Patents

Literature

560 results about "Anodic oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

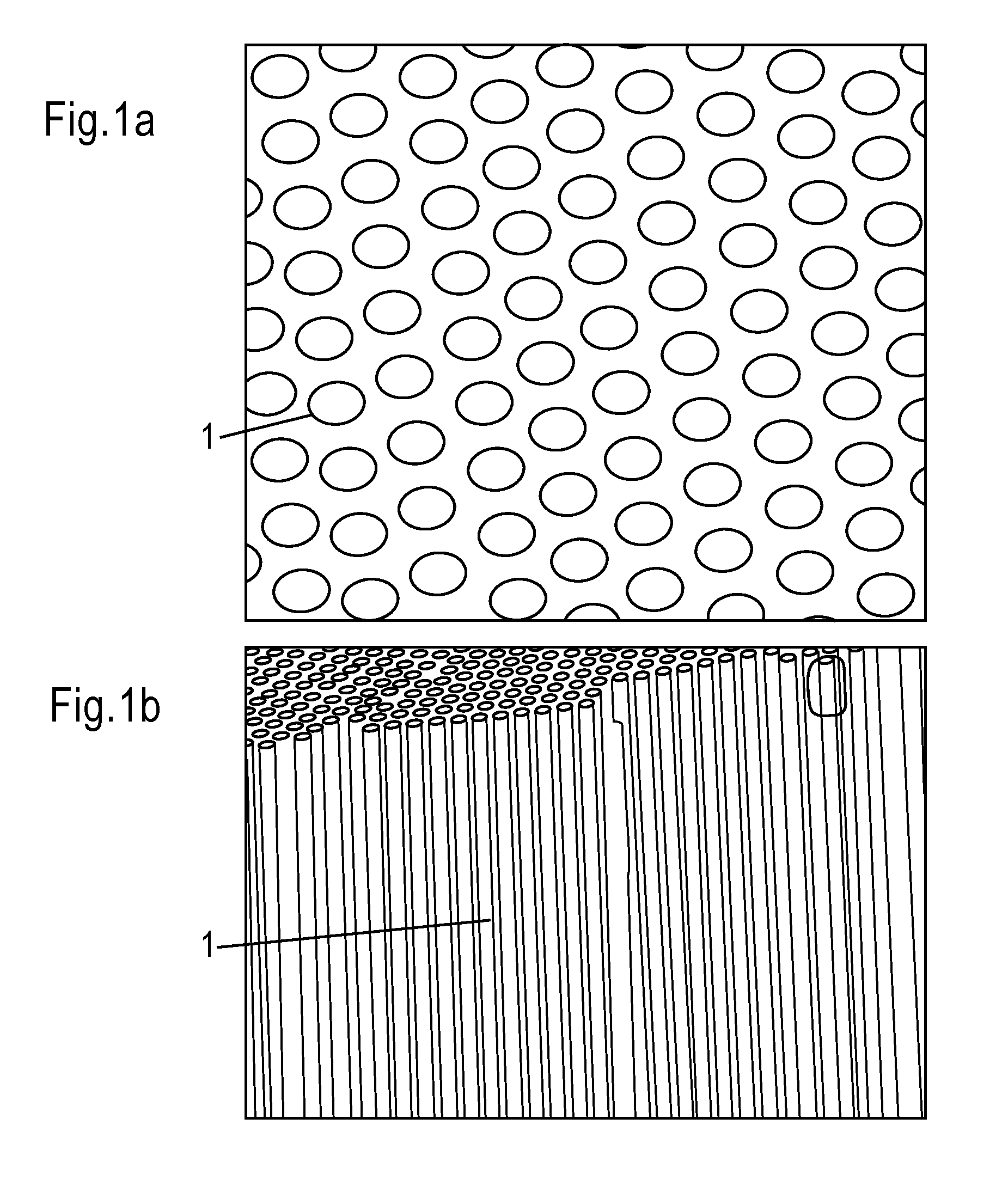

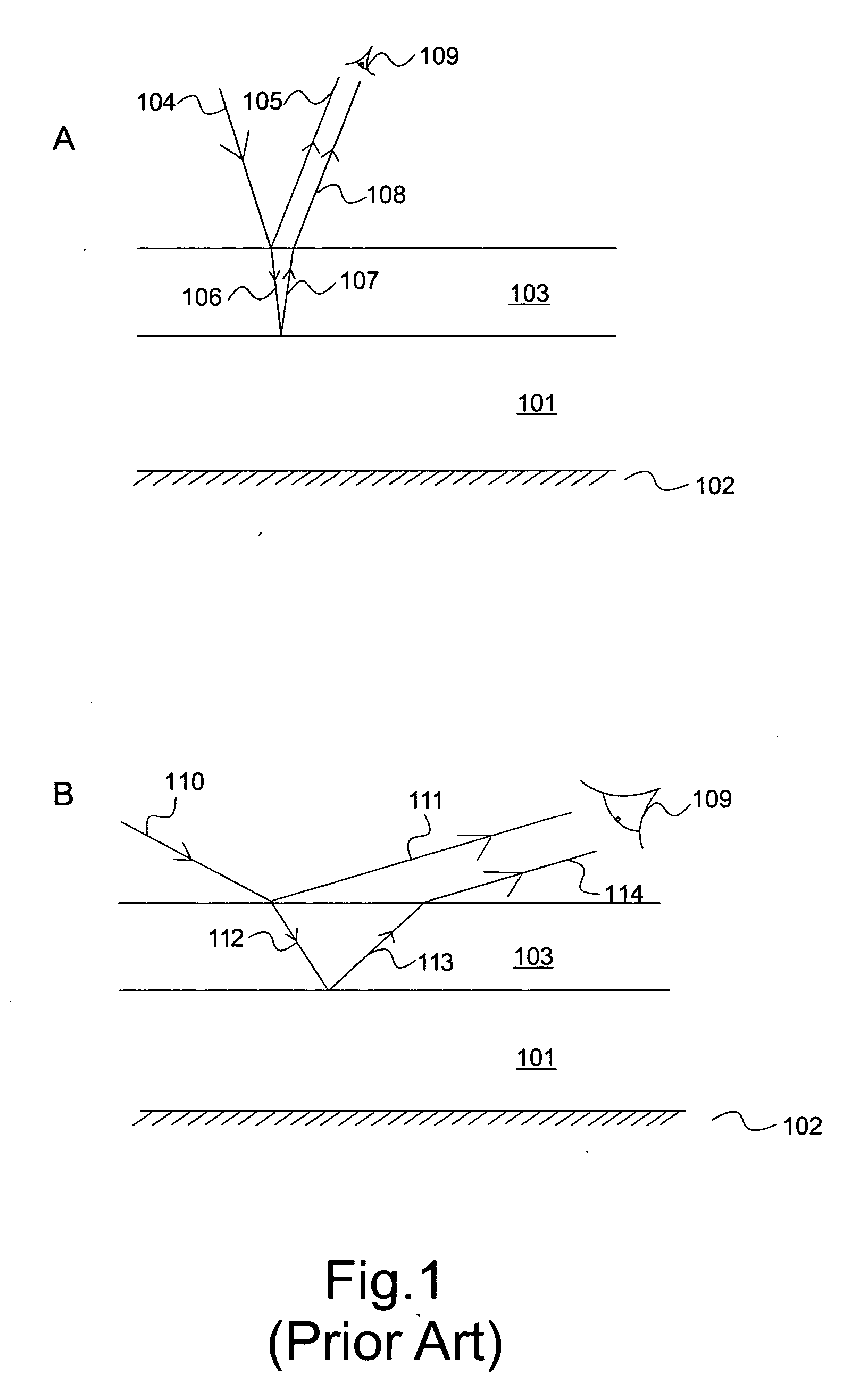

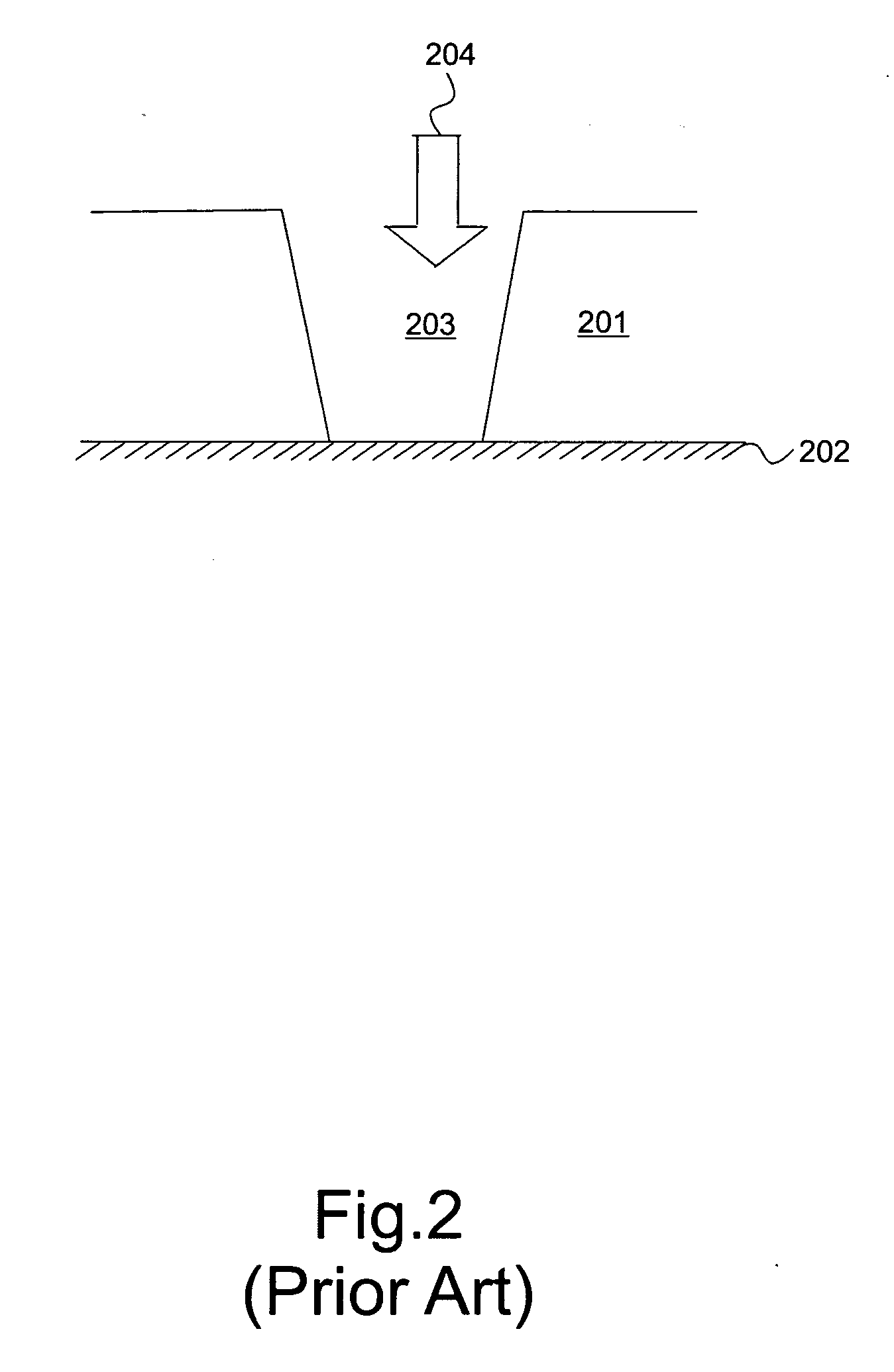

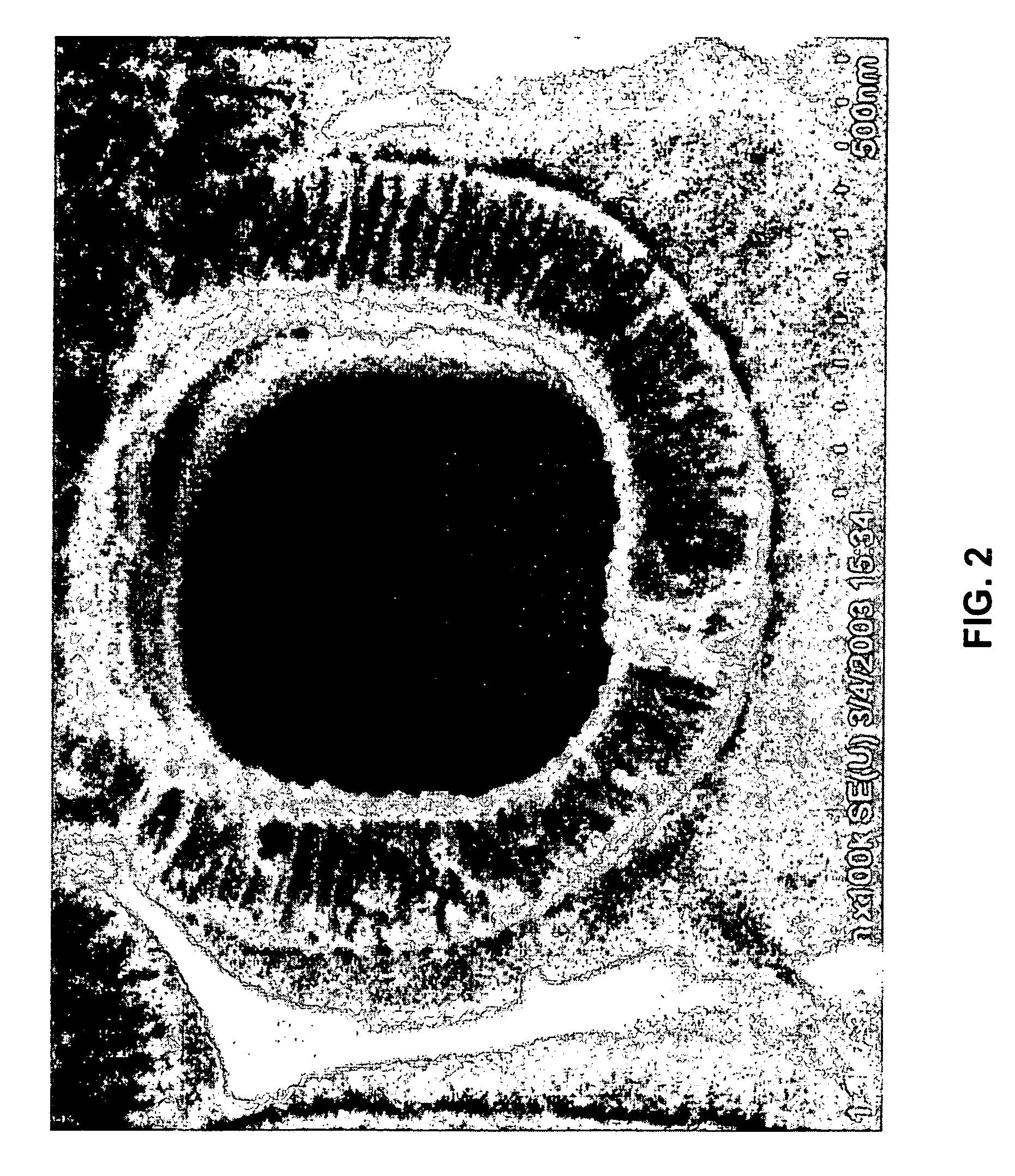

Anodic Aluminum Oxide. Nanoporous Anodic Aluminum Oxide or AAO (also known as Porous Aluminum Oxide – PAO, or NanoPorous Alumina Membranes – NPAM) is a self-organized material with honeycomb-like structure formed by high density arrays of uniform and parallel nanopores.

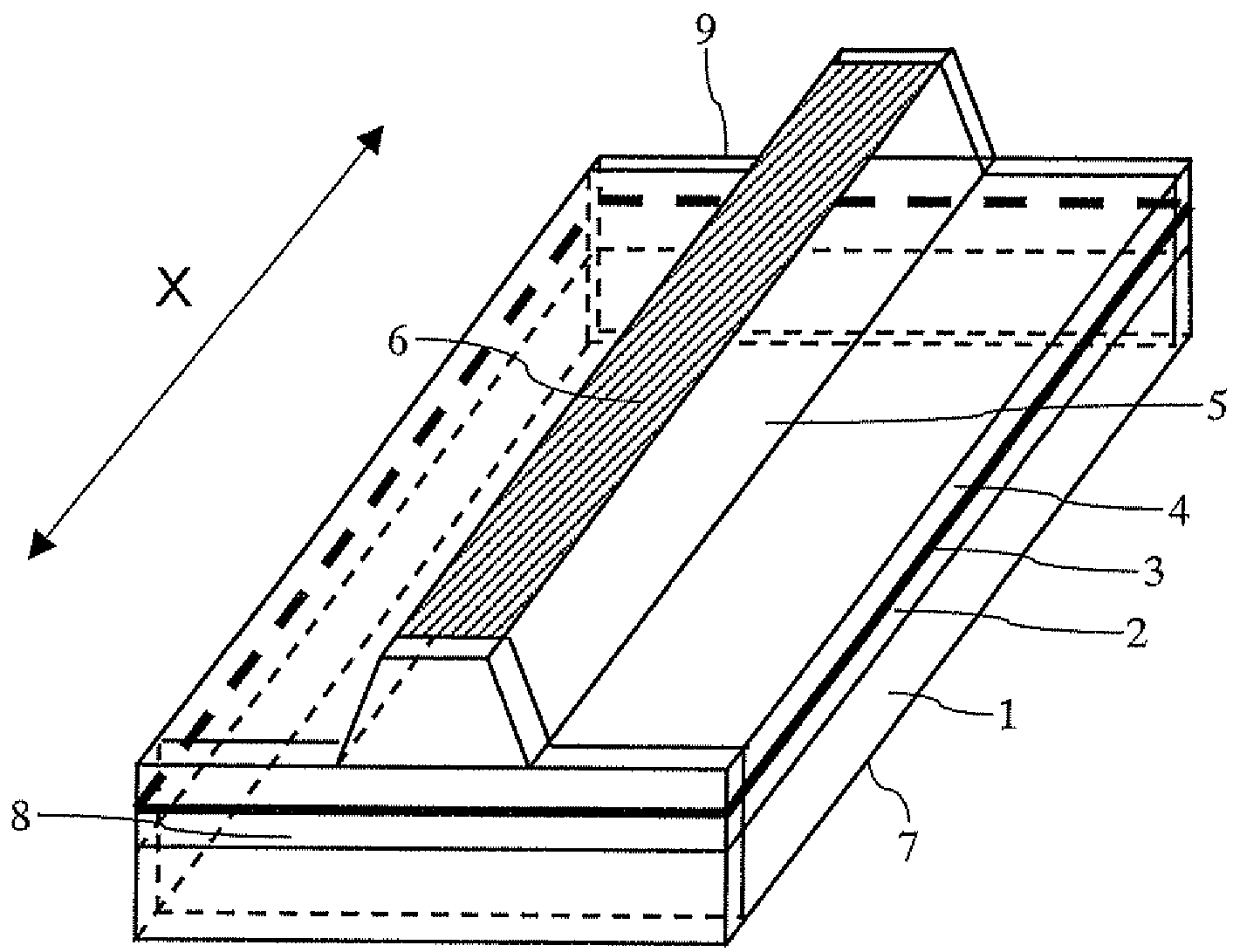

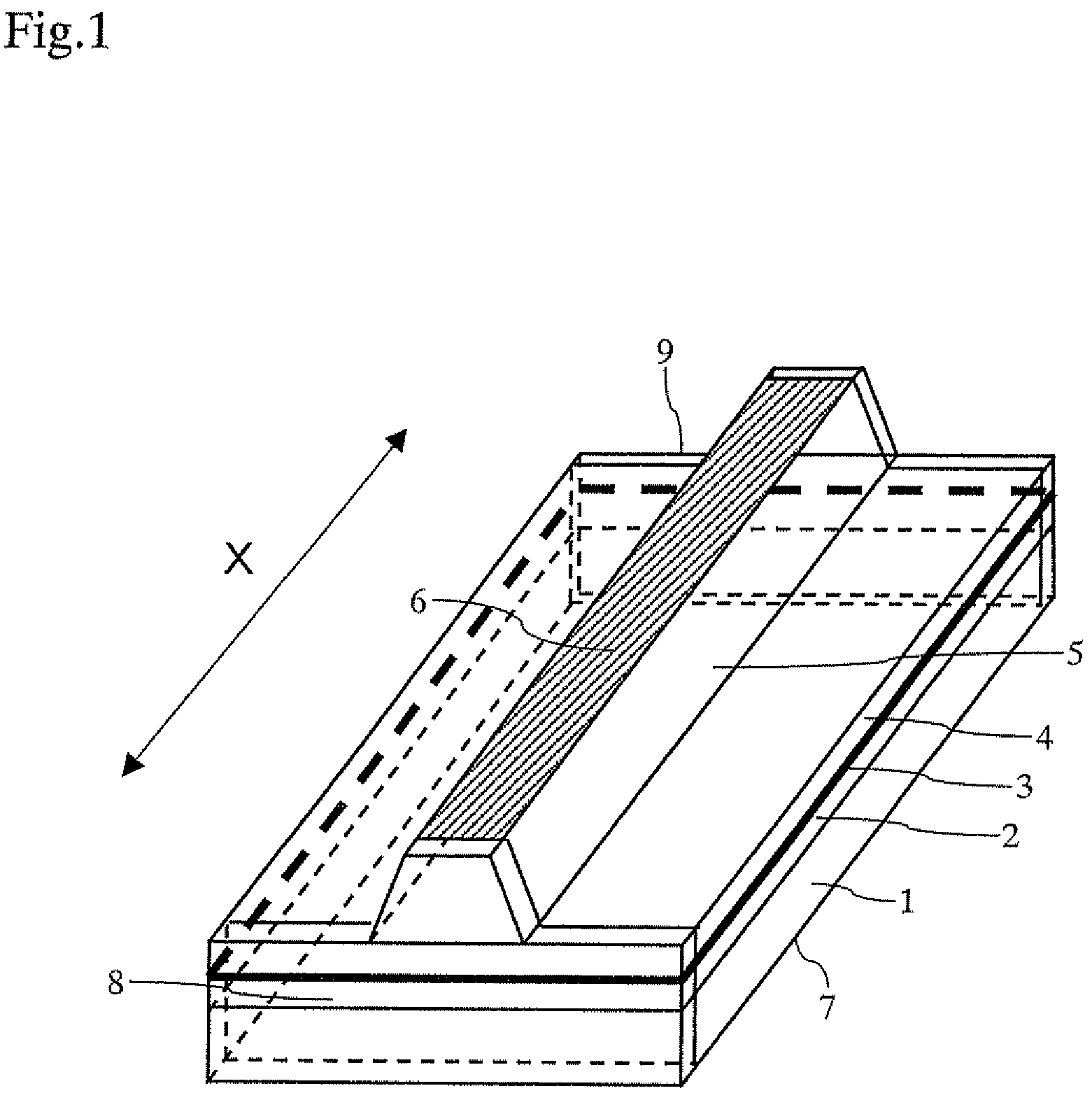

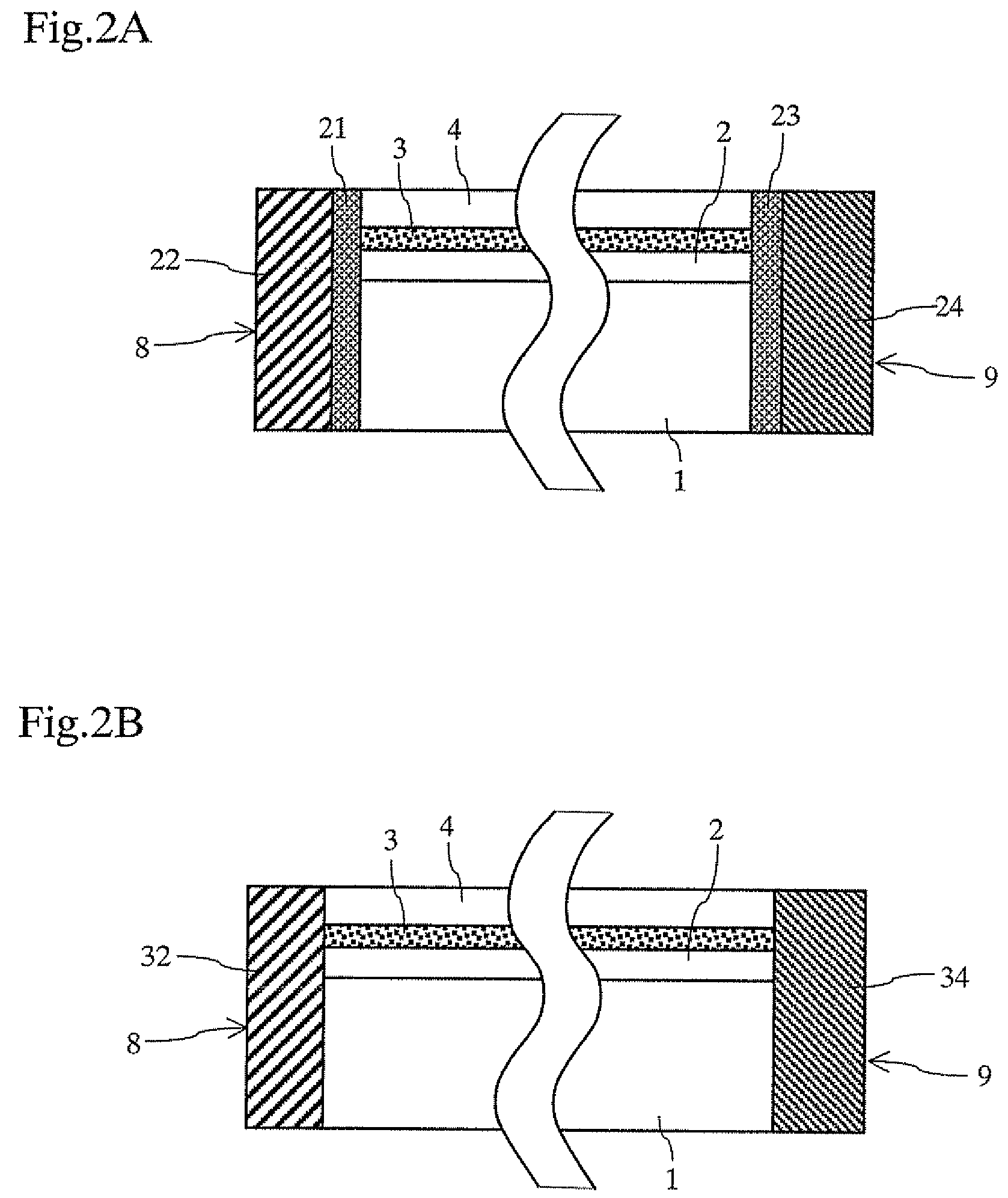

Semiconductor laser device

A semiconductor laser device includes a cavity extending in a propagation direction of a laser beam (X-direction). A front facet is on one end of the cavity through which the laser beam is emitted. A rear facet is on the other end of the cavity. Further, an adhesive layer and a coating film are on the front facet, and an adhesive layer and a coating film are on the rear facet. The adhesive layers preferably have a thickness of 10 nm or less and preferably include an anodic oxide film of one of Al, Ti, Nb, Zr, Ta, Si, and Hf.

Owner:MITSUBISHI ELECTRIC CORP

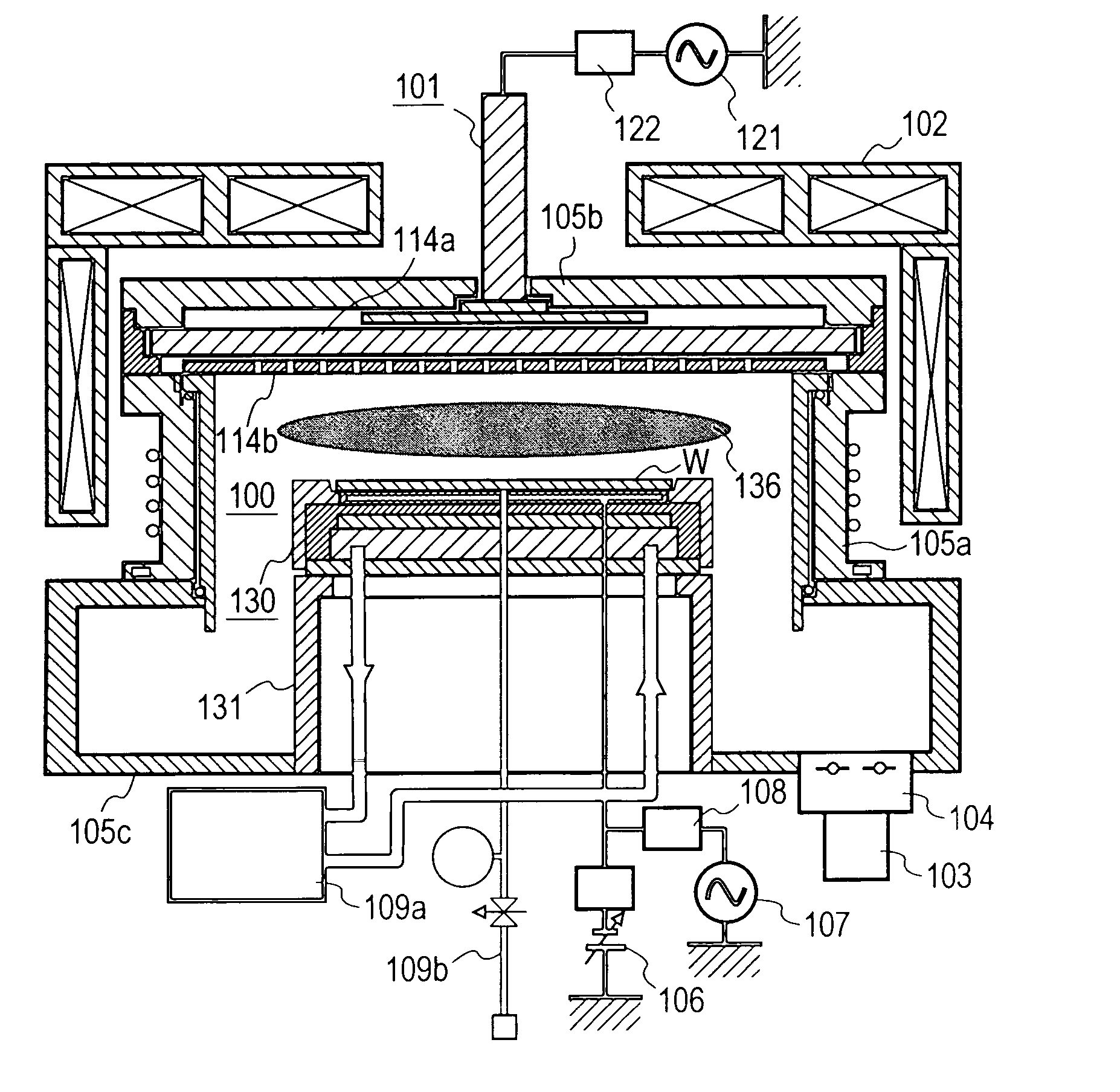

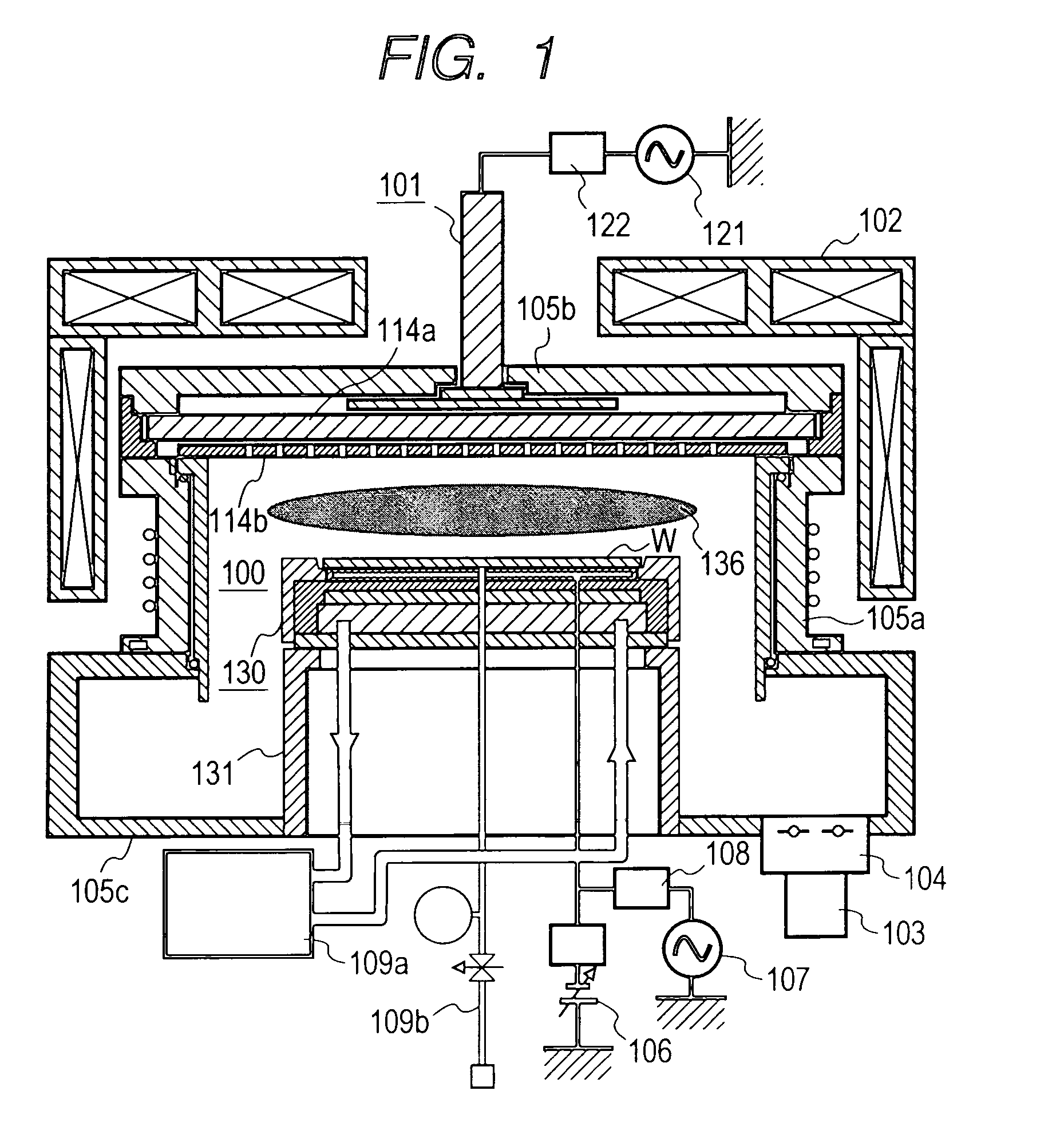

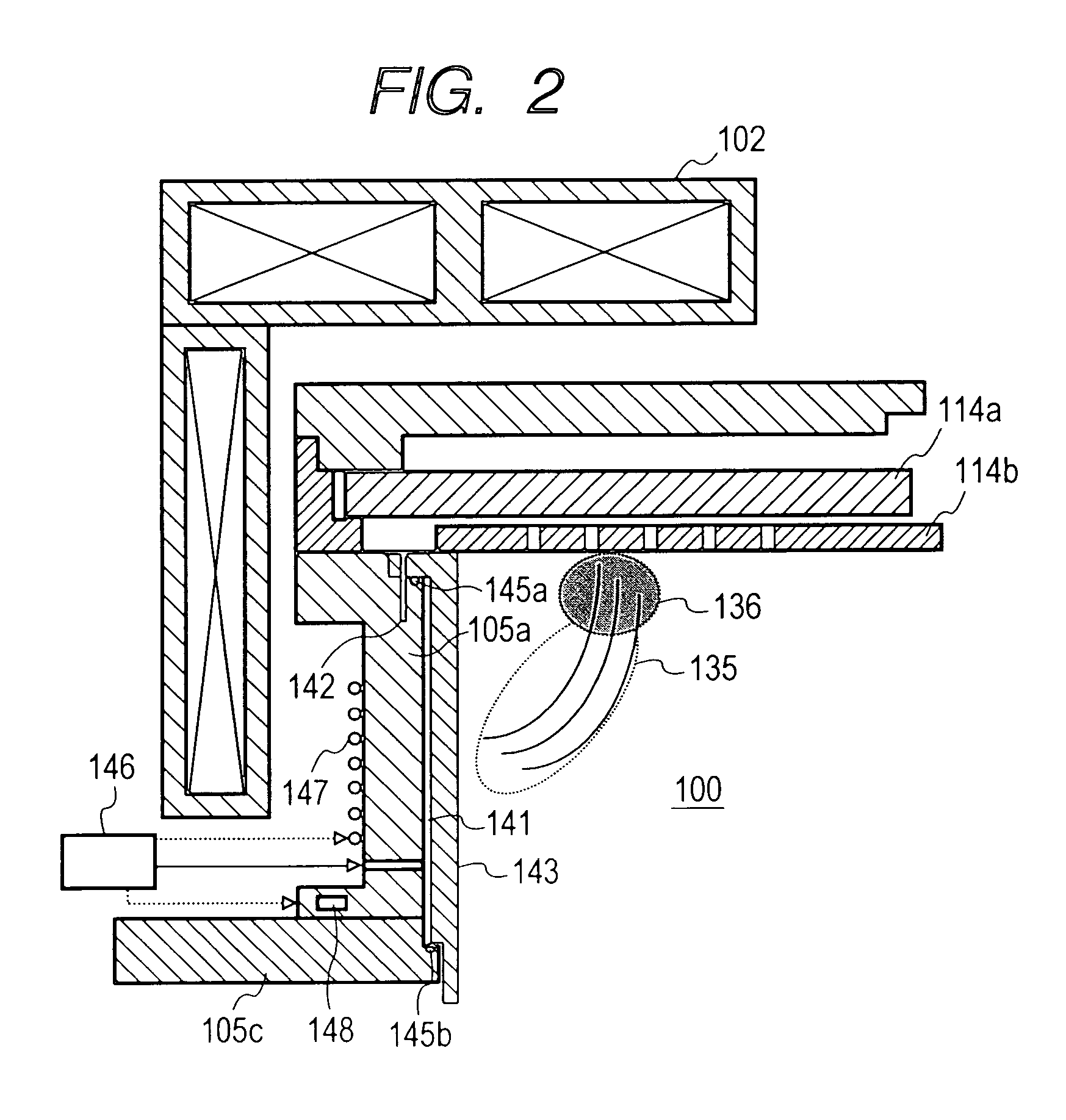

Plasma etching apparatus and method for forming inner wall of plasma processing chamber

InactiveUS20070215278A1Reduce corrosionDecreasing amountElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateHeat resistance

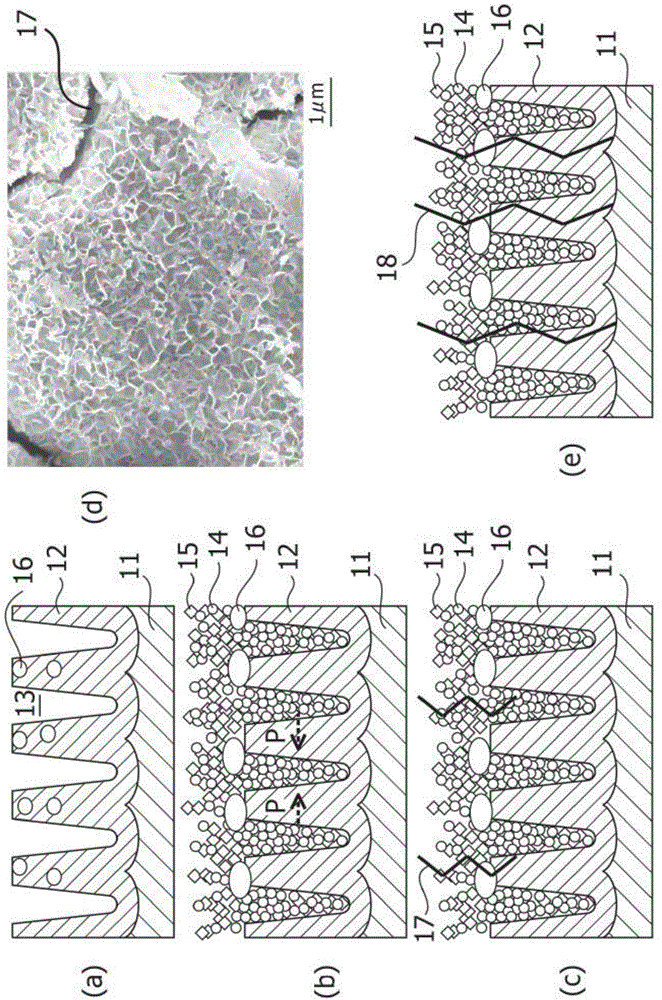

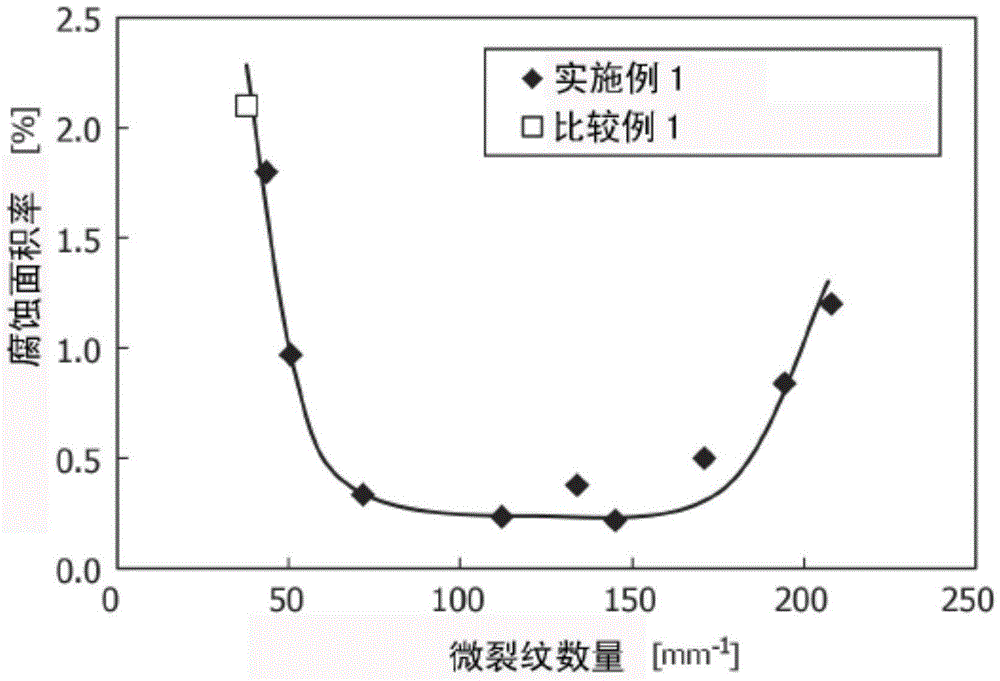

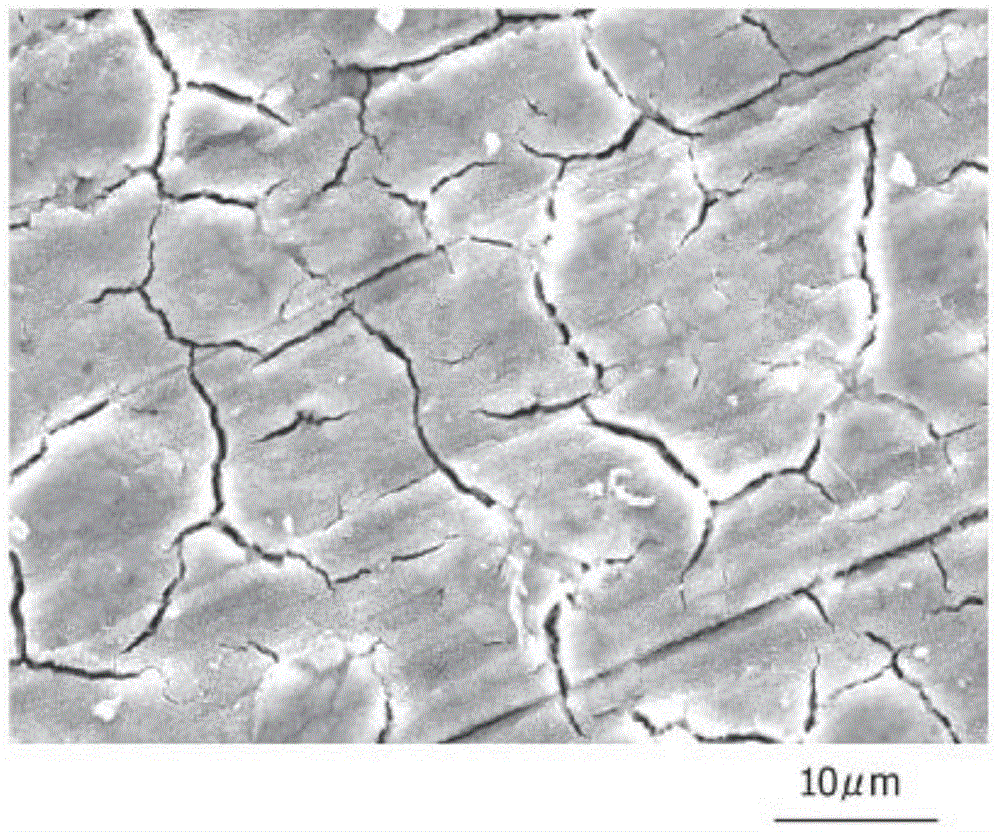

A plasma etching apparatus is provided which can prevent corrosion of an aluminum substrate constituting an etching processing chamber or an inside component thereof, thereby avoiding a reduction in productivity due to scattering of a sprayed coating. In the plasma etching apparatus, an anodic oxide film is disposed between a ceramic sprayed coating with excellent resistance to plasma, and the etching processing chamber and the inside component thereof made of aluminum alloy. The anodic oxide film has a thickness of 5 μm or less to have heat resistance.

Owner:HITACHI HIGH-TECH CORP

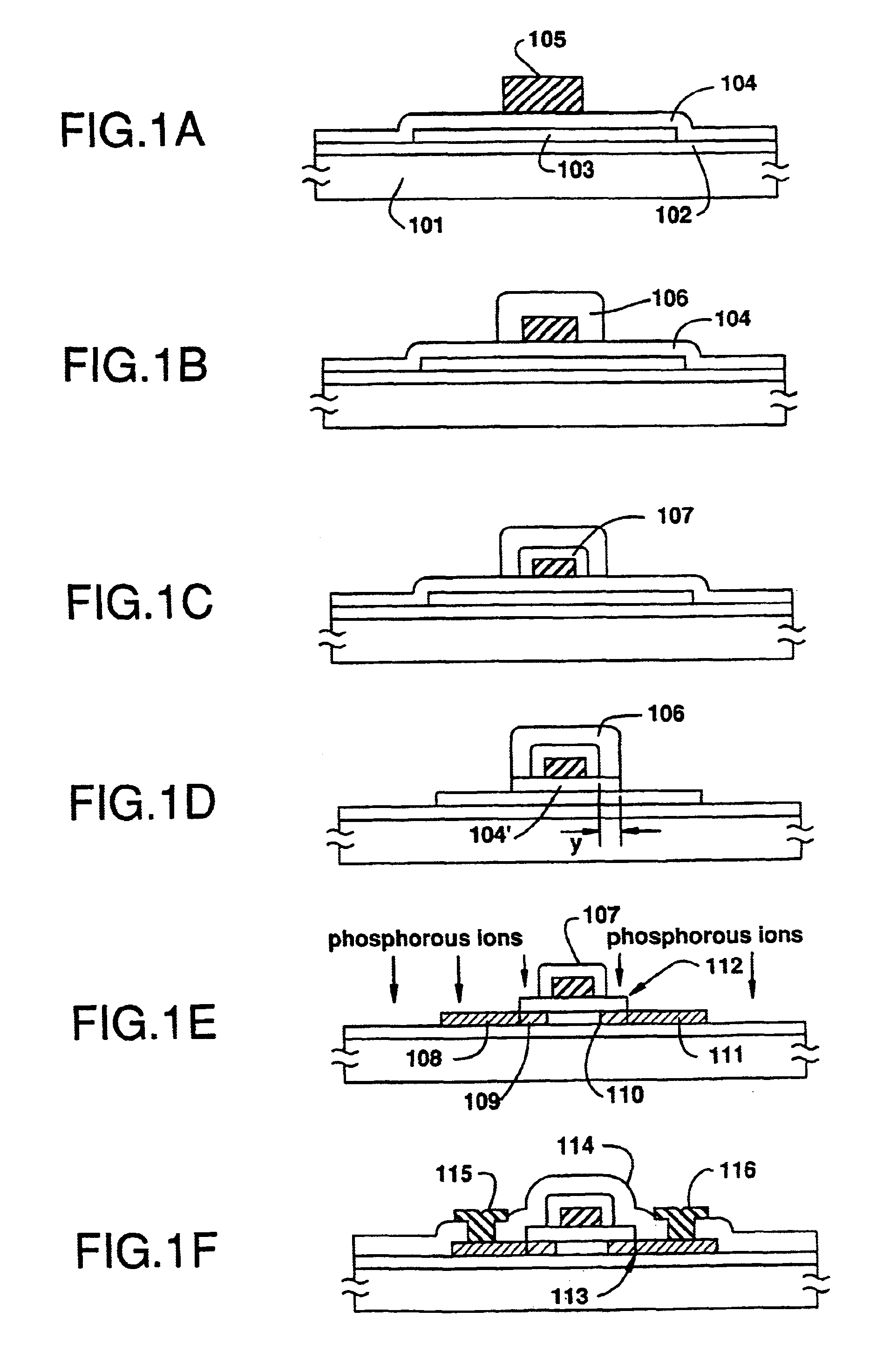

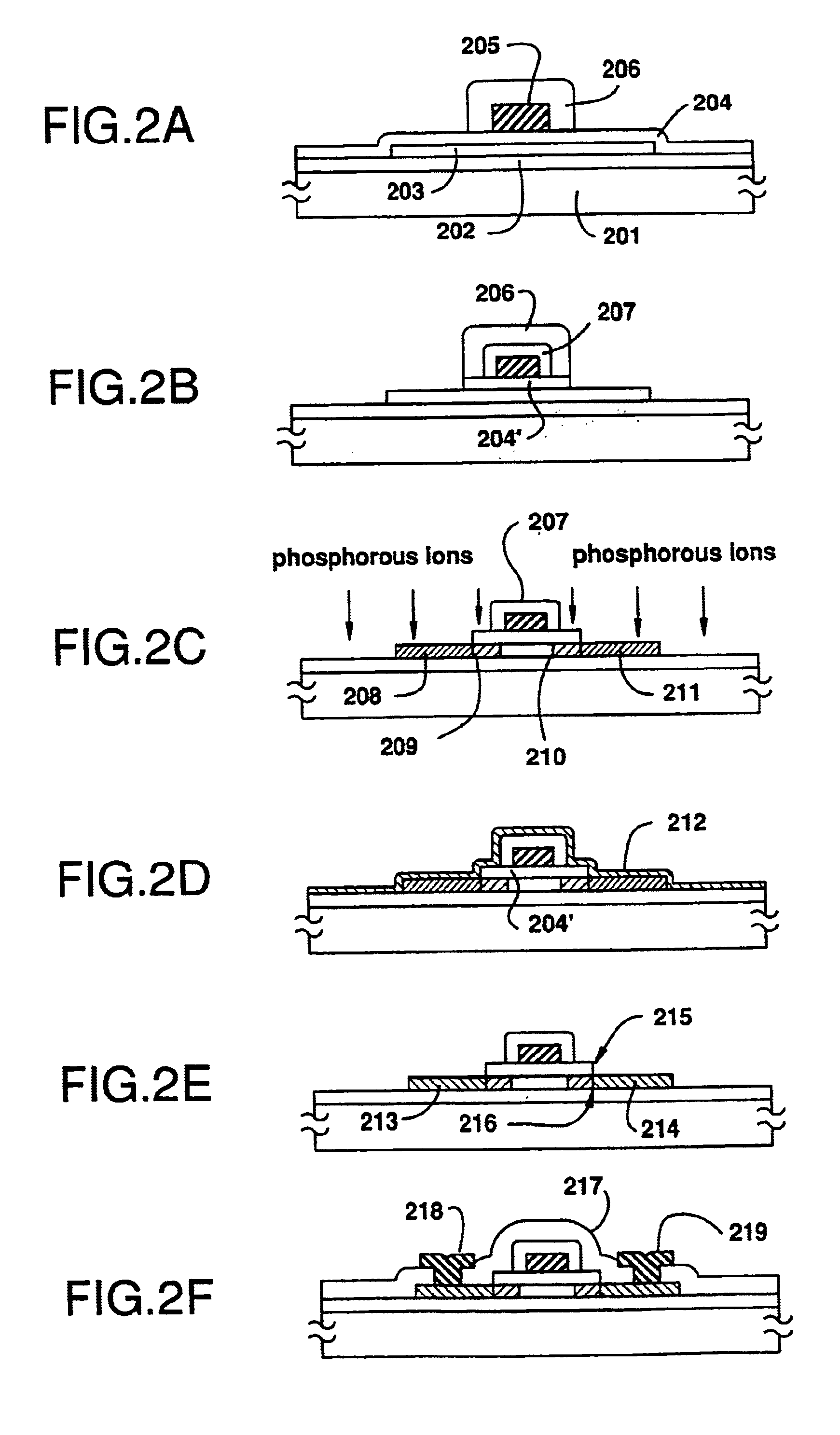

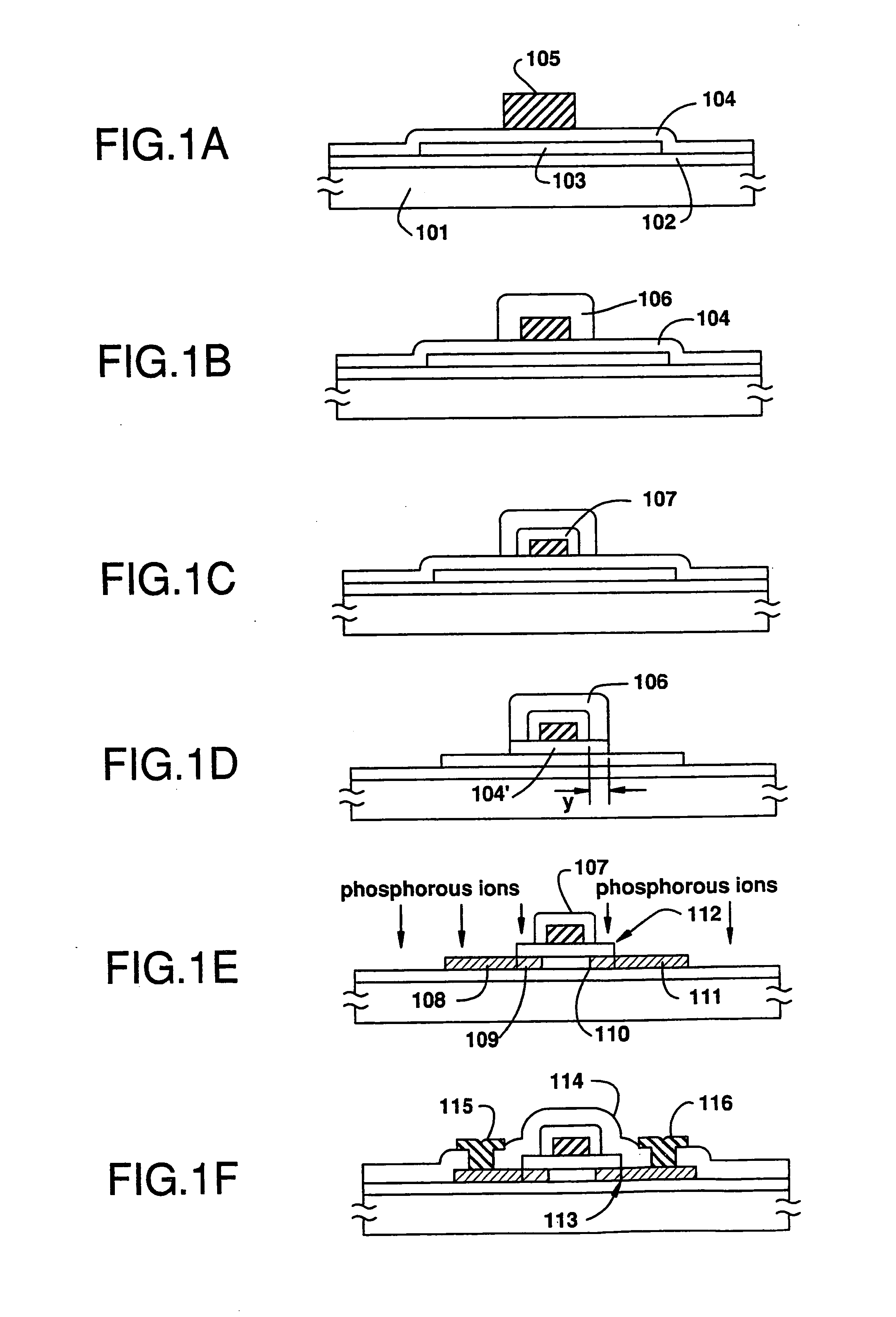

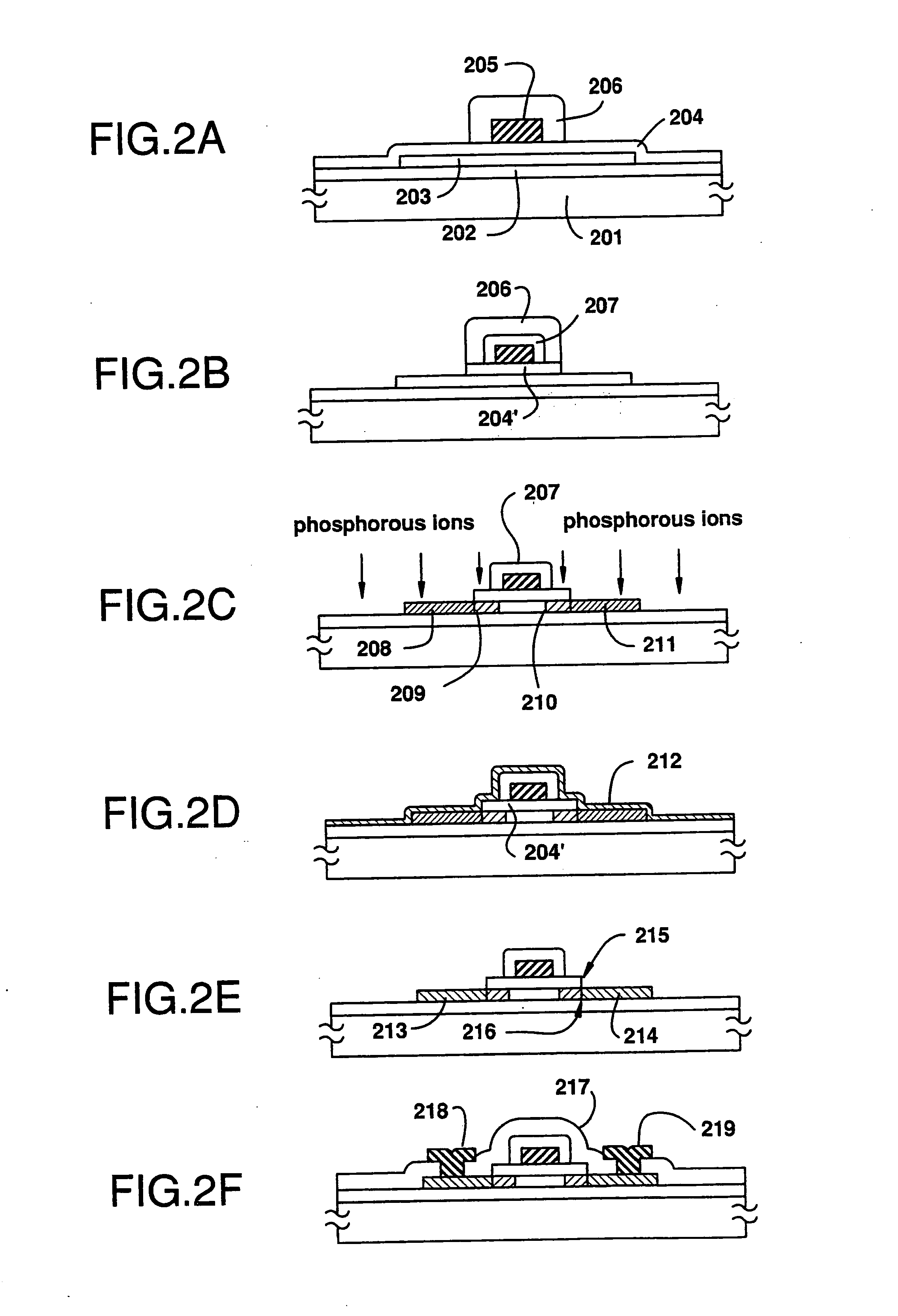

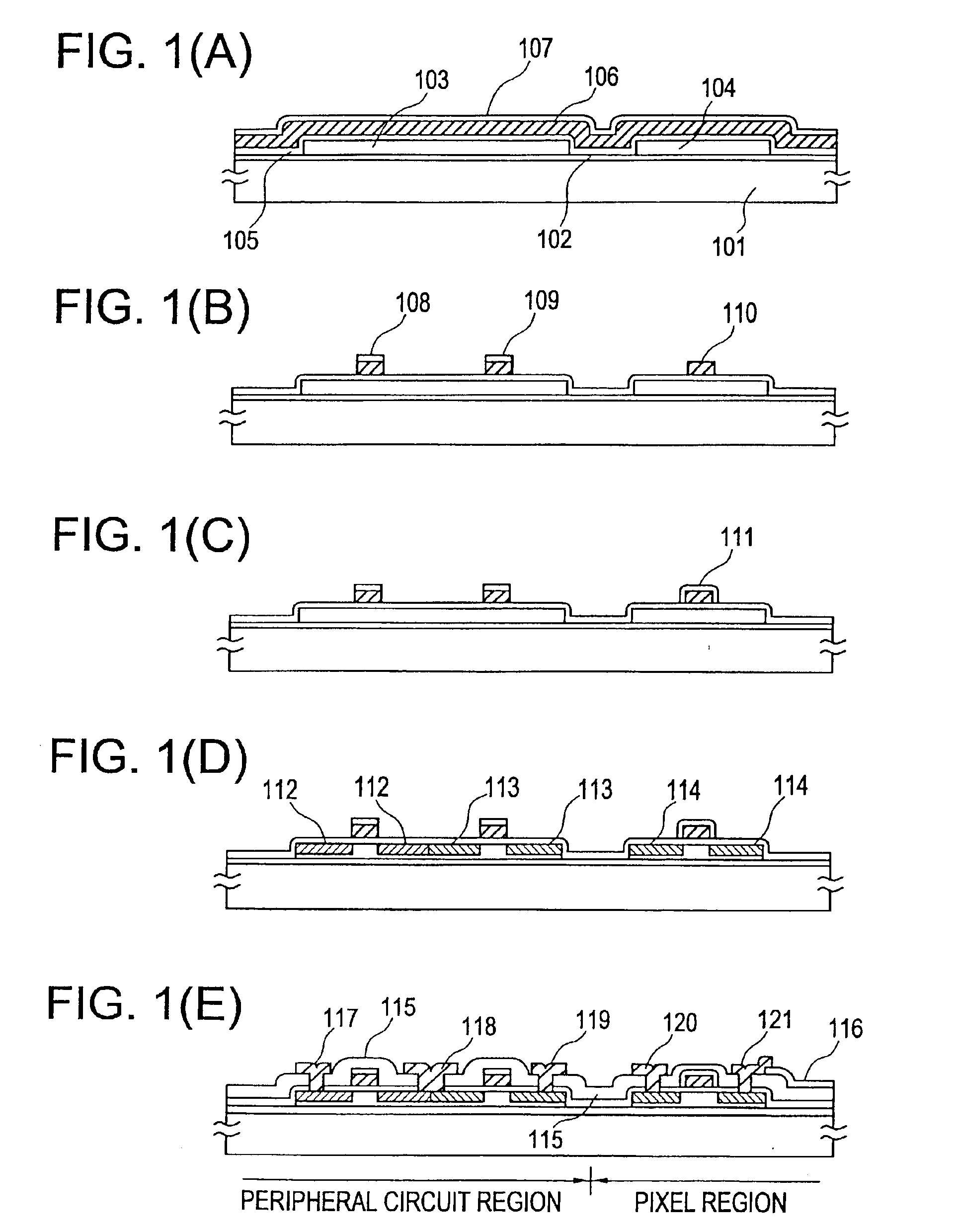

Semiconductor device and method for manufacturing the same

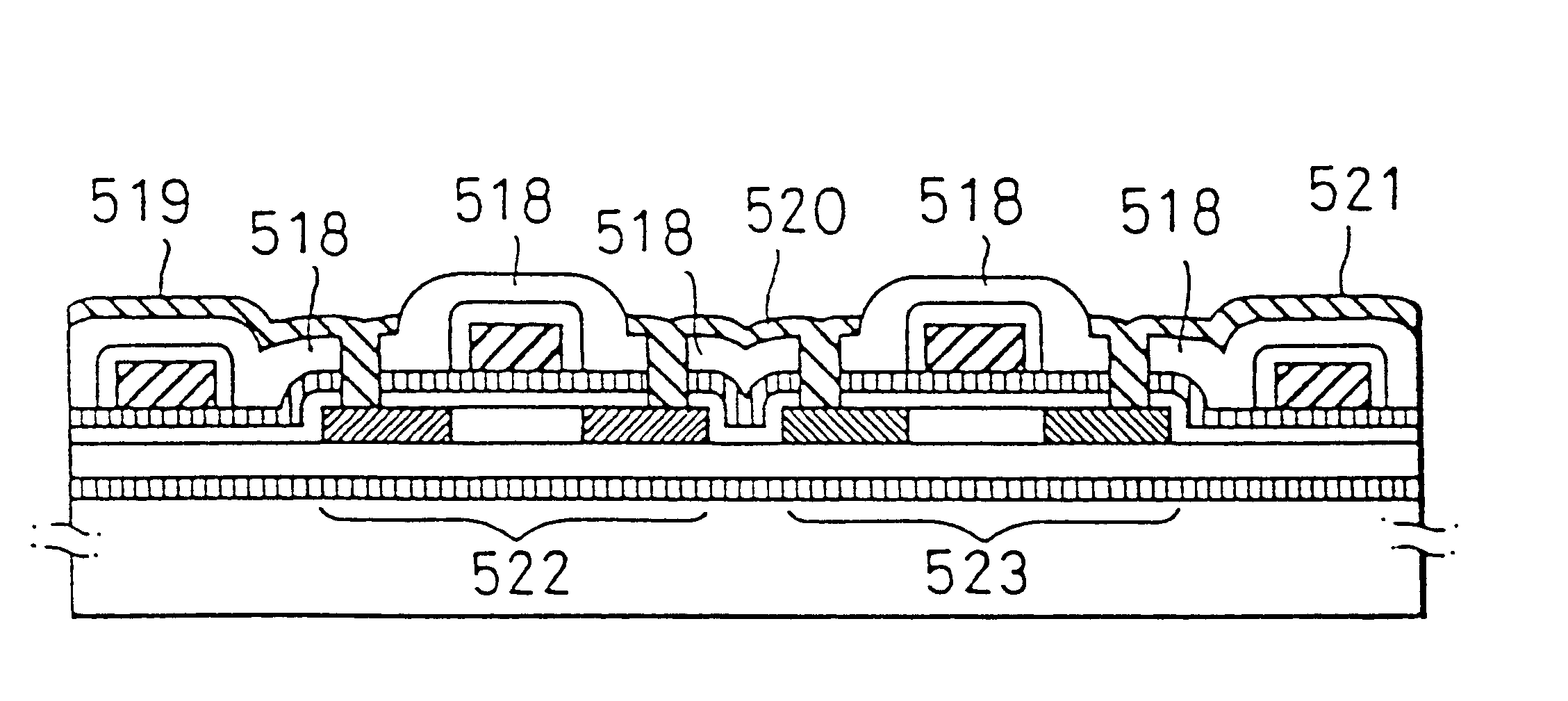

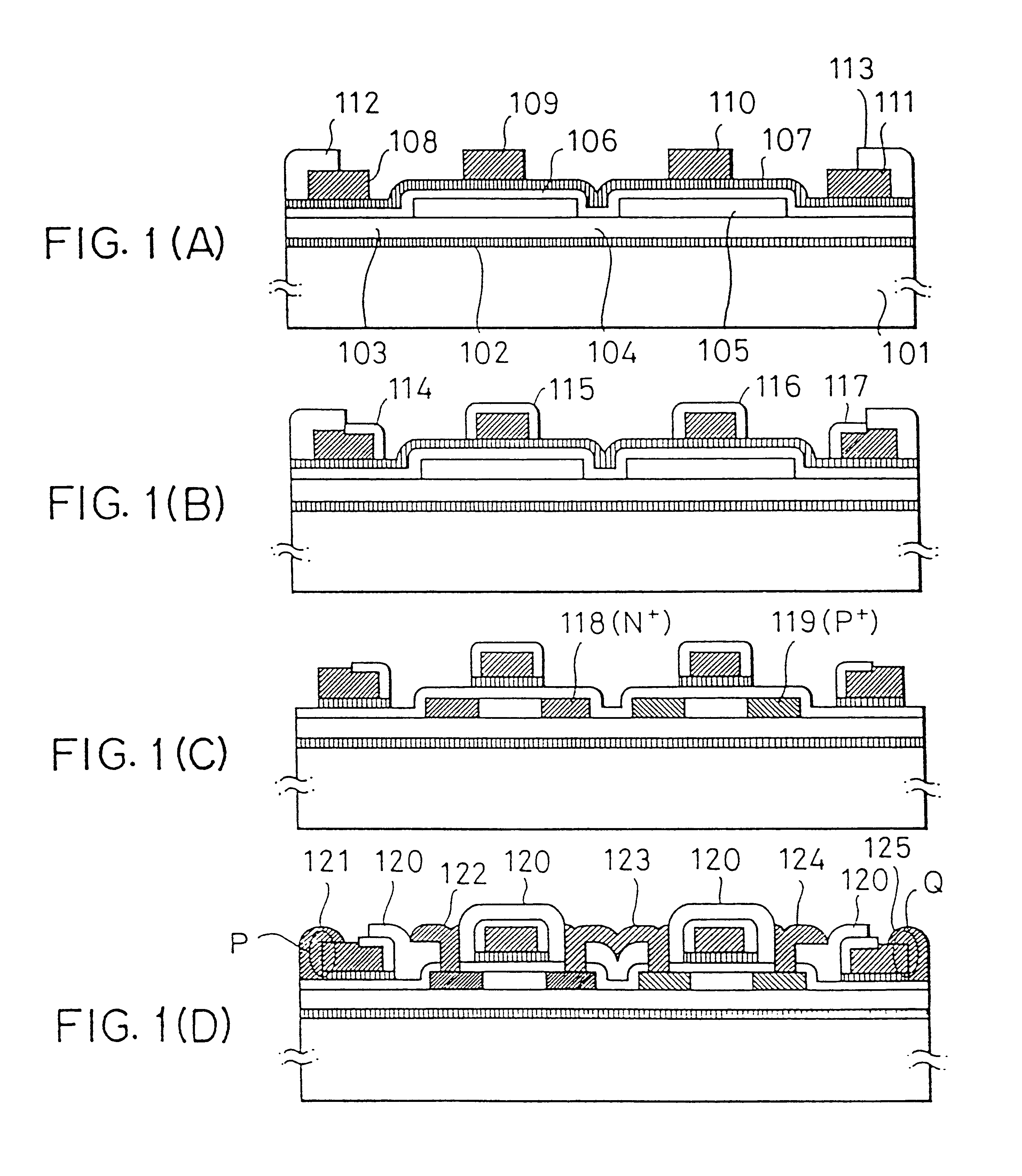

A TFT formed on an insulating substrate source, drain and channel regions, a gate insulating film formed on at least the channel region and a gate electrode formed on the gate insulating film. Between the channel region and the drain region, a region having a higher resistivity is provided in order to reduce an Ioff current. A method for forming this structure comprises the steps of anodizing the gate electrode to form a porous anodic oxide film on the side of the gate electrode; removing a portion of the gate insulating using the porous anodic oxide film as a mask so that the gate insulating film extends beyond the gate electrode but does not completely cover the source and drain regions. Thereafter, an ion doping of one conductivity element is performed. The high resistivity region is defined under the gate insulating film.

Owner:SEMICON ENERGY LAB CO LTD

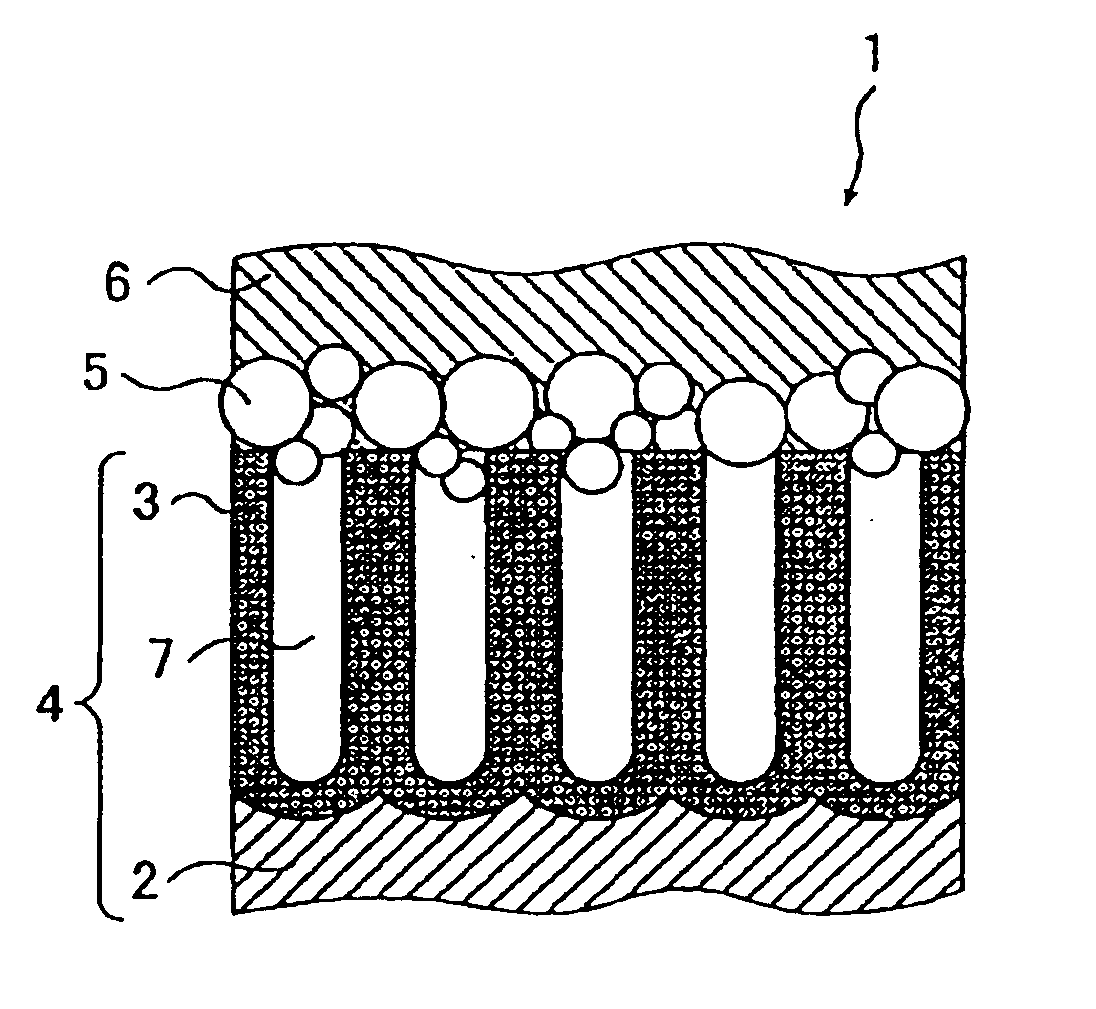

Electron-emitting device provided with pores that have carbon deposited therein

An electron-emitting device disclosed has stable electron emission characteristics with little variation, in high electron emission efficiency, in high definition, and at low driving voltage. The electron-emitting device disclosed is constructed in such structure that on a substrate there are a lower electrode, an insulating layer having pores, and an upper electrode stacked in this order, the insulating layer is an anodic oxide layer, and a carbon deposit is formed in the pores.

Owner:CANON KK

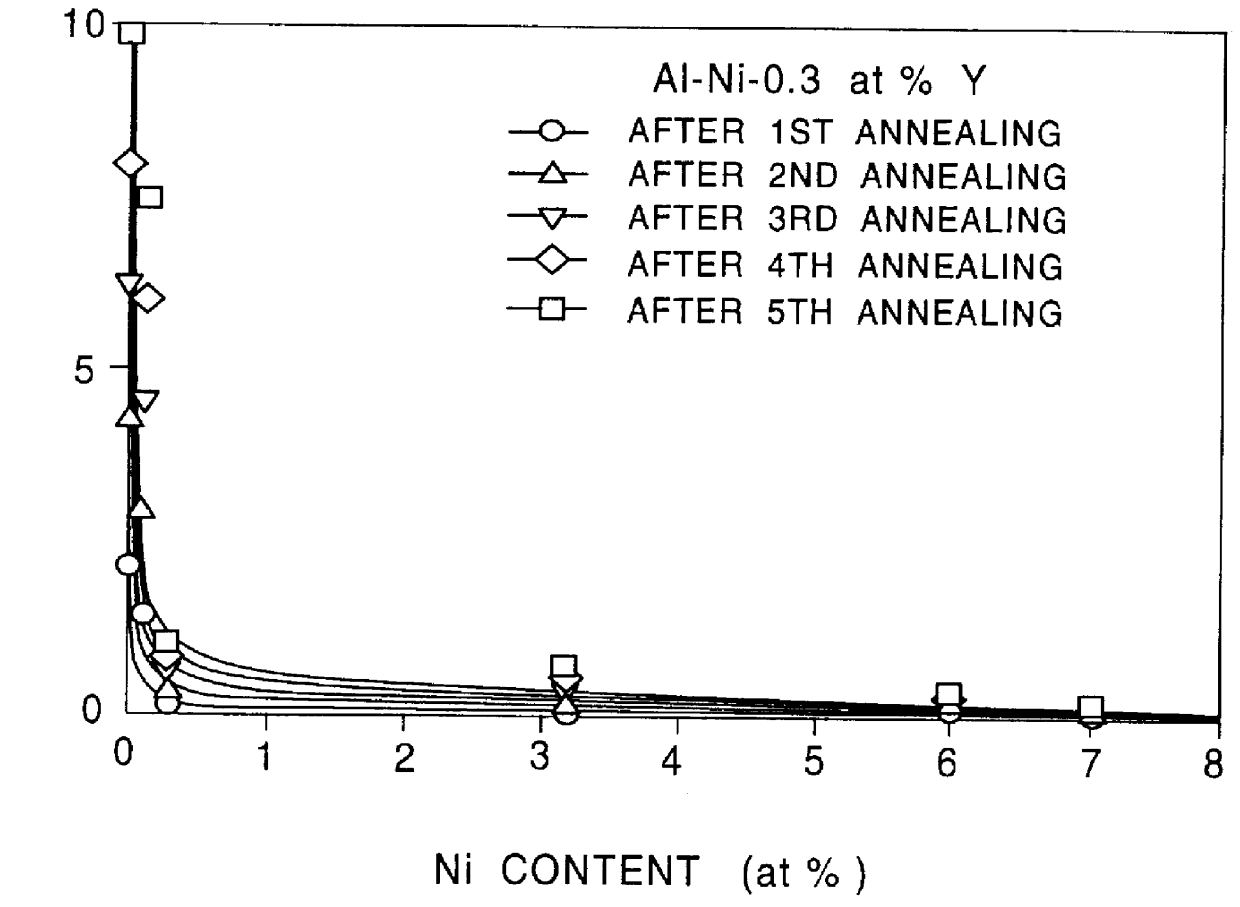

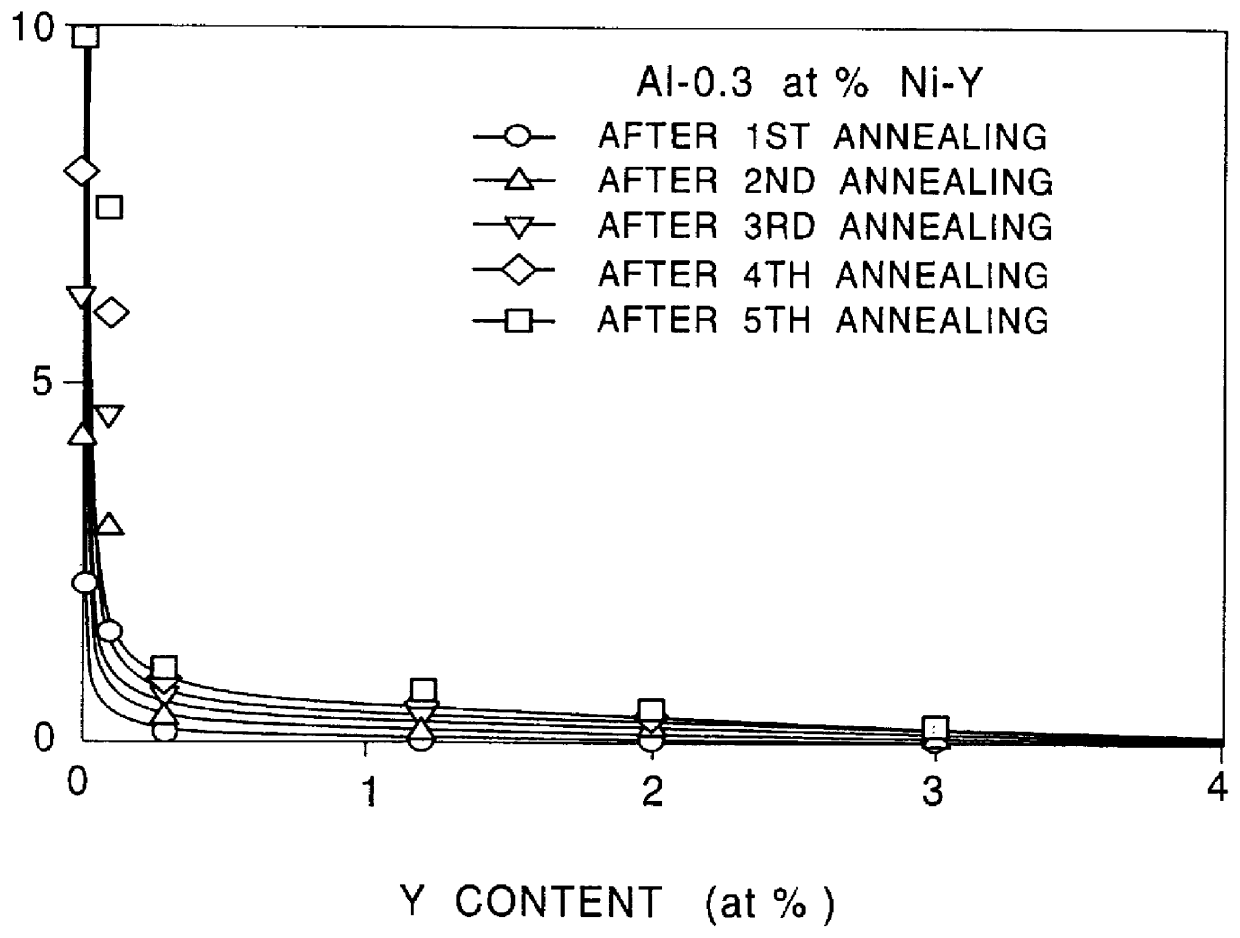

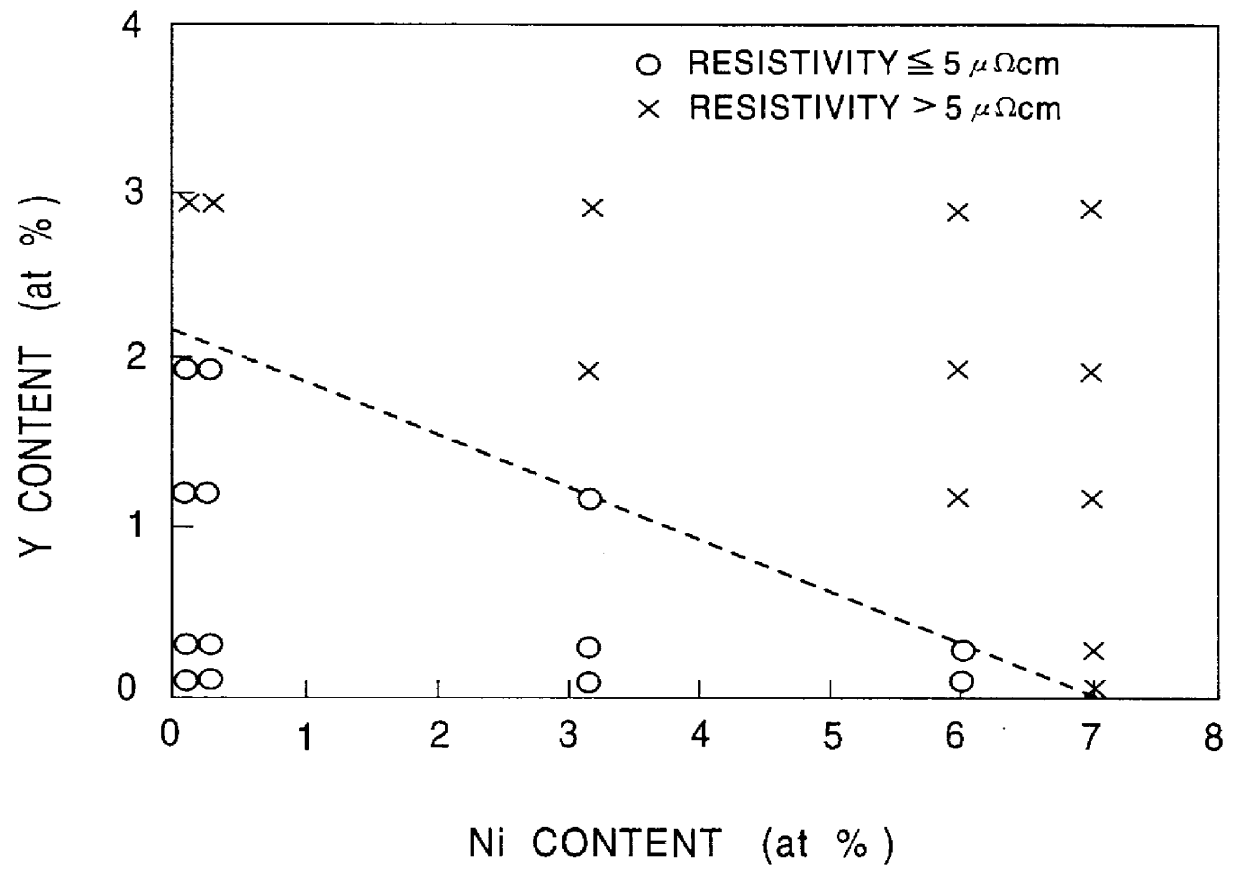

A1-N1-Y alloy films for electrodes of semiconductor devices and sputtering targets for depositing the A1-N1-Y alloy films

The invention provides an Al alloy film for use as an electrode of a semiconductor device and also provides an Al alloy sputtering target used to produce such an Al alloy film wherein the Al alloy film has not only a low resistivity equal to or less than 5 mu OMEGA cm and a high hillock resistance (property of hillock suppression) but also a high dielectric strength when it is anodized into an anodic oxide film and wherein the Al alloy film has a composition such that the Ni content is equal to or greater than 0.3 at % and the Y content is equal to or greater than 0.3 at % and such that 0.22 CNi+0.74 CY<1.6 at % where CNi denotes the Ni content (at %) and CY denotes the Y content (at %) and further wherein, in order to deposit the Al alloy film by sputtering, a spray forming Al alloy target containing Ni and Y is used.

Owner:KOBE STEEL LTD

Semiconductor device and method for forming the same

InactiveUS6624450B1Improve flatnessImprove equipment reliabilityTransistorSolid-state devicesEtchingMetallic materials

In a thin-film insulated gate type field effect transistor having a metal gate in which the surface of the gate electrode is subjected to anodic oxidation, a silicon nitride film is provided so as to be interposed between the gate electrode and the gate insulating film to prevent invasion of movable ions into a channel, and also to prevent the breakdown of the gate insulating film due to a potential difference between the gate electrode and the channel region. By coating a specific portion of the gate electrode with metal material such as chrome or the like for the anodic oxidation, and then removing only the metal material such as chrome or the like together with the anodic oxide of the metal material such as chrome or the like, an exposed portion of metal gate (e.g. aluminum) is formed, and an upper wiring is connected to the exposed portion. Further, an aluminum oxide or silicon nitride is formed as an etching stopper between the gate electrode and the gate insulating film or between the substrate and the layer on the substrate, so that the over-etching can be prevented and the flatness of the element can be improved. In addition, a contact is formed in no consideration of the concept "contact hole".

Owner:SEMICON ENERGY LAB CO LTD

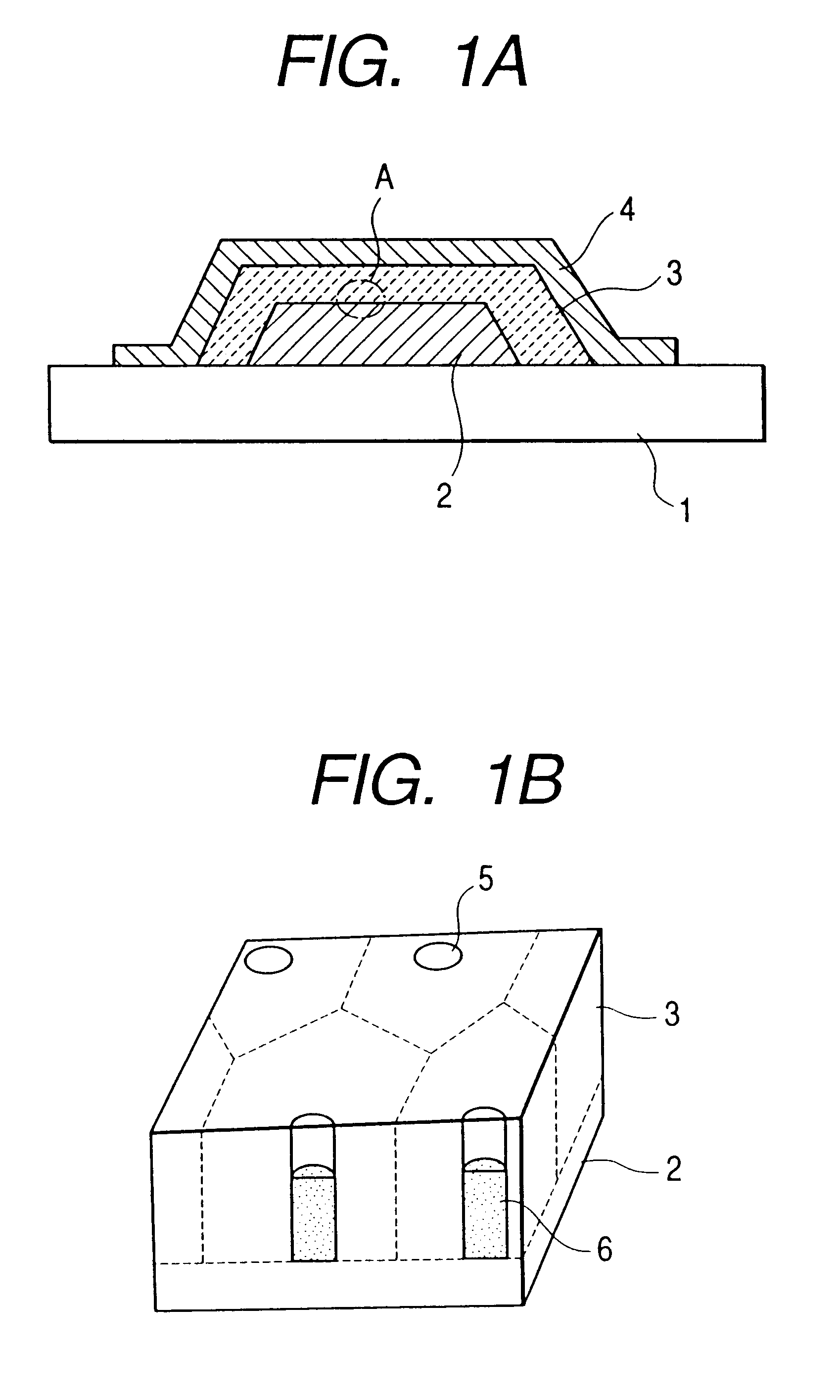

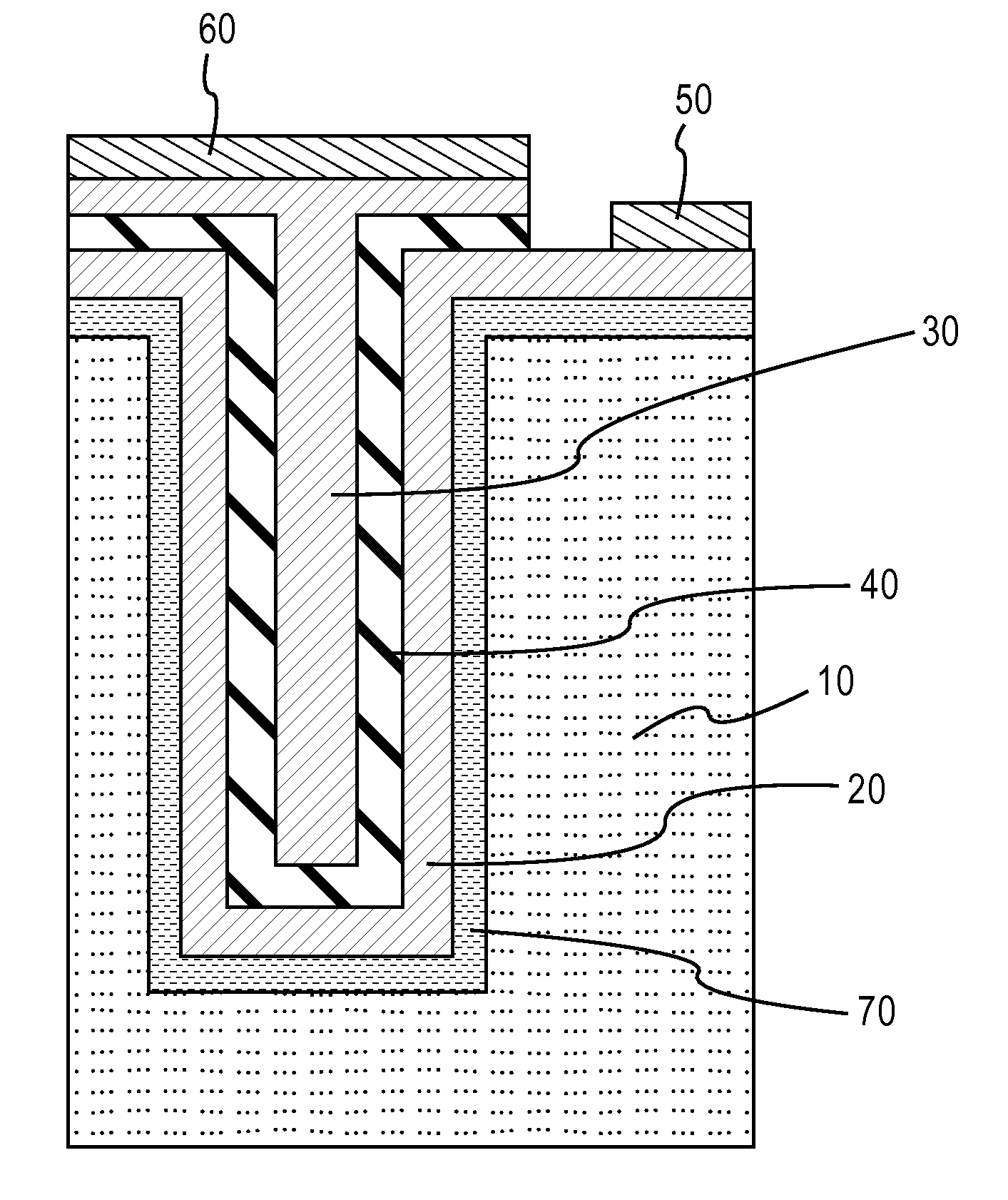

Nanodevice arrays for electrical energy storage, capture and management and method for their formation

An apparatus, system, and method are provided for a vertical two-terminal nanotube device configured to capture and generate energy, to store electrical energy, and to integrate these functions with power management circuitry. The vertical nanotube device can include a column disposed in an anodic oxide material extending from a first distal end of the anodic oxide material to a second distal end of the anodic oxide material. Further, the vertical nanotube device can include a first material disposed within the column, a second material disposed within the column, and a third material disposed between the first material and the second material. The first material fills the first distal end of the column and extends to the second distal end of the column along inner walls of the column. The second material fills the first distal end of the column and extends to the second distal end of the column within the first material. Both the first material and the second material are exposed at the first distal end of the column.

Owner:UNIV OF MARYLAND

Semiconductor device and method for manufacturing the same

InactiveUS20050142705A1High regionImprove uniformityTransistorSolid-state devicesEngineeringHigh resistivity

Owner:SEMICON ENERGY LAB CO LTD

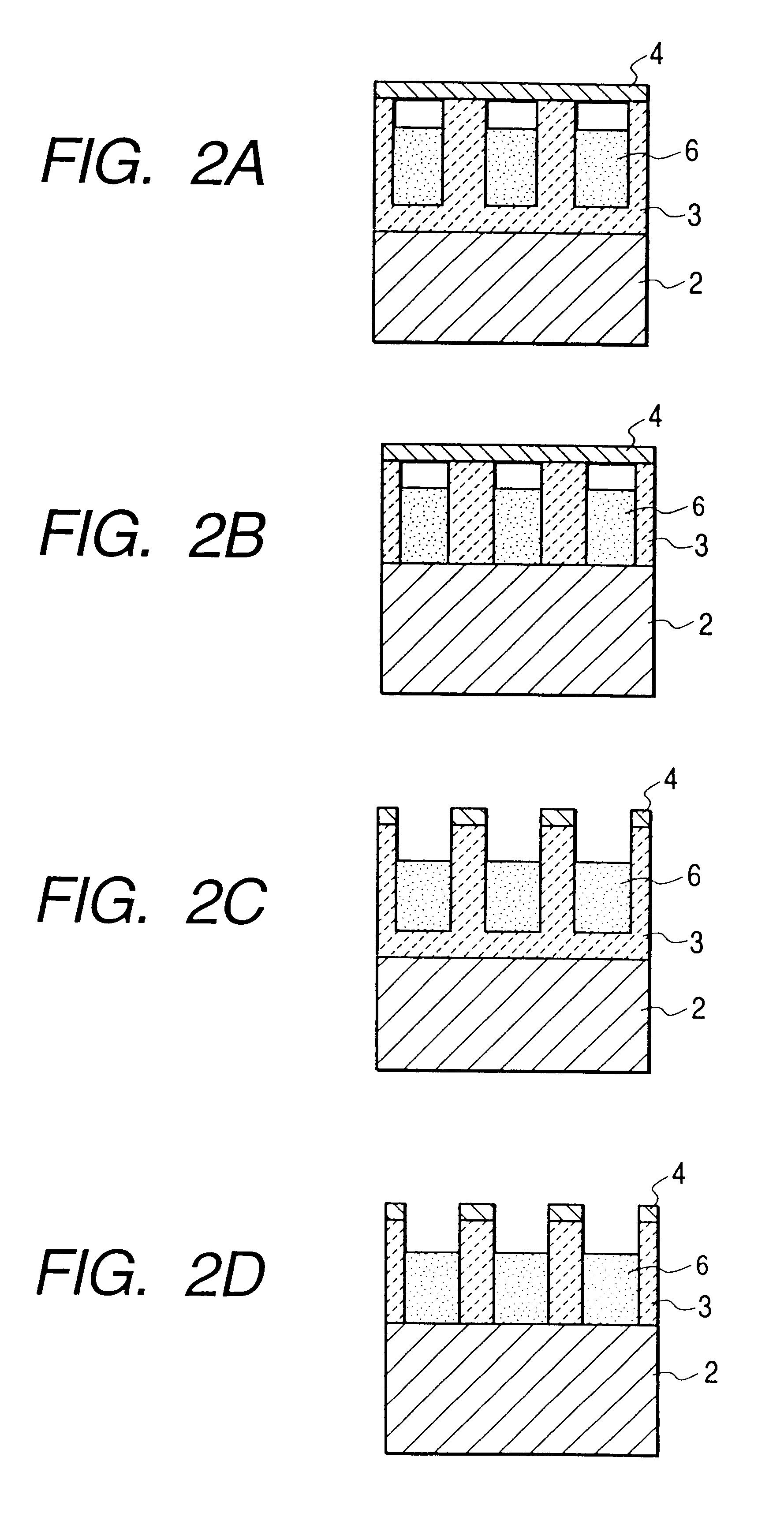

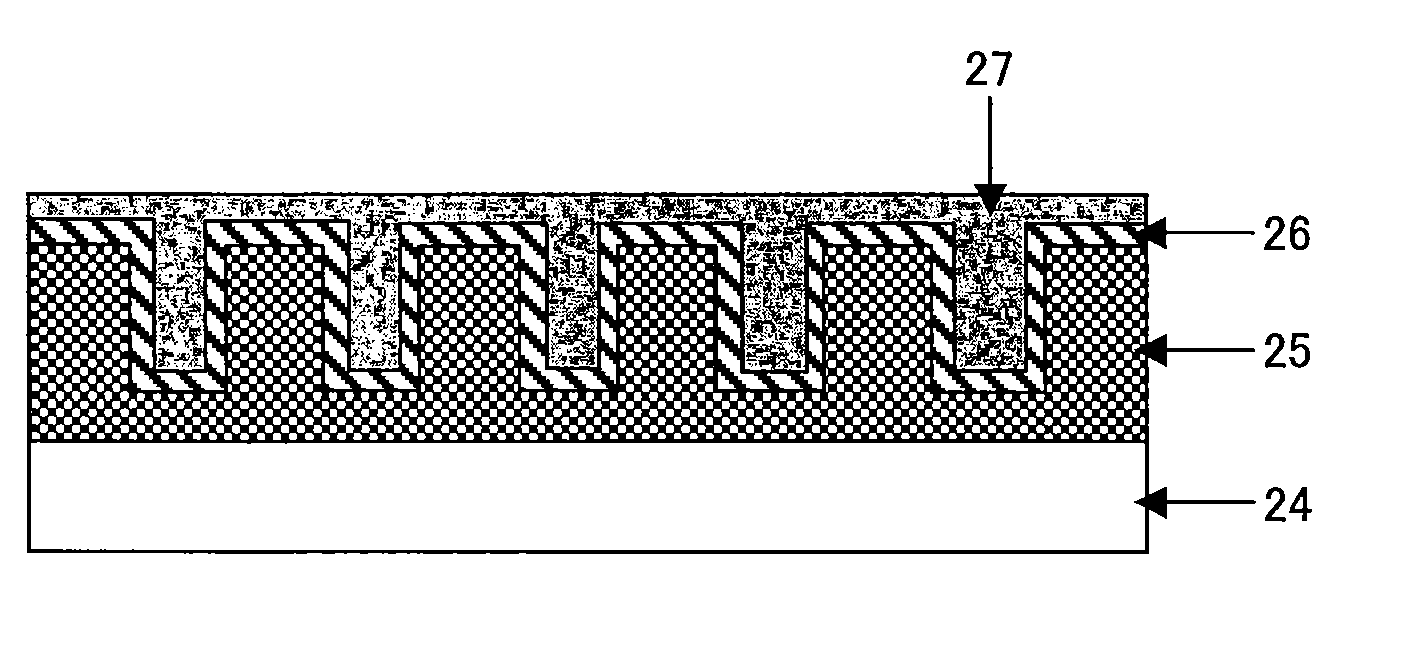

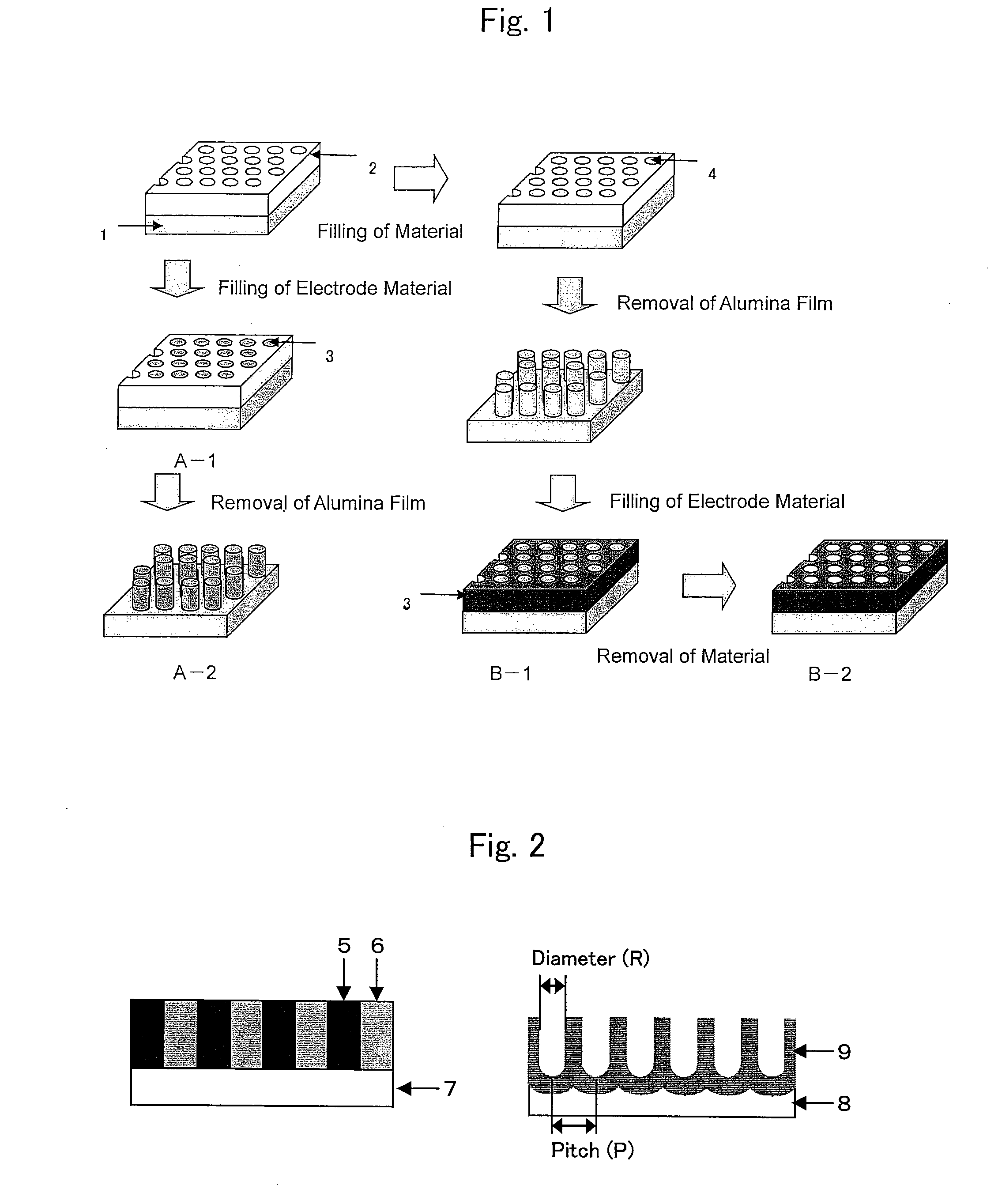

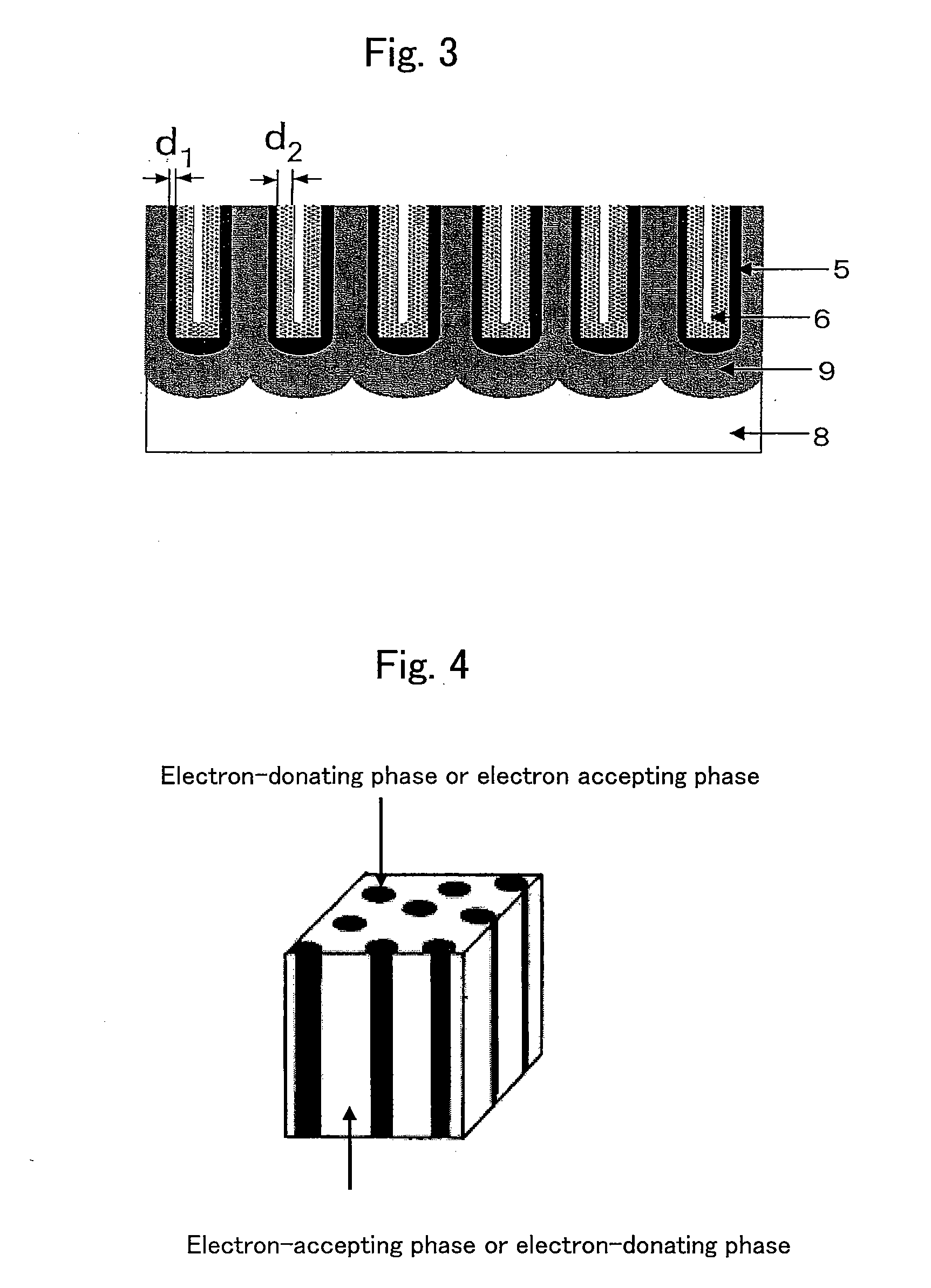

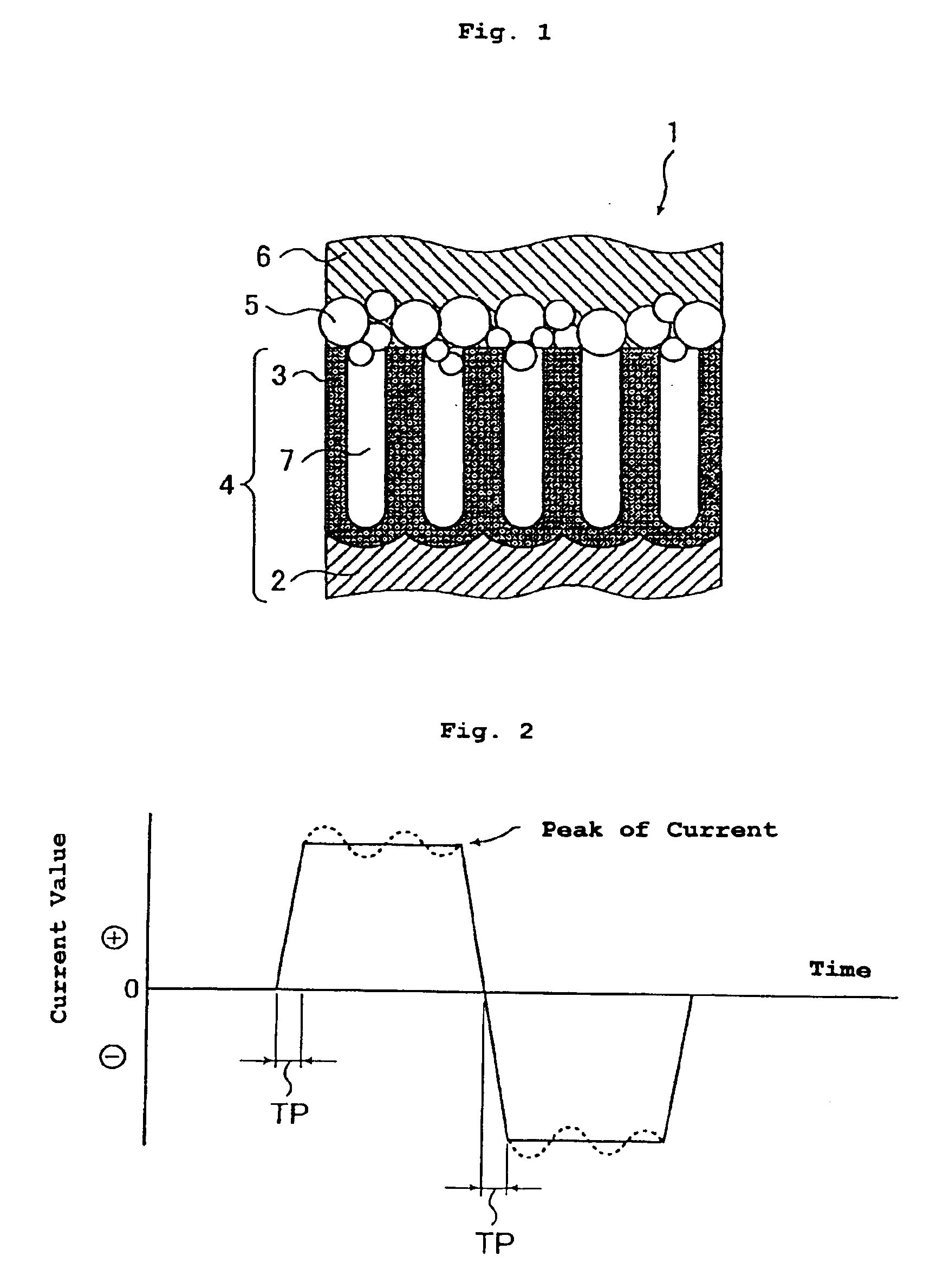

Method for manufacturing nano-array electrode and photoelectric conversion device using same

InactiveUS20060234505A1Improve efficiencyEfficient charge separationAnodisationFinal product manufactureNano structuringPhotoelectric conversion

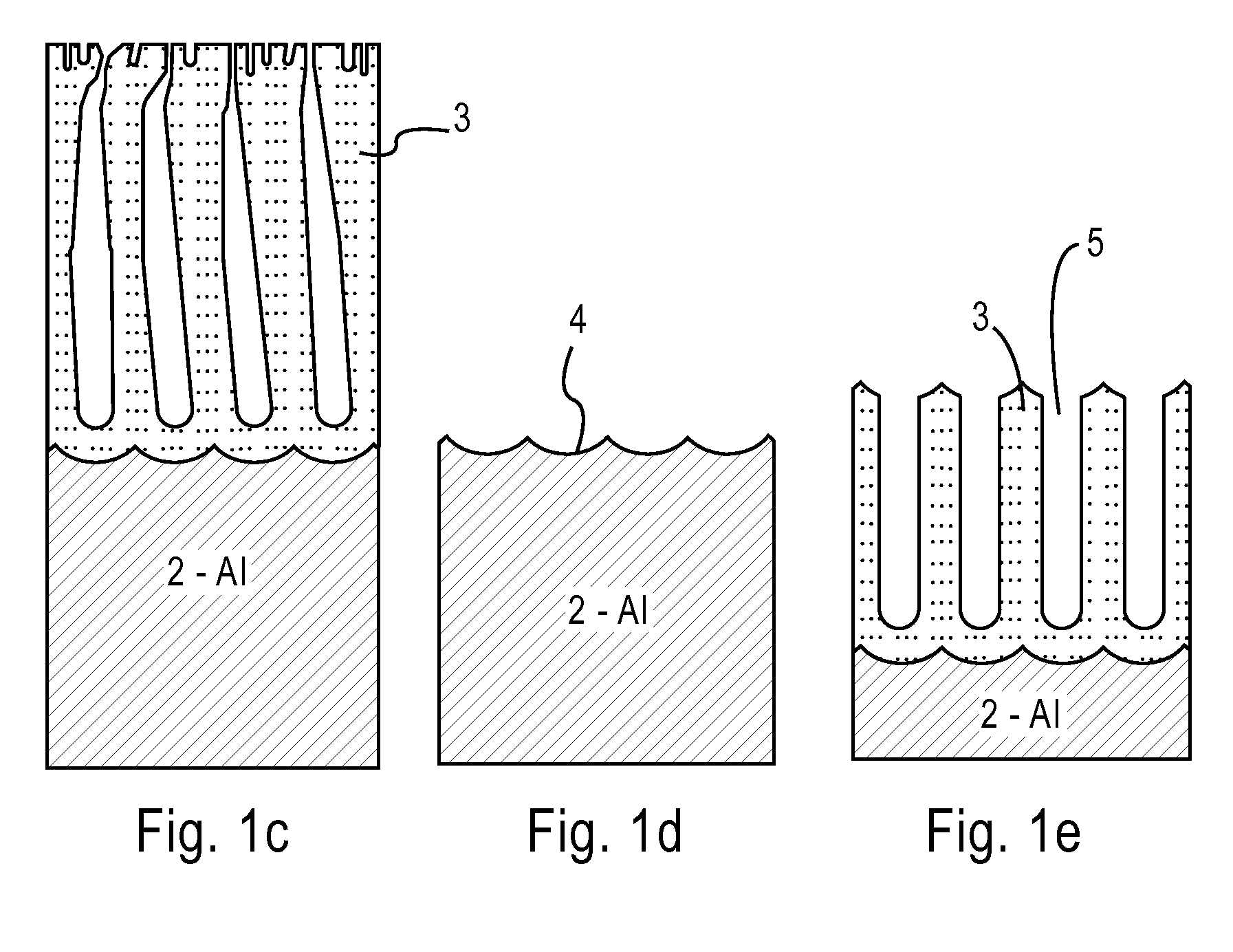

The present invention provides a method of manufacturing a nano-array electrode with a controlled nano-structure by filling an electrode material into the fine pores of an anodic-oxide porous alumina film obtained by anodically oxidizing aluminum in electrolyte, or by filling a material into the fine pores of an anodic-oxide porous alumina film obtained by anodically oxidizing aluminum in electrolyte and then filling an electrode material into the spaces defined by the nano-array formed by removing the anodic-oxide porous alumina film, or by filling repeatedly an electrode material in the fine pores of the anodic-oxide porous alumina film to fill a plurality of electrode materials. A high-performance, high-efficiency photoelectric converting device comprising a nano-array electrode manufactured by the method is also disclosed.

Owner:NIPPON OIL CORP

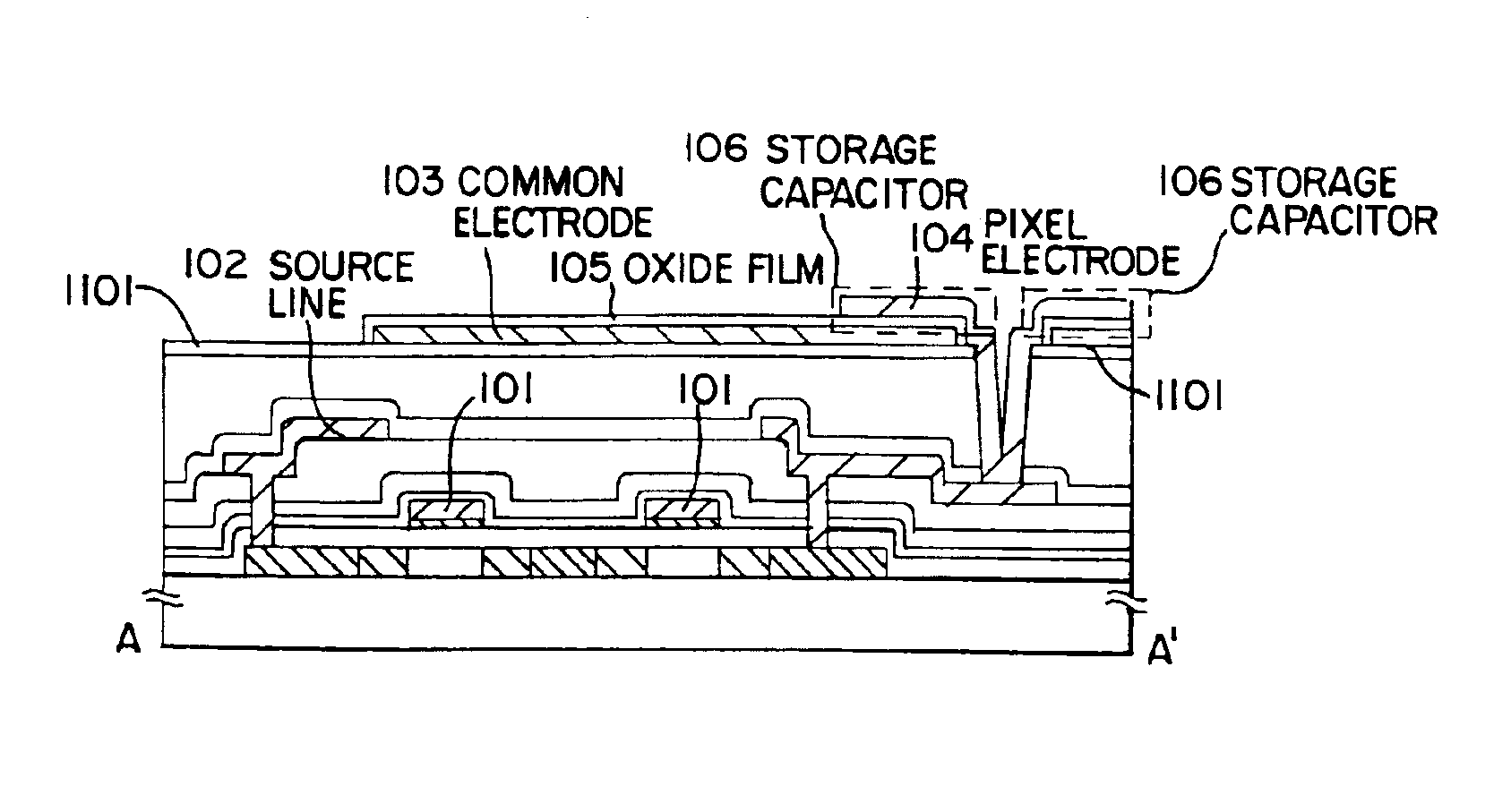

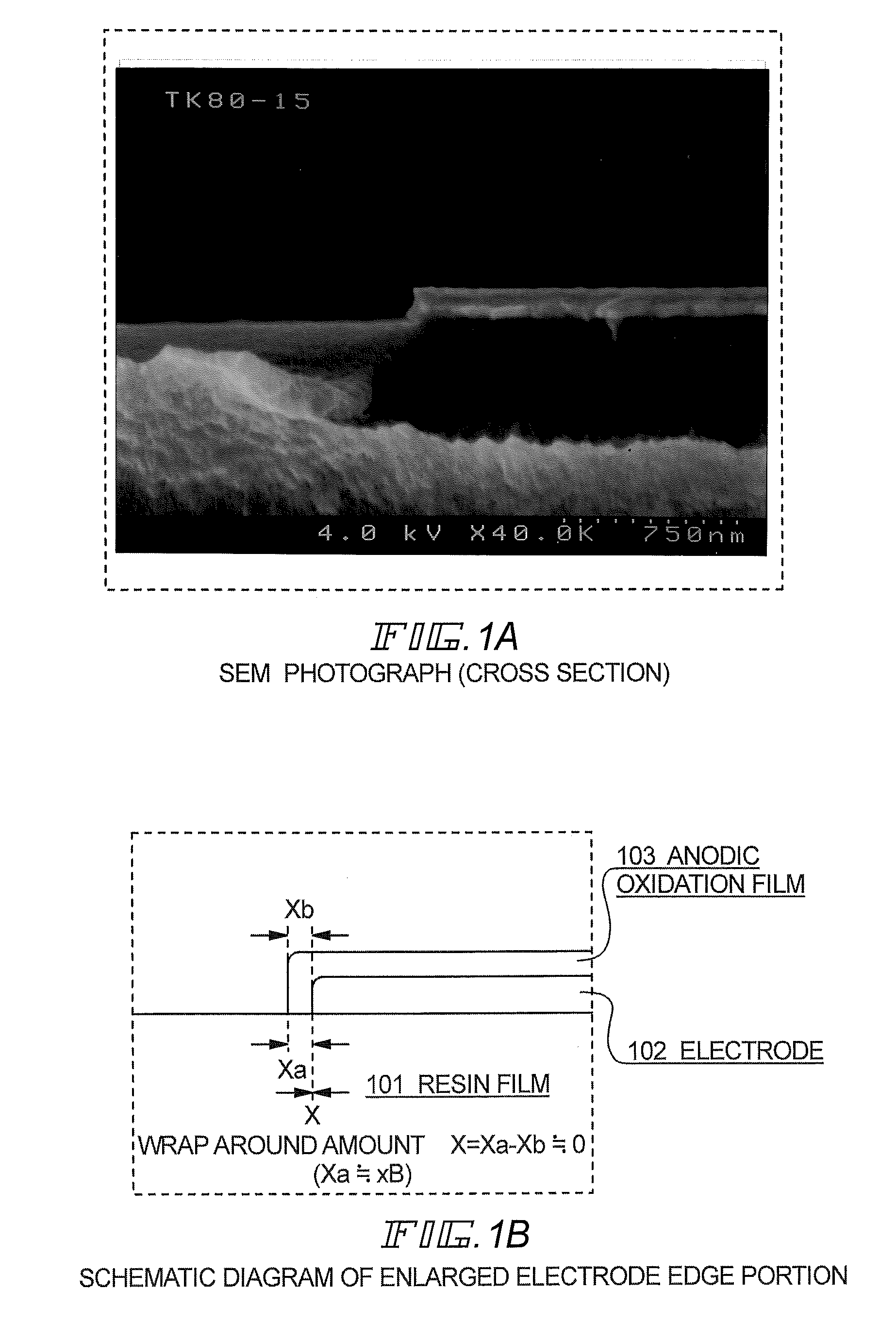

Semiconductor device with capacitor formed around contact hole

A method of forming a storage capacitor in an IPS liquid crystal display device is proposed, and a technique of forming a pixel region having a high aperture ratio is provided. An anodic oxidation process at an applied voltage / voltage supply time ratio of 11 V / min is performed for insulating films used in each circuit of an electro-optical device, typically an IPS method LCD, in particular for the surface of a common electrode formed on a resin film. The amount of formation of the extra anodic oxide film can be reduced by covering with an anodic oxide film, and a liquid crystal display device with high reliability and having an electrode with superior adhesion can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

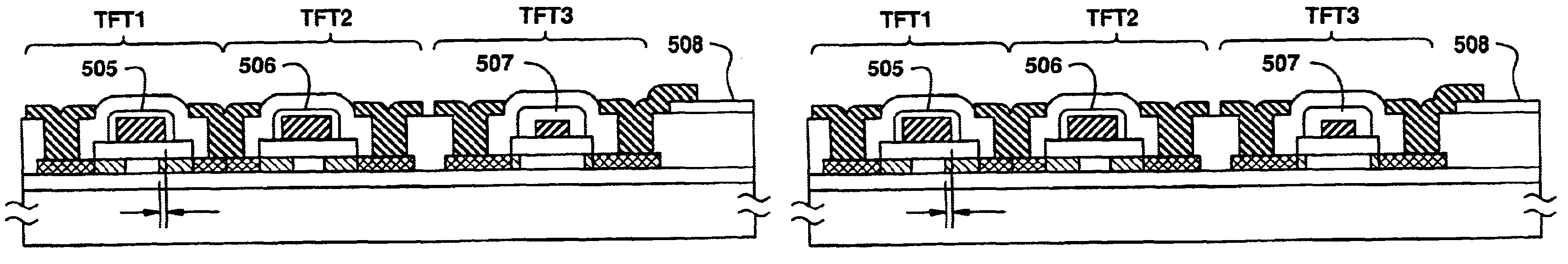

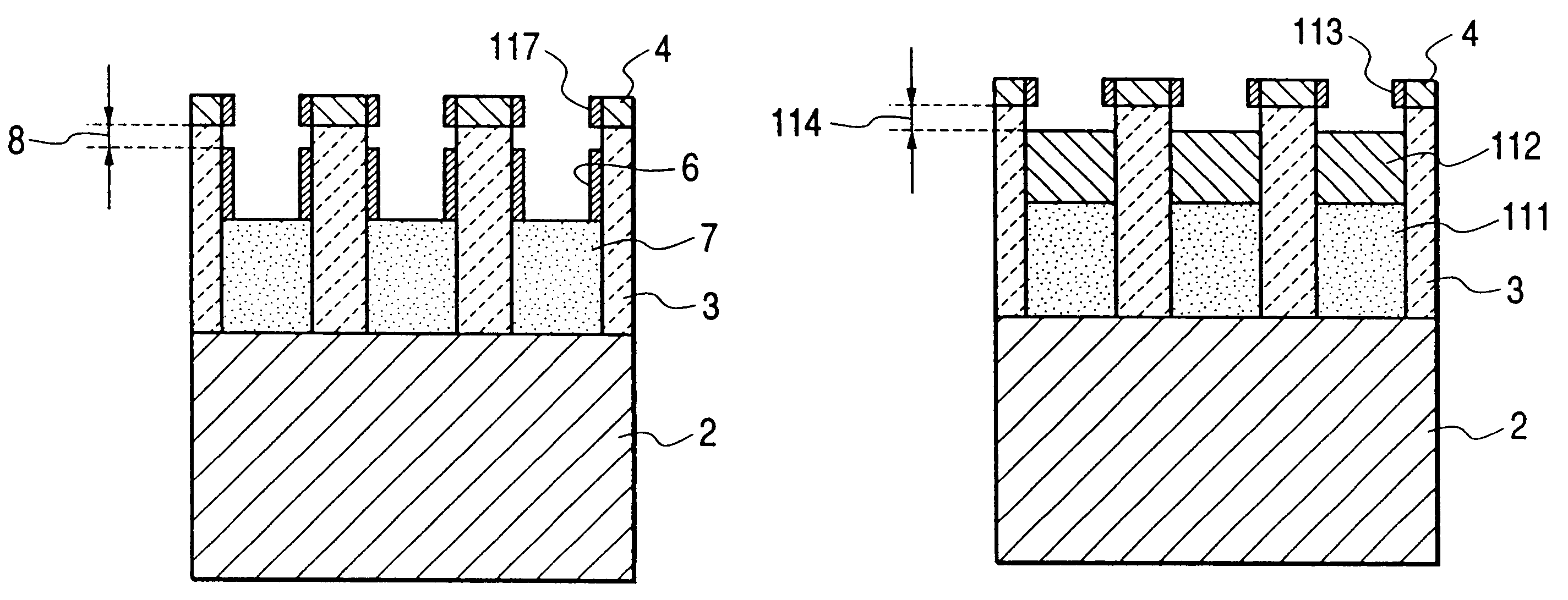

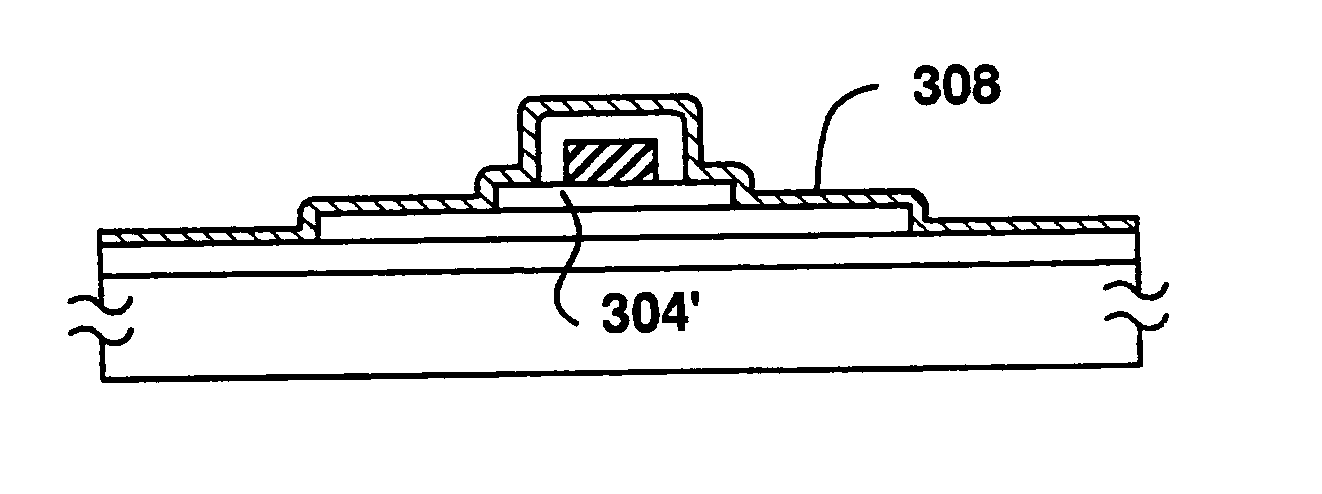

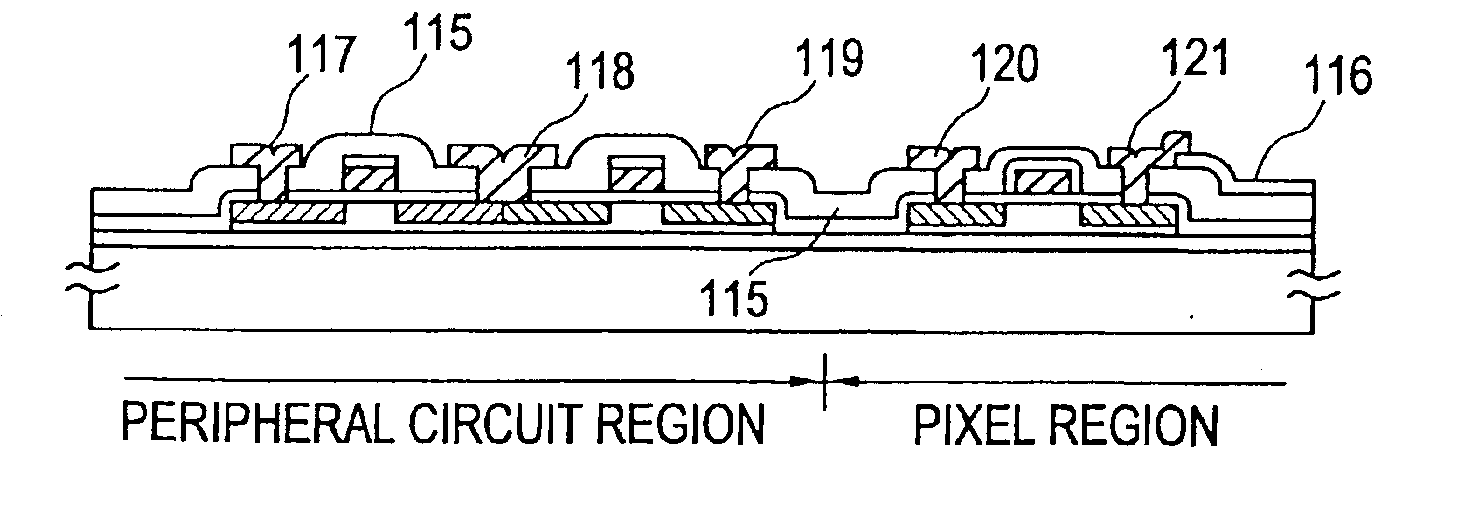

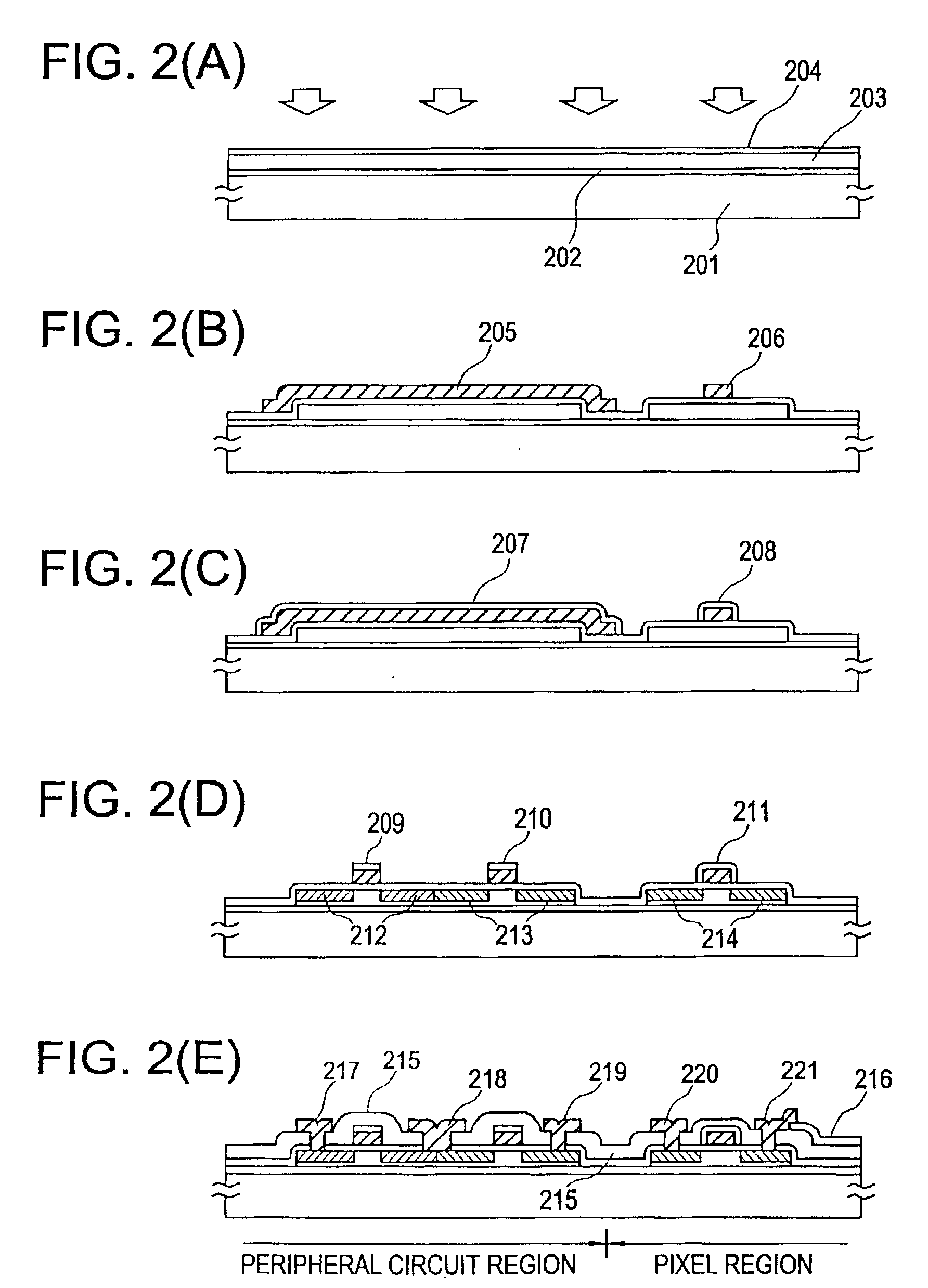

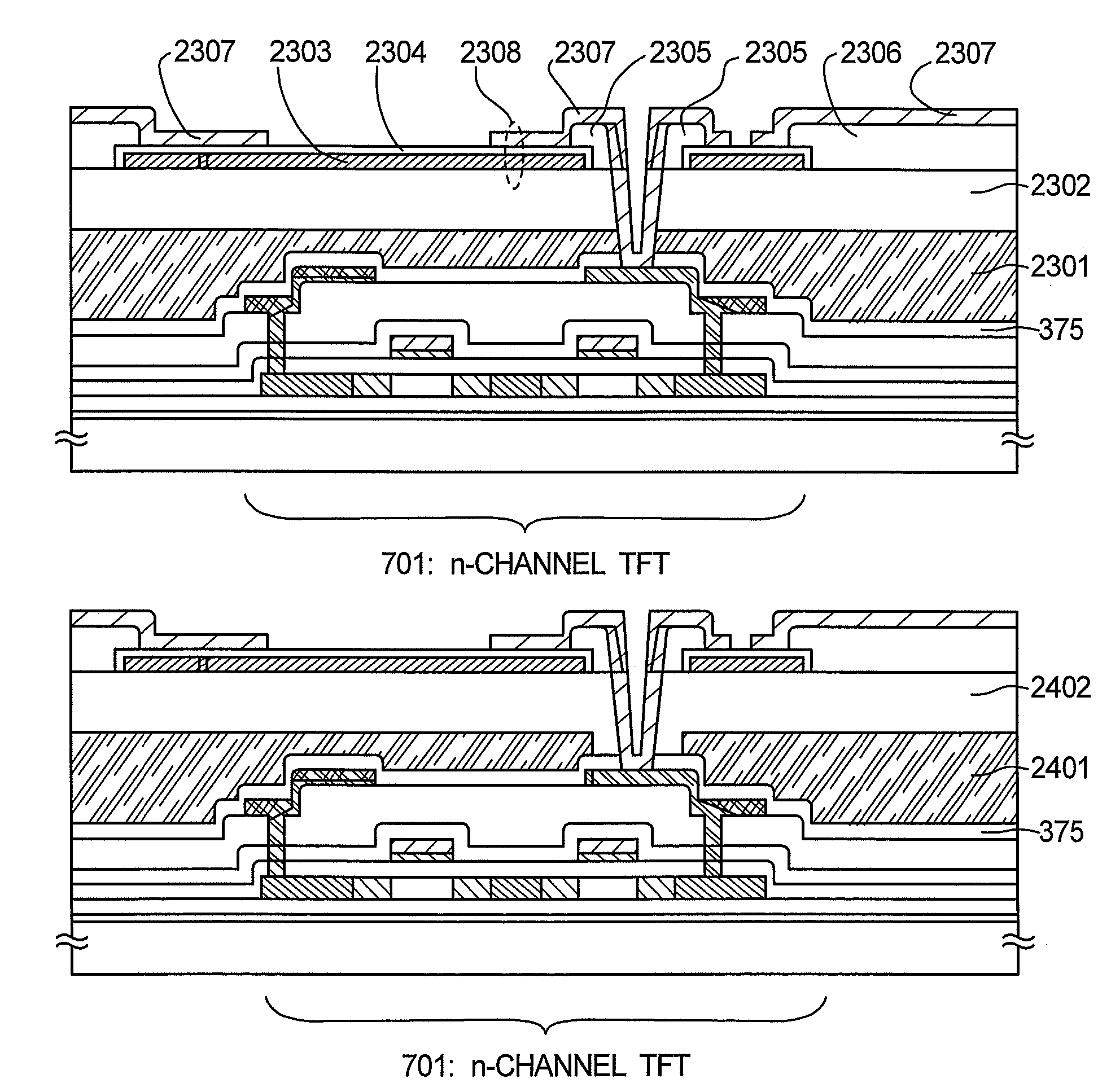

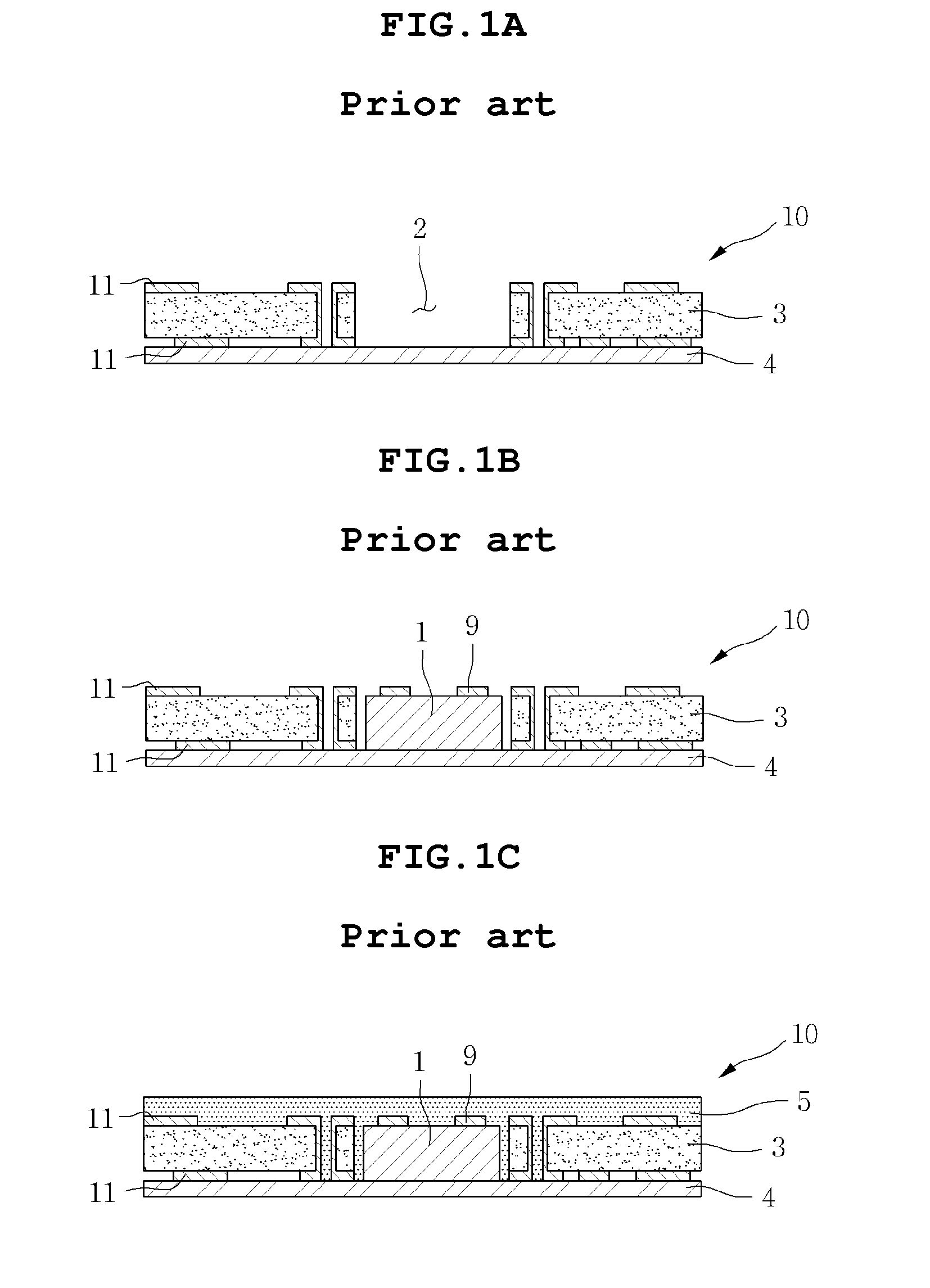

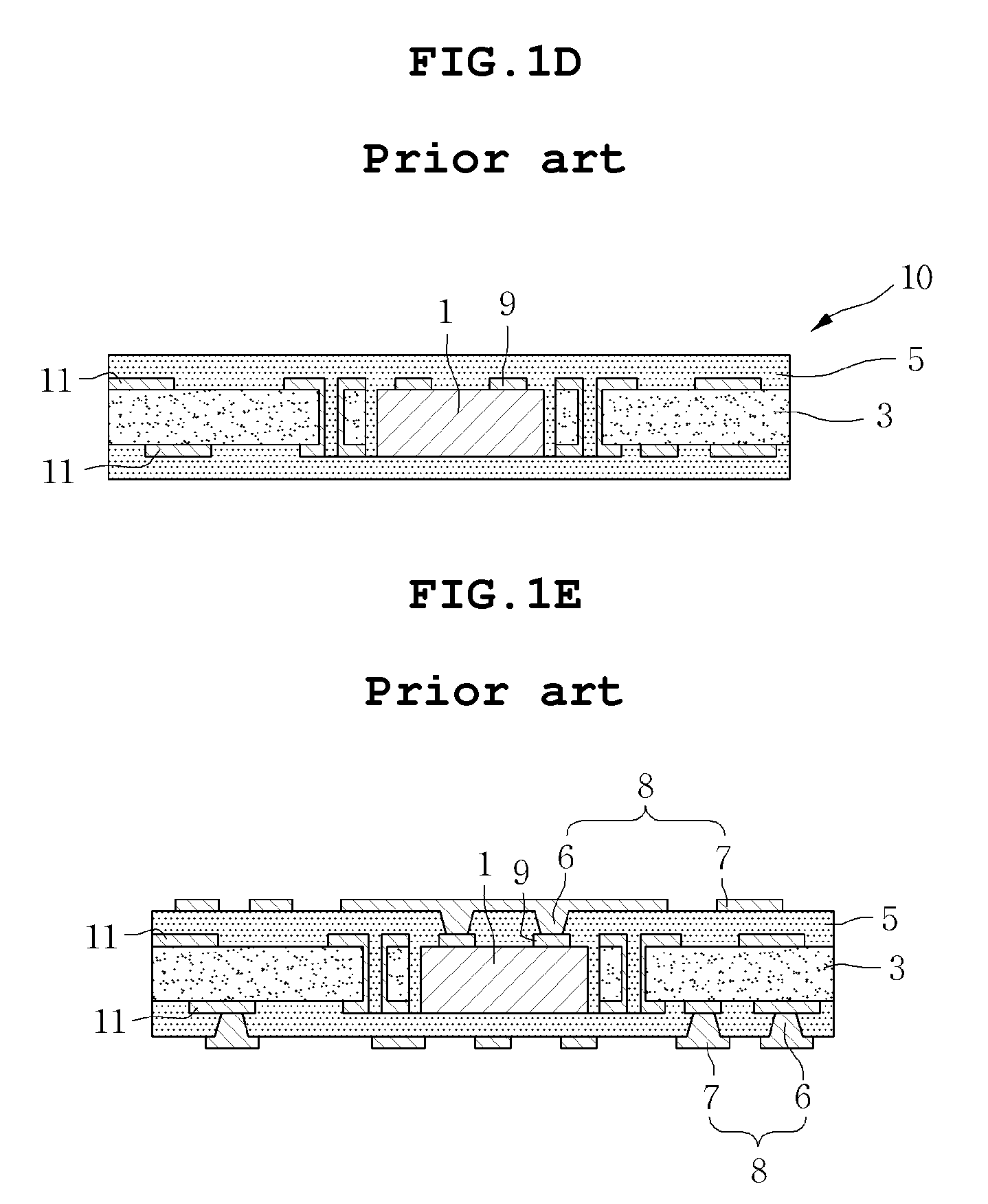

Semiconductor device and method of fabricating the same

InactiveUS6872605B2Simple preparation processStatic indicating devicesSolid-state devicesDriver circuitActive matrix

Two kinds of TFTs are fabricated by the same process with a high production yield to manufacture an active-matrix circuit and a peripheral driver circuit on the same substrate. The active-matrix circuit is required to have a high mobility and a high ON / OFF current ratio. The peripheral driver circuit needs a complex interconnection structure. The active-matrix circuit and the peripheral driver circuit comprising the TFTs are fabricated monolithically. In this step, the gate electrodes of the TFTs of the active-matrix circuit is coated with an anodic oxide on their top and side surfaces. The gate electrodes of the TFTs of the peripheral driver circuit is coated with the anodic oxide on only their top surfaces; substantially no anodic oxide is present on the side surfaces.

Owner:SEMICON ENERGY LAB CO LTD

Lithographic printing plate precursor

InactiveUS6890700B2Improving residual color residualImproving residual residual filmPhotosensitive materialsRadiation applicationsImage formationLaser exposure

A lithographic printing plate precursor is disclosed, comprising a metal support having formed thereon an anodic oxide film, and an image-forming layer containing a light-to-heat converting agent, or a light-sensitive layer capable of image-forming with infrared laser exposure provided in this order from the support.

Owner:FUJIFILM CORP

Anodized aluminum alloy material having both durability and low polluting property

InactiveUS20090050485A1High hardnessIncreased durabilityAnodisationDuplicating/marking methodsHardnessImpurity

An anodized aluminum alloy material is formed of an aluminum alloy having a Mg content between 0.1 and 2.0% by mass, a Si content between 0.1 and 2.0% by mass, a Mn content between 0.1 and 2.0% by mass, and an Fe, a Cr and a Cu content of 0.03% by mass or below and containing Al and unavoidable impurities as other components, and is coated with an anodic oxide film. Parts of the anodic oxide film at different positions with respect to thickness of the anodic oxide film have different hardnesses, respectively, and the difference in Vickers hardness between a part having the highest hardness and a part having the lowest hardness is Hv 5 or above.

Owner:KOBE STEEL LTD

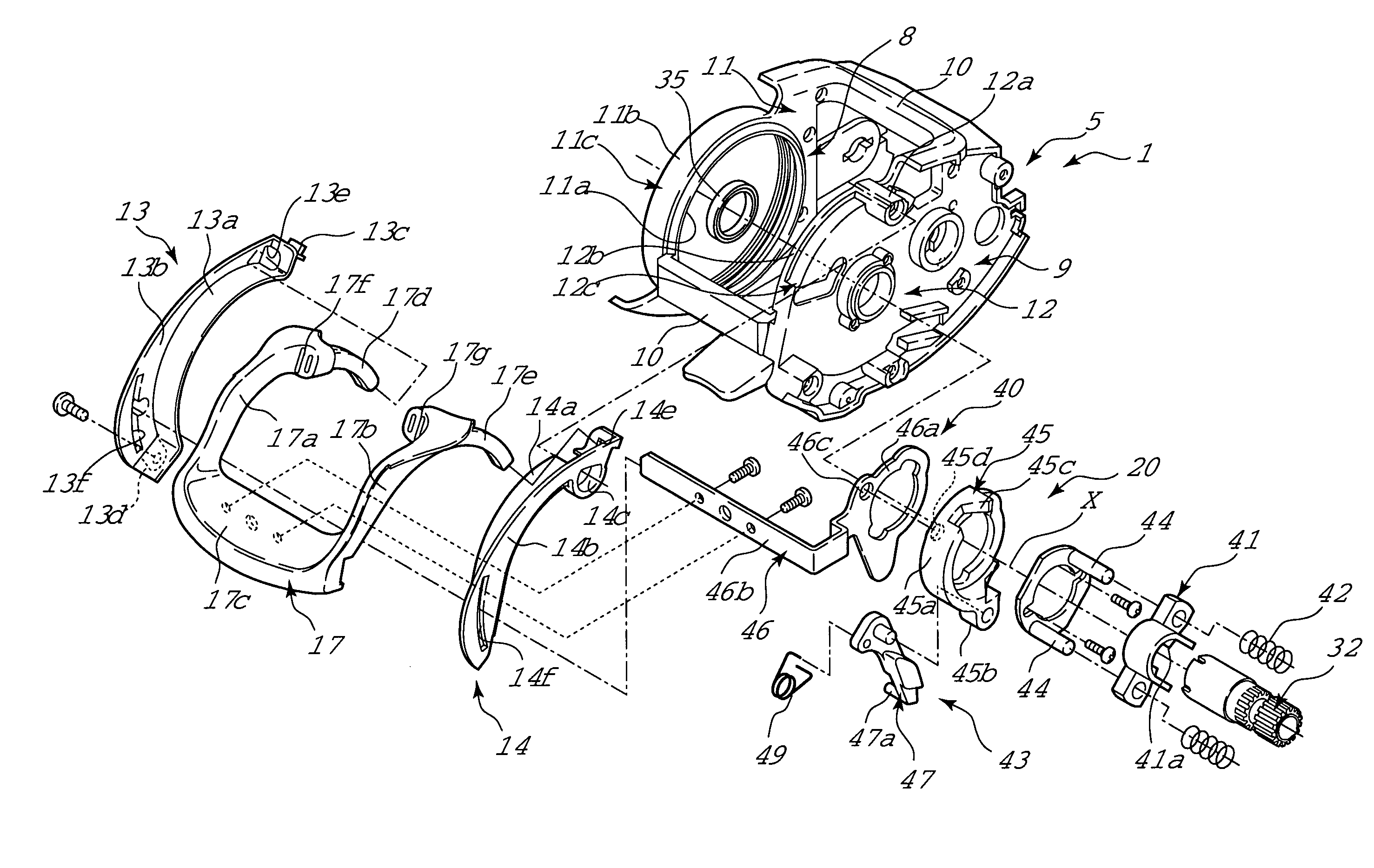

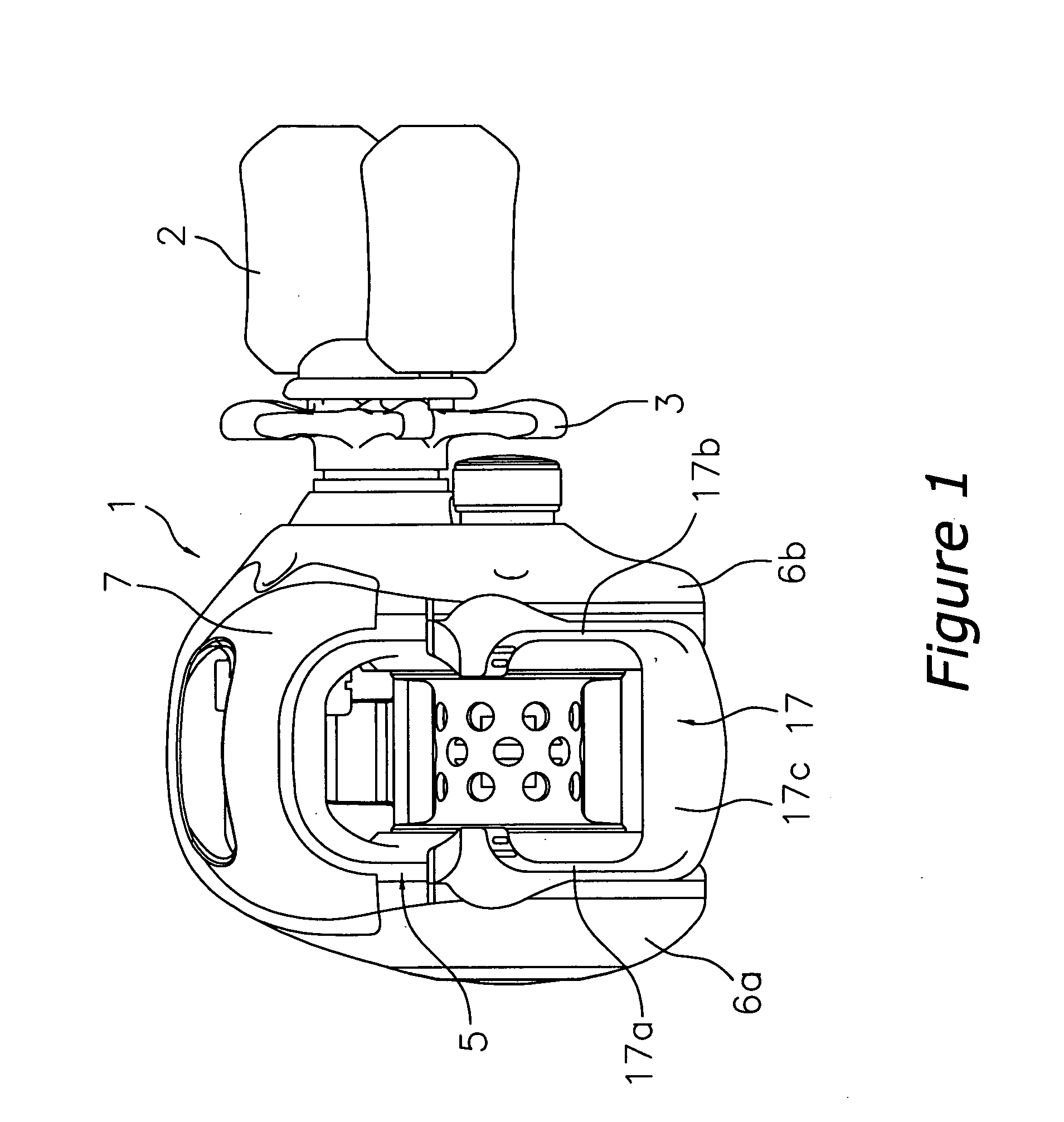

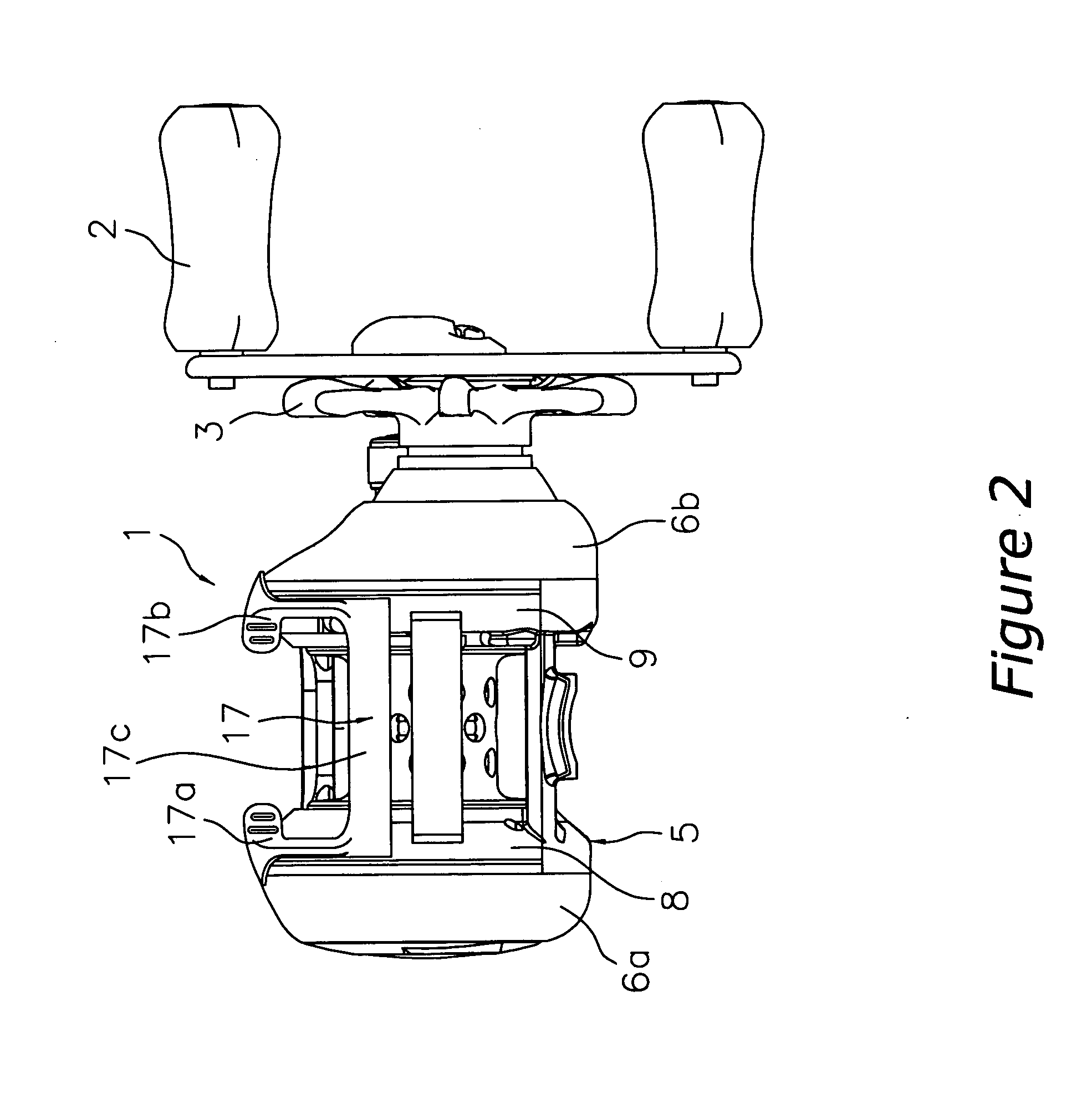

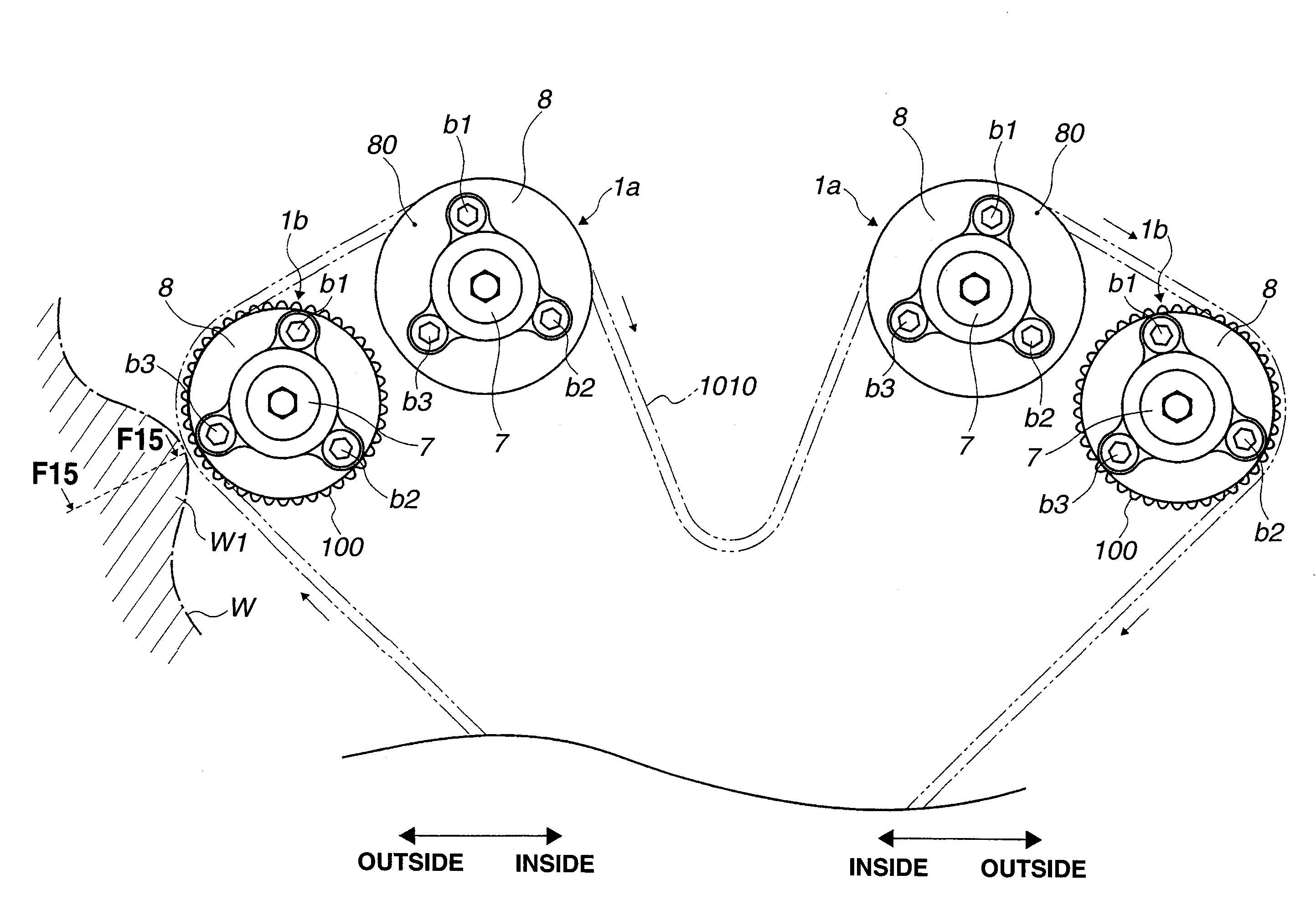

Fishing component

ActiveUS20070181728A1Avoid contactReliably prevent galvanic corrosionReelsAnti-corrosive paintsClutch controlSurface layer

A fishing component for preventing corrosion in a fishing reel includes a first component body that composes a portion of a reel unit of the fishing reel and a second component body that composes a clutch control mechanism of the fishing reel. The first component body is made of a magnesium alloy and the second component body is made of a stainless steel alloy. An anodic oxide film layer is provided on a surface layer side of the first component body. A first insulating film layer is formed on a surface layer side of the anodic oxide film layer. A second insulating film layer is formed on a surface layer side of the second component body.

Owner:SHIMANO INC

Base for decorative layer

InactiveUS20060019035A1Improve toleranceImproves tolerance of thicknessAnodisationLiquid surface applicatorsOptoelectronicsMetal

A base for a decorative layer is provided comprising a first material capable of forming an anodic oxide and a second capable of forming an interference metal oxide formed on the first material. The material capable of forming an anodic oxide layer may comprise a barrier layer formed on a substrate. A decorative layer is formed by anodic oxidation of the layer comprising a material capable of forming an interference metal oxide to form an oxide layer formed on the material capable of forming an interference metal oxide, wherein the oxide layer is configured to have a thickness suitable to cause interference of incident light.

Owner:SHEFFIELD HALLAM UNIVERSITY

Composite material and preparation method thereof

ActiveCN101768770ARich surface colorRetain glossAnodisationThin material handlingColor filmAnodic oxidation

The invention relates to a composite material and a preparation method thereof, which belong to the field of aluminum alloys. The invention provides the composite material against the defects of unevenness, no metal luster, easy scratch and easy abrasion of a gradient color film layer on the surface of the aluminum alloy, the composite material comprises a substrate, a porous anodic oxide film layer is arranged on the surface of the substrate, the substrate is aluminum or the aluminum alloy, at least one dye is filled in pores of the porous anodic oxide film layer, and the content of the same dye in part of the pores of the porous anodic oxide film layer is in gradient distribution. The preparation method of the composite material comprises the following steps: using the anodic oxidation method for forming the porous oxide film layer on the surface of the aluminum alloy; and dyeing the porous oxide film layer, wherein the dyeing method is to control the time of entering into the dye of different regions of the porous oxide film layer and further lead the content of the dye filled in the pores of the porous anodic oxide film layer to be in the gradient distribution. The composite material has the advantages of evenness, metal luster, difficult scratch and difficult abrasion of the film layer and is mainly applied on electronic products.

Owner:BYD CO LTD

Metal salt-free sealing agent for aluminum alloy anodic oxide film

ActiveCN101864589AImprove corrosion resistanceGood gloss and color retentionSurface reaction electrolytic coatingCobaltOrganic compound

The invention provides a metal salt-free sealing agent for an aluminum alloy anodic oxide film, belonging to the technical field of aluminum alloy anodic oxide film post treatment. The sealing agent of the invention is prepared by water solution composed of 1.0-10g / L of a hydration accelerator, 0.01-2g / L of a wetting agent, 0.01-3g / L of an ash inhibitor and 1-15g / L of a pH buffering agent, wherein the pH of workpiece fluid is 5.5-6.5, the operating temperature is 70-90 DEG C, and the sealing speed is 1.0-2.0min / um. The metal salt-free sealing agent creatively adopts organic compounds which are easily subject to biodegradation, does not contain any metal ions of nickel, cobalt, magnesium, calcium, lithium and the like as well as fluorinions, and obtains satisfactory sealing effect of the nano-pores of the aluminum alloy anodic oxide film by virtue of the scientific and coordinated component formula of the water solution; the aluminum alloy anodic oxide film obtained by seal treatment through the sealing agent has the advantages of good corrosion resistance, capability of meeting the requirements of GB 14952.1-94, good light-protection and color-protection properties of a film layer, no ash and pruina, no water stain after drying as well as light flowing color and small color difference change in case of sealing the organic dyeing film; and the metal salt-free sealing agent is widely applicable to sealing treatment of an original-color anodic oxide film, an electrolytic coloring anodic oxide film, a hard oxide film and a dyeing anodic oxide film.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Semiconductor device comprising a thin film transistor comprising a semiconductor thin film and method of manufacturing the same

InactiveUS7821065B2Improve reliabilityUniform film thicknessTransistorElectroluminescent light sourcesSemiconductorCapacitor

Owner:SEMICON ENERGY LAB CO LTD

Mixed acid anodizing and hole sealing method of magnesium-containing high-silicon-content wrought aluminum alloy surface

The invention belongs to the technical field of alloy surface treatment, and particularly relates to a mixed acid anodizing and hole sealing method of a magnesium-containing high-silicon-content wrought aluminum alloy surface, which comprises the following steps that: after a magnesium-containing high-silicon-content wrought aluminum alloy workpiece with the silicon content of up to 10-15wt% is pre-treated, a mixed acid liquid of 150-180g / L of H2SO4 and 5-15g / L of organic acid is used as an electrolytic liquid, the magnesium-containing high-silicon-content wrought aluminum alloy workpiece is subjected to DC (direct current) anodic oxidation for 20-25min at room temperature at the current density of 1.2-1.8A / dm<2>, and then is subjected to boiling water sealing, cold sealing, nickel acetate sealing or stearic acid hole sealing. In the acid anodizing and hole sealing method, a layer of anodic oxide film is prepared on the surface of magnesium-containing high-silicon-content wrought aluminum alloy by controlling anodizing process parameters and hole sealing process conditions, thereby improving the corrosion resistance of the surface of the magnesium-containing high-silicon-content wrought aluminum alloy.

Owner:NORTHEASTERN UNIV

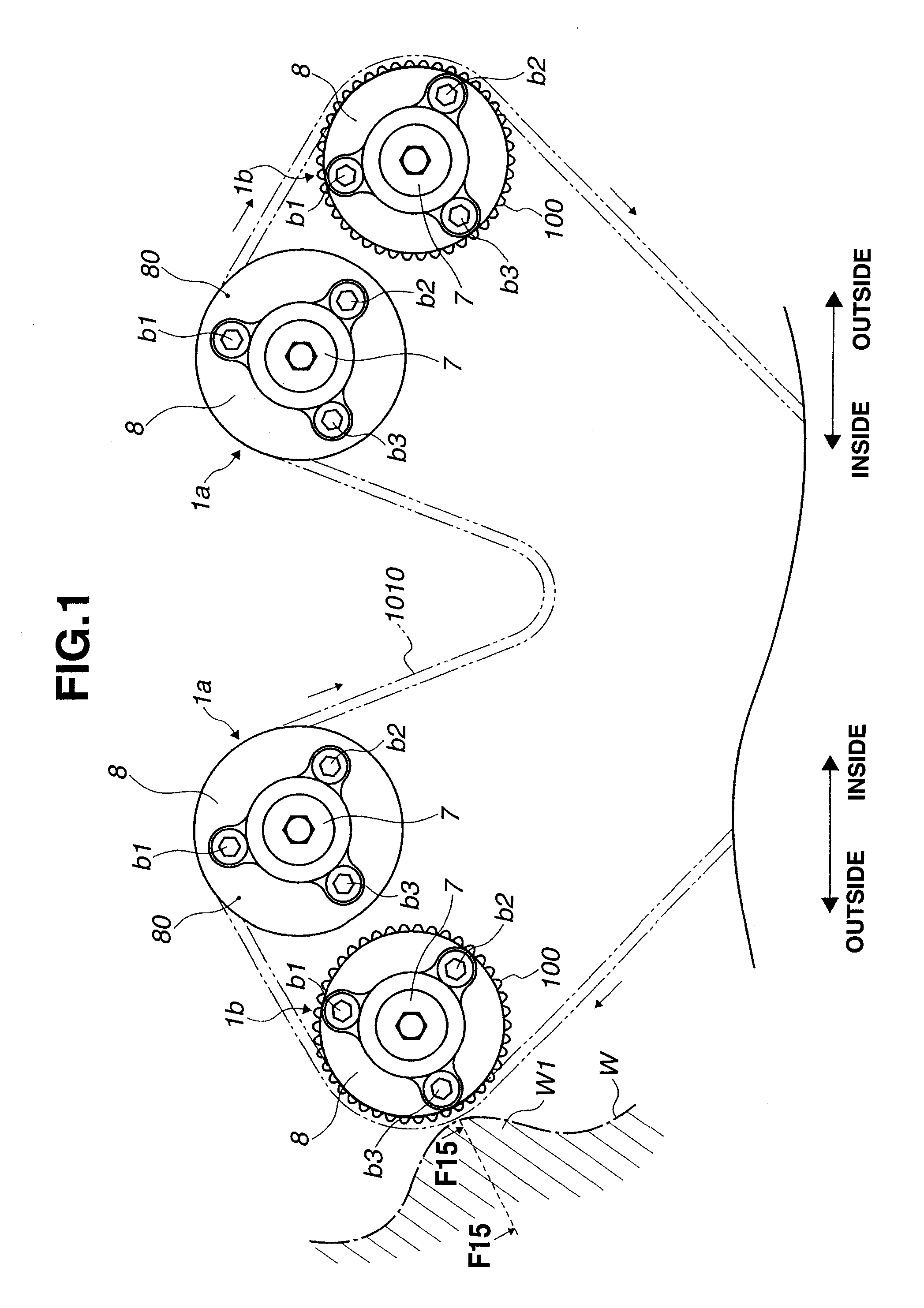

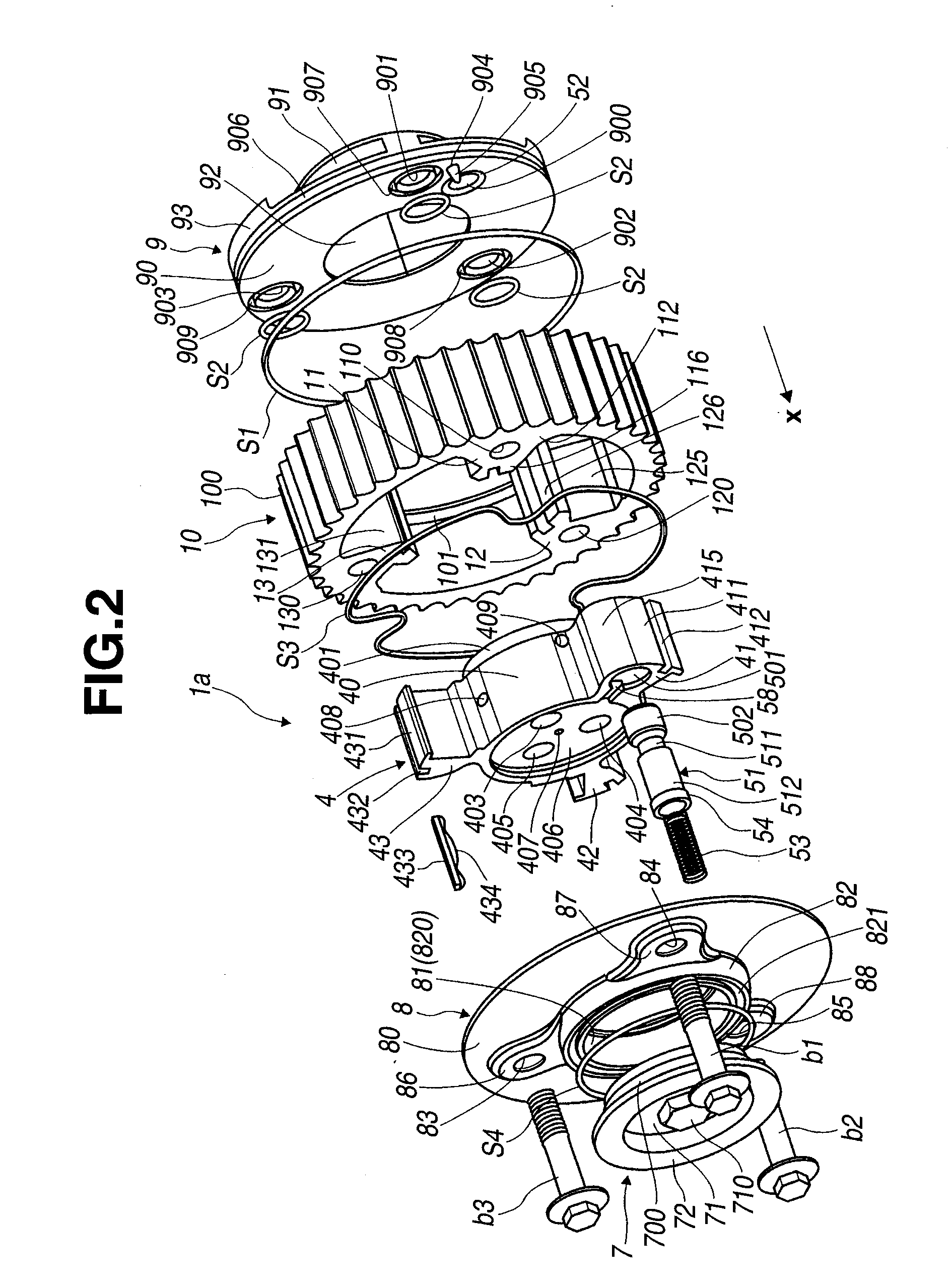

Valve Timing Control Apparatus for Internal Combustion Engine, and Method of Producing Same

InactiveUS20110061616A1Valve drivesMachines/enginesExternal combustion engineInternal combustion engine

A valve timing control apparatus for an internal combustion engine, includes a housing body, a sealing plate, a vane rotor, and a sealing ring. The housing body includes an opening at an axial end which is closed by the sealing plate. The sealing ring is disposed between the housing body and the sealing plate. The housing body is formed of an aluminum-based metal material and anodized, wherein the housing body includes a base layer and an anodic oxide coating film layer. The sealing ring abuts on the base layer of the housing body at the axial end.

Owner:HITACHI AUTOMOTIVE SYST LTD

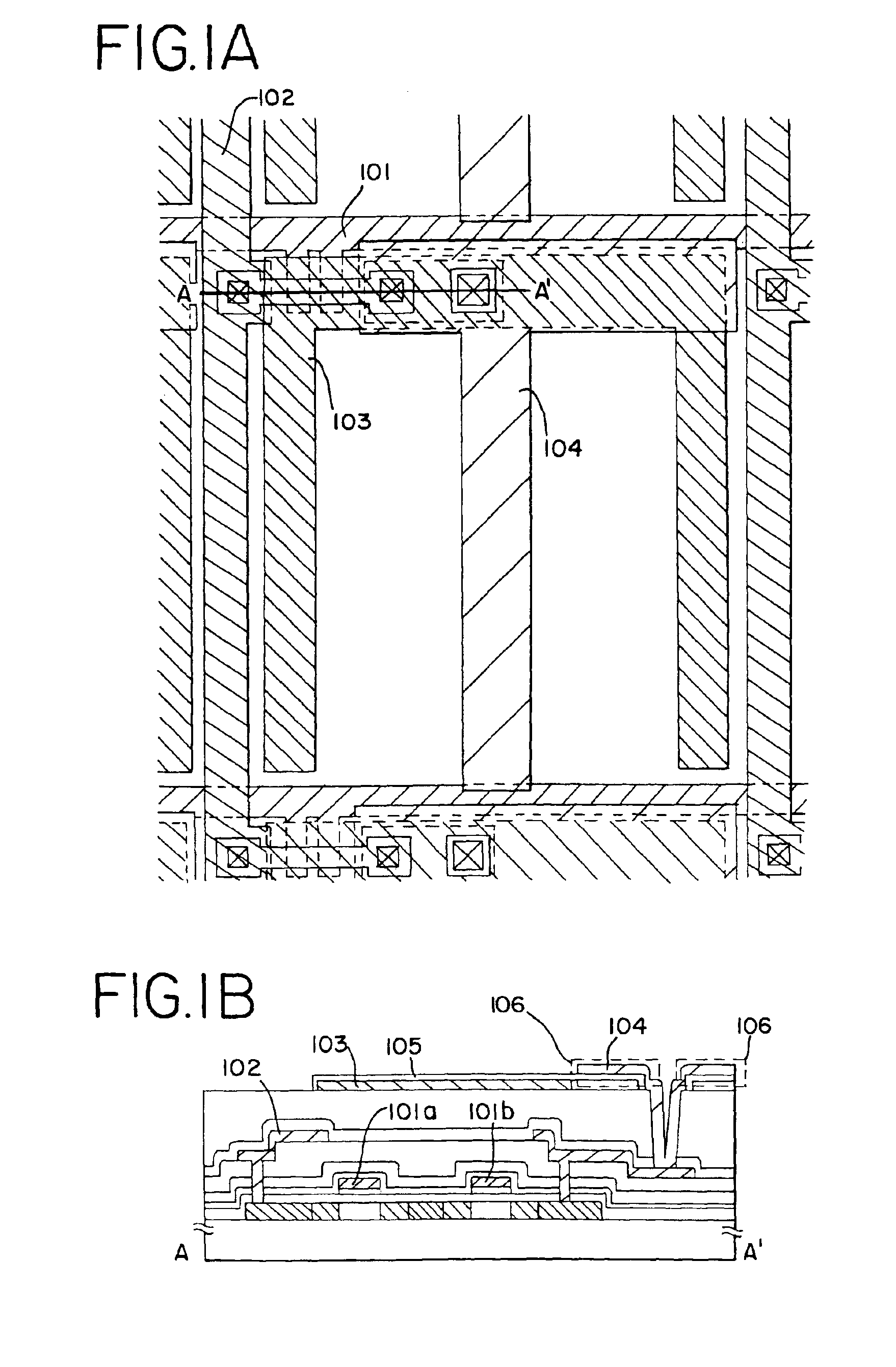

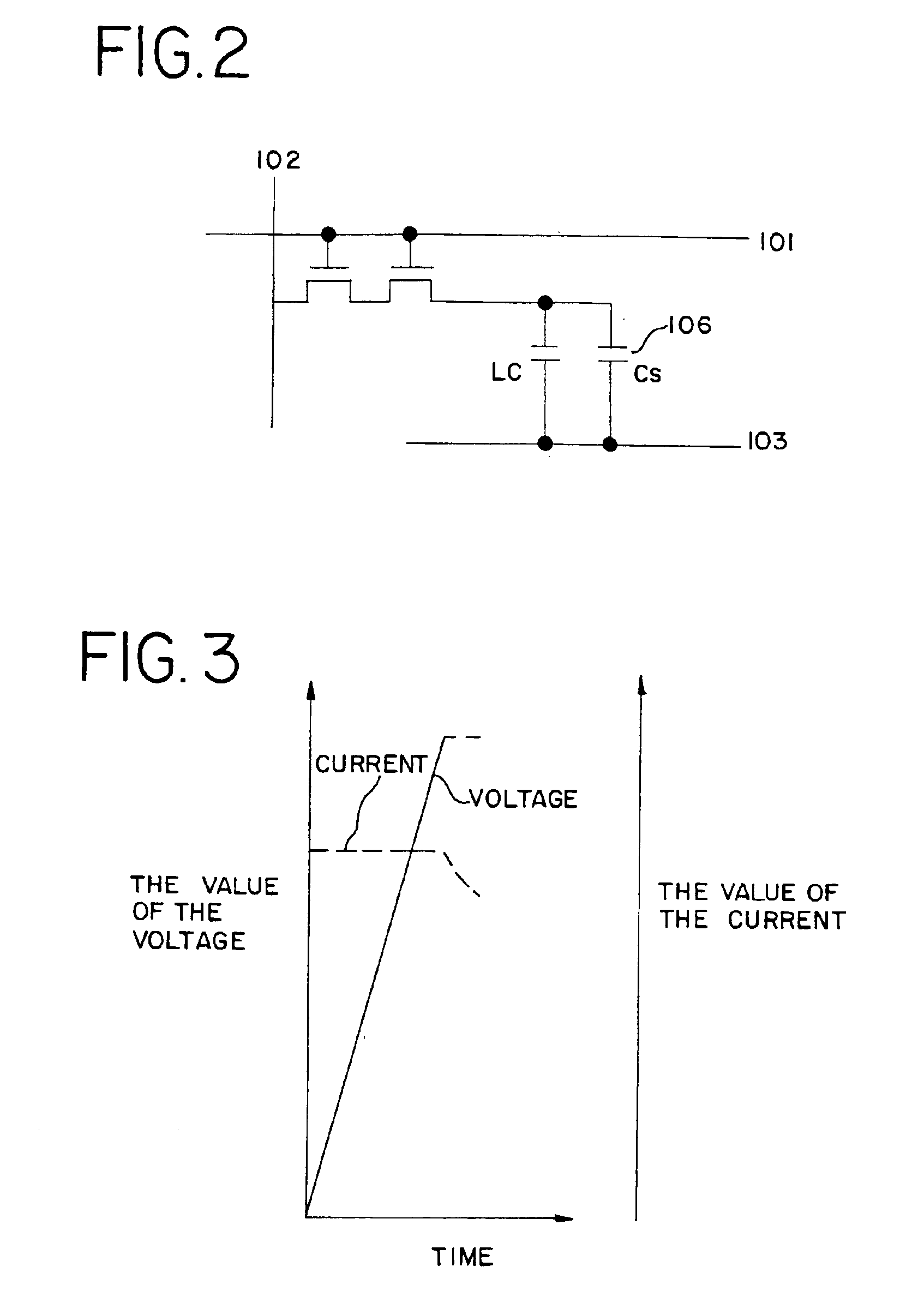

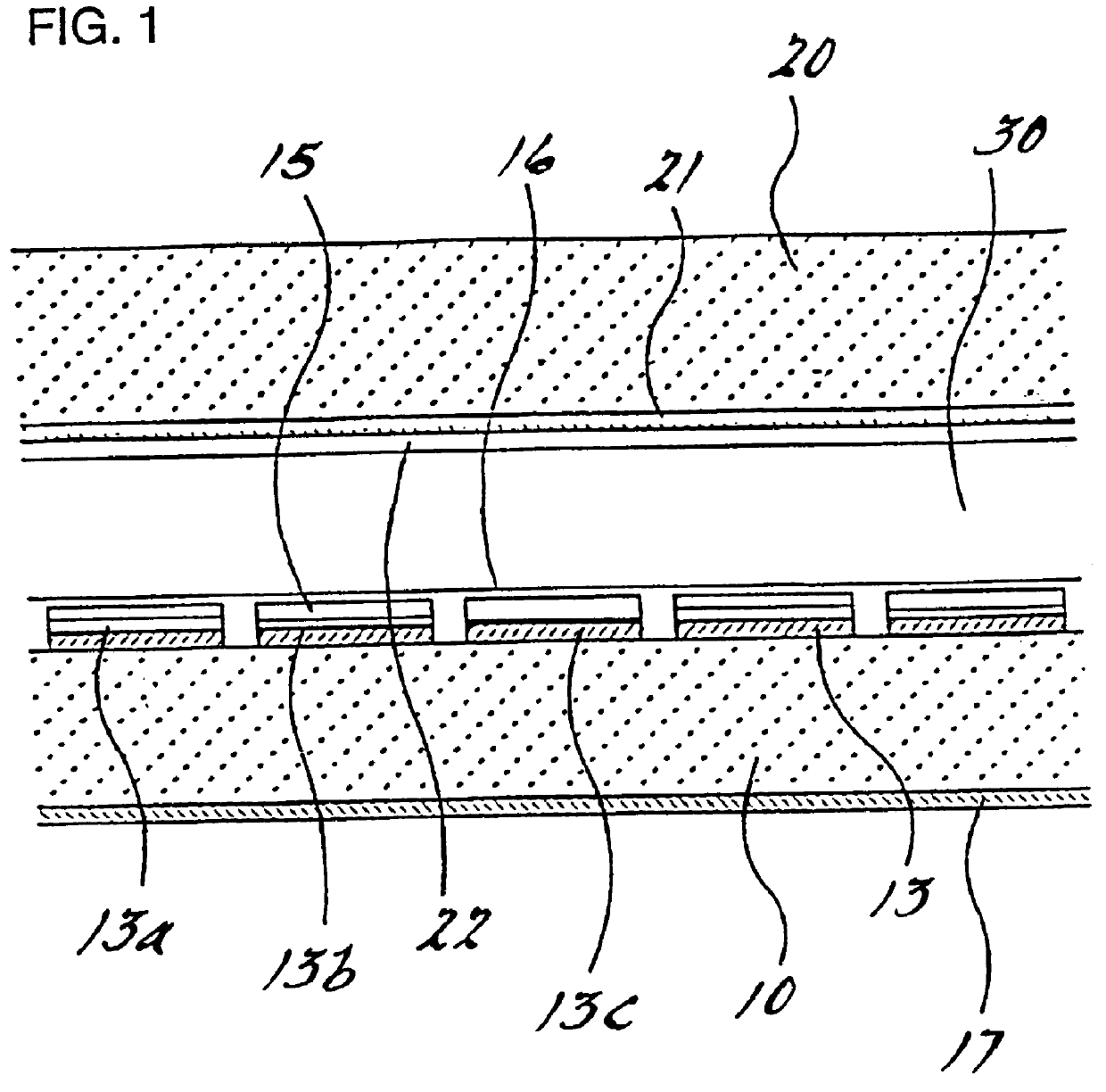

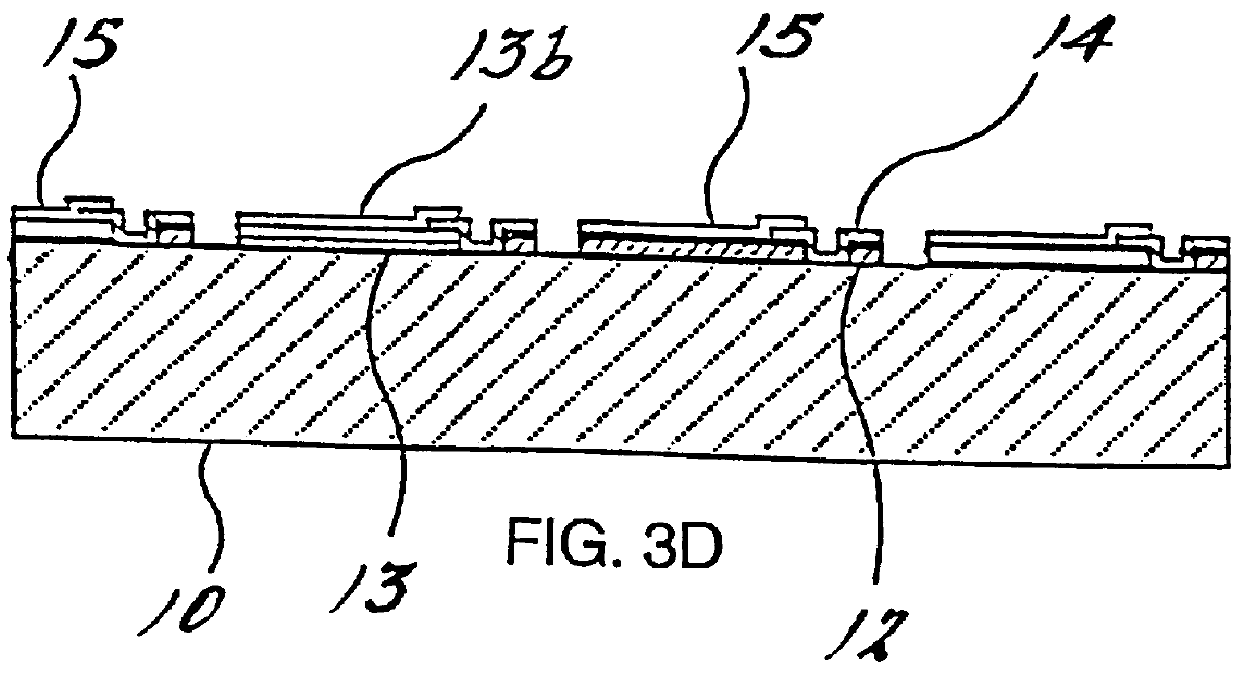

Liquid-crystal display unit, and process for manufacturing the same

InactiveUS6104459AExpansion quantityEasy to manufactureNon-linear opticsLiquid-crystal displayEngineering

PCT No. PCT / JP97 / 02426 Sec. 371 Date Mar. 10, 1998 Sec. 102(e) Date Mar. 10, 1998 PCT Filed Jul. 11, 1997 PCT Pub. No. WO98 / 02775 PCT Pub. Date Jan. 22, 1998The present invention provides a liquid-crystal display device and a process for manufacturing the same, wherein the unit achieves an inhibition of reduction in the displaying brightness even when used for a color reflection-type liquid-crystal display device, and a restriction of variation in the color tone which varies depending on the quantity of incident light. For each of the pixel regions, a pixel reflective layer 13 is formed with Ta. On the surface of each of a plurality of the pixel regions, three anodic oxide films 13a, 13b and 13c are formed with mutually different thicknesses. The thicknesses of the anodic oxide films are determined such that light reflected by the pixel reflective layer 13 is colored into three different colors.

Owner:SEIKO EPSON CORP

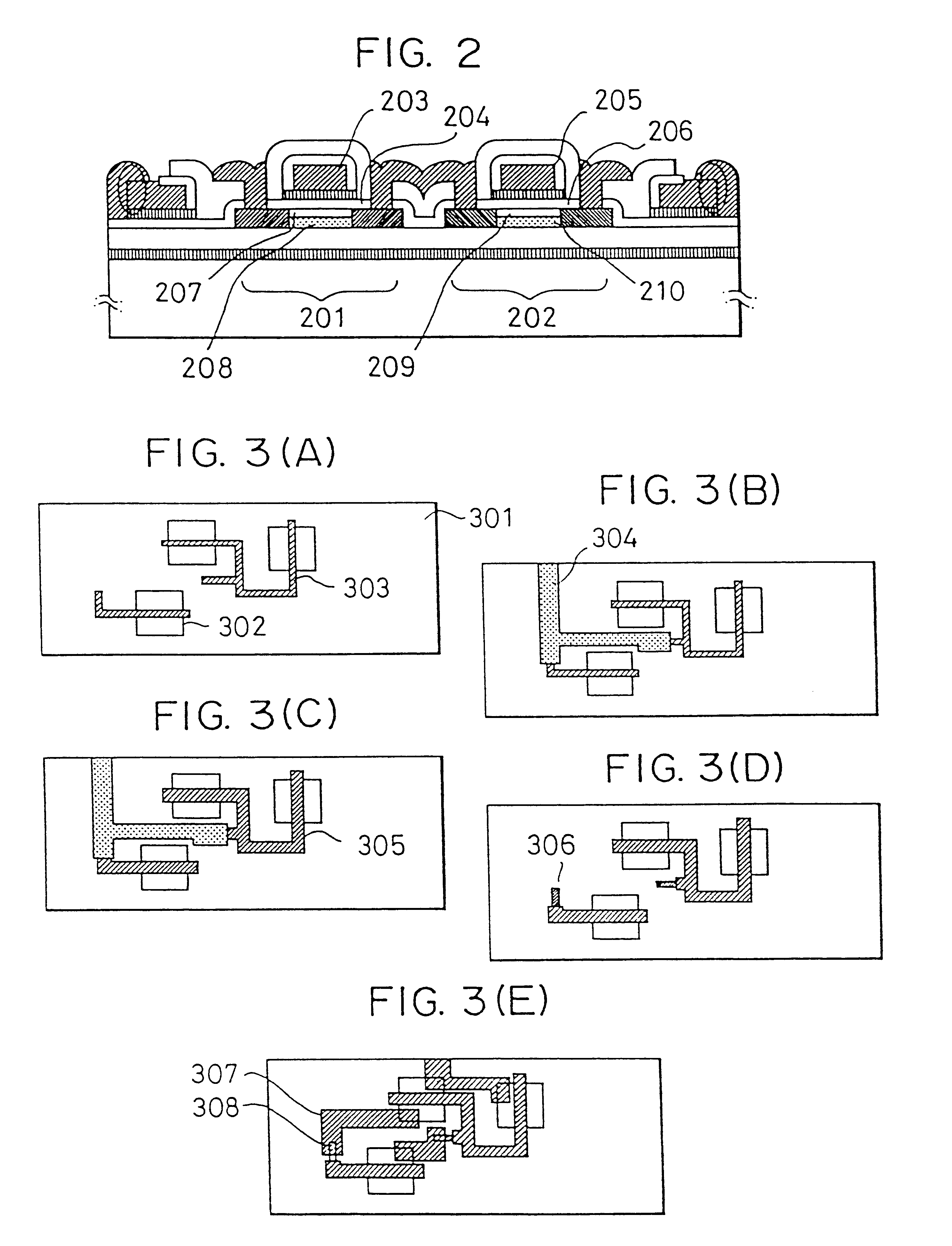

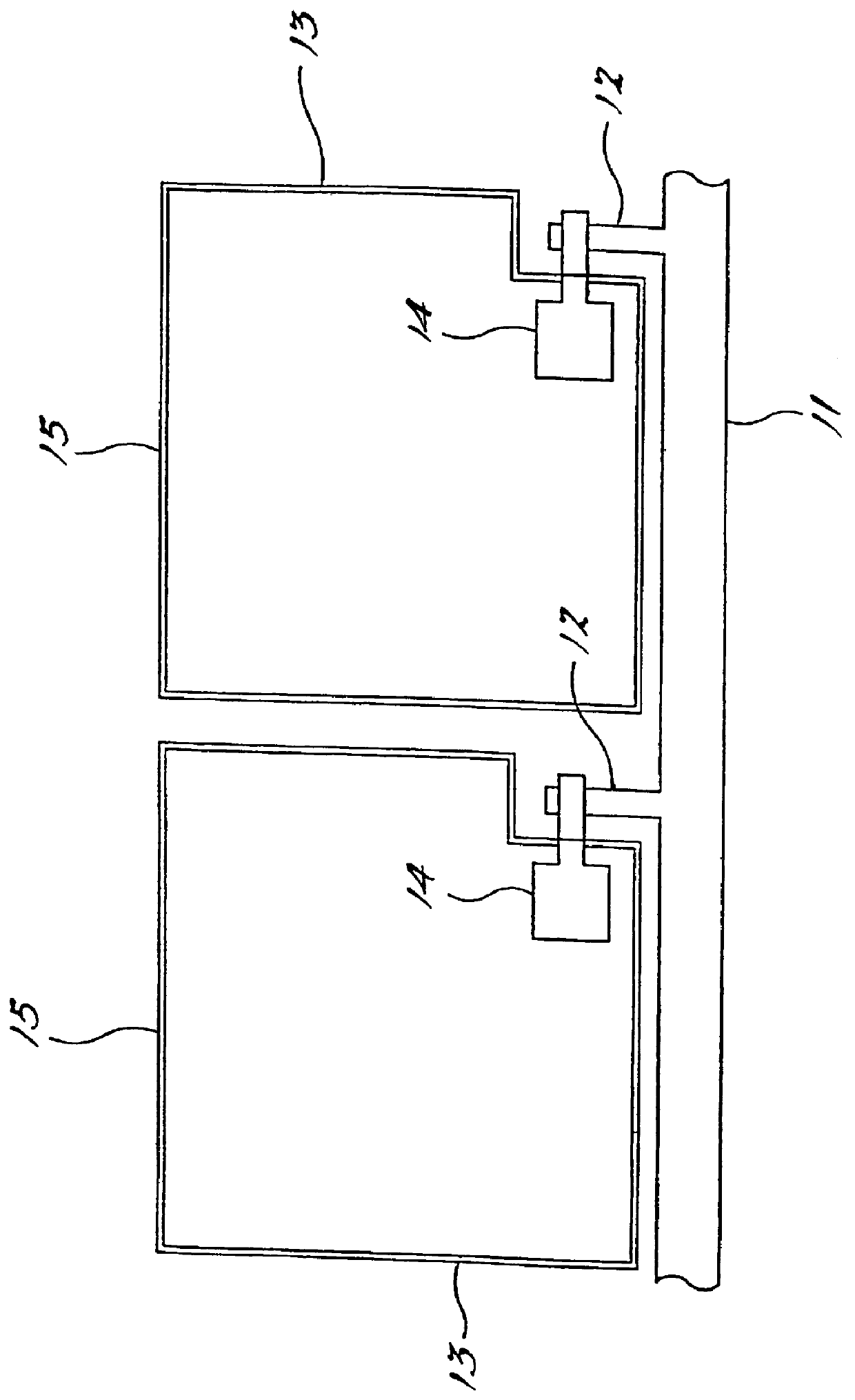

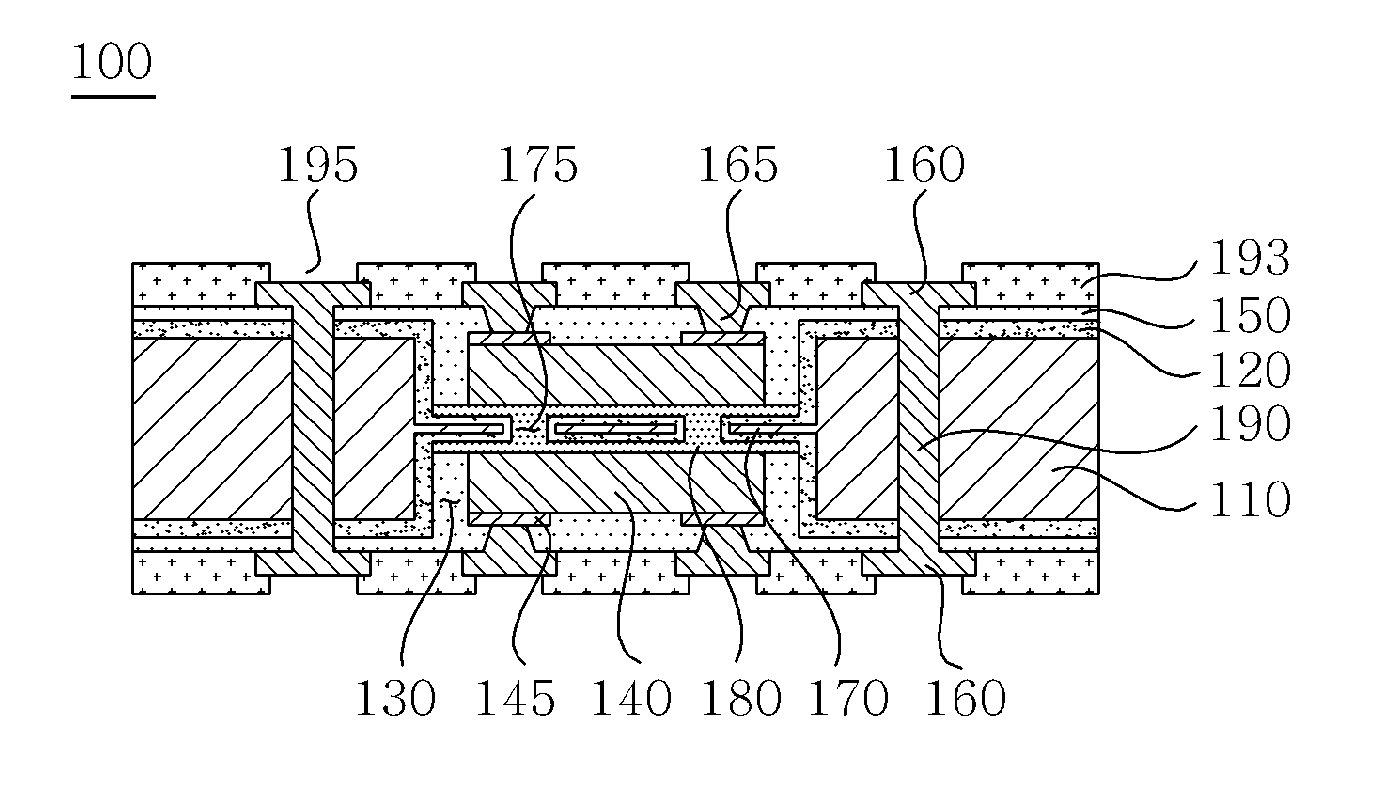

Electronic component-embedded printed circuit board and method of manufacturing the same

InactiveUS20110164391A1Improve performanceEnsure structural stabilitySemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

Disclosed herein is an electronic component-embedded printed circuit board, including: a metal substrate including an anodic oxide film formed over the entire surface thereof; two electronic components disposed in a cavity formed in the metal substrate in two stages; an insulation layer formed on both sides of the metal substrate to bury the electronic components disposed in the cavity; and circuit layers including vias connected with connecting terminals of the electronic components and formed on the exposed surfaces of the insulation layer. The electronic component-embedded printed circuit board is advantageous in that its radiation performance of radiating the heat generated from an electronic component can be improved, and its production cost can be reduced, because a metal substrate is used instead of a conventional insulating material.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Process for anodizing aluminum-alloy substrate

The invention relates to a process for anodizing an aluminum-alloy substrate. The process comprises the following steps of: (S1) degreasing; (S2) washing for the first time; (S3) washing by an alkali; (S4) washing for the second time; (S5) polishing; (S6) washing for the third time; (S7) anodizing; (S8) washing for the fourth time; (S9) carrying out electrolytic coloring; (S10) washing for the fifth time; (S11) sealing holes; (S12) washing for the sixth time to finally obtain a dense anodic oxide film. The whole anodizing process is carried out in the environment of normal temperature, less energy is consumed, the sulfuric acid used for anodizing can be reused for degreasing, the utilization rate of raw materials is high, the production cost is low, the holes are sealed after carrying out the anodizing reaction, the anodizing film can effectively protect the aluminum and the aluminum-alloy, the surface of the anodizing film has no honeycomb-like porous structure, is highly smooth and can be kept to be smooth for a long time.

Owner:CHENGDU SUNSHINE ALUMINUM

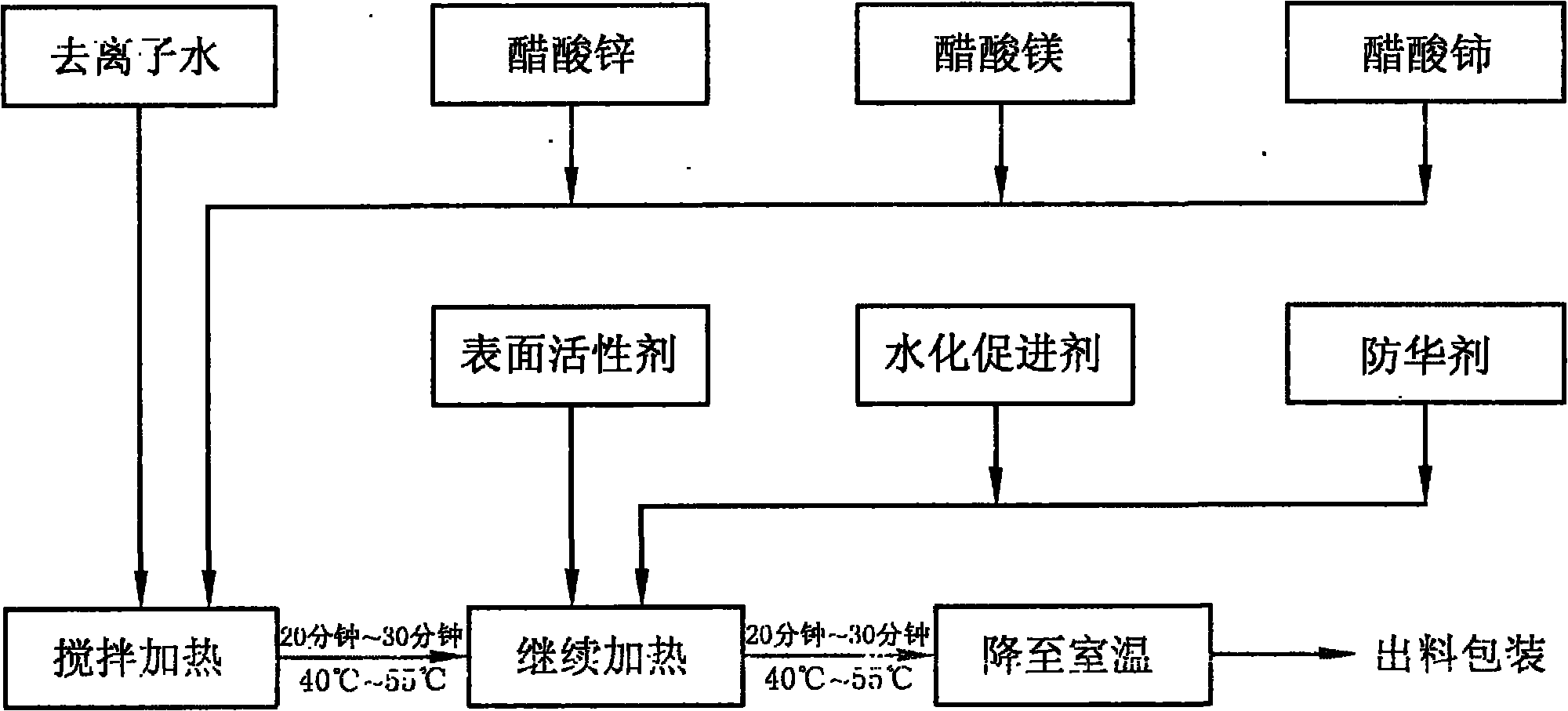

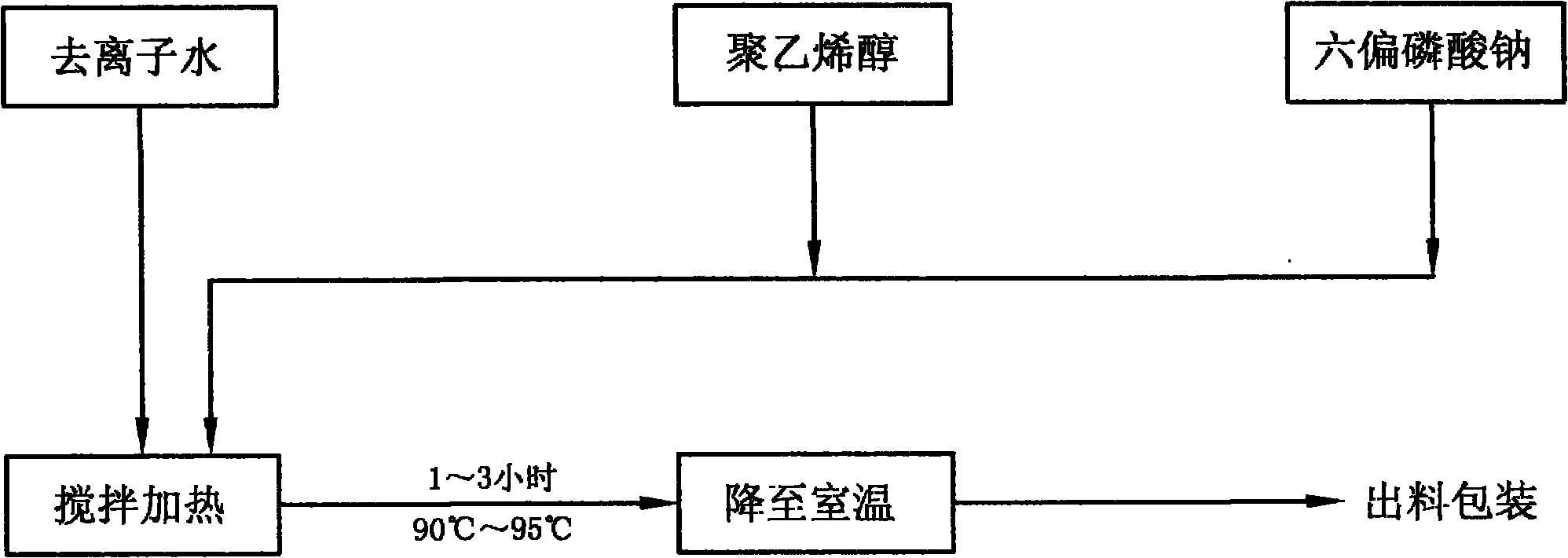

Method for preparing aluminum alloy anodic oxide film sealant

InactiveCN101812713AImprove pass rateImprove protectionSurface reaction electrolytic coatingSODIUM METAPHOSPHATEPolyvinyl alcohol

The invention discloses a method for preparing an aluminum alloy anodic oxide film sealant, which comprises the main processes of adding deionized water, zinc acetate, magnesium acetate, cerium acetate, surfactant, hydration promoter and sublimation preventing agent into a reaction kettle in turn, and mixing, stirring and heating the components to form the sealant. One of the important components of the sealant is sublimation preventing agent which is prepared by mixing the deionized water, polyvinyl alcohol and sodium hexametaphosphate together and then stirring and heating the mixture in the reaction kettle. The raw materials adopted by the preparation method do not contain nickel and fluorine elements, so the sealant is favorable for environmental protection; and the sealant reduces energy consumption during use, and improves the qualification rate of aluminum alloy products.

Owner:李继光

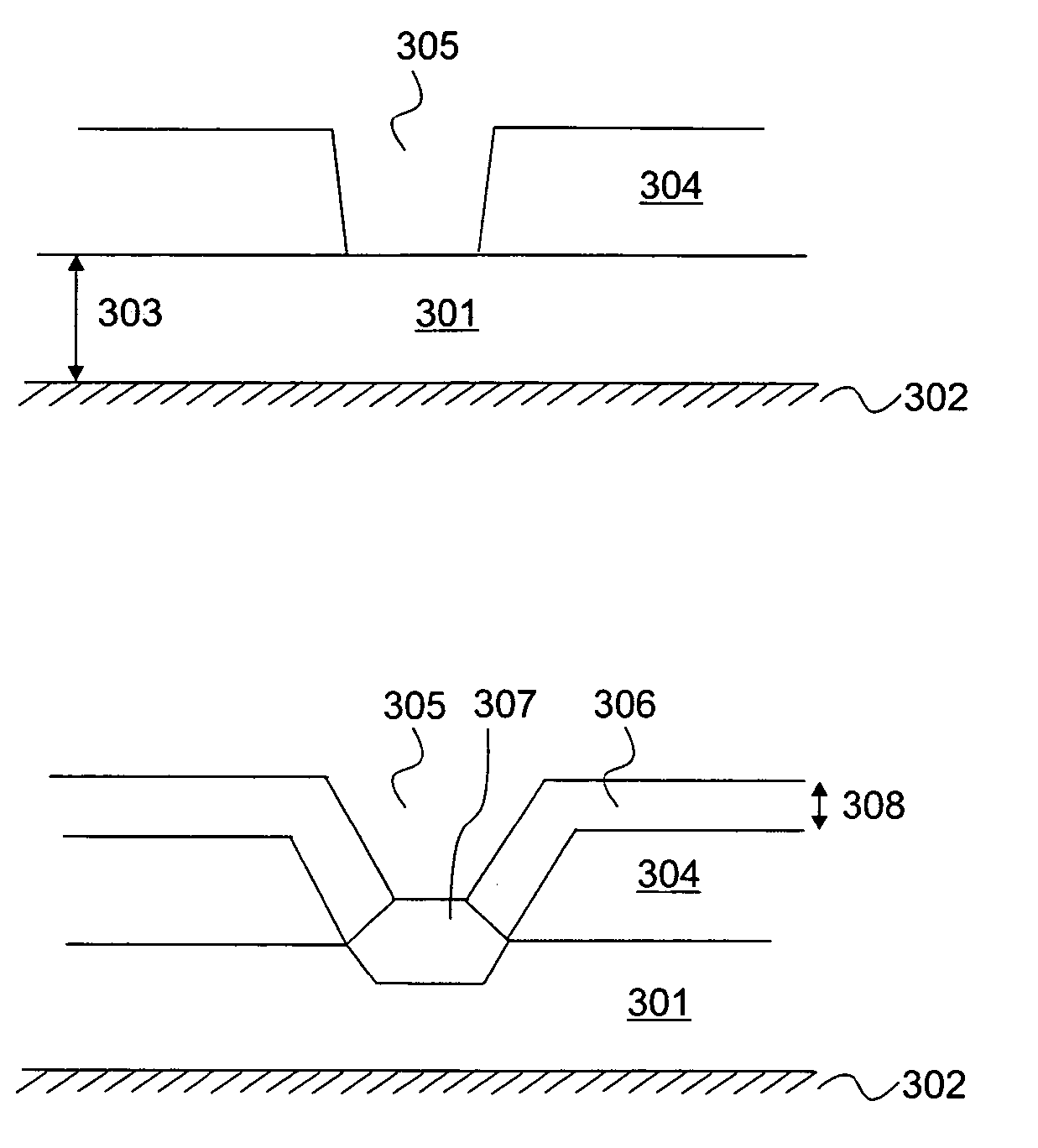

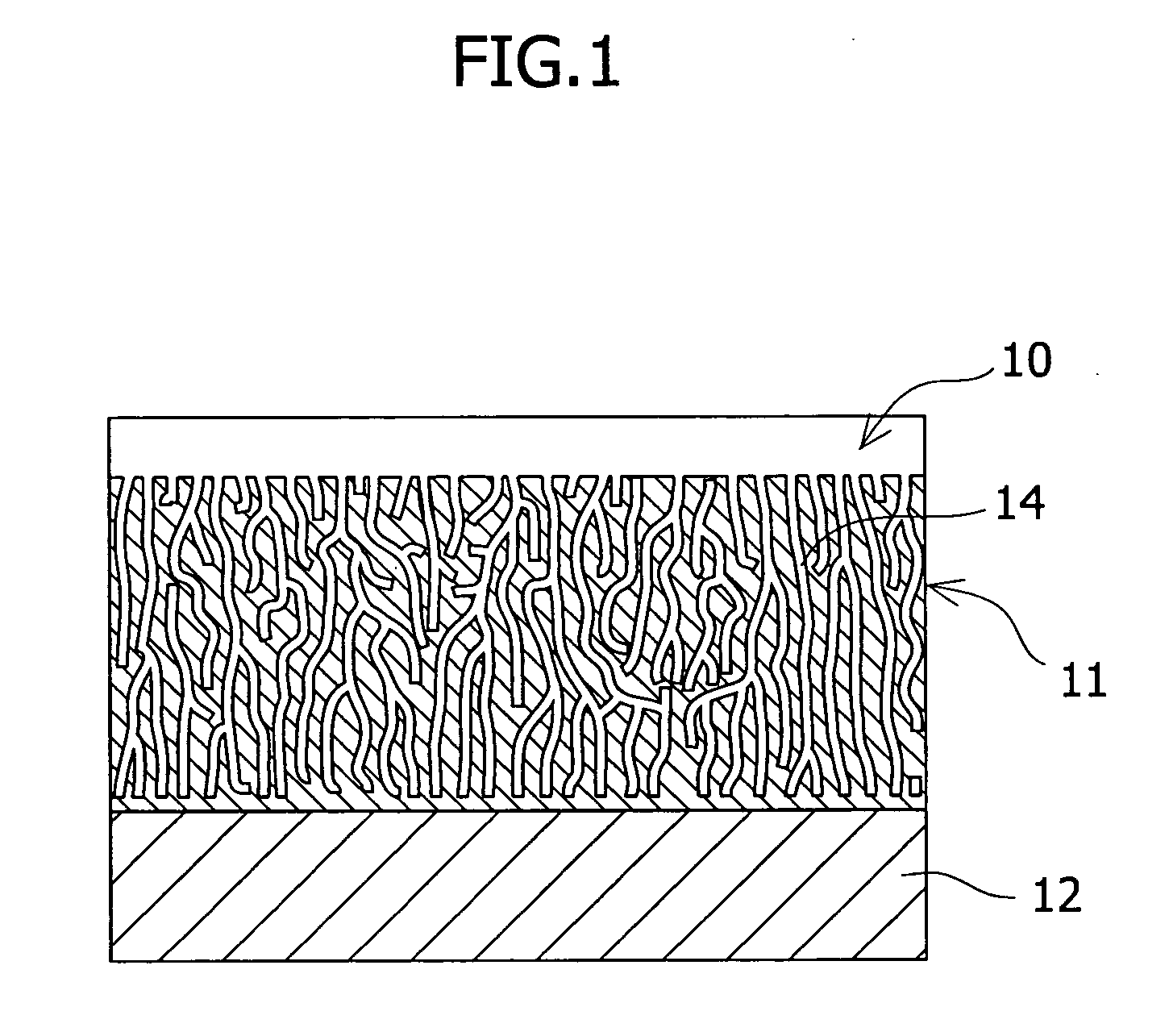

Anodic oxide film and anodizing method

ActiveUS20060037866A1Promote formationLow costAnodisationMetal layered productsAnodic oxidationAnodic oxide

An object of the present invention is to obtain an aluminum or aluminum alloy member having a uniform and dense anodic oxide film having sufficient corrosion and impact resistances. Provided is an anodic oxide film which has been formed on the surface of aluminum or aluminum alloy, the film comprising cells which have grown in random directions relative to the surface of the aluminum or aluminum alloy and thus have no orientation.

Owner:SUZUKI MOTOR CORP

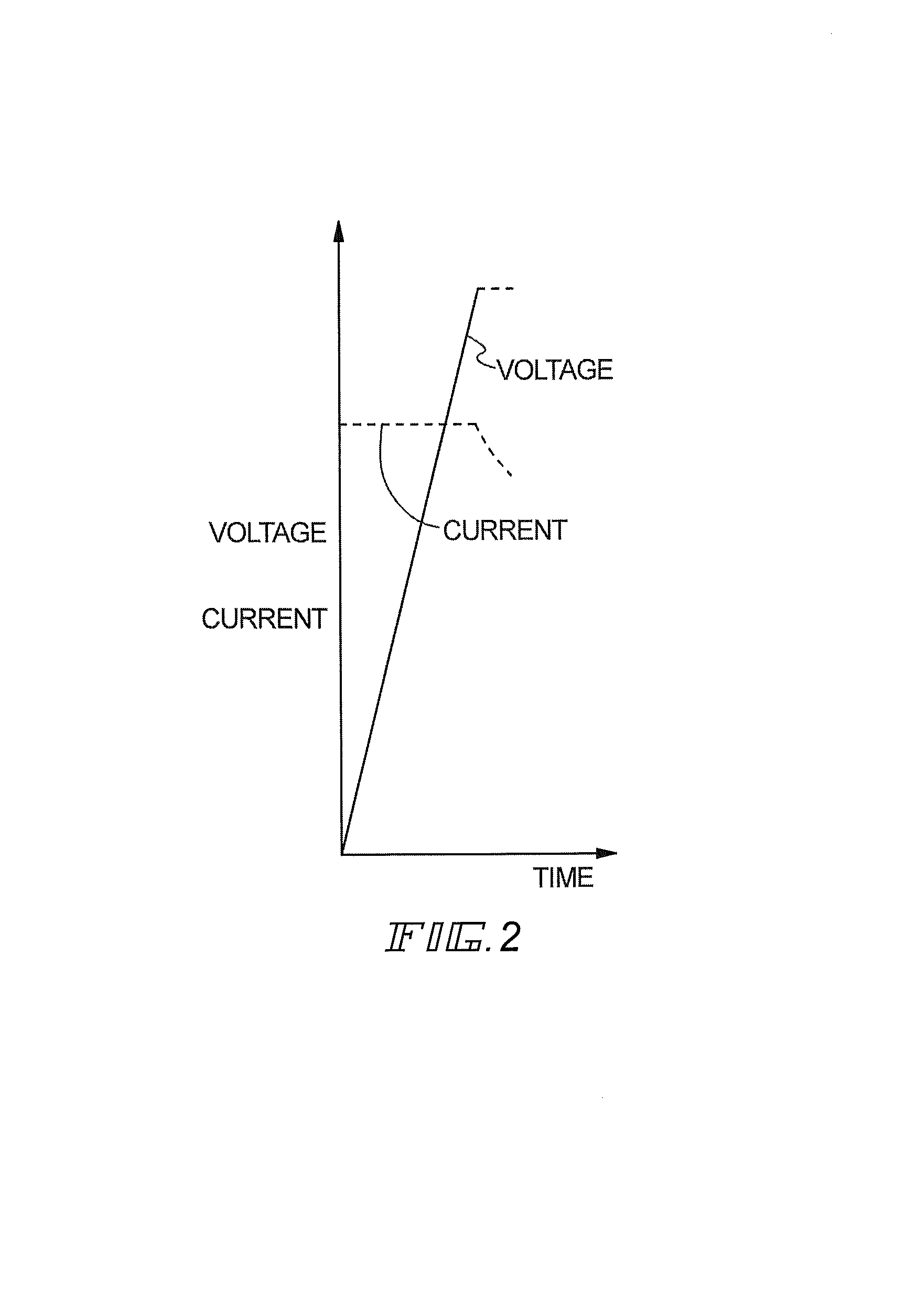

Process for manufacturing high-stability crystalline anodic aluminum oxide for pulse discharge capacitors

ActiveUS7175676B1Improve the crystallization processSave battery powerLiquid electrolytic capacitorsSemiconductor/solid-state device manufacturingMetallurgyPulse discharge

A process for producing high stability crystalline anodic aluminum oxide includes anodizing an anodic foil, hydrating the foil, and forming a barrier oxide layer on the foil. Anodizing the anodic foil produces nano-porous amorphous oxides which can then be converted to a crystalline precursor material by hydrating the foil. Next, an oxide layer formation step is utilized to form a barrier oxide layer on the surface of the anodized and hydrated foil. The resulting anodic oxides have very low levels of defects, voids and tensile stresses and have rise times as low as about 1 second to about 3 seconds after exposure of the formed samples to boiling water for 2 hours.

Owner:PACESETTER INC

Normal-temperature sealer for anodic oxide film of aluminum and aluminum alloy and sealing method thereof

InactiveCN101665970AQuick sealImprove sealing efficiencySurface reaction electrolytic coatingTetramineDodecylsulfonic acid

The invention provides a normal-temperature sealer for an anodic oxide film of aluminum and aluminum alloy. The sealer is characterized by comprising the following components in concentration (g / L): Ni<2+>0.8-1.3, F<-> 0.4-0.8, triethanolamine 0.1-5.0, hexamethylene tetramine 0.1-1.0, sodium dodecanesulphonate0.001-0.1, bloom inhibitor 0.01-2.0 and the balance of water. The invention also discloses a sealing method for the sealer. Compared with the prior art, the sealer has the advantages of low cost, easy preparation, easy operation, and great improvement on the surface anti-pollution ability, the anti-corrosion property and the electric insulativity of the anodic oxide film of the aluminum alloy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for depositing composite ceramic film by differential arc oxidation

InactiveCN101230474AChanging the history of inability to perform composite depositionChange surface propertiesAnodisationElectrolytic inorganic material coatingParticulatesMicro arc oxidation

The invention relates to a method of preparing a composite ceramic film through micro-arc oxidation and composite deposition, is characterized in that the method includes the following steps: firstly, the workpiece is used as the anode; secondly, other particulates are added to the normal micro-arc oxidation electrolyte; and thirdly a composite deposition is realized while the micro-arc oxidation is conducted. The invention has the advantages that the method changes the history that a composite deposition fails to be conducted for the anodic oxide film, and through the technique, particulates of various types can be added to the electrolyte to change the surface property of the material, wearing resistance, corrosion resistance as well as other special performances are improved, and the application range of the valve metal is enlarged.

Owner:NANCHANG HANGKONG UNIVERSITY

Anodic oxide film and methods for manufacturing same

The present invention provides an anodic oxide film which is able to maintain a high corrosion resistance, and a method for manufacturing the anodic oxide film. The method for manufacturing the anodic oxide film comprises the steps of: forming an anodic oxide film on a surface of an aluminum or aluminum alloy material, treating a surface of the anodic oxide film by using a lithium ion-containing sealing treatment liquid, and heating the sealing-treated anodic oxide film.

Owner:SUZUKI MOTOR CORP

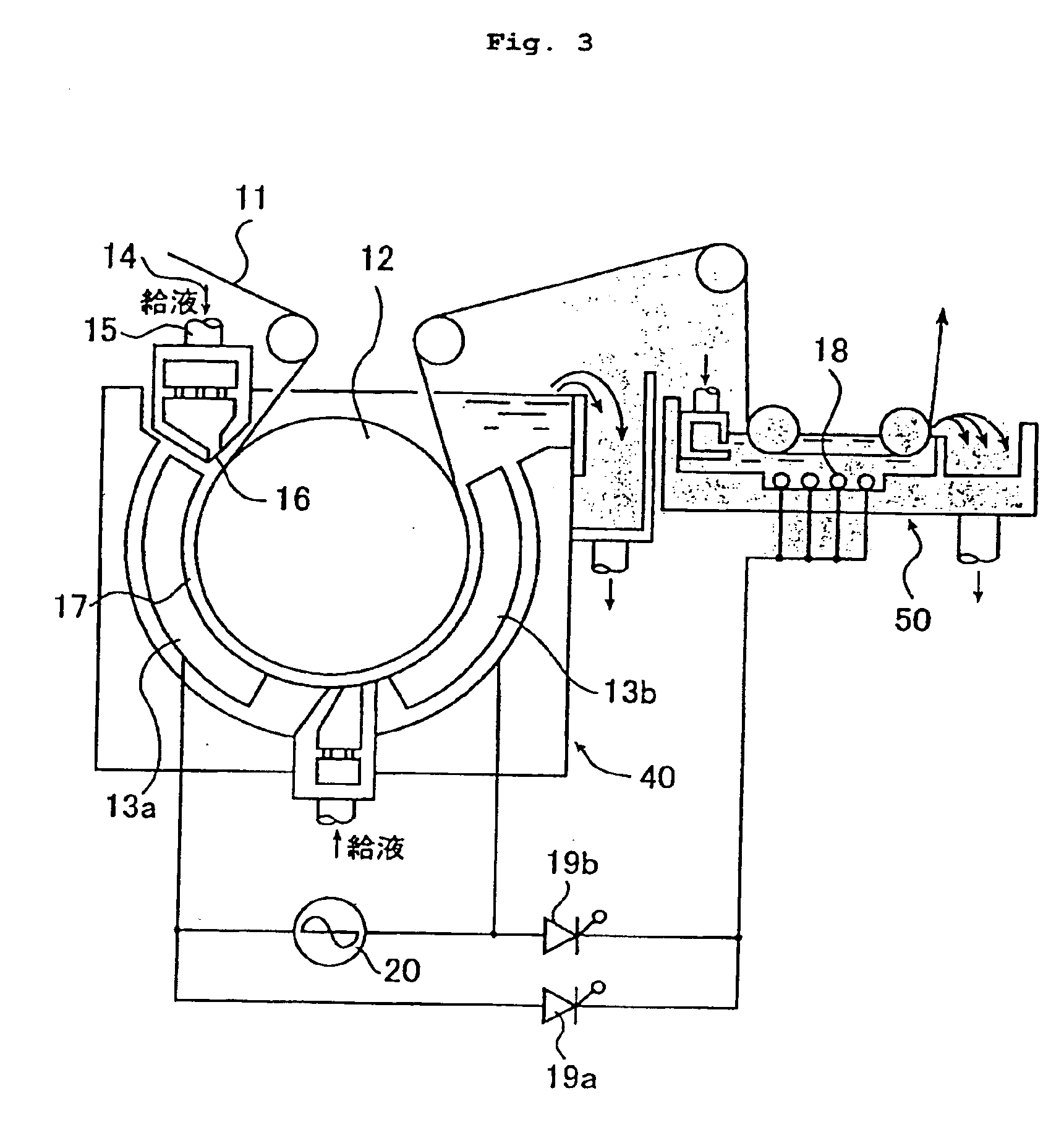

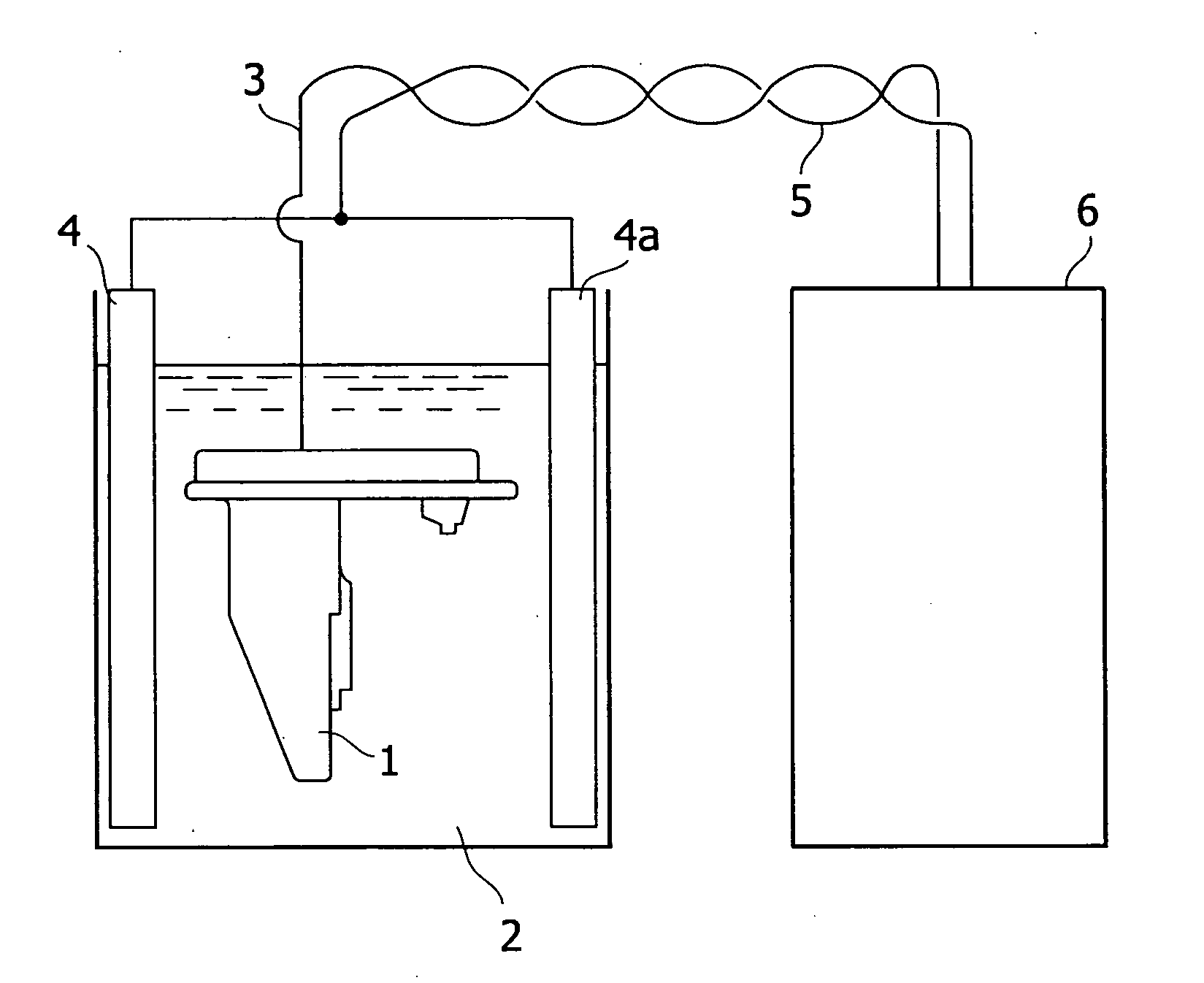

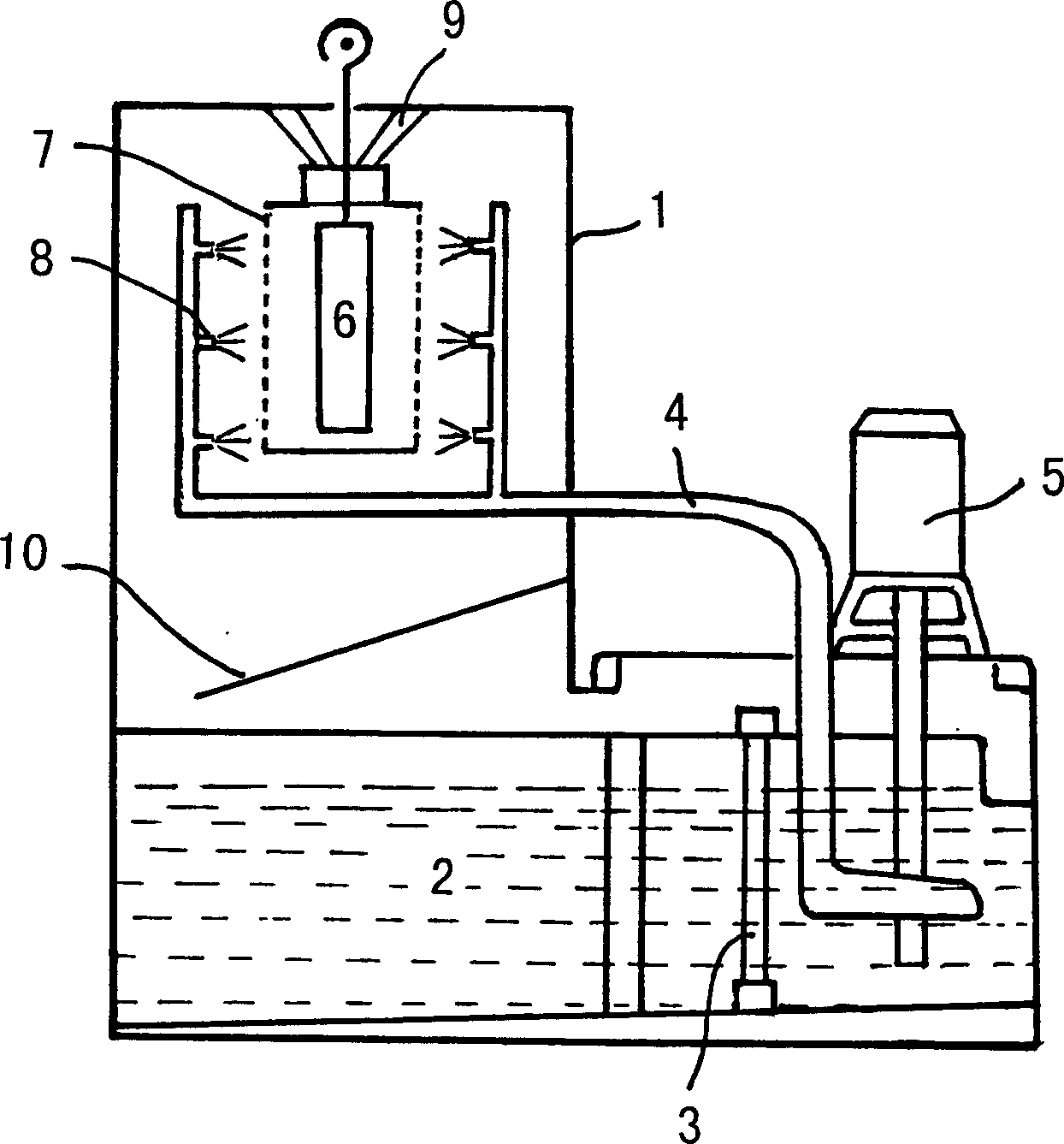

Method and apparatus for rapid preparation of anodic oxidation film on aluminium alloy products

InactiveCN1632178AImprove corrosion resistanceMeet the requirements of industrial productionAnodisationElectrolysis componentsElectrolyteAnodic oxidation

A method and equipment for quickly preparing an anodized film on an aluminum alloy product, characterized in that: the aluminum alloy product is suspended on the upper part of the casing, the aluminum alloy product is used as the anode, and 15-30% sulfuric acid is used as the electrolyte, The electrolyte is sprayed from multiple nozzles on the pipelines on both sides of the anode, and is continuously sprayed onto the anode after passing through the auxiliary cathode to form an anodized film; the voltage between the anode and the auxiliary cathode is 20-30V, and the anode The upper current density is 3-5A / dm2, and the electrolyte temperature is 20-30°C. Compared with the prior art, the present invention has the following outstanding advantages: 1) the anodic oxide film forming speed is 1.0-2.2 μm per minute; 2) the anodic oxide film thickness is 1-4 μm, and its corrosion resistance is better than that of chemical oxide film; 3) The anodic oxidation current density is 3-5A / dm2, which is increased by 3-5 times, which can meet the production requirements for the rapid formation of anodic oxidation film before coating of aluminum alloy products.

Owner:李瓯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com