Patents

Literature

164 results about "Grid alloy" patented technology

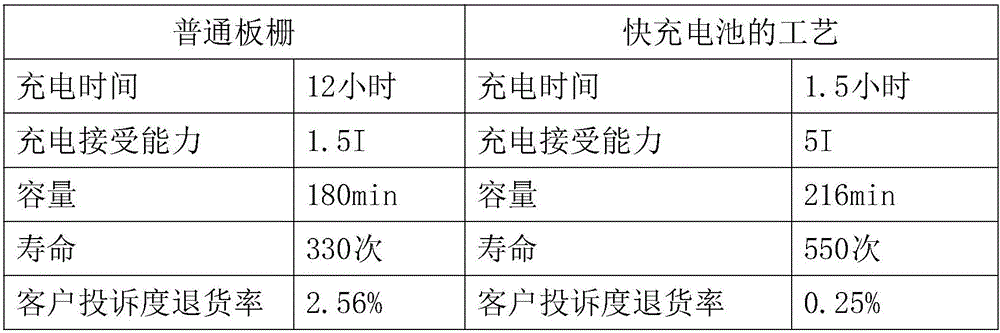

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-lead alloy as well as preparation method and application thereof

The invention discloses a graphene-lead alloy as well as a preparation method and application thereof. The graphene-lead alloy is prepared from the following components in percentage by weight: 0.0015-0.1 percent of graphene, 96.96 percent of lead and any one, two, three or four of 0.1-1.6 percent of tin, 0.015-0.05 percent of aluminum, 0.05-1.2 percent of strontium and 0.05-0.09 percent of copper. The invention also discloses the preparation method and the application to a grid alloy. The graphene-lead alloy used by a grid is high in rigidity, good in toughness, mobility and creep resistance, strong in corrosion resistance and firm in combination of the grid and an active substance without a barrier layer. According to the invention, a battery manufactured by the graphene-lead alloy is little in water loss and long in cycle life.

Owner:XIAMEN MATE HI TECH NEW ENERGY CO LTD

Positive grid alloy of lead-acid battery and manufacturing method of alloy

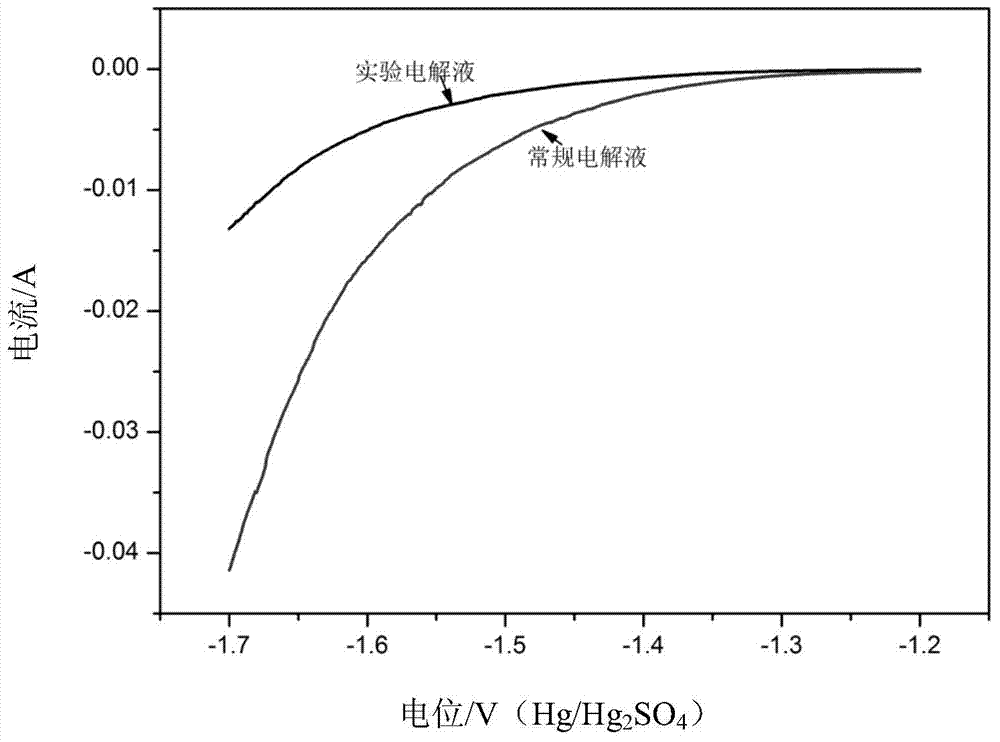

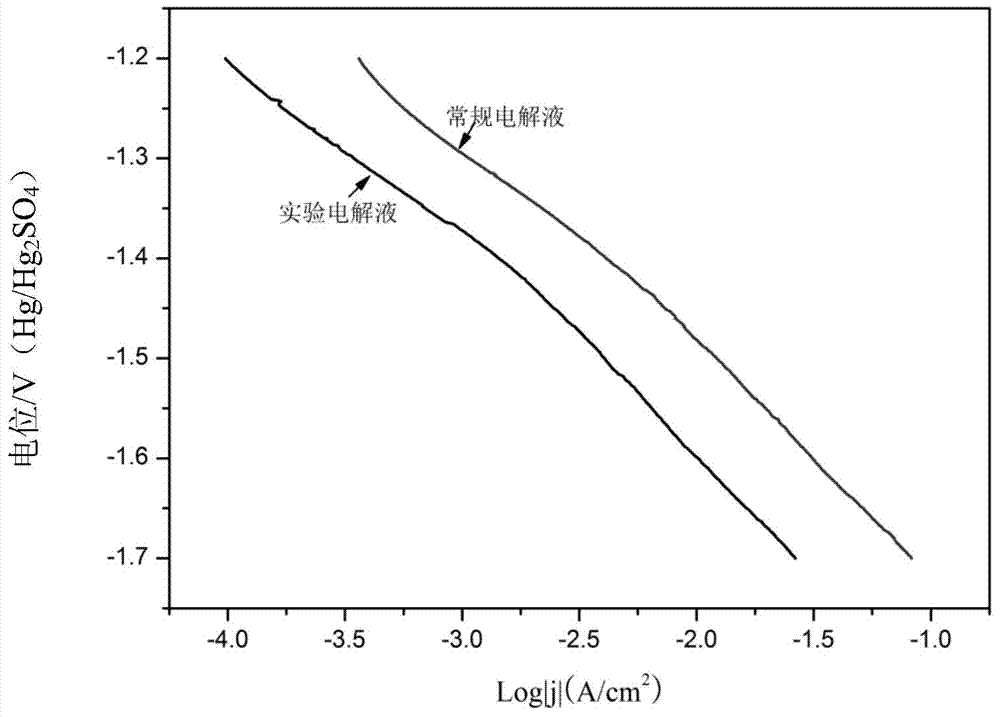

ActiveCN103199263AReduce severe dehydrationLower reduction potentialElectrode carriers/collectorsAlloyOverpotential

The invention discloses a positive grid alloy of a lead-acid battery and a manufacturing method of the alloy. The alloy includes lead, calcium, tin, aluminum and silver. The positive grid alloy containing silver of the lead-acid battery is helpful to the reduction of reduction potentials of Pb and PbSO4, thereby enabling Pb2+ to be easily reduced into metal Pb. The silver has an inhibiting effect on the formation of PbO when a constant potential is polarized, the intensity and the creeping strength of the positive grid alloy are improved, and an over-aging effect of the positive grid alloy in a use process is slowed down; and the addition of the sliver can inhibit the increase of a corrosive layer of the positive grid alloy, thereby facilitating the deep discharge cycle of the lead-acid battery, and preventing capacity fading phenomena in the early stage. Meanwhile, through the addition of the sliver, hydrogen evolution overpotentials are enhanced, the separation of hydrogen on a cathode of the alloy is inhibited, the problem of serious water loss of the battery is reduced, and the cycle life of the battery is prolonged. Moreover, the manufacturing process of the alloy is simple.

Owner:CHERY AUTOMOBILE CO LTD

Environmental protection recovery processing method for waste lead acid accumulator

InactiveCN101098031AImprove protectionEasy to reuseSolid waste disposalWaste accumulators reclaimingRed mudEngineering

The invention discloses an environment-friend recycle processing method of waste lead-acid accumulator, comprising that first separating acid solution of waste lead-acid accumulator, using breaker to break waste lead-acid accumulator, using selector to select the broken mixture, processing following treatment on metal lead, relative oxide and lead plate grid particles, feeding metal lead and relative oxides into a band filter to filter out water and obtain lead mud, putting lead mud into a furnace to obtain rough lead, putting rough lead into a fining furnace, to remove foreign materials to obtain pure lead, putting lead plate grid particles into an alloy furnace, to adjust the components of alloy until qualified, using casting machine to cast lead alloy into lead alloy ingot, using smoke recycle processor to recycle the smoke and dust generated in furnace. The invention smelts and recycles plastic casing, PVC baffle plate, metal lead, and plate grid alloy of waste lead-acid accumulator according to different physical and chemical properties, with environment-friend property, which can repeatedly recycle resource.

Owner:上海飞轮有色冶炼厂

Cathode protection-based valve control type lead-acid battery capacity activation solution

ActiveCN102013534AEffective protectionAvoid softening and falling offWaste accumulators reclaimingSecondary cells servicing/maintenanceSodium bicarbonatePhosphate ion

The invention relates to the technical field of capacity recovery for valve control type lead-acid batteries and is characterized in that the formula comprises the following components by weight percent: 2-5% of sodium sulfate, 2-4% of potassium sulfate, 0.2-0.5% of aluminum sulfate, 1-3% of sodium bicarbonate, 1-2% of ammonium sulfate, 0.5-2% of phosphoric acid, 1-1.5% of sodium pyrophosphate, 0.05-0.15% of citric acid, 0.2-0.4% of ethylenediaminetetraacetic acid disodium and the balance of deionized water. Phosphate ions are fully utilized for protecting a cathode plate of the battery, thereby preventing active substances from being softened and shedding during the high-frequency pulse activation process and reducing the corrosion of a grid alloy; the action of a complexing agent is utilized for leading lead ions in a sulfide crystal to form a coordination compound and be further dissolved; and the action of replacing the lead ions in the sulfide crystal of active metal ions is simultaneously utilized for leading sulfate ions and the lead ions in the crystal to return into electrolyte. Not only can a cathode of the battery be effectively protected during the activation process based on the coaction of the components in the compound, but also the irreversible sulfation can be well eliminated, thereby greatly recovering the battery capacity with failure.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST

Casting process of plate grid of lead-acid storage battery

ActiveCN105280927AAvoid deformationNot easy to fall offElectrode carriers/collectorsRare-earth elementCerium

The invention discloses a casting process of a plate grid of a lead-acid storage battery and belongs to the technical field of machining of the lead-acid storage batteries. The casting process comprises the following steps: preparing a plate grid alloy solution from the following components in weight percent: 0.946% of tin, 0.02% of lanthanum, 0.01% of yttrium, 0.01% of cerium, 0.003% of silver, 0.003% of manganese, 0.002% of barium, 0.002% of iron, 0.0015% of chromium, 0.0015% of silicon, 0.001% of potassium and 99% of lead; spraying a de-molding agent in a pre-heated mold cavity; casting by using a casting machine to prepare the plate grid. According to the casting process, by adding the tin, rare earth elements, the silicon and the potassium into the lead, the coefficient of thermal expansion is reduced, so that the plate grid is not easy to deform when being circularly charged and discharged; by adding the silver, the manganese, the barium, the iron and the chromium, the adhesion force between the plate grid and an active substance can be enhanced, so that the active substance is not easy to fall off, and deep charging and deep discharging capabilities of the storage batteries are facilitated and the circular charging and discharging service life is prolonged.

Owner:JIESHOU HUAYU POWER SUPPLY

Rareearth lead based grid alloy and mfg. process thereof

A Pb-base RE alloy used for grid electrode of lead-acid accumulator is prepared through smelting the mixture of RE (0.02-0.06 wt.%), Sn (0.4-1.2 wt.%) and Pb (98.65-99.56 wt.%) at 400-650 deg.C, adding Ca (0.02-0.09 wt.%), casting and fast cooling. Its advantages are high tension strenth (45 MPa) and high corrosion resistance in sulfuric acid.

Owner:XI AN JIAOTONG UNIV

Non-cadmium lead stibium slab lattice alloy for traction type accumulator

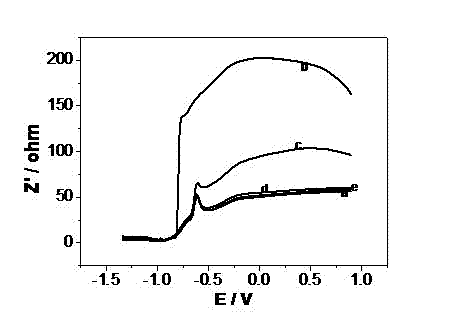

InactiveCN101295789ASolve the problem of thermal crackingSmall and uniform crystal grainsElectrode carriers/collectorsRare-earth elementAlloy

The invention discloses a cadmium free lead-antimony grid alloy for traction batteries. The lead-antimony alloy contains antimony, mischmetal and lead and the weight percentage of the antimony in the lead-antimony alloy is 0.5 to 4.5 percent, that of the mischmetal is 0.05 to 2 percent and the rest is the lead. The grid alloy adds rare earth elements into the lead-antimony alloy and causes the grains of the alloy to become small and even, thereby solving the problem of the hot cracking of the lead-antimony alloy and obviously improving and increasing the toughness, aging strength and corrosion resistance of the alloy. Meanwhile, the adding of the rare earth obviously inhibits the growth of the Pb(II) oxide film and reduces the impedance thereof, thus improving the charging and discharging performance and the deep circulation of the battery. Batteries for electric vehicles combined by lead-acid battery grids produced by the alloy have the advantages of corrosion resistance, deep circulation, high-current discharge and long service life.

Owner:上海飞轮有色冶炼厂

Ultralow-water-loss high-temperature-resistant solution-enriched lead-acid storage battery and preparation method thereof

ActiveCN107819124ALower oxygen evolution potentialReduce lossFinal product manufactureElectrode carriers/collectorsRare earthEngineering

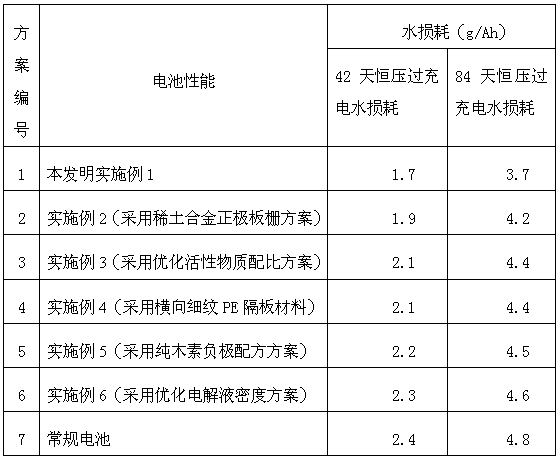

The invention relates to an ultralow-water-loss high-temperature-resistant solution-enriched lead-acid storage battery and a preparation method thereof. According to the technical scheme, through providing a rare-earth alloy positive pole grid, a pure-lignin negative pole formula, electrolyte concentration, a PE partition plate structure and a positive and negative pole active substance proportioning ratio, the water loss speed of the lead-acid storage battery is comprehensively lowered, the capacity matching of positive and negative poles of a single-unit storage battery is achieved, partial-pressure paramount gassing aggravation caused by mismatched active substance amount is reduced, the water loss speed of the battery is lowered, and the oxygen evolution potential of pole plates is lowered. According to the pure-lignin negative pole formula provided by the invention, humic acid is replaced with lignin, thus, the impurity content of the pole plates is lowered, the water loss of thebattery is lowered, and other properties are not lowered. Through applying and optimizing plate grid alloy, a process formula, electrolyte concentration and functional materials, the difficult problemof the traditional solution-enriched lead-acid storage batteries that the water loss speed is high is solved.

Owner:CAMEL GRP XIANGYANG BATTERY

Lead-acid battery grid alloy for power

ActiveCN102660697AExtended service lifeImprove bindingElectrode carriers/collectorsElectrical batteryAlloy

The invention discloses a lead-acid battery grid alloy for power. The lead-acid battery grid alloy for power comprises the following raw materials by weight percentage: 0.05-0.50% of Ca, 1-5% of Sn, 0.05-0.50% of Na, 0.01-0.50% of Al and 93.5-98.89% of Pb. The invention further discloses a method for preparing the lead-acid battery grid alloy for power. The metal Na and the metal Sn added in the grid alloy improve combination performance of the grid and activate substances, prolong service life of the battery and reduce the ohmic resistance of the prepared lead-acid battery grid alloy for power by about 30% compared with the existing lead-acid battery grid alloy for power prepared by grid alloys, and deep discharging performance and circulation service life are improved by about 15%.

Owner:TIANNENG BATTERY GROUP

Heat treatment process of storage battery grid

InactiveCN102324500AHigh bonding strengthImprove crystal structureLead-acid accumulator electrodesChemical reactionInternal resistance

The invention discloses a heat treatment process of a storage battery grid. The process comprises the following steps: (1) placing the grid that is just cast and molded in a curing chamber for 12-48 hours, wherein the humidity of the curing chamber is not less than 98%, the CO2 concentration of the curing chamber is not less than 13% and the temperature of the curing chamber is 60-70 DEG C; (2) placing the grid in a drying chamber with the temperature of 80-90DEG C for 2-6 hours; (3) naturally cooling and then placing the grid in a room-temperature ventilated environment for no less than 10 hours. According to the method, the grid can be placed in different environments for realizing chemical reaction and lattice parameter variation, so that a layer of rough basic carbonate and carbonate is generated on the surface of the grid, the bonding strength of the grid with active substances can be increased, the crystalline phase structure of a grid alloy can be improved, the battery plate ohm internal resistance can be reduced, and then consistency and stability of the electrochemical performances of the battery plate can be improved greatly.

Owner:TIANNENG BATTERY GROUP +4

Grid alloy and diachylon formula of battery plate of electrombile

InactiveCN102839296AEasy to useAvoid pollutionLead-acid accumulator electrodesElectrical batteryElectric-vehicle battery

The invention relates to a grid alloy and a diachylon formula of a battery plate of an electrombile. The grid alloy of the positive electrode comprises the following components by weight: 1.3-1.5% of tin, 0.07-0.09% of calcium, and 0.01-0.03% of aluminum; the grid alloy of the negative electrode comprises the following components by weights: 0.6-0.8% of tin, 0.09-0.11% of calcium and 0.01-0.03% of aluminum; the diachylon formula comprises the following components by weight: 1000kg of lead powder served as the main material, and additive auxiliary materials including 0.2-0.3% of active carbon, 0.1-0.12% of short fiber, 0.1-0.12% of stannous mono-sulphate, and 0.2-0.22% of antimonous oxide; and the materials for mixing are as follows 11.0%-11.5% of pure water, 10.5-11.0% of sulfuric acid with 1.40g / ml under 25 DEG C based on the concentration. The pollution of the cadmium to the environment is removed; the stannous mono-sulphate and the antimonous oxide are added to the diachylon formula; and a high-temperature high-humidity solidifying technology is adopted, so that the strength of the polar plate is ensured, and the circulating capacity of a battery can be improved.

Owner:SHAOGUAN QUJIANG GREATBASE POWER TECH

Production process of storage battery positive plate

ActiveCN110690454AImprove microstructureImprove corrosion resistanceElectrode carriers/collectorsLead-acid accumulator electrodesElectrical batteryEngineering

The invention discloses a production process of a storage battery positive plate. The production process comprises the following steps: step 1, preparing an alloy grid; step 2, preparing a positive lead paste and uniformly coating the positive lead paste on the surface of the grid through a plate coating machine; step 3, solidifing the wet grid; and step 4, forming the pole plate, wherein the positive lead paste is made of the following raw materials in parts by weight: 90-100 parts of lead powder, 8-12 parts of sulfuric acid aqueous solution, 14-18 parts of deionized water, 0.5-1 part of sodium perborate and 0.15-0.2 part of graphene. The corrosion resistance of the grid is improved by modifying the grid alloy; the modification treatment of the lead paste can improve the bonding force between the lead paste and the grid and effectively inhibit sulfation of the negative electrode and prolong the service life of the storage battery. Meanwhile, the curing is divided into two stages and the temperature and humidity parameters are optimized so that the active substances in the lead paste are firmly combined with the grid and the discharge performance of the battery is improved.

Owner:JIESHOU HUAYU POWER SUPPLY

Preparation method of graphene-lead grid alloy for plumbic acid cell

InactiveCN106058267AImprove mechanical propertiesImprove creep resistanceElectrode carriers/collectorsSimple Organic CompoundsCarbide

The invention discloses a preparation method of a graphene-lead grid alloy for a plumbic acid cell. The preparation method comprises selecting a metallic carbide or a solid carbonaceous organic compound, decomposing the metallic carbide or the solid carbonaceous organic compound at a high temperature to obtain a carbon source, feeding the carbon source into a lead solution at a high temperature so that atom-level bonding of carbon and lead is formed and carrying out cooling so that the graphene can be uniformly dispersed in the lead alloy. The preparation method can be carried out at the normal temperature under normal pressure so that a cost is greatly reduced. The graphene grid alloy improves grid alloy mechanical properties so that a creep resistance capability is improved. The graphene-lead grid alloy effectively reduces alloy specific gravity, improves alloy mechanical properties, improves alloy conductivity and electrochemical activity and improves grid resistance to corrosion.

Owner:CHAOWEI POWER CO LTD

Power type lead accumulator positive grid alloy and preparation method thereof

ActiveCN106636737AGood casting performanceImprove conductivityElectrode carriers/collectorsAluminum canBismuth

The invention belongs to the technical field of lead-acid accumulators, and particularly relates to a power type lead accumulator positive grid alloy formula and a preparation method thereof. The alloy comprises the following raw materials in percentage by weight: 0.03-0.12% of calcium, 0.03-1.50% of tin, 0.01-0.05% of aluminum, 0.04-0.08% of sodium, 0.008-0.016% of silver, 0.02-0.03% of bismuth and the balance of Pb. A preparation process of a positive grid comprises the following steps: adding tin, silver and bismuth which are less prone to air oxidation and a small amount of aluminum into molten lead; and then adding sodium and calcium which are prone to air oxidation, wherein the first added aluminum can be floated on the surface of the molten lead alloy to protect the later added sodium and calcium. Thus, the composition uniformity of the molten alloy is ensured.

Owner:HENAN CHAOWEI POWER SUPPLY

Positive grid alloy of lead-acid storage battery

InactiveCN102925747AHigh strengthStrong deep discharge recovery abilityCell electrodesTrace elementAlloy

The invention discloses positive grid alloy of a lead-acid storage battery. The positive grid alloy of the lead-acid storage battery is characterized by being high in tin content and low in calcium content, and comprises, by weight percentage, 0.04 %-0.07 % of calcium, 1.3 %-1.8 % of tin, 0.01 %-0.05 % of aluminum, 0.02 %-0.07 % of silver, and lead as the rest. The positive grid alloy of the lead-acid storage battery has the advantages of being strong in corrosion resistance, high in strength, and strong in the ability to recover from deep discharging. The aluminum not only reduces the loss of the calcium, but also plays a role in refining grains, the silver reduces corrosion and improves (refines) the structure of the grains, rare elements are capable of reducing the loss of water, and therefore the service life of the storage battery is largely prolonged.

Owner:徐永生

Plate-type polar plate lead acid storage battery

ActiveCN102623753AImprove corrosion resistanceLong cycle lifeLead-acid accumulatorsElectrode carriers/collectorsMaterials scienceCorrosion

The invention relates to a plate-type polar plate lead acid storage battery, and belongs to the field of power storage batteries. The plate-type polar plate lead acid storage battery is characterized in that the thickness of a positive plate grid is 2.8mm-6mm, and the components of positive and negative plate grid alloys, a positive active material and a negative active material are as follows: the positive plate grid alloy comprises the following components in percentage by weight: 0.06%-0.08% of Ca, 1%-1.60% of Sn, 0.02%-0.04% of Al, 0.01%-0.04% of Cu, 0.008%-0.05% of Ag, 0.002%-0.0085% of La, and the balance of lead. Through the reasonable formula, the corrosion resistance of the storage battery in a sulfuric acid system is improved greatly, and the cycle service life of the plate-type polar plate lead acid storage battery is prolonged effectively.

Owner:淄博明泰电器科技有限公司

High performance battery plate grid alloy

The invented alloy is applied to complete enclosed maintenance free lead acid cell. The ingredient is Cd:1.5%-2.0%, Sb:1.5%-2.0%, RE:0.01-0.05%, Sn:0.01-0.05%; ingredient of RE is Ce, La, Pr, Nd etc. Adding Pb, Cd, mixed rare earths, stannum etc. constitutes alloy of Pb-Cd-Sb-Re-Sn. Features of the alloy are strong corrosion resistance, high deep cycle duty. Method for manufacturing the alloy includes producing Pb-RE intermediate alloy about 660 deg.C by using general crucible furnace or iron-lead pan; adding prepared antimony and stannum to molten lead at 450-500 deg.C; adding the molten fluid into cadmium and Ph-RE. Qualified alloy is casting into ingot for making sheet grating further.

Owner:上海飞轮有色冶炼厂 +1

Positive pole plate lead paste of lead storage battery, preparation method of lead paste and lead storage battery

ActiveCN107452947AEasy to apply and adhereImprove the ability to receive high-current chargingLead-acid accumulatorsCell electrodesFiberLEAD TETROXIDE

The invention relates to the technical field of a lead storage battery, in particular to positive pole plate lead paste of a lead storage battery, a preparation method of the lead paste and the lead storage battery employing the positive pole plate lead paste. The positive pole plate lead paste comprises the following substances based on parts by weight: 1,000 parts of lead powder, 2-5 parts of colloidal graphite, 0.1-2 parts of antimony oxide, 1-15 parts of tetrabasic lead sulfate, 20-50 parts of lead tetroxide, 0.1-2 parts of fiber, 60-100 parts of dilute sulphuric acid, 60-100 parts of pure water and 2-15 parts of processing powder. With the positive pole plate lead paste of the lead storage battery, provided by the invention, the corrosion of the lead paste on grid alloy is reduced, and the binding force between the lead paste and the grid alloy is improved; and by the addition of graphite in a relatively large proportion, the conductivity of the battery is greatly improved, and the large-current charging receiving capability of the battery is good.

Owner:JIESHOU HUAYU POWER SUPPLY

Plate grid alloy for positive plate of lead-acid storage battery

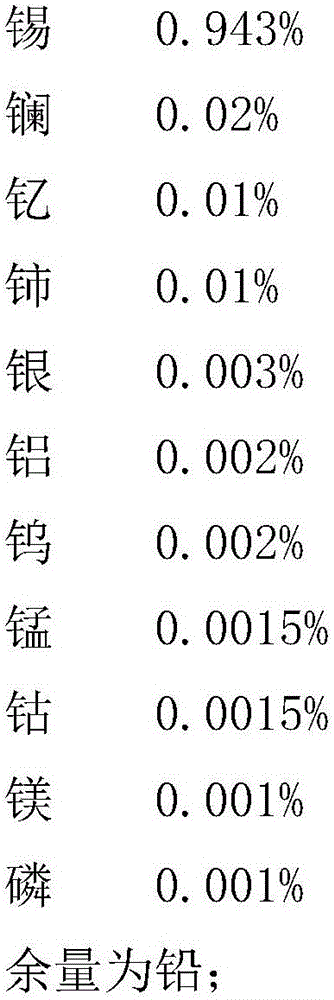

ActiveCN106099118AHigh mechanical strengthDelay Linear DeformationElectrode carriers/collectorsCeriumManganese

The invention discloses a plate grid alloy for a positive plate of a lead-acid storage battery, and relates to the technical field of processing of lead-acid storage batteries. The plate grid alloy is prepared from the following components in percentage by weight: 0.943% of tin, 0.02% of lanthanum, 0.01% of yttrium, 0.01% of cerium, 0.003% of silver, 0.002% of aluminum, 0.002% of tungsten, 0.0015% of manganese, 0.0015% of cobalt, 0.001% of magnesium, 0.001% of phosphorus and the balance of lead. The prepared plate grid alloy is a rare-earth alloy; and the mechanical strength of a plate grid can be improved through addition of the tin, rare earth and the silver, so that linear deformation of the plate grid is delayed. Meanwhile, the oxygen-evolution potential of a positive electrode can be regulated and controlled through addition of the tungsten, the manganese and the cobalt; and corrosion of the plate grid is reduced, so that the service lifetime of the plate grid is prolonged. The casting property can be improved through addition of the aluminum, the magnesium and the phosphorus; the molten alloy liquid has good mobility; a mold cavity can be easily filled with the alloy liquid; and the plate grid alloy is easy to mold during casting.

Owner:JIESHOU HUAYU POWER SUPPLY

Lead-acid accumulator grid alloy additive and preparation method thereof

InactiveCN103805809AExtended service lifeImprove casting effectElectrode carriers/collectorsCollocationSulfur

The invention discloses a lead-acid accumulator grid alloy additive and a preparation method thereof. The lead-acid accumulator grid alloy additive comprises the following raw materials in parts by weight: 940-960 parts of lead, 20-40 parts of antimony, 5-12 parts of tin, 0.55-0.65 part of selenium, 0.7-0.9 part of copper and 0.1-0.2 part of sulfur. The preparation method of the lead-acid accumulator grid alloy additive comprises the steps of preparing an alloy which contains selenium, copper and sulfur elements and lead into a lead-selenium-copper-sulfur alloy for later use; then placing the lead into a high-temperature furnace for heating and melting, and then adding all additives in batches; carrying out stirring treatment, then removing residues, and casting an ingot to obtain a lead-acid accumulator grid alloy; melting to obtain the lead-acid accumulator grid alloy additive. The lead-acid accumulator grid alloy additive disclosed by the invention has the advantages of good flowability and uniformity, convenience for accumulator grid casting and reasonability in alloy component collocation; an accumulator grid poured by using the lead-acid accumulator grid alloy additive has good corrosion resistance and tensile strength and prolongs the service life of a grid in the charge and discharge circulation of the accumulator.

Owner:GUANGXI SHAHU STORAGE BATTERY

Preparation method of lead storage battery grid alloy

ActiveCN108467968AComposition is stableUniform compositionCellsElectrode carriers/collectorsRare-earth elementElectrolysis

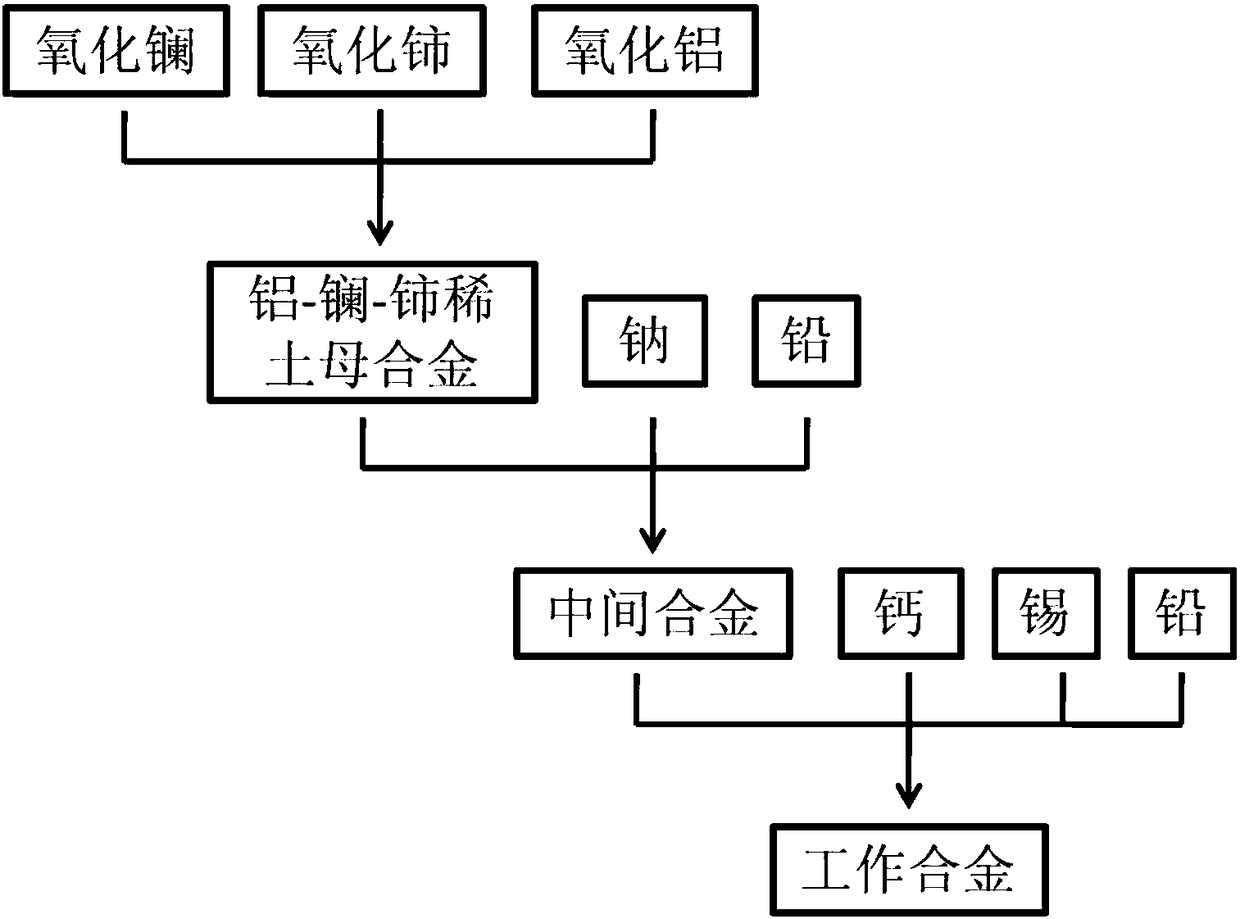

The invention discloses a preparation method of lead storage battery grid alloy. The preparation method comprises the following steps that 1, aluminum-lanthanum-cerium rare earth master alloy is prepared through a molten salt electrolysis method; 2, the aluminum-lanthanum-cerium rare earth master alloy, sodium and part of lead are fused and evenly stirred to prepare intermediate alloy; 3, the intermediate alloy, calcium, tin and residual lead are fused and uniformly stirred to prepare the lead storage battery grid alloy. The rare earth master alloy is prepared through the molten salt electrolysis method, compared with the mode that rare earth element elementary substances are prepared from oxide first and then the simple substances are directly used for preparing alloy, the rare earth master alloy prepared through the preparation method is stable in component and less in impurity content, and the utilization rate of raw materials is higher; the rare earth oxide is directly used as theraw material, the raw materials are more easily available, and the utilization rate of rare earth metal reaches 90% or above; then the intermediate alloy is prepared to produce work alloy; the components are more uniform; the process controllability is high.

Owner:TIANNENG BATTERY GROUP

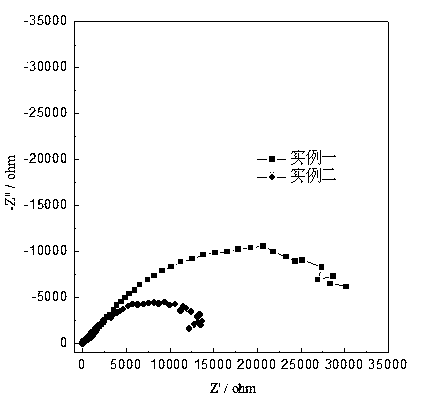

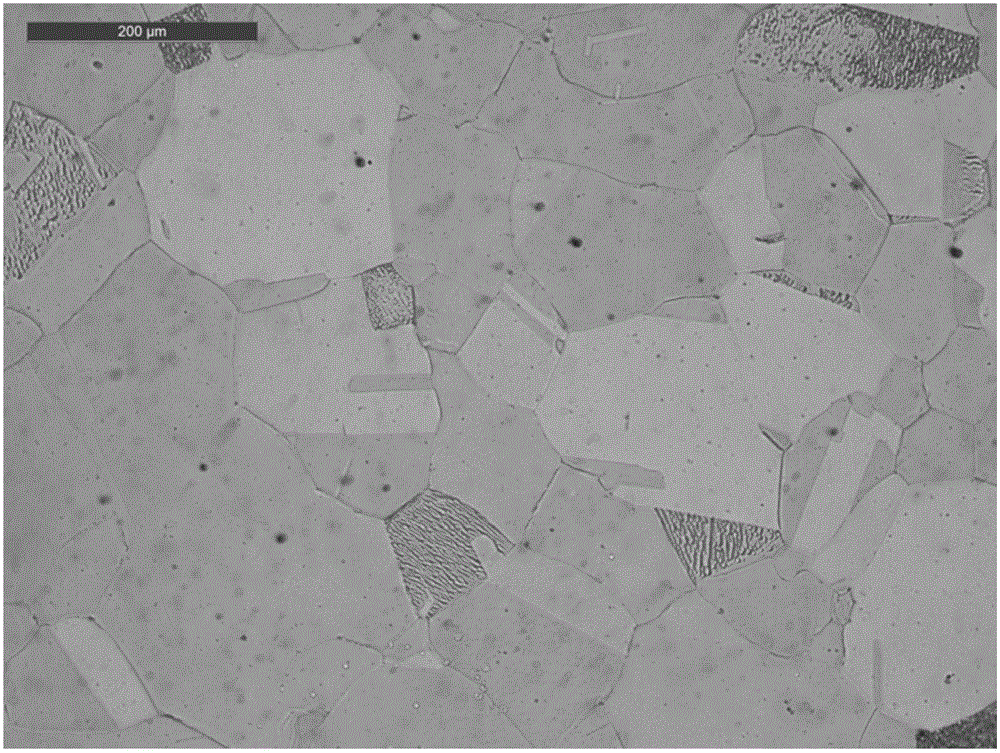

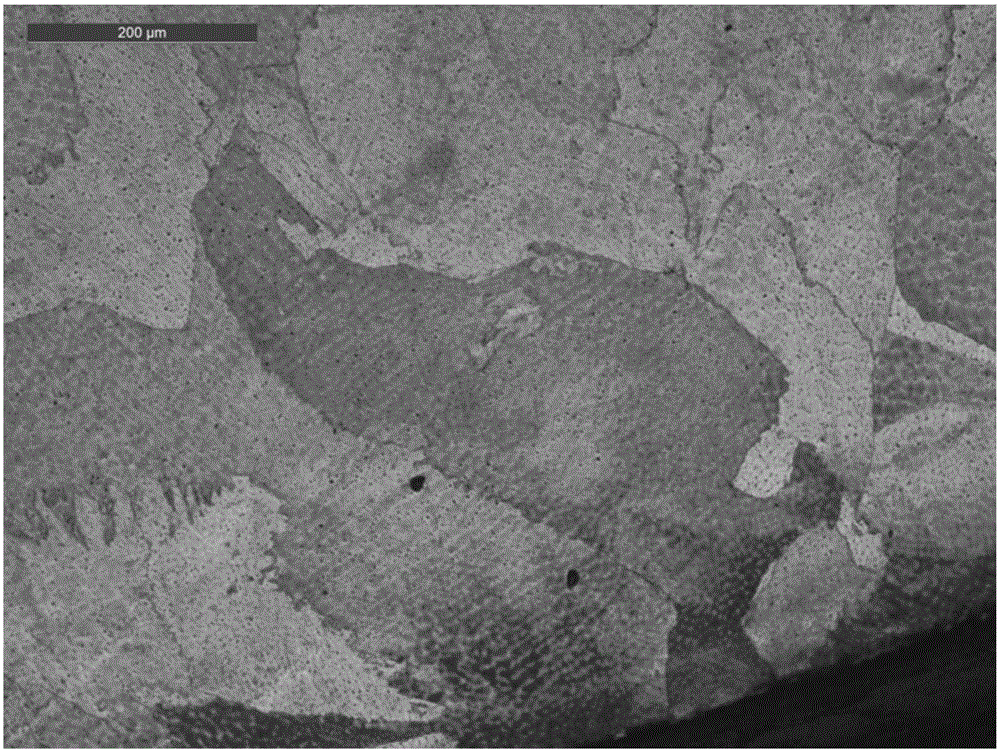

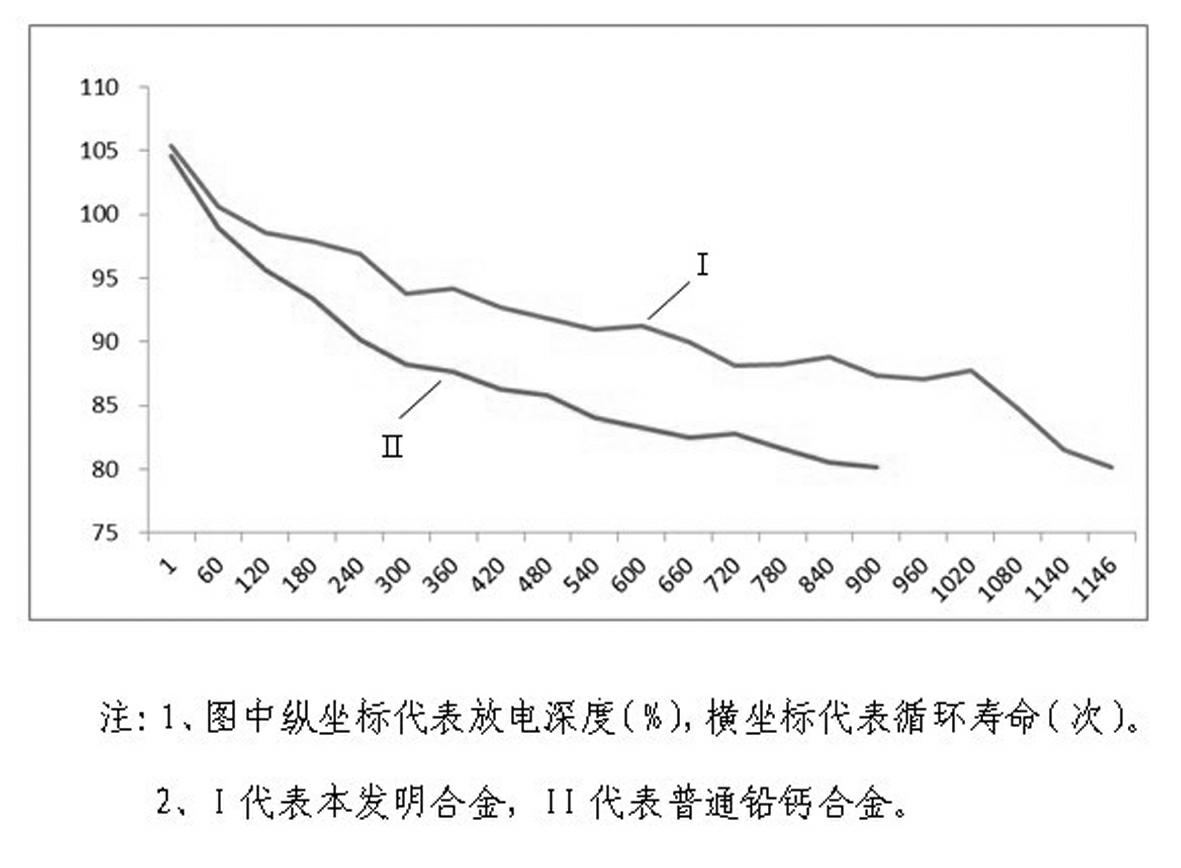

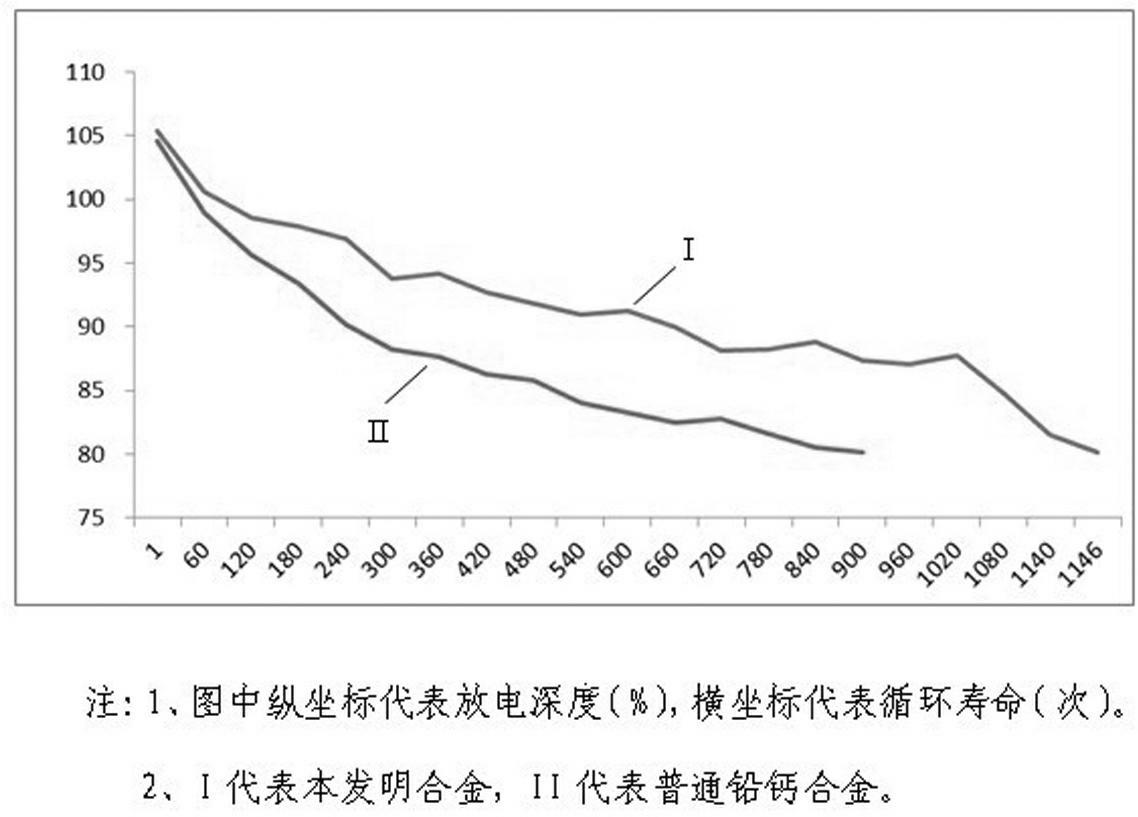

Long-service-life deep-cycle positive grid alloy and preparation method thereof

ActiveCN104073682AImprove corrosion resistanceDoes not affect deep cycle performanceElectrical batteryAlloy

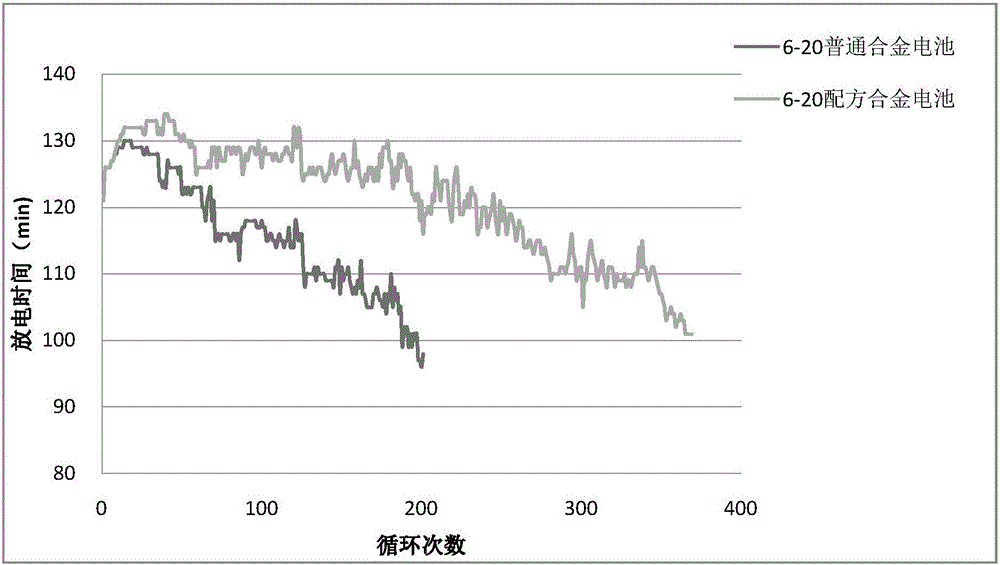

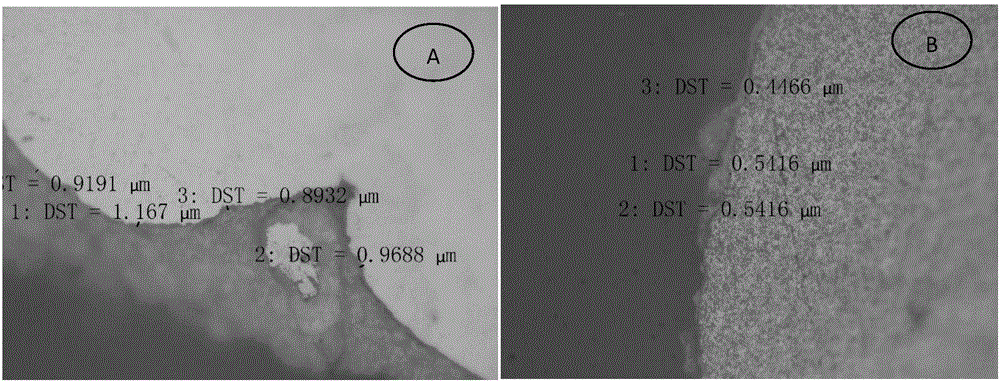

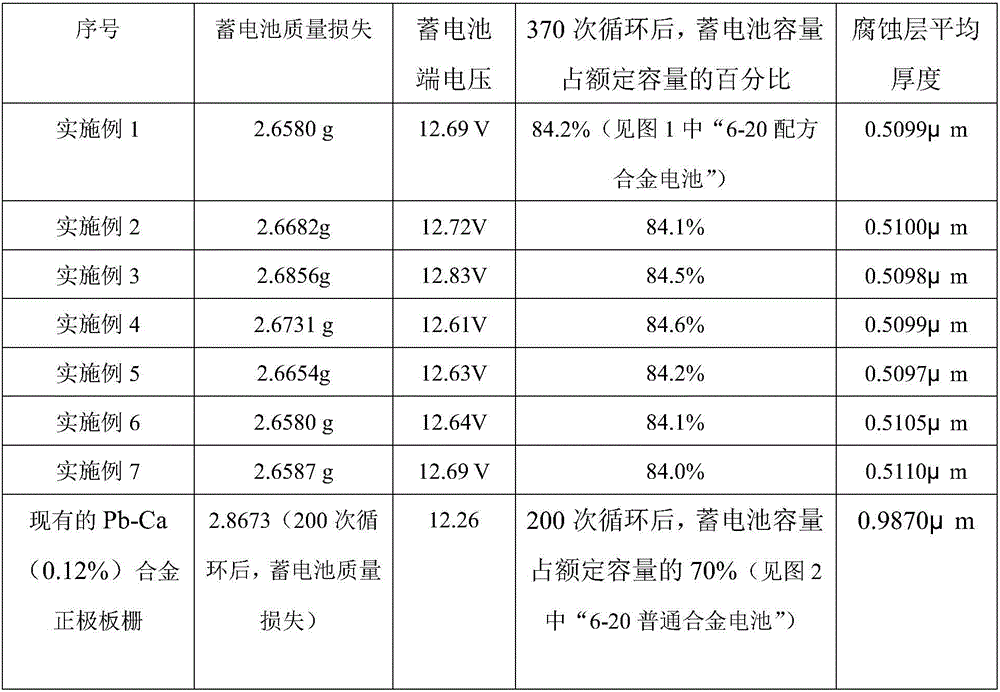

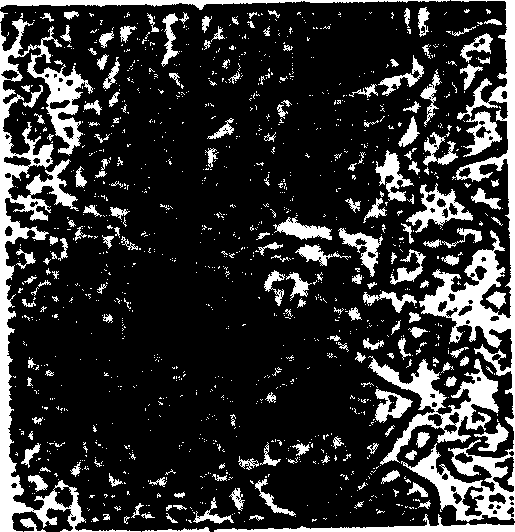

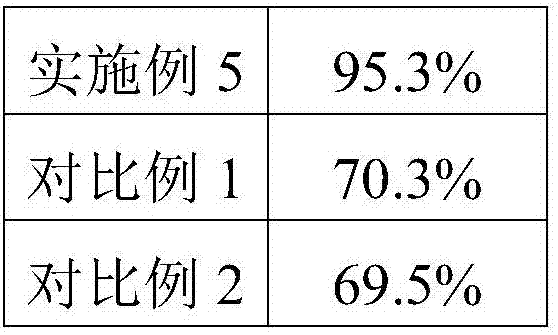

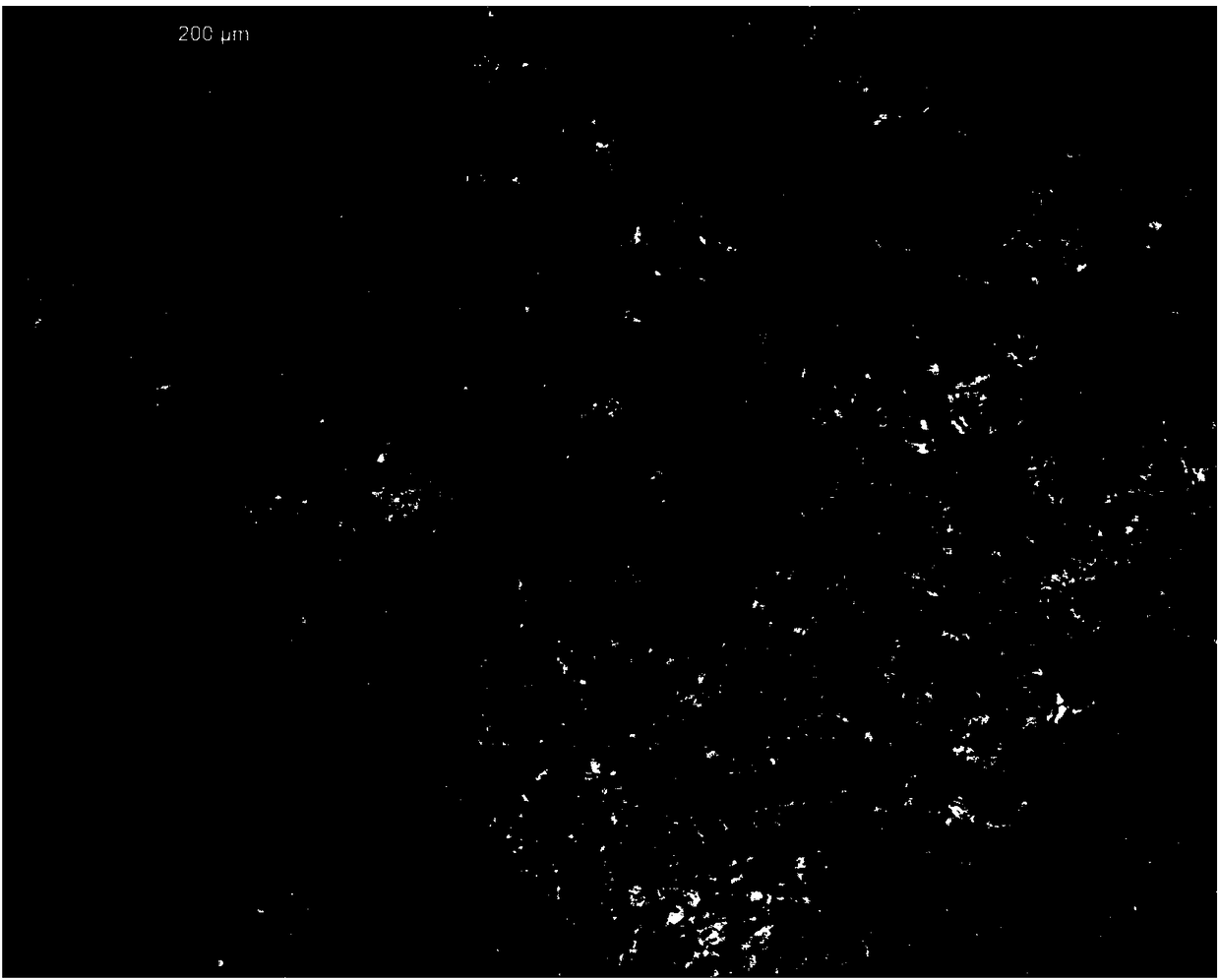

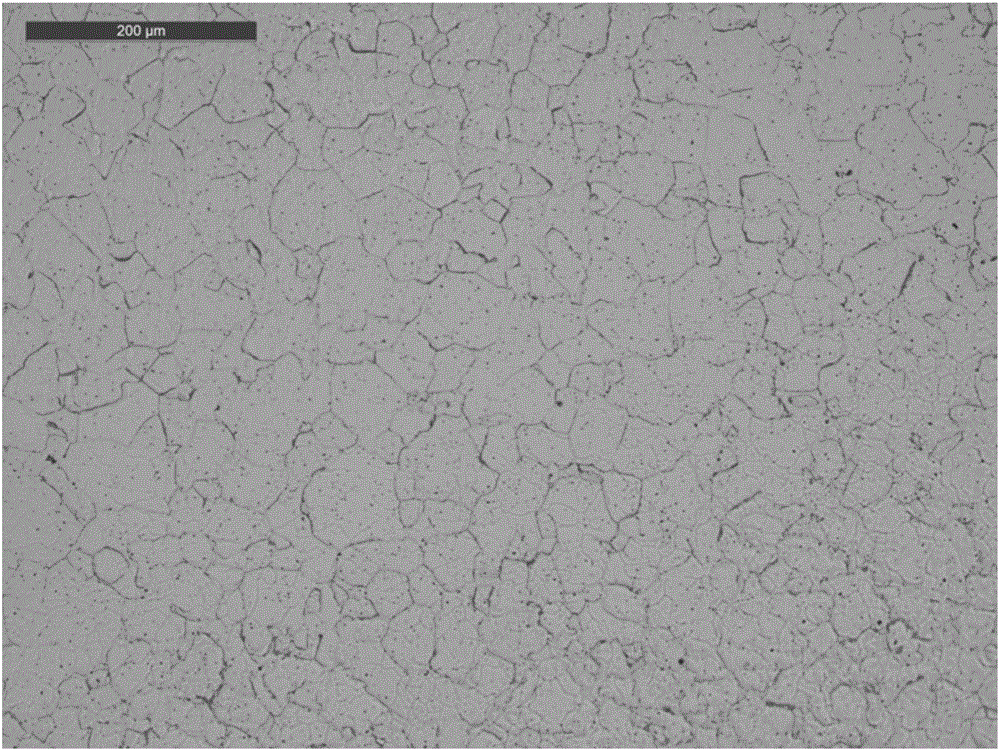

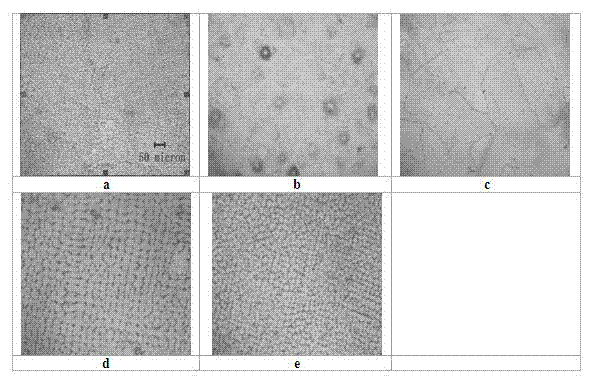

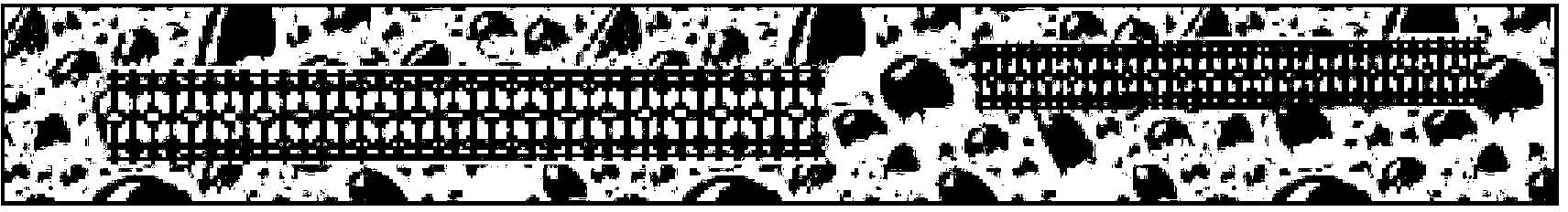

The invention discloses a long-service-life deep-cycle lead-acid battery positive grid alloy which is composed of the following raw materials in percentage by mass: 0.05-0.12% of calcium, 0.1-2.0% of tin, 0.01-0.1% of aluminum, 0.01-0.2% of zinc, 0.01-0.2% of silver and the balance of lead. The alloy has favorable corrosion resistance, and does not influence the deep cycle performance of the battery. The addition of the zinc can well enhance the deep cycle performance and low-temperature properties of the battery. The addition of the silver can enhance the corrosion resistance of the grid alloy; and the comparison between Figure 1 and Figure 2 indicates that the silver can be enriched at the grain sub-boundary and grain boundary along with the tin, and the silver enriched at the grain boundary can enhance the corrosion resistance of the grain boundary, thereby prolonging the service life of the alloy grid.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

Preparation method of lead-acid battery grid alloy containing lead tin-rare earth-graphene

ActiveCN105977496AImproved grain boundary propertiesSmall grain sizeLead-acid accumulatorsElectrode carriers/collectorsRare-earth elementCerium

The present invention discloses a preparation method of a lead-acid battery grid alloy containing lead tin-rare earth-graphene. The method includes a first step of preparing a lead-graphene composite material; a second step of preparing a grid mother alloy; and a third step of preparing the grid alloy, wherein the grid alloy includes the following components by mass percentage: 0.1-1.0% of tin, 0.01-0.2% of lanthanum, 0.05-0.5% of cerium, 0.5-10.0% of lead-graphene composite material, and the balance of lead. In the method, due to addition of the rare earth element, grain and grain boundary characteristics of the alloy are improved remarkably, grain size is reduced substantially, grain boundary area is increased, and corrosion amount is reduced substantially under the same current density. A lead-graphene composite material is deposited on a pure lead plate by using a composite electroplating technology, so as to be directly used as a material to be smelted in later preparation process of the grid alloy, so that the preparation method of the grid alloy is simplified.

Owner:TIANNENG BATTERY GROUP

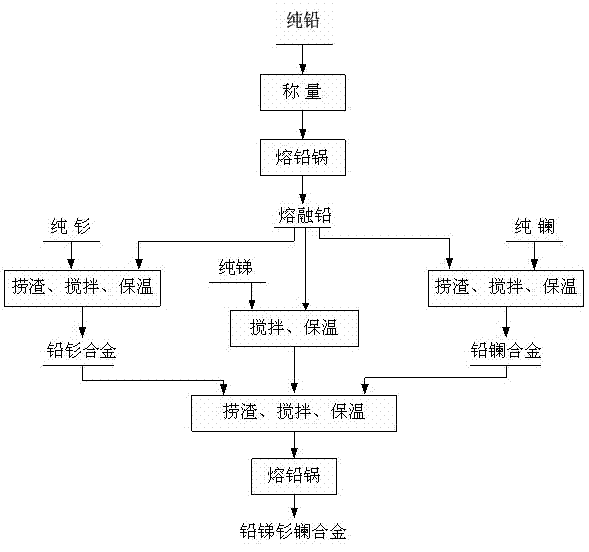

Lead-antimony rare-earth positive grid alloy and preparation method thereof

ActiveCN102329982AFine and uniform grainsImprove mechanical propertiesElectrode carriers/collectorsLanthanoid Series ElementsLanthanum

The invention belongs to the field of metallurgy, and relates to a lead-antimony rare-earth positive grid alloy and a preparation method thereof. The alloy comprises the following metal elements in percentage by mass: 0.5 to 1 percent of antimony, 0.005 to 0.1 percent of lanthanum, 0.005 to 0.1 percent of samarium, and the balance of lead. The preparation method comprises the following steps: preparing lead-lanthanum and lead-samarium alloy as master alloys; adding pure antimony into molten lead, stirring until the pure antimony is completely molten; and adding the lead-lanthanum and lead-samarium master alloys to perform mixed melting to prepare the lead-antimony rare-earth positive grid alloy. Grains of the prepared alloy become fine, uniform and regular, so that the comprehensive mechanical performance of the alloy can be improved, the impedance of an oxide film can be reduced, and the charge and discharge acceptance and deep cycle performance of a storage battery can be improved. Meanwhile, rare-earth element serves as an additive to prepare the lead-antimony grid alloy, arsenic, cadmium and other elements harming the environment and workers on the forefront of production severely are not contained. Therefore, lead alloy pollution can be reduced furthest.

Owner:TIANNENG BATTERY GROUP +1

Grid alloy for single-walled carbon nano-tube storage battery and preparation method thereof

ActiveCN104232990AImprove conductivityExcellent current distribution capabilityMaterial nanotechnologyElectrode carriers/collectorsInternal resistanceCarbon nanotube

The invention belongs to the technical field of battery production, relates to a grid alloy for manufacturing a valve regulated sealed lead-acid storage battery, and particularly relates to a grid alloy for a single-walled carbon nano-tube storage battery and a preparation method of the grid alloy. The grid alloy of the single-walled carbon nano-tube storage battery comprises the following components in percentage by mass: 0.002-0.02 percent of a single-walled carbon nano-tube, 0.008-0.02 percent of copper, 0.15-0.45 percent of tin, 0.0005-0.0015 percent of aluminum and the balance of lead. The internal resistance of the grid alloy is close to that of pure lead since the produced single-walled carbon nano-tube has an excellent electrical conductivity, so that a single-walled carbon nano-tube grid has an excellent current distributing capability, and the storage battery has good charge and discharge performances.

Owner:CHAOWEI POWER CO LTD

Lead plaster desulfurization transforming method for waste lead-acid storage batteries

InactiveCN103000968AHigh recovery rateReduce pollutionWaste accumulators reclaimingProcess efficiency improvementThermodynamicsProcess engineering

The invention discloses a lead plaster desulfurization transforming method for waste lead-acid storage batteries, which belongs to the field of waste battery disposal. The method comprises the following steps: (1) the preparation of a lead plaster original sample: carrying out decomposition on waste lead-acid storage batteries, taking out a grid alloy, taking out lead plaster from a grid, removing impurities in the lead plaster, drying the lead plaster in an environment at a temperature of 80-90 DEG C, and grinding the lead plaster in a grinding machine for 10-30 min so as to obtain the lead plaster original sample with a particle size of 50-300 mu m; (2) the configuration of a desulfurization transforming agent: preparing a desulfurization transforming agent into transforming liquid, and heating the desulfurization transforming liquid to 20-90 DEG C by using a constant-temperature water bath bed; (3) full reaction: adding weighted lead plaster into the transforming liquid obtained in step (2), and stirring the obtained mixture, so that the mixture is fully reacted; and (4) after the transforming is completed, cooling and filtering the obtained product, and carrying out repeated washing and residue filtering on the obtained product for many times by using distilled water. According to the method, the desulfurization transforming process parameters of lead plaster in waste lead-acid storage batteries are determined, PbSO4 is effectively transformed into easily-decomposed PbCO3, the energy consumption is lowered, and the environmental pollution is reduced.

Owner:高金菊

Accumulator grid alloy material and its preparing method

The lead based alloy material contains following elements in weight ratio: stibium 1.5%-1.6%, arsenic 0.12%-0.14%, stannum 0.18%-0.20%, selenium 0.03-0.04%, sulfur 0.004-0.005%, and copper 0.04-0.05%. The invention also discloses method for preparing the alloy material. The alloy material possesses advantages of low wastage of water, high circulation endurance, and high service life.

Owner:赵恒祥

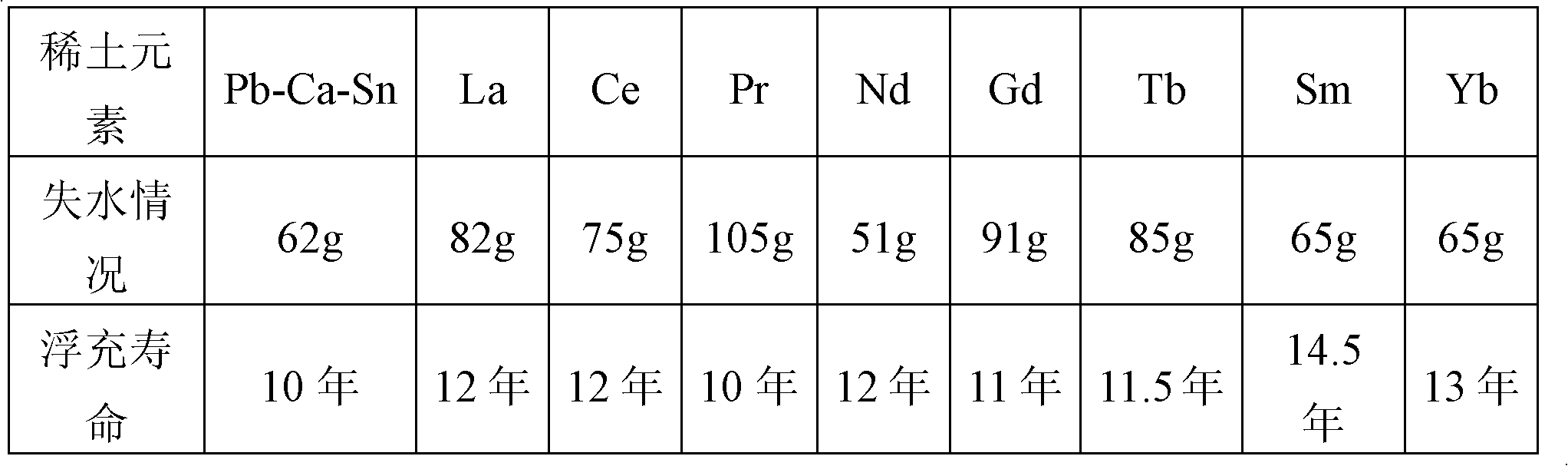

Positive plate grid alloy for lead-acid storage battery

InactiveCN102208649AReduce dehydrationImprove float charge lifeElectrode carriers/collectorsRare-earth elementUltrasound attenuation

The invention provides a positive plate grid alloy for a lead-acid storage battery. The alloy consists of lead, calcium, tin and rare-earth element; the rare-earth element is selected from samarium or terbium; and the alloy comprises the following components in percentage by weight: 0.03 to 0.18 percent of calcium, 0.1 to 2 percent of tin, 0.005 to 0.2 percent of rare-earth element and the balance of lead. The corrosion resistance of the plate grid alloy is improved, the breakage of plate grid ribs is reduced, and the floating charge life of the battery is prolonged. In addition, the charge accepting capability of the battery is improved, capacity attenuation of the battery in the charge / discharge process is prevented, and the cycle life of the battery is prolonged.

Owner:POWERSON SHANGHAI FORWARD GROUP +1

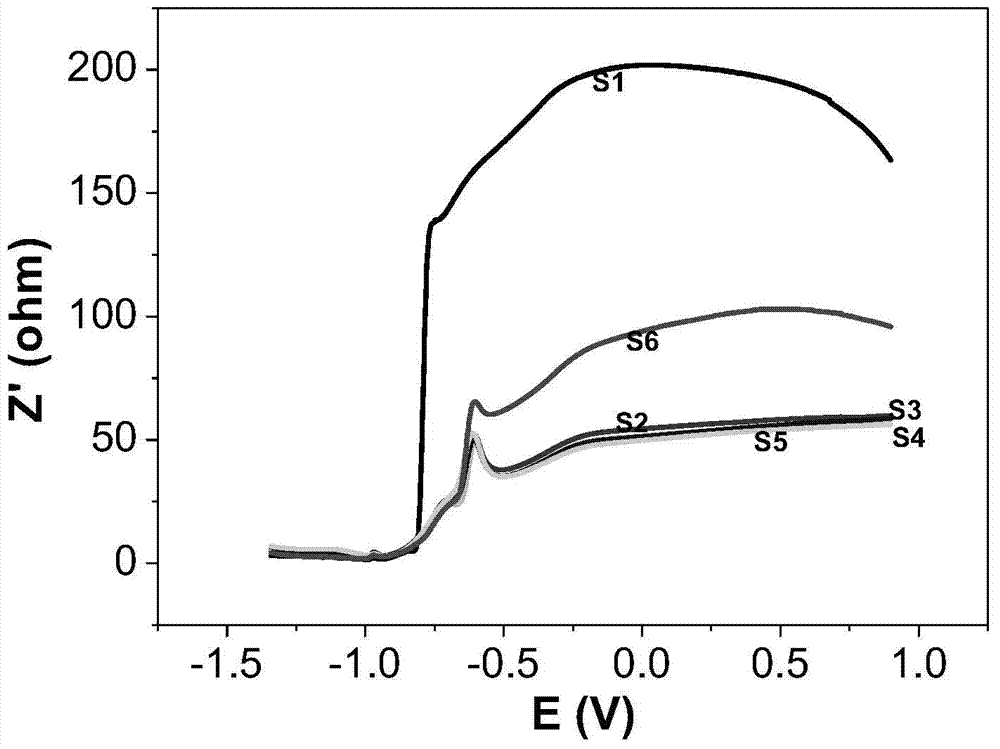

Lead-acid battery electrolyte

InactiveCN103594739APromote growthExtended service lifeLead-acid accumulatorsCyclic processUltrasound attenuation

The invention discloses a lead-acid battery electrolyte which comprises a sulfuric acid water solution, 3,5-diamidobenzoic acid and bismuth ions. Compared with the prior art, the lead-acid battery electrolyte disclosed by the invention can effectively slow down growth of a passivation film in the charge / discharge process of a grid alloy, so that active substances of a battery can not easily fall off due to passivation of the grid in the deep cyclic use process, thereby avoiding early capacity attenuation of the lead-acid battery; and meanwhile, the hydrogen evolution overpotential of the lead-acid battery can be obviously increased, the water loss of the battery in the cyclic process can be reduced, and the service life of the battery under the deep cyclic use condition can be prolonged.

Owner:TIANNENG BATTERY GROUP

Anode grid alloy of lead acid storage battery for energy storage

InactiveCN102437342AIncrease contentLower impedanceElectrode carriers/collectorsHigh conductivityEnergy storage

The invention provides anode grid alloy of lead acid storage battery for energy storage. The grid alloy is characterized in that silver element is added in lead calcium tin aluminum alloy, wherein the mass percentage content of silver is 0.007%-0.12%. The grid alloy has strong corrosion resistance and high conductivity, so that the shadow cycle life and charging acceptable capability of the lead acid storage battery in a same structure can be improved remarkably.

Owner:JIANGSU SHUANGDENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com