Patents

Literature

339results about "Flexible wall reciprocating engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroactive polymer-based pump

Owner:ETHICON ENDO SURGERY INC

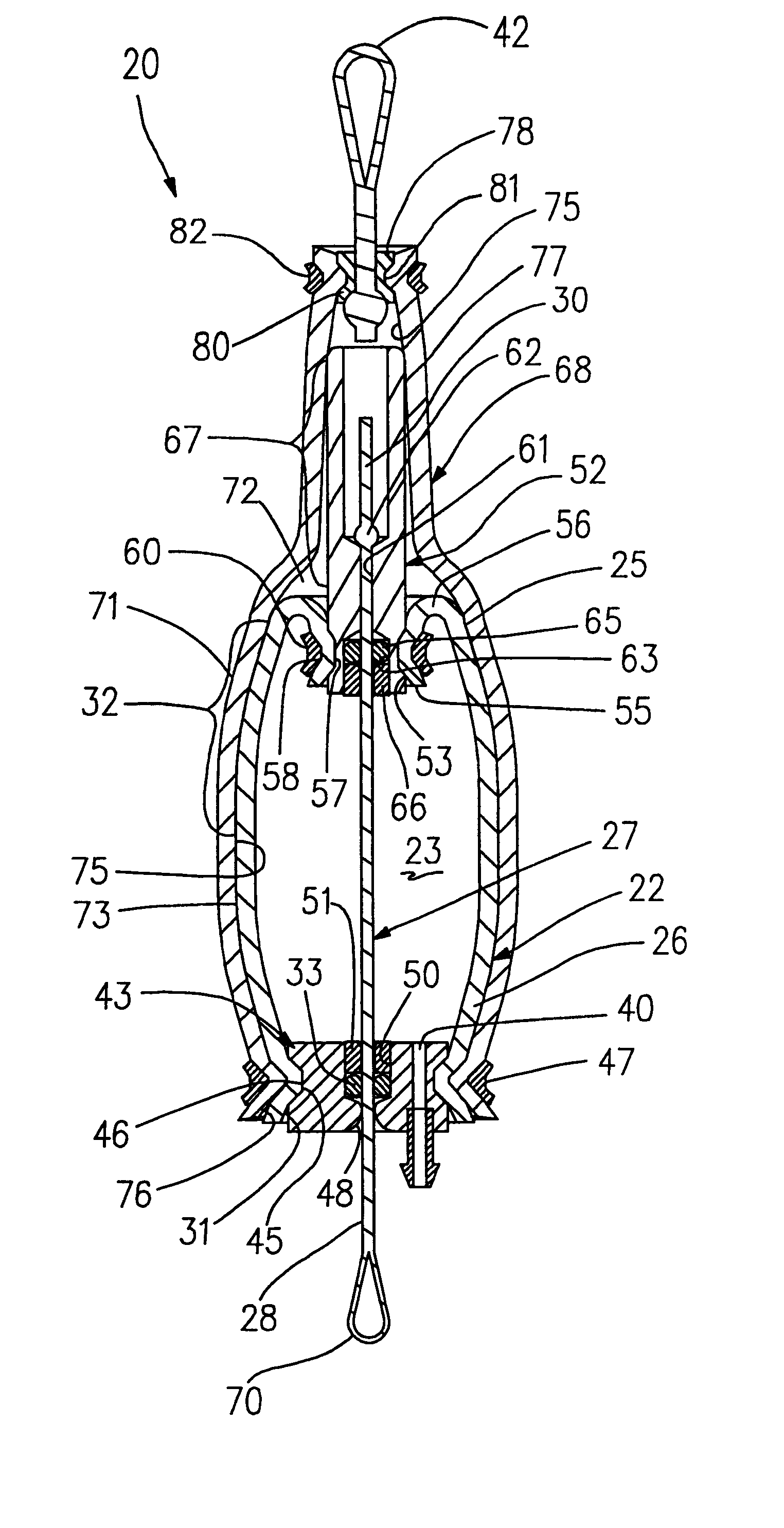

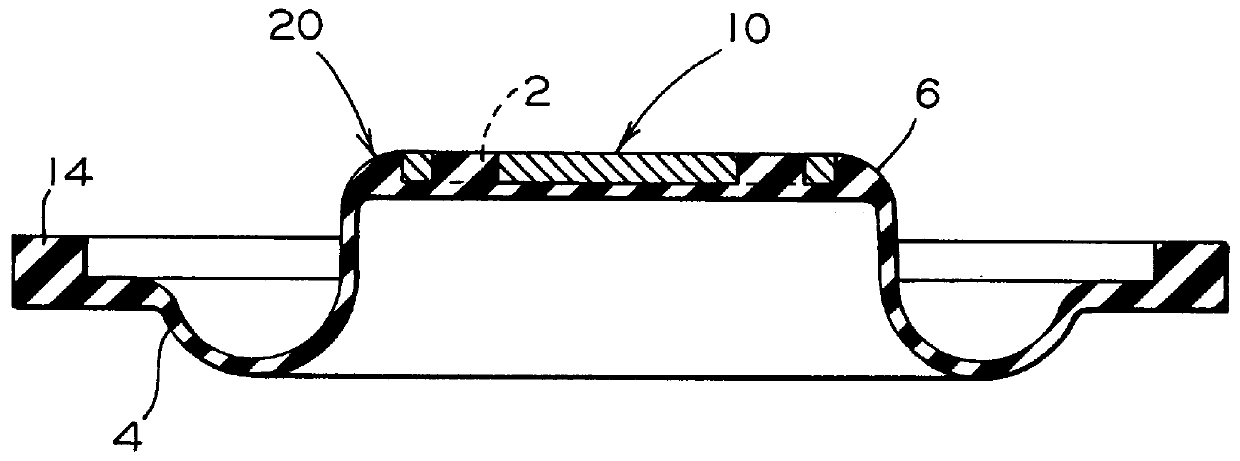

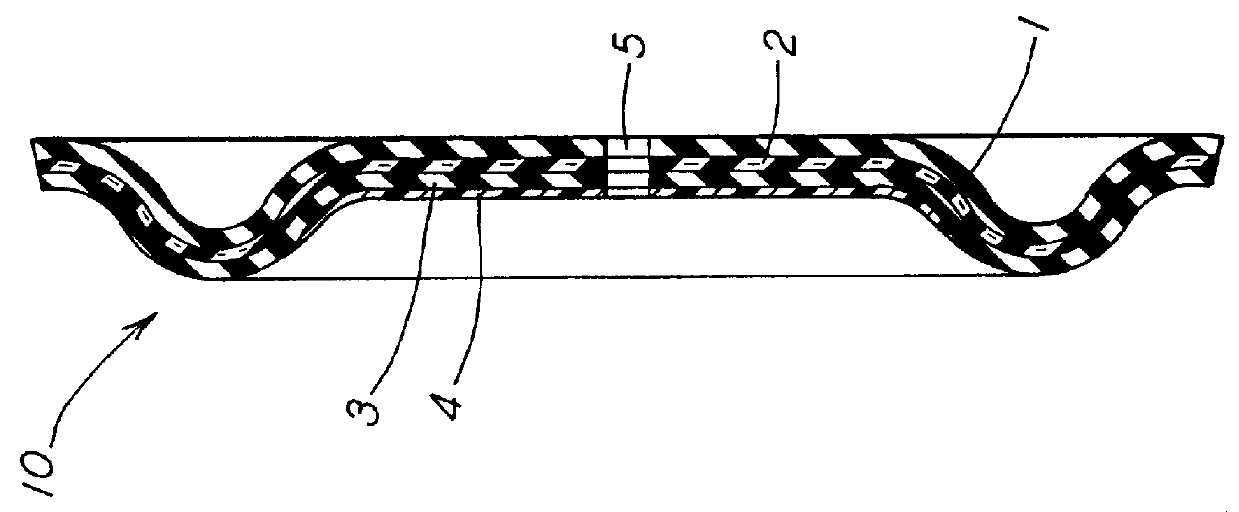

Artificial muscle actuator assembly

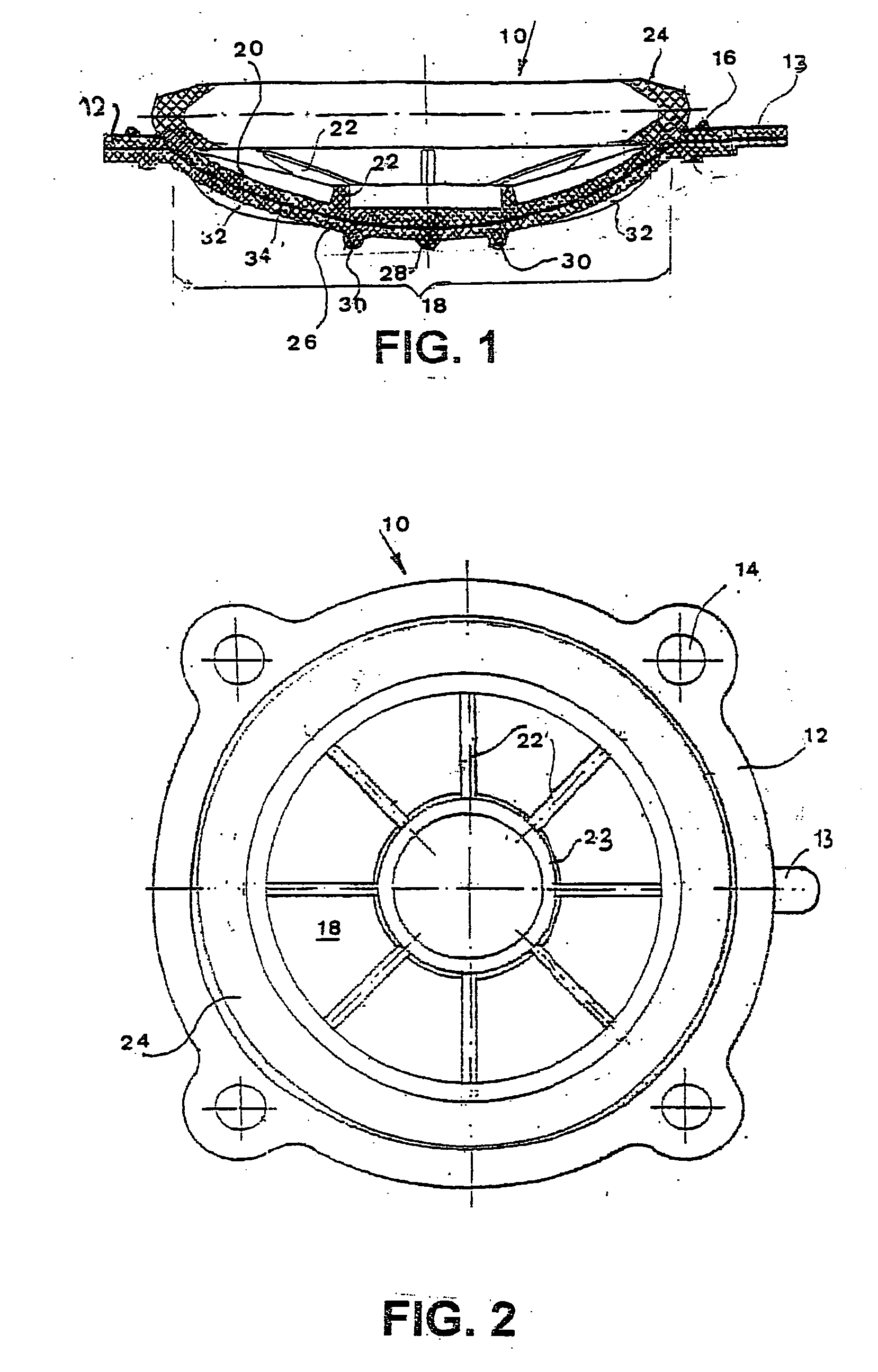

InactiveUS6223648B1Substantially flexibleAvoid formingFlexible wall reciprocating enginesFluid-pressure actuatorsDistal portionEngineering

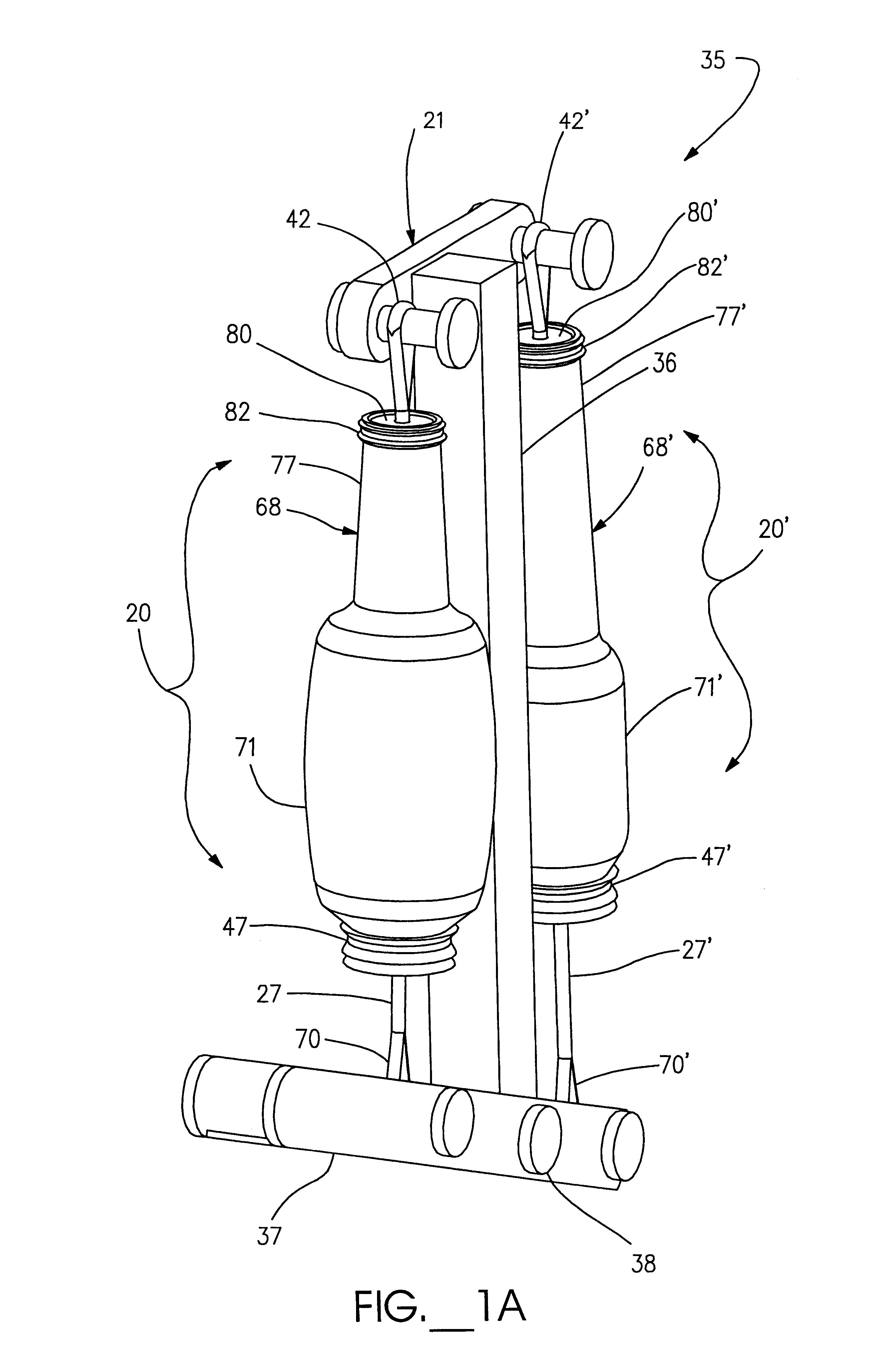

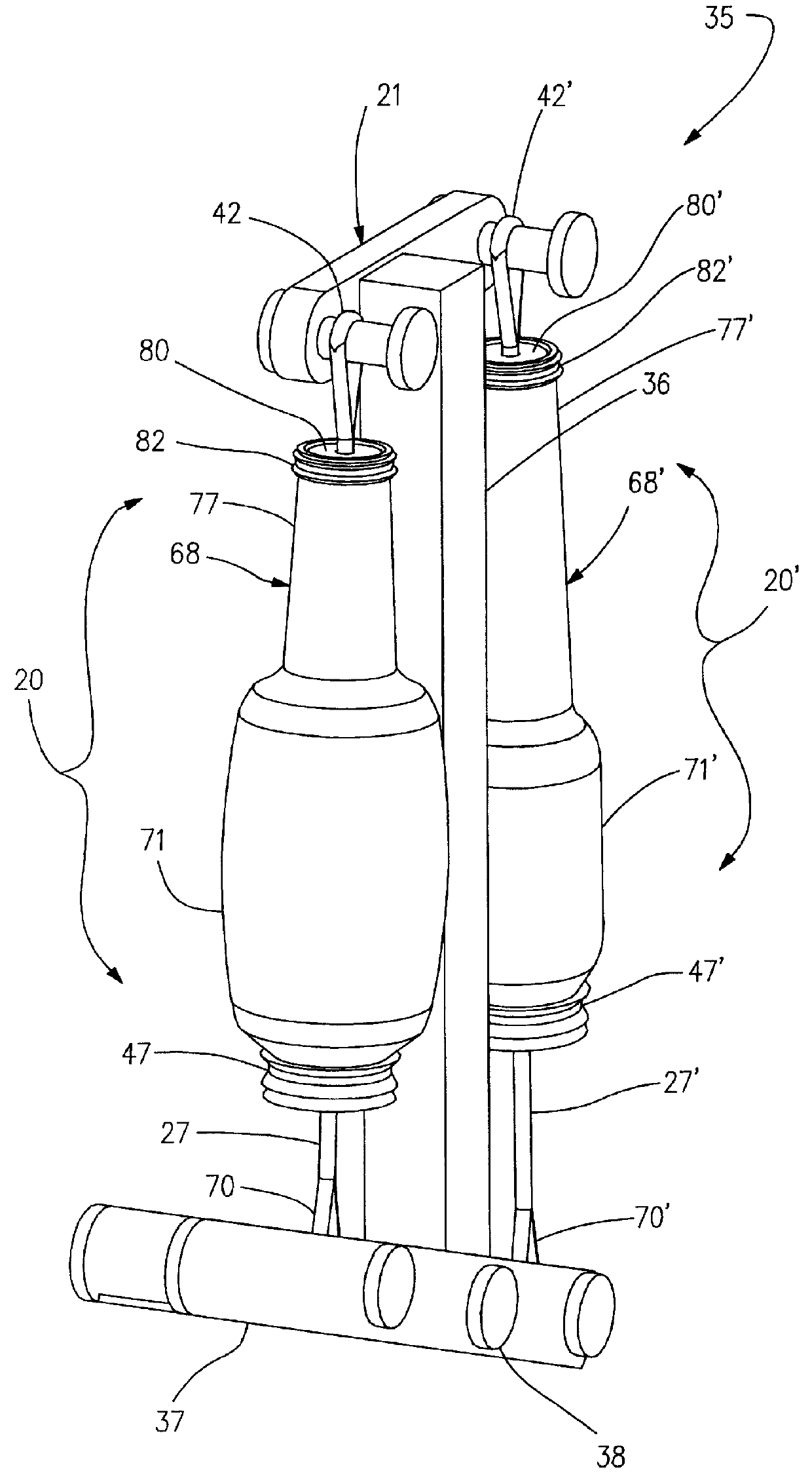

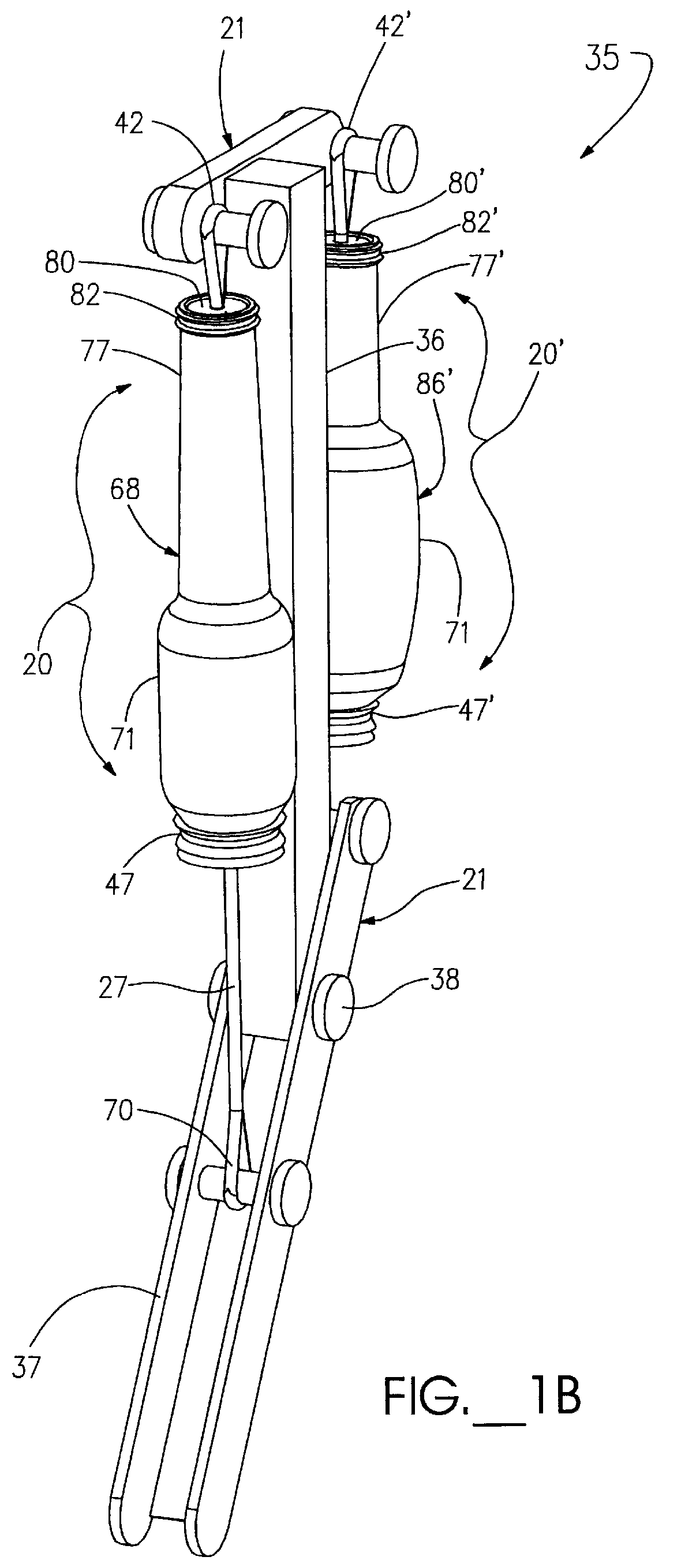

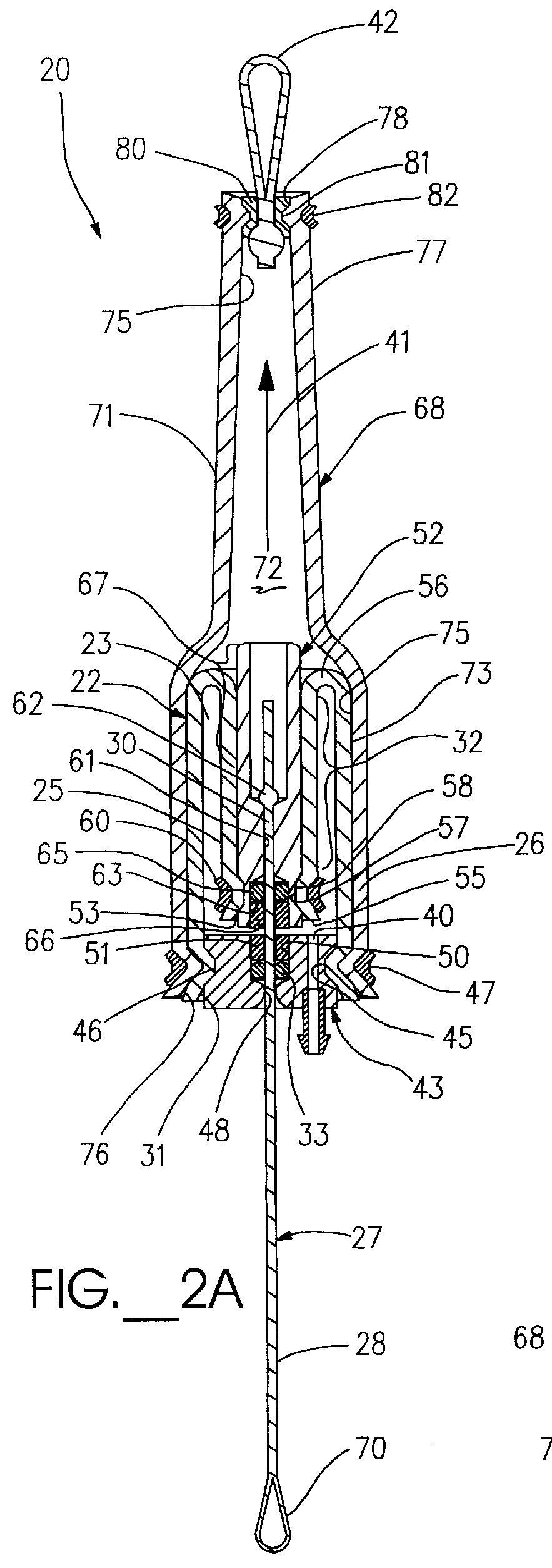

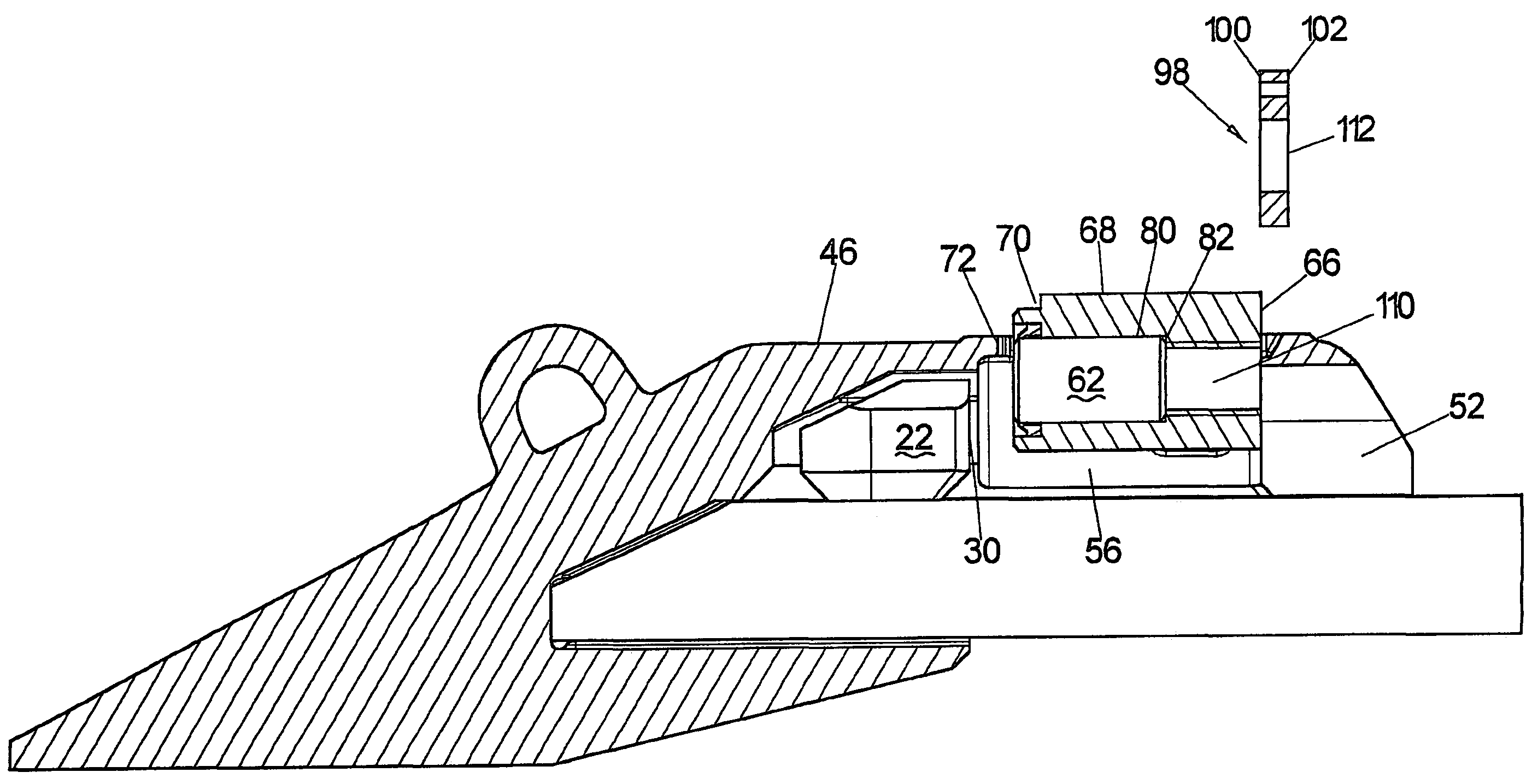

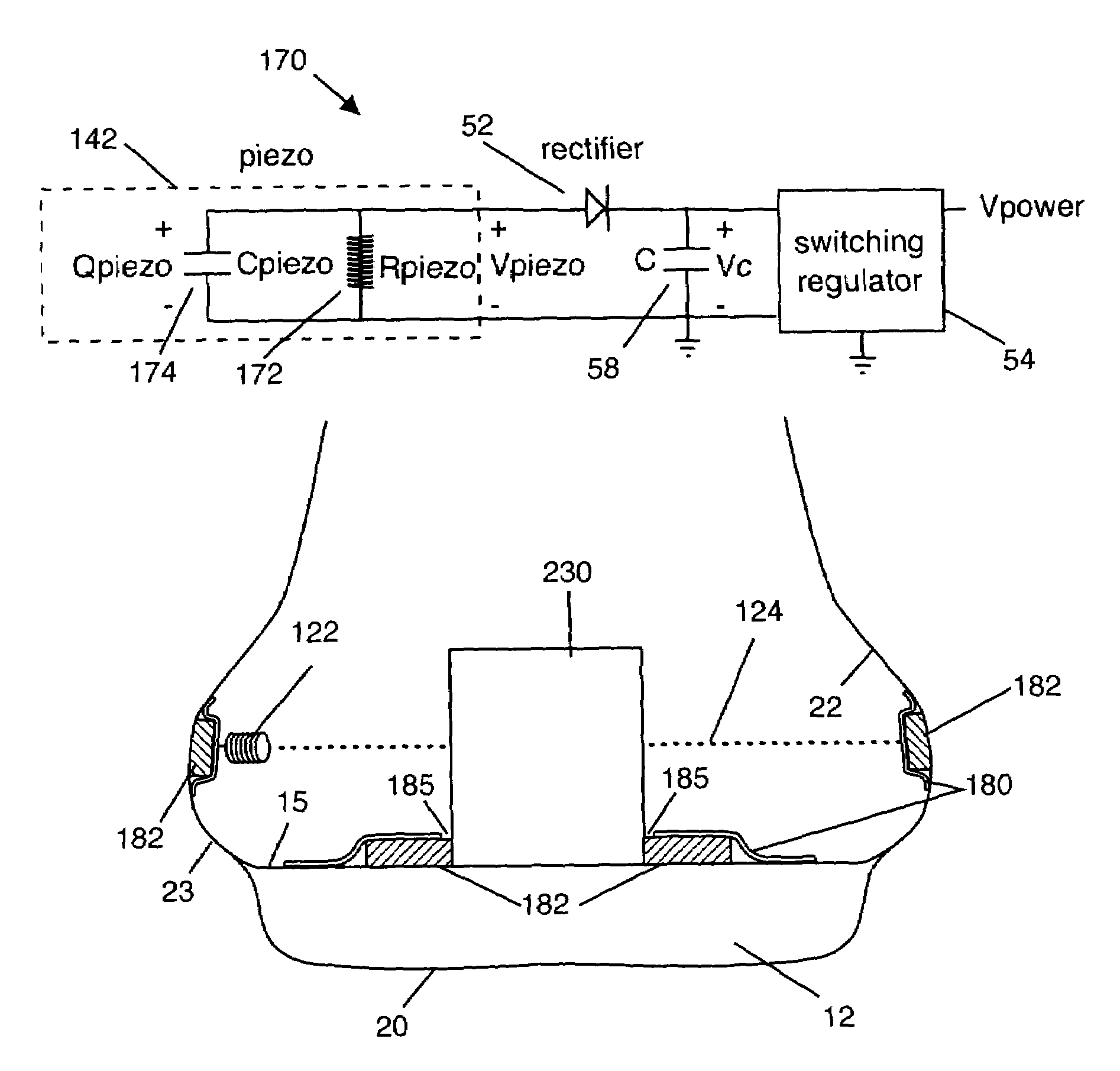

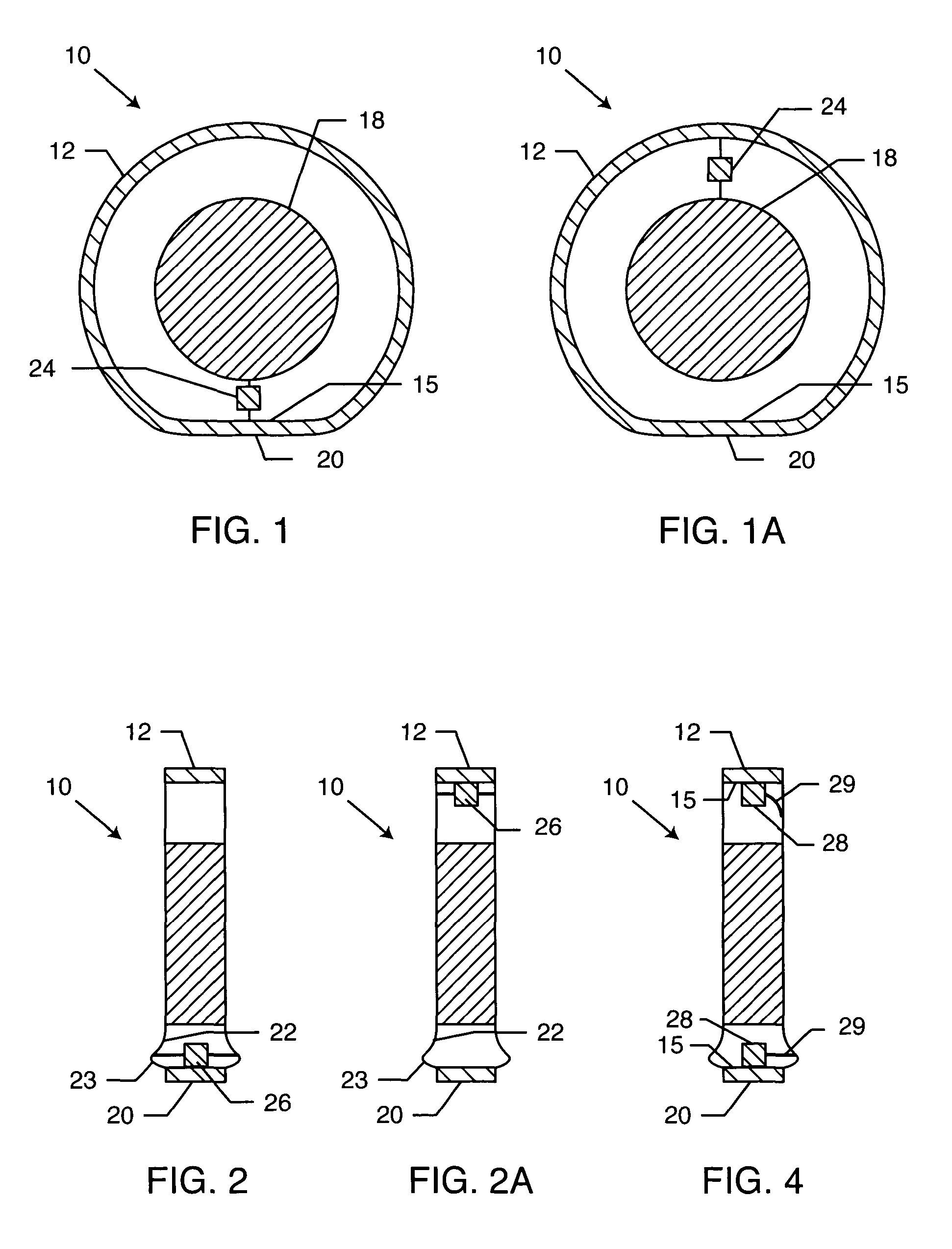

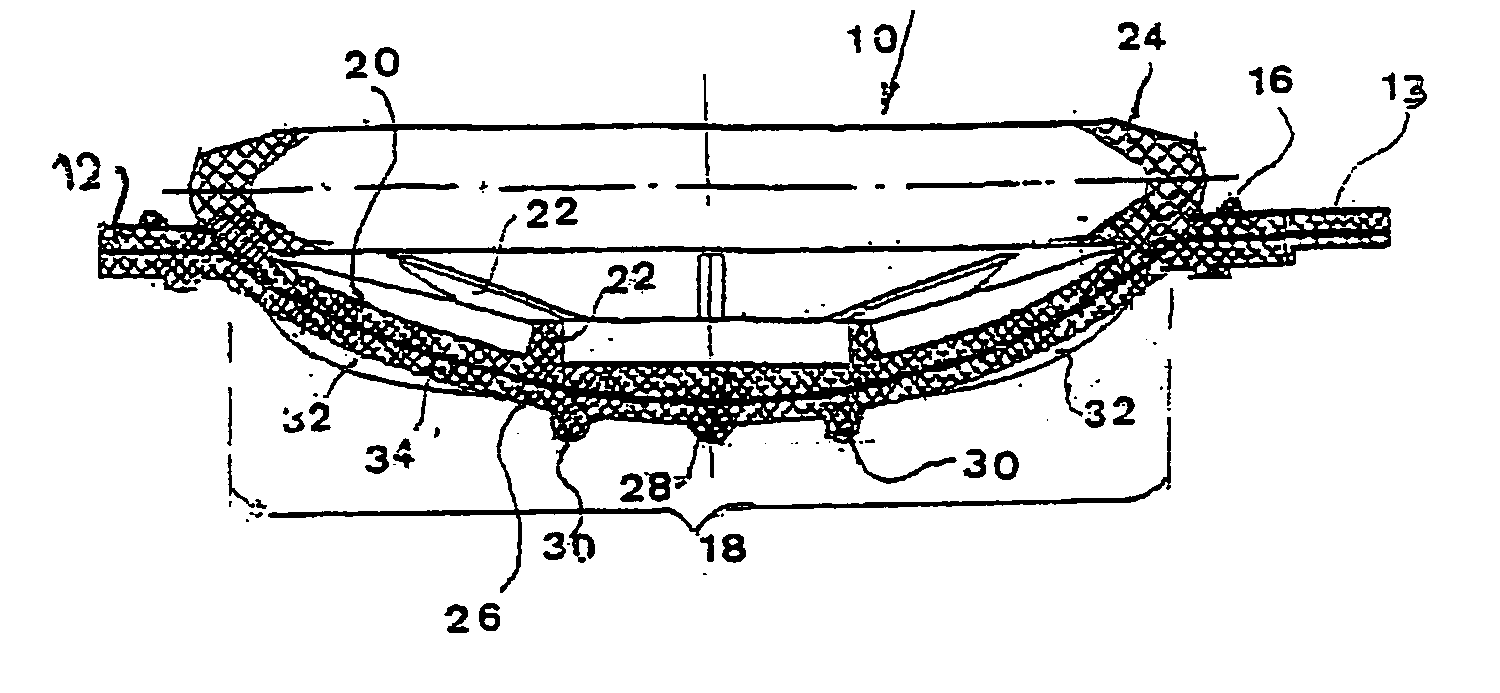

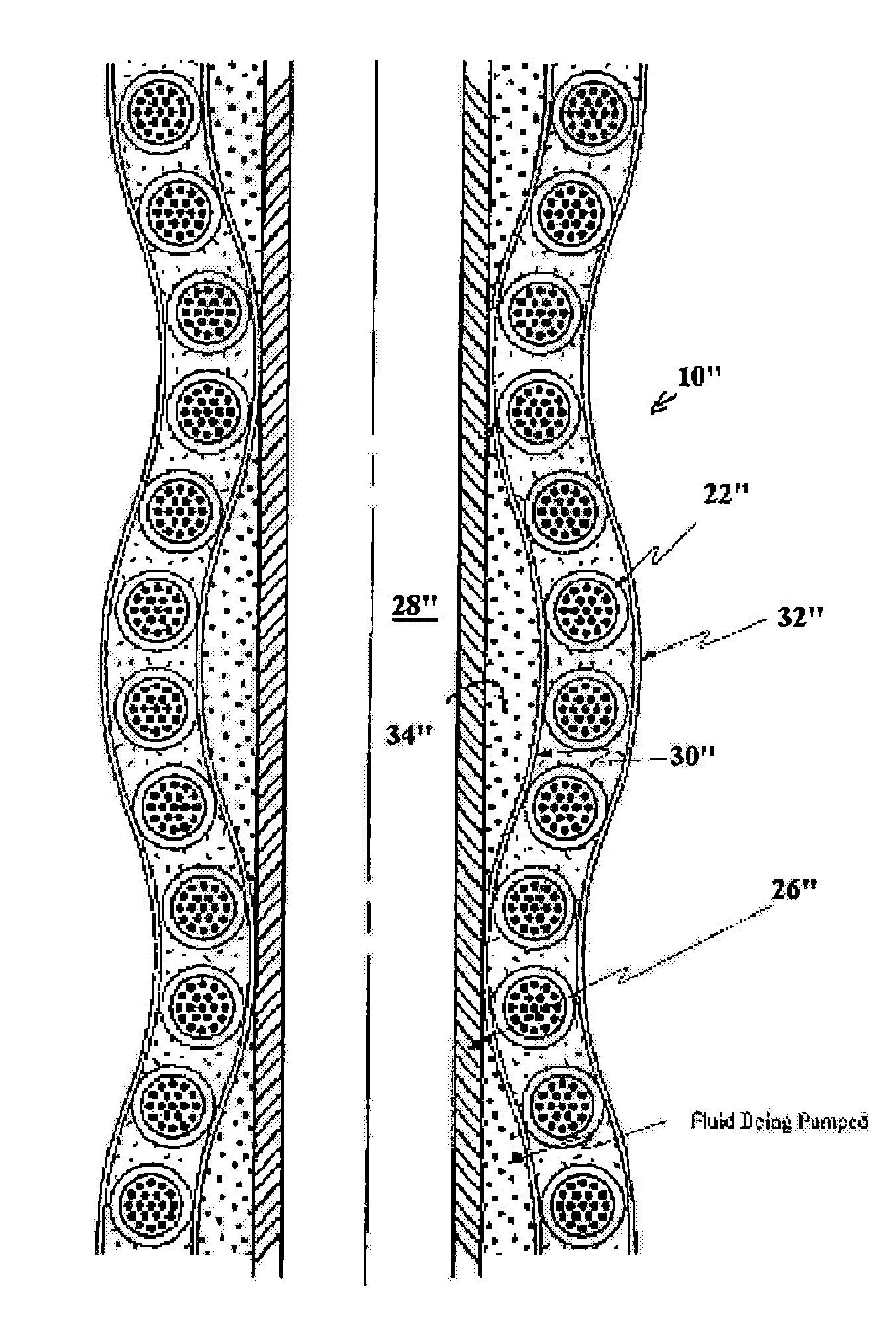

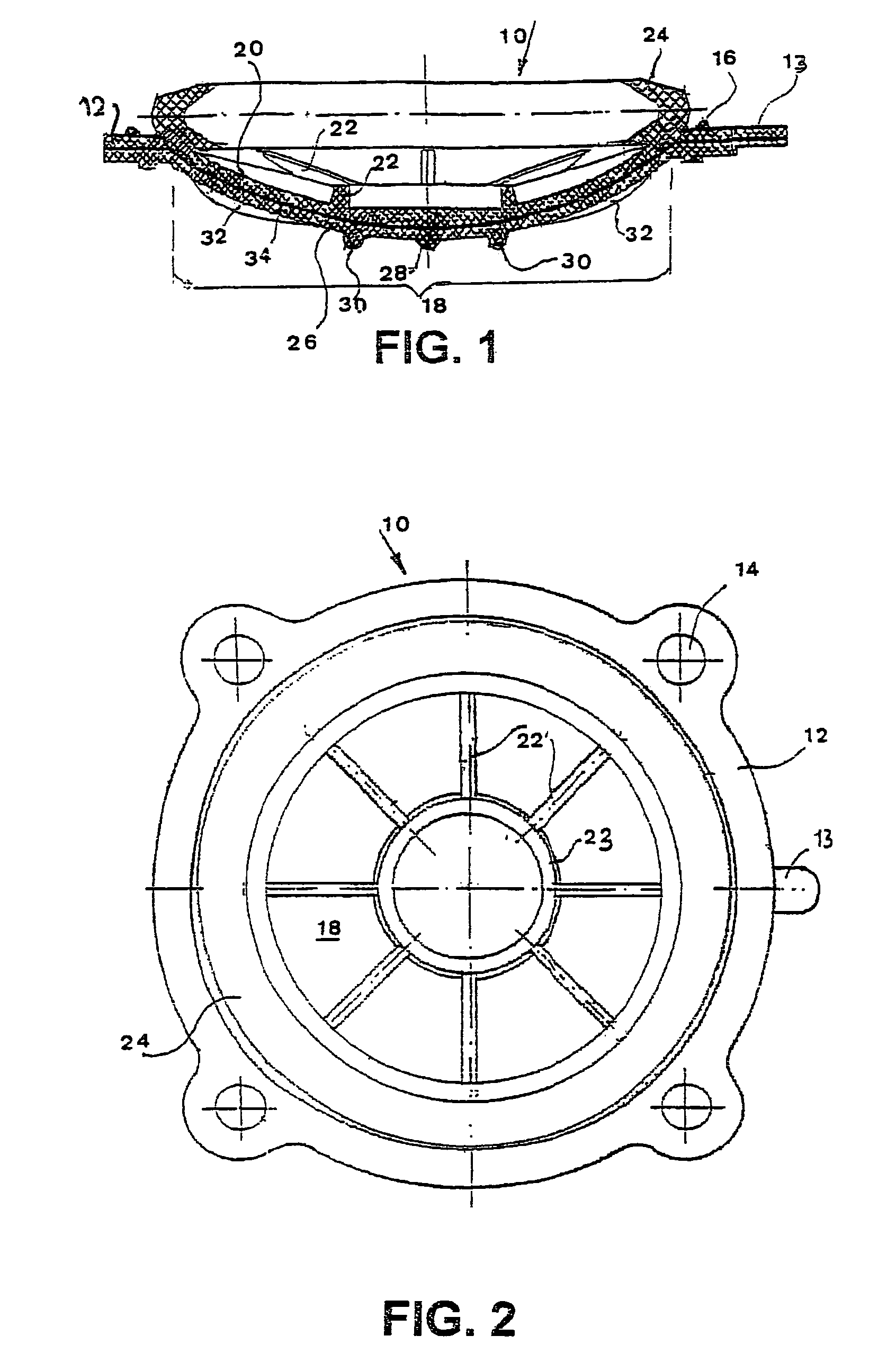

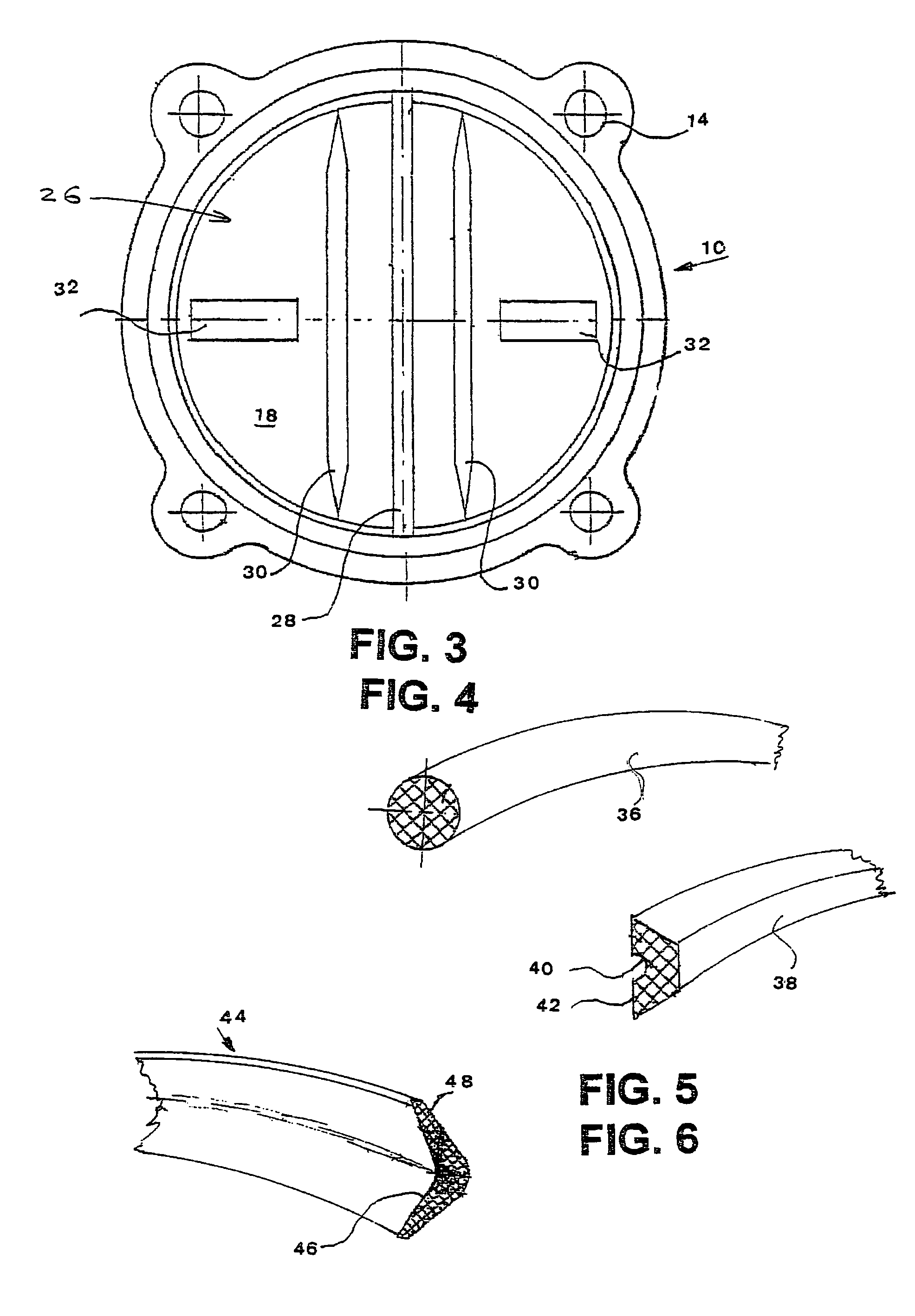

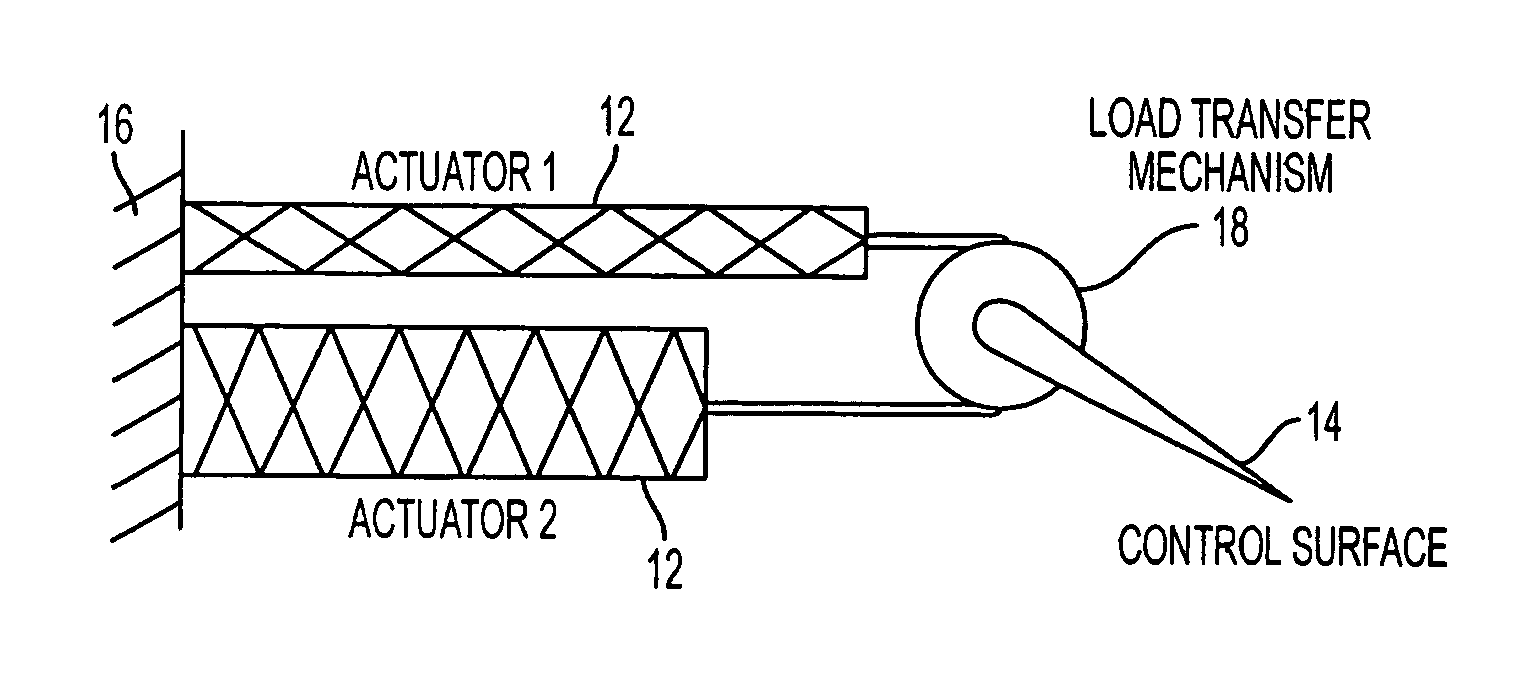

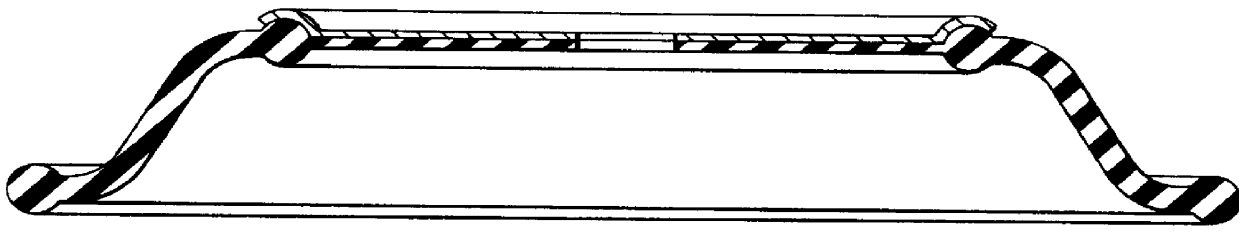

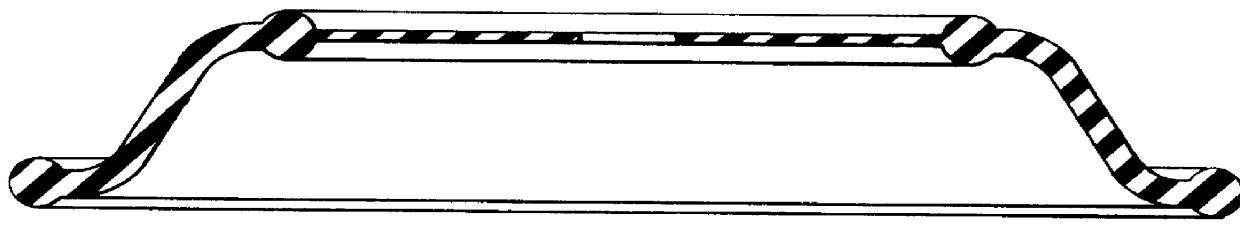

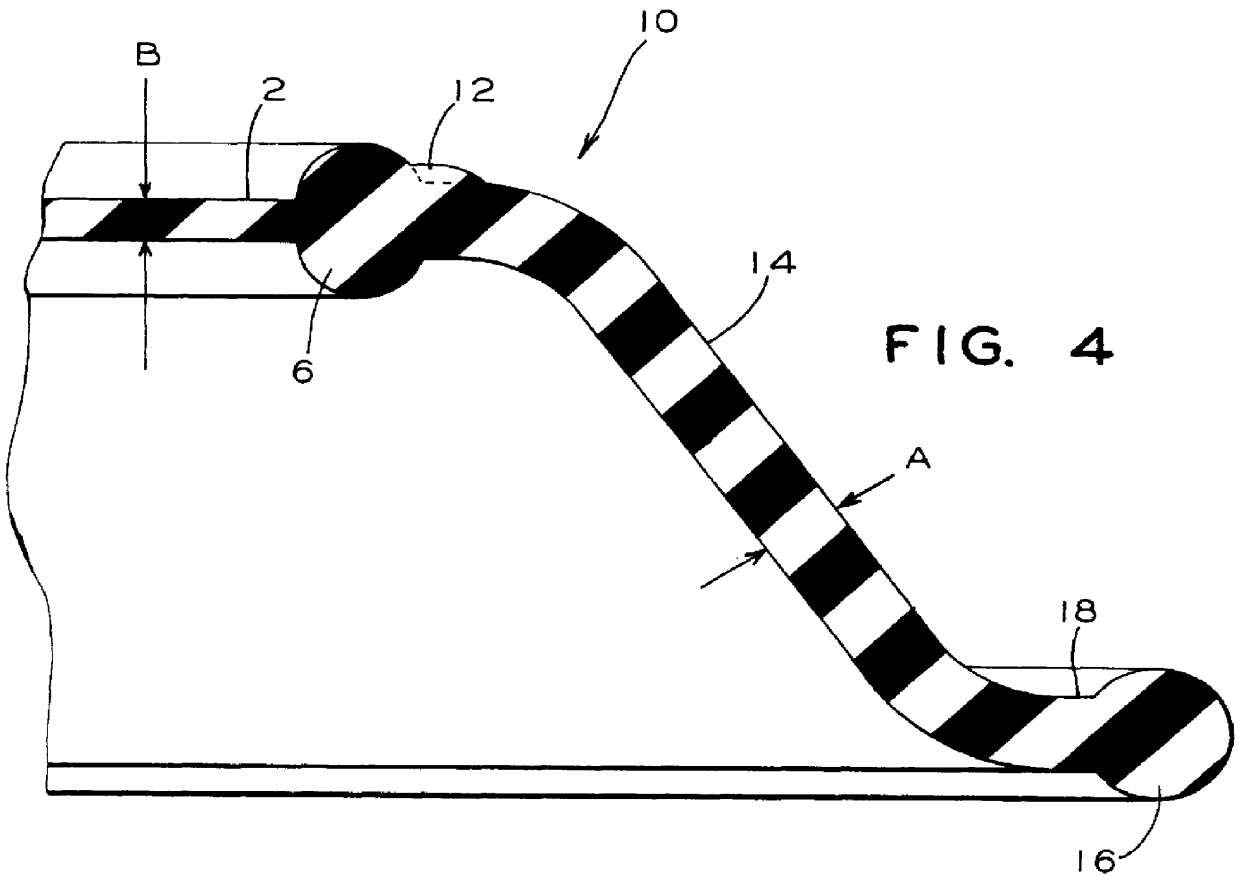

A flexible actuator assembly (20) including a flexible bladder device (22) having an expandable sealed chamber (23) adapted to substantially directionally displace between a deflated condition and an inflated condition, displacing a proximal portion (25) of the bladder device (22) away from a distal portion (26) thereof. An elongated tendon member (27) includes a distal portion (28) oriented outside the chamber (23), while an anchor portion (30) extends into the chamber (23) through a distal opening (31) in the bladder device (22). The tendon anchor portion (30) is further coupled proximate to the bladder proximal portion (25) in a manner adapted to: selectively invert displaceable portions (32) of the bladder device (22) when urged toward the deflated condition to position the anchor portion (30) and the bladder proximal portion (25) relatively closer to the bladder distal portion (26); and selectively evert the inverted displaceable portions (32) of the bladder device (22) when displaced toward the inflated condition which positions the anchor portion (30) and the bladder proximal portion (25) relatively farther away from the bladder distal portion (26) for selective movement of the tendon distal portion (28) between an extended condition and a retracted condition, respectively.

Owner:ERICKSON JOEL R

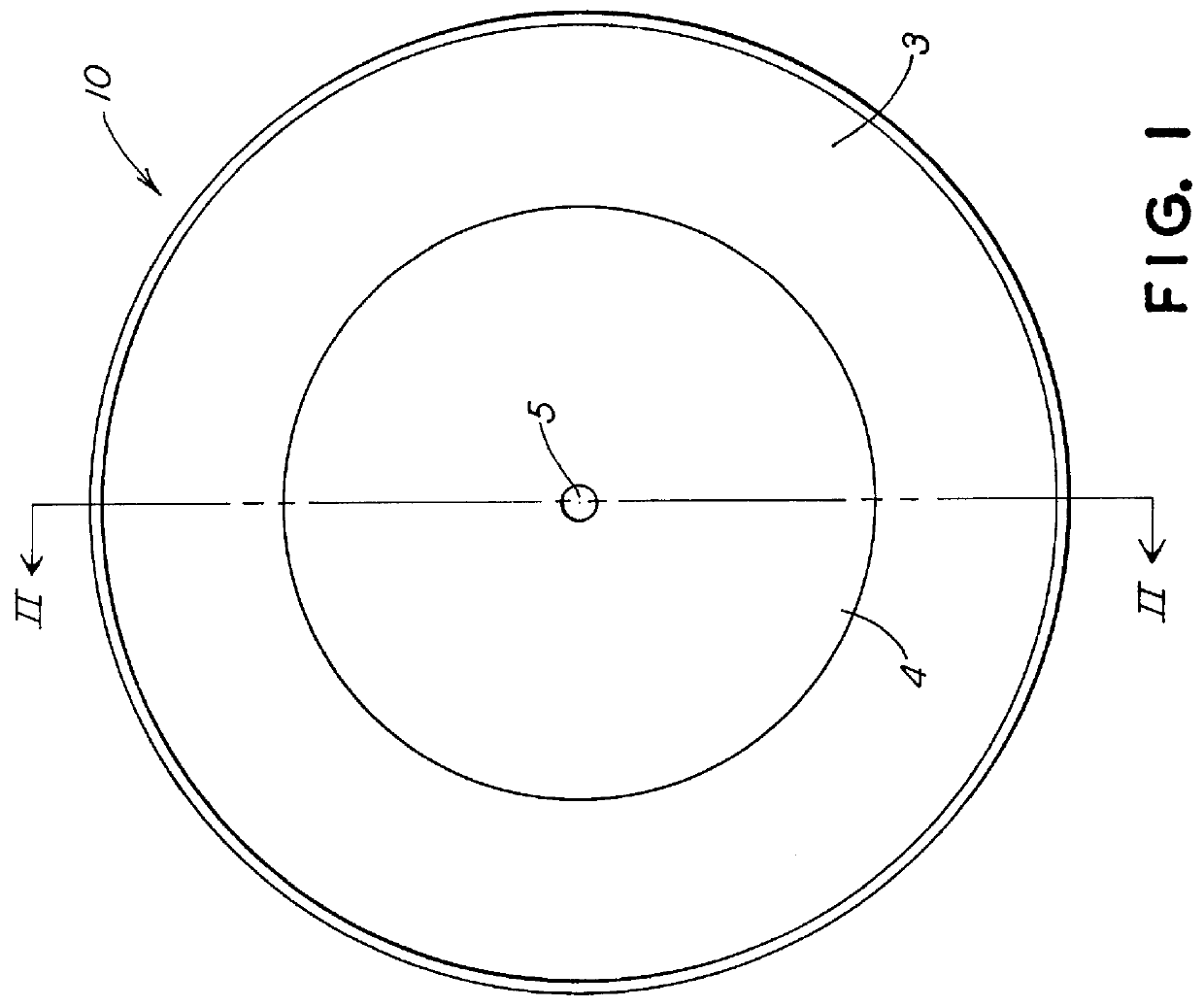

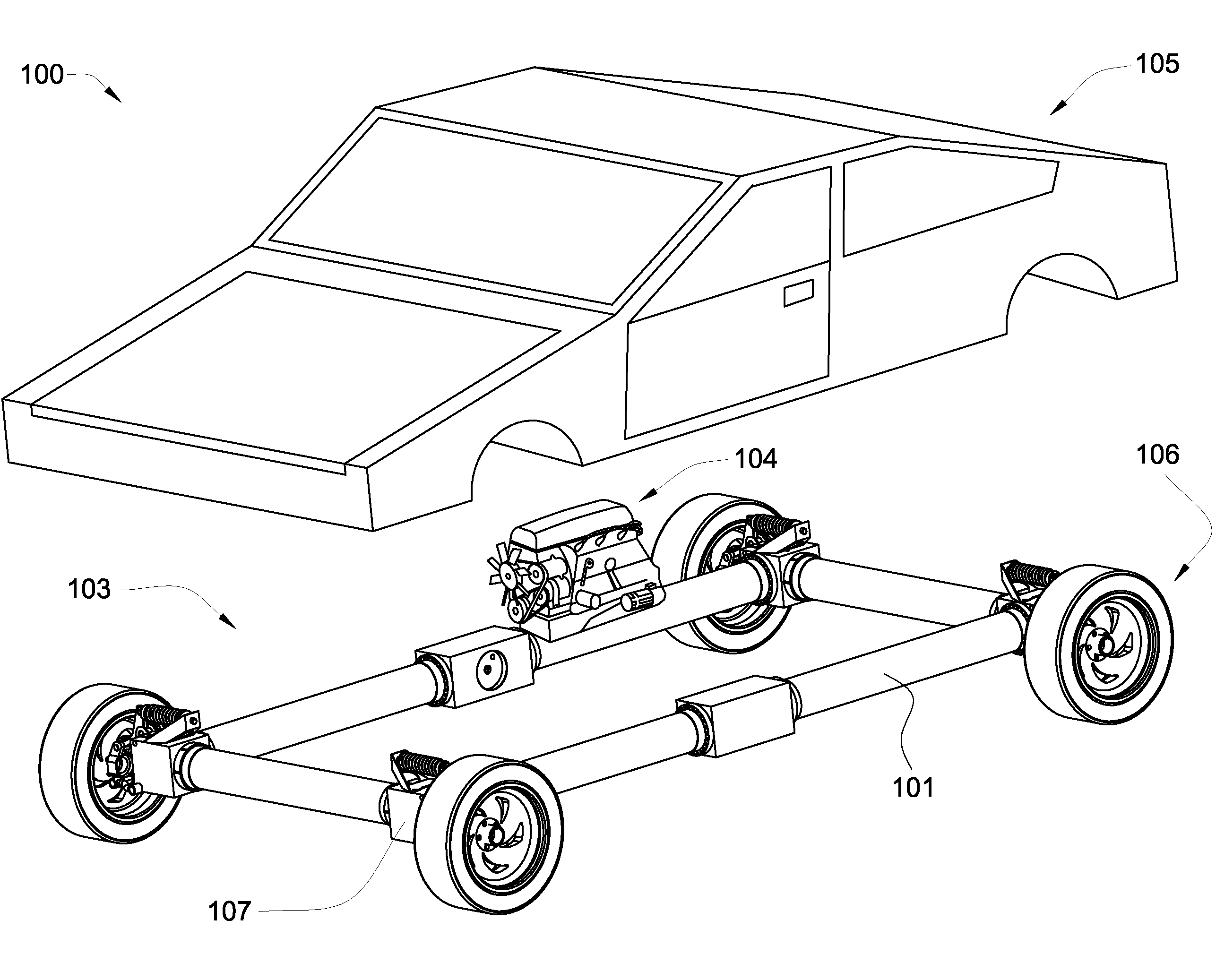

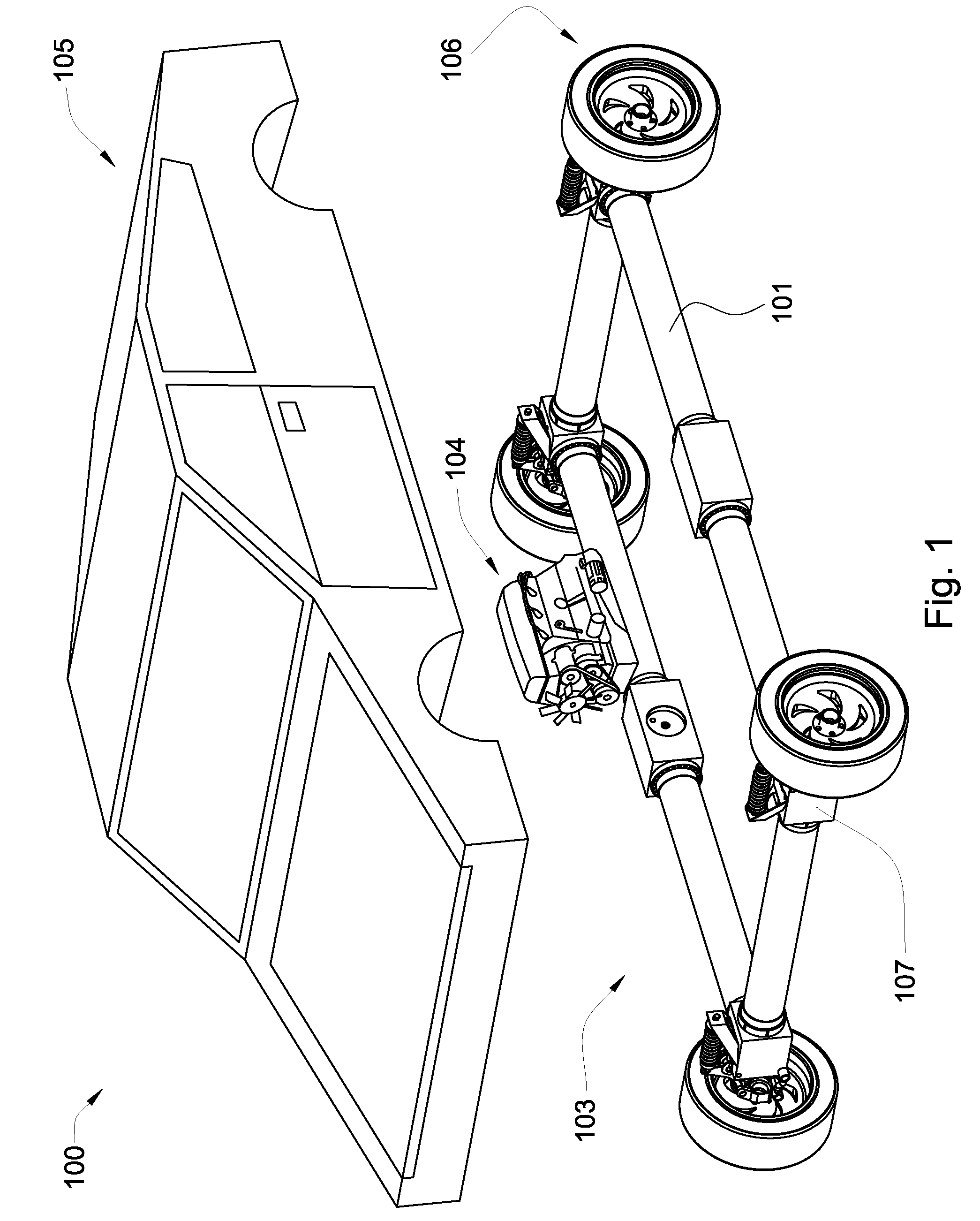

Apparatus and method for energy generation within a tire

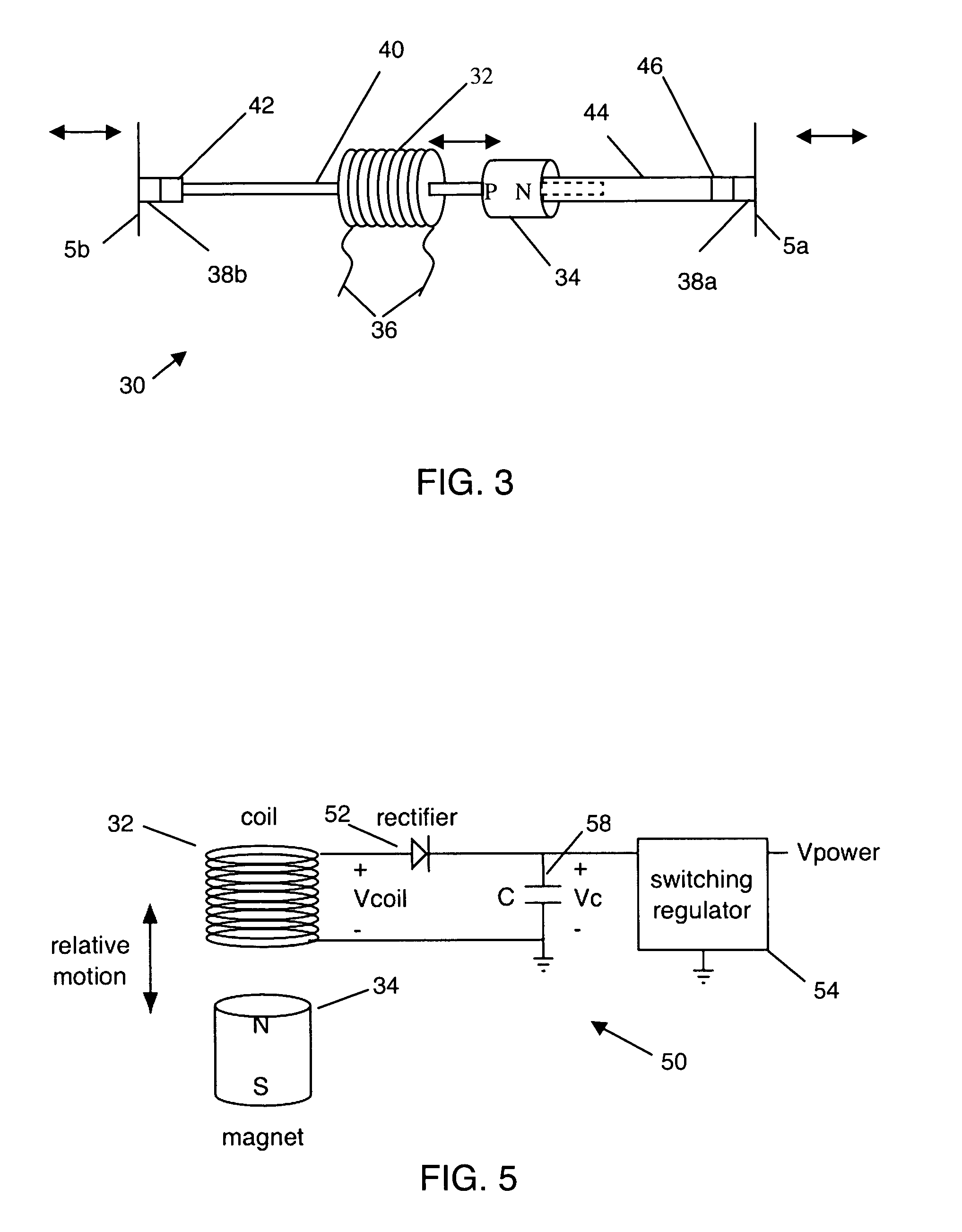

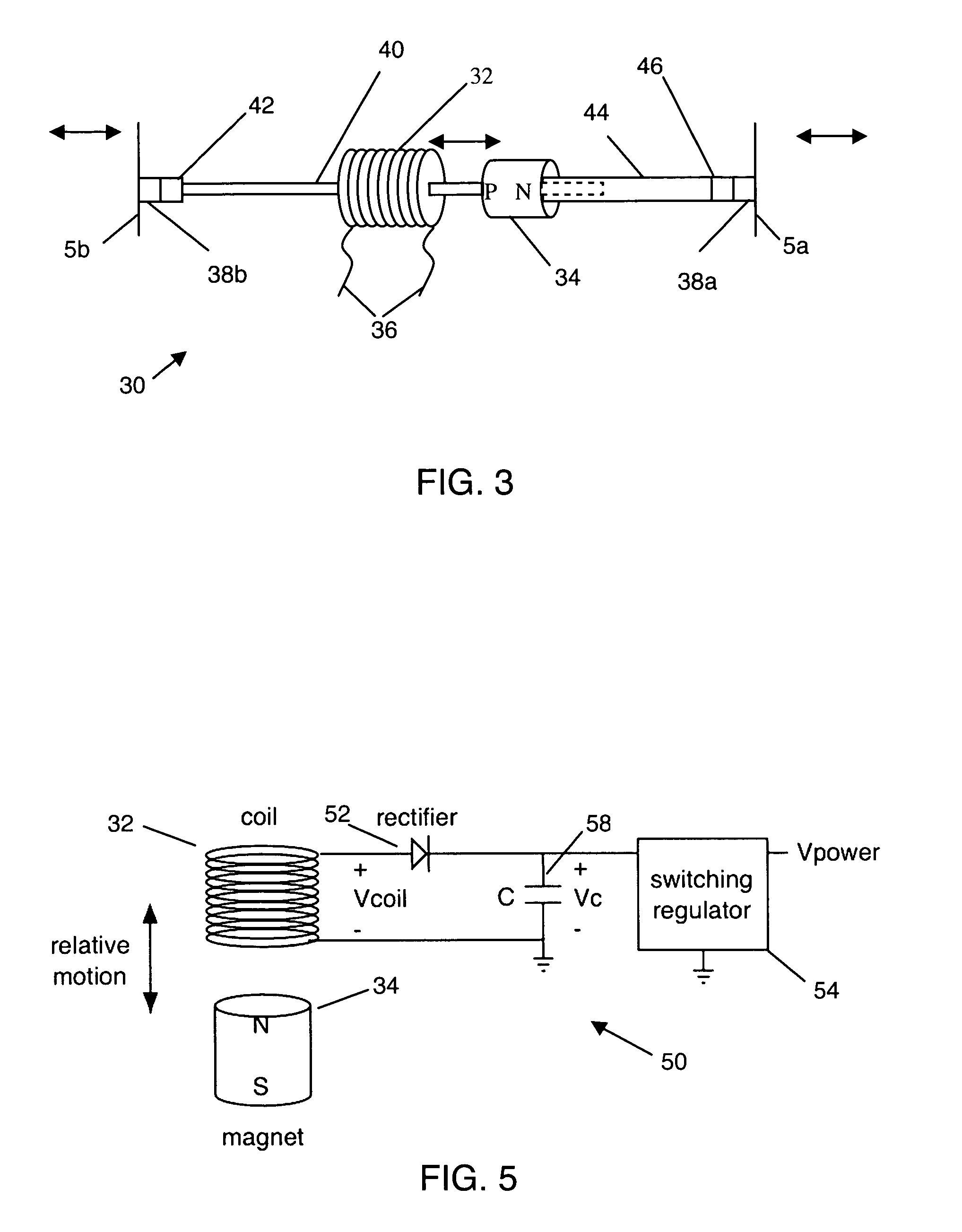

InactiveUS20040100100A1No damageNot to damageFlexible wall reciprocating enginesTyre measurementsCapacitanceRotary pump

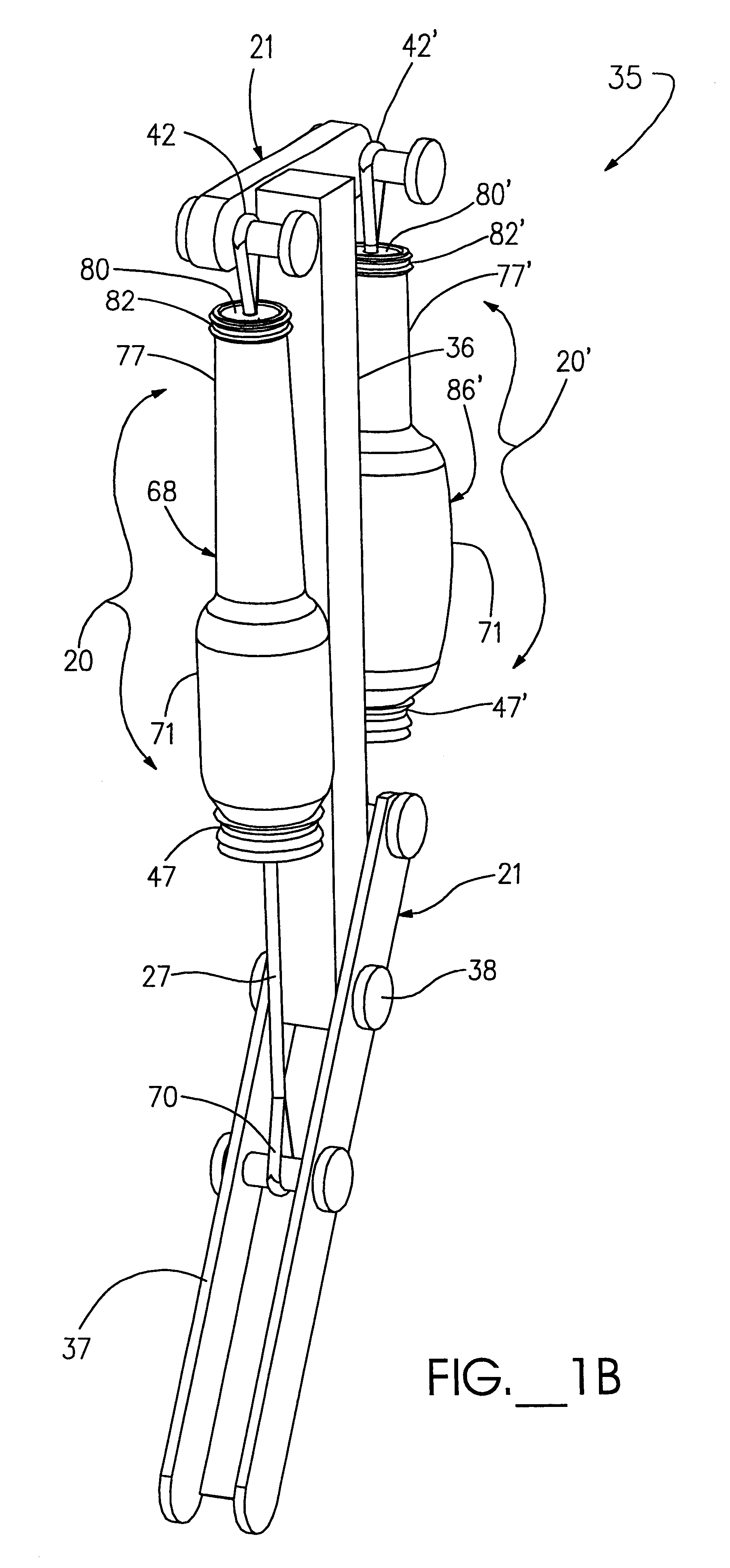

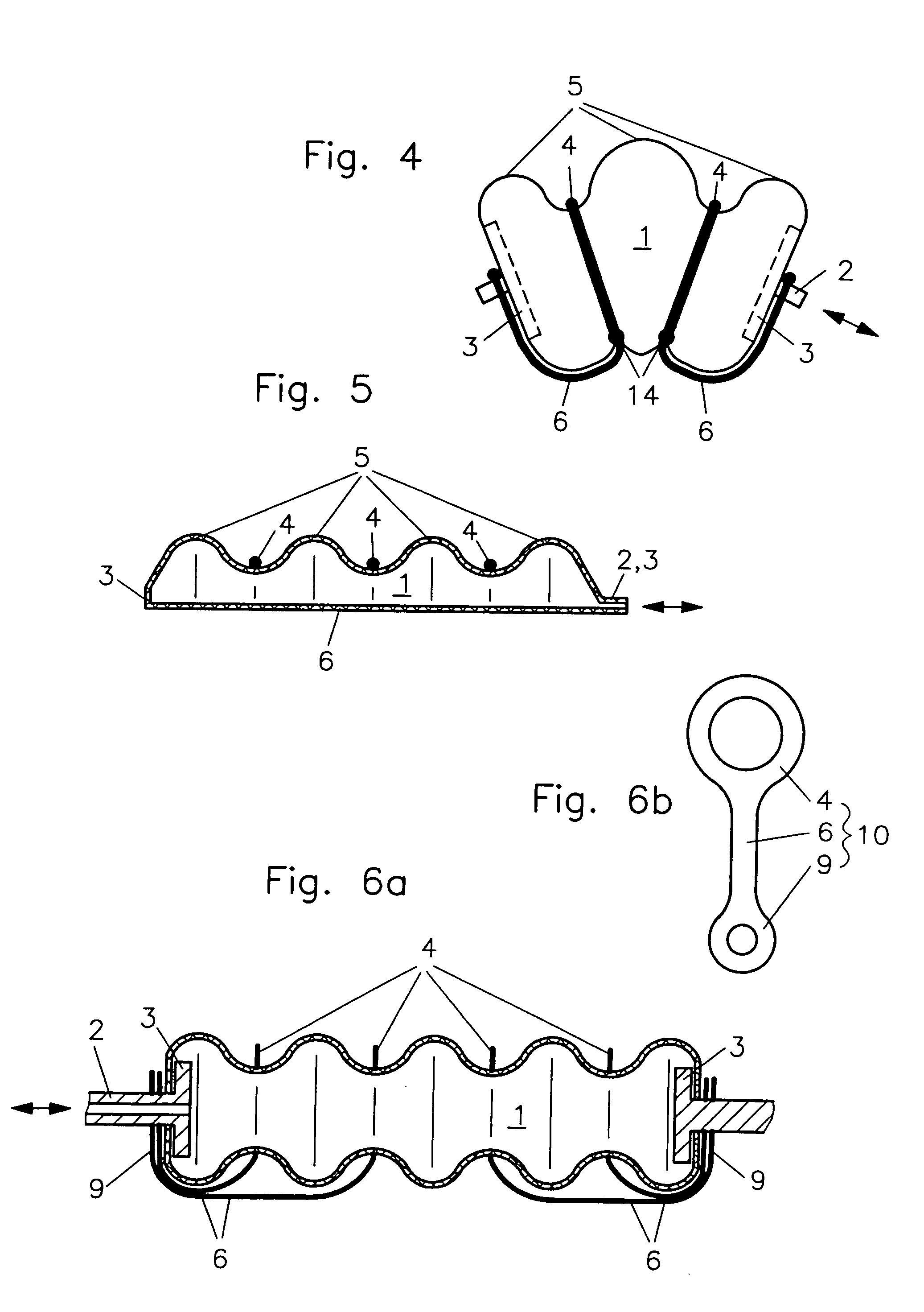

Energy for in-tire use is generated from the load induced reciprocating deflection of the tire inner walls above the tire-to-road contact patch adjacent to the shoulder of the tire. This energy is used to power in-tire monitoring electronics. For pulsatile energy generation with capacitive capture, the capacitor is optimally selected in real-time as a function of pulse width to maximize energy capture, or as a function of the pulse-captured energy. The resulting energy pulses are also used to measure the time duration of the contact patch from which the contact patch length is determined thus providing real-time tire geometry and, with tire pressure, real time tire load and, with temperature, tire air molar content. The loads on all tires provide real time vehicle mass and mass distribution. For electrical energy generation, magnet-coil, piezo-electric, and other power conversions are applicable. For non-electric energy generation, fluid bellows, rotary pump, and other power conversions are applicable. Further, run flat tires are designed with a cutout to accommodate and protect electronic devices mounted on an inner surface when running flat.

Owner:WILSON KITCHENER CLARK

Artificial muscle actuator assembly

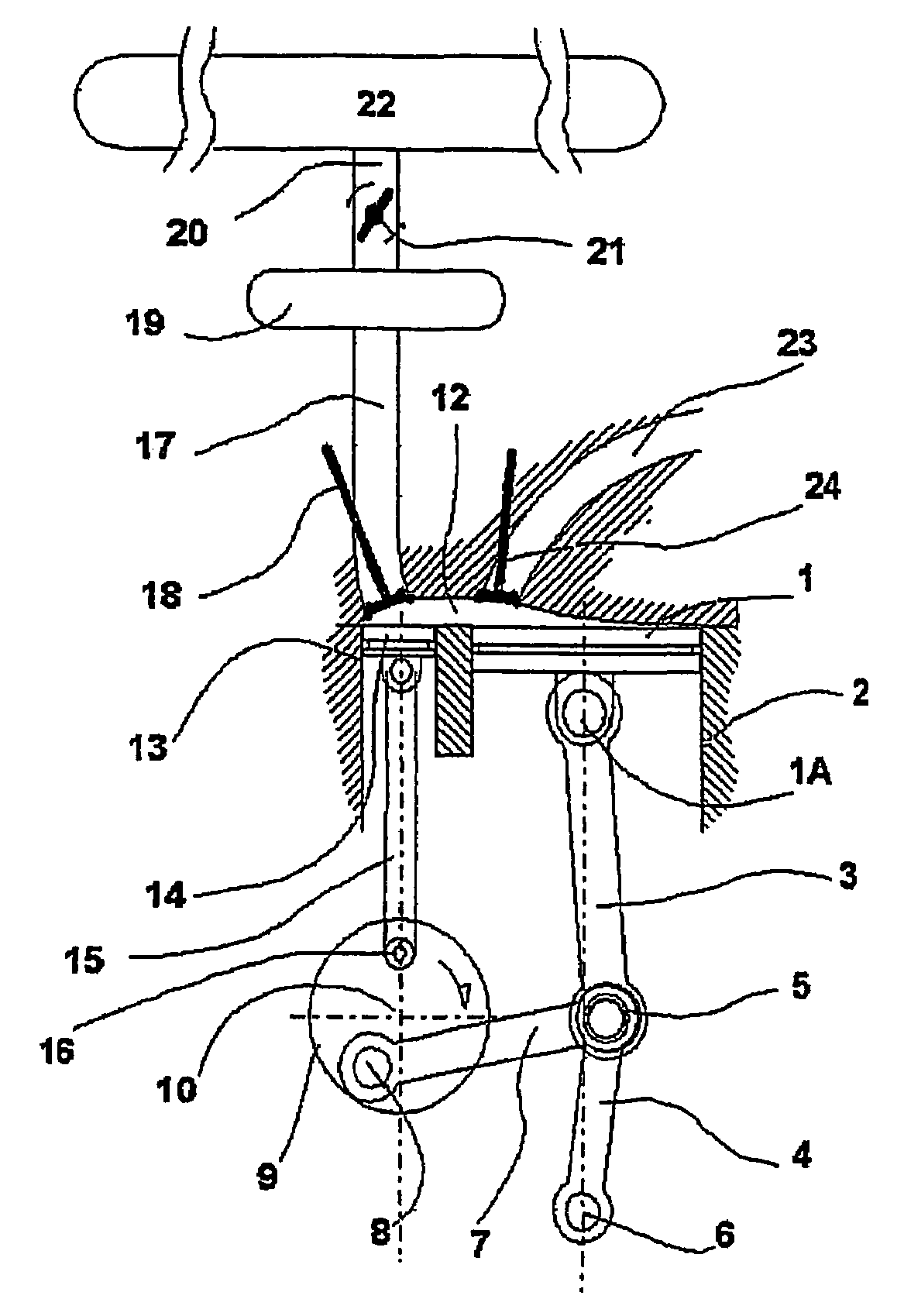

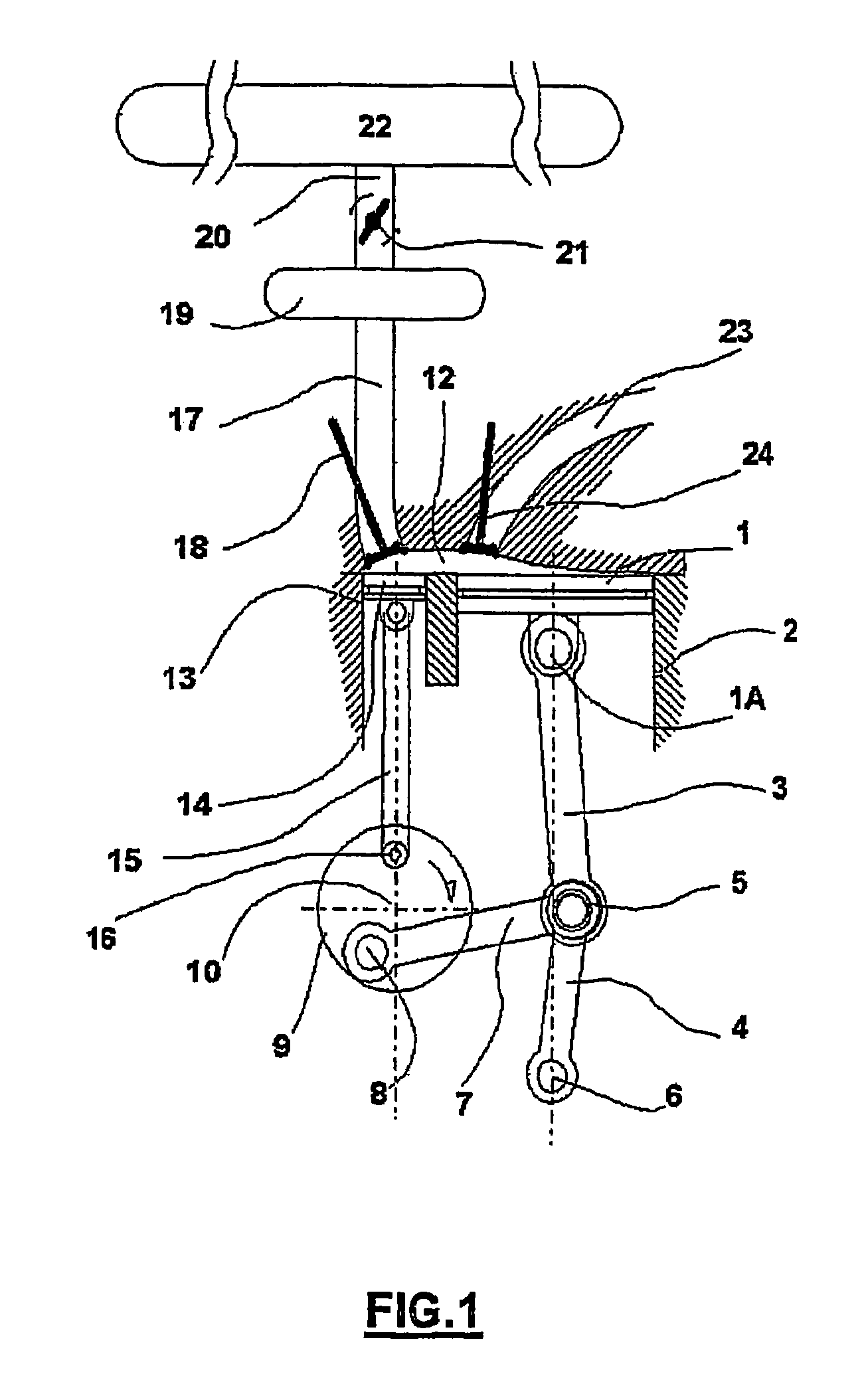

InactiveUS6067892ASubstantially flexibleAvoid formingFlexible wall reciprocating enginesFluid-pressure actuatorsDistal portionEngineering

A flexible actuator assembly (20) including a flexible bladder device (22) having an expandable sealed chamber (23) adapted to substantially directionally displace between a deflated condition and an inflated condition, displacing a proximal portion (25) of the bladder device (22) away from a distal portion (26) thereof. An elongated tendon member (27) includes a distal portion (28) oriented outside the chamber (23), while an anchor portion (30) extends into the chamber (23) through a distal opening (31) in the bladder device (22). The tendon anchor portion (30) is further coupled proximate to the bladder proximal portion (25) in a manner adapted to: selectively invert displaceable portions (32) of the bladder device (22) when urged toward the deflated condition to position the anchor portion (30) and the bladder proximal portion (25) relatively closer to the bladder distal portion (26); and selectively evert the inverted displaceable portions (32) of the bladder device (22) when displaced toward the inflated condition which positions the anchor portion (30) and the bladder proximal portion (25) relatively farther away from the bladder distal portion (26) for selective movement of the tendon distal portion (28) between an extended condition and a retracted condition, respectively.

Owner:ERICKSON JOEL R

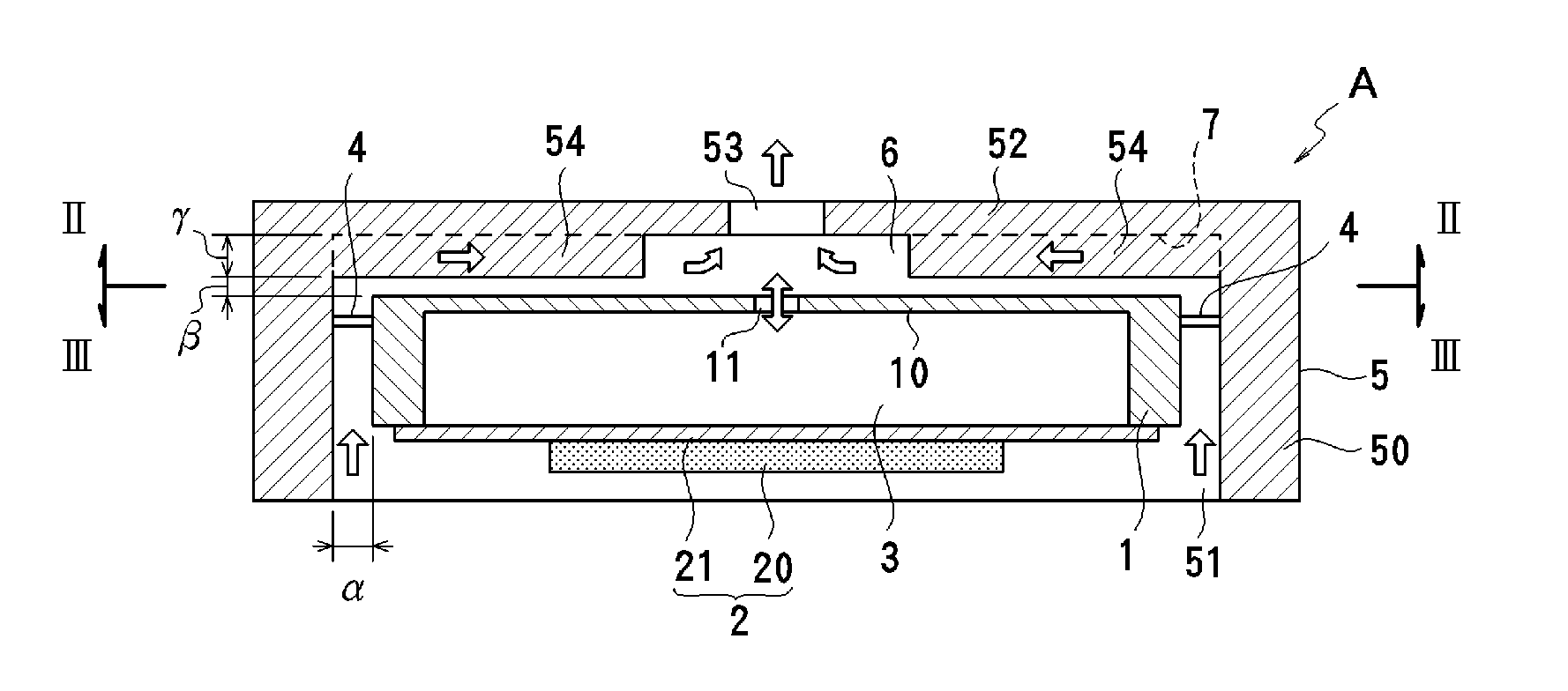

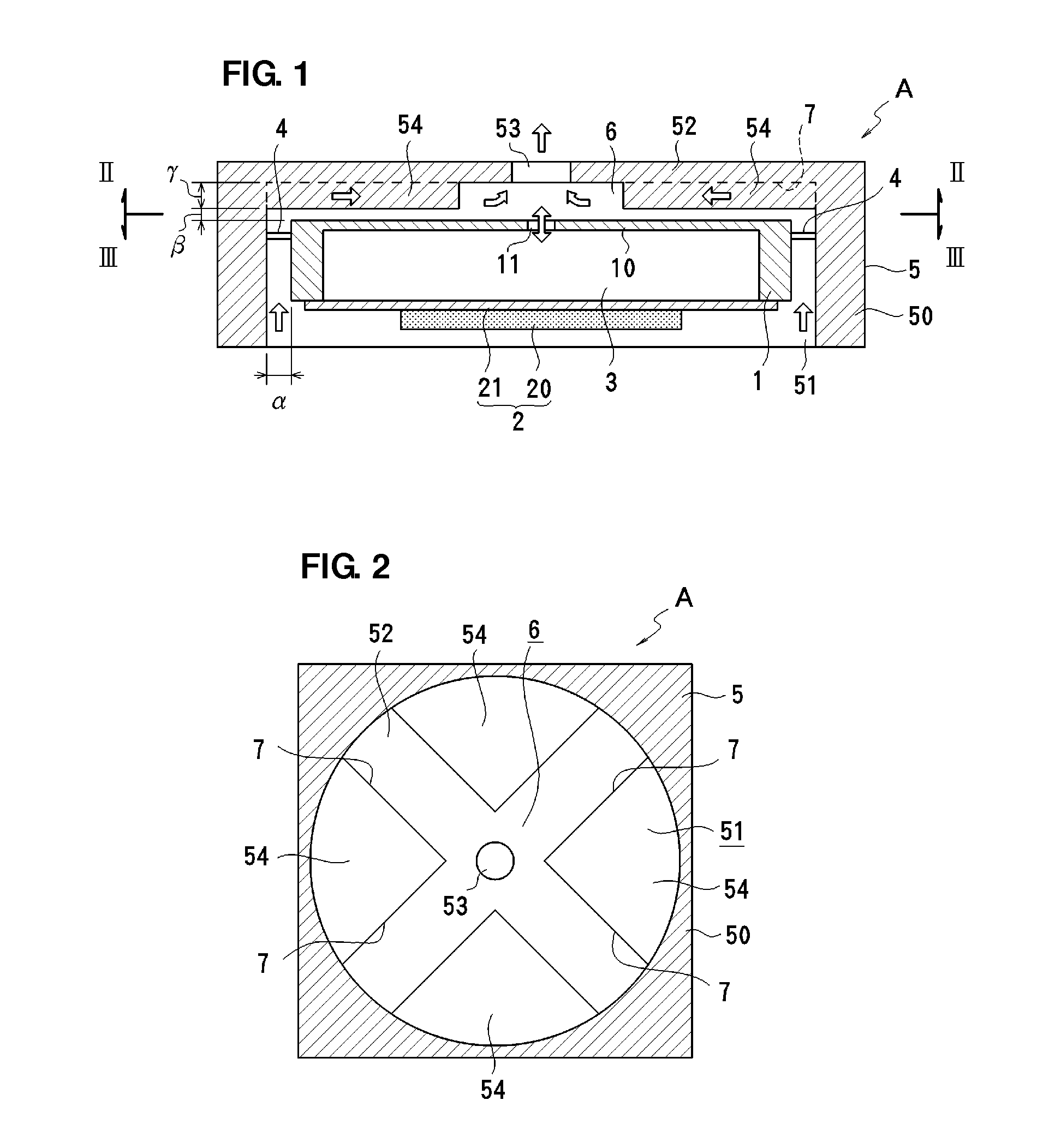

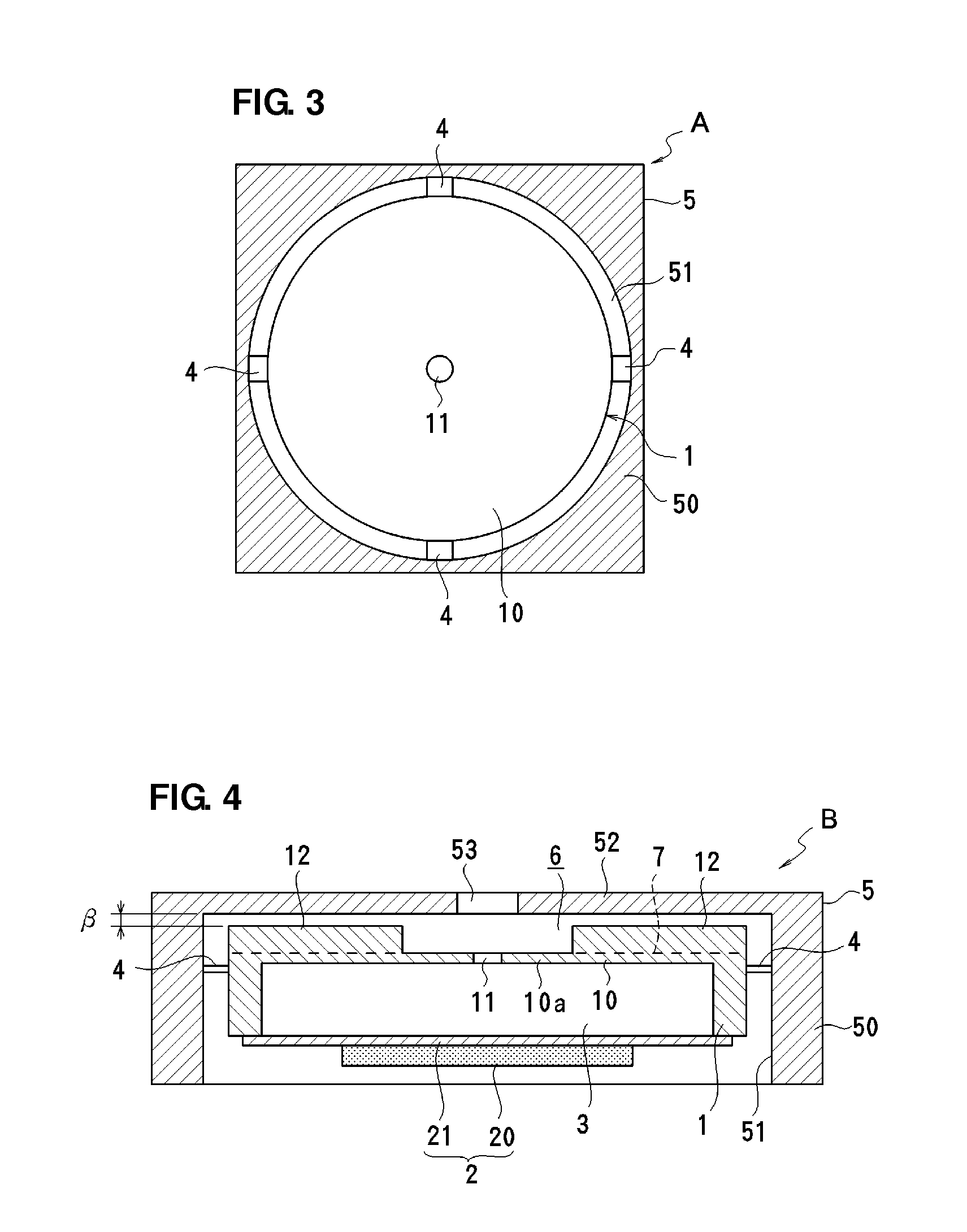

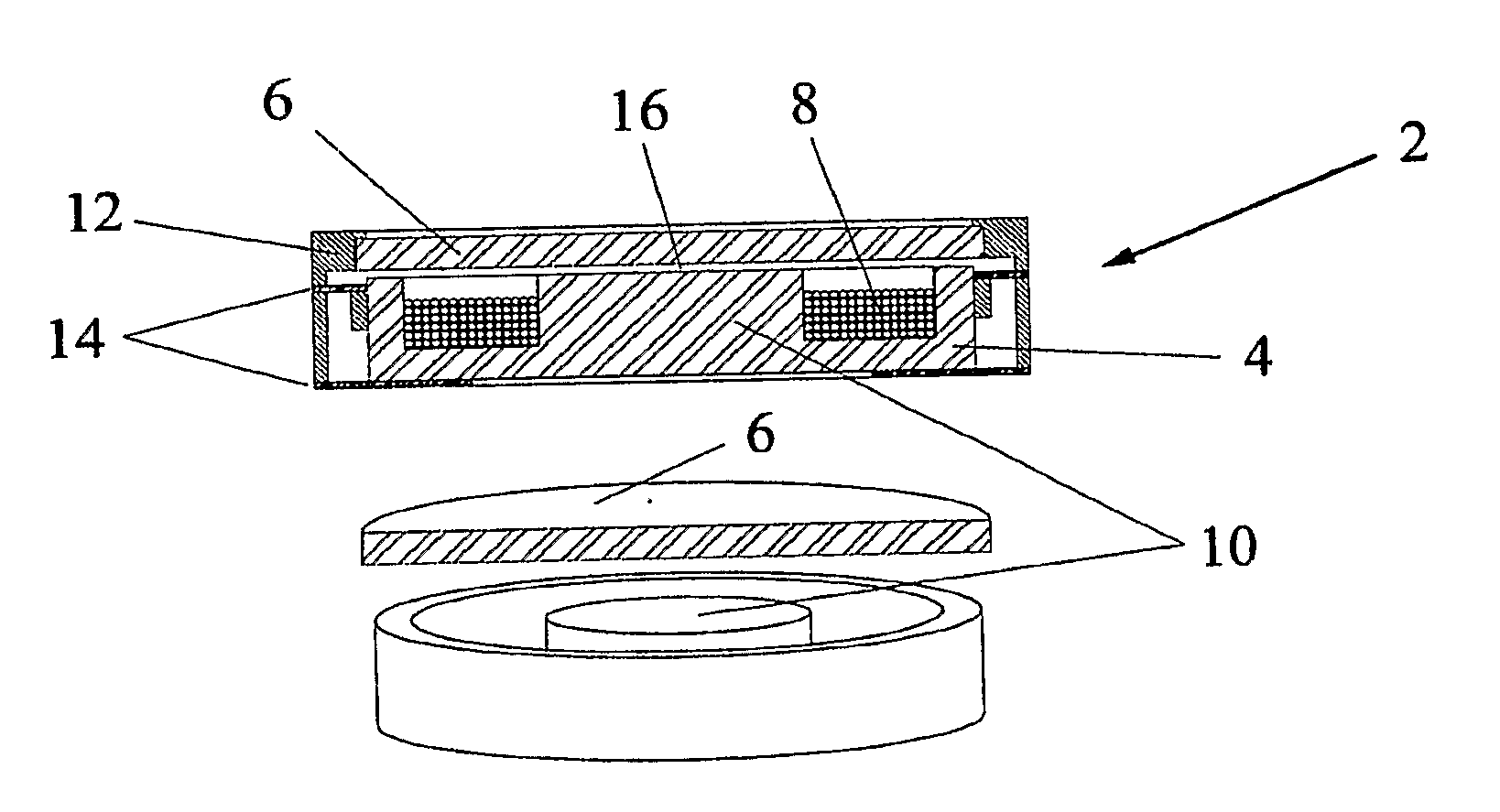

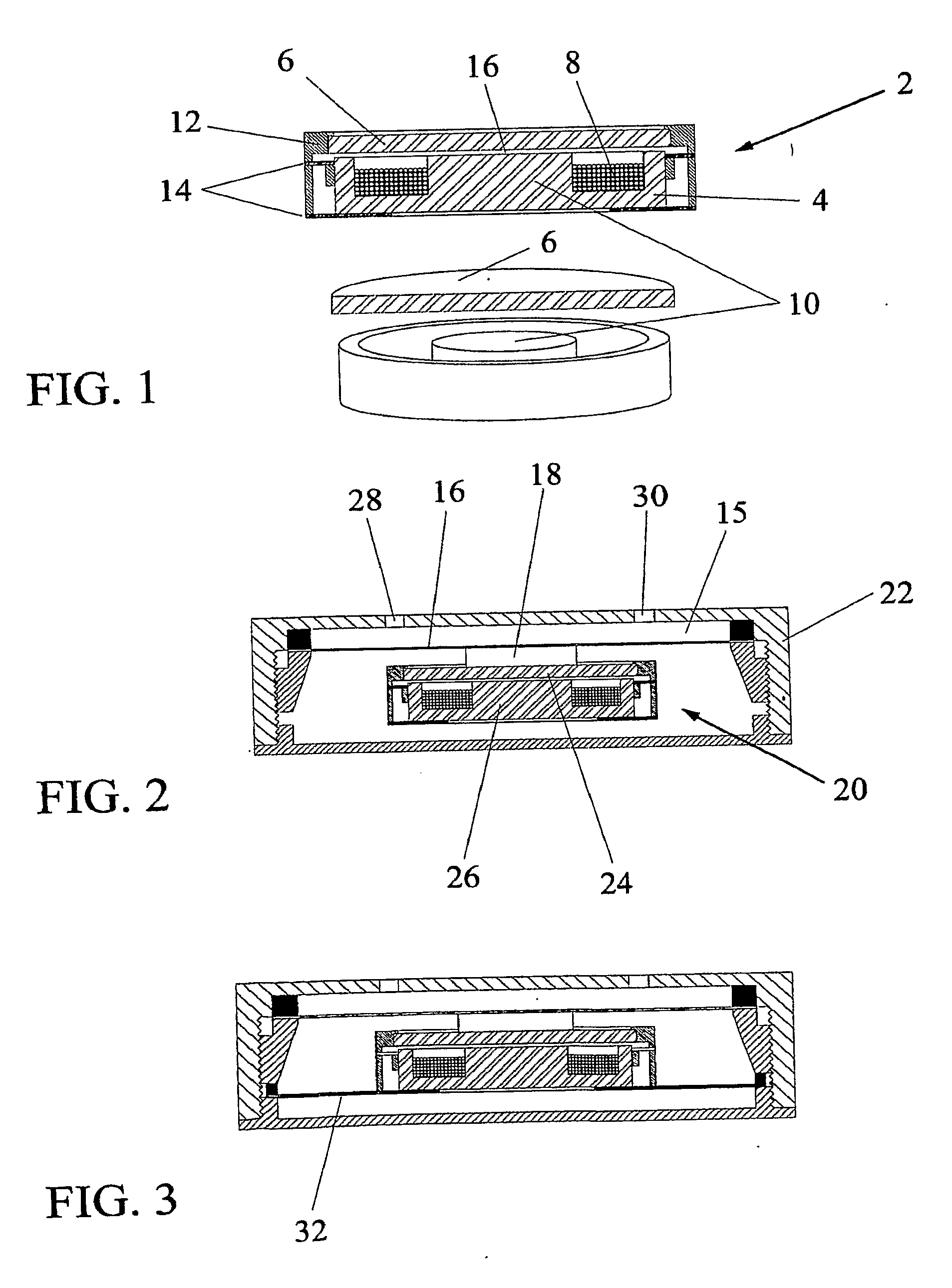

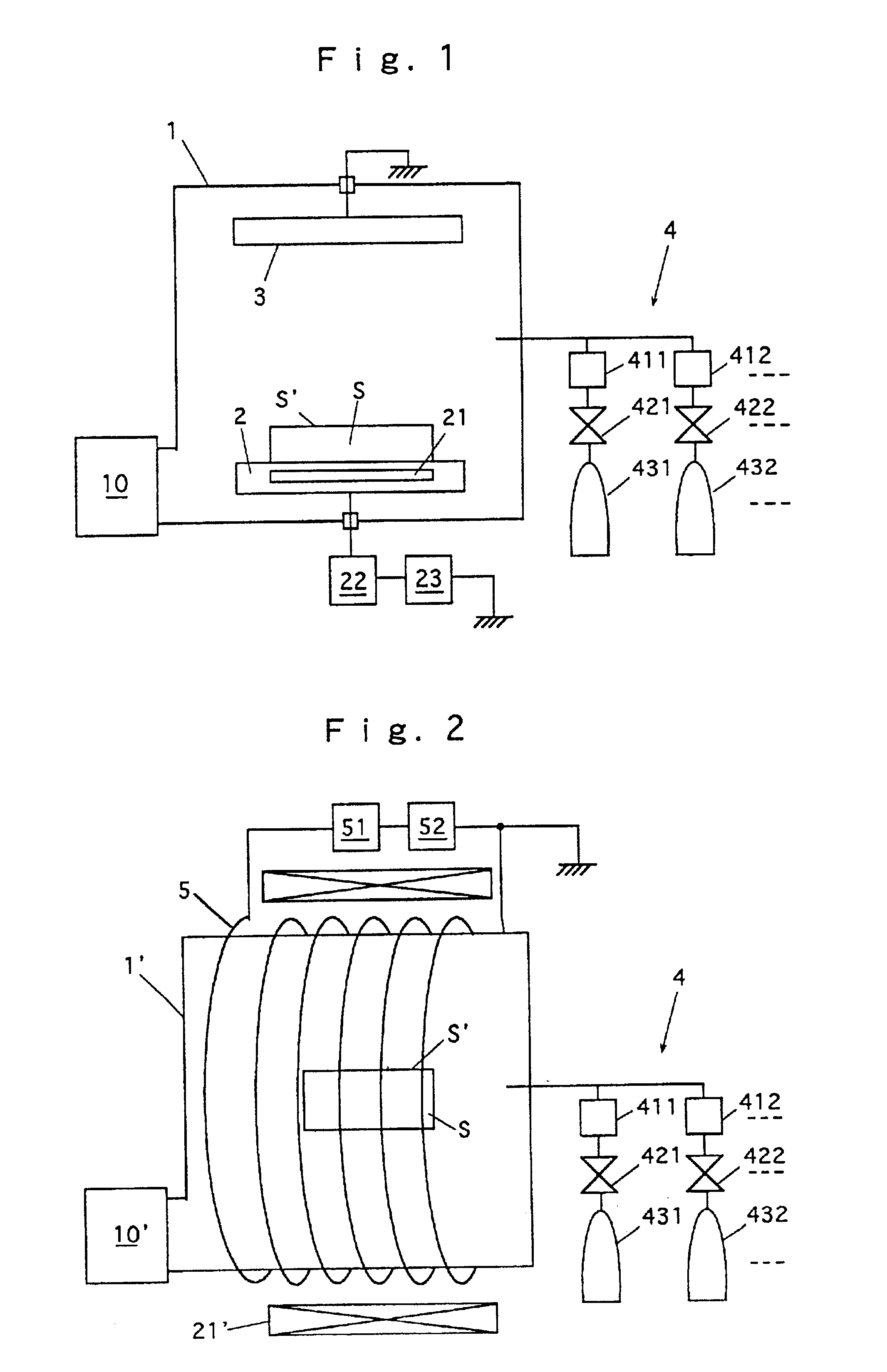

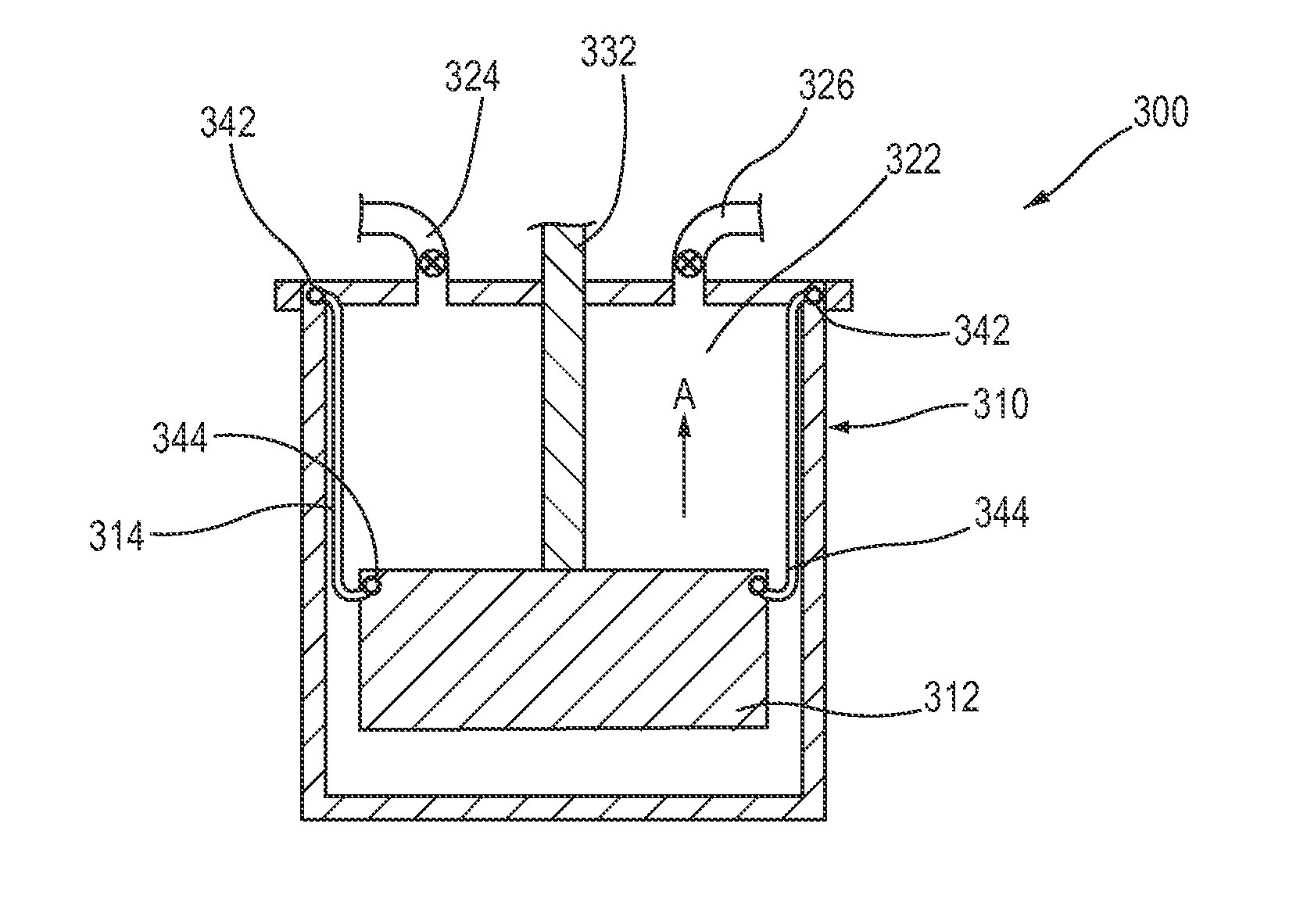

Piezoelectric micro-blower

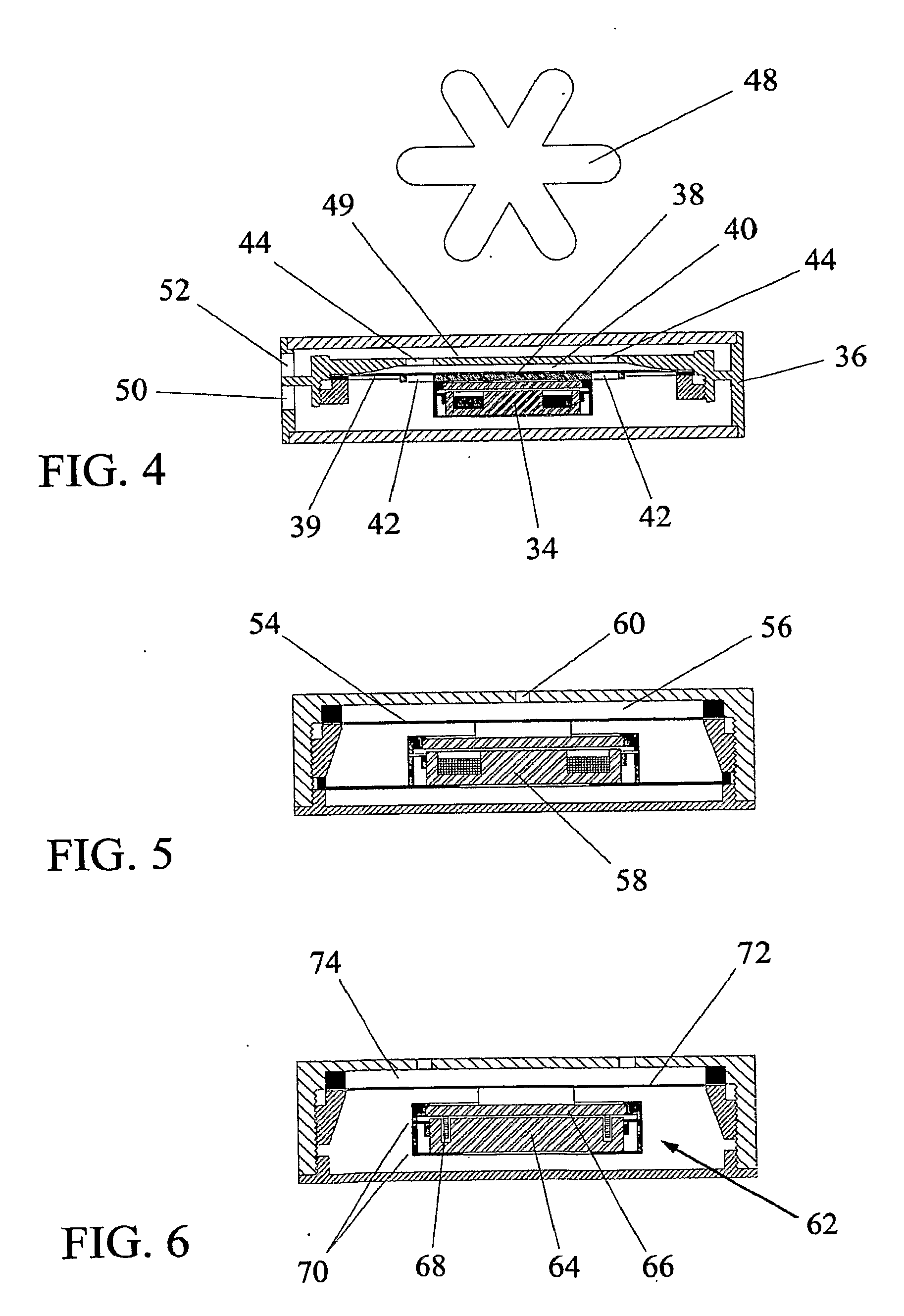

ActiveUS20110076170A1Improve vibrationIncrease displacementFlexible wall reciprocating enginesFlexible member pumpsElectricityEngineering

A piezoelectric micro-blower includes an inner case to which a peripheral portion of a vibrating plate including a piezoelectric element is fixed such that a blower chamber is defined between the inner case and the vibrating plate and an outer case arranged to cover an outer periphery of the inner case with a gap therebetween. The inner case is elastically retained in the outer case by a plurality of connecting portions. A first opening is provided in a top plate portion of the inner case that faces a central portion of the vibrating plate, and a second opening is provided in a top plate portion of the outer case that faces the first opening. A central space is provided between the top plate portions, and fluid introduced from the outside is guided to the central space through the gap between the inner and outer cases. The vibrating plate is driven in a bending mode so that air is sucked into the central space and is discharged through the second opening. The connecting portions prevent leakage of vibration of the vibrating plate from the inner case to the outer case, thereby reducing energy loss.

Owner:MURATA MFG CO LTD

Attachment system

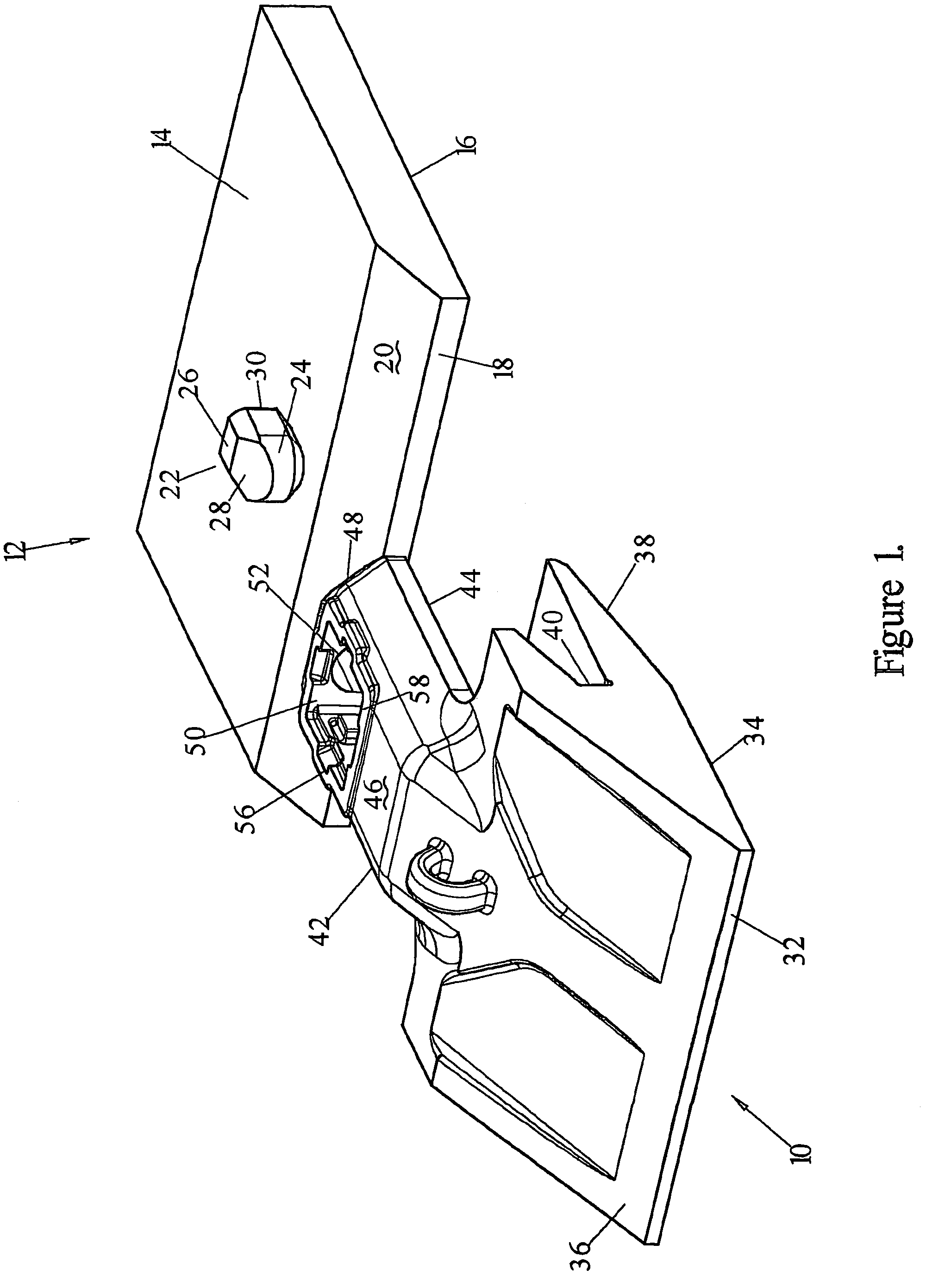

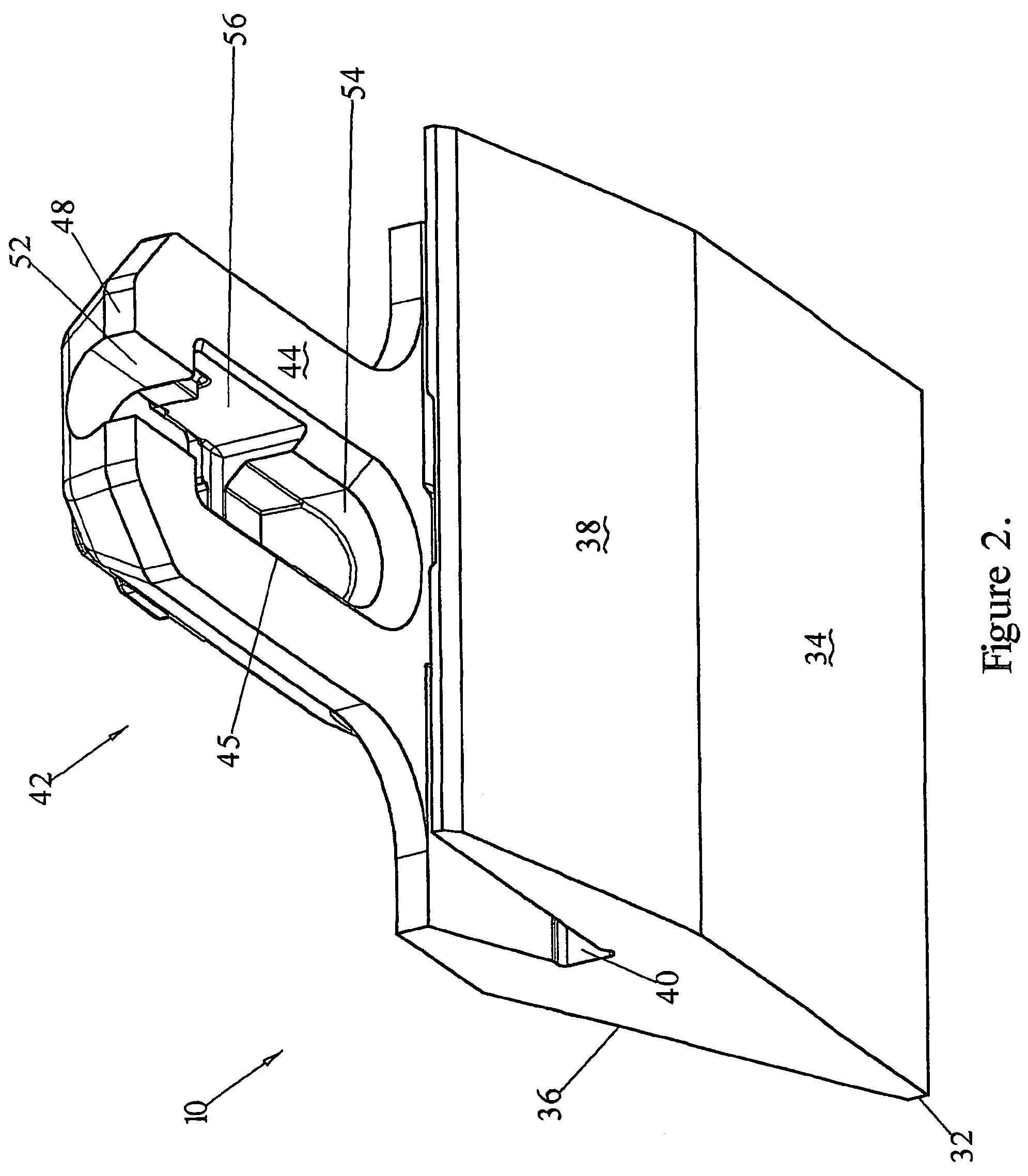

InactiveUS7219454B2Yielding couplingFlexible wall reciprocating enginesEngineeringMechanical engineering

An attachment system for connecting a first member such as a lip plate (12) of a mechanical digging device to a second member such as a ground engaging tool (10). The first member has a lug portion (22) attached thereto the second member has a recess (50) arranged, in use, about the lug portion. A clamping member (60) is disposed between the lug portion (22) and the second member (10) such that the supply of pressure to the clamping member (60) acts to restrain disengagement of the second member (10) from the lug portion (22).

Owner:SANDVIK SHARK

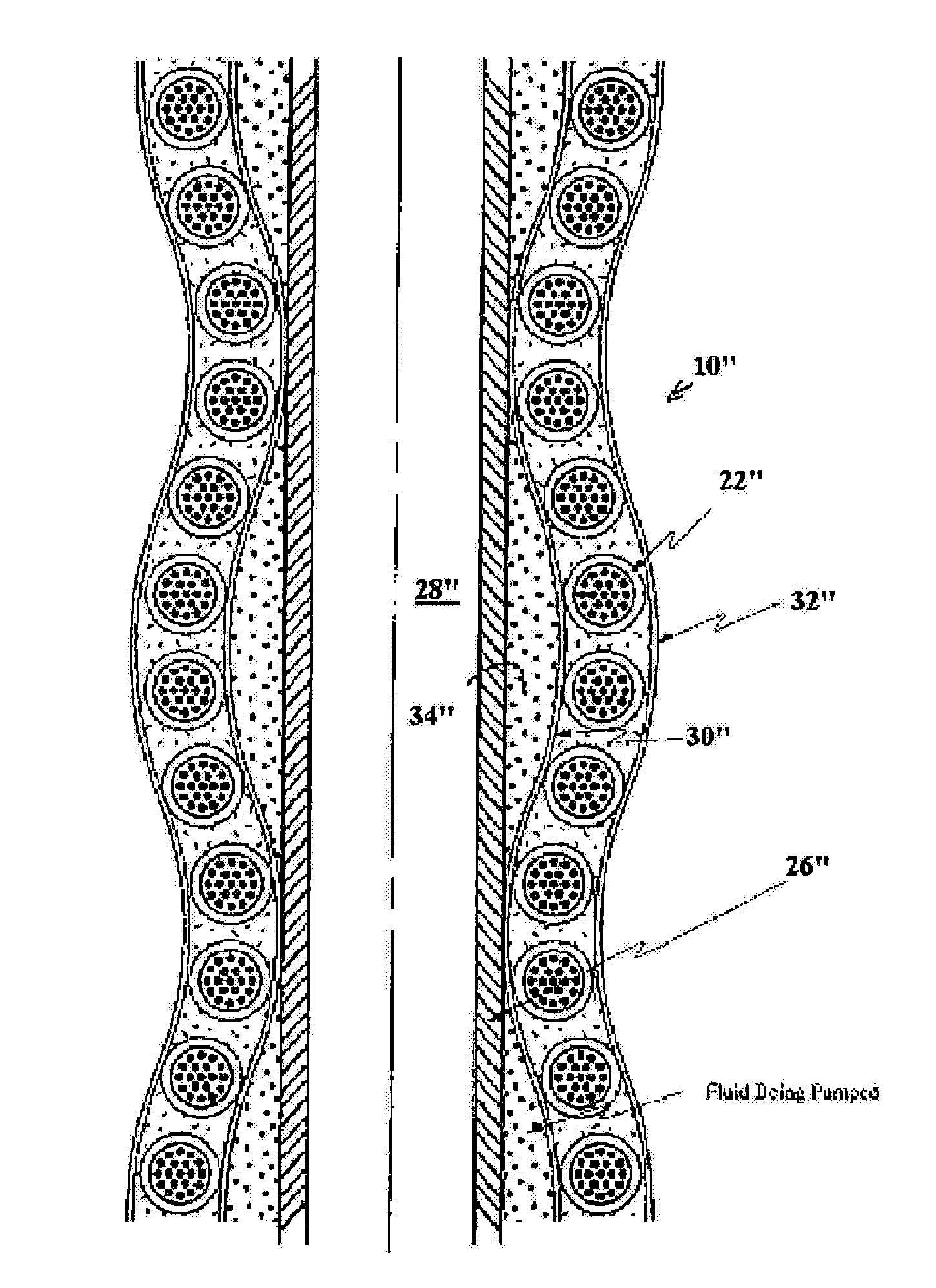

Fluidic Energy Transfer Devices

ActiveUS20090148320A1Increase volume of chamberReduce chamber volumeFlexible wall reciprocating enginesOscillating piston pumpsEngineeringActuator

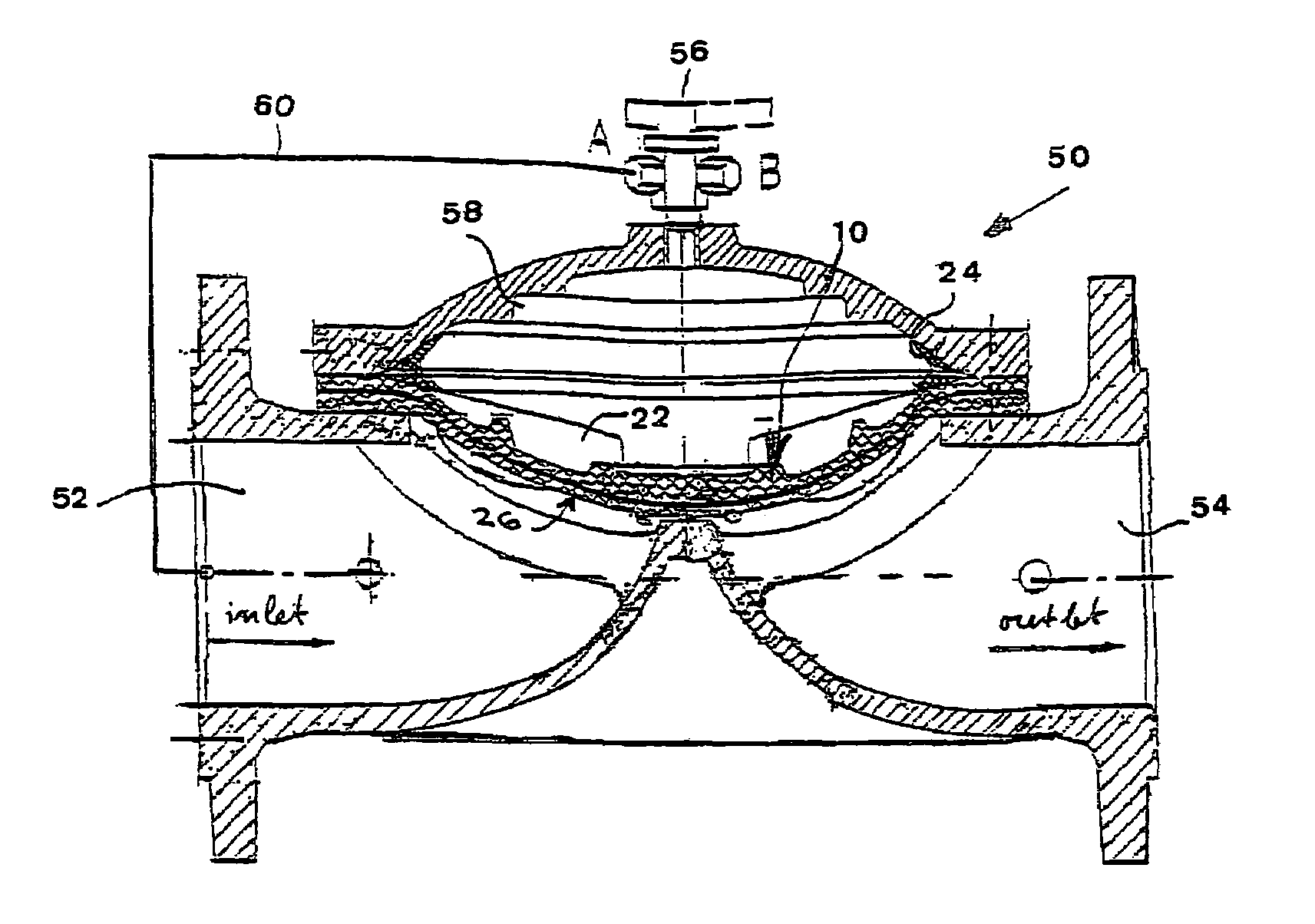

A fluid energy transfer device, including a chamber for receiving a fluid, at least a portion of the chamber comprising a movable portion relative to another portion of the chamber, the movable portion being adapted to change the volume of the chamber from a first volume to a second volume by movement of the movable portion. The device further includes an actuator attached to the movable portion, wherein the displacements of the movable portion can be larger than the displacement of the actuator.

Owner:AAVID THERMALLOY LLV

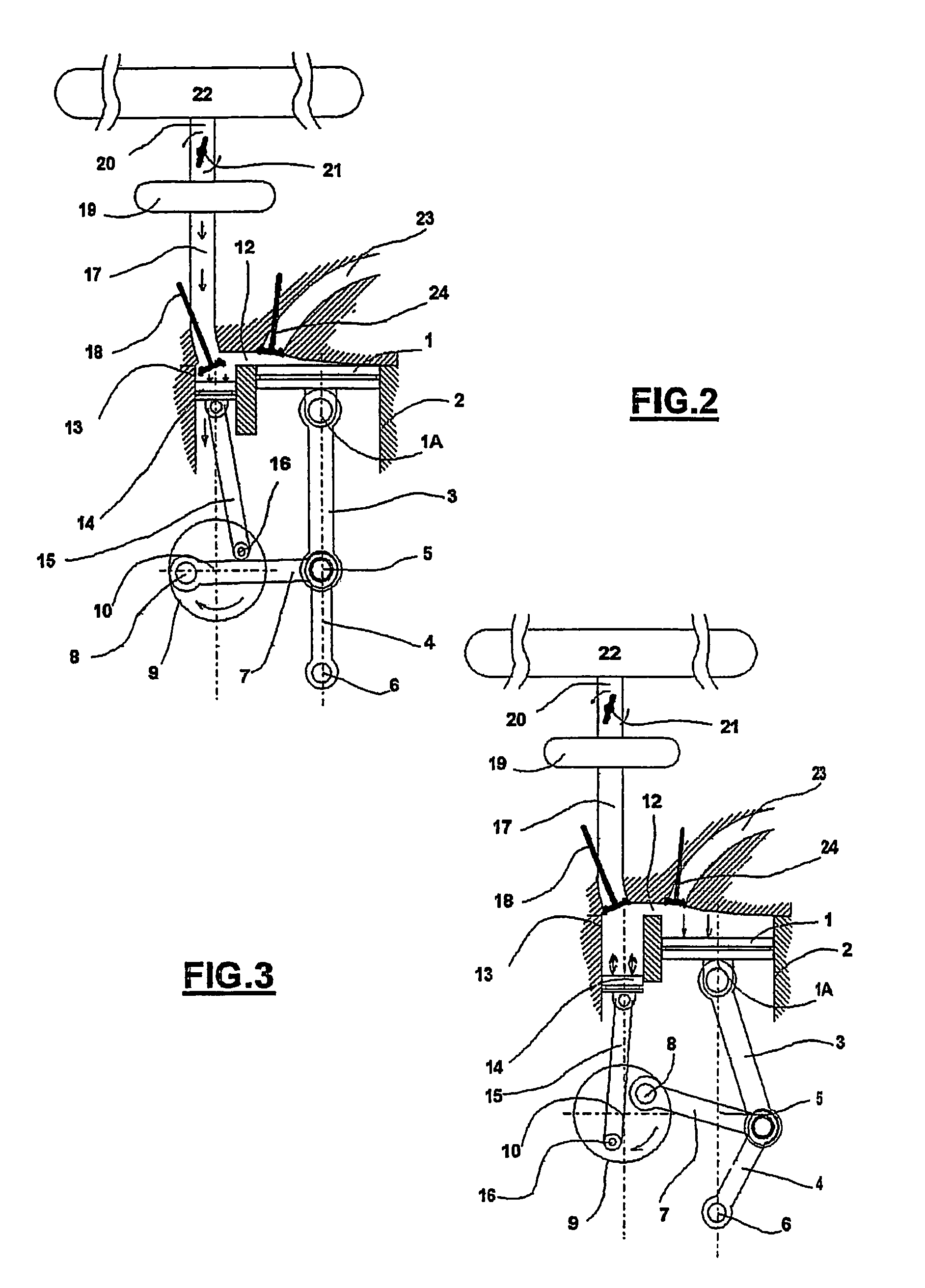

Engine with an active mono-energy and/or bi-energy chamber with compressed air and/or additional energy and thermodynamic cycle thereof

ActiveUS7469527B2Usable and available energyQuantity of usable and availableFlexible wall reciprocating enginesCombustion enginesTop dead centerEngineering

An engine uses a top dead center piston stop device. It is fed by compressed air, via a working capacity, which, in the bi-energy version, includes a device for heating the air supplied by additional energy. The active expansion chamber consists of a variable volume or charge piston sliding in a cylinder, coupled to a space above the engine piston via a passage. When stoped at upper dead center, the pressurized air is admitted into the expansion chamber with the smallest volume thereof and, under the effect of thrust, increases the volume thereof by producing work; the expansion chamber is then kept at a maximum volume during expansion of the engine cylinder driving back the engine piston in its downward stroke, providing work of its own. During exhaust, the two pistons travel in an upward stroke and simultaneously reach top dead center in order to resume a new cycle.

Owner:MDI MOTOR DEV INT SA

Fluidic device

InactiveUS7086322B2Easy to controlAccurate doseFlexible wall reciprocating enginesFluid-pressure actuatorsEngineeringRing element

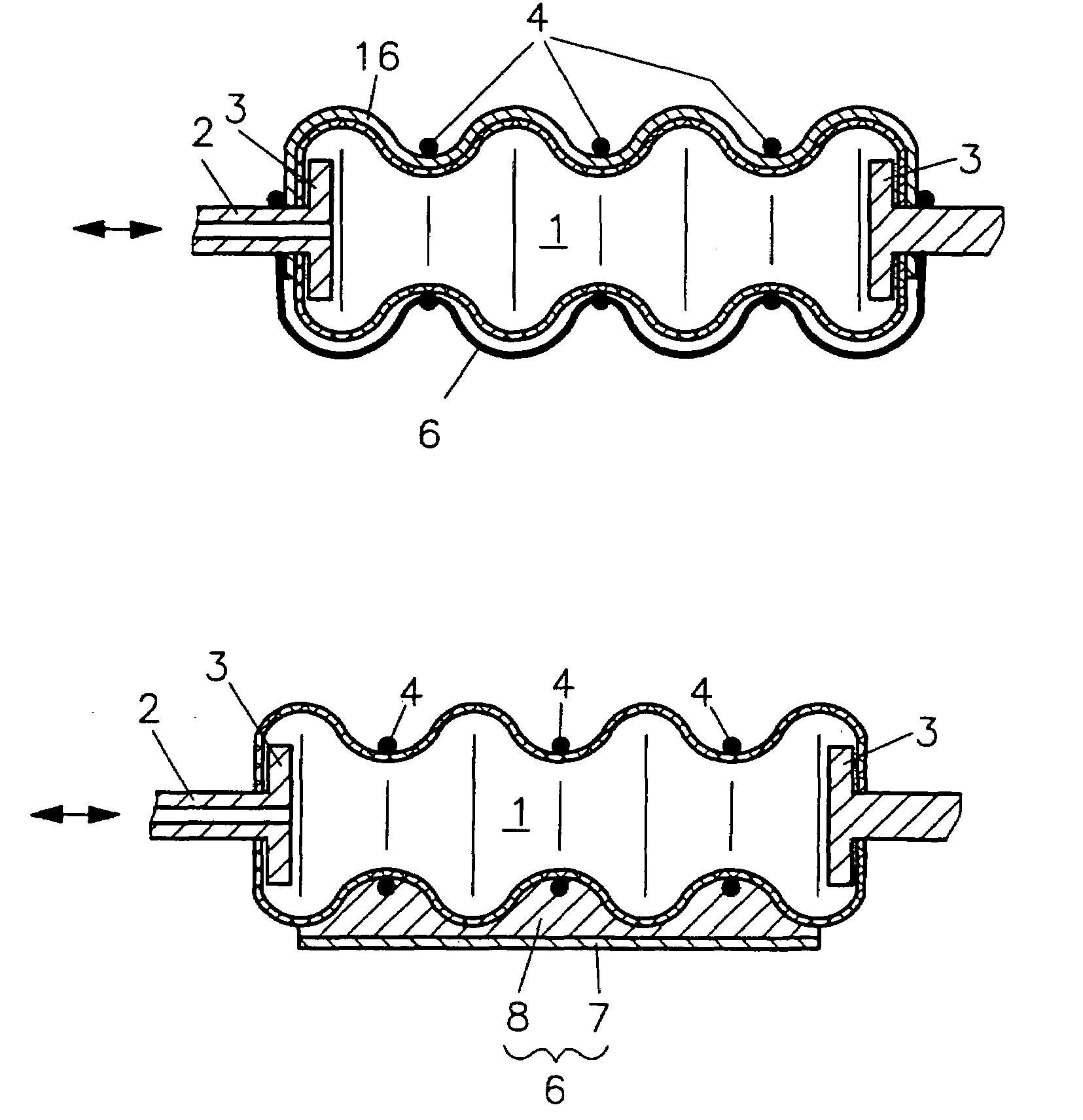

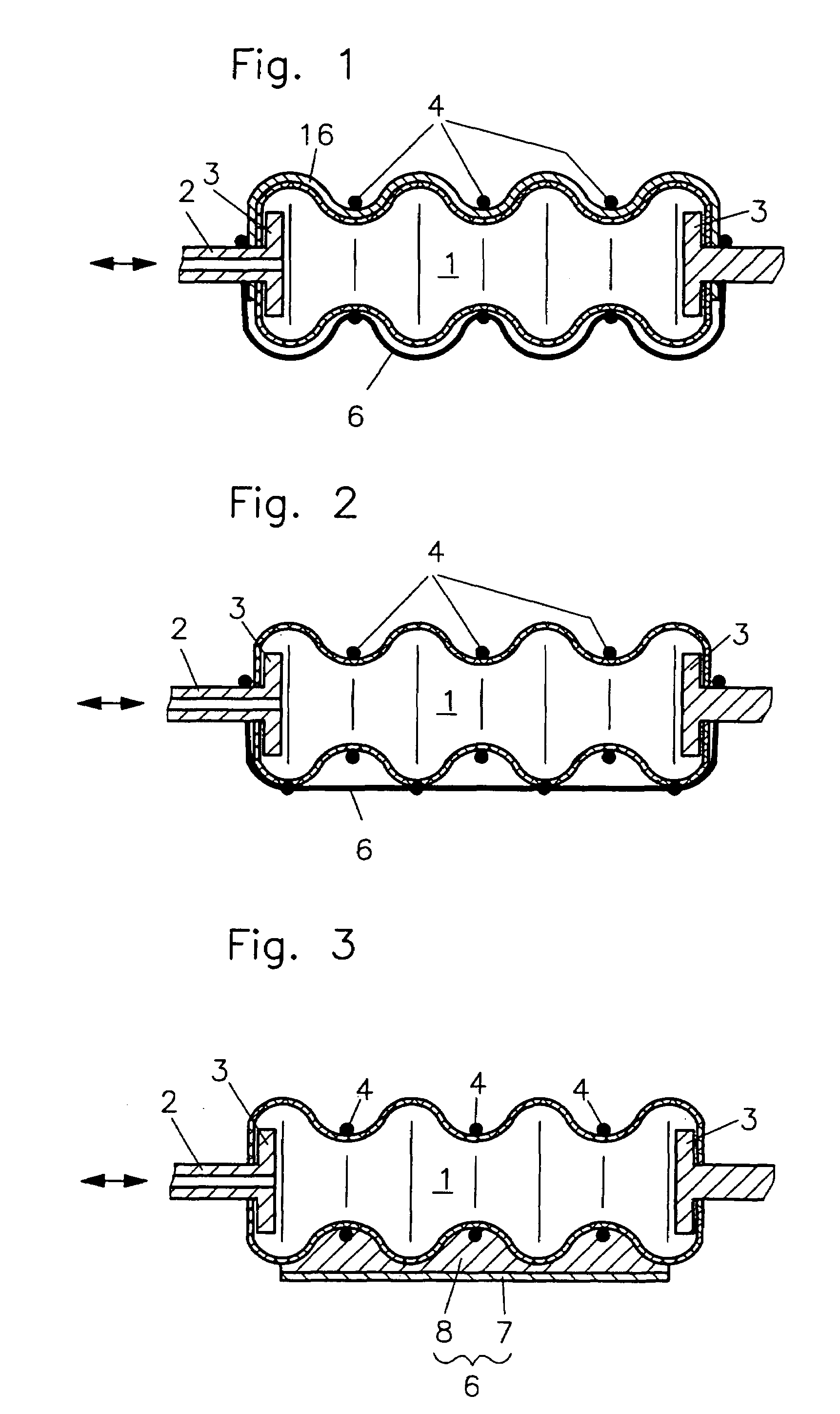

In a fluidic drive for disposition between two components which are movable relative to each other comprising a hollow body with a duct for supplying fluid to, and discharging it from, the hollow body wherein the hollow body consists at least partially of a bellows structure, non-resilient ring elements extend around the hollow body in each of its pleats and a connecting structure extends at least at one side of the hollow body and interconnects the non-resilient ring elements.

Owner:GSI HELMHOLTZZENT FUR SCHWERIONENFORSCHUNG

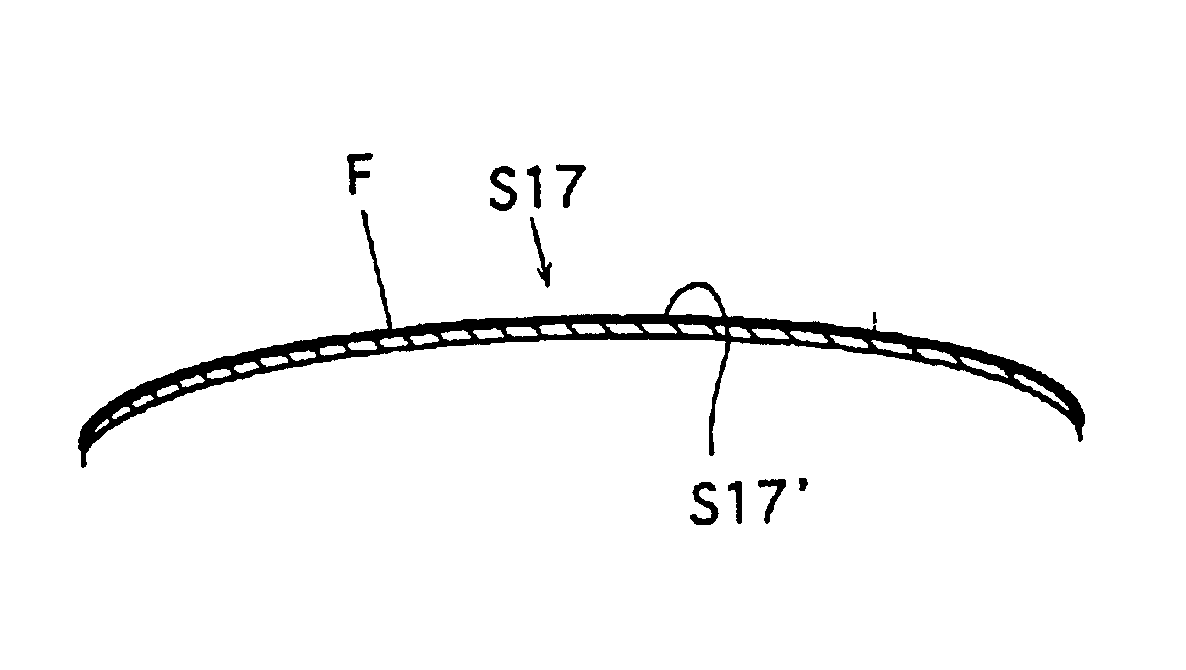

Apparatus and method for energy generation within a tire

InactiveUS7285868B2Sufficient powerEliminate needFlexible wall reciprocating enginesTyre measurementsCapacitanceRotary pump

Energy for in-tire use is generated from the load induced reciprocating deflection of the tire inner walls above the tire-to-road contact patch adjacent to the shoulder of the tire. This energy is used to power in-tire monitoring electronics. For pulsatile energy generation with capacitive capture, the capacitor is optimally selected in real-time as a function of pulse width to maximize energy capture, or as a function of the pulse-captured energy. The resulting energy pulses are also used to measure the time duration of the contact patch from which the contact patch length is determined thus providing real-time tire geometry and, with tire pressure, real time tire load and, with temperature, tire air molar content. The loads on all tires provide real time vehicle mass and mass distribution. For electrical energy generation, magnet-coil, piezo-electric, and other power conversions are applicable. For non-electric energy generation, fluid bellows, rotary pump, and other power conversions are applicable. Further, run flat tires are designed with a cutout to accommodate and protect electronic devices mounted on an inner surface when running flat.

Owner:WILSON KITCHENER CLARK

Flexible hydraulic muscle

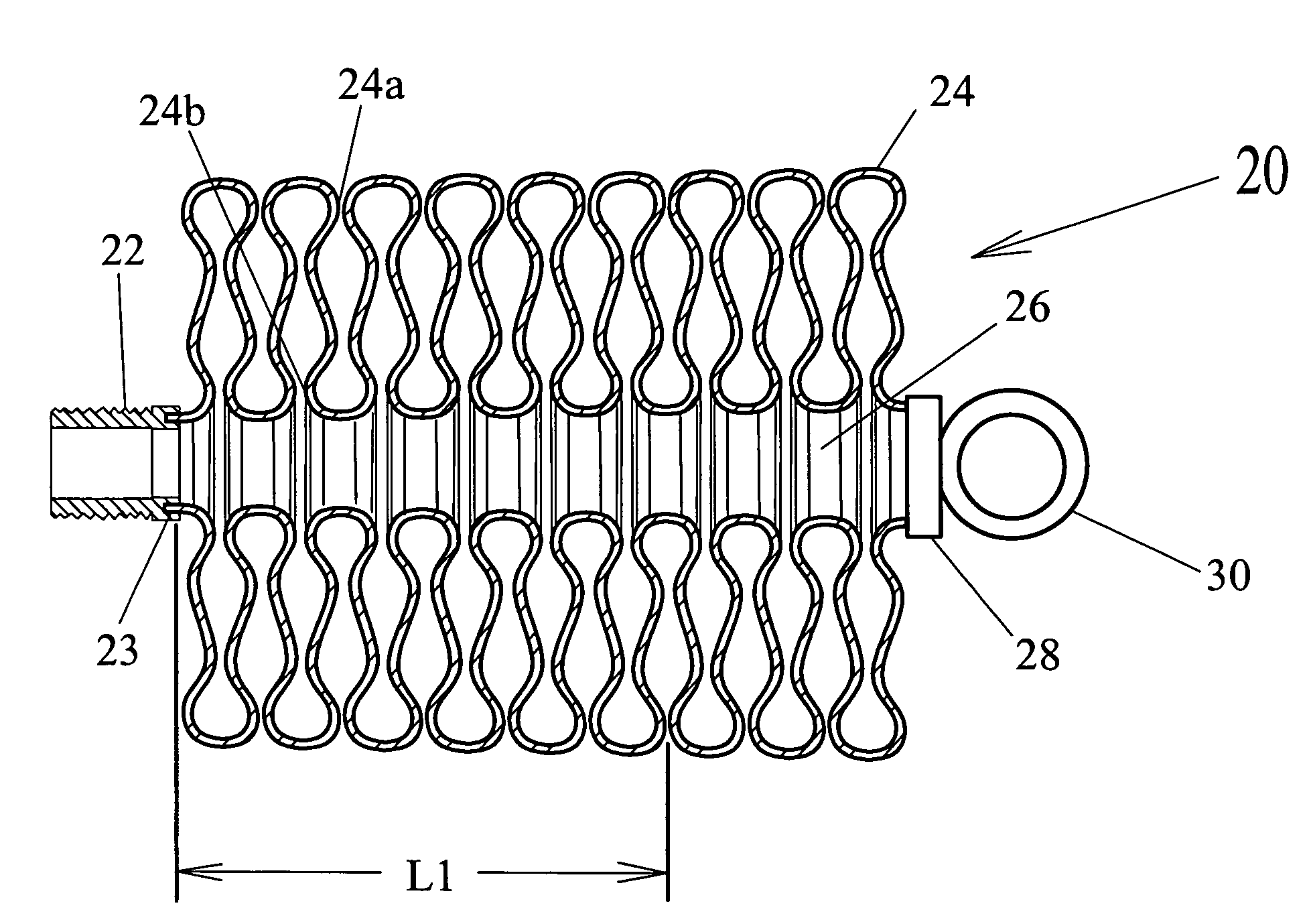

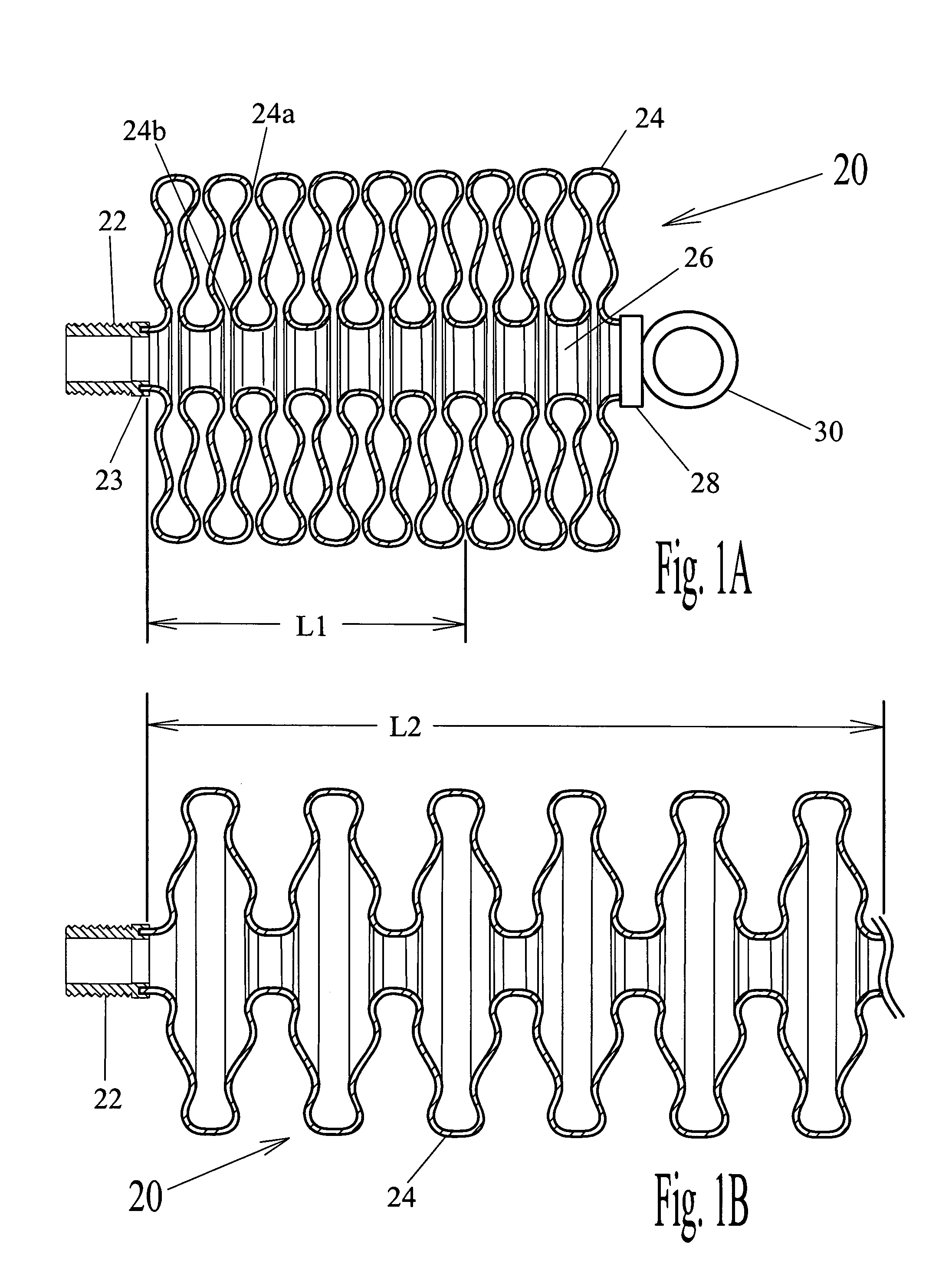

A flexible hydraulic muscle (20) comprising a fluid port (22), bellow (24), end seal (28) and attachment ring (30). Bellow (24) also defines a retracting spring bias for generating contracting forces within muscle (20). Fluid port (22) is designed to provide an anchor point for the muscle, while at the same time, providing a means to introduce and remove hydraulic fluid from bellow (24). End seal (28) and attachment ring (30) provide the second connecting point for the muscle. These two anchor points on each end of bellow (24) provide connection points to communicate contracting force from bellow (24) into useful work. End seal (28) is securely attached or bonded to the end of bellow (24) to provide a fluid tight seal, and designed to resist longitudinal forces on the connection.

Owner:RAGNER GARY DEAN

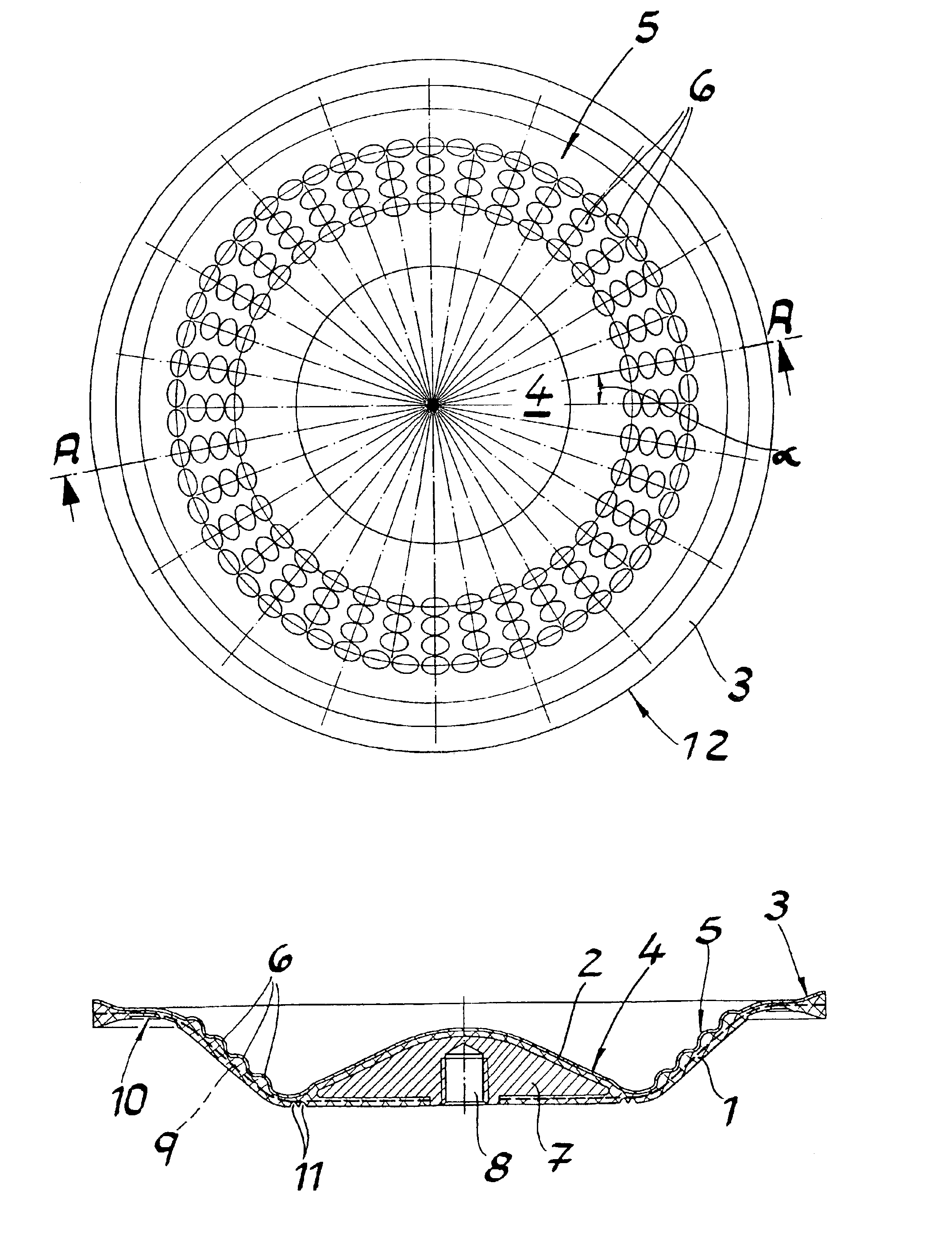

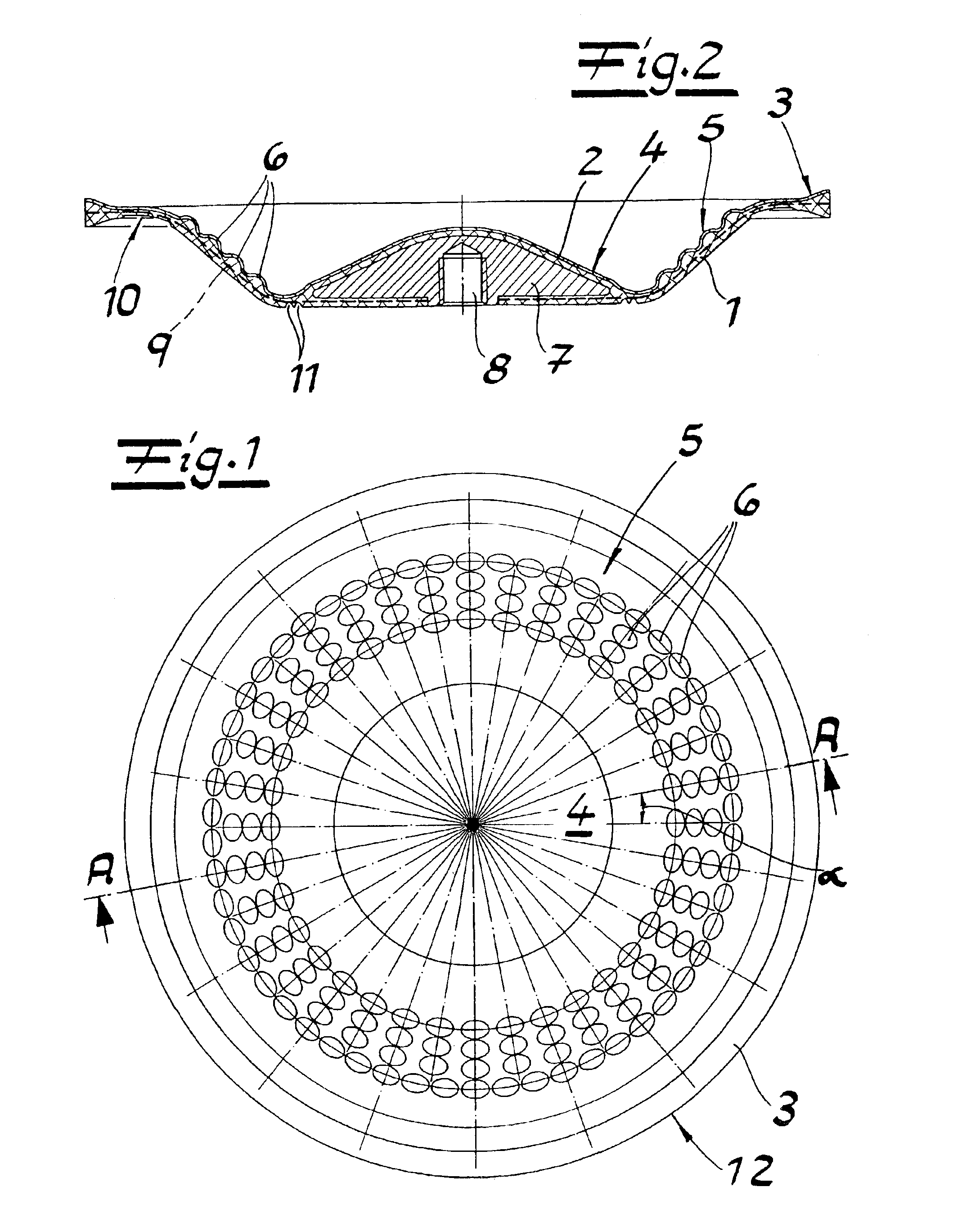

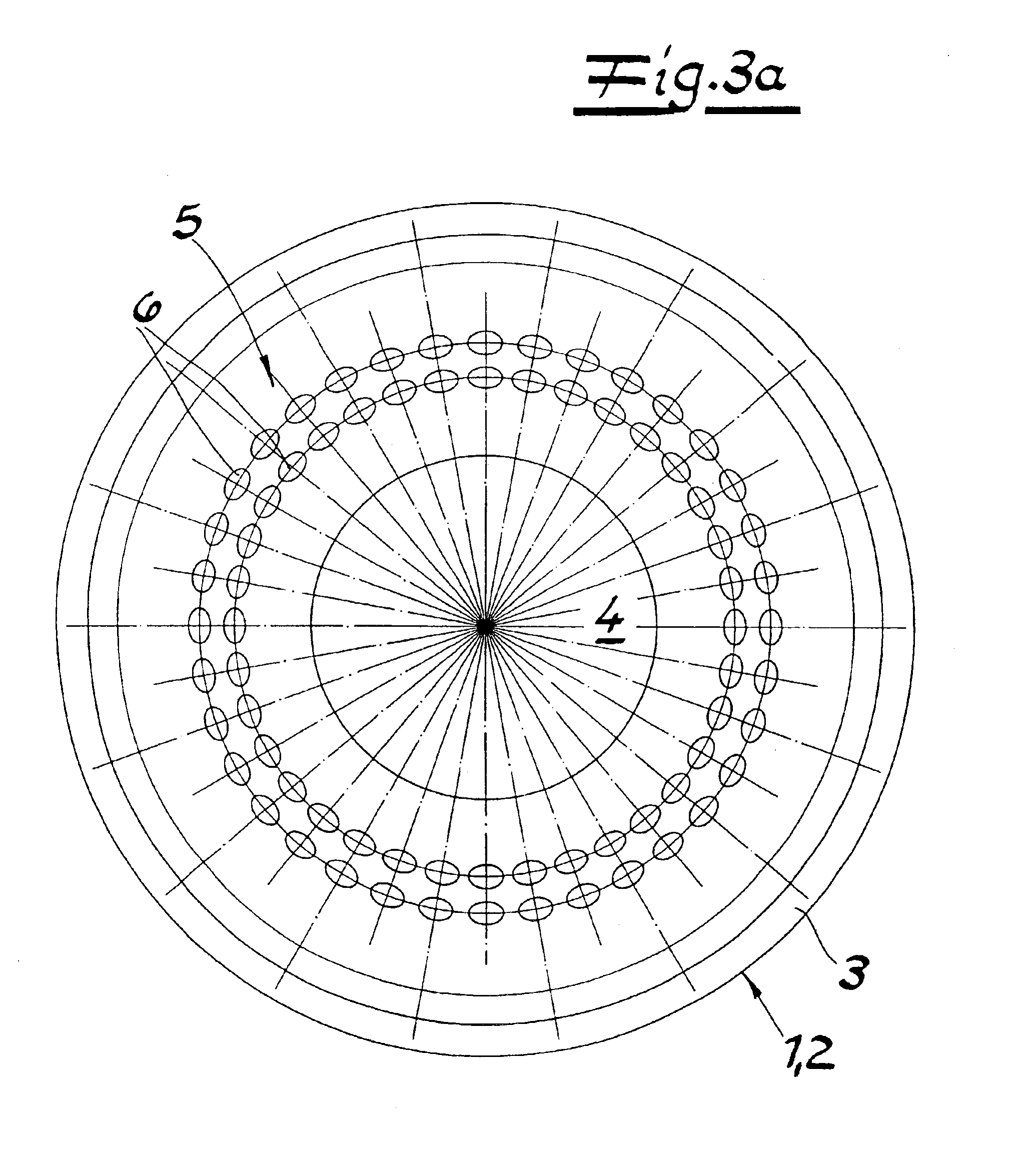

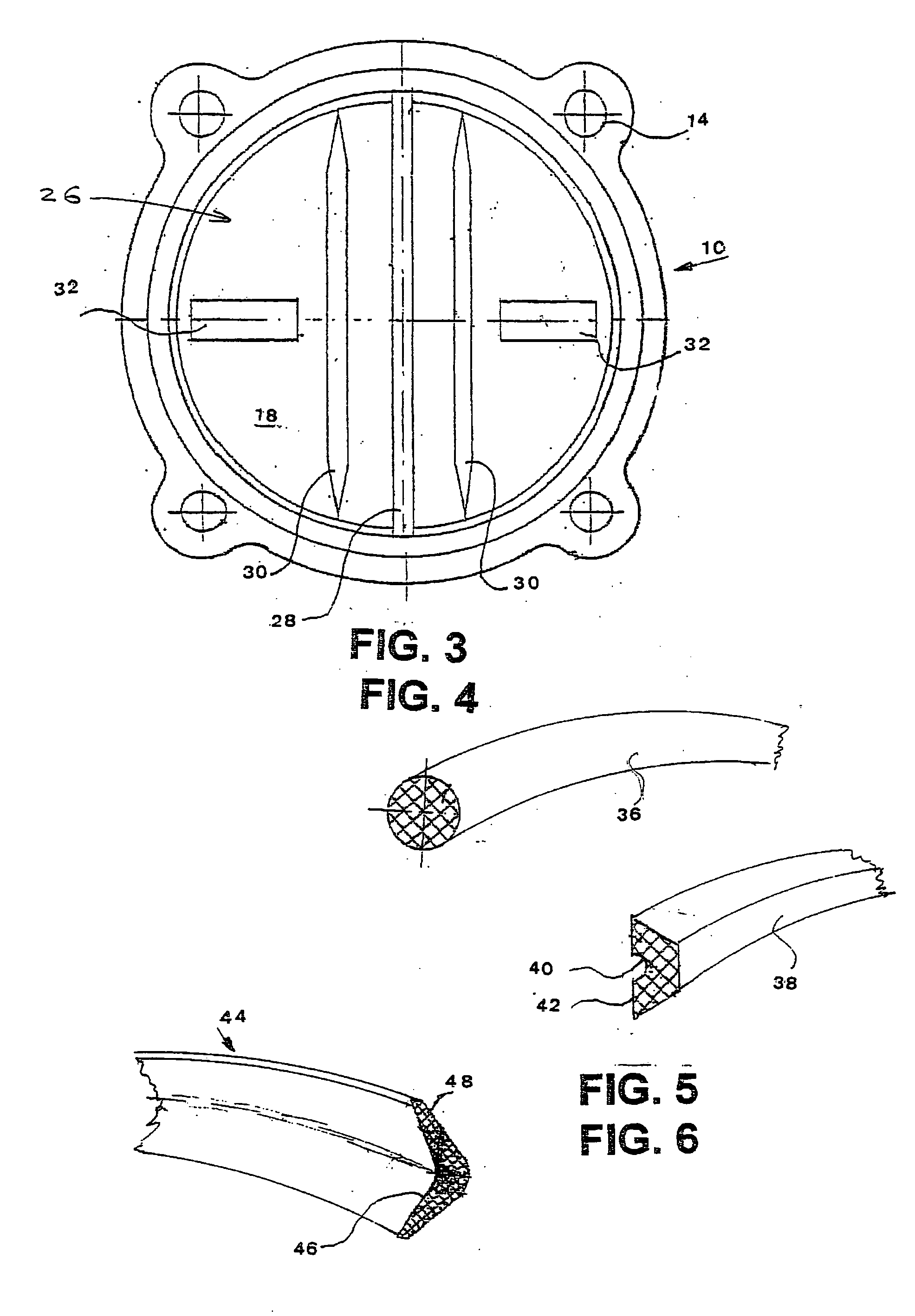

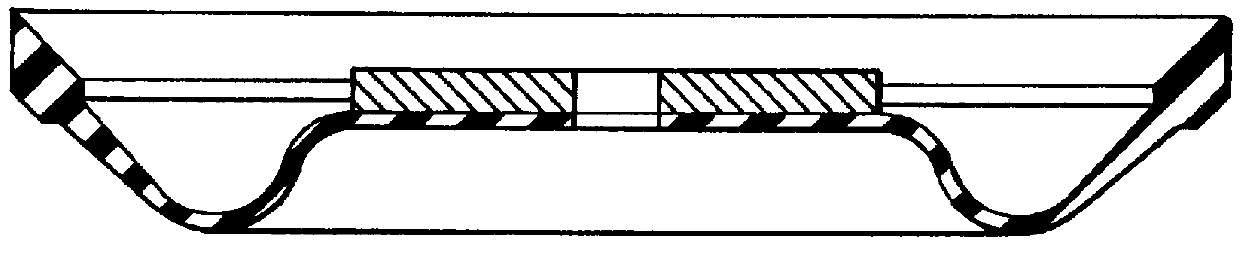

Composite diaphragm for diaphragm pumps

InactiveUS6877419B2Good roll-off propertyLong useful lifeFlexible wall reciprocating enginesEngine diaphragmsElastomerDiaphragm pump

A composite diaphragm for diaphragm pumps comprises an elastomer body and a polytetrafluoroethylene (PFTE) coating on its back side. The elastomer body has a shape of a circular dish that has an edge region with a clamping area, a bottom and a flexible section of the diaphragm that connects the edge of the dish with the bottom. The flexible section of the diaphragm comprises a multitude of naps forming elevations on the coated side of the elastomer body. The PFTE coating is a plane ring surface with the area of the flexible section of the diaphragm.

Owner:ULMAN DICHTUNGSTECHN

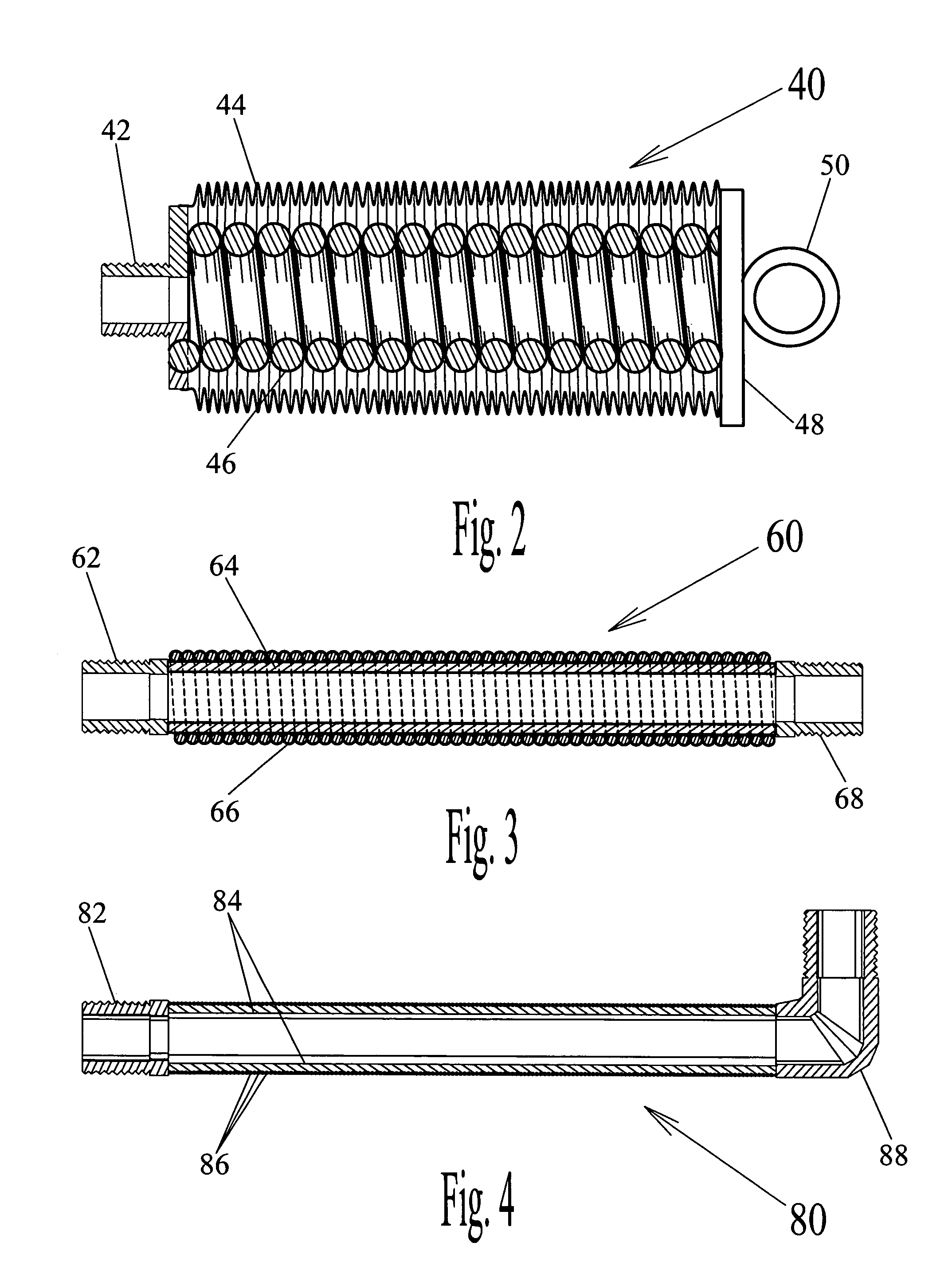

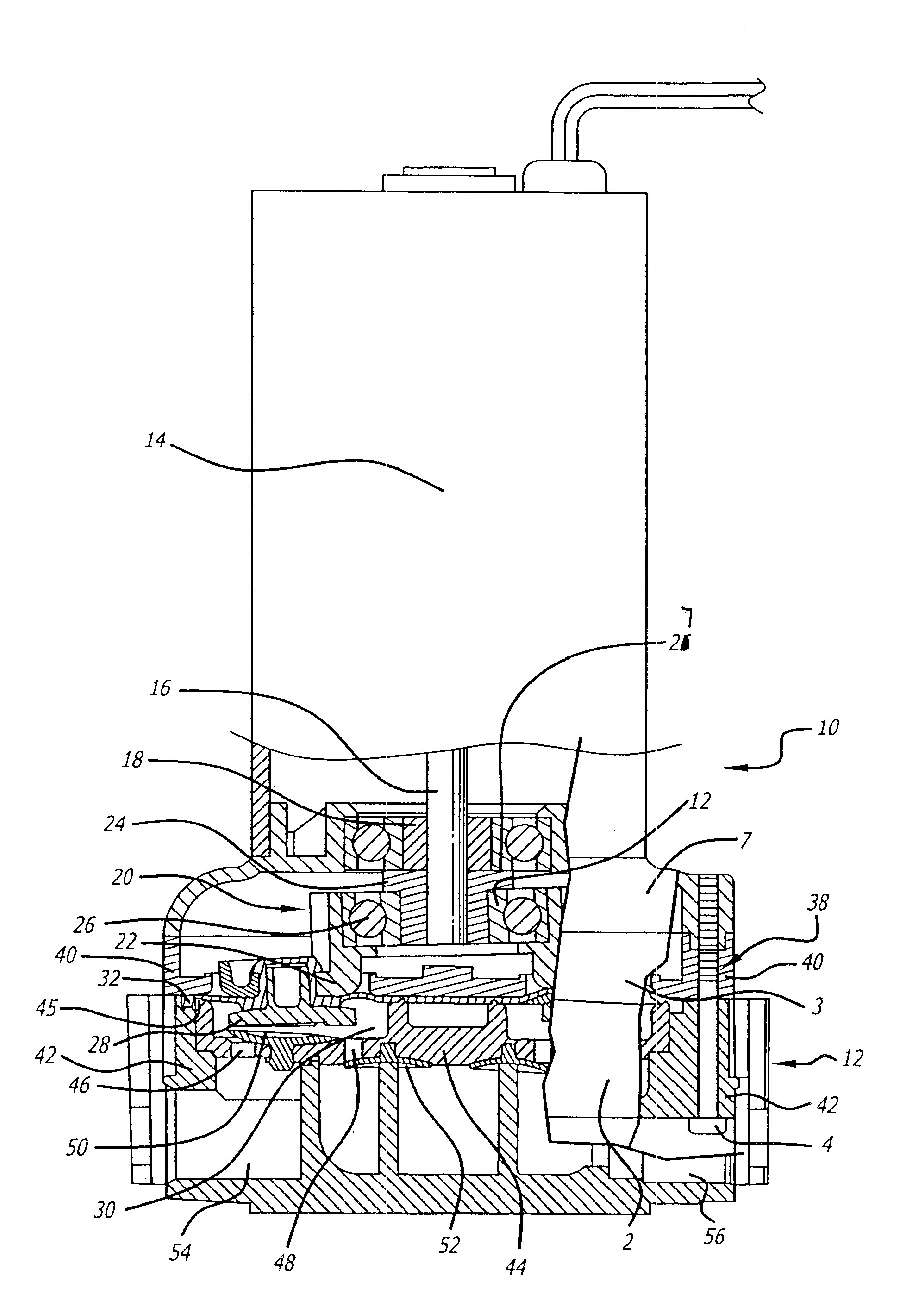

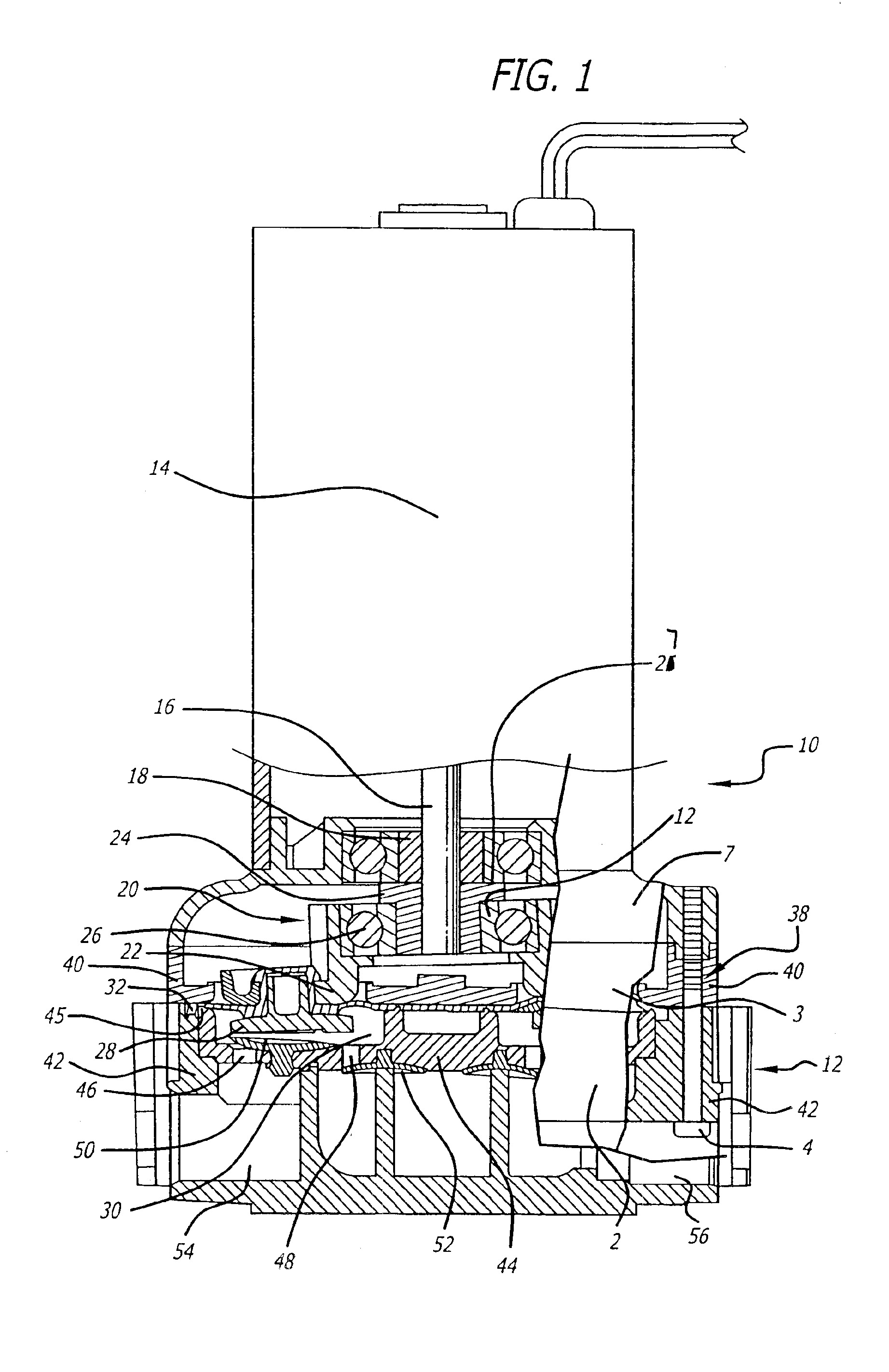

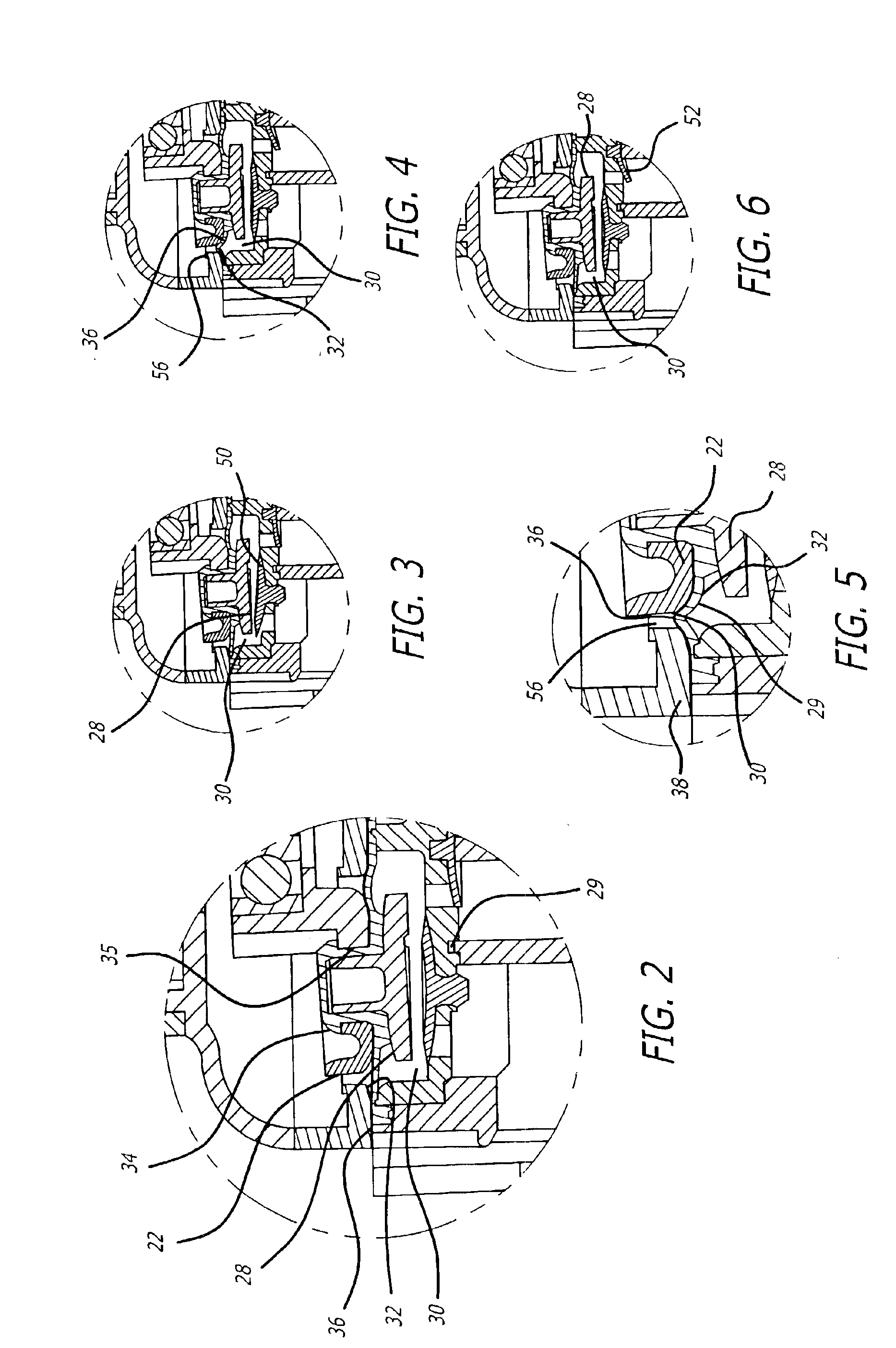

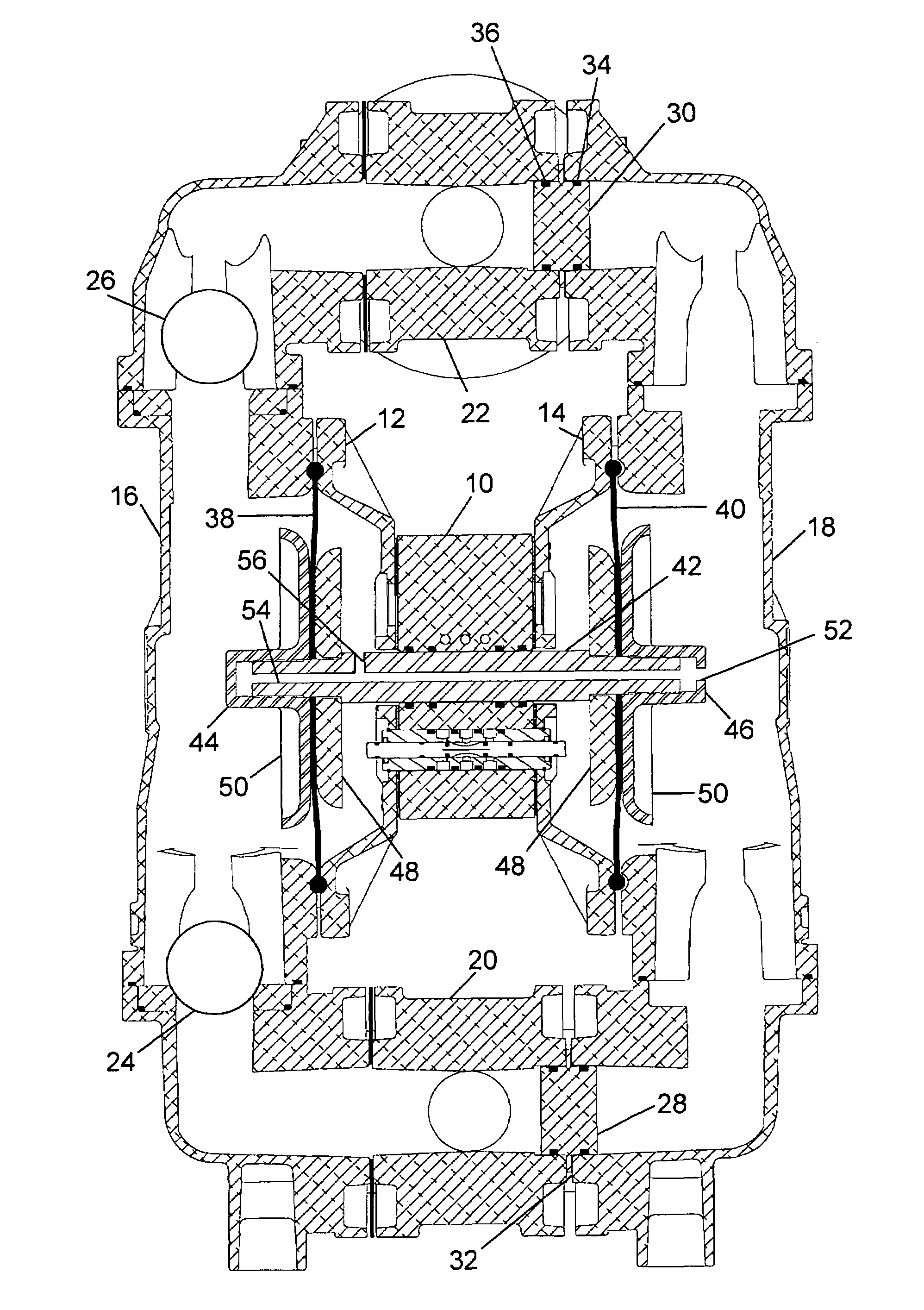

Enhanced wobble plated driven diaphragm pump

InactiveUS6892624B2Flexible wall reciprocating enginesFlexible member pumpsDiaphragm pumpThermal insulation

A pump that has a flexible liner located adjacent to a diaphragm. The liner provides structural support for the diaphragm. The flexible liner can slide relative to the diaphragm. This relative movement reduces the stiffness of the diaphragm / liner assembly. The diaphragm / liner assembly is therefore both flexible and strong. Additionally, the liner provides a thermal insulator for the diaphragm. The flexible liner may be constructed from a low friction material to lower the friction between the liner and a wobble plate of the pump. Lowering the friction reduces the heat generated within the pump. The structural reinforcement, thermal insulation and lower friction features of the liner increase the life of the diaphragm and the pump.

Owner:AQUATEC WATER SYST

Diaphragm and hydraulically-operated valve using same

InactiveUS20050205815A1Increased operating lifeClose reliableDiaphragm valvesFlexible wall reciprocating enginesElastomerFluid control

The present invention relates to fluid control valves. The invention provides an improved diaphragm useful for a large hydraulically-operated valve or pressure regulating valve of the type used in pipelines to transport water, oil, gas, acids, alkalis and other fluids. The diaphragm being provided with an upper face arranged to be exposed to a control hydraulic pressure and a lower face arranged to selectively seal and open a passage between a valve inlet and a valve outlet, ribs on said upper face urging the diaphragm towards a sealing position. The diaphragm being characterized by the addition of an elastomer ring element disposed adjacent to the upper face and adjacent to the largest diameter of the diaphragm exposed inside a valve to which it may be assembled, an upper face of the flexible ring element being in pressure contact with a portion of the rigid body of the valve. The flexible ring element further urging the diaphragm towards its lower position and allowing closure of the valve without use of a metallic compression spring.

Owner:RAPHAEL VALVES INDS 1975

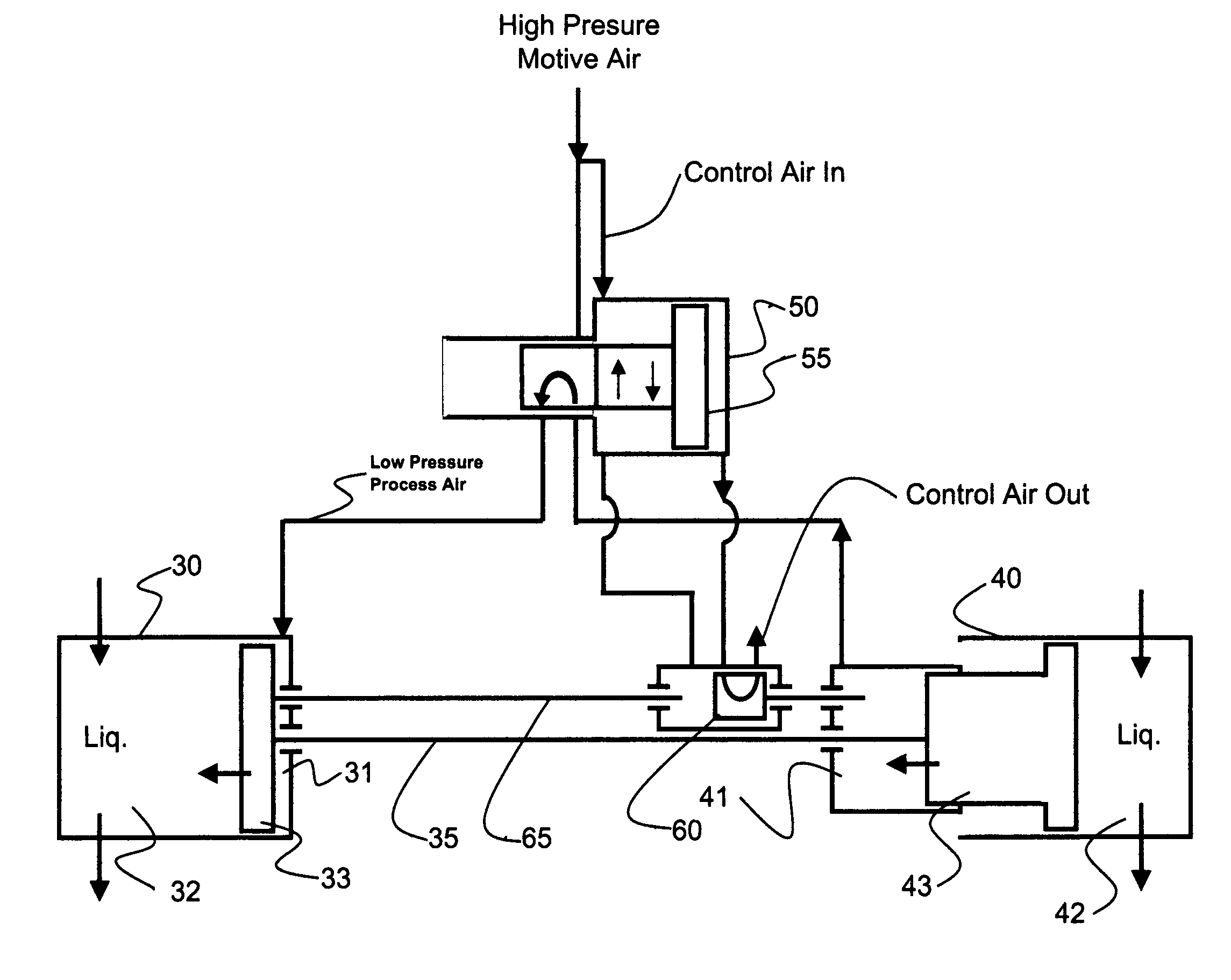

Expansible chamber pneumatic system

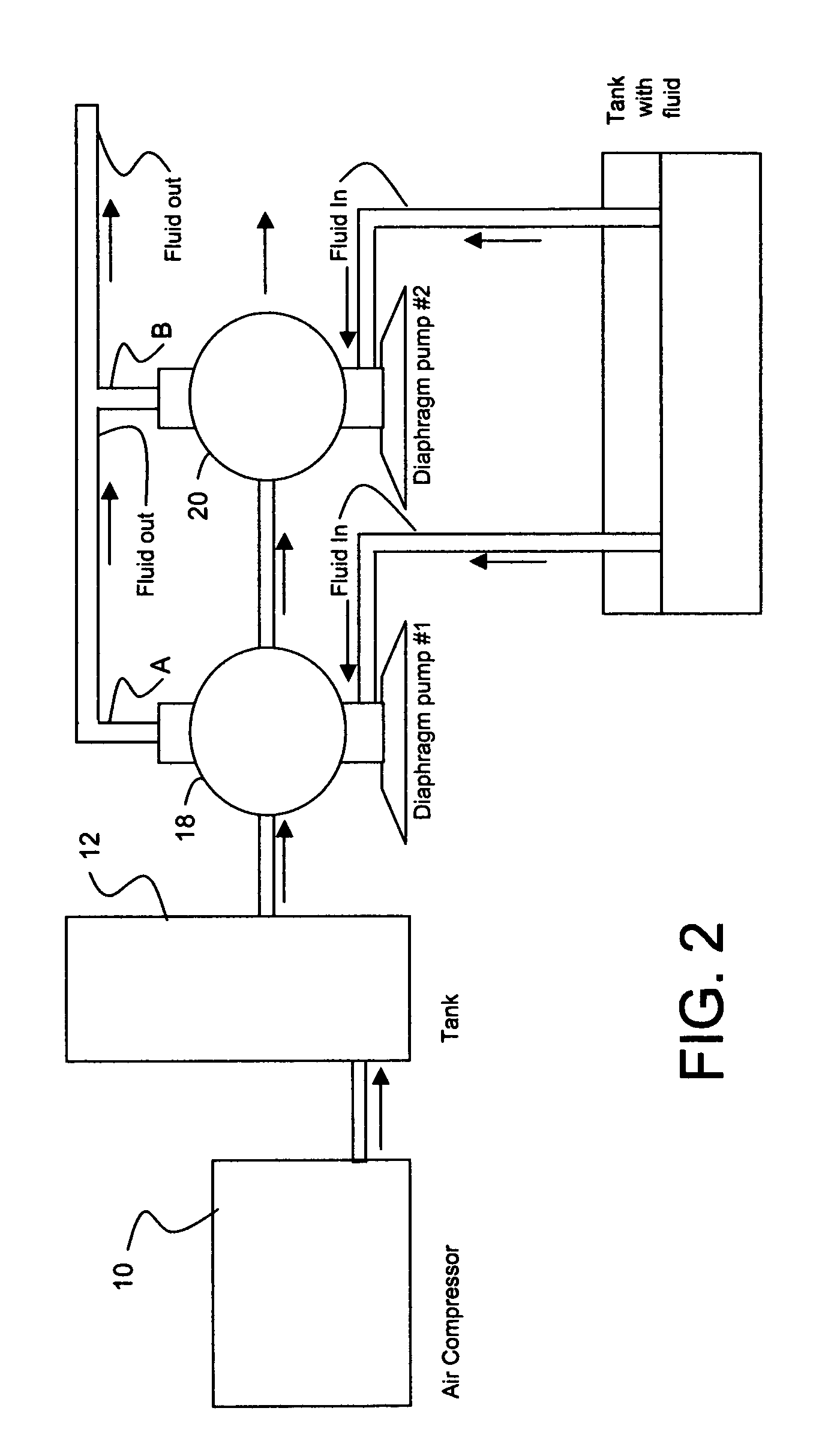

An expansible chamber pneumatic system, for example a fluid pump system, includes two or more double-acting diaphragm pumps, each with symmetrical left and right pump housings, each housing including an air chamber and a fluid chamber separated by a movable diaphragm. The diaphragms are connected for reciprocating movement in unison to pump fluid through their respective fluid chambers. Each pump includes an air valve actuated by Control air to direct Process air into one of the air chambers, simultaneously releasing used Process air from the other air chamber to thereby move the diaphragms, thereby to pump fluid. A pilot valve directs Control air to the air valve to position the air valve. The pilot valve is responsive to diaphragms reaching their travel limit in one direction to direct Control air to reverse the directions of Process air flow through the air valve to thereby reverse the movement of the pump diaphragms. Control air exhausts through the pilot valve to atmosphere. Process air exhausts through the air valve from one pump to become input or motive air for the next pump.

Owner:PSG CALIFORNIA LLC

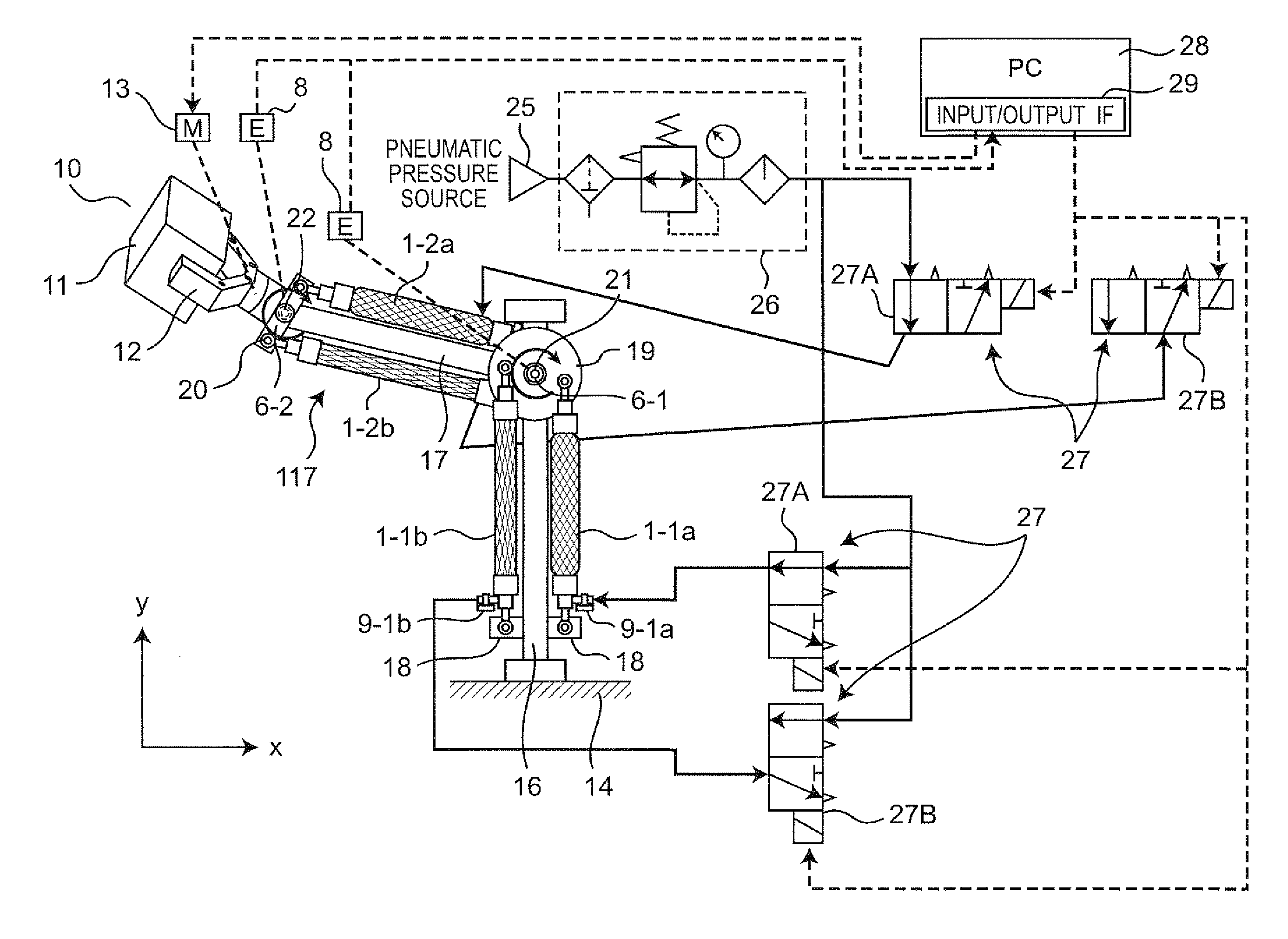

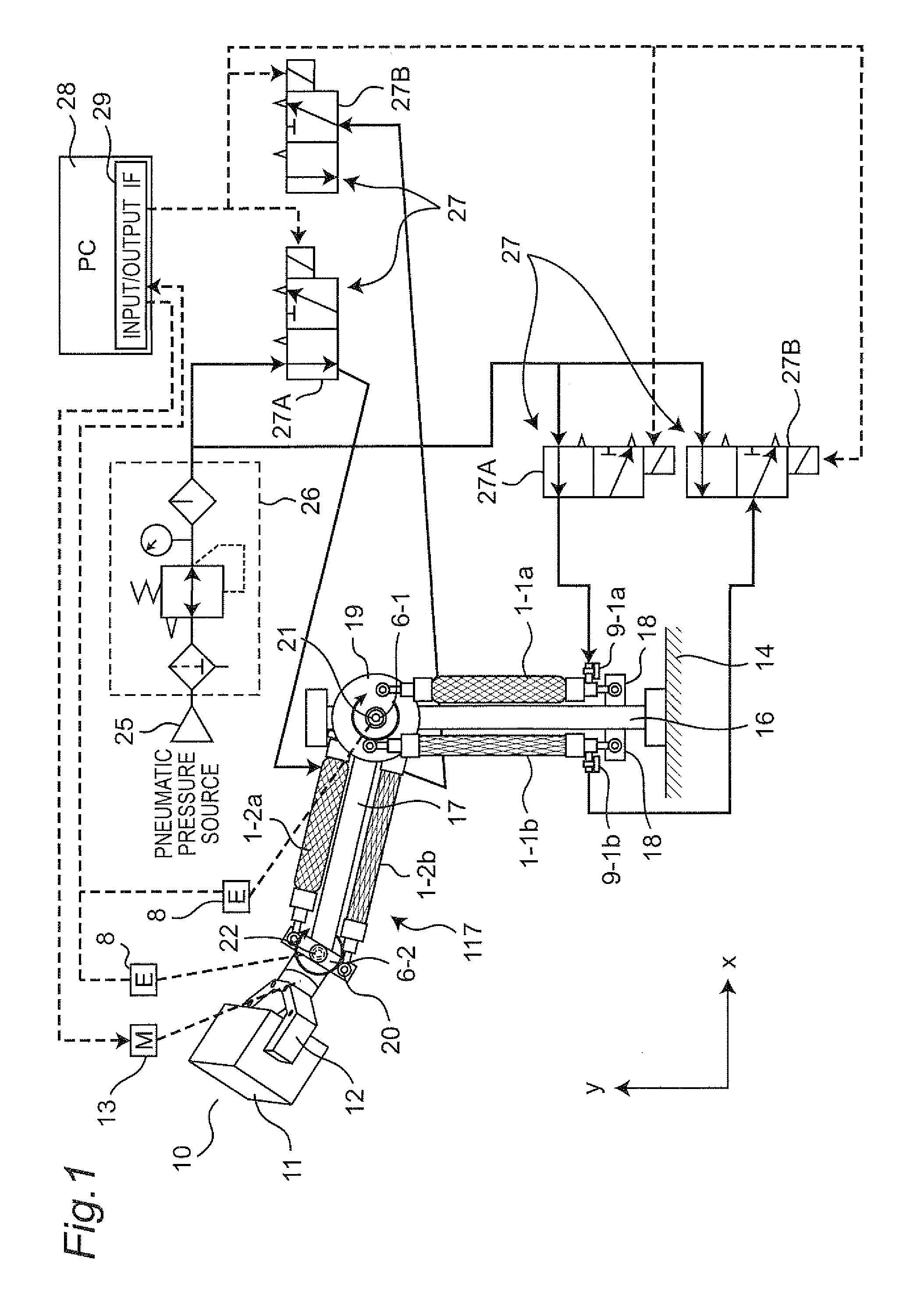

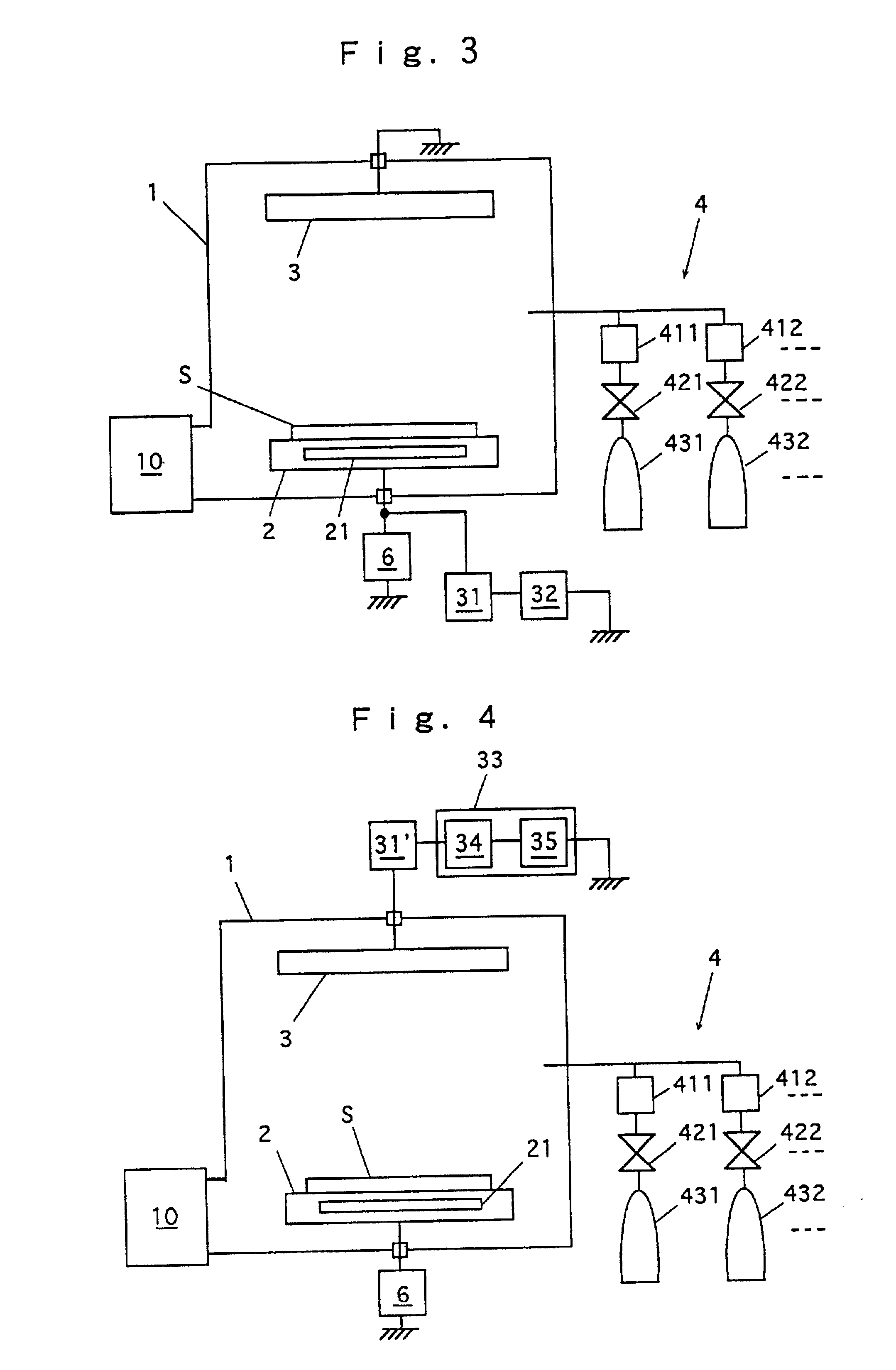

Control apparatus, control method, and control program for elastic actuator drive mechanism

ActiveUS20130000480A1Continuous operationOperableProgramme controlProgramme-controlled manipulatorState modelActuator

There is provided an abnormality determination unit that determines whether or not an output measurement unit is abnormal, in order to determine abnormality of the output measurement unit. When the output measurement unit is abnormal, the operation of an elastic actuator is controlled not in accordance with a measurement result of the output measurement unit but in accordance with an internal state model.

Owner:PANASONIC CORP

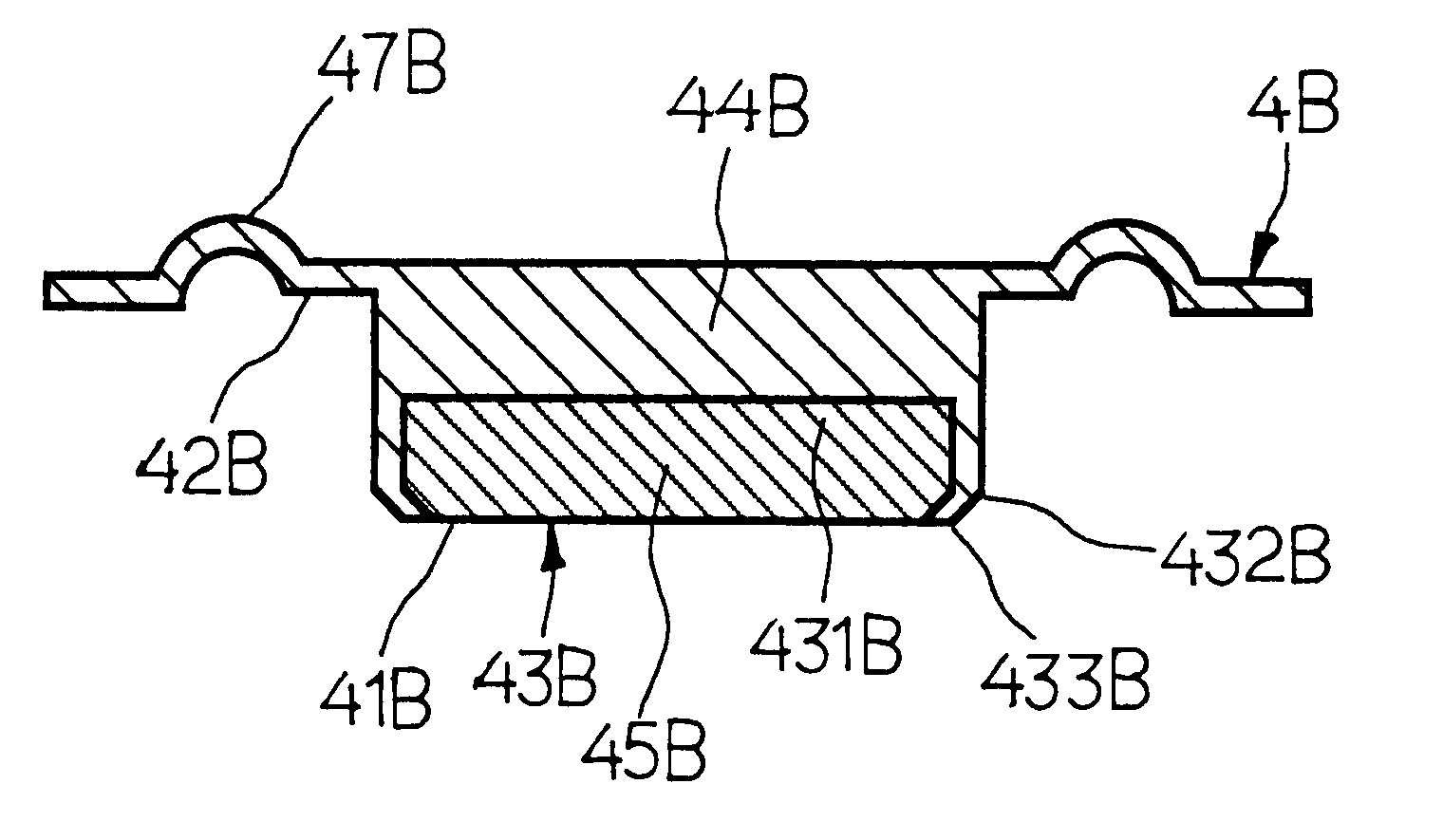

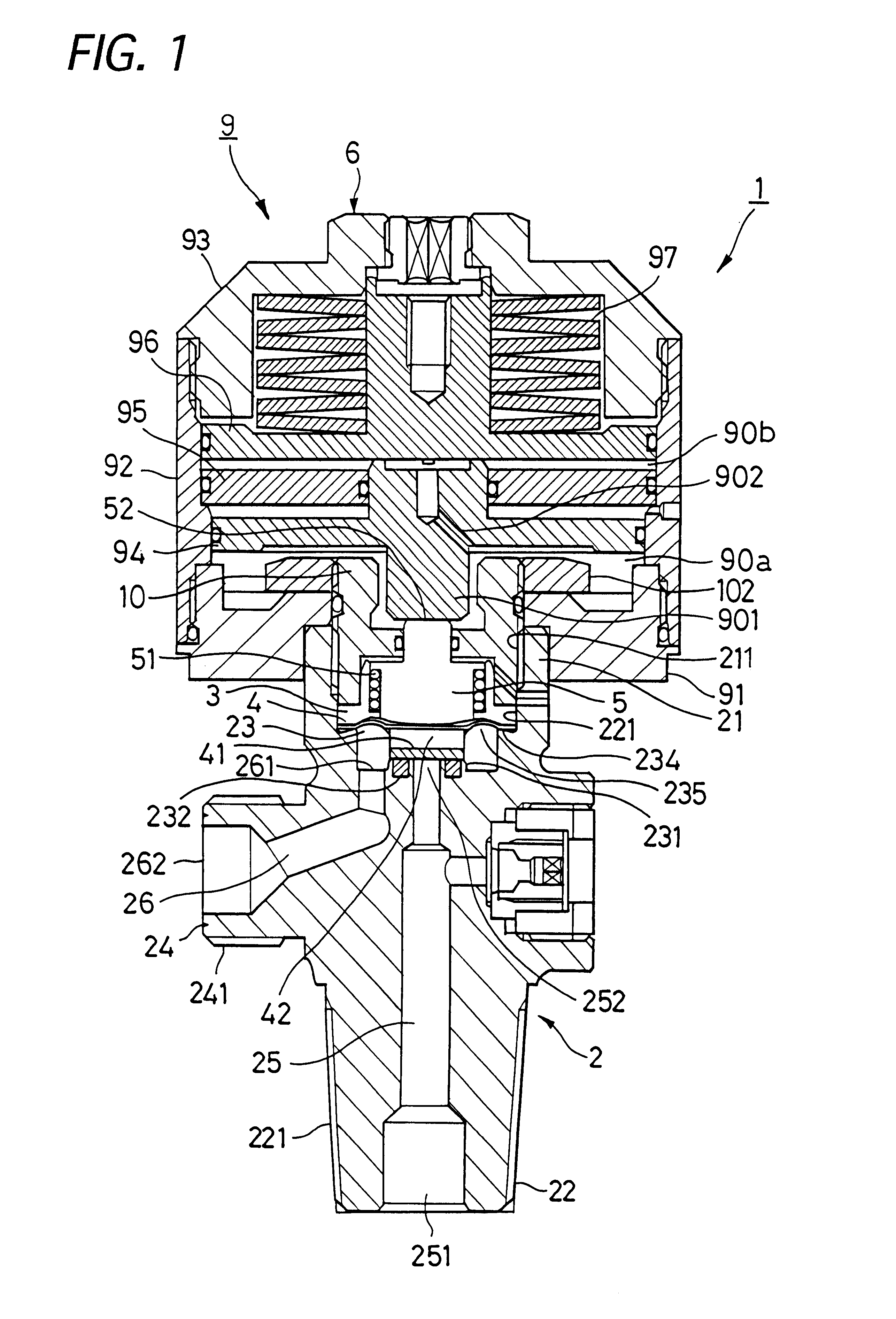

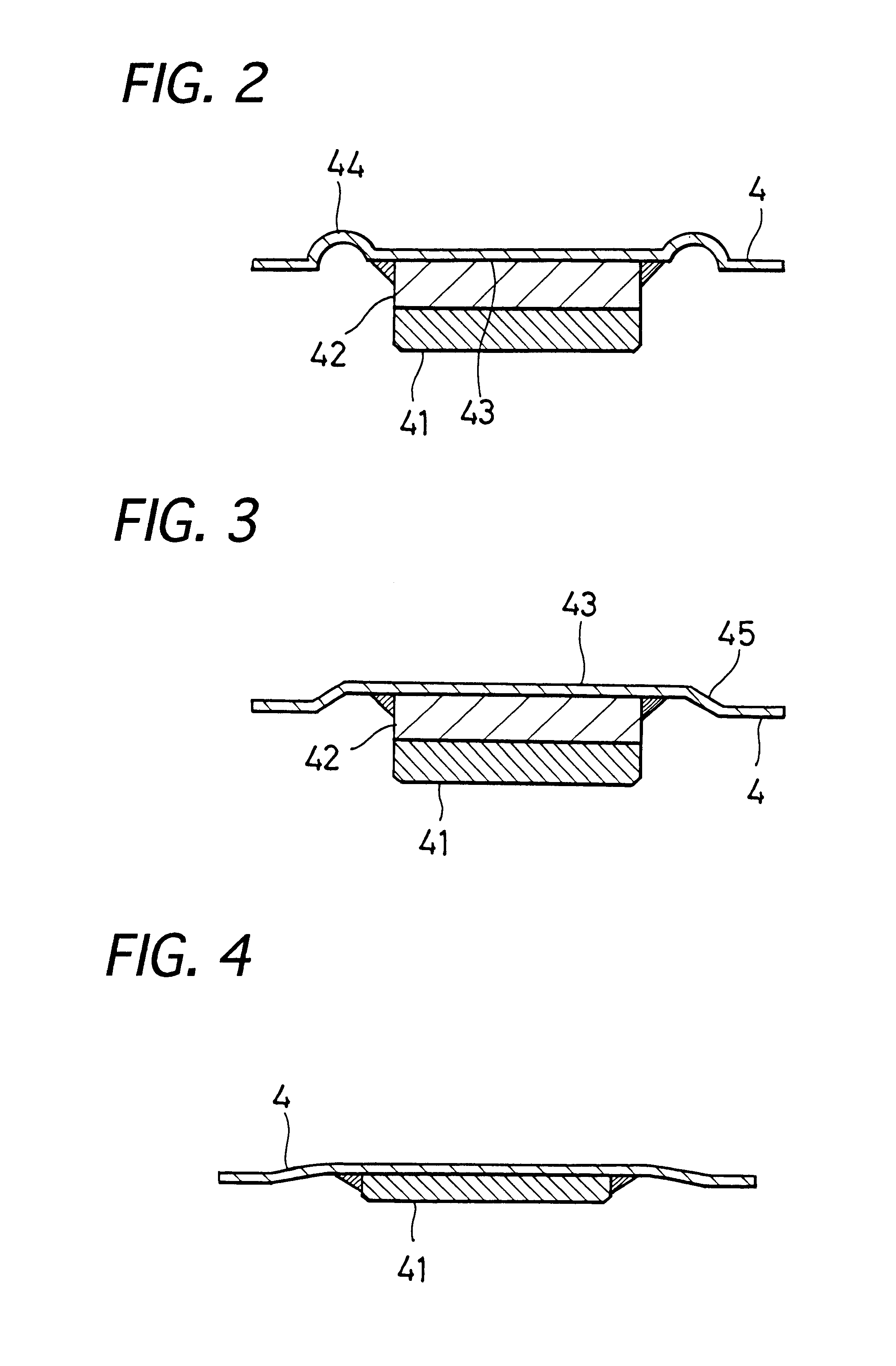

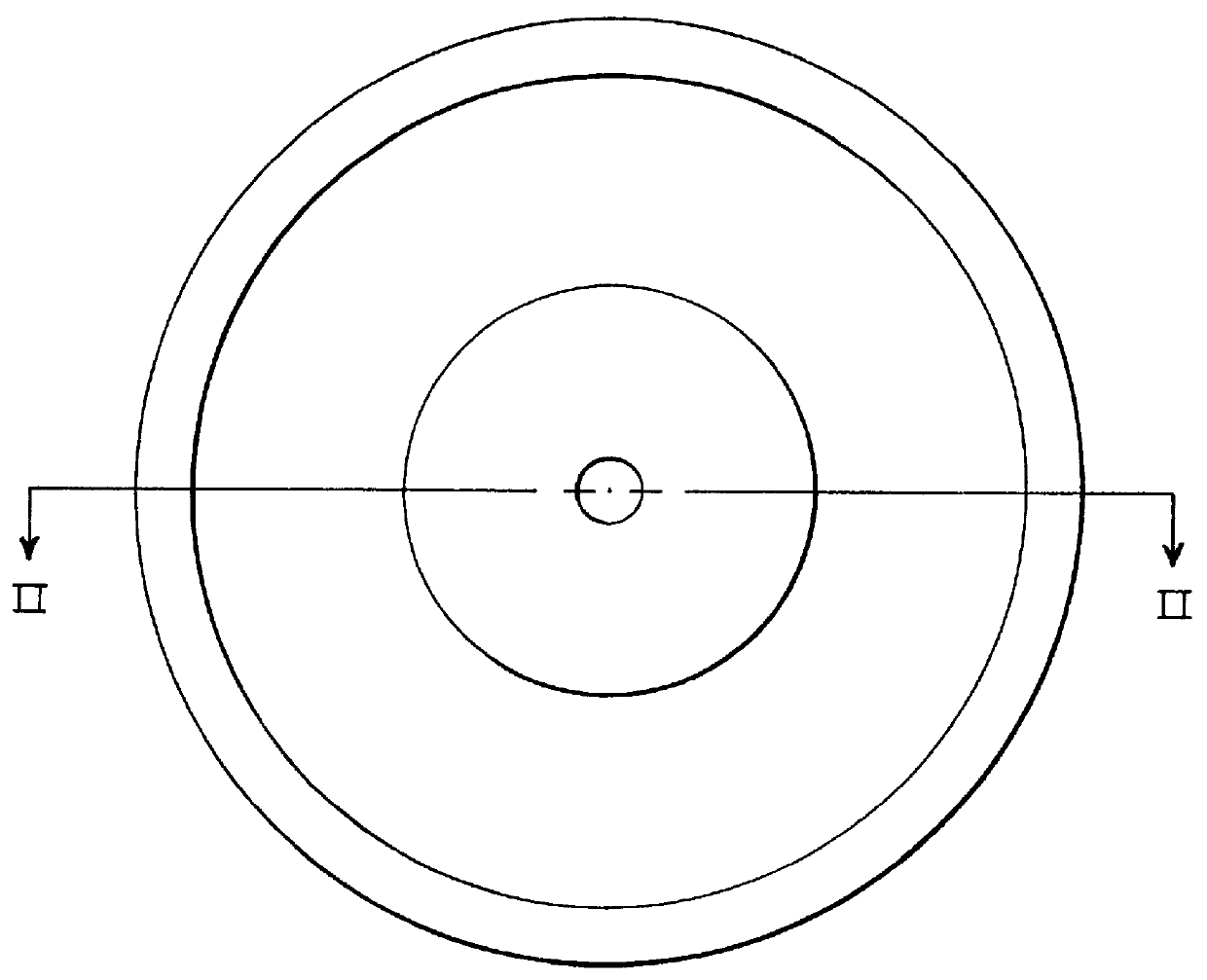

Control valve and diaphragm for use in the control valve

The control valve according to the present invention has a high durability, so that the valve is not easily damaged even in case that the valve is provided in a corrosion gas current path. The valve has a construction such that a diaphragm (4) is contained in the valve body (2), which has a valve chamber (23) between the gas current in path (25) and the gas current out path (26). The diaphragm 4 is urged against an opening (252) formed in the center of the valve seat 231 in the valve chamber (23) to open and close the opening. The valve has a valve control member (5), which has a clamping member (3) to clamp the diaphragm and is made to contact to the diaphragm from outside to open and close the opening. The diaphragm has an urging member (41) made of ceramic, which is fixed to the opening (252) side of the diaphragm so that the resistance to corrosion of the diaphragm is improved.

Owner:HAMAI INDS

Diaphragm with modified insert

InactiveUS6142062AEasy to useReduce pointsFlexible wall reciprocating enginesEngine diaphragmsElastomerEngineering

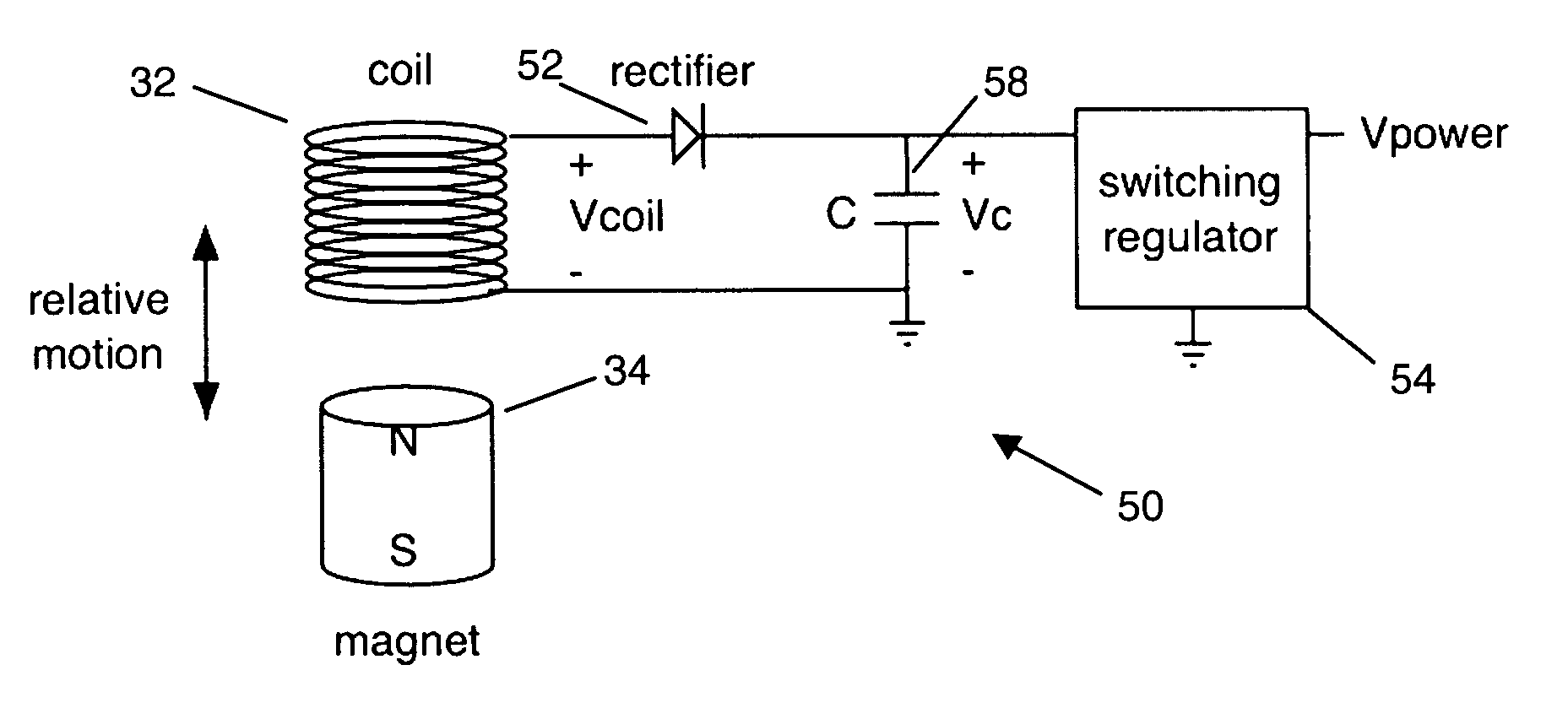

The present invention provides a diaphragm member for use in certain valve assemblies. Such diaphragm member comprises a generally circular diaphragm having a first predetermined diameter and having a first surface and a second surface. Such generally circular diaphragm is formed from at least one layer of a preselected elastomeric material. Such generally circular diaphragm includes a nonflexing center portion, a generally annular flexure portion extending around an outer periphery of such nonflexing center portion and a non flexing outer portion extending around an outer periphery of such generally annular flexure portion, such non flexing outer portion is engageable with a body portion of such valve assembly. Such diaphragm member further includes a generally circular insert member, having a second predetermined diameter, disposed within the first surface of such nonflexing center portion of such generally circular diaphragm. Such generally circular insert member has a plurality of apertures formed through such generally circular insert member, such plurality of apertures provide a predetermined open area for receiving a predetermined rubber compound for bonding such generally circular insert member to such nonflexing center portion of such generally circular diaphragm.

Owner:WESTINGHOUSE AIR BRAKE CO

Object coated with carbon film and method of manufacturing the same

InactiveUS6893720B1Improve wear resistanceEasy to slideFlexible wall reciprocating enginesLayered productsCarbon filmMachine parts

An object such as an automobile part, an image forming apparatus part, a bicycle part, other machine parts, a sport article or its part, a toy or its part, or a rain article or its part has a portion to be in contact with a contact object. The contact portion is made of at least one kind of material selected from a group including polymer material such as resin or rubber as well as glass, and the contact portion has a surface entirely or partially coated with a carbon film (typically, a DLC film) having a wear resistance as well as at least one of a lubricity, a water repellency and a gas barrier property. The carbon film is formed on the object with a good adhesion.

Owner:NISSIN ELECTRIC CO LTD

Abrasion resistant plastic bonded to a diaphragm

InactiveUS6080685AWithout substantially affecting such diaphragm's flexibilityFlexible wall reciprocating enginesEngine diaphragmsEngineeringReinforced rubber

An improved diaphragm substantially resistant to abrasive wear for use in certain applications in which at least a portion of such diaphragm is in contact with another surface which would tend to abrade such diaphragm, such diaphragm comprising at least one layer of a flexible material selected from a group including natural rubber, synthetic rubber, fabric reinforced rubber, plastic and mixtures thereof and an abrasion resistant polymeric material having a predetermined thickness. This abrasion resistant polymeric material is adhered to such diaphragm at least in the portion that such diaphragm is in contact with another surface and is subject to abrasion. This type of abrasion generally occurs in the flange area of the diaphragm.

Owner:WESTINGHOUSE AIR BRAKE CO

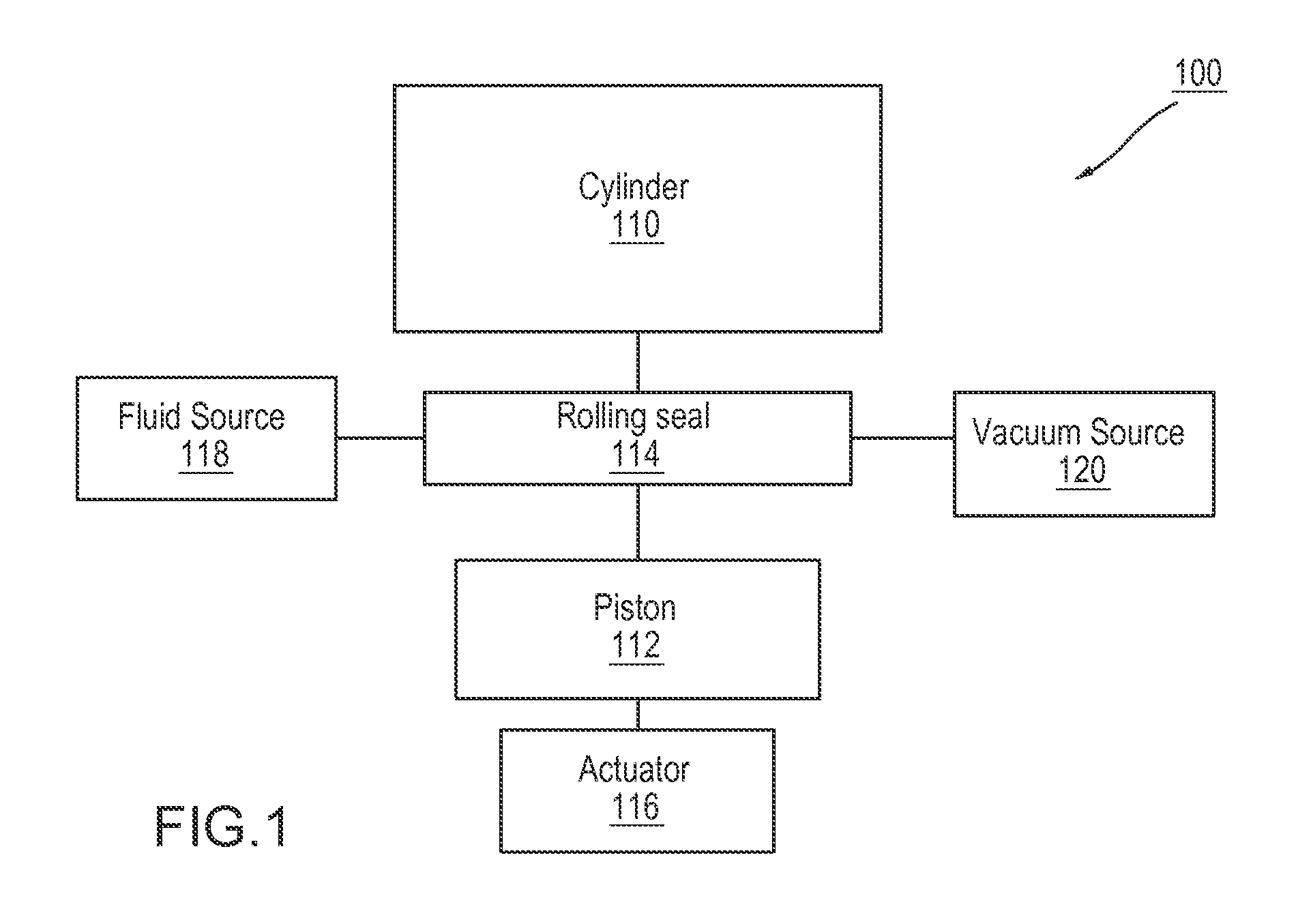

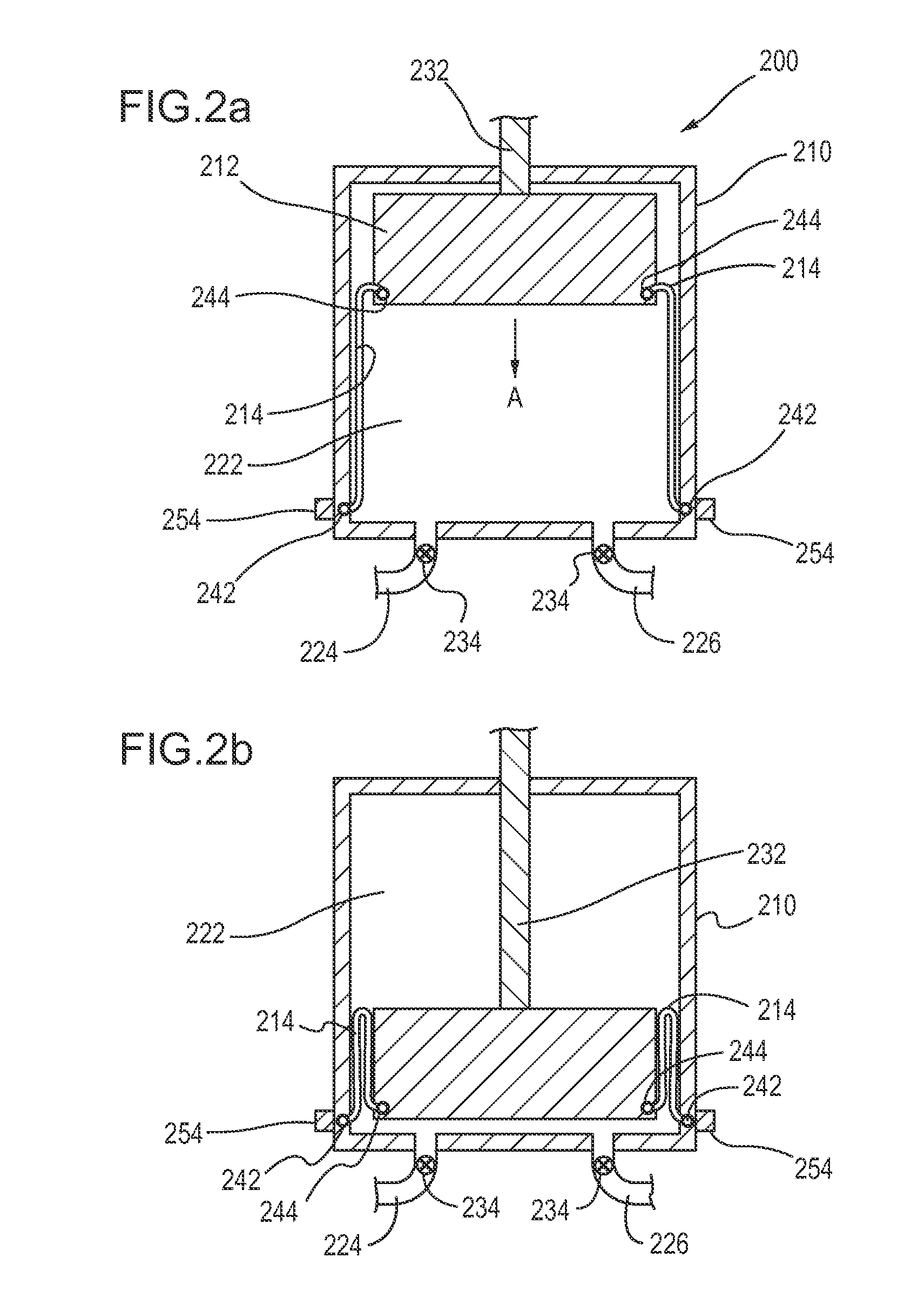

Compressor and/or expander device with rolling piston seal

An apparatus can include a piston movably disposed within a pressure vessel and defines a first interior region and a second interior region. The piston has a first position in which the first interior contains a gas having a first pressure and has a volume greater than the second interior region, and a second position in which the second interior region contains a gas having a second pressure and has a volume greater than the first interior region. A seal member is attached to the piston and to the pressure vessel. The seal member has a first configuration in which at least a portion of the seal member is disposed at a first position when the piston is in its first position, and a second configuration in which the portion of the seal member is disposed at a second position when the piston is in its second position.

Owner:GENERAL COMPRESSION

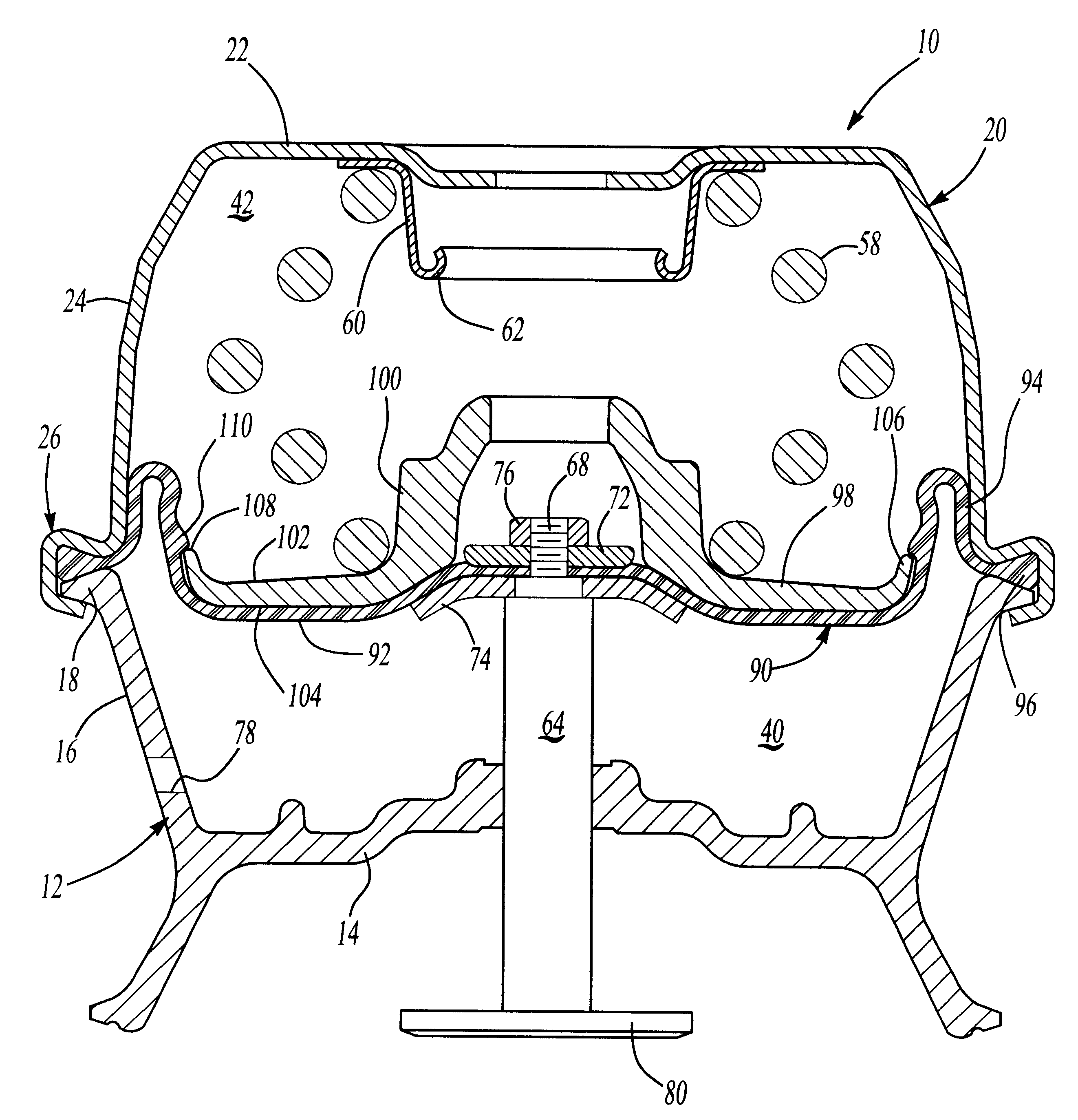

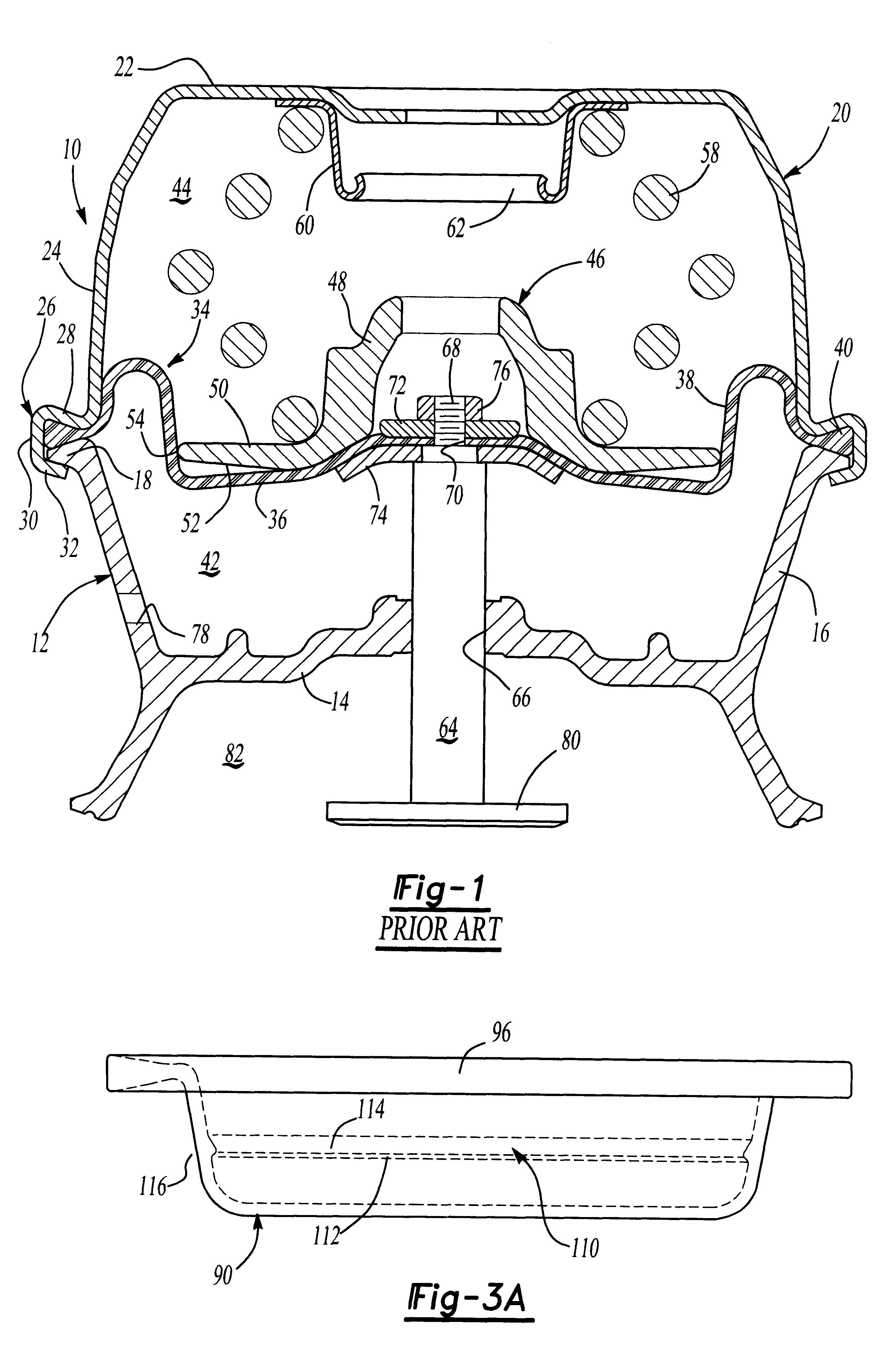

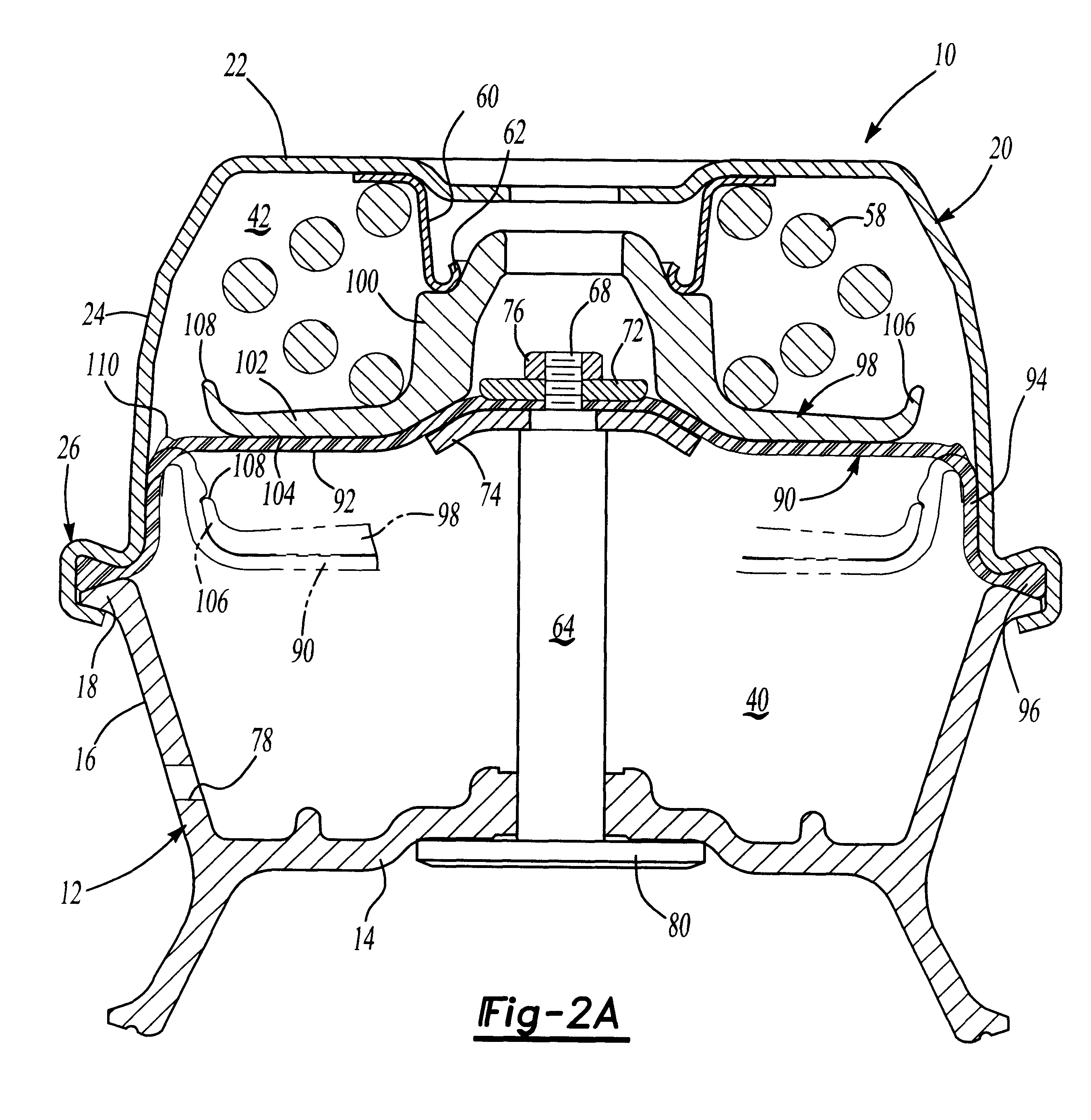

Brake actuator

An improved diaphragm-type pneumatic brake actuator wherein the diaphragm is releasably secured to the piston as the diaphragm is inverted during actuation of the braking system of a vehicle thereby reducing wear of the flexible diaphragm and improving the performance of the brake actuator. In the disclosed embodiment, a rib or lip is formed on the surface of the diaphragm which receives the periphery of the piston as the diaphragm is inverted forming a mechanical interlock between the diaphragm and the piston thereby preventing spacing of the contact surface of the piston and the central portion of the diaphragm and frictional wear between the peripheral edge of the piston and the diaphragm. In the preferred embodiment, the piston includes an arcuate rim which extends away from the central portion of the diaphragm when the diaphragm is located in its extended cup-shaped position prior to actuation of the vehicle braking system and the diaphragm then conforms to the arcuate rim as the diaphragm is inverted and the diaphragm rib snaps over the piston rim as the diaphragm is inverted to actuate the vehicle braking system. The diaphragm rib may be molded on the surface of the diaphragm when the diaphragm is molded without any substantial increase in cost.

Owner:INDIAN HEAD INDUSTRIES INC

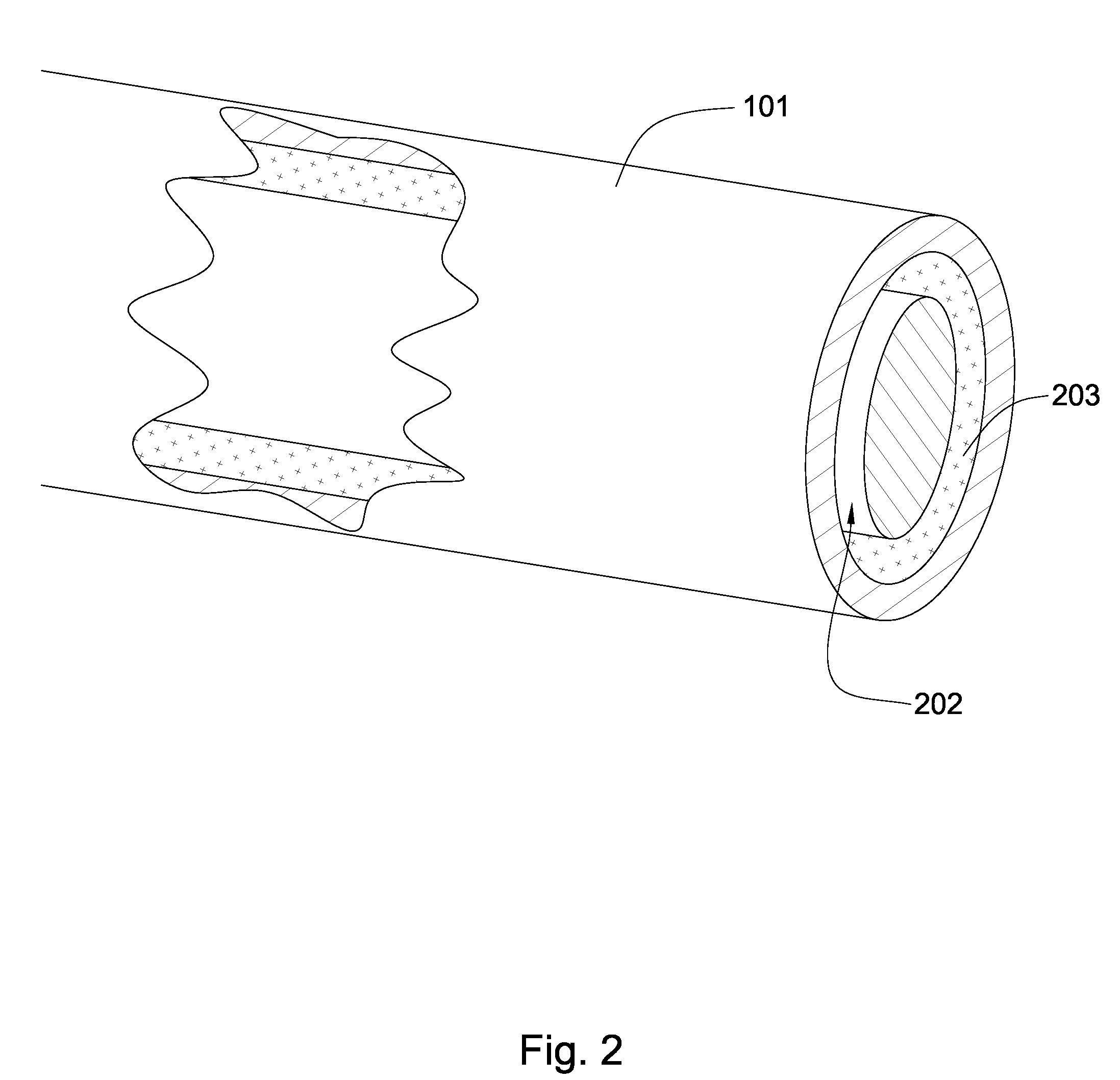

Hydraulic Energy Storage with an Internal Element

InactiveUS20090008173A1Bulk modulusRelative density is smallAuxillary drivesFlexible wall reciprocating enginesHydraulic circuitEngineering

In one aspect of the present invention, a system for performing work having a hydraulic circuit comprising a length of hose a hydraulic fluid in the circuit in communication with the hose, a hydraulic actuator for doing the work, at least one compressible element disposed within the hose, and a mechanism for pressurizing the hydraulic circuit such that at least 50 foot pounds of energy is stored within the hose to perform the work.

Owner:HALL DAVID R MR

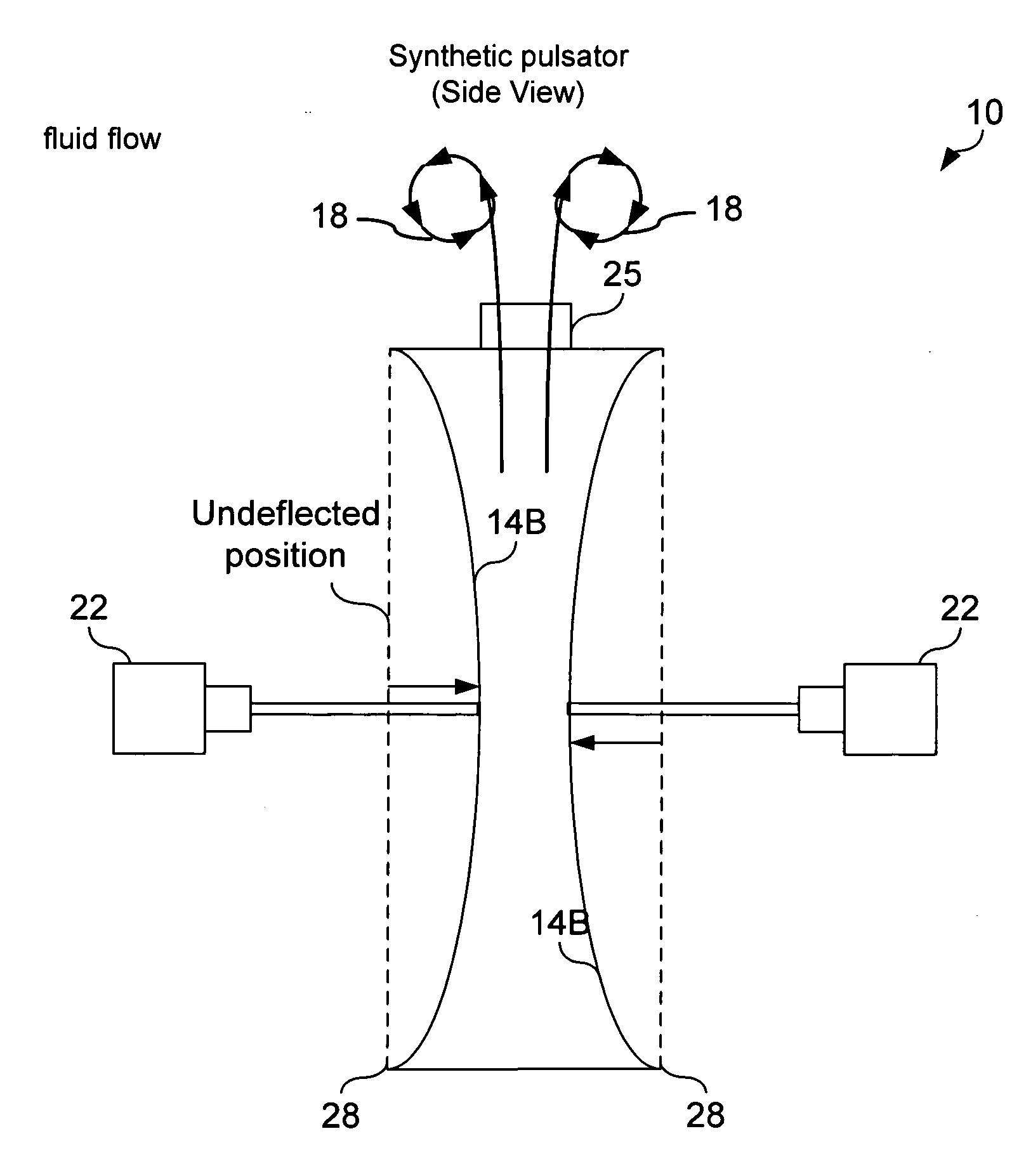

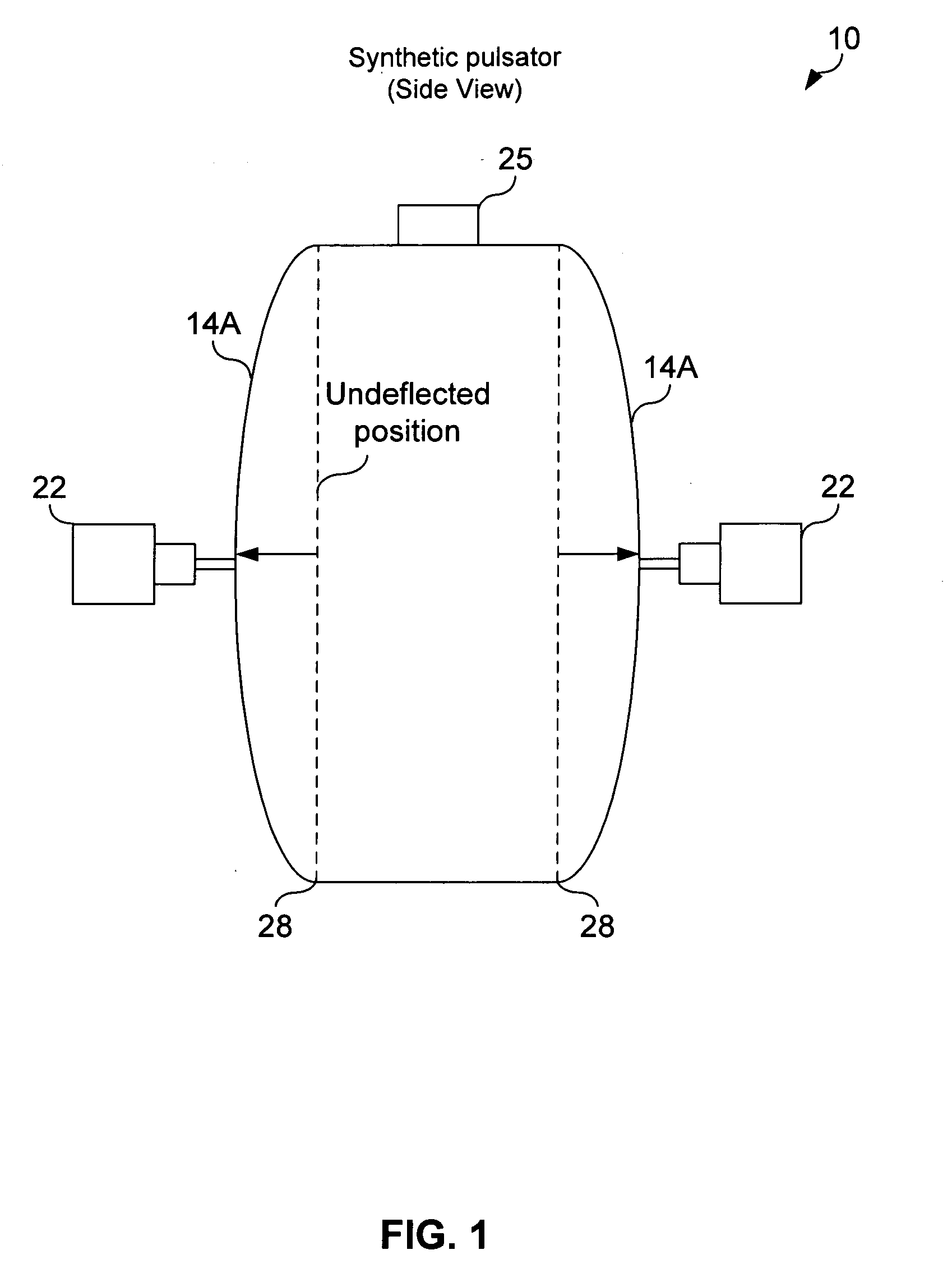

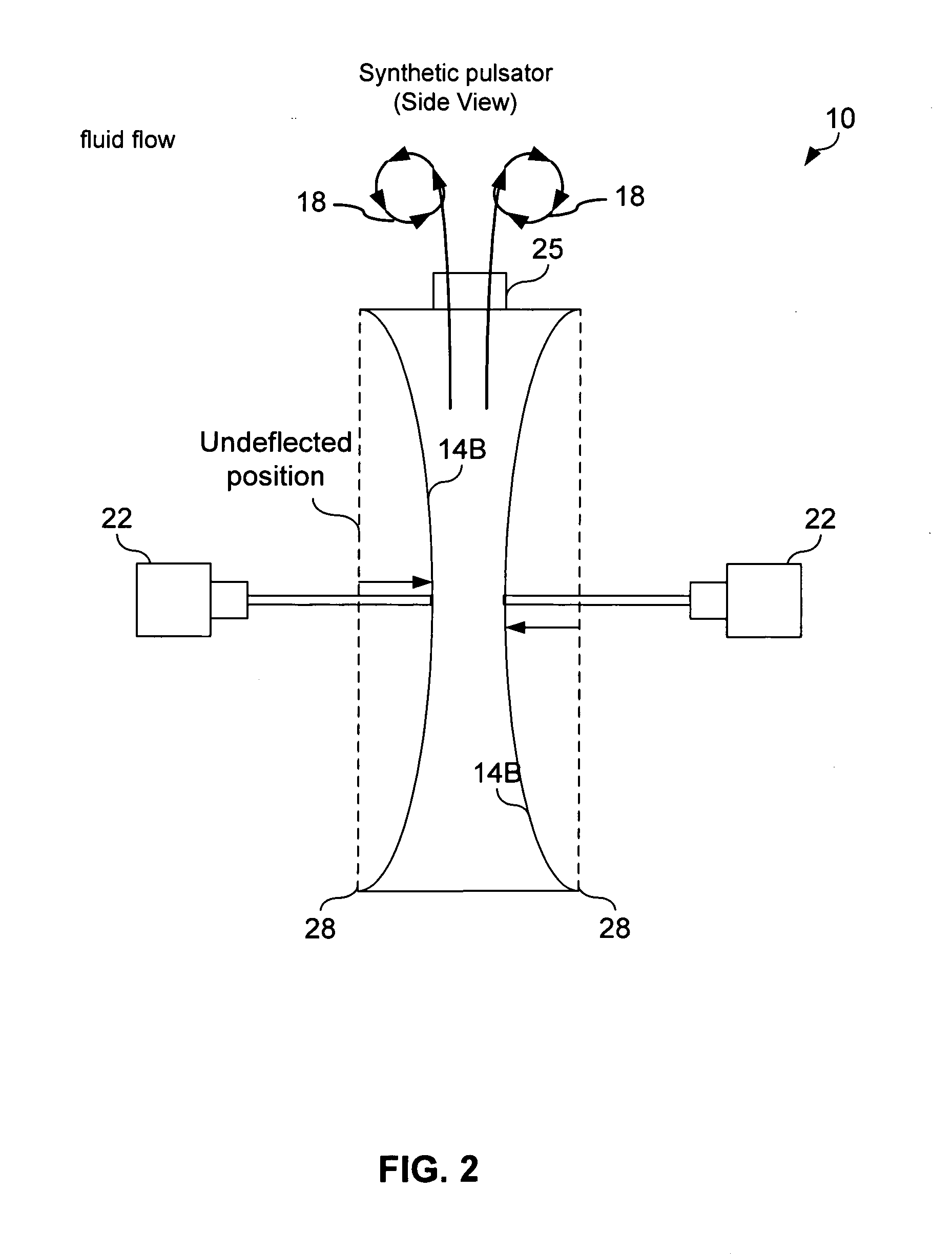

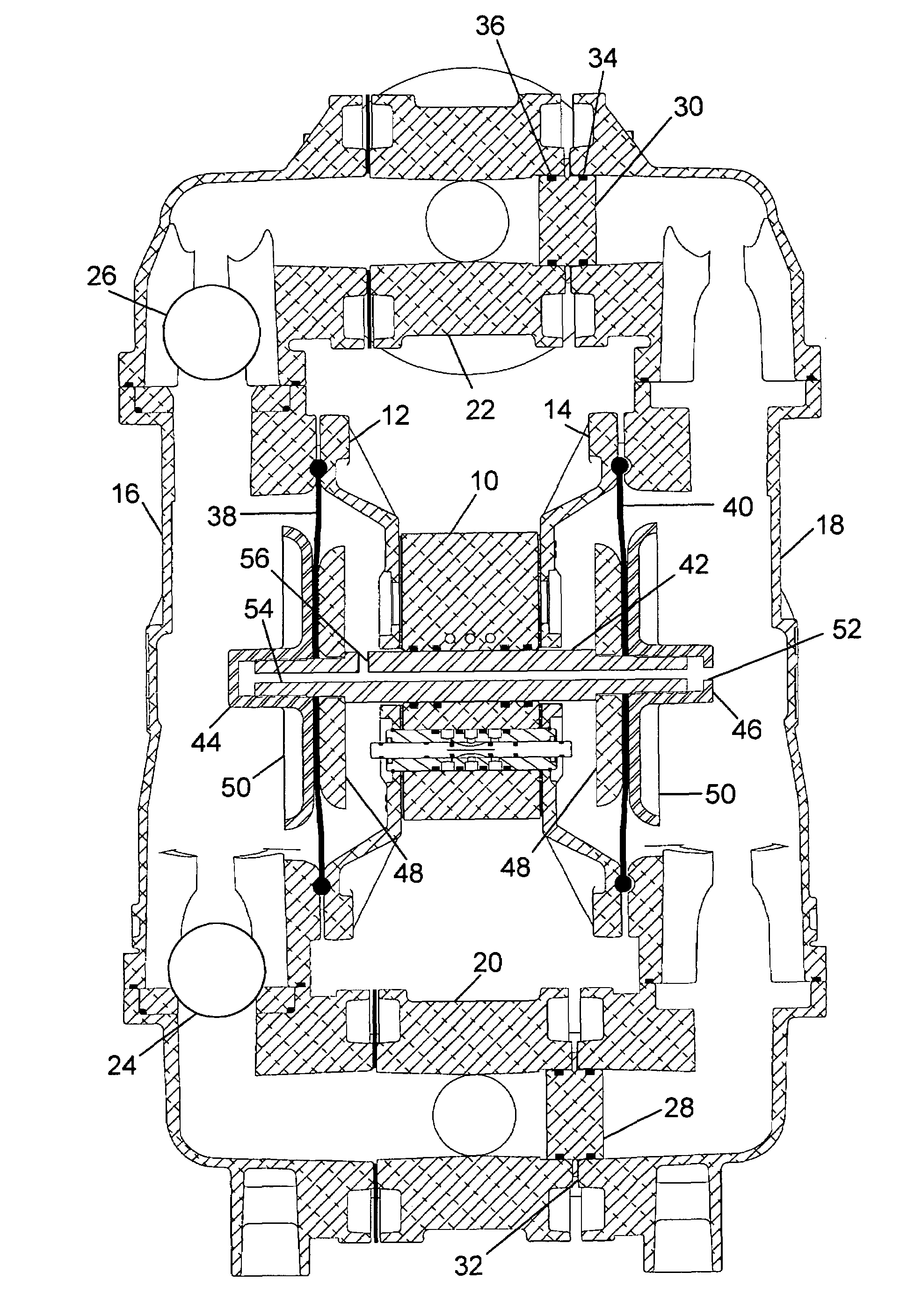

High performance synthetic valve/pulsator

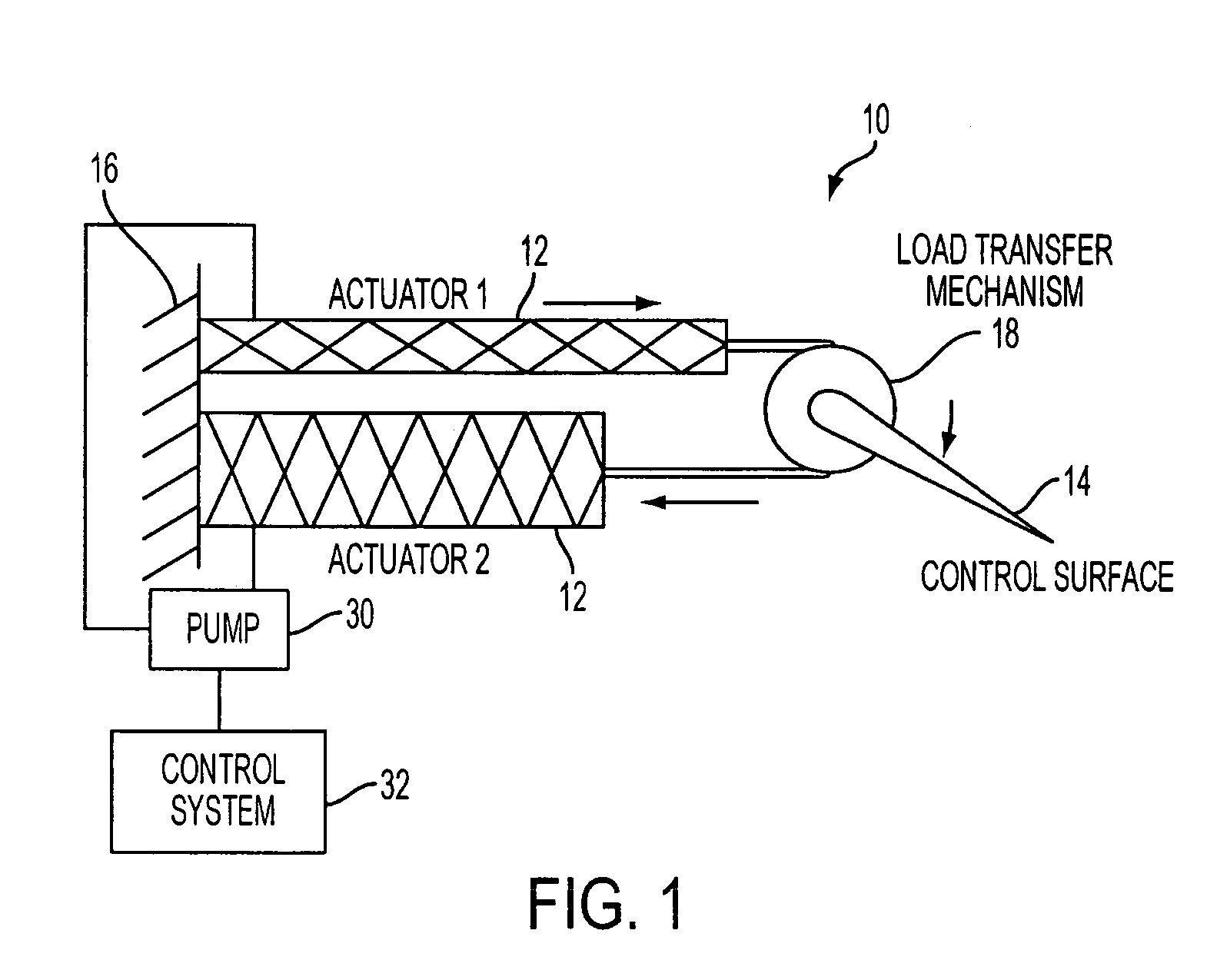

ActiveUS20080087771A1Well mixedImprove performanceAircraft navigation controlFlexible wall reciprocating enginesEngineeringActuator

The present invention provides a system and method for actively manipulating fluid flow over a surface using synthetic pulsators. Synthetic pulsators produce pulsed jet operable to manipulate the primary fluid flow proximate to the synthetic pulsator. The synthetic pulsator includes a dual diaphragm synthetic jet coupled to high performance dual actuator solenoids, wherein the synthetic jet is operable to produce an oscillatory flow. The oscillatory flow of the synthetic jet(s) produces the pulsed jet operable to manipulate the primary fluid flow. These synthetic pulsators may then be actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

Air driven diaphragm pump

ActiveUS7399168B1Improve pumping capacityImprove stress resistanceFlexible wall reciprocating enginesFlexible member pumpsDiaphragm pumpExhaust valve

An air driven diaphragm pump includes two diaphragms affixed to a common shaft. The shaft extends through an air valve providing reciprocating pressurized air to the diaphragms through associated air chambers. A pump chamber with intake and exhaust valves is associated with one of the two diaphragms while a further air chamber replaces a pump chamber and is associated with the other of the diaphragms. A passage extends through the shaft and is in communication with the air chamber adjacent to the pump chamber and with the further air chamber converted from the pump chamber.

Owner:PSG CALIFORNIA LLC

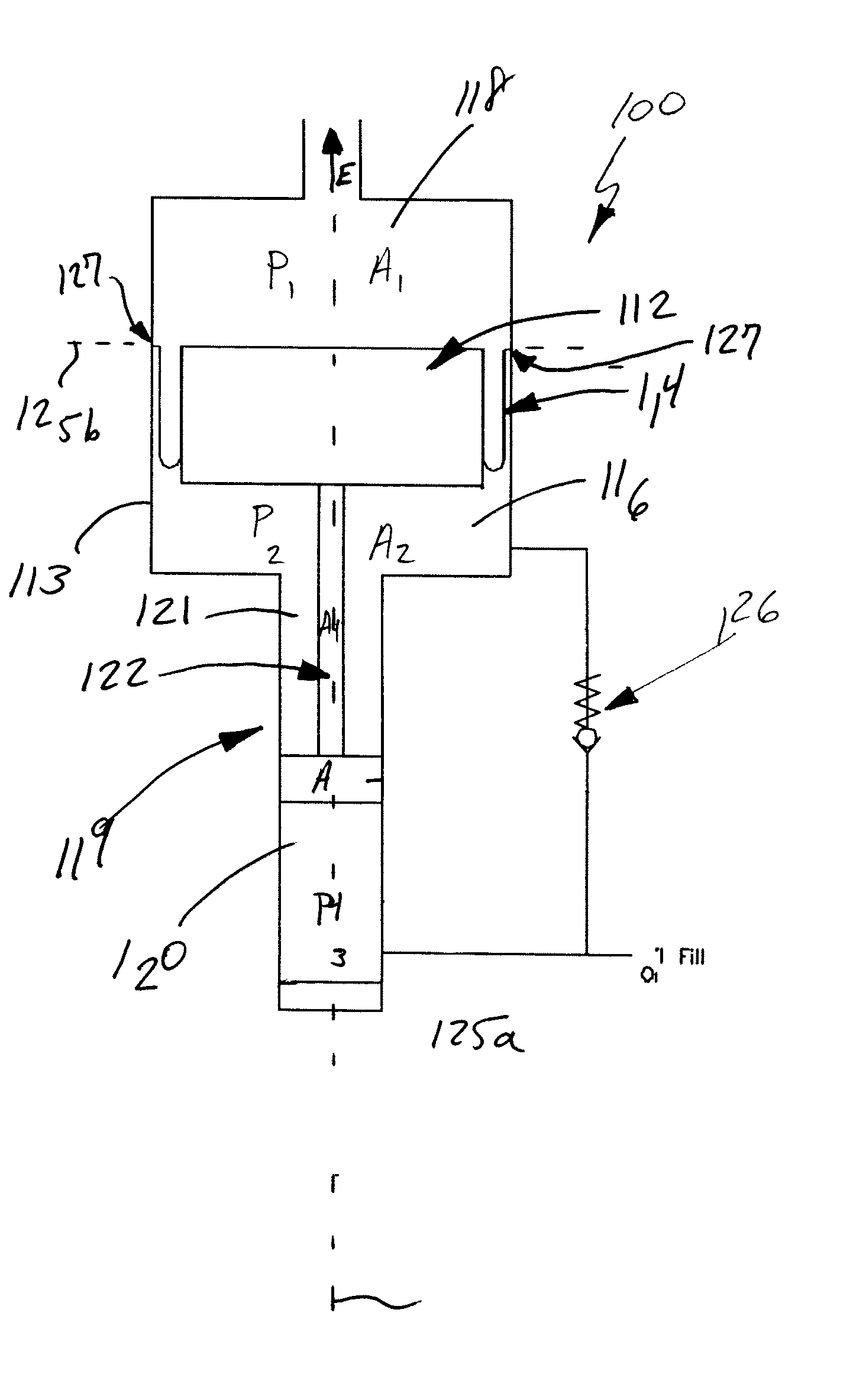

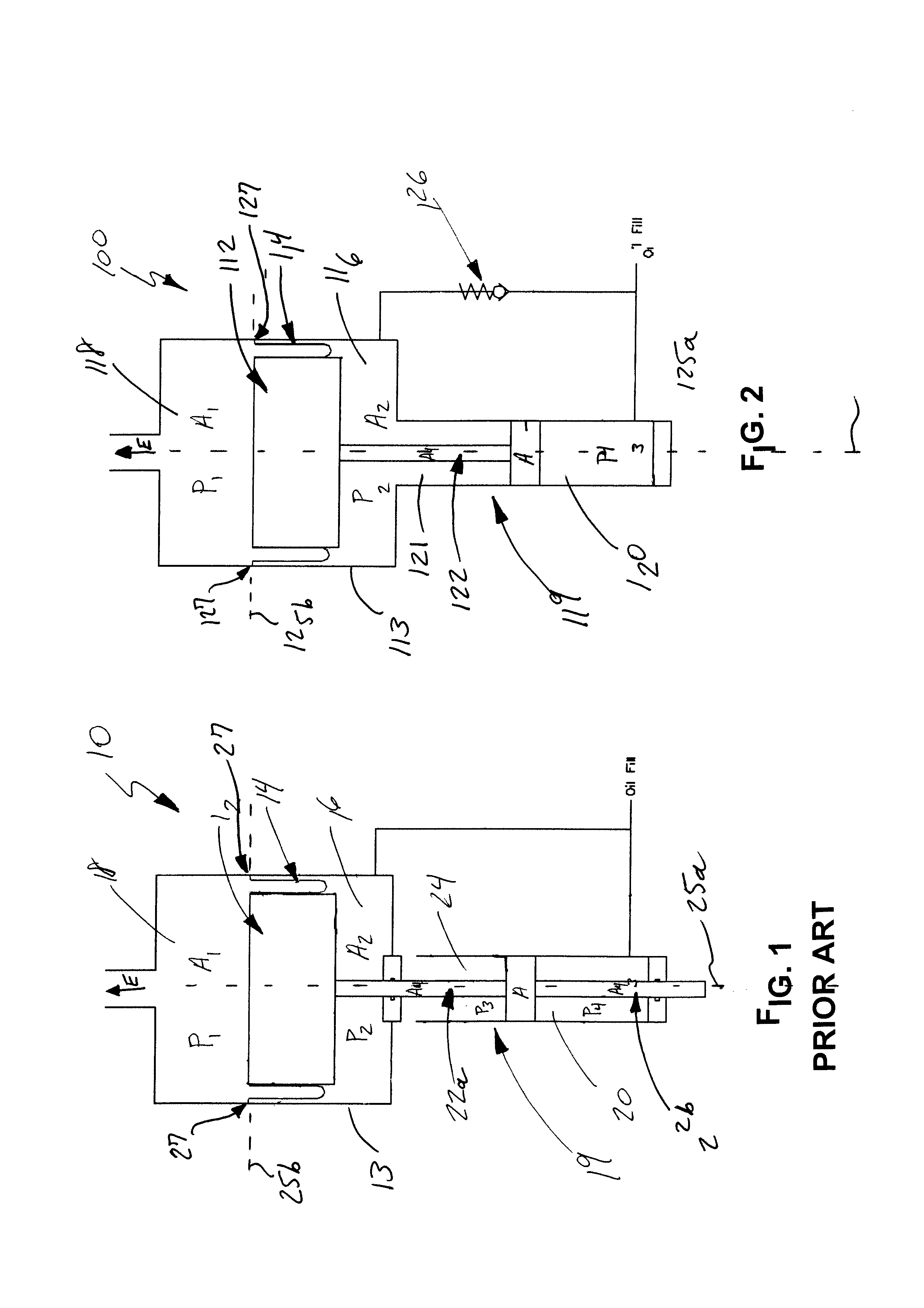

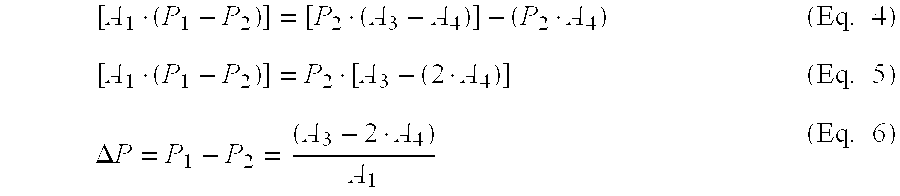

Rolling diaphragm pump

InactiveUS20080260551A1Increased pressure rangeVariable controlFlexible wall reciprocating enginesFlexible member pumpsDiaphragm pumpWorking fluid

A rolling diaphragm pump includes a housing, a rolling seal diaphragm disposed in the housing, a piston for driving the diaphragm, and a valve for regulating the flow of working fluid in a portion of the housing. A constant differential pressure is maintained across the diaphragm independent of discharge pressure of the pump. A method of pumping a viscous medium includes pumping the viscous medium by maintaining a constant differential pressure across a rolling seal diaphragm independent of discharge pressure of the viscous medium, with the diaphragm disposed between the viscous medium and a working medium and being driven by a piston.

Owner:TERRASIMCO

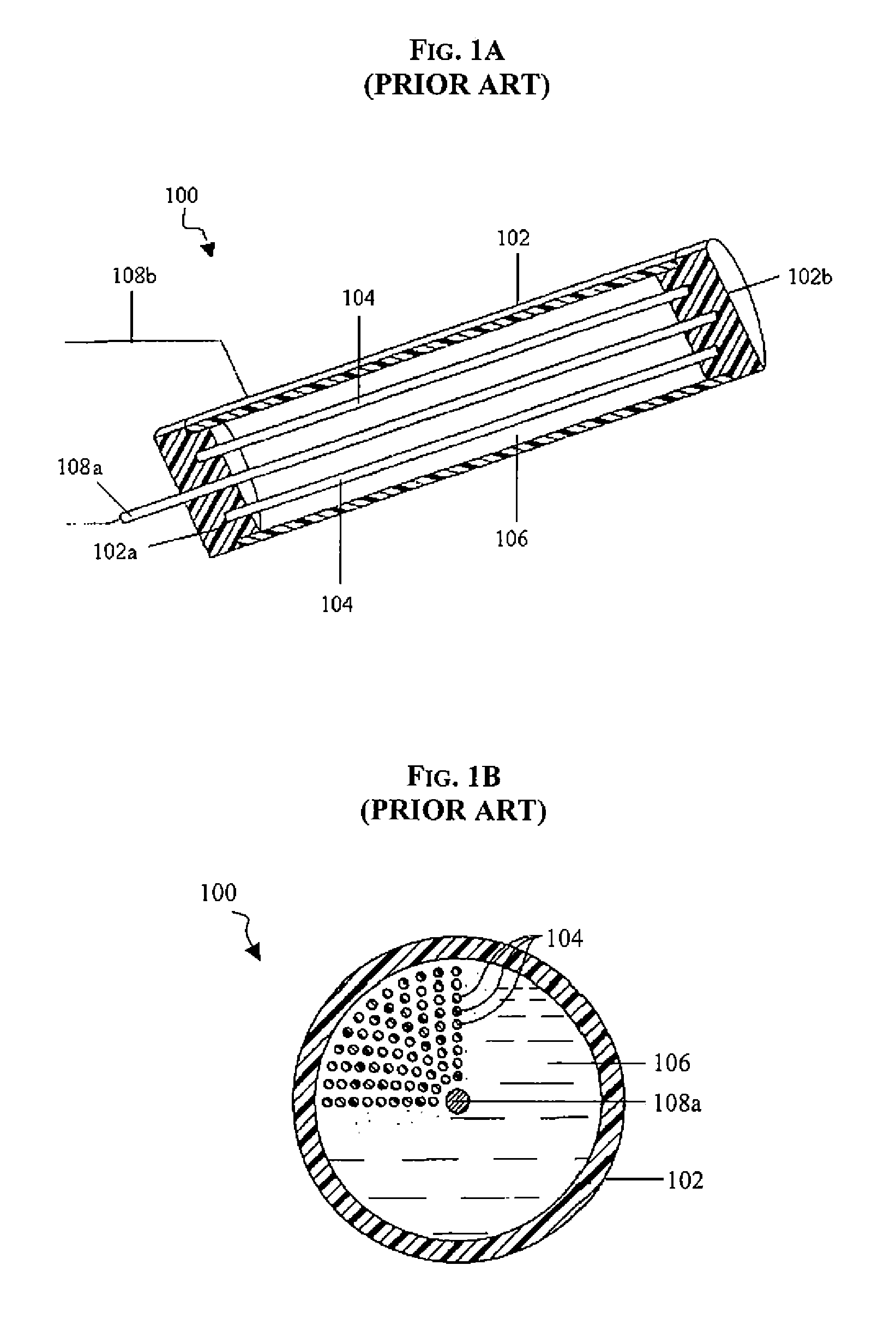

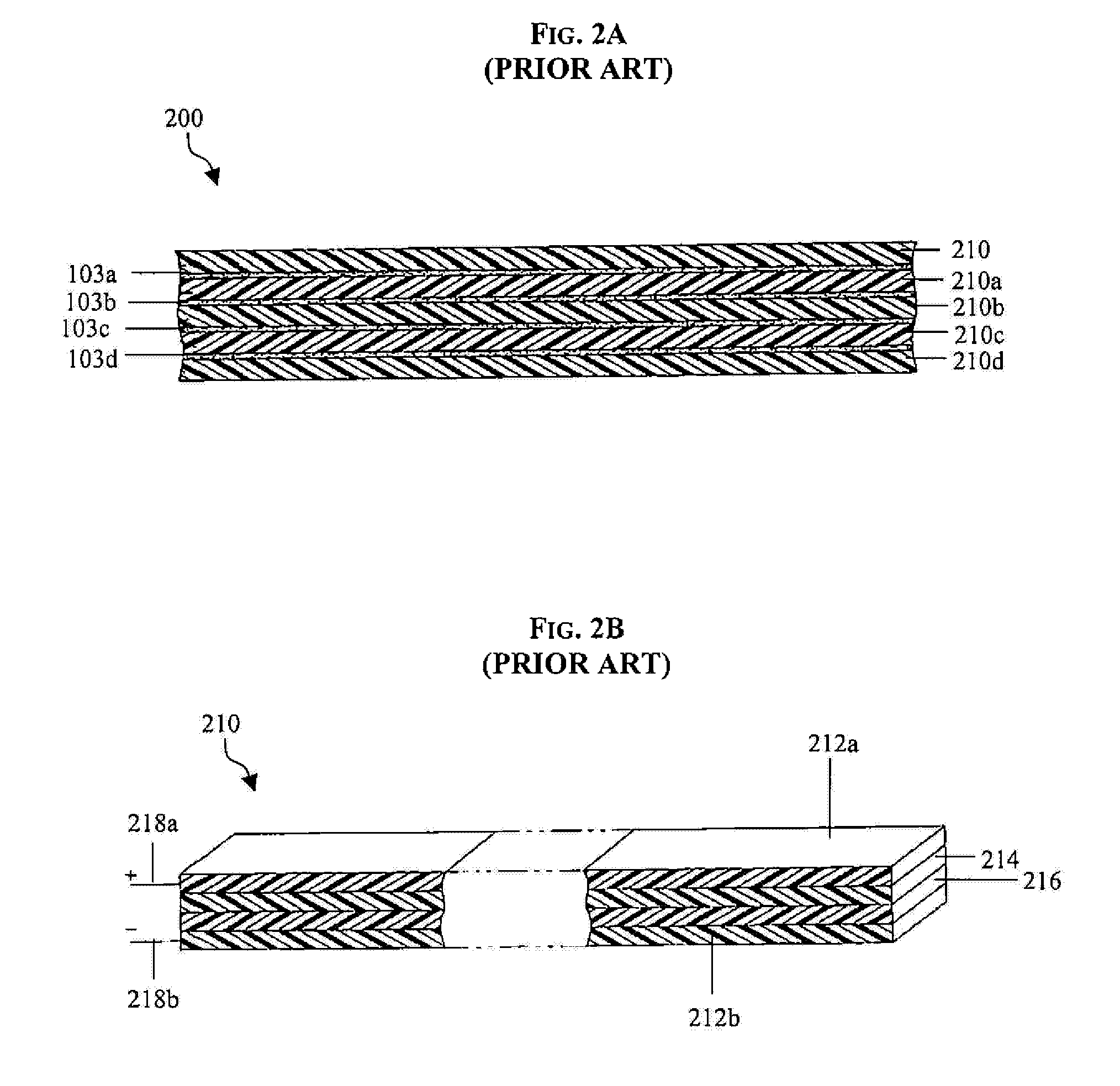

Electroactive polymer-based pump

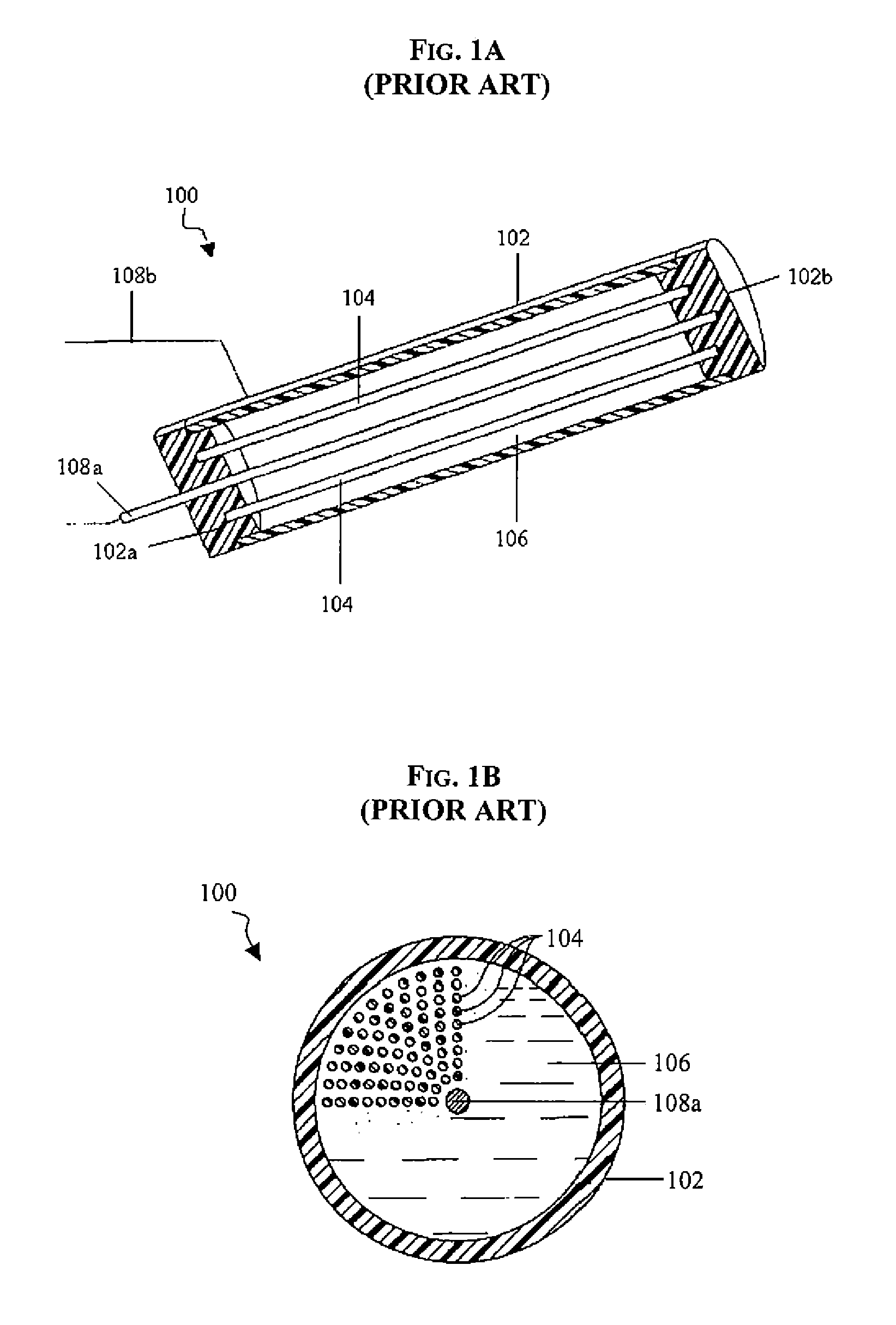

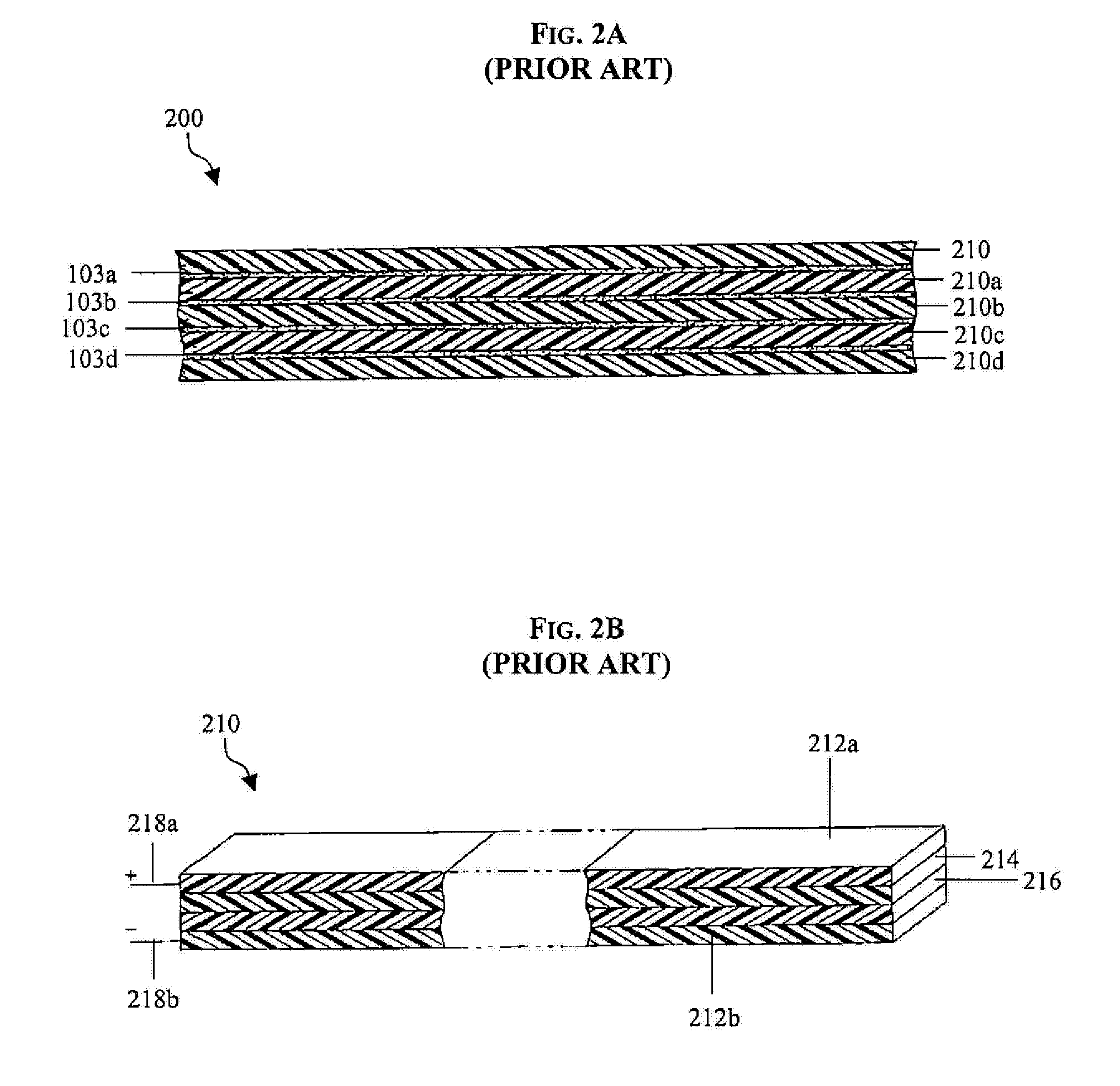

ActiveUS20070025868A1Flexible wall reciprocating enginesFlexible member pumpsBiological activationBiomedical engineering

Owner:ETHICON ENDO SURGERY INC

Diaphragm and hydraulically-operated valve using same

InactiveUS7059578B2Increased operating lifeClose reliableDiaphragm valvesFlexible wall reciprocating enginesElastomerFluid control

The present invention relates to fluid control valves. The invention provides an improved diaphragm useful for a large hydraulically-operated valve or pressure regulating valve of the type used in pipelines to transport water, oil, gas, acids, alkalis and other fluids.The diaphragm being provided with an upper face arranged to be exposed to a control hydraulic pressure and a lower face arranged to selectively seal and open a passage between a valve inlet and a valve outlet, ribs on said upper face urging the diaphragm towards a sealing position. The diaphragm being characterized by the addition of an elastomer ring element disposed adjacent to the upper face and adjacent to the largest diameter of the diaphragm exposed inside a valve to which it may be assembled, an upper face of the flexible ring element being in pressure contact with a portion of the rigid body of the valve. The flexible ring element further urging the diaphragm towards its lower position and allowing closure of the valve without use of a metallic compression spring.

Owner:RAPHAEL VALVES INDS 1975

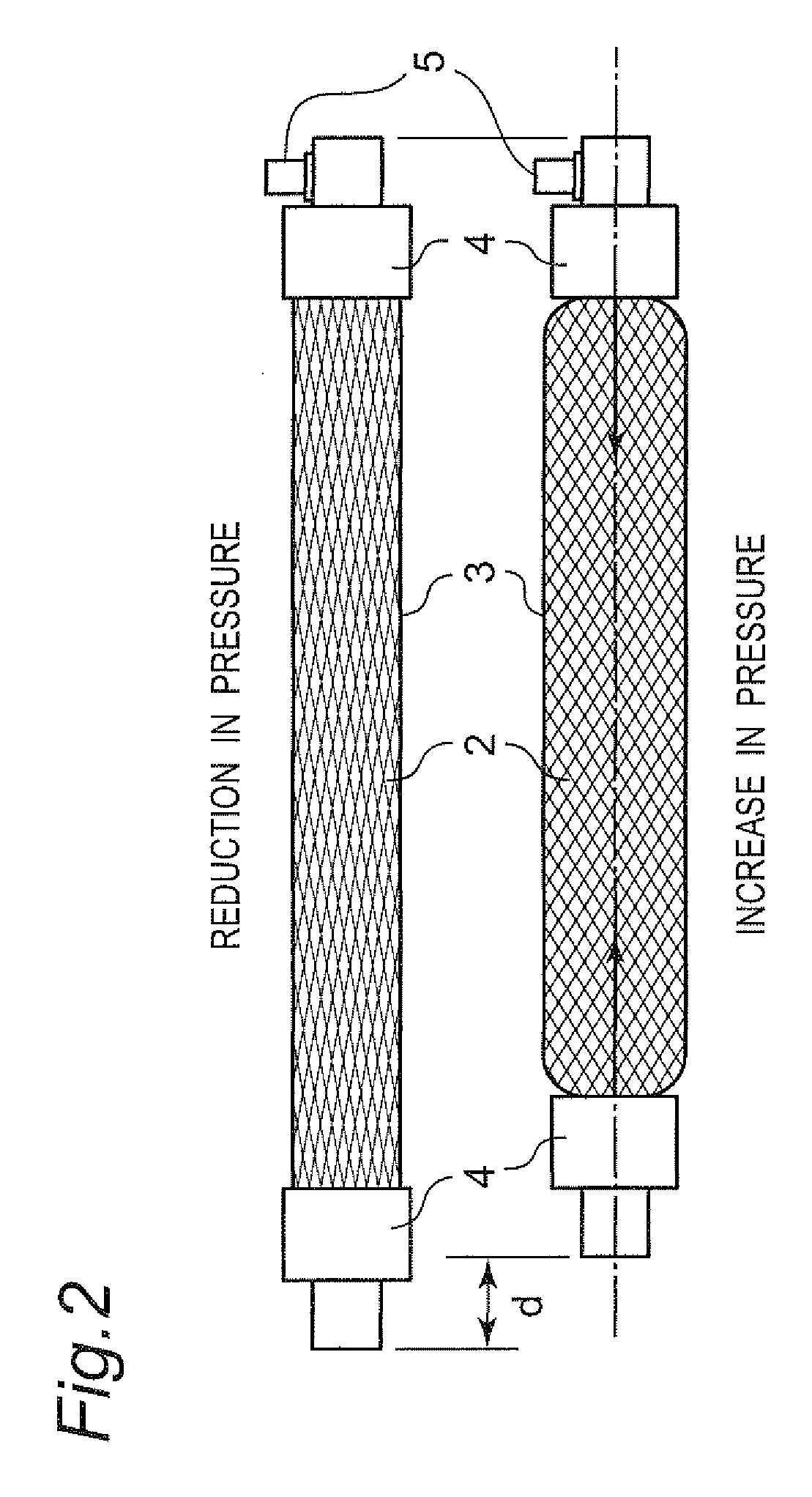

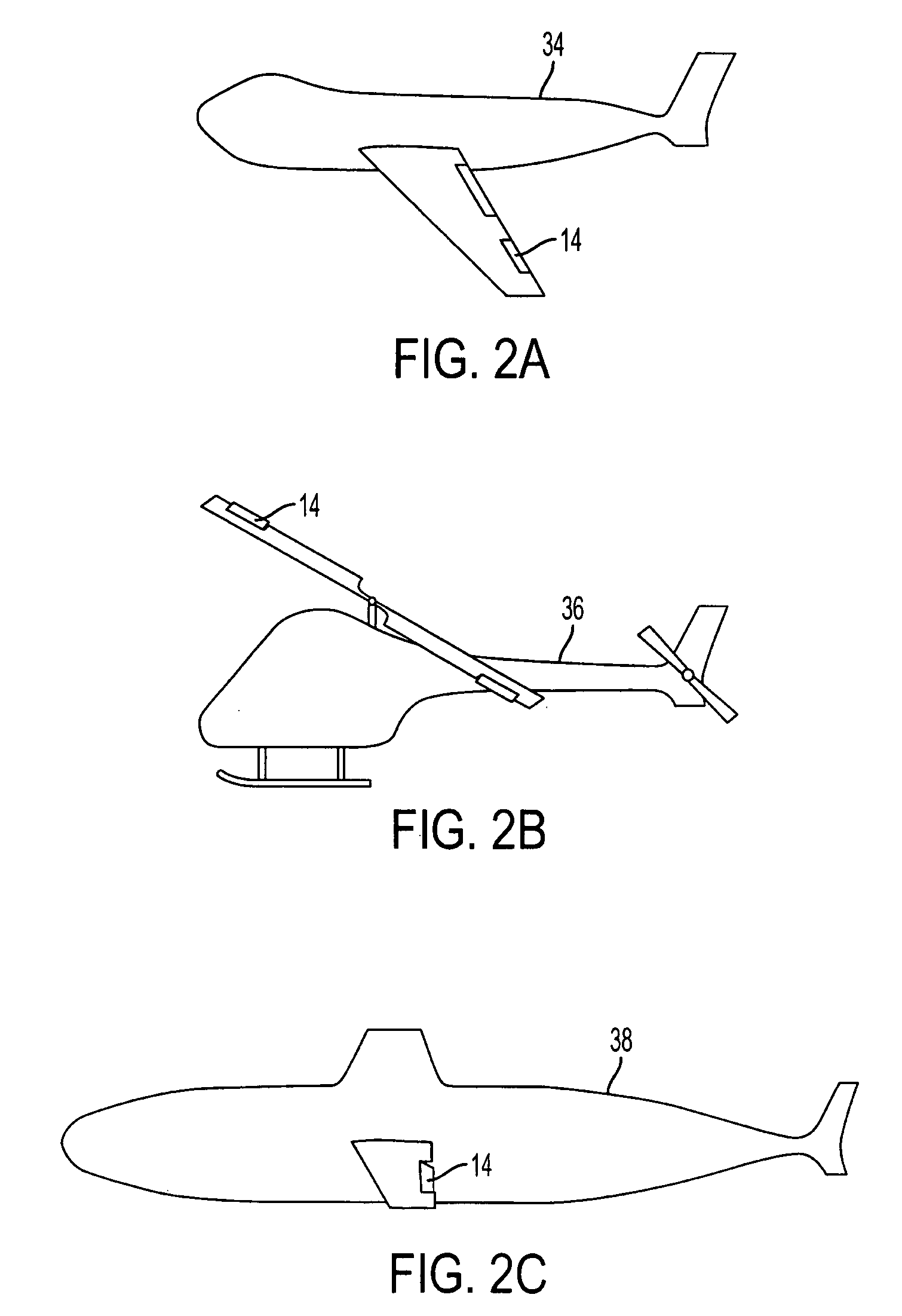

Fluid-driven artificial muscles as mechanisms for controlled actuation

InactiveUS7837144B2AdaptableEasily interchangeableFlexible wall reciprocating enginesAircraft stabilisationBiomedical engineeringArtificial muscle

A fluid contact surface actuation system for a vehicle, including a first fluid contact surface constructed and arranged to act against a first fluid passing over the first fluid contact surface; and a first fluid actuator coupled to the first fluid contact surface to move the first fluid contact surface between a first position and a second position to enable control of the vehicle in a predetermined manner, the first fluid actuator having a first resilient bladder that receives a second fluid such that pressure of the second fluid moves the first bladder between a contracted configuration and an expanded configuration.

Owner:MARYLAND UNIV OF +2

Extended wear pump diaphragm

InactiveUS6158327AResist significant wearEasy to wearFlexible wall reciprocating enginesEngine diaphragmsArcuate shapeMechanical engineering

The present invention provides a diaphragm for use in pump applications in which at least a predetermined portion of such diaphragm is in contact with such outer piston which would tend to abrade such diaphragm. Such diaphragm is formed from at least one layer of a preselected flexible material. Such diaphragm comprises an outer bead like portion for securing the diaphragm to a pump housing. There is a annular flexure portion having a first end and a second end, such first end and such second end being generally flat and an arcuate shaped middle portion formed contiguously with the first end and the second end. Such first end is formed contiguously with the outer bead like portion. Such annular flexure portion has a substantially uniform first predetermined thickness. An enlarged bulbous portion is formed contiguously with the second end and extends around an inner periphery thereof. Such enlarged bulbous portion has a predetermined configuration. Such diaphragm has an enlarged section formed as a protrusion that extends outwardly from an outer surface of the generally flat second end. Such enlarged section is formed contiguously with the enlarged bulbous portion and extends around an outer periphery thereof. The enlarged section causes the second end to be thicker than such first predetermined thickness. Further, there is a generally flat center portion that is formed contiguously with the enlarged bulbous portion and extends around an inner periphery thereof.

Owner:WESTINGHOUSE AIR BRAKE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com