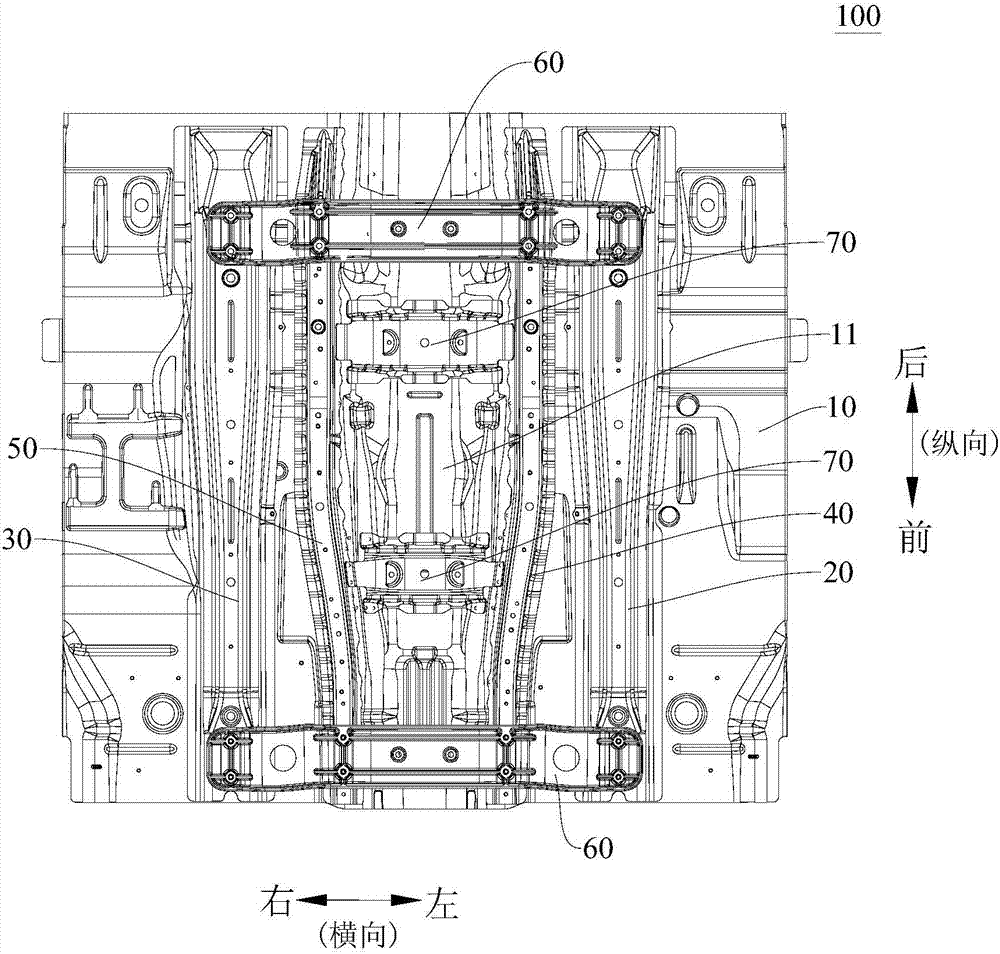

Vehicle and front floor assembly thereof

The invention provides a vehicle and a front floor assembly thereof. The front floor assembly comprises a front floor, a first left longitudinal beam, a first right longitudinal beam, a second left longitudinal beam, a second right longitudinal beam, at least one first cross beam and at least one second cross beam. An intermediate channel extending in the longitudinal direction is formed in the front floor; the first left longitudinal beam and the first right longitudinal beam are located on the lower portion of the front floor and fixedly connected with the front floor; and the second left longitudinal beam and the second right longitudinal beam are located between the first left longitudinal beam and the first right longitudinal beam and on the two sides of the intermediate channel, located below the front floor and fixedly connected with the front floor. The first cross beams are sequentially connected with the first left longitudinal beam, the second left longitudinal beam, the second right longitudinal beam and the first right longitudinal beam. The second cross beams are connected with the second left longitudinal beam and the second right longitudinal beam. The front floor assembly has good side collision prevention performance.

Owner:GREAT WALL MOTOR CO LTD

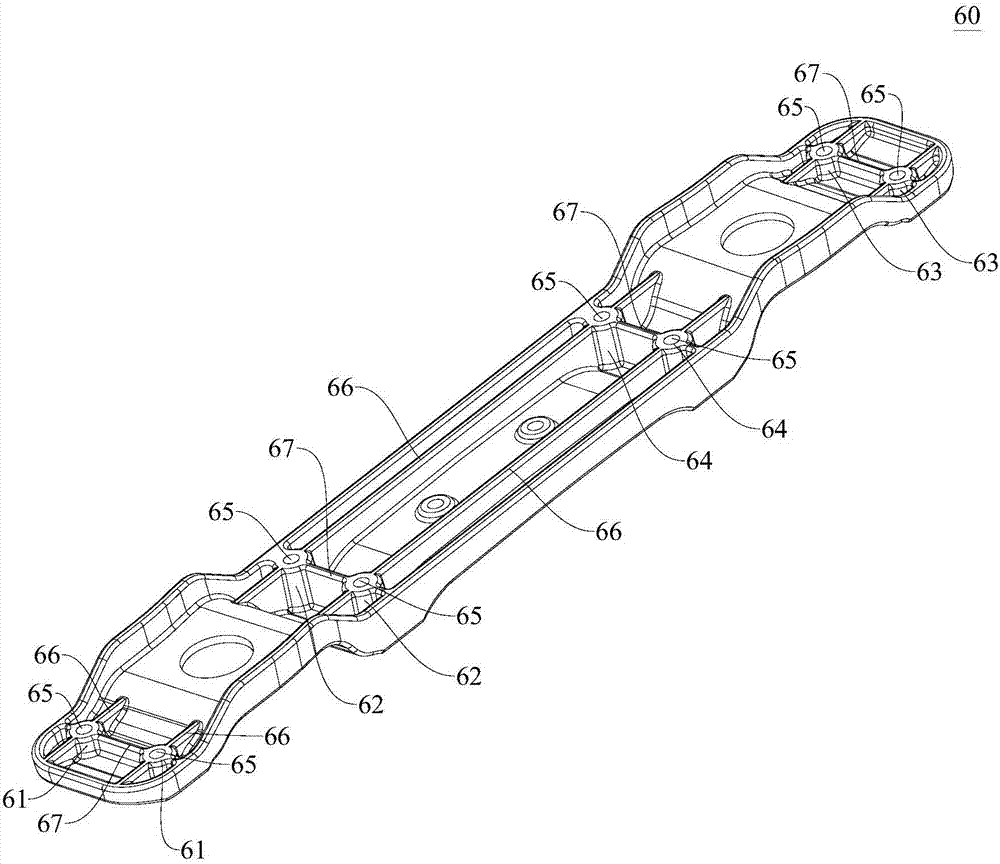

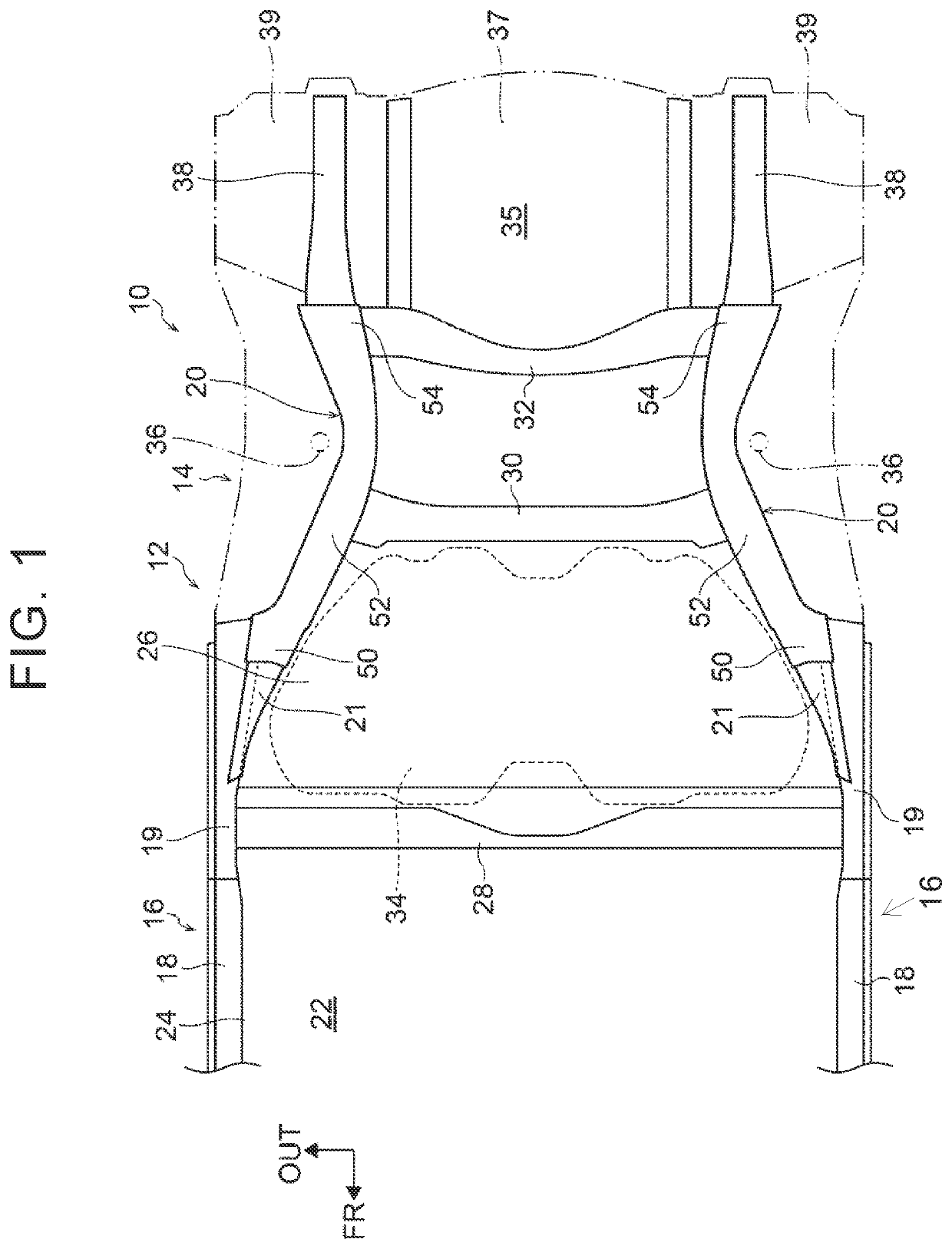

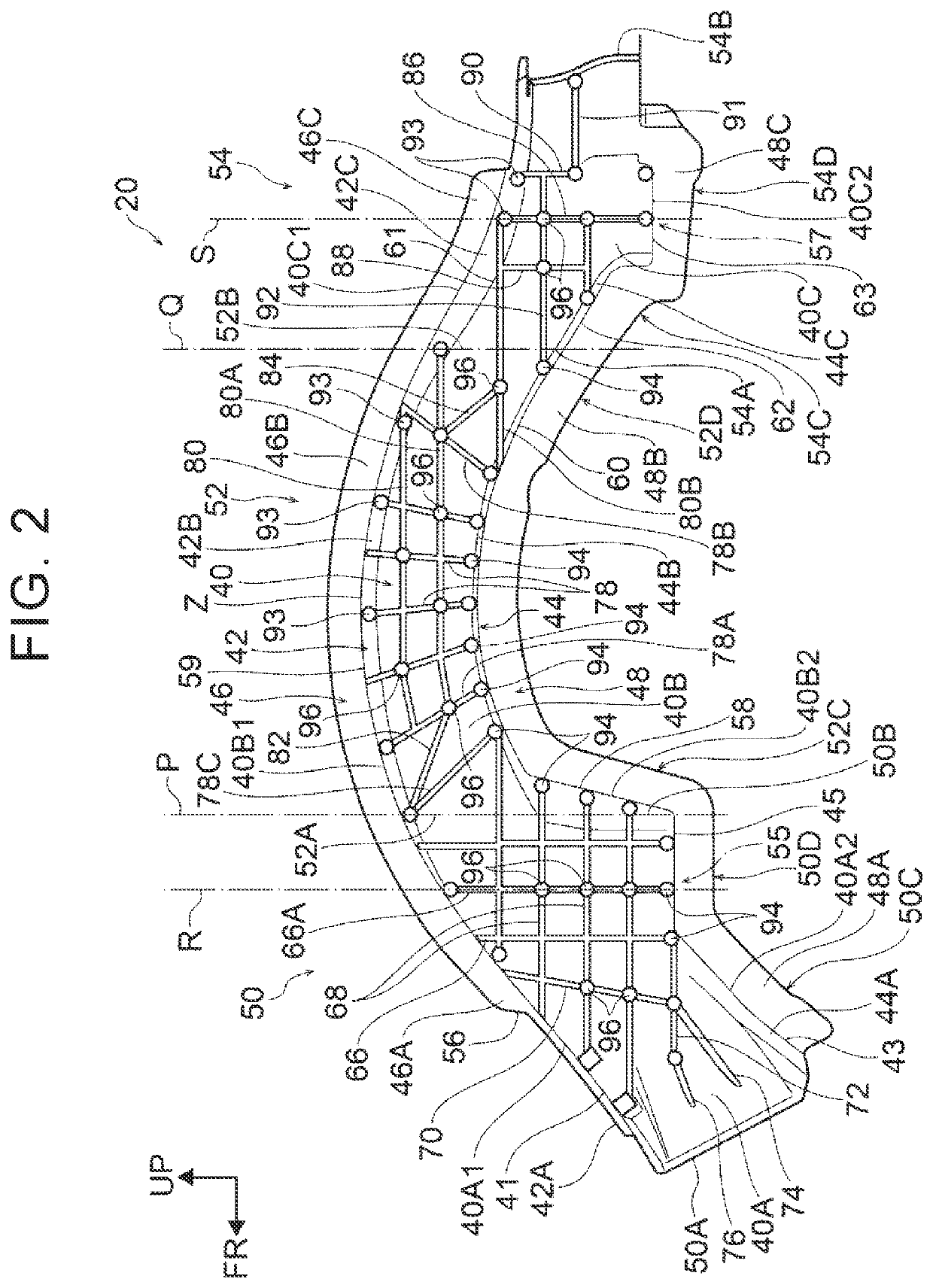

Vehicle body structure member

ActiveUS20200231213A1Suppresses bending deformationMisrun can be preventedUnderstructuresSuperstructure subunitsMechanical engineeringAutomotive engineering

Owner:TOYOTA JIDOSHA KK

Liquid ejection device

InactiveUS8777400B2Large easilyEasy to bendOther printing apparatusSupport surfaceElectrical and Electronics engineering

A liquid ejection device includes a transport unit, a medium support unit and a liquid ejection head. The medium support unit includes a plurality of first recesses and a plurality of second recesses arranged on a medium support surface along a width direction orthogonal to a transport direction. The first and second recesses are configured and arranged to be imparted with negative pressure. A width dimension of an opening of the first recess in the width direction is larger on the downstream side than on an upstream side. A width dimension of an opening of the second recess in the width direction is smaller than the width dimension of the opening of the first recess in the width direction on the downstream side with respect to the transport direction. The second recesses are configured and arranged to accept the liquid ejected toward the ejection medium from the liquid ejection head.

Owner:SEIKO EPSON CORP

vehicle rear structure

ActiveCN107521567BImprove rigiditySuppresses bending deformationUnderstructuresSuperstructure subunitsEngineeringStructural engineering

Owner:SUZUKI MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com