Patents

Literature

12634 results about "Exhaust valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

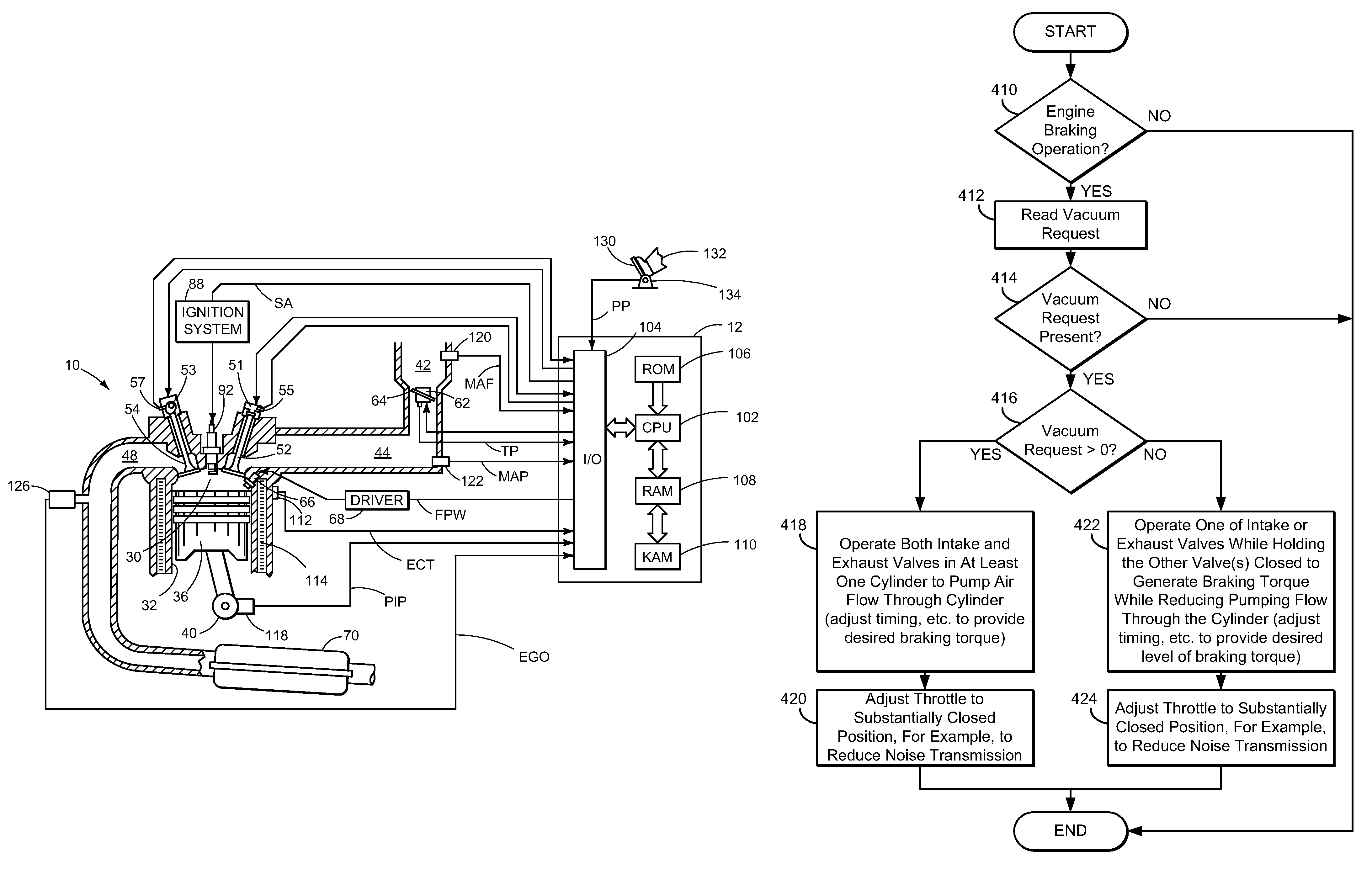

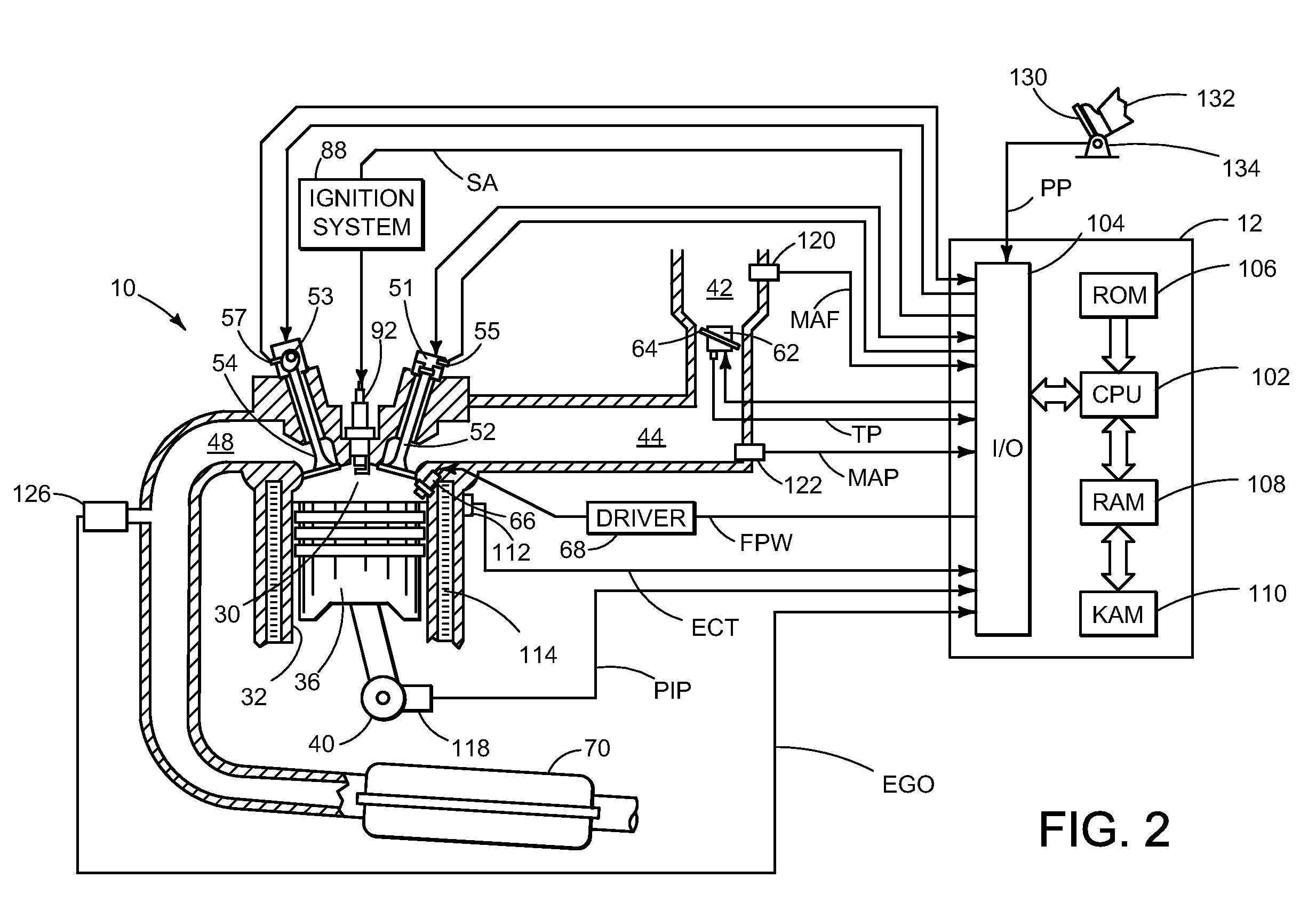

Vehicle braking control

ActiveUS7930087B2Reduced effectivenessImprove fuel economyElectrical controlInternal combustion piston enginesExhaust valveInlet valve

A method of operating an engine for a vehicle having at least a first cylinder, the method comprising of operating the first cylinder to provide at least one of compression braking and expansion braking by holding one of an intake valve and an exhaust valve of the first cylinder closed while opening, closing, and opening the other of the intake valve and the exhaust valve during a cycle of the first cylinder and during a first vacuum level of an intake manifold upstream of the first cylinder; and operating the first cylinder to provide at least one of compression braking and expansion braking by operating both the intake valve and the exhaust valve of the first cylinder during a cycle of the first cylinder to allow at least some air to flow through the first cylinder during a second vacuum level of the intake manifold.

Owner:FORD GLOBAL TECH LLC

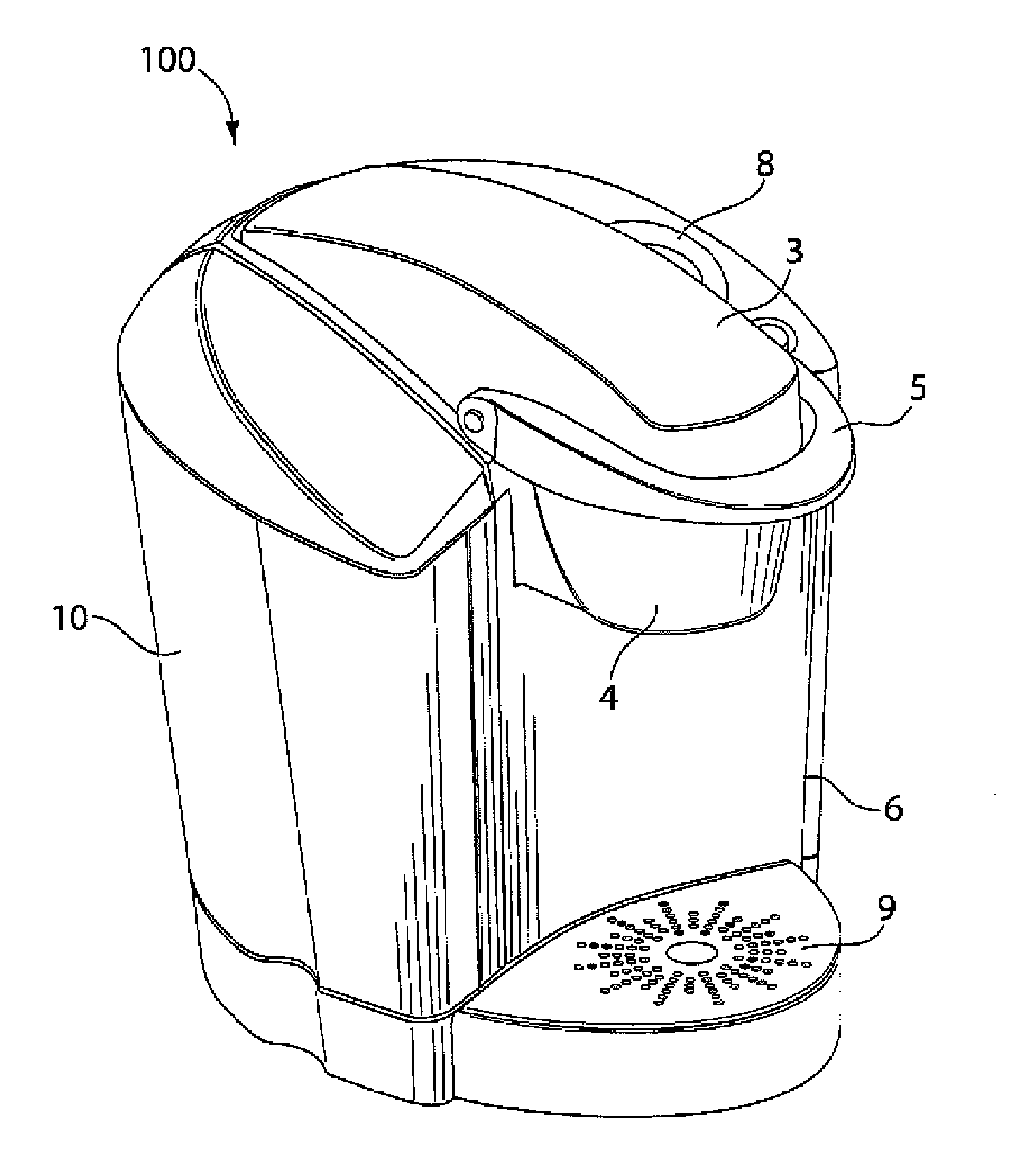

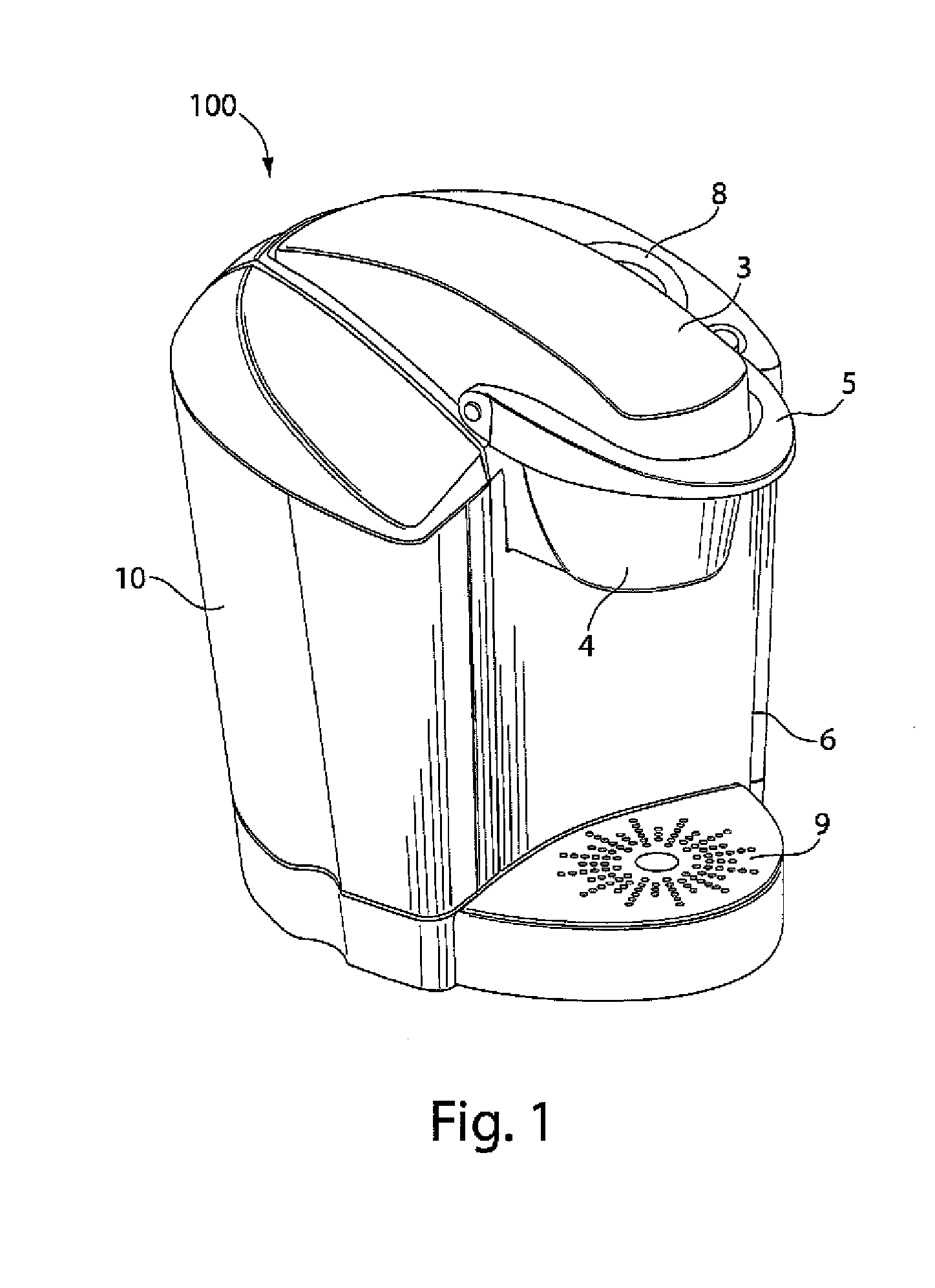

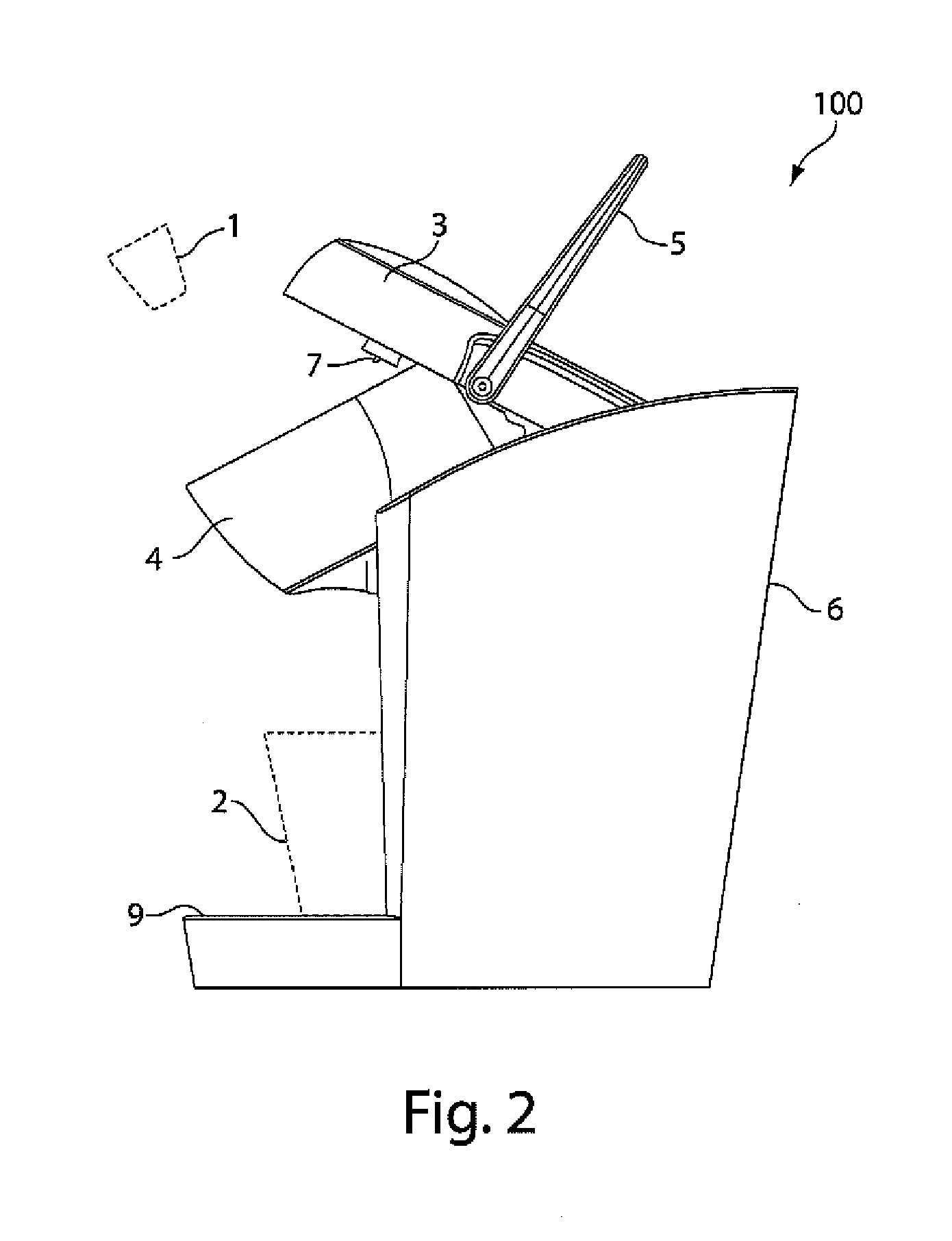

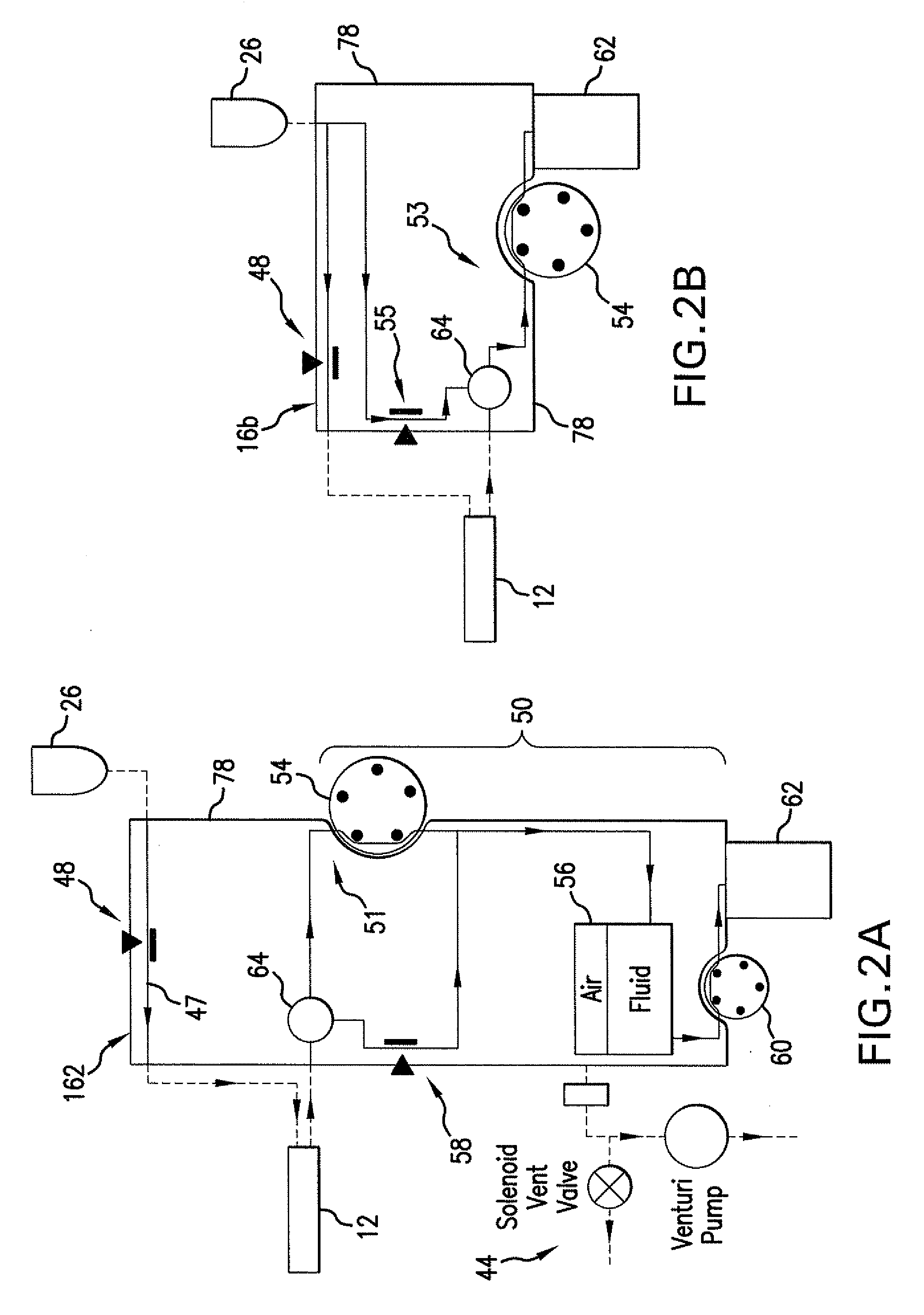

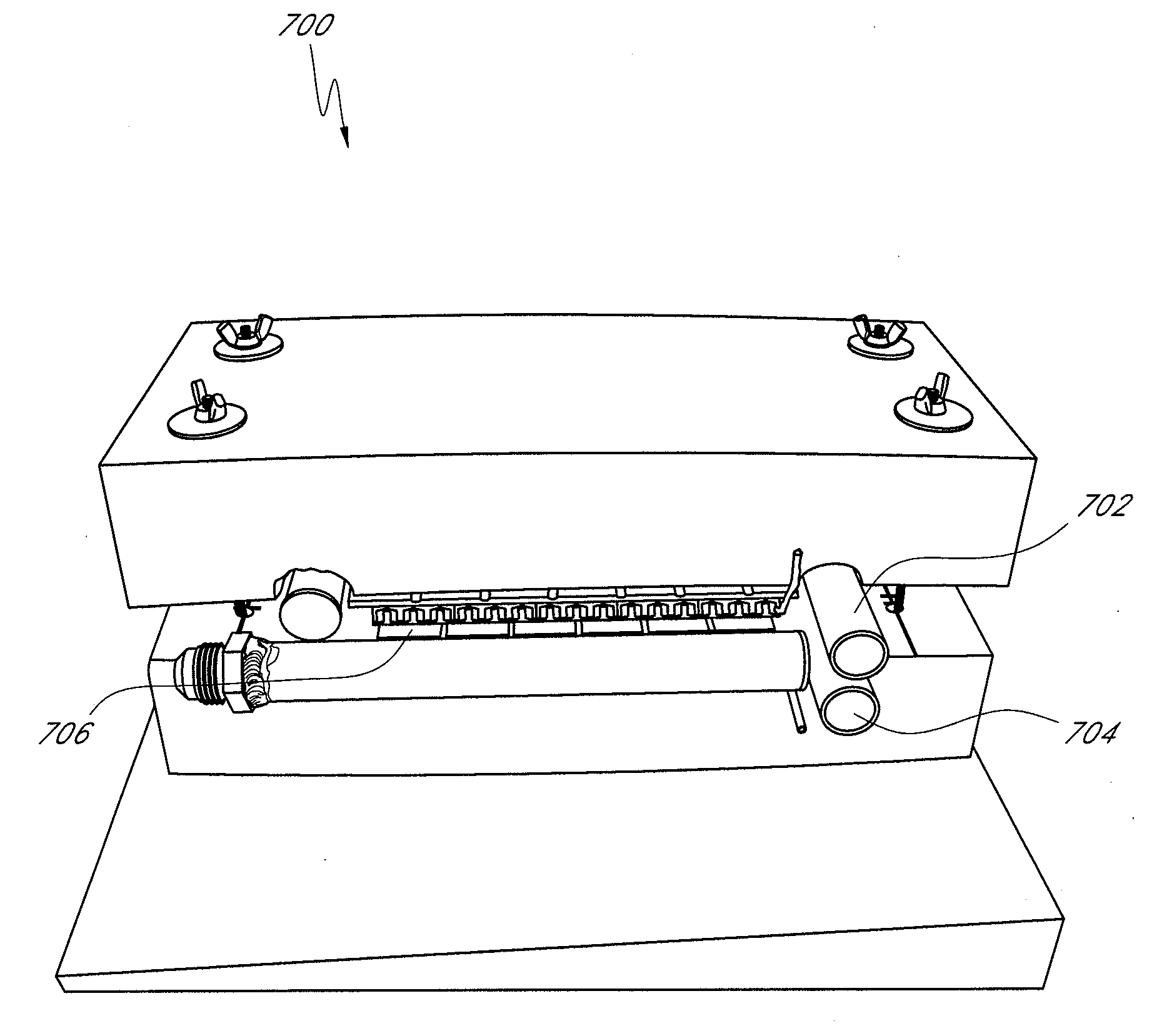

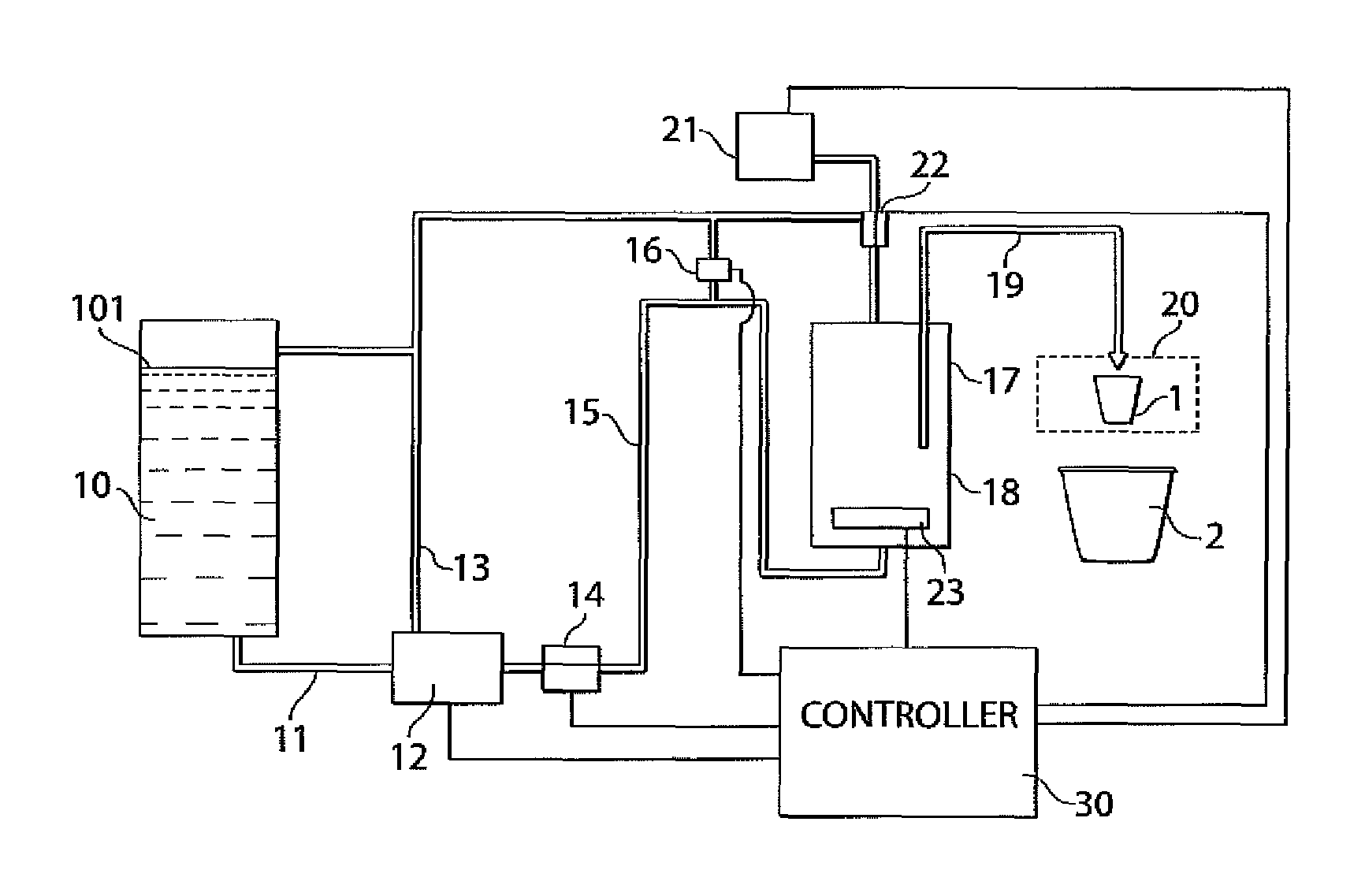

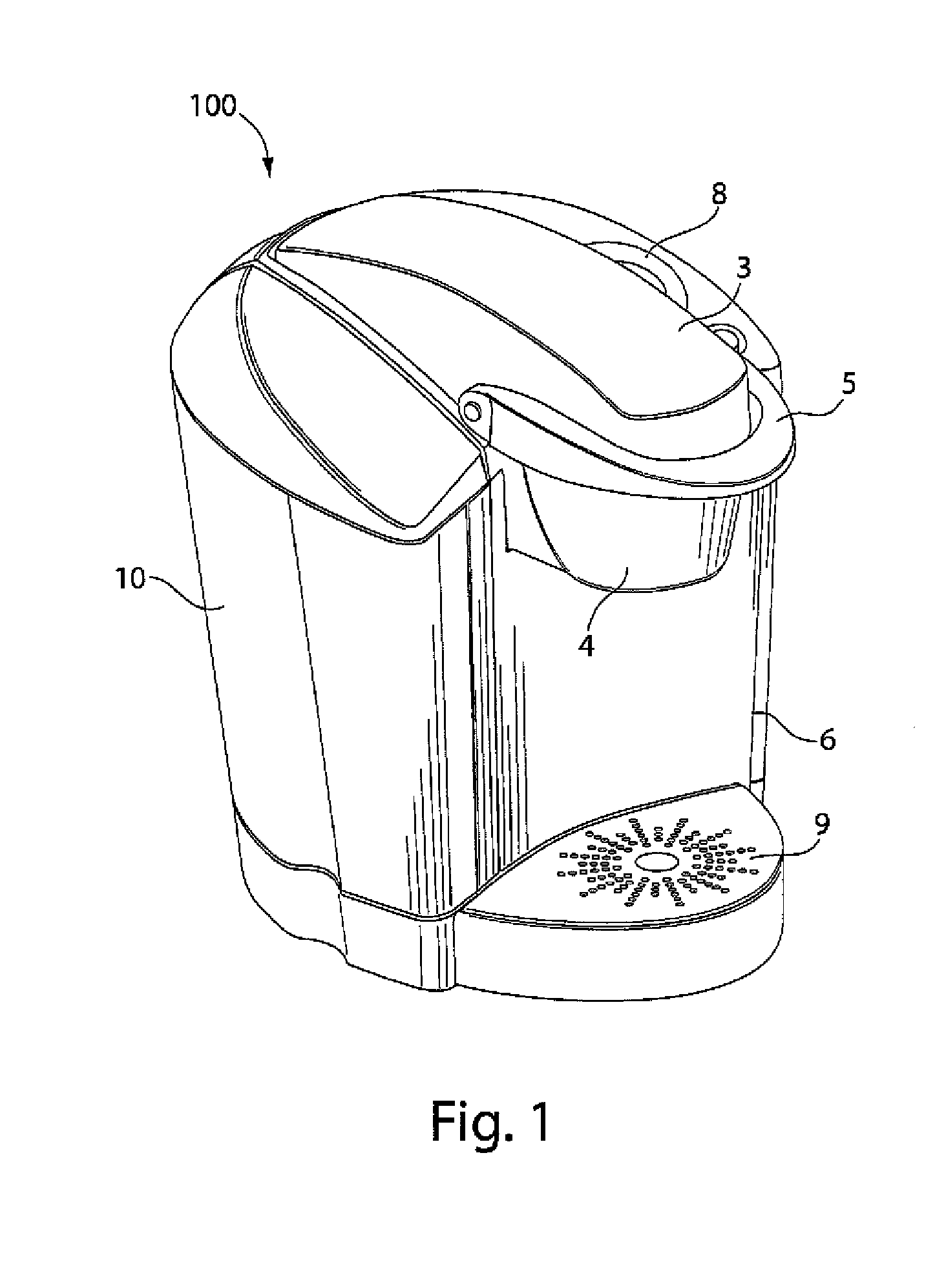

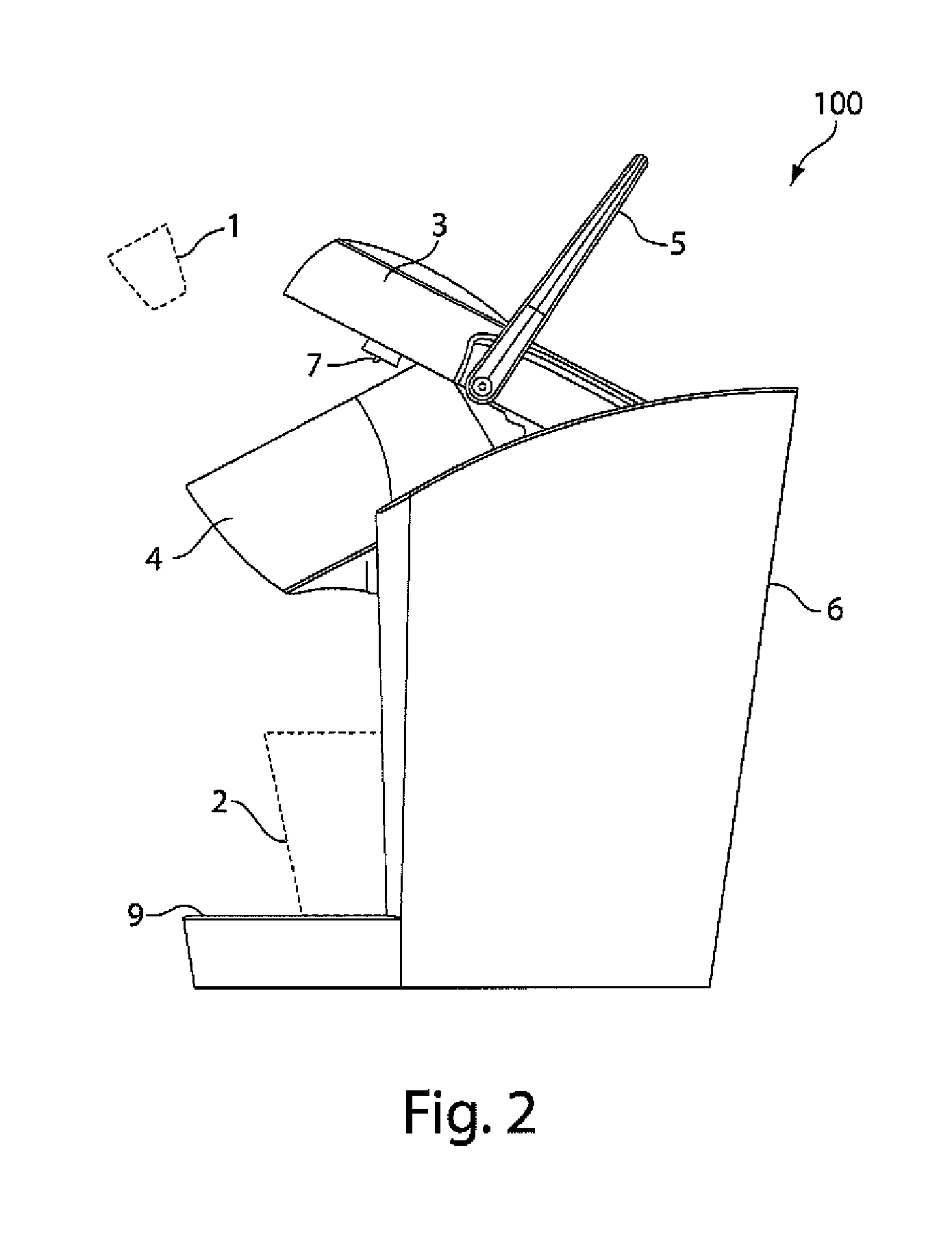

Beverage forming apparatus with centrifugal pump

ActiveUS20100024658A1Prevent substantial leakageAdequate flowBeverage vesselsFood preparationExhaust valveControl valves

A beverage forming apparatus includes a storage tank, and a centrifugal pump having an inlet connected to the storage tank by a supply conduit. The centrifugal pump may include a priming vent located below a full level of the storage tank and permit air to vent as liquid primes the pump. A metering tank may have an inlet connected to the centrifugal pump by a pump conduit, and an outlet connected to a brew chamber that forms a beverage using liquid received from the metering tank. In one embodiment, a flow control valve, such as a check valve, may be provided in the pump conduit to allow flow from the pump to the metering tank, but resist flow in reverse. In another embodiment, a vent valve in the pump conduit may be arranged to vent at least a portion of the pump conduit, e.g., to ambient air pressure.

Owner:KEURIG GREEN MOUNTAIN INC

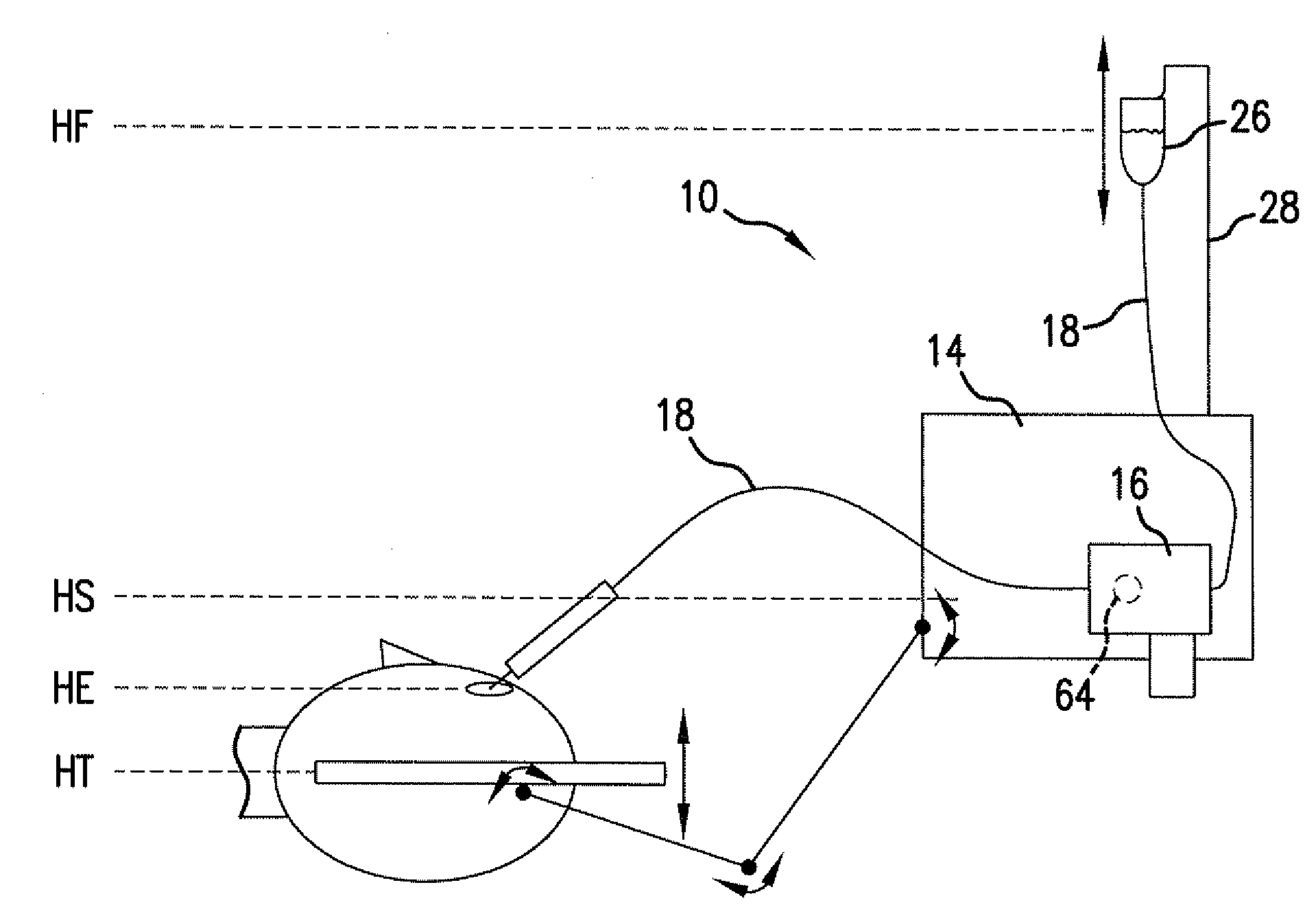

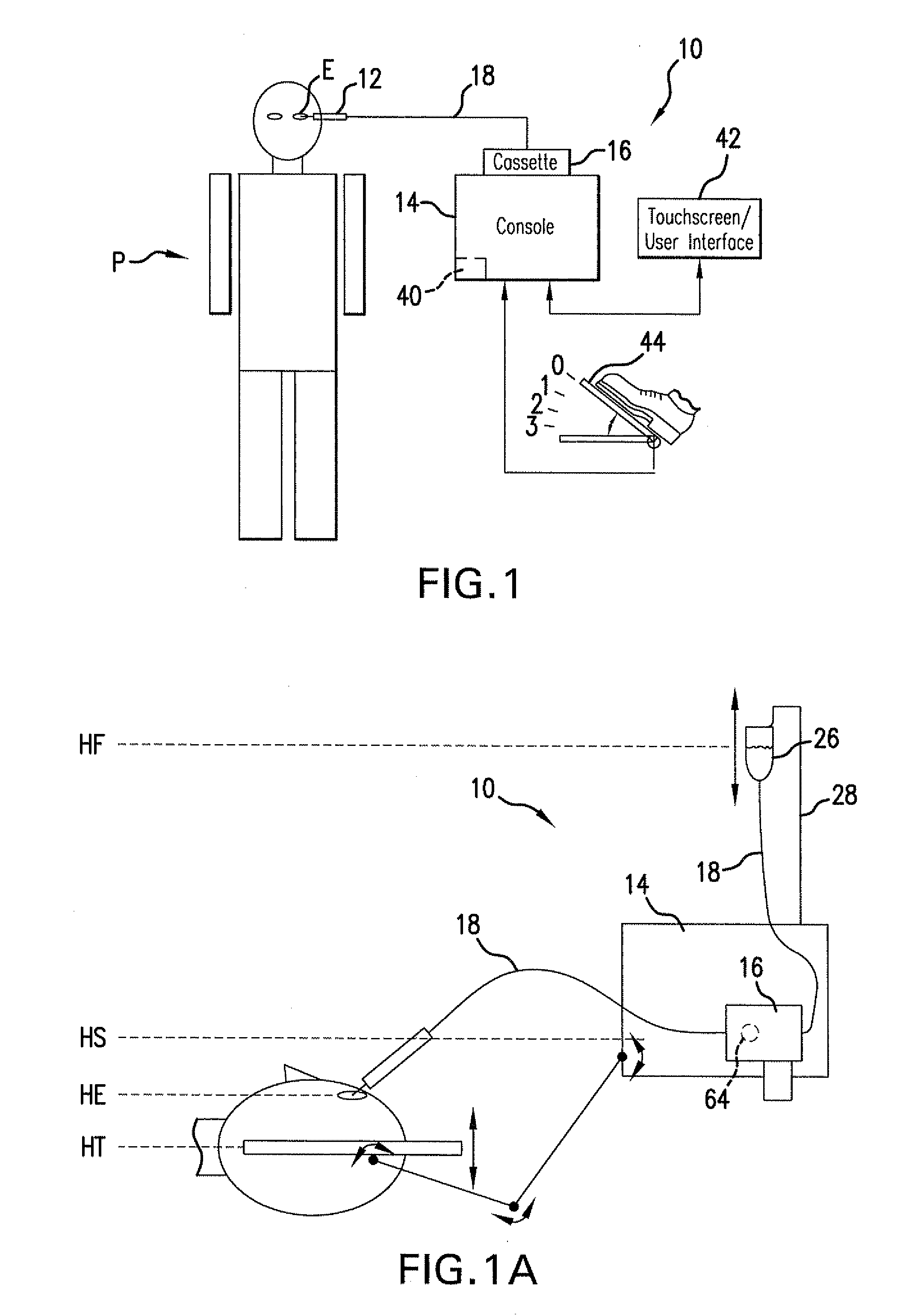

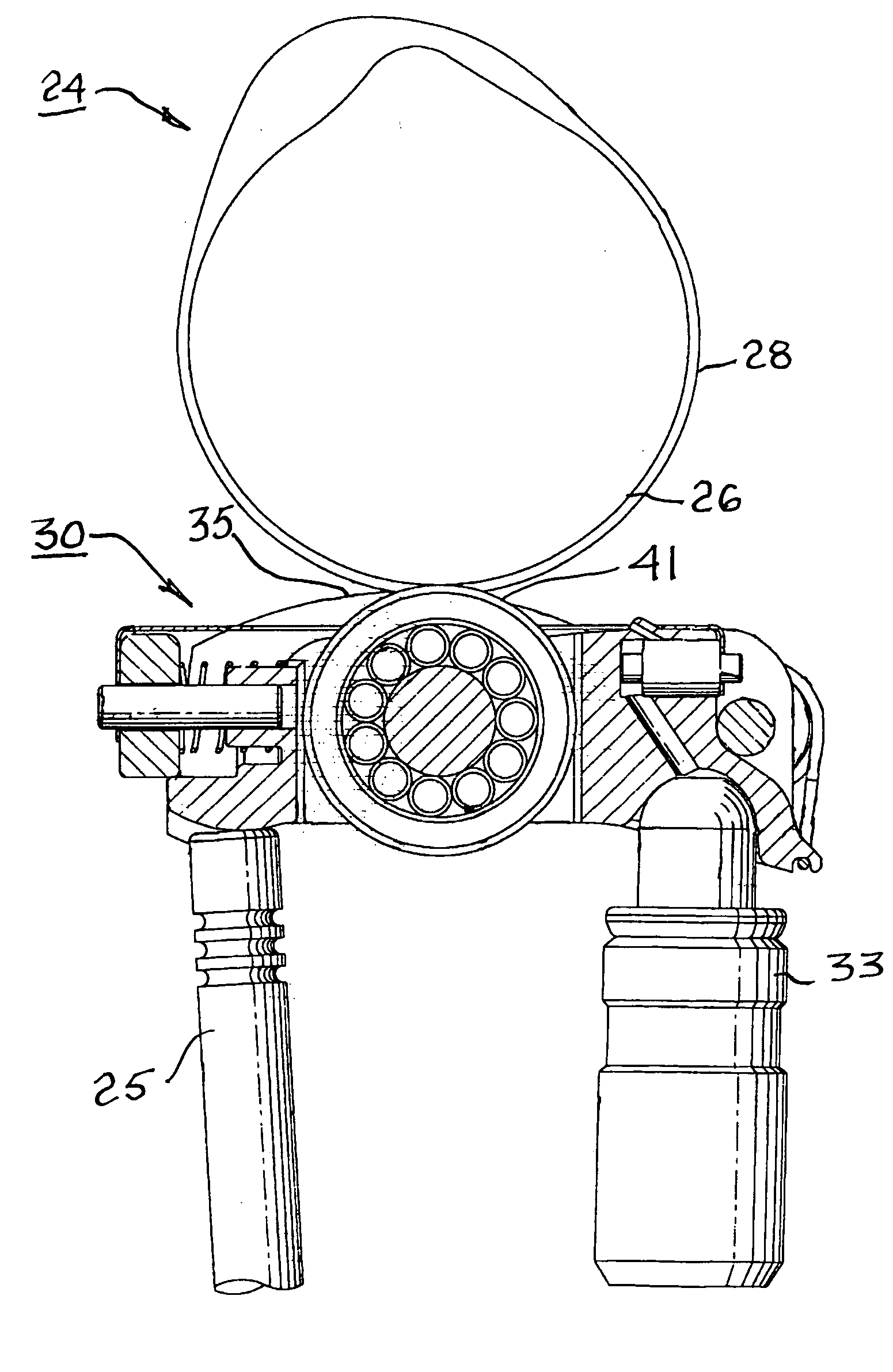

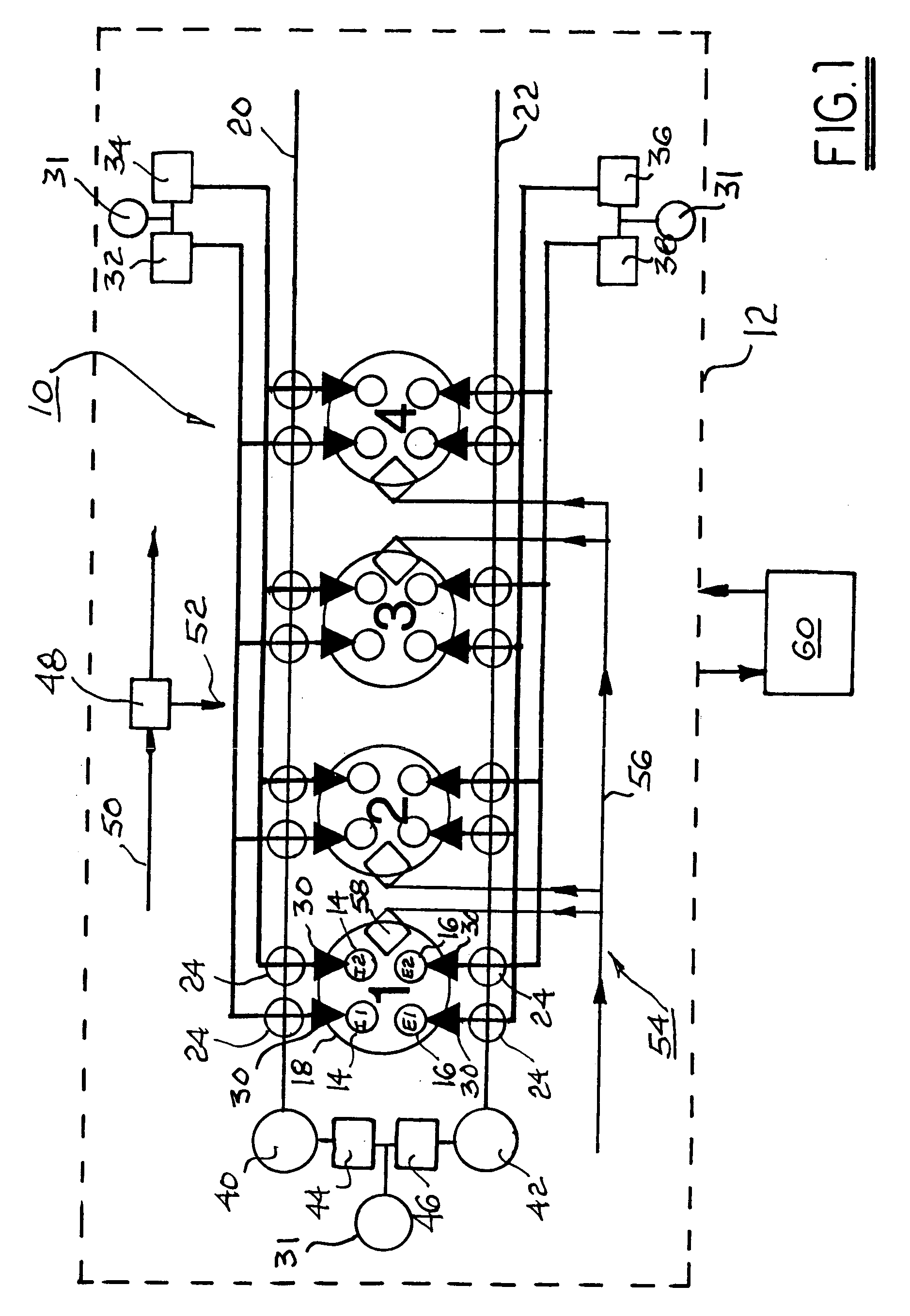

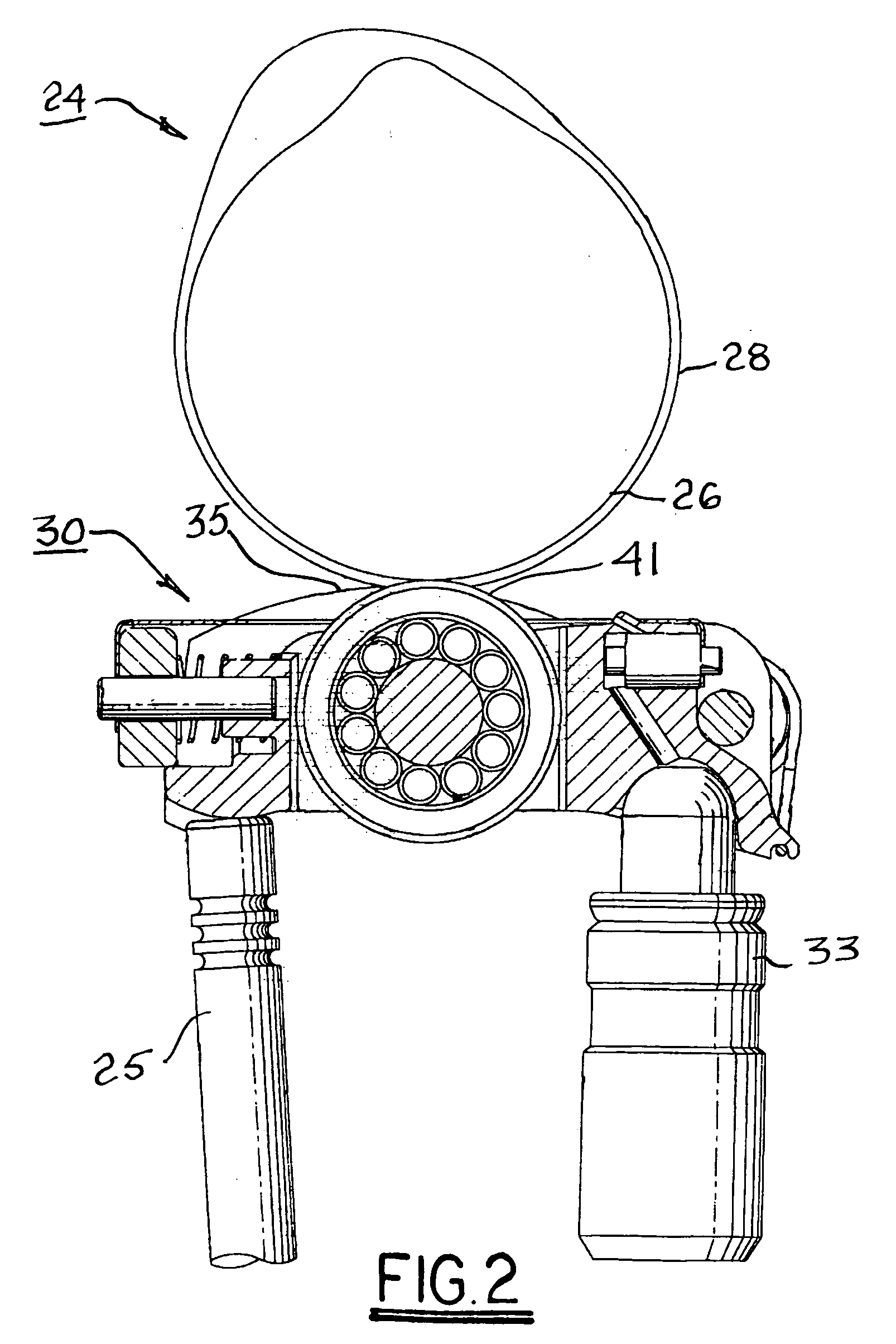

Reversible peristaltic pump and other structures for reflux in eye surgery

Devices, systems, and methods for treatment of an eye alter aspiration flow from the eye in response to an occlusion of the aspiration conduit pathway. Where aspiration is drawn from the eye using a volumetric pump, the pump can be reversed so as to induce fluid reflux from the aspiration conduit pathway into the eye to help clear the occlusion. The pump may vary the reverse flow in response to sensed aspiration pressure or the like, and the reverse flow may be halted before the pressure within the aspiration conduit pathway adjacent the eye significantly exceeds the irrigation fluid pressure and / or the pressure within the eye. Reflux may alternatively be generated by modulating a vent valve disposed between an irrigation conduit pathway and the aspiration conduit pathway.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

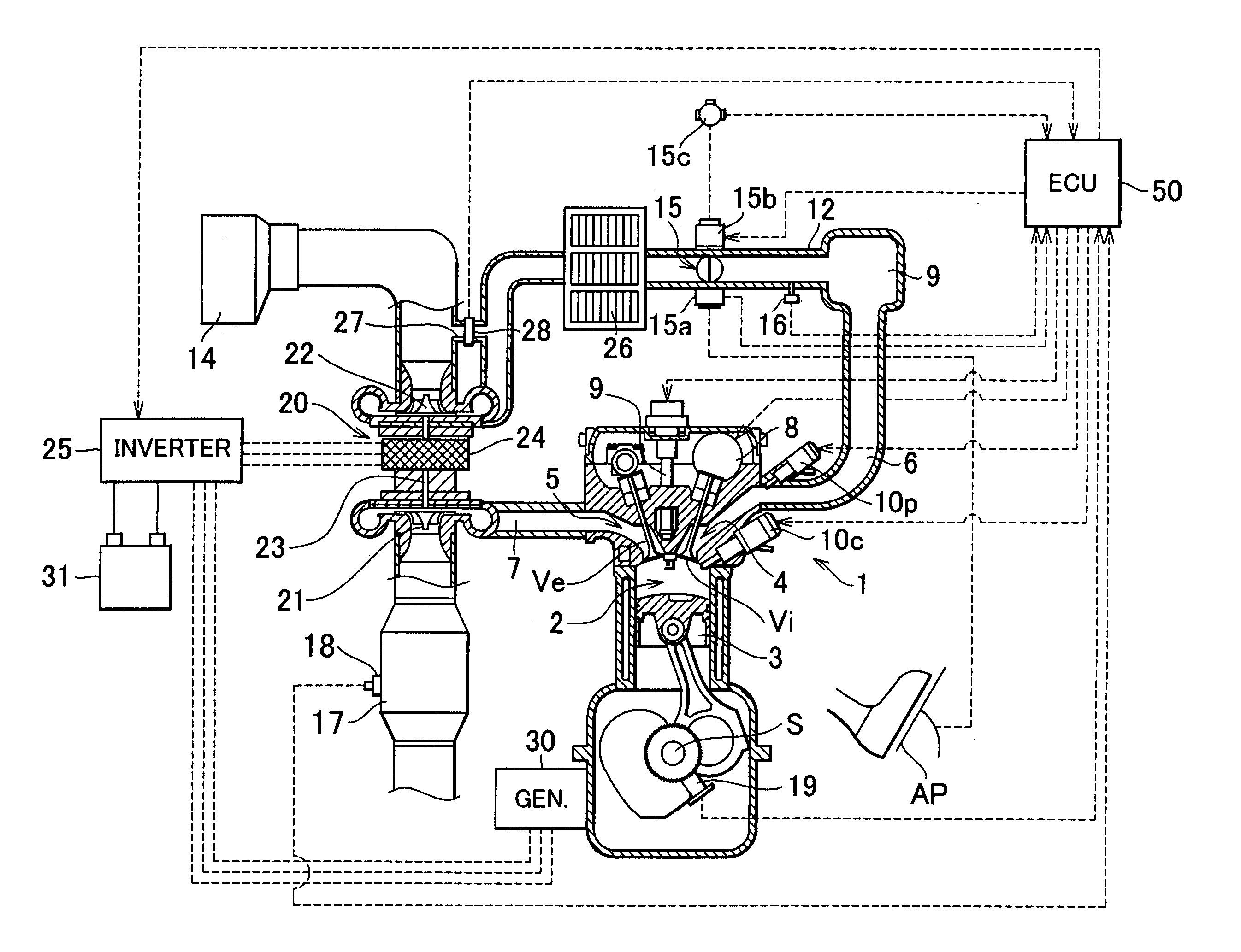

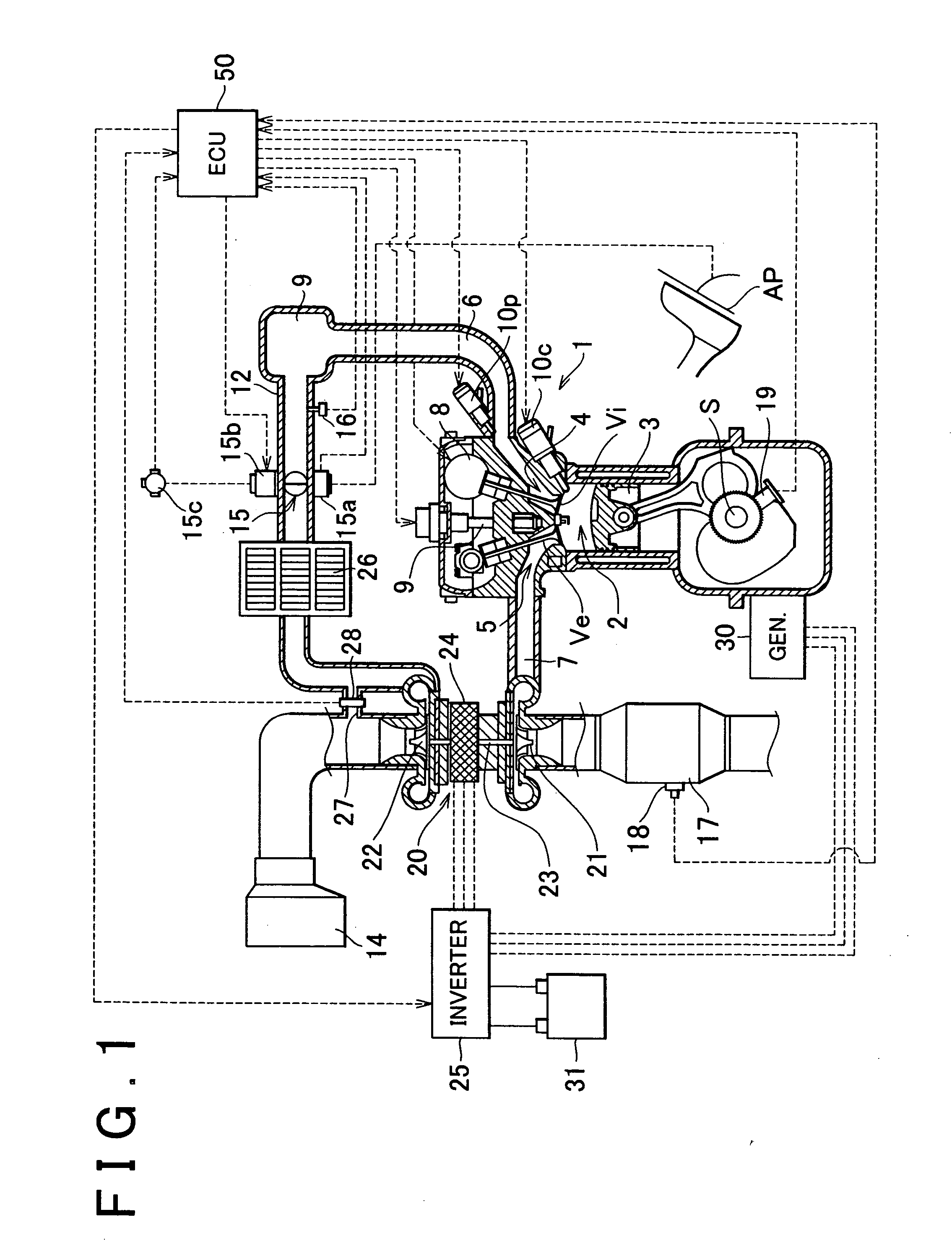

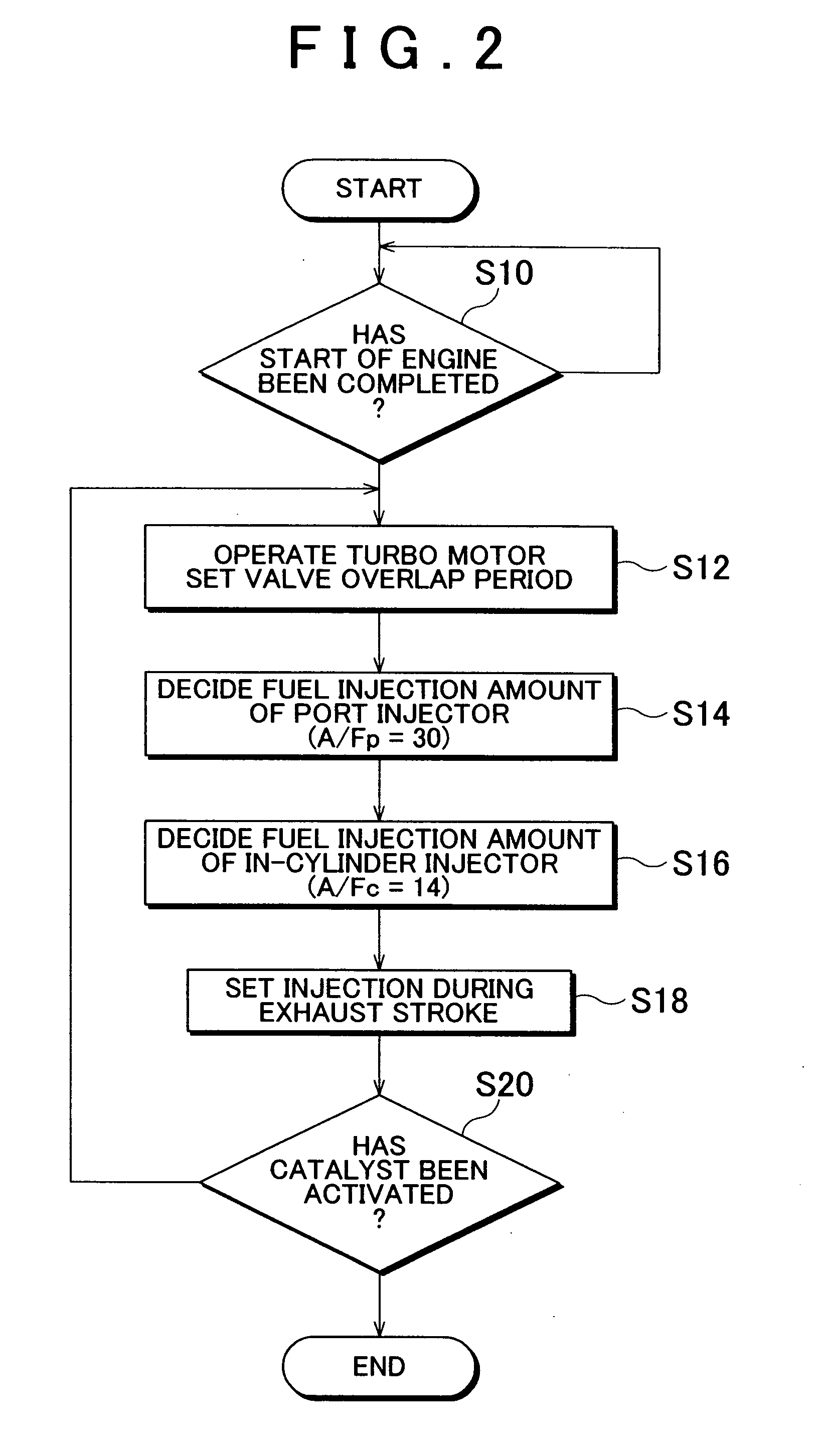

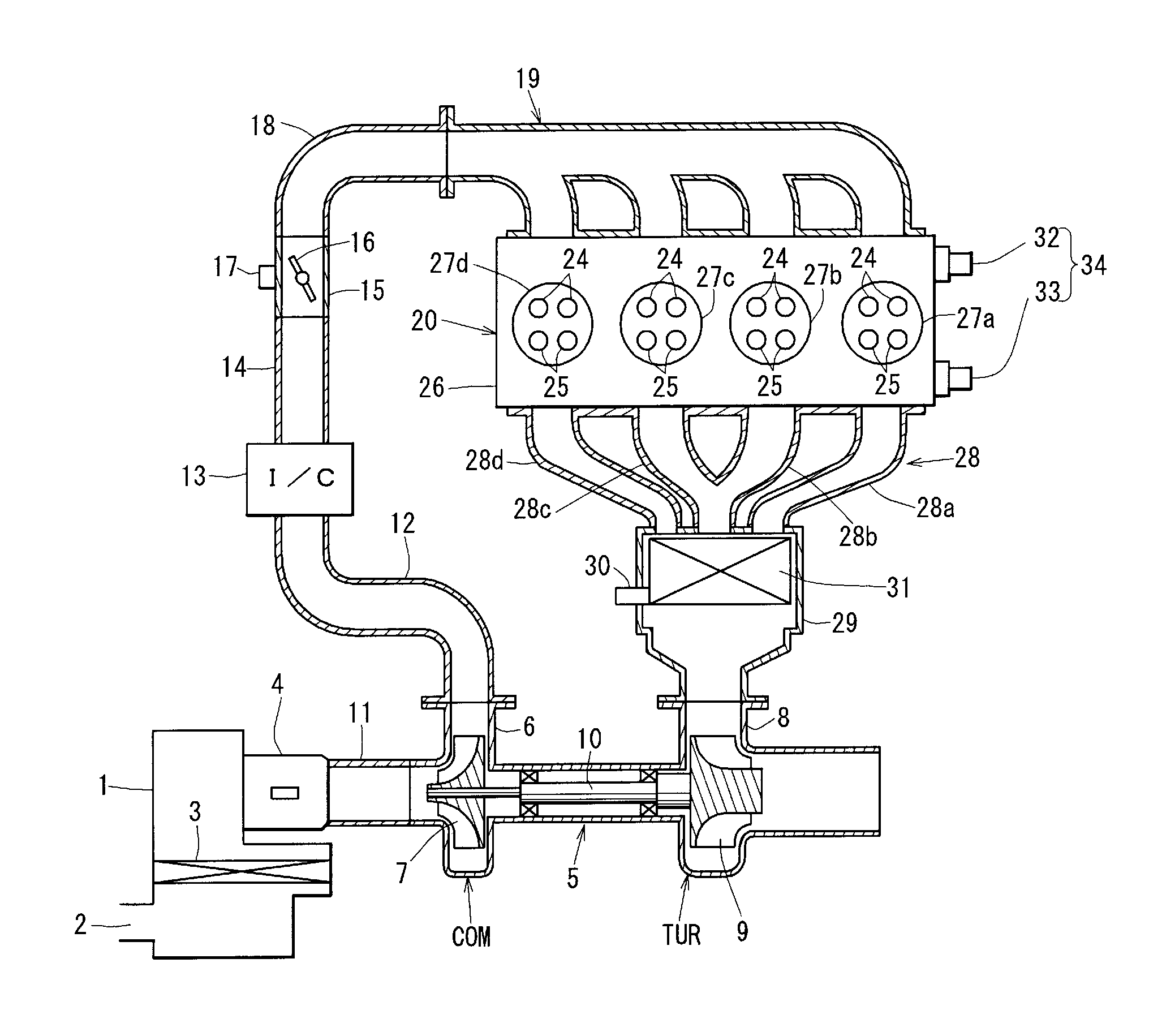

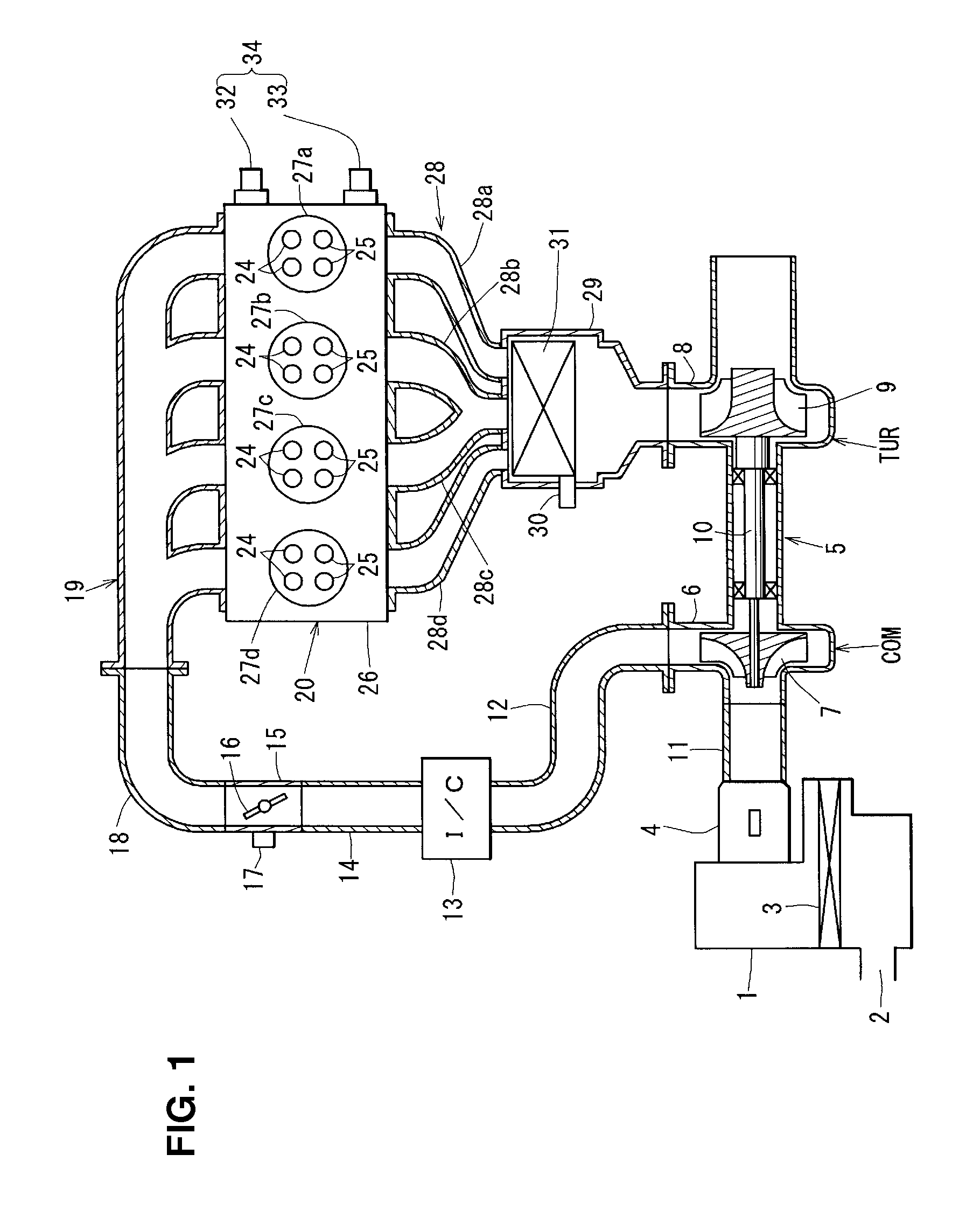

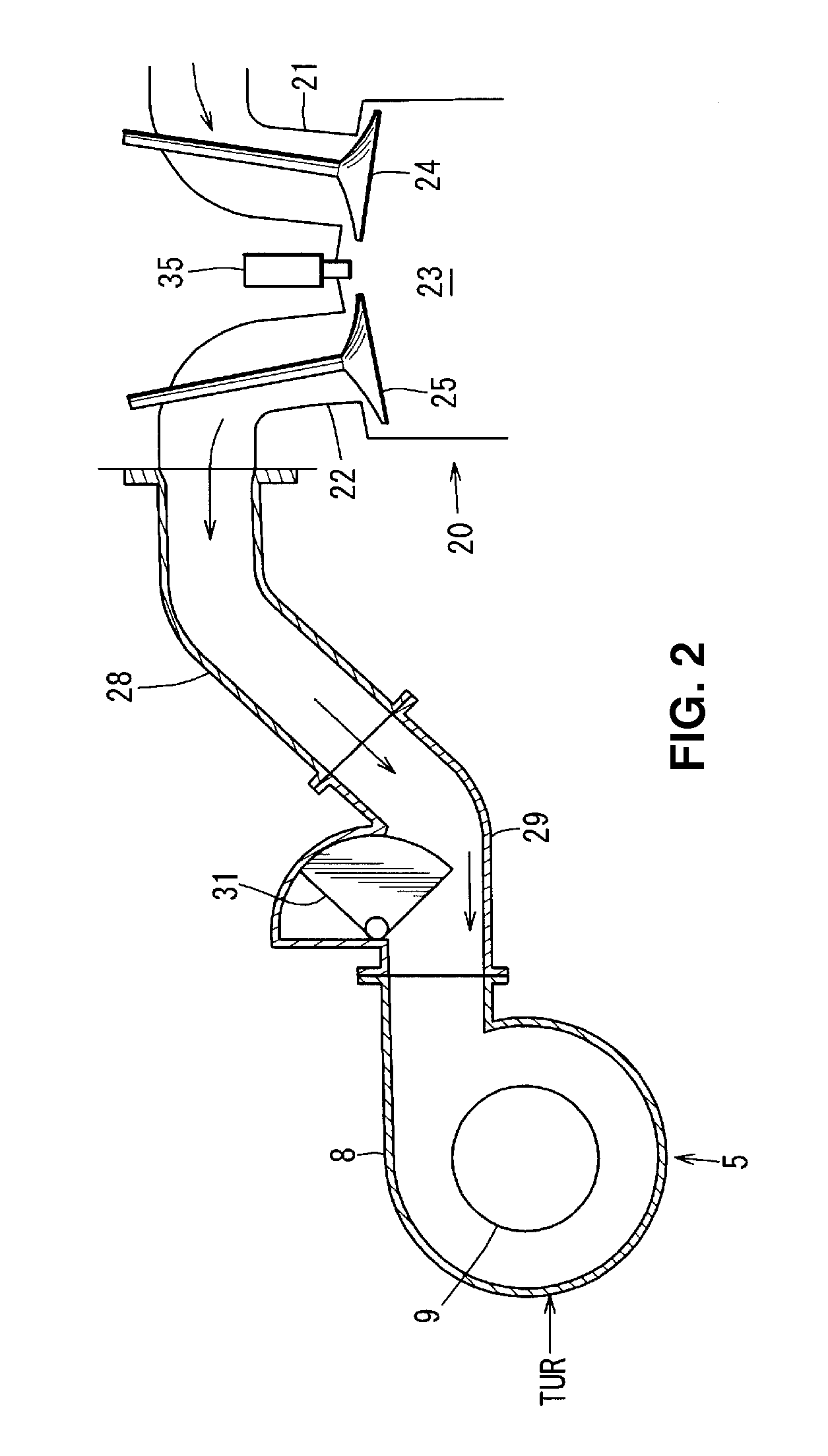

Internal combustion engine and control method thereof

InactiveUS20050097888A1Reliably activatedReduce exhaust emissionsElectrical controlInternal combustion piston enginesCombustion chamberExhaust valve

An internal combustion engine in which power is generated by burning a mixture of fuel supplied from a port injector and / or an in-cylinder injector and air in a combustion chamber, includes a valve drive mechanism which can change a valve opening characteristic of at least one of an intake valve and an exhaust valve; a turbocharger which supercharges air taken into the combustion chamber; a turbo motor which changes supercharging pressure generated by the turbocharger; a catalyst device including a catalyst which purifies exhaust gas discharged from the combustion chamber; and an ECU which controls the turbo motor such that pressure of the air taken into the combustion chamber becomes larger than back pressure until it is determined that the catalyst has been activated, and which sets a valve overlap period during which both of the intake valve and the exhaust valve are opened.

Owner:TOYOTA JIDOSHA KK

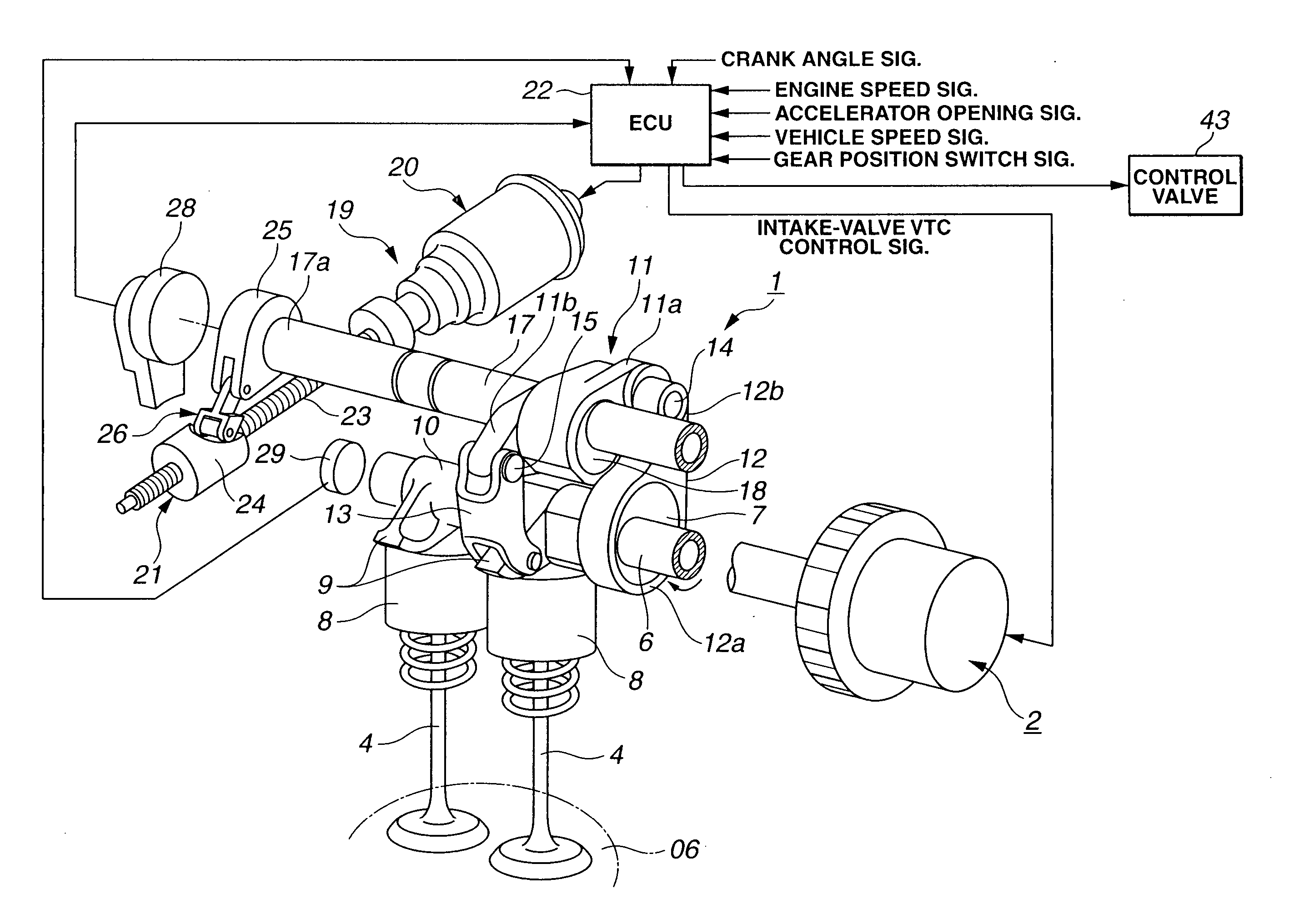

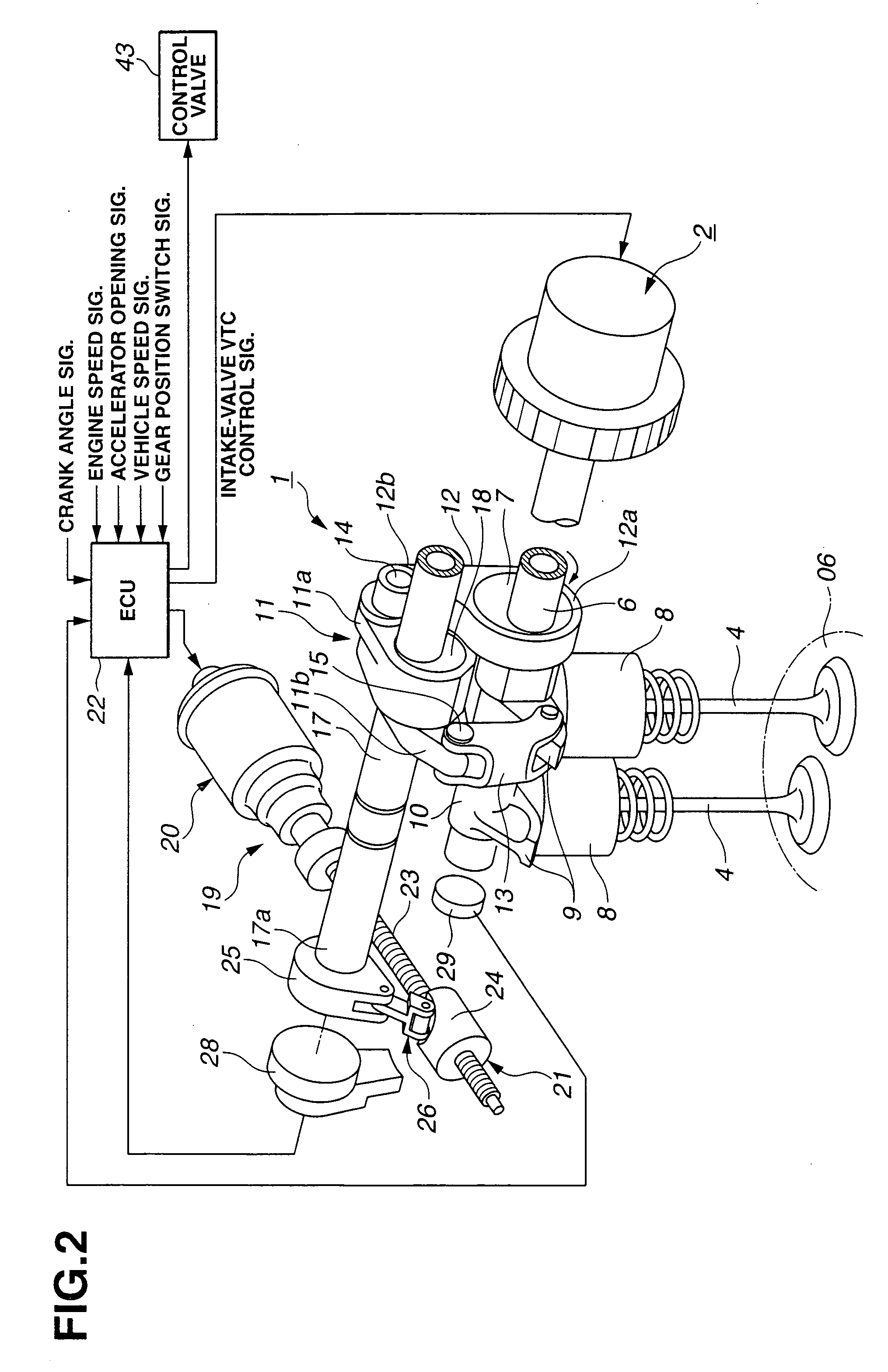

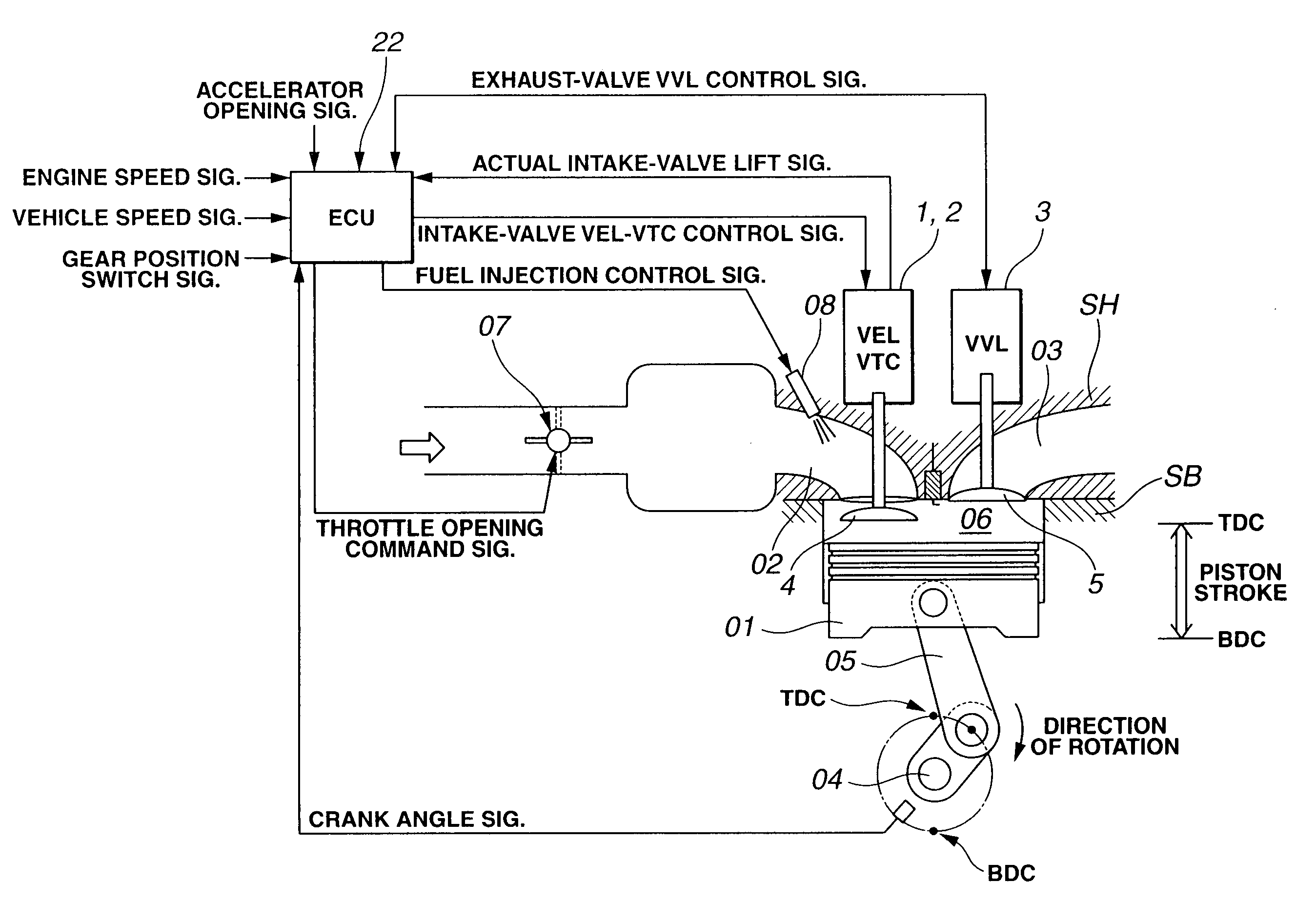

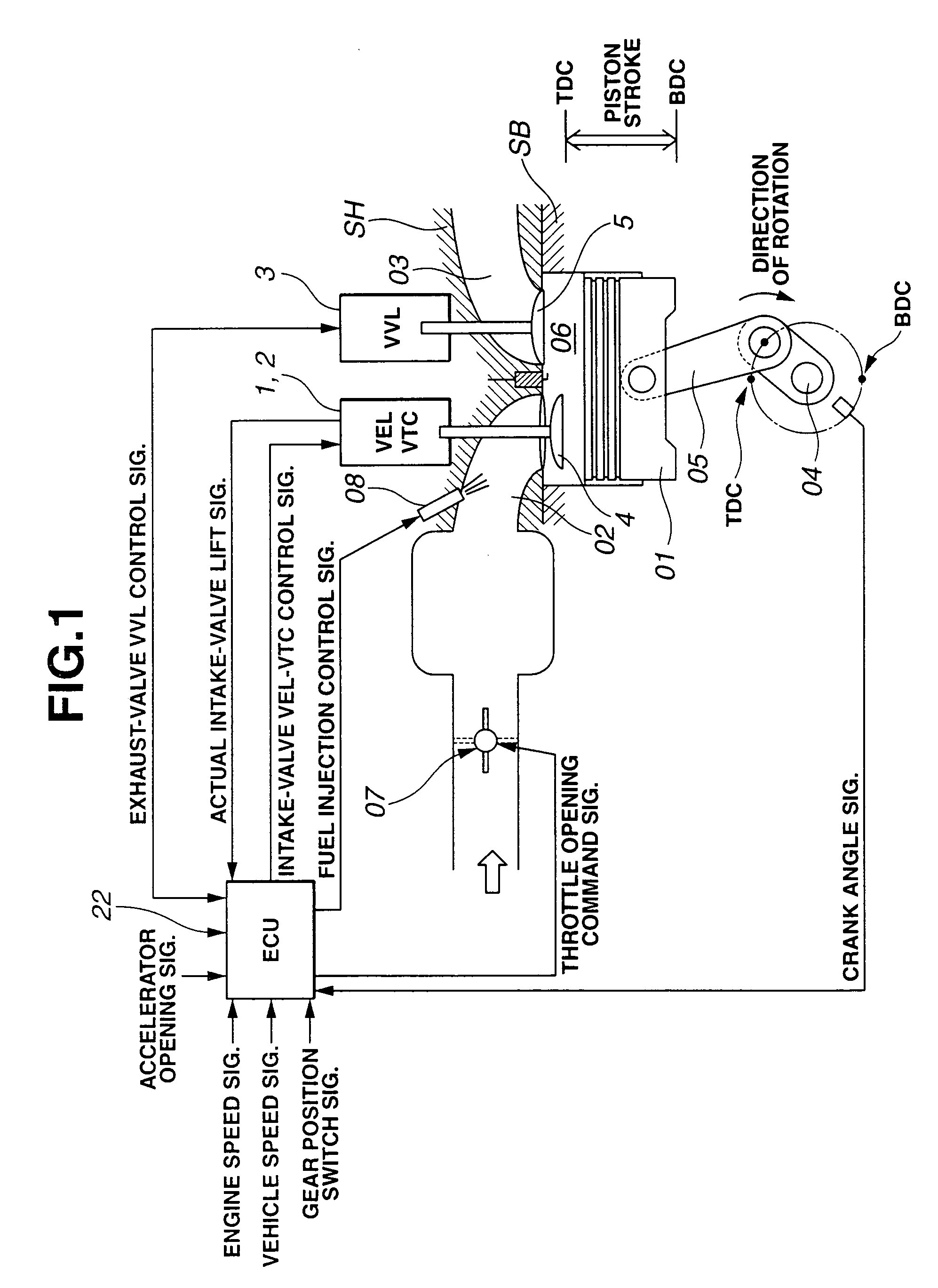

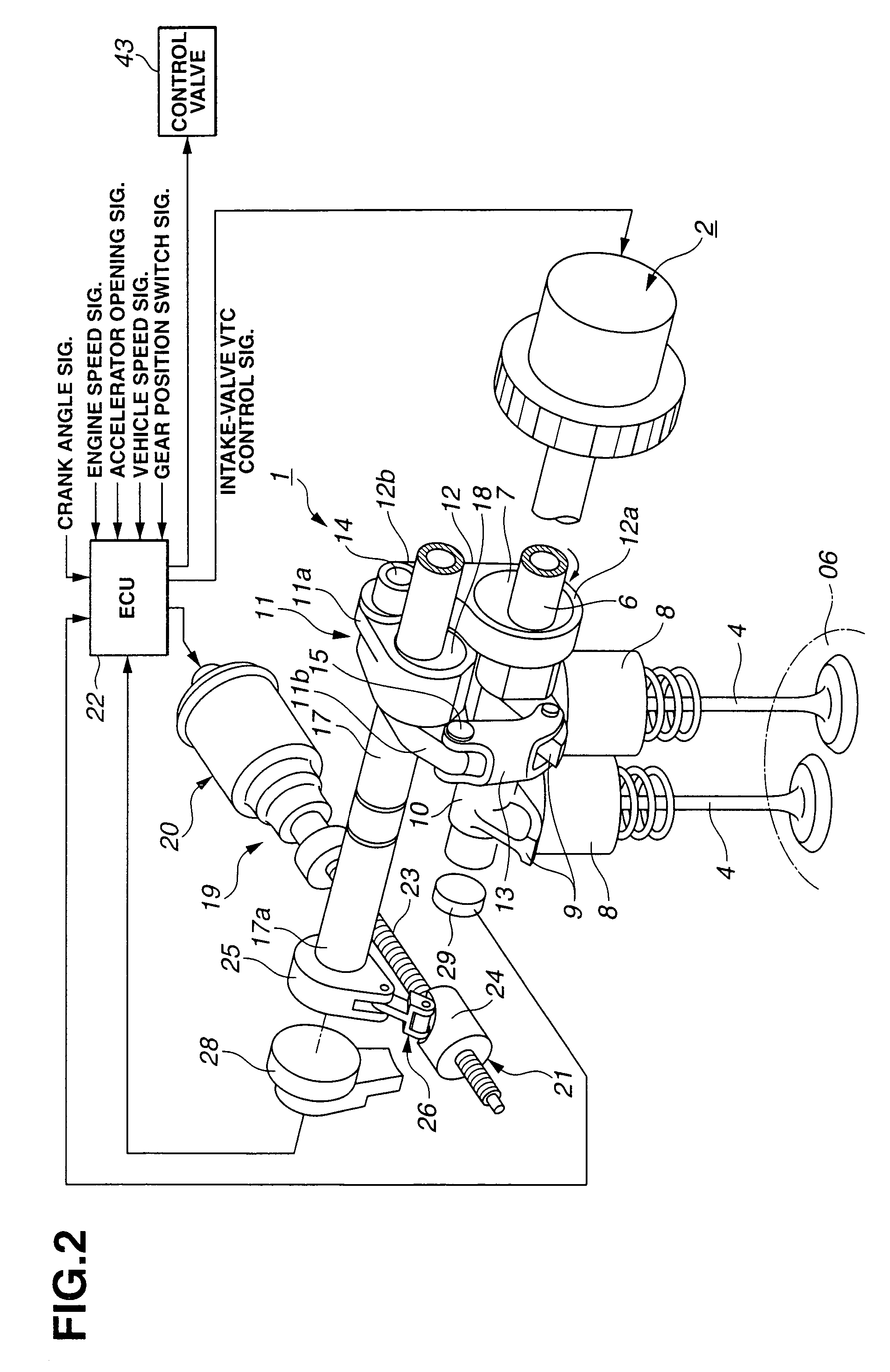

Cylinder cutoff control apparatus of internal combustion engine

InactiveUS20060037578A1Reduced engine braking effectTendency increaseValve arrangementsElectrical controlExhaust valveTop dead center

A cylinder cutoff control apparatus of an engine initiates a cylinder cutoff mode only when two conditions, namely a low load condition such as a vehicle cruising condition and an intake valve closure timing controlled to a given timing value before a bottom dead center, are both satisfied. A fuel cutoff mode is executed prior to the cylinder cutoff mode. During a transition to the cylinder cutoff mode, the control apparatus holds an intake valve open timing at a given timing value substantially corresponding to a top dead center, simultaneously with reducing an intake valve lift amount of each intake valve, subjected to cylinder cutoff control, to a zero lift. Immediately when the intake valve lift amount is reduced to below a lift threshold value, an exhaust valve lift amount of each exhaust valve, subjected to the cylinder cutoff control, is controlled to a zero lift.

Owner:HITACHI LTD

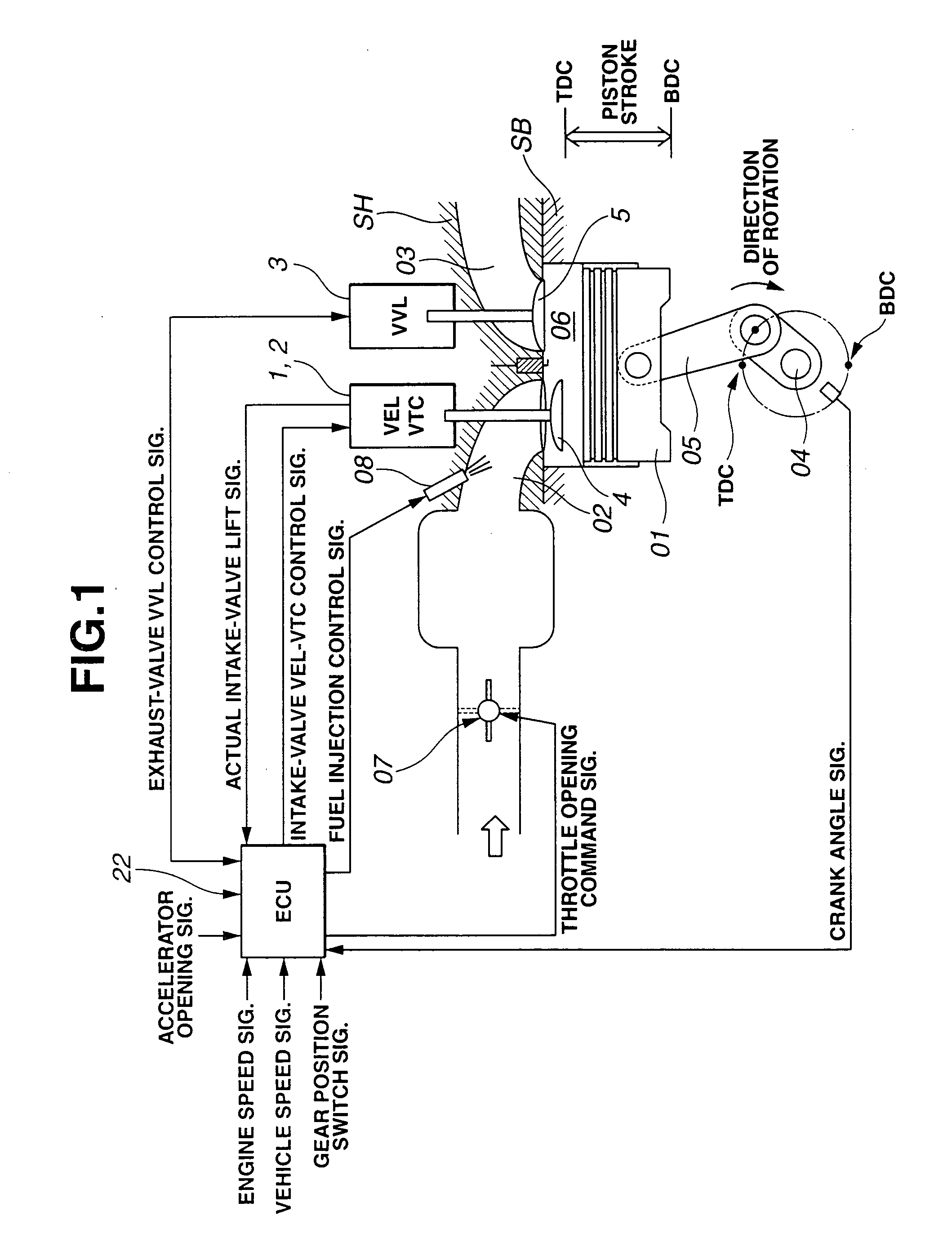

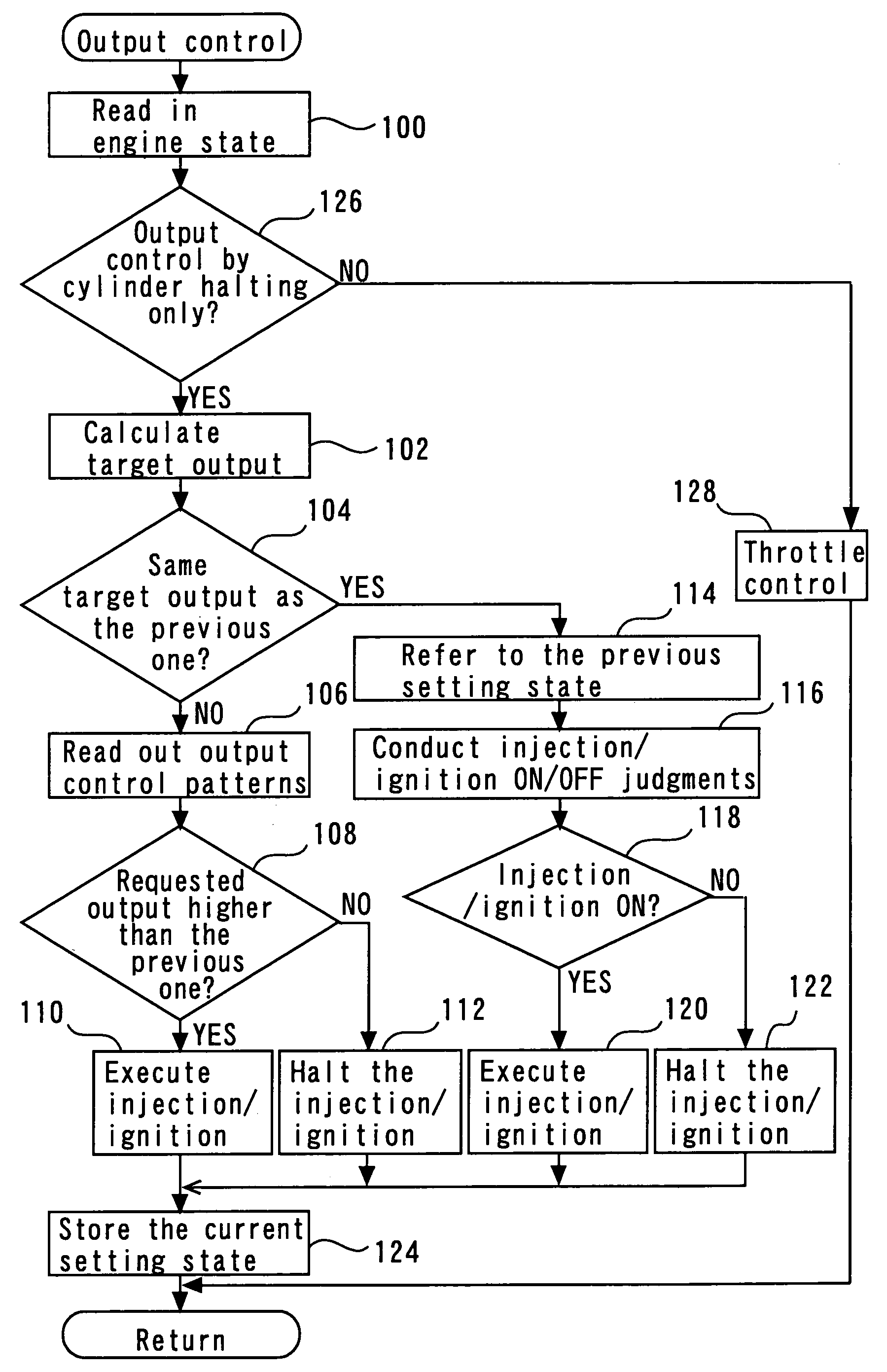

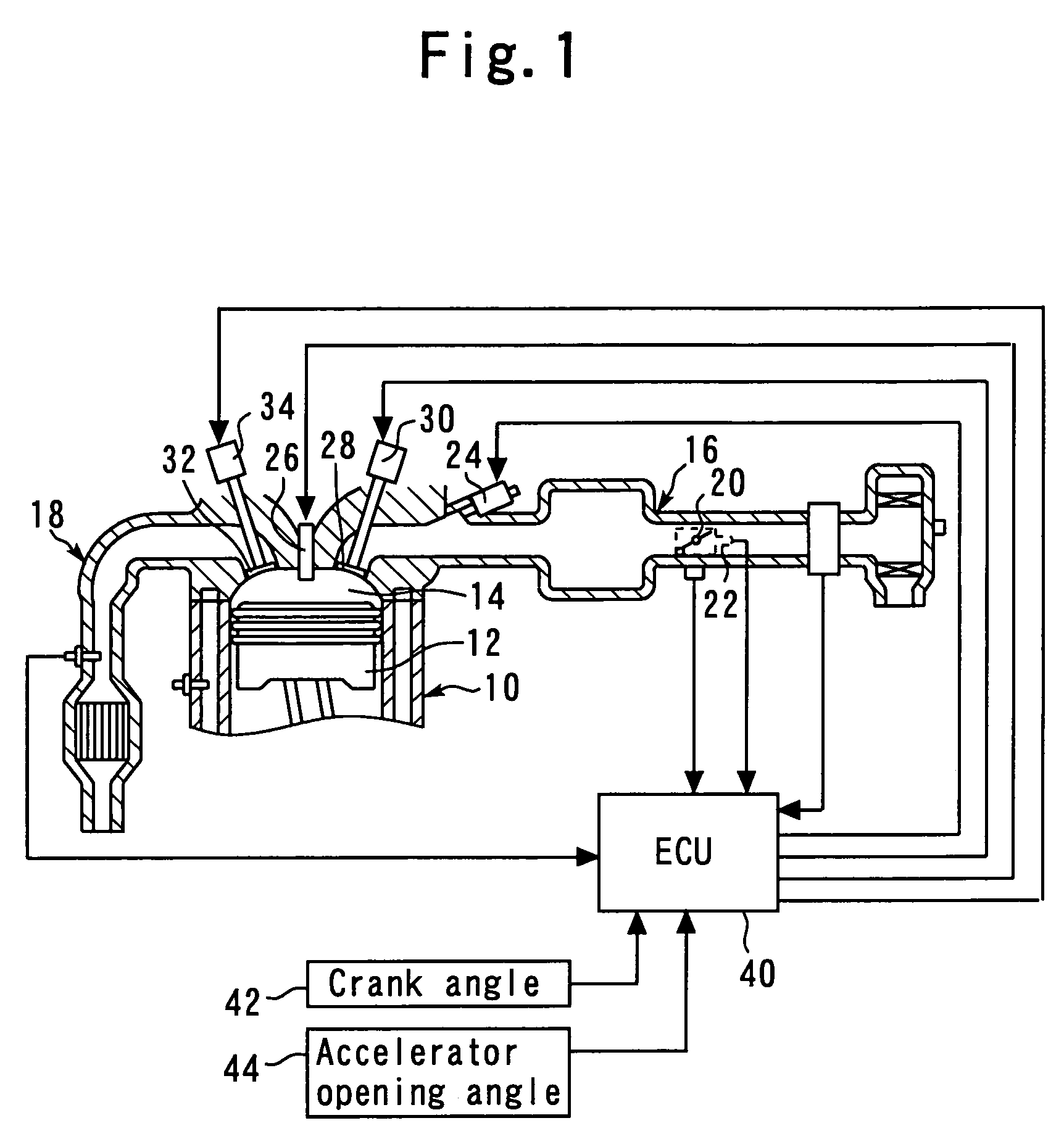

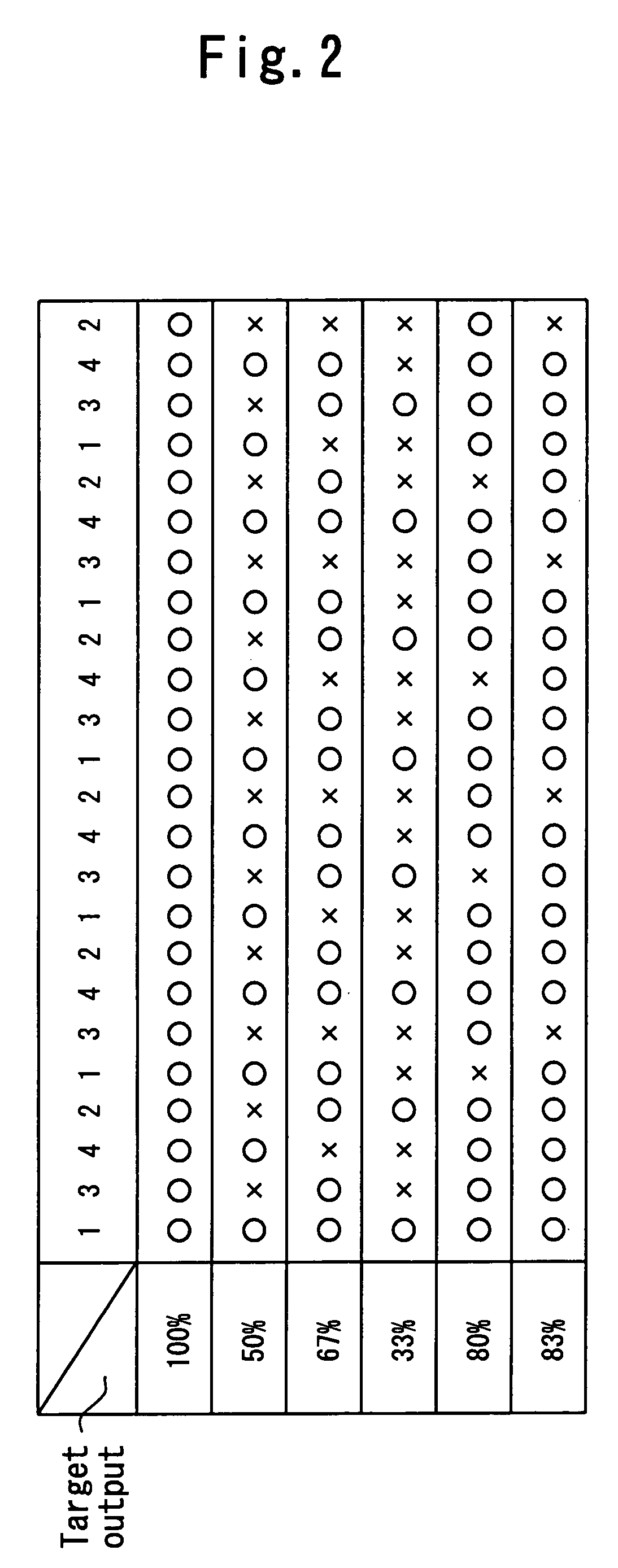

Output control system for internal combustion engine

InactiveUS7066136B2Easy to controlElectrical controlInternal combustion piston enginesCombustionExhaust valve

An intake electromagnetic driving valve and an exhaust electromagnetic driving valve are provided which use electromagnetic force to drive an intake valve and an exhaust valve, respectively. In step 102, the ratio between the number of combustion execution cycles and the number of combustion halts is set to obtain a desired target output value. Output control patterns that each consist of combustion execution timing equivalent to the required number of combustion execution cycles, and combustion halt timing equivalent to the required number of combustion halts are set in step 106, 114. In steps 108 to 112, or 118 to 122, in accordance with the output control patterns, whether combustion is to be executed is set with respect to the explosion timing that arrives in each cylinder in order.

Owner:TOYOTA JIDOSHA KK

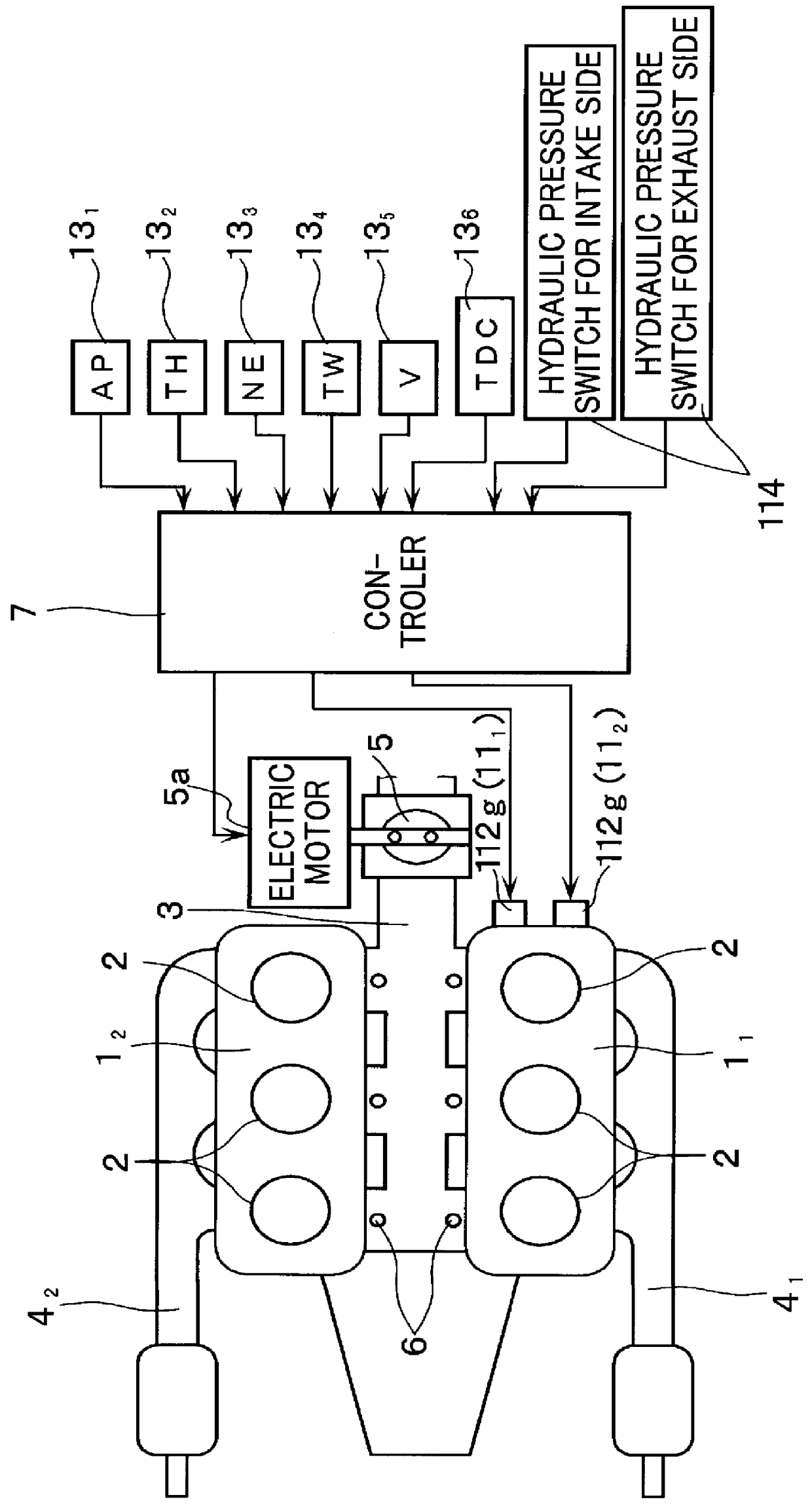

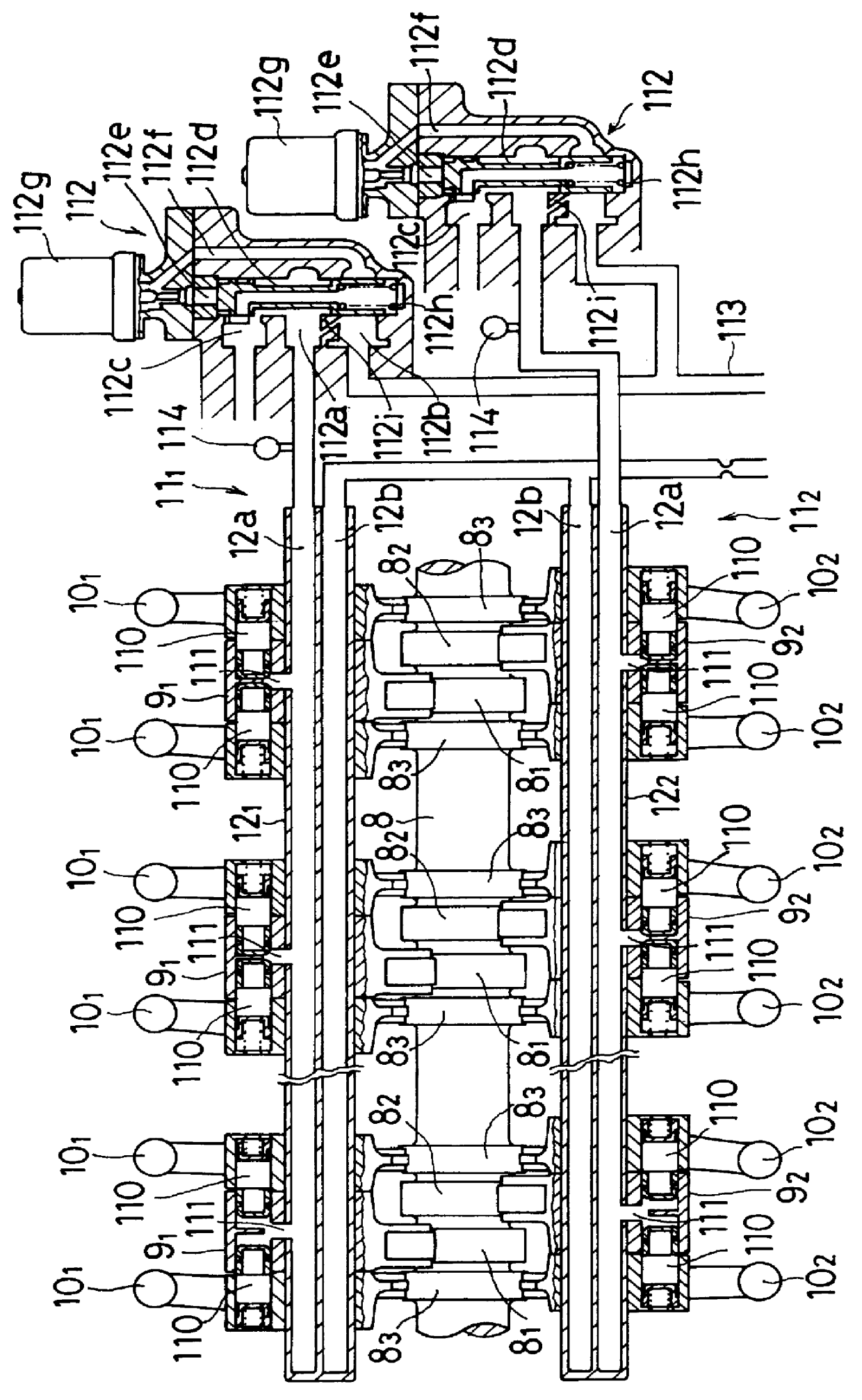

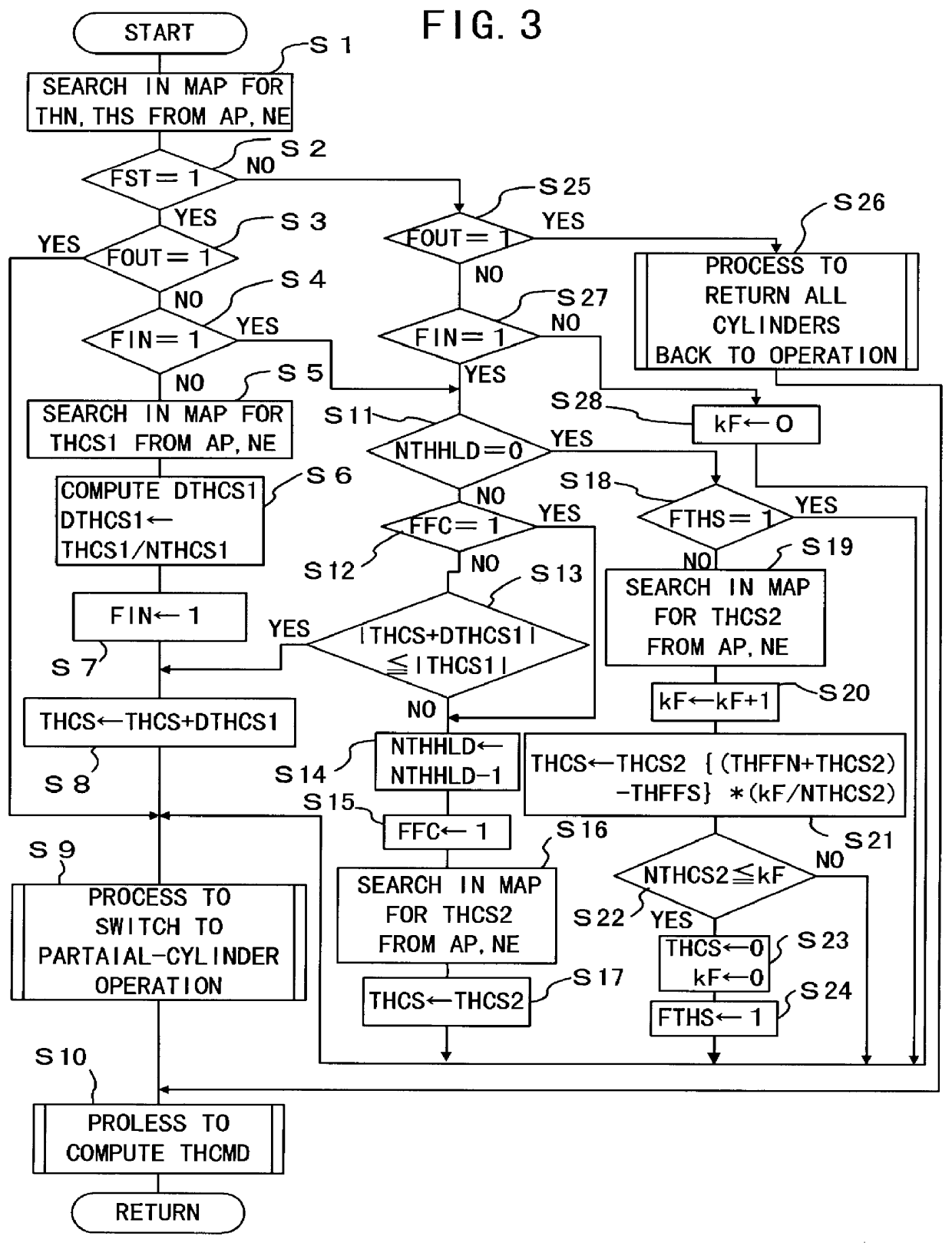

Apparatus for controlling multi-cylinder internal combustion engine with partial cylinder switching-off mechanism

In an apparatus for controlling a multi-cylinder internal combustion engine with partial cylinder switch-off mechanism which is switchable between an all-cylinder operation mode in which all cylinders are operated and a partial-cylinder operation mode in which operation of partial cylinders is suspended, the operation of intake valves and exhaust valves is suspended or resumed in a predetermined order with respect to all of the suspended cylinders irrespective of a rotational frequency of the engine. There are provided a solenoid valve on an intake side and a solenoid valve on an exhaust side for switching input hydraulic pressures for hydraulically operated switching devices respectively on the intake side and on the exhaust side between the driving state and the drive-free state. At the time of switching the operation, one of the solenoid valves on the intake side and the exhaust side is driven in advance. The subsequent number of rotations of a crankshaft is counted. When the number of this counting has reached a predetermined value, the solenoid valve on the other side is driven.

Owner:HONDA MOTOR CO LTD

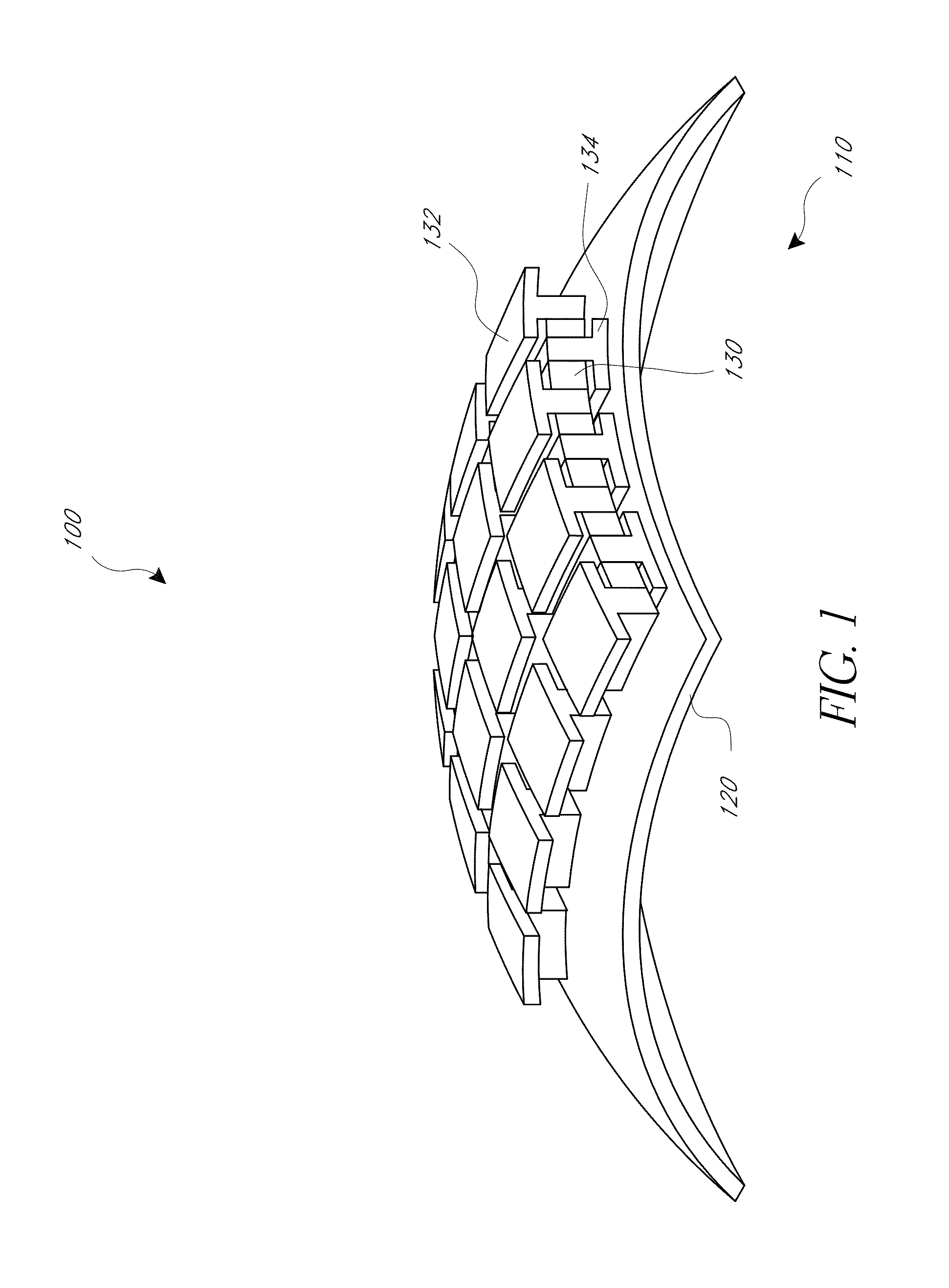

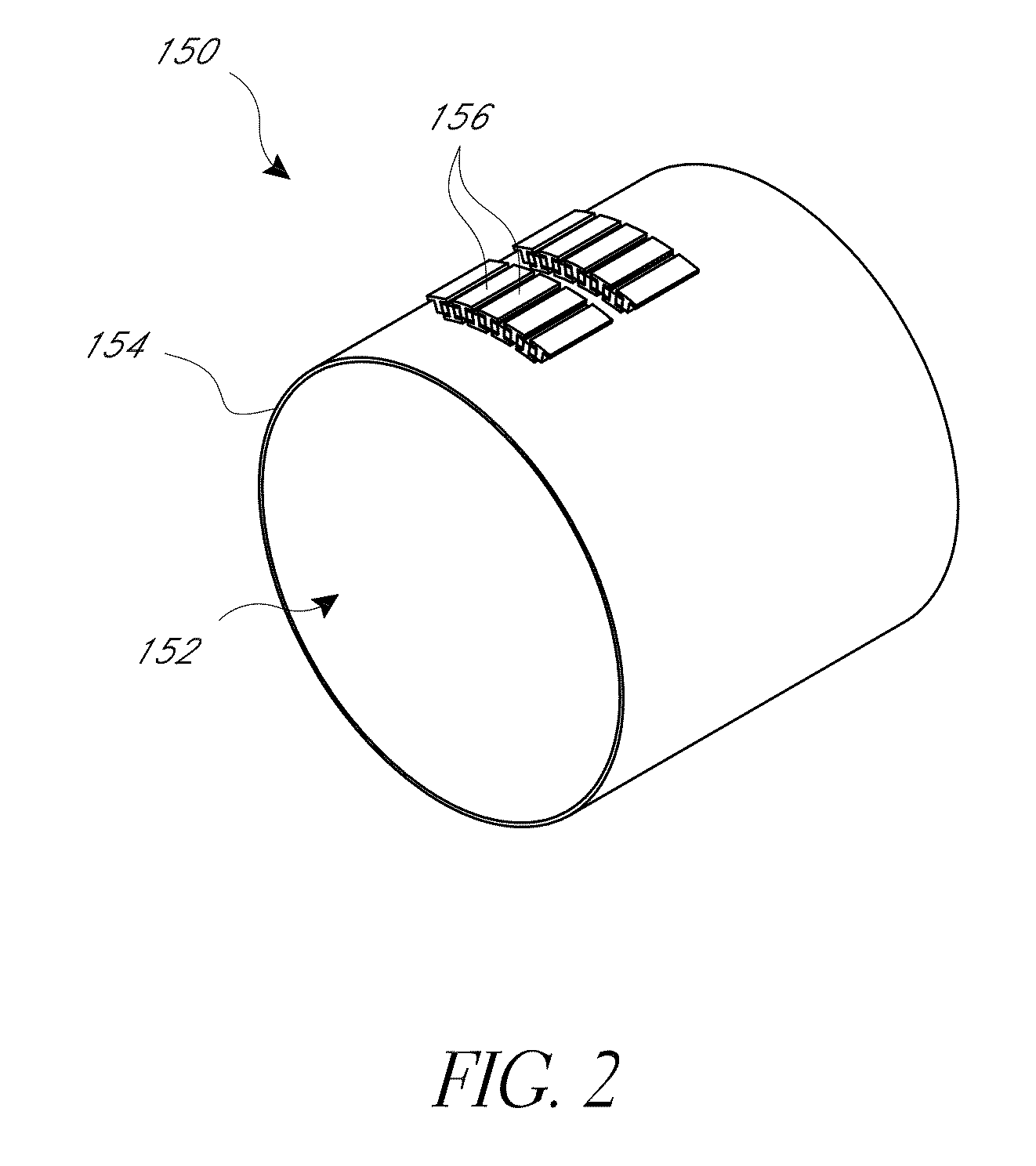

Thermoelectric-based power generation systems and methods

InactiveUS20110067742A1Lower overall pressure dropInternal combustion piston enginesRecuperative heat exchangersExhaust valveEngineering

Some embodiments provide a waste heat recovery apparatus including an exhaust tube having a cylindrical outer shell configured to contain a flow of exhaust fluid; a first heat exchanger extending through a first region of the exhaust tube, the first heat exchanger in thermal communication with the cylindrical outer shell; a second region of the exhaust tube extending through the exhaust tube, the second region having a low exhaust fluid pressure drop; an exhaust valve operatively disposed within the second region and configured to allow exhaust fluid to flow through the second region only when a flow rate of the exhaust fluid becomes great enough to result in back pressure beyond an allowable limit; and a plurality of thermoelectric elements in thermal communication with an outer surface of the outer shell.

Owner:GENTHERM INC

Constant EGR rate engine and method

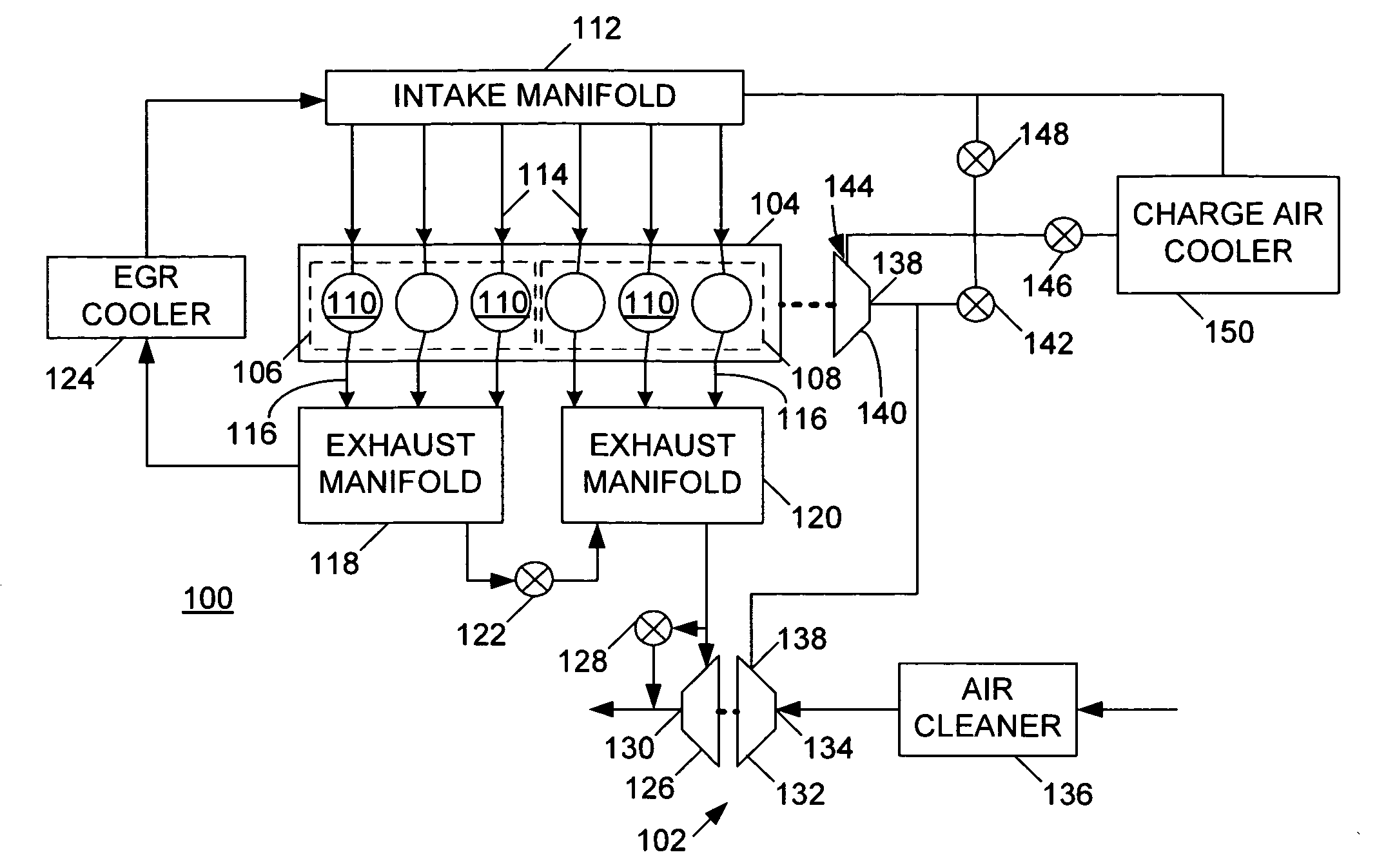

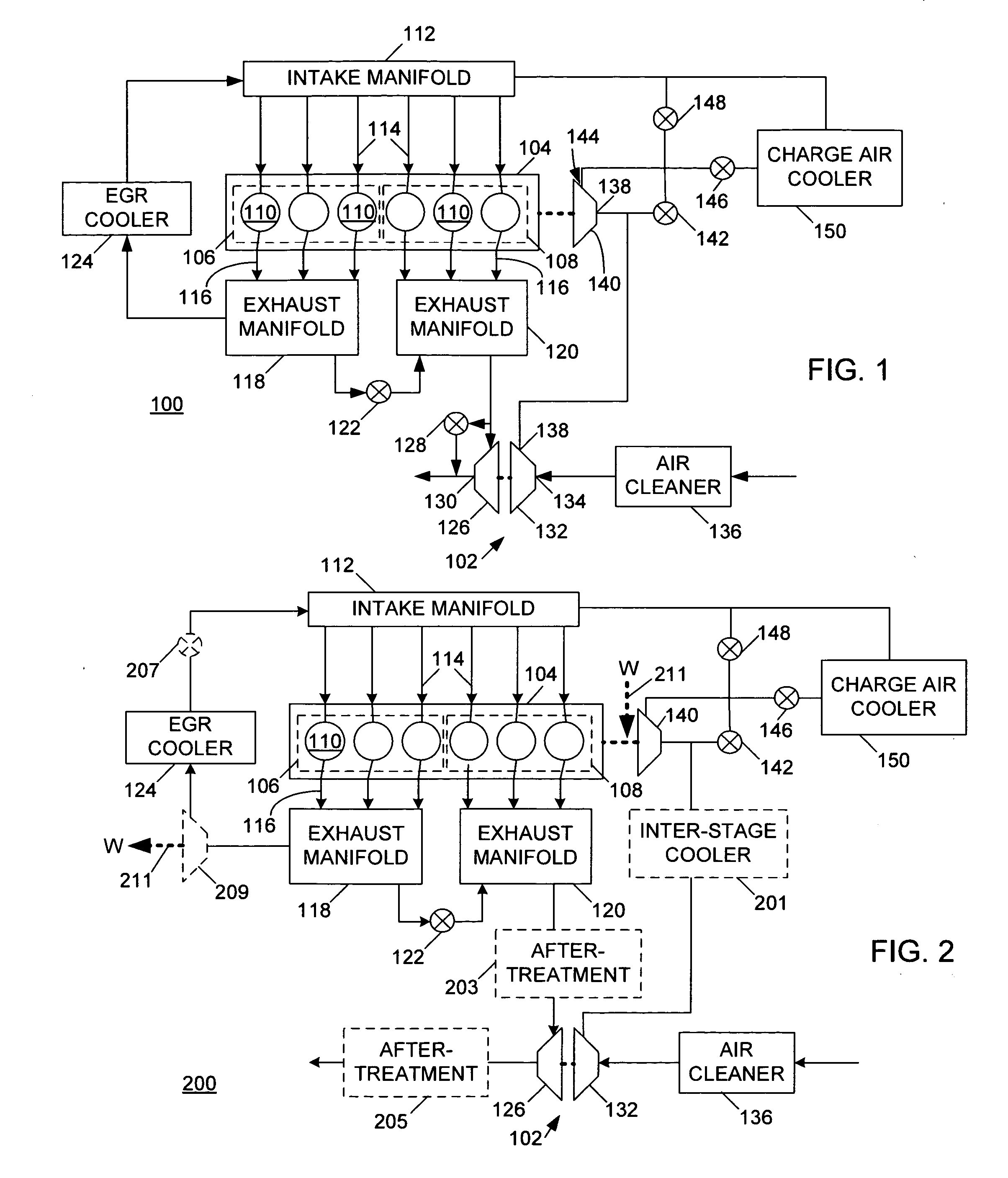

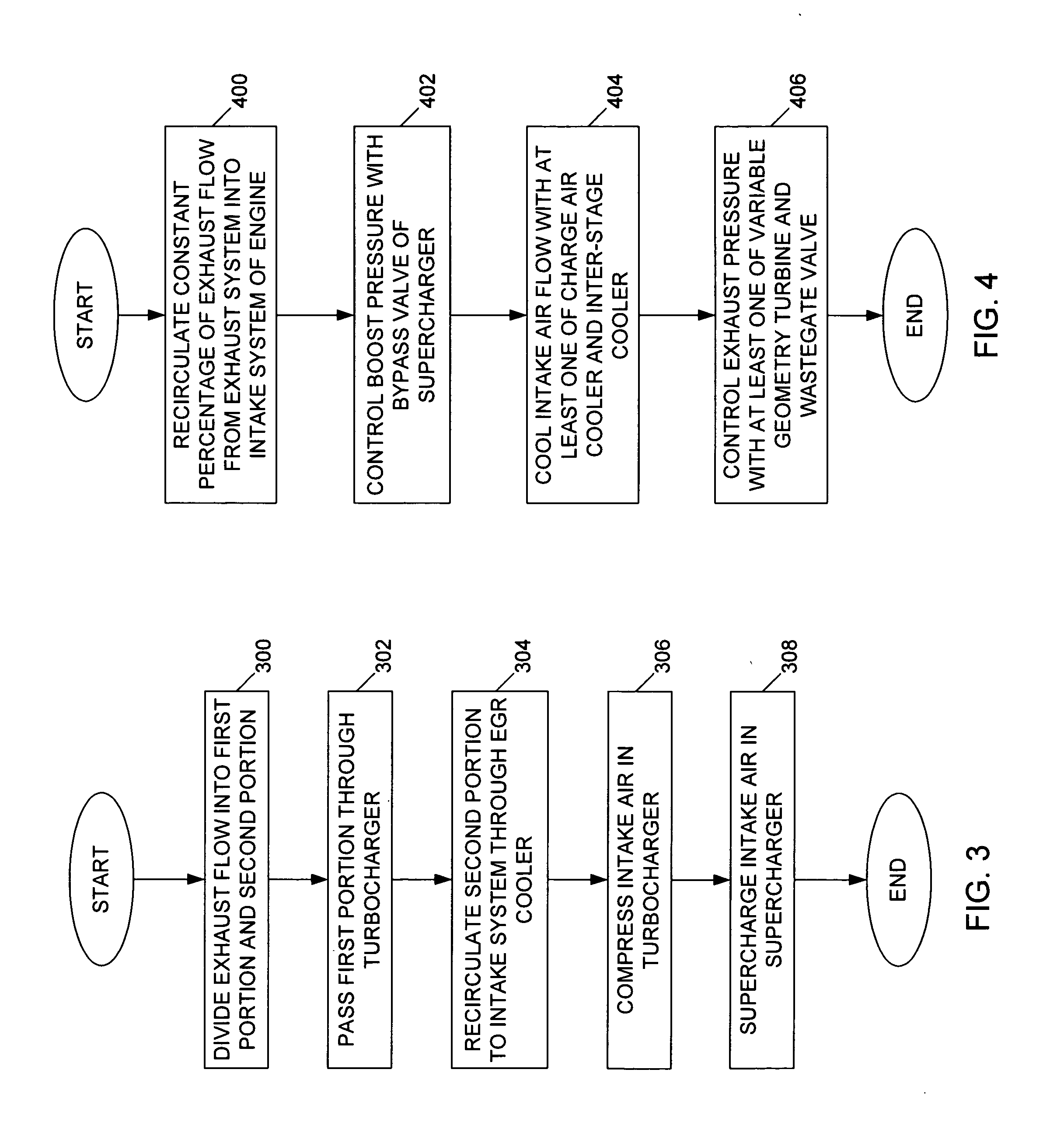

ActiveUS20070175215A1Non-fuel substance addition to fuelInternal combustion piston enginesExhaust valveTurbocharger

An internal combustion engine (100) includes a first exhaust manifold (120), and a second exhaust manifold (118) fluidly connected to the first exhaust manifold (120) through an exhaust valve (122). An exhaust gas recirculation (EGR) cooler (124) constantly fluidly connects the second exhaust manifold (118) with an intake manifold (112). A turbocharger (102) has a turbine (126) in fluid communication with the first exhaust manifold (120), and a compressor (132) in fluid communication with a supercharger (140). A charge air cooler (150) fluidly connects the supercharger (140) with the intake manifold (112).

Owner:INT ENGINE INTPROP CO LLC

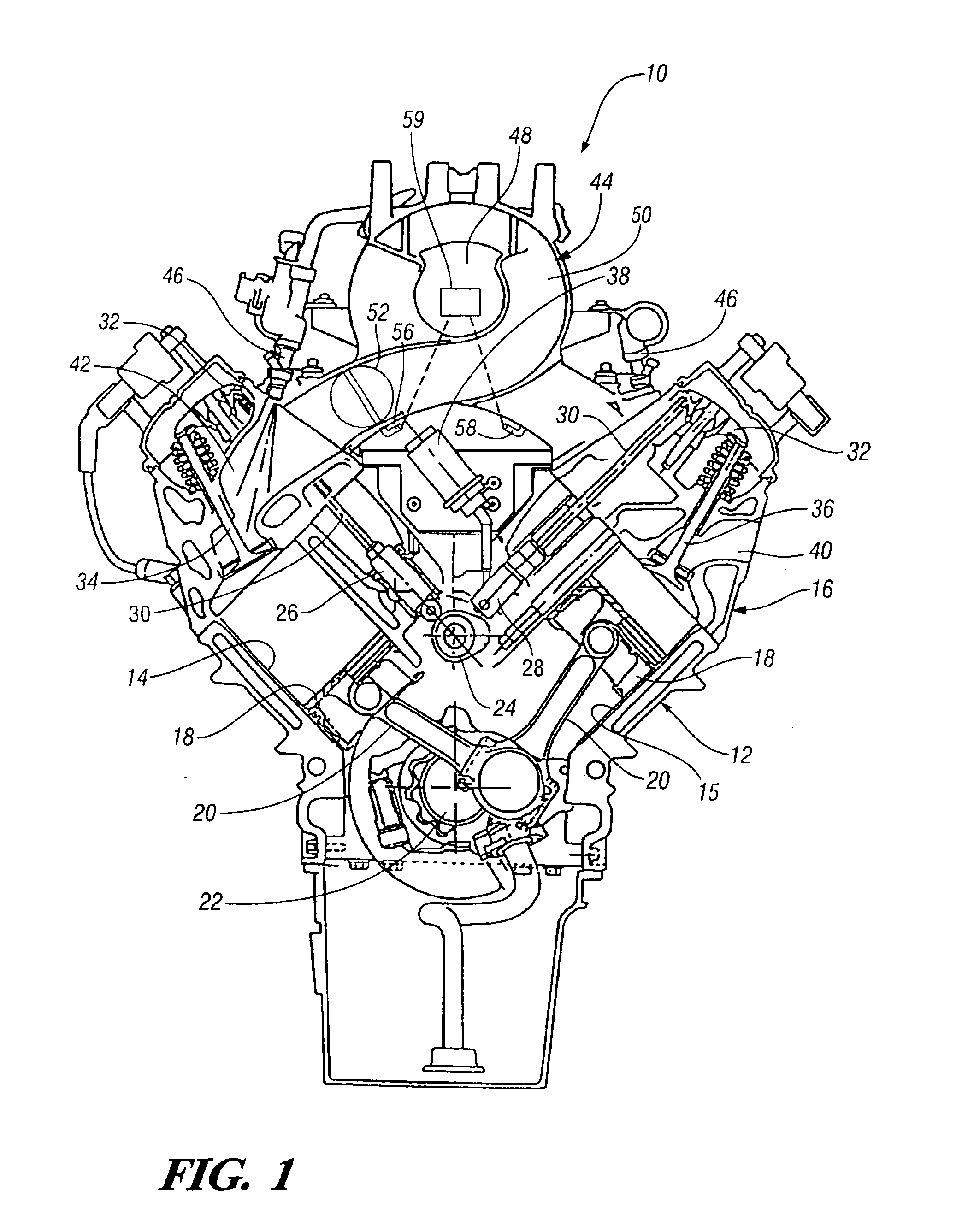

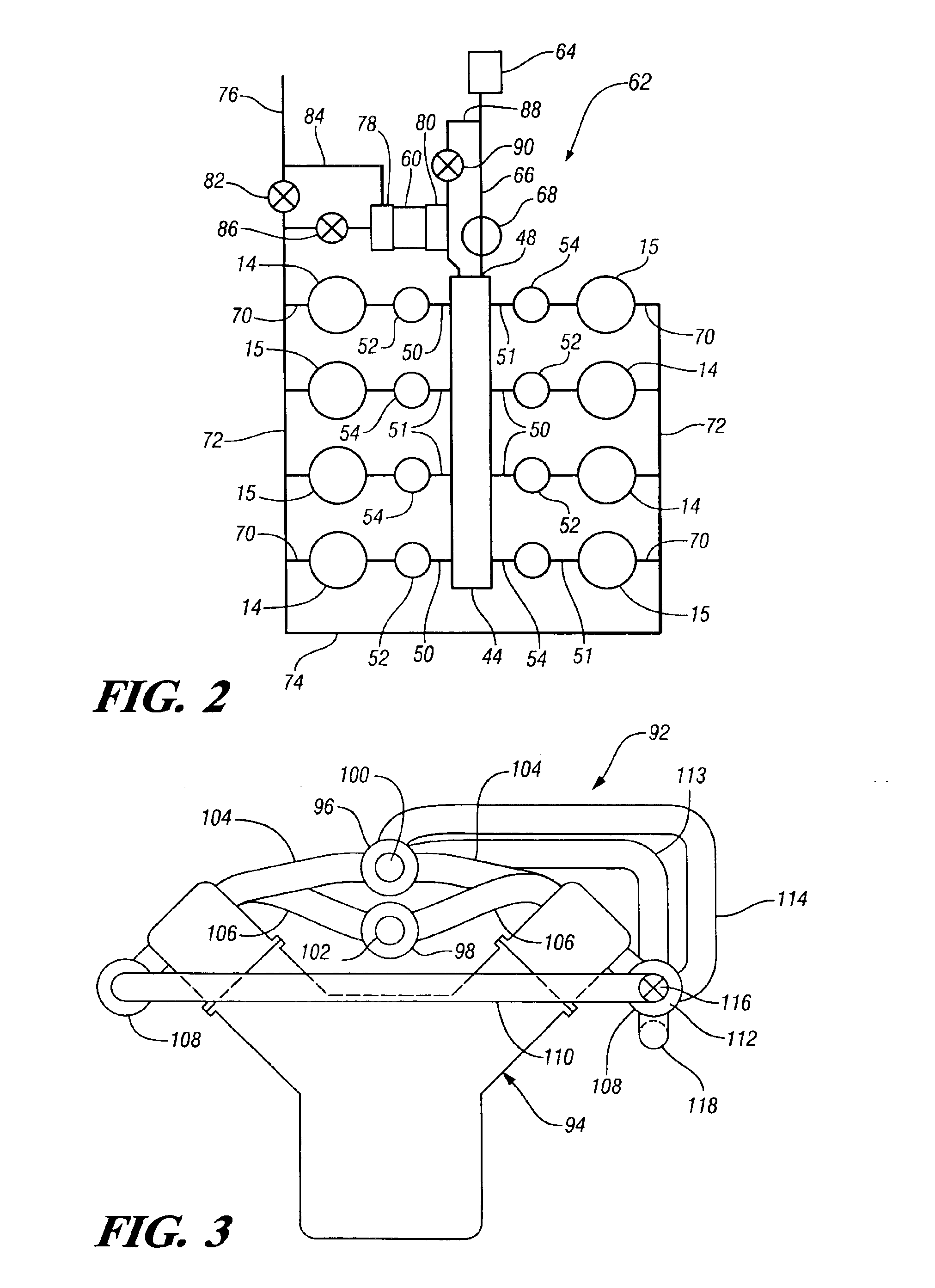

Engine and method of operation with cylinder deactivation

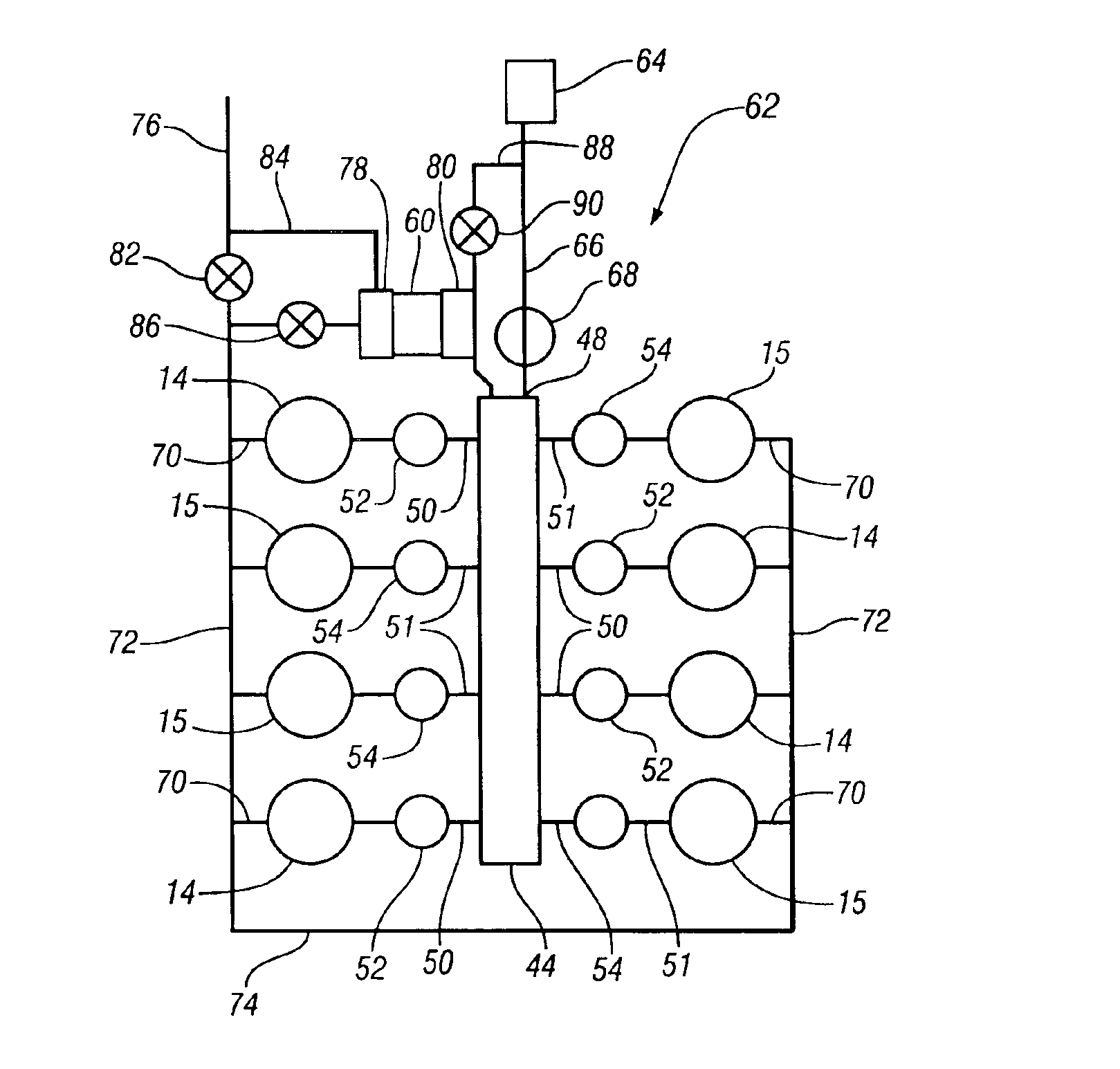

ActiveUS6874463B1Improvement in DOD operationEasy to operateElectrical controlInternal combustion piston enginesExhaust valveCylinder Valve

An engine with cylinder deactivation (Displacement on Demand or DOD™) includes standard (STD) cylinders which are not deactivated and DOD cylinders which can be deactivated by closing their intake and exhaust valves and shutting off their fuel supply. To provide smooth transitions, the STD and DOD cylinders form separate groups each supplied with charge air through one or more separate throttles. When switching to DOD operation, the throttles are oppositely actuated to cut out the DOD cylinders and maintain torque in the active cylinders prior to deactivation of the cylinder valves. When returning to STD operation, the valves are reactivated before oppositely actuating the throttles to enable full cylinder operation. In DOD operation, a small supercharger may be operated to boost torque of the operating STD cylinders and thus increase the DOD operating range.

Owner:GM GLOBAL TECH OPERATIONS LLC

Internal combustion engine having two exhaust gas turbocharger

InactiveUS7540150B2Simple meansNon-fuel substance addition to fuelInternal combustion piston enginesExhaust valveTurbocharger

In an internal combustion engine provided with two exhaust gas turbochargers which each comprise a turbine in an exhaust line and one compressor in an intake section of the engine, two exhaust lines are provided which are each assigned to at least one of the exhaust gas turbines, an exhaust gas recirculation device being arranged between an exhaust line upstream of an exhaust gas turbine and the intake section downstream of a compressor and the two exhaust lines including bypass lines with a control valve for selectively permitting the exhaust gas to bypass the turbine closer to the engine.

Owner:DAIMLER AG

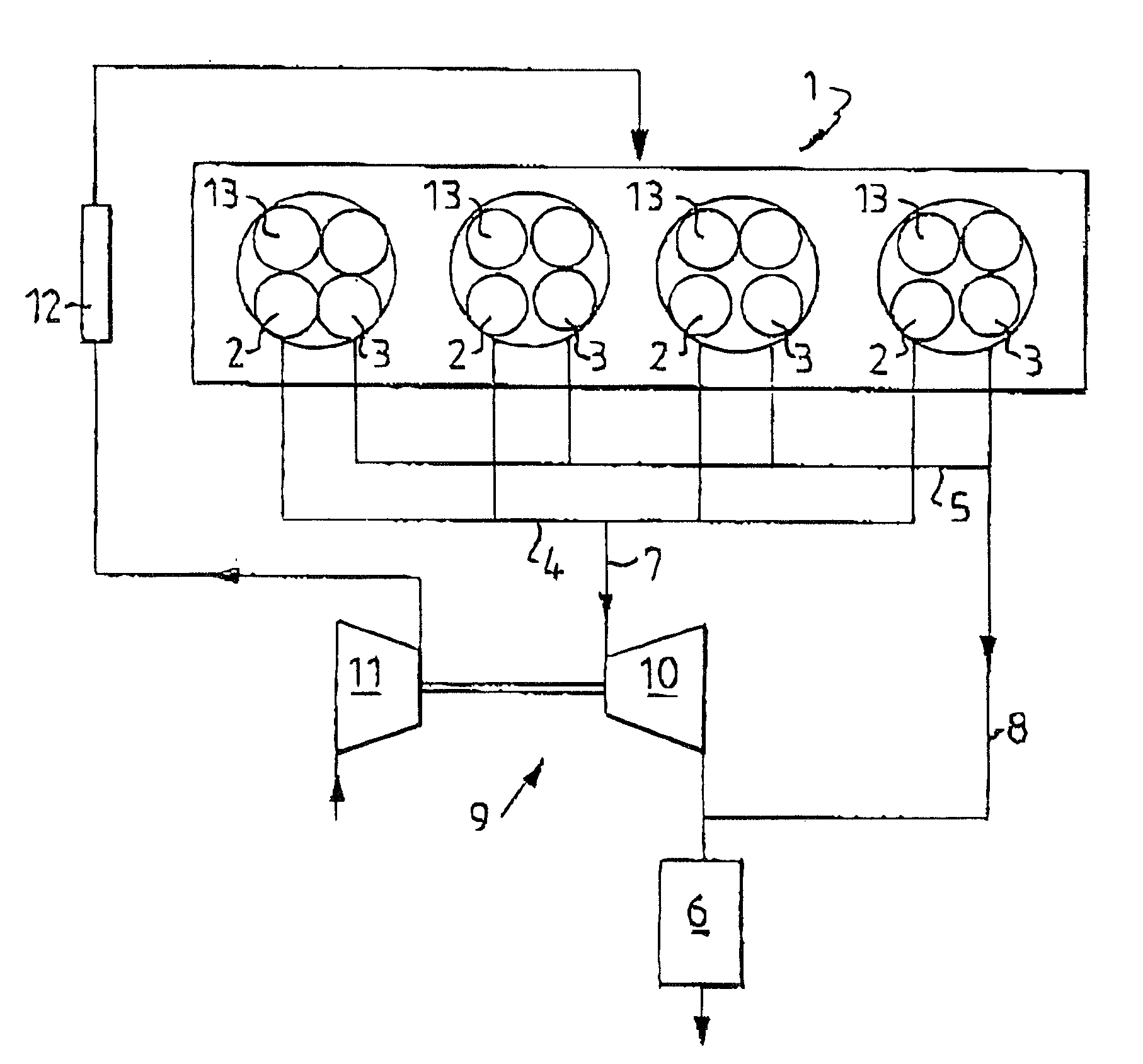

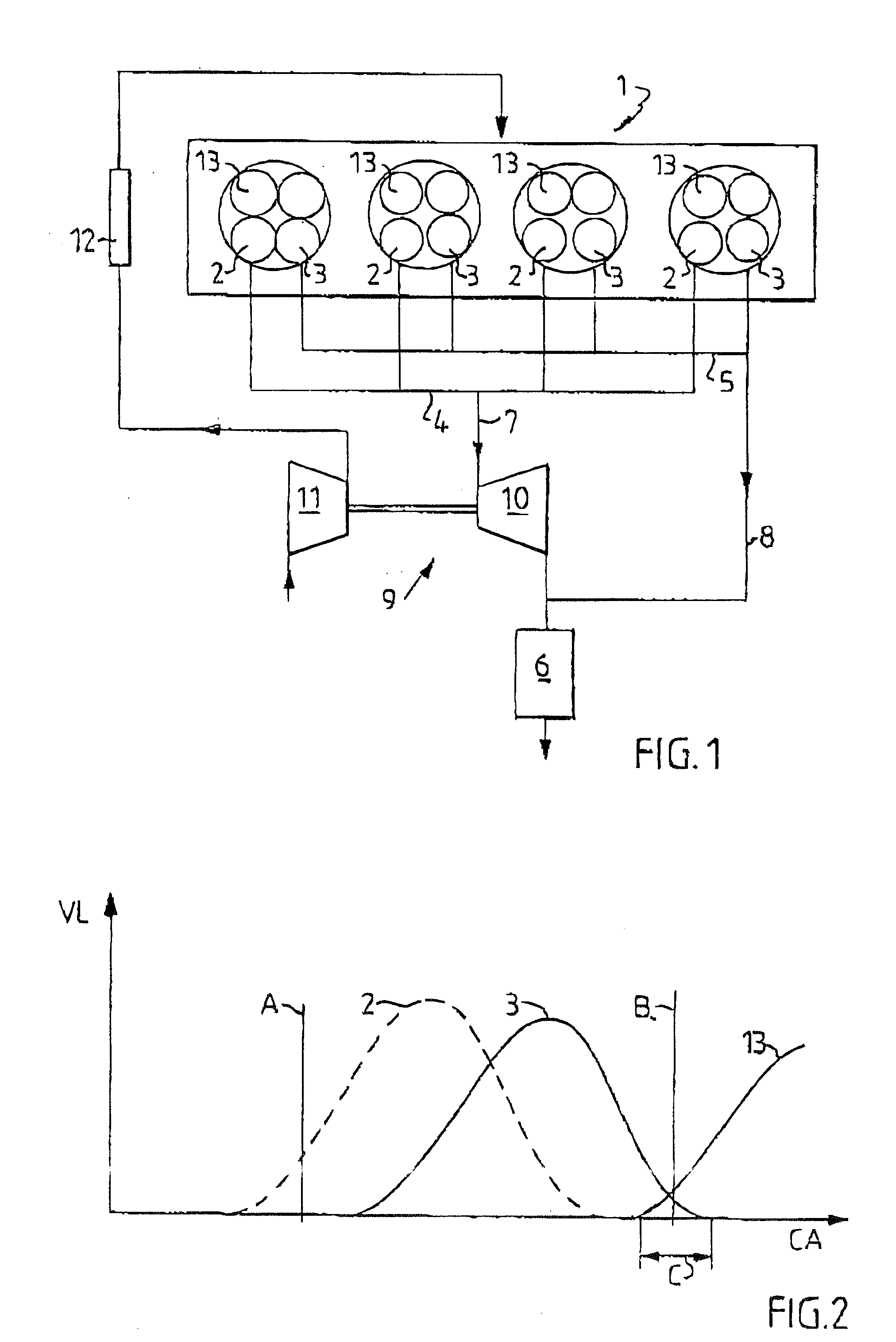

Internal combustion engine

InactiveUS6595183B1Increase mass flowIncrease torqueValve arrangementsElectrical controlExhaust valveTop dead center

A multicylinder internal combustion engine with an exhaust-driven turbocompressor and with a divided exhaust flow has at least two exhaust valves and one intake valve per cylinder. A first exhaust valve is connected to a first exhaust manifold which leads to the turbine of the compressor, while a second exhaust valve is connected to a second exhaust manifold which opens downstream of the turbine. In the top dead center position of the piston, the second exhaust valve and the intake valve are open at the same time for a period. The synchronization between these valves is such that the length of the period during which they are open together increases with the engine speed when the engine is driven at high load. In this way, the possibilities are improved of the engine providing good torque over a wide engine speed range.

Owner:SAAB AUTOMOBILE AB

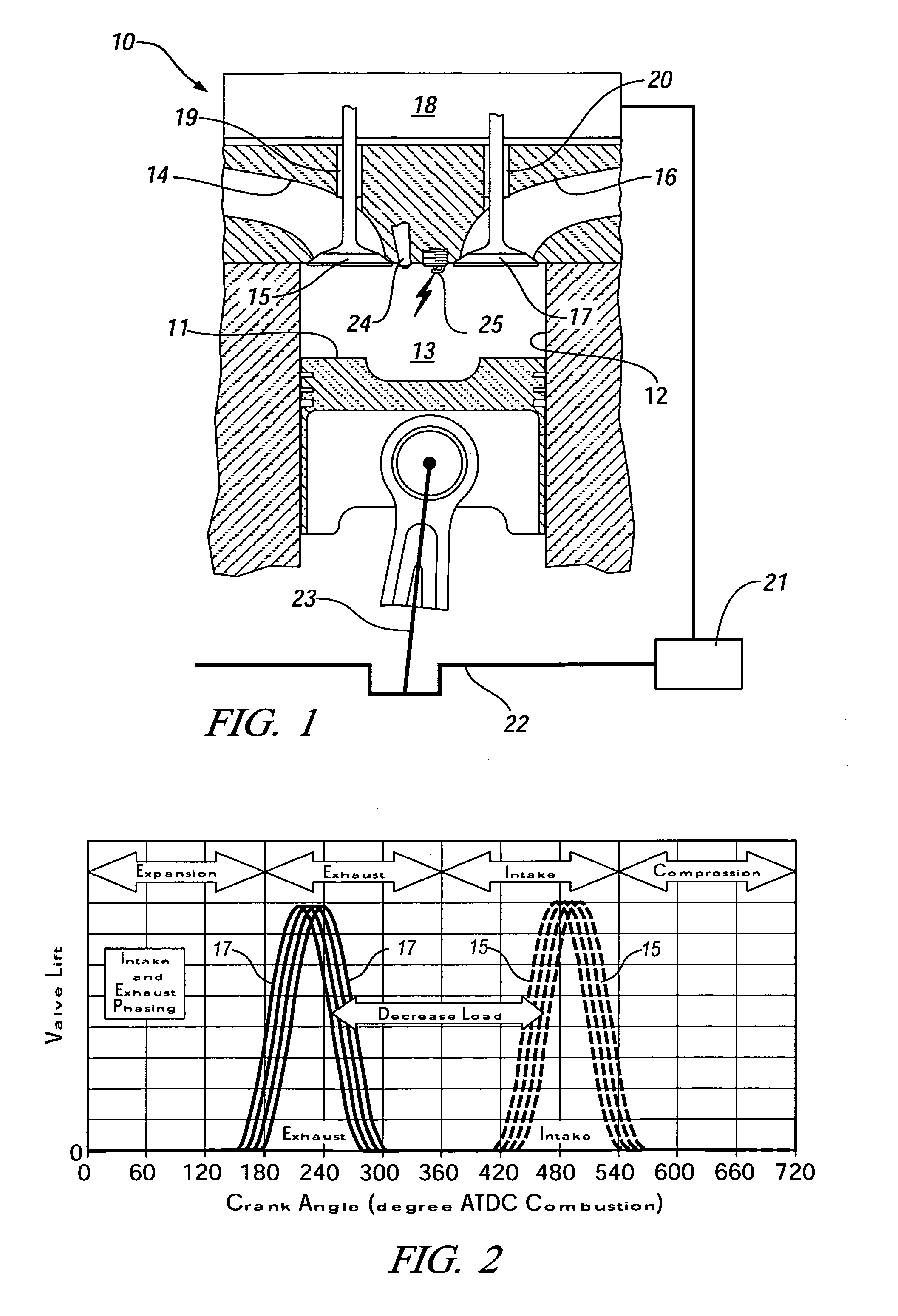

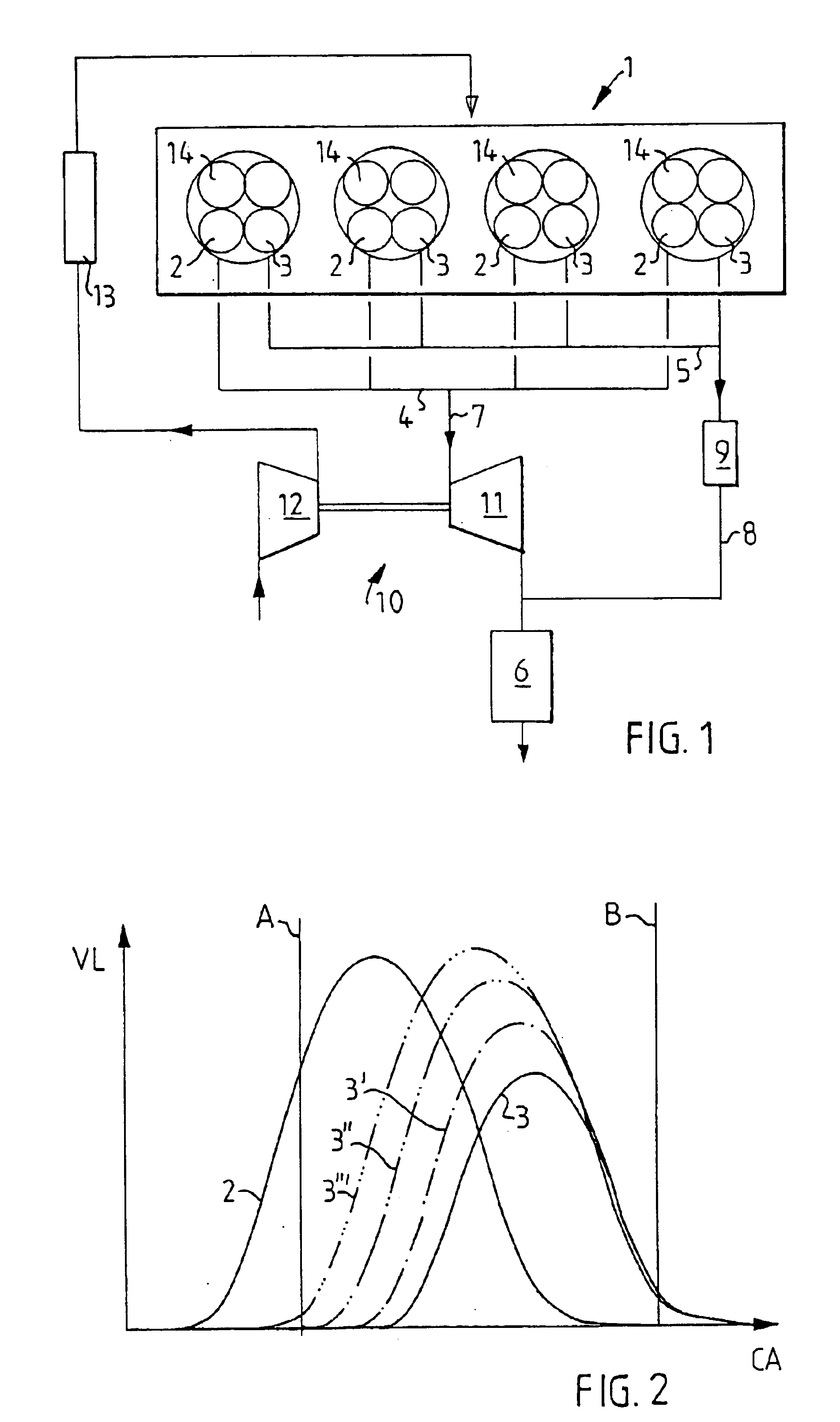

Method for transition between controlled auto-ignition and spark ignition modes in direct fuel injection engines

InactiveUS20060196466A1Eliminate misfiringEliminate partial burnValve arrangementsElectrical controlHomogeneous charge compression ignitionExhaust valve

A method is provided for control of transition between combustion modes of a direct-injection engine operable in a homogeneous charge compression ignition (HCCI) mode at lower loads and a spark ignition flame propagation (SI) mode at higher loads. The engine includes a variable valve actuation system including two-step high and low lift valve actuation and separate cam phasing for both intake and exhaust valves. The method includes operating the engine at steady state, with fuel-air-exhaust gas mixtures at predetermined conditions, for each speed and load, and controlling the engine during mode changes between the HCCI mode and the SI mode by switching the exhaust and intake valves between low lift for HCCI operation and high lift for SI operation. High load may be an SI throttled mode with an intermediate unthrottled mode (SI / NTLC} in which transition between HCCI and SI / NTLC modes requires switching only the exhaust valve lift and transition between SI / NTLC and SI throttled modes requires switching only the intake valve lift, with predetermined phase adjustments in the valve timing phasing.

Owner:GM GLOBAL TECH OPERATIONS LLC

Beverage forming apparatus with centrifugal pump

ActiveUS8151694B2Adequate flowSufficient pressureBeverage vesselsFood preparationExhaust valveControl valves

Owner:KEURIG GREEN MOUNTAIN INC

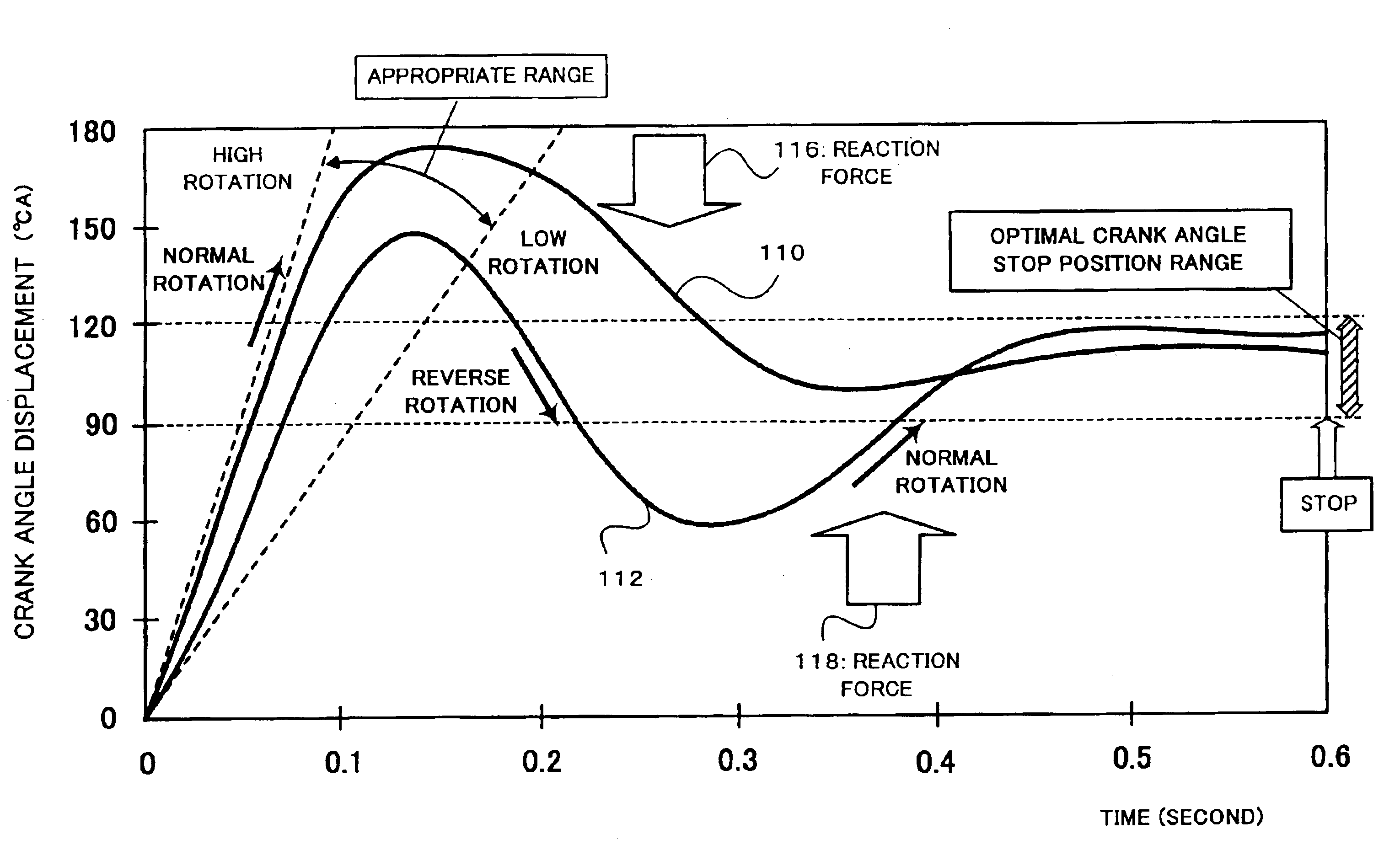

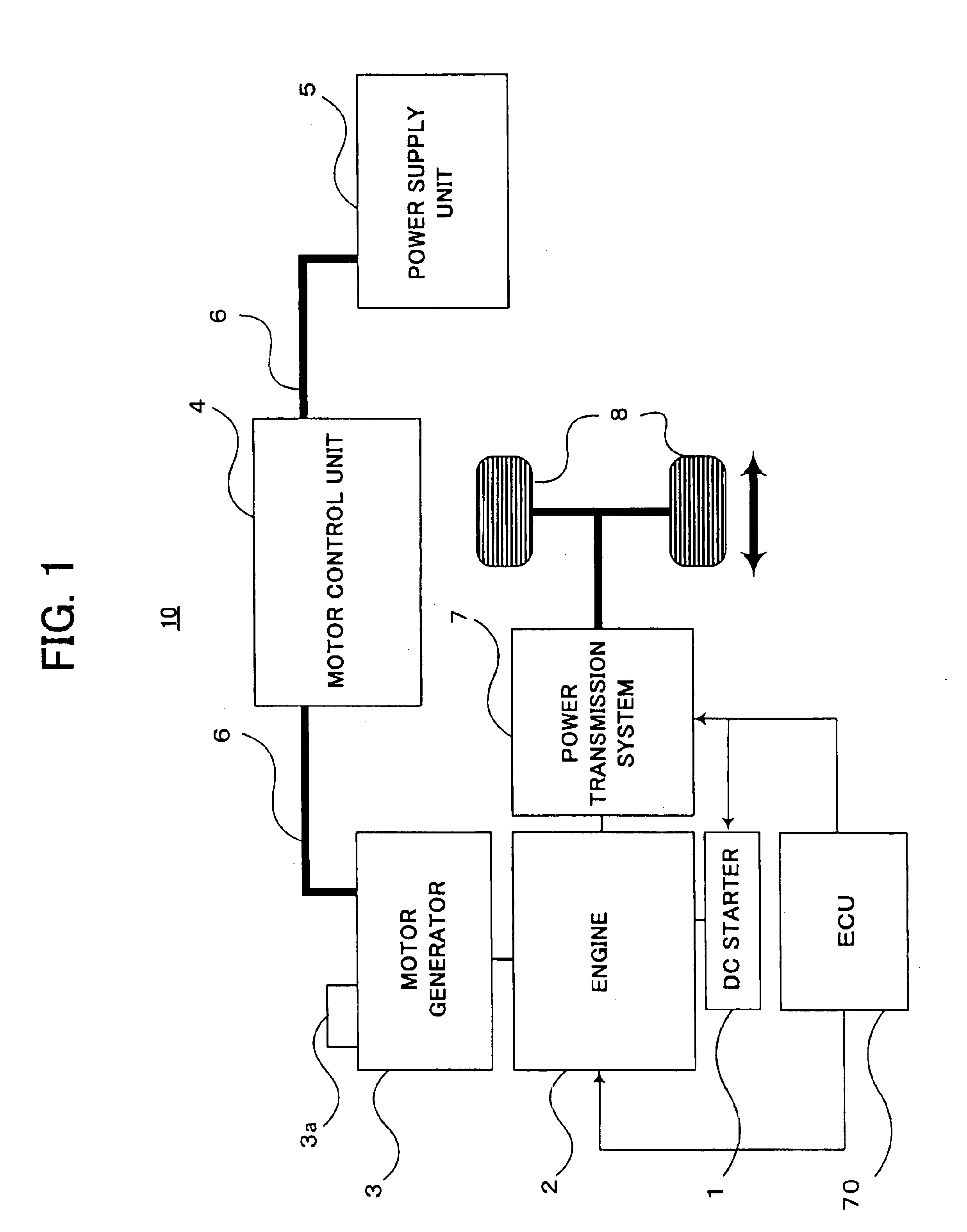

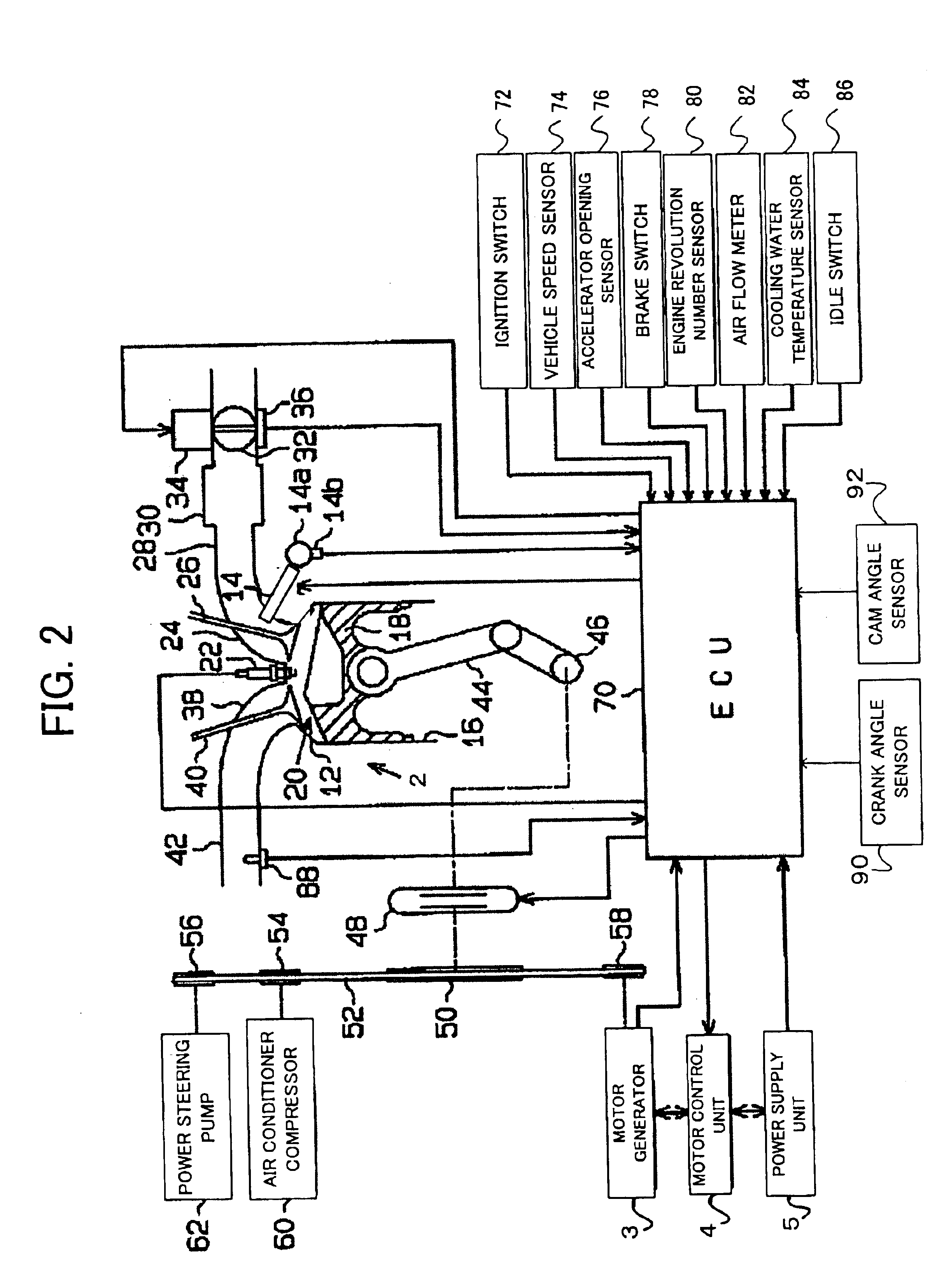

Stop and start control apparatus of internal combustion engine

A stop and start control apparatus of an internal combustion engine prevents fuel supplied in a specific cylinder at the time of stopping the engine from being discharged in an unburned state. When an ignition switch is turned off in a state that the unburned fuel is sealed in the combustion chamber of a specific cylinder during idling stop, the unburned fuel is combusted to prevent the unburned fuel from being discharged. The vibration occurring at that time can be suppressed by rotating the motor generator in the counter direction to the rotation direction of the crankshaft. After the unburned fuel is sealed in the combustion chamber of the specific cylinder, if it is estimated that the unburned fuel is discharged, the exhaust valve corresponding to the specific cylinder is closed at the predetermined timing, or the unburned fuel is combusted, whereby the unburned fuel is prevented from being discharged. Thus, deterioration of emission can be avoided.

Owner:TOYOTA JIDOSHA KK

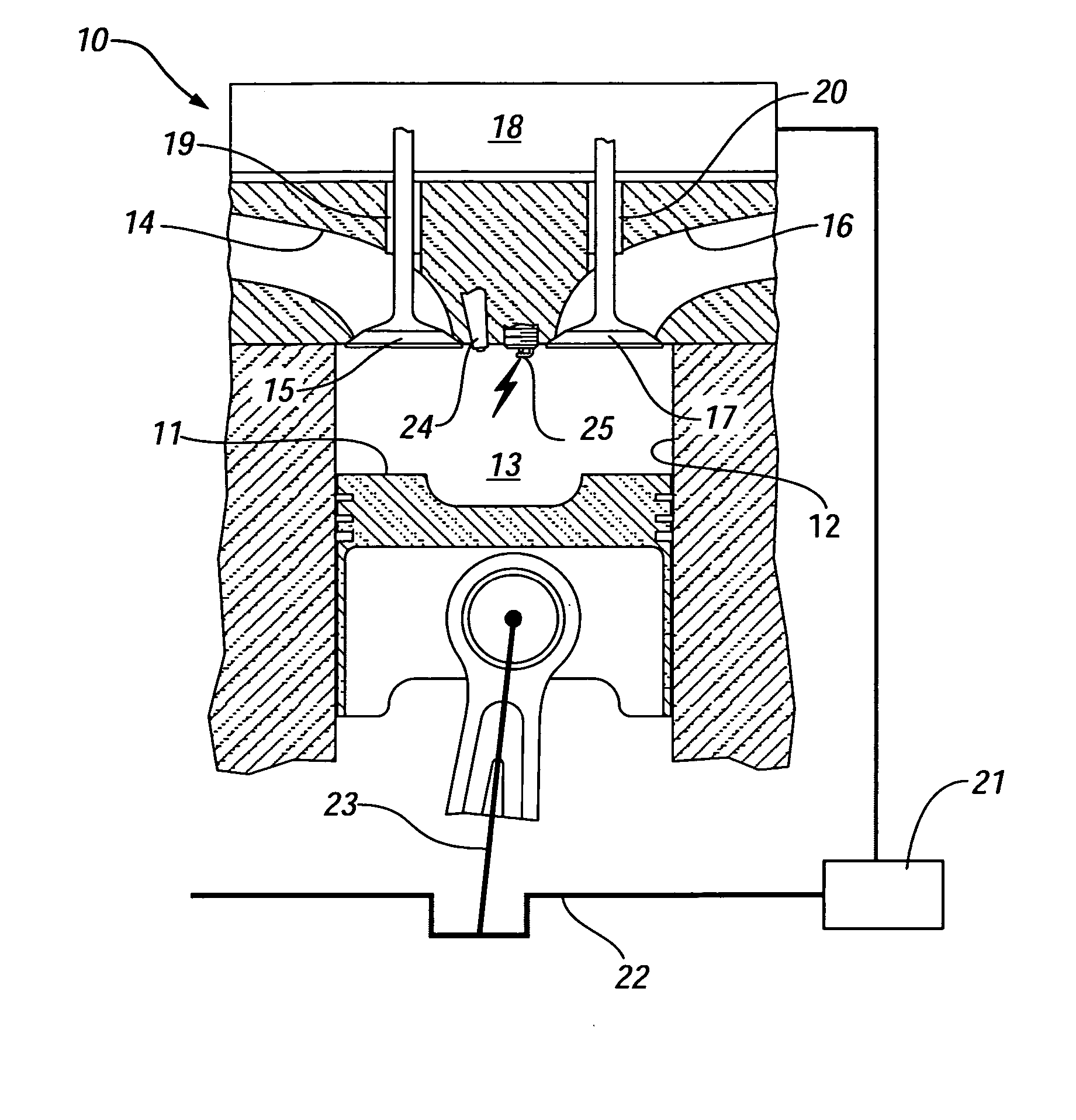

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS20060144356A1Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

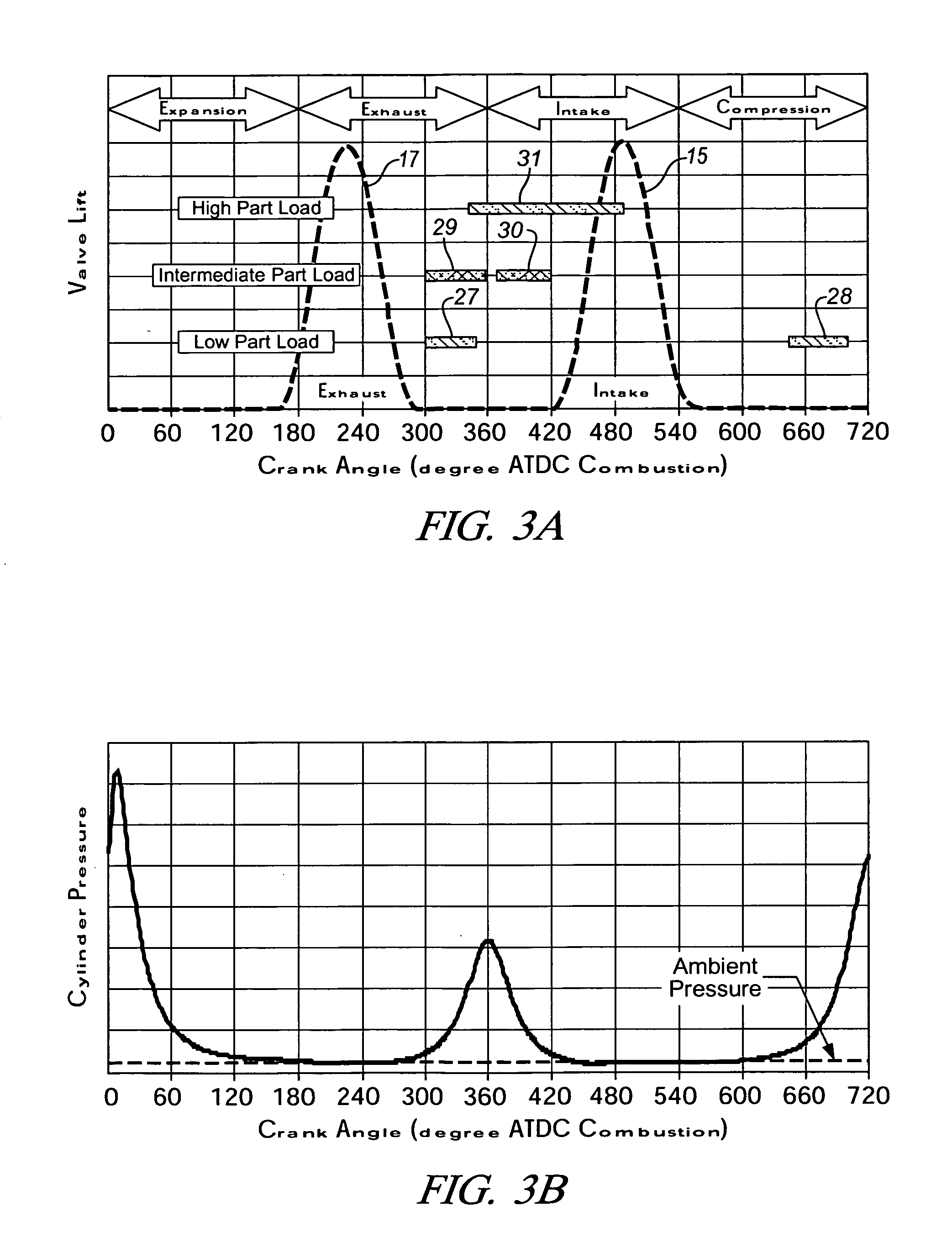

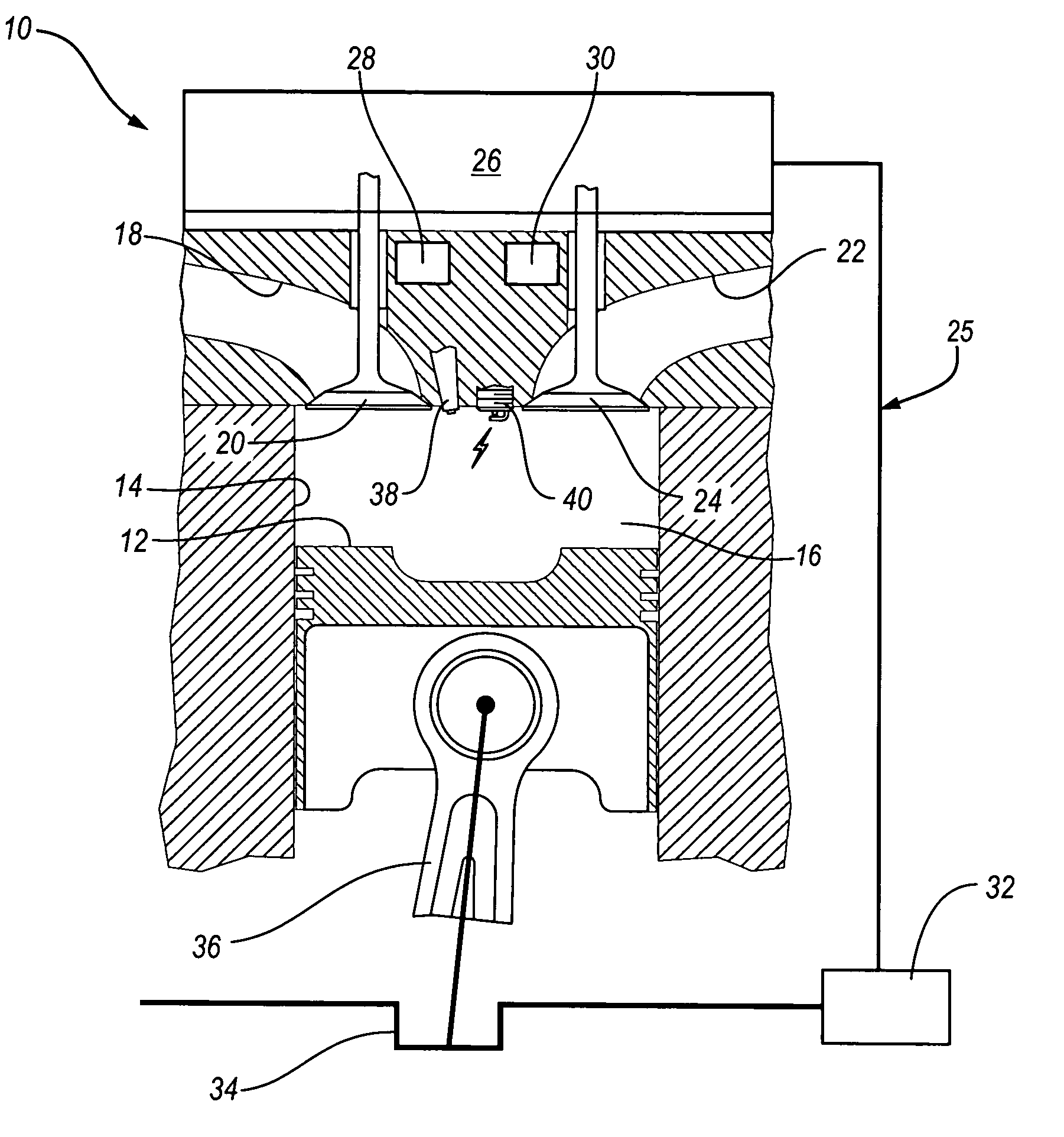

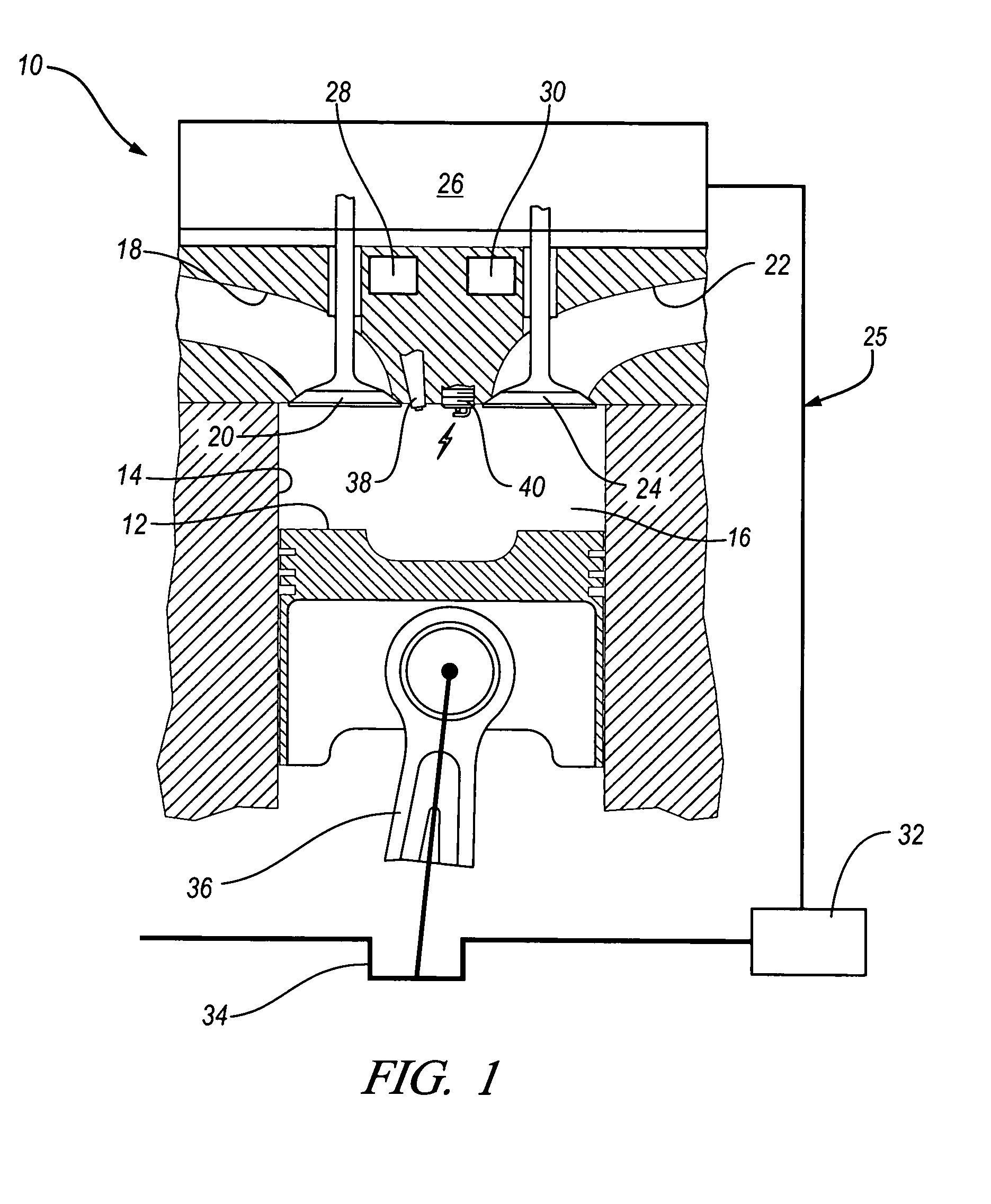

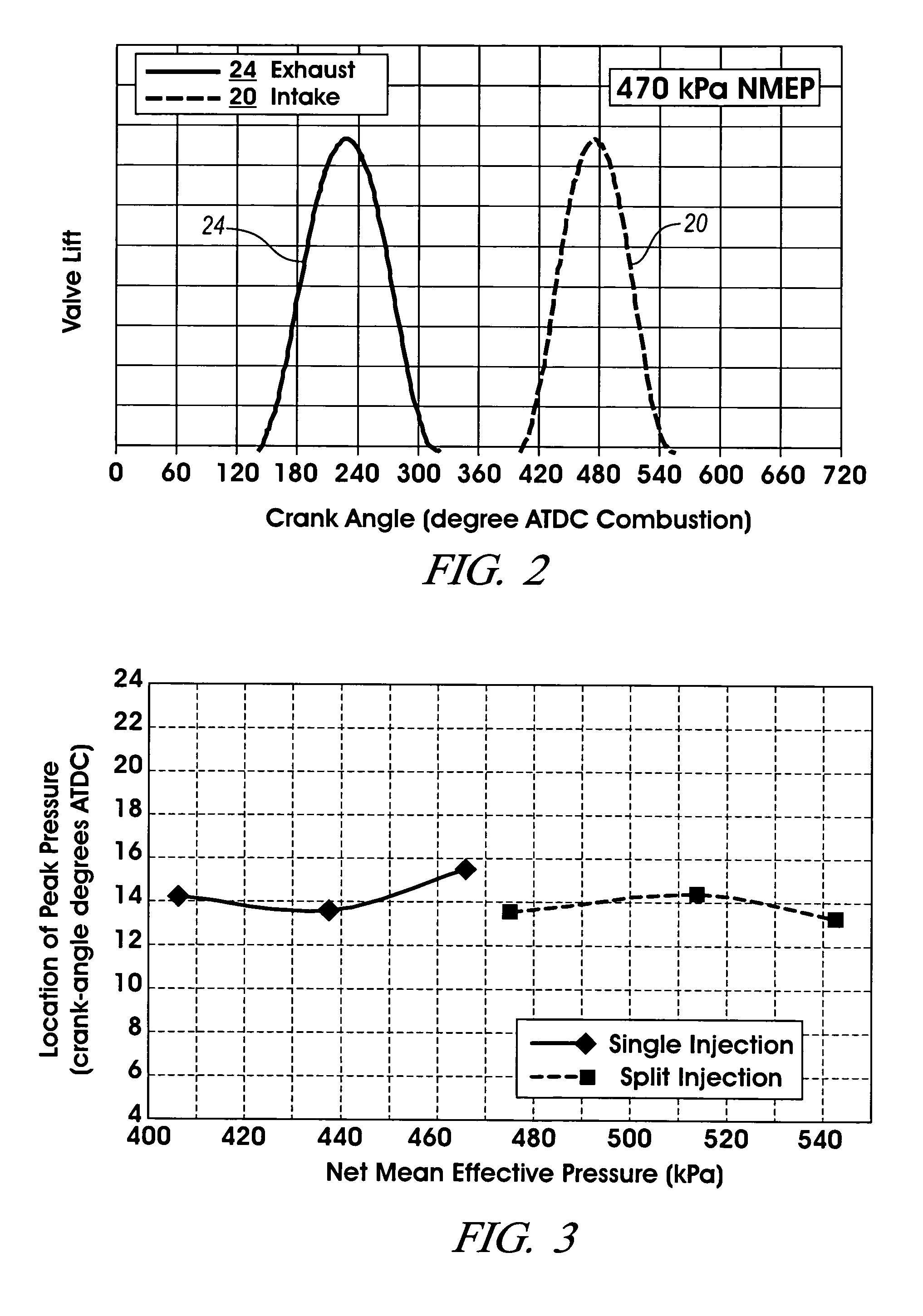

Method for mid load operation of auto-ignition combustion

ActiveUS6994072B2Electrical controlNon-fuel substance addition to fuelPressure riseMultiple injection

A method is disclosed for expanding the mid load operation limit in a four-stroke gasoline direct-injection controlled auto-ignition combustion engine. A system is employed for variably actuating the intake and exhaust valves and for operating the valves with an exhaust re-compression or exhaust re-breathing valve strategy. A spark plug is provided. A fuel injector having multiple injection capability is employed. A first fuel charge is injected into the combustion chamber to form a lean air-fuel mixture. A second fuel charge is injected into the combustion chamber to form a stratified air-fuel mixture having an ignitable mixture located near the spark plug. The ignitable mixture is ignited at the spark gap, thereby causing spark-ignition combustion that causes a sufficient increase in chamber pressure and temperature to trigger auto-ignition of the lean air-fuel mixture, resulting in the obtaining of a higher engine load before a pressure rise rate in the combustion chamber exceeds a prescribed threshold value.

Owner:GM GLOBAL TECH OPERATIONS LLC

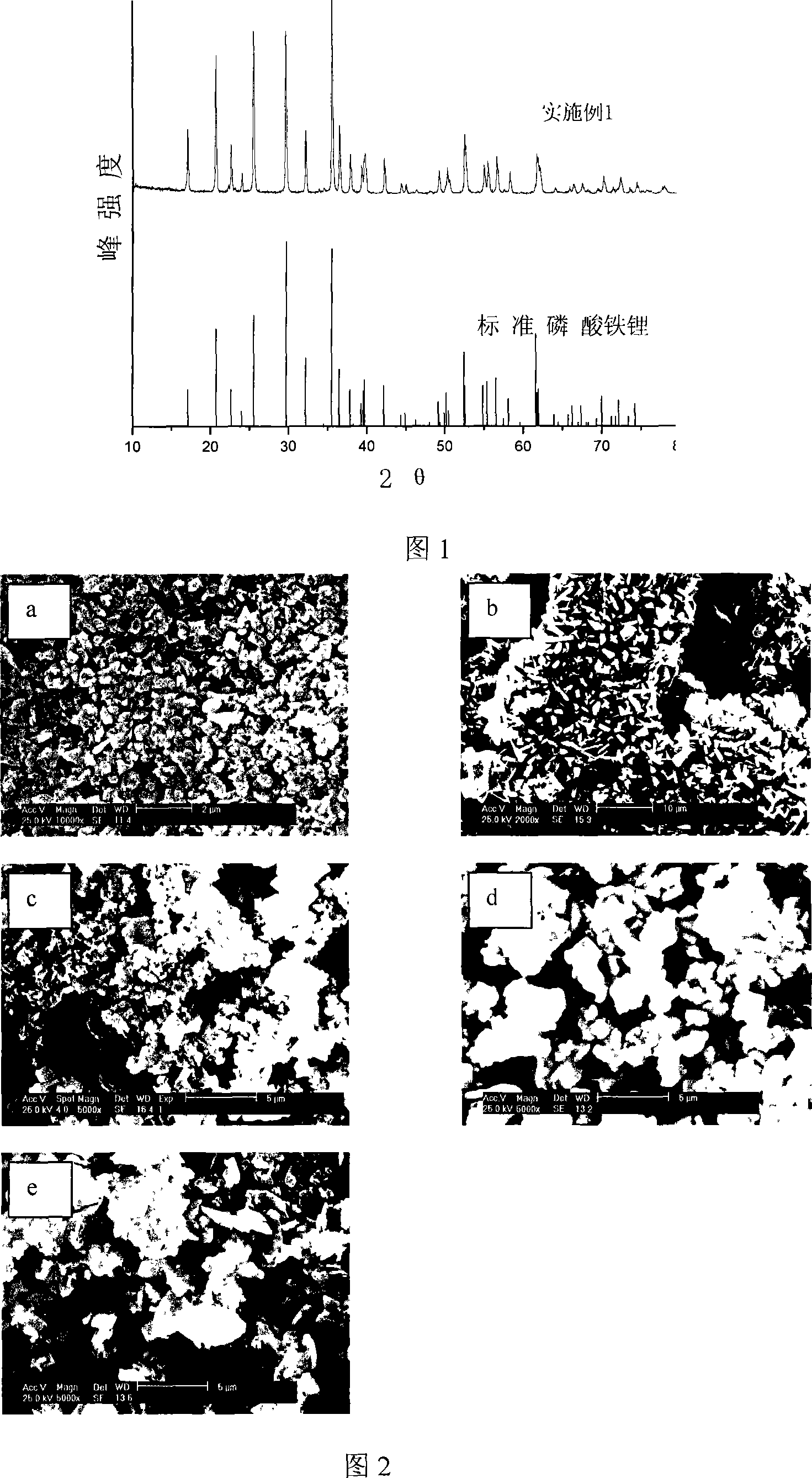

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

Cylinder cutoff control apparatus of internal combustion engine

A cylinder cutoff control apparatus of an engine initiates a cylinder cutoff mode only when two conditions, namely a low load condition such as a vehicle cruising condition and an intake valve closure timing controlled to a given timing value before a bottom dead center, are both satisfied. A fuel cutoff mode is executed prior to the cylinder cutoff mode. During a transition to the cylinder cutoff mode, the control apparatus holds an intake valve open timing at a given timing value substantially corresponding to a top dead center, simultaneously with reducing an intake valve lift amount of each intake valve, subjected to cylinder cutoff control, to a zero lift. Immediately when the intake valve lift amount is reduced to below a lift threshold value, an exhaust valve lift amount of each exhaust valve, subjected to the cylinder cutoff control, is controlled to a zero lift.

Owner:HITACHI LTD

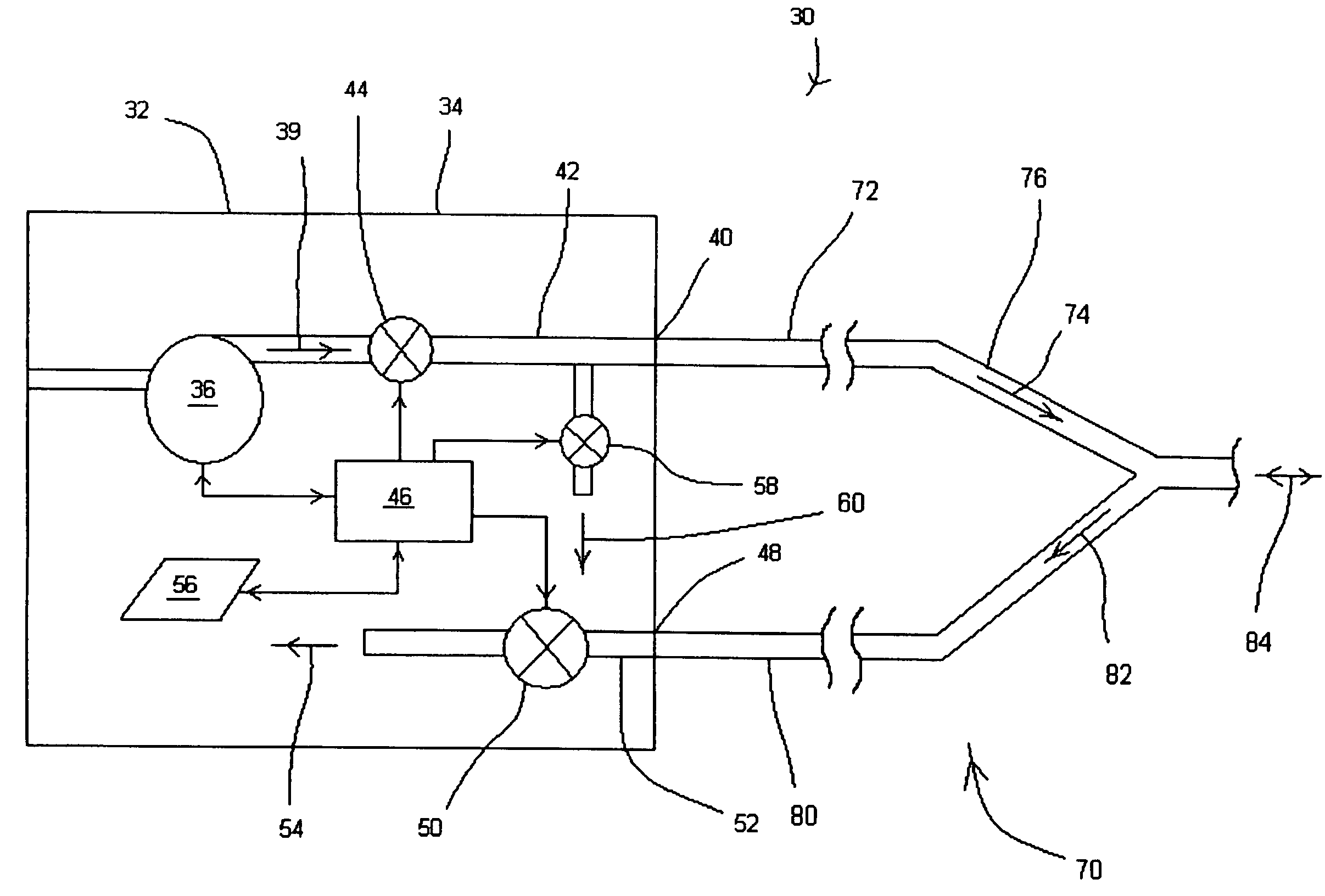

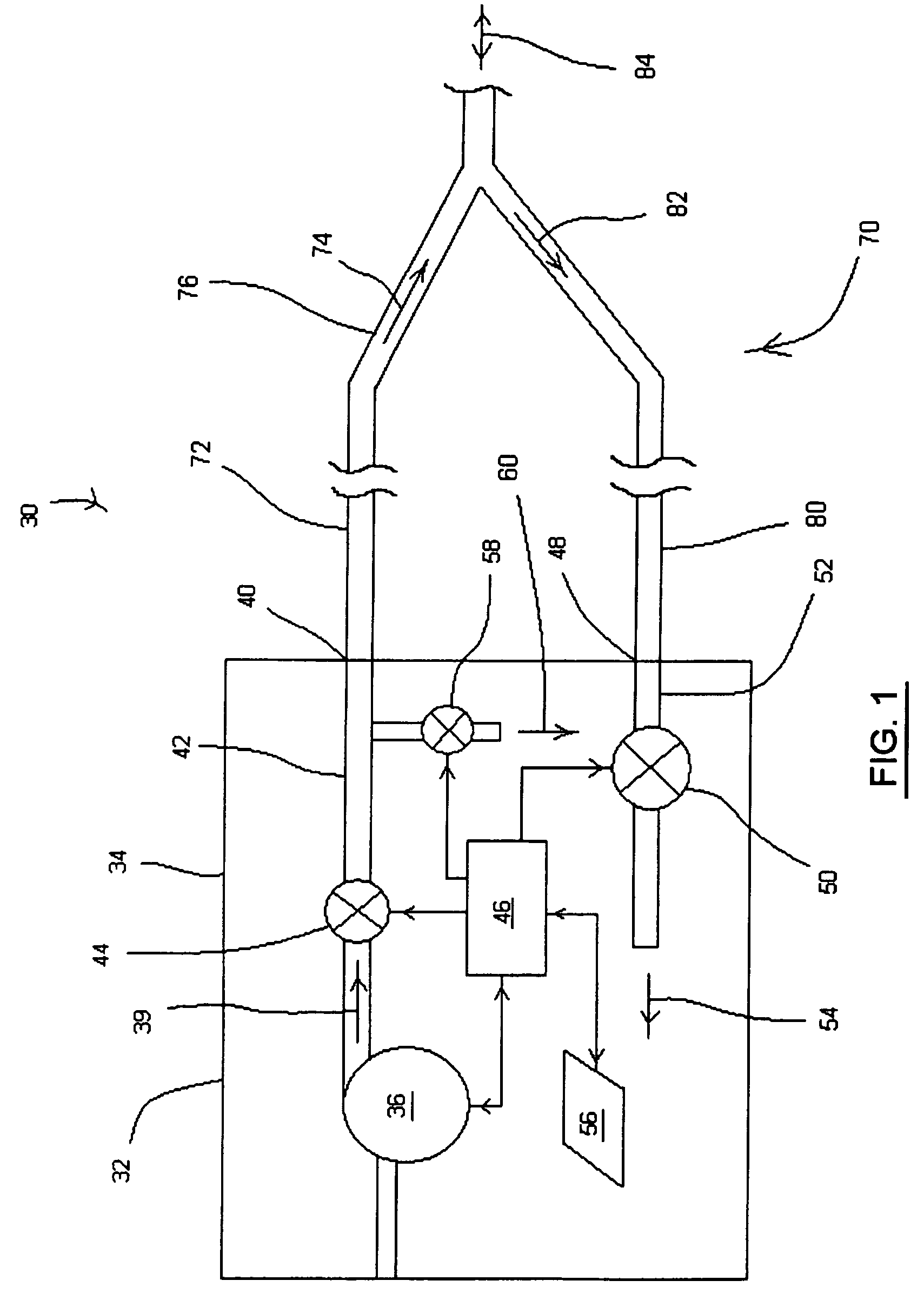

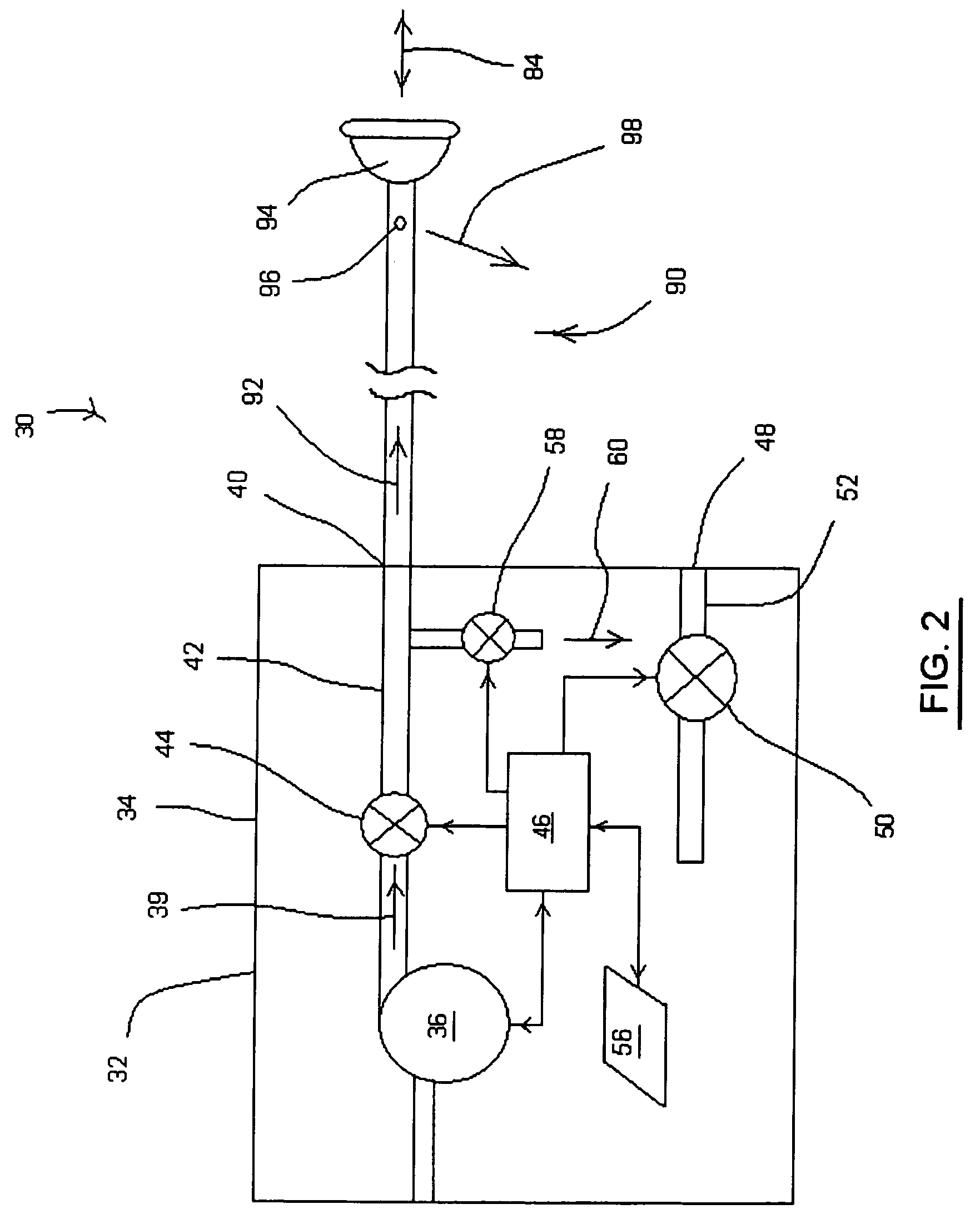

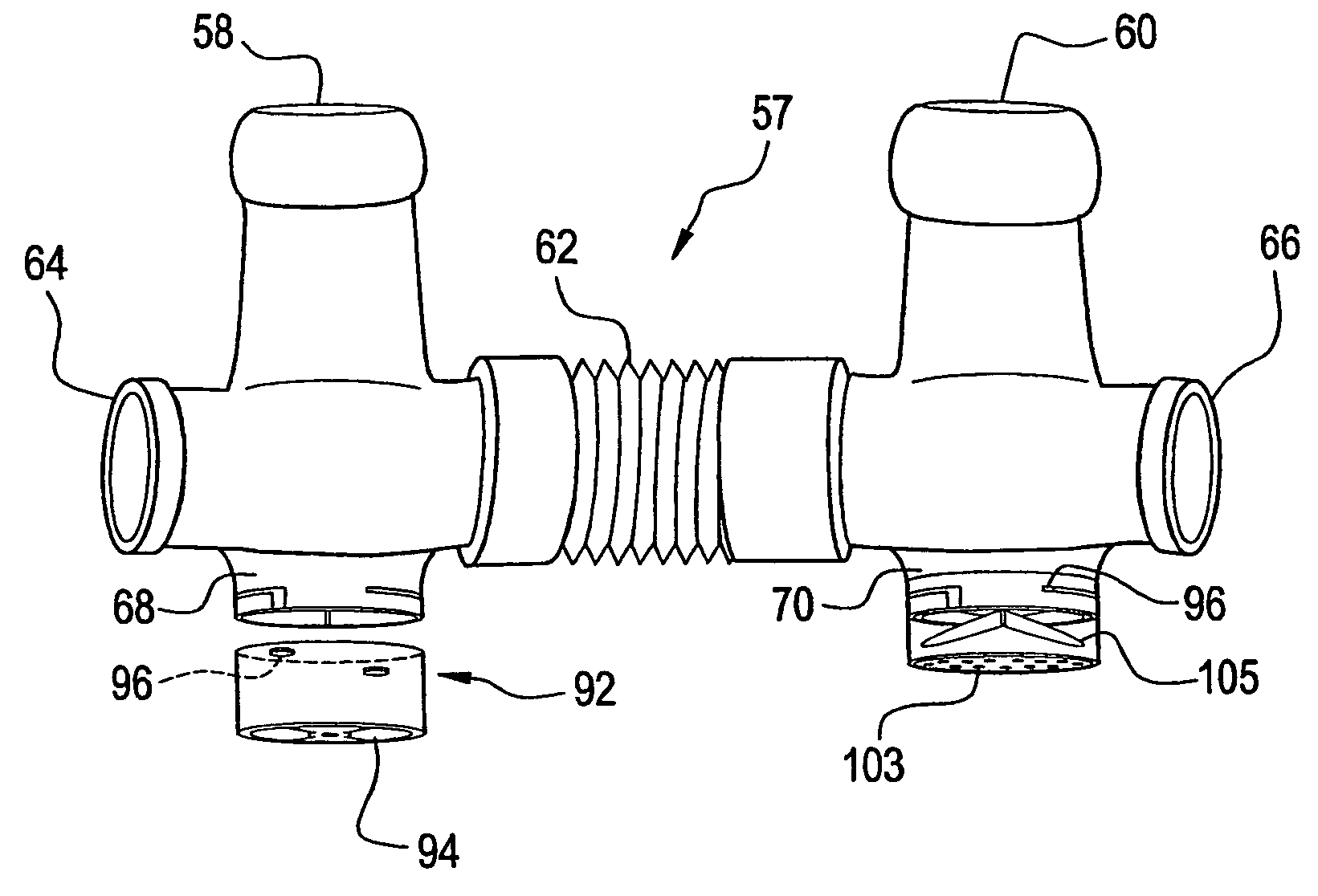

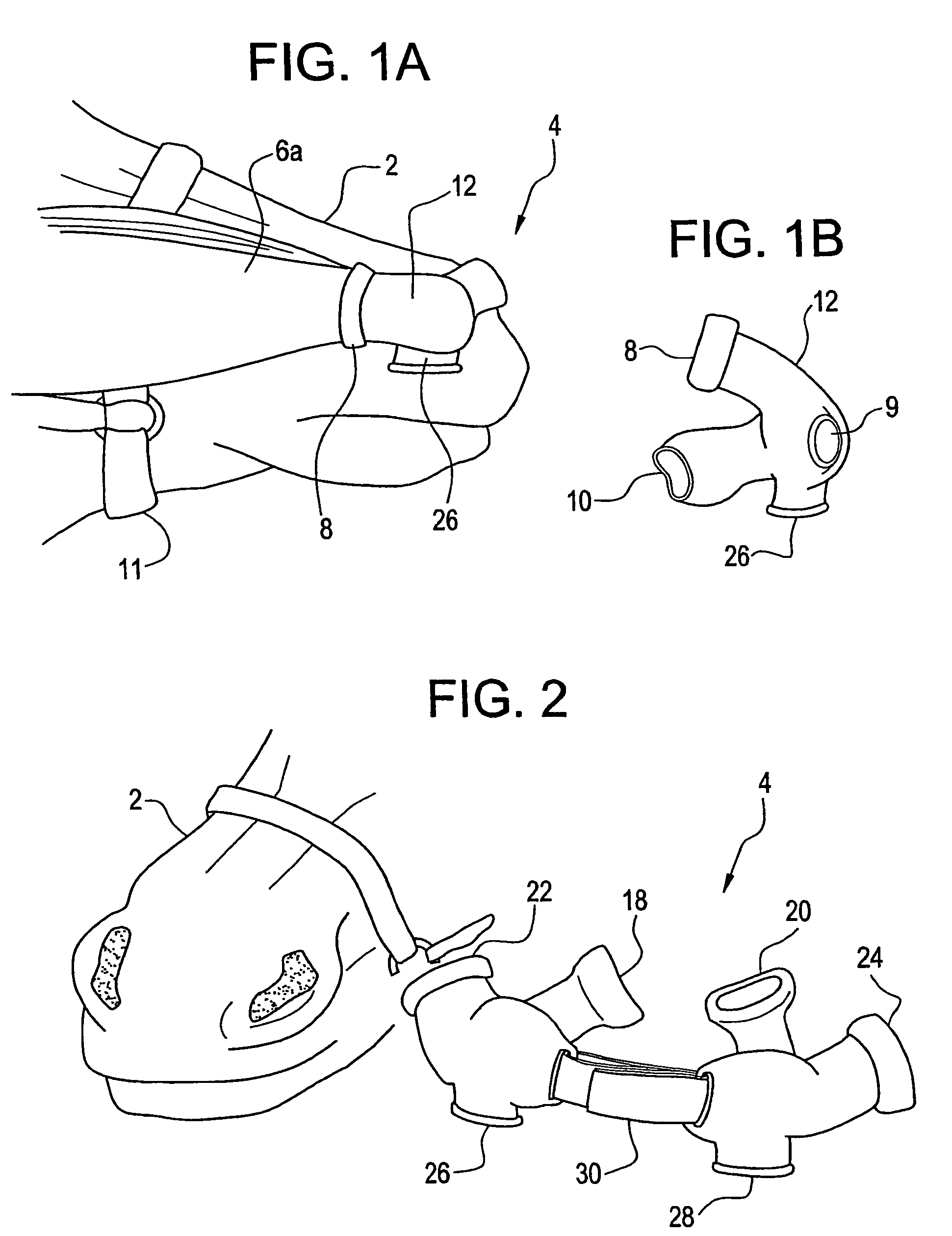

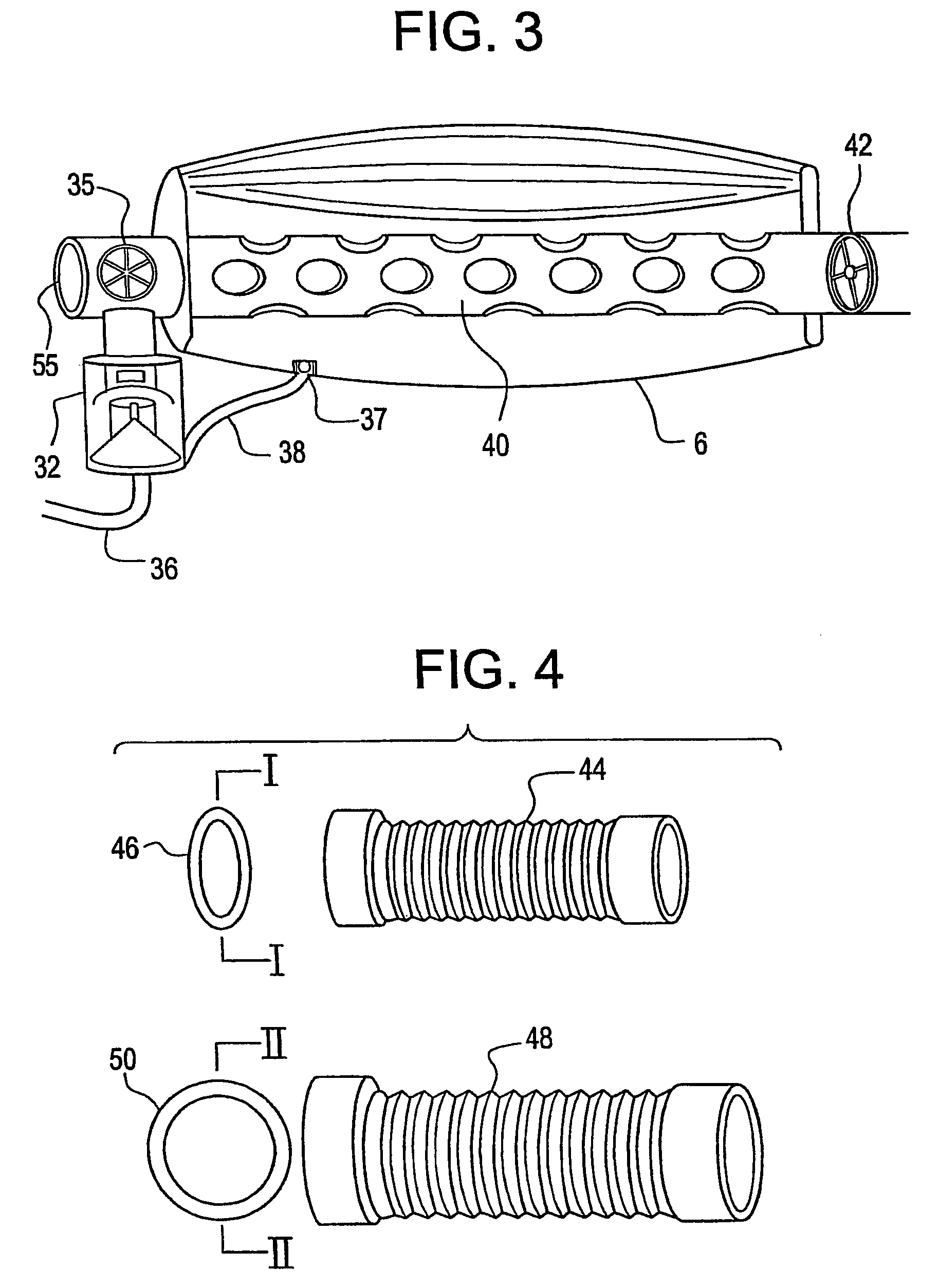

Ventilator adaptable for use with either a dual-limb circuit or a single-limb circuit

ActiveUS7617824B2Overcomes shortcomingRespiratorsOperating means/releasing devices for valvesExhaust valveRespiratory phase

A ventilator of the present invention includes a housing, a gas flow generator disposed in the housing, a gas outlet port provided on an exterior surface of the housing, and a first conduit coupling the gas flow generator to the gas outlet port. A gas inlet port is also provided on an exterior surface of the housing. A second conduit couples the gas inlet port to a first exhaust valve in the housing that regulates a flow of exhaust gas from the second conduit. A second exhaust valve in the housing is coupled to the first conduit and regulates a flow of exhaust gas from the first conduit. A controller coupled to second exhaust valve causes the second exhaust valve to change a degree of flow restriction based on a respiratory phase of a patient coupled to the ventilator when the ventilator is operating in a single-limb ventilation configuration.

Owner:PHILIPS RS NORTH AMERICA LLC

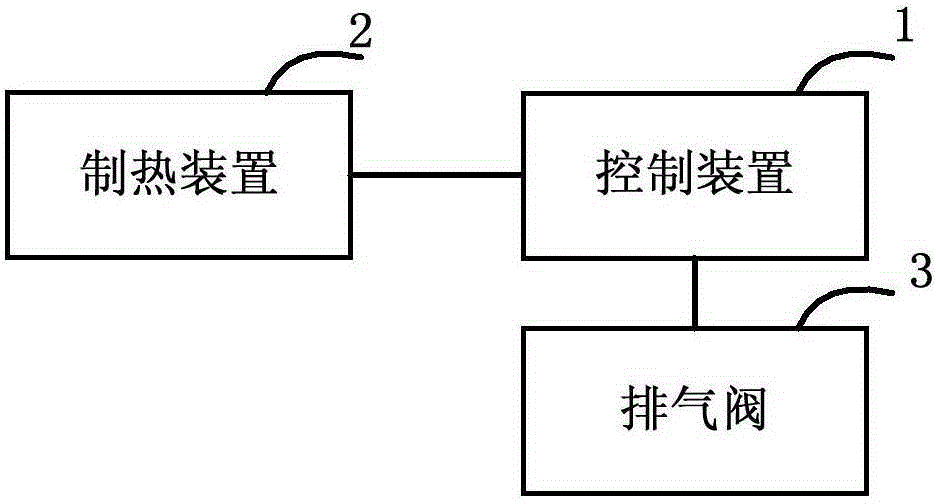

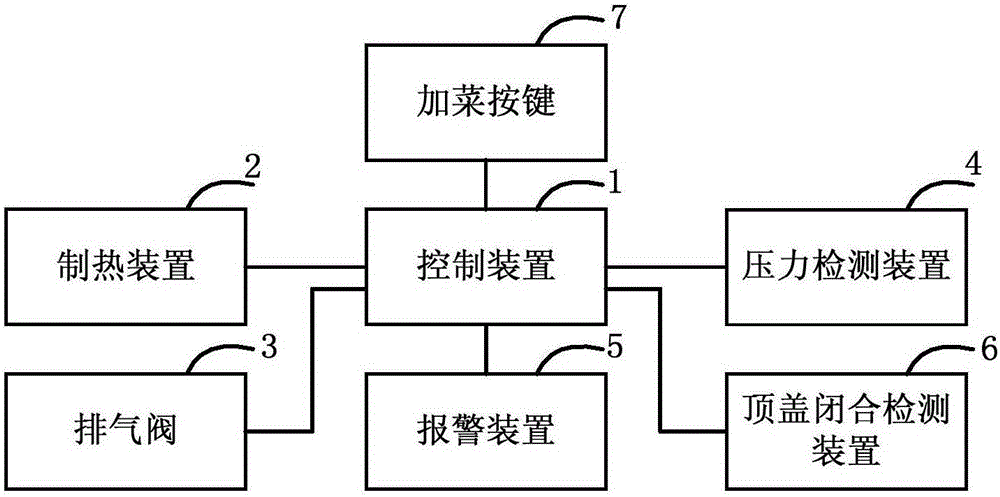

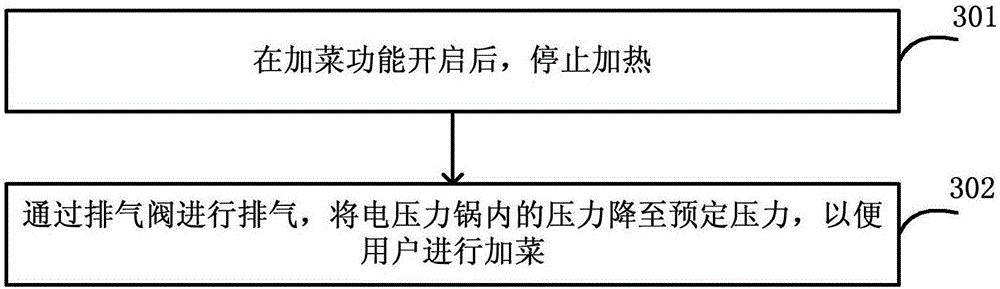

Electric pressure cooker and control method thereof

ActiveCN105231811AAdding vegetables is safe and convenientImprove experiencePressure-cookersExhaust valveEngineering

The invention discloses an electric pressure cooker and a control method thereof, and relates to the field of control. After the vegetable adding function is started, a control device indicates a heating device to stop heating and indicates an exhaust valve to exhaust air, the pressure in the electric pressure cooker is reduced to the predetermined pressure accordingly, and a user can add vegetables conveniently. As the heating device and the exhaust valve are controlled, the user can safely and conveniently add the vegetables at any time in the cooking process, and the user experiences are improved.

Owner:GREE ELECTRIC APPLIANCES INC

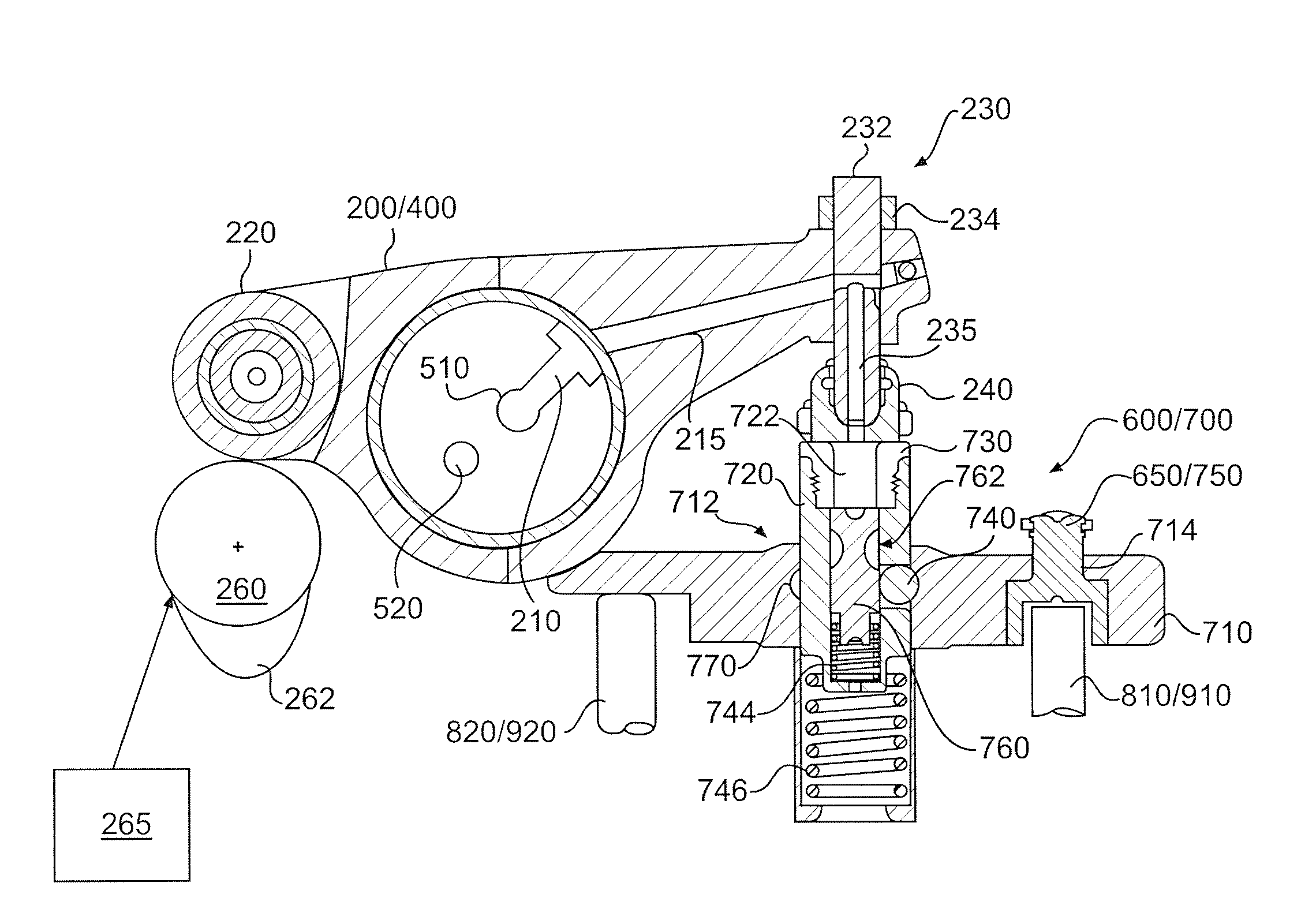

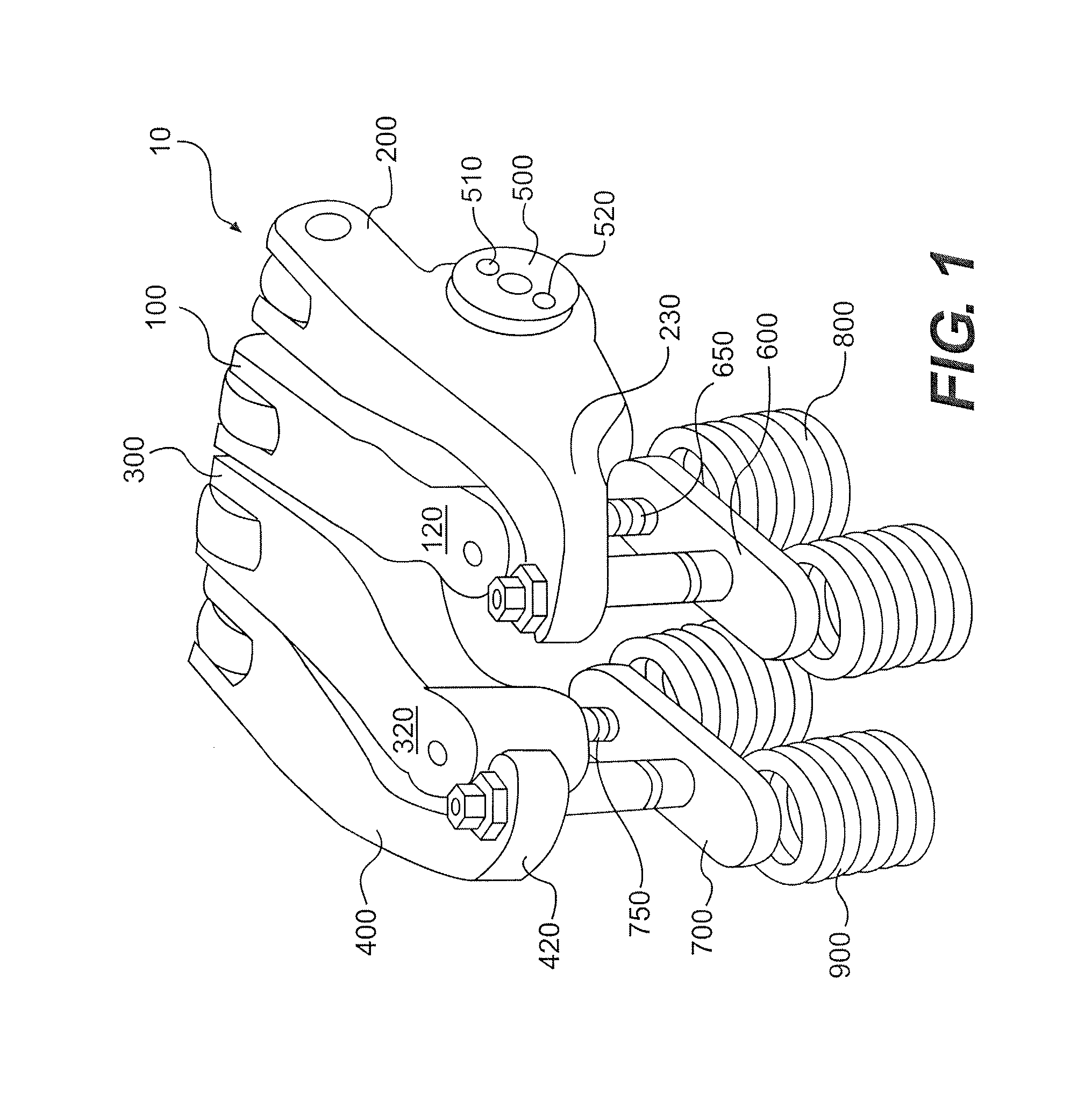

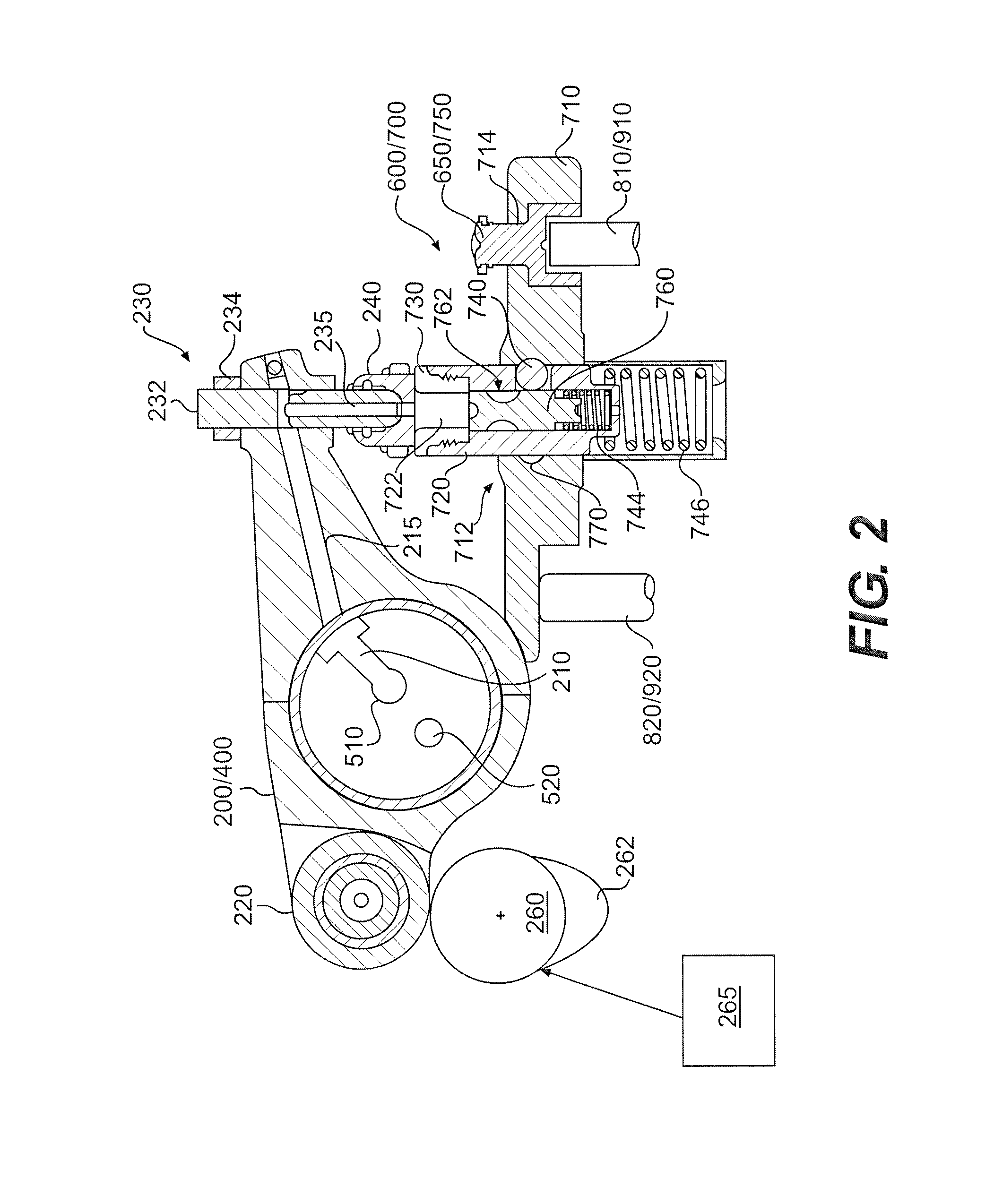

Combined engine braking and positive power engine lost motion valve actuation system

A system for actuating one or more engine valves for positive power operation and engine braking operation is disclosed. In a preferred embodiment, an exhaust valve bridge and intake valve bridge each receive valve actuations from two sets of rocker arms. Each valve bridge includes a sliding pin for actuating a single engine valve and an outer plunger disposed in the center of the valve bridge to actuate two engine valves through the bridge. The outer plunger of each valve bridge may be selectively locked to its valve bridge to provide positive power valve actuation. During engine braking, application of hydraulic pressure to the outer plungers may cause the respective valve bridges and outer plungers to unlock so that all engine braking valve actuations are provided from a rocker arm acting on one engine valve through the sliding pin.

Owner:JACOBS VEHICLE SYST

Medicine delivery interface system

Medicine delivery interface for delivery of therapeutic aerosols or gases, including at least one hollow body having at least one nasal aperture defined therein at least one nasal insert tube associated with each nasal aperture of the hollow body is capable of being inserted into a nostril. The interface also may include at least one exhaust aperture having at least one exhaust valve configured to exhaust exhaled gases and configured to block inflow of air through the exhaust aperture and at least one intake aperture.

Owner:INNOMED HEALTHSCI INC

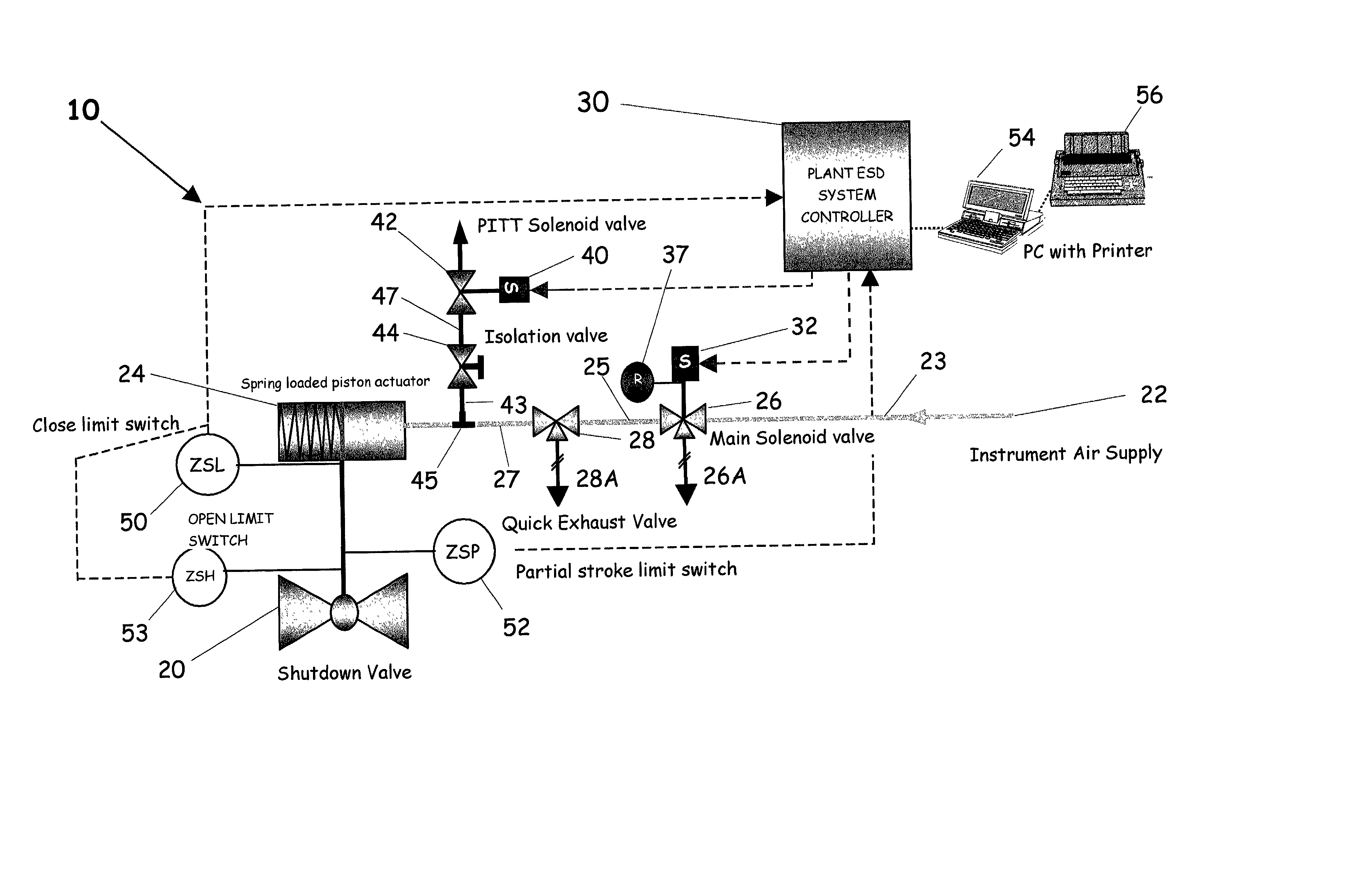

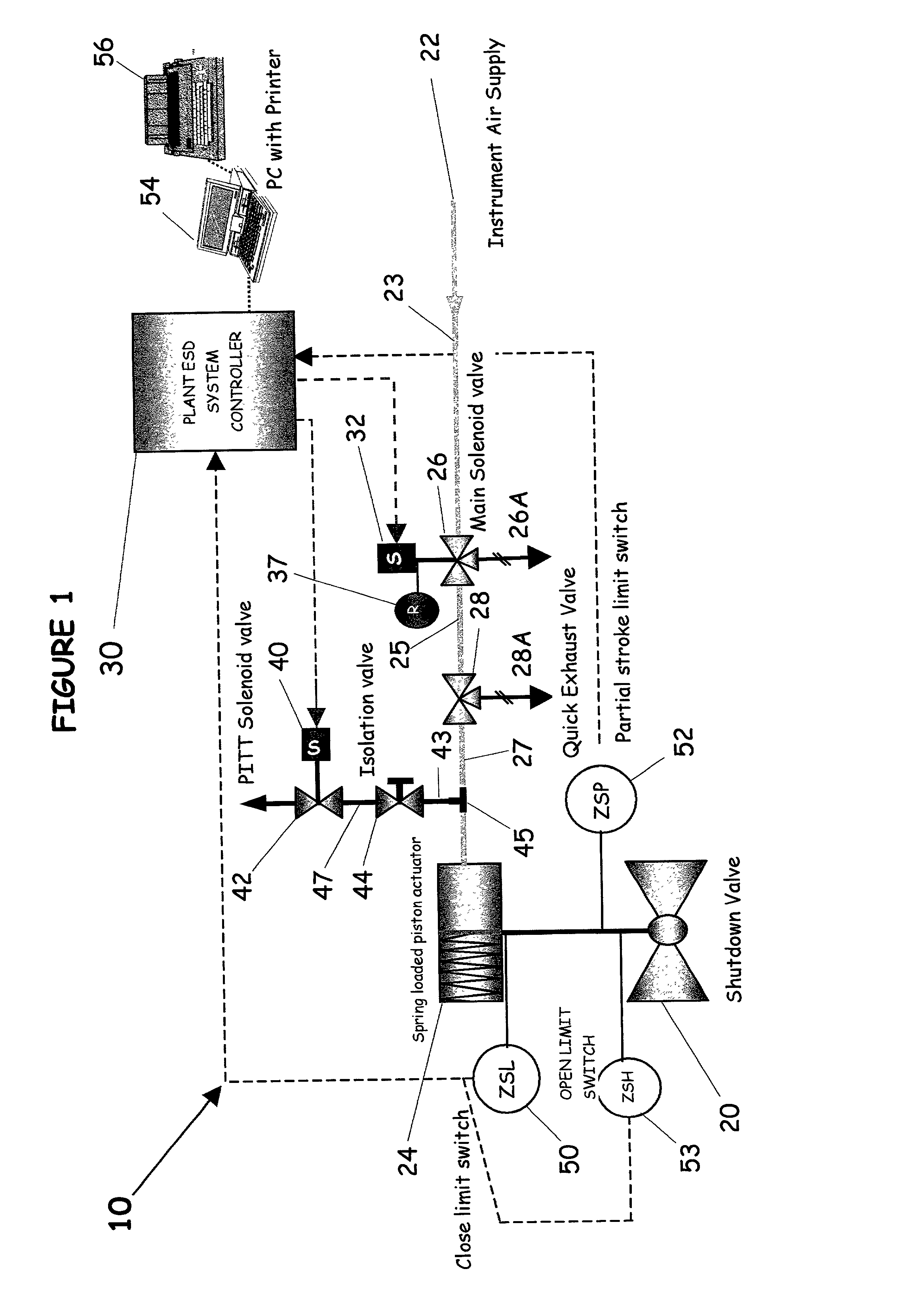

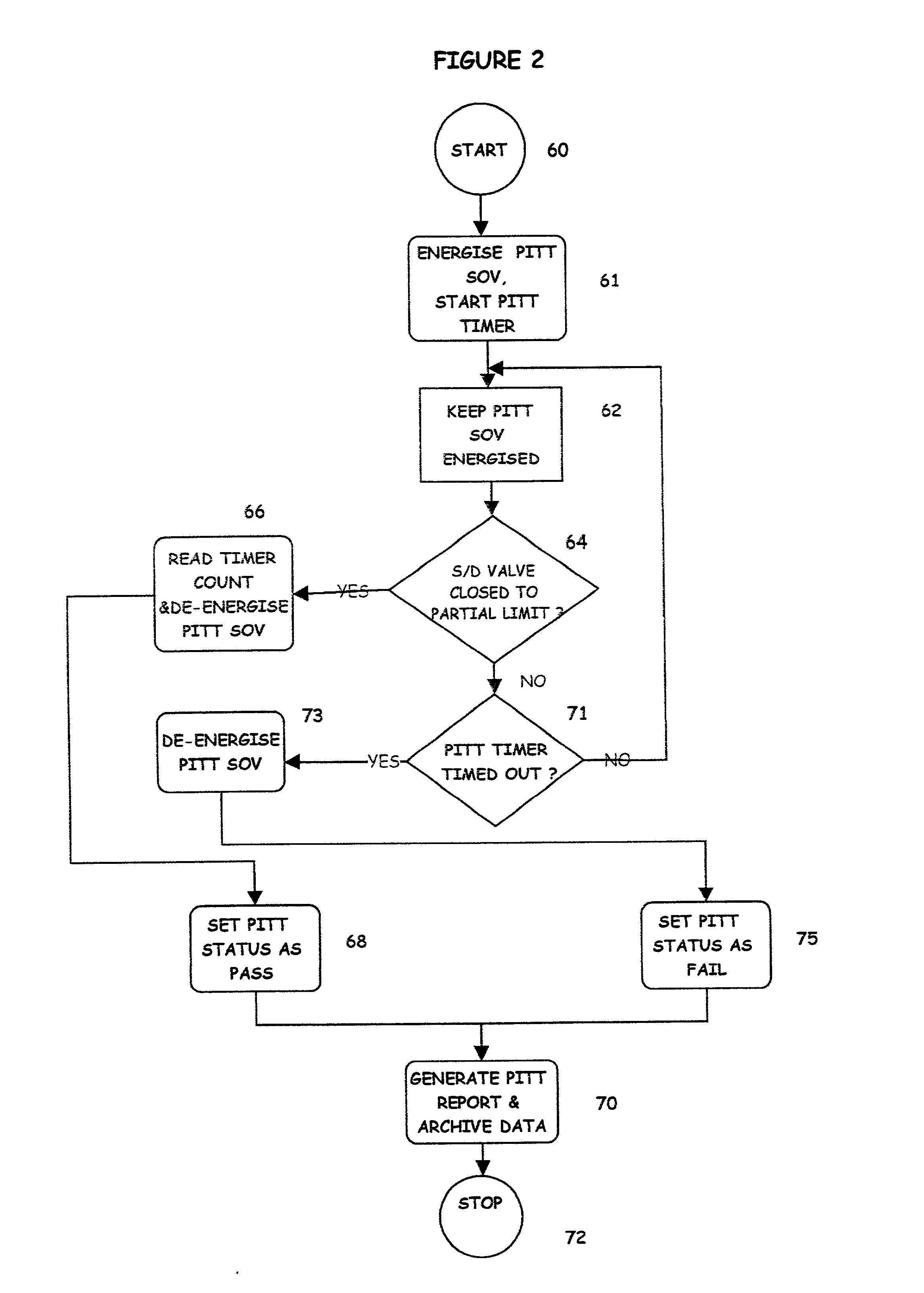

Partial stroke testing system

InactiveUS20020108436A1Quick closeLow costValve arrangementsUsing mechanical meansSystems designExhaust valve

A partial stroke testing system for online testing of emergency shut-off valve, said system is designed for implementation on an emergency shut-off valve with a main solenoid with manual reset, main solenoid valve, quick exhaust valve and a pneumatic actuator connected to a source of pressurized air supply for opening and closing the said emergency shut-off valve and the said shut-off valve normally movable between a fully open and fully closed position. The system also include control means programmed into the plant emergency shutdown system controller for initiating electrical signal for initiating a test and for enhancing the bleed rate from the said pneumatic actuator in the event of a emergency trip signal. Test means for testing the said emergency shut-off valve without fully closing the emergency shut-off valve in response to signal from the said control means is included in the system. The said test means, controlled by the said control means, include a second solenoid and a second solenoid valve for bleeding off pressurized air to thereby move the said emergency shut-off valve from full opened position to partially closed position. Means for limiting the movement of said emergency shut-off valve to a partially closed position because of the bleeding of pressurized air is included in the system. The system also includes an isolation valve for isolating the said test means for maintenance purpose.

Owner:ALBUAIJAN TAREQ NASSER

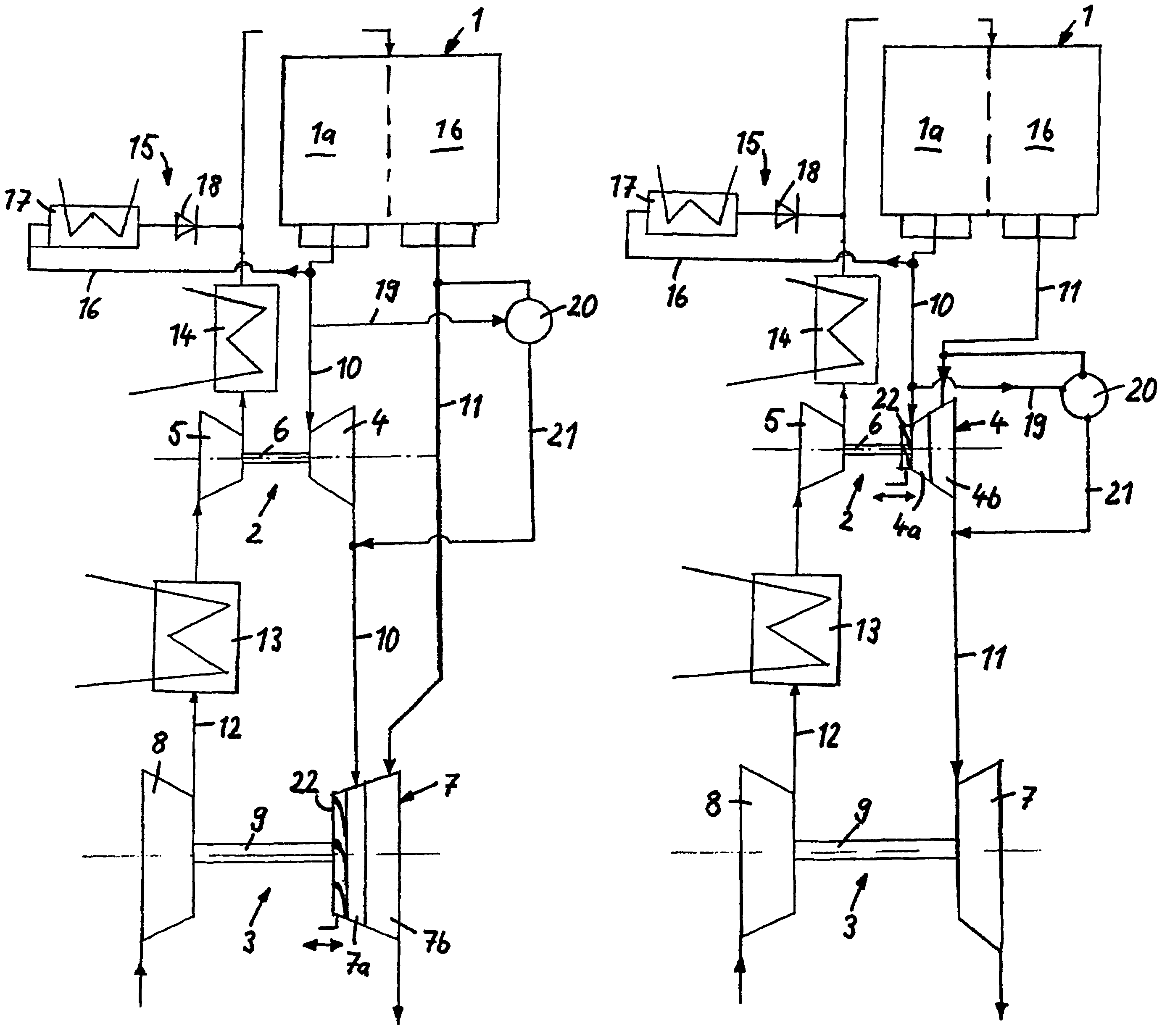

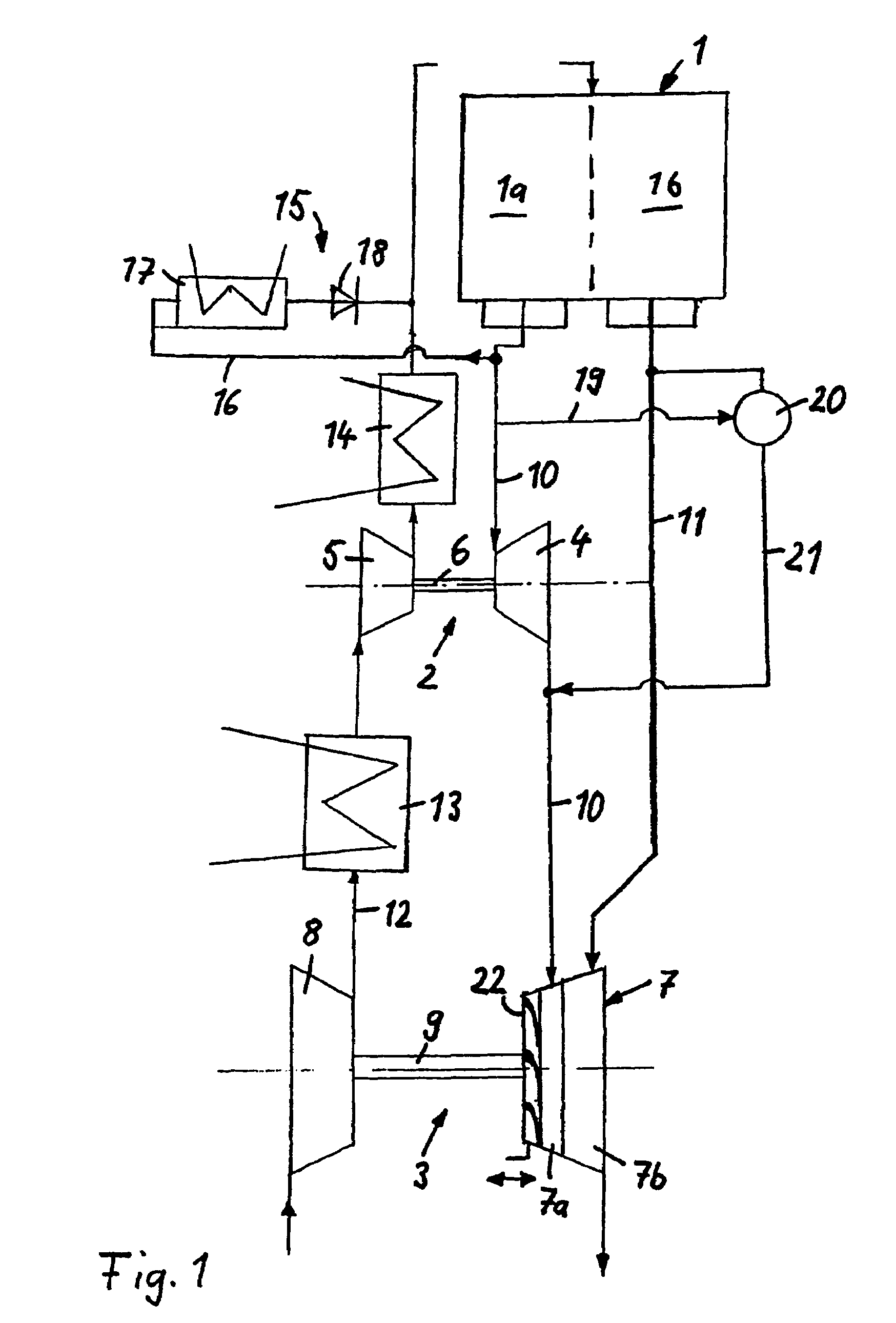

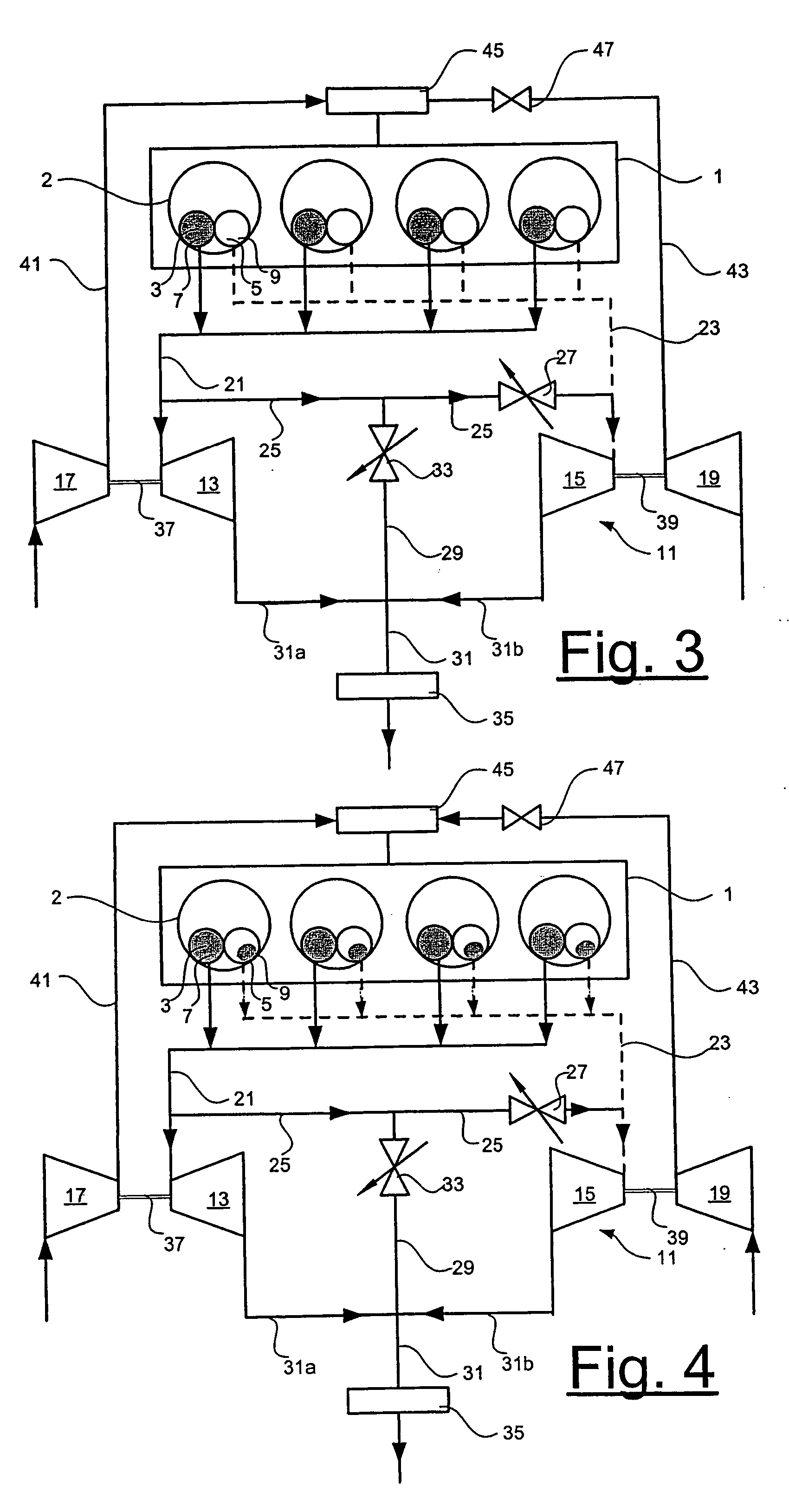

Combustion engine

InactiveUS6460337B1Improve performanceReduce the temperatureValve arrangementsInternal combustion piston enginesExhaust valveCombustion

A turbo-fed internal combustion engine has a first and a second exhaust-gas valve per cylinder, these exhaust-gas valves each being connected to their respective exhaust manifold. One exhaust manifold conducts exhaust gases to an exhaust-gas turbine and the other exhaust manifold conducts subsequent exhaust gases past this exhaust-gas turbine which drives a compressor for charge air. The intake valve of the cylinder is arranged so as, as the engine speed increases, to close either earlier, before the piston reaches its bottom dead center, or later, after the piston has passed its bottom dead center. In this way, the temperature increase resulting from compression in the cylinder is reduced. Cooled air from the compressor can be taken in so as to obtain an adequate degree of filling in the cylinder, with a lower final temperature.

Owner:SAAB AUTOMOBILE AB

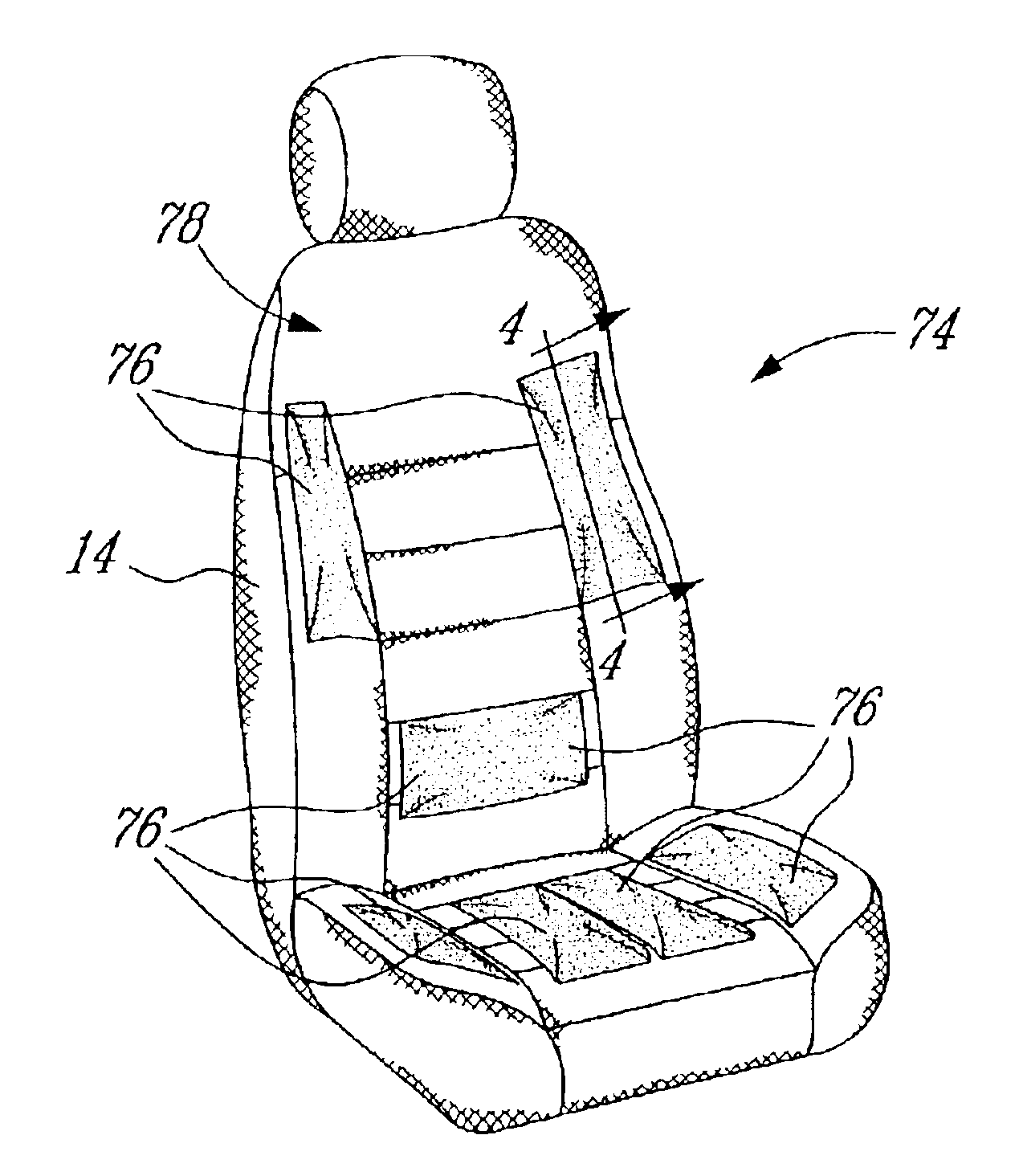

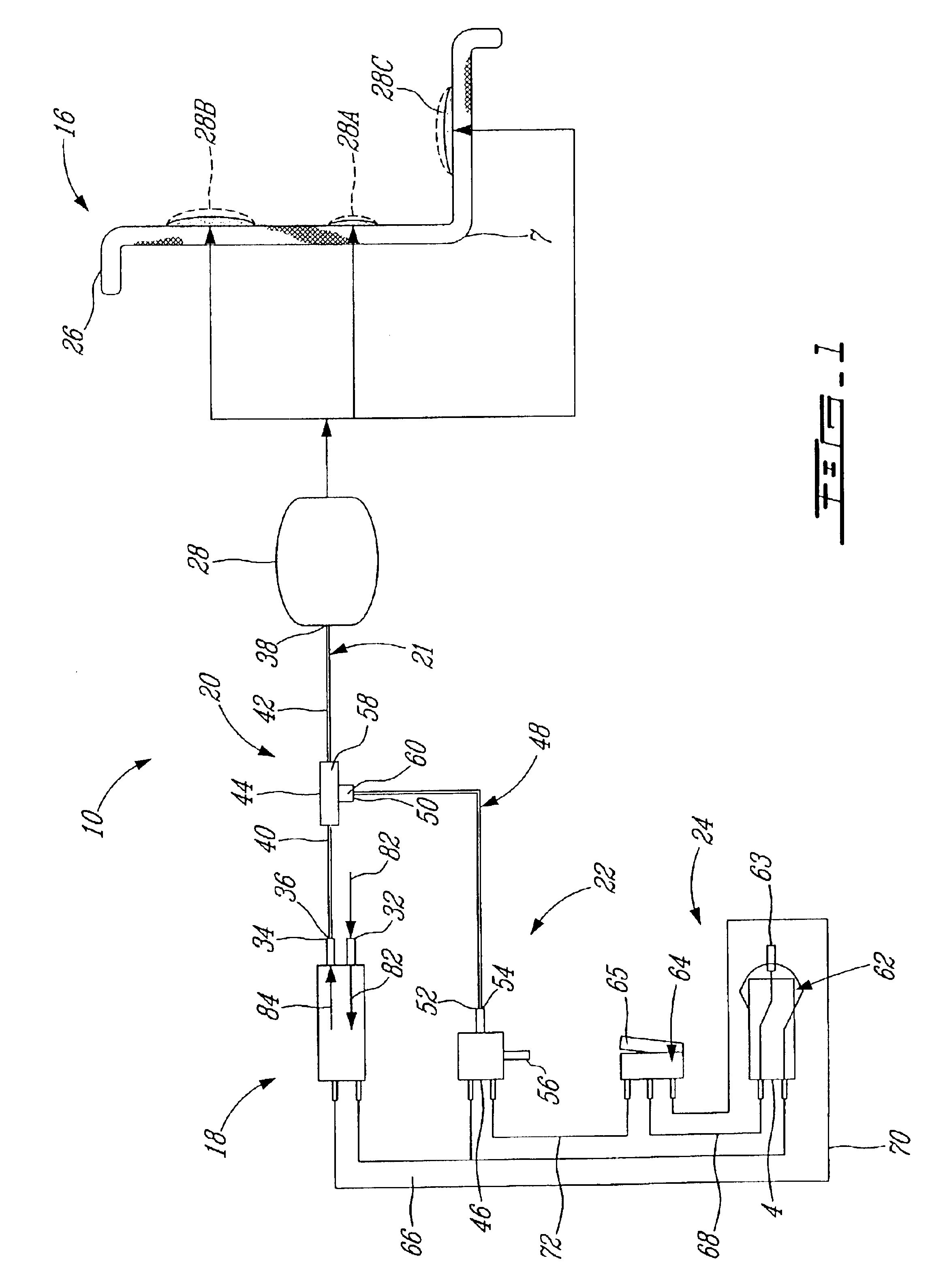

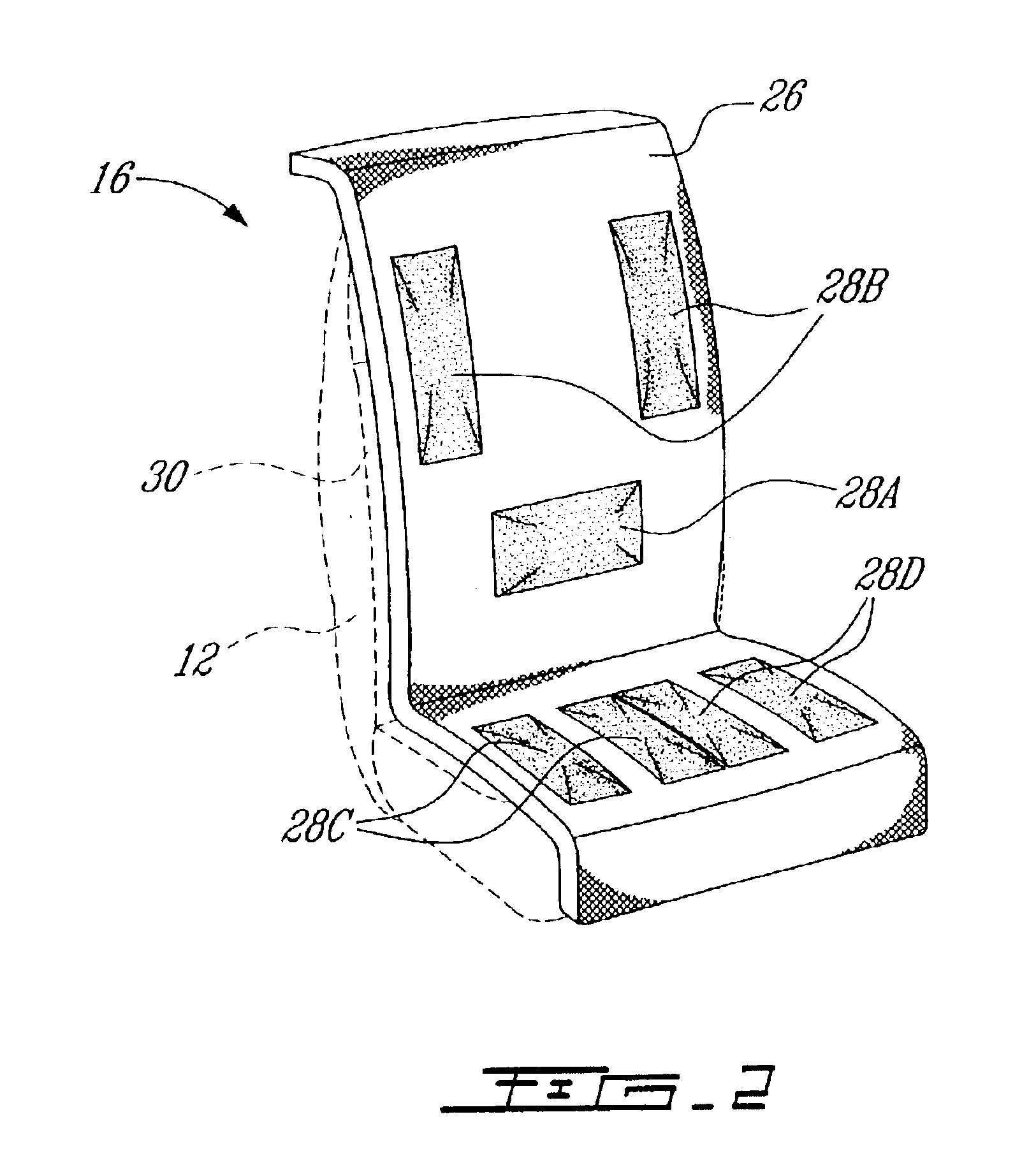

Portable air-pressure applying assembly for seats

An air-pressure applying assembly for a seat, having an occupant holding portion, for selectively applying a desired pressure to the body of a seat occupant. This assembly includes an air-bag assembly, an air-pressure source, an inlet-conduit assembly, an exhaust valve assembly, and a control assembly. The air-bag assembly is removably mountable to the seat occupant holding portion. The inlet-conduit assembly is in fluid communication at one end to the air-pressure source and at another to the air-bag assembly. The exhaust valve assembly is in fluid communication at one end to the inlet conduit assembly and has an air-outlet at the other end. A control assembly is linked to the air pressure source and to the exhaust valve assembly. The control assembly is so configured as to selectively signal the air-pressure source to inflate the air bag assembly so as to apply the desired pressure to the body of the seat occupant and as to selectively signal the exhaust valve assembly to release air from the air-bag assembly.

Owner:LADRON DE GUEVARA JULIO OSWALDO

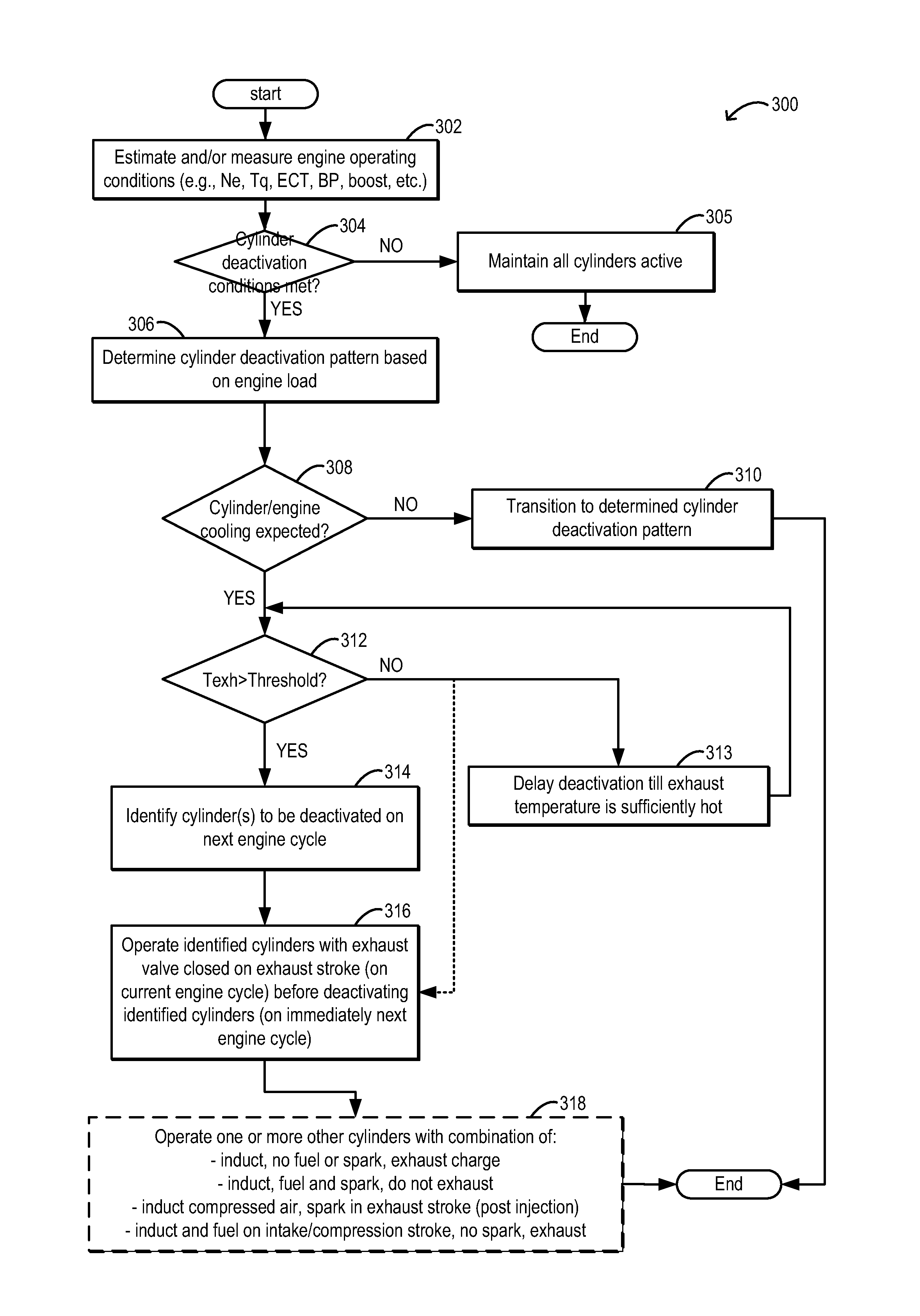

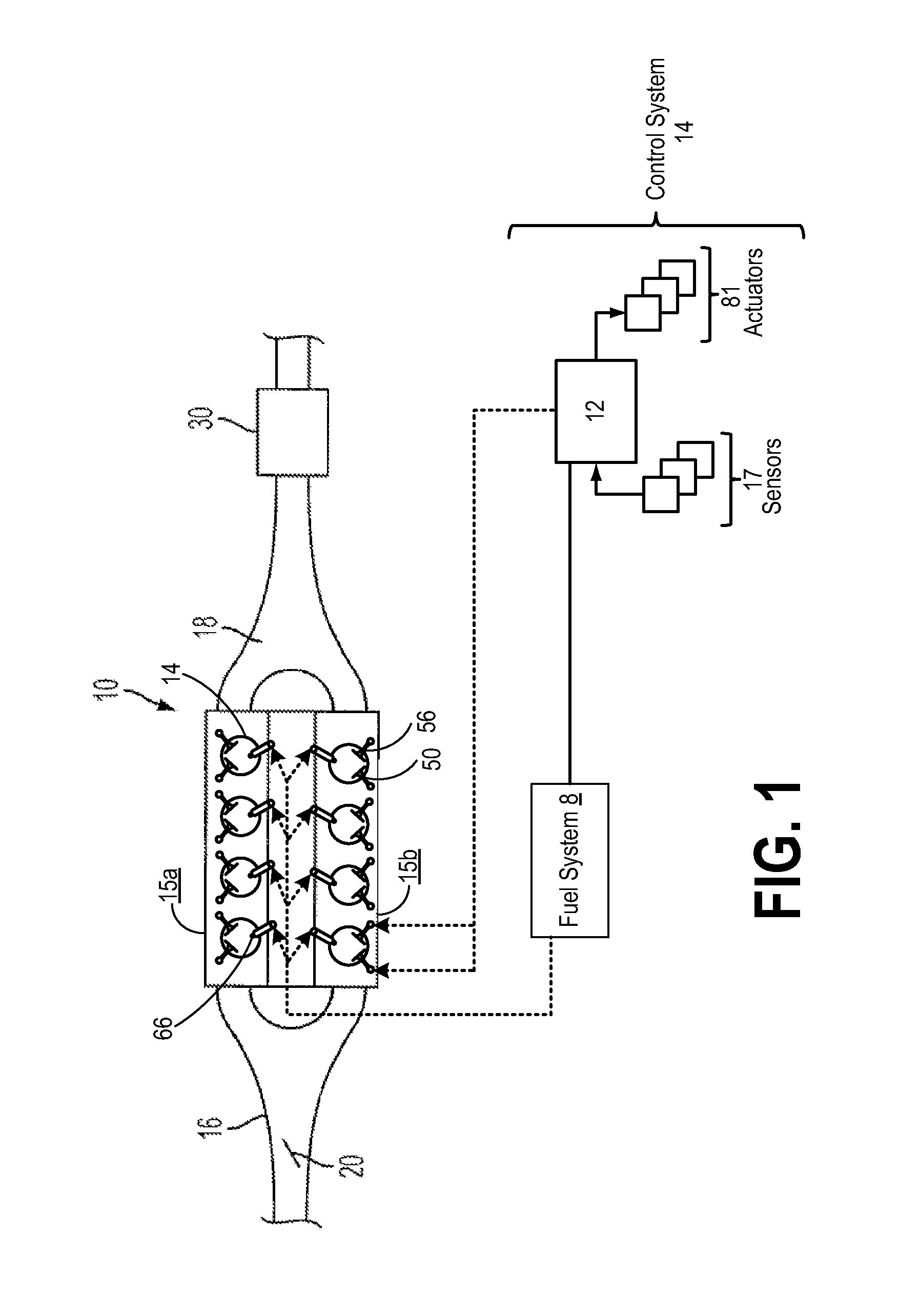

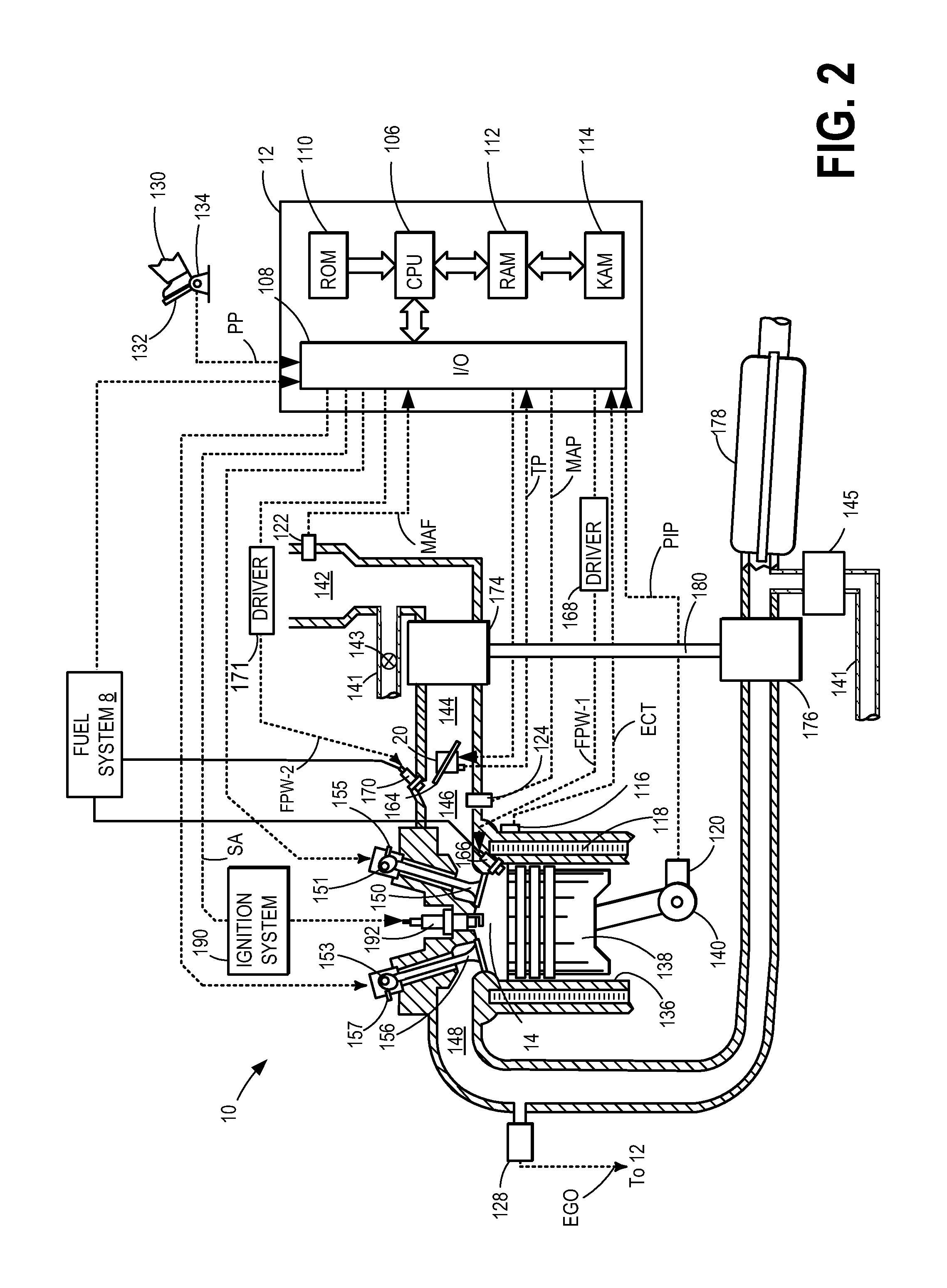

Method and system for engine temperature control

ActiveUS20160115884A1Increased hydrocarbonExhaust emission be highElectrical controlInternal combustion piston enginesTemperature controlExhaust valve

Methods and systems are provided to improve engine temperature control. Cylinders scheduled for deactivation may have their exhaust retained in the cylinder by holding an exhaust valve closed on the preceding firing cycle. In this way soot emissions on reactivation are reduced.

Owner:FORD GLOBAL TECH LLC

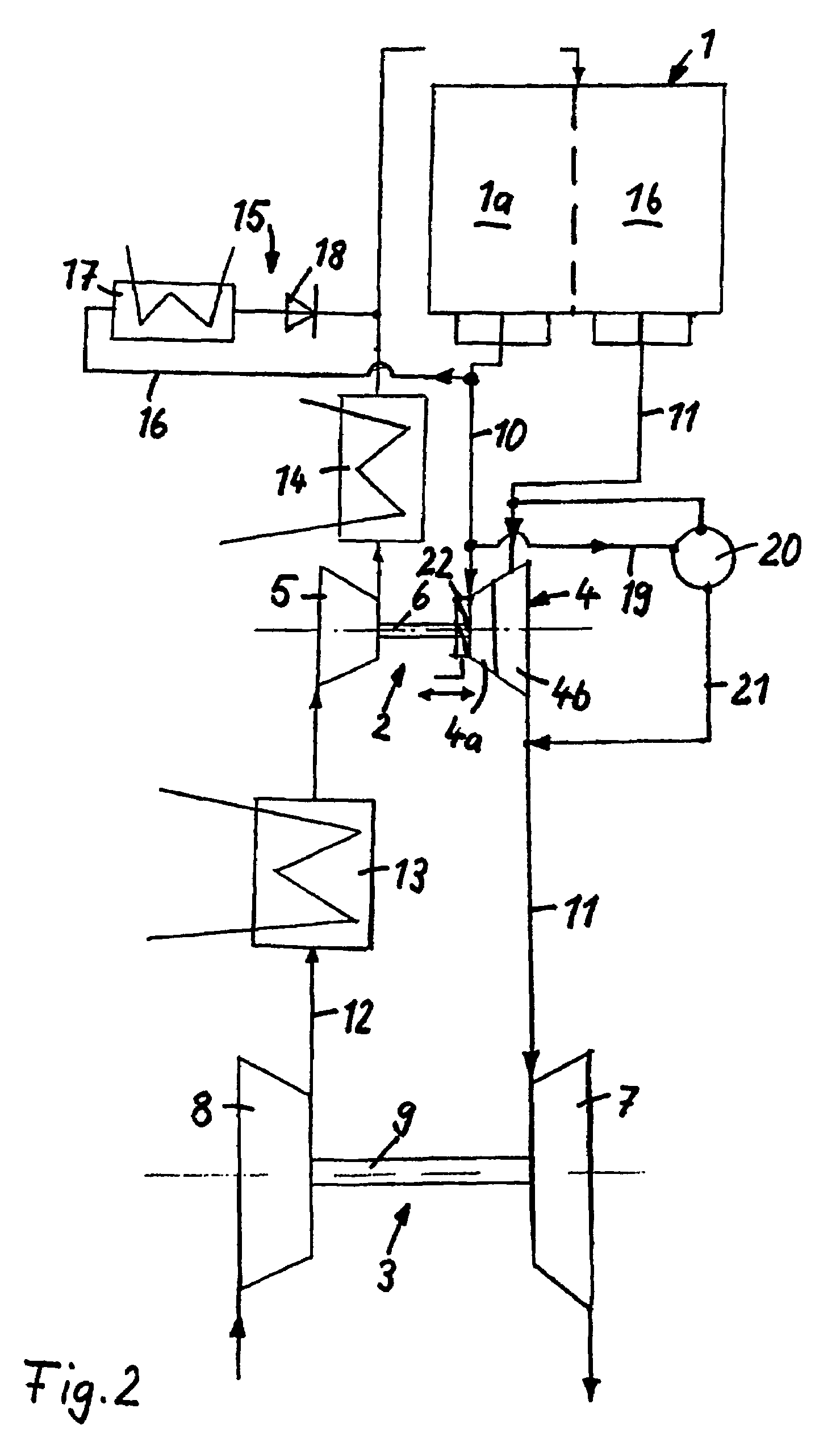

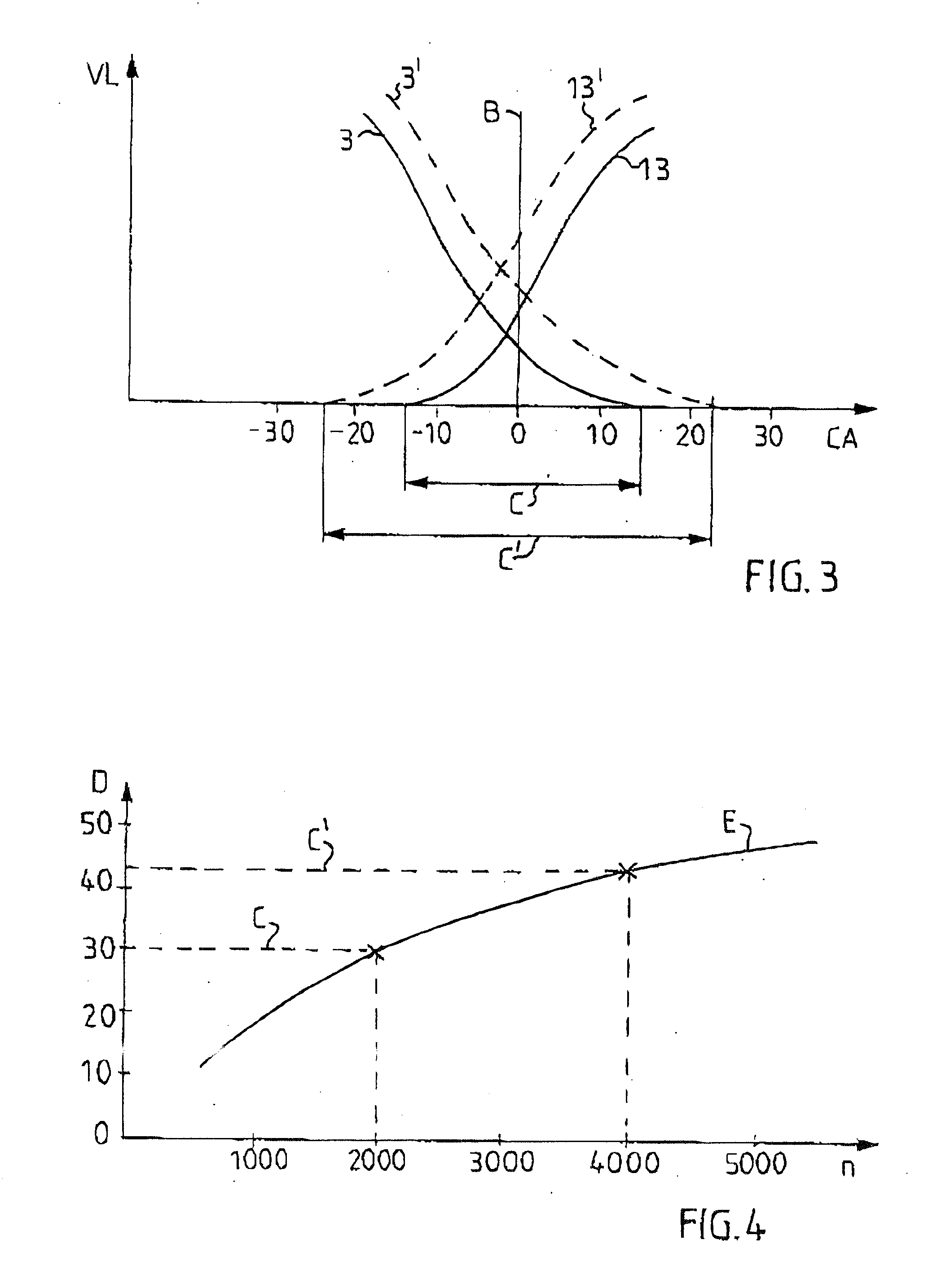

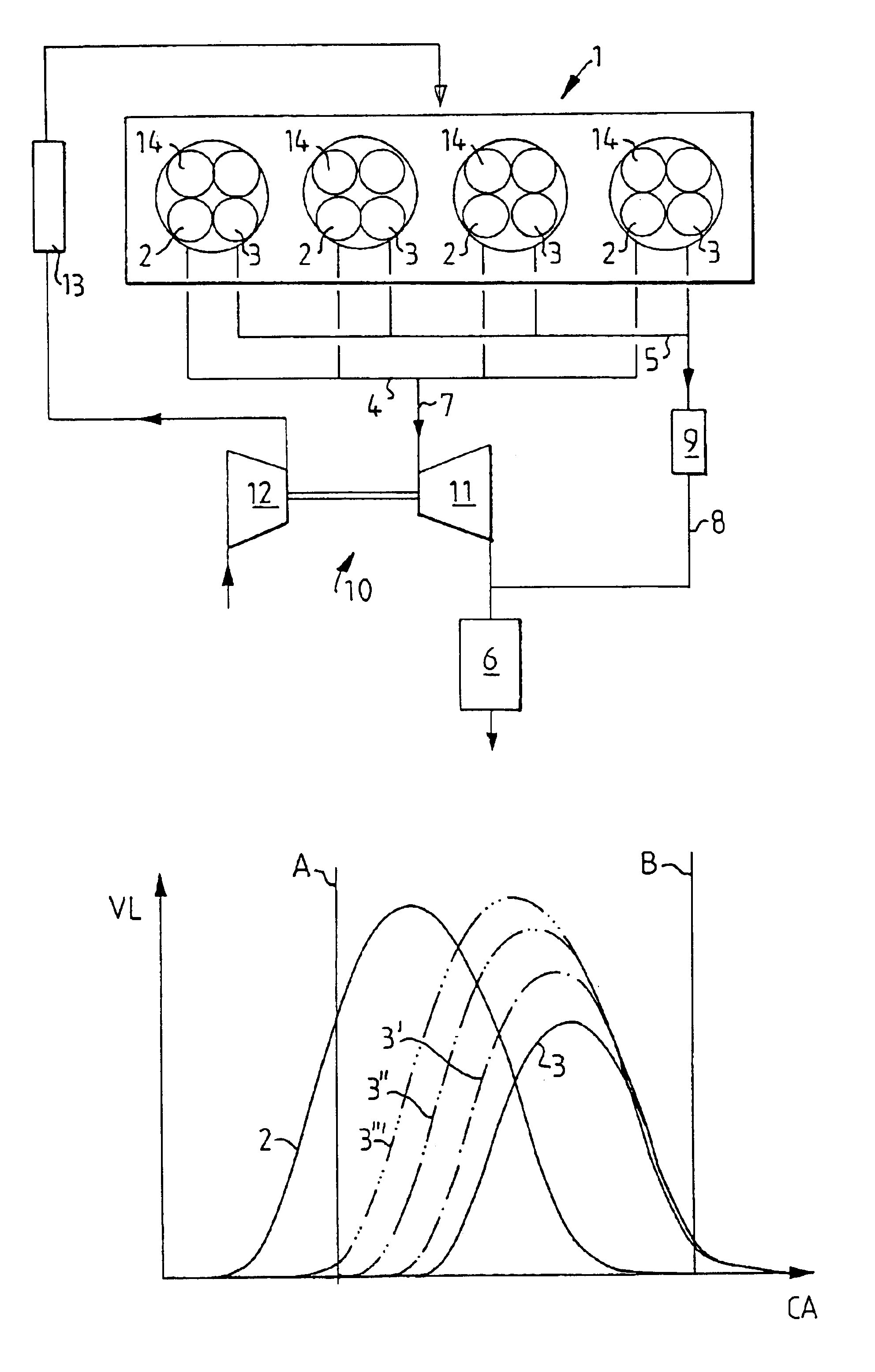

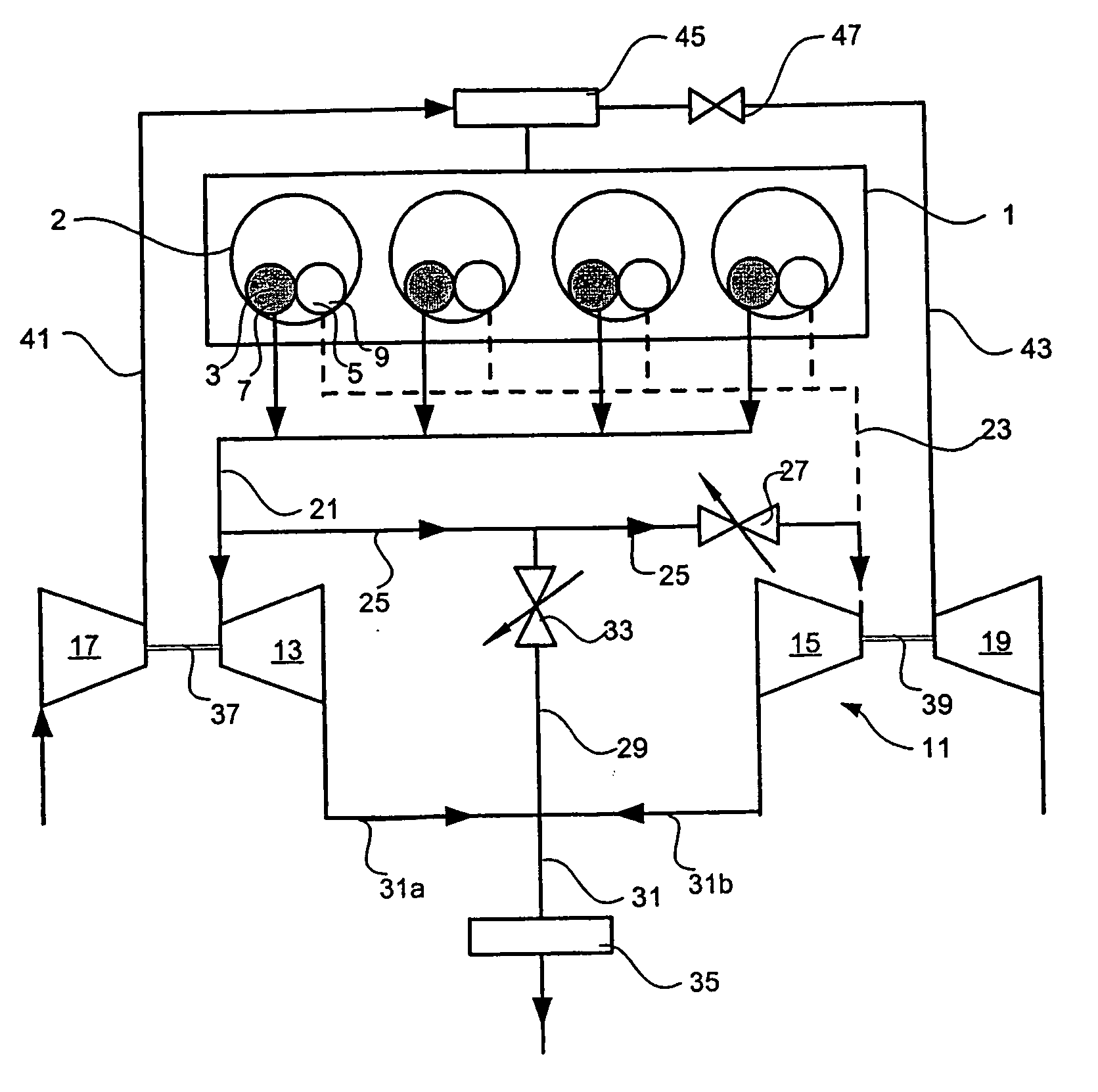

Method for controlling the charging pressure at a turbocharged combustion engine, and a corresponding combustion engine

InactiveUS6883319B2Reduce chargeLimit charging pressureValve arrangementsElectrical controlExhaust valveCombustion

A multicylinder internal combustion engine with an exhaust-driven turbocompressor and with a divided exhaust gas flow has at least two exhaust valves (2,3) and one intake valve per cylinder. A first exhaust valve (2) is connected to a first exhaust manifold which leads to the turbine of the compressor, while a second exhaust valve (3) is connected to a second exhaust manifold which opens downstream of the turbine. The charging pressure in the engine can be regulated by virtue of the opening periods of the exhaust valves (2,3) being varied in relation to one another in order to adapt the flow through the exhaust turbine to a value which provides the desired charging pressure in the engine. By opening the second exhaust valve (3) increasingly earlier, an increasingly lower charging pressure can be achieved.

Owner:SAAB AUTOMOBILE AB

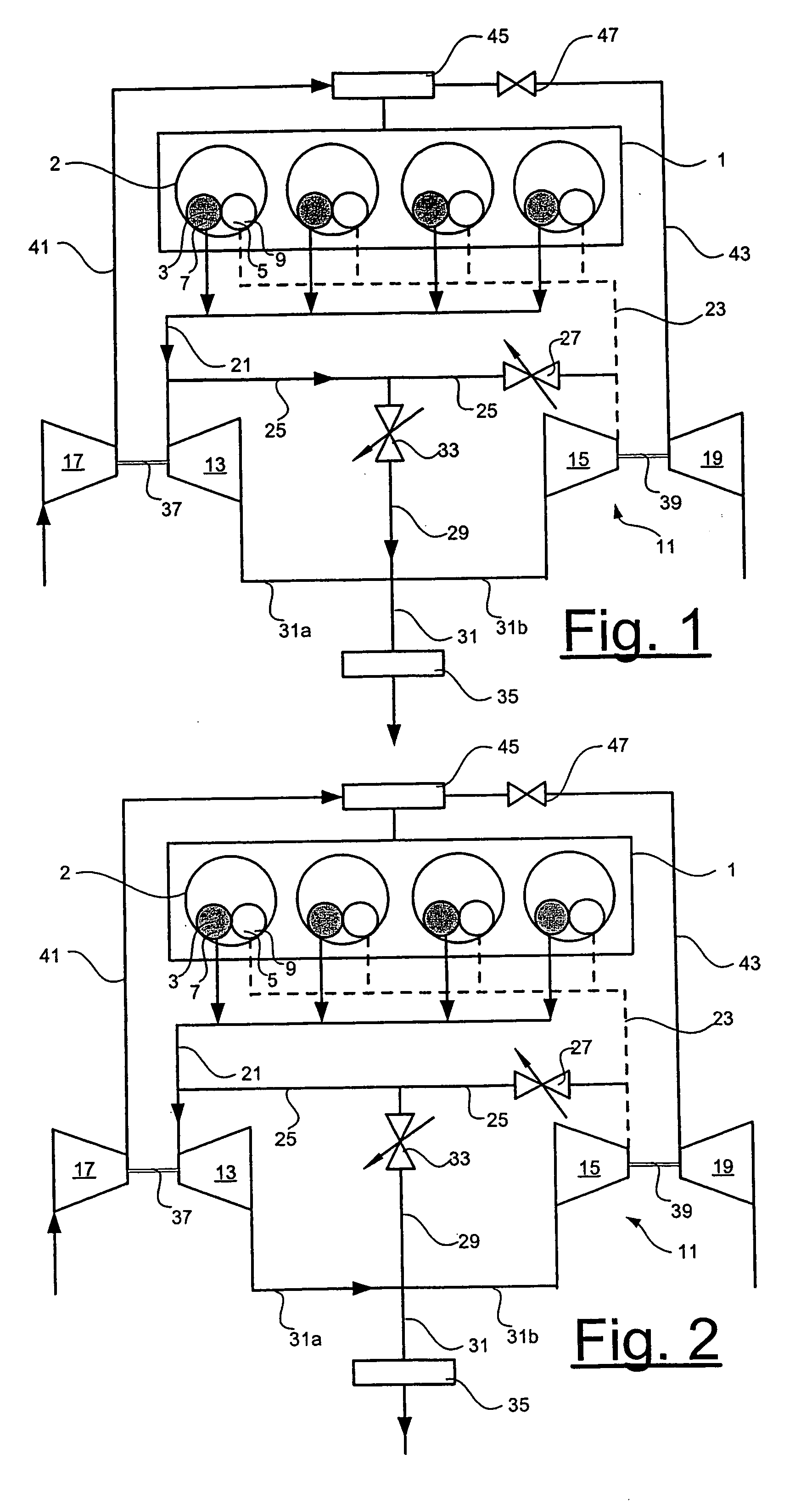

Control of exhaust to a turbo of internal combustion engine

InactiveUS20060070382A1Improve balanceReduce exhaust back pressureElectrical controlInternal combustion piston enginesExhaust valveTurbine

An internal combustion engine has a plurality of cylinders, and each cylinder has at least one first and one second exhaust port with associated respective first and second exhaust valves. At least one first and one second exhaust manifold are flow-connected to the respective first and second exhaust ports. A turbo unit for supercharging the charge air delivered to the cylinders comprises at least one first and one second exhaust gas turbine respectively flow connected to the first and the second exhaust manifolds. An exhaust gas chamber flow-connects the first and the second exhaust manifolds upstream of the exhaust gas turbines. The first and second exhaust valves can be deactivated / activated during operation. A throttle valve in the exhaust gas chamber may assume a closed position in order to separate the first and the second exhaust manifolds. A method of operating includes opening and closing different valves at different engine speeds.

Owner:SAAB AUTOMOBILE AB

Method of controlling engine system and engine system

InactiveUS20100217504A1Improve drivabilitySmooth torque curveAnalogue computers for vehiclesValve arrangementsExhaust valveInlet valve

A valve overlap period is increased as a desired torque of an engine increases by advancing an opening timing of an intake valve at a rate greater than that of retarding a closing timing of an exhaust valve in a low engine-torque area in which the desired torque of the internal combustion engine is relatively low (step S16). The valve overlap period is increased as the desired torque of the engine increases by retarding the closing timing of the exhaust valve at a rate greater than that of advancing the opening timing of the intake valve in a high engine-torque area in which the desired torque of the internal combustion engine is relatively high (step S17). Accordingly, the drivability can be improved by obtaining the proper torque and the smooth torque curve in the wide driving area.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com