Patents

Literature

10089results about How to "Reduce corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

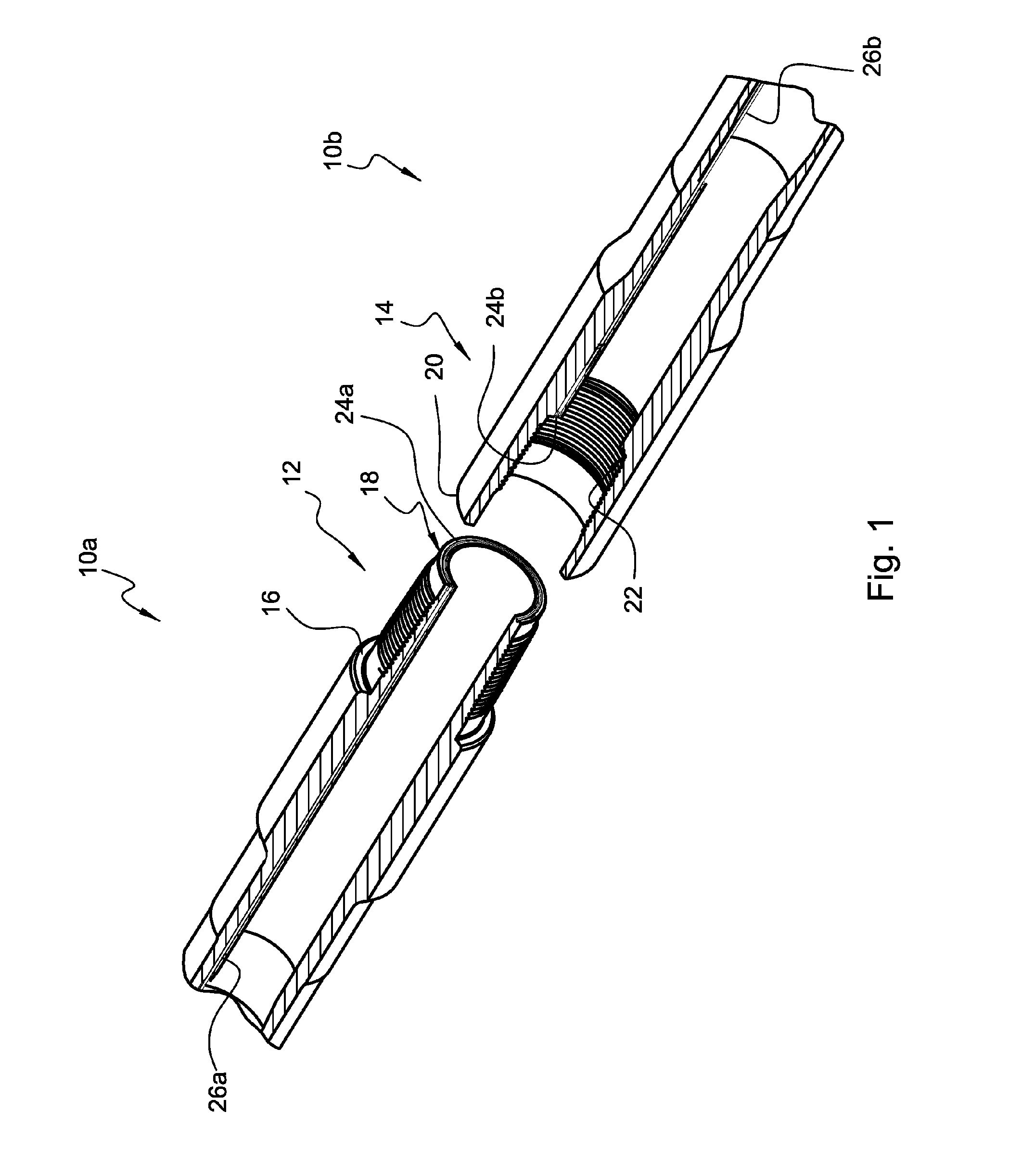

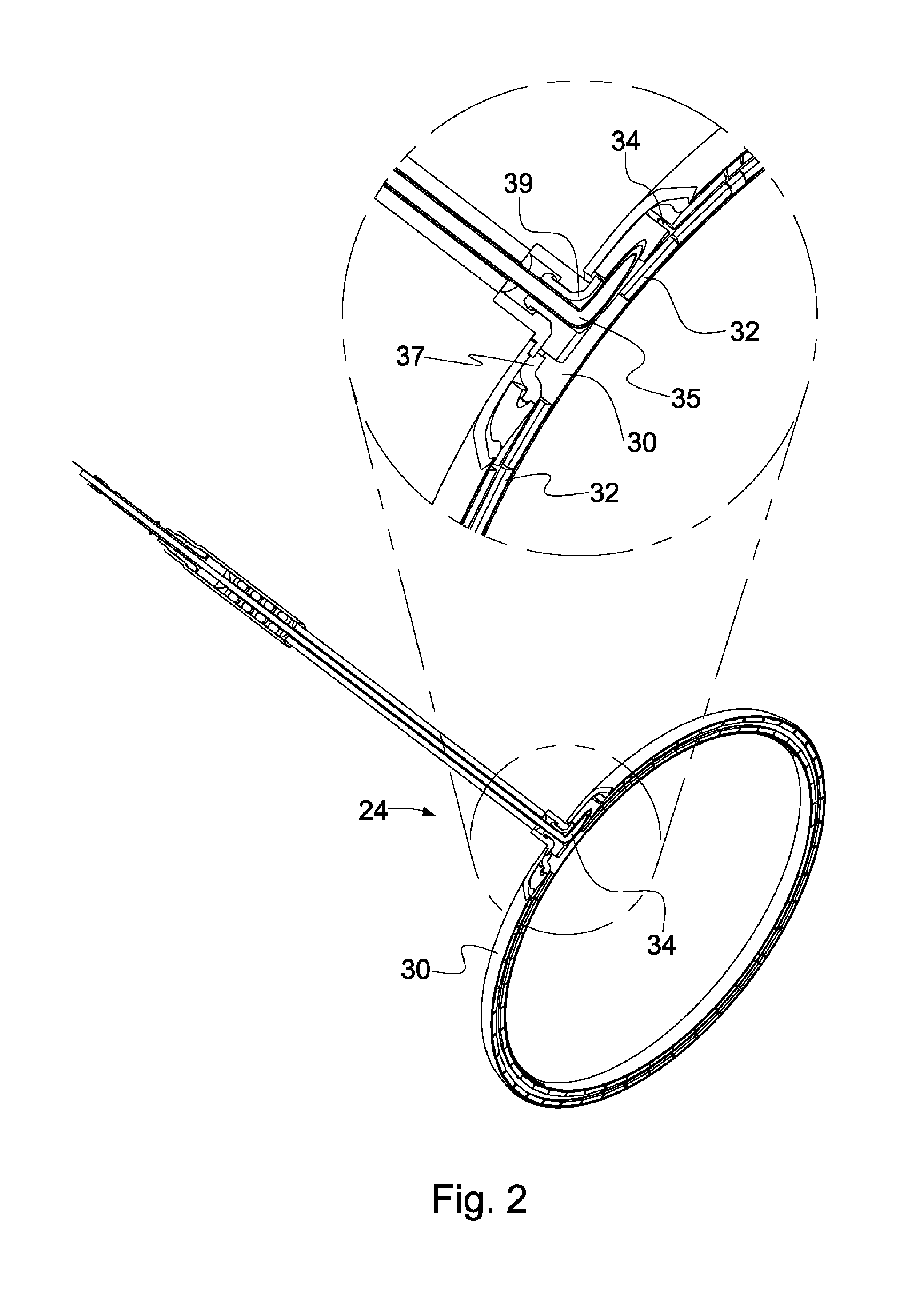

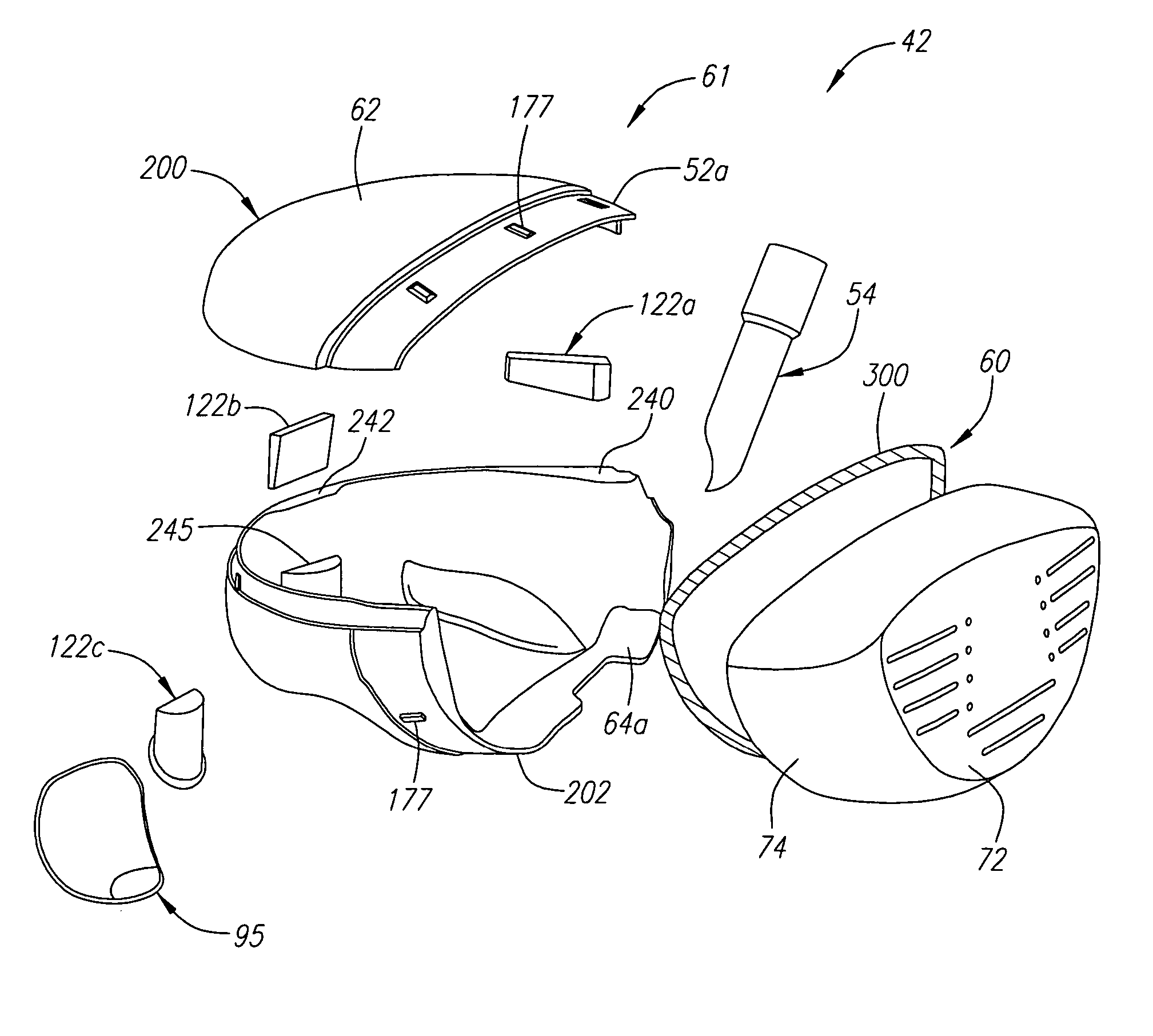

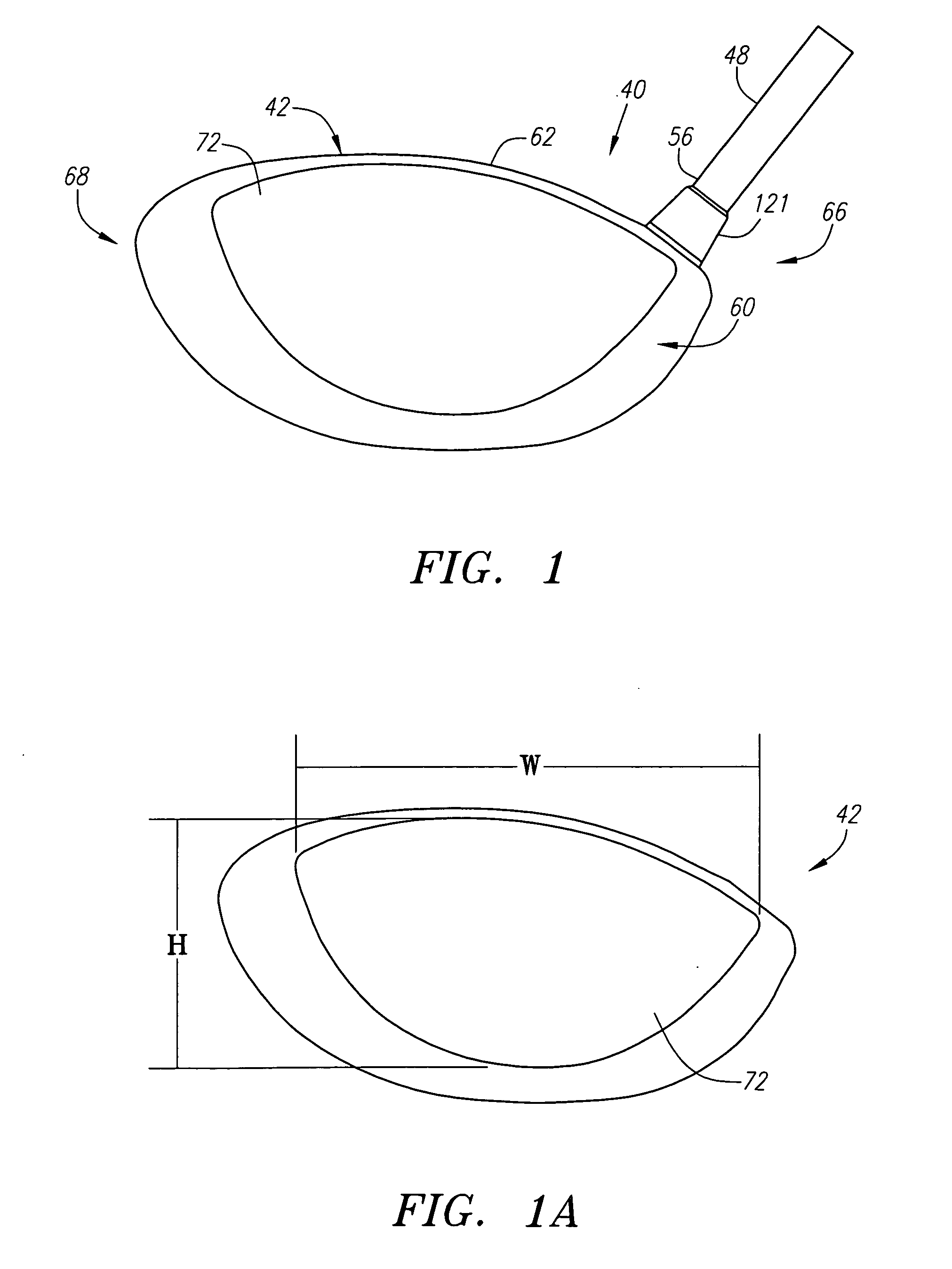

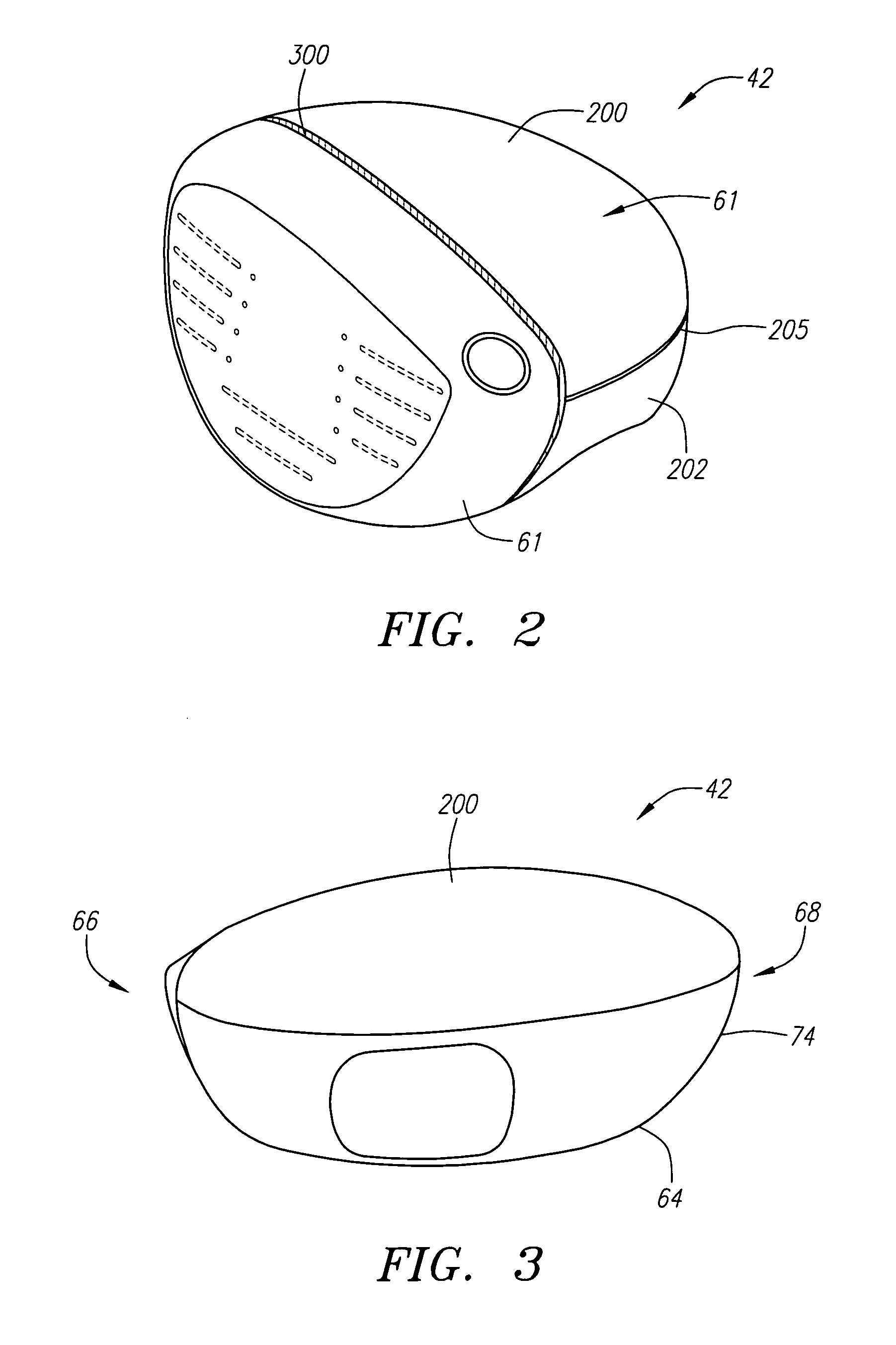

Golf club head with gasket

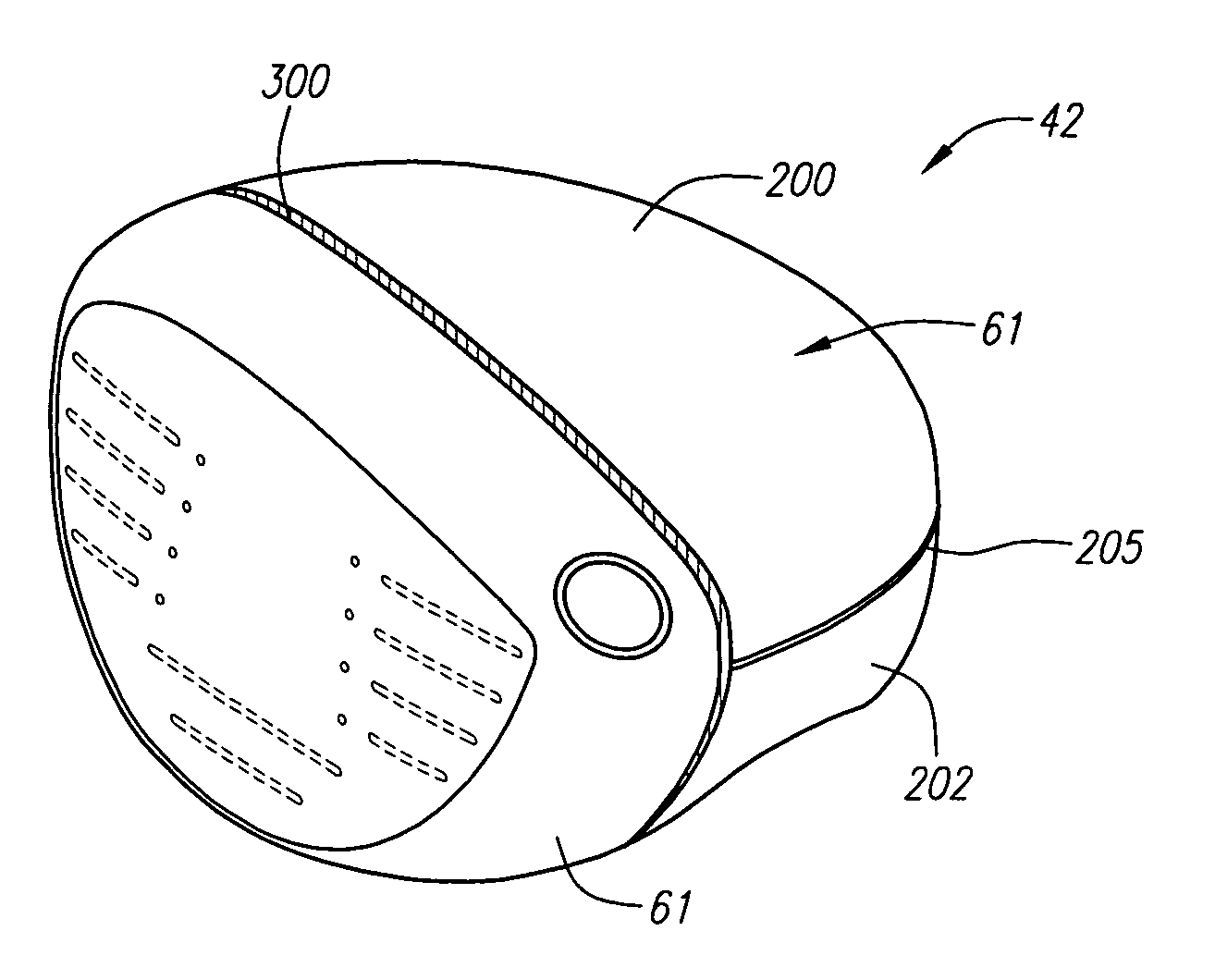

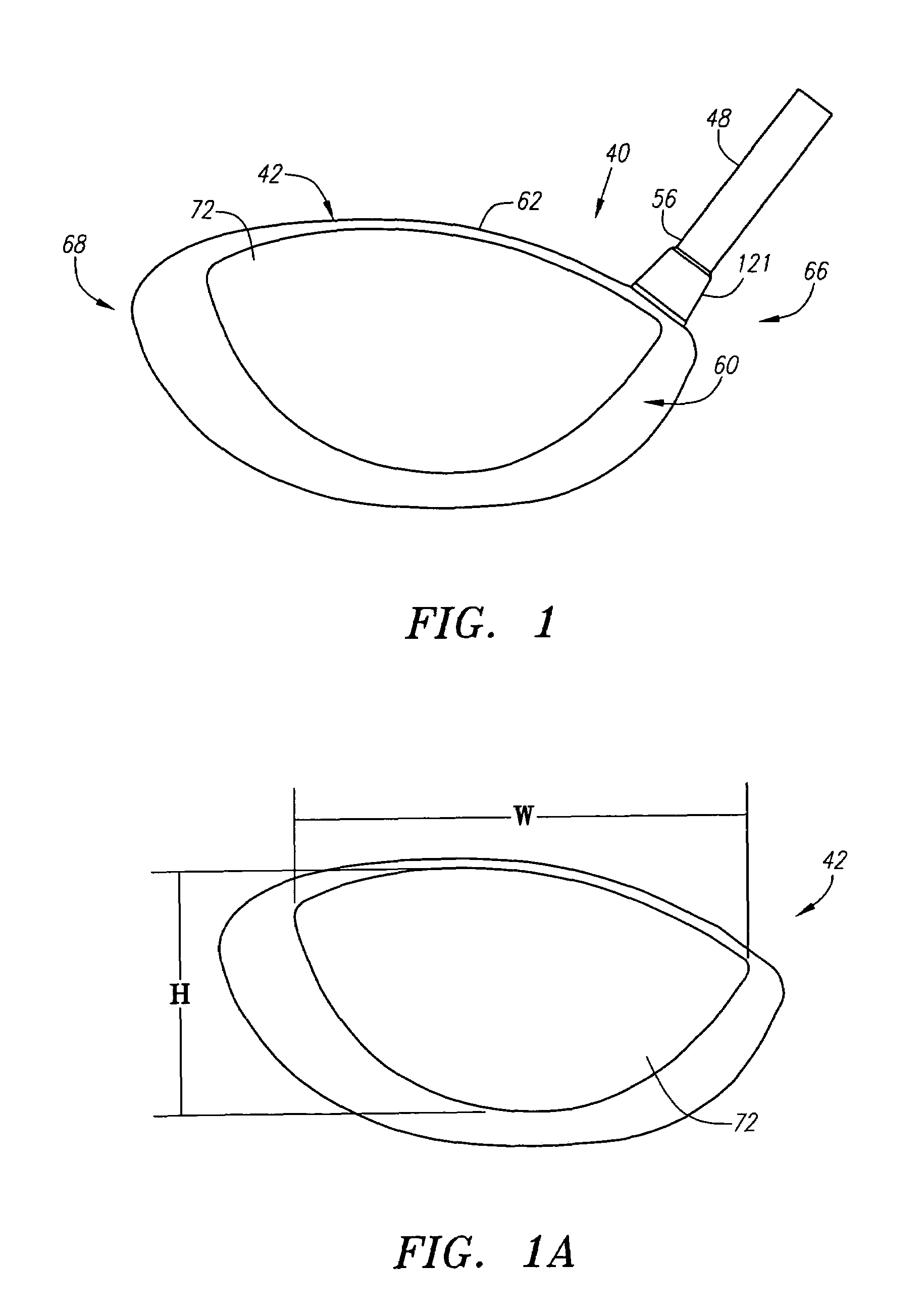

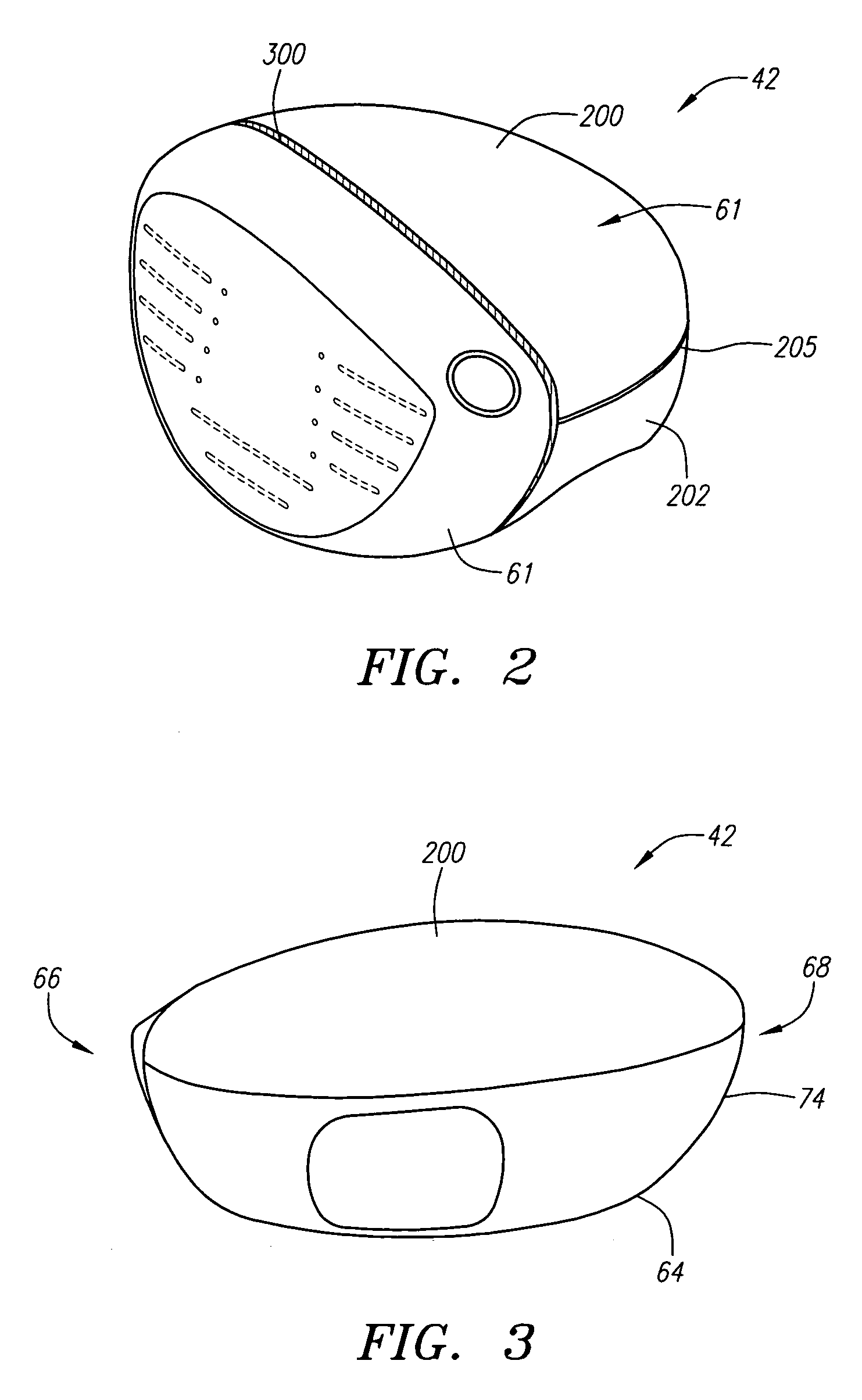

A golf club (40) having a club head (42) with a face component (60), an aft body (61) and a gasket (300) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is preferably composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The gasket (300) provides an interface between the face (60) and the aft-body (61) that reduces corrosion and improves manufacturing costs of the club head. The club head (42) preferably has a volume in the range of 290 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches.

Owner:TOPGOLF CALLAWAY BRANDS CORP

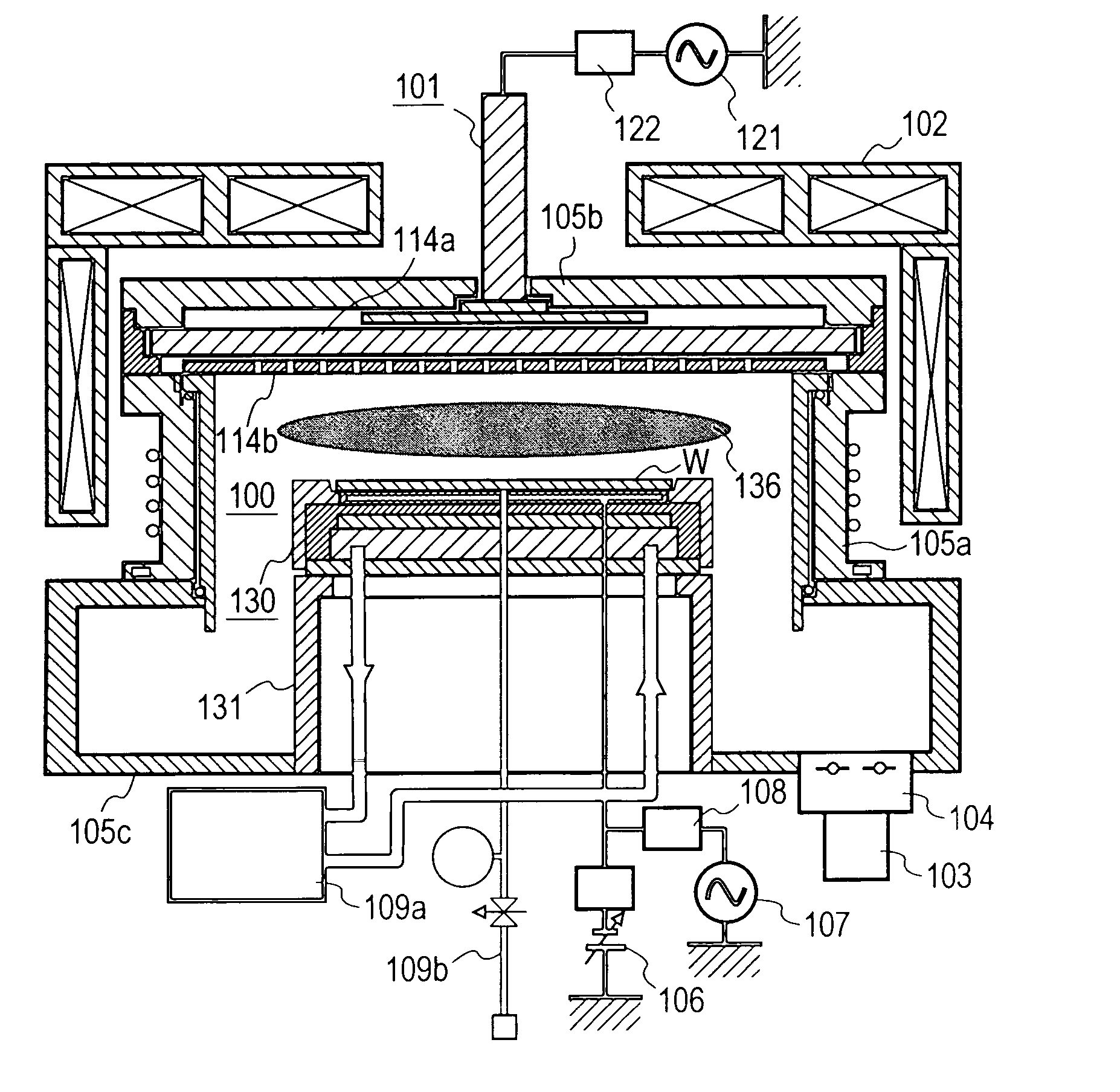

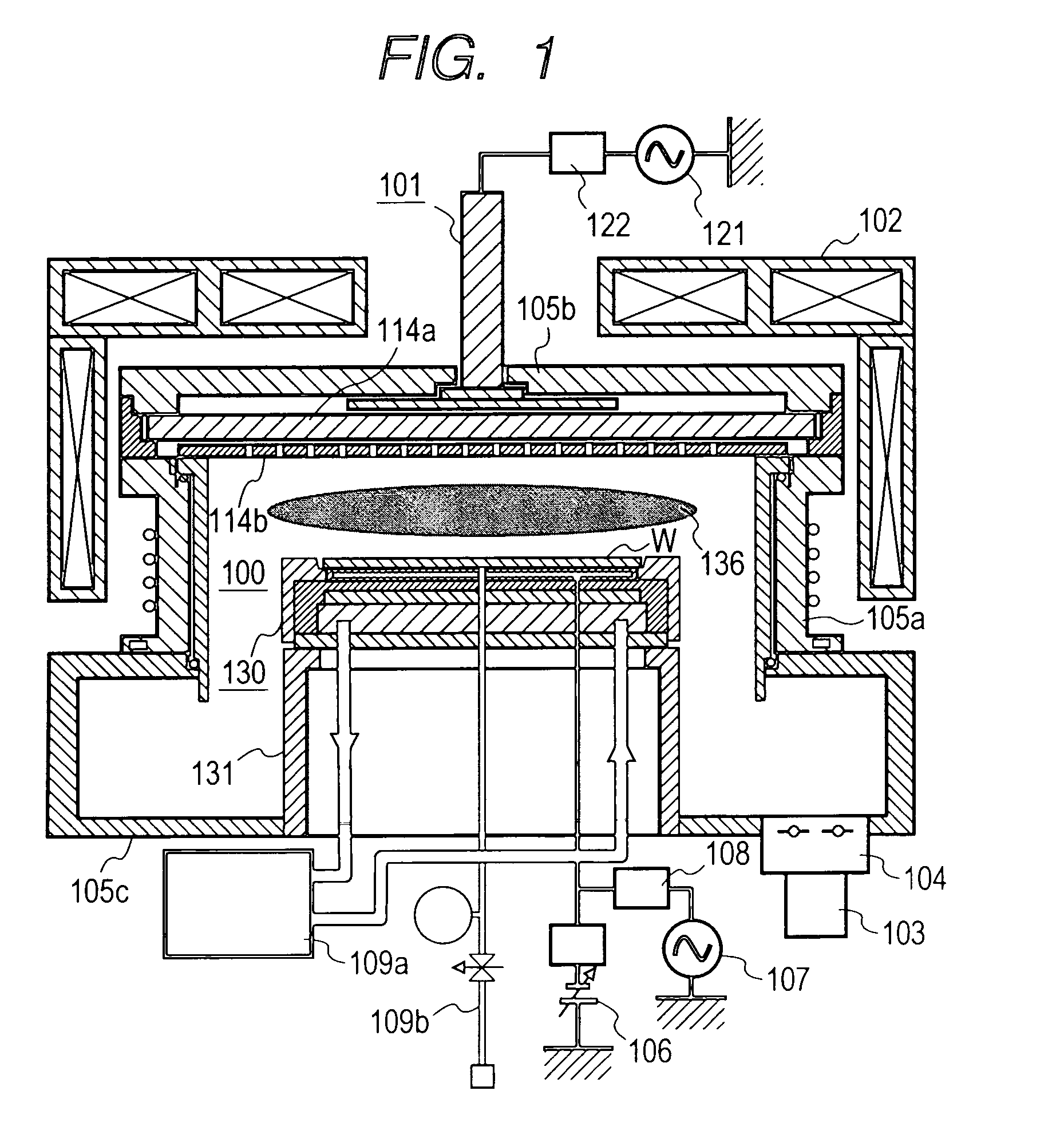

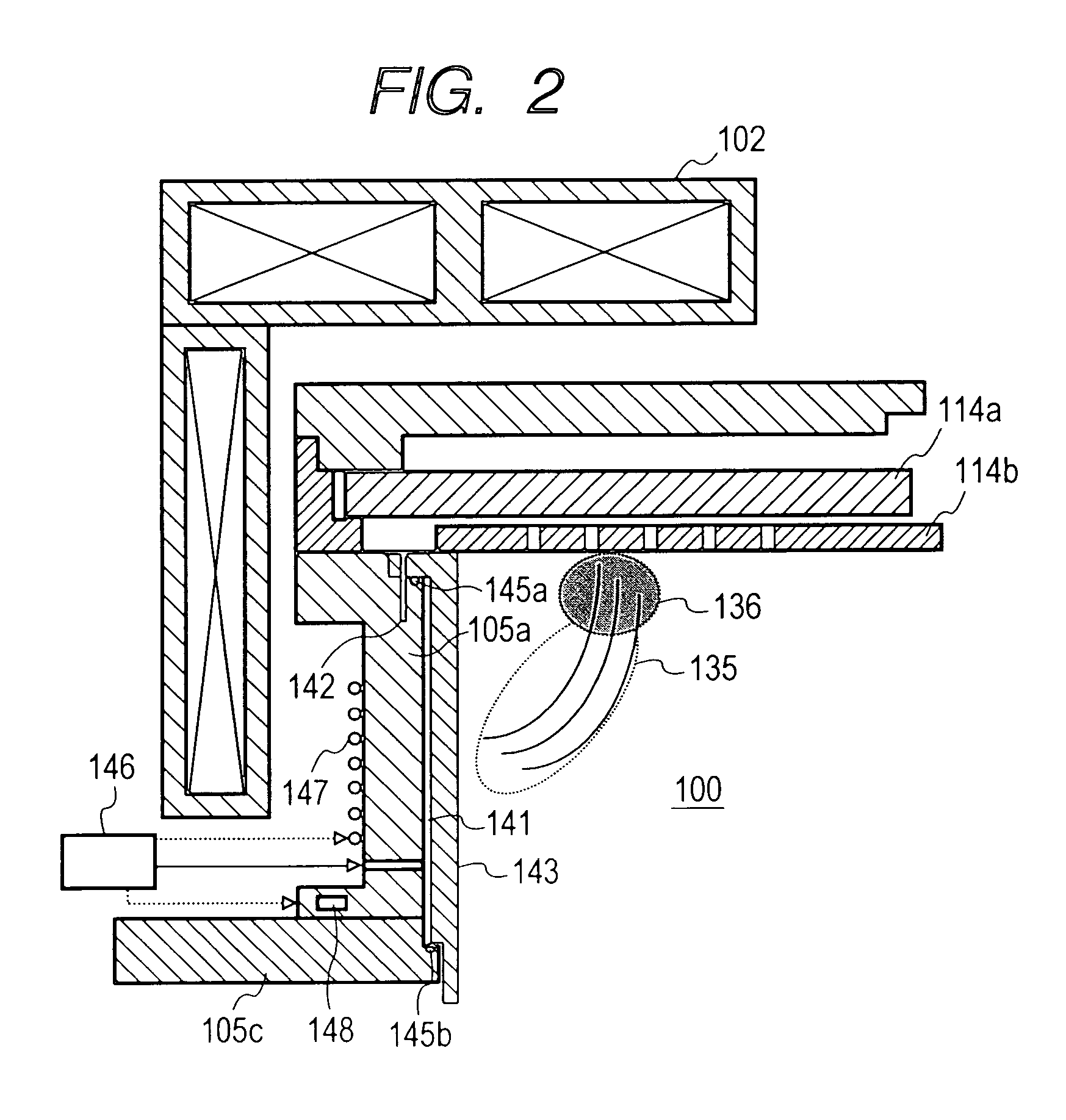

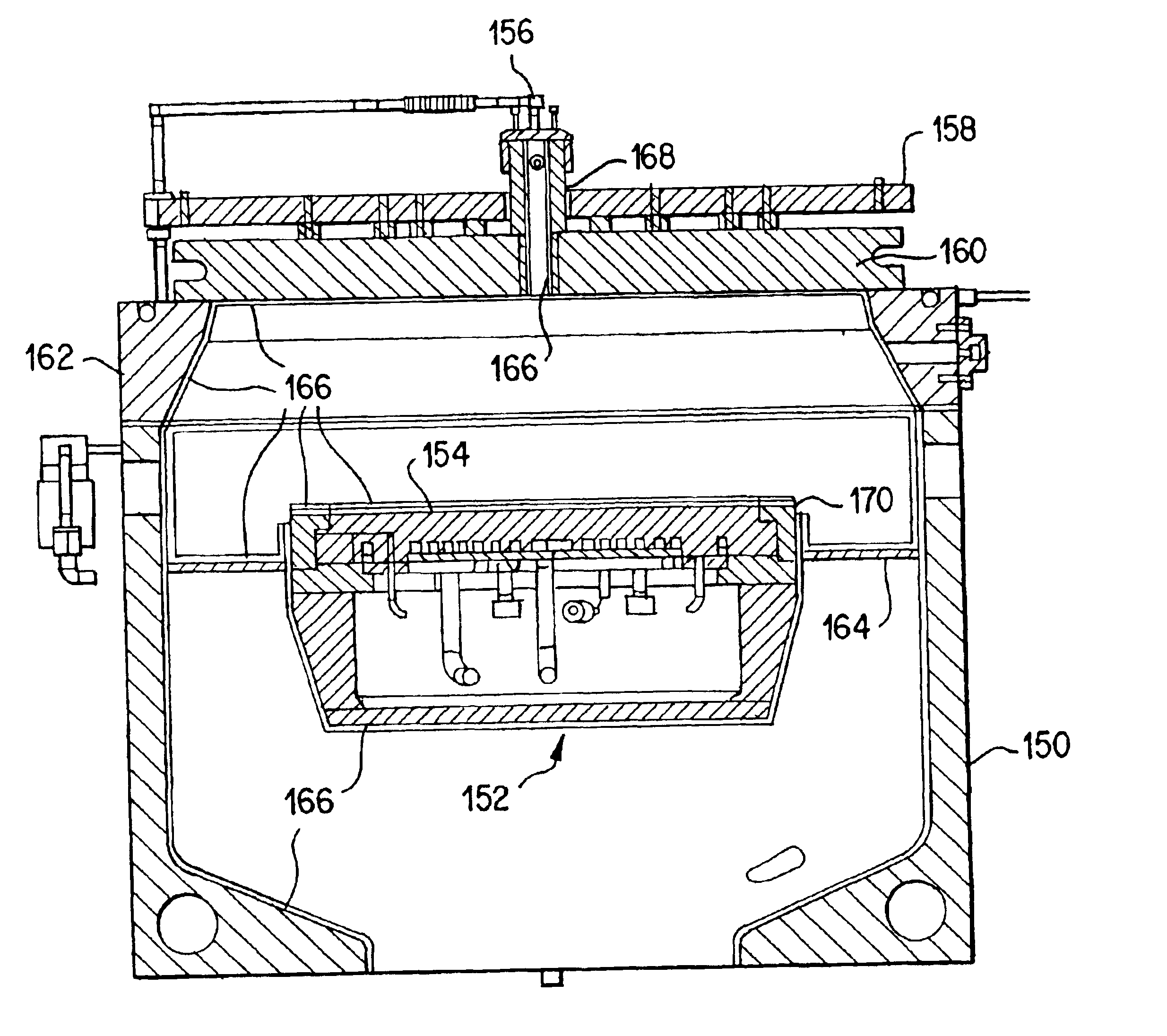

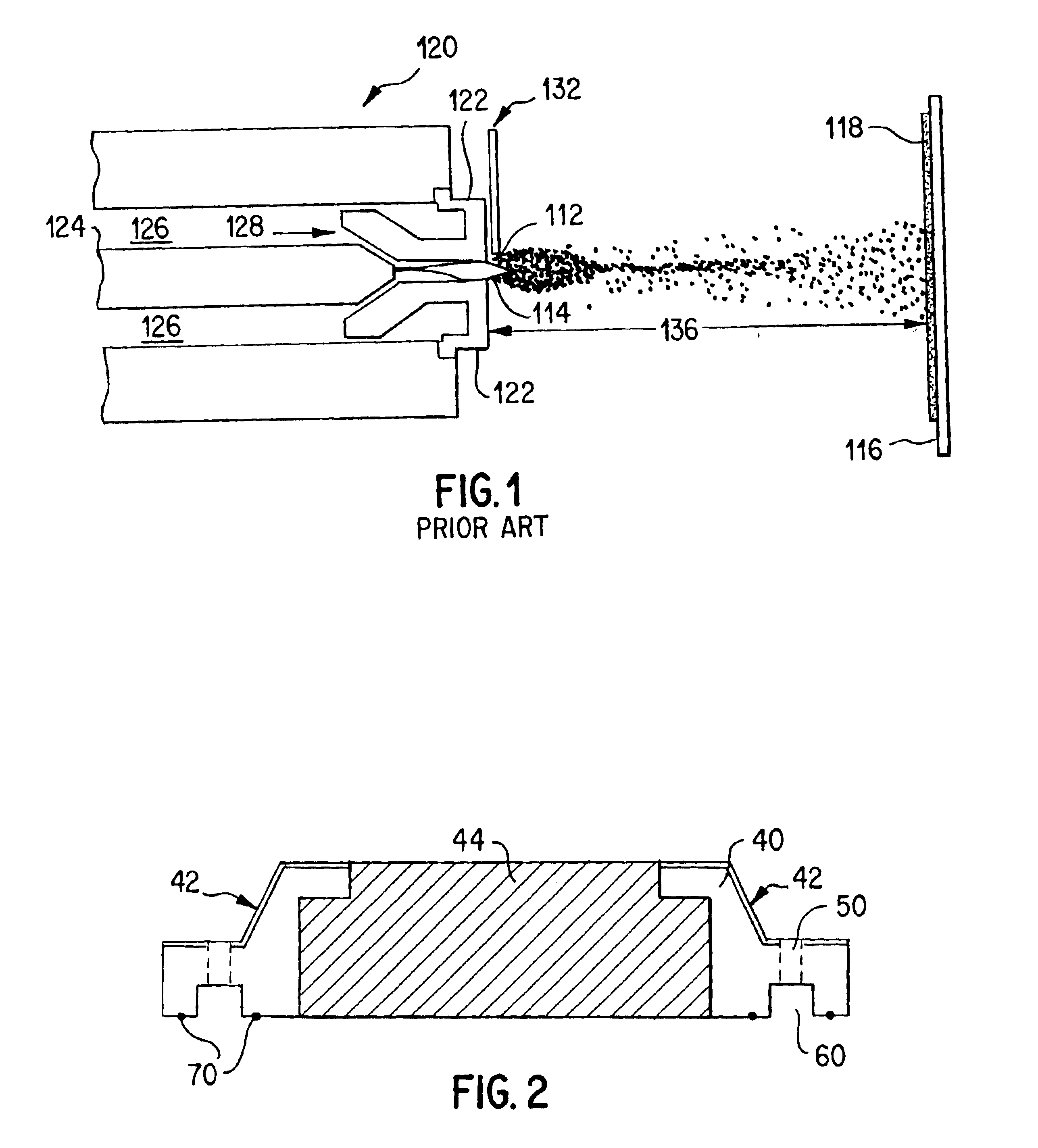

Plasma etching apparatus and method for forming inner wall of plasma processing chamber

InactiveUS20070215278A1Reduce corrosionDecreasing amountElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateHeat resistance

A plasma etching apparatus is provided which can prevent corrosion of an aluminum substrate constituting an etching processing chamber or an inside component thereof, thereby avoiding a reduction in productivity due to scattering of a sprayed coating. In the plasma etching apparatus, an anodic oxide film is disposed between a ceramic sprayed coating with excellent resistance to plasma, and the etching processing chamber and the inside component thereof made of aluminum alloy. The anodic oxide film has a thickness of 5 μm or less to have heat resistance.

Owner:HITACHI HIGH-TECH CORP

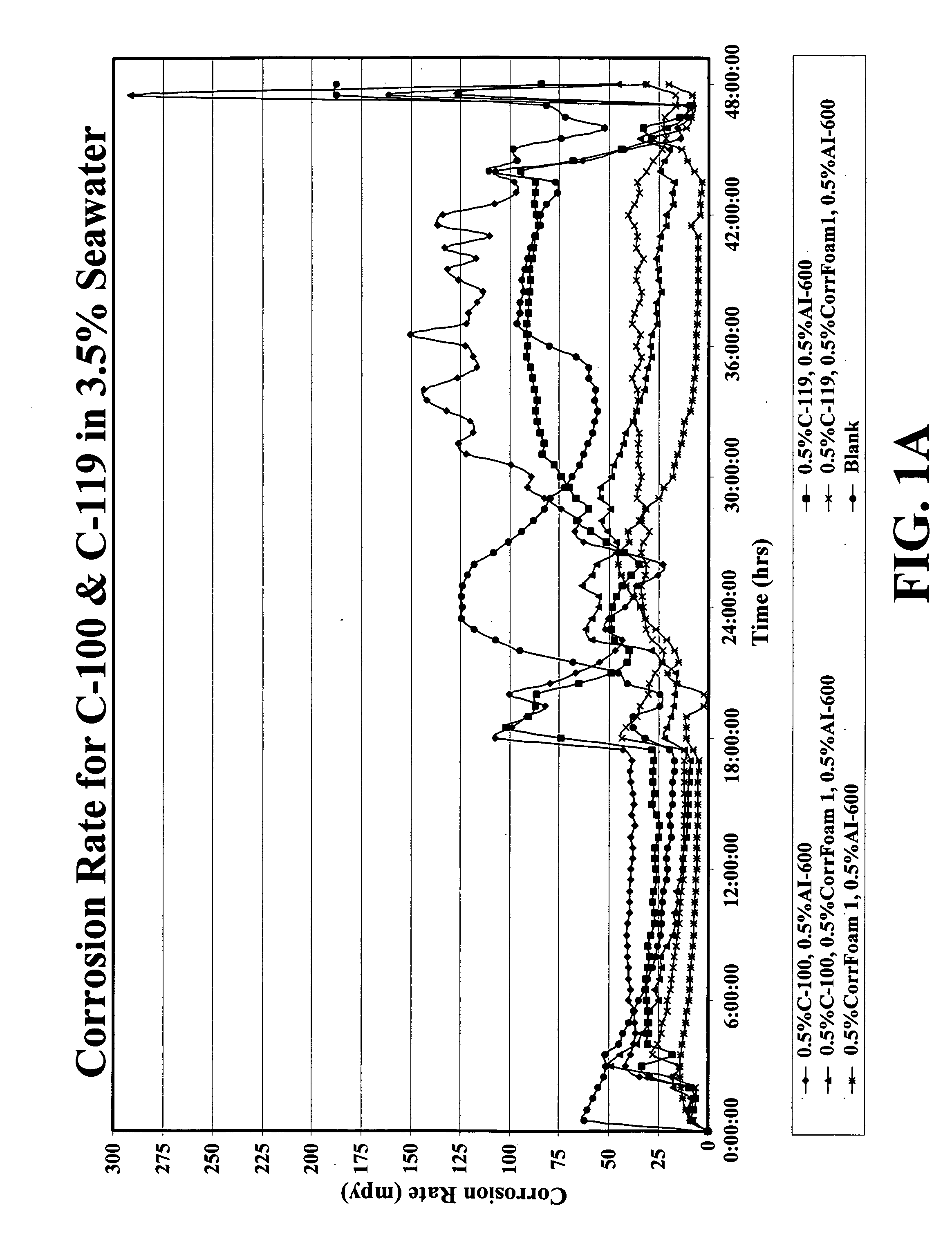

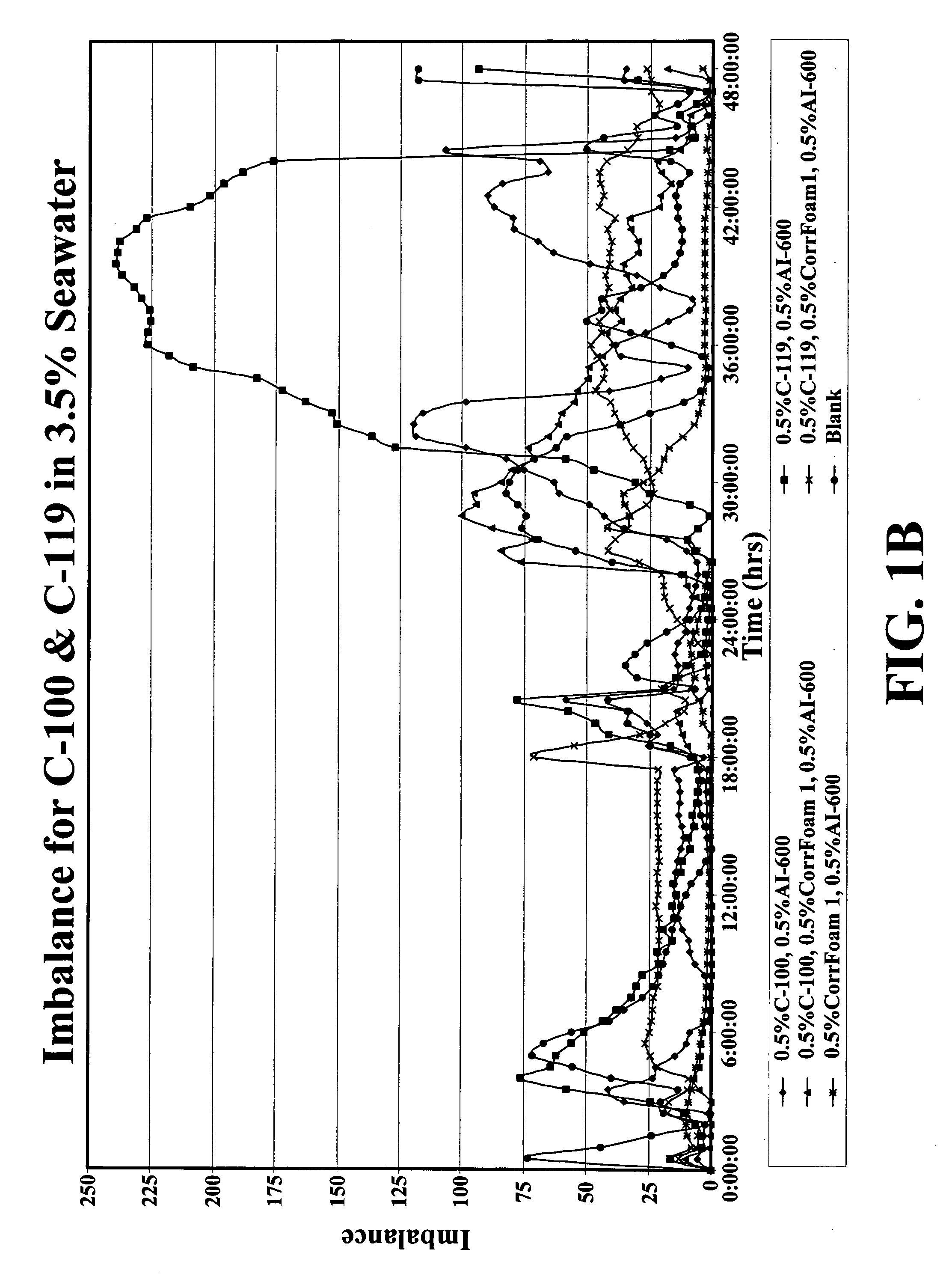

Corrosion inhibitor systems for low, moderate and high temperature fluids and methods for making and using same

A corrosion control system is disclosed including an anionic oxygen inhibitor, a cationic acid inhibitor or dispersant, and a noxious species inhibitor or scavenger for use in a fluid in contact with a metallic surface at low temperature, moderate temperature and especially at high temperature. A drilling fluid, a completion fluid, a production fluid and a geothermal fluid including an effective amount of the corrosion control system is also disclosed as well as methods for making and using same.

Owner:WEATHERFORD TECH HLDG LLC

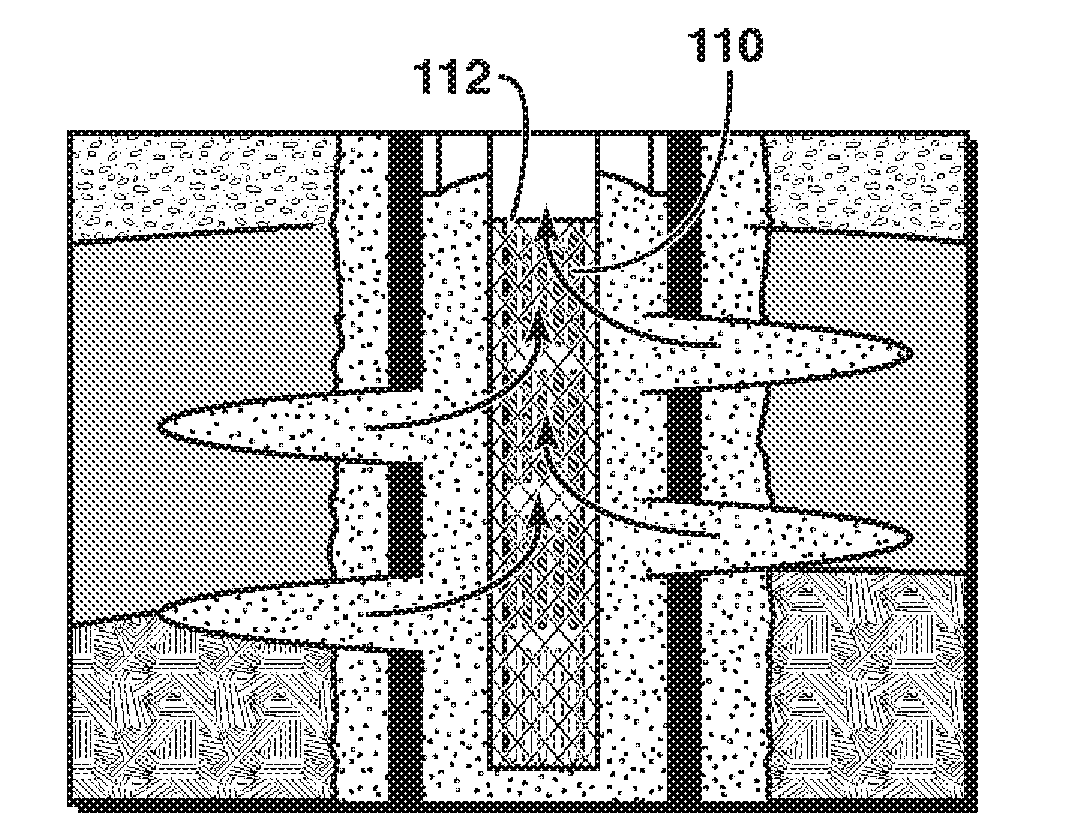

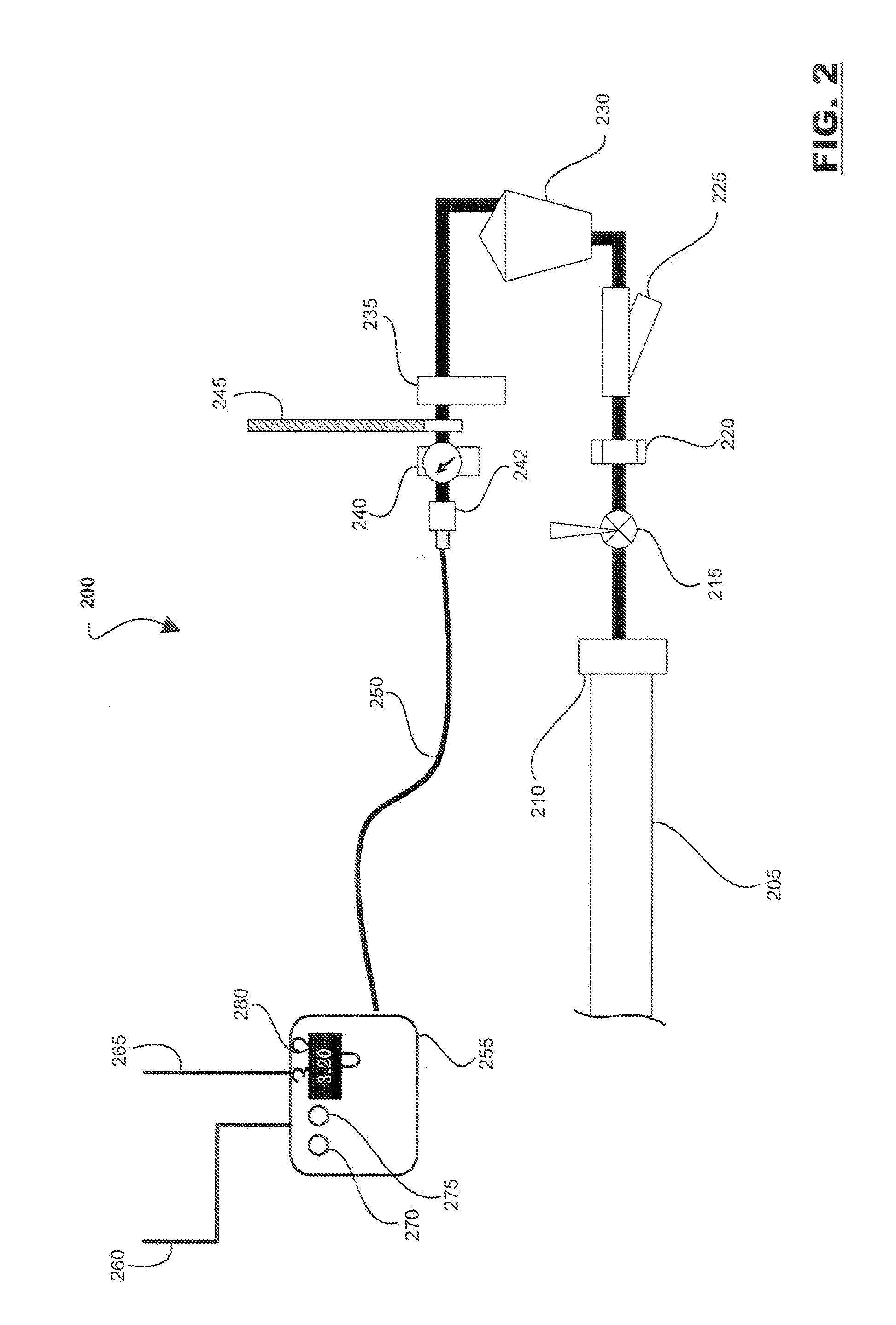

Corrosion-Resistant Downhole Transmission System

An apparatus in accordance with the invention may include a downhole tool and a data transmission path incorporated into the downhole tool. The data transmission path may include one or more contact surfaces providing electrical continuity to the data transmission path. To protect the contact surfaces from corrosion while maintaining electrical conductivity, a coating may be attached to one or more of the contact surfaces. The coating may include any of various materials that increase the corrosion-resistance of the underlying base metal, including but not limited to cobalt, nickel, tin, tin-lead, platinum, palladium, gold, silver, zinc, or combinations thereof.

Owner:INTELLISERV

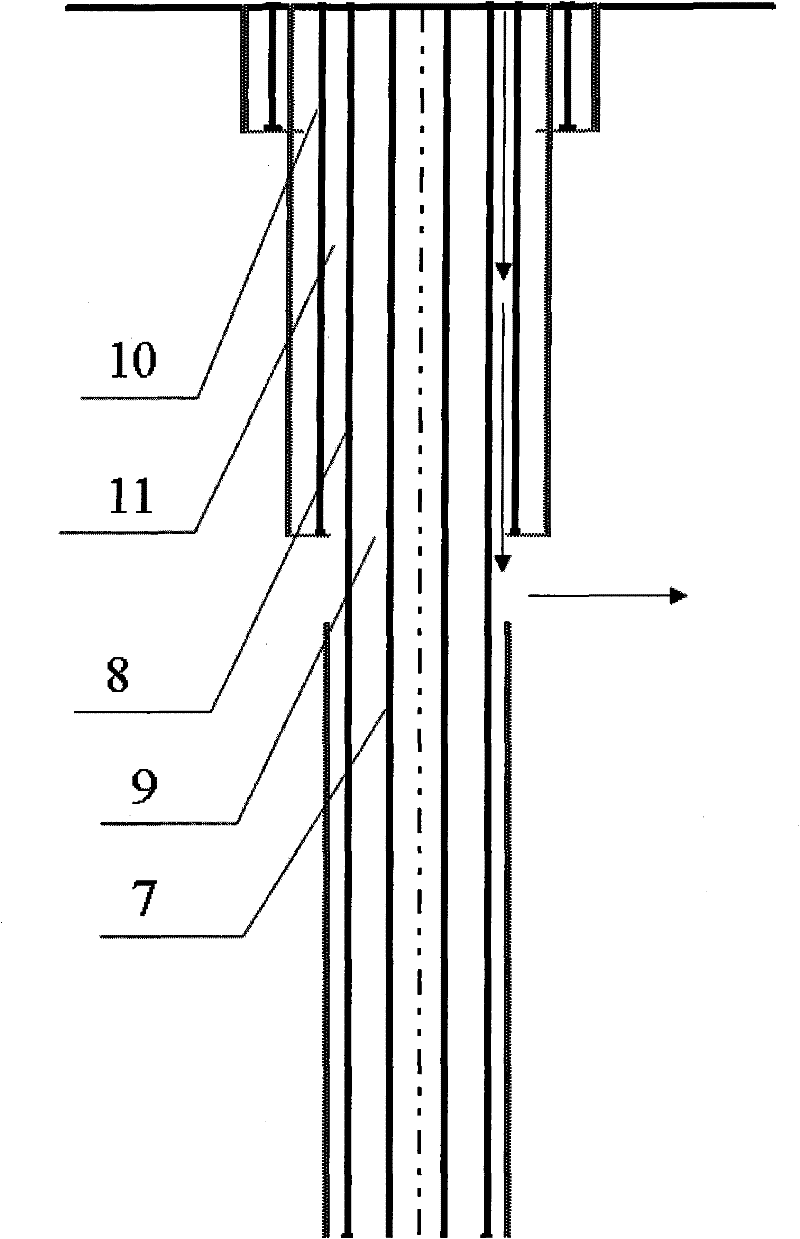

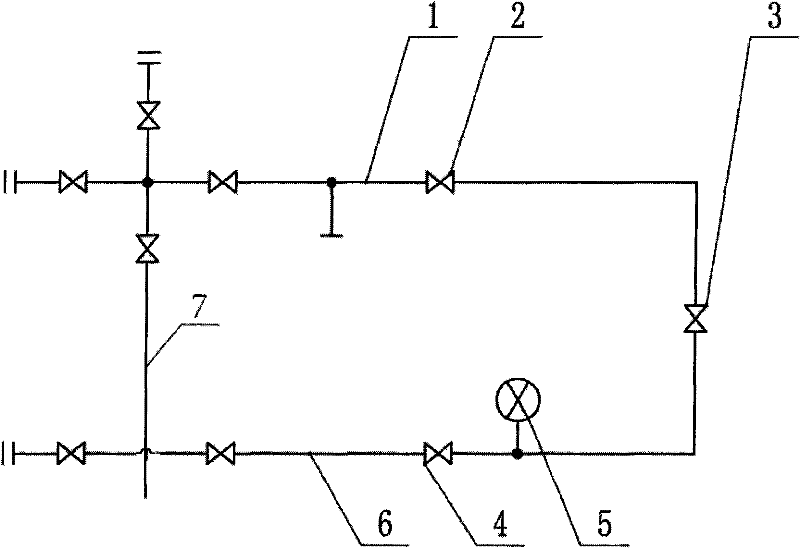

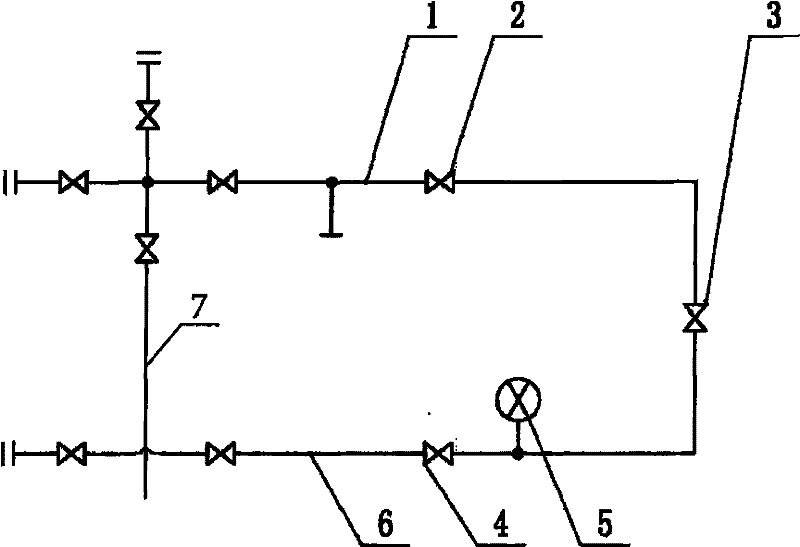

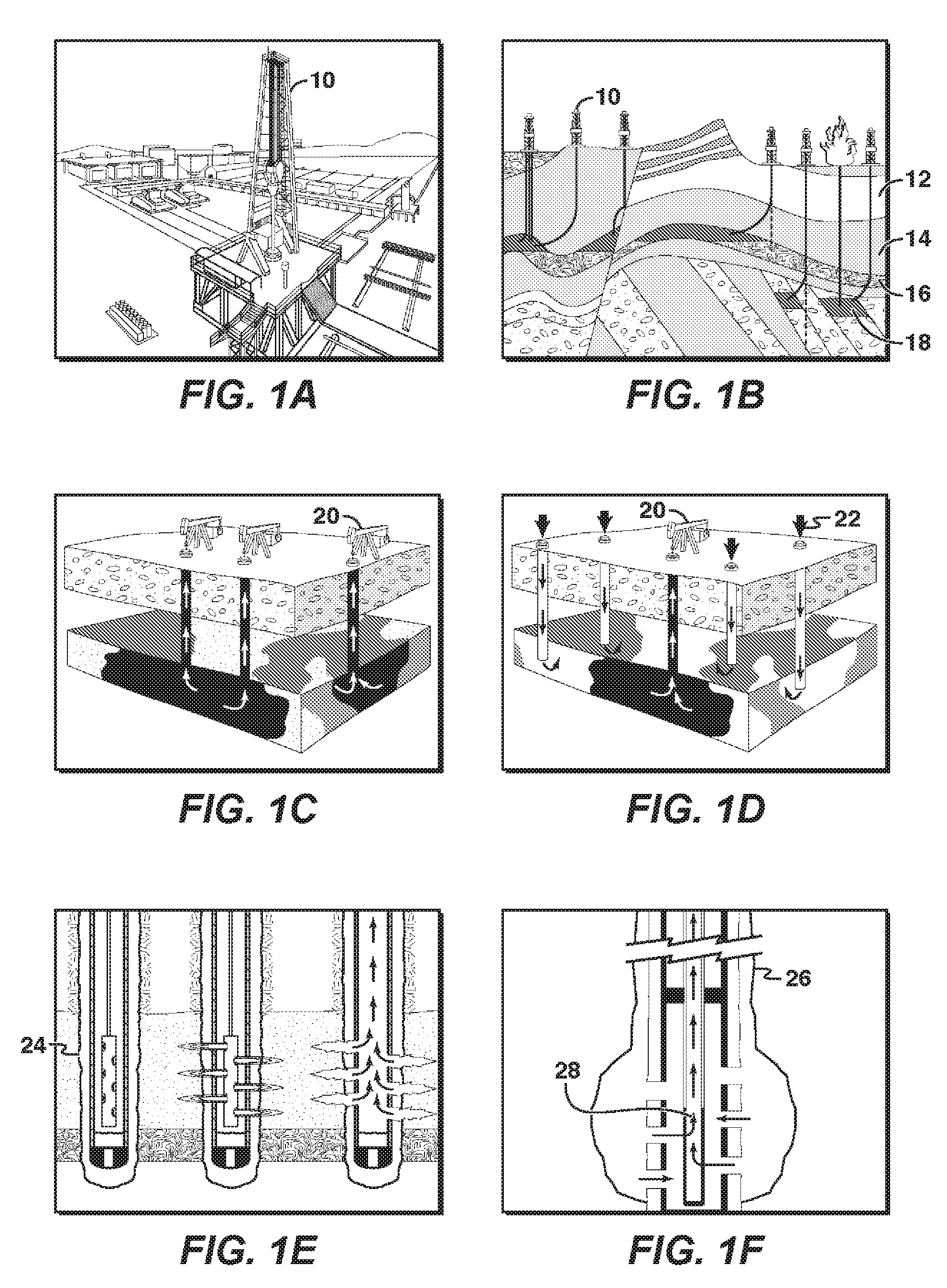

Rock debris annulus reinjection device and control method thereof

The invention discloses a rock debris annulus reinjection system. A water injection well is taken as a reinjection well, an inner annulus (9) is formed between a water injection pipeline (7) in the middle and a 9-5 / 8' sleeve (8), and an outer annulus (11) is formed between the 9-5 / 8' sleeve (8) and a 13-3 / 8' sleeve (10). The system is characterized in that: a water injection pipeline isolating valve (2), a pressure control valve (3), an inner annulus isolating valve (4) and an inner annulus pressure meter (5) are arranged between an extension pipe (1) of the water injection pipeline (7) and an outlet pipeline (6) of the inner annulus (9). The system is used for the rock debris reinjection operation technology of offshore oilfield drilling; and when rock debris is reinjected into the outer annulus between the 13-3 / 8' sleeve and the 9-5 / 8' sleeve, the allowable outlet pressure of the pressure control valve is adjusted, and the inner annulus is pressurized, so that rock debris reinjection slurry cannot flow into the inner annulus, the space of the inner annulus is protected, and the completeness of the water injection well is protected.

Owner:JEREH ENERGY SERVICES

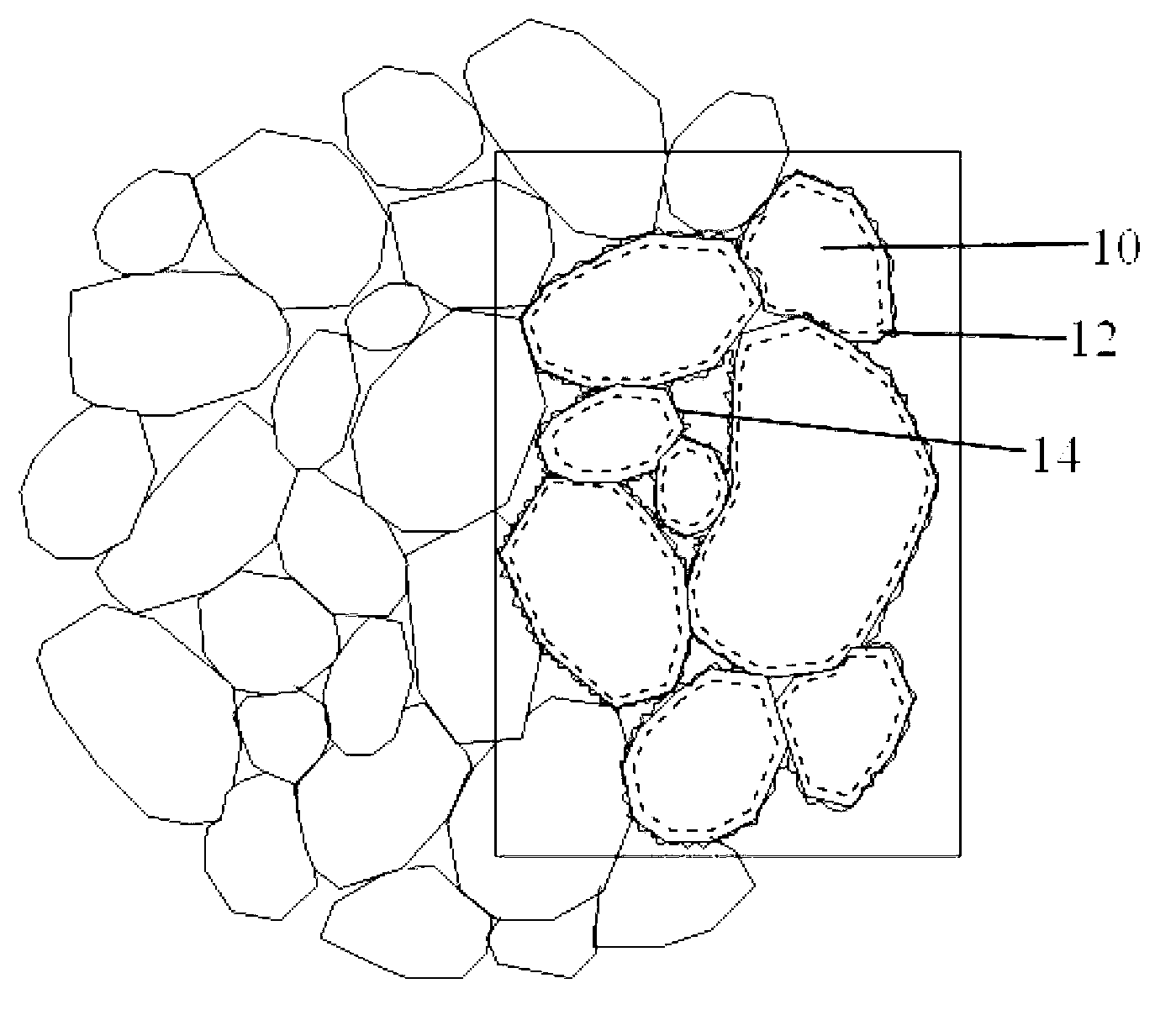

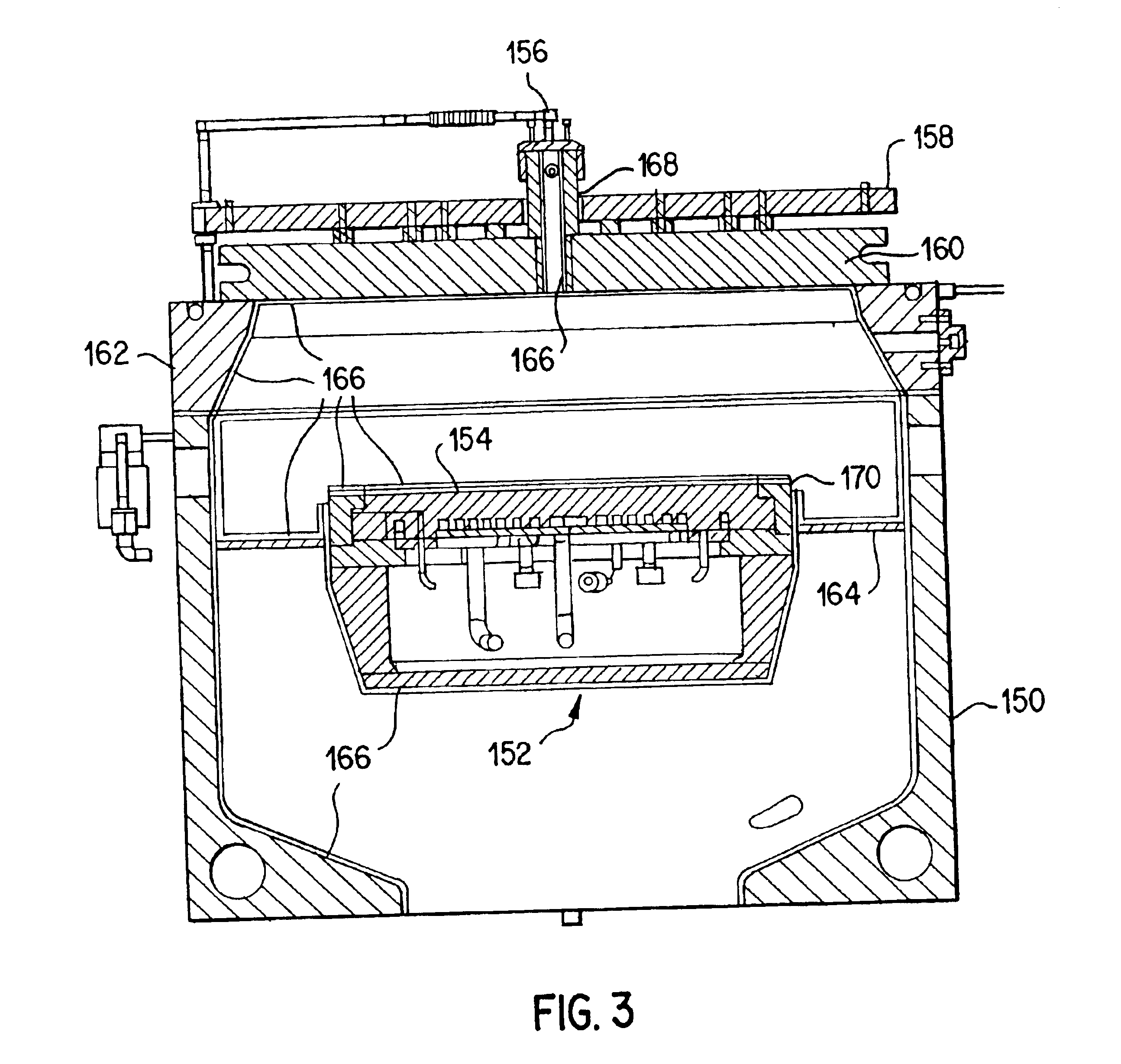

Golf club head with gasket

ActiveUS20050266933A1Cost effective productionImprove performanceGolf clubsRacket sportsGramGolf Ball

A golf club (40) having a club head (42) with a face component (60), an aft body (61) and a gasket (300) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is preferably composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The gasket (300) provides an interface between the face (60) and the aft-body (61) that reduces corrosion and improves manufacturing costs of the club head. The club head (42) preferably has a volume in the range of 290 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches.

Owner:TOPGOLF CALLAWAY BRANDS CORP

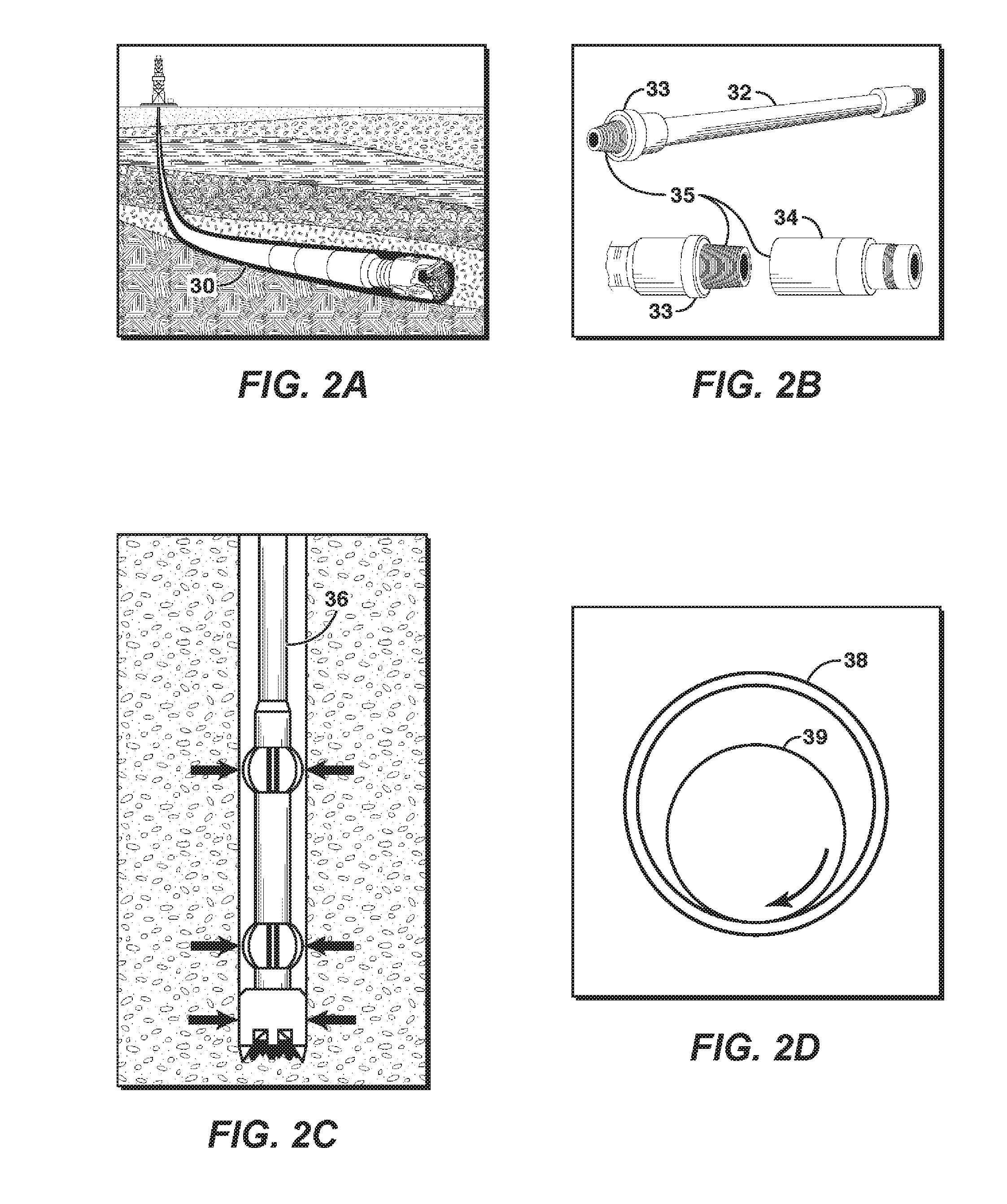

Coated sleeved oil and gas well production devices

ActiveUS20110203791A1Reduce frictionReduce wearDrilling rodsFluid removalLow frictionPetroleum engineering

Provided are coated sleeved oil and gas well production devices and methods of making and using such coated sleeved devices. In one form, the coated sleeved oil and gas well production device includes one or more cylindrical bodies, one or more sleeves proximal to the outer diameter or inner diameter of the one or more cylindrical bodies, hardbanding on at least a portion of the exposed outer surface, exposed inner surface, or a combination of both exposed outer or inner surface of the one or more sleeves, and a coating on at least a portion of the inner sleeve surface, the outer sleeve surface, or a combination thereof of the one or more sleeves. The coating includes one or more ultra-low friction layers, and one or more buttering layers interposed between the hardbanding and the ultra-low friction coating. The coated sleeved oil and gas well production devices may provide for reduced friction, wear, erosion, corrosion, and deposits for well construction, completion and production of oil and gas.

Owner:EXXONMOBIL UPSTREAM RES CO

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

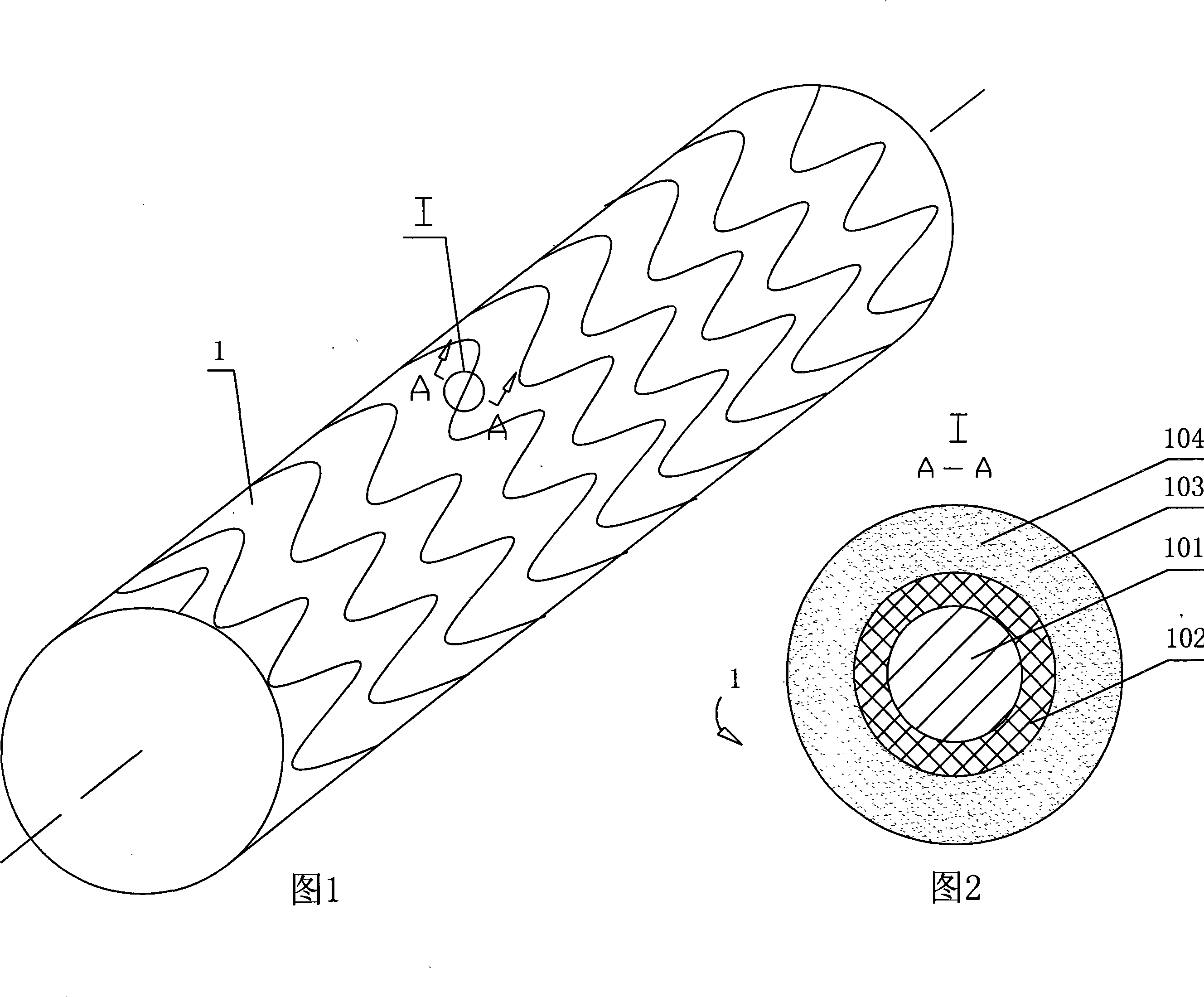

Controlled degradation magnesium alloy coating bracket and preparation thereof

InactiveCN101214396AImprove mechanical propertiesExcellent pharmacological propertiesAnodisationStentsSurface cleaningPolymer chemistry

The invention relates to a controlled degradation magnesium alloy coating stent and a preparation method. The stent body is made of medical high purity magnesium or magnesium alloy by mechanical processing or laser carving; the stent body is provided with a drug-loading coating which bears curative drug; the surface of the stent body is provided with an anti-corrosive coating; the surface of the anti-corrosive coating is provided with a degradable polymer film drug-loading coating; the preparation method includes surface cleaning, preparation of the degradable polymer film drug-loading coating, and application of curative drug; through (1)surface cleaning, (2)preparation of the degradable polymer film drug-loading coating, and (3)application of curative drug, an oxide film is formed on the surface; different drugs and dosage can be fixed by regulating the molecular weight and the thickness of the polymer layer, the drug-loading quantity is more than 30 percent, which improves the fixed stability of the drug, greatly reduces the degradation speed of the magnesium alloy and controls release of the drug, delays corrosion of the magnesium alloy, extends the service life of the stent, is safe in use, and meets the clinical requirement.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

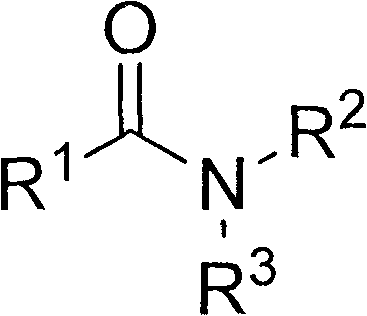

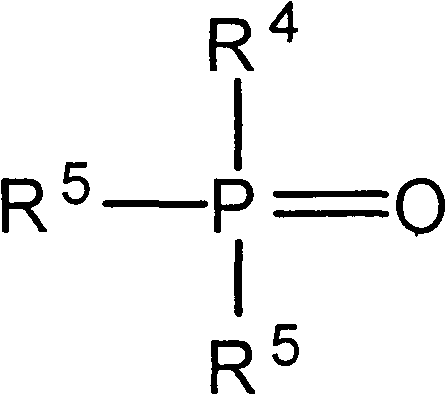

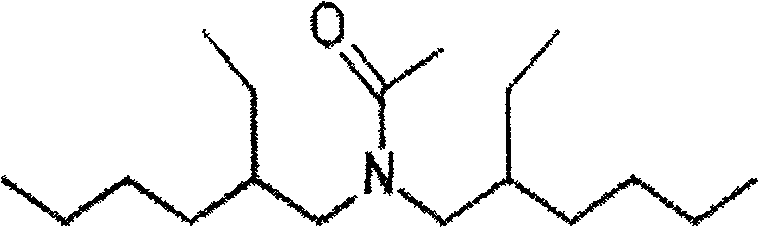

Method for extracting lithium salts in lithium-containing brine

ActiveCN103055539AReduce dosageReduce corrosionLithium compoundsLiquid solutions solvent extractionLithiumStructural formula

The invention provides a method for extracting lithium salts in lithium-containing brine. Lithium is extracted through a co-extraction agent, an extraction agent and a diluent, wherein the extract is a mixture of an amide compound and a neutral phosphorus oxide compound, the structural formula of the amide compound is shown in the specification, and the structural formula of the neutral phosphorus oxide compound is shown in the specification. The method provided by the invention further optimizes the properties of extracted lithium, so that the method is more applicable to the industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

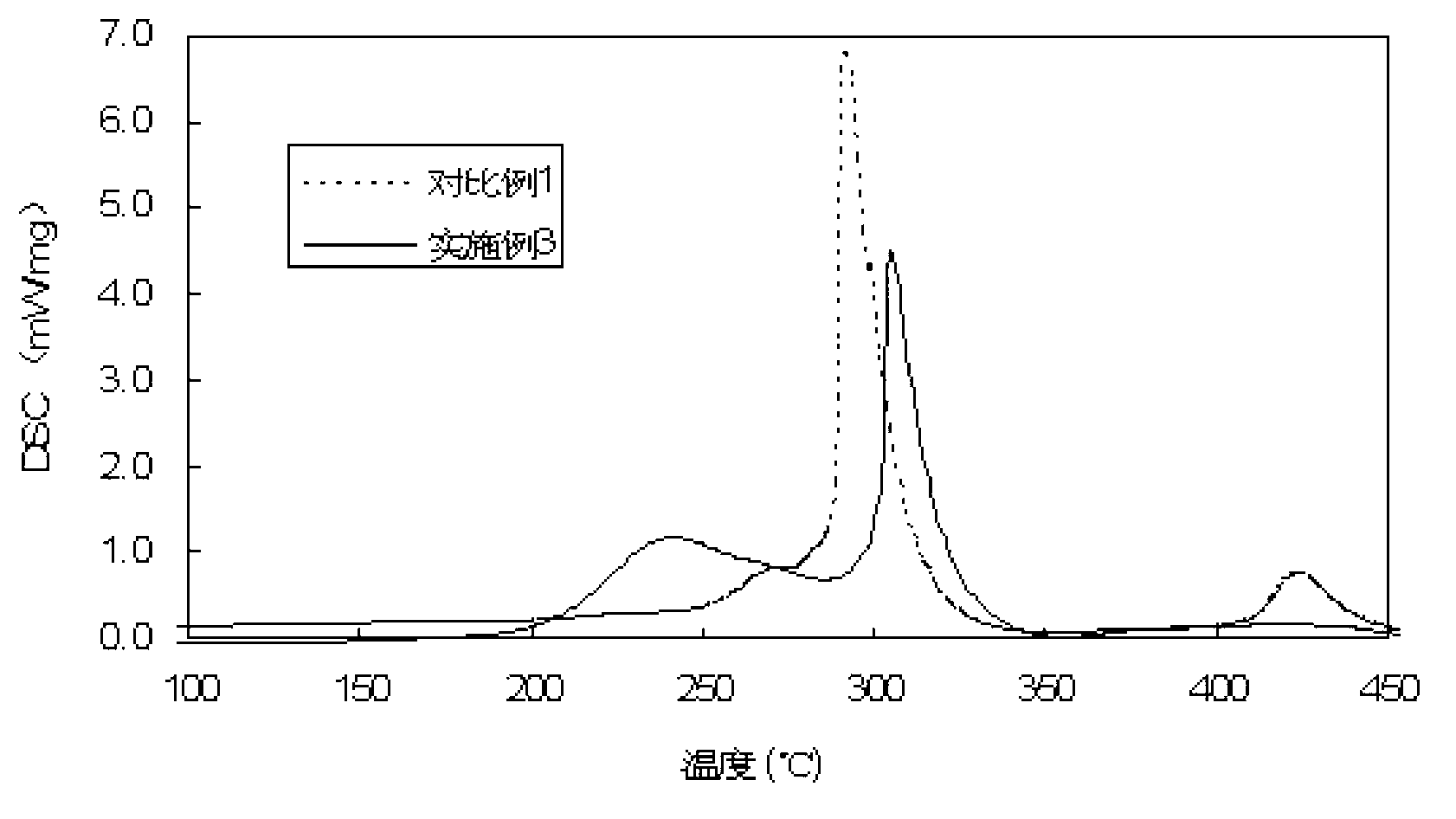

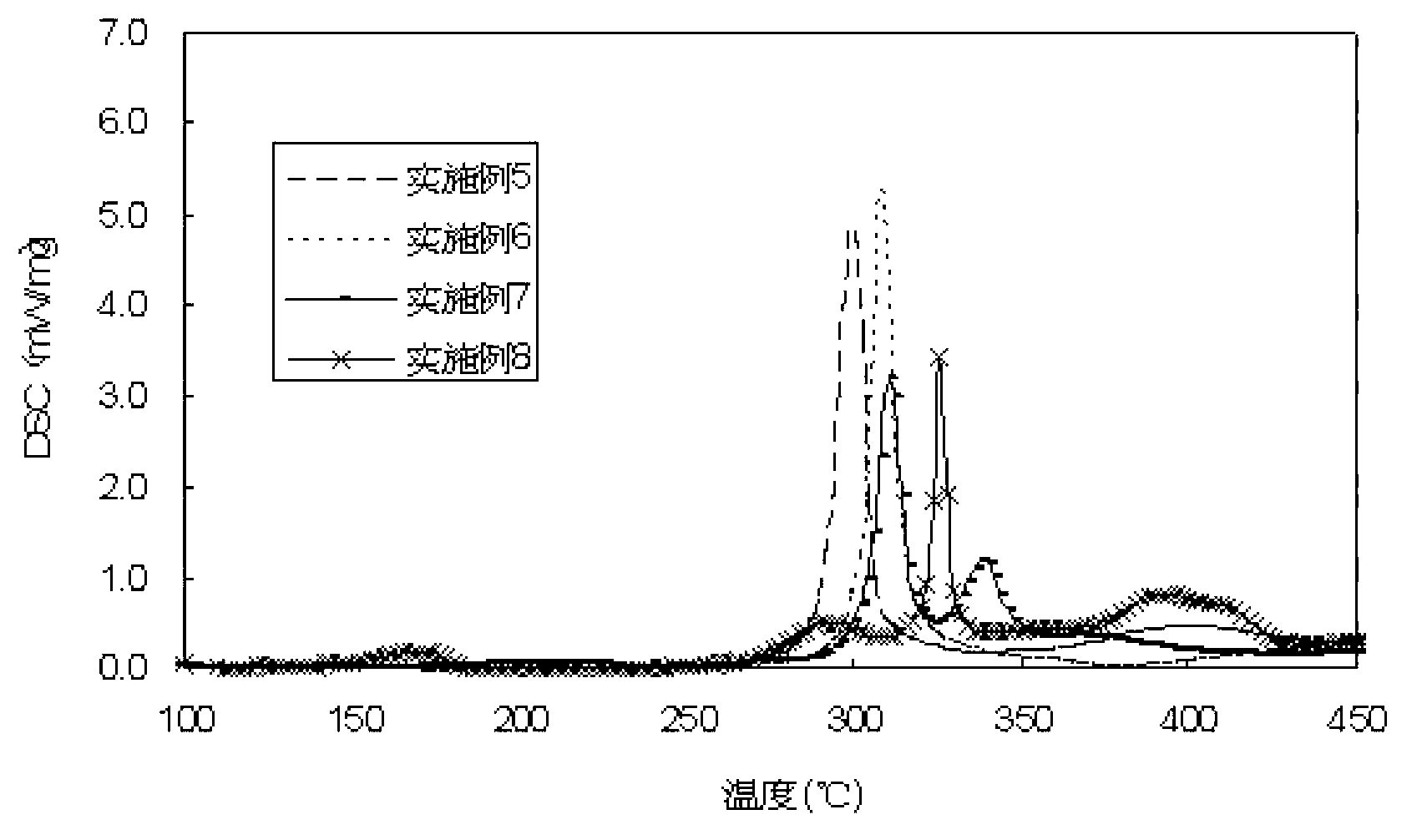

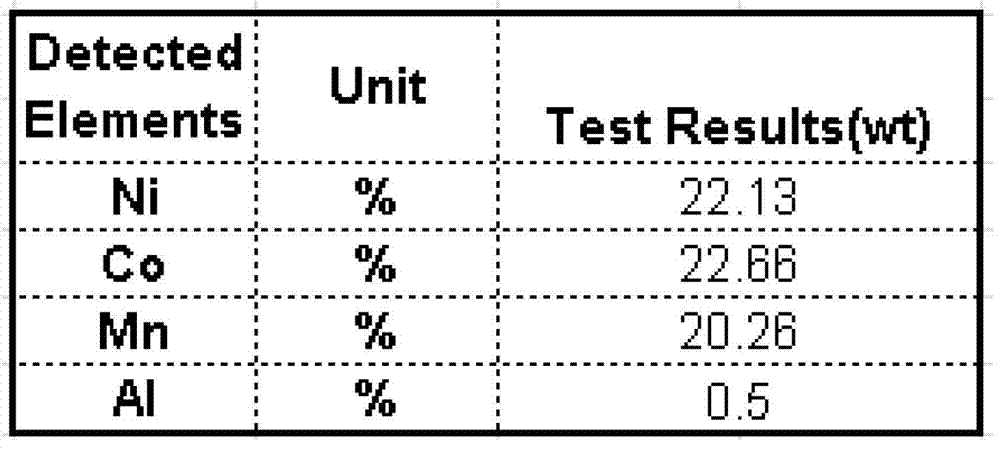

Doped modified lithium nickel cobalt manganese material, preparation method thereof and lithium ion battery

ActiveCN103296249AHigh surface energyImprove adsorption capacityElectrode carriers/collectorsSecondary cellsLithium electrodeOxide

The invention discloses a doped modified lithium nickel cobalt manganese material, a preparation method thereof and a lithium ion battery. A secondary particle of the doped modified lithium nickel cobalt manganese material is composed of a primary particle and is spherical or spherical-like in shape, and the surface of the primary particle is non-uniformly doped with a nano metal oxide layer. In the preparation method, a precursor of the lithium nickel cobalt manganese material is doped with nano metal oxides during a synthesis stage and undergoes doping modification. Compared with the prior art, the doped modified lithium nickel cobalt manganese material is used as an anode activity material of the lithium ion battery, under a charge / discharge condition of 4.45 V, has good circulation and good thermal stability, and can meet requirements of high energy density, high power density, long service life and high safety of the lithium ion battery.

Owner:NINGDE AMPEREX TECH

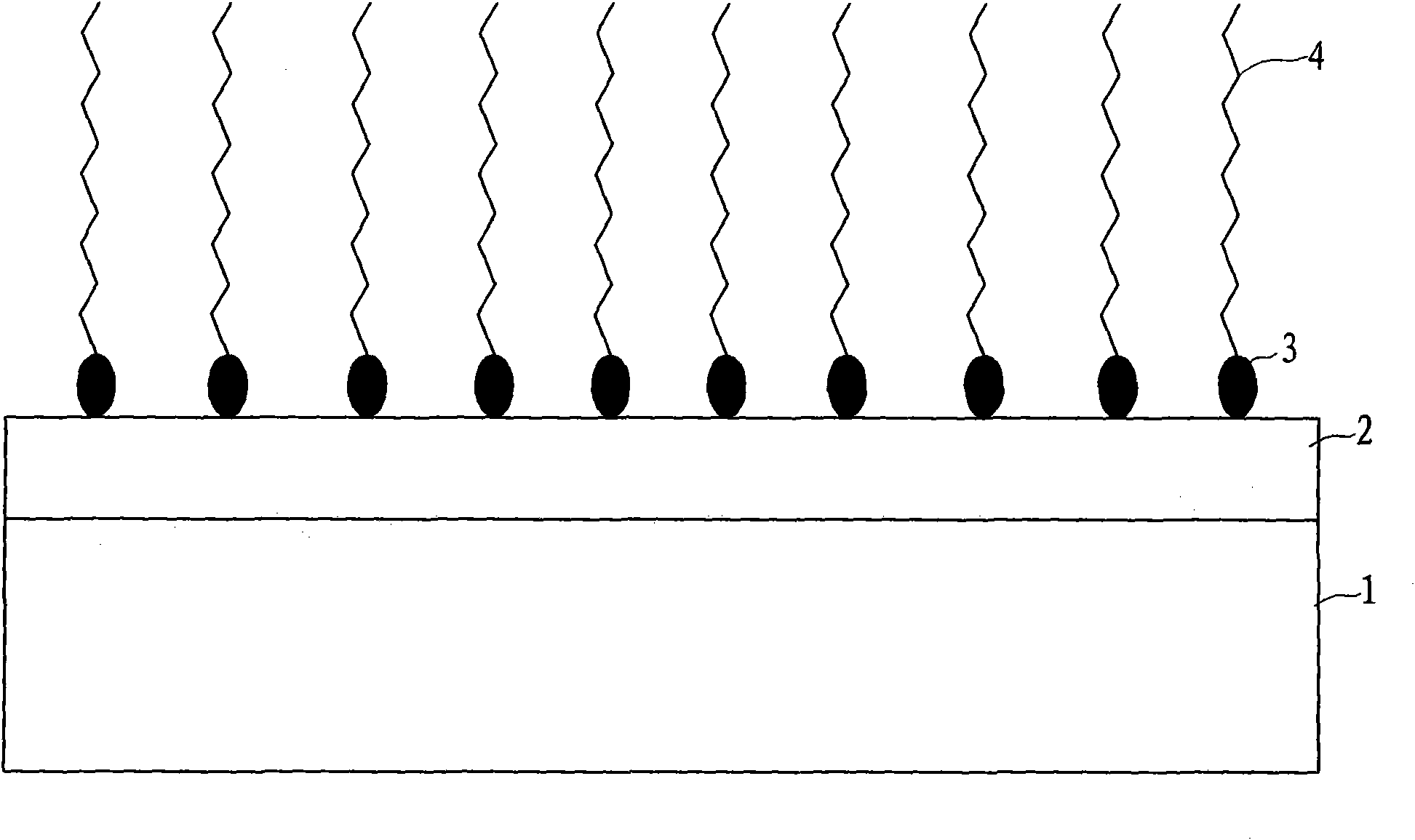

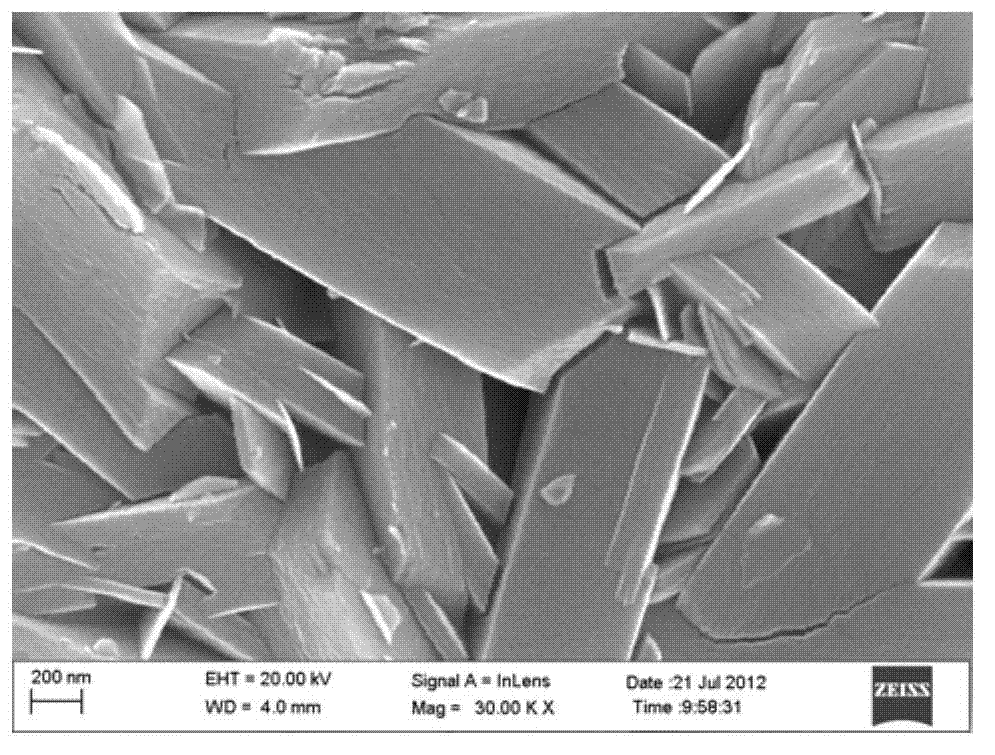

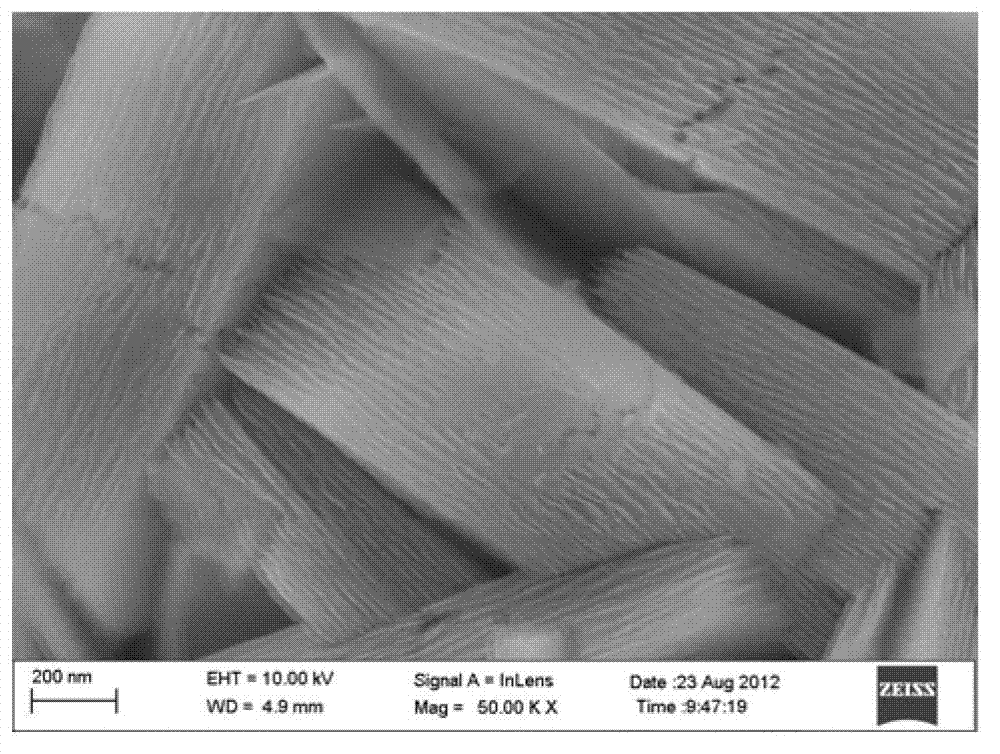

Super-hydrophobic and super-oleophobic surface preparation technology

The invention discloses super-hydrophobic and super-oleophobic surface preparation technology. In the preparation technology, aluminum or aluminum alloy sheets are subjected to two-step electrochemical treatment, and then are modified by using perfluorinated octadecyl trichlorosilane or perfluorinated polymethacrylate to prepare the super-hydrophobic and super-oleophobic surface. The surface has super-hydrophobic property on aqueous solution of which the pH value is between 1 and 14 and super-oleophobic property on various oil drops, wherein a contact angle of the surface on water is 171 degrees, and a rolling angle is less than 1 degree; the surface expresses the super-oleophobic property on various oil drops except for perfluorinated polymer liquid, and all contact angles between the oil drops and the surface are more than 150 degrees, and rolling angles are generally less than 10 degrees; and the surface can also be put in air for a long time and can still maintain the super-hydrophobic property and super-oleophobic property.

Owner:中科润泉(烟台)工业科技有限公司

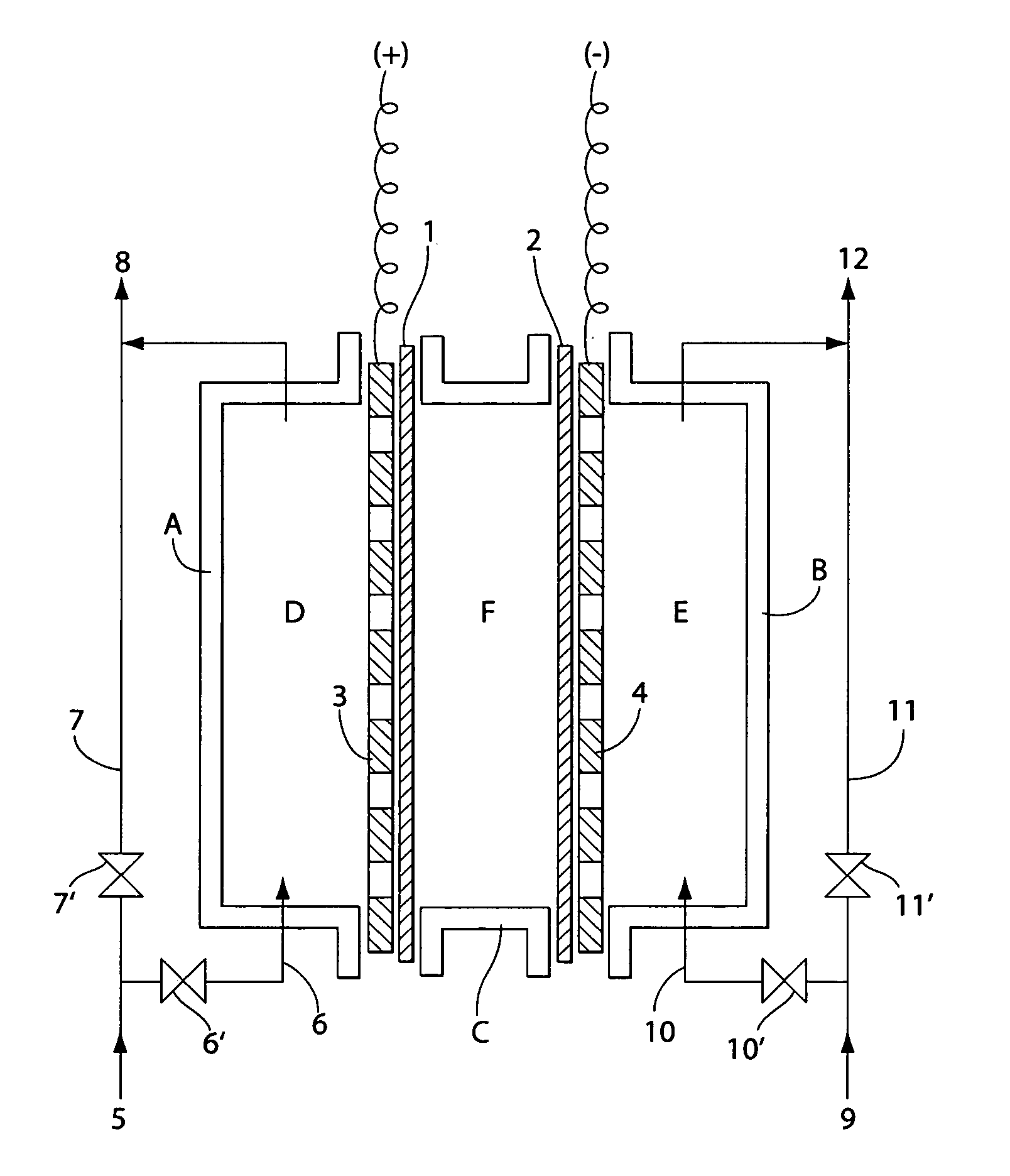

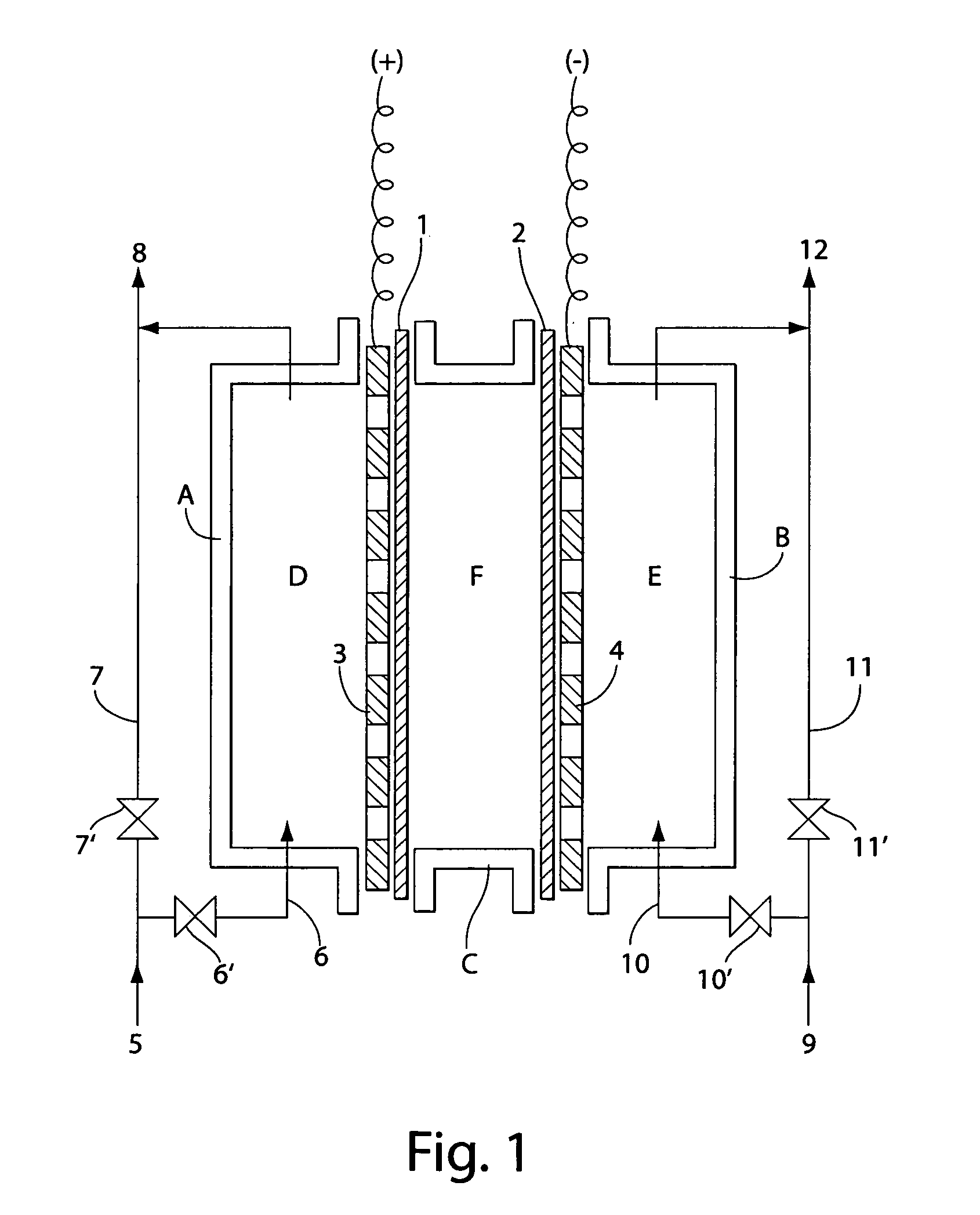

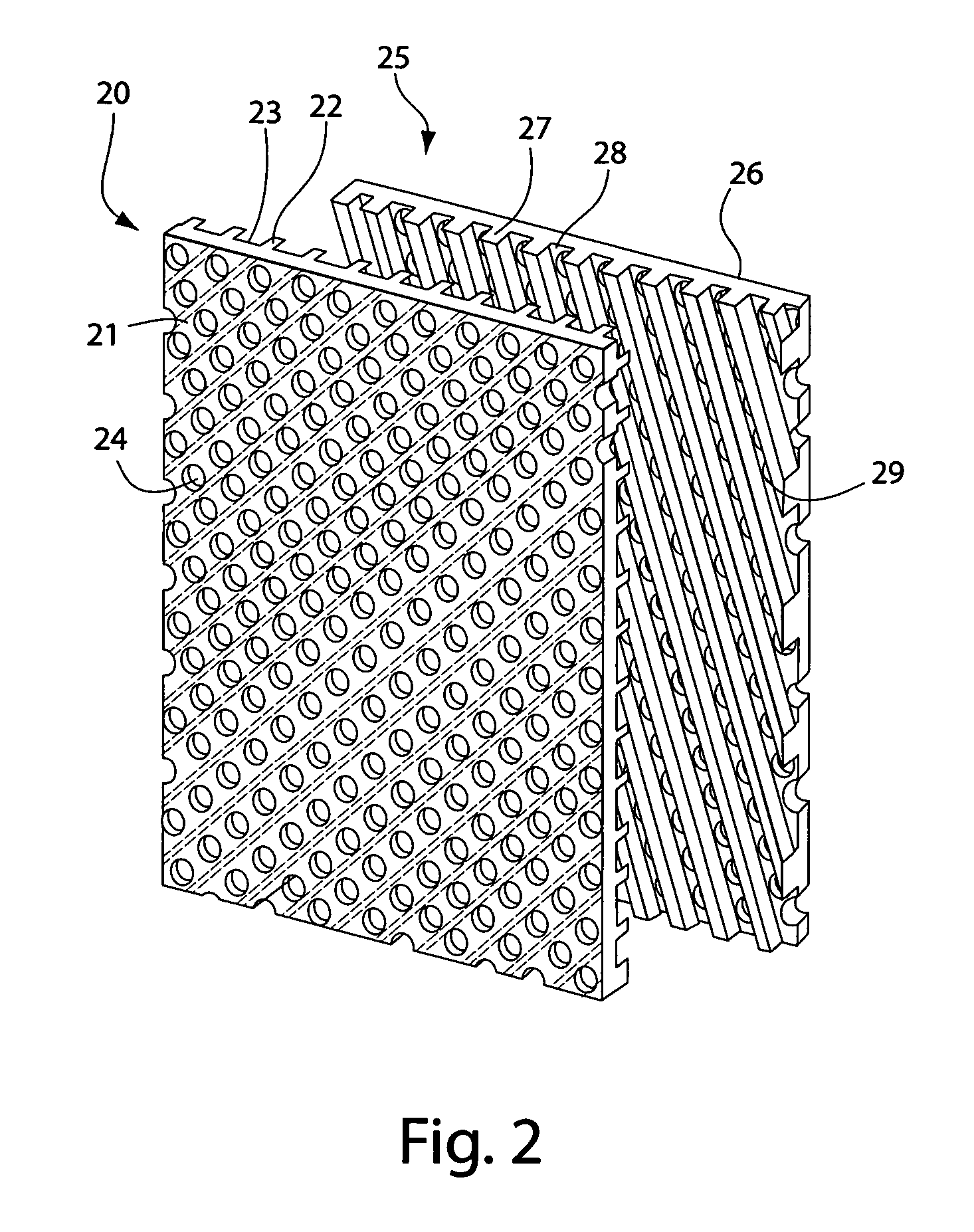

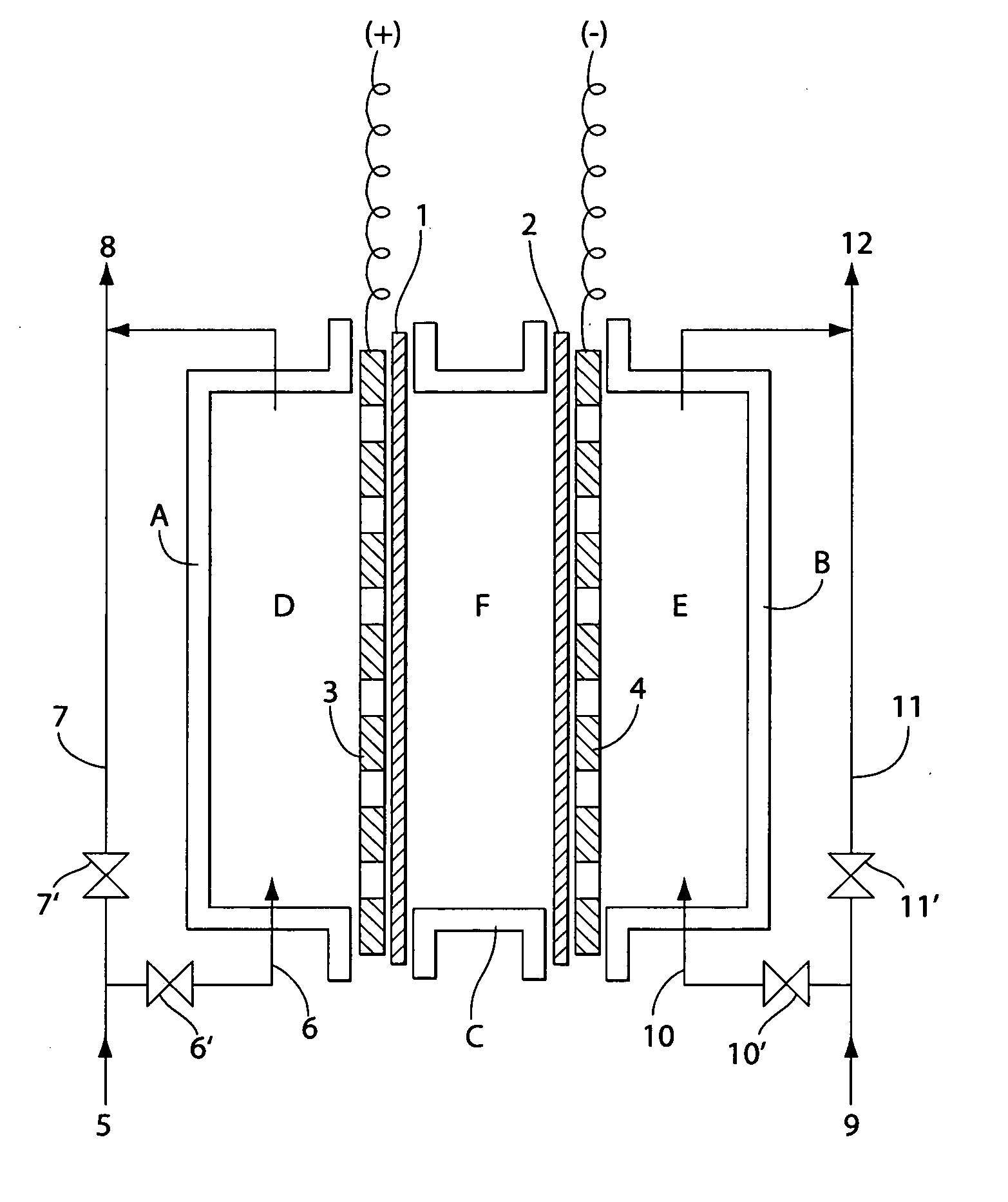

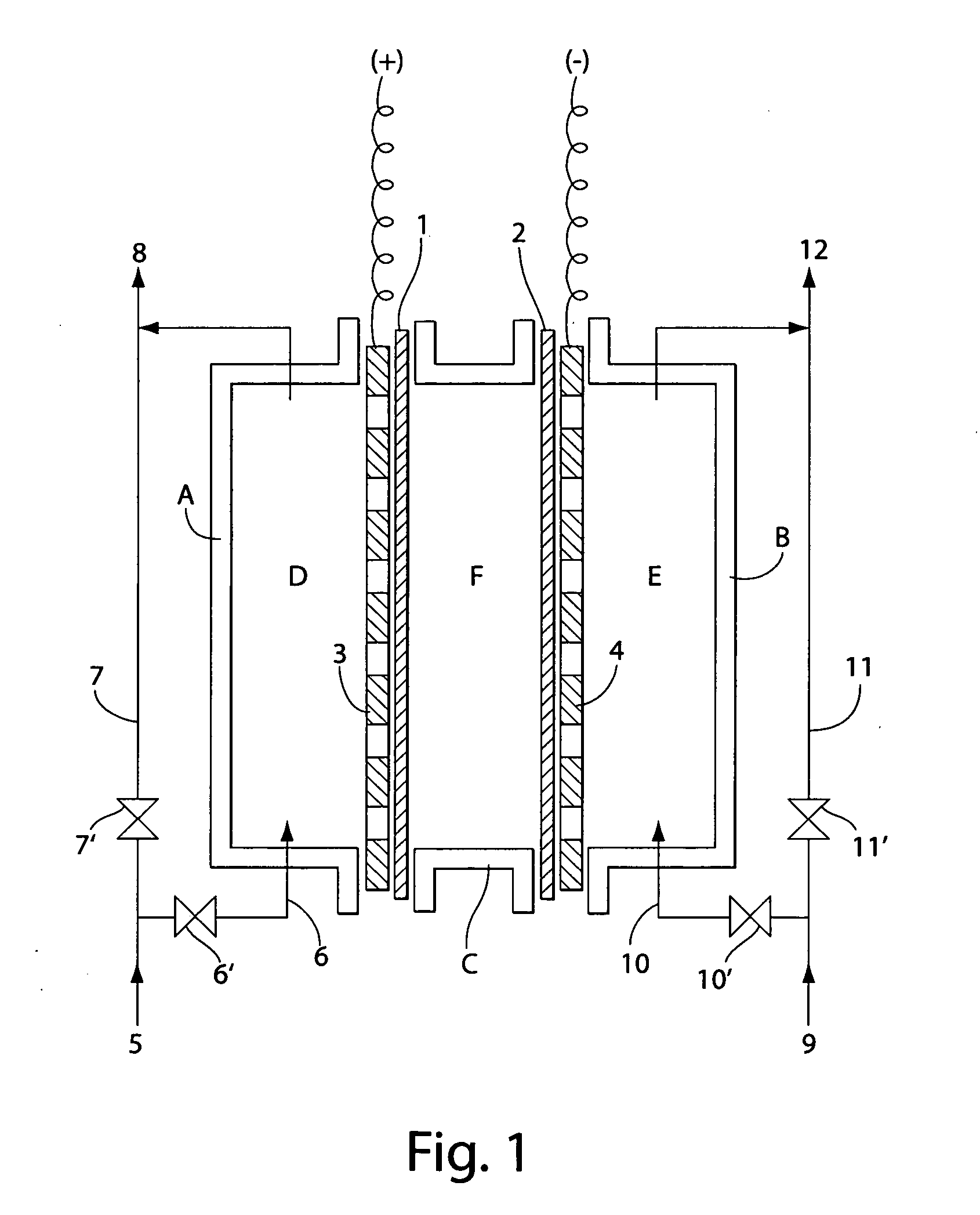

Production of electrolytic water

InactiveUS7238272B2Prevent adhesionIncrease productivityCellsLiquid separation by electricityWater useElectrolysed water

Apparatus and methods are provided for producing electrolytic water using three chambers, rigid plates and ion exchange membranes. Benefits include reduced scale production and increased long-term bactericidal effects of the water produced.

Owner:ELECTROLYZER

Preparation method of photovoltaic glass surface antireflection film

The invention discloses a preparation method of a photovoltaic glass surface antireflection film, which is characterized by comprising the following steps of firstly, preparing inorganic-organic hybrid silicasol; secondly, coating; thirdly, hydrophobic treatment; and fourthly, solidification treatment. Compared with the prior art, the invention has the advantages that the film-substrate cohesion between an antireflection film and substrate photovoltaic glass is stronger, and therefore, the wiping resistance of the coated photovoltaic glass surface antireflection film is enhanced; a layer of hydrophobic group with low surface energy is formed on the surface of the antireflection film, and therefore, the corrosion of moisture to a film microstructure is reduced, and the long service life of the coated photovoltaic glass is ensured; and the invention has low whole process cost and simple technical route and is suitable for industrial and large-scale application.

Owner:CHANGZHOU ALMADEN

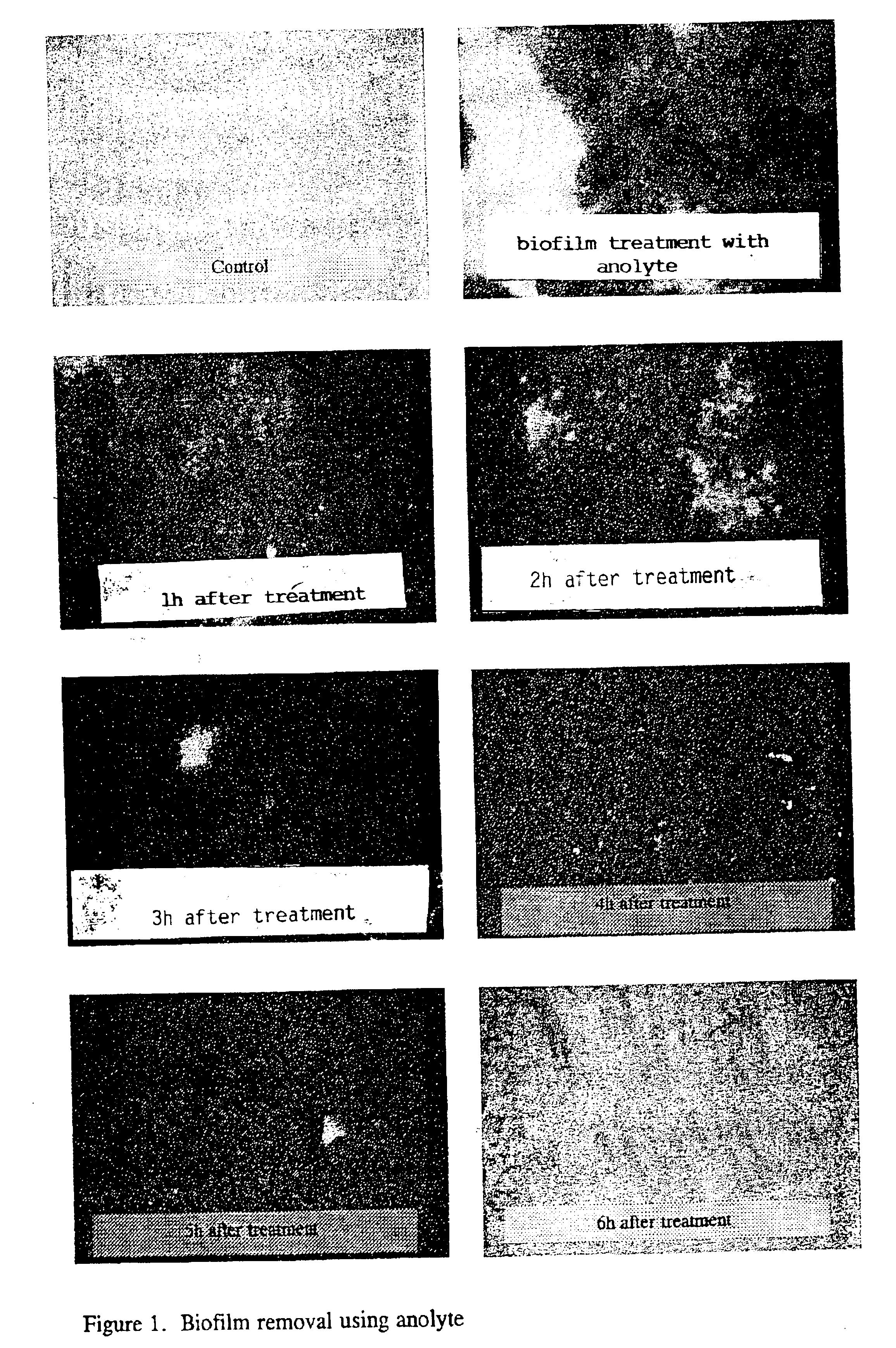

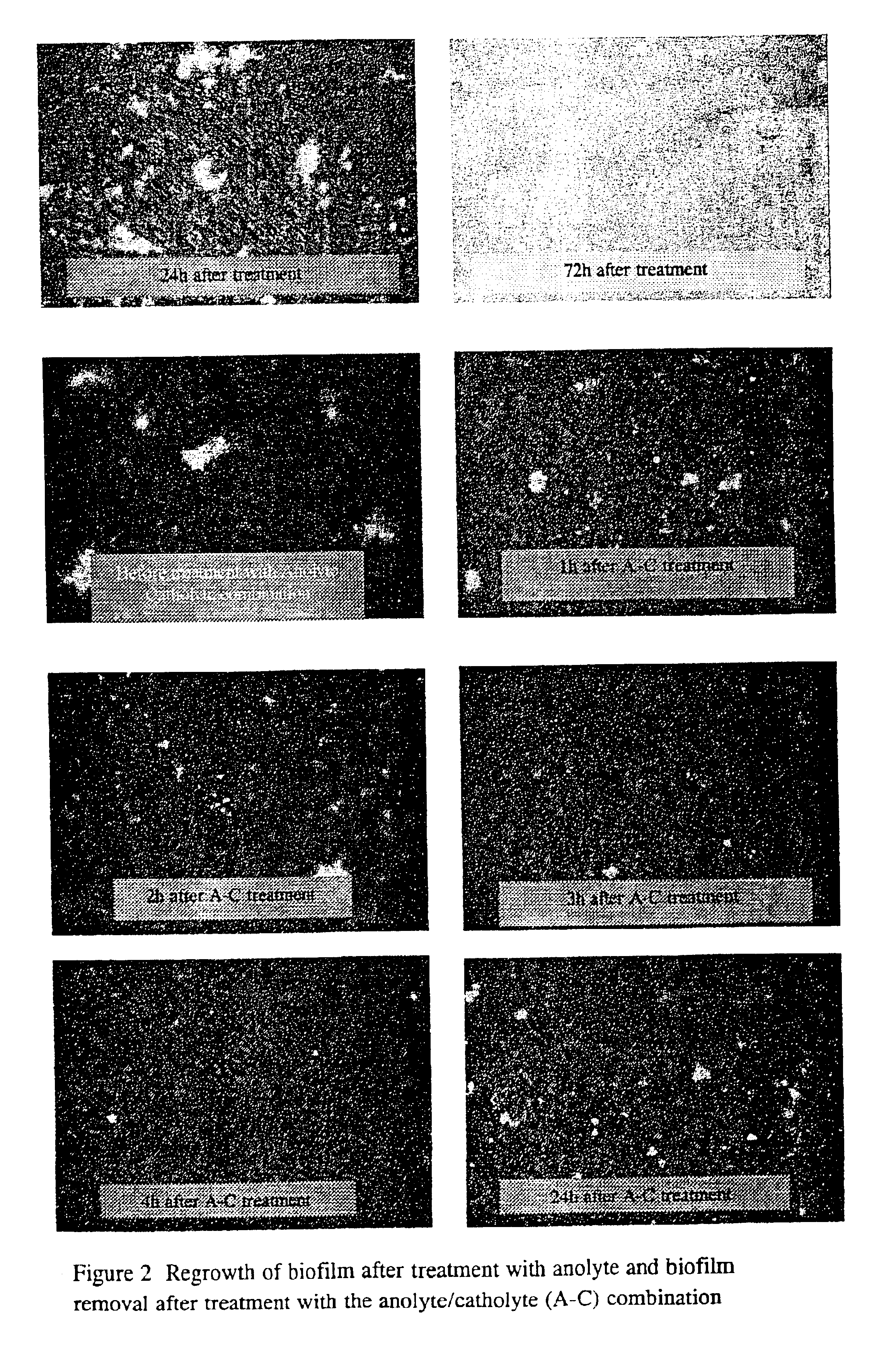

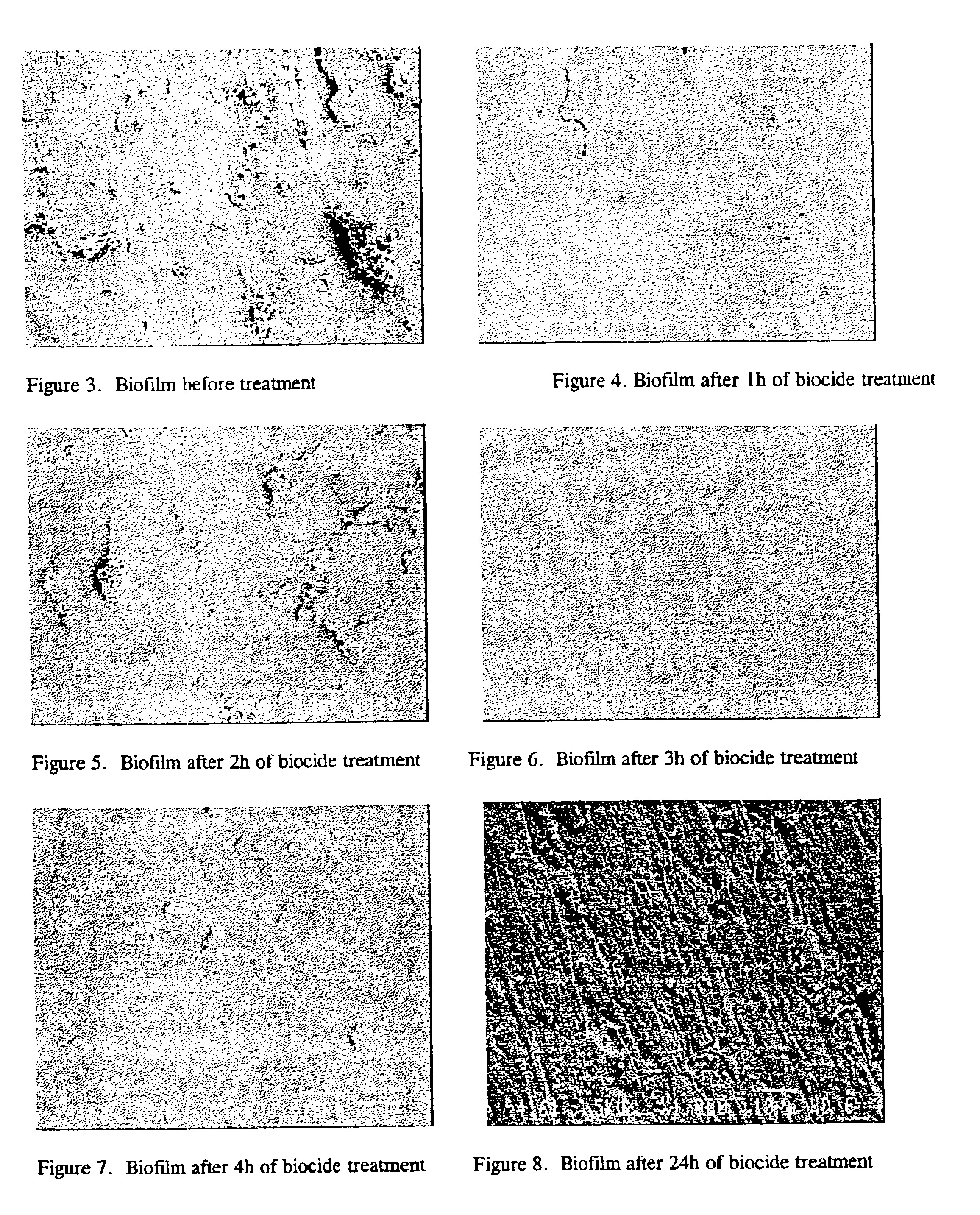

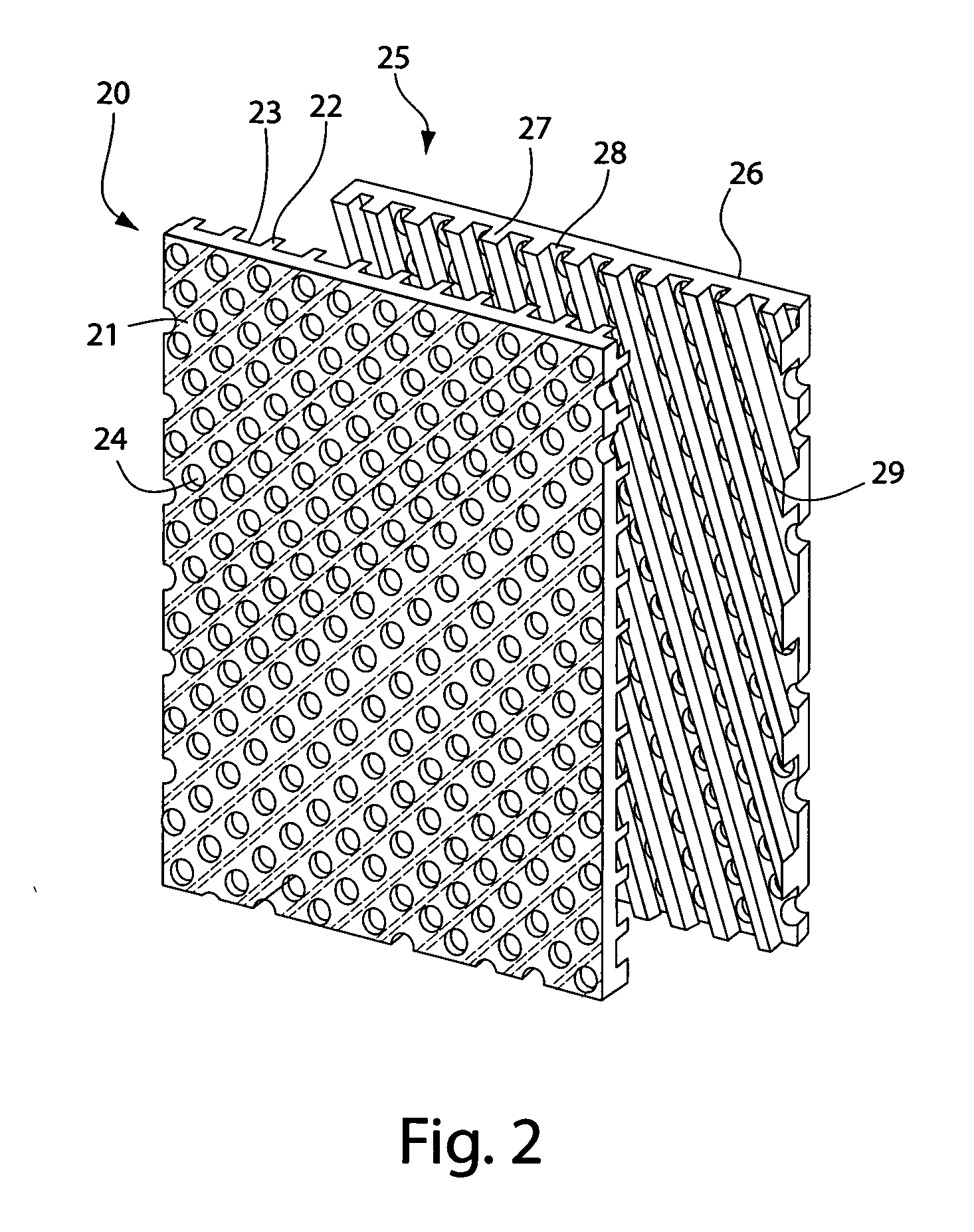

Dental equipment and method of operating such equipment

InactiveUS6878287B1Suitable for useEliminate biofilmElectrostatic separatorsElectrolysis componentsElectrolysisDental Equipment

An electrolytically activated, microcidal aqueous solution is disclosed which is used in the elimination and control of biofilm in dental unit water lines. The solution has a pH between 6.75 and 10 with microcidal as well as anti-oxidising, dispersing and surfactant properties, rendering the solution bio-compatible and non-corrosive, as well as capable of eliminating biofilm in dental unit water lines, while simultaneously dispersing and dislodging the biofilm from the water lines so as reduce the micro-organisms in the dental water to a predetermined level. The aqueous solution is produced using an electrolytic device that allows the independent manipulation of specific individual properties of two separate product streams (a cation-rich stream and an anion-rich stream), the manipulation being performed by separate and independent recirculation through the same electrode chamber or counter-electrode chamber of the electrolytic device to modulate the respective properties of the anion-containing and the cation-containing solutions.

Owner:RADICAL WATERS IP

Production of electrolytic water

InactiveUS20050189237A1Increase free chlorine production efficiencyPrevent adhesion of scaleCellsLiquid separation by electricityWater useElectrolysed water

Apparatus and methods are provided for producing electrolytic water using three chambers, rigid plates and ion exchange membranes. Benefits include reduced scale production and increased long-term bactericidal effects of the water produced.

Owner:ELECTROLYZER

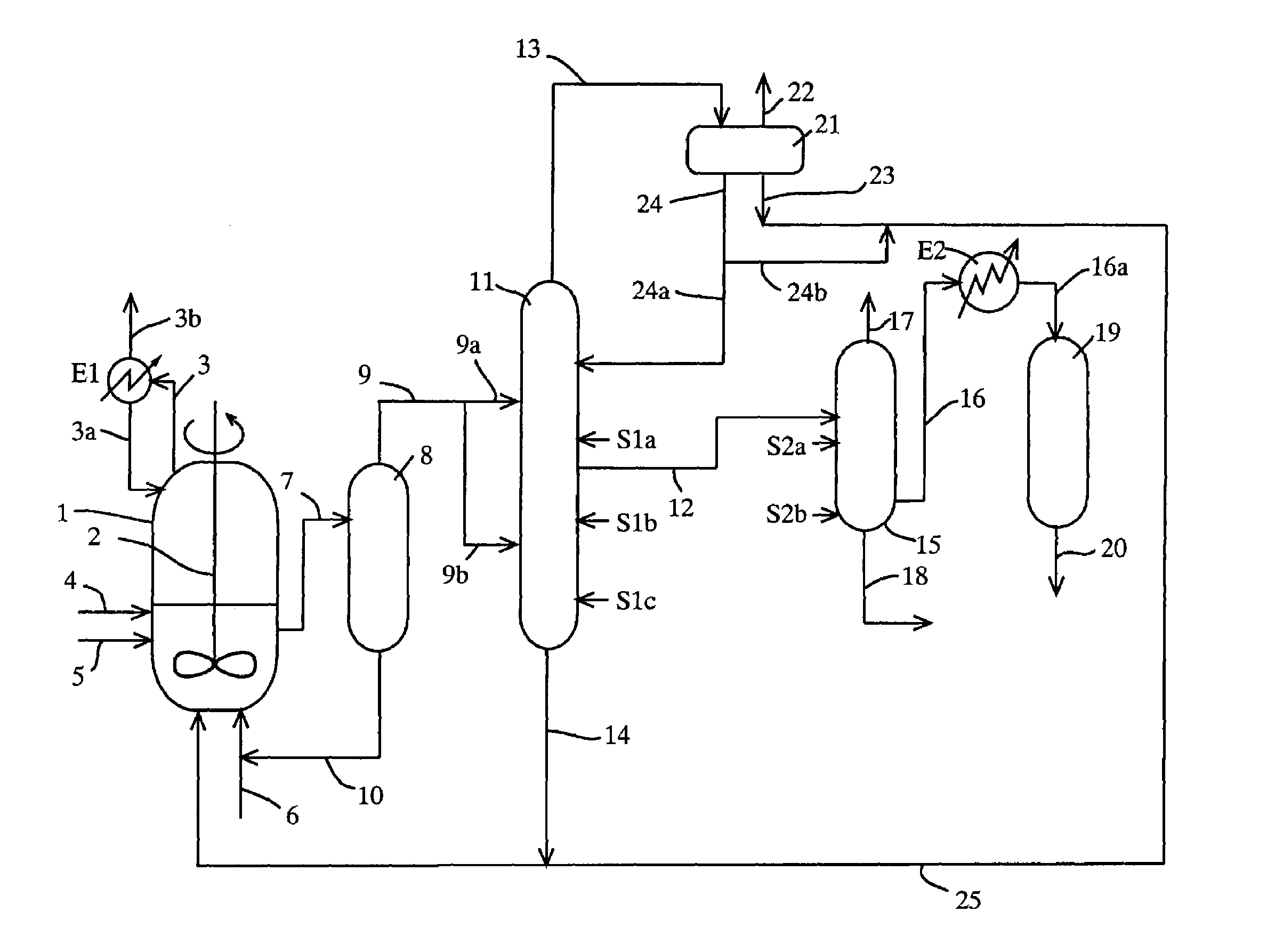

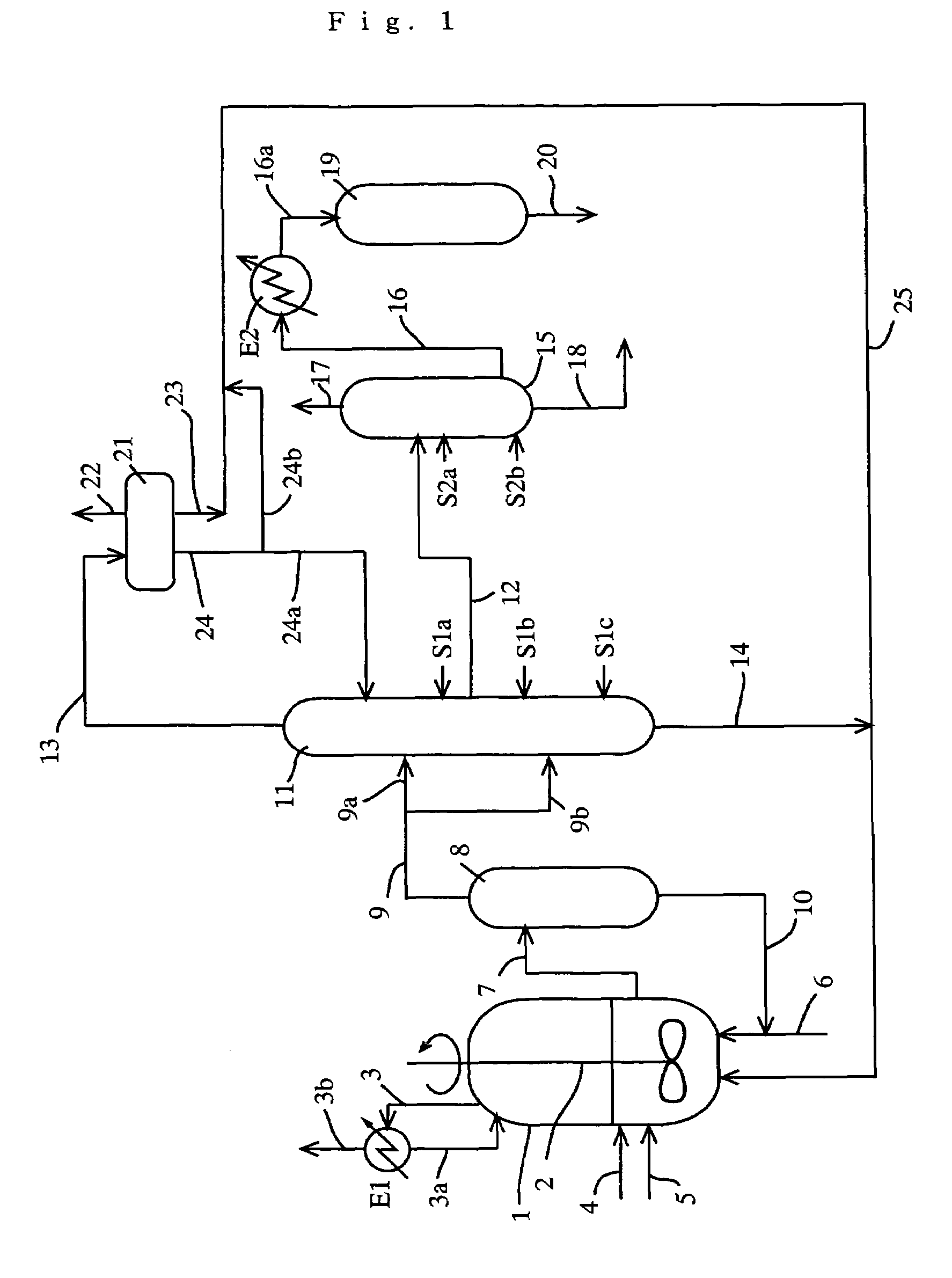

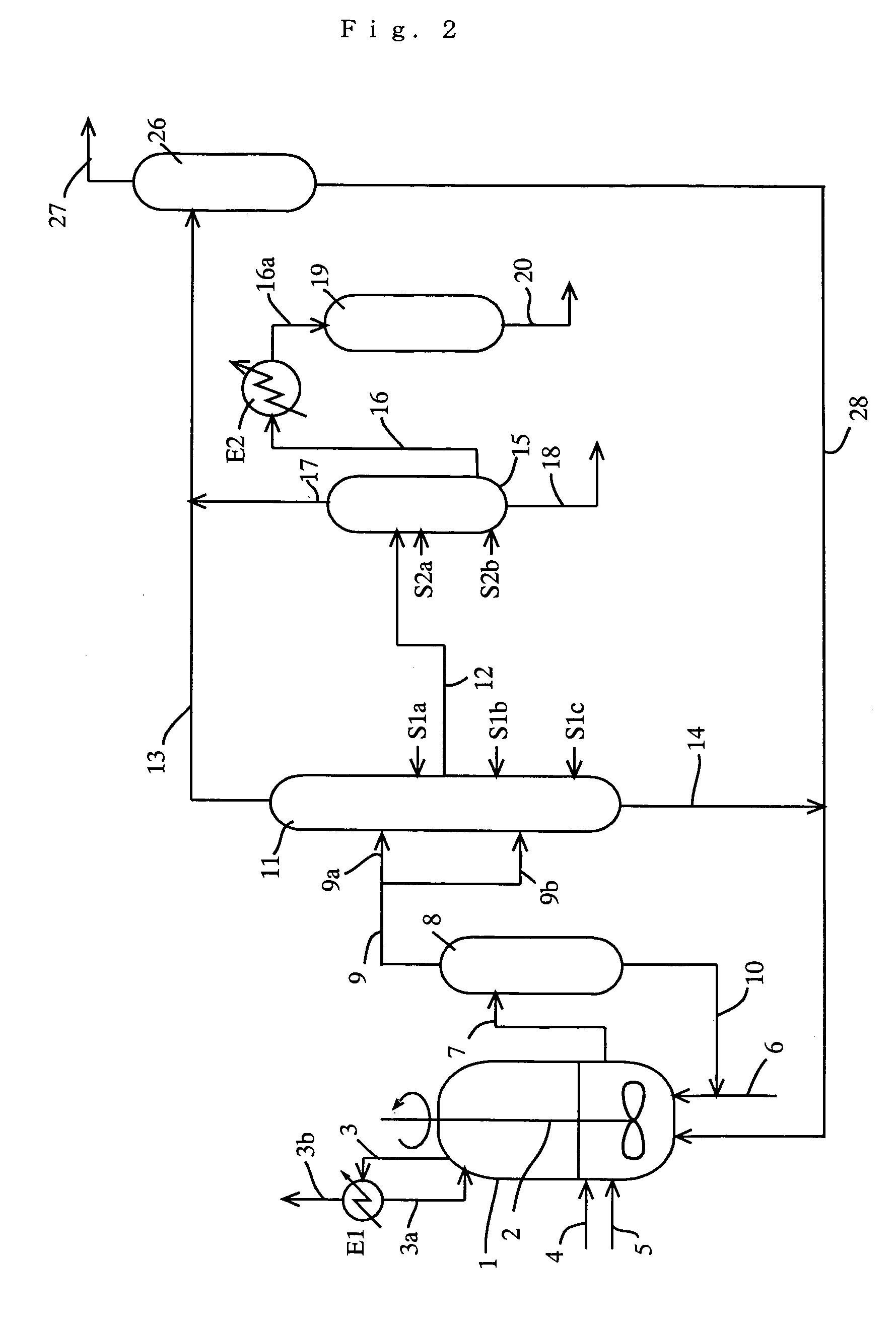

Process for producing carboxylic acid

InactiveUS7678940B2Efficient separationHigh purityOrganic compound preparationCarboxylic compound separation/purificationHydrogen halideAlcohol

A process for producing a purified carboxylic acid having “n+1” carbon atoms comprises feeding a carboxylic acid stream containing a carboxylic acid having “n+1” carbon atoms, a hydrogen halide, a lower boiling point (bp) component, a higher bp component, and others to a first distillation column; separating a lower bp fraction containing part of the lower bp component and a higher bp fraction containing part of the higher bp component in the first column; withdrawing a side stream containing at least the carboxylic acid by side cut from the first column; feeding the side stream to a second distillation column; separating a lower bp fraction containing part of the lower bp component and a higher bp fraction containing part of the higher bp component in the second column; and withdrawing a side stream containing the carboxylic acid by side cut from the second column to recover a purified carboxylic acid; and the process further comprises feeding at least one first component (A) selected from the group consisting of an alcohol, corresponding to the carboxylic acid, having “n” carbon atom(s), and an ester of the alcohol with the carboxylic acid to the first column, and if necessary water. Such a process ensures reduction of the concentration of the hydrogen halide in the purified carboxylic acid.

Owner:DAICEL CHEM IND LTD

Method for preparing aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material

ActiveCN103178258AAdvantages of preparation methodInhibition of agglomerationCell electrodesManganates/permanganatesLamellar crystalsReaction temperature

The invention discloses a method for preparing an aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material. The method comprises the following steps of: (1) preparation of a precursor: mixing water-soluble metallic nickel salt, cobalt salt and manganese salt into a mixed solution, dripping the mixed solution, a precipitator and a morphological control agent into a reaction container, controlling the pH value and reaction temperature of a system, and performing filtering, washing and vacuum drying after reaction to obtain a (NixCoyMn1-x-y)(OH)2 precursor, wherein x, y and x+y are more than 0 and less than 1; (2) preparation of an aluminum oxide coated precursor: dispersing the (NixCoyMn1-x-y)(OH)2 precursor, water-soluble aluminum salt and a disperser into deionized water, stirring while heating until the disperser is hydrolyzed, filtering to obtain an Al(OH)3-coated (NixCoyMn1-x-y)(OH)2 precursor, roasting the precursor in a sintering furnace to obtain Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder; and (3) uniformly mixing the Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder with lithium salt powder, and calcinating at high temperature to obtain an aluminum oxide coated modified Li(NixCoyMn1-x-y)O2 cathode material with a lamellar crystal structure.

Owner:NINGDE AMPEREX TECH

Cerium oxide containing ceramic components and coatings in semiconductor processing equipment and methods of manufacture thereof

InactiveUS6830622B2Reduce corrosionReduce erosion rateLiquid surface applicatorsMolten spray coatingCeramic coatingCerium

Owner:LAM RES CORP

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

Low-carbon steels of superior mechanical and corrosion properties and process of making thereof

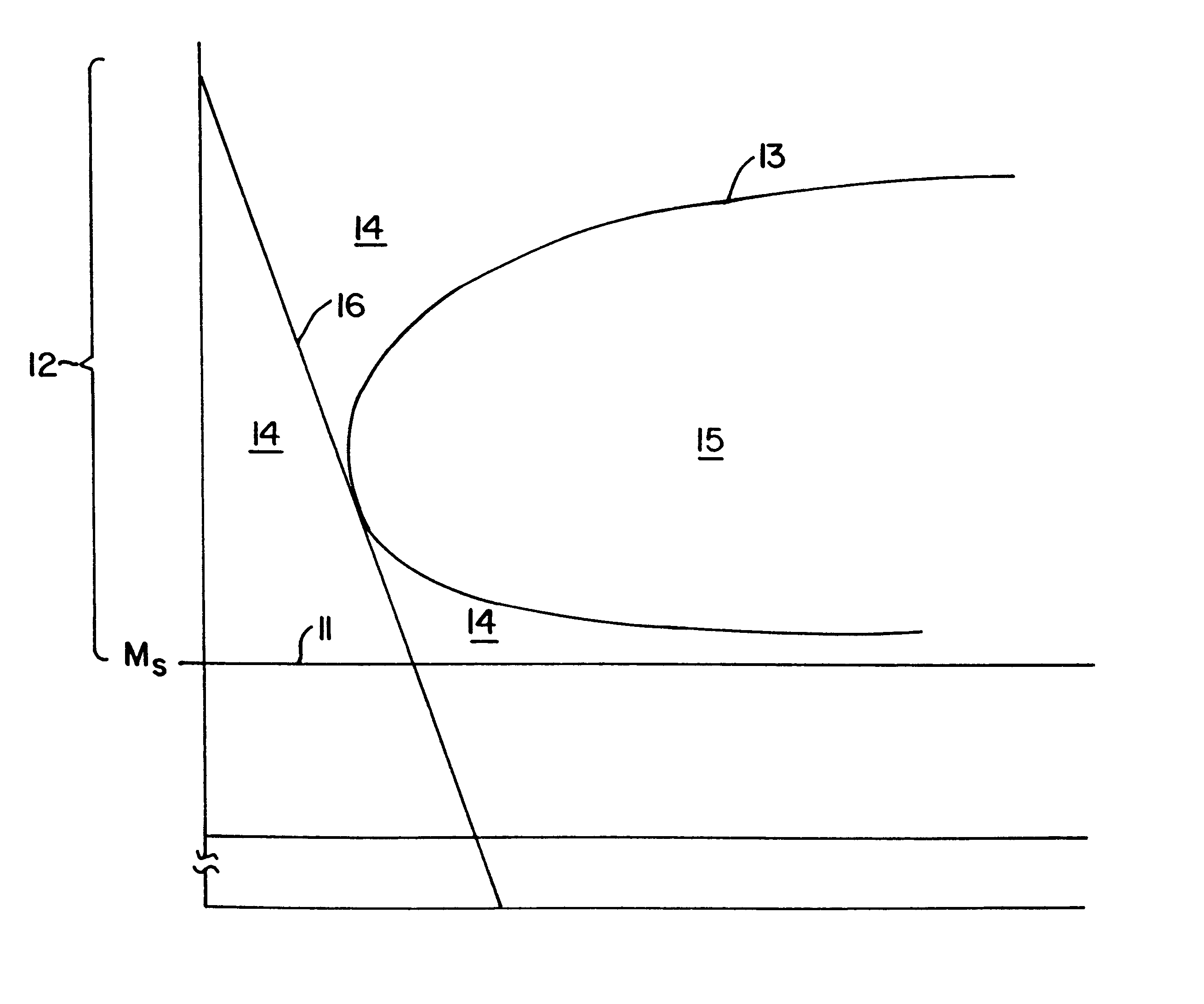

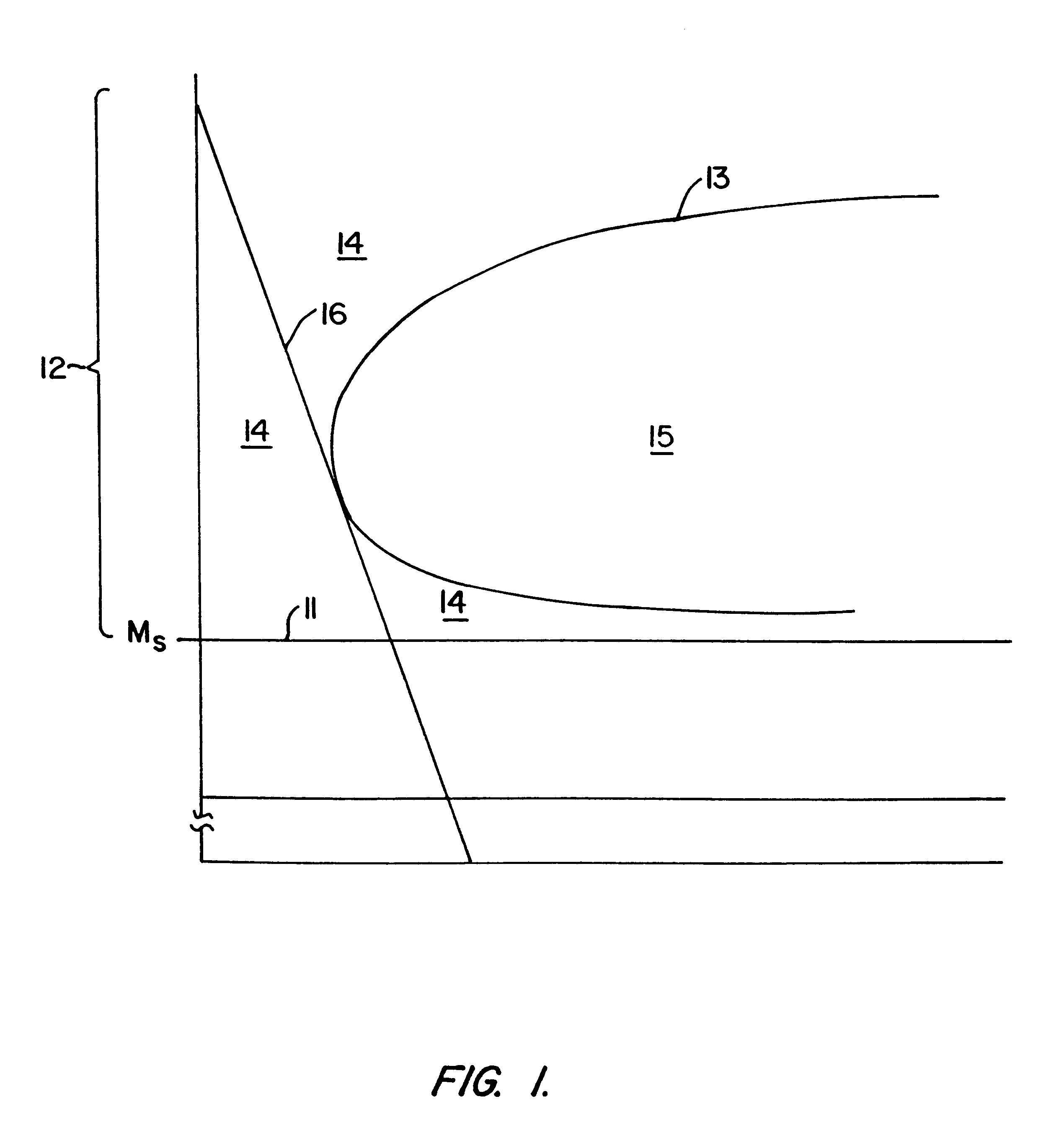

InactiveUS6273968B1Simple structureAccelerated corrosionFurnace typesHeat treatment furnacesCrystal twinningCarbide

Alloy steels that combine high strength and toughness with high corrosion resistance are achieved by a dislocated lath microstructure, in which dislocated martensite laths that are substantially free of twinning alternate with thin films of retained austenite, with an absence of autotempered carbides, nitrides and carbonitrides in both the dislocated martensite laths and the retained austenite films. This microstructure is achieved by selecting an alloy composition whose martensite start temperature is 350° C. or greater, and by selecting a cooling regime from the austenite phase through the martensite transition region that avoids regions in which autotempering occurs.

Owner:CMC STEEL FABTORS

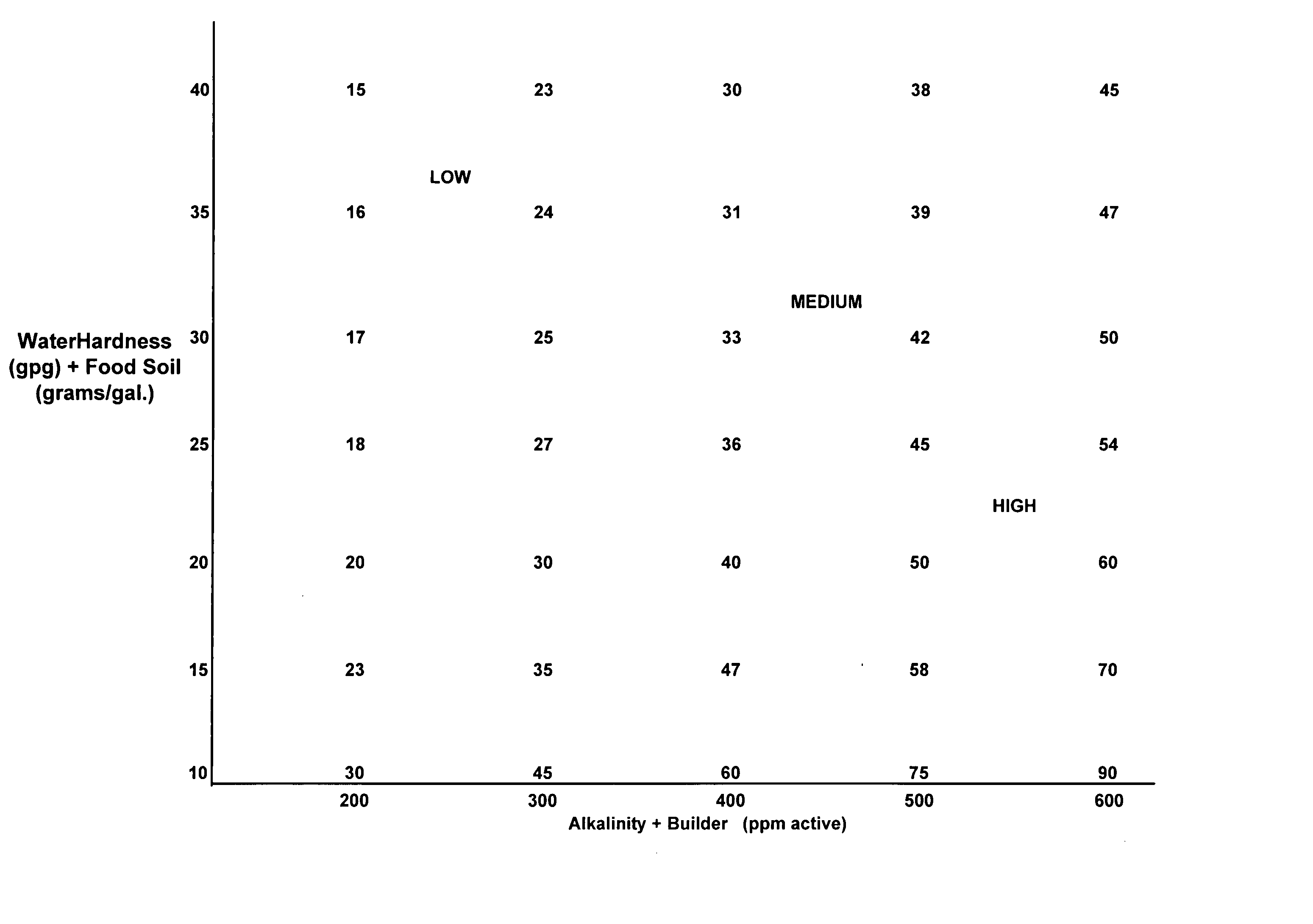

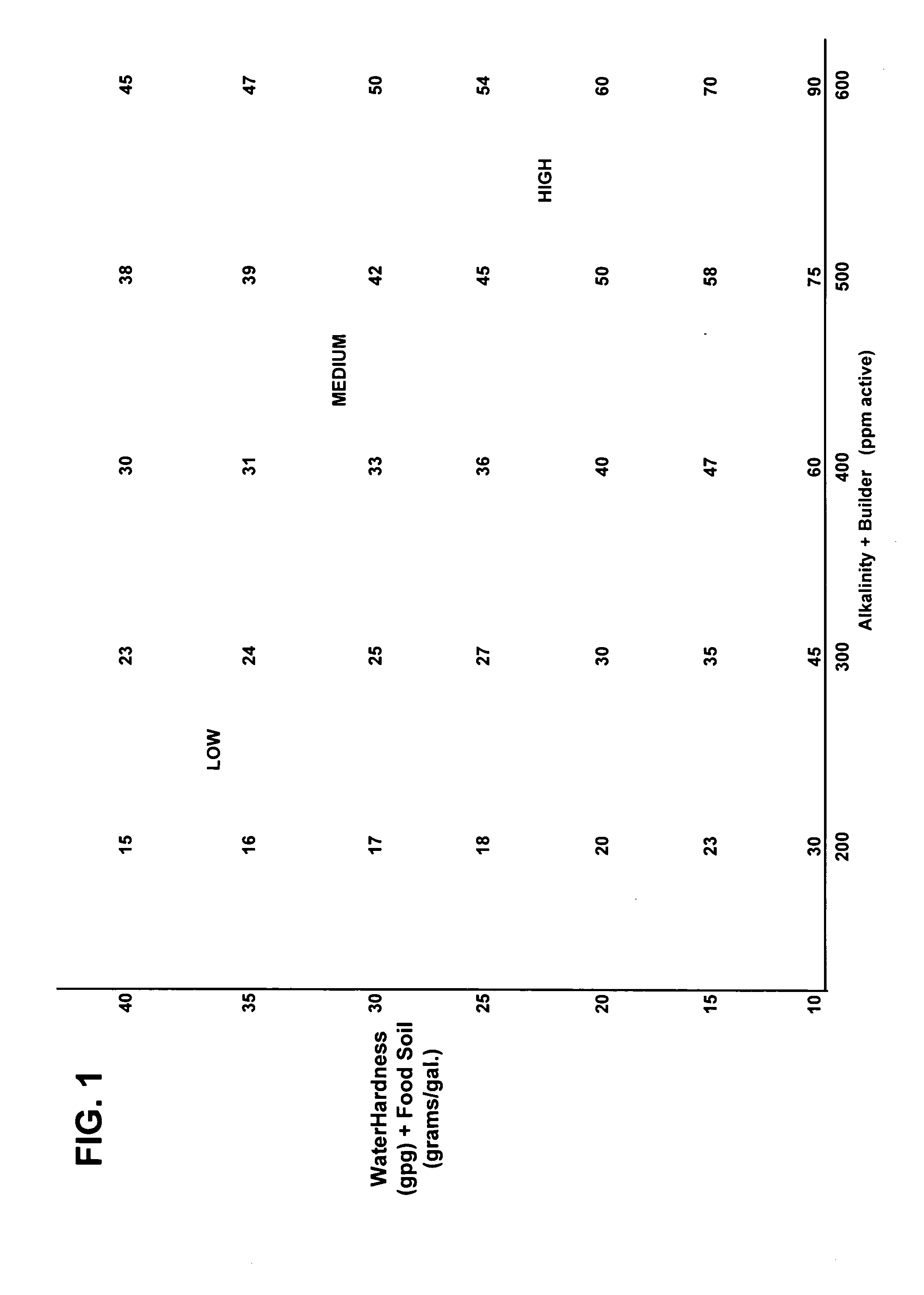

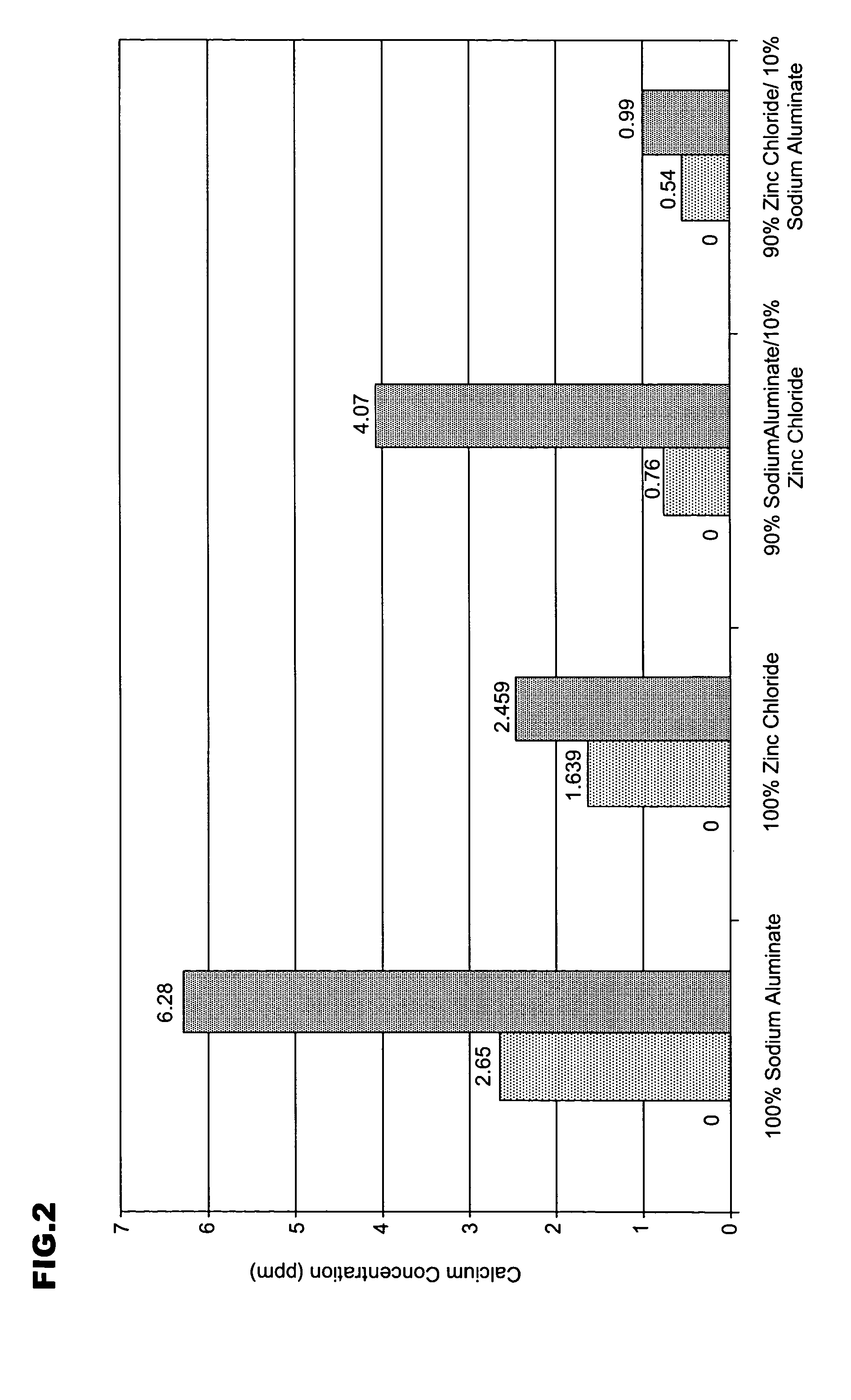

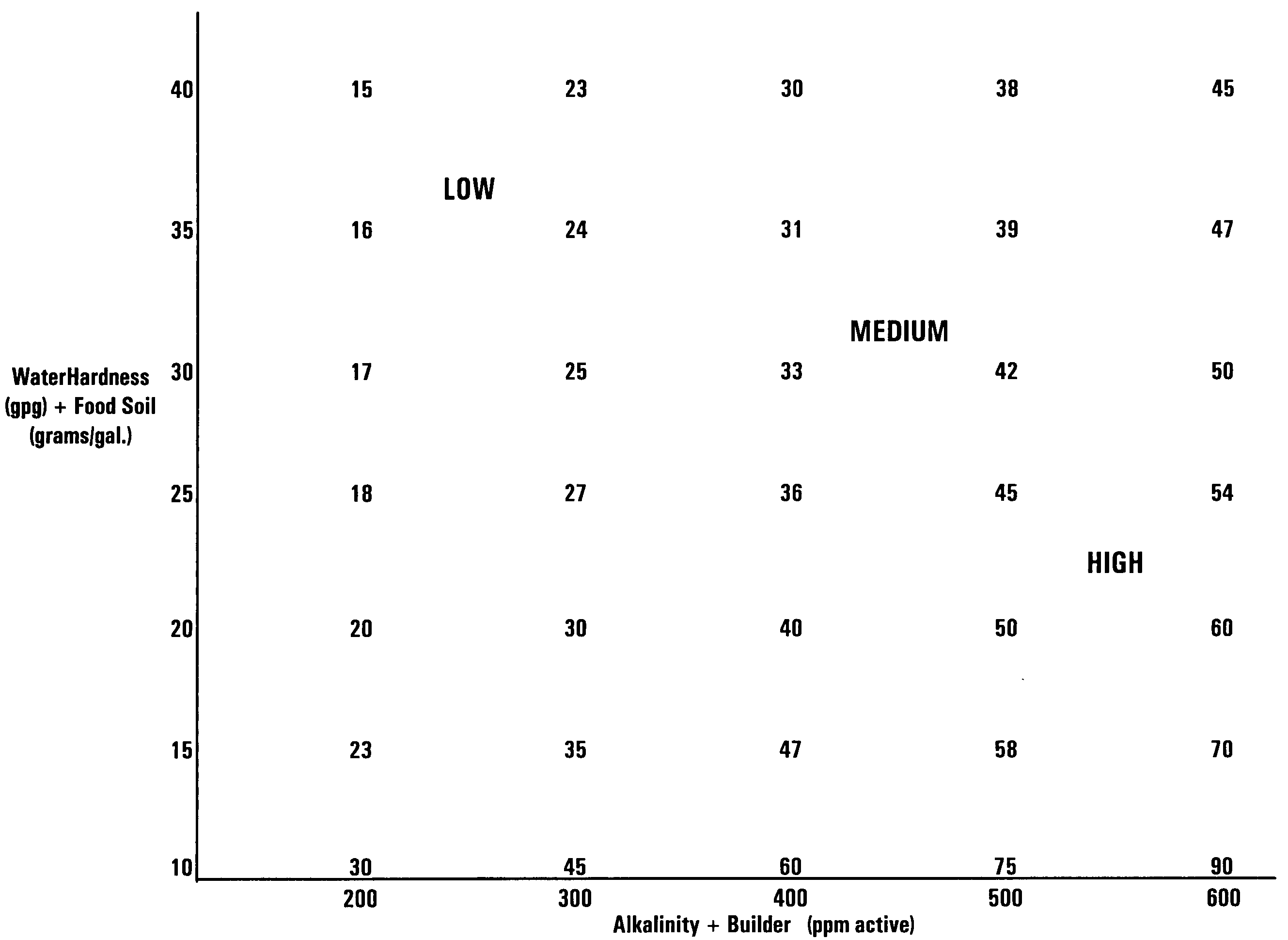

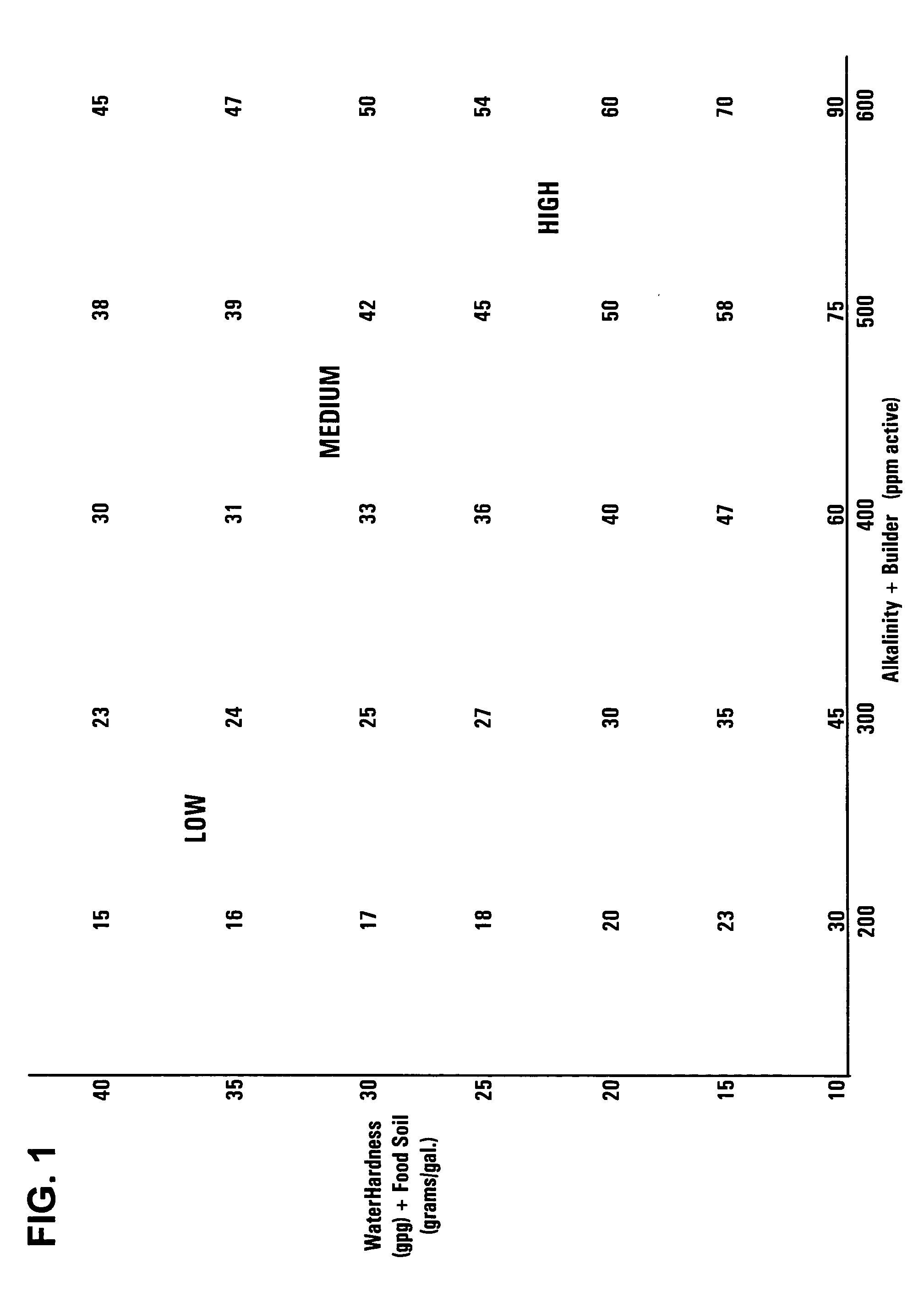

Warewashing composition for use in automatic dishwashing machines, and methods for manufacturing and using

InactiveUS20050020464A1Reduce corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAluminum IonHard water

A warewashing detergent composition is provided according to the invention. The warewashing detergent composition includes a cleaning agent, an alkaline source, and a corrosion inhibitor. The cleaning agent comprises a detersive amount of a surfactant. The alkaline source is provided in an amount effective to provide a use composition having a pH of at least about 8. The corrosion inhibitor includes a source of aluminum ion and a source of zinc ion. The relative amounts of the source of zinc ion and the source of aluminum ion can be controlled to reduce visible filming when the warewashing detergent composition is used in the presence of hard water. Methods for using and manufacturing a warewashing detergent composition are provided.

Owner:ECOLAB USA INC

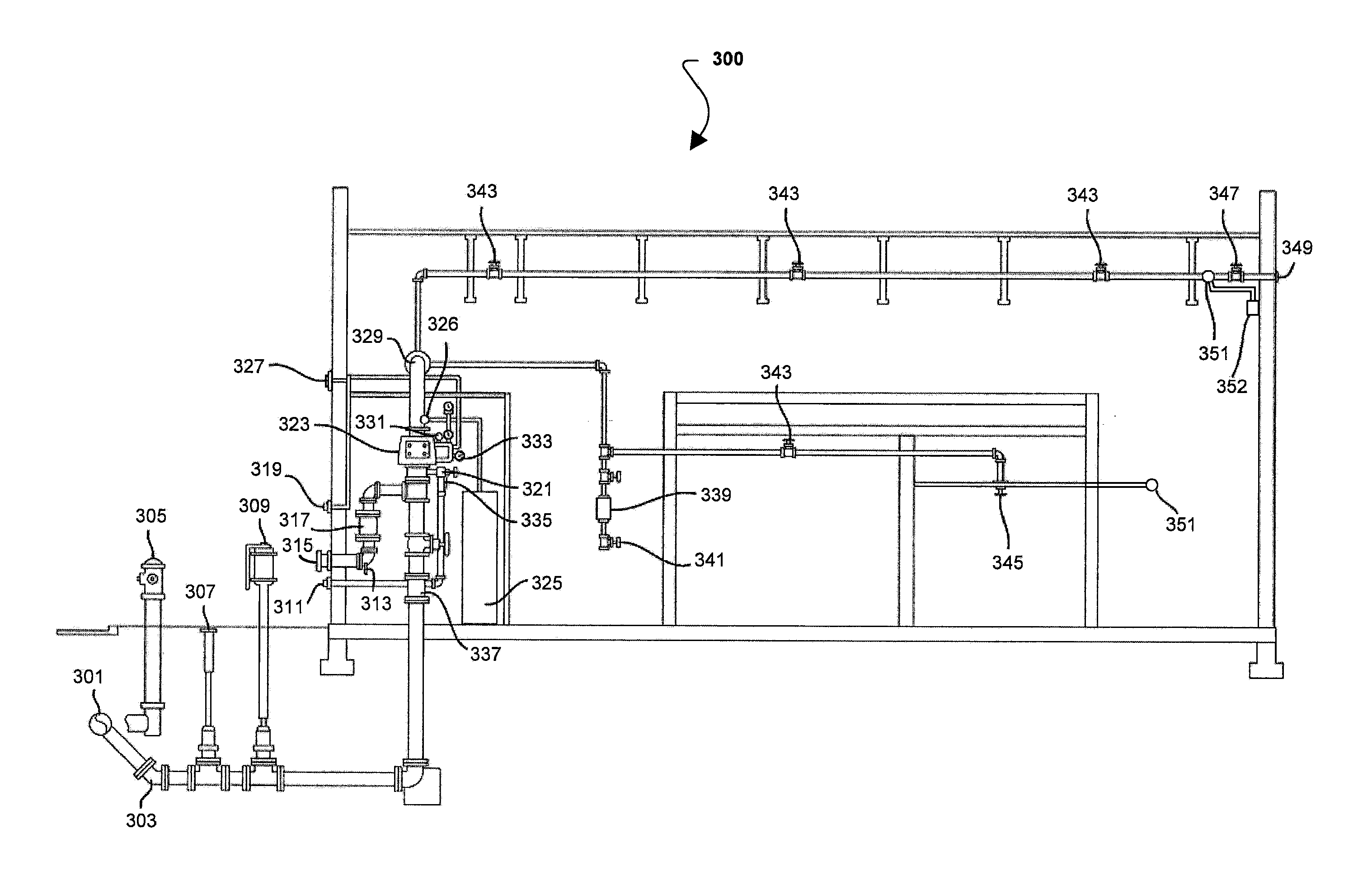

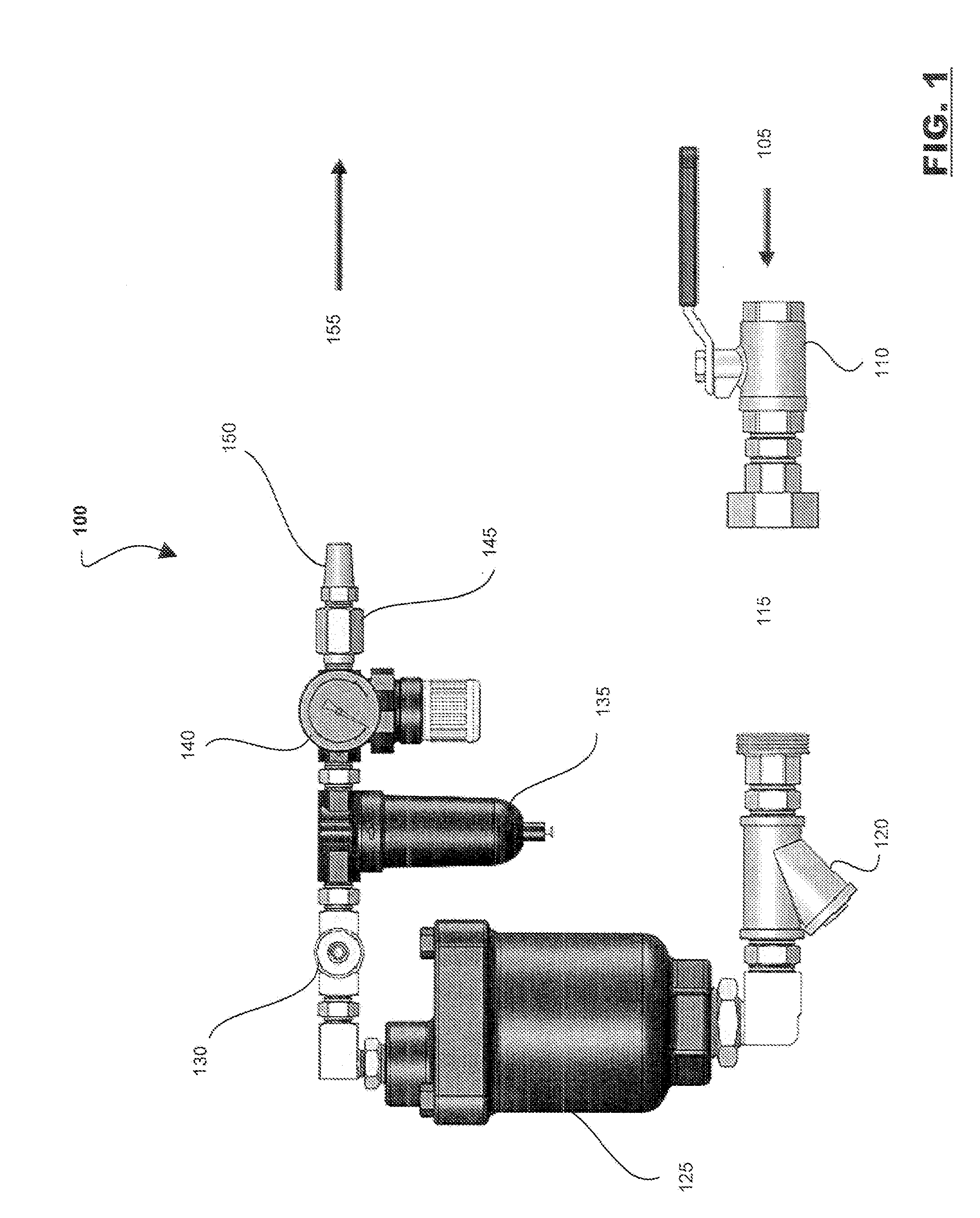

Controlled discharge gas vent

ActiveUS20110094758A1Reduce corrosionPrevent openingFire rescueThin material handlingFire protectionWater vapor

A fire protection system includes a dry pipe system and a controlled discharge gas vent. The dry pipe system and controlled discharge gas vent operate using a breathing cycle to displace oxygen and / or water vapor from within the piping network of the dry pipe system. The controlled gas discharge vent allows displacement of pressurized air with nitrogen, for example, using manual or automated processes that can employ one or more sensors. Corrosion resulting from oxygen, water, and / or microbial growth is reduced or nearly eliminated.

Owner:ENGINEERED CORROSION SOLUTIONS

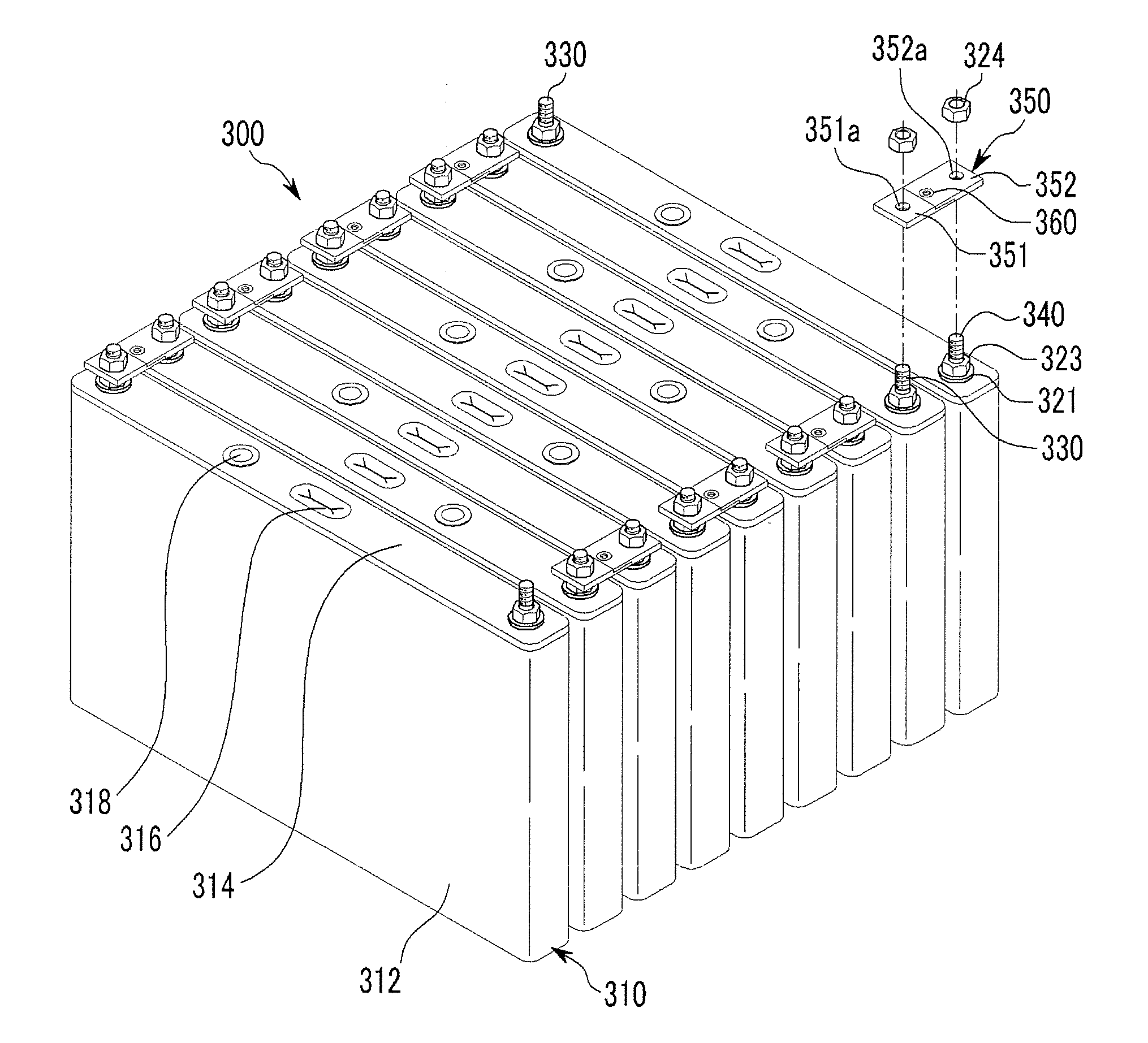

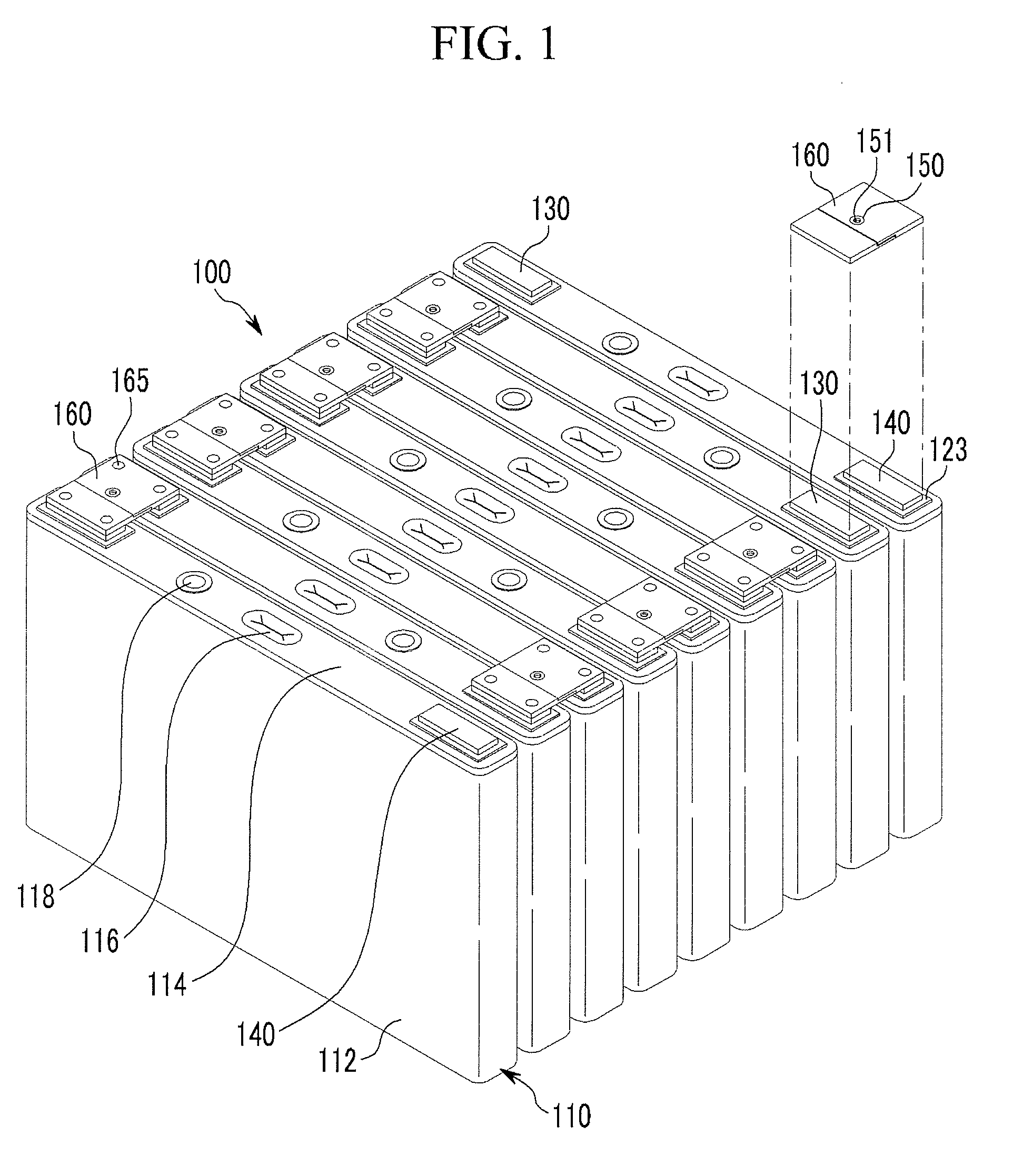

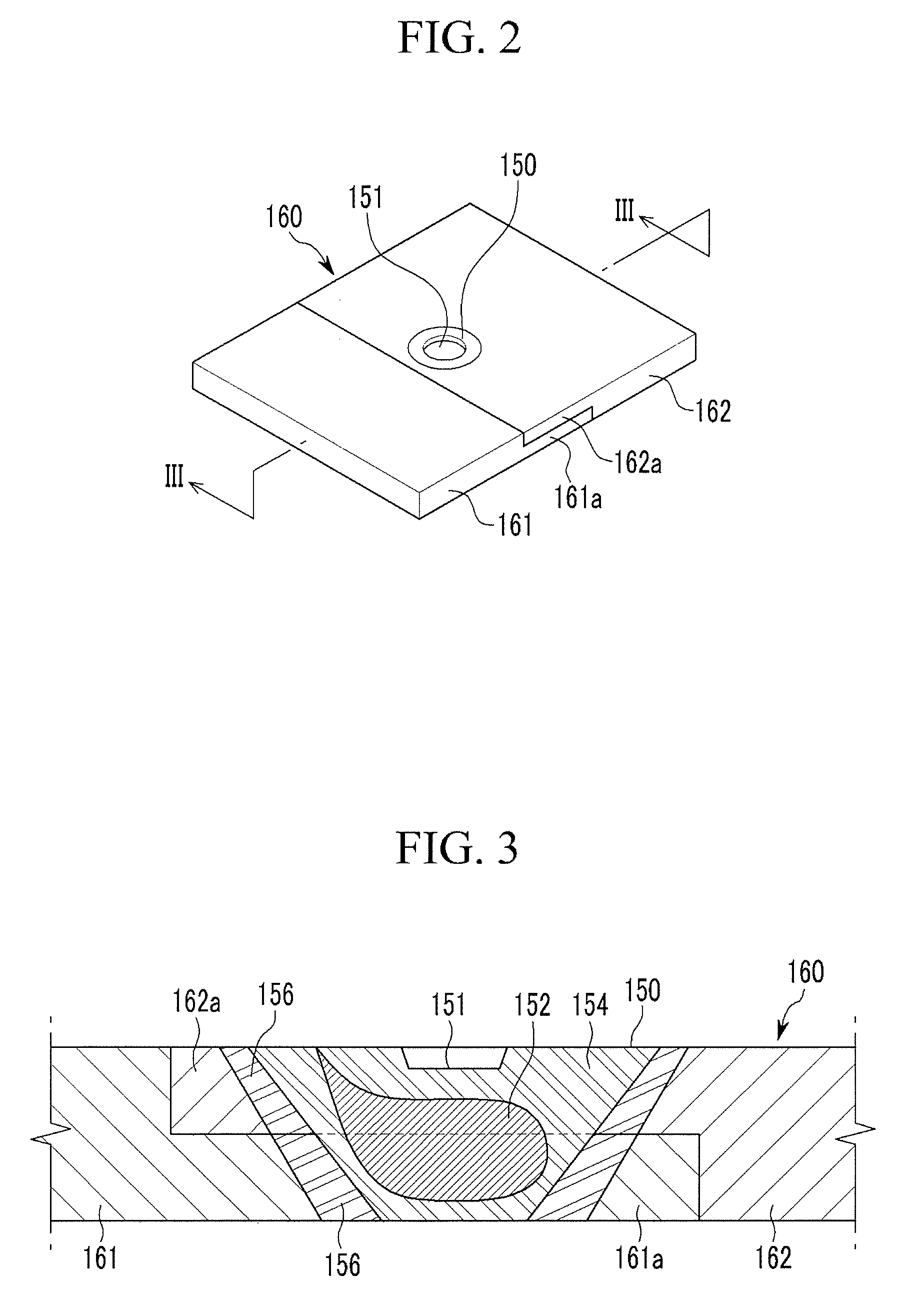

Battery module

ActiveUS20110081568A1Reduce contact resistanceReduce corrosionPrimary cell to battery groupingCurrent conducting connectionsEngineeringElectrical and Electronics engineering

Owner:ROBERT BOSCH GMBH +1

Concrete superficial hardener and construction method thereof

InactiveCN101407428AHigh mechanical strengthHigh surface hardnessUltimate tensile strengthMaterials science

The invention discloses a concrete surface hardener and a construction method thereof, wherein, the concrete surface hardener comprises the compositions by weight percent of 10-40 percent of inorganic silicate, 1-10 percent of alkali, 0.1-5 percent of catalyst, 0.1-2 percent of wetting dispersant, 1-5 percent of stabilizer and rest of water. The hardener prepared by the invention is characterized by easily-obtained material, simple production and convenient construction, unhealthy and environmentally harmful VOC avoidance, etc. In addition, the hardener can penetrate into the interior of the concrete to seal the capillary of the concrete, thus improving the surface density of the concrete, strengthening the impervious capability and strength of the concrete and prolonging the service life of the concrete. As the hardener does not comprise unhealthy and environmentally harmful substances, the increasingly improved requirements of the present environmental protection can be met, thus having extensive application prospect.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

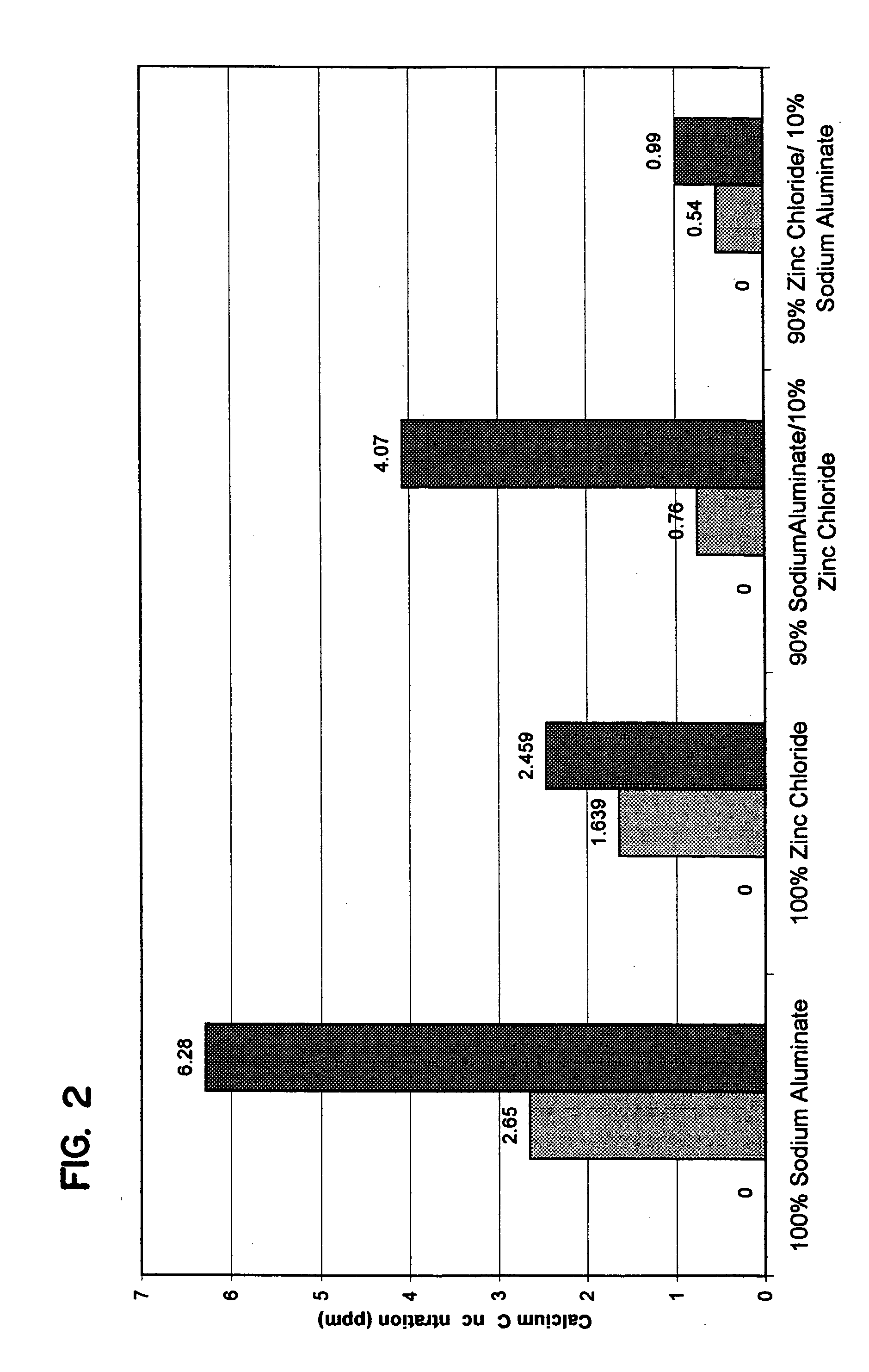

Warewashing composition for use in automatic dishwashing machines, comprising a mixture of aluminum and zinc ions

ActiveUS20050003979A1Reduce corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsZincCorrosion inhibitor

A warewashing detergent composition is provided according to the invention. The warewashing detergent composition includes a cleaning agent, an alkaline source, and a corrosion inhibitor. The cleaning agent comprises a detersive amount of a surfactant. The alkaline source is provided in an amount effective to provide a use solution having a pH of at least about 8. The corrosion inhibitor includes a source of aluminum ion and a source of zinc ion. Methods for using and manufacturing a warewashing detergent composition are provided.

Owner:ECOLAB USA INC

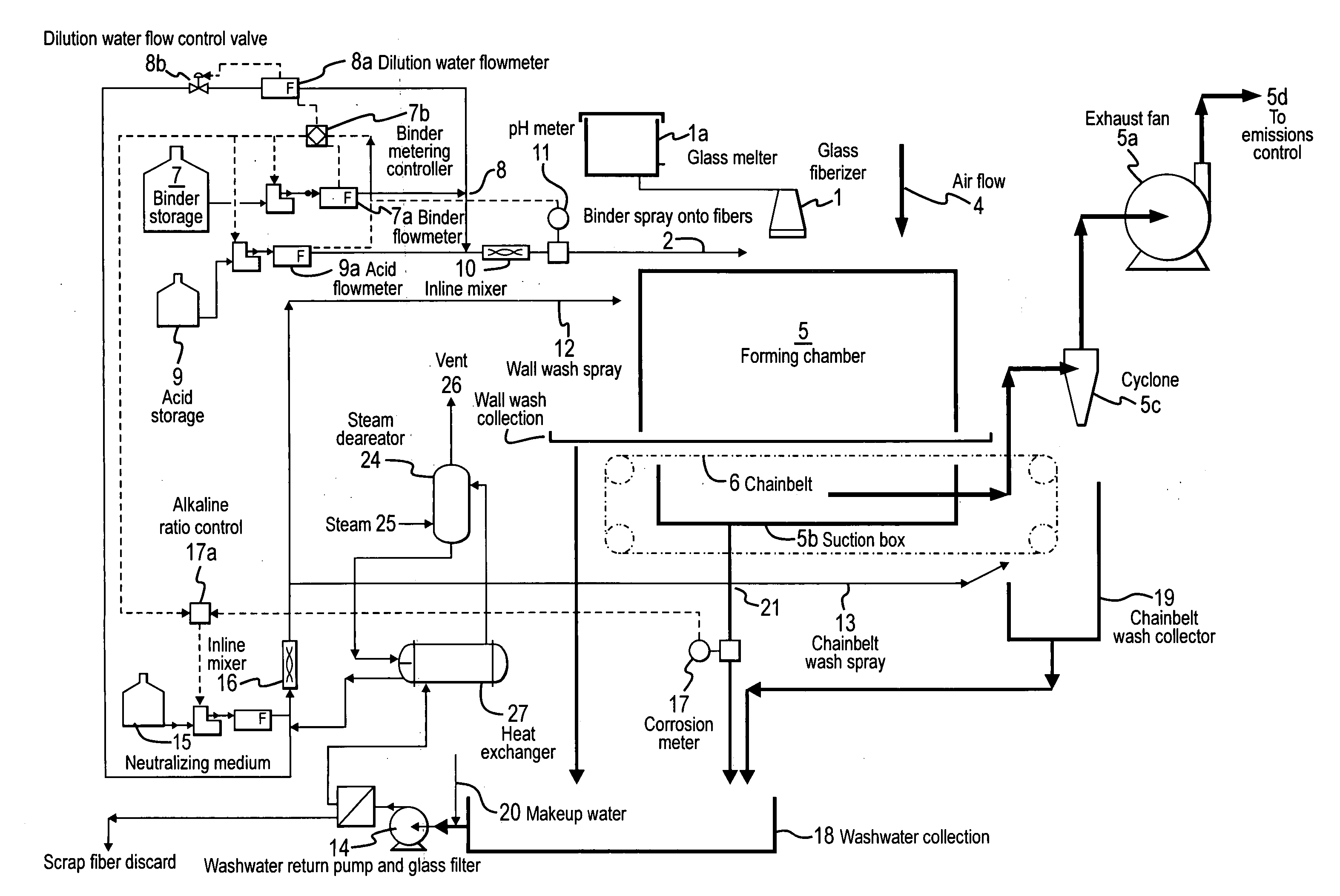

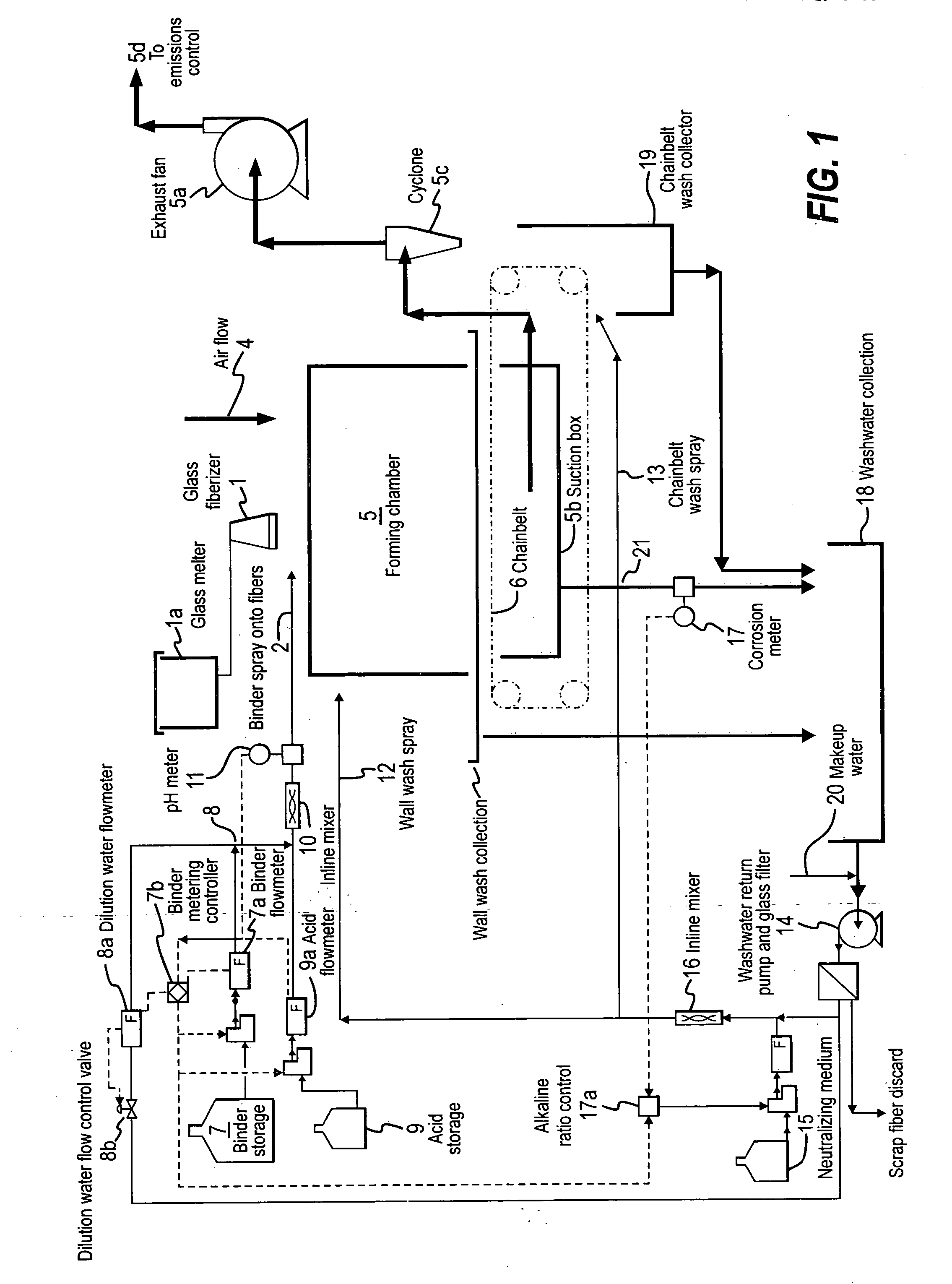

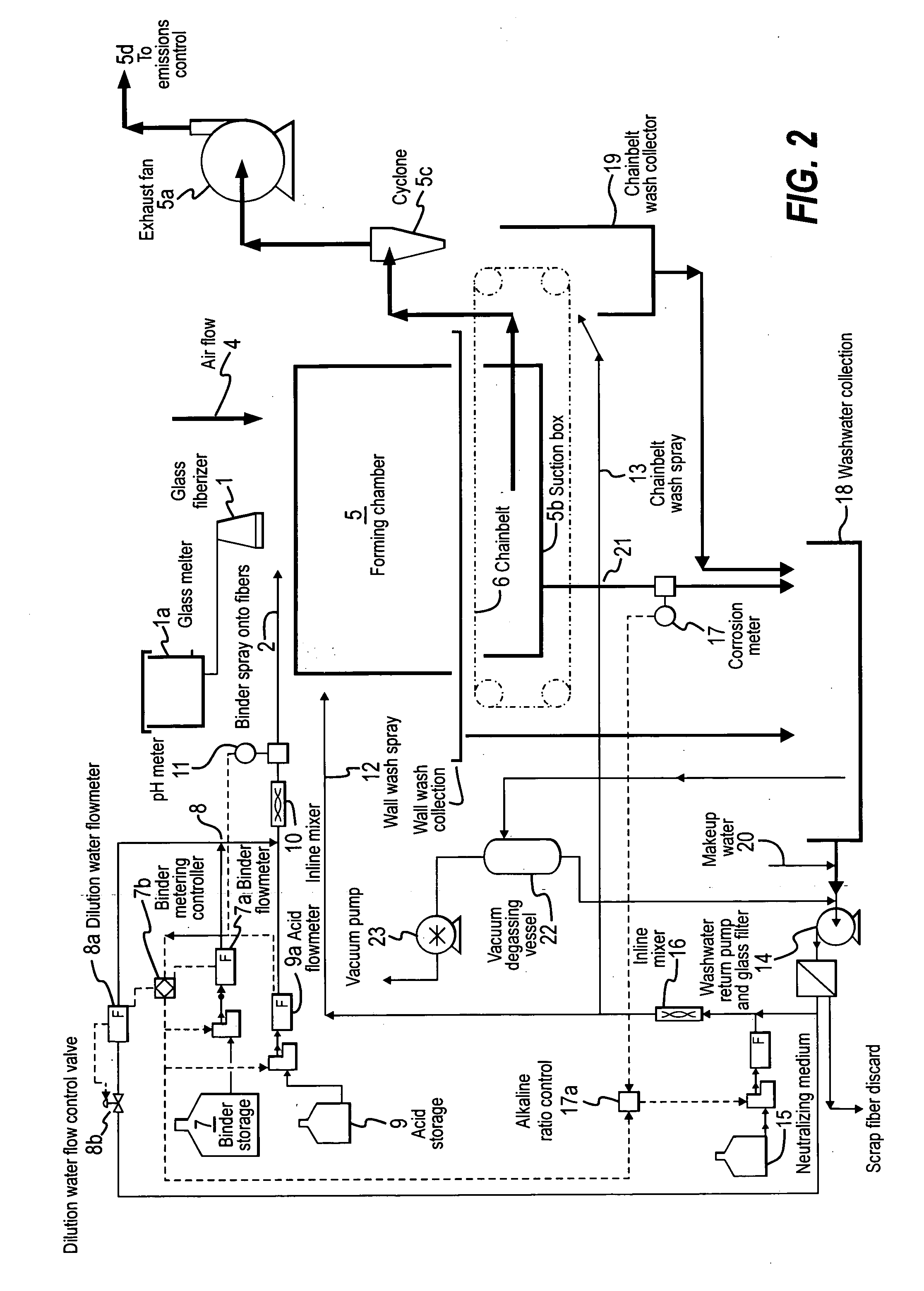

Method for reducing corrosion

InactiveUS20060198954A1Limiting amount of downtimeAvoid damageGlass making apparatusLiquid surface applicatorsGlass fiberWash water

A method for reducing corrosion of a wash water system for glass forming lines, by using a corrosion meter, is provided. Also provided is a fiberglass manufacturing process that utilizes the method.

Owner:FRECHEM BART SHANNON +2

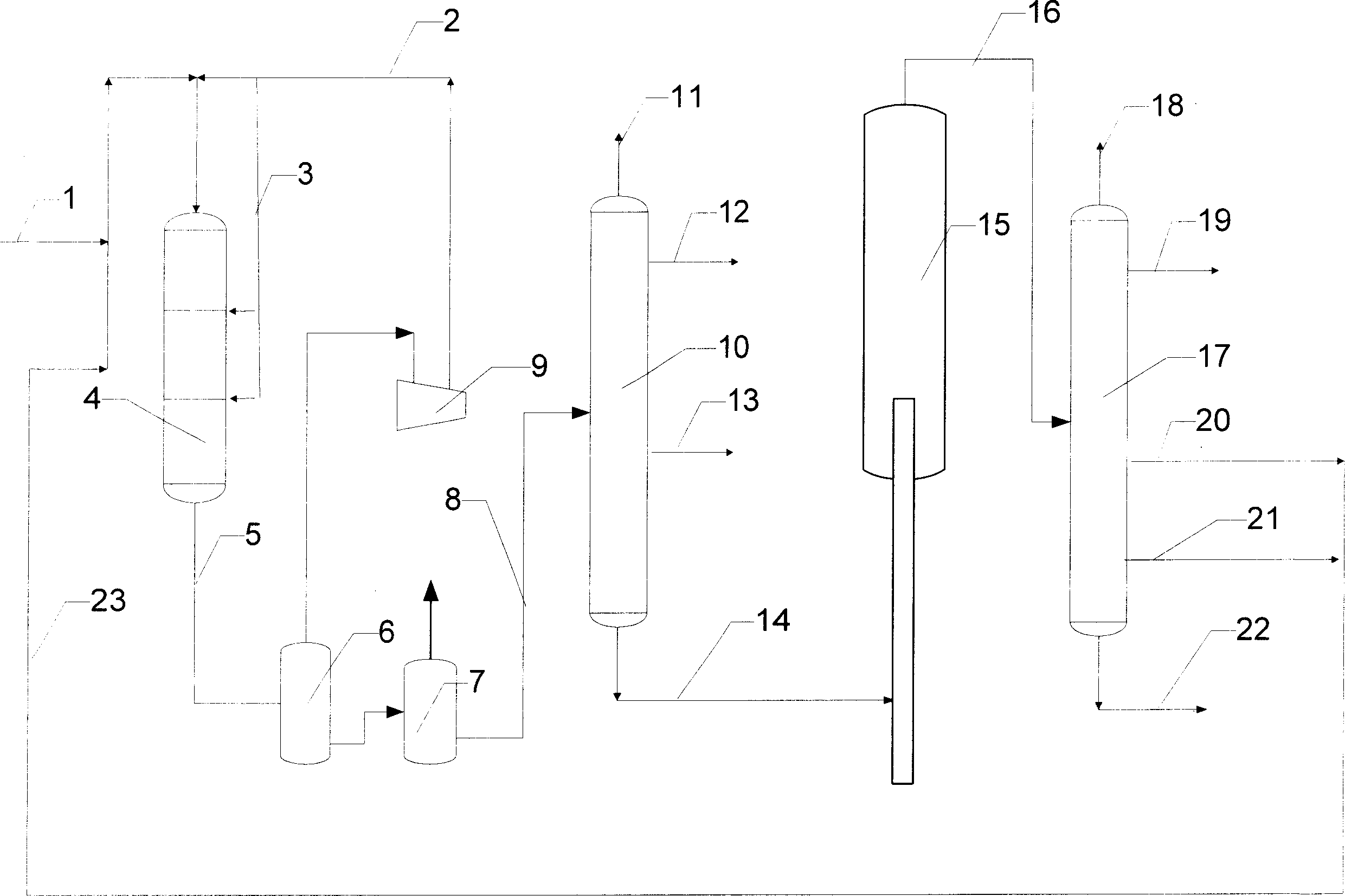

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods for producing and using a Cu(I)-based wood preservative

Soluble copper(I)-amine complexes, particularly copper(I)-ammonia complexes and copper(I)-monoethanmolamine complexes, are useful injectable wood preservatives. Wood treated with the copper(I)-amine complexes contains less amines, and is less corrosive to metals, than woods treated with the prior art copper(II)-amine complexes. A method of preparing an aqueous wood preservative that includes soluble copper(I) complexes comprises reacting a solution comprising a copper(II)-amine complex with metallic copper to form a copper(I)-amine complex. One aspect of the invention comprises injecting a solution comprising a copper(I)-amine complex into wood and allowing the copper(I)-amine complex to precipitate within the wood.

Owner:OSMOSE

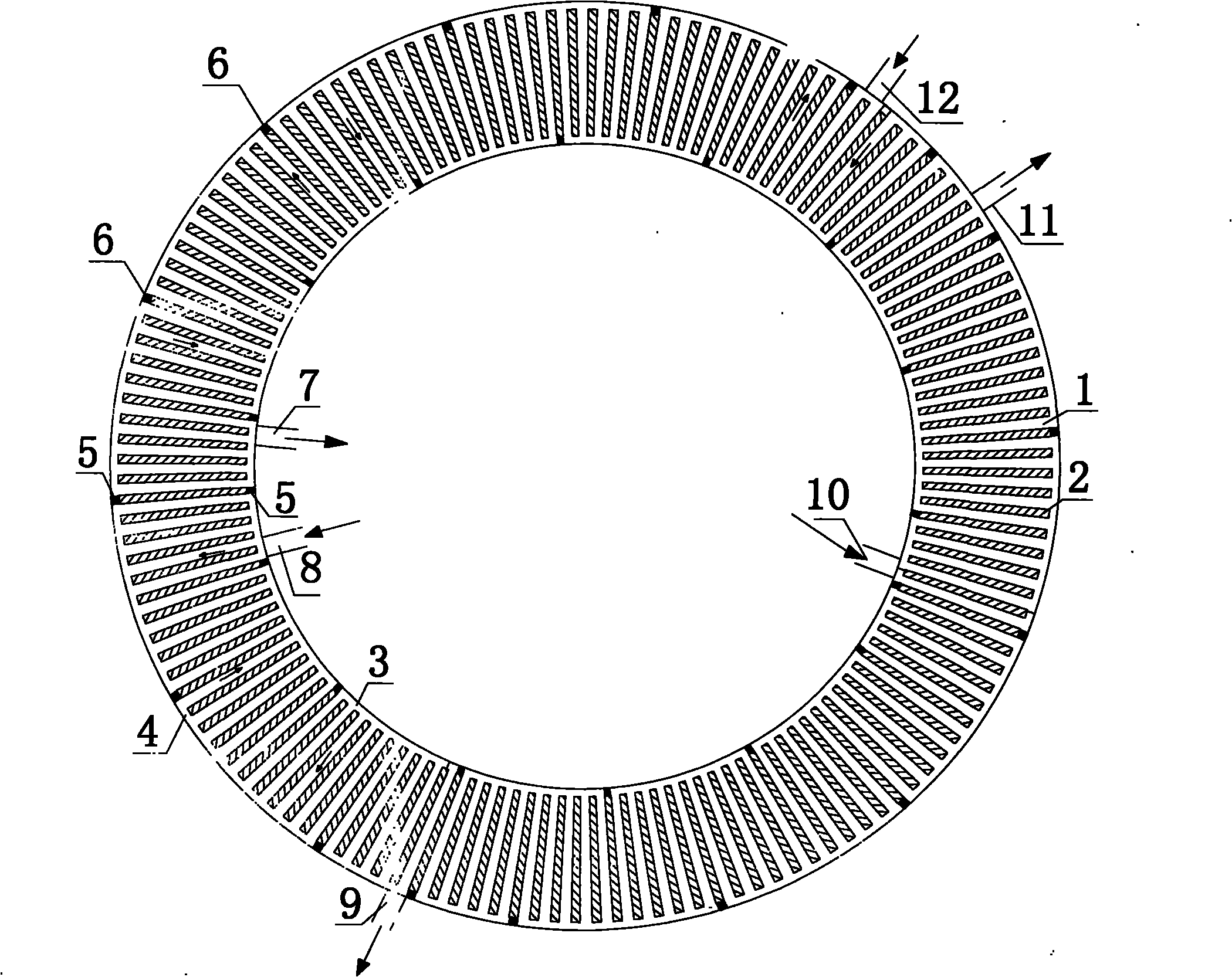

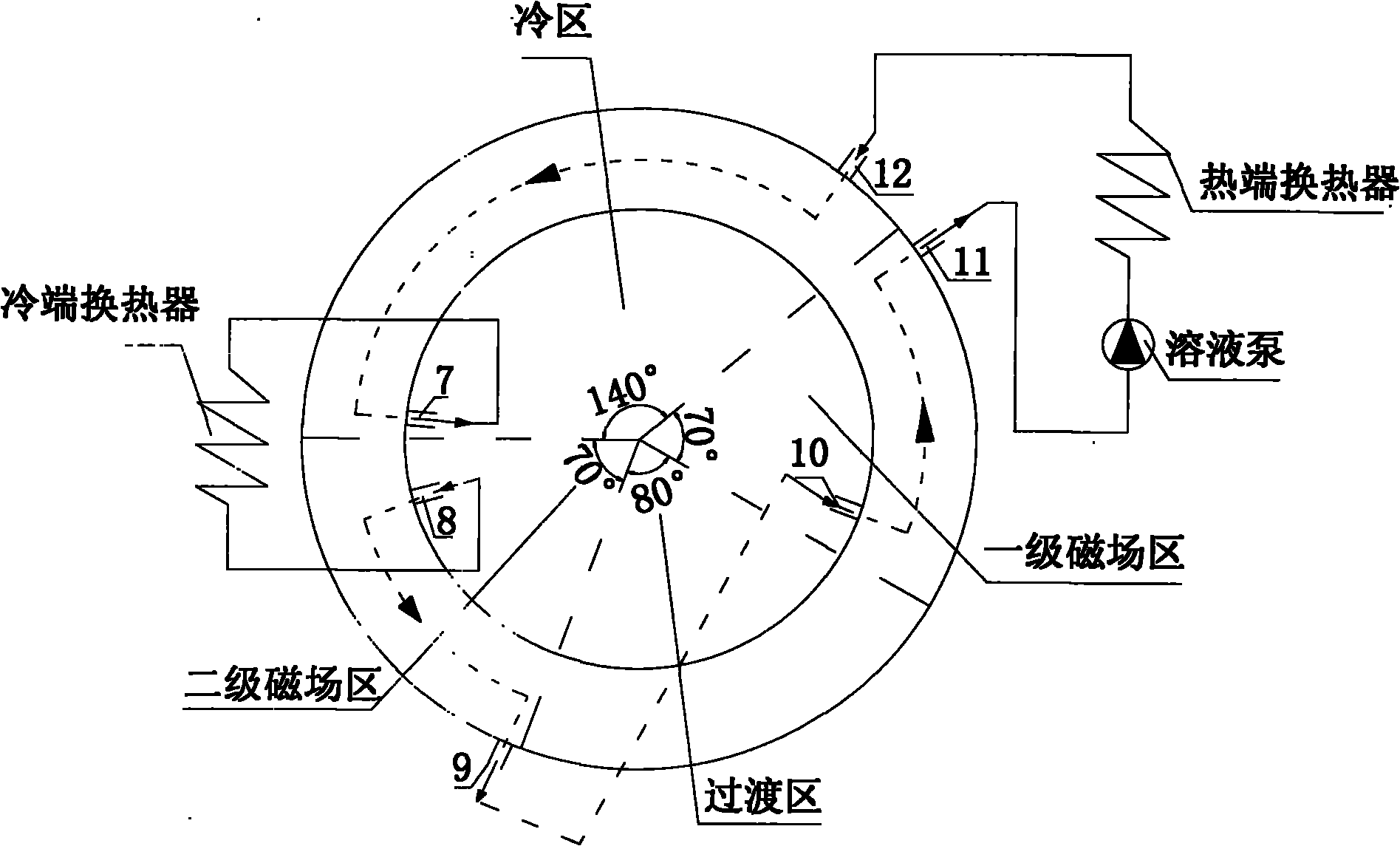

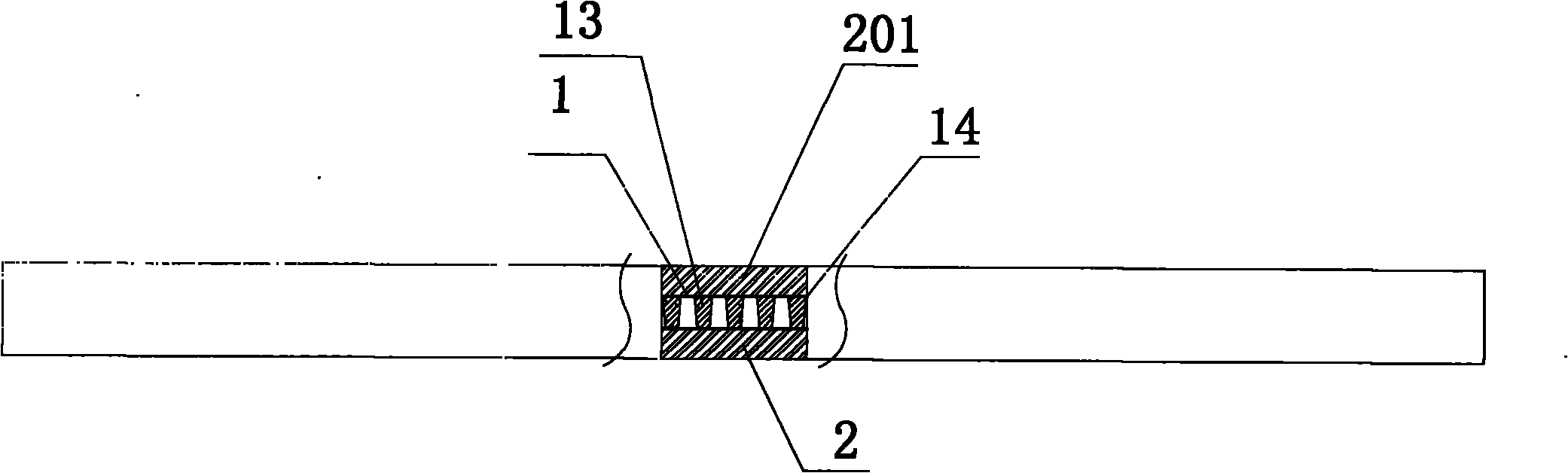

Microchannel enhanced heat exchange system of rotary room-temperature magnetic refrigerator and heat transfer method thereof

InactiveCN101788207AAchieve refrigerationGuaranteed safe operationEnergy efficient heating/coolingMachines using electric/magnetic effectsRoom temperatureEngineering

The invention discloses a microchannel enhanced heat exchange system of a rotary room-temperature magnetic refrigerator and a heat transfer method thereof. The system comprises a refrigerant disc, a cold end heat exchanger, a hot end heat exchanger and a solution pump, wherein the cold end heat exchanger and the hot end heat exchanger are connected with the refrigerant disc. the refrigerant disc comprises a refrigerant bed, an inner circle collecting tank, an outer circle collecting tank, four pairs of interzone adiabatic baffles and a plurality of intra-zone adiabatic baffles; the refrigerant bed comprises a plurality of trapezoidal microchannel flat tubes, an upper magnetic refrigerant plate and a lower magnetic refrigerant plate; the trapezoidal microchannel flat tubes, the upper magnetic refrigerant plate and the lower magnetic refrigerant plate are arranged between the inner circle collecting tank and the outer circle collecting tank; and the trapezoidal microchannel flat tubes are arranged between the upper magnetic refrigerant plate and the lower magnetic refrigerant plate. The heat transfer method is characterized in that the heat transfer fluid experiences a cycle of adiabatic excitation and demagnetization after passing through the different zones of the microchannel enhanced heat exchange system; and the rotary magnetic refrigerator recirculates the processes to realize refrigeration. In the invention, the characteristic that the microchannel can effectively enhance heat exchange due to scale effect is adopted and the microchannel is applied to the refrigerant bed, thus improving the efficiency of the refrigerating system and reducing corrosion of the heat transfer fluid to the magnetic refrigerant.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com