Patents

Literature

2993 results about "Degreasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degreasing, often called defatting or fat trimming, is the removal of fatty acids from an object. In culinary science, degreasing is done with the intention of reducing the fat content of a meal.

Processing technique of cellphone shell with metal luster

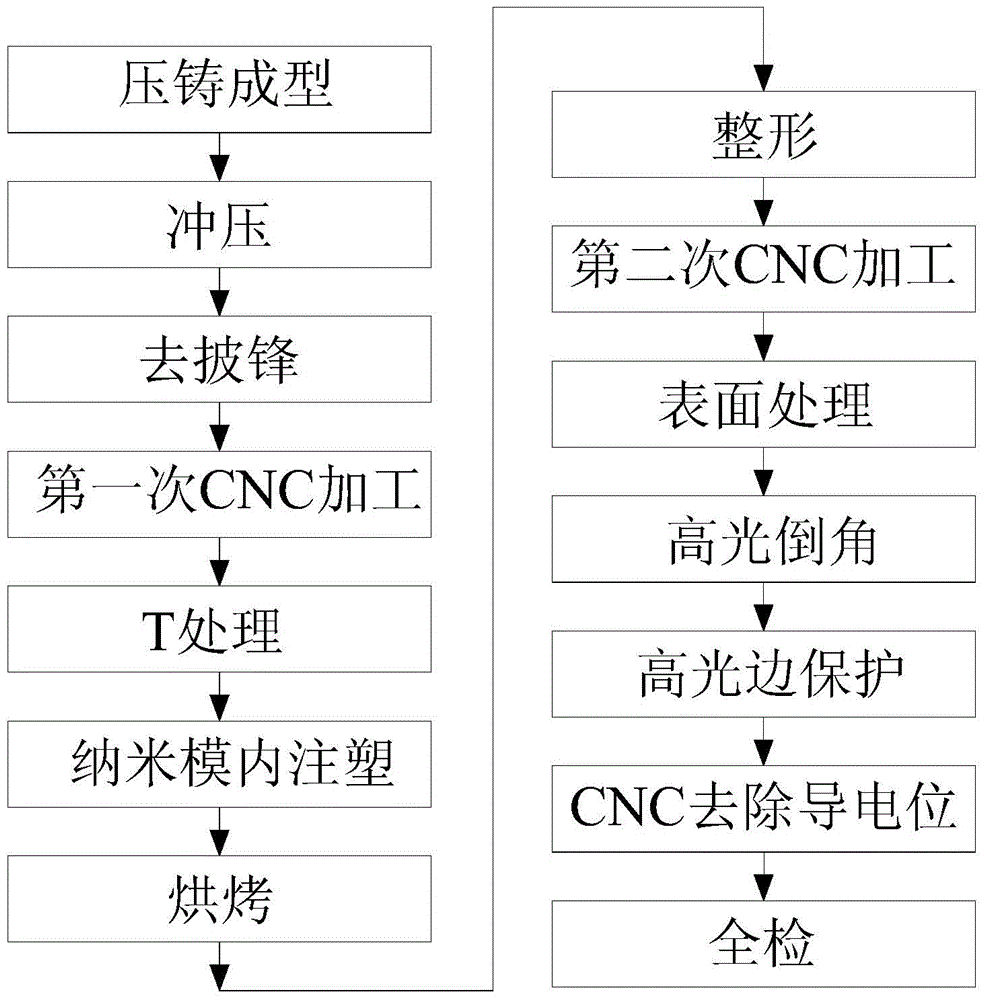

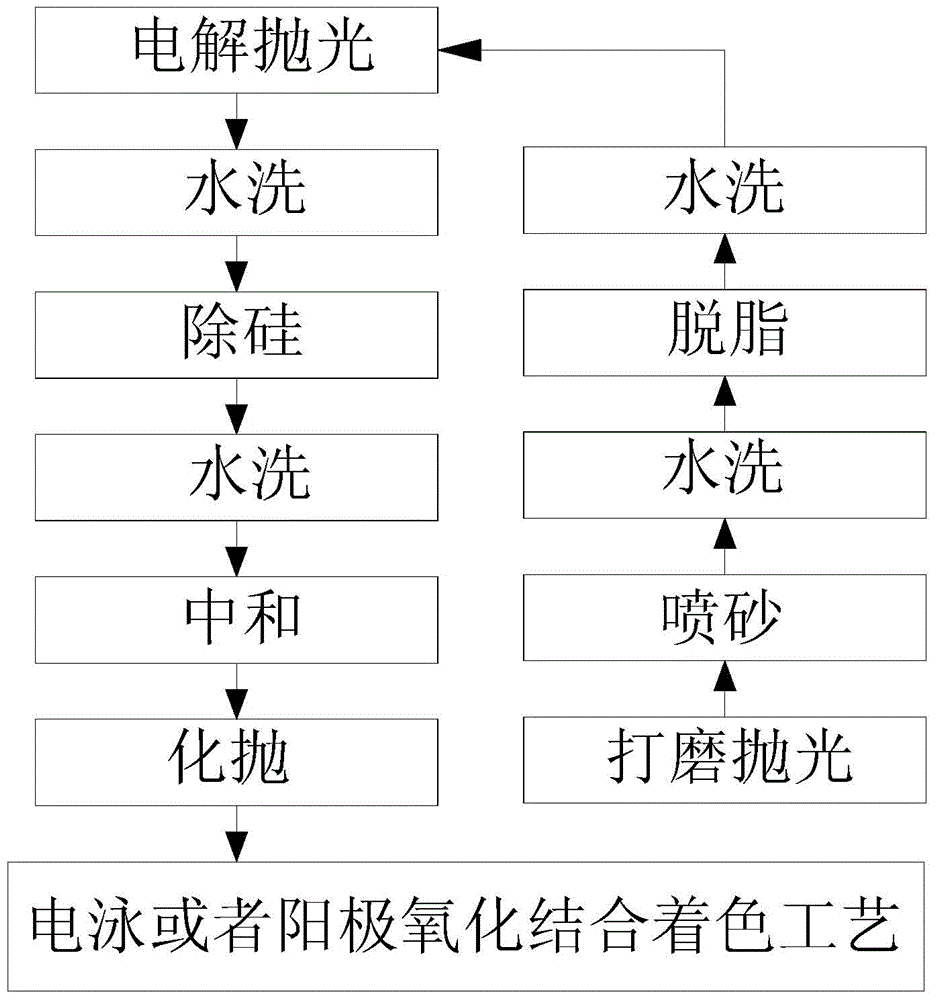

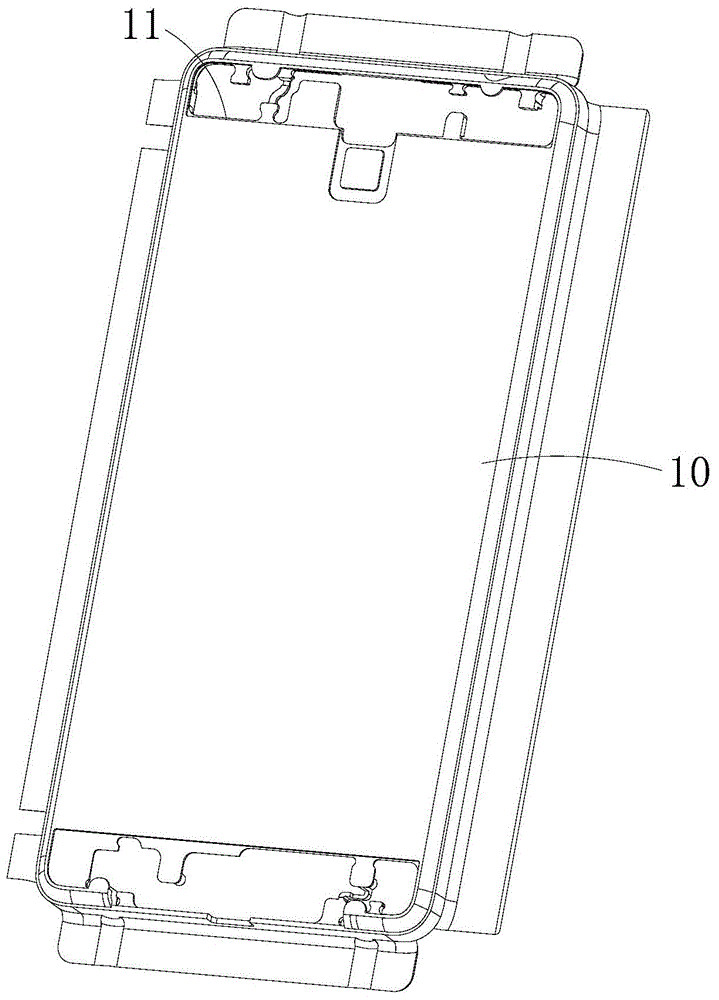

ActiveCN104607884AGuaranteed StrengthReduce processing costsCoatingsNumerical controlAbrasive blasting

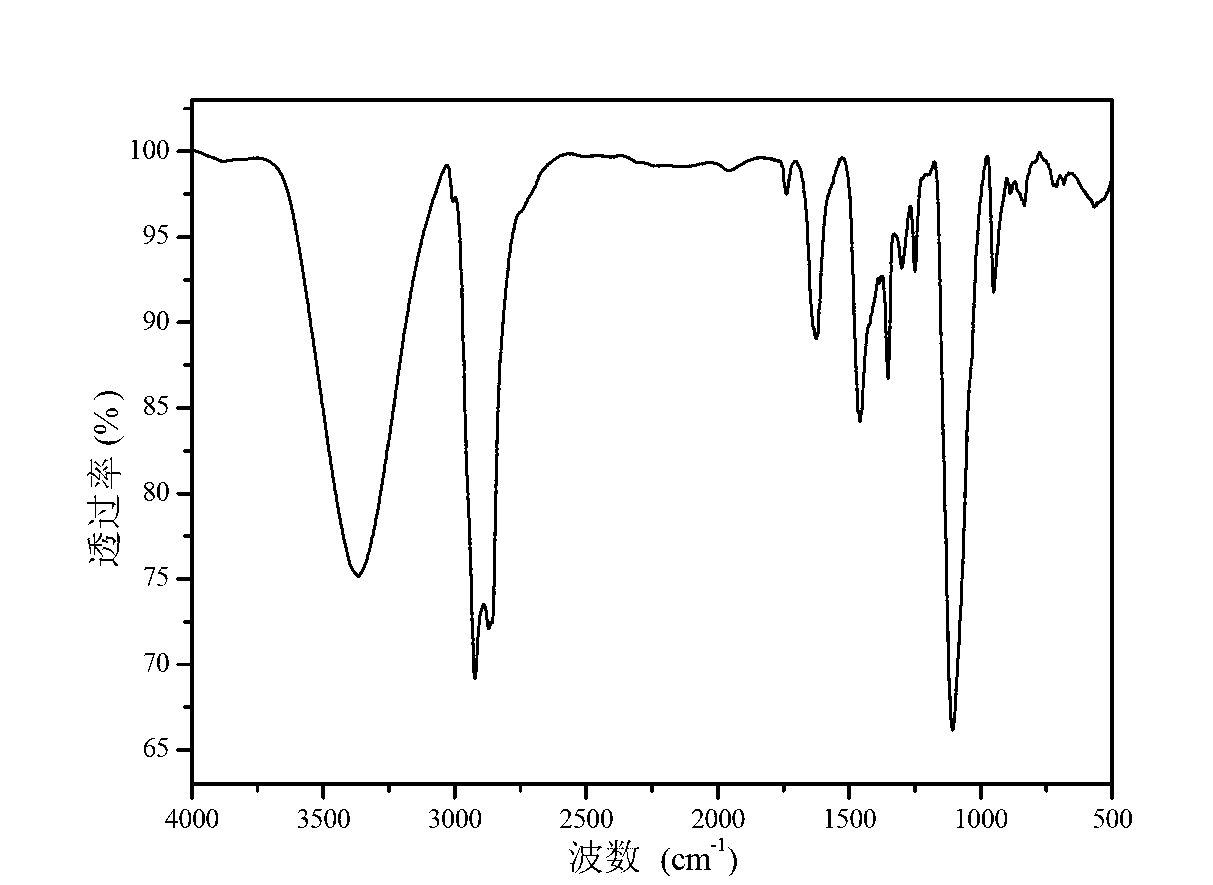

The invention provides a processing technique of a cellphone shell with metal luster. The processing technique includes the steps of S1, performing compression molding; S2, performing stamping; S3, performing primary CNC (computer numerical control) machining; S4, performing T treatment; S5, performing injection molding in a nano mold; S6, performing secondary CNC machining; S7, performing surface treatment, to be specific, performing a, polishing, b, shot-blasting, c, degreasing, d, washing, e, electrolytic polishing, f, washing, g, silicon removal aiming to decrease silicon content of the polished surface of the cellphone shell, h, neutralizing, i, chemical polishing, and j, electrophoresis or combination of anodic oxidation and coloring, aiming to impart metal luster to the polished surface of the cellphone shell. The compete cellphone shell is made through the steps S1 to S6, the silicon content of the polished surface of the cellphone shell is processed, the cellphone shell never produces compounds of intervals such as Al-Mg-Si-Fe during following anodic oxidation, defects such as oxide film darkening, bluing or milky-whiting are avoided, and the metal-lustered cellphone shell is manufactured through the complete process.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

Cold-rolled sheet rolling emulsified oil containing modified nano copper and preparation method thereof

The invention relates to a cold-rolled sheet rolling emulsified oil containing a modified nano copper and preparation method thereof, which belong to the field of organic chemistry. The emulsified oil comprises the following components, in percentage by weight: 54-80% of a base oil, 15-32% of an oiliness agent, 0.1-1% of a modified nano copper particle, 2-4% of an extreme pressure agent, 0.5-2% of an anti-rusting agent, 2-6% of an emulsifier, 0.4-1% of an anti-oxidant, 0.03-0.1% of an anti-foaming agent, and 0.2-0.6% of an anti-mildew agent. The cold-rolled sheet rolling emulsified oil containing the modified nano copper is diluted with water into a 2-6 wt% emulsion, and the emulsion is directly used in the cold rolling process of the strip steel and has very good lubrication, cleaning property of the rolling mill and annealing cleaning property, after annealing, the steel plate not subjected to degreasing has a clean surface without pollutants, so as to satisfy rolling production requirement under high pressure at high speed.

Owner:NORTHEASTERN UNIV

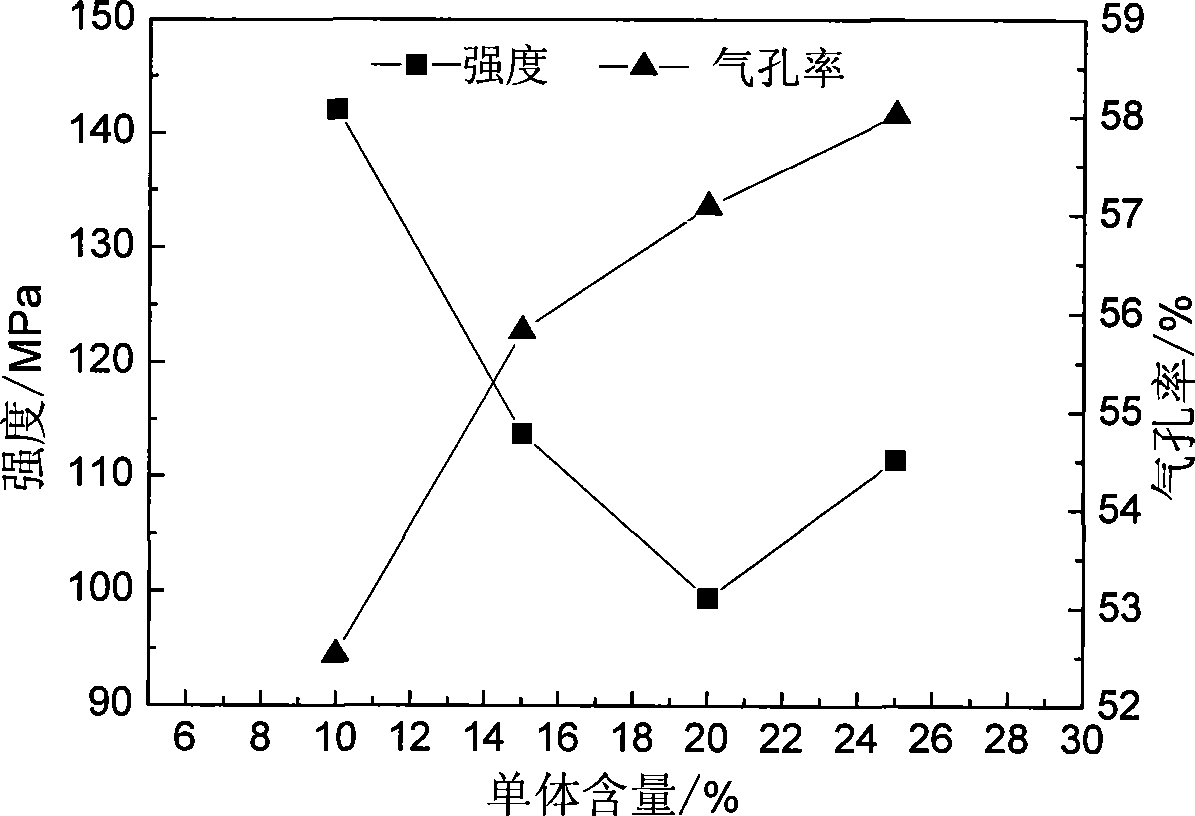

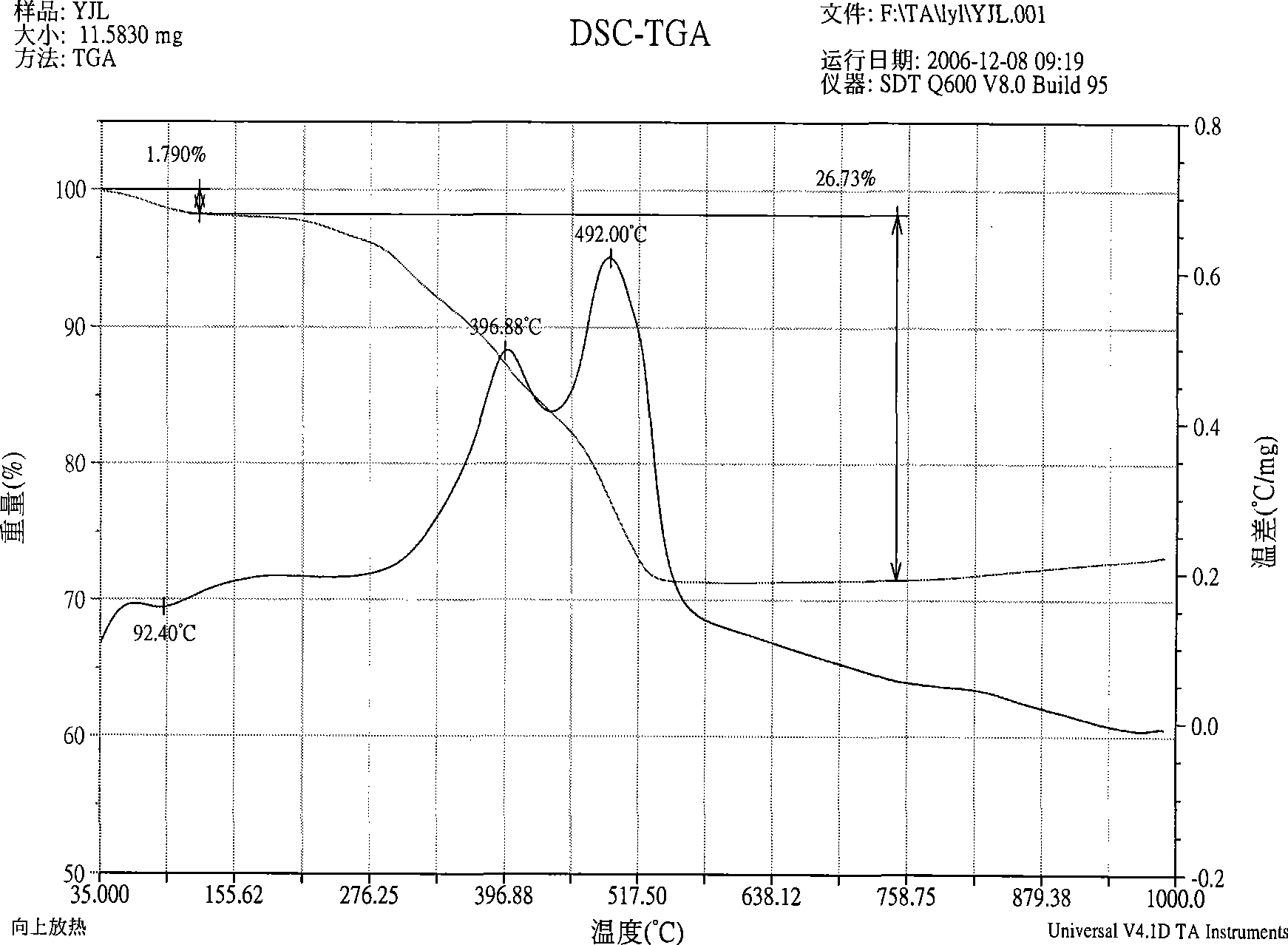

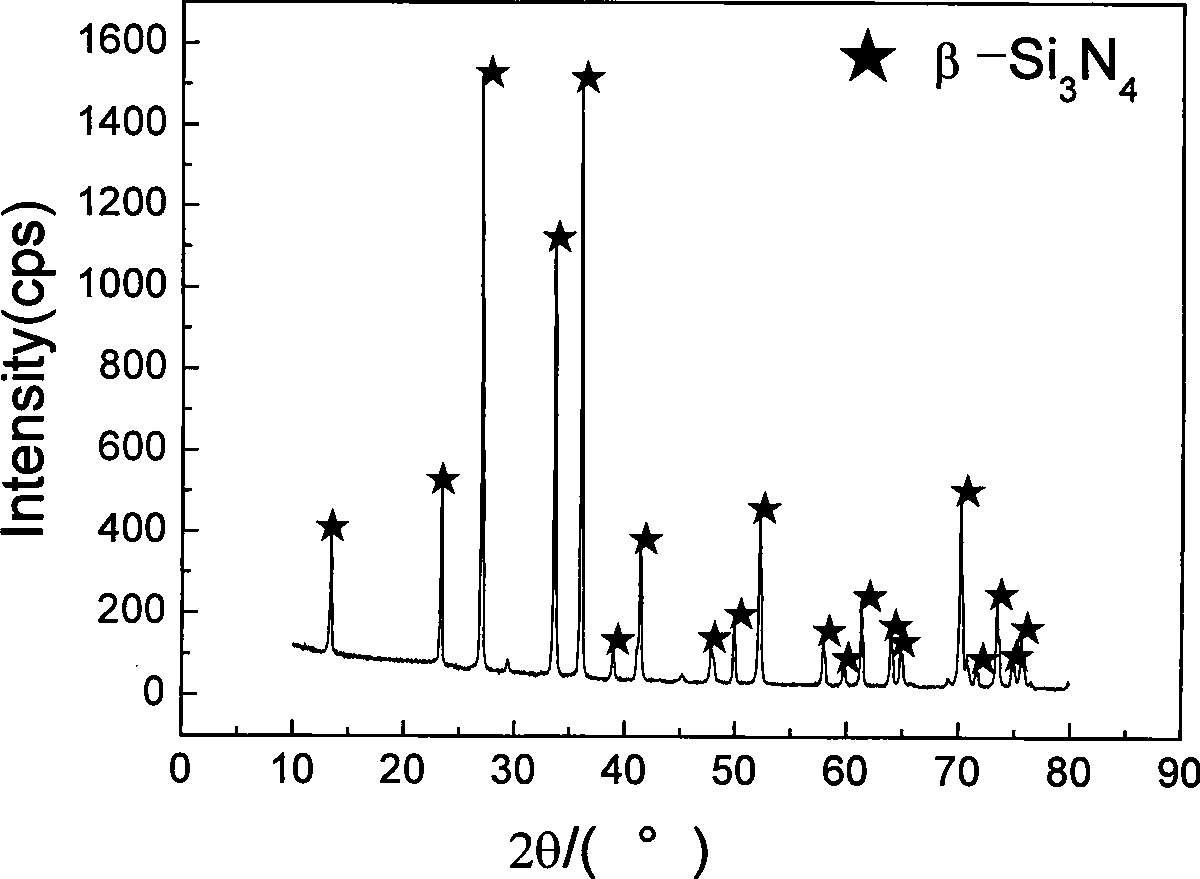

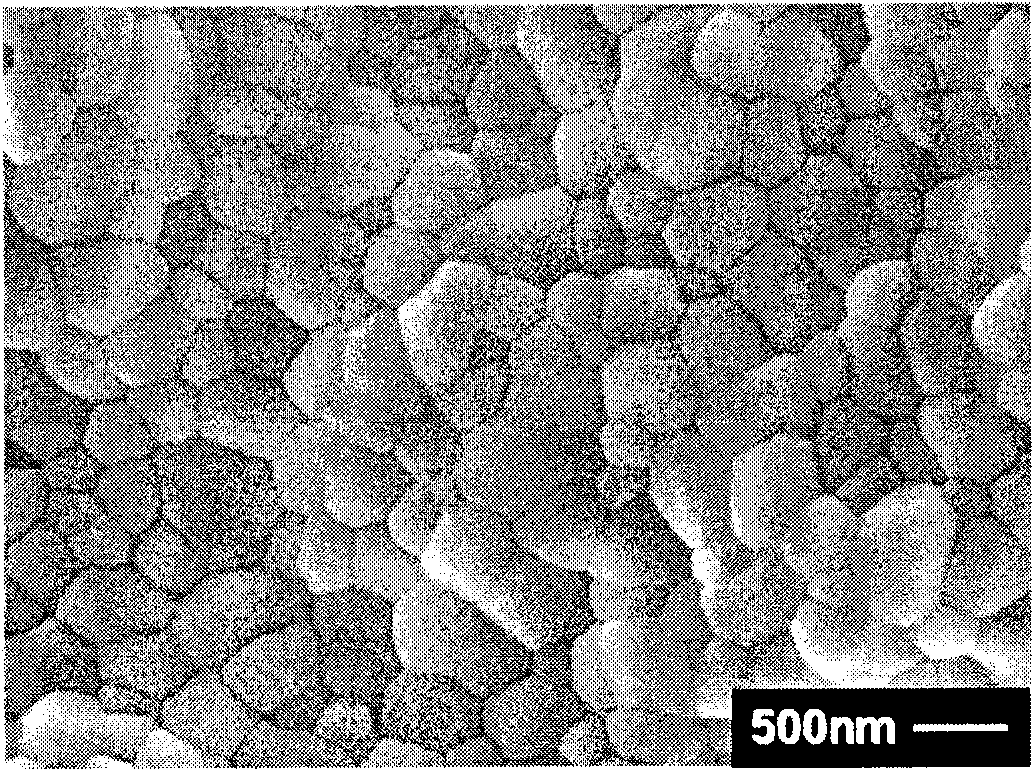

Method for preparing silicon nitride porous ceramic by gel injection moulding

The invention discloses a method for preparing silicon nitride porous ceramic by a gel mold injection method. The method comprises slurry preparation, blank preparation and degreasing and sintering of the blank to obtain the silicon nitride porous ceramic with porosity ranging from 49 to 63 percent, buckling strength ranging from 54 to 234MPa and pore-size distribution ranging from 0.1 to 1.0 mum. The method can prepare the silicon nitride porous ceramic with high performance and high strength only by utilizing numerous gel micromolecules formed by organic monomer solidification in a high temperature oxidation decomposition process. The porous ceramic prepared by the method has fine pores and narrow pore-size distribution. Meanwhile, the method can prepare porous ceramic products with large size and complicated shape.

Owner:XI AN JIAOTONG UNIV +1

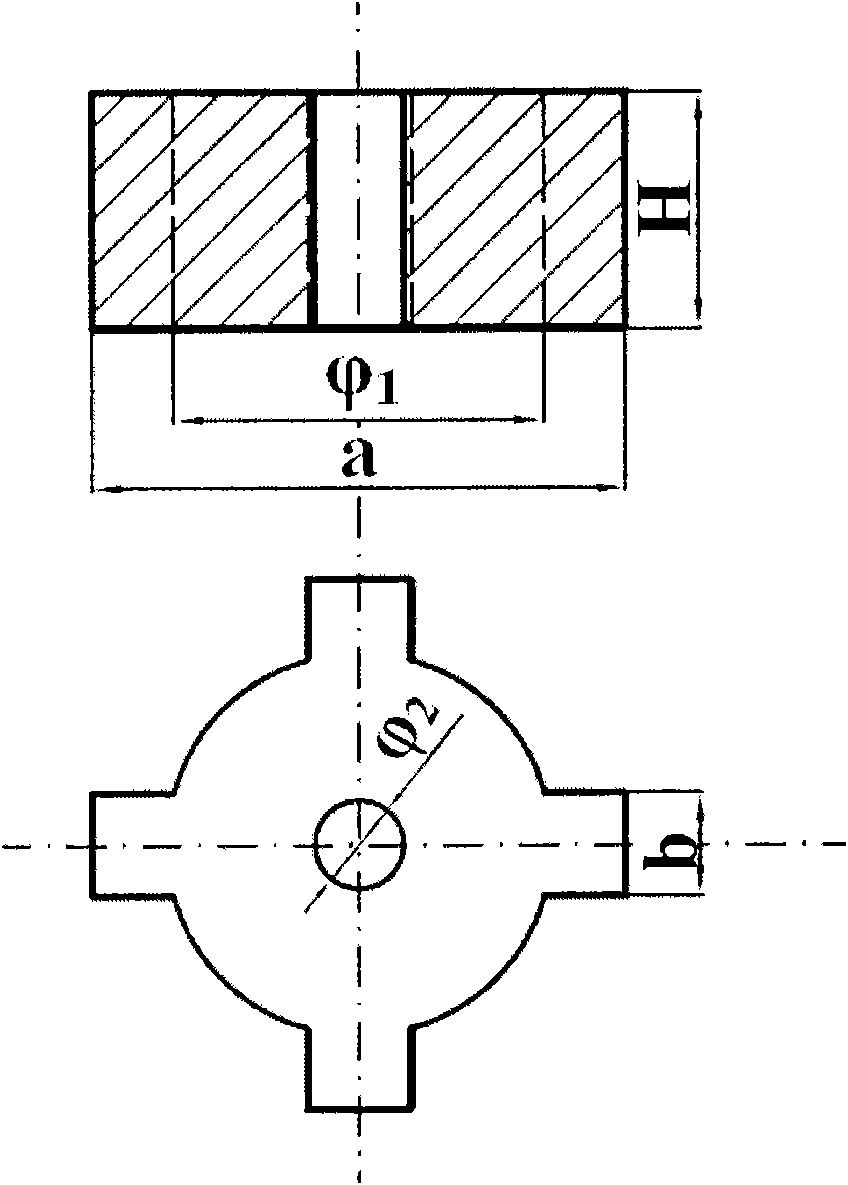

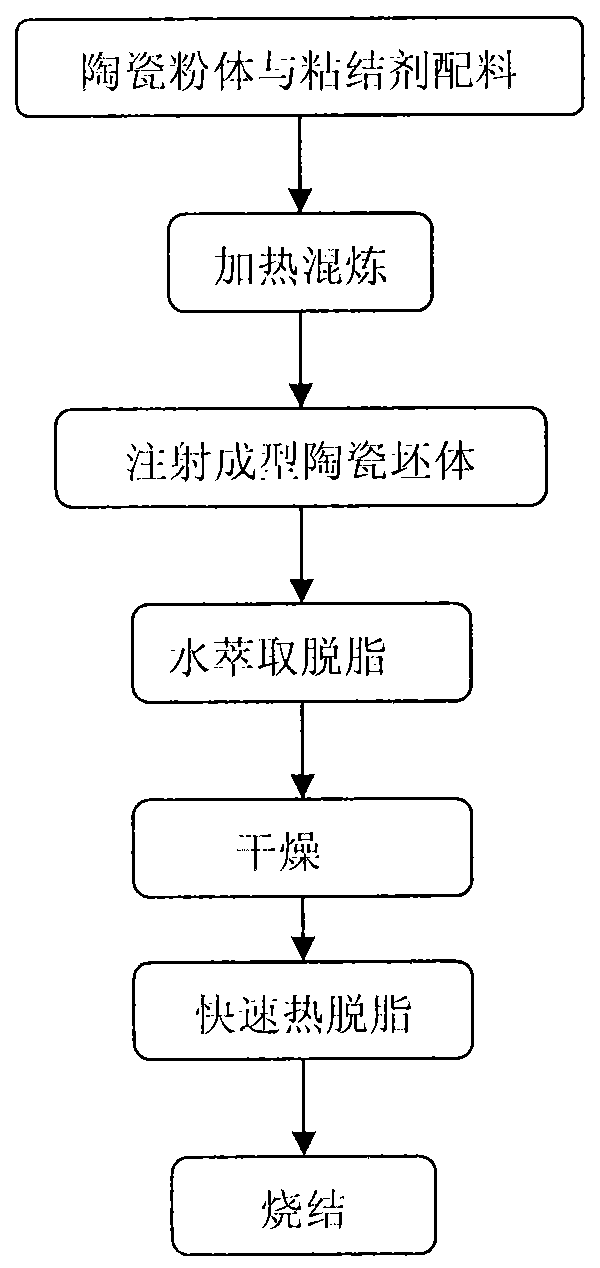

Method for manufacturing dentate special-shaped ceramic components by injection molding

InactiveCN101643360AEfficient preparationHigh precision manufacturingCeramic shaping apparatusSurface finishHigh dimensional

The invention discloses a method for manufacturing dentate special-shaped ceramic components by injection molding, belonging to the technical field of high-performance ceramic preparation. The methodcomprises the following steps: evenly mixing 81wt% to 90wt% of ceramic powder and 10wt% to 19wt% of organic binders by weight percentage to obtain an injection-molding mixture, injection-molding the injection-molding mixture on an injection-molding machine with the injection temperature being 175 to 195 DEG C, to obtain a green body, and de-molding within 2 minutes after the injection, so as to obtain a molded green body; and then, subjecting the molded green body to water-extraction degreasing and thermal degreasing, sintering the degreased green body at 1,350 to 1,550 DEG C, holding for 1 to4 hours and furnace-cooling to obtain the ceramic components. The invention has the advantages of high automation degree, high molding and degreasing efficiencies, even green body, high dimensional accuracy and surface smoothness of sintered products, and environment-friendly and energy-saving manufacture.

Owner:TSINGHUA UNIV +1

Chrome-free tannage producing technique for goat glove leather

The invention relates to a processing technique of leather, in particular to a chrome-free tannage manufacturing technique of goat glove leather, aims at solving the problem of heavy environment pollution caused by the chrome sewage in the prior art of chrome tannage. The processing technique of leather adopts a technical proposal that the chrome-free tannage manufacturing technique of goat glove leather comprises a plurality of successively steps as followings: softening, dipping in acid, organophosphor tanning, oxidation, stacking, sammying and extension, shaving, washing, degreasing, rinse, washing, retanning and stuffing, washing, and routine following chrome tanning technique. The processing technique of leather has the advantages of eliminating the environment pollution caused by the heavy metal chrome, reducing the cost of sewage treatment, producing environment-friendly goat glove leather with soft, plumpy, highly resilient, and flowing hand feeling, smooth grain, brilliant color, qualified formaldehyde content as ecological leather, over 88 DEG C shrinkage temperature, and completely same mechanical property as routine chrome tannage leather.

Owner:HAINING SHANGYUAN LEATHER

Cold rolling manufacture method of copper and aluminum composite plate strips

InactiveCN102615102ADiffuse fullyFull responseAuxillary arrangementsMetal rolling arrangementsChemical reactionCopper

The invention discloses a cold rolling manufacture method of copper and aluminum composite plate strips. The cold rolling manufacture method comprises the following steps that: 1, a copper plate and an aluminum plate are subjected to homogenization annealing treatment; 2, surface treatment is carried out: firstly, the copper plate and the aluminum plate subjected to the homogenization annealing treatment are subjected to soaking degreasing, then, the copper plate and the aluminum plate subjected to the soaking degreasing are taken out for drying, and next, the composite surfaces to be rolled of the copper plate and the aluminum plate are ground by a stainless steel wire brush; 3, the copper plate and the aluminum plate are subjected to cold rolling compounding by a cold rolling mill, so copper and aluminum composite plate blanks are obtained; and 4, the copper and aluminum composite plate blanks subjected to the cold rolling are subjected to the diffusion annealing treatment. The cold rolling manufacture method has the advantages that through improving the cold rolling process operation and the process parameters, the copper plate and the aluminum plate are subjected to full diffusion and chemical reaction on the composite surfaces in the manufacture process, so the transition structure with excellent performance is obtained at the composite surfaces, and the bonding intensity of finished products is effectively improved.

Owner:HONGGUANG ELECTRIC GROUP CO LTD

Method for preparing colored zirconium oxide ceramic component

InactiveCN101857433ASuitable for industrial productionStain depth regulationMaterials preparationZirconia ceramic

The invention discloses a method for preparing a colored zirconium oxide ceramic component and belongs to the technical field of ceramic material preparation and ceramic injection molding. The method comprises the following steps of: mixing the following injection molding ingredients in percentage by mass: 85 to 90 percent of zirconium oxide powder, 8 to 12 percent of low-melting-point binder and2 to 4 percent of non-soluble skeleton binder; performing injection molding and blank degreasing; soaking a degreased blank in coloring ion-containing solution; and removing the binder from the blankand sintering the blank to obtain colored zirconium oxide ceramic, wherein dying degree can be controlled by controlling soaking time. The method provided by the invention has the advantages of simple process, low cost, capability of saving coloring agent, environmental friendliness, combination of ceramic material preparation and molding technology and suitability for industrial production of colored zirconium oxide ceramic.

Owner:TSINGHUA UNIV

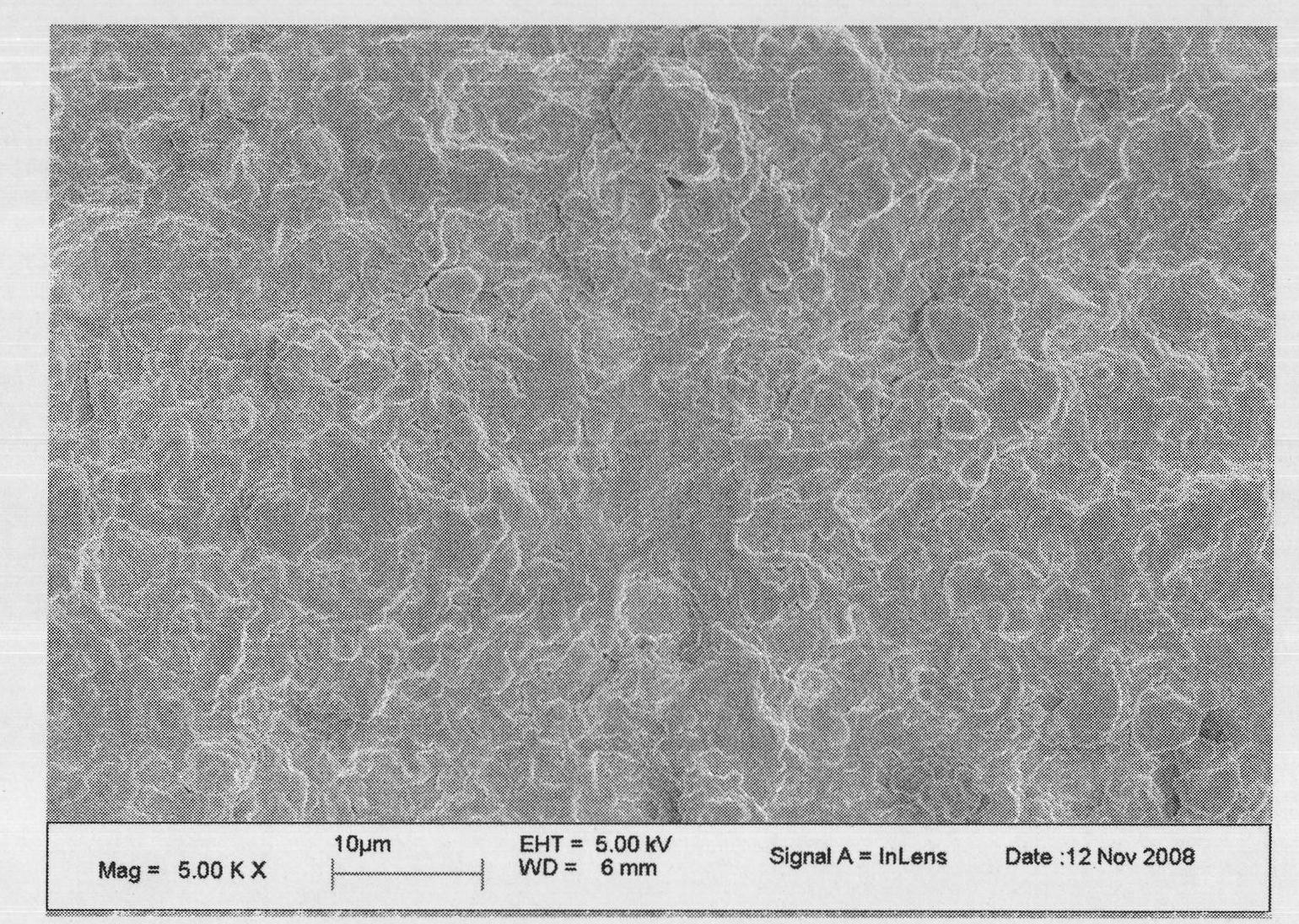

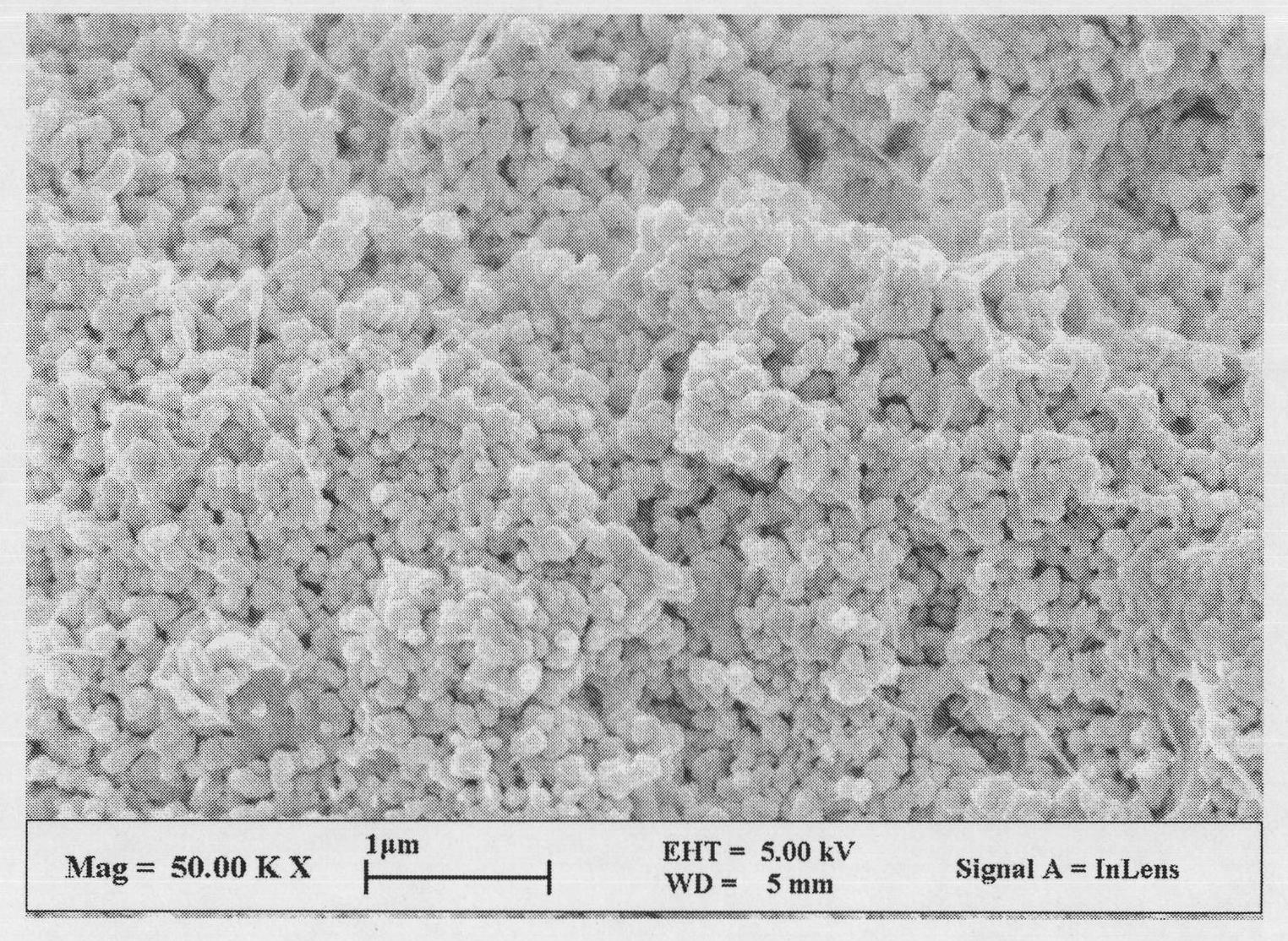

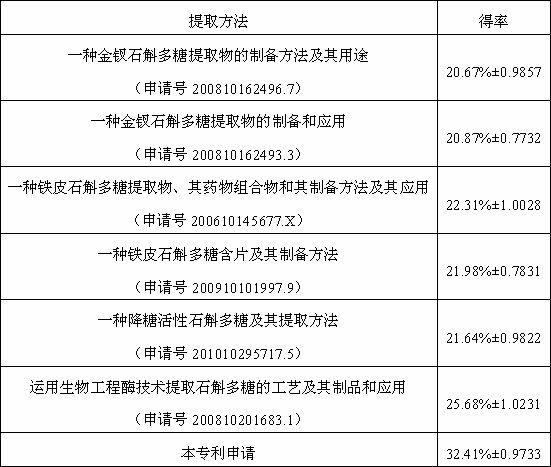

Separation and purification method for dendrobium polysaccharide

The invention relates to a separation and purification method for dendrobium polysaccharide. The process steps comprise: raw material selecting, crushing, screening, degreasing, microwave assisted solvent extraction, enzyme extraction, filtering, water extraction, suction filtration, vacuum concentration, alcohol precipitation, centrifugal separation, freeze drying, crude product obtaining, protein removing, freeze drying, and dendrobium polysaccharide obtaining. The technical effect of the present invention is that: the extraction rate of the dendrobium polysaccharide is improved, the extraction time is shortened, the energy consumption is reduced, and the biological activity of the dendrobium polysaccharide is effectively maintained.

Owner:云南金九地生物科技有限公司

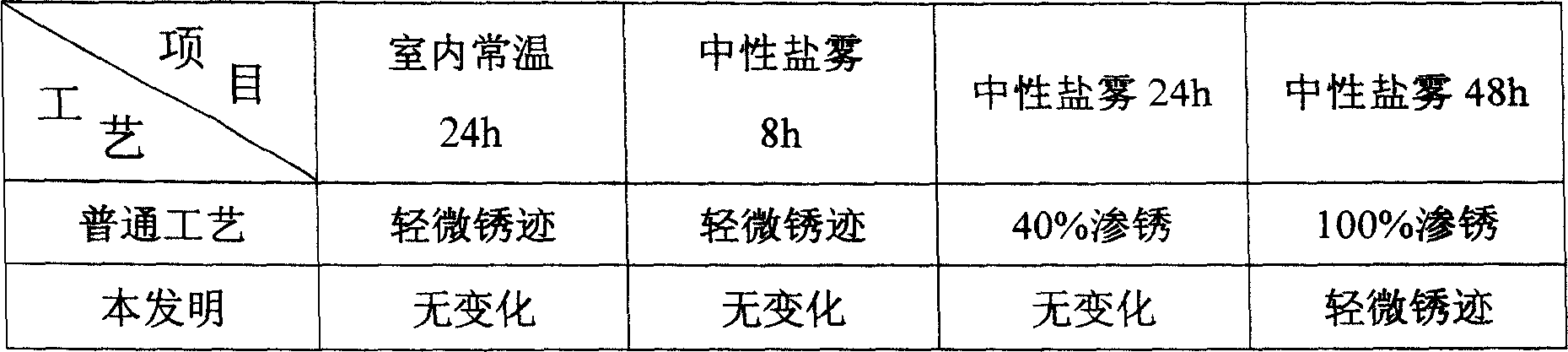

Pretreatment for coating iron and steel member

InactiveCN101029401AReduce concentrationQuality assuranceMetallic material coating processesThermal waterCorrosion

Pretreatment of iron and steel construction member coating is carried out by treating edge, shot blasting, degreasing, washing by water, washing by acid, adjusting surface, phosphorizing, washing by water, deactivating, washing by hot water and coating. It's efficient and has no corrosion.

Owner:徐州兰德交通科技有限公司

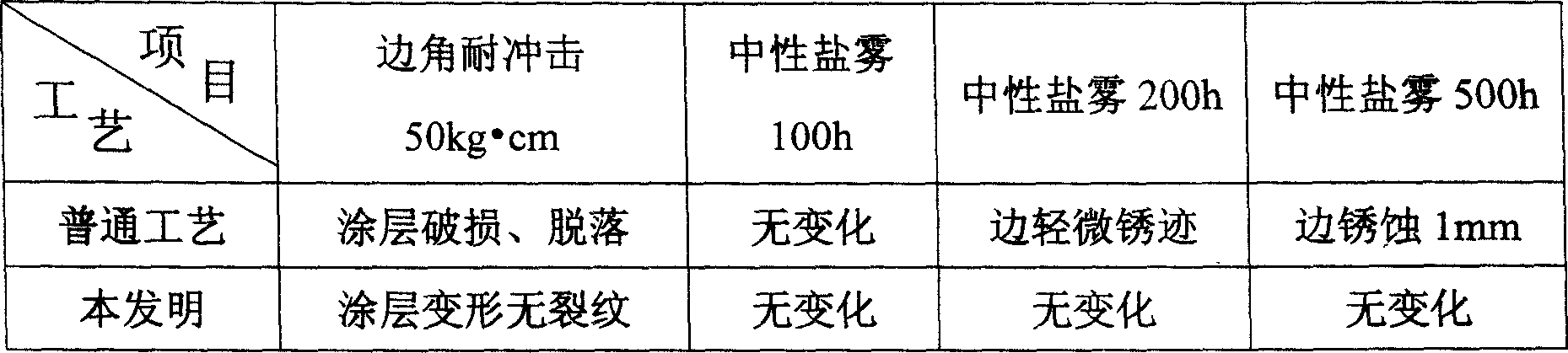

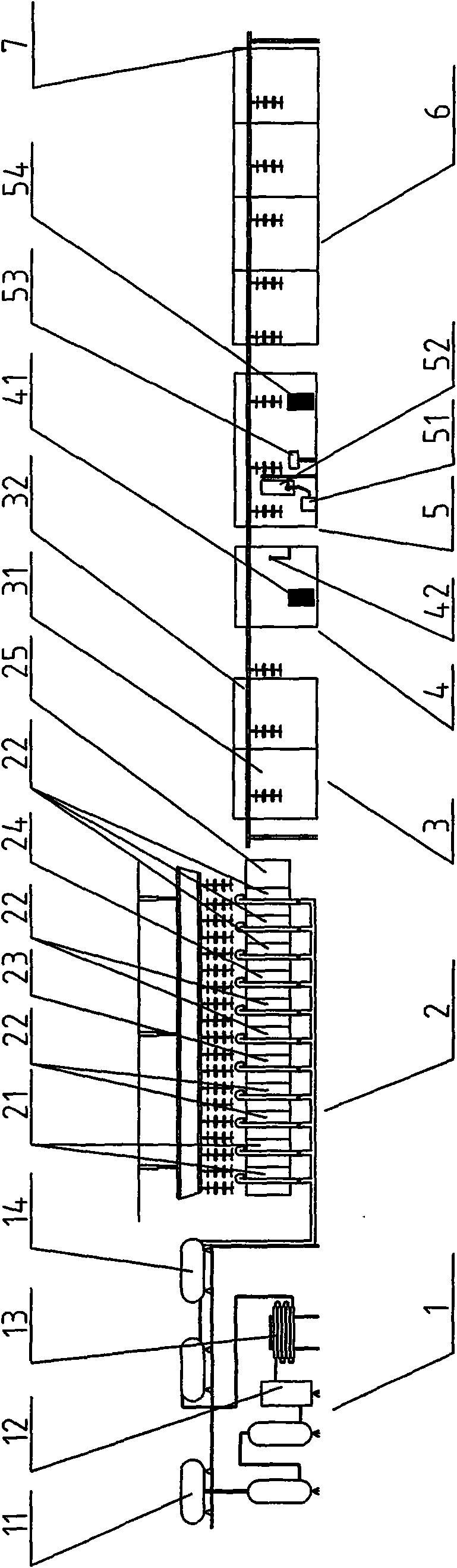

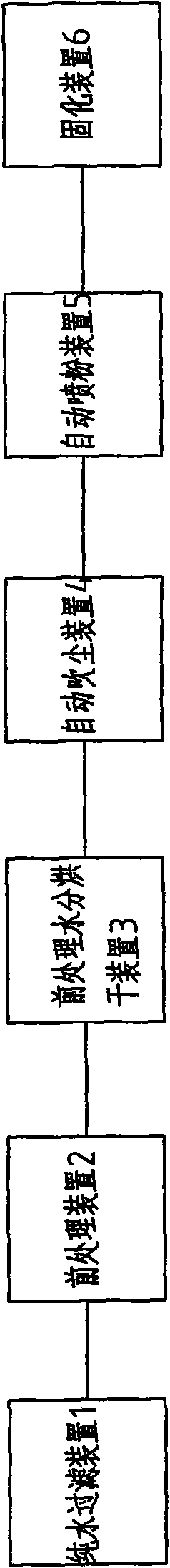

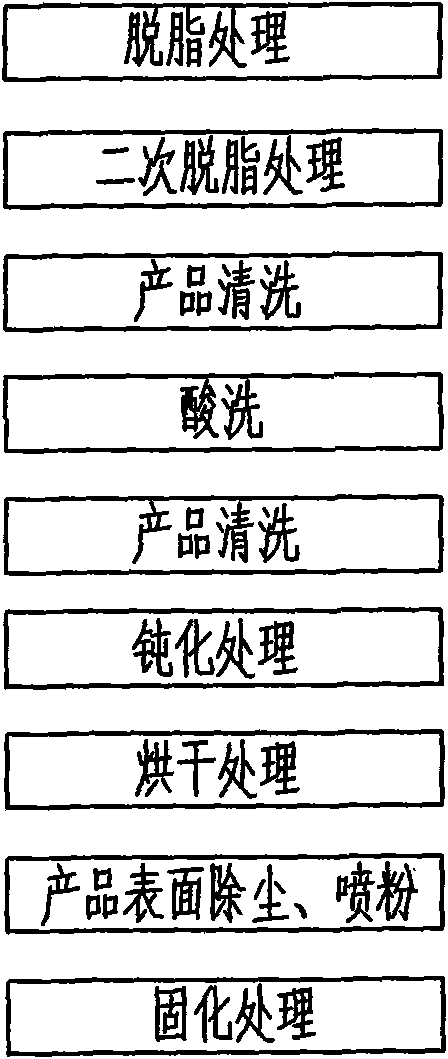

Automatic powder spraying line for automobile wheel hub finishing components and technique thereof

ActiveCN101602042AEvenly distributedSave resourcesLiquid spraying plantsPretreated surfacesSurface cleaningFiltration

The invention relates to an automatic powder spraying line for automobile wheel hub finishing components and a technique thereof; the production line comprises a pure water filtration system for providing pure water for the power spraying line, a pretreatment device, a pretreatment water content drying device, an automatic dust blowing device, an automatic powder spraying device, a solidifying device and a conveying lead rail; wherein, the pretreatment device sequentially comprises a pickling tank, alkaline wash tank and a passivation tank; the automatic powder spraying device comprises a tank body, a powder spraying gun, a powder storage tank, a powder sucking device, a constant temperature and humidity device. The production technique has the following steps: 1) alkali degreasing, 2) product surface cleaning, 3) drying, 4) dust abatement, 5) power spraying, 6) solidification. The production line of the invention features high degree of automation, suitability for mass production, high output benefits and low cost; in addition, the production technique equipped with the production line is more reasonable, components produced by the coating method of powder spraying has more uniform surface color and thickness.

Owner:GUANGZHOU JINZHONG AUTO PARTS MFG

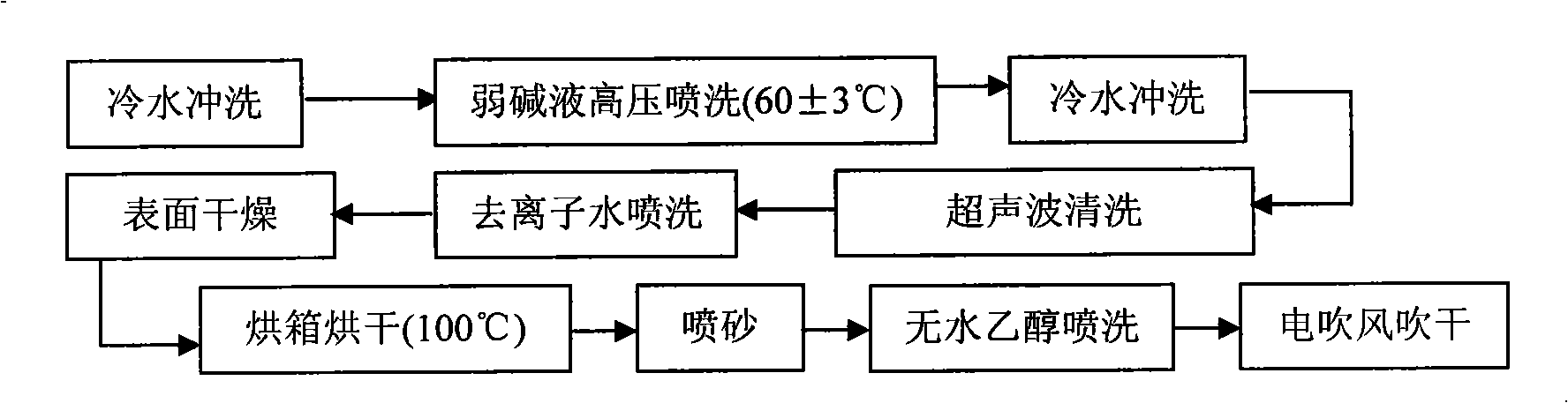

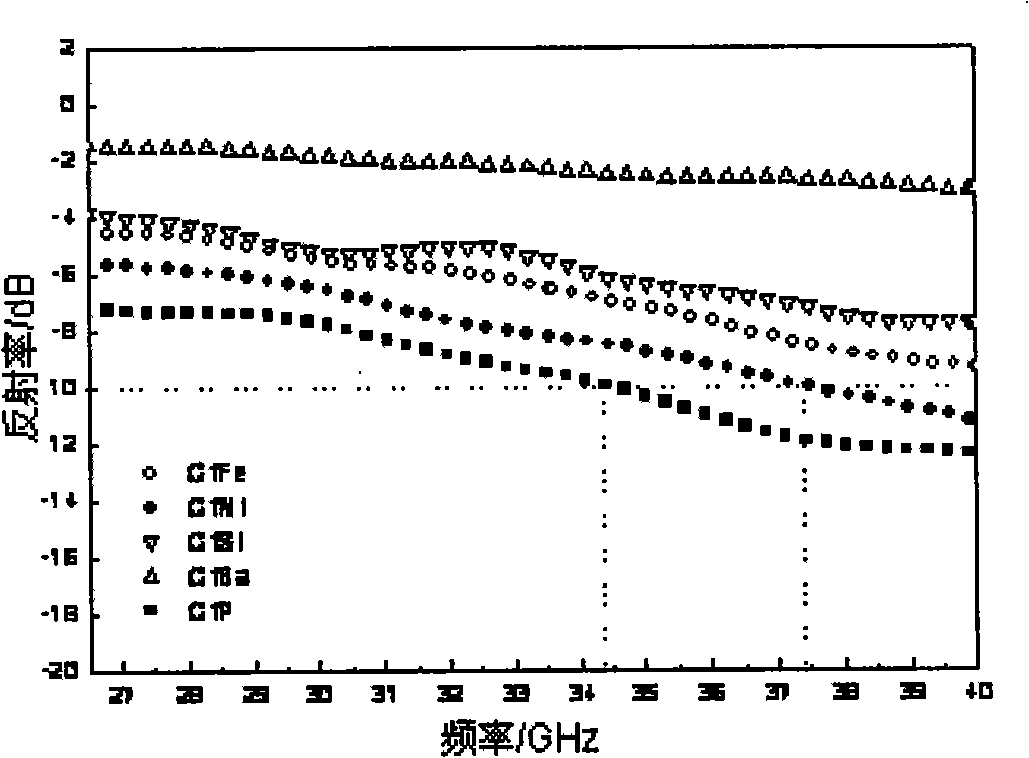

Preparation of foam aluminum alloy base wave-absorbing material

InactiveCN101259463AHigh porosityGood mechanical propertiesPretreated surfacesRadiation-absorbing paintsDegreasingAluminium alloy

The invention discloses a preparation method for a foam aluminum alloy-based wave absorbing material and includes the steps of a surface pretreatment of the foam aluminum alloy material, a preparation of wave absorbing agent material and a spraying of the foam aluminum alloy material; the preparation method of the invention is characterized in that the foam aluminum alloy material through degreasing and sand spraying treatments is took as a basic body, and a single wave absorbing material or compound wave absorbing materials are coated on the surface of the basic body to prepare a foam aluminum alloy-based absorbing material of single wave absorbing agent or foam aluminum alloy-based absorbing material of compound wave absorbing agent. The product of the invention provides a new thought for a development of wave absorbing material, and a new field for the popularization and application of foam metal materials and establishes theory and technique foundations for the developing of porous material-based wave absorbing materials.

Owner:NORTHEASTERN UNIV

Method for electroplating magnesium and magnesium alloy

The present invention provides an electroplating method of magnesium and magnesium alloy. The technology comprises dehydrogen, chemical degreasing, shining, neutralization, activation, pre-plating, functional plating, decorative plating and post treatment. The cast workpiece must be water-washed between every two procedures. The current density of pre-plating is 5-15 A / dm2, cell voltage 4-12 V, pH value of pre-plating solution 1.0-1.2, and Baume degree at room temperature is 30-35. Pre-plating solution recipe contains: copper fluoborate, fluoboric acid, alanine, polyethylene glycol and alizarin dye, mixture of itaconic acid and MBT, 3-S isothiourea onium salt propane sulfonate ,R-S-S(CH2)SO3Na and deionization water. The pre-plating solution of the present invention is cyanogen free, non-toxic and non-hazardous. Bond strength between pre-plating layer and substrate material and between pre-plating layer and the post functional plating layer or decorative plating layer is good. The plating layer is bright and has good corrosion resistance, wear resistance and decorative effect.

Owner:SHENYANG POLYTECHNIC UNIV

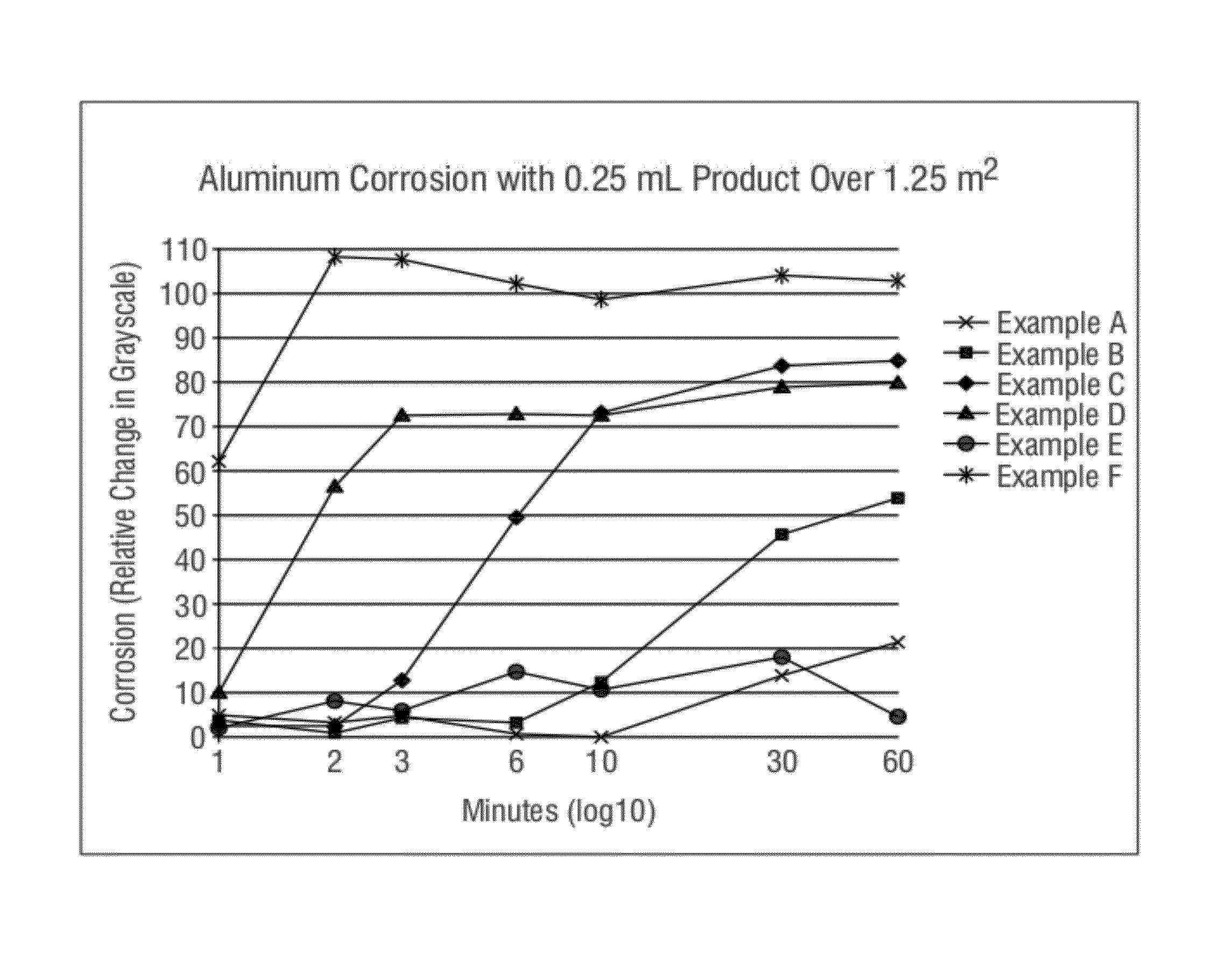

Non-corrosive oven degreaser concentrate

ActiveUS9023782B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPersonal protective equipmentPhysical chemistry

The invention relates to a non-corrosive degreasing concentrate and ready to use formulation. In particular, non-corrosive compositions capable of removing polymerized grease as effectively as some alkali metal hydroxide (i.e. caustic) based degreasers without requiring the use of personal protective equipment are disclosed.

Owner:ECOLAB USA INC

Method for reclaiming metals from molybdenum-containing waste catalyst

ActiveCN102051483APrevents the problem of easy leachingSolve pollutionProcess efficiency improvementFiltrationImpurity

The invention discloses a method for reclaiming metals from a molybdenum-containing waste catalyst, which comprises the following steps of: mixing the waste catalyst and a magnesium-containing compound, roasting, degreasing, removing carbon, then crushing, mixing the powder and sodium carbonate, roasting the mixture, and leaching the roasted materials by using aqueous solution, wherein ammonium salt or aqueous ammonia is added in the aqueous solution leaching step, the molybdenum in the waste catalyst enters the solution in a form of sodium molybdate or ammonium molybdate, the impurities such as silicon, phosphorus and the like entering the aqueous solution form sediment, and the sediment is kept in solid residue in a filtration step; and after the solid is separated, performing acidification, extraction, re-extraction and the like to reclaim the molybdenum and other metals. The method solves the pollution problem caused by sulfur dioxide in the discharged gas in the roasting, degreasing and carbon removal processes; and the salts formed by the reclaimed sulfur and magnesium can play a role in removing impurities in the subsequent steps so as to save the consumption of chemical reagents in the metal reclaiming process and reduce the cost. In addition, the method reduces the operation steps, reduces equipment, improves the operation effect, and also can improve the molybdenum yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

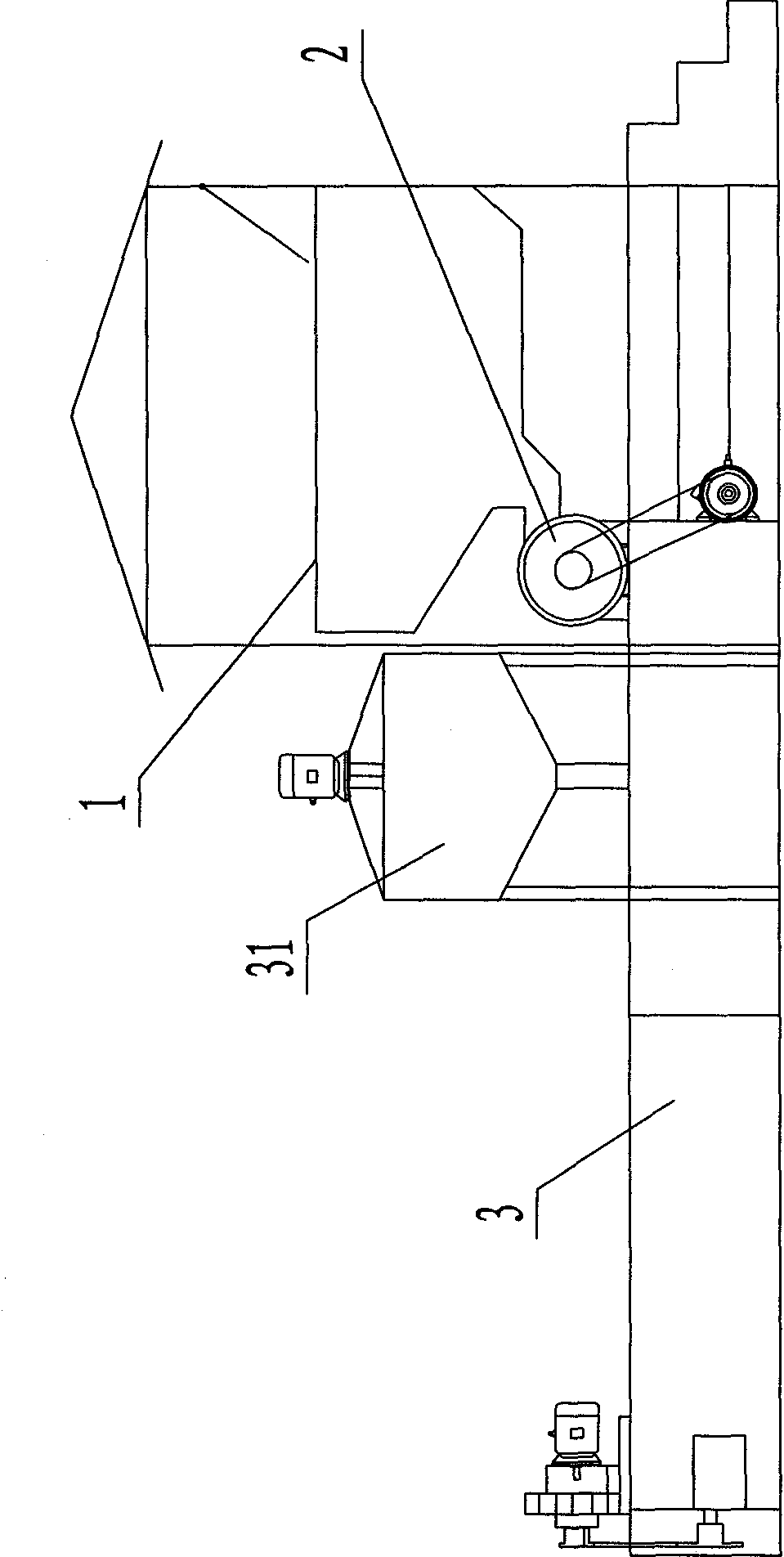

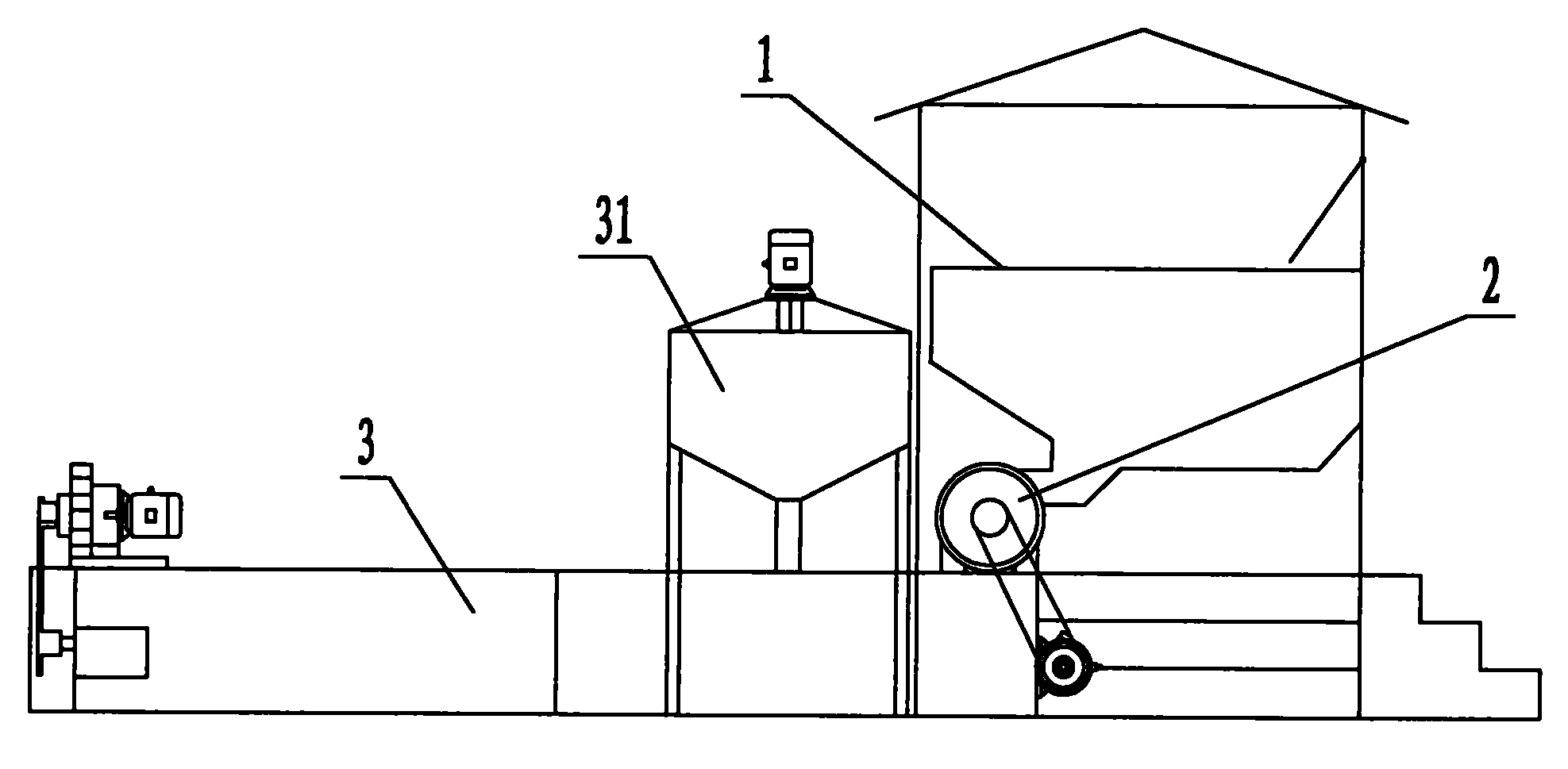

Domestic organic food waste treatment method and treatment equipment

InactiveCN101844940ASolve perishable deteriorationTroubleshoot technical issues that create foul odorsClimate change adaptationMultistage water/sewage treatmentLiquid wasteDecomposition

The invention relates to a domestic organic food waste treatment method and domestic organic food waste treatment equipment. The treatment method comprises the following steps of: a, performing solid-liquid separation on domestic organic food wastes on the spot; b, treating solid wastes, namely, putting the solid wastes produced in crushing into a fermentation machine and adding more than one microorganism for deodorization, fermentation and decomposition to obtain a primary bio-organic fertilizer; and c, treating waste liquor, namely, adding more than one microorganism into the waste liquor produced in dehydration and performing degreasing and purification treatment. The treatment equipment comprises a dehydration platform, a crusher, a waste liquor purification tank and the fermentation machine, wherein the crusher is positioned below the dehydration platform. Through the method and the device, before rotten, the domestic organic food wastes are treated to produce the primary bio-organic fertilizer, which reduces waste flow links, and the harmless in-place treatment of the domestic organic food wastes is realized.

Owner:张岳清

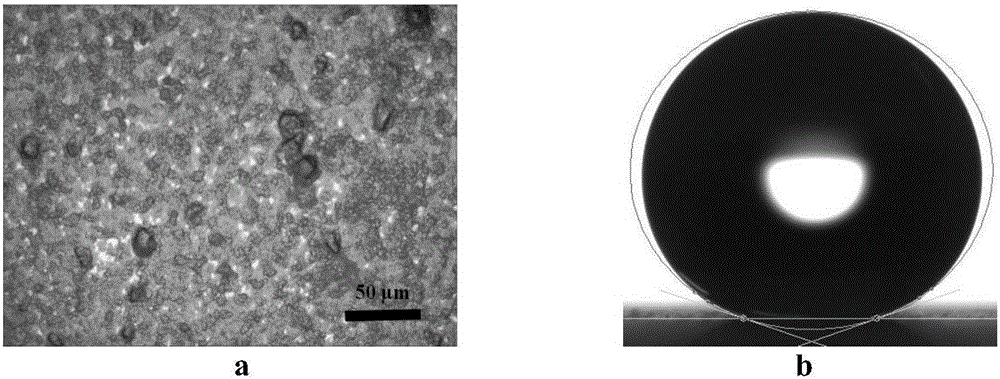

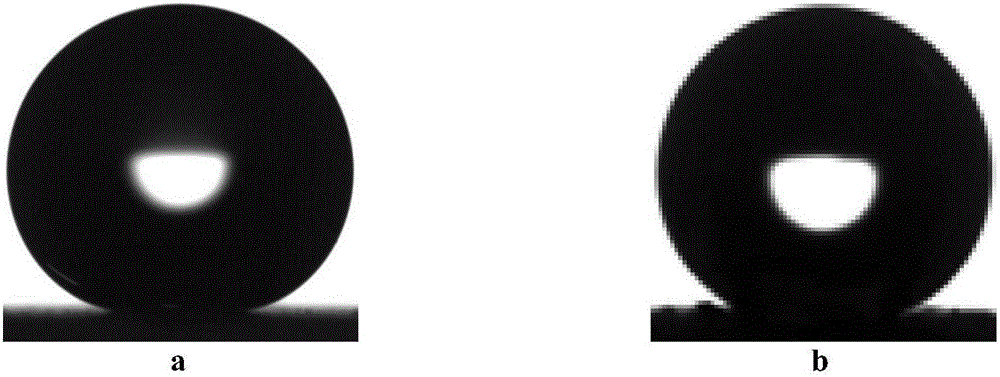

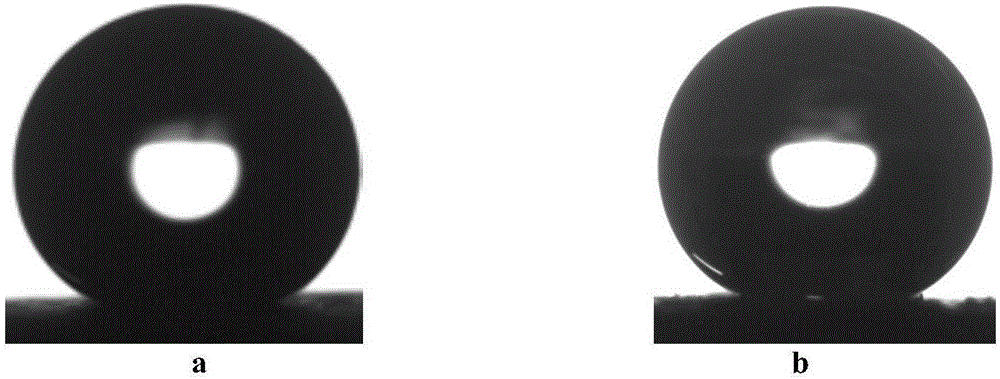

Transferable wearing-resistant flexible super-hydrophobic film and preparation method thereof

ActiveCN106366912AReduce the binding forceIntegrity guaranteedPretreated surfacesPolyurea/polyurethane coatingsWear resistantRoom temperature

The invention discloses a transferable wearing-resistant flexible super-hydrophobic film and a preparation method thereof. The preparation method comprises the following steps: by using a two-step coating method, coating the surface of a smooth substrate which is subjected to degreasing and decontamination treatment or is coated with a resin film releasing agent with soft and hard compounded resin, further coating the surface of the half-cured compounded resin with a super-hydrophobic nano coating, performing room-temperature or high-temperature curing, and separating from the substrate, or coating the surface of a base film, and curing, thereby obtaining the transferable wearing-resistant flexible super-hydrophobic film directly. The transferable wearing-resistant flexible super-hydrophobic film has the advantages of being simple in process, simple and easy to operate, low in cost and the like, and has industrial on-scale production prospects. The transferable wearing-resistant flexible super-hydrophobic film disclosed by the invention is relatively good in wearing resistance, good in resistance on external force such as finger friction and sand paper grinding and good in flexibility, and can be adhered to complex substrate surfaces along with shapes after being cut.

Owner:SOUTHEAST UNIV

Stainless steel weldless steel tube for ship and producing technique

InactiveCN101220443AHigh mechanical strengthGood extensibilityFurnace typesHeat treatment furnacesNo productionUltimate tensile strength

The invention relates to a stainless steel seamless pipe in metallurgical industry and the manufacturing process for the stainless steel seamless pipe; wherein, the steel pipe is made of 00Cr24Ni6Mo2N dual phase stainless steel; the manufacturing process for preparing the ship borne stainless steel seamless pipe comprises the following production steps of a. round steel preparation; b. heating; c. hot-puncturing process; d. end cropping; e. pickling; f. repair grinding; g. lubrication; h. cold rolling processing; i. degreasing; j. solution heat treatment; k. straightening; l. pipe cutting; m. pickling; n. inspection of finished products. The invention solves the problems of lower mechanical strength and extensibility, shorter service life and high prices in present 316L stainless steel pipes used in ship seawater channels and provides a novel ship borne dual phase stainless steel seamless pipe and the manufacturing process and has the advantages of no production of pitting corrosion and grain boundary corrosion of the steel pipes, higher mechanical strength and extensibility, longer service life as well as low price and low cost.

Owner:江苏长盈不锈钢管有限公司

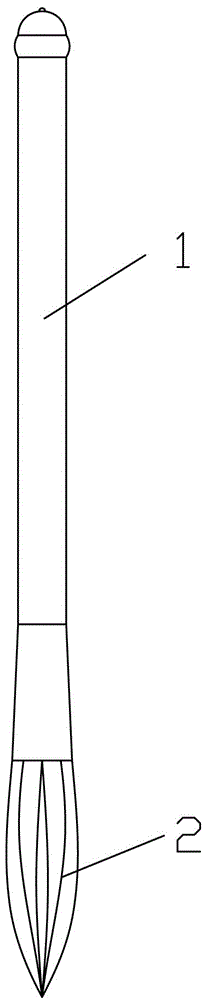

Writing brush and manufacturing method thereof

The invention discloses a writing brush and a manufacturing method thereof. The writing brush comprises a brush rod and a brush head, and the brush head is made of 10-15 wt.% of flax wool and 85-90 wt.% of goat hair. The manufacturing method includes steps of (a) coarse degreasing, (b) refined degreasing and (c) cleaning and degreasing. The writing brush is soft and hard, good in elasticity, large in ink containing quantity and high in corrosion resistance.

Owner:湖州王一品斋笔庄有限责任公司

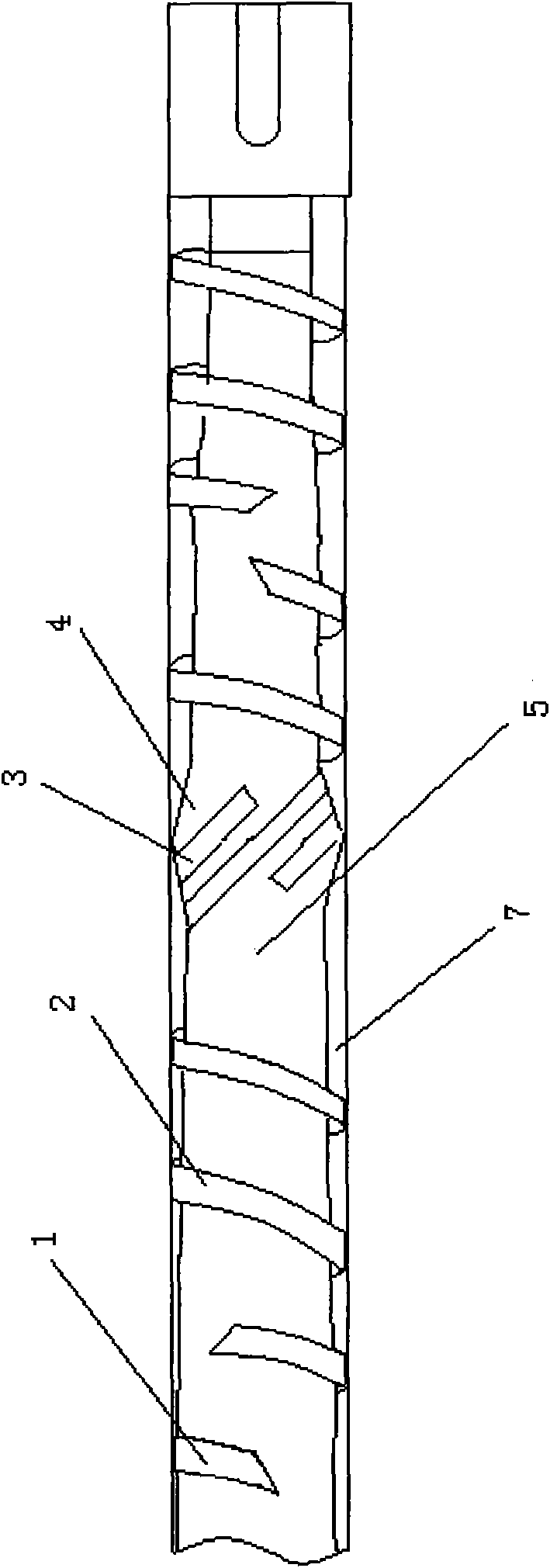

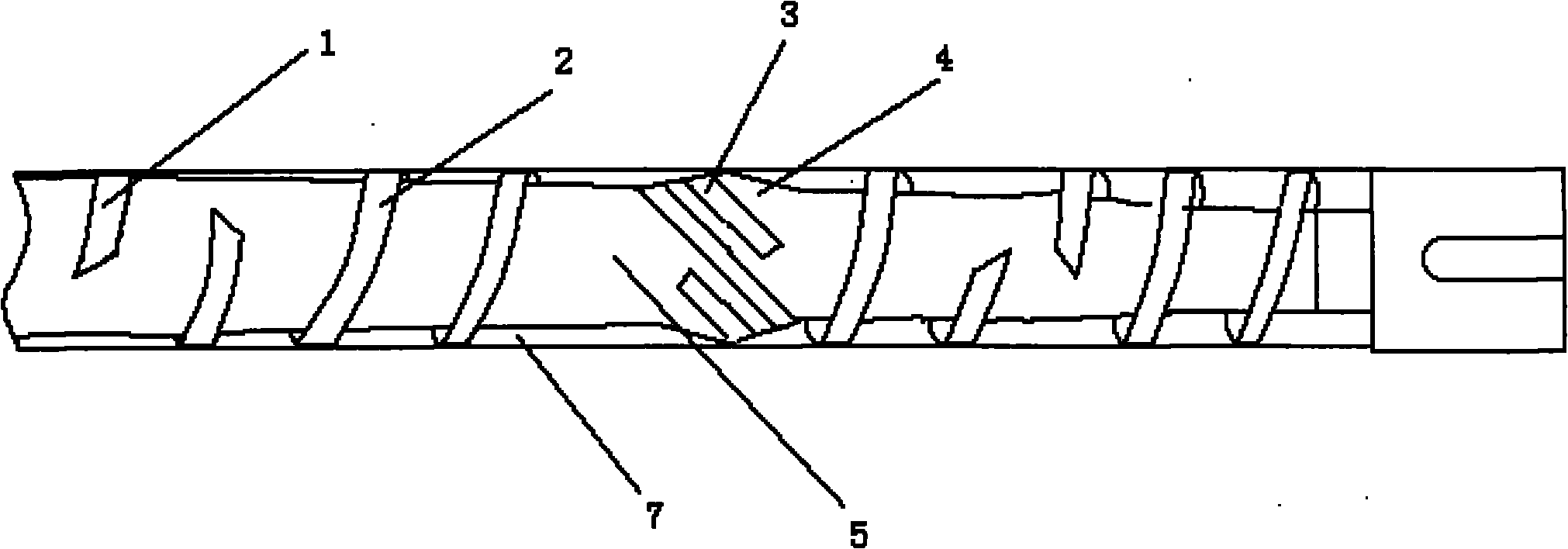

Metal ceramic cutter with gradient structure and preparation method thereof

The invention discloses a metal ceramic cutter with a gradient structure and a preparation method thereof, belongs to a metal ceramic material, and solves the problem that the conventional method for preparing the metal ceramic cutter has higher cost and lower comprehensive mechanical property. The metal ceramic cutter of the invention is characterized in that a hard phase in finally generated phases is (Ti, W, Mo, Ta, Nb) (C, N) and a bonding phase is Ni, wherein the hard phase and the bonding phase are in symmetrical gradient distribution from a surface layer to a middle layer. The method of the invention sequentially comprises the steps of raw material preparation and mixing, layer-by-layer paving and compression molding, degreasing and vacuum sintering. The method is simple and has low cost; the surface hardness of the manufactured metal ceramic cutter is 92.5 to 92.8HRA, the bending strength is more than or equal to 2,000MPa, and the fracture toughness KIC is more than or equal to 12.0MPa.m<1 / 2>; and the metal ceramic cutter has the advantages of good high-temperature red hardness, abrasion resistance, chemical stability and impact toughness resistance and strong high-temperature oxidation resistance, is suitable for high-speed efficient cutting and processing and dry cutting, and can reduce the using amount of cutting fluid or does not use cutting fluid.

Owner:HUAZHONG UNIV OF SCI & TECH

Asymetric membrane FeAl intermetallic compound porosint filter element and application thereof

ActiveCN101524609AGood degree of pore structure controlWide range of regulationIncreasing energy efficiencyManufacturing convertersPorosityVulcanization

The invention belongs to the field of inorganic porosint and particularly relates to an asymetric membrane FeAl intermetallic compound porosint filter element and the application thereof. The filter element of the invention consists of a multiaperture support body and complex film; wherein, the multiaperture support body is in tubular shape or platy shape, the complex film is made in the following steps: a compound sizing agent is coated on outer surface of a single side of the multiaperture support body; and degreasing, bias diffusion, reaction synthesis and sintering are carried out to form thin-layer complex film with millipores. The millipores on the surface of the filter element is small and uniform, porosity is high, no dust is blocked inside filter material, filtering gas circuit is smooth, and resistance is small; in addition, the element has good resistance to high temperature oxidation / vulcanization and good normal temperature and high temperature mechanical properties. The element can directly carry out solid-gas separation on industrial gasses, bear top load and high-pressure and high-speed back washing, thus saving relative cooling devices, saving a large amount of water resources, avoiding cooling water treatment, lowering energy loss, shortening process flow and improving work efficiency.

Owner:CHENGDU INTERMENT TECH

Vegetarian lunch meat and preparation method and equipment thereof

The invention relates to vegetarian lunch meat and a preparation method thereof. The preparation method comprises the following steps of: mixing raw materials of 60 to 70 percent of low-temperature defatted soy flour, 5 to 10 percent of wheat gluten, 10 to 20 percent of isolated soy protein powder and 10 to 15 percent of low-temperature soya bean meal and / or 5 to 8 percent of bean dregs, read yeast rice accounting for 1 to 2 weight percent of the raw materials and water accounting for 50 to 60 weight percent of the raw materials; under the conditions of high temperature, high pressure and high shear force and the propulsion of a screw, and repeatedly mixing, extruding and shearing to make the fiber structures of the raw materials change to form a blank with a structure similar to a meat fiber structure, wherein the pressure is 1 to 1.2MPa, and the temperature is divided into three sections, namely a feeding section between 100 and 130 DEG C, a middle section between 130 and 170 DEG C and a discharging section between 170 and 180 DEG C; frying the raw materials, and blending with 1 to 3 percent of seasoning; and pressurizing for forming, and sterilizing. The vegetarian lunch meat has all nutrient components of soybeans, does not contain any chemical additive and preservative, is the optimal food for hyperpietics, diabetics and obese people, and does not generate waste water or waste residue.

Owner:刘健

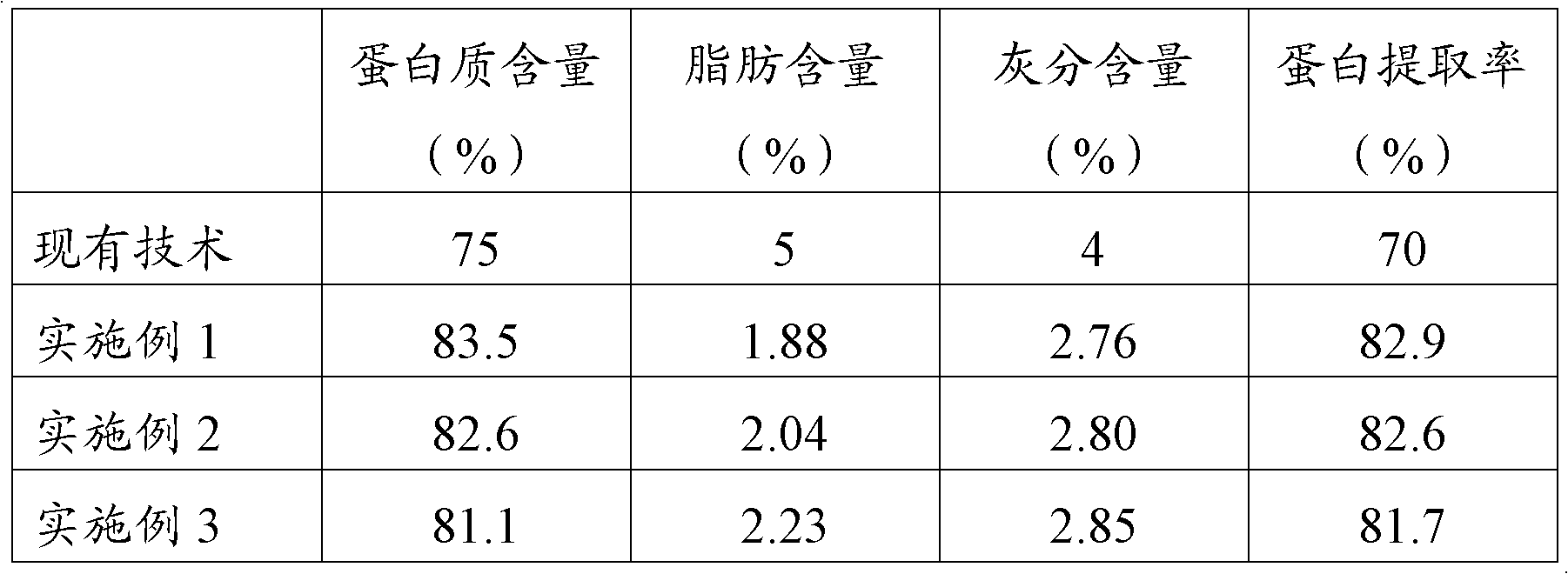

Method for preparing high-purity rice protein and acquired products by using same

The invention relates to a method for preparing high-purity rice protein. The method comprises the following steps: sizing mixing and grinding, degreasing, enzymolysis reaction, separating washing and blanching and sterilization. The invention also relates to the high-purity rice protein acquired by using the method, wherein the rice protein contains following components by weight percent: more than 80% of protein, less than 3% of fat, and less than 3% of ash content. The protein extraction ratio is more than 80% and the additional value of rice residue is greatly increased.

Owner:WUXI JINNONG BIOTECH CO LTD

Shortened method for producing oxygen-free copper belt

InactiveCN101502872AUniform performanceEliminates effects on product surface qualityElectrolysisProduct gas

The invention provides a short process oxygen-free copper strip production method which is characterized in that the method comprises the following steps: an electrolytic copperplate is cleaned and dried, melted and insulated; after an upward continuous casting step, a copper rod is obtained; a continuous squeezing step is carried out on the copper rod to obtain a strip stock; after cold rolling, annealing and post treatment, the strip stock is made into a copper strip finished product. An upward casting rod is used by the invention to be continuously squeezed into the strip stock. The upward casting rod is directly made into the thickness of the finished product by cold rolling without surface milling and middle annealing. The continuous bright non-oxidation annealing is realized under the protection of air. Hot water degreasing is adopted for substituting the natron degreasing. The advantages of the up-draw process and the continuous squeezing method are combined. The product has the advantages of low oxygen content, pure tissue, small grain and perfect comprehensive performance. The short process oxygen-free copper strip production method has the advantages of brief process, energy saving, environment protection, pollution-free and the like.

Owner:SHANGHAI KANGCHENG COPPER GROUP +1

Method for performing anticorrosive hydrophobic modification on surface of aluminum alloy

InactiveCN101885934ACoating thickness is thinImprove adhesionAnti-corrosive paintsMetallic material coating processesSpray coatingLayer thickness

The invention discloses a method for performing anticorrosive hydrophobic modification on the surface of an aluminum alloy, which belongs to the technical field of corrosion prevention. The method specifically comprises the following steps of: (1) performing surface degreasing and oil removing on an aluminum alloy material by using conventional alkaline degreasing solution first, performing surface activation treatment by using reductive acidic cleaning solution, and then performing inactivation and sealing treatments on the activated surface; (2) preparing a composition with a hydrophobic effect, wherein the composition consists of a first component and a second component in a weight ratio of 9-16:1, the first component is prepared from the following materials in percentage by weight: 35 to 60 percent of fluorocarbon resin, 10 to 40 percent of anticorrosive pigment, 1 to 8 percent of organosilicon compound, 0.5 to 5 percent of dispersing agent, 0.5 to 3 percent of anti-settle agent and 10 to 40 percent of organic solvent, and the second component is a fatty series / aromatic series curing agent; and (3) performing anticorrosive hydrophobic modification on the surface of the aluminum alloy, namely coating the composition with the hydrophobic effect in the step (2) on the surface of the aluminum alloy after treatment in a brush coating, spray coating or dip coating mode, and curing the surface for about 12 hours. The anticorrosive hydrophobic coating layer obtained on the surface of the aluminum alloy by using the technique of the invention has the advantages of thin coating layer thickness, high adhesive force, sea water corrosion resistance, surface super-hydrophobic property and the like.

Owner:BEIJING UNIV OF CHEM TECH

Biological degreasing agent used in metal processing pretreatment of oil removing and degreasing, and method for processing metal surface greasy dirt

The invention discloses a biological degreaser for degreasing pretreatment in metal processing industry and method for processing greasy dirt on metal surfaces, which integrates the two independent processes of grease removing and greasy dirt decomposing, the biological degreaser containing oil-degraded microorganisms can not only scale off greasy dirt from metal surfaces, but also decompose the greasy dirt simultaneously.

Owner:TANTZ ENVIRONMENTAL TECH

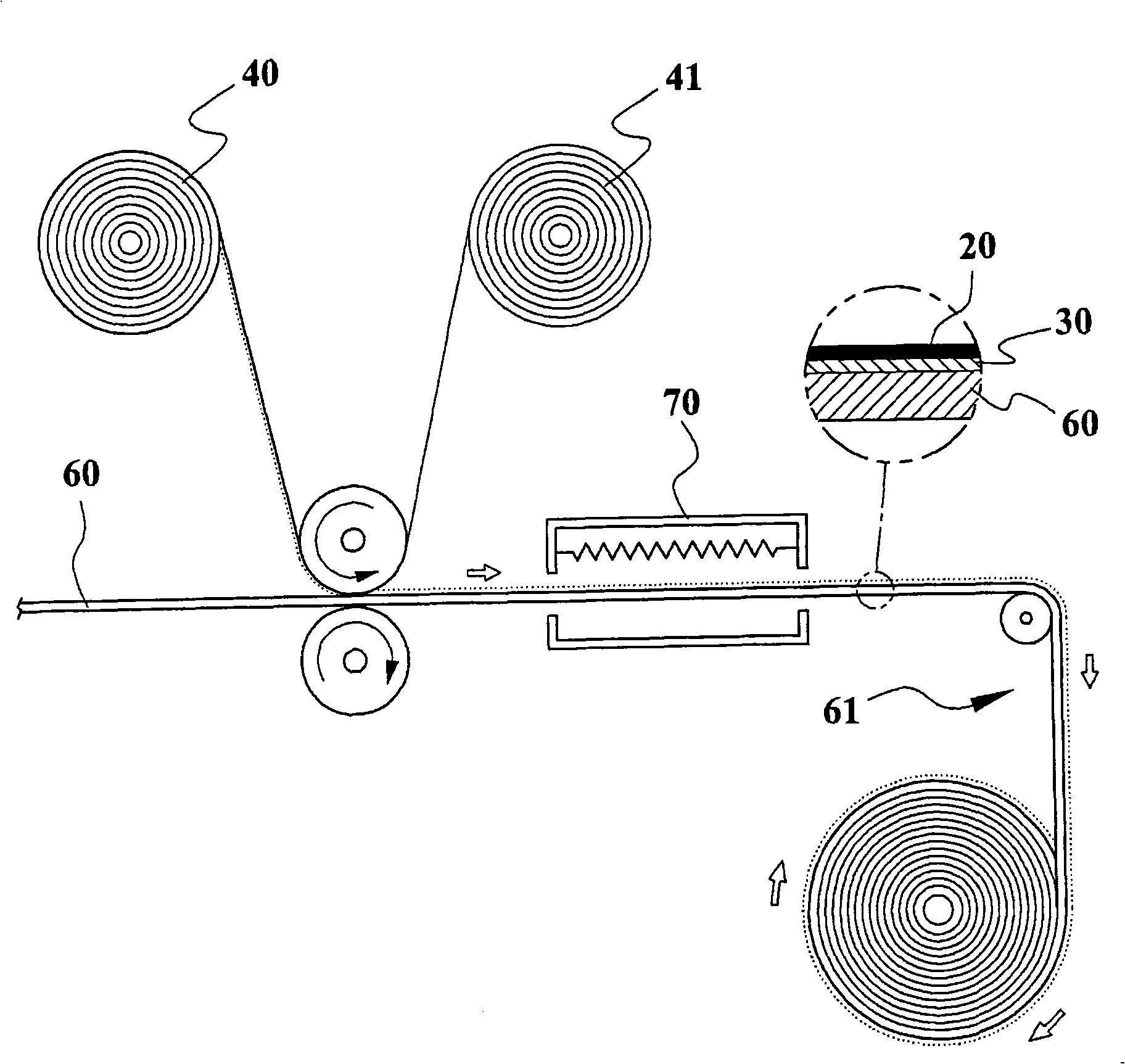

Heat-transferring die, manufacturing process and heat-transferring manufacturing process

InactiveCN101318420AGood film structure strengthDecorative surface effectsDuplicating/marking methodsEngineeringTemperature resistance

A thermal transfer film which can carry out continuous thermal transfer in a large area directly forms a single-color or colorful printing pattern with excellent layer film structure intensity on the transferred surfaces of various metal, glass or ceramic substances. The manufacturing technique of the thermal transfer film includes that printing is carried out a whole volume of continuous plastic film material or paper material the surface of which comprises a release layer with the ink of a high temperature-resistance dye by a gravure printer to generate the ink layer of the high temperature-resistance dye; the layer of a high temperature-resistance thermal reaction hot melt adhesive is coated on the surface of the ink layer of the high temperature-resistance dye. The thermal transfer steps include: a. the steps of degreasing, dust removing, purifying of the transferred surface of a substance; b. the step of fictitiously fixing: the thermal transfer film comprising the ink of the high temperature-resistance dye and the layer of the high temperature-resistance thermal reaction hot melt adhesive are taken to carry out thermal transfer on the transferred surface of the step a to lead the ink layer of the high temperature-resistance dye and the layer of the high temperature-resistance thermal reaction hot melt adhesive to be fictitiously fixed on the transferred surface; c. the step of roasting for leading the ink of the high temperature-resistance dye and the layer of the high temperature-resistance thermal reaction hot melt adhesive to be firmly combined with the transferred surface.

Owner:白洪城

Method for plasticizing biological specimen

ActiveCN102125025AShrinkage reductionEasy to observeDead plant preservationDead animal preservationCooking & bakingPlasticizer

The invention discloses a method for plasticizing a biological specimen. The method is characterized by comprising the following steps of: a, immobilizing the biological specimen, namely completely immobilizing the biological specimen by using formalin; b, dehydrating and degreasing, namely manufacturing the immobilized biological specimen, and then replacing by using acetone until the water content of the specimen is less than 1 percent; c, performing vacuum impregnation, namely impregnating the completely replaced biological specimen in a biological vacuum impregnation plasticizer to finishthe replacement in a vacuum negative-pressure freezer; d, baking by a baking oven, namely putting the completely replaced biological specimen into the baking oven for high-temperature baking, and completely removing the excessive biological vacuum impregnation plasticizer in the biological specimen; and e, hardening, namely putting the biological specimen baked by the baking oven into an airtightcontainer for hardening. The method effectively shortens the manufacturing time of the specimen, and is easy to operate; and the overall shape of the specimen is not changed, and the specimen has strong sense of reality and certain flexibility, so that the specimen observation at the later stage is facilitated.

Owner:山东聚众数字医学科技开发有限公司

Environmentally friendly steel degreasing and derusting agent

InactiveCN102260875AImprove performanceImprove the working environment of degreasing and derustingSURFACTANT BLENDOxalic acid

The invention relates to a metal degreasing and rust removing agent, in particular to an environment-friendly type steel degreasing and rust removing agent, which belongs to the technical field of chemical industry. It includes hydrochloric acid, oxalic acid, surfactants, complexing agents, and corrosion inhibitors. The content of hydrochloric acid is the main factor affecting rust removal. The addition of oxalic acid can significantly reduce acid mist. Surfactants have the functions of degreasing and fog suppression. Due to the synergistic effect of each component of the formula, the process has the characteristics of normal temperature, rapidity, high efficiency, and environmental protection.

Owner:郭方全

Production process of tin-copper alloy strip

The invention discloses a production process of a tin-copper alloy strip, which comprises the steps of casting, annealing, surface milling, cold rough rolling, intermediate annealing, intermediate rolling, intermediate annealing, degreasing and cleaning, pre finish rolling, annealing, finish rolling, low-temperature annealing, degreasing and cleaning, bend straightening, shearing and packaging. Through the improvements on casting, annealing and finish rolling, processing difficulties caused by the improvement of the performance of a copper alloy strip after the increase of tin content can be solved, the tin content in copper alloy is increased, and after the process flows, the measured tin content in the tin-containing copper alloy strip is 9-11%. The invention can effectively increase the tin content in the copper alloy and effectively improves the elastic properties and the wear resistance of the tin copper alloy, the tensile strength of the strip produced by the production process disclosed by the invention is larger than 830MPa and can reach the peak of 920MPa.

Owner:ANHUI XINKE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com