Methods and apparatus for combined variable damping and variable spring rate suspension

a technology of variable damping and spring rate suspension, which is applied in the direction of mechanical equipment, shock absorbers, transportation and packaging, etc., can solve problems such as inability to adap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

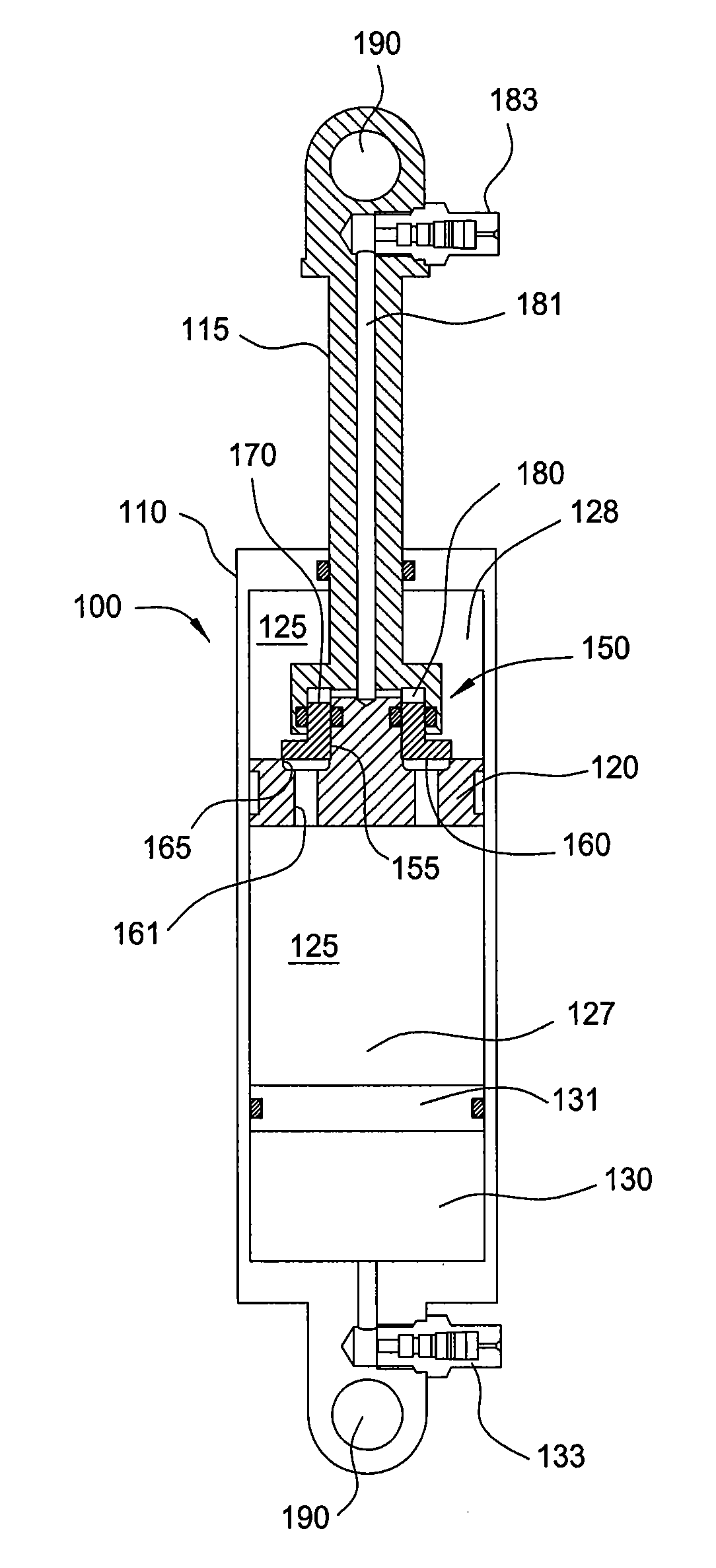

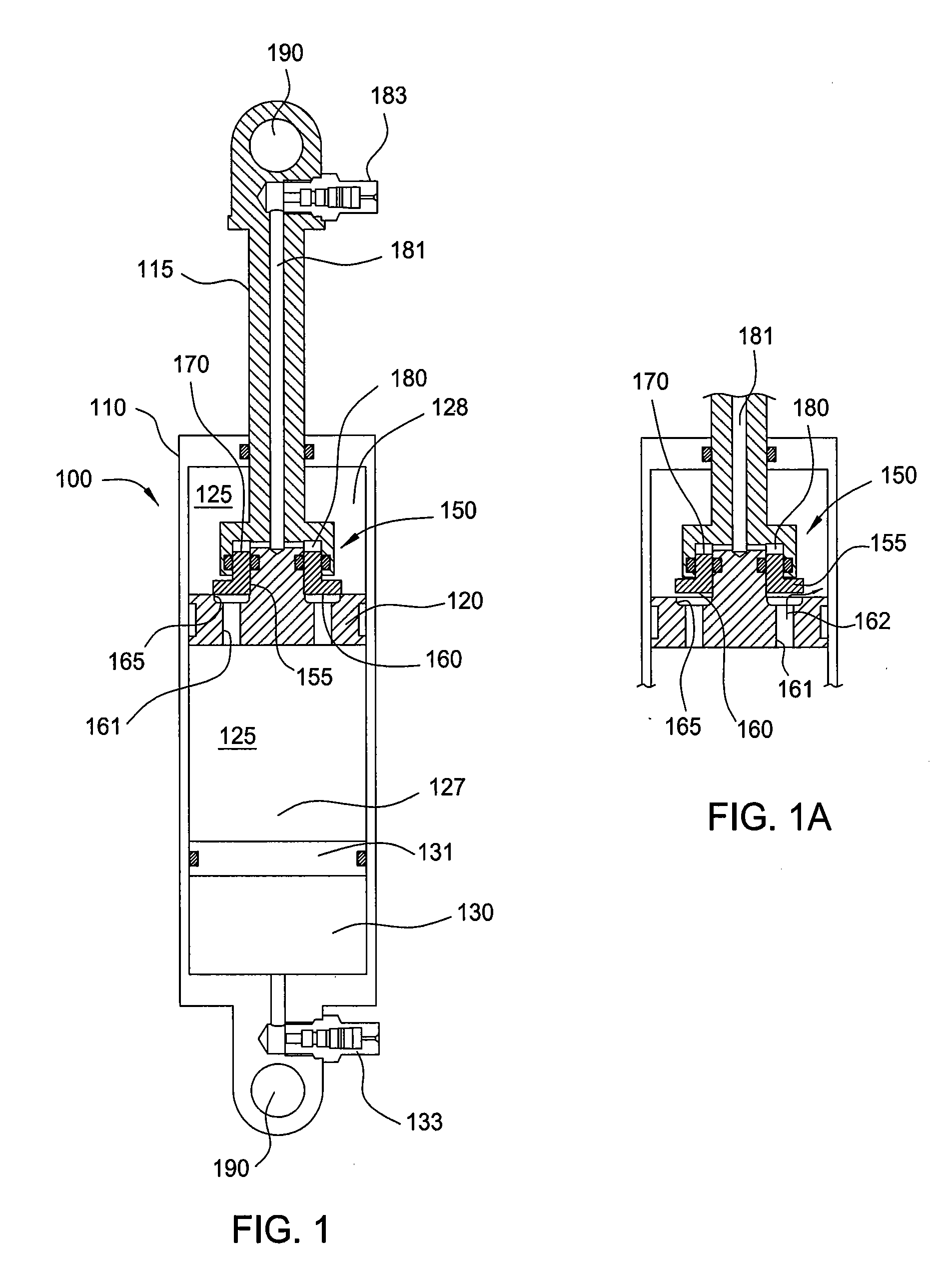

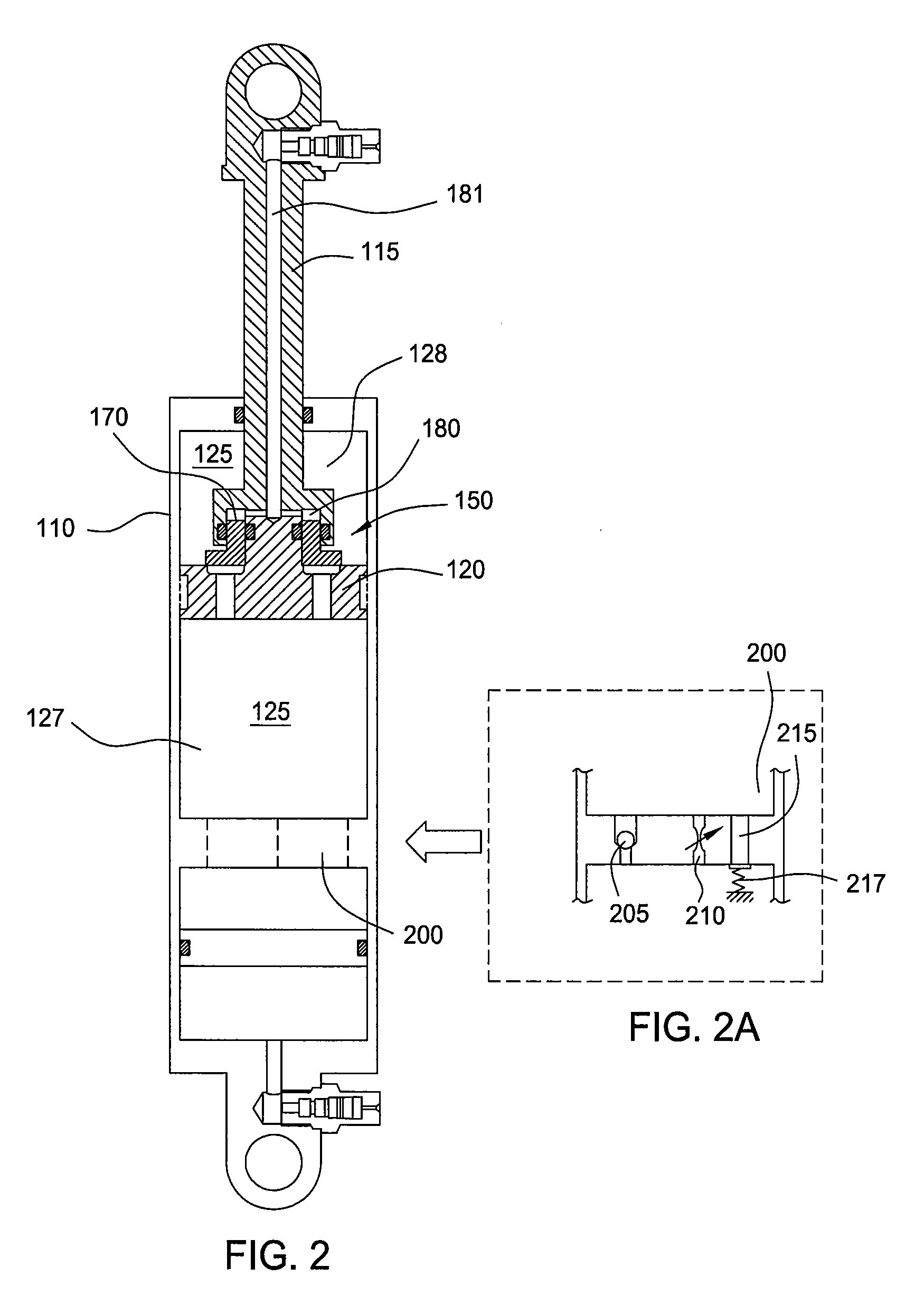

[0016]FIG. 1 is a section view showing one embodiment of a suspension damper 100. The damper includes a housing 110 with a rod 115 and piston 120 arranged to move downward into the housing 110 during a compression stroke and upward back out of the housing during a rebound stroke. A working fluid (e.g. damping fluid such as hydraulic oil) 125 in the housing passes through the piston 120 during each stroke and, depending upon the dampening needs, is metered to control a rate of movement of the piston 120 in the housing 110. A gas filled reservoir 130 at one end of the housing 110 and separated from the working fluid by a floating piston 131 provides additional volume as the rod 115 moves into the housing and displaces the working fluid 125. The gas in the reservoir 130 is user-adjustable via a fill valve 133 (such as for example a Schrader or Presta type gas fill valve) mounted externally and in fluid communication with the reservoir 130. Eyelets 190 formed at each end of the damper 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com