Patents

Literature

6594 results about "Centrifugal pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits.

Rotary blood pump and control system therefor

Owner:TC1 LLC +1

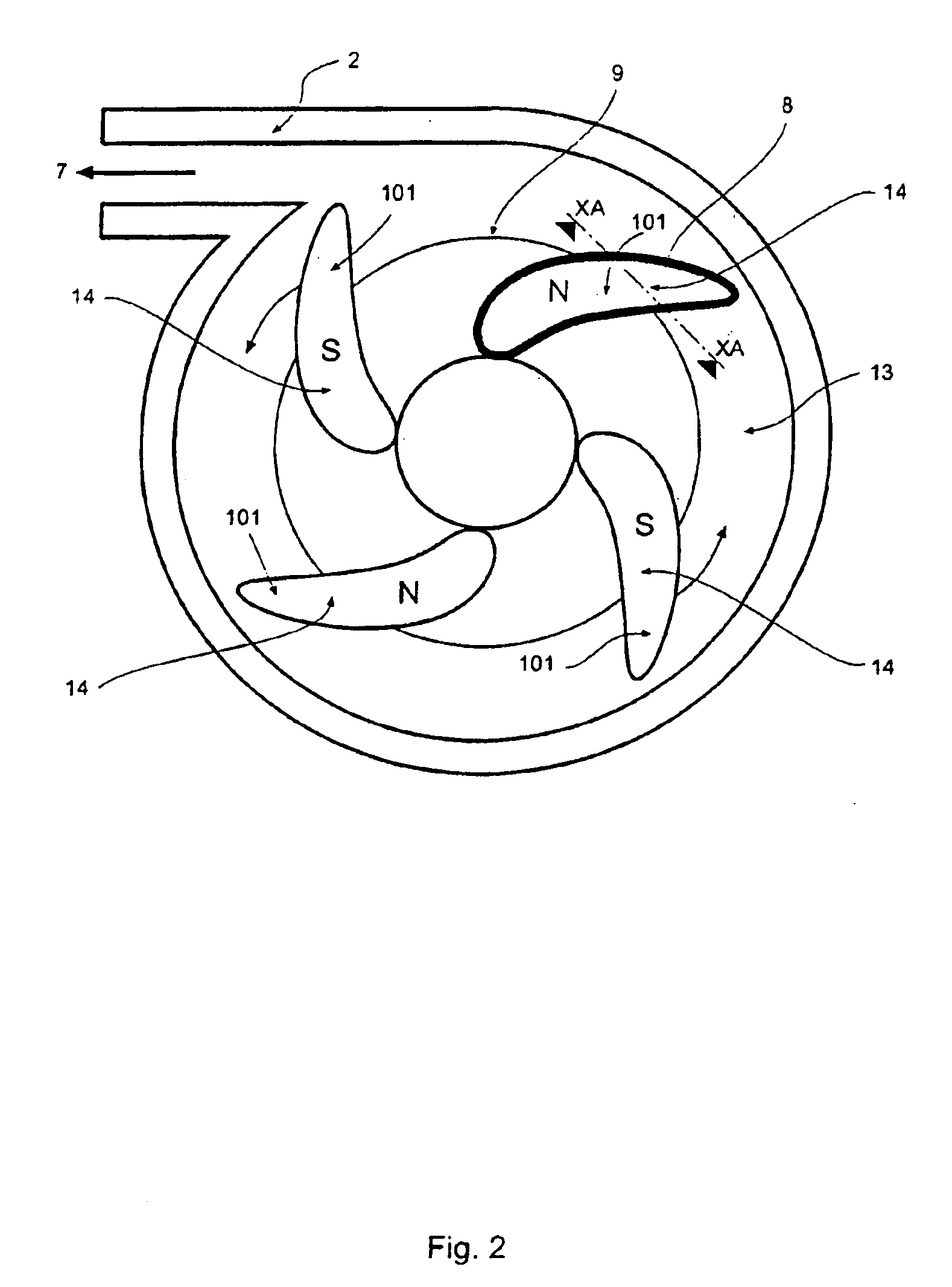

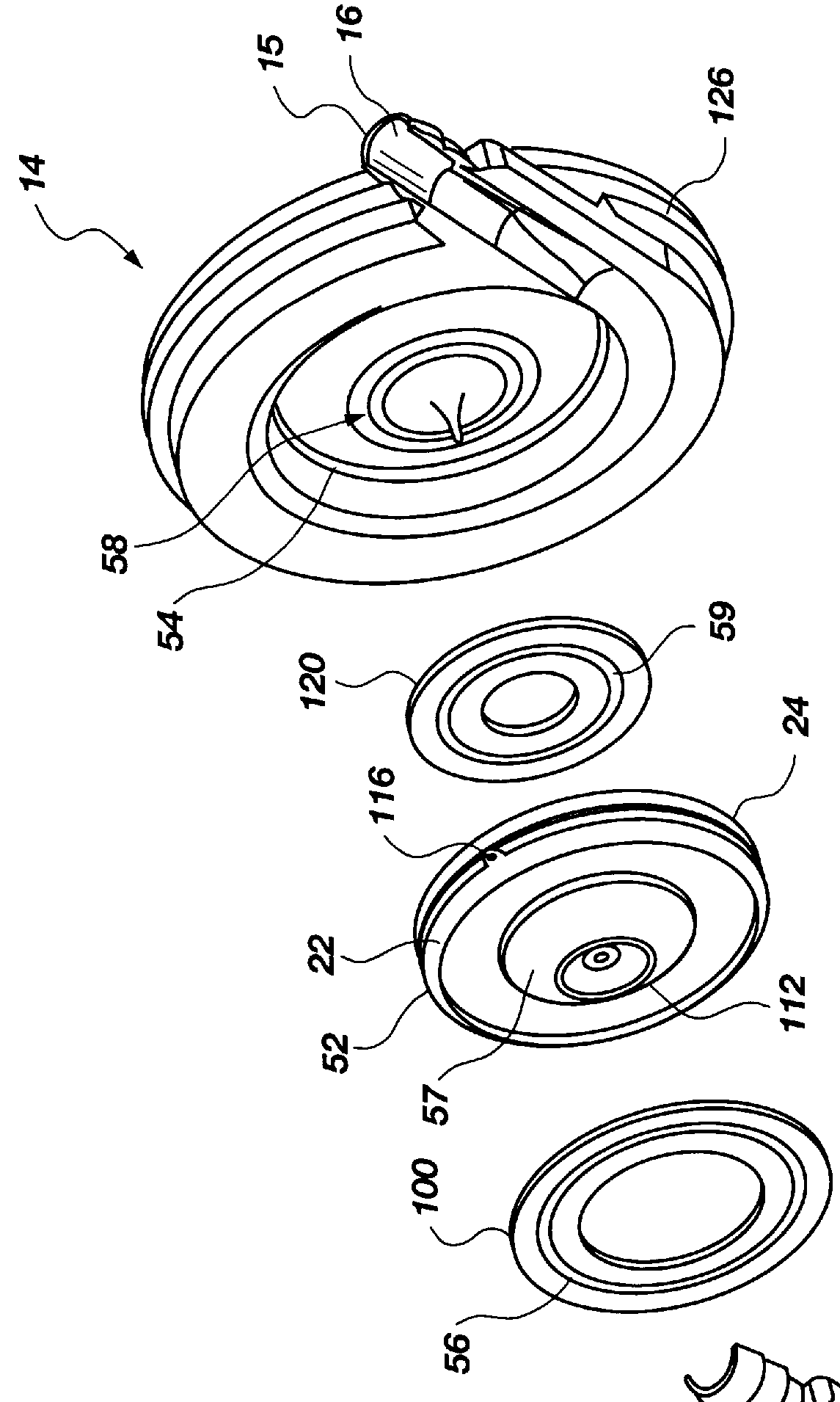

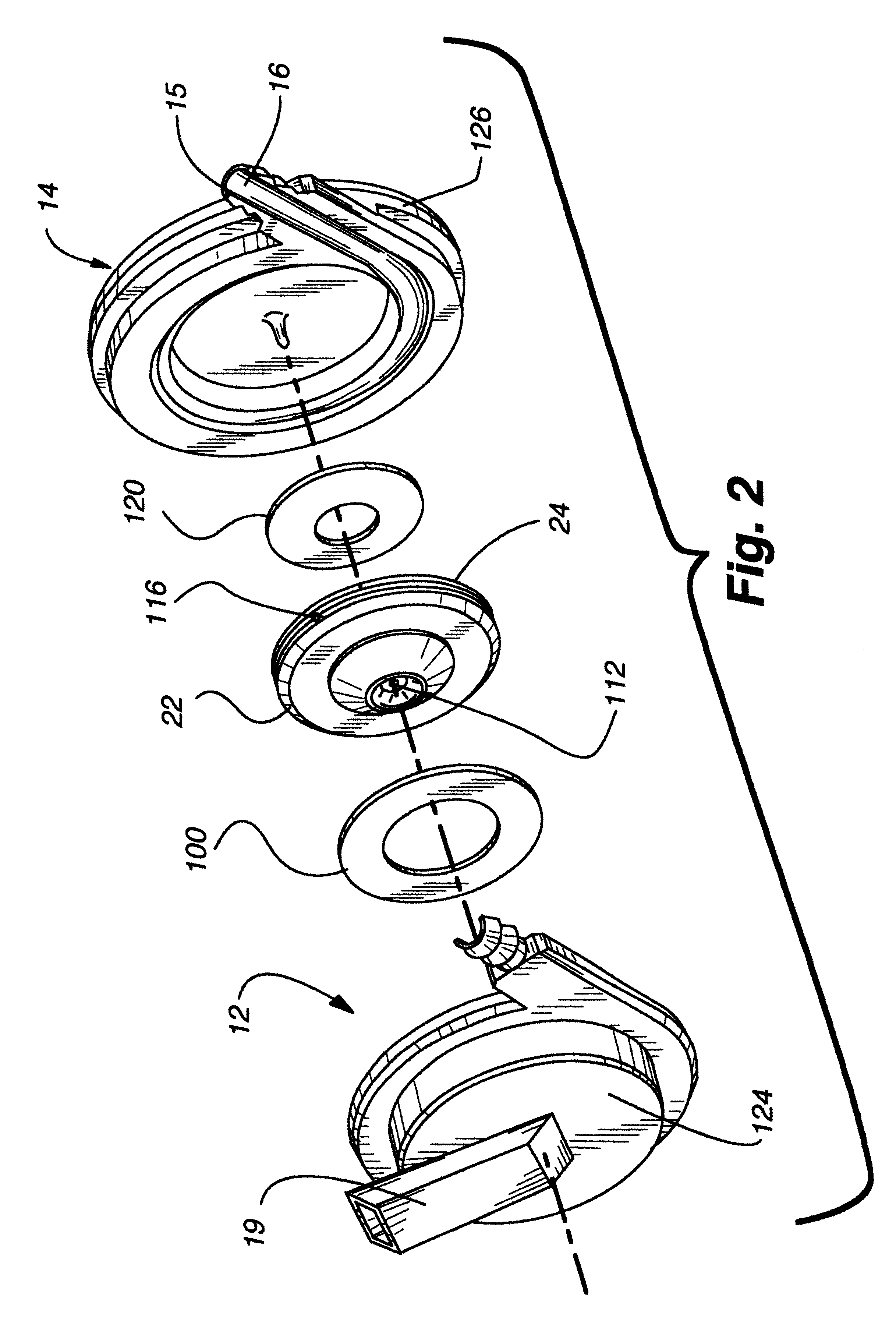

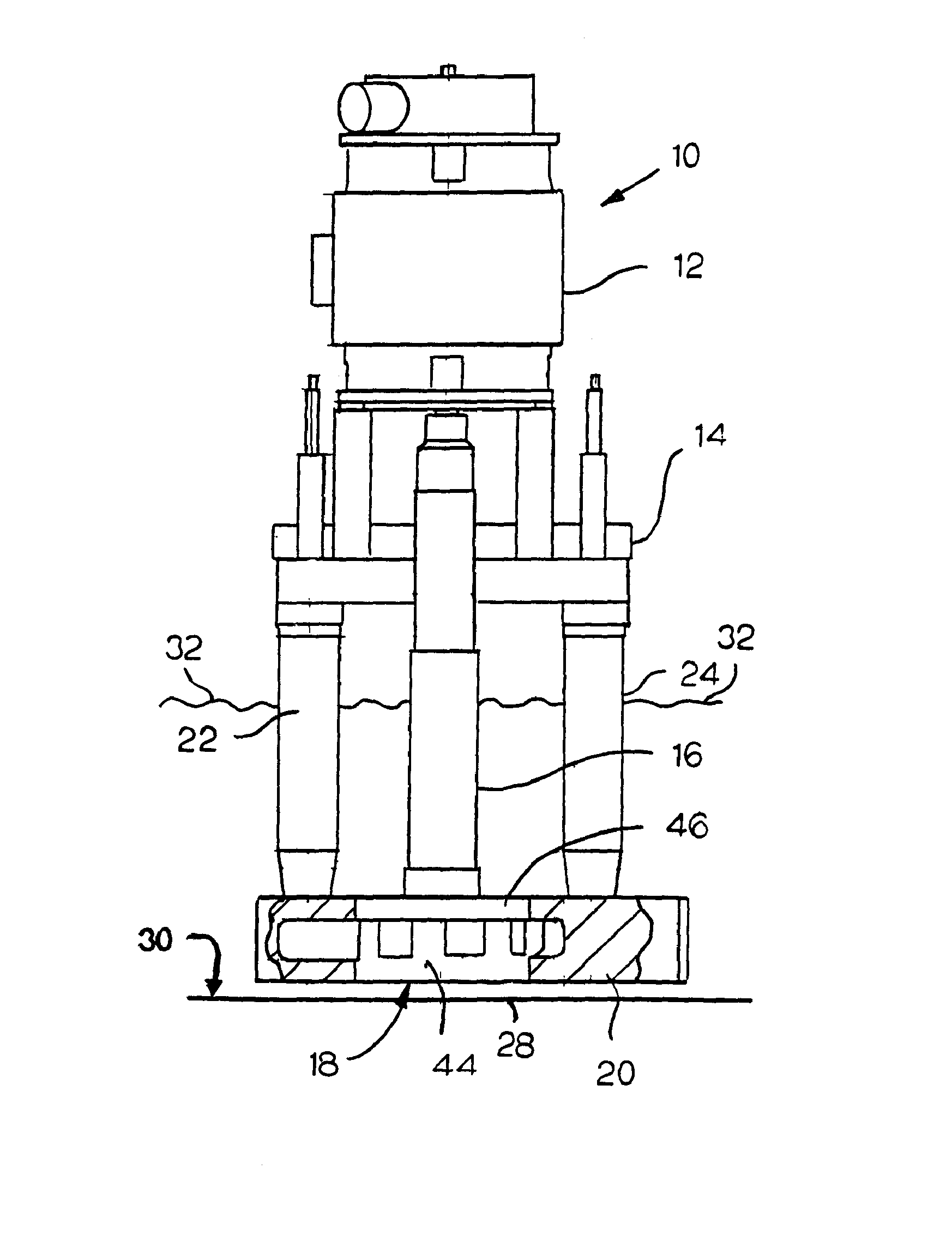

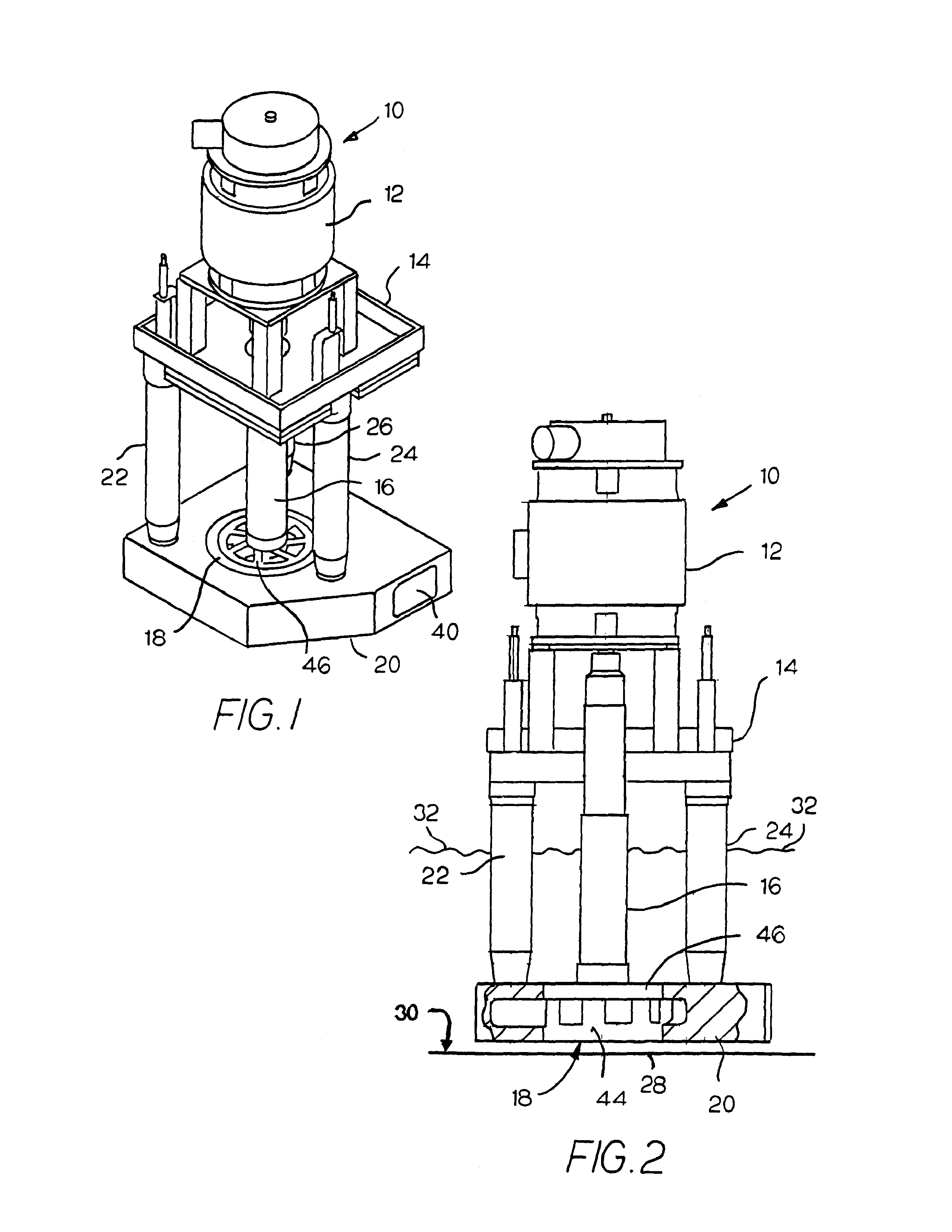

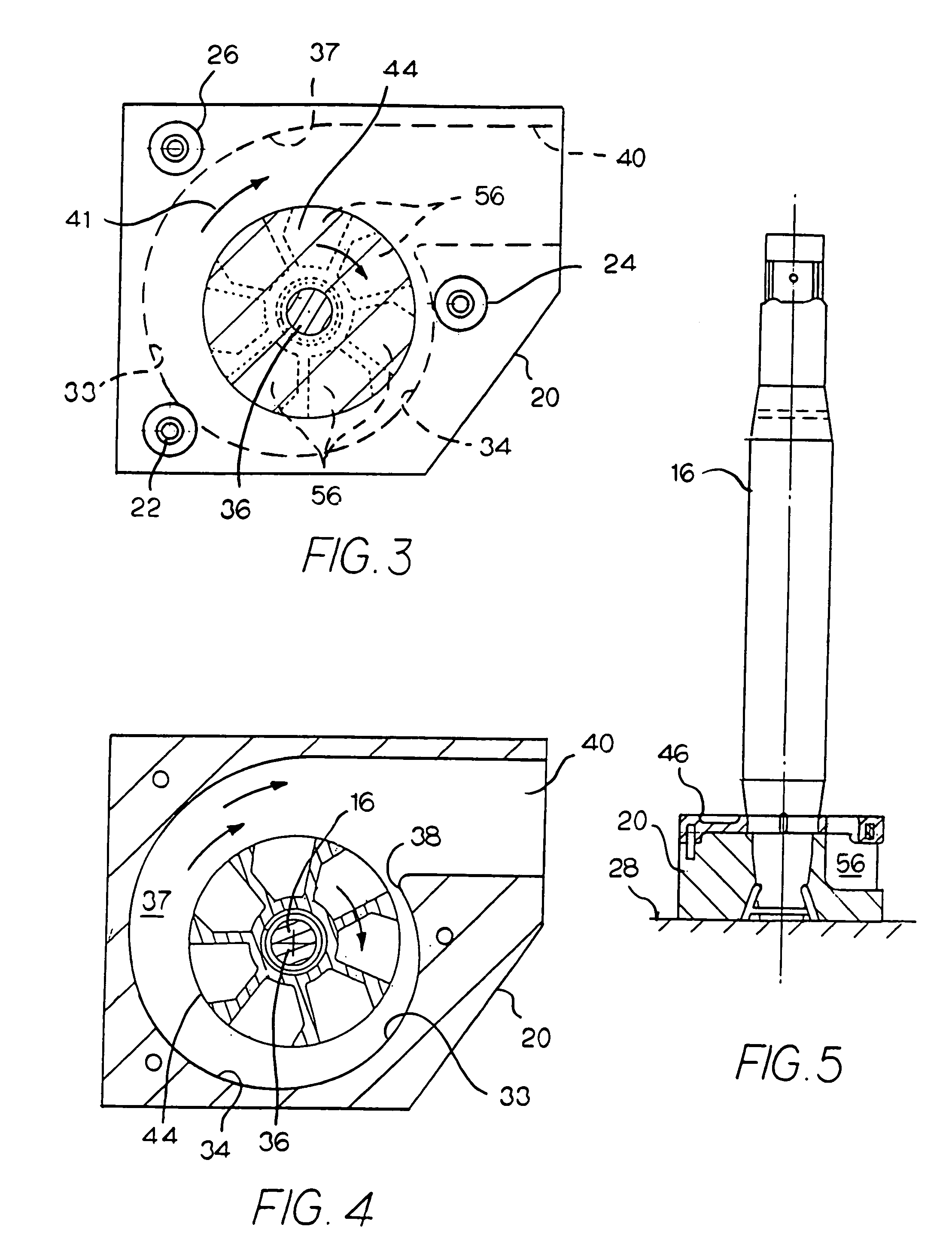

Hybrid magnetically suspended and rotated centrifugal pumping apparatus and method

InactiveUS6074180AAvoid displacementEfficient startSpecific fluid pumpsPump componentsMotor speedRotary pump

An apparatus and method for a centrifugal fluid pump for pumping sensitive biological fluids, which includes (i) an integral impeller and rotor which is entirely supported by an integral combination of permanent magnets and electromagnetic bearings and rotated by an integral motor, (ii) a pump housing and arcuate passages for fluid flow and containment, (iii) a brushless driving motor embedded and integral with the pump housing, (iv) a power supply, and (v) specific electronic sensing of impeller position, velocity or acceleration using a self-sensing method and physiological control algorithm for motor speed and pump performance based upon input from the electromagnetic bearing currents and motor back emf-all fitly joined together to provide efficient, durable and low maintenance pump operation. A specially designed impeller and pump housing provide the mechanism for transport and delivery of fluid through the pump to a pump output port with reduced fluid turbulence.

Owner:WORLD HEART +2

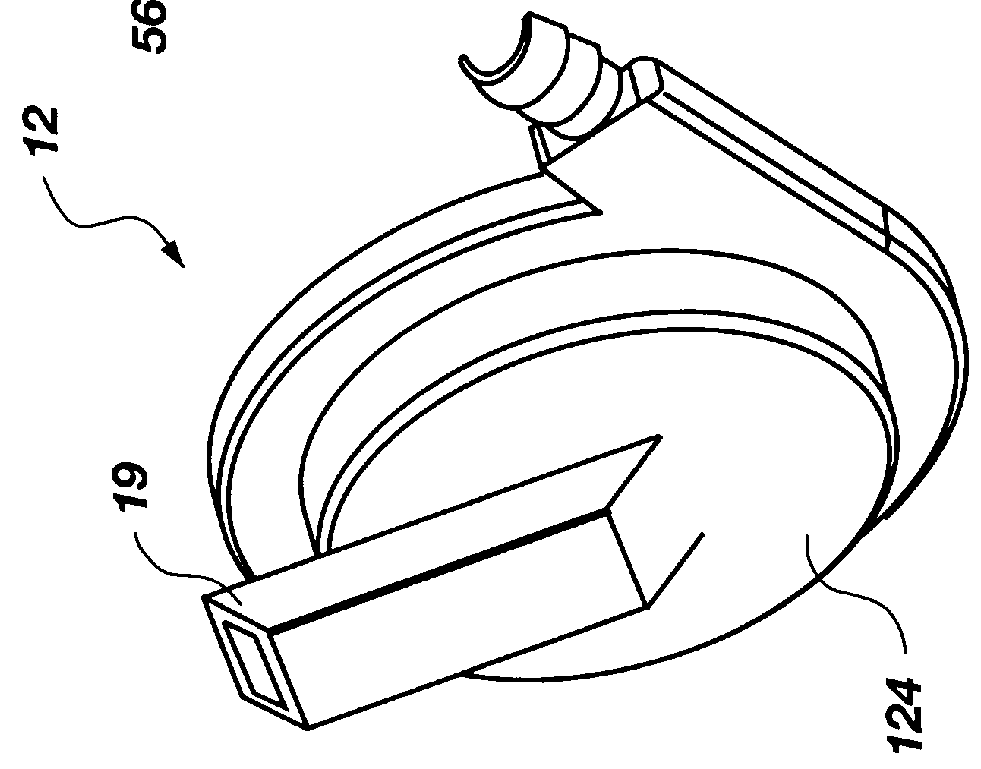

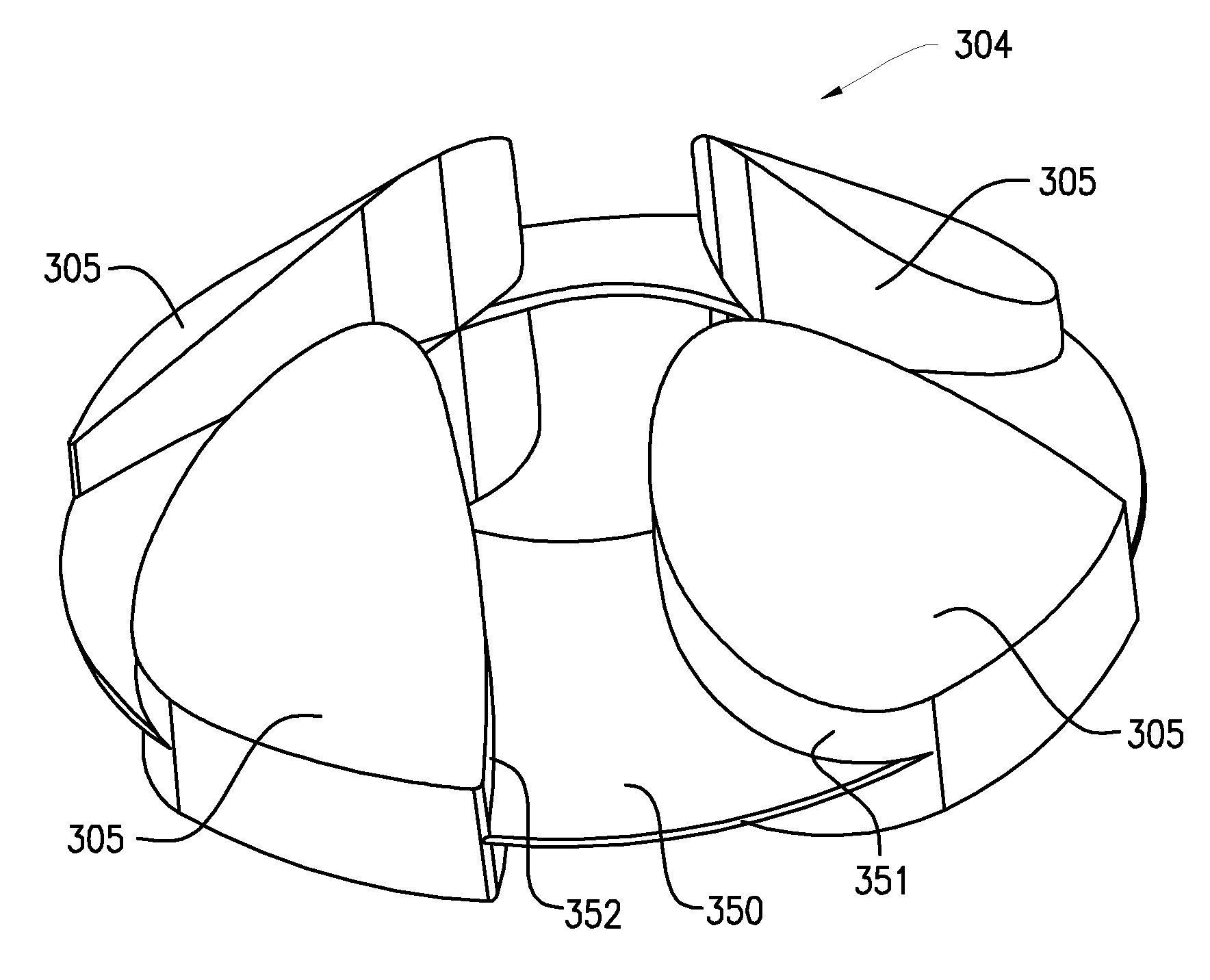

Impeller assembly for centrifugal pumps

InactiveUS20030231959A1Shorten the time periodExpedite evacuationPropellersRotary propellersEngineeringEye opening

An impeller assembly for centrifugal pumps that enables self-priming in a relatively short time period includes an impeller and at least one winglet (e.g., six winglets with a trapezium cross-sectional shape). The impeller includes an impeller body with an eye opening therein. The eye opening is configured for the passage of a fluid (e.g., water) therethrough when the impeller assembly is in use. The impeller body also includes at least one vane, with a leading end, disposed about the eye opening. The at least one winglet is positioned to protrude into the eye opening of the impeller body and may, for example, be coupled to the leading end of the vane.

Owner:HACKETT WILLIAM FRANKLIN JR

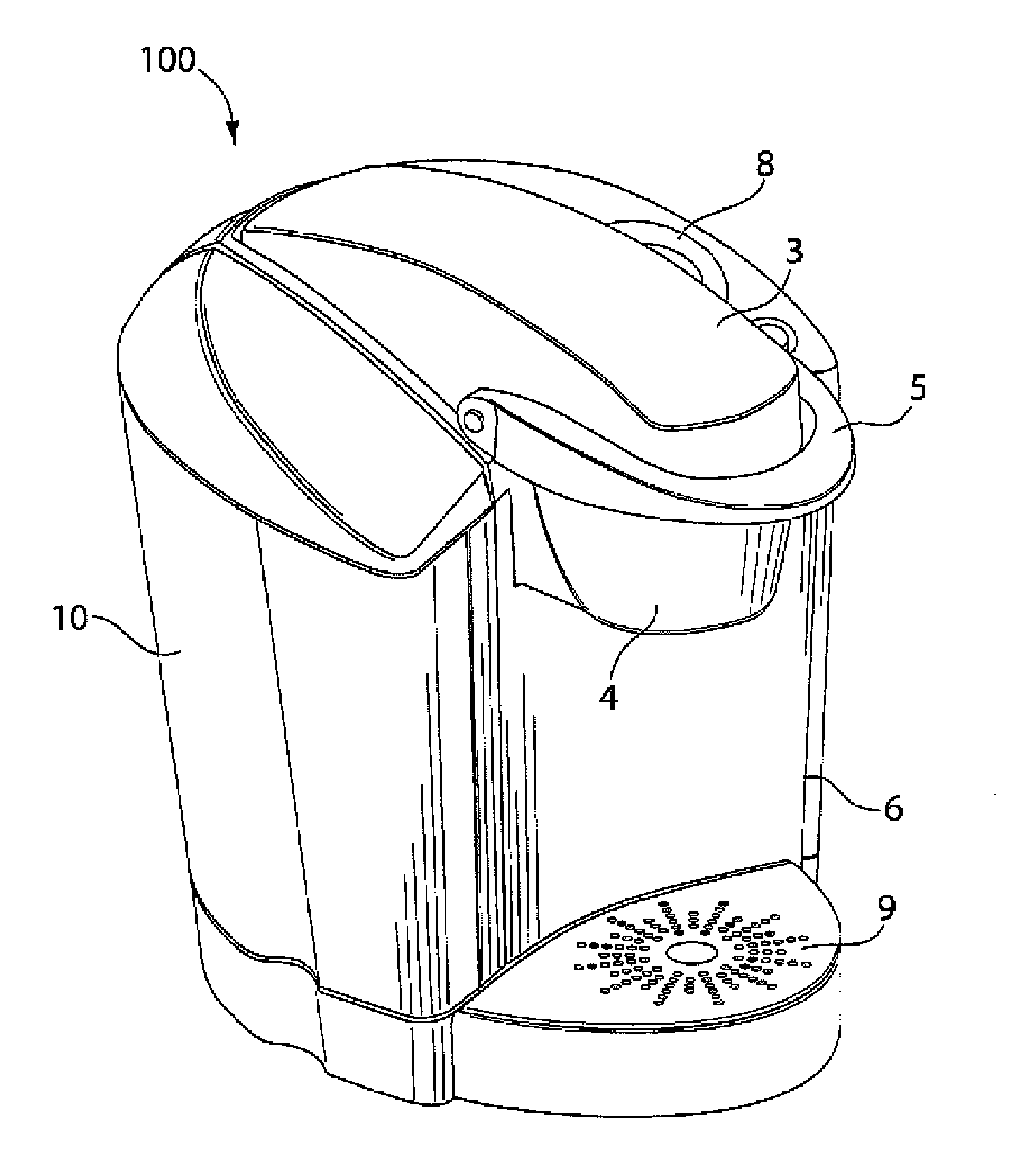

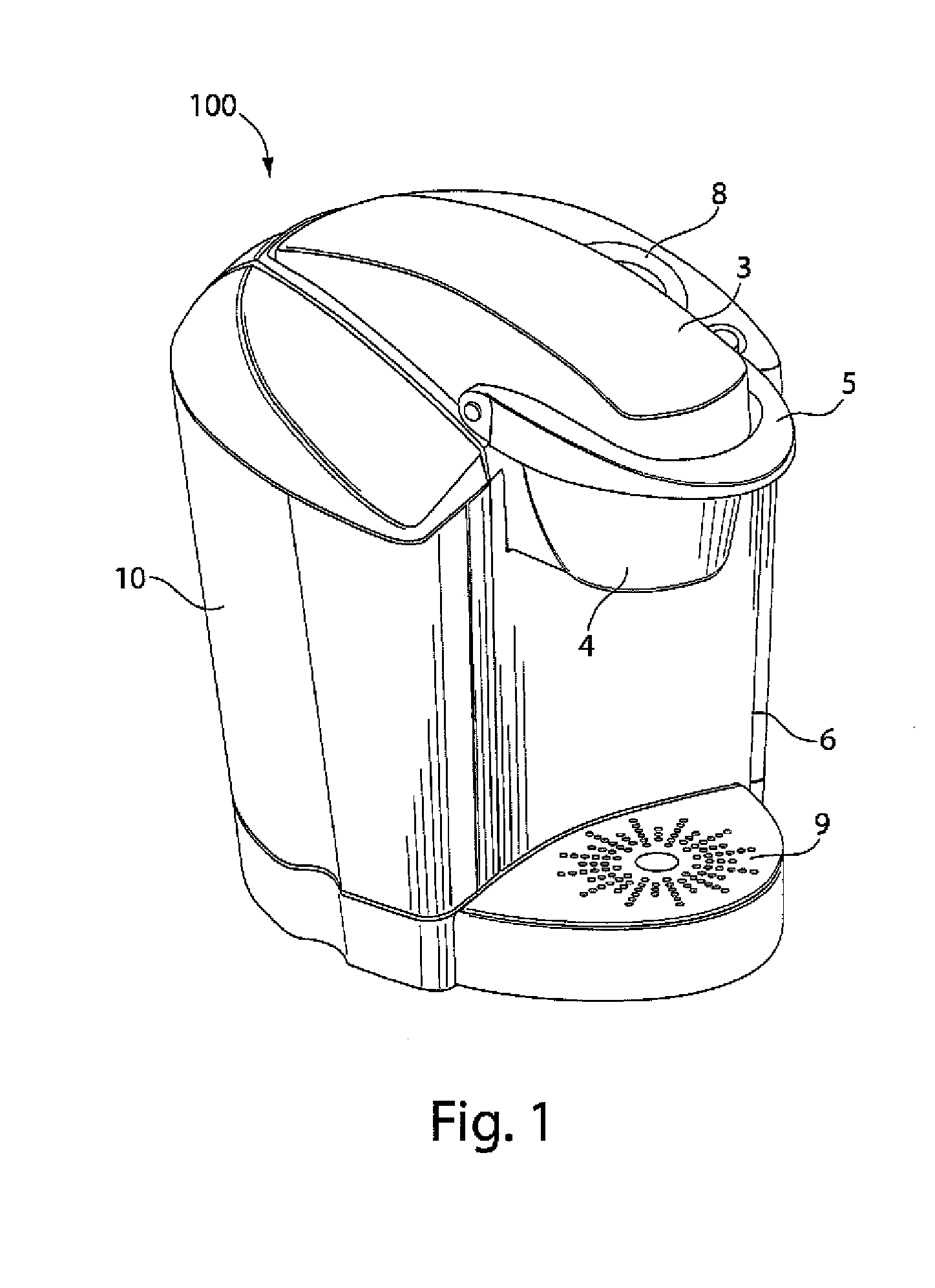

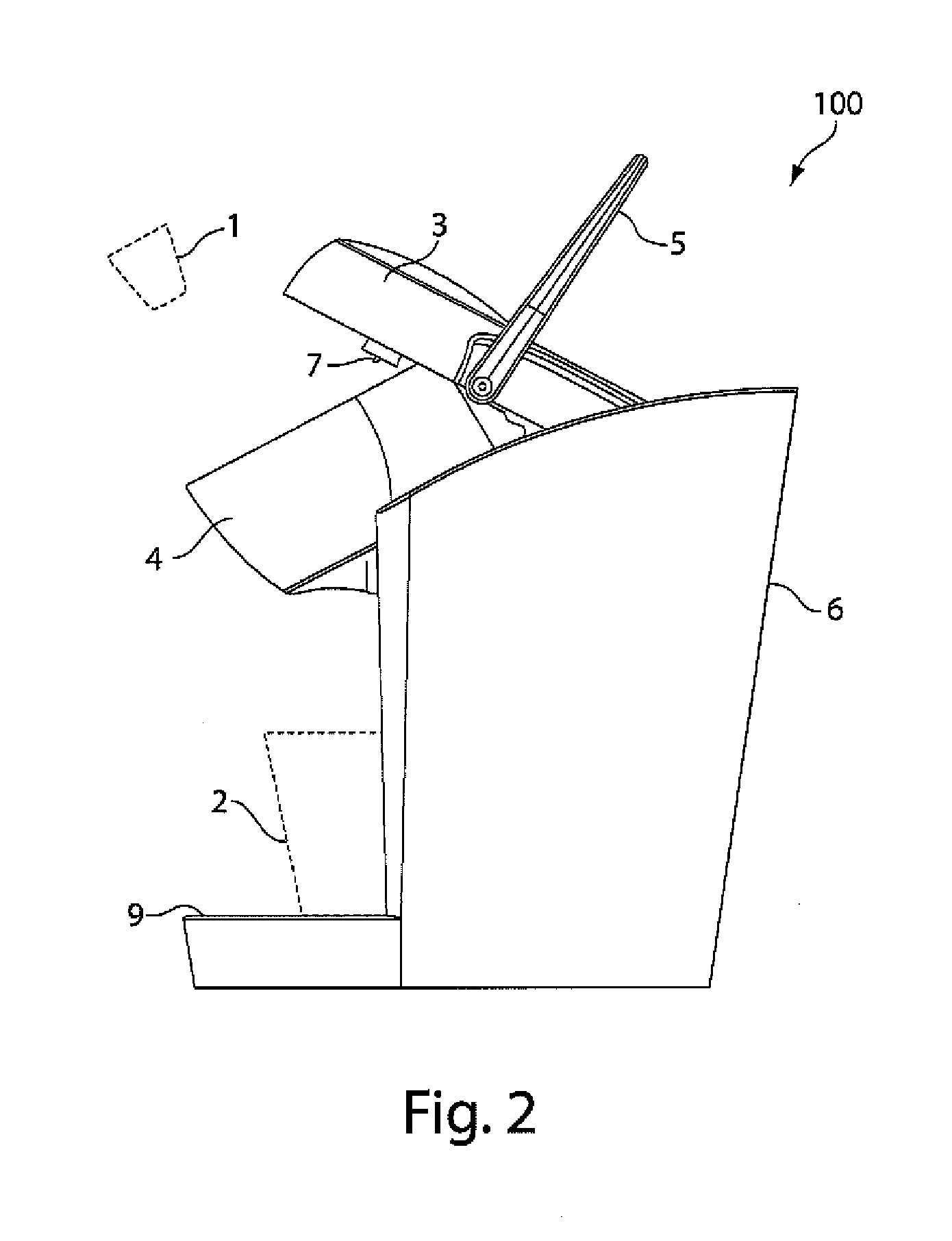

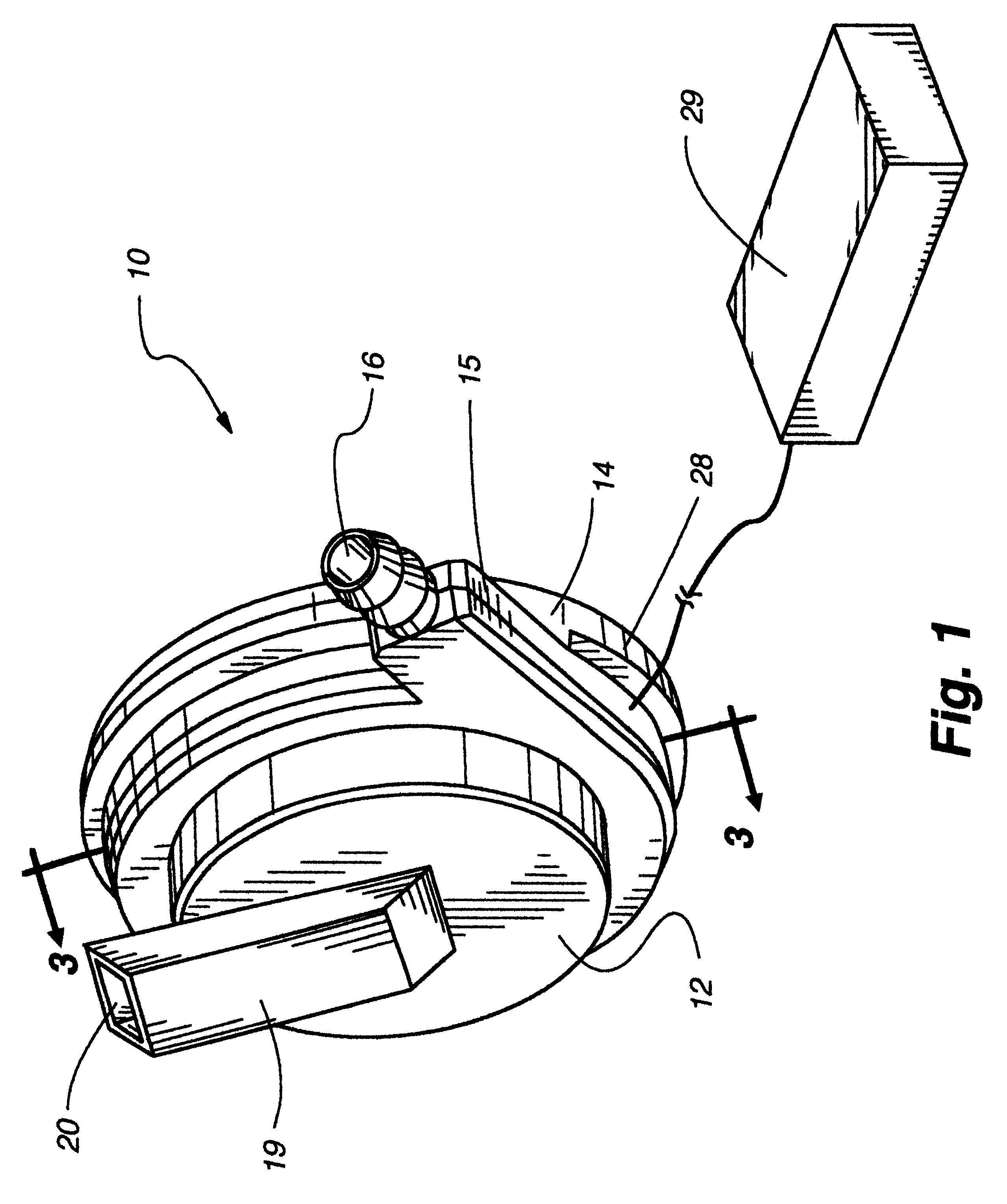

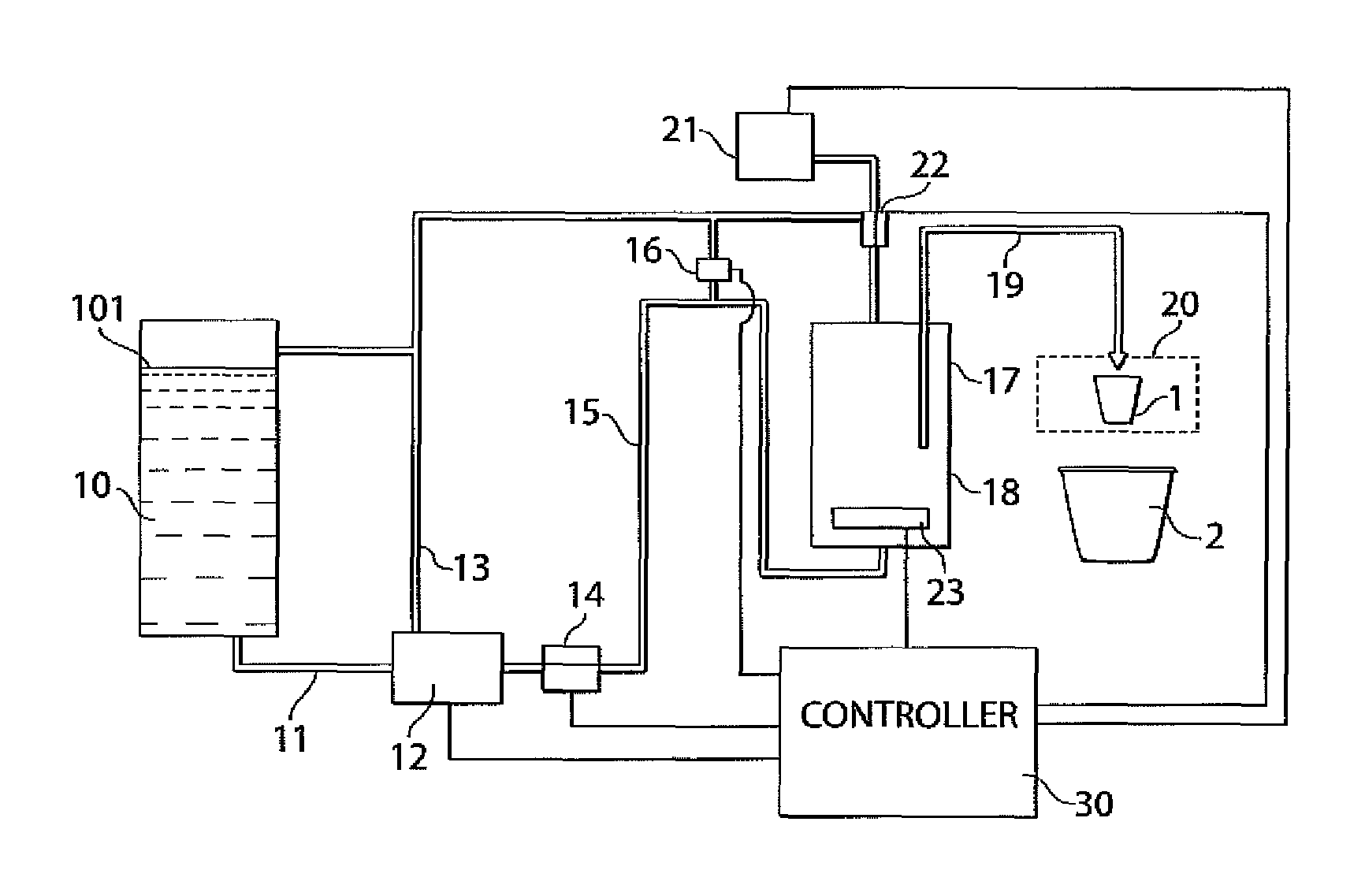

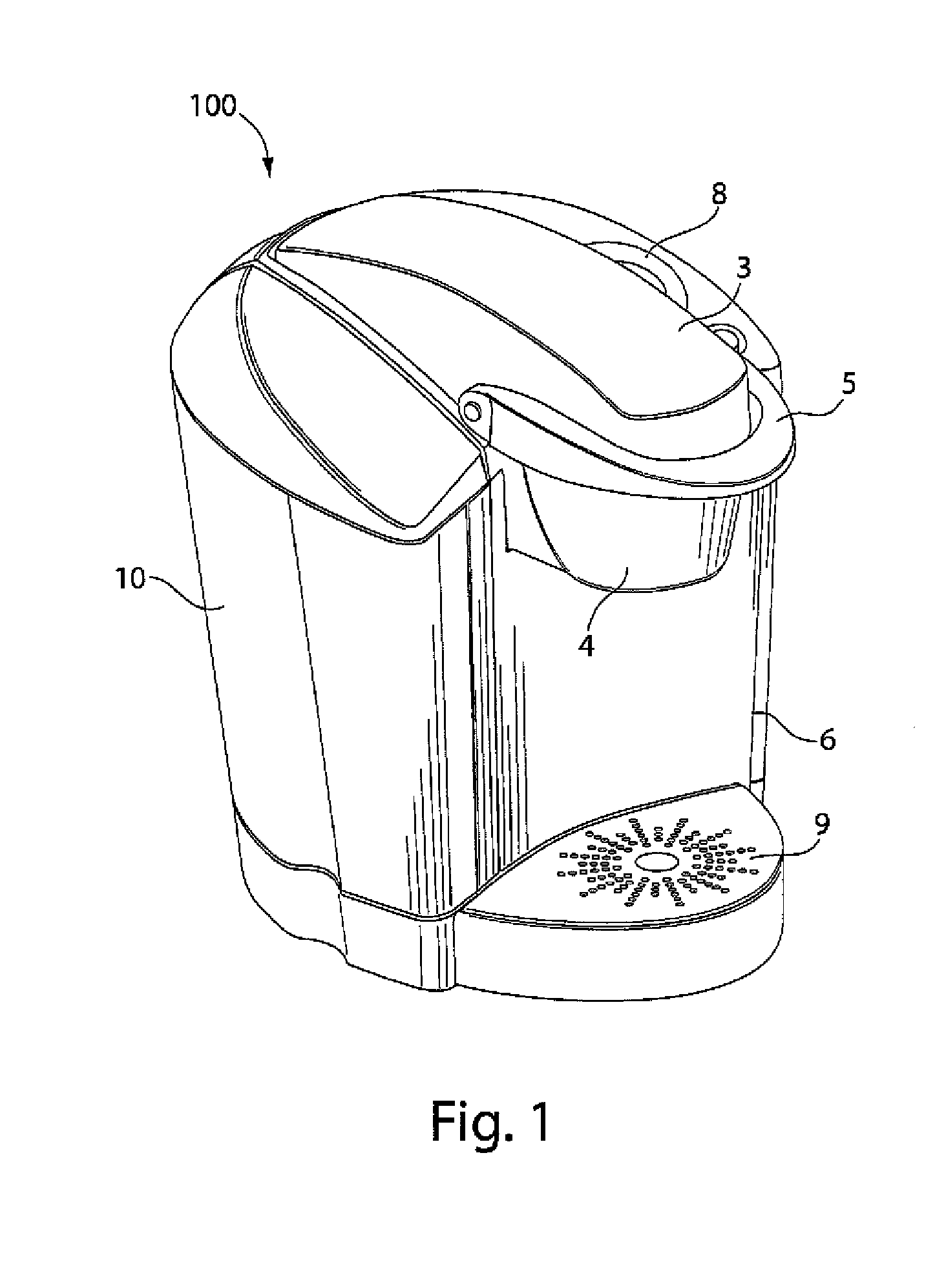

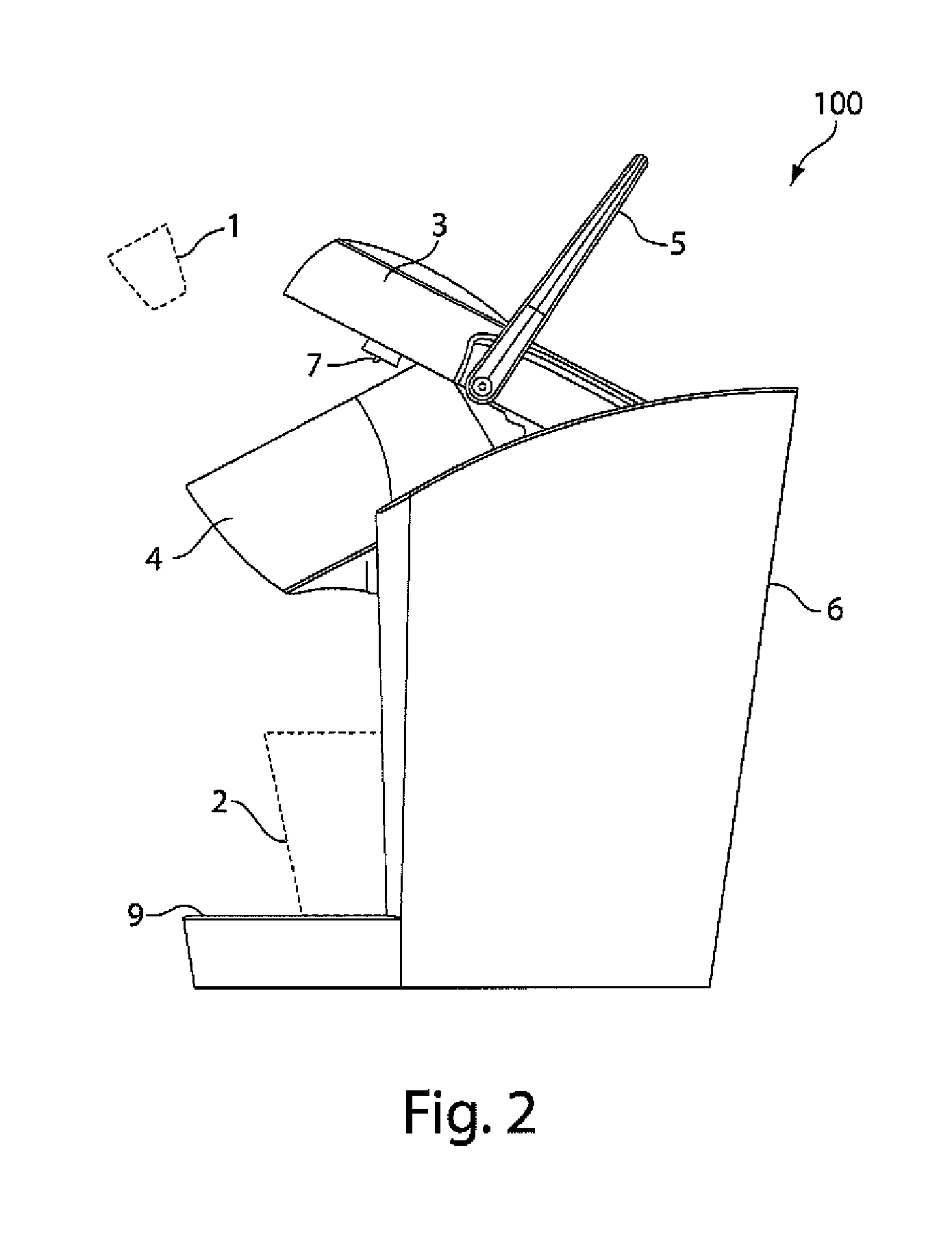

Beverage forming apparatus with centrifugal pump

ActiveUS20100024658A1Prevent substantial leakageAdequate flowBeverage vesselsFood preparationExhaust valveControl valves

A beverage forming apparatus includes a storage tank, and a centrifugal pump having an inlet connected to the storage tank by a supply conduit. The centrifugal pump may include a priming vent located below a full level of the storage tank and permit air to vent as liquid primes the pump. A metering tank may have an inlet connected to the centrifugal pump by a pump conduit, and an outlet connected to a brew chamber that forms a beverage using liquid received from the metering tank. In one embodiment, a flow control valve, such as a check valve, may be provided in the pump conduit to allow flow from the pump to the metering tank, but resist flow in reverse. In another embodiment, a vent valve in the pump conduit may be arranged to vent at least a portion of the pump conduit, e.g., to ambient air pressure.

Owner:KEURIG GREEN MOUNTAIN INC

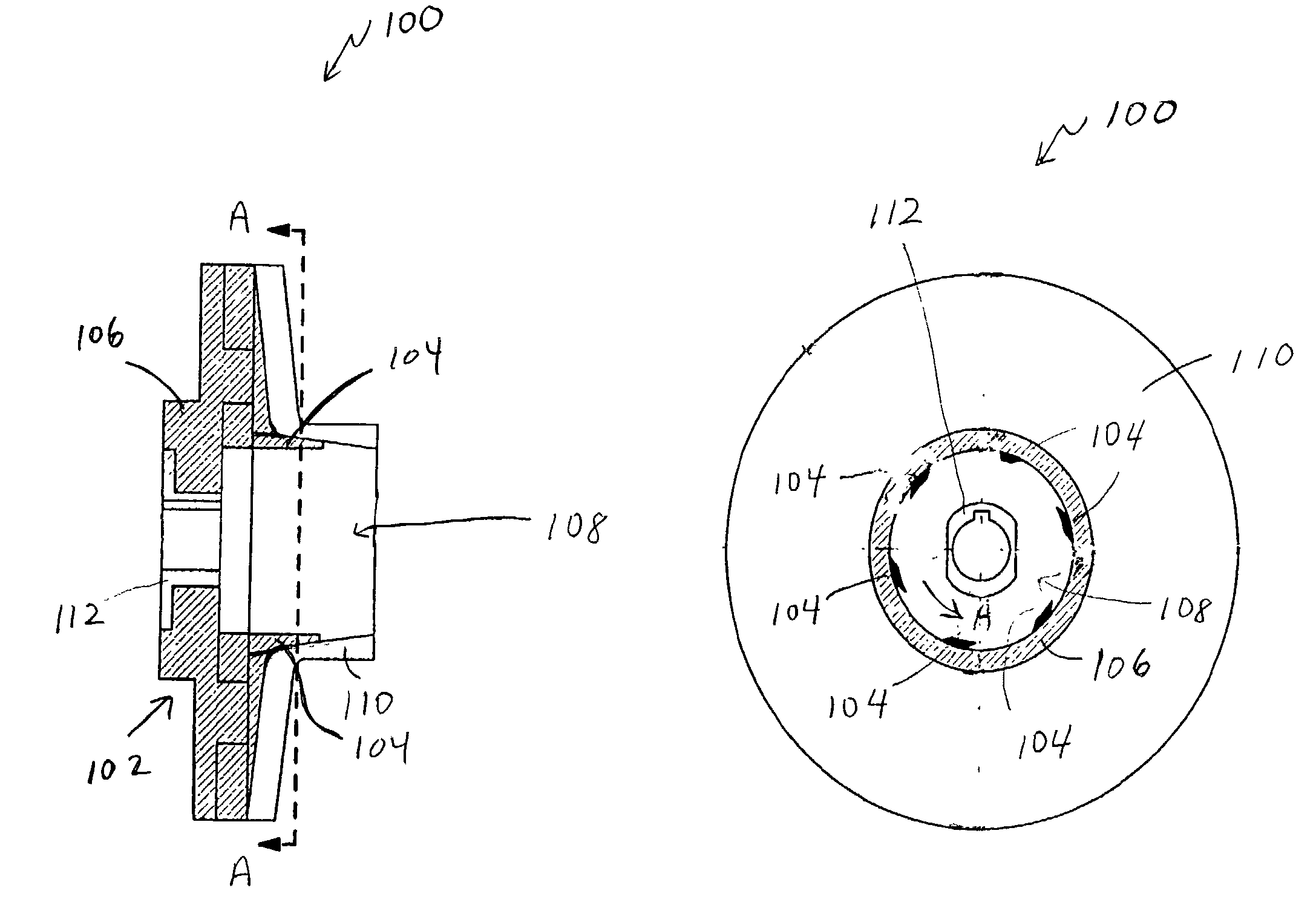

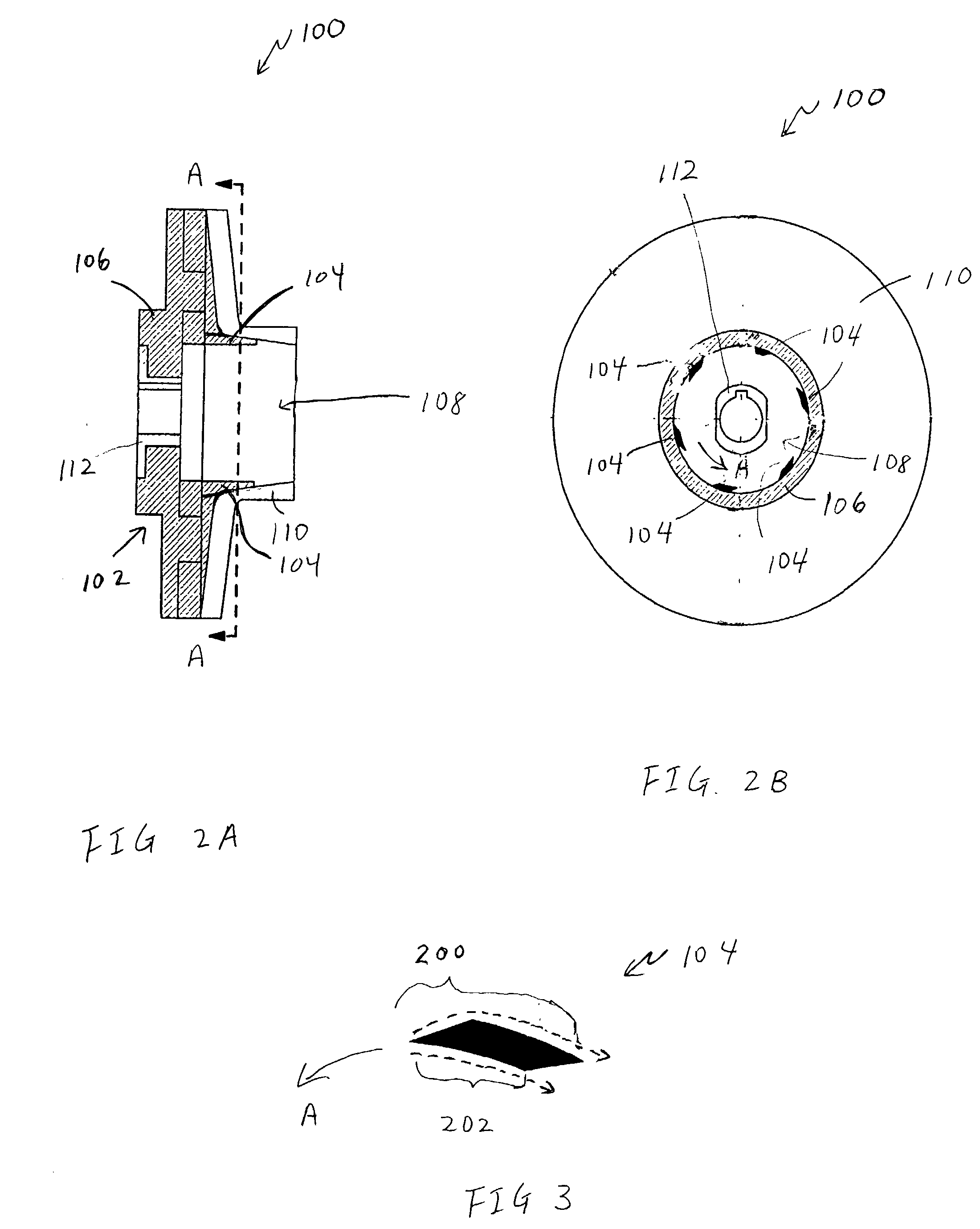

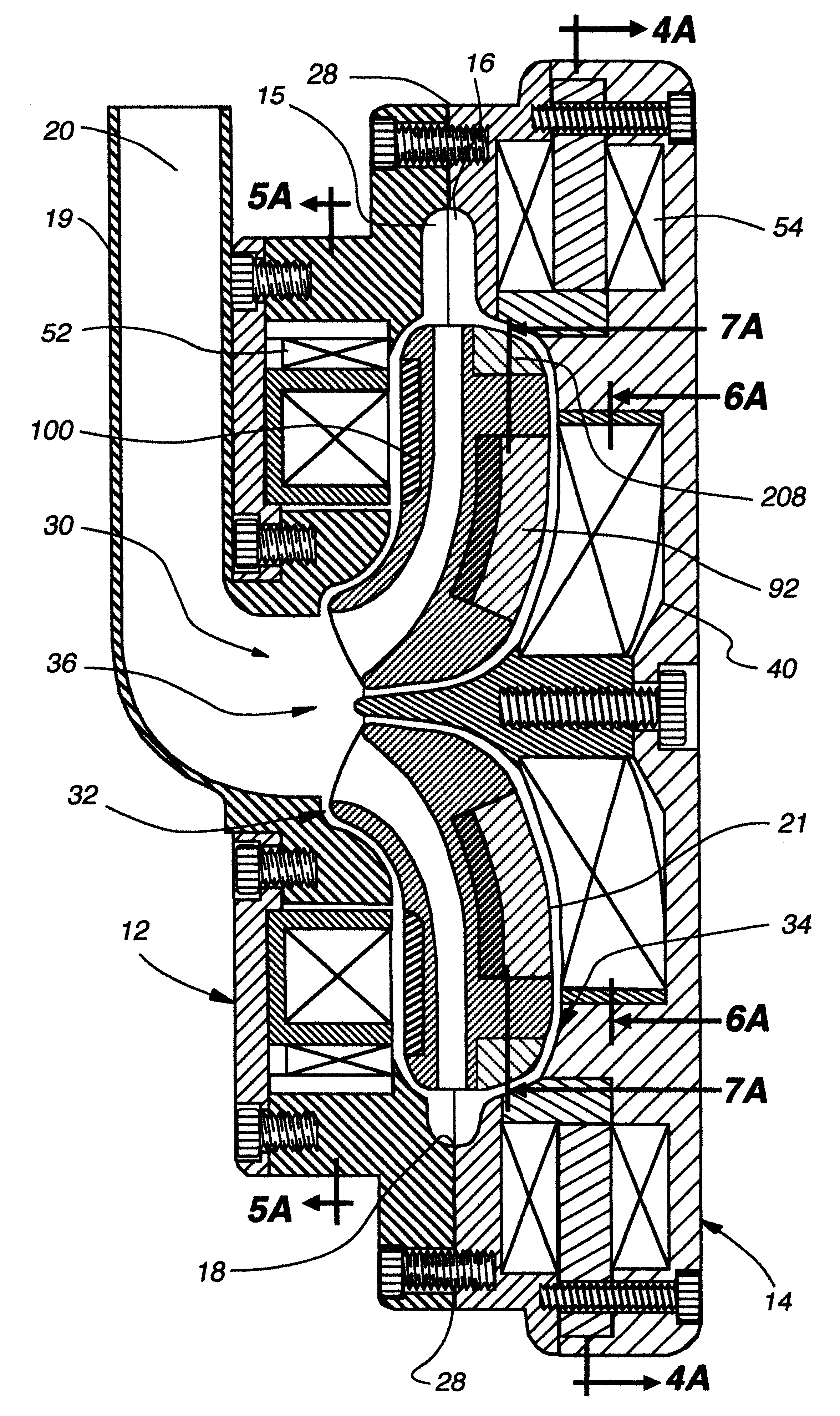

Electromagnetically suspended and rotated centrifugal pumping apparatus and method

InactiveUS6302661B1Increase energy lossIncrease frictionSpecific fluid pumpsPump componentsElectric machineryEngineering

An apparatus and method for a centrifugal pump for pumping sensitive biological fluids which includes (i) an integral impeller and rotor which is electromagnetically supported and rotated, (ii) a pump housing and arcuate passages for fluid flow and containment, (iii) a brushless driving motor embedded and integral with the pump housing, (iv) a power supply, and (v) specific electronic sensing and control algorithms-all fitly joined together to provide efficient, durable and low maintenance pump operation. A specially designed impeller and pump housing provide the mechanism for transport and delivery of fluid through the pump to a pump output port with reduced fluid turbulence.

Owner:WORLD HEART

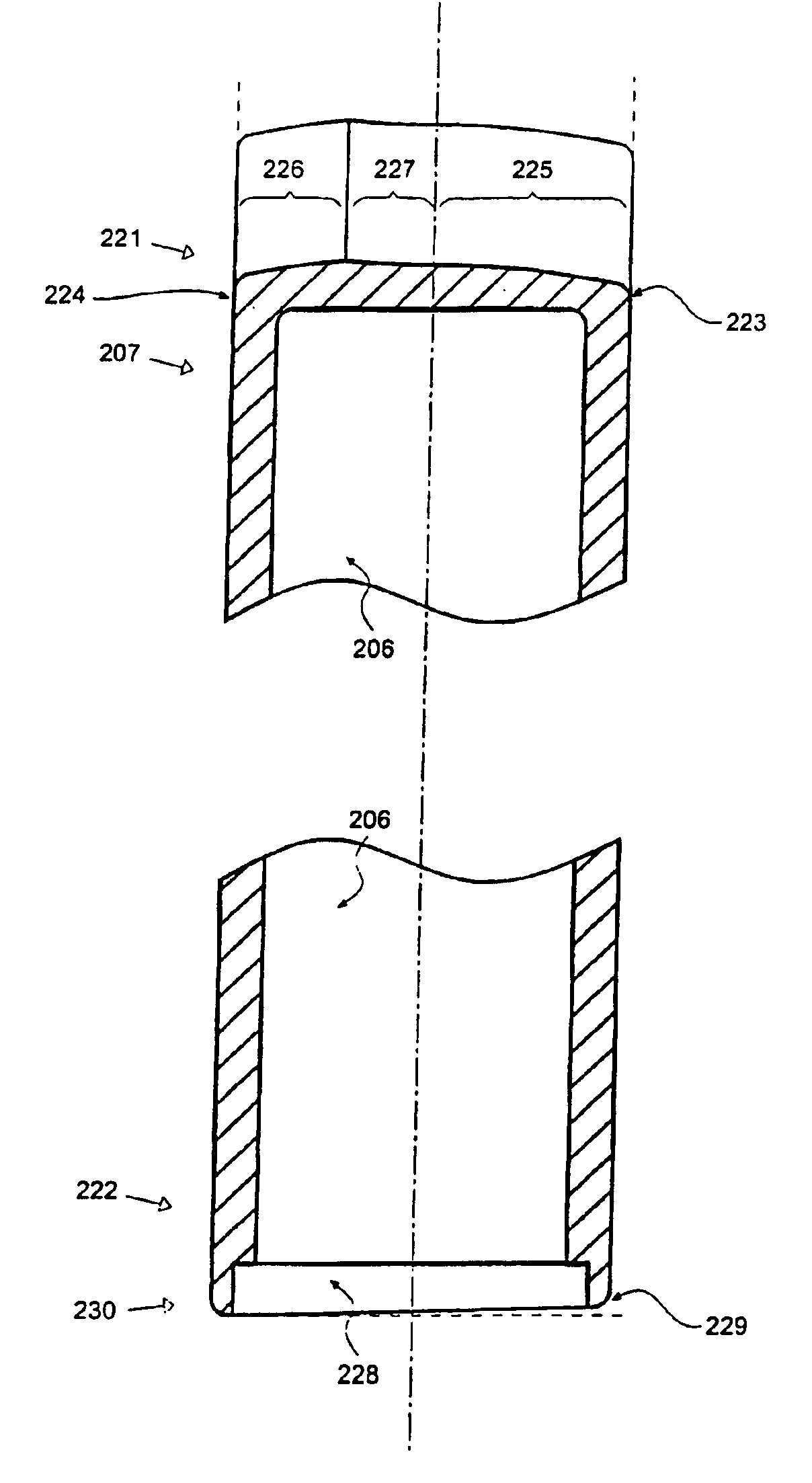

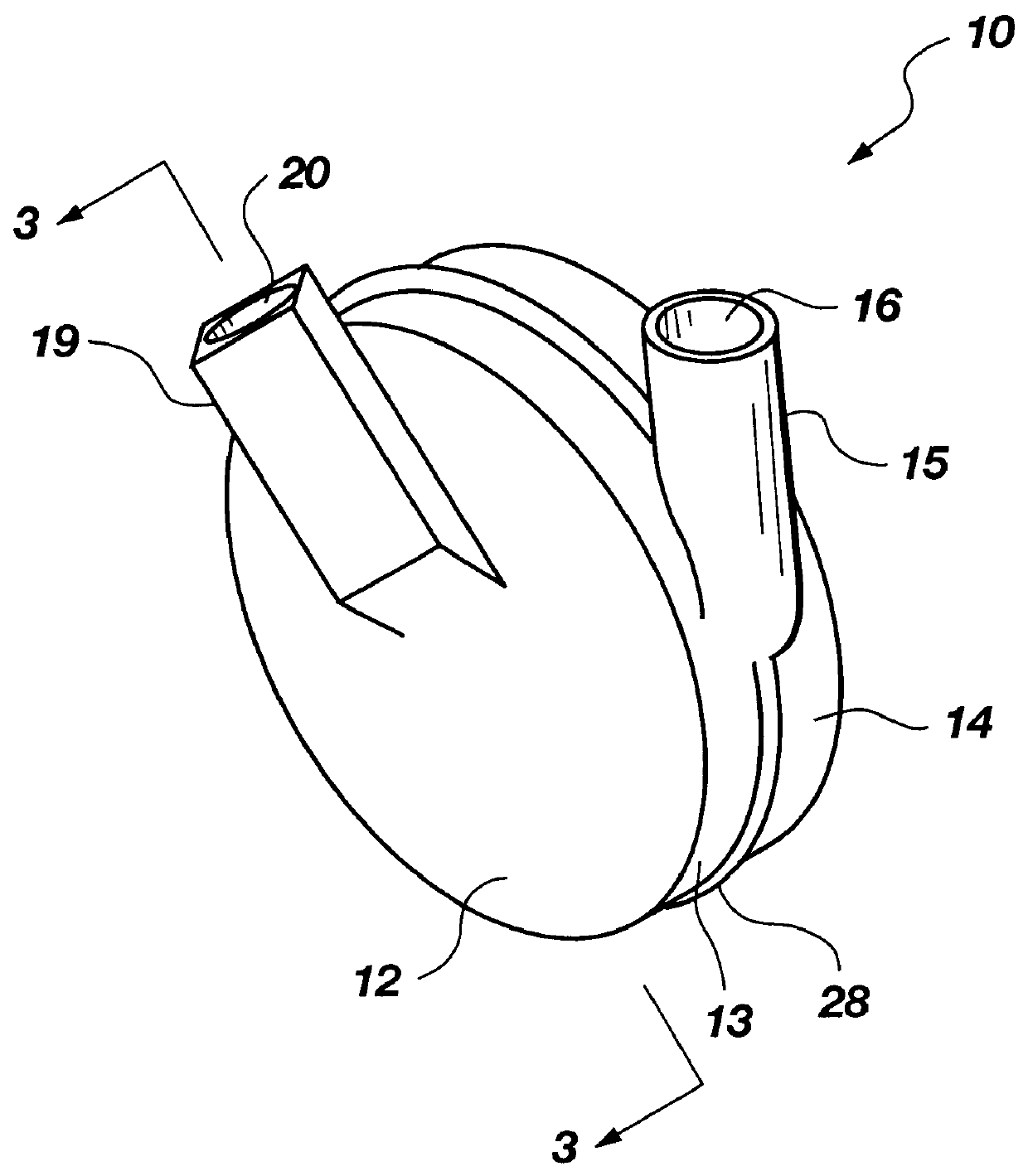

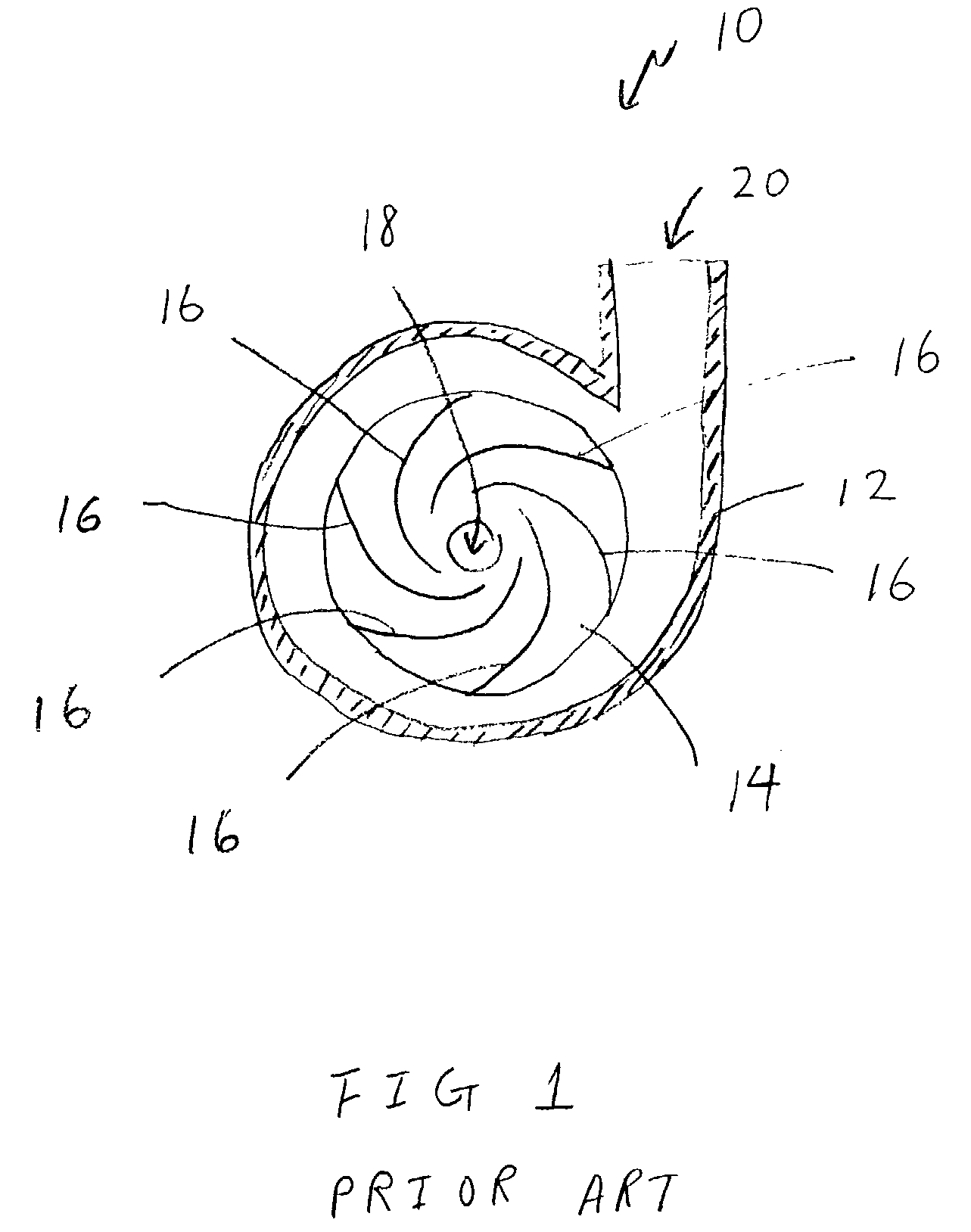

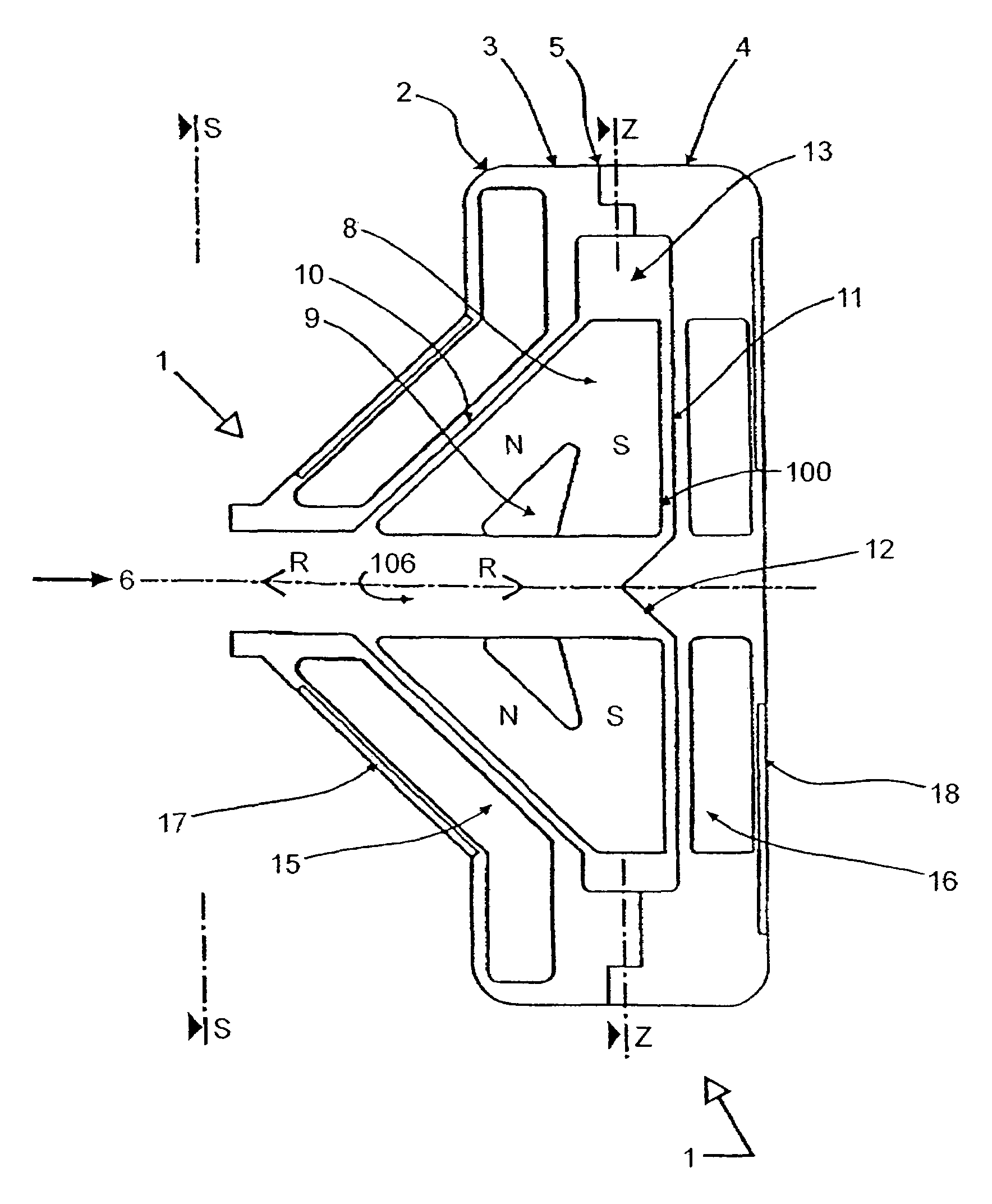

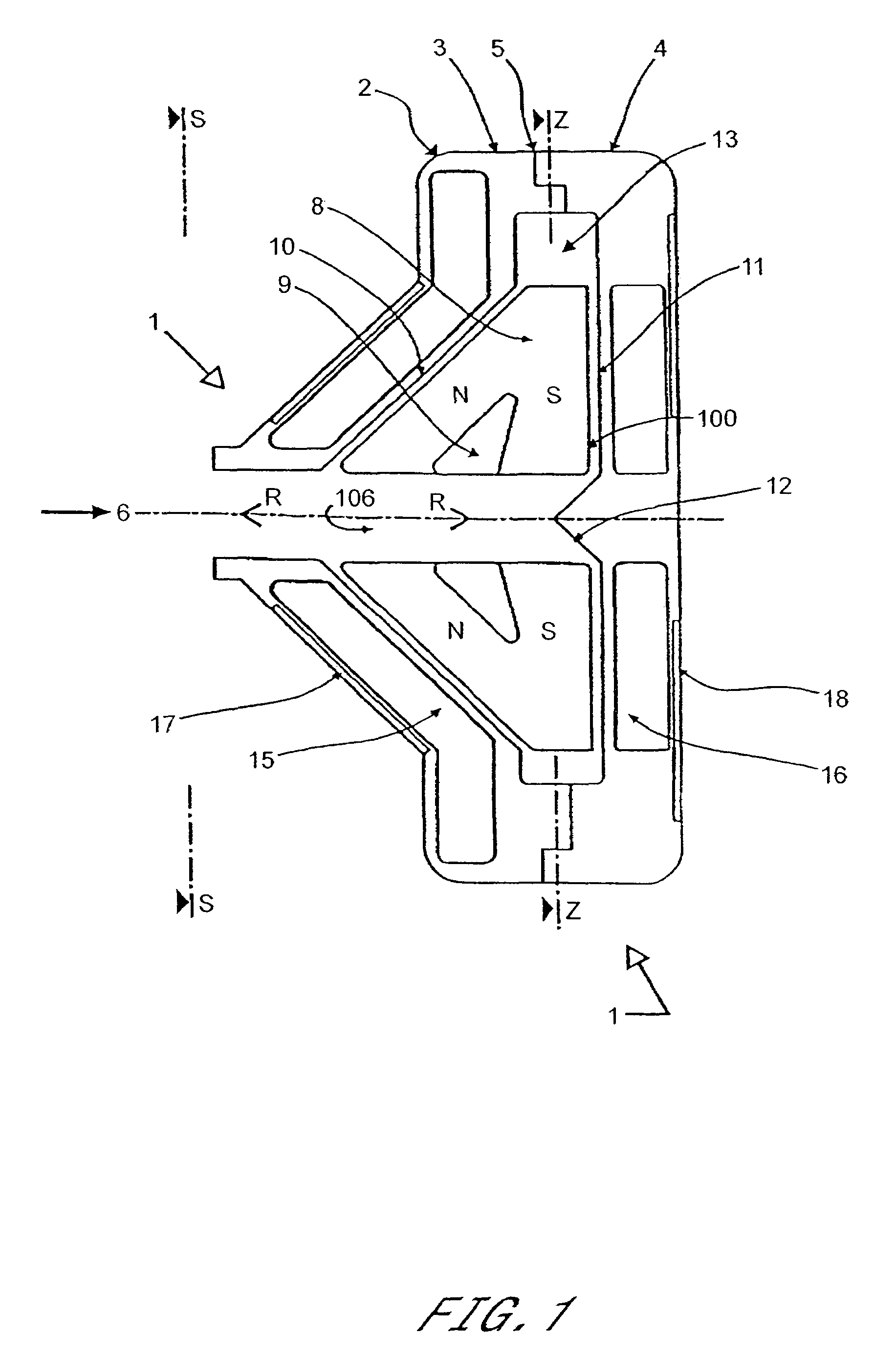

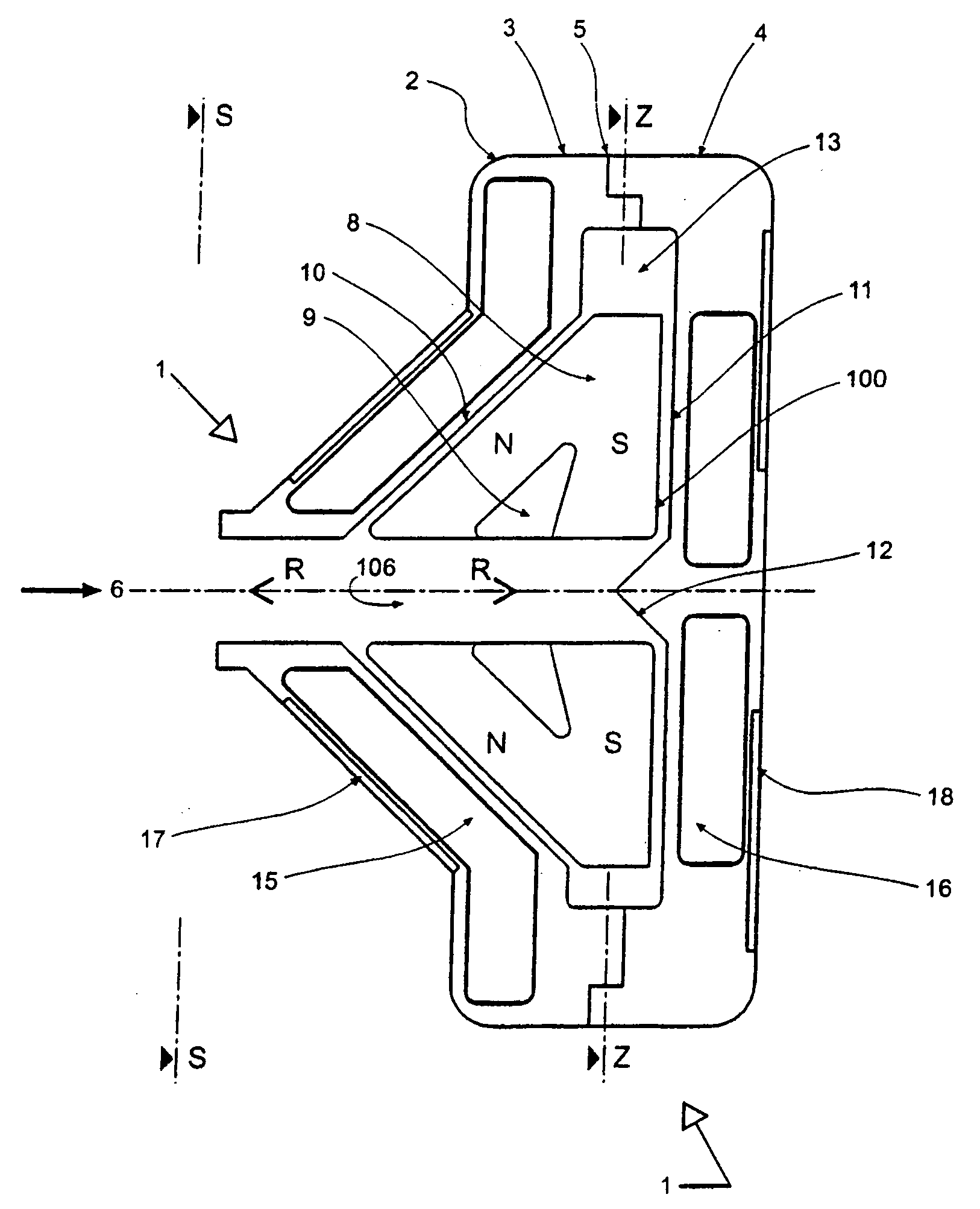

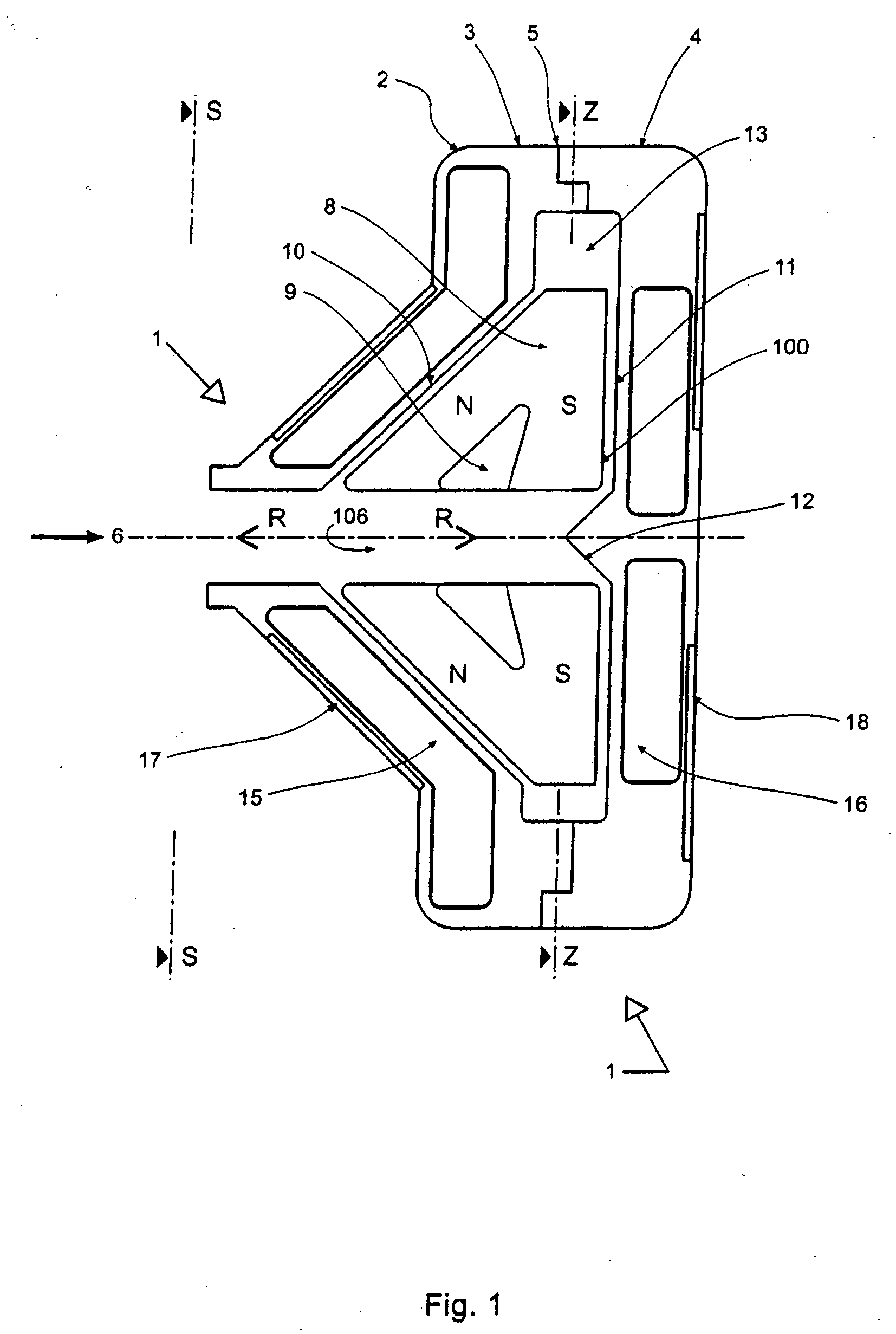

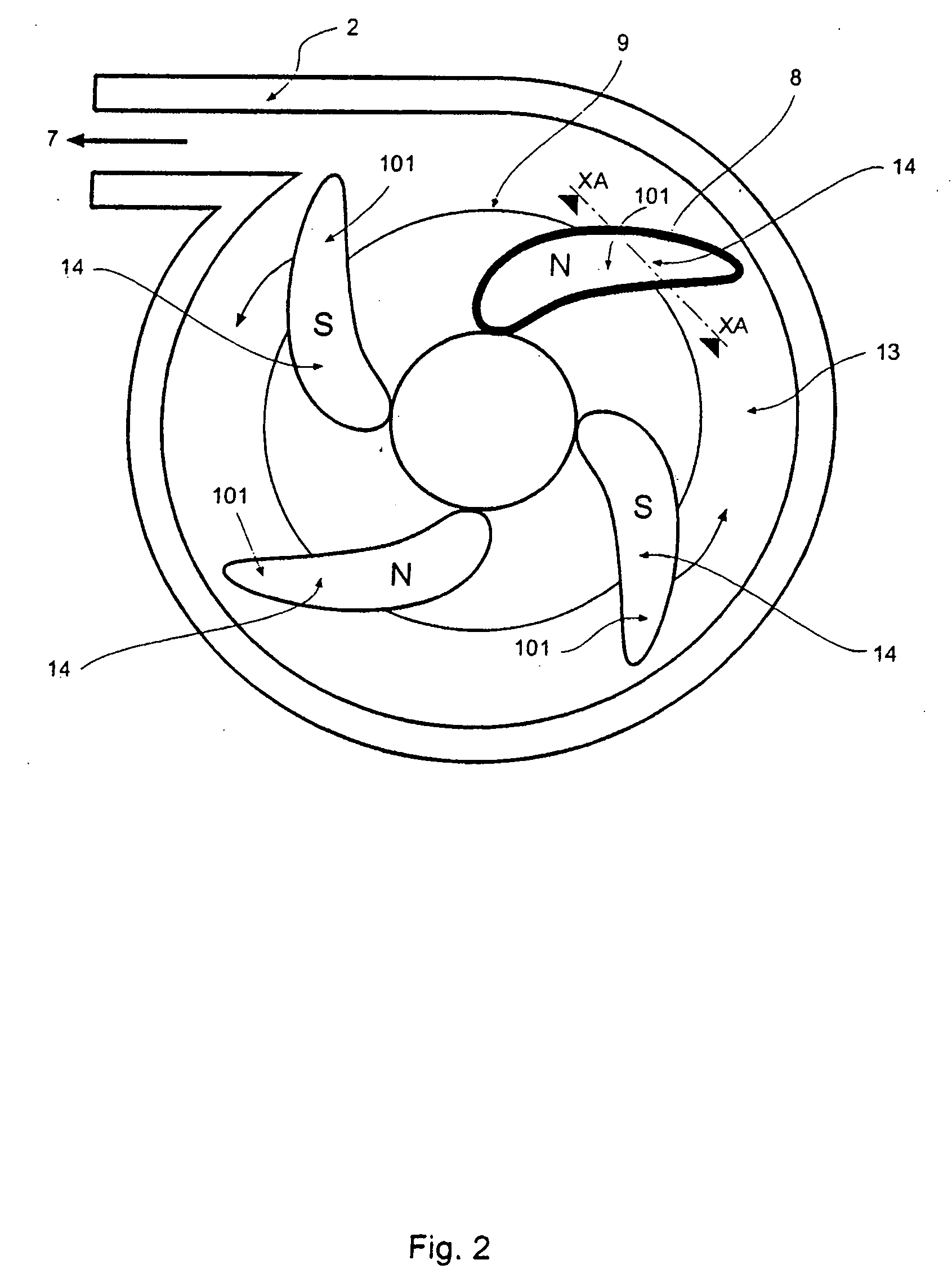

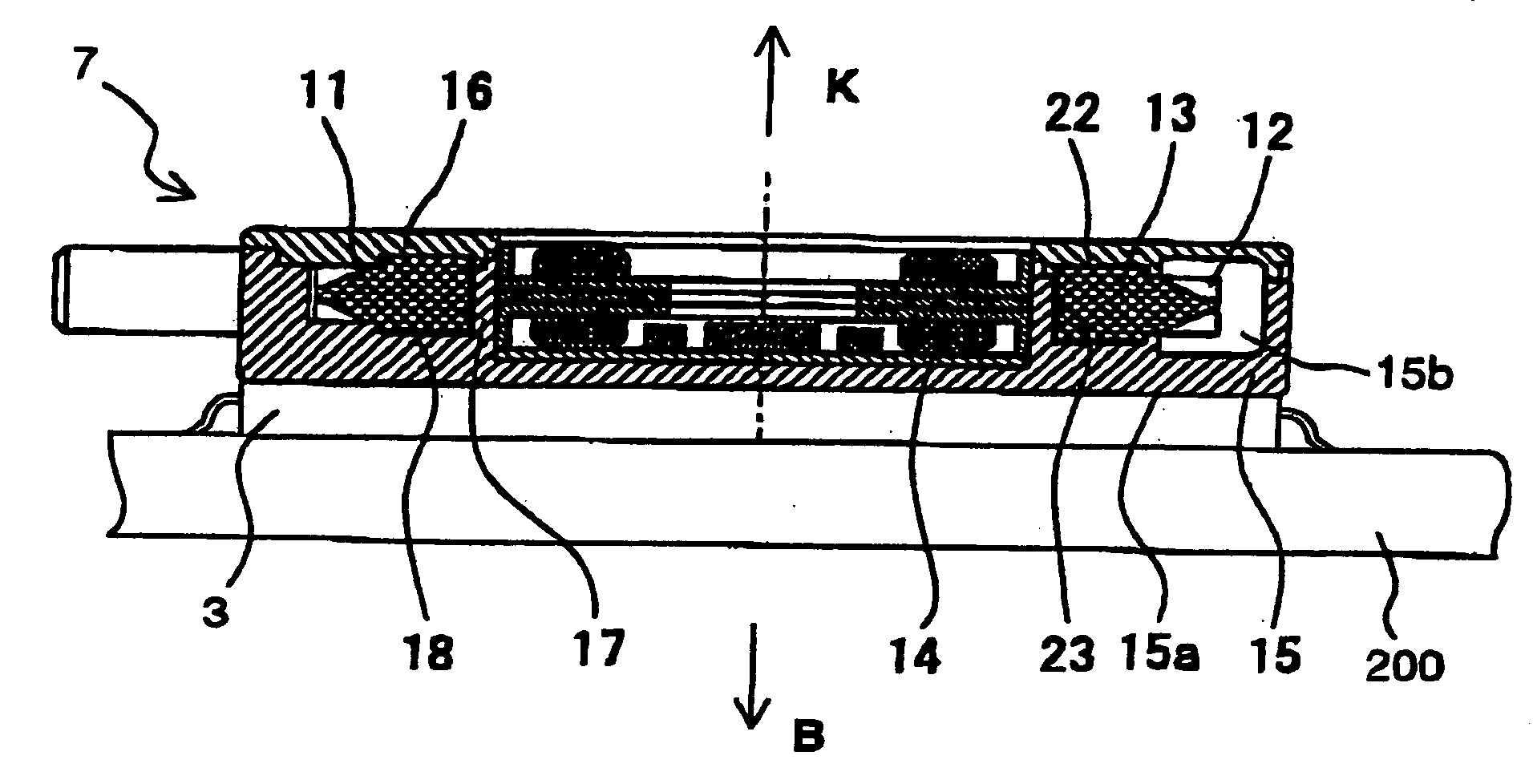

Rotary pump with exclusively hydrodynamically suspended impeller

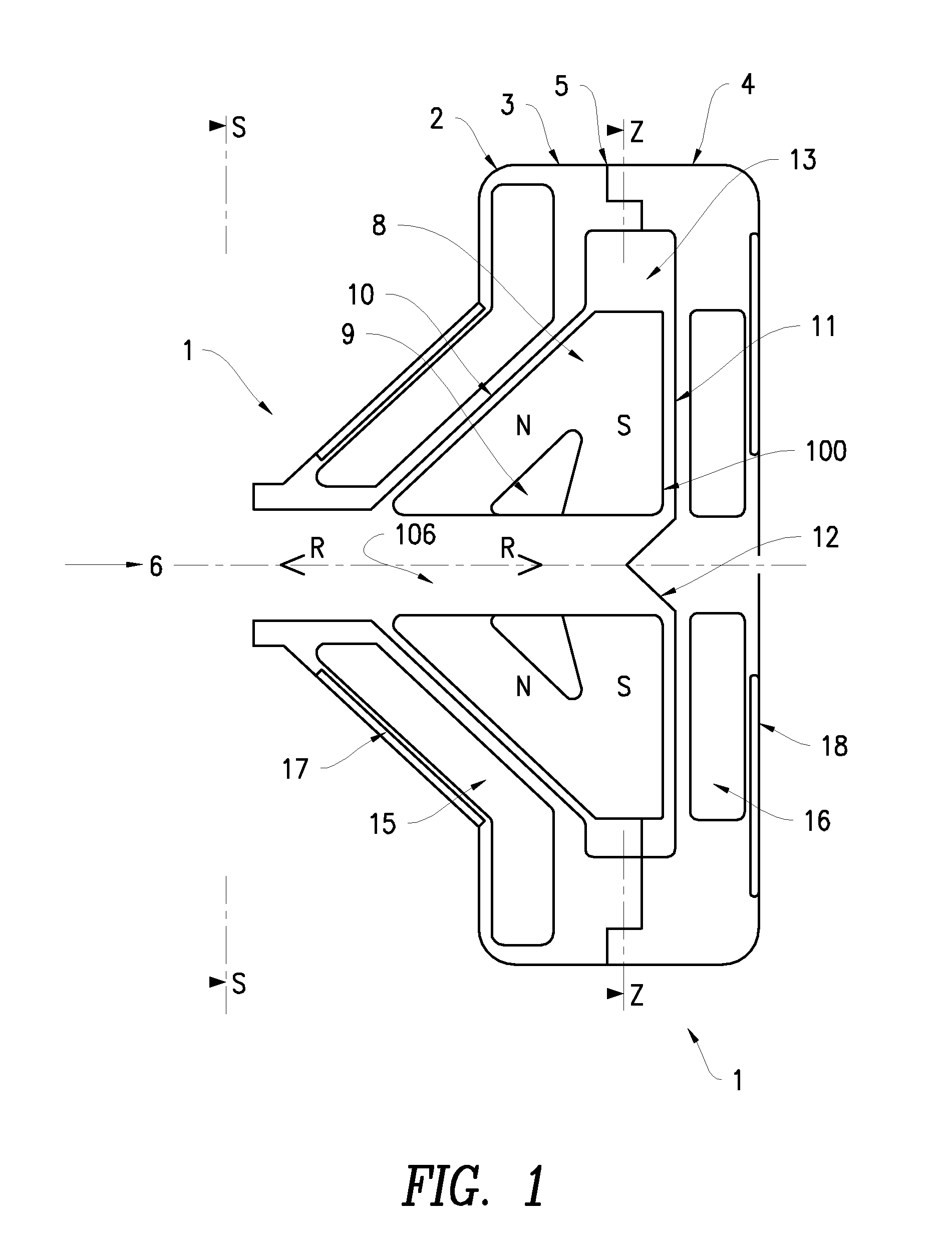

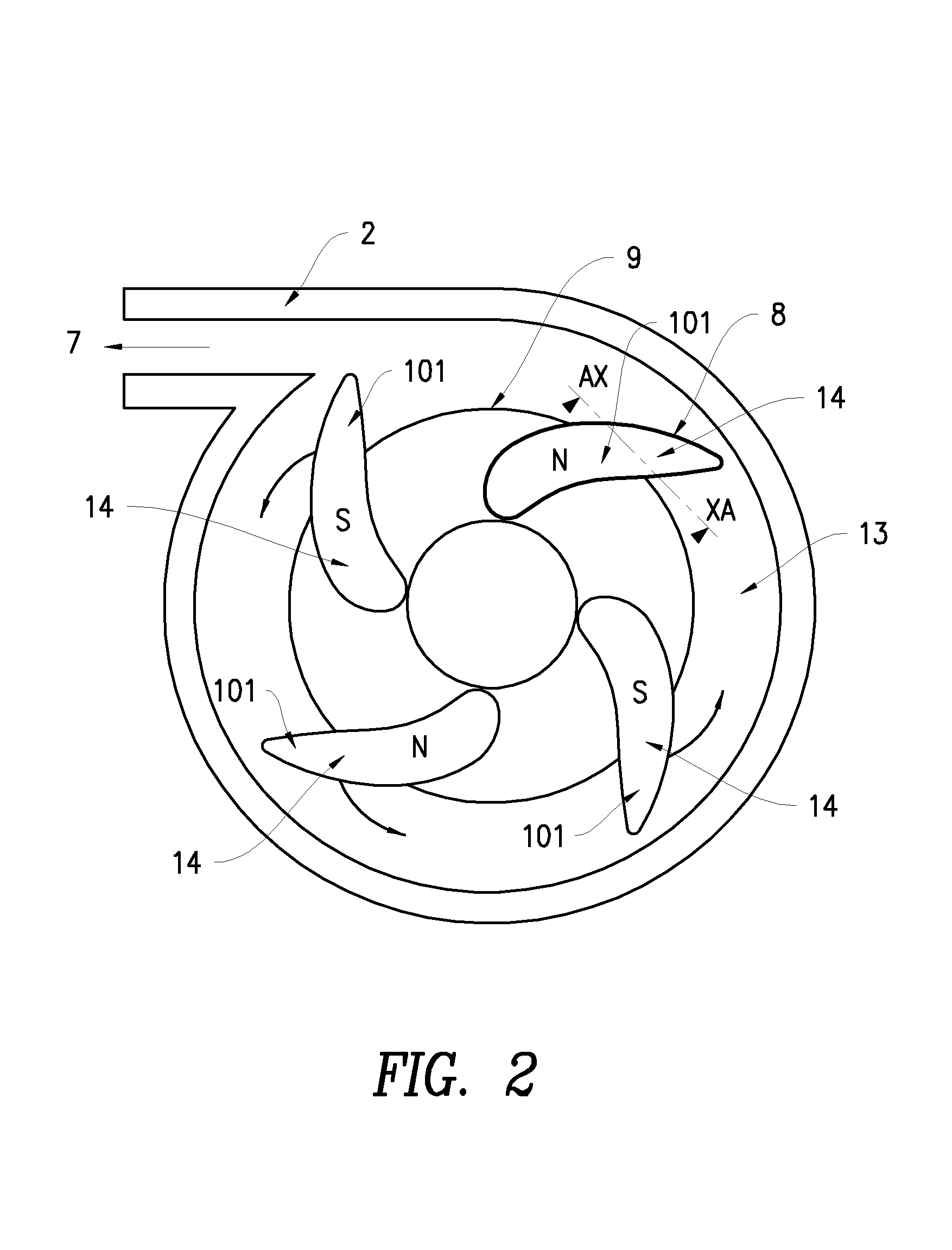

A pump assembly 1, 33, 200 adapted for continuous flow pumping of blood. In a particular form the pump 1, 200 is a centrifugal pump wherein the impeller 100, 204 is entirely sealed within the pump housing 2, 201 and is exclusively hydrodynamically suspended therein as the impeller rotates within the fluid 105 urged by electromagnetic means external to the pump cavity 106, 203. Hydrodynamic suspension is assisted by the impeller 100, 204 having deformities therein such as blades 8 with surfaces tapered from the leading edges 102, 223 to the trailing edges 103, 224 of bottom and top edges 221, 222 thereof.

Owner:TC1 LLC +2

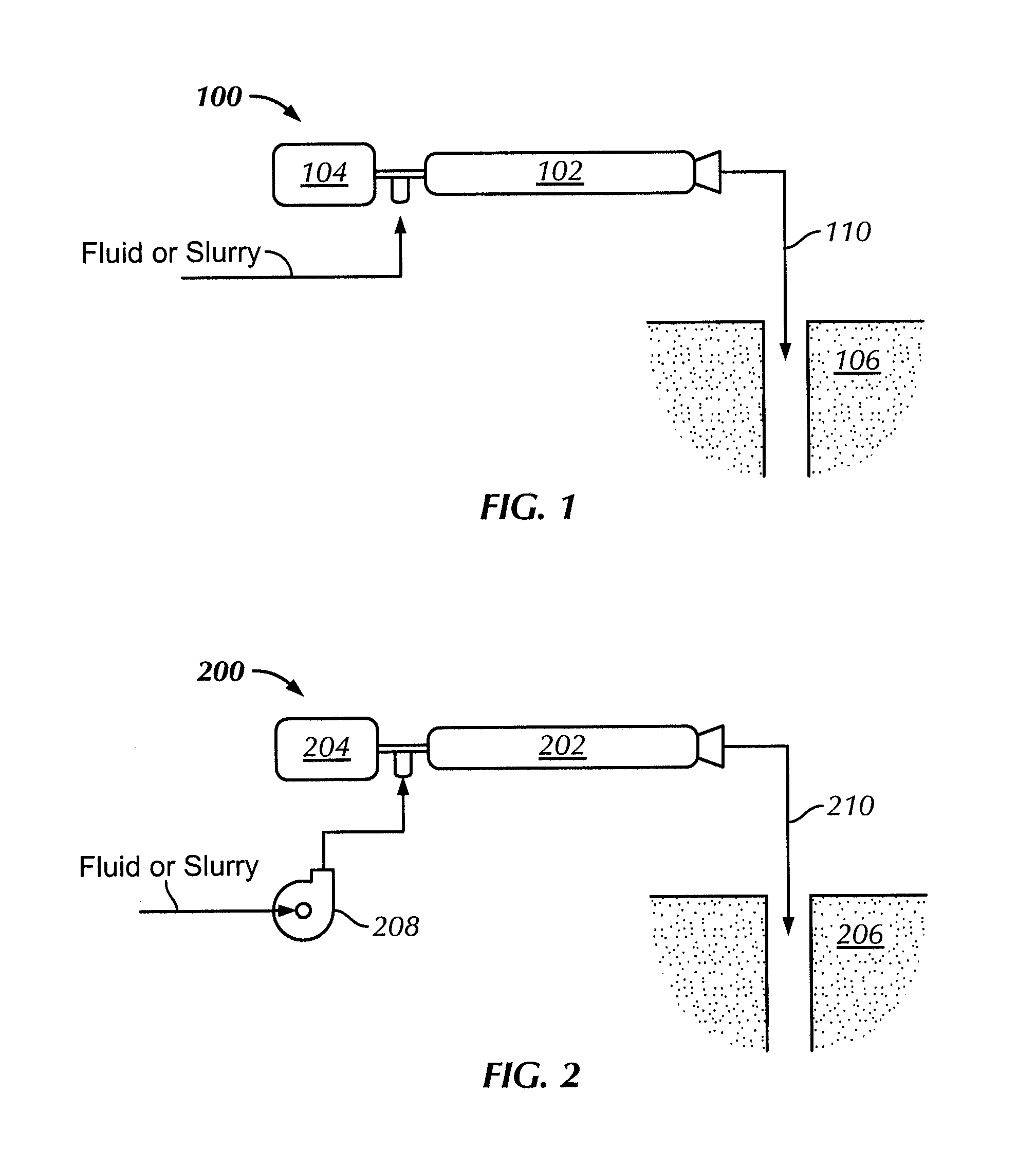

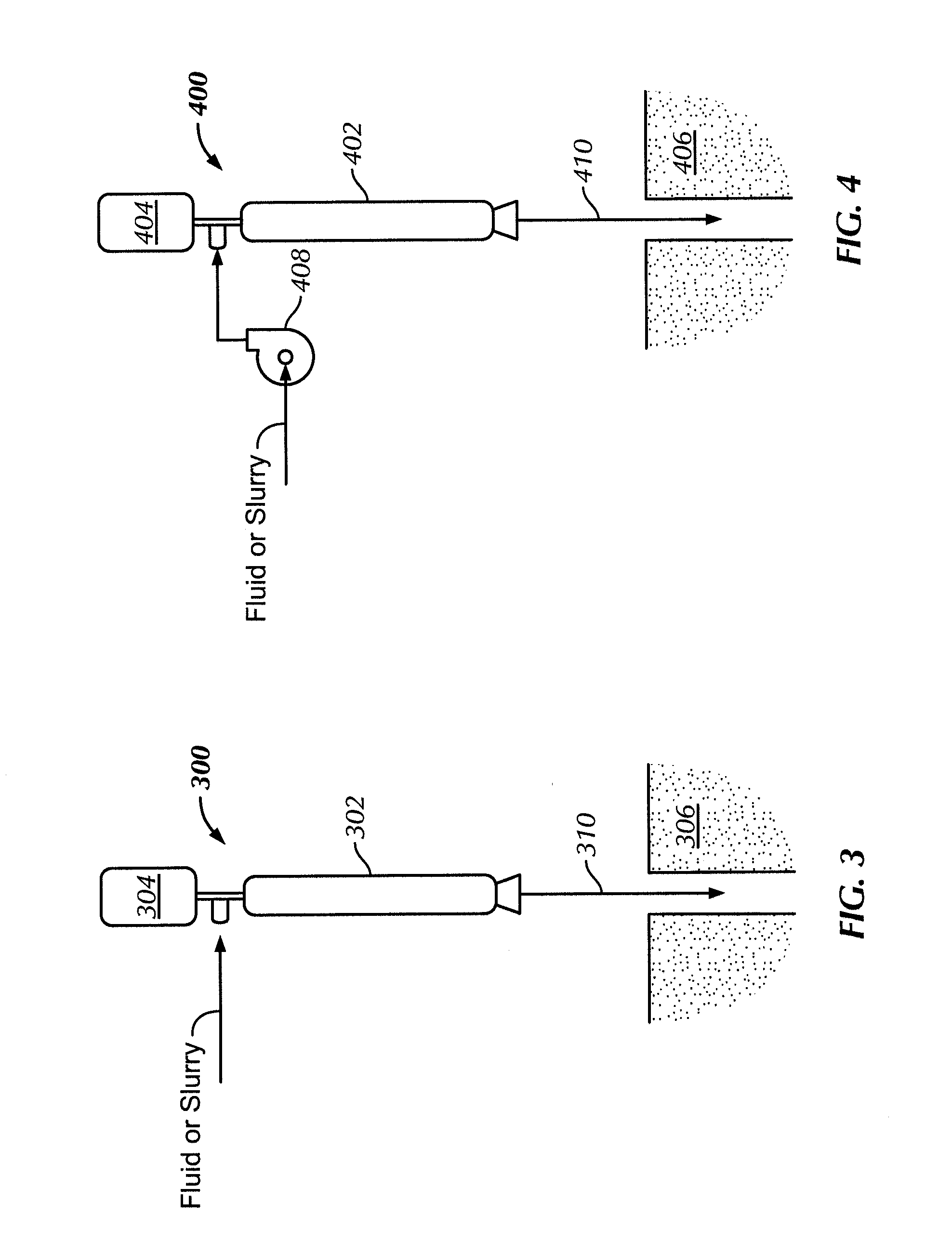

Method and system for injection of viscous unweighted, low-weighted, or solids contaminated fluids downhole during oilfield injection process

A system for injecting a fluid into a formation including a fluid, and at least one injection pump configured to receive the fluid, the at least one pump including a centrifugal pump having at least two stages configured to increase the pressure of the received fluid is disclosed. The system further includes a drive device coupled to the injection pump. A method of injecting a fluid downhole including providing a fluid to an injection pump, the injection pump including a centrifugal pump having at least two stages, pumping the fluid through the at least two stages of the centrifugal pump, thereby increasing the pressure of the fluid, and injecting the fluid from the injection pump into a wellbore is also disclosed.

Owner:MI

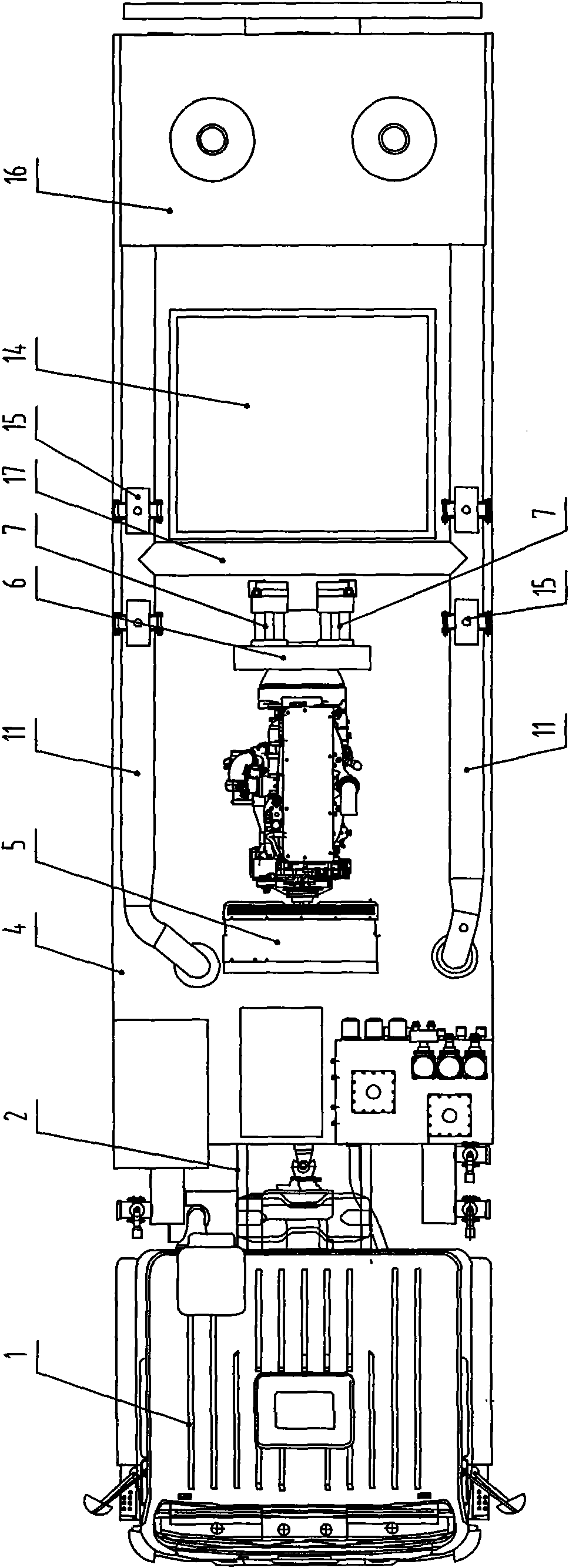

Liquid supply vehicle

ActiveCN101885307ALower suction heightImprove inhalation performanceFluid removalItem transportation vehiclesVehicle frameSewage

The invention discloses a liquid supply vehicle, which comprises a frame with a cab. The lower part of the frame is provided with wheels, the rear upper part of the frame is provided with a bedplate, a power driving device is arranged on the bedplate, a centrifugal pump is arranged below the bedplate, the power driving device is in transmission connection with the centrifugal pump, and an inlet and an outlet of the centrifugal pump are connected with a suction pipe and a discharge pipe respectively. The liquid supply vehicle has the advantages of improving the self-sucking effect of a fracturing truck, improving the operation efficiency of the fracturing truck and shortening the operation time, along with reasonable design, simple structure, easy assembly and manufacture, and also can be used for liquid delivery in other industries of flood drainage, sewage clearing and the like.

Owner:ZYT GASOLINEEUM EQUIP

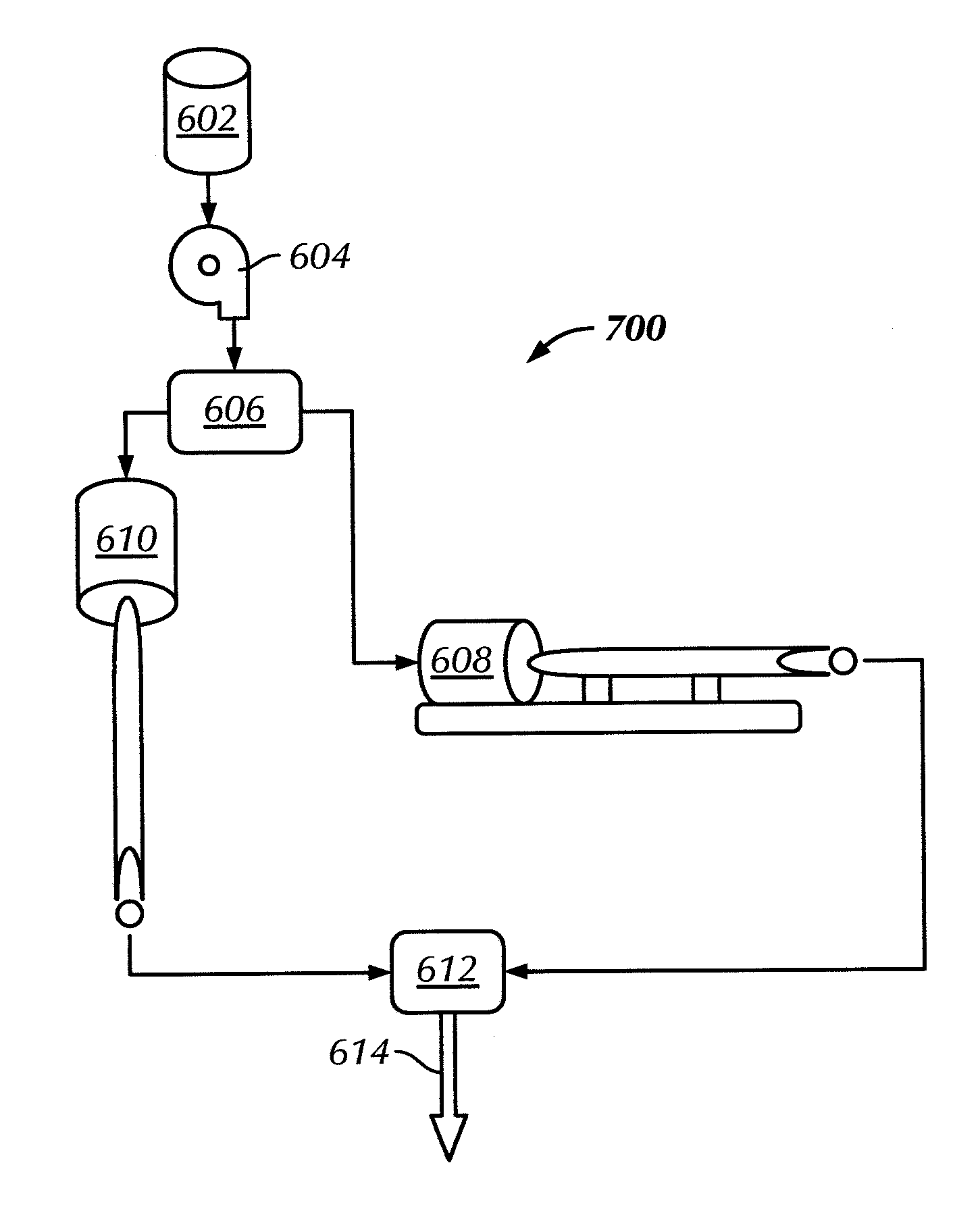

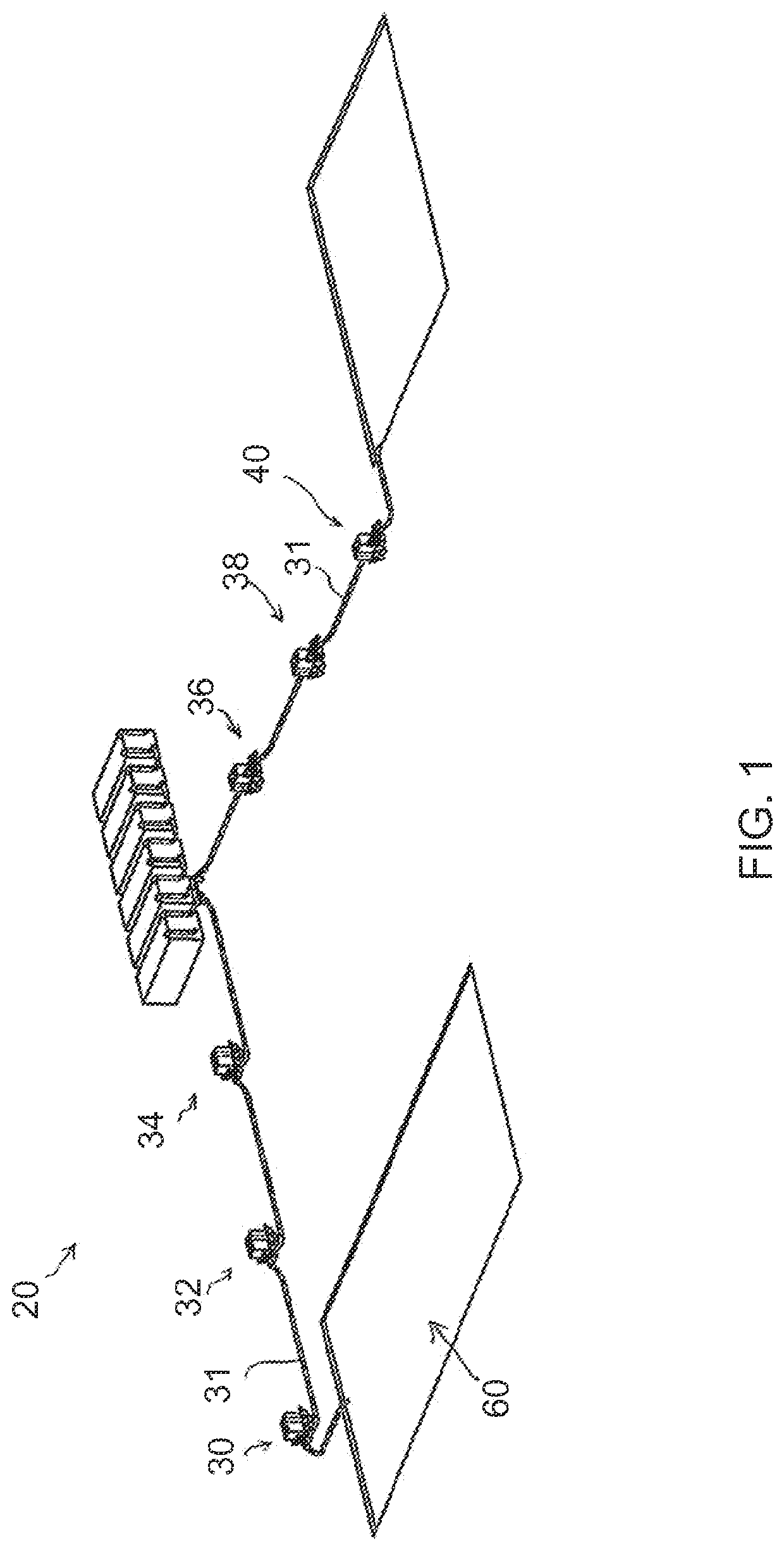

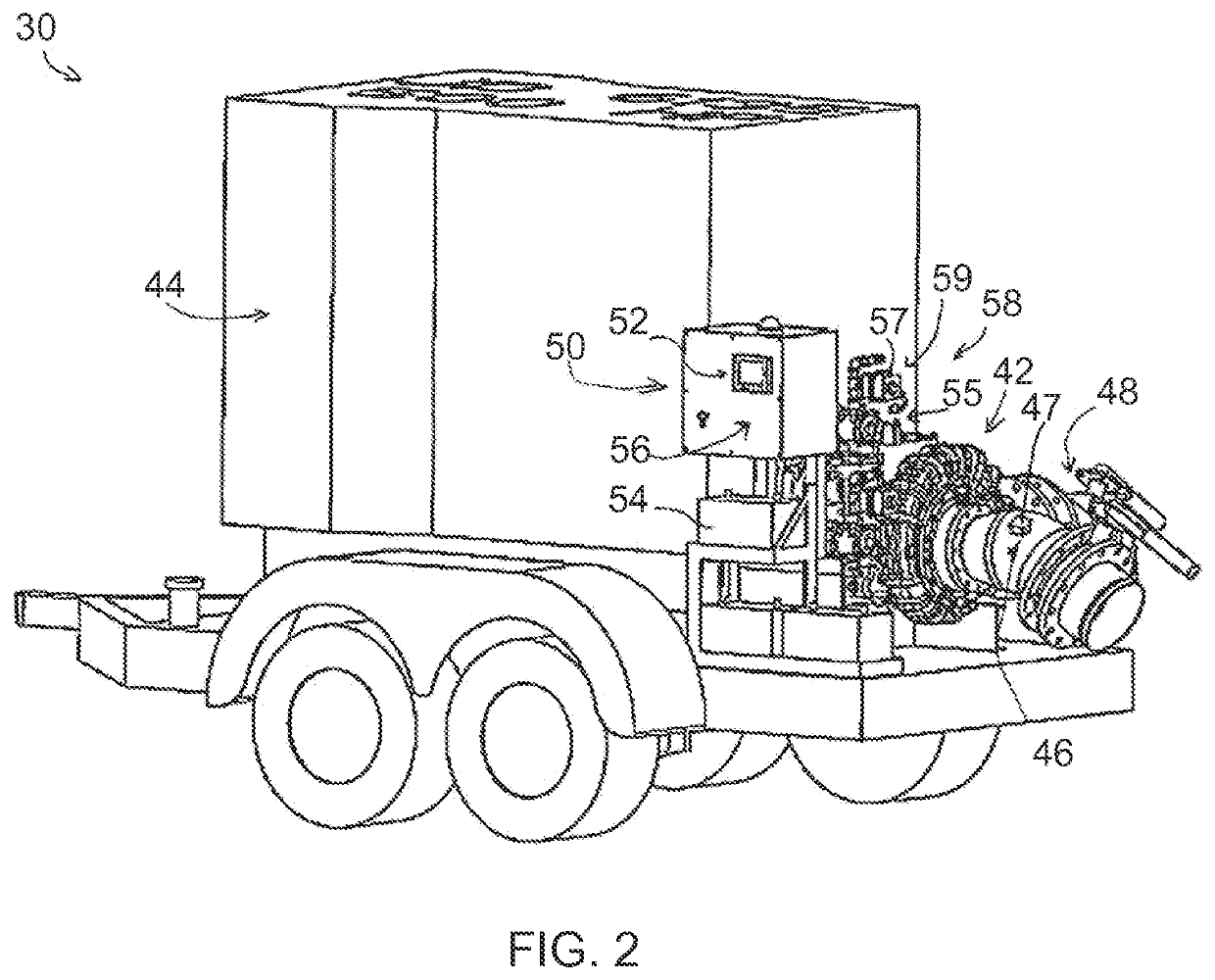

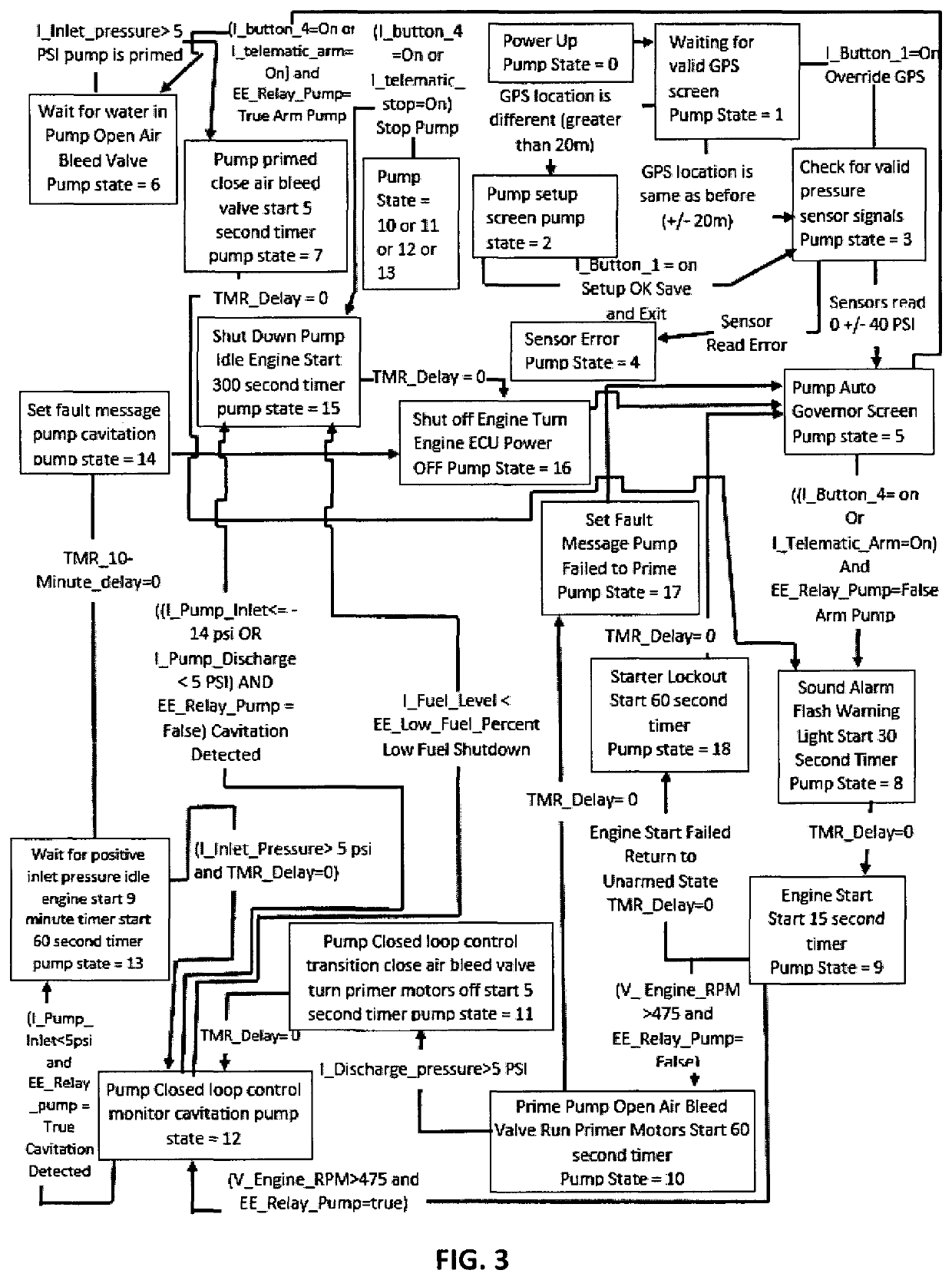

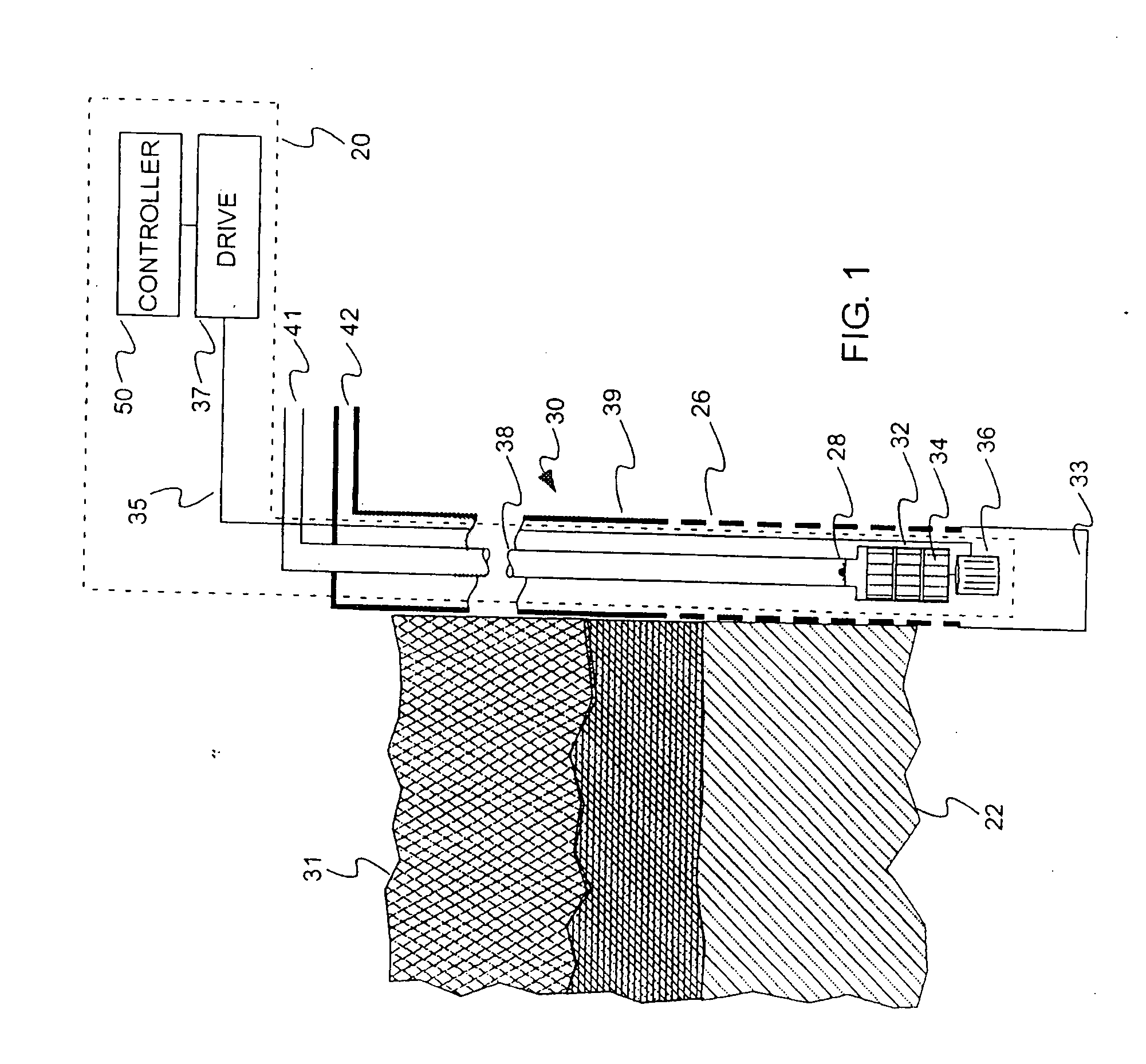

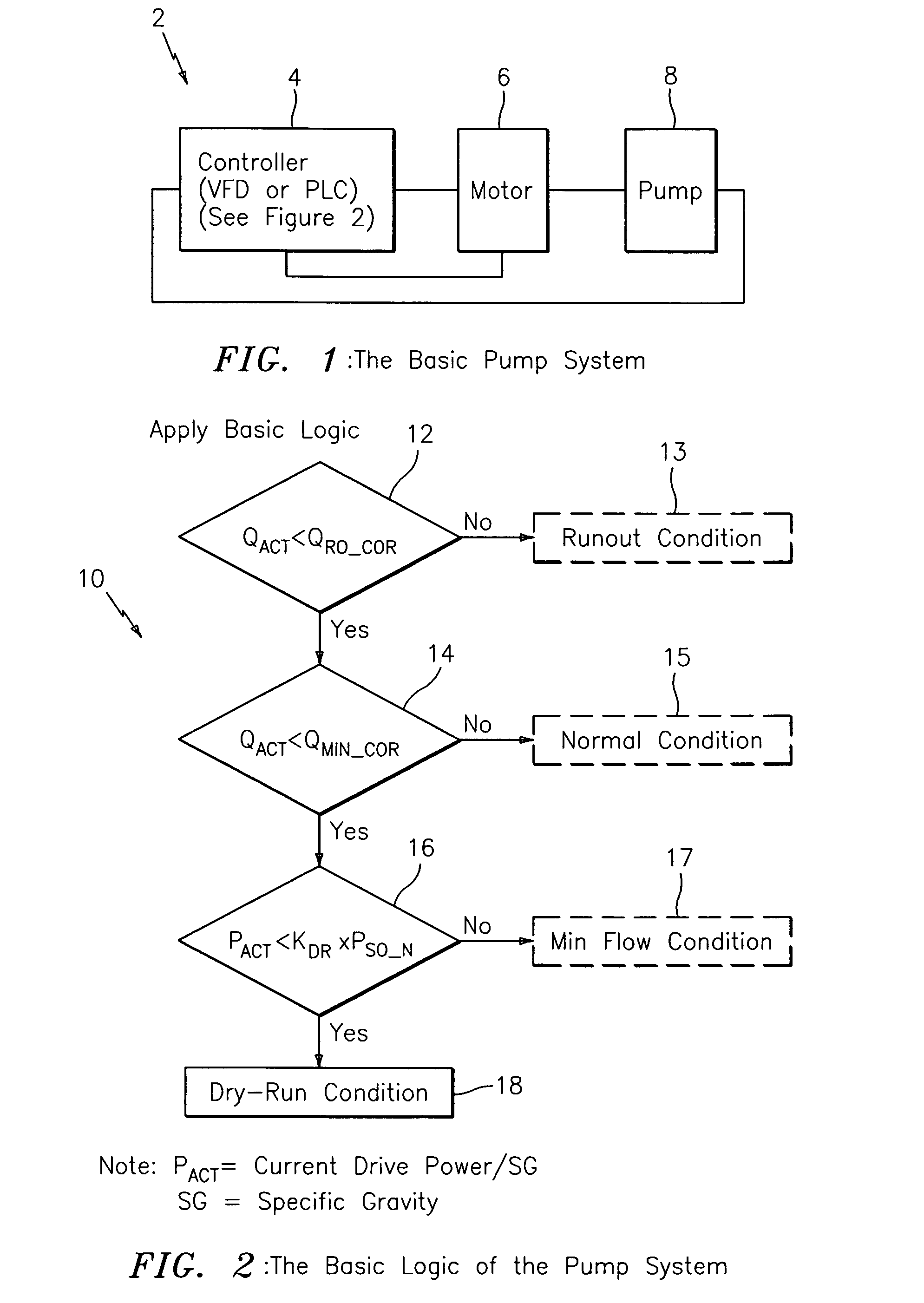

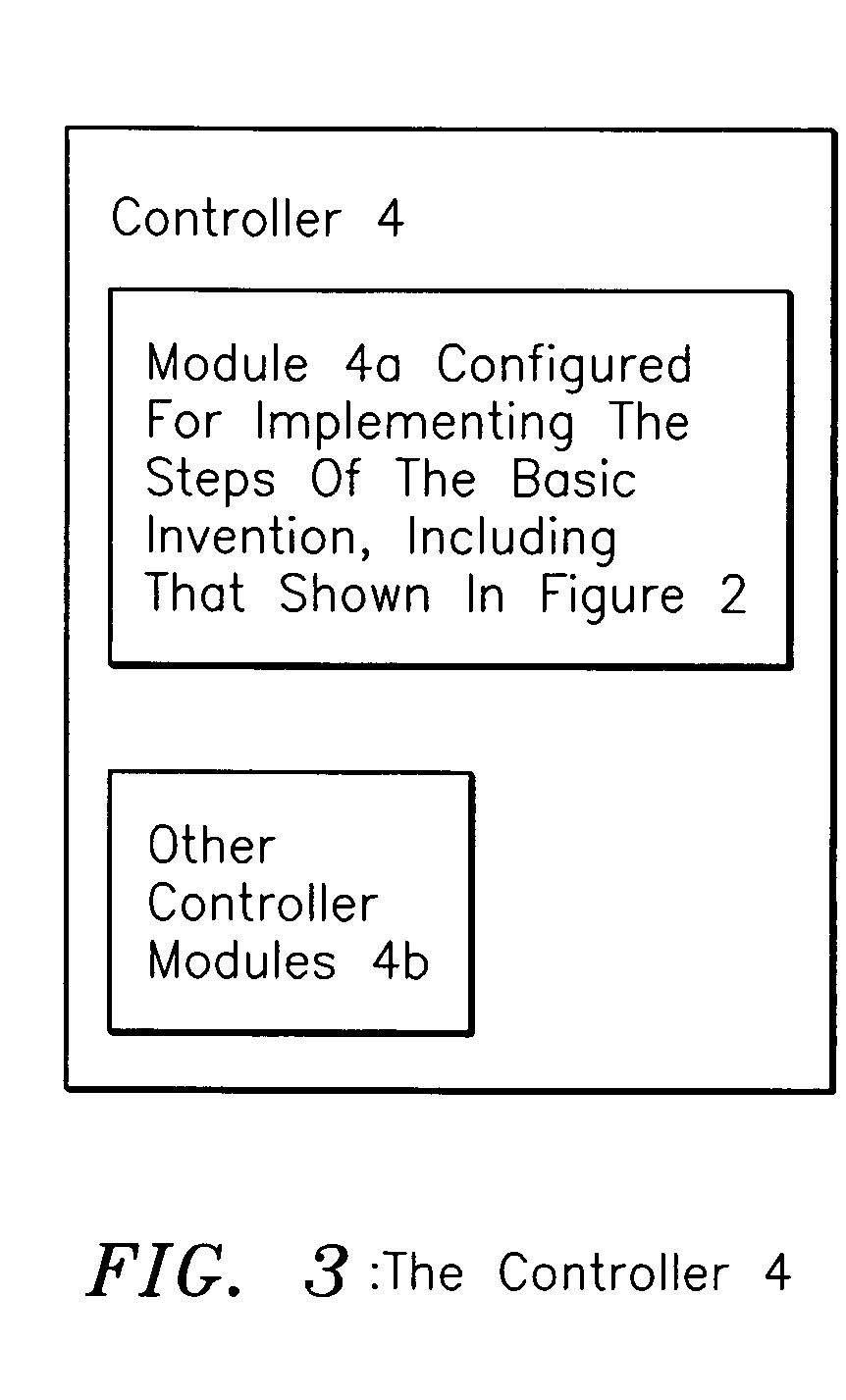

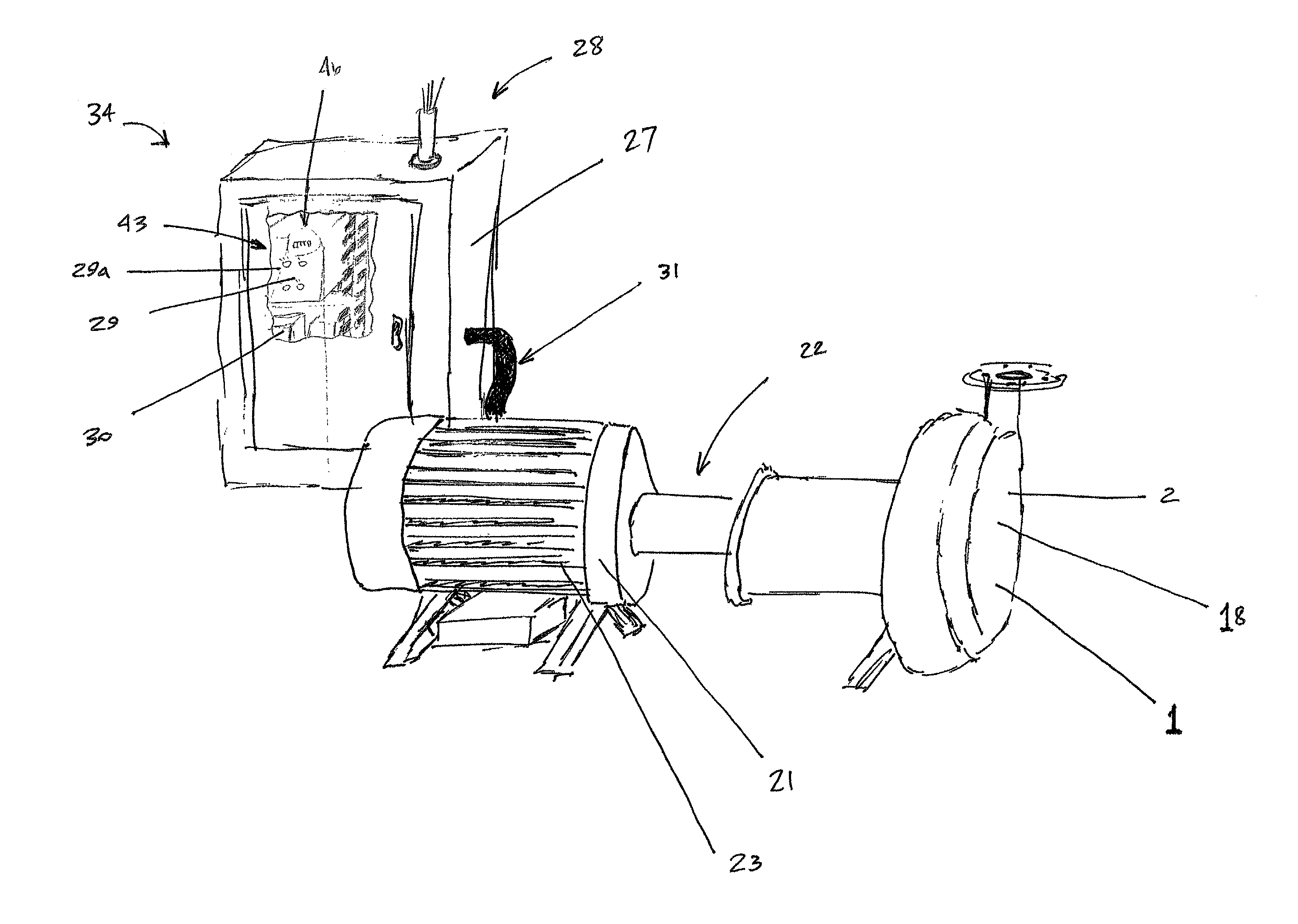

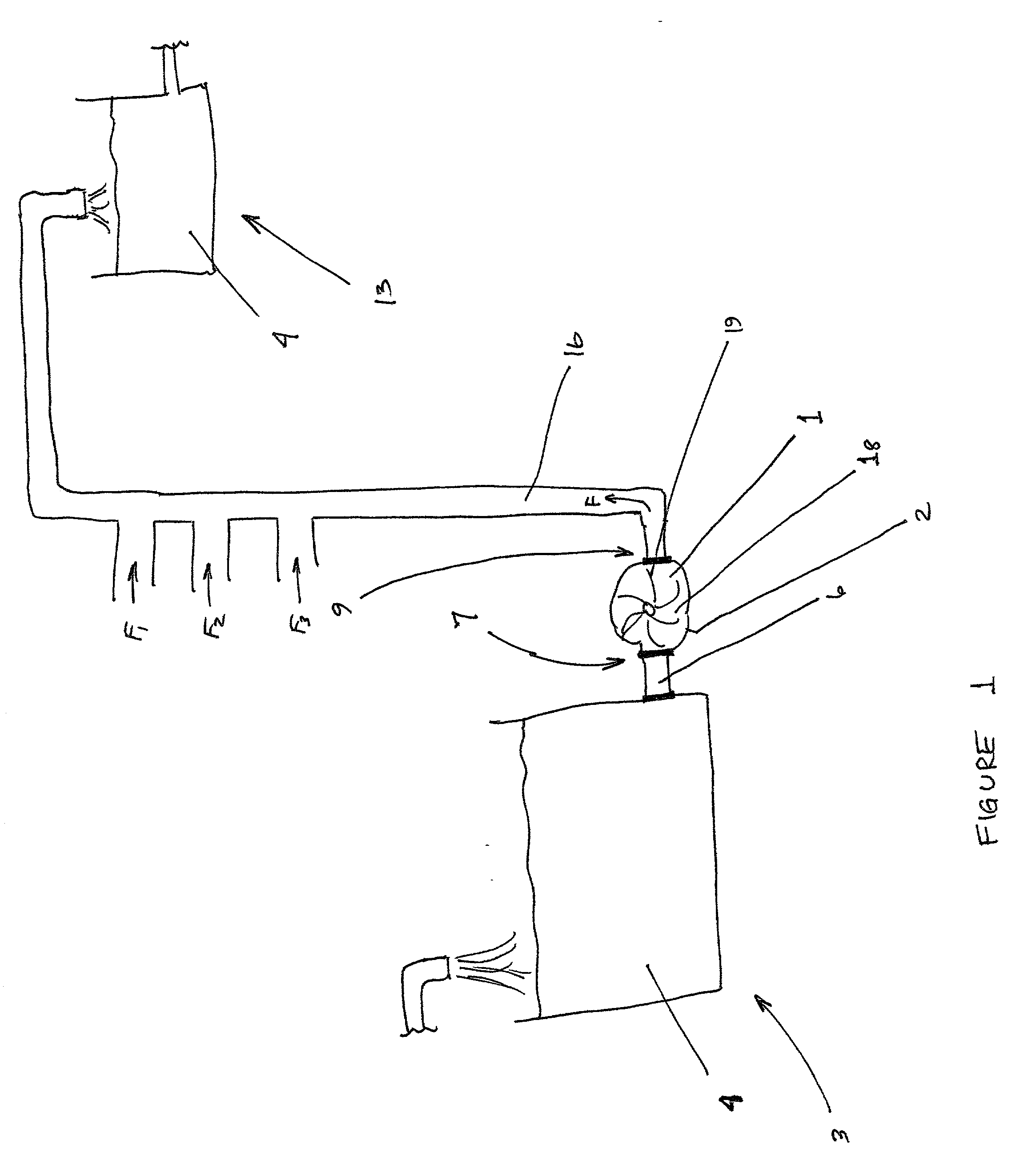

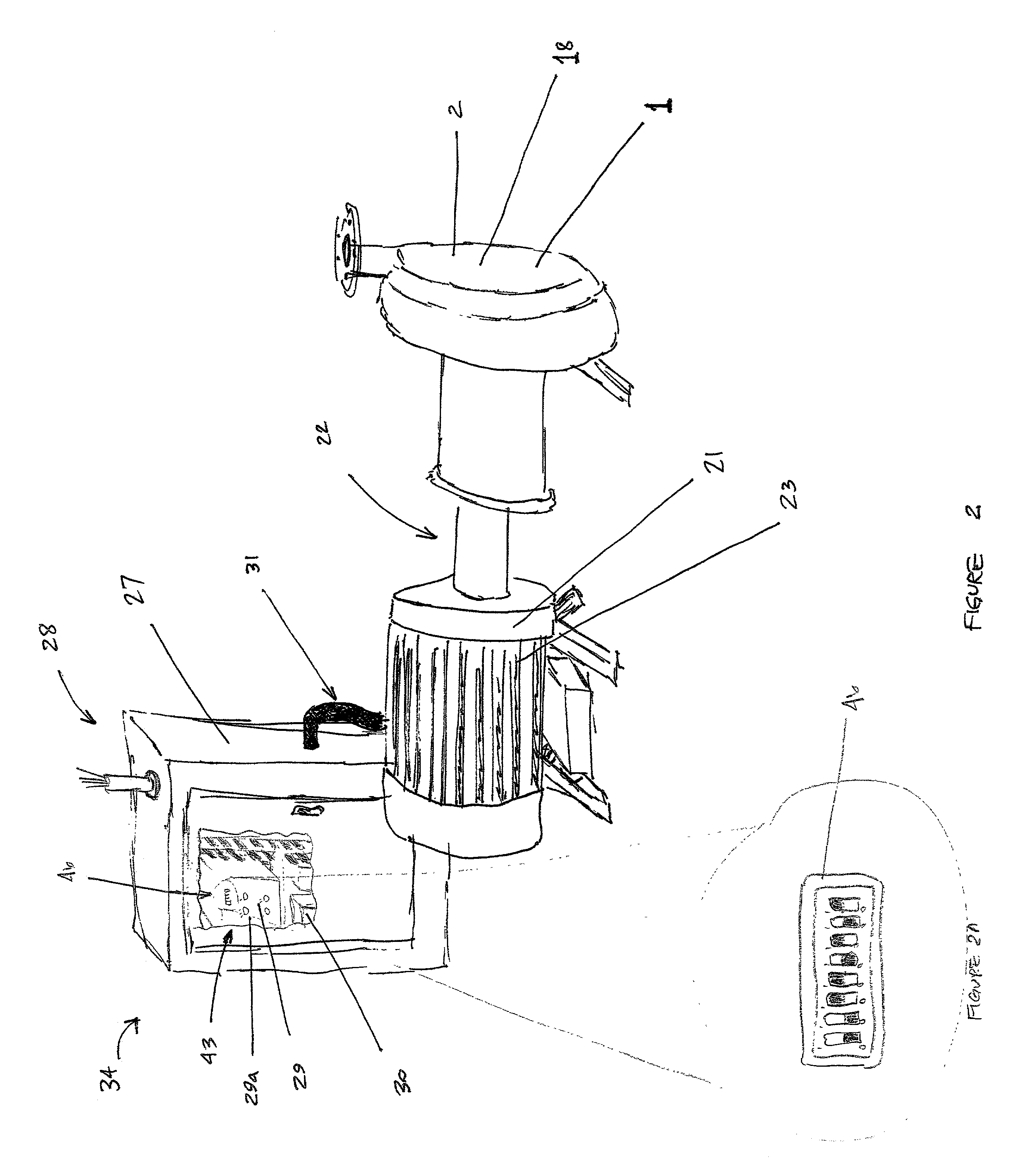

Pumping facilities and control systems

ActiveUS10711787B1Optimize fuel costEasy to operatePump componentsPump controlControl systemEngineering

A portable pump facility, pump facilities systems, and system to monitor and control a centrifugal pump include a controller configured to receive pressure and speed data from a centrifugal pump and automatically adjust the speed of an engine which drives the pump to control cavitation of the pump and to also optimize load balancing of fluid among pumping facilities. Multiple pumping facilities are provided and communicate for efficient fluid delivery, and include remote control monitoring and operation.

Owner:W S DARLEY & CO

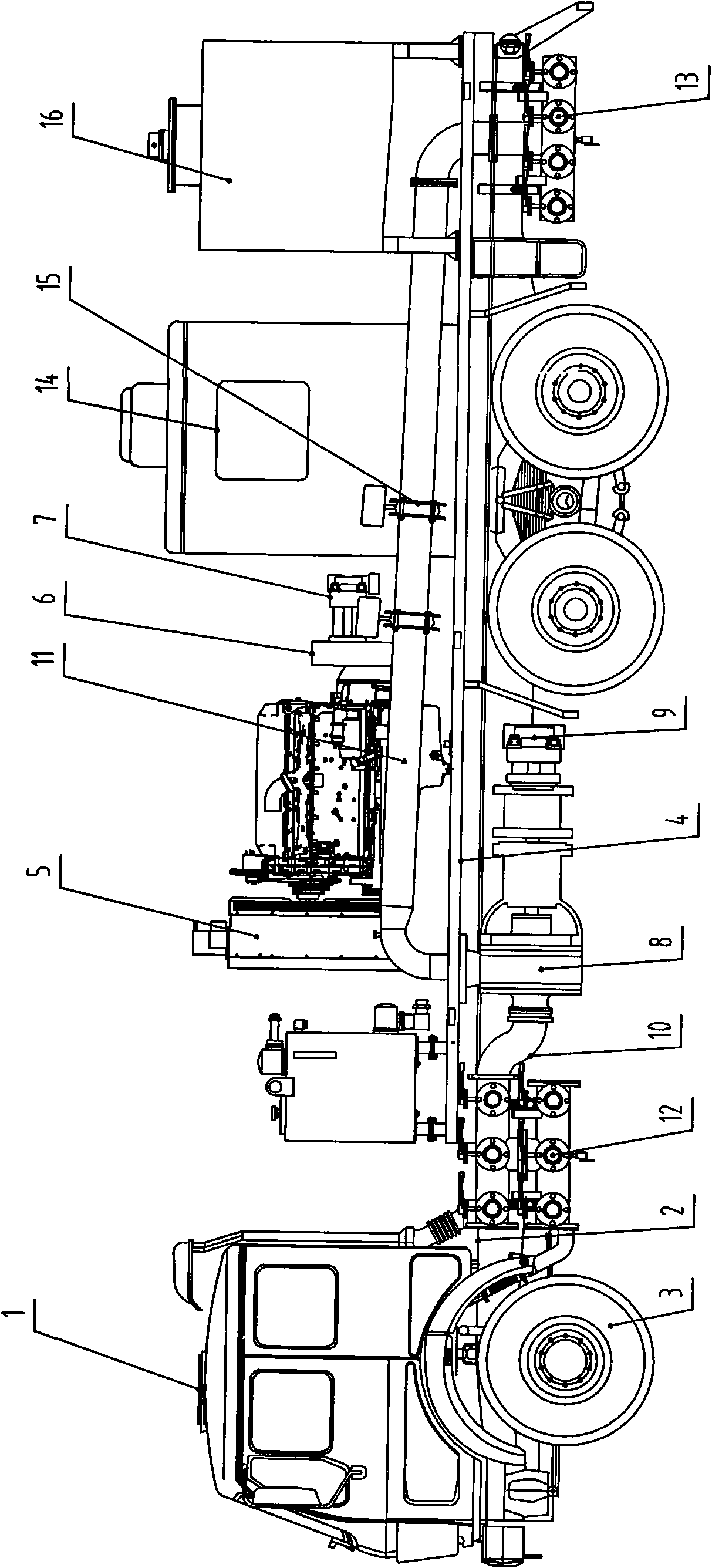

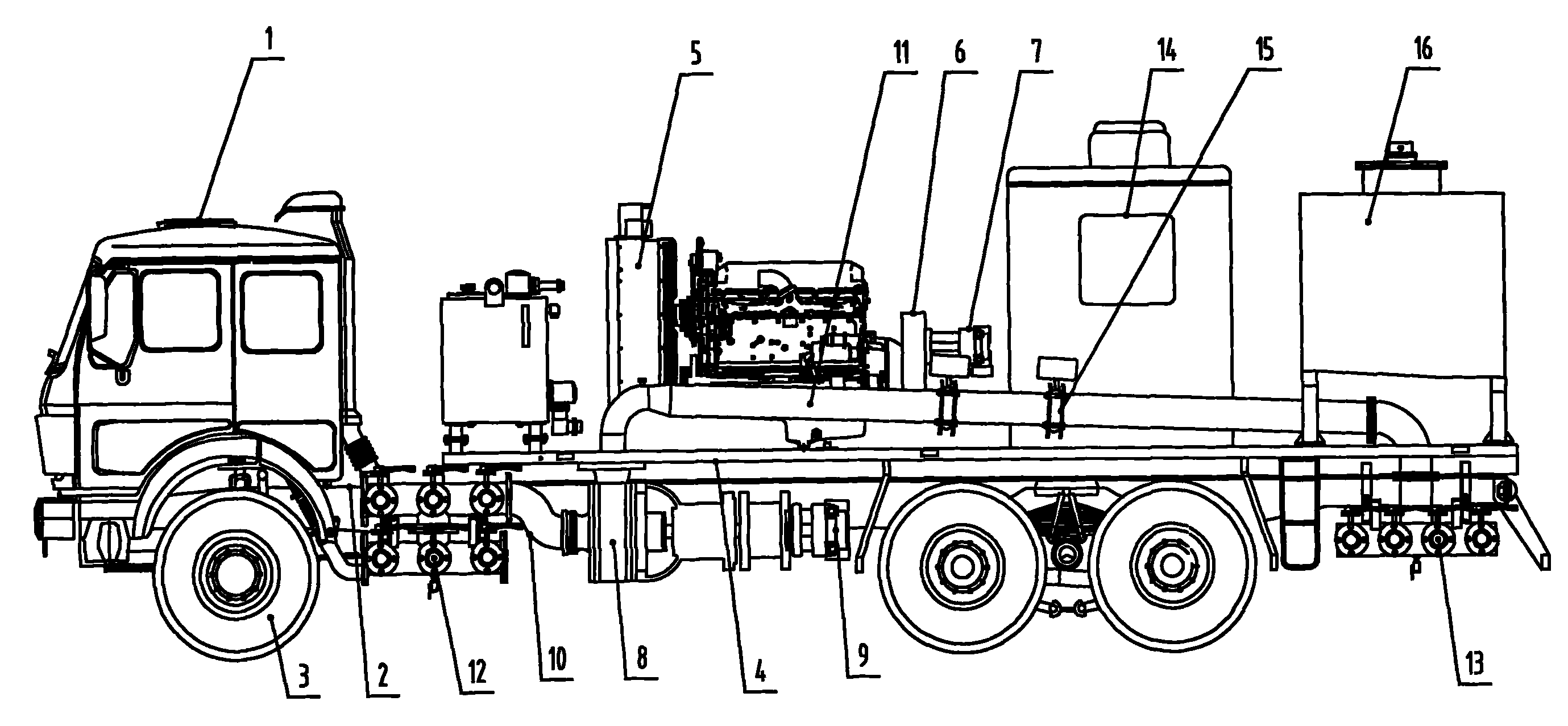

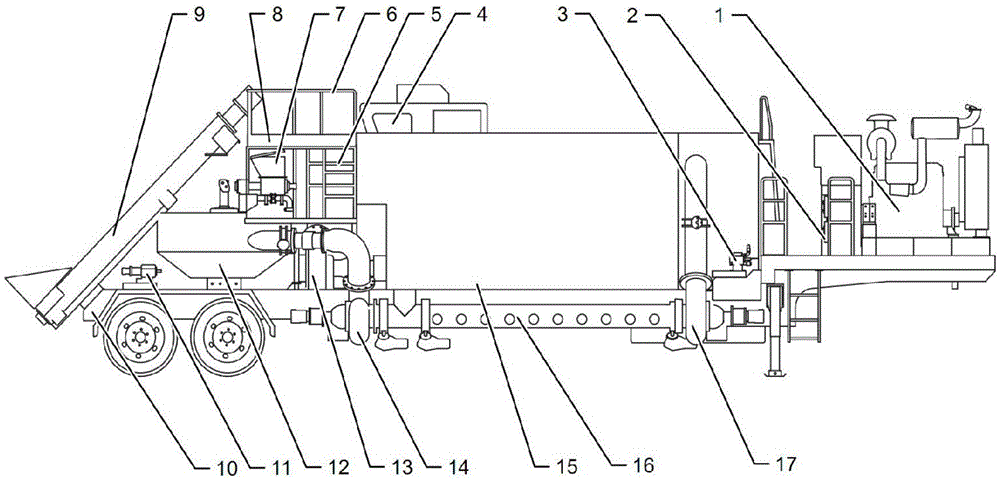

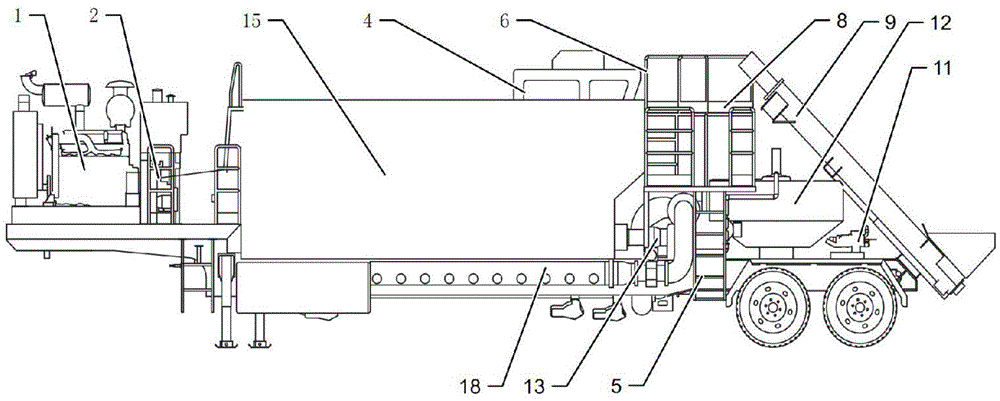

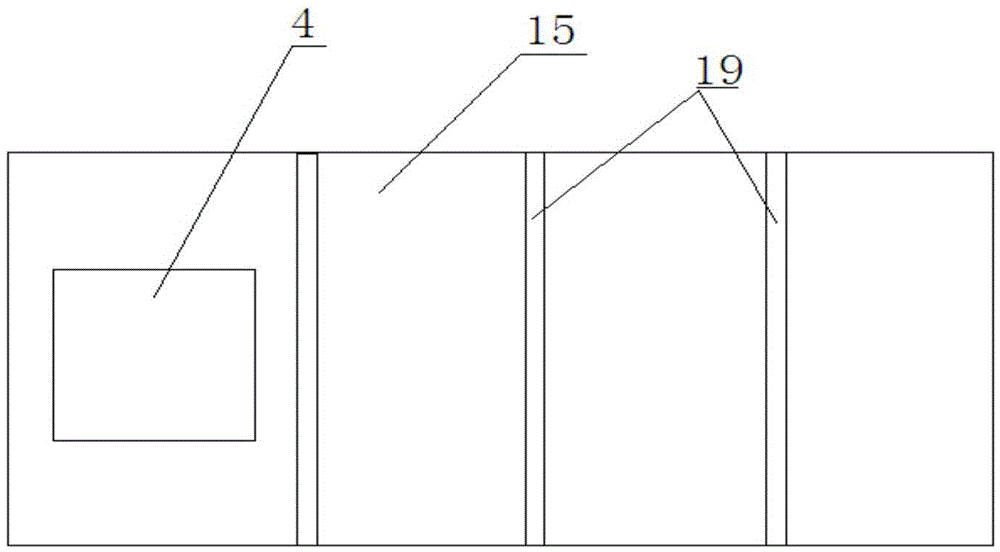

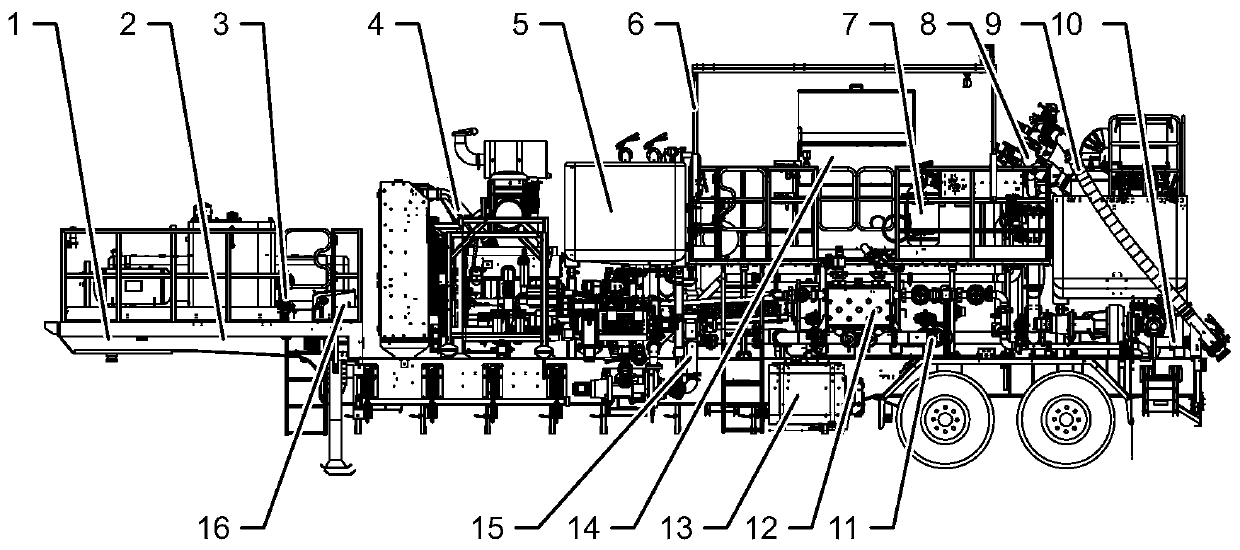

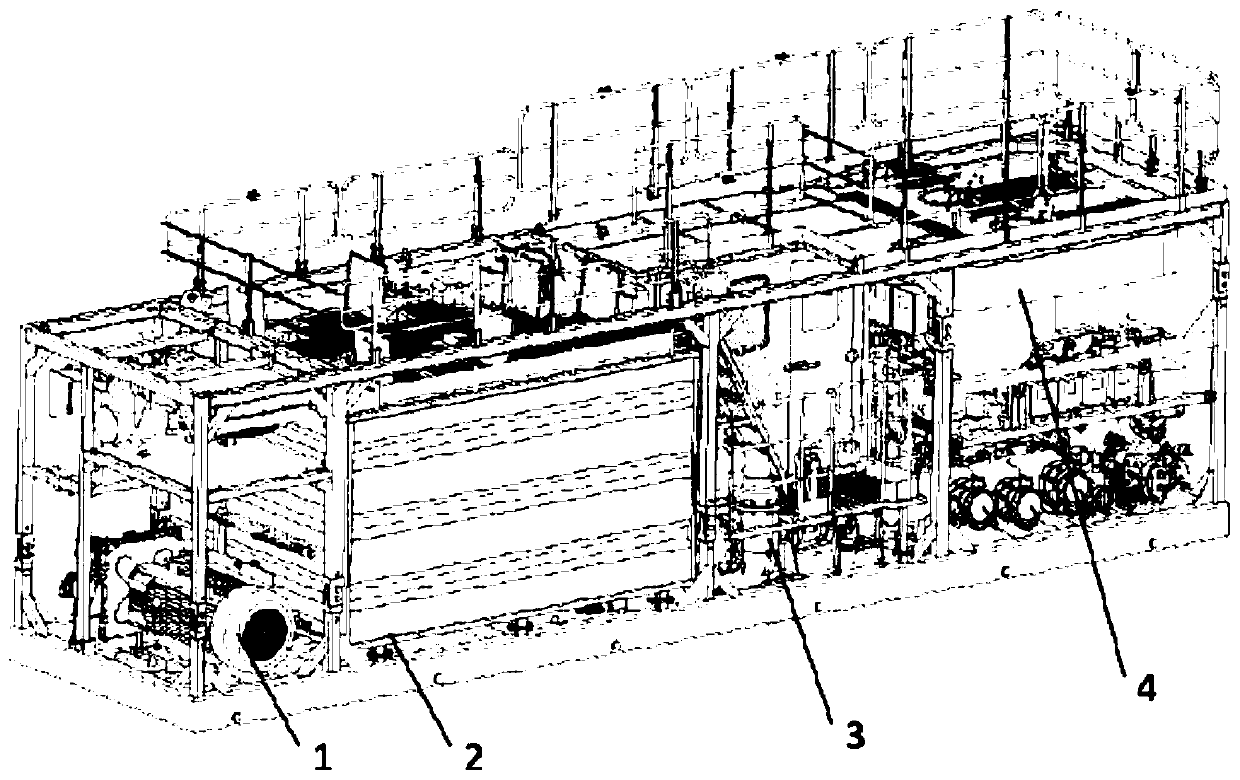

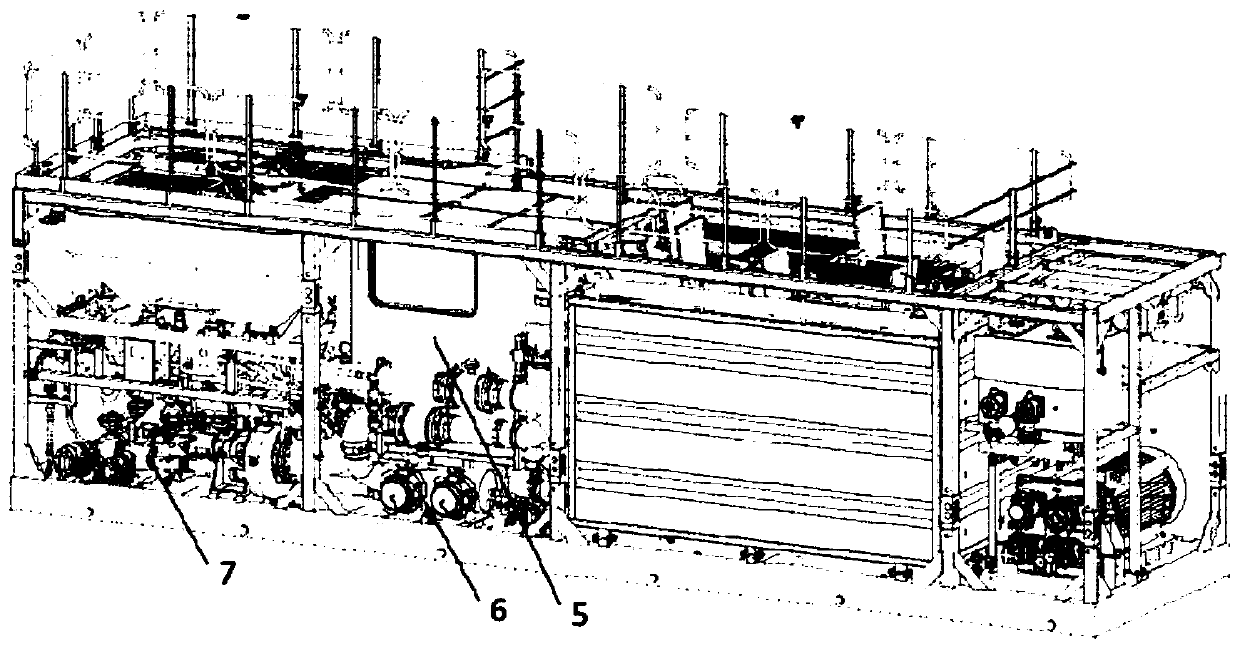

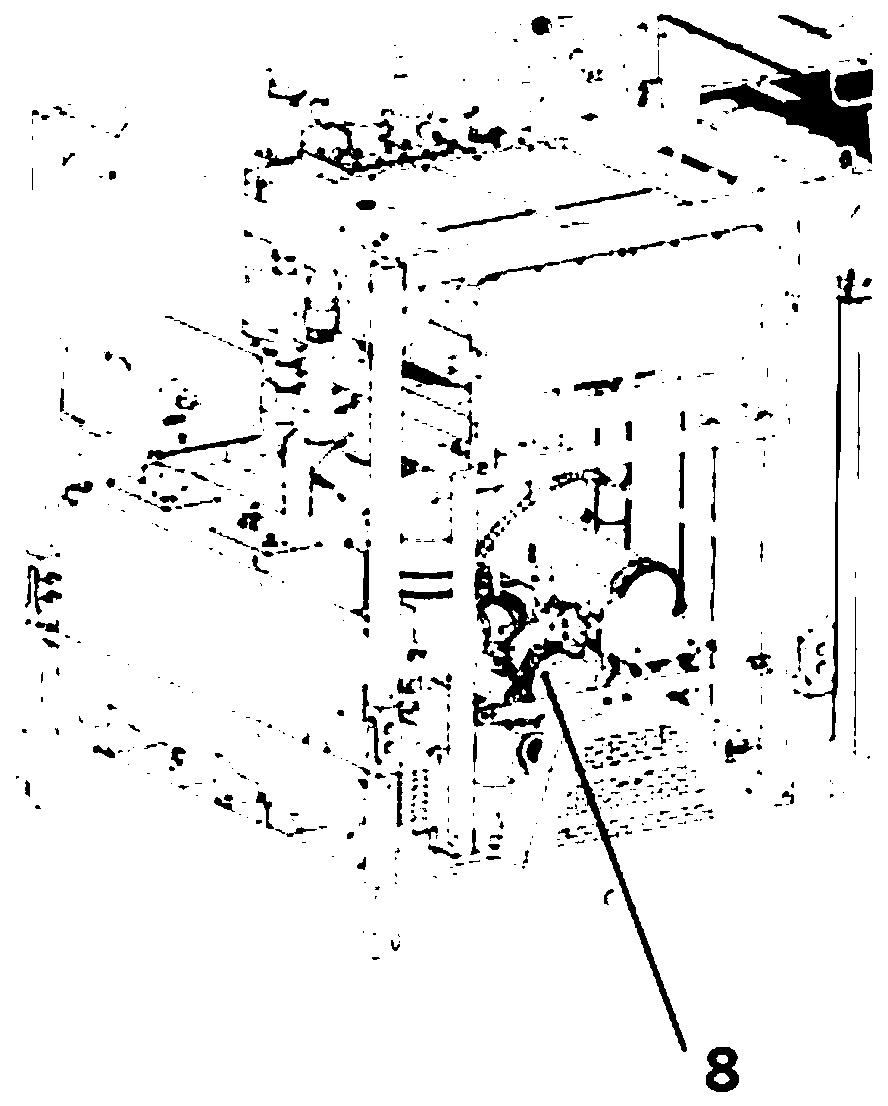

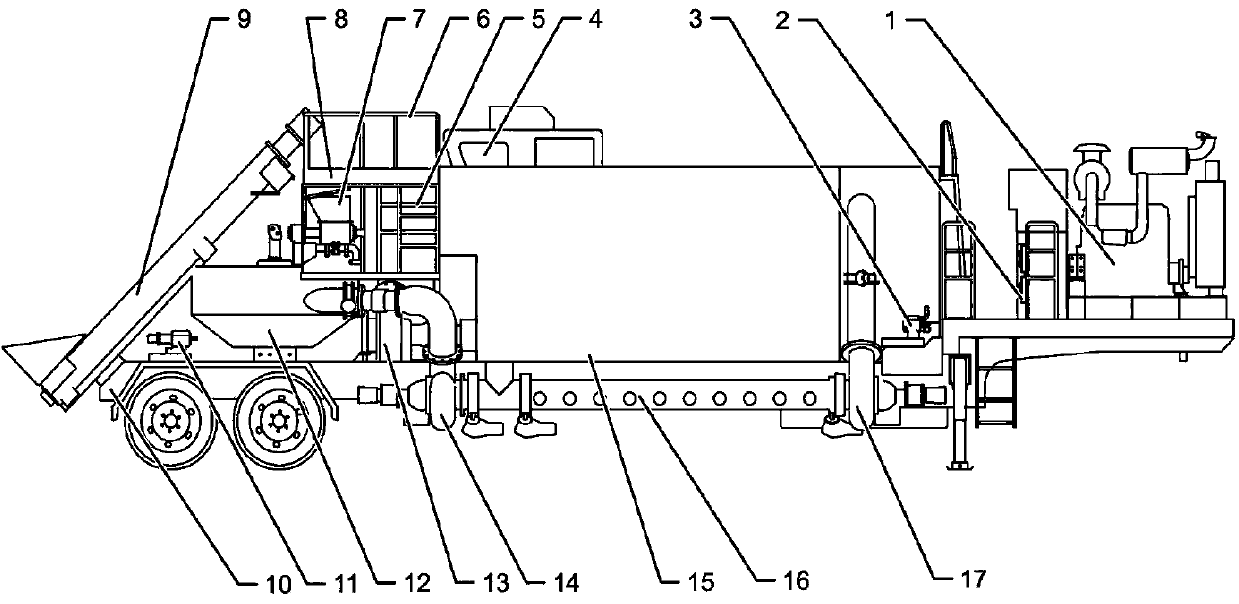

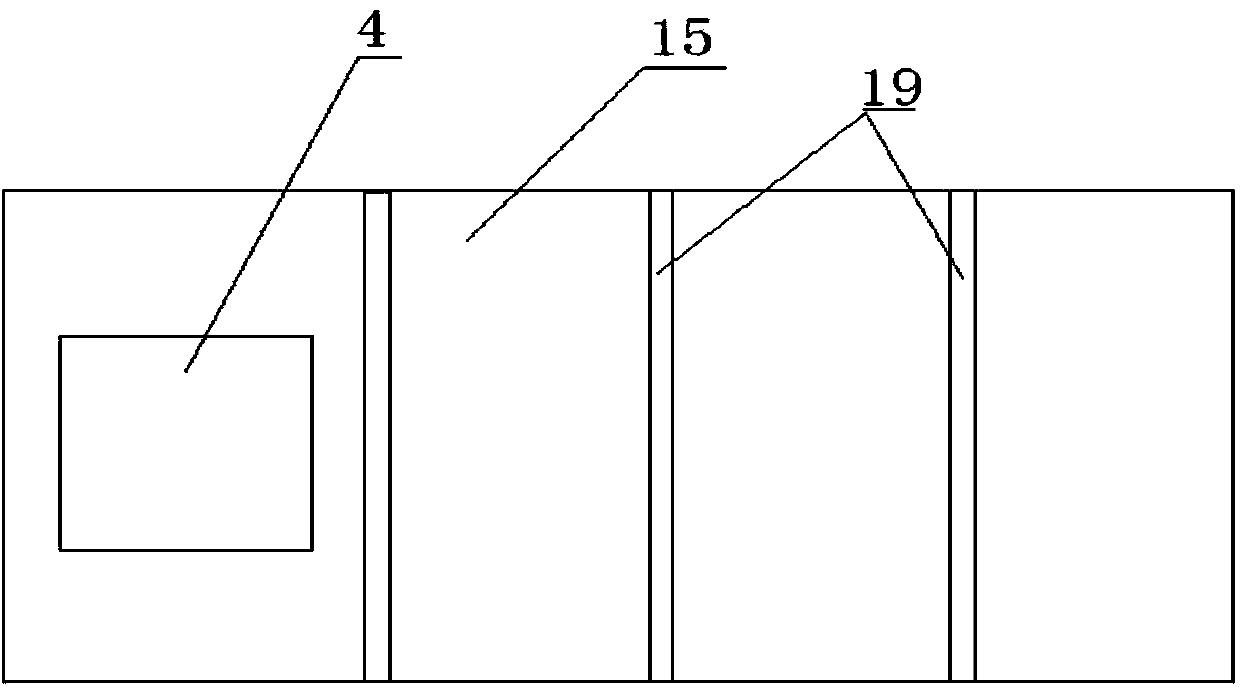

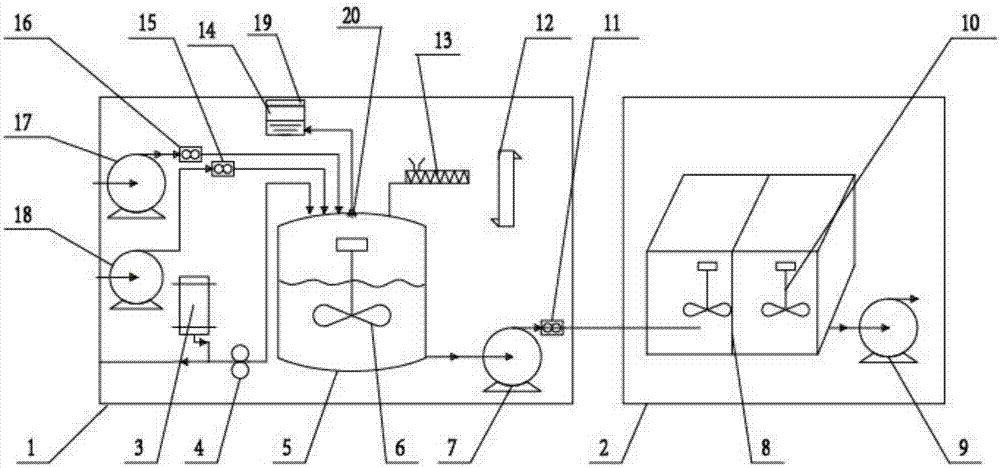

A fracturing fluid mixing sand mixing semi-trailer

ActiveCN103993869BReduce workloadLess supporting equipmentFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

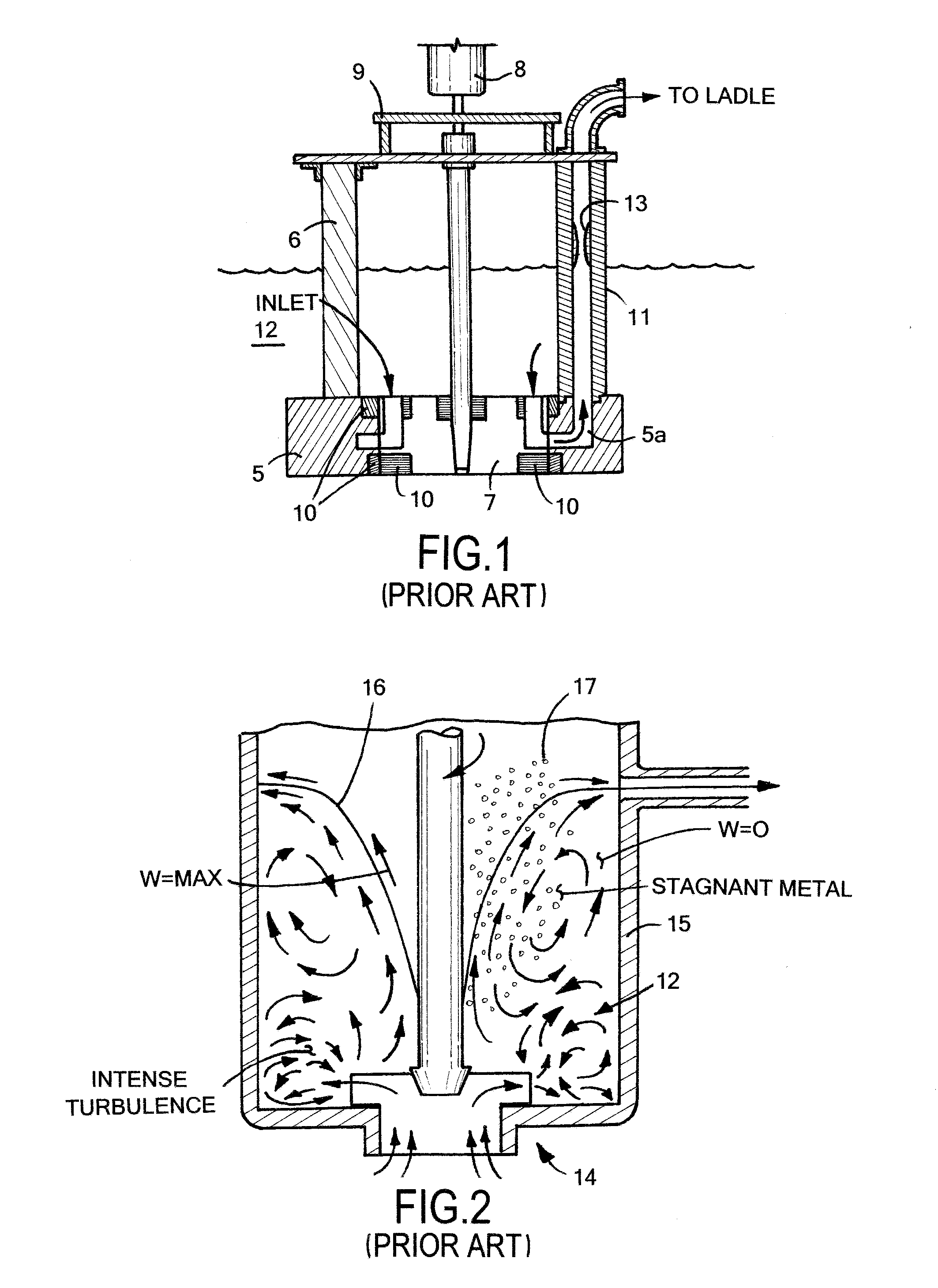

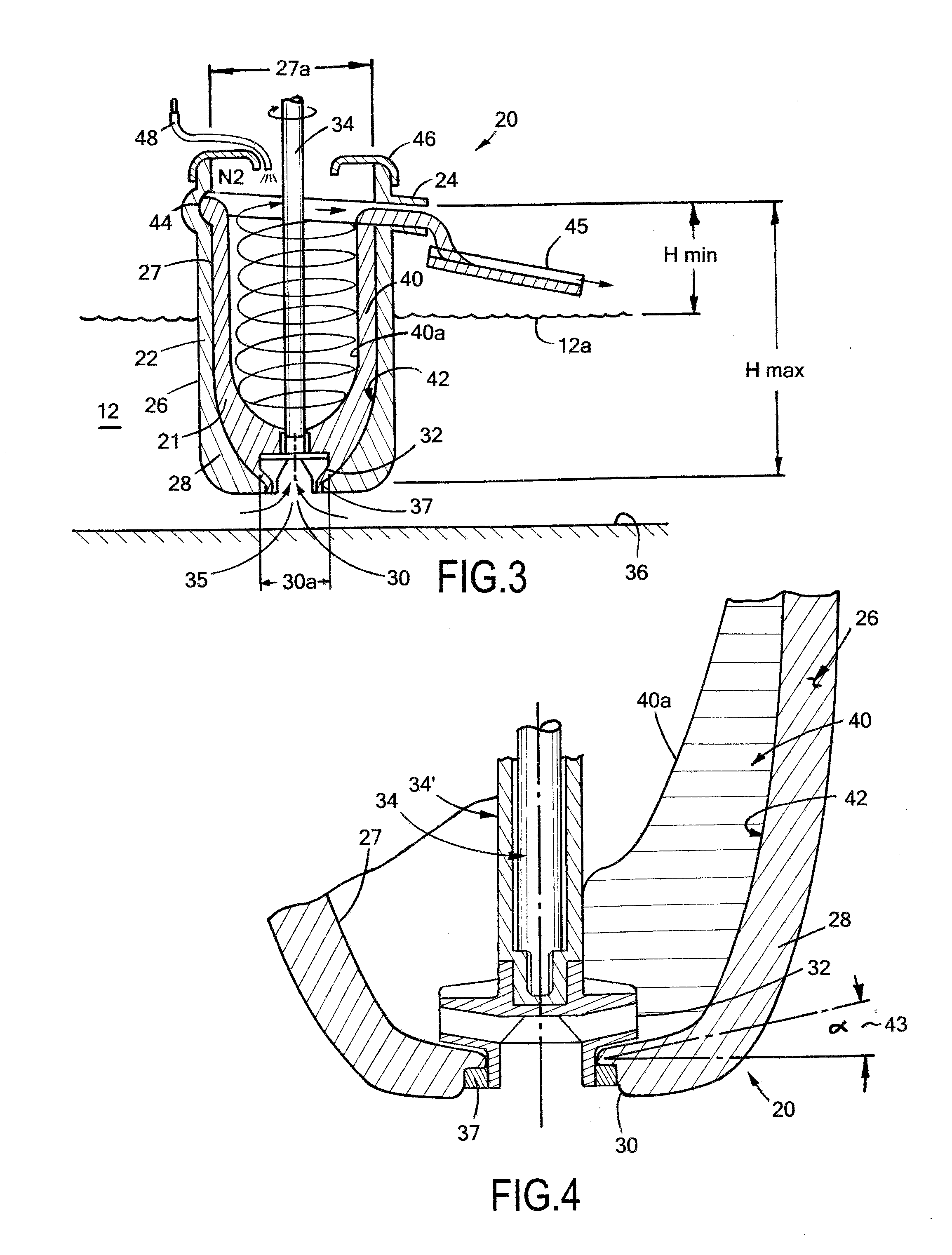

High flow/dual inducer/high efficiency impeller for liquid applications including molten metal

A centrifugal pump has a pump base with inlet inducer openings that receive molten metal into an impeller chamber. An impeller structure in the impeller chamber passes the metal in a radial direction through an outlet inducer opening into a volute passage for discharge into the pool of metal in which the pump is located.

Owner:MORANDO JORGE A

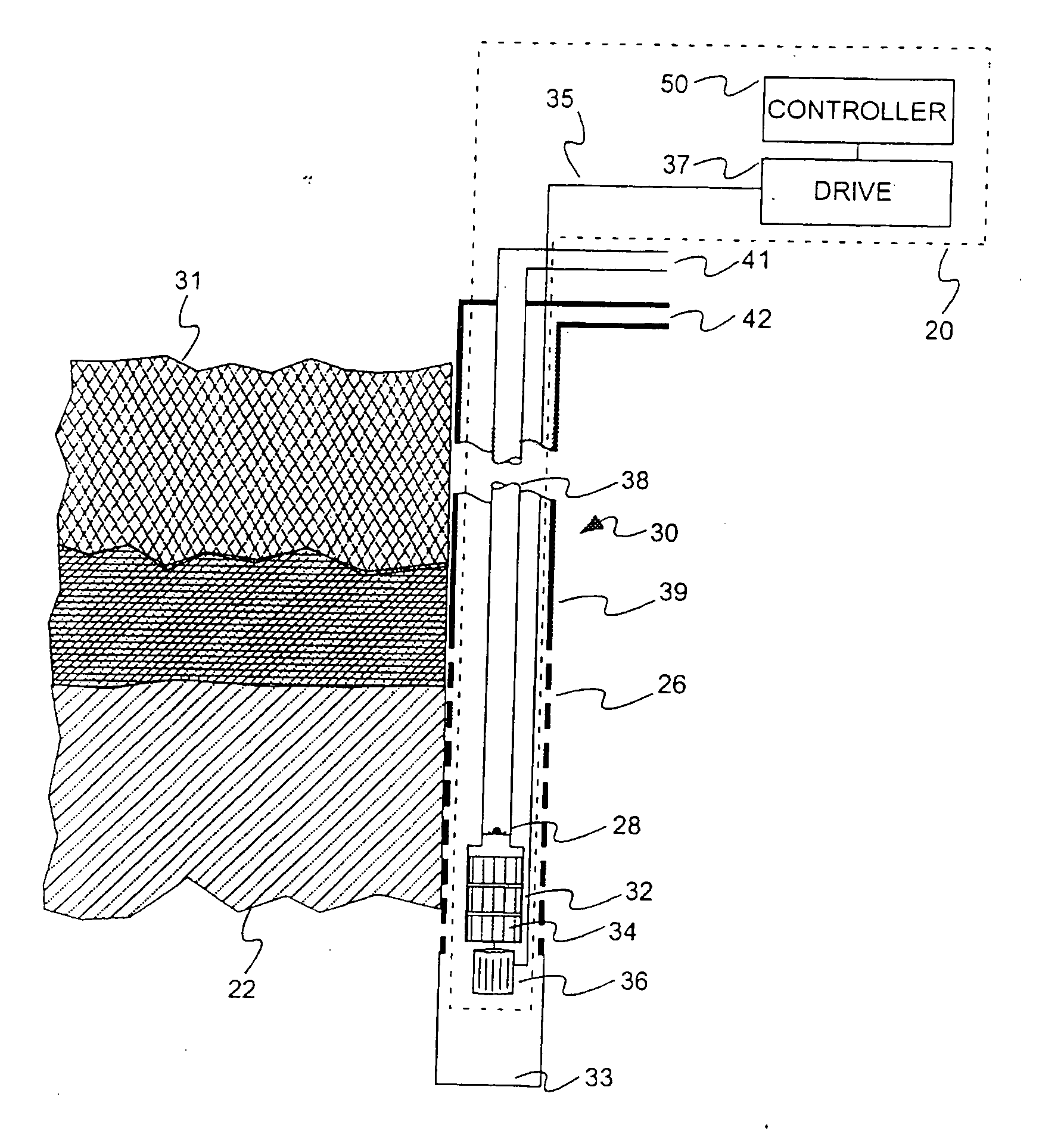

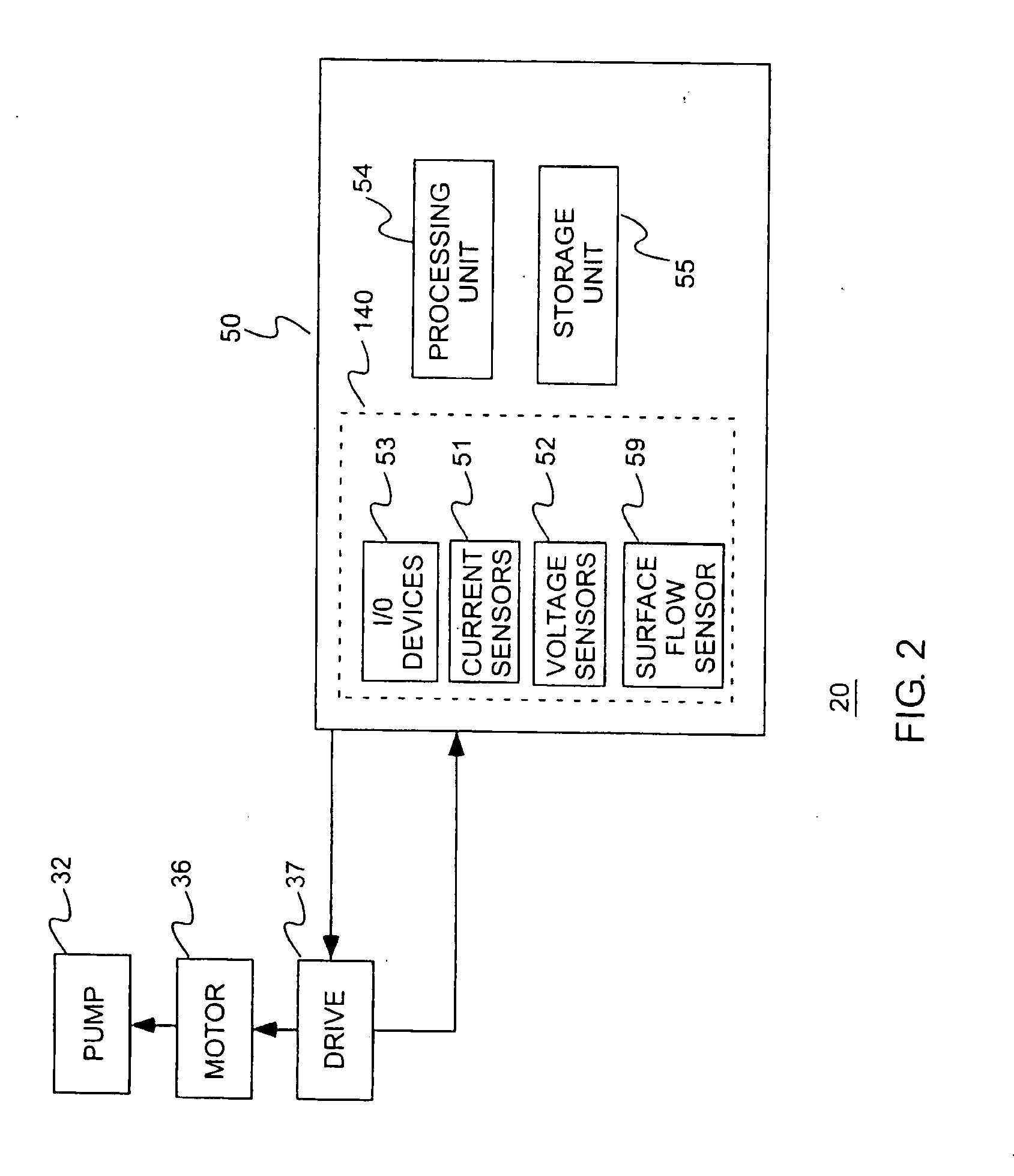

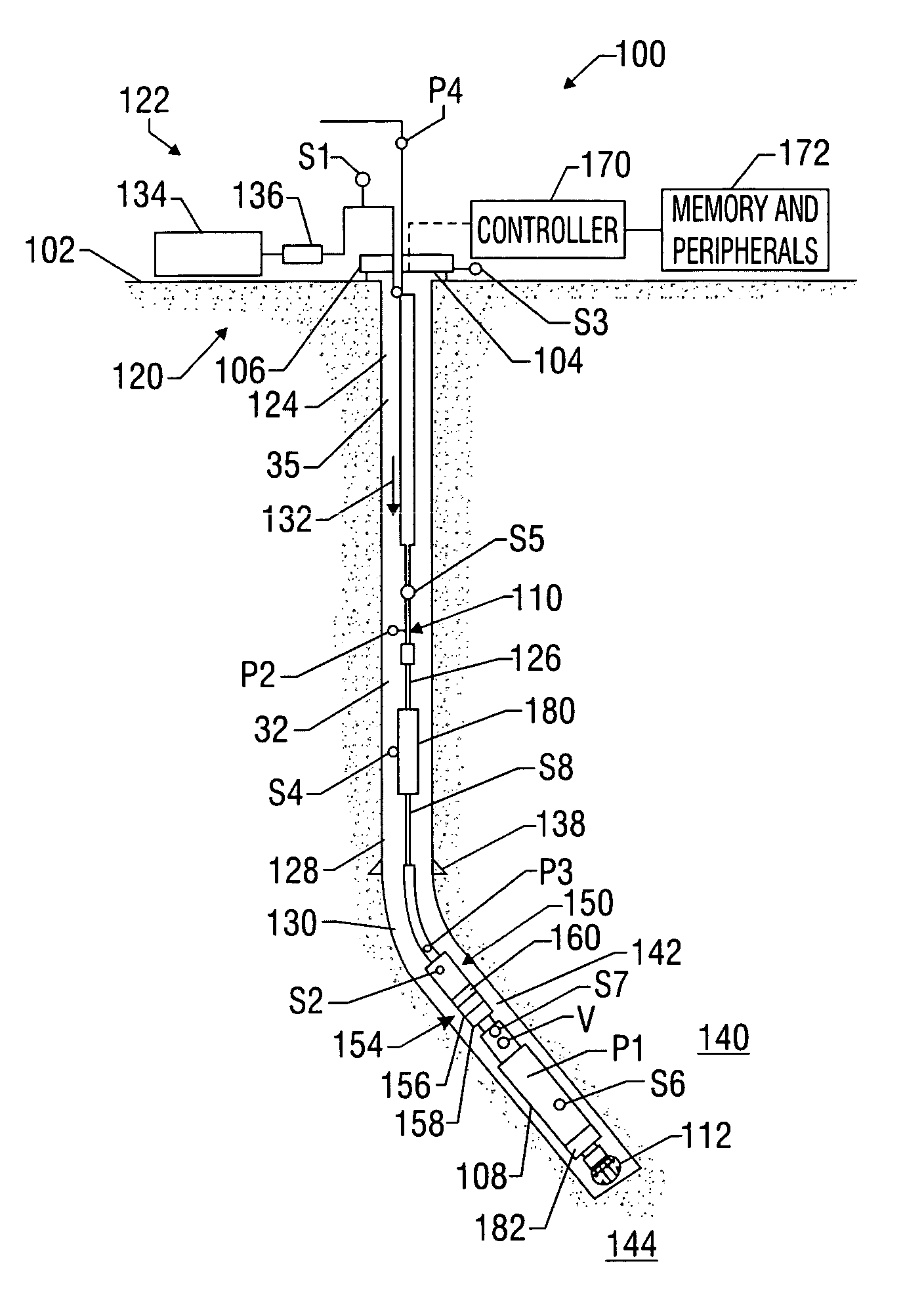

Determination And Control Of Wellbore Fluid Level, Output Flow, And Desired Pump Operating Speed, Using A Control System For A Centrifugal Pump Disposed Within The Wellbore

ActiveUS20080067116A1Enhance market appealBroad possible marketLevel controlWind motor controlEngineeringSystem parameters

A method and apparatus for determining a fluid level and / or output flow during operation of a centrifugal pump, are provided, which may be used for production of gas and / or oil from a well, and include a vector feedback model to derive values of torque and speed from signals indicative of instantaneous current and voltage drawn by the pump motor, a pump model which derives values of the fluid flow rate and the head pressure for the pump from torque and speed inputs, a pumping system model that derives, from the estimated values of the pump operating parameters, an estimated value of fluid level and other pumping system parameters. Controllers responsive to the estimated values of the pumping system parameters control the pump to maintain fluid level at the pump input, near an optimum level, or within a safe operating range and / or output flow from the pump.

Owner:UNICO LLC

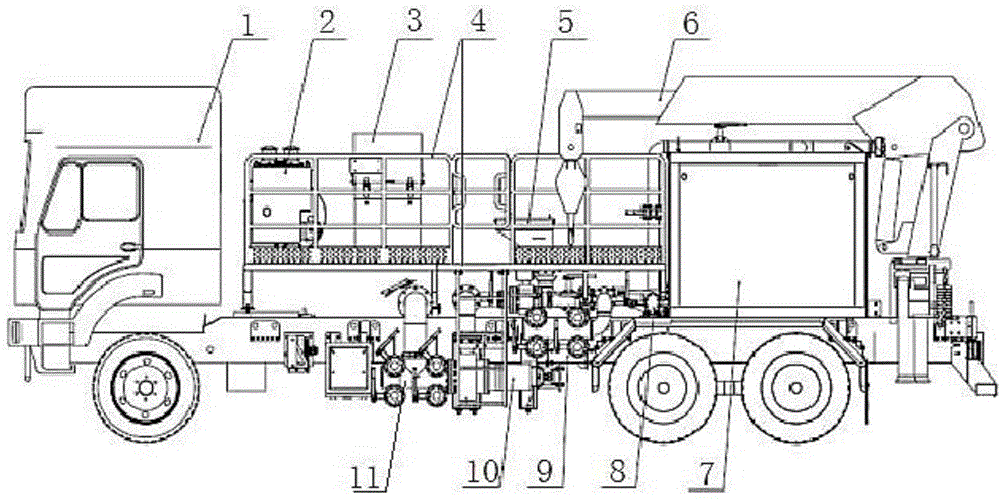

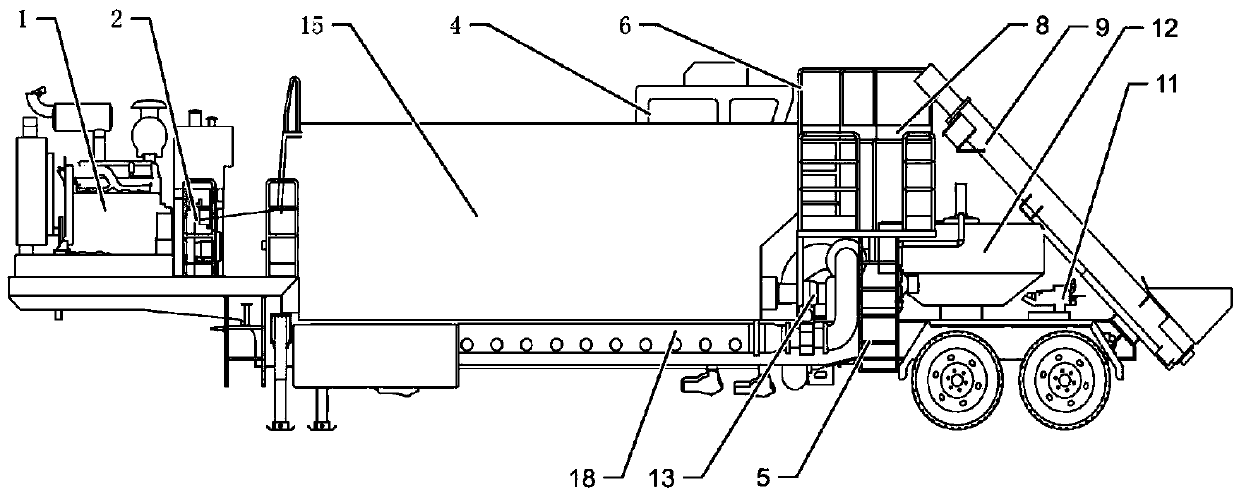

Multifunctional blending and liquid supplying vehicle

InactiveCN104057864AReduce labor costsAchieve mixingFluid removalItem transportation vehiclesControl systemElectrical control

The invention relates to a multifunctional blending and liquid supplying vehicle, which comprises a chassis, wherein an operation platform, a hydraulic oil tank, a dry powder feeder, an operation box for an electrical control system, a lorry-mounted crane and a liquid adding tank are fixedly arranged above the main beam of the chassis, wherein a centrifugal pump, an exhaust manifold and a suction manifold are arranged on each of two sides of the middle part of the main beam of the chassis, the exhaust manifold is communicated with the water outlet of the centrifugal pump, and the suction manifold is communicated with the water inlet of the centrifugal pump; the liquid adding pump is fixedly arranged on the side wall of the liquid adding tank, the water inlet of the liquid adding pump is communicated with the liquid adding tank, and the water outlet of the liquid adding tank is communicated with the exhaust manifold; a discharge opening in the lower end of the dry powder feeder is communicated with the exhaust manifold; the engine of the chassis is connected with a hydraulic pump, and the hydraulic pump is connected with the centrifugal pump, the lorry-mounted crane, the liquid adding tank and the liquid adding pump through a hydraulic multiway valve; the electrical control system is connected with the engine of the chassis, the hydraulic pump and the hydraulic multiway valve. The multifunctional blending and liquid supplying vehicle provided by the invention is low in cost, high in working efficiency, and can achieve various oil field operation functions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

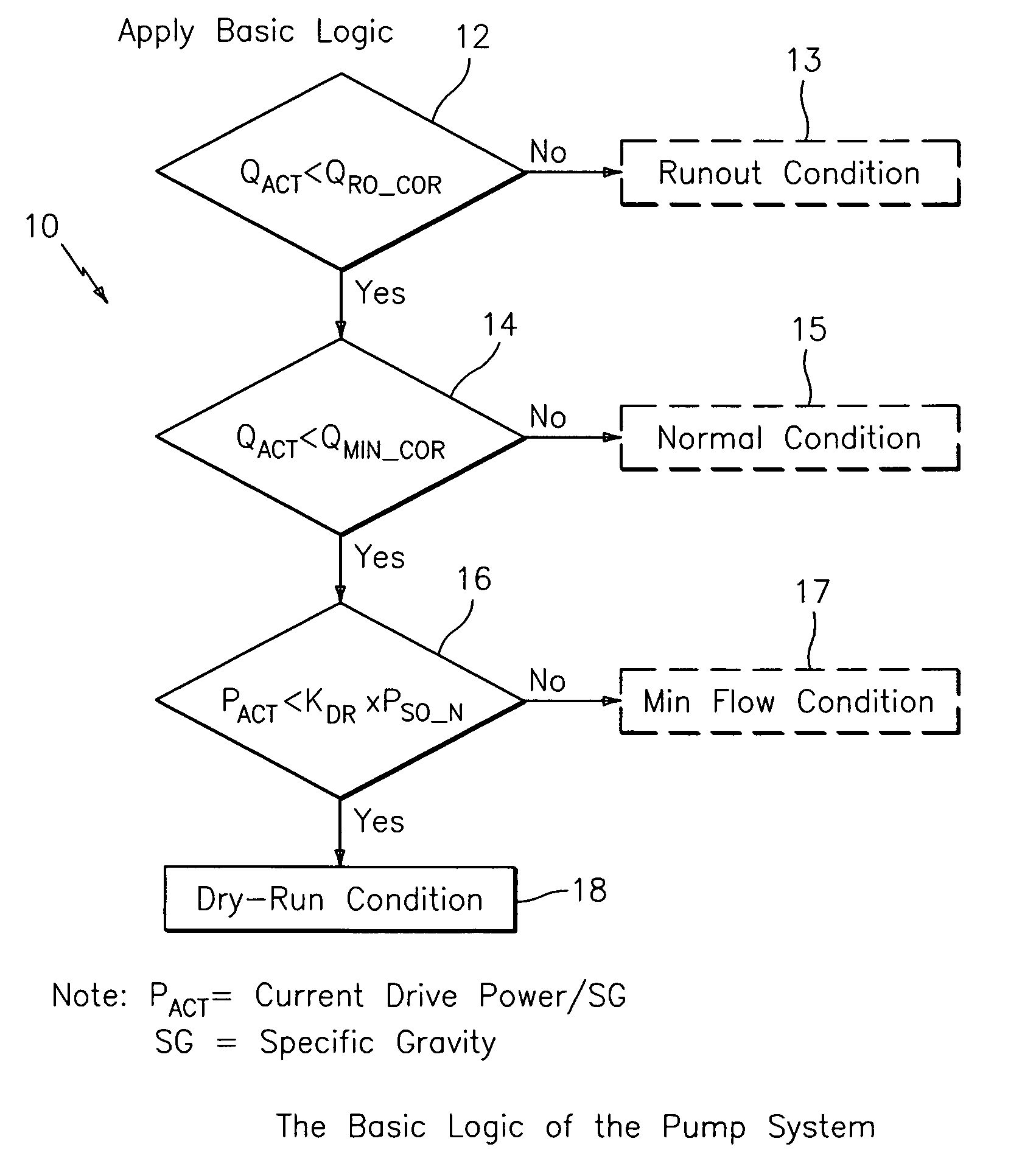

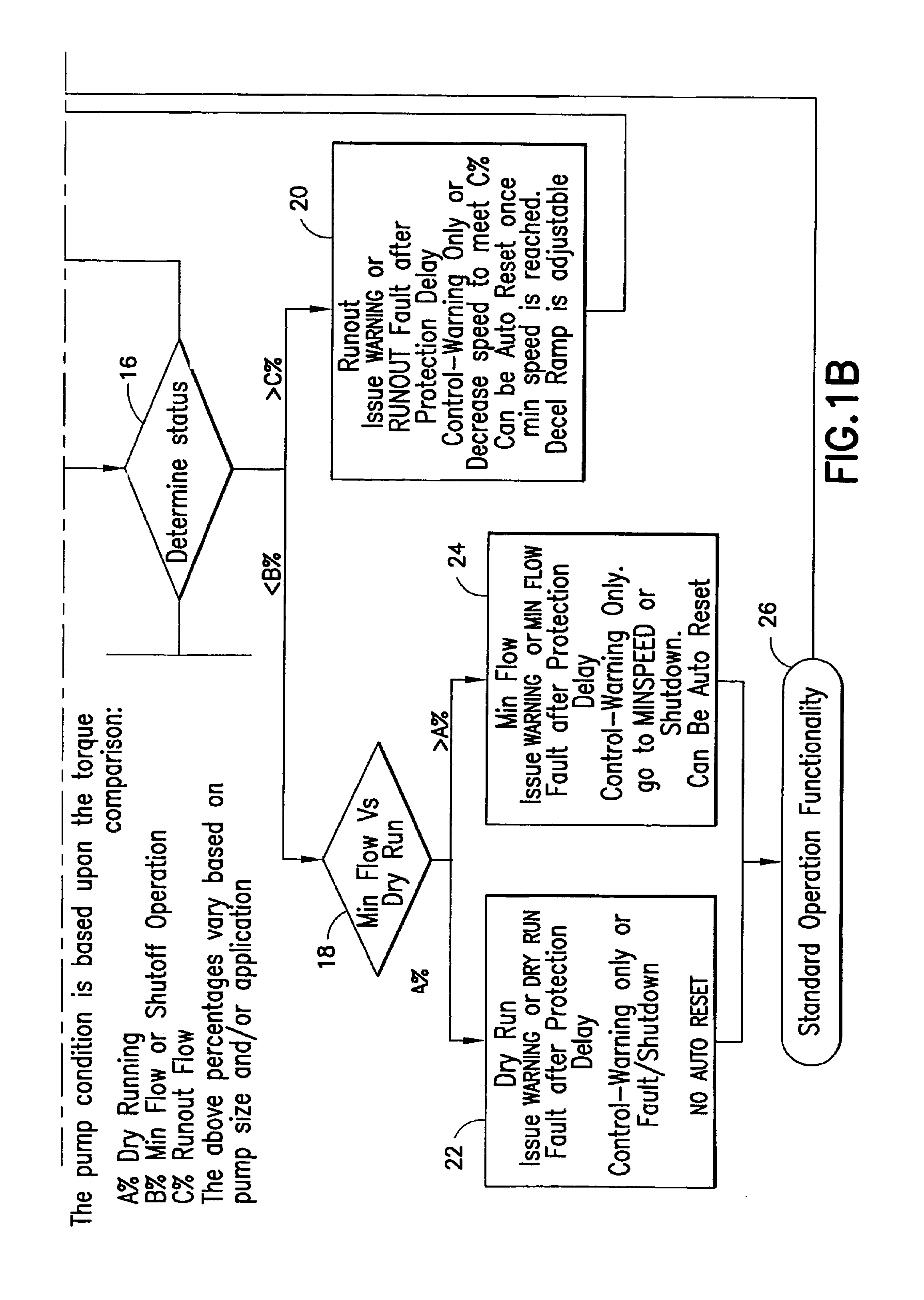

Method and apparatus for pump protection without the use of traditional sensors

ActiveUS20070212229A1Precise processAccurately determine power v flowVolume/mass flow measurementFlexible member pumpsDifferential pressureFlow curve

The present invention provides protection for centrifugal pumps while differentiating between dangerous operating conditions (e.g. dry running, minimum flow and runout) and / or conditions where transient conditions (e.g. closed valve operation) may occur and the protection can be revoked once the condition clears. The methodology utilizes a calculated flow value which can be mathematically determined from a calibrated closed valve power vs speed curve and / or various pump and motor parameters such as speed, torque, power and / or differential pressure or from calibrated flow curves stored in the evaluation device. The calculated flow value is then compared to threshold values of flow associated with these adverse operating conditions.

Owner:ITT MFG ENTERPRISES LLC

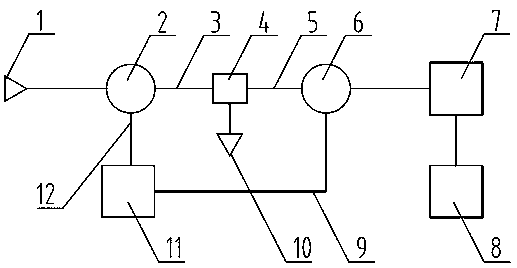

Cement truck densimeter automatic cleaning device and method

PendingCN110947681ASave cleaning laborWill not polluteCleaning using liquidsControl systemProcess engineering

The invention provides a cement truck densimeter automatic cleaning device and method. The cement truck densimeter automatic cleaning device comprises a liquid feeding pipeline, a centrifugal pump, atee joint, a densimeter mounting seat, a signal acquisition system, a control system and a cleaning tank, wherein the liquid feeding pipeline is connected with an inlet of the centrifugal pump, the tee joint is arranged between the centrifugal pump and the densimeter mounting seat, the third end of the tee joint is provided with a discharge pipeline in a connected manner; the densimeter mounting seat is connected with the cleaning tank; and the densimeter mounting seat is in electric signal connection with the signal acquisition system, and the signal acquisition system is electrically connected with the control system. According to the cement truck densimeter automatic cleaning device, the problem that cement adheres to the inner part of a densimeter is solved, the measuring precision ofthe densimeter is improved and the service life of the device is prolonged; cleaning liquid is automatically fed, the cleaning process is automatically circulated, the cleaning progress is automatically detected; and the cement truck densimeter automatic cleaning device is used for densimeter automatic cleaning, the operation is safer and more efficient, and on-site manpower is greatly saved.

Owner:CHANGQING GUJING OF CNPC CHUANQING DRILLING ENG +1

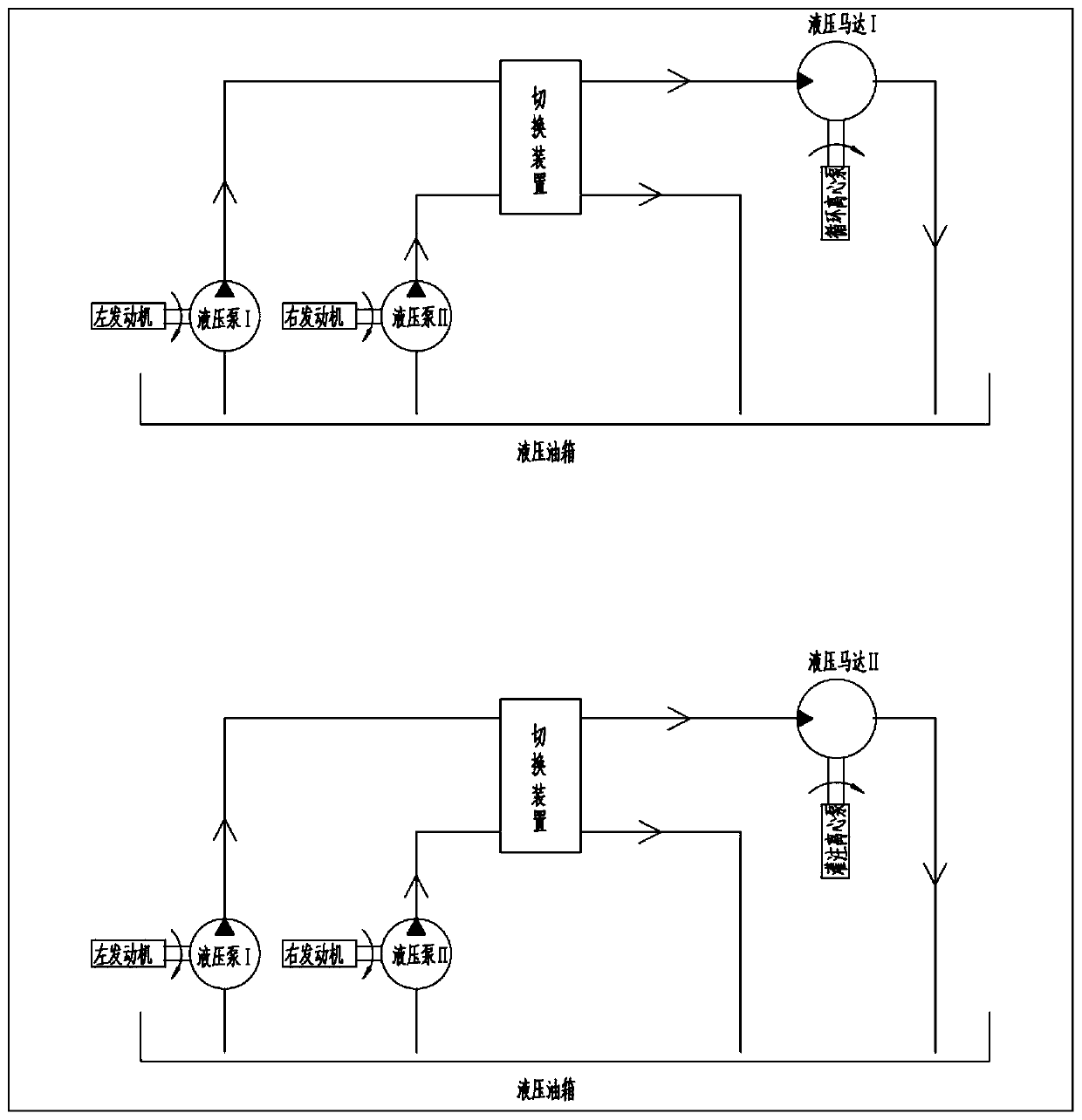

Cementing equipment with mutually standby hydraulic systems

PendingCN110284854AImprove reliabilityImprove securityPump installationsSealing/packingControl systemHydraulic pump

The invention discloses cementing equipment with mutually standby hydraulic systems. The cementing equipment comprises a loading system, a hydraulic system connected with the loading system and a power system for driving the hydraulic system. The hydraulic system at least comprises a hydraulic pump, a switching device and an overflow valve, the hydraulic system is connected with a mixing system, and the hydraulic system is connected with a slurry mixing system provided with an AMS automatic slurry mixing system, a centrifugal pump circulating and filling system; the slurry mixing system is controlled and adjusted through a control system, the control system is arranged on a computer control platform, and the control platform is arranged on the loading system; and the loading system is based on one or more of a vehicle-mounted chassis or a trailer chassis or a skid-mounted chassis, wherein a semi-trailer based on the trailer chassis can be fixedly connected with a plurality of engines, a plurality of gear boxes, a plurality of plunger pumps, at least one metering tank, the slurry mixing system, a high-low pressure manifold, the control system, the hydraulic system and an electrical system.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Electric-drive mixing device

PendingCN110252191ALow calorific valueSmall footprintMixing methodsTransportation and packagingElectricityFrequency conversion

The invention discloses an electric-drive mixing device, and relates to the technical field of mixing equipment. The electric-drive mixing device comprises a motor power unit, a mixing tank, a discharge centrifugal pump, a suction centrifugal pump, a powder tank, a control chamber, a drainage manifold, a water-powder mixing manifold, a chemical adding pump and a suction header. The mixing tank is fixedly mounted on one side of the motor power unit, and the control chamber is fixedly mounted on one side of the mixing tank. The electric-drive mixing device has the advantages that a selected motor is a variable-frequency all-in-one machine, that is to say, a frequency converter is integrated with the motor, and there is no independent frequency conversion cabinet, so that the occupied space is remarkably saved, and the device is suitable for vehicle transportation; the variable-frequency all-in-one machine has much lower heat than the motor, a radiator is integrated to a cabinet casing of the motor and the frequency converter, and no plate-fin radiating holes are provided; a large-channel air duct is arranged at a motor and frequency converter casing position of a fan, and accordingly, blockage is avoided.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Fracturing fluid mixing and sand mixing semitrailer

ActiveCN103993869ALess supporting equipmentReduce workloadFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

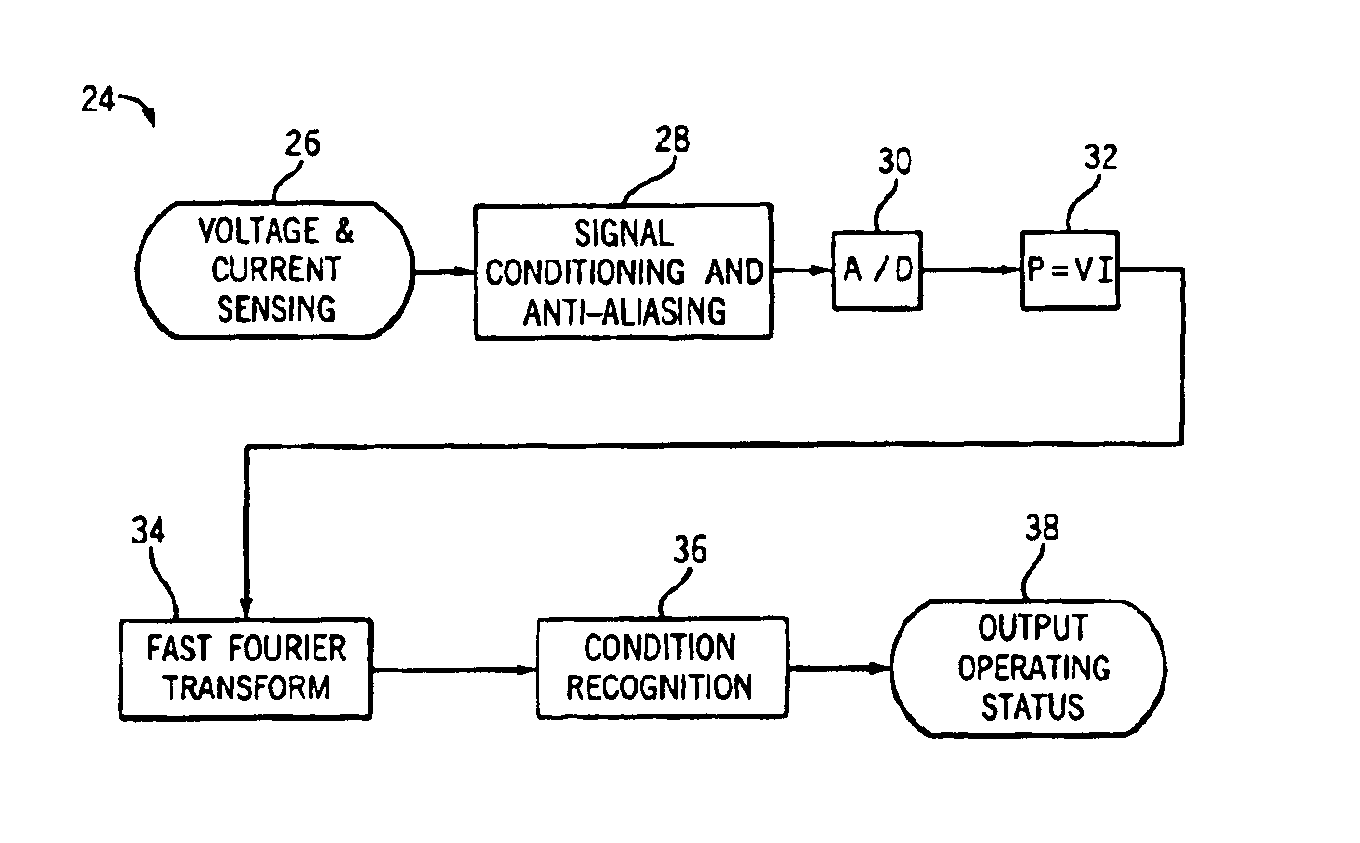

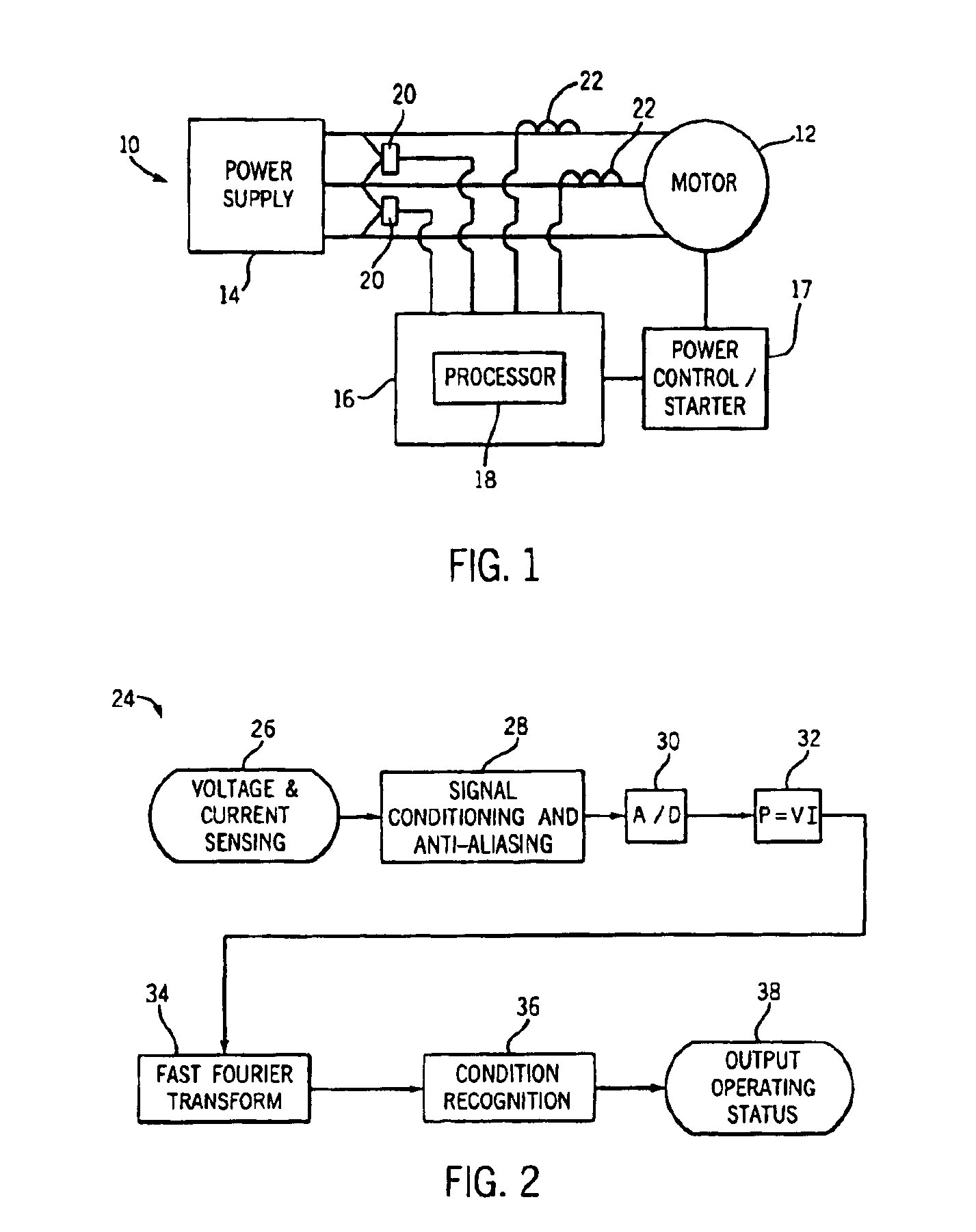

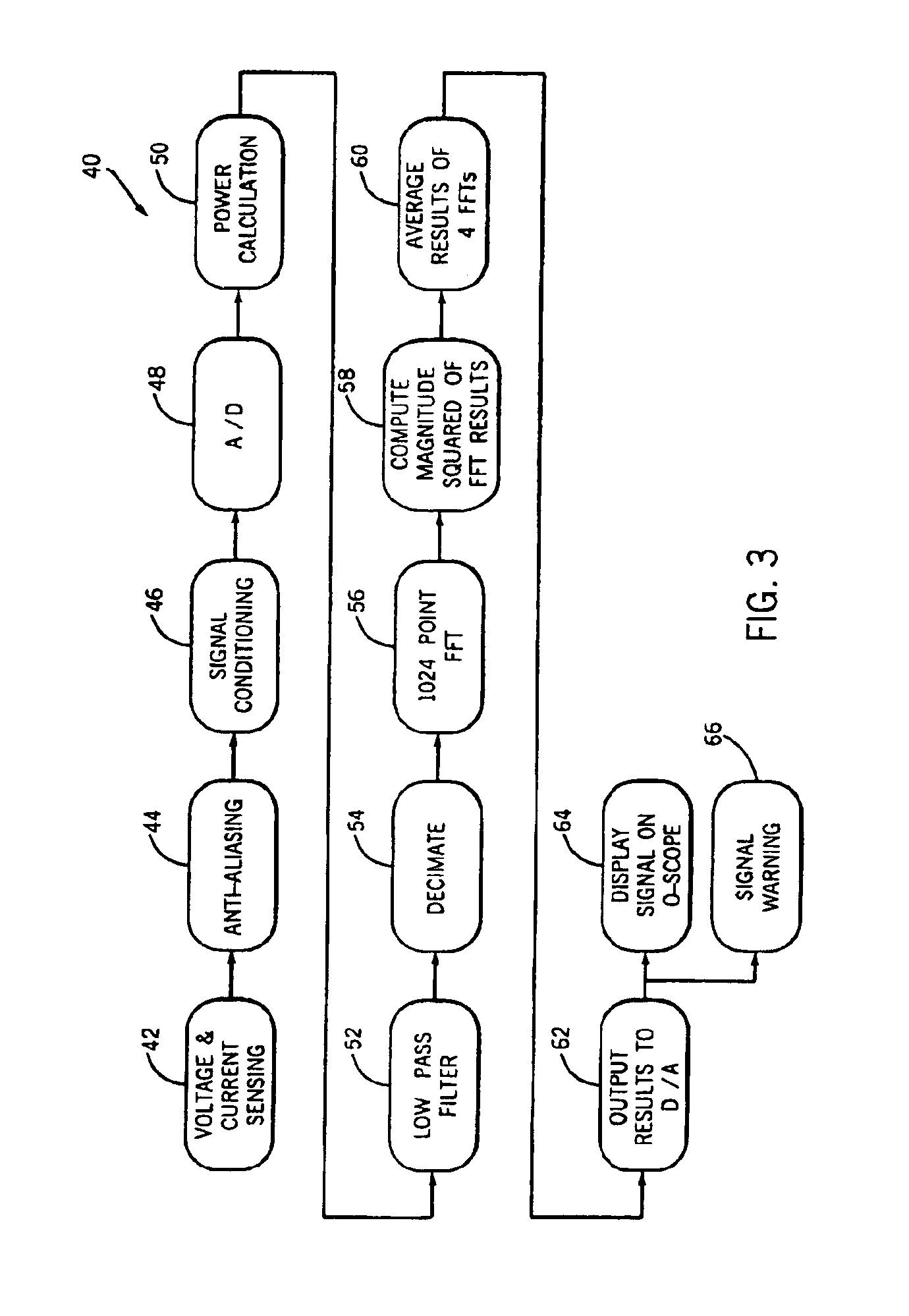

Method and apparatus of detecting disturbances in a centrifugal pump

The present invention is directed to a centrifugal pump wherein voltage and current data are detected from voltage and current sensors in the motor controller of a pump motor. A power signal is then generated from the voltage and current data and spectrally analyzed to determine the presence of unwanted harmonics which are indicative of mechanical disturbances in the pump. As such, anomalies resulting from mechanical interference may be detected and a warning flag provided without additional transducers and other instruments on the motor or pump.

Owner:EATON INTELLIGENT POWER LTD

Continuous acid mixing equipment

PendingCN107261975AEnables continuous mixingEfficient removalTransportation and packagingMixersCentrifugal pumpEngineering

The invention provides continuous acid mixing equipment which comprises a continuous acid preparing vehicle and a skid-mounted buffer tank. The continuous acid preparing vehicle comprises a chassis vehicle, a liquid adding pump, an original acid centrifugal pump, a clear water centrifugal pump, a discharging centrifugal pump, an acid mixing tank, an acid-alkali tank, an automatic feeding machine and a dry powder adding device, the liquid adding pump, the original acid centrifugal pump, the clear water centrifugal pump, the discharging centrifugal pump, the acid mixing tank, the acid-alkali tank, the automatic feeding machine and the dry powder adding device are arranged on the chassis vehicle, the clear water centrifugal pump is connected with the acid mixing tank through a clear water manifold, the original acid centrifugal pump is connected with the acid mixing tank through an original acid manifold, a first stirrer and a nozzle are arranged inside the top of the acid mixing tank, and an acid-alkali indicator for displaying acidity and alkalinity in the acid-alkali tank is arranged on the acid-alkali tank; the skid-mounted buffer tank comprises a skid frame, a buffer tank, a skid-mounted engine and a centrifugal pump, the buffer tank, the skid-mounted engine and the centrifugal pump are arranged on the skid frame, the discharging centrifugal pump on the continuous acid preparing vehicle is connected with the buffer tank through a discharging manifold, and a second stirrer is arranged in the buffer tank. Through combined use of the continuous acid preparing vehicle and the skid-mounted buffer tank, continuous mixing of acid is realized; by arranging an acid mist removing device in the acid mixing tank, a lot of acid mist and foam generated during acid mixing are removed effectively, so that the whole continuous acid mixing equipment is safer in operating performance.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

Beverage forming apparatus with centrifugal pump

ActiveUS8151694B2Adequate flowSufficient pressureBeverage vesselsFood preparationExhaust valveControl valves

Owner:KEURIG GREEN MOUNTAIN INC

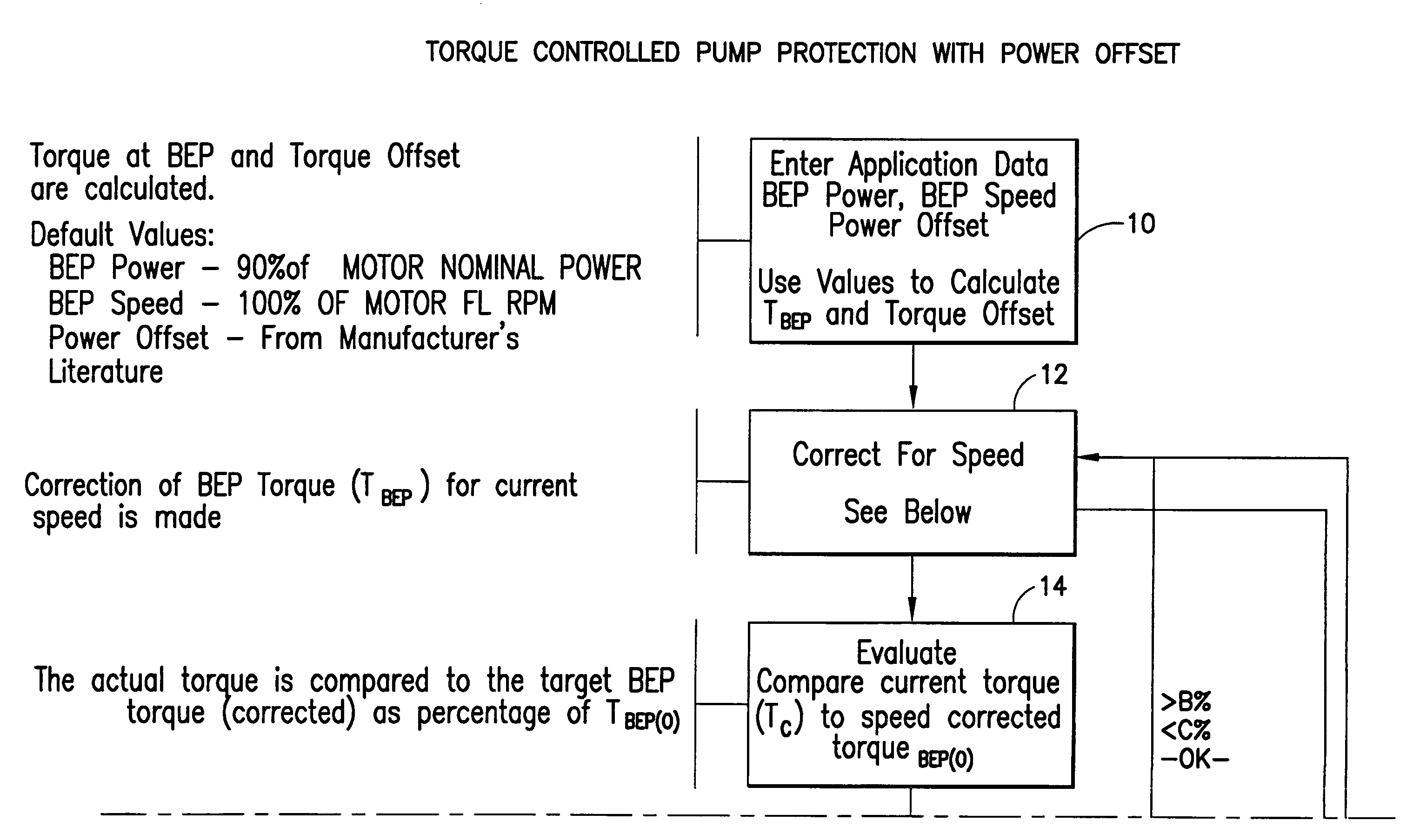

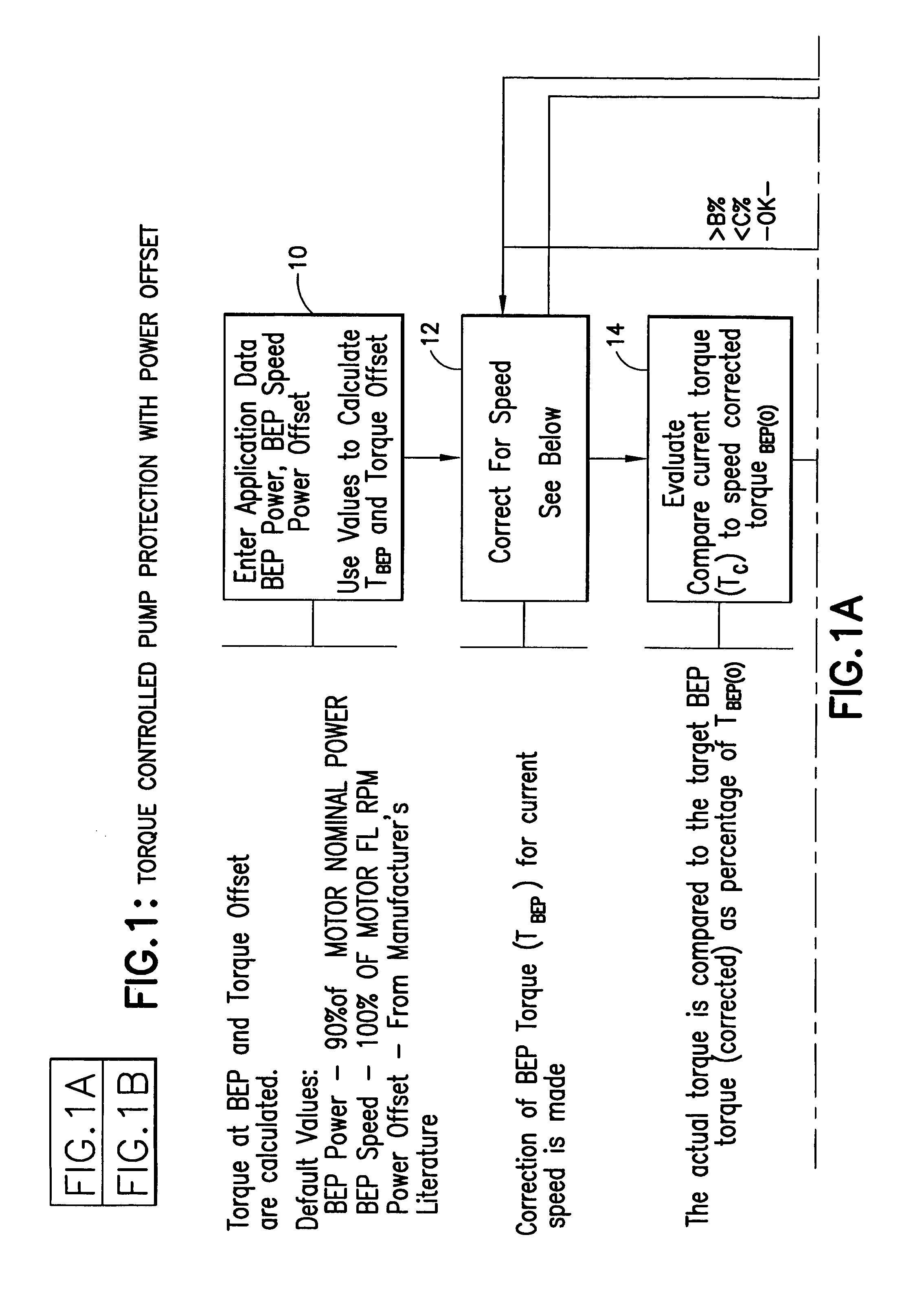

Torque controlled pump protection with mechanical loss compensation

ActiveUS7080508B2Eliminate needExtended speed rangeFluid couplingsFlexible member pumpsEngineeringControl theory

A method and apparatus are provided for controlling the operation of a pump, such as a centrifugal pump, featuring steps of either adjusting the operation of the pump, or issues a warning to a user of the pump of an undesirable operating condition, or both, based on a comparison of an actual torque value and a corrected torque value either alone or in combination with a further step of compensating the corrected torque value based on a mechanical power offset correction. The corrected torque value may include a Best Efficiency Point (BEP) torque value and may also be compensated for based on at least the current operating speed of the pump. The pump has a controller for performing the steps of the method. The controller can compensate the corrected torque value based on the square of the speed change of the pump. The comparison may include a ratio of the actual torque value to the corrected torque value.

Owner:ITT MFG ENTERPRISES LLC

Rotary blood pump and control system therefor

A pump assembly and estimation and control system therefor, the pump adapted for continuous flow pumping of blood. In a particular form, the pump is a centrifugal pump wherein the impeller is entirely sealed within the pump housing and is exclusively hydrodynamically suspended therein against movement in three translational and two rotational degrees of freedom as the impeller rotates within the fluid urged by electromagnetic means external to the pump cavity. Hydrodynamic suspension is assisted by the impeller having deformities therein such as blades with surfaces tapered from the leading edges to the trailing edges of bottom and top surfaces thereof.

Owner:THORATEC CORPORTION +1

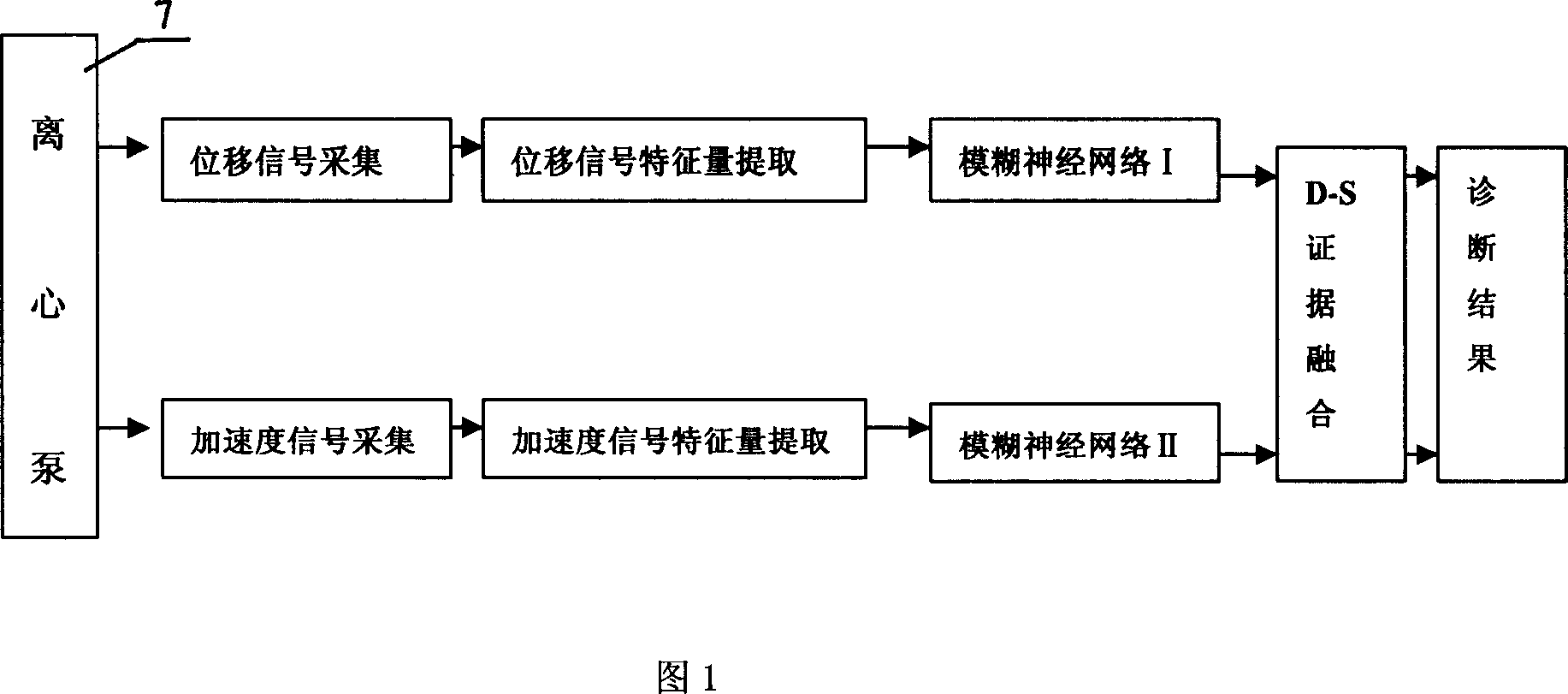

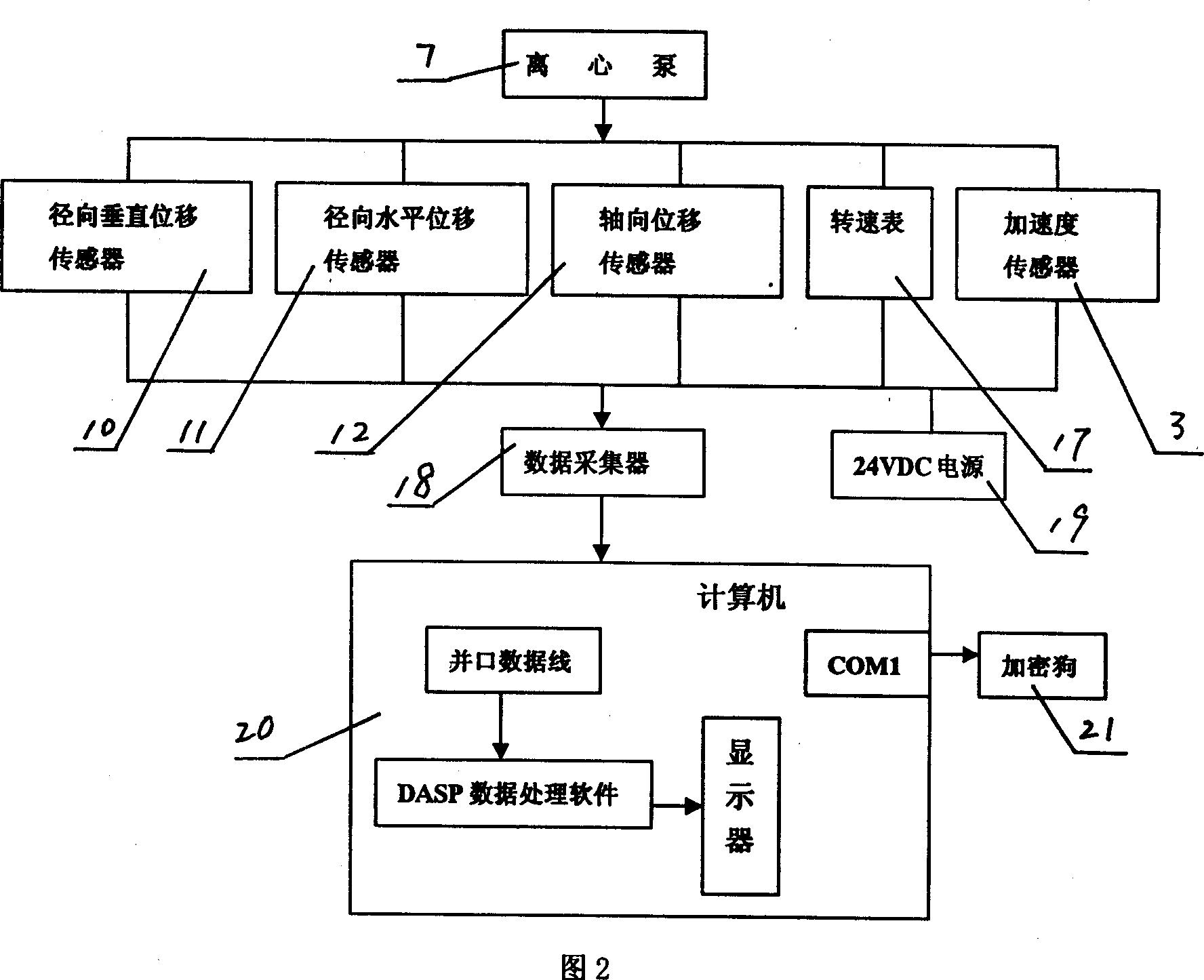

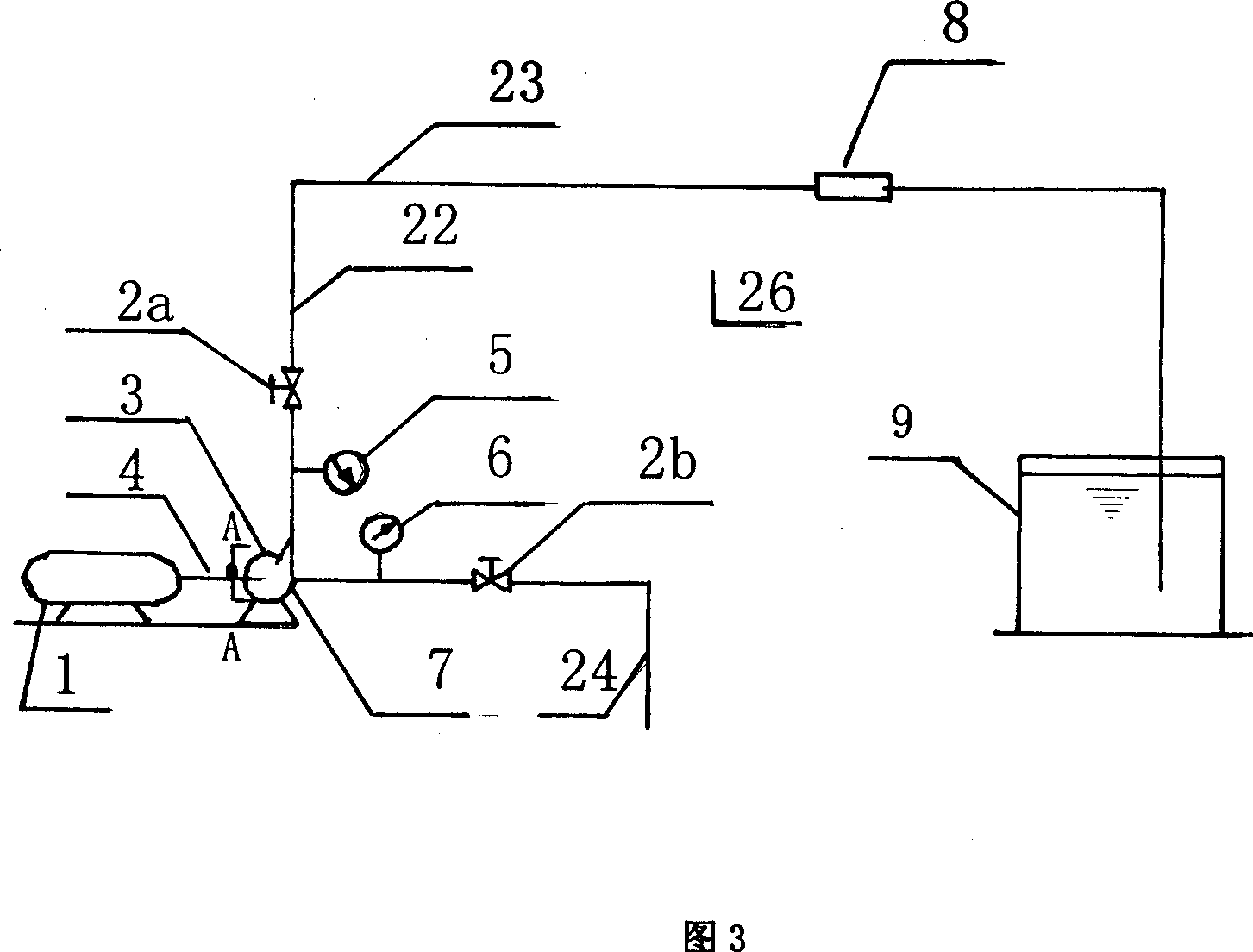

Fusion diagnosing method of centrifugal pump vibration accidents and vibration signals sampling device

InactiveCN1920511AImplementing a normal status signalComprehensive signal acquisitionMachine part testingPump testingEngineeringNormal state

The invention relates to an eccentric pump vibration accidence fusion diagnose method and relative vibration signal collector, wherein said invention is characterized in that: it uses the eccentric pump vibration signal collector to collect the normal state, the quantity imbalance, asymmetry rotate and loose base of eccentric pump; uses wavelet decomposition and reconstruction to extract the character of vibration signal; and inputs the character vectors into sub fuzzy neural networks I and II; to be treated and replace the relation factor matched with sensor signal function; the whole fuzzy neural network comprises data fuzzy layer, input layer, hidden layer and output layer; uses D-S theory to obtain the fused signal function distribution, realize the fusion diagnose on normal state, quantity imbalance, asymmetry rotate and loose base. The invention has simple structure and high effect.

Owner:NORTHEAST DIANLI UNIVERSITY

Rotary pump with exclusively hydrodynamically suspended impeller

Owner:TC1 LLC +1

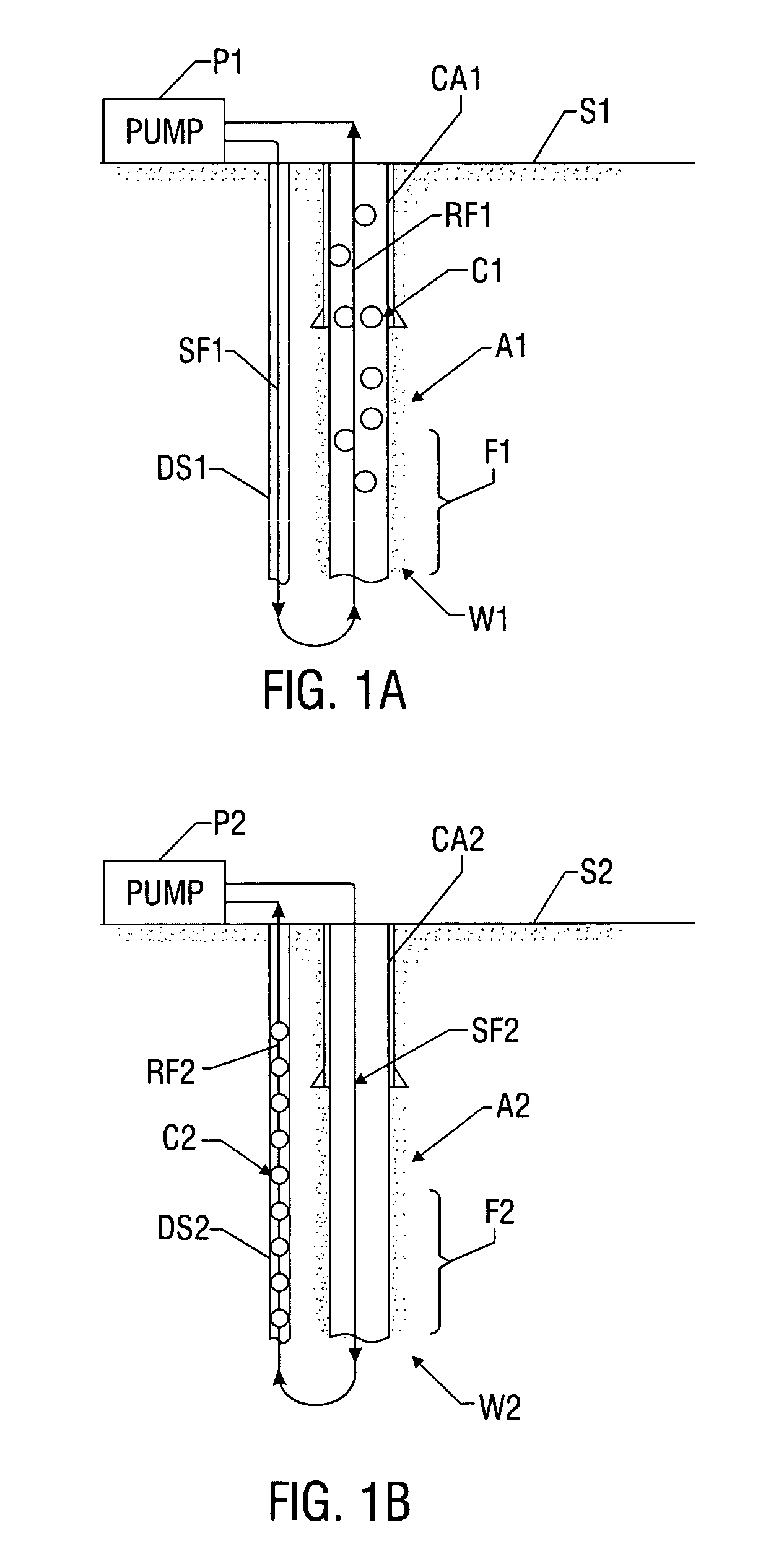

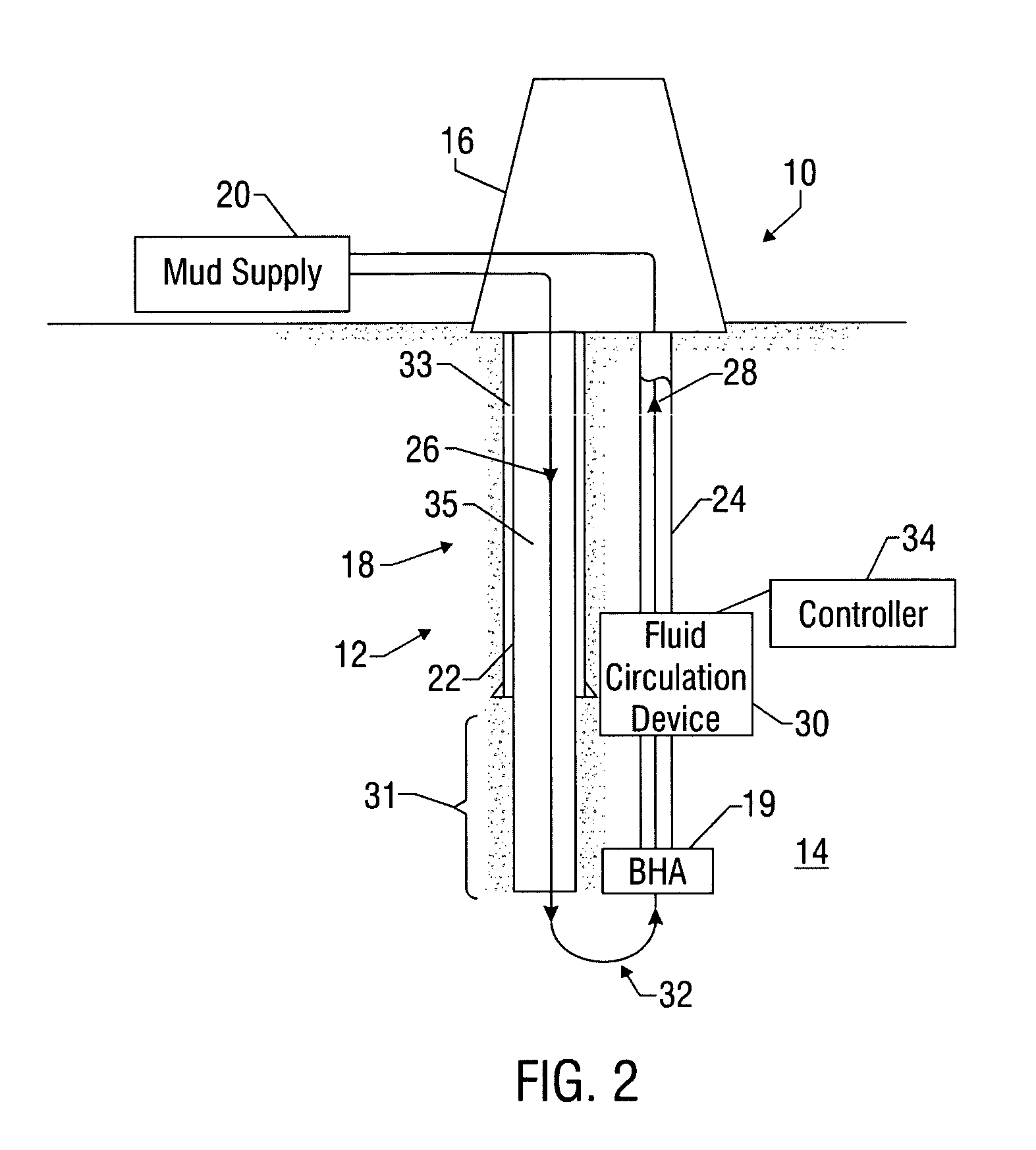

Wellbore fluid circulation system and method

ActiveUS7055627B2Improve bit cleaningLoss of circulationConstructionsFluid removalLine tubingWell drilling

The present invention provides drilling systems for drilling wellbores. The drilling system includes an umbilical that passes through a wellhead and carries a drill bit. A drilling fluid system supplies drilling fluid into an annulus (supply line) between the umbilical and the wellbore, which discharges at the drill bit bottom and returns to the wellhead through the umbilical (return line) carrying the drill cuttings. A fluid circulation device, such as a turbine or centrifugal pump, is operated in the return line to provide the primary motive force for circulating drilling fluid through a fluid circuit formed by the supply line and return line. Optionally, a secondary fluid circulation device in fluid communication with the return line can cooperate with the fluid circulation device to circulate drilling fluid and / or a near bit fluid circulation device can be used to provide localized flow control or suction pressure to improve bit cleaning.

Owner:BAKER HUGHES INC

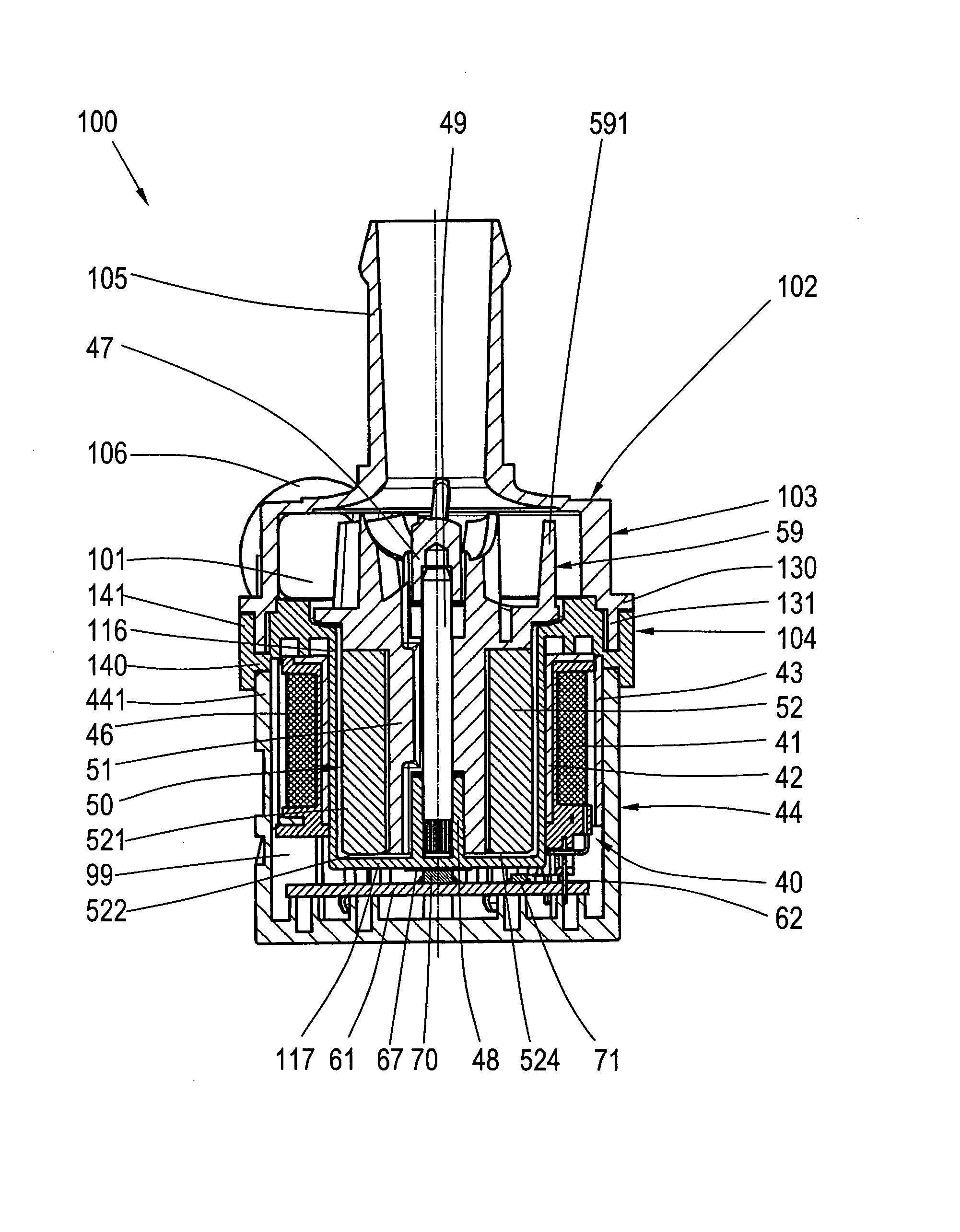

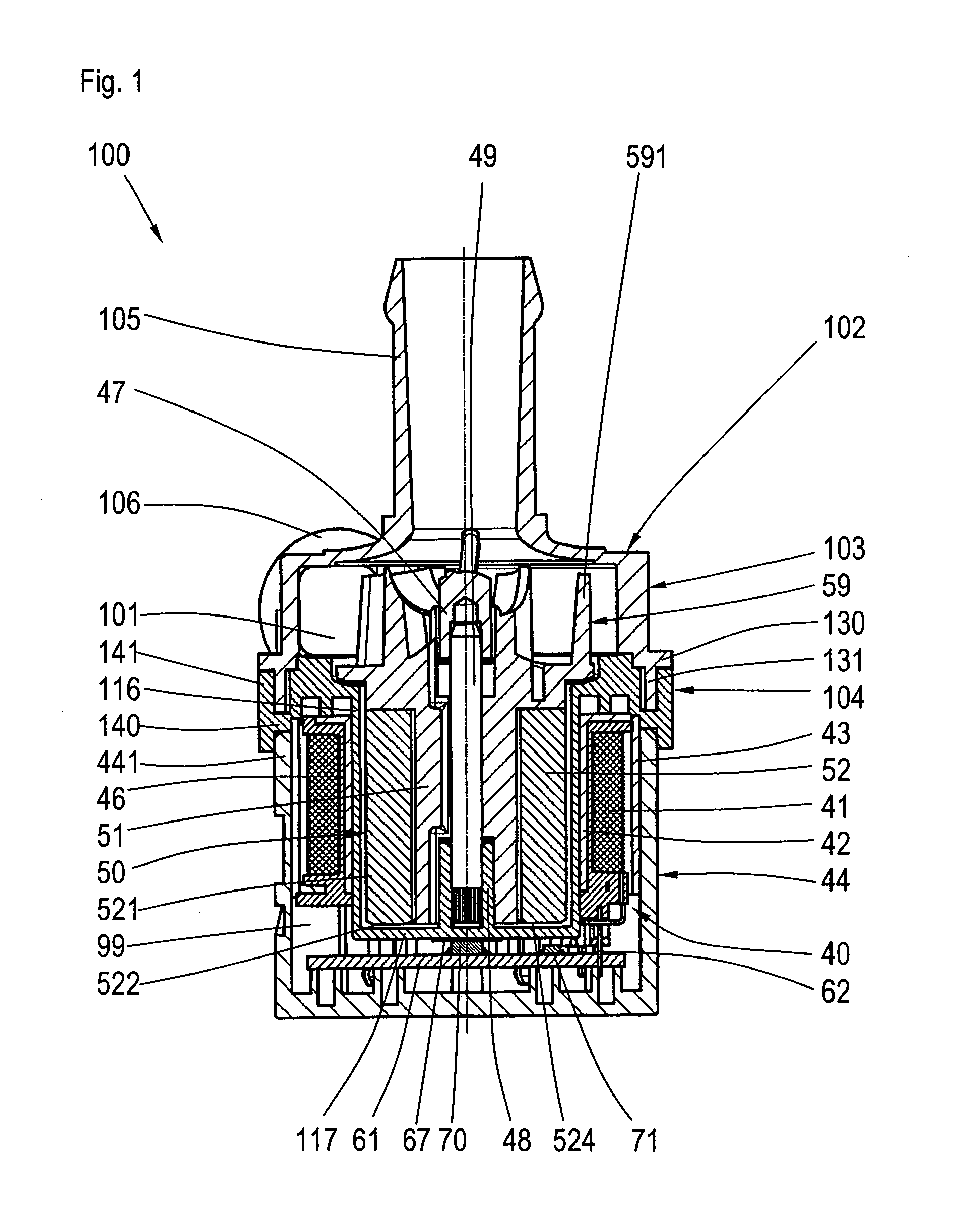

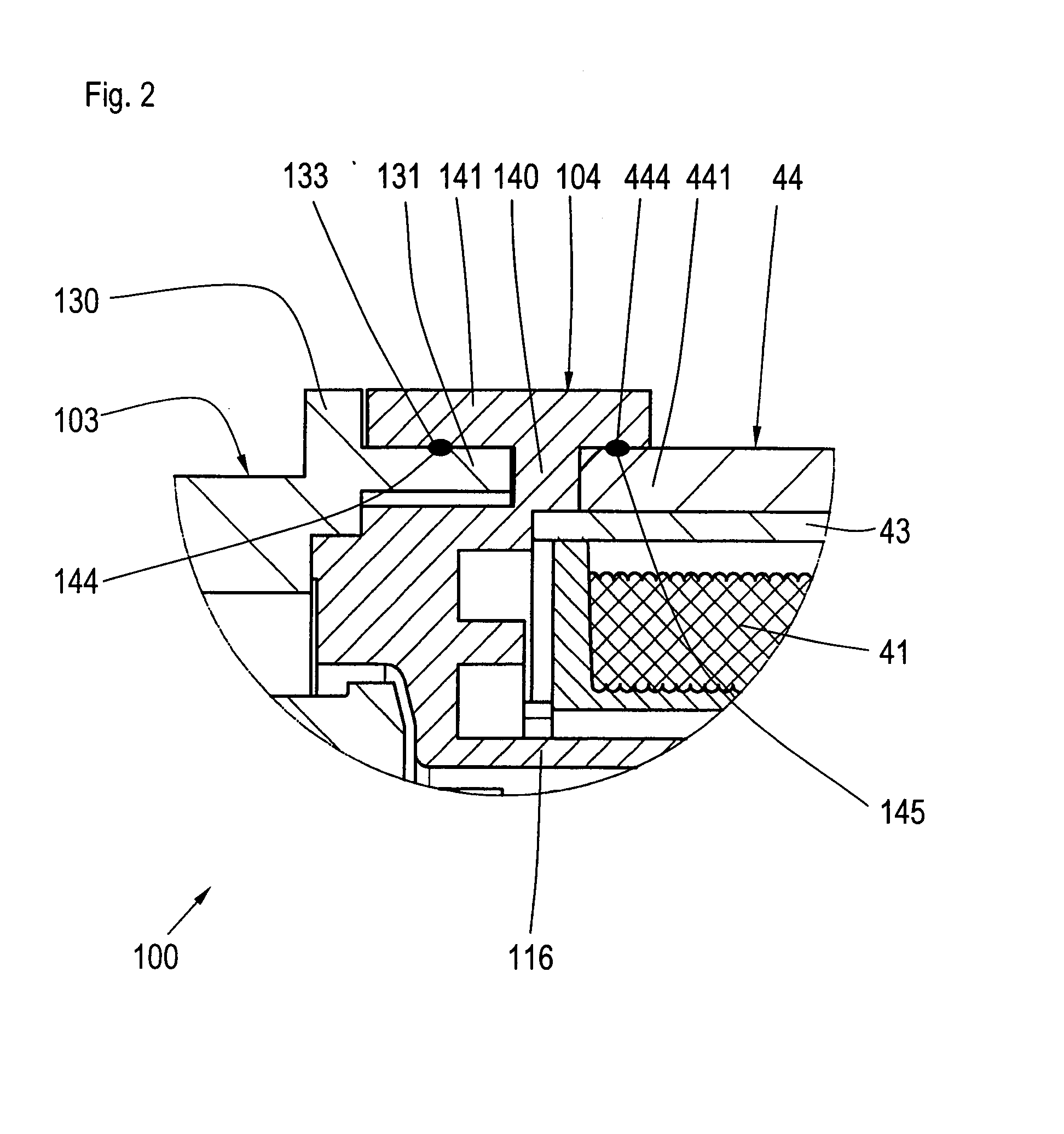

Centrifugal pump

ActiveUS20080031748A1Improve sealingCost of assembly minimalPump componentsReaction enginesMinimum weightLaser light

The invention relates to a centrifugal pump comprising a pump housing made of injection-molded plastics with a first housing part, which is designed as a single piece with a suction connection and a pressure connection, and comprises a sealing area, by means of which said first housing part is joined in a liquid-tight manner to a second housing part, that receives an electric motor, and a motor housing part. It is the object of the present invention to provide a centrifugal pump, in which very good leak tightness is achieved with minimum number of parts, minimum weight and minimum assembly costs with universal applicability without impairing the visual overall impression of the centrifugal pump. This objective is achieved according to the invention in that the second housing part is made of a material that is permeable to laser light of a wavelength or a wavelength range, and the first housing part is made of a material that absorbs the same laser light, and the first housing part and the second housing part are heat-sealed to one another.

Owner:BUHLER MOTOR GMBH

Speed control for a pumping system

A wastewater pumping system includes a centrifugal pump operatively connected to an electric motor via a coupling. The speed of the electric motor is automatically varied responsive to the head or load realized by the pump of the system as it varies with the composition of the slurry mixture. A variable frequency drive is operatively connected to the motor and the electrical power supply that affects a shift or change in electrical frequency delivered to the electrical motor so that the speed of the motor and consequently the pump is varied. This allows the electrical power deliver to the system to remain substantially unchanged for varying loads realized by the pump.

Owner:F E MEYERS

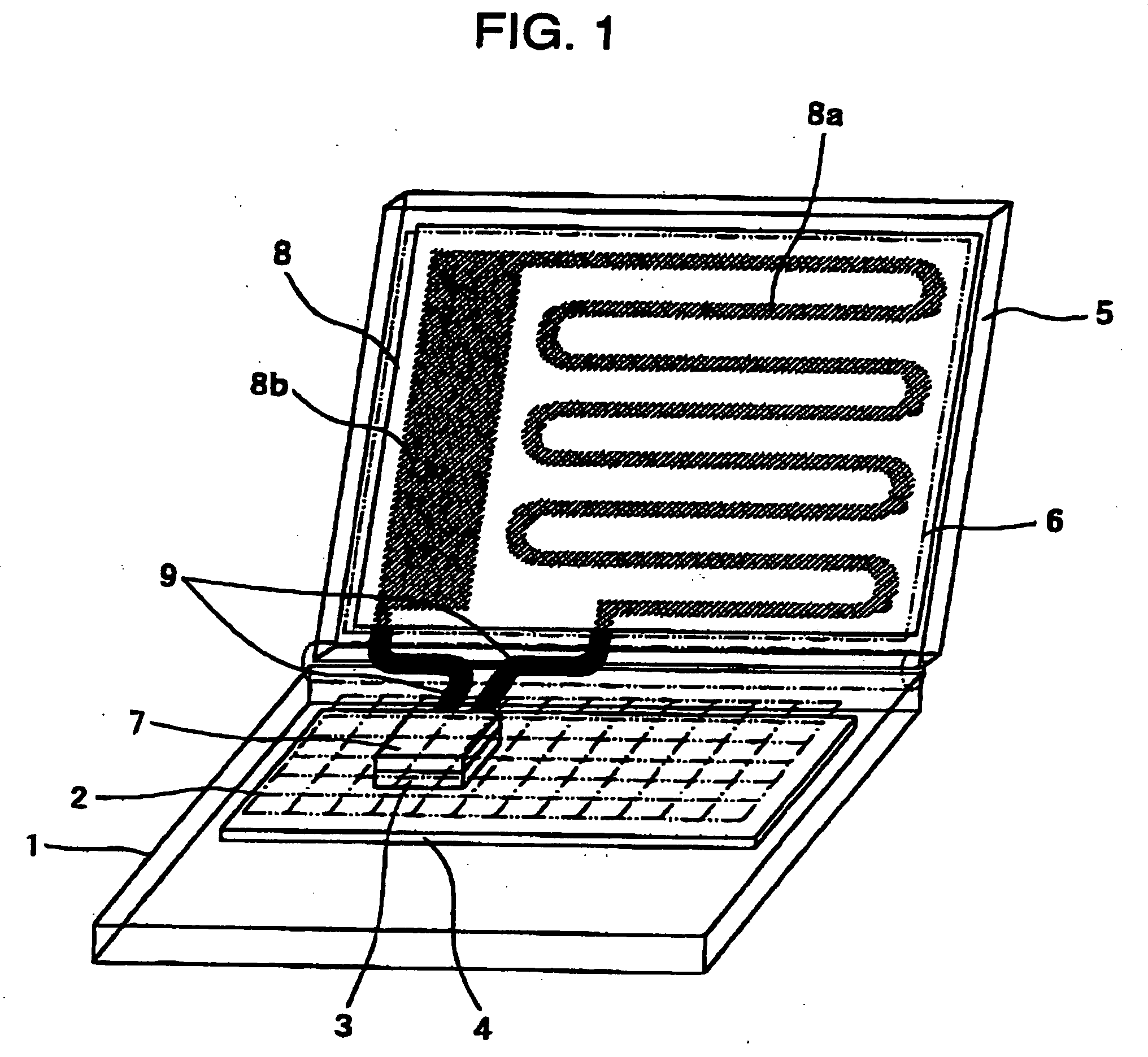

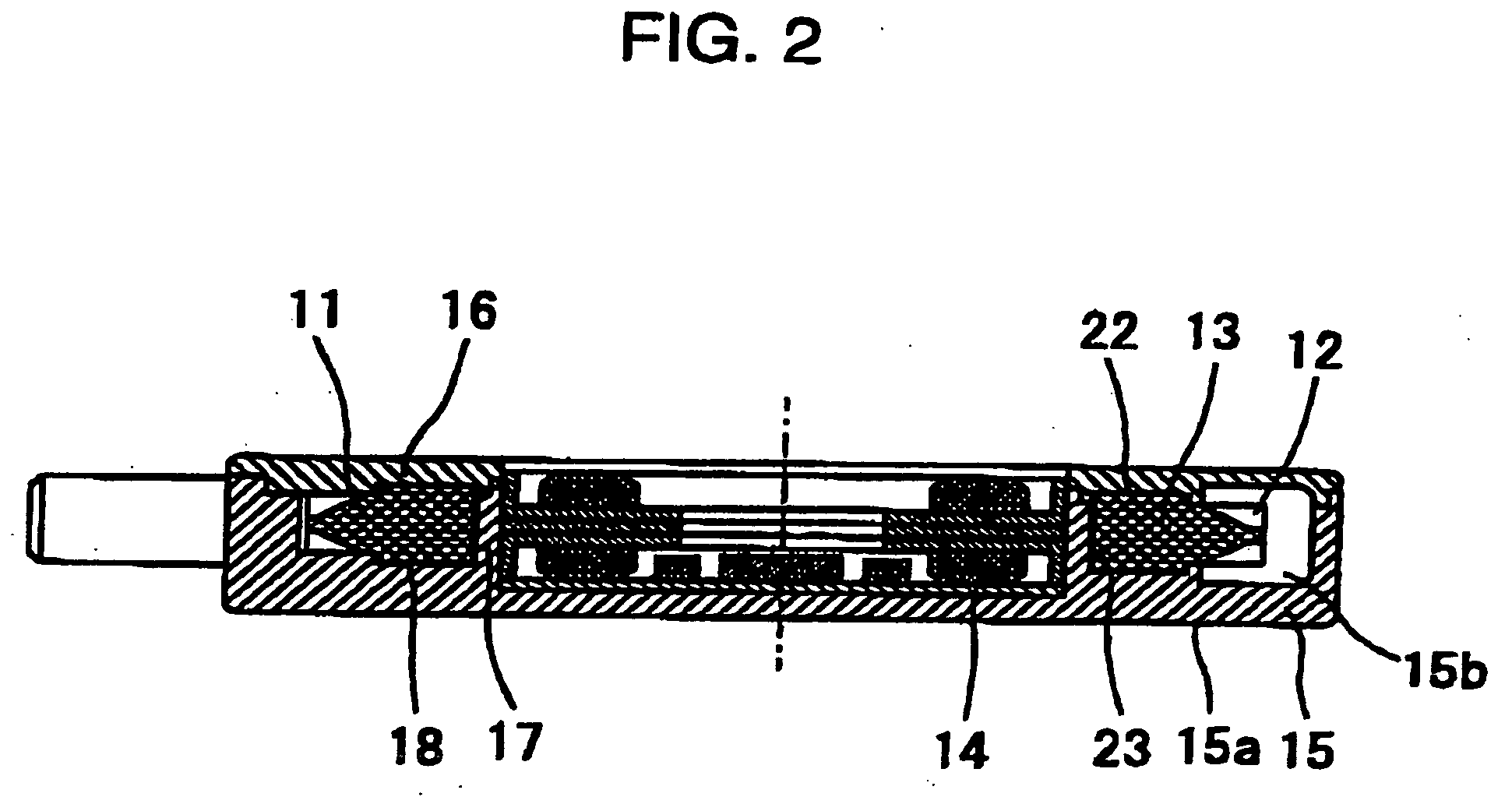

Cooling device and an electronic apparatus including the same

InactiveUS20050117298A1Improve cooling efficiencyEasy constructionDigital data processing detailsSemiconductor/solid-state device detailsCoolant flowNuclear engineering

A cooling device for cooling a heat-generating component includes a circulating passage arranged to have coolant circulate therein, a centrifugal pump including a first case made of metallic material, a second case made of resin material, and an impeller accommodated in the pump chamber, and a radiator provided at the circulating passage and being operable to release heat from the coolant. The first case has a surface arranged to contact the heat-generating component. The second case forms a pump chamber between the first case and the second case. The pump chamber stores the coolant therein. The impeller includes open-type vanes arranged to pressurize the coolant as to have the coolant flow through the circulating passage. The cooling device has a high cooling efficiency as well as a high operating efficiency of the motor while having a simple construction and a small overall size and a small thickness.

Owner:PANASONIC CORP

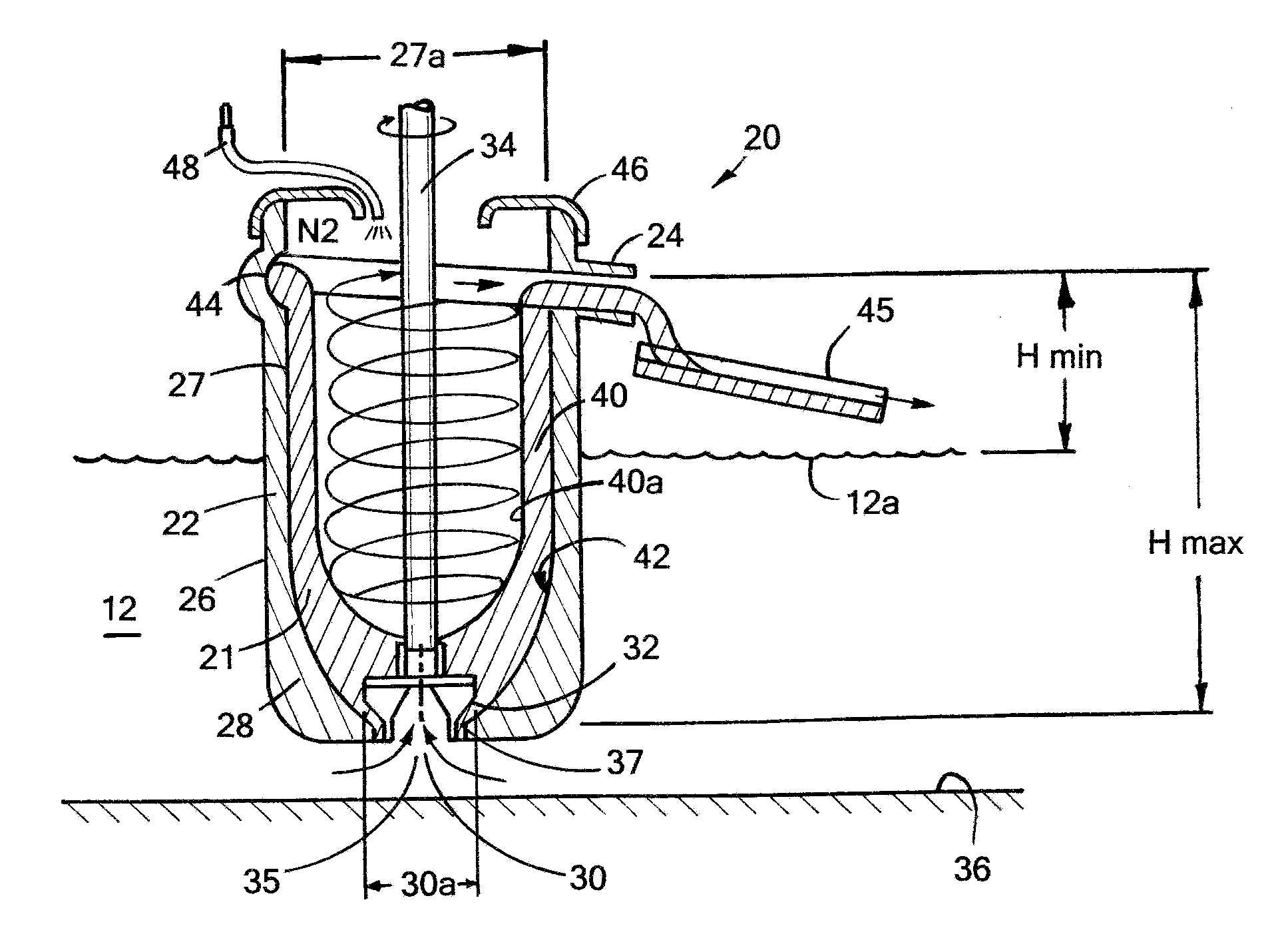

Riserless recirculation/transfer pump and mixer/pre-melter for molten metal applications

ActiveUS20120163959A1Large diameterEasy accessSpecific fluid pumpsPump componentsCurve shapeEngineering

A pump for processing molten metal having an enlarged tubular body which houses a centrifugal lifting pump at its bottom end. The bottom end has a curved shape that aids in the formation and sustainability of: a) a forced vortex; b) a highly forced vortex; and c) a super forced vortex, depending on the application when it which receives the ejected molten metal from the lifting pump's impeller. The lifting pump is controlled to cause the vortex to climb up the inner wall of the body up to and out of an outlet formed in the upper end of the body. A recirculation centrifugal pump is mounted coaxially to and rotates with the lifting impeller.

Owner:MORANDO JORGE A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com