Polar group fastening structure for lead-acid storage battery

A lead-acid battery, fastening structure technology, applied in lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing and other directions, can solve the problem of thin grid ribs, large deformation space, increased internal resistance, etc. problems, to achieve the effect of improving cycle life, suppressing longitudinal elongation, and improving float life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

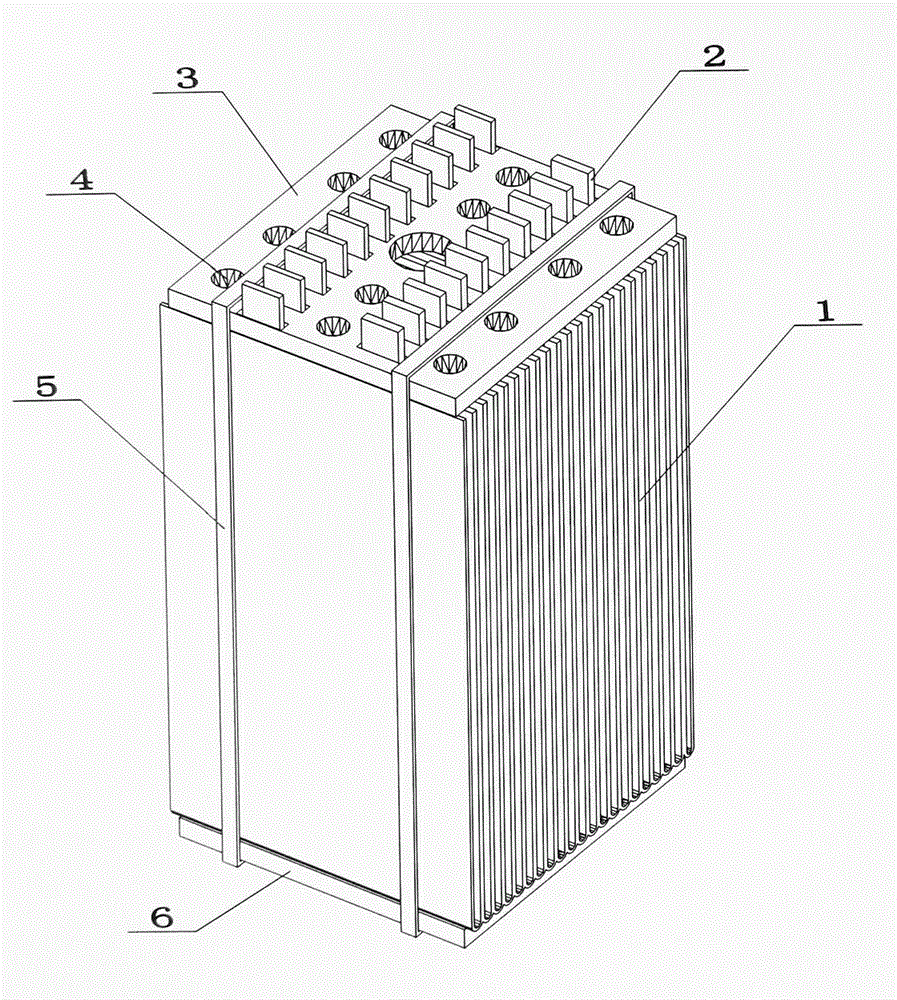

[0010] see figure 1 , the top of the lead-acid battery electrode group 1 is provided with an upper splint 3, and the bottom is provided with a lower splint 6, both of which are fastened by a packing belt 5. On the upper splint, there are ear holes corresponding to the tabs 2 with gaps and acid permeable Hole 4, the diameter of the acid penetration hole in the middle is larger than the other acid penetration holes, the thickness of the upper splint is 6mm, and the thickness of the lower splint is 5mm, both of which are made of PC-ABS alloy material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com