Patents

Literature

122 results about "Direct process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Direct Process, also called the Direct Synthesis, Rochow Process, and Müller-Rochow Process is the most common technology for preparing organosilicon compounds on an industrial scale. It was first reported independently by Eugene G. Rochow and Richard Müller in the 1940s.

Process aid for preparing a flowable slurry

A process for preparing a flowable slurry comprising mixing 25-70 wt. % water; an alkaline material selected from the group consisting of chlorosilicon manufacturing byproducts, direct process residue gels, cement kiln dust, and mixtures thereof; and a process aid selected from the group consisting of sucrose, raffinose, lignin, methylglucopyranoside, lactose, fructose, sodium polyphosphate, trehalose and mixtures thereof to form a flowable slurry. This slurry is especially useful in the manufacture of cement.

Owner:DOW CORNING CORP

Conversion of direct process high-boiling residue to monosilanes

InactiveUS6013235APromote conversionSilicon organic compoundsPhysical/chemical process catalystsHydrogenBoiling point

A process for the production of monosilanes from the high-boiling residue resulting from the reaction of hydrogen chloride with silicon metalloid in a process typically referred to as the "direct process." The process comprises contacting a high-boiling residue resulting from the reaction of hydrogen chloride and silicon metalloid, with hydrogen gas in the presence of a catalytic amount of aluminum trichloride effective in promoting conversion of the high-boiling residue to monosilanes. The present process results in conversion of the high-boiling residue to monosilanes. At least a portion of the aluminum trichloride catalyst required for conduct of the process may be formed in situ during conduct of the direct process and isolation of the high-boiling residue.

Owner:DOW SILICONES CORP

Bulk silicon carbide aerogel material and preparation method thereof

ActiveCN102897764AOmit the replacement processSimple processCarbon compoundsAmbient pressureMesoporous material

The invention belongs to the technical field of preparation of bulk silicon carbide mesoporous materials, and relates to a bulk silicon carbide aerogel material and a preparation method thereof. The silicon carbide aerogel is a celadon bulk material, the pore size distribution is 10-100 nm, the BET (Brunauer, Emmett and Teller) specific surface area is 130-330 m2 / g, and the apparent density is 0.200-0.300 g / cm3. The preparation method comprises the following steps of: preparing RF-SiO2 composite aerogel from benzenediol, formaldehyde, a silicon source, water and alcohol by using the one-pot method through sol-gel, aging and ambient pressure drying, carrying out a carbothermic reduction reaction on the RF-SiO2 composite aerogel under the protection of argon, and calcining the reaction product in the air to obtain the bulk silicon carbide aerogel material. The bulk silicon carbide mesoporous material has the advantages of simple and cheap raw materials, and the method has simple and direct process, is easy to control and is easy to realize mass production and the like.

Owner:NANJING UNIV OF TECH

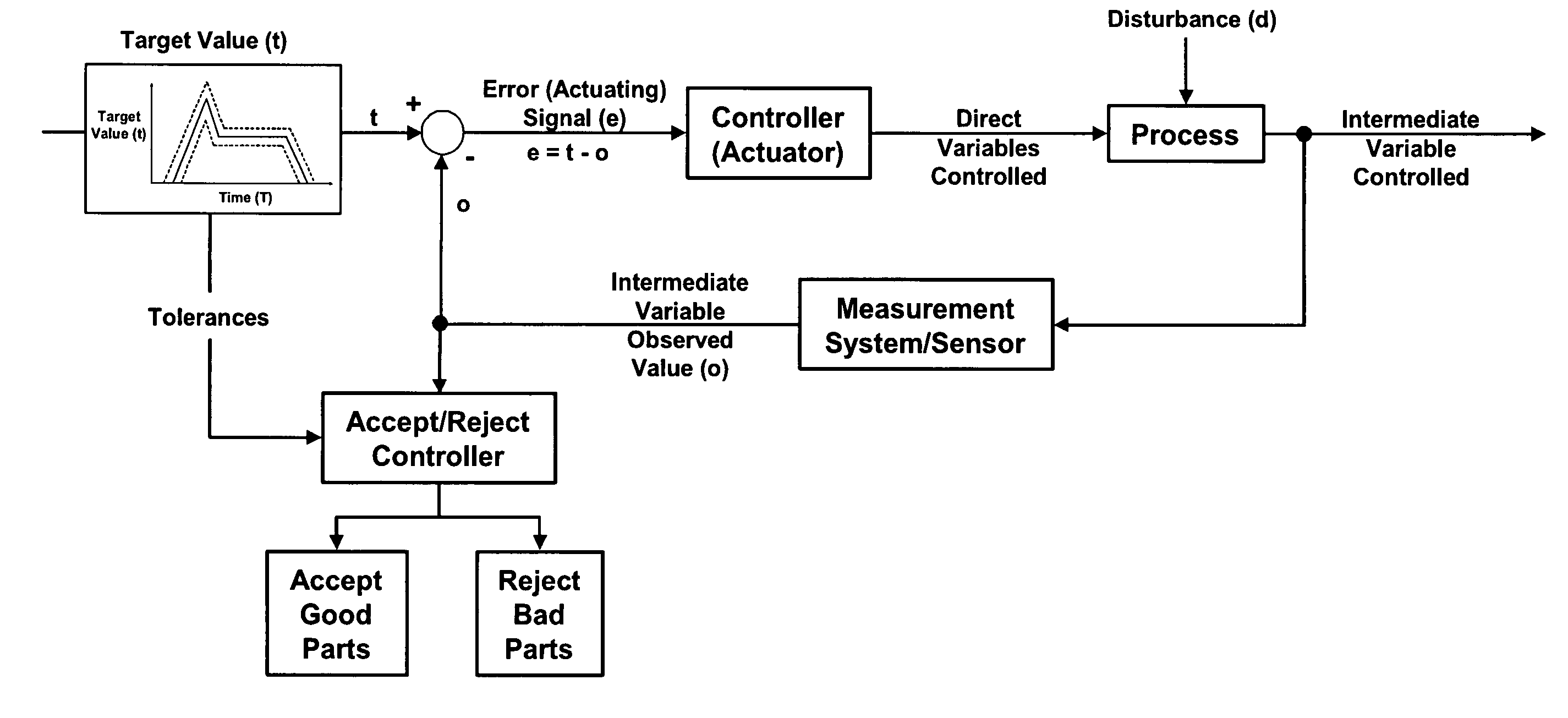

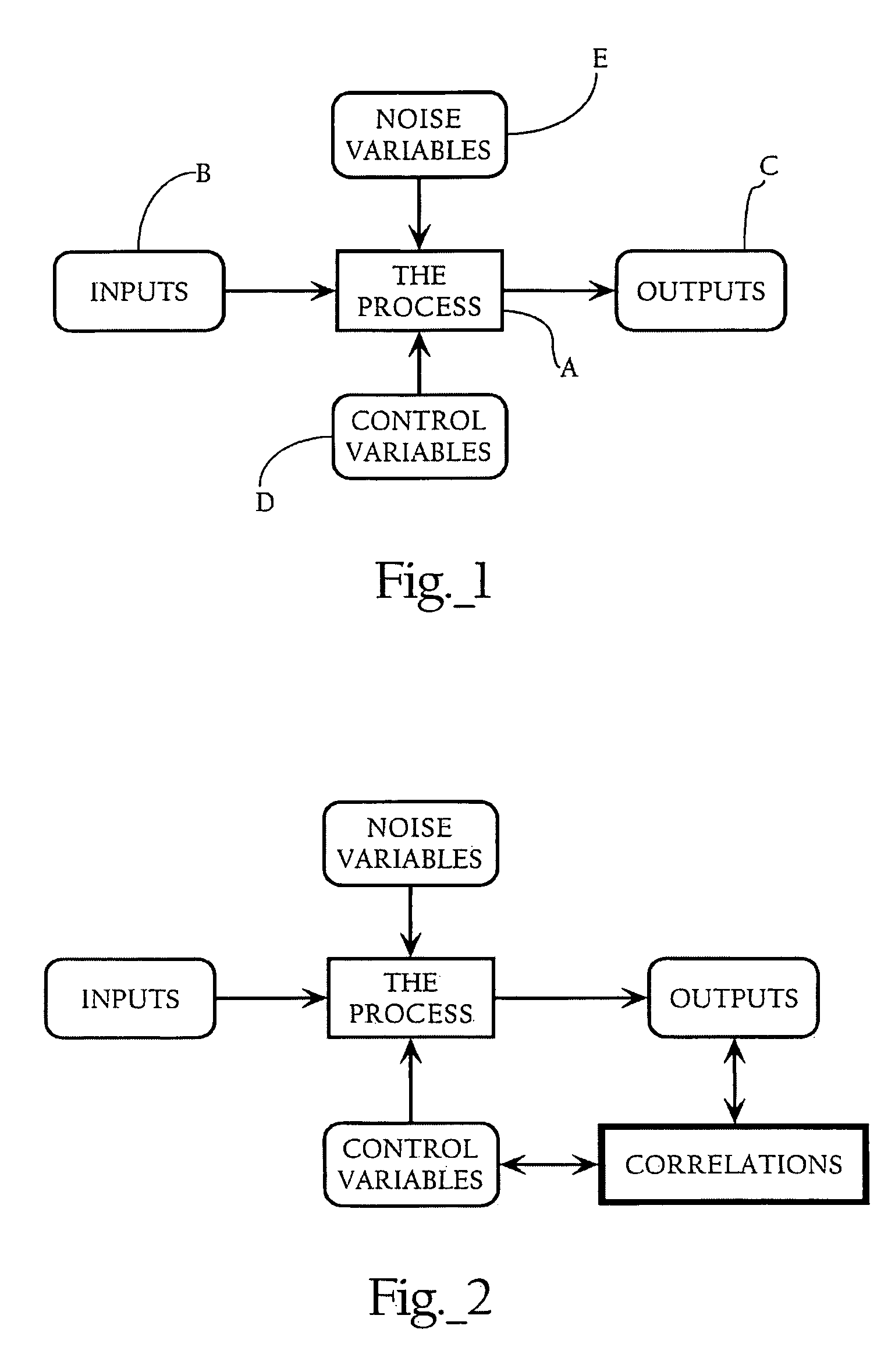

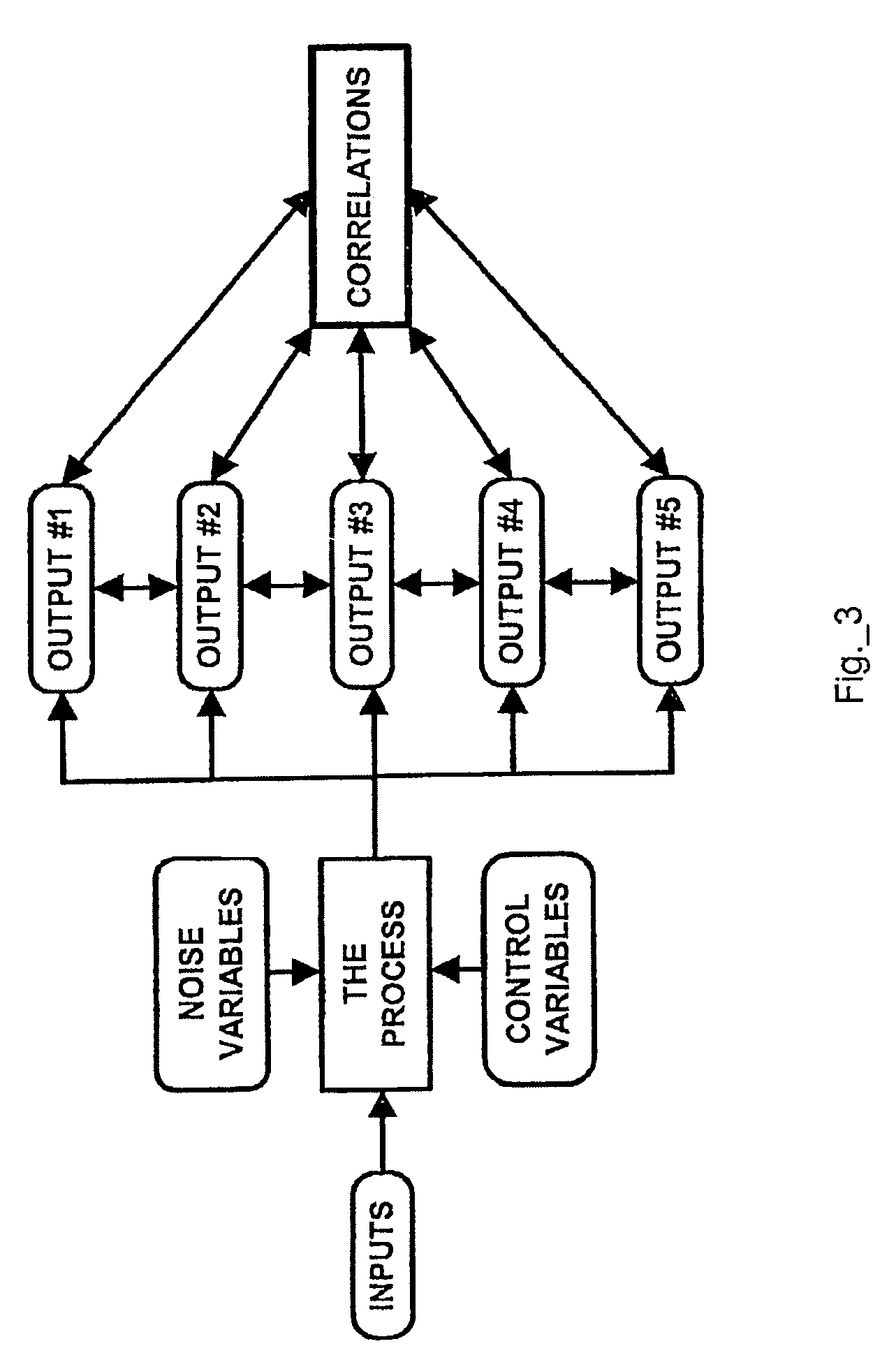

Dynamic control system for manufacturing processes including indirect process variable profiles

InactiveUS7840297B1Designed withReduce cost of measurementProgramme controlDigital computer detailsEngineeringOperating limit

Methods, apparatuses and systems that facilitate the design, production, control and / or measurement tasks associated with manufacturing and other processes. In one implementation, the present invention facilitates or enables the use of indirect process variables for use in manufacturing or other processes that yield articles or parts. For example, it enables determining a desired value profile for an indirect process variable based on the operating target, the lower operating limit and the upper operating limit for the predictor characteristic, and observations of the process. In one implementation, the present invention facilitates qualifying articles resulting from the process by comparing the desired versus observed value profiles for an indirect process variable. In another implementation, the present invention facilitates controlling a direct process variable based on the observed versus desired values of an indirect process variable.

Owner:TUSZYNSKI STEVE W

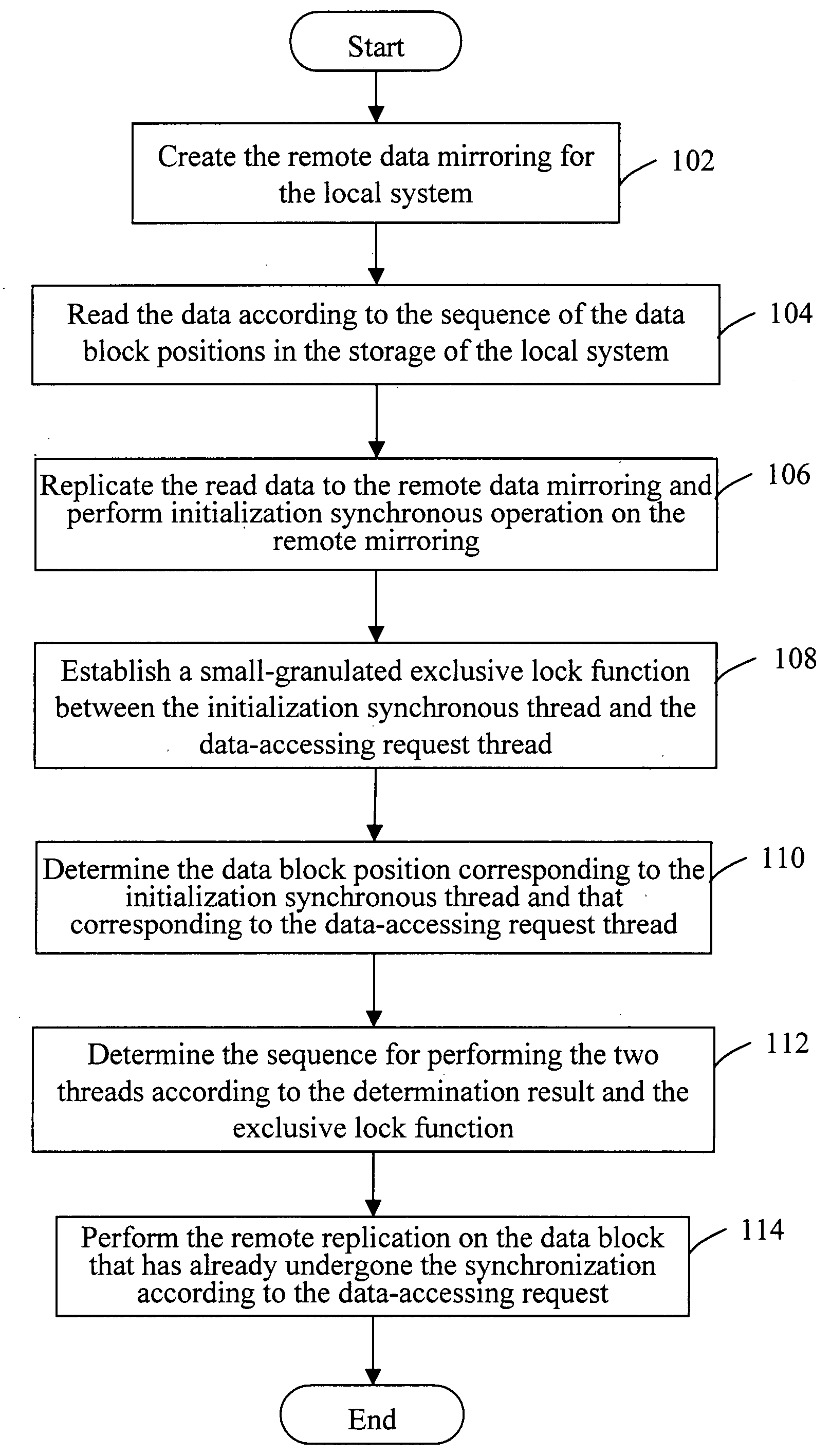

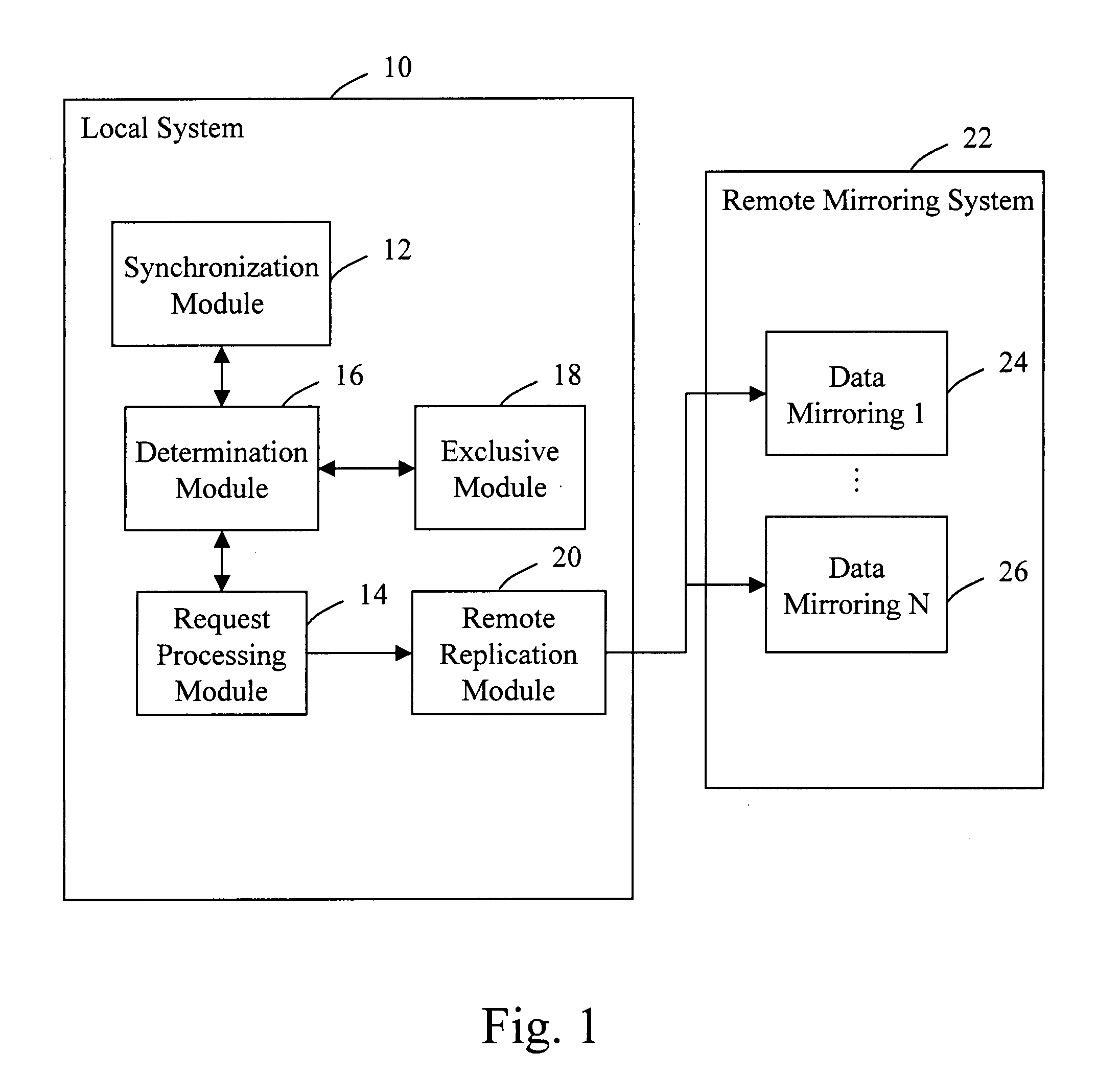

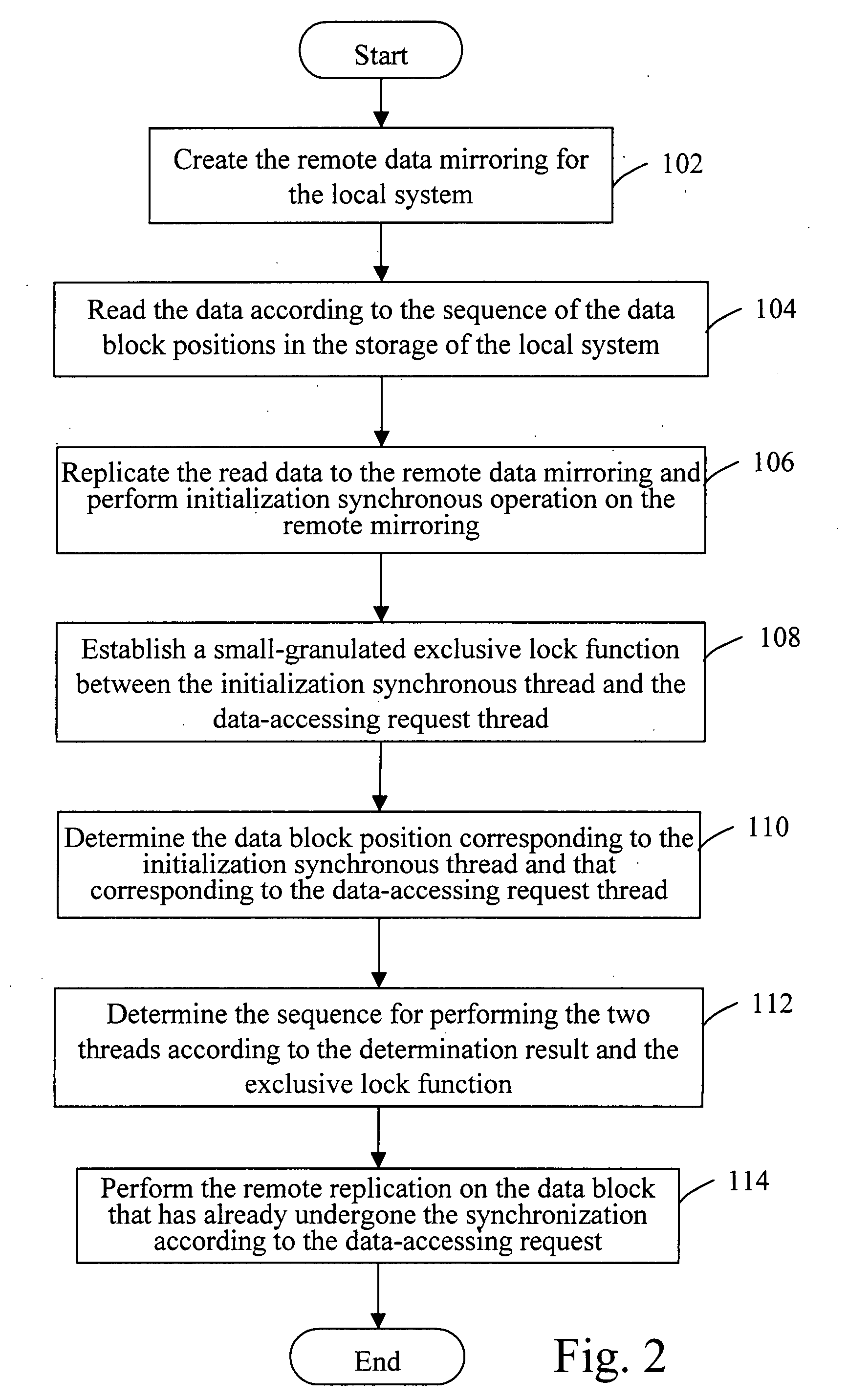

Remote replication synchronizing/accessing system and method thereof

InactiveUS20090132534A1Increasing data accessing accuracyImprove access accuracyDigital data information retrievalSpecial data processing applicationsData accessSeries data

A remote replication synchronizing / accessing system and a method thereof applied between a local system and a remote mirroring system of the local system. After the remote mirroring system is created, an initialization synchronous operation of the remote mirroring system is sequentially performed according to a sequence of data blocks in storage of the local system. A small-granulated exclusive lock function is established between the initialization synchronous operation and a data-accessing request operation of the local system. During the initialization synchronous process of the remote mirroring system, it is determined whether a data block position corresponding to the current initialization synchronous operation is the same as that corresponding to the data-accessing request operation or not. Finally, according to a position determination result and the small-granulated exclusive lock function, a data-accessing request is directed processed or processed after finishing the initialization synchronous operation.

Owner:INVENTEC CORP

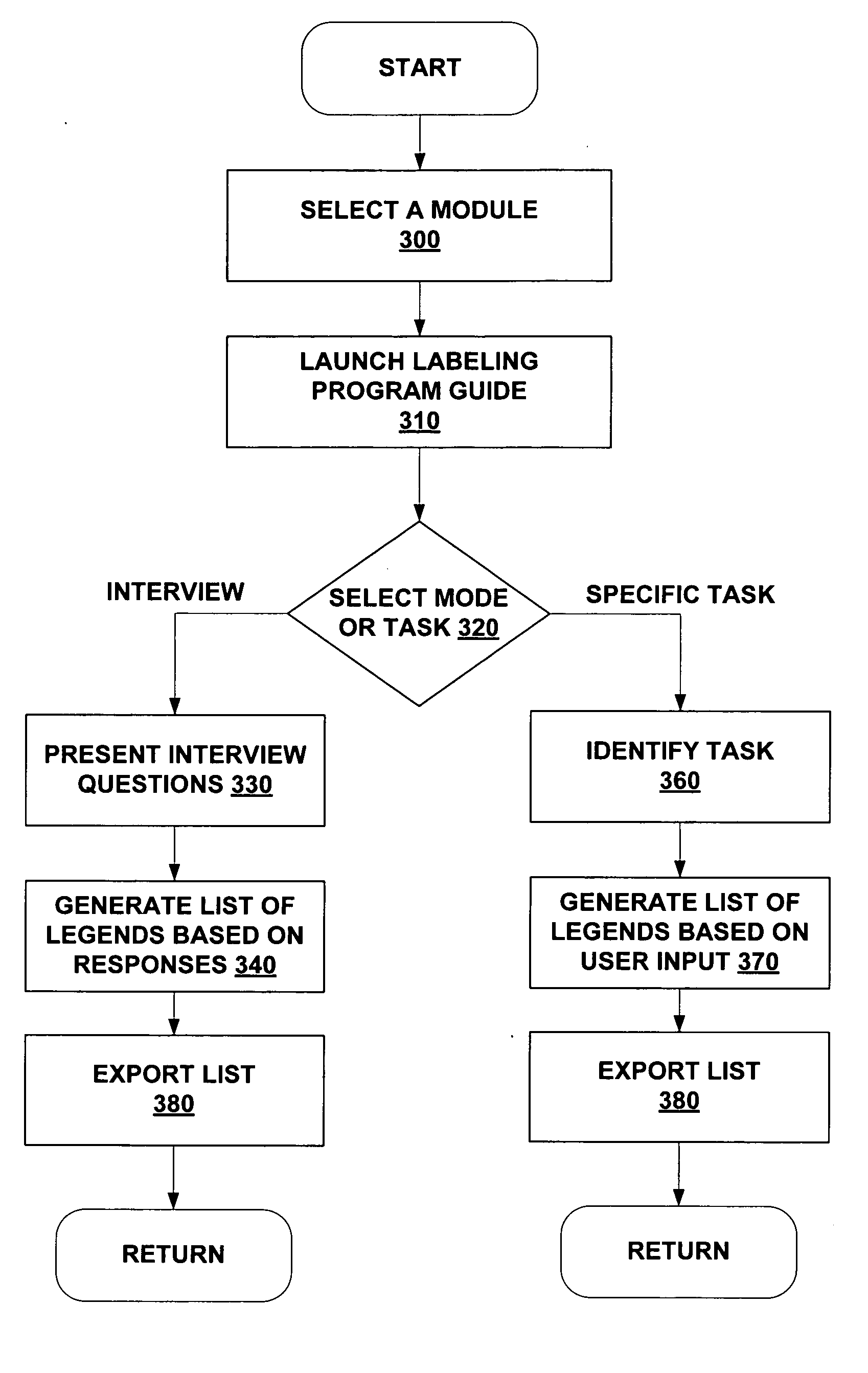

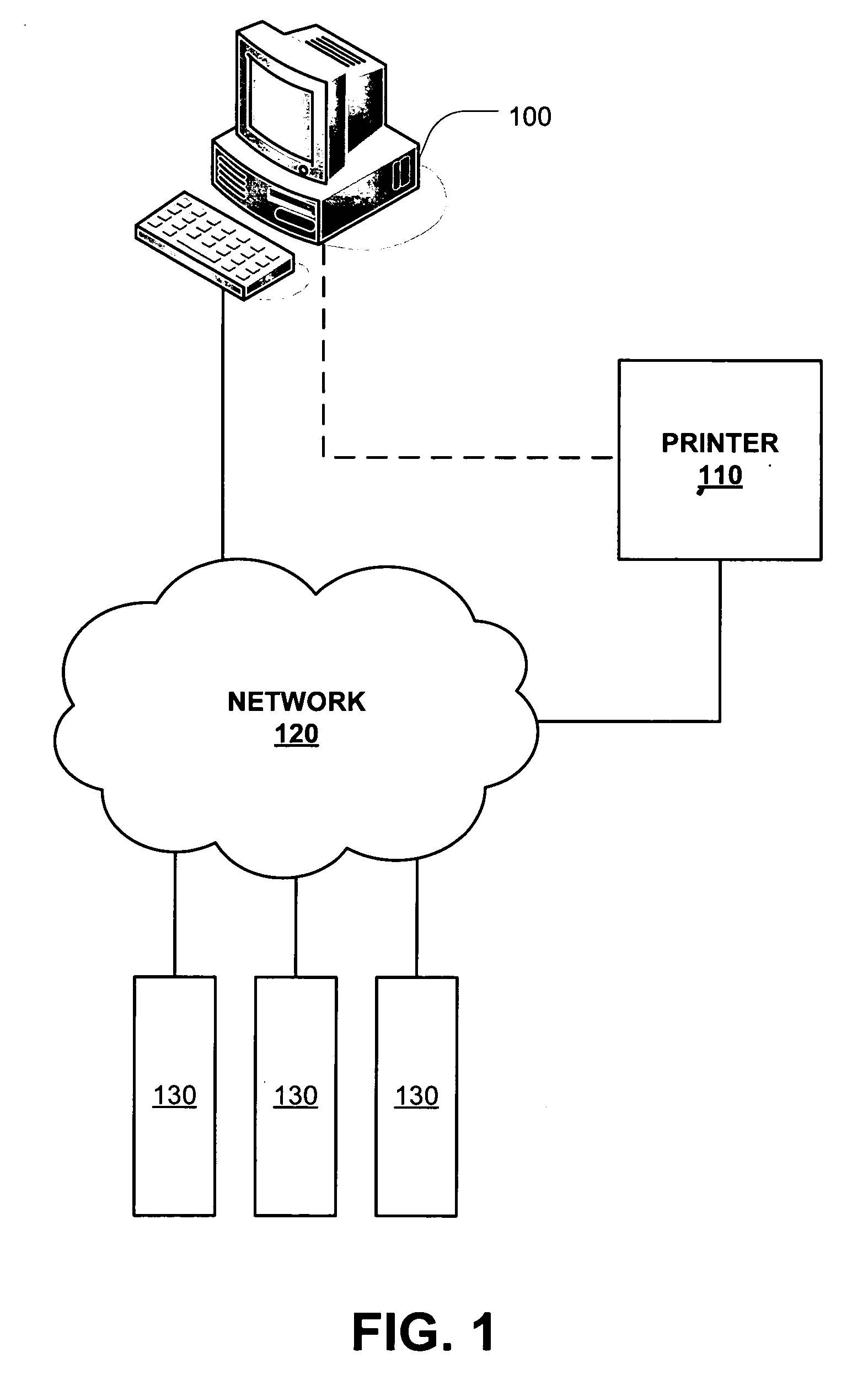

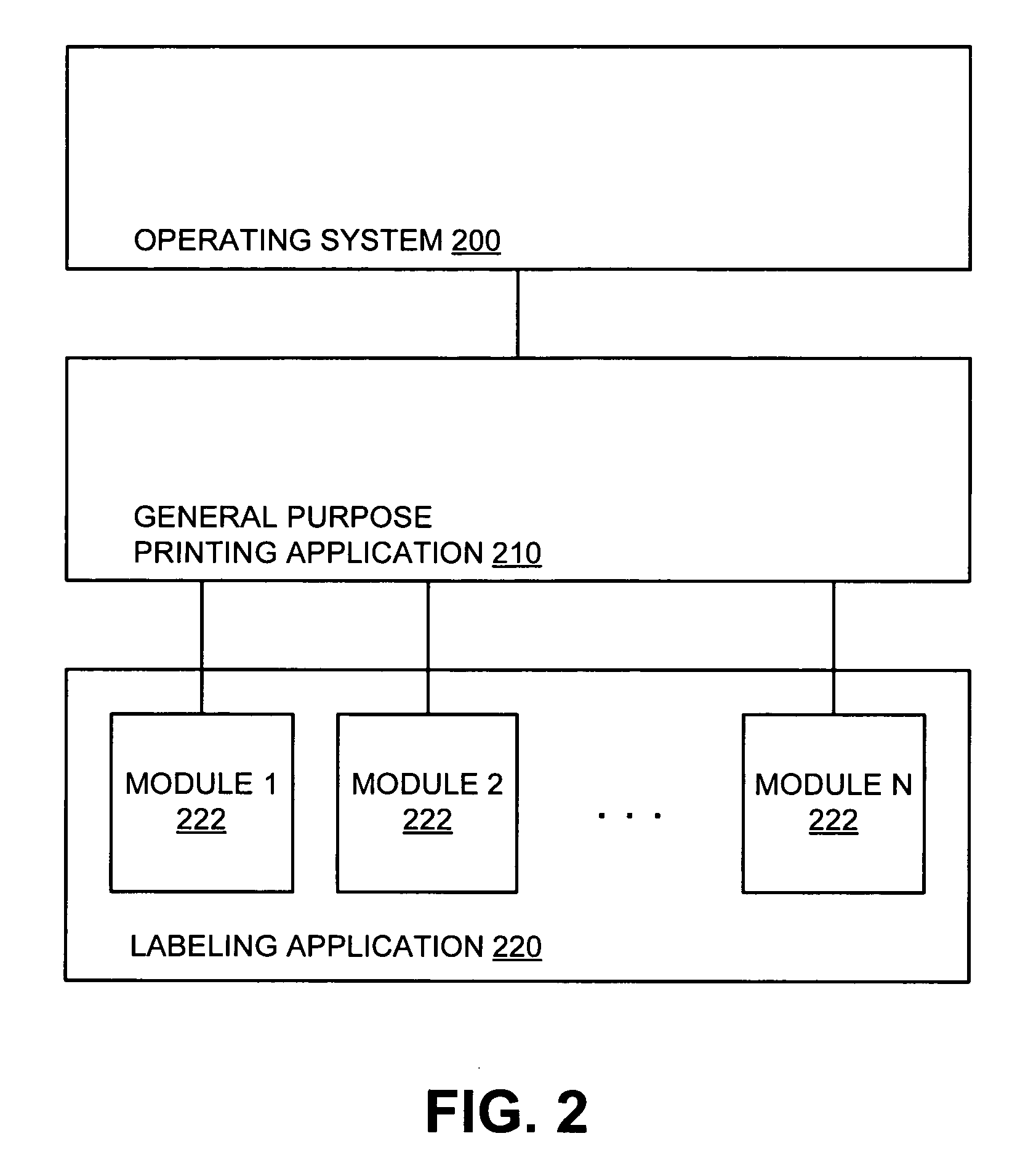

Market-based labeling system and method

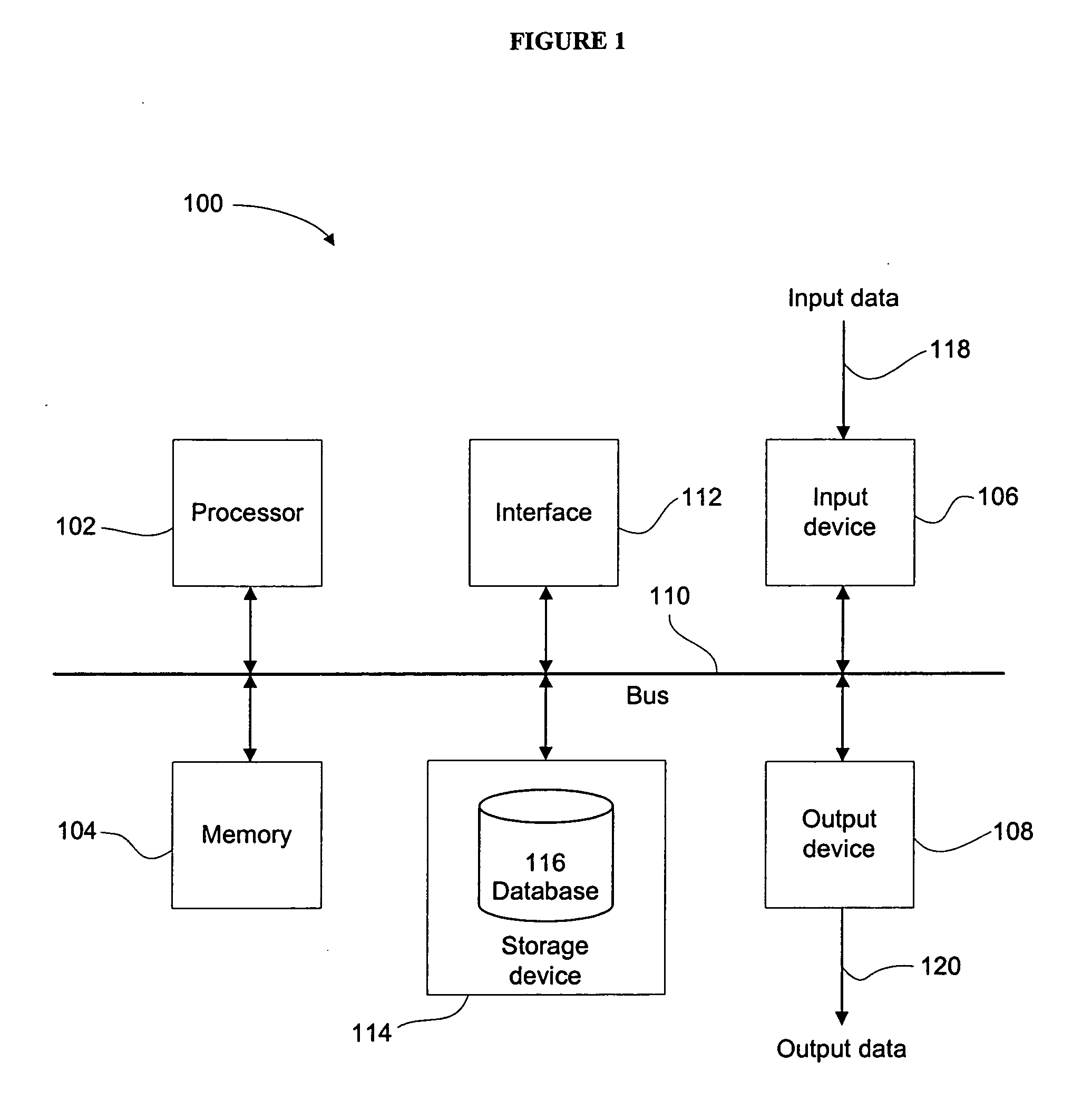

A market-based labeling system and method provides tools to assist a user in accurately generating labels. The system includes a processor-based device, such as a computer, that has associated input / output devices, such as a keyboard and a display. The processor-based device also includes a user-friendly labeling application, which may be implemented as a set of instructions to be executed by the processor. The labeling application may guide the user through a series of steps to produce a set of labels. The labeling application preferably generates the user interfaces and a file that may be viewed, edited, saved and / or printed on an associated printer. The labeling application may include one or more modules, each module being geared toward labels for a particular market. This labeling application tool may run on a general purpose processor, such as a computer, and may interface with general purpose labeling software. Alternatively, the labeling application tool may be embedded in a labeling device, such as a portable hand-held printer. Also, methods are provided for quickly and accurately generating labels by adapting a labeling application tool to the user and the user's market. For example, one method allows a user to select between a guided, interview-type process for identifying labeling requirements and a user-directed process for identifying labeling requirements. The methods may be implemented in software.

Owner:PANDUIT

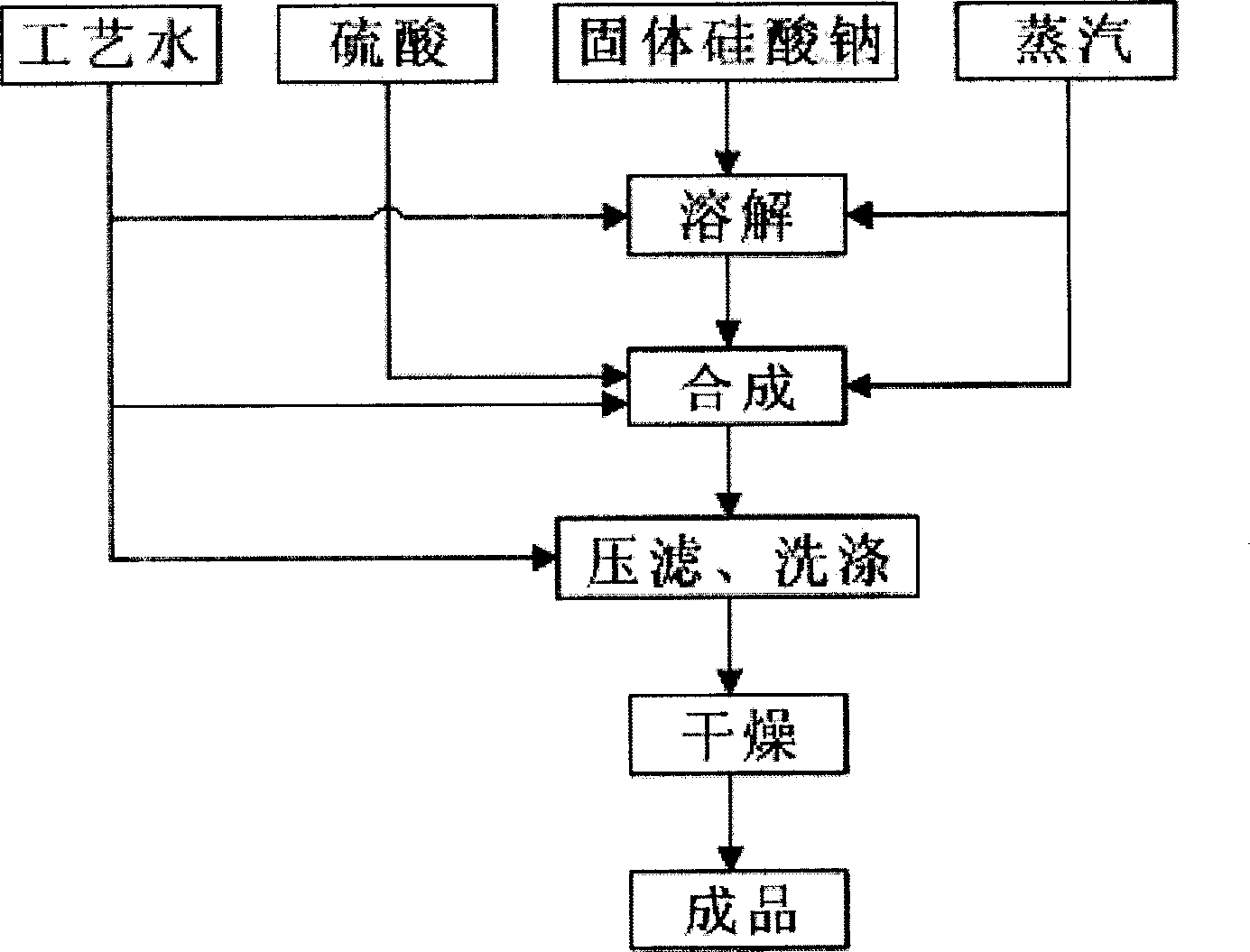

High dispersion gel-free white carbon black and its preparing method

InactiveCN1899961AGood dispersionMethod to save energy and reduce consumptionSilicaNanotechnologySpray drying

The present invention discloses a kind of high dispersion gel-free white carbon black, which contains SiO2 over 99 wt%, and has specific surface area of 320-380 sq m / g and particle diameter smaller than 11 nm. The present invention also discloses the preparation process of the high dispersion gel-free white carbon black, and the preparation process is one direct process including dissolving, synthesis, filtering and spray drying. The preparation process has low production cost.

Owner:周玉芳 +3

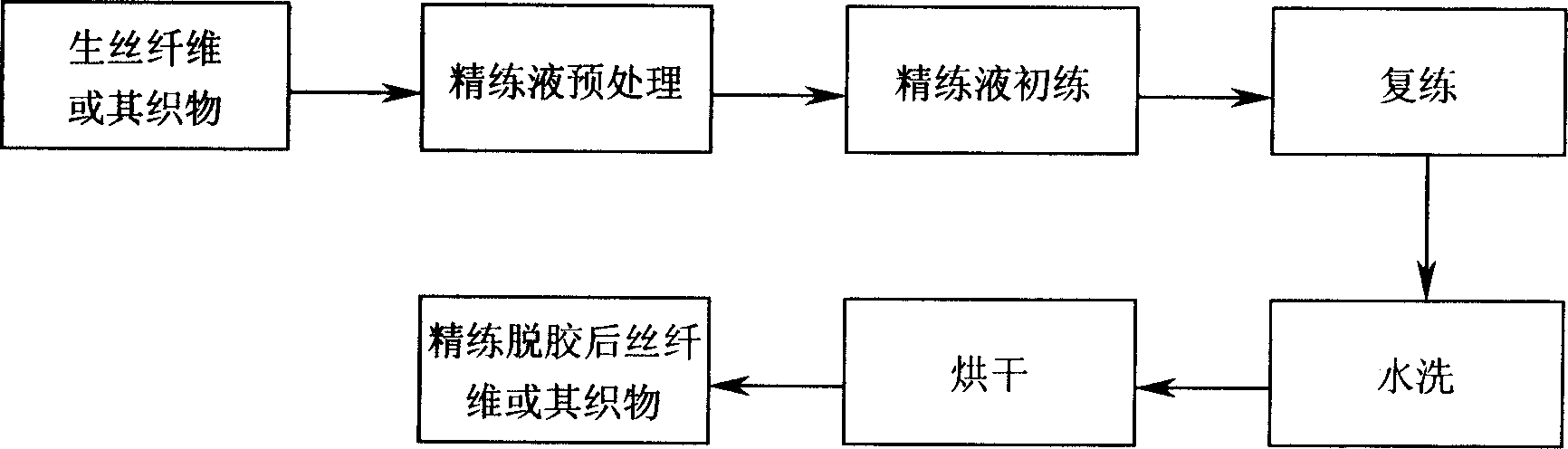

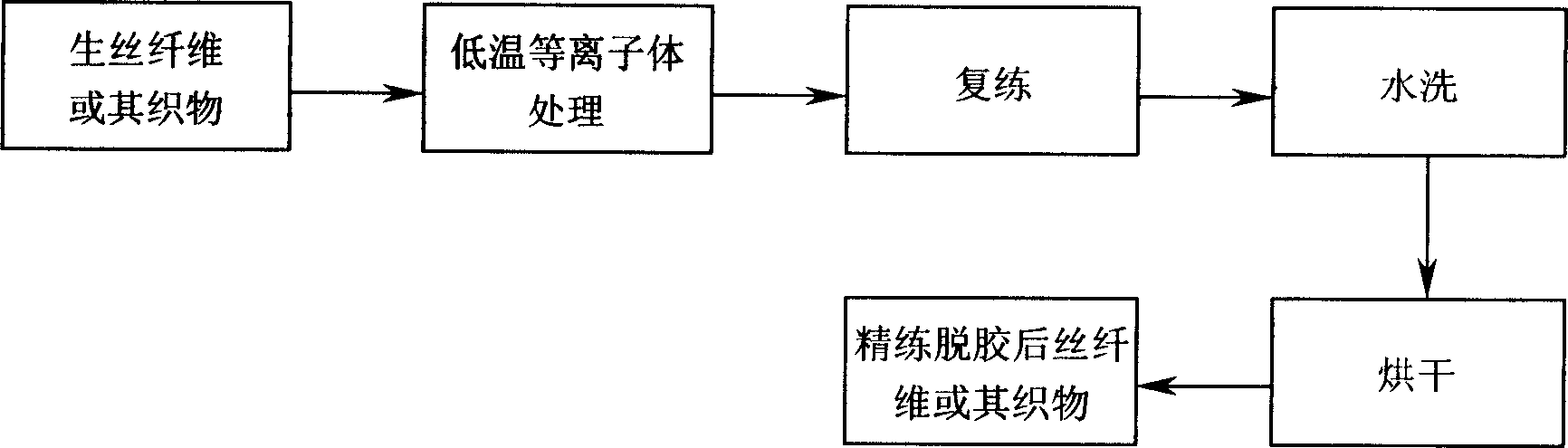

Refining degumming method for silk fiber and its fabrics

InactiveCN1570258AAccelerates and enhances penetrationSpeed up and enhanceUltrasonic/sonic fibre treatmentTextile fiberEngineering

This invention discloses one kind of silk textile fiber and its fabric fining come unglued method. Front it uses the low temperature plasma technology carries on to the raw silk textile fiber and its the fabric processes, substitutes the conventional fining come unglued center's pretreatment, initially practices working procedure, then the direct process duplicate practices, achieves to the silk textile fiber and its the fabric concise come unglued's goal. Because the low temperature plasma physical ability sericin the macro-molecule carries on to the raw silk textile fiber and its fabric surface shells and splatters sculpture, causes its stopped chain or sculpture dehiscence, loose, duplicate causes to practice the fining medicinal preparation to be able fast to seep, bulked, degrades (hydrolisis or enzymolysis) sericin, therefore, has the craft simply, the energy conservation is highly effective, is advantageous to the clean production and the environmental protection merit.

Owner:SUZHOU UNIV

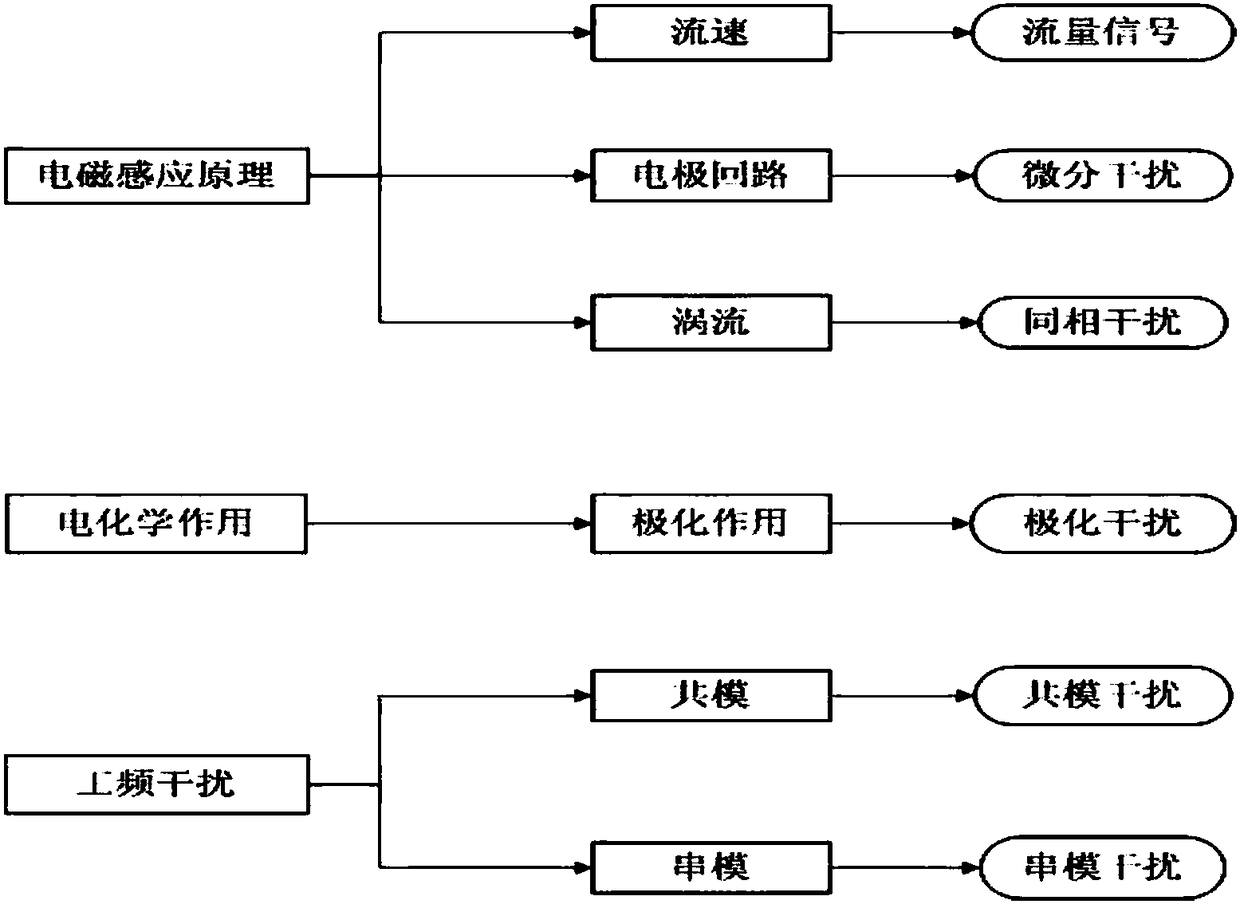

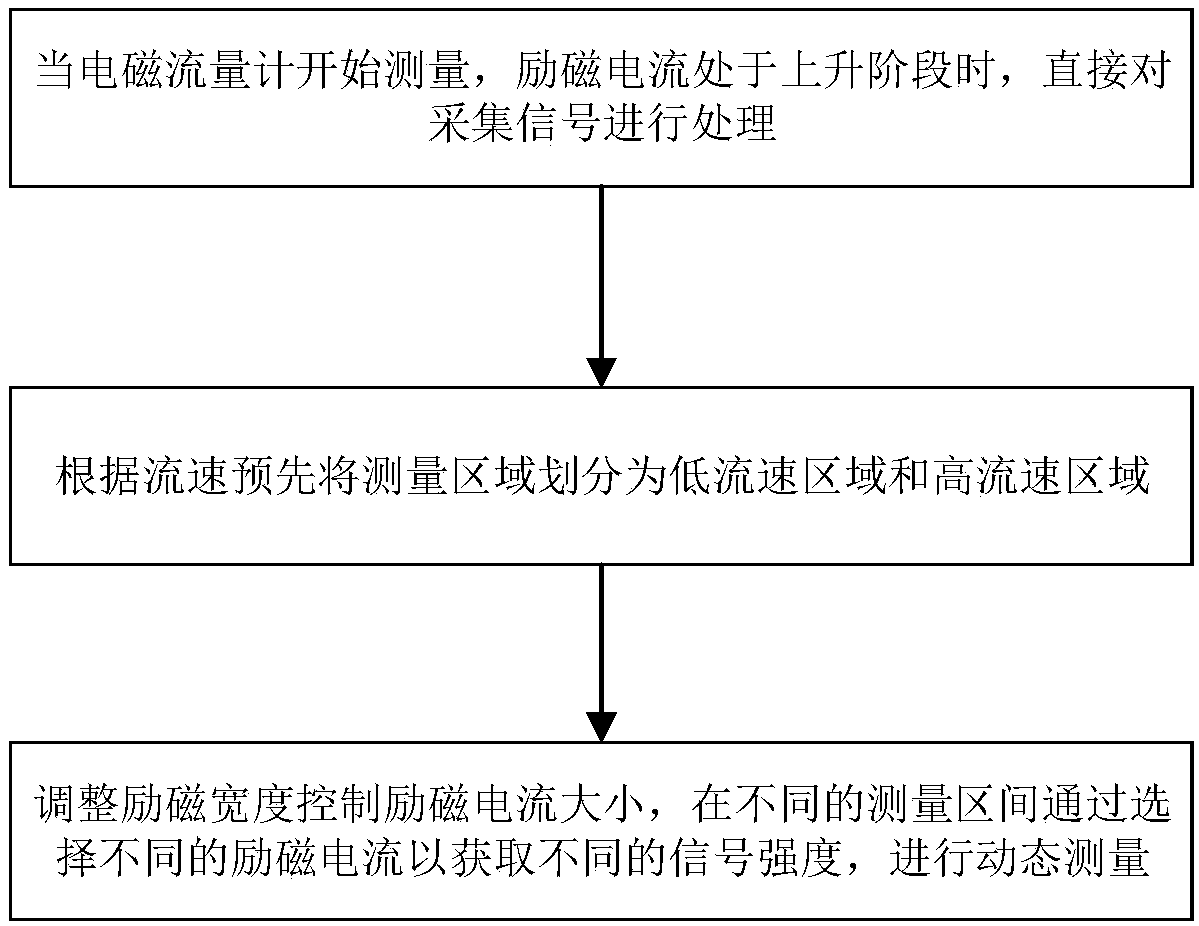

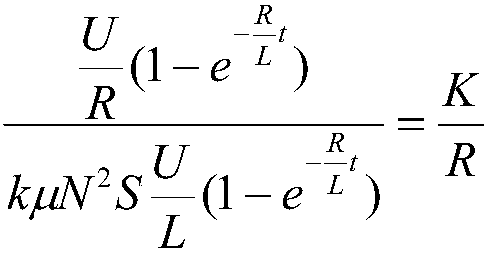

Electromagnetic flowmeter based on dynamic detection and detection method

ActiveCN108534852AImprove signal-to-noise ratioGuaranteed service lifeVolume/mass flow by electromagnetic flowmetersExcitation currentTransducing Unit

The invention provides an electromagnetic flowmeter based on dynamic detection and a detection method. The electromagnetic flowmeter comprises a power supply unit for performing exciting power supply,a sensor unit for acquiring a flow signal, an analog-digital conversion unit for conducting analog-digital conversion on the acquired signal, and a control processing unit for processing the acquiredsignal, wherein when the electromagnetic flowmeter begins to perform measurement and exciting current is at a rising stage, the control processing unit directs processes the acquired signal, the exciting current is controlled by adjusting the exciting width, and different signal intensities are obtained by selecting different exciting currents in different measurement intervals to perform dynamicmeasurement. The electromagnetic flowmeter meets the measurement requirements under different conditions, meanwhile ensures the service life, achieves the electric quantity saving purpose and inhibits interference signals to highlight measurement signals, the circuit design difficulty is remarkably reduced, the use quantity of components and devices is remarkably decreased, and accordingly the production cost is reduced.

Owner:CHONGQING CHUANYI AUTOMATION

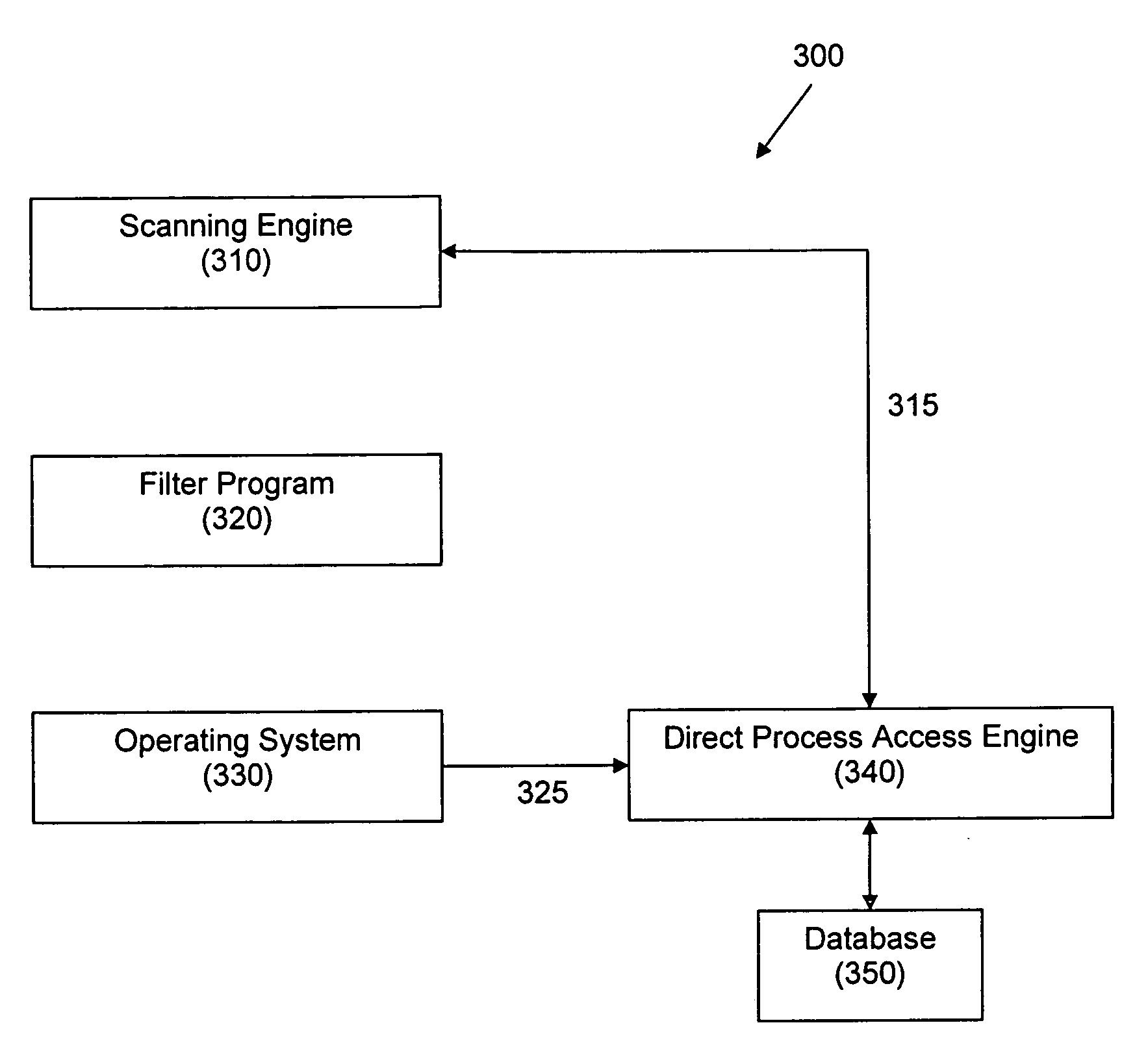

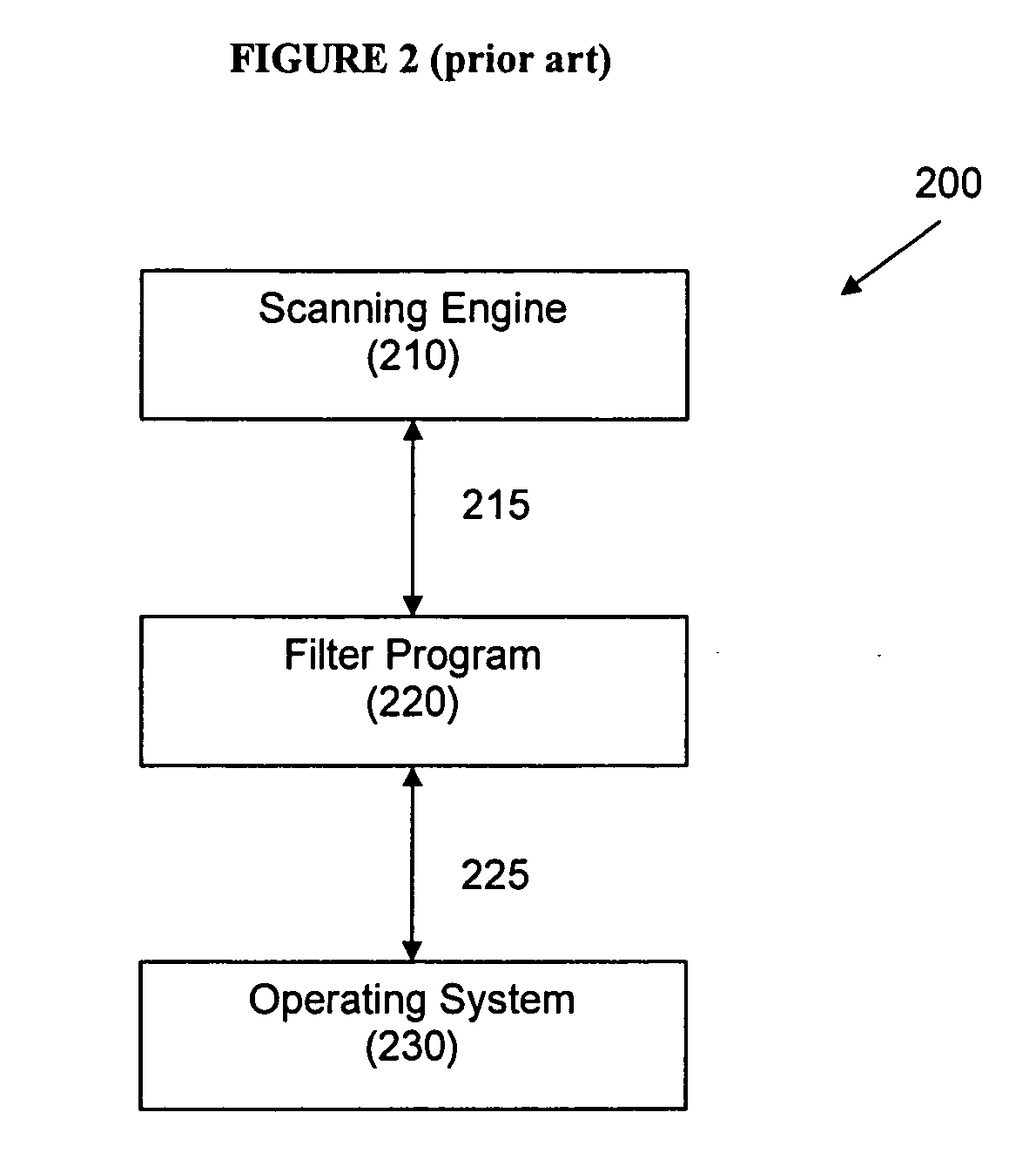

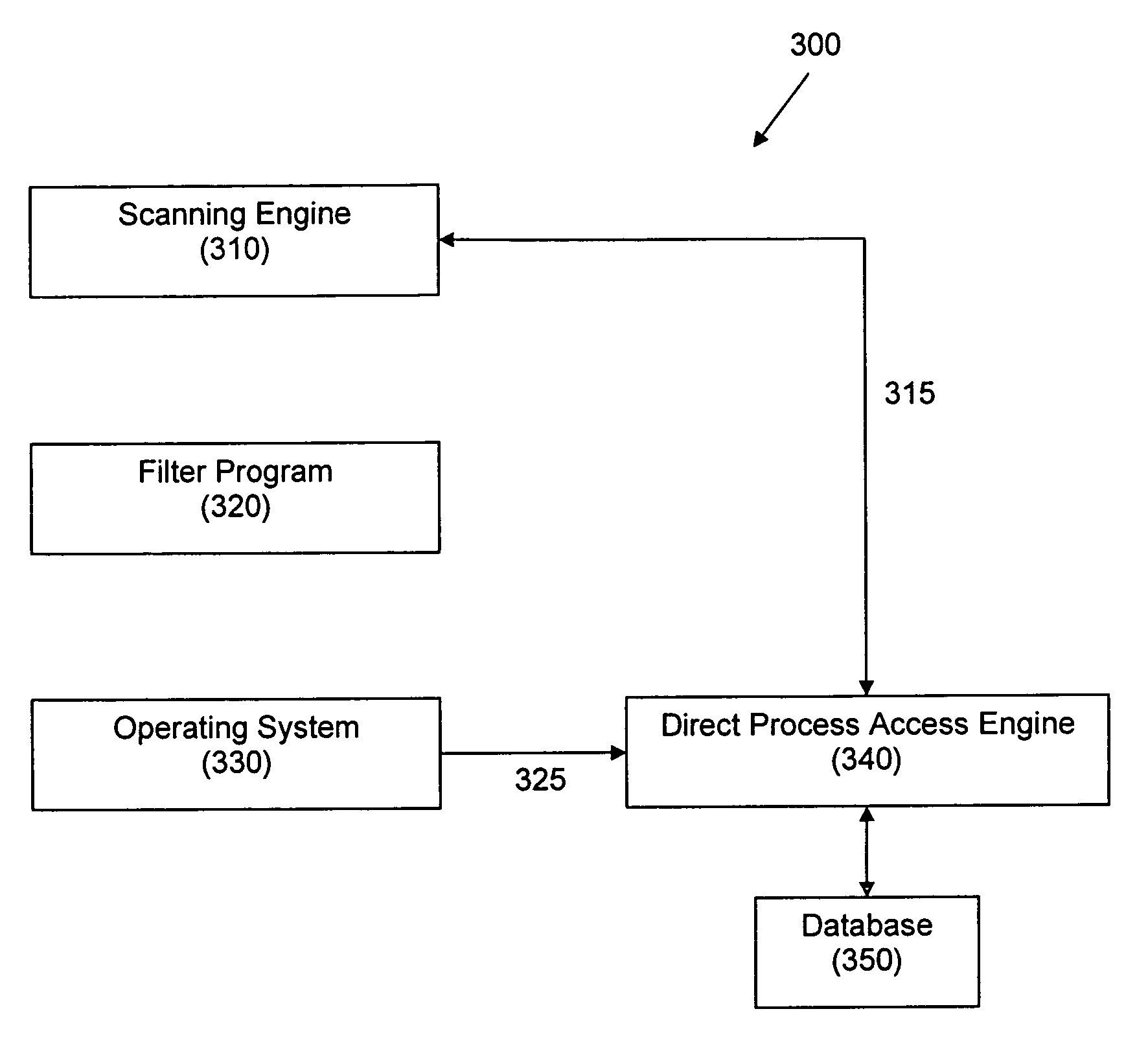

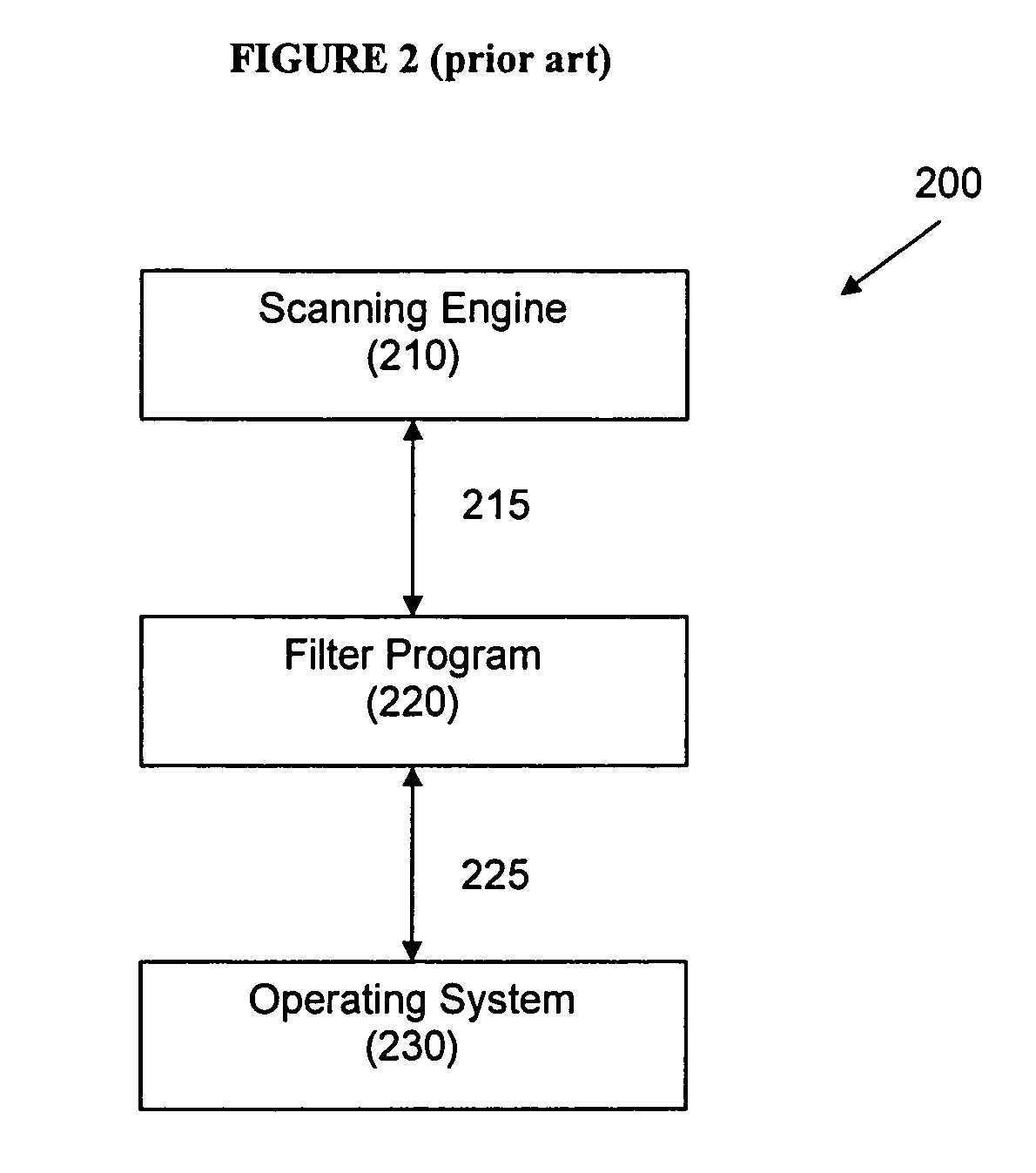

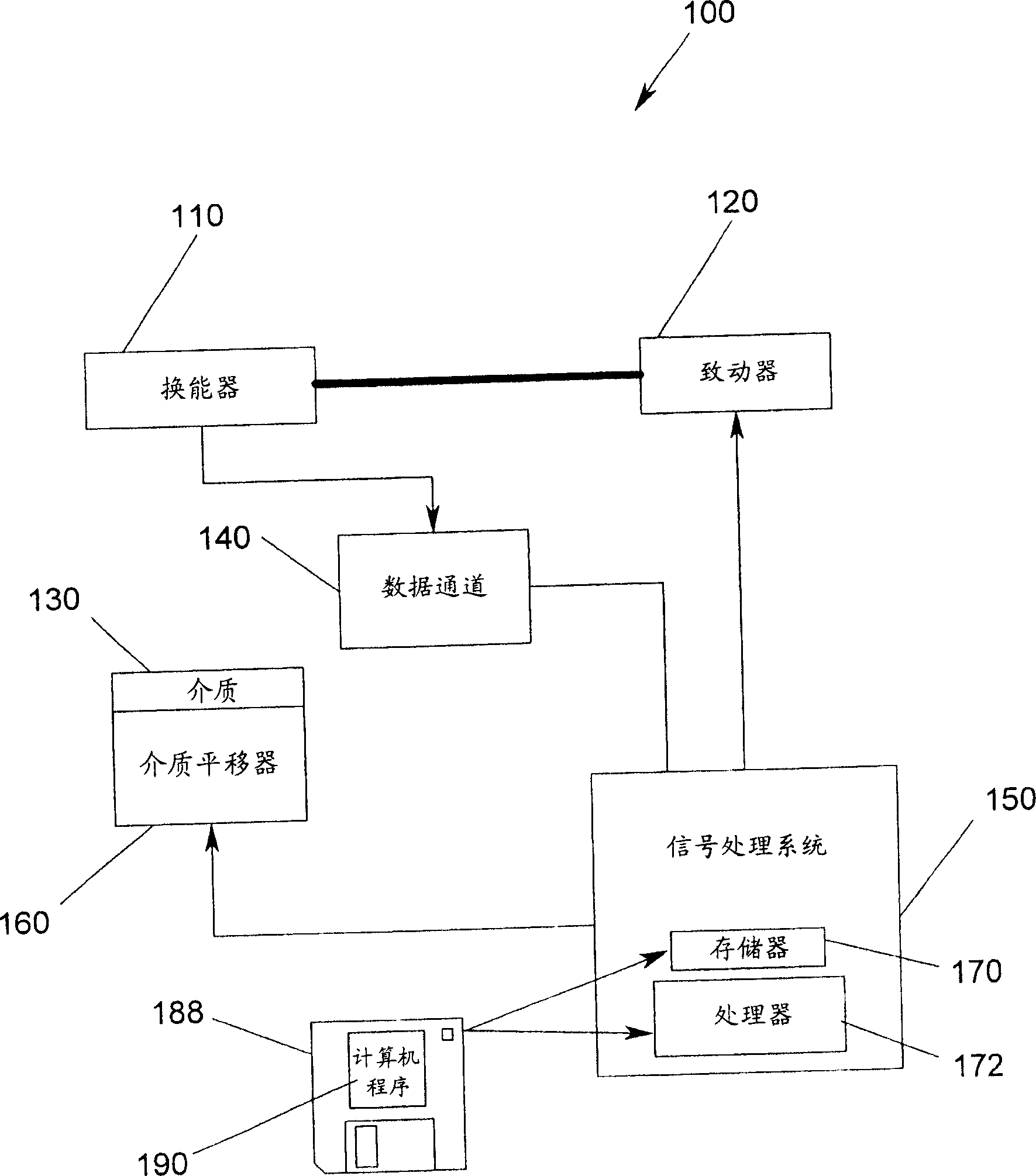

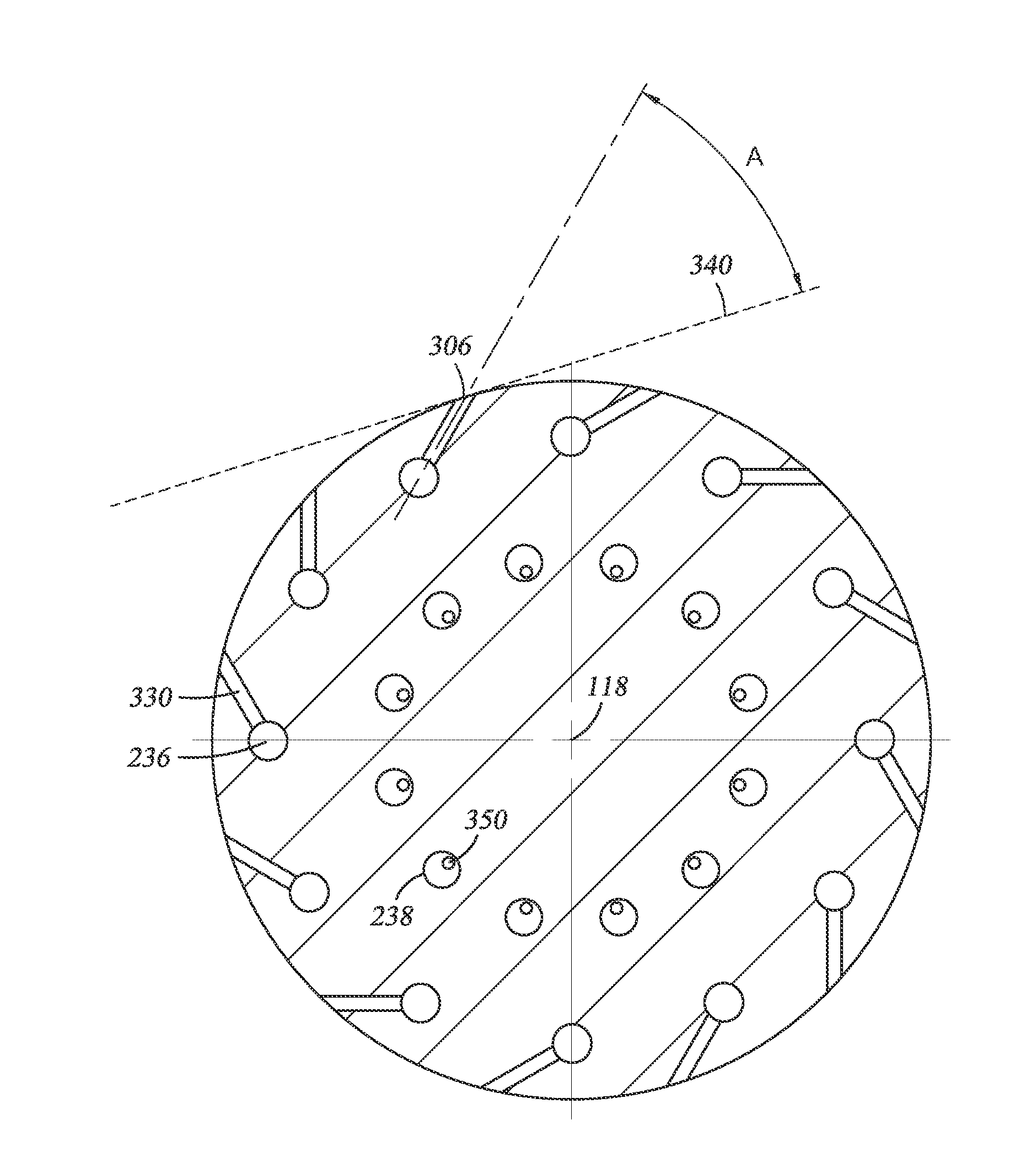

Direct process access

InactiveUS20080046977A1Memory loss protectionDigital data processing detailsComputer programReal-time computing

A method, computer program product and system for obtaining notification information about the state of an operating system 330. The method 300 includes the steps of receiving, by a Direct Process Access (DPA) engine 340, a request 315 for the notification information from a requesting program 310. The notification information is obtained from a database 350 associated with the DPA engine 340 and the notification information is provided to the requesting program 310. The DPA engine 340 receives update information 325 indicative of changes in the notification information directly from the operating system 330 and causes the notification information to be updated in the database 350.

Owner:NORTONLIFELOCK INC

Direct process access

InactiveUS7814549B2Memory loss protectionError detection/correctionOperational systemInformation provision

A method, computer program product and system for obtaining notification information about the state of an operating system. The method includes the steps of receiving, by a Direct Process Access (DPA) engine, a request for the notification information from a requesting program. The notification information is obtained from a database associated with the DPA engine and the notification information is provided to the requesting program. The DPA engine receives update information indicative of changes in the notification information directly from the operating system and causes the notification information to be updated in the database.

Owner:NORTONLIFELOCK INC

Method of making organohalosilanes

Owner:DOW SILICONES CORP

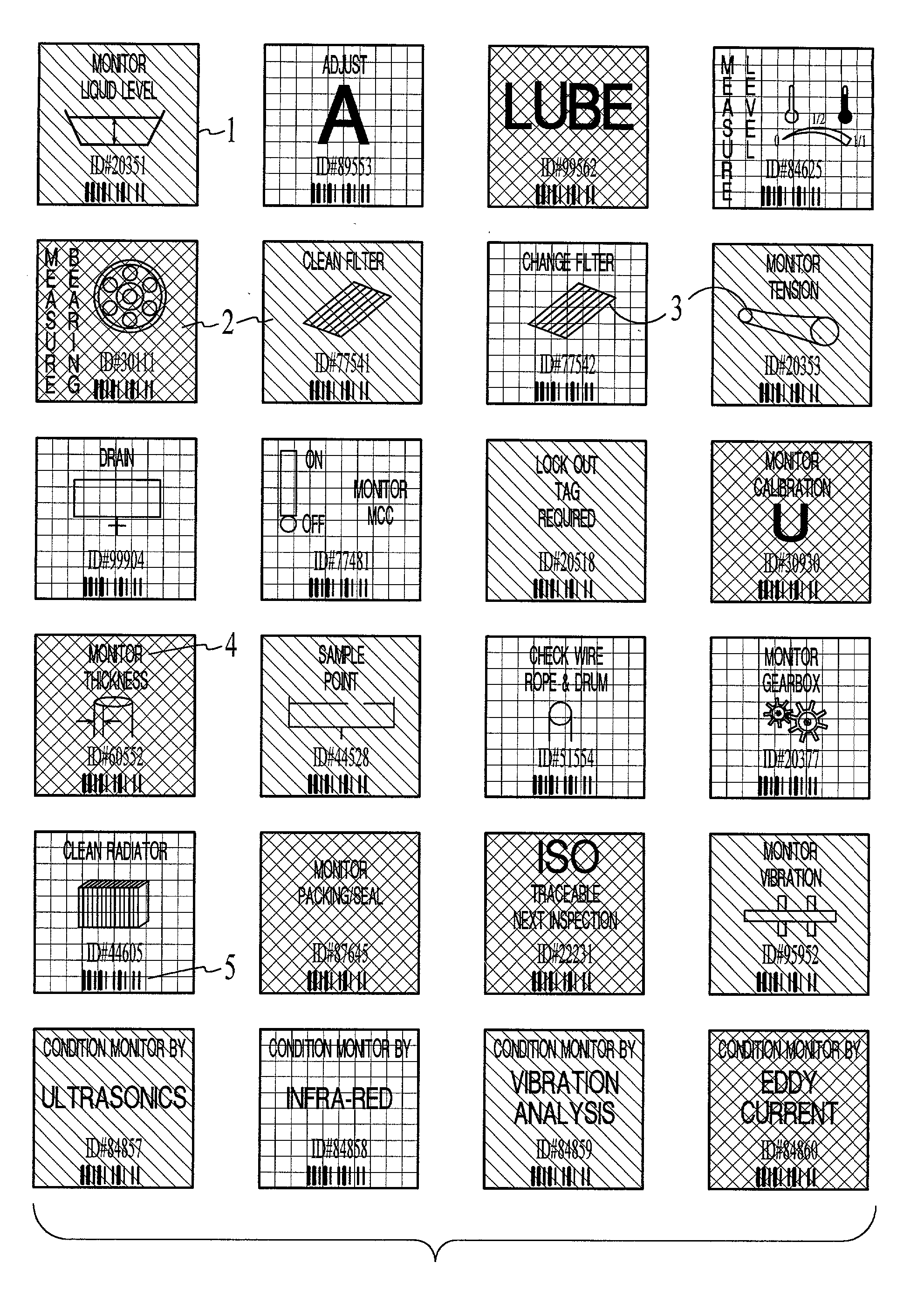

Task indicator decals for preventive maintenance and condition monitoring systems

InactiveUS20010000086A1Save hand transcription timeEasy accessStampsArticle advertisingBarcodeCondition monitoring

The task indicator decals imprinted with coding means including informative colors, symbolic pictographs, alphanumeric descriptors and / or bar codes and having adhesive backing means for mounting on equipment or equipment components to express preventive maintenance or condition monitoring task information at the point of service. Computer directed processes of making task indicator decals and the use of task indicator decals in preventive maintenance or condition monitoring systems.

Owner:LEWIS JEFFREY

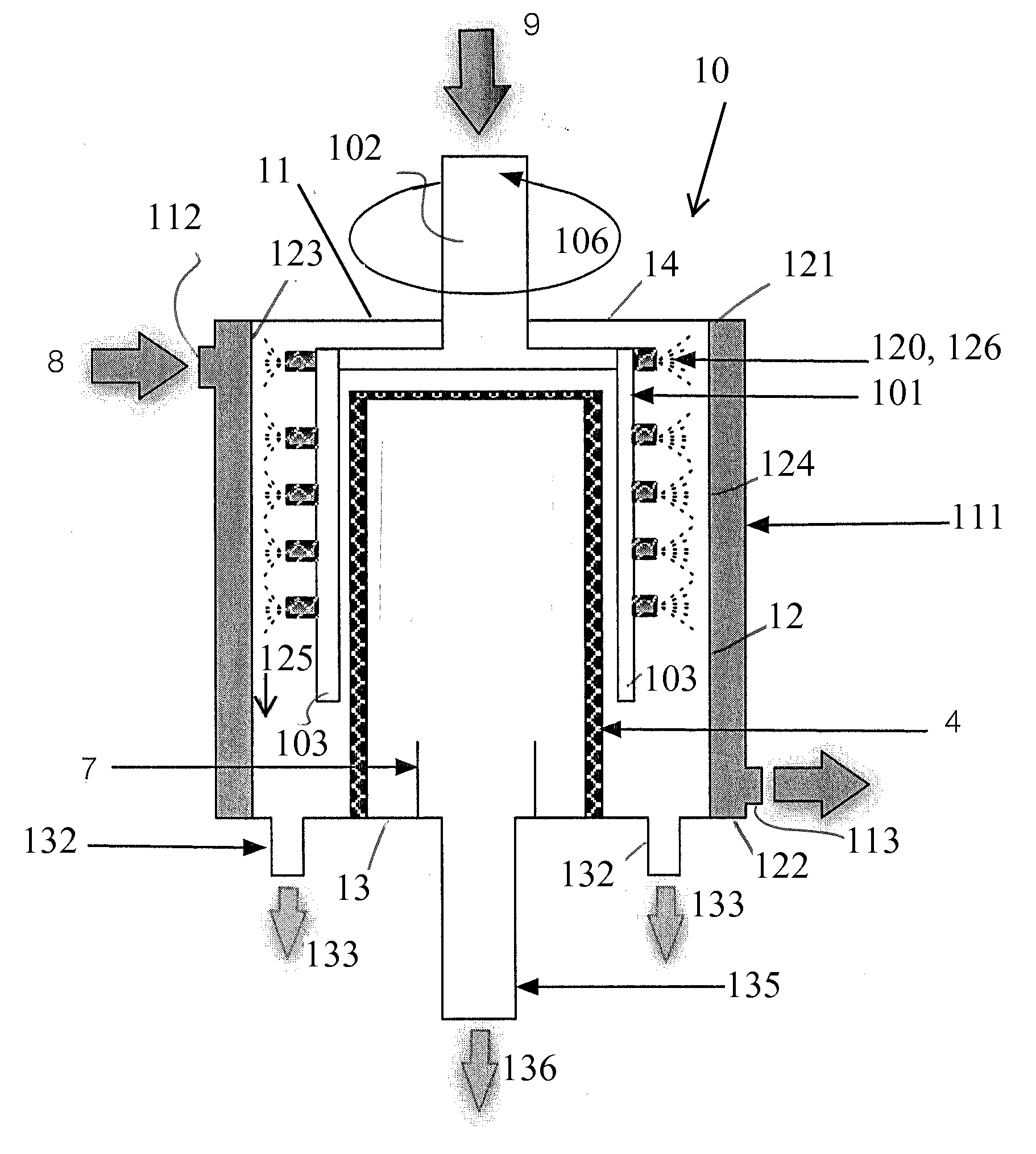

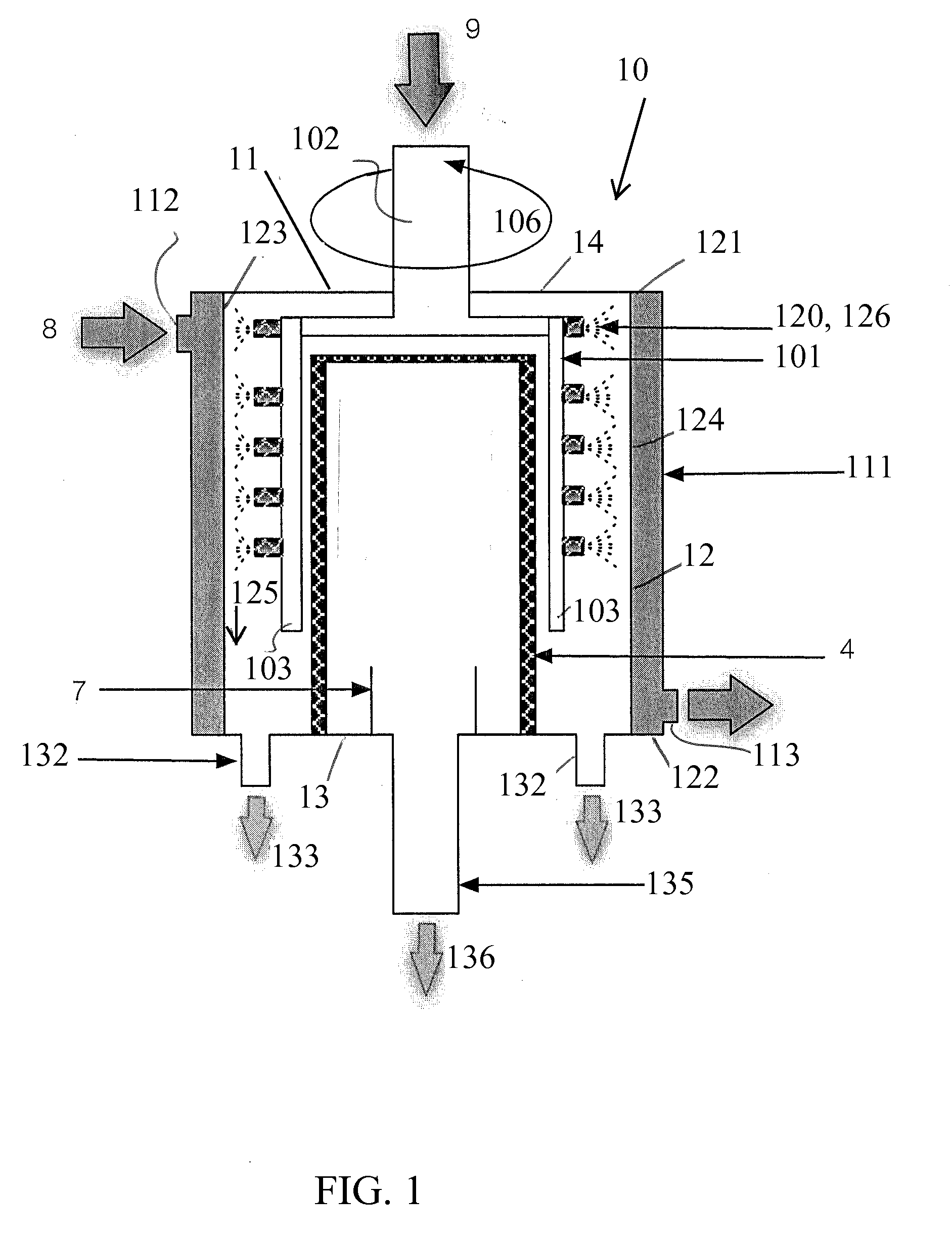

Controlled Thin Film Vapor Generator for Liquid Volume Reduction

InactiveUS20140367244A1Minimize energy consumptionIncrease heatWaste water treatment from quariesAuxillariesFirst pathwayControl manner

A reactor comprising a vessel; a fluid dispensing system having a plurality of ports arranged lengthwise along the inner surface of the vessel to distribute the fluid thereon in a controlled manner to maintain substantially uniform thin film flow along the length of the inner surface; and an outlet for removing vapor. A system comprising a fluid source; a first vessel; a heat exchanger for preheating the fluid; a first pathway for directing a preheating fluid from the first vessel to the heat exchanger; and a second pathway for directing preheated fluid toward the first vessel for processing. A method comprising introducing a fluid; distributing the fluid in a controlled manner to form a substantially uniform thin film flow an inner surface of a vessel; evaporating fluid; and removing vapor. A method comprising introducing a fluid; processing the fluid; directing processed fluid into another vessel; and further processing the fluid.

Owner:R3 FUSION

Method for extracting lentinan from foot of lentinus edodes

A method for extracting lentinan from the foot of lentinus edodes belongs to the technical field of polyose and derivatives processing and is used for solving the problem of improving the extraction rate of lentinan in the foot of lentinus edodes. The technical proposal is as follows: the foot of lentinus edodes is taken as raw material to prepare the lentinan through the steps of pretreatment, extraction, concentration, alcohol sedimentation and separation, drying and the like. After improvement, the extraction step is as follows: pretreated degreased lentinus edodes foot powder is extracted under decompressed hot reflux at the temperature of 40-70 DEG C; leaching liquor is 0.1-0.4mol / L diluted acid solution; the mass ratio of the diluted acid solution and the lentinus edodes foot powder is 30-50:1 when leaching; the leaching time is 40-90min; the pressure adopted in leaching is 2.5-15MPa; and the diluted acid solution is volatile acid solutions of hydrochloric acid, acetic acid and the like. The method increases the rate of extracting the lentinan from the foot of the lentinus edodes to a great degree, effectively improves the utilization rate of the raw material, reduces production cost, has simple and direct process route and little equipment investment, and is easy for industrialization and an effective method for comprehensively processing and using the foot of the lentinus edodes.

Owner:何颖娜

Direct process for producing nitric acid

InactiveCN105936501ANo harmEasy to separateNitric oxideNitric acidNitrogen monooxideNitrogen dioxide

The invention discloses a direct process for producing nitric acid. The direct process comprises the following steps: (1) compressing oxygen; (2) compressing ammonia gas; (3) preparing nitrogen monoxide; (4) preparing nitrogen dioxide; (5) preparing nitric acid through a spraying method; (6) refluxing nitrogen monoxide. The direct process has the advantages that no intermediate that is harmful to the environment is generated during the production process of nitric acid; no product that affects the nitric acid is generated; the final byproduct namely nitrogen monoxide can be repeatedly used; the whole preparation technology is simple, the product quality is high, and the direct process is easy to popularize and use.

Owner:TIANJIN CITY PO MOIST CHEM

Redistributing silalkylenes in an alkyl-rich silalkylene-containing residue

A process for redistributing an alkyl-rich silalkylene-containing residues. The process comprises contacting an alkyl-rich silalkylene-containing residue with a halosilane selected from the group consisting of alkyltrihalosilanes and tetrahalosilanes in the presence of an effective amount of a redistribution catalyst at a temperature within a range of about 150 DEG C. to 500 DEG C. thereby forming a redistribution product comprising dialkyldihalosilane. At least a portion of the catalyst in the present process may be formed in situ during conduct of the direct process and isolation of the resulting monosilanes.

Owner:DOW SILICONES CORP

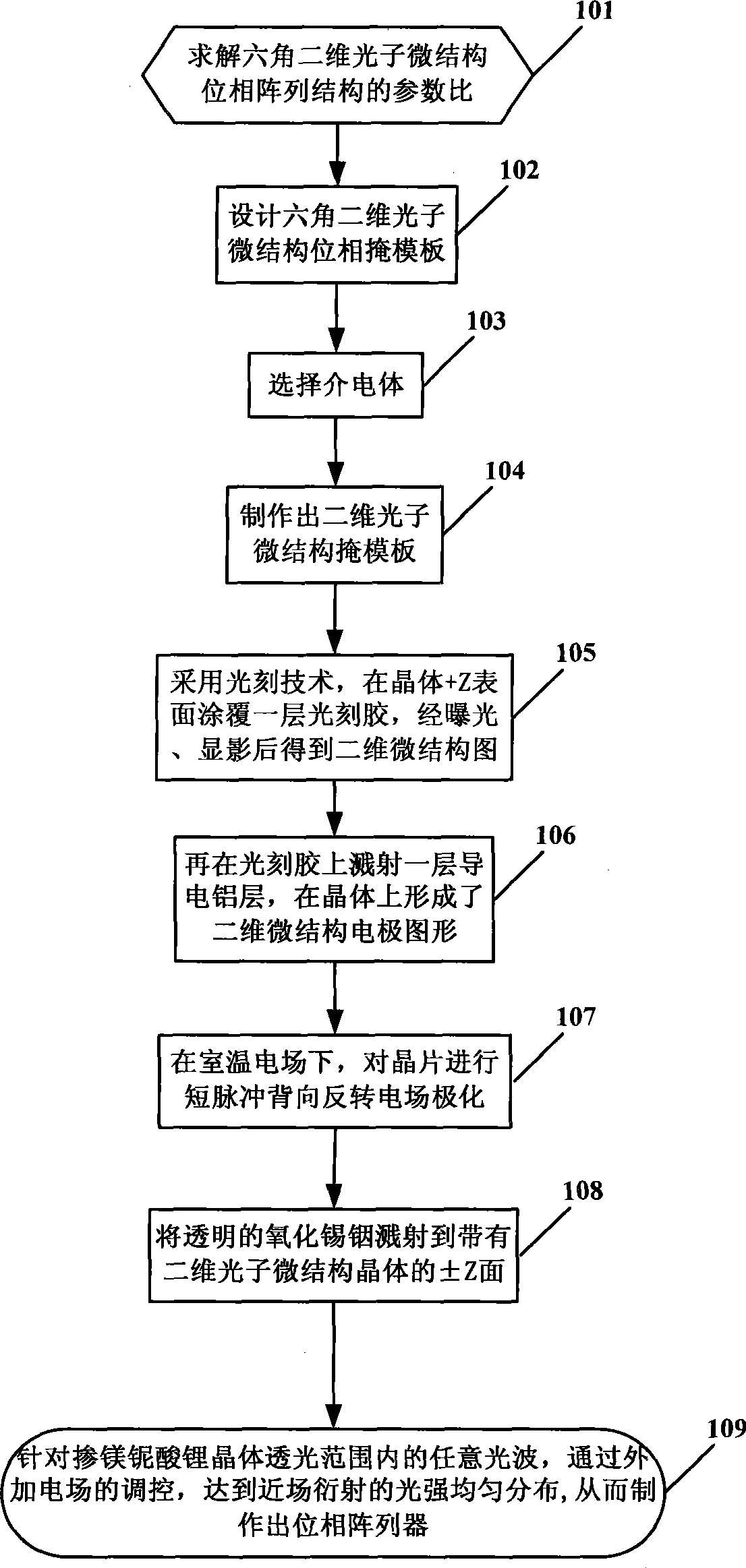

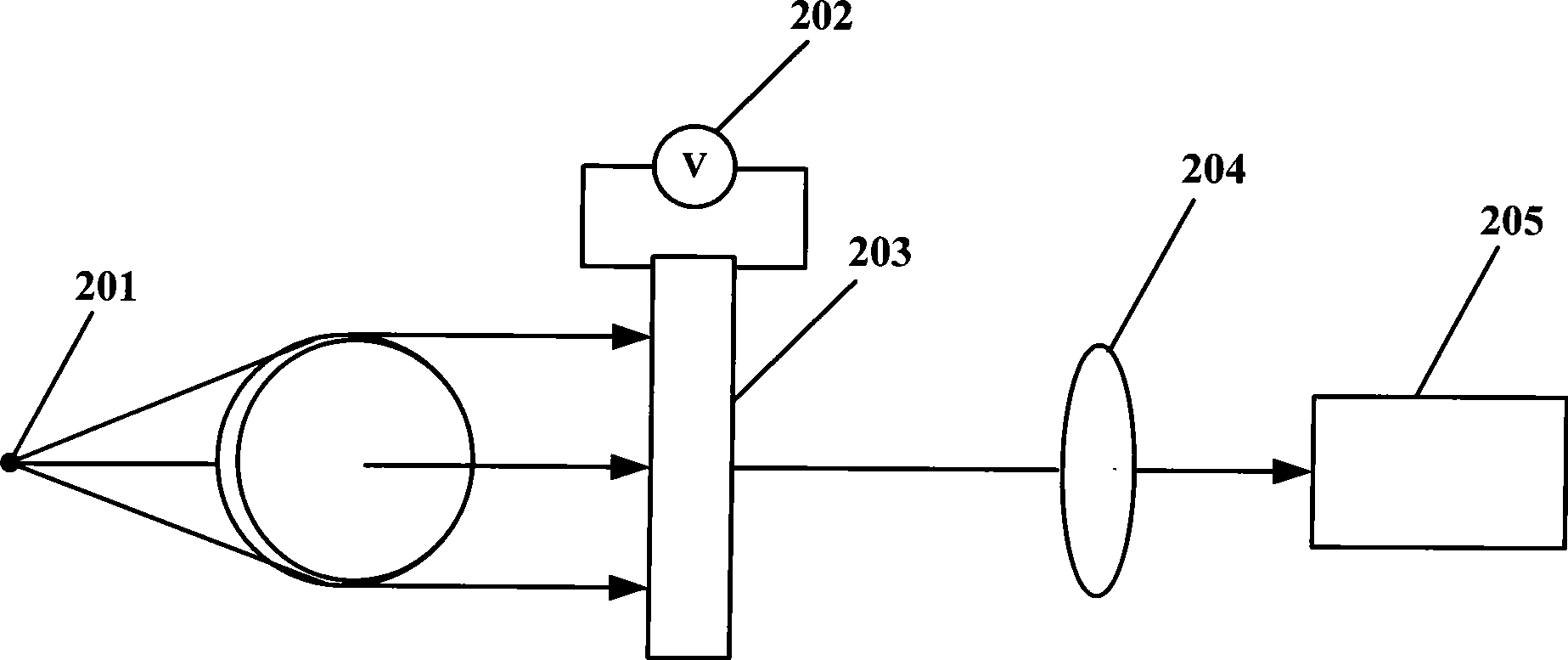

Method for manufacturing position phase array machine capable of adjusting two-dimensional photon microstructure

InactiveCN101373282AAchieve glowEasy to processPhotomechanical apparatusNon-linear opticsArray elementOptical communication

The invention discloses a manufacturing method for an adjustable two-dimensional photon microstructure phase array device, and belongs to the technical fields of optical communication and optical multi-path imaging. The technical proposal is that the hexangular two-dimensional photon microstructure phase array can be manufactured on a substrate of LiNbO3 crystals doped with Mg by utilizing the mature semiconductor photoetching technique process and adopting the trailing direction reversion burst pulse polarization electric field technique. The LiNbO3 crystals doped with Mg has better electro-optical properties, so that through the regulation and the control of an external electric field added on the plus or minus Z surface of the substrate with the two-dimensional photon microstructure, the continuous change of the phase between 0 to 2Pi can be realized, and a random light wave within the transmission range (5Mum-320nm) of the LiNbO3 crystals doped with Mg can realize the phase period distribution field to enable the light intensity of near field diffraction to be distributed uniformly. Through using the LiNbO3 crystals doped with Mg, the invention can direct process and manufacture micro-optical array elements, thereby realizing the array irradiancy of the random light wave within the transmission range of the crystals, and simplifying the manufacturing procedure at the same time.

Owner:BEIJING JIAOTONG UNIV

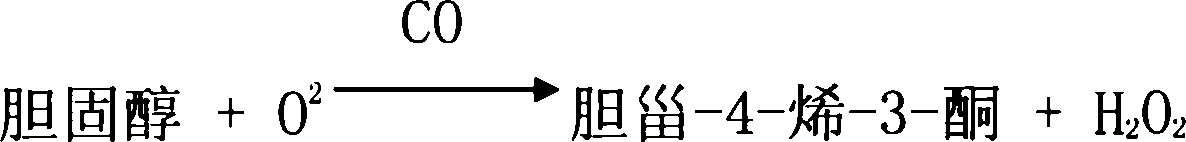

Method for determining cholesterol concentration in remnant lipoprotein by immunobinding direct process or immuno-precipitation separation process

InactiveCN1880956AAccurate detectionInhibition of relaxationBiological testingCoronary heart diseaseBlood plasma

The invention discloses a serum or RLP density in the plasma testing method, which is characterized by the following: adopting immune combined direct method or immune sediment separating method; providing effective estimation and reference accordance for atherosclerotic disease, coronary disease and relative metabolic disease of atherosclerotic disease.

Owner:上海北加生化试剂有限公司 +4

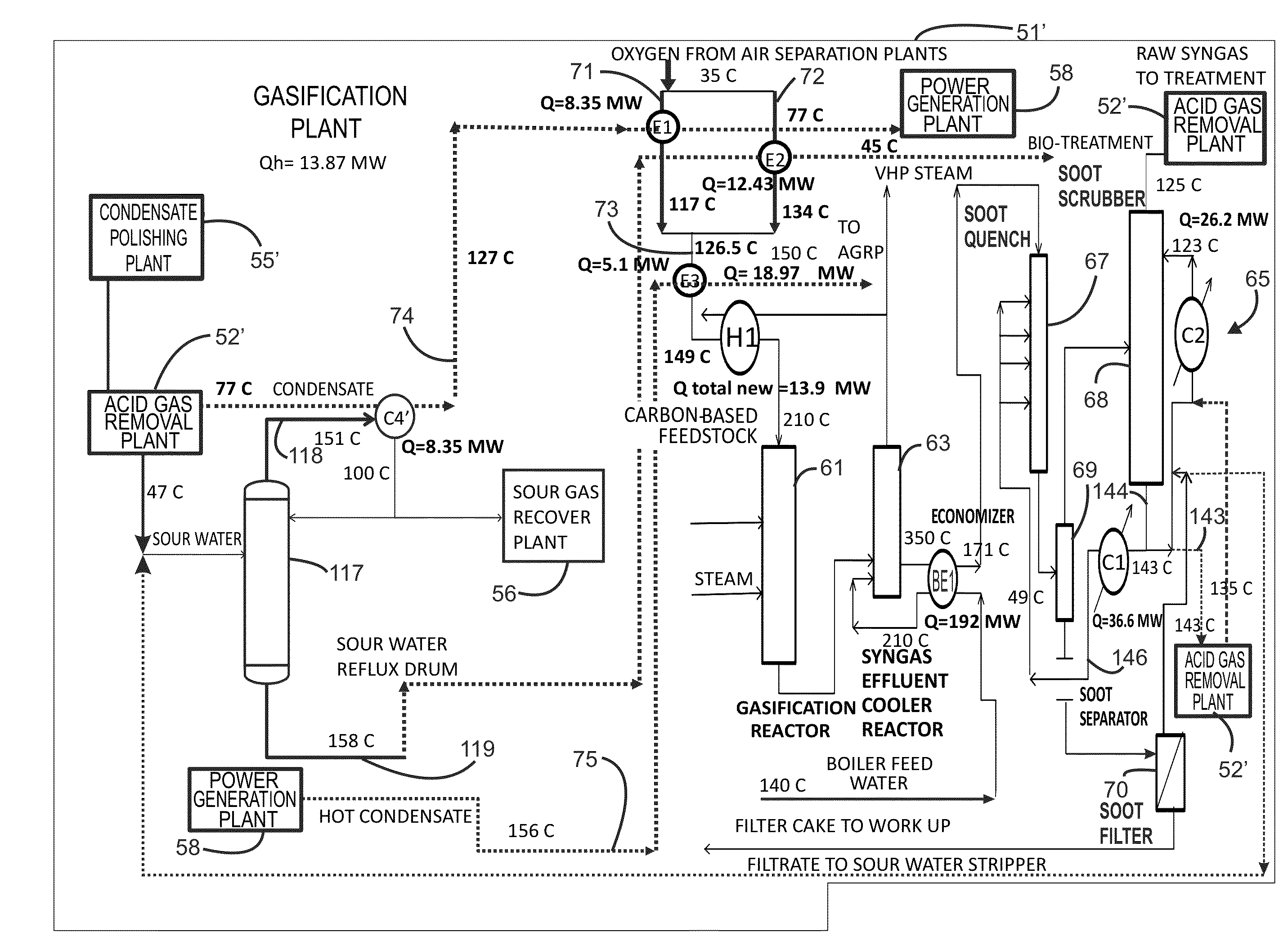

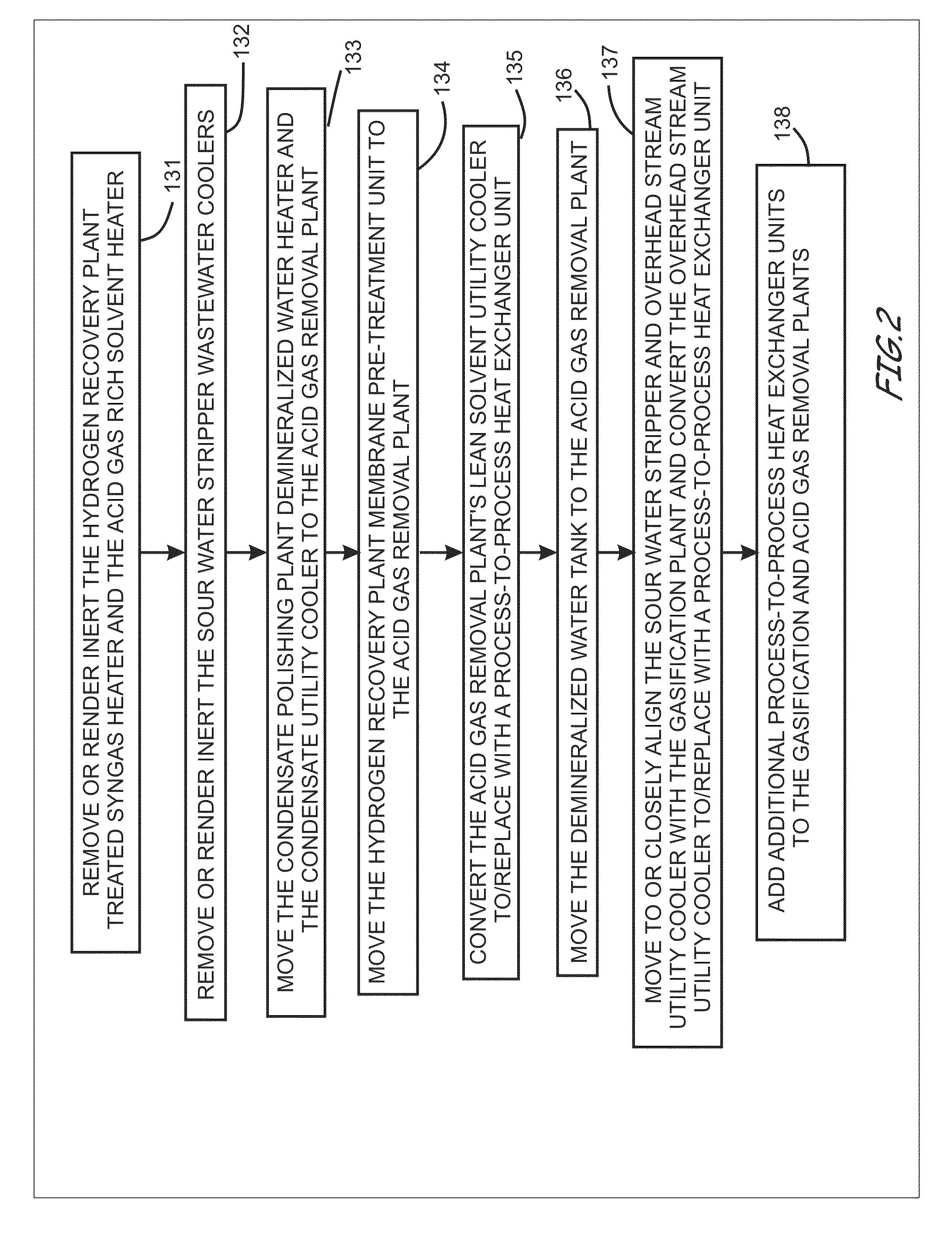

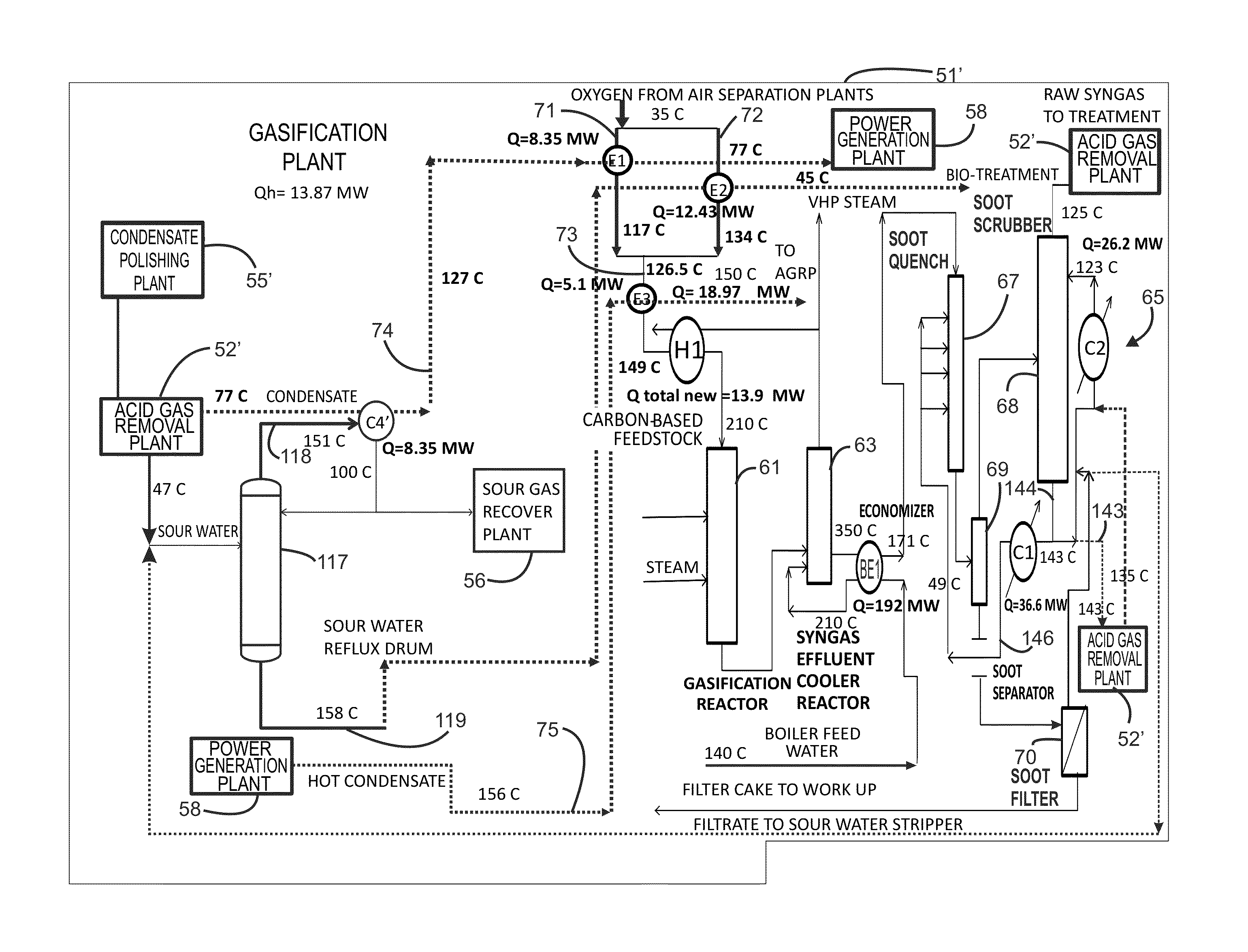

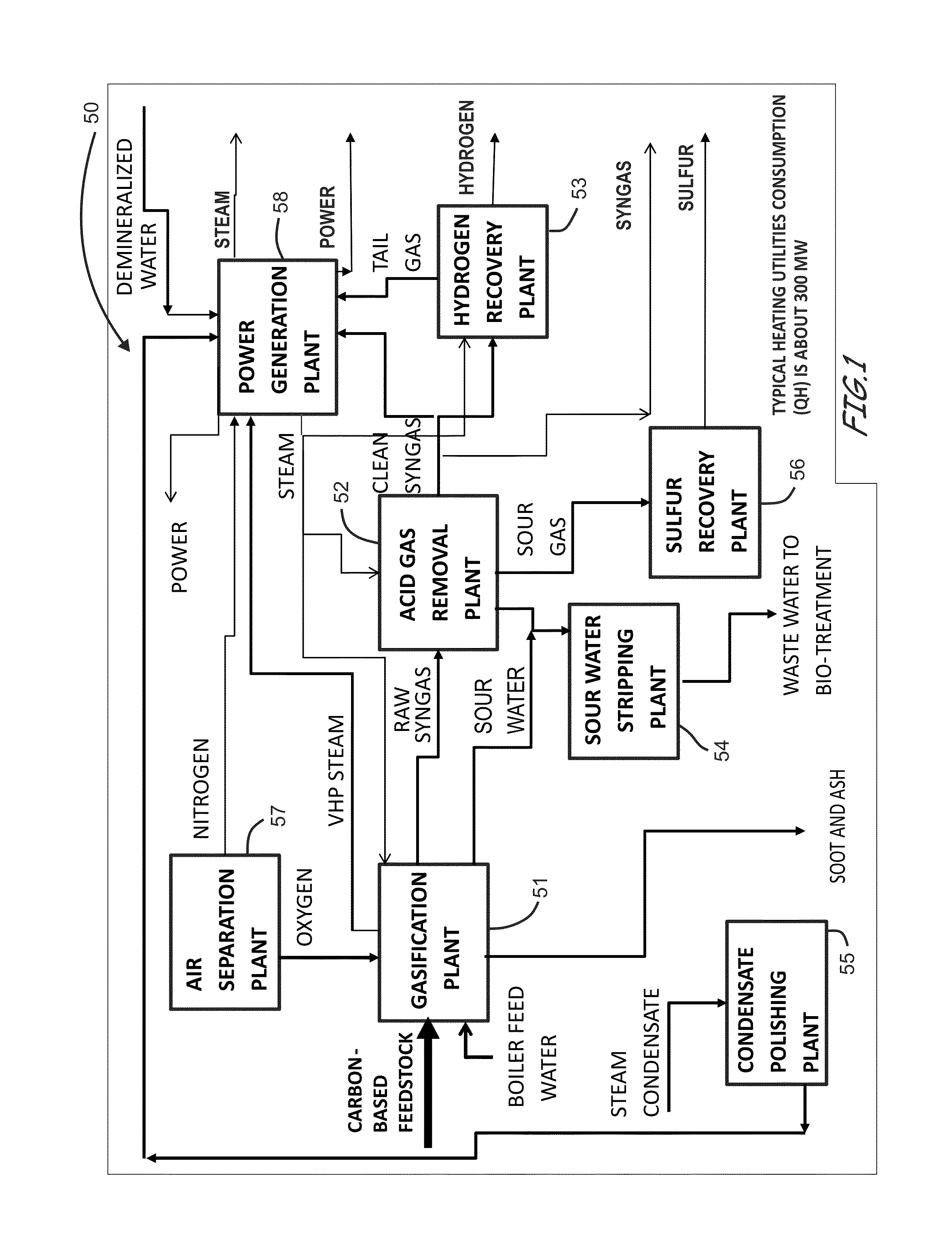

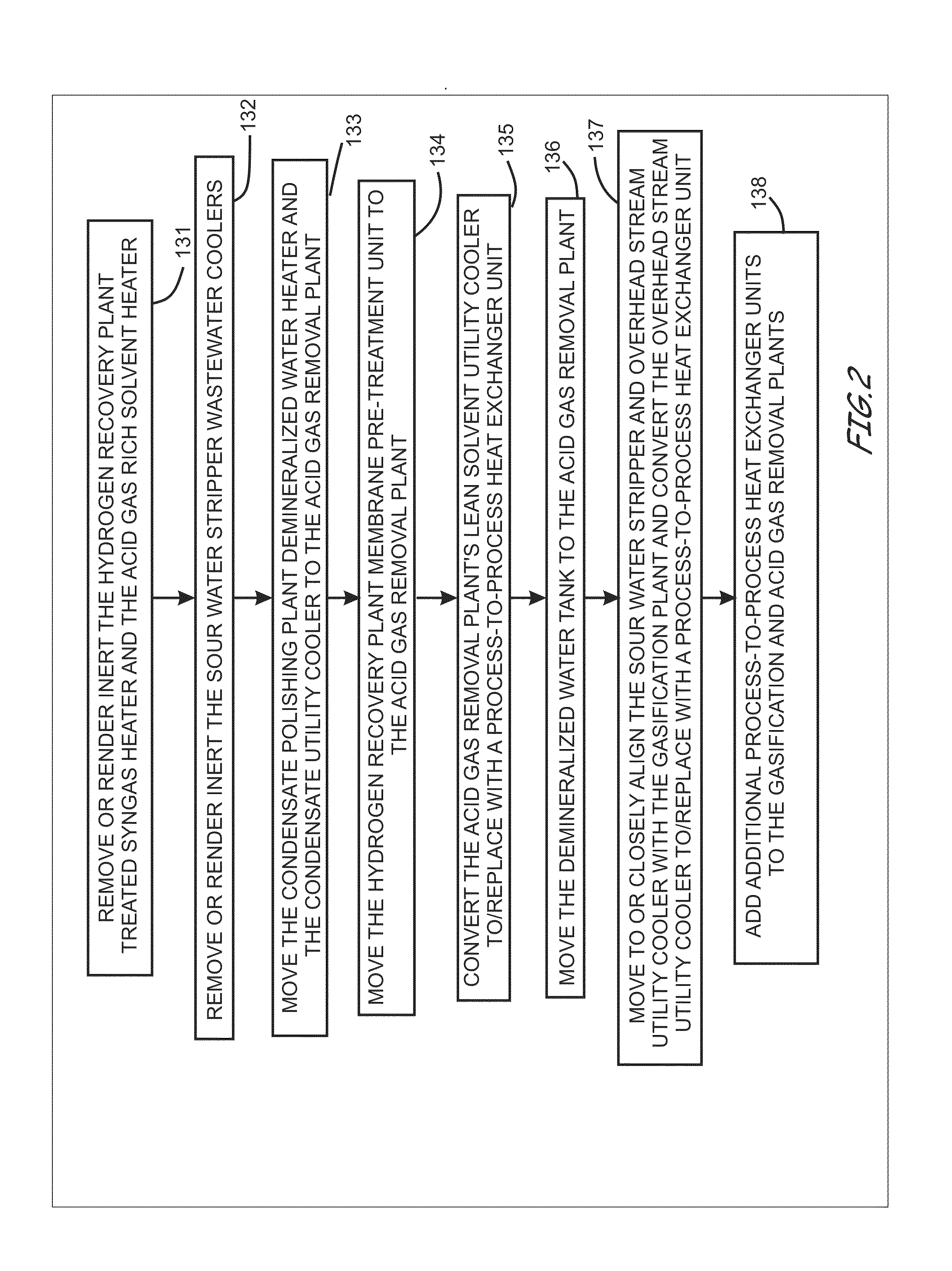

Energy efficient gasification-based multi generation apparatus employing energy efficient acid gas removal plant-directed process schemes and related methods

ActiveUS20150376521A1Reduce heating energy-utility-based GHG emissionMore energy efficientProcess control/regulationGasifier mechanical detailsSyngasSolvent

Energy-efficient gasification-based multi-generation apparatus, facilities, or systems, and methods of modifying existing gasification-based multi-generation apparatus and the various conventional thermal coupling arrangements, are provided. An exemplary gasification-based multi-generation apparatus comprises an acid gas removal system configured to remove acidic contaminants from a raw syngas feed to thereby provide a treated syngas feed and an acid gas removal plant or facility; a gasification system configured to generate the raw syngas feed from a carbon-based feedstock and comprising a gasification plant or facility; and a condensate polishing plant or facility. The acid gas removal system comprises an acid gas contaminant absorber, a solvent regenerator, a contaminant hydrolysis reactor, and an acid gas removal system energy management system. The acid gas removal system energy management system comprises a sixth acid gas removal system process-to-process heat exchanger unit positioned to receive at least a portion of a polished cold condensate stream from the condensate polishing plant or facility to provide heat energy to the at least a portion of the polished cold condensate stream. The gasification system comprises a gasification reactor and a gasification system energy management system. The acid gas removal plant or facility is integrated with the condensate polishing plant or facility through the at least a portion of the polished cold condensate stream received by the sixth acid gas removal system process-to-process heat exchanger unit.

Owner:SAUDI ARABIAN OIL CO

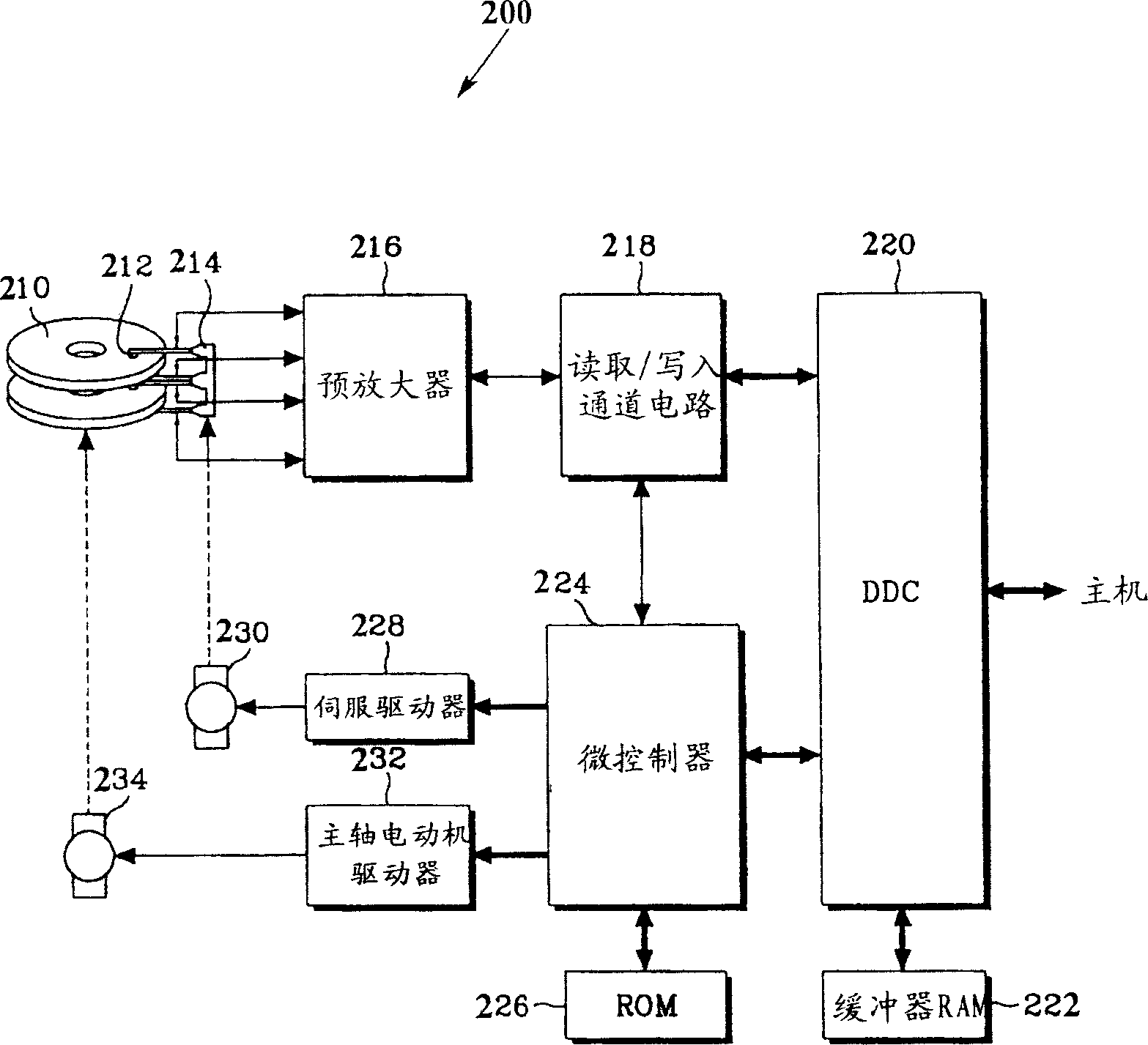

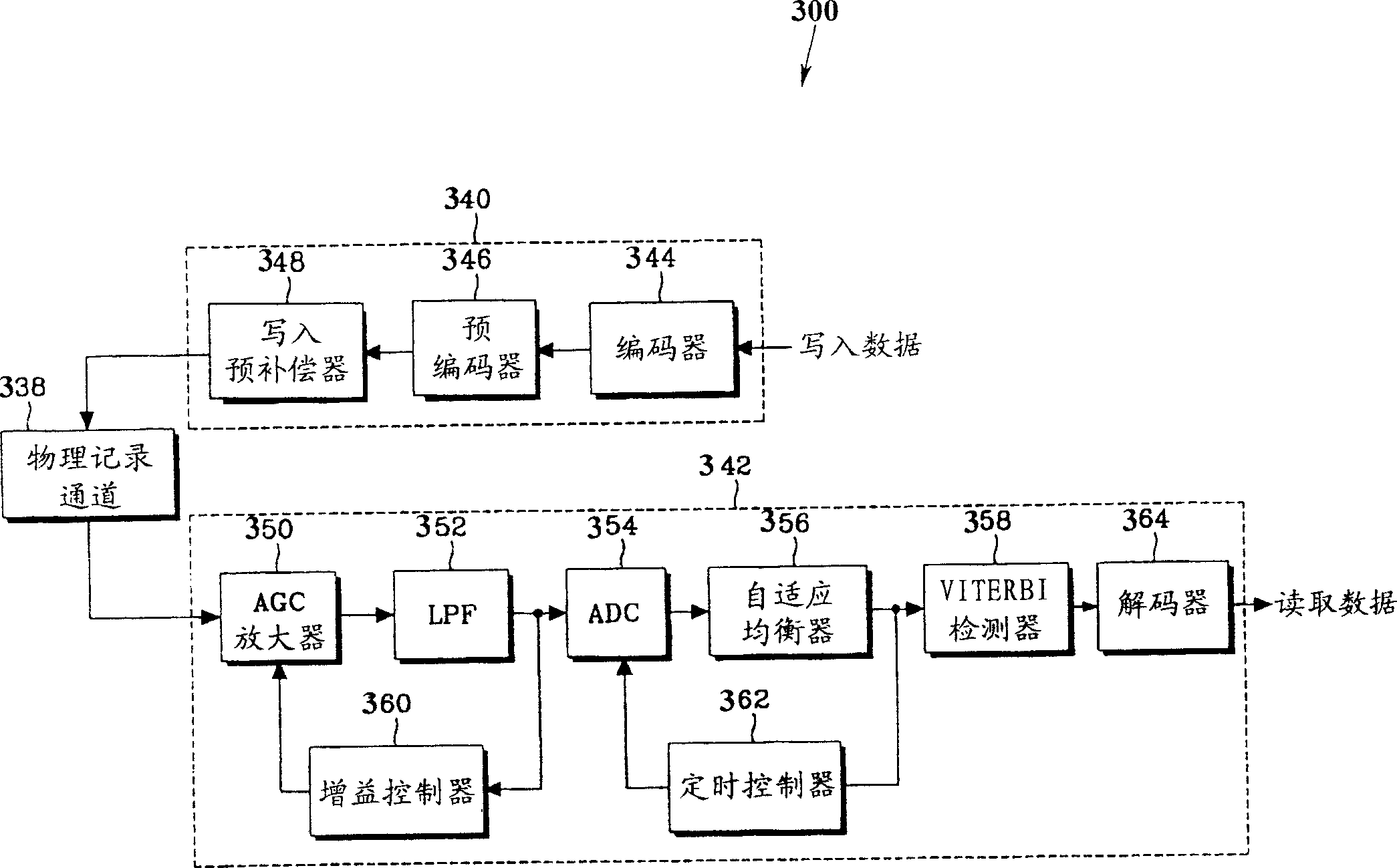

Apparatus for providing dynamic equalizer optimization

InactiveCN1674133AAnalogue recording/reproducingRecord information storageSelf adaptiveComputer engineering

An apparatus for providing dynamic equalizer optimization is disclosed. The present invention solves this by providing an equalizer coefficient update that converges towards the same solution as the direct method without having to first write a known pattern to the disc or requiring any prior knowledge of the data already written on the disc above question. Adaptive cosine functions can be used to modify only the DFIR tap settings, only the j and k parameters of the cosine equalizer, or both the tap settings of the DFIR filter and the j and k parameters of the cosine equalizer. Other algorithms, such as the LMS algorithm, can be used to modify parameters not modified by the cosine algorithm.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Straw-based amphoteric liquid manure controlled-release agent and application thereof

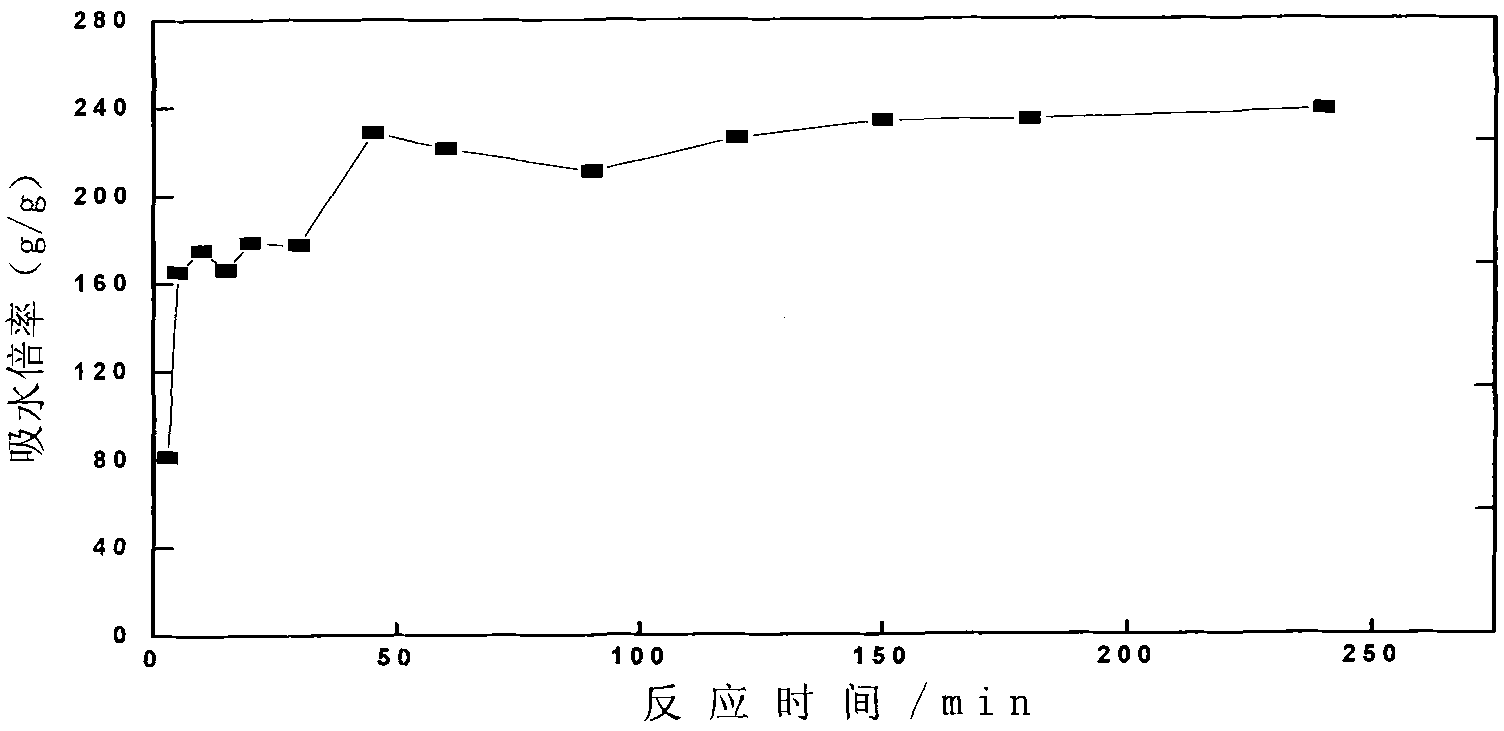

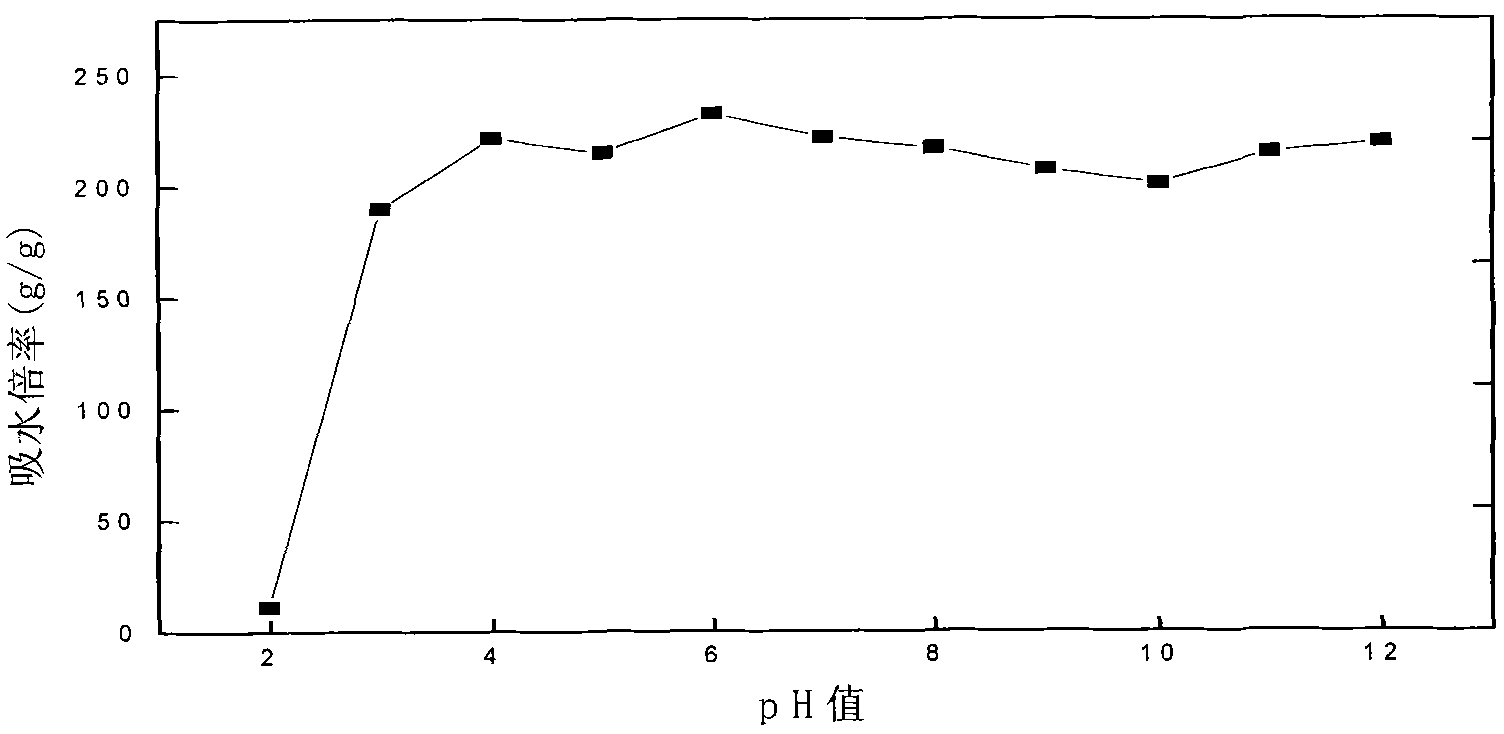

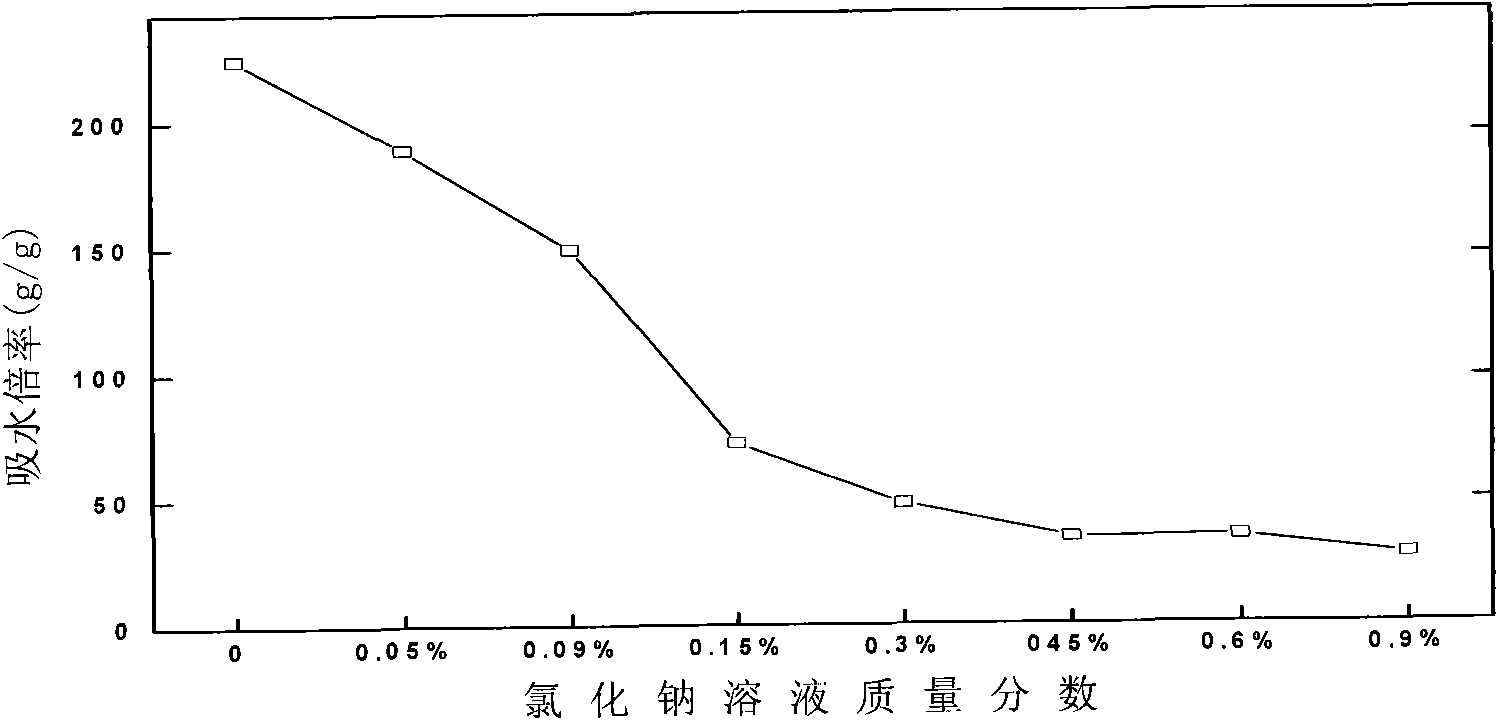

InactiveCN101838171AImprove water absorptionApplicable to a wide range of pHFertilizer mixturesCerium nitrateSulfite salt

The invention discloses a straw-based amphoteric liquid manure controlled-release agent, which is prepared under a condition that wheat straws, acrylic acid, acrylamide and dimethyl diallyl ammonium chloride are used as raw materials and persulfate, cerium nitrate amine and sodium sulfite as composite initiators. The straw-based amphoteric liquid manure controlled-release agent has the characteristics of high water absorbency, wide pH value application range, strong salty ion concentration adjustment, long useful substance storage time, biodegradability and low cost, is very favorable for liquid manure control, and can be widely applied to agricultural moisture maintenance and / or fertilizer maintenance. Simultaneously, a preparation method of the straw-based amphoteric liquid manure controlled-release agent has the advantages of simple and direct process, low cost, economical efficiency, practicability and the like.

Owner:SHANDONG UNIV

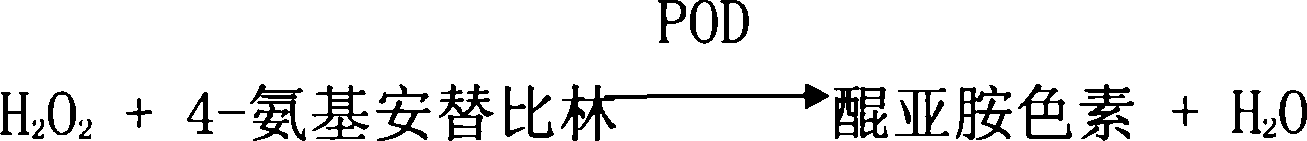

Energy efficient gasification based multi generation apparatus employing energy efficient gasification plant-directed process schemes and related methods

ActiveUS20150376520A1Less pollutionEasy to modifyProcess control/regulationGasifier mechanical detailsSyngasWastewater

Energy-efficient gasification-based multi-generation apparatus, facilities, or systems, and methods of modifying existing gasification-based multi-generation apparatus and the various conventional thermal coupling arrangements, are provided. An exemplary gasification-based multi-generation apparatus includes a gasification system configured to generate the raw syngas feed from a carbon-based feedstock. The gasification system includes a gasification plant or facility, a sour water stripping plant or facility comprising a sour water stripper, a gasification reactor, and a gasification system energy management system. The gasification system energy management system comprises a third gasification system process-to-process heat exchanger unit positioned to receive a wastewater bottom stream from the sour water stripper and to receive at least a portion of an oxygen feed to the gasification reactor to provide heat energy to the at least a second portion of the oxygen feed to the gasification reactor and to cool the wastewater bottom stream from the sour water stripper. The sour water stripping plant or facility is integrated into the gasification plant or facility through at least the wastewater bottom stream from the sour water stripper.

Owner:SAUDI ARABIAN OIL CO

Blackened composite electroless nickel coatings

InactiveUS20140287208A1Anti-corrosive paintsLiquid/solution decomposition chemical coatingElectroless nickelParticulates

In particular, the present invention is directed processes and product related to blackened coatings, blackened electroless nickel coatings, blackened electroless nickel coatings including particulate matter, coatings with cover coats, coatings with voids, and the methods of application and products with such coatings. Examples of parts which it may be beneficial to plate using the present invention include, but are not limited to textile parts electronics components and firearm parts

Owner:SURFACE TECH

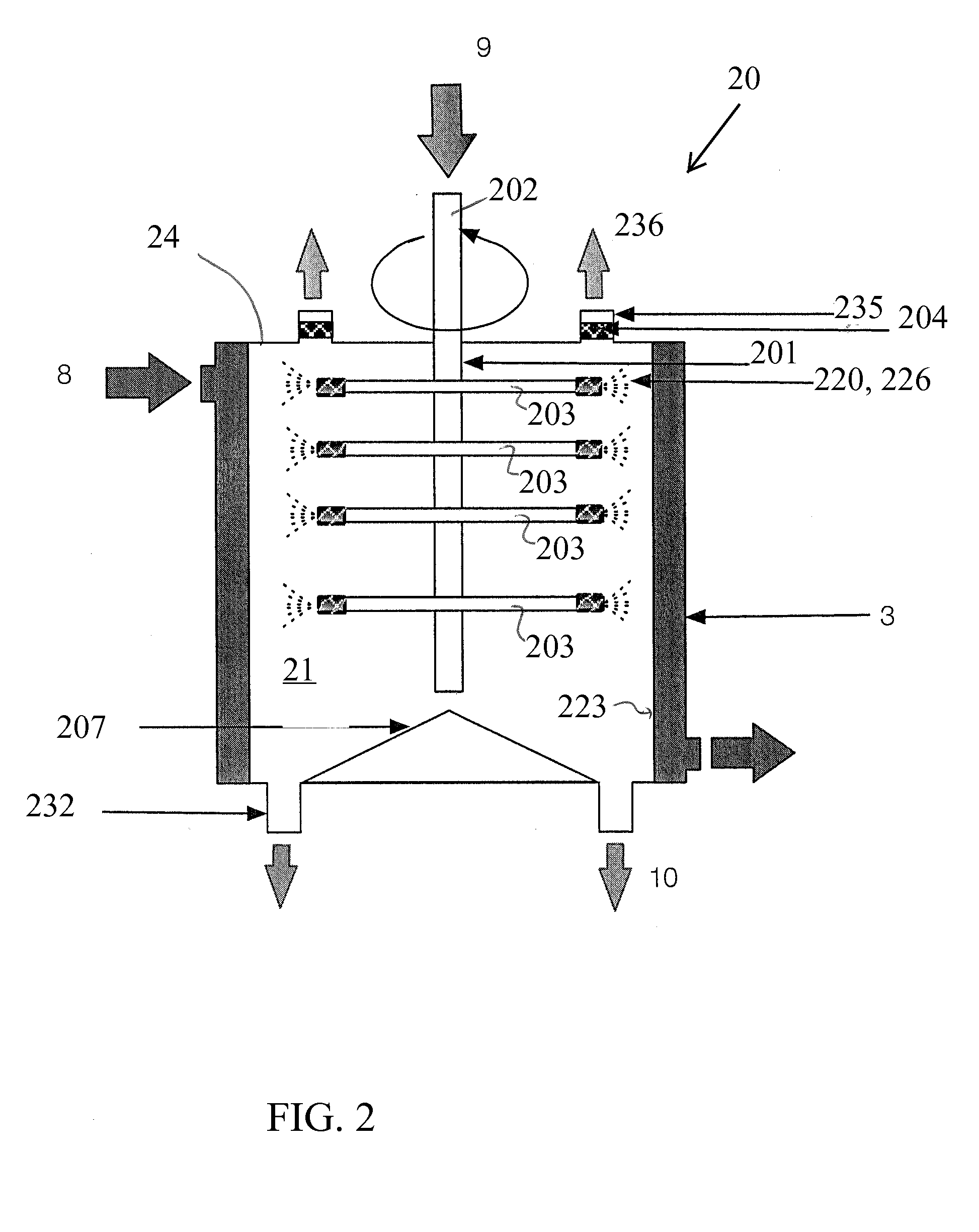

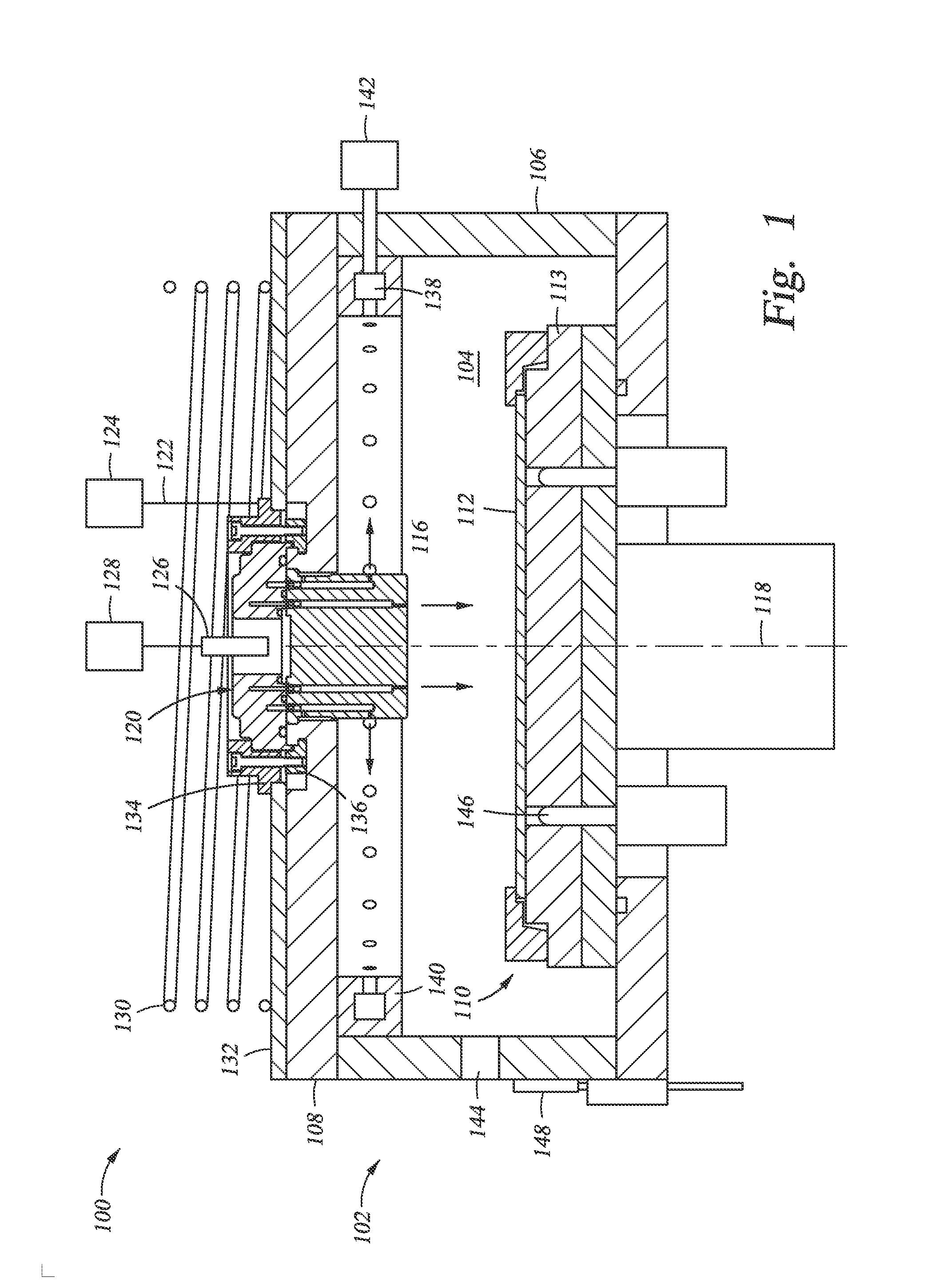

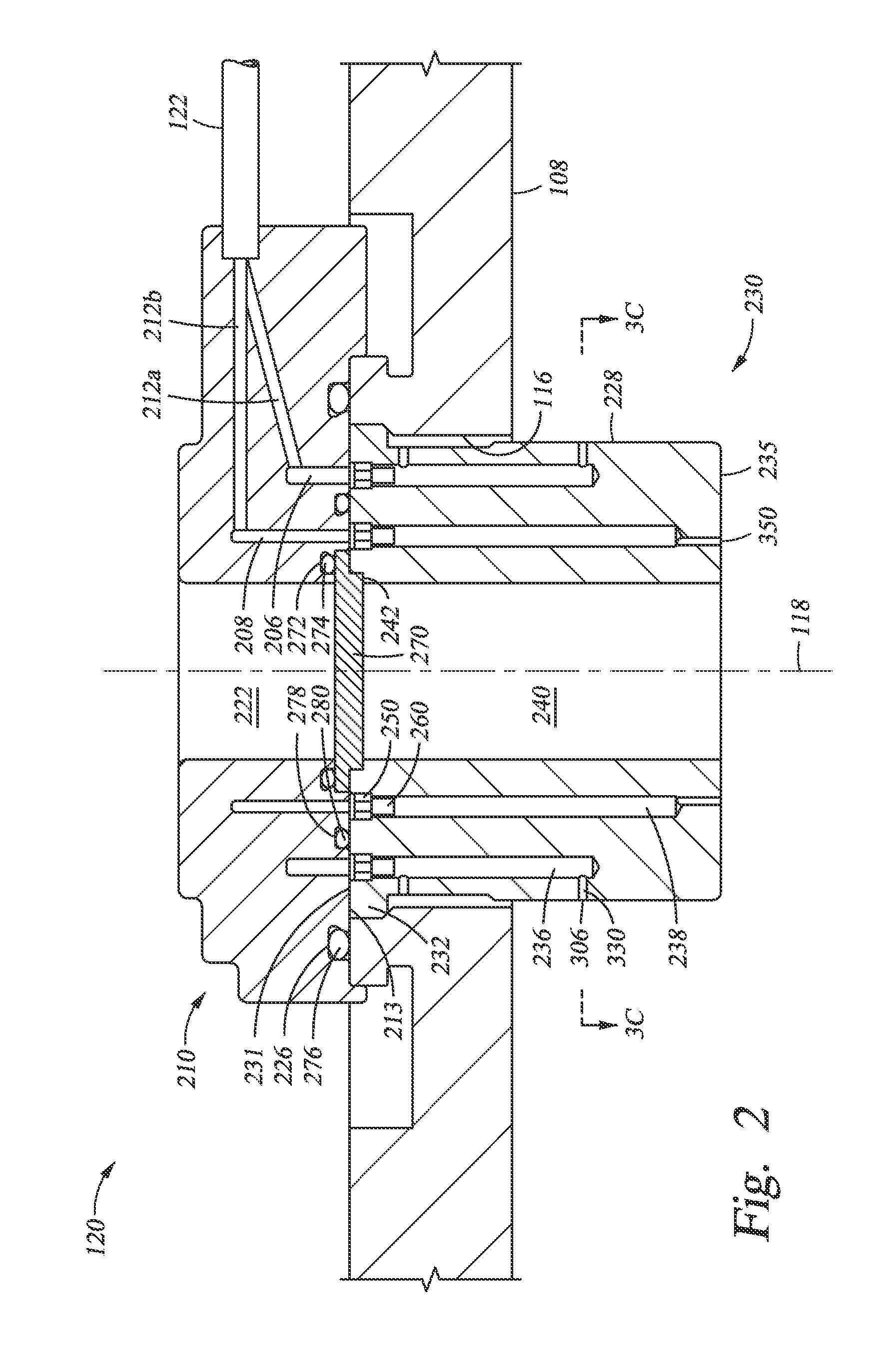

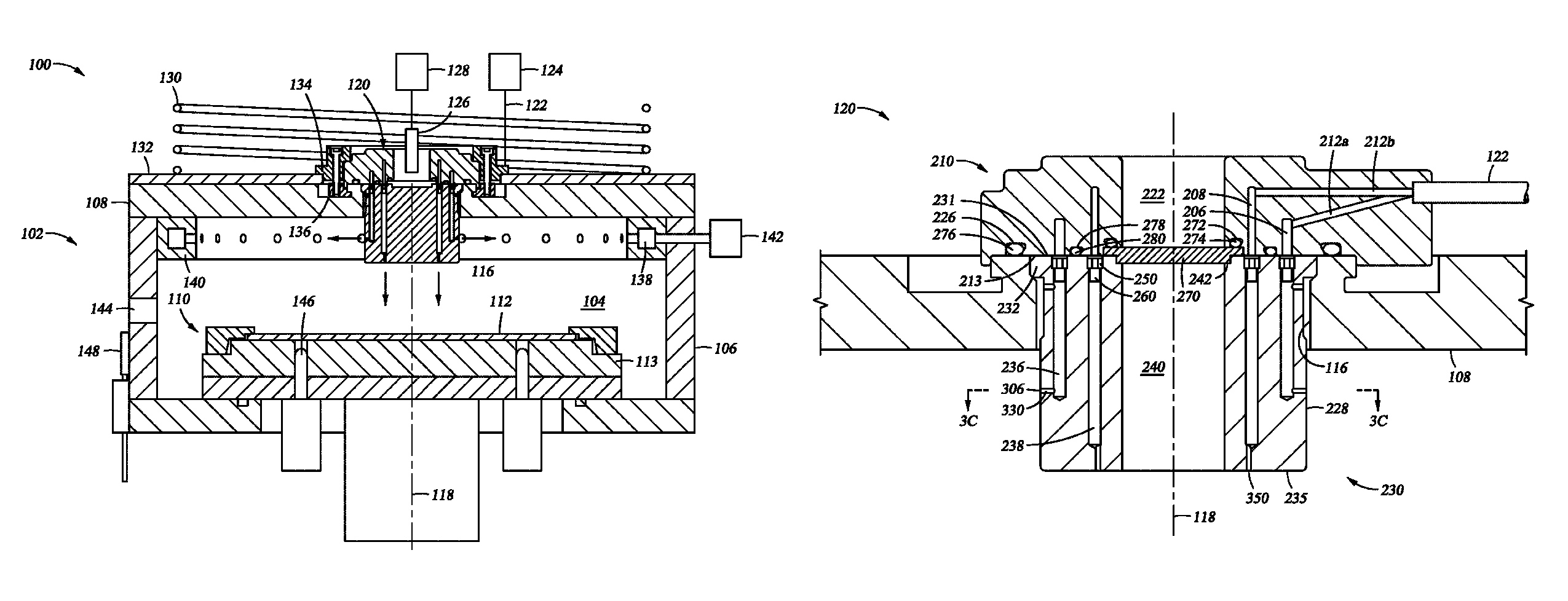

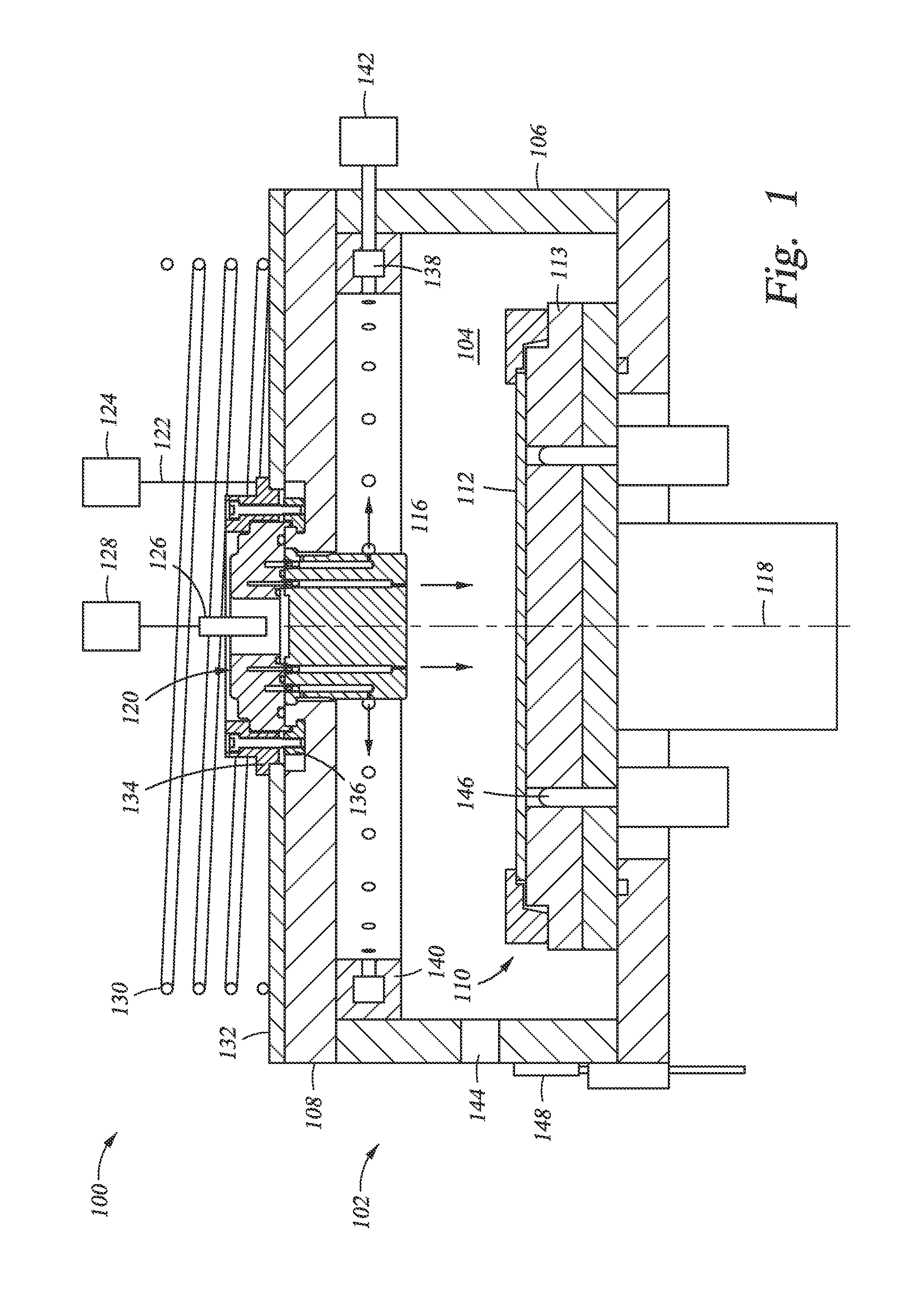

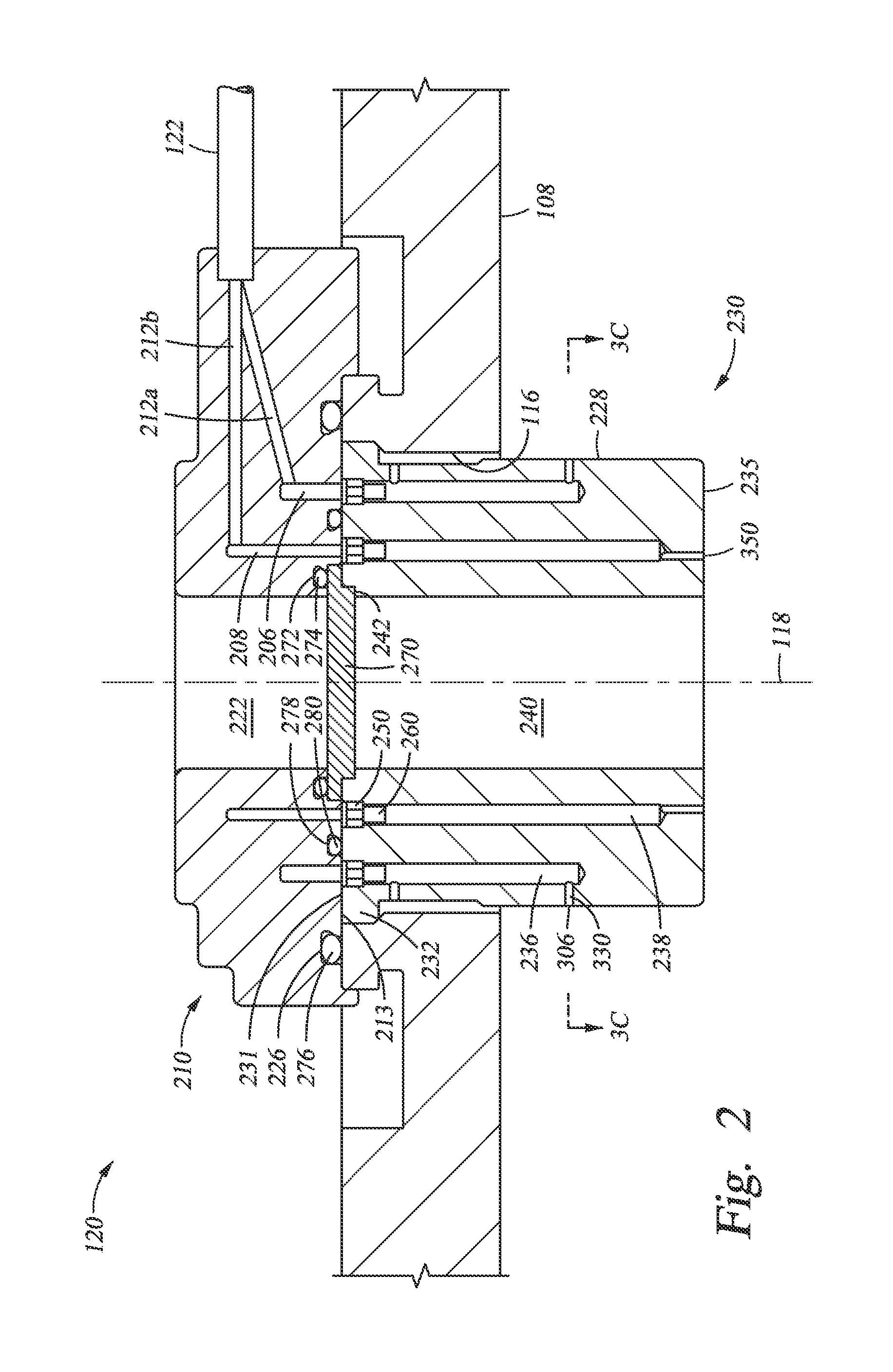

Tunable gas delivery assembly with internal diffuser and angular injection

ActiveUS20140237840A1Improve uniformityElectric discharge tubesDrying gas arrangementsEngineeringMechanical engineering

Embodiments of the present invention relate to an apparatus for providing processing gases to a process chamber with improved uniformity. One embodiment of the present invention provides a gas delivery assembly. The gas delivery assembly includes a hub, a nozzle, and one or more gas diffusers disposed in the nozzle. The nozzle has a cylindrical body with a side wall and a top surface. A plurality of injection passages are formed inside the nozzle to deliver processing gases into the process chamber via a plurality of outlets disposed in the side wall. The injection passages are configured to direct process gases out of each outlet disposed in the side wall in a direction which is not radially aligned with a centerline of the hub.

Owner:APPLIED MATERIALS INC

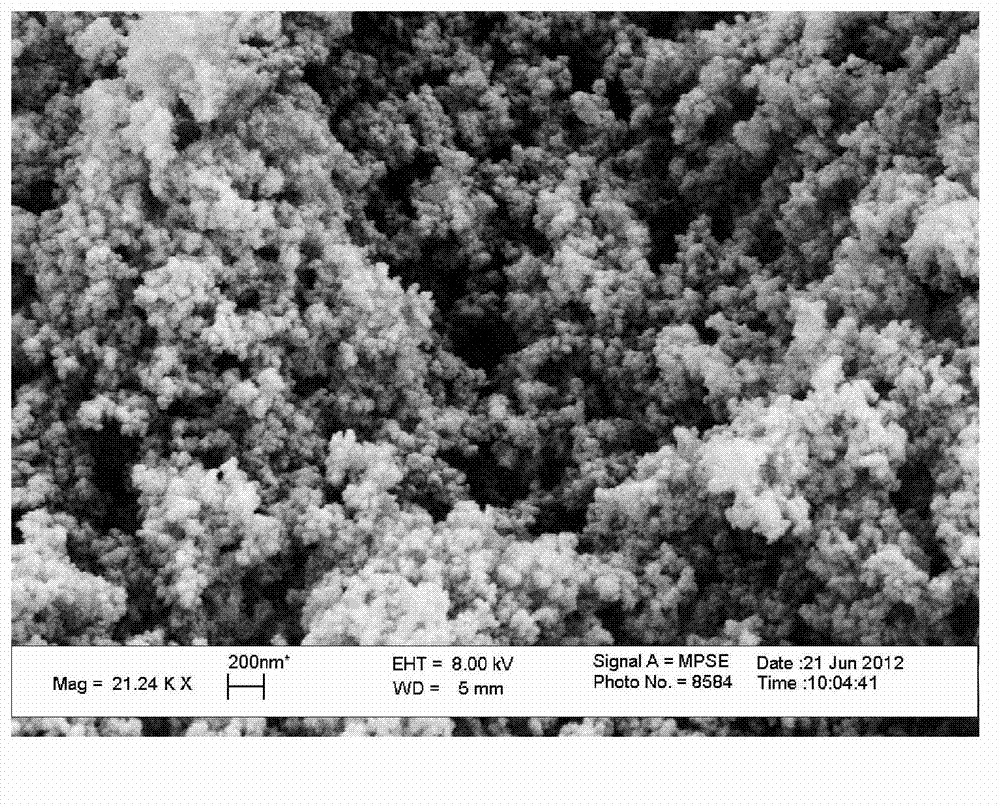

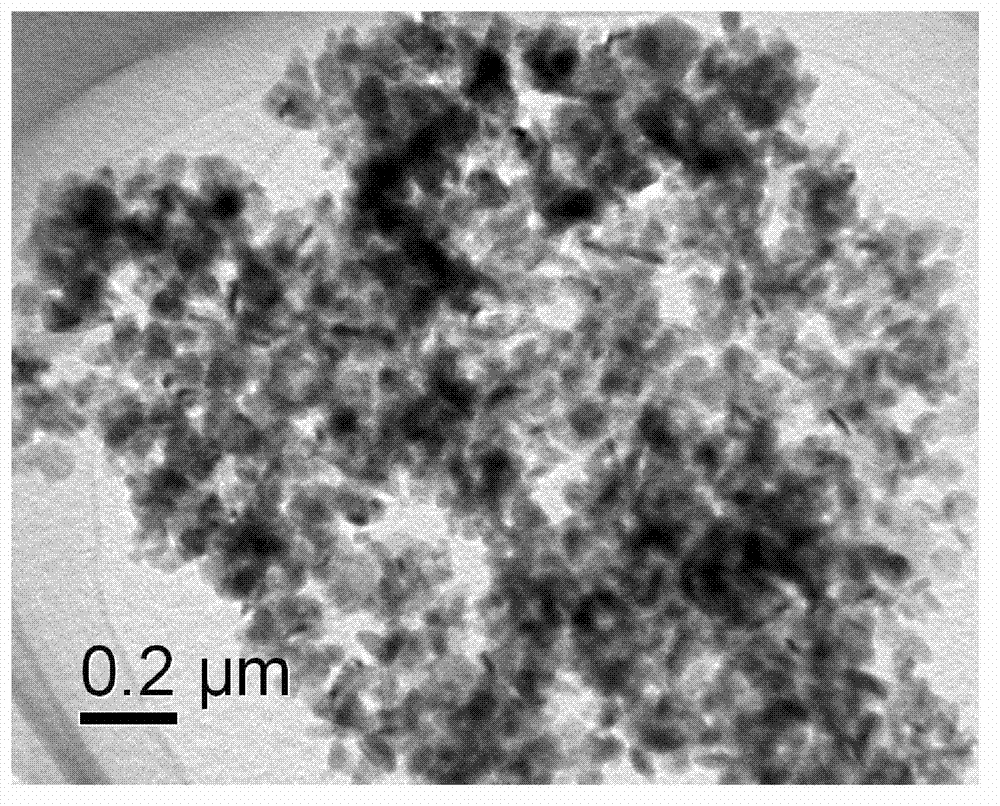

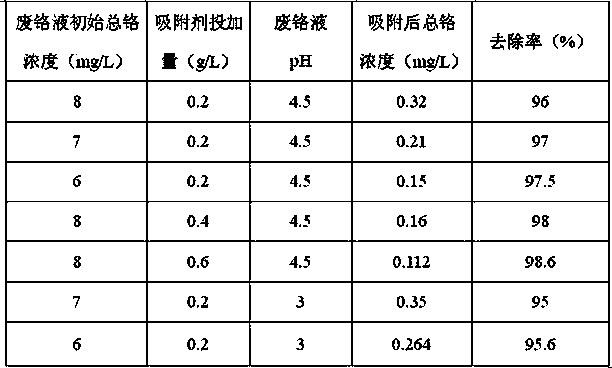

Nano-composite adsorbent preparation method directly processing waste water containing chrome tanning

ActiveCN103450393AReduce economic costsImprove adsorption capacityOther chemical processesWaste water treatment from animal processingIon exchangePolymer

The invention discloses a nano-composite adsorbent preparation method directly processing waste water containing chrome tanning. Low-concentration heavy metal waste water is commonly processed by an adsorption method, an ion exchange method and the like currently, and the methods selectively adsorb chrome. According to the nano-composite adsorbent preparation method direct processing the waste water containing chrome tanning, diallyl dimethyl ammonium chloride, methacrylic acid, acrylamide, hydroxyethyl acrylate and nanometer titania are used as raw materials, and aqueous solution free radicals are polymerized to prepare vinyl-based polymer / nanometer titania P (DMDACC-MAA-AM-HEA) / TiO2 nano composite adsorbent. According to the nano-composite adsorbent preparation method directly processing the waste water containing chrome tanning, the adsorbent can directly process low-concentration chrome tanning waste water, chrome removal rate can be 98.6 %, the adsorbent has wide pH value adaptability, has highly-selective adsorbability to Cr, is not prone to being polluted by other pollutant in the waste water, and is large in adsorption capacity, high in processing efficiency, and particularly suitable for processing acidic low-concentration chrome tanning waste water.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing zinc stearate having hydrophilicity

InactiveCN101914006AImprove hydrophilicityHydrophilic size controllableCarboxylic acid salt preparationSocial benefitsPolymer science

The invention relates to the technical field of plastic processing auxiliary agents, in particular to a method for preparing zinc stearate. The obtained product is mainly used as isolating agents in a rubber industry and lubricating and releasing agents in amino molding materials. The method comprises the following steps of: putting stearic acid into a reaction kettle under normal pressure and heating the stearic acid to 125 to 175 DEG C; adding zinc oxide into the reaction kettle in two steps; reacting the mixture under the action of a catalyst, then adding a modifying auxiliary agent into the obtained product and stirring; then discharging, wherein the temperature in the whole reaction process is kept to be 125 to 175 DEG C; and finally crushing the obtained product to obtain the finished product. The zinc stearate prepared by the method has excellent hydrophilicity which is unreachable to an ordinary direct process; moreover, by the method, the magnitude of the hydrophilicity of the zinc stearate is controllable; and the catalyst and the modifying auxiliary agent have no pollution on the environment so as to meet the environment protection requirements of energy saving and emission reduction. The process is simple and easy to implement and has extremely high economic and social benefits, and the application field of the zinc stearate is expanded by the process.

Owner:DONGGUAN CHNV TECH CO LTD

Filled polyamide molding material with low water absorption rate

The present invention relates to filled polyamide molding materials, in particular polyamide molding materials with medium filler content, which are producible from a polyamide blend and for example by compounding with chopped or endless fibers on two-screw extruders, and have a combination of reduced water absorption and good mechanical properties, which results in very good dimensional stability and reduced variation of the electrical properties of the produced molded part, such as an antenna housings of stationary or mobile communication devices. The thermoplastic polyamide molding materials according to the present invention are suitable for manufacturing molded parts and other semi-finished or finished parts, for example by extrusion, injection molding, pressing, direct process or direct compounding, respectively, wherein the compounded polyamide molding material is directly processed by injection molding or other shaping methods.

Owner:EMS CHEM AG

Substrate processing method for improving gallium nitride base material epitaxial layer quality

InactiveCN1588622AImprove integrityQuality improvementSemiconductor/solid-state device manufacturingCrystal orientationGallium nitride

The invention relates to a method of enhancing quality of GaN base material epitaxial film by patterning surface of the lase material. The steps are: before epitaxy growth, the direct process surface of base material of Al2O3, Si, GaAs etc. by pattening, to etch a group of parallel wedge slots in width 0.2-20 mum and depth 0.2-2 mum along a crystal orientation to form parallel bar graph on surface of base material, or to etch a other groups of wedge slots along a other crystal orientation on the base material to form diamond or rectangular graph, finally, cleaned dry patterned base material is send into epitaxying devie to be processed by programmed GaN film layer epitaxial growth. By the invention, dislocation density of epitaxial layer is reduced to order of magnitude 10 to the power 6 square cm. The invention method can be used for high quality film layer epitaxial growth of any base material in state that lattice of the epitaxial film layer material is obvious mismatchable.

Owner:TONGJI UNIV

Tunable gas delivery assembly with internal diffuser and angular injection

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com