Patents

Literature

2145results about How to "Improve magnetic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin film write head with improved laminated flux carrying structure and method of fabrication

InactiveUS6233116B1High resistivityExcellent soft magnetic propertiesConstruction of head windingsHeads using thin filmsLower poleHigh resistivity

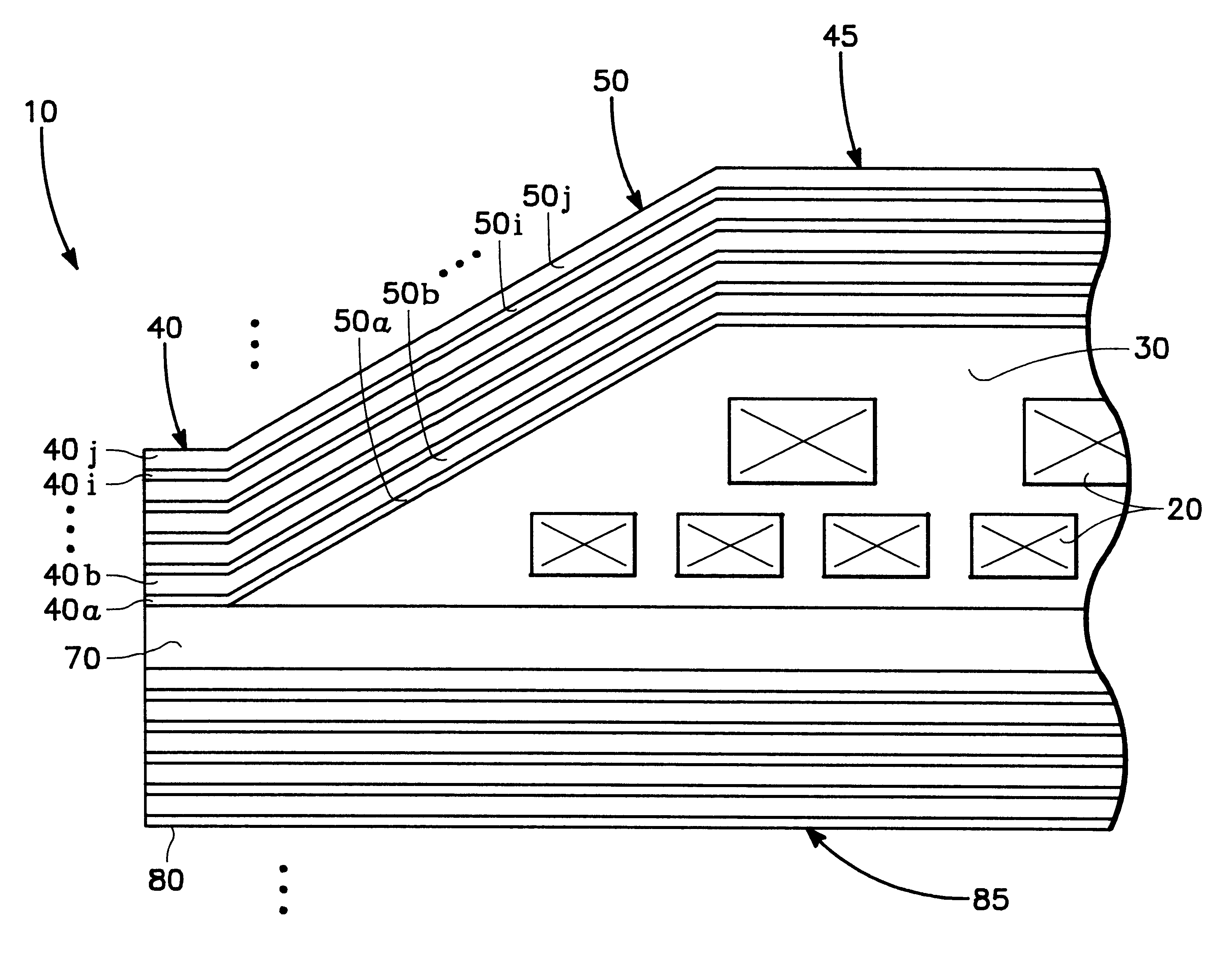

The present invention provides a thin film write head having an improved laminated flux carrying structure and method of fabrication. The preferred embodiment provides laminated layers of: high moment magnetic material, and easily aligned high resistivity magnetic material. In the preferred embodiment, the easily aligned laminating layer induces uniaxial anisotropy, by exchange coupling, to improve uniaxial anisotropy in the high moment material. This allows deposition induced uniaxial anisotropy by DC magnetron sputtering and also provides improved post deposition annealing, if desired. It is preferred to laminate FeXN, such as FeRhN, or other crystalline structure material, with an amorphous alloy material, preferably Co based, such as CoZrCr. In the preferred embodiment, upper and lower pole structures may both be laminated as discussed above. Such laminated structures have higher Bs than structures with insulative laminates, and yokes and pole tips and may be integrally formed, if desired, because flux may travel along or across the laminating layers. The preferred embodiment of the present invention improves soft magnetic properties, reduces eddy currents, improves hard axis alignment while not deleteriously affecting the coercivity, permeability, and magnetostriction of the structure, thus allowing for improved high frequency operation.

Owner:WESTERN DIGITAL TECH INC +1

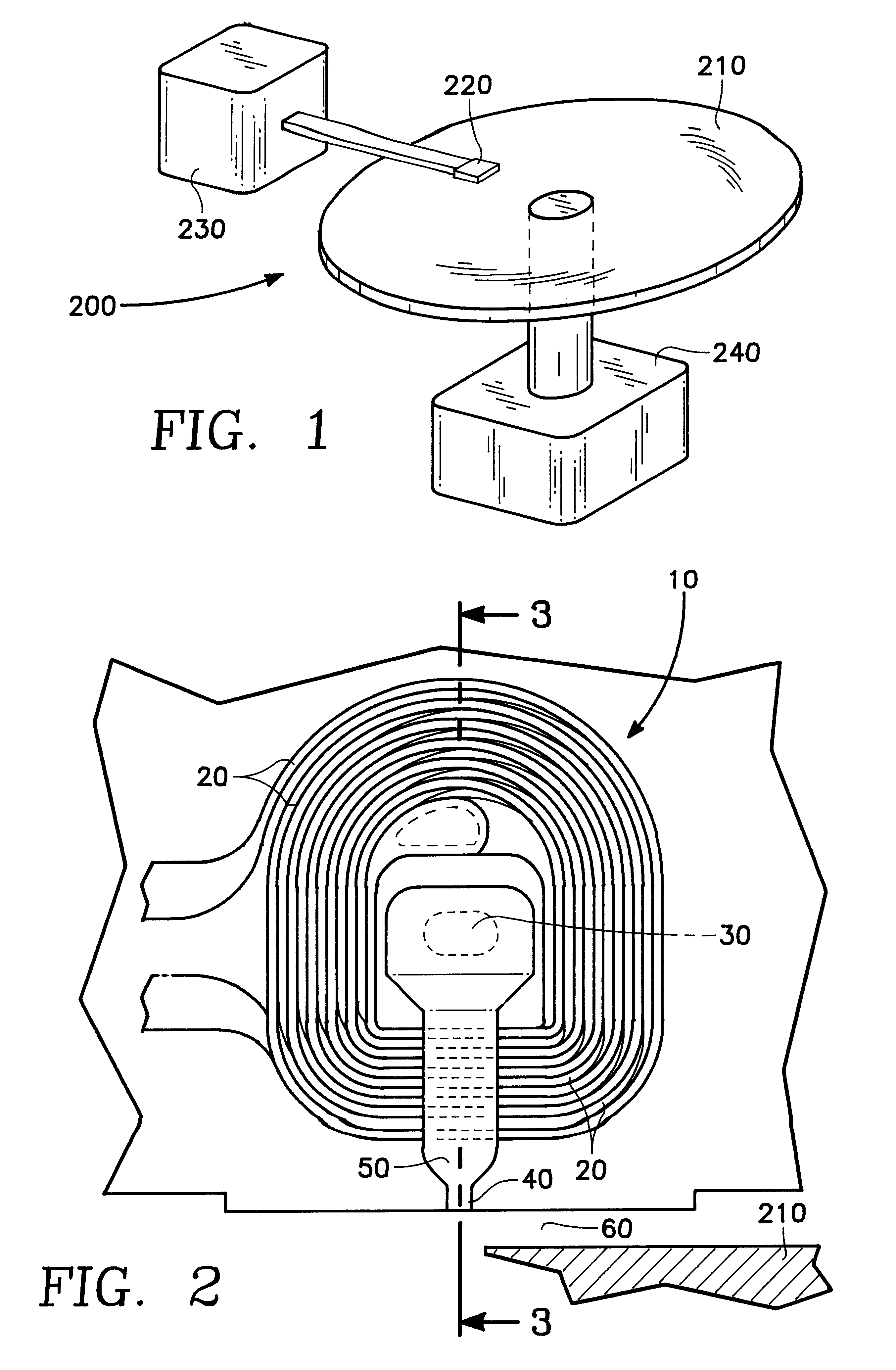

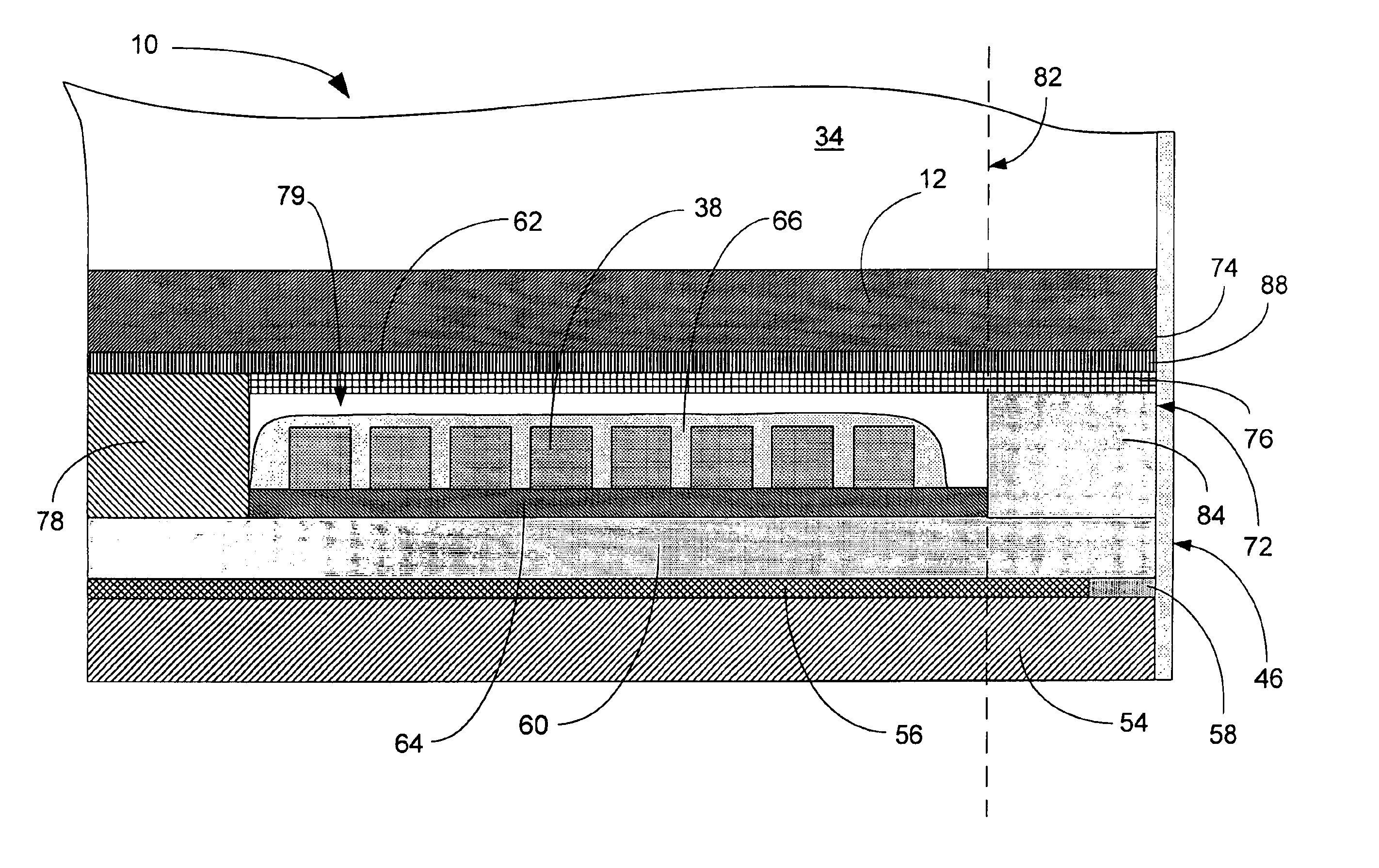

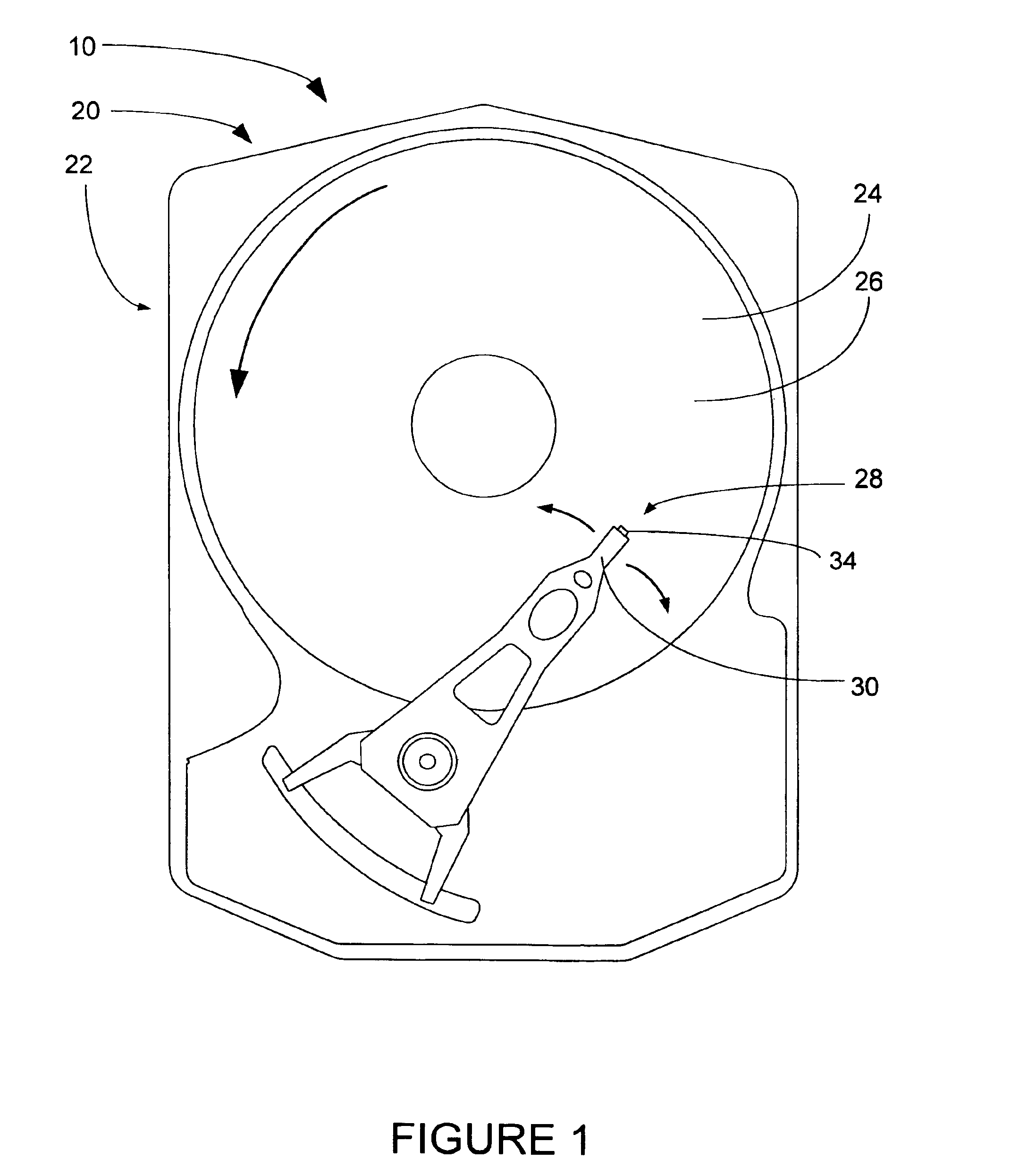

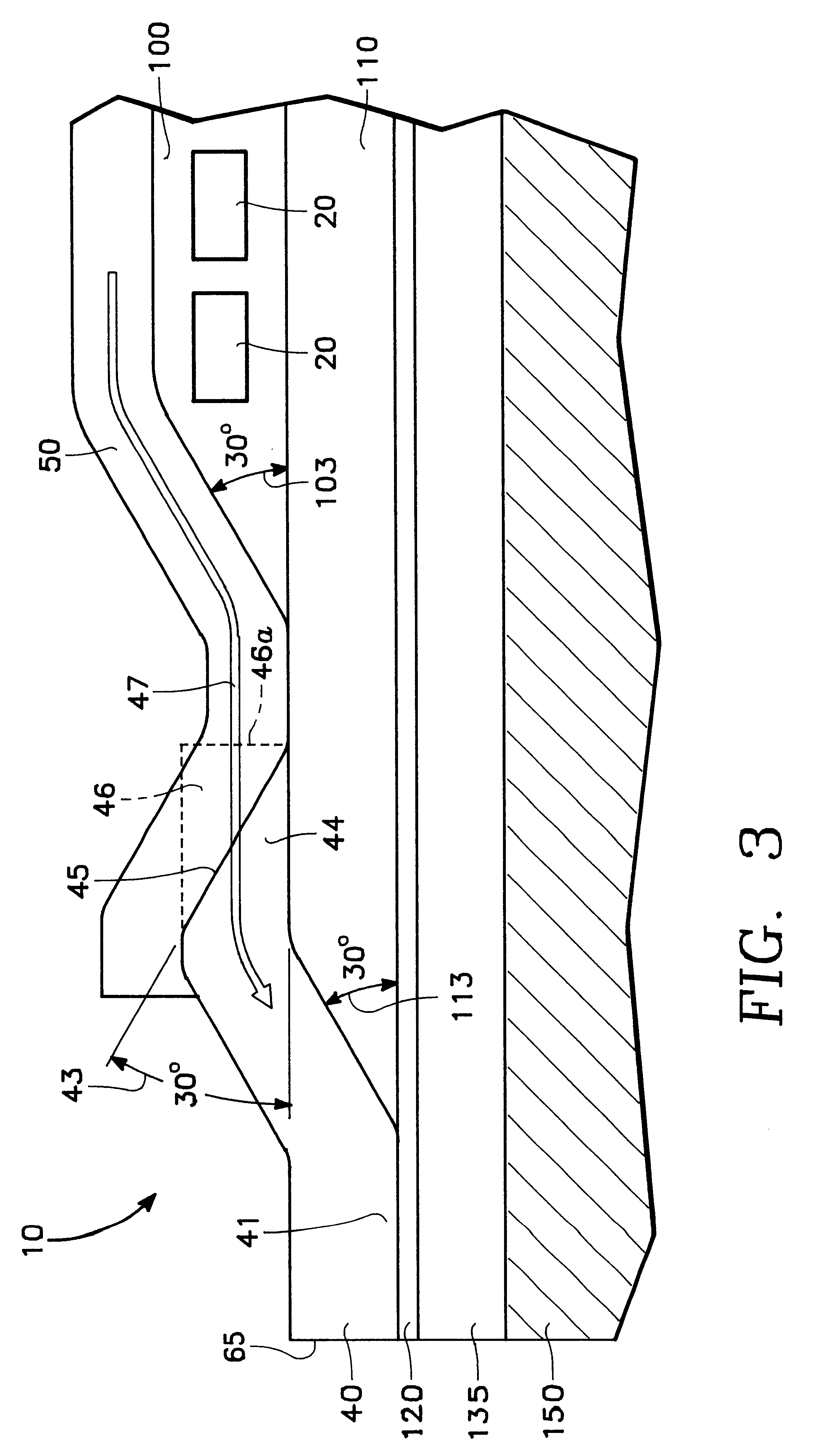

Inductive writer with flat top pole and pedestal defined zero throat

InactiveUS6870712B2Critical dimensions are more easily controlledEasy to controlElectrical transducersHeads using thin filmsEngineeringElectrical and Electronics engineering

A disk drive write head (10) having a bottom pole (60), a first insulation layer (64) formed on the bottom pole (60), a coil (38) formed on the first insulation layer (64), a second insulation layer (66) formed on the coil (38), a write gap layer (76) formed on the second insulation layer (66), and a top pole (12) formed on the write gap layer (76), where the top pole (12) is substantially flat.A second embodiment (100) is described which is produced by a damascene process.

Owner:WESTERN DIGITAL TECH INC

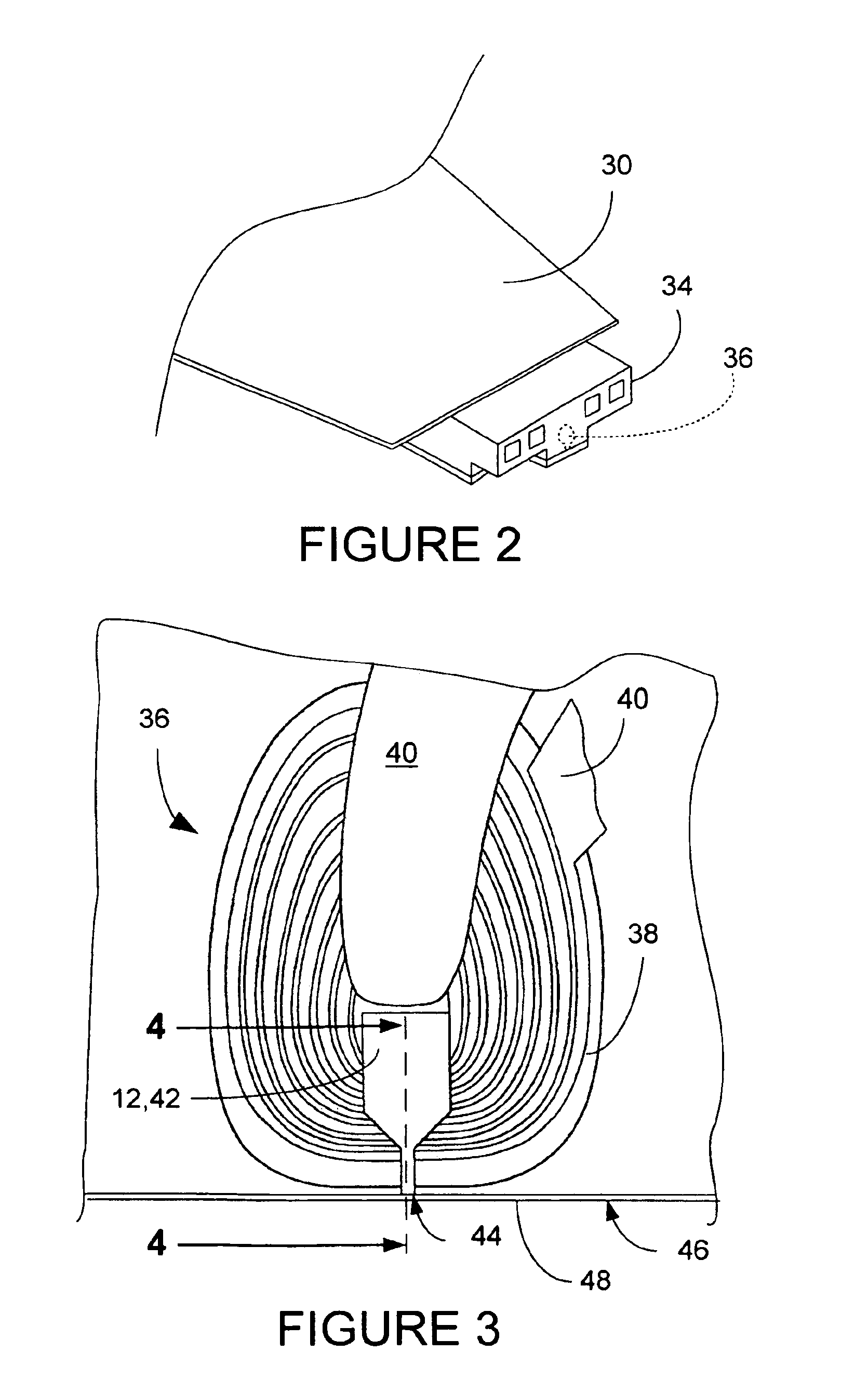

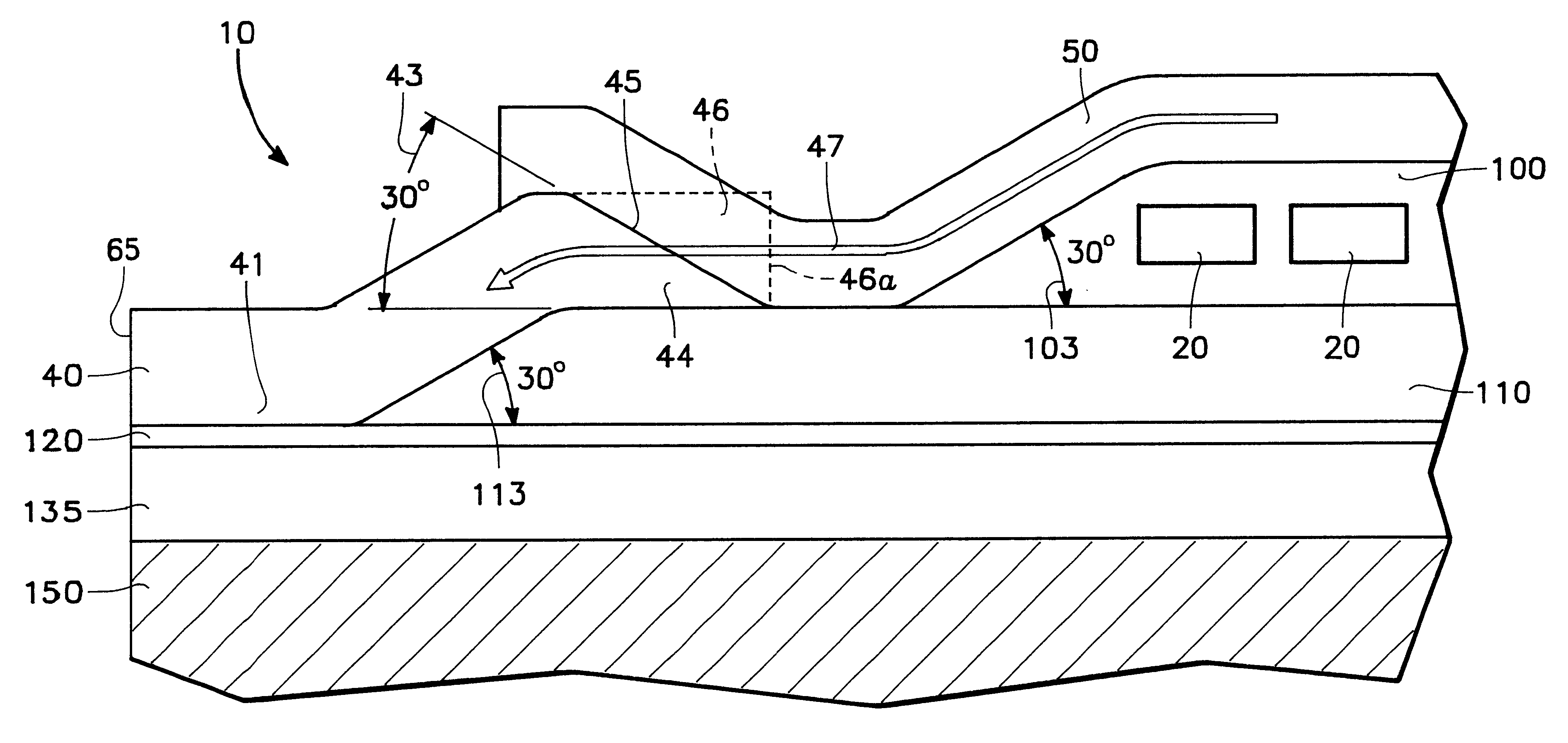

Thin film write head with improved yoke to pole stitch

InactiveUS6490125B1Improve magnetic propertiesWithout sacrificing yoke material property and flux flowConstruction of head windingsHeads using thin filmsAir bearing surfaceEngineering

The present invention provides an write head having an improved upper pole tip-to-yoke stitch. The upper pole tip is formed having an open faced sloping surface at an end of the pole tip distal from an air bearing surface. Preferably the angle of the sloping surface is about 30 degrees. The sloping surface provides a shallow angle for depositing the yoke material over which improves the magnetic properties of the yoke material, particularly in the case of sputtered high moment magnetic materials, and improves the flux flow path through the yoke. As such, the present invention allows conductor coils to be located closer to the air bearing surface without sacrificing yoke material properties and flux flow. The upper pole tip may have a back portion which is formed over an insulation layer located between a write gap layer and a conductor layer. Preferably the insulation layer and the conductor layer or layers are formed having sloping edges with shallow angles of about 30 degrees. An advantage of the present invention is that it allows the yoke and the yoke-to-pole tip stitch to be recessed from the air bearing surface, if desired, to prevent the yoke or yoke-to-pole stitch from inadvertently writing to the media.

Owner:WESTERN DIGITAL TECH INC

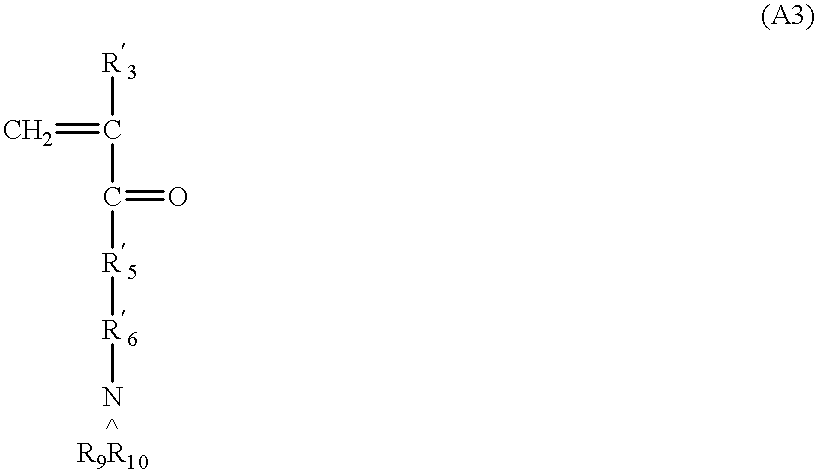

Ink-jet printing ink compositions having magnetic properties and specific core/shell binder

InactiveUS6248805B1Improve propertiesImprove magnetic propertiesIron oxides/hydroxidesDuplicating/marking methodsCharge-transfer complexPrinting ink

Specific core-shell binders and magnetic additives for use in ink-jet printing ink compositions are provided. One class of specific core / shell binders has the general formula [AmBnC'p]x, where A and B are hydrophobic components in which A exhibits a glass transition temperature Tg between about -150° and +25° C. and B exhibits a glass transition temperature greater than 25° C., C' is a component that forms hydrophilic or water-soluble component in the polymer chain, and has an ionic or non-ionic structure, m<30 wt %, n>40 wt %, and p<30 wt %, with the total of m+n+p=100 wt %, and x=1 to 100,000. The molecular weight (weight average) of the polymer is between about 1,000 and 2,000,000. The polymers useful in the practice of the invention are prepared by emulsifying the monomers and then conducting a free-radical polymerization in water. The foregoing binder polymer is used in conjunction with magnetic additives comprising either (a) inorganic magnetic compound containing at least one of iron, cobalt, and nickel or (b) organic magnetic complexes containing at least one of iron, cobalt, and nickel or (c) organic charge transfer complexes that exhibit magnetic properties. The ratio of binder (I) to colorant (pigment) is greater that 1 to 10. The concentration of the magnetice additive is within the range of 1 to 30 wt %. The general ink formulation comprises: 5 to 50 wt % water-miscible solvent; 0.5 to 10 wt % colorant; 1 to 30 wt % magnetice additive; and water.

Owner:HEWLETT PACKARD DEV CO LP

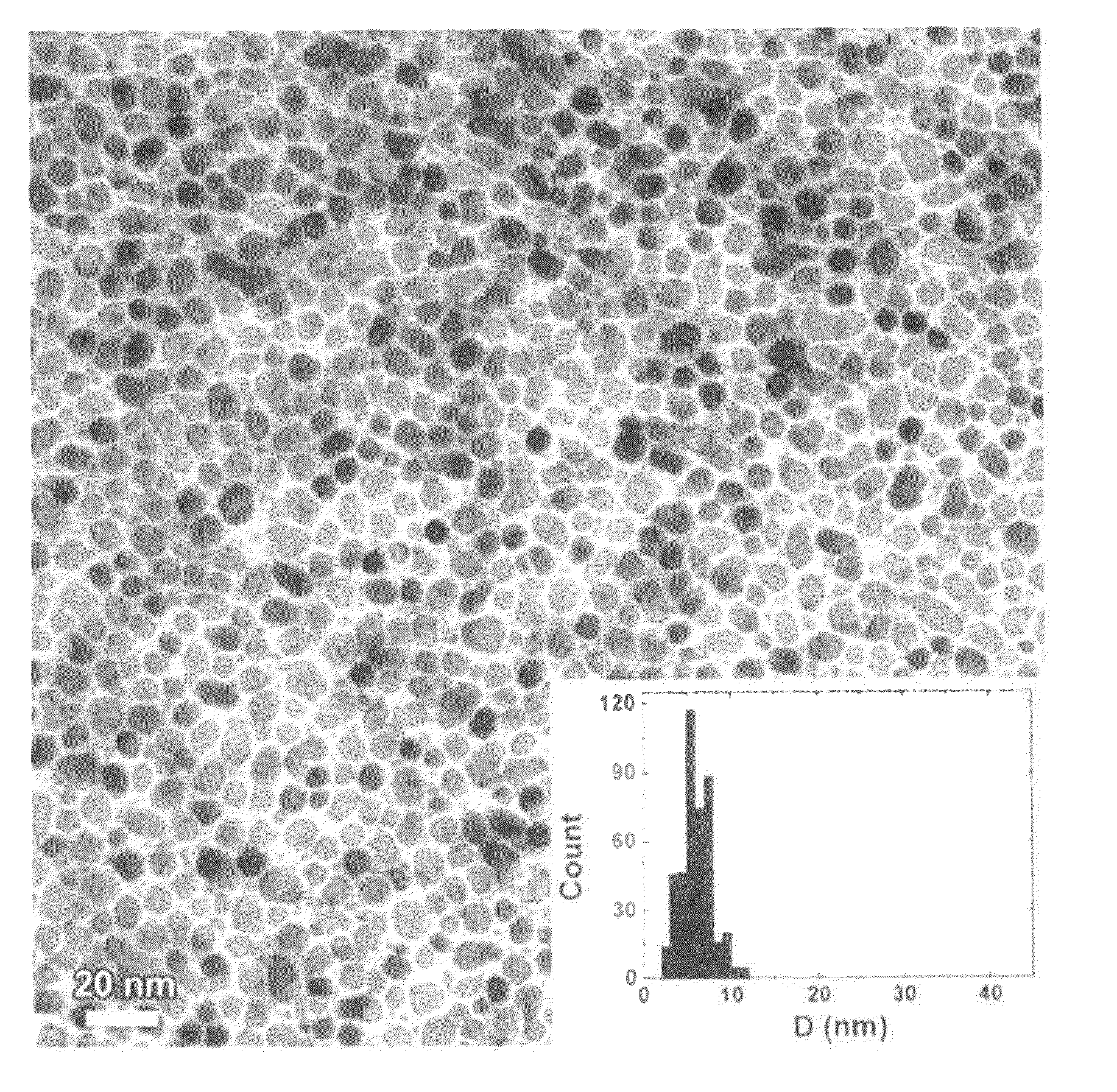

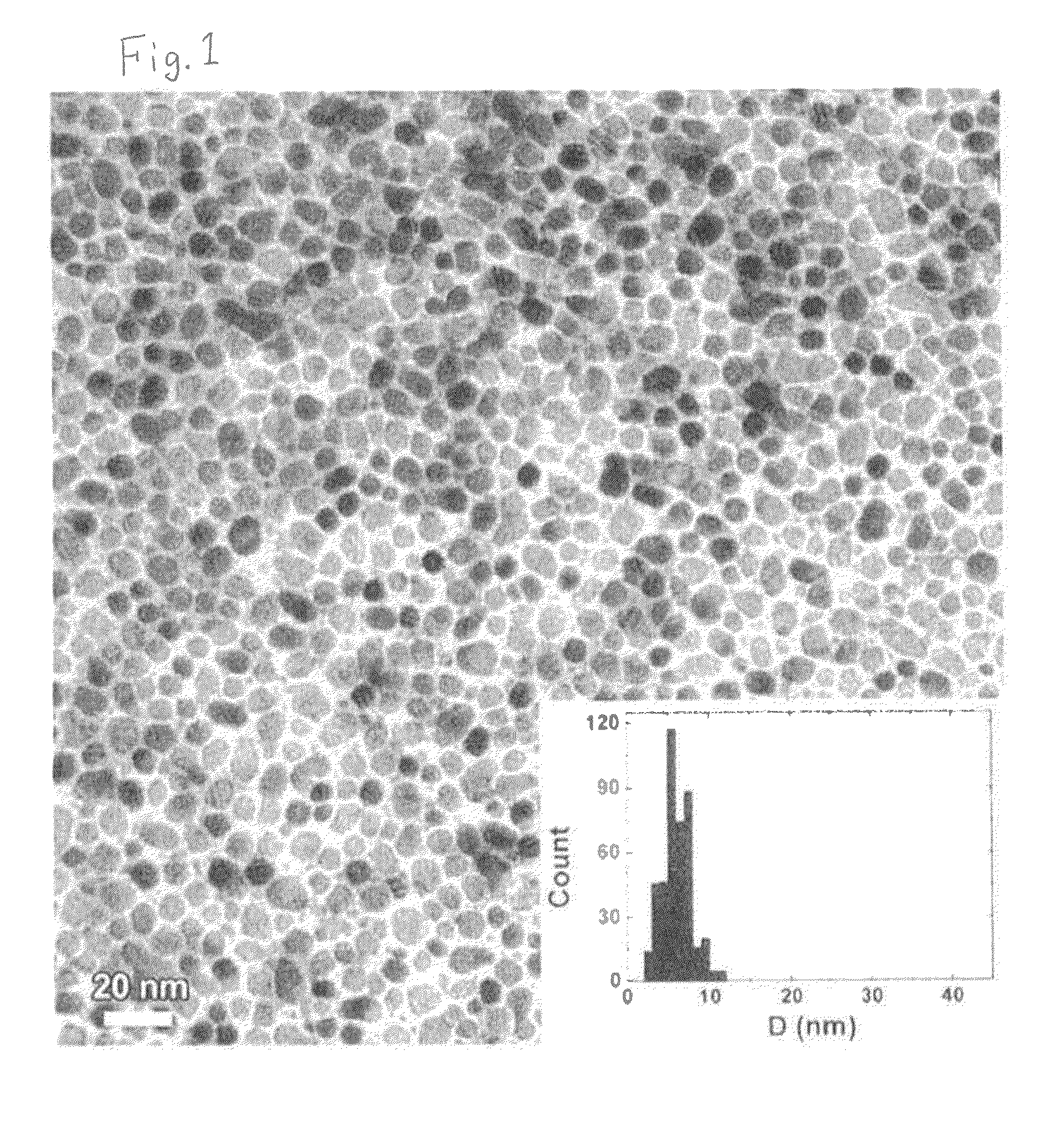

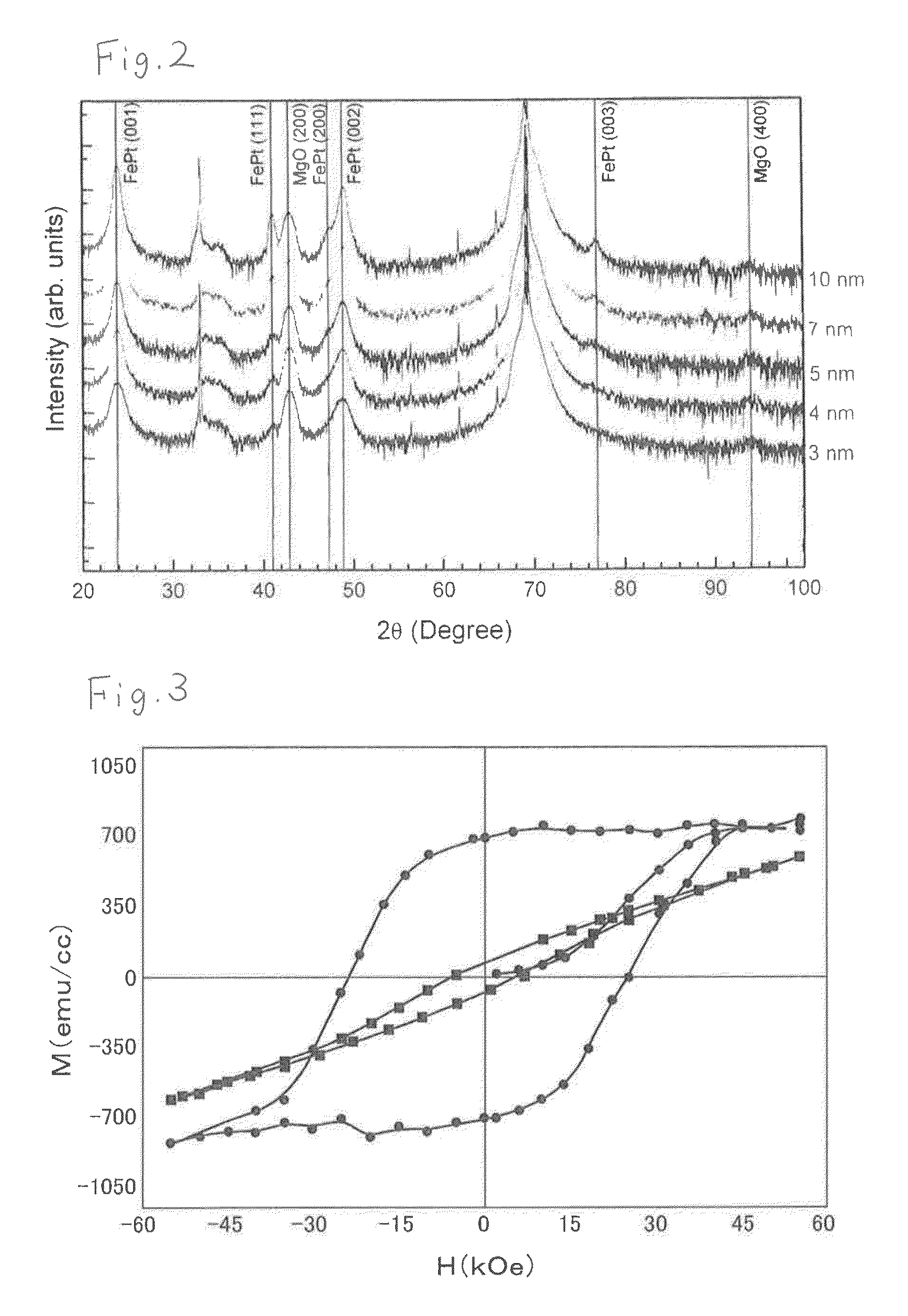

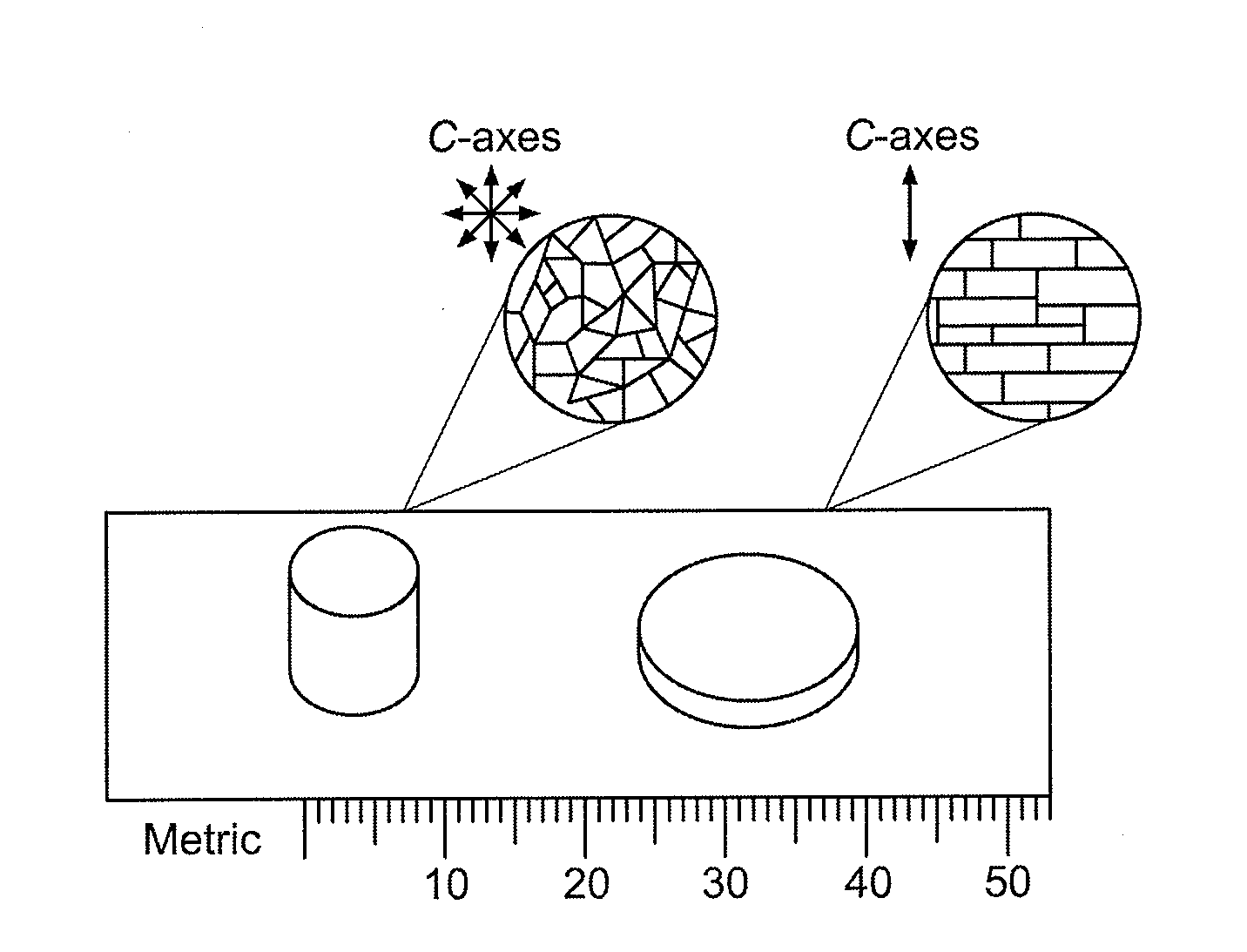

Perpendicular magnetic recording medium and its manufacturing method

InactiveUS20130040167A1Suppress interferenceIncrease in ultra-high recording densityRecord information storageCoating by sputteringSputteringAlloy

It is aimed to provide a perpendicular magnetic recording medium capable of dealing with an ultra-higher recording density than before and its manufacturing method.The present invention concerns a perpendicular magnetic recording medium including at least a seed layer made of noncrystalline ceramic, a crystalline orientation control layer and a magnetic layer made of a material mainly containing a FePt alloy in this order on a substrate. This perpendicular magnetic recording medium is suitably manufactured by forming at least the seed layer, the orientation control layer and the magnetic layer made of the material mainly containing the FePt alloy in this order on the substrate by sputtering, wherein the magnetic layer is formed at a predetermined temperature of 500° C. or less.

Owner:WD MEDIA SINGAPORE PTE +1

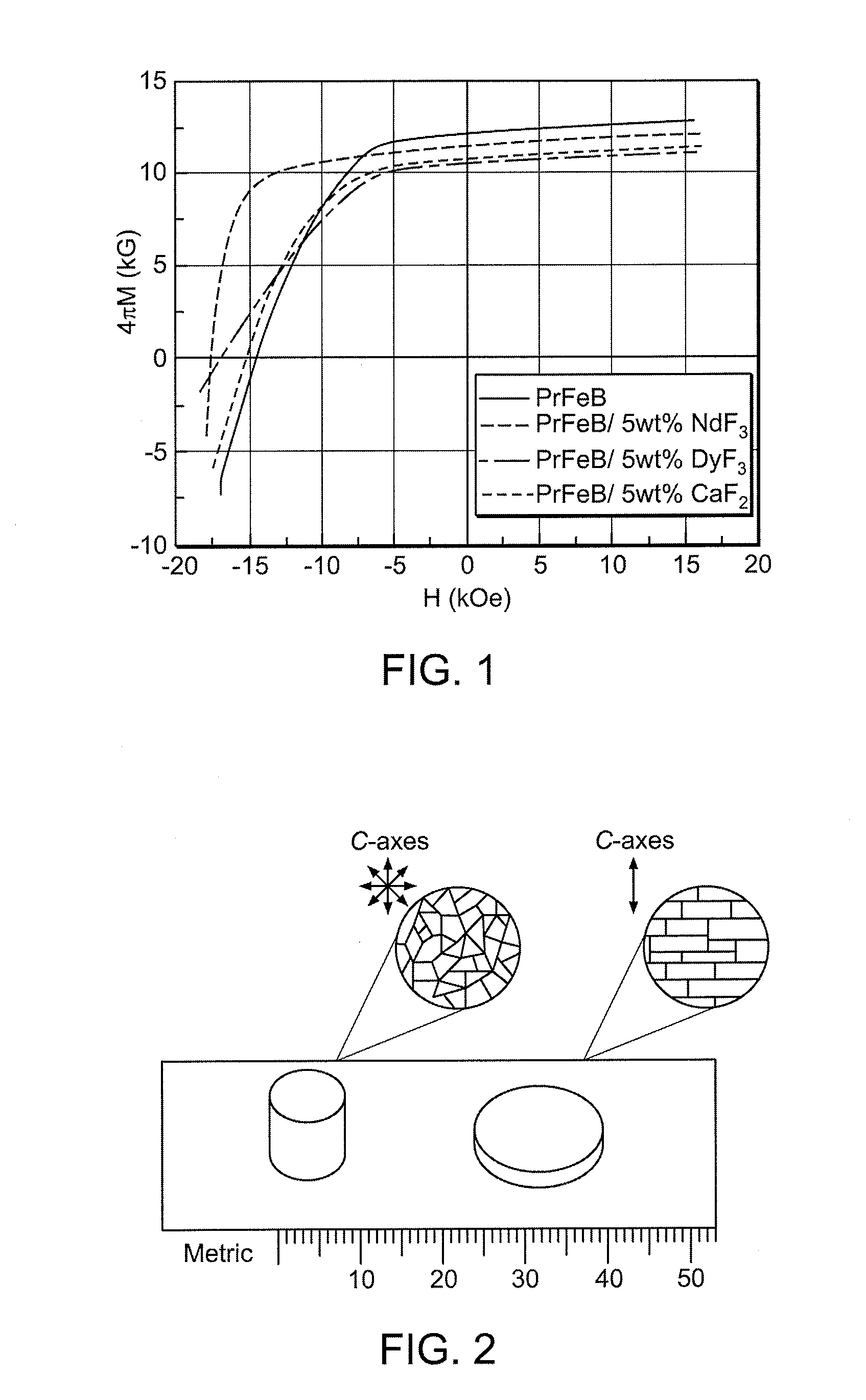

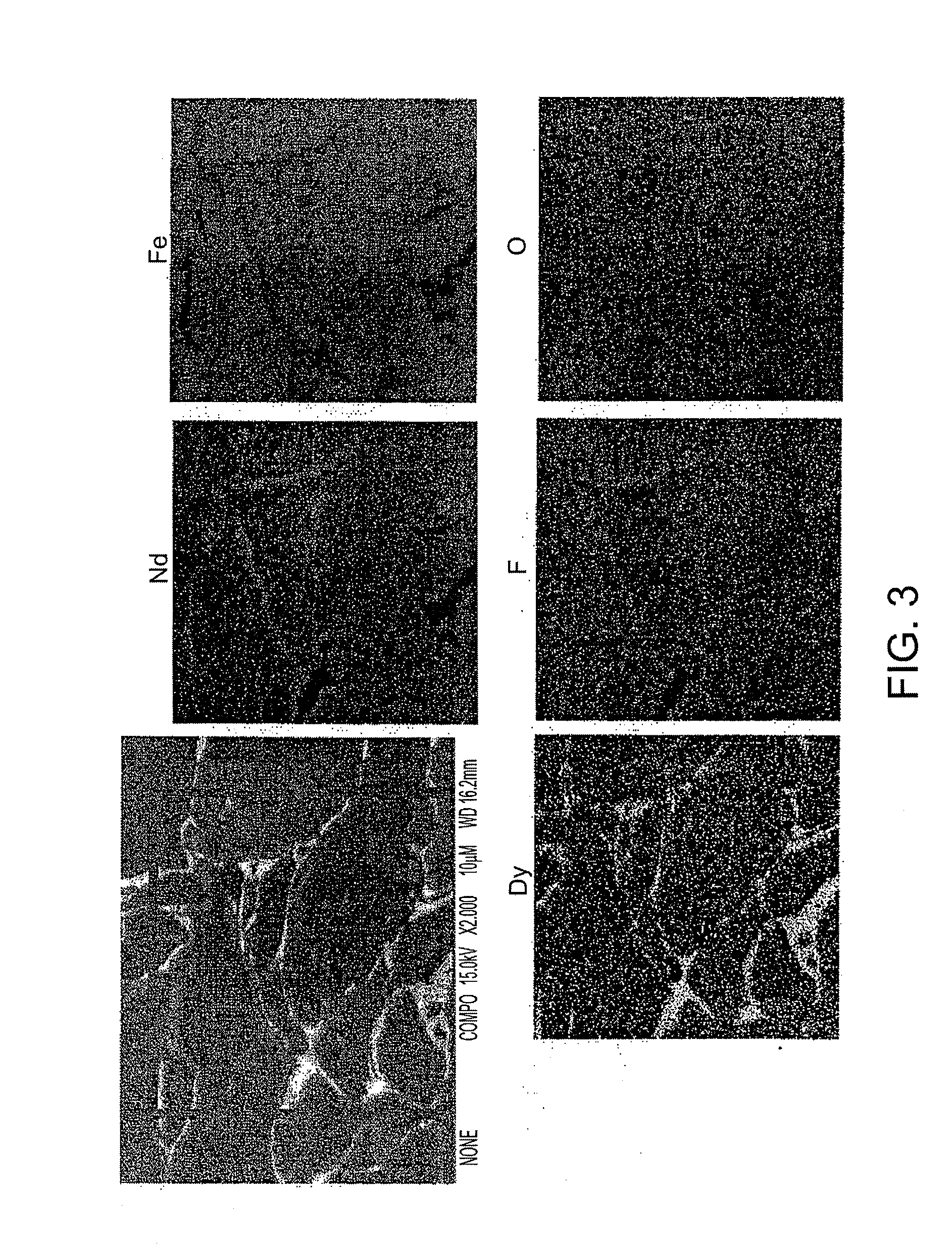

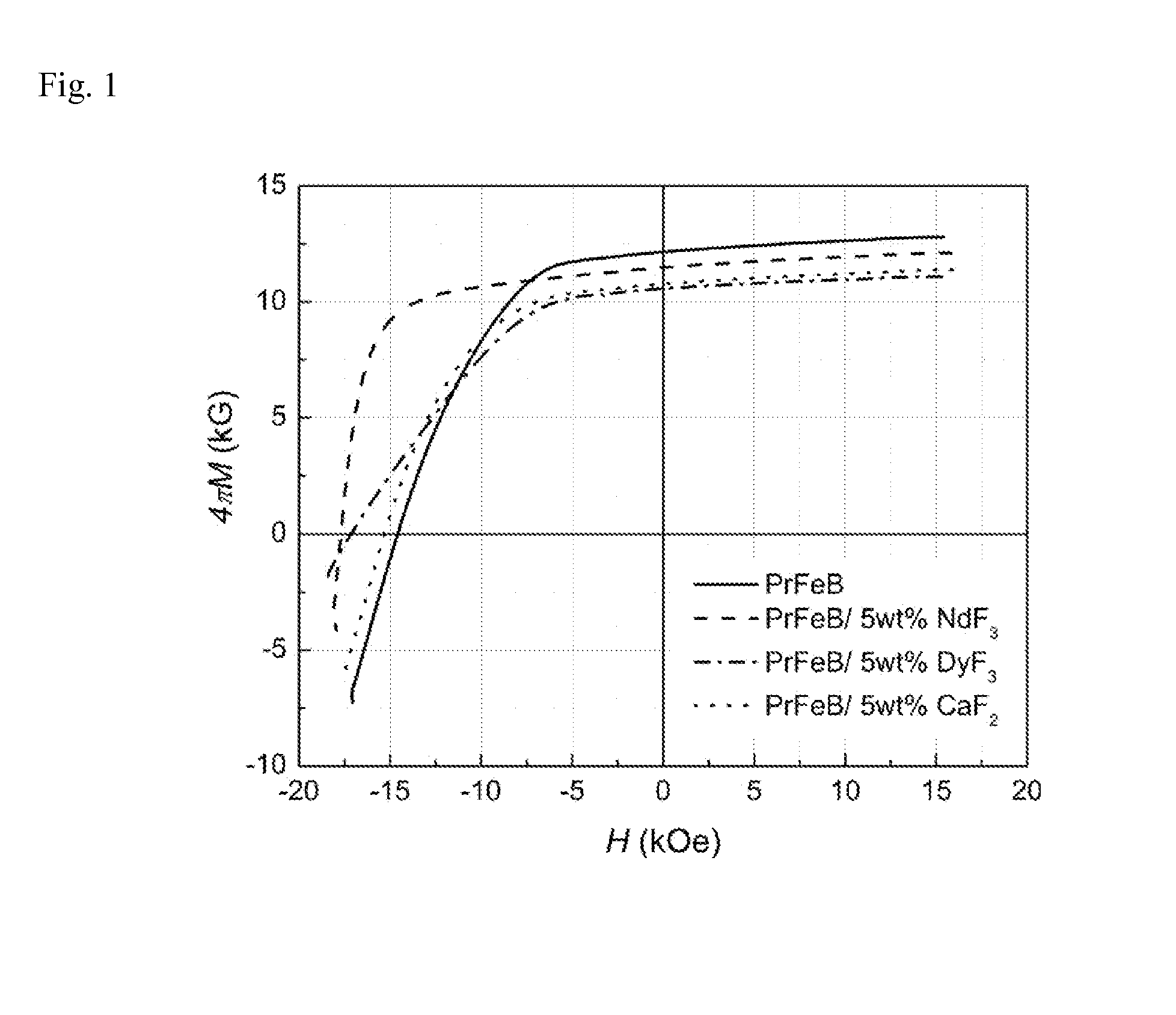

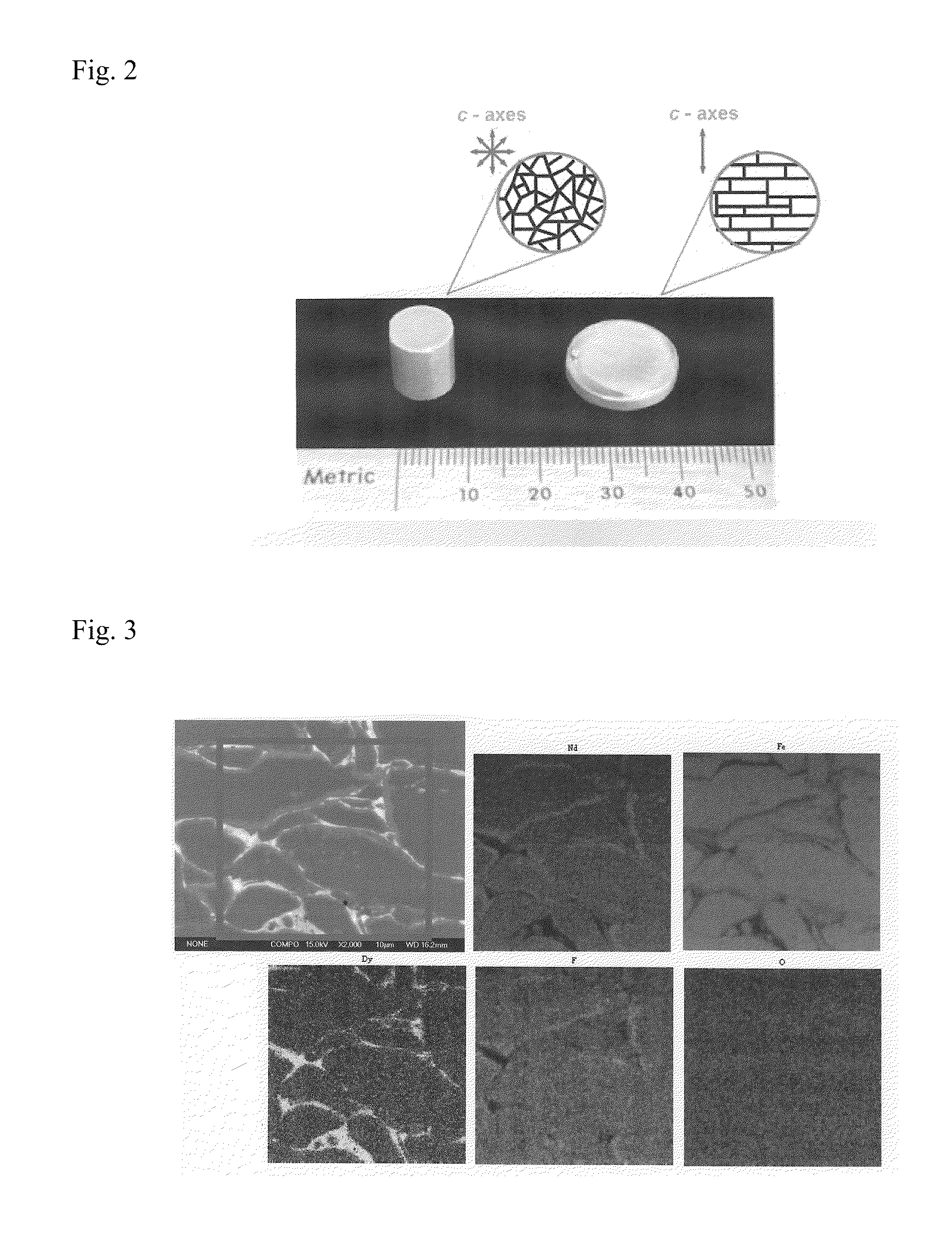

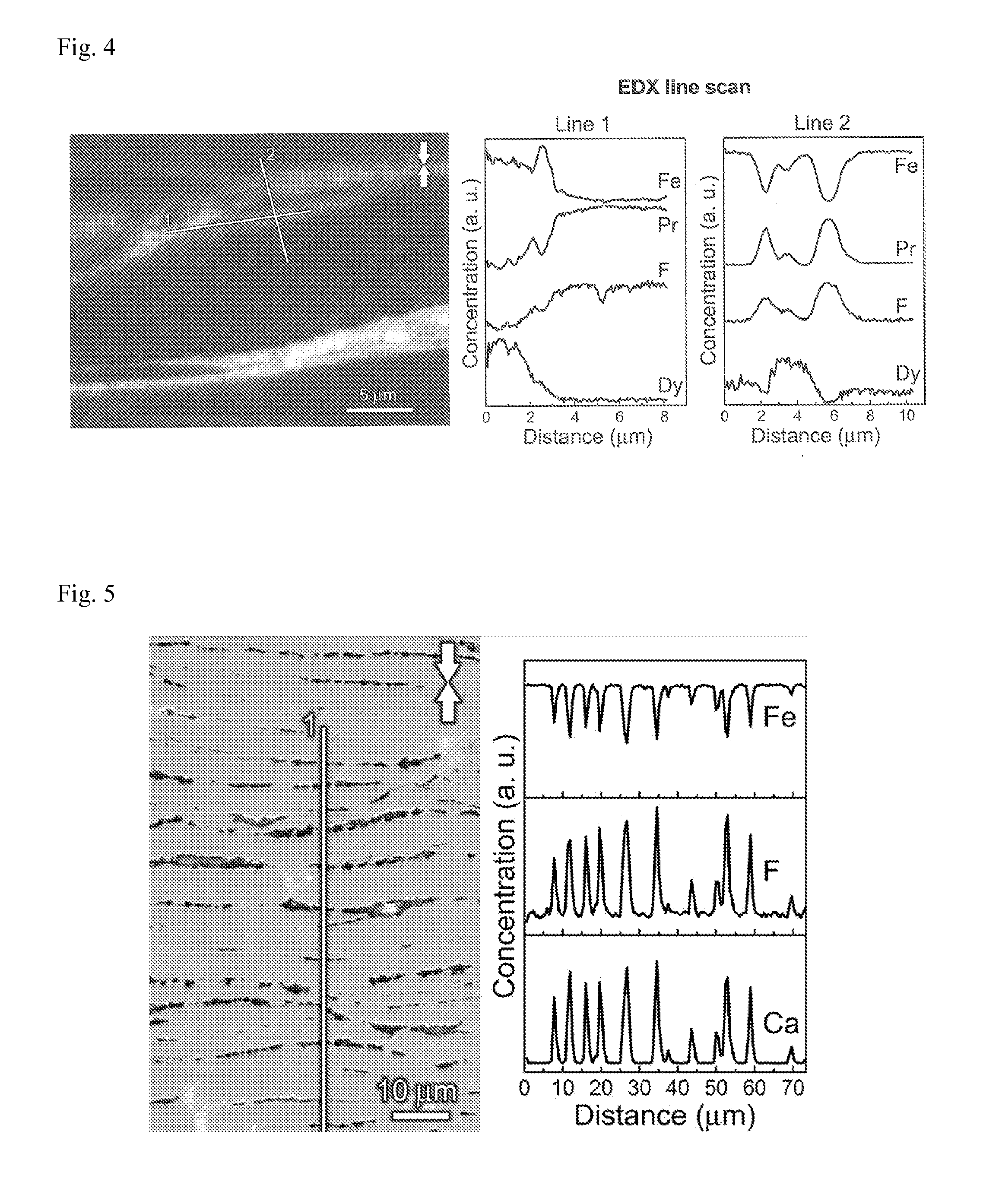

Rare Earth Composite Magnets with Increased Resistivity

InactiveUS20110057756A1Increased electrical resistivityReduce eddy current lossTransportation and packagingMetal-working apparatusDielectricHigh resistivity

Dielectric rare earth fluorides are blended with rare earth magnet powders to produce high-resistivity fluoride composite rare earth magnets.

Owner:ELECTRON ENERGY CORP +1

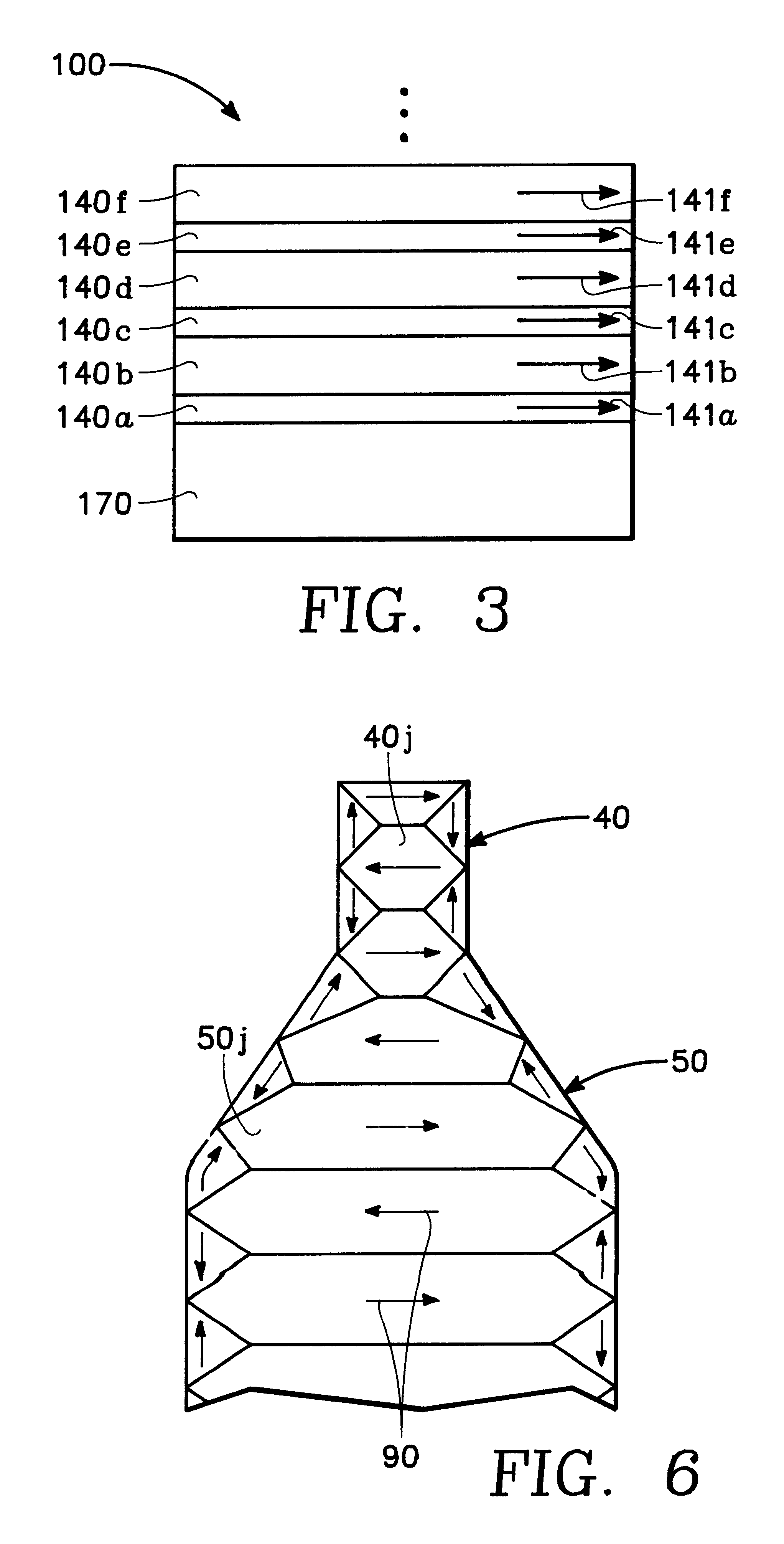

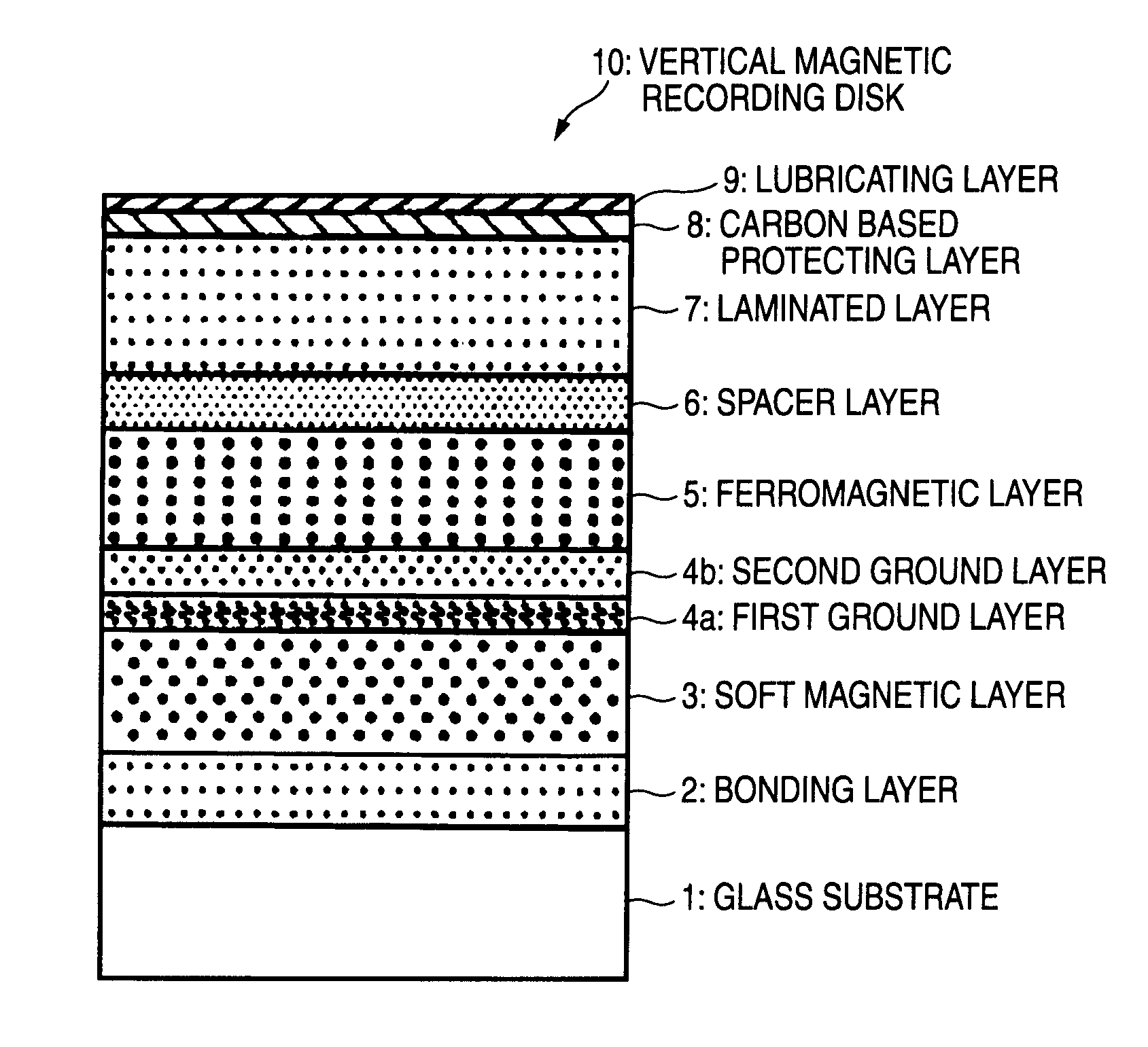

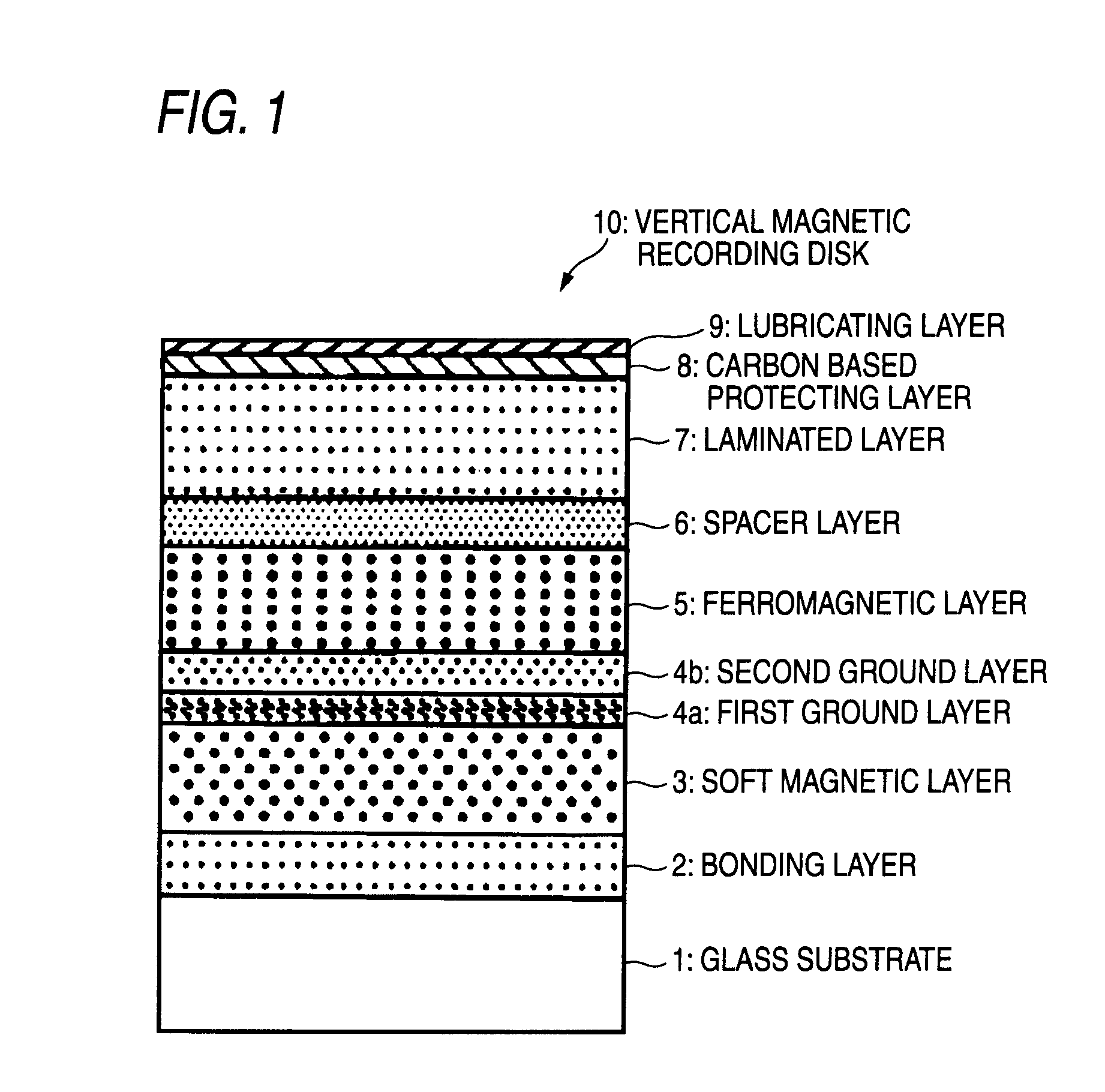

Vertical magnetic recording disk manufacturing method and vertical magnetic recording disk

ActiveUS20090202866A1Improve magnetic propertiesImprove recording densityVacuum evaporation coatingSputtering coatingKryptonSputtering

In a method of manufacturing a magnetic disk including at least a magnetic recording layer on a substrate 1 and used for vertical magnetic recording, in a step of forming, on the substrate 1, the magnetic recording layer composed of a ferromagnetic layer 5 having a granular structure and an exchange energy control layer 7 constituted by a laminated layer formed on the ferromagnetic layer 5, at least the exchange energy control layer 7 is formed through sputtering in an atmosphere of a rare gas having a greater mass than an argon gas. The rare gas having a greater mass than the argon gas is a krypton (Kr) gas, for example. The exchange energy control layer 7 is a laminated layer composed of a first layer containing Co or a Co-alloy and a second layer containing palladium (Pd) or platinum (Pt), for example.

Owner:WESTERN DIGITAL TECH INC

Method for manufacturing cold-rolled orientation-free electrical sheet

This is about the manufacturing method of cold-rolled non-oriented electrical steel, including the following steps: a) the continuous casting of blanks: the liquid steel is continuously cast into a blank of 120-170mm at a pulling speed of 2-3 m / min; b) hot rolling: the blanks are directly hot-rolled or heated into the hot-rolled plate of 900-1150 deg.C and the thickness of the blank is hot-rolled to 0.8-4mm with finishing temperature 800-900deg.C and coiling temperature 500-900deg.C; c) cold rolling: the hot-rolled band undergoes annealing or non annealing treatment and acidwashing, and then the first cold-rolling or the second cold-rolling with annealing until the goal thickness reaches. When the finishing annealing is carried out, the non-oriented electrical steel is produced.

Owner:BAOSHAN IRON & STEEL CO LTD

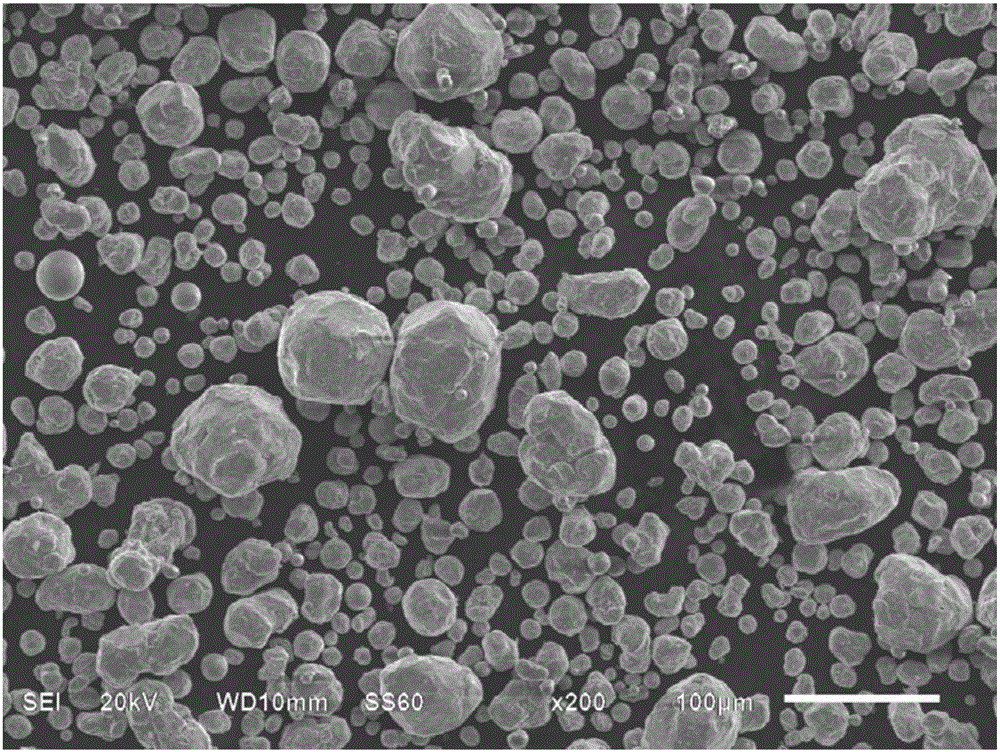

Soft magnetic composite powder and magnetic powder core preparation method thereof

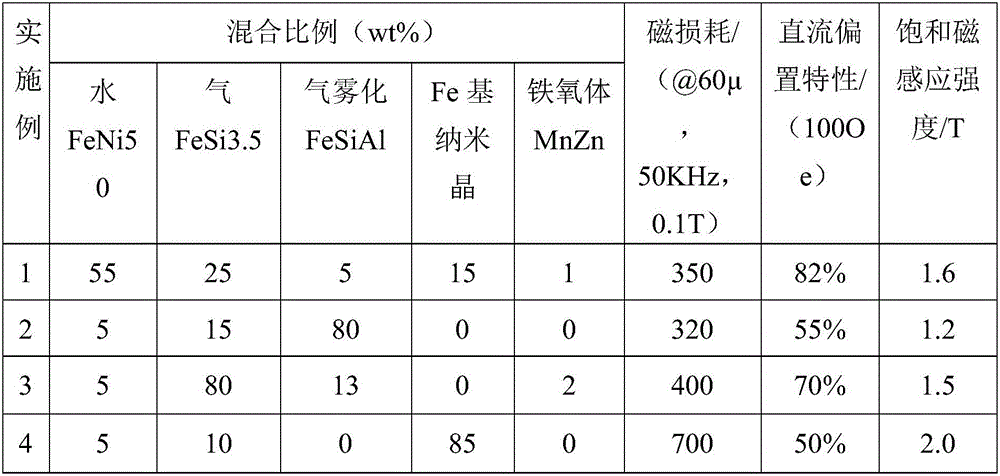

InactiveCN106229104AHigh bulk densityCost-effectiveTransportation and packagingMetal-working apparatusPowder metallurgyMagnetic powder

The invention relates to soft magnetic composite powder and a magnetic powder core preparation method thereof, and belongs to the technical field of powder metallurgy and magnetic materials. According to different magnetic performance characteristics of metal soft magnetic powder, amorphous and nano-crystalline powder and ferrite powder, magnetic performances are linearly calculated and optimally designed, so that the requirements of different magnetic properties are met. Besides, powder sizes are calculated and coordinately designed, the powder is shaped, screened, annealed, coated in an insulated manner and mixed, and the powder with different components is respectively passivated and insulated, weighed according to weight ratio and uniformly mixed to form the composite powder. The prepared soft magnetic composite powder is regular in morphology and good in dispersity and has good apparent density and flowability. In addition, the magnetic performance of a magnetic powder core prepared from the soft magnetic composite powder can be calculated and designed as required, the magnetic powder core has high cost performance and good comprehensive magnetic performance, and the blank of the performance and application of an existing magnetic powder core is effectively filled in.

Owner:BEIJING COMPO ADVANCED TECH

Magnets with varying magnetization direction and method of making such magnets

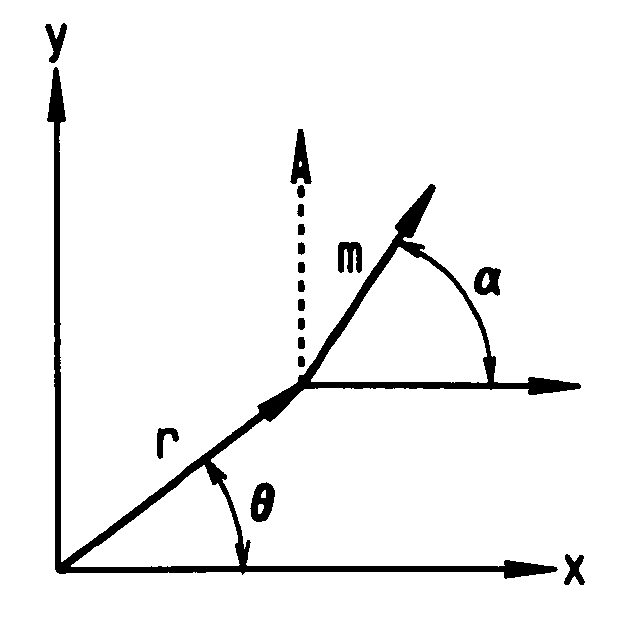

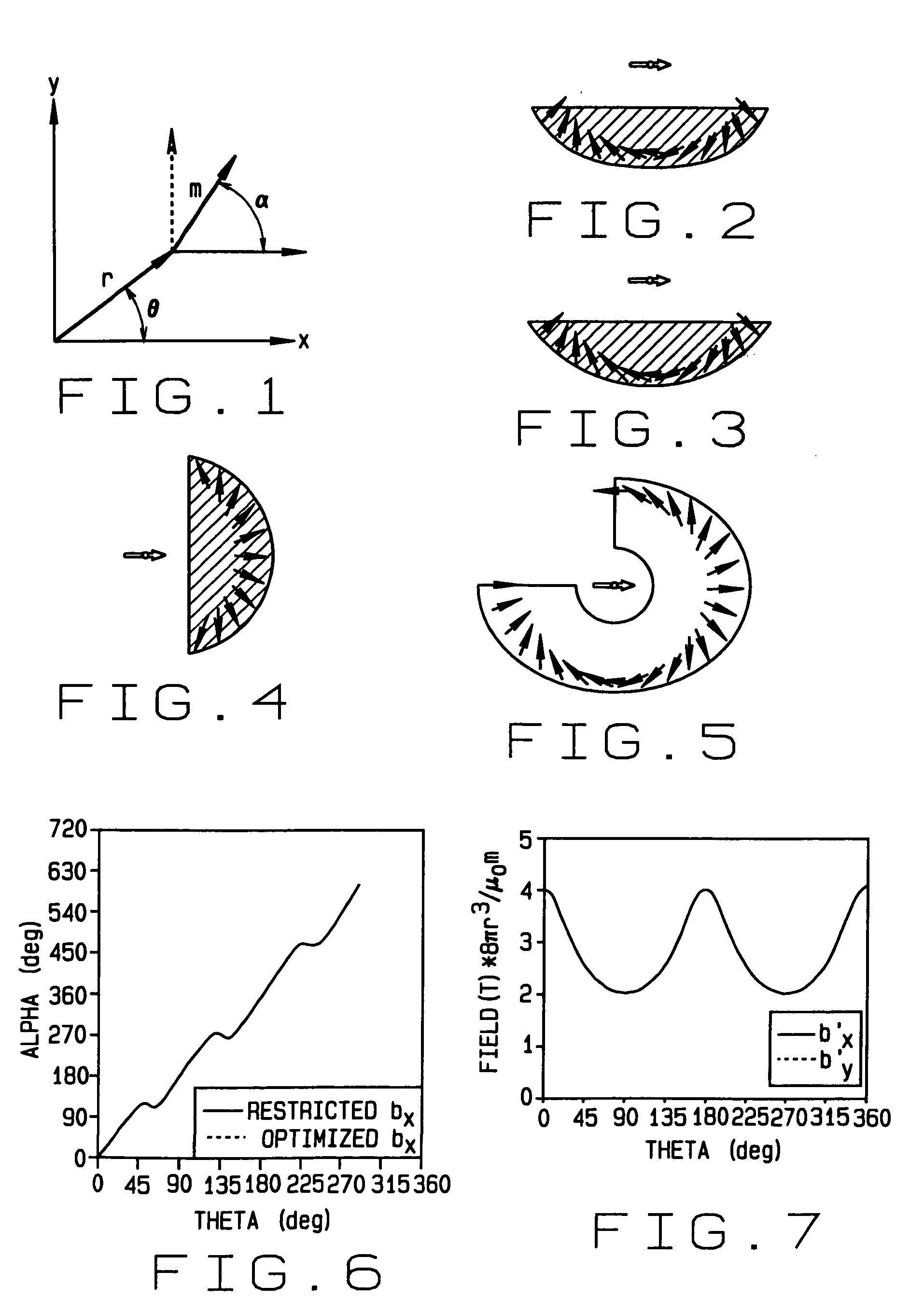

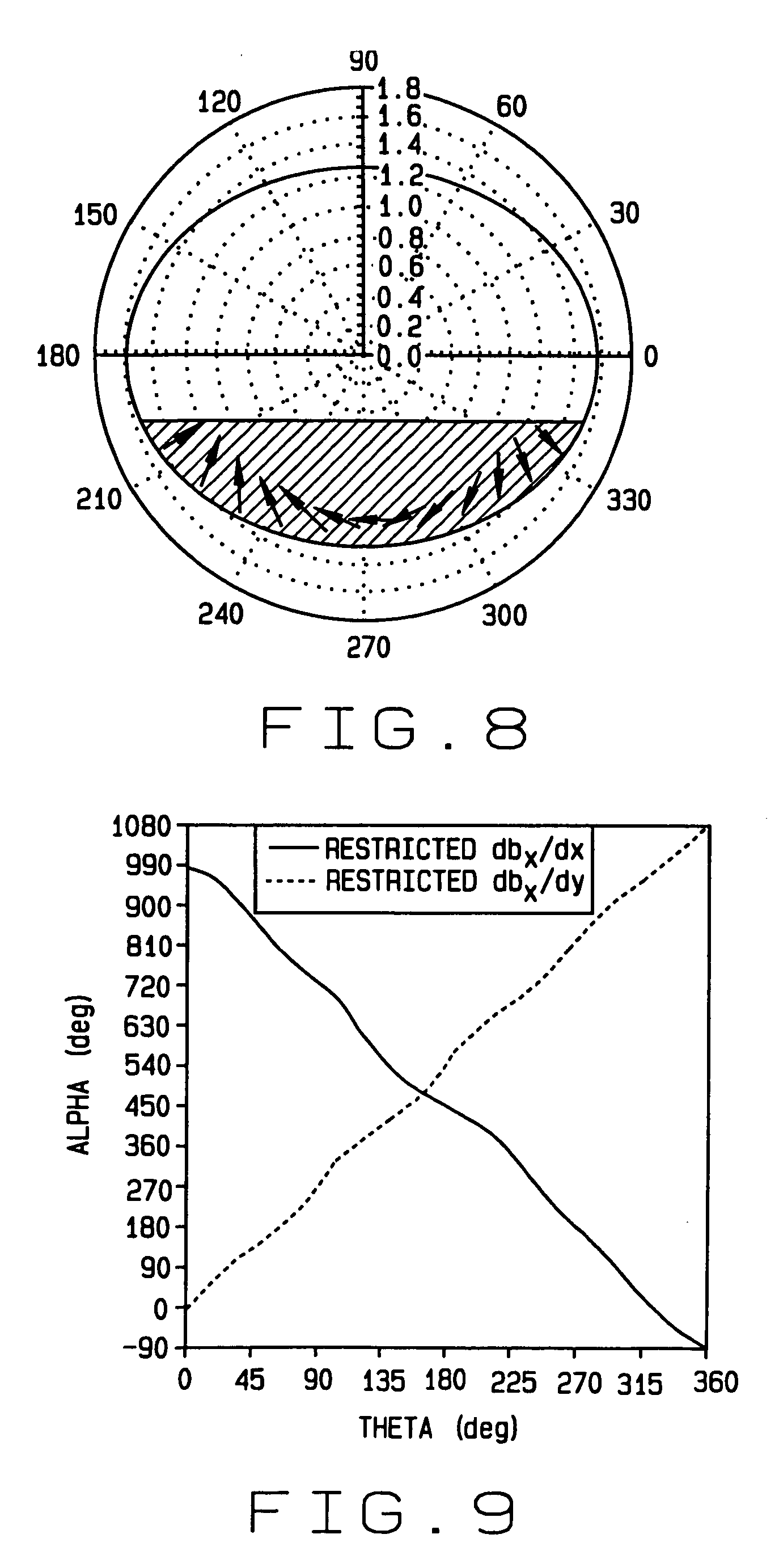

InactiveUS20060061445A1Maximize selected magnetic propertyReduces opportunity of interferenceDiagnosticsPermanent magnetsMagnetizationTransverse magnetic field

A permanent magnet in which the magnetization direction varies with location to optimize or restrict a magnetic field property in a selected direction at a selected point. The magnetic field property may be, for example, the transverse magnetic field, axial magnetic field, axial gradient of the transverse magnetic field, transverse gradient of the transverse magnetic field, axis gradient of the axial magnetic field, transverse gradient of the axial magnetic field, the product of the transverse magnetic field and the transverse gradient of the transverse magnetic field, the product of the transverse magnetic field and the axial gradient of the transverse magnetic field, the product of the axial magnetic field and the transverse gradient of the axial magnetic field, or the product of the axial magnetic field and the axial gradient of the axial magnetic field. The magnet may be formed of one or more segments in which the magnetization direction varies smoothly and continuously, or the magnet may be formed of a plurality of segments in which the magnetization direction is constant. A method of making and using such magnets is also disclosed.

Owner:STEREOTAXIS

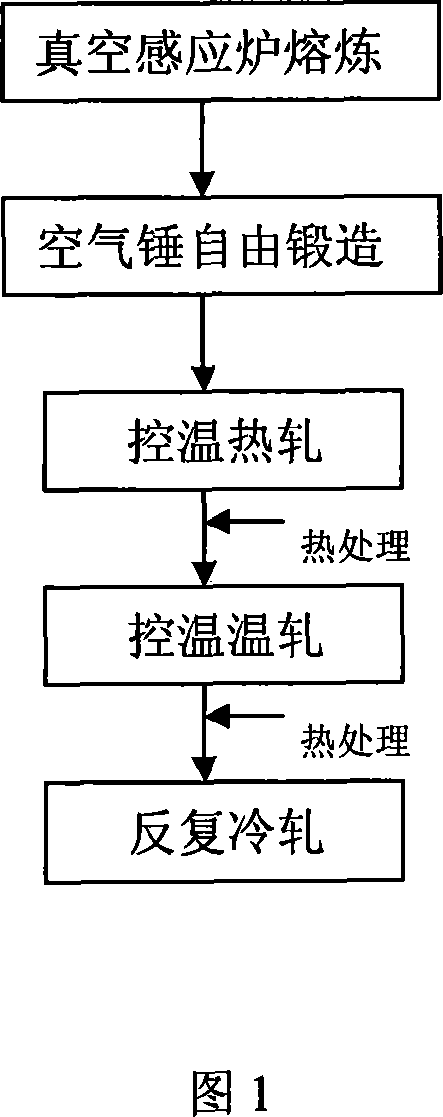

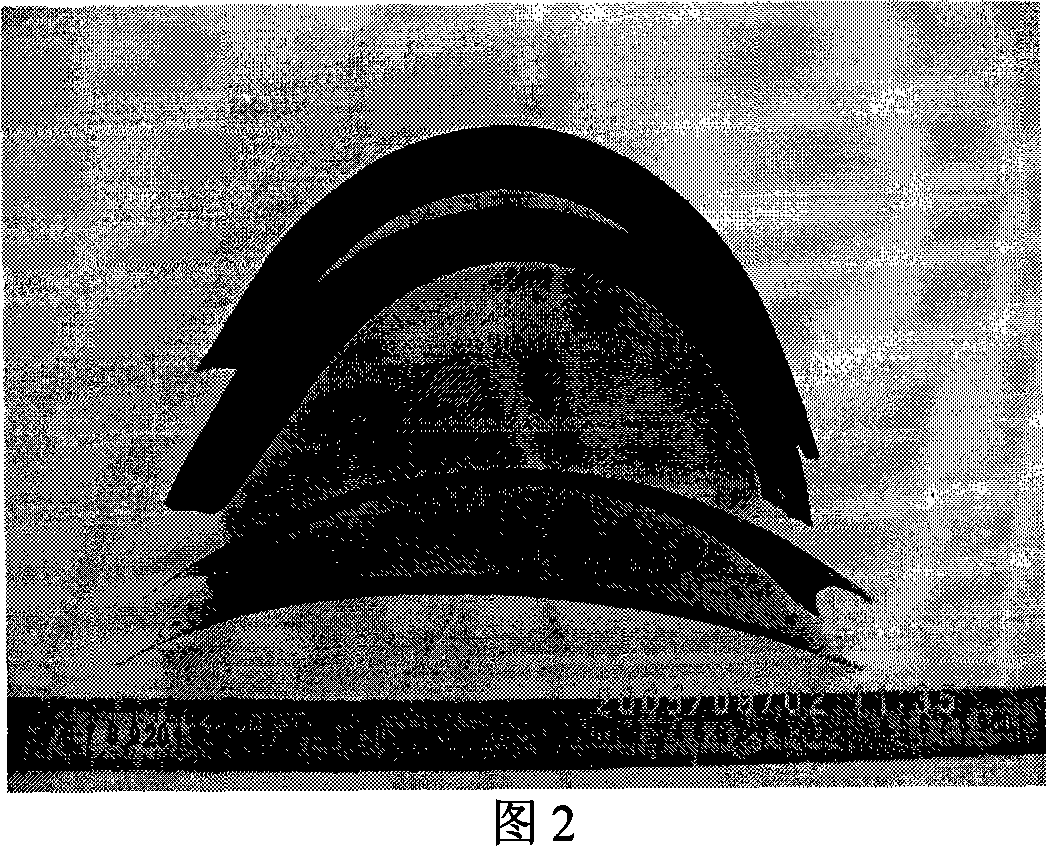

Preparation method for cold rolling sheet of duriron

InactiveCN101049669AWide applicabilityLow purityRoll force/gap control deviceTemperature control deviceAlloyThin sheet

A cold rolling method for preparing high-Si steel sheet containing Fe (85-96 Wt%) and Si (4-15) includes such steps as providing raw material containing Si, B and Fe, smelting, casting, forging, hot rolling, warm rolling, heat treating and cold rolling.

Owner:UNIV OF SCI & TECH BEIJING

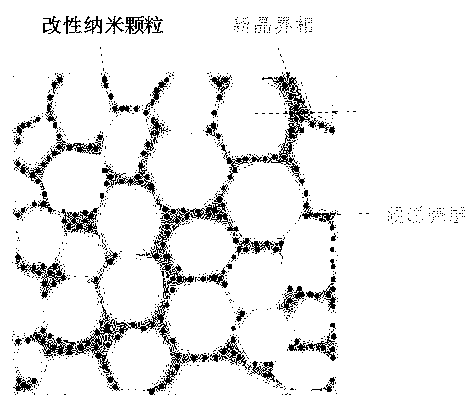

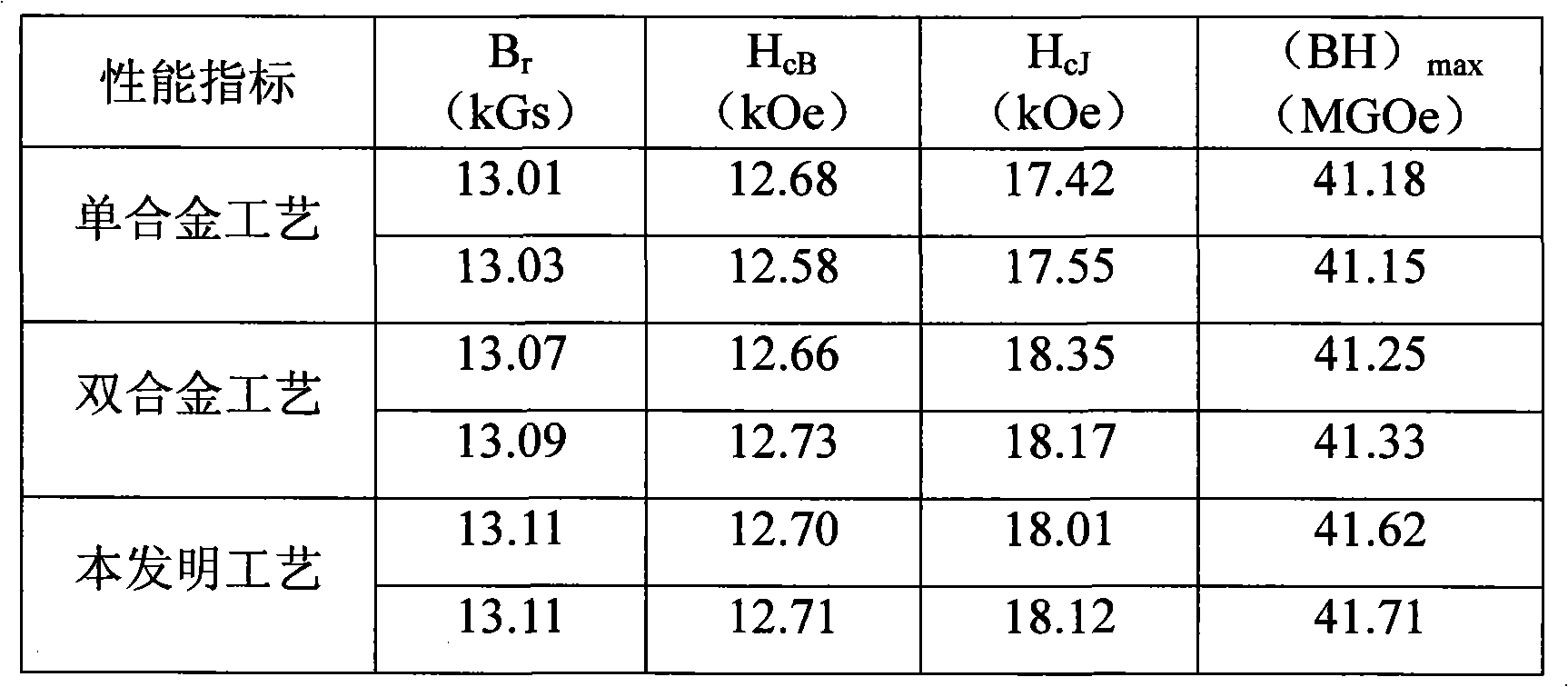

Rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and preparation method thereof

ActiveCN103123839AReduce production and sales balancePromote the balance of production and salesInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementCost Controls

The invention discloses a rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and a preparation method of the rare earth permanent magnet produced by applying abundant rare earth Ce. Based on a double-alloy process, main phase alloy formula uses Ce to partly replace neodymium (Nd), an optimized composition design enables a main alloy to form Ce2Fe14B phase and Nd2Fe14B phase to a greatest extent, and therefore high intrinsic magnetic property is guaranteed. A brand new crystal boundary phase is prepared by a crystal boundary reconstitution technology, and high integral magnetic property and corrosion resistant property are guaranteed, and meanwhile a nanometer powder crystal modification method is supplemented, a micro organization structure of a magnet is optimized, crystal boundary distribution is improved, and the magnetic property and the corrosion resistant property are further improved. By applying abundant rare earth cerium, cost is effectively reduced, and meanwhile balance between production and marketing is promoted. Praseodymium (Pr), Nd, and the like are chosen to form a hard magnetic shell layer of a main phase boundary in a composition design of crystal phase auxiliary alloy at the same time, compared high price heavy rare earth elements of dysprosium (Dy) and terbium (Tb) with the elements, and cost control can be further achieved.

Owner:ZHEJIANG UNIV +1

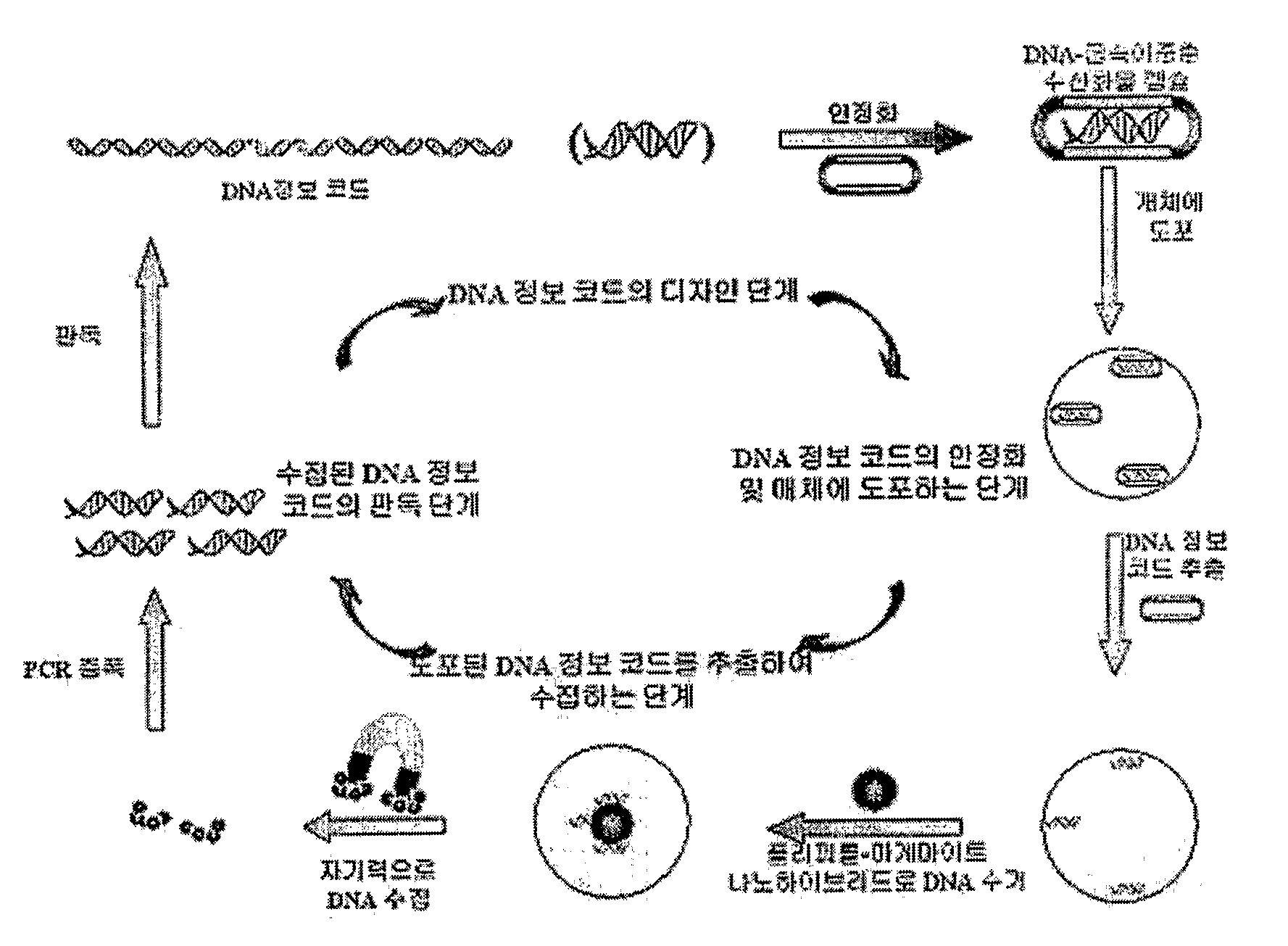

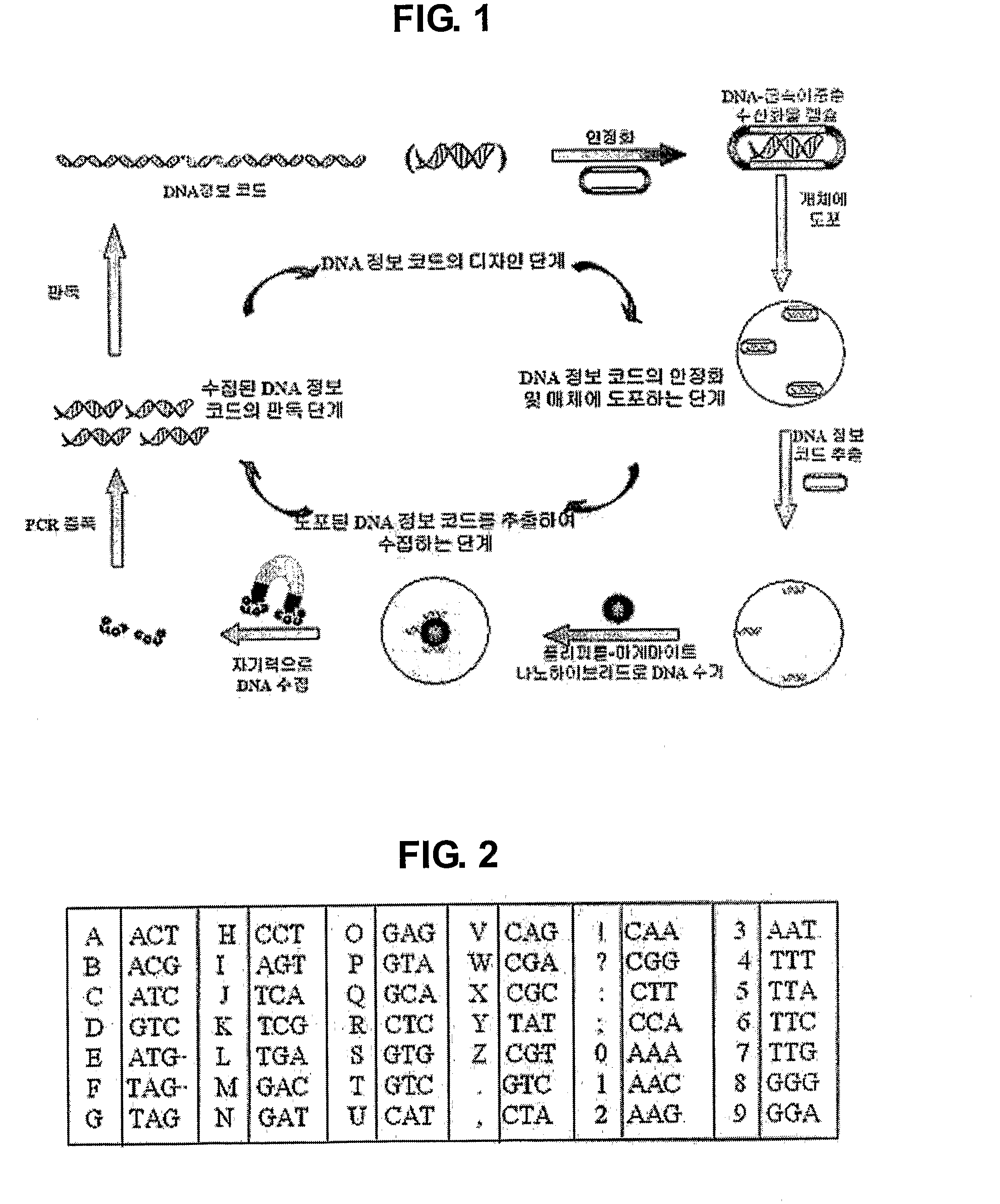

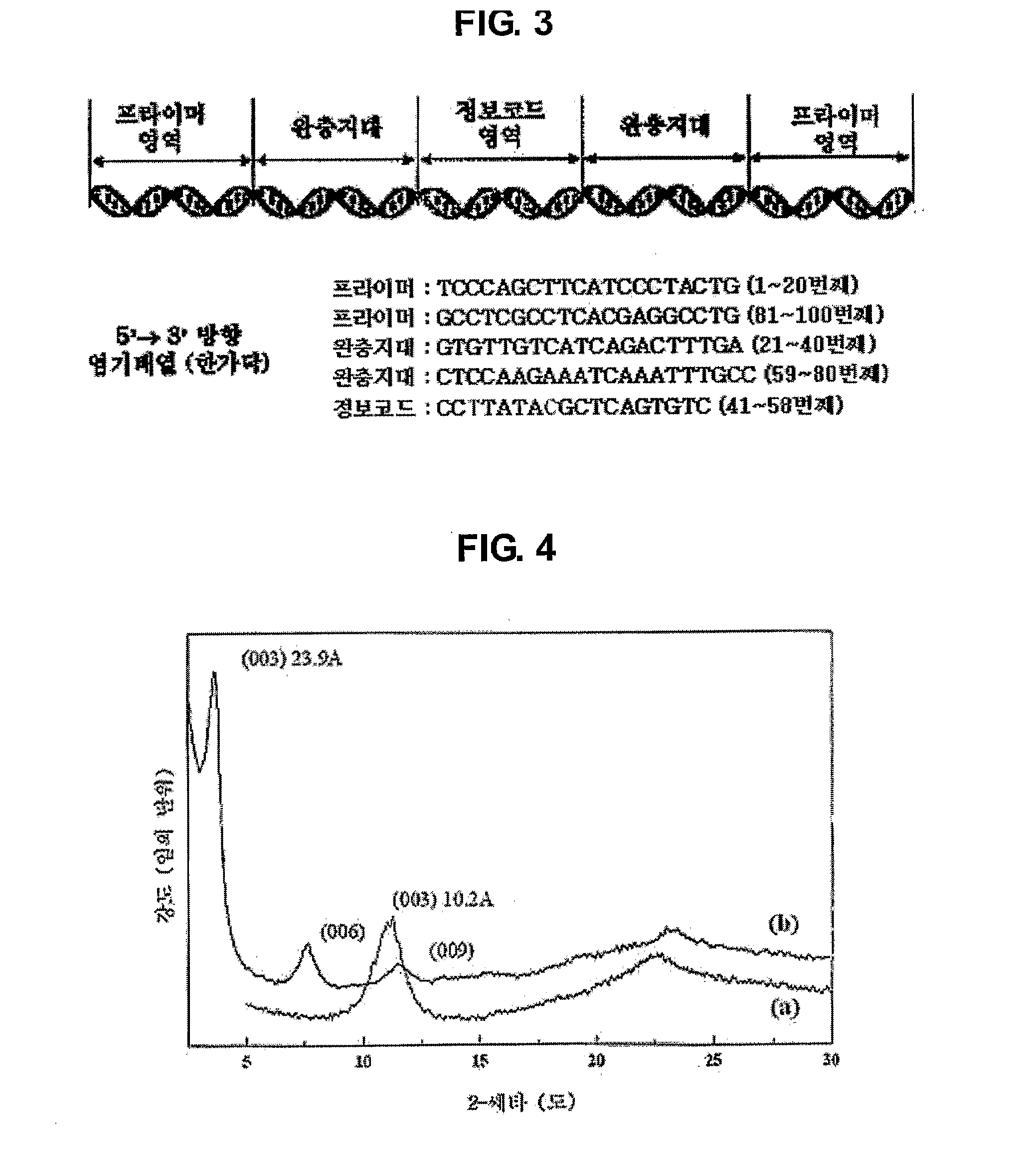

Information Code System Using Dna Sequences

InactiveUS20080268431A1Easy to detectImprove magnetic propertiesSugar derivativesMicrobiological testing/measurementPolypyrroleA-DNA

The present invention provides a molecular level of DNA information code which uses a base pair sequence as an information code unit. Also, the present invention provides a molecular code system which includes designing and coding DNA which is an information code unit; stabilizing the DNA information code by encapsulating it with an inorganic capsule and coating the DNA-inorganic capsule to a medium; taking and extracting the coated DNA information code which is present in a trace amount, collecting the DNA information code using a polypyrrole-maghemite nanohybrid; and amplifying the collected DNA information code using a polymerase chain reaction and reading the amplified DNA information code. According to the present invention, the DNA information code having high security is prepared by assigning a security unit to a DNA which has an excellent accumulating capacity, and then the DNA information code is stabilized so as to be coated to a medium. Only the DNA information code may be extracted, collected, and read, if necessary. Thus, a unified molecular code system can be established.

Owner:CNPHARM

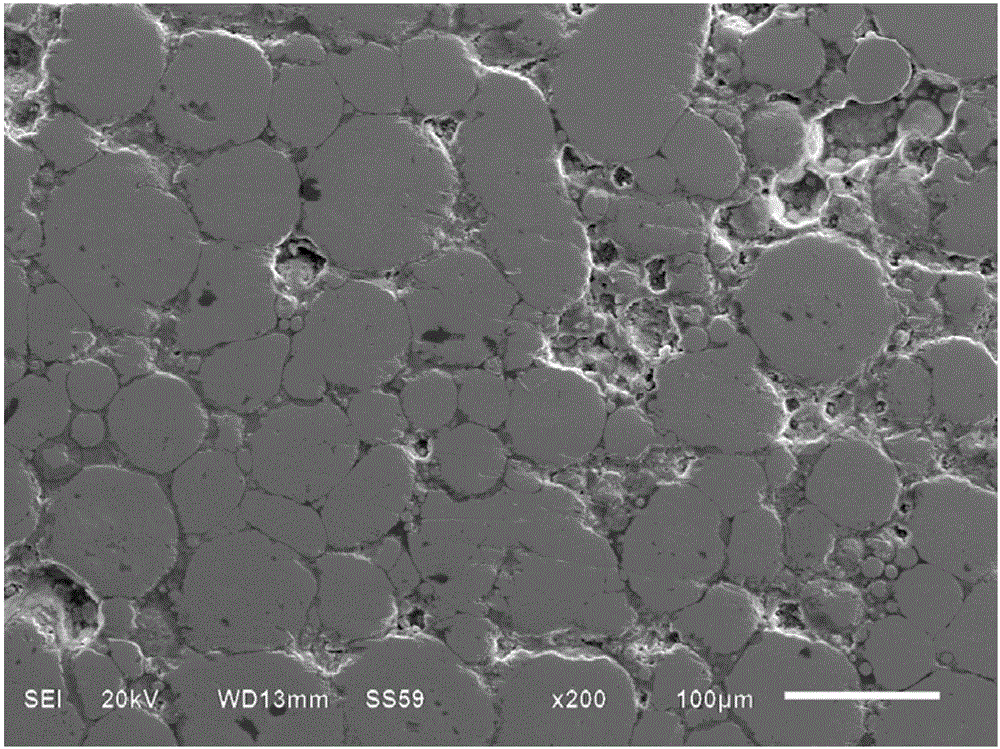

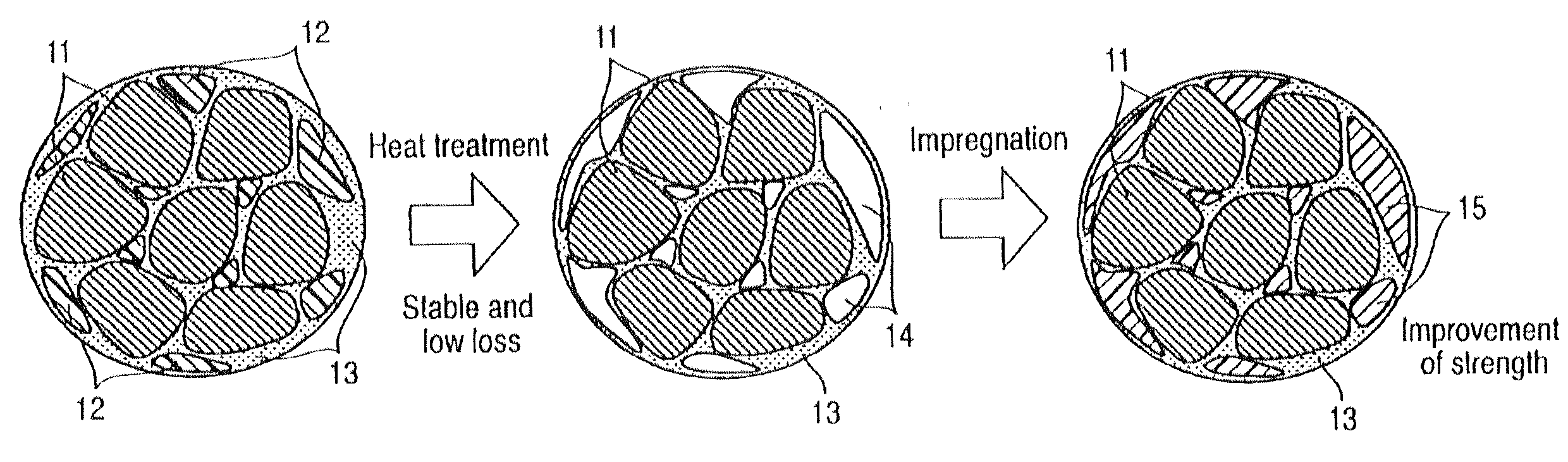

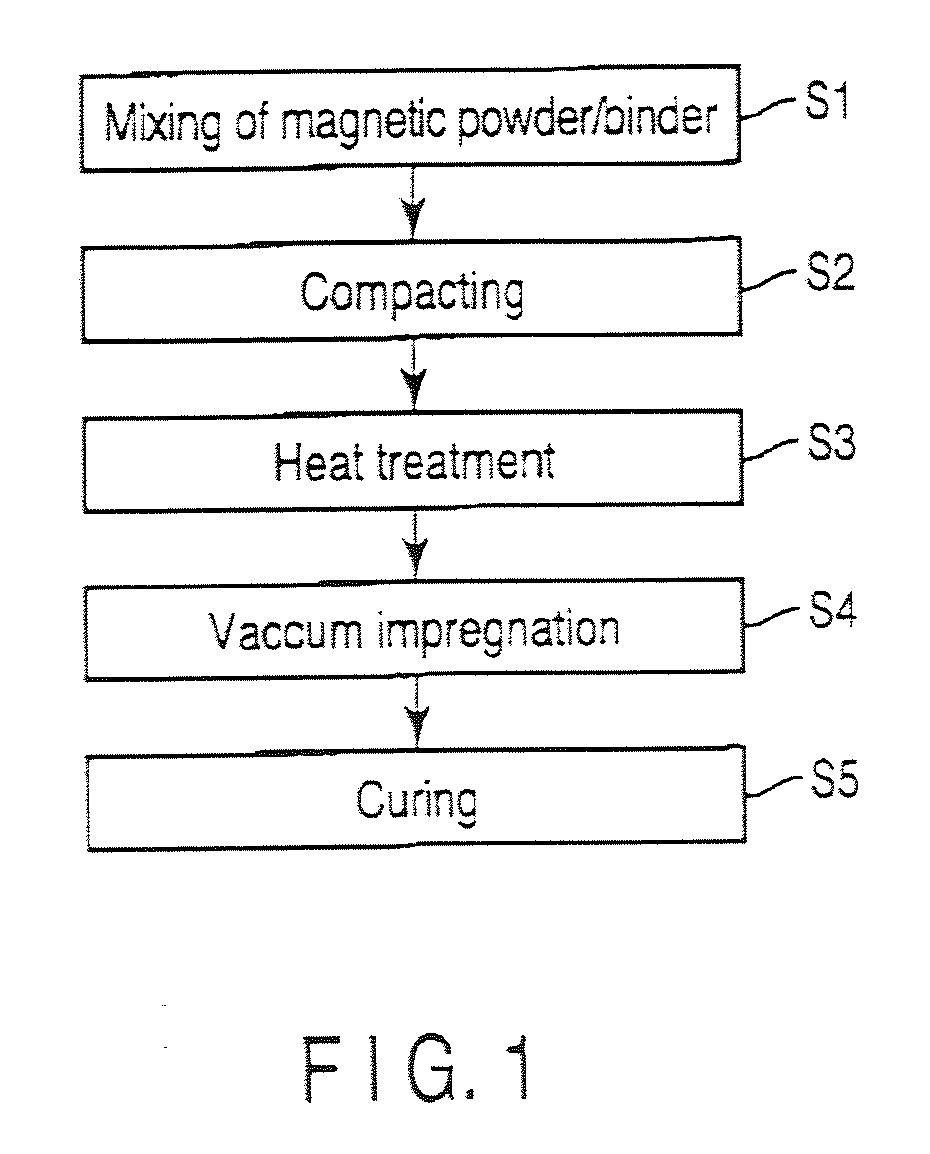

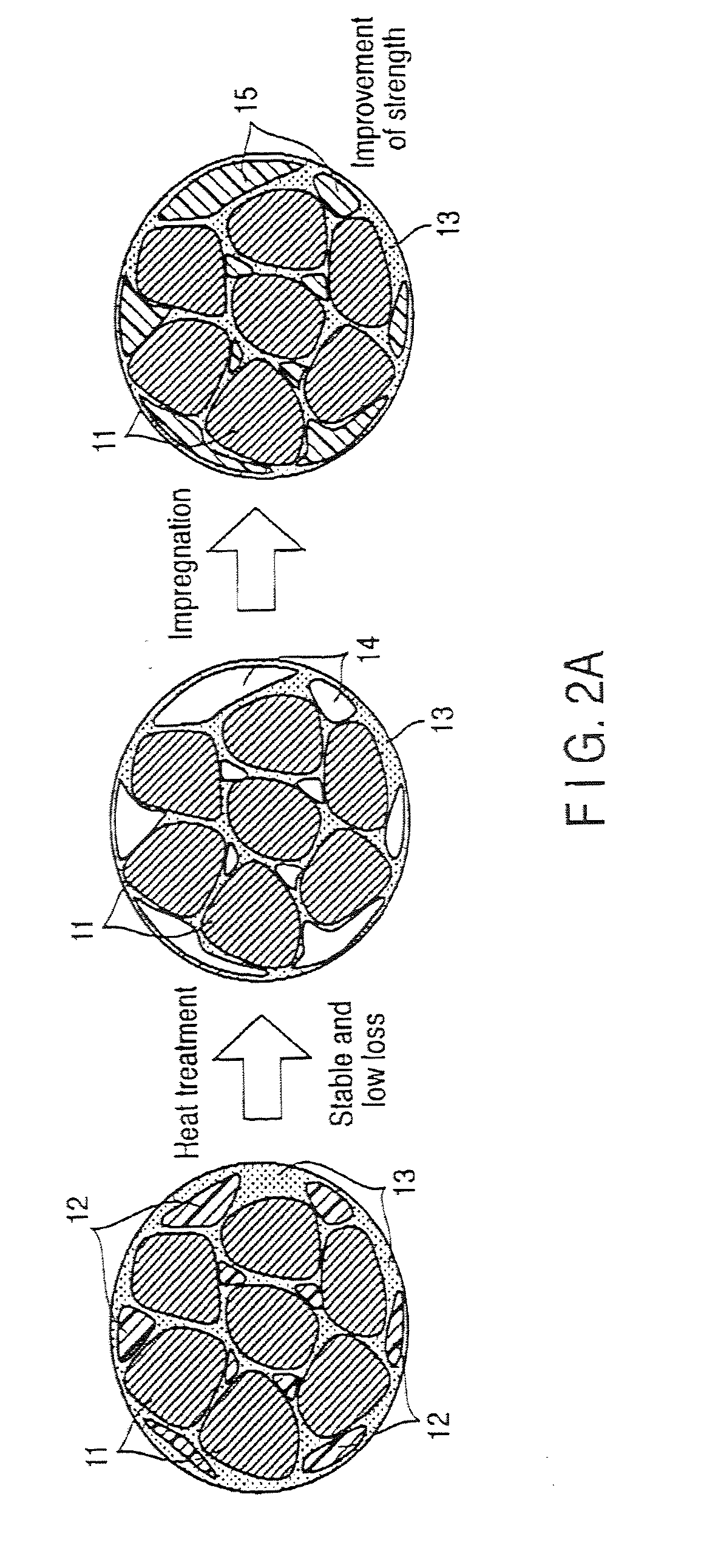

Composite magnetic material and method of manufacturing the same

InactiveUS20110024670A1Good molding effectReduce the amount requiredTransportation and packagingMetal-working apparatusSpherical shapedInductor

Certain embodiments provide a composite magnetic material for an inductor, wherein a non-magnetic material contains a first binder as a compacting additive, and is added to and mixed with the soft magnetic metal powder, and a second binder that is impregnated to a compact as a binder after the heat treatment of the compact obtained by adding the first binder to the soft magnetic metal powder and compacting it, and the soft magnetic metal powder contains 40% by mass or more (including 100%) of spherical particles of which the ratio L2 / L1 between a perimeter L1 of a particle cross-section in the two dimensional plane view and a perimeter L2 of a circle having equivalent cross-sectional area is 0.5 or more.

Owner:TOHO ZINC

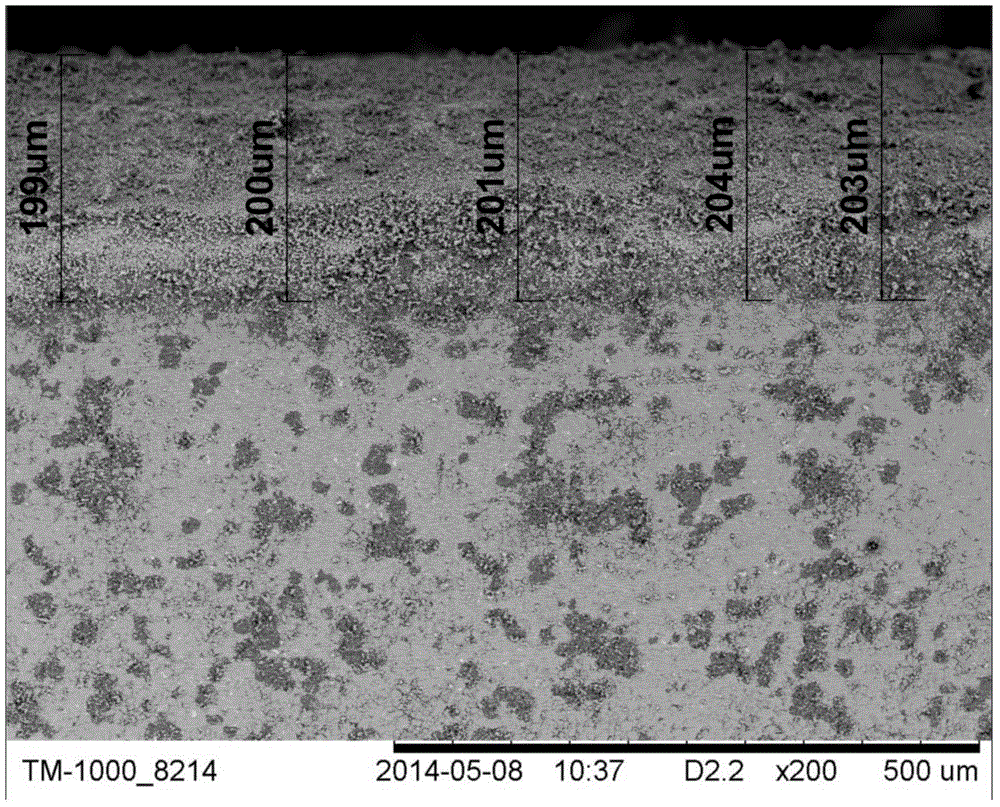

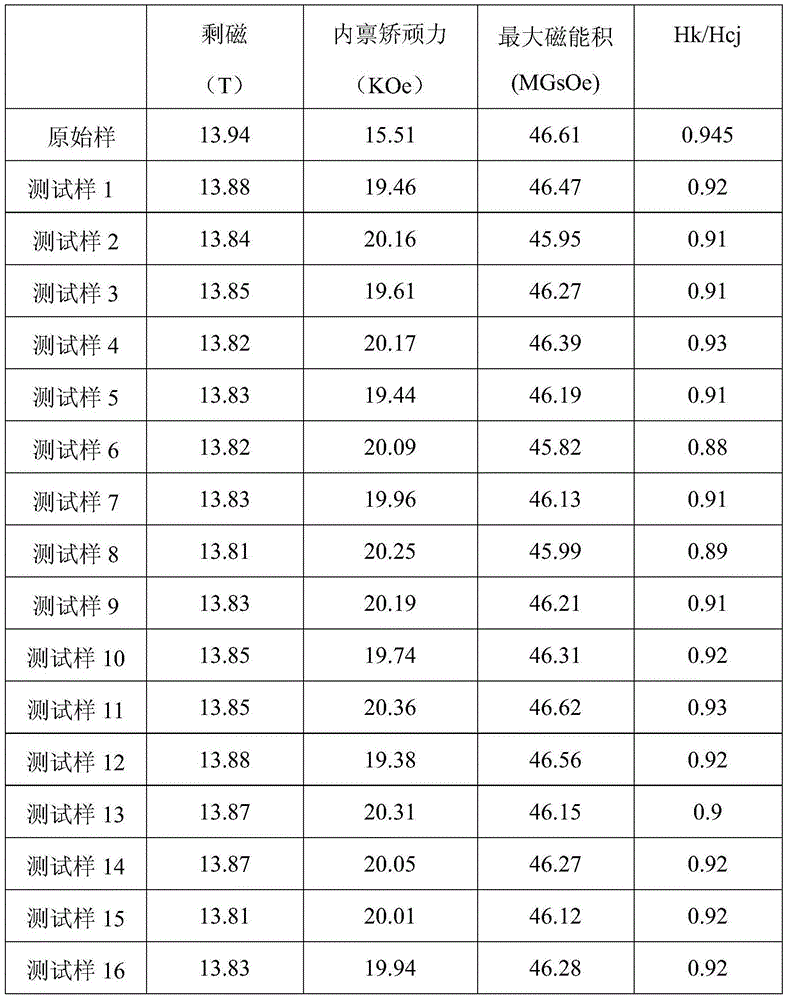

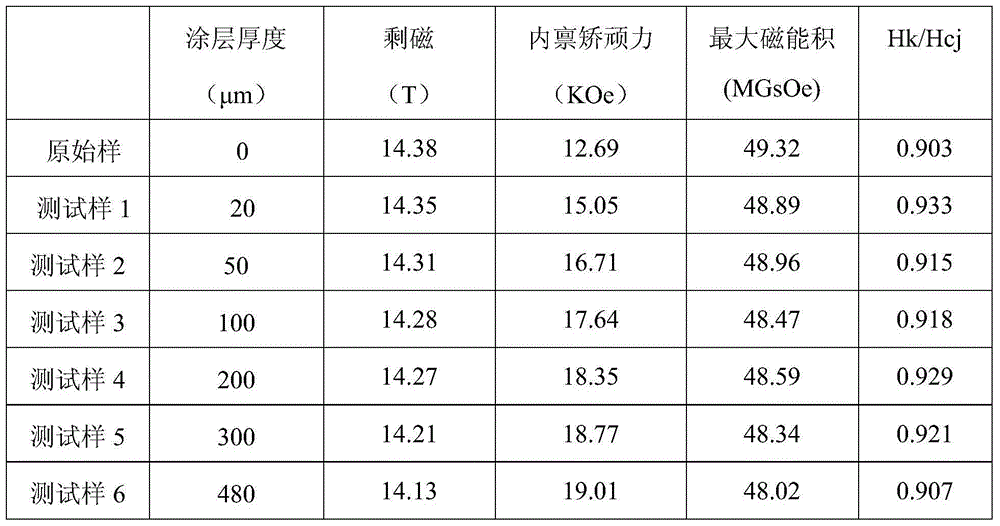

Method for improving the magnetic property of sintered NdFeB flaky magnets

ActiveCN104134528AImprove magnetic propertiesImprove organizationInorganic material magnetismSolid state diffusion coatingRare-earth elementMetallurgy

The invention discloses a method for improving the magnetic property of sintered NdFeB flaky magnets. First, suspension liquid containing heavy rare earth elements and having the viscosity of 0.1 to 500 mpa.s in the conditions of normal temperature and pressure is sprayed onto the surface of a sintered NdFeB flaky magnet uniformly. Second, the sintered NdFeB flaky magnet is dried, and then a coating containing heavy rare earth elements is obtained on the surface of the sintered NdFeB flaky magnet. Finally, the diffusion treatment and the ageing treatment are carried out on the dried sintered NdFeB flaky magnet in the environment of inert gas. The method has the advantages that the spraying technology can be applied to the grain boundary diffusion technique successfully, more specifically, a coating with high distribution uniformity and thickness distribution can be obtained on the surface of sintered NdFeB flaky magnets, and the grain boundary diffusion technology can be applied industrially for improving the magnetic property of sintered NdFeB flaky magnets.

Owner:NINGBO YUNSHENG +2

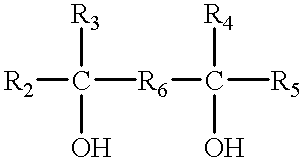

Method for preparing rare-earth system sintered magnet

InactiveUS6187259B1Improve magnetic propertiesEasy to produceInorganic material magnetismInductances/transformers/magnets manufactureChemical reactionSintered magnets

The object of the present invention is to provide rare-earth system sintered magnets such as R-Fe-B system or R-Co system having excellent magnetic properties, unique configuration of a small size, thin wall thickness and intricate geometry. With the method for preparing the present invention, a granulation of alloy powders can be achieved easily, a chemical reaction between rare-earth system and binder substances can be suppressed, so that the residual oxygen and carbon levels in the sintered products can be reduced. Moreover, by this production method, the flowability and lubricant capability during the forming process can be improved. The dimension accuracy and productivity are also enhanced. A certain type of binder is added to rare-earth alloy powders and kneaded into a slurry state. The slurry is then formed into granulated powders by spray-dryer equipment. The thus granulated powders are molded, and sintered through a powder metallurgy technique.

Owner:HITACHI METALS LTD

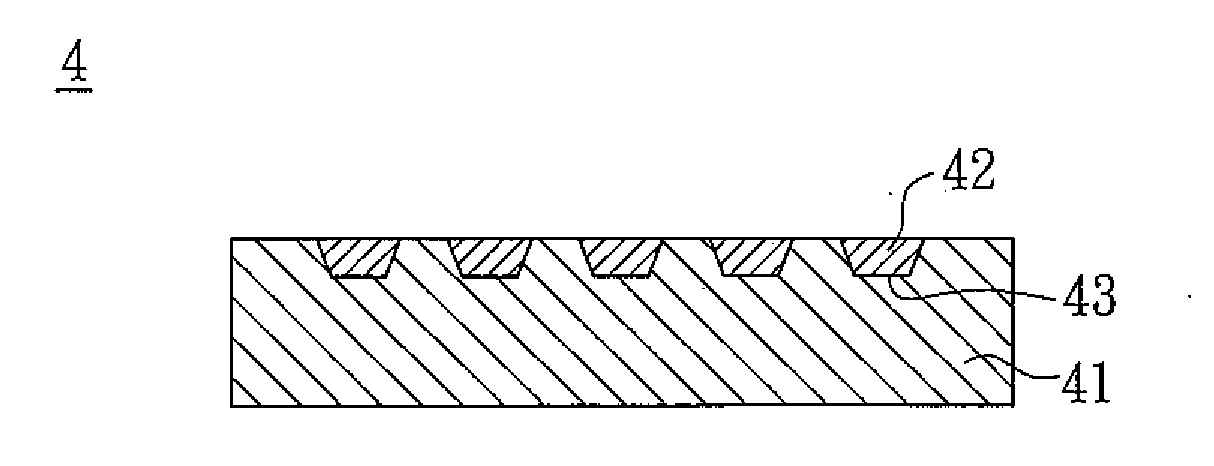

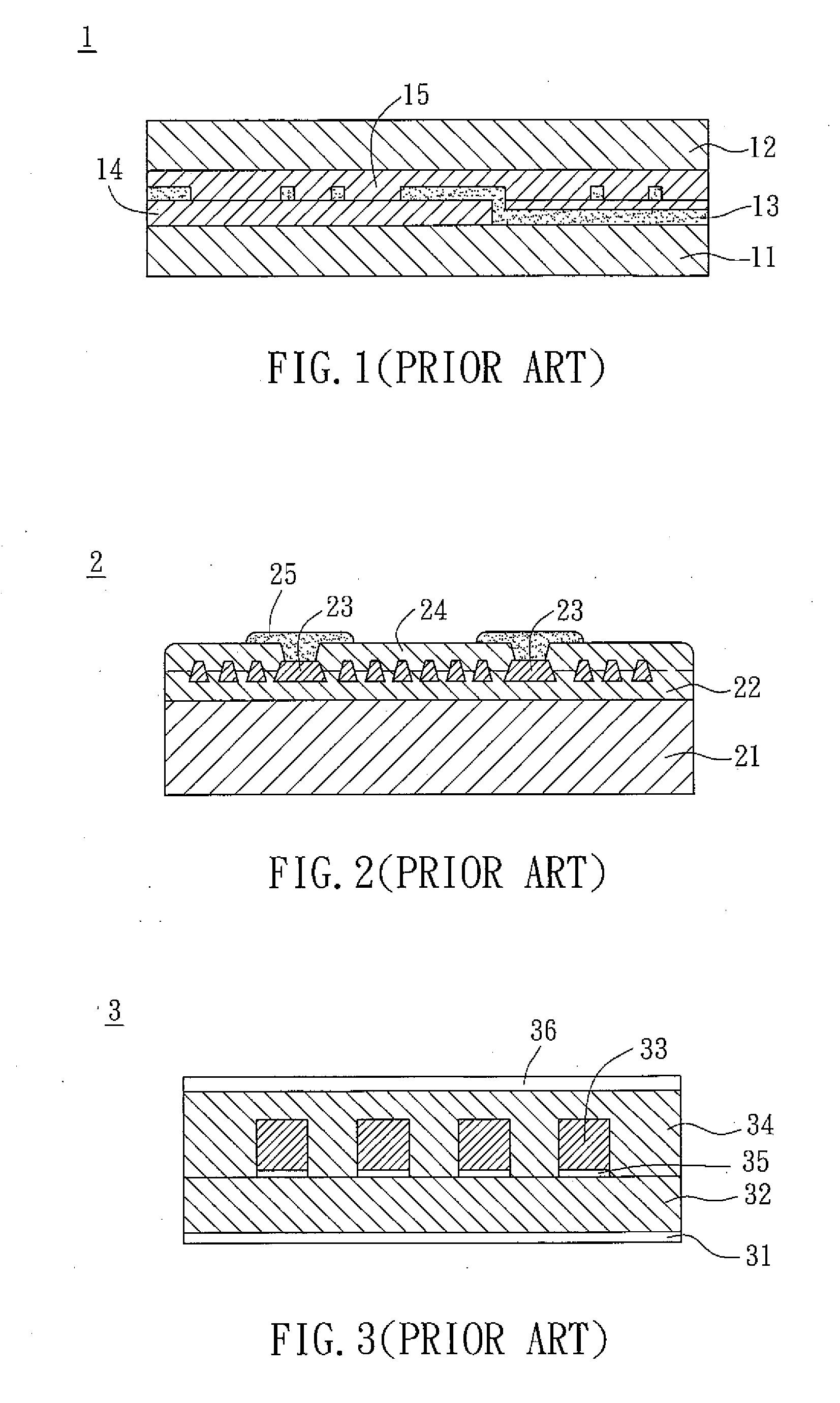

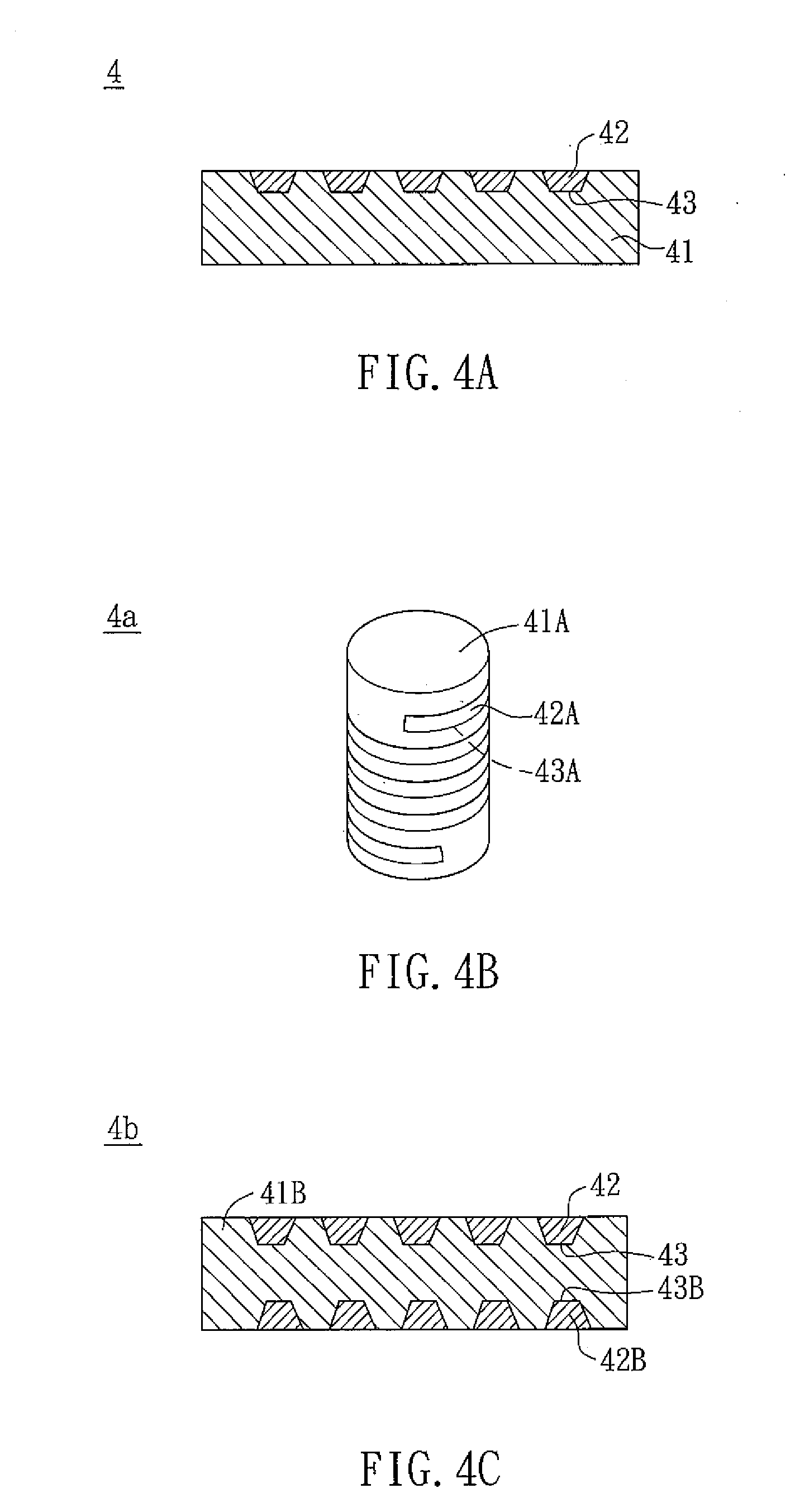

Magnetic device and manufacturing method thereof

InactiveUS20090029185A1Increase inductanceThin thicknessMouldsLayered productsElectrical and Electronics engineering

Owner:DELTA ELECTRONICS INC

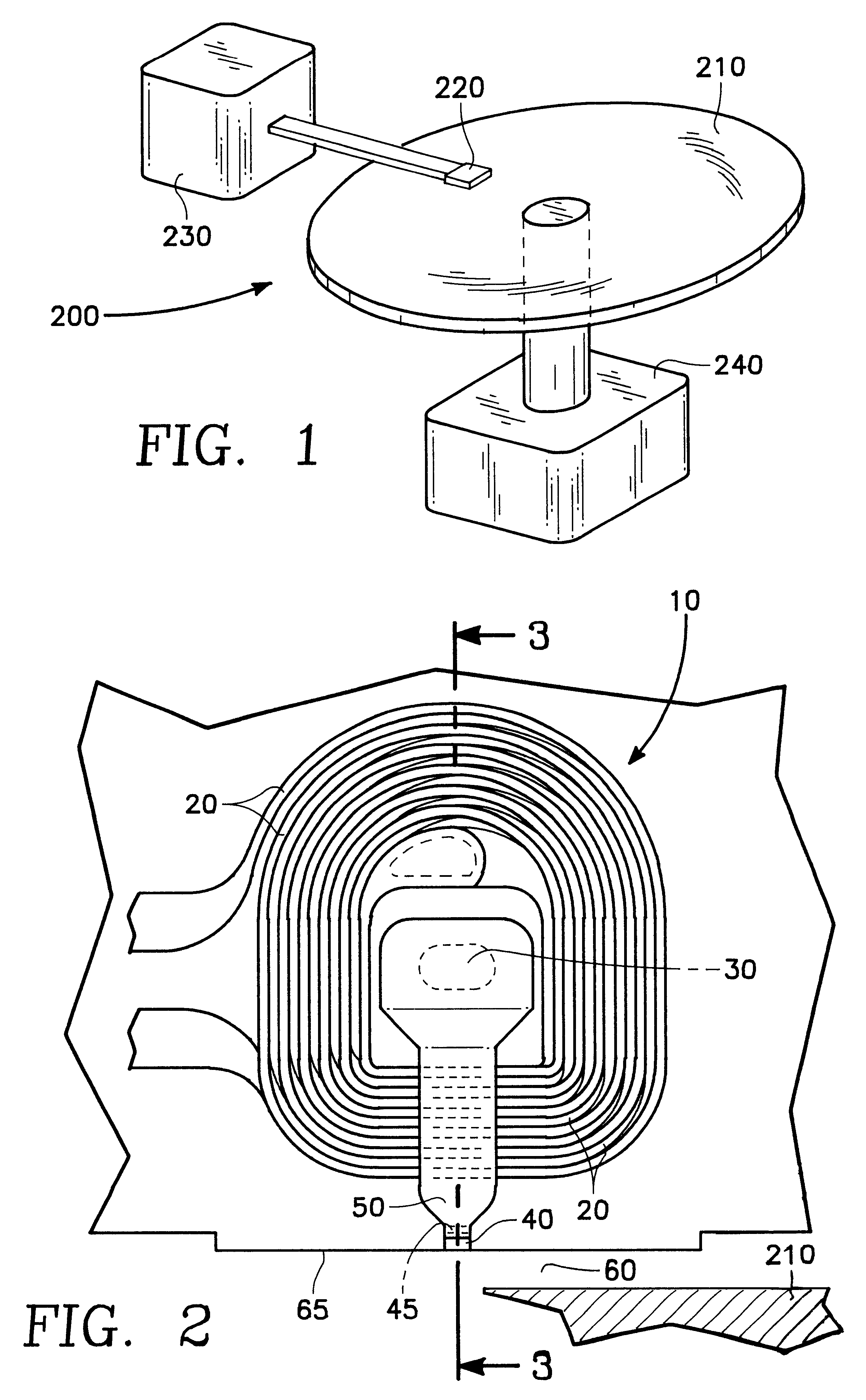

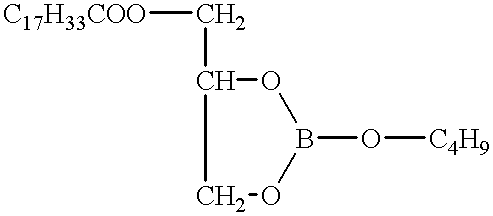

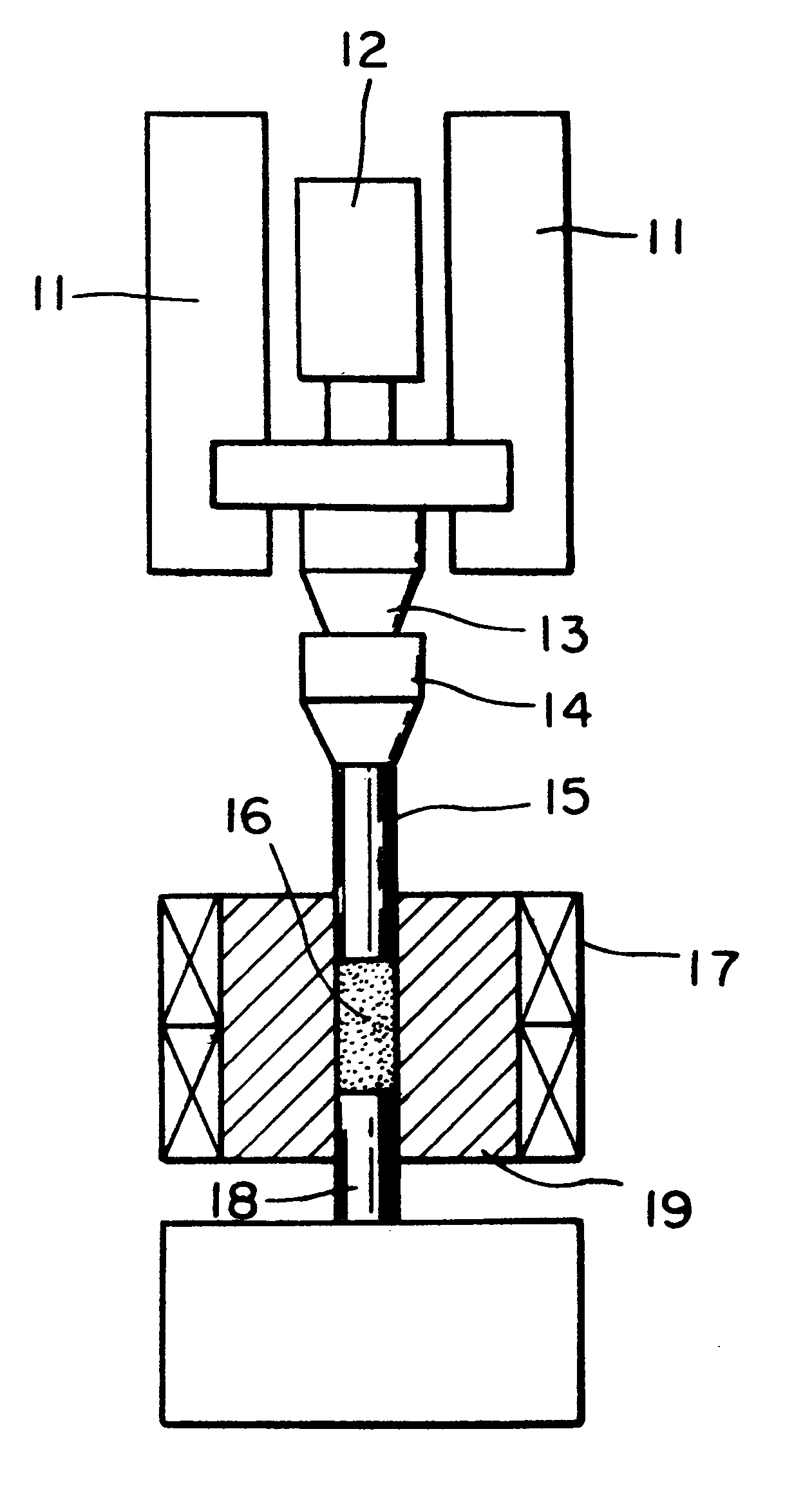

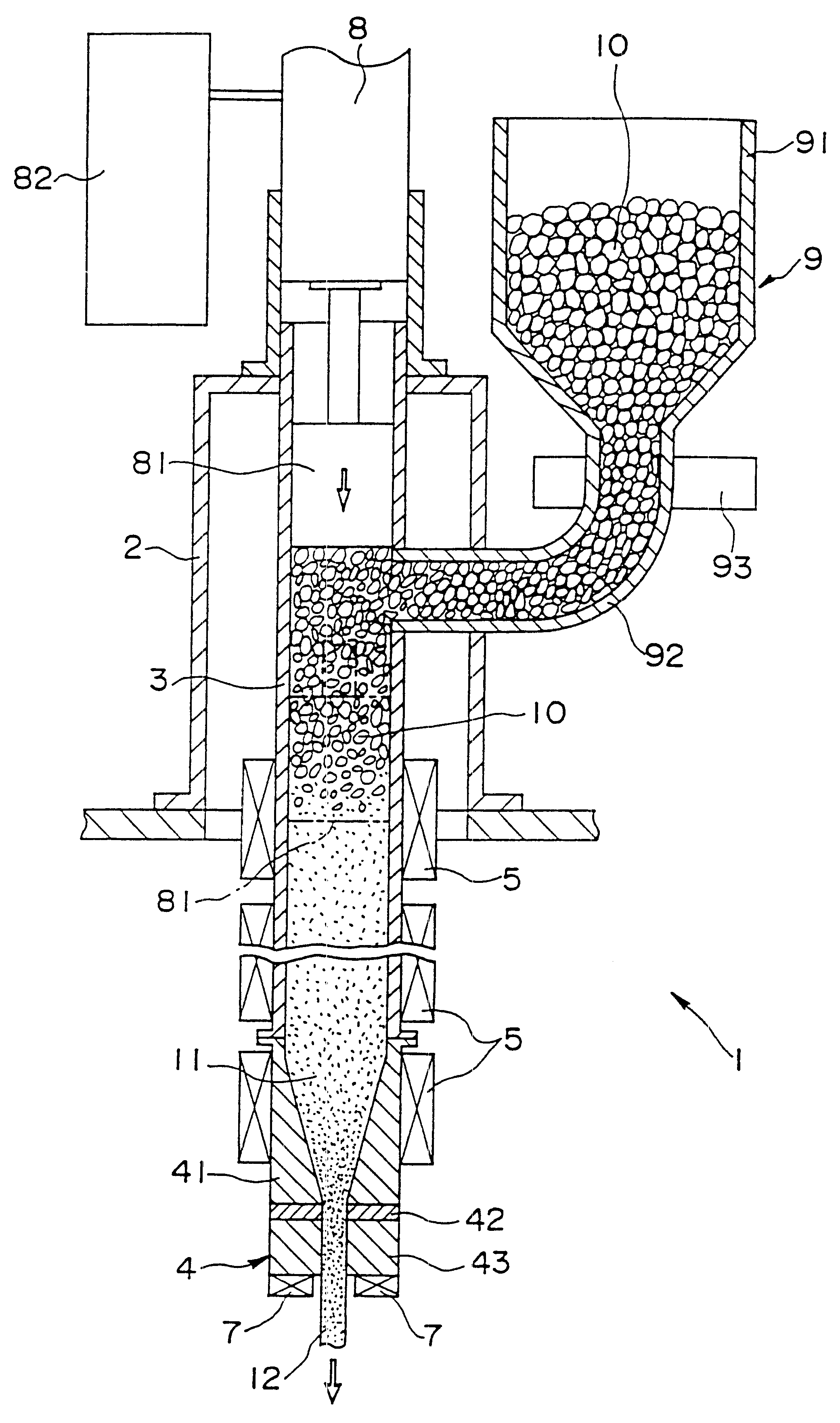

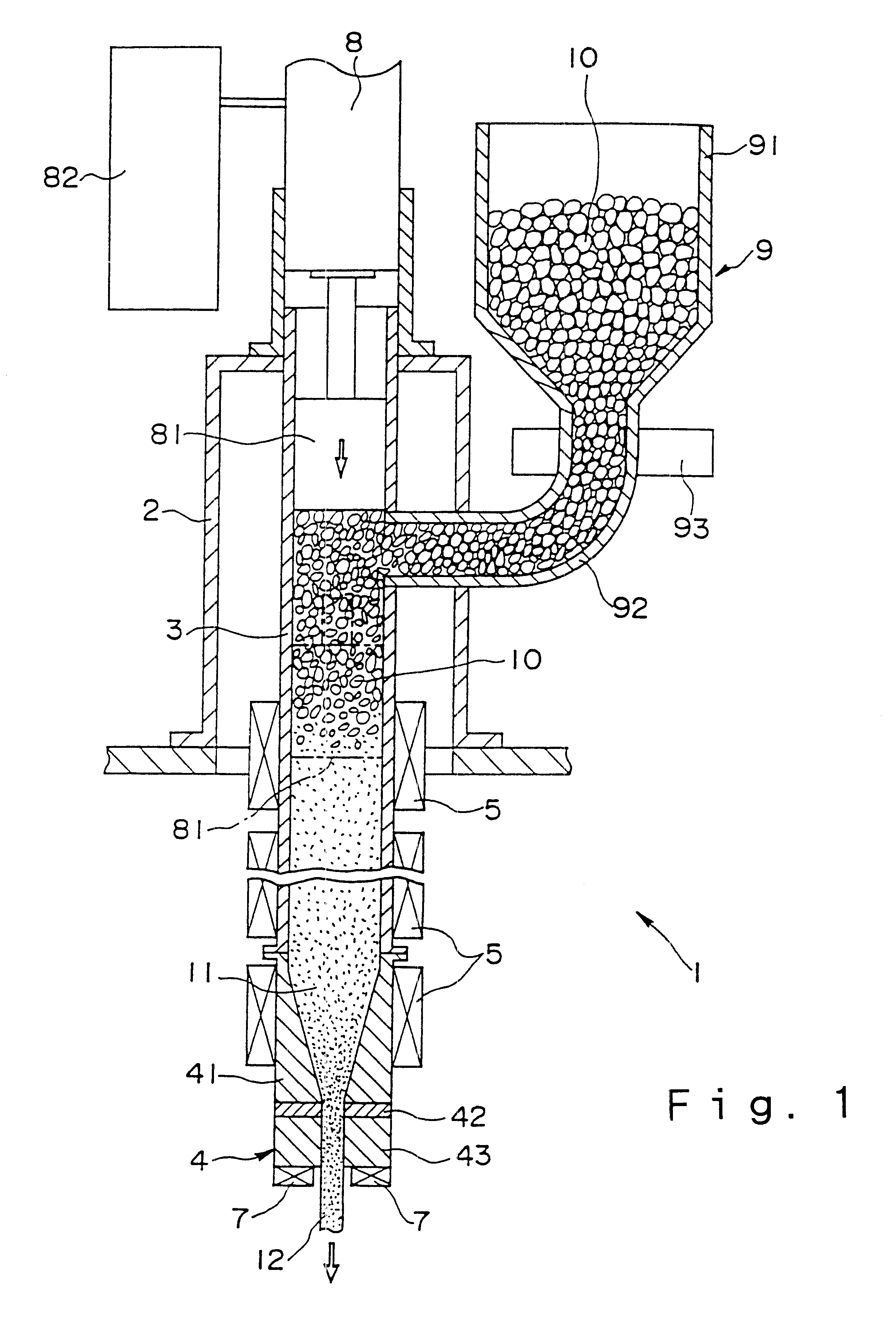

Method of manufacturing bonded magnets of rare earth metal, and bonded magnet of rare earth metal

InactiveUS6500374B1Improve magnetic propertiesOther chemical processesInductances/transformers/magnets manufacturePistonAntioxidant

The present invention provides a method for manufacturing a rare-earth bonded magnet as follows: A compound 10, prepared by pelletizing a kneaded mixture of a rare-earth-bonded-magnet composition containing a rare-earth magnet powder, a binder resin and an antioxidant, is stored in a hopper 91, and fed into a cylinder 3 through a feeding pipe 92. Meanwhile, piston 81 is extended by driving an oil-hydraulic cylinder 8, and moved downward to compact the compound 10 fed into the cylinder 3 while gradually transferring the compound downward inside the cylinder 3. The cylinder 3 and a heating portion 41 are heated by heaters 5, the compound 10 passing therethrough is heated to become a melted material 11, and the melted material 11 is continuously extruded out from a die 4 in the downward-vertical direction, and is then cooled and solidified when passing through a tip portion 43, thus obtaining a molded body 12 of a rare-earth-bonded-magnet.

Owner:SEIKO EPSON CORP

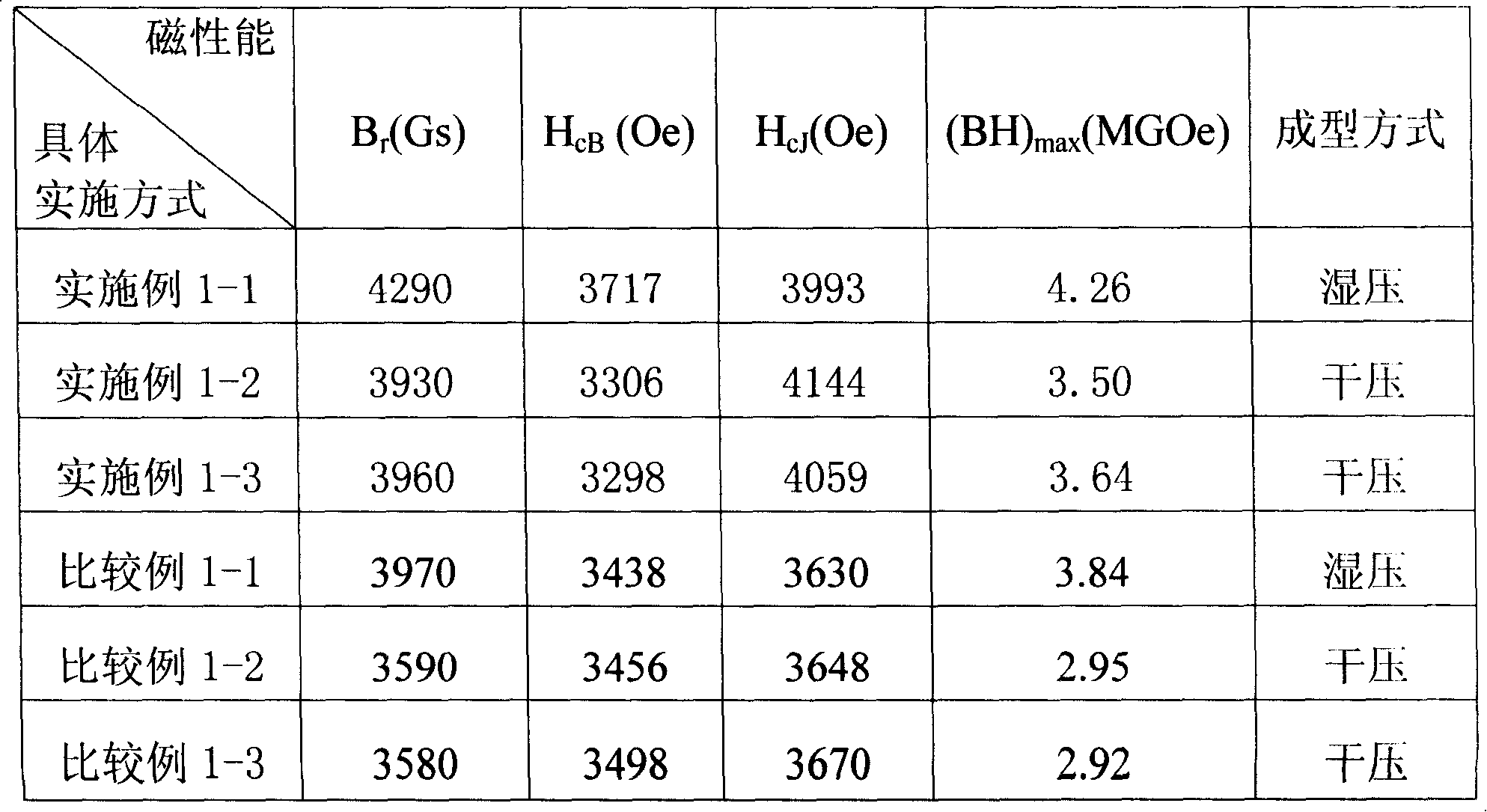

Permanent ferrite magnetic tile and preparation method thereof

InactiveCN101202138AIncrease solid solutionImprove performancePermanent magnetsInorganic material magnetismFiberSilicon oxide

The invention relates to a permanent ferrite magnetic arc and the manufacturing method thereof, belonging to a manufacturing field of a motor permanent ferrite. Weight proportions of main material components and additive components are as the following: main materials: 8.7 to 9.0 percent of strontium oxide; 86 to 87 percent of iron oxide red; additives: 0.6 to 1.0 percent of calcium carbonate; 0.6 to 1.0 percent of aluminum oxide; 0.4 to 0.8 percent of chrome oxide; 0.3 to 0.6 percent of boric acid; 0.3 to 0.5 percent of silicon oxide; 0.2 to 0.4 percent of cobalt oxide; 0.2 to 0.4 percent of lanthanum oxide and 0.1 to 0.3 percent of silicate fiber. The invention is provided with high surplus magnetic induction strength and high intrinsic coercivity so as to enhance a mechanical strength of the magnetic arc.

Owner:CHANGZHOU DIER MAGIC MATERIALS

Rare Earth Composite Magnets with Increased Resistivity

InactiveUS20150132174A1High resistivityReduce eddy current lossTransportation and packagingMetal-working apparatusDielectricHigh resistivity

Owner:ELECTRON ENERGY CORP

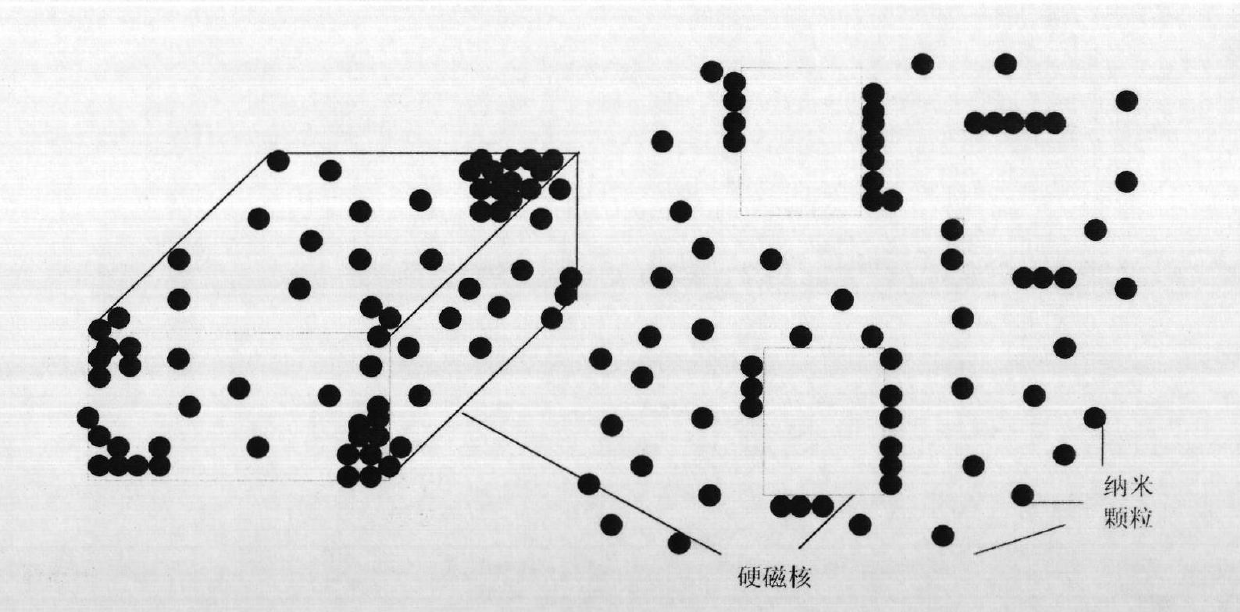

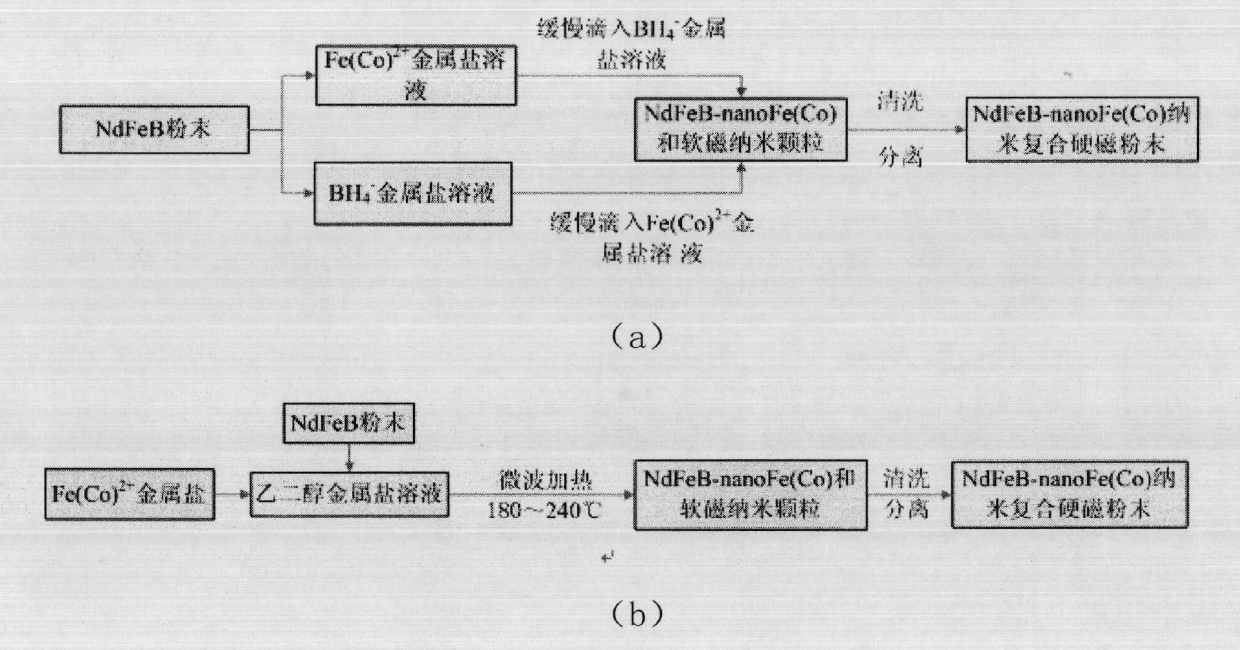

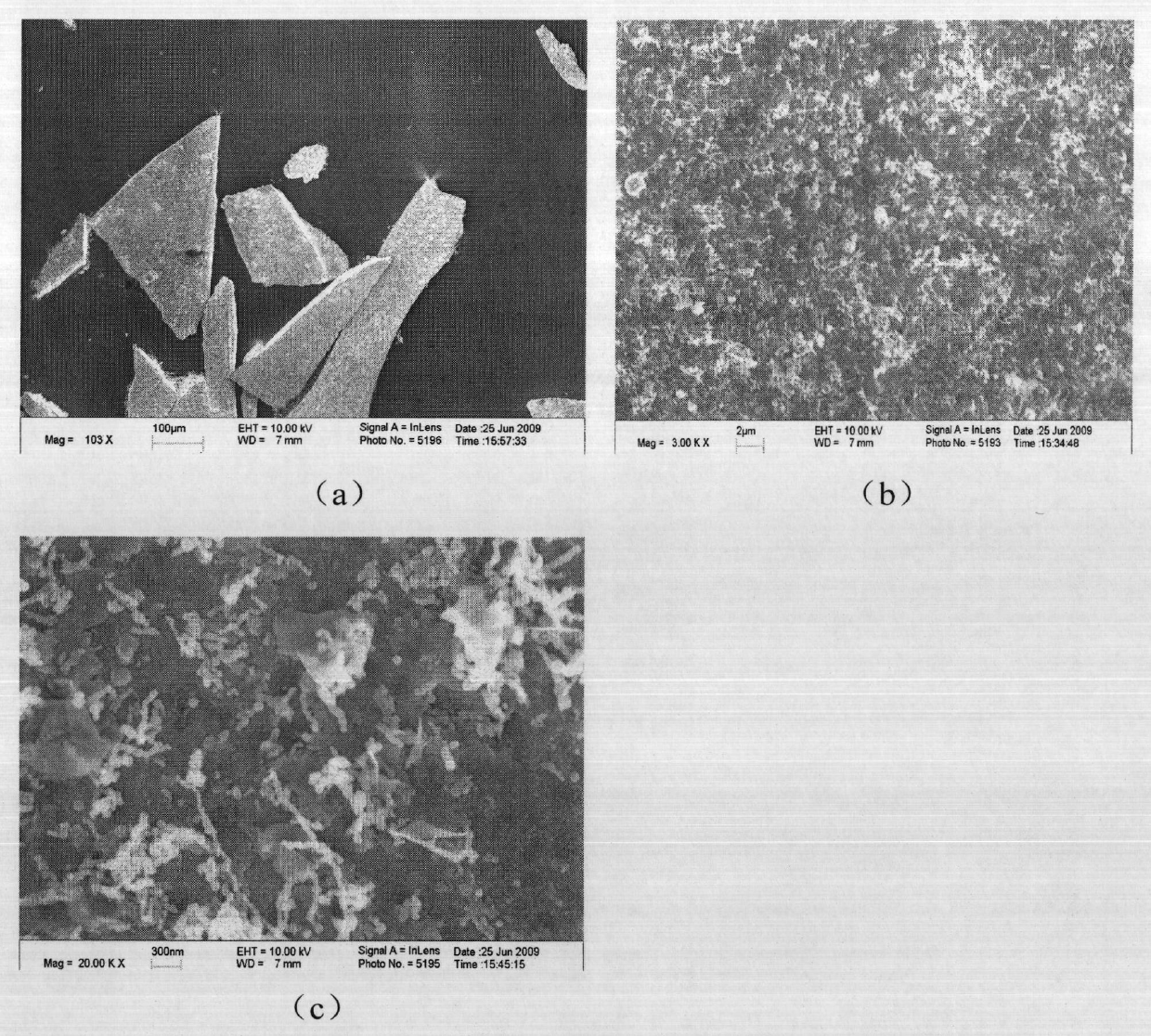

Exchange coupling dual-phase nano composite permanent magnet particles and preparation method thereof

InactiveCN102000816AGood size controlEvenly distributedInorganic material magnetismNanoparticleMicrowave assisted

The invention discloses exchange coupling dual-phase nano composite NdFeB permanent magnet particles and a preparation method thereof. The nano composite rare-earth permanent magnet particles are formed by uniformly distributing soft magnetic nano particles on the surface of hard magnetic particles, wherein the soft magnetic nano particles are iron, cobalt or iron cobalt alloy nano particles and account for 3-20 percent by weight of the nano composite rare-earth permanent magnet particles, and the hard magnetic particles are NdFeB magnetic powder. In the invention, the nano composite permanent magnet powder is prepared by wrapping the iron, cobalt or iron cobalt alloy nano particles on the surfaces of the single-phase hard magnet particles NdFeB by using a coprecipitation method or microwave-assisted polyalcohol reduction method. The preparation method of the invention has simple process and relatively lower cost and is suitable for mass production, the permanent magnet powder obtained by the method disclosed in the invention can be prepared into high-performance nano composite permanent magnets after being sintered, bonded or densified subsequently; in addition, the invention canremarkably reduce the rare-earth content in a permanent magnet material, decrease the production cost and improve the magnetic performance of the prepared product.

Owner:SOUTH CHINA UNIV OF TECH

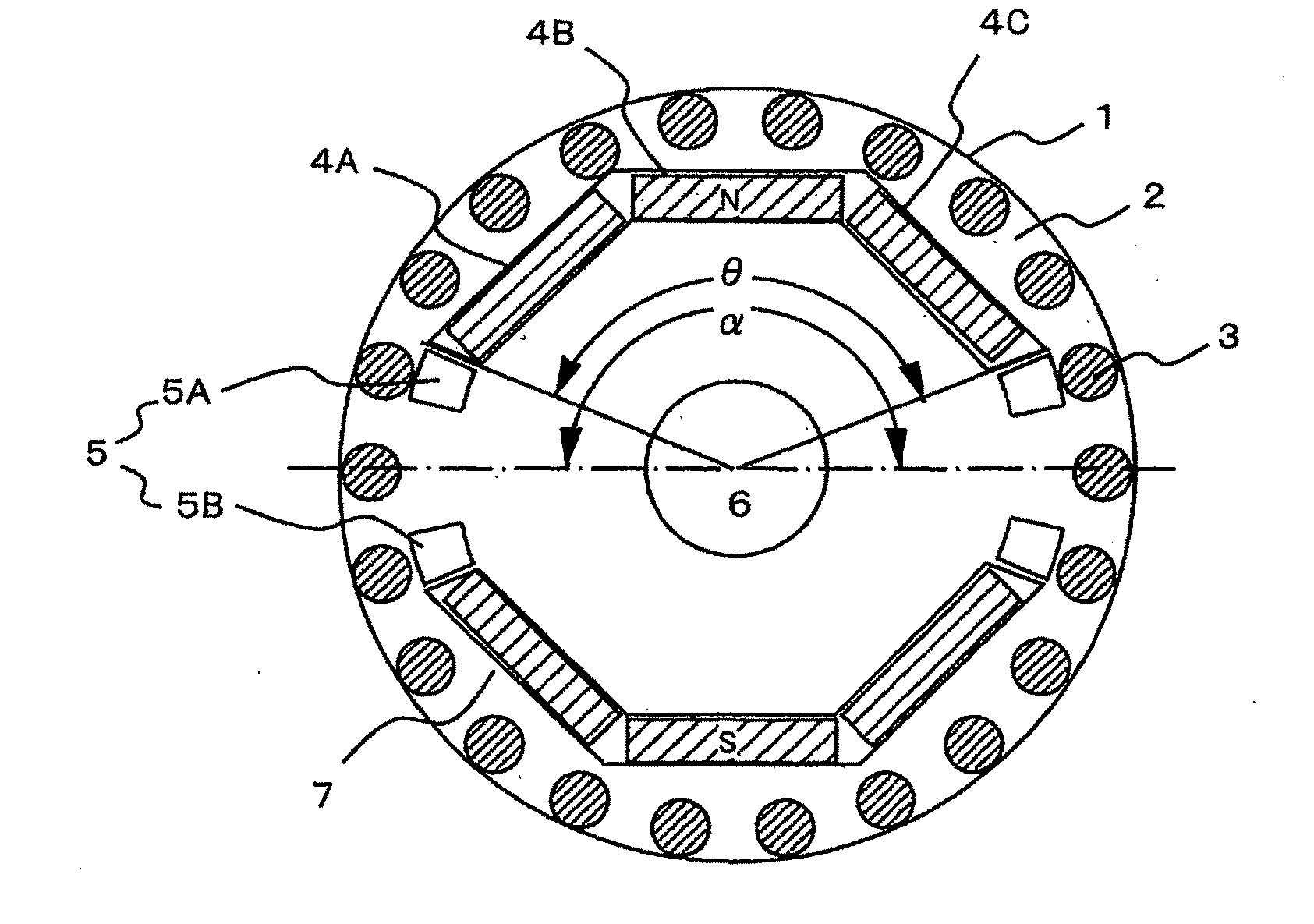

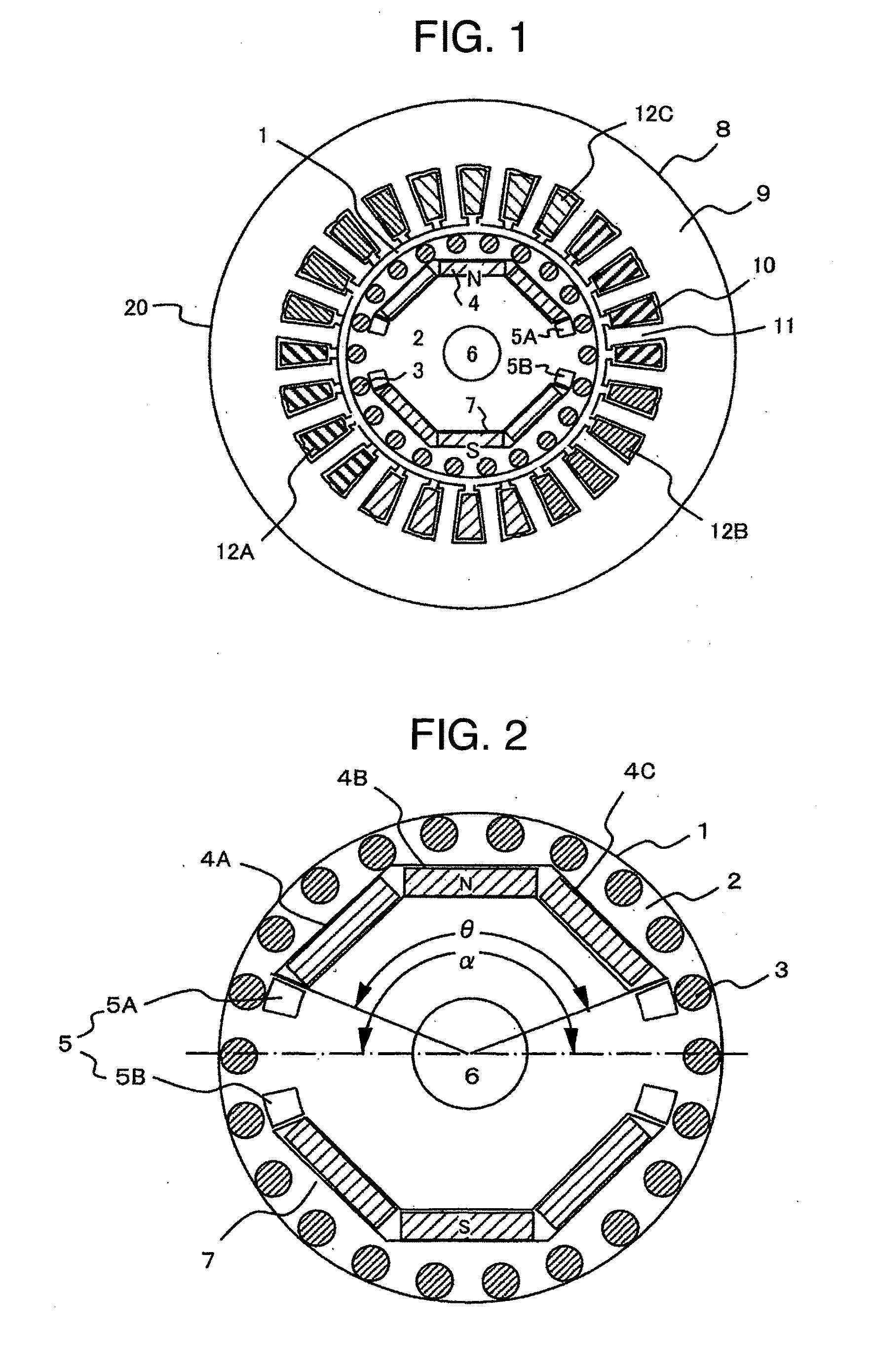

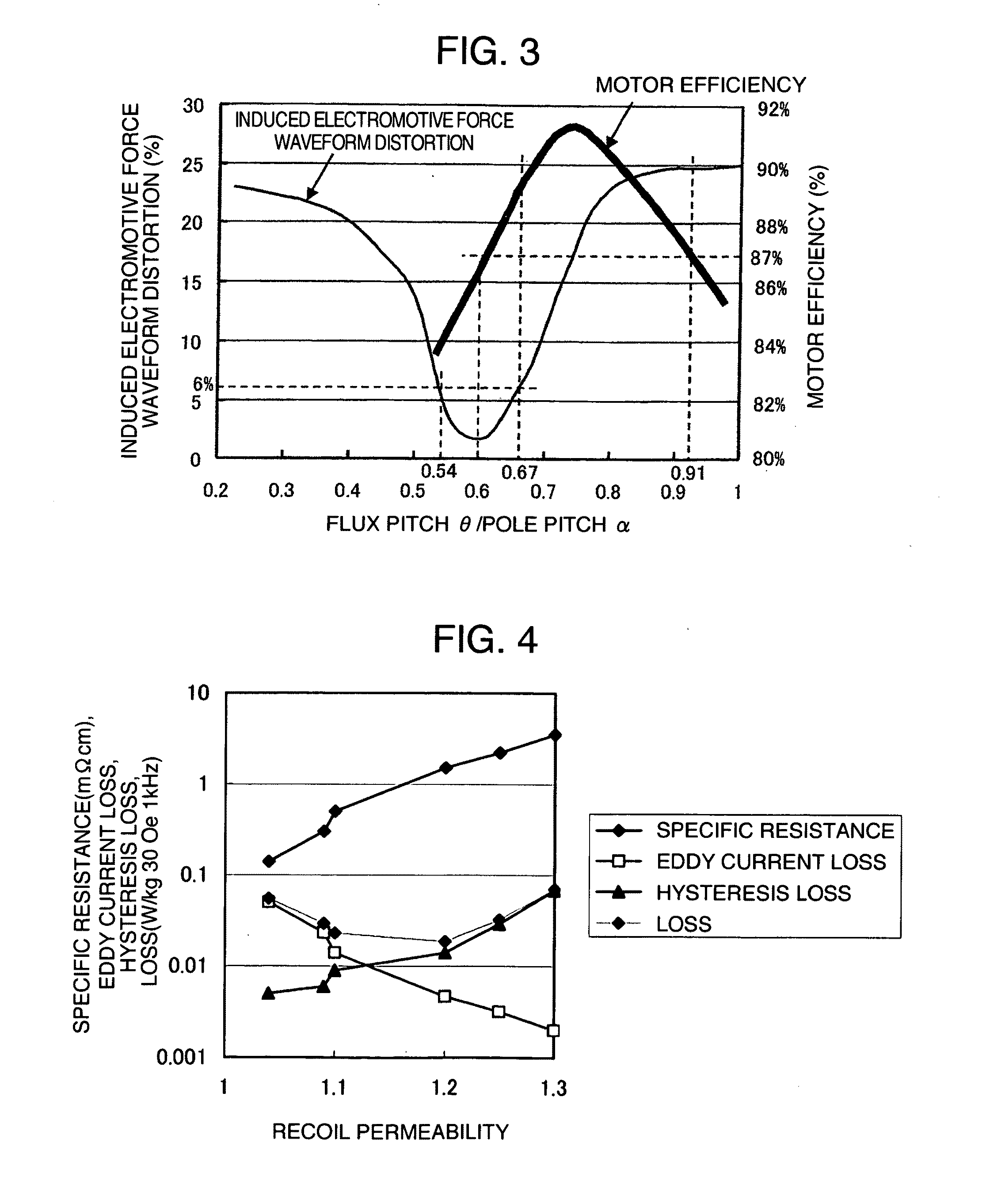

Self starting permanent magnet synchronous motor

InactiveUS20090200885A1Increase resistanceImprove the immunityTransportation and packagingMetal-working apparatusMagnetizationPermanent magnet synchronous motor

The present invention provides a permanent magnet that a fluorine compound is formed on the surfaces of Fe-based magnetic particles, and a recoil permeability is determined in a range of 1.05 to 1.30 by controlling an iron concentration in the fluorine compound to a range of 1 to 50% to reduce a loss due to magnetization rotation, thereby remedying reduction of a residual magnetic flux density and degradation of steady-state characteristics.

Owner:HITACHI LTD

Rare earth permanent magnetism material and its making method

ActiveCN101266855AReduce manufacturing costImprove magnetic propertiesMagnetic materialsHydrogenAdditive ingredient

The invention relates to a rare earth permanent magnet and a manufacturing method thereof, more particularly a neodymium ferroboron permanent magnet material and a manufacturing method thereof. The rare earth permanent magnet comprises a rapid hardening alloy and a crystal boundary object, the crystal boundary object is one or more of metal Nd, Pr, Sm, Eu, Gd, Tb, Dy, Ho, Al, Cu, Sn, Zn, the crystal boundary mixture is 0.3-2% of the total weight. The crystal boundary object, without melting, directly crushes pure metals or the metal mixture with hydrogen and adds gas stream to mill into powder, then mixes with main phase rapid hardening alloy powder to form and sinter, the performance of magnet is more improved than the magnet with the same ingredients in traditional procedure. The invention omits a melting procedure of the crystal boundary object, directly adds the powder and saves the production cost of the magnet.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

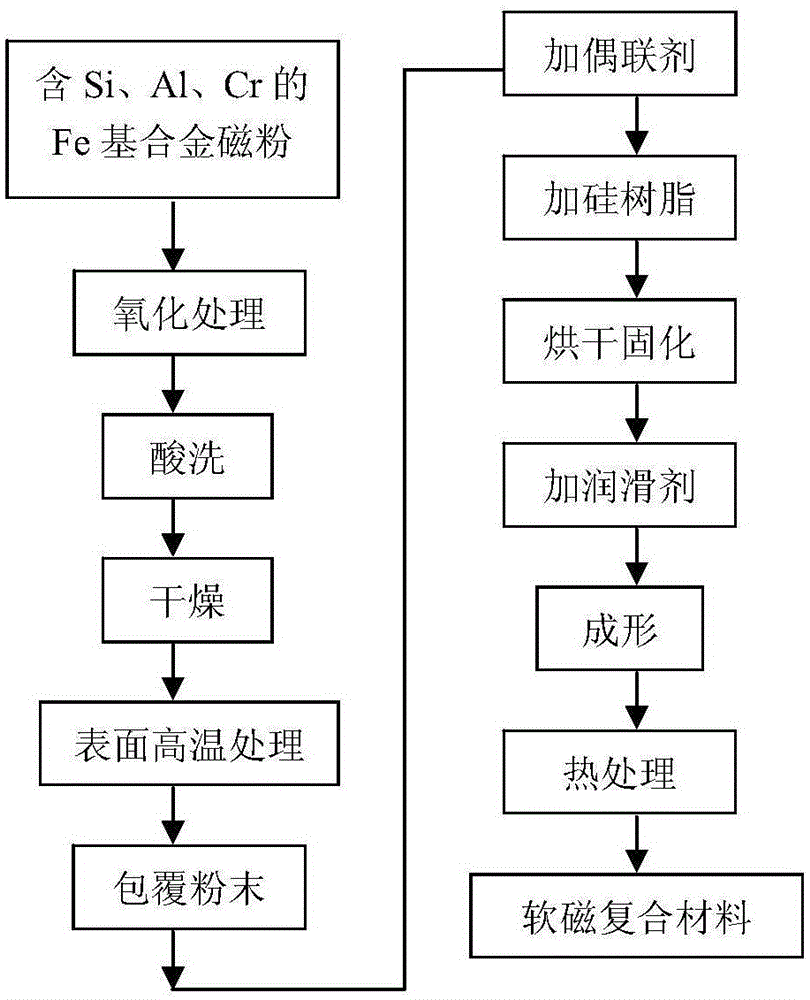

Coating method iron-based magnetically soft alloy powder and preparation method of soft magnet composite material

ActiveCN105149574AHigh resistivityImprove compactnessInorganic material magnetismMagnetic powderOxide

The invention relates to a coating method for iron-based magnetically soft alloy powder and a preparation method of soft magnet composite material. The coating method for iron-based magnetically soft alloy powder comprises the following steps: carrying out accelerated oxidation on iron-based magnetic metal powder at high temperature, forming an oxide layer on the surface of the powder and then carrying out acid pickling, thus obtaining powder with surface coated with SiO2, Al2O3 and Cr2O3 oxides. The preparation method of the soft magnet composite material comprises the following steps: adding coupling agent, silicon resin and lubricating agent to the coated powder, carrying out pressing forming, and then carrying out annealing heat treatment, thus obtaining the soft magnet composite material. According to the invention, the advantage that an oxide produced in reaction of elements including Si, Al and Cr contained in the iron-based magnetically soft alloy powder with oxygen is high in electrical resistivity, small in thermal expansion coefficient and steady in chemical performance and can resist high temperature is fully utilized; the adopted coating technology is to produce a coating layer in situ on the surface of the alloy magnetic powder, and is simple in process, easy to operate and low in cost; the metal soft magnet composite material prepared by adopting the method disclosed by the invention has good magnetic property and frequency stability.

Owner:CENT SOUTH UNIV

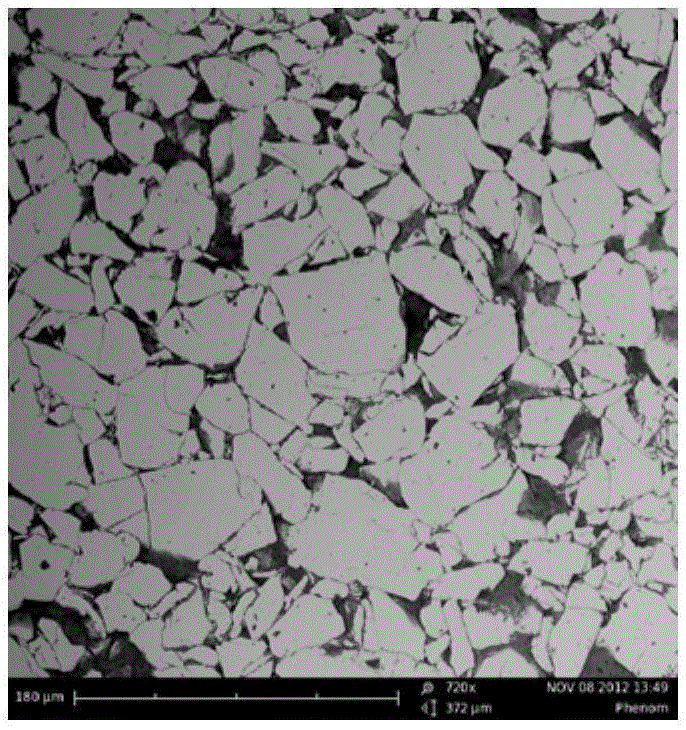

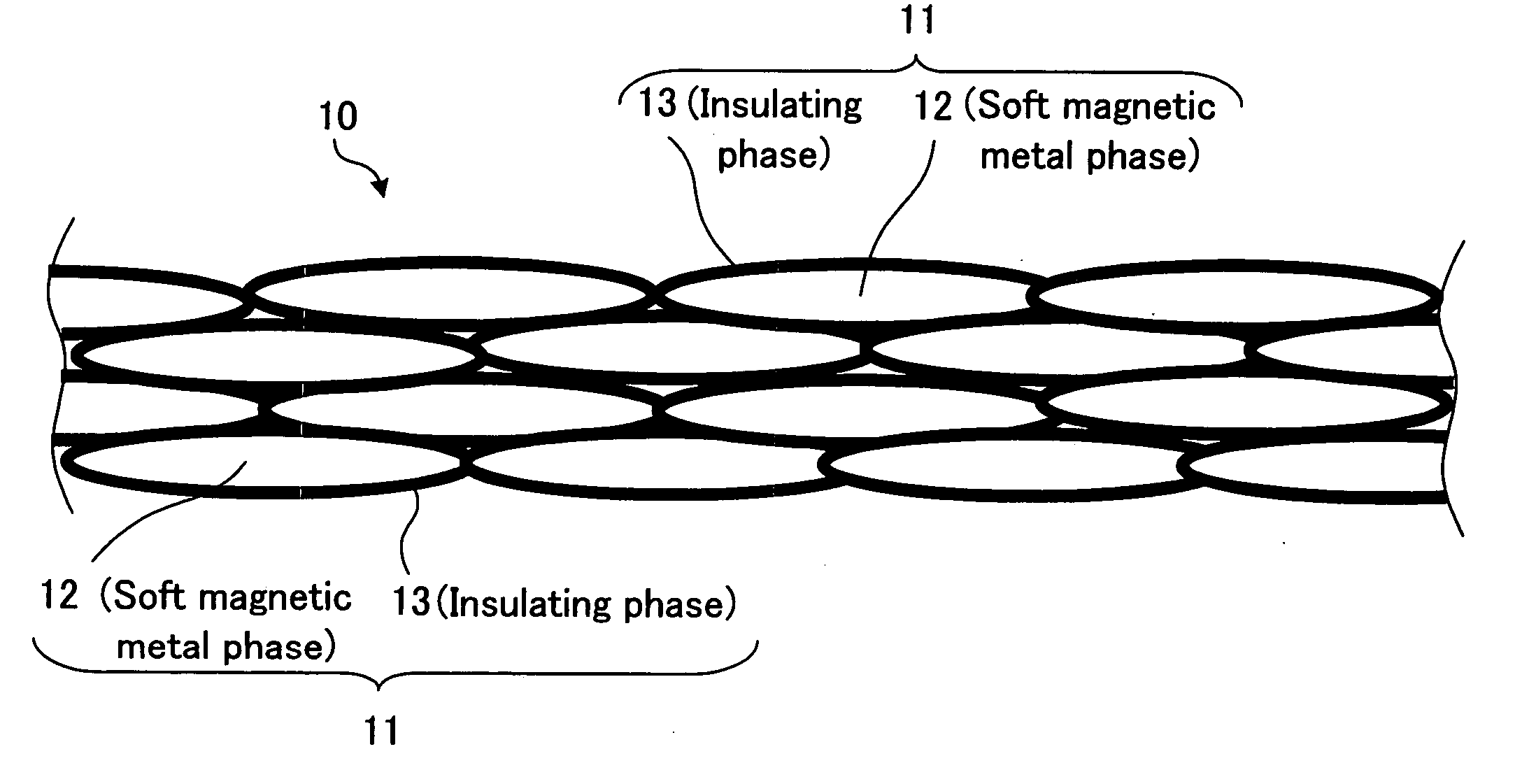

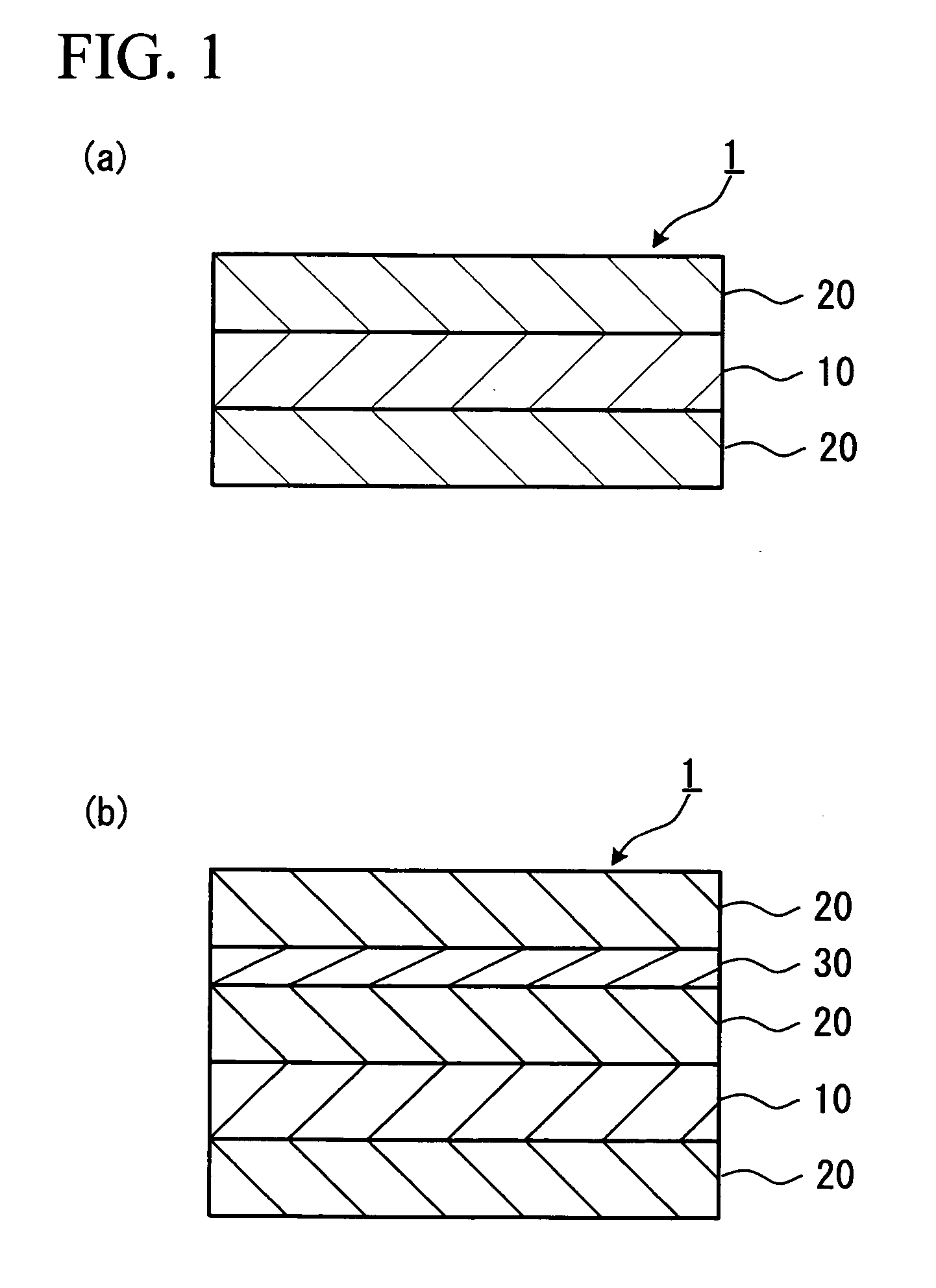

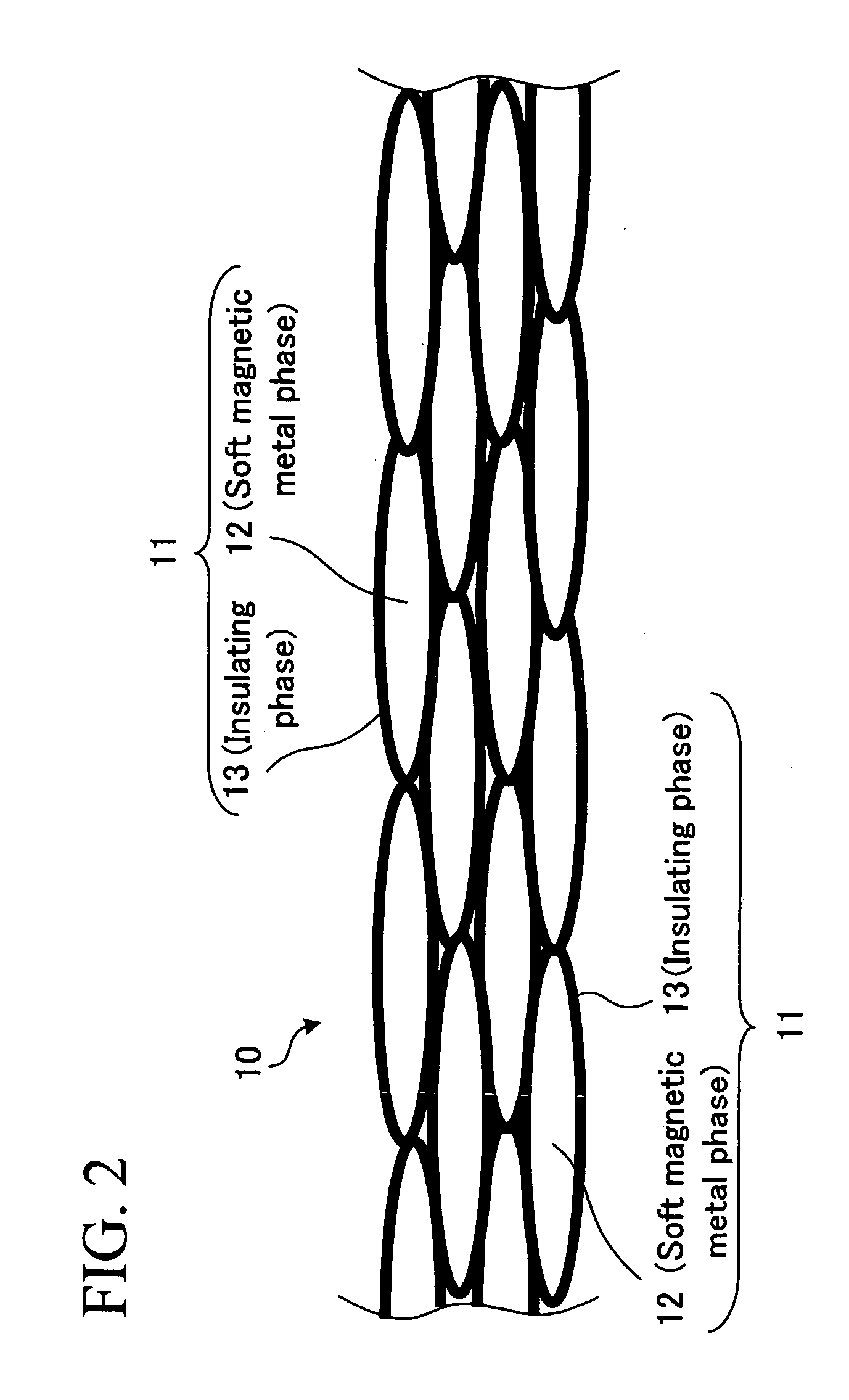

Composite magnetic material electromagnetic wave absorbing sheet method for manufacturing sheet-like product and method for manufacturing electromagnetic wave absorbing sheet

InactiveUS20050012652A1Improve magnetic propertiesShielding materialsInorganic material magnetismMetal powderMaterials science

The object of the present invention is to provide an electromagnetic wave absorbing sheet excellent in permeability in high frequencies and to provide a method for manufacturing the same. The electromagnetic wave absorbing sheet of the present invention comprises insulating layers on the both sides of a magnetic layer. The magnetic layer is formed by densely depositing a large amount of magnetic powder such that the powder undergoes plastic deformation. Each magnetic powder is made to be a composite magnetic material formed of the soft magnetic metal phase consisting of a flaky soft magnetic metal powder and the insulating phase consisting of an insulating film formed on the surface of the soft magnetic metal phase. Additionally, another configuration can be taken in which a conductive layer is arranged on one of the insulating layers arranged on both sides of the magnetic layer, and the conductive layer is covered with an insulating layer.

Owner:TDK CORPARATION

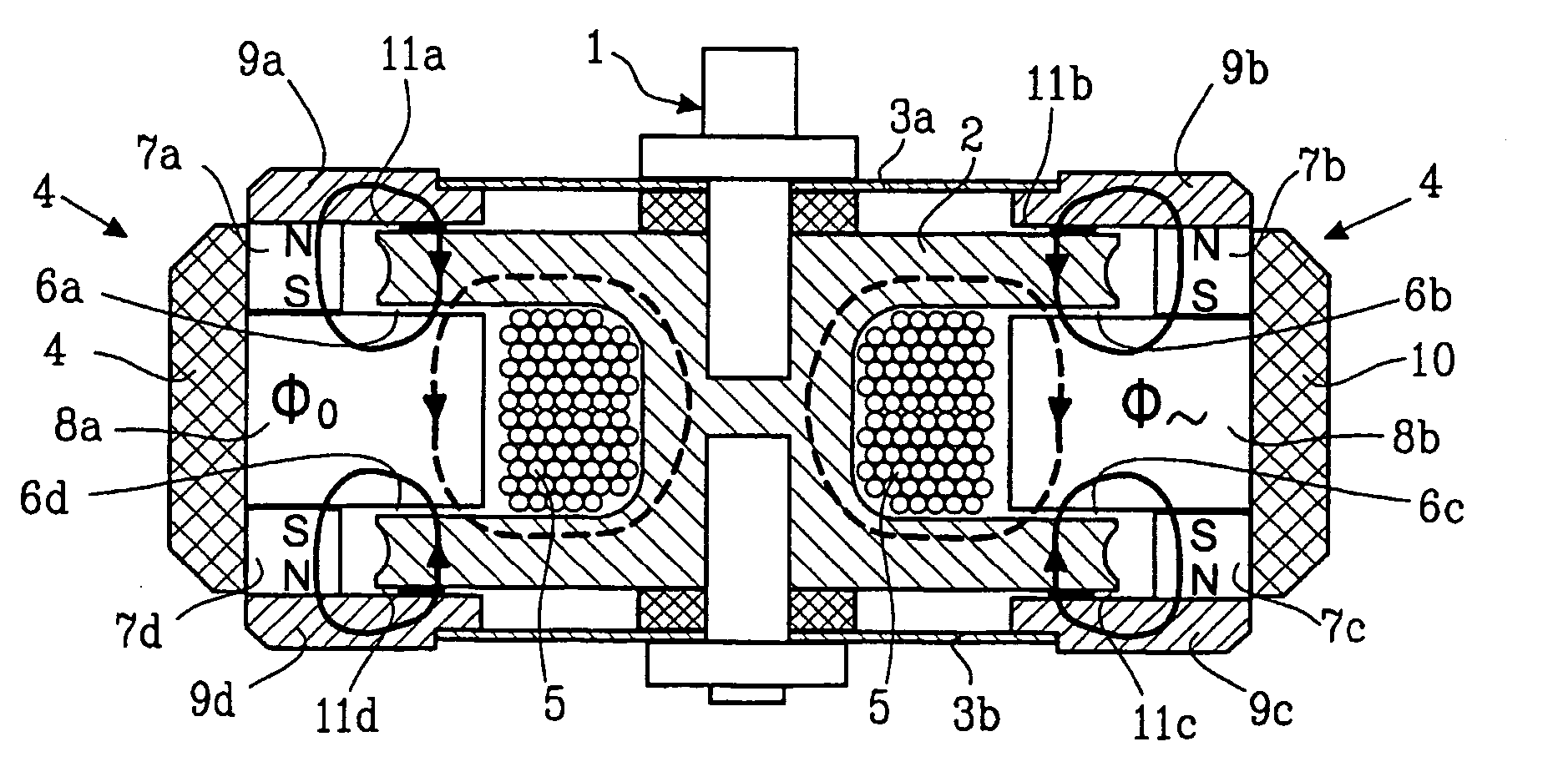

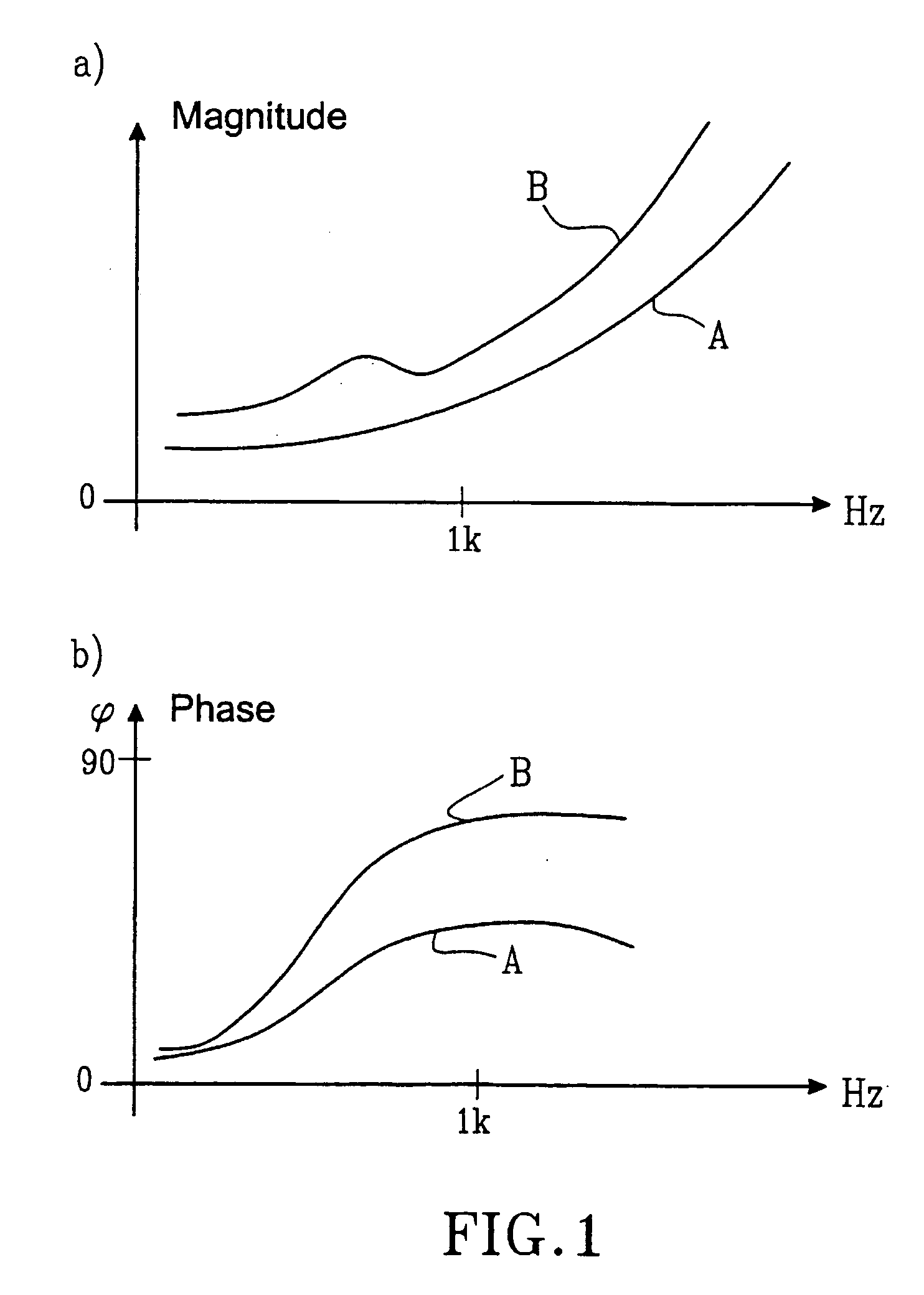

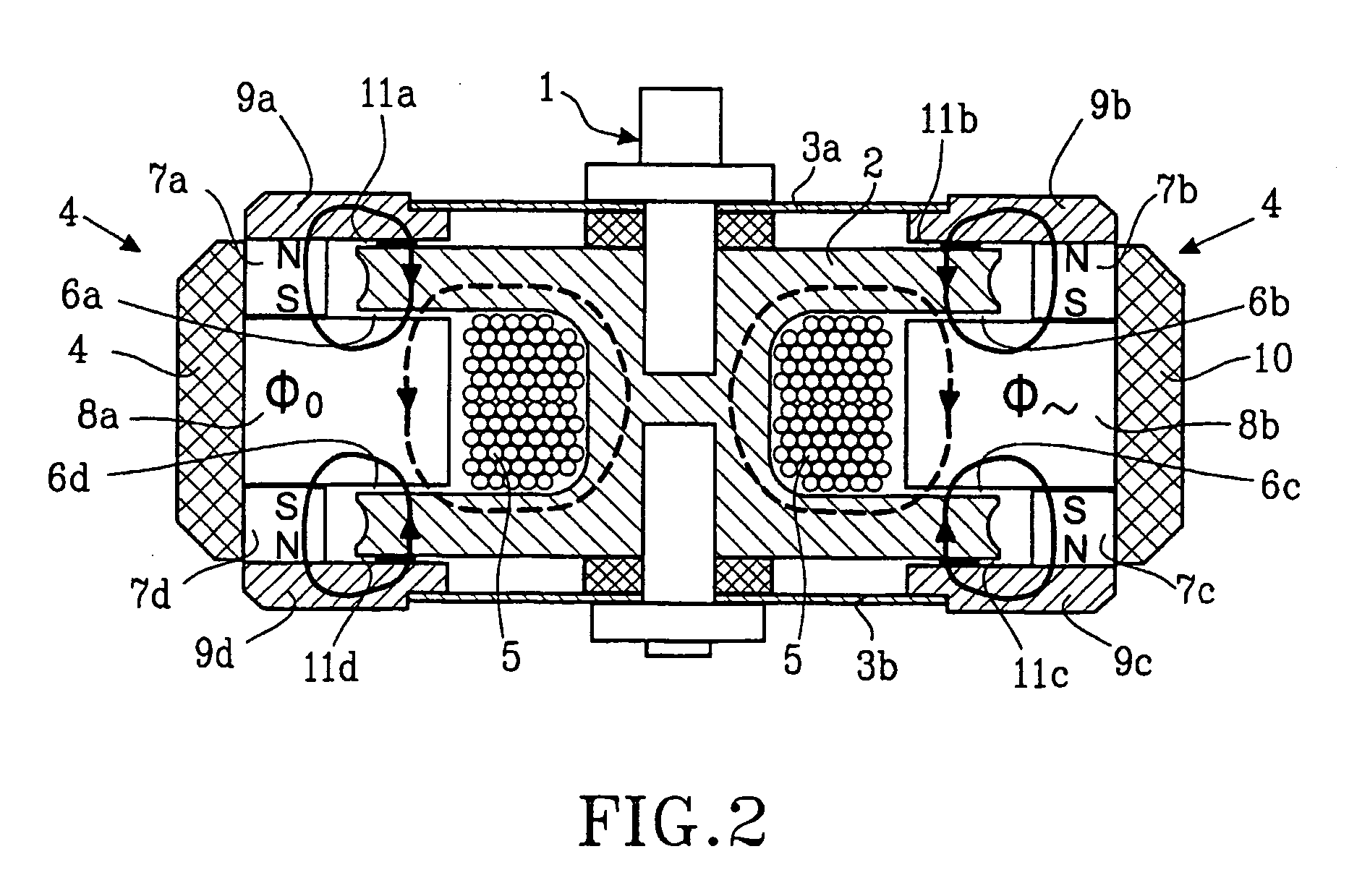

Means at electromagnetic vibrator

InactiveUS20050135651A1Improve magnetic propertiesIncrease inductanceTransducer detailsBone conduction transducer hearing devicesMagnetic signalElectromagnetic vibration

The present invention relates to an electromagnetic vibrator of variable reluctance type, according to a new principle which provides higher efficiency, smaller dimension, and higher reliability compared to known technology. This has been obtained by that the magnetic signal flux generated by the coil is closed through a bobbin body and one or more yokes, and wherein the bobbin body and the yokes are made of laminated metal sheets having good magnetic properties.

Owner:OSSEOFON

Method for manufacturing dry-pressing formed sintered permanent ferrite

InactiveCN101205137AIncrease productivityEasy to realize automatic moldingMetallurgyPolyethylene glycol

The invention relates to a manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding. The method comprises following working procedures: crushing process, the preparation process of dry pressing the magnetic powder, dry pressing process and sinter process. The organic dispersant added in the crushing process is one or a plurality among polyethylene glycol, calcium stearate and calcium gluconate, and the content of the organic dispersant is 0.1wtpercent-1.5wtpercent; the bond added in the he preparation process of dry pressing the magnetic powder is one or a plurality among PVA, polyethylene glycol, camphor and stearate, and the content of the bond is 0.1wtpercent-1.5wtpercent. 1. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention has the advantages of that the productivity effect is high, the molding mould is simple and the automation molding is easy to be realized; the surface of the molded finished product is lubricous and even, the fettling is not needed, and the workload of the post processing is decreased greatly; 2. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention adopts the unique preparation technique of dry pressing the magnetic powder, and the orientation in the process of magnetic field press is relatively good, and the high Br and high HCJ dry-pressing sintering permanent magnetism ferrite is easy to be gained; 3. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention adopts the pre-sintering material with a better performance of ion substitutional main prescription, and a dry-pressing anisotropic sintering permanent magnetism ferrite with a better magnetism performance can be achieved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

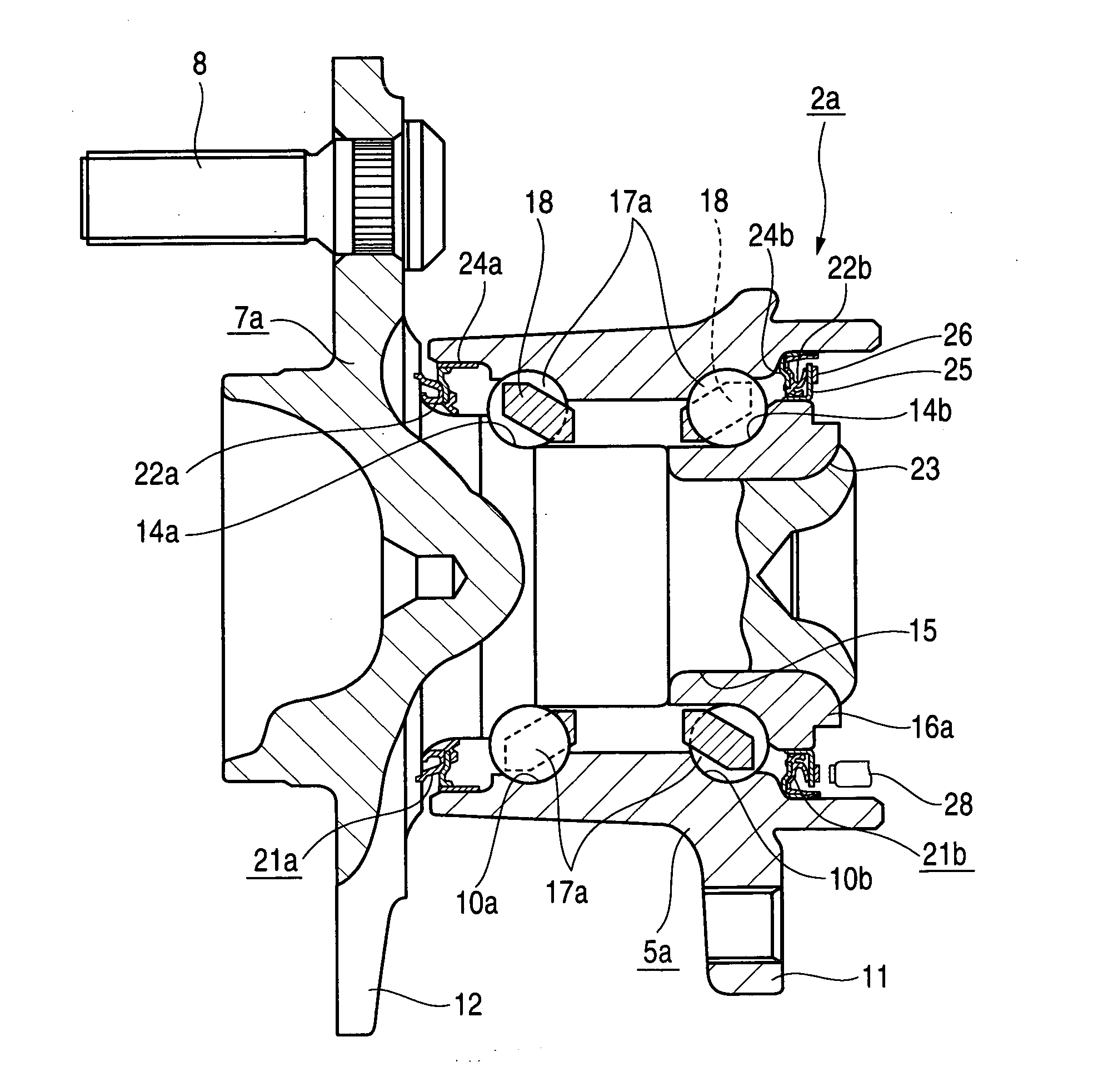

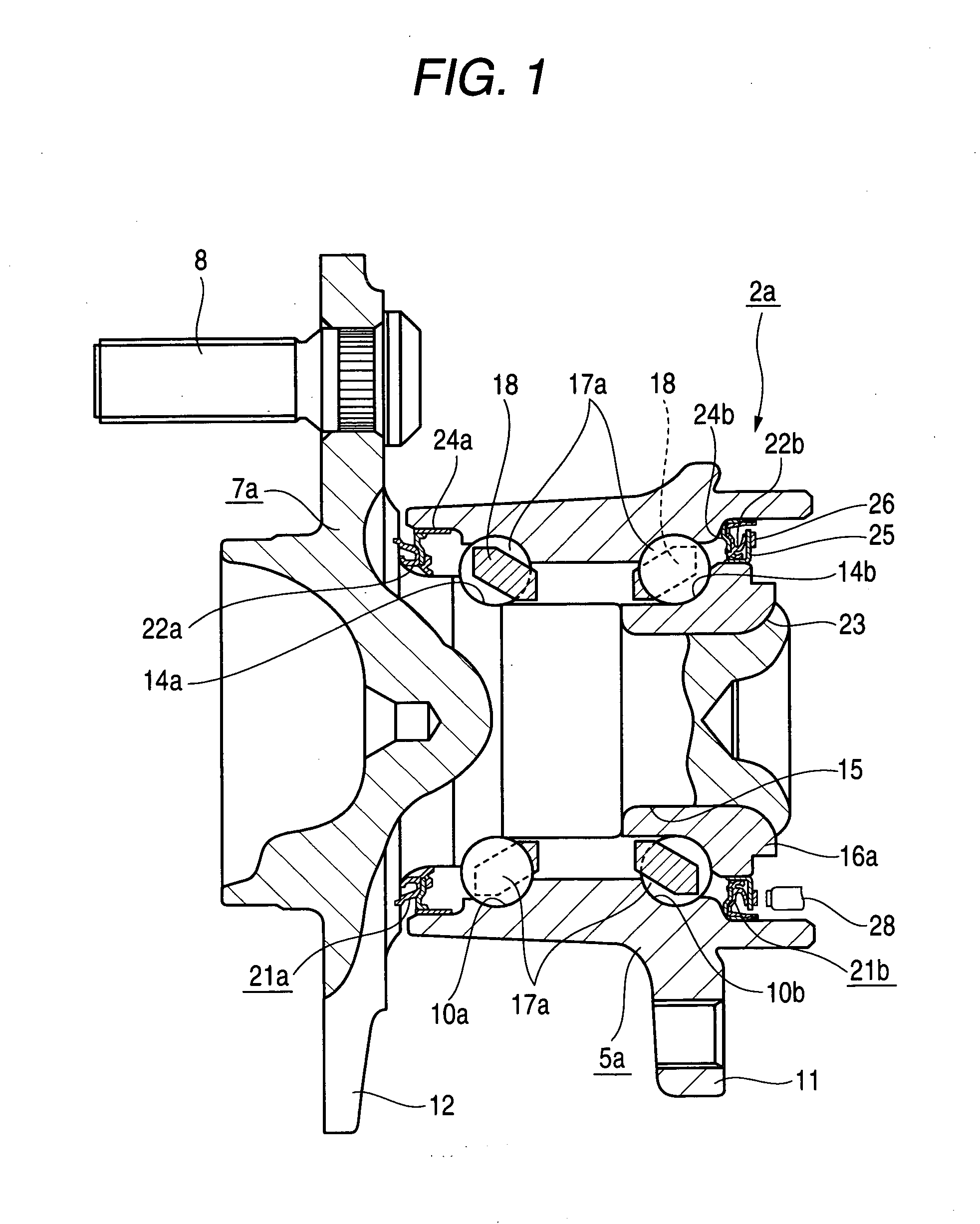

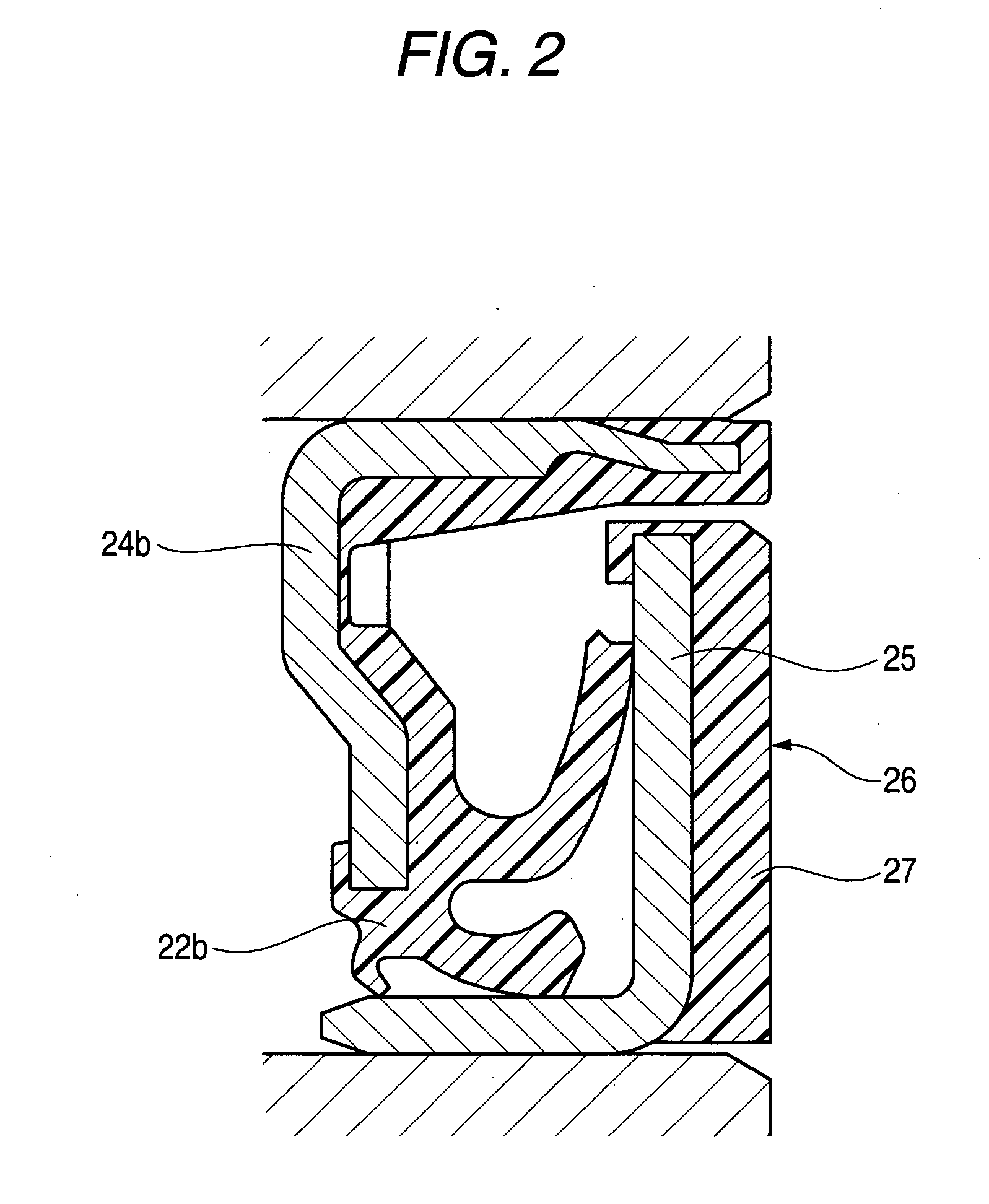

Magnetic encoder and bearing

ActiveUS20070152657A1Excellent magnetic propertyReliability be promoteEngine sealsRolling contact bearingsMagnetSoft segment

A magnet portion 27 of a magnetic encoder 26 includes a magnetic member and a resin, and a highly reliable magnetic encoder 26 having a high magnetic property and enabling to detect a rotational number with high accuracy, and a hub unit bearing 2a are provided. Further, the resin is preferably a thermoplastic resin and further preferably includes a thermoplastic resin including a soft segment in a molecule. Further, the magnetic encoder 26 further includes a fixed member 25 attached with the magnet portion 27 and comprising a magnetic material, and the magnet portion 27 and the fixed member 25 are bonded by an adhering agent including at least one of a phenolic resin based and an epoxy resin based.

Owner:NSK LTD

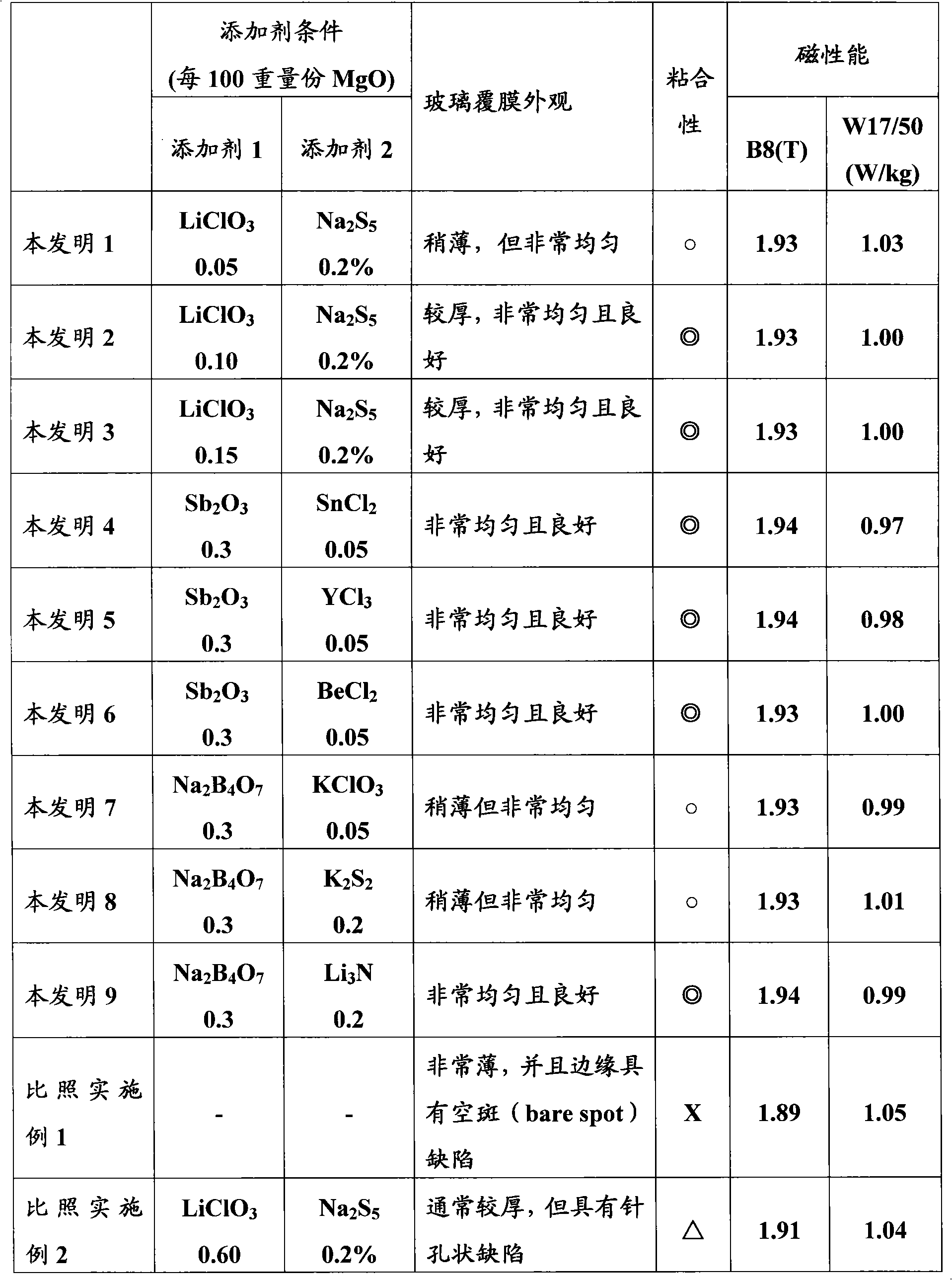

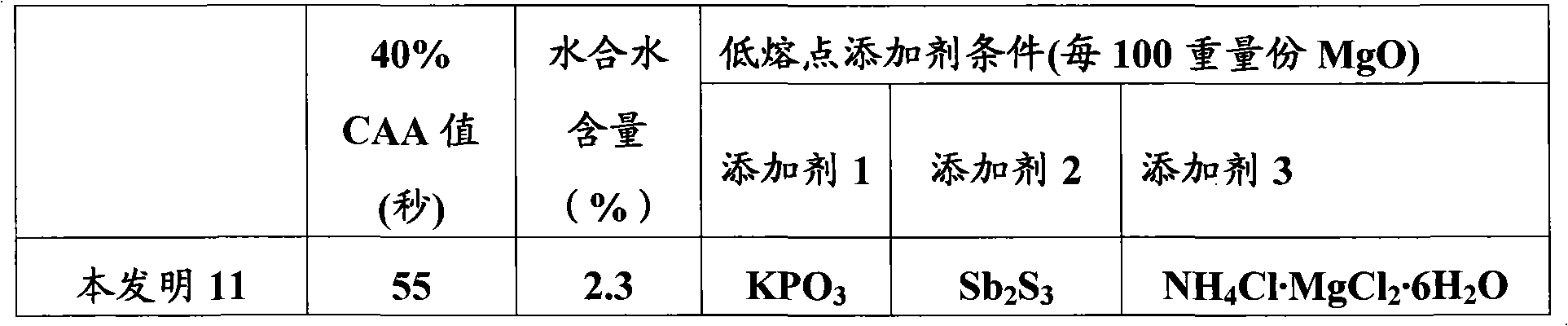

Annealing separating agent for grain oriented electrical steel sheet having uniform glass film and excellent magnetic properties and method of manufacturig the same

ActiveCN101528950APromote formationGood coating effectSolid/suspension decomposition chemical coatingSheet steelElectrical steel

Disclosed herein are an annealing separator for grain-oriented electrical steel sheets having excellent surface properties and a method for producing grain-oriented electrical steel sheets using the same. More particularly, the annealing separator comprises: 100 parts by weight of MgO, consisting of 40-95% of active MgO and 5-60% of inactive MgO; and 0.01-5 parts by weight of a low-melting-point compound having a melting point lower than 900 DEG C. The method for producing grain-oriented steel sheets comprises applying said annealing separator in the form of slurry to a steel sheet, after stirring the annealing separator in a mixing tank at a revolution speed of 1500-3000 rpm for more than 10 minutes.

Owner:浦项股份有限公司

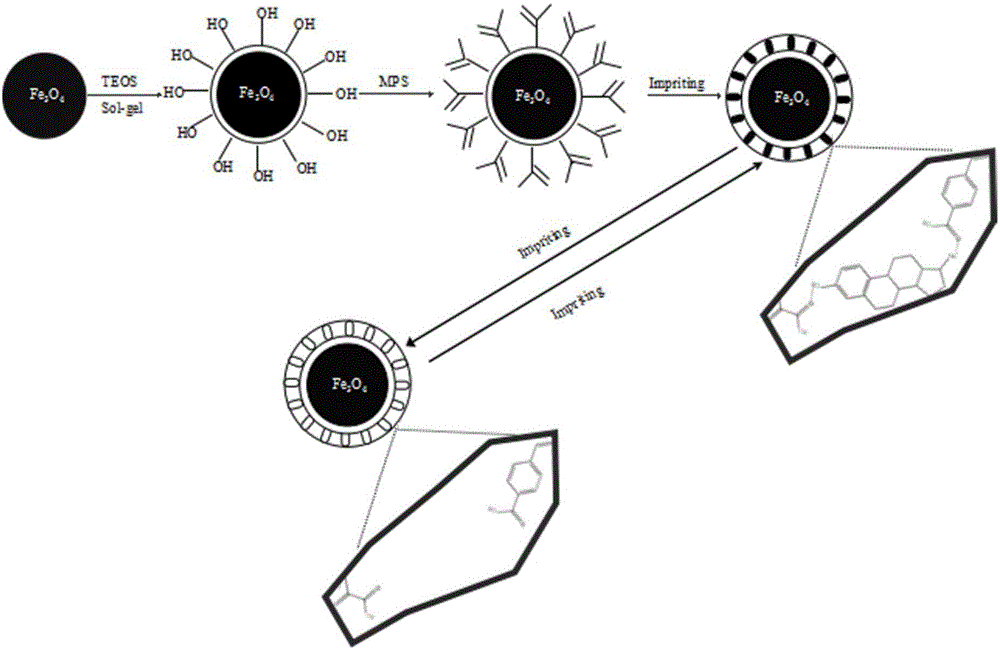

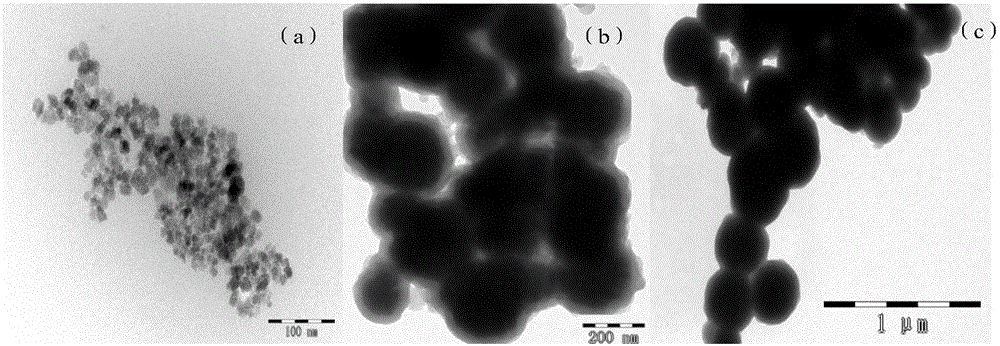

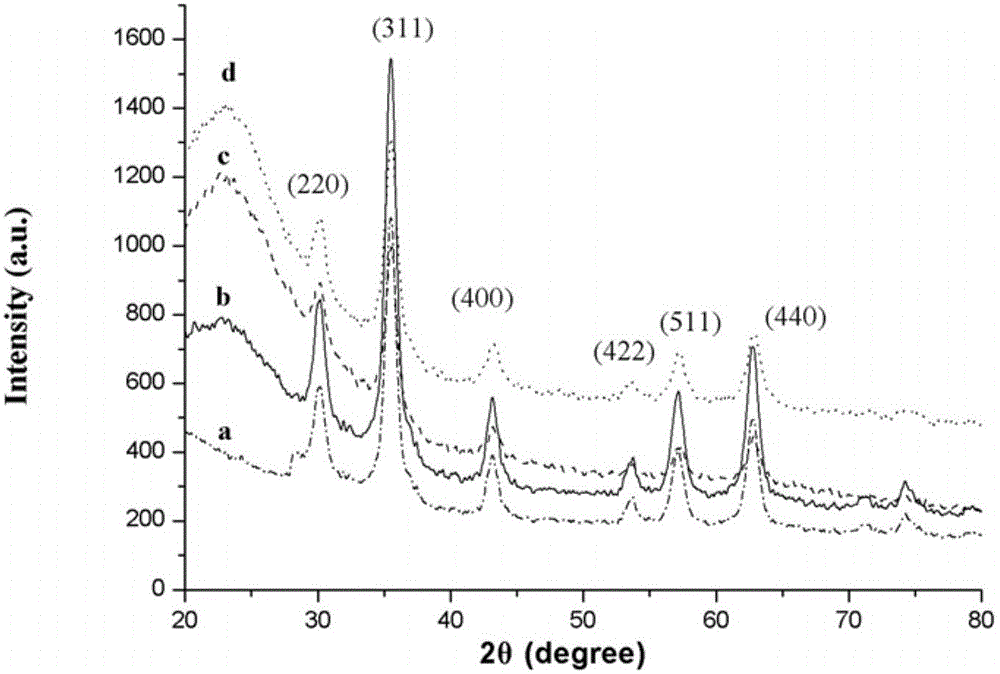

Preparation method for molecular imprinting material and molecular imprinting material prepared through preparation method

InactiveCN105107482AGood biocompatibilityImprove antioxidant capacityOther chemical processesAlkali metal oxides/hydroxidesSolubilityFunctional monomer

The invention provides a preparation method for a molecular imprinting material and the molecular imprinting material prepared through the preparation method. The preparation method comprises the steps that silicon oxide is coated on the surfaces of magnetic ferroferric oxide nanometer particles, the magnetic ferroferric oxide nanometer particles are modified with gamma-(methacryloyl chloride) amino propyl trimethoxy silane to obtain magnetic ferroferric oxide nanometer particles with propenyl on the surfaces, the magnetic ferroferric oxide nanometer particles with the propenyl on the surfaces serve as carriers, estrogen receptors are simulated, functional monomers are optimized, a surface imprinting technology is adopted, and then the molecular imprinting material which can simultaneously identify seven kinds of environmental endocrine disrupting chemicals is prepared. According to the preparation method, the easy separation of a magnetic nanometer material, the good water solubility of a silicon oxide nanometer material, the specific recognition ability of molecular imprinting polymers and the surface imprinting technology are mutually combined, the preparation technology is simple, the conditions are mild, the prepared molecular imprinting material is large in adsorption capacity, fast to respond, high in magnetism, good in chemical stability and high in repeating utilization rate, and the problems that at present, multiple trace, steroid and phenol environmental endocrine disrupting chemicals are difficult to simultaneously identify, separate and enrich are solved.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com