Patents

Literature

4030 results about "Gas chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas chamber is an apparatus for killing humans or other animals with gas, consisting of a sealed chamber into which a poisonous or asphyxiant gas is introduced. The most commonly used poisonous agent is hydrogen cyanide; carbon dioxide and carbon monoxide have also been used.

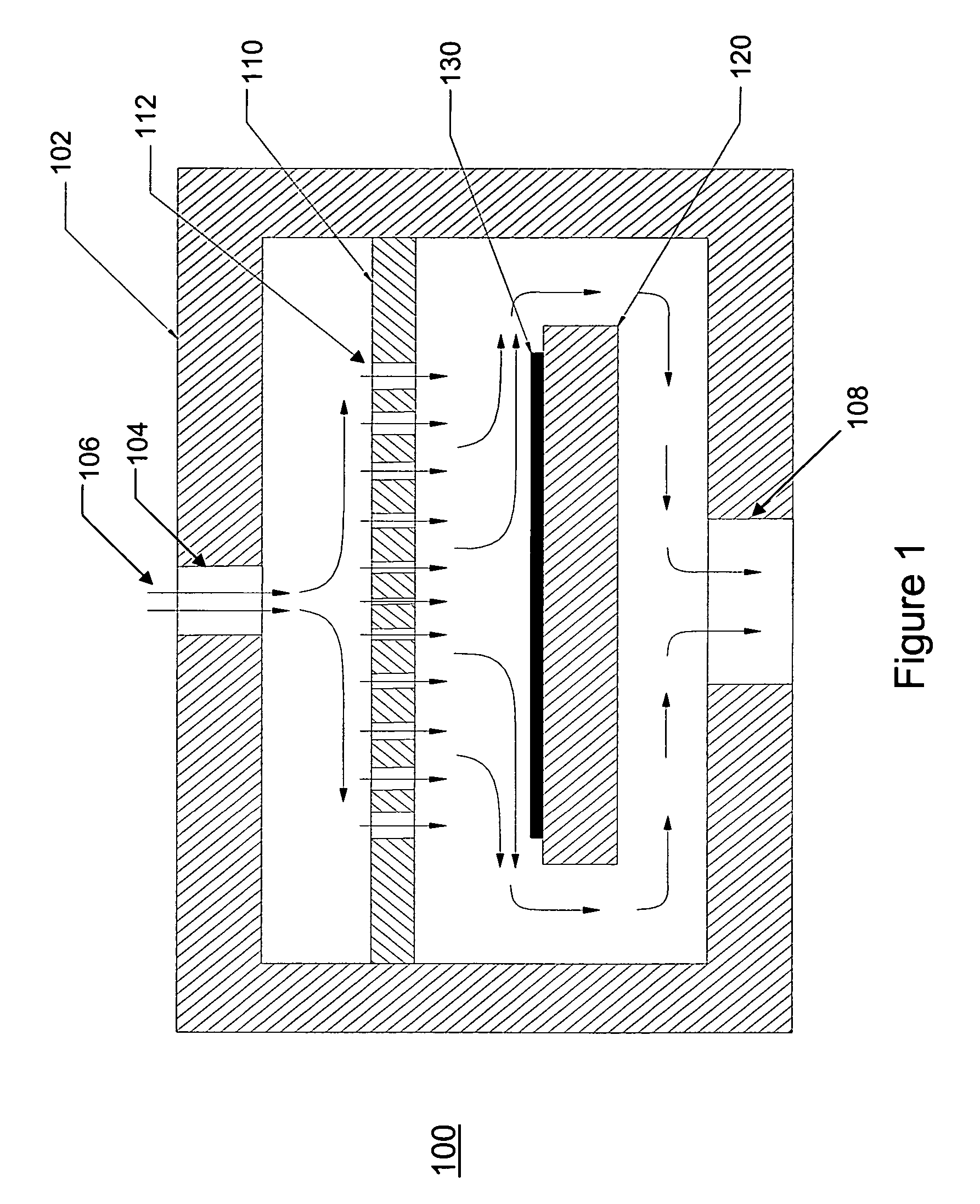

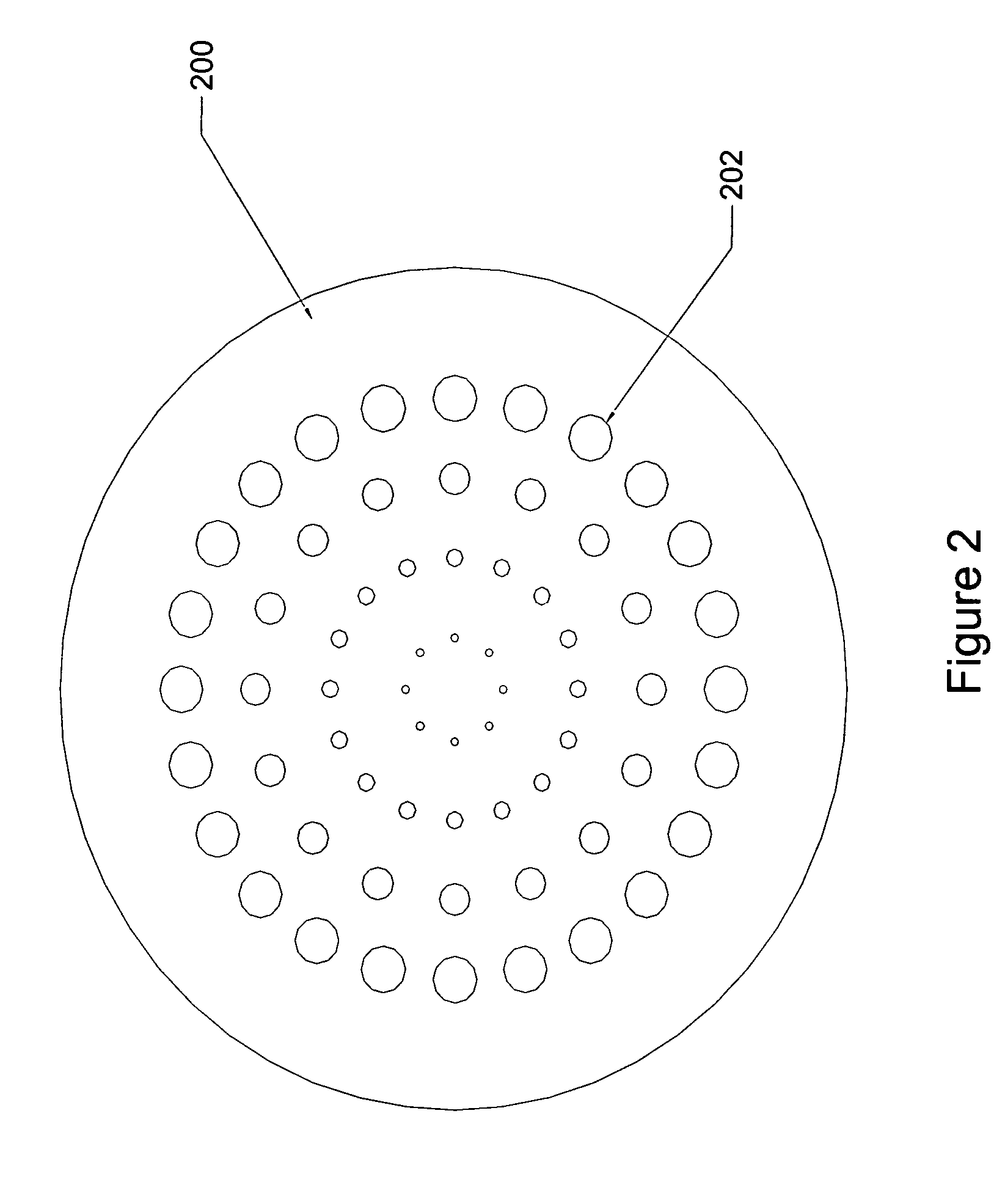

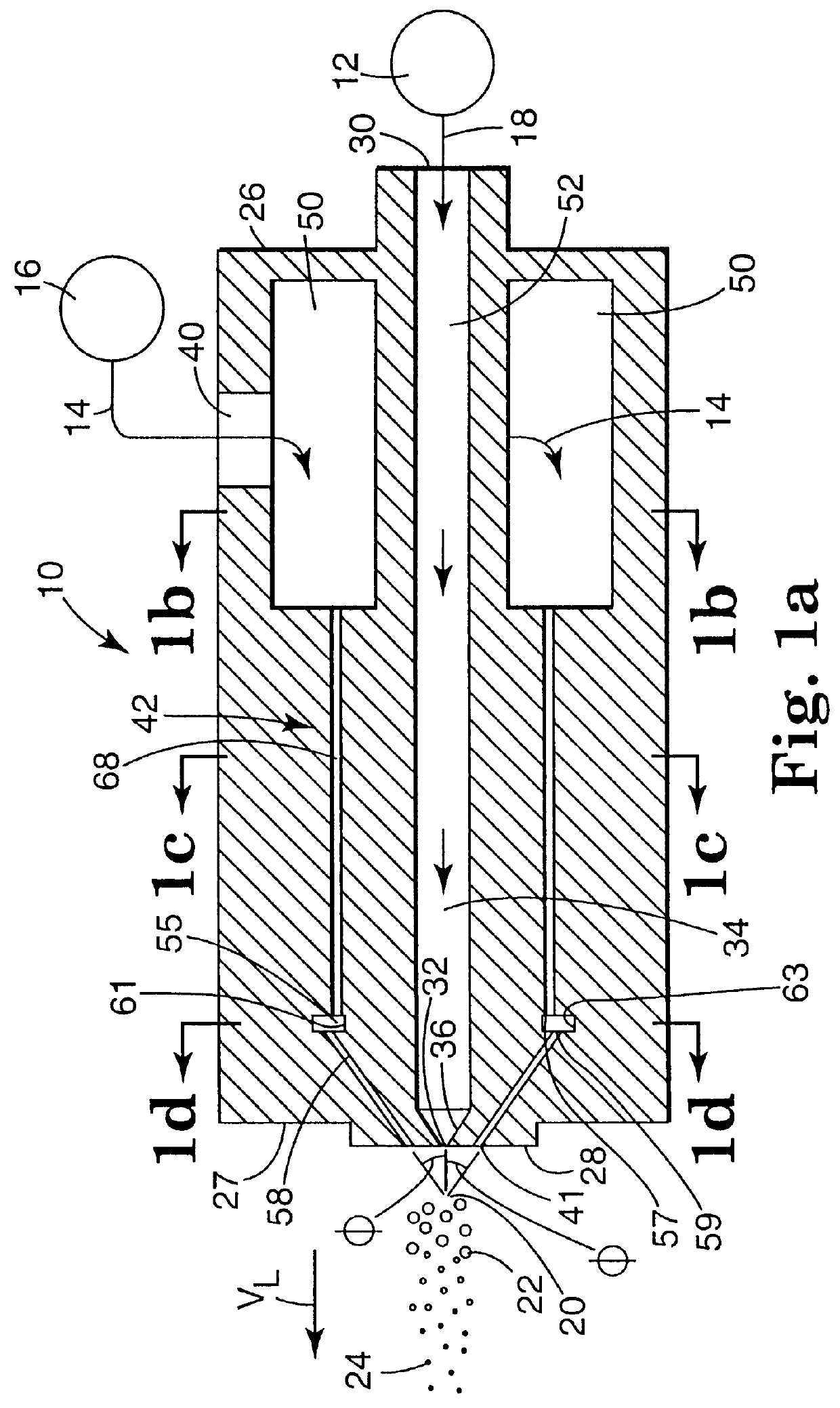

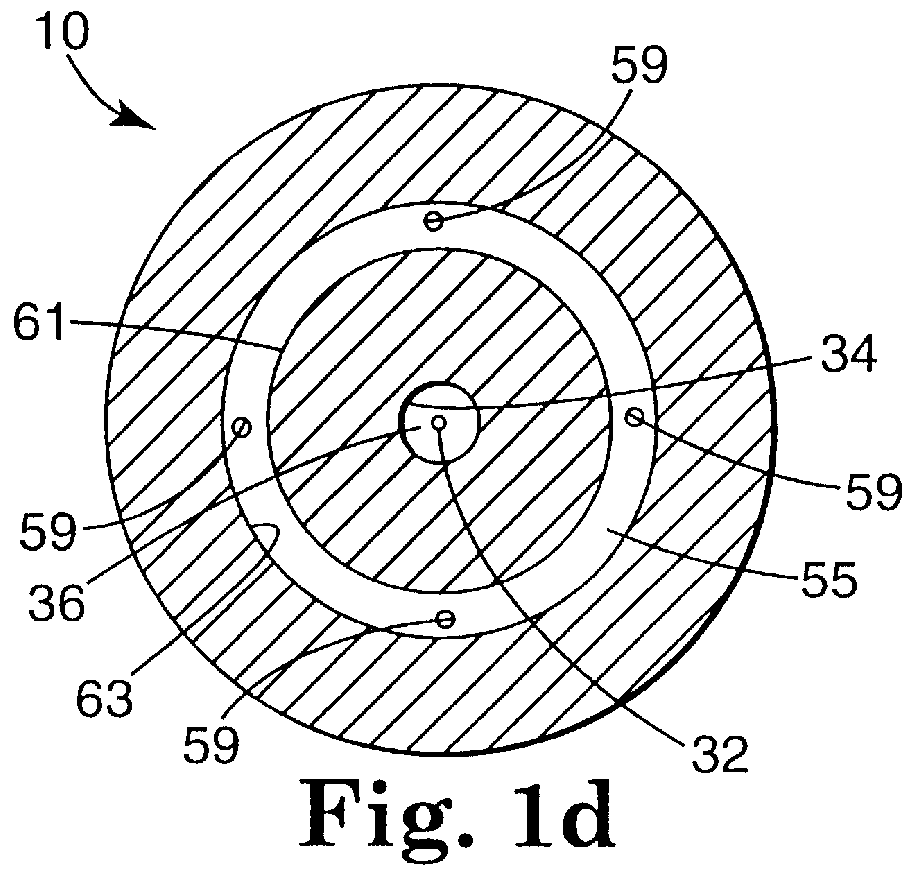

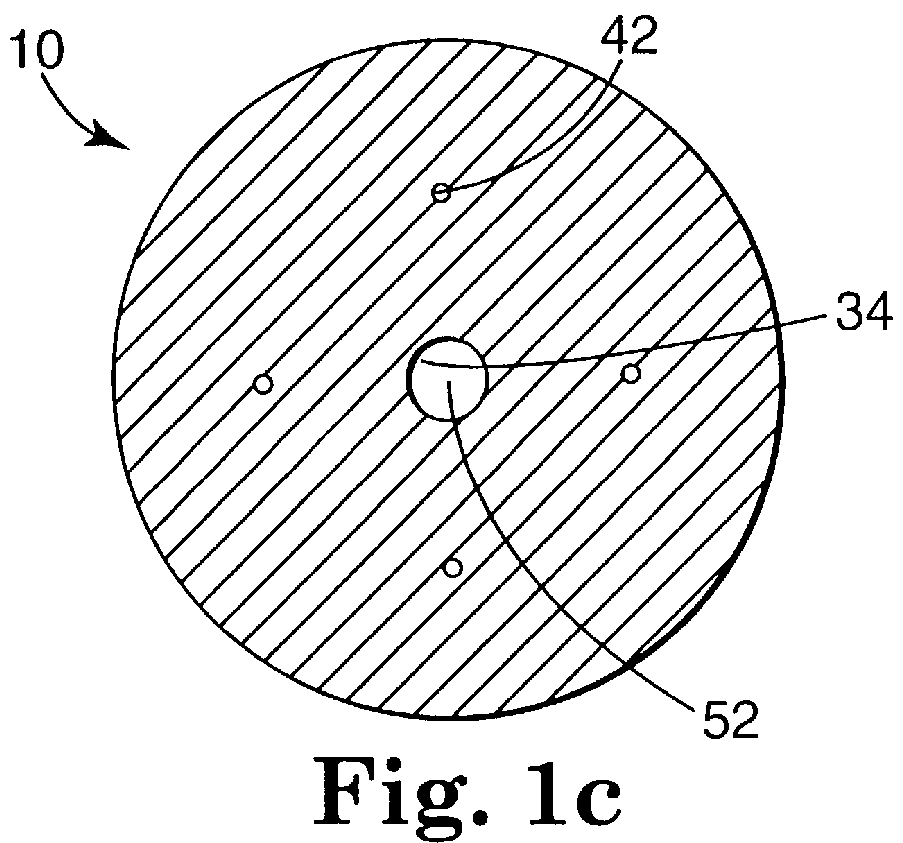

High strip rate downstream chamber

ActiveUS8298336B2Avoid radiationAbsorb thermal expansionElectric discharge tubesDecorative surface effectsSpray nozzleThermal expansion

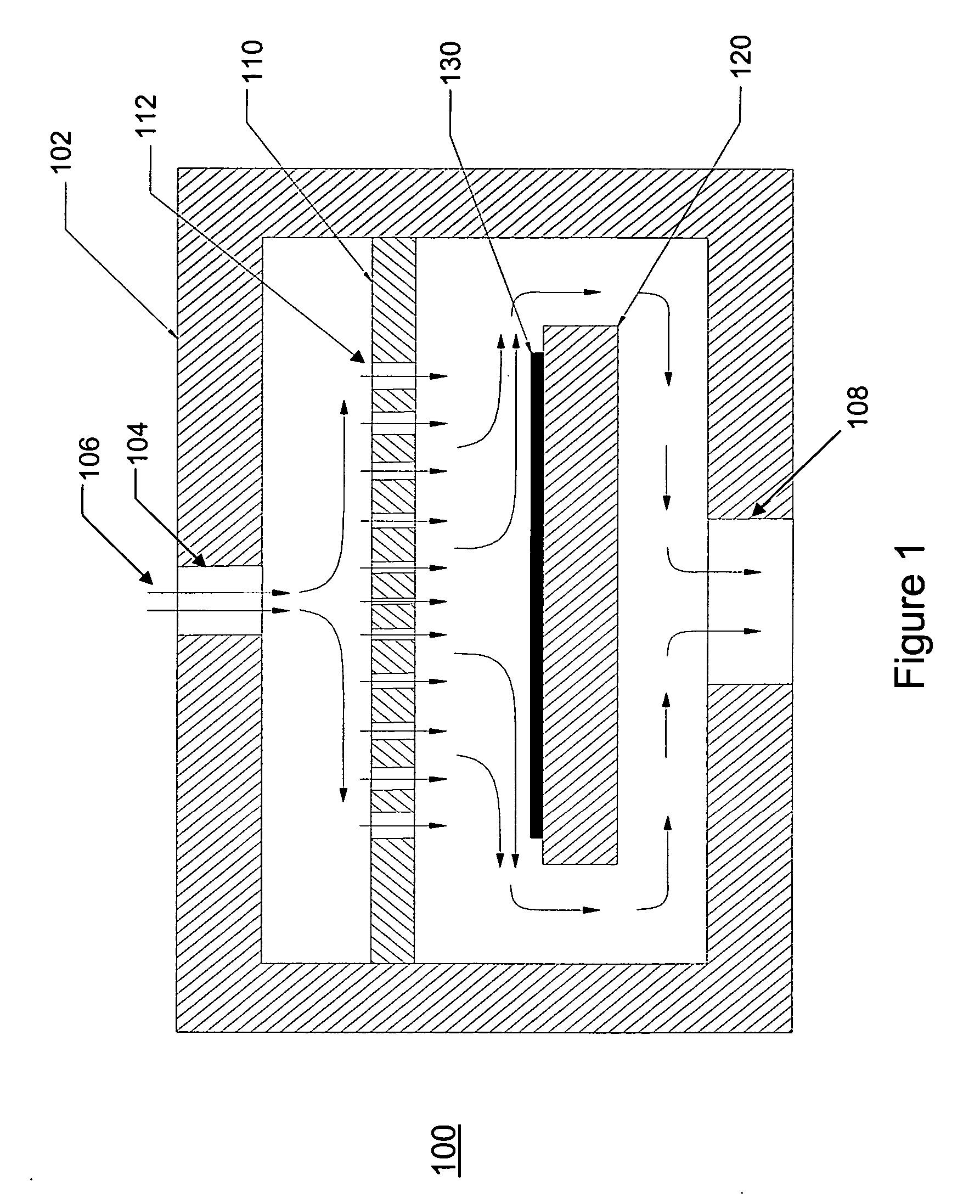

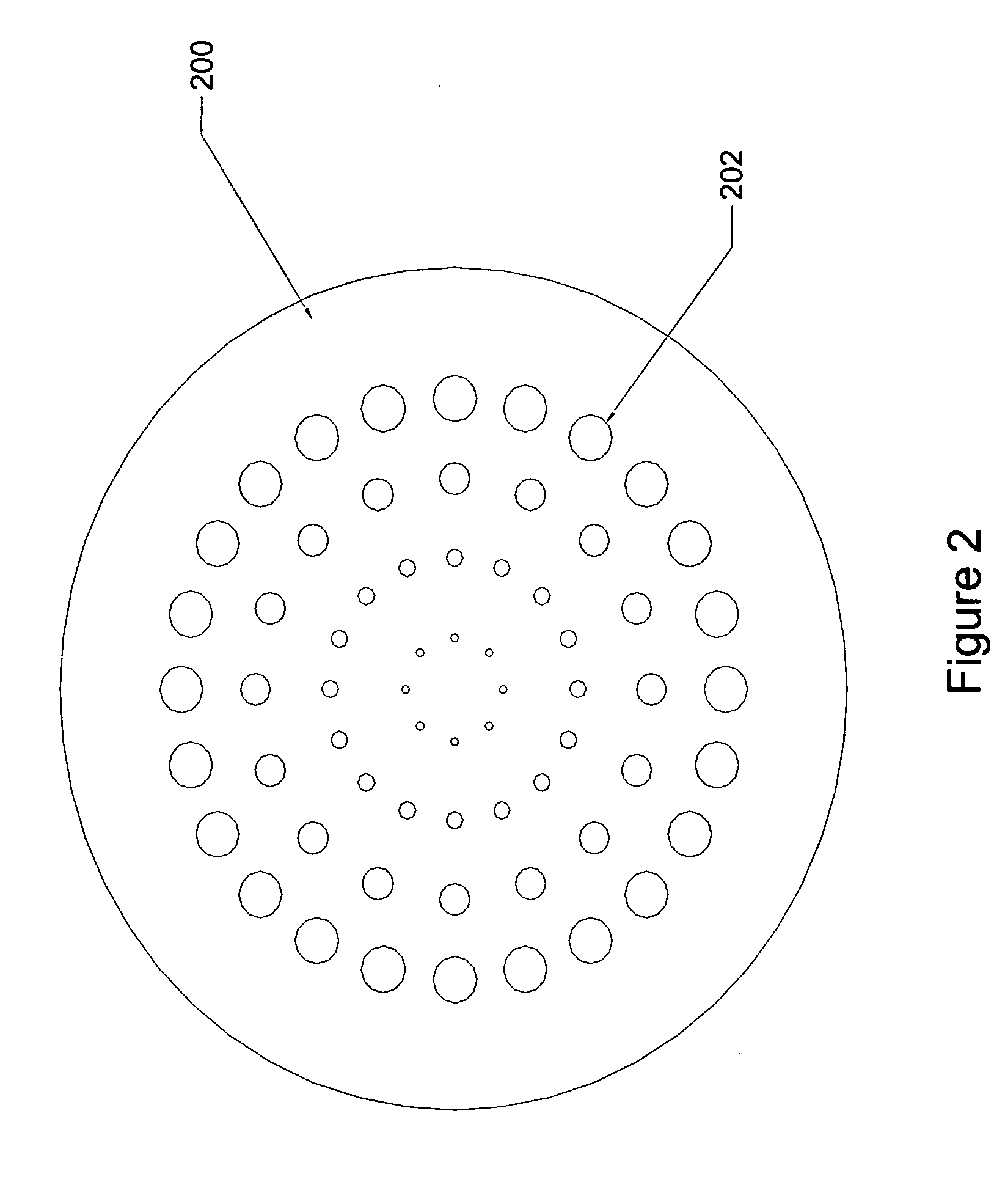

A gas chamber contains upper and lower chamber bodies forming a cavity, a heating chuck for a wafer, a remote gas source, and an exhaust unit. Gas is injected into the cavity through channels in an injector. Each channel has sections that are bent with respect to each other at a sufficient angle to substantially eliminate entering light rays entering the channel from exiting the channel without reflection. The channels have funnel-shaped nozzles at end points proximate to the chuck. The injector also has thermal expansion relief slots and small gaps between the injector and mating surfaces of the chamber and gas source. The temperature of the injector is controlled by a cooling liquid in cooling channels and electrical heaters in receptacles of the injector. The upper chamber body is funnel-shaped and curves downward at an end of the upper chamber body proximate to the chuck.

Owner:LAM RES CORP

High strip rate downstream chamber

ActiveUS20060219361A1Avoid radiationAbsorb thermal expansionElectric discharge tubesDecorative surface effectsSpray nozzleGas passing

A gas chamber contains upper and lower chamber bodies forming a cavity, a heating chuck for a wafer, a remote gas source, and an exhaust unit. Gas is injected into the cavity through channels in an injector. Each channel has sections that are bent with respect to each other at a sufficient angle to substantially eliminate entering light rays entering the channel from exiting the channel without reflection. The channels have funnel-shaped nozzles at end points proximate to the chuck. The injector also has thermal expansion relief slots and small gaps between the injector and mating surfaces of the chamber and gas source. The temperature of the injector is controlled by a cooling liquid in cooling channels and electrical heaters in receptacles of the injector. The upper chamber body is funnel-shaped and curves downward at an end of the upper chamber body proximate to the chuck.

Owner:LAM RES CORP

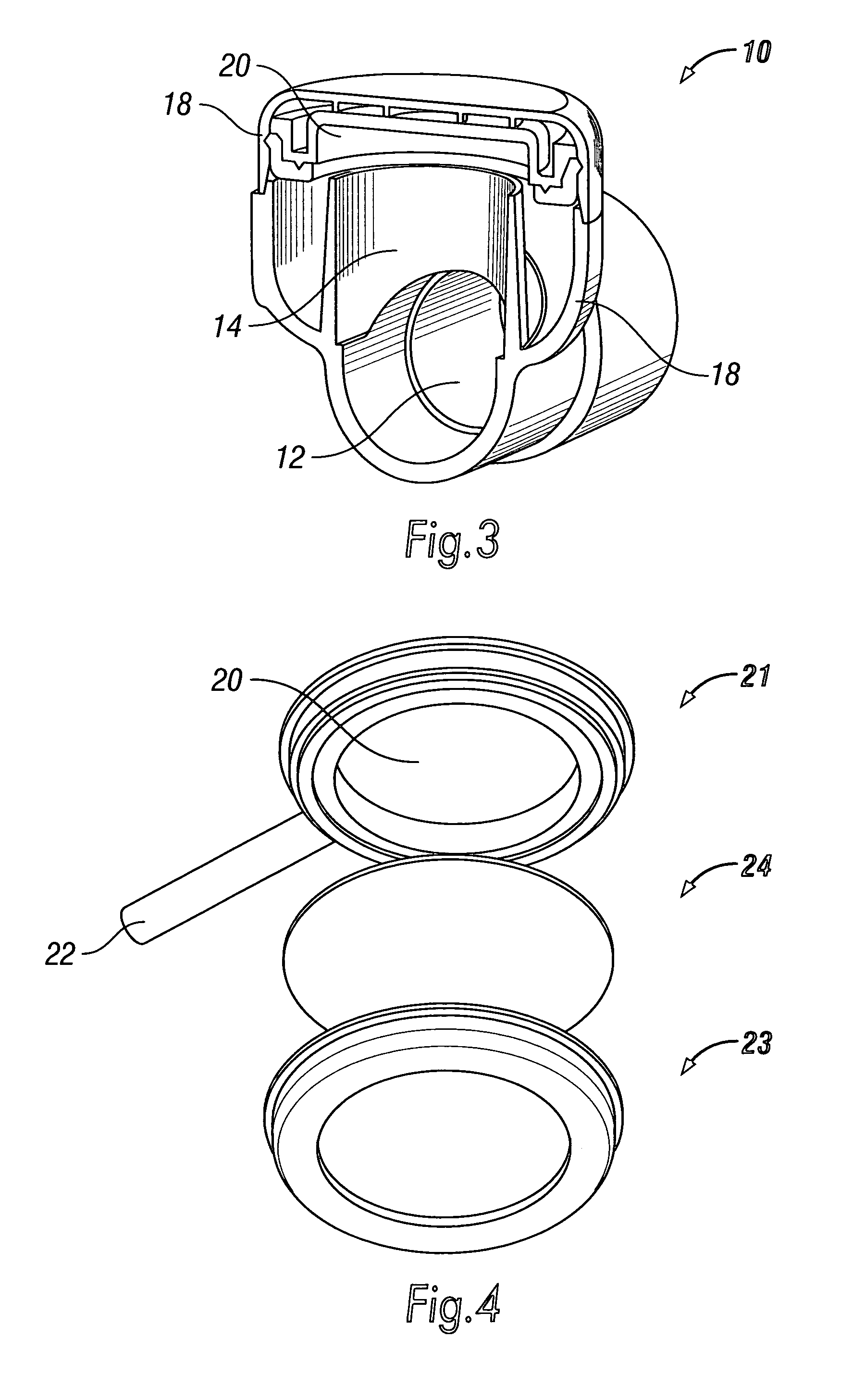

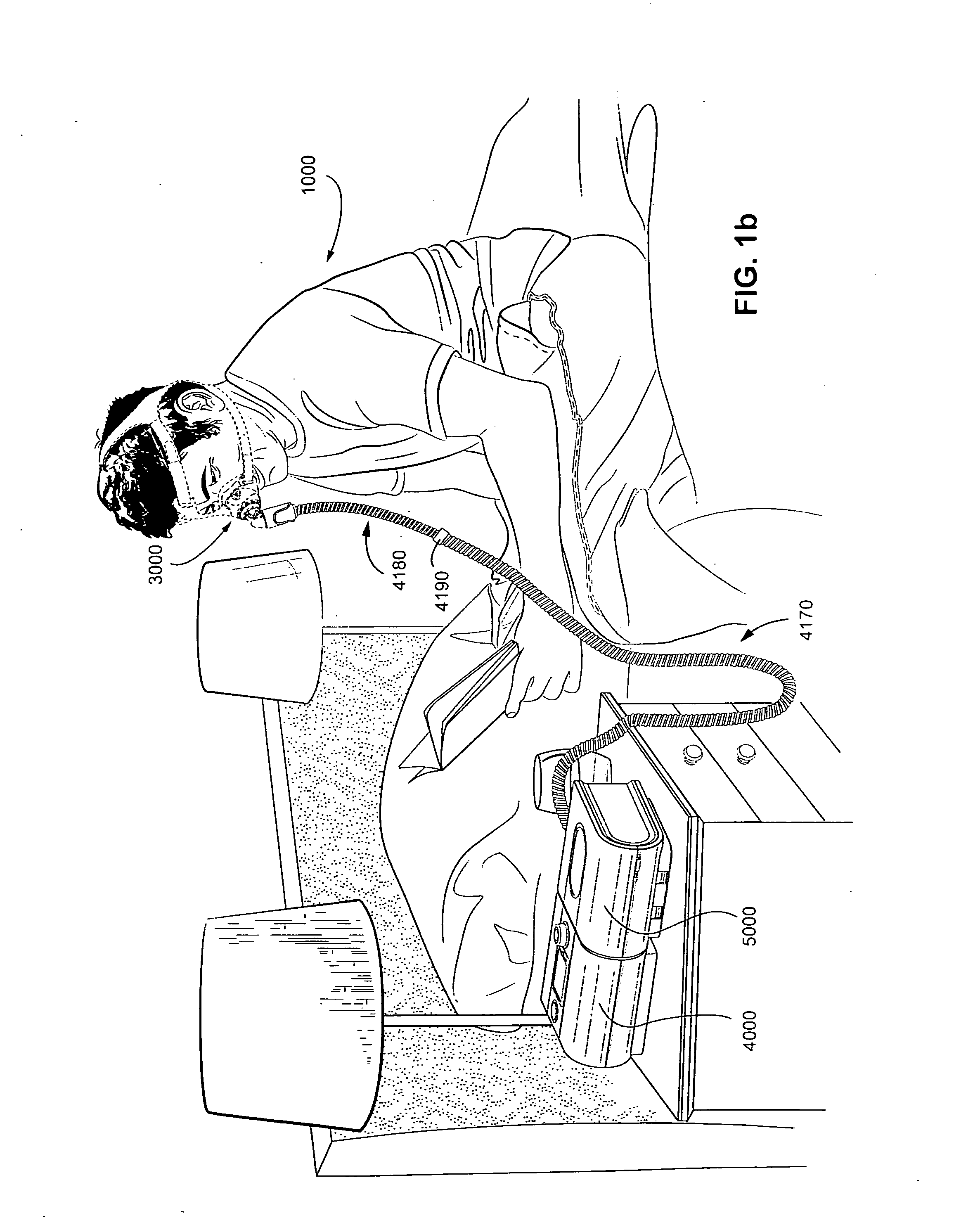

Hand access port device

InactiveUS6908430B2Reduce leakagePrevent substantial leakage of gasEar treatmentCannulasEngineeringGas chamber

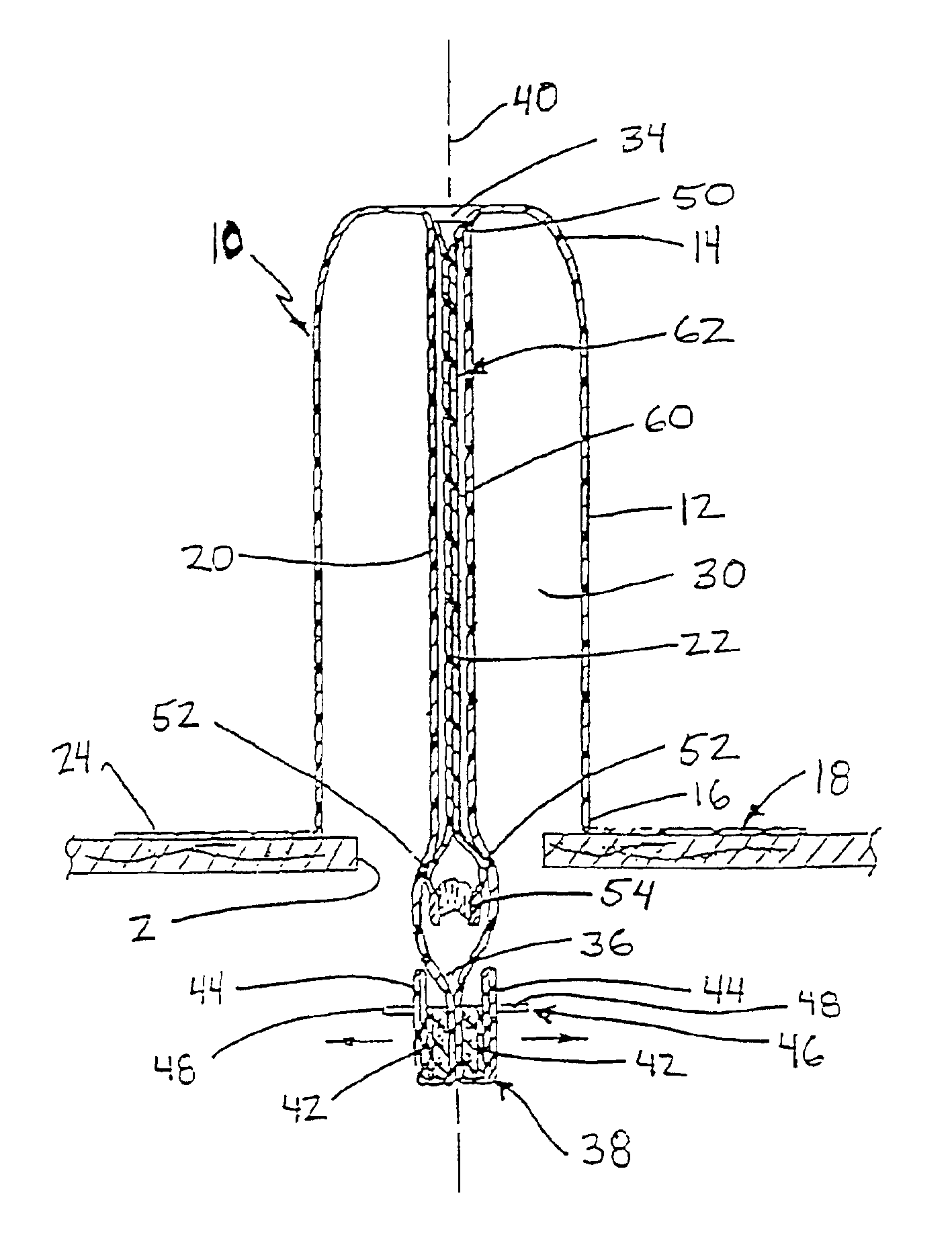

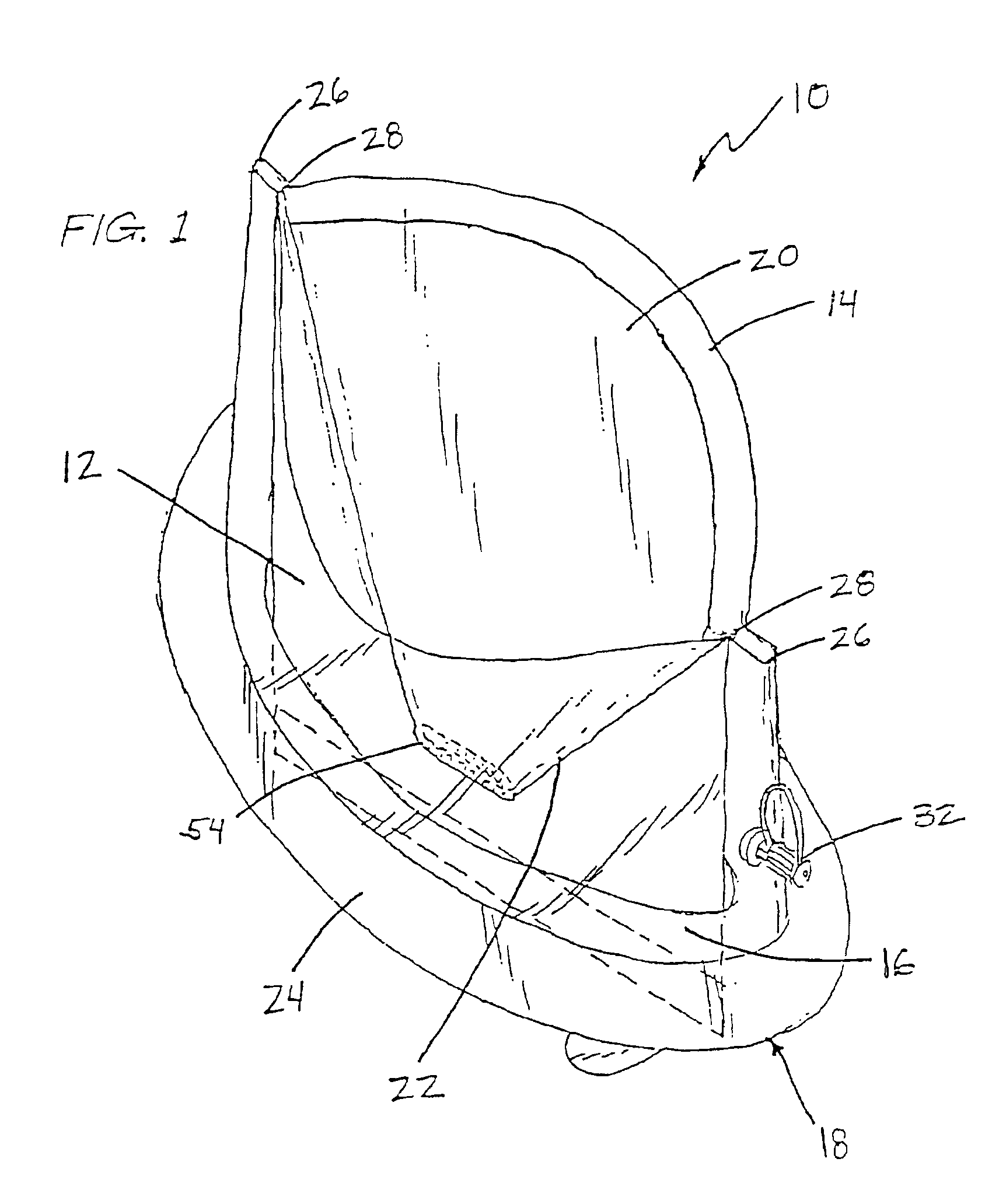

An access port device is provided which enables hand access to a patient's body cavity while retaining pneumoperitoneum by minimizing gas leakage through the access port device. In one embodiment, the access port device includes first and second sleeves forming an inflatable chamber and a third sleeve mounted within the second sleeve including an elastic band for sealingly engaging a hand or wrist. The access port device may also include an exit opening seal for positioning within the patient's body cavity and a second sleeve retraction prevention device for preventing inadvertent movement of the second sleeve outwardly from the patient's body cavity through the incision. In another embodiment, an access port device provided which includes an inner annular sealing device and a non-adhesive outer annular sealing device for creating a non-adhesive seal against the outer surface of a patient. An access component forming an inflatable chamber and including an integral sleeved glove may also be provided. In another embodiment, a sealing force applying feature includes a biasing surface formed on a generally flat annular extension and exposed to gas pressure in an adjacent gas chamber positioned to receive leakage gas leakage between the access port device an the patient to create sealing forces which tend to enhance the seal between the flexible annular extension and patient's skin.

Owner:APPL MEDICAL RESOURCES CORP

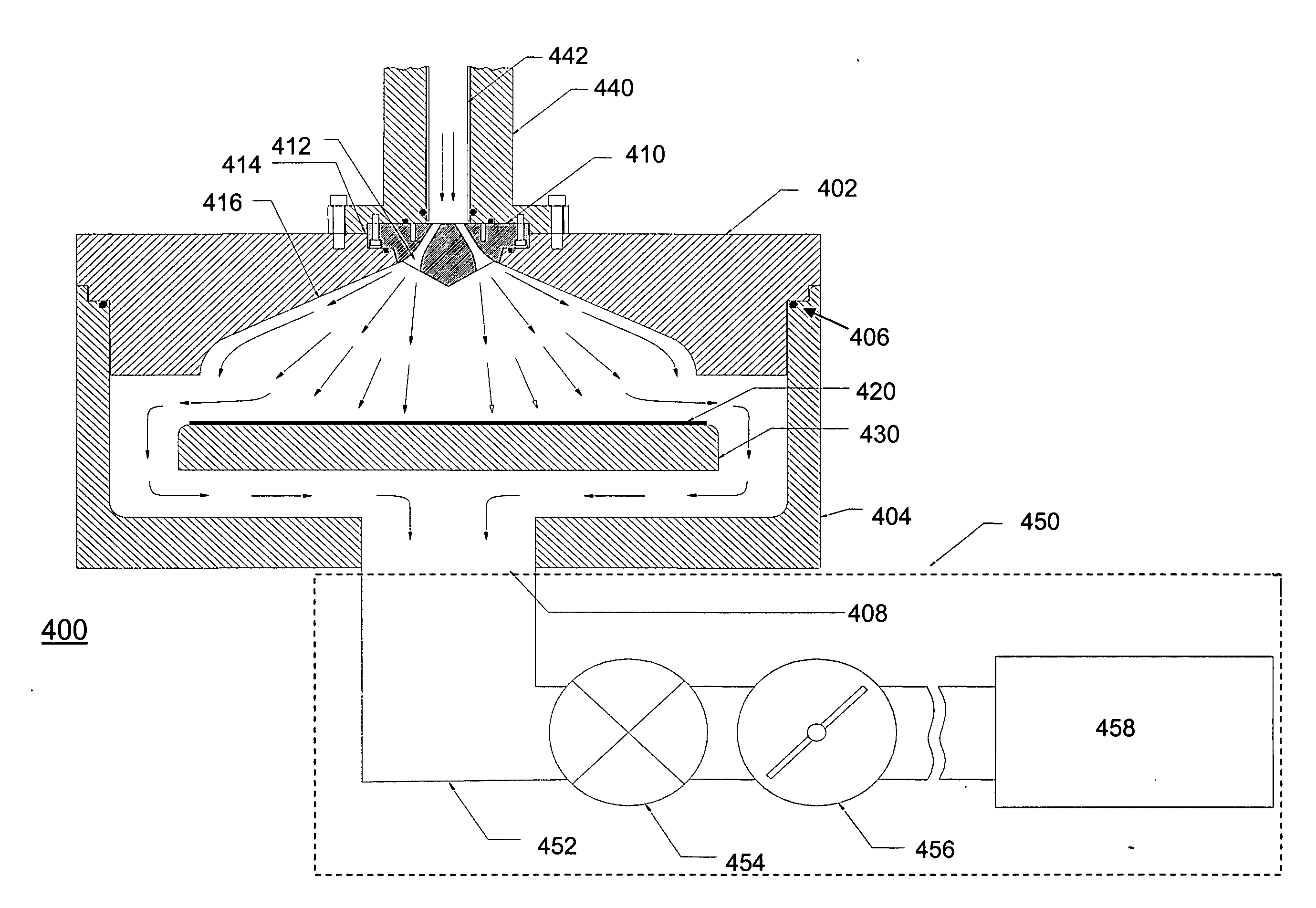

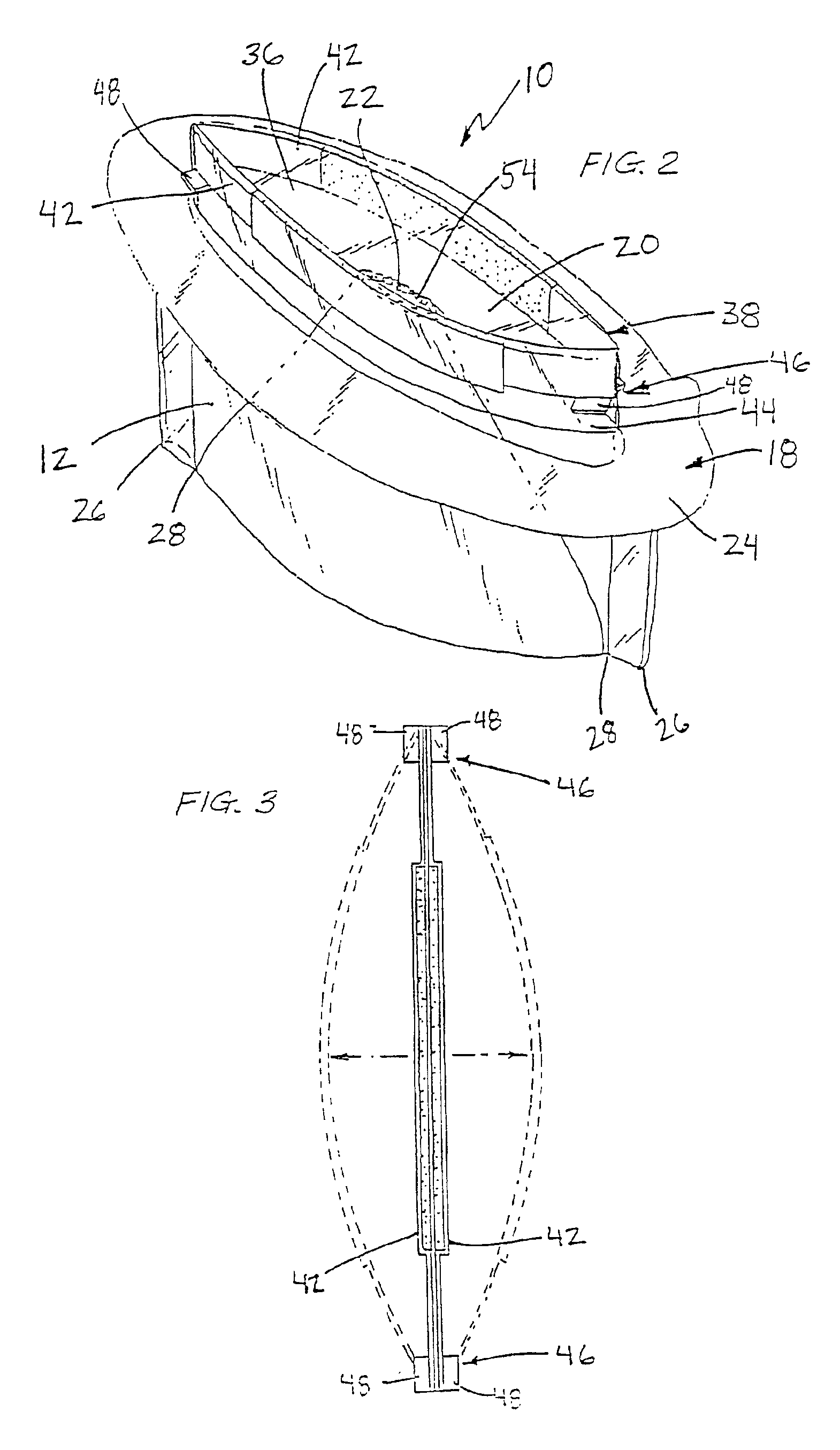

Apparatus and method of atomizing and vaporizing

InactiveUS6012647AMinimal slippageVaporization fastBurnersSpray nozzlesGas passingProcess engineering

Apparatus suitable for atomizing and vaporizing at least a first liquid by colliding at least one gas with the first liquid. The apparatus includes a gas inlet through which the gas enters the apparatus and a first liquid inlet through which the first liquid enters the apparatus. A discharge end of the apparatus includes at least one first liquid discharge outlet through which at least one stream of the first liquid is discharged from the apparatus. The discharge end also includes at least one gas discharge outlet through which at least one stream of gas is discharged from the apparatus to collide with and thereby atomize the discharged stream of the first liquid. A first liquid passageway interconnects the first liquid inlet with the first liquid discharge outlet. A gas passageway interconnects the gas inlet with the at least one gas discharge outlet. In one embodiment, the gas passageway comprises at least one gas chamber in thermal contact with an initial portion of the first liquid passageway such that a heated quantity of the gas in the chamber preheats the first liquid in the initial portion of the first liquid passageway. In alternative embodiments, the gas passageway includes a pressure dampening chamber allowing gas to be continuously discharged without pulsating.

Owner:3M INNOVATIVE PROPERTIES CO

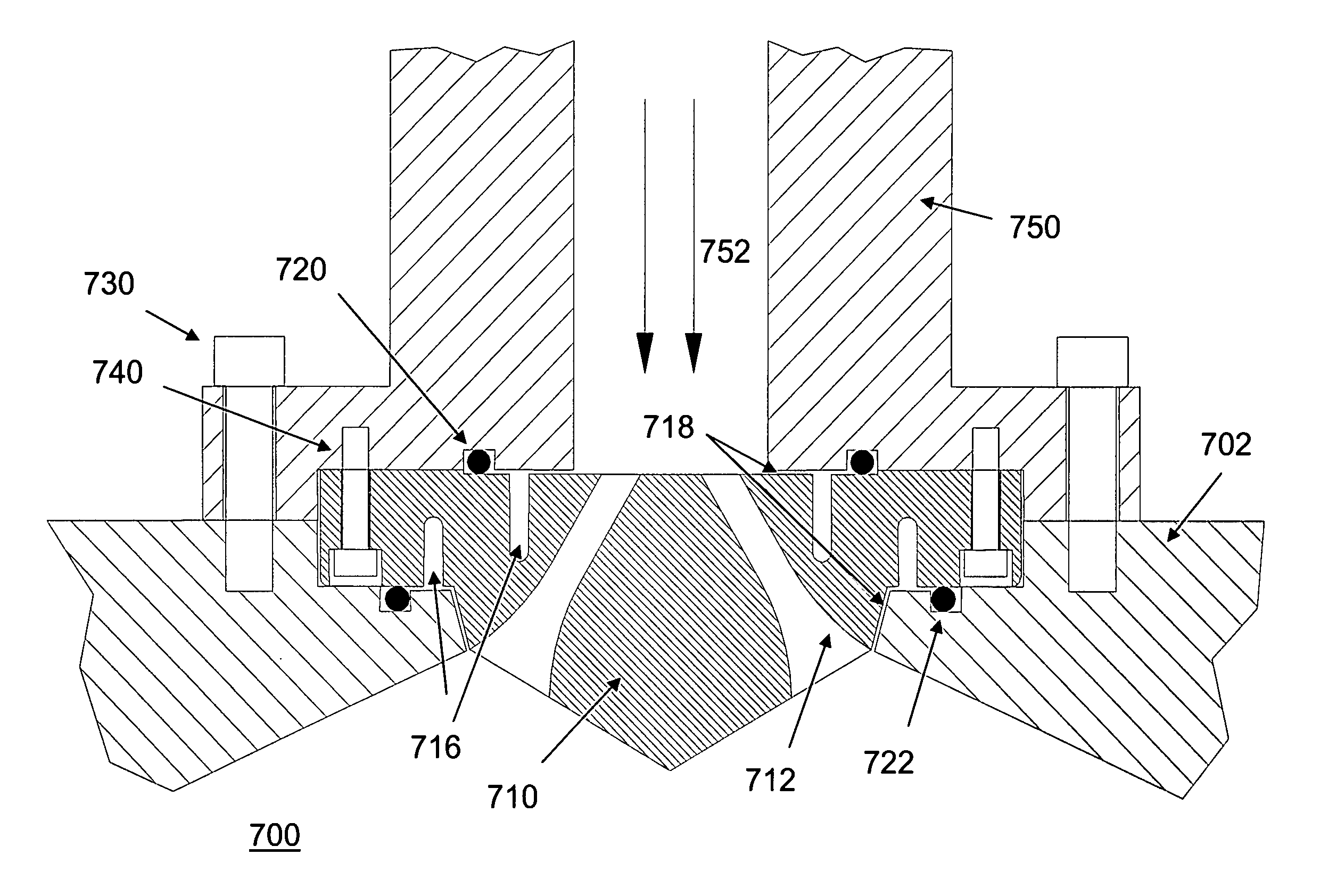

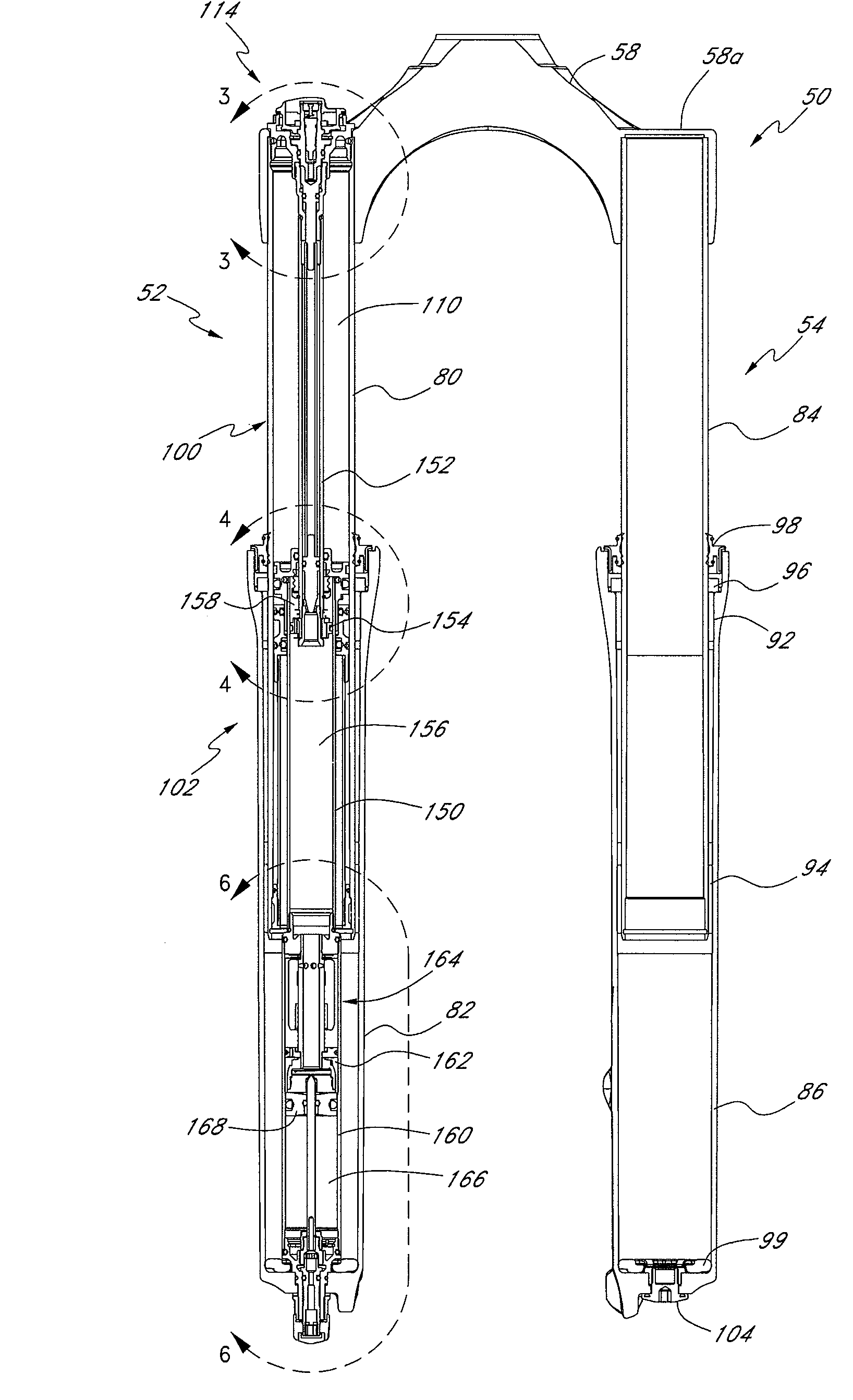

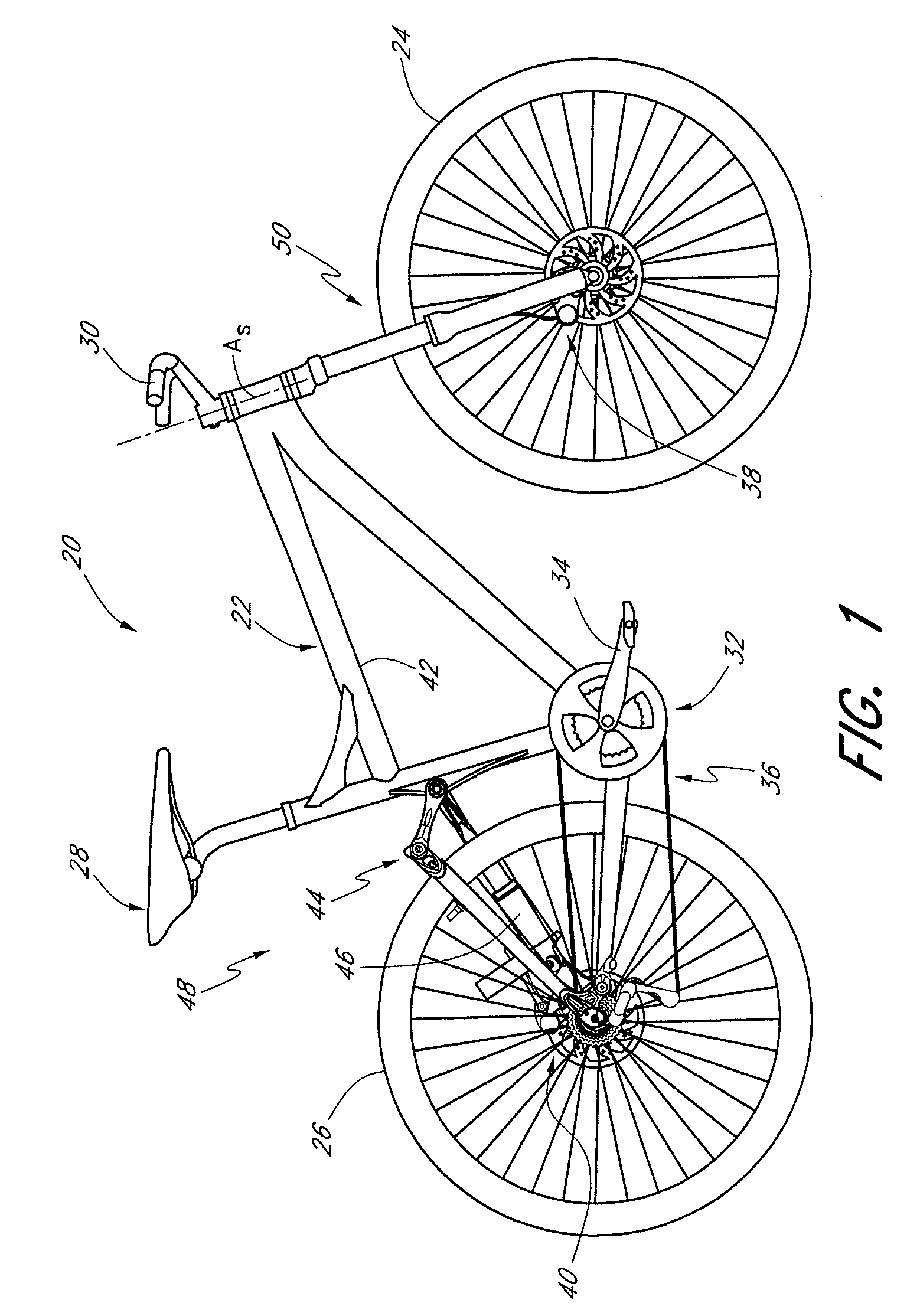

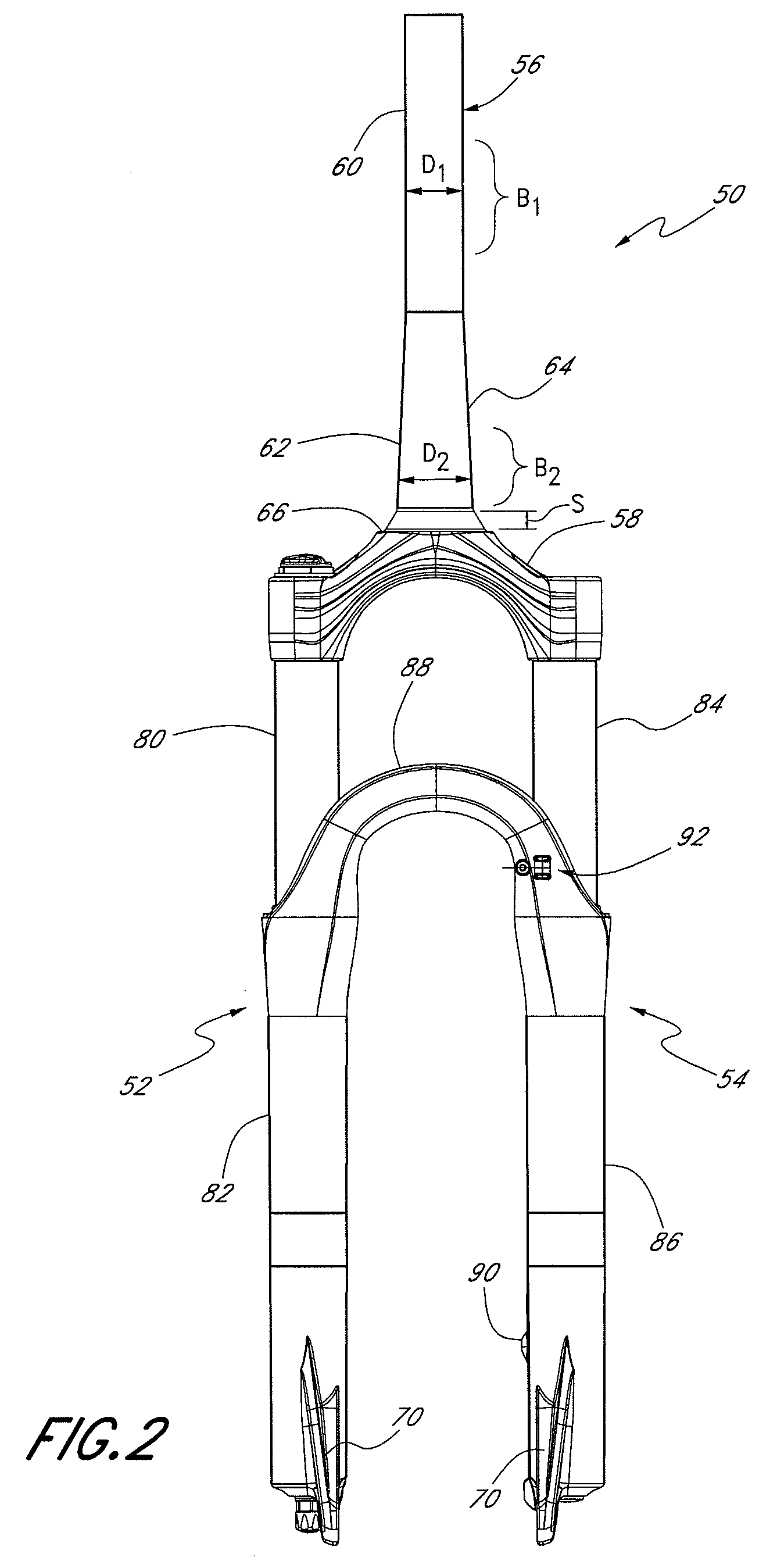

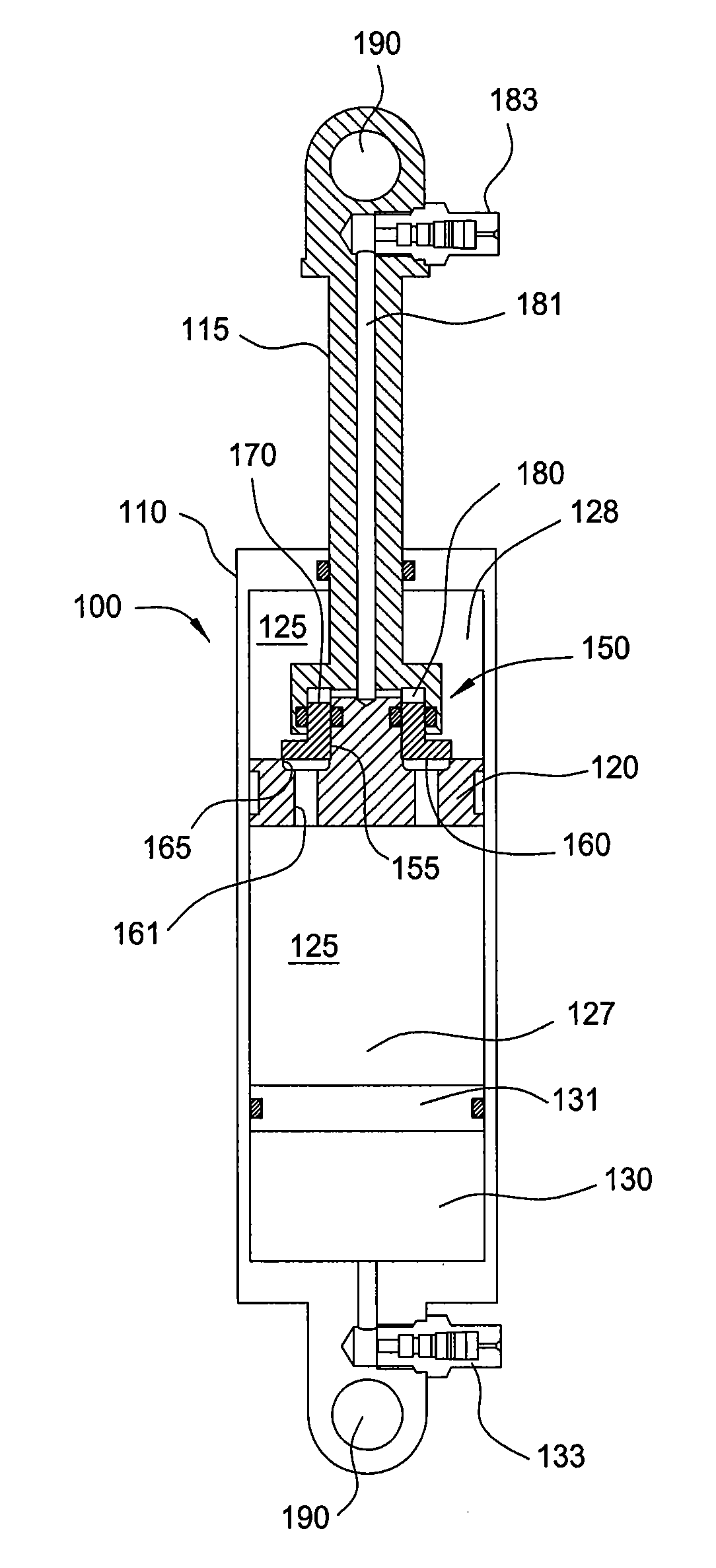

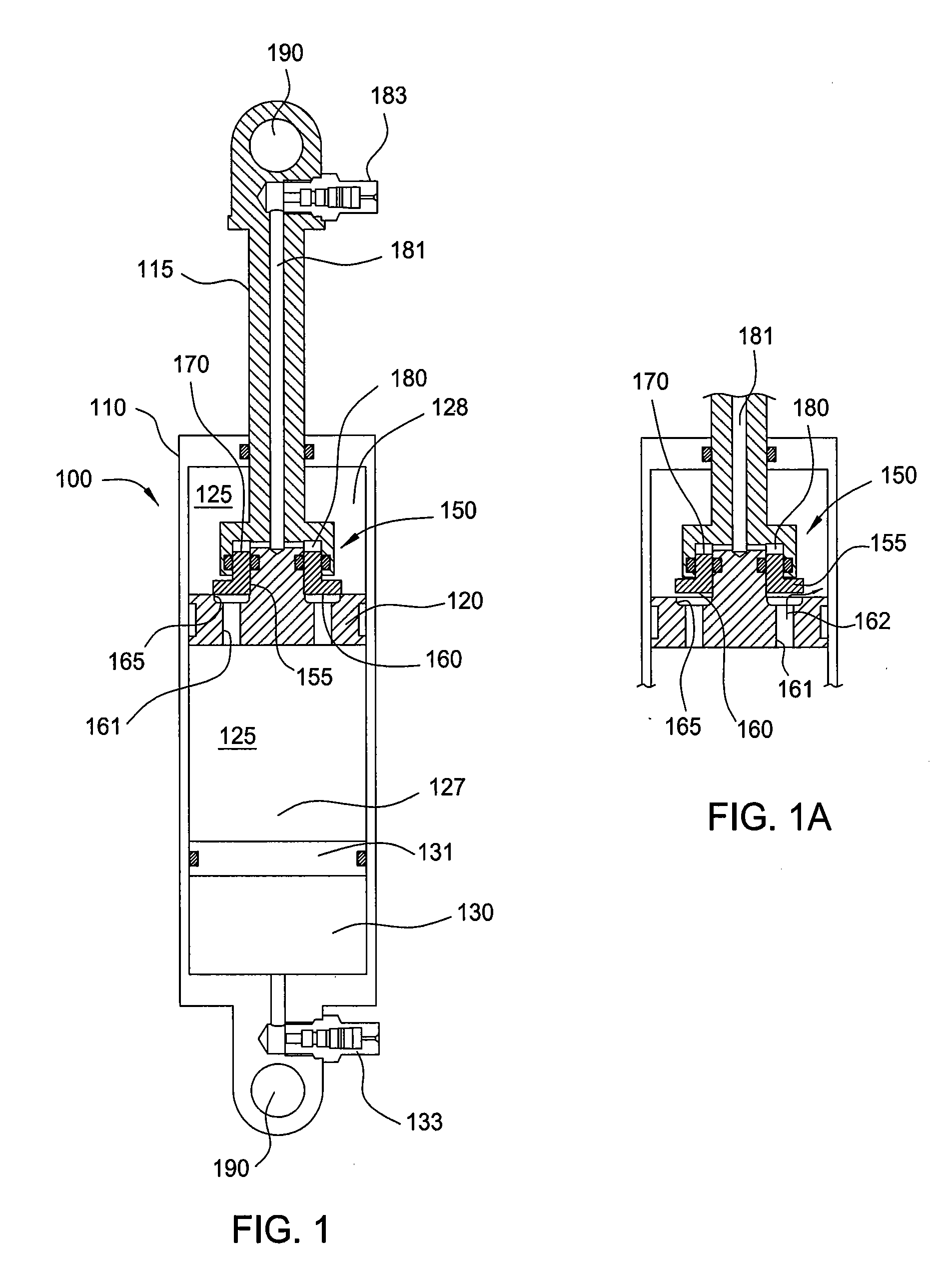

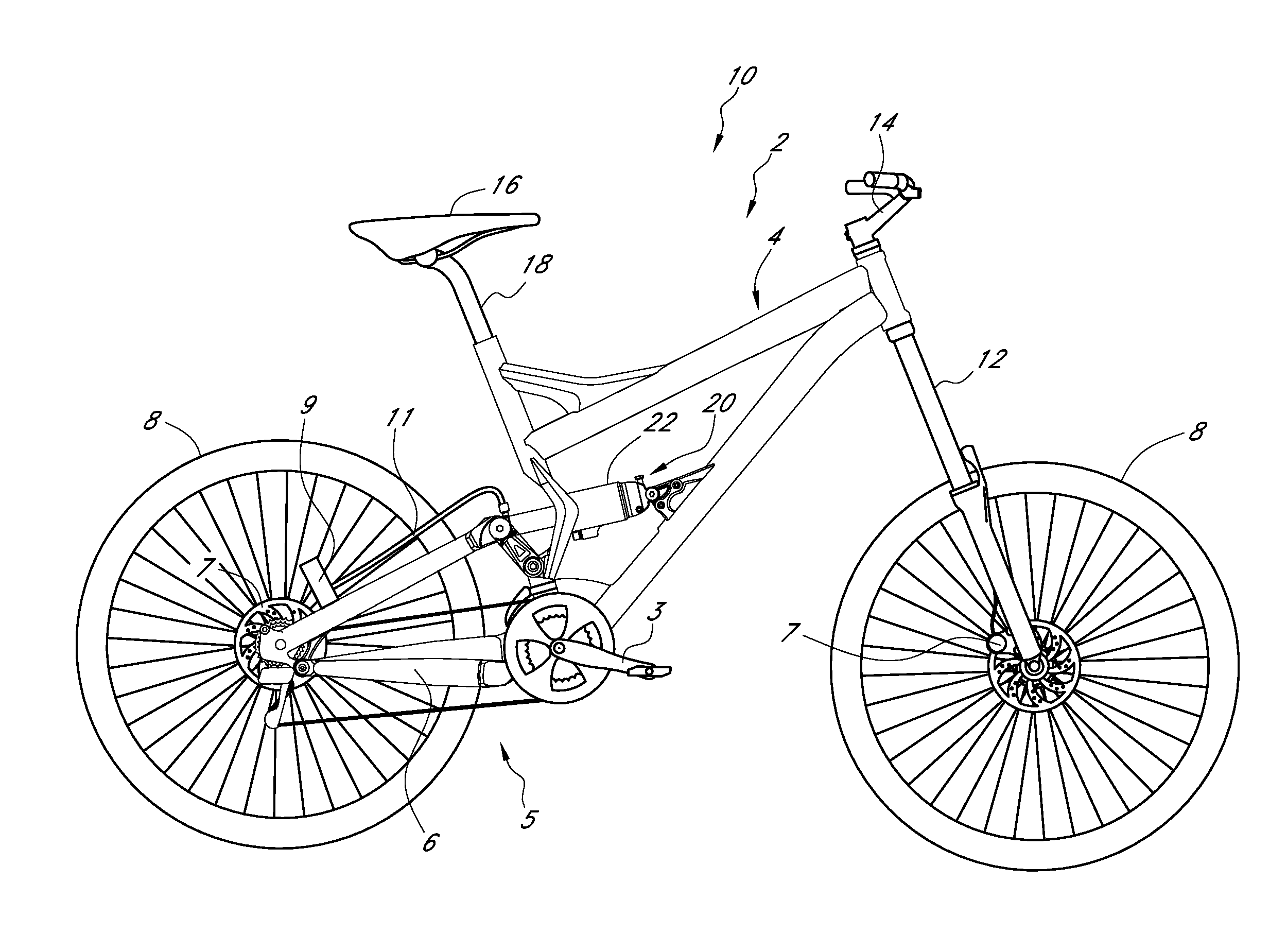

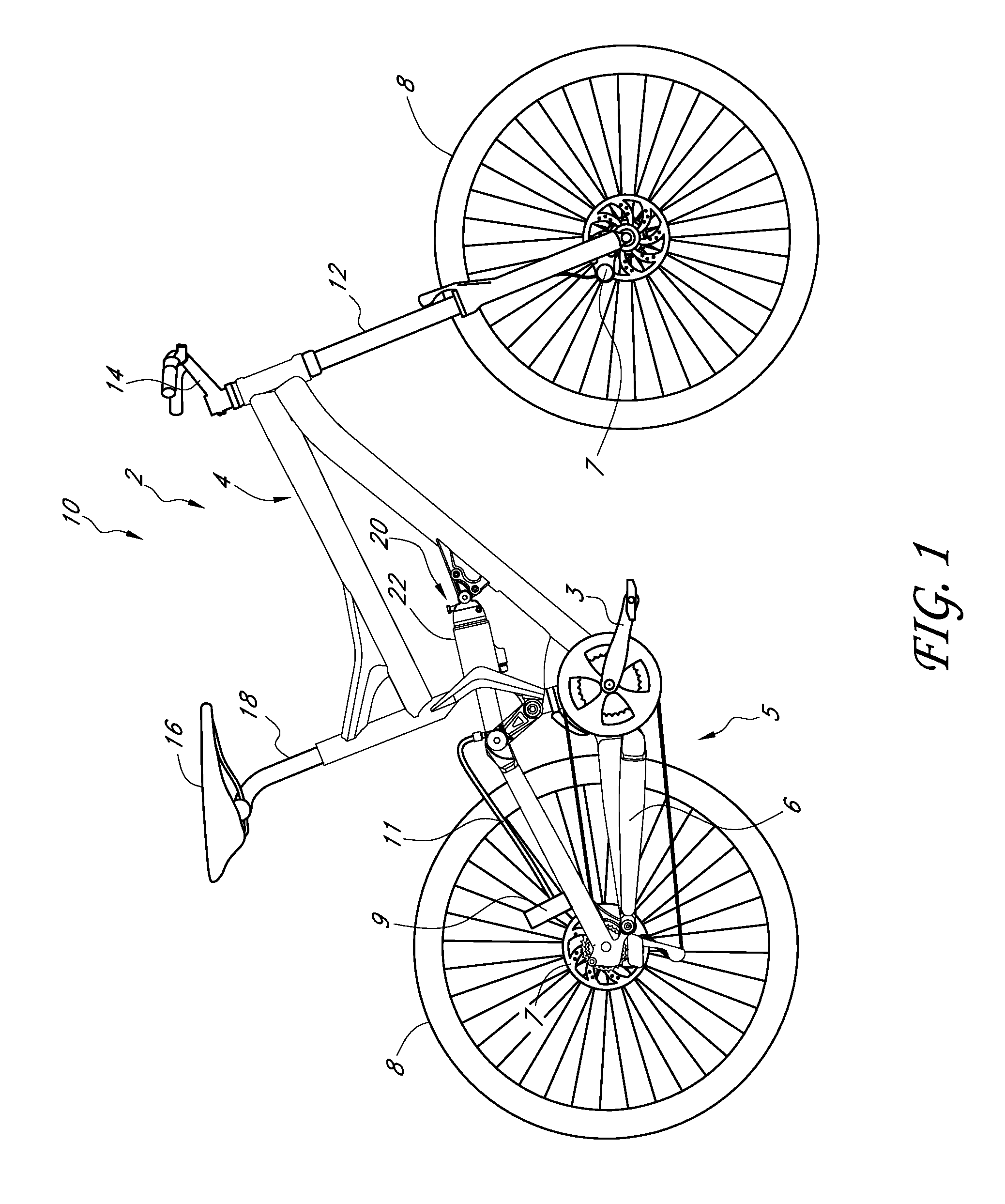

Bicycle suspension assembly

InactiveUS20090001684A1Wheel based transmissionFrictional rollers based transmissionDual stageGas spring

A bicycle suspension assembly may be in the form of a bicycle front suspension fork. The suspension fork may include a pair of telescoping fork legs. In one arrangement, a suspension spring and a damper are provided in only one of the pair of fork legs. The suspension spring assembly may include a negative spring. In one arrangement, the negative spring is a dual stage negative gas spring in which a negative spring gas chamber includes a first chamber section and a second chamber section. The first chamber section and the second chamber section are uncoupled in a first position of the suspension spring and the first chamber section and the second chamber section are coupled in a second position of the suspension spring.

Owner:SPECIALIZED BICYCLE COMPONENTS INC

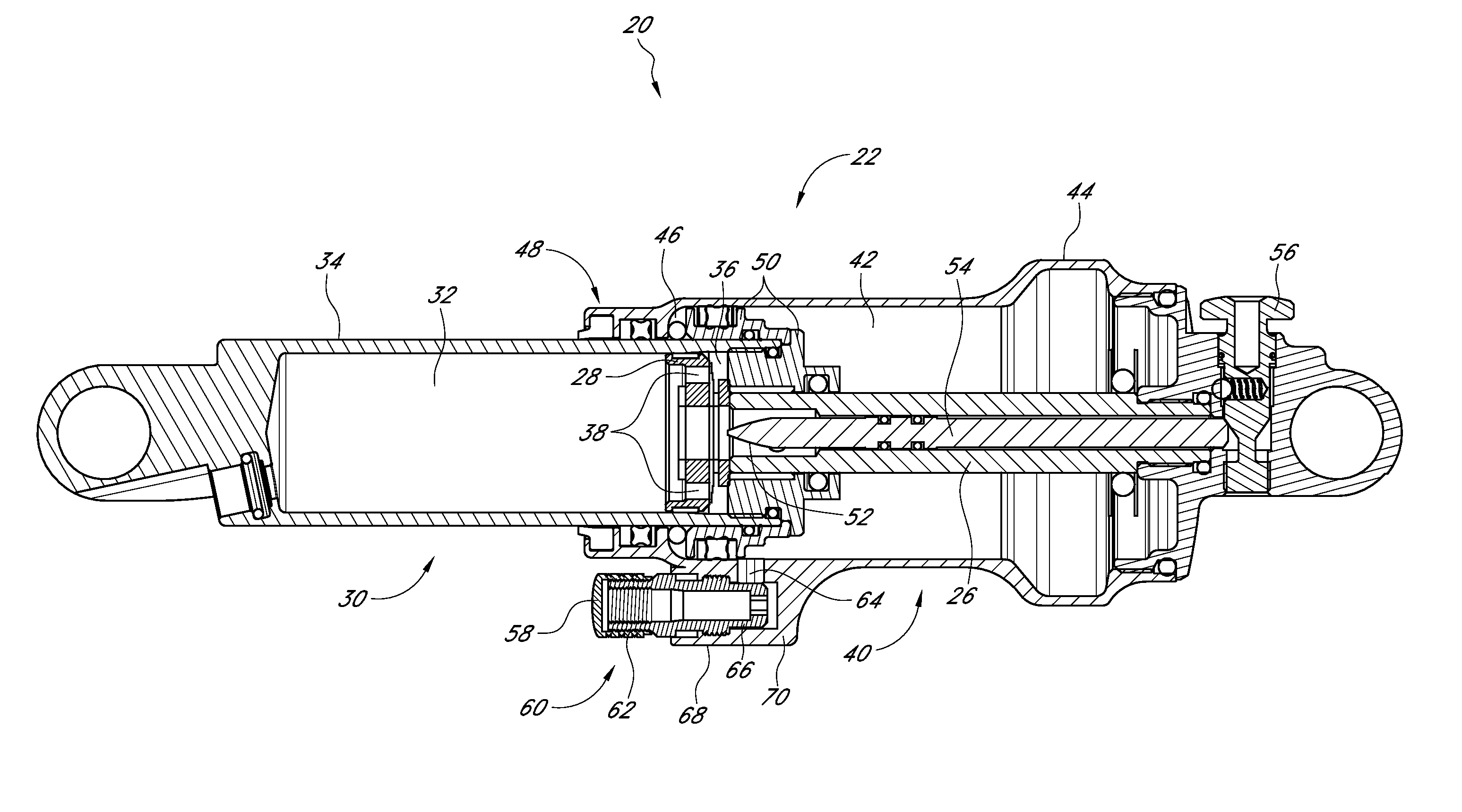

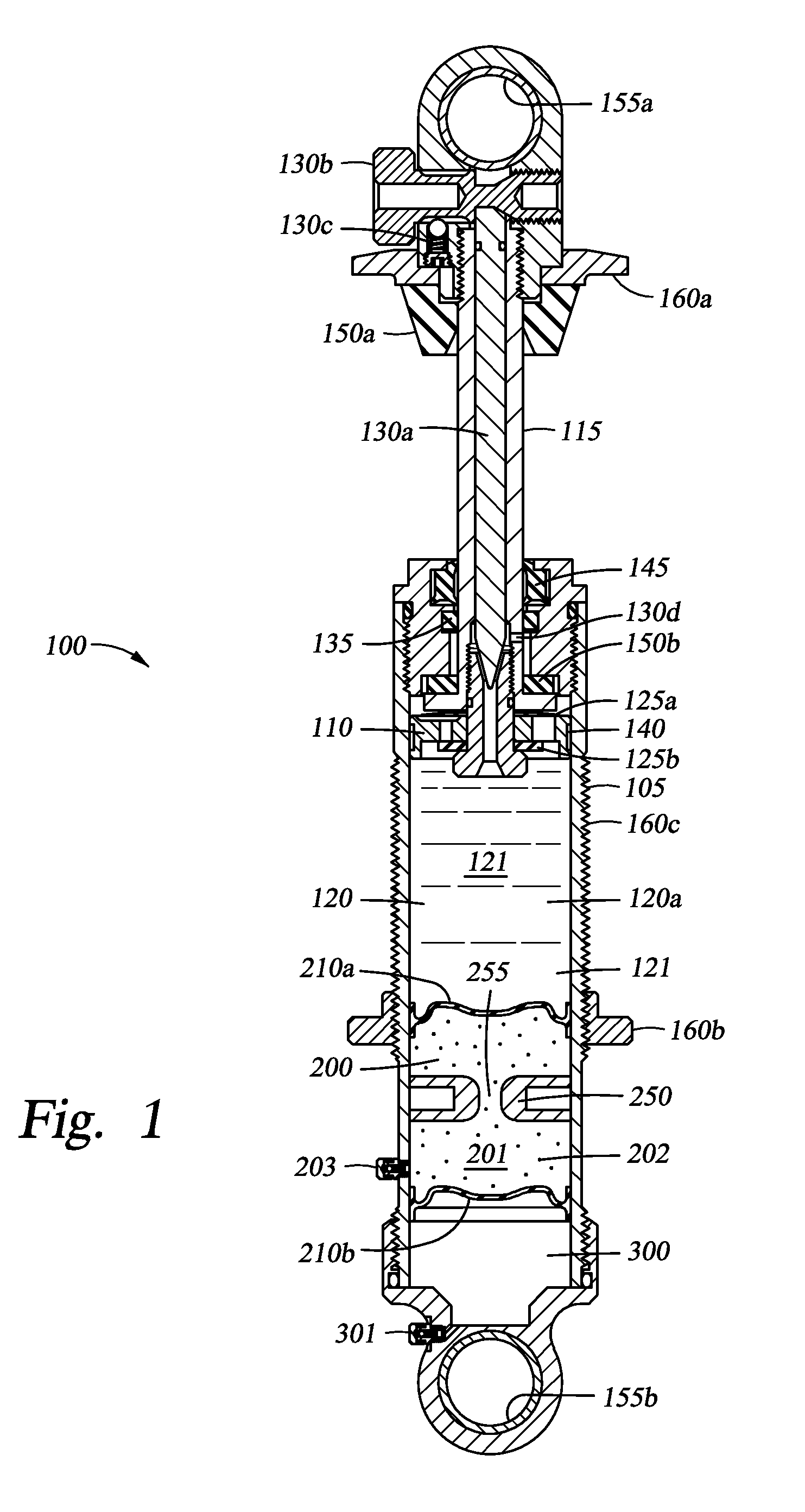

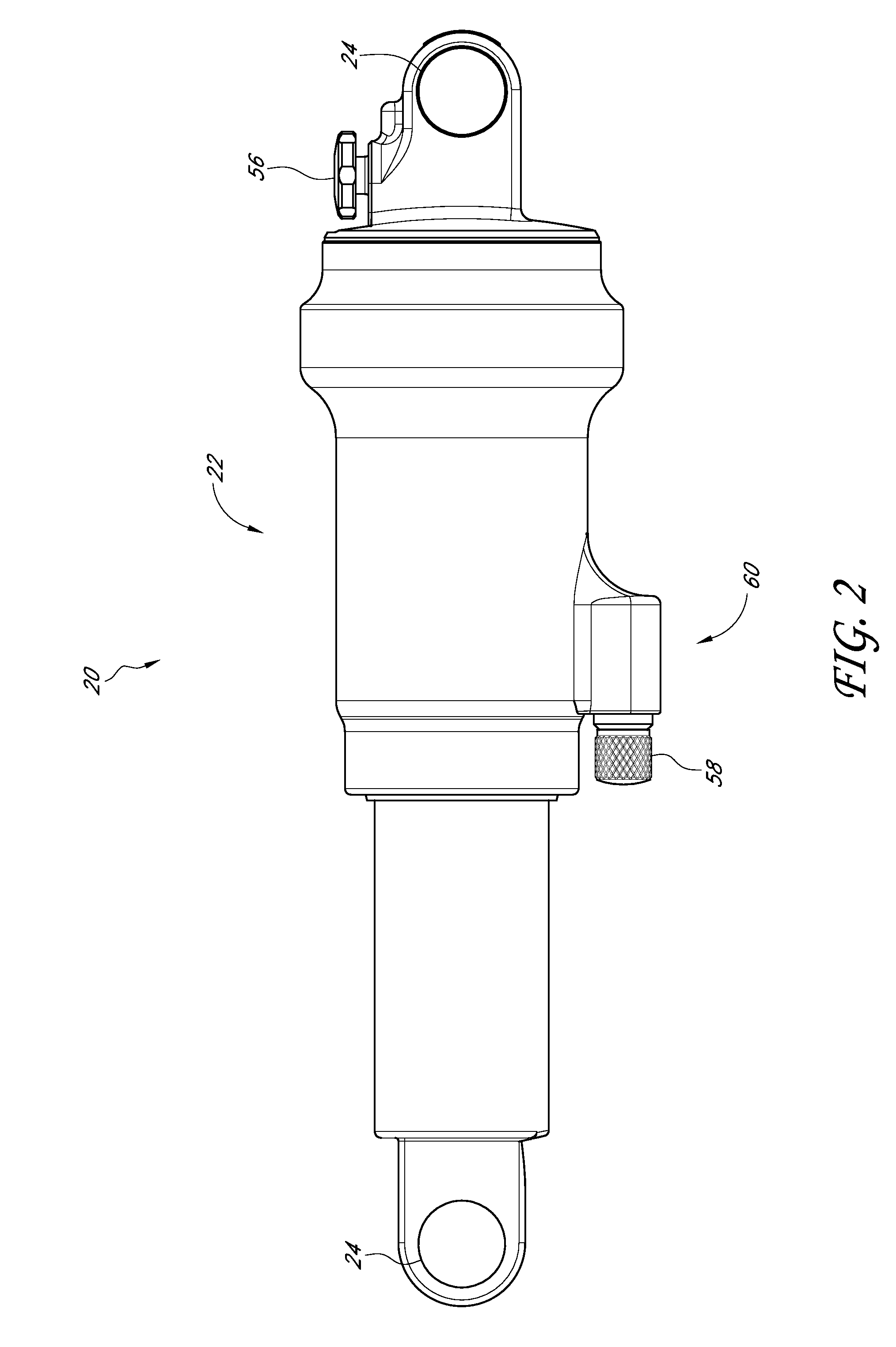

Methods and apparatus for combined variable damping and variable spring rate suspension

Pressure-sensitive vales are incorporated within a dampening system to permit user-adjustable tuning of a shock absorber. In one embodiment, a pressure-sensitive valve includes an isolated gas chamber having a pressure therein that is settable by a user.

Owner:FOX FACTORY

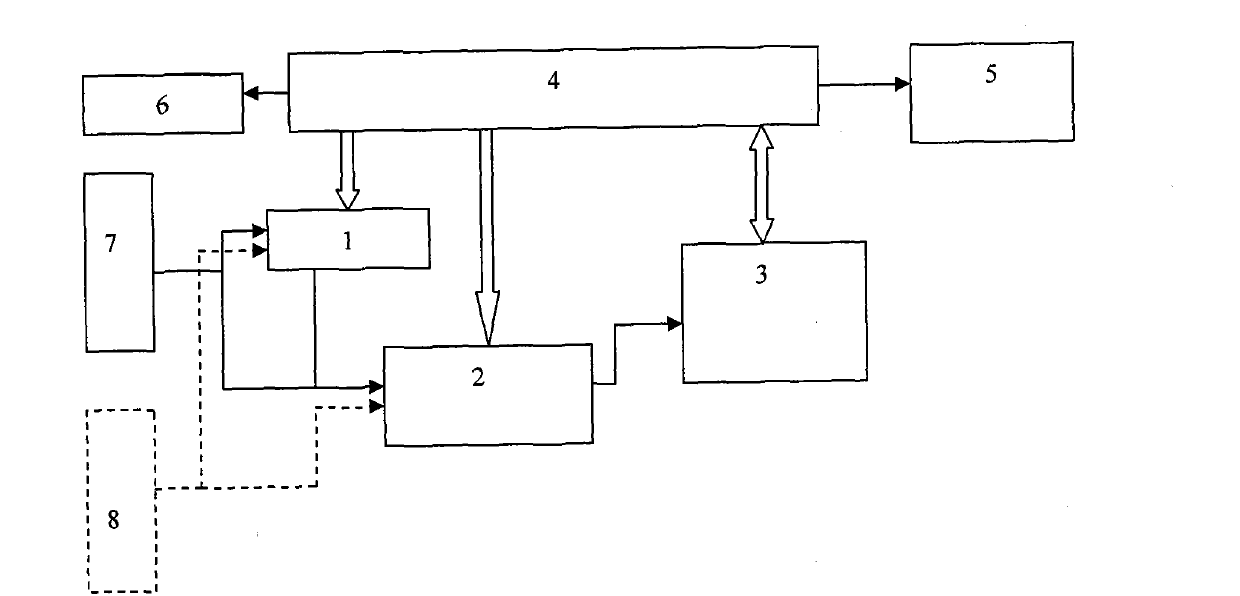

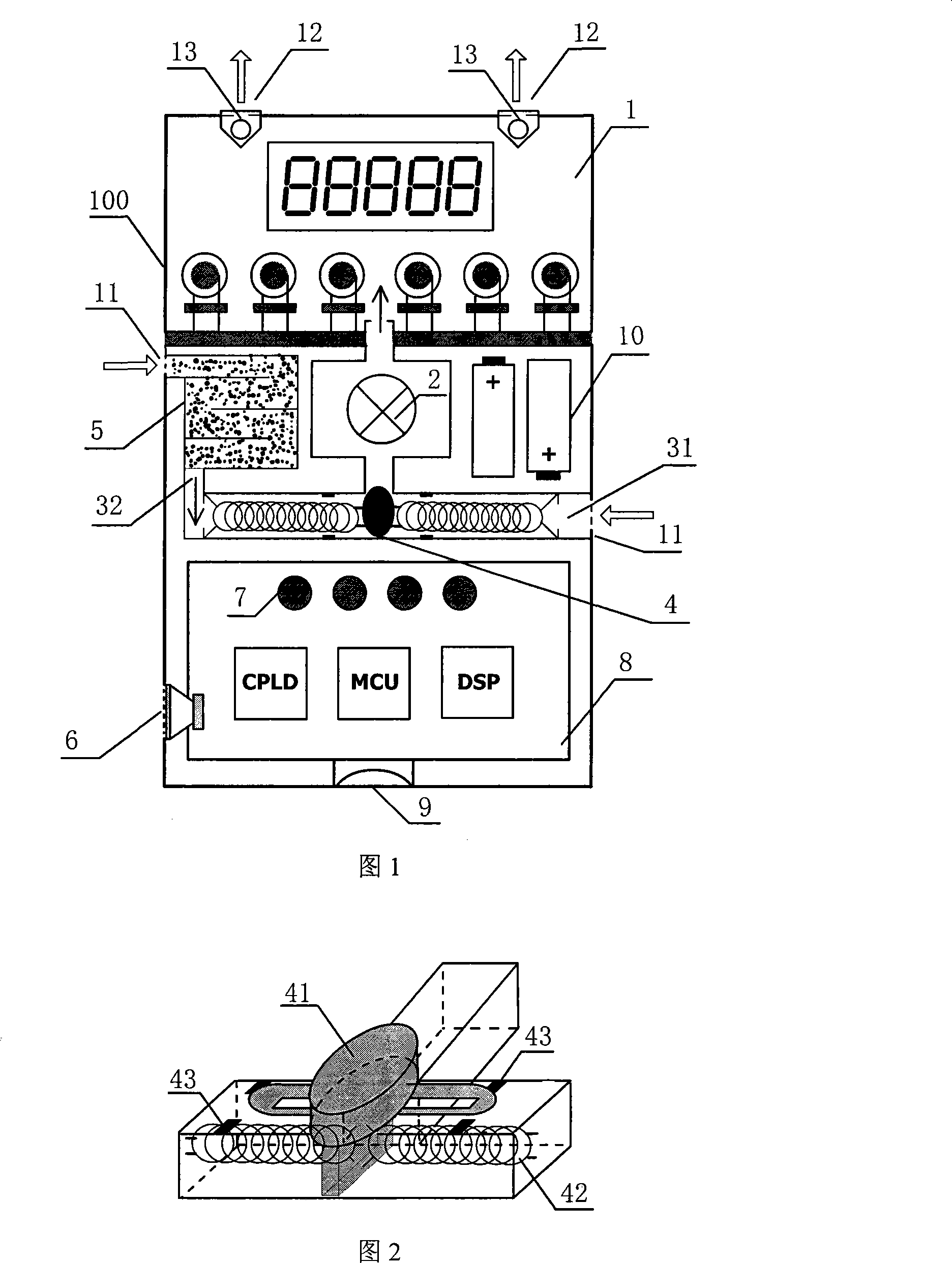

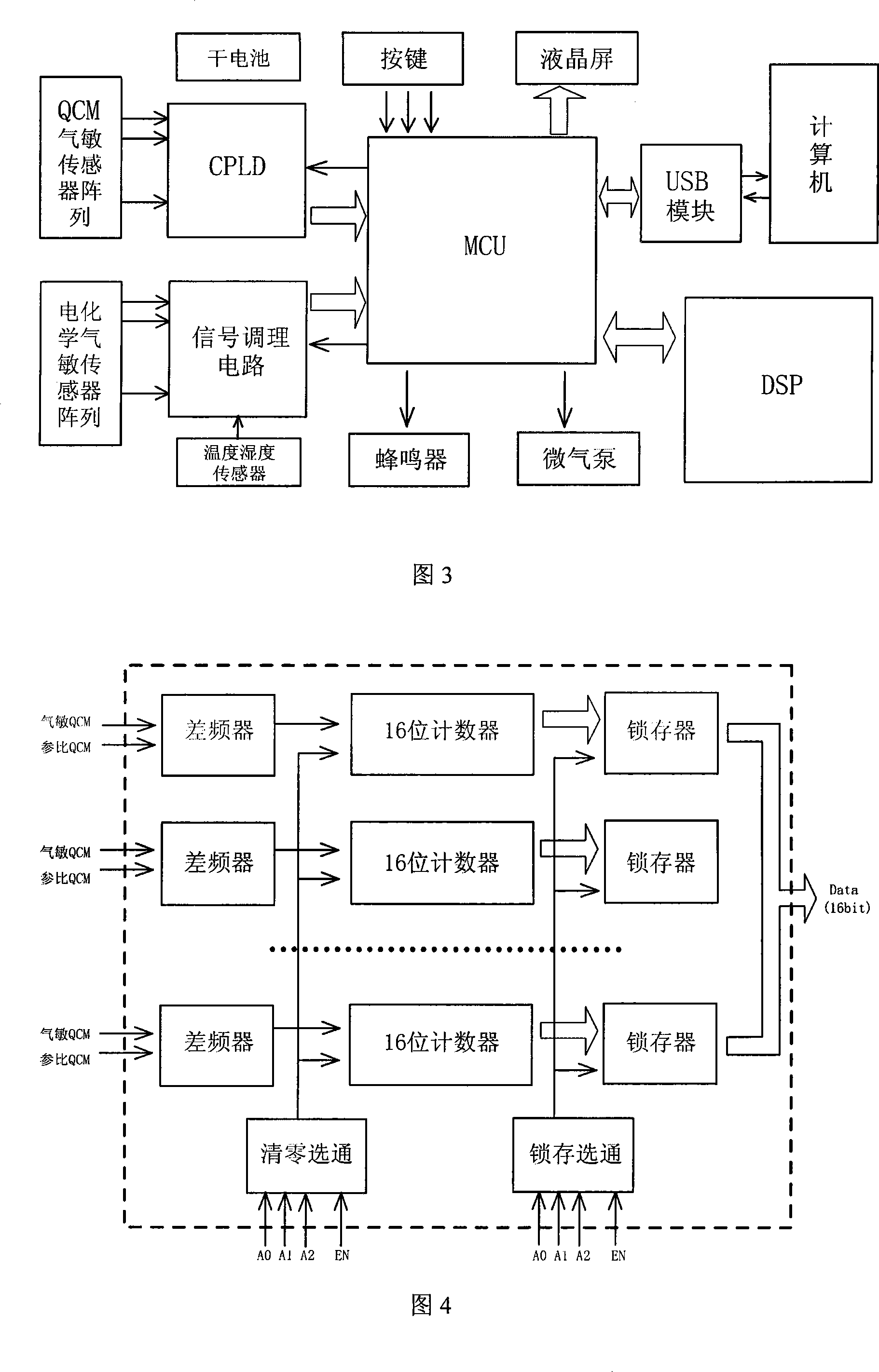

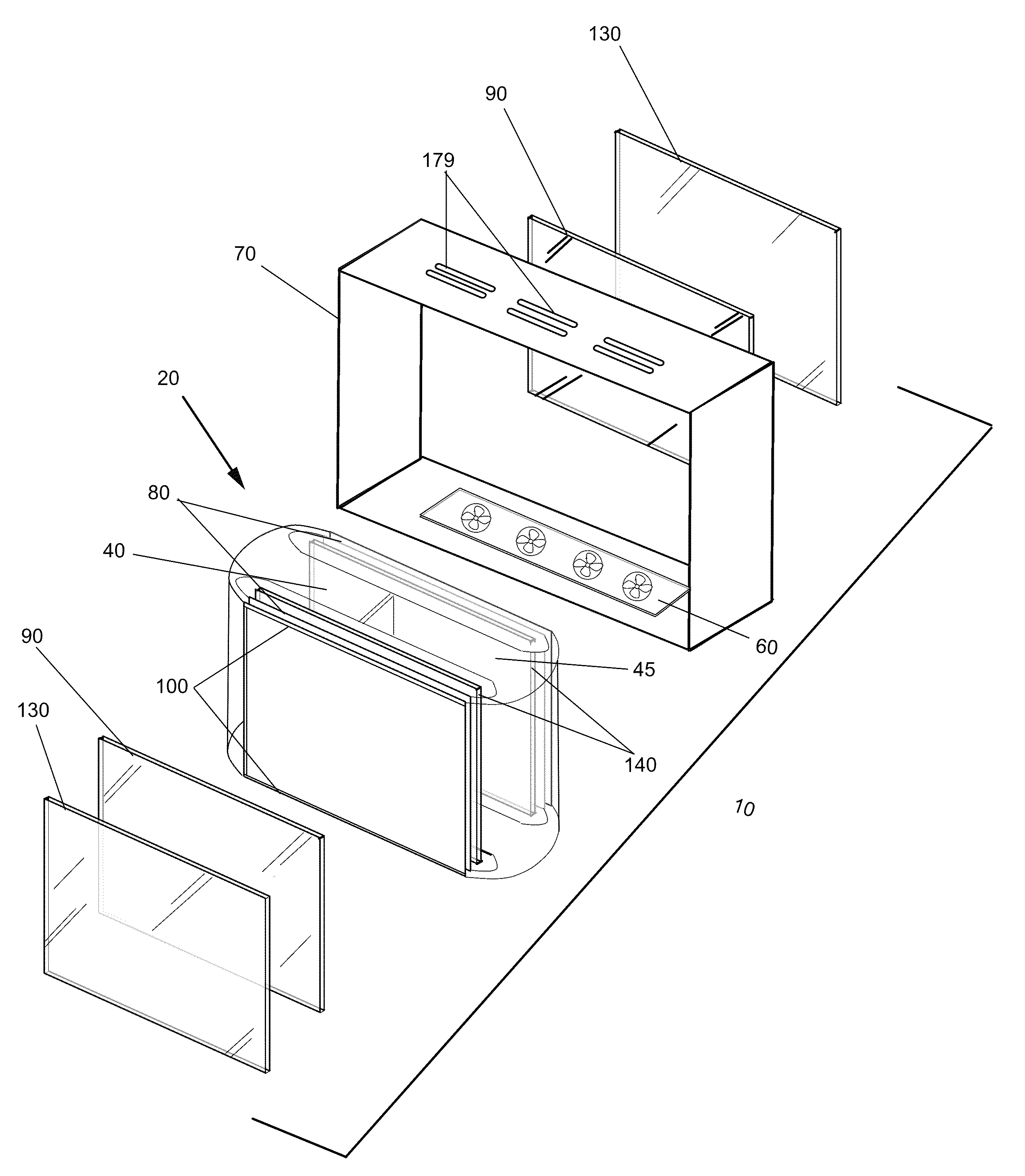

Electronic nose system for detecting quality of agricultural products

InactiveCN101769889AReduce volumeEasy to carryWithdrawing sample devicesMaterial electrochemical variablesSensor arrayTemperature control

An electronic nose system for detecting quality of agricultural products mainly comprises a gas enrichment module mainly for collecting the low-concentration smell, a gas chamber and gas circuit module and a sensor array mainly for converting the smell signal into the electric signal, a sensor conditioning circuit and a data preprocessing module mainly for filtering, analog-to-digital converting and feature extracting of the output signal of the sensor array, an embedded system with data storage for identifying and judging the signal and a display and result output module, wherein the gas enrichment module consists of an adsorption tube filled with adsorbent, an electric heating wire and a temperature control device. The electronic nose system has the characteristics of small size, convenient carrying, high sensitivity of the system and wide application range of the system.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG

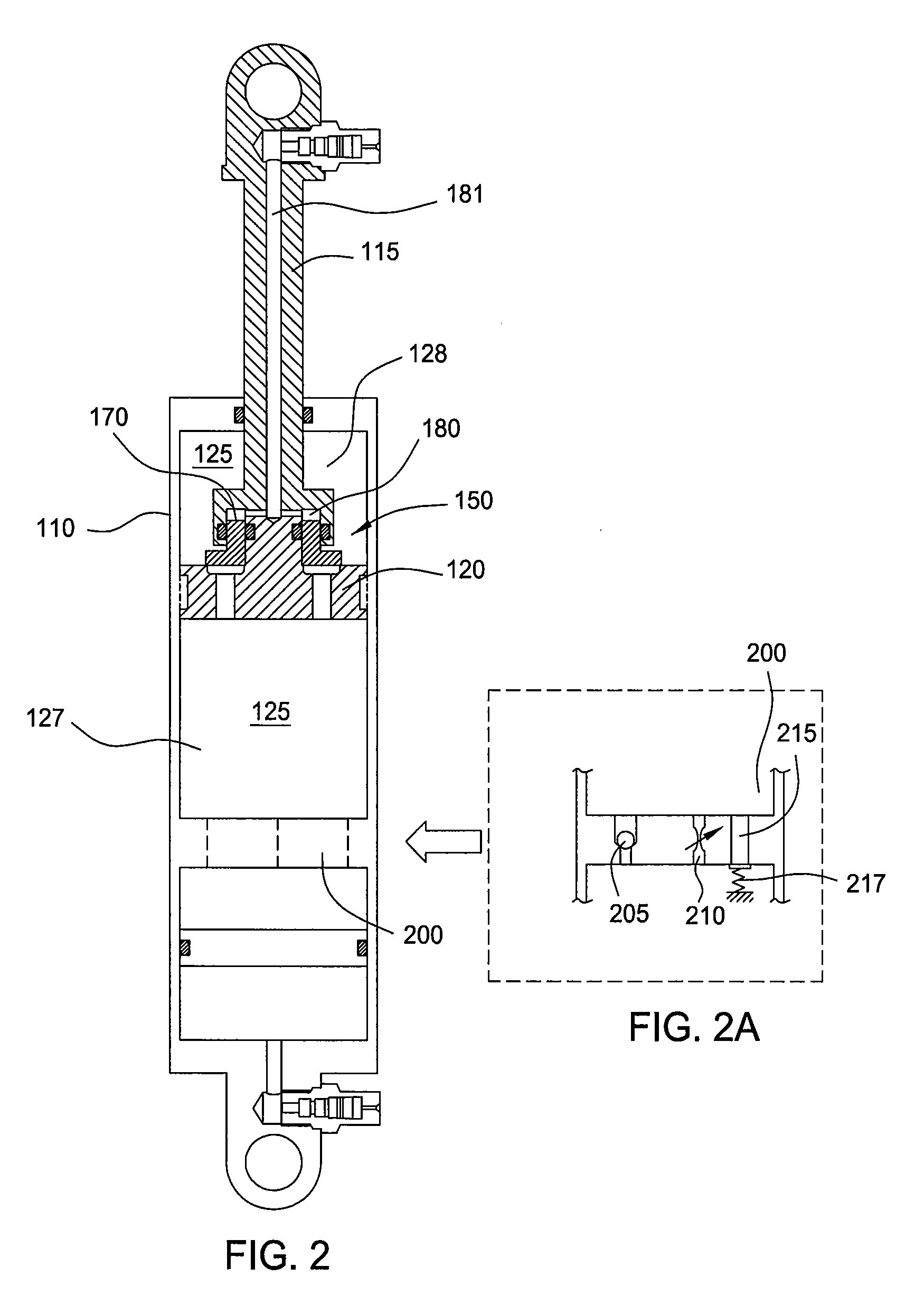

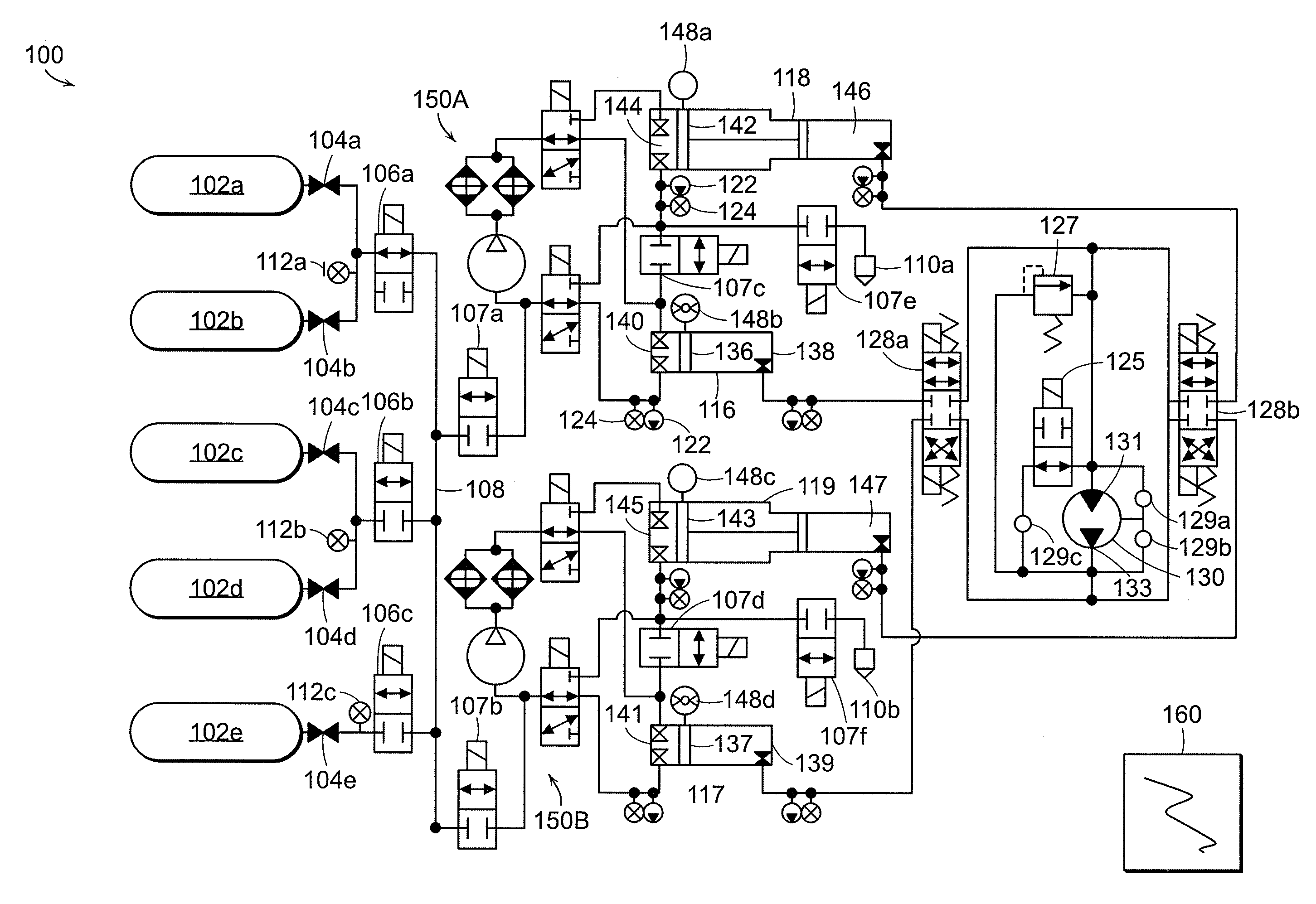

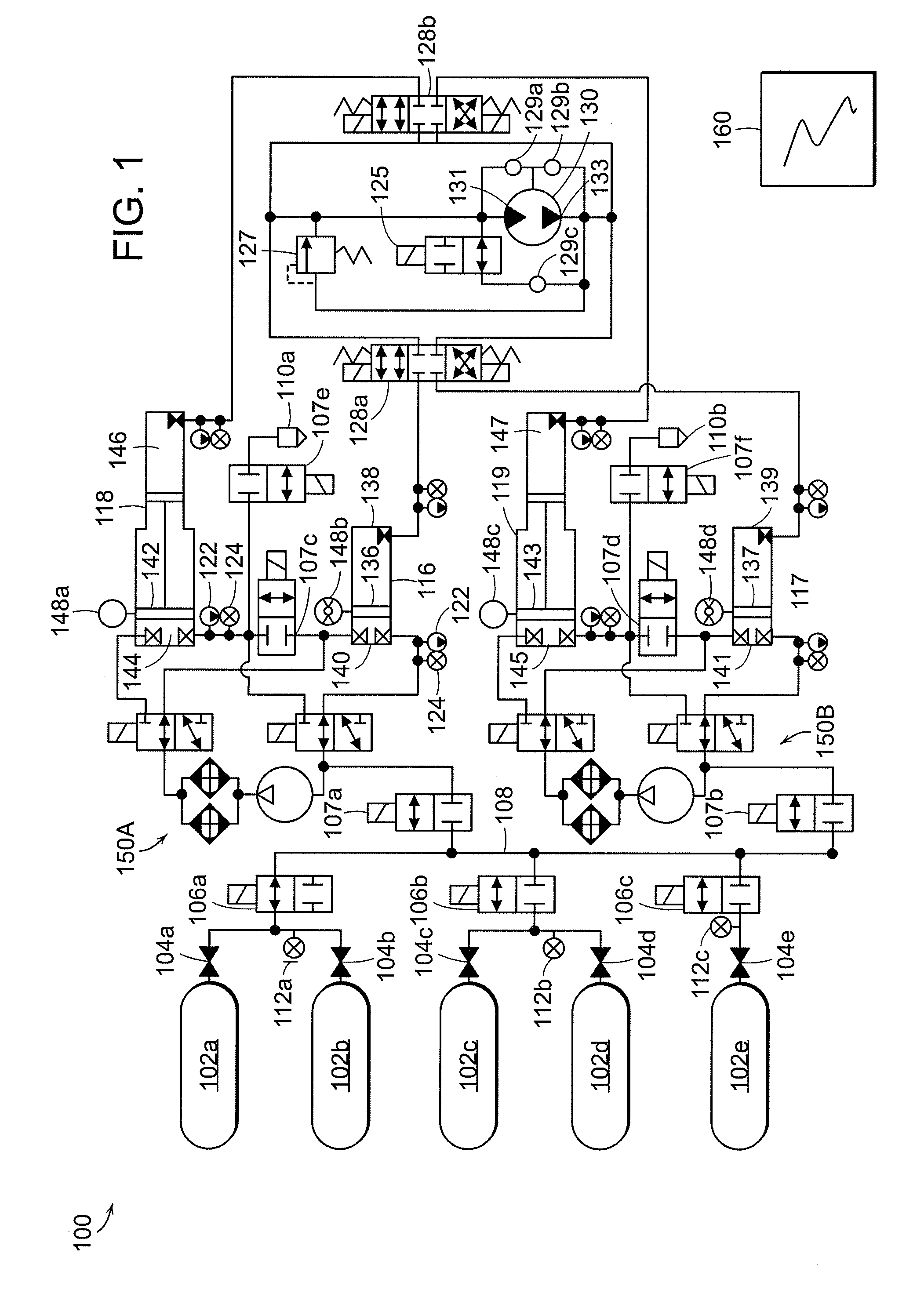

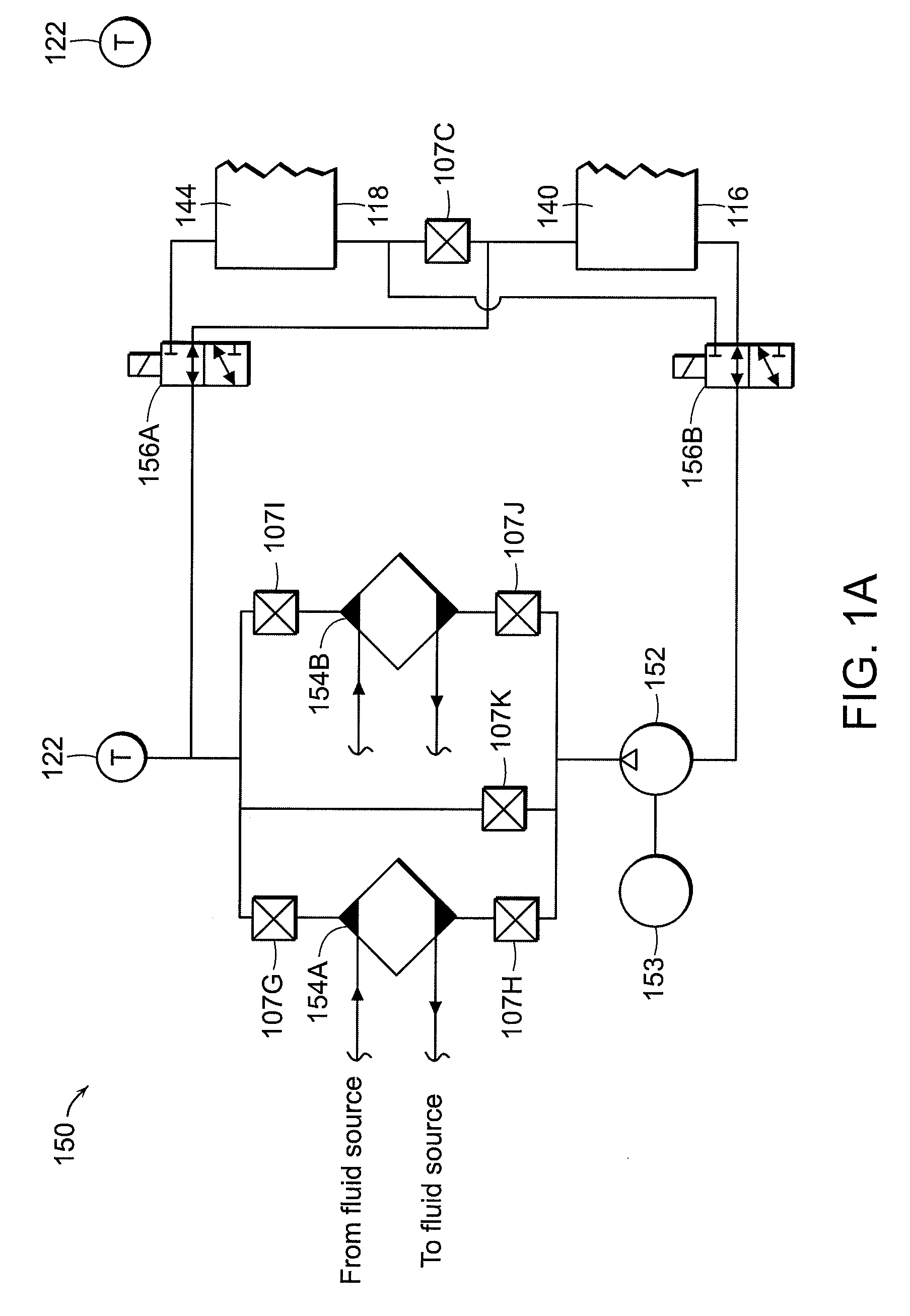

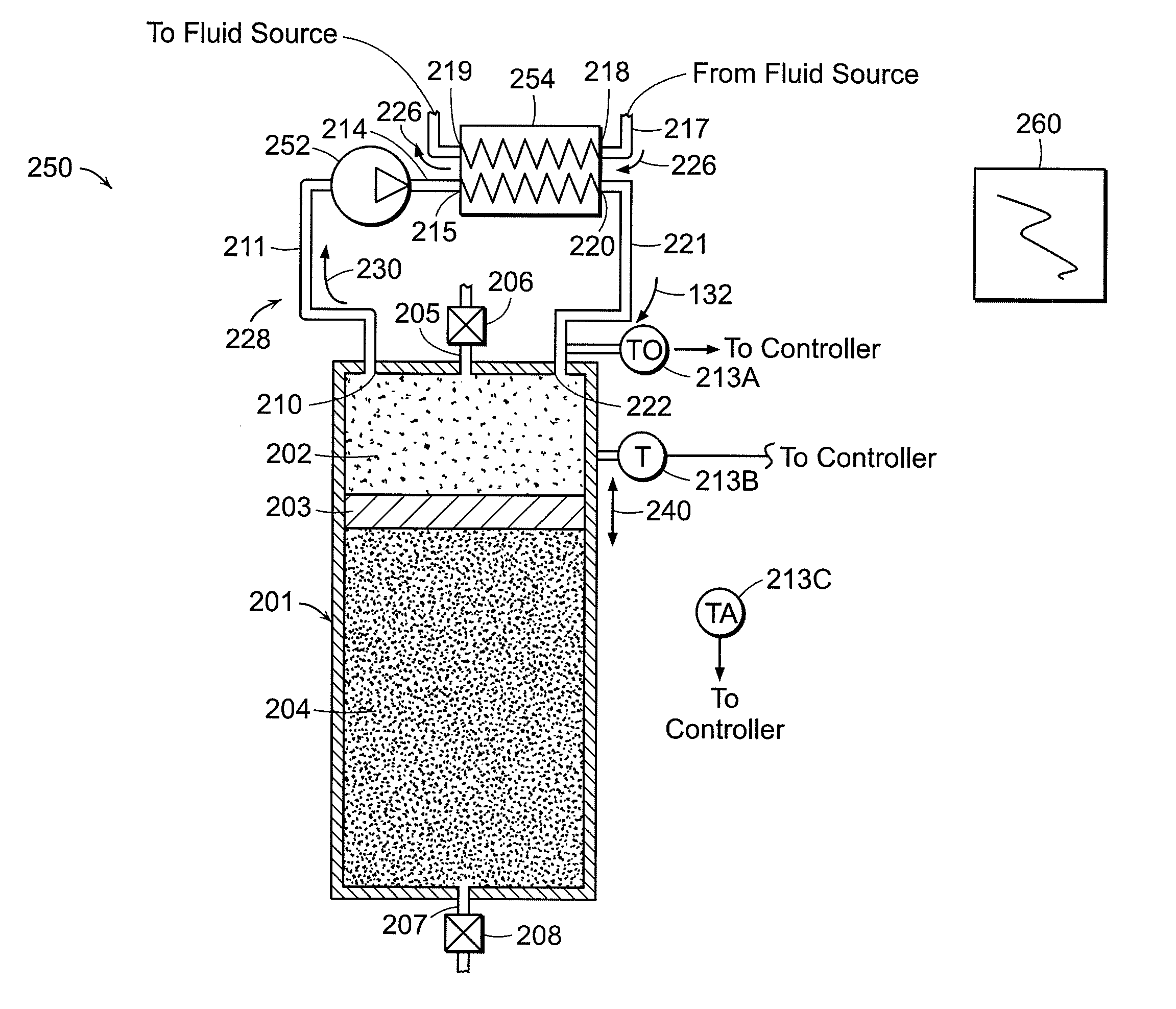

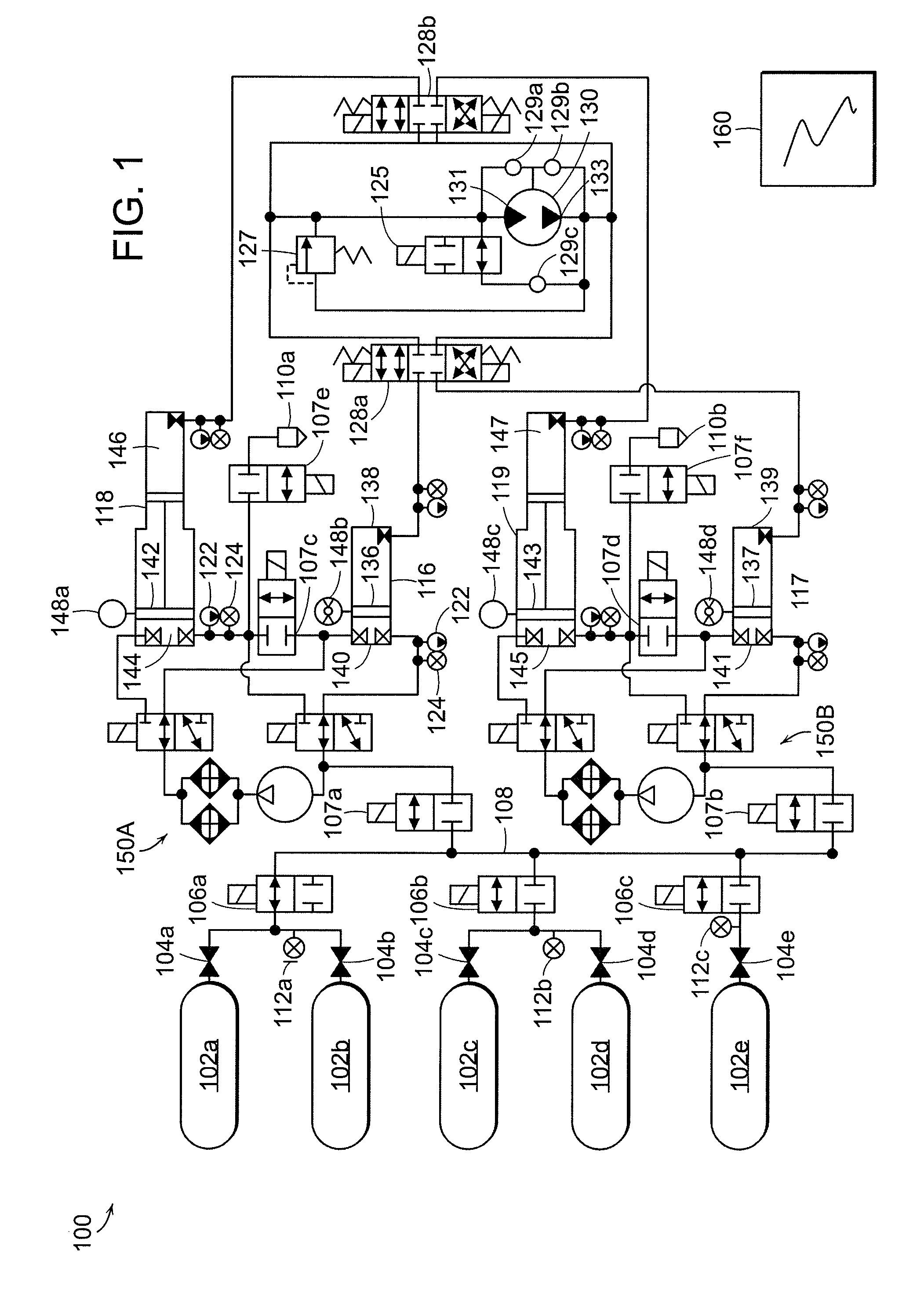

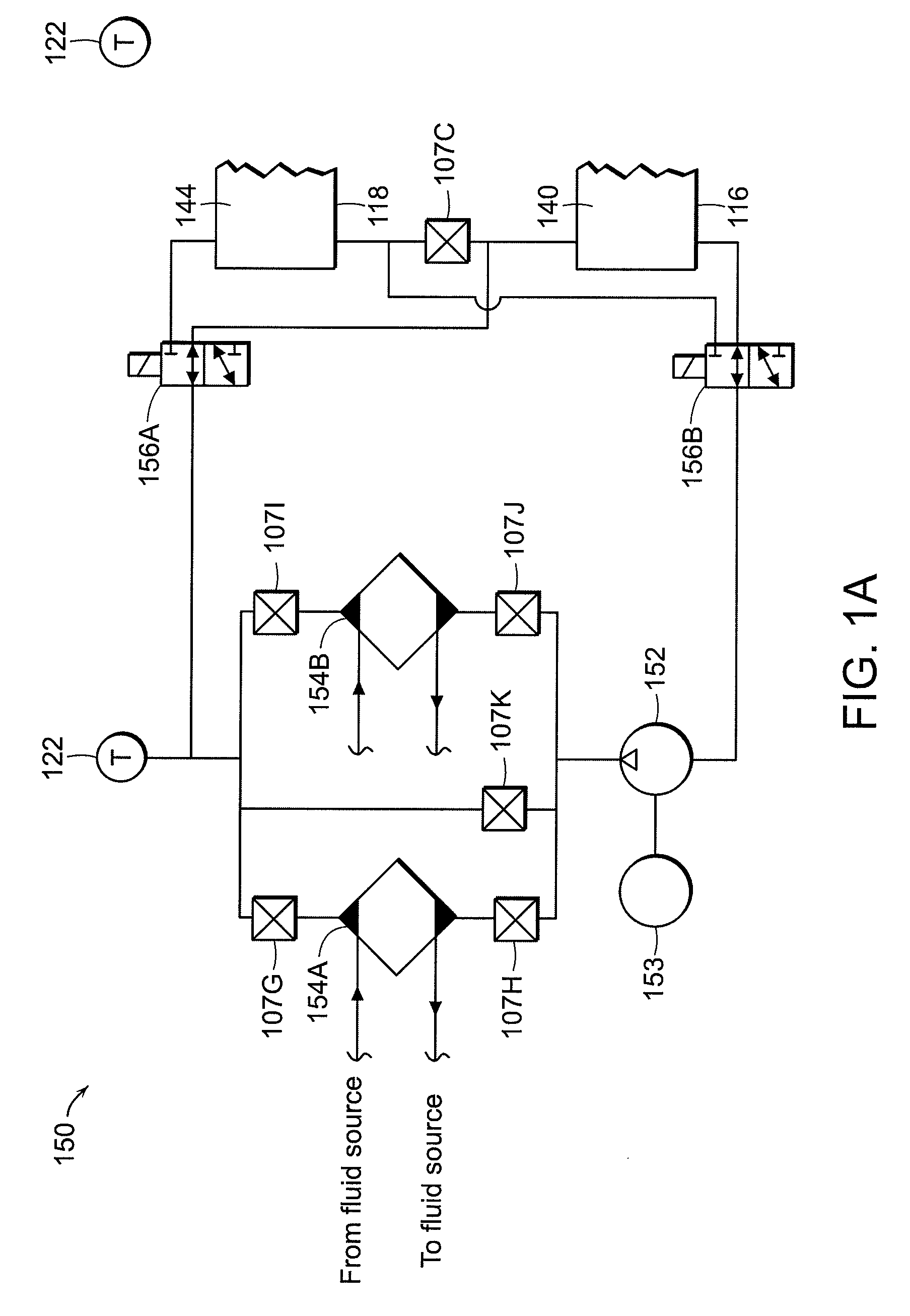

System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage

InactiveUS20090301089A1Overcome disadvantagesInhibit migrationElectrical storage systemFluid couplingsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

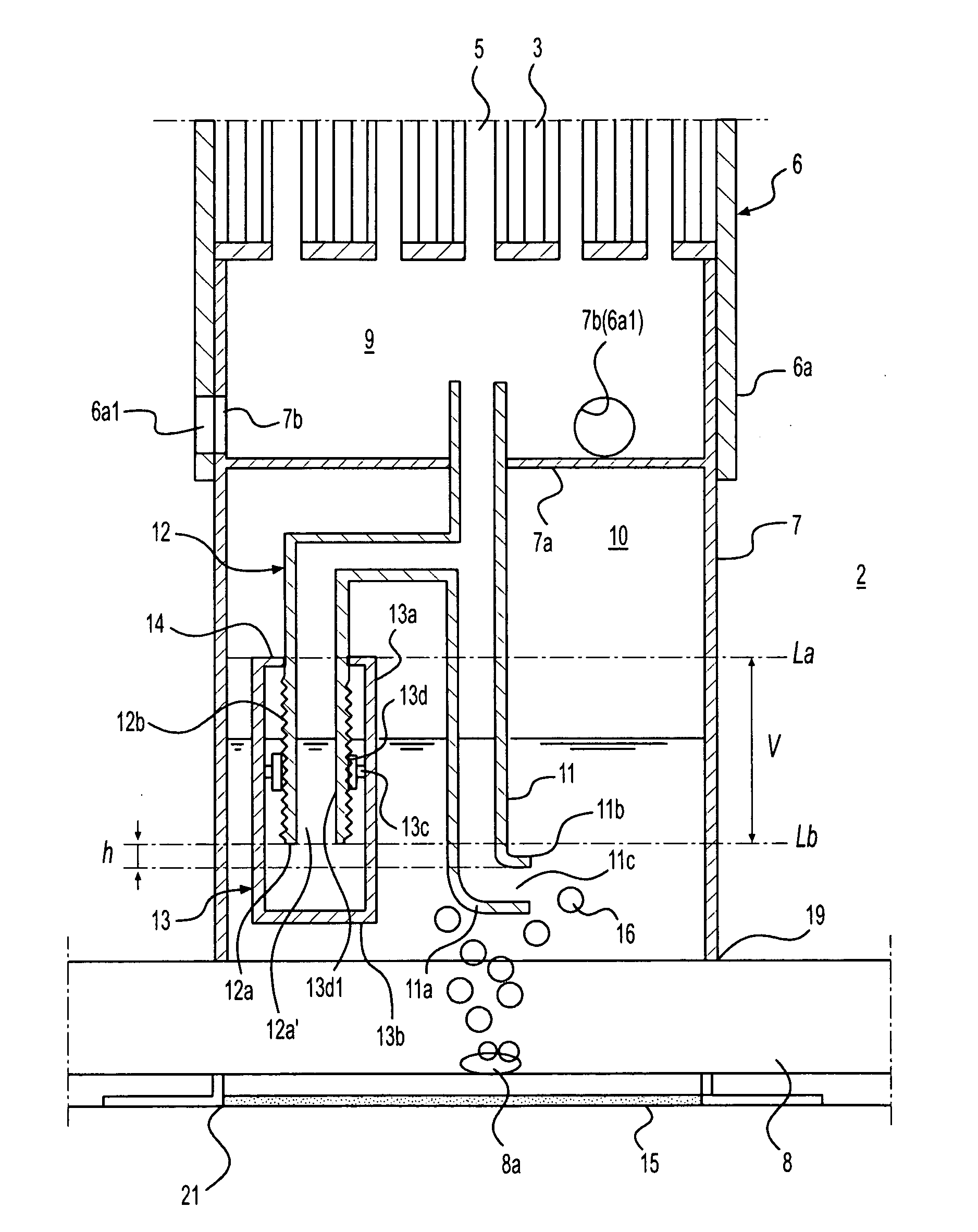

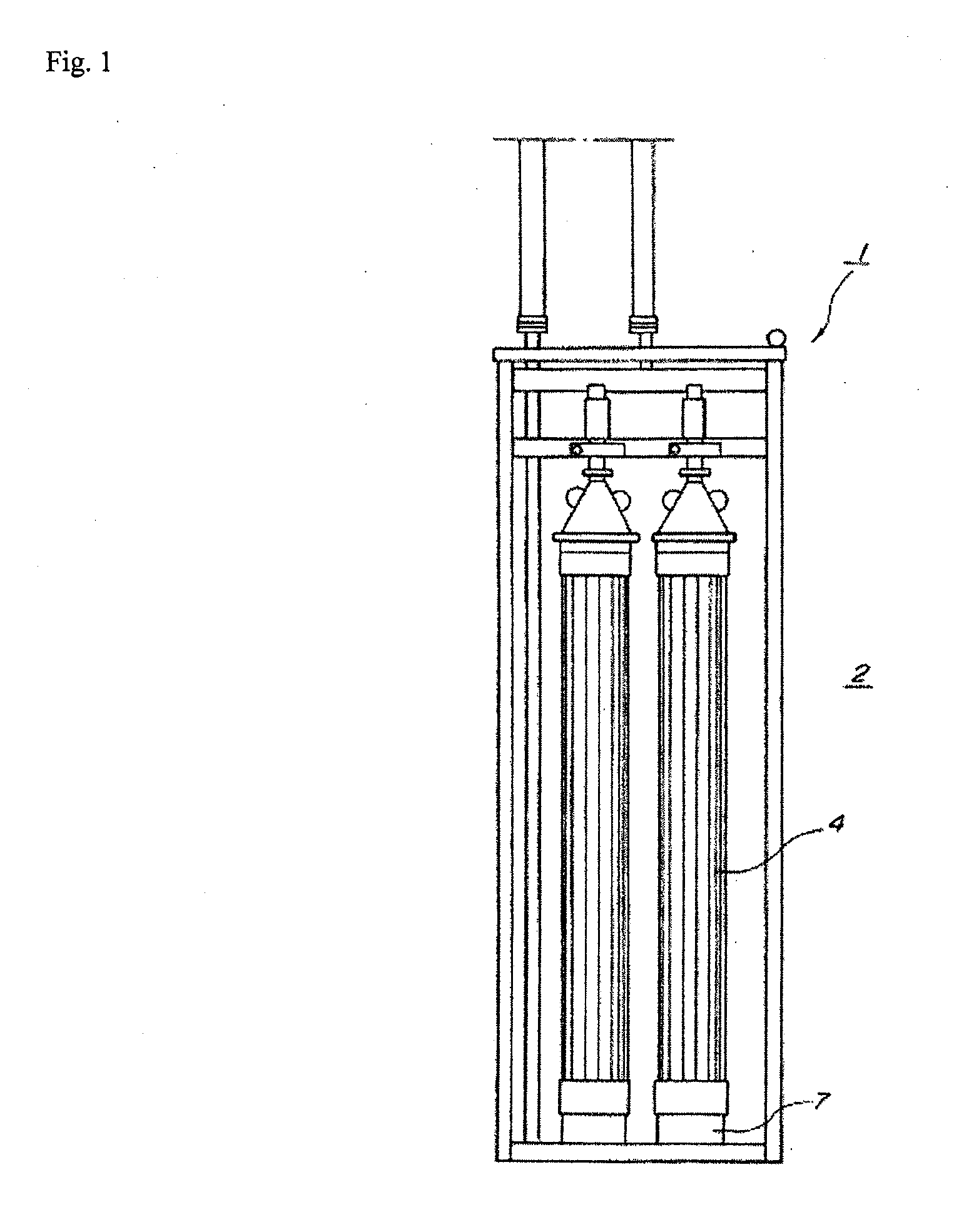

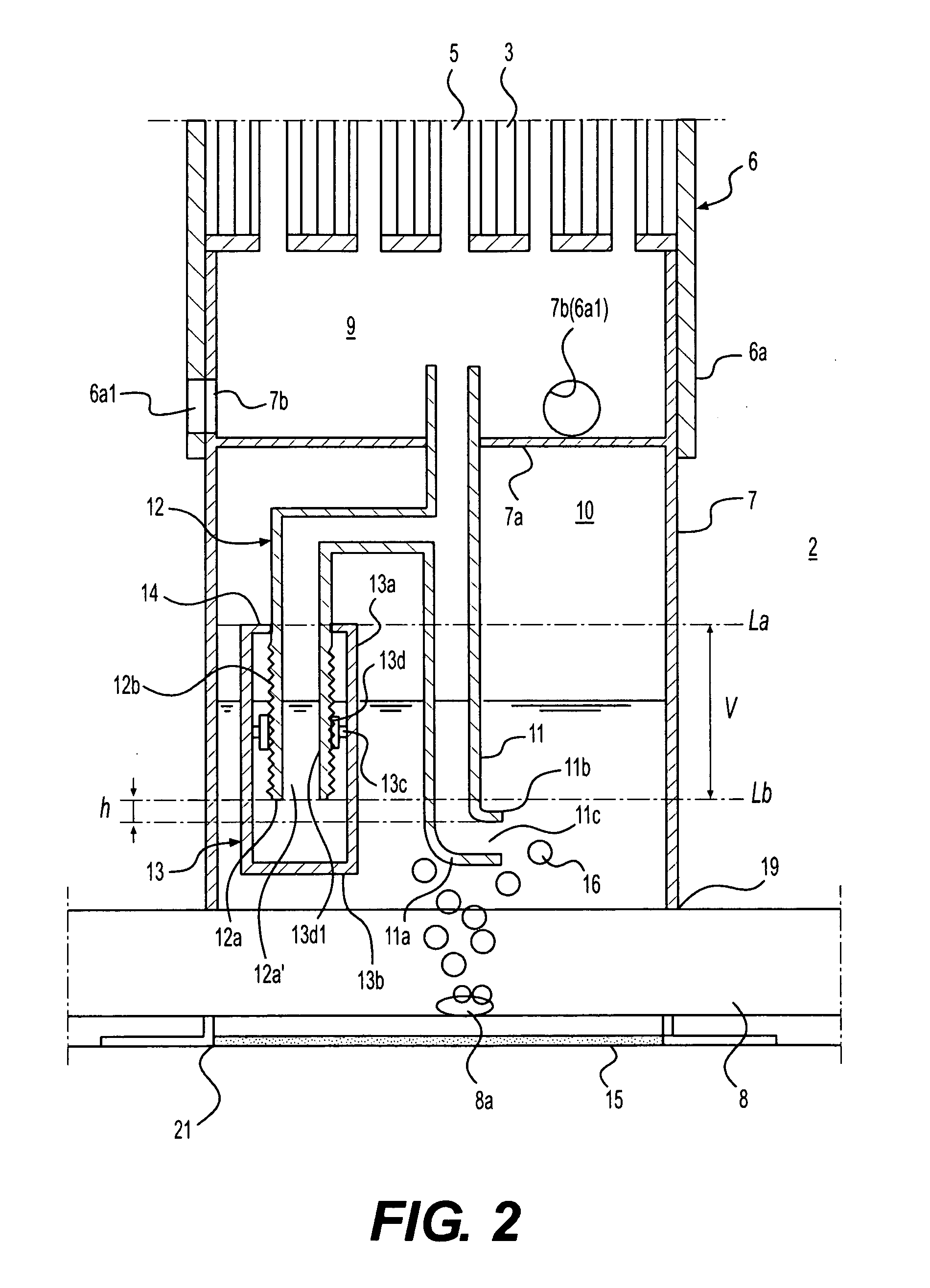

Intermittent gas flow apparatus and membrane separation apparatus

InactiveUS20090194477A1Easy constructionProlong lifeMembranesSpecific water treatment objectivesEngineeringGas chamber

Intermittent gas flow and membrane separation apparatus and methods of use including an internal gas chamber including an upper wall; at least one inlet for supplying gas to the internal gas chamber; a column pipe that extends above the upper wall of the internal gas chamber, the column pipe including a lower end portion including a lower end portion opening in the internal gas chamber, the column pipe linking the internal gas chamber to an area external to the internal gas chamber for fluid flow between the internal gas chamber and the external area; an auxiliary pipe including one end portion connected to the column pipe for fluid flow between the auxiliary pipe and the column pipe, and another end portion branched off from the column pipe, the another end portion including an opening located in the internal gas chamber at a position higher than the lower end portion opening of the column pipe by a predetermined height; and an auxiliary pipe external tubular member including a closed end, the auxiliary pipe external tubular member surrounding the another end portion of the auxiliary pipe with the closed end being positioned below the opening in the another end portion of the auxiliary pipe, and spaced from the another end portion by a predetermined distance permitting fluid flow into the space between the wall of the tubular member and the auxiliary pipe.

Owner:ASAHI KASEI CHEM CORP

System and method for rapid isothermal gas expansion and compression for energy storage

InactiveUS7802426B2Overcome disadvantagesInhibit migrationElectrical storage systemServomotorsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

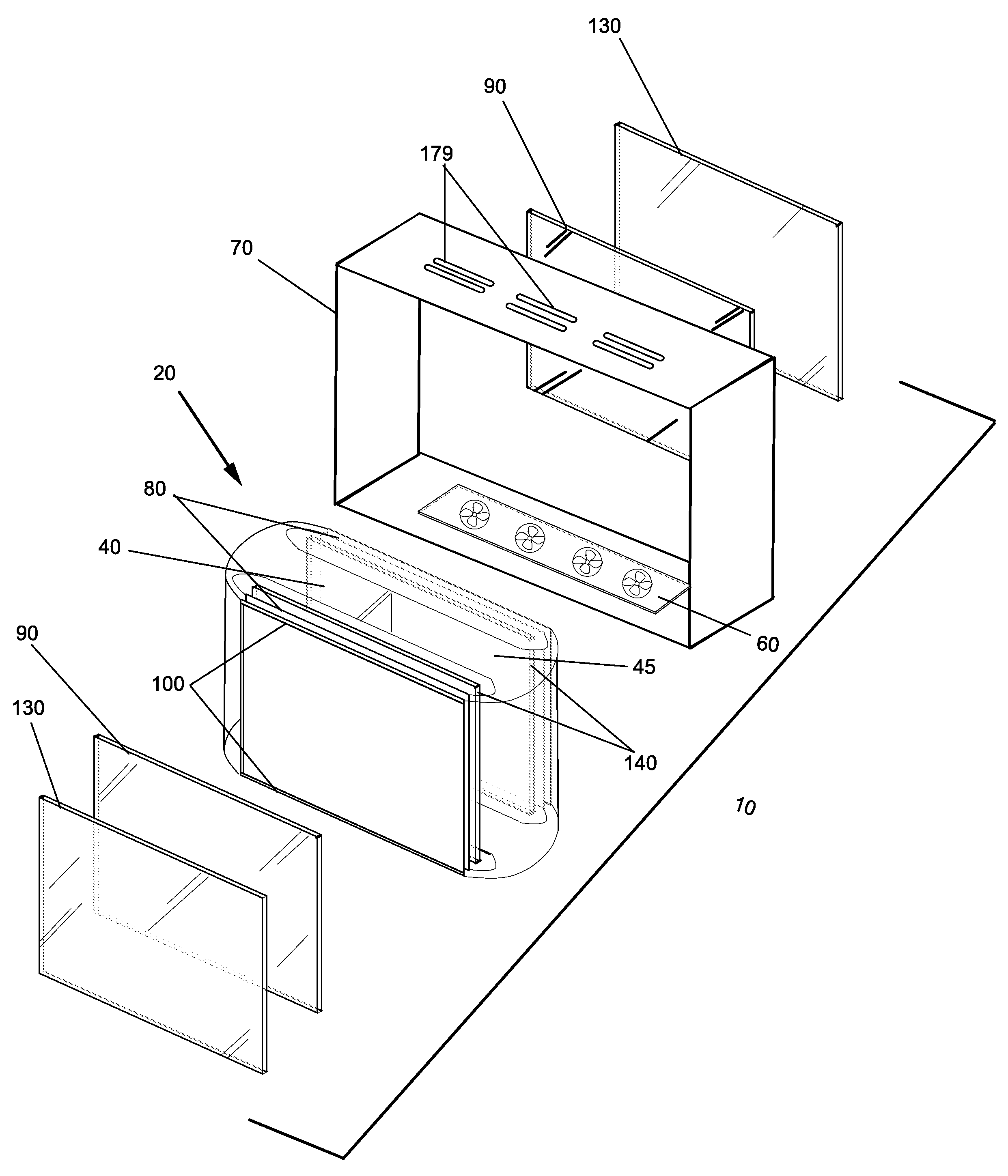

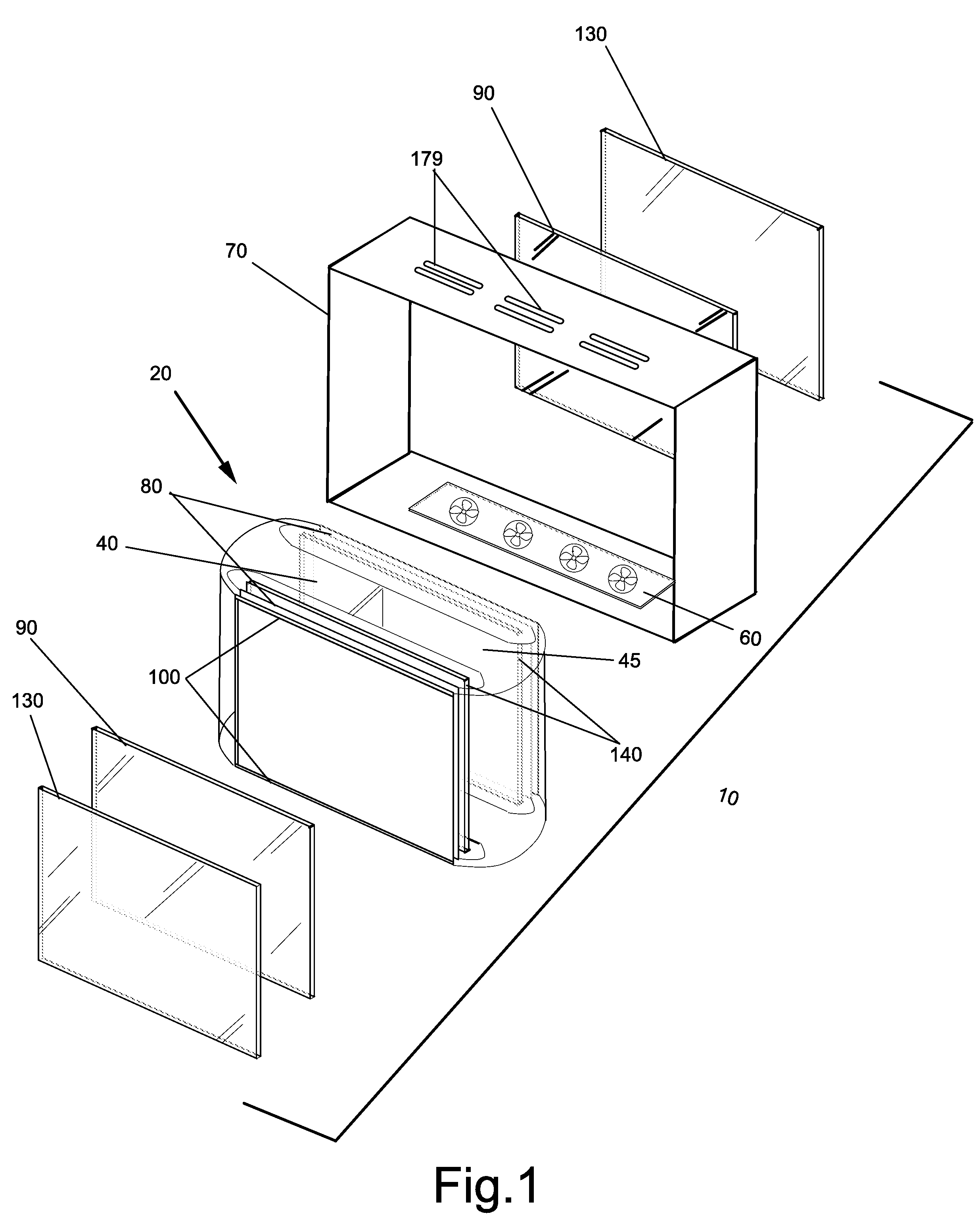

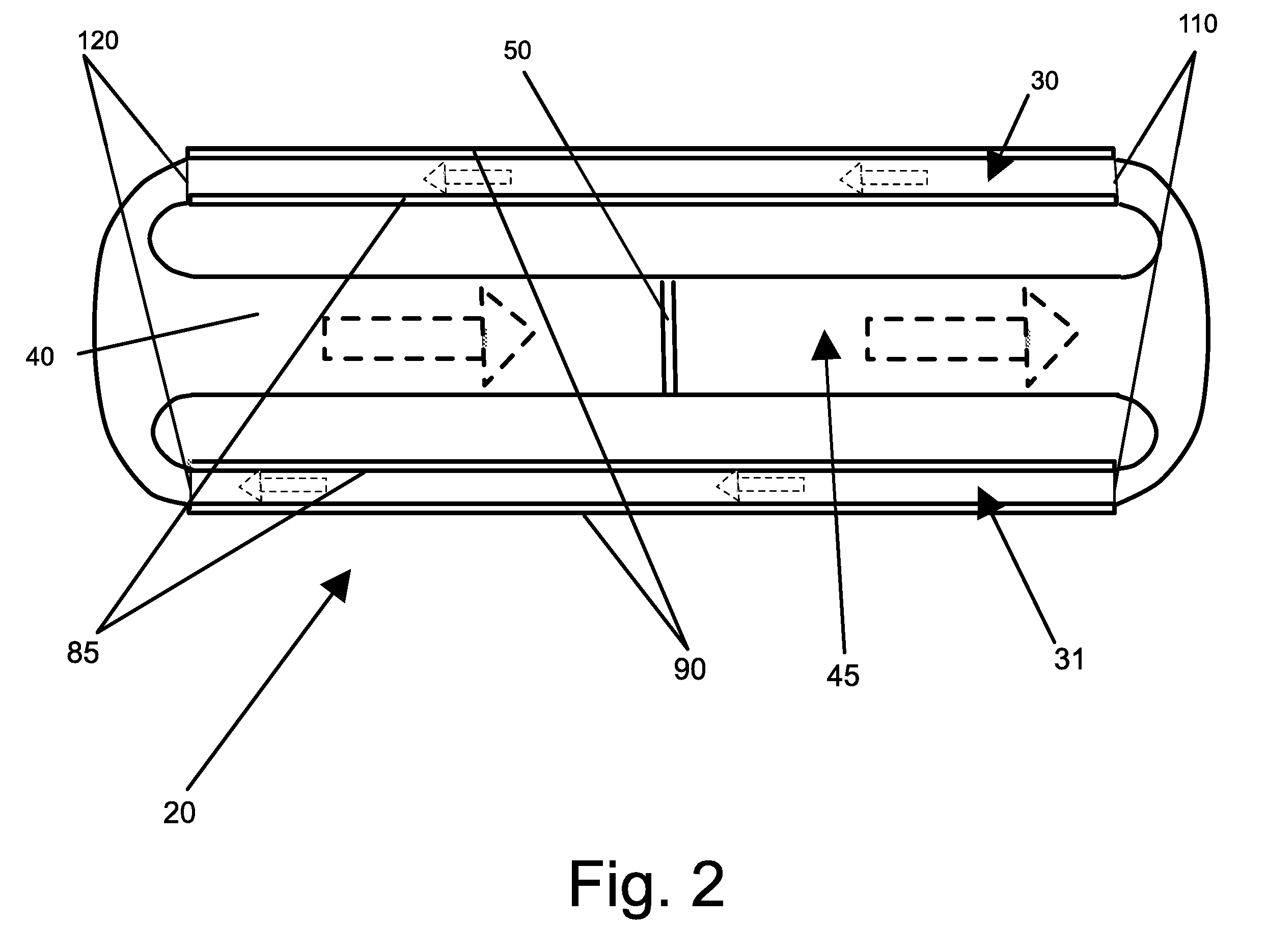

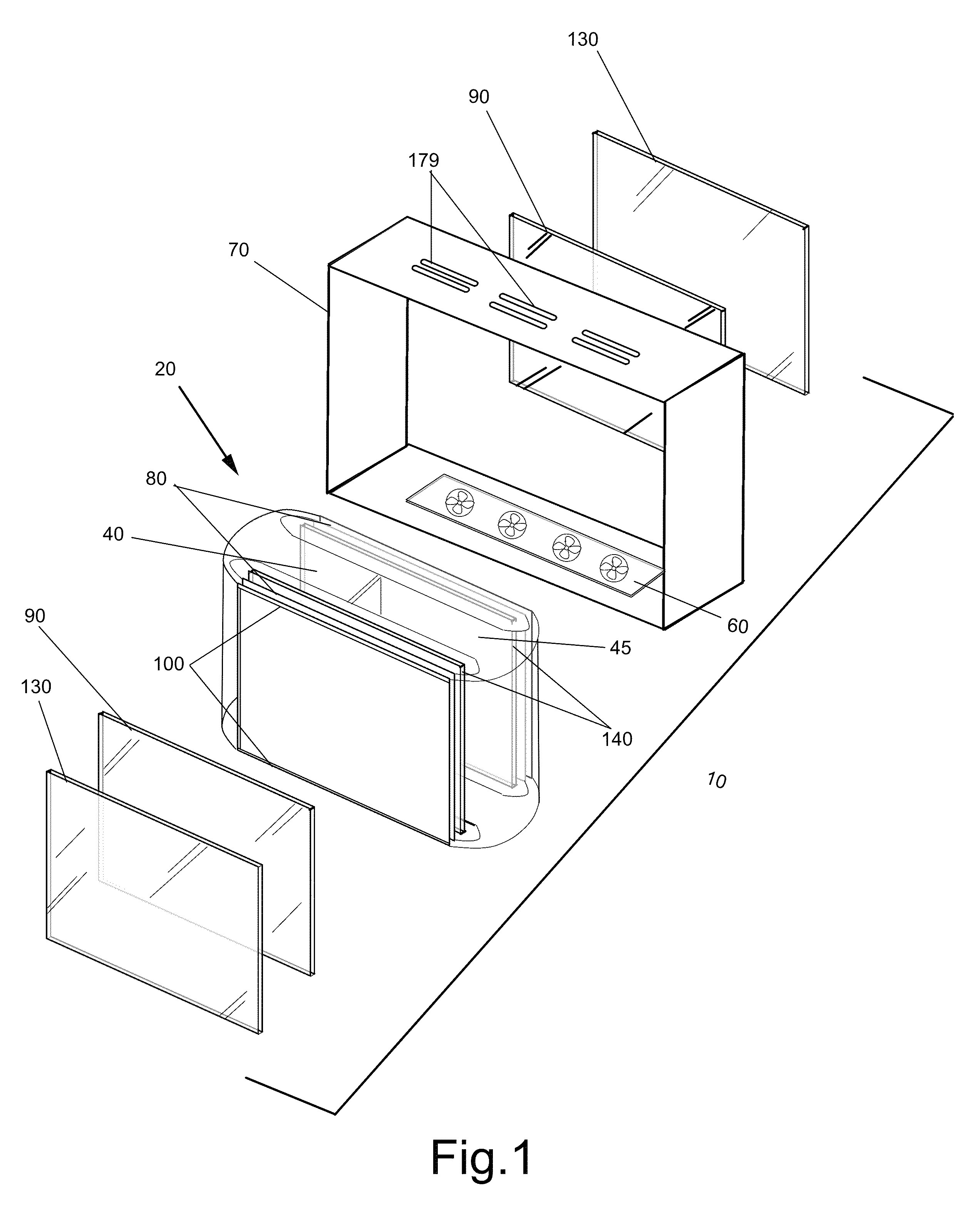

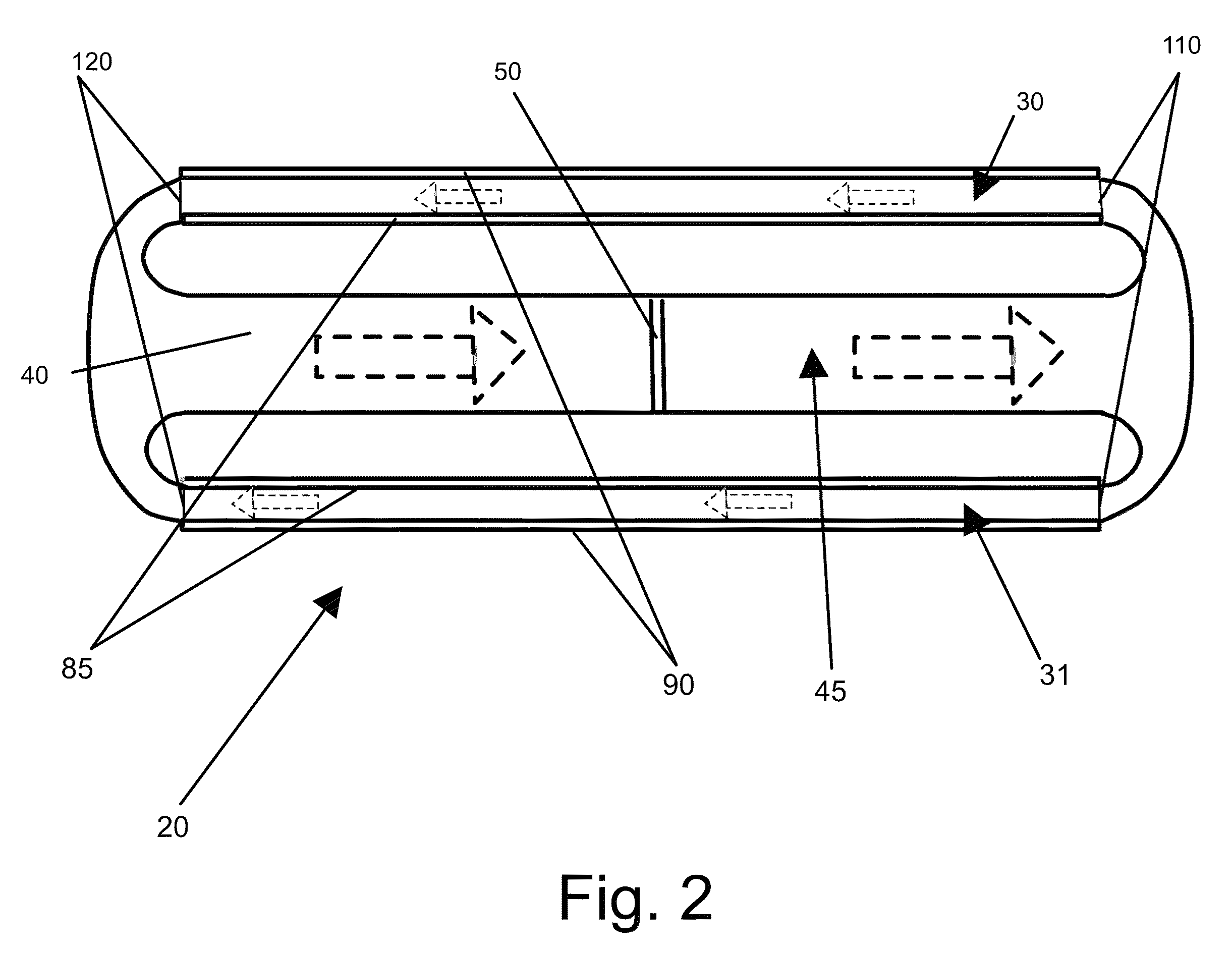

Shared Isolated Gas Cooling System for Oppositely Facing Electronic Displays

ActiveUS20100226091A1Increase heat productionBrighter backlightsSemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringImaging quality

A system and method for cooling back to back electronic displays. Transparent first and second gas chambers are co-existive with the front display surfaces of the first and second electronic displays. A closed loop of isolated gas enters the first and second gas chambers and contacts the front surfaces of the electronic displays, where it may extract heat from the front display surfaces. The isolated gas is then directed into a cooling chamber where it is cooled and re-introduced into the first and second gas chambers. Fans may be used to propel the isolated gas through the cooling chamber and the first and second gas chambers. The circulating gas removes heat directly from the electronic display surfaces. The isolated gas is transparent or at least semi-transparent to ensure that the image quality of the electronic displays is minimally impacted.

Owner:MFG RESOURCES INT INC

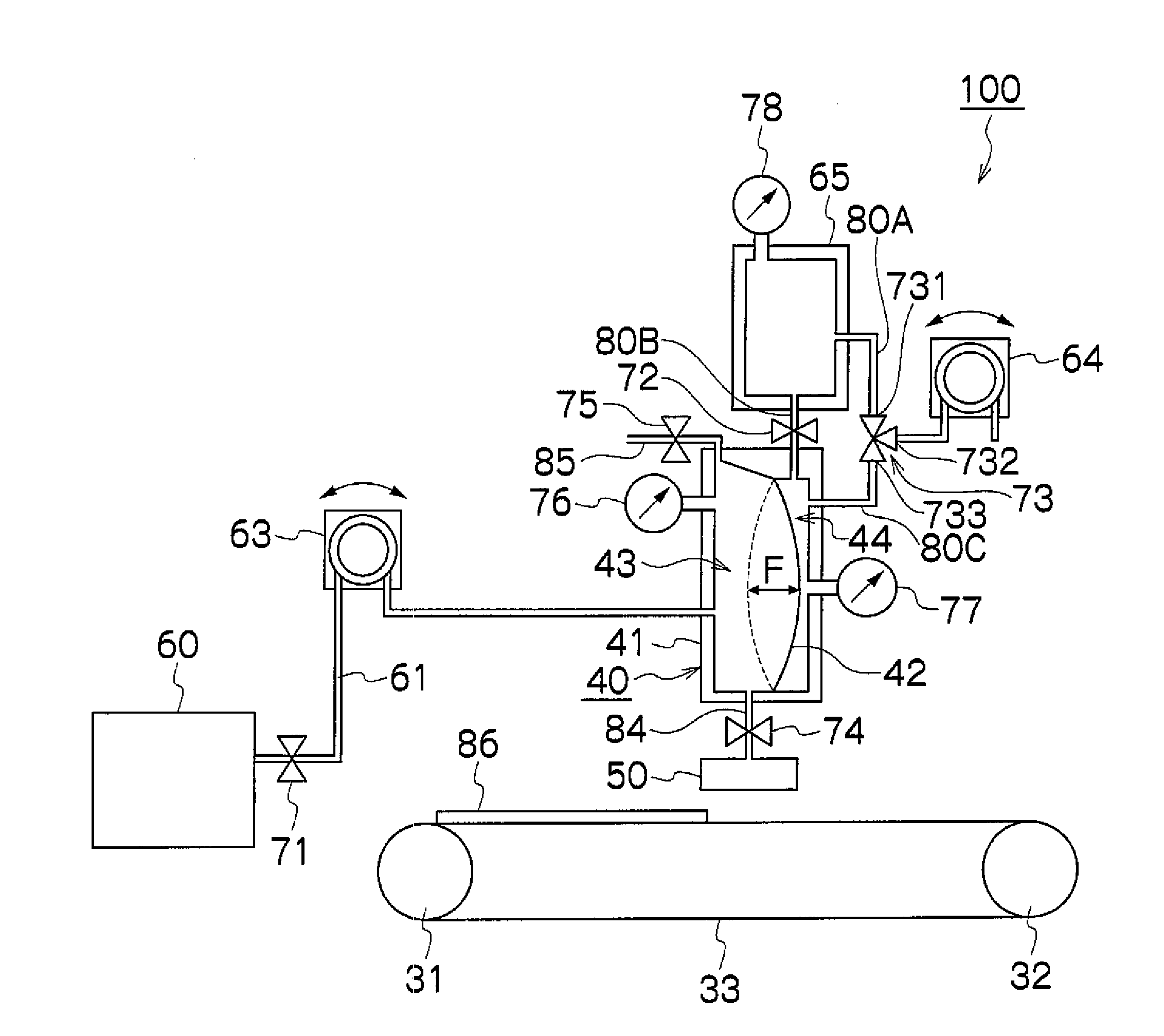

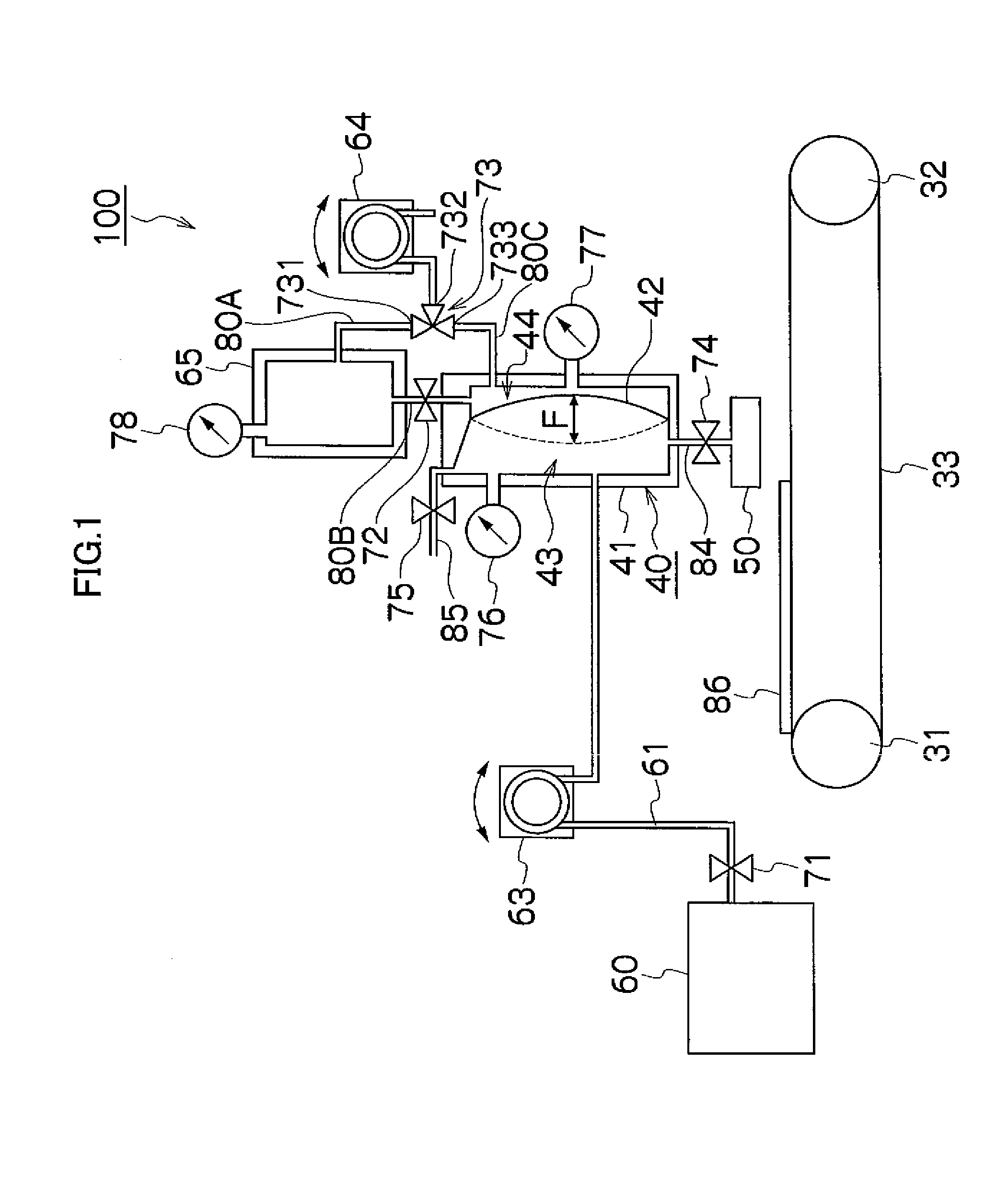

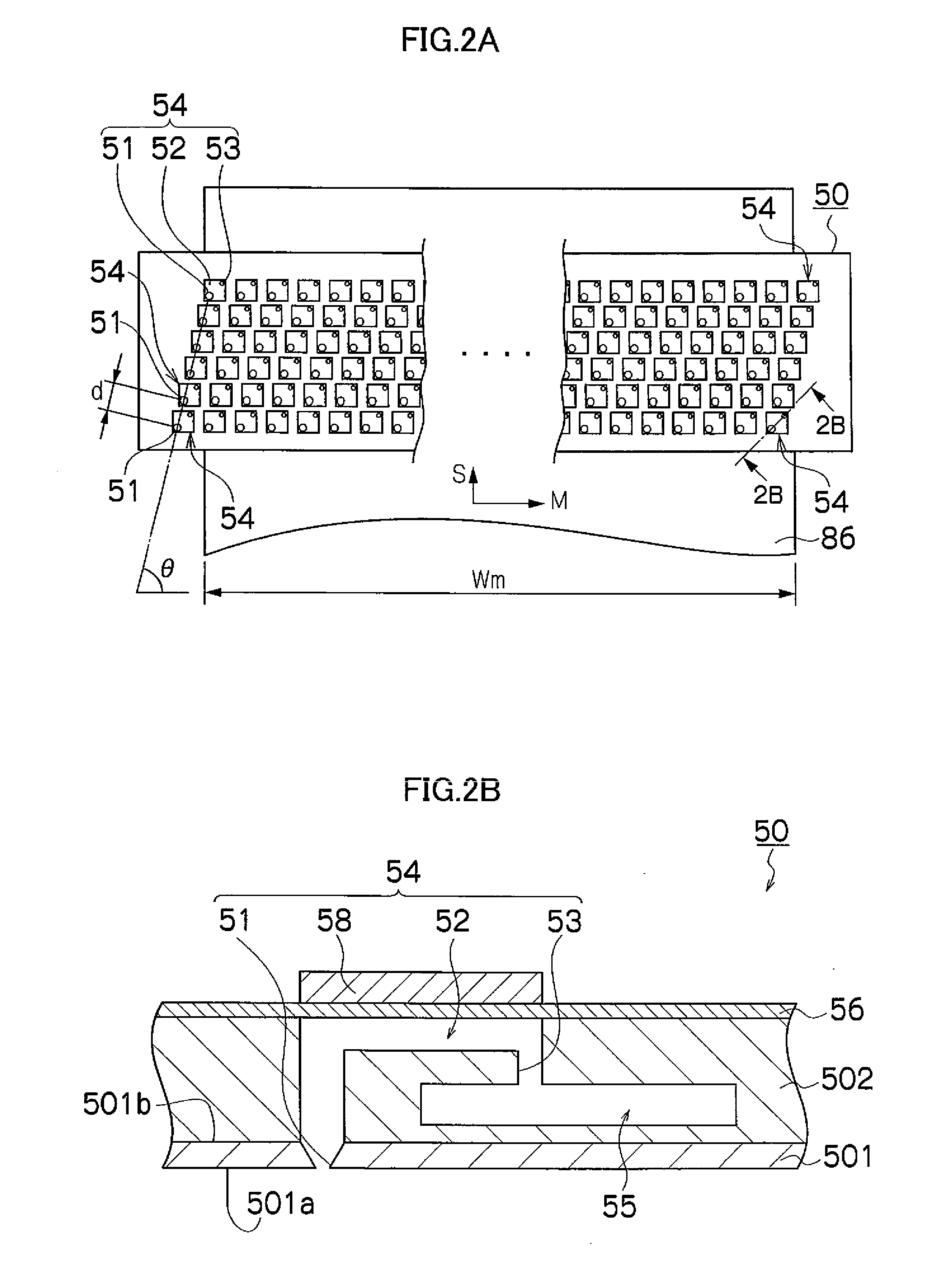

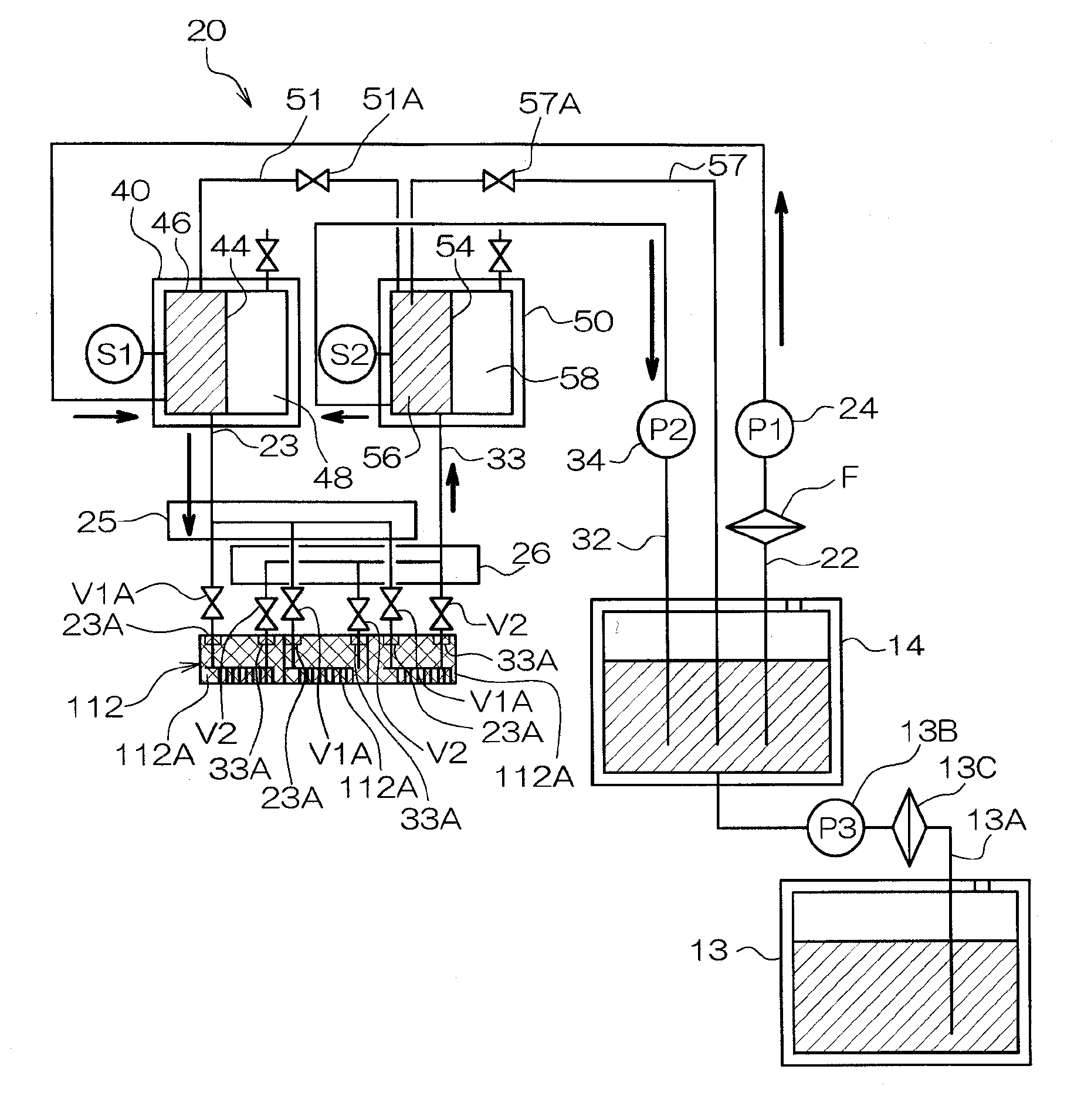

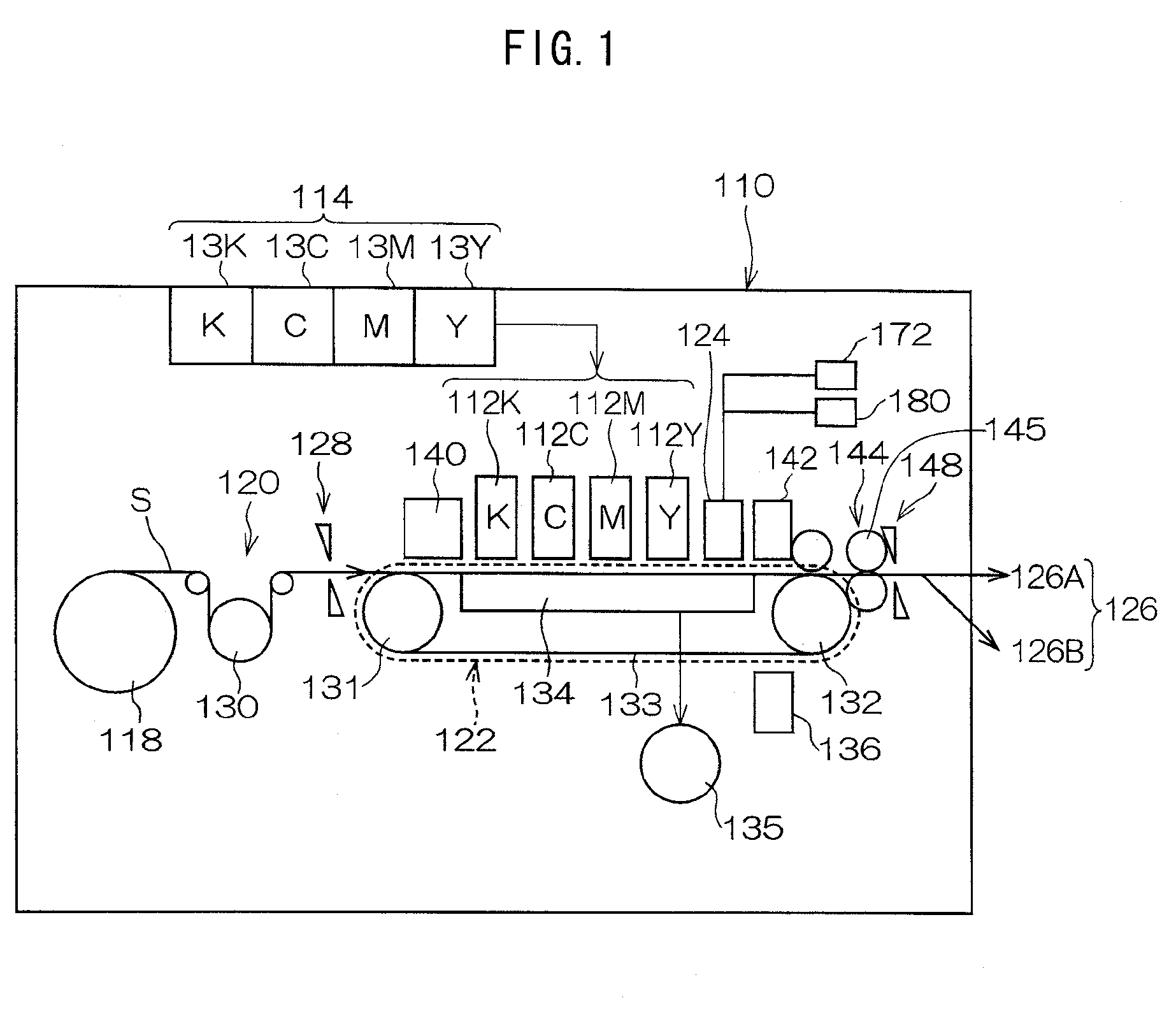

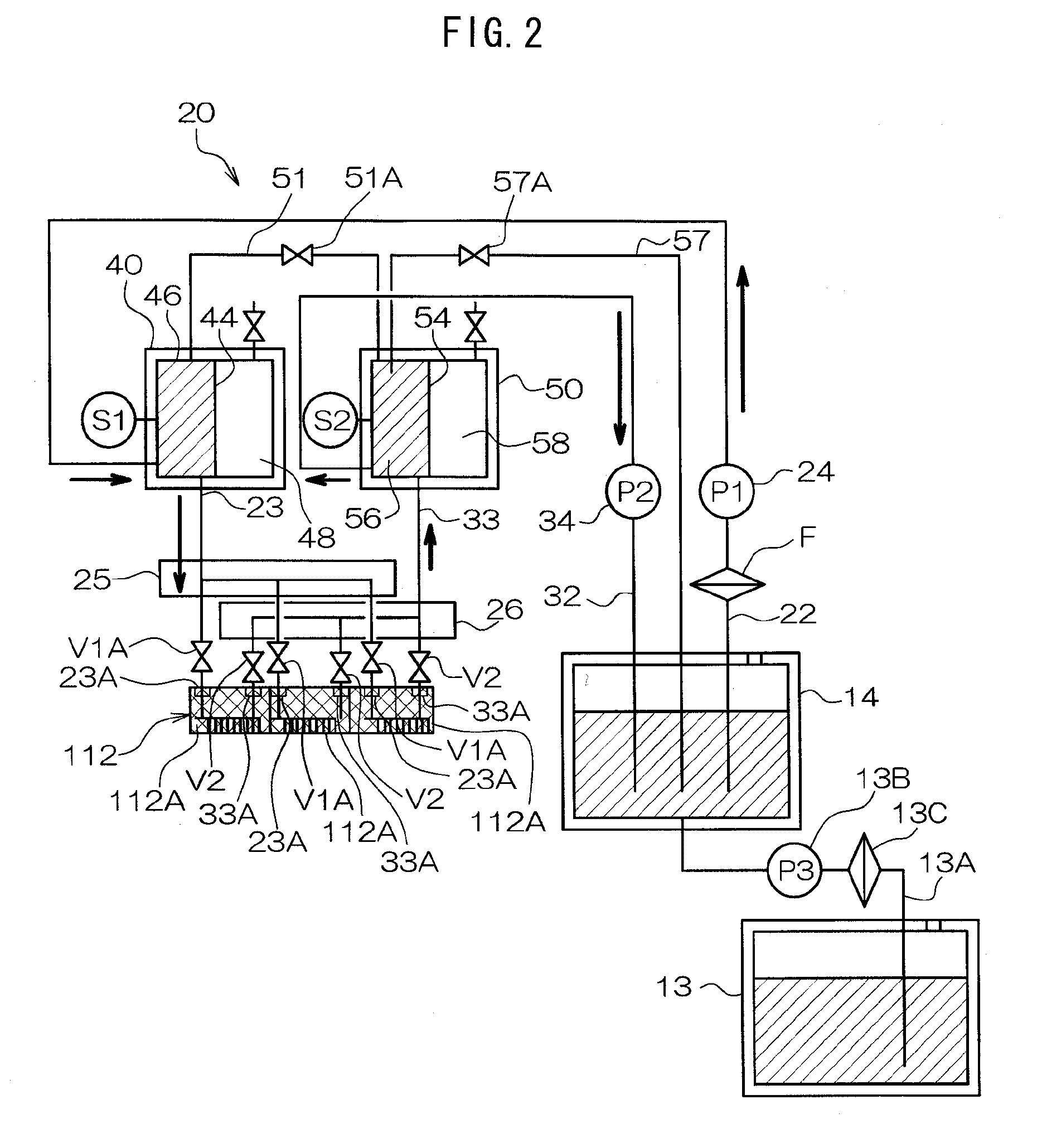

Pressure adjustment apparatus and image forming apparatus, and pressure adjustment method and liquid remaining amount determination method

InactiveUS20080198207A1Reduce flowShorten the timeOther printing apparatusHermetic sealImage formation

A pressure adjustment apparatus for adjusting a pressure of liquid inside a liquid ejection head including nozzles and flow channels includes: a tank; a pump; a buffer chamber; a first switching device; and a second switching device. The tank includes a movable film and a hermetically sealed container of a prescribed volume, the movable film dividing the hermetically sealed container into a gas chamber filled with gas and a liquid chamber filled with the liquid to be supplied to the liquid ejection head. The pump changes a pressure of the gas inside the gas chamber so as to adjust a pressure of the liquid inside the liquid chamber. The buffer chamber is filled with the gas and damps gas-flow pulsations caused by the pump. The first switching device connects and disconnects the buffer chamber and the gas chamber. The second switching device switches between a state where the pump is connected to the gas chamber without through the buffer chamber, and a state where the pump is connected to the buffer chamber.

Owner:FUJIFILM CORP

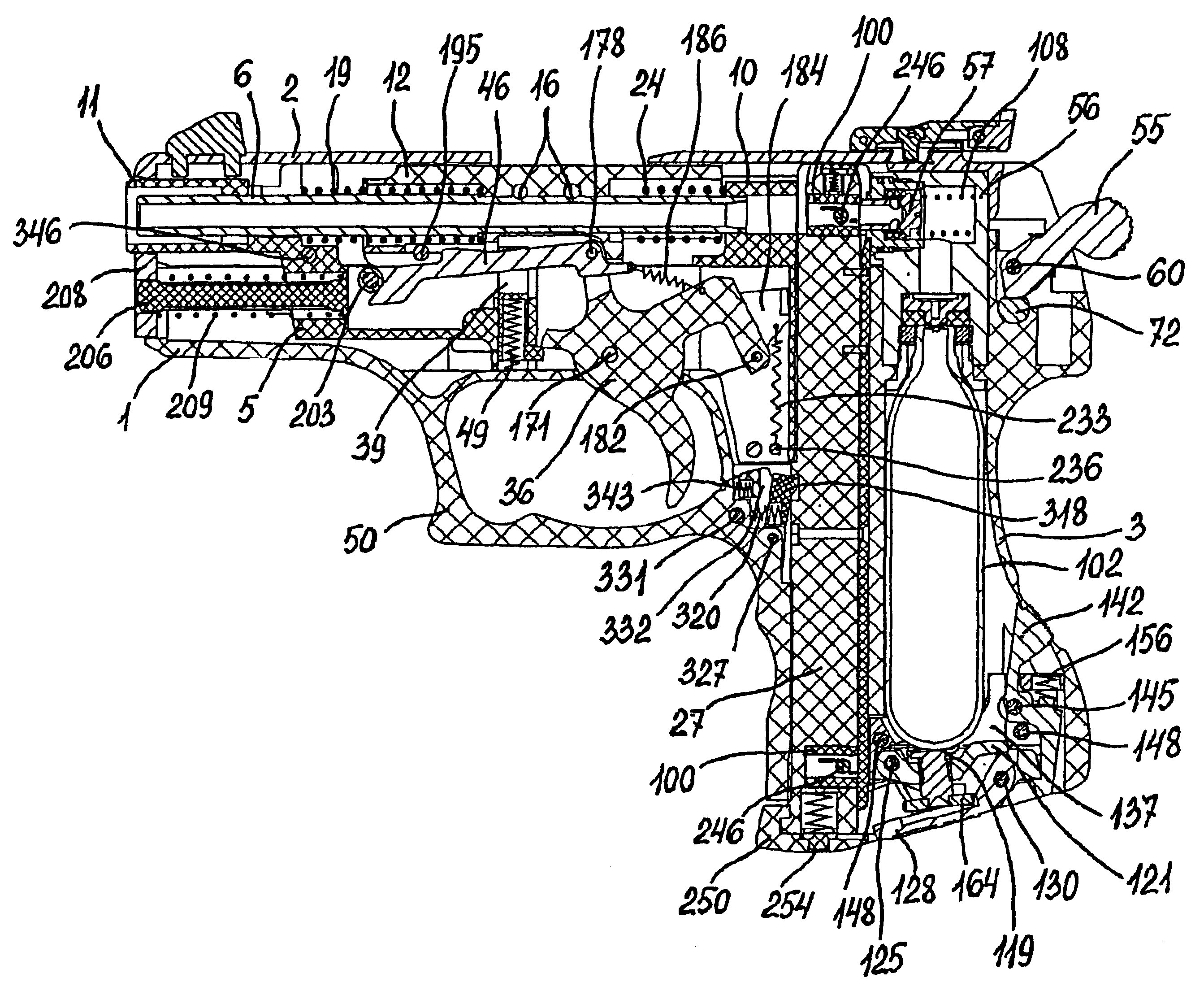

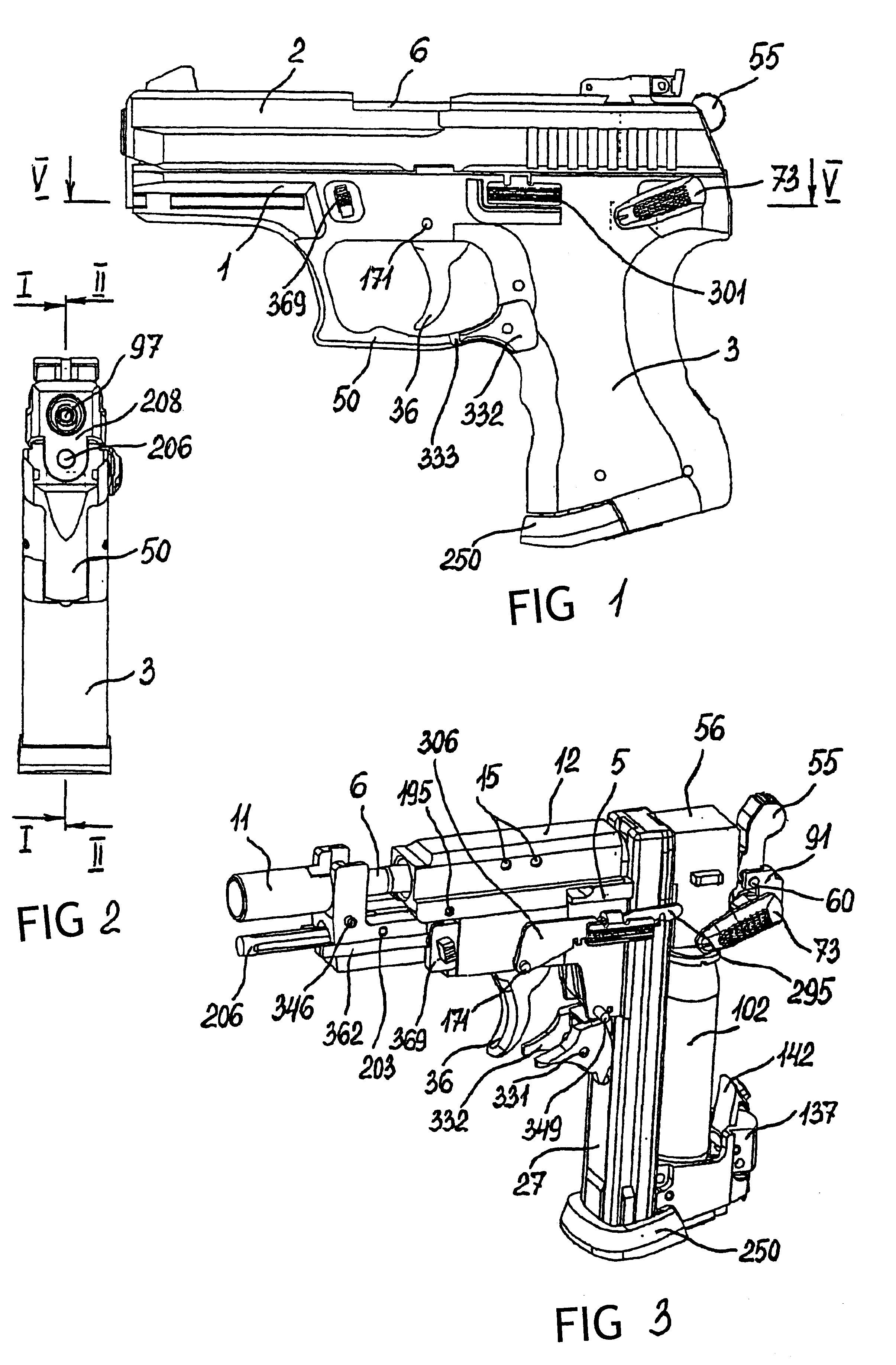

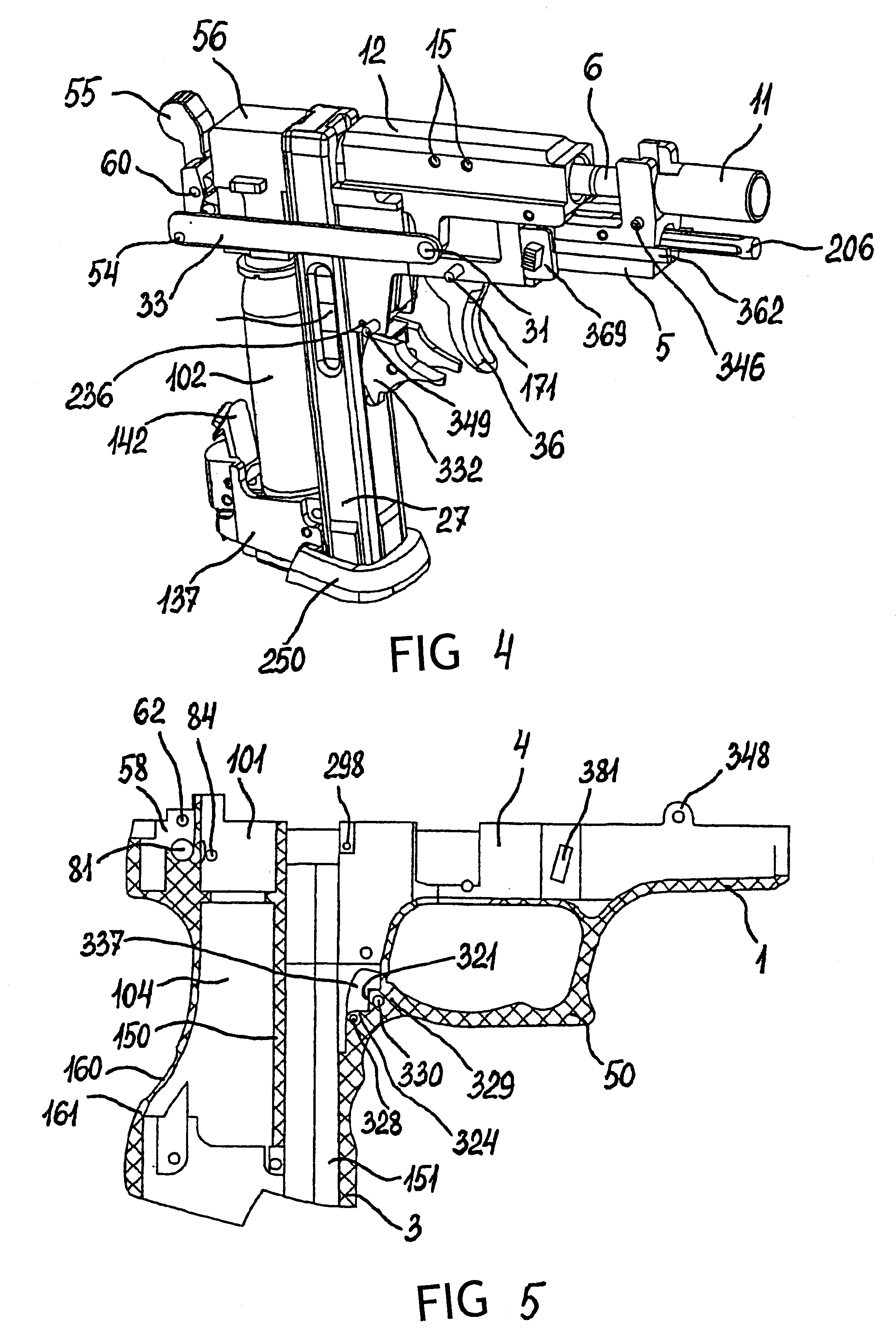

Multi-charge gas-cylinder pistol

InactiveUS6494194B2Improve reliabilityHigh performance featuresFiring/trigger mechanismsAmmunition loadingGas cylinderMainspring

Owner:ZAKRYTOE AKTSIONERNOE OBSHCHESTVO GRP ANICS

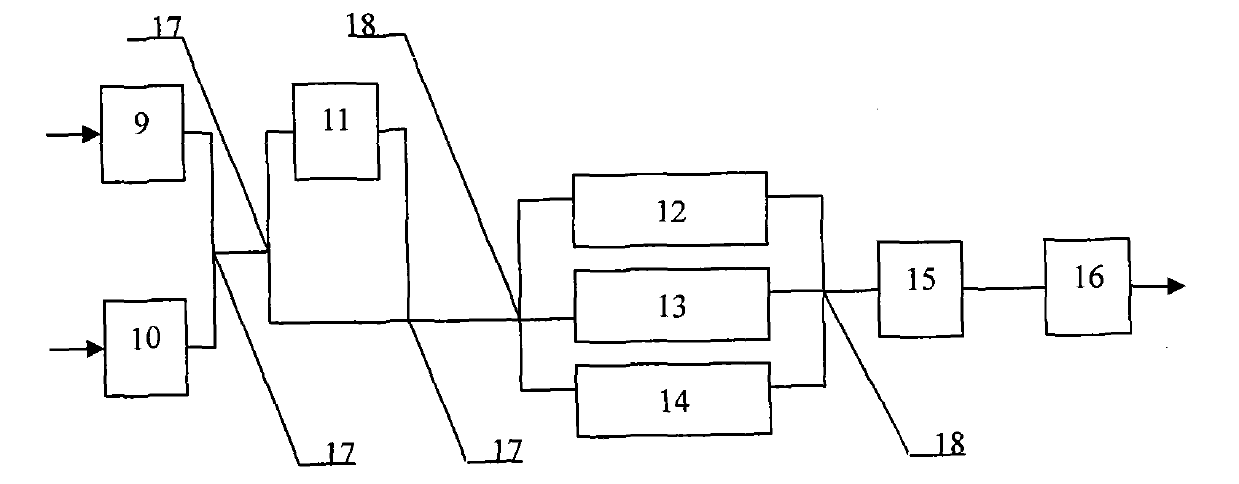

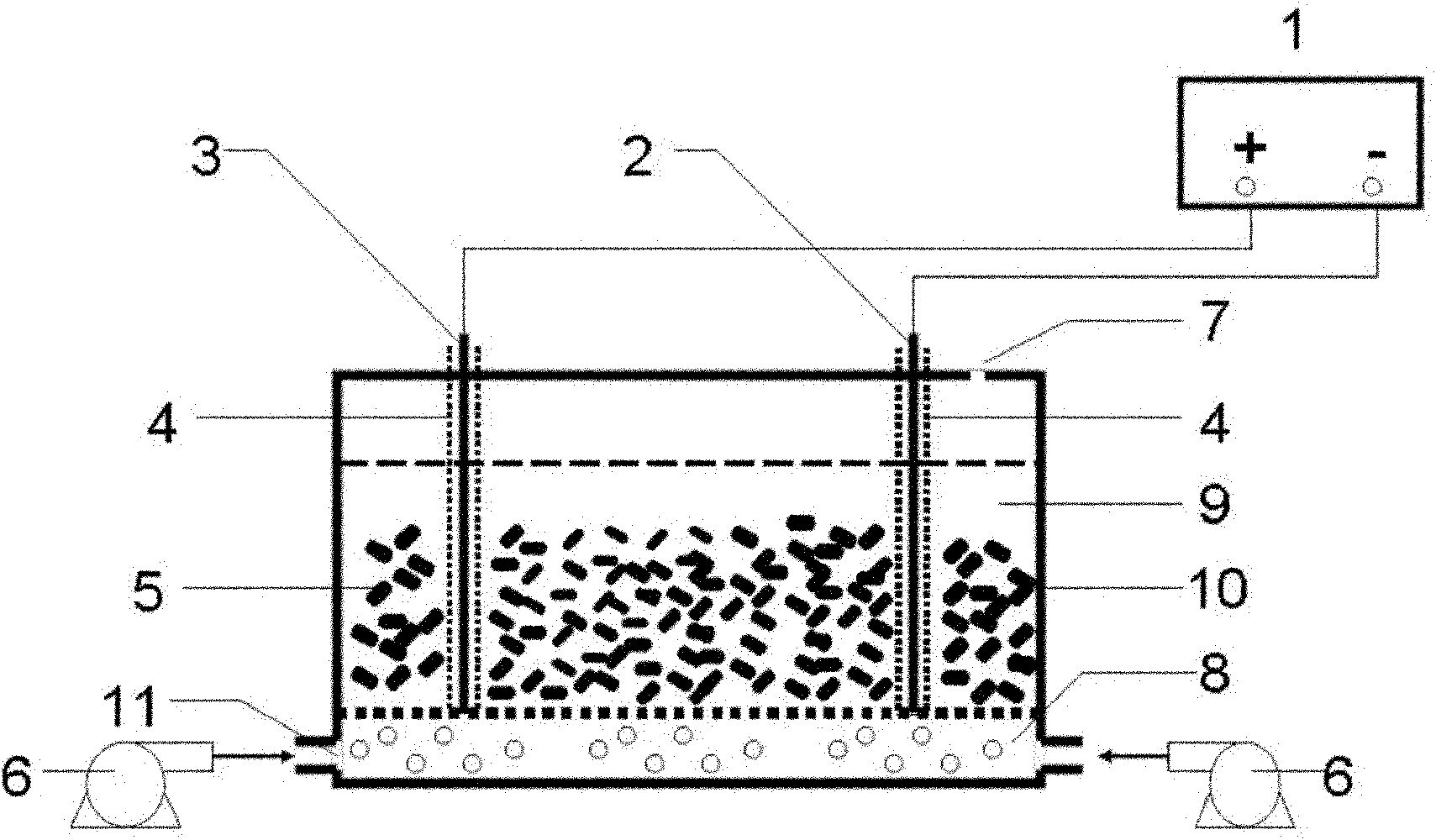

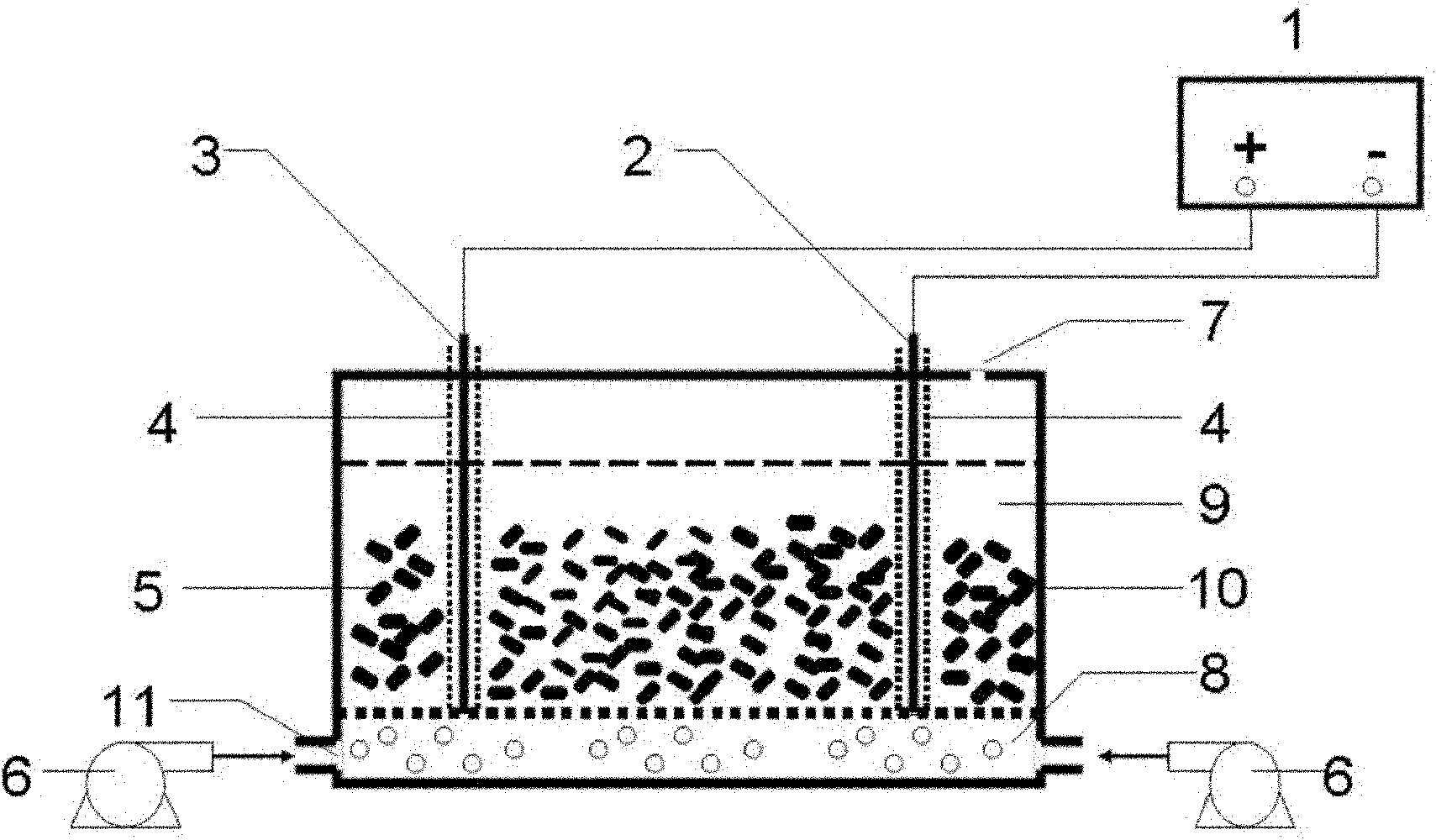

Method for removing organic matters in water by utilizing three-dimensional electrode electro-fenton and device thereof

InactiveCN102070230AIncrease contact areaExtension of timeWater/sewage treatment by oxidationFenton reagentFixed bed

The invention relates to a method for carrying out oxidation treatment on organic waste water by utilizing a three-dimensional electrode electro-fenton and a device thereof. The device comprises a reactor shell, a carbon material cathode, an iron plate anode, a three-dimensional particle electrode of a fixed bed, a direct-current voltage-stabilizing power supply, a microporous aeration plate and an air pump, wherein a reactor consists of a reaction chamber and a gas chamber; the carbon material cathode, the iron plate anode and the particle electrode are positioned in the reaction chamber at the upper part of the reactor; and the gas chamber is formed between the bottom of the reactor and the microporous aeration plate. After direct current is introduced, the iron anode is oxidized to generate iron ions, oxygen in the gas chamber is reduced on the surface of the cathode to generate hydrogen peroxide, and the iron ions and the hydrogen peroxide form a fenton reagent to oxidize and remove organic matters in waste water; and simultaneously, due to the particle electrode, the contact area and the contact time of the waste water and the fenton reagent are increased, and the mass transfer effect of the waste water in the reactor is reduced. The invention is applicable to treatment of various types of organic waste water, the equipment is compact, the operation is easy, the whole reactor is easy to control, and the requirements of an actual water treatment unit are met.

Owner:HUAZHONG NORMAL UNIV

Liquid droplet ejecting apparatus and method of controlling liquid droplet ejecting apparatus

Owner:FUJIFILM CORP

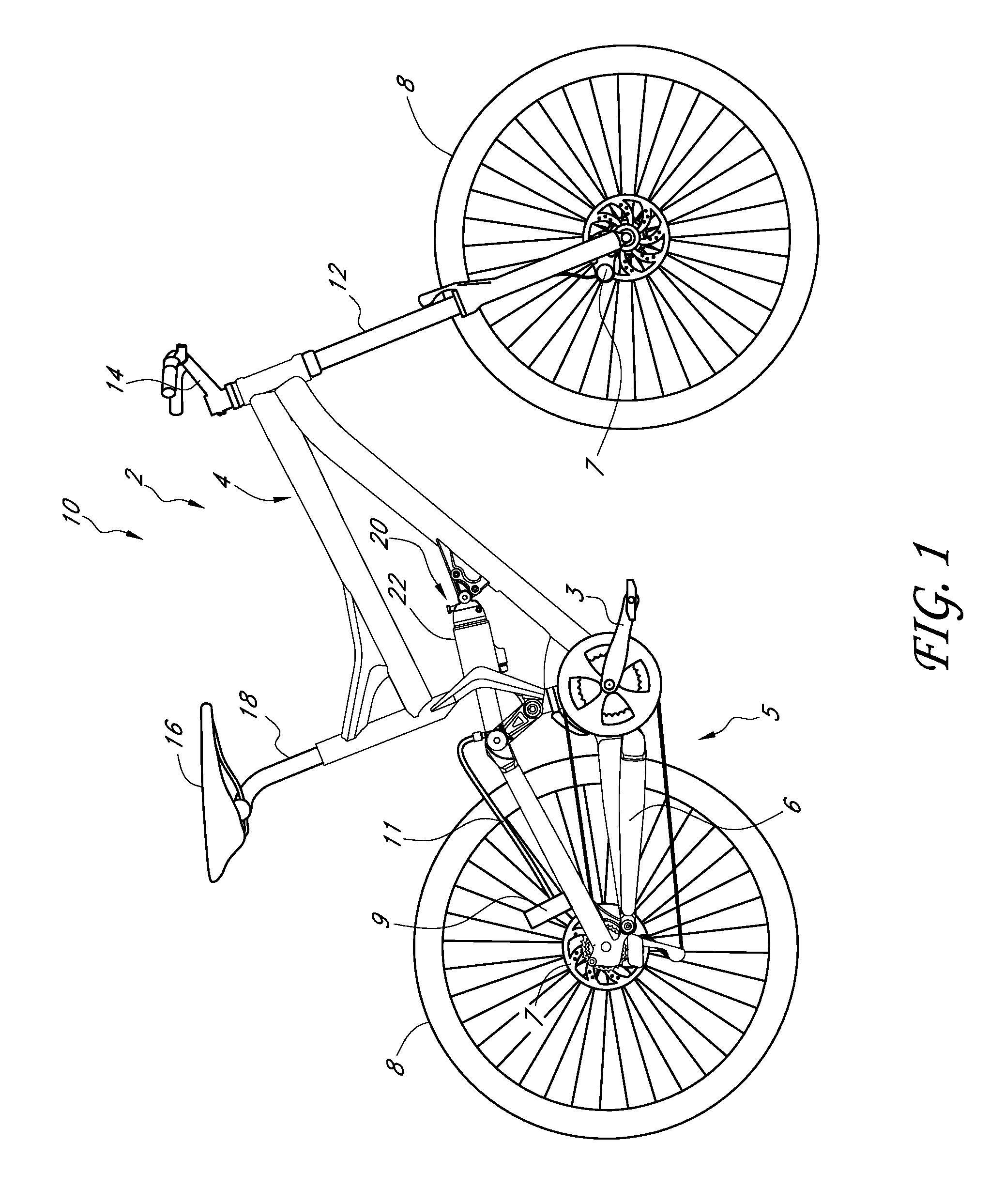

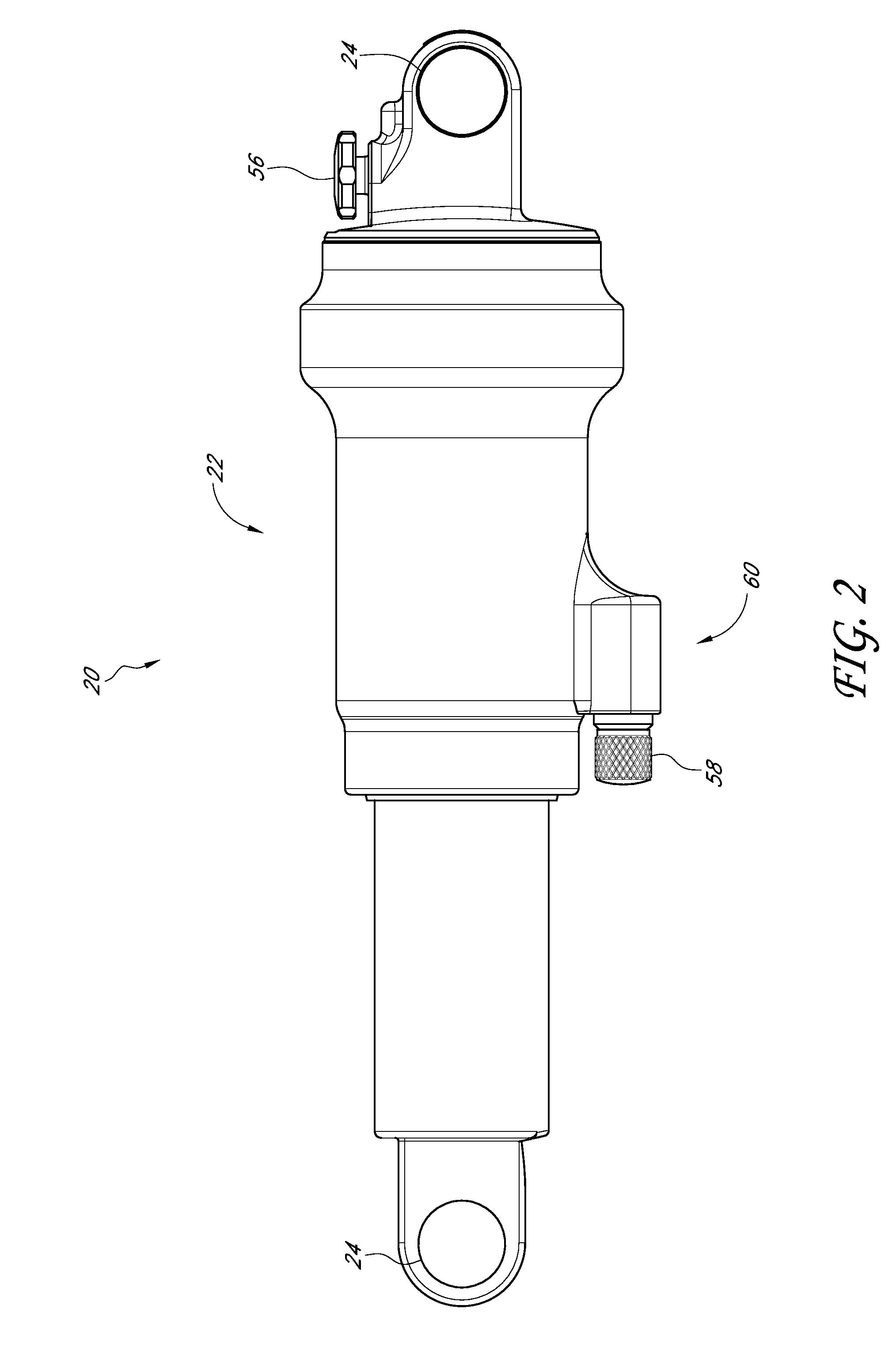

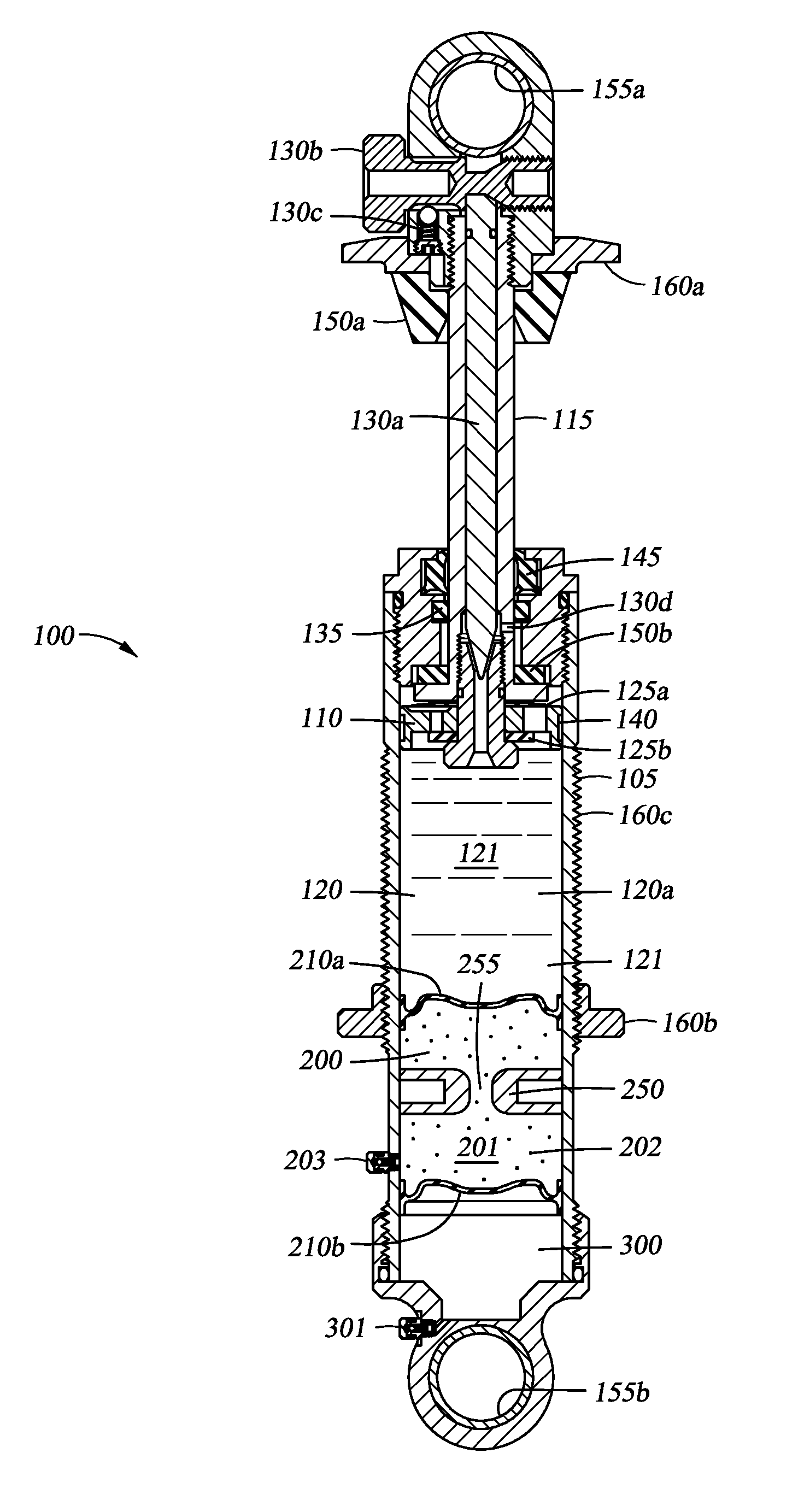

Bicycle with suspension

A bicycle can include a suspension system with a shock absorber. The shock absorber can have a sag position which can be adjustable. Sag refers to the amount of movement experienced by the suspension under a static load, such as that of the weight of a rider. Methods and systems to set sag can include at least one valve in fluid communication with a gas chamber of the shock absorber. In some embodiments, the at least one valve can be used to automatically set the sag position based on an individual's weight and riding position.

Owner:SPECIALIZED BICYCLE COMPONENTS INC

Methods and apparatus for controlling a fluid damper

A method and apparatus for a fluid damper comprising a first fluid-filled chamber, a second chamber filled with a fluid having variable flow characteristics and at least partially displaceable by the first fluid, and a gas chamber, the gas chamber compressible due to the displacement of the second chamber. In one embodiment, the fluid in the second chamber is a variable rheology fluid.

Owner:FOX FACTORY

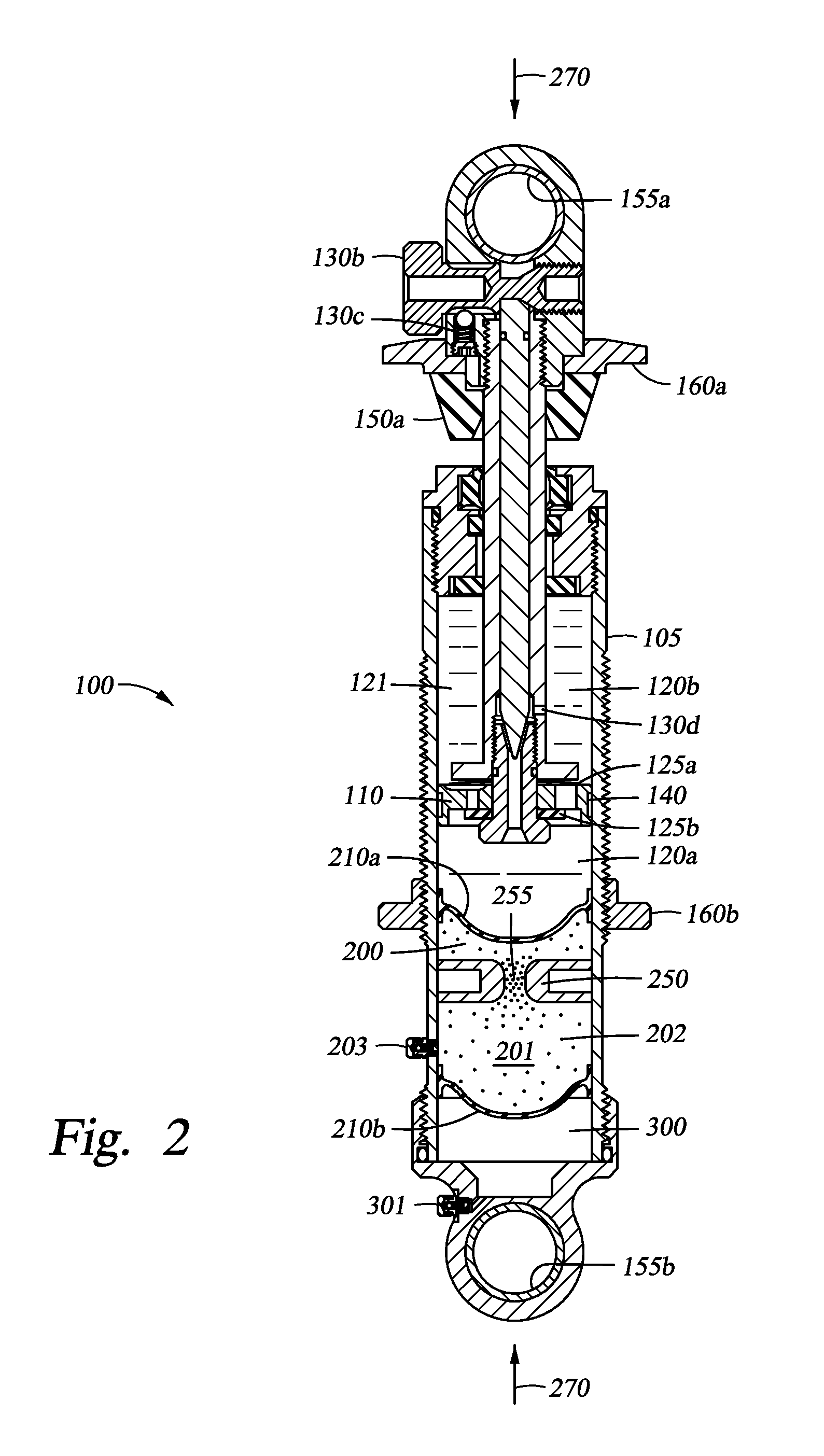

Exhalation valves

ActiveUS7066177B2Control flowReduce manufacturing costRespiratorsBreathing masksHermetic sealEngineering

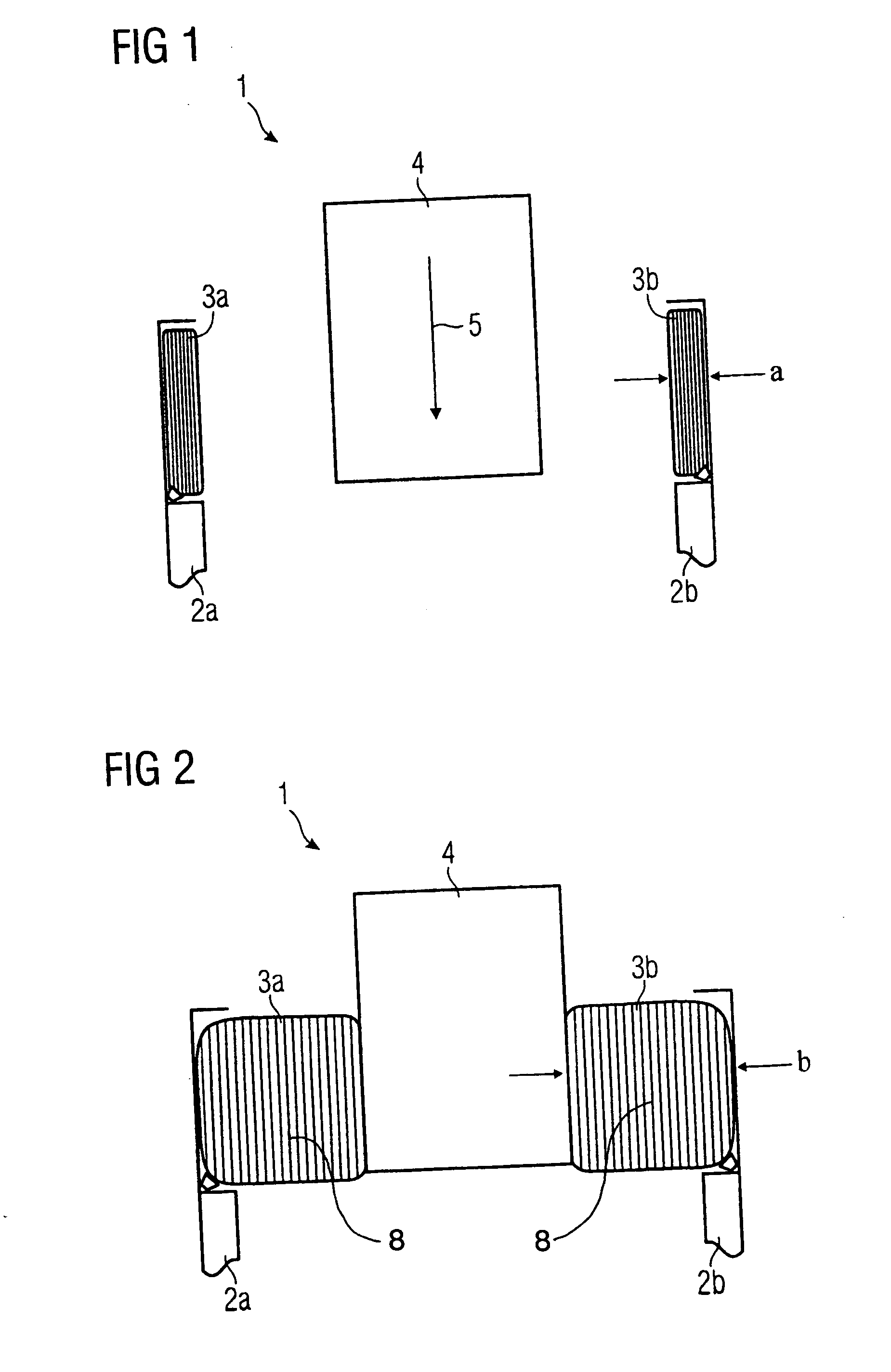

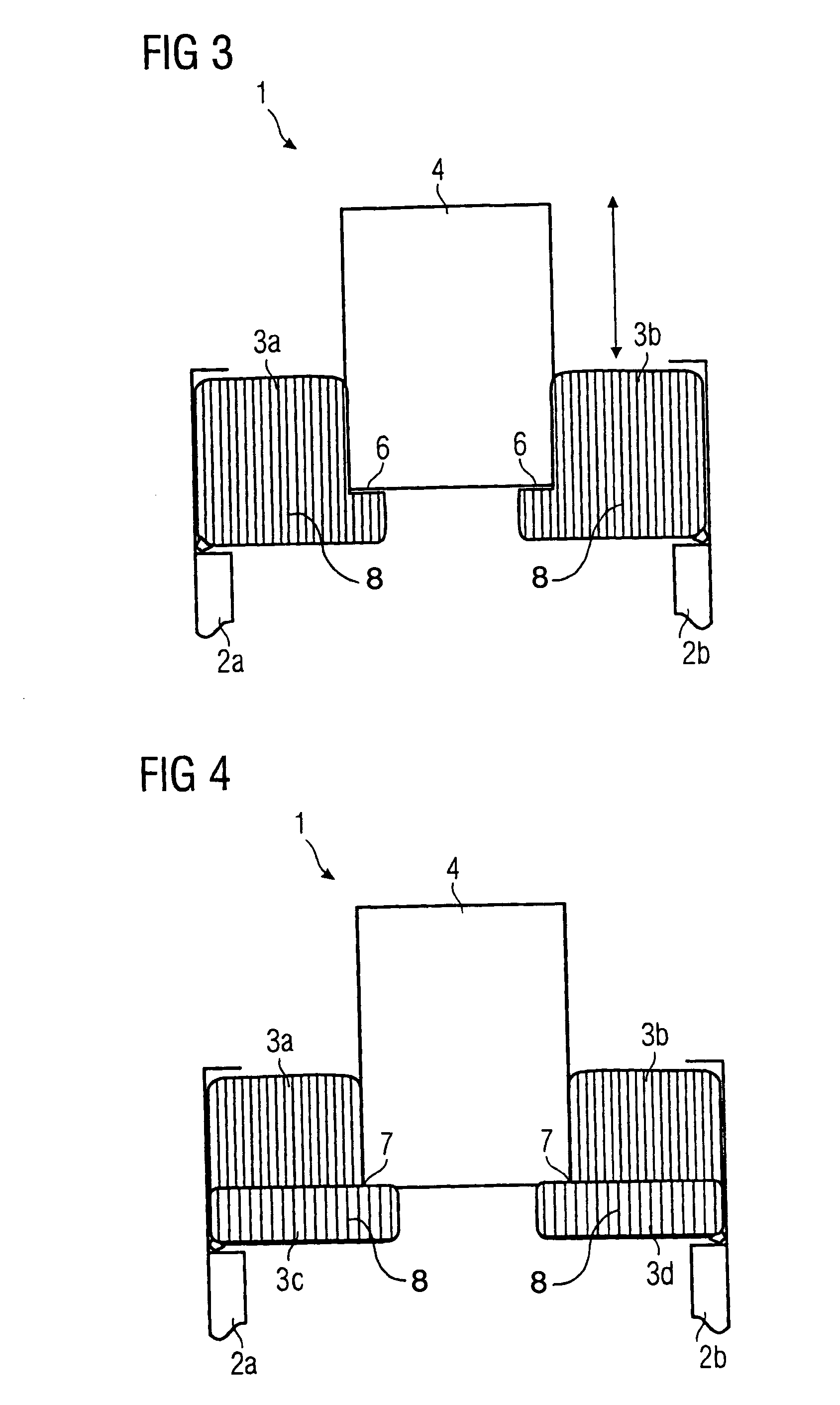

An exhalation valve (10) is disclosed for use with an exhalation port (14) of a respiratory circuit. The exhalation valve comprises a hermetically sealed gas chamber (20,120), a gas inlet (22,122) for supplying gas to the gas chamber, and a membrane (24,124) of flexible material that defines at least part of a wall of the gas chamber. The membrane is deformable by a change in the pressure differential between the gas within the gas chamber and the gas within the exhalation port between an inoperative configuration and an operative configuration in which the membrane restricts the flow of gas from the exhalation port to a greater extent than in said inoperative configuration. The membrane is inherently planar but is mounted within the exhalation valve such that deformation of the membrane to its operative configuration occurs substantially without increase of the surface area of the membrane.

Owner:INTERSURGICAL AG

Bicycle with suspension

A bicycle can include a suspension system with a shock absorber. The shock absorber can have a sag position which can be adjustable. Sag refers to the amount of movement experienced by the suspension under a static load, such as that of the weight of a rider. Methods and systems to set sag can include at least one valve in fluid communication with a gas chamber of the shock absorber. In some embodiments, the at least one valve can be used to automatically set the sag position based on an individual's weight and riding position.

Owner:SPECIALIZED BICYCLE COMPONENTS INC

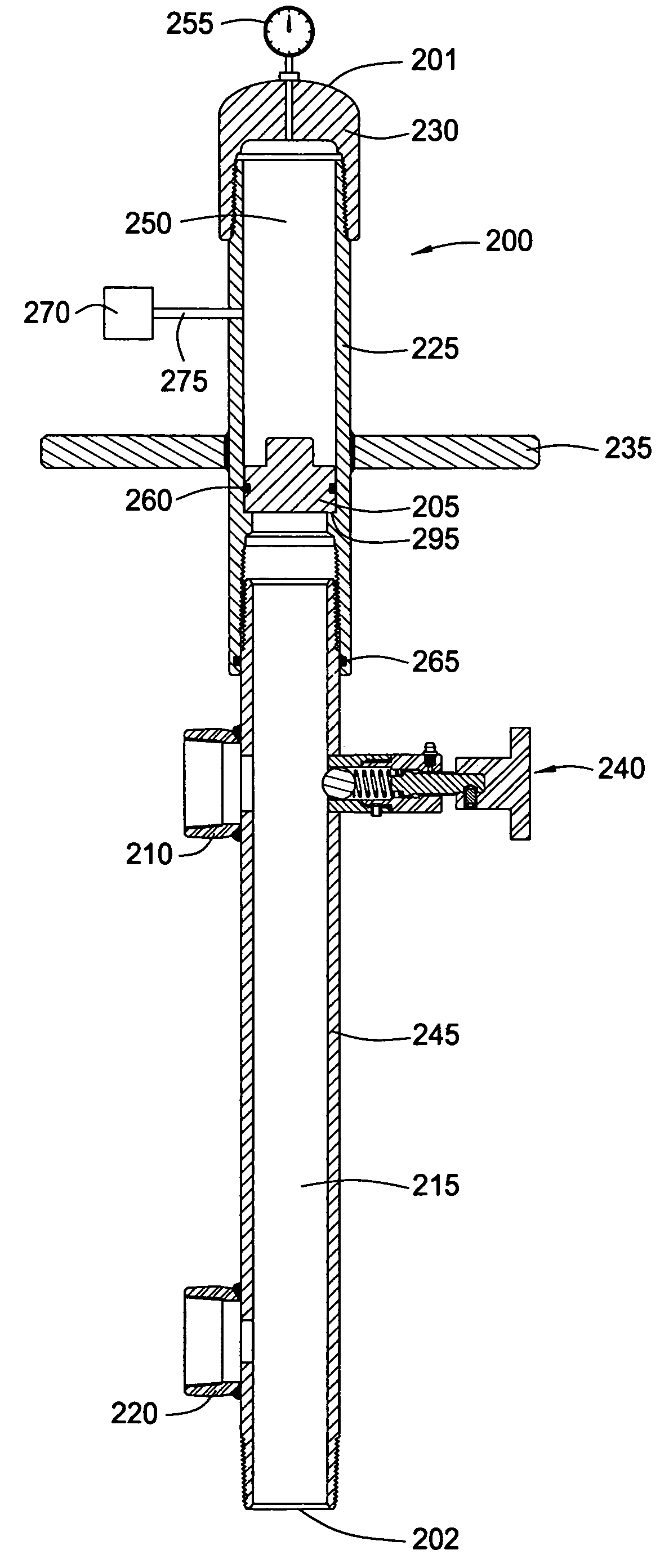

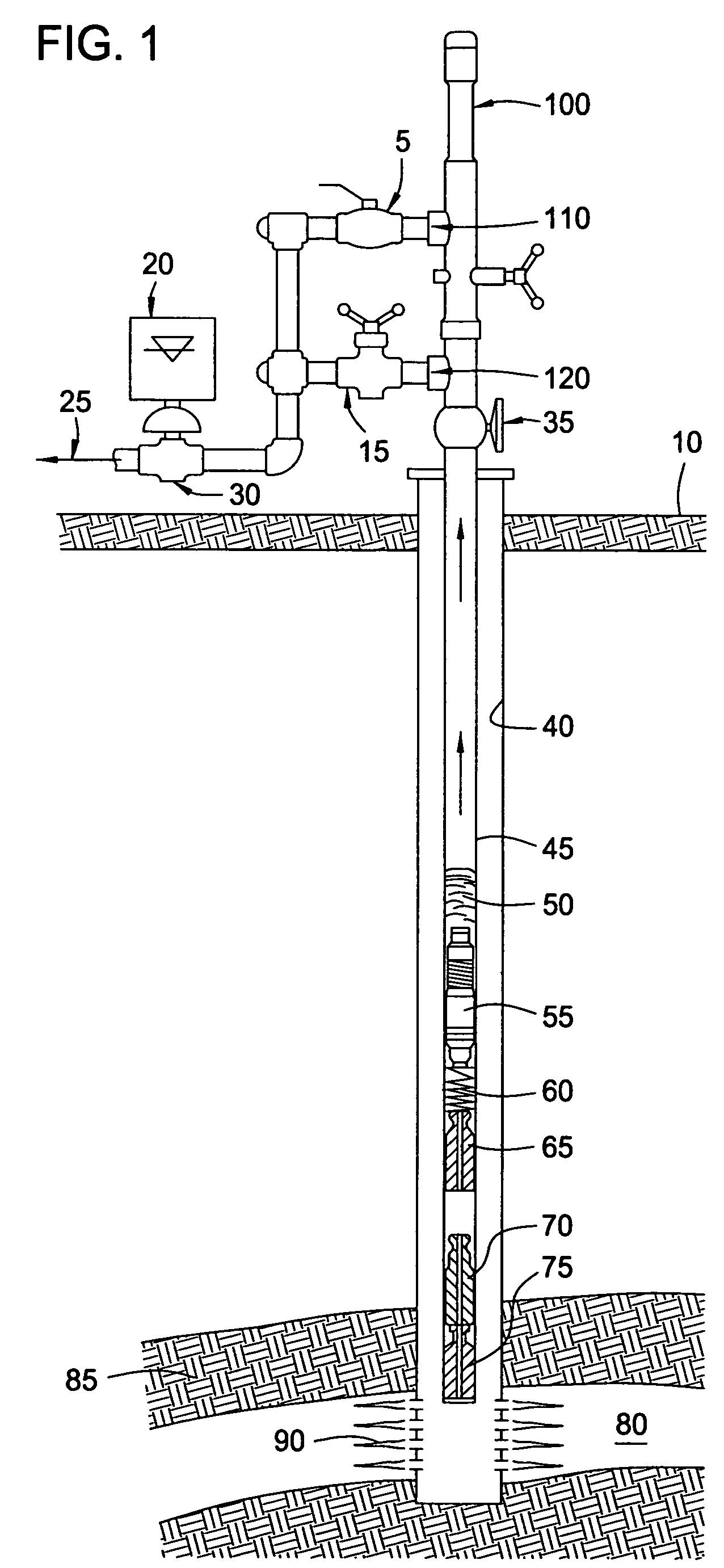

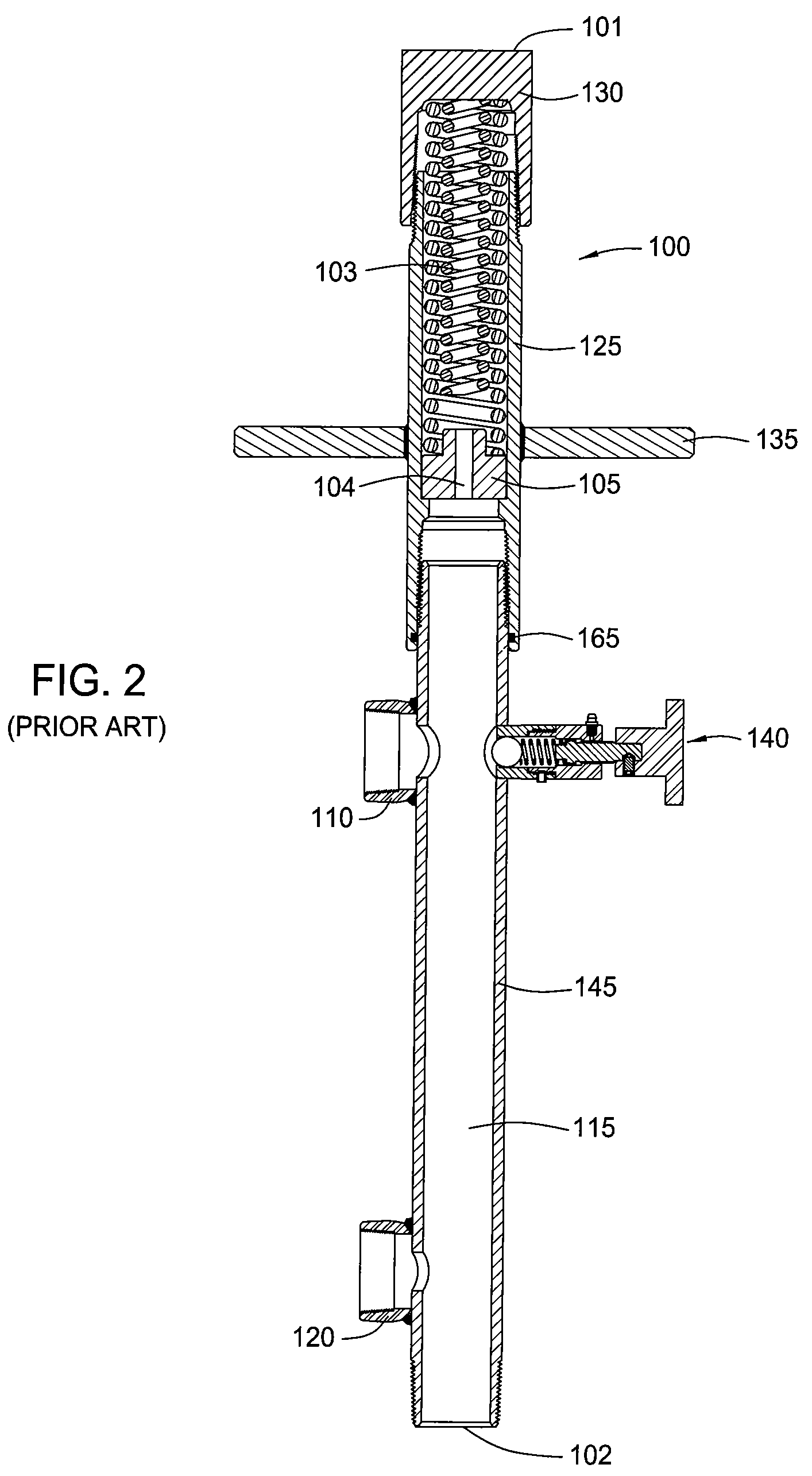

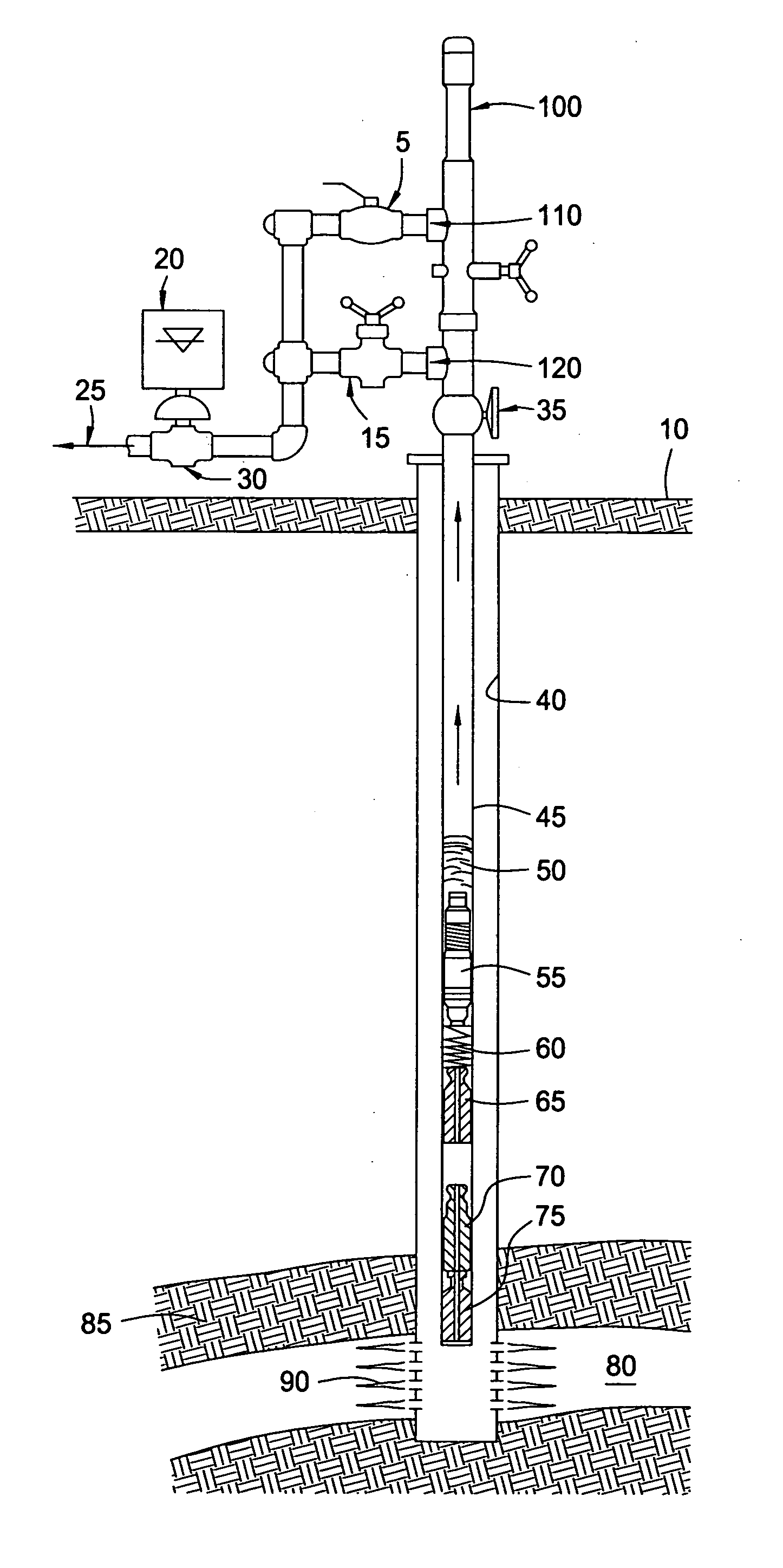

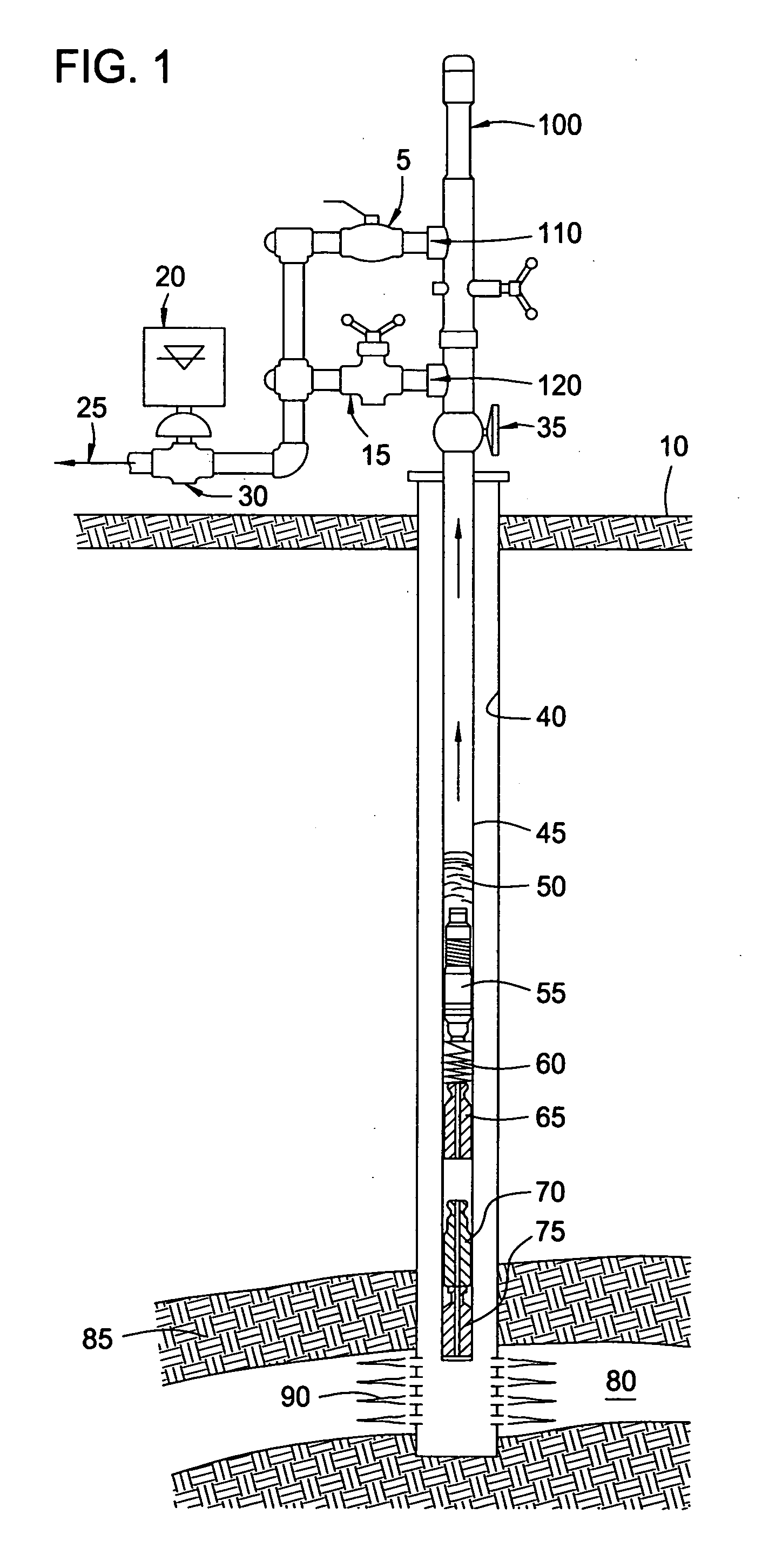

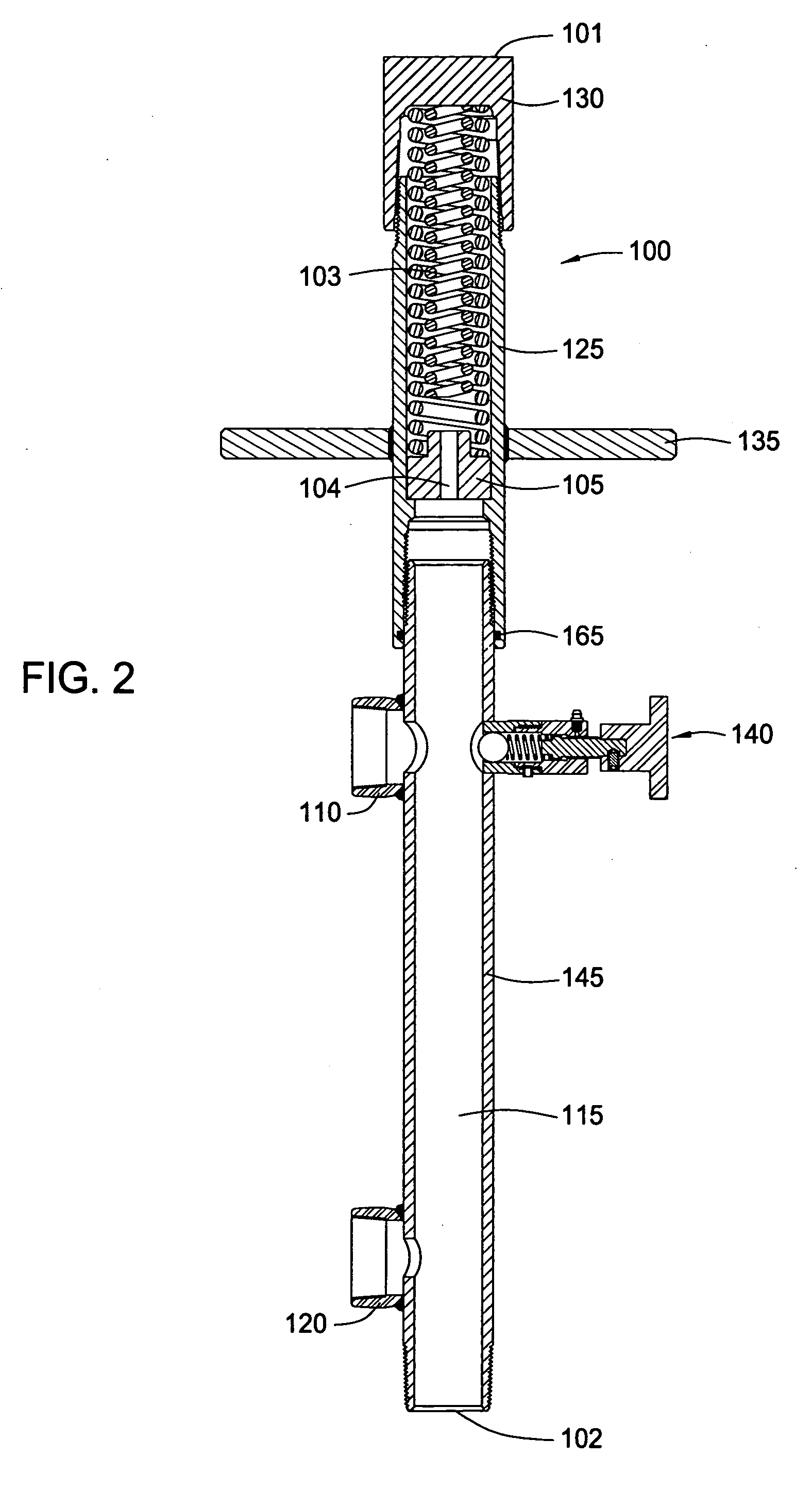

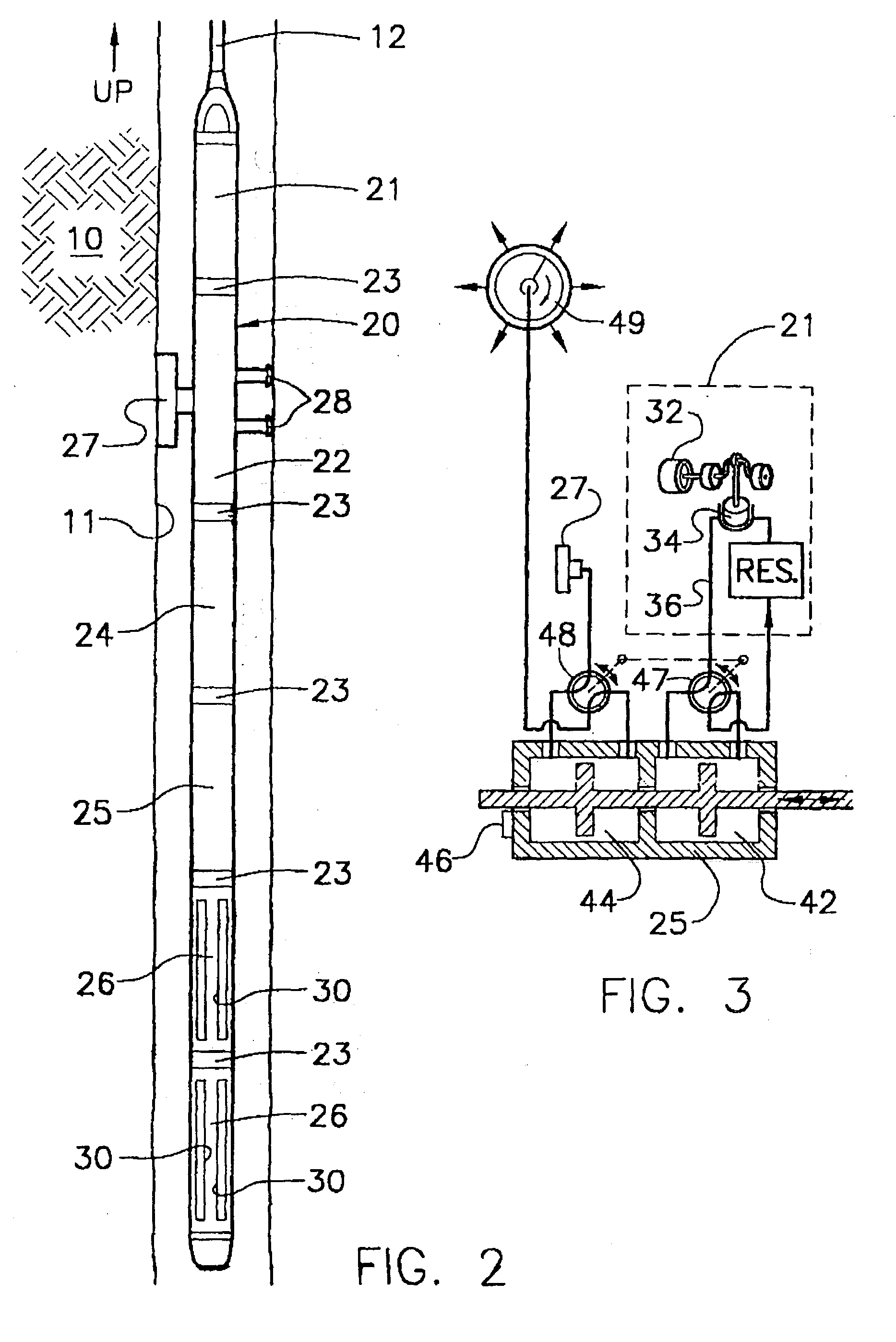

Gas-pressurized lubricator and method

InactiveUS7337854B2Reduce kinetic energyReduce shockFlexible member pumpsFluid removalEngineeringGas chamber

Embodiments of the present invention provide methods and apparatus for reducing kinetic energy of a plunger within a plunger lift system. In one aspect, a lubricator is provided at a surface of a wellbore, the lubricator having a sealed, pressurized chamber therein to cushion the plunger upon impact. In another aspect, a method is provided for reducing the kinetic energy of the plunger by providing a compressed gas chamber within a lubricator, moving a kinetic energy-reducing surface which is partially bounding the chamber, and compressing the gas within the chamber to reduce kinetic energy of the plunger and cushion the impact force of the plunger.

Owner:WEATHERFORD TECH HLDG LLC

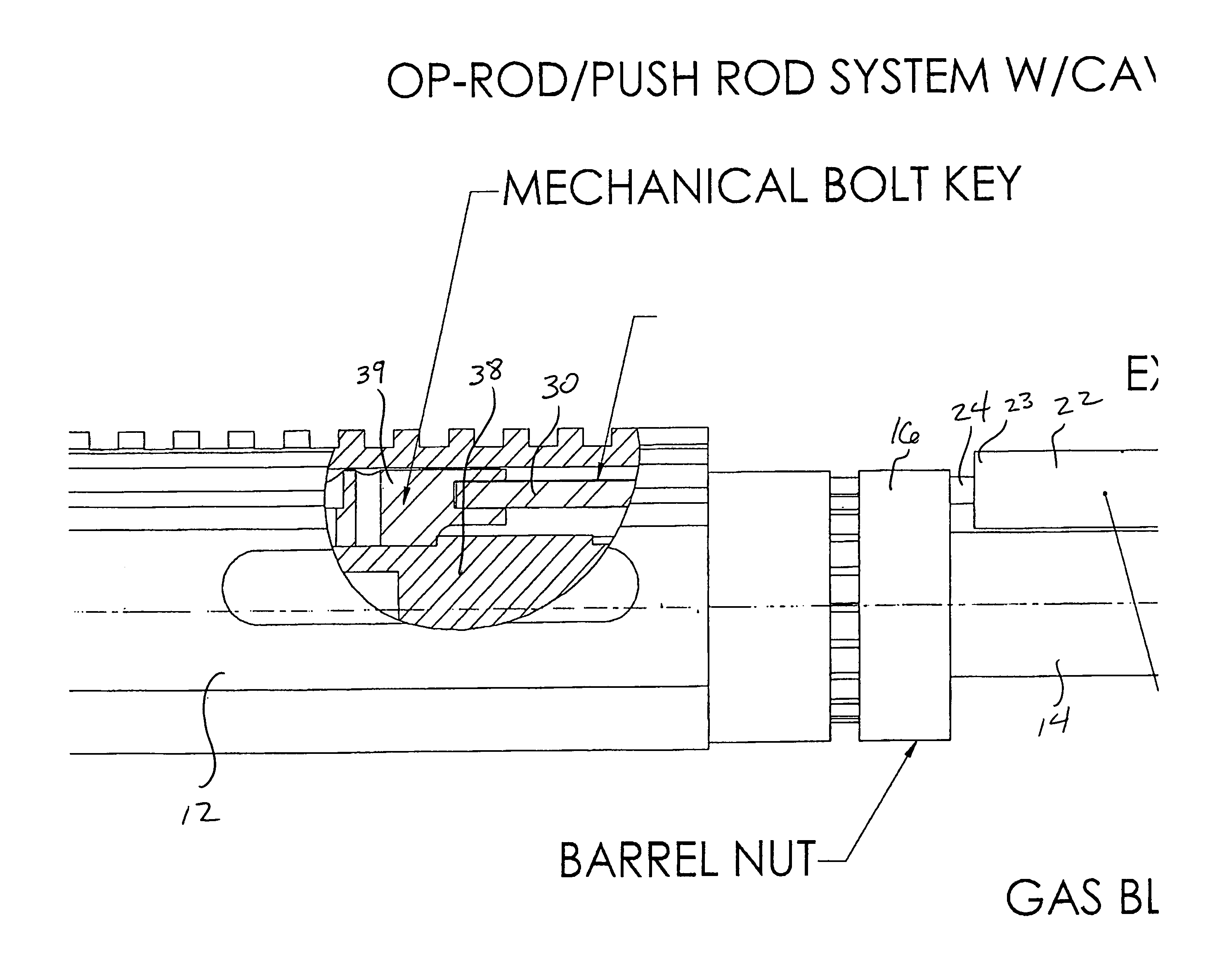

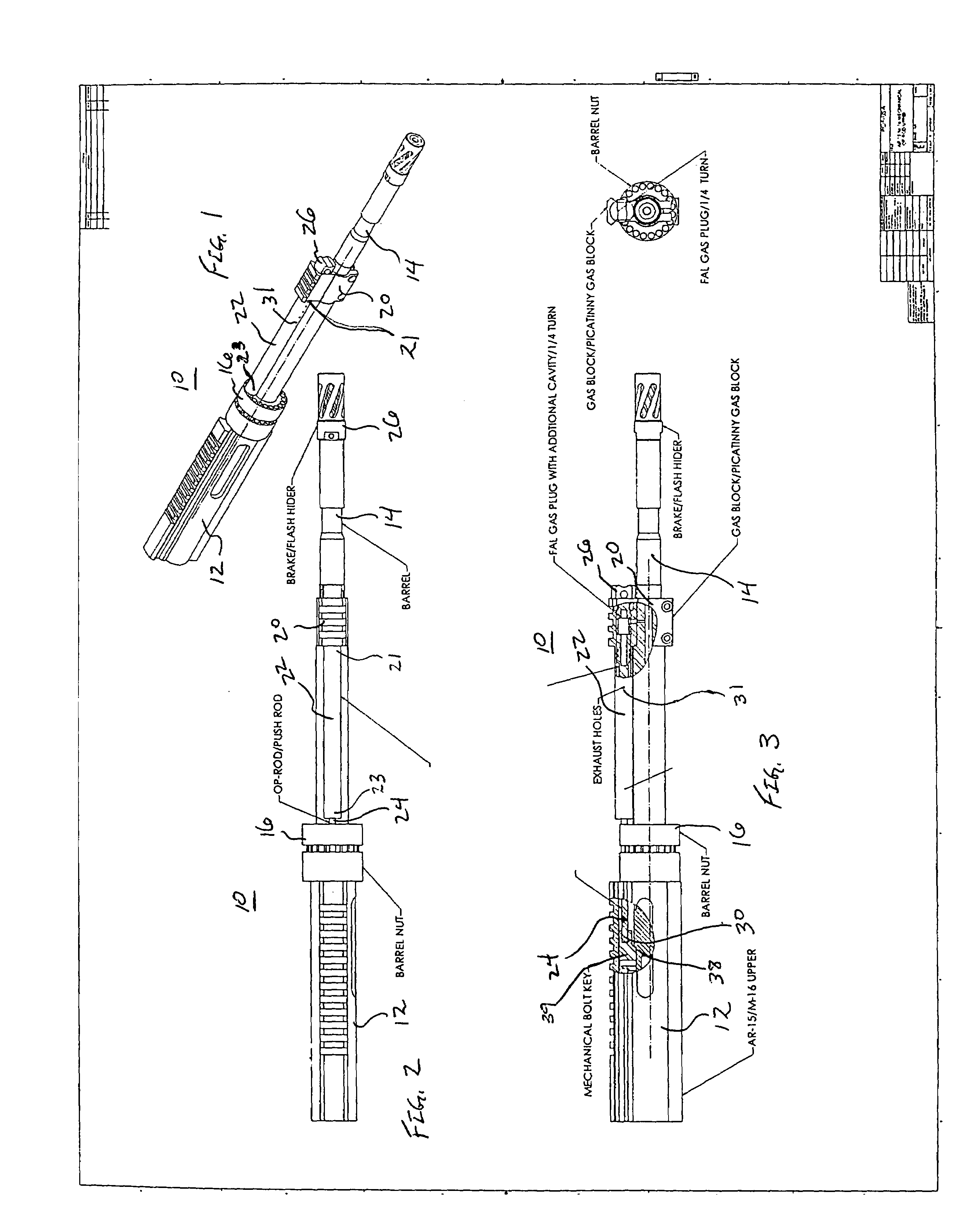

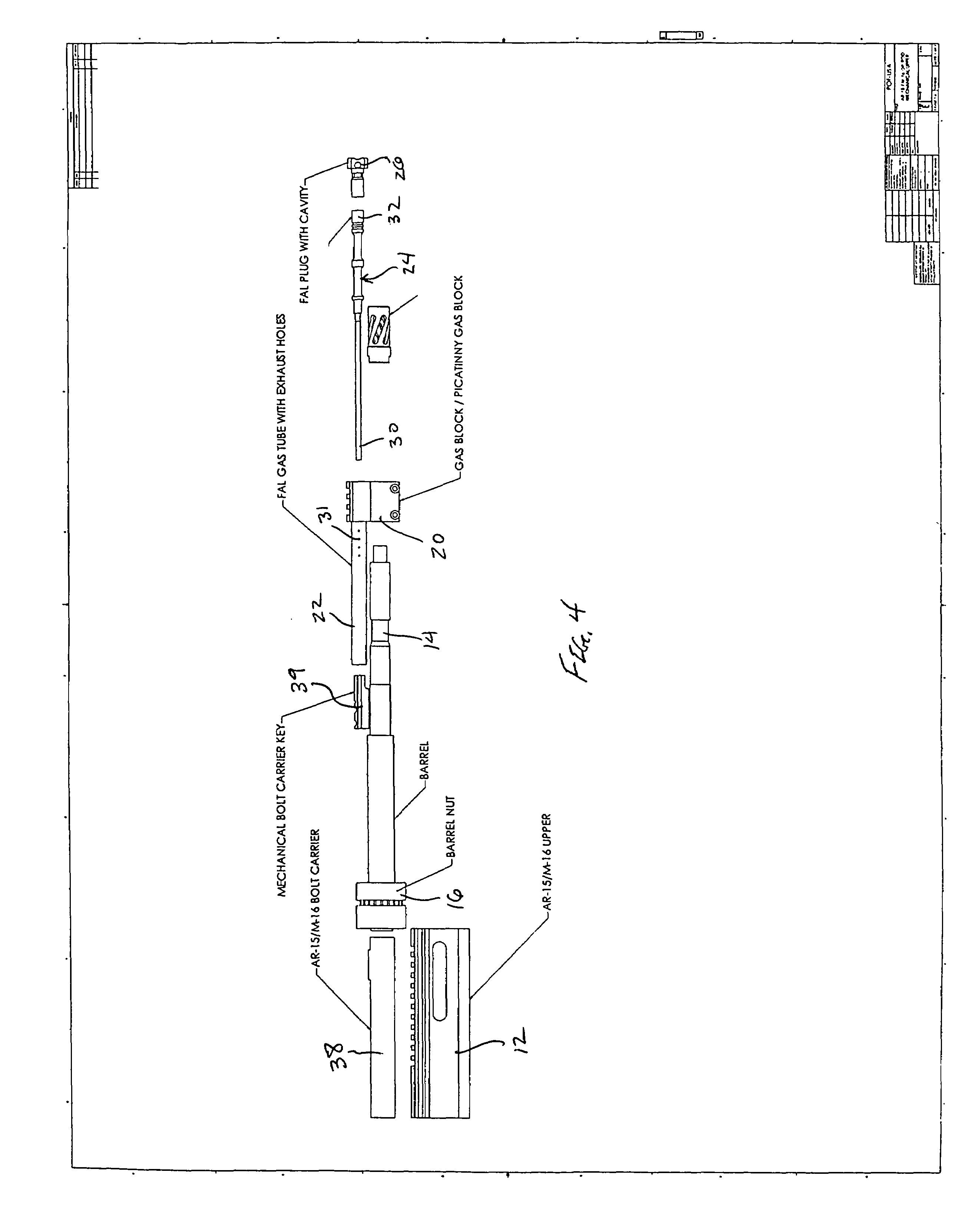

M16 modified with pushrod operating system and conversion method

A push rod operating system for an AR-15 / M-16 rifle includes an AR-15 / M-16 rifle having a barrel coupled to an upper receiver, a bolt carrier carried by the upper receiver, and a mechanical key coupled to the bolt carrier. A gas block is coupled to the barrel, the gas block having a bore therethough. A rod tube extends from the gas block in communication with the bore, toward the upper receiver. A gas plug has a gas chamber closing the bore of the gas block opposite the rod tube. A discharge gas pathway permits discharge gasses to enter the gas chamber from the barrel. A piston rod element is carried in the rod tube with a piston portion thereof reciprocally received within the bore of the gas block and movable between a first position abutting the gas plug to define an operating volume, and a second position. A push rod element is carried by the rod tube and engages the mechanical key and the piston rod element.

Owner:PATRIOT ORDNANCE FACTORY INC

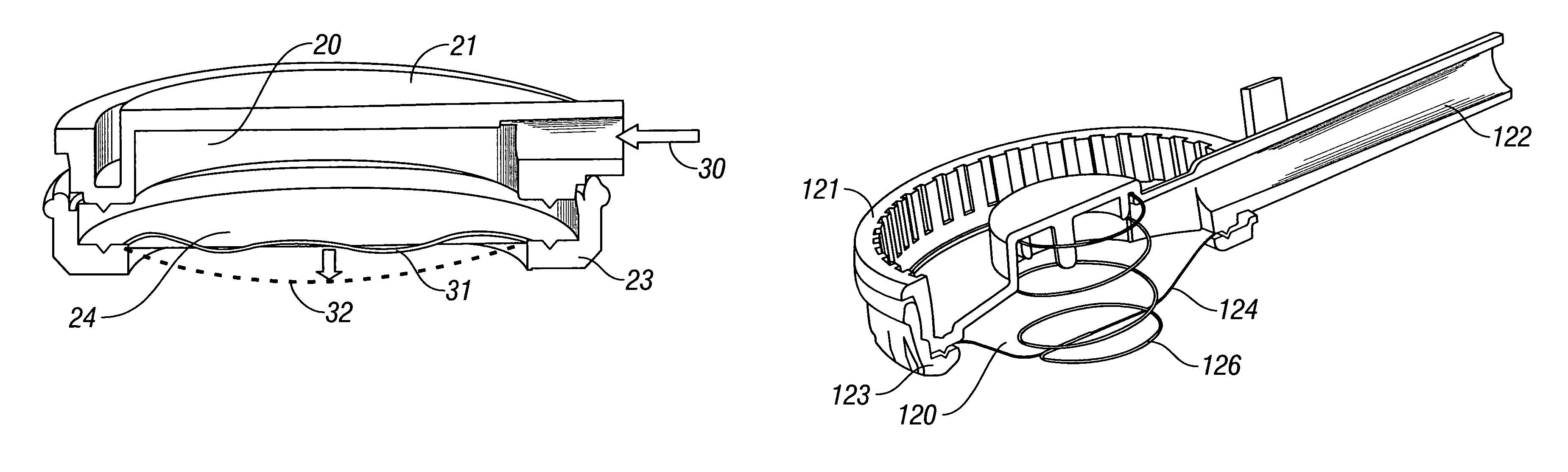

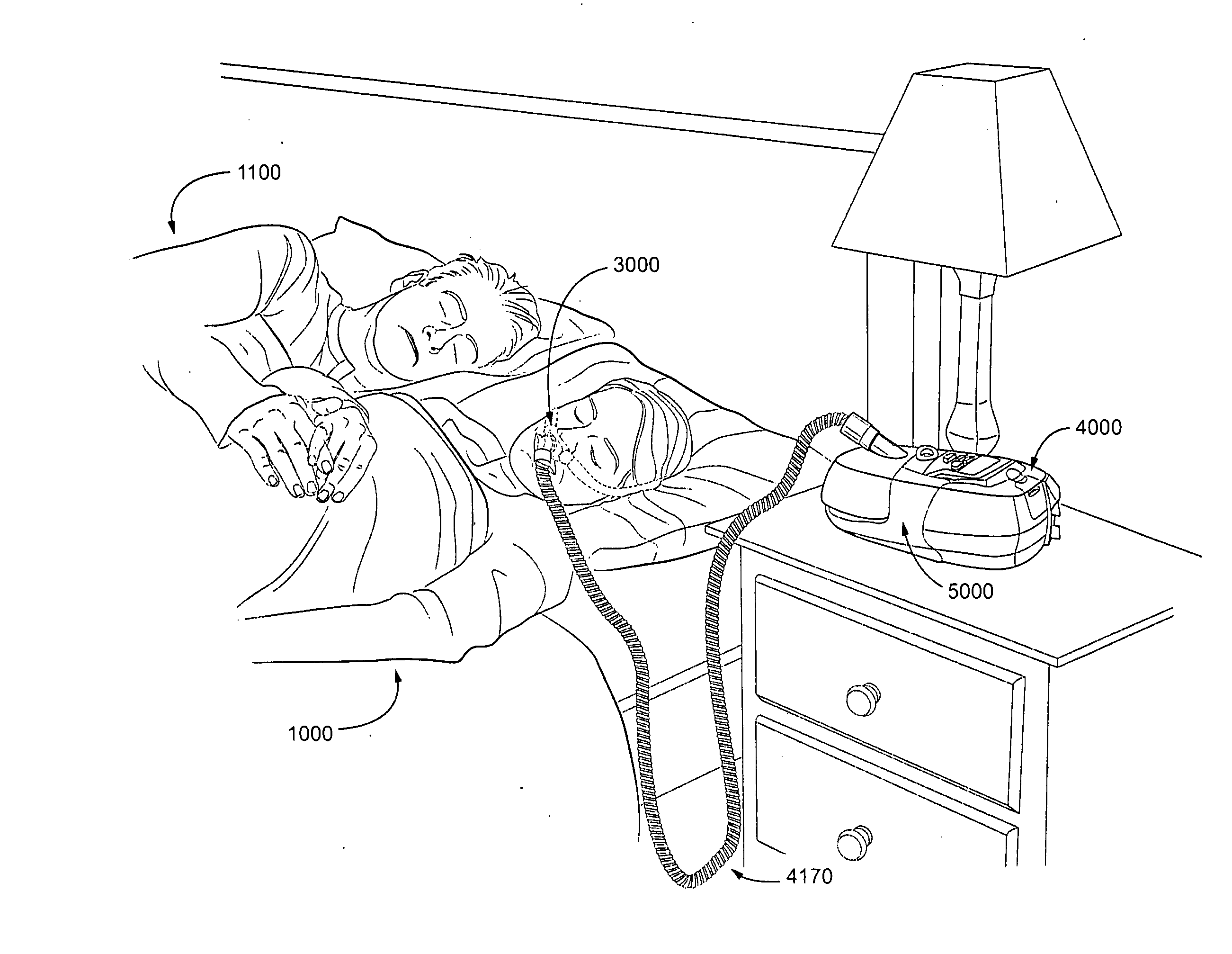

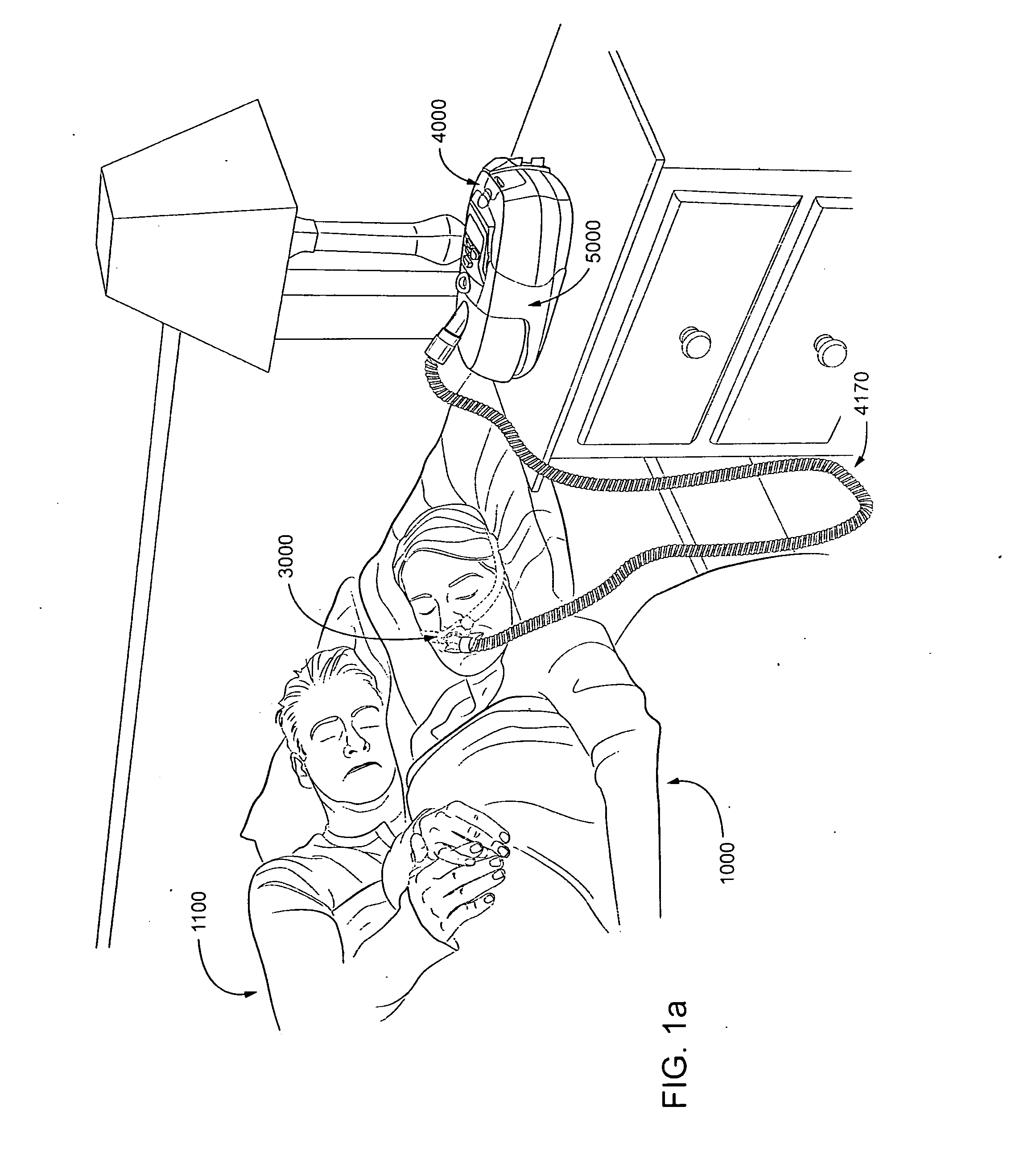

Patient interface

ActiveUS20150335846A1Improve efficacyImprove manufacturabilityBreathing masksRespiratory masksAnterior surfaceEngineering

A patient interface for delivery of a supply of pressurised air or breathable gas to an entrance of a patient's airways includes a frame member, a cushion assembly provided to the frame member, and an anterior wall member repeatedly engageable with and disengageable from the cushion assembly. The frame member includes connectors operatively attachable to a positioning and stabilizing structure. The cushion assembly includes a seal-forming structure and a void defined by an anterior surface of the cushion assembly. The anterior wall member has a predetermined surface area to seal the void of the cushion assembly and form a gas chamber when the anterior wall member and the cushion assembly are engaged. The void of the cushion assembly is sized such that the patient's nose and / or mouth is substantially exposed when the anterior wall member is disengaged from the cushion assembly thereby improving breathing comfort of the patient.

Owner:RESMED LTD

Gas-pressurized lubricator

Embodiments of the present invention provide methods and apparatus for reducing kinetic energy of a plunger within a plunger lift system. In one aspect, a lubricator is provided at a surface of a wellbore, the lubricator having a sealed, pressurized chamber therein to cushion the plunger upon impact. In another aspect, a method is provided for reducing the kinetic energy of the plunger by providing a compressed gas chamber within a lubricator, moving a kinetic energy-reducing surface which is partially bounding the chamber, and compressing the gas within the chamber to reduce kinetic energy of the plunger and cushion the impact force of the plunger.

Owner:WEATHERFORD TECH HLDG LLC

Low-power consumption hand-hold electric nasus system for testing on-site

InactiveCN101226166AReduce power consumptionMeet power consumptionMaterial analysis by electric/magnetic meansSensor arrayHand held

The invention provides a low power consumption hand-held electric nose system for on-site check, which comprises an electric nose box provided with a gas flow control system which gas chamber is at least provided with a mixture sensor array composed of low power consumption gas sensitive sensors, wherein the electric nose box is further provided with a necessary electric checking circuit, a wireless communication module and / or a USB module, a single chip and a DSP system for data processing and mode recognition, the electric checking circuit is provided with a CPLD circuit for checking QCM gas-sensitive sensor signal and a circuit for regulating electrochemical gas-sensitive sensor signal check and temperature humidity senor signal check. The invention can independently work without computer and automatically realize gas flow control, smell check, signal pretreatment and character extraction, mode recognition and display alarm or the like in an independent instrument, to meet the real-time, low power consumption and hand-held demands of on-site check.

Owner:ZHEJIANG UNIV

Shared isolated gas cooling system for oppositely facing electronic displays

ActiveUS8373841B2Temperature fluctuationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringImaging quality

A system and method for cooling back to back electronic displays. Transparent first and second gas chambers are co-existive with the front display surfaces of the first and second electronic displays. A closed loop of isolated gas enters the first and second gas chambers and contacts the front surfaces of the electronic displays, where it may extract heat from the front display surfaces. The isolated gas is then directed into a cooling chamber where it is cooled and re-introduced into the first and second gas chambers. Fans may be used to propel the isolated gas through the cooling chamber and the first and second gas chambers. The circulating gas removes heat directly from the electronic display surfaces. The isolated gas is transparent or at least semi-transparent to ensure that the image quality of the electronic displays is minimally impacted.

Owner:MFG RESOURCES INT INC

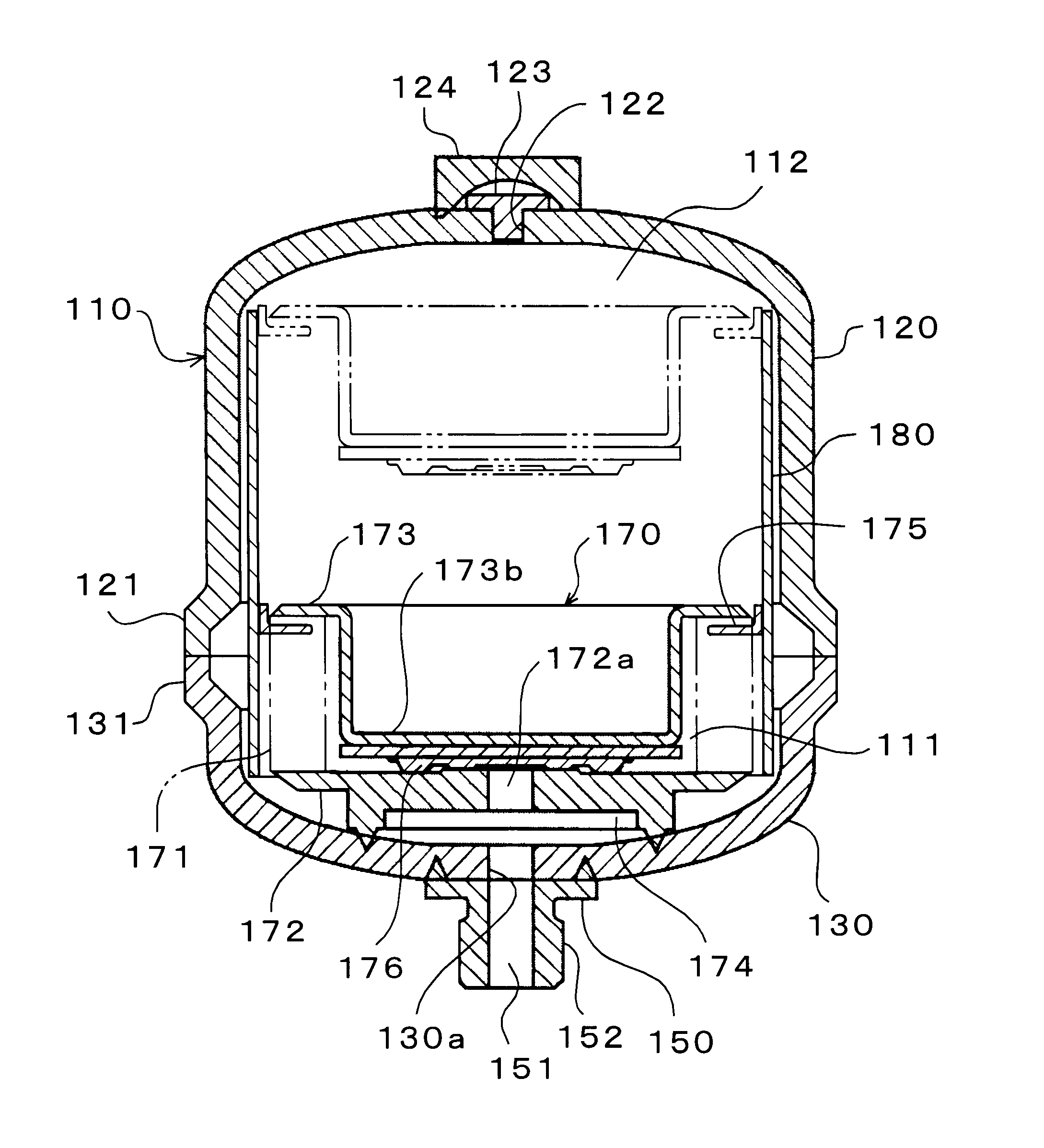

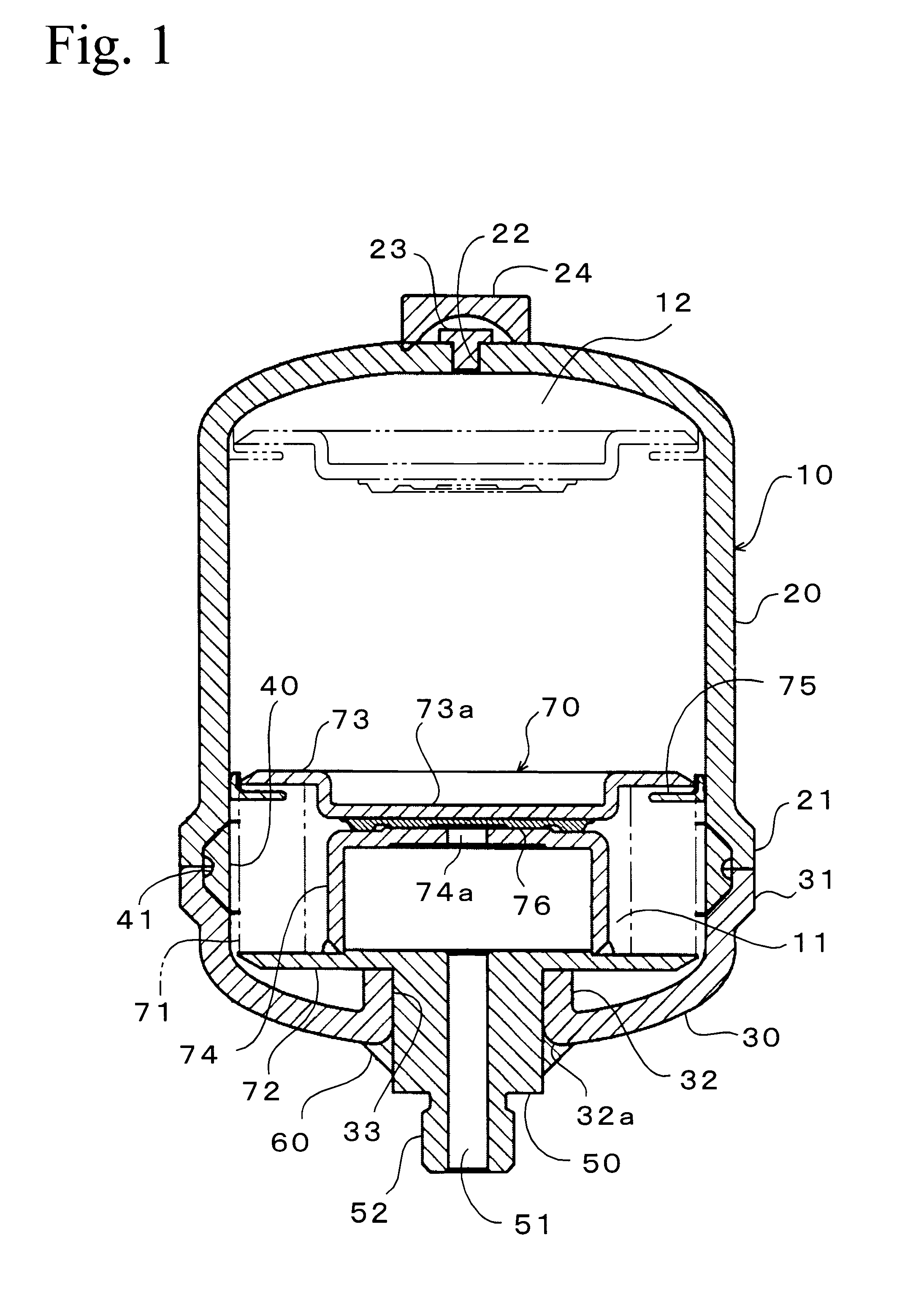

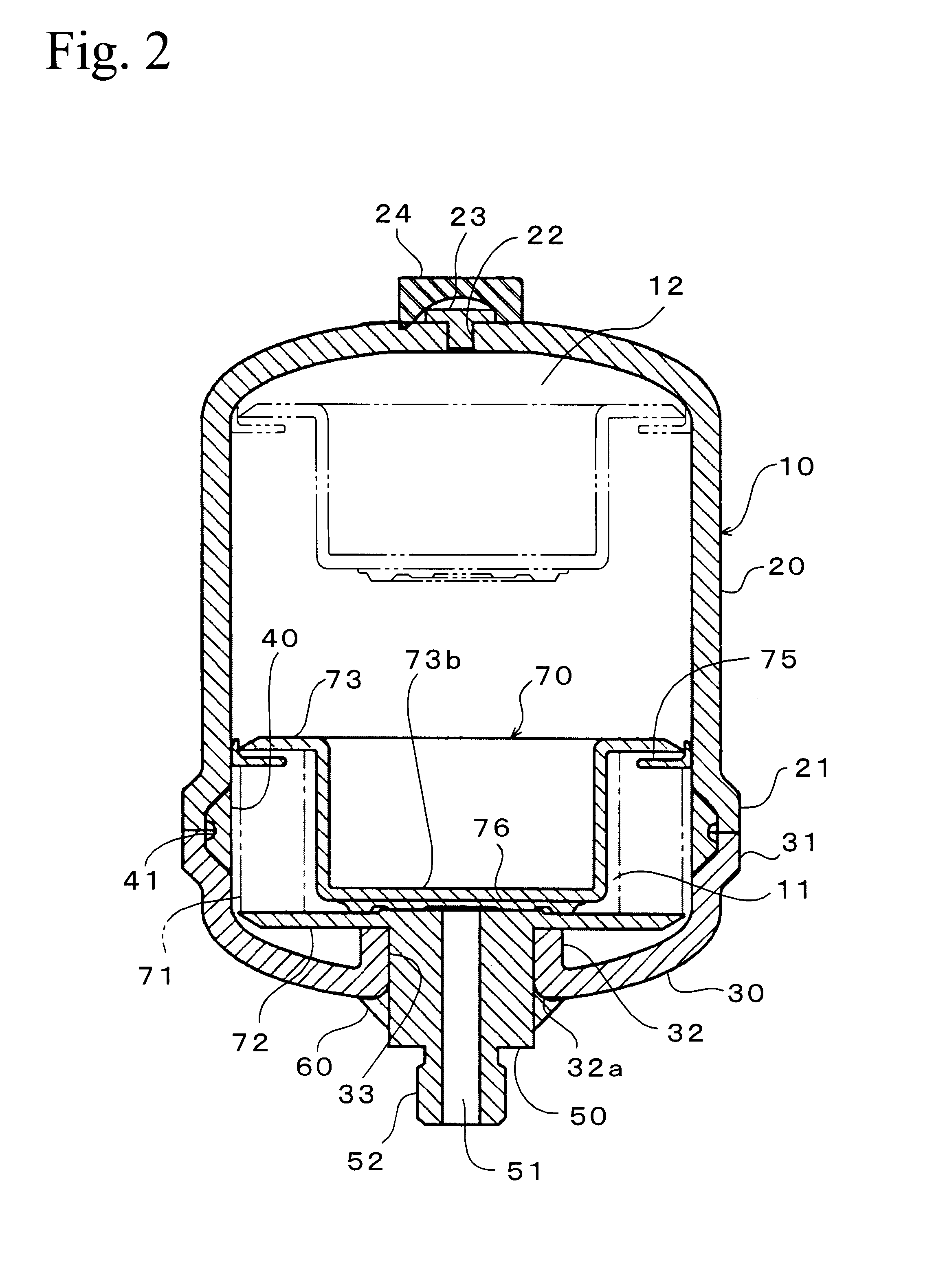

Accumulator

Disclosed is an accumulator comprising a cylindrical shell including a cylindrical portion, a partitioning member for partitioning the interior of the shell into a hydraulic chamber and a gas chamber, and a port including a hydraulic fluid flow path for communicating the exterior of the shell and the hydraulic chamber. The variation of the pressure of a hydraulic fluid flowing into the hydraulic chamber is accommodated by expansion and compression of a gas in the gas chamber according to expansion and contraction of the partitioning member. The port is approximately airtightly inserted into the cylindrical portion of the shell, and is welded to an outer circumference of the cylindrical portion by means of welding.

Owner:NHK SPRING CO LTD

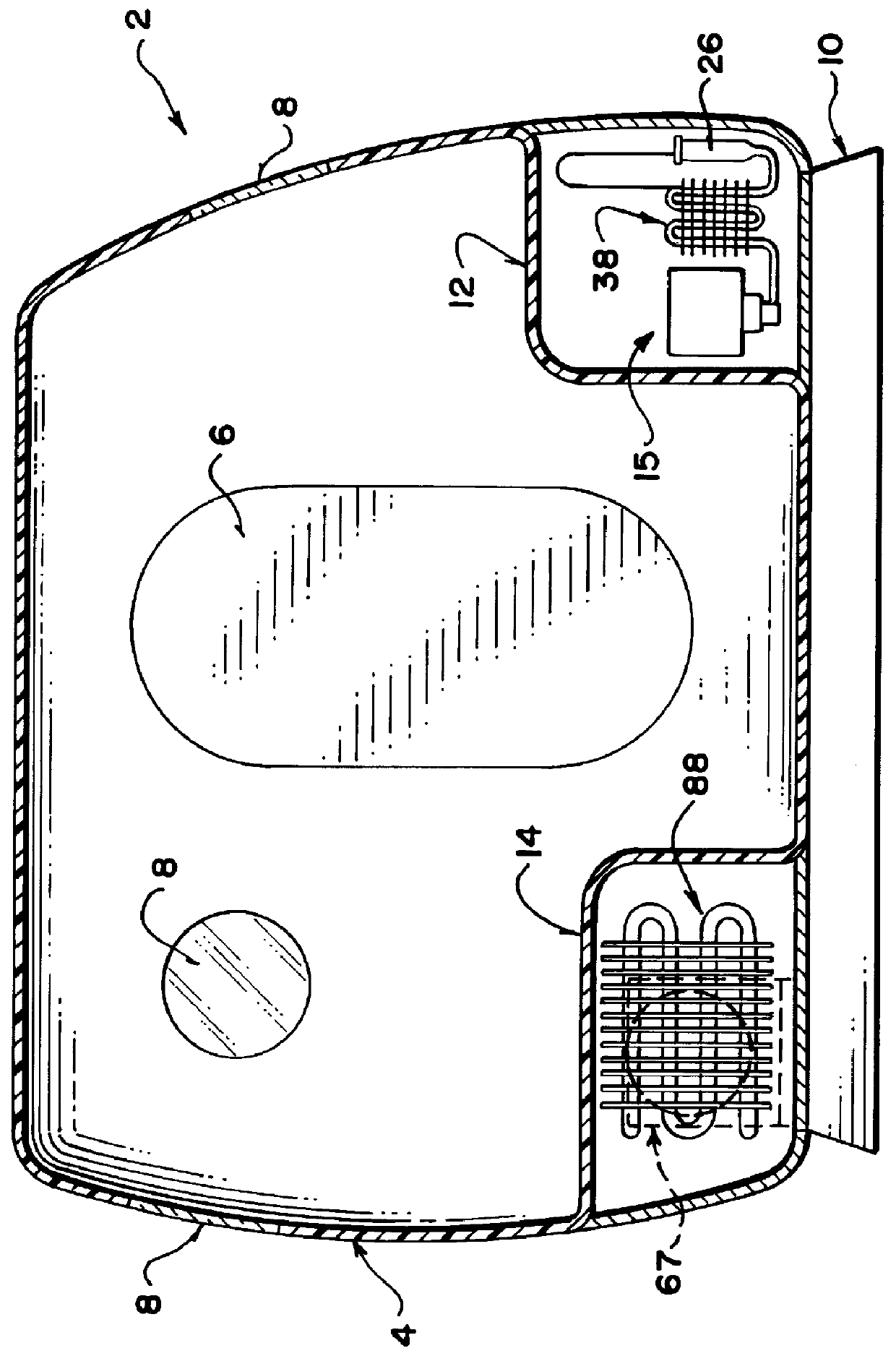

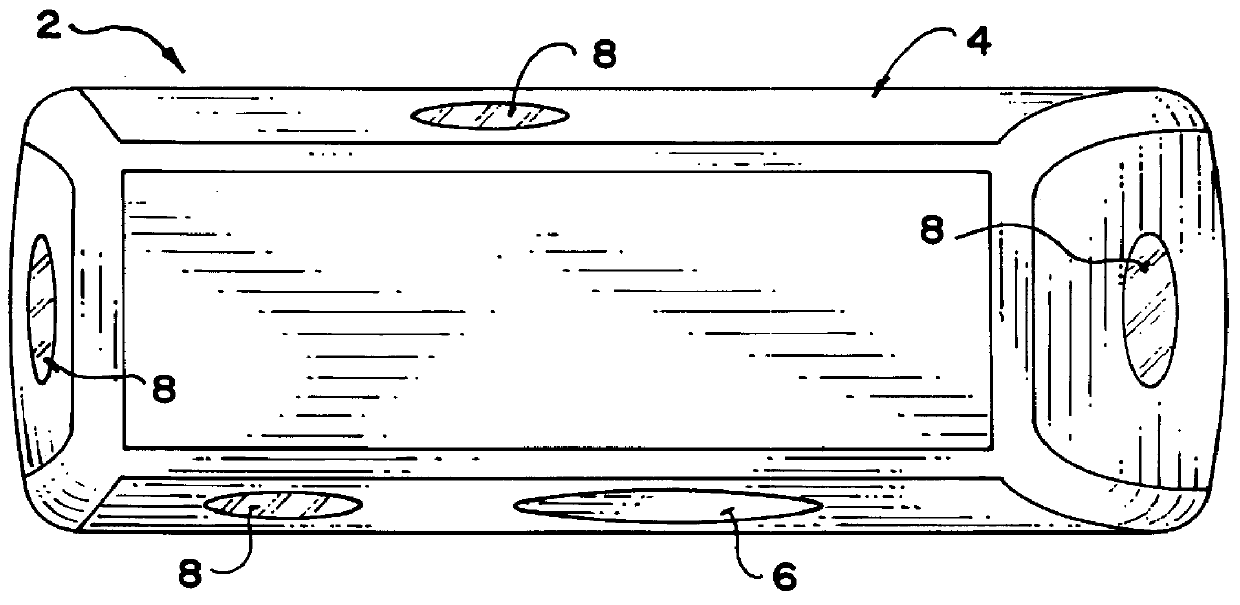

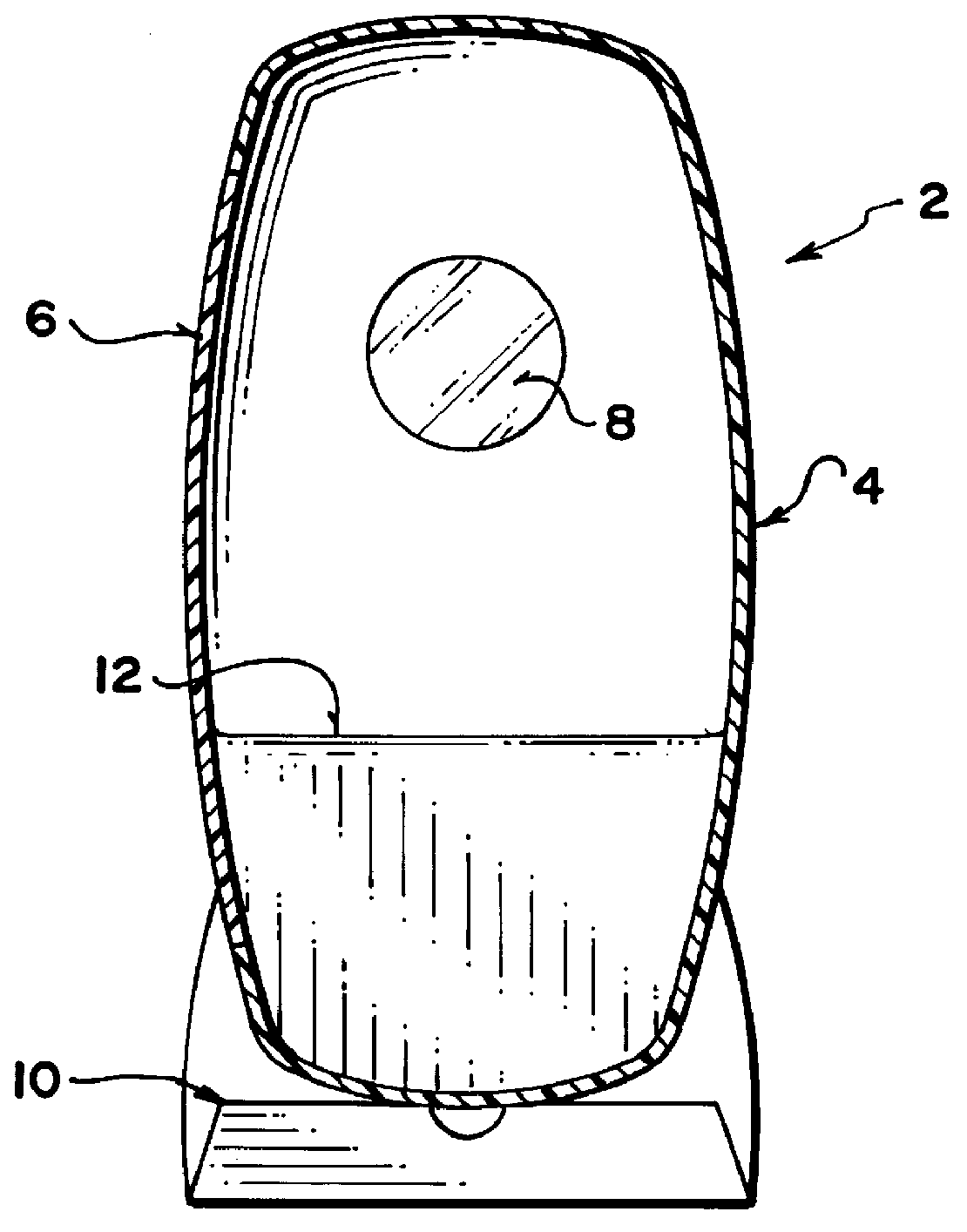

Self-contained hyperbaric chamber

This invention relates to a novel self-contained hyperbaric chamber. More particularly, this invention pertains to a hyperbaric chamber which contains all necessary gas processing equipment, conserves gas pressures and recovers oxygen from the waste gas. A self-contained hyperbaric chamber comprising: (a) a sealed gas chamber; (b) a first housing sealed from the sealed gas chamber; (c) a first air compressor within the first housing for withdrawing air from atmosphere and compressing the air for delivery to the interior of the sealed chamber; (d) a second housing sealed from the sealed gas chamber; and (e) a second compressor within the second housing for compressing air withdrawn from the interior of the sealed chamber and delivering the compressed air to an oxygen enriching molecular sieve and directing recovered oxygen enriched gas to the interior of the sealed chamber.

Owner:VOLBERG WALTER +1

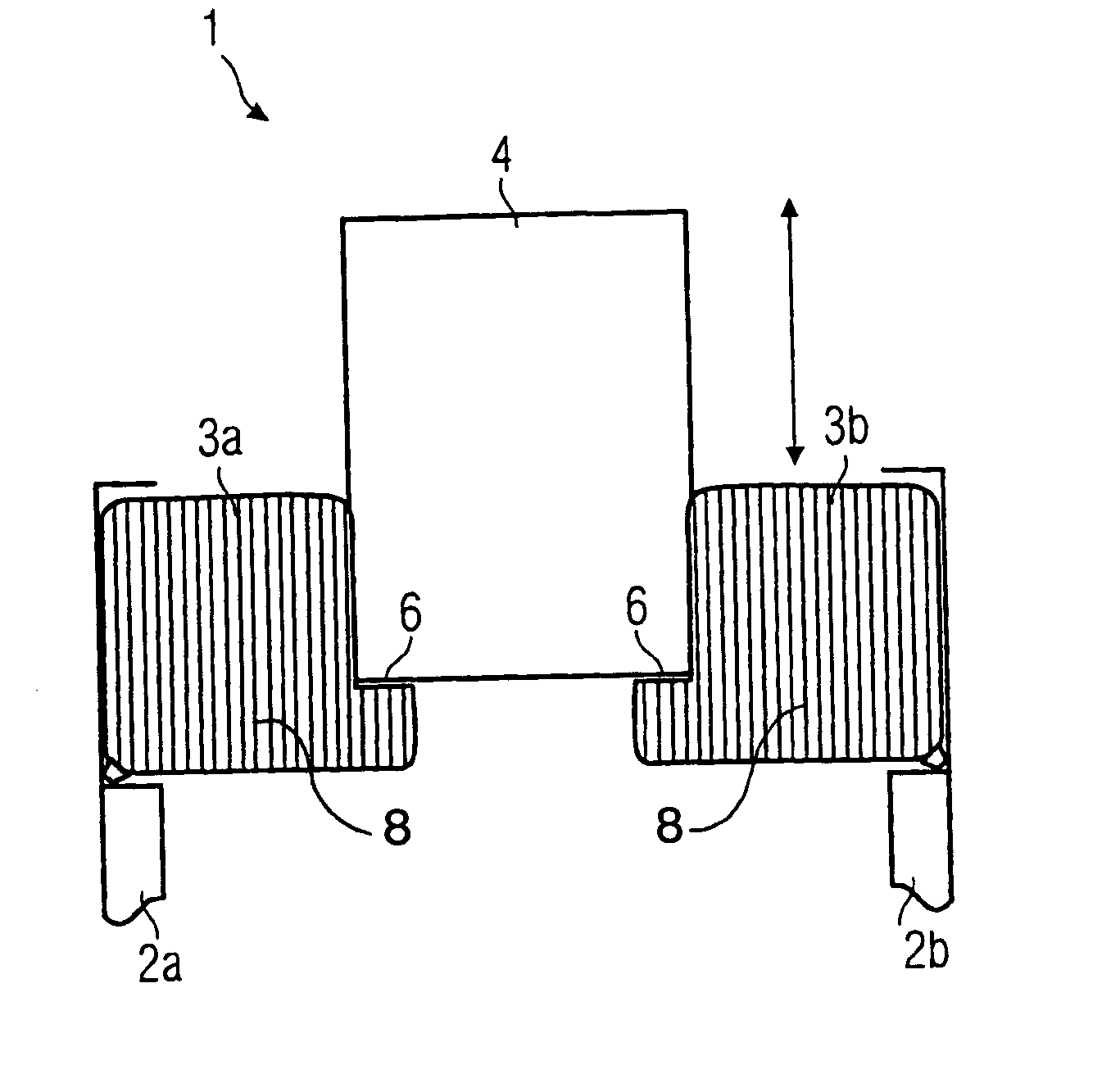

Load-lifting device for handling items

InactiveUS20060033350A1Rapidly and reliably and securely gripGripping headsMetal-working hand toolsCartonEngineering

The invention relates to a load-lifting device for handling items, comprising two spaced-apart, mutually opposite gripper arms which are equipped on the mutually facing sides with flexibly inflatable gas chambers that can be filled and emptied and between which the item is held when the gas chambers are in the inflated state. In order to be able to quickly, reliably and securely grip items, including cartons and loads with irregular contours or nonplanar gripping faces and / or those with significantly different dimensions, the gas chambers are constructed as collapsible cushions or bellows whose inflated thickness, measured in the direction of action, corresponds in each case to a multiple of the thickness of the bellows or cushions in the deflated state.

Owner:SIEMENS AG

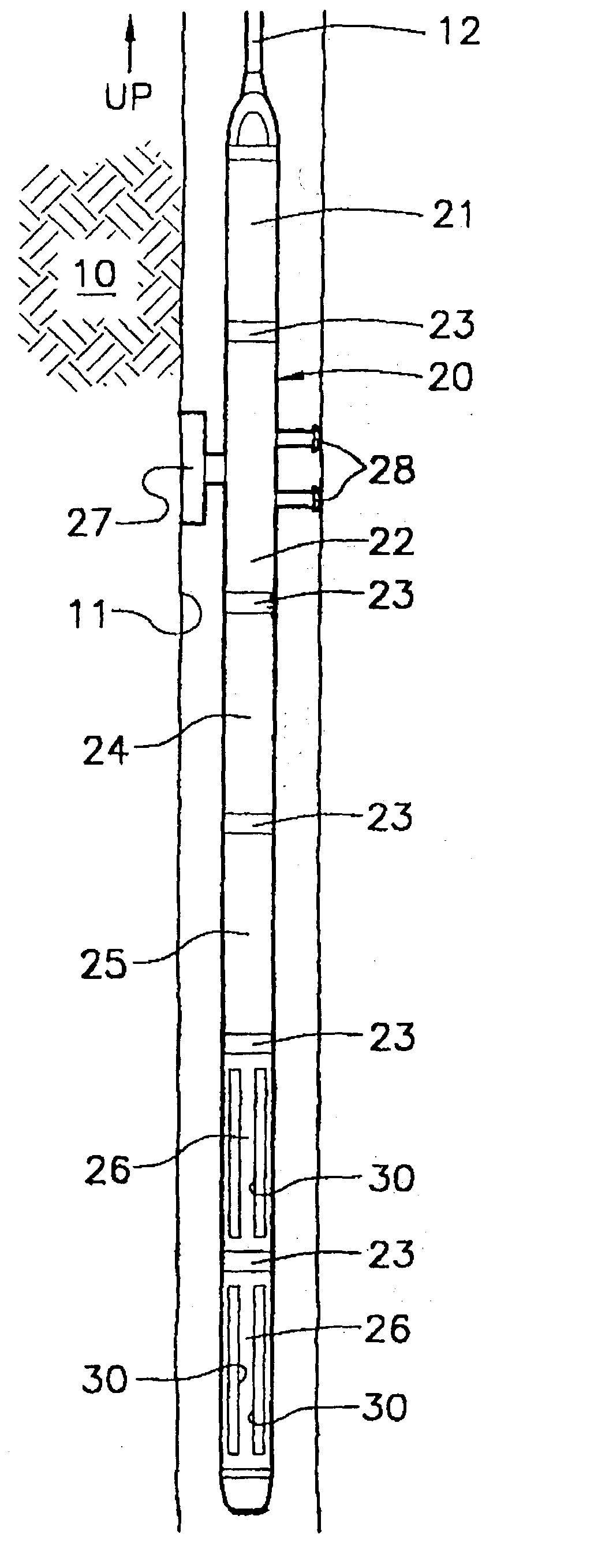

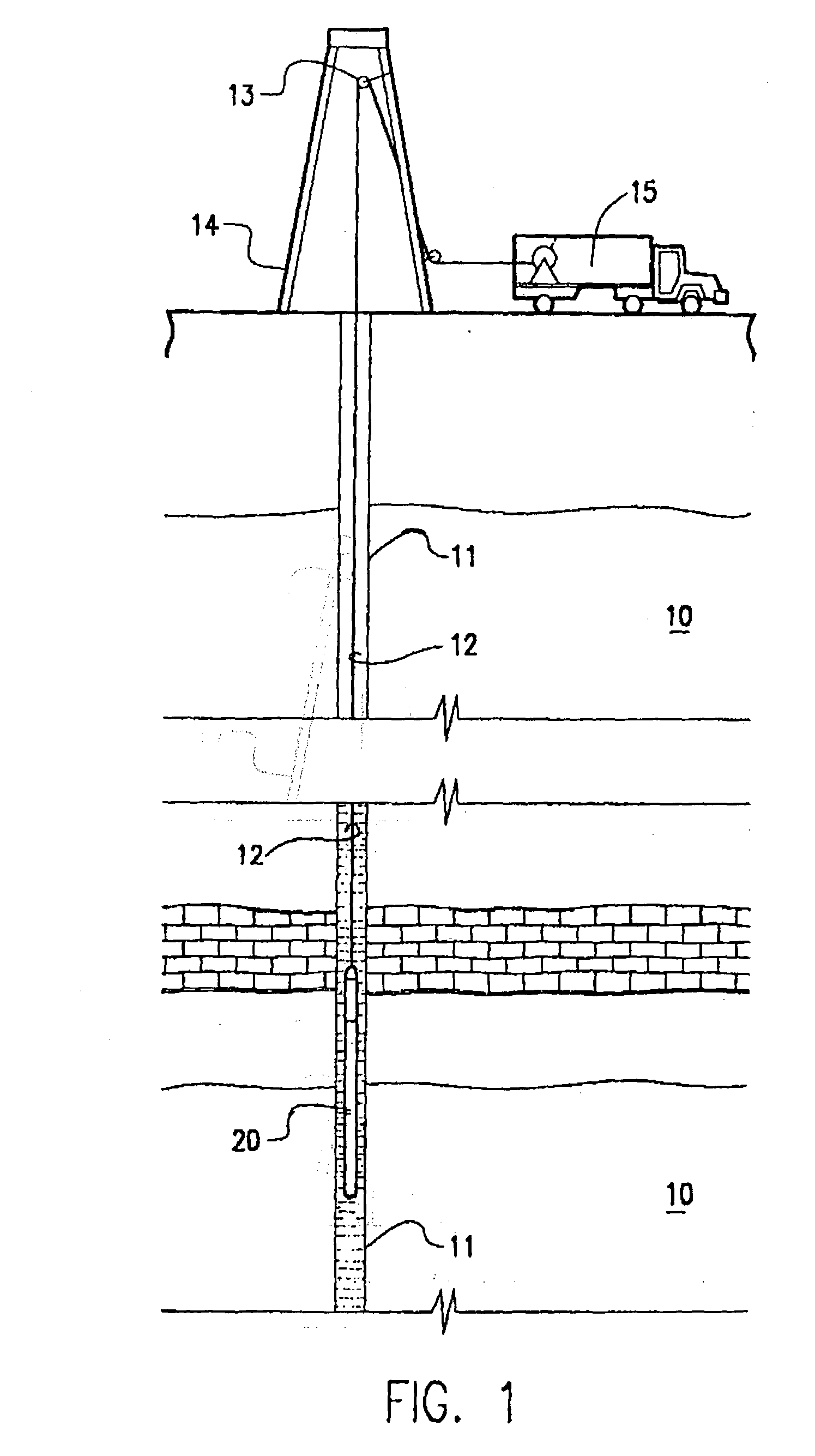

Method and apparatus for supercharging downhole sample tanks

A tank contains both Zeolite and a hydrate in a gas chamber formed beneath a piston in the sample tank. Out of safety considerations, we avoid using source cylinders of nitrogen whose pressures exceed 4000 psi. Thus, the gas chamber of the sample tank is initially pressurized by the source cylinder to no more than 4000 psi of nitrogen at room temperature at the surface. Nitrogen gas is sorbed onto the zeolite at room temperature. As the tank is heated by being lowered downhole, nitrogen desorbs from the zeolite and the gas pressure increases. However, once this tank reaches a temperature high enough to release the hydrate's water of hydration, the released water is preferentially sorbed by zeolite, displacing sorbed nitrogen, and causing the pressure in the gas volume to increase even further. Because well temperatures are not high enough to desorb water from zeolite, any water sorbed onto a Zeolite sorption site will permanently block released nitrogen from resorbing at that site. The process of lowering the tank downhole provides the necessary heating to make the entire process occur. Thus, if returned to the surface at room temperature with the original gas-chamber volume, the tank's pressure would not fall back to the original pressure (e.g., 4000 psi) but would be at a substantially higher pressure (e.g., 6000 psi or more depending on the amount of Zeolite used and gaseous nitrogen gas released).

Owner:BAKER HUGHES INC

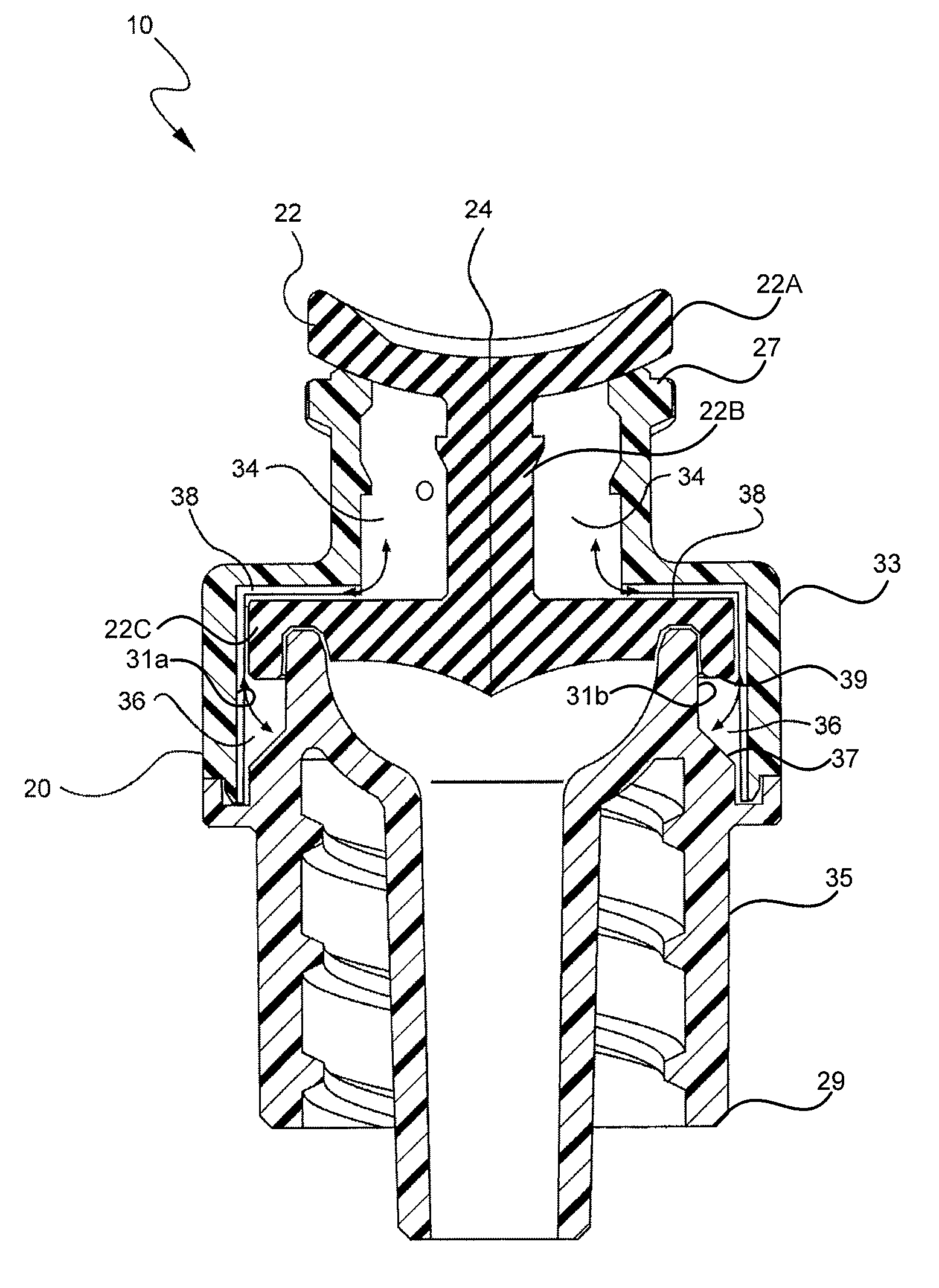

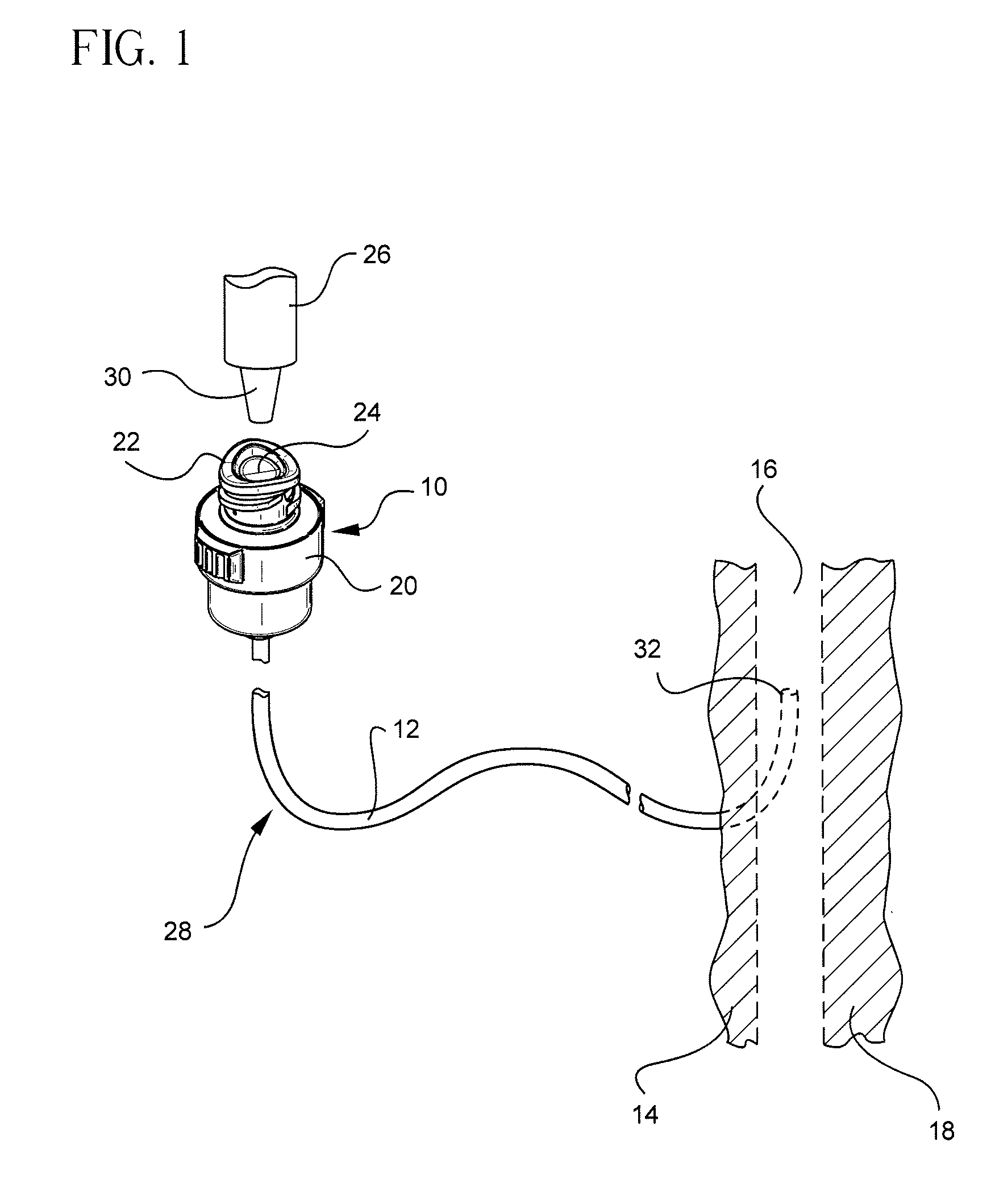

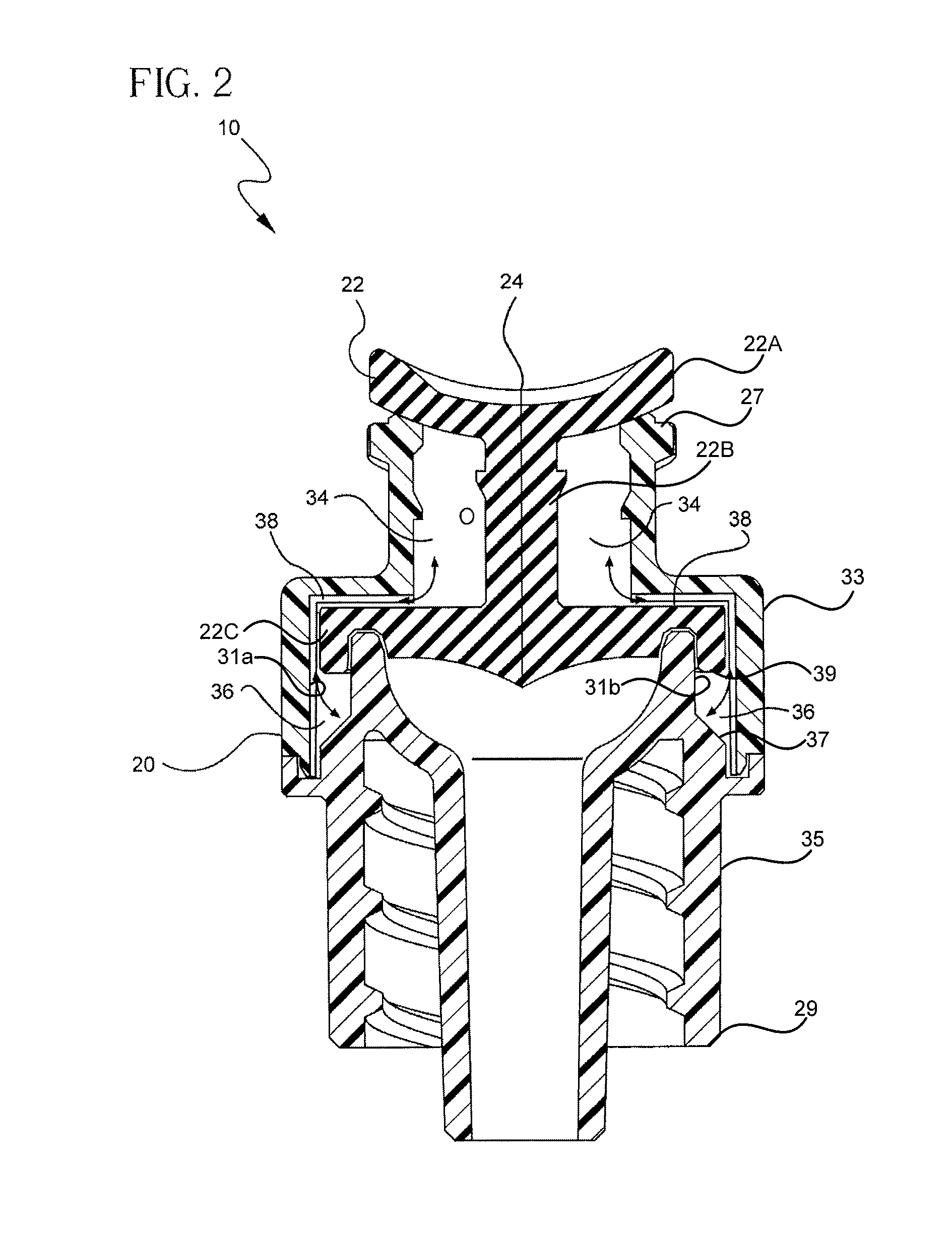

Vascular access device gas displacement

ActiveUS8366676B2Increase effective volumeIncrease volumeInfusion syringesCheck valvesVascular Access DevicesGas chamber

A vascular access device may include a gas chamber housed between a body and a septum, and a receptacle in communication with the gas chamber. A method of displacing gas in a medical device may include transferring gas between a gas chamber of a vascular access device and a receptacle housed within the vascular access device.

Owner:BECTON DICKINSON & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com