Special pouring material for coal injection pipe

A technology of castables and coal injection pipes, applied in the field of refractory materials, can solve the problems of restricting the operation rate of cement kiln production lines, affecting the economic benefits of cement manufacturers, and the castables of coal injection pipes are not wear-resistant, so as to achieve high strength and reduce internal stress , Improve the effect of seismic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

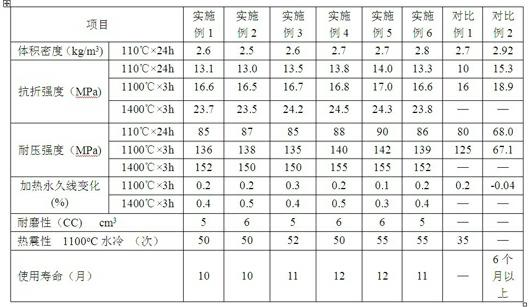

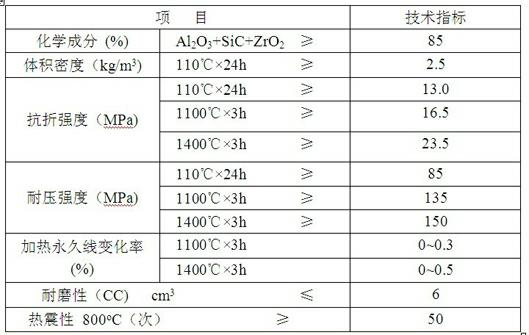

Examples

Embodiment 1

[0050] A special castable for coal injection pipe, the weight percentage of the components contained in it is:

[0052] Andalusite 30%

[0053] Corundum 20%

[0055] Zircon mullite powder 10%

[0056] Alumina fine powder 10%

[0057] Microsilica 3%

[0058] Pure calcium aluminate cement 2%

[0059] And accounting for 0.5% of the total weight of the above-mentioned components of explosion-proof fiber and 0.2% of sodium tripolyphosphate.

Embodiment 2

[0061] A special castable for coal injection pipe, the weight percentage of the components contained in it is:

[0063] Andalusite 15%

[0064] Corundum 35%

[0066] Zircon mullite powder 5%

[0067] Alumina fine powder 5%

[0068] Microsilica 6%

[0069] Pure calcium aluminate cement 4%

[0070] And accounting for 0.5% of the total weight of the above-mentioned components of explosion-proof fiber and 0.2% of sodium tripolyphosphate.

Embodiment 3

[0072] A special castable for coal injection pipe, the weight percentage of the components contained in it is:

[0073] Silicon carbide 15%

[0074] Andalusite 20%

[0075] Corundum 29%

[0077] Zircon mullite powder 6%

[0078] Alumina fine powder 7%

[0079] Microsilica 8%

[0080] Pure calcium aluminate cement 5%

[0081] And accounting for 0.5% of the total weight of the above-mentioned components of explosion-proof fiber and 0.2% of sodium tripolyphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com