Patents

Literature

2095 results about "Cement kiln" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates. Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant. As the main energy-consuming and greenhouse-gas–emitting stage of cement manufacture, improvement of kiln efficiency has been the central concern of cement manufacturing technology.

Alkali activated supersulphated binder

The invention describes an activated supersulphated aluminosilicate binder containing aluminosilicates, calcium sulphate and an activator containing alkali metal salts, wherein the aluminosilicates are selected from the group consisting of blast furnace slag, clay, marl and industrial by-products such as fly ash with the proviso that the Al2O3 content is greater than 5% by weight, wherein blast furnace slag is present in an amount exceeding 35% by weight and clay, marl and / or fly ash is present in an amount exceeding 5% per weight and wherein cement kiln dust in an amount of from 3 to 10% by weight is added to the mixture as an activator and calcium sulphate is used in an amount exceeding 5% by weight.

Owner:HOLCIM

Methods of cementing in subterranean formations using cement kiln dust in compositions having reduced Portland cement content

The present invention includes methods of cementing in subterranean formations using cement kiln dust in compositions having reduced Portland cement content. An embodiment of a method comprises placing a sealant composition that comprises cement kiln dust and is essentially free of Portland cement in a subterranean formation; and allowing the sealant composition to set.

Owner:HALLIBURTON ENERGY SERVICES INC

Composition and method for forming a sprayable materials cover

InactiveUS20050084334A1Improve performanceImprove adhesionSolid waste disposalLandfill technologiesWater dispersibleSlurry

An alternative cover for landfill may be formed from a slurry mixture of water, cementitious binder, adhesion enhancing admixture and fiber. These constituents may be mixed and applied to cover landfilled wastes, granular material piles or for soil erosion control. The cover will harden to minimize water infiltration, wind blown dust, odor and affinity to birds, flies and other insects. The water may include tap water, landfill leachate and wastewater. The binder may include Portland cement, blended cement, cement kiln dust, class C fly ash, and / or calcium sulphate hemihydrate. The adhesion enhancing admixture includes water-dispersible polymers. The fibers may comprise shredded paper or wood or plastic fibers.

Owner:CJS TECH

Activated aluminosilicate binder

An activated aluminosilicate binder containing aluminosilicates, calcium sulphate and an activator containing alkali metal salts is disclosed. The aluminosilicates are selected from a group consisting of blast furnace slag, clay, marl and industrial by-products, such as fly ash, and has an Al2O3 content greater than 5% by weight. Blast furnace slag is present in an amount less than 35% by weight, and cement kiln dust, in an amount of from 1 to 20% by weight, is added to the mixture as an activator.

Owner:HOLCIM

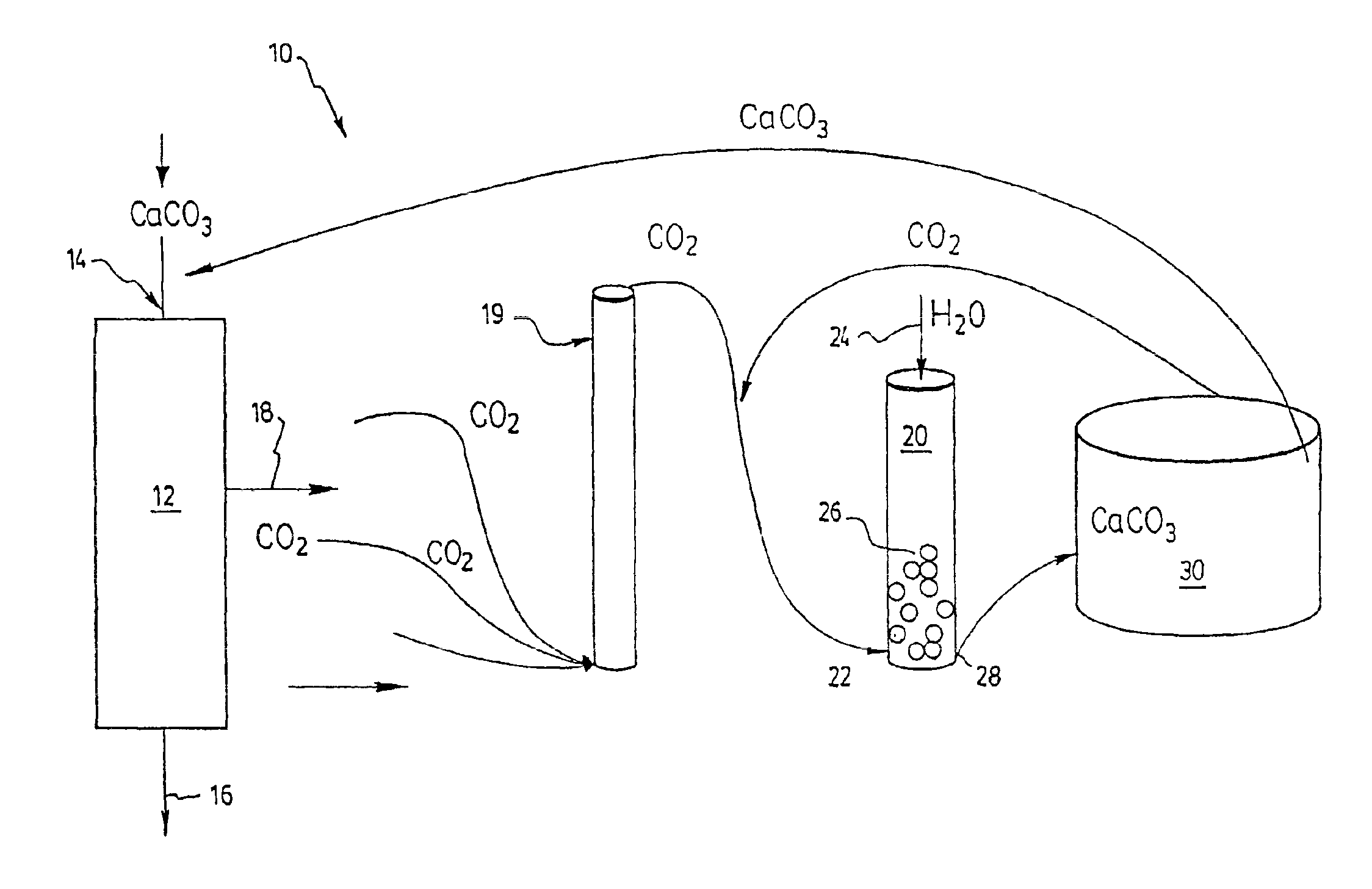

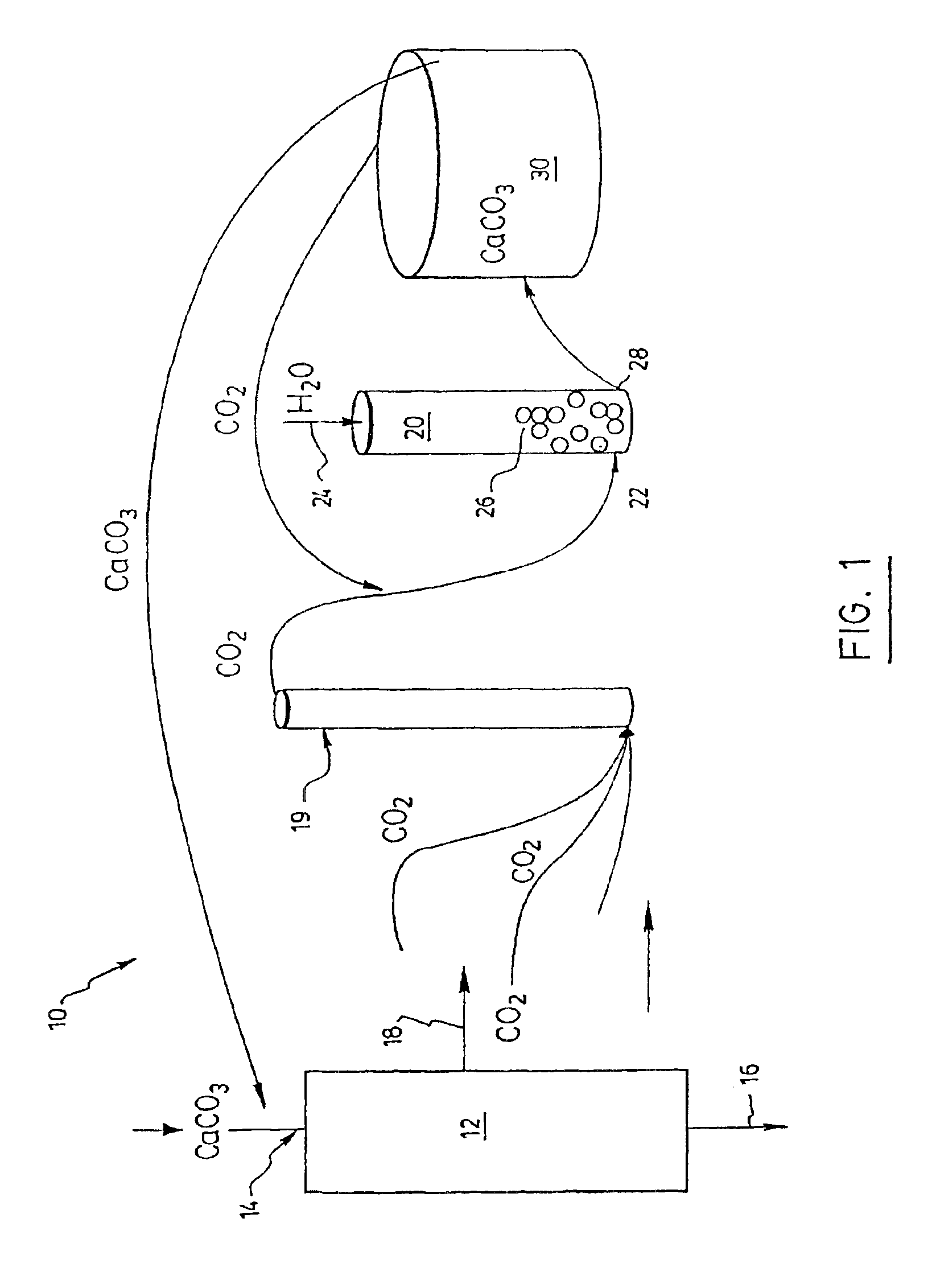

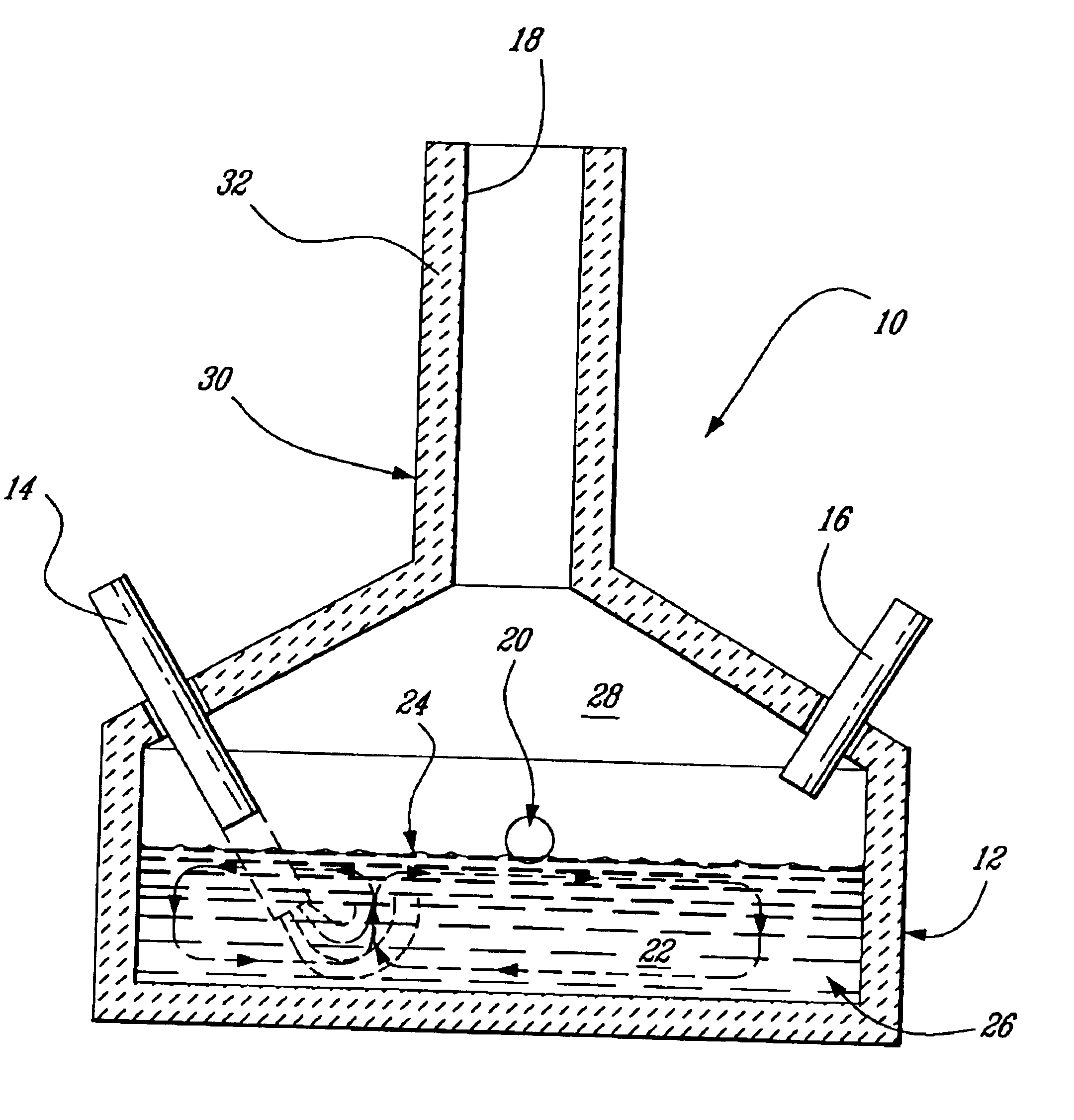

Process and a plant for the production of Portland cement clinker

InactiveUS6908507B2Emission reductionReduce carbon dioxide emissionsGas treatmentDispersed particle separationCalcium in biologyHydrogen

A process is disclosed for producing cement clinker, comprising the steps of: a) providing a mixture of ground calcareous materials and ground argillaceous materials; b) heating the mixture of step a) to a temperature sufficient to calcine and fuse the ground materials to form the cement clinker, and thereby producing an exhaust gas containing CO2; c) catalysing the hydration of at least a portion of the CO2 contained in the exhaust gas and producing a solution containing bicarbonate ions and hydrogen ions; and d) adding to the solution obtained in step c) metal ions, and adjusting the pH of the solution to precipitate a carbonate or said metal. Preferably, the metal ions are Ca++ obtained from the dissolution of a material selected from the group consisting of CaCl2, cement kiln dust and sea salts and the carbonate is CaCO3 which is advantageously recycled into the process by adding the CaCO3 to the mixture of step a). A cement plant for performing this process is also disclosed.

Owner:CO2 SOLUTION

Cement compositions comprising high alumina cement and cement kiln dust

The present invention provides cement compositions that comprise water, high alumina cement, a soluble phosphate, and cement kiln dust. The cement compositions optionally may be foamed with a gas. Methods of cementing also are provided that comprise: providing the cement composition; introducing the cement composition into a location to be cemented; and allowing the cement composition to set therein. The location to be cemented may be above ground or in a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

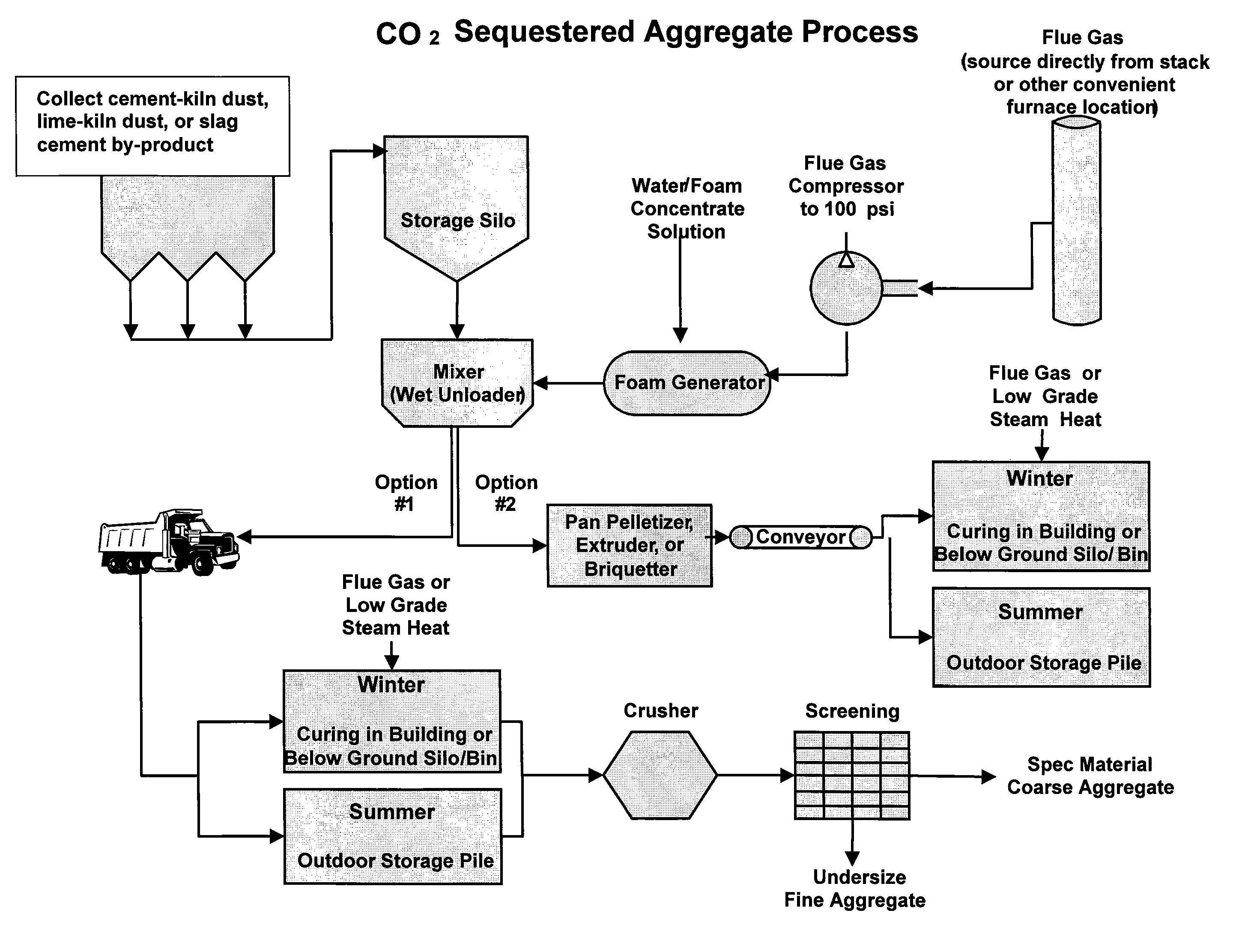

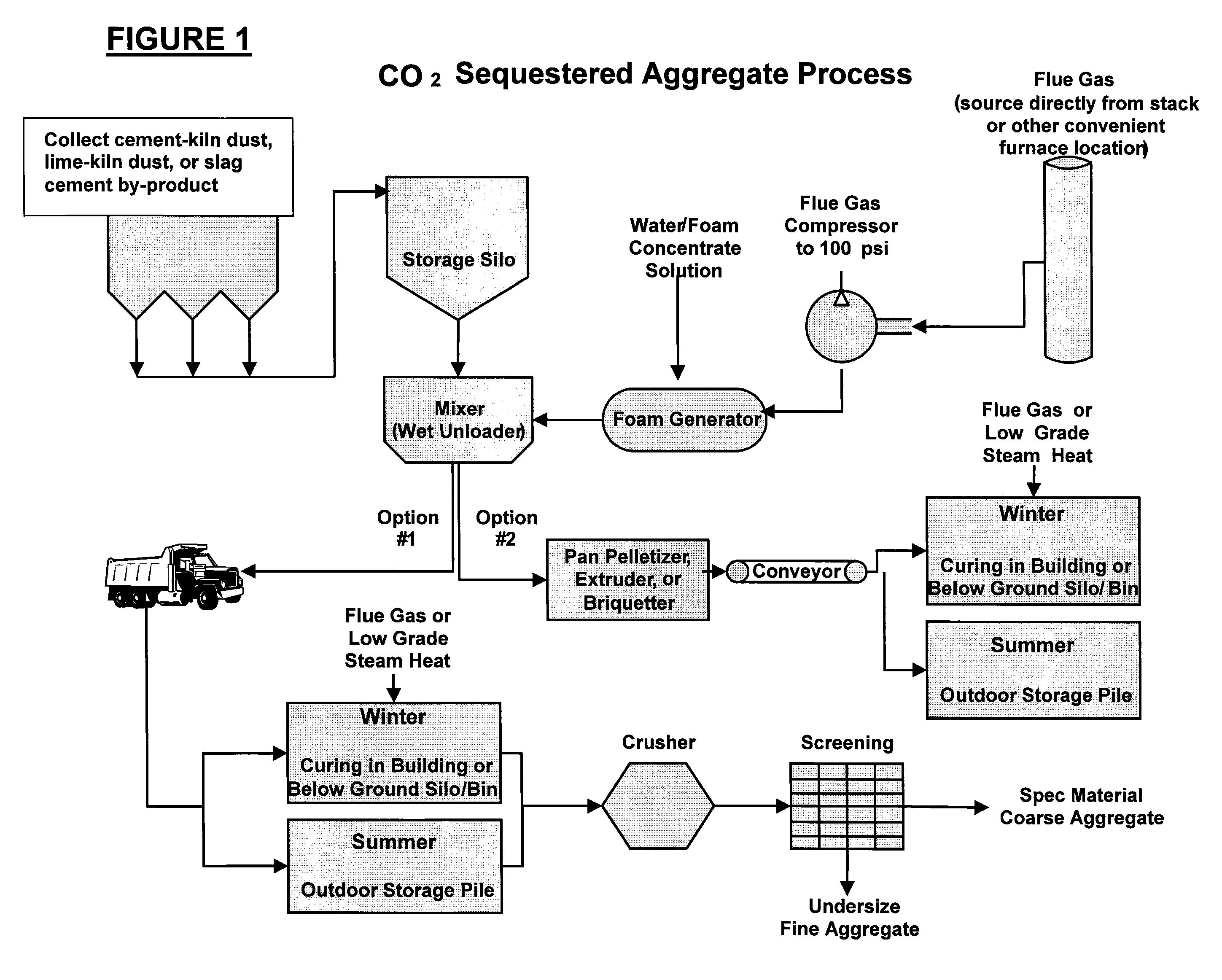

Carbon Dioxide Sequestration in Foamed Controlled Low Strength Materials

A process for sequestering carbon dioxide from the exhaust gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the exhaust gas is formed, and the foam is added to a mixture including a cementitious material (e.g., cement-kiln dust, lime kiln dust, or slag cement) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the exhaust gas reacts with hydration products in the controlled low-strength material and in turn sequesters the carbon dioxide.

Owner:WISCONSIN ELECTRIC POWER

Process aid for preparing a flowable slurry

A process for preparing a flowable slurry comprising mixing 25-70 wt. % water; an alkaline material selected from the group consisting of chlorosilicon manufacturing byproducts, direct process residue gels, cement kiln dust, and mixtures thereof; and a process aid selected from the group consisting of sucrose, raffinose, lignin, methylglucopyranoside, lactose, fructose, sodium polyphosphate, trehalose and mixtures thereof to form a flowable slurry. This slurry is especially useful in the manufacture of cement.

Owner:DOW CORNING CORP

Use of high carbon coal ash

InactiveUS6755905B2Avoid insufficient heatingReduce flowCharge manipulationHandling discharged materialSlagHigh carbon

A synthetic slag is produced by a high temperature combustion reaction between coal ash having a high carbon content, and a source of lime such as cement kiln dust. The carbon content of the coal ash is oxidized by oxygen gas, which typically is derived from air or an air / oxygen combination in an exothermic reaction and the heat generated is exploited in the melting process. In this way the gaseous products will typically comprise nitrogen, unreacted oxygen and carbon dioxide, and heat energy can be readily recovered from the hot off gas products evolving during the combustion reaction. The synthetic slag may be pelletized and employed as lightweight mineral aggregate or milled to cement fineness to provide slag cement.

Owner:LAFARGE CANADA INC

Methods and devices for reducing hazardous air pollutants

ActiveUS20090081093A1Reduce pollutionReduce the amount requiredCombination devicesCyanogen compoundsSlagSolid particle

The disclosure provides methods and systems for sequestering and / or reducing sulfur oxides, nitrogen oxides and / or carbon dioxide present in industrial effluent fluid streams. A solid particulate material comprising a slag component, a binder component (distinct from the slag component), and optionally water is formed and then contacted with the effluent fluid stream to reduce at least one of the sulfur oxides, nitrogen oxides, and / or carbon dioxide. The contacting of the effluent stream may occur in a packed bed reactor with the solid dry particulate material. Methods of reducing pollutants from exhaust generated by combustion sources, lime and / or cement kilns, iron and / or steel furnaces, and the like are provided.

Owner:C QUEST TECH

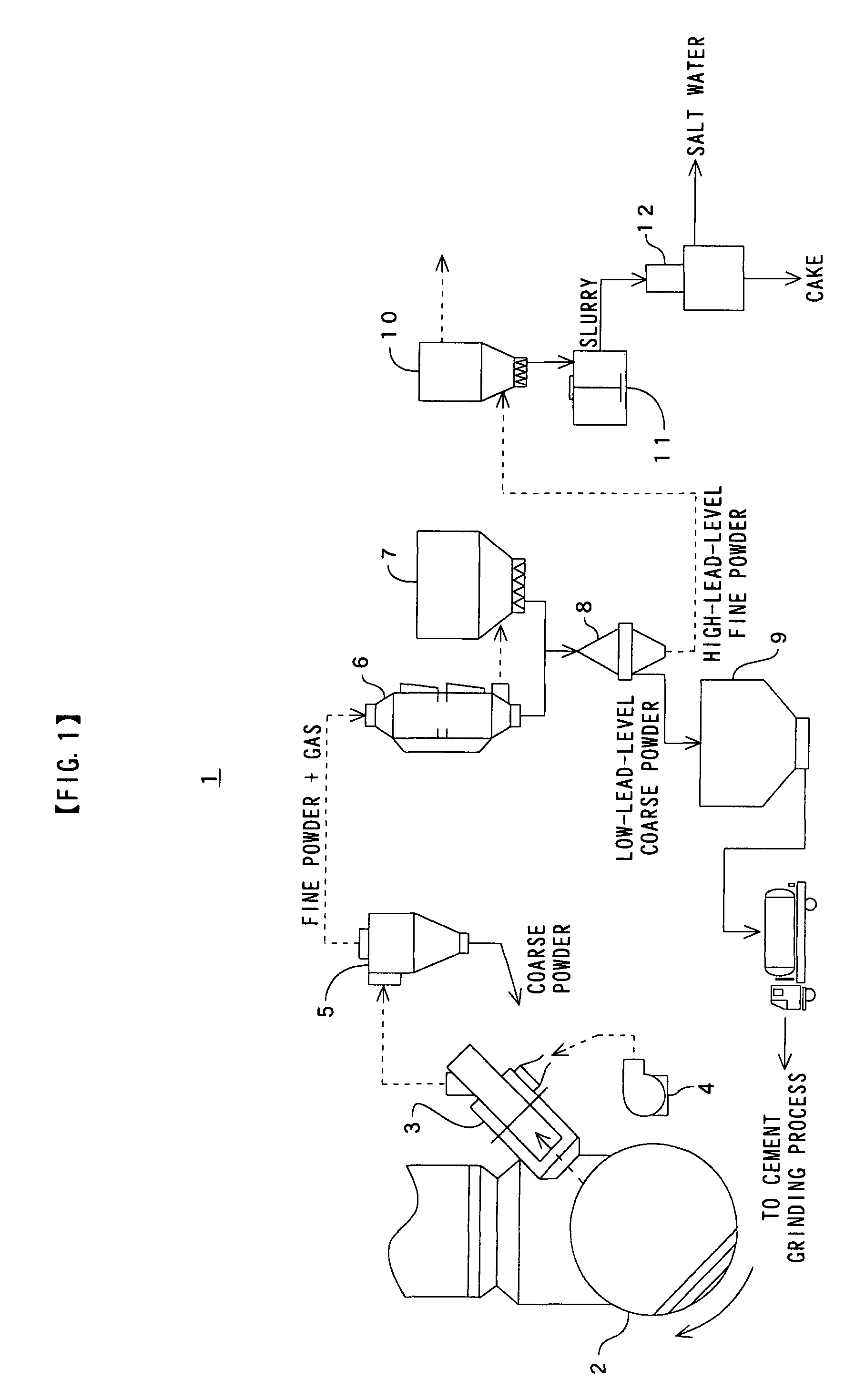

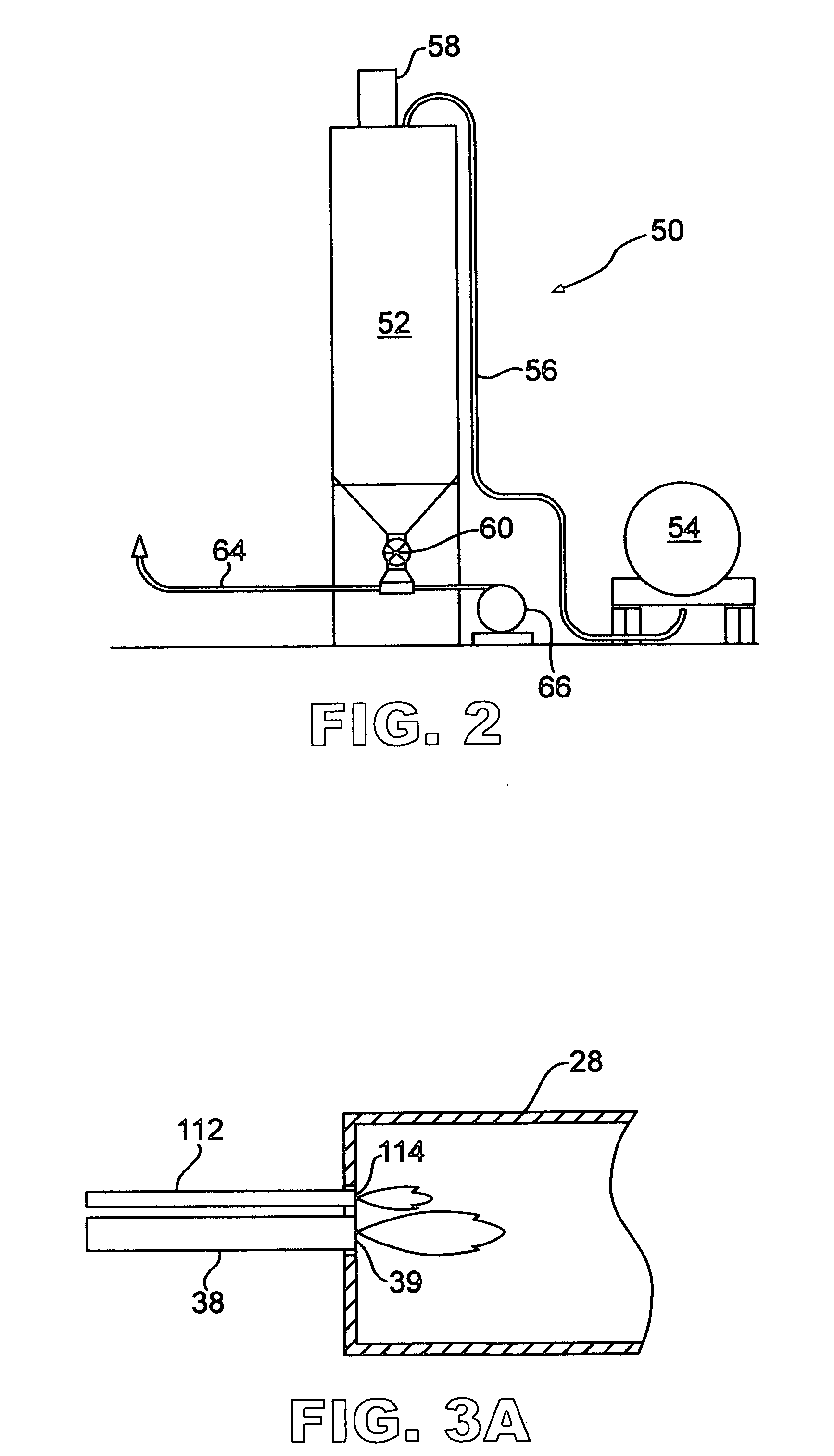

System and method for treating dust contained in extracted cement kiln combustion gas

InactiveUS7789944B2Effectively remove dustLow facility requirementsCombination devicesUsing liquid separation agentCycloneSlurry

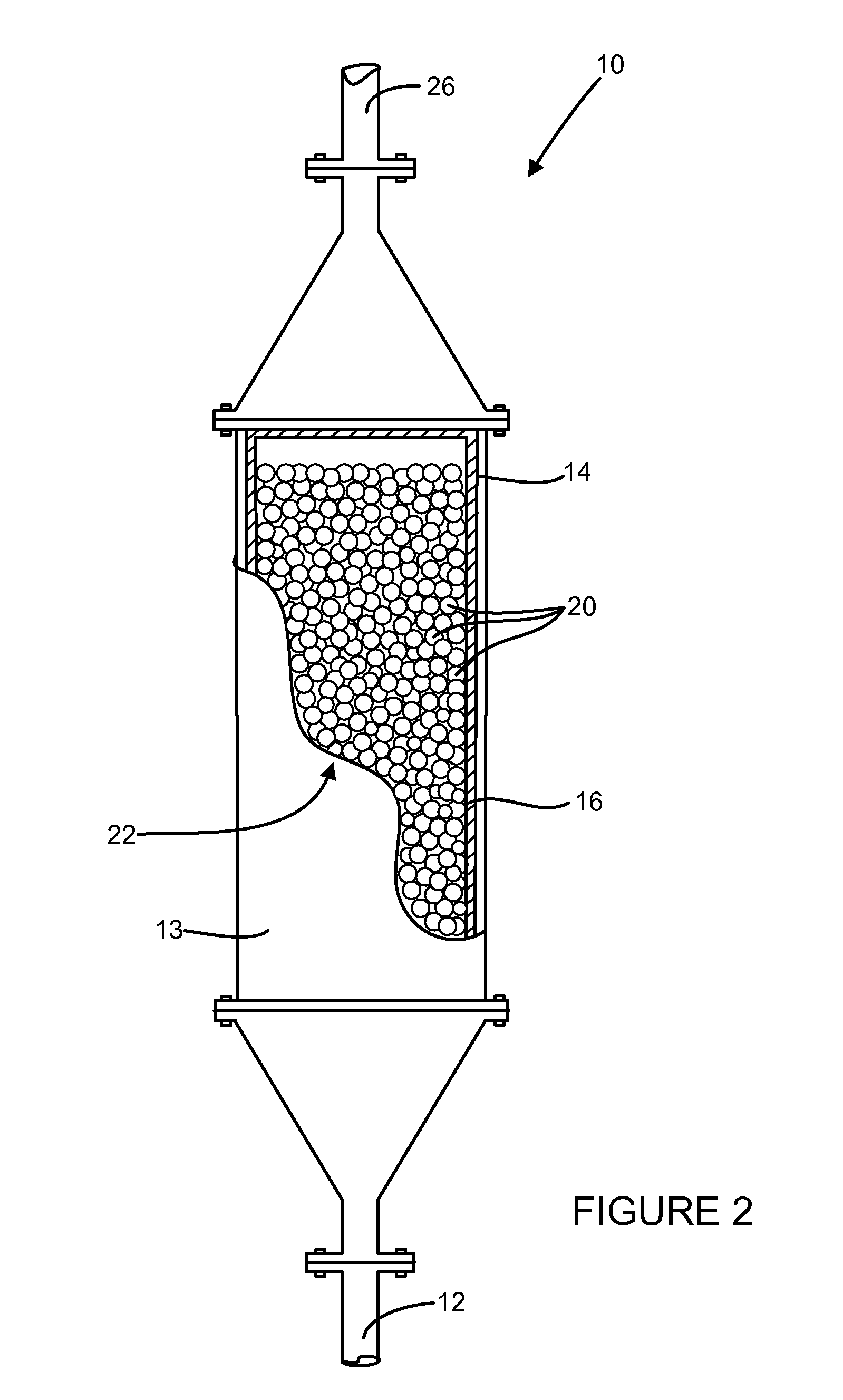

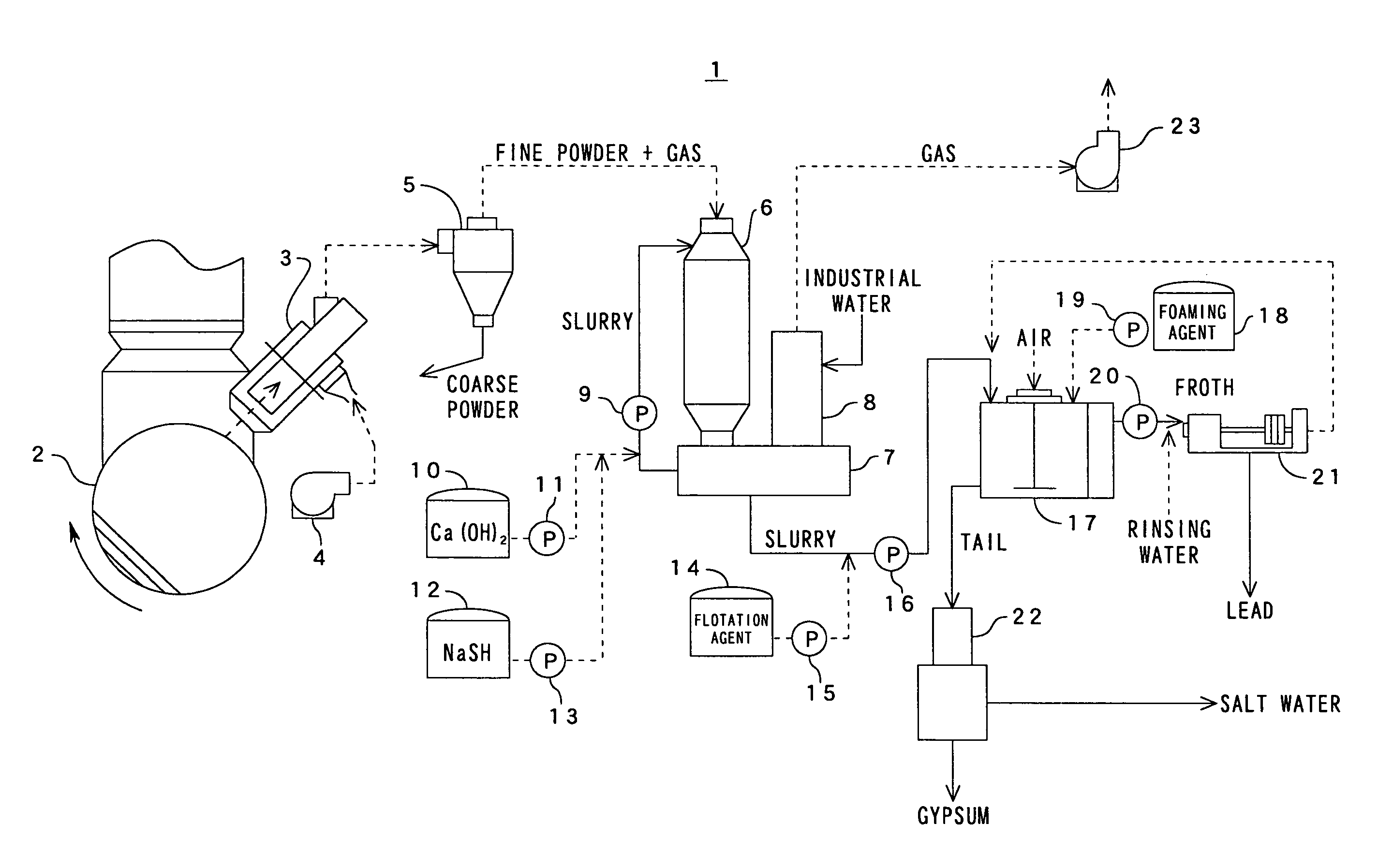

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising: a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a classifier 5 for separating coarse powder from dust contained in the combustion gas extracted by the probe 3; a wet dust collector 6 for collecting dust from the extracted gas containing fine powder discharged from the classifier 5; and devices 12, 13 for feeding sulfurizing agent for sulfurizing lead contained in the kiln exhaust gas to the wet dust collector 6, and others. From the sulfurizing-agent feeders 12, 13 are preferably added the sulfurizing agents to a circulation liquid tank 7 or a pump 9 for circulating slurry. The slurry obtained by the wet dust collector 6 is separated into froth including lead and tail side slurry including gypsum by a flotation facility 14, 17, 18.

Owner:TAIHEIYO CEMENT CORP

System and method for treating dust contained in extracted cement kiln combustion gas

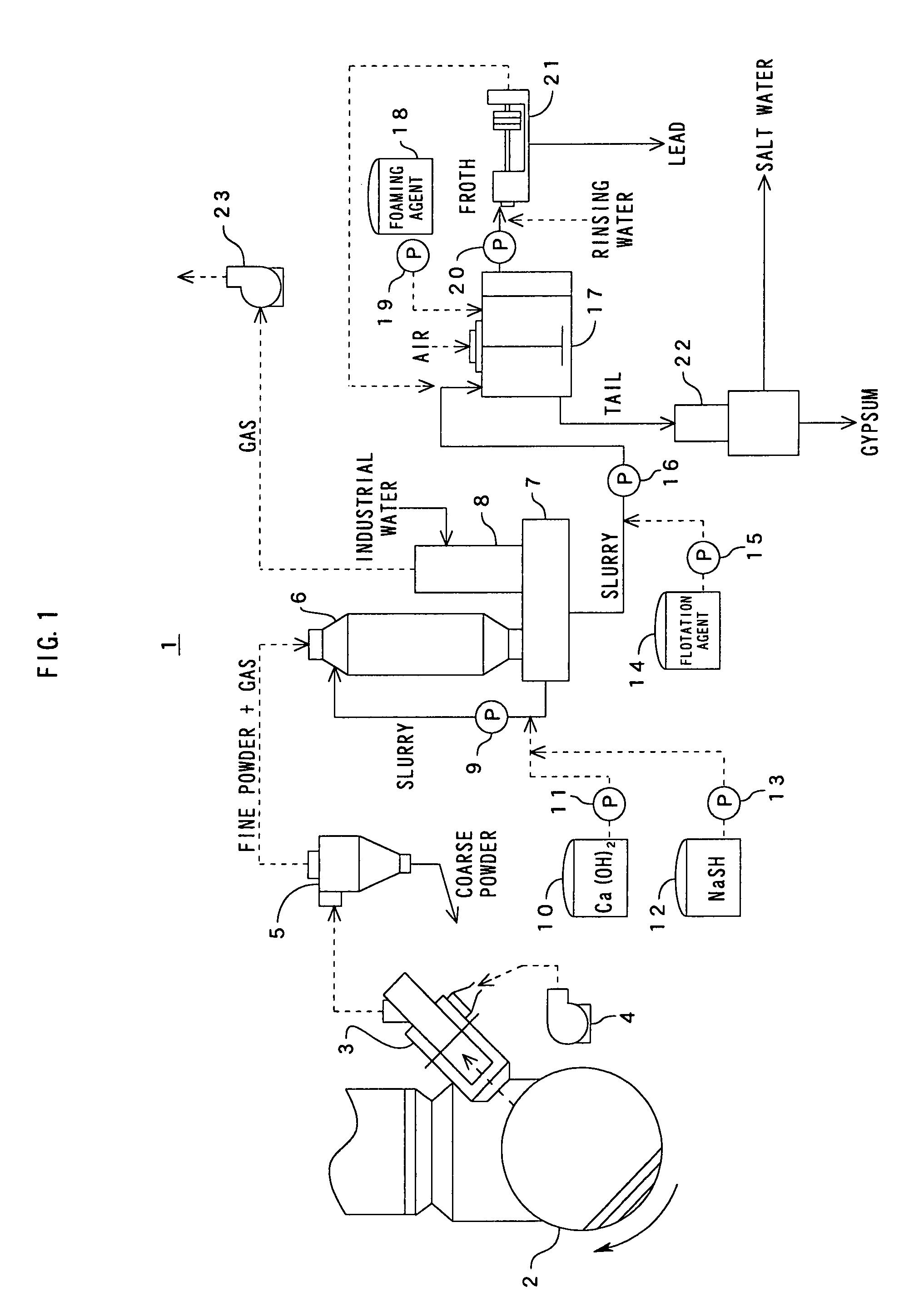

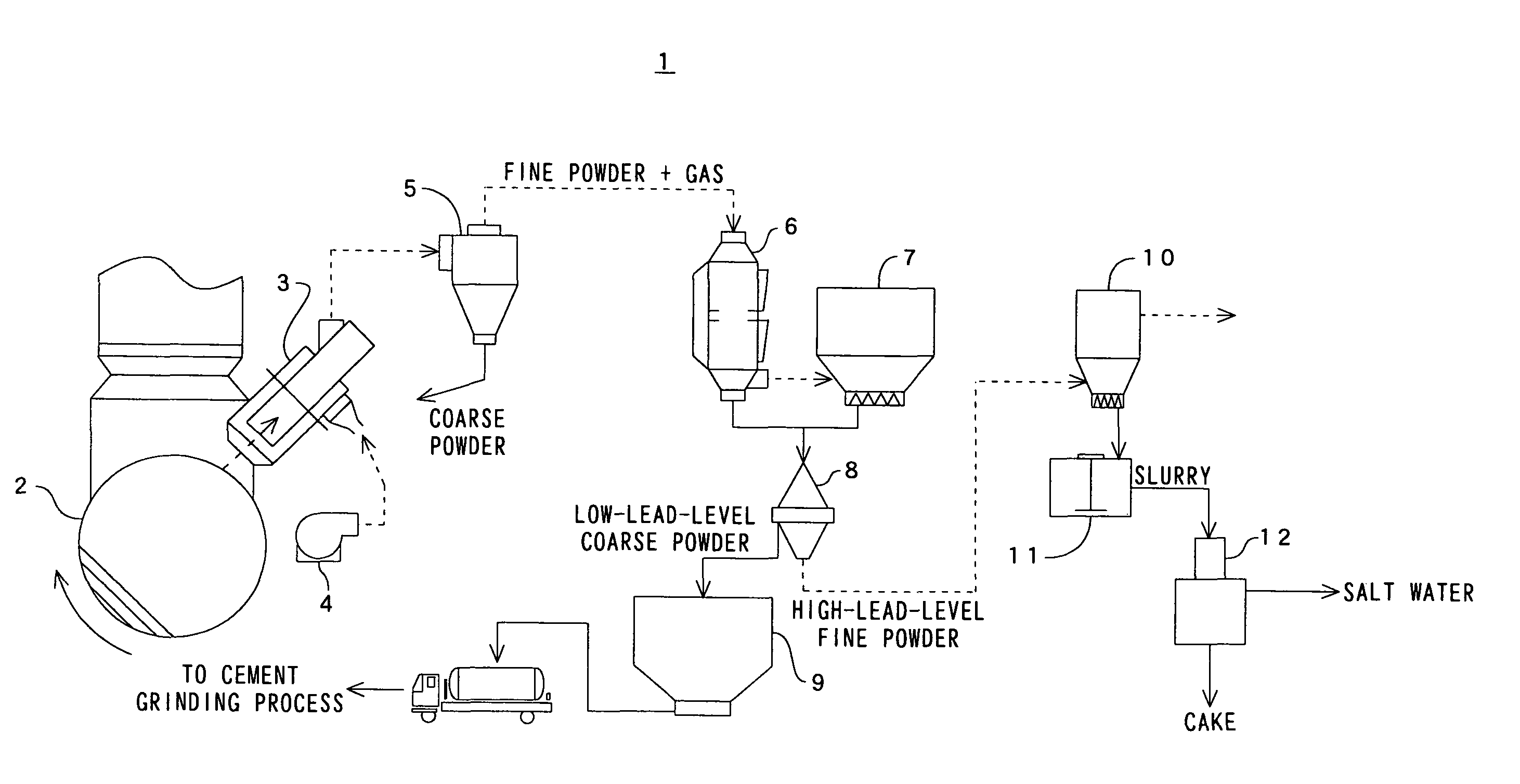

ActiveUS7749311B2Effectively remove dustLow facility requirementsCombination devicesLiquid degasificationCycloneEngineering

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a first classifier 5 for separating coarse powder from dust contained in the combustion gas extracted; a dust collector 7 for collecting dust from the extracted gas containing fine powder discharged from the first classifier 5; and a second classifier 8 for dividing dust discharged from the dust collector 7 into fine powder and coarse powder, and others. Since more lead is distributed on the fine powder side classified by the second classifier 8, lead can efficiently be removed without using chemicals and the like. The fine powder classified by the classifier 8 may be desalted by washing; high-lead-level cake obtained after the washing can be recycled; or salt water can be added to a cement mill. The coarse powder may be added to a cement grinding process or returned to cement material grinding process after the desaltation through washing.

Owner:TAIHEIYO CEMENT CORP

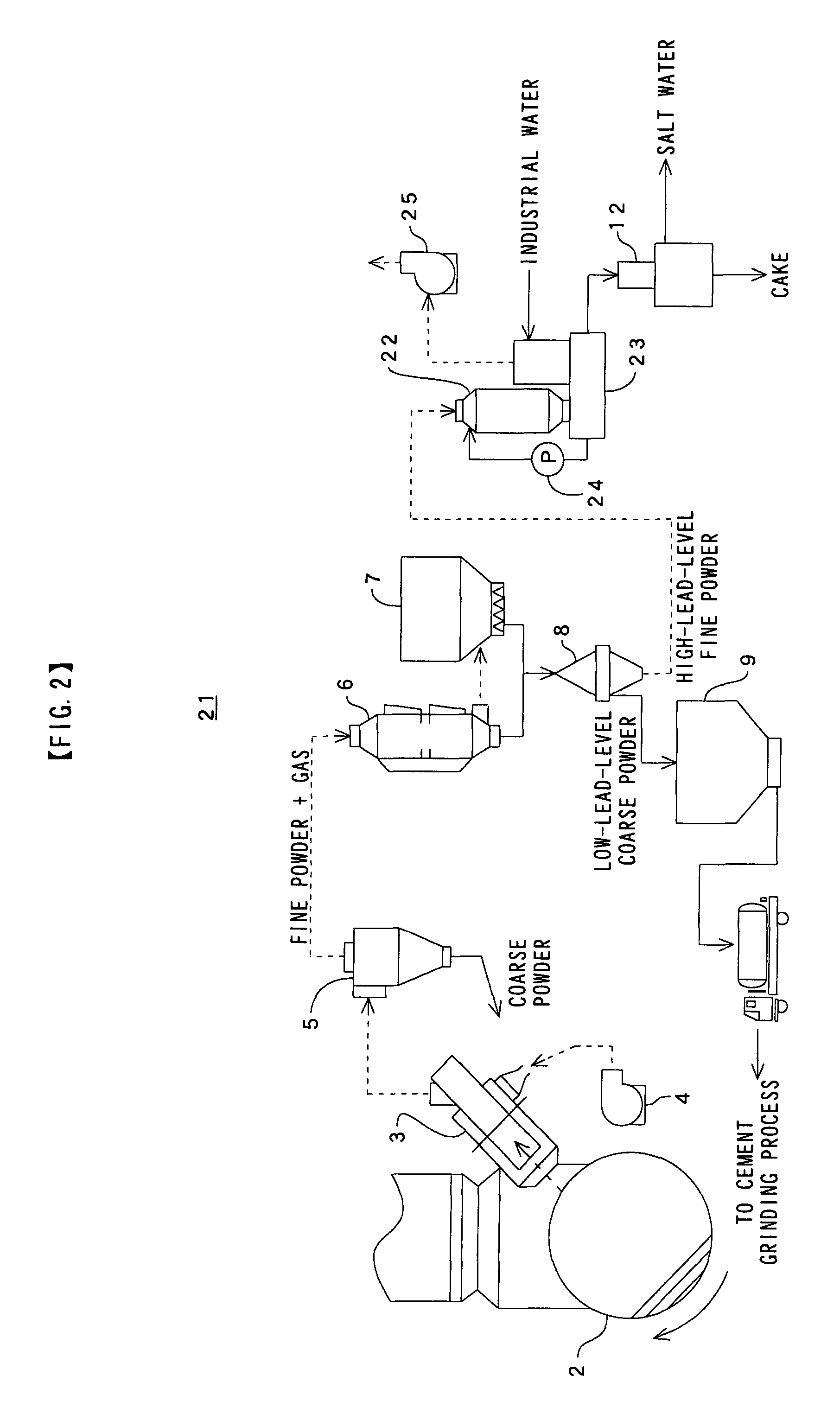

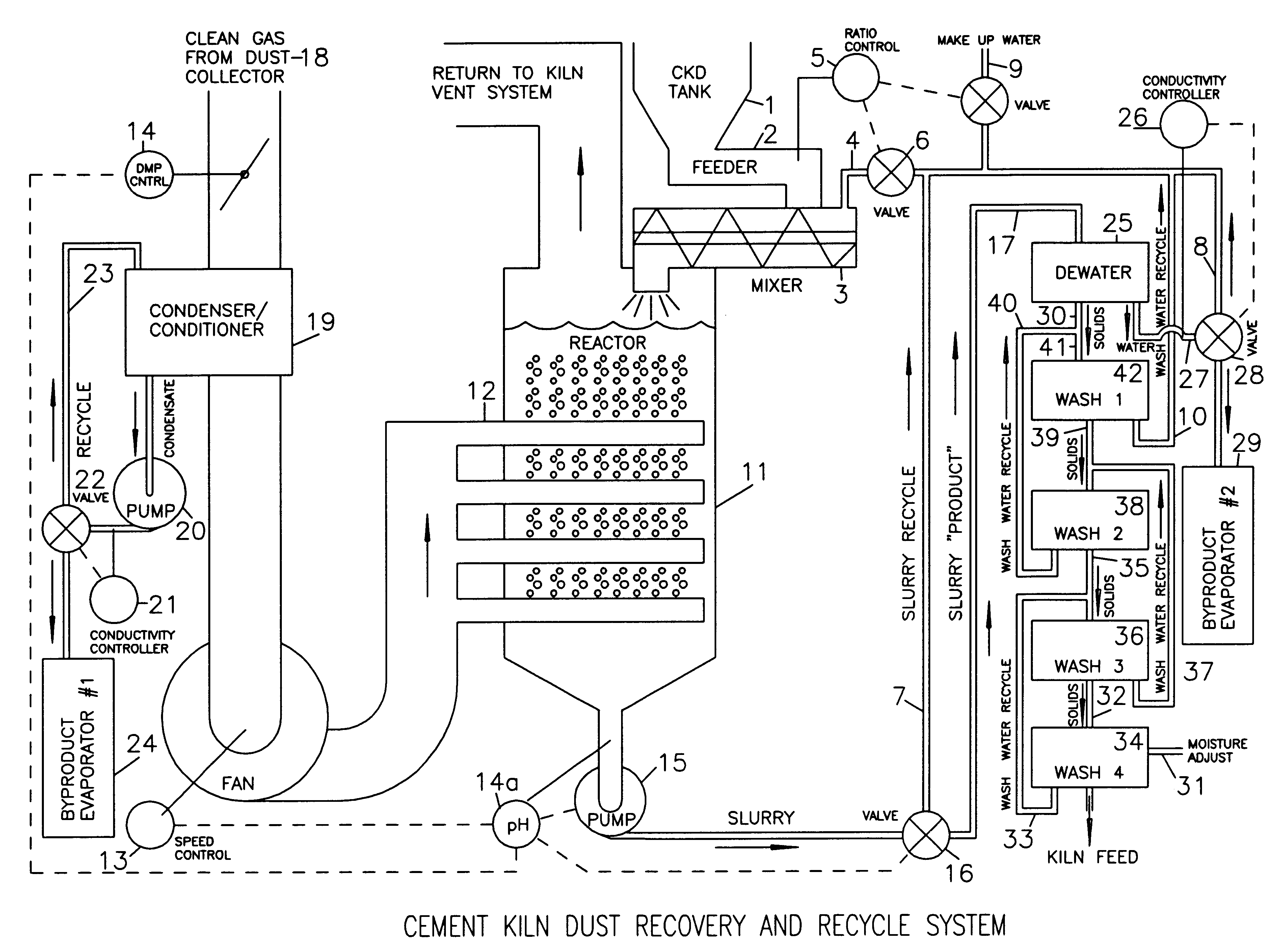

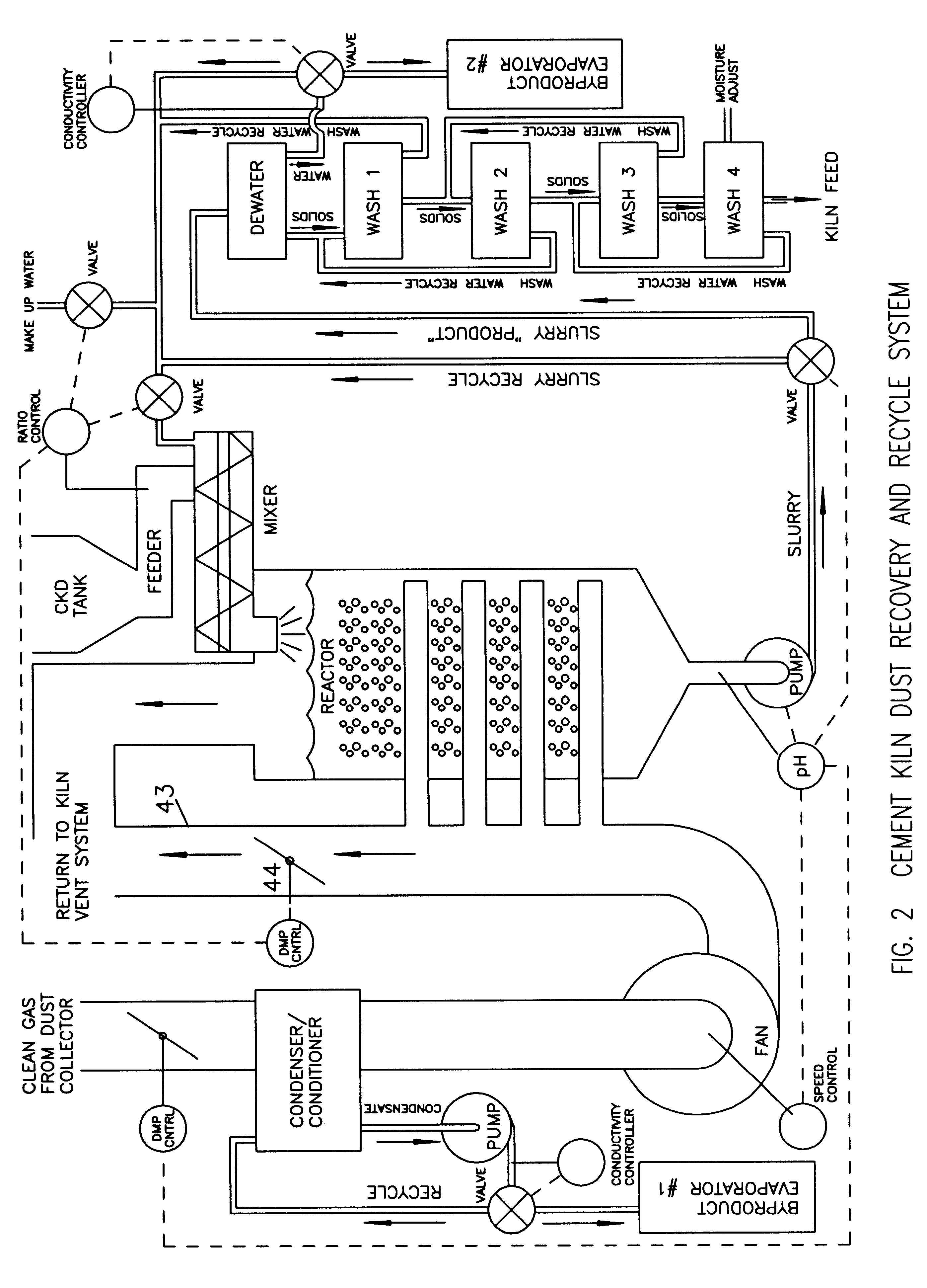

Method of treating cement kiln dust for recovery and recycle

Fresh or stockpiled cement kiln dust is moistened with sufficient water so that the amount of total free and combined water relative to dust is about 3 parts water to 1 part dust by mass, or less. The wet solids are treated with carbon dioxide to convert compounds, such as calcium hydroxide, to carbonates, such as calcium carbonate. The degree of carbonation is controlled so that the solubility of calcium becomes minimum for the dust being treated; this is also when hydroxyl and bicarbonate ions in solution are about at their minima. As the carbonation reactions occur, the water combined in hydroxides is released as free water so that the mixture becomes a slurry and the potentially soluble alkalies and sulfate (and any chlorides present) are released to the liquid phase. The solids are separated from the liquid, and the solids, which may be washed, provide a material suitable for return as feed to the kiln. The liquid, which contains the dissolved alkali compounds, is recycled to reclaim additional dust or treated to recover alkali salts when the alkali salts are sufficiently concentrated.While any source of carbon dioxide may be used, the preferred source is exit gases from the kiln. The gases are conditioned by condensation of water and removal of ammonium compounds, such as sulfate and chloride. The conditioning condensate may be treated to recover useful byproduct salts.

Owner:GEBHARDT RONALD FR

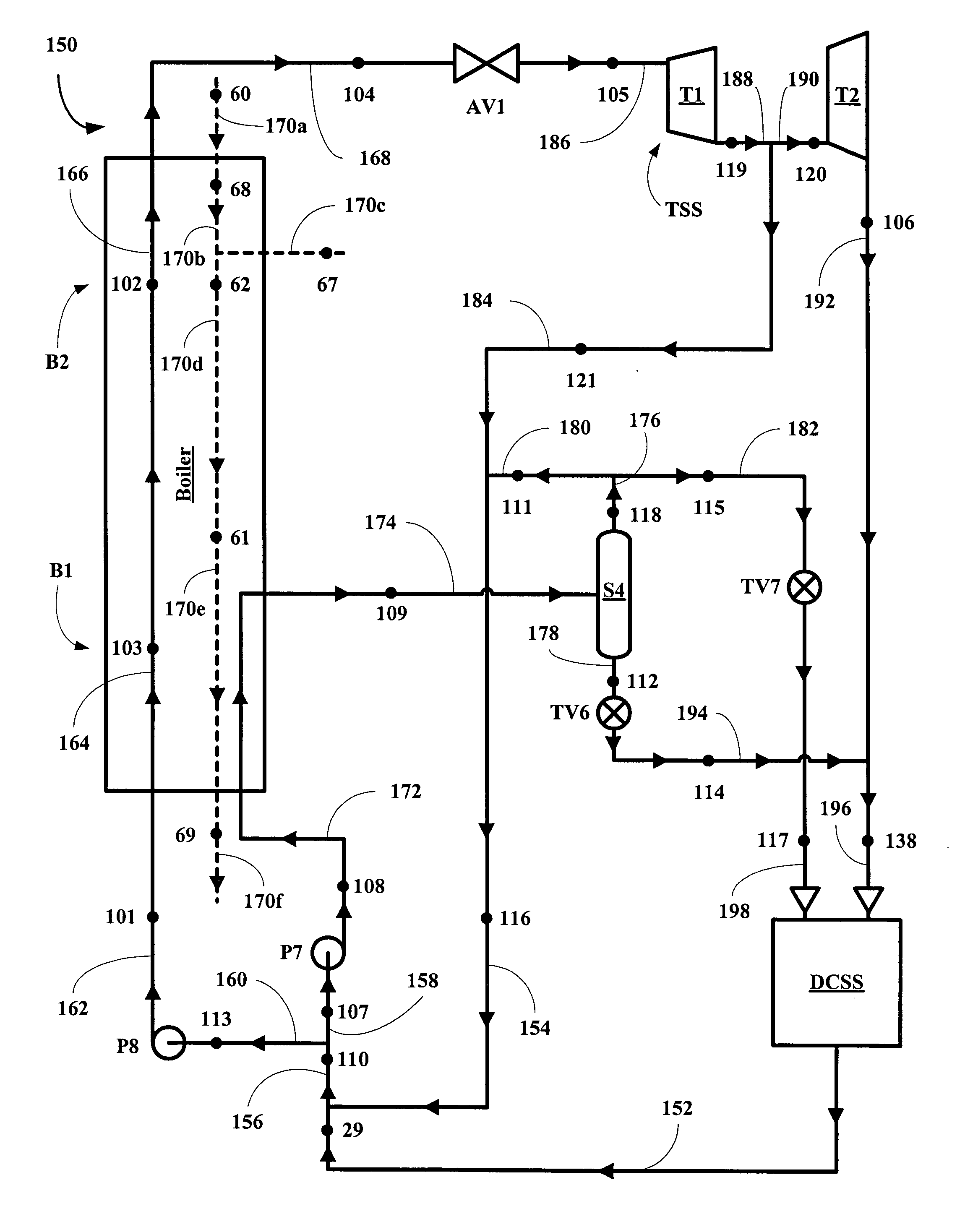

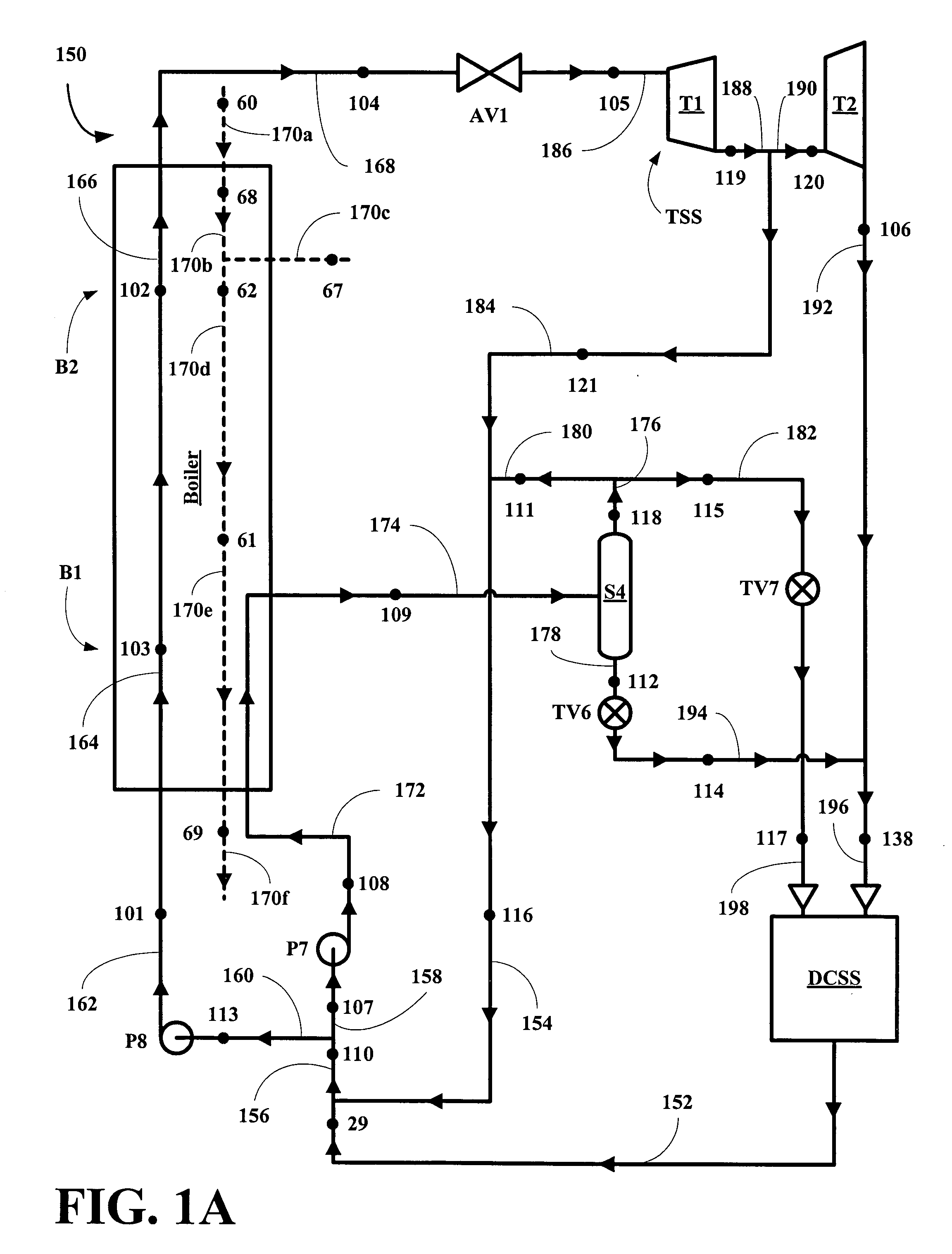

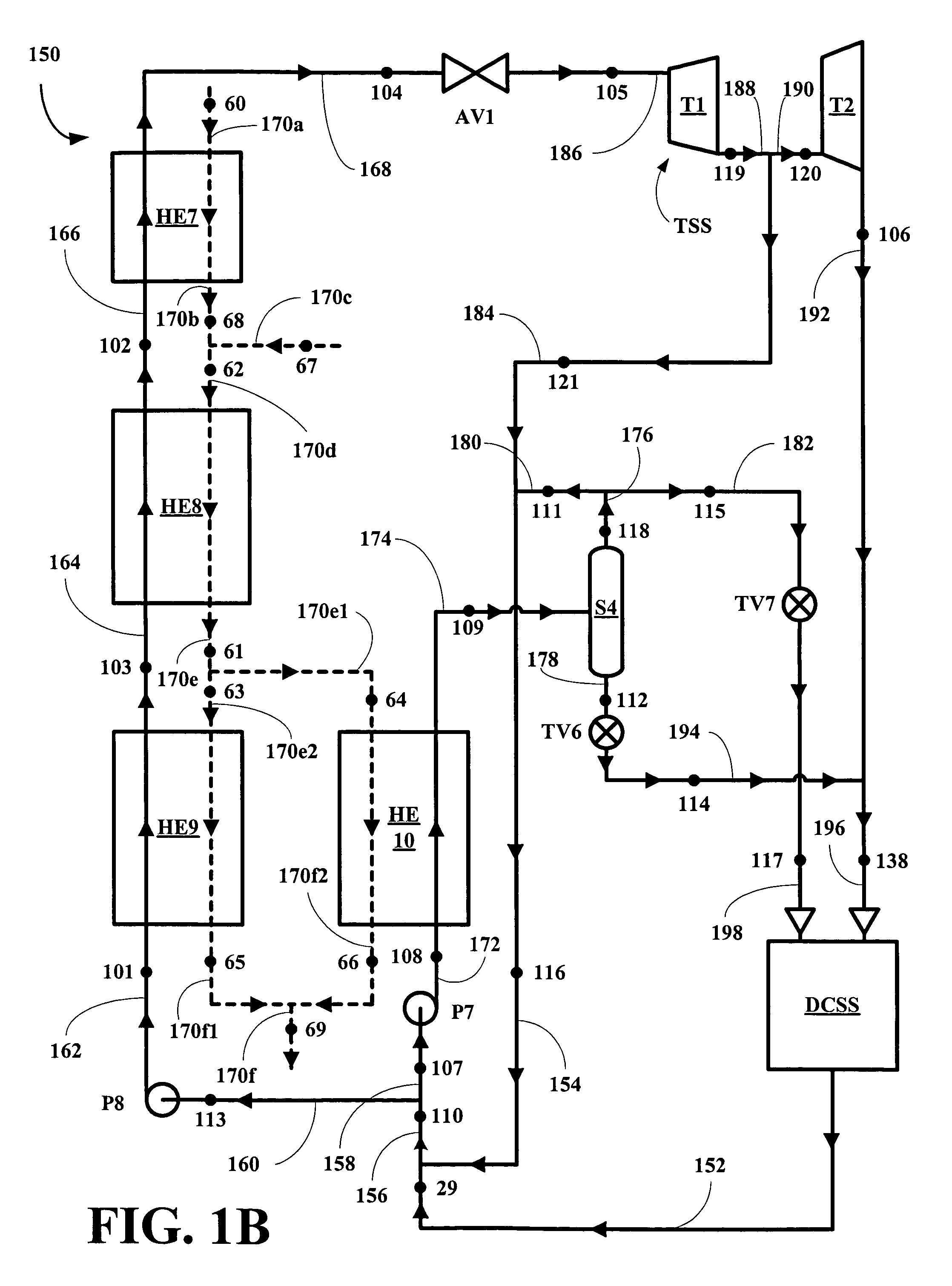

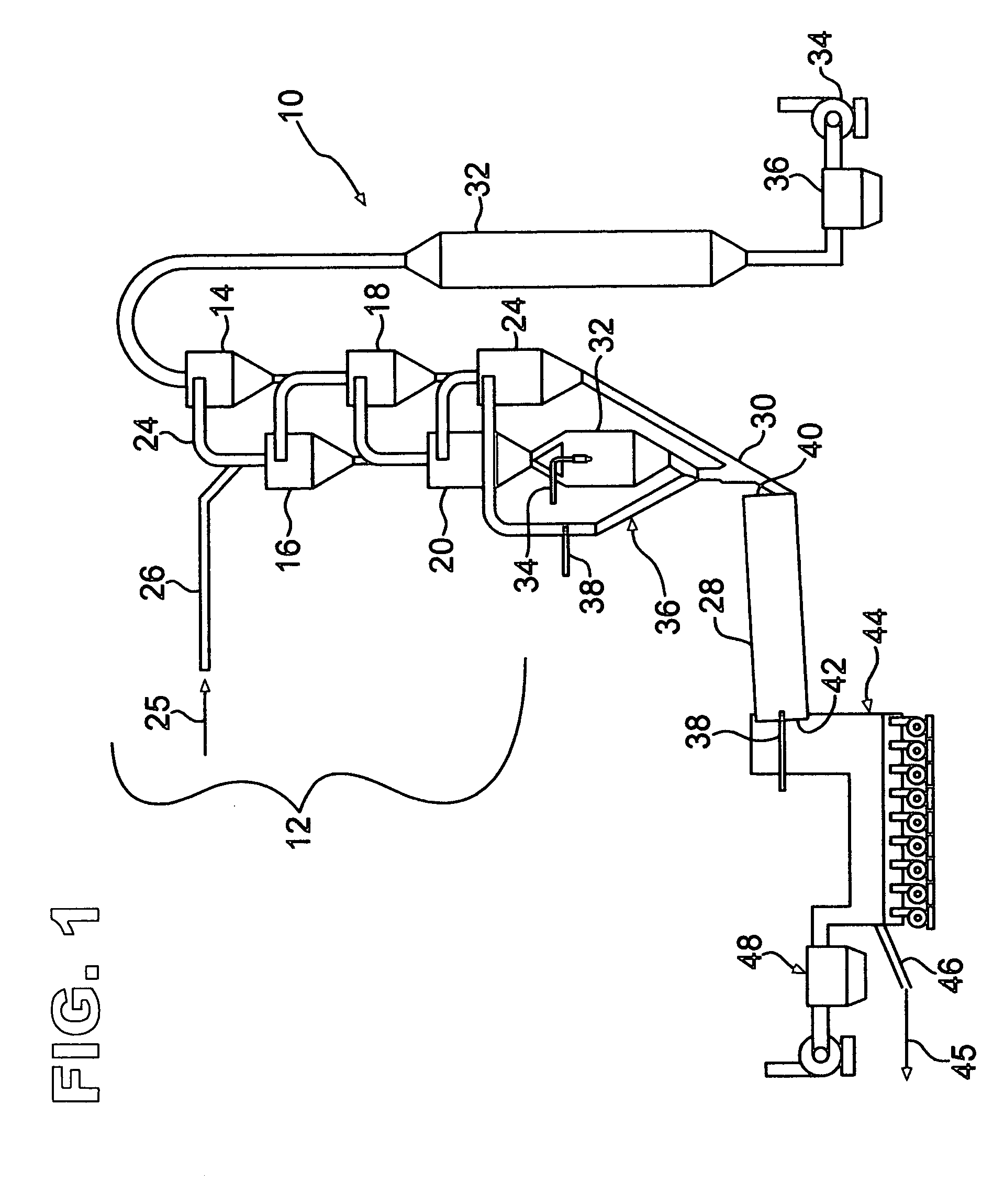

Power system and apparatus for utilizing waste heat

ActiveUS6968690B2Increase temperatureAvoid componentsSteam engine plantsReciprocating piston enginesWorking fluidDistillation

A new Kalina thermodynamic cycle is disclosed where a multi-component working fluid is fully vaporized in a boiler utilizing waste heat streams such as flue gas streams from cement kilns so the energy can be extracted from the streams and converted to usable electrical or mechanical energy in a turbine subsystem and after extraction, the spent stream is fully condensed in a distillation-condensation subsystem using air and / or water coolant streams. A new method for implementing the improved Kalina thermodynamic cycle is also disclosed.

Owner:KALINA POWER LTD

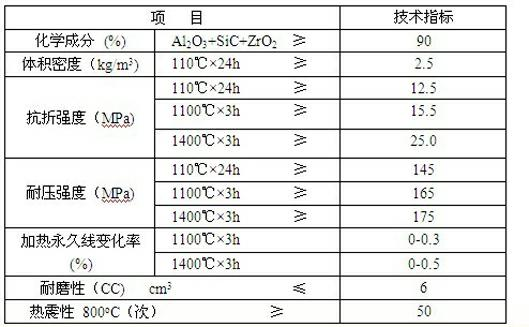

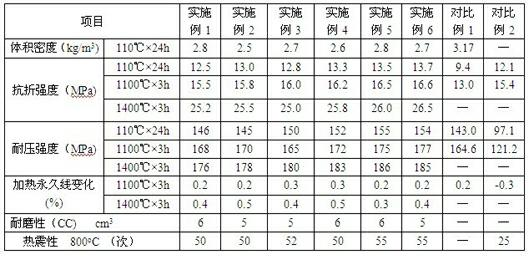

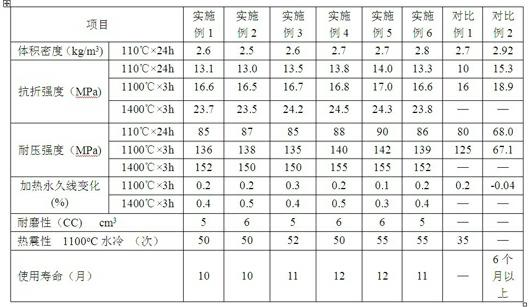

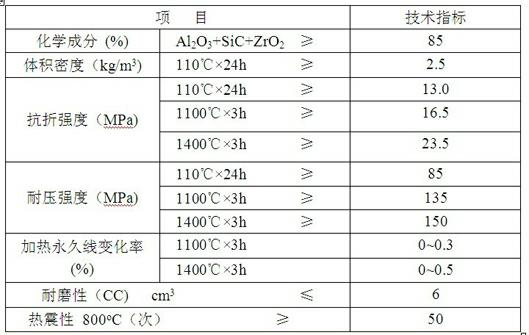

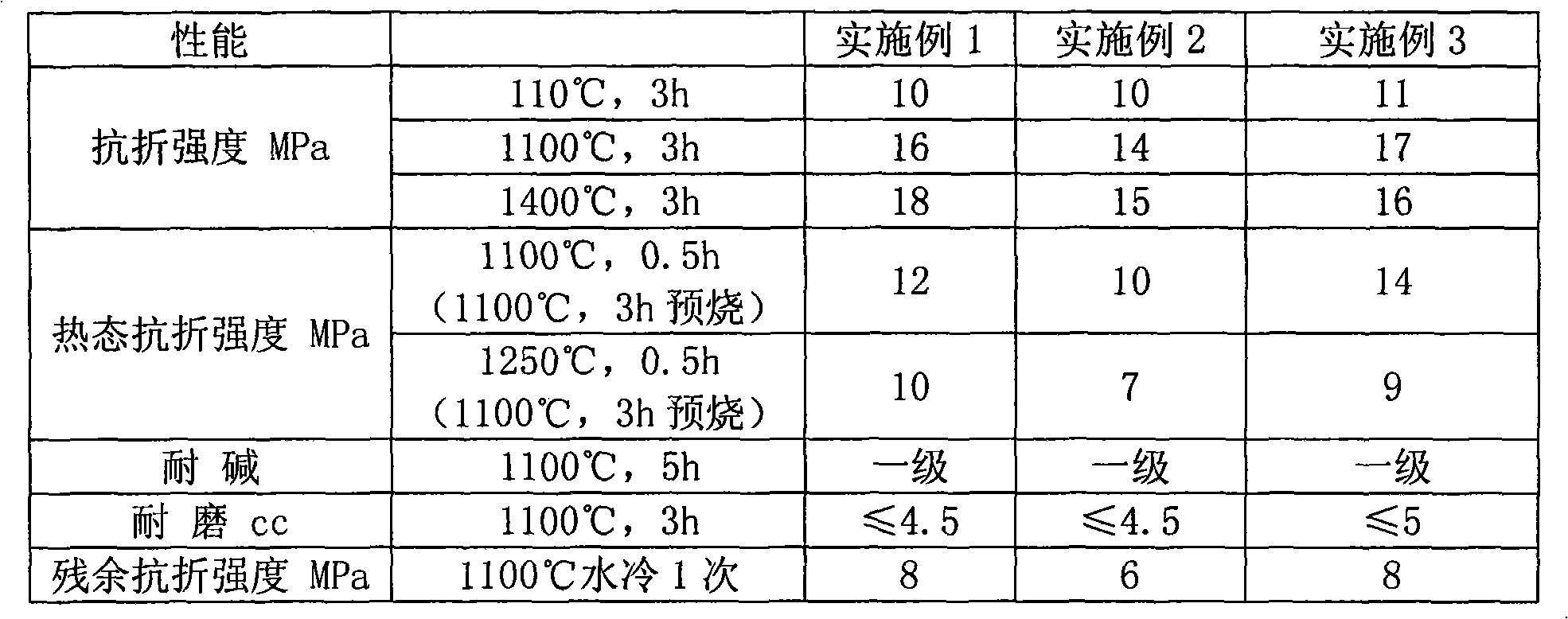

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

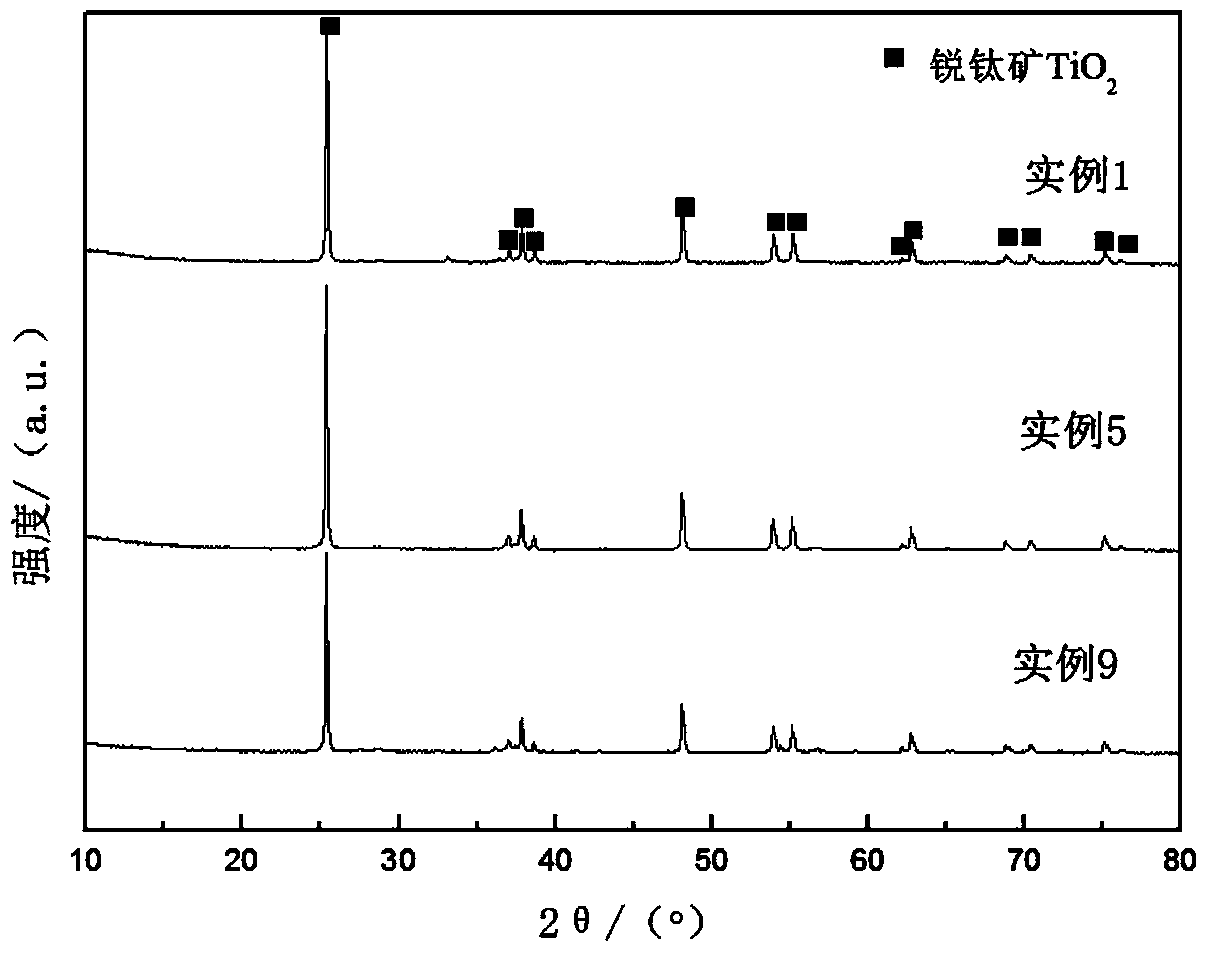

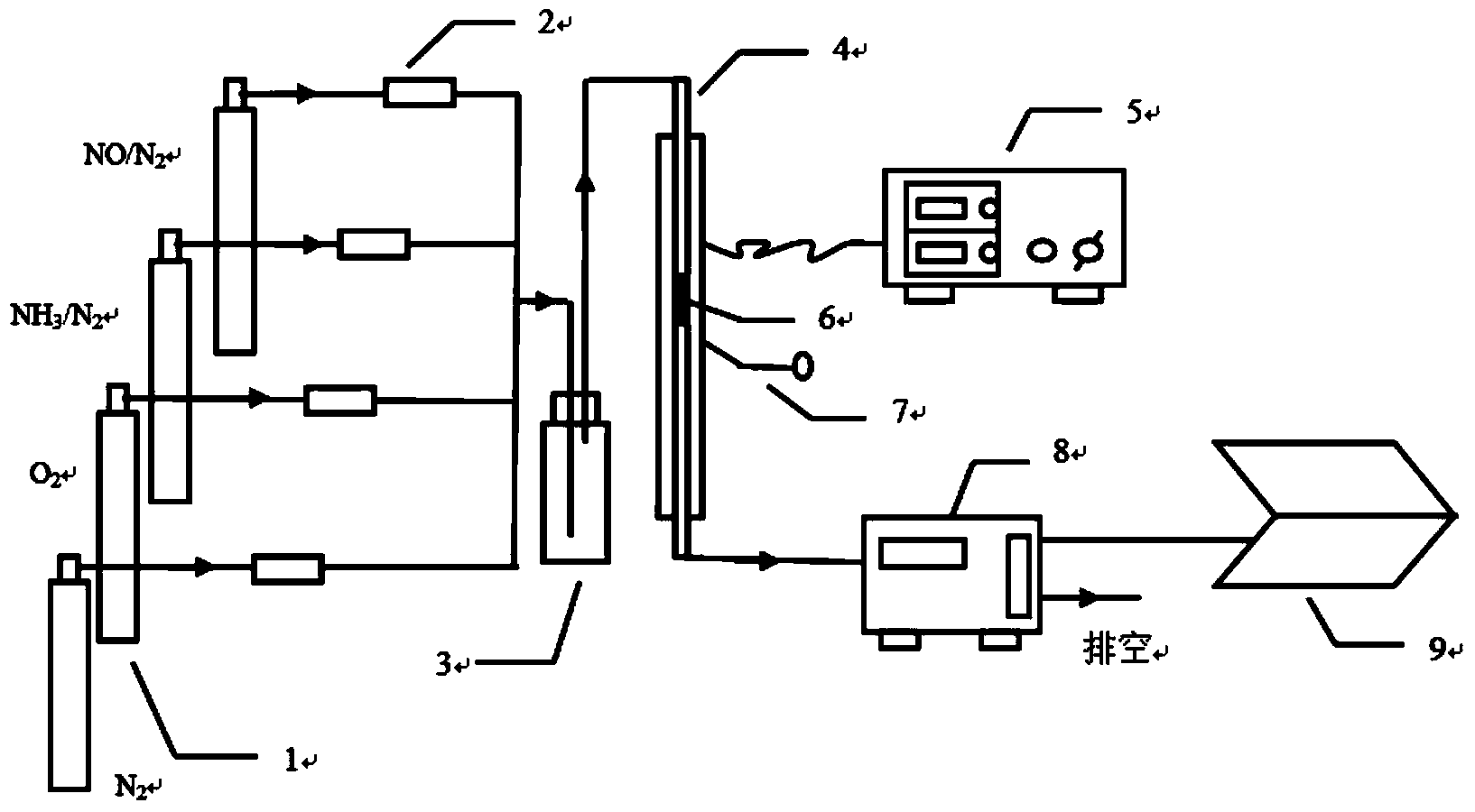

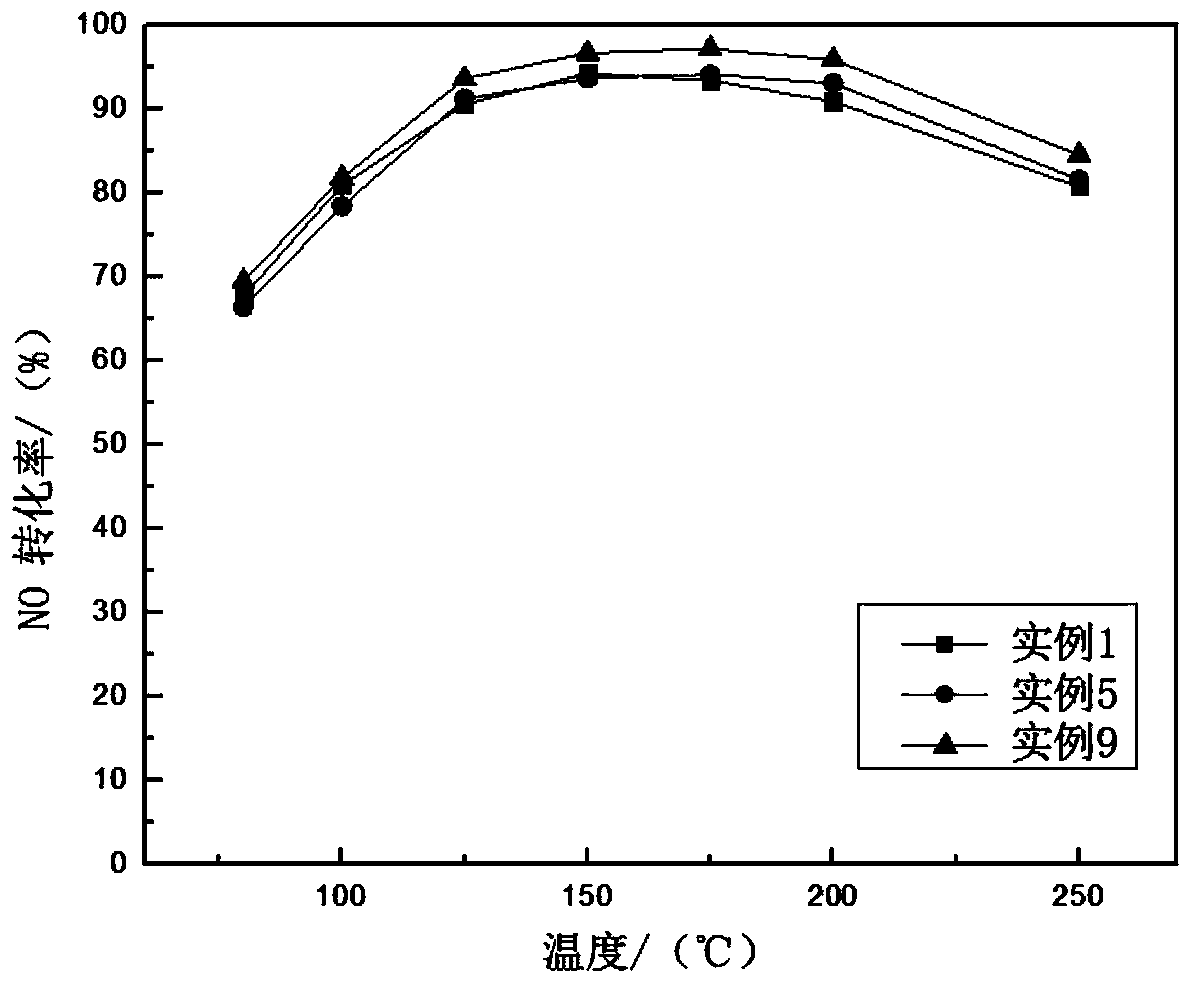

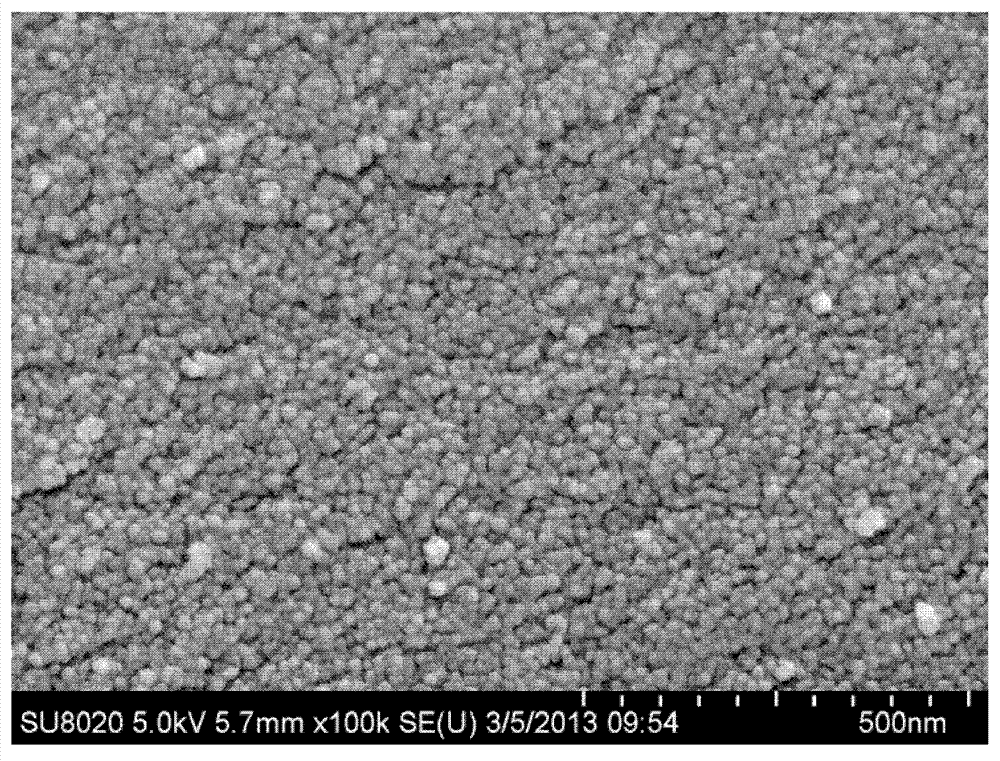

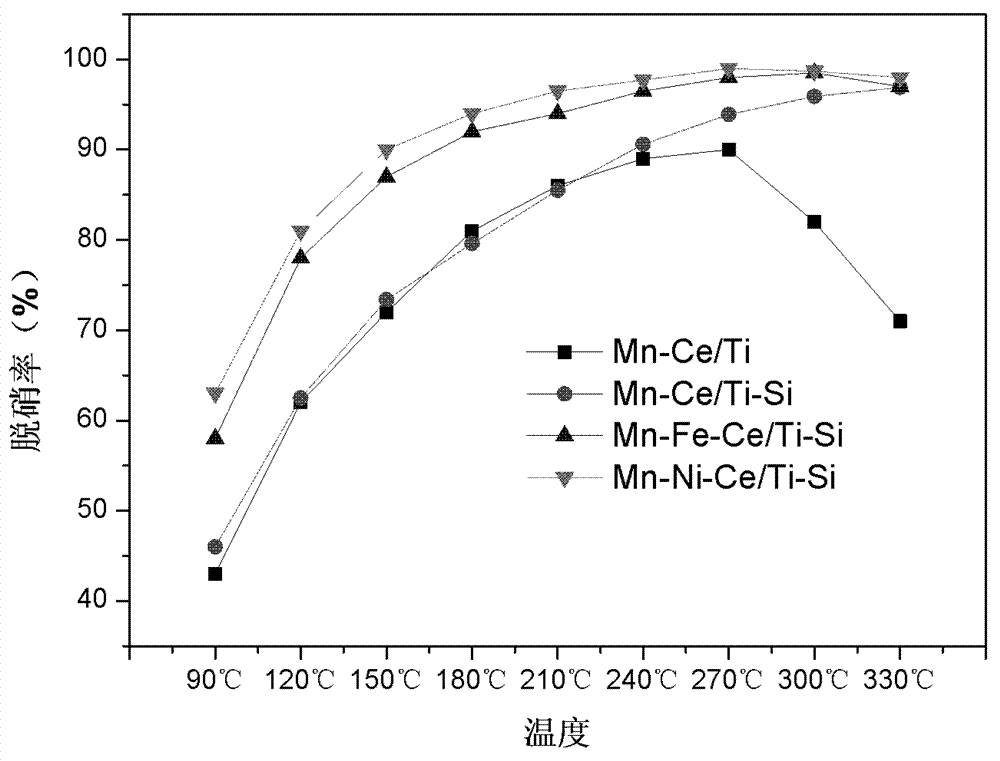

SCR (selective catalytic reduction) catalyst for denitrating low-temperature smoke of cement kiln and preparation method thereof

ActiveCN103638942AHigh low temperature activityImprove anti-poisoning performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNiobiumManganese

The invention provides an SCR (selective catalytic reduction) catalyst for denitrating low-temperature smoke of a cement kiln and a preparation method thereof. The SCR catalyst is characterized in that by adjusting the technological conditions such as proportions of active components, mass ratio of carriers and active components, calcining temperature and the like, a composite metal oxide which is formed by one or more metal elements out of manganese (Mn), ferrum (Fe), copper (Cu), cerium (Ce), lanthanum (La), bismuth (Bi), niobium (Nb), tantalum (Ta) and the like is loaded on a carrier by adopting an impregnation method, and tungsten and molybdate are used as active assistants. The active components in the SCR catalyst are uniformly distributed on the surface of the carrier in an unformed shape, the low-temperature activity of the catalyst is improved by utilizing the synergistic effect of multiple metals, the SCR catalyst is particularly suitable for the denitration of the smoke which is discharged from a dust collector on the tail of the cement kiln, the denitration rate can reach higher than 70 percent at the temperature of 80 DEG C, the denitration rate is higher than 90 percent in the temperature range of 125 DEG C to 200 DEG C, and the toxicity resistance is strong.

Owner:CHINA BUILDING MATERIALS ACAD

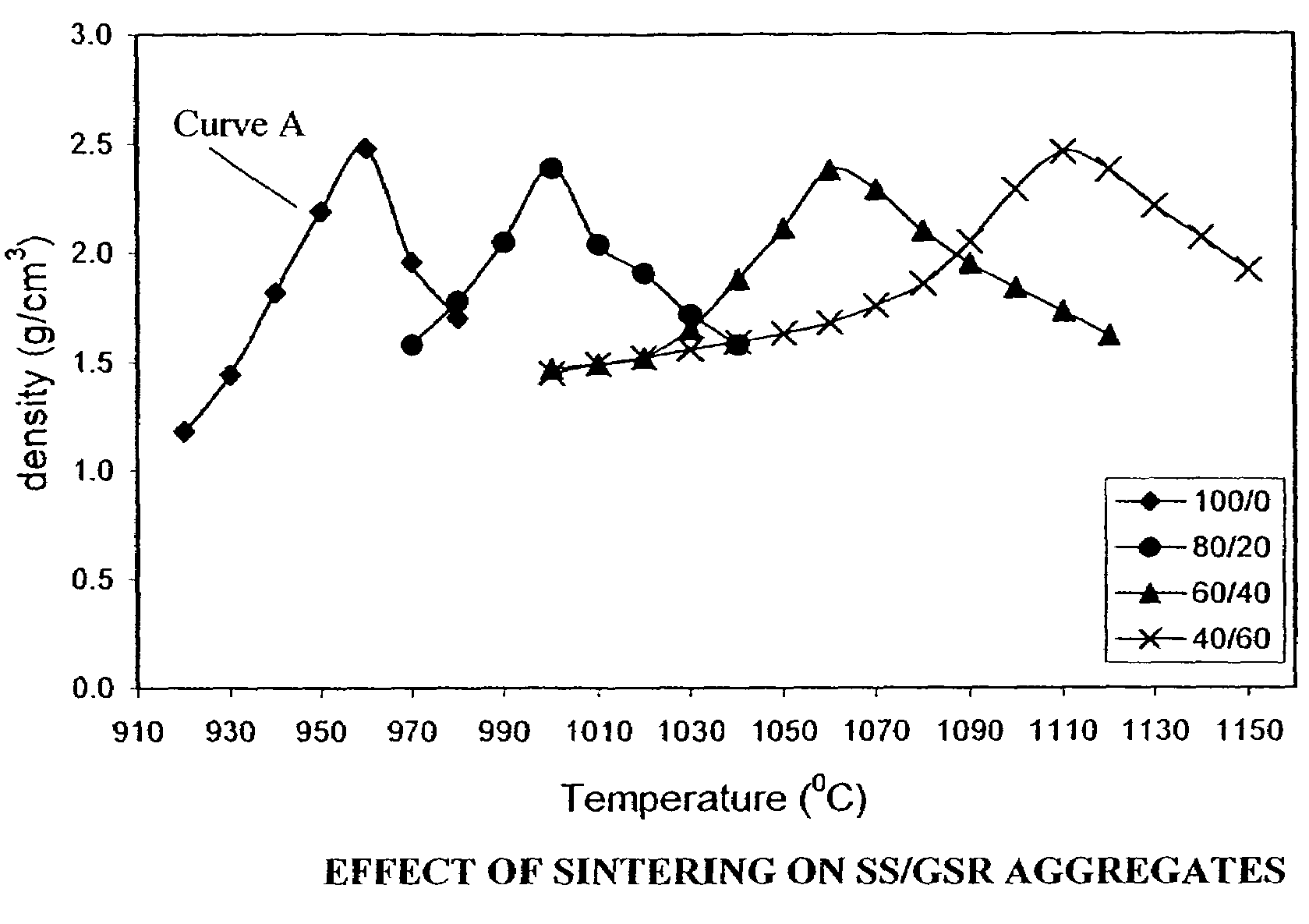

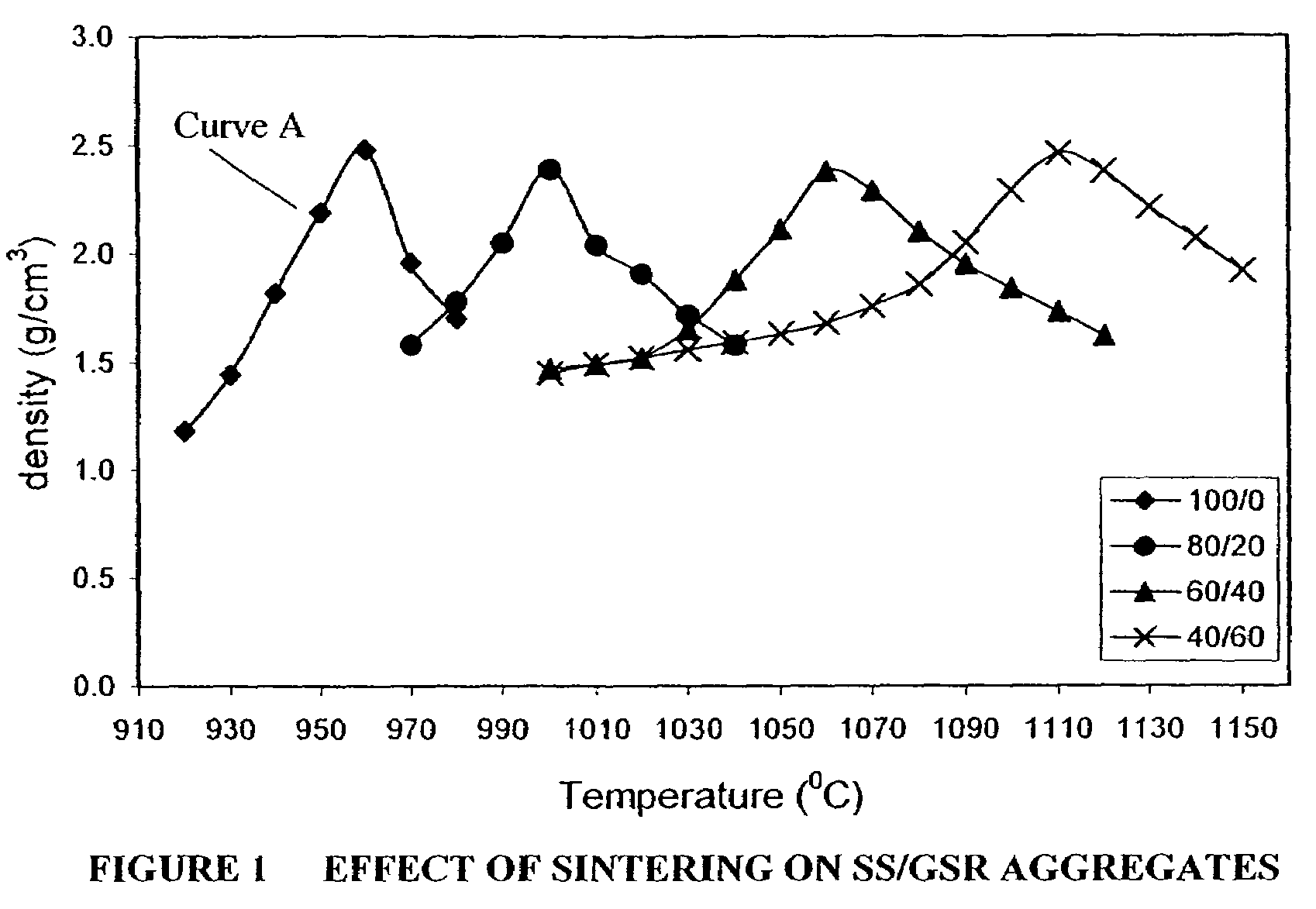

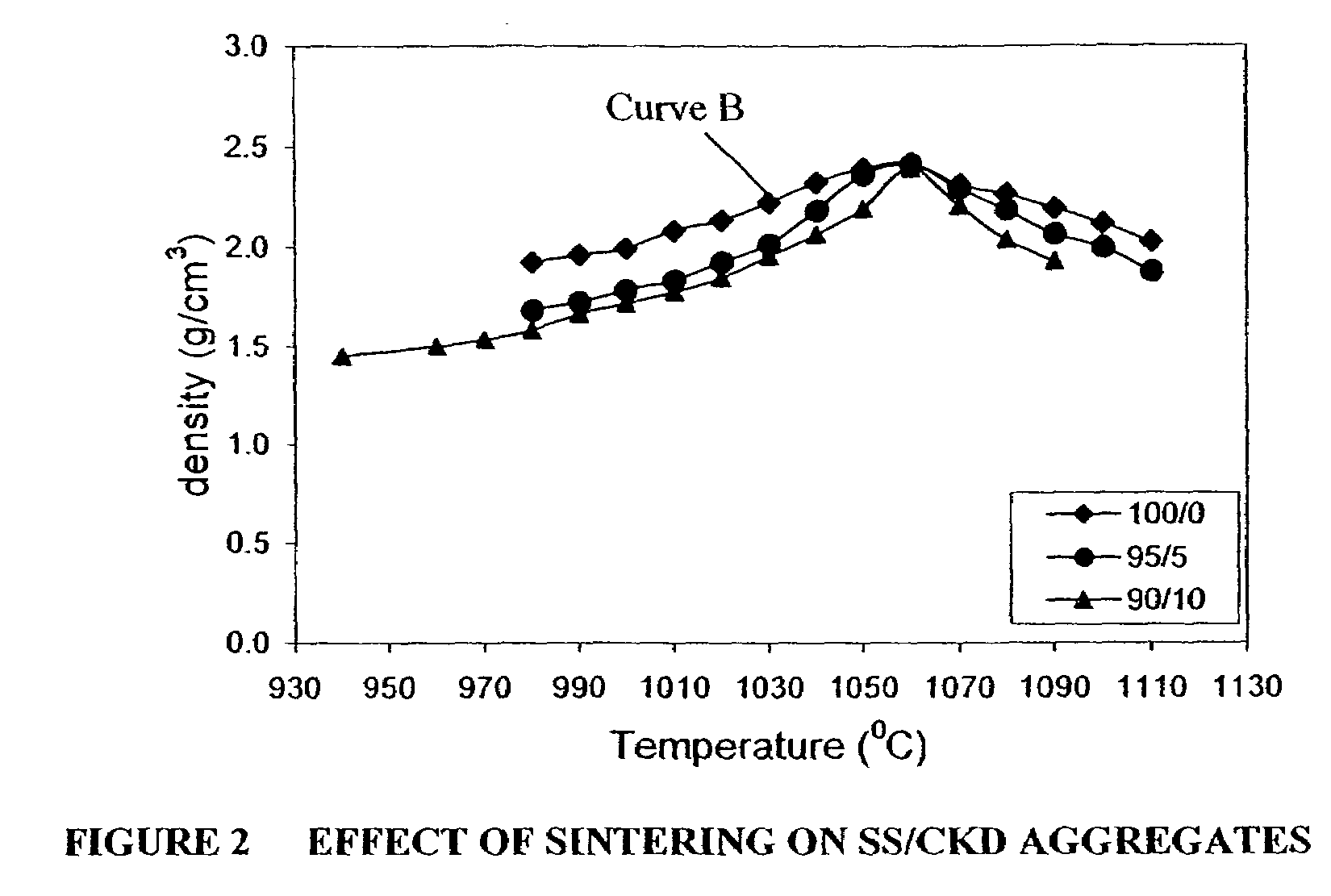

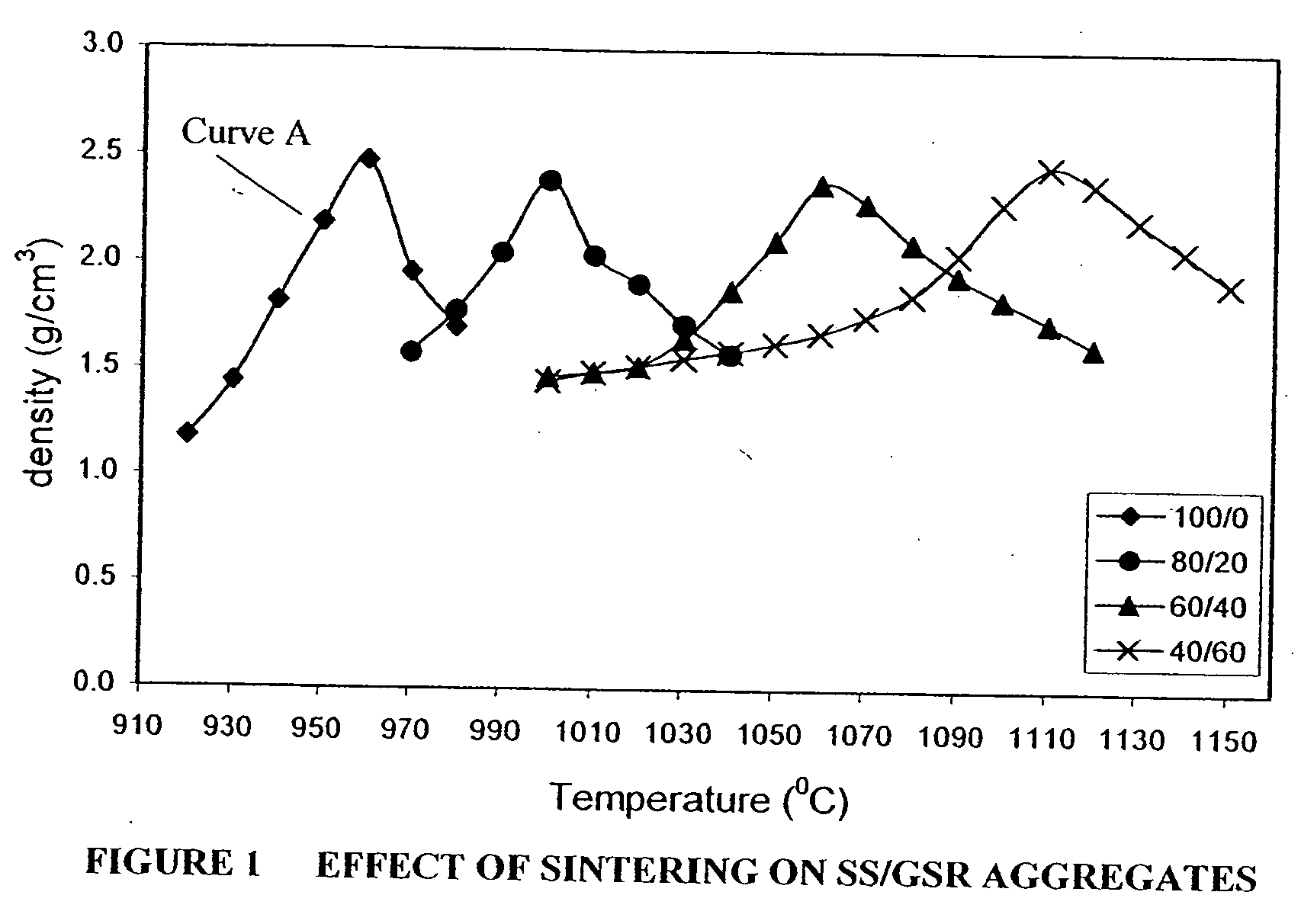

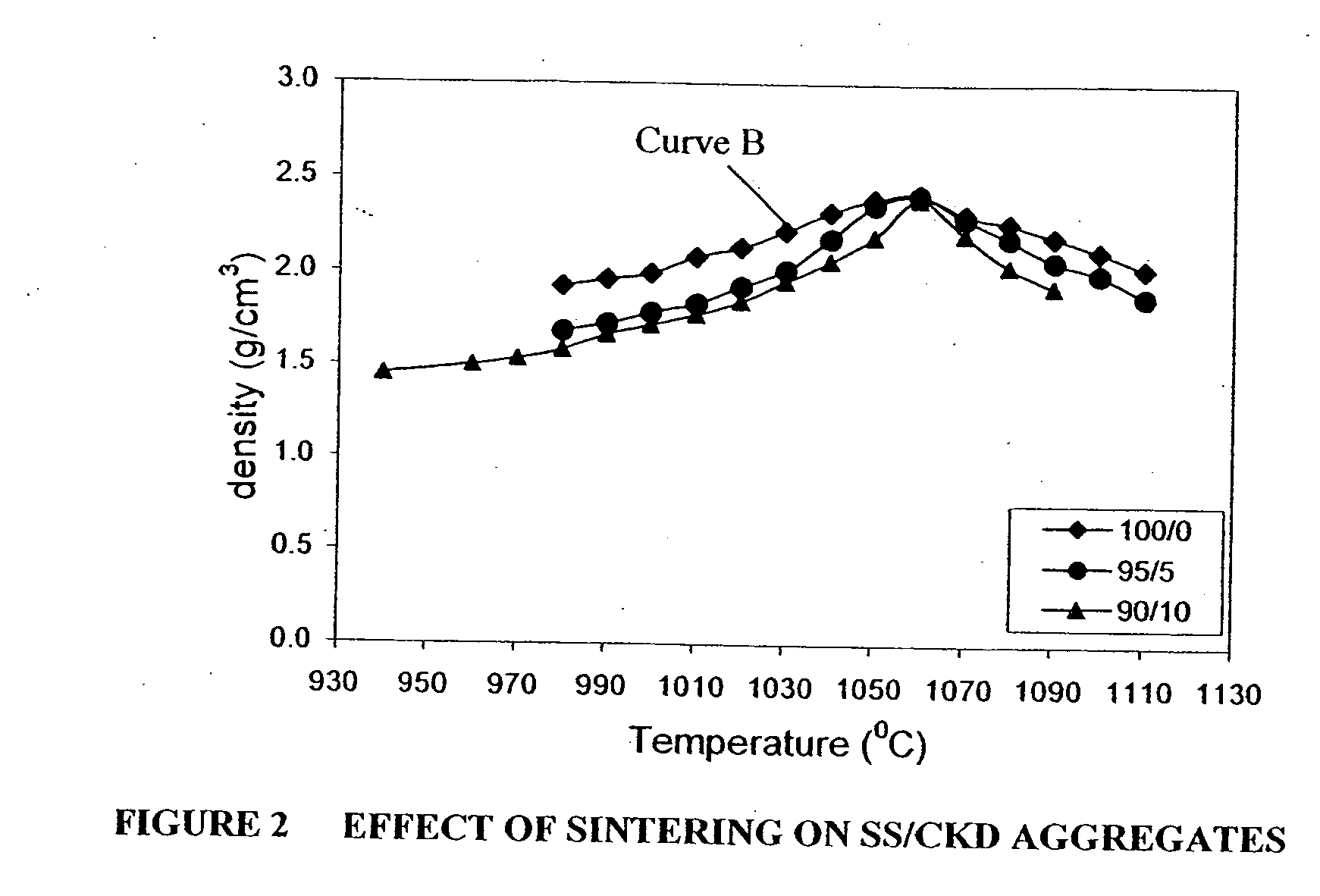

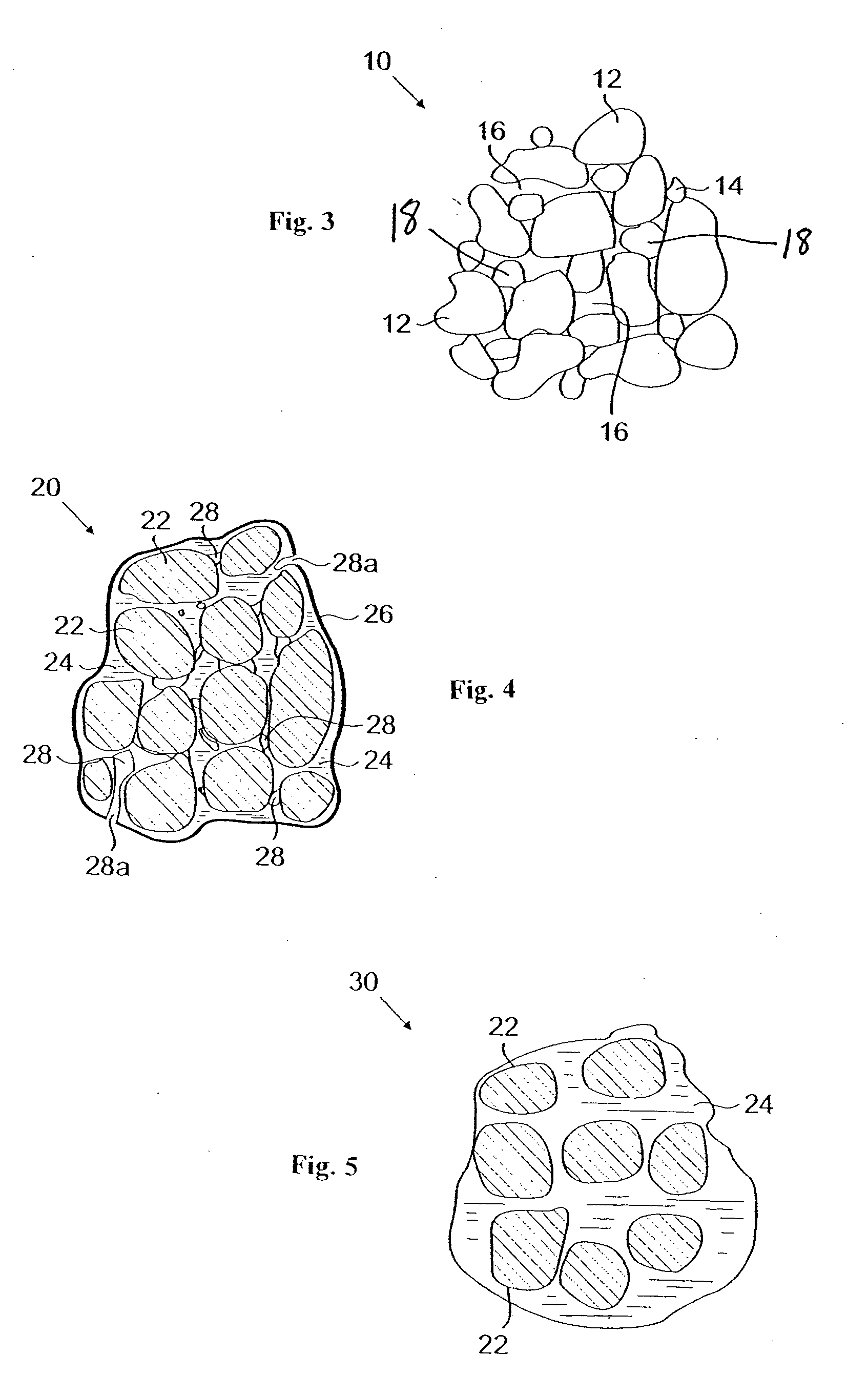

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

Geothermal grout, and methods of preparing and utilizing same

A thermally enhanced, single component, geothermal grout from recycled materials, such as class F fly ash and cement kiln dust. Additional components can include a mid-range water reducer and a dry caustic.

Owner:KONCZAK JEFFREY J

Low temperature denitration catalytic addictive and preparation method thereof

ActiveCN103537279ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganese oxideCement kiln

The invention discloses a low temperature denitration catalytic addictive and a preparation method thereof, and belongs to the field of low temperature denitration catalyst. According to the low temperature denitration catalytic addictive, TiO2-SiO2 is taken as carrier, manganese oxide (MnOx) is taken as active substance, and cerium oxide (CeO2), nickel oxide (NiO) and iron oxide (FeOx) are taken as auxiliary agents. The preparation method comprises following steps: TiO2-SiO2 composite carrier is prepared by sol-gel method; loading of CeO2, NiO or FeOx is realized by one-step dipping; and then the low temperature denitration catalytic addictive is obtained by calcination. The low temperature denitration catalytic addictive possesses high low-temperature denitration catalytic efficiency, wide active temperature window, and relatively high alkali metal poisoning resistance. TiO2-SiO2 is low in cost, and specific area of TiO2-SiO2 is larger than that of pure TiO2 carrier, so that it is beneficial for dispersion of active substances on the surface of TiO2-SiO2, and stability of the active substances. Auxiliary agent NiO or FeOx are capable of increasing low-temperature activity and alkali metal poisoning resistance of the low temperature denitration catalytic addictive, so that the low temperature denitration catalytic addictive is suitable for denitration in dedusted cement kiln at low temperature or even under conditions with unstable temperature.

Owner:BEIJING UNIV OF TECH

Special castable for kiln outlet

The invention discloses a special castable for a kiln outlet, which belongs to the field of refractory materials. According to the invention, the special castable comprises the following components in percentage by weight: 8-25% of silicon carbide, 10-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 1-5% of zirconium diboride, 1-5% of silicon nitride,5-15% of alumina micropowder, 3-6% of pure calcium aluminate cement, 0.5-1% of explosion-proof fiber and 0.06-0.2% of sodium tripolyphosphate, which is an additive. By using the special castable for the kiln outlet, disclosed by the invention, the phenomenon of poor wear resistance, block falling and the like in the kiln outlet can be effectively improved; the service life of the cement kiln outlet can be largely prolonged; and the special castable for the kiln outlet, disclosed by the invention, has the advantages of high temperature resistance, heat shock resistance, wear resistance, high strength, irreversible micro expansion and the like.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Special pouring material for coal injection pipe

The invention discloses a special pouring material for a kiln opening and belongs to the field of a refractory material. The special pouring material comprises the following components by weight percent: 10-25% of silicon carbide, 15-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 5-15% of aluminum oxide micro powder, 3-8% of silicon micro powder, 2-5% of pure calcium aluminate cement, and 0.5% and 0.2% of anti-explosion fibers and sodium tripolyphosphate serving as additives. The special pouring material is capable of efficiently improving the wear resistance and avoiding the hot peeling phenomenon of the cement kiln coal injection pipe, has the characteristics of high temperature resistance, heat vibration resistance, wear resistance, high strength, irreversible micro inflation, and the like, and is capable of greatly prolonging the service life of the cement kiln coal injection pipe.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

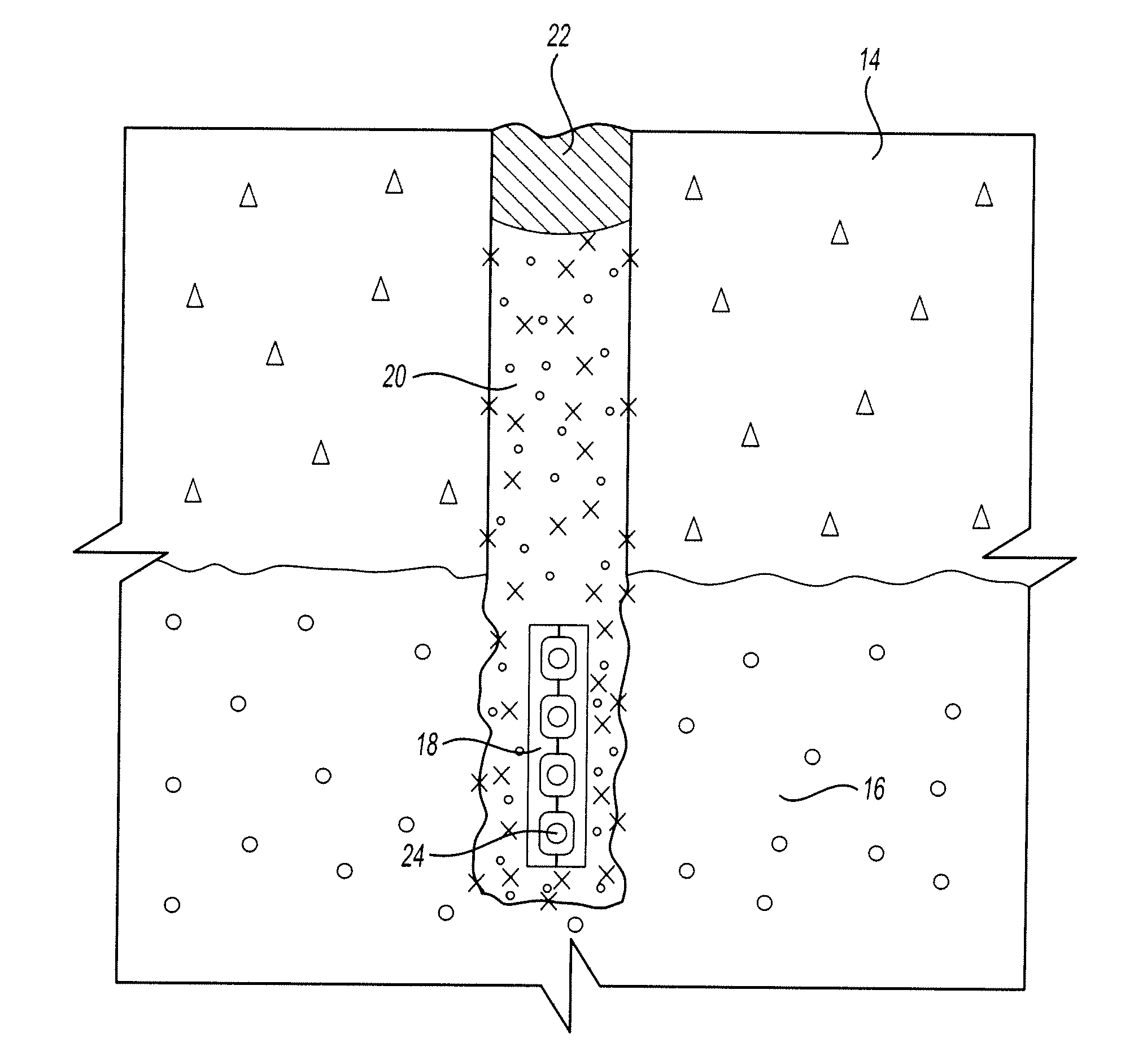

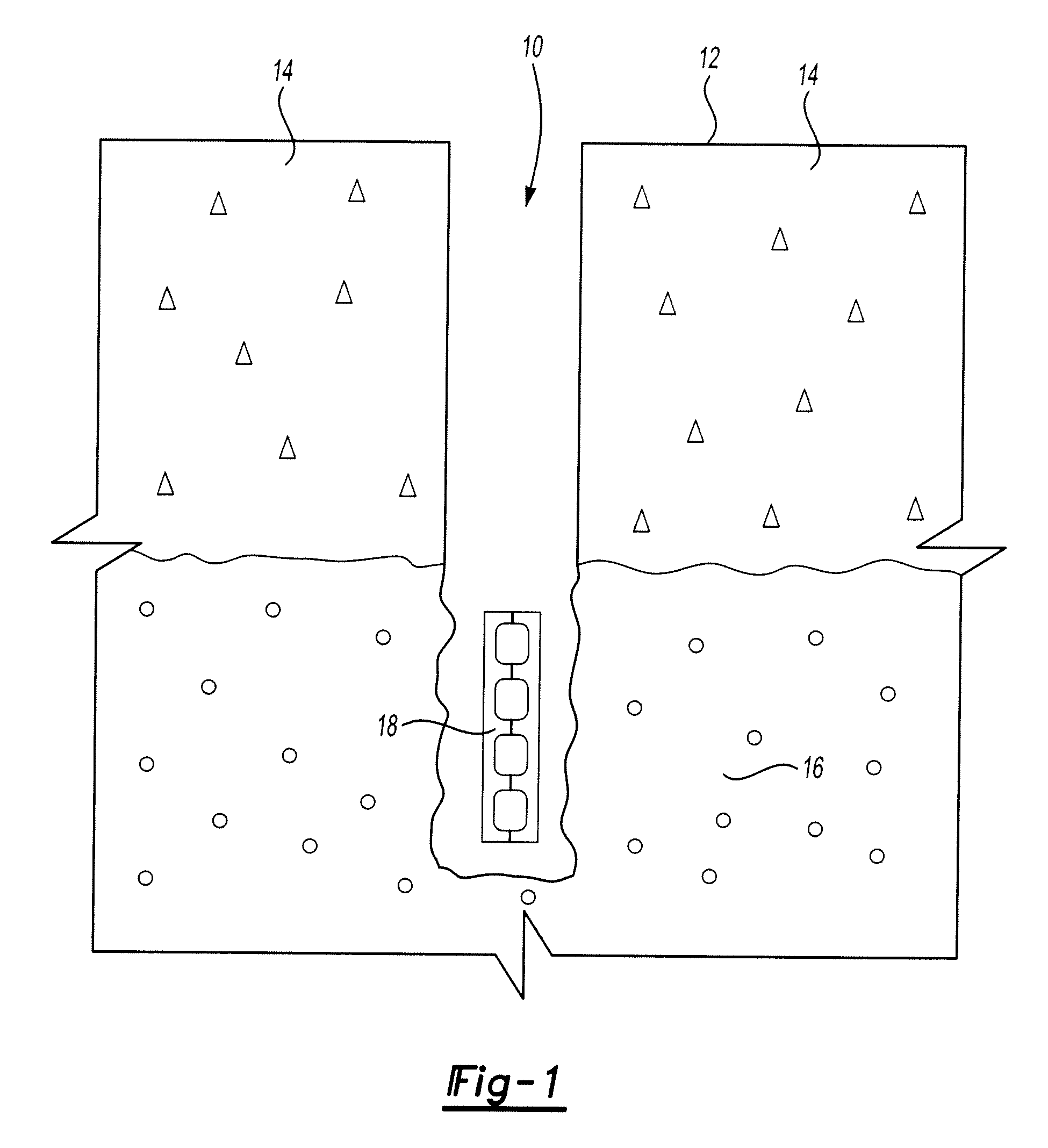

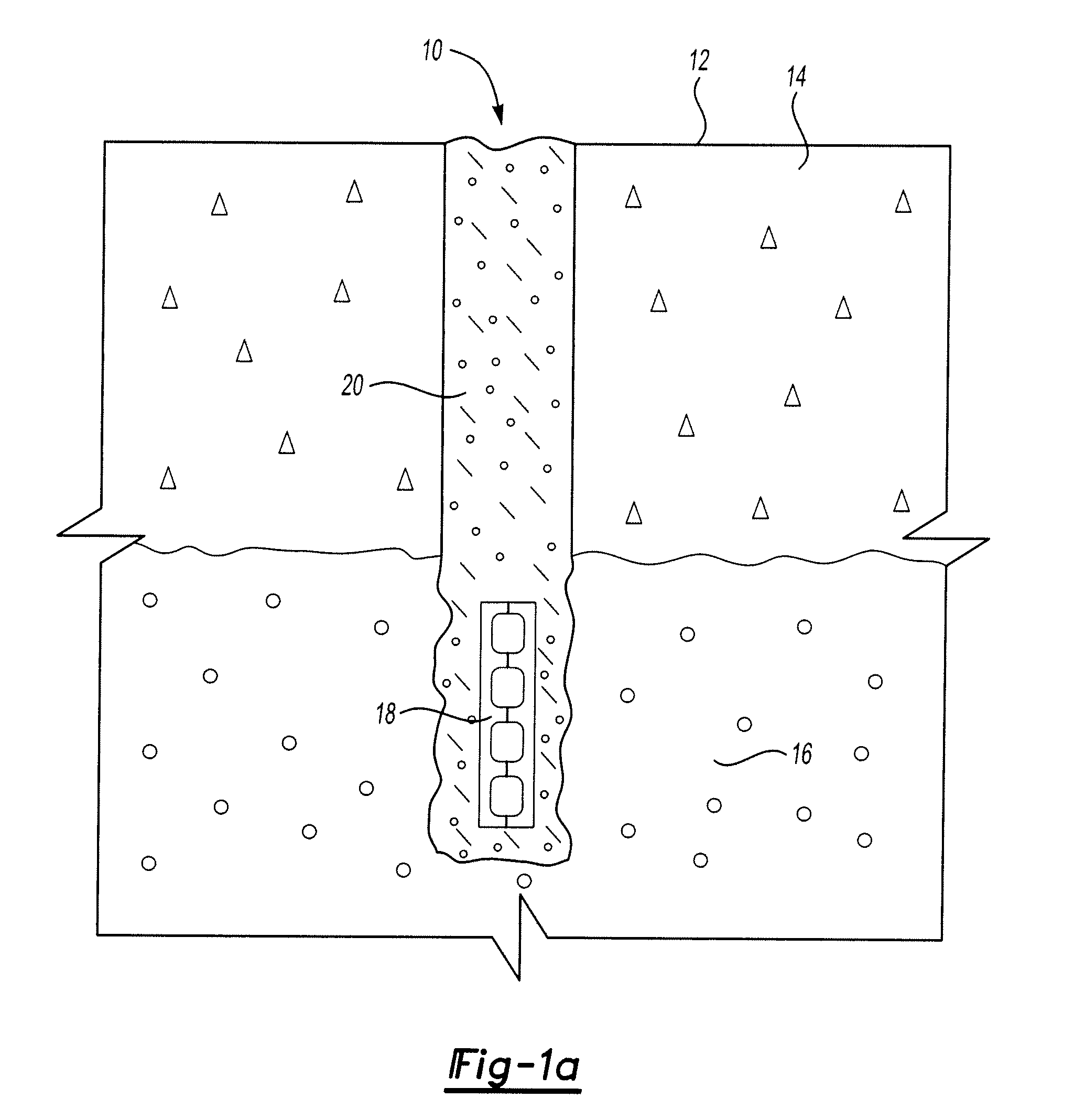

Grout for filling a micro-trench

InactiveUS20120195694A1Precise functionResists shrinkage and crackingArtificial islandsSolid waste managementFly ashCement kiln

Owner:KONCZAK JEFFREY J

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

Composite combined aluminum oxide-silicon carbide-(carbon) system amorphous refractory material

The invention relates to a complex combination alumina-carborundum-(carbon) series amorphous fire proof material, and the formula comprises: 36 to 32 percent of 8-3mm corundum or bauxite, 18 to 26 percent of 3-1mm corundum or bauxite, 10 to 22 percent of 1-0.0088mm corundum or bauxite, 0 to 15 percent of 1-0.088mm carborundum, 0 to 3 percent of 1-0.0088 spherical asphalt, 0 to 20 percent of d90 less than 0.088mm corundum or bauxite, 0 to 20 percent of d90 less than 0.088 carborundum, 0 to 3 percent of d90 less than 0.088mm high-carbon materials, 0 to 5 percent of alpha alumina micro powder, 1 to 8 percent of alumina hydrate, 1 to 6 percent of silicon ash, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of plus super-plasticizer (polycarboxylic acids+sulfonated naphthalene formaldehyde polymer+sulfonated melamine polymer), 1 to 6 percent of plus polypropylene acid series latex and 1 to 6 percent of plus water. Compared with low-cement aluminum carborundum carbon material, the material has good anti-corrosion performance. Therefore, the service life of a kilneye of a cement kiln and a main groove slag line of a blast furnace can be prolonged when a product is combined by the complex combination alumina-carborundum-(carbon) series amorphous fire proof material instead of the cement.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

ActiveCN101885617AUniform structureSmall fluctuations in water addition during constructionPliabilityCement kiln

The invention discloses wear corrosion resistant castable prepared from a bauxite-based homogenous material and a preparation method thereof, which belong to the technical field of castable refractory. In the invention, by using the characteristics of the bauxite-based homogenous material, such as homogeneous chemical components and structure, stable performance, mulite main crystal phase, small linear change, high high-temperature strength and certain flexibility due to mutual insertion of micro crystals and the like, the shortcomings of low middle-temperature strength and poor wear resistance and alkali corrosion resistance of the conventional high-aluminum bauxite castable are overcome, and the problems of low middle-temperature strength, poor wear resistance and poor alkali, chloride and sulphur corrosion resistance of the conventional high-aluminum and corundum castable are effectively solved. The wear and corrosion resistant castable with high middle-temperature performance is prepared. The wear corrosion resistant castable and the preparation method thereof have the advantages of small fluctuation of water adding amount in construction, stable usability, reduction rate of partial corrosion, prolonged service life and wide application to a kiln hood, a grate cooler, a tertiary air duct and a decomposing furnace of a dry process cement kiln and relative parts of other ceramic and petrified thermo-technical kilns and the like.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

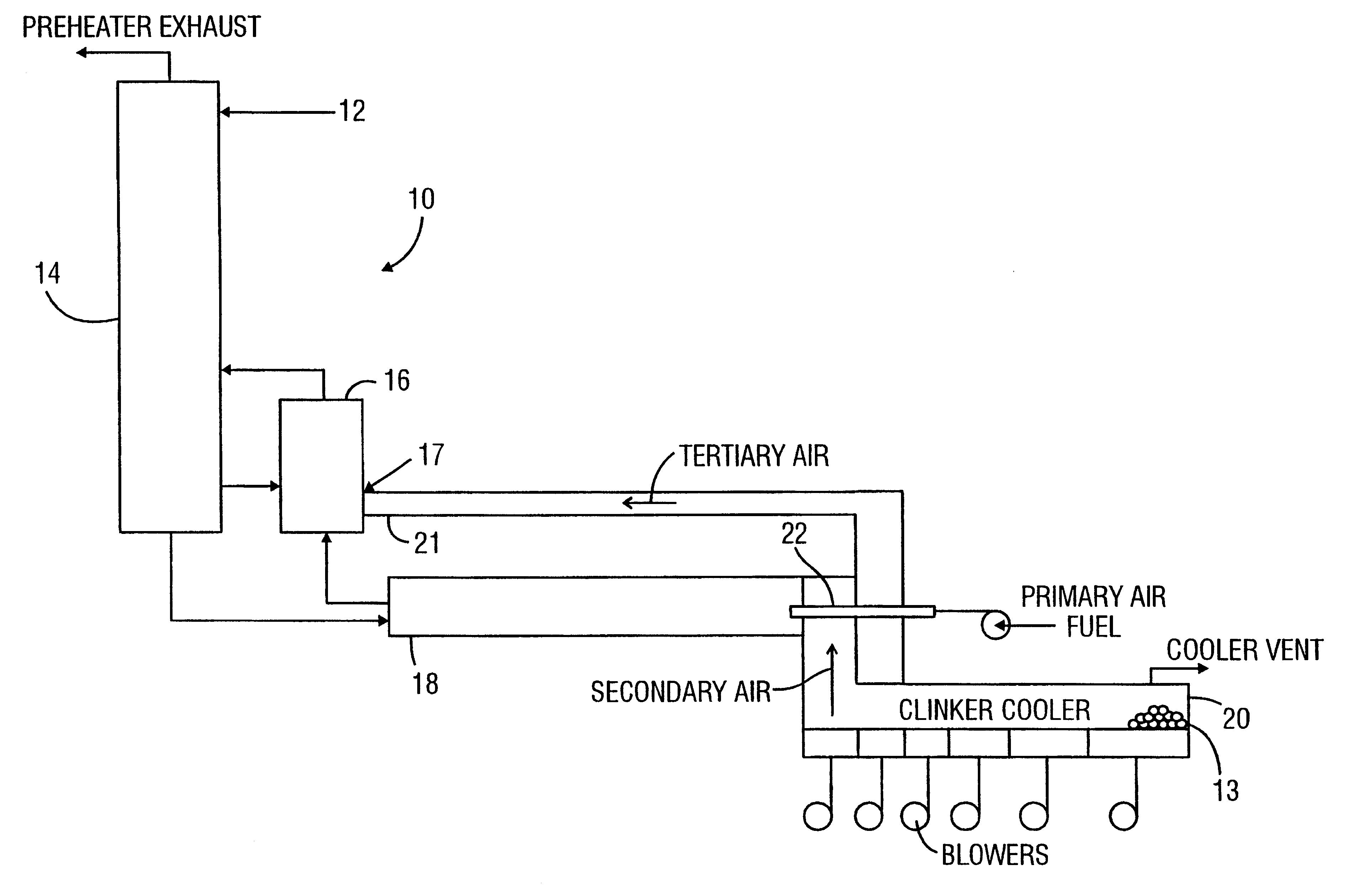

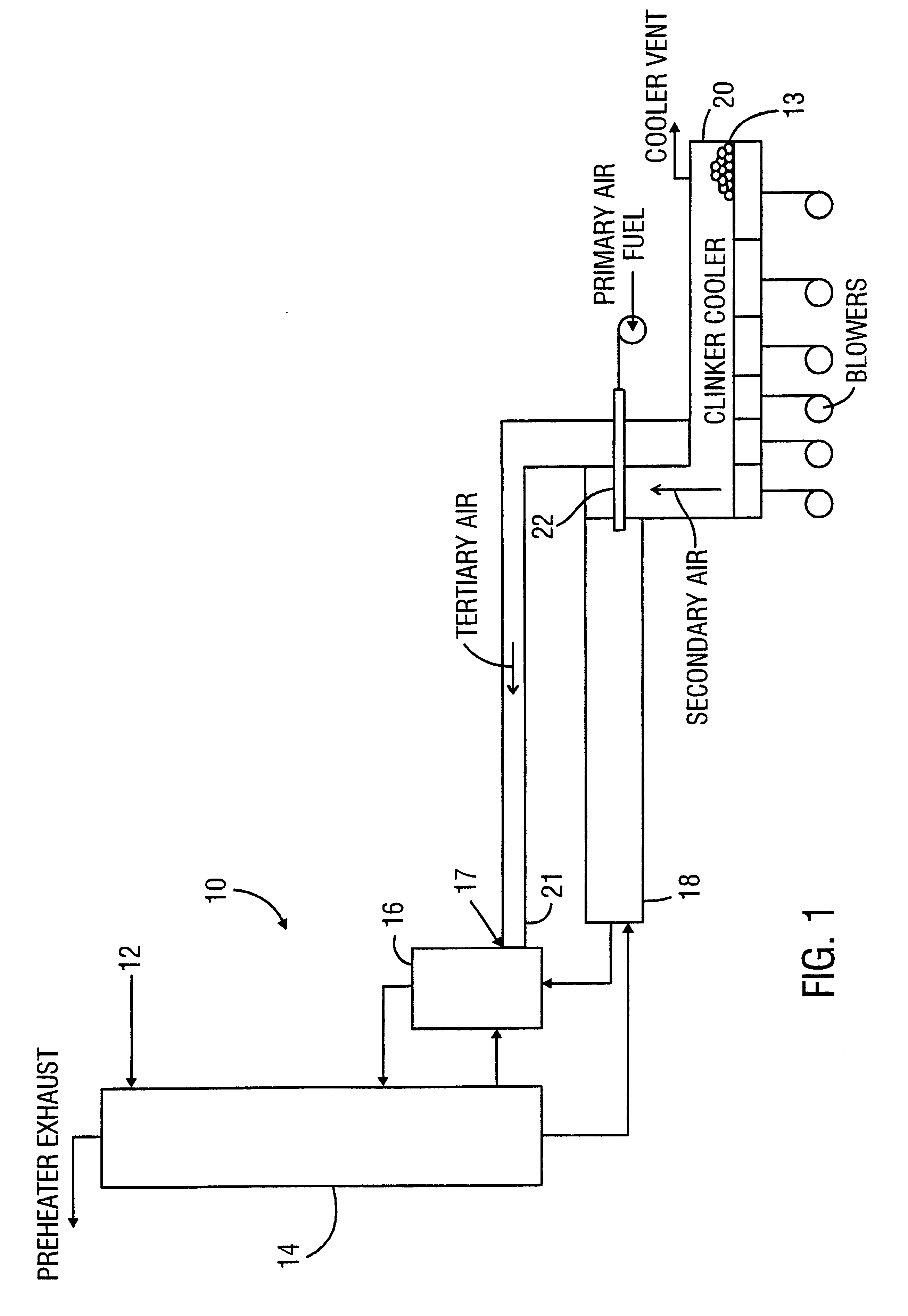

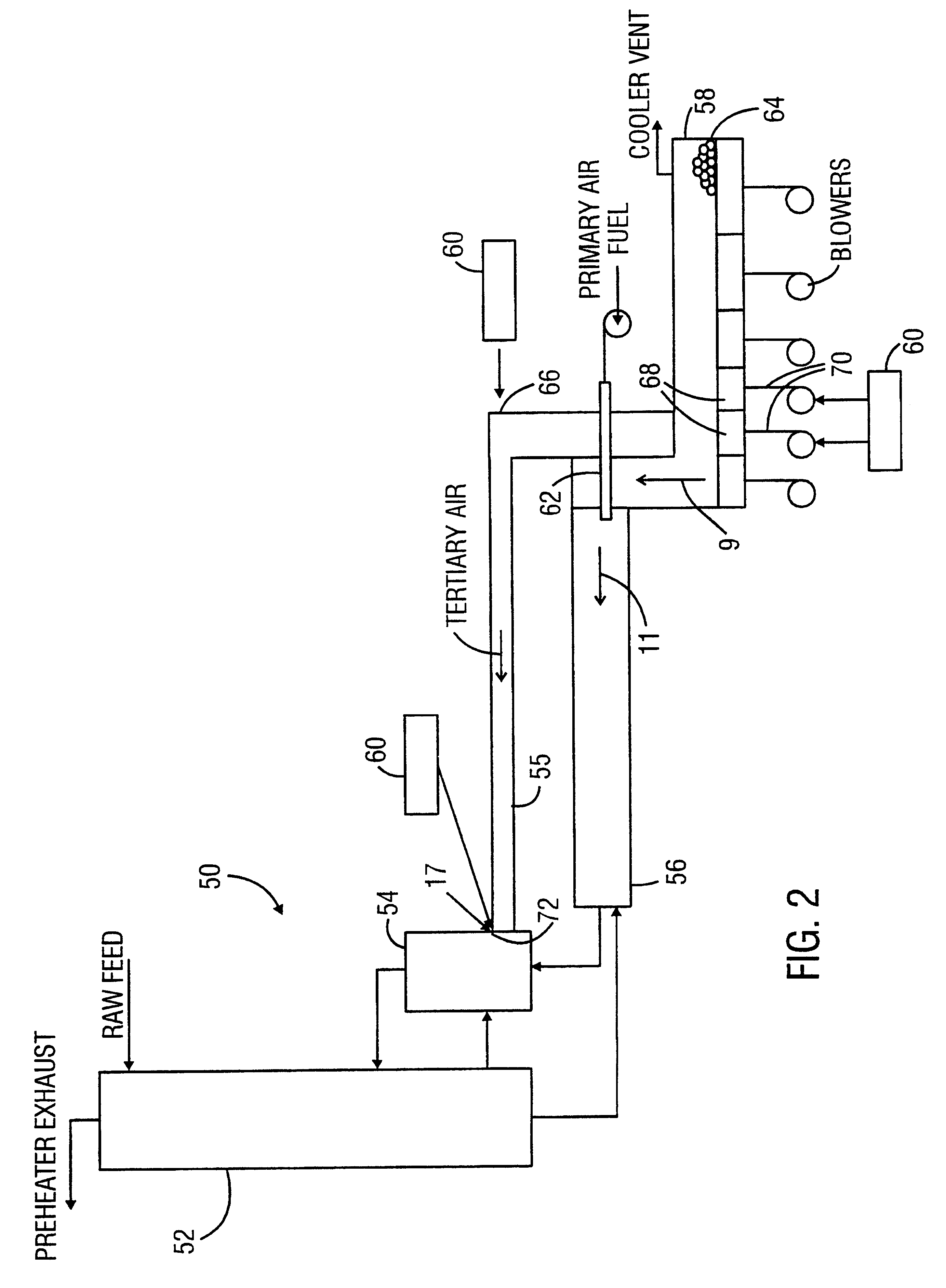

Oxygen enrichment of cement kiln system combustion

The invention in its various embodiments includes an apparatus and a method for improving combustion in a cement kiln system. The apparatus in one embodiment includes a precalciner and an oxygen source coupled to the precalciner. The method in one embodiment includes introducing oxygen into the precalciner of a cement kiln system.

Owner:CEMEX

Composite bonding wear-resistant castable refractory

The invention relates to a composite bonding wear-resistant castable refractory, which can be used for high-temperature kiln engineering. The amorphous castable refractory which is normal in coagulation, quick in hardening, low in porosity, high in strength and high in abrasive resistance is prepared from silica sol serving as a bonding agent, aluminate cement serving as a curing agent, alumina micro powder and wollastonite which serve as a compact agent, heat resistant steel filters serving as a reinforcing agent and corundum and alumina which serve as an aggregate. The composite bonding wear-resistant castable refractory is suitable for positions such as air pipeline elbows for the cogeneration of cement kilns, cyclone cones and linings for triple air pipe gates which are easy to wear in high-temperature kilns.

Owner:ANHUI RUITAI NEW MATERIALS TECH

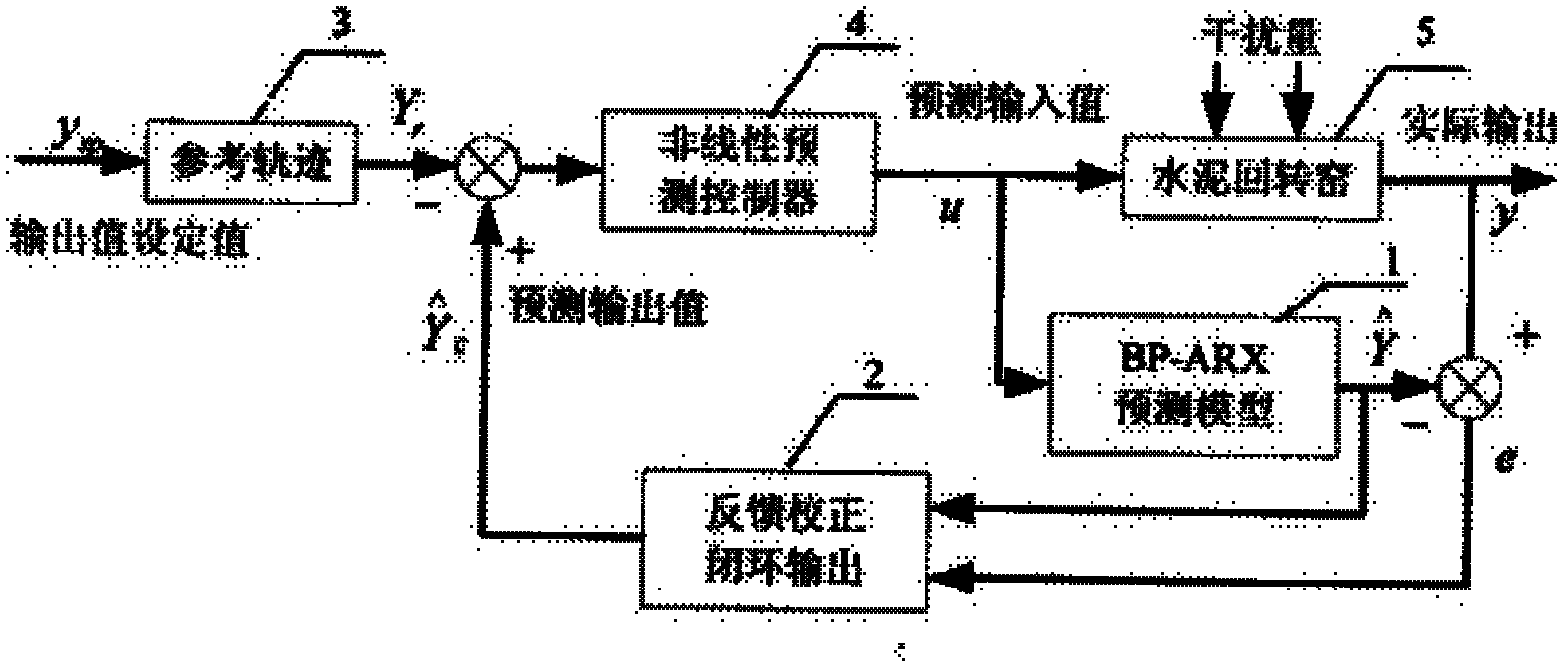

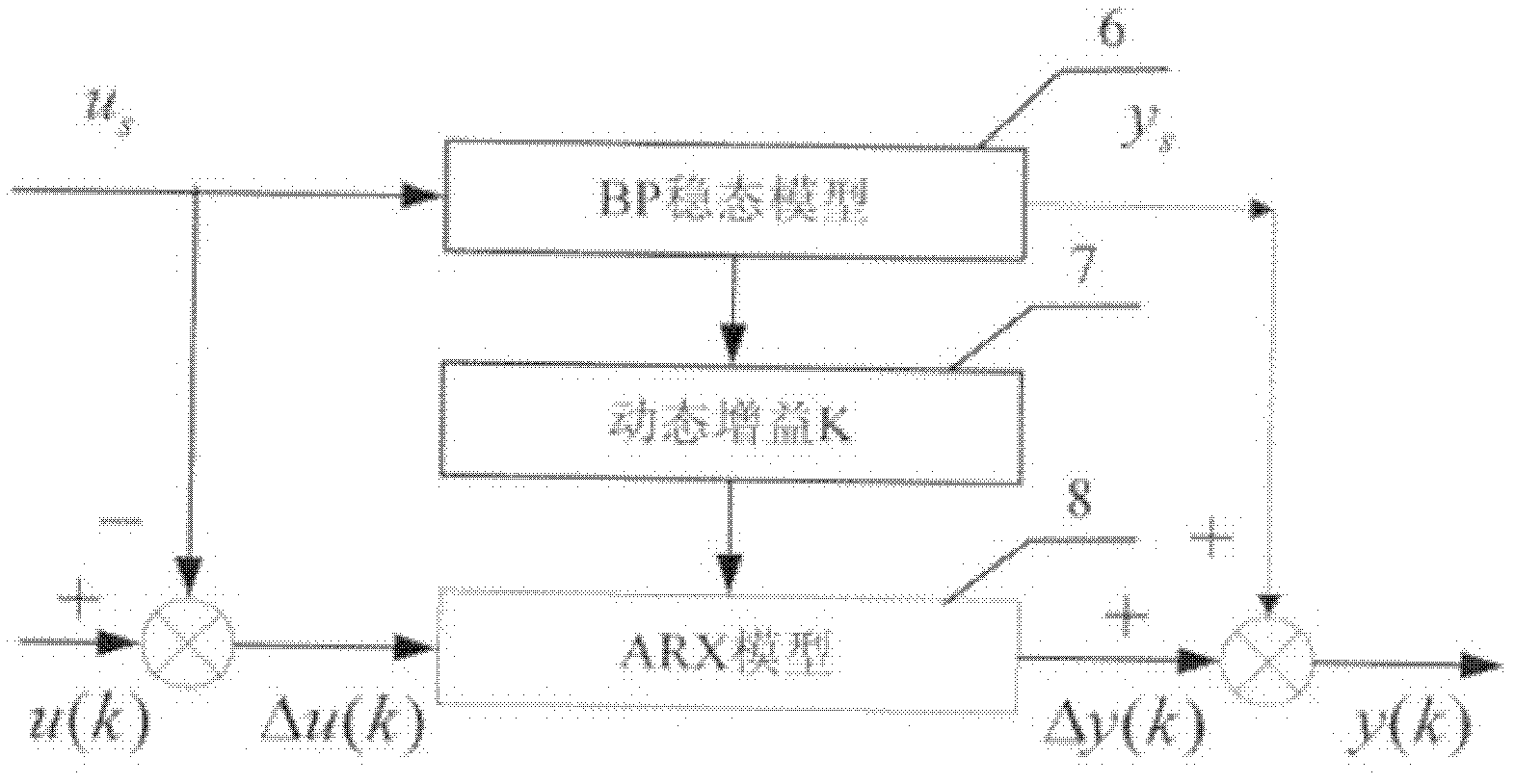

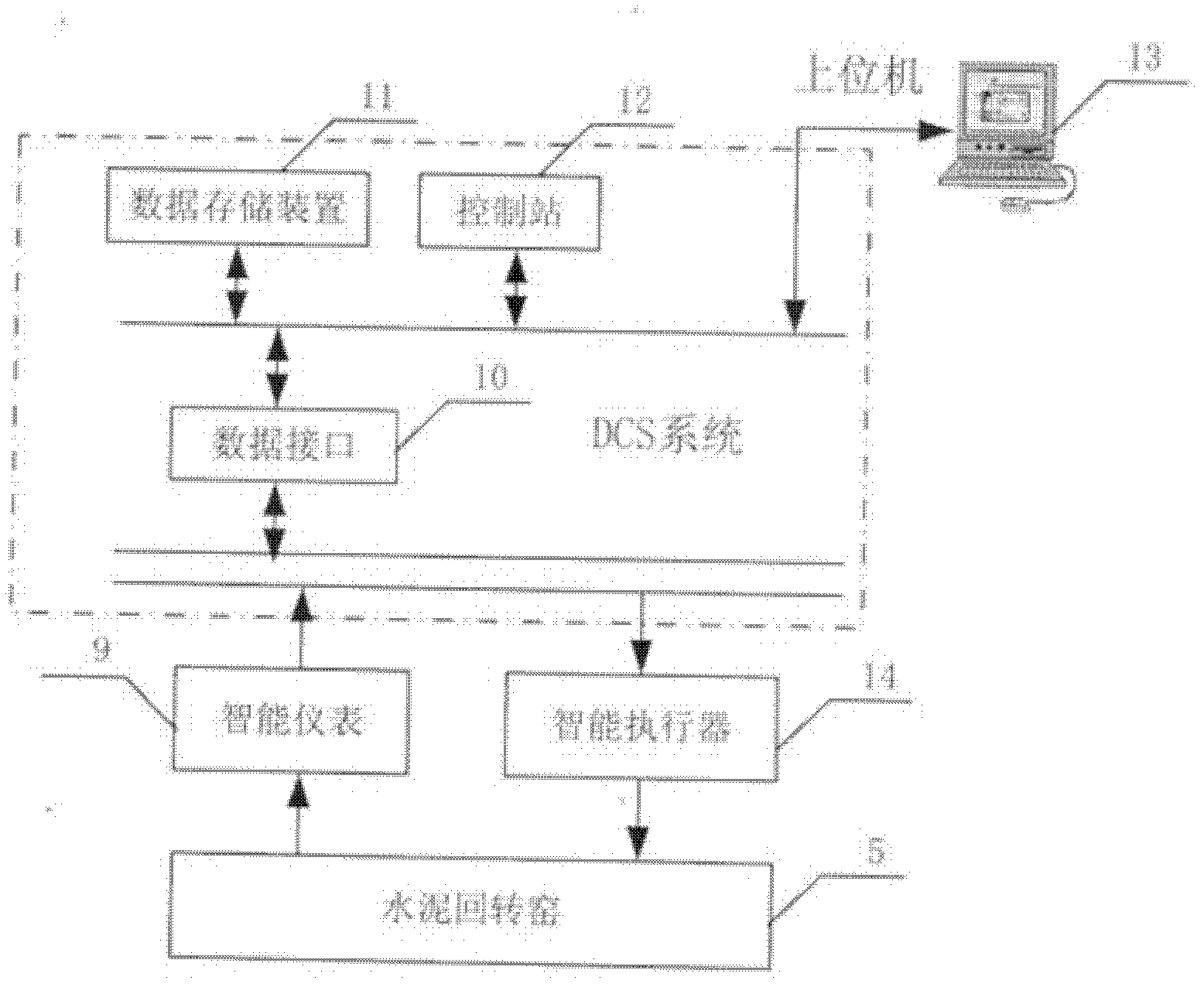

Calcination predictive control system and method for rotary cement kiln

InactiveCN102629104AStable temperatureTaking into account energy consumption per unit of productionRotary drum furnacesAdaptive controlData informationClosed loop

The invention relates to a calcination predictive control method and a calcination predictive control system for a rotary cement kiln. The method comprises the following steps of: (1) acquiring field data of the calcining process of the rotary cement kiln and classifying the field data; (2) respectively carrying out model identification on the data and organically combining the data to establish a prediction model; (3) carrying out prediction on historical and future data information on the calcining process by the prediction model to obtain an output of the calcining process and outputting error feedback correction by utilizing the model to obtain a closed-loop prediction output of the calcining process; and (4) according to the closed-loop prediction output and a reference output trace,constructing a non-linear target function and carrying out solution of a optimal solution on the target function by using a sequential quadratic programming method to obtain a predicted value of the calcination controlling quantity. The system comprises an intelligent detection instrument and an actuator which are connected with the rotary cement kiln, a data storage device and an upper computer,wherein a calcination predictive control algorithm is embedded in the upper computer. The calcination predictive control method and the calcination predictive control system for the rotary cement kiln can be suitable for the dynamism of the calcining process of the rotary cement kiln and the coupling, nonlinearity and obsoleteness between multiple variables, and obtain good control effect.

Owner:YANSHAN UNIV

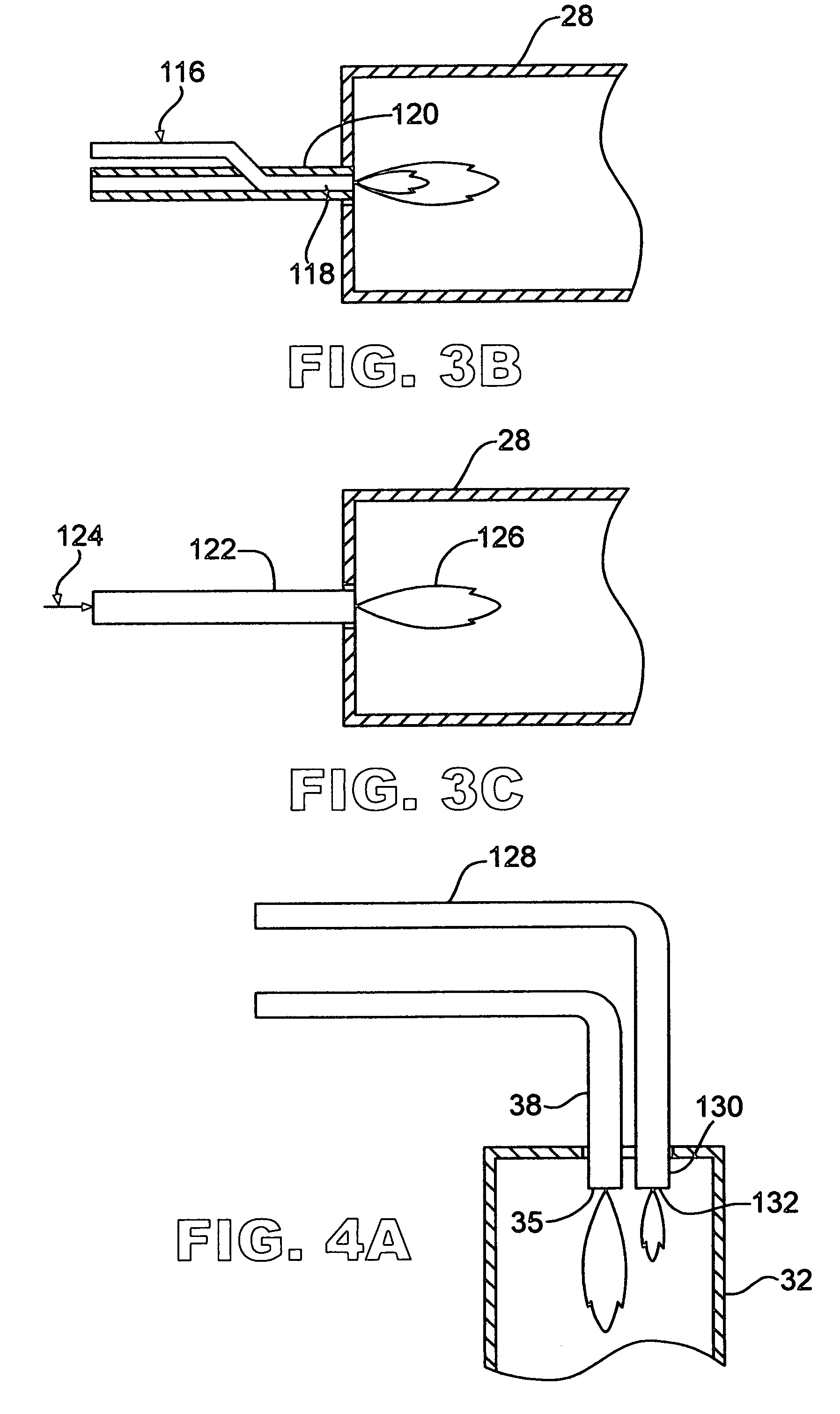

Bio-solid materials as alternate fuels in cement kiln, riser duct and calciner

InactiveUS20050274068A1Avoid landfill disposalBiofuelsSolid fuelsAlternative fuelsProcess engineering

Owner:LEHIGH CEMENT

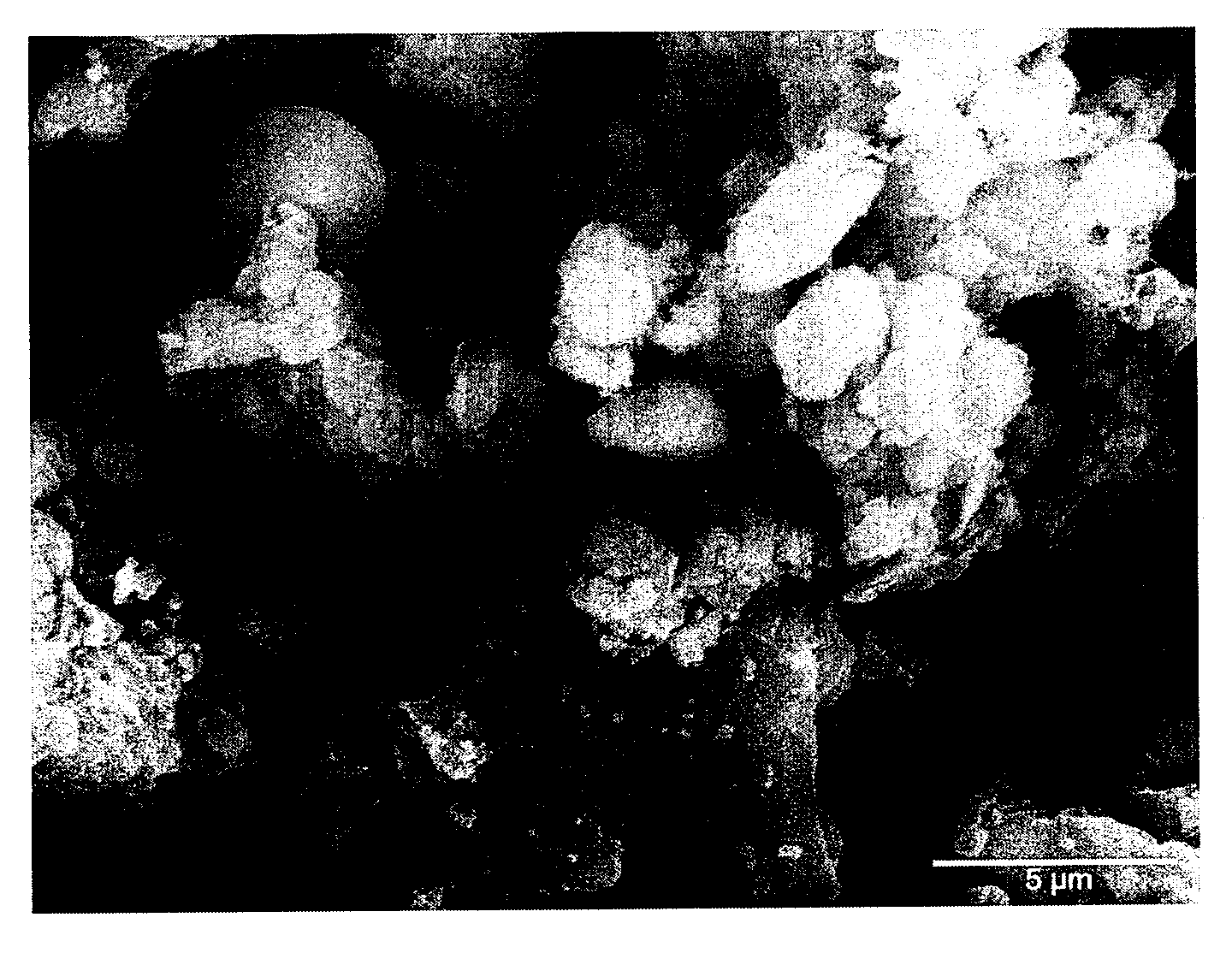

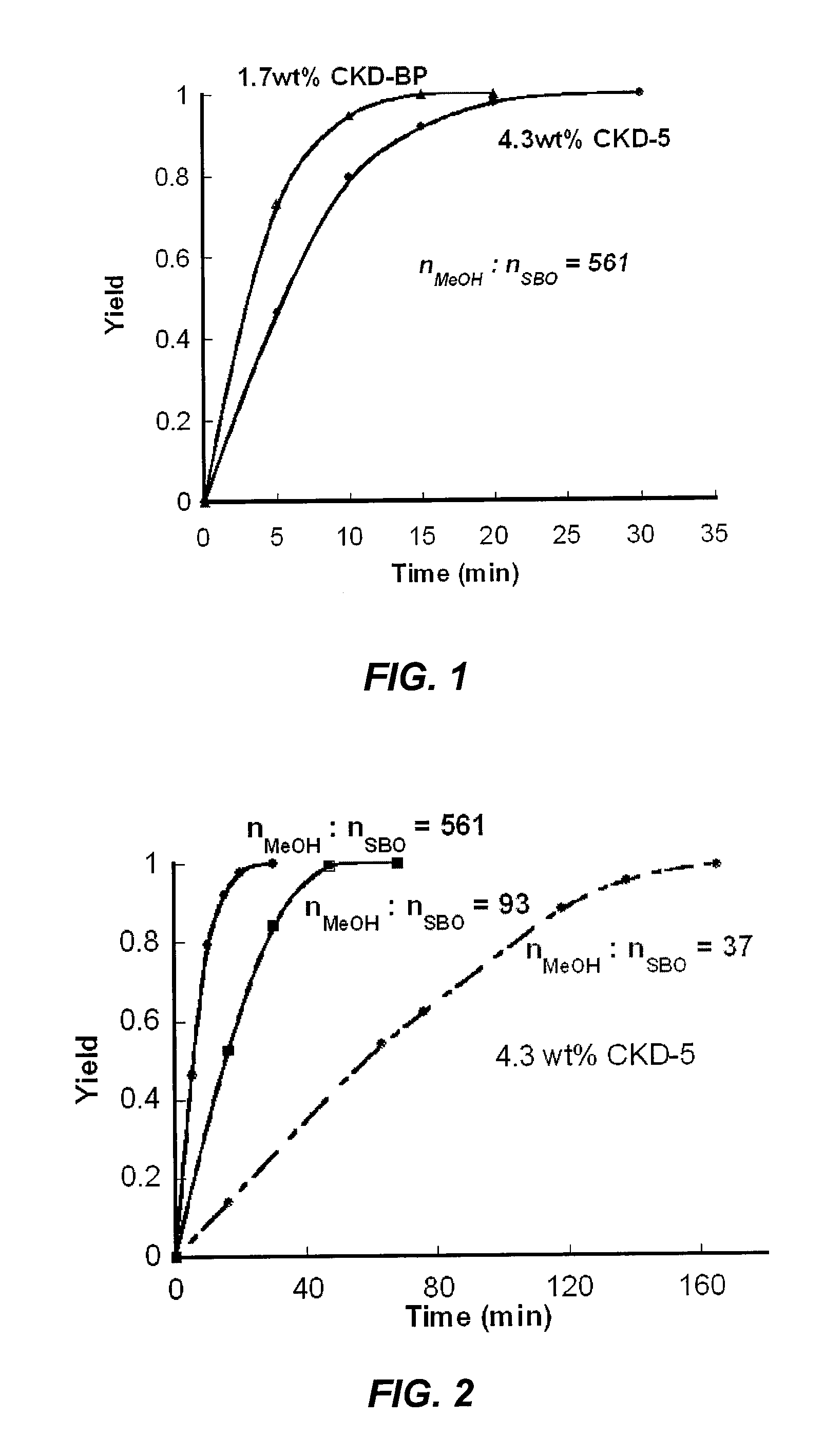

Solid catalyst system for biodiesel production

ActiveUS20090112007A1Increase contact areaRapid responseFatty acid chemical modificationFatty acids production/refiningMETHYL SOYATEVegetable oil

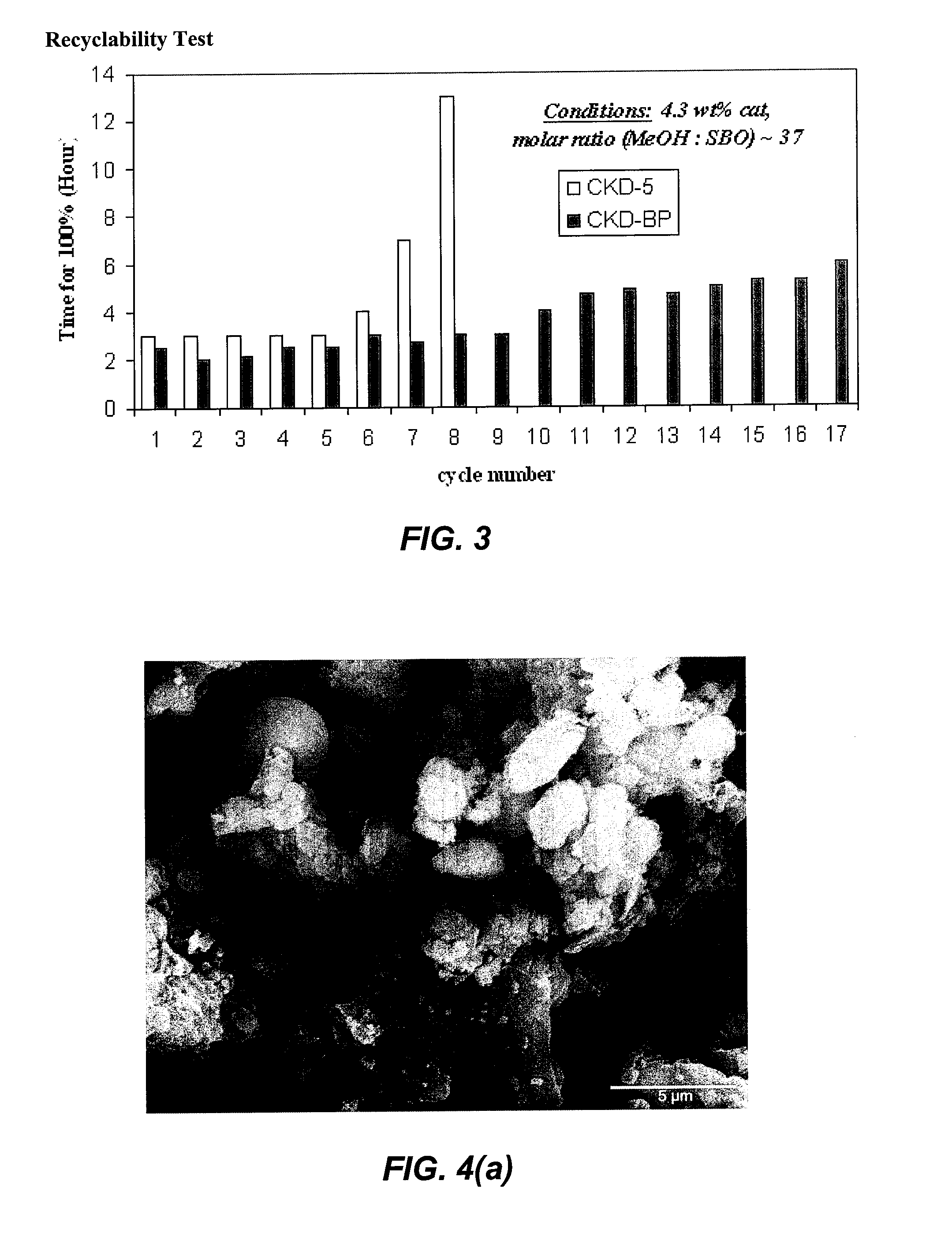

The invention provides efficient, inexpensive, and environmental friendly catalysts and catalyst systems. The catalysts can be used to catalyze esterification and / or transesterification reactions, for example, for the preparation of biodiesel. Kiln dust, such as cement kiln dust (CKD) or lime kiln dust (LKD) can be used to convert a variety of feedstock acids and / or esters to biodiesel in high yield under mild conditions. The CKD and LKD catalyst systems are recyclable esterification or transesterification catalysts that can be used to prepare biodiesel, such as methyl soyate, from various feedstocks, including vegetable oils and animal fats.

Owner:PINNAVAIA THOMAS J PH D +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com