TiAlN/TiAlCN multilayer coating of substrate surface and preparing method thereof

A multi-layer film and coating technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of large interlayer thickness, internal stress accumulation, increase of defects, etc., to improve the bonding force, The effect of reducing internal stress accumulation and low internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

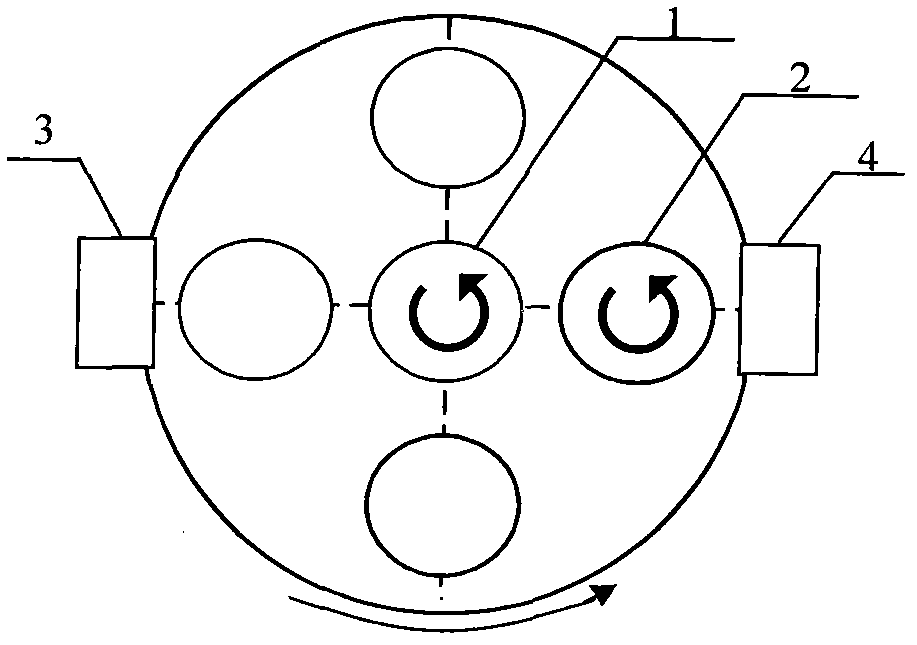

[0021] Example 1: With Korloy cemented carbide milling cutter as the substrate, the substrate was ultrasonically cleaned with acetone and alcohol water for 15 minutes, dried, placed in the coating cavity, heated, and vacuumed to make the vacuum degree lower than 2×10 -3 Pa, turn on public rotation and rotation.

[0022] (1) Introduce 30 sccm argon gas into the coating chamber to maintain the argon gas pressure at 0.1Pa, maintain the ion source current of the linear anode layer at 2A, apply a pulse bias voltage of -500V on the substrate, and etch the substrate surface for 30 minutes;

[0023] (2) Introduce nitrogen gas with a flow rate of 30 sccm and argon gas with a flow rate of 6 sccm into the coating cavity, keep the partial pressure of nitrogen at 0.5 Pa, the partial pressure of argon at 0.1 Pa, and control the temperature in the cavity at 400 ° C. The transition coating TiN is prepared by pulsed magnetron sputtering technology. The target material is a Ti target with a pur...

Embodiment 2

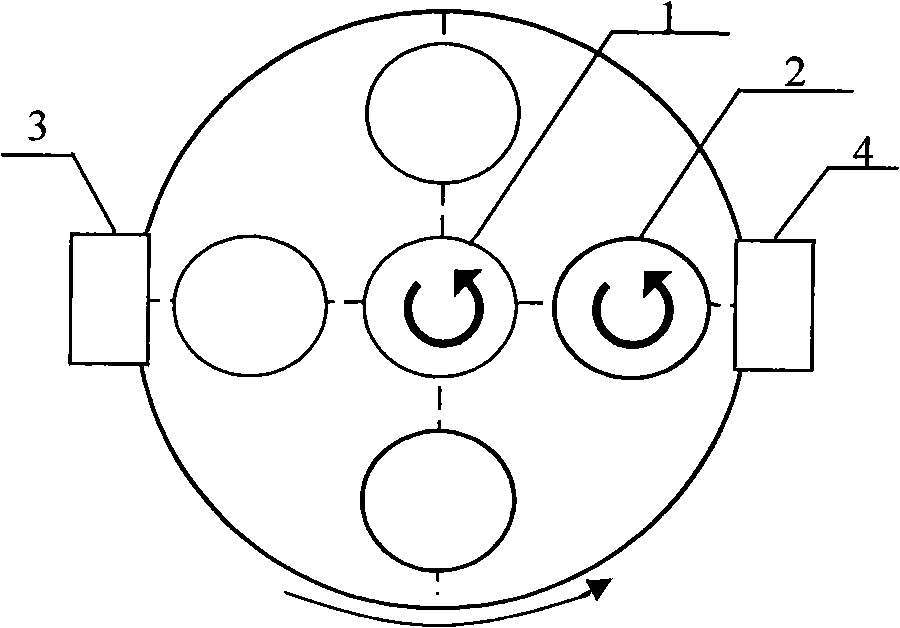

[0027] Example 2: Take the high-speed steel rotor as the substrate, clean the substrate with degreasing cleaning solution, then ultrasonically clean it with deionized water and acetone for 15 minutes, dry it, place it in the coating cavity, heat it, turn on the motor and rotation, Vacuum to make the vacuum degree below 2×10 -3 Pa.

[0028] (1) Pass 30sccm argon gas into the coating cavity, keep the argon gas pressure at 0.1Pa, maintain the ion source current of the linear anode layer at 2A, apply a pulse bias voltage of -500V on the substrate, and etch the substrate for 30 minutes;

[0029] (2) Introduce nitrogen gas with a flow rate of 30 sccm and argon gas with a flow rate of 6 sccm into the coating cavity, keep the partial pressure of nitrogen at 0.5 Pa, the partial pressure of argon at 0.1 Pa, and control the temperature in the cavity at 400 ° C. The transition coating TiN is prepared by pulsed magnetron sputtering technology. The target material is a Ti target with a pur...

Embodiment 3

[0033] Embodiment 3: This embodiment can be used for anticorrosion of titanium alloys. With titanium alloy blocks as the substrate, the substrate is mirror-polished, cleaned with degreasing cleaning solution, then ultrasonically cleaned with deionized water and acetone for 15 minutes, and dried. Put it in the coating chamber, heat it, turn on the motor and rotate it, and evacuate it so that the vacuum degree is lower than 2×10 -3 Pa.

[0034] (1) Introduce 40 sccm argon gas into the coating chamber to maintain the argon gas pressure at 0.2Pa, maintain the linear anode layer ion source current at 2A, apply a pulse bias voltage of -500V on the substrate, and etch the substrate for 30 minutes;

[0035] (2) Introduce nitrogen gas with a flow rate of 36 sccm and argon gas with a flow rate of 6 sccm into the coating cavity, keep the partial pressure of nitrogen at 0.6Pa, the partial pressure of argon at 0.1Pa, and control the temperature in the cavity at 400°C. The transition coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com