Patents

Literature

3324 results about "Damper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A damper is a valve or plate that stops or regulates the flow of air inside a duct, chimney, VAV box, air handler, or other air-handling equipment. A damper may be used to cut off central air conditioning (heating or cooling) to an unused room, or to regulate it for room-by-room temperature and climate control. Its operation can be manual or automatic. Manual dampers are turned by a handle on the outside of a duct. Automatic dampers are used to regulate airflow constantly and are operated by electric or pneumatic motors, in turn controlled by a thermostat or building automation system. Automatic or motorized dampers may also be controlled by a solenoid, and the degree of air-flow calibrated, perhaps according to signals from the thermostat going to the actuator of the damper in order to modulate the flow of air-conditioned air in order to effect climate control.

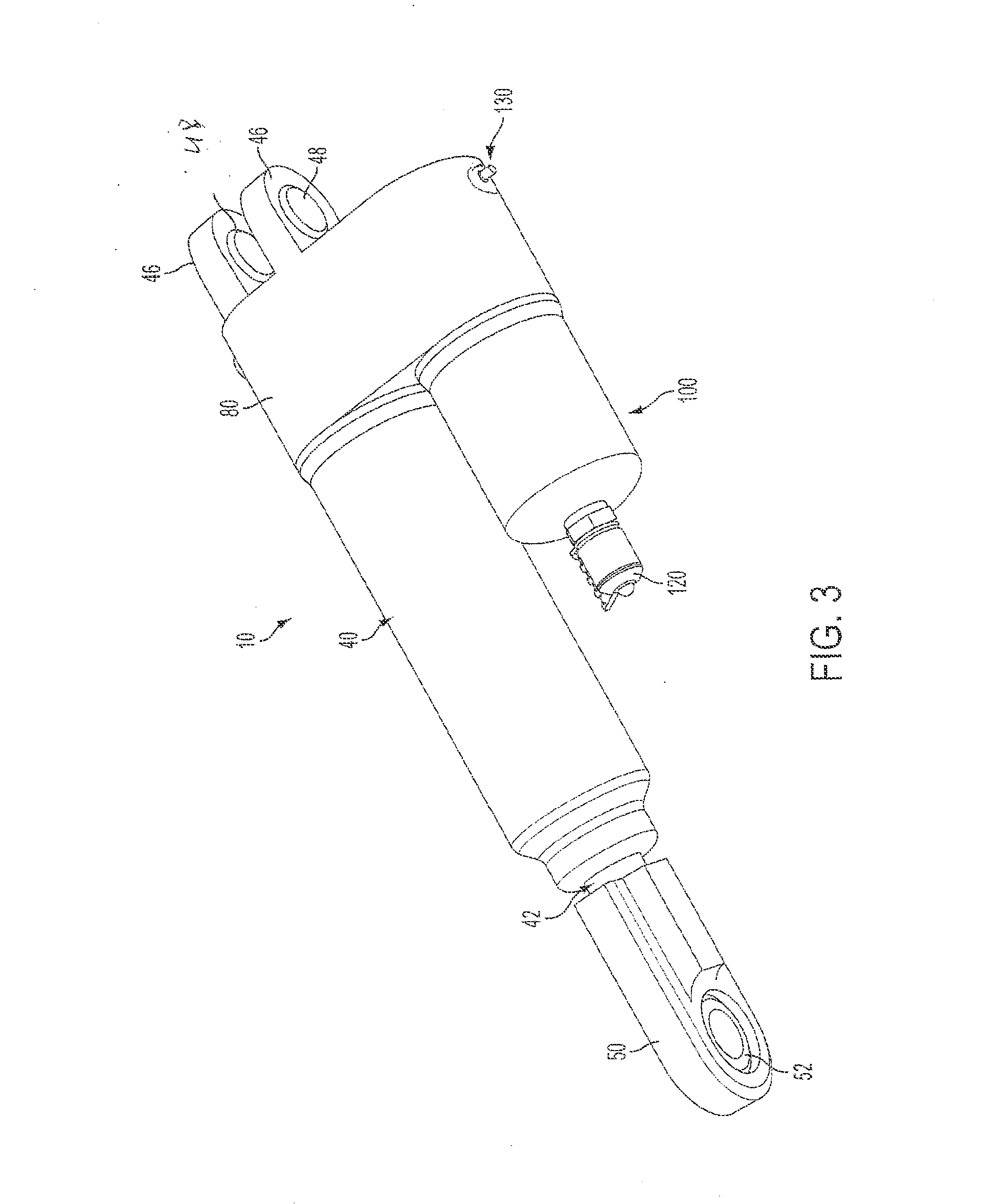

Damper with pressure-sensitive compression damping

InactiveUS20060289258A1Quickly and easily tunedQuickly and easily and adjustedSpringsShock absorbersElectrical resistance and conductanceSpring force

A damper includes a piston rod, a damping piston, at least one cylinder containing a damping liquid, a fixed partition member for partitioning the interior of the damper into two liquid chambers, a pressure source, and a valve in communication with the pressure source which reacts as a function of the pressure. The valve can also be in communication with additional forces, such as mechanical spring forces, which can be adjustable. The valve can include a pressure intensifier. The valve generates fluid flow resistance during flow of liquid in a first direction through the partition member. The fluid flow resistance in the first direction varies according to the amount of force communicated to the valve by the pressure source and any additional forces. The partition member can include means for providing low-resistance return flow of liquid in a second direction.

Owner:FOX FACTORY

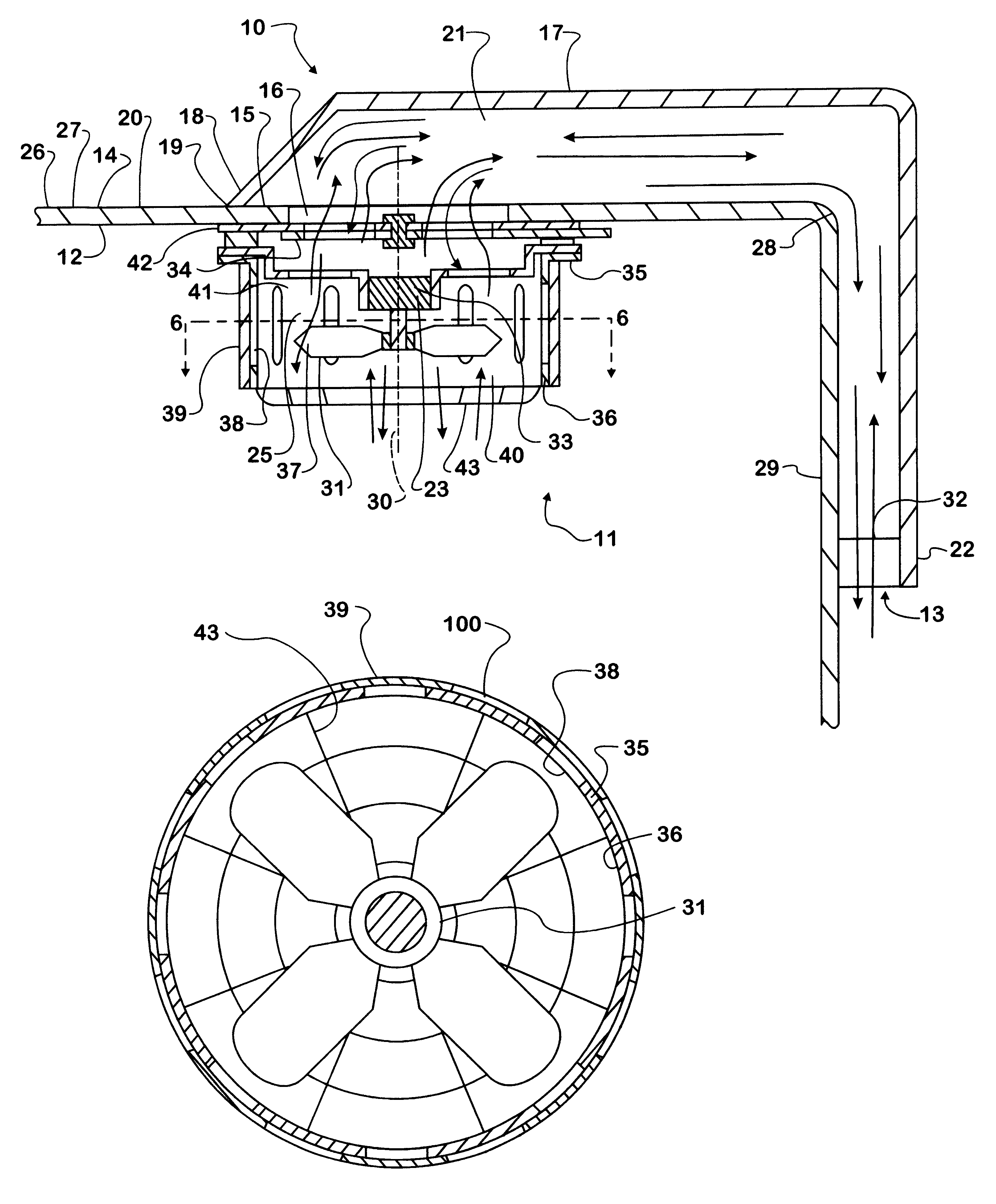

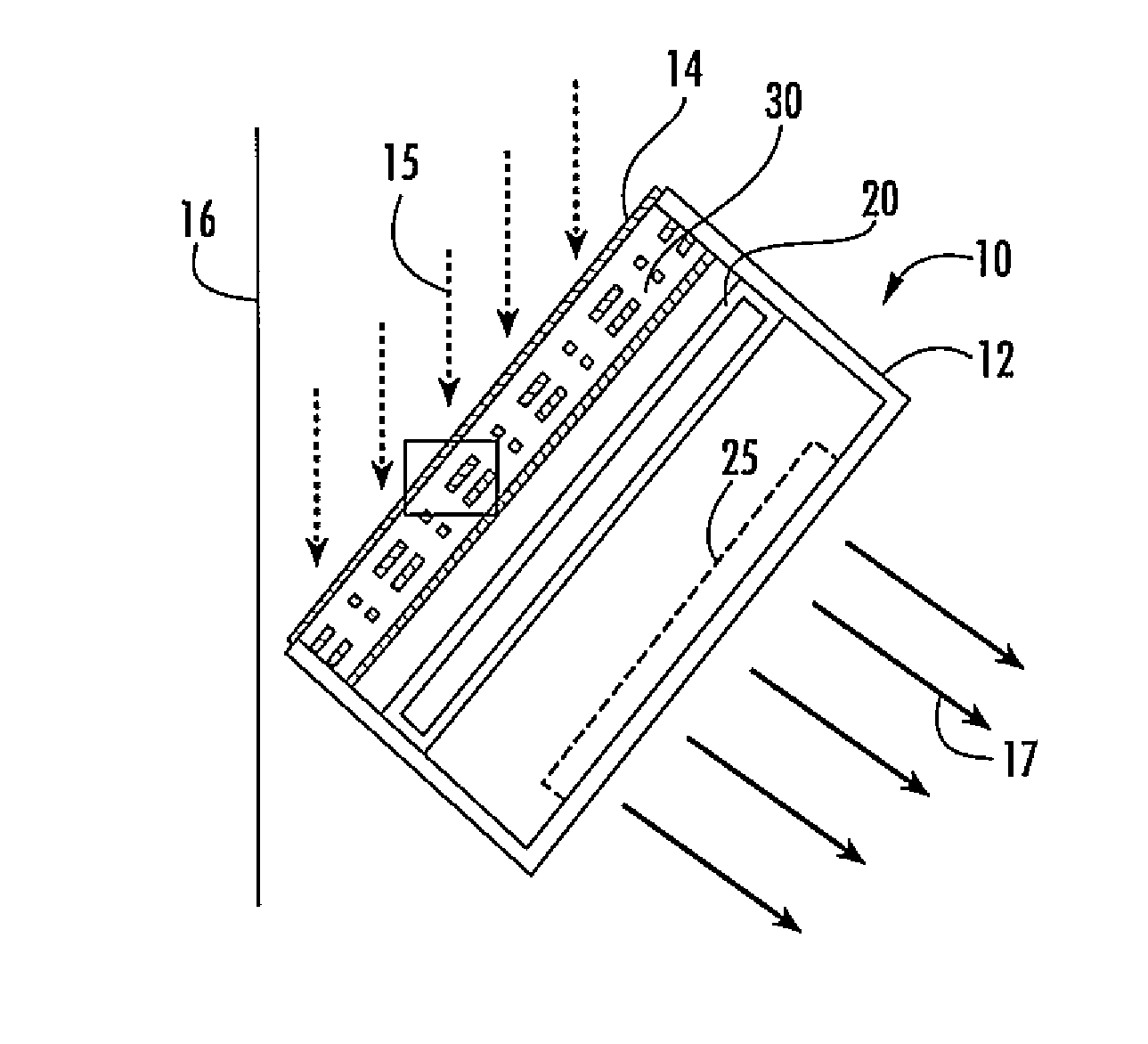

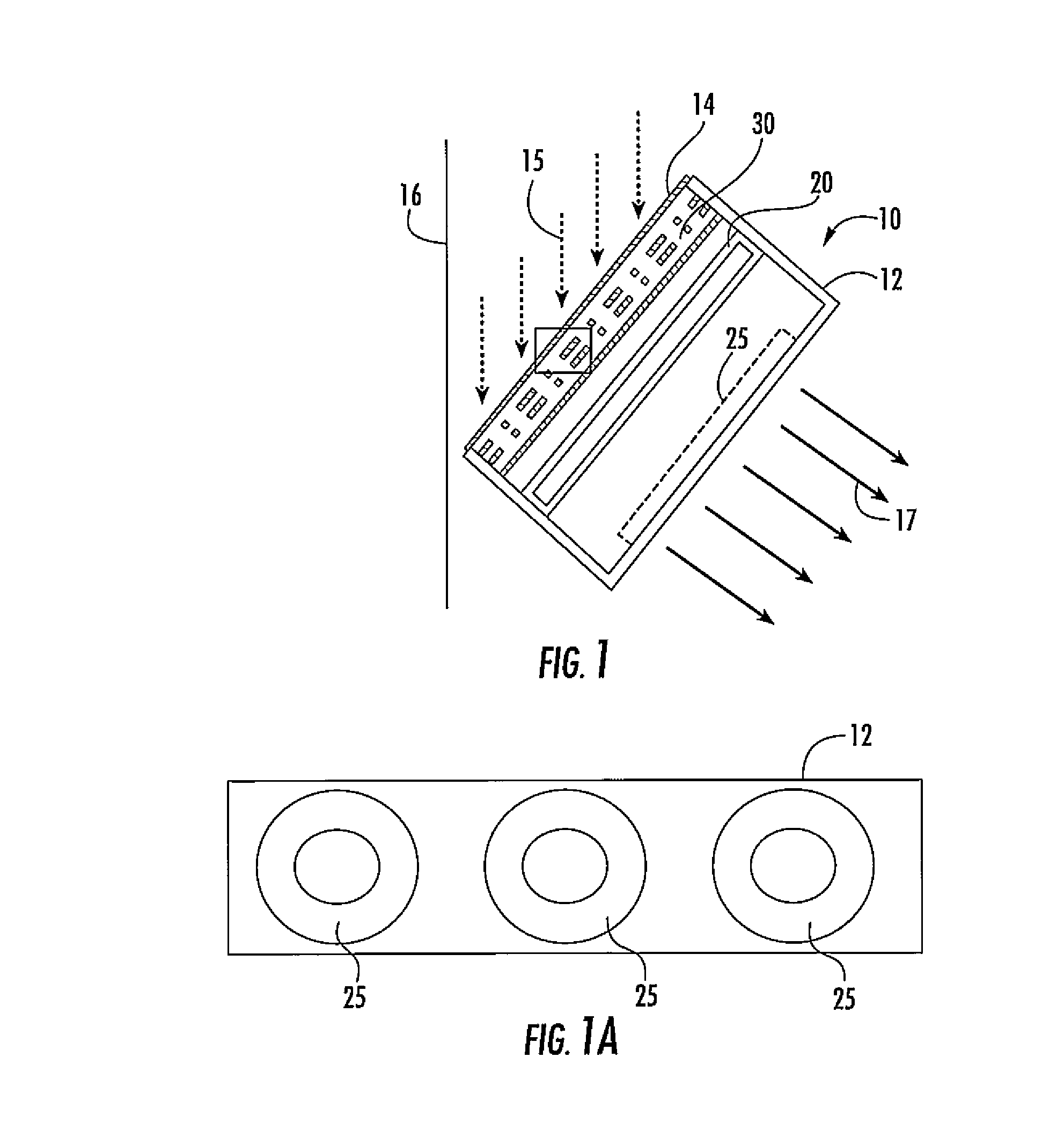

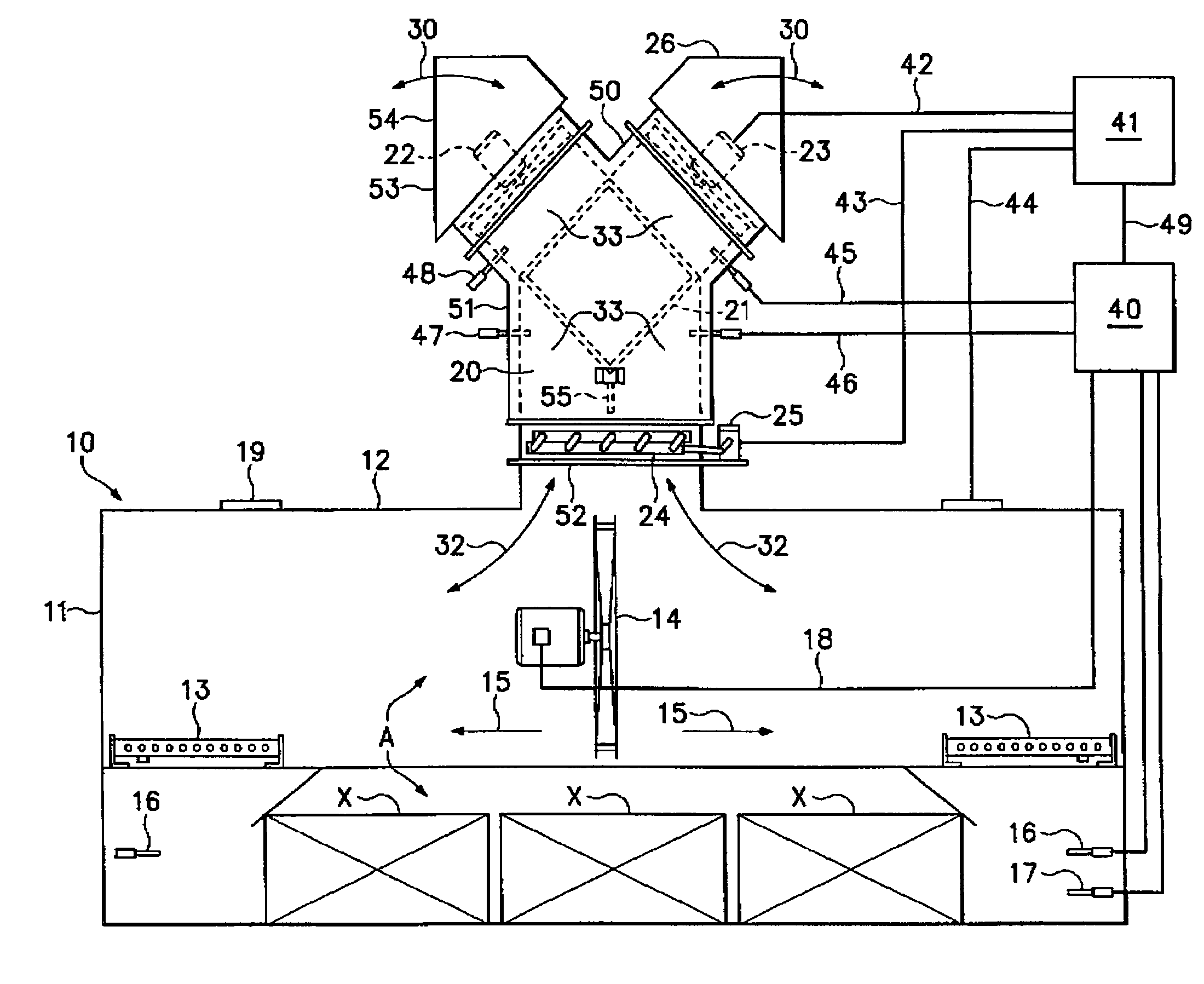

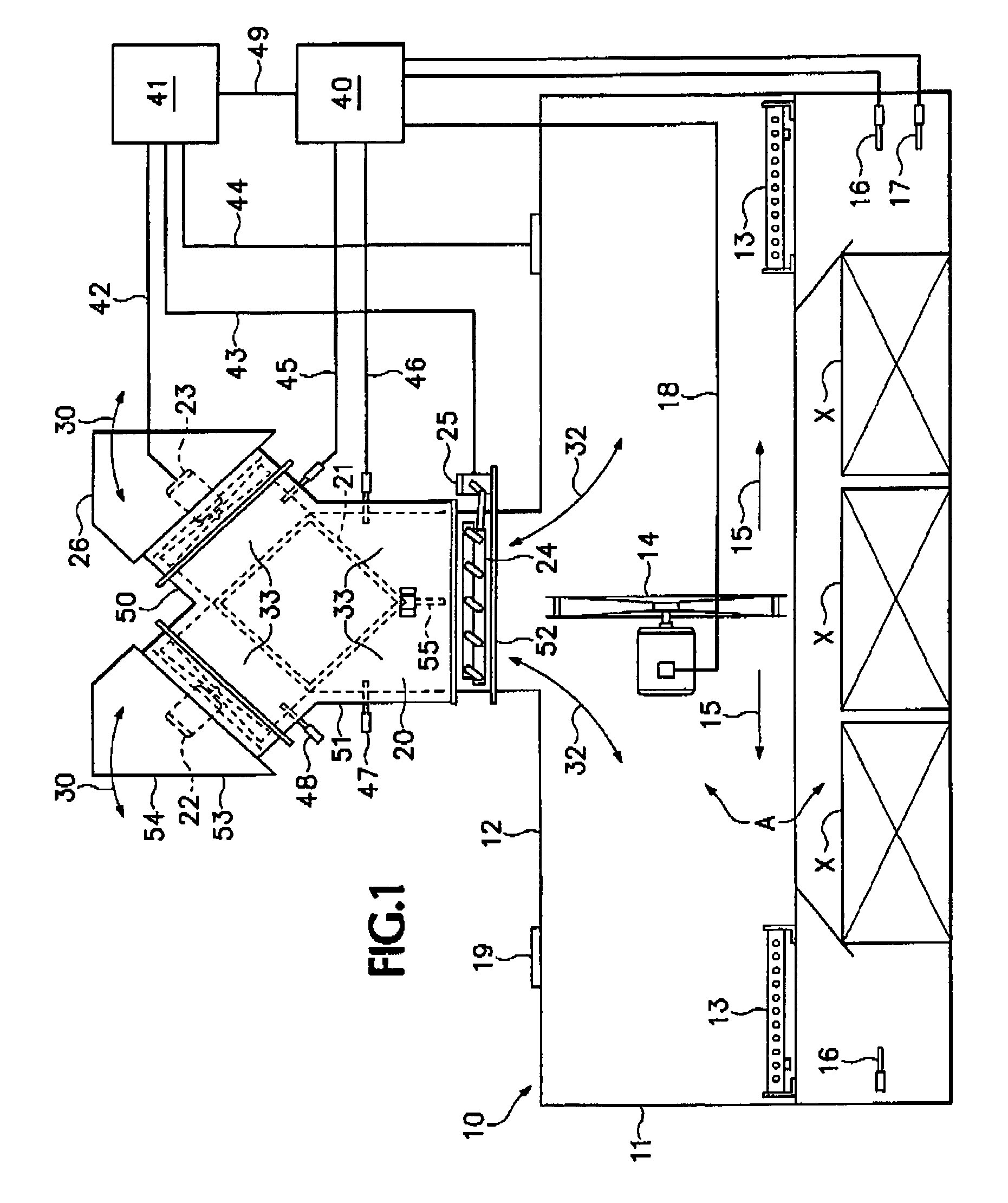

Stabilization system for sensors on moving platforms

ActiveUS20110175604A1Improve mass balanceSmall biasAcceleration measurementFrequency analysisRotational stabilityAir bearing

A stabilized field sensor apparatus collects field data, in particular magnetic field data, with reduced motion noise. The apparatus includes a tear drop shaped housing, a tow frame in the housing, a plurality of vibration isolating dampers spaced around the frame, a base assembly mounted to the dampers, a support pedestal having a bottom end fixed to the base assembly and an upper free end, a single spherical air bearing connected to the upper free end of the pedestal, an instrument platform with a lower hollow funnel having an upper inside apex supported on the air bearing for a one point support, principal and secondary gyro stabilizers for maintaining pivotal and rotational stability, and at least one field sensor mounted to the instrument platform for collecting the field data while being stabilized against motion noise including vibration, pivoting and rotation from the base assembly, from the tow frame and from the housing. Stabilization of the instrument platform is enhanced by preserving accurate balance through a dynamic balancing system whereby small masses are moved under computer control to maintain the center of mass of the instrument platform at the center of rotation of the spherical air bearing. The dynamic stabilization process is made more precise by actively vibrating the instrument platform by a set of linear vibrators.

Owner:VALE LIMITED

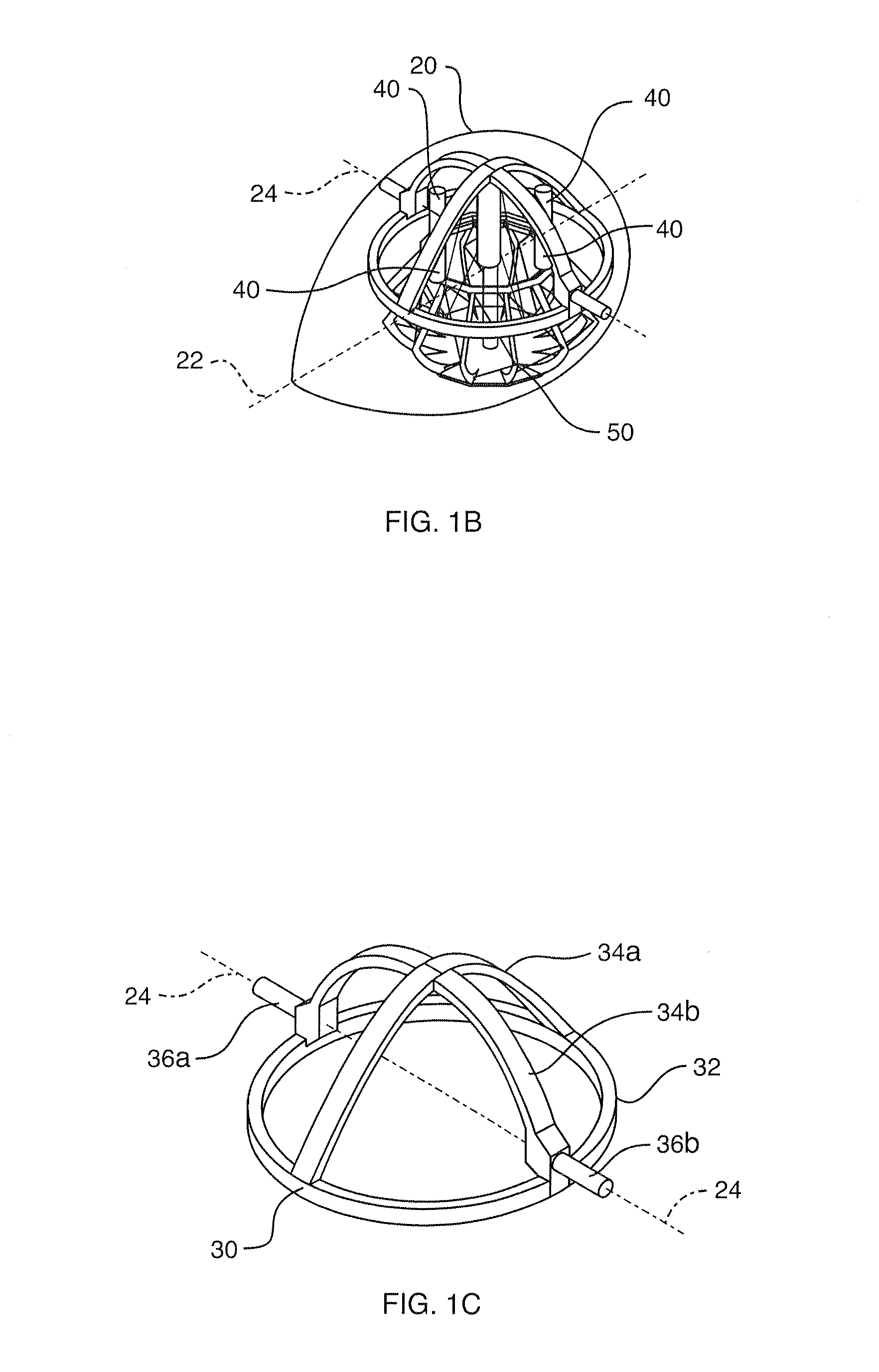

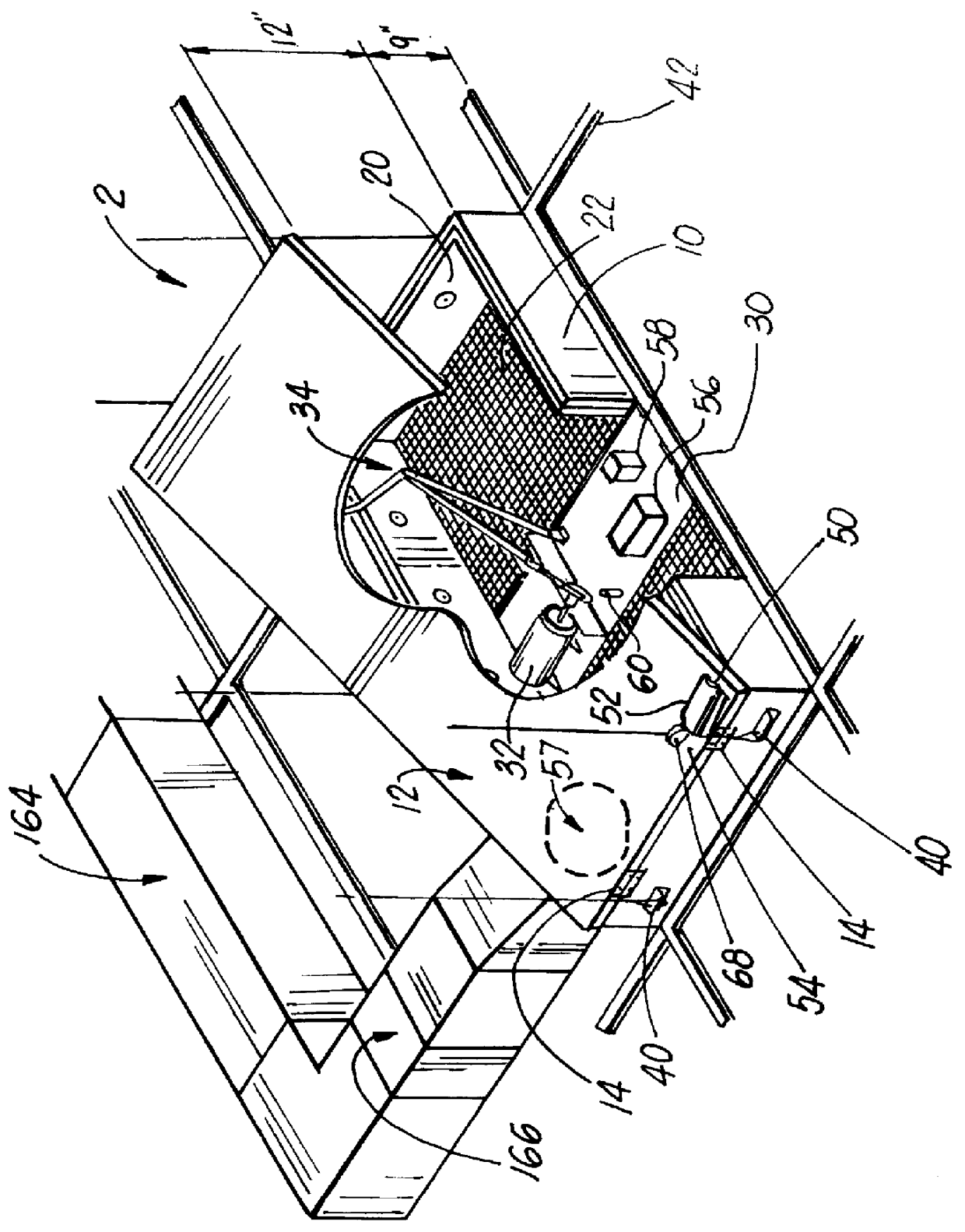

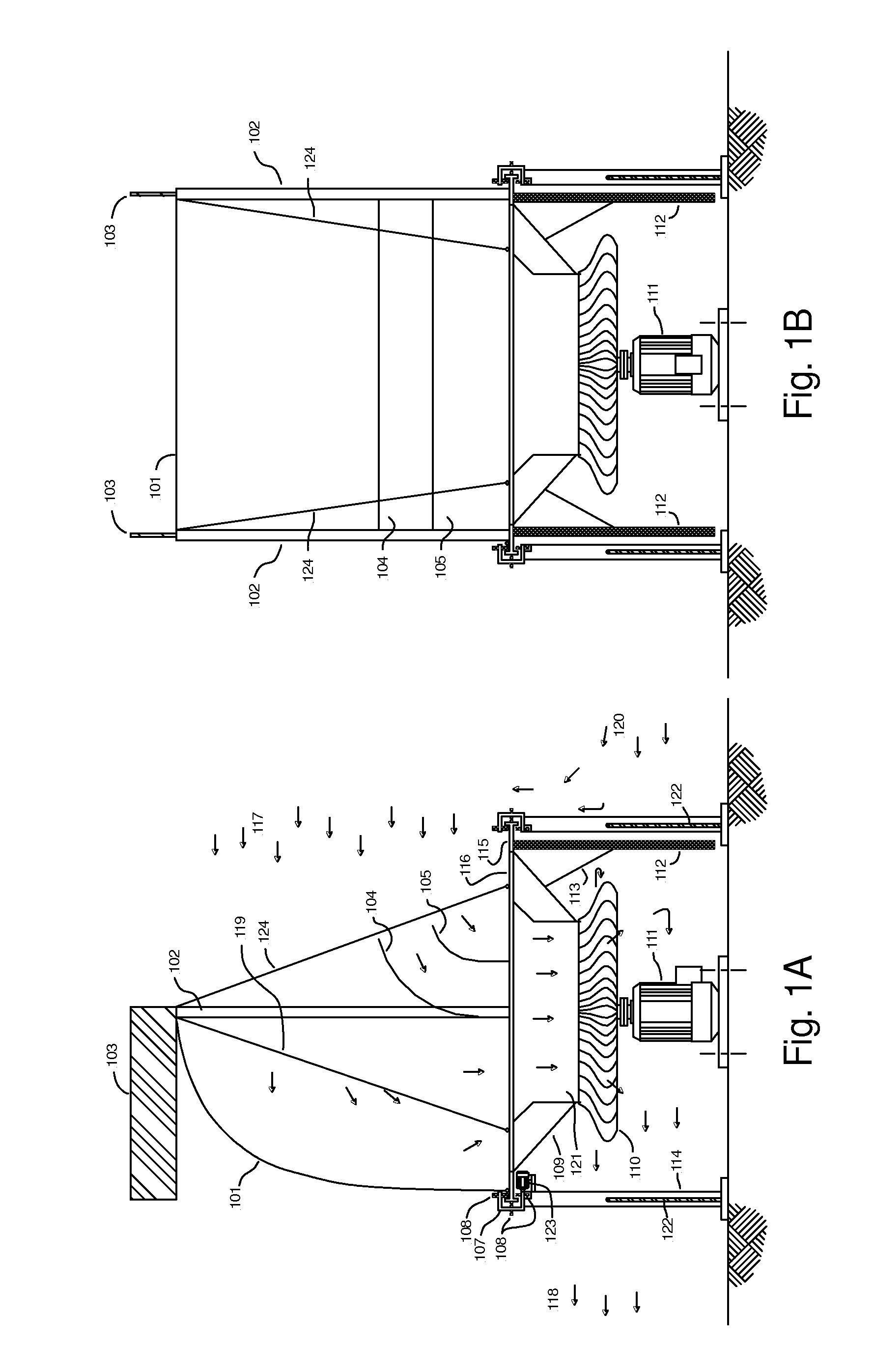

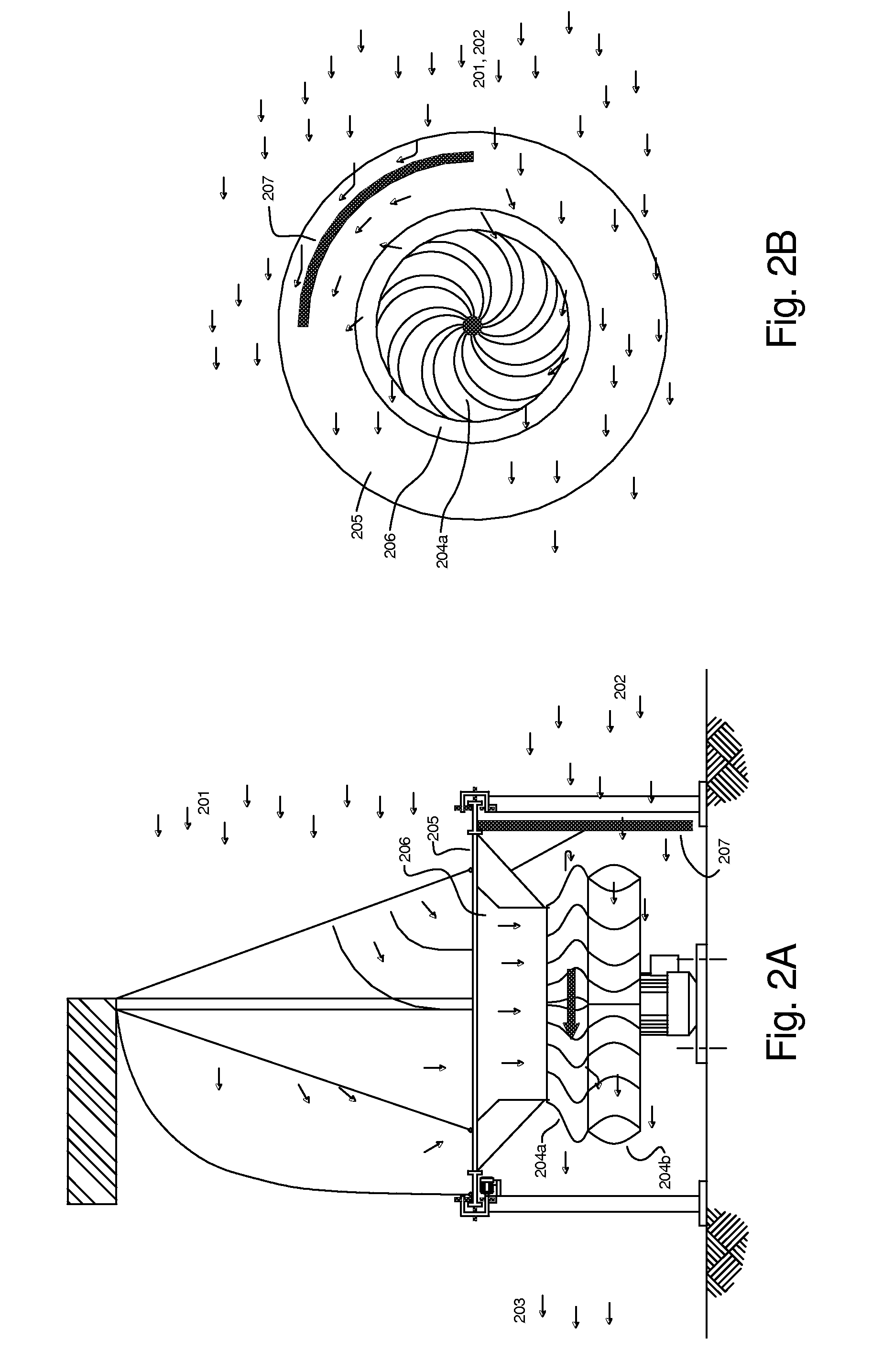

Vehicle ventilation system

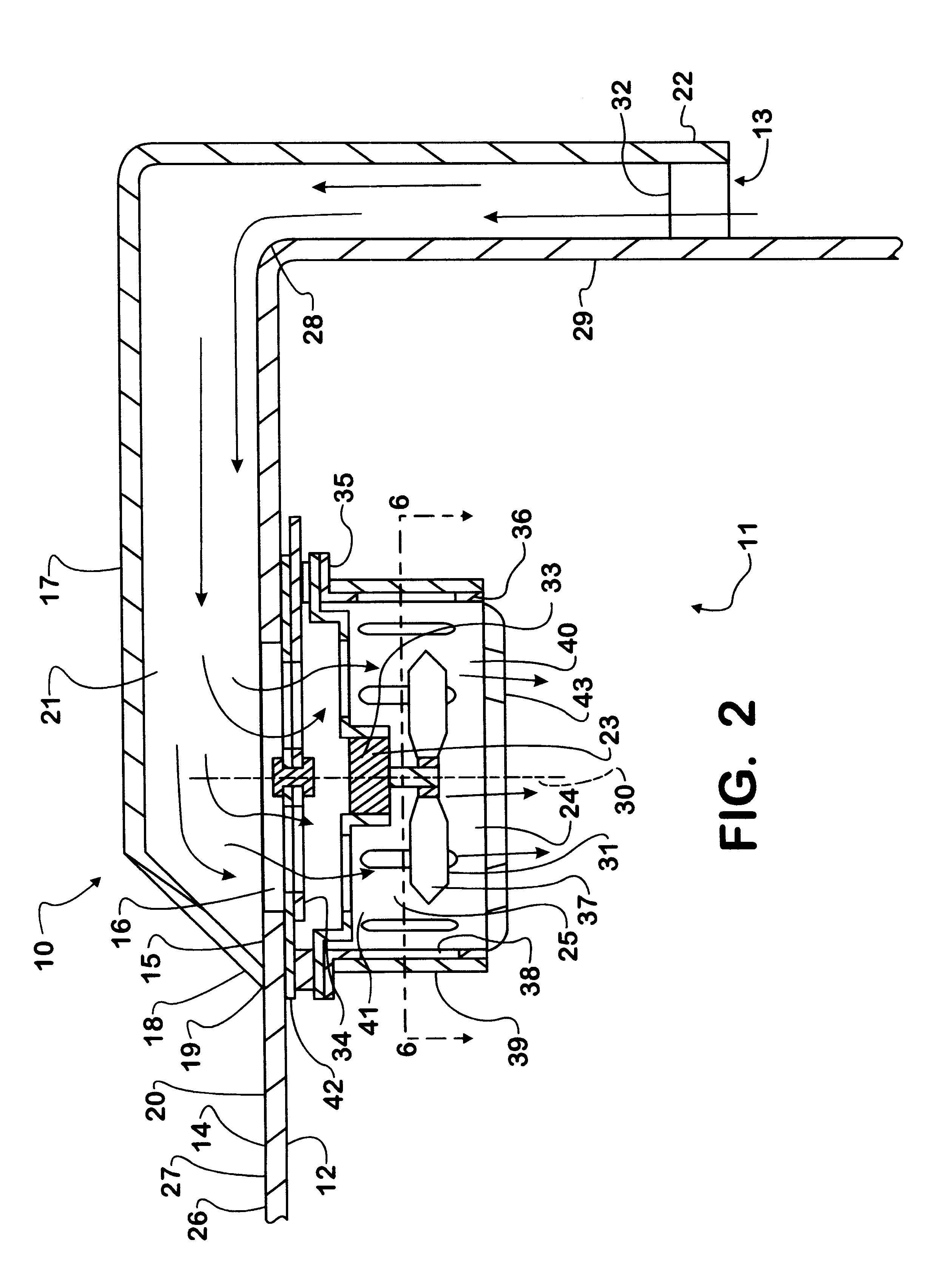

A vehicle ventilation system mounted to the upper portion of the exterior structure of a vehicle's occupant cabin. The components of the exterior structure of the occupant cabin define an opening through the exterior structure of the occupant cabin in the upper portion of the occupant cabin. A duct is mounted to the exterior structure of the occupant cabin and has a first end in fluid communication with the opening in the exterior structure of the occupant cabin. A second end of the duct is positioned below the first end of the duct and is open to and in fluid communication with the outside atmosphere. A fan is mounted to the exterior structure of the occupant cabin and is positioned such that when in operation it can be operated to move air through the opening in the exterior structure of the occupant cabin. The fan is controllable to change the rate and direction of the flow of air which it creates. A first rotary damper is mounted over the opening in the exterior structure of the occupant cabin and can be selectively opened or closed to allow or prevent air flow through the opening in the exterior structure of the occupant cabin. A second damper is mounted in a position such that it radially surrounds the impeller of the fan and can be used to control the flow of air radially outward from or radially inward toward the impeller of the fan.

Owner:INT TRUCK INTPROP LLC

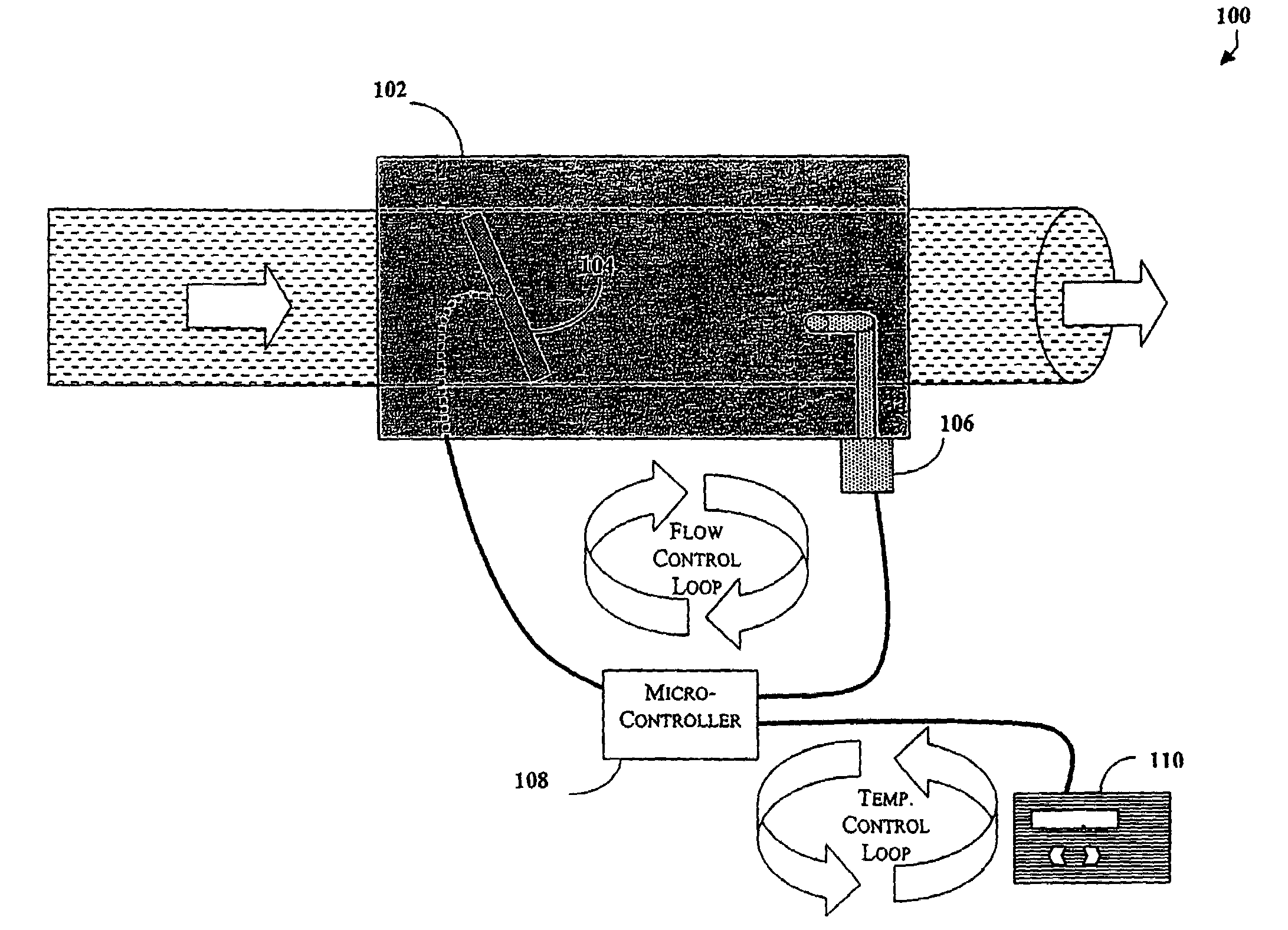

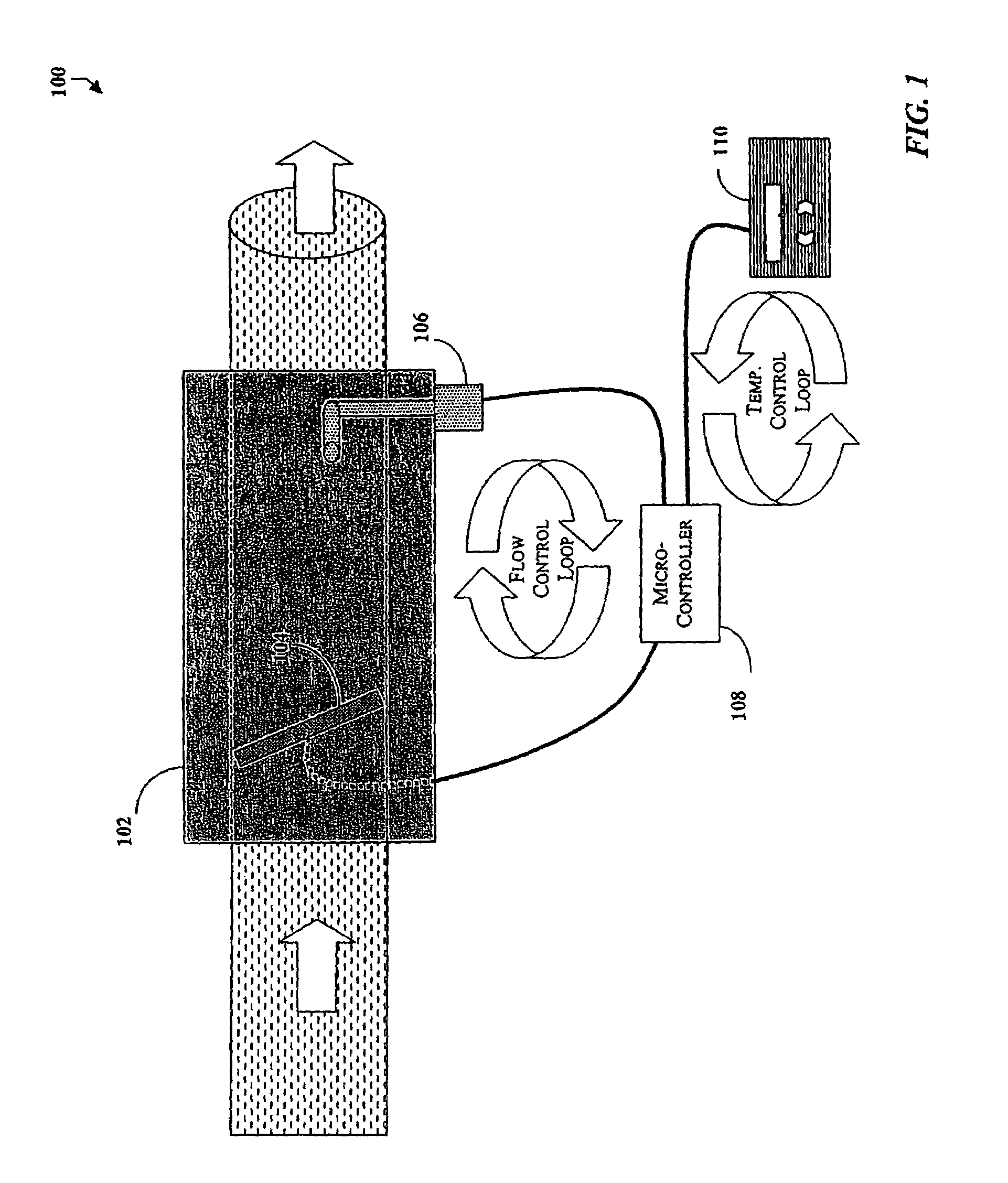

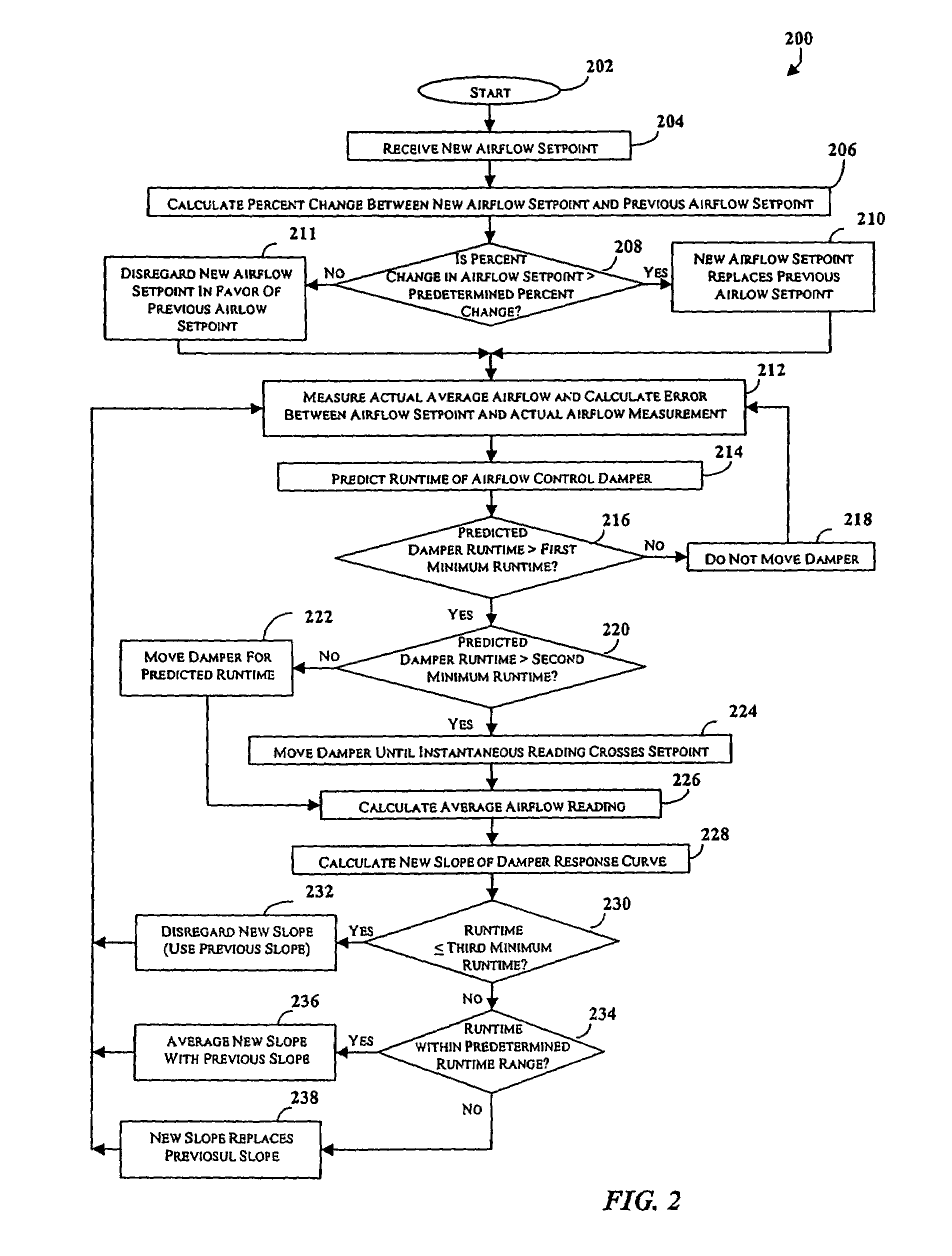

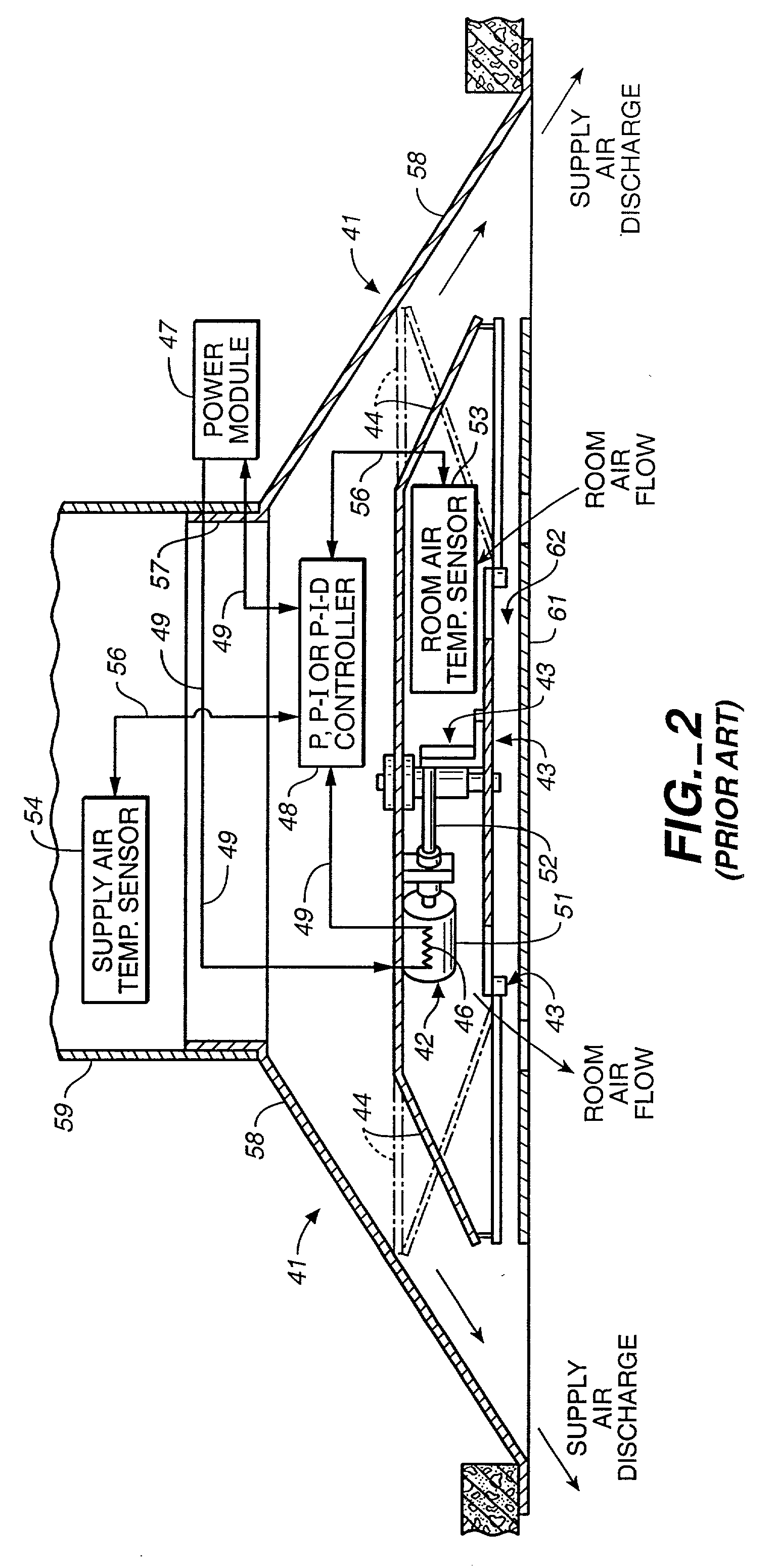

Slope predictive control and digital PID control

InactiveUS7216497B2Minimize movementProlong lifeMechanical apparatusSpace heating and ventilation safety systemsRoom temperatureSnubber

Owner:AUTOMATED LOGIC CORP

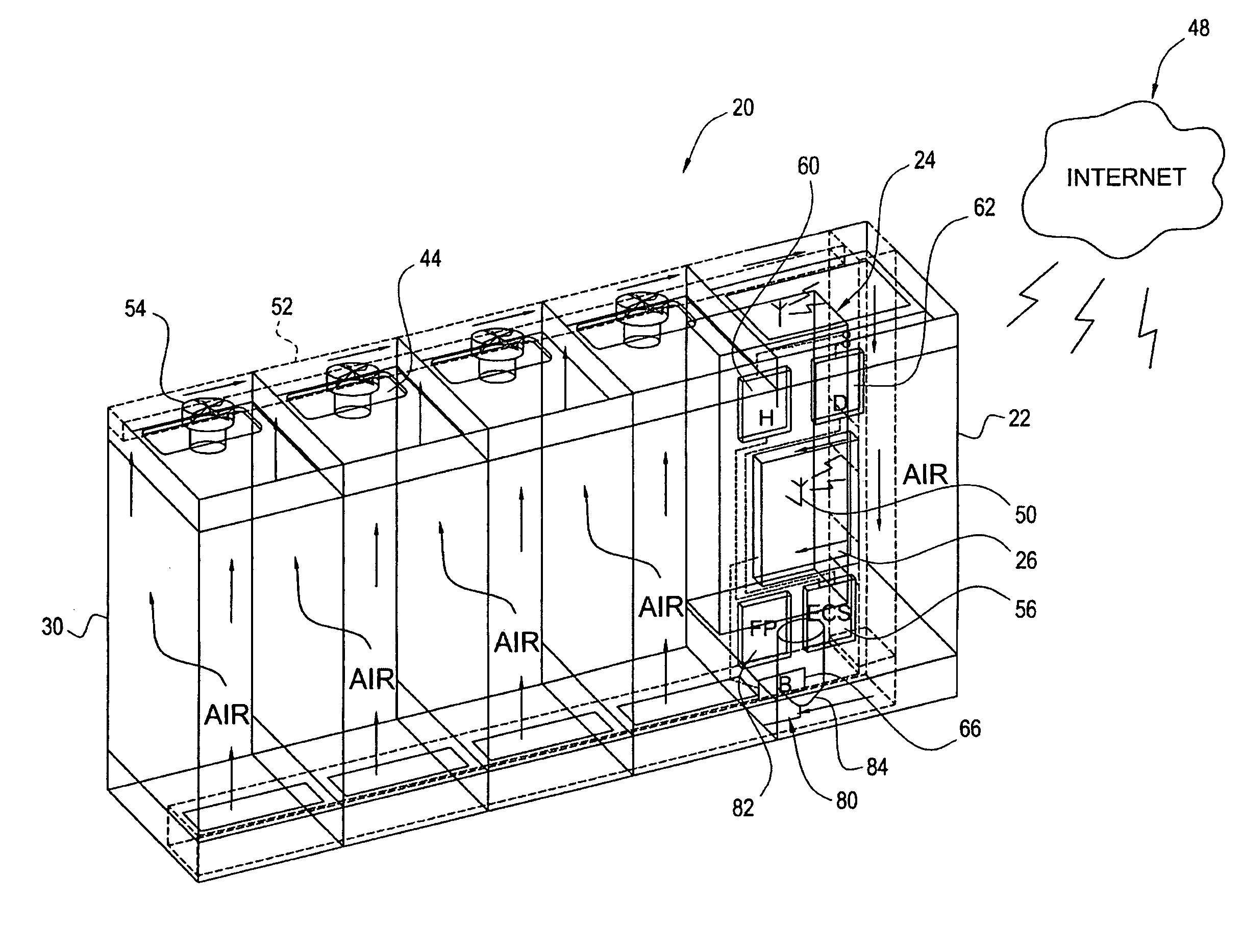

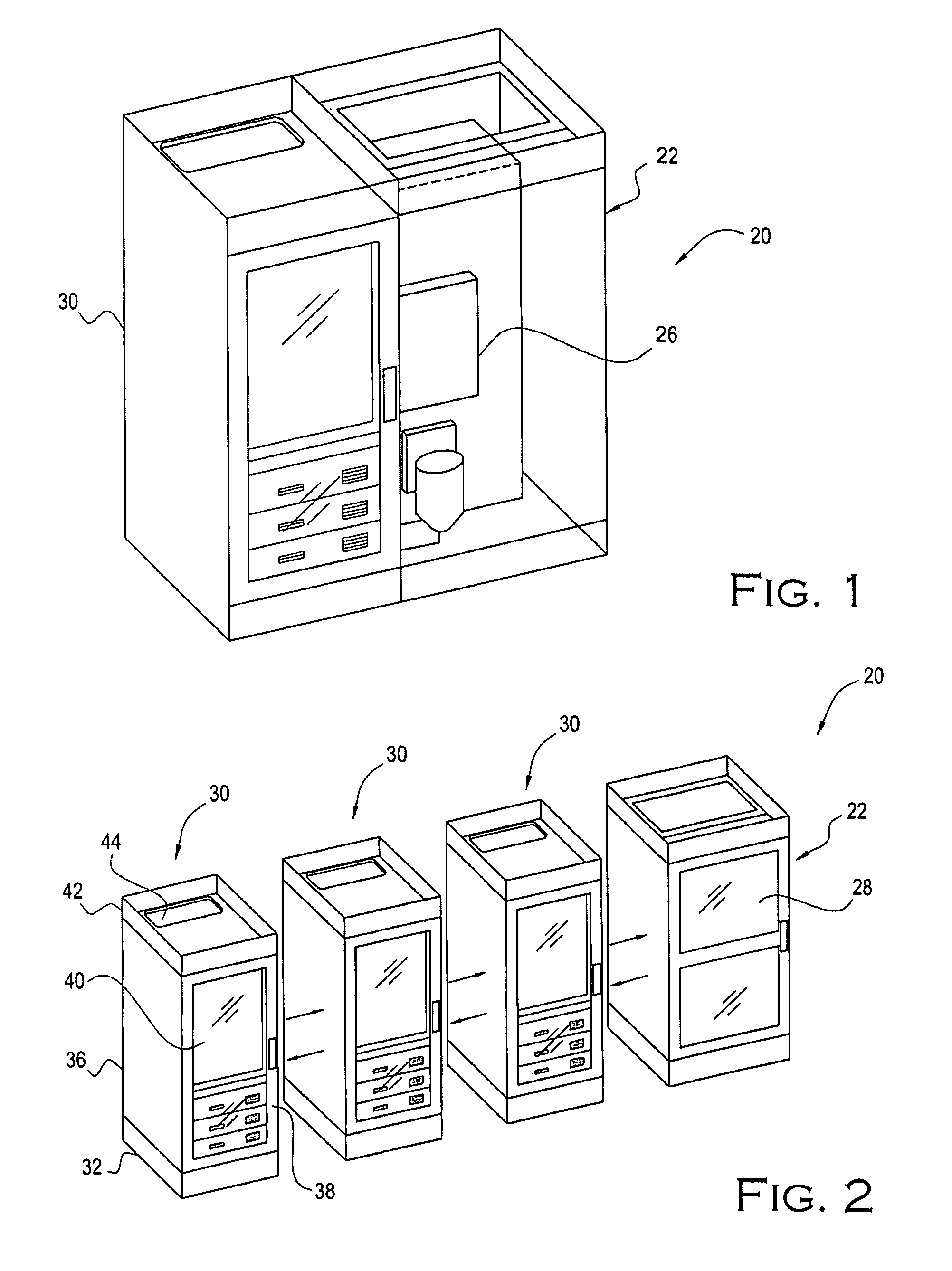

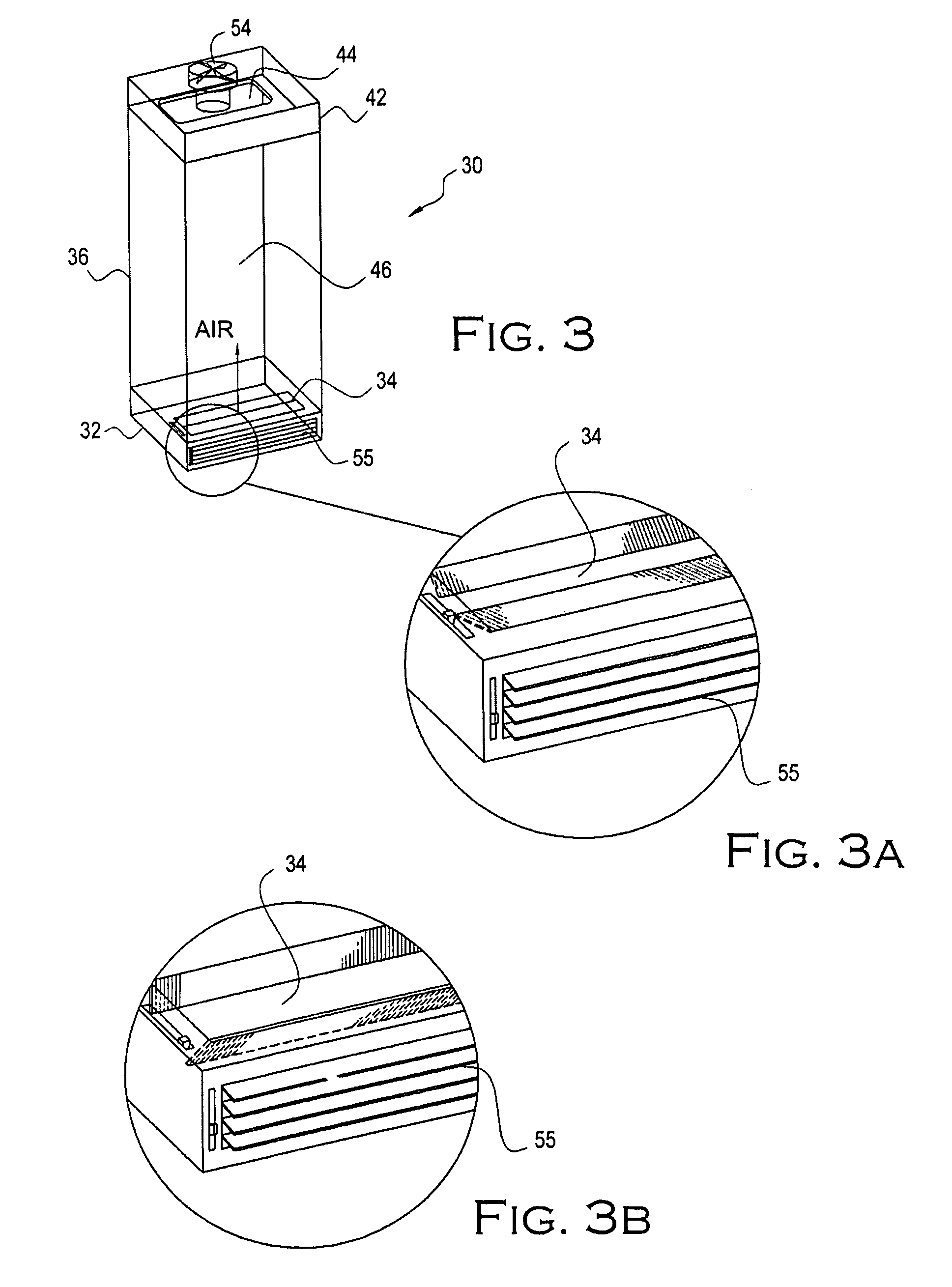

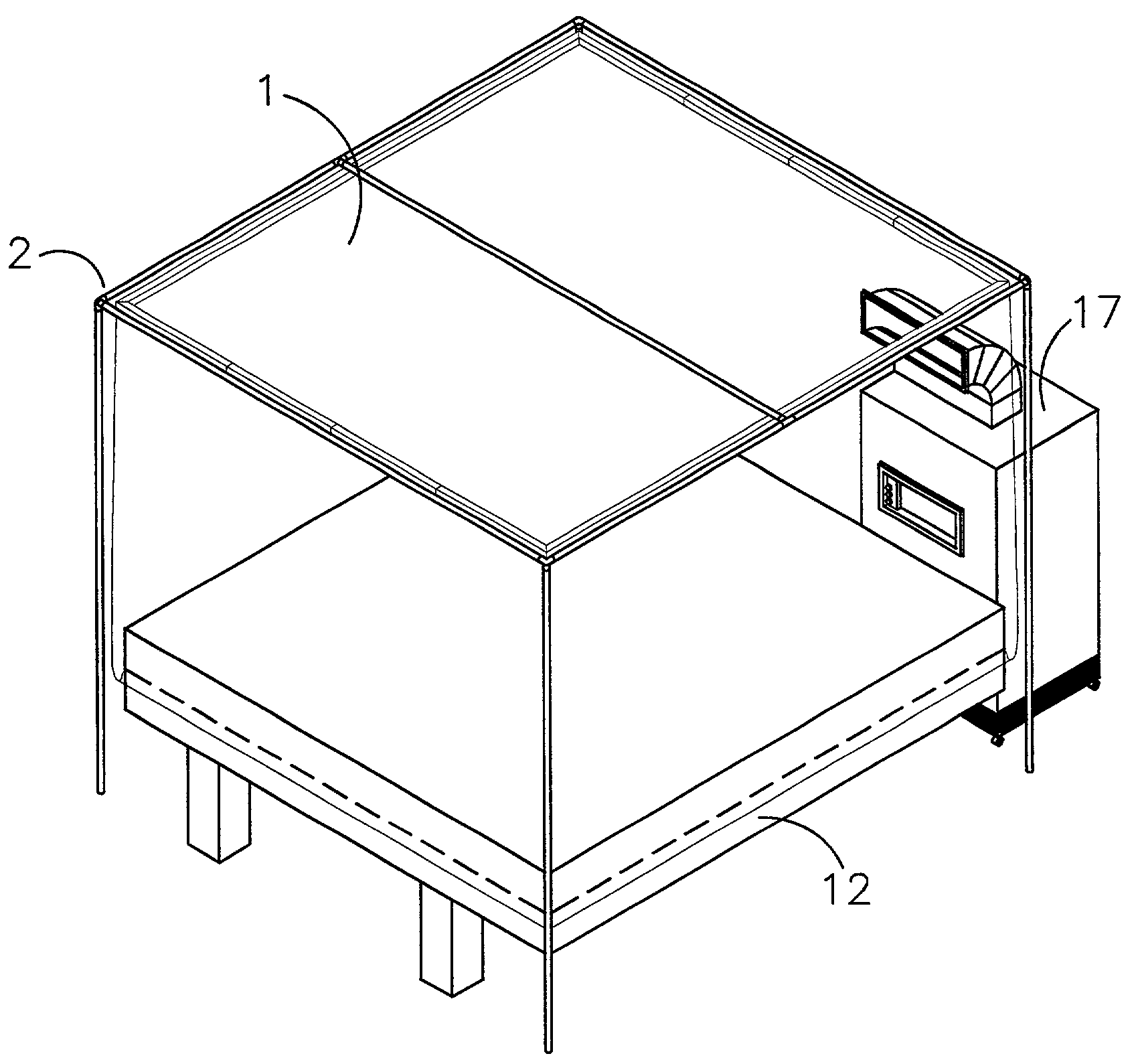

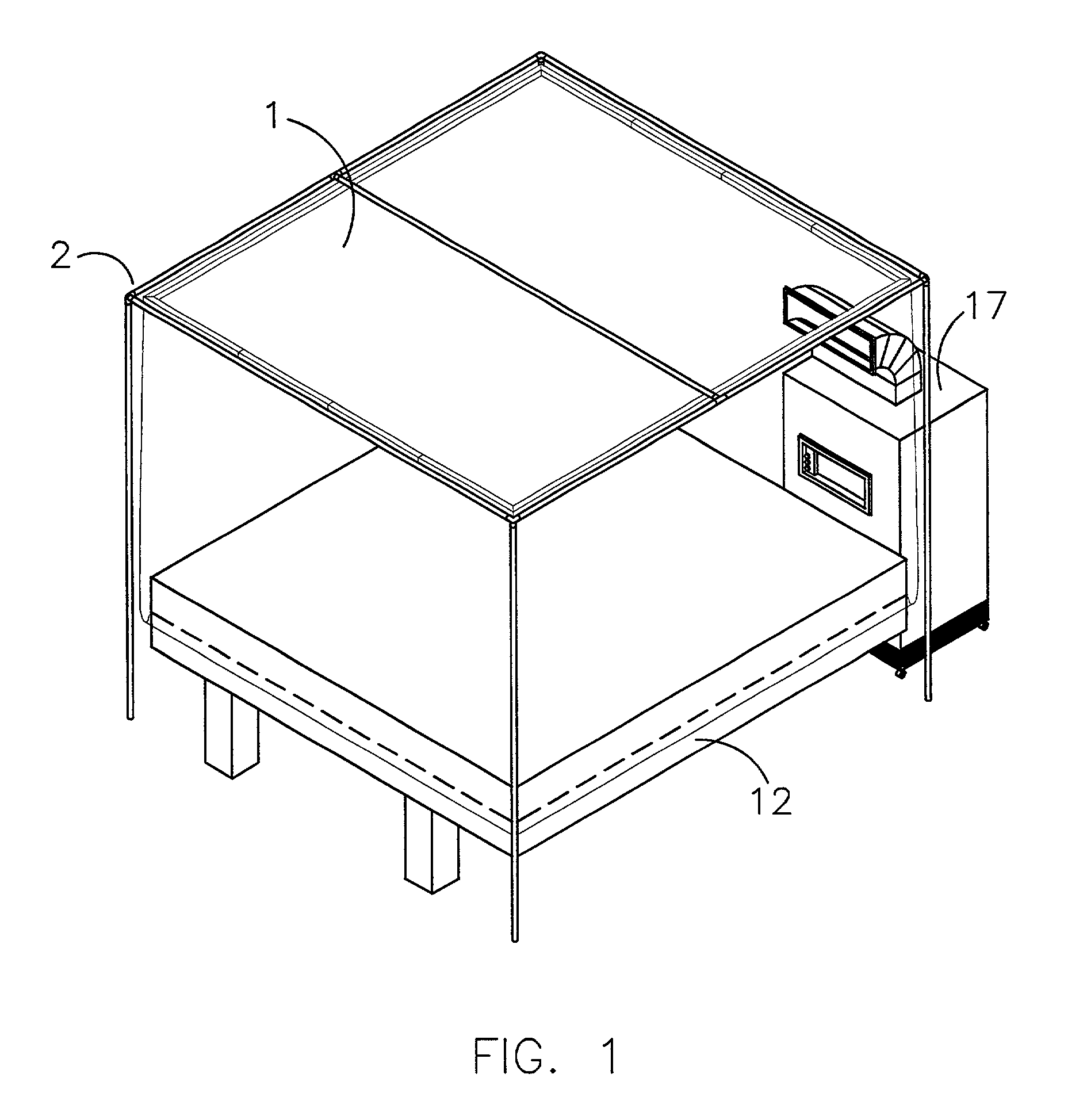

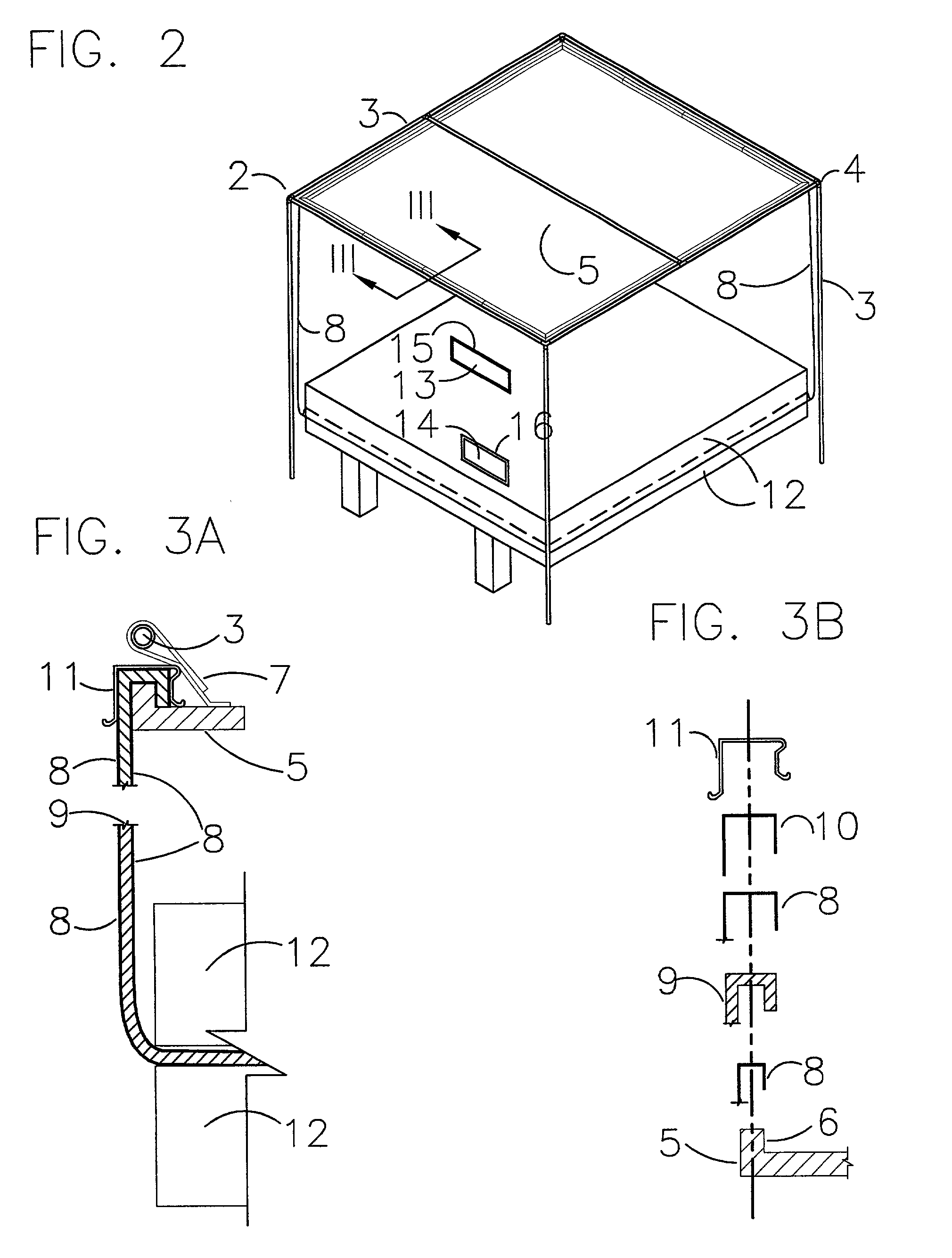

Closed data center containment system and associated methods

ActiveUS7895855B2Easily and economically expandableSampled-variable control systemsDomestic cooling apparatusCold airData center

A containment system includes a control unit comprising a cooling system and a control panel in communication with the cooling system. The containment system also includes a containment unit in communication with the control unit for containing a plurality of electronic components. The containment unit includes a base including a damper, a plurality of sidewalls extending upwardly from the base, and a top overlying the base and having a passageway formed area. The base, the plurality of sidewalls and the top define a containment area there between for containing the plurality of electronic components. Cold air is passed from the cooling system to the base of the containment unit through the damper and into the containment area. Warm air is removed from the containment area through the passageway formed in the top thereof and back to the cooling system. The warm air removed from the containment area is cooled by the cooling system, and the control panel is adapted to be in communication with the electronic components contained in the containment area.

Owner:VERTIV CORP

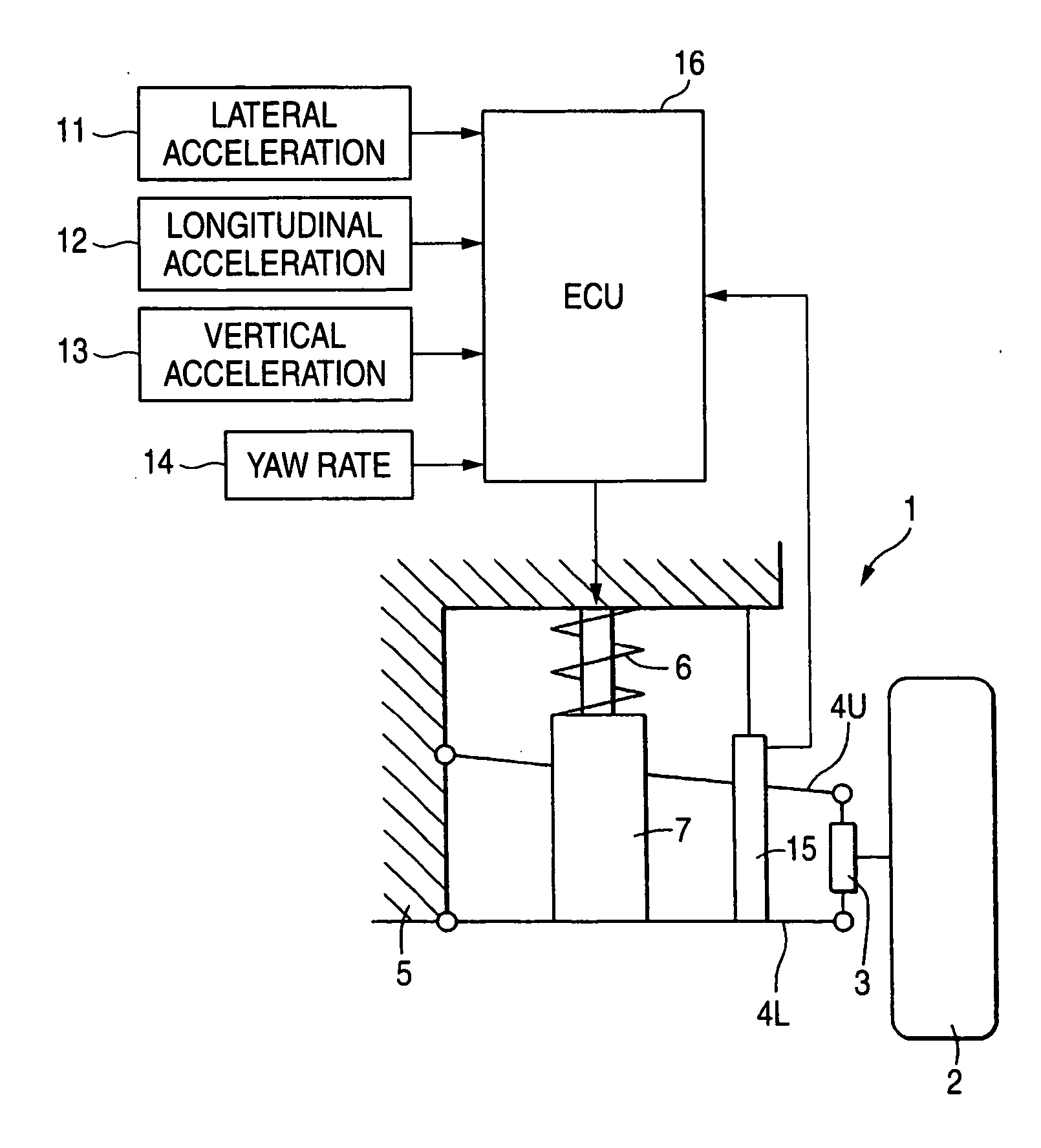

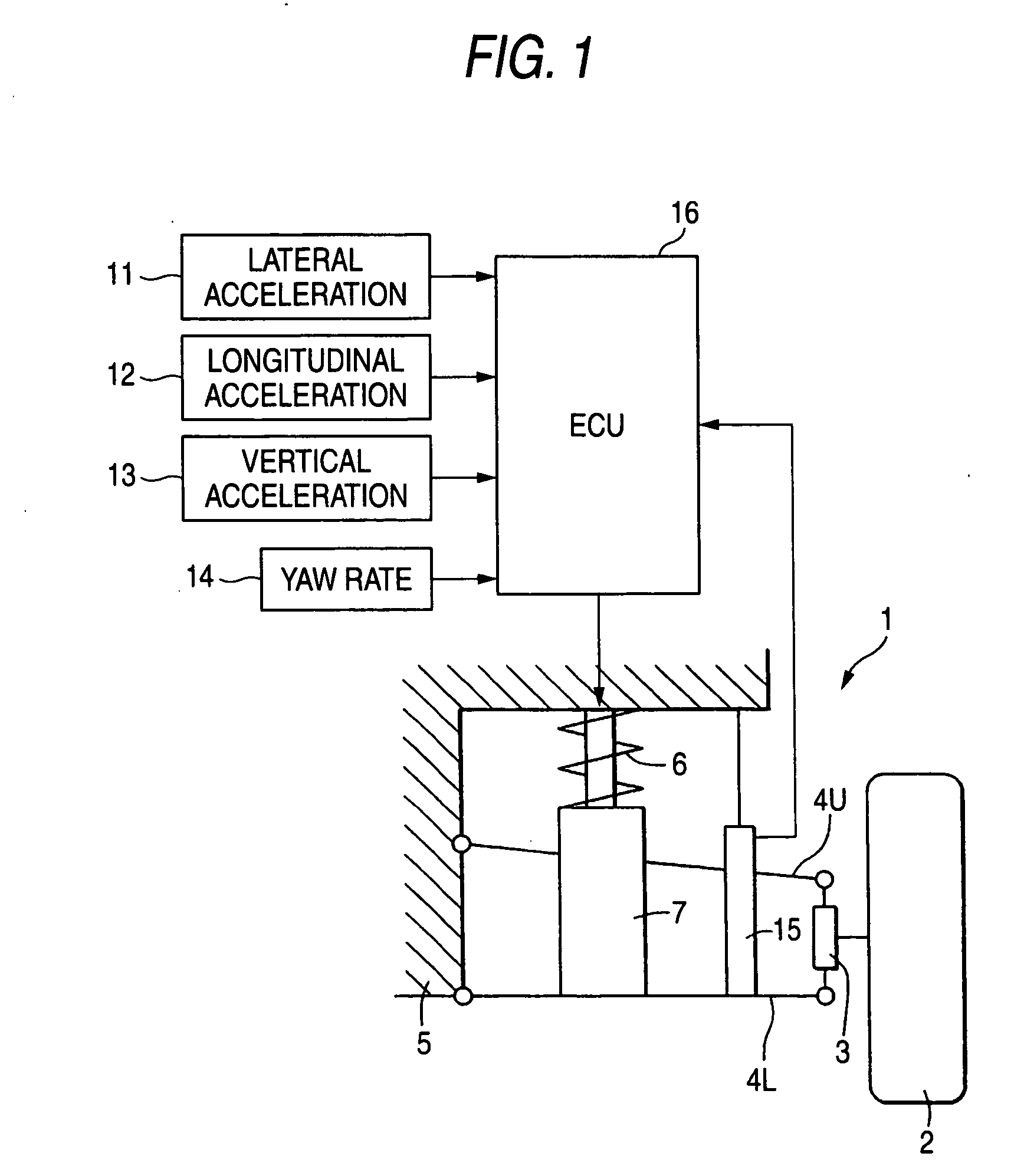

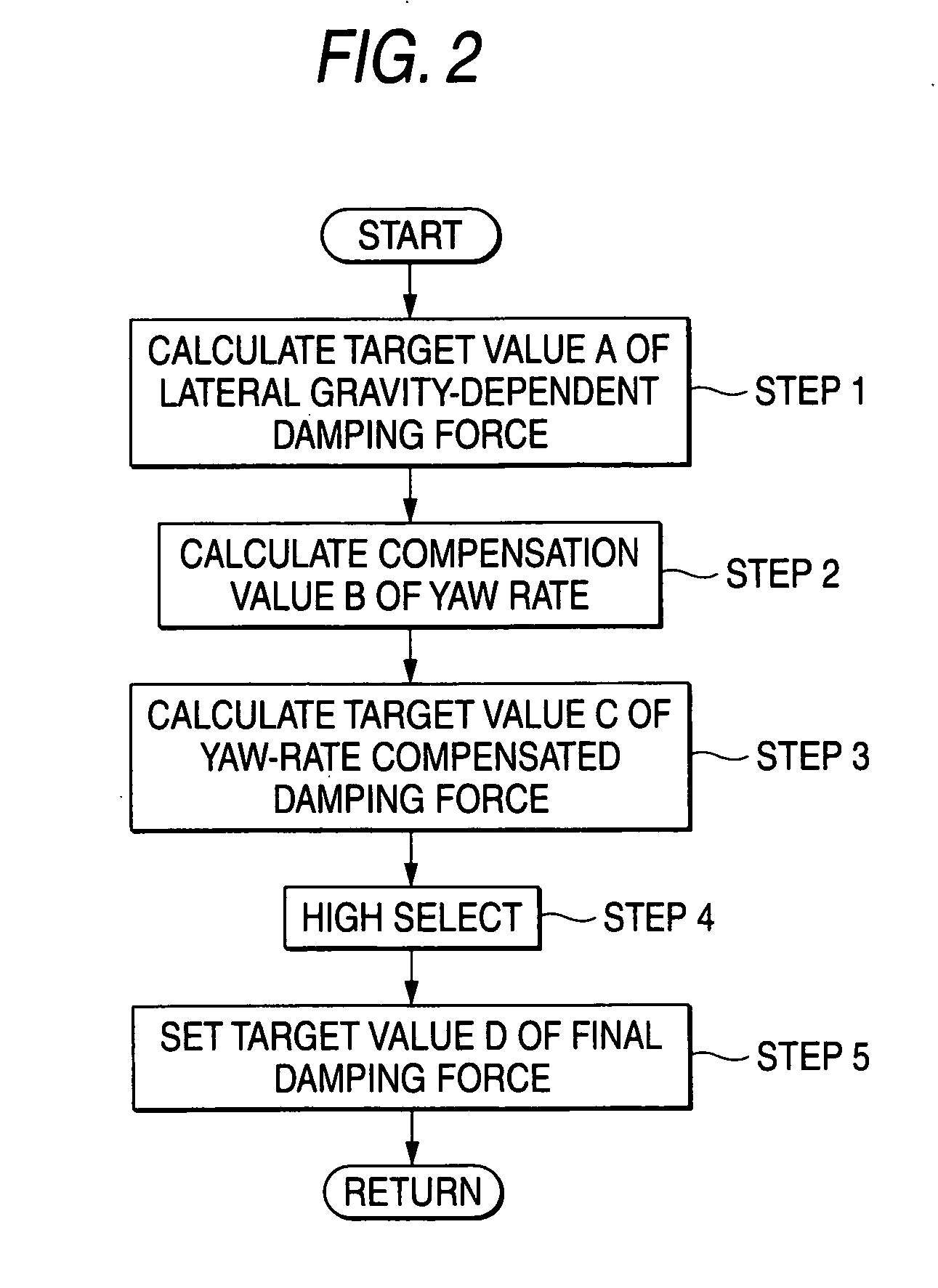

Control system for adjustable damping force damper

ActiveUS20060224287A1Good precisionWithout a deterioration of a high responsibilityVehicle testingRegistering/indicating working of vehiclesControl systemTarget control

A control system for an adjustable damping force damper of a suspension apparatus of a vehicle, includes a lateral acceleration detecting unit detecting a lateral acceleration of the vehicle at a gravity point thereof, a yaw rate detecting unit detecting a yaw rate of the vehicle and a control unit controlling a damping force of the damper. The control unit calculates a first target damping force based on an output of the lateral acceleration detecting unit, calculates a second target damping force based on a lateral acceleration at an axel position which is estimated by an output of the yaw rate detecting unit, compares an absolute value of the first target damping force with that of the second target damping force and sets a target controlling value of the damping force in accordance with the first or second target damping force which has a larger absolute value.

Owner:HONDA MOTOR CO LTD

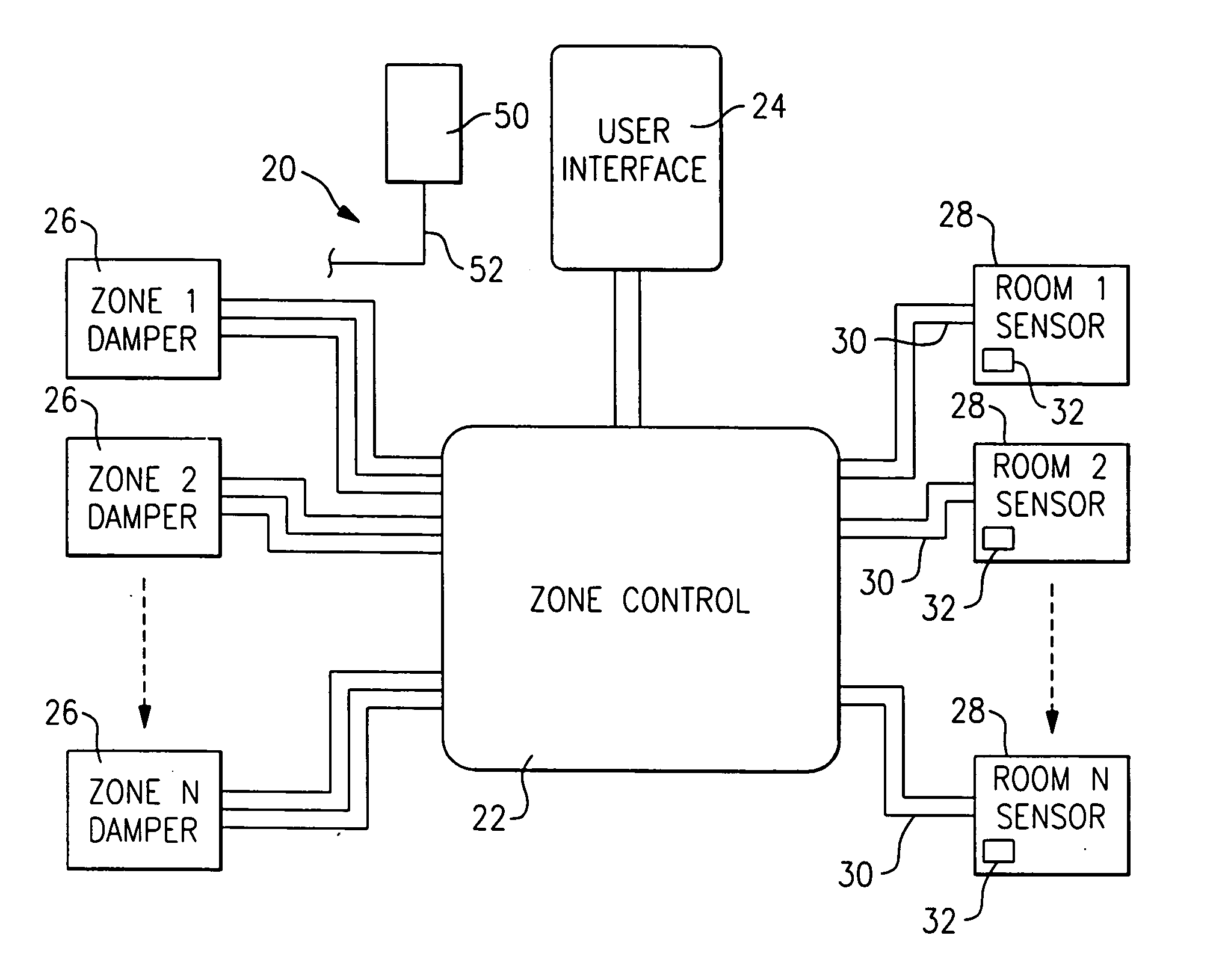

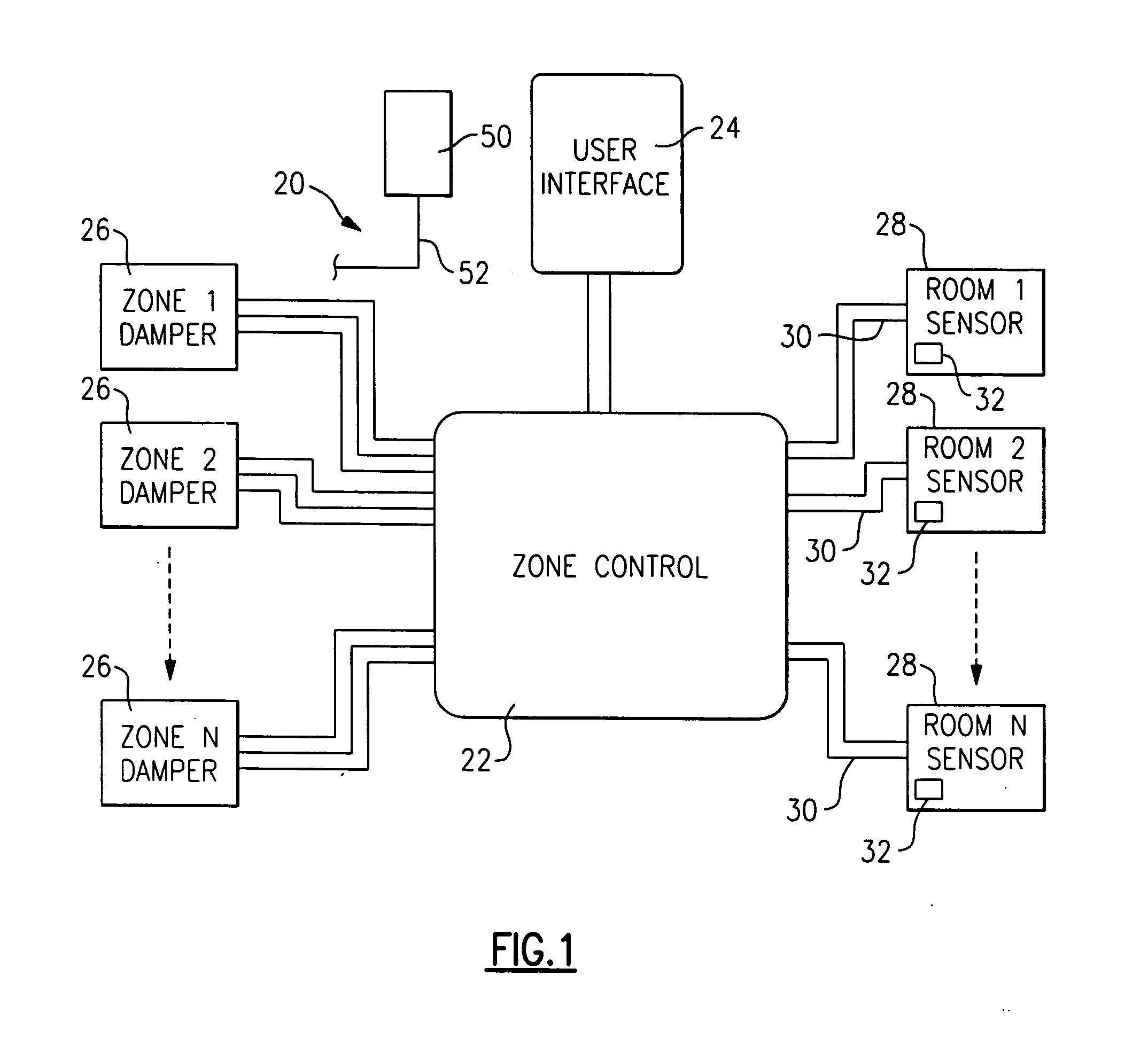

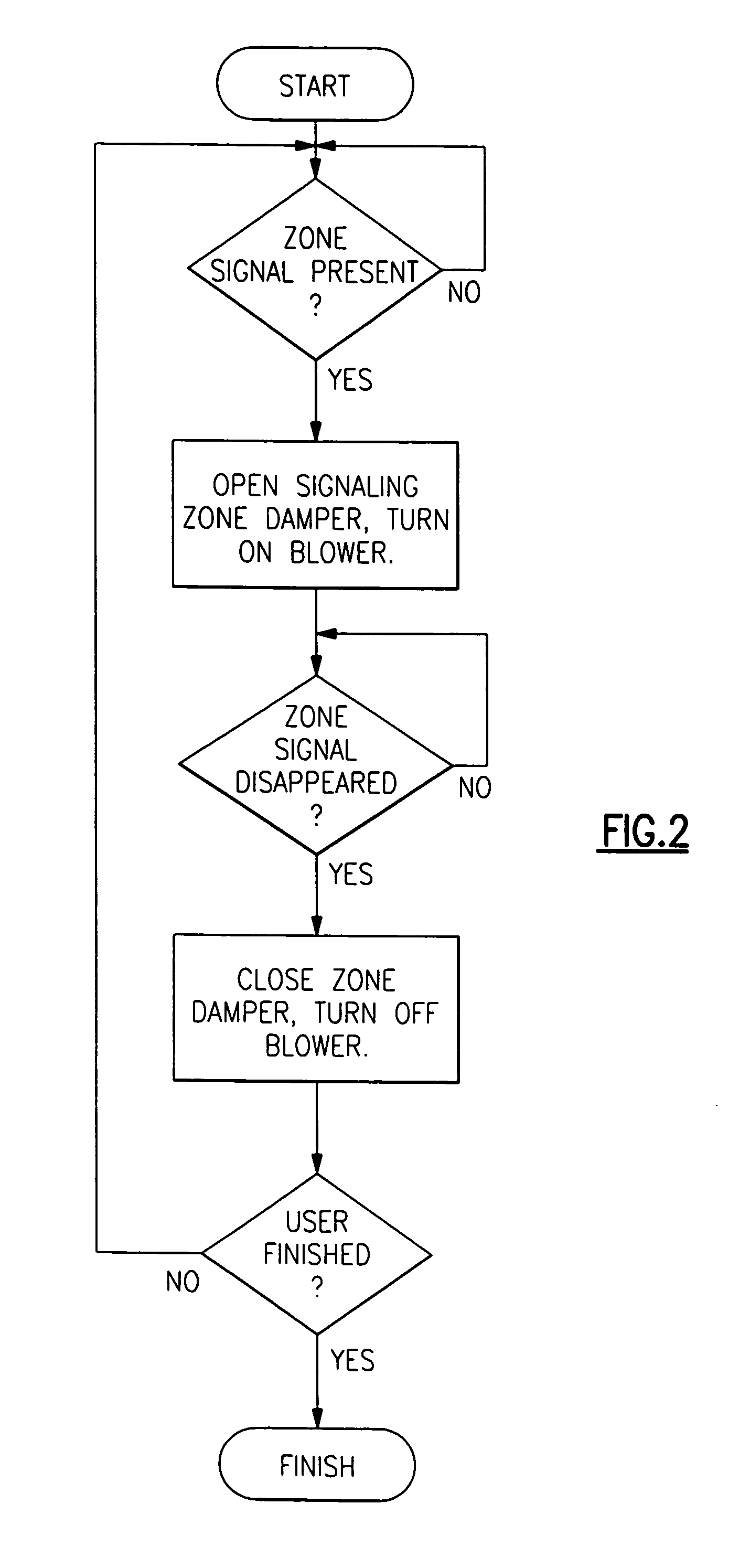

Method of verifying proper installation of a zoned HVAC system

A method and control is provided wherein the sensors in a plurality of zones are properly associated with the dampers associated for each of the zones after installation. A technician goes to each zone and sends a signal from the sensor, and the control then makes a change at the associated damper. The technician can then ensure the two are properly associated within the control.

Owner:CARRIER CORP

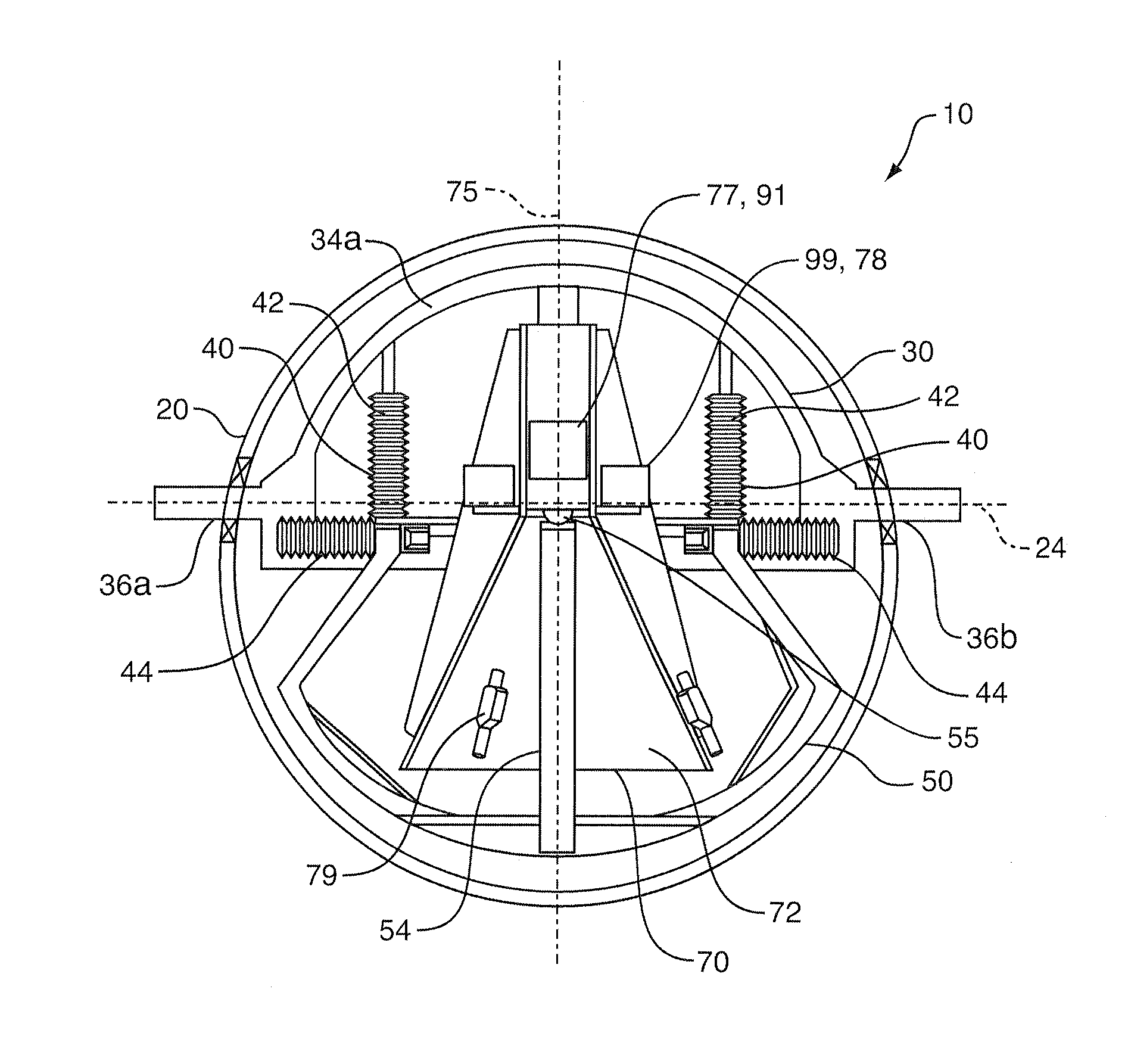

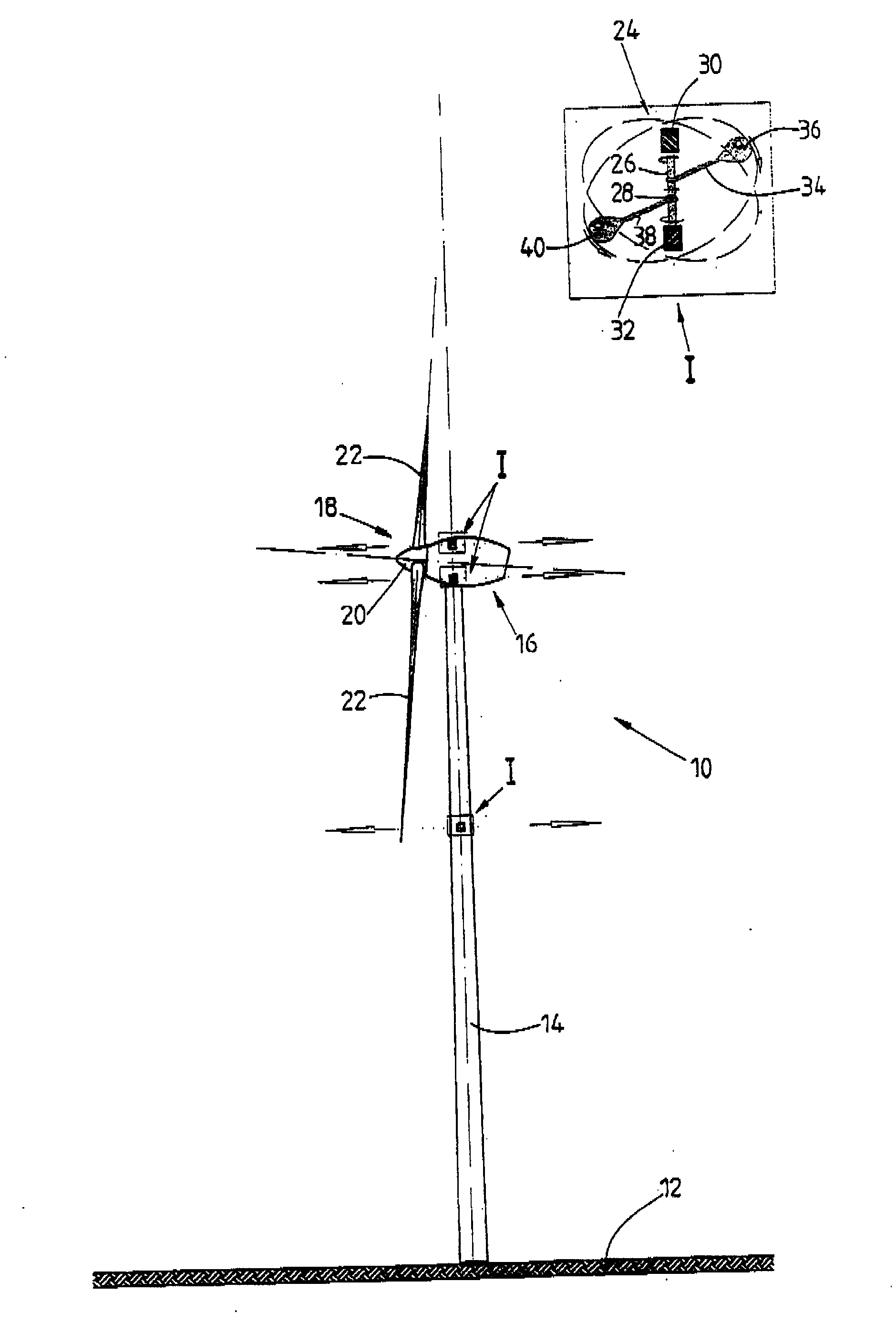

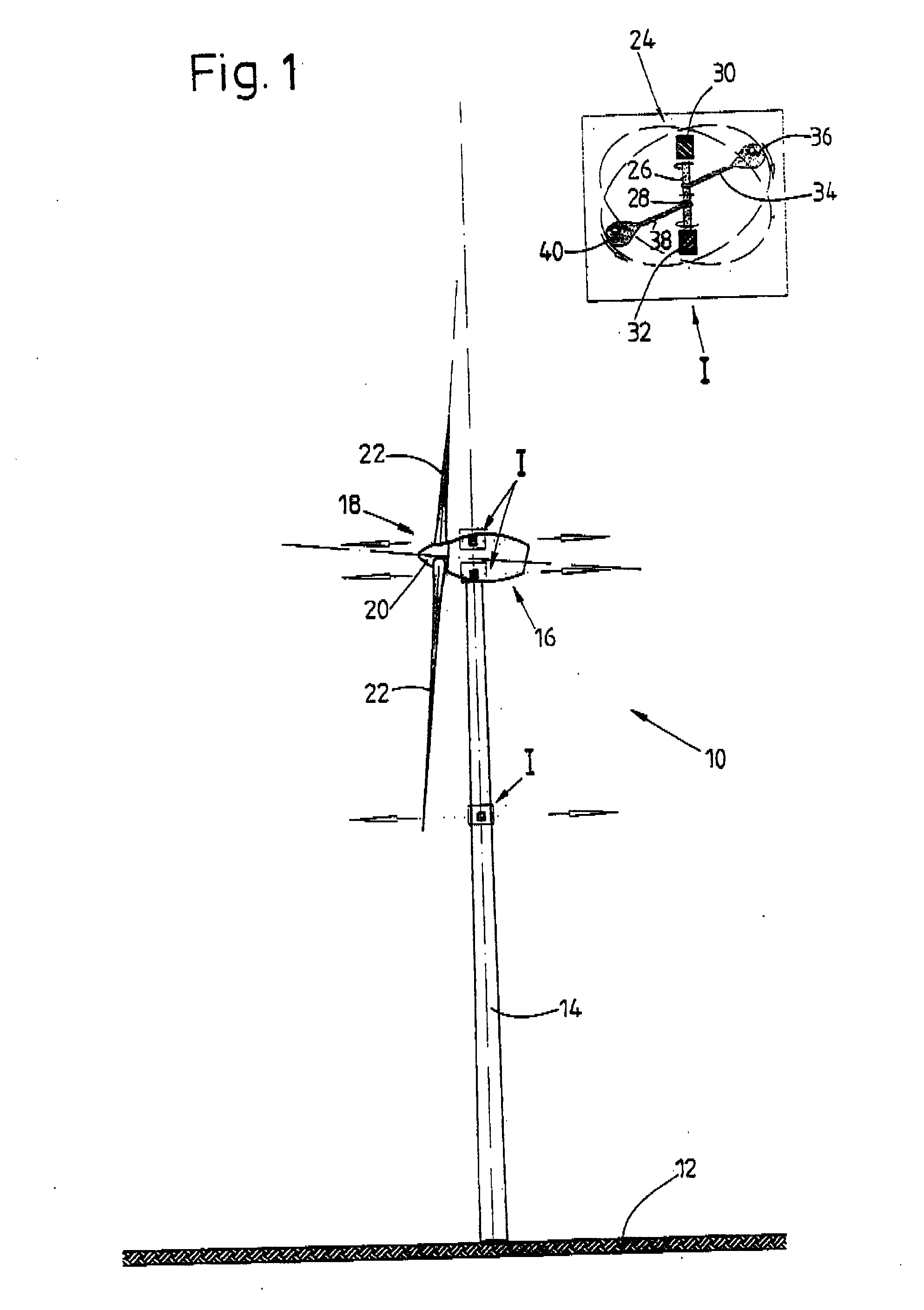

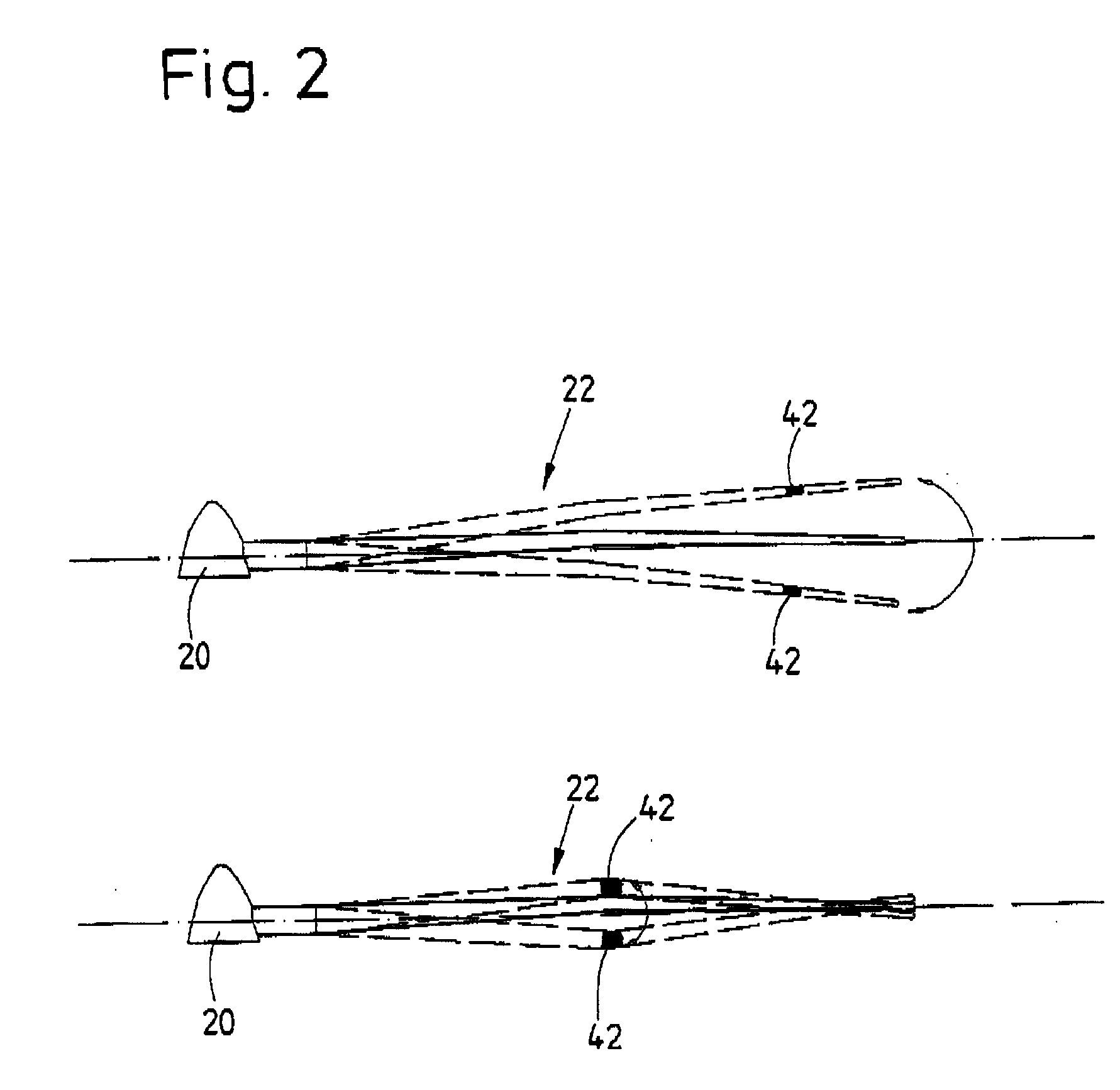

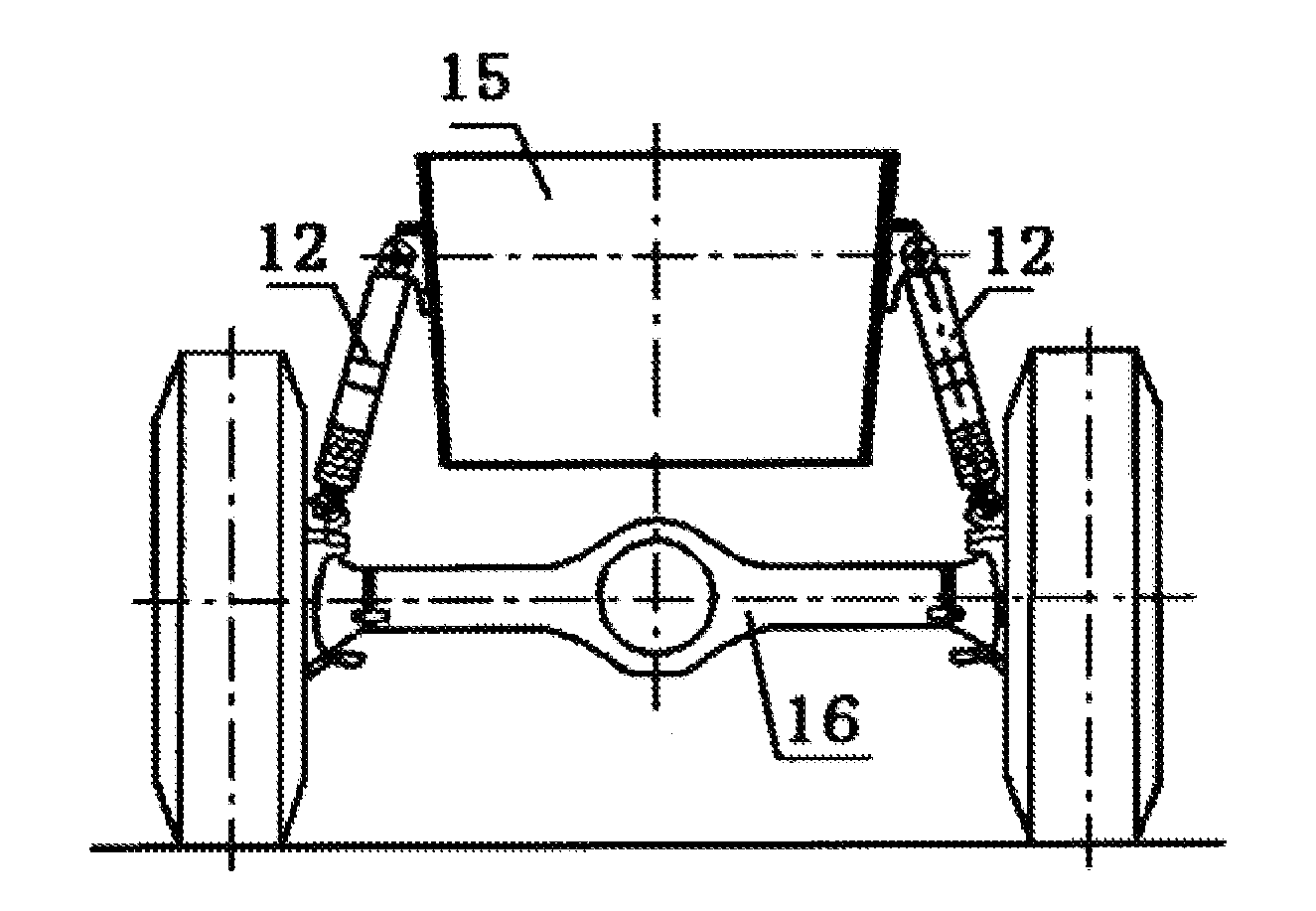

Wind energy installation

The invention relates to a wind energy installation (10) having a rotor (18) which can be driven by wind and has at least one rotor blade (22), having a generator for conversion of the mechanical energy of the rotor (18) to electrical energy, and having a tower (14) on which the rotor (18) is arranged, in which the rotor blade (22) has one or more additional masses (36, 40) and / or active and / or passive oscillation dampers (24), which are designed in such a manner that movements of the rotor blade (22), in particular oscillations, which are initiated by external influences and are directed towards the tower or away from it are prevented and / or damped. The invention also relates to a method for operation of a wind energy installation, preferably of an off-shore wind energy installation, in which one or more components of the wind energy installation, preferably the tower (14), have opposing vibration applied to them in order to reduce / prevent sound waves which result from component vibration and disturb animals and / or people, which opposing vibration counteracts vibration (which produces sound) of the component (14), and reduces or prevents this component vibration.

Owner:DAUBNER & STOMMEL BAU WERK PLANUNG

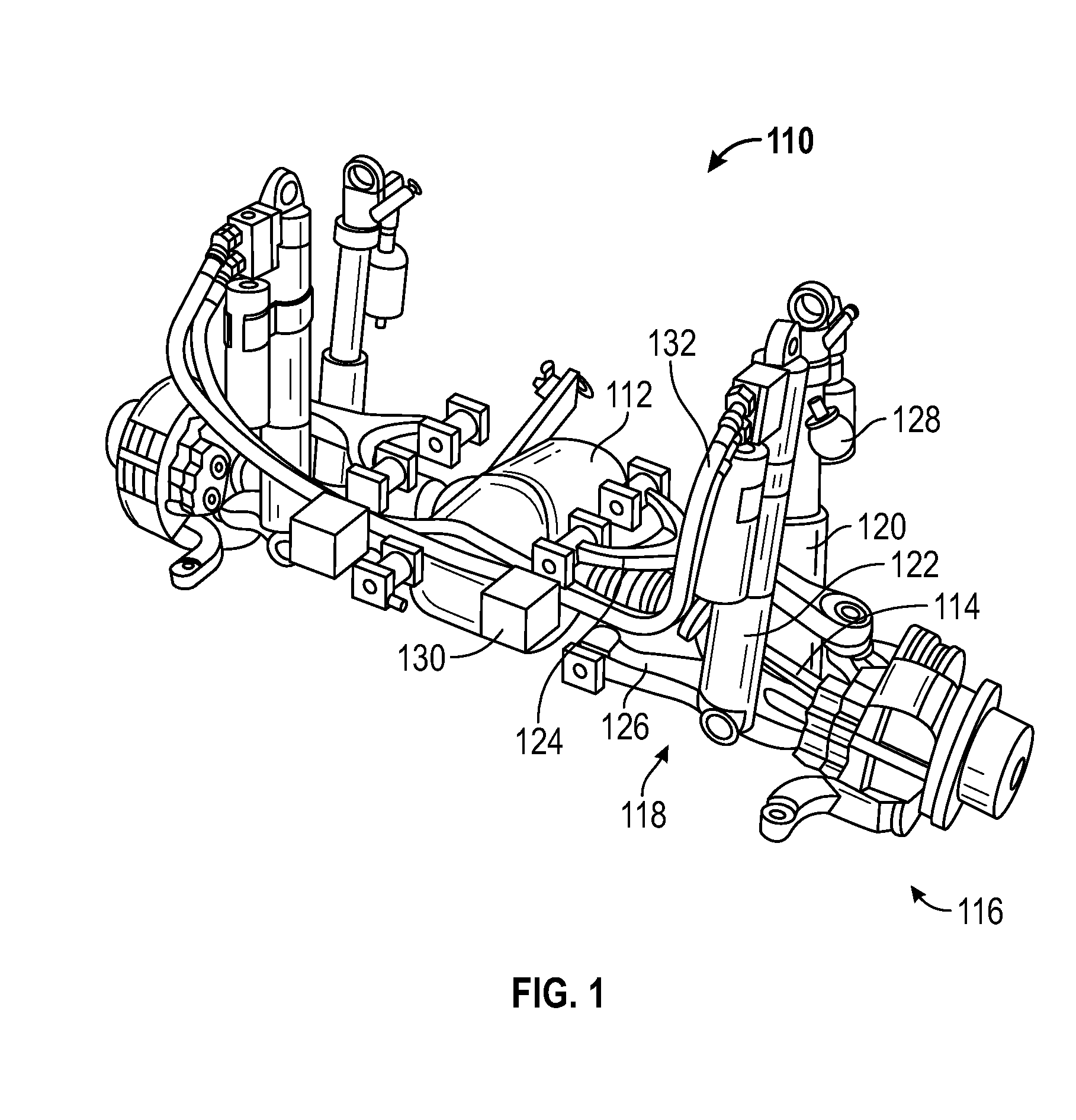

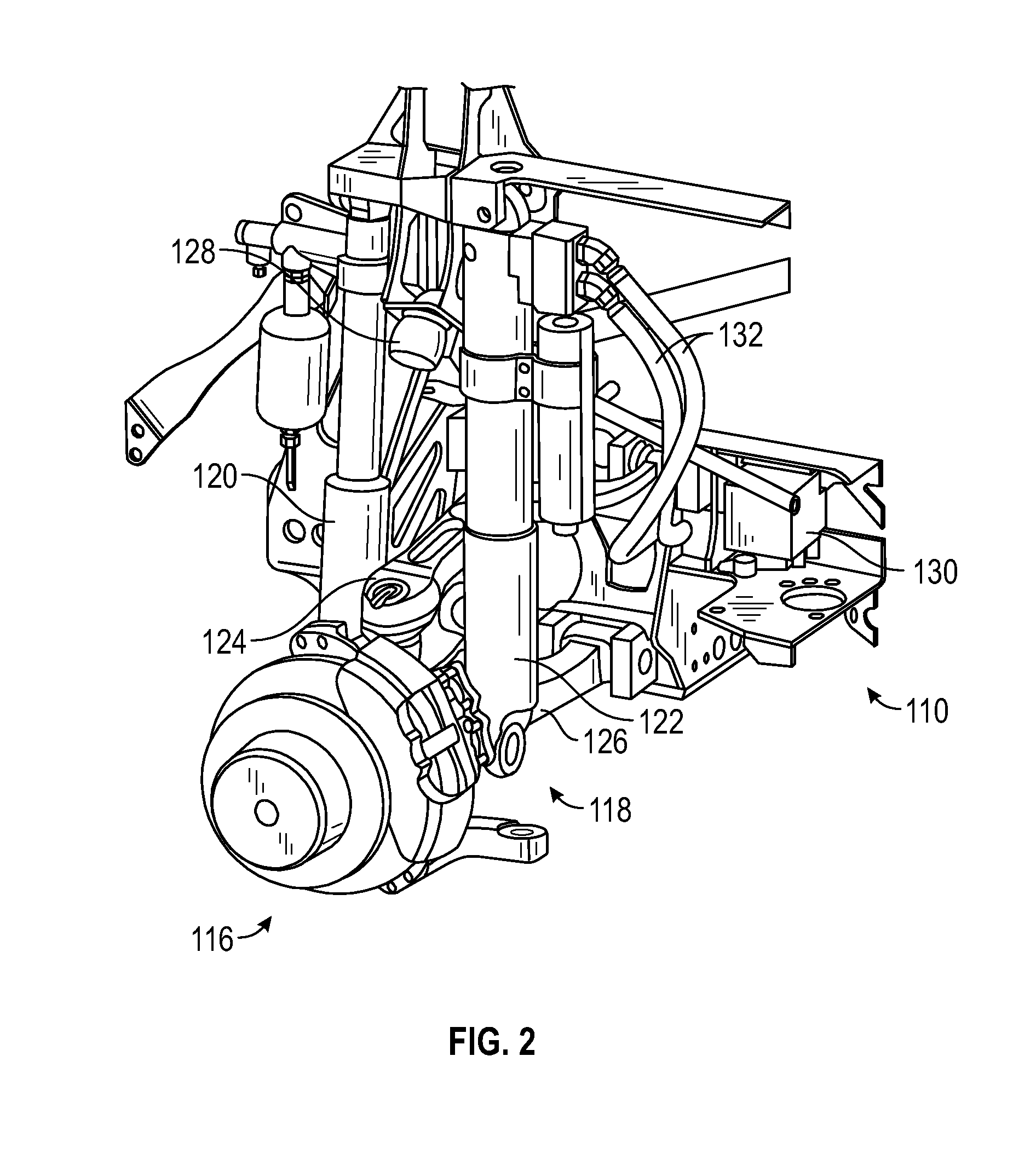

Load dependent damper for a vehicle suspension system

A damper assembly for a vehicle suspension system includes a damper and a manifold. The damper includes a tubular sidewall that defines an inner damper volume and a plunger separating the inner damper volume into a first chamber and a second chamber. The damper defines a first opening in fluid communication with the first chamber and a second opening in fluid communication with the second chamber. The manifold includes a housing having a pilot and defining a flow path between an inlet port and an outlet port, a flow controller coupled to the housing and positioned along the flow path, and a piston including a pilot end coupled to the pilot and an interface end that engages the flow controller with a pilot force. The inlet port is in fluid communication with at least one of the first opening and the second opening of the damper.

Owner:OSHKOSH DEFENSE

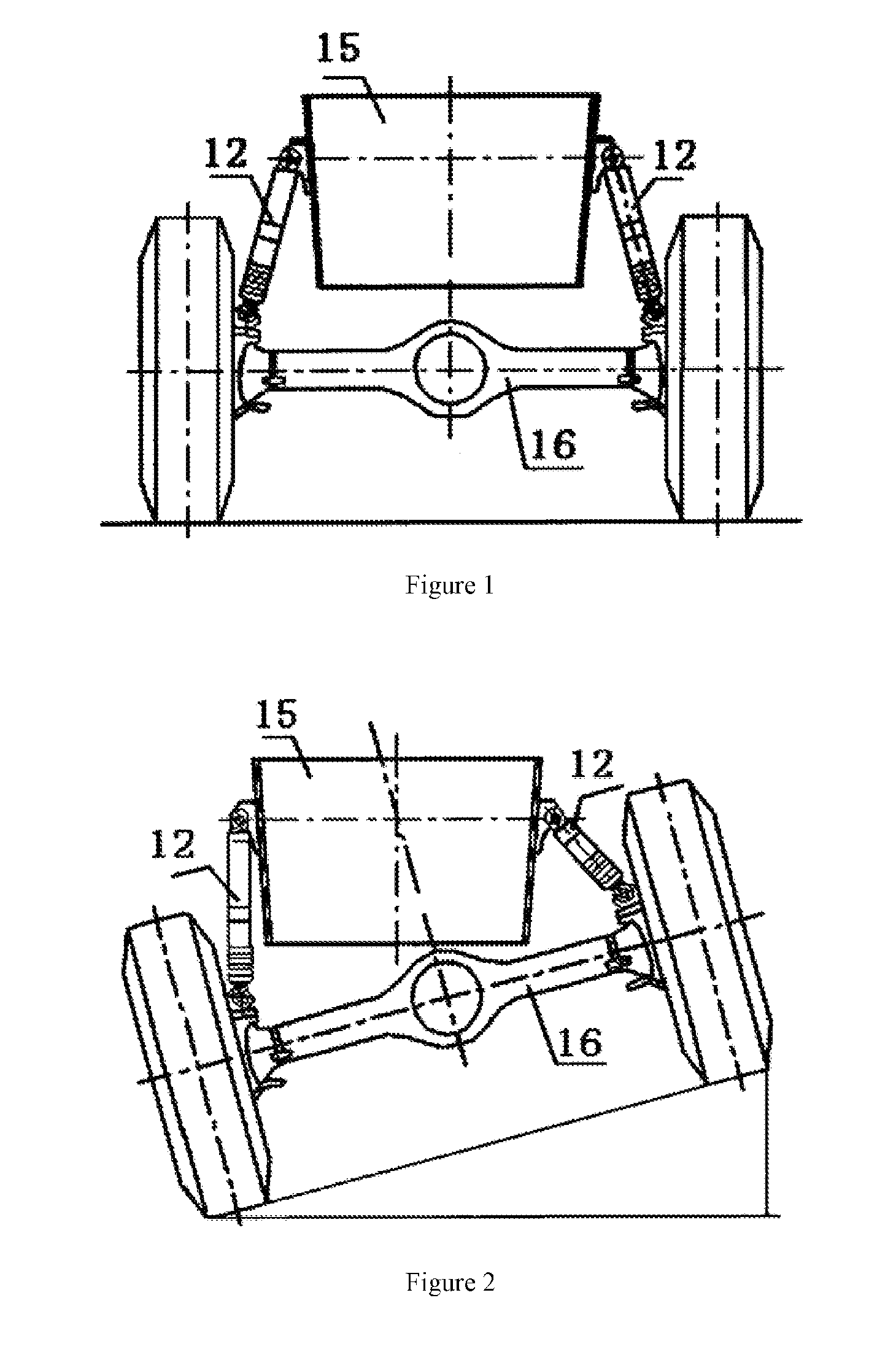

Vehicle body inclination-angle regulating uint, hydropneumatic suspension mechanism and mobile crane

InactiveUS20130220110A1Improve securityIncrease dynamicsServomotor componentsInterconnection systemsHydropneumatic suspensionFuel tank

A vehicle body inclination angle regulating unit (17) includes a balancing oil cylinder (10). One chamber of the balancing oil cylinder (10) is connected with an oil tank (5) and an oil source for leveling operation via a first one-way damper valve (8) and an electric controlled switch valve (7), and the other chamber of the balancing oil cylinder (10) is connected with a non-rod chamber of a suspension oil cylinder via an electric controlled shutoff valve (14) and a second one-way damper valve (9). In addition, an automatically-leveling hydropneumatic suspension mechanism includes at least two pairs of suspension oil cylinders (12), vehicle body inclination angle regulating units (17), a vehicle body transverse inclination angle sensor (1) and a control unit (3). Each suspension oil cylinder (12) is correspondingly provided with the vehicle body inclination angle regulating unit (17) including the balancing oil cylinder (10). The present invention realizes effectively dynamic leveling function of different road conditions, especially transverse slopes, of the mobile crane. The mobile crane is provided with simple operation that are all automatically performed by the control unit, which improves driving safety remarkably and prevents an accident of vehicle overturning.

Owner:ZOOMLION HEAVY IND CO LTD +1

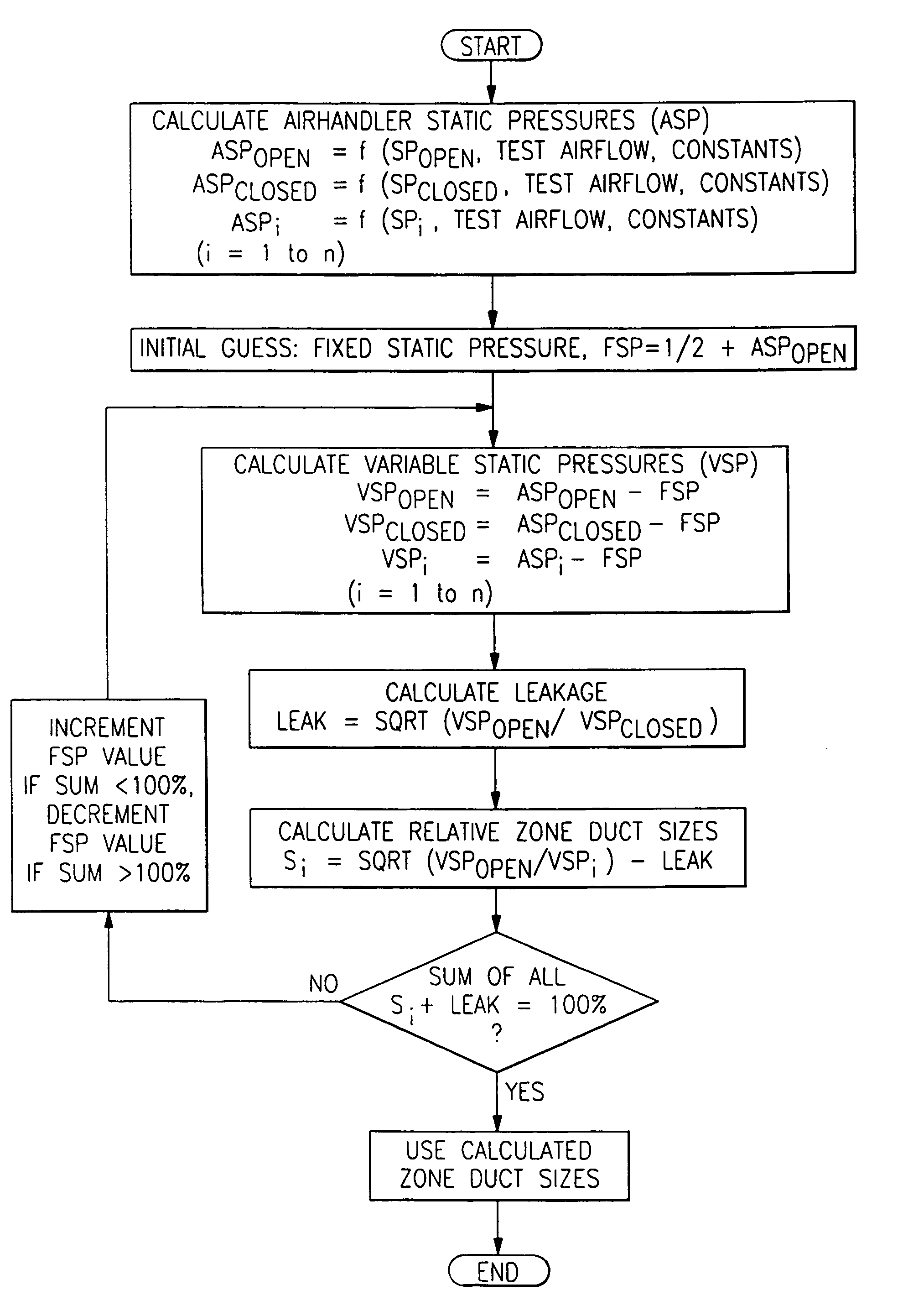

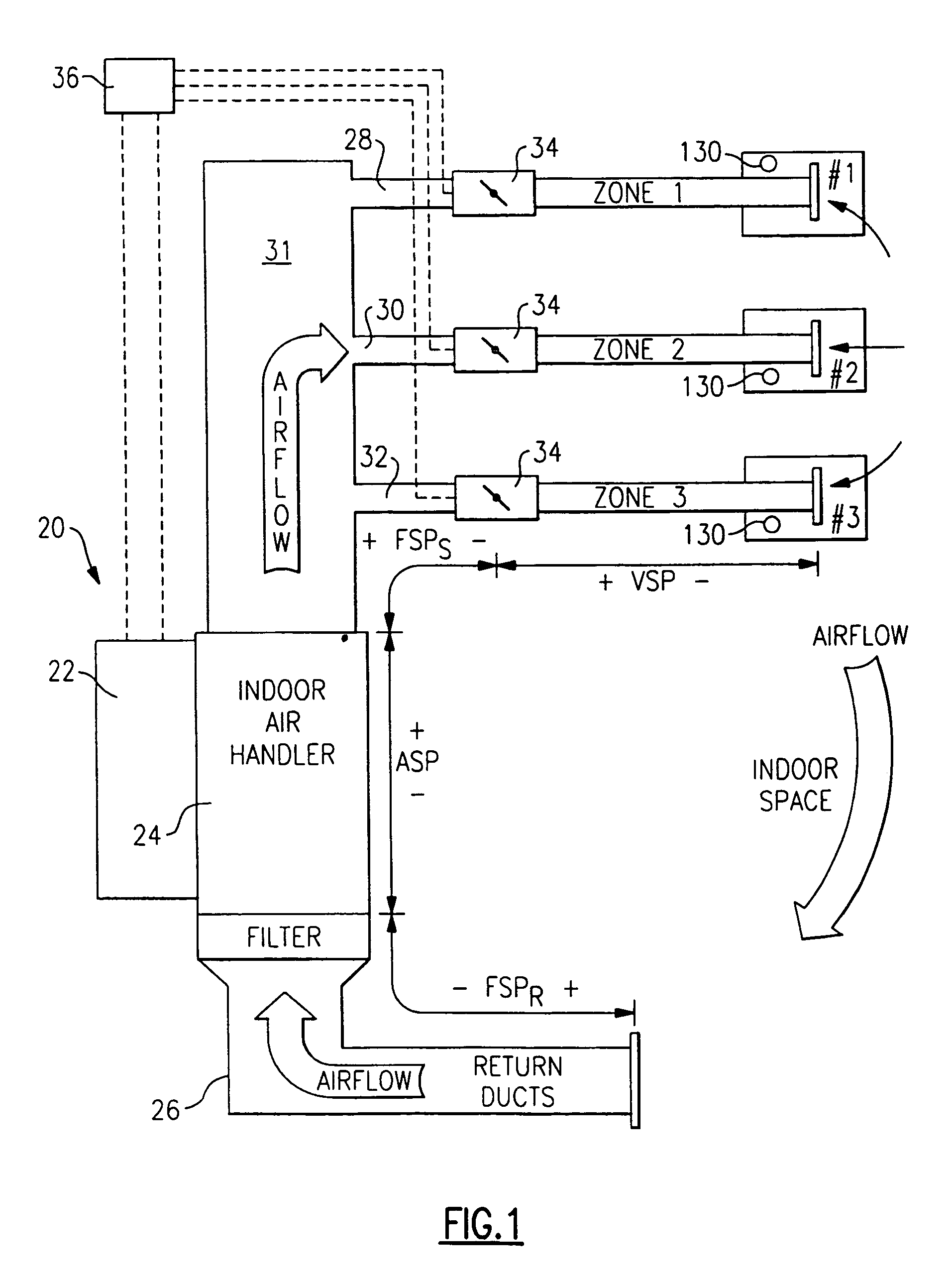

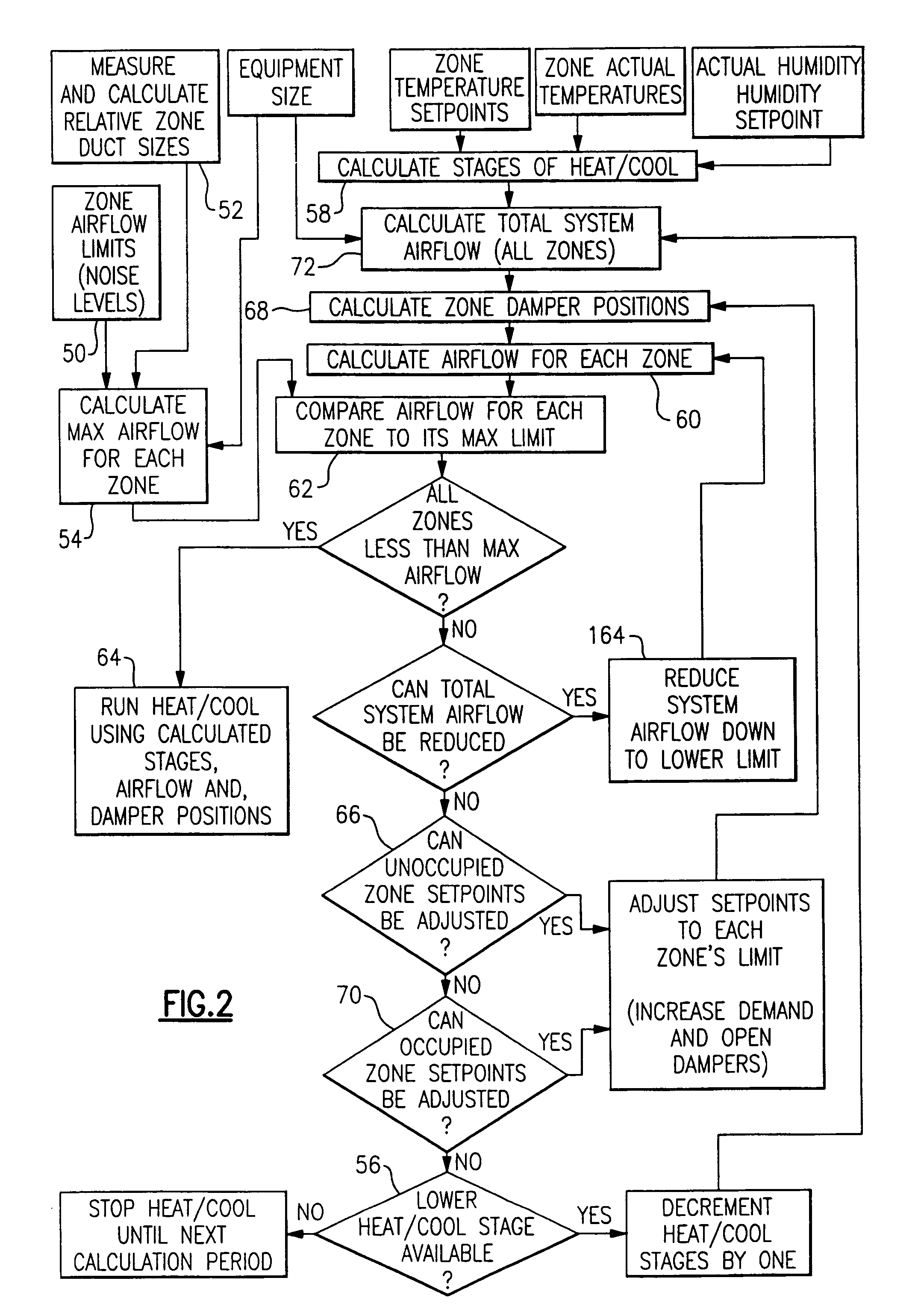

Method and system for determining relative duct sizes by zone in an HVAC system

ActiveUS6964174B2Easy to controlDucting arrangementsLighting and heating apparatusMonitoring systemEngineering

A control and method are disclosed to determine the relative duct sizes of a plurality of ducts leading to a plurality of zones in a multi-zone HVAC system. In a disclosed method, the dampers leading to each of the zones are operated such that one damper is held more open than the remaining dampers, and a system component is monitored as air is blown through the duct. In particular, a blower speed may be monitored. Once the blower speed is monitored, for one damper being open, with the remaining dampers being relatively closed, another damper is opened and the first is closed. This process continues until relative information is gathered for each of the zones. This relative information is then utilized to determine the relative sizes of the ducts leading to each of the zones as a percentage of the total duct size. The relative duct size information is then utilized to perform various control methods.

Owner:CARRIER CORP

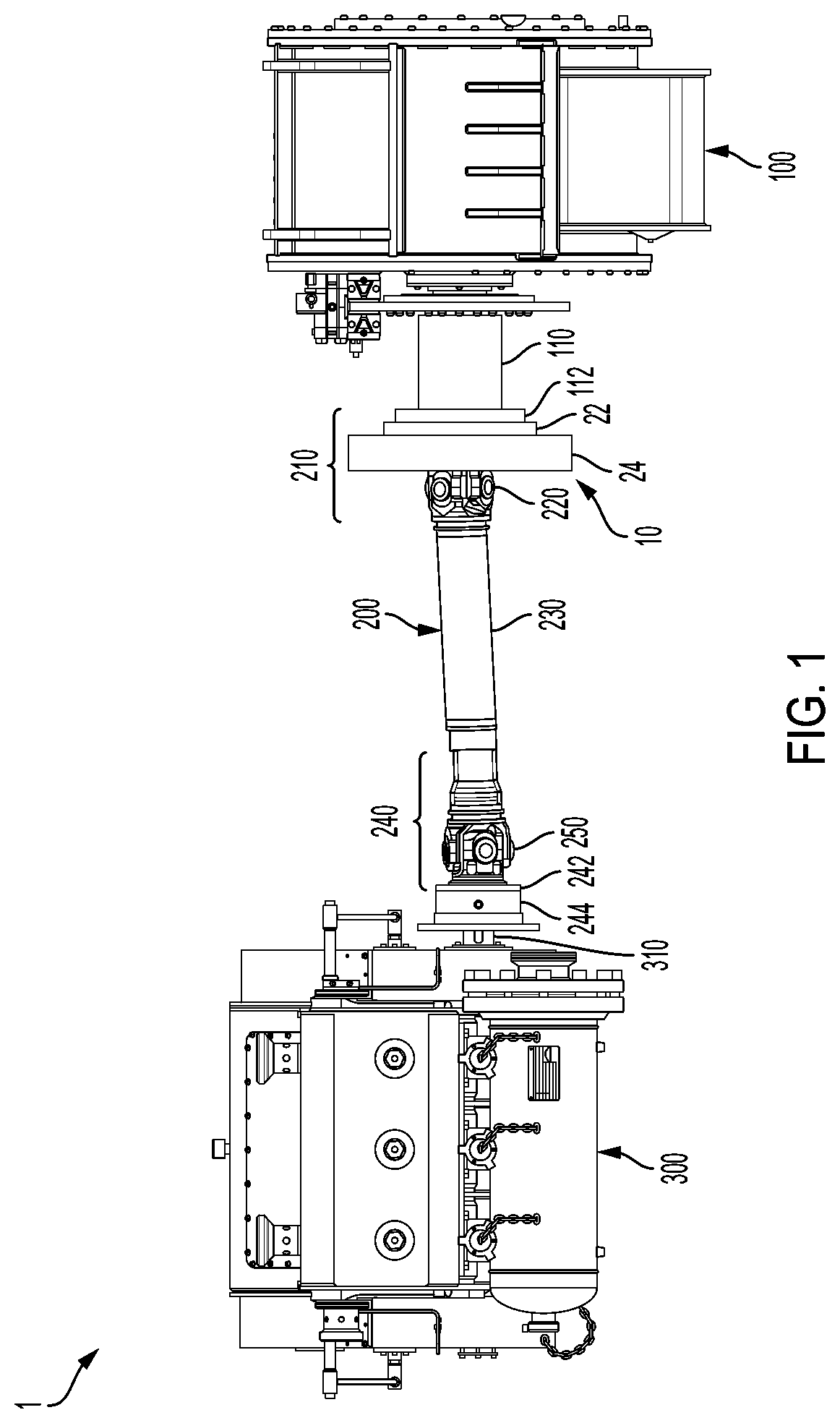

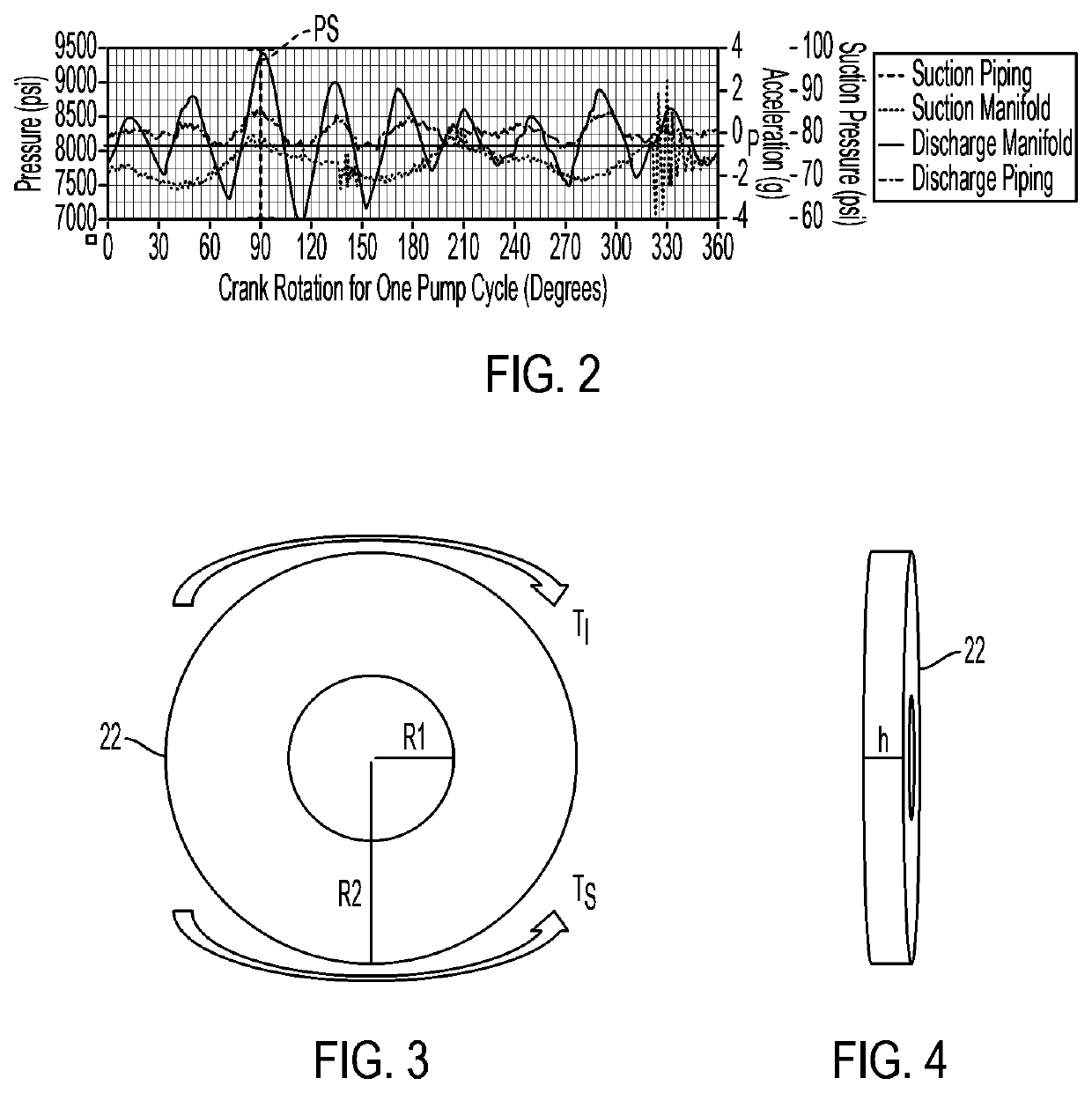

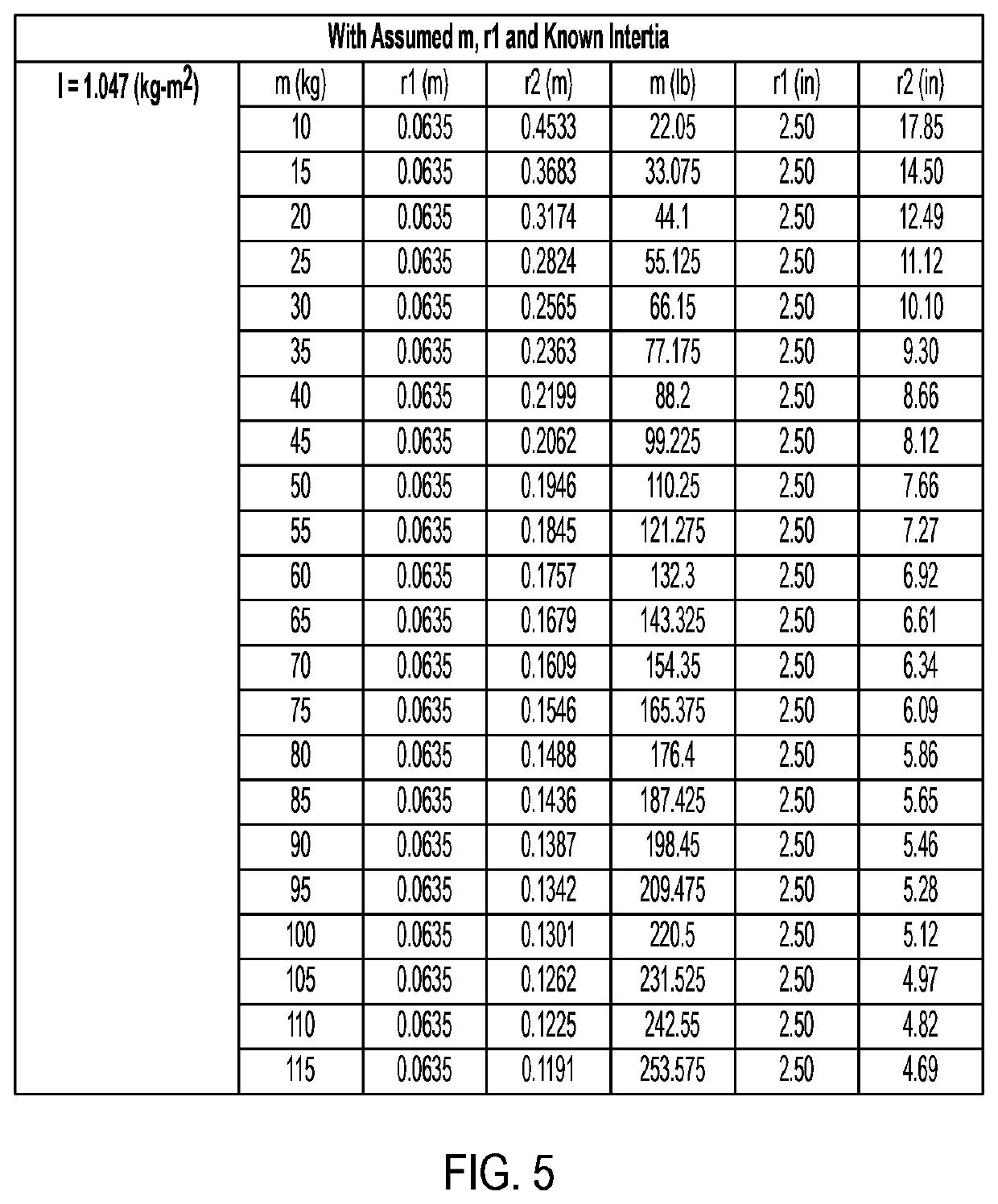

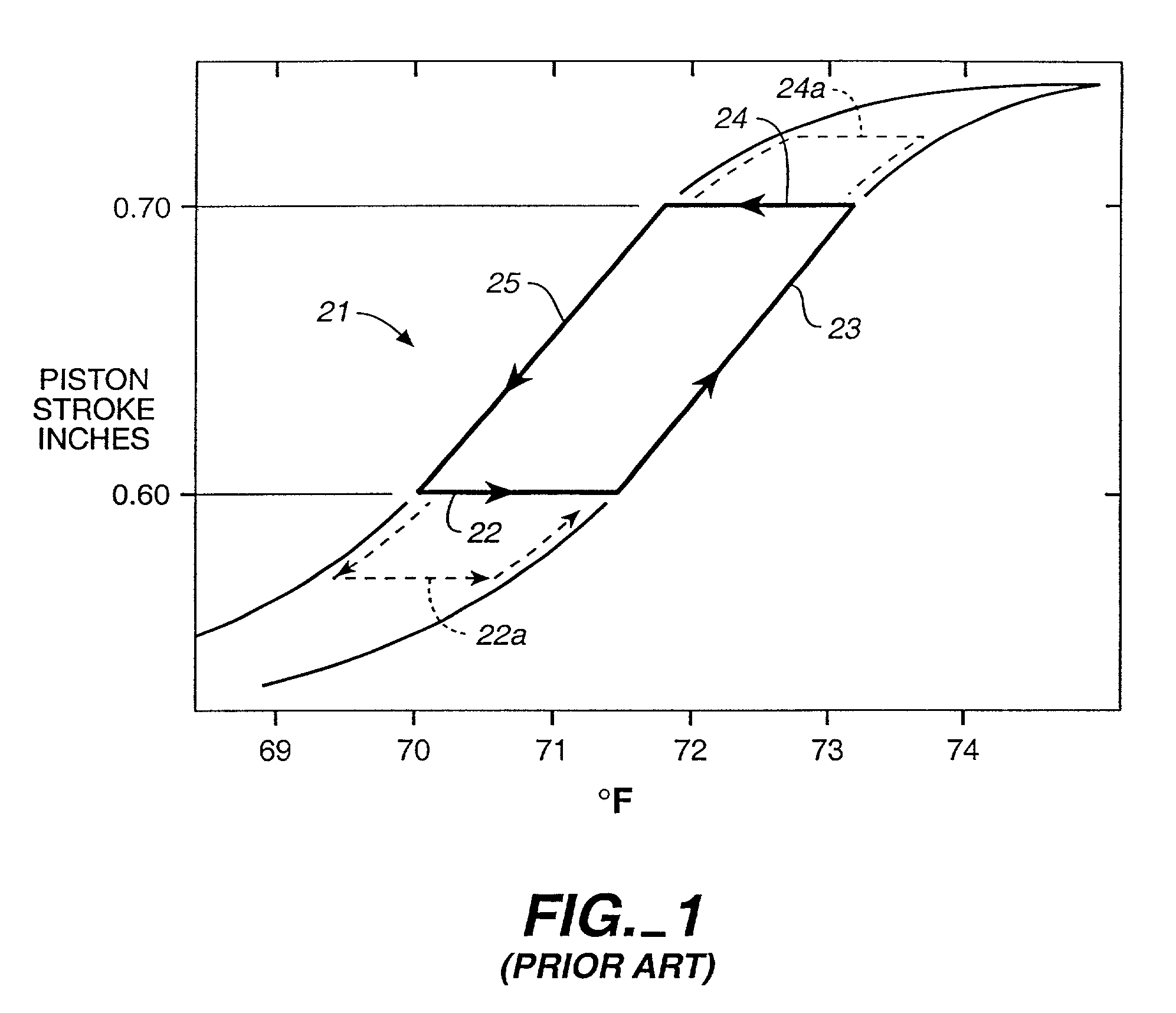

Systems and method for use of single mass flywheel alongside torsional vibration damper assembly for single acting reciprocating pump

ActiveUS11015594B2Reduce and eliminate shock loadingDampen torsional resonanceRotating vibration suppressionSpringsRotary pumpClassical mechanics

A pump system may include a pump, a driveshaft, driving equipment, and a vibration dampening assembly configured to reduce pump-imposed high frequency / low amplitude and low frequency / high amplitude torsional vibrations. The pump may have an input shaft connected to the driveshaft. The driving equipment may include an output shaft having an output flange connected to the driveshaft. The driving equipment may be configured to rotate the driveshaft to rotate the input shaft of the pump therewith. The vibration dampening assembly may include one or more flywheels operably connected to the input shaft and configured to rotate therewith.

Owner:BJ ENERGY SOLUTIONS LLC

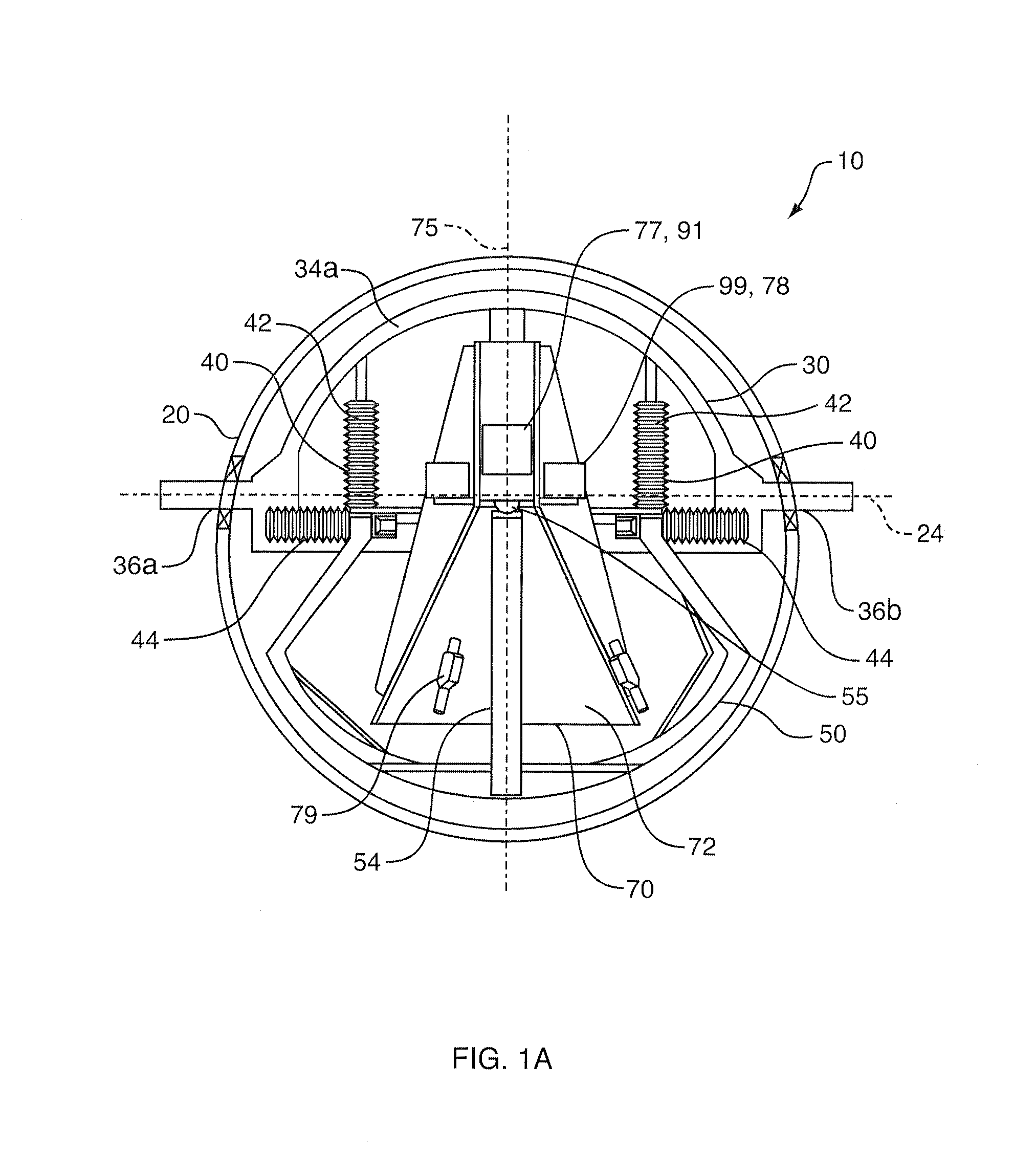

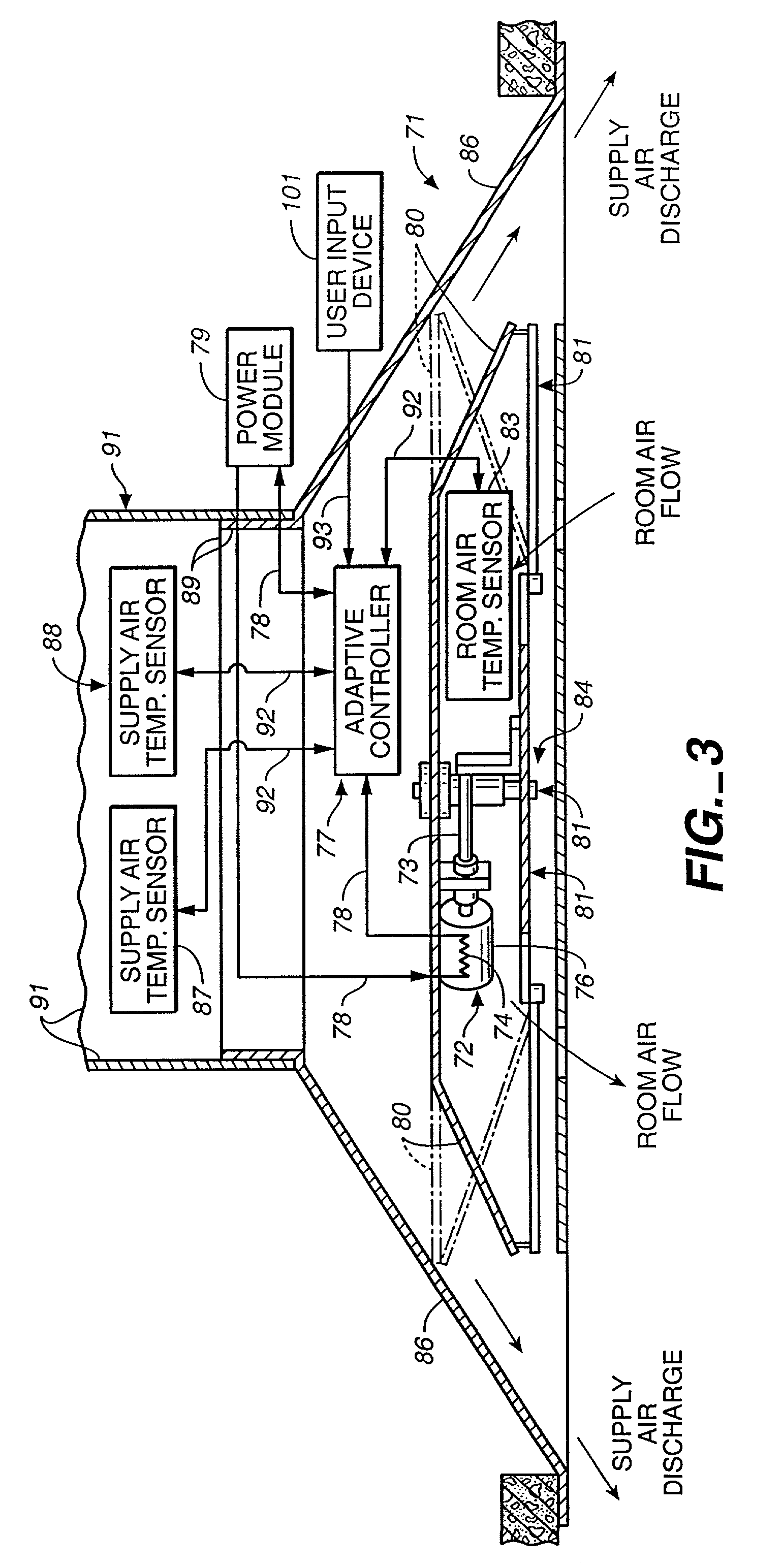

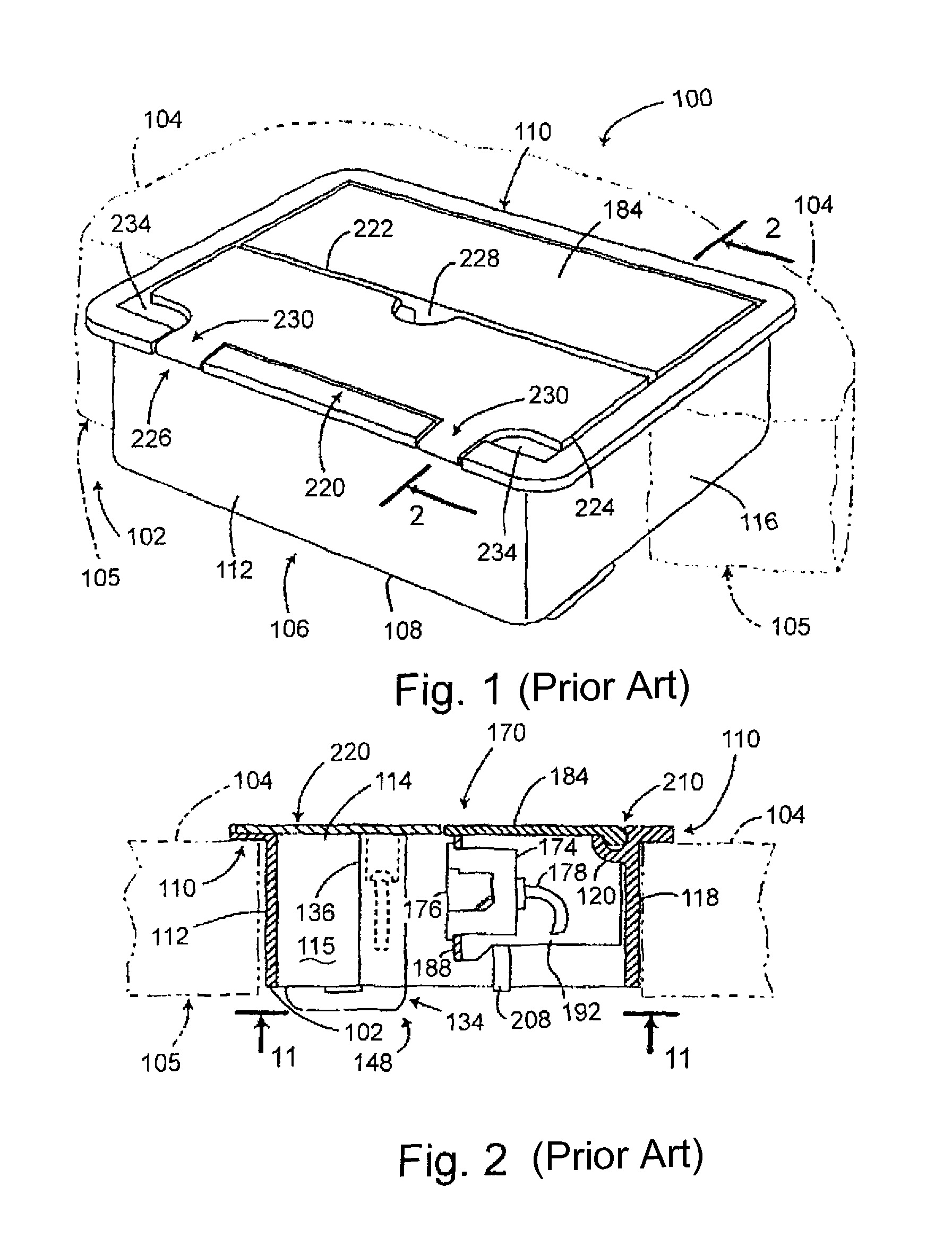

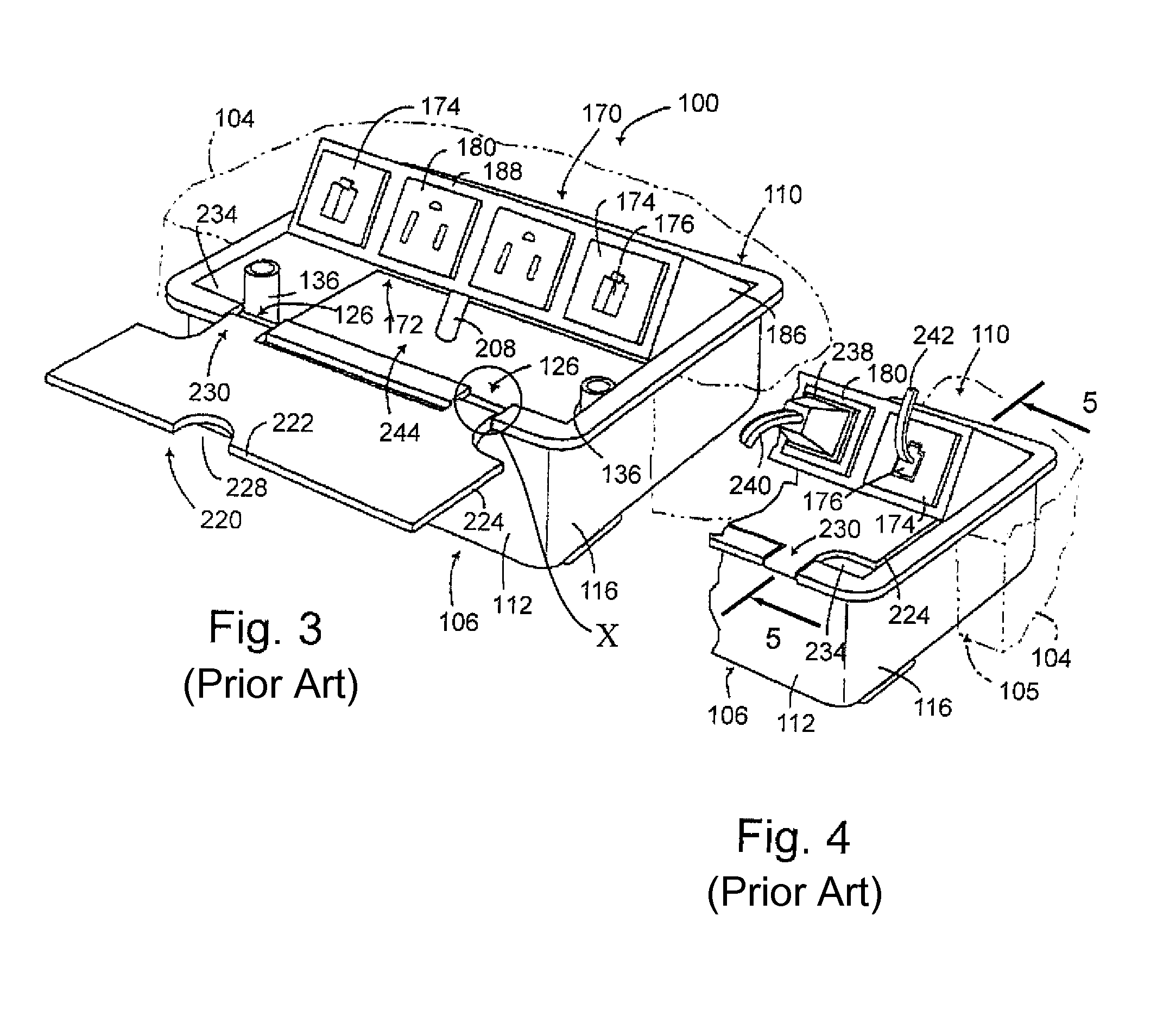

Variable-air-volume diffuser, actuator assembly and method

InactiveUS20010042792A1Thermometer detailsDucting arrangementsVariable air volumeTemperature control

An adaptive control device (77) and method (102-108) for control of the operation of an actuator (72), and particularly thermally-powered actuator (72) of the type used in a variable-air-volume diffuser (71). The preferred adaptive control device is an expert system circuit which controls a heater (74) provided on a thermally-powered actuator (72) to implement an adaptive process (102-108) in which a sensed variable, such as room air temperature, is driven toward a target temperature control range (±0.25° F.). Most preferably, the process steps (106) include driving the room air temperature toward a gross (broader) temperature control range (±1.0° F.) by moving a diffuser damper assembly (80) to a substantially fully open or substantially fully closed position. Thereafter, and while inside the gross temperature control range, the process steps (107, 108) include adjustments to the position of the damper assembly (80) are made only when a sensed parameter, preferably the supply air flow rate, is in a stable condition. Most preferably, the damper (80) is temporarily "kicked" farther open or farther closed than necessary, to minimize hysteresis effects, and then adjusted to a posiiton which tends to drive the room air temperature into the narrower, targeted temperature control range.

Owner:ACUTHERM

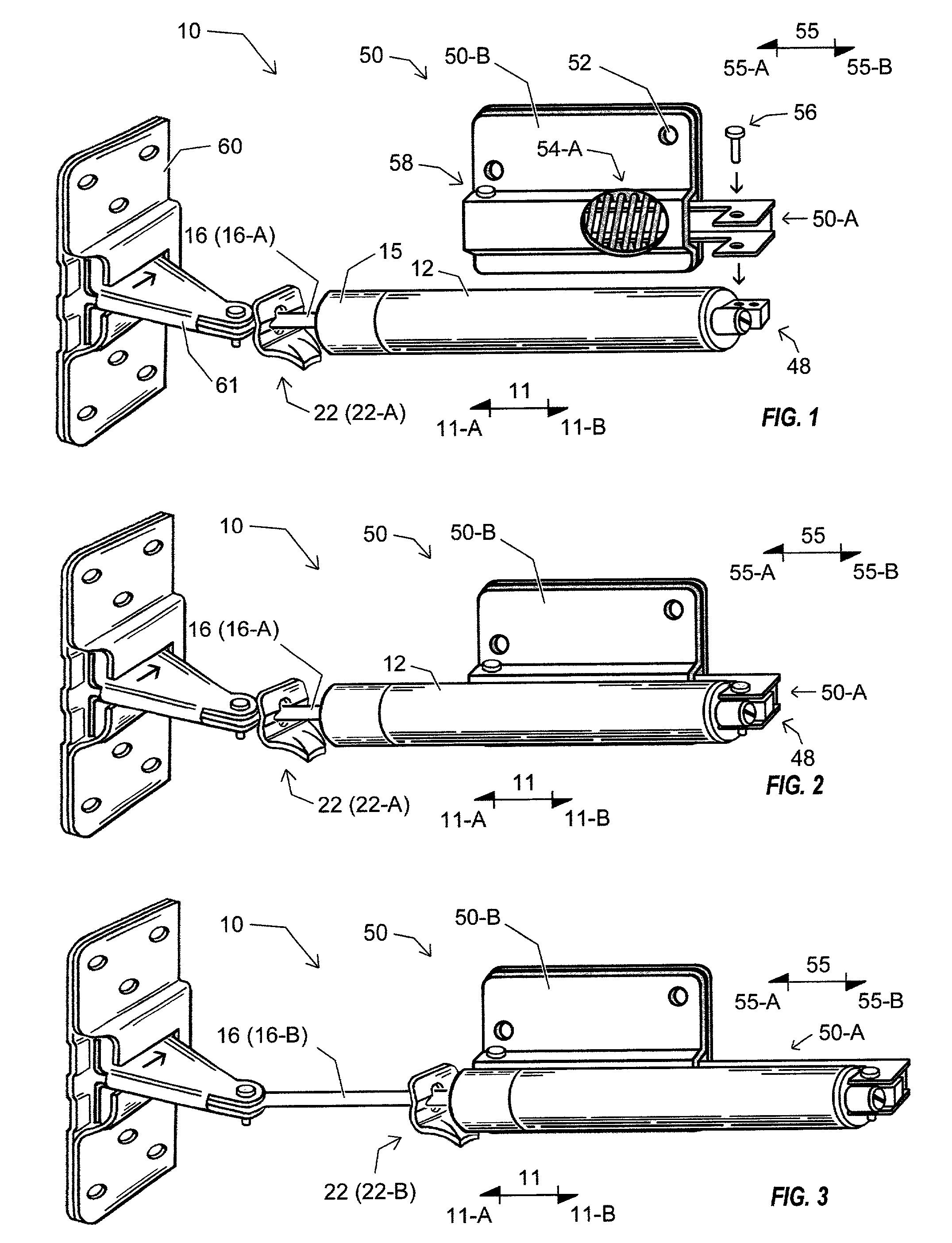

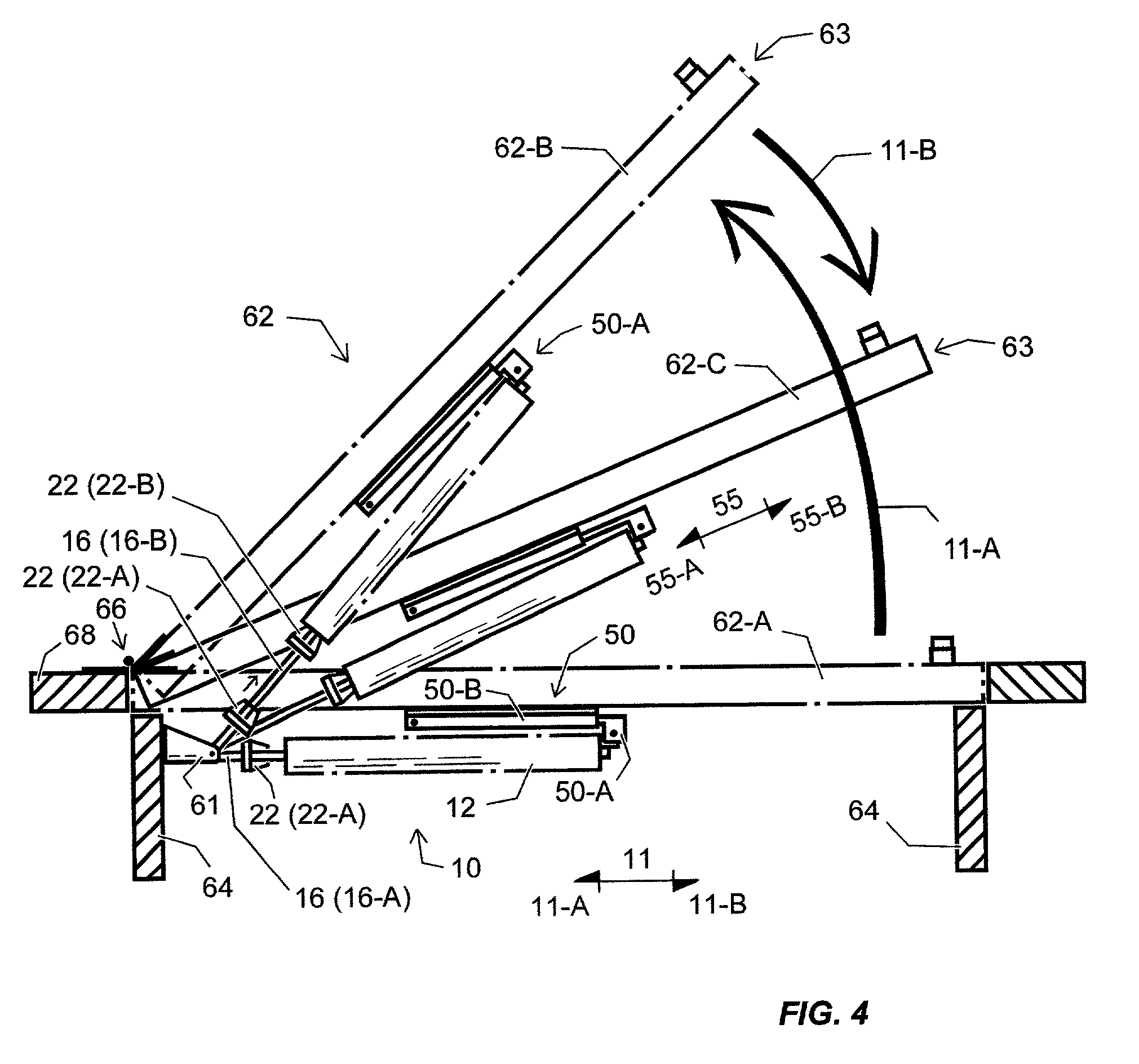

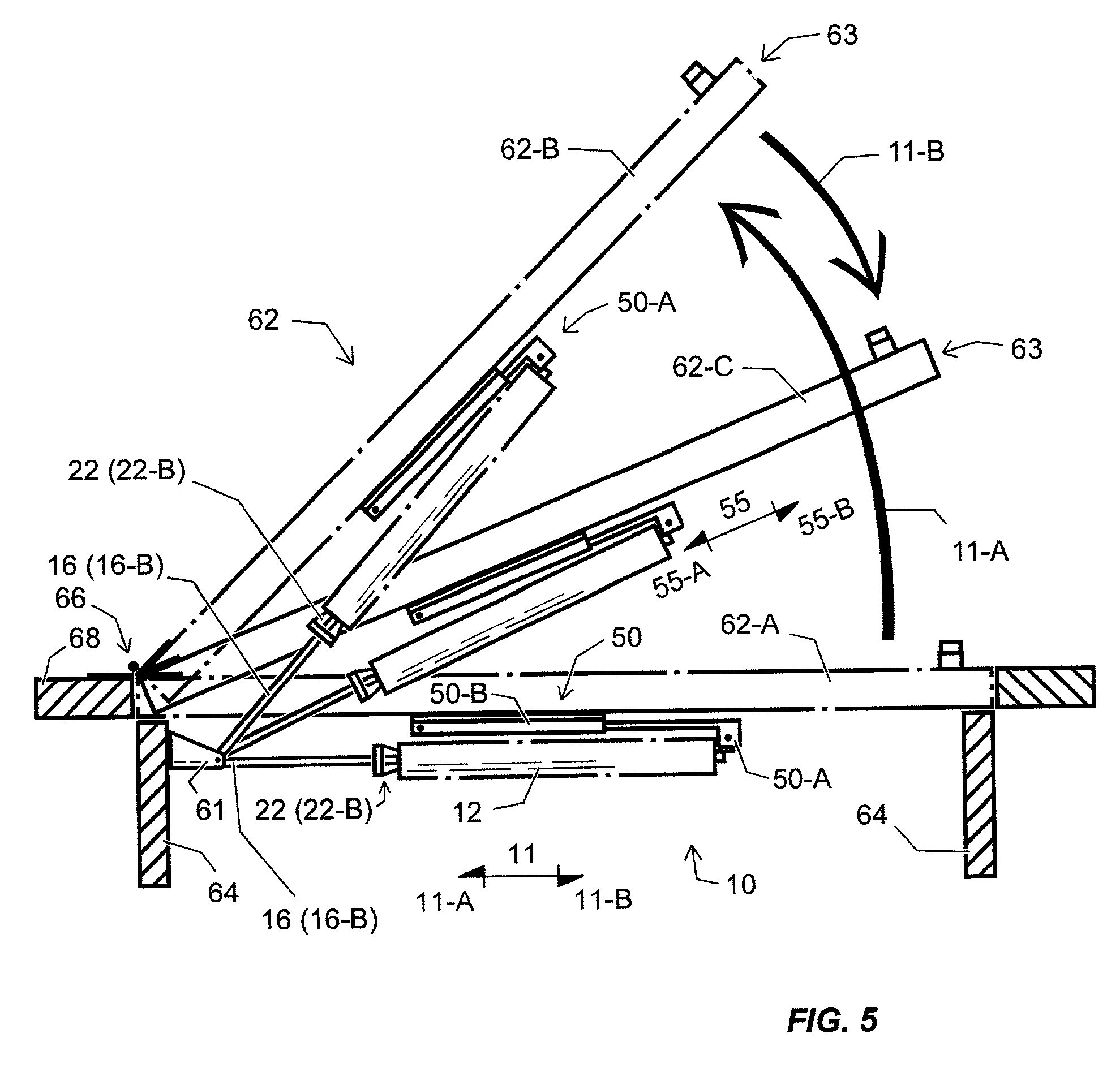

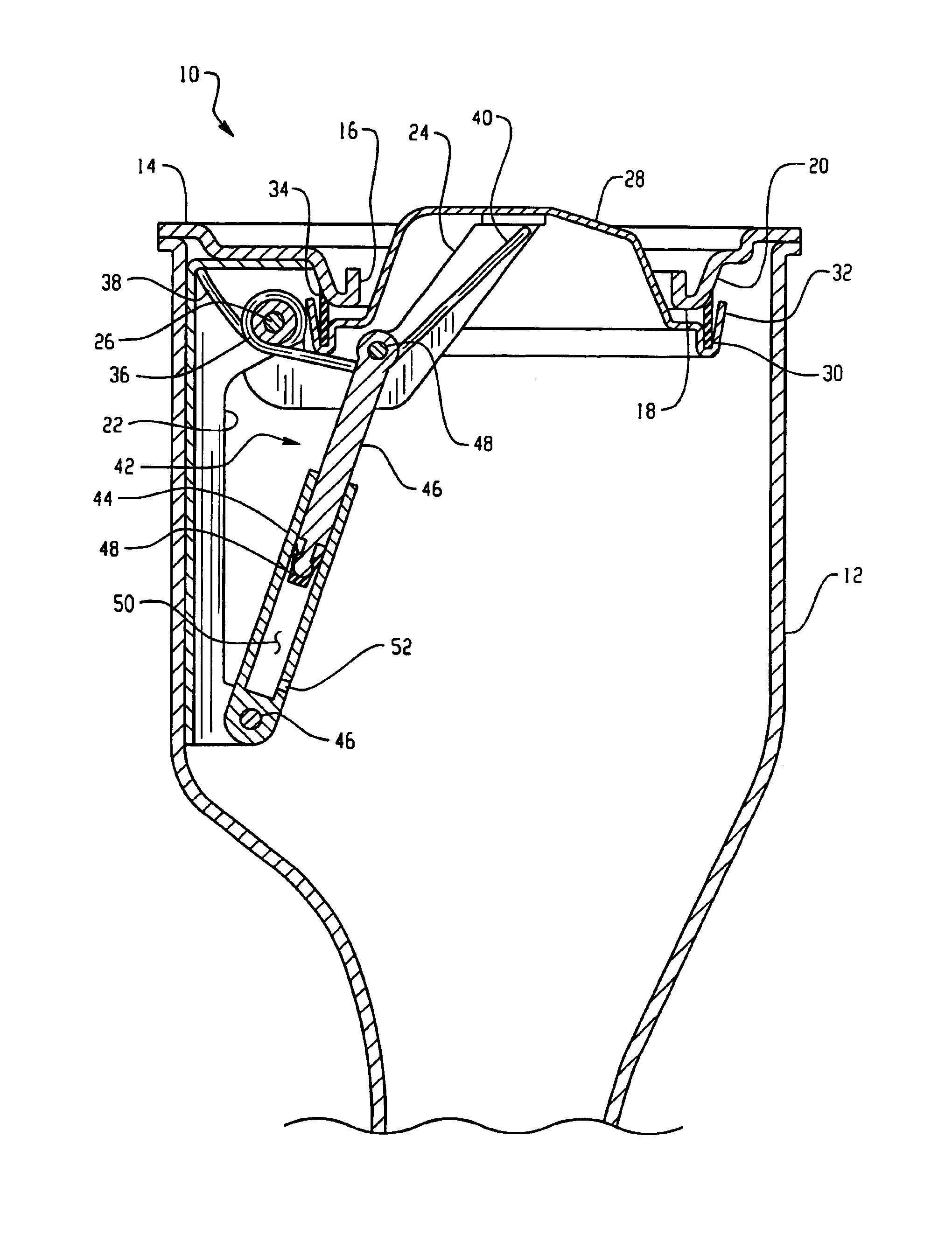

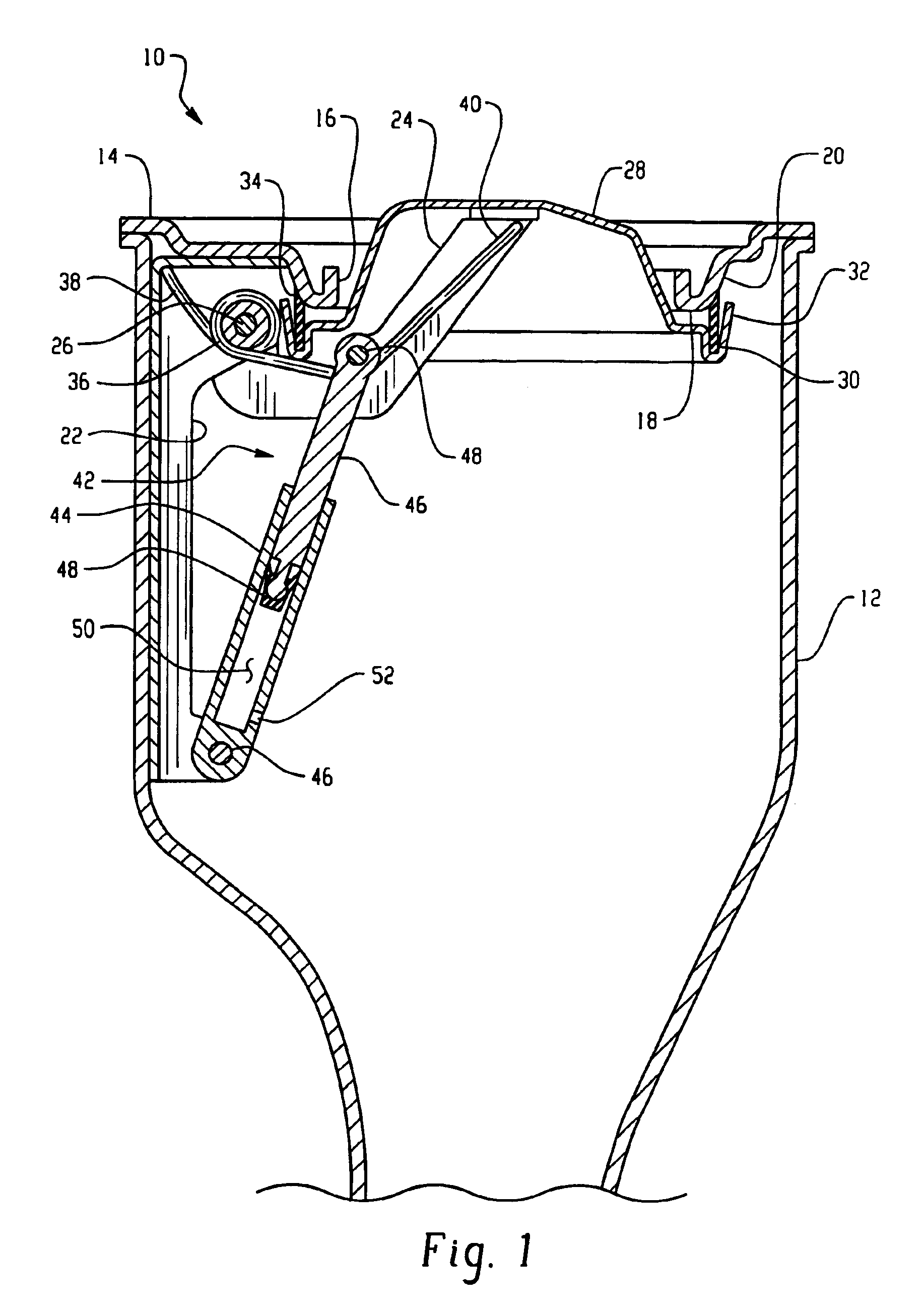

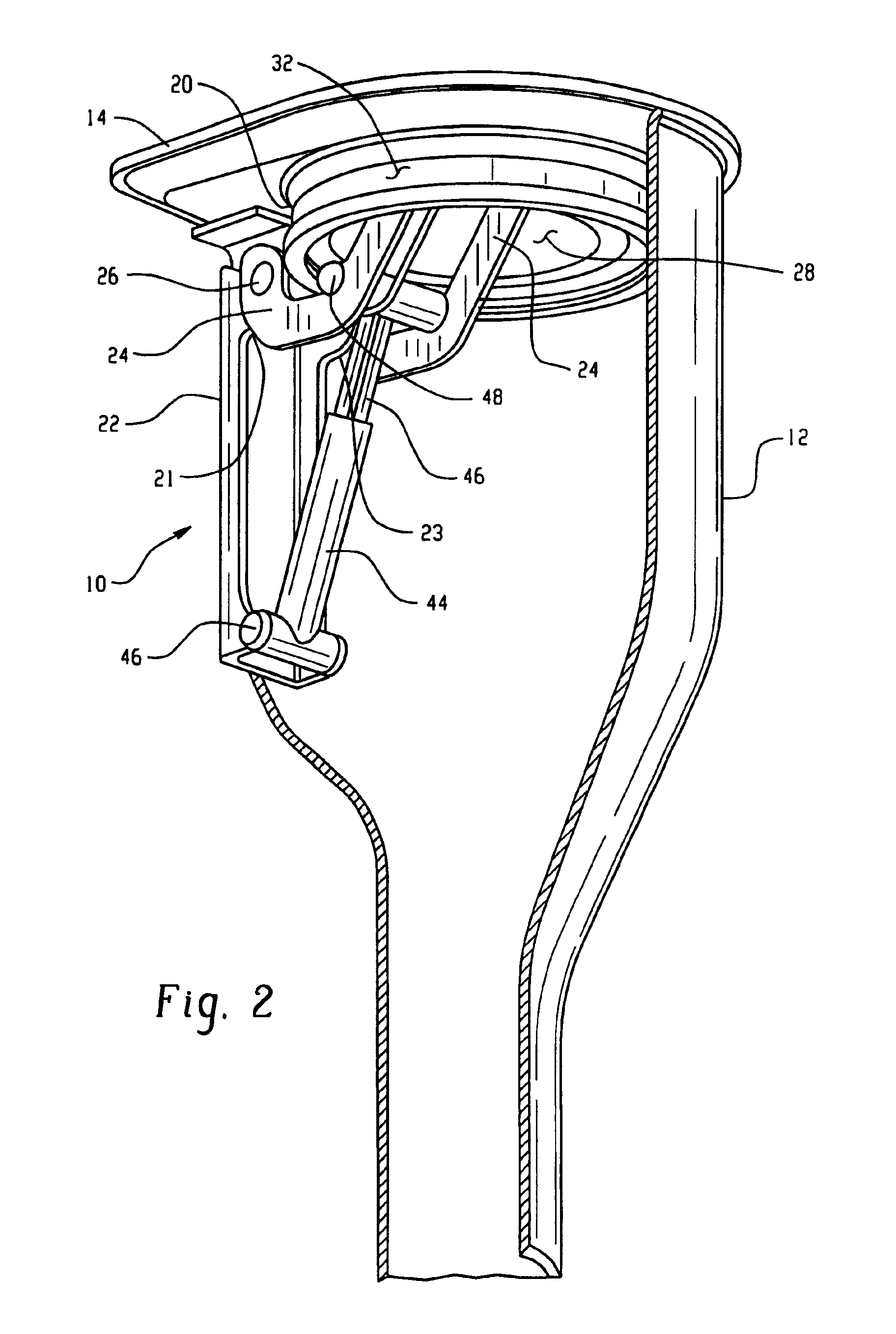

Damper assembly that opts to open doors for usage with reciprocating door closer devices

A damper assembly (50) adapted to a reciprocative door closer device (10) and contingent door (62), the device (10) comprising a piston rod (16) which functions reciprocatively from within a piston body (12) controlling a biasing means (11); the rod (16) normally loosely mounted with a checking mechanism (22) for variably holding both the rod (16) in an extended position (16-B) and a door (62) in an open position (62-B); the assembly (50) comprising a fixated bracket (50-A) with an offsetting fastener means (52) for universal attachment to left and right hinging doors (62), and, similar to the reciprocative device (10), the assembly (50) comprising an extensible bracket (50-A) controlling a counter biasing means (55) by use of an operator (54) selected from a group including a spring operator means (54-A) that acts to dampen, counter, and protect the device (10) and the door (62) from damage due to excessive inward biasing forces (11-B), and, acts to compensate for a superior checking mechanism (22) such as when the extended rod (16-B) is being held with the engaged mechanism (22-B) and the opened door (62-B) is moved towards the closed position (62-A) without first disengaging the mechanism (22-B), which, simultaneously now commissions the device (10) to return the door (62) to the exact opened position (62-B) determined by the engaged mechanism (22-B) holding the extended rod 16-B.

Owner:ALONSO RICARDO

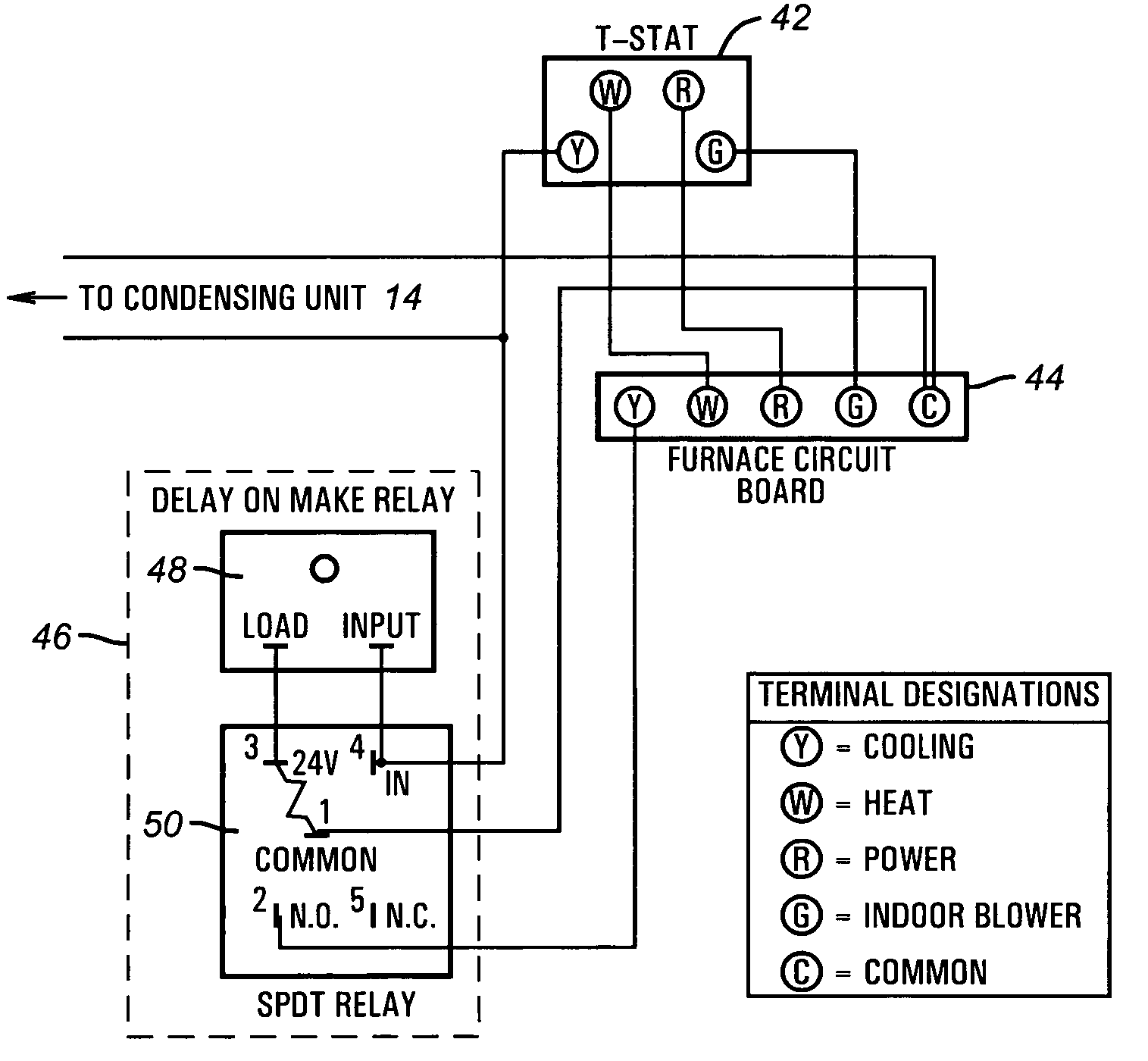

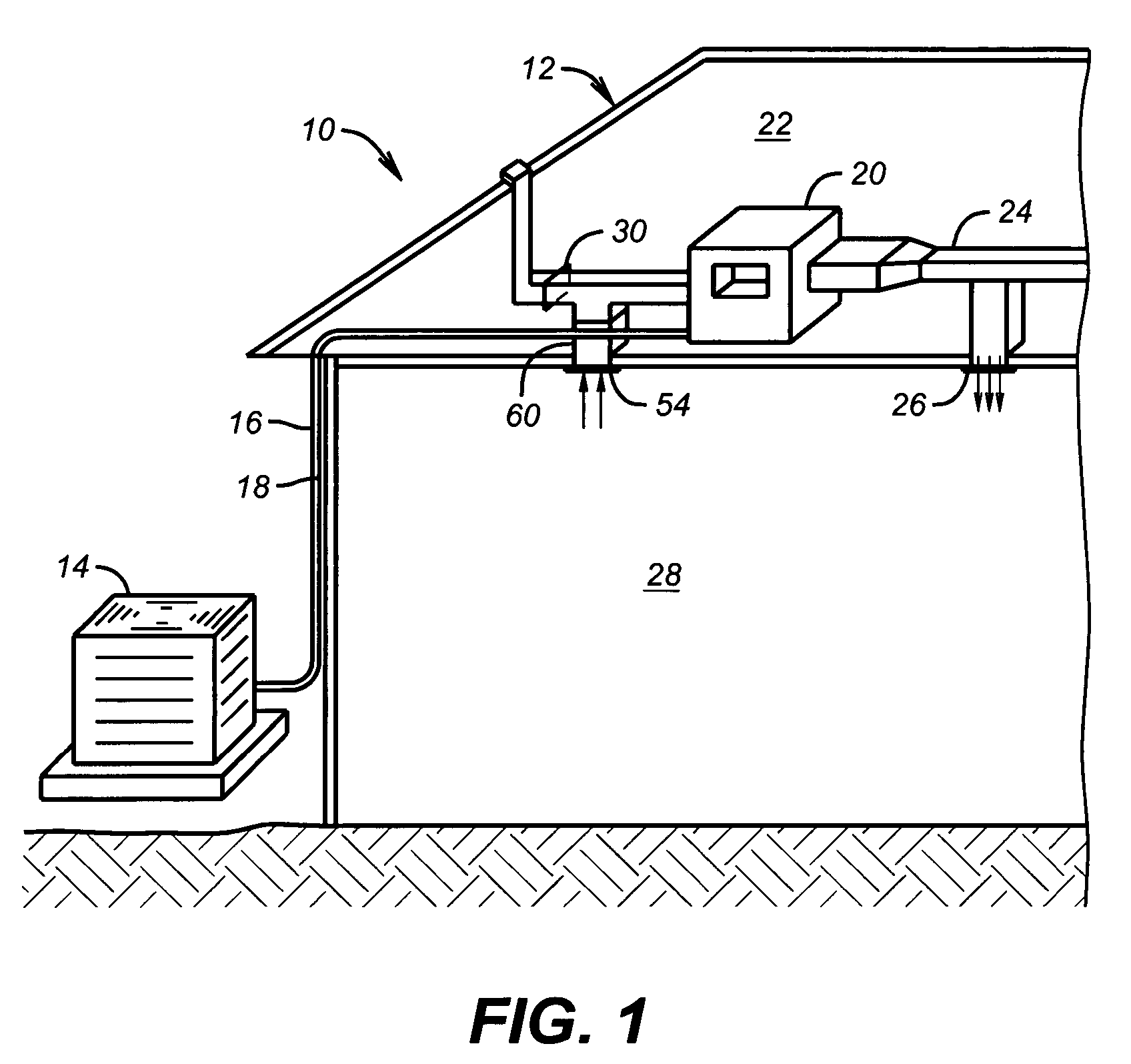

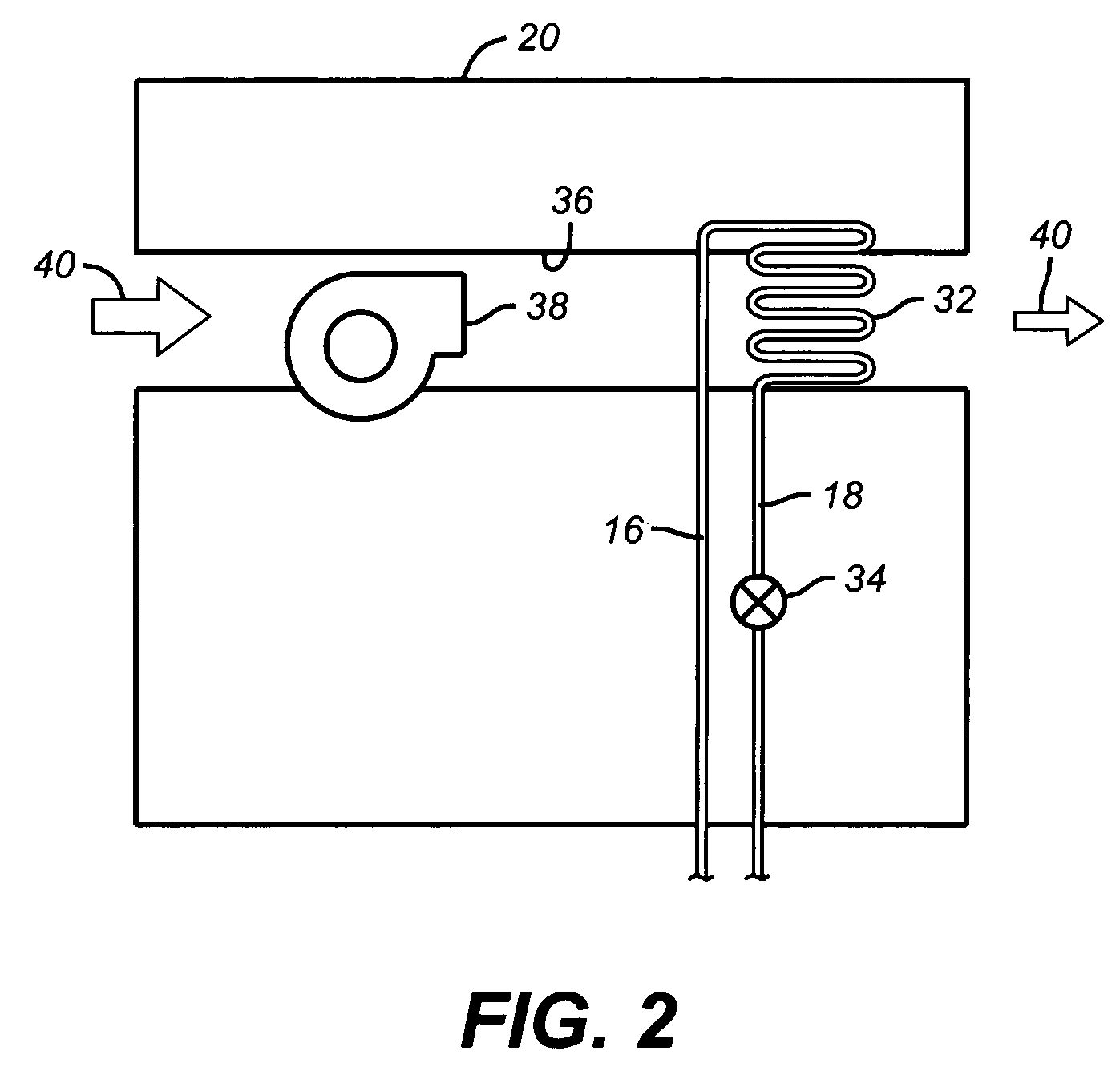

Air conditioning system with moisture control

ActiveUS7191607B2Speed up dehumidificationPrevent buildupDC motor speed/torque controlSpace heating and ventilationAir cycleLow speed

Devices and methods for moisture removal from conditioned air. A speed control is provided that selectively operates the blower motor of an air conditioning system at a lower speed. The speed control may include a time delay circuit and single pole, double throw relay. The speed control is used to slow the speed of the air cycler during the initial stage of a cooling cycle. This initial stage is typically the first 5–7 minutes of the air conditioning cycle. In a further aspect, a humidistat is operably associated with the system for detection of humidity levels within the air of a home or other structure. The system is programmed to close the motorized outside air damper in the event that humidity levels exceed a predetermined level, thereby limiting further entry of humid outside air into the home.

Owner:CURTIS MORTON

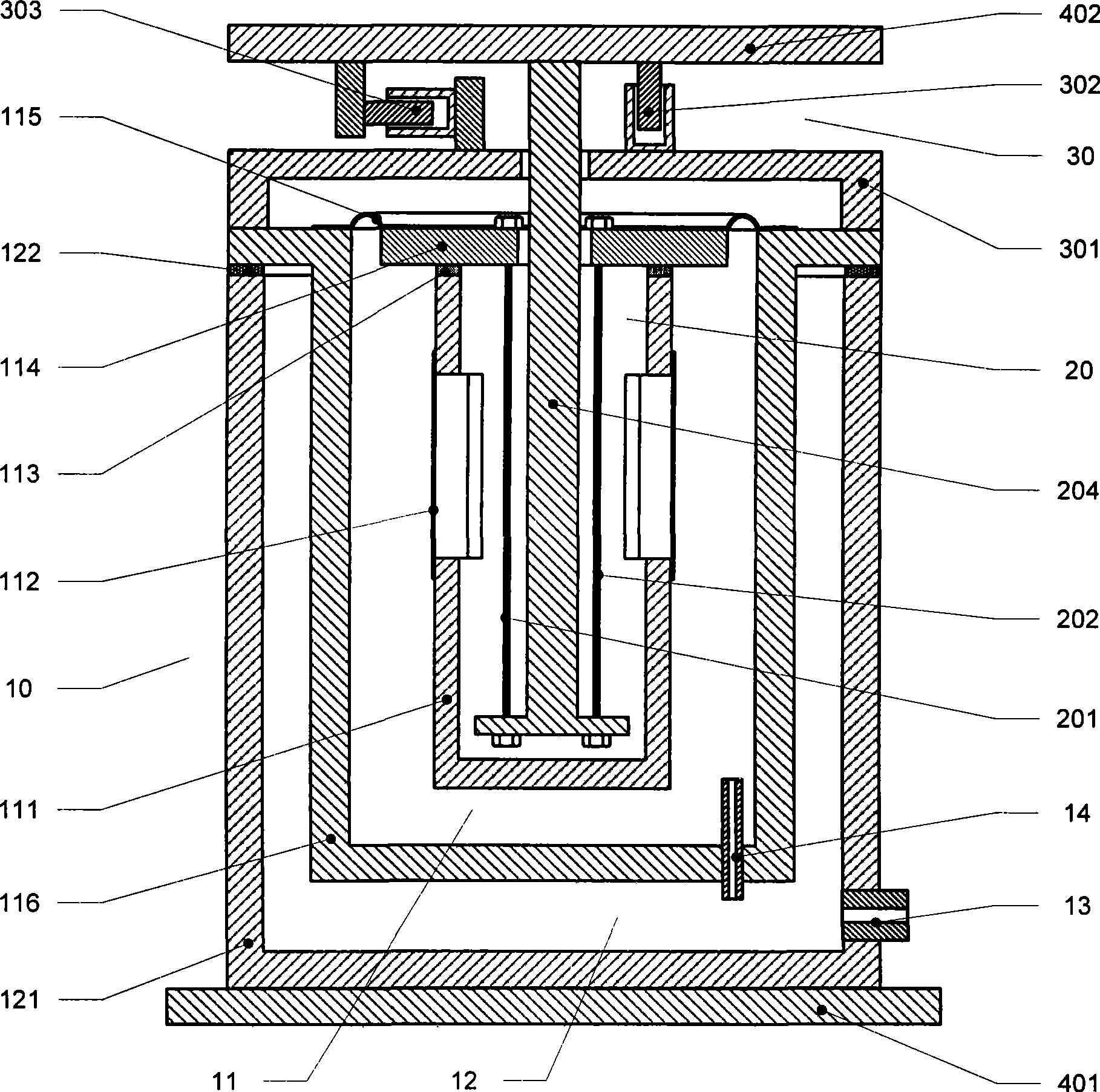

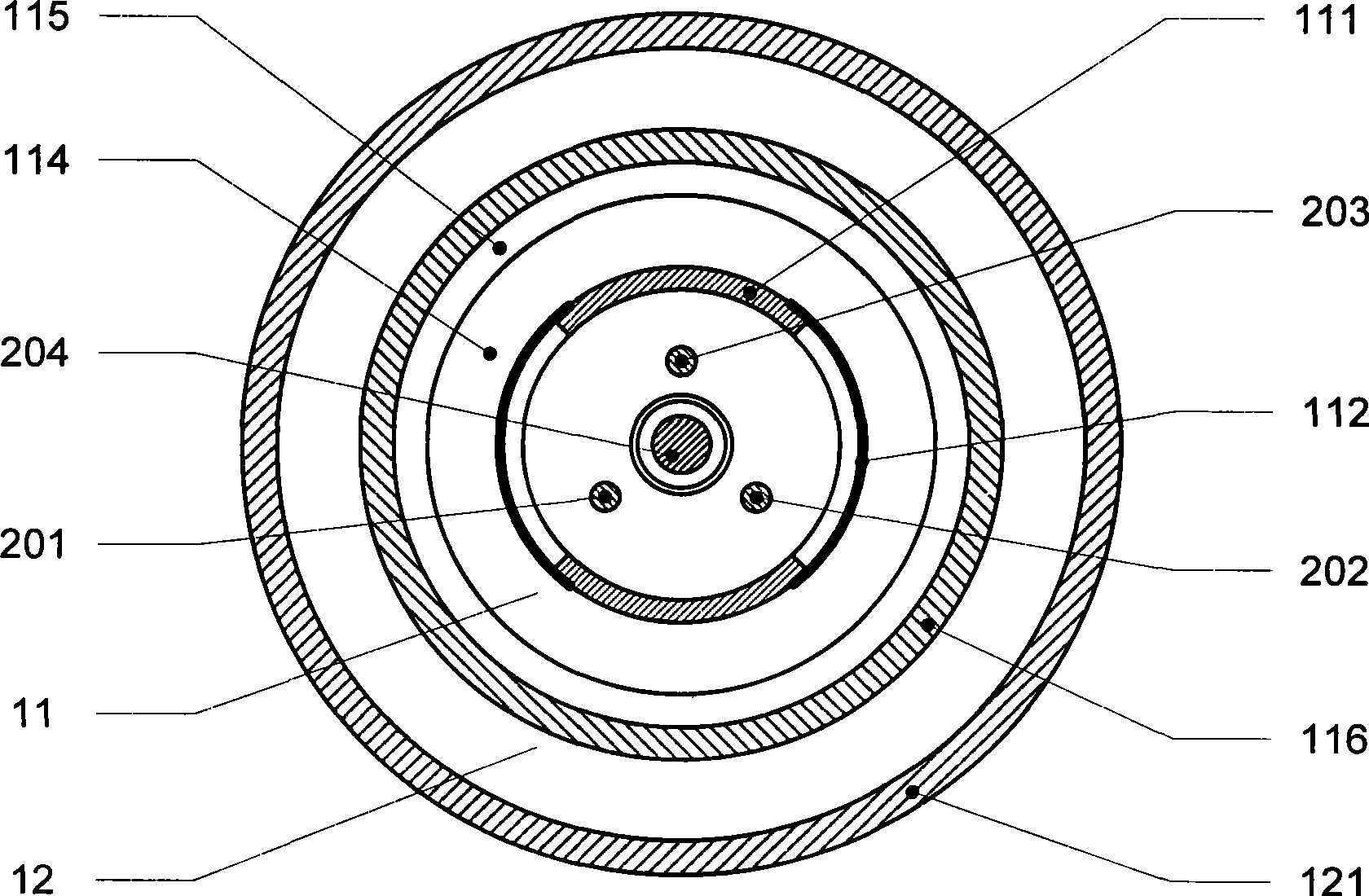

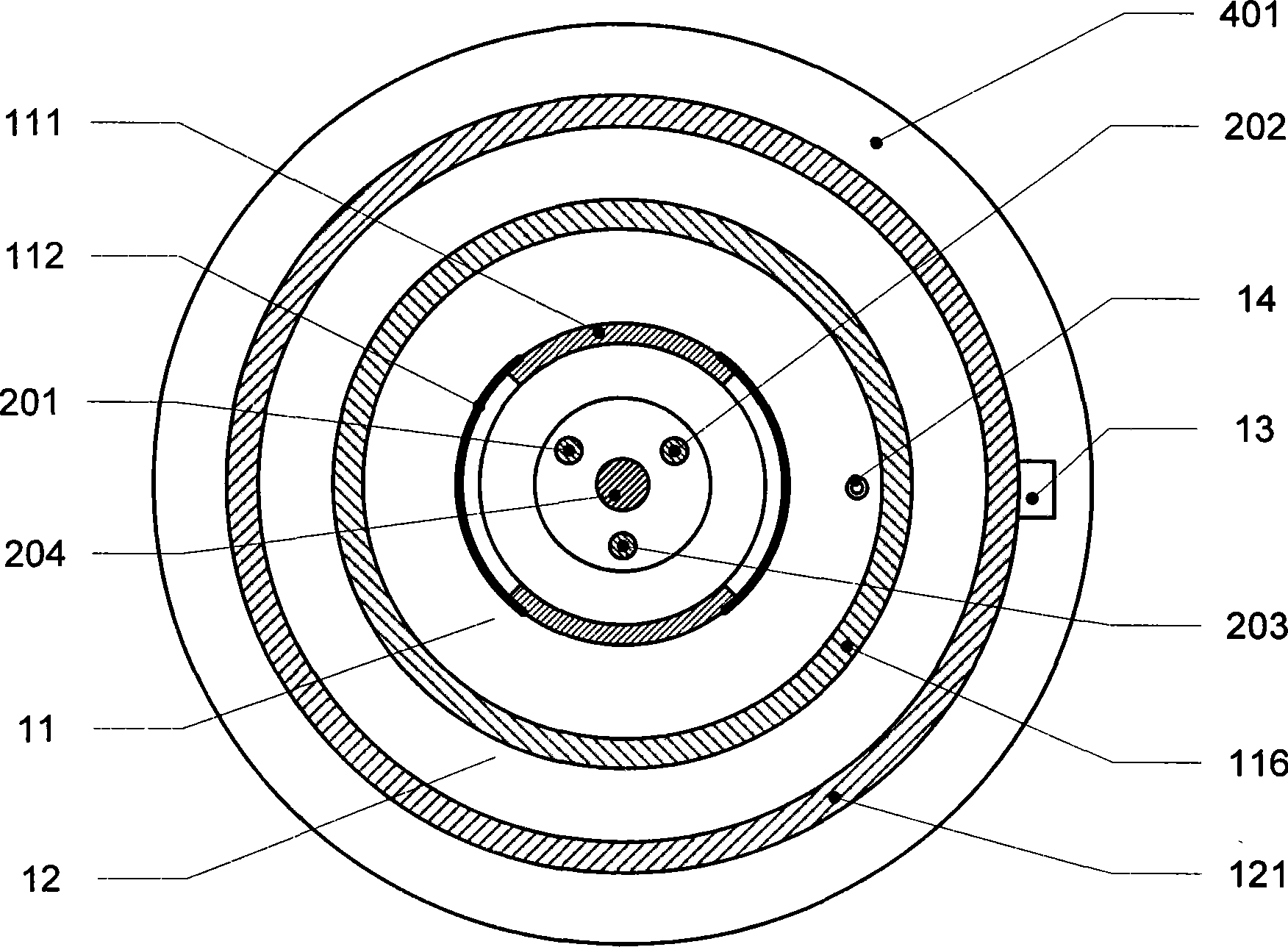

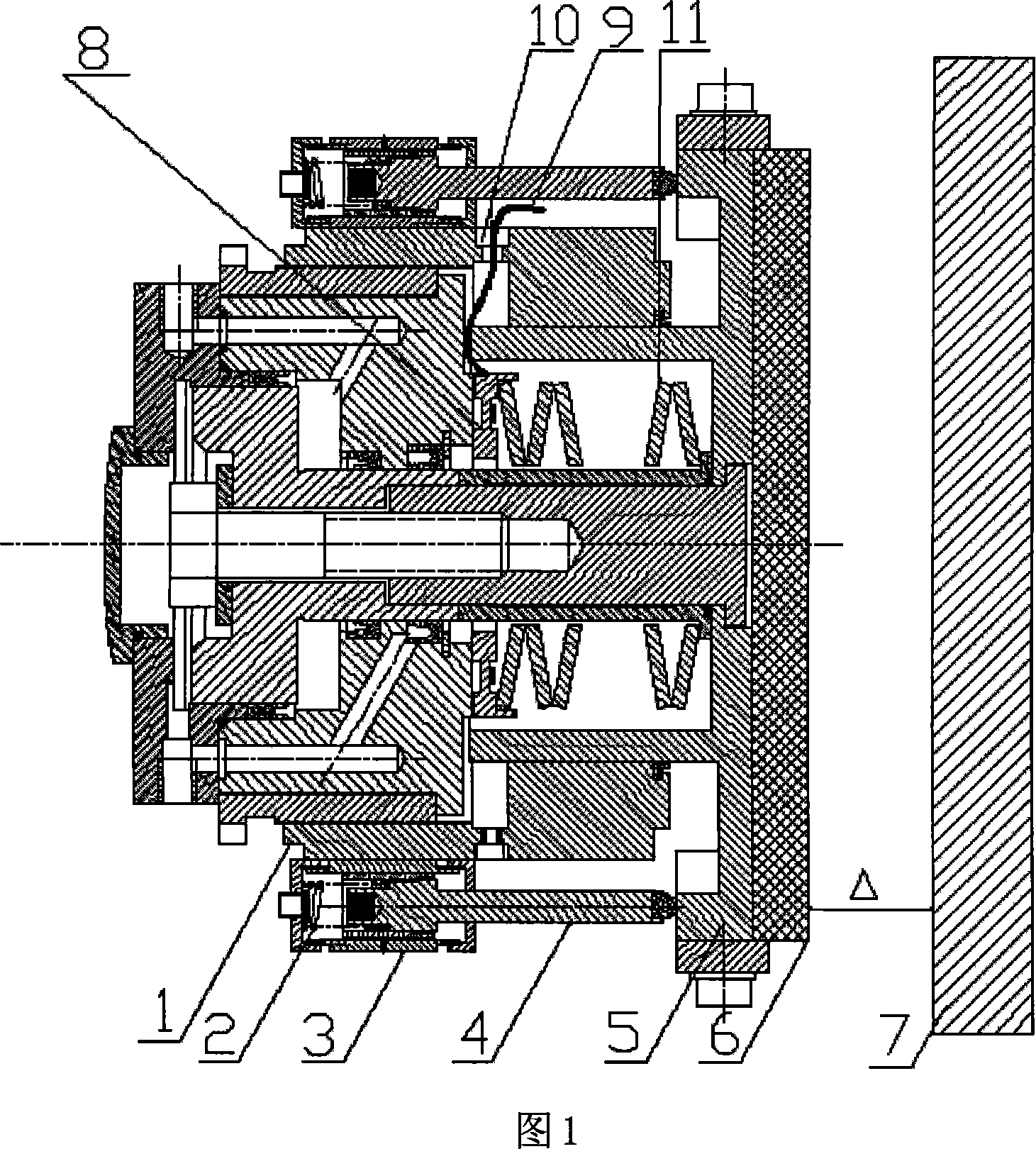

Heavy load precision damper and vibration reduction system formed thereby

InactiveCN101398052AMany degrees of freedomMulti-subwooferGas based dampersVibration suppression adjustmentsEngineeringActuator

The invention pertains to the technical field of precision damping, and is a heavy-load precision damper and a damping system comprising thereof. The damper comprises a low-rigidity air spring with variable damp, an inverted-pendulum structure with low horizontal rigidity and a group of three-degree-of-freedom active damping actuators. The structure of the air spring is external-internal annularity double air chambers communicated with a throttling hole; the inverted-pendulum structure comprises a main supporting rod and at least two flexible swing rods and is located in an annular air chamber; and the active damping actuator comprises three linear motors arranged in an orthogonal manner. The heavy-load precision damper vertically generates large bearing force by the air spring, respectively separates vertical and horizontal vibration transmission by the air spring and the inverted-pendulum structure, and actively controls the damp vibration by acting force of the vertical and horizontal linear motors. The damping system comprises at least three heavy-load precision dampers arranged in the shape of a polygon, and realizes six-degree-of-freedom precision damping of a vibration-isolation device by the mutual action of every heavy-load precision dampers.

Owner:HUAZHONG UNIV OF SCI & TECH

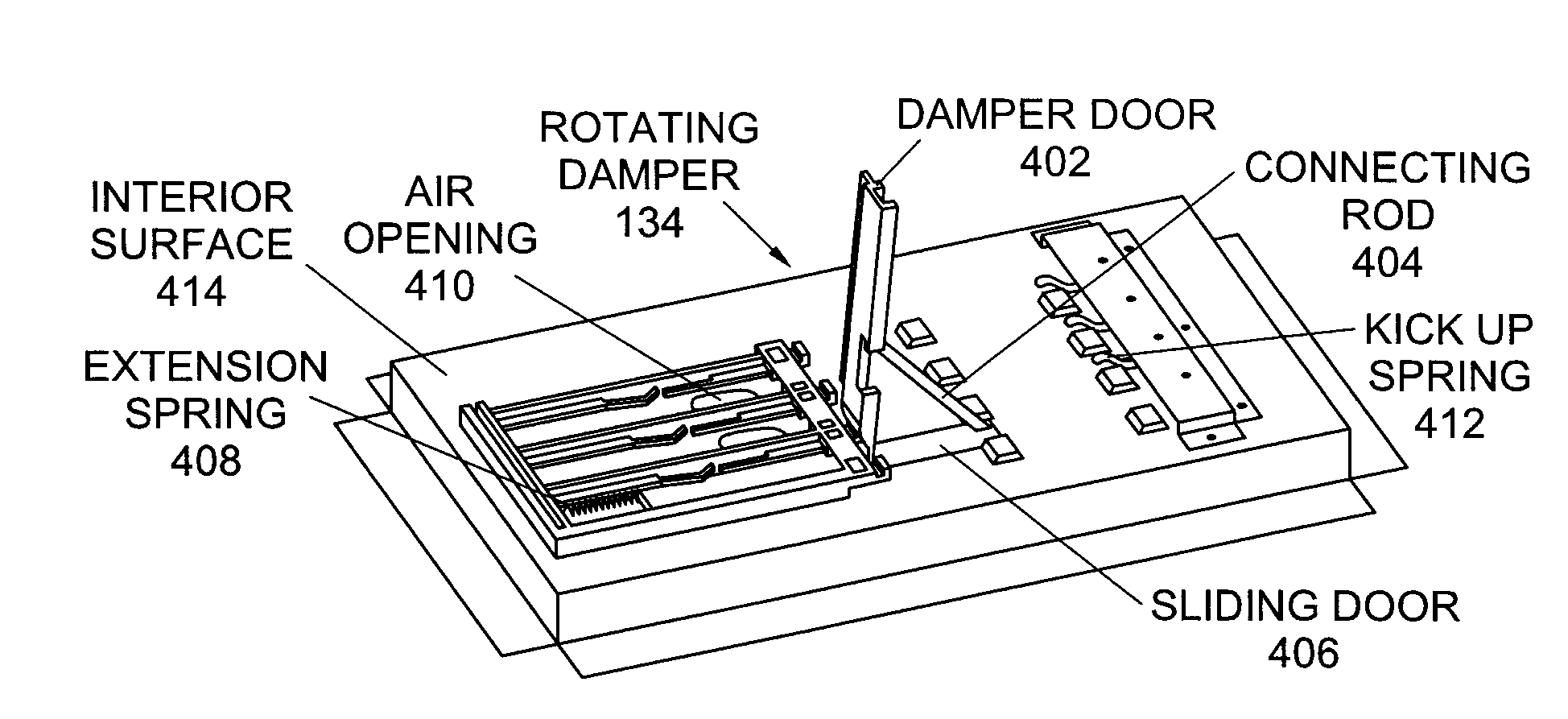

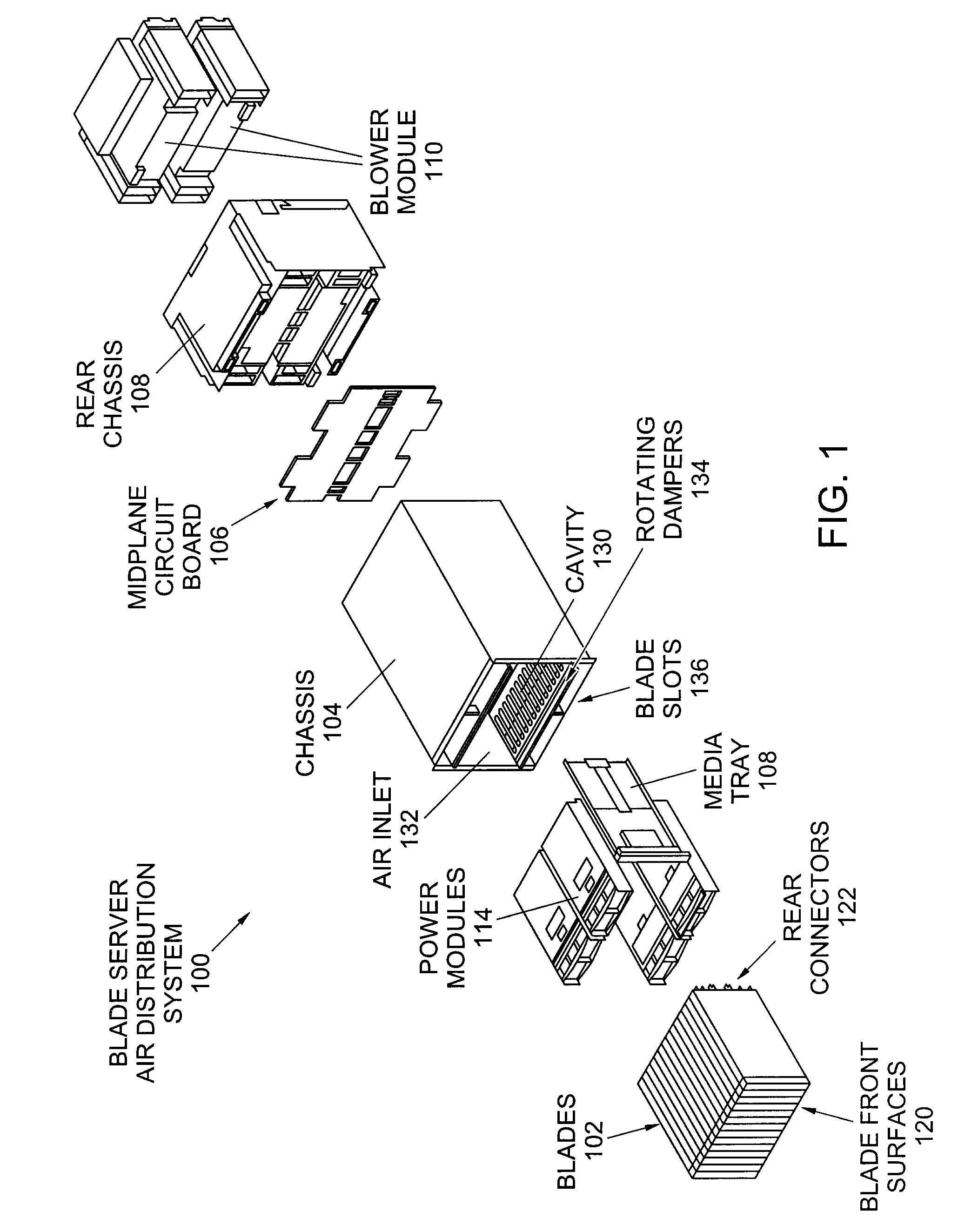

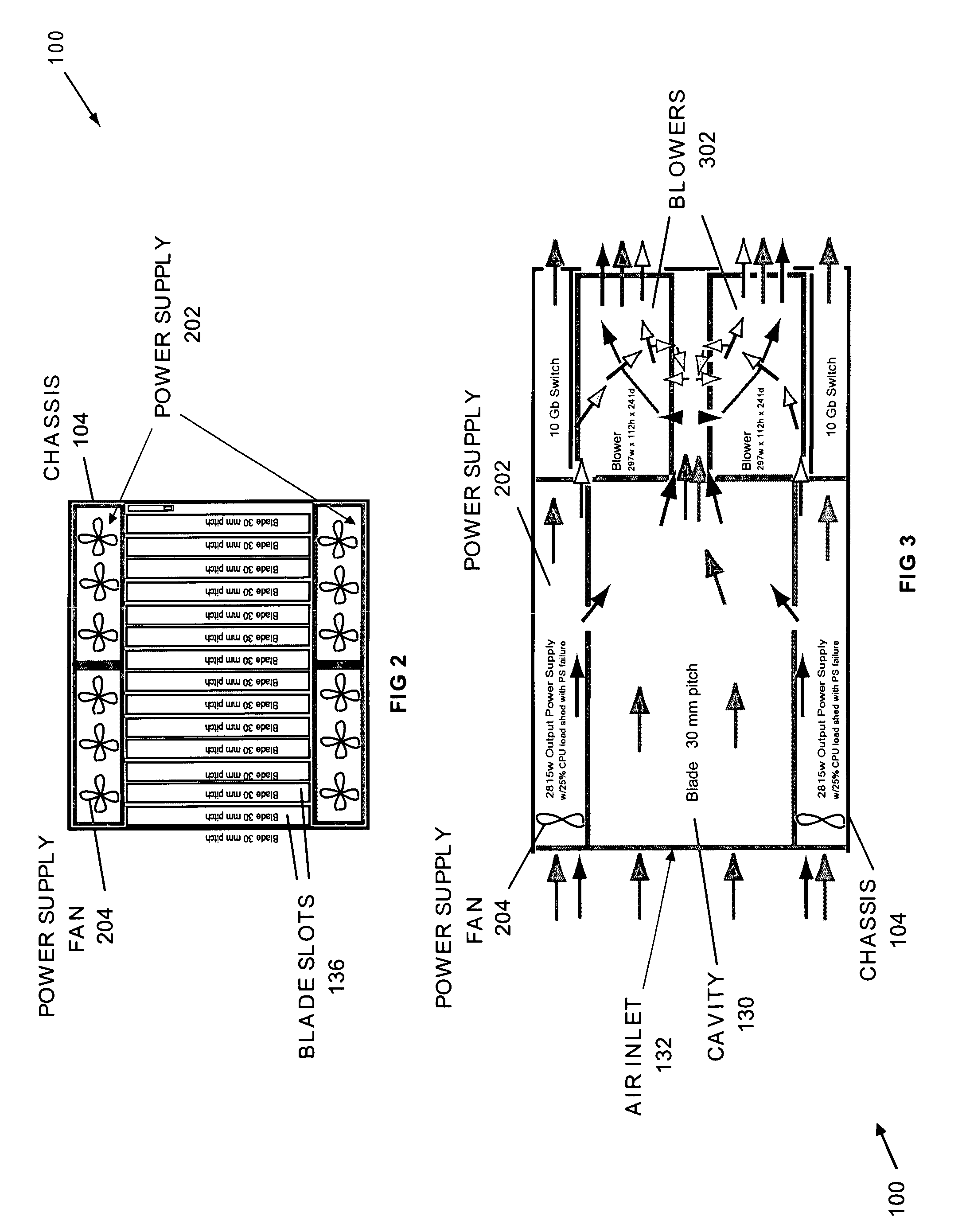

System, method, and apparatus for distributing air in a blade server

ActiveUS7344439B2Digital data processing detailsCooling/ventilation/heating modificationsClassical mechanicsDamper

A system, method, and apparatus for distributing air in a blade server are disclosed. Embodiments may include a rotating damper having a damper door, sliding door, and connecting rod. The damper door may be rotatably attached to a blade server having a plurality of blade slots for receiving blades and may rotate between a blocking position and a flat position, where the damper door impedes air through a blade slot when in the blocking position. The sliding door may move between an open position and a closed position, where the sliding door allows airflow through an air opening while in the open position and blocks airflow through the air opening while in the closed position. A further embodiment may include an extension spring to apply a pulling force to the sliding door and a kick up spring to apply a pushing force to the damper door in the flat position.

Owner:LENOVO GLOBAL TECH INT LTD

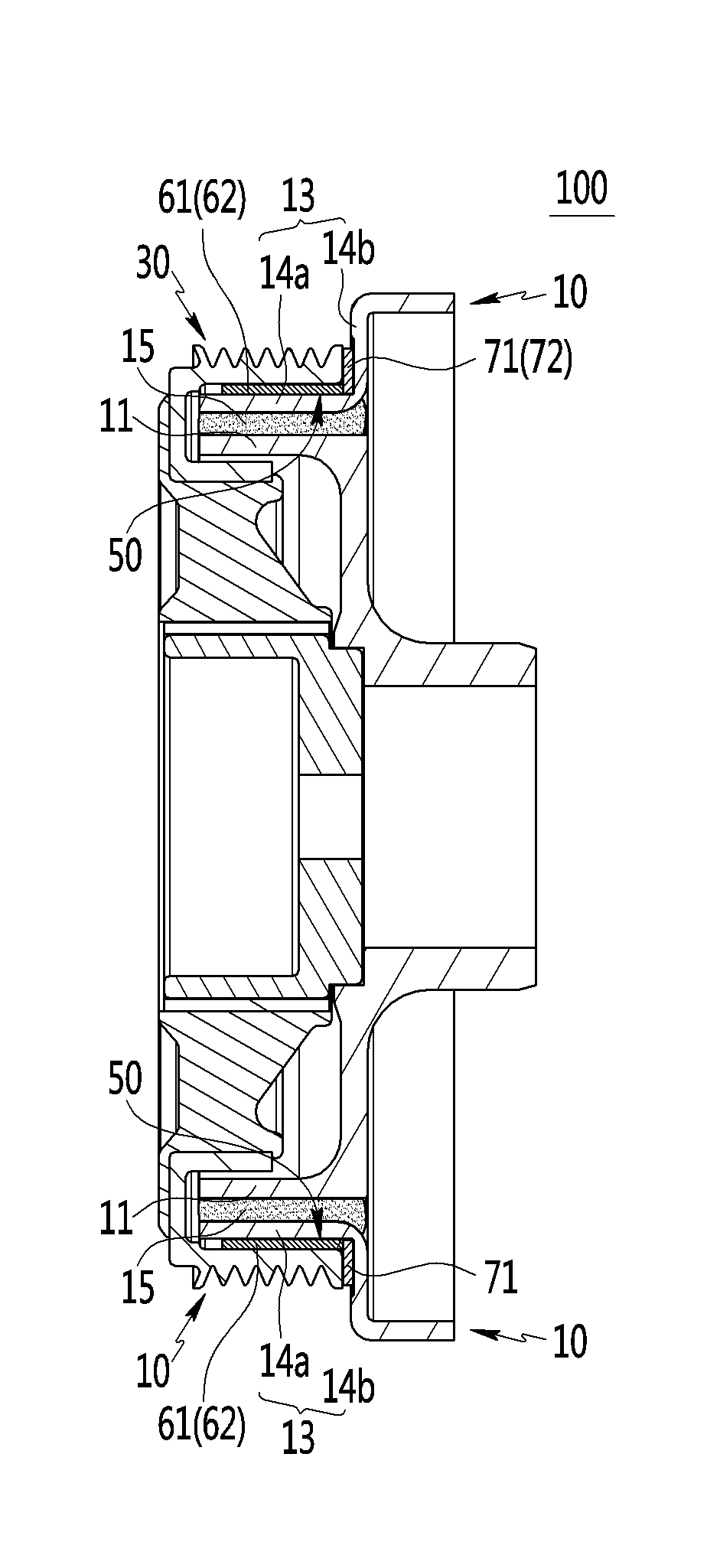

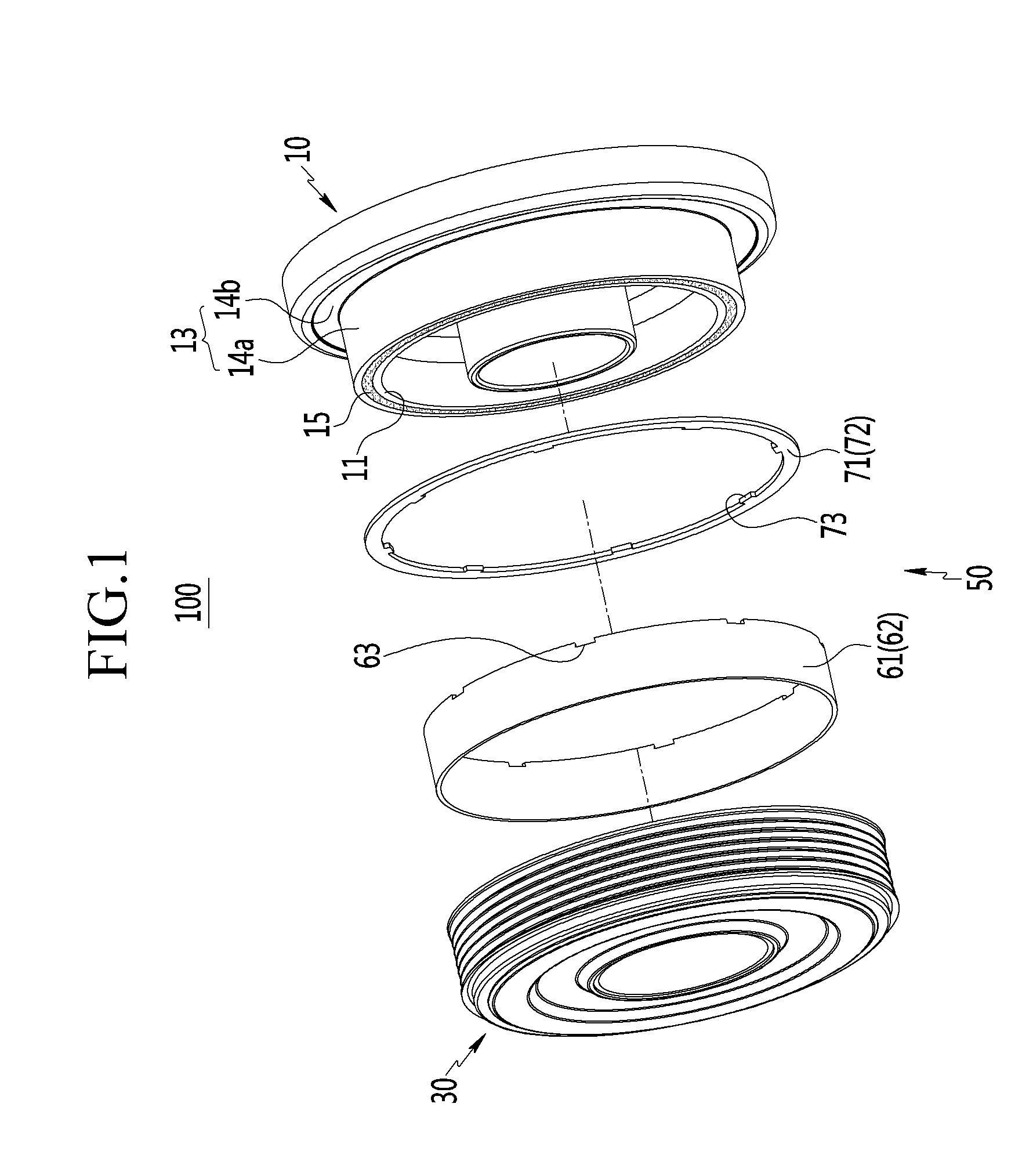

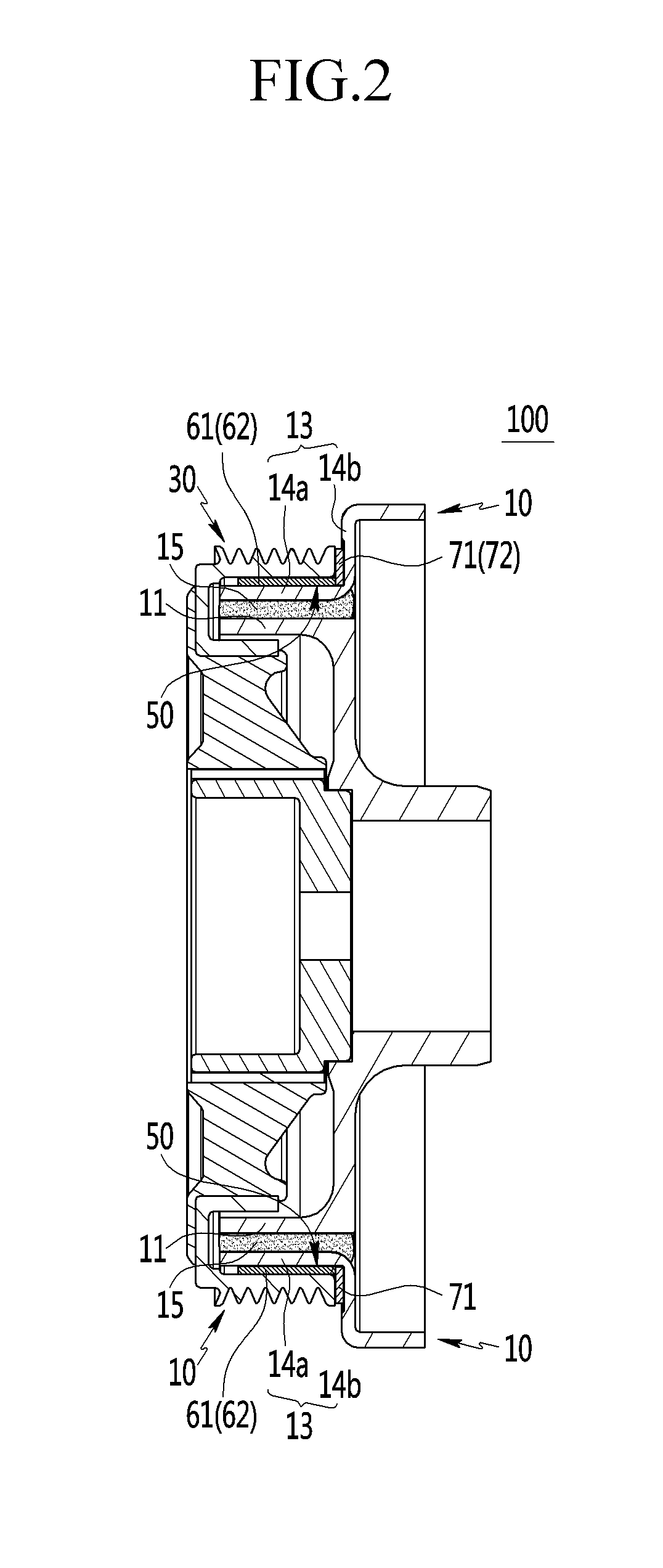

Isolation damper pulley for vehicle

InactiveUS20120094791A1Avoid friction and noiseReduce frictionRotating vibration suppressionYielding couplingCrankshaftPulley

A damper pulley for a vehicle may include a damper portion connected to a crankshaft, a pulley portion connected to the damper portion, and a bearing portion disposed between the damper portion and the pulley portion, wherein the bearing portion includes a first bearing supporting a load applied in an axial direction and a second bearing supporting a load applied in a direction perpendicular to the axial direction, and the first and second bearings are engaged through protrusions and depressions.

Owner:HYUNDAI MOTOR CO LTD +1

Air conditioner with selective filtering for air purification

InactiveUS20150354874A1Great and less degree of filtrationReduce energy useMechanical apparatusEvaporators/condensersAir filtrationDamper

A split air conditioner has a cabinet with a fan and evaporator for mounting within a structure. The cabinet includes one or more movable dampers or movable filters positioned in the flow path between the air inlet and the outlet for selectively filtering contaminants from the air to provide a greater or lesser degree of filtration of the air. The movable filters include sliding and / or pivot mounting structure which may accommodate stacking multiple filters with different filtering characteristics. The system may operate in a filtering only mode with no cooling, a cooling only mode with no filtering, or a combination of cooling and selective filtering.

Owner:WHIRLPOOL CORP

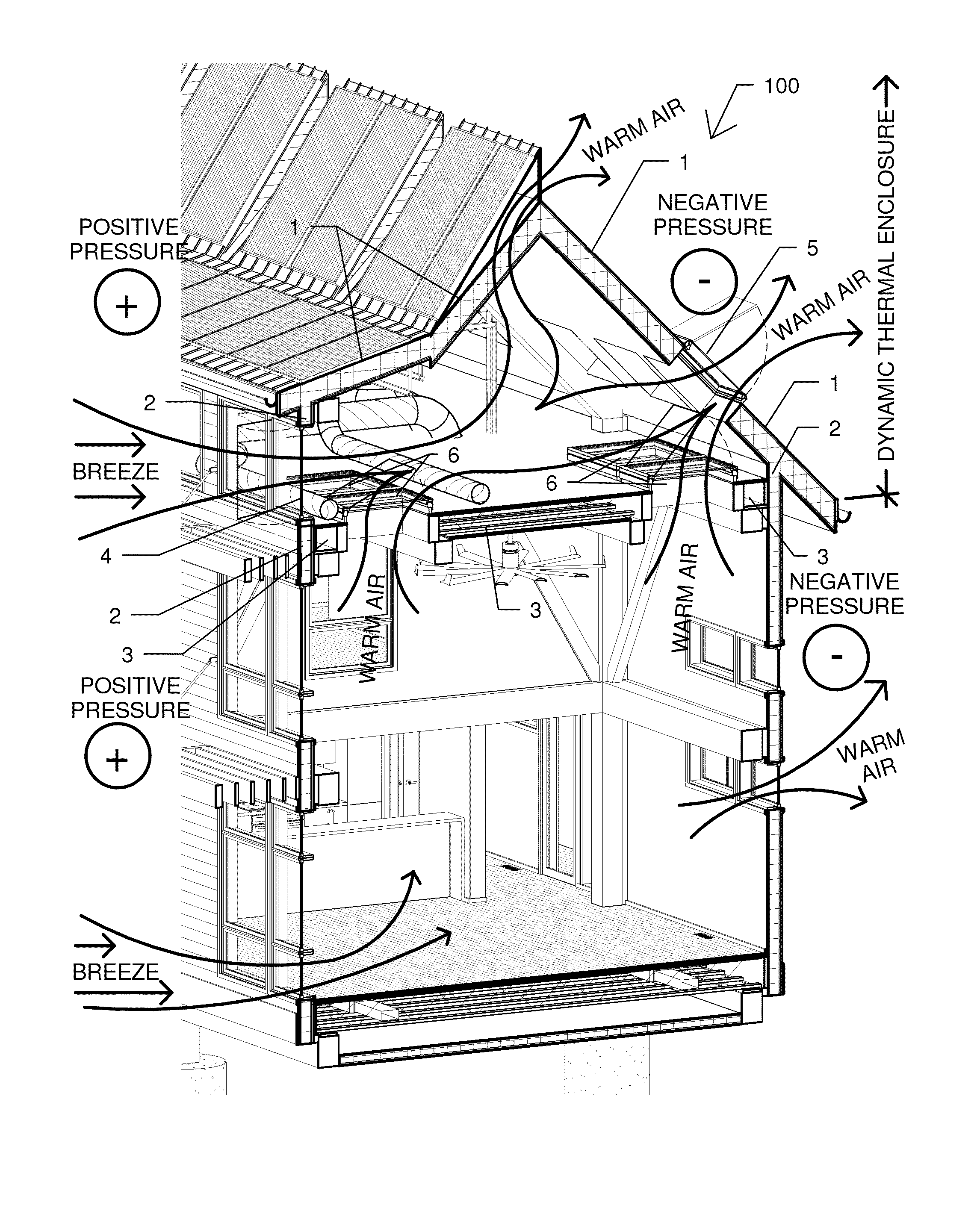

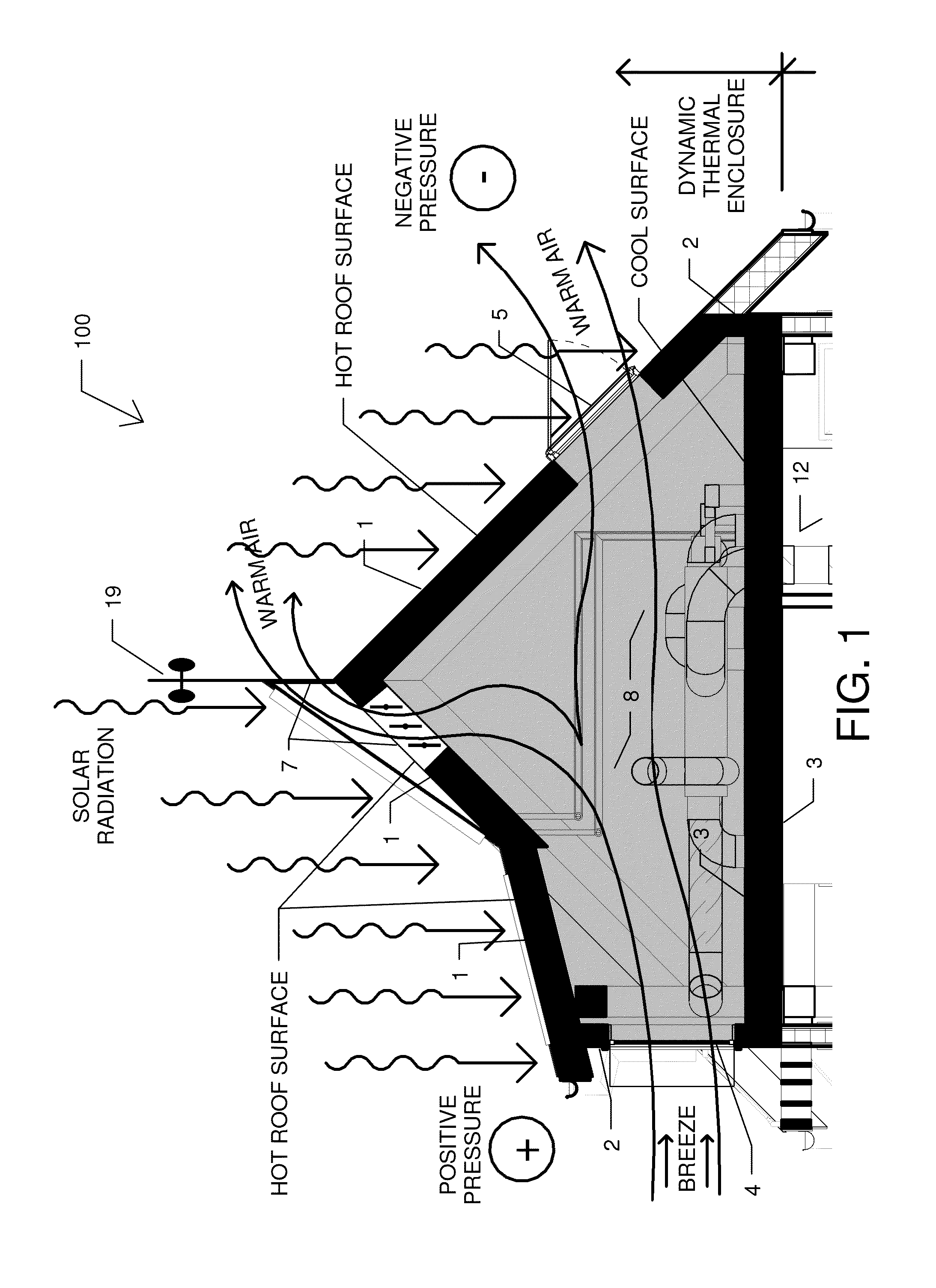

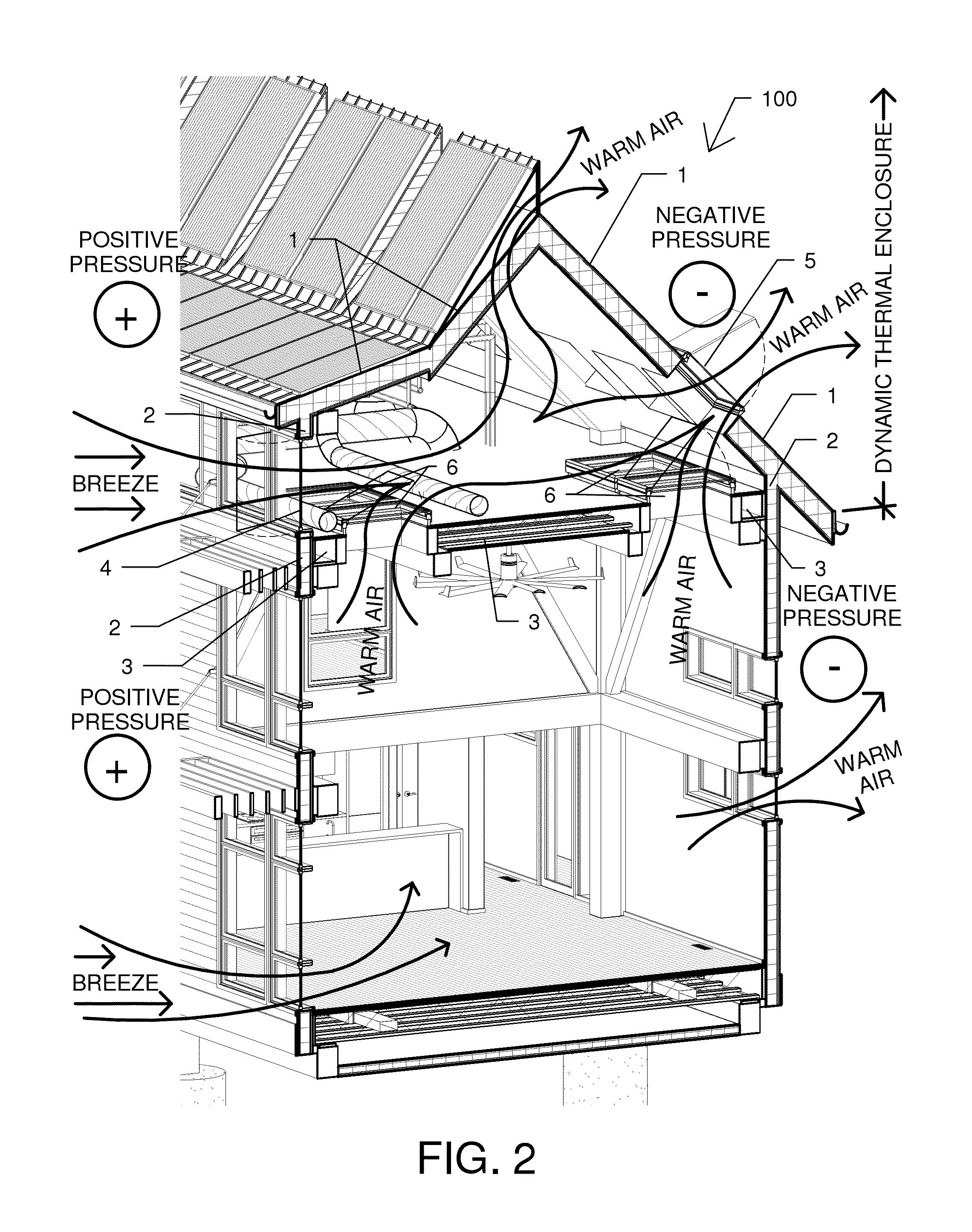

Energy-efficient building structure having a dynamic thermal enclosure

ActiveUS8726586B1Eliminate the problemEasy to disassembleLighting and heating apparatusSpace heating and ventilation detailsControl cellFresh air

A constructed enclosure, adjacent to an interior habitable space, uses a microprocessor-based control unit to operate enclosure openings to provide a multi-layer insulation barrier containing or creating heat, or providing a radiant barrier, isolating by open air, a thermal insulating layer from warm exterior surfaces, maximizing insulation values. The enclosed space, through the use of openings, which in one embodiment are windows, skylights and dampers connected to louvers, is heated by radiant exposure or cooled by natural air flow or exhaust fan. Return air is heated upstream from a forced air heating unit by traversing ductwork heated by the enclosure and by direct solar exposure from enclosure windows. Enclosure openings to the habitable interior spaces create air displacement drawing warm air out of the interior and fresh air in through exterior windows. The energy efficient system is tailored for immediate climate specific conditions.

Owner:STEVENS KIRK RUSSELL +4

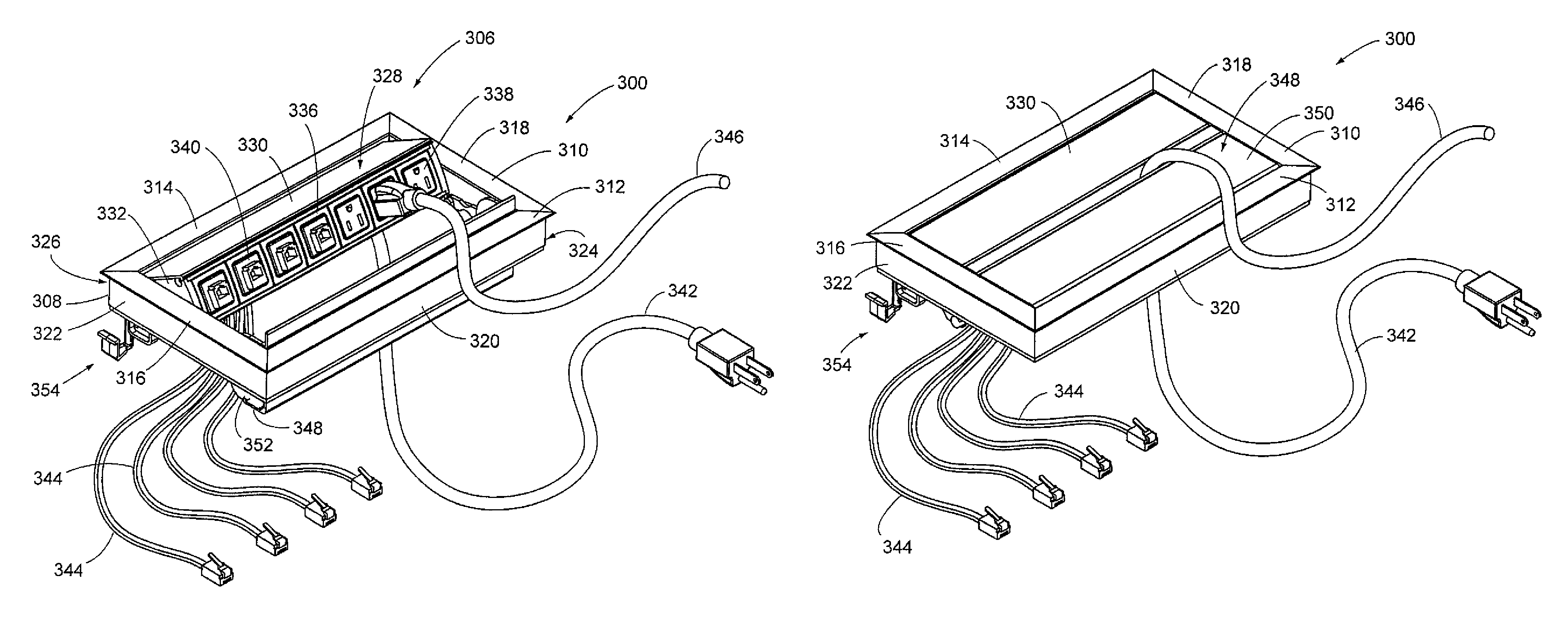

One touch pivoting expandable power and data center

An expandable power and data center (300) is adapted to be mounted within a slot (304) of a work surface (302). The power and data center (300) includes a stationary housing (306) and a carriage (328). The carriage (328) includes socket areas where power receptacles (338) and data ports (340) can be inserted. A top surface (330) of the carriage (328) and a top surface (350) of a frontal cover (348) form a pressure area (360). With the carriage in a closed position (328), a user can exert a downward pressure on the pressure area (360), causing the carriage (328) to move to an open position. A damper (368) restricts the speed at which the carriage (328) moves between the closed position and an open position.

Owner:BYRNE NORMAN R

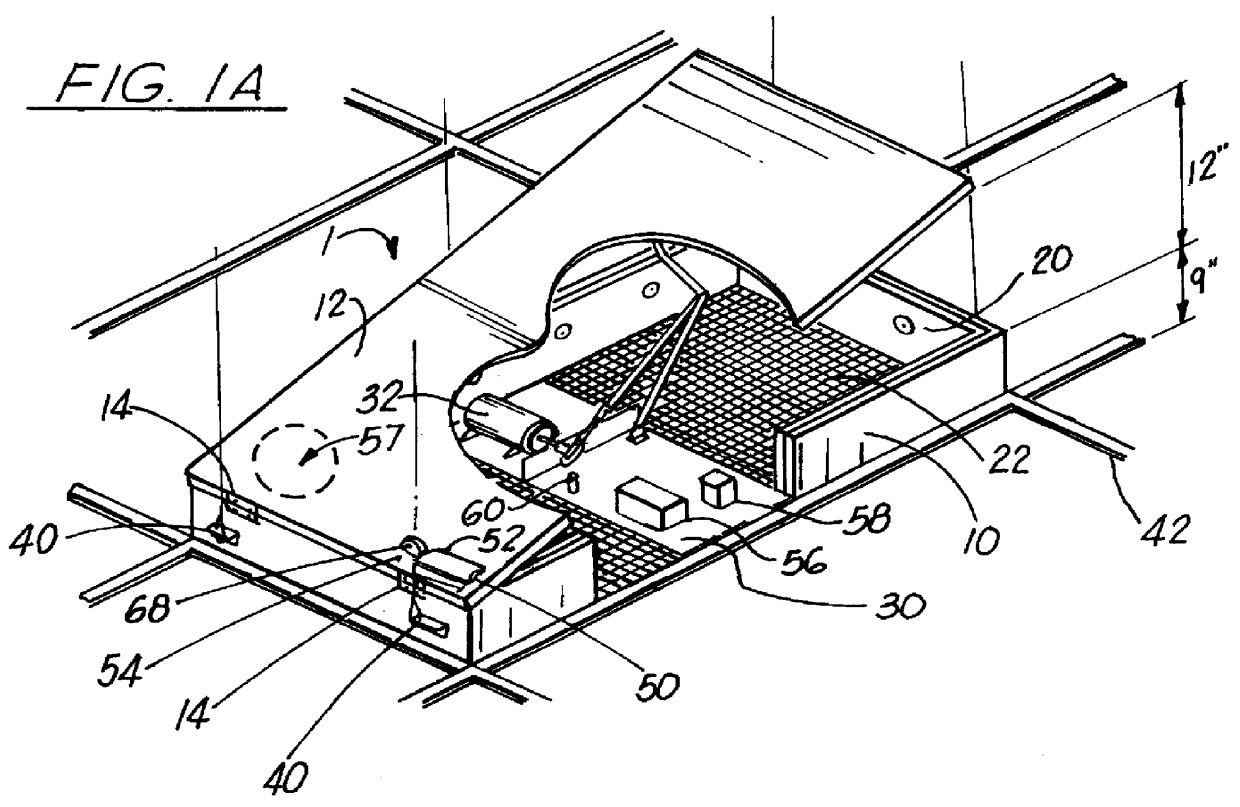

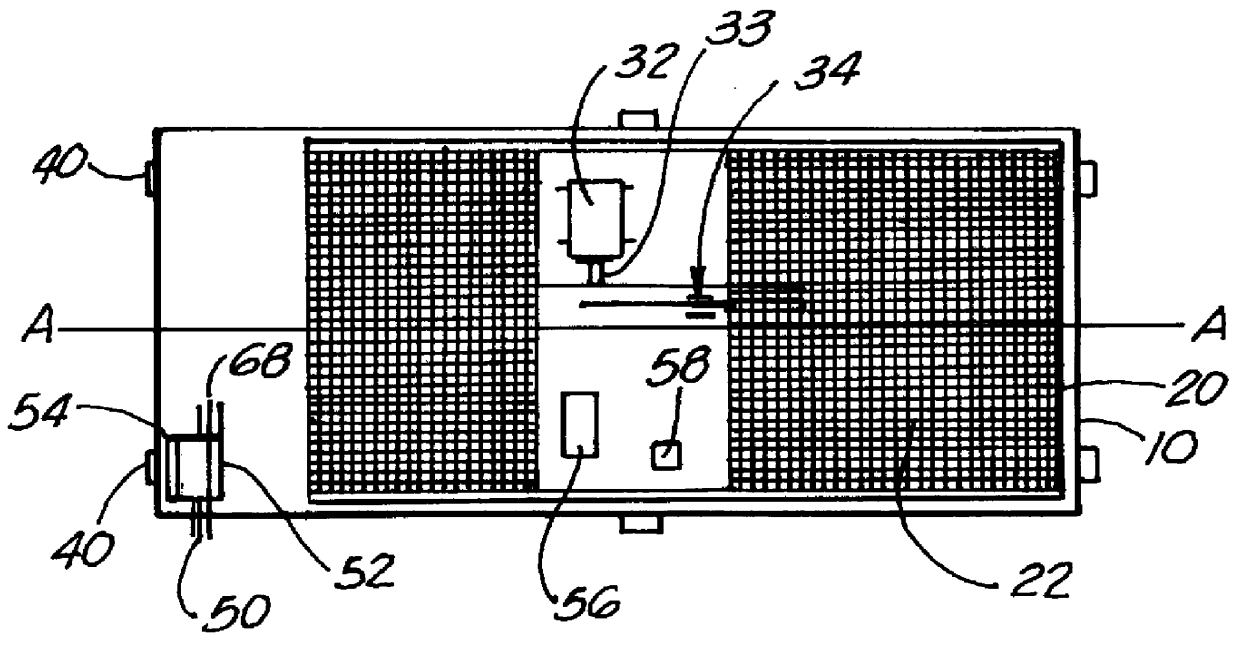

Smoke detection and ventilation system

InactiveUS6053809AAvoid property damagePrevent smoke inhalationMechanical apparatusSpace heating and ventilation safety systemsSmoke detectorsEngineering

A system for detecting the presence of smoke within a building and providing means to remove the smoke, into the airspace above the ceiling thereby preventing or at least alleviating smoke inhalation, property damage, and allowing more time for the safe evacuation from the premises. The system is comprised of a conventional smoke detector which activates control means for raising and lowering a generally planar panel which is installed in a ceiling. Smoke is removed from the airspace below the ceiling to the airspace above the ceiling. An optional fan, remote fan relay, exhaust vent and back draft damper further aid in the exhausting of the smoke from the building. A fusible link in the control means protects the ceiling fire rating.

Owner:MIRACLE VENT

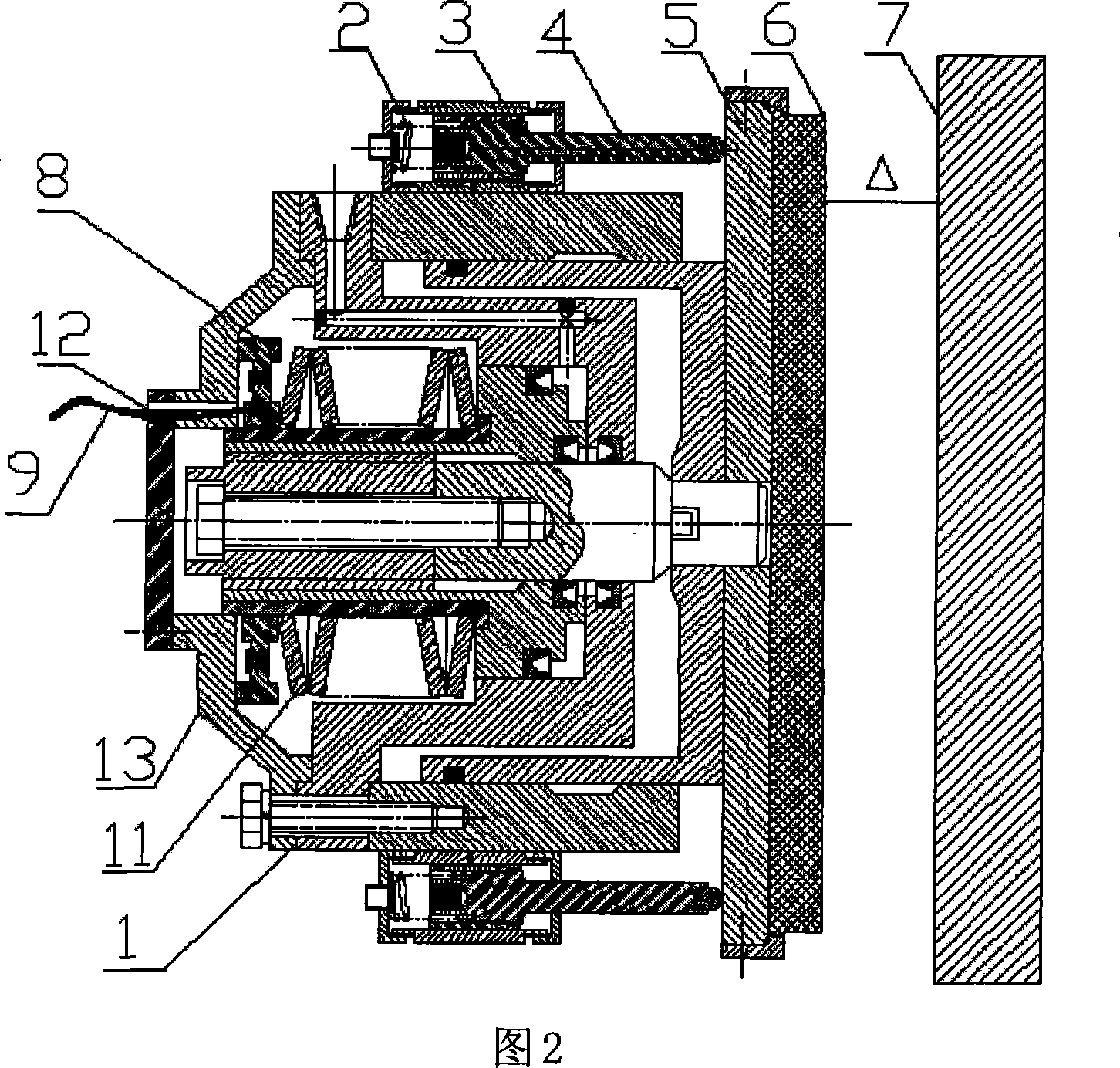

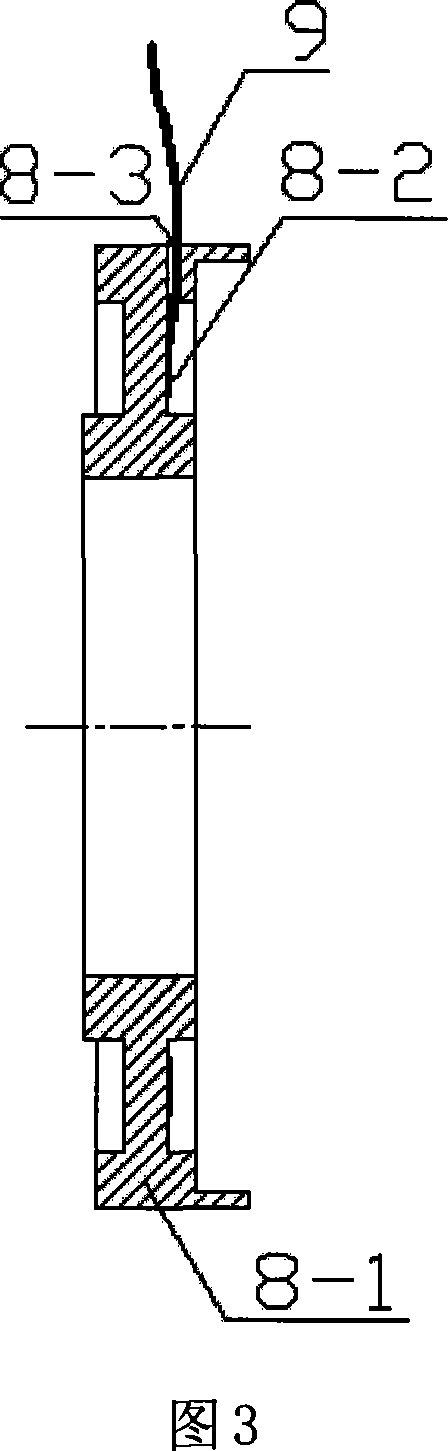

Disc type brake performance detection method and the device

InactiveCN101059398AEasy to installLittle changeMachine part testingApparatus for force/torque/work measurementProcess systemsInterference resistance

The invention relates to a brake property check method of disc damper brake, and a relative device, wherein the back end of a disc spring of the disc damper brake is arranged with a sensor which signal is output via a lead wire. When the damper brake works, the pressure on the disc spring via the sensor can directly be used to measure the positive pressure on the disc damper brake. A support of the disc damper brake along the axle of the damper brake is arranged with a touch Hall displacement sensor which measuring rod is contacted with the side end of a block base to effectively measure the displacement of brake space. The invention uses a data pickup and process system to measure the idle time and brake decelerate value of the damper brake. The inventive method can confirm the reliability of damper brake in use, with high measurement accuracy, strong interference resistance, small volume, and long service life, more particularly to be used for checking the brake property of disc damper brake. The inventive method has simple and easy operation, high check accuracy, simple structure, easy installment, easy maintenance, and wide application.

Owner:CHINA UNIV OF MINING & TECH

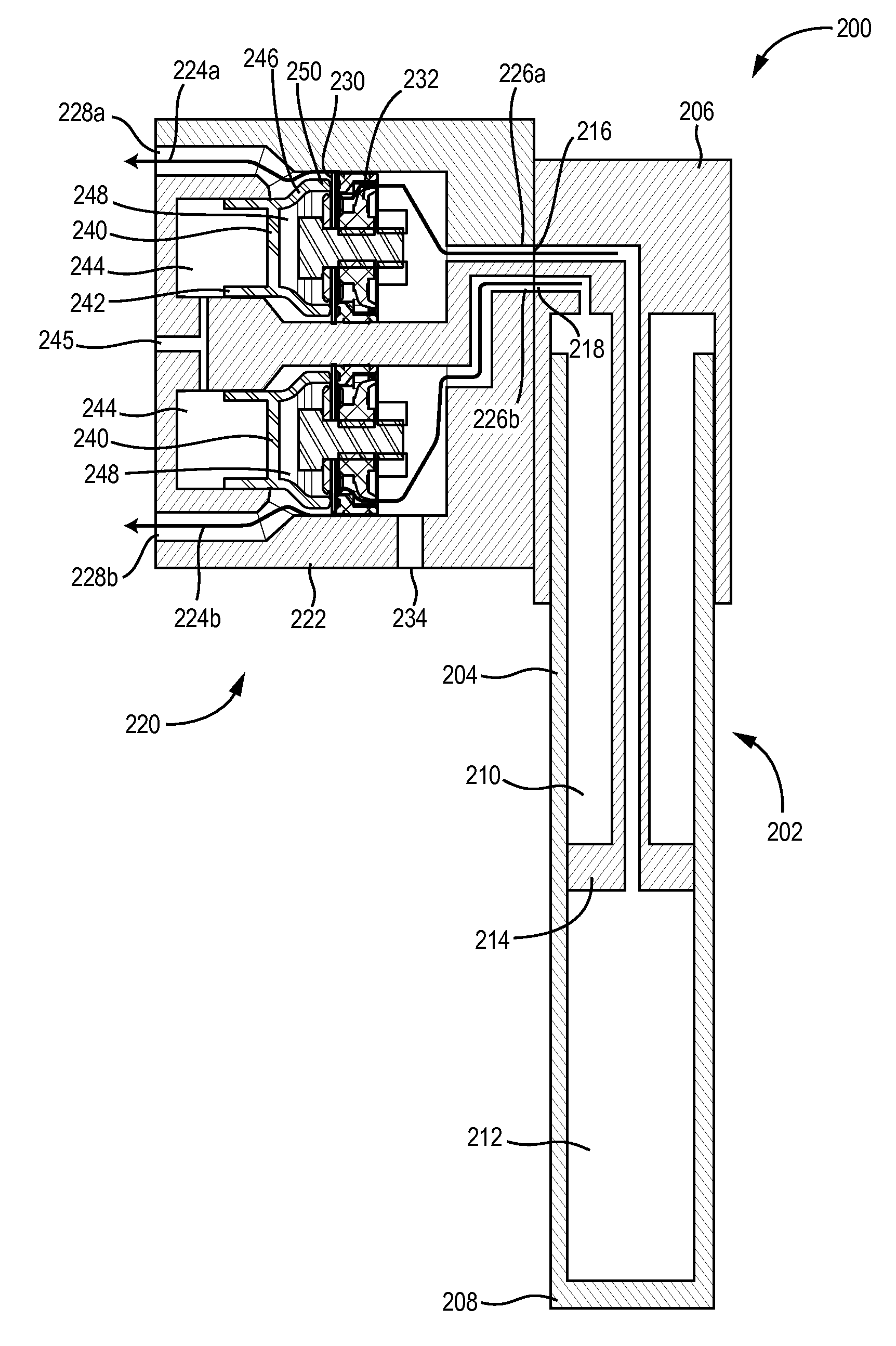

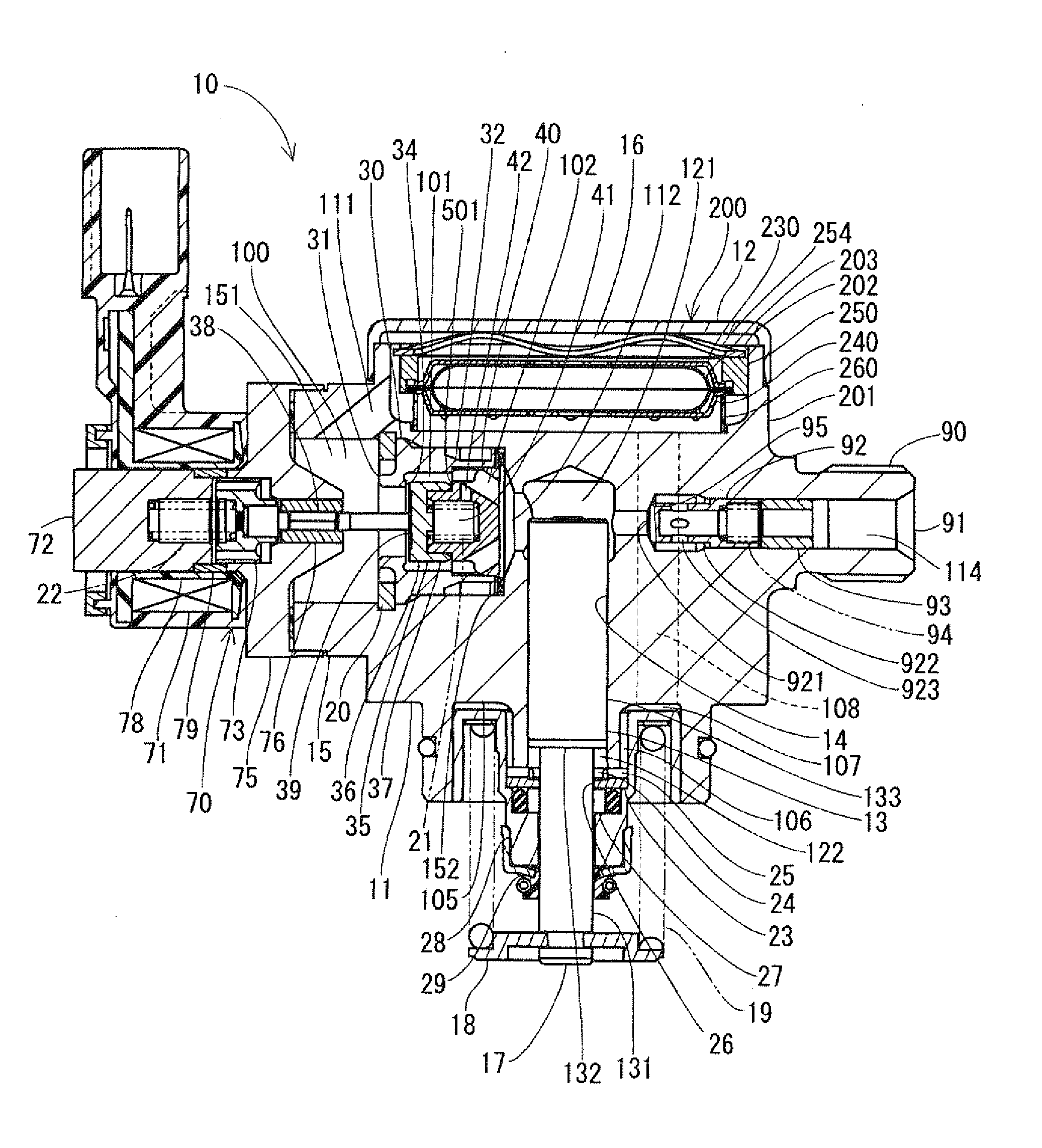

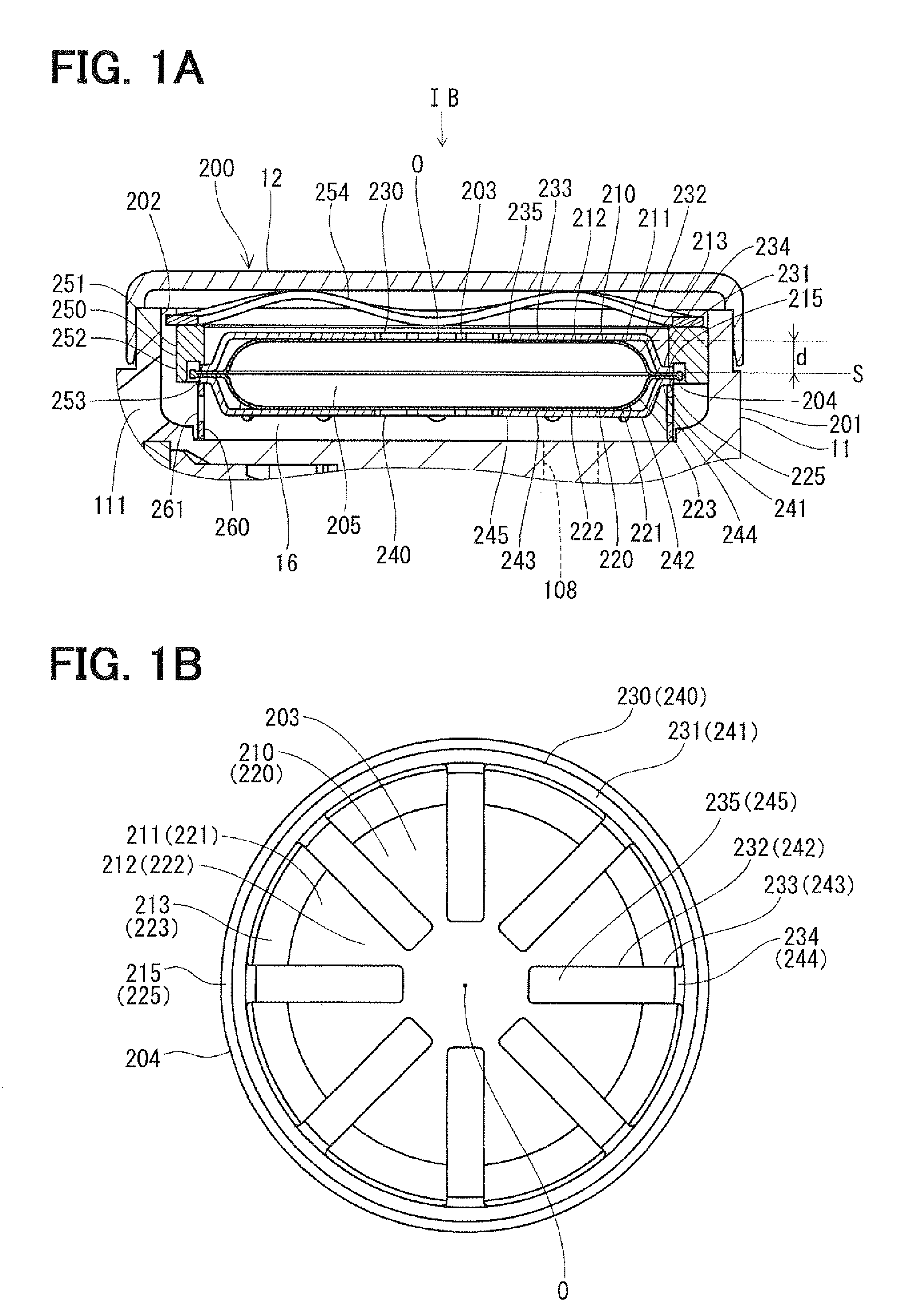

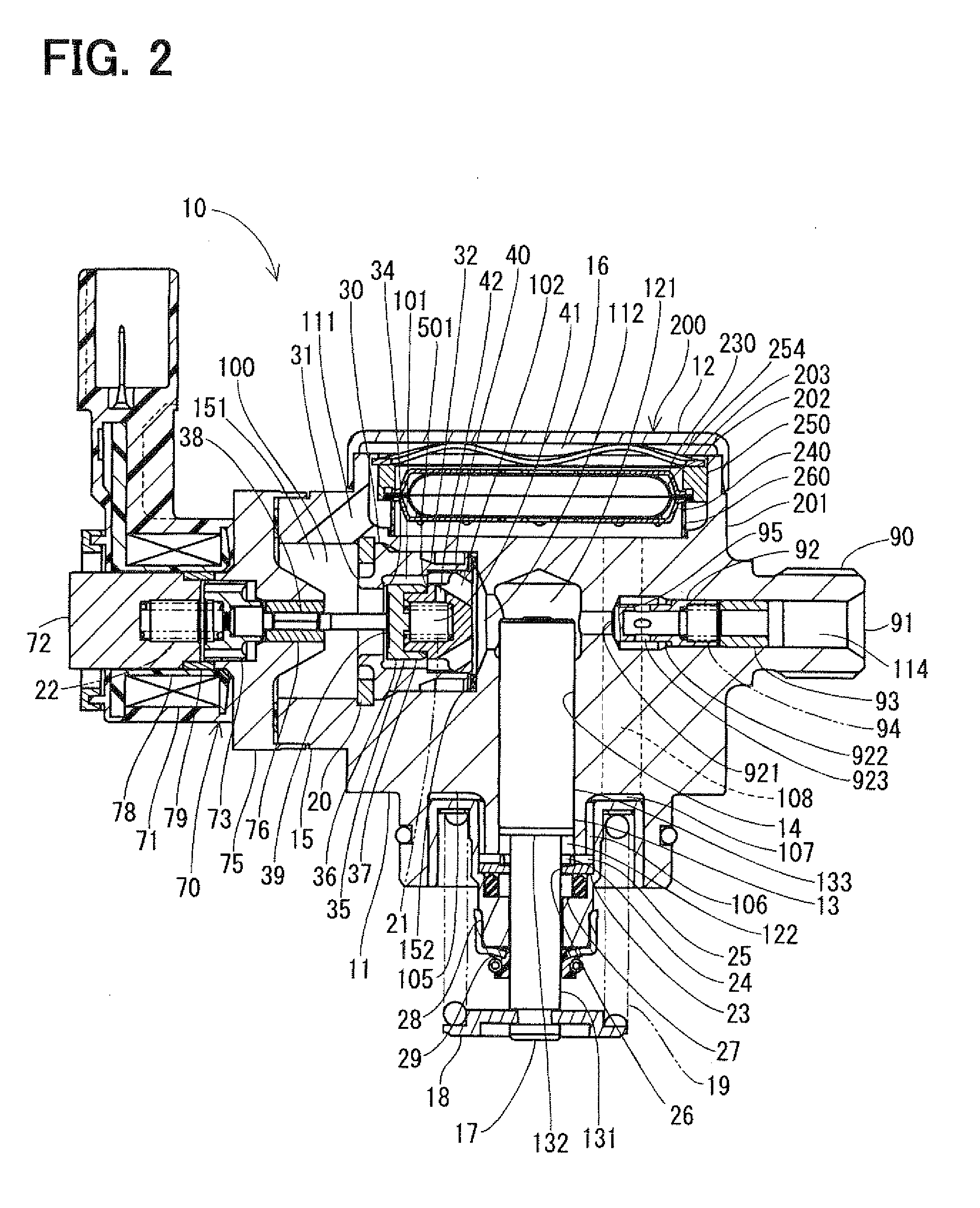

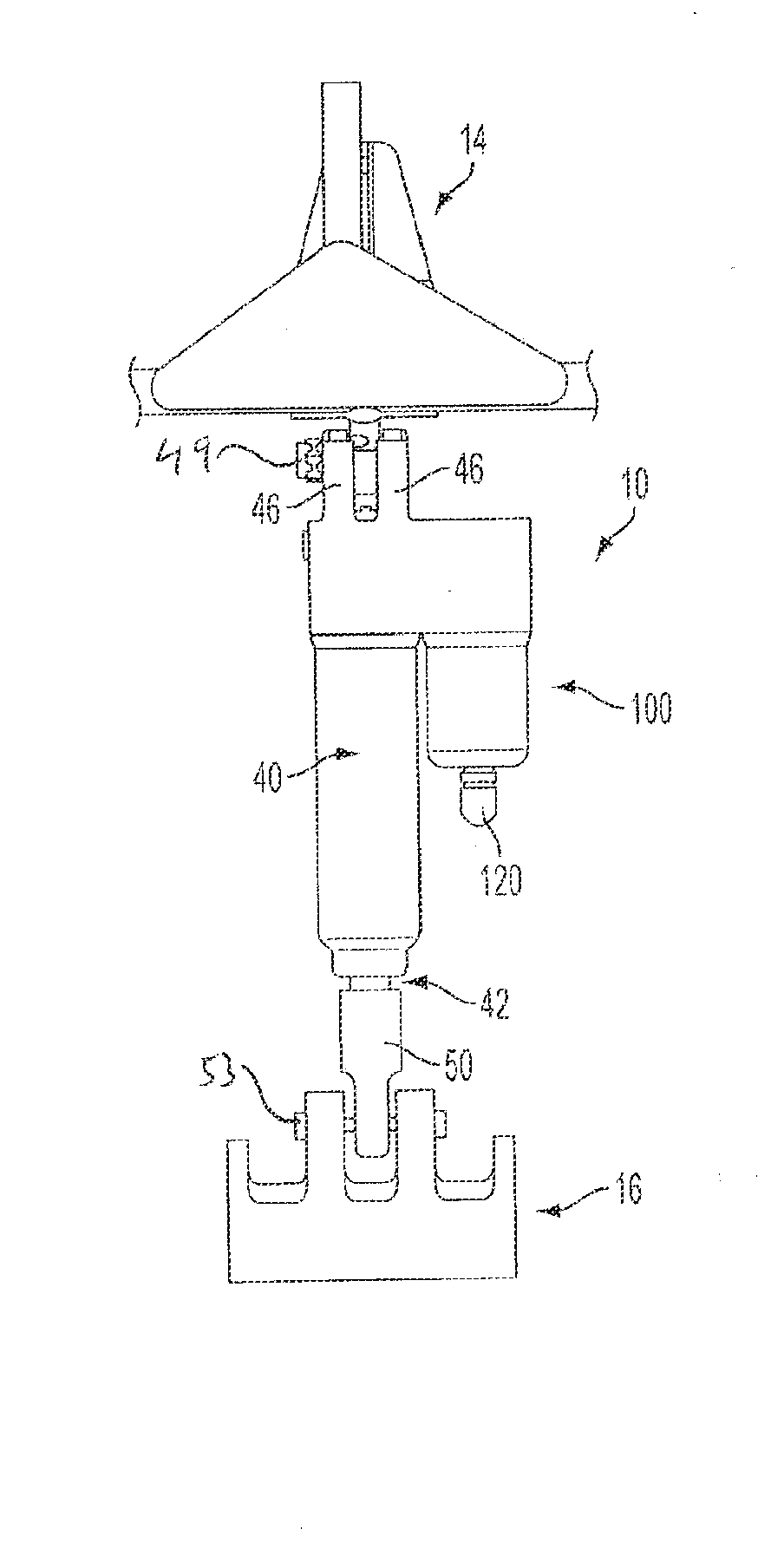

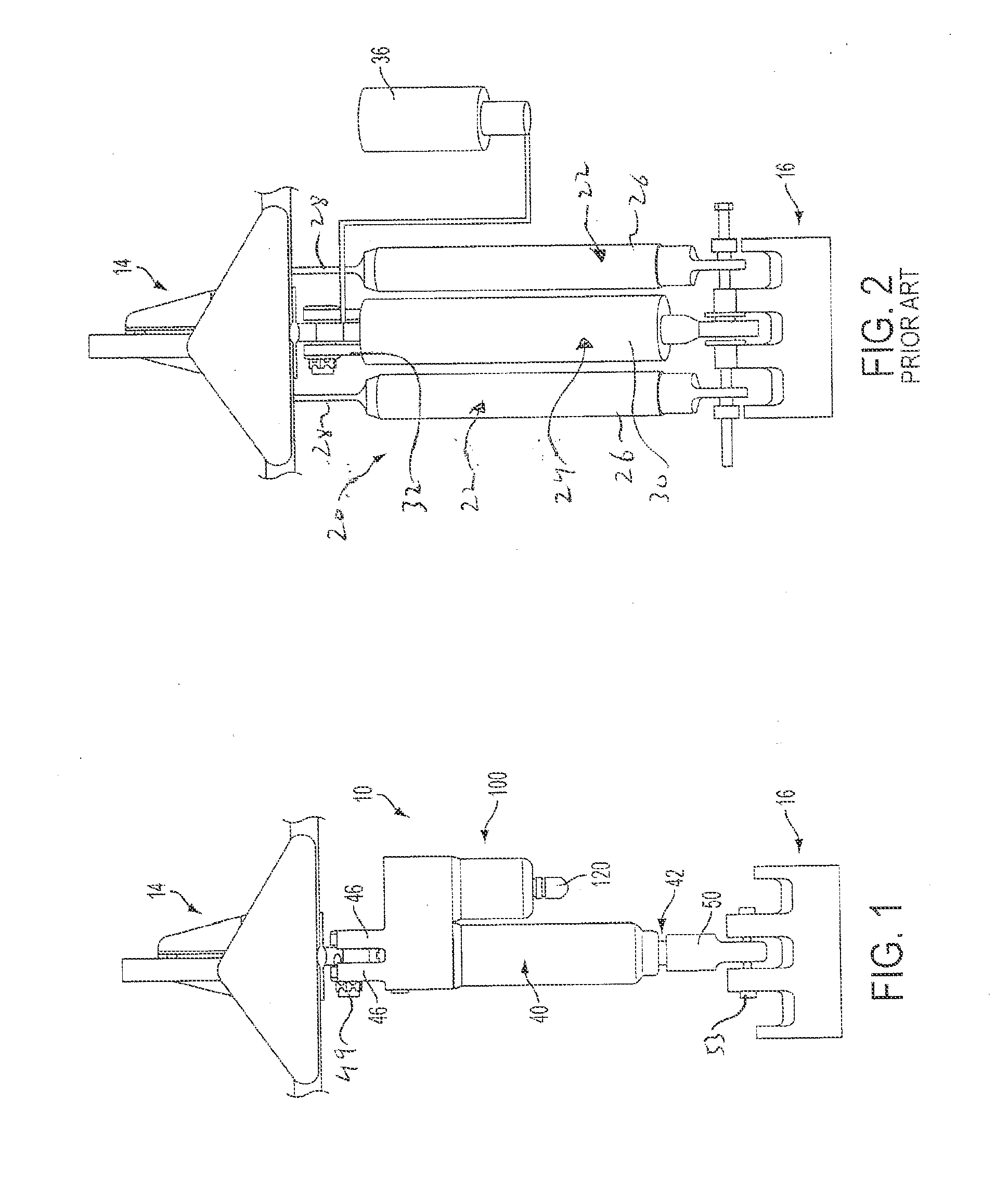

Damper device, high pressure pump having the same and manufacturing method of the same

ActiveUS20100215529A1Reduce stressFlexible wall reciprocating enginesPositive displacement pump componentsAtmospheric pressureHigh pressure

Gas of a predetermined pressure, which is equal to or higher than the atmospheric pressure, is filled in a damper chamber of a damper member that includes first and second-side diaphragms. A first-side limiting portion of a first-side cover member and a second-side limiting portion of a second-side cover member are engageable with a first-side concave portion of the first-side diaphragm and a second-side concave portion of the second-side diaphragm, respectively, to limit bulging of the damper member when a pressure of a fluid chamber is equal to or less than the predetermined pressure.

Owner:DENSO CORP

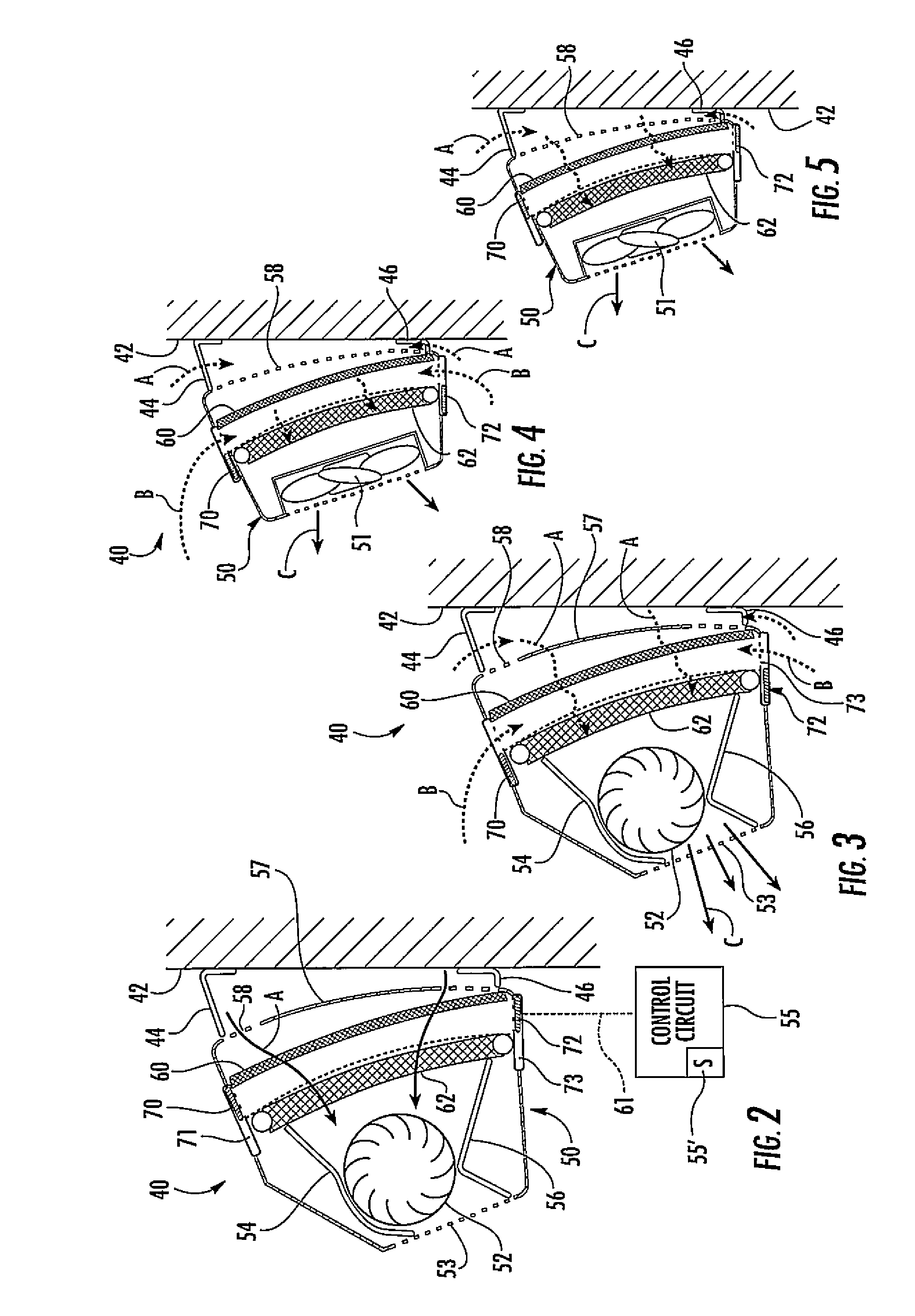

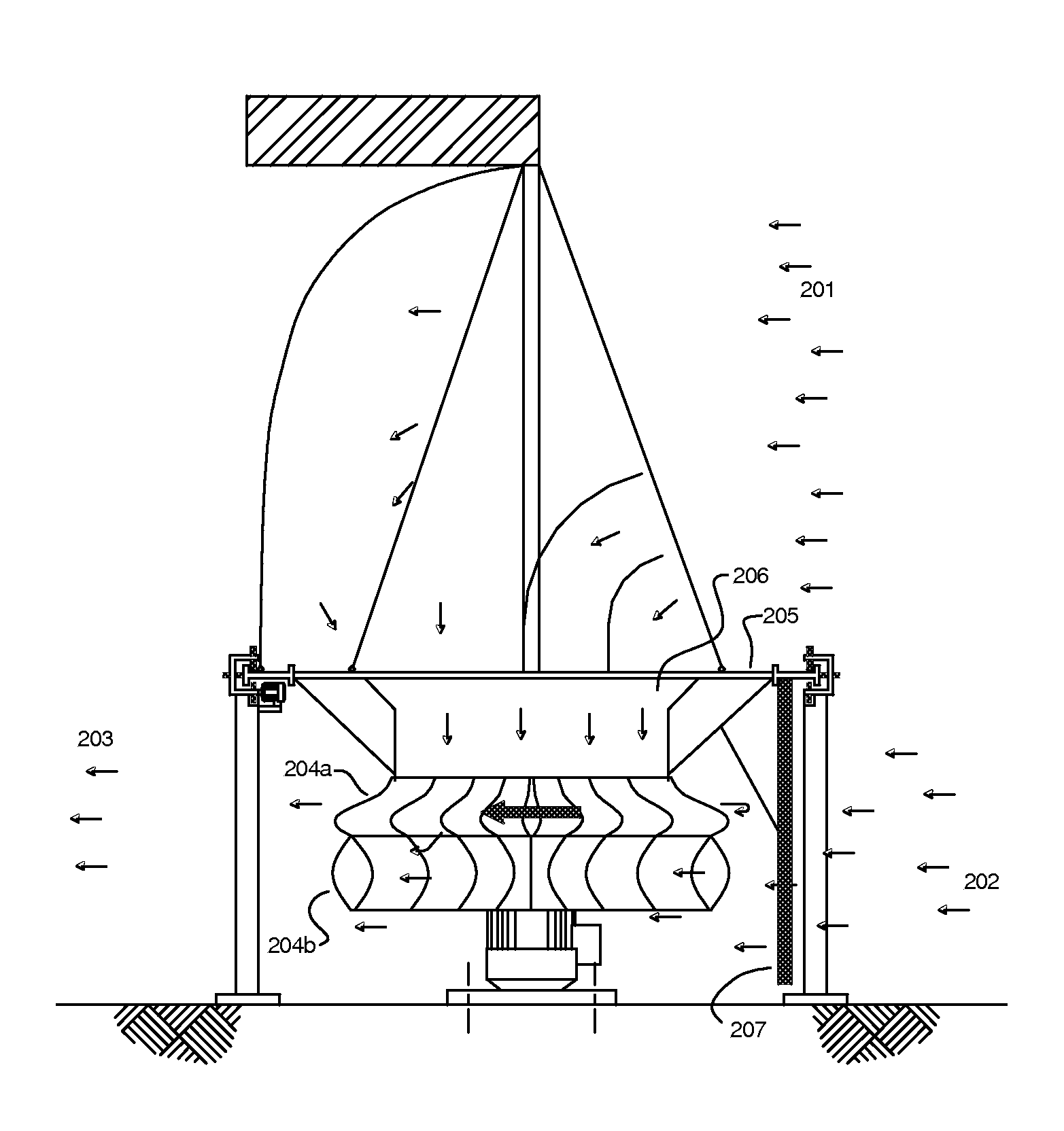

Vertical Multi-Phased Wind Turbine System

InactiveUS20100278629A1Pump componentsWind motor supports/mountsRotational axisDifferential pressure

A rotational axis multi-phased wind turbine power generating system is disclosed. A differential pressure is created by utilizing the prevailing wind, and air from the prevailing wind is directed into air blades for the creation of power. Optimally, the air blades directly utilize the prevailing wind in combination with the created differential pressure to create power. An adjustable air scoop, adjustable exit drag curtain or barrier, orienting systems, and air flow directing dampers are disclosed.

Owner:KRIPPENE BRETT C

Method and arrangement for sealing a capless fuel tank filler tube

A flapper door is spring biased closed against a valve seat on the underside of a filler tube bulkhead having a refueling nozzle aperture. The valve seat has an annular tapered surface and a resilient annular seal on the flapper door contacts the valve seat in wiping engagement. A pneumatic dampener retards the speed of closure of the flapper door onto the valve seat.

Owner:EATON CORP

Apparatus and method of automatically regulating intake of air into heating unit

InactiveUS6041771ACounteracting forceDischarge cleaningCombustion-air/flue-gas circulation for stovesCheck valvesCombustion chamberGas pressure

This invention relates to a novel apparatus and method for automatically and dynamically regulating the intake of air into the combustion chamber of a heating unit such as a wood burning stove, furnace, or fireplace to ensure even and efficient burning of fuel. More particularly, this invention pertains to a method and apparatus that uses negative gas pressure in the heating unit's flue, and no additional temperature or pressure sensors, to automatically and dynamically control a damper regulating intake of air into the combustion chamber in inverse relation to changes in negative flue gas pressure. This method and apparatus are especially useful in combination with a heating unit having two combustion chambers, one chamber for combustion of solid fuel and a second chamber for further combustion of exhaust gases and other byproducts from combustion in the first chamber. The two-stage combustion in a dual chamber heating unit is an especially dynamic situation where traditional static controls are not very effective.

Owner:HAYES CECIL JOSEPH

Self-contained air-conditioned enclosure

InactiveUS20020121101A1Lower initial costLighting and heating apparatusHeating and ventilation casings/coversFresh airEngineering

A Self-Contained Air-Conditioned Enclosure; comprises of an Enclosure (1), connected through plurality of openings (13,14) to air ducts (20,21) of an Air-conditioning Unit (17). The Enclosure has a Roof (5), and sidewalls assembled with plurality of Wall Sheets (8) interspaced with Spacer Strips (9) to enhance thermal resistance of the sidewalls. The bottom of the sidewall is inserted under the structure that forms the floor to create an isolated enclosure. The Air-conditioning Unit (17) supplies the Enclosure through the Supply Air Duct (21) and withdraws air through Exit Air Duct (20). Part of the withdrawn air is reconditioned and supplied to the enclosure; the other part is replaced by fresh air. Energy is conserved from the replaced air in Heat Transfer Duct (37) and transferred to fresh air in Fresh Air Chamber (36). Unit efficiency is improved by mixing the exhausted withdrawn air in the Compressor Chamber (31) and exhausted by the Exhaust Air Duct (28). Flow of fresh air is controlled through the Air Damper (39) and Control Knob (38).

Owner:JEBARAJ ASIR IYADURAI

Systems for drying moisture-containing work pieces and methods for drying same

ActiveUS7194822B2Easy to operateReduce in quantityDrying solid materials with heatWood treatment detailsAtmospheric airEngineering

A system and method are provided for controllably drying moisture-containing work pieces. The system comprises a drying compartment defining an internal workspace for housing and drying the moisture-containing work pieces by introducing heat into the internal workspace and heating the moisture-containing work pieces located in the internal workspace by removing heated moisture from the work pieces and absorbing the heated moisture into the air in the workspace to produce heated humidified air. A multi-directional air flow heat exchanger is employed for receiving heated humidified air and atmospheric air and for recycling waste heat from exhaust air from the drying compartment, and for heating the atmospheric air in the heat exchanger using recovered heat extracted from the heated humidified air to a temperature higher than ambient temperature thereby reducing energy costs and drying time and preventing the loss of circulation air. First and second reversible variable speed fans are also included in the system. Each of the fans is independently controllable at respective intake and exhaust modes and at variable air flow rates, without employing a damper for controlling the flow of exhaust air and atmospheric air to and from the heat exchanger.

Owner:AMERICAN WOOD DRYERS LLC

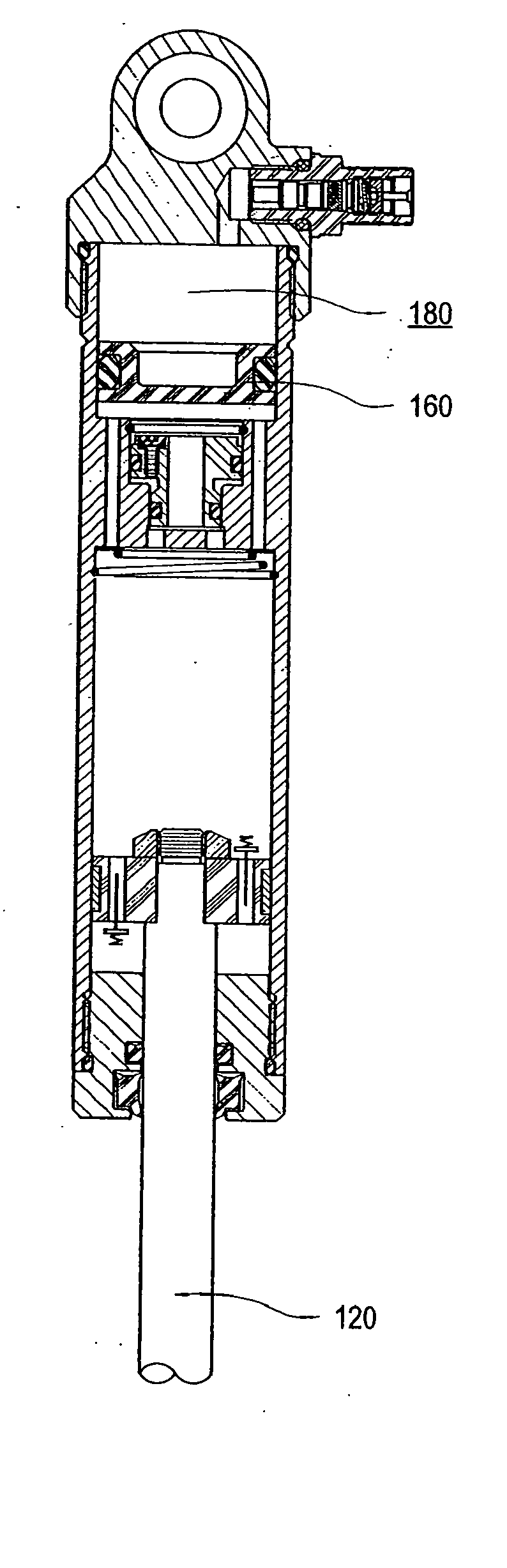

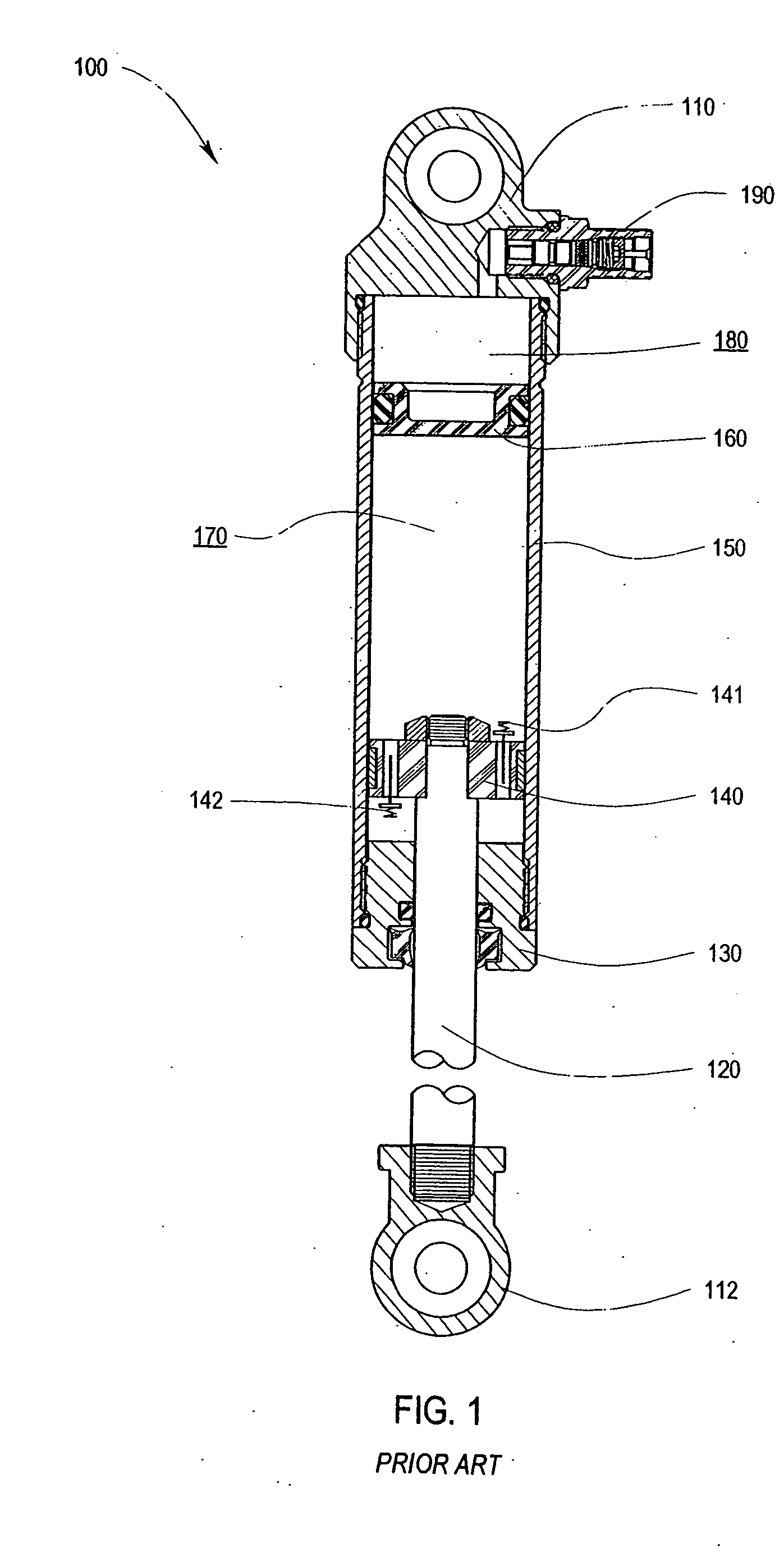

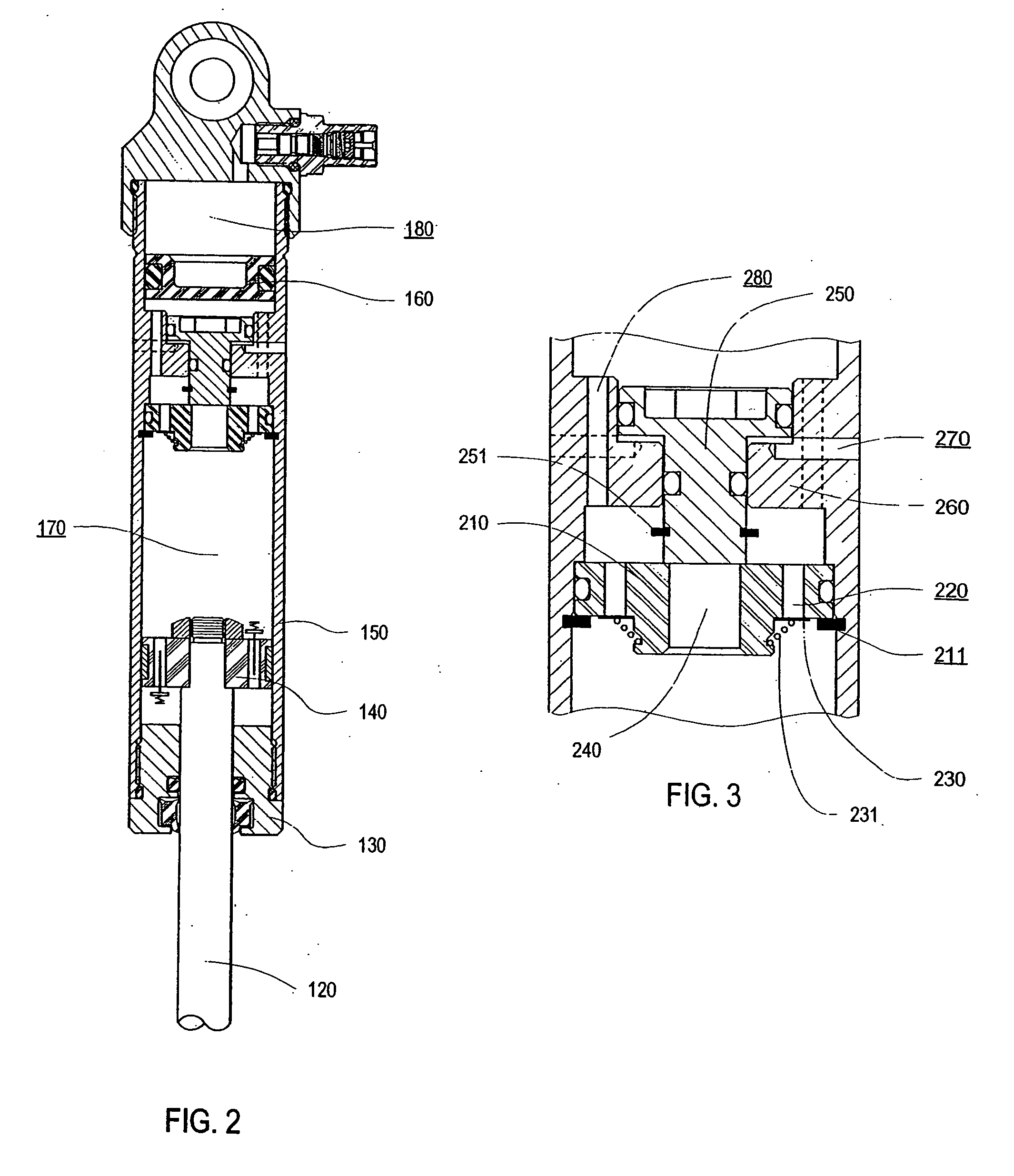

Hydraulic-pneumatic actuator

An actuator for relatively moving two parts in a damped manner. The actuator includes a damper housing for connection to a first of the parts. The damper housing includes a damper chamber. The actuator includes a drivable damper rod for connection to a second of the parts and being movable relative to the damper housing. The damper rod includes a damper unit located within the damper chamber. The damper unit is relatively movable within the damper chamber with the damper unit movement corresponding to the relative movement between the damper housing and damper rod and the relative movement between the first and second parts. The damper unit is movable in response to hydraulic pressure force upon the damper unit. The actuator includes a pneumatic pressure source for providing a pneumatic pressure force that is transferred to provide the hydraulic pressure force upon the damper unit. The actuator includes a selectively actuatable blocking device for permitting transfer of the pneumatic pressure force from the pneumatic pressure source and blocking return of force to the pneumatic pressure source until the selectively actuatable blocking device is actuated.

Owner:CURTISS WRIGHT CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com