Patents

Literature

43 results about "Bluing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bluing is a passivation process in which steel is partially protected against rust, and is named after the blue-black appearance of the resulting protective finish. True gun bluing is an electrochemical conversion coating resulting from an oxidizing chemical reaction with iron on the surface selectively forming magnetite (Fe₃O₄), the black oxide of iron. Black oxide provides minimal protection against corrosion, unless also treated with a water-displacing oil to reduce wetting and galvanic action. A distinction can be made between traditional bluing and some other more modern black oxide coatings, although bluing is a subset of black oxide coatings.

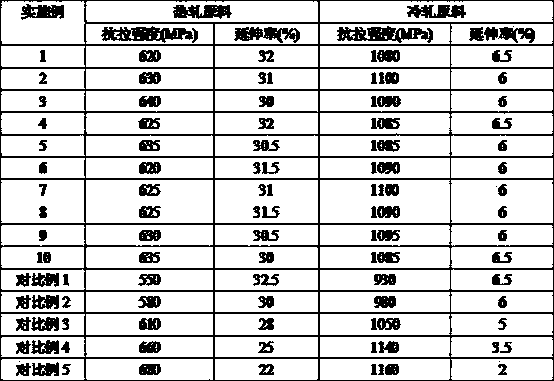

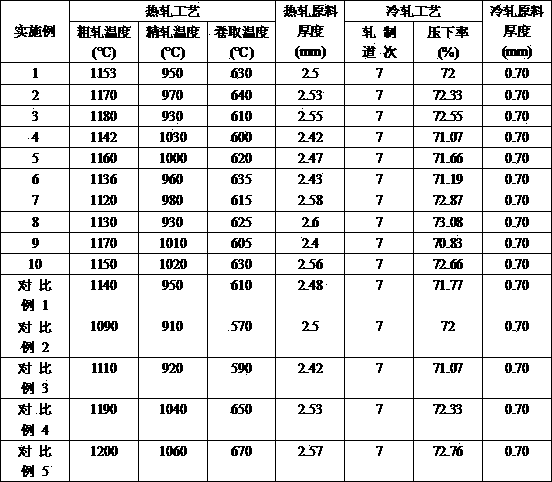

High strength cold rolling packaging steel belt and production method thereof

InactiveCN101487097AHigh tensile strengthHigh elongationManufacturing convertersChemical compositionHigh intensity

The invention relates to a cold rolling packaging steel belt and a preparation method thereof, which belong to the metallurgical technology field. The technological problem to be solved by the invention is that a high strength cold rolling packaging steel belt with higher tensile strength and low cost and a preparation method thereof are provided. The chemical components of the packaging steel belt are as follows (wt percent): 0.11 percent to 0.17 percent of C, 0 to 0.05 percent of Si, 0.25 percent to 0.55 percent of Mn, 0 to 0.025 percent of P, 0 to 0.020 percent of S, 0.02 percent to 0.08 percent of Al and 99.099 percent to 99.618 percent of Fe. The preparation method comprises the steps of billet heating, hot rolling, cooling, coiling, pickling, cold rolling and bluing. The tensile strength of the made steel belt finished product is more than or equal to 800MPa, the elongation is more than or equal to 10 percent. The steel belt has good performance of repeated bending, simple craft, low cost and wide application in the packaging of steel products.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

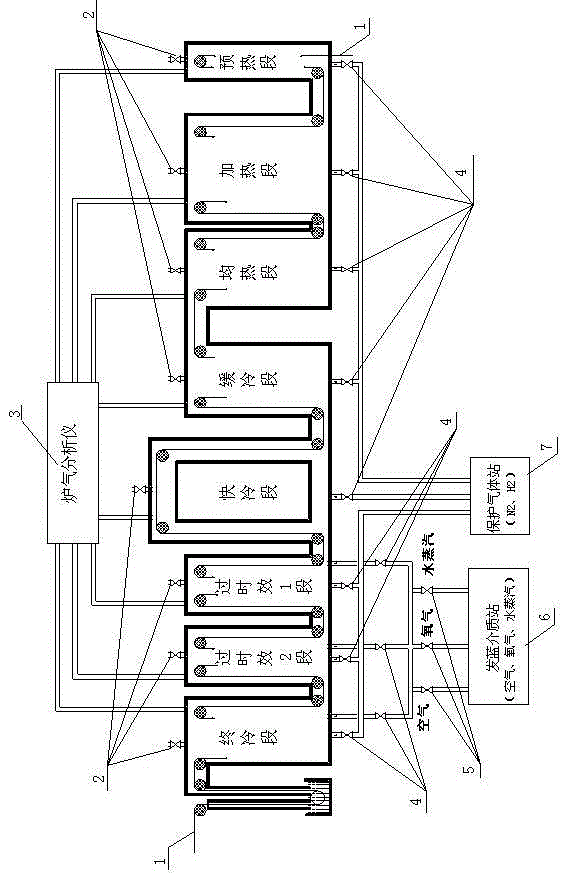

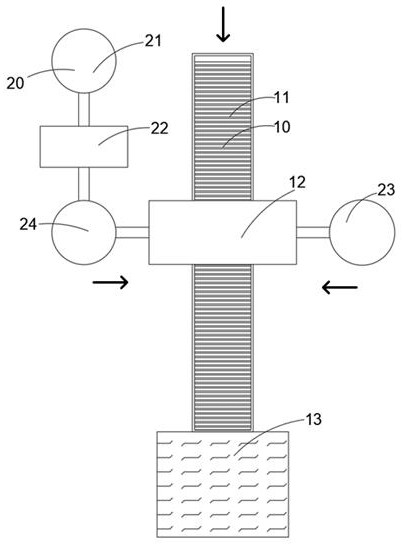

Vertical continuous annealing furnace bluing device and bluing technology thereof

InactiveCN103147084AAvoid reheatingBlue implementationSolid state diffusion coatingFurnace typesHearthBluing

The invention relates to a heat treatment device and heat treatment technology thereof and discloses a vertical continuous annealing furnace bluing device and bluing technology thereof. A bluing medium station is arranged and is communicated with a rapid cooling section, an overaging section and a final cooling section of a hearth through medium pipelines to control opening degree of a control adjusting valve and a relief valve. Oxygen content in the rapid cooling section and / or the overaging section and / or the final cooling section of the hearth is adjusted to be in a range of 0.03%-1.00%. An existing vertical continuous annealing furnace is used and a bluing device is added so that two processes of annealing and bluing of a bluing steel belt are finished by once in the vertical continuous annealing furnace, and therefore device investment and following heat treatment energy consumption are saved; continuous mass production is achieved, production cost is low, performance of a product is stable, surface bluing effect is good and production efficiency is high.

Owner:XINYU IRON & STEEL CO LTD

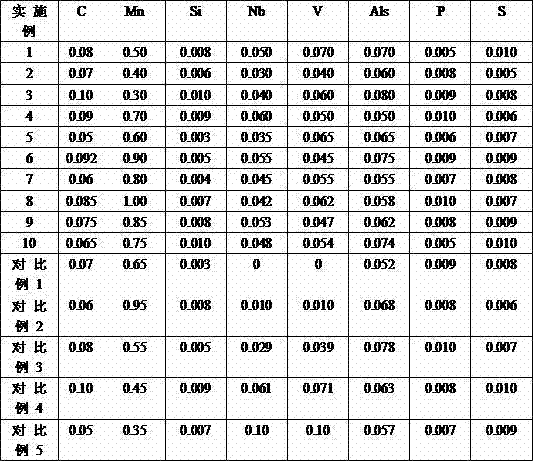

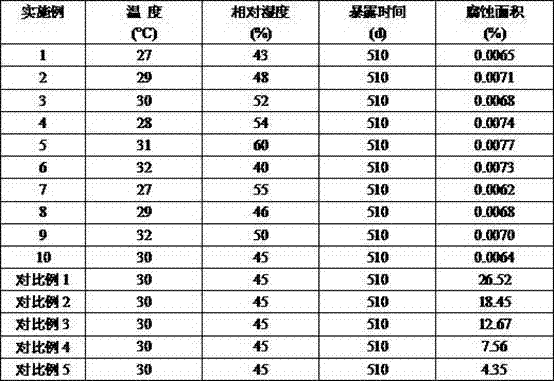

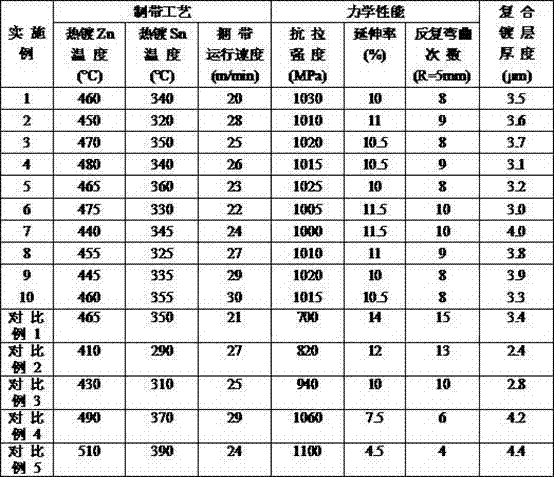

Zn-Sn composite coating bundling belt for bundling precision electronic component and production method thereof

InactiveCN104120340AStrong adhesionStrength is not low adhesionHot-dipping/immersion processesMicrometerHardness

Disclosed is a Zn-Sn composite coating bundling belt for bundling a precision electronic component. The Zn-Sn composite coating bundling belt comprises, by weight, C ranging from 0.05 percent to 0.10 percent, Mn ranging from 0.30 percent to 1.00 percent, Si smaller than or equal to 0.010 percent, P smaller than or equal to 0.010 percent, S smaller than or equal to 0.010 percent, Nb ranging from 0.030 percent to 0.060 percent, V ranging from 0.040 percent to 0.070 percent and Als ranging from 0.050 percent to 0.080 percent. A production method comprises the steps of smelting and continuous casting to form a blank, conventional casing blank heating, hot rolling, conventional pickling, cold rolling, conventional degreasing and belt manufacturing. The thickness of the product is 0.5 mm, the tensile strength is not smaller than 1000MPa, the extending rate is not smaller than 10 percent, the time of alternating bending is not smaller than eight (R is equal to 5mm), a Zn-Sn composite coating is generated on the surface of the belt, the coating is even and compact, and strong in adhesive force, the thickness of the coating is three micrometers to four micrometers, the coating has the beautiful luster appearance, and when the belt is placed in the indoor atmospheric environment, the service life of the belt is prolonged to be 510 days and the belt is not obviously corroded compared with a blue and painted bundling belt with the corrosion resistance time not exceeding two months to the highest. The bundling belt completely meets the requirement of the precision electronic component for bundling and packaging, the surface hardness of the bundling belt is low, the bundling belt is relatively soft, and the damage to the precision electronic component hardly exists.

Owner:武汉钢铁有限公司

Blued packing tape with tensile strength of more than 1500MPa and production method of blued packing tape

ActiveCN104264048AMeet strength requirementsGood welding performanceFlexible elementsSolid state diffusion coatingHeat-affected zoneAustenite grain

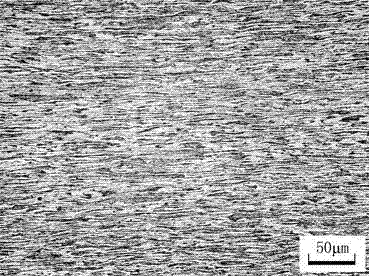

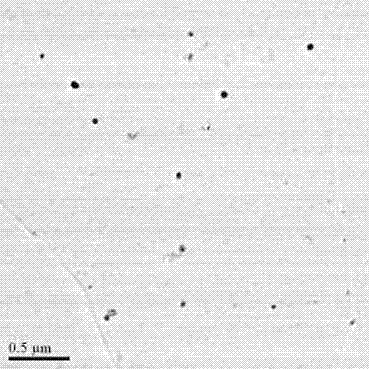

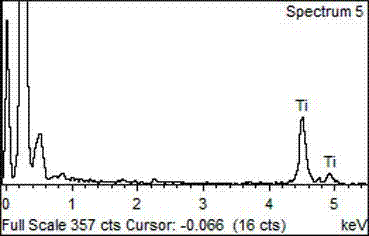

The invention discloses a blued packing tape with tensile strength of more than 1500MPa. The blued packing tape comprises the following components in percentage by weight: 0.03-0.25 percent of C, 0.05-0.20 percent of Si, 0.50-2.50 percent of Mn, 0.01-0.10 percent of P, 0-0.015 percent of S, 0.01-0.20 percent of Als, 0.05-0.20 percent of Ti and 0.004-0.010 percent of N. The process comprises the following steps: smelting, performing controlled rolling and controlled cooling, and bluing and annealing. After a proper amount of Ti is added, Ti and C are combined to form nano-scale TiC, TiN and TiCN, and the product serves as the second phase precipitate which is small and disperses in steel so as to achieve the important precipitation strengthening effect; and according to the Ti in the packing tape, the austenite grain size can be controlled under extremely high soaking temperature, grain control in a heat affected zone is facilitated, and the welding performance of the high-strength packing tape is improved. Although lead bath furnace annealing is adopted, the temperature is only 200 to 300 DEG C and is far lower than volatilization temperature of lead, so that lead volatilization is avoided, and the environmental pollution is avoided. The blued packing tape disclosed by the invention is low in cost, good in performance, simple and feasible in process and high in production efficiency, and ultrahigh-strength packing tapes with the tensile strength of larger than 1500MPa are produced.

Owner:武汉钢铁有限公司

Annealing and bluing process of common cold-rolled coil

InactiveCN112176158AImprove annealing qualityUniform bluish effectSolid state diffusion coatingFurnace typesFree coolingEngineering

The invention discloses an annealing and bluing process of a common cold-rolled coil. The annealing and bluing process comprises the following steps that (1) the common cold-rolled coil heated to be at the process temperature of 650-710 DEG C is subjected to heat preservation for 6-9 hours under the protection of nitrogen for annealing; (2) a common cold-rolled coil strip cover is cooled to 400 DEG C along with air cooling of a furnace under the protection of nitrogen; (3) air cooling is stopped, the common cold-rolled coil is naturally and slowly cooled to 360 DEG C in the cover, the time is60-120 Min, and the effect of homogenizing the temperature of the whole cold-rolled coil is achieved; (4) the common cold-rolled coil is discharged from the furnace at the high temperature of 360 DEGC and placed on a final cooling table, a cooling fan is kept to carry out 8000 Pa forced air cooling till the temperature of the steel coil is reduced to 160 DEG C, and the oxidation bluing treatmenttemperature of the steel coil is 160-360 DEG C; and (5) forced air cooling, and is stopped and the steel coil is naturally cooled to be at a room temperature. By adopting the method to treat the common cold-rolled coil, good annealing quality can be ensured, and meanwhile a uniform bluing effect can be obtained.

Owner:XINJIANG BAYI IRON & STEEL

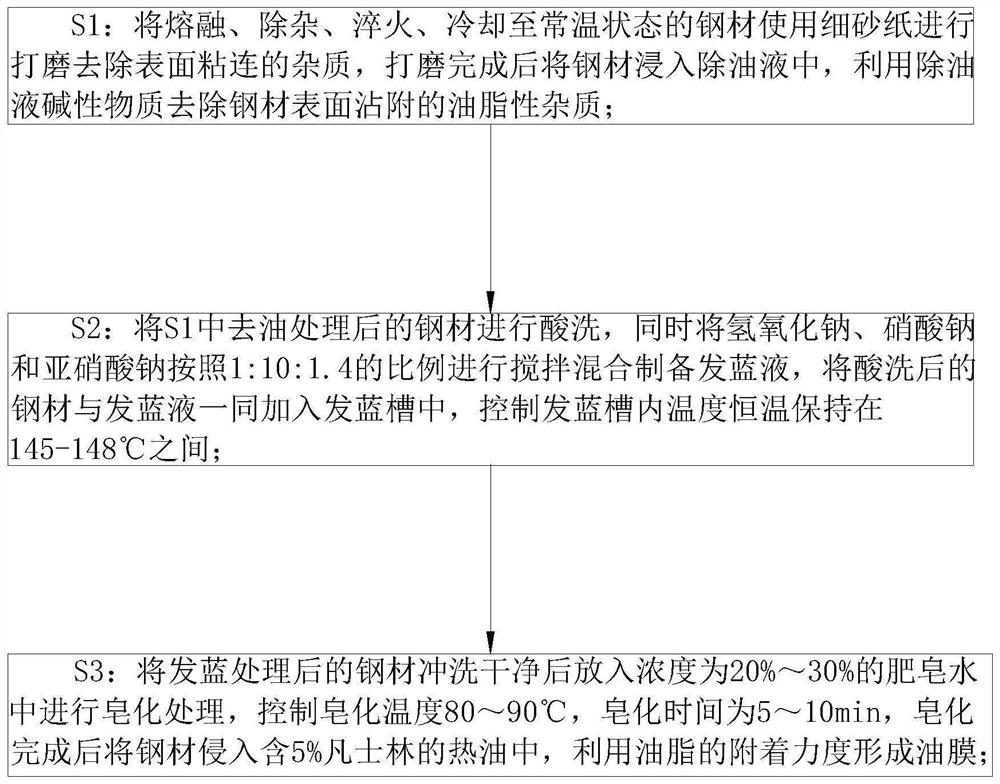

Surface bluing technique for steel piece

InactiveCN105734549AImprove work efficiencyEnhanced bluish effectMetallic material coating processesIron oxideStearate

The invention discloses a surface bluing technique for a steel piece. The surface bluing technique is characterized by comprising the following steps that (1) degreasing is conducted; (2) acid pickling is conducted; (3) bluing is conducted; (4) saponification is conducted, and according to saponification, iron in micropores of an iron oxide film generated by bluing of a workpiece is converted into iron stearate and is in a passive state, so that the corrosion resistance is improved; a saponification solution is soapy water with the mass fraction being 2%-3%, the saponification solution is used in a boiled state for 5 min, and water drops should not exist on the saponified workpiece; and (5) oil immersion is conducted, specifically, the saponified workpiece is soaked into hot oil with the temperature being 105-115 DEG C for 1-3 min, the moisture is evaporated, and thus an oil film is formed. By the adoption of the bluing technique, a plurality of repetitive procedures are omitted, the working efficiency is improved, and the bluing effect is improved.

Owner:CHONGQING YU NAN POLYTRON TECH

Reaction tank for bluing process of chain

The invention discloses a reaction tank for a bluing process of a chain. The reaction tank comprises a tank body and medicament boxes arranged on the tank body, a plurality of medicament boxes are arranged, control discs matched with the medicament boxes are arranged on the side wall of the tank body, a first cover plate is arranged at the top of each medicament box, one end of each first cover plate is movably connected to the top of the corresponding medicament box, a push plate is arranged on the side wall of each first cover plate, a first through cavity communicating with the medicament boxes is formed in the side wall of the tank body, a cavity is formed in the bottom of the first through cavity, a material loading box is arranged in the cavity, a second through cavity is formed in the bottom of the cavity, the second through cavity is in communication with the interior of the tank body, and a weight inductor is arranged in the material loading box.

Owner:ZHEJIANG ANJI CHANGHONG CHAIN MFG

Iron picture surface treatment method and iron picture

InactiveCN106427360AReaction to prevent galvanic corrosionImprove rust resistanceSpecial ornamental structuresMetallic material coating processesSurface finishingMetal

The invention discloses an iron picture surface treatment method and an iron picture. The method comprises the following technological steps of cleaning, specifically, the manufactured iron picture is cleaned; blueing, specifically, the cleaned iron picture is soaked in blueing liquid; rinsing, specifically, the blued iron picture is rinsed with rinsing liquid, washed with water and dried; and coating, specifically, the rinsed iron picture is coated with coating. Since a compact oxidation layer structure can be formed on the surface of the iron picture after blueing, and can isolate contact between water vapor as well as oxygen and the metal surface of the iron picture, an electrochemical corrosion reaction on the metal surface is prevented, and the anti-rust ability of the iron picture can be obviously improved accordingly. The iron picture is treated through the method provided by the invention so that the integrity of the surface paint layer of the iron picture can sustain 10 years or over.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

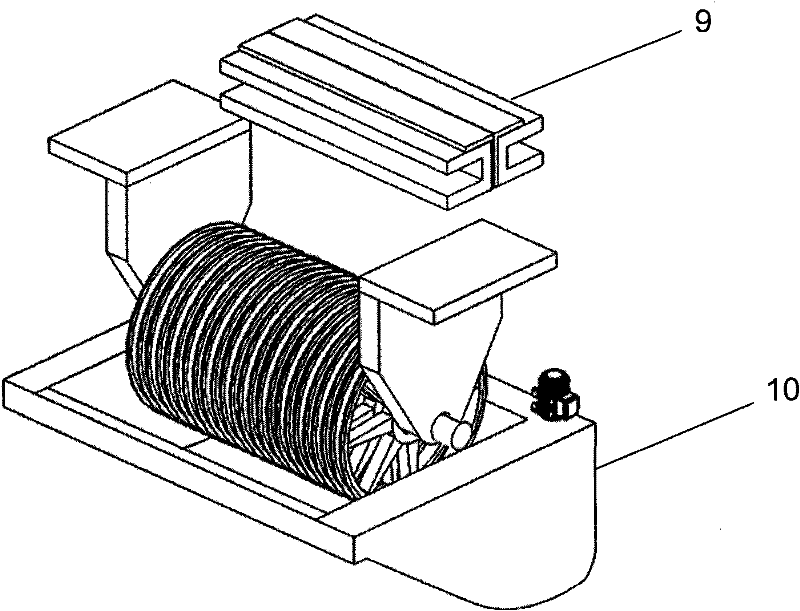

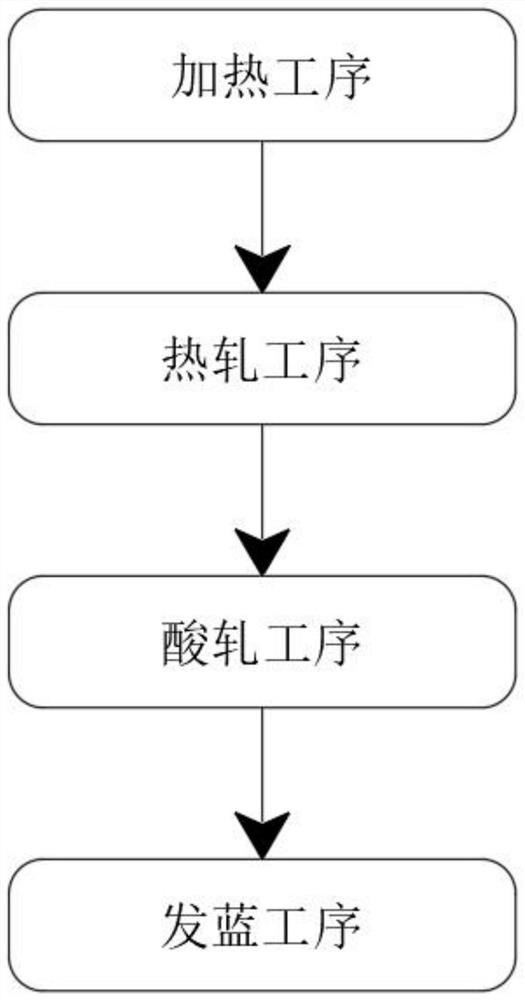

Preparation process of bundling strip for packaging

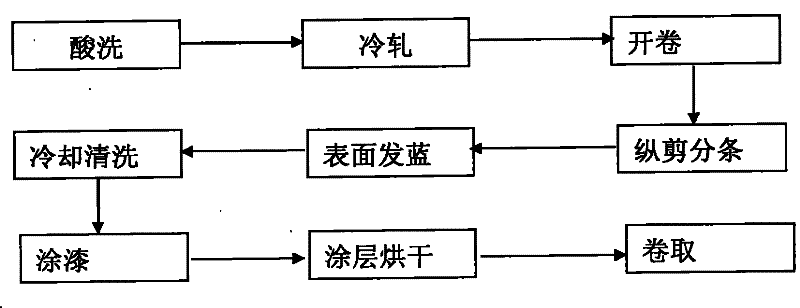

InactiveCN104233088AImprove toughnessImprove efficiencyFlexible elementsIncreasing energy efficiencyTemperature controlIntermediate frequency

The invention discloses a preparation process of a bundling strip for packaging. A cold-rolled steel coil is used as a raw material. The preparation process comprises the following steps of uncoiling, welding, stripping by longitudinally shearing a steel belt, deburring and leveling, surface bluing, cooling, cleaning, surface zinc coating, coating drying, waxing and rolling, wherein the surface bluing step is realized in a way of heating at intermediate frequency by using an electromagnetic induction coil, the bluing temperature is controlled at 360-370 DEG C, and the heat preservation time is controlled within 25-35s; and in the surface zinc coating step, the mass ratio of an original paint to water is 1:2.5, the coating temperature ranges from 40 DEG C to 45 DEG C, and the surface zinc coating speed is controlled at 14-16m / min.

Owner:WUXI FANGZHENG METAL LIGATURE

Welding flux used in filigree gold tire welding cloisonné products and method for making cloisonne products

ActiveCN103624863BFiligree positioning is preciseHigh hardnessDecorative surface effectsSpecial ornamental structuresPolishingBluing

The invention relates to a welding powder used in filigree gold tire fusion welding cloisonné products and a method for making the cloisonne products. The method includes the steps of tire making, filigreeing, threading, welding, pickling, bluing, bluing, bright white glaze, bluing again, polishing, gold plating, etc., wherein the welding powder composition is: 55‑60% Gold, 6‑8% silver, 27‑32% red copper, 4‑7% cadmium, plus 22‑26% of the above weight of arsenic trioxide; when pickling, pickle the welded gold body three times, each time 10‑ 12 minutes; the sintering temperature is 790-820°C after bluing. The flux used for welding in the present invention has good fluidity, firm welding, and is easy to weld. The obtained cloisonné filigree is precisely positioned, wear-resistant, high in hardness, and never fades; it adopts the bright white glaze process and twice-grinded blue to obtain The handicrafts are better in color, look new with time, never rust, have high collection value, and can satisfy people's high-level artistic enjoyment.

Owner:赵爱民

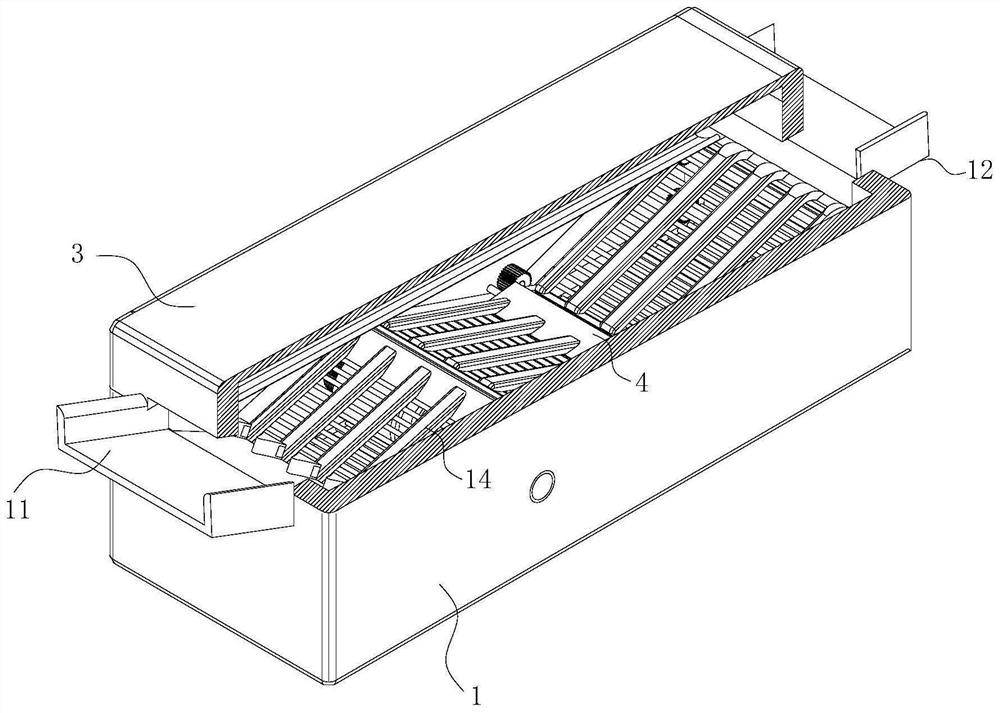

Anti-corrosion method of steel and anti-corrosion steel

InactiveCN111636059AHomogenize surface oxide filmUniform chemical compositionMetallic material coating processesStructural engineeringBluing

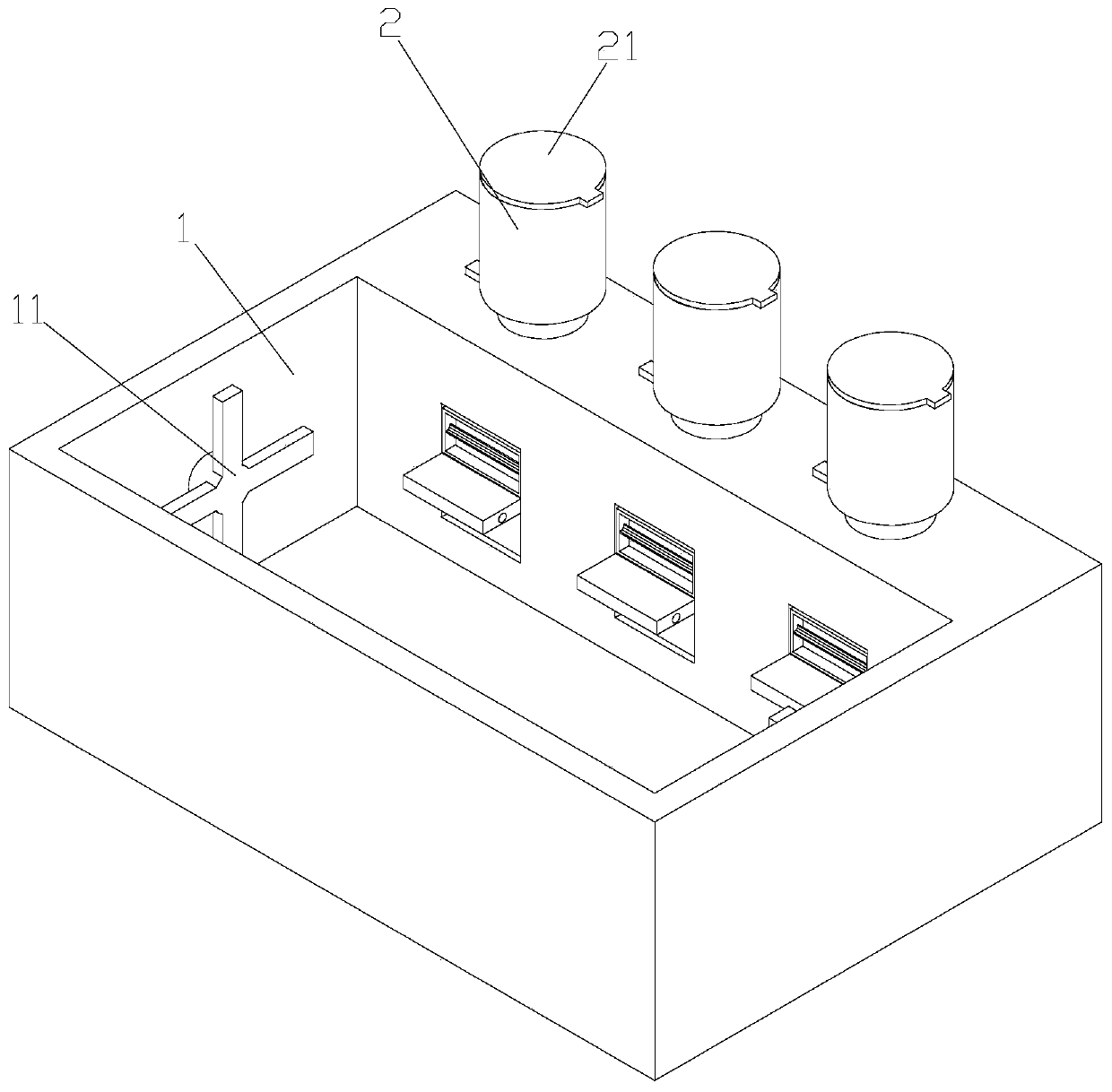

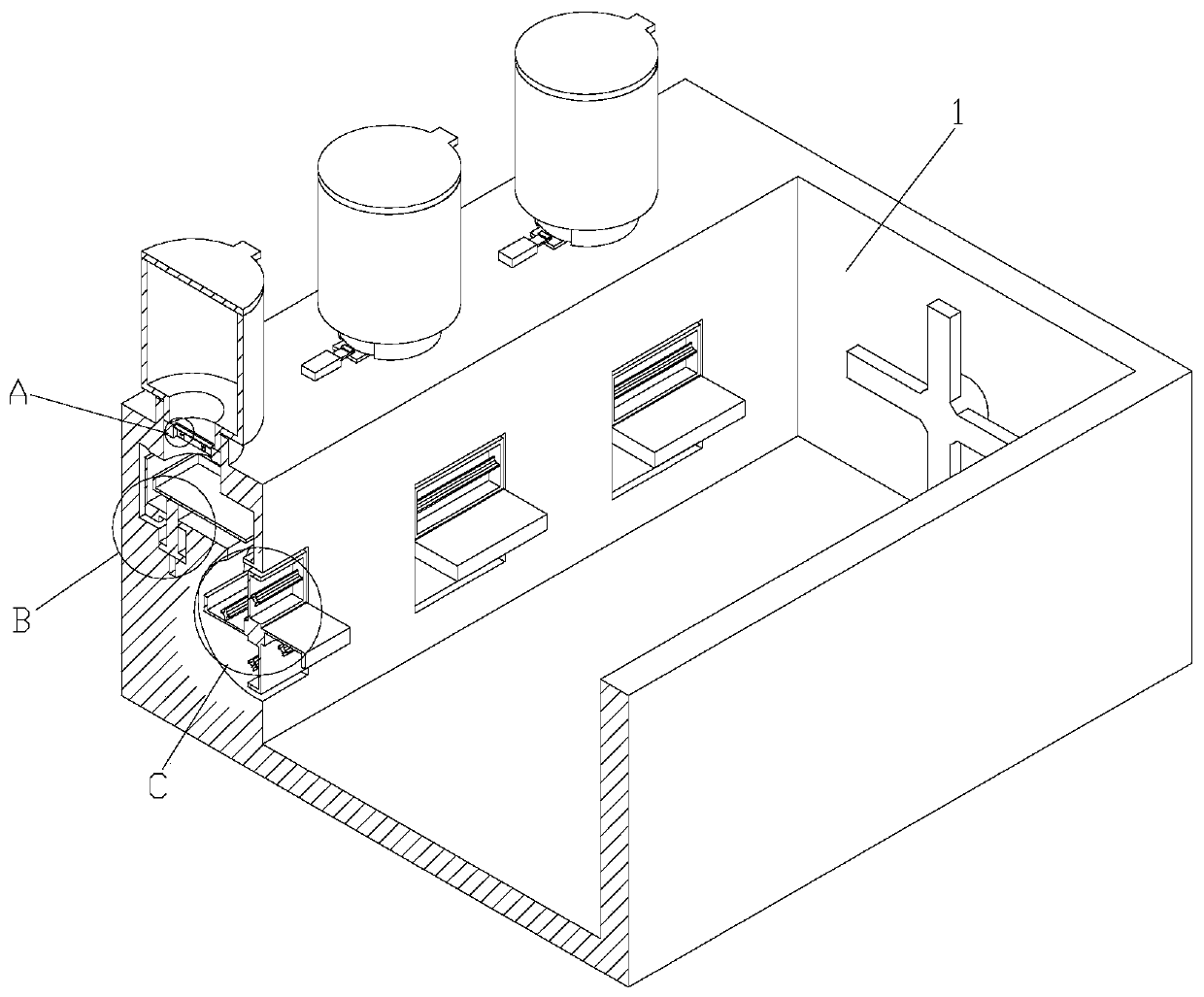

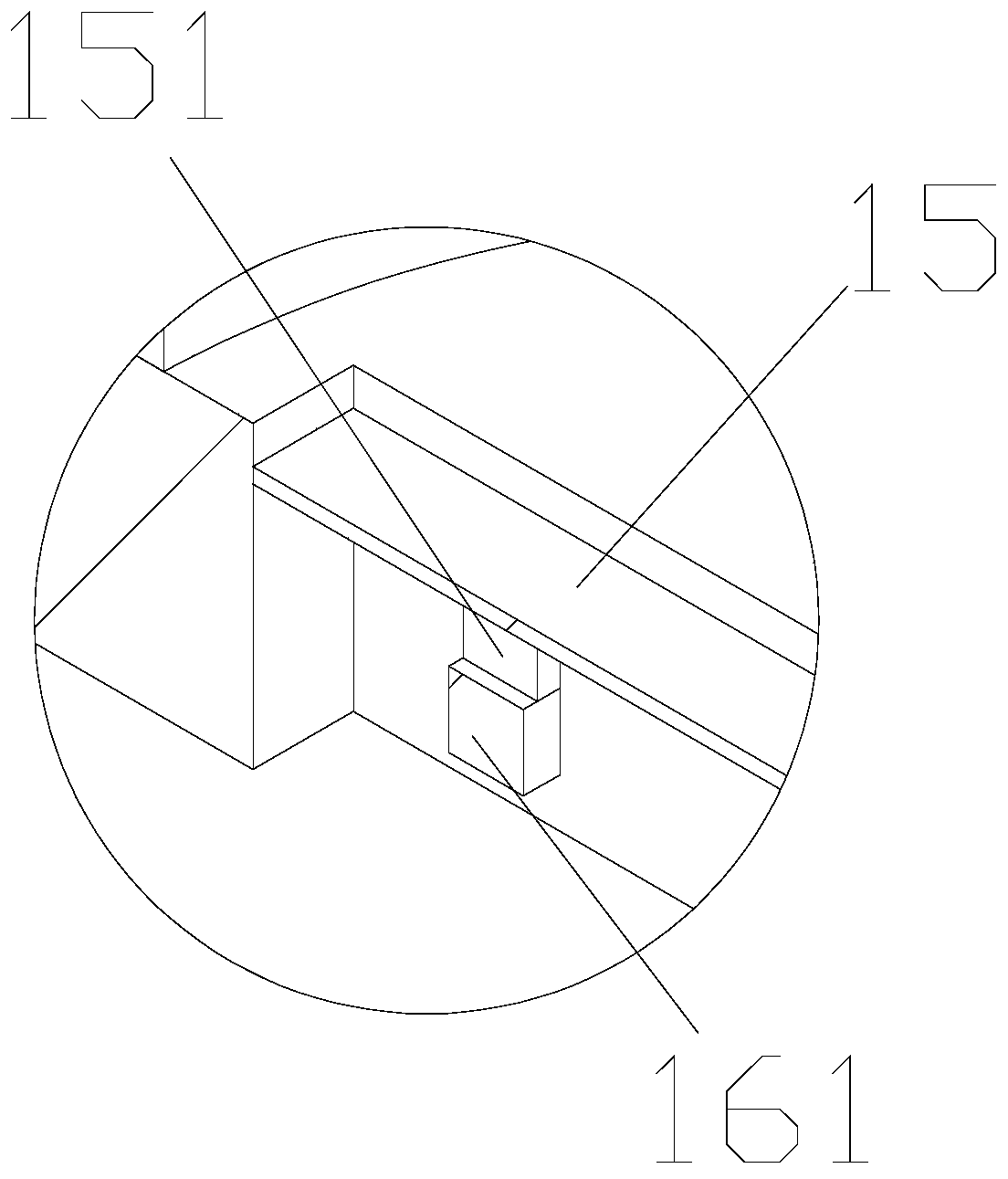

The invention belongs to the technical field of metal protective materials, and particularly relates to an anti-corrosion method of steel and the anti-corrosion steel. A bluing tank comprises a tank body, a conveyor belt, a sealing cover and an electromagnetic heating device; the tank body is of a cuboid structure with a cavity formed inside; the sealing cover is mounted at the opening in the upper end of the tank body; a feeding hole is formed in one side of the tank body, and a discharging hole is formed in the other side of the tank body; a feeding tank is fixedly connected to the position,outside the feeding hole, of the tack body, and a discharging tank is fixedly connected to the position, outside the discharging hole, of the tank body; the feeding tank and the discharging tank areboth obliquely formed; the electromagnetic heating device is connected to the bottom of the tank body in an embedded manner; guide rods which are uniformly distributed are rotationally connected intothe cavity of the tank body; each guide rod is sleeved with a rotating wheel; the conveying belt meshes with the rotating wheels; and according to the method and the steel, the conveying belt is usedfor driving a component to be subjected to bluing reaction in the slow moving process, the component is automatically turned over in the moving process, and then contact between the component and bluing liquid is uniform.

Owner:夏鹏宇

Alkaline surface bluing liquid and bluing treatment process thereof

InactiveCN106637178AImprove the problem of uneven film formationImprove protectionMetallic material coating processesPotassium nitrateChemical composition

The invention discloses an alkaline surface bluing liquid which comprises the following chemical components by weight percent: 8%-12% of sodium phosphate, 7%-9% of sodium nitrate, 16-18% of sodium hydroxide, 4%-8% of sodium nitrite, 3%-5% of triethanolamine, 6%-12% of potassium nitrate, 5%-6% of passivator, 3%-5% of phosphorization accelerant and the balance of water. According to the invention, low-cost sodium nitrate is adopted for replacing the high-cost sodium nitrite, so that the bluing cost can be lowered; the operation process is simple; the experiment condition is easily realized; the surface bluing treatment process provided by the invention is easy in operation, short in time consumption, simple in operation process, easy in meeting the experiment condition and capable of effectively solving the problem of uneven molded bluing film.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Cloisonne manufacturing process free of wire inlaying

InactiveCN112277519AEliminate the problem of low efficiency and slow speedExpressiveDecorative surface effectsOrnamental structuresBletilla striataPolishing

The invention discloses a cloisonne manufacturing process free of wire inlaying. The cloisonne manufacturing process comprises the following steps that (1) material selection is conducted, and a qualified copper sheet is blanked according to a drawing, cut and formed; (2) the drawing is made, a thin copper plate or a thin aluminum plate with the shape and the size being matched with those of the copper sheet is selected, and the required patterns are hollowed on the thin copper plate or the thin aluminum plate; (3) bonding is performed, one surface of the hollowed thin copper plate or thin aluminum plate is dipped with bletilla striata lint paste to be bonded onto the surface of the copper plate; (4) wire welding is carried out; (5) a blank is made, and the copper sheet dipped with the hollowed thin copper plate or thin aluminum plate is made into a copper blank; (6) bluing is performed; (7) enameling is conducted; and (8) polishing and gold plating are carried out. The cloisonne manufacturing process free of wire inlaying has the beneficial effects that the wire inlaying process steps are changed into the steps that the patterns are manufactured on the thin copper plate or the thin aluminum plate in advance, then the patterns are bonded onto the surface of the copper sheet, and afterwards, the copper sheet is manufactured into the blank, so that the problems of low efficiencyand low speed caused by wire inlaying on the surface of the copper blank are solved, and the patterns obtained through plane drawing are more attached to the surface of the copper blank and have stronger expressive force.

Owner:铜陵铜官府文化创意股份公司

A kind of production method of galvanized steel strip for packaging

ActiveCN101734422BSolve pollutionSolve the costPretreated surfacesFlexible elementsBluingDip-coating

The invention relates to a production method of a steel strip, in particular to a production method of a zinc-coated steel strip for packaging. The production method of the galvanized steel strip for packaging includes uncoiling, welding, strip slitting and stripping, deburring and leveling, surface bluing, cooling, cleaning, surface coating with zinc, coating drying, waxing, coiling and other steps, the zinc coating on the surface adopts the dip coating process, the mass ratio of the original paint and water is 1:2.8~1:3.2, the temperature range of the coating is 20~35°C, and the zinc coating speed on the surface is 20~35m / min. The production method of the galvanized steel strip for packaging proposed by the invention solves the problems of pollution in the current galvanizing process and high production cost of galvanizing.

Owner:上海宝钢新材料技术有限公司

High-strength spot welding strapping band and production method thereof

The invention discloses a high-strength spot welding strapping band which comprises the following components in percent by weight: 0.15-0.24 percent by weight of C, 0.7-1.30 percent by weight of Mn, less than 0.010 percent by weight of Si, less than or equal to 0.010 percent by weight of P, less than or equal to 0.010 percent by weight of S, 0.020-0.050 percent by weight of V and 0.030-0.070 percent by weight of Als. A production method comprises the steps: smelting and continuously casting to form a blank, and heating a casting blank; roughly rolling; finish-rolling; coiling; conventionally pickling; cold-rolling; and making the strapping band. The thickness of the high-strength spot welding strapping band is 0.70 mm, the tensile strength of the high-strength spot welding strapping band is not lower than 980 MPa, the percentage elongation is not lower than 10 percent, the number of alternating bending is not less than 10 times (R=5 mm), and no brittle failure and layering exist; an Fe3O4 bluing layer with a thickness of 0.3-0.5 mu m, and uniformity and densification and strong adhesive force is formed on the surface. No cracks exist on a weld line, and a welding point is stable in surface quality and better in welding property; no remarkable corrosion is caused in an indoor atmospheric environment for 30 days; no blockage, breakage and coil loosening are caused during packing.

Owner:武汉钢铁有限公司

A kind of high-strength spot welding strap and its production method

InactiveCN103805846BGood welding performanceHigh tensile strengthFlexible elementsBluingSpot welding

Owner:武汉钢铁有限公司

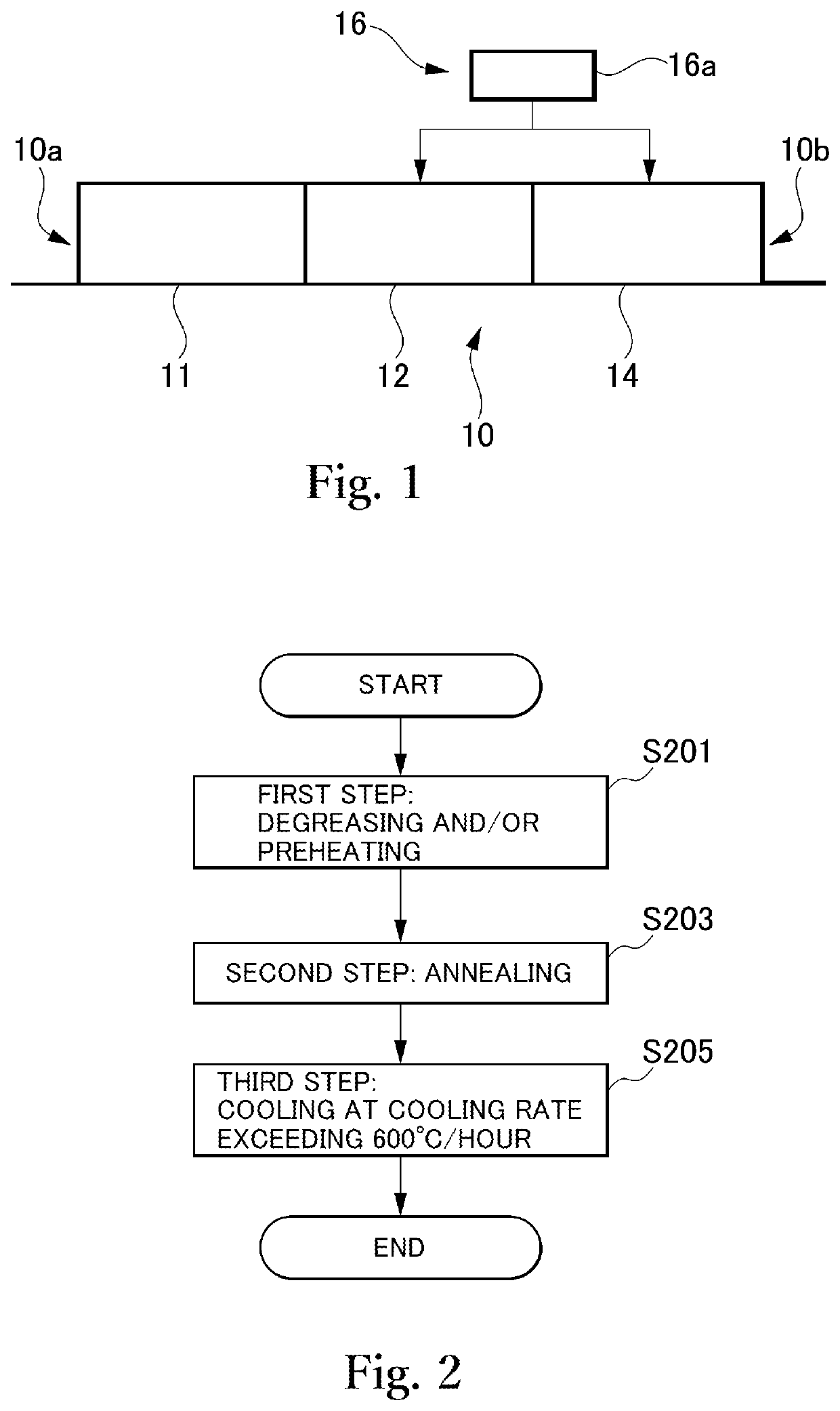

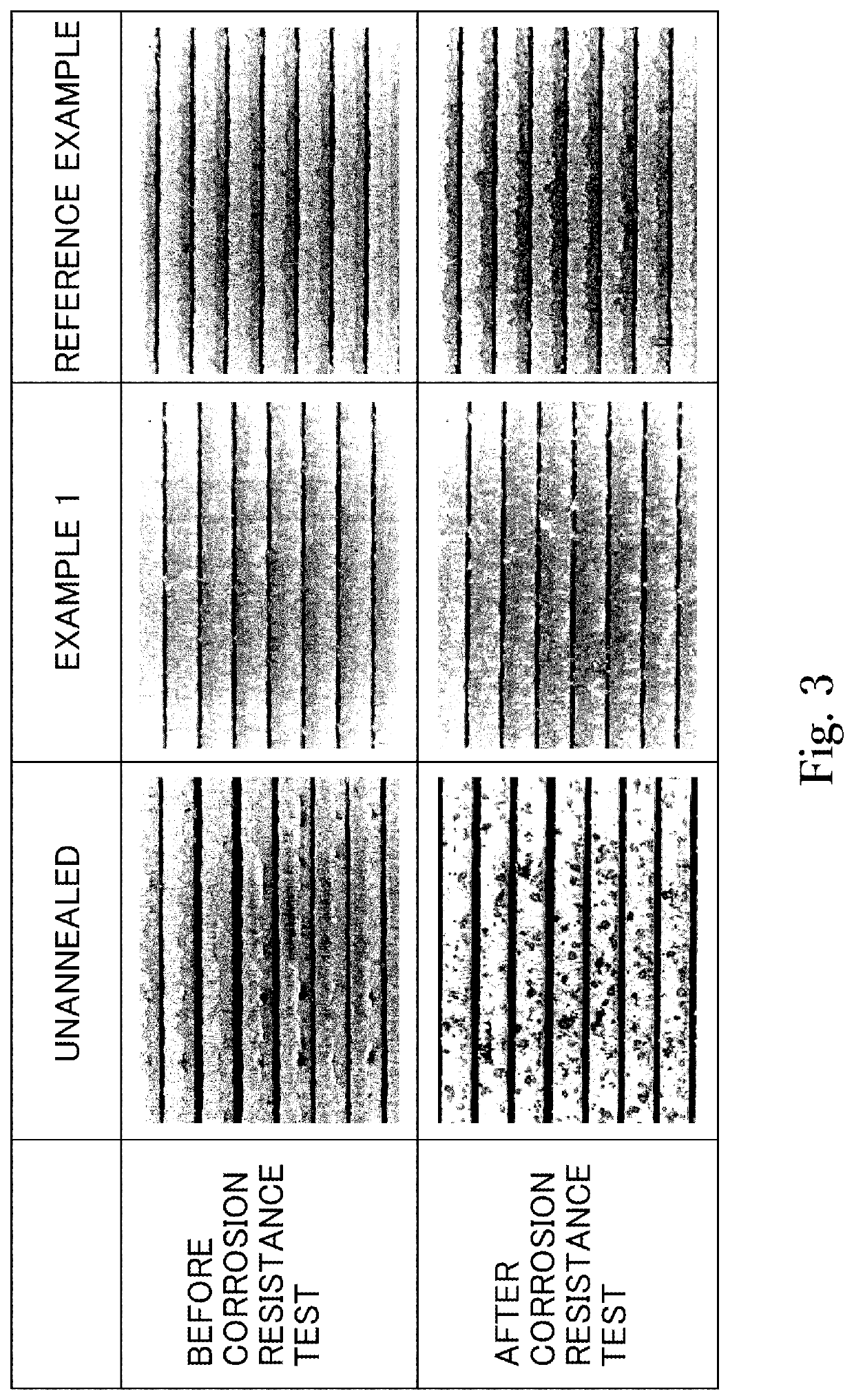

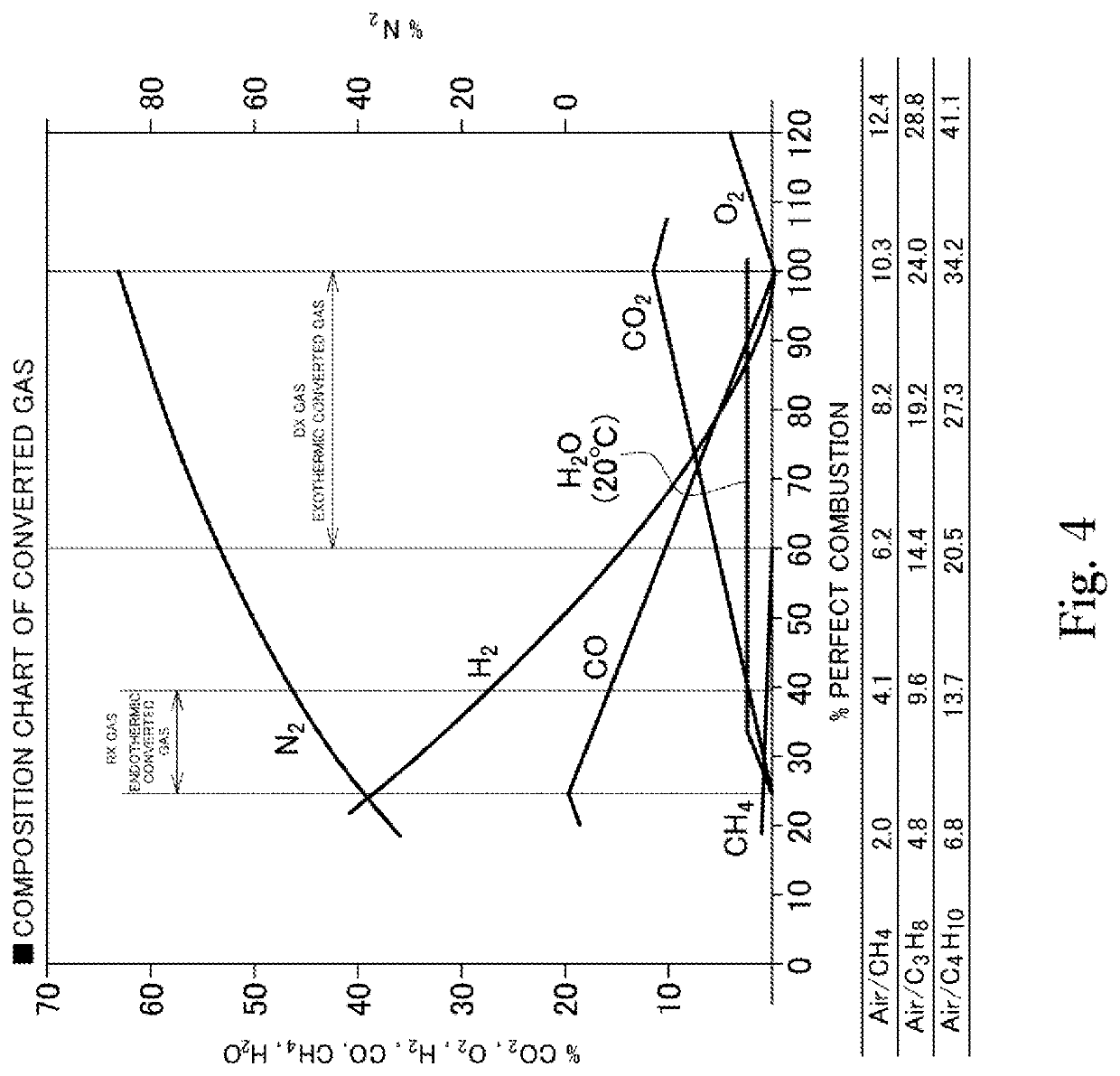

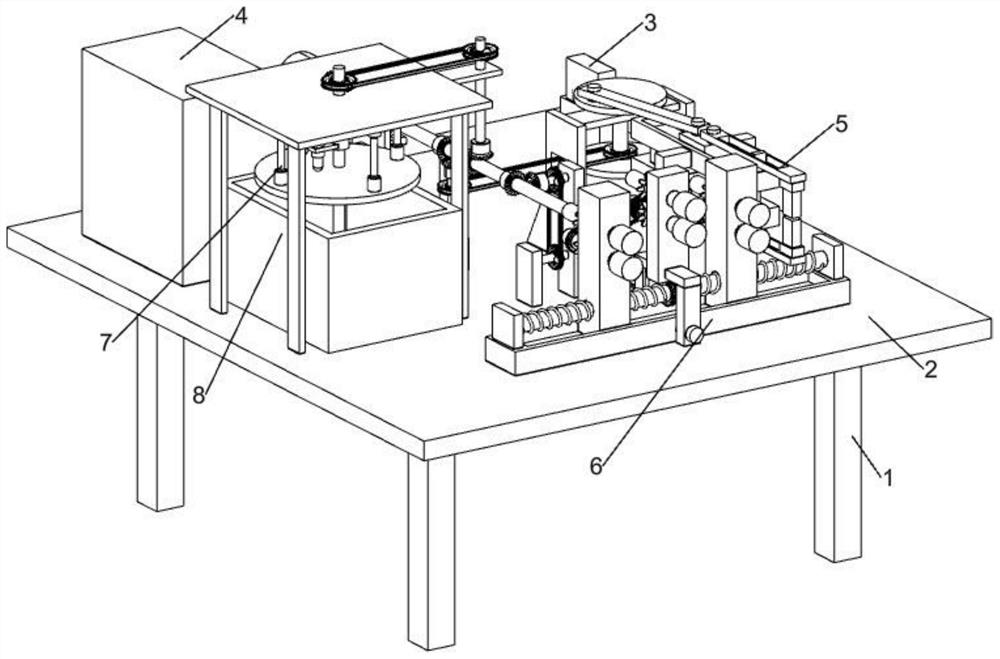

Heat treatment method and heat treatment furnace

The present disclosure relates to a heat treatment method and a heat treatment furnace that enable characteristics on an equal level to those when bluing processing is performed to be obtained without the bluing processing being performed in stress-relief annealing of a motor core. A heat treatment method according to one aspect is a heat treatment method in stress-relief annealing of a motor core. The heat treatment method includes an annealing step of annealing the motor core by using an exothermic converted gas as a furnace atmospheric gas, and a cooling step of cooling the motor core obtained in the annealing step, by using an exothermic converted gas as a furnace atmospheric gas, in a temperature range from a temperature in the annealing step to 500° C. at a cooling rate exceeding 600° C. per hour.

Owner:TOYOTA BOSHOKU KK +1

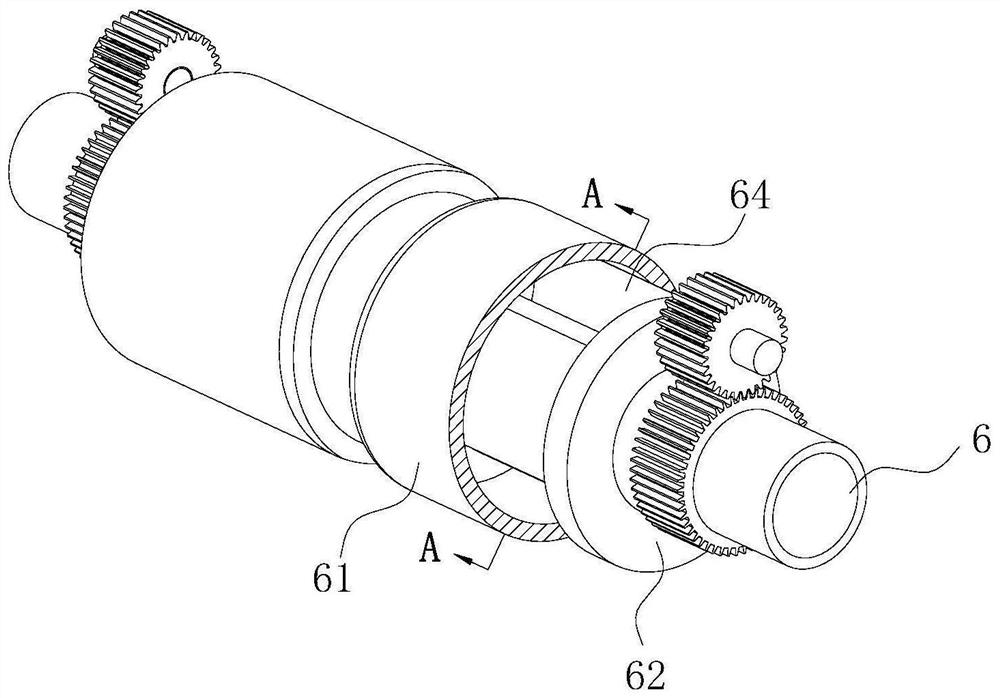

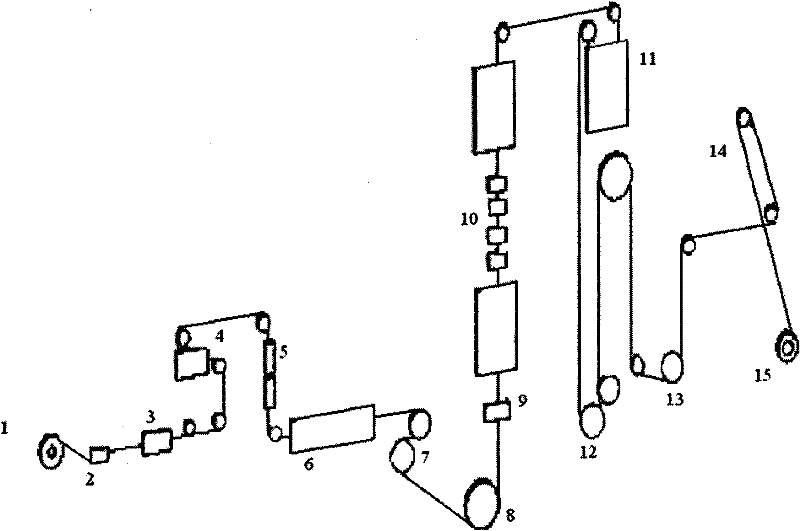

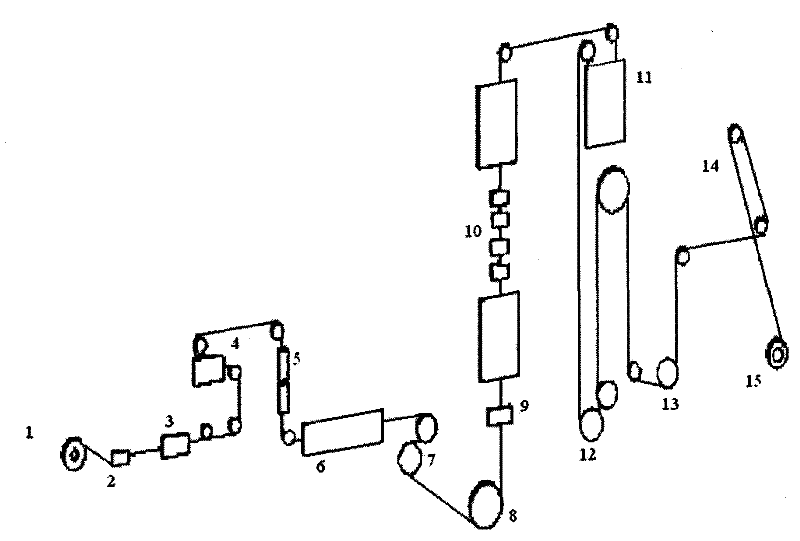

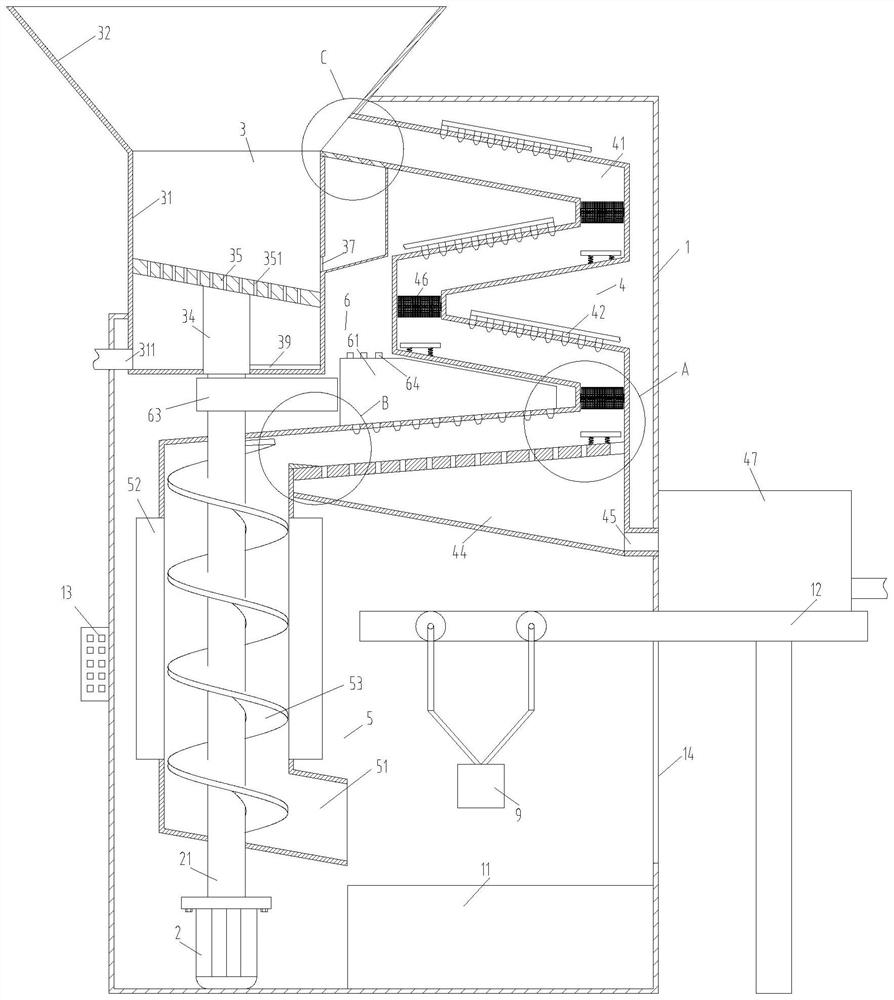

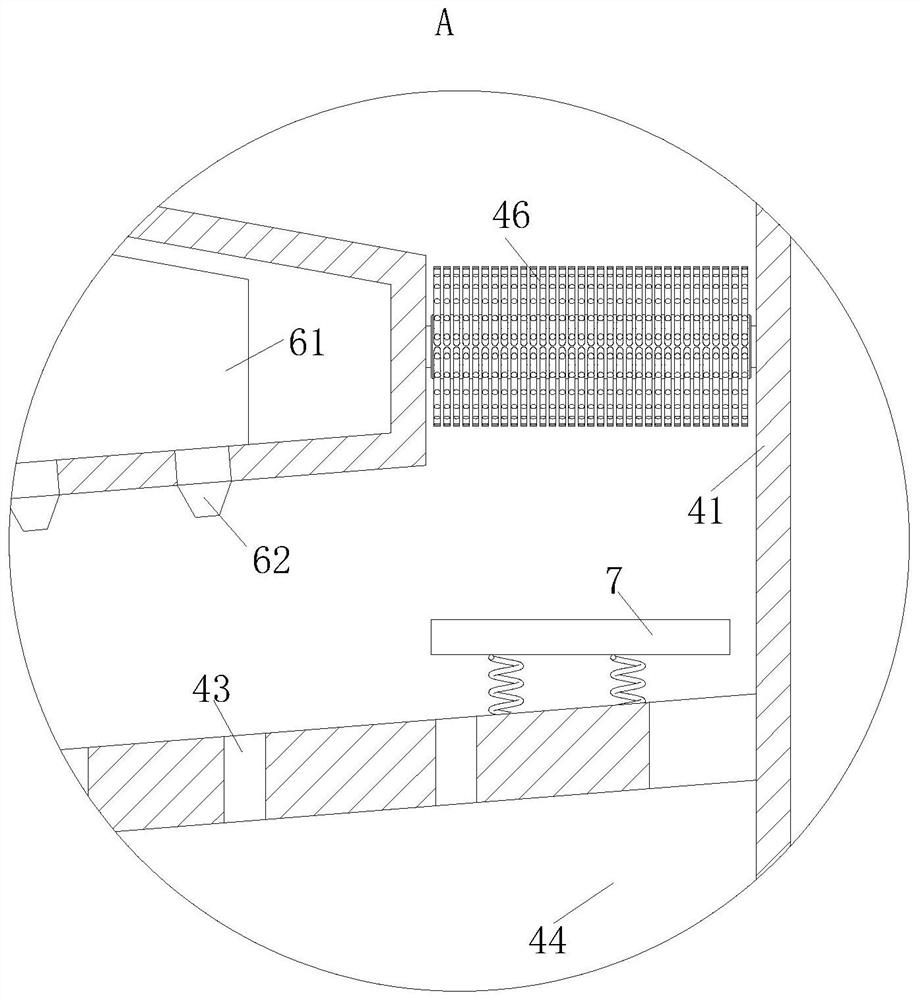

Chemical bluing pretreatment device

InactiveCN111872822ARealize the effect of oxidation blueGuaranteed bending elastic stateGrinding drivesMetallic material coating processesEngineeringBluing

The invention relates to the field of chemical engineering, in particular to a chemical bluing pretreatment device. The technical problem to be solved by the invention is to provide the chemical bluing pretreatment device. According to the technical scheme, the chemical bluing pretreatment device comprises a lathe bed plate, a work control screen, a tool storage box, a mechanical cleaning mechanism and the like; and the middle left portion of the top end of the lathe bed plate is connected with a workpiece fixing bluing auxiliary mechanism, and the middle portion of the right end of the workpiece fixing bluing auxiliary mechanism is connected with a limiting pulling mechanism. According to the chemical bluing pretreatment device, dust on the surface of a spring steel sheet is removed whilethe bending state of the spring steel sheet is maintained; and under the condition that the original curly shape and elasticity of the spring steel sheet which is bent into a coil are not changed, the inner surface and the outer surface of the spring steel sheet are subjected to continuous synchronous rust removal treatment, and the spring steel sheet is subjected to oxidation bluing under the condition of high-frequency vibration after rust removal is completed.

Owner:李月珍

A kind of forging method of high-purity niobium rod

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

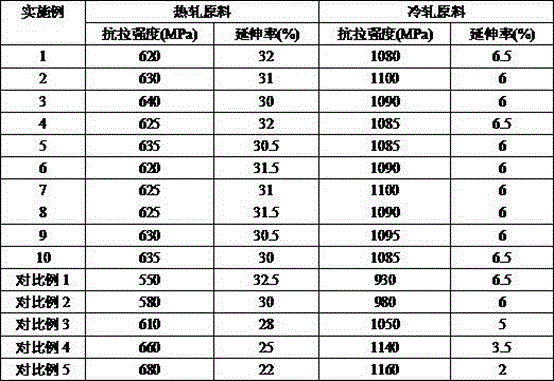

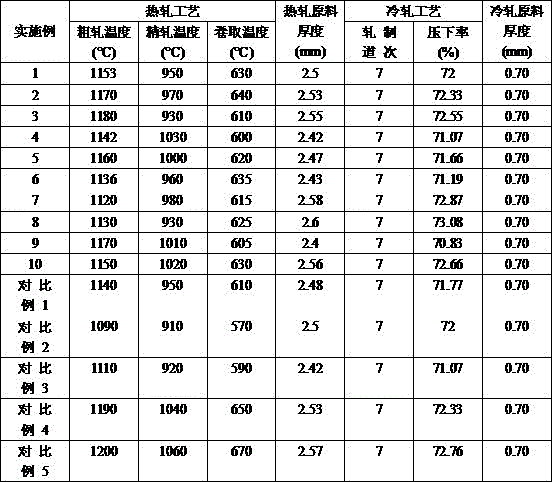

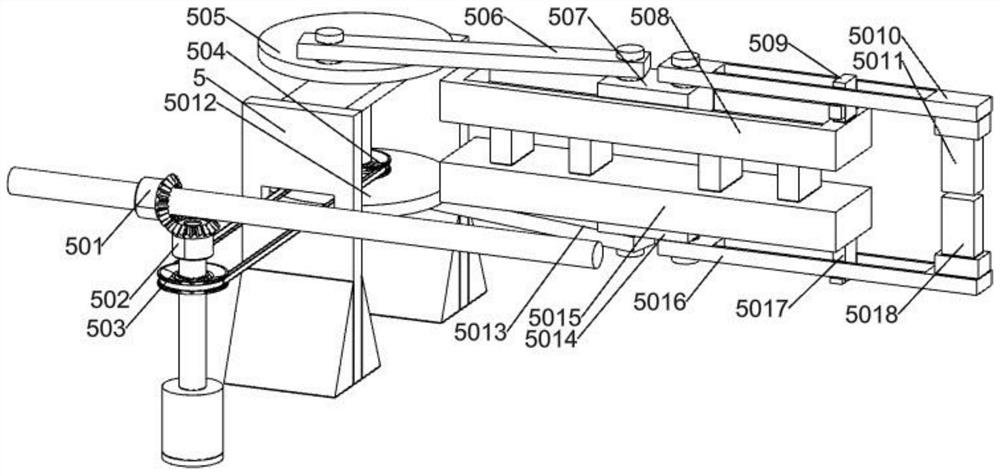

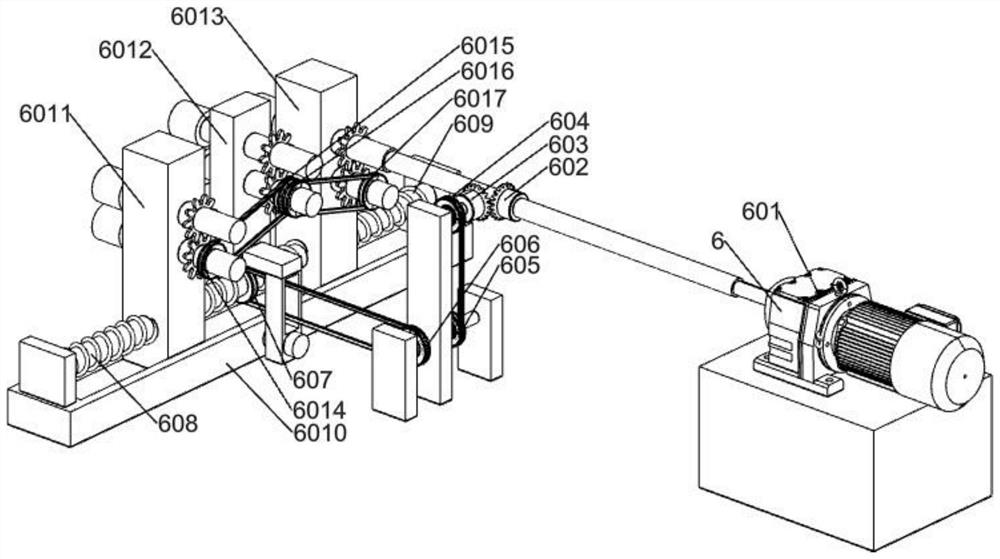

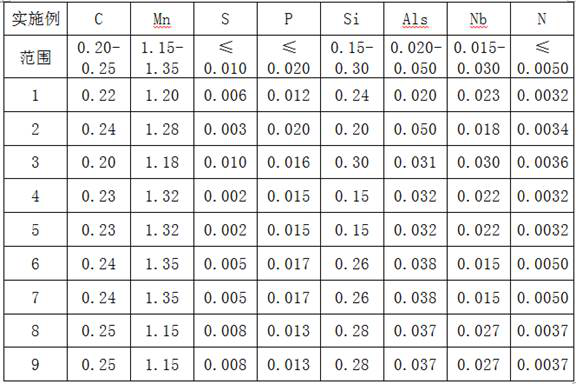

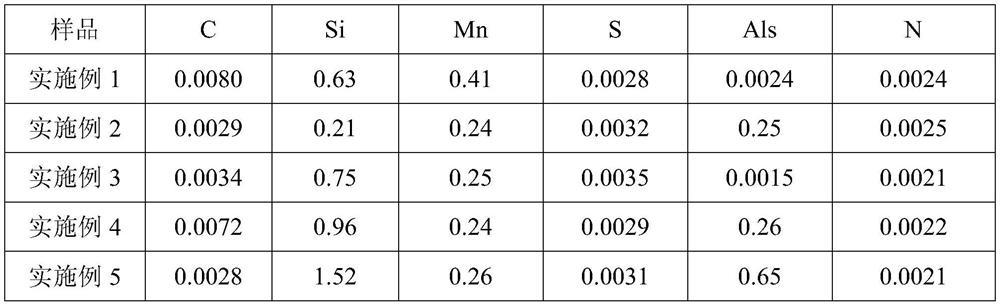

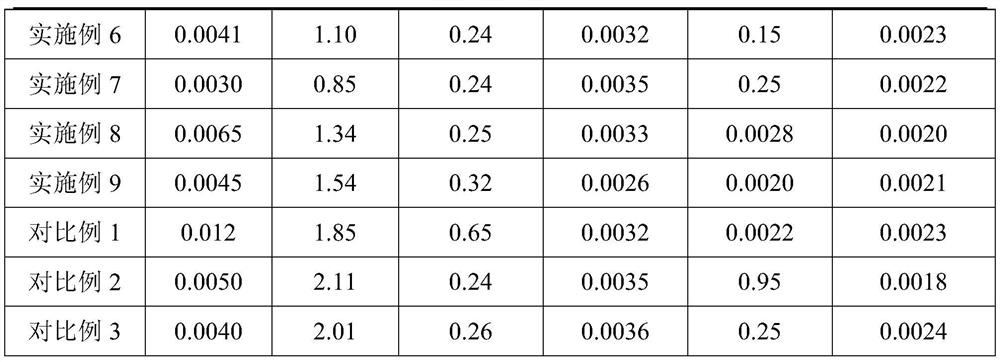

A kind of 1100mpa grade high-strength strapping steel and its production method

The invention discloses a 1100MPa high-strength strap steel and a production method thereof. The chemical composition and mass percentage of the strap steel are: C: 0.20-0.25%, Si: 0.15-0.30%, Mn: 1.15- 1.35%, P≤0.020%, S≤0.010%, Als: 0.020~0.050%, Nb: 0.015~0.030%, N≤0.0050%, the balance is Fe and unavoidable impurities; the production method includes steelmaking, Continuous casting, hot rolling, cold rolling, blueing process. The composition design of the present invention adopts medium and low C, conventional Mn content, adds a small amount of Si and Nb elements, and under the condition of reasonable control of C, Mn, Si content and alloy cost, through hot rolling controlled rolling and controlled cooling, large reduction cold rolling, Low temperature bluing and other process control to obtain high-strength strapping steel with tensile strength ≥ 1100MPa and elongation A30 ≥ 8%.

Owner:唐山钢铁集团高强汽车板有限公司 +2

Process for bluing surface of heating tube by adding color

PendingCN114752929ANot easy to rustExtended service lifeSolid state diffusion coatingProcess engineeringEnvironmental engineering

The invention discloses a heating tube surface adding color bluing process, which comprises a transmission unit and an adding unit, the transmission unit is provided with a conveyor belt, an oven and a water tank, the conveyor belt is provided with the oven, the oven is provided with a spray gun and a mixing chamber, the conveyor belt passes through the lower end of the oven, and the spray gun is arranged in the water tank. The water tank is arranged at one end of the conveying belt, cooling water is arranged in the water tank, the adding unit is provided with a liquid ammonia tank, a decomposer and a carbon dioxide tank, the liquid ammonia tank is connected with the decomposer through a pipeline, the liquid ammonia tank is decomposed into hydrogen after passing through the decomposer, and the carbon dioxide tank is connected with the liquid ammonia tank through a pipeline. The hydrogen and the carbon dioxide are connected with an oven through a pipeline, and the hydrogen and the carbon dioxide are mixed in the mixing chamber of the oven.

Owner:白道华 +1

Corrosion-resistant and rust-proof equipment for metal parts

PendingCN114310617AImprove the effect of anti-corrosion and anti-rust treatmentImprove grinding efficiencyEdge grinding machinesPolishing machinesTreatment pondElectric machinery

The invention belongs to the technical field of metal surface treatment, and particularly relates to corrosion-resistant and rust-proof equipment for metal parts. Comprising a shell, a bluing treatment pond, a controller, a motor and a rotating shaft, the rust removal device further comprises a rust removal assembly fixedly connected with the shell, and the rust removal assembly is used for rust removal treatment of the spherical metal part. The washing assembly is arranged in the shell, and the washing assembly is used for carrying out washing treatment on the spherical metal part subjected to rust removal; the drying assembly is arranged below the rust removal assembly, and the drying assembly is used for drying the washed spherical metal part; the spherical metal part is poured into the rust removal barrel, the grinding gravels in the rust removal barrel conduct rust removal and grinding on the spherical metal part under the rotary stirring action of the top plate, rust on the surface of the spherical metal part is ground and removed, and the smoothness of the surface of the spherical metal part is improved; further, the subsequent corrosion-resistant and rust-proof treatment effect of the spherical metal part is improved; and the grinding efficiency of the spherical metal piece is further improved.

Owner:龚晓林

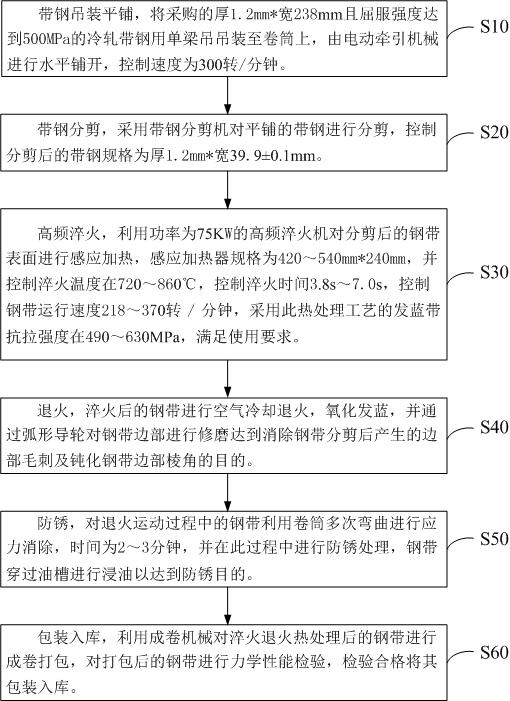

Production method of bluing tape for round steel packaging

InactiveCN111761314AGuaranteed tensile strengthSatisfy the bending operationFurnace typesHeat treatment furnacesStrip steelBluing

The invention discloses a production method of a bluing tape for round steel packaging. The tensile strength of the bluing tape is 530-580 MPa, and the size of the bluing tape is 1.2 mm thick *400 mmwide. The production method of the bluing tape comprises the steps of hoisting and spreading of strip steel, shearing of the strip steel, high-frequency quenching, annealing, rust prevention, and packaging warehousing. According to the technical scheme of the production method provided by the invention, the bluing tape is obtained through shearing quenching and secondary production and can be suitable for bundling and packaging of various sizes of round steel. The bluing tape is neither too hard nor too soft, ensures the tensile strength, meets the requirement of operators for bending the bluing tape during manual bundling, reduces the labor intensity, prevents the bluing tape from fracturing in the hoisting process, shortens the bundling and packaging time of the round steel, improves thebundling and packaging efficiency, avoids personal or equipment safety hazards caused by fracturing of the bluing tape and guarantees the transport safety of the round steel.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

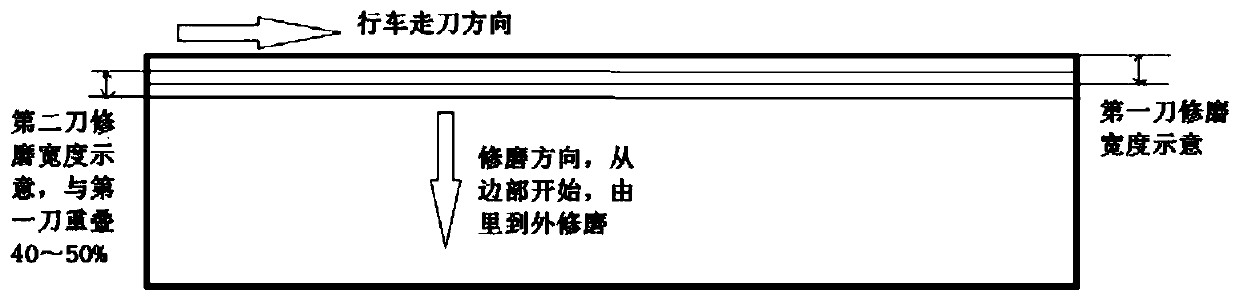

Rolled square billet peeling method

PendingCN111136555AGuaranteed surface qualityGuaranteed surfaceEdge grinding machinesGrinding feed controlEngineeringBluing

The invention relates to the field of steel, in particular to a rolled square billet peeling method. The method comprises the following steps that the peeling depth of the plane part is 0.30-0.95 mm,the peeling depth of the corner angle part is less than 1.05 mm, in a peeling process, and the ratio K of the rotating speed of a grinding wheel to the speed of a trolley is 70 to 125. The surface ofthe peeled billet obtained through the peeling method of the rolled square billet is free of peeling defects such as grinding residues, residual black rust, flashes and burrs, corner transition is smooth, surface defects of a decarburized layer and cogging rolling are completely removed, the surface is free of bluing, the ratio K of the rotating speed VZ of the grinding wheel to the longitudinal travelling speed VL of the trolley ranges from 70 to 125, peeling can be carried out accurately, the ratio K of the rotating speed VZ of the grinding wheel to the travelling speed VL of the trolley iscontrolled to range from 70 to 125, the peeling efficiency can be improved, the risk of billet surface burn can be well reduced, and peeled billet surface quality is improved.

Owner:SGIS SONGSHAN CO LTD

Manufacturing process of loudspeaker iron core

InactiveCN113949953AStrong damage resistanceExtended service lifeTransducer casings/cabinets/supportsManufacturing technologyManufactured material

The invention discloses a manufacturing process of a loudspeaker iron core. The manufacturing process comprises the following steps of 1, manufacturing an iron core raw material, 2, obtaining a solid iron core raw material, 3, conducting heat treatment, 4, carrying out bluing treatment, 5, obtaining a semi-finished product of the loudspeaker iron core, 6, coating insulating paint on the body surface of the semi-finished product of the loudspeaker iron core, and 7, performing finish machining to obtain a finished product of the loudspeaker iron core. The manufacturing process has the beneficial effects that the anti-damage capability is high, rusting can be effectively prevented, and the service life of the loudspeaker iron core is greatly prolonged; the rejection rate is low, and resource waste is effectively reduced; the manufacturing cost of the technology is low, the production cost of the loudspeaker iron core is effectively reduced, and wide popularization of the loudspeaker iron core is facilitated.

Owner:佛山市南海雅心五金有限公司

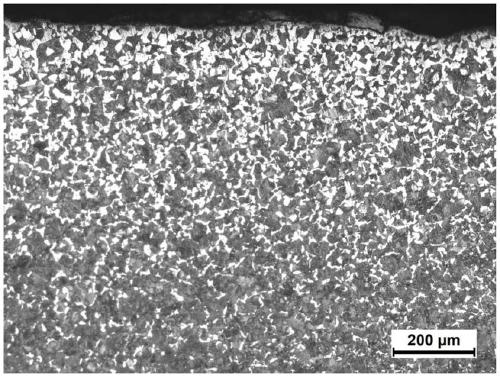

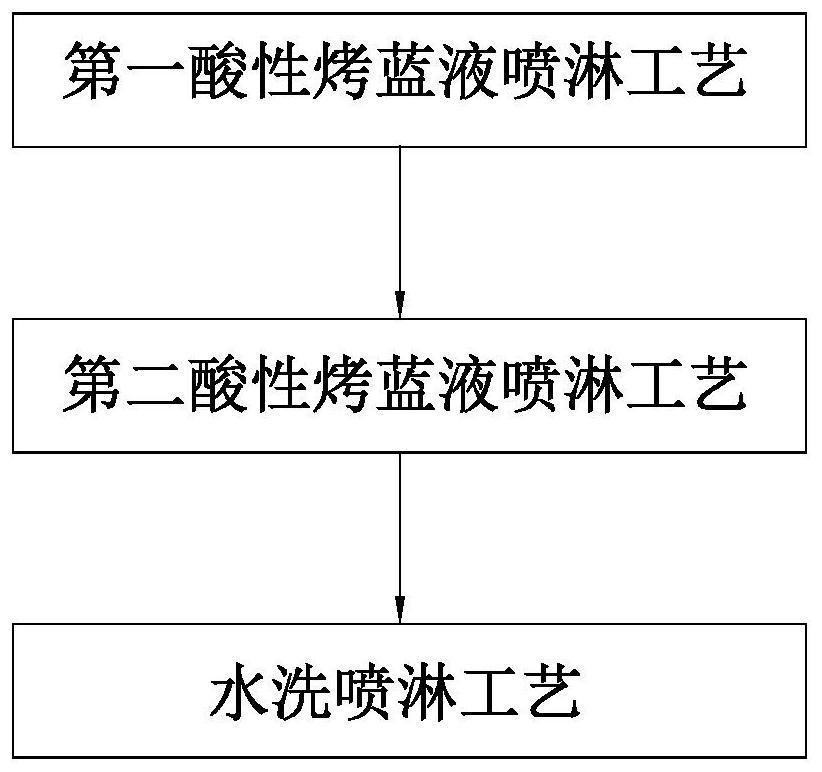

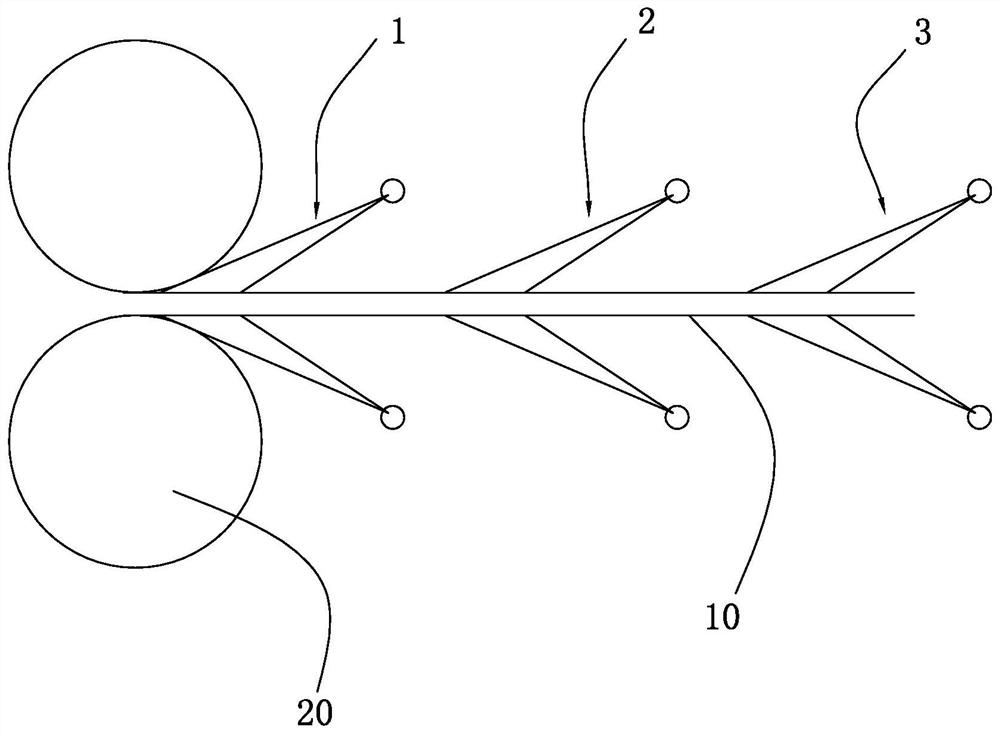

On-line acid blueing method for hot-rolled steel bars

ActiveCN110306179BAvoid corrosionImprove anti-corrosion and anti-rust performanceMetallic material coating processesBluingRebar

The invention provides an online acid bluing method for hot-rolled steel bars. The hot-rolled steel bar online acid bluing method, the invention point is: after the hot-rolled steel bar is output by the hot rolling mill, the acid bluing liquid spraying process and the water washing spraying process are carried out in sequence, and a dense layer is quickly formed on the surface of the hot-rolled steel bar. Fe 3 o 4 The protective layer. The hot-rolled steel bar online acid bluing method provided by the invention can quickly generate a layer of dense Fe on the surface of the hot-rolled steel bar. 3 o 4 The protective layer has the effect of preventing corrosion of steel bars, and has the advantages of low cost and simple process.

Owner:HUNAN 3T NEW MATERIAL

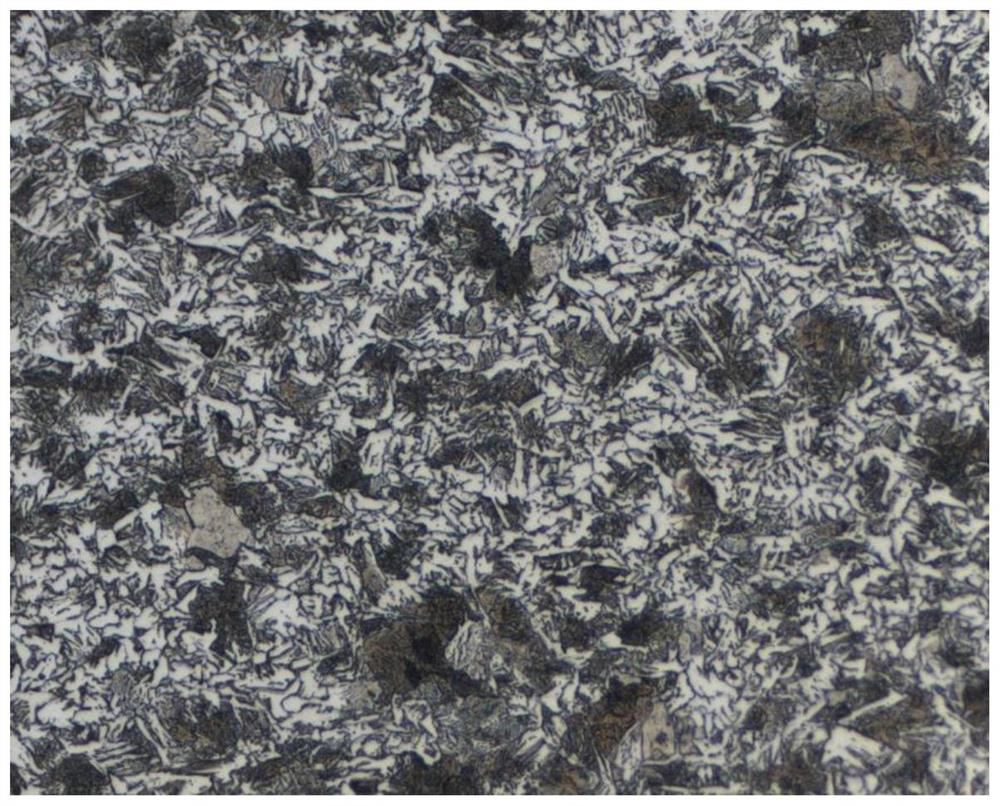

Non-quenched and tempered 950MPa-grade high-strength strapping steel and production method thereof

PendingCN114645187AConvenience guaranteedQuality assuranceTemperature control deviceSolid state diffusion coatingStrappingBluing

The invention discloses non-quenched and tempered 950 MPa-grade high-strength strapping steel and a production method thereof.The non-quenched and tempered 950 MPa-grade high-strength strapping steel is prepared from, by mass, 0.18%-0.25% of C, 0.15%-0.25% of Si, 0.65%-0.85% of Mn, smaller than or equal to 0.035% of P, smaller than or equal to 0.025% of S, 0.005%-0.035% of Al and the balance iron and inevitable impurities, the non-quenched and tempered 950 MPa-grade high-strength strapping steel is suitable for production of the strapping steel, C and Mn serve as strengthening elements, a proper amount of Al is added to refine grains, and therefore the strength of the strapping steel is improved; and meanwhile, granular bainite is obtained by adopting ultralow-temperature coiling and laminar flow front-section concentrated cooling in hot rolling, and a proper bluing process with a large compression ratio is adopted in cold rolling, so that the excellent performance and the surface quality of a final product are ensured.

Owner:ANYANG IRON & STEEL +1

Temporary protection ink for optical glass and preparation method thereof

The invention relates to temporary protection ink (IPC classification number: C09D11 / 107), in particular to temporary protection ink for optical glass and a preparation method of the temporary protection ink. The coating at least comprises the following raw materials in parts by weight: 40-50 parts of an alcohol-soluble resin binder, 10-20 parts of a micron-sized filler, 10-20 parts of a solvent containing ether bonds and hydroxyl groups, 2-4 parts of fumed silica, 1-2 parts of a dimethylsilane modified defoaming agent, 1-2 parts of an acrylate aid and 1-2 parts of a silane coupling agent. According to the temporary protection ink for the optical glass, the neutral environment-friendly solvent propylene glycol methyl ether acetate (PMA) or alcohol can be used for deinking, the deinking time is within 30 seconds, the fogging and bluing phenomena of alkali liquor deinking are avoided, and the cleaning process is convenient and safe. Meanwhile, the prepared temporary protection ink is good in film-forming property, not prone to cracking and good in adhesive force and flexibility.

Owner:惠州市百时达化工有限公司

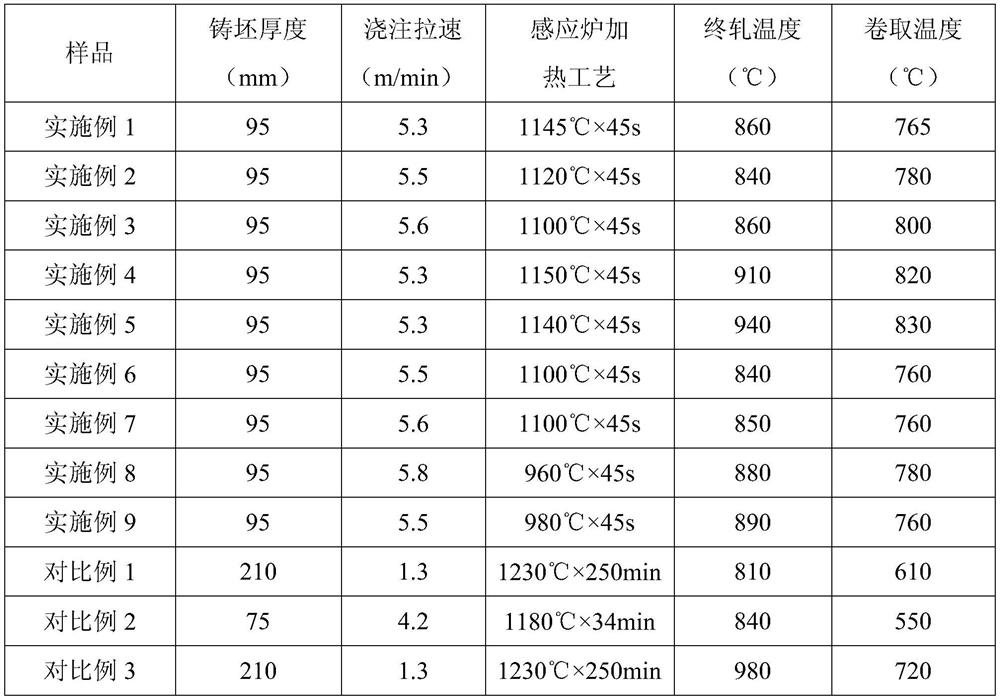

A method for producing semi-process non-oriented electrical steel by endless rolling

The invention relates to a method for producing semi-process non-oriented electrical steel by endless rolling. The production step is a smelting process; continuous casting-hot rolling process: wherein the pouring speed is 4.0-7.0 m / min, and the thickness of the slab is 91-91. 110mm, the induction heating temperature is 950-1150°C, the holding time is 30-60s, the final rolling temperature is 850-950°C, and the coiling temperature is ≥750°C; (3) pickling and critical pressure; (4) decarburization Stress annealed and blued. In the endless rolling process of the present invention, the billet is directly rolled into a thin plate without heating in a soaking furnace at a high drawing speed, coiled at high temperature, critical reduction, stress relief and blueing annealing, eliminating the need for one cold rolling and intermediate annealing, No coating, no environmental pollution; it has the advantages of short process, green and low carbon, and high efficiency.

Owner:RIZHAO STEEL HLDG GROUP

Medium-strength packaging steel strip and production method thereof

ActiveCN101886217BReduce manufacturing costImprove high temperature resistanceLiquid surface applicatorsSolid state diffusion coatingBluingUltimate tensile strength

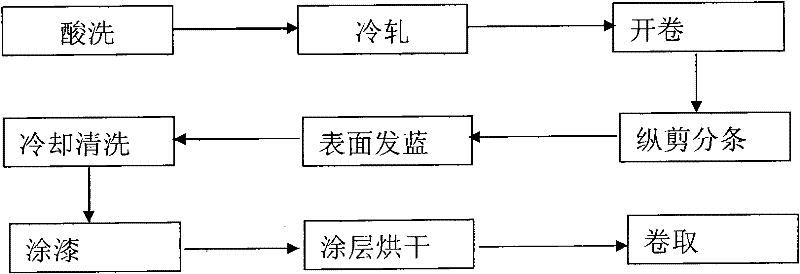

The invention relates to a steel strip, in particular to a medium-strength packaging steel strip and a production method thereof. The medium-strength packaging steel strip comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, 0.10 to 0.15 percent of Si, 1.00 to 1.55 percent of Mn, less than or equal to 0.05 percent of P, less than or equal to 0.050 percent of S and the balance of Fe. The production method of the medium-strength packaging steel strip comprises the following steps: a) cold-rolled roll unrolling; b) steel strip longitudinal cutting and stripping;c) surface blueing; d) cooling and washing; e) painting; f), drying coatings; and g) rolling. The medium-strength packaging steel strip solves the technical problem that the packaging steel strip produced by using a cold-rolled roll with a carbon content of less than 0.10 percent has a tensile strength which cannot be kept over 800MPa stably and a breakage elongation of more than 6 percent.

Owner:上海宝钢新材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com