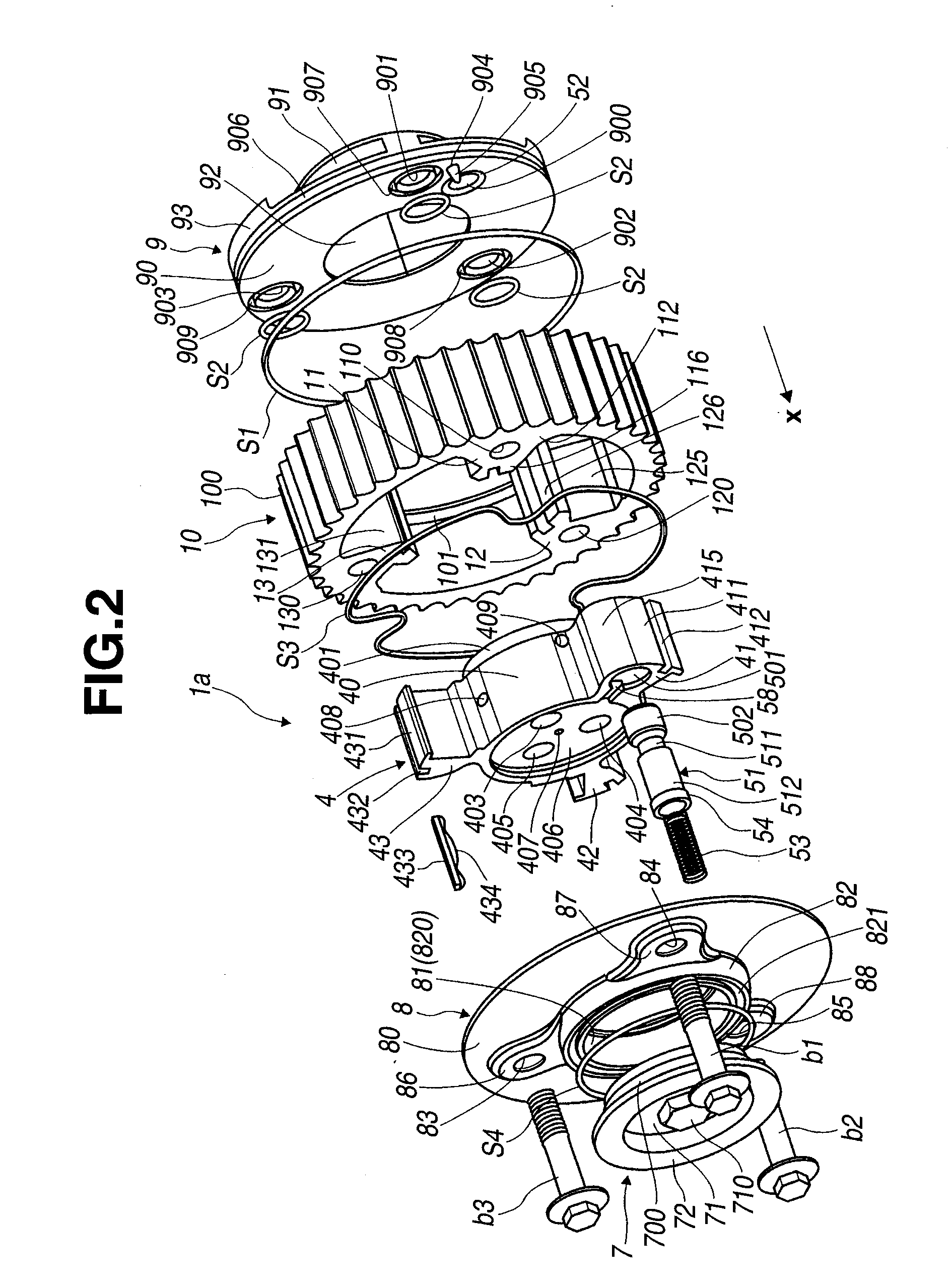

[0005]According to another aspect of the present invention, a valve timing control apparatus for an internal combustion engine, comprises: a housing body having a tubular shape including an opening at an axial end, wherein the housing body is formed integrally with a pulley at an outside periphery of the housing body, and wherein the pulley is adapted to receive torque from a crankshaft of the internal combustion engine; a sealing plate facing an axial end surface of the housing body, and closing the opening of the housing body; a phase change mechanism mounted in the housing body, and adapted to change a rotational phase of a camshaft of the internal combustion engine with respect to the housing body in response to supply and drainage of working fluid; and a sealing ring disposed between the housing body and the sealing plate, wherein: the housing body is formed of an aluminum-based metal material and anodized, wherein the housing body includes a base layer and an anodic oxide coating film layer; and the anodic oxide coating film layer is present at the outside periphery and an inside periphery of the housing body, and absent at the axial end surface of the housing body facing the sealing plate.

[0006]According to a further aspect of the present invention, a valve timing control apparatus for an internal combustion engine, comprises: a housing body having a tubular shape including an opening at an axial end, wherein the housing body is formed integrally with a pulley at an outside periphery of the housing body, and wherein the pulley is adapted to receive torque from a crankshaft of the internal combustion engine; a sealing plate fixed to the axial end of the housing body, the sealing plate closing the opening of the housing body; a phase change mechanism mounted in the housing body, and adapted to change a rotational phase of a camshaft of the internal combustion engine with respect to the housing body in response to supply and drainage of working fluid; and a sealing ring disposed between the housing body and the sealing plate, wherein: the housing body is formed of an aluminum-based metal material and anodized, wherein the housing body includes a base layer and an anodic oxide coating film layer; and the anodic oxide coating film layer is present at the outside periphery of the housing body, and absent at a surface of the housing body on which the sealing ring abuts.

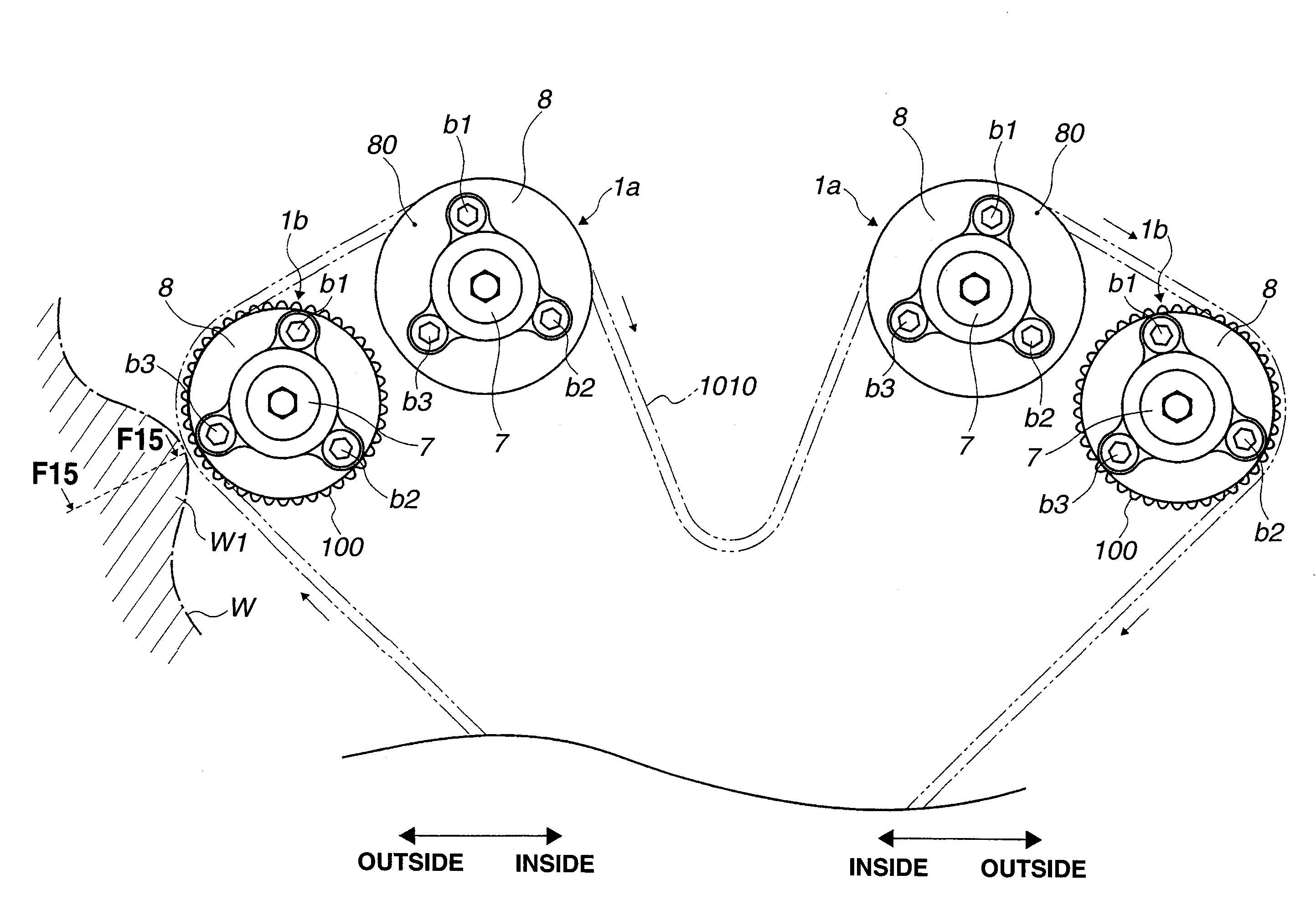

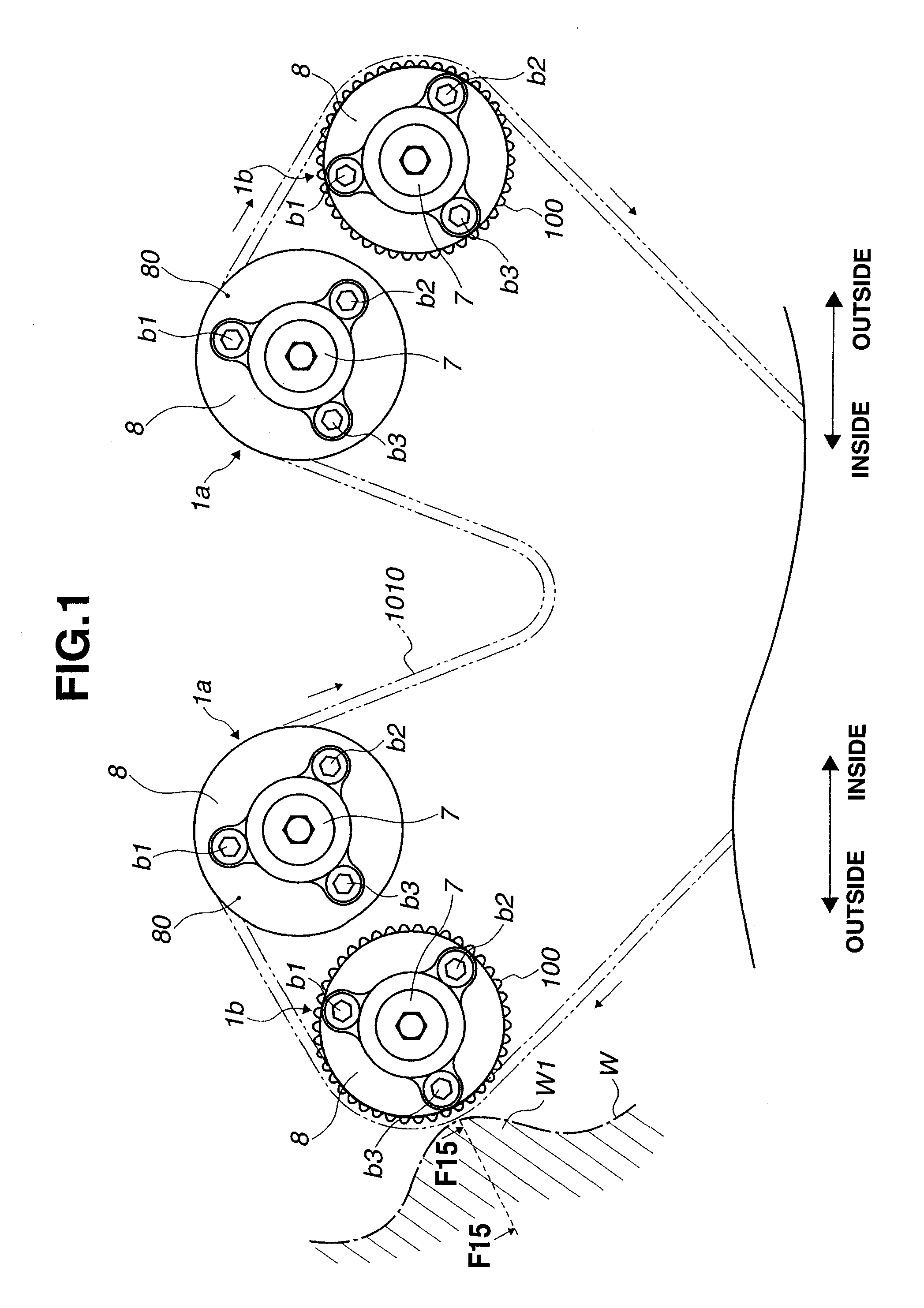

[0007]According to a still further aspect of the present invention, a method of producing a valve timing control apparatus for an internal combustion engine, the valve timing control apparatus comprising: a housing body having a hollow cylindrical shape including an opening at each axial end, wherein the housing body is formed integrally with a pulley at an outside periphery of the housing body, and formed integrally with a shoe at an inside periphery of the housing body, wherein the pulley is adapted to receive torque from a crankshaft of the internal combustion engine, and wherein the shoe projects inwardly in a radial direction of the housing body; at least one sealing plate fixed to an axial end surface of the housing body, the sealing plate closing a corresponding one of the openings of the housing body; a vane rotor adapted to be fixed to a camshaft of the internal combustion engine, and rotatably mounted in the housing body, wherein the vane rotor includes a vane, wherein the vane and the shoe define an advance chamber and a retard chamber between the vane rotor and housing body, and wherein the advance chamber and the retard chamber are adapted to supply and drainage of fluid; and at least one sealing ring disposed between the sealing plate and the axial end surface of the housing body, the method comprises a process of producing the housing body, the process comprising: an extruding operation of forming a first workpiece by extruding an aluminum-based metal material, wherein the first workpiece extends in a direction of extrusion; a coating operation of forming a second workpiece by anodizing an entire surface of the first workpiece; and a cutting-off operation of forming a third workpiece by cutting out of the second workpiece to a predetermined length so as to form the third workpiece with a cut surface forming the axial end surface of the housing body on which the sealing ring abuts.

[0008]According to another aspect of the present invention, a method of producing a valve timing control apparatus for an internal combustion engine, the valve timing control apparatus comprising: a housing body having a hollow cylindrical shape including an opening at each axial end, wherein the housing body is formed integrally with a pulley at an outside periphery of the housing body, and formed integrally with

Login to View More

Login to View More  Login to View More

Login to View More