Patents

Literature

2806 results about "Exhaust manifold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word manifold comes from the Old English word manigfeald (from the Anglo-Saxon manig [many] and feald [fold]) and refers to the folding together of multiple inputs and outputs (in contrast, an inlet or intake manifold supplies air to the cylinders).

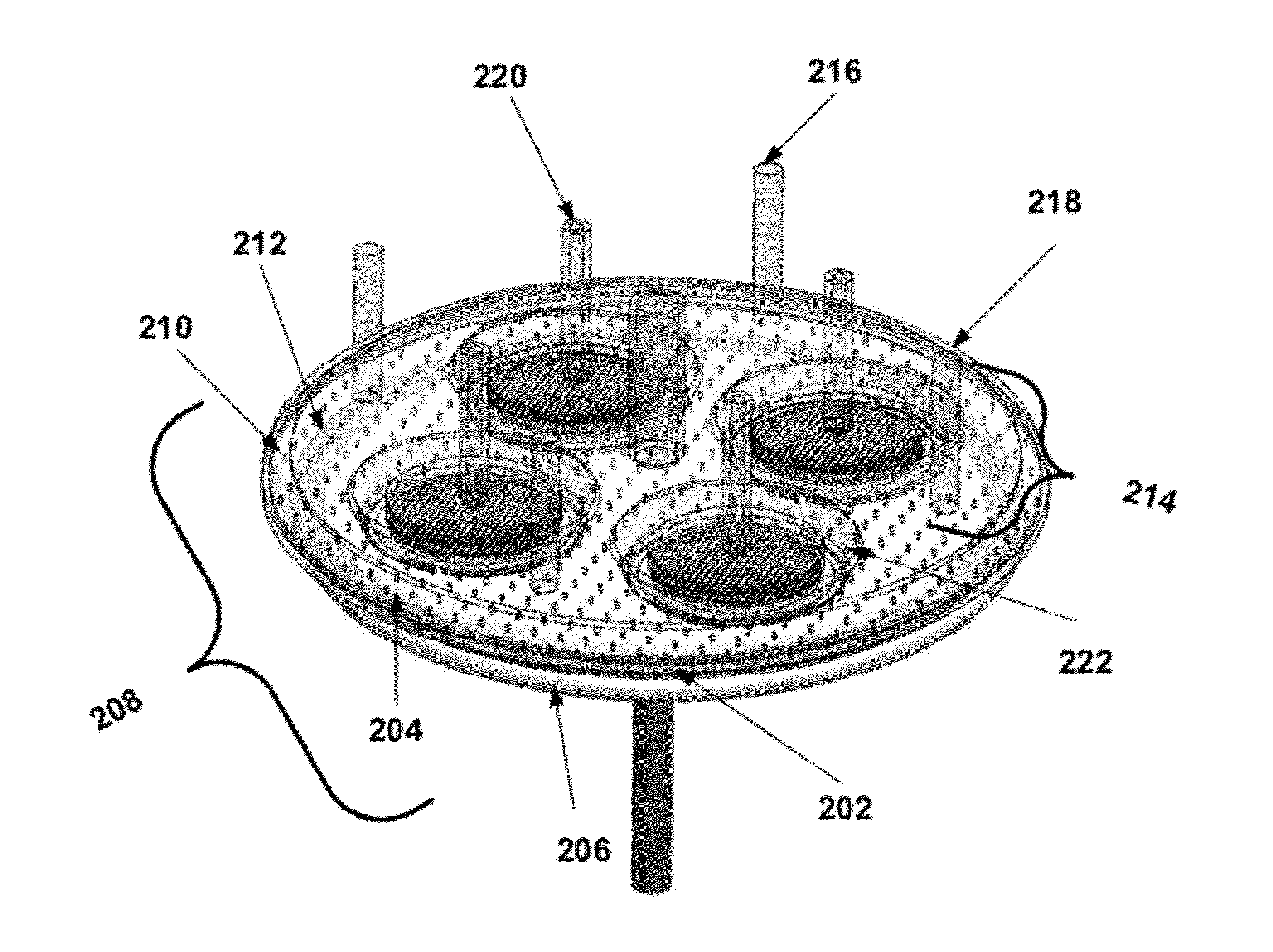

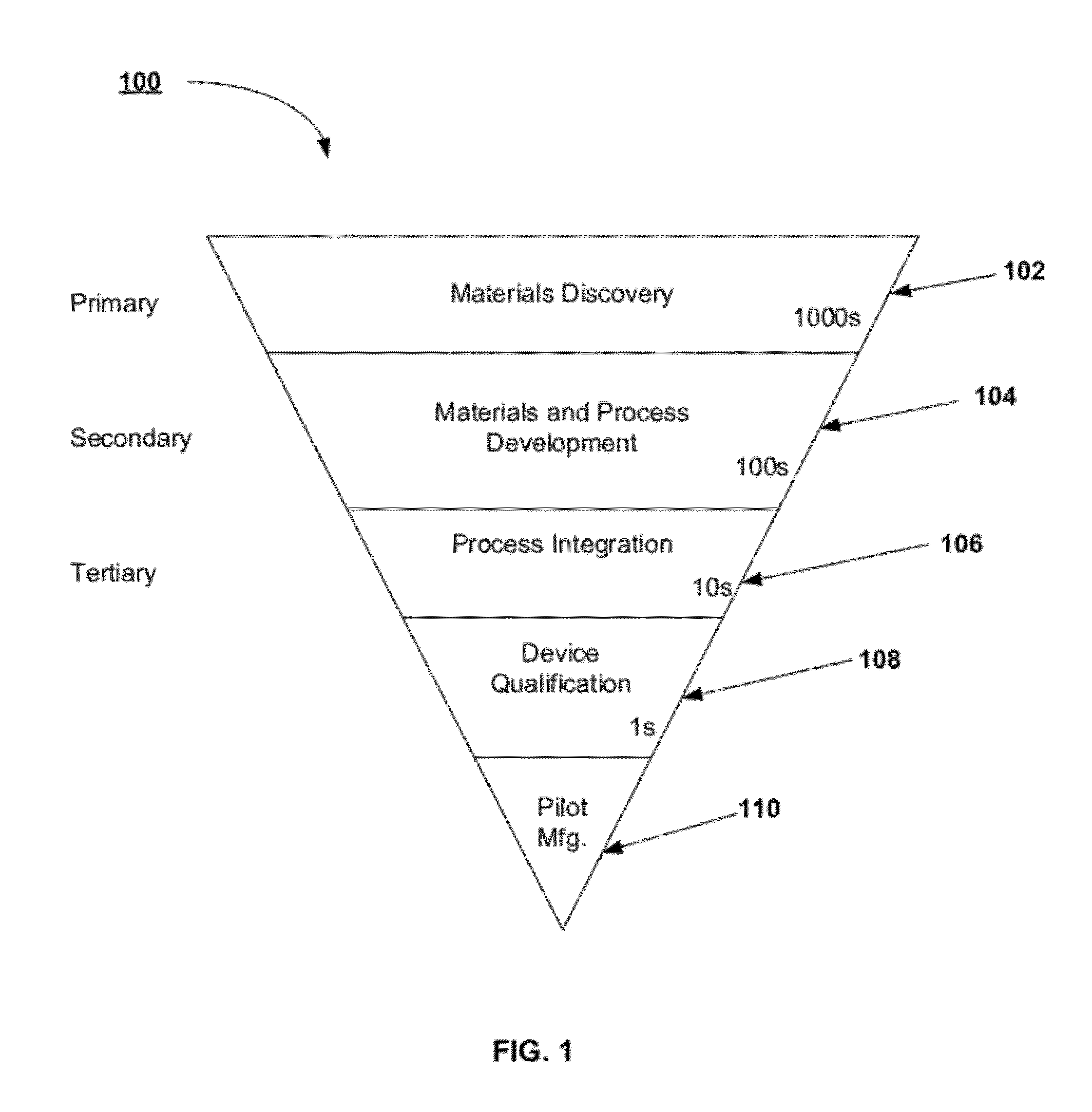

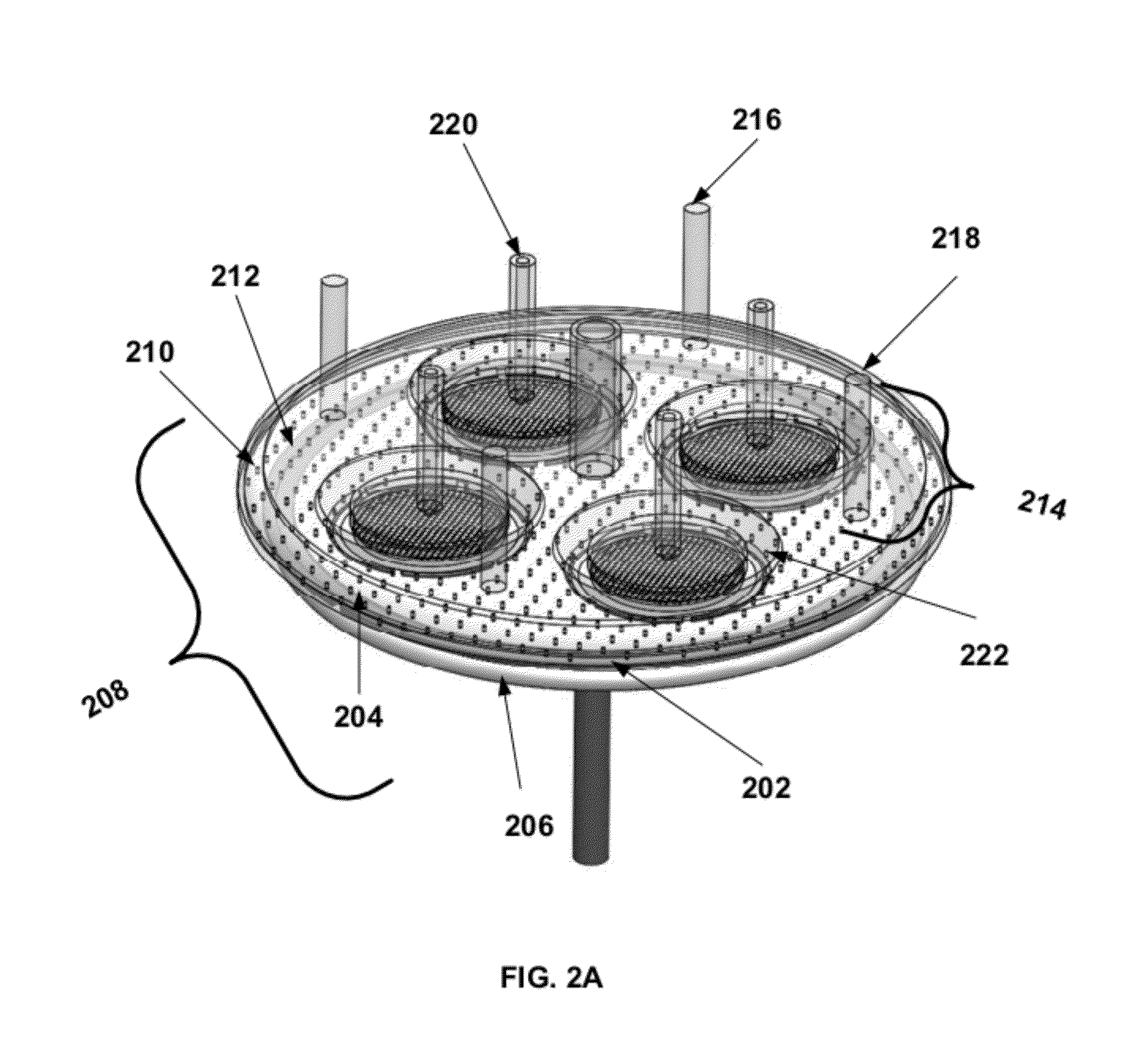

System for multi-region processing

ActiveUS20120321786A1Avoid cross contaminationChemical vapor deposition coatingReactive gasEngineering

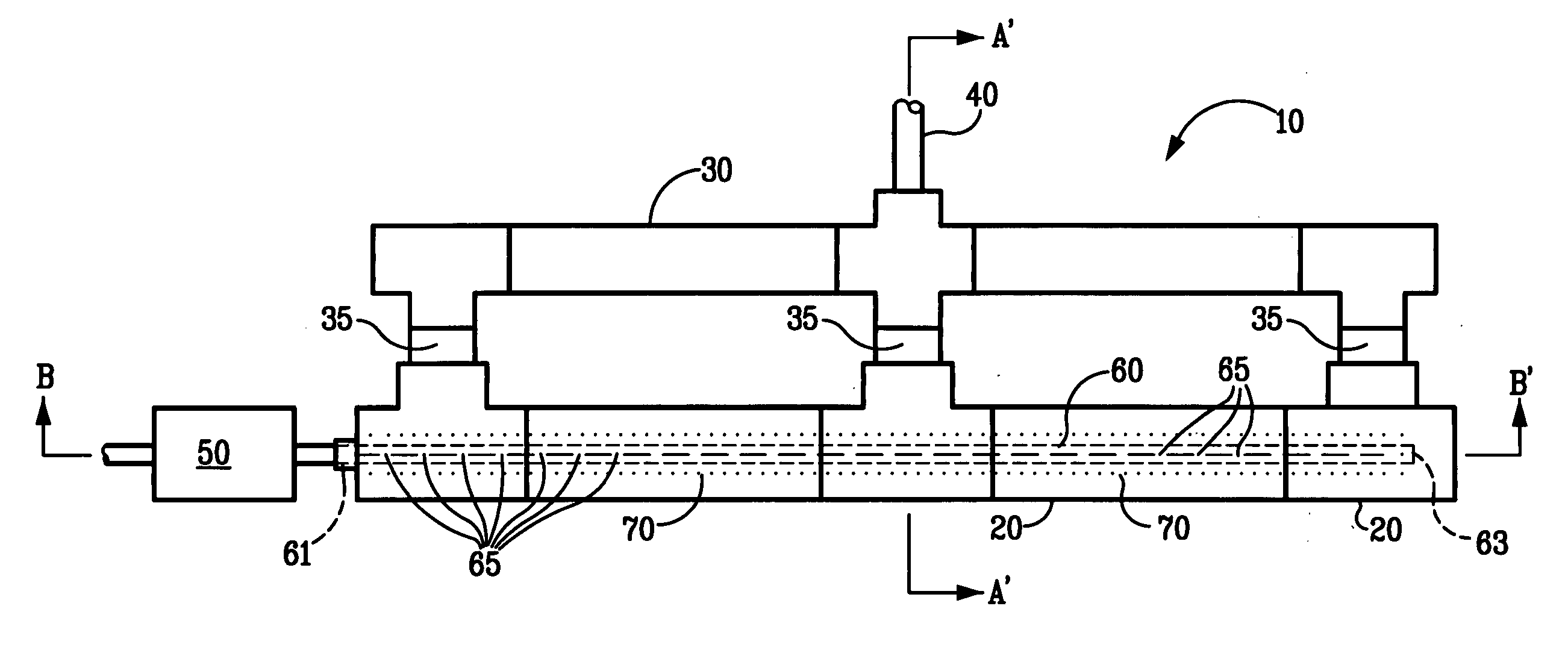

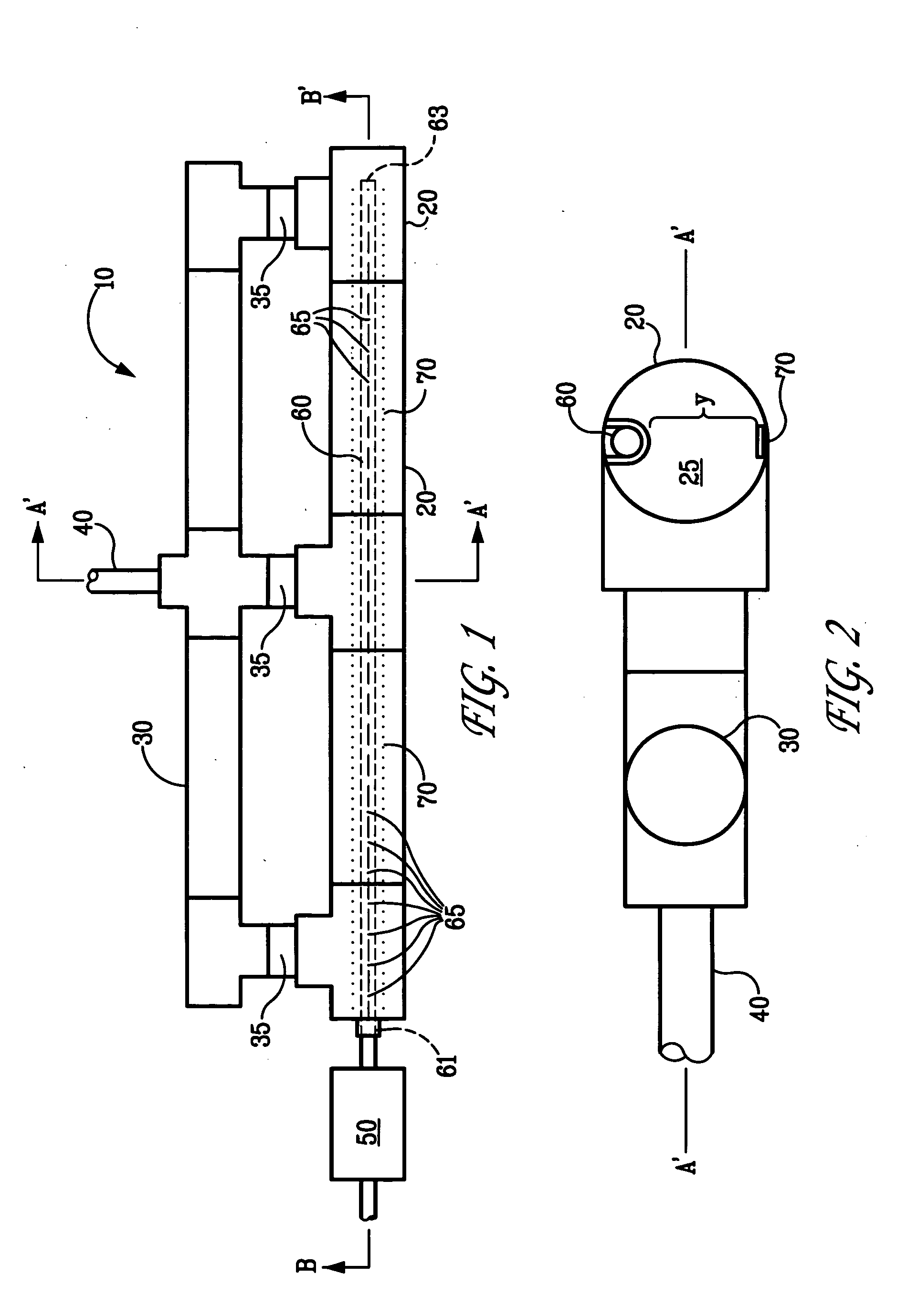

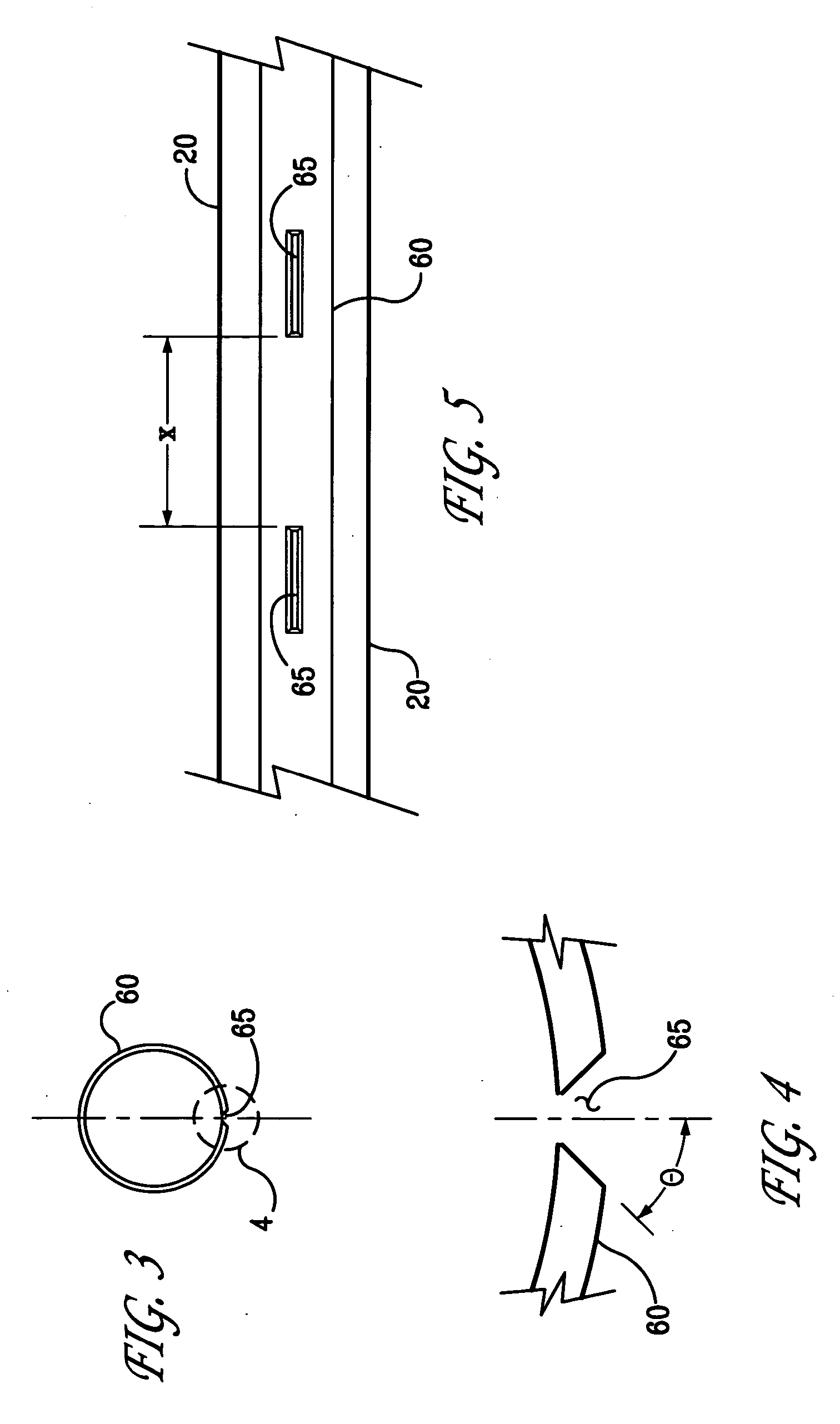

A gas distribution structure for supplying reactant gases and purge gases to independent process cells to deposit thin films on separate regions of a substrate is described. Each process cell has an associated ring purge and exhaust manifold to prevent reactive gases from forming deposits on the surface of the wafer between the isolated regions. Each process cell has an associated showerhead for conveying the reactive gases to the substrate. The showerheads can be independently rotated to simulate the rotation parameter for the deposition process.

Owner:INTERMOLECULAR

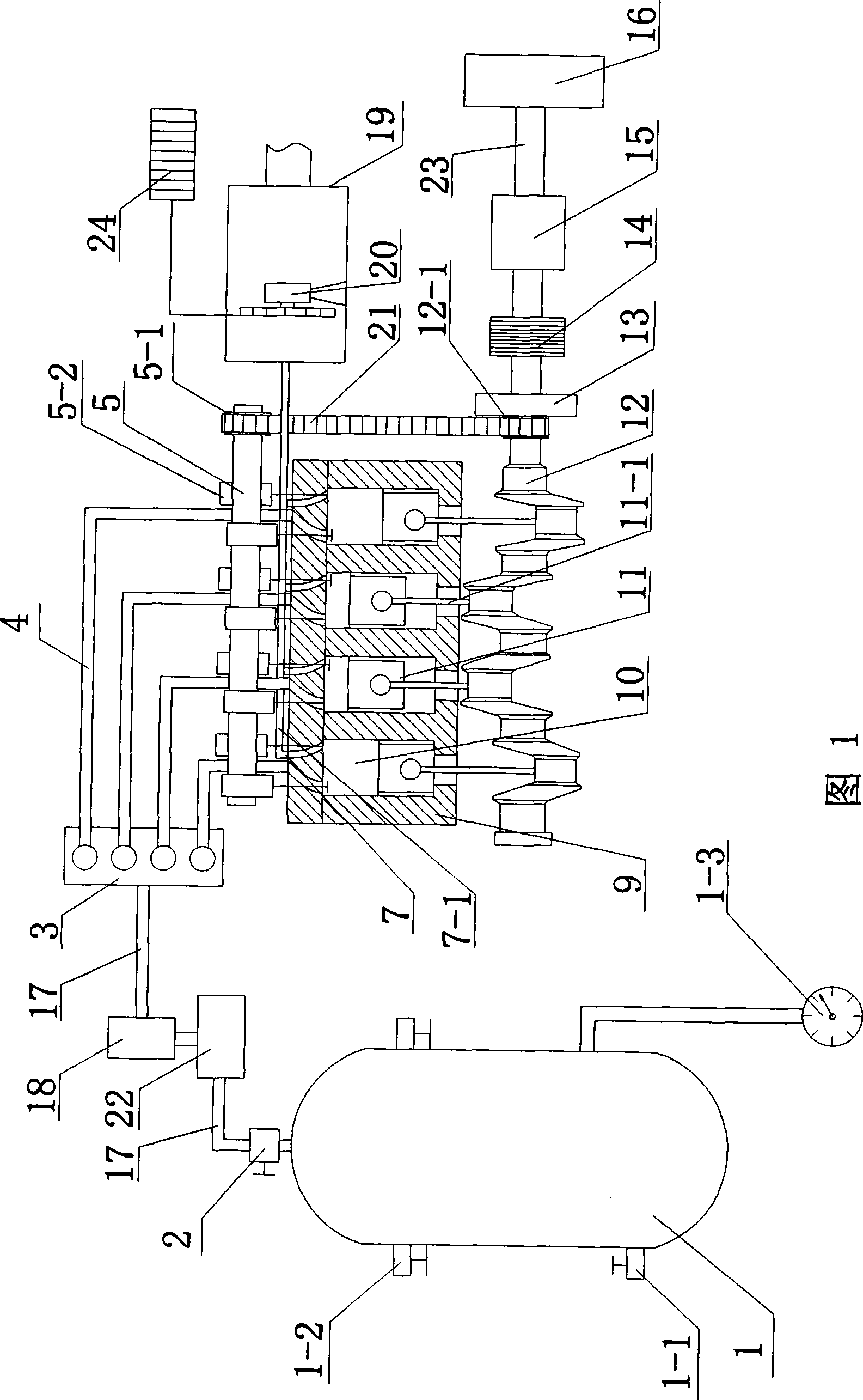

Air power engine assembly

InactiveCN101413403ALow costNo pollutionMechanical power devicesEngines characterised by uniflow principleDistributorPiston

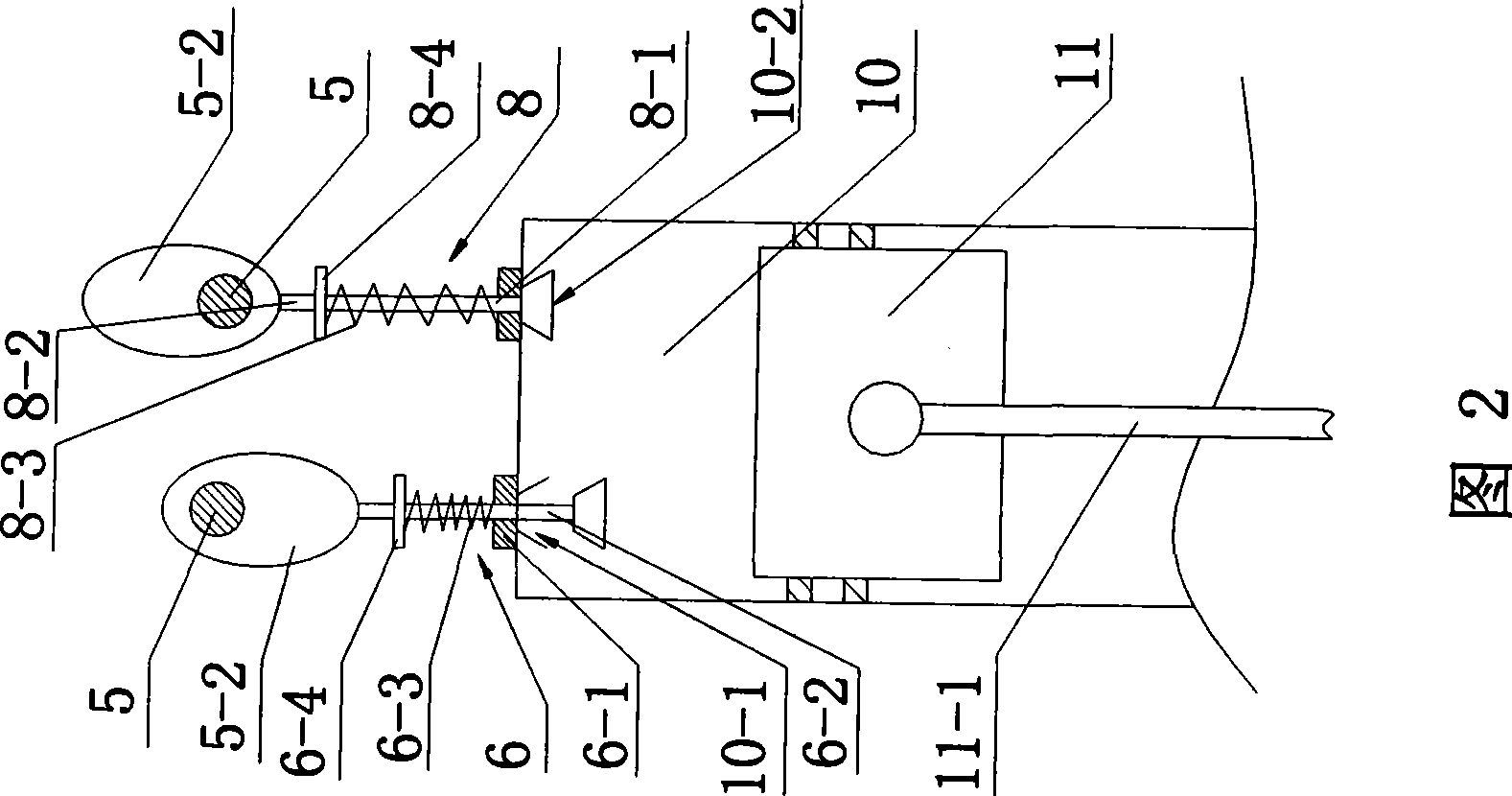

The invention relates to an air-powered engine assembly, which comprises an air tank, an air valve, an air distributor, an intake pipe, camshafts, an intake duct, an exhaust control device, air cylinders, pistons, crankshafts, couplers, clutches, automatic gearboxes and differentials connected with the outside. The assembly is characterized in that the air valve, a constant pressure chamber and a pressure controller are arranged between the air tank and the air distributor; the air distributor is connected with a plurality of air cylinders on an air cylinder gasket; each air cylinder is connected with an exhaust chamber through an exhaust manifold; the exhaust chamber is provided with a turbine generator which is connected with a storage batter; the air cylinders are provided with the camshafts for controlling the air intake and exhaust of the air cylinders; the air cylinders are provided inside with the pistons for driving the crankshafts to rotate; the camshafts and the crankshafts are connected by chains; and the crankshafts are connected with the differentials through the couplers, the clutches and the gearboxes in turn. Therefore, doing work through air compression rather than fuel, the air-powered engine assembly has the advantages of avoiding waste gas discharge and air pollution, along with reliable operation, convenient operation, economical efficiency, practicality and so on. In addition, due to recycle of the waste gas for power generation, the air-powered engine assembly saves energy and reduces costs.

Owner:周登荣 +1

Apparatus and process for surface treatment of substrate using an activated reactive gas

InactiveUS20060062914A1Electric discharge tubesChemical vapor deposition coatingReactive gasProduct gas

An apparatus and process for treating at least a portion of the surface of a substrate is described herein. In one aspect, the apparatus a processing chamber comprising an inner volume, the substrate, and an exhaust manifold; an activated reactive gas supply source wherein a process gas comprising one or more reactive gases and optionally an additive gas is activated by one or more energy sources to provide the activated reactive gas; and a distribution conduit, which is in fluid communication with the inner volume and the supply source, comprising: a plurality of openings that direct the activated reactive gas into the inner volume, wherein the activated reactive gas contacts the surface and provides a spent activated reactive gas and / or volatile products that are withdrawn from the inner volume through the exhaust manifold.

Owner:AIR PROD & CHEM INC

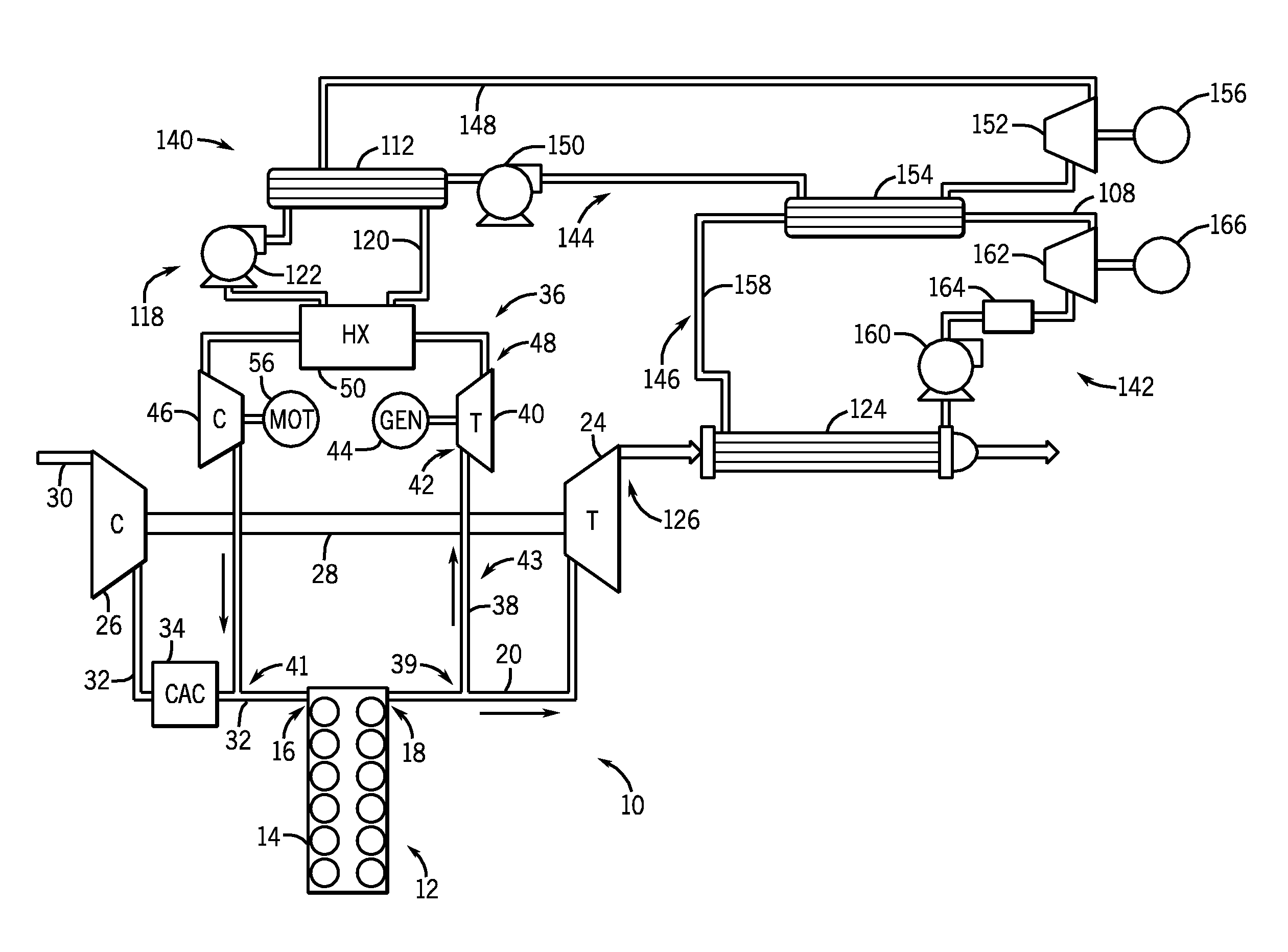

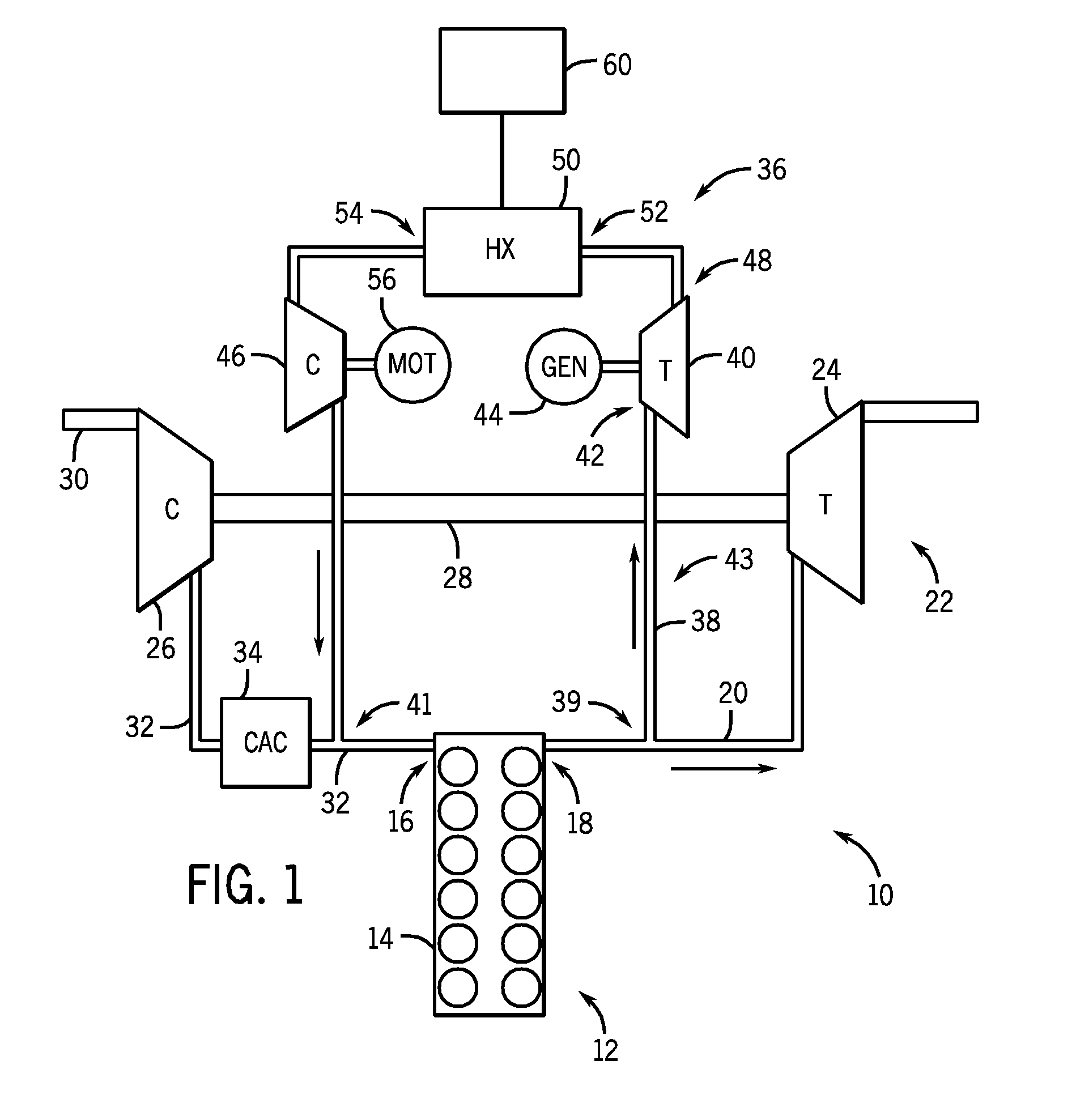

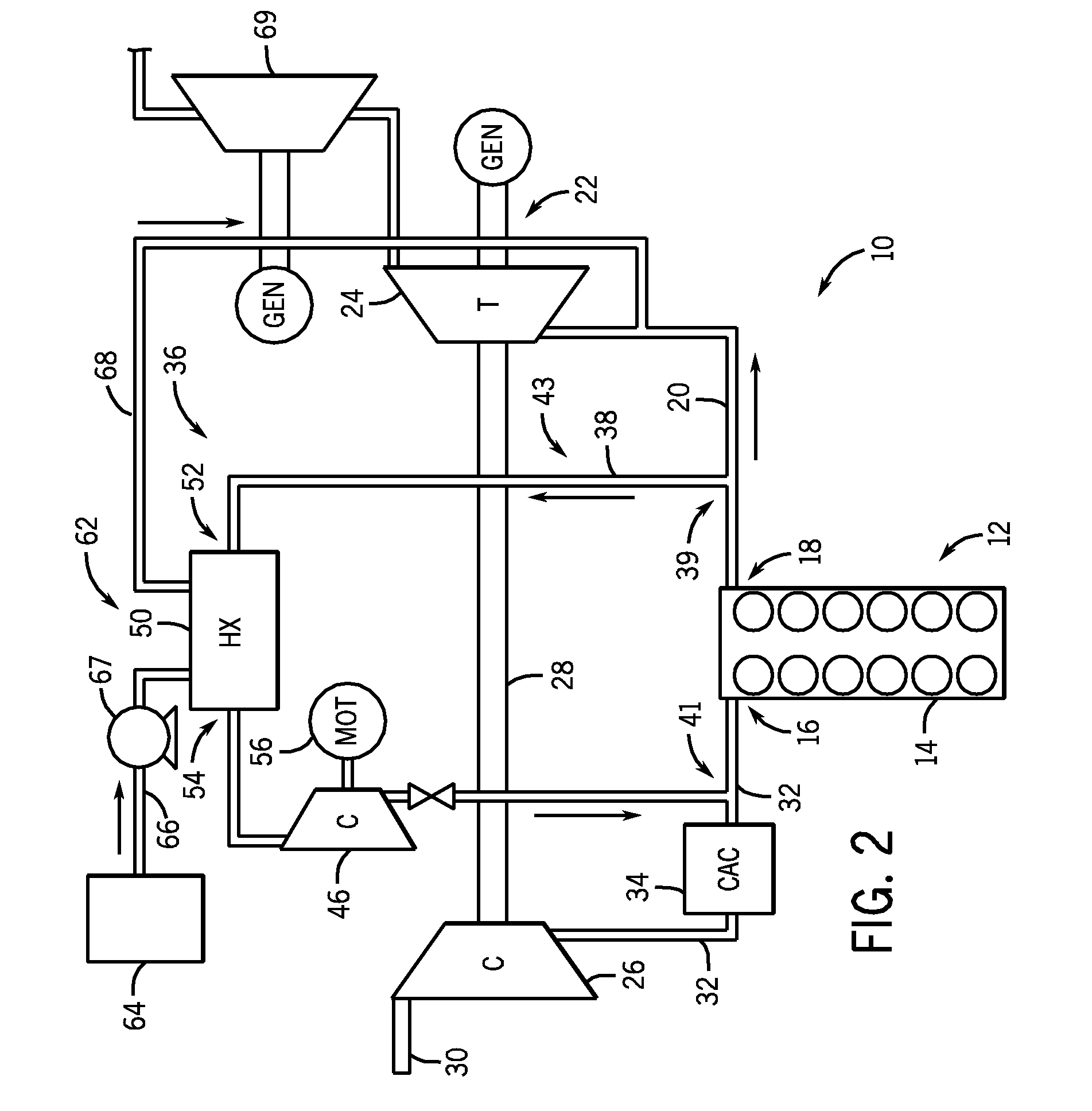

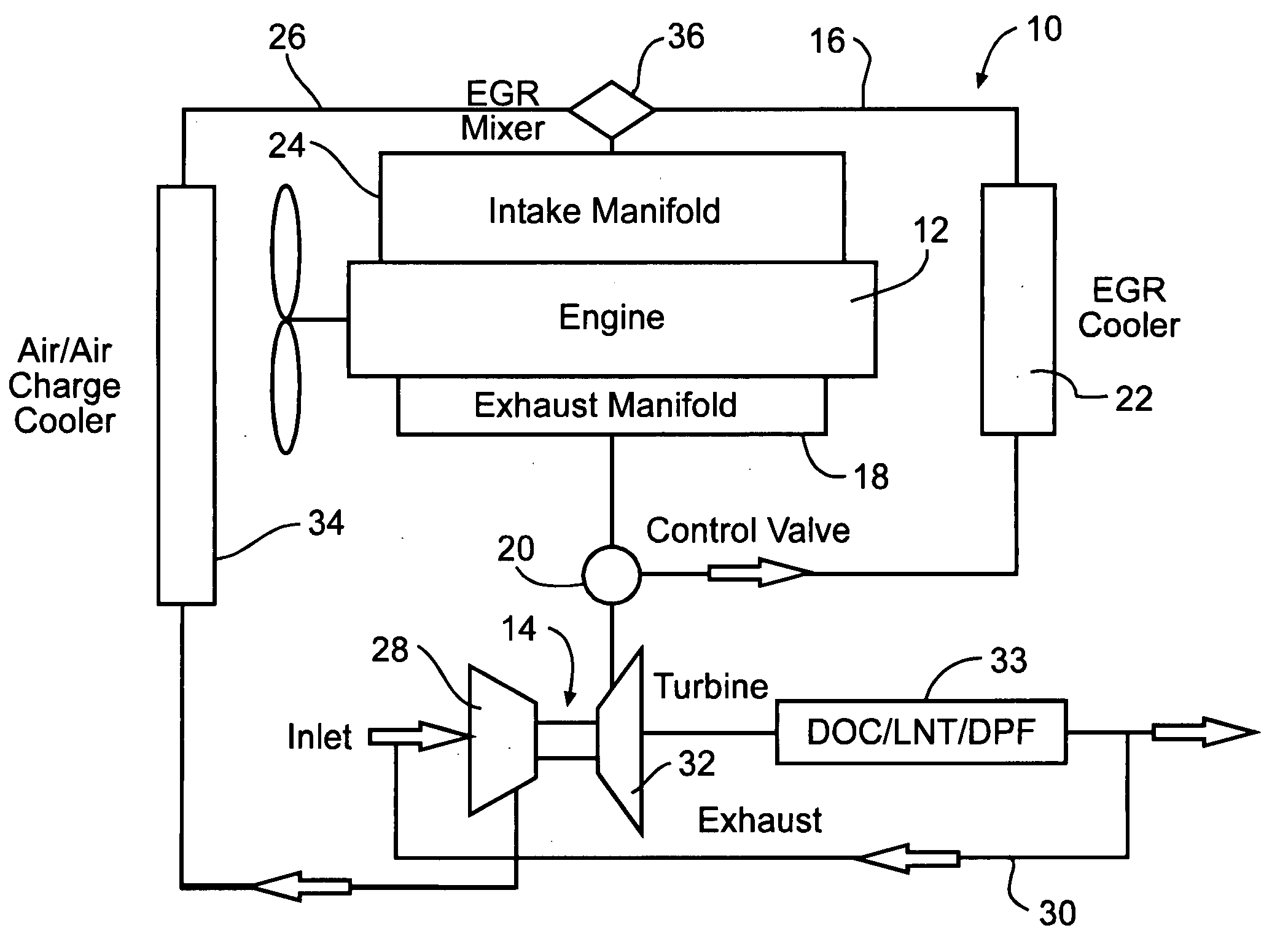

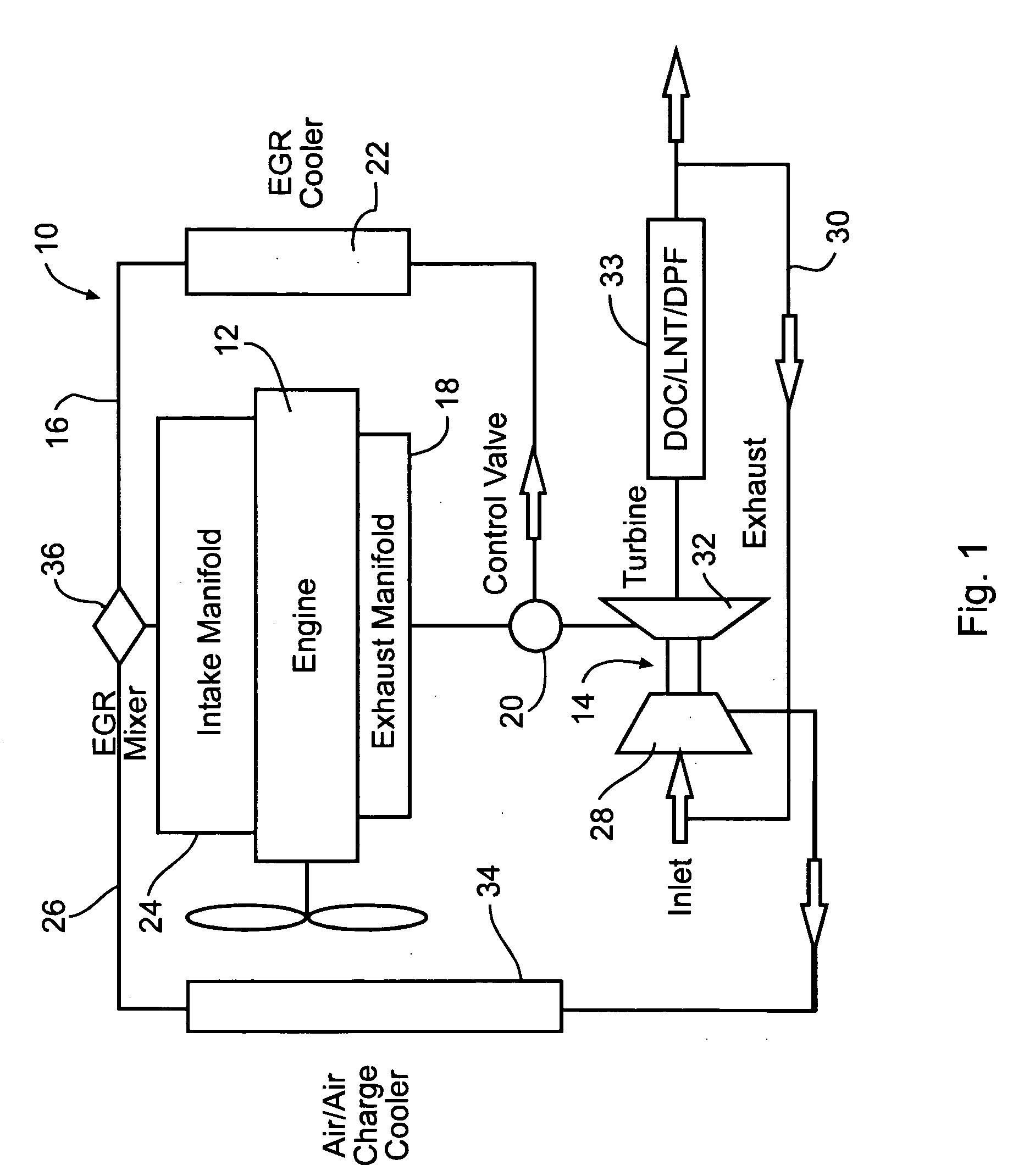

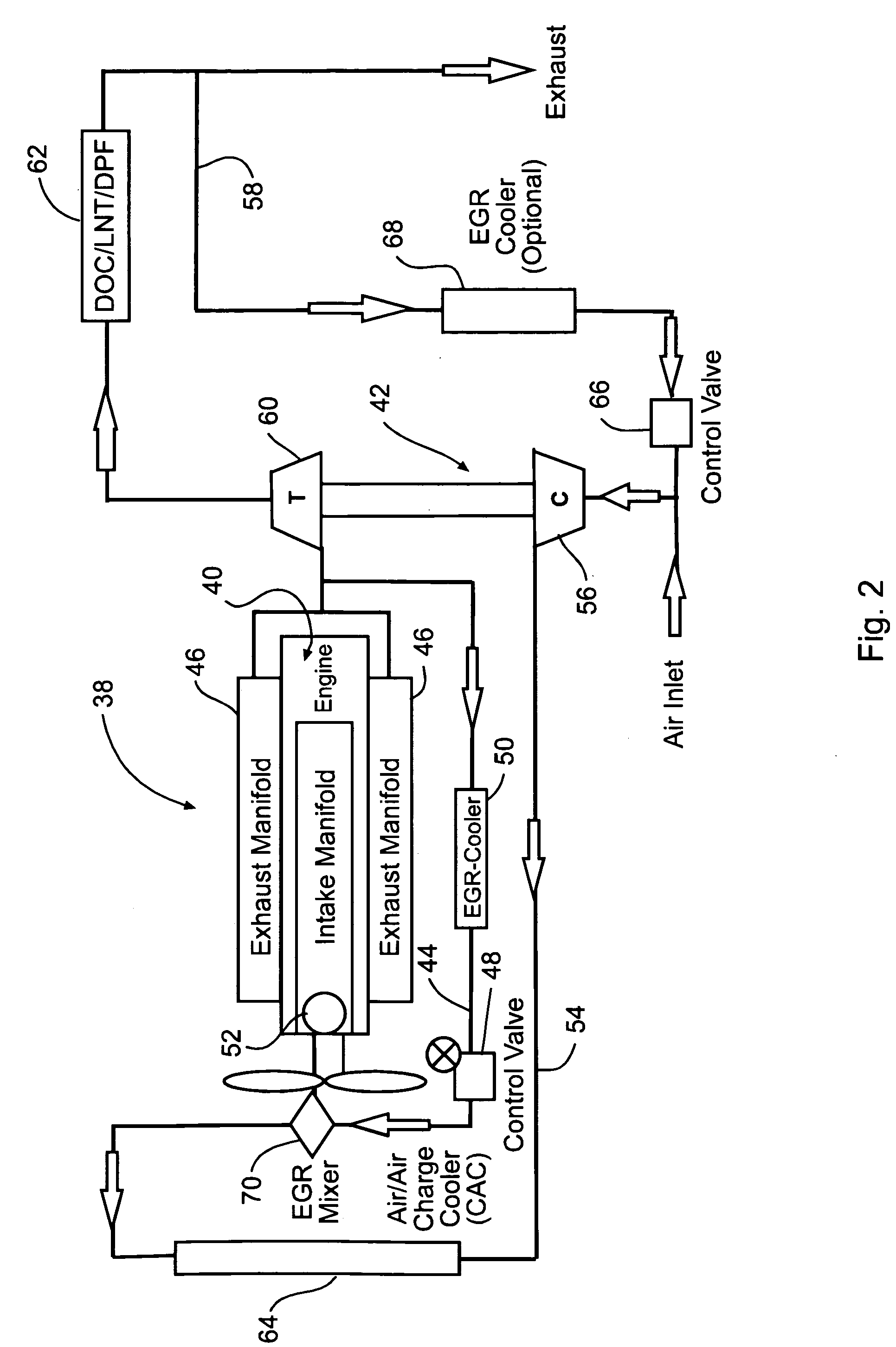

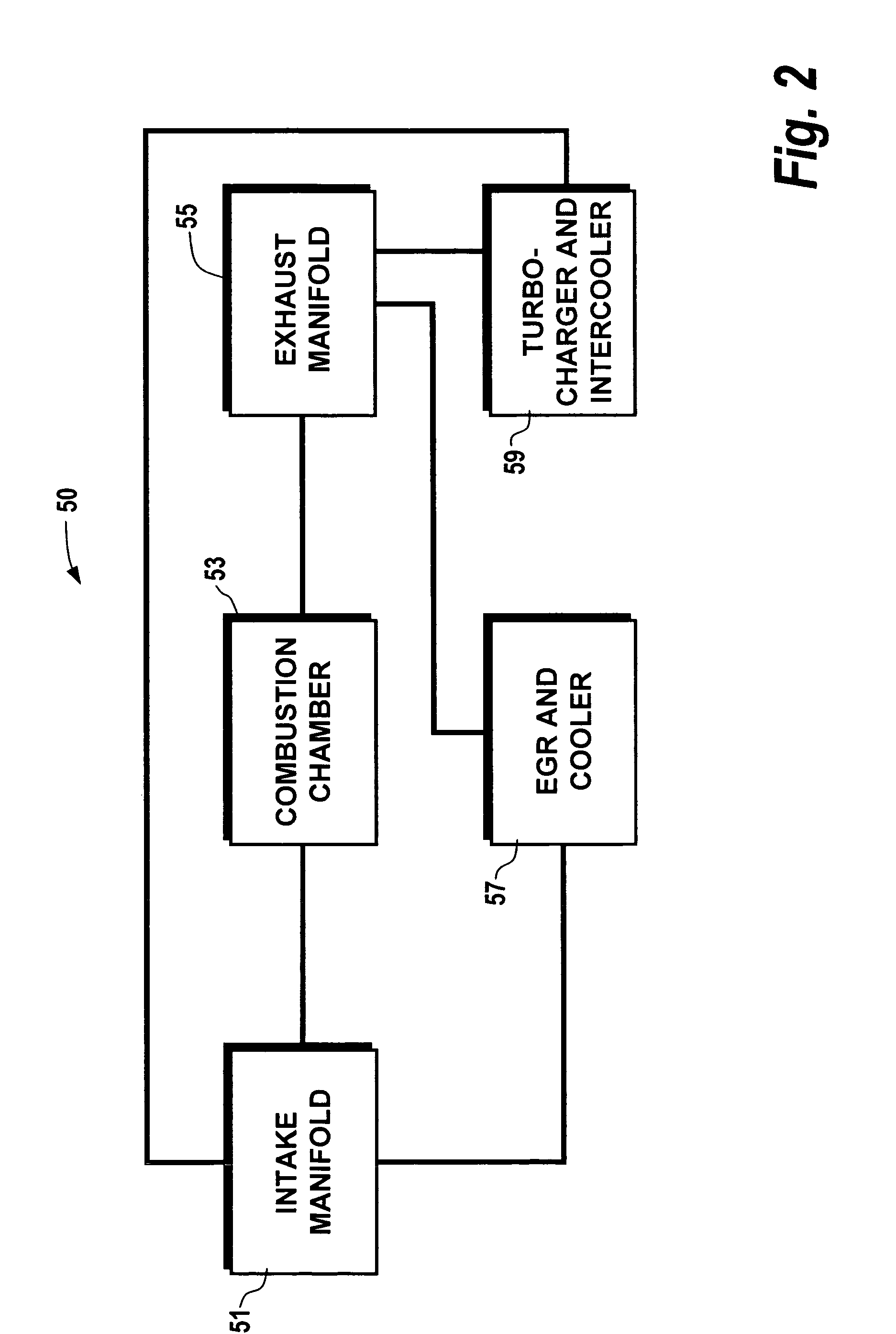

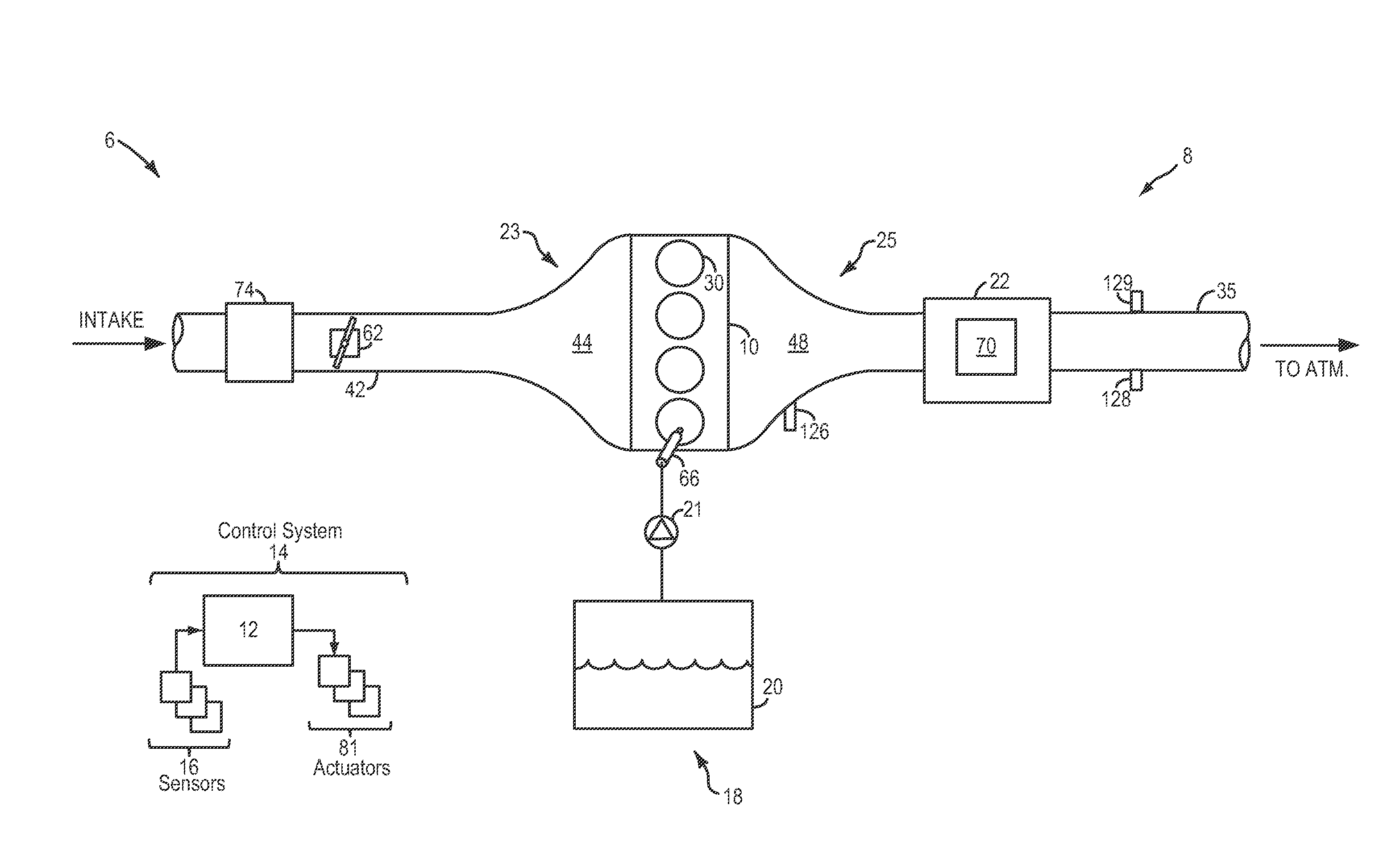

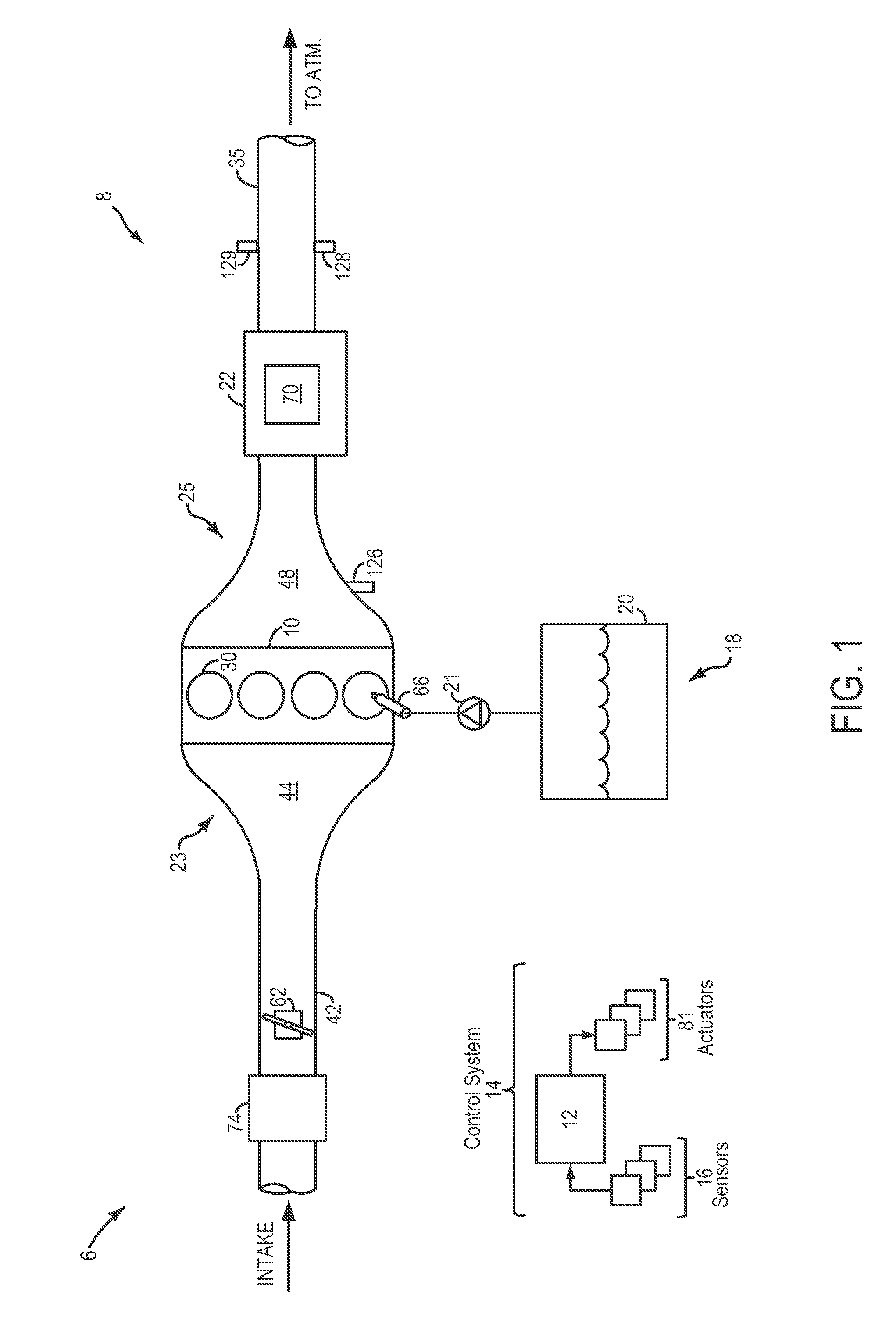

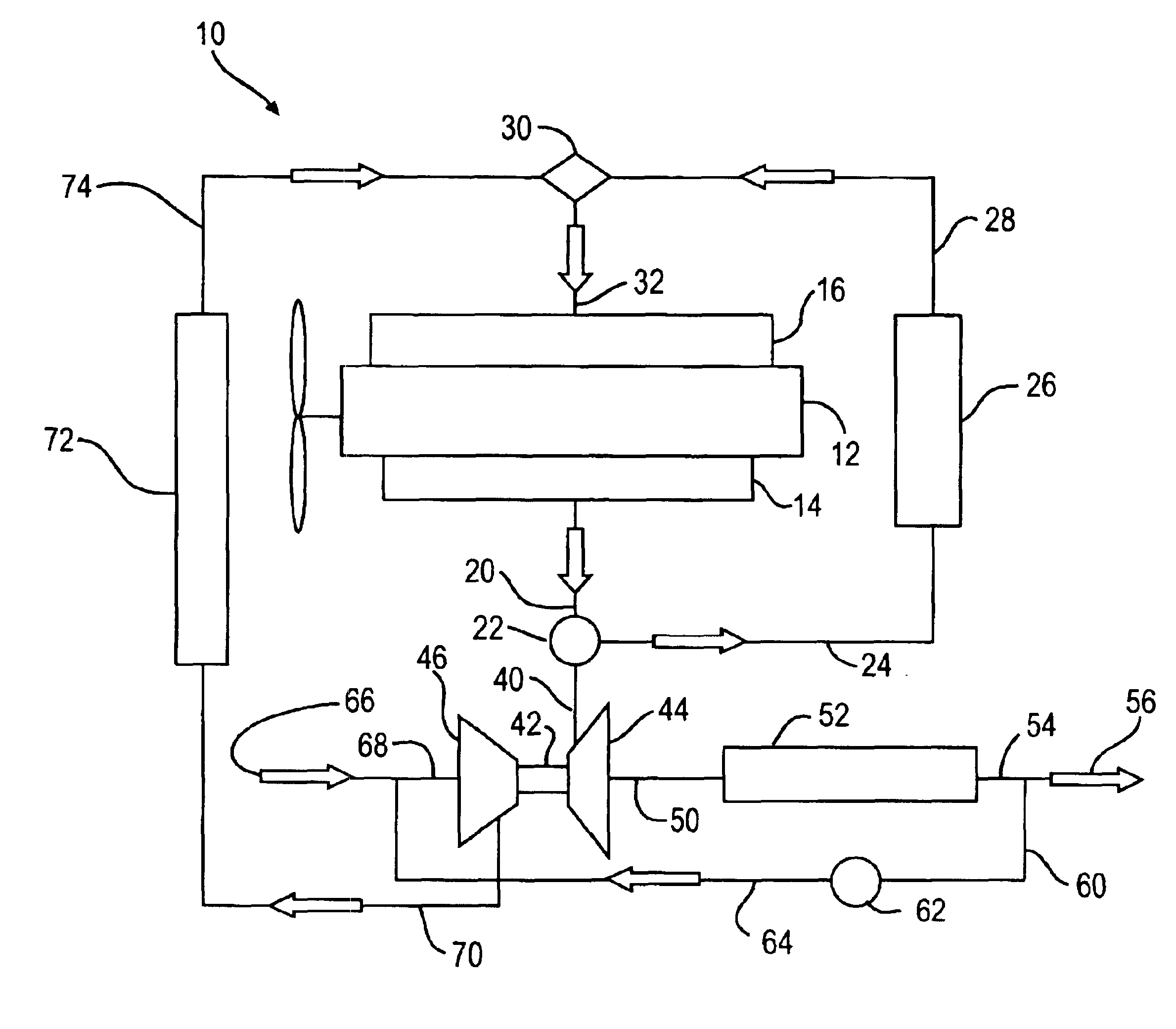

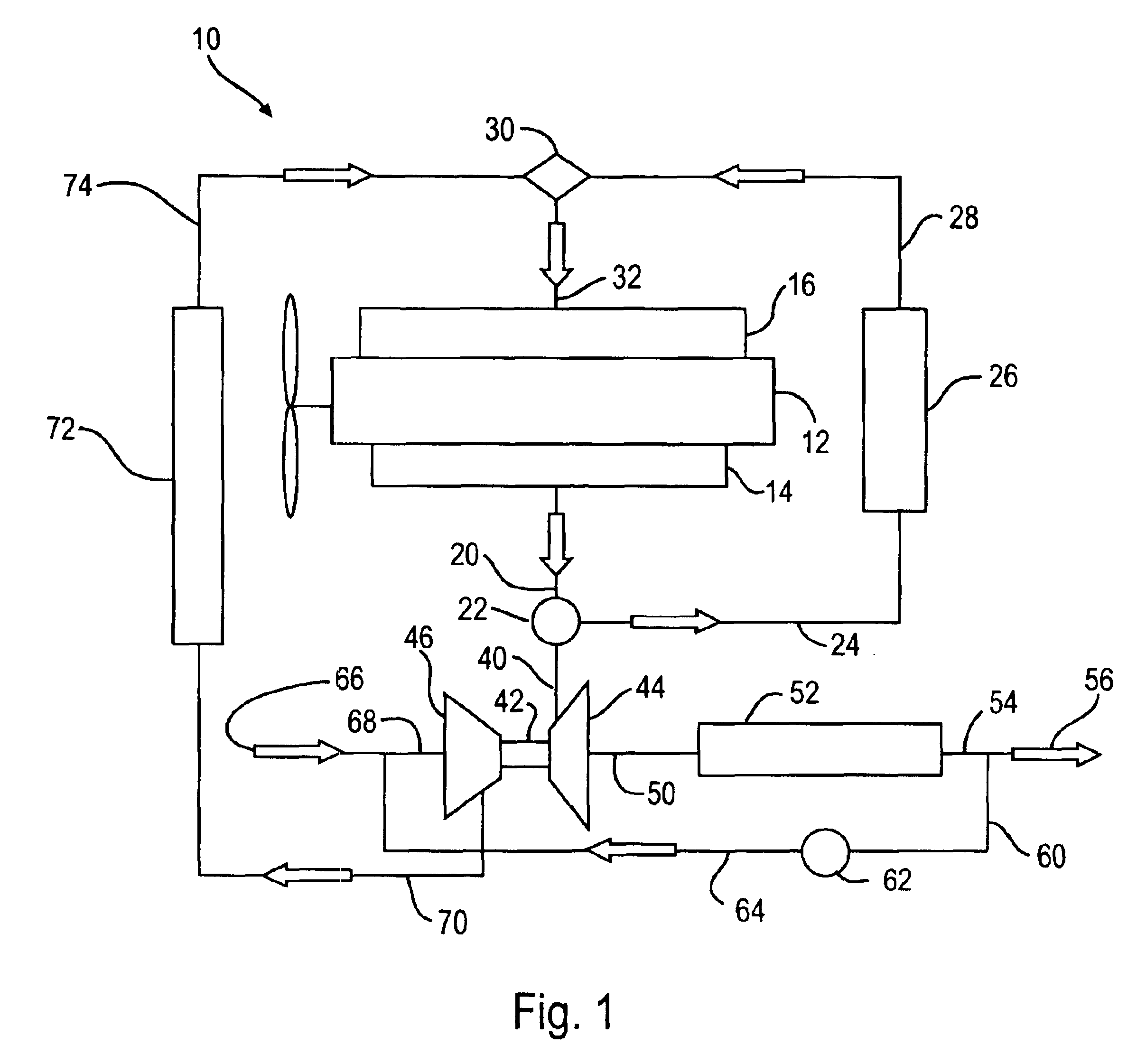

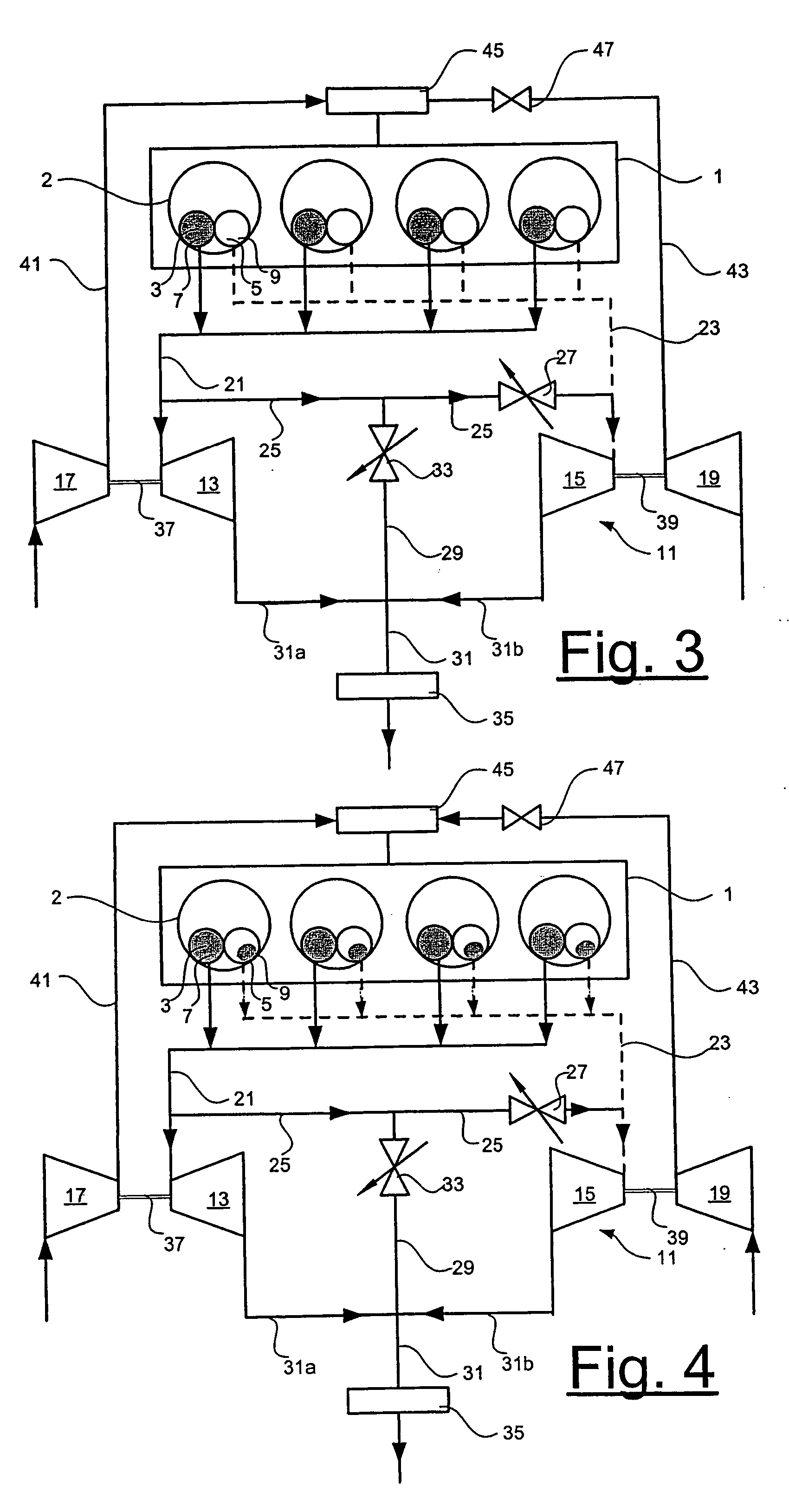

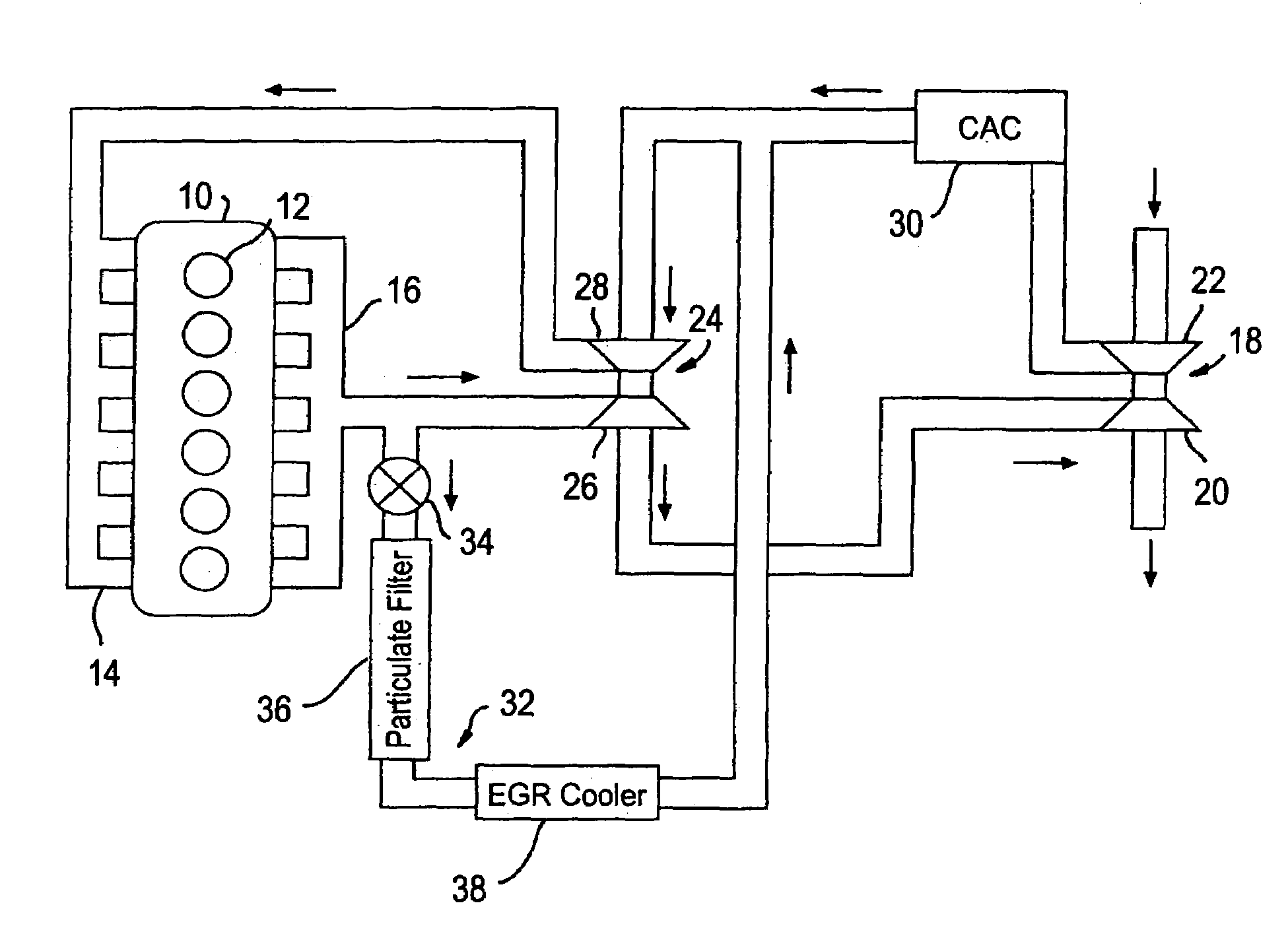

System and method for waste heat recovery in exhaust gas recirculation

InactiveUS20110209473A1Liquid degasificationInternal combustion piston enginesTurbochargerExhaust fumes

A system and method for waste heat recovery in exhaust gas recirculation is disclosed. The system includes an engine having an intake manifold and an exhaust manifold, an exhaust conduit connected to the exhaust manifold, and a turbocharger having a turbine and a compressor, the turbine being connected to the exhaust conduit to receive a portion of the exhaust gas from the exhaust manifold. The system also includes an EGR system connected to the exhaust conduit to receive a portion of the exhaust gas, with the EGR system including an EGR conduit that is connected to the exhaust conduit to receive a portion of the exhaust gas, a heat exchanger connected to the EGR conduit and being configured to extract heat from the exhaust gas, and a waste heat recovery system connected to the heat exchanger and configured to capture the heat extracted by the heat exchanger.

Owner:GENERAL ELECTRIC CO

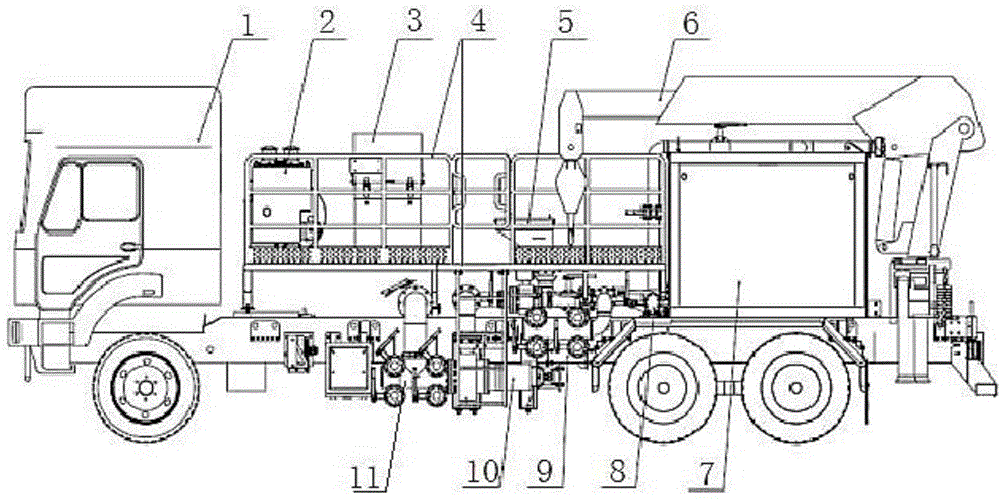

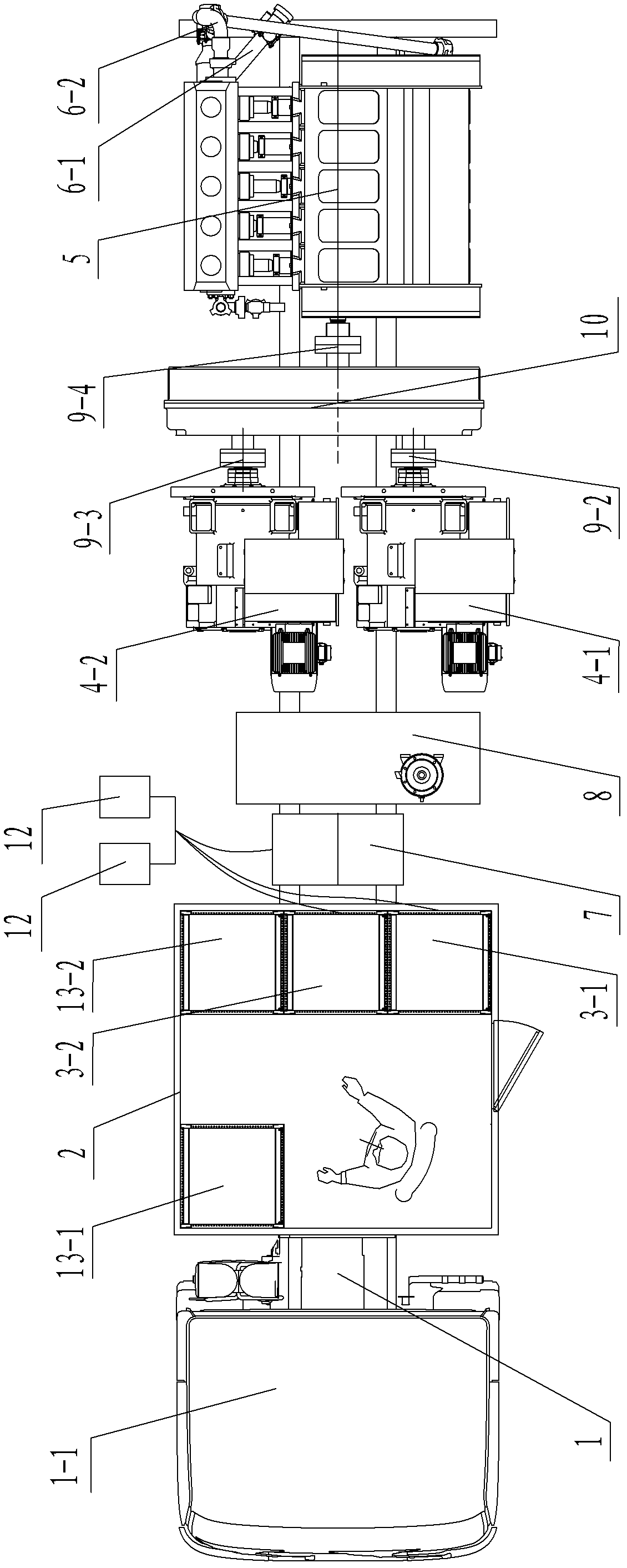

Multifunctional blending and liquid supplying vehicle

InactiveCN104057864AReduce labor costsAchieve mixingFluid removalItem transportation vehiclesControl systemElectrical control

The invention relates to a multifunctional blending and liquid supplying vehicle, which comprises a chassis, wherein an operation platform, a hydraulic oil tank, a dry powder feeder, an operation box for an electrical control system, a lorry-mounted crane and a liquid adding tank are fixedly arranged above the main beam of the chassis, wherein a centrifugal pump, an exhaust manifold and a suction manifold are arranged on each of two sides of the middle part of the main beam of the chassis, the exhaust manifold is communicated with the water outlet of the centrifugal pump, and the suction manifold is communicated with the water inlet of the centrifugal pump; the liquid adding pump is fixedly arranged on the side wall of the liquid adding tank, the water inlet of the liquid adding pump is communicated with the liquid adding tank, and the water outlet of the liquid adding tank is communicated with the exhaust manifold; a discharge opening in the lower end of the dry powder feeder is communicated with the exhaust manifold; the engine of the chassis is connected with a hydraulic pump, and the hydraulic pump is connected with the centrifugal pump, the lorry-mounted crane, the liquid adding tank and the liquid adding pump through a hydraulic multiway valve; the electrical control system is connected with the engine of the chassis, the hydraulic pump and the hydraulic multiway valve. The multifunctional blending and liquid supplying vehicle provided by the invention is low in cost, high in working efficiency, and can achieve various oil field operation functions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

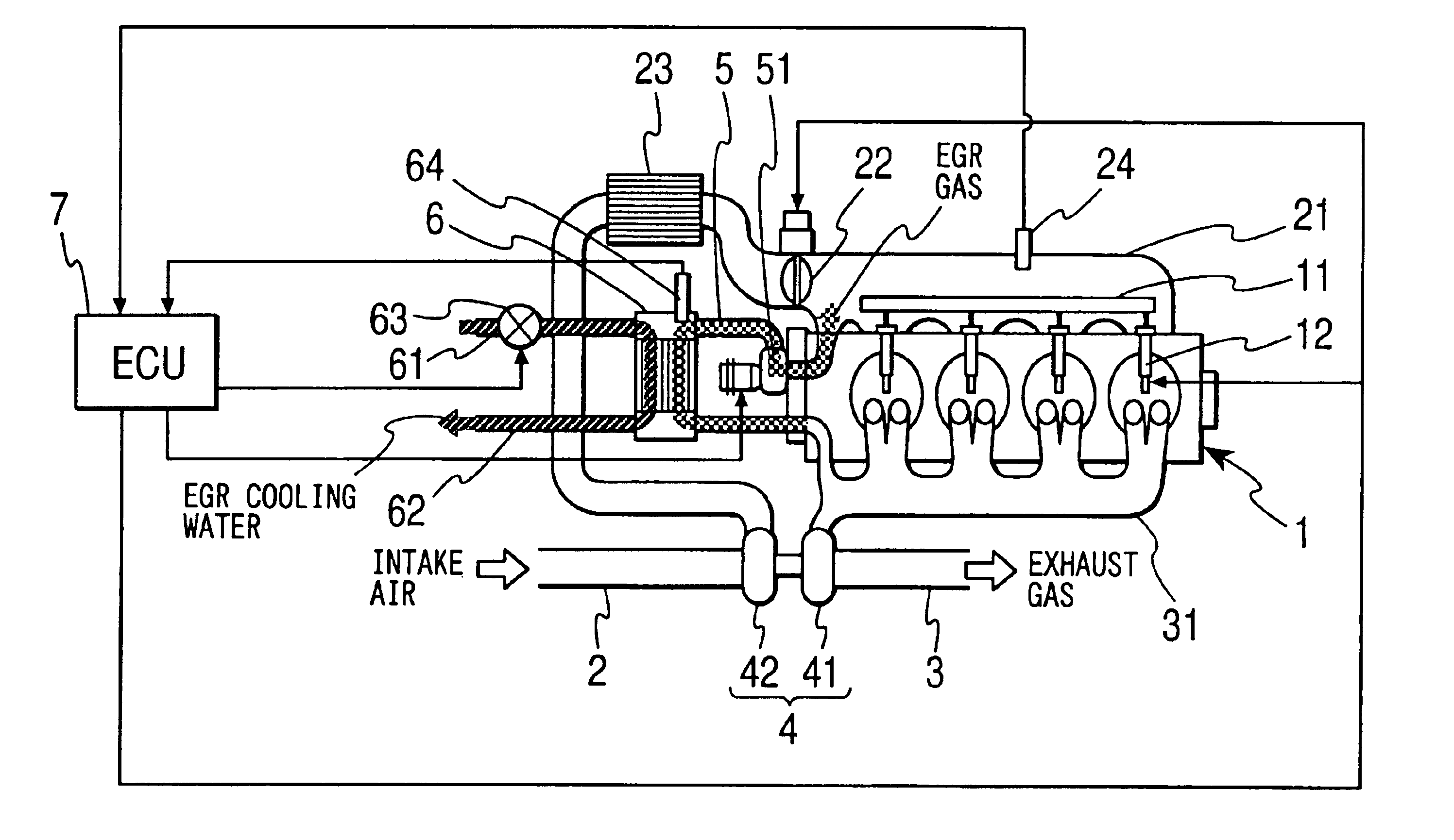

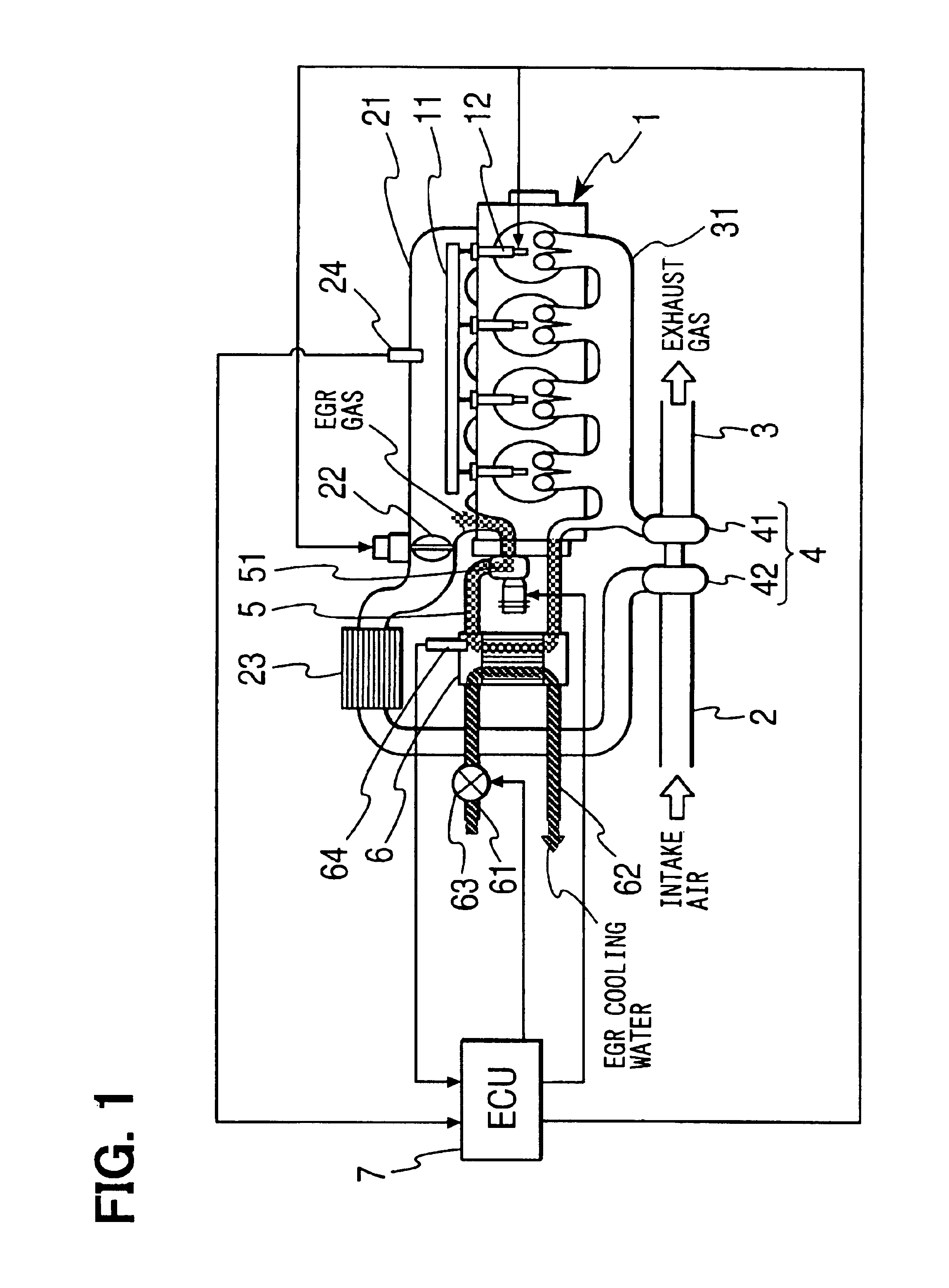

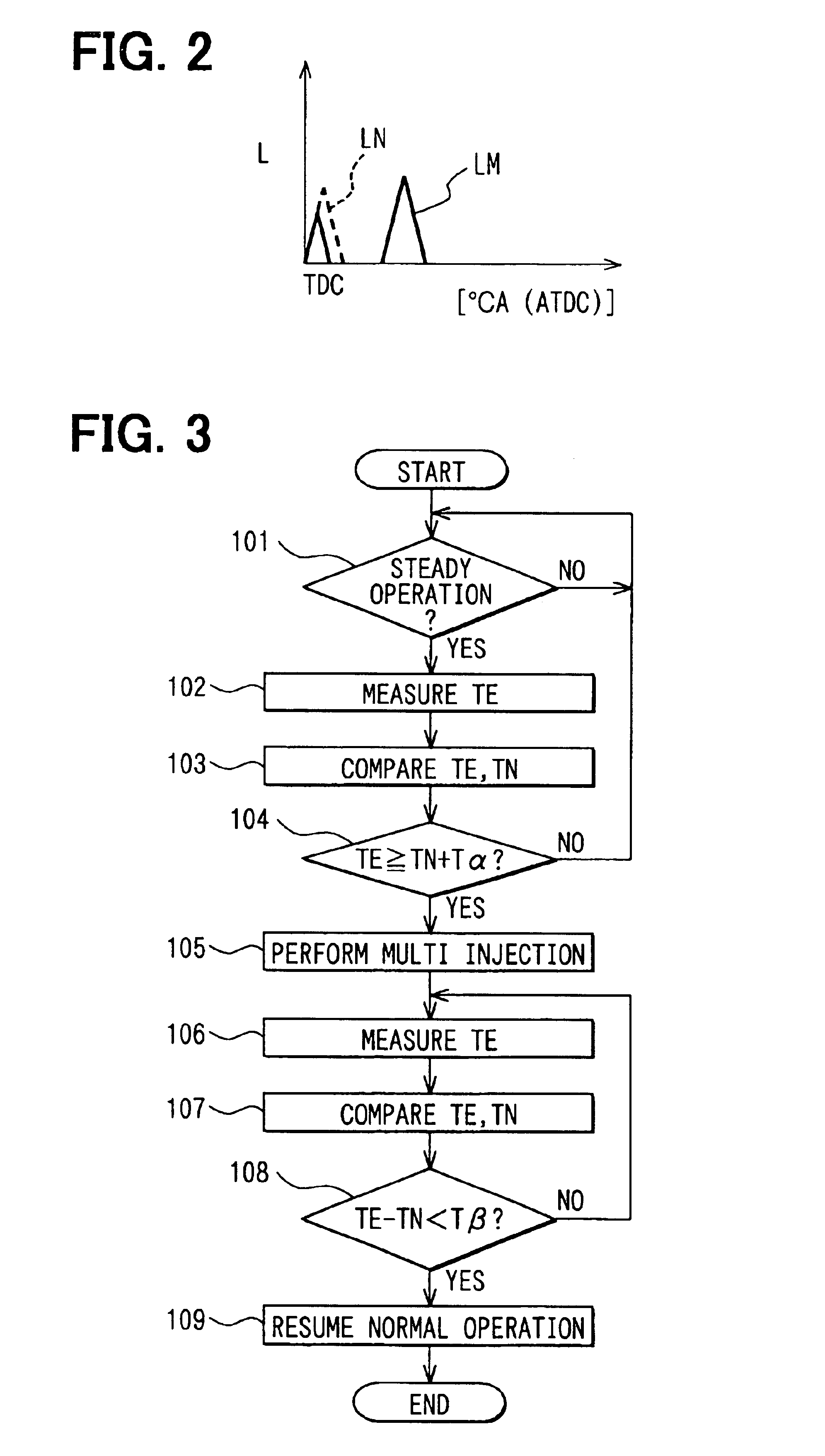

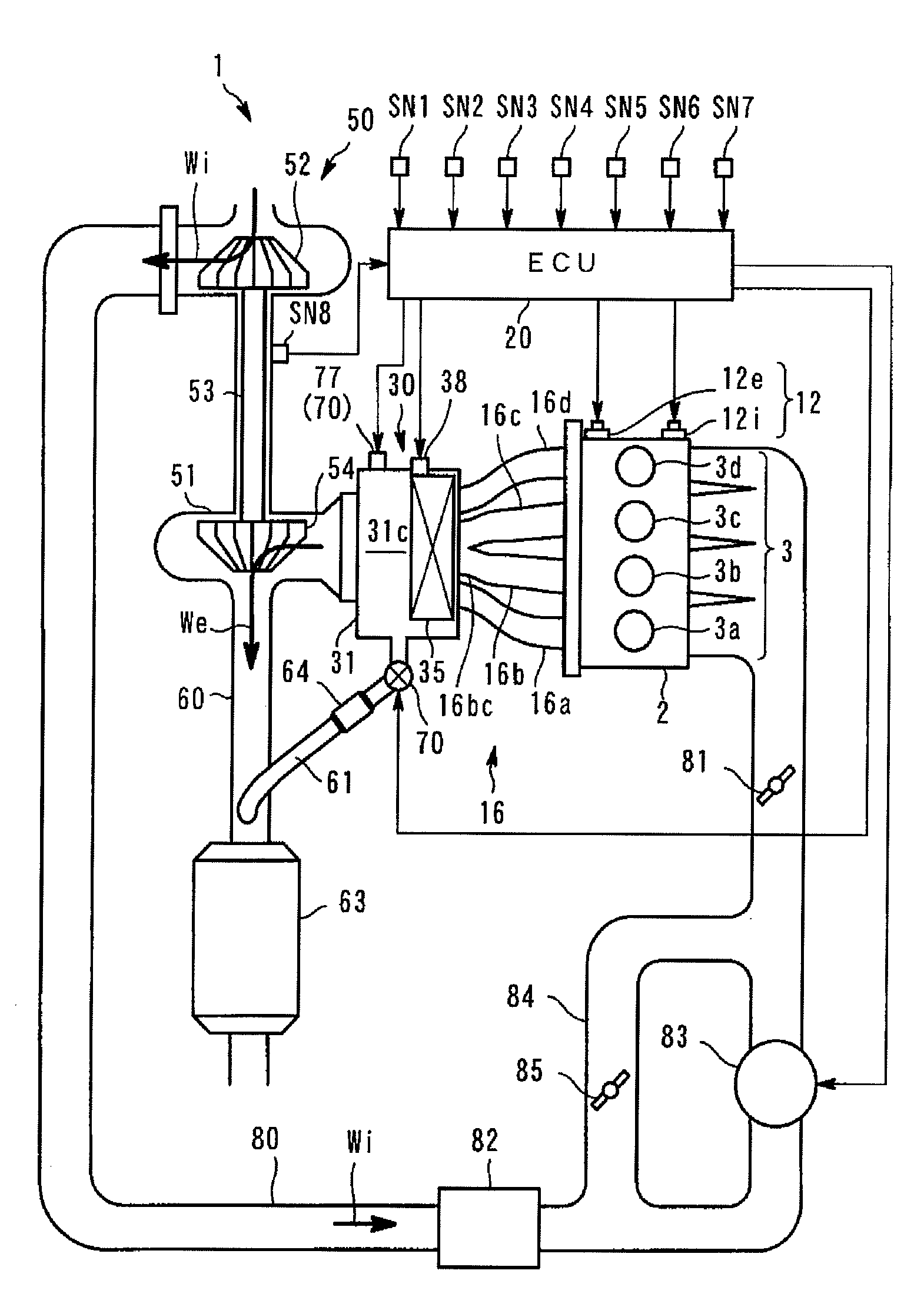

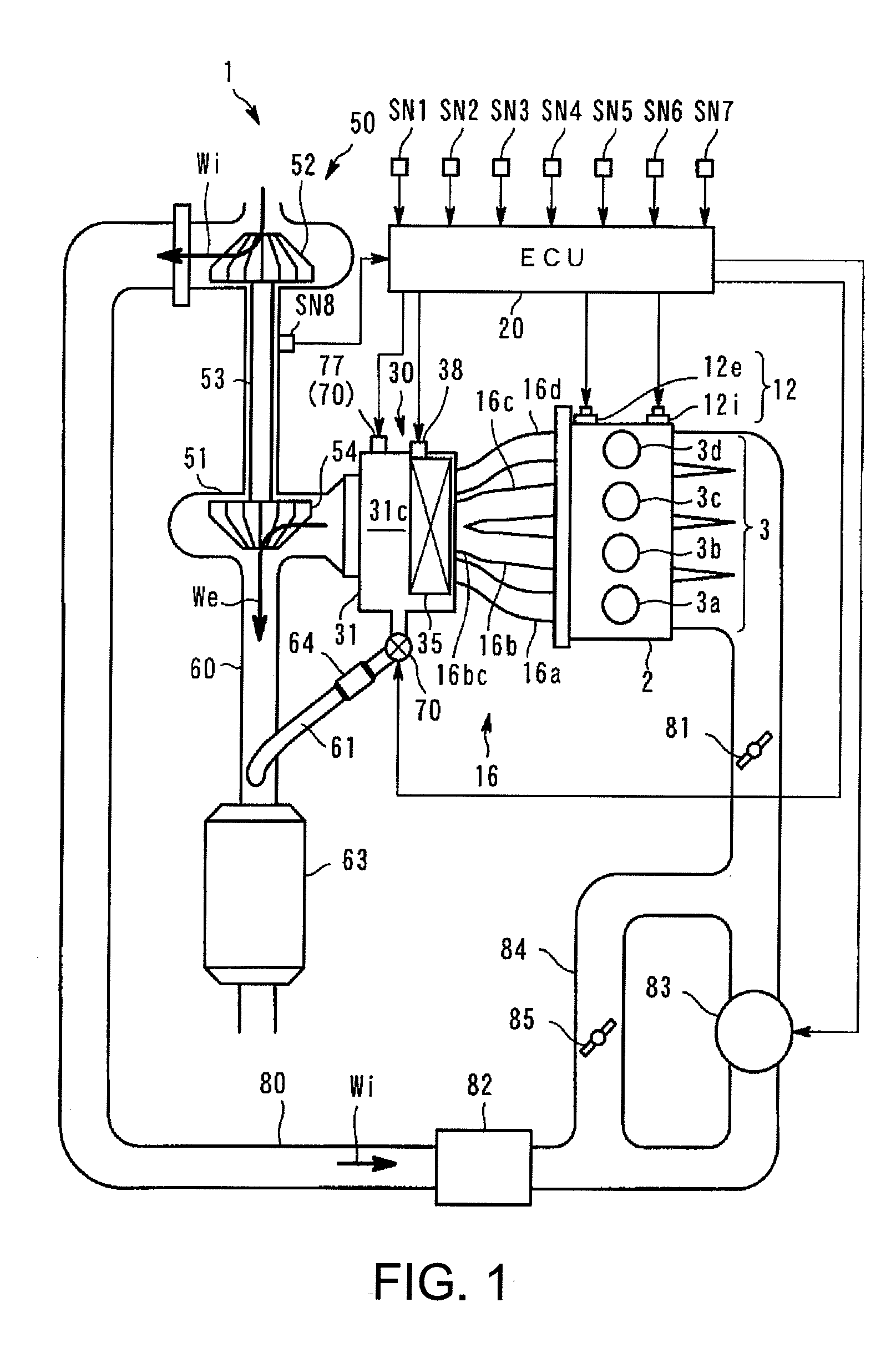

Exhaust gas recirculation system having cooler

InactiveUS6826903B2Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

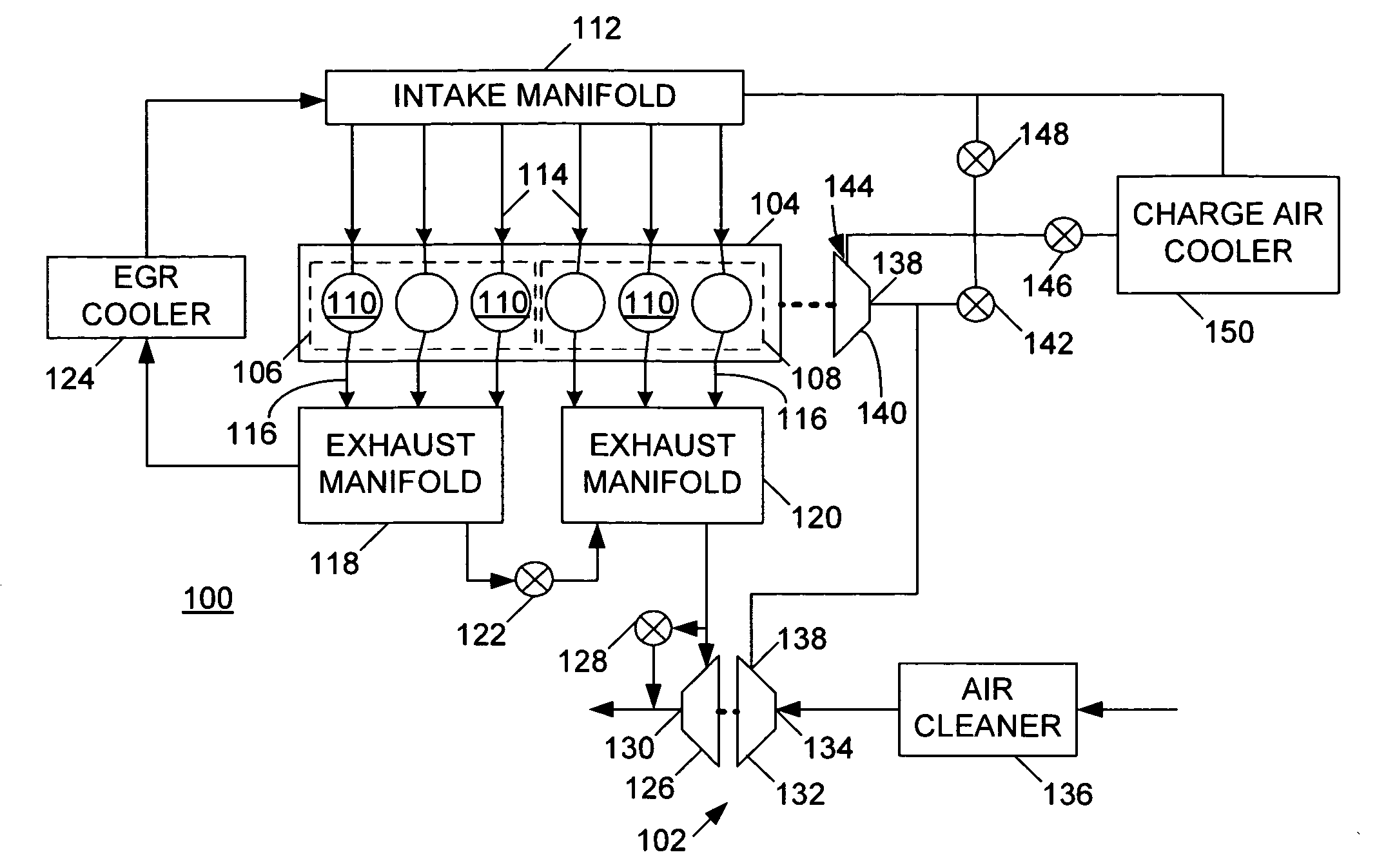

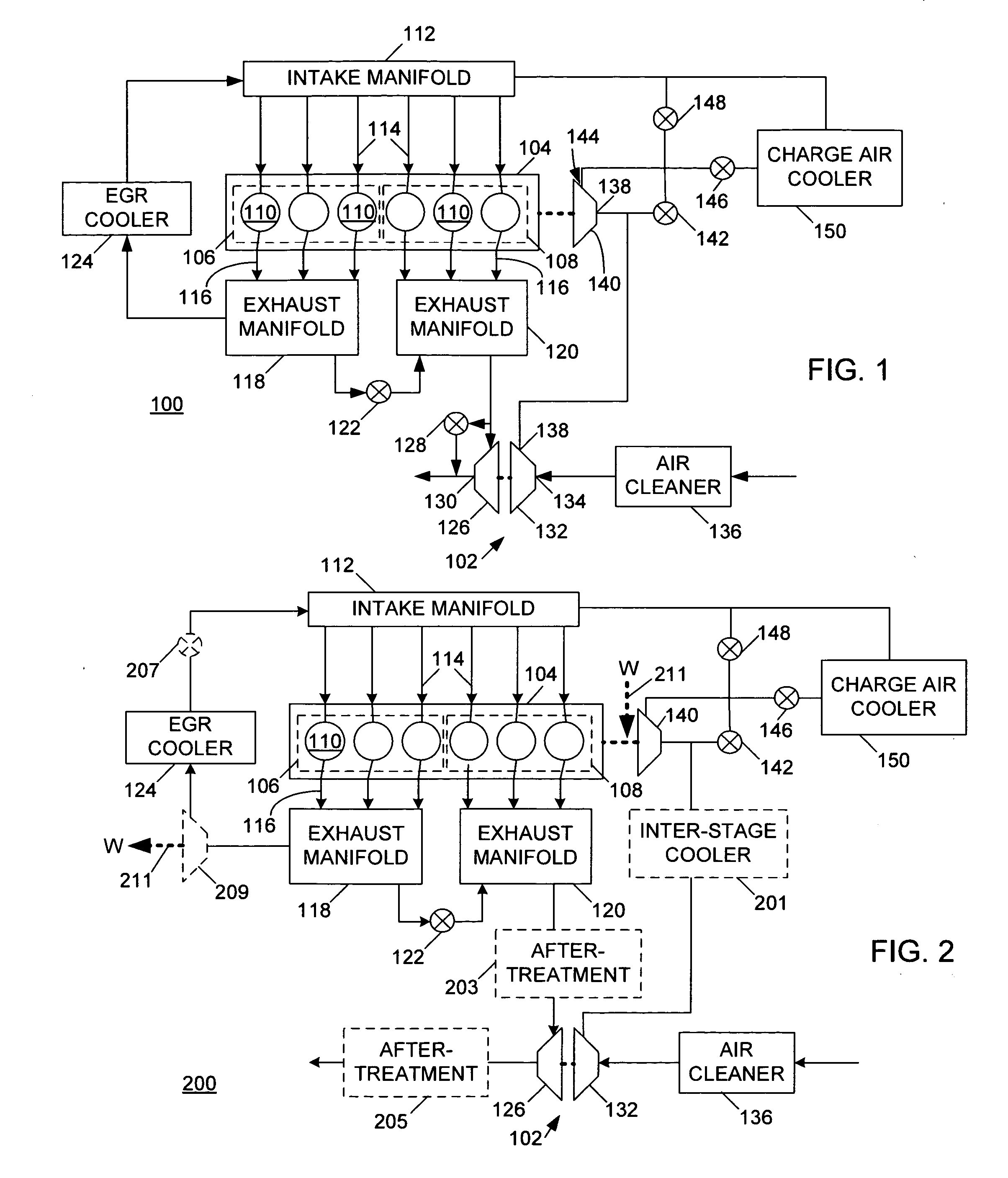

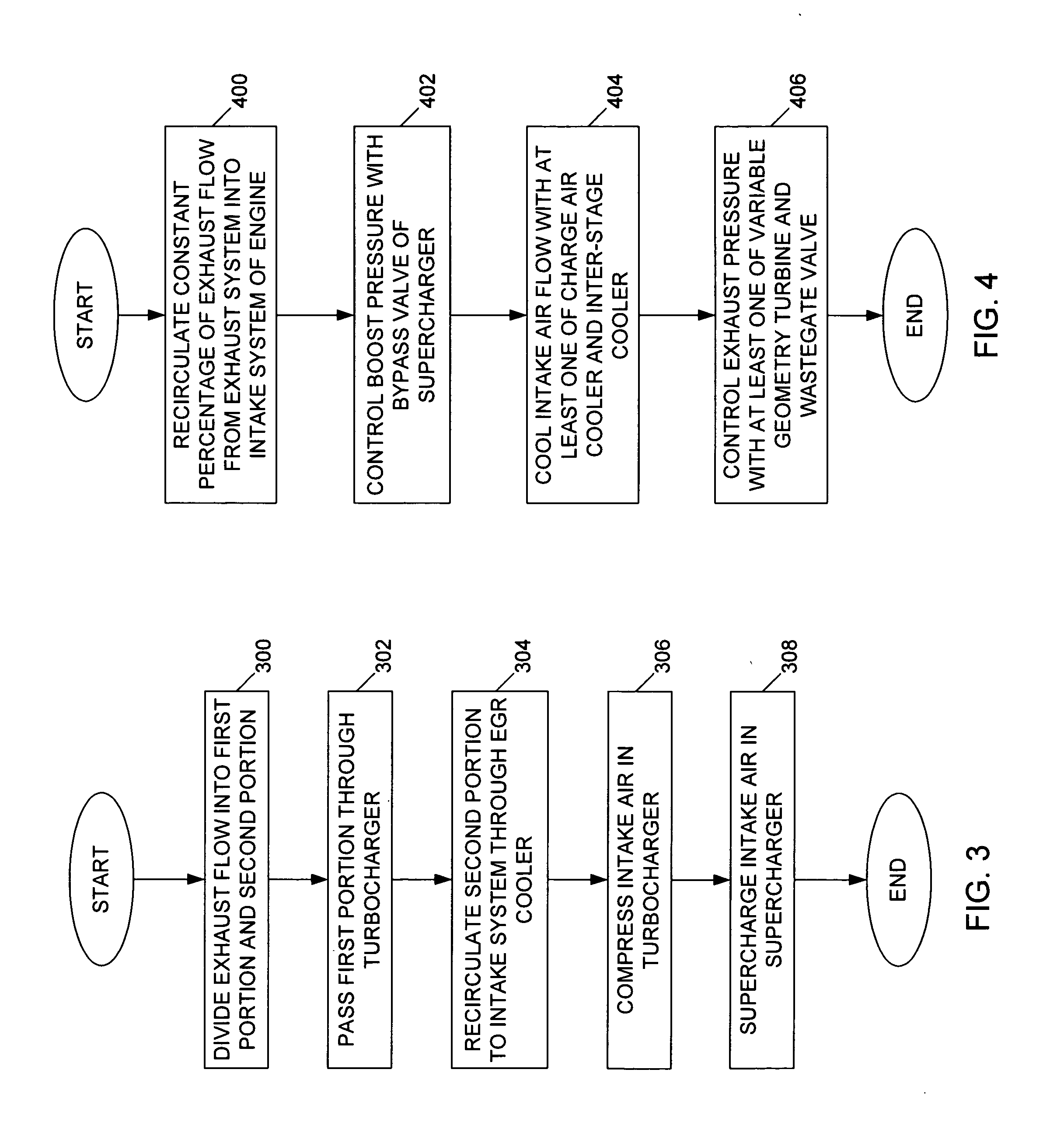

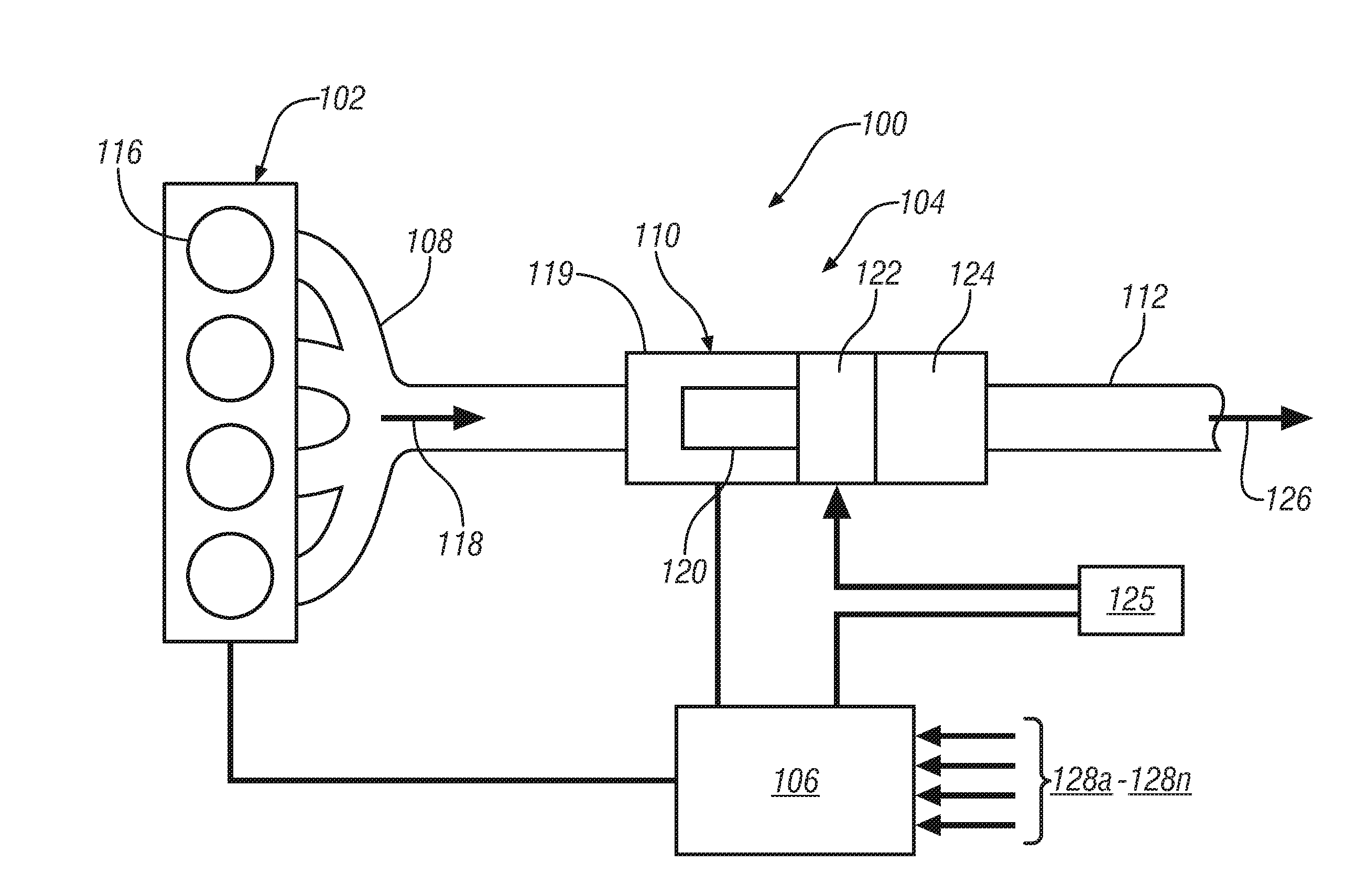

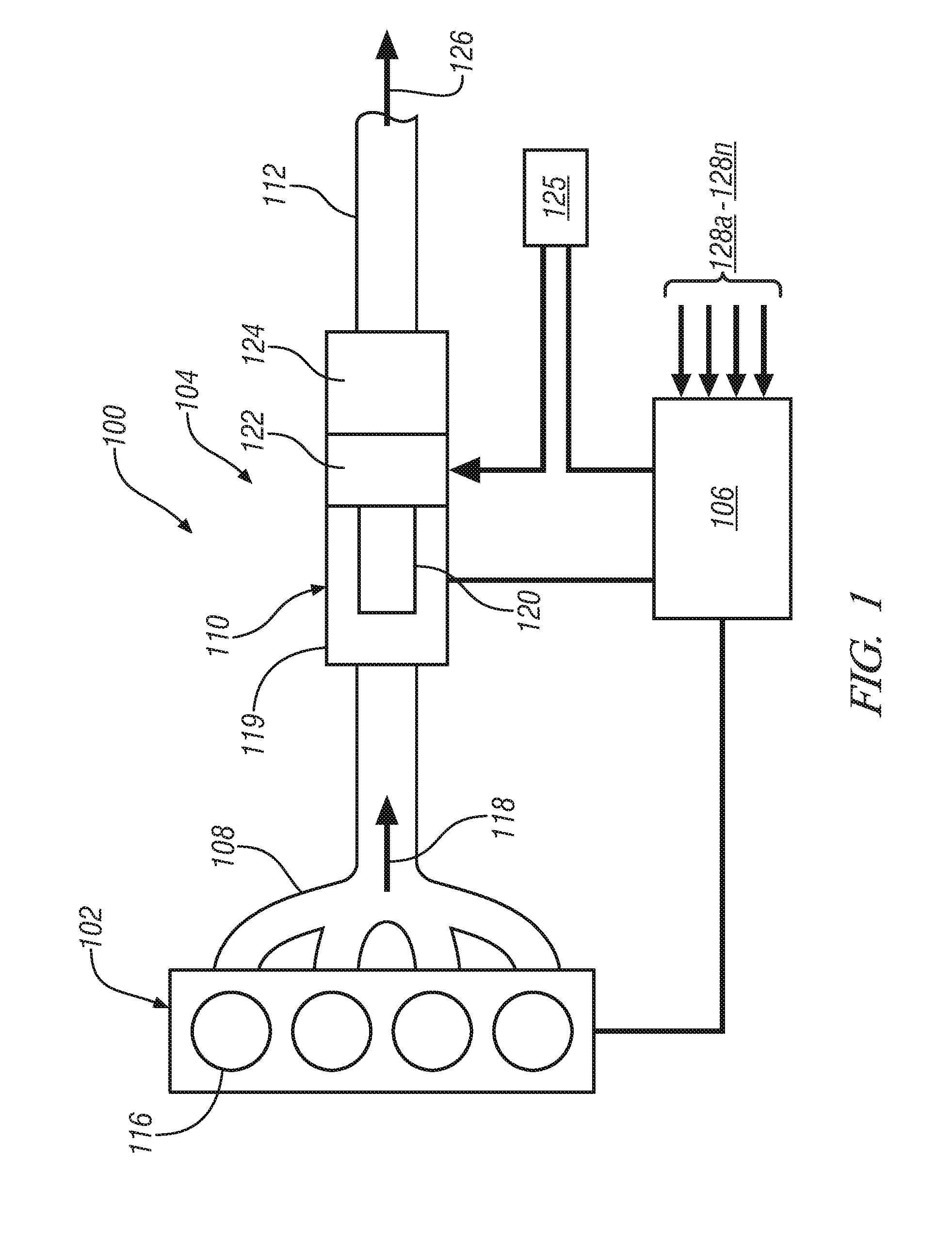

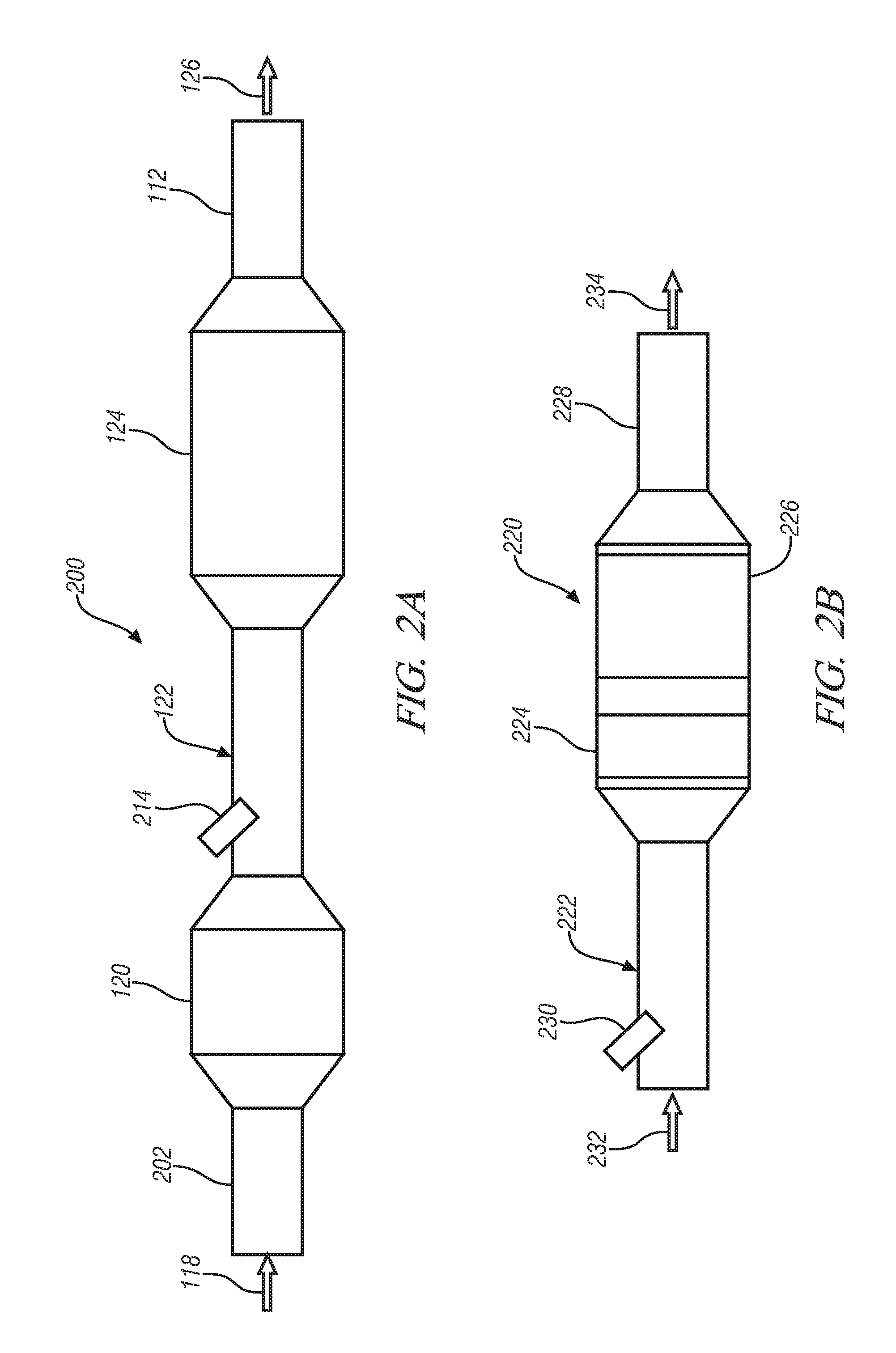

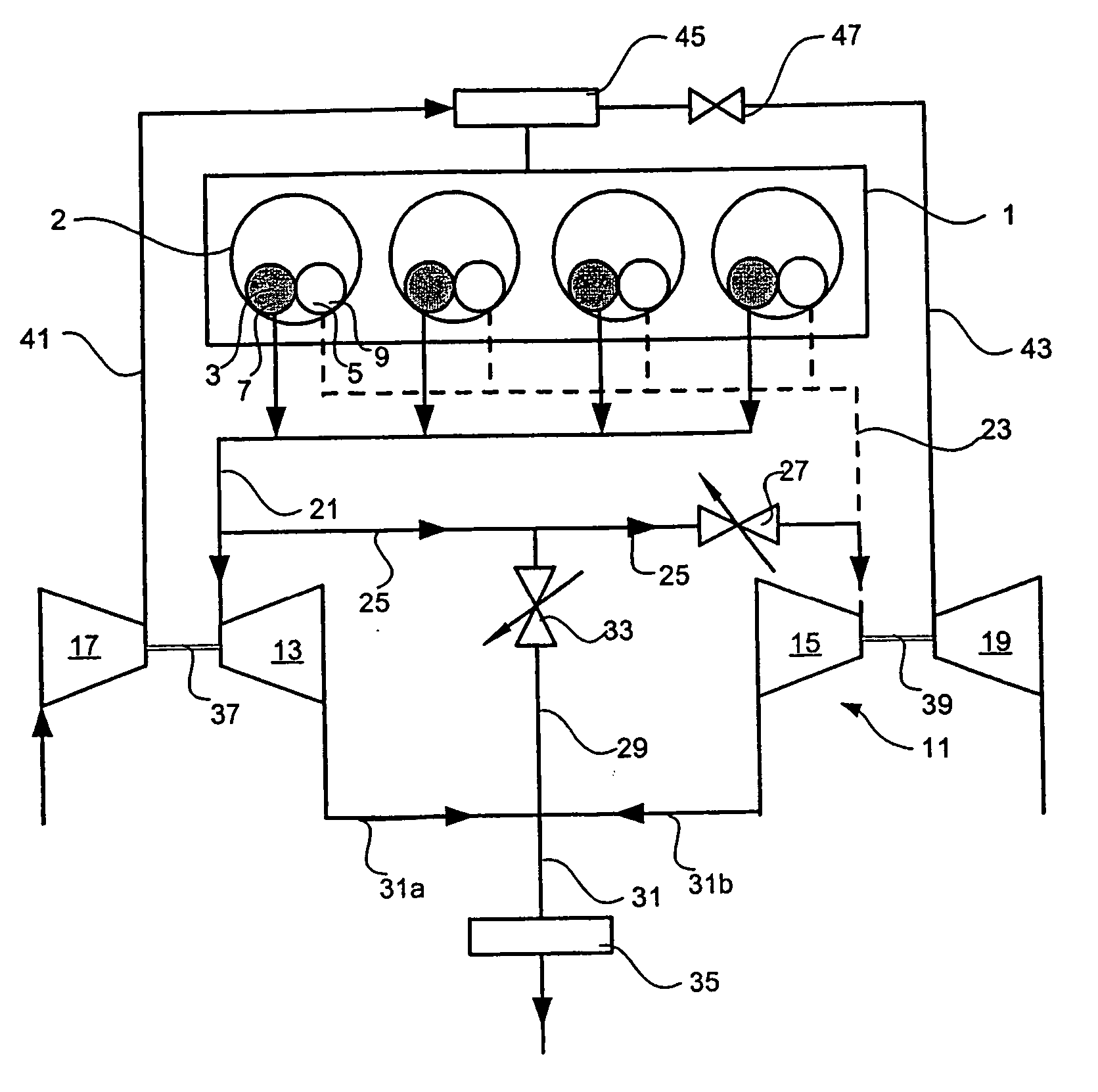

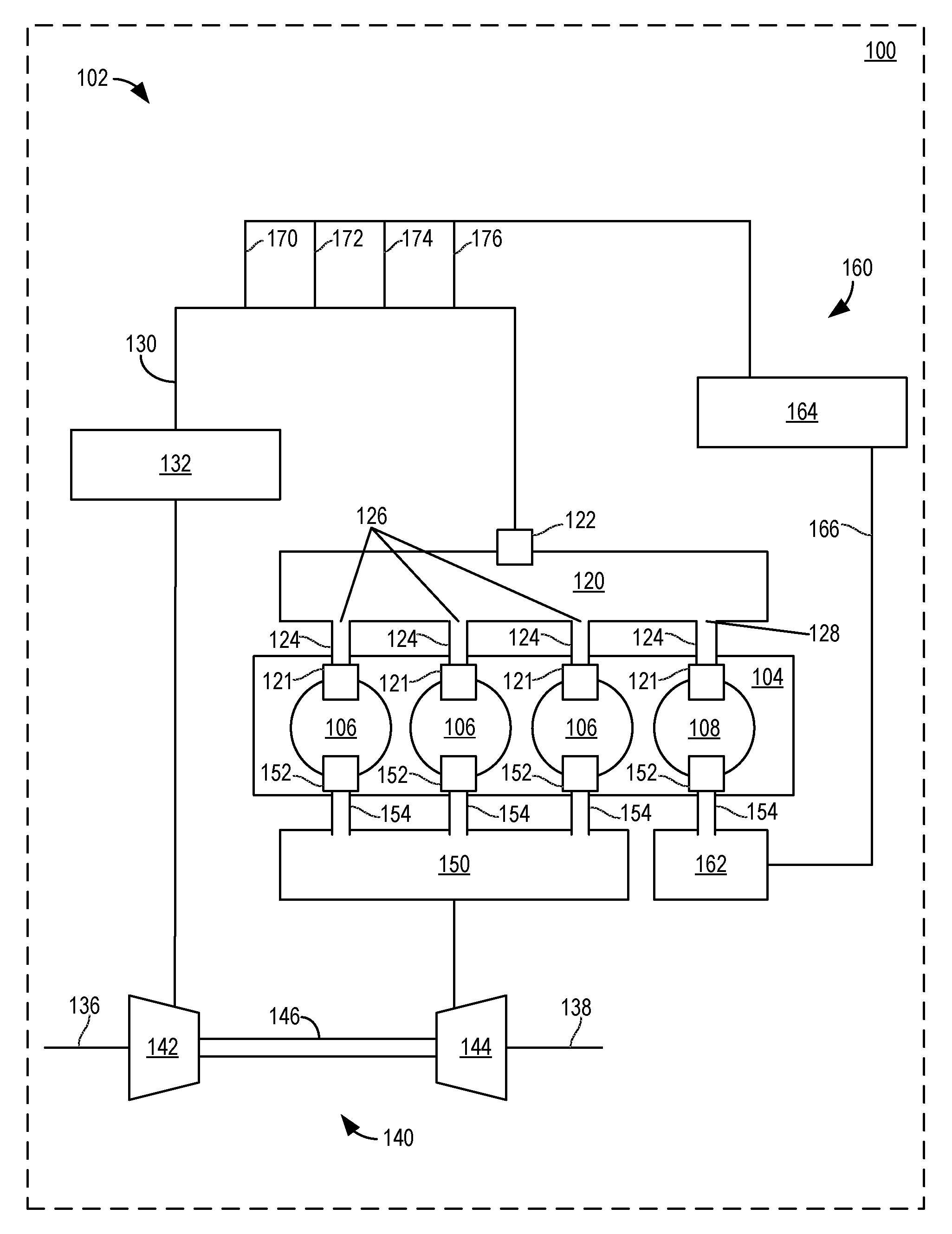

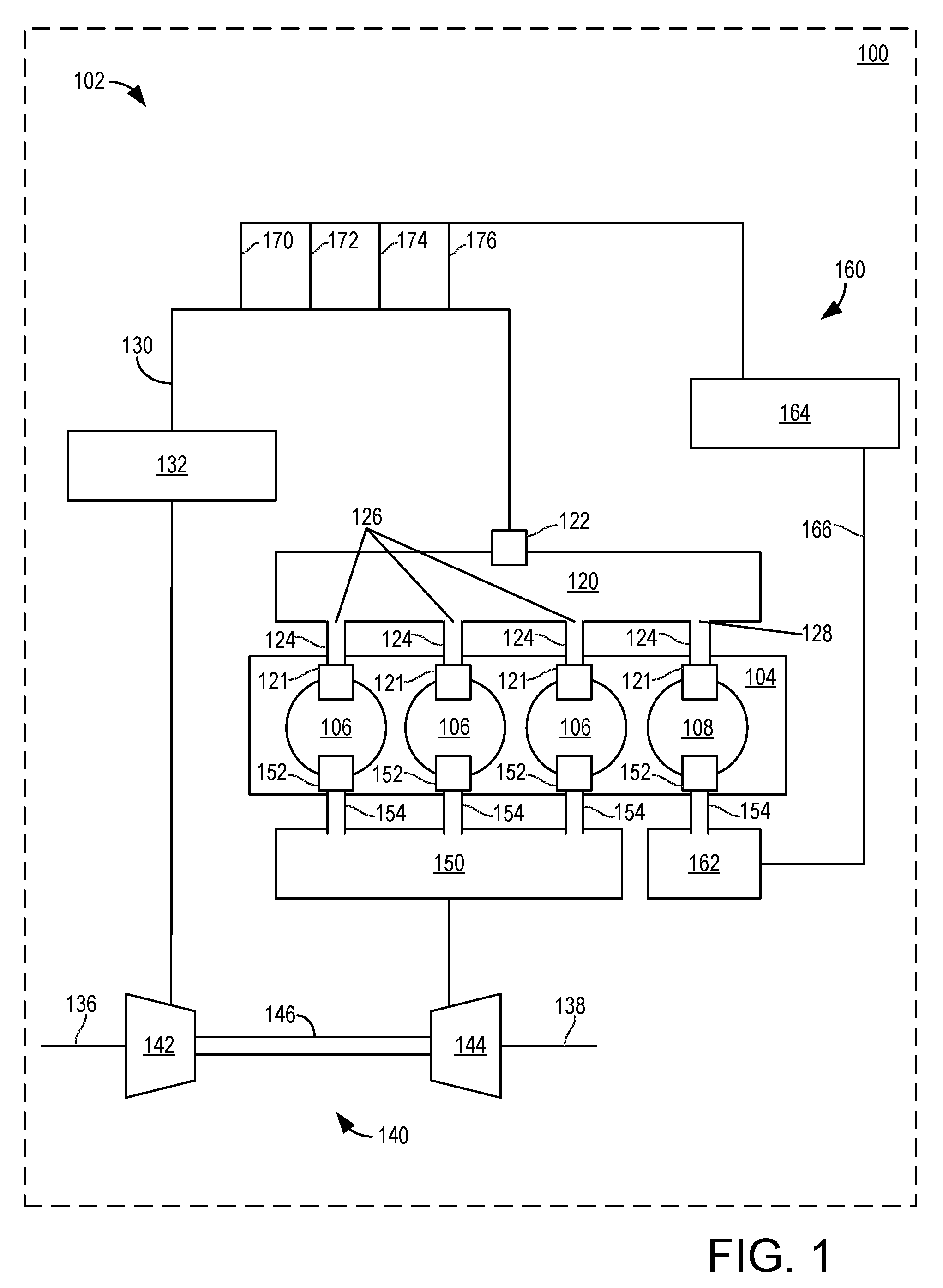

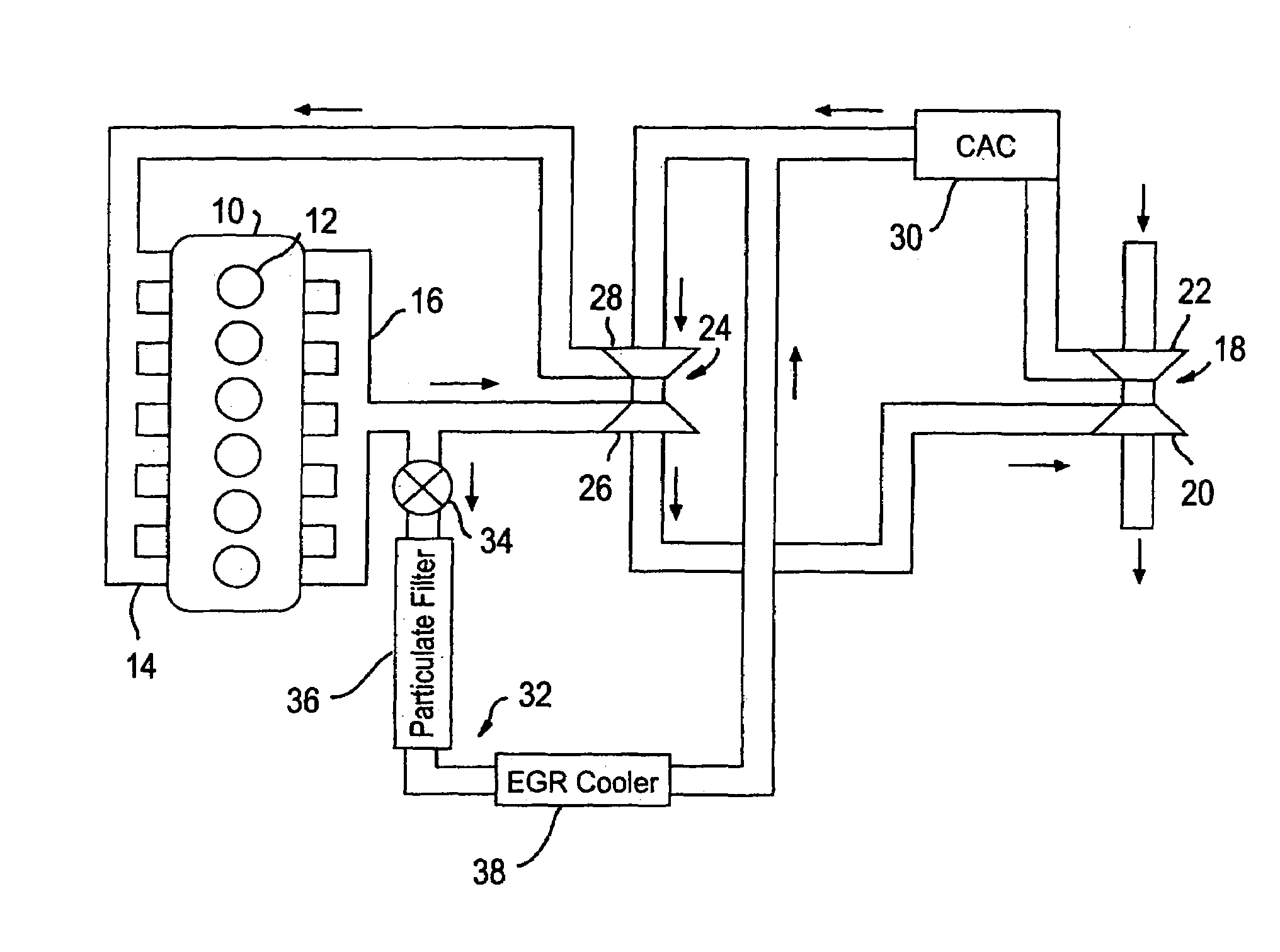

Constant EGR rate engine and method

ActiveUS20070175215A1Non-fuel substance addition to fuelInternal combustion piston enginesExhaust valveTurbocharger

An internal combustion engine (100) includes a first exhaust manifold (120), and a second exhaust manifold (118) fluidly connected to the first exhaust manifold (120) through an exhaust valve (122). An exhaust gas recirculation (EGR) cooler (124) constantly fluidly connects the second exhaust manifold (118) with an intake manifold (112). A turbocharger (102) has a turbine (126) in fluid communication with the first exhaust manifold (120), and a compressor (132) in fluid communication with a supercharger (140). A charge air cooler (150) fluidly connects the supercharger (140) with the intake manifold (112).

Owner:INT ENGINE INTPROP CO LLC

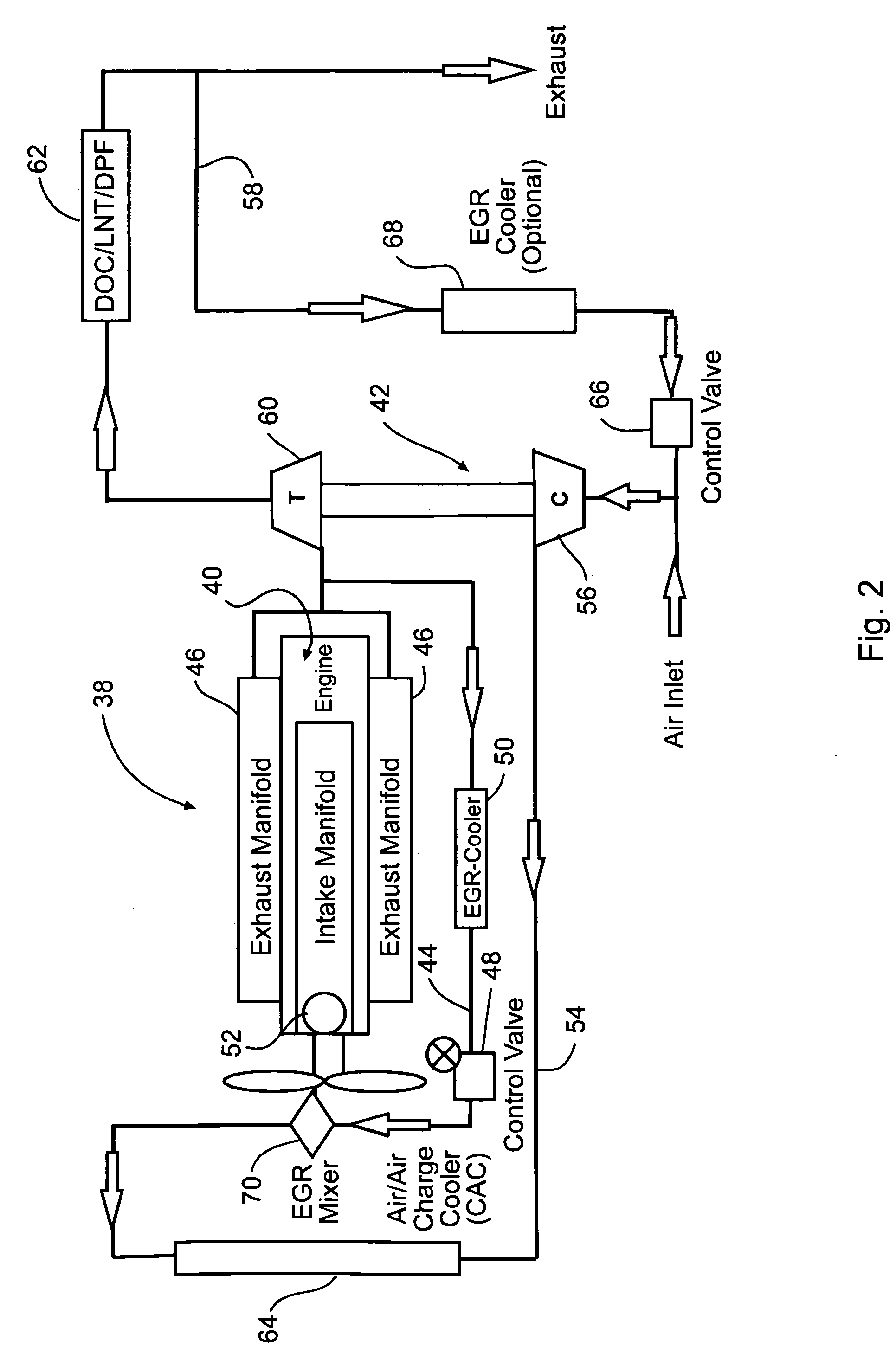

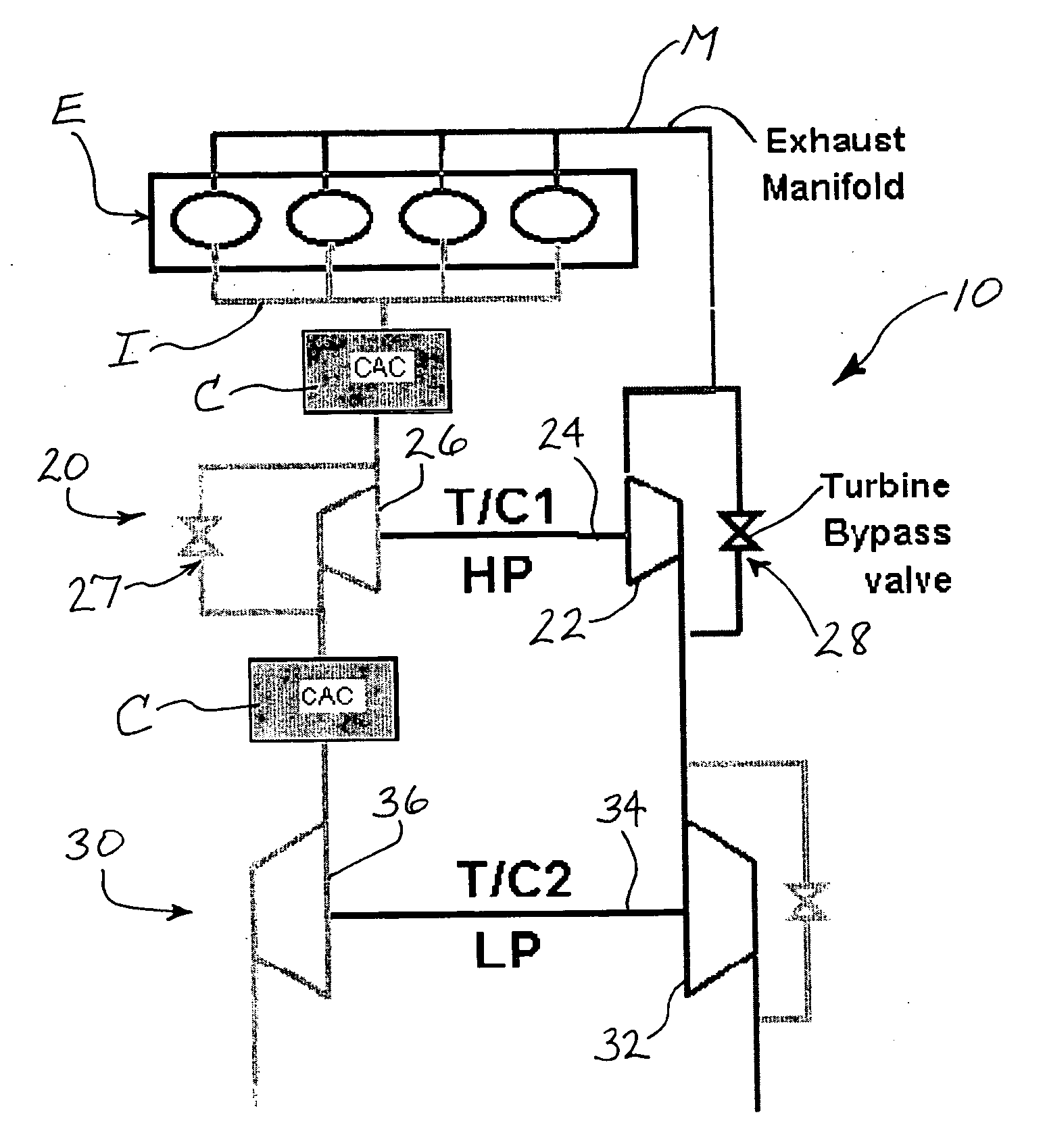

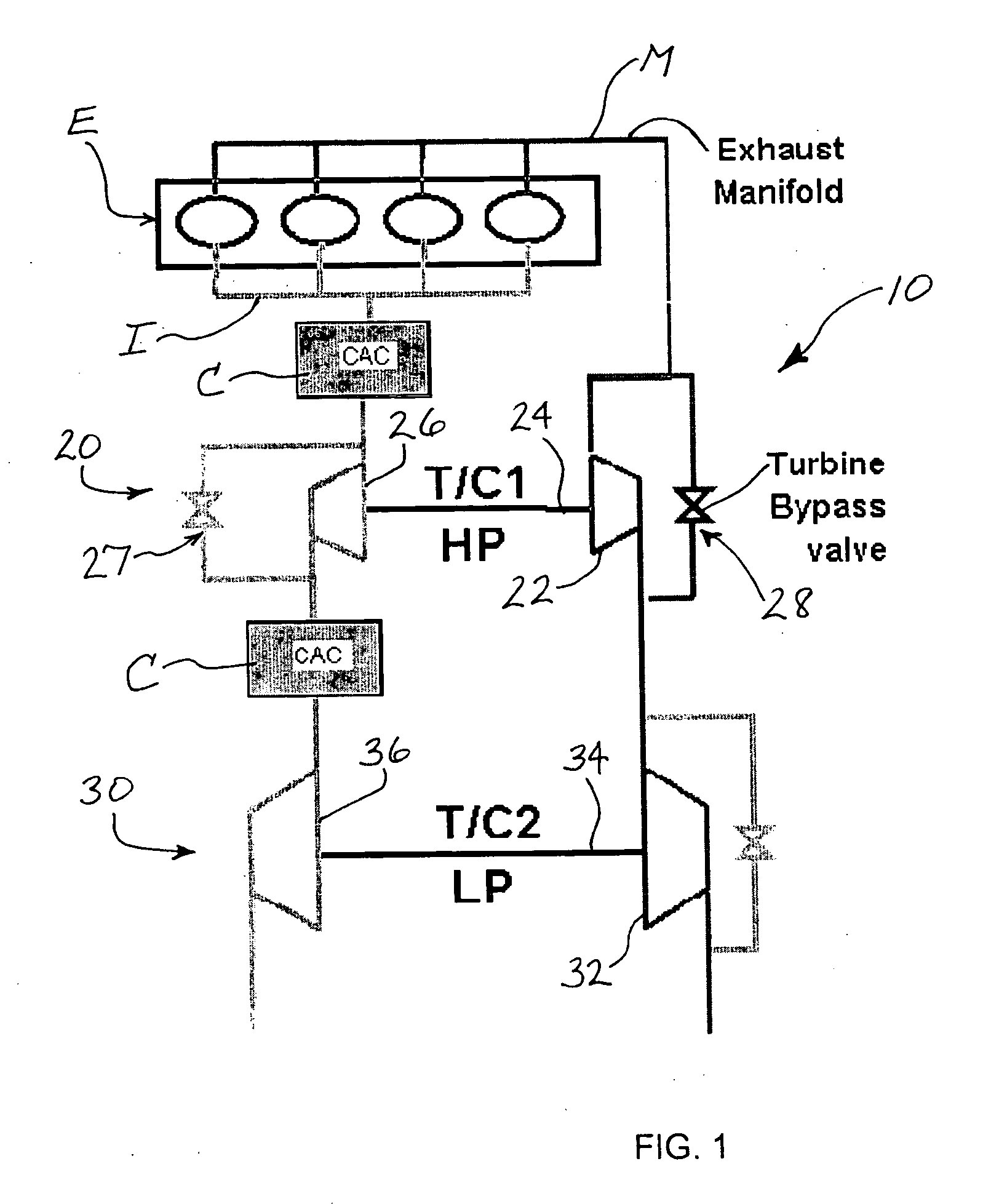

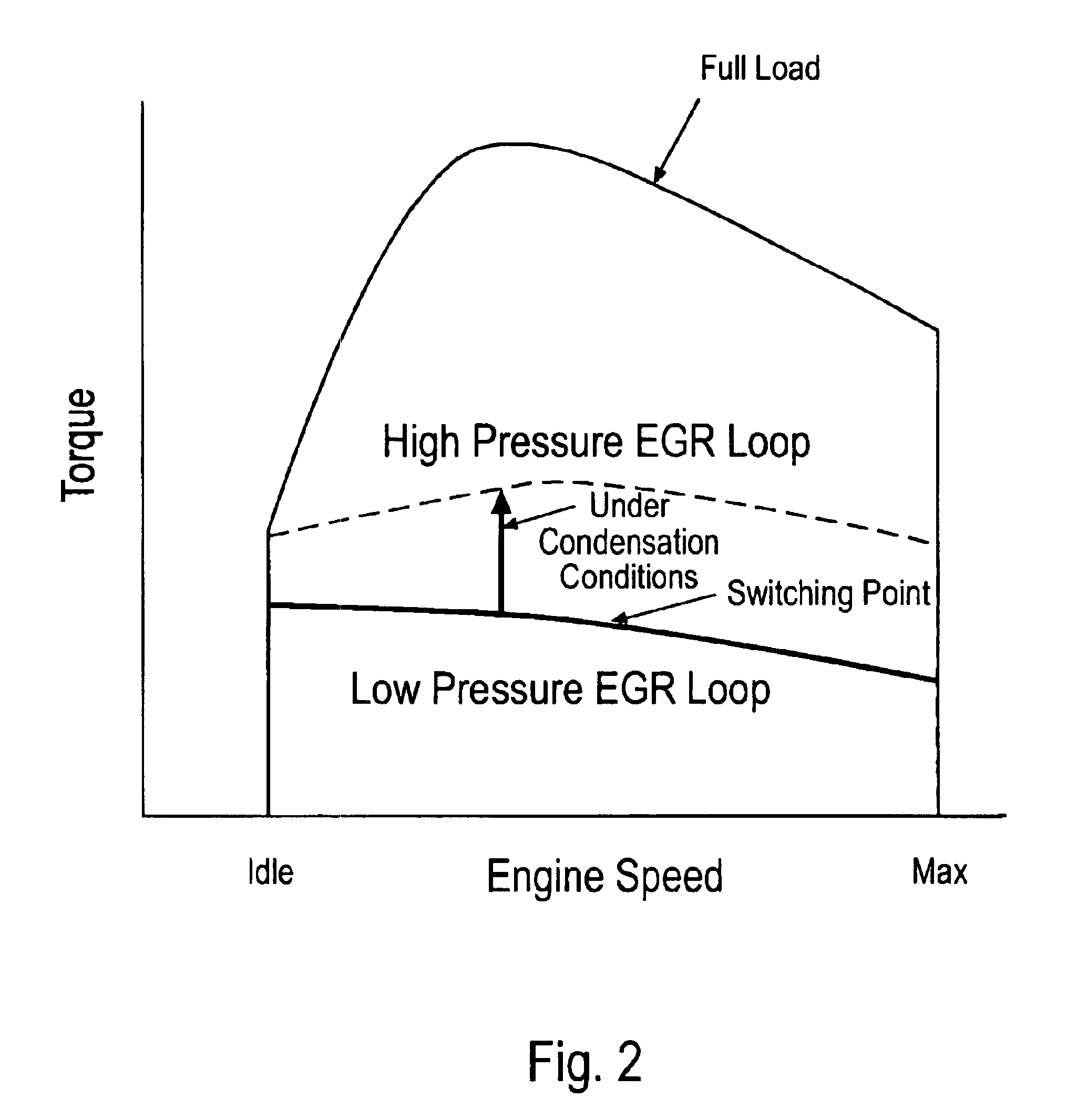

Dual and hybrid EGR systems for use with turbocharged engine

ActiveUS20050103013A1Non-fuel substance addition to fuelInternal combustion piston enginesSingle stageTurbocharger

EGR systems for an internal combustion engine configured to operate using multiple-staged turbochargers, or a pair of single stage turbochargers, to provide exhaust gas recirculation to meet emissions requirements while not affecting engine performance. One or two EGR loops operating at low, intermediate, or high pressures may be employed. EGR exhaust gases may be taken directly from the exhaust manifold, or after the exhaust stream has passed through a turbocharger turbine. EGR exhaust gases may be injected at an intermediate pressure between stages of a multiple stage turbocharger, or alternatively between a low pressure turbocharger compressor and high pressure turbocharger compressor, before being boosted to a pressure high enough to ensure the desired mass flow to the engine and delivered to the intake manifold. Intake air may be pressurized prior to mixing with the EGR exhaust gases.

Owner:GARRETT TRANSPORATION I INC

Internal combustion engine

InactiveUS6595183B1Increase mass flowIncrease torqueValve arrangementsElectrical controlExhaust valveTop dead center

A multicylinder internal combustion engine with an exhaust-driven turbocompressor and with a divided exhaust flow has at least two exhaust valves and one intake valve per cylinder. A first exhaust valve is connected to a first exhaust manifold which leads to the turbine of the compressor, while a second exhaust valve is connected to a second exhaust manifold which opens downstream of the turbine. In the top dead center position of the piston, the second exhaust valve and the intake valve are open at the same time for a period. The synchronization between these valves is such that the length of the period during which they are open together increases with the engine speed when the engine is driven at high load. In this way, the possibilities are improved of the engine providing good torque over a wide engine speed range.

Owner:SAAB AUTOMOBILE AB

Dual and hybrid EGR systems for use with turbocharged engine

InactiveUS7013879B2Non-fuel substance addition to fuelInternal combustion piston enginesSingle stageTurbocharger

EGR systems for an internal combustion engine configured to operate using multiple-staged turbochargers, or a pair of single stage turbochargers, to provide exhaust gas recirculation to meet emissions requirements while not affecting engine performance. One or two EGR loops operating at low, intermediate, or high pressures may be employed. EGR exhaust gases may be taken directly from the exhaust manifold, or after the exhaust stream has passed through a turbocharger turbine. EGR exhaust gases may be injected at an intermediate pressure between stages of a multiple stage turbocharger, or alternatively between a low pressure turbocharger compressor and high pressure turbocharger compressor, before being boosted to a pressure high enough to ensure the desired mass flow to the engine and delivered to the intake manifold. Intake air may be pressurized prior to mixing with the EGR exhaust gases.

Owner:GARRETT TRANSPORATION I INC

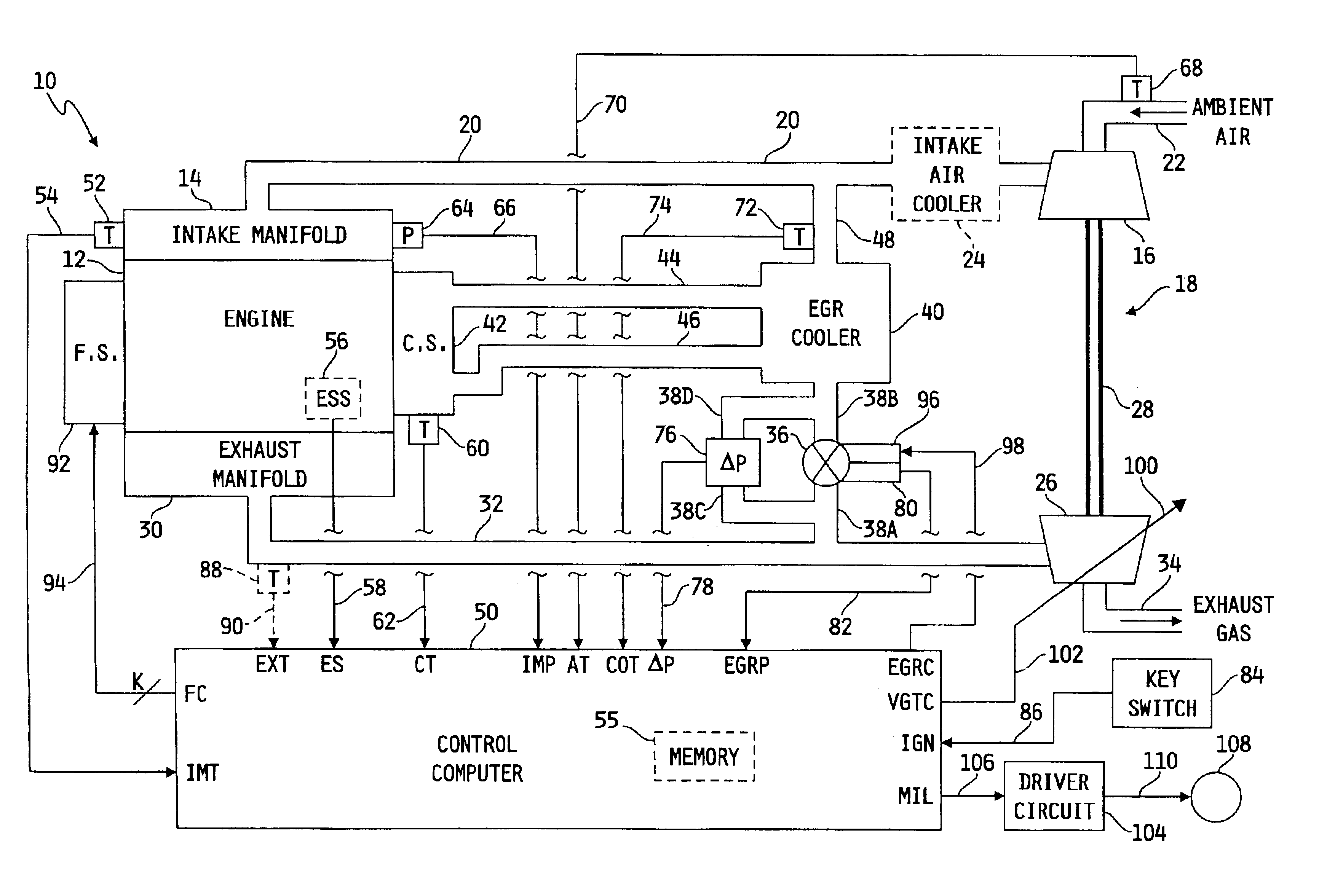

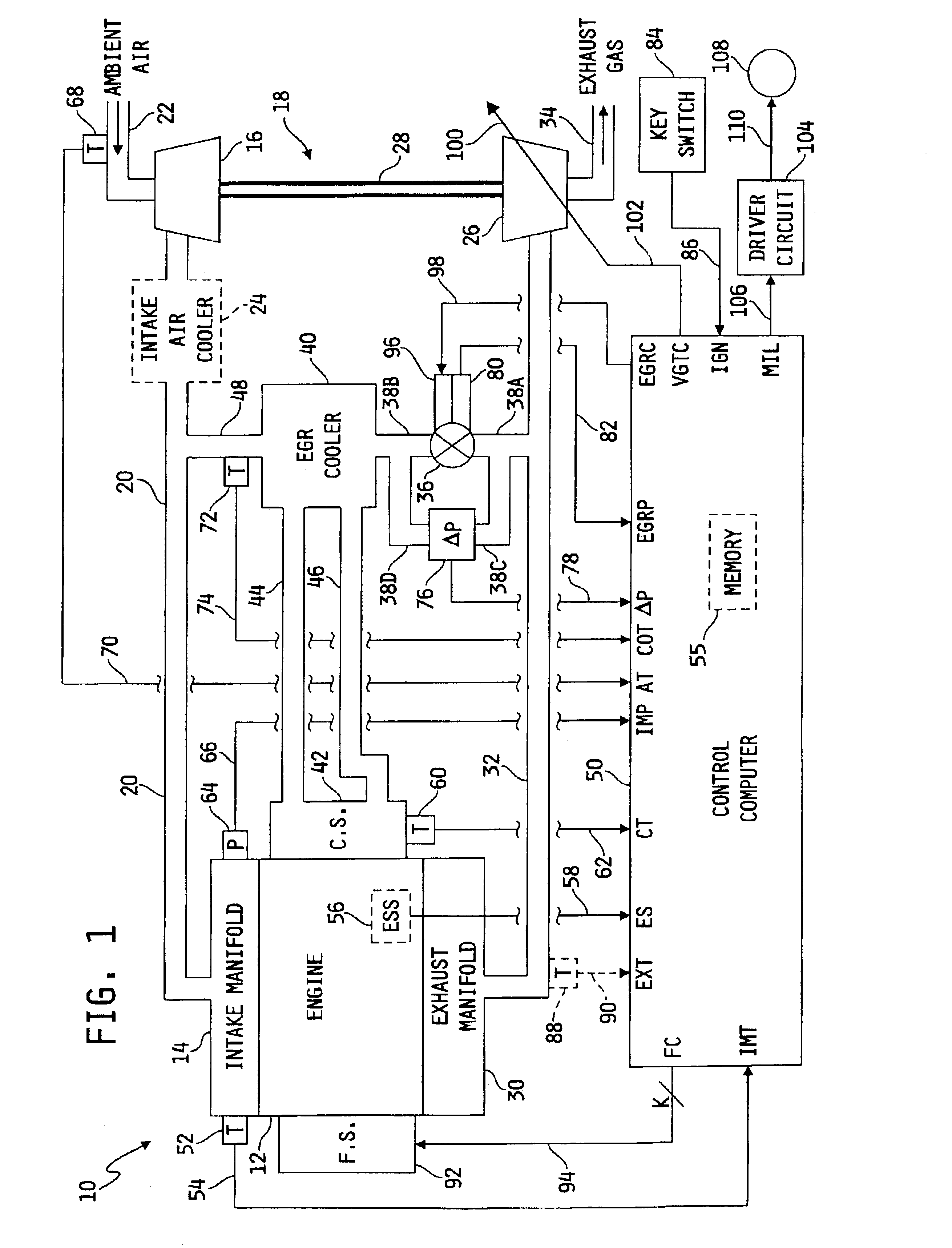

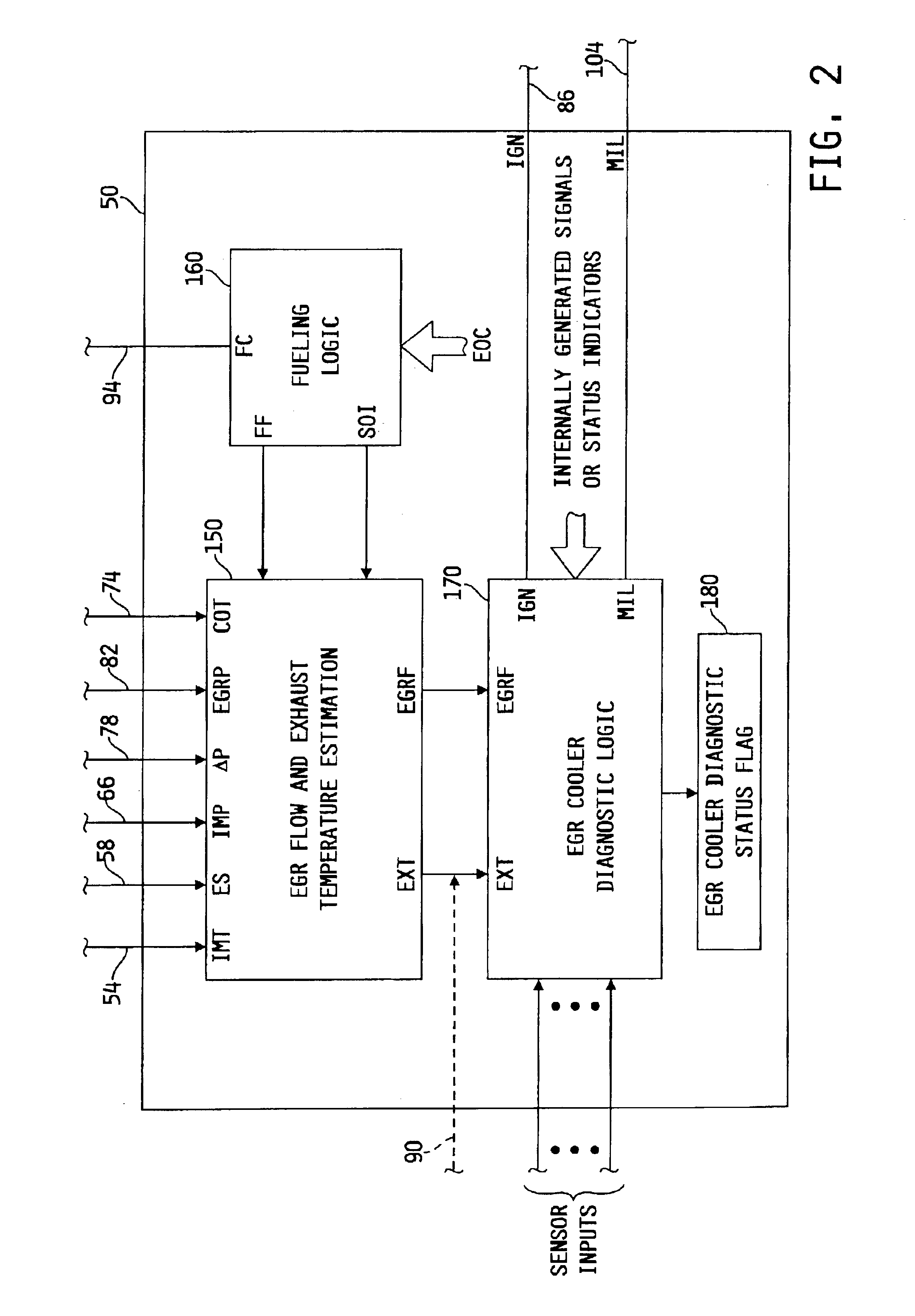

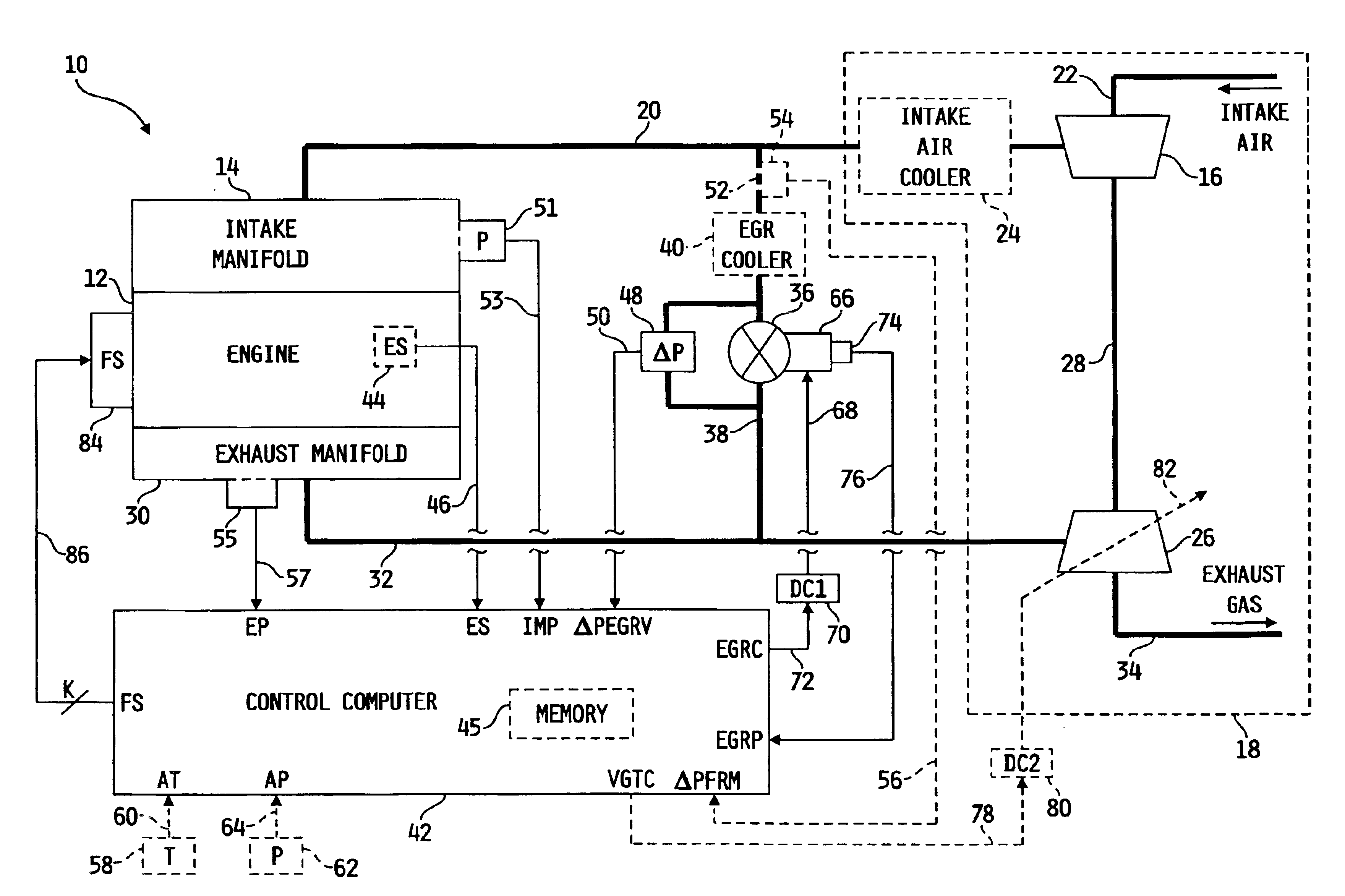

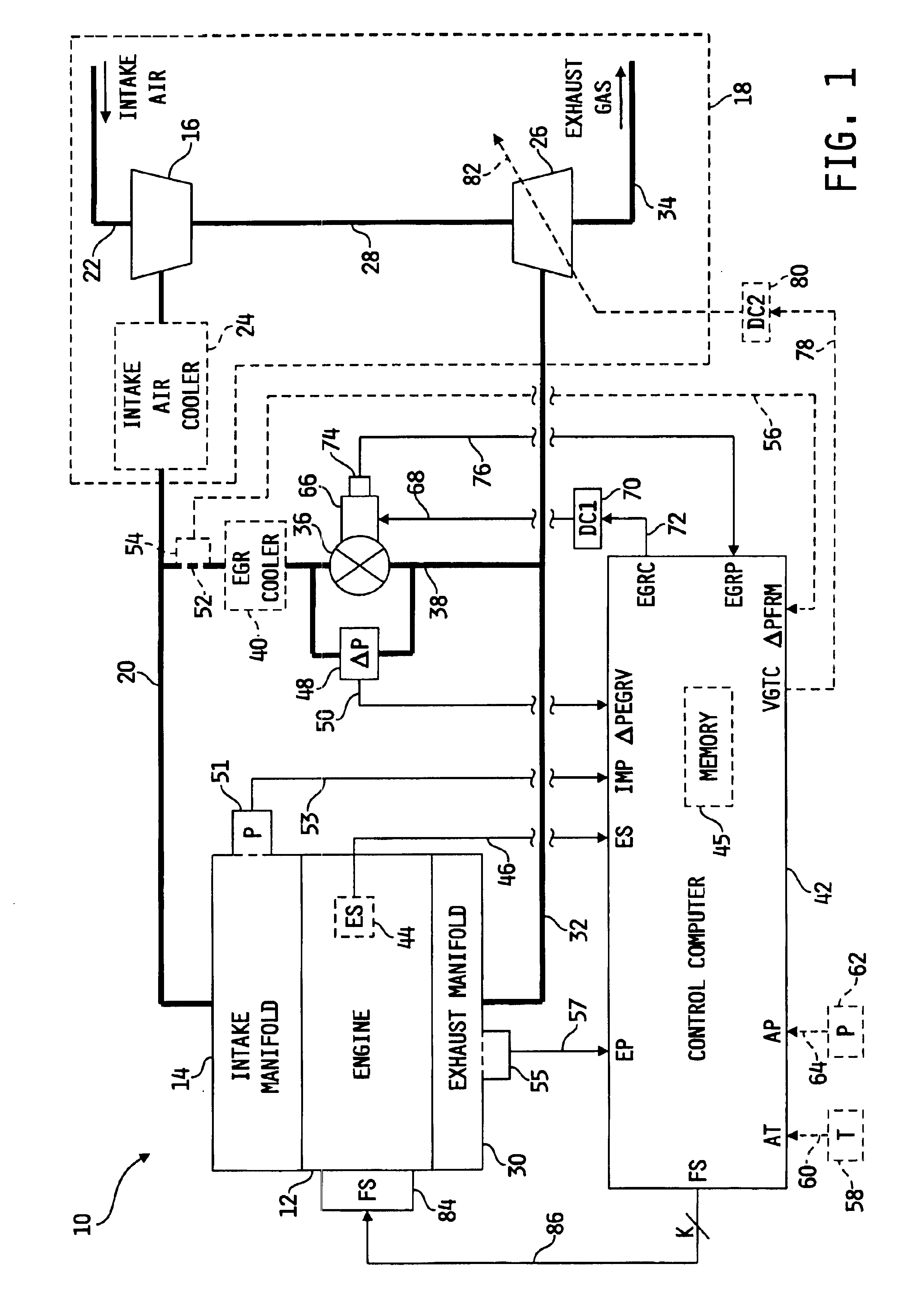

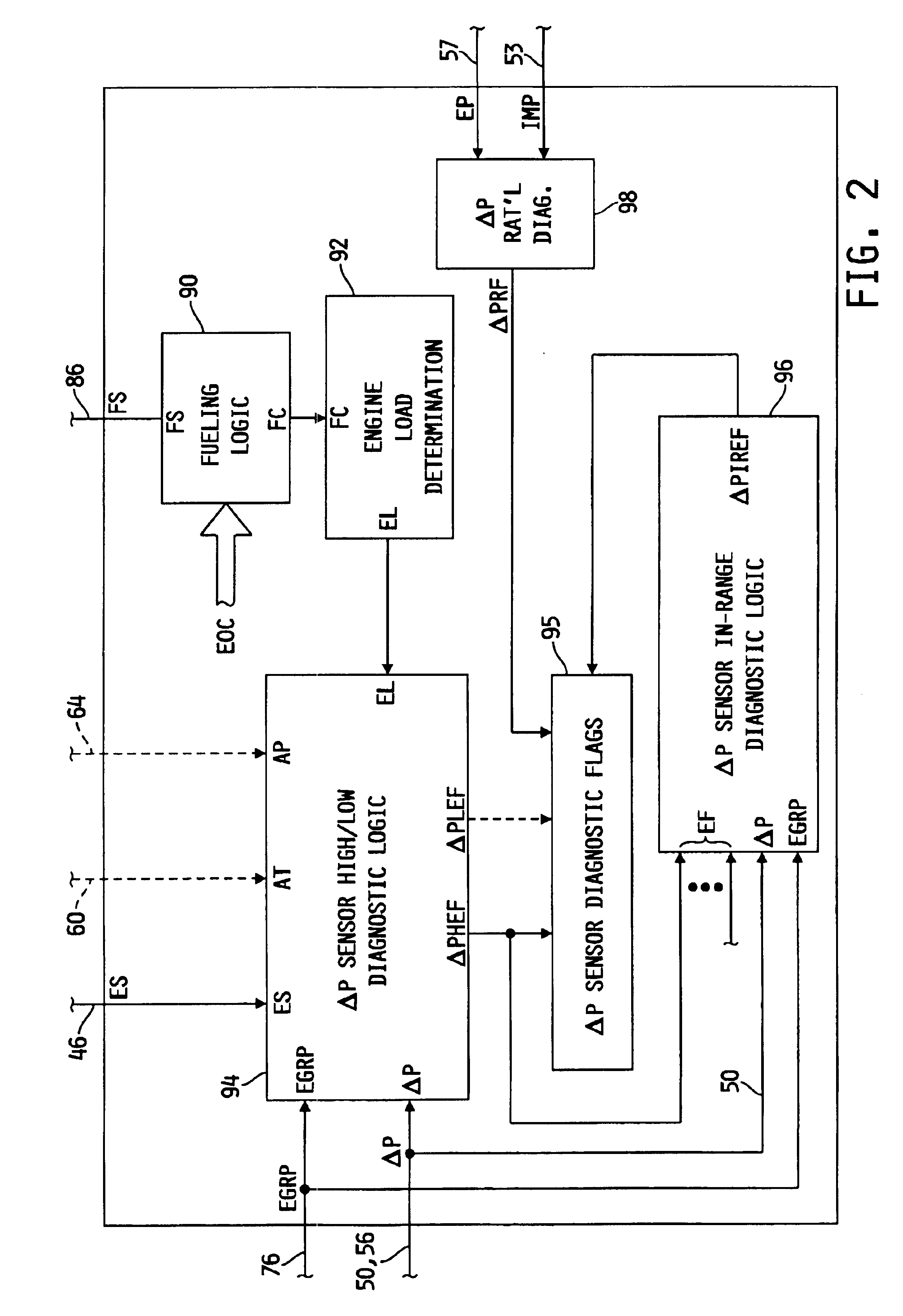

System for diagnosing operation of an EGR cooler

InactiveUS6848434B2Internal combustion piston enginesNon-fuel substance addition to fuelCoolant flowEngineering

A system is disclosed for diagnosing operation of an EGR cooler disposed in-line with an EGR conduit fluidly coupled between an intake manifold and an exhaust manifold of the engine such that exhaust gas flowing through the EGR conduit also flows through the EGR cooler. The EGR cooler is coupled to an engine cooling system such that coolant fluid circulating through the engine also circulates through the EGR cooler. Means are provided for determining a temperature of exhaust gas produced by the engine, a temperature of exhaust gas exiting the EGR cooler, a temperature of the coolant fluid and a flow rate of exhaust gas through the EGR conduit. A control computer is configured to diagnose operation the EGR cooler as a function of the temperature of exhaust gas produced by the engine, the EGR cooler outlet temperature, the engine coolant temperature and the EGR flow rate.

Owner:CUMMINS INC

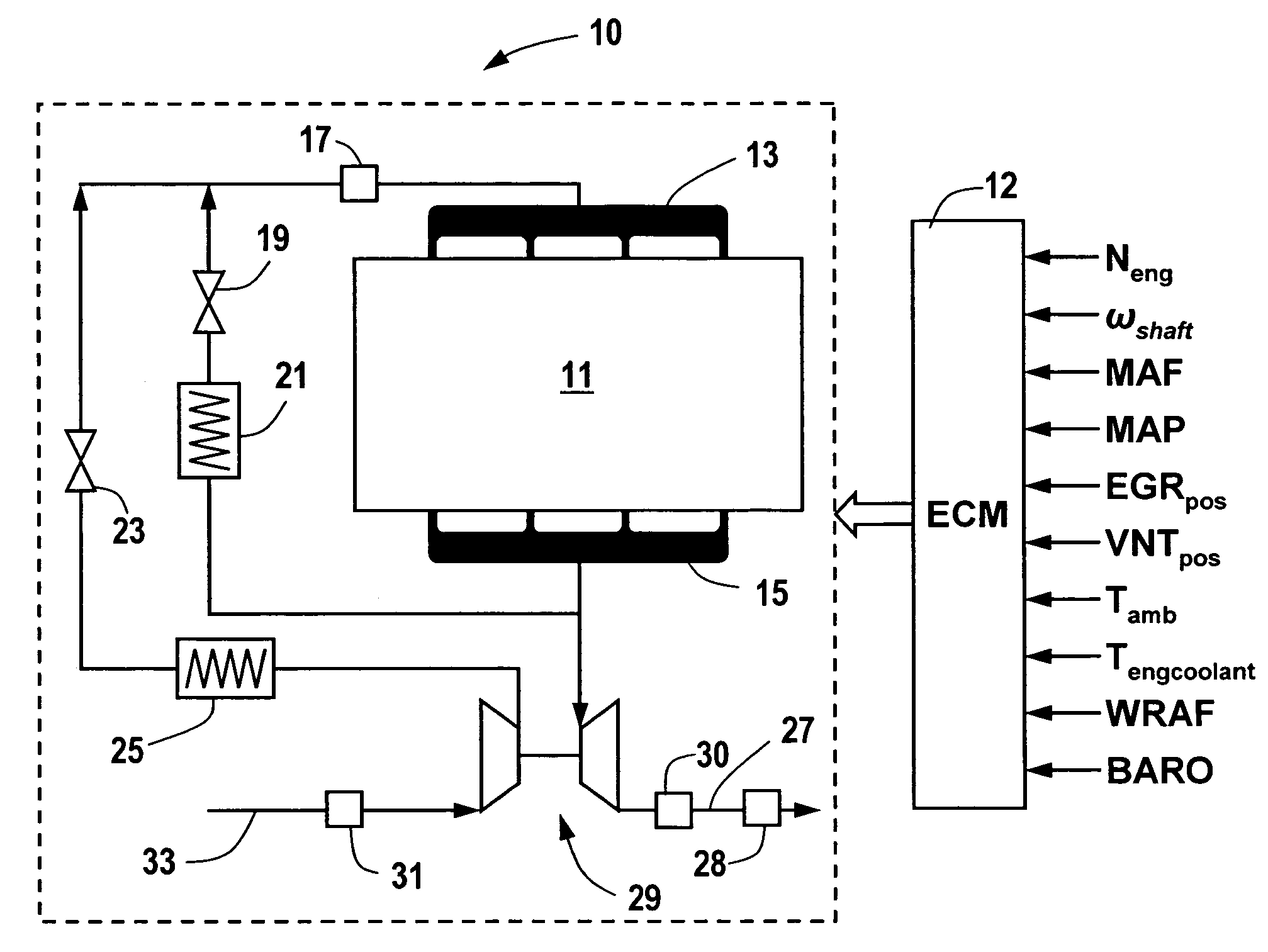

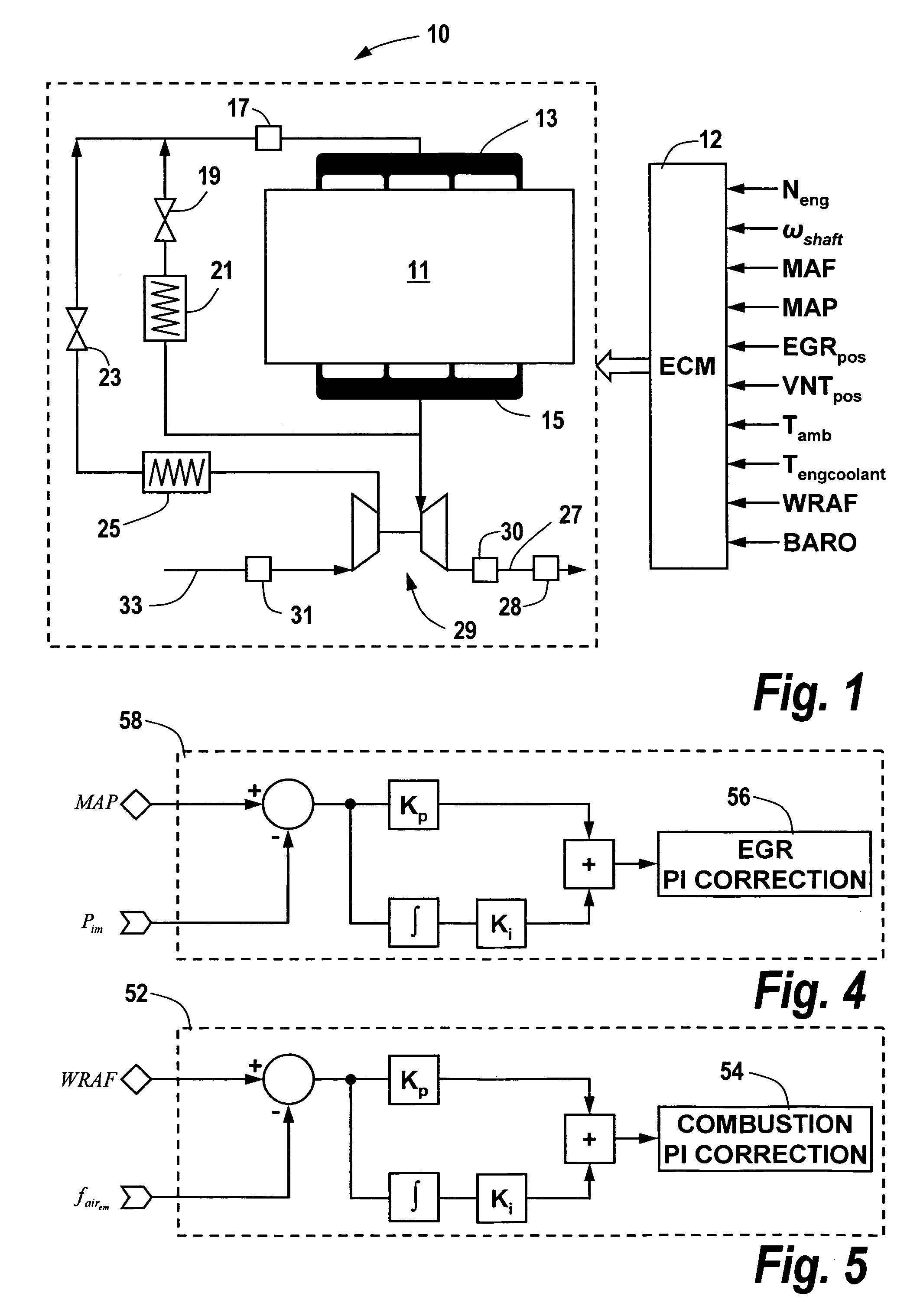

Intake oxygen estimator for internal combustion engine

ActiveUS7117078B1Electrical controlDigital data processing detailsExternal combustion engineExhaust gas recirculation

An internal combustion engine system includes an intake manifold, a combustion chamber, an exhaust manifold and exhaust gas recirculation apparatus for recirculating a portion of the exhausted gases from the exhaust manifold to the intake manifold. An estimate intake manifold oxygen concentration is determined from the air fraction within the intake manifold which is determined from an engine system model that provides interdependent air mass fractions at various locations within the engine system.

Owner:GM GLOBAL TECH OPERATIONS LLC

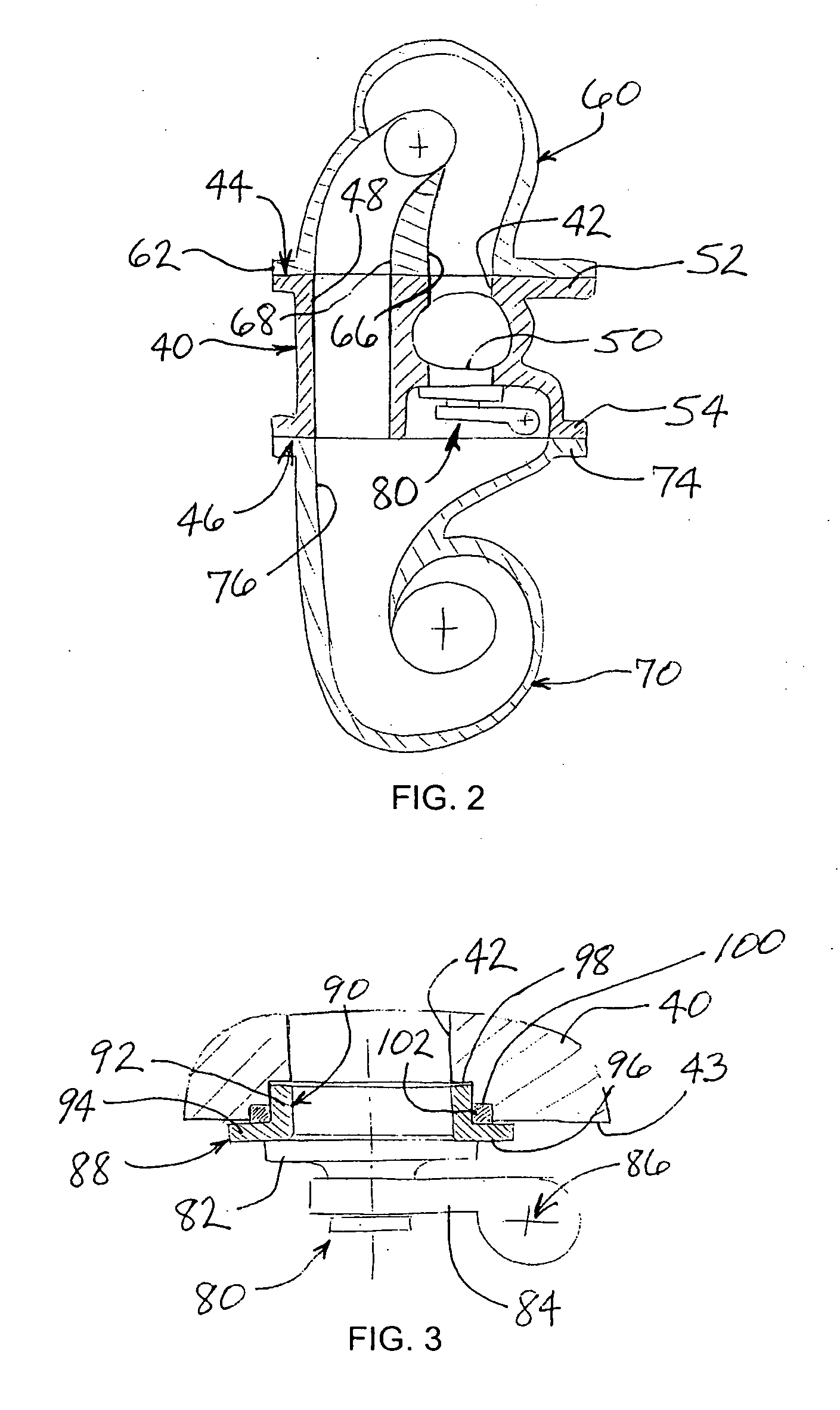

Two-stage turbocharger system with integrated exhaust manifold and bypass assembly

A two-stage turbocharger system includes an exhaust manifold formed separately from the high-pressure and low-pressure turbine housings. The exhaust manifold defines a bypass passage, and a bypass valve is disposed in the bypass passage for opening and closing the passage. The exhaust manifold also defines an inter-turbine passage. The turbine housings of the high-pressure and low-pressure turbochargers are releasably connected to the exhaust manifold such that exhaust gas received into the exhaust manifold bypasses the high-pressure turbine and flows through the bypass passage to the low-pressure turbine when the bypass valve is in the open position, and the exhaust gas flows through the high-pressure turbine and then through the inter-turbine passage to the low-pressure turbine when the bypass valve is in the closed position.

Owner:GARRETT TRANSPORATION I INC

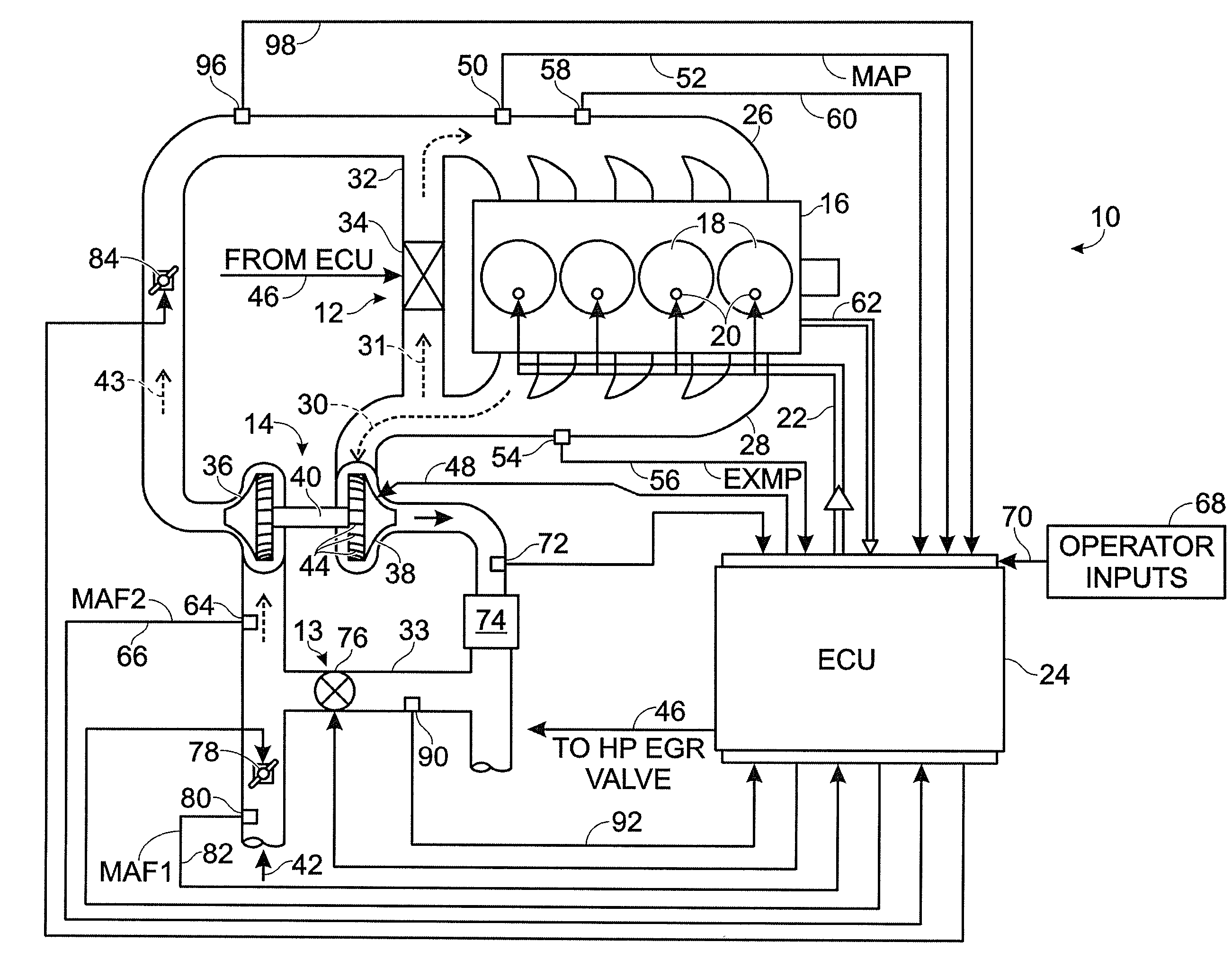

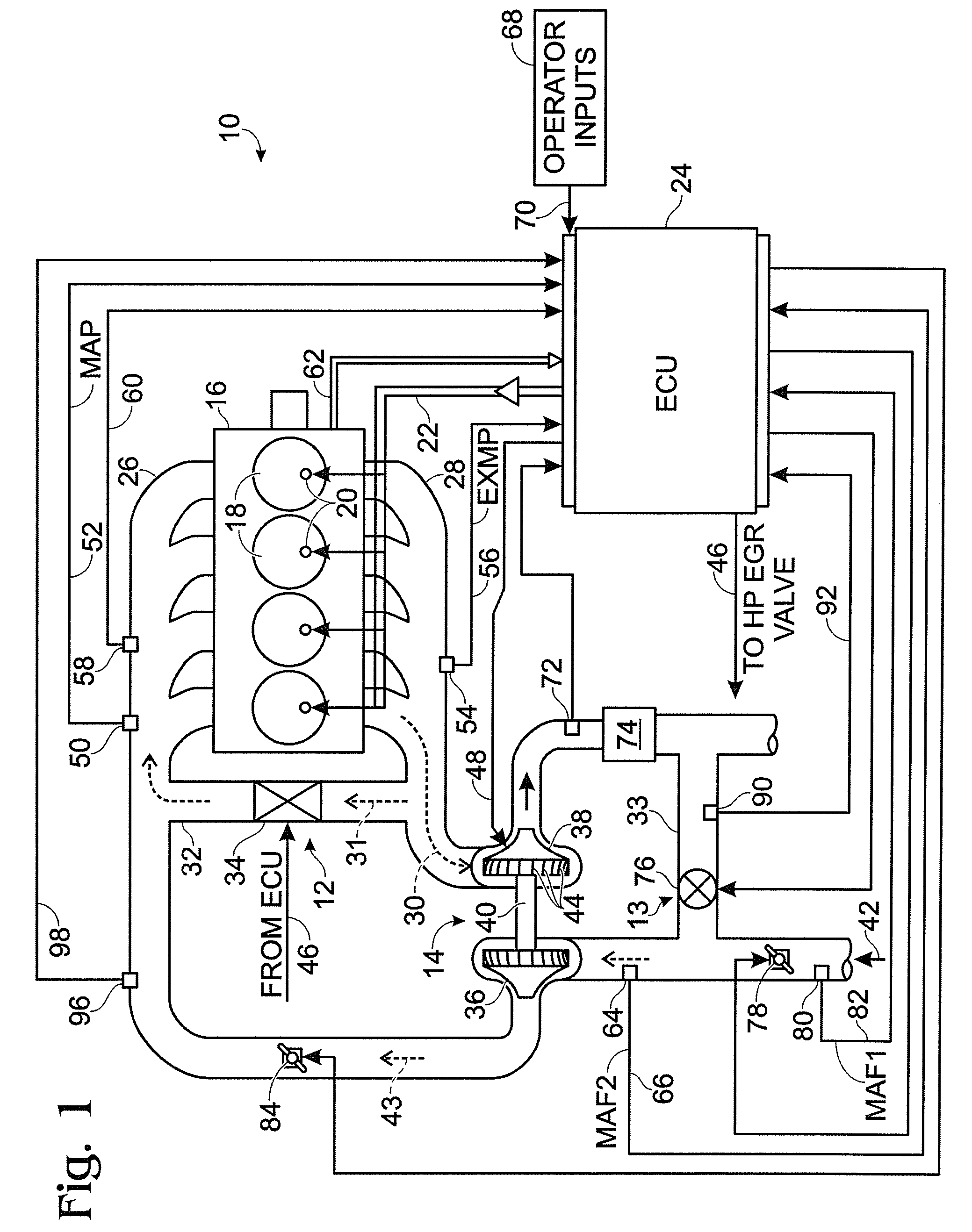

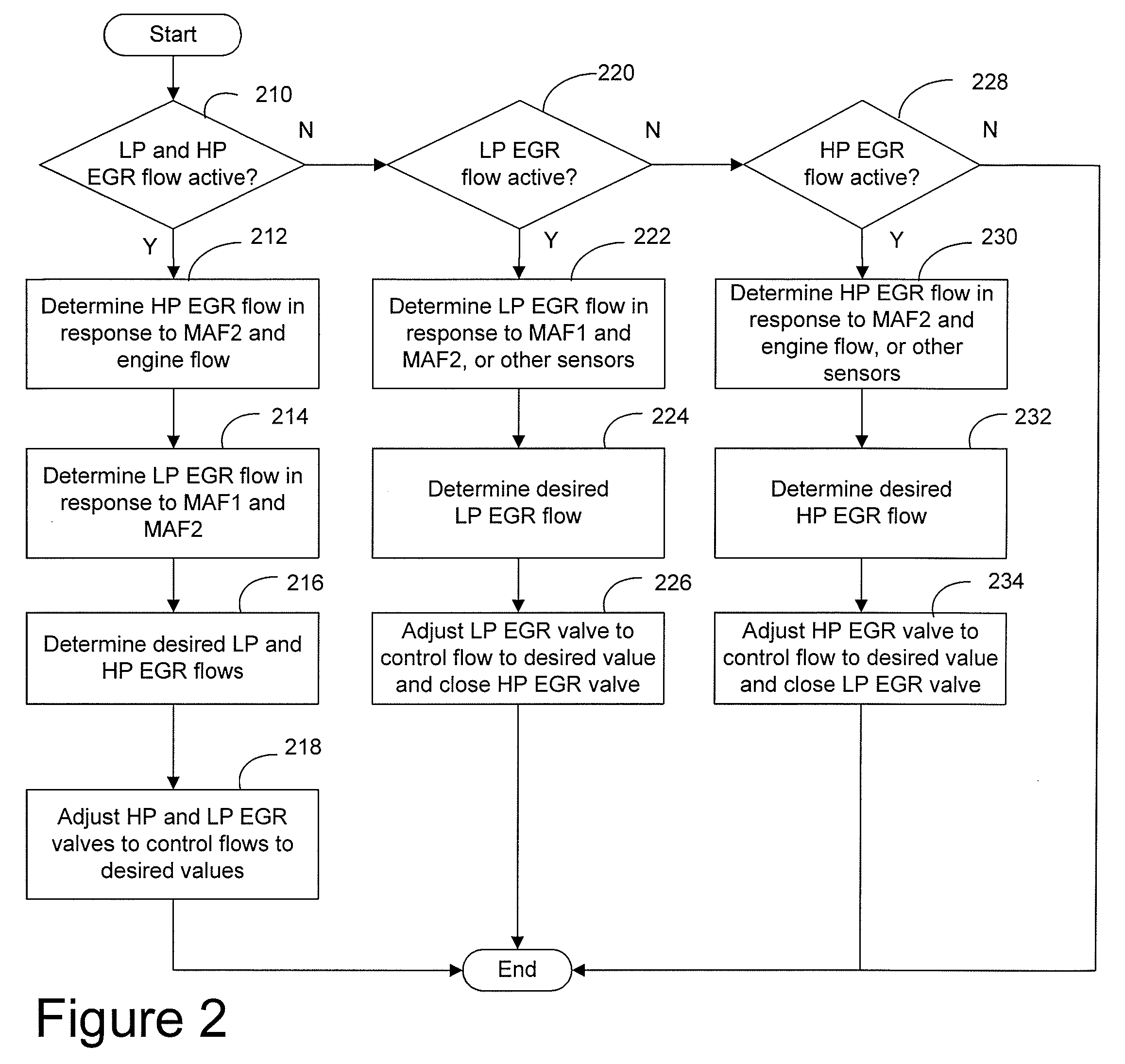

System and Method for Diagnostic of Low Pressure Exhaust Gas Recirculation System and Adapting of Measurement Devices

ActiveUS20080022677A1Reduce the formation of nitrogen oxidesImprove fuel economyVehicle testingElectrical controlMeasurement deviceTurbocharger

A system for a diesel engine having an intake manifold and an exhaust manifold, comprises a turbocharger between the intake and exhaust manifolds of the engine; a low pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold downstream of the turbocharger and a second end couple to the intake manifold upstream of the turbocharger, said low pressure exhaust gas recirculation having a first valve coupled thereto for regulating flow; a high pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold upstream of the turbocharger and a second end coupled to the intake manifold downstream of the turbocharger, said high pressure exhaust gas recirculation having a second valve coupled thereto for regulating flow; a first mass airflow sensor coupled in the engine intake manifold upstream of an inlet of said second end of said low pressure exhaust gas recirculation system; and a control system configured to diagnose the degradation of said first mass airflow sensor.

Owner:FORD GLOBAL TECH LLC

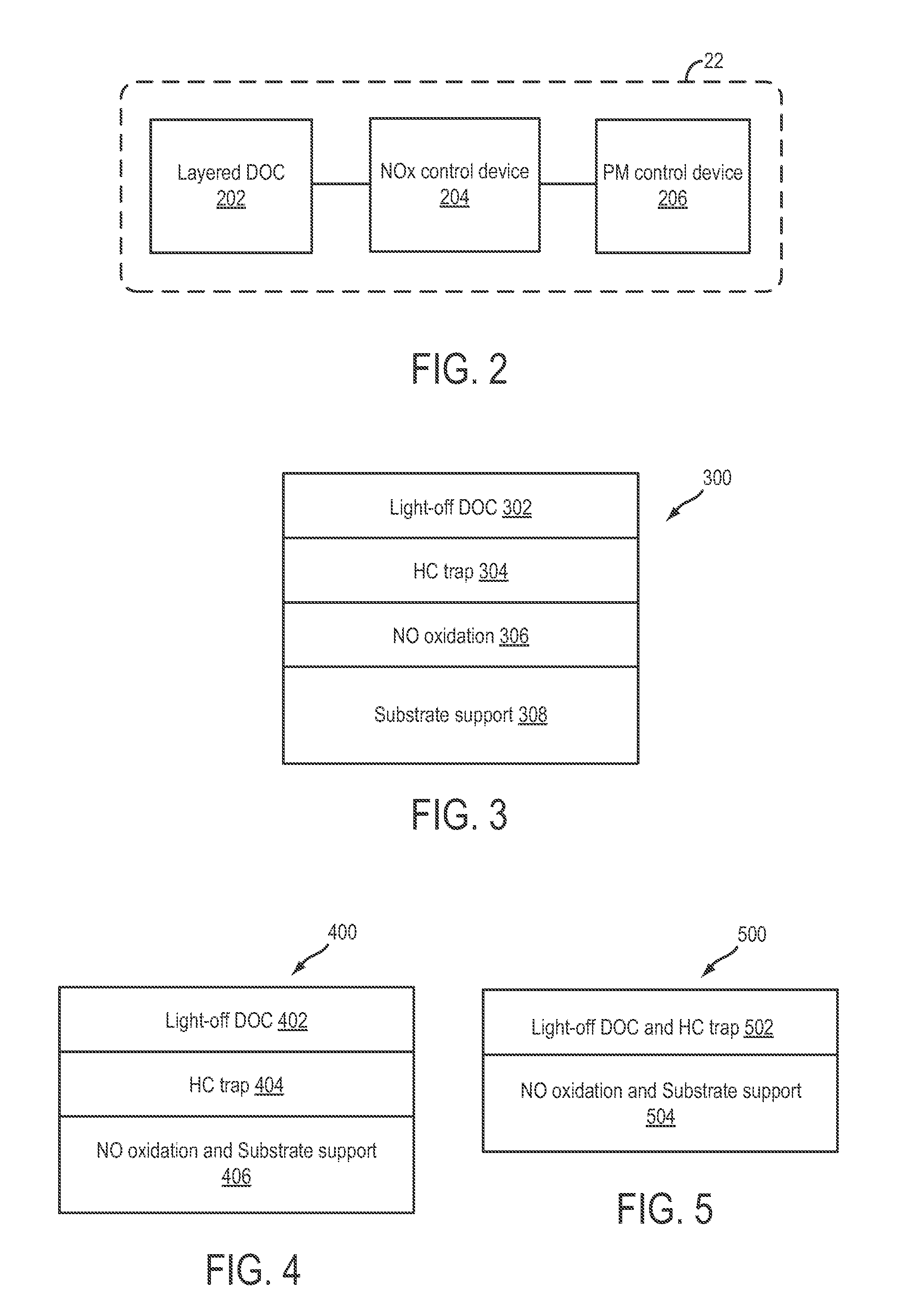

Methods and systems for an engine emission control system

ActiveUS20120023909A1Improve NO formationReduce back pressureNitrogen compoundsDispersed particle separationControl systemFunctional interference

Systems and methods are provided for a layered emission control device coupled to an exhaust manifold. Various formulations may be incorporated in a plurality of layers of the device to enable various emission control functions to be grouped within spatial constraints. The layers may be organized to reduce functional interference and improve functional synergy between the various emission control functions.

Owner:FORD GLOBAL TECH LLC

Dual path EGR system and methods

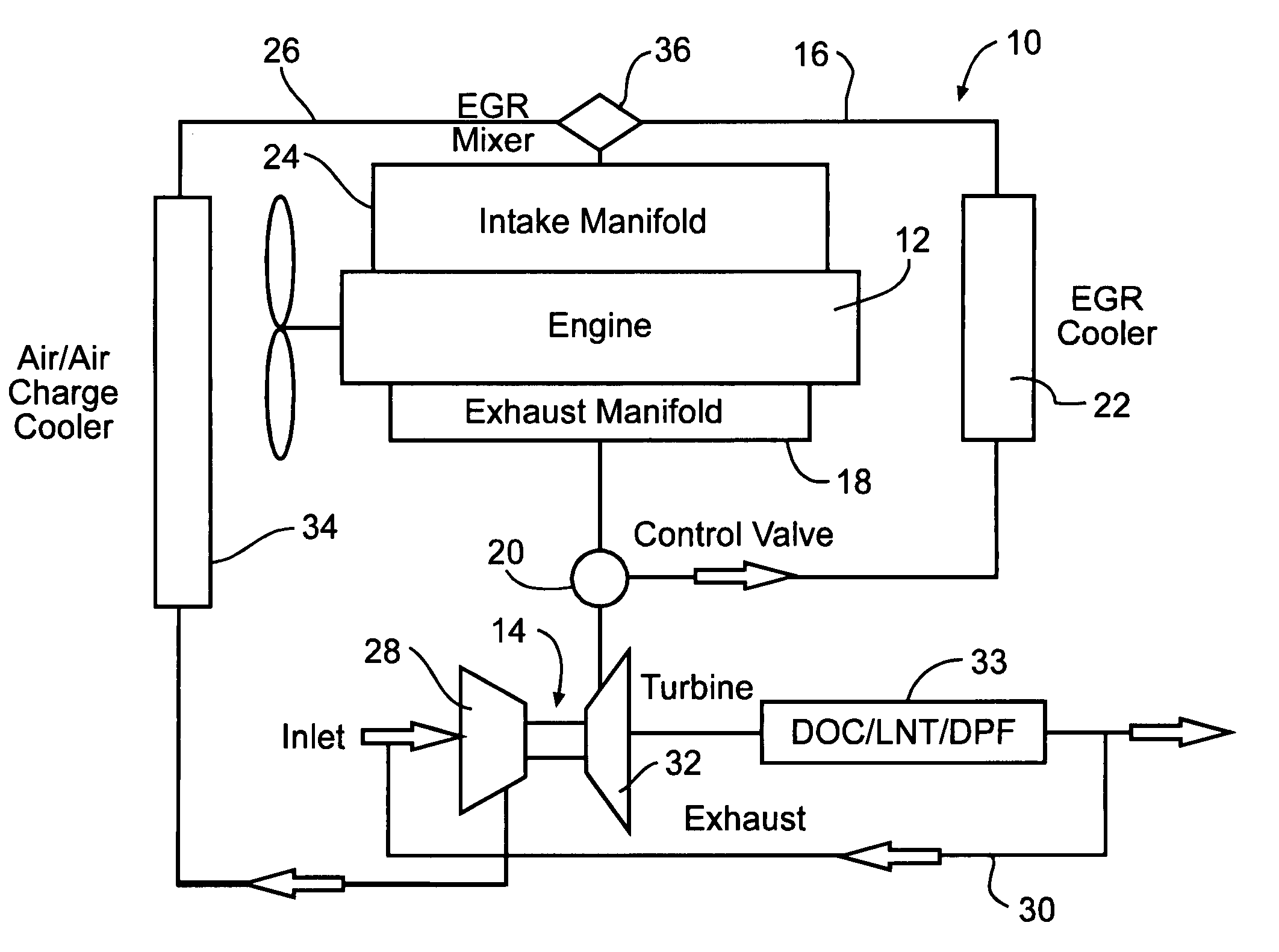

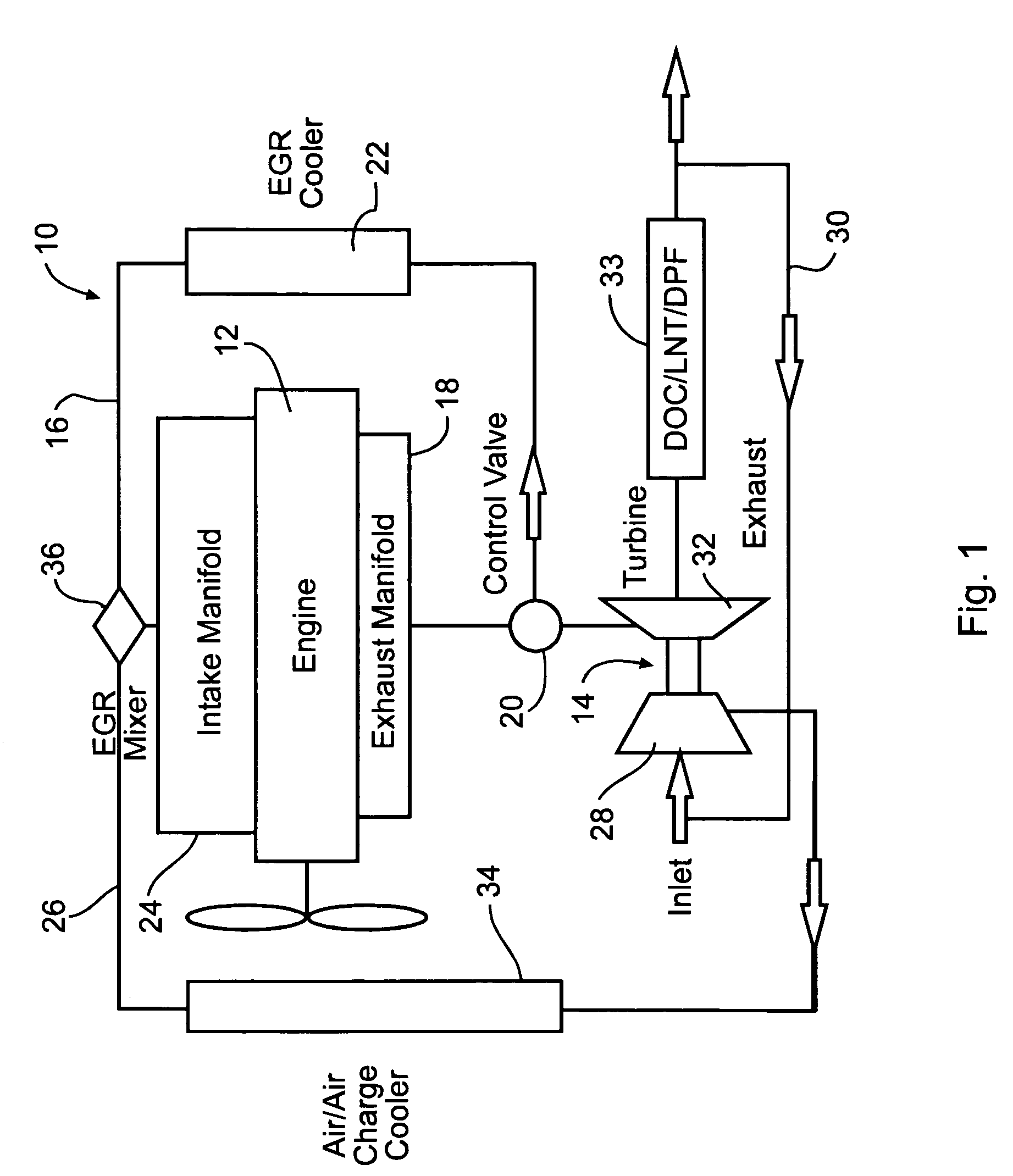

InactiveUS6899090B2Reduce condensationElectrical controlInternal combustion piston enginesFresh airHigh pressure

An internal combustion engine system, dual loop EGR system and method is provided, with a high pressure EGR loop, controlled by a control valve, in fluidic connection with the exhaust outlet of the exhaust manifold and the air inlet of the intake manifold, and a low pressure EGR loop, wherein exhaust, in proportions controlled by a control valve, enters a compressor from a point downstream of an exhaust emissions controller, together with fresh air, the low pressure EGR loop being in fluidic connection with an output of the compressor and the air inlet of the intake manifold.

Owner:GARRETT TRANSPORATION I INC

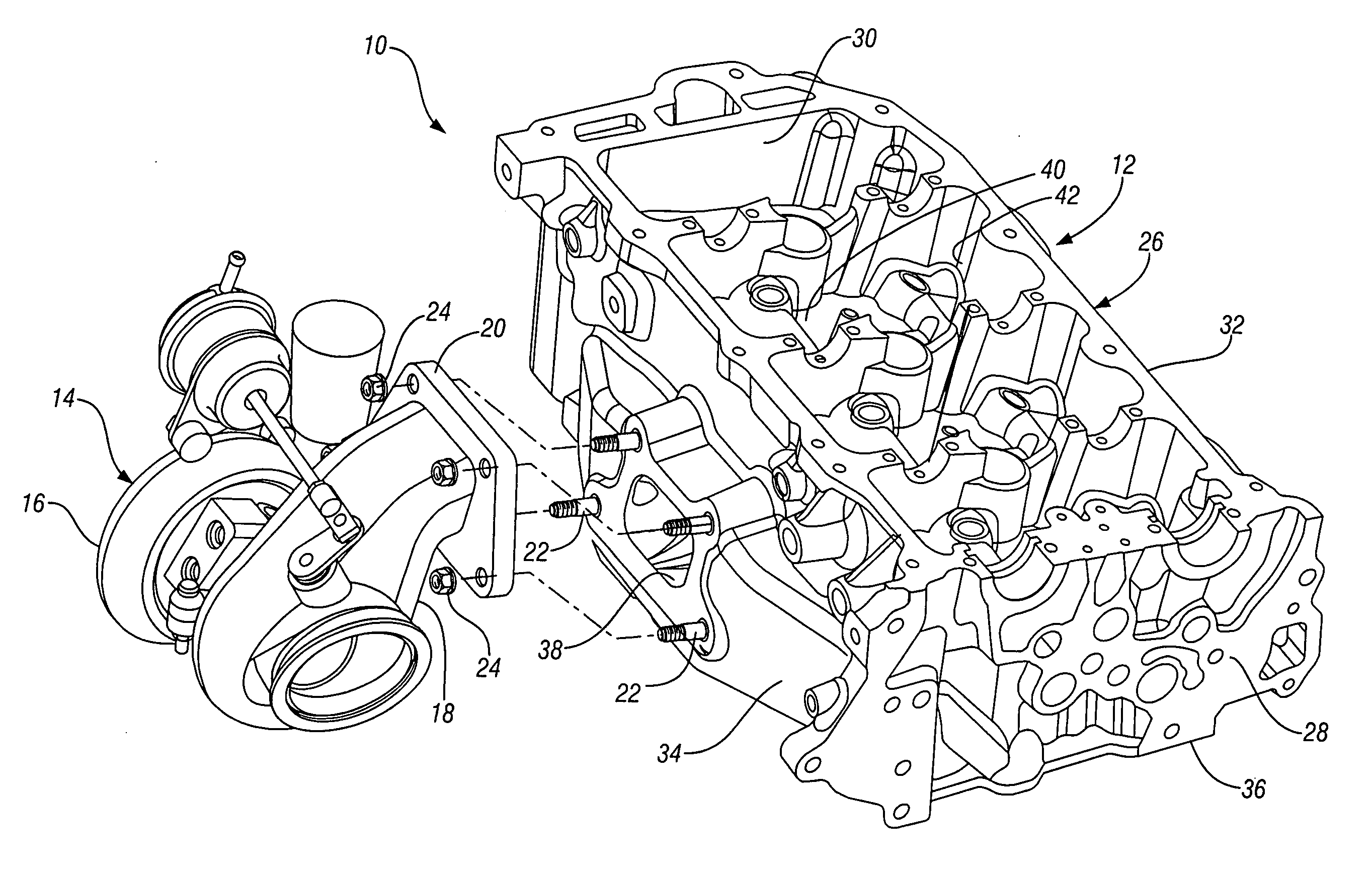

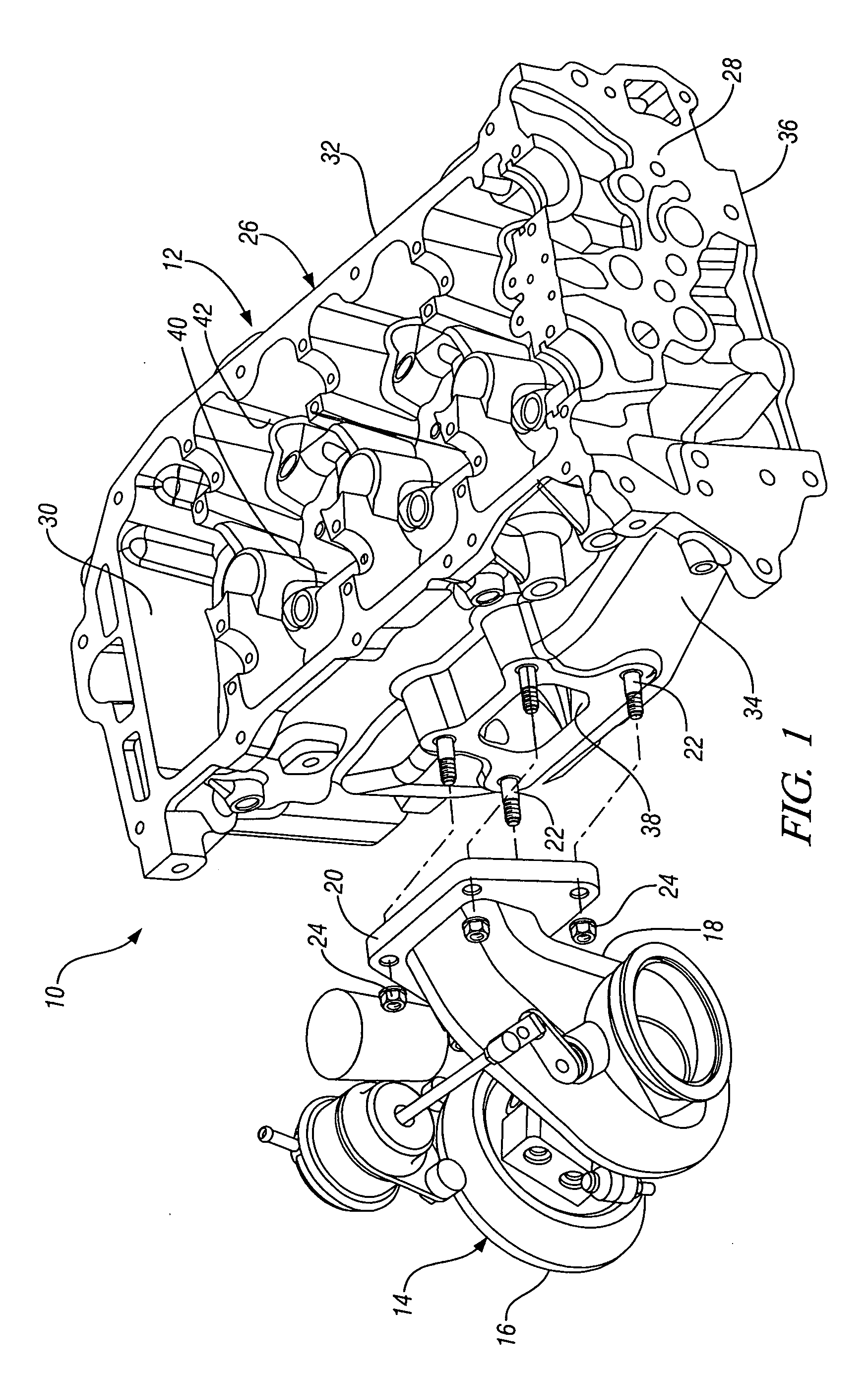

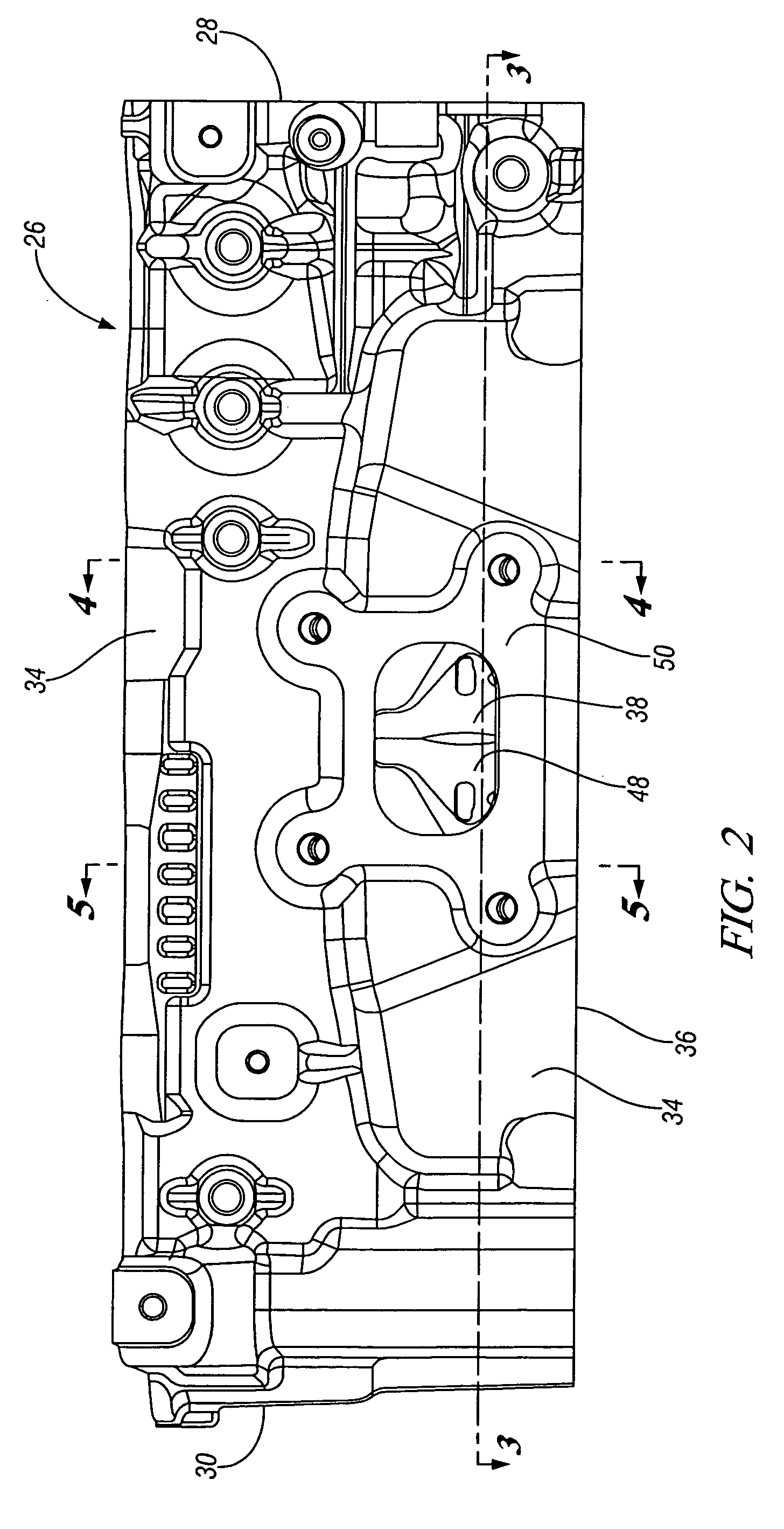

Turbocharged engine cylinder head internal cooling

InactiveUS20090126659A1Reduce metal temperatureReduce stepsInternal combustion piston enginesAir coolingCylinder headTurbocharger

An engine cylinder head has an exhaust manifold cast in the cylinder head. A turbocharger with a turbine body is adapted to mount directly to an exhaust outlet mounting face of the exhaust manifold. A dual level water jacket within the cylinder head has separate coolant feeds for upper and lower cooling jackets. The cooling jackets extend above and below the exhaust outlet and are connected inward of the exhaust mounting face to reduce metal temperatures of the mounting face below those of the turbocharger exhaust inlet flange. Separate cores for the upper and lower jackets are connected at coolant inlet and outlet locations at opposite ends. Intermediate core print connectors form controlled flow passages between the upper and lower jackets and exhaust ports in the cylinder head and integrated manifold. The improved cooling in these areas lowers operating temperatures in the cylinder head and obviates the need for a separate exhaust manifold.

Owner:GM GLOBAL TECH OPERATIONS LLC

System for diagnosing delta pressure sensor operation

ActiveUS6850833B1Testing/calibration apparatusInternal combustion piston enginesInlet manifoldPressure sensor

A system for diagnosing operation of a delta pressure sensor used with an internal combustion engine comprises an intake manifold and an exhaust manifold each operatively coupled to the engine, an EGR conduit fluidly coupled between the intake and exhaust manifolds, and a flow restriction mechanism disposed in-line with the EGR conduit, wherein the delta pressure sensor produces a delta pressure signal indicative of a pressure differential across the flow restriction mechanism. A control computer compares the delta pressure signal to a modeled delta pressure value modeled as a function of at least engine speed and one of engine load and engine output torque percentage, and diagnoses a fault state of the delta pressure sensor based on the comparison.

Owner:CUMMINS INC

Combustion engine

InactiveUS6460337B1Improve performanceReduce the temperatureValve arrangementsInternal combustion piston enginesExhaust valveCombustion

A turbo-fed internal combustion engine has a first and a second exhaust-gas valve per cylinder, these exhaust-gas valves each being connected to their respective exhaust manifold. One exhaust manifold conducts exhaust gases to an exhaust-gas turbine and the other exhaust manifold conducts subsequent exhaust gases past this exhaust-gas turbine which drives a compressor for charge air. The intake valve of the cylinder is arranged so as, as the engine speed increases, to close either earlier, before the piston reaches its bottom dead center, or later, after the piston has passed its bottom dead center. In this way, the temperature increase resulting from compression in the cylinder is reduced. Cooled air from the compressor can be taken in so as to obtain an adequate degree of filling in the cylinder, with a lower final temperature.

Owner:SAAB AUTOMOBILE AB

Exhaust mixer element and method for mixing

According to one aspect of the invention, a mixer element to be placed between an internal combustion engine exhaust manifold and catalytic converter is provided. The mixer element includes a tubular conduit that receives an exhaust gas flow from the internal combustion engine, a first mixer configured to induce a first vortex of the exhaust gas flow in a first rotational direction and an injector disposed in the tubular conduit downstream of the first mixer, the injector being configured to inject a diesel emission fluid flow into the exhaust gas flow. The mixer element also includes a second mixer positioned downstream of the injector and a third mixer positioned downstream of the second mixer, the third mixer being configured to induce a second vortex of the exhaust gas flow and the diesel emission fluid mixture in a second rotational direction, opposite of the first rotational direction.

Owner:GM GLOBAL TECH OPERATIONS LLC

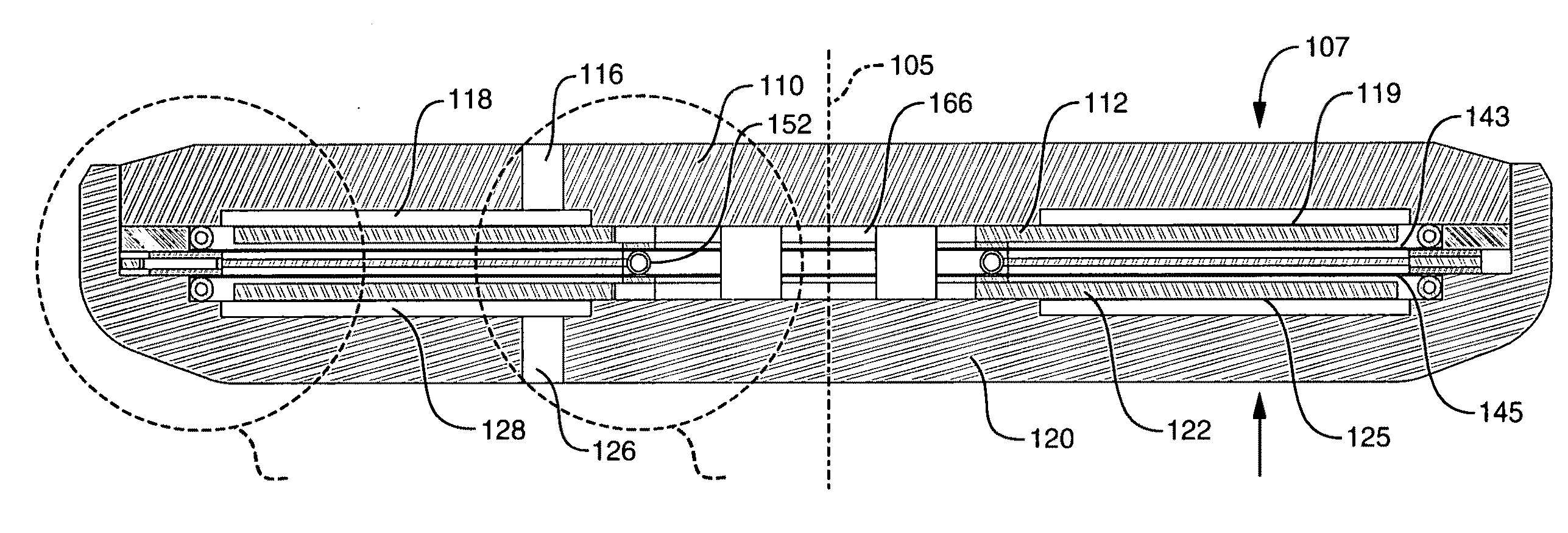

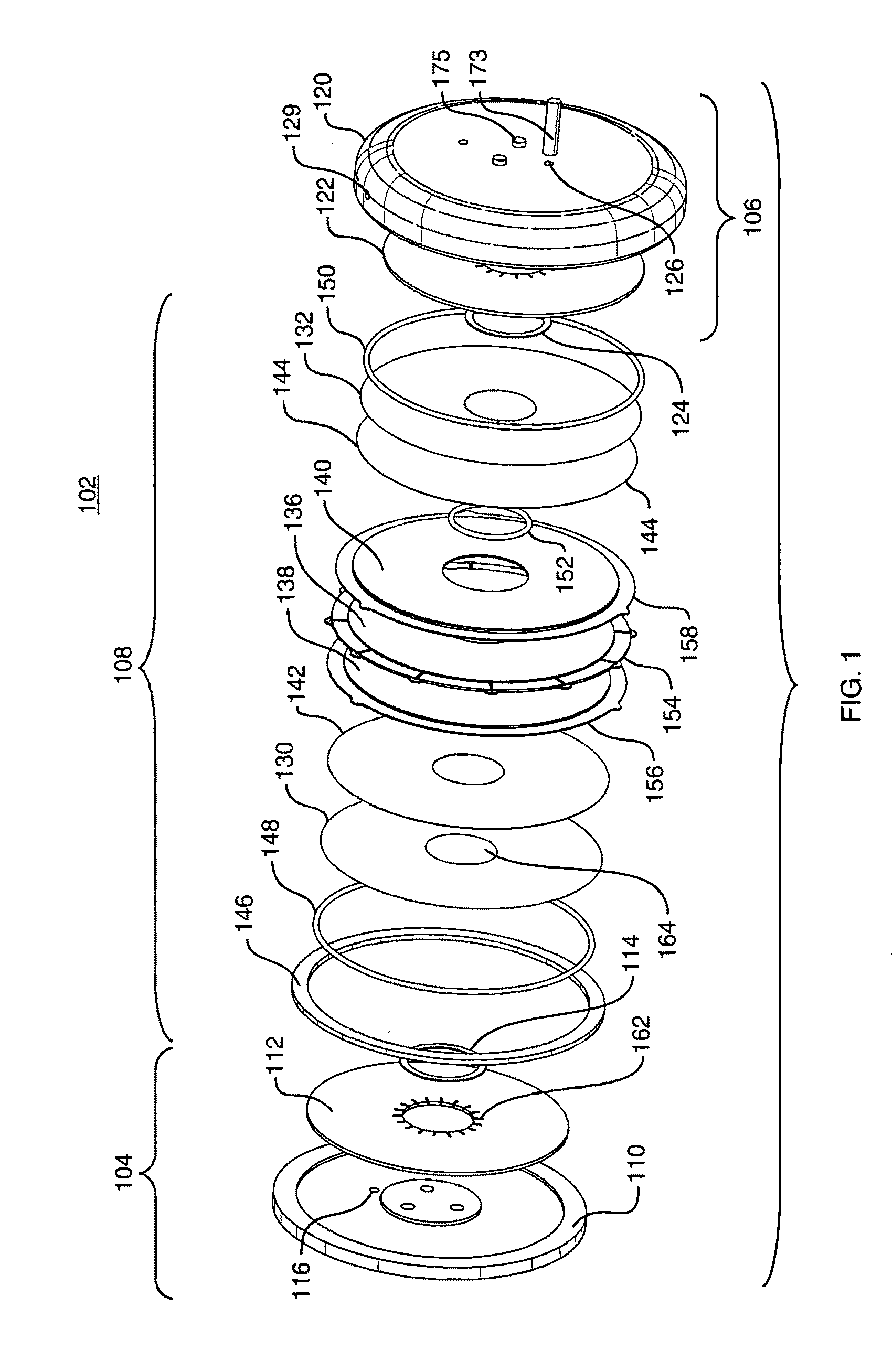

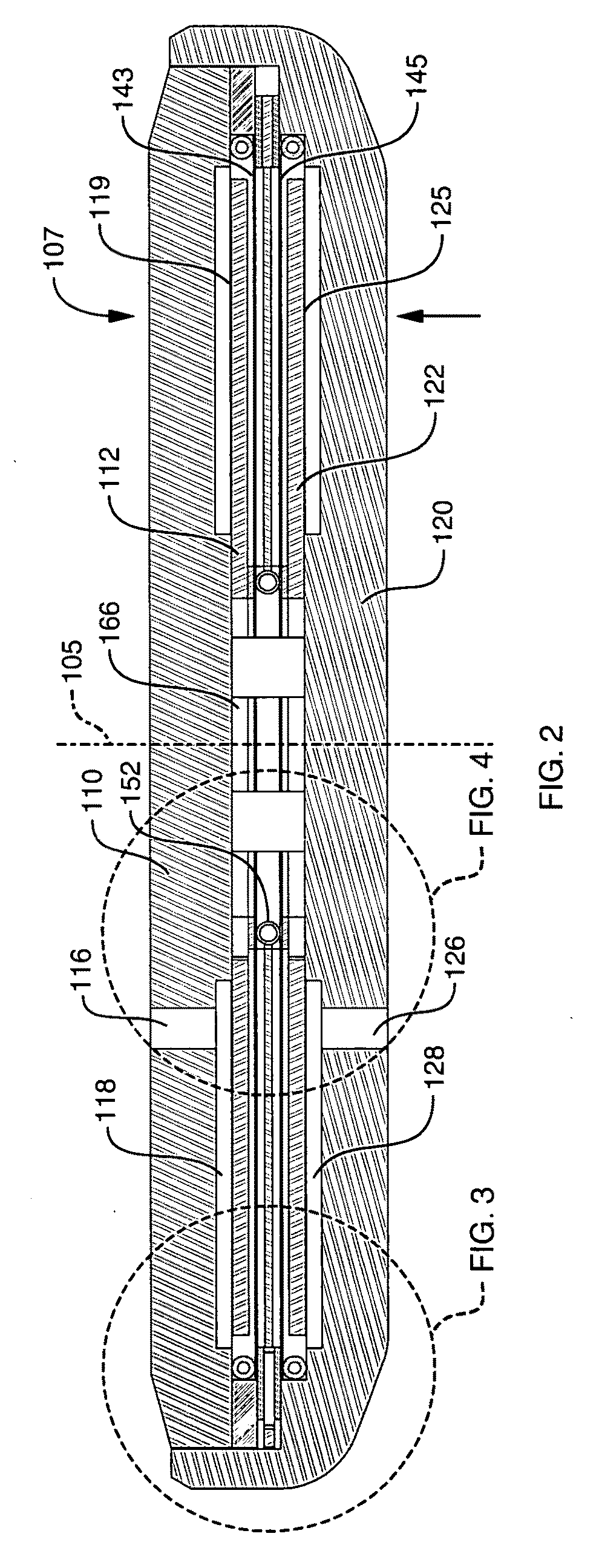

Membrane support module for permeate separation in a fuel cell

ActiveUS20100064887A1Simple structureAvoid breakingMembranesSemi-permeable membranesFuel cellsMembrane configuration

A gas separation unit 102, 200, 300 for permeating a gas out from a pressurized feed mixture includes an input manifold 104, 204, an exhaust manifold, 106, 206 and a permeate assembly 108, 208, 303. The permeate assembly supports one or more permselective foils 130, 132, 218, 232, 318 over a hollow cavity 134, 272, 306 supported by a microscreen element 142, 144, 228, 230, 326. The microscreen element includes non-porous perimeter walls 190, 192, 278 supported on a frame surface and a porous central area 194, 280 supported over the hollow cavity. A porous spacer 138, 140, 174, 234 disposed inside the hollow cavity structurally supports the entire microscreen surface spanning the hollow cavity while also providing a void volume for receiving fluid passing through the porous central area and for conveying the fluid through the hollow cavity.

Owner:SILICON VALLEY BANK

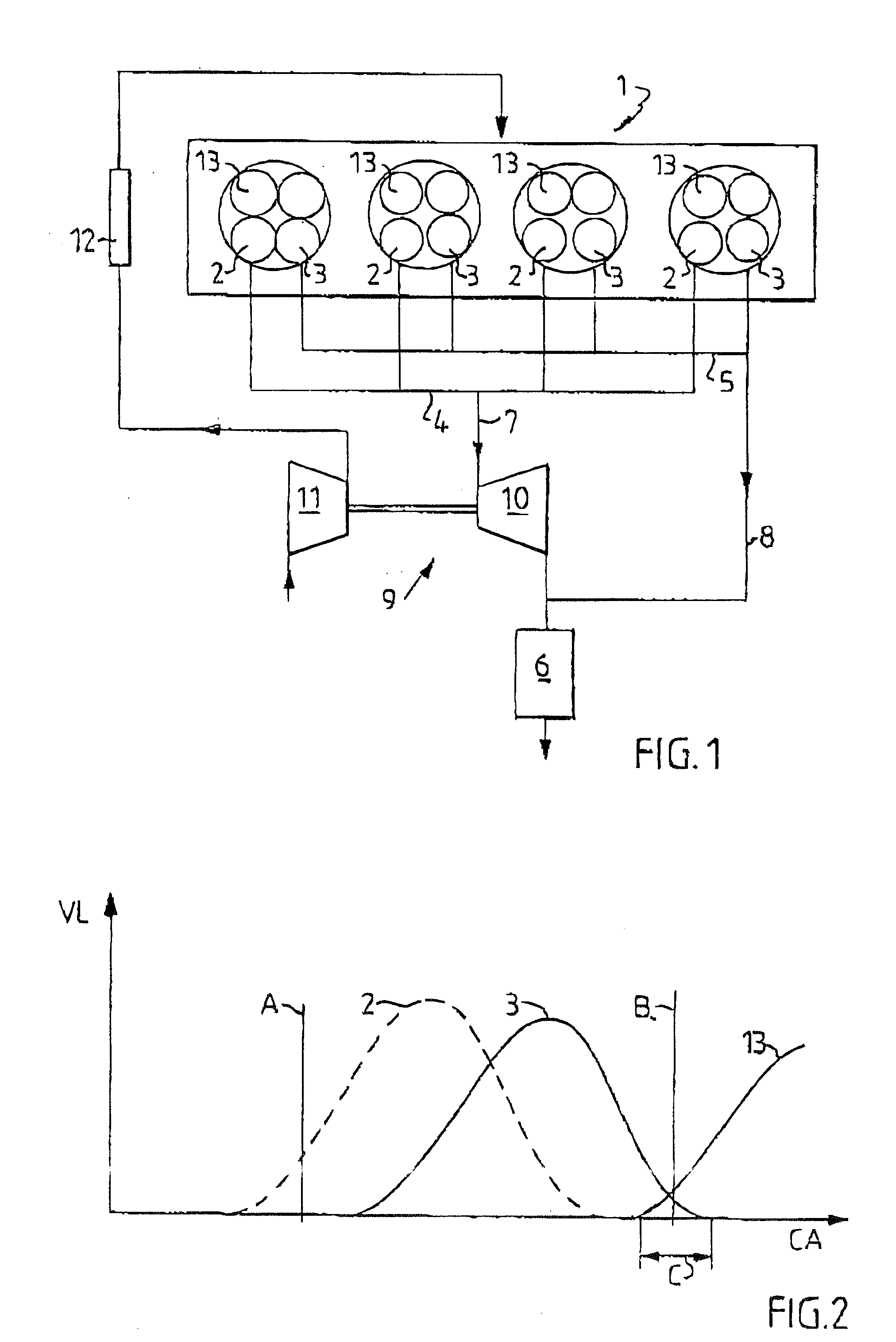

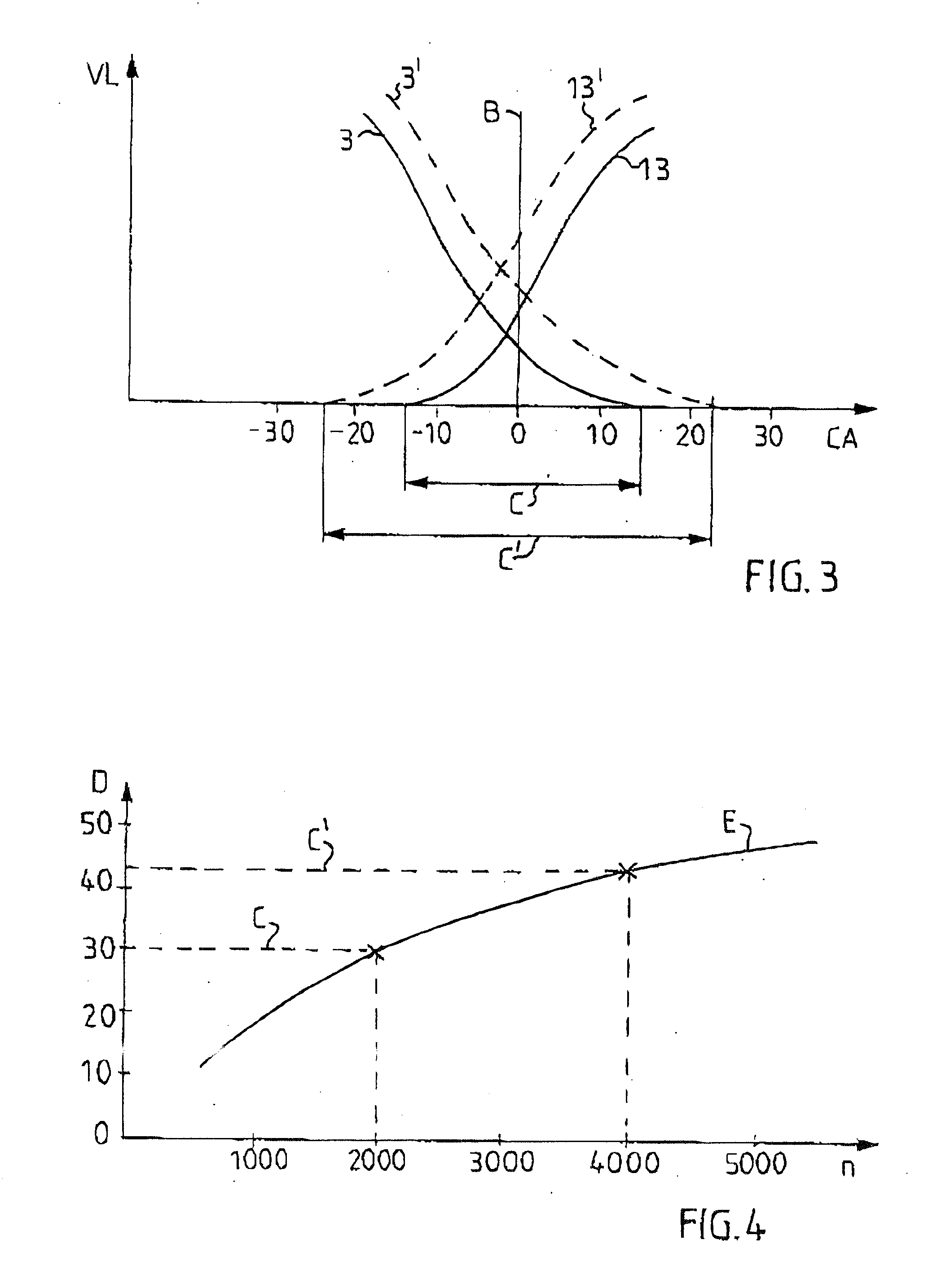

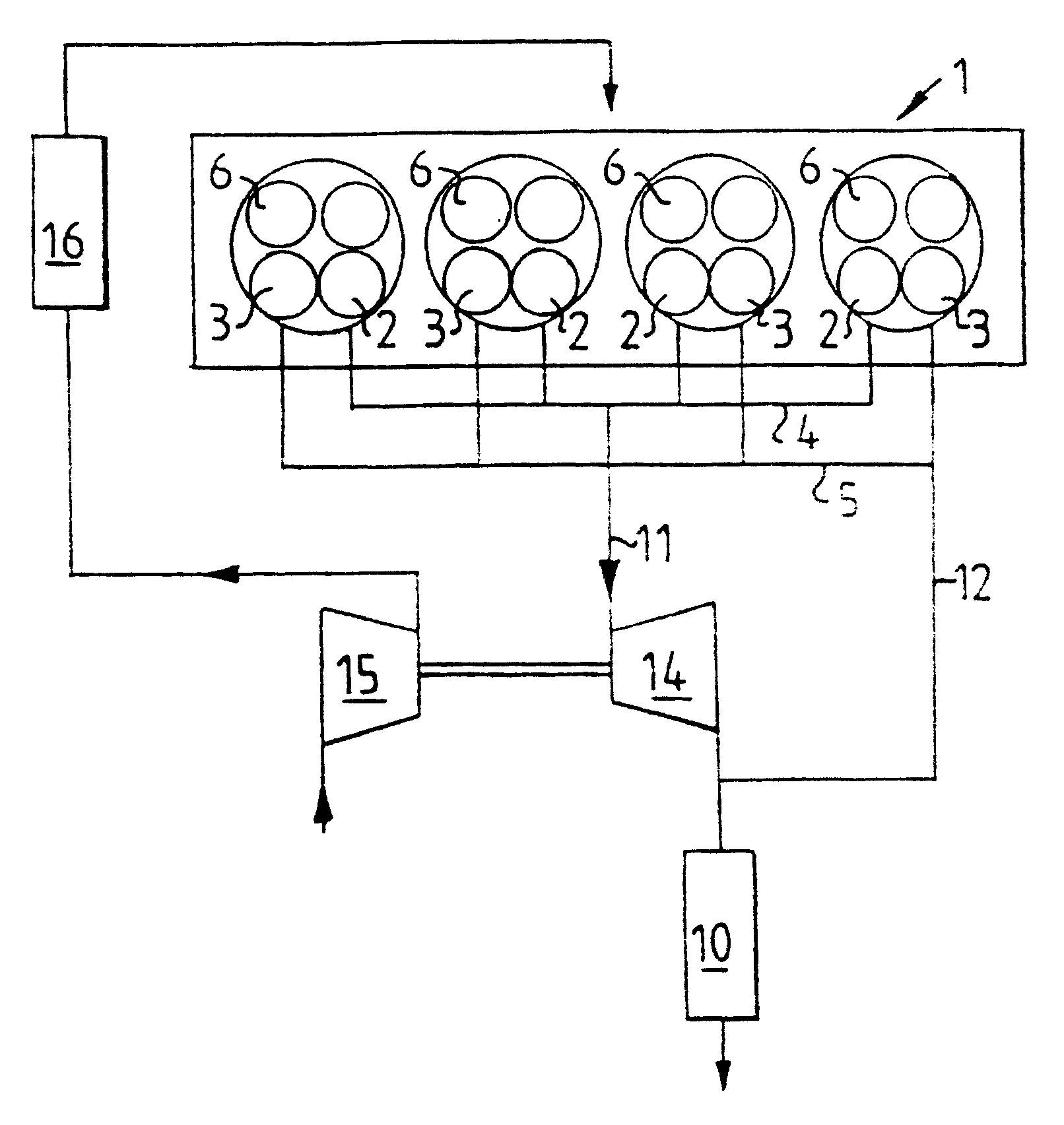

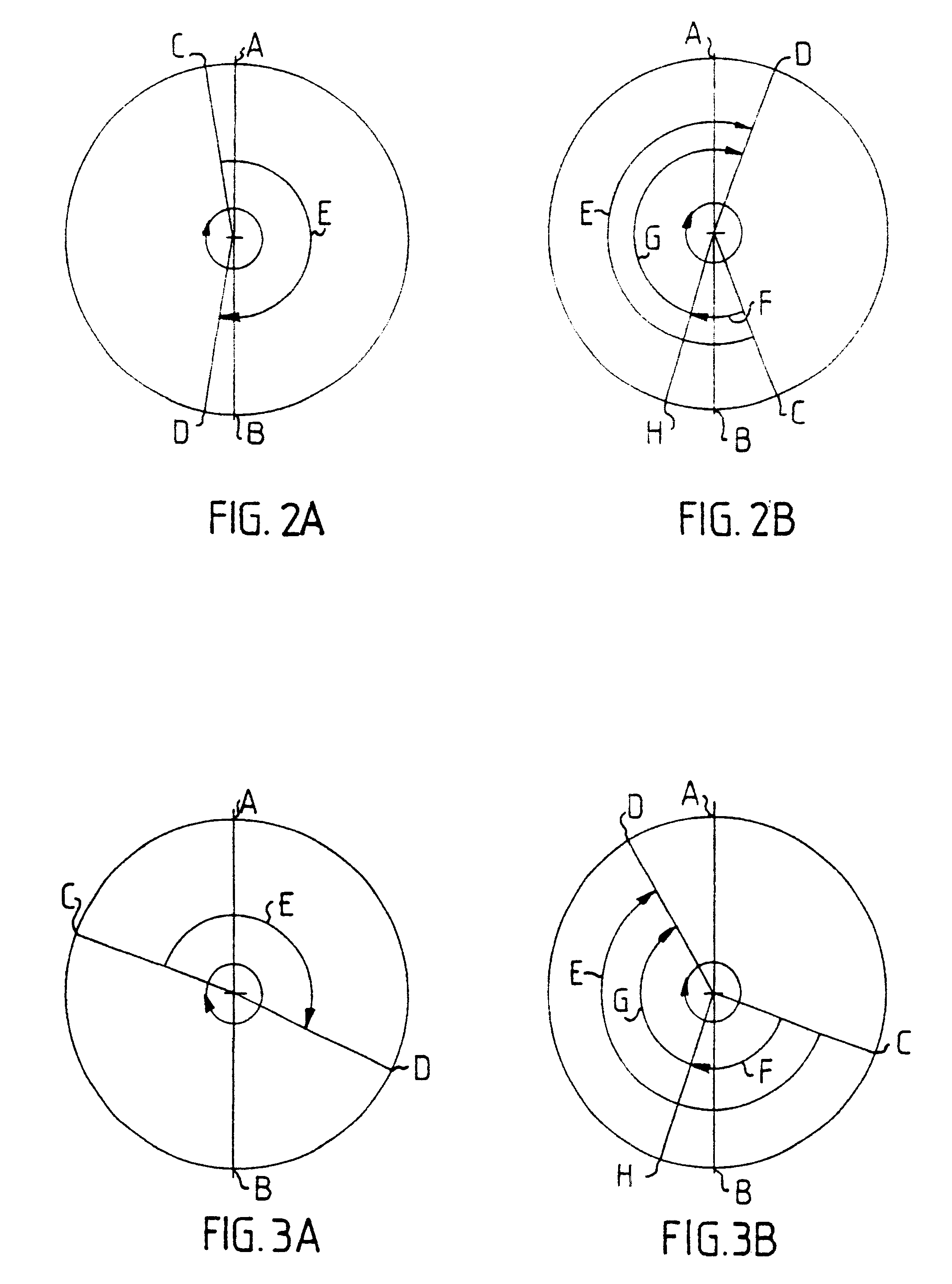

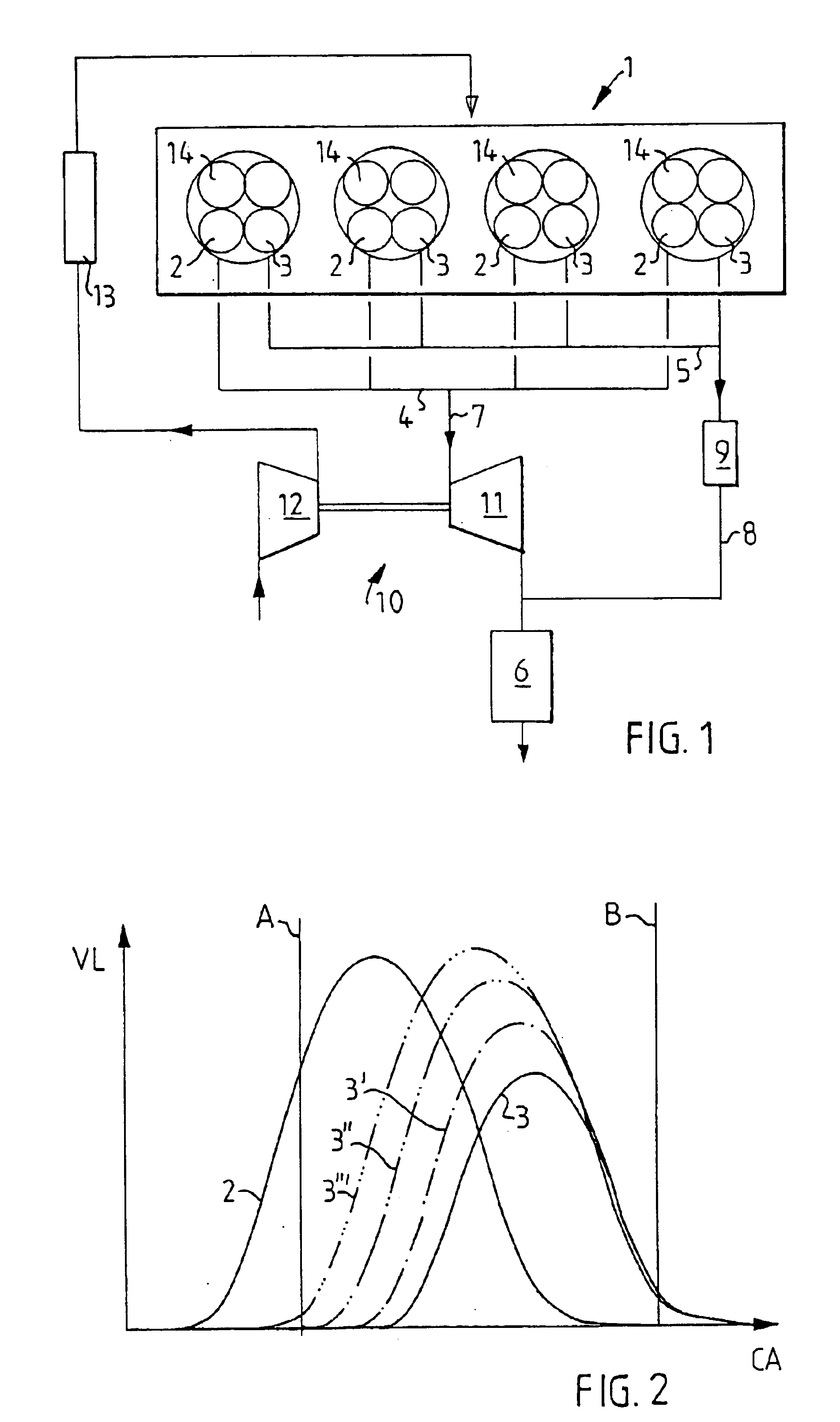

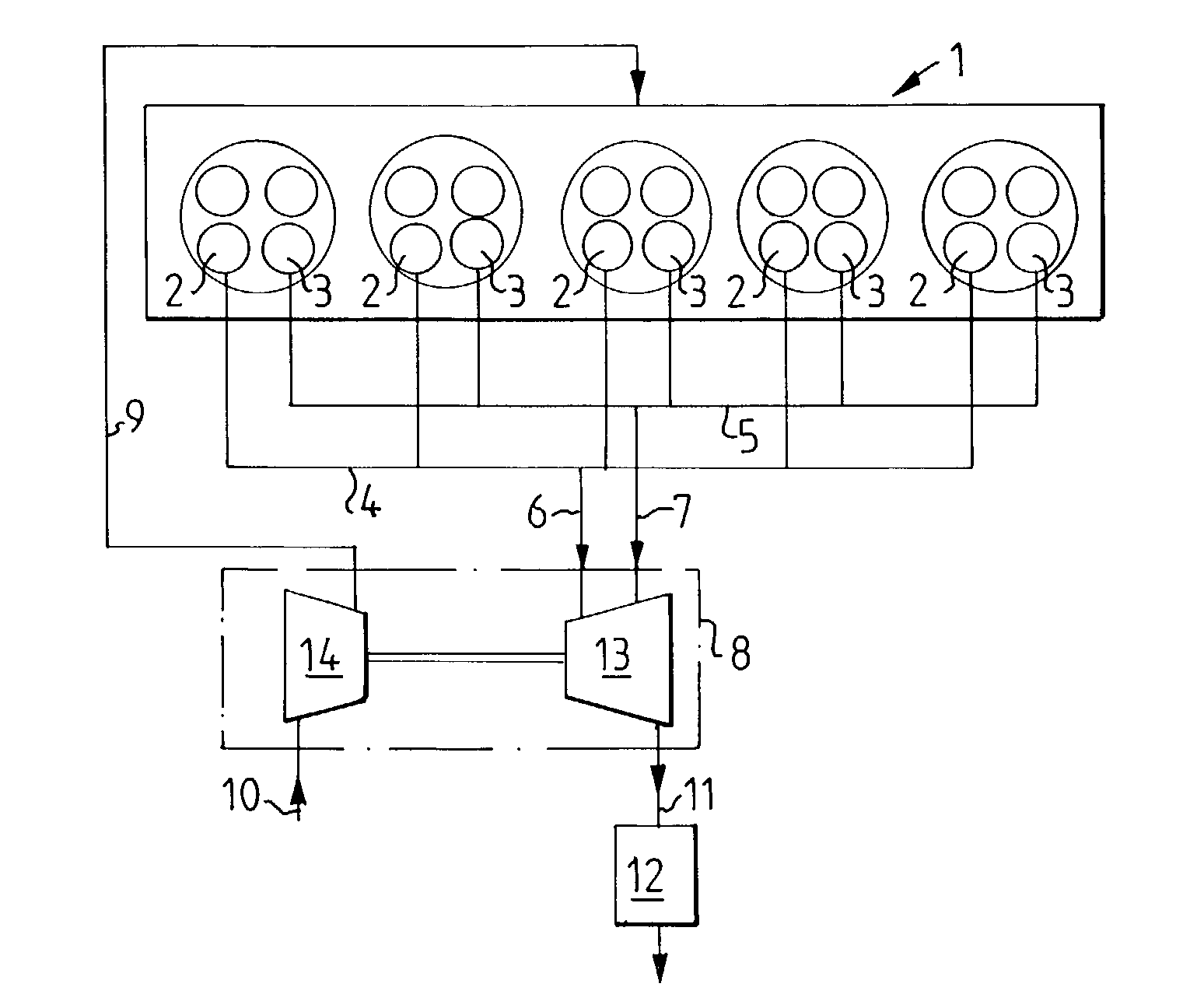

Method for controlling the charging pressure at a turbocharged combustion engine, and a corresponding combustion engine

InactiveUS6883319B2Reduce chargeLimit charging pressureValve arrangementsElectrical controlExhaust valveCombustion

A multicylinder internal combustion engine with an exhaust-driven turbocompressor and with a divided exhaust gas flow has at least two exhaust valves (2,3) and one intake valve per cylinder. A first exhaust valve (2) is connected to a first exhaust manifold which leads to the turbine of the compressor, while a second exhaust valve (3) is connected to a second exhaust manifold which opens downstream of the turbine. The charging pressure in the engine can be regulated by virtue of the opening periods of the exhaust valves (2,3) being varied in relation to one another in order to adapt the flow through the exhaust turbine to a value which provides the desired charging pressure in the engine. By opening the second exhaust valve (3) increasingly earlier, an increasingly lower charging pressure can be achieved.

Owner:SAAB AUTOMOBILE AB

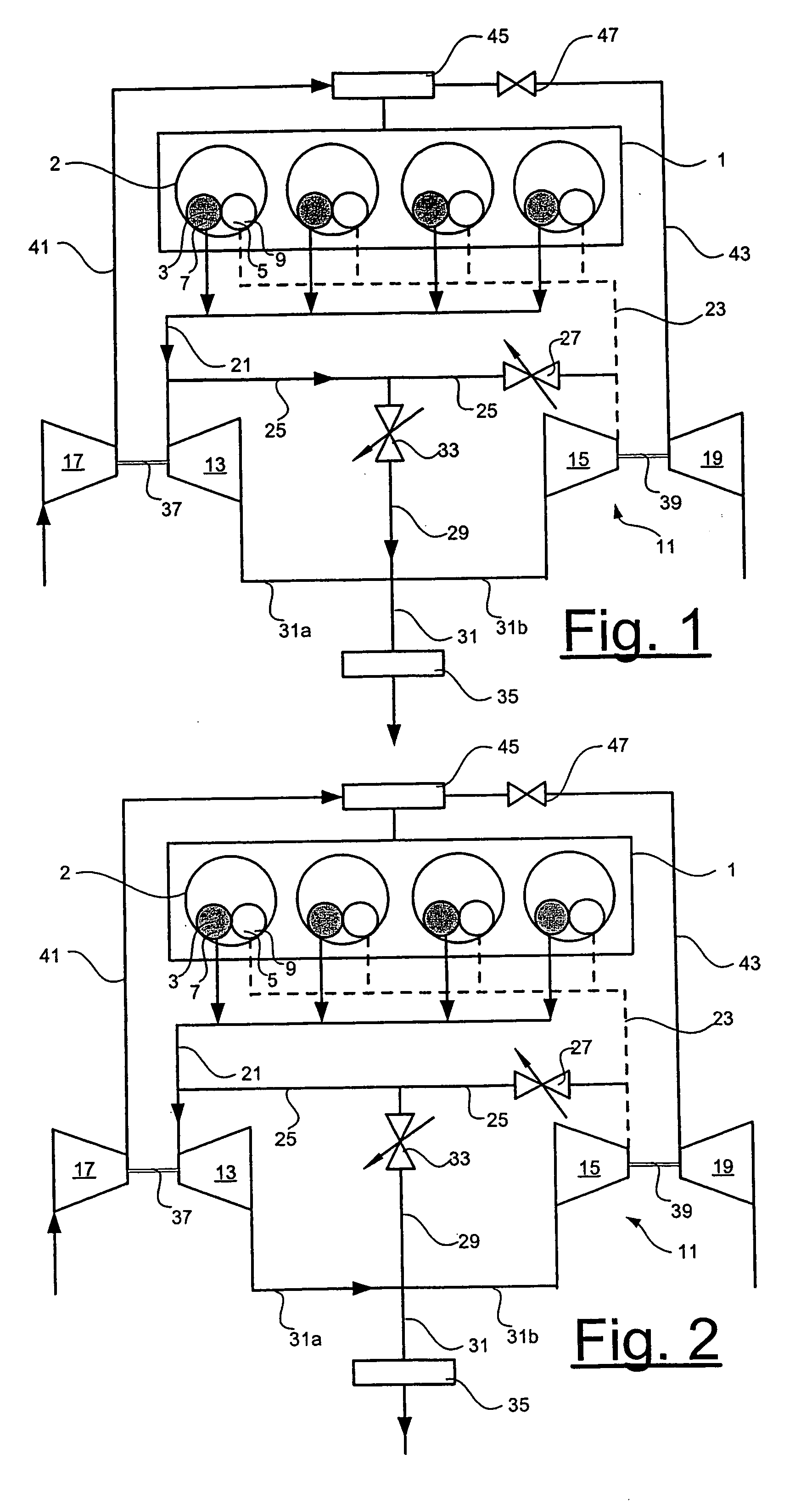

Control of exhaust to a turbo of internal combustion engine

InactiveUS20060070382A1Improve balanceReduce exhaust back pressureElectrical controlInternal combustion piston enginesExhaust valveTurbine

An internal combustion engine has a plurality of cylinders, and each cylinder has at least one first and one second exhaust port with associated respective first and second exhaust valves. At least one first and one second exhaust manifold are flow-connected to the respective first and second exhaust ports. A turbo unit for supercharging the charge air delivered to the cylinders comprises at least one first and one second exhaust gas turbine respectively flow connected to the first and the second exhaust manifolds. An exhaust gas chamber flow-connects the first and the second exhaust manifolds upstream of the exhaust gas turbines. The first and second exhaust valves can be deactivated / activated during operation. A throttle valve in the exhaust gas chamber may assume a closed position in order to separate the first and the second exhaust manifolds. A method of operating includes opening and closing different valves at different engine speeds.

Owner:SAAB AUTOMOBILE AB

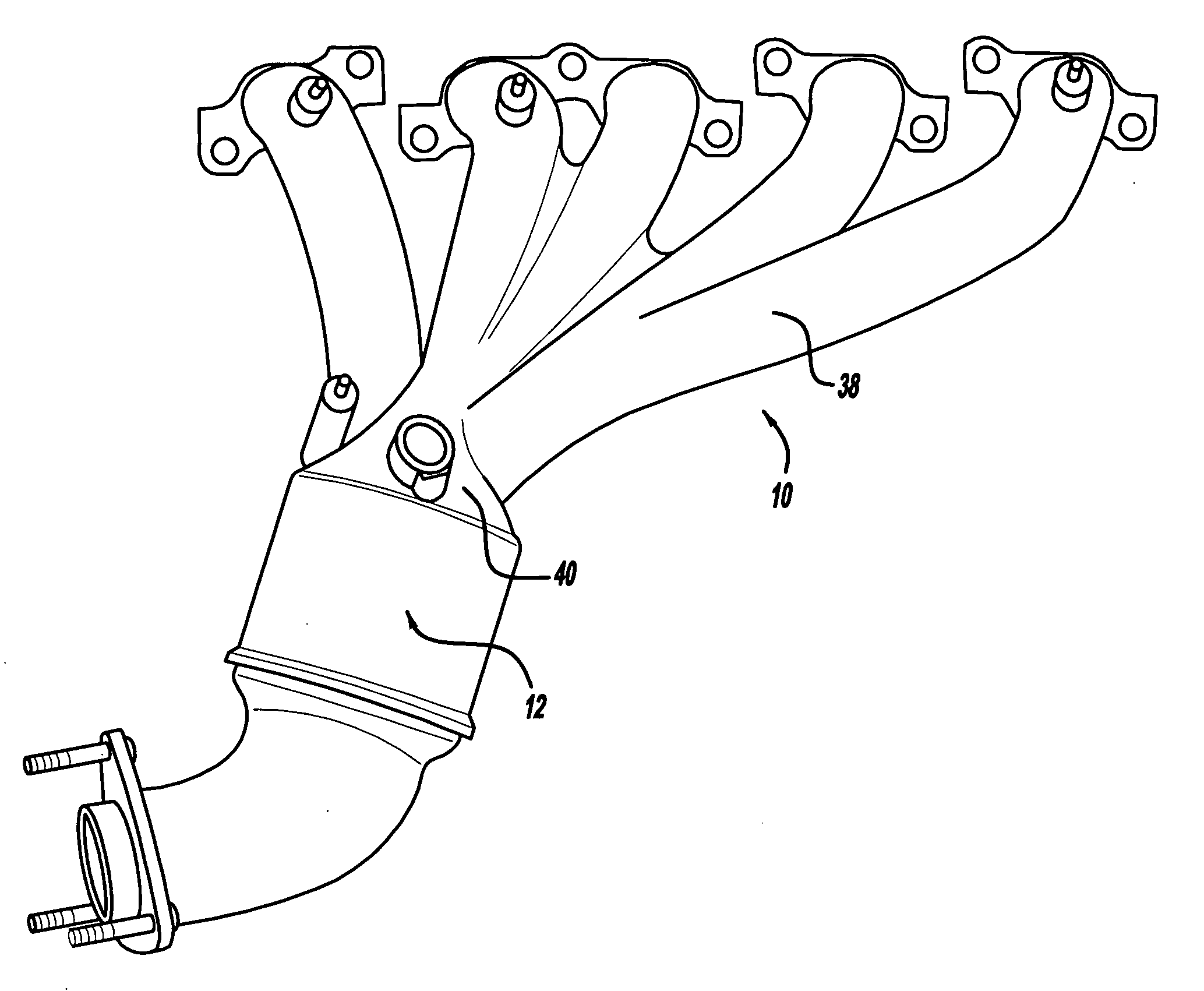

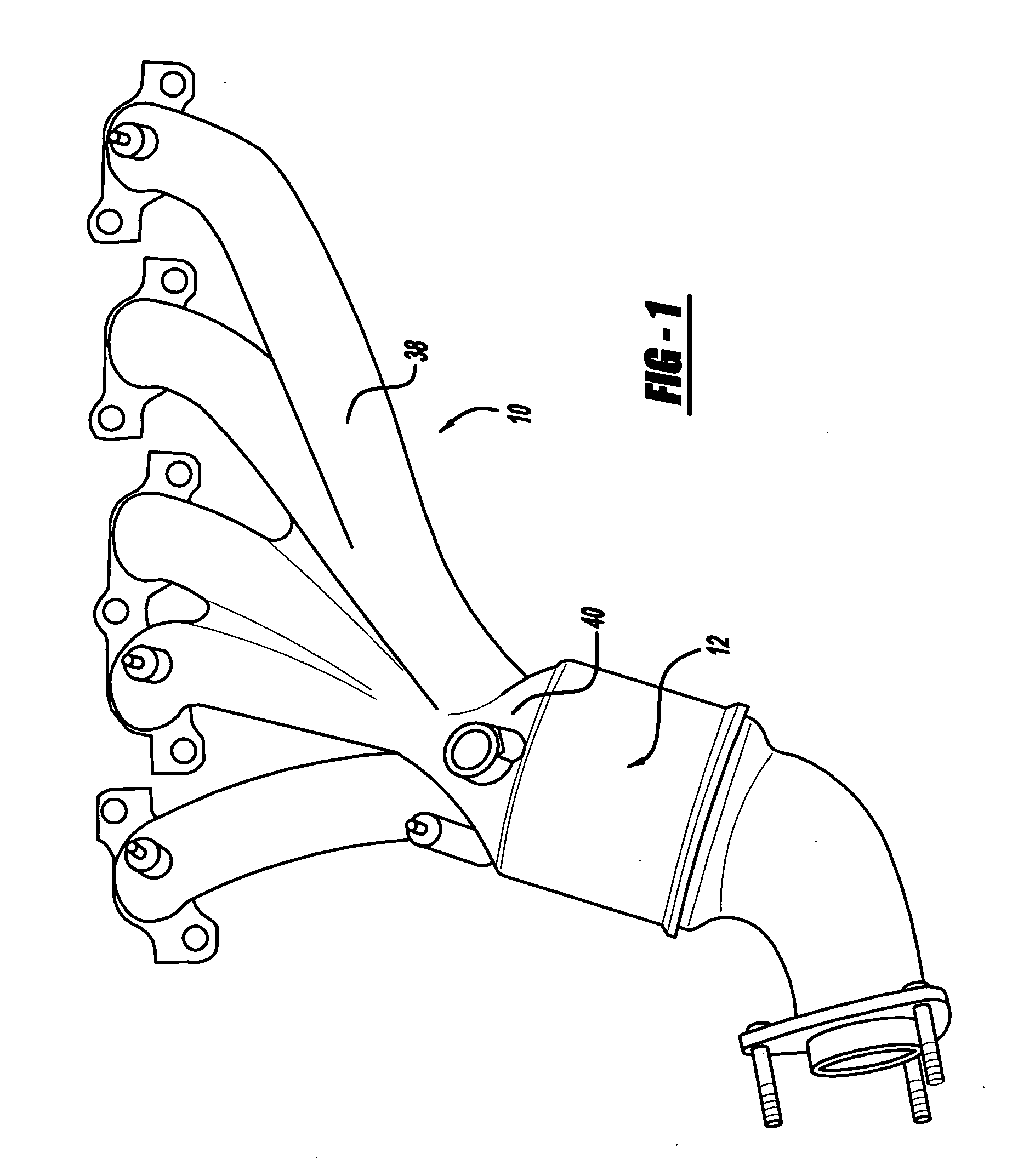

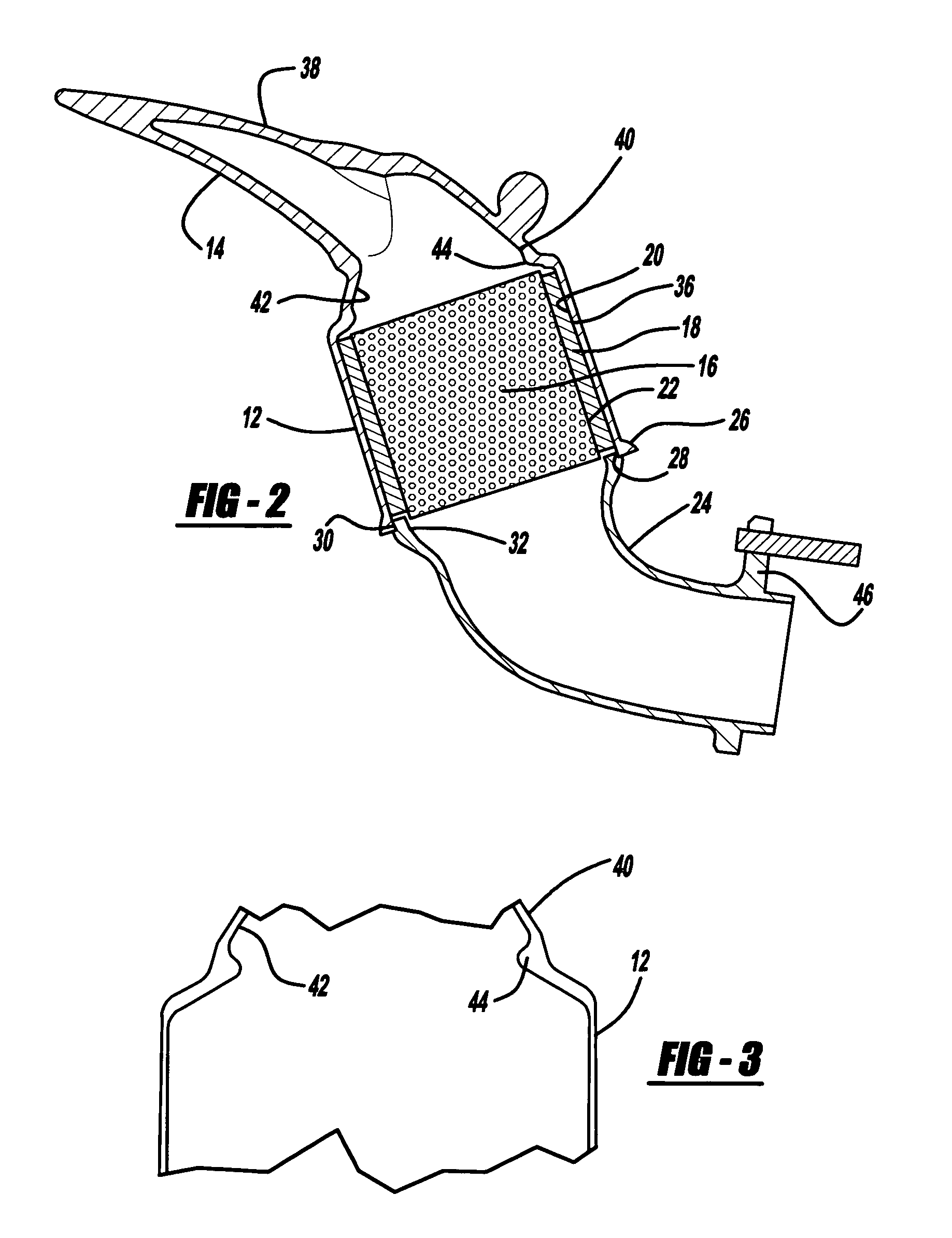

One piece catalytic converter with integral exhaust manifold

InactiveUS20050150222A1Reduce in quantityExhaust apparatusSilencing apparatusEngineeringExhaust manifold

The present invention relates to exhaust system assemblies and, more particularly, to a one piece catalytic converter can with an integral exhaust manifold. Disposed within the catalytic converter can are the catalytic conversion components. Coupled to the one piece converter can and integral exhaust manifold is a second end cone to provide a substantially air tight seal to the assembly.

Owner:WESCAST USA

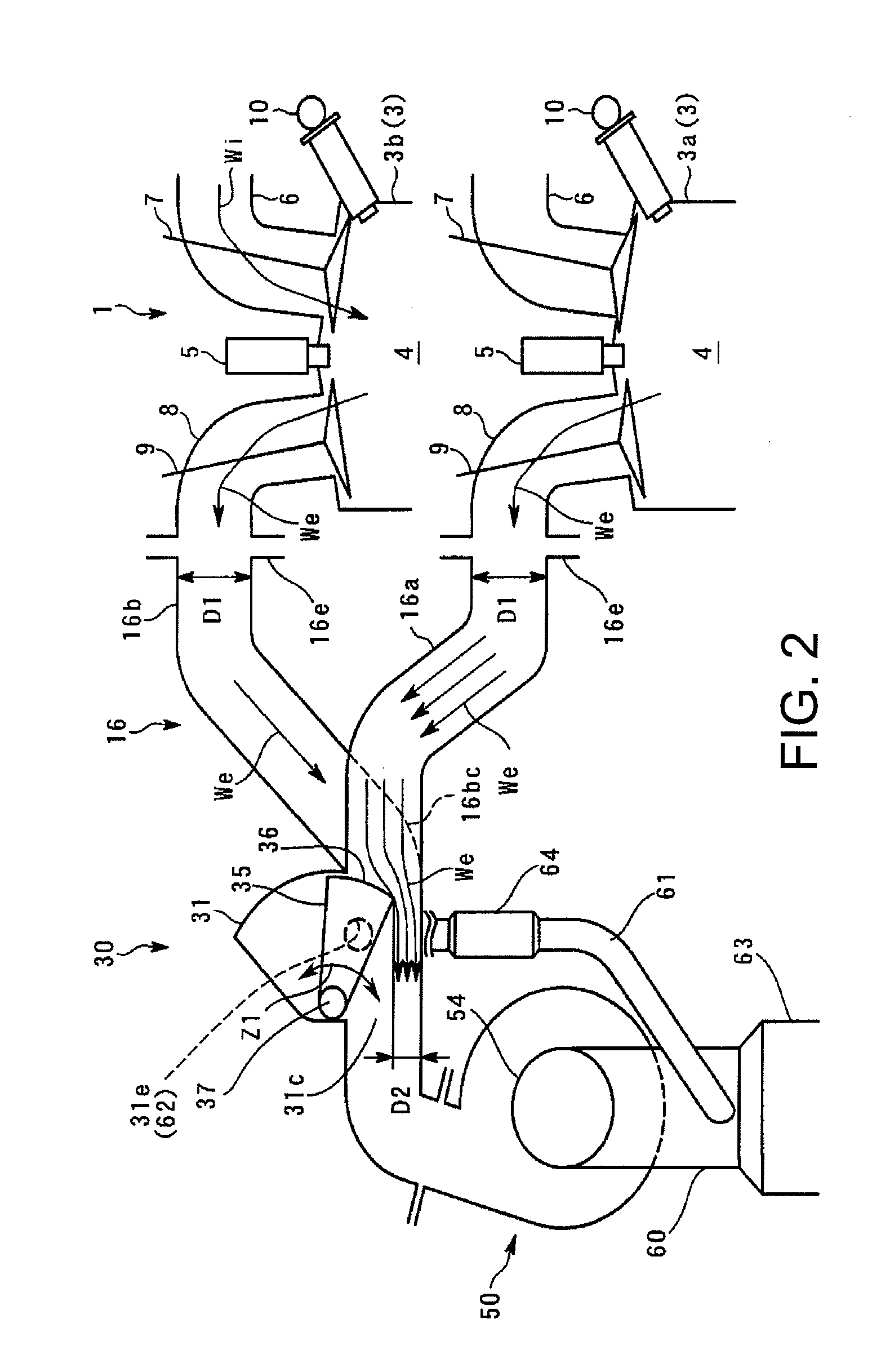

Supercharger for an engine

ActiveUS20090094978A1Improve performanceImprove charging effectInternal combustion piston enginesExhaust apparatusThrottle controlExhaust valve

An engine system with a turbocharger is provided. The system may include an exhaust manifold having plural independent exhaust passages, each of the exhaust passages being connected to an exhaust port of a corresponding engine cylinder. The system may further include a collective part formed by gathering said independent exhaust passages in said exhaust manifold or on a downstream side of said exhaust manifold. The system may further include an exhaust turbocharger connected to a downstream side of said collective part. The system may further include a variable exhaust valve for changing each passage cross-sectional area of said independent exhaust passage at an upstream side of said collective part. The system may further include a controller for controlling said variable exhaust valve, wherein said controller is configured to perform independent exhaust throttle control for reducing a passage cross-sectional area of at least one of said independent exhaust passages.

Owner:MAZDA MOTOR CORP

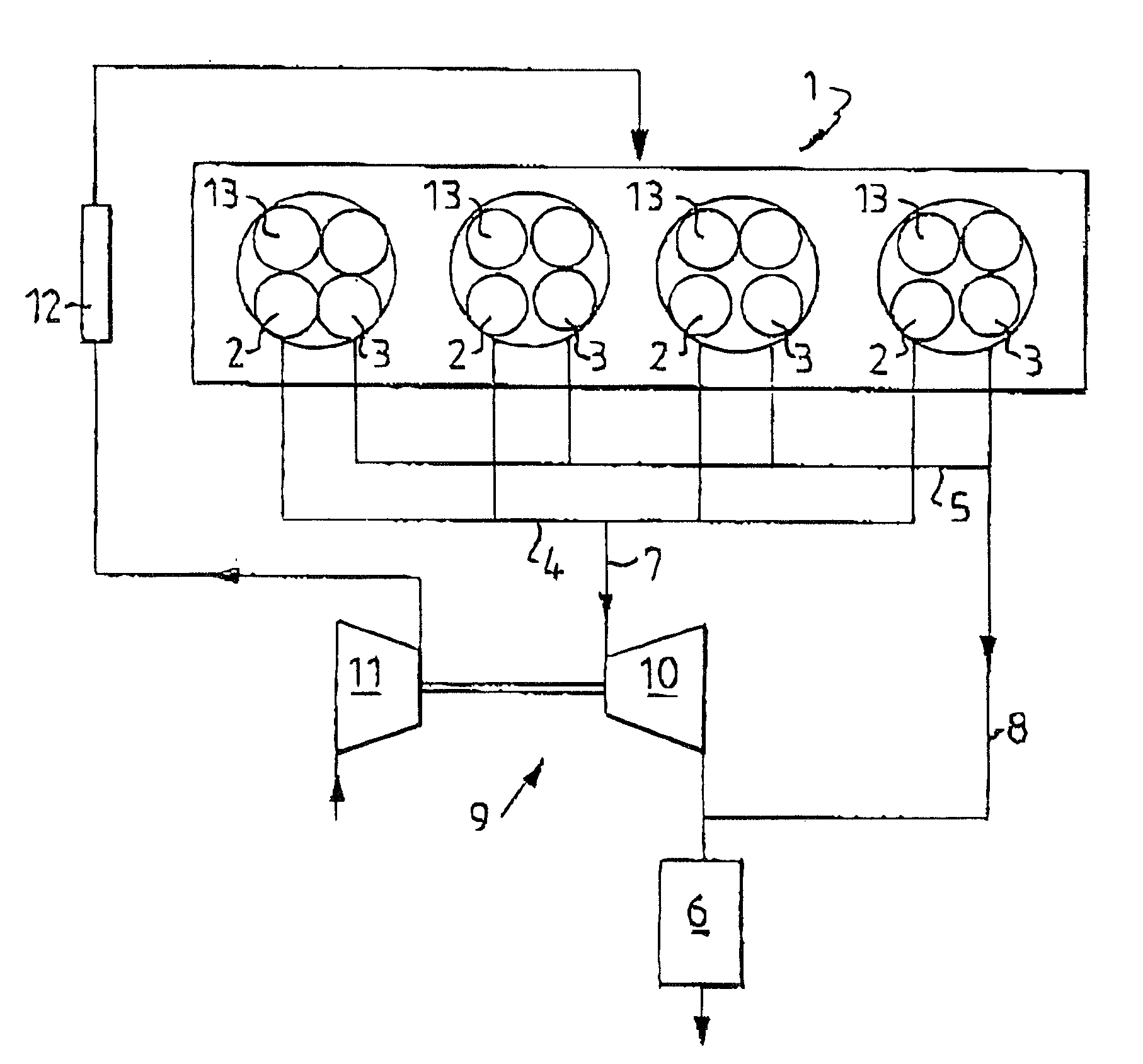

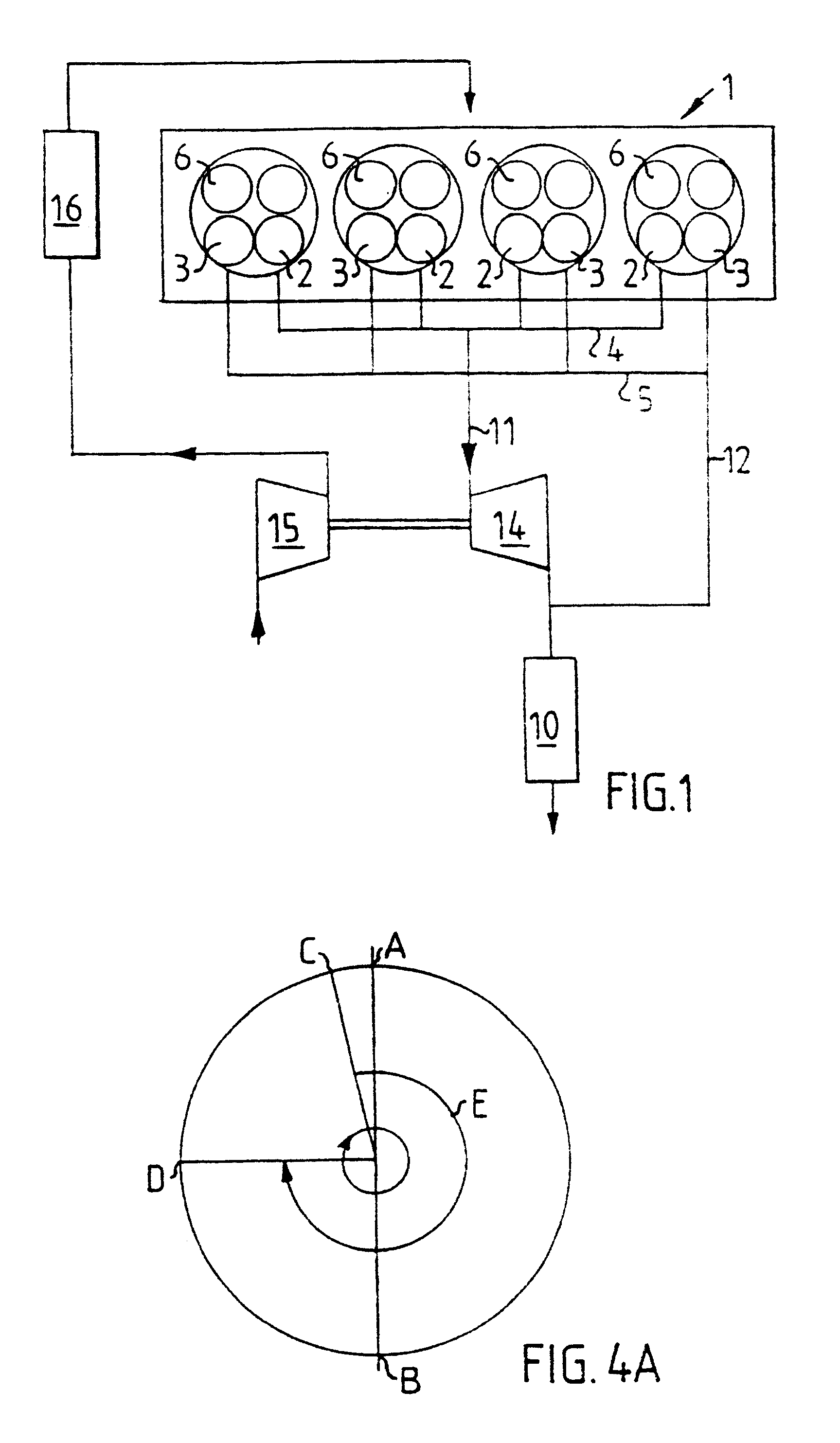

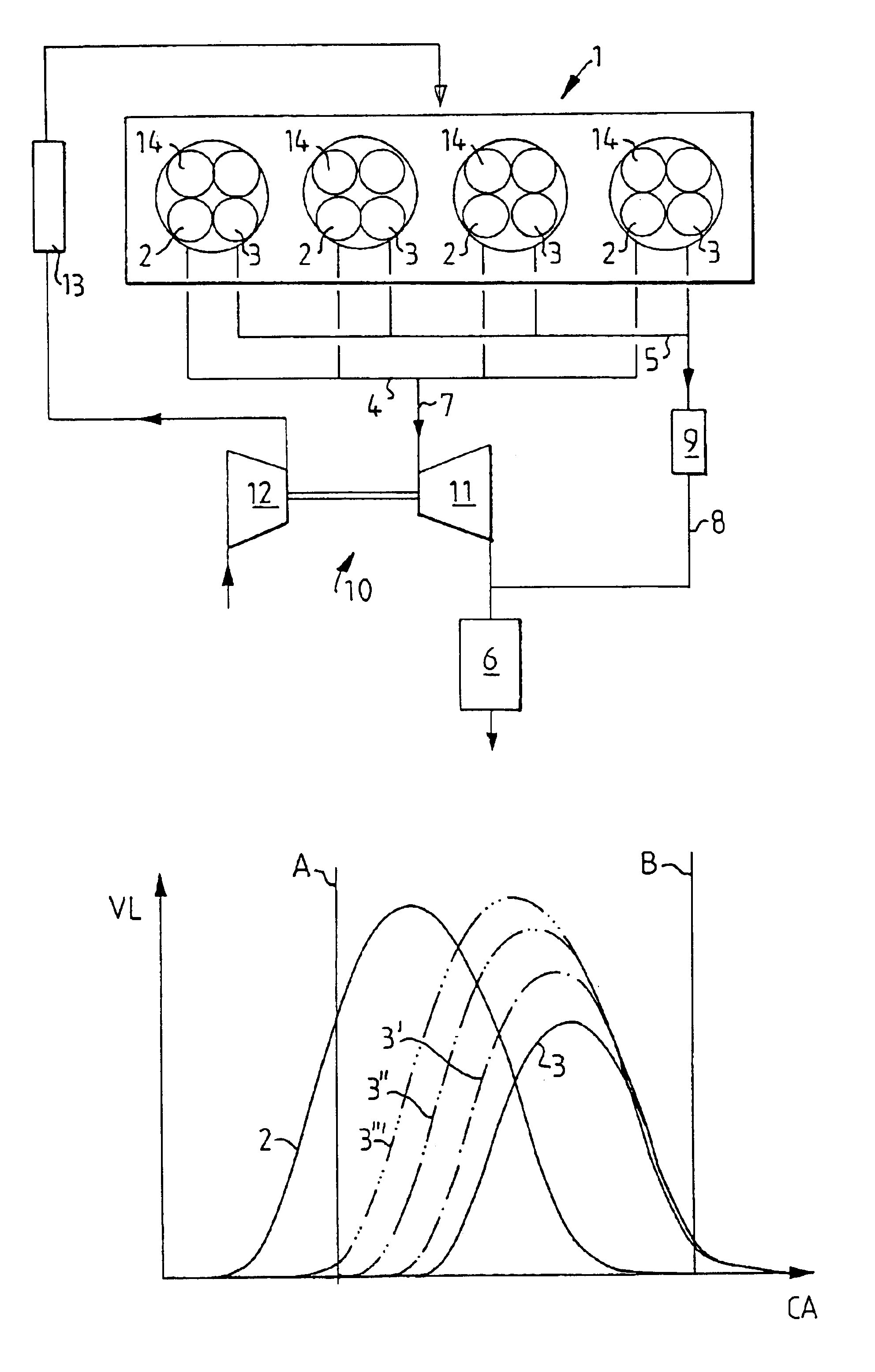

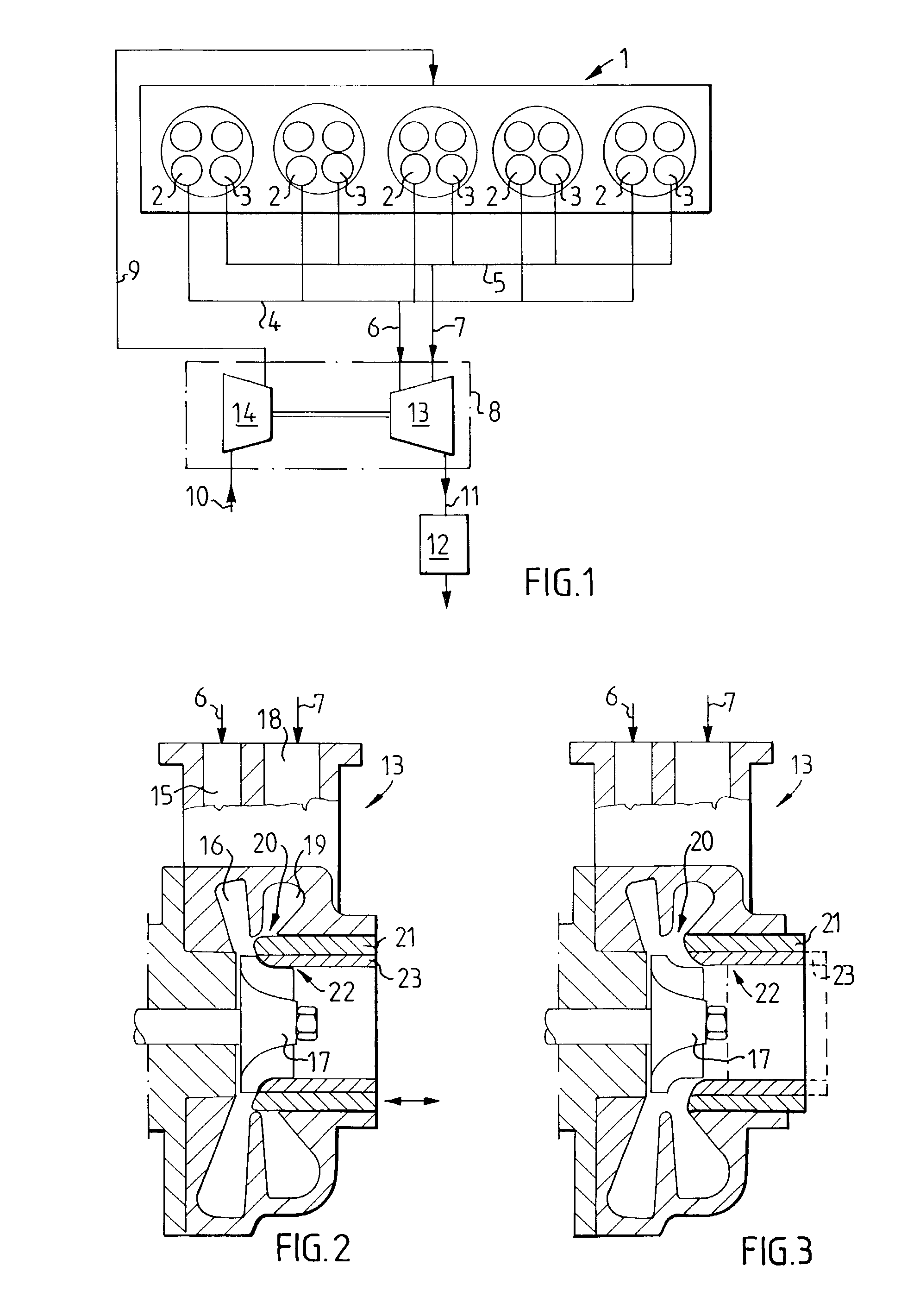

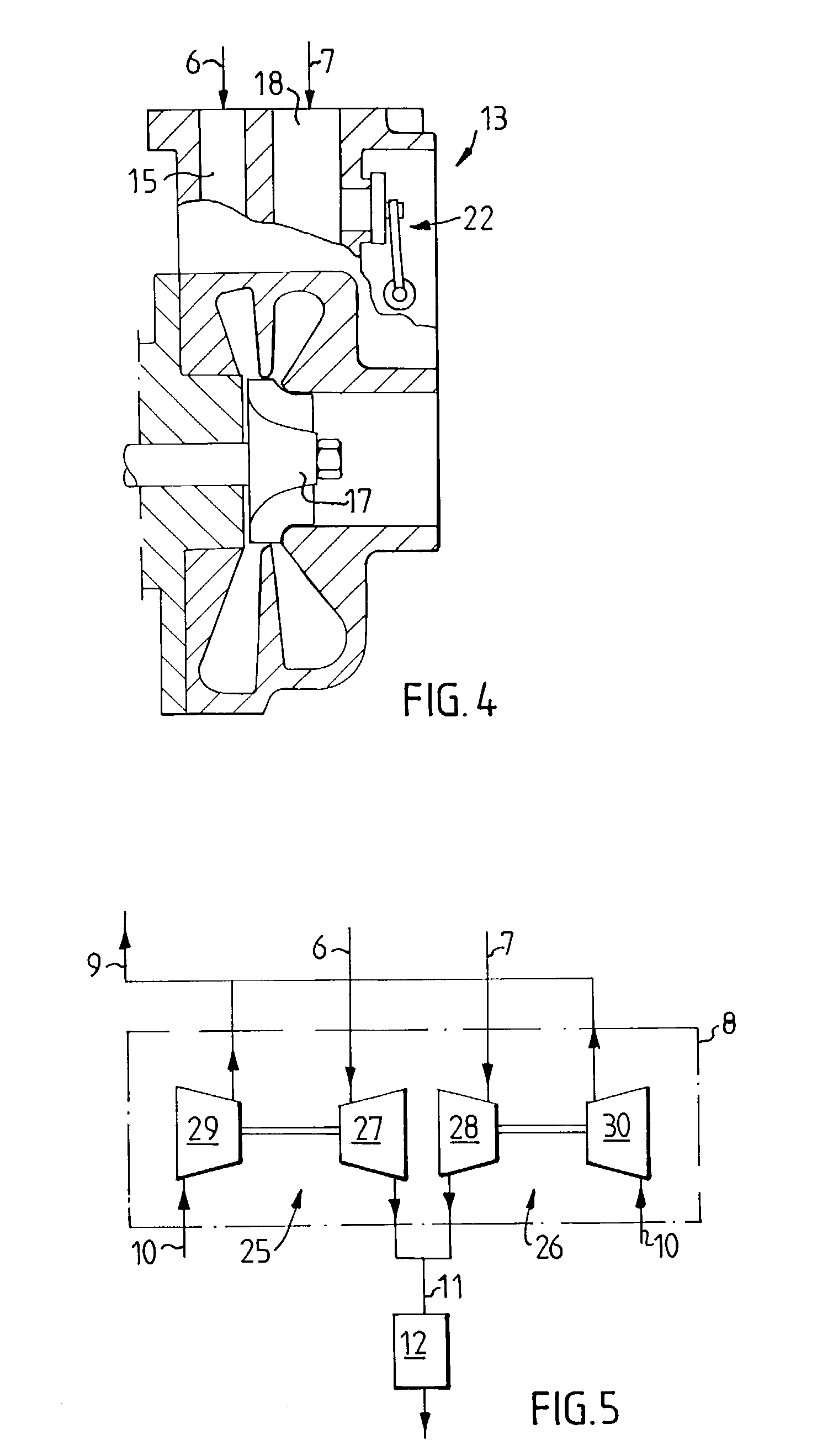

Method for driving an internal-combustion engine and an internal-combustion engine

InactiveUS20030000211A1Reduce deliveryEasy to solveElectrical controlInternal combustion piston enginesExhaust valveTurbine

In an internal-combustion engine having an exhaust-gas driven supercharger (8) and having at least two exhaust-gas valves (2, 3) per cylinder, a first exhaust-gas valve (2) in each cylinder is connected to a first exhaust manifold (4), whilst a second exhaust-gas valve (3) in each cylinder is connected to a second exhaust manifold (5). The two exhaust manifolds (4, 5) lead to at least one exhaust-gas turbine in at least one turbo compressor and the first exhaust-gas valves (2) are arranged to be opened at all engine speeds, whilst the second exhaust-gas valves (3) are arranged to be opened only at higher engine speeds. The first exhaust manifold (4) has a smaller flow area than the second exhaust manifold (5). By choosing which exhaust-gas valves are to be used, the size of the flow ducts between engine and exhaust-gas turbine can easily be suited to the size of the exhaust-gas flow which is available at the time.

Owner:SAAB AUTOMOBILE AB

Systems and methods for exhaust gas recirculation

InactiveUS20110041495A1Uniform EGR distributionElectrical controlInternal combustion piston enginesExhaust gas recirculationInlet manifold

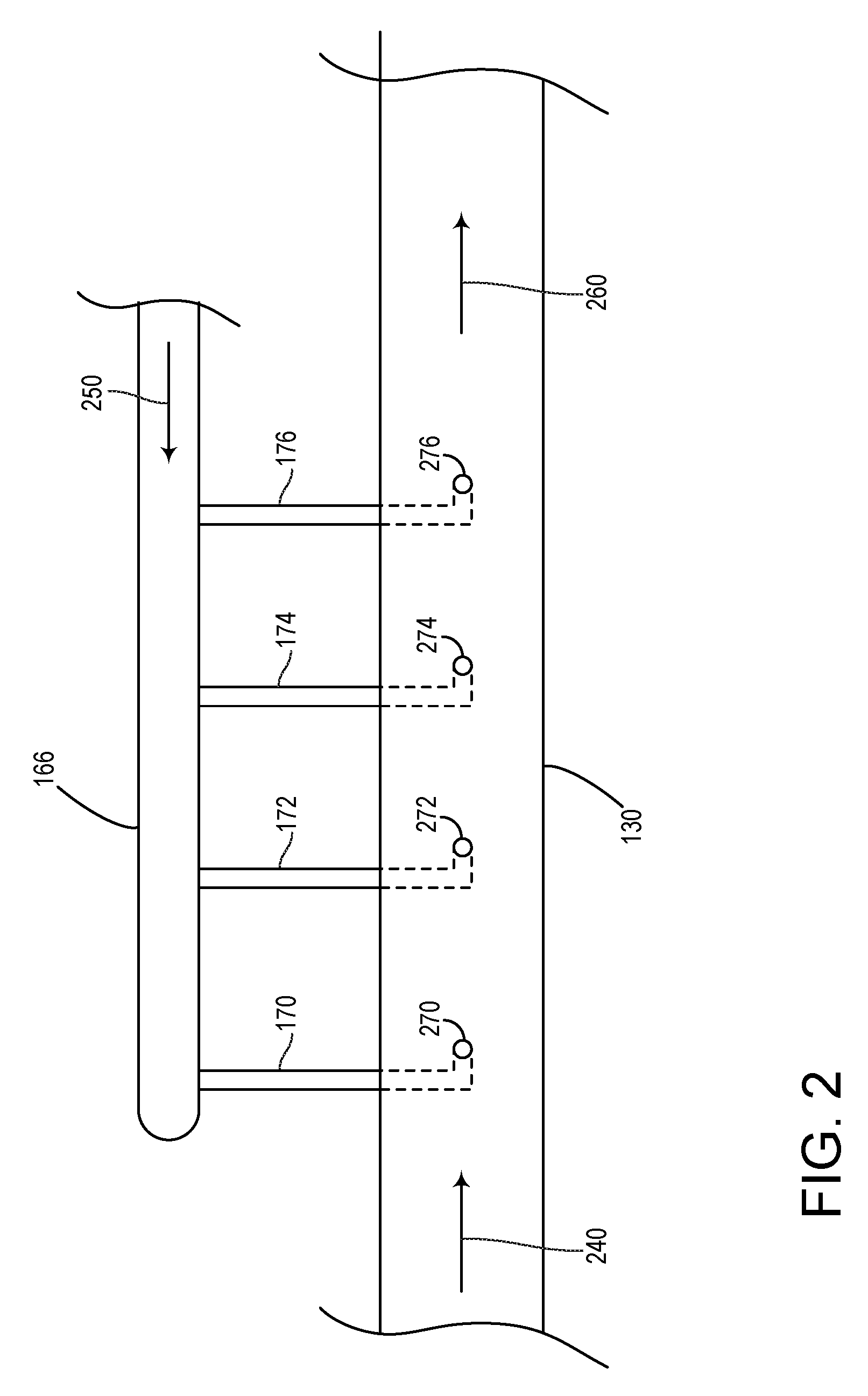

Exhaust gas recirculation systems and methods related to internal combustion engines are provided. In one embodiment, a system comprises an engine having at least a first cylinder group and a second cylinder group, with at least one cylinder in each cylinder group, an intake manifold having an inlet and a first outlet coupled to the first cylinder group and a second outlet coupled to the second cylinder group, an intake passage coupled to the intake manifold inlet, and first and second exhaust manifolds coupled to the first and second cylinder groups, respectively. An exhaust gas recirculation system is further coupled between the second exhaust manifold and the intake passage, and has a number of openings positioned within the intake passage, the number of openings equal to or greater than a number of cylinders having an intake event between successive exhaust events occurring in the second cylinder group.

Owner:GENERAL ELECTRIC CO

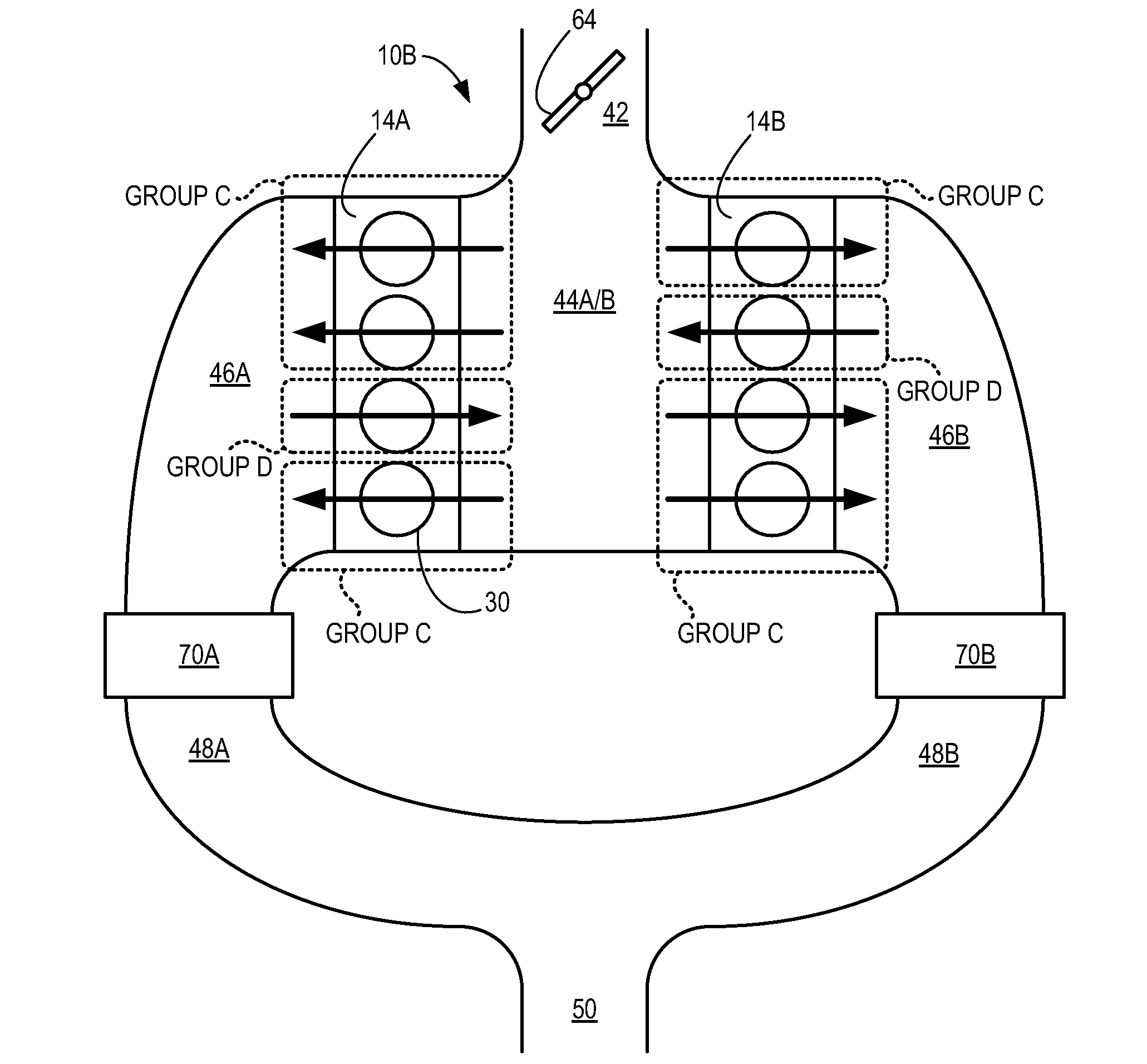

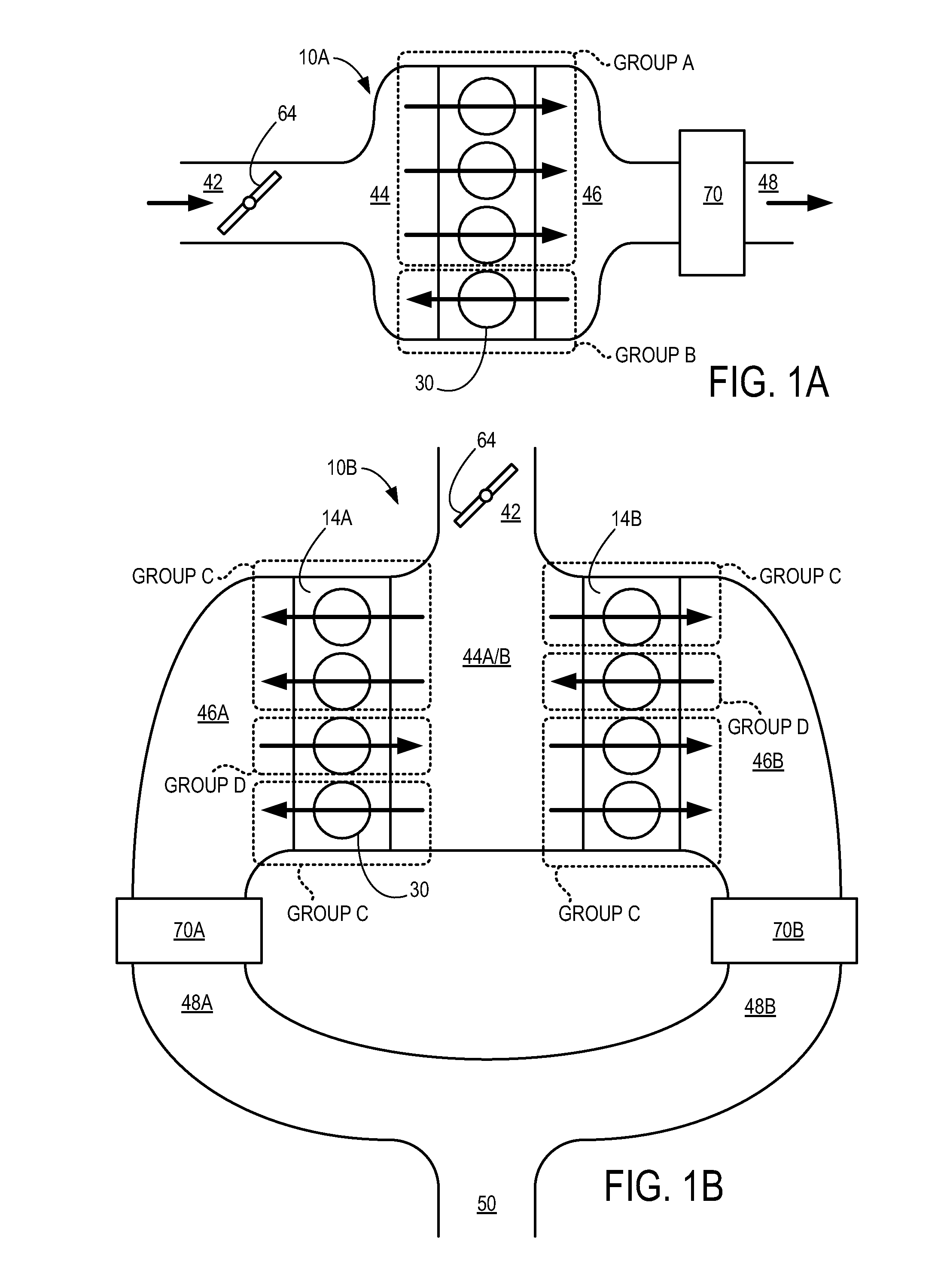

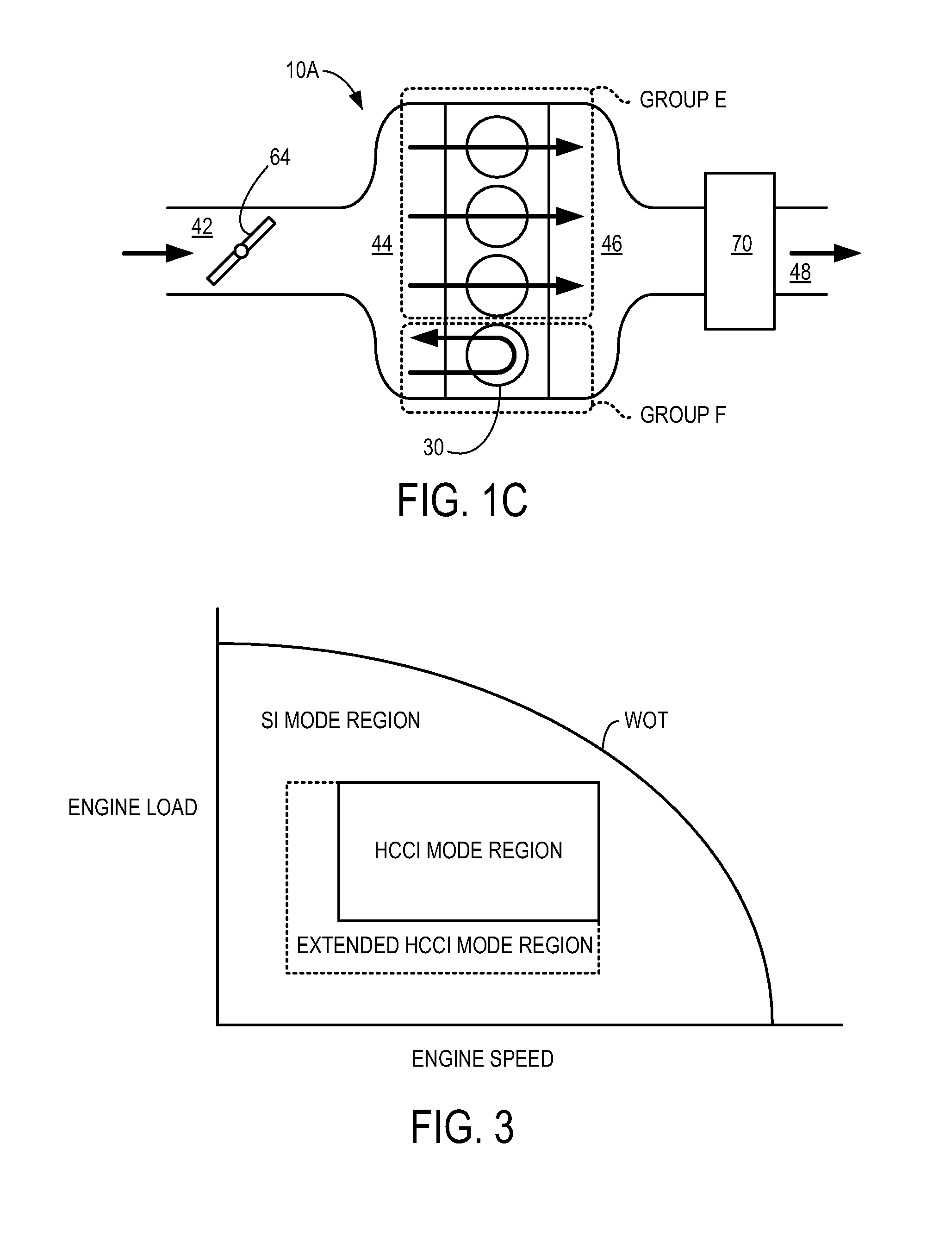

Cylinder Charge Temperature Control for an Internal Combustion Engine

InactiveUS20090013969A1Expand the scope of operationIncreasing cost and complexityAnalogue computers for vehiclesValve arrangementsTemperature controlCombustion

A method of operating an engine is provided. The engine includes at least one cylinder communicating with an intake manifold via an intake manifold valve and an exhaust manifold via an exhaust manifold valve, the cylinder including a piston arranged within the cylinder, wherein the piston is coupled to a crankshaft of the engine. The method comprises discontinuing combustion in the cylinder during a plurality of cycles of the engine; during the plurality of cycles, operating the exhaust manifold valve and the intake manifold valve to provide a net flow of gases from the exhaust manifold to the intake manifold via the cylinder and adjusting a torque signature provided to the crankshaft during each cycle by the piston responsive to an operating condition.

Owner:FORD GLOBAL TECH LLC

Turbocharged internal combustion engine with EGR flow

InactiveUS6981375B2Internal combustion piston enginesNon-fuel substance addition to fuelTurbochargerExhaust gas recirculation

A turbocharged internal combustion engine is operated such that the intake manifold pressure generally exceeds the exhaust manifold pressure. A low pressure turbocharger and a high pressure turbocharger are provided in series. An exhaust gas recirculation (EGR) system passively routes a portion of the exhaust gases to the high pressure turbocharger compressor inlet.

Owner:DETROIT DIESEL CORP

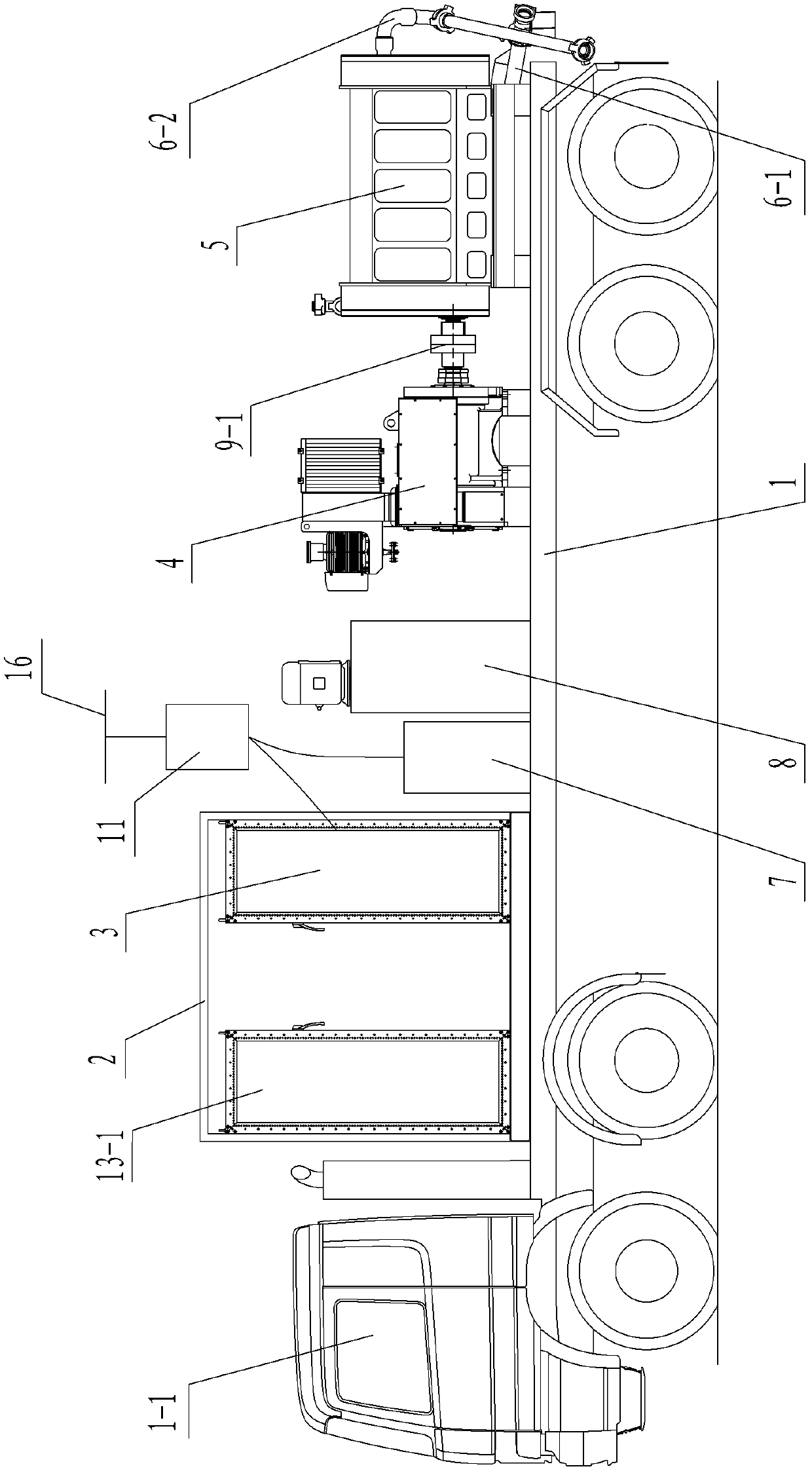

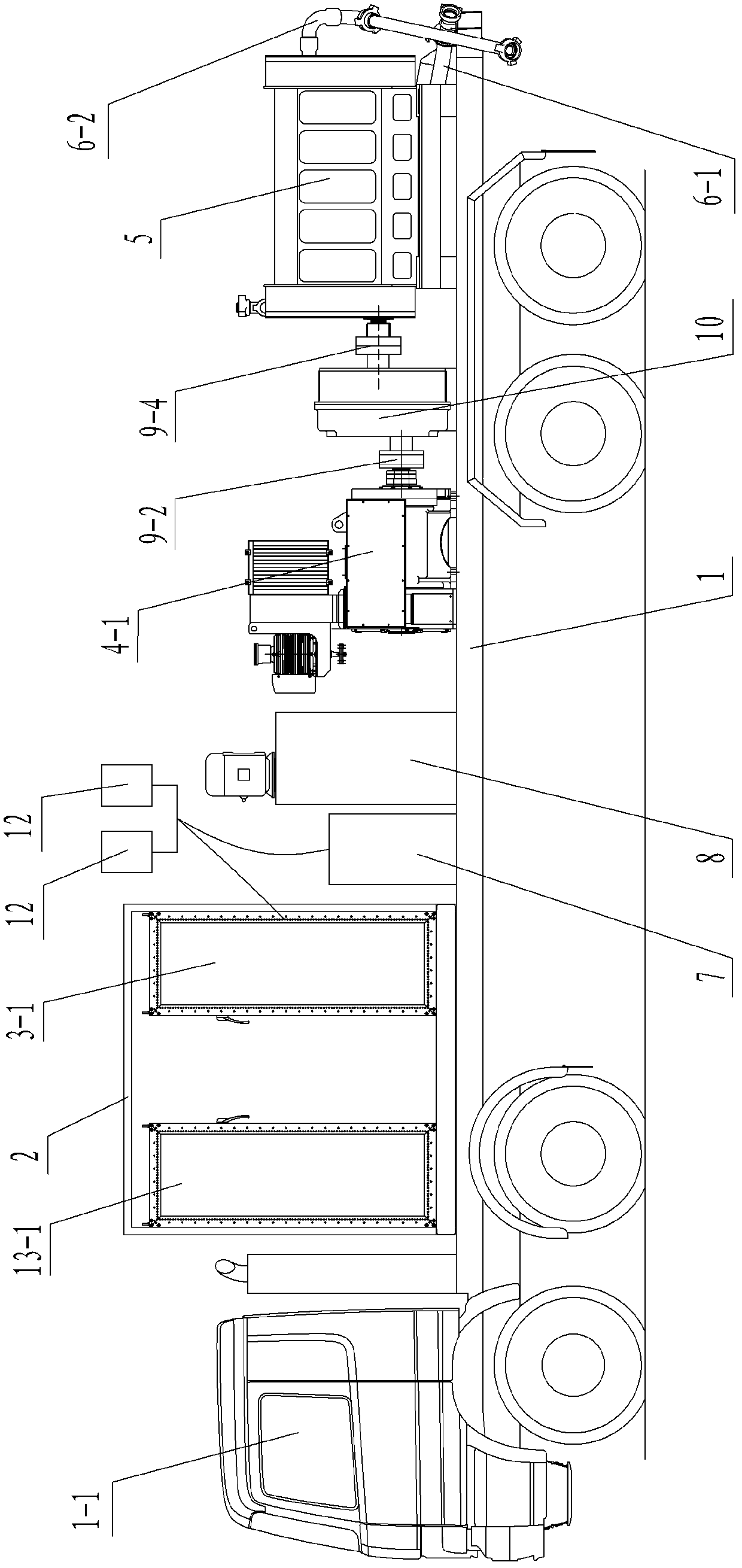

Electrically-driven fracturing pump truck

InactiveCN102602322ASimple structureNovel and reasonable designItem transportation vehiclesElectricityMotor drive

The invention discloses an electrically-driven fracturing pump truck, which comprises a truck chassis with a cab. A lubricating and cooling system, a fracturing pump, a suction manifold, an exhaust manifold, an electrically-driven system and a control system, the suction manifold and the exhaust manifold are connected with the fracturing pump, the electrically-driven system comprises a motor and a motor-driven device, the motor is used for driving the fracturing pump to run, the control system comprises a main power control system and an auxiliary power control system, the main power control system is used for controlling the motor-driven device, the auxiliary power control system is used for controlling the lubricating and cooling system, and the motor-driven device, the main power control system and the auxiliary power control system are powered by an external power source. The electrically-driven fracturing pump truck is simple in structure, reasonable in design, convenient in matching, low in manufacture cost, high in work efficiency and reliability, convenient in energy supply, fine in emission reducing effect, easy in maintenance, capable of overcoming defects and shortcomings of high fuel consumption, difficulty in matching of an engine and a torque converter and the like of a fracturing pump truck in the prior art, and convenient in popularization and use.

Owner:XIAN BANGPU IND AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com