Positive pole plate lead paste of lead storage battery, preparation method of lead paste and lead storage battery

A technology for lead-acid batteries and positive electrode pastes, applied in lead-acid batteries, battery electrodes, circuits, etc., which can solve problems such as poor charge acceptance, low utilization of active materials, and large resistance, and achieve low polarization voltage and high current The effect of good charging receiving ability and uniform current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

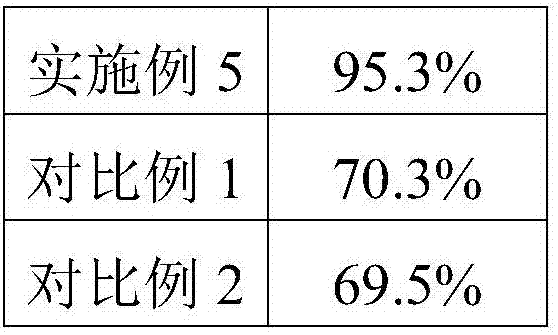

Examples

Embodiment 1

[0030] A lead-acid battery positive plate lead paste, comprising the following substances by weight:

[0031] 1000 parts of lead powder, 4 parts of colloidal graphite, Sb 2 o 3 0.8 parts, 8 parts of tetrabasic lead sulfate, 40 parts of trilead tetroxide, 1 part of short fiber, 90 parts of dilute sulfuric acid, 90 parts of pure water, 8 parts of recycled powder;

[0032] The average length of the short fibers is 80mm; the processed recycled powder is 40 mesh;

[0033] The preparation method of the lead-acid battery positive plate lead paste comprises the following steps:

[0034] (1) Weighing: weigh each raw material component according to the formula of positive electrode lead paste;

[0035] (2) Feeding, first add at least half of the lead powder in the formula to the paste machine to make it spread as flat as possible, and then add antimony oxide, tetrabasic lead sulfate, trilead tetraoxide, fiber and processed back Use powder, and finally add the remaining lead powder,...

Embodiment 2

[0039] A lead-acid battery positive plate lead paste, comprising the following substances by weight:

[0040] 1000 parts of lead powder, 3.0 parts of colloidal graphite, Sb 2 o 3 0.6 parts, 5 parts of tetrabasic lead sulfate, 25 parts of trilead tetroxide, 0.6 parts of short fiber, 80 parts of dilute sulfuric acid, 80 parts of pure water, 6 parts of recycled powder;

[0041] The average length of the short fiber is 40mm; the processed recycled powder is 30 mesh;

[0042] The preparation method of the lead-acid battery positive plate lead paste comprises the following steps:

[0043] (1) Weighing: weigh each raw material component according to the formula of positive electrode lead paste;

[0044] (2) Feeding, first add at least half of the lead powder in the formula to the paste machine to make it spread as flat as possible, and then add antimony oxide, tetrabasic lead sulfate, trilead tetraoxide, fiber and processed back Use powder, and finally add the remaining lead pow...

Embodiment 3

[0048] A lead-acid battery positive plate lead paste, comprising the following substances by weight:

[0049] 1000 parts of lead powder, 4.5 parts of colloidal graphite, Sb 2 o 3 1.2 parts, 10 parts of tetrabasic lead sulfate, 50 parts of trilead tetroxide, 1.2 parts of short fiber, 100 parts of dilute sulfuric acid, 100 parts of pure water, 10 parts of recycled powder;

[0050] The average length of the short fiber is 90mm; the processed recycled powder is 50 mesh;

[0051] The preparation method of the lead-acid battery positive plate lead paste comprises the following steps:

[0052] (1) Weighing: weigh each raw material component according to the formula of positive electrode lead paste;

[0053] (2) Feeding, first add at least half of the lead powder in the formula to the paste machine to make it spread as flat as possible, and then add antimony oxide, tetrabasic lead sulfate, trilead tetraoxide, fiber and processed back Use powder, and finally add the remaining lead...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com