Patents

Literature

1009results about How to "Reduce eddy current loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

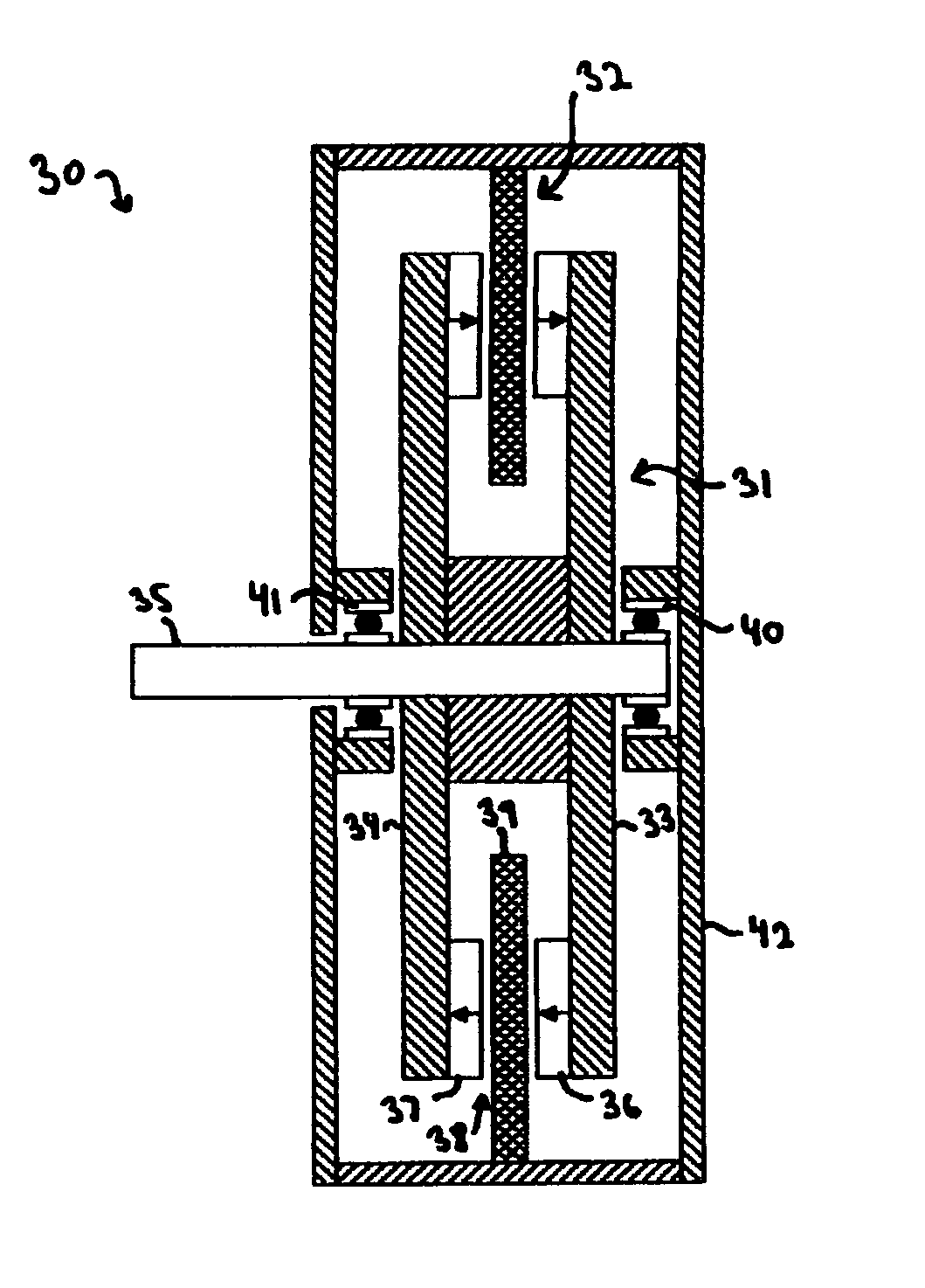

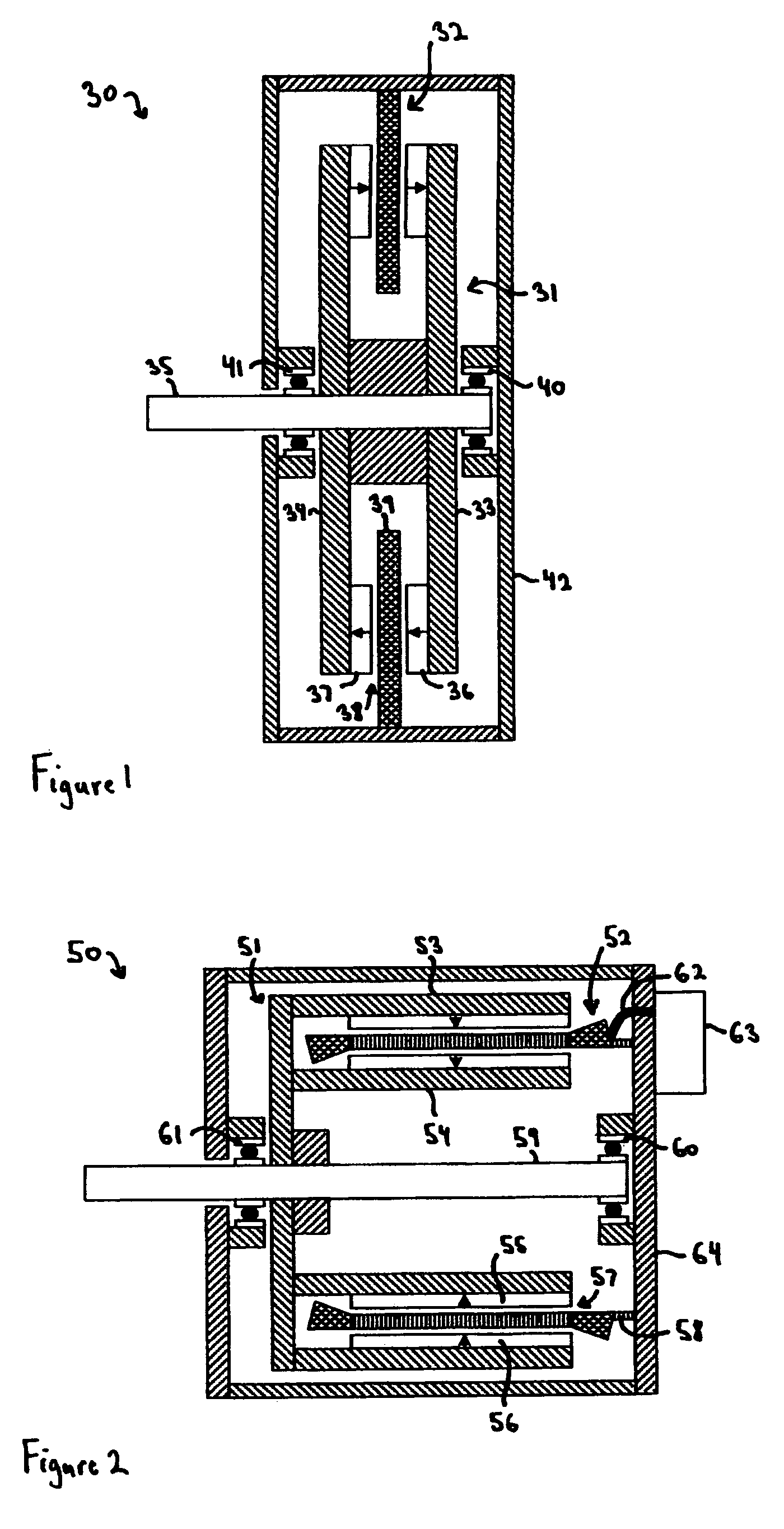

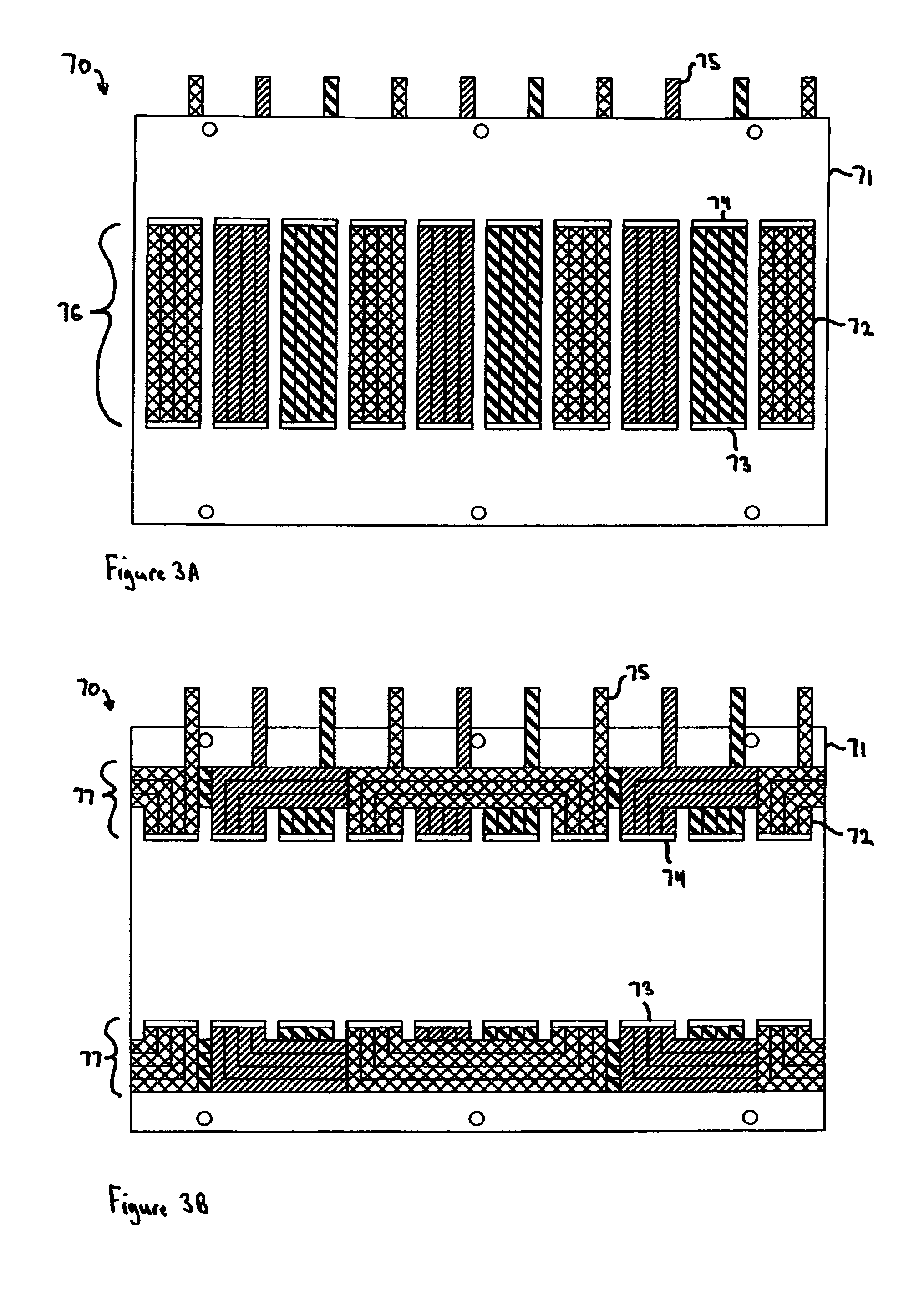

High performance air core motor-generator winding

InactiveUS7402934B1Long and reliable operating lifeIncrease winding densitySynchronous generatorsWindingsMagnetic polesRotational energy

A motor-generator for converting between electrical and rotational energy includes a rotor mounted for rotation about an axis of rotation relative to a stationary a stator that magnetically interacts with the rotor. The rotor has two spaced apart rotor portions that define therebetween an armature airgap. Magnetic poles on the rotor portions drive magnetic flux across the airgap. An air core armature is located in the airgap, such that opposite sides of the air core armature face the two opposed rotating surfaces of the rotor. The air core armature has windings in which AC voltage is induced as the rotor rotates. The windings are wound with multiple individually insulated strand conductor wire wrapped with a wrapping of a thin dielectric tape film over the multiple individually insulated strand conductor wire.

Owner:REVOLUTION ELECTRIC MOTOR

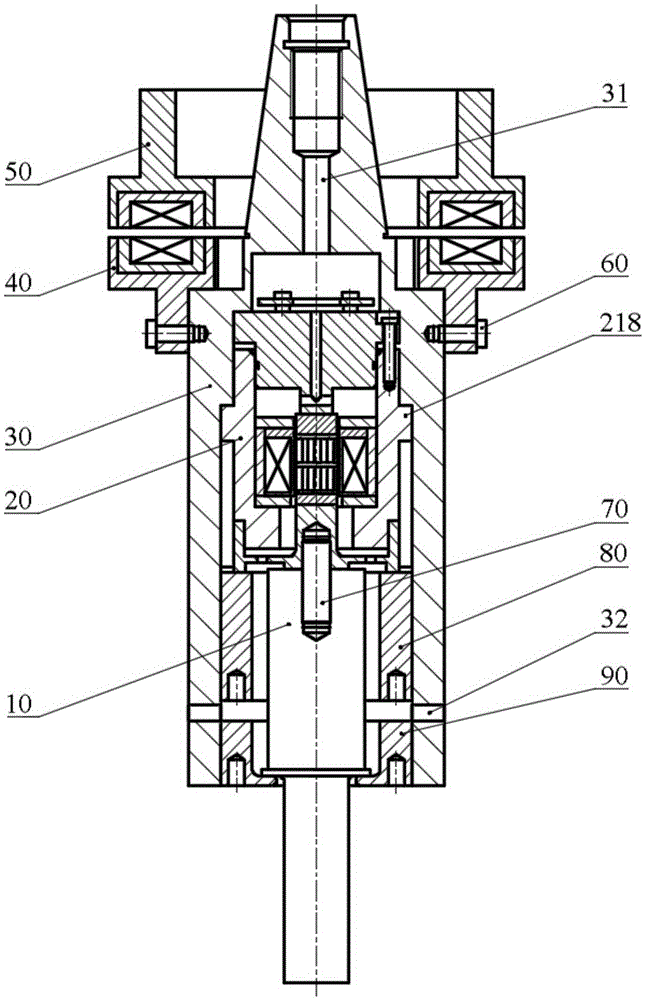

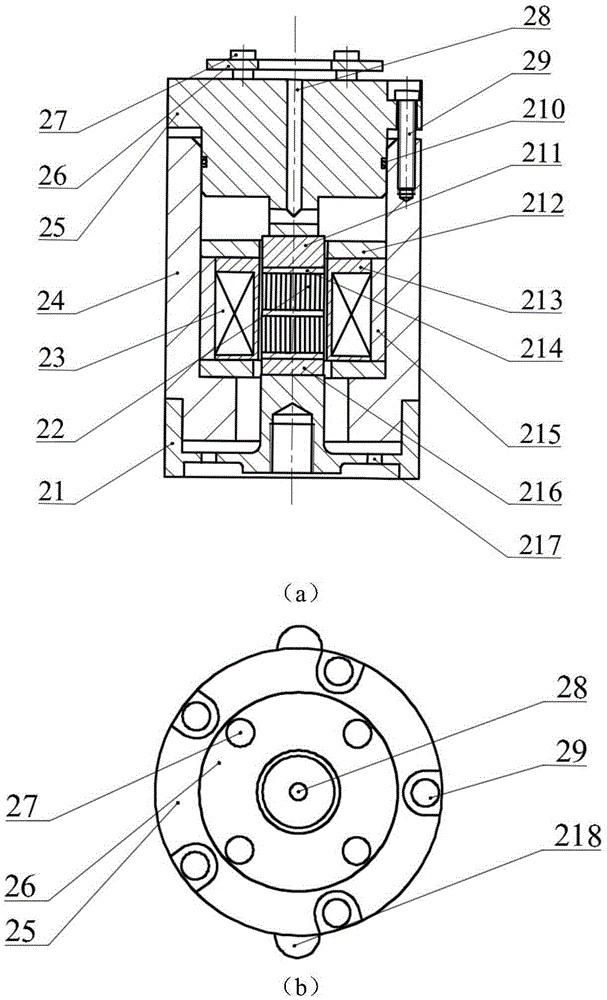

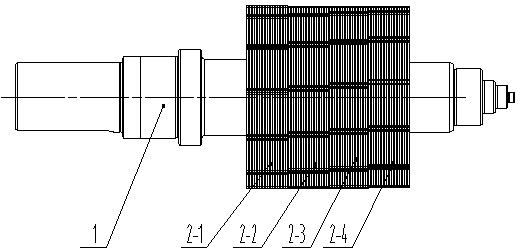

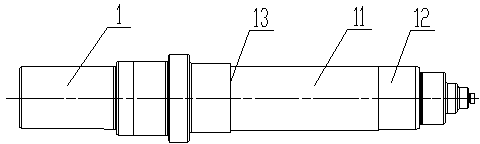

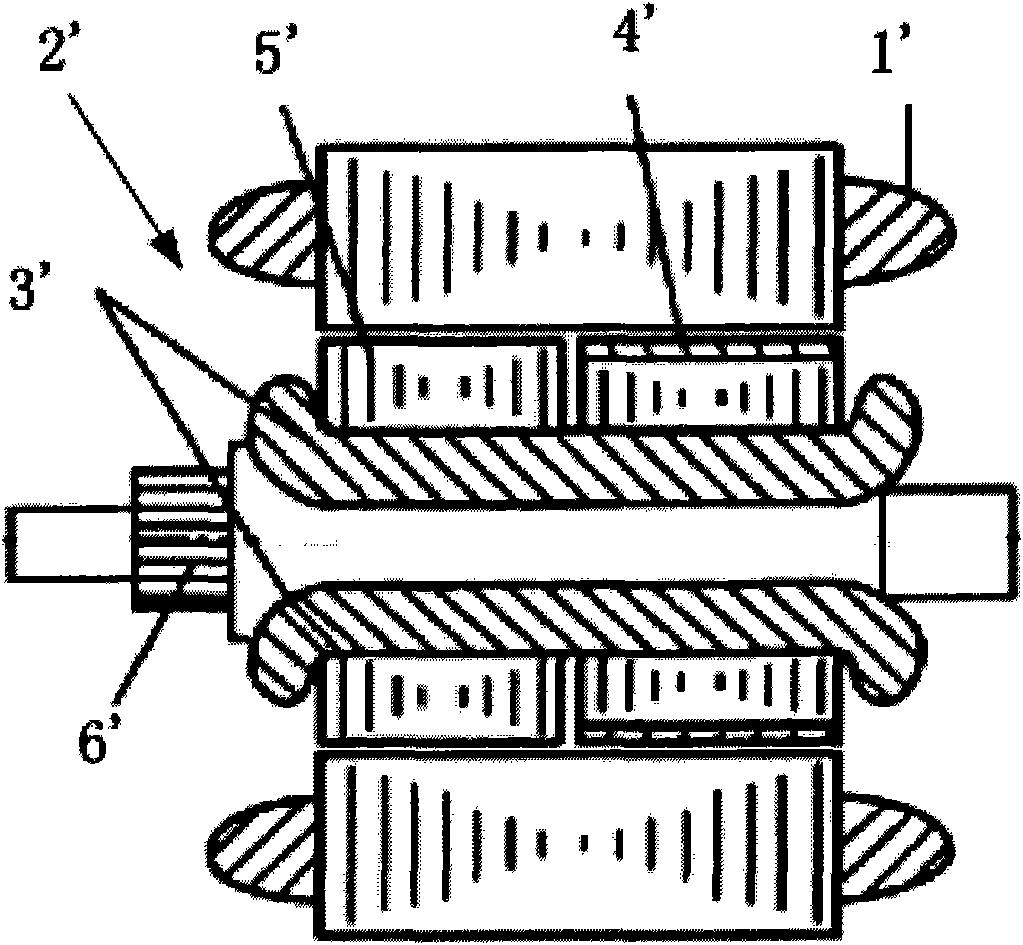

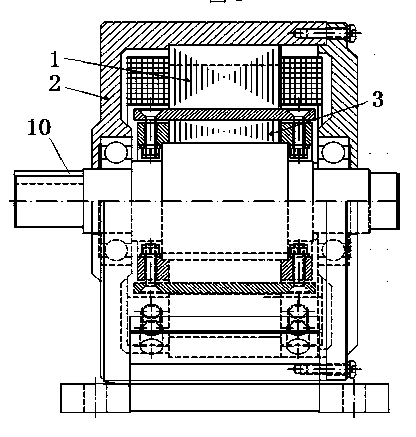

Giant magnetostrictive rotary ultrasonic vibration knife handle

ActiveCN105397920AHigh magnetostriction coefficientIncrease output powerMechanical vibrations separationStone-like material working toolsTransducerAir cooling system

The invention relates to a giant magnetostrictive rotary ultrasonic vibration knife handle and belongs to the technical field of ultrasonic precise special machining. The knife handle comprises an amplitude-change pole, a giant magnetostrictive ultrasonic transducer, a hollow knife handle body, an auxiliary side component, a primary side component and a threaded pressing block, wherein the giant magnetostrictive ultrasonic transducer is connected with the amplitude-change pole through a threaded rod and installed in a cavity in the lower portion of the knife handle body; an ultrasonic vibrator formed by connecting the giant magnetostrictive ultrasonic transducer with the amplitude-change pole makes contact with the inner wall of the knife handle body, the lower end of the giant magnetostrictive ultrasonic transducer is tightly pressed onto the knife handle body through the threaded pressing block, and the threaded pressing block is connected with the knife handle body through threads; the lower end of the amplitude-change pole is tightly pressed through the threaded pressing block, and the threaded pressing block is connected with the knife handle body; the lower end of the auxiliary side component is fixed to the knife handle body through a screw, and the primary side component is fixed to the end face of a machine tool spindle. According to the giant magnetostrictive rotary ultrasonic vibration knife handle, the problem of heating of the transducer is effectively solved by means of a giant magnetostrictive material of a slice structure and an air cooling system. By the adoption of the knife handle, the machining efficiency can be improved. In addition, the knife handle can be suitable for any knife handle connection standards.

Owner:TSINGHUA UNIV

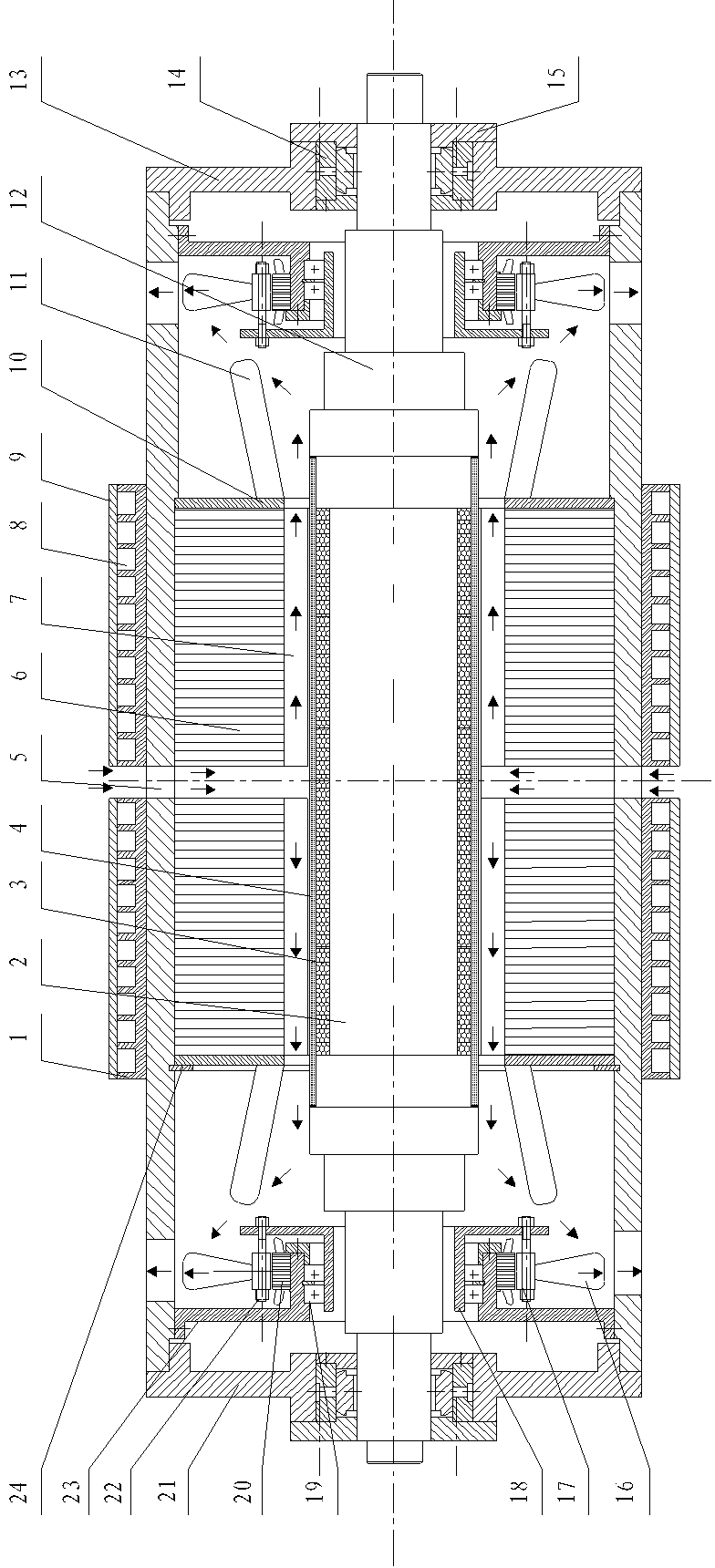

Air and water hybrid cooling high-speed permanent-magnet motor

InactiveCN102983680AReduce eddy current lossLow heat generationMagnetic circuit rotating partsMagnetic circuit stationary partsWater flowPermanent magnet motor

The invention discloses an air and water hybrid cooling high-speed permanent-magnet motor and belongs to the technical field of motors. The large-power high-speed permanent-magnet motor comprises a casing, a cooling water jacket, a stator core, a stator radial air duct, a stator inner air duct, a motor rotor, an outer rotor axial fan, an outer rotor fan fixing frame and two sliding bearings. The stator core is divided into two sections, the radial air duct is reserved in the middle, and the inner air duct is reserved in a stator slot close to the air gap position. The cooling water jacket is arranged outside the stator casing, a spiral water way is arranged in the water jacket, and water flows into the water way from the middle of the water way and flows out from a left spiral water outlet and a right spiral water outlet which are arranged at two ends of the water way. The air and water hybrid cooling high-speed permanent-magnet motor can mechanically solve the problem that a permanent magnet is broken when bearing large pulling stress during high-speed rotating, further solves the problems that the large-power high-speed motor is large in loss density, difficult in heat dissipation and over high in temperature rising, and prevents the permanent magnet from having irreversible demagnetization easily at high temperature.

Owner:SHENYANG POLYTECHNIC UNIV

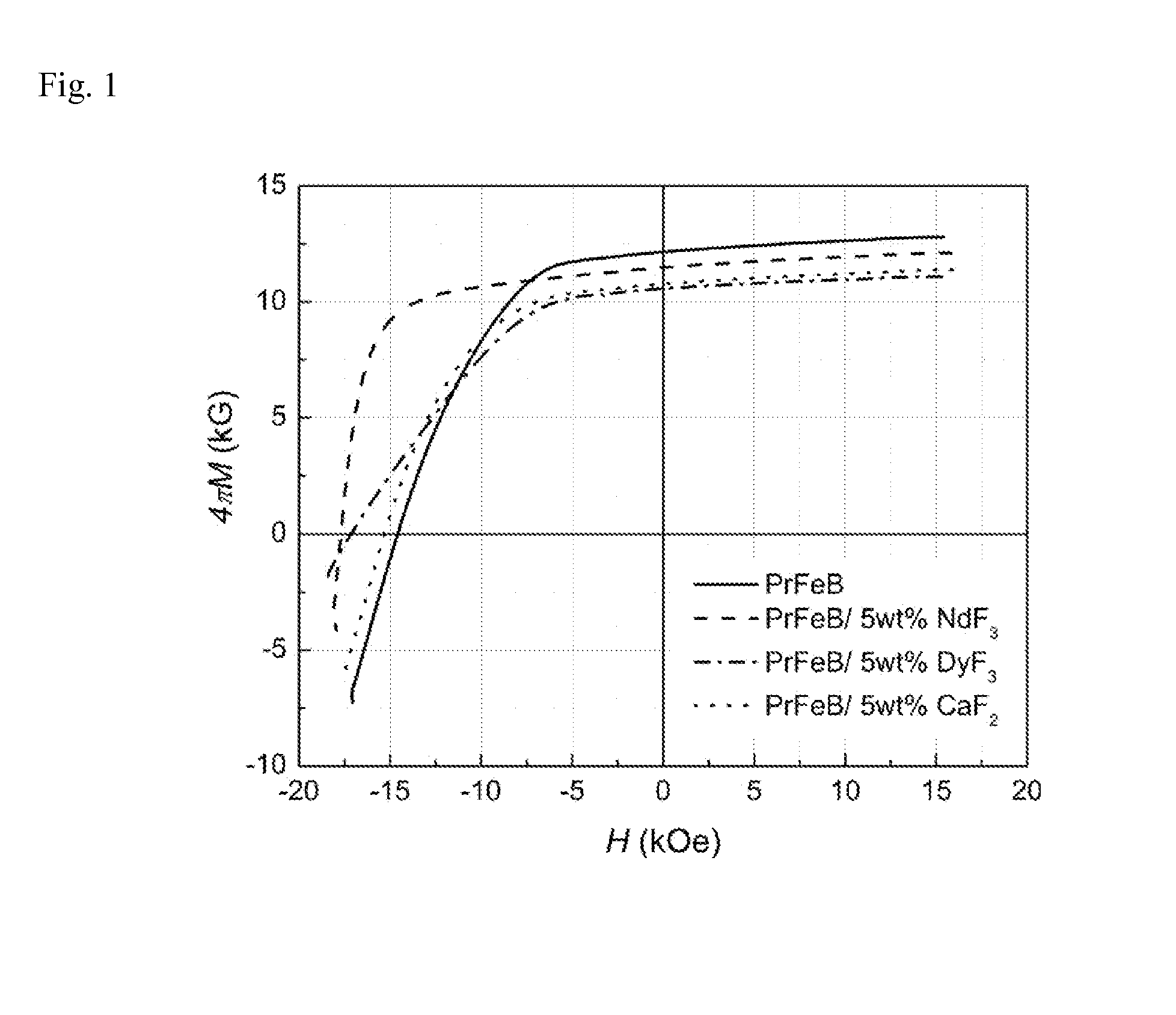

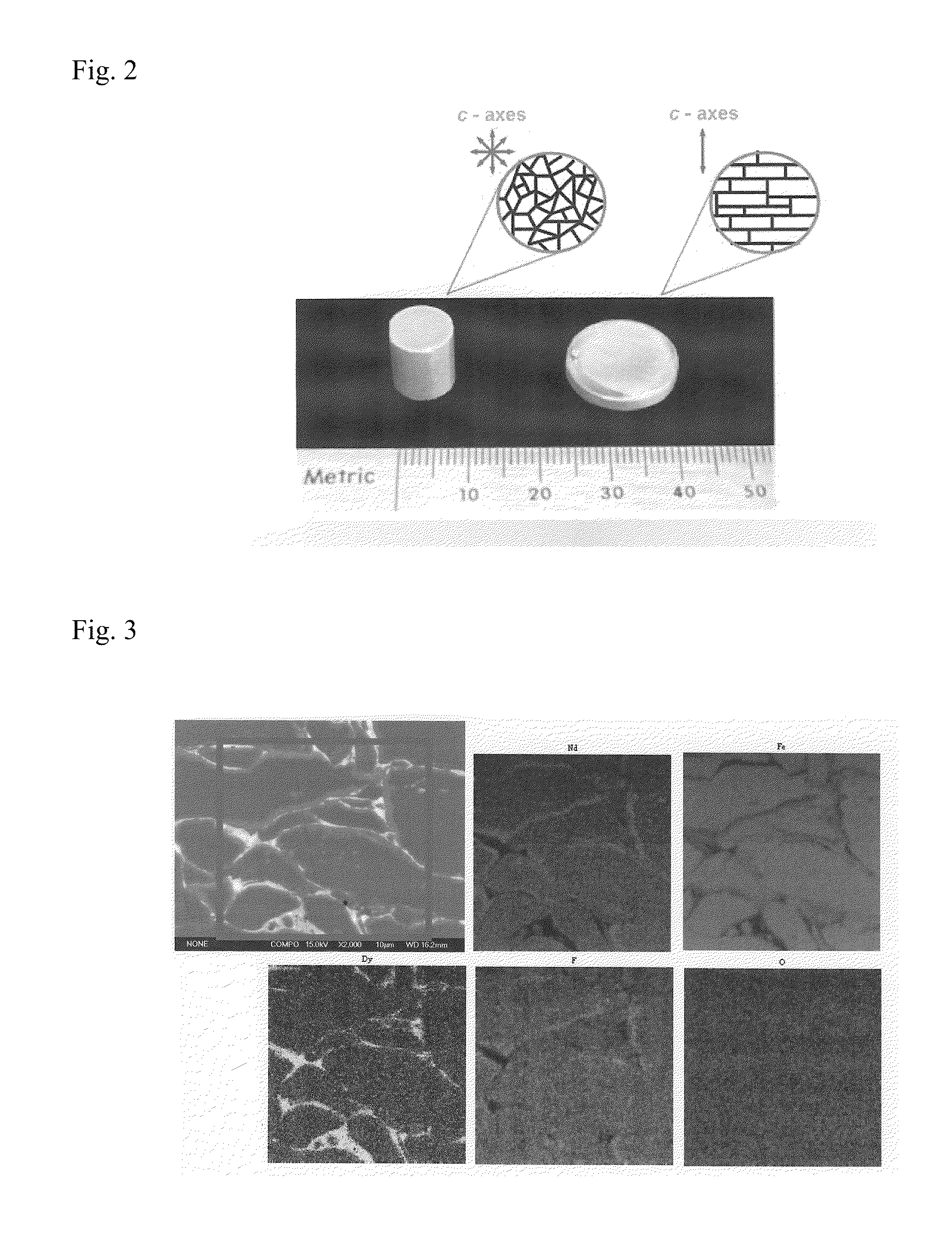

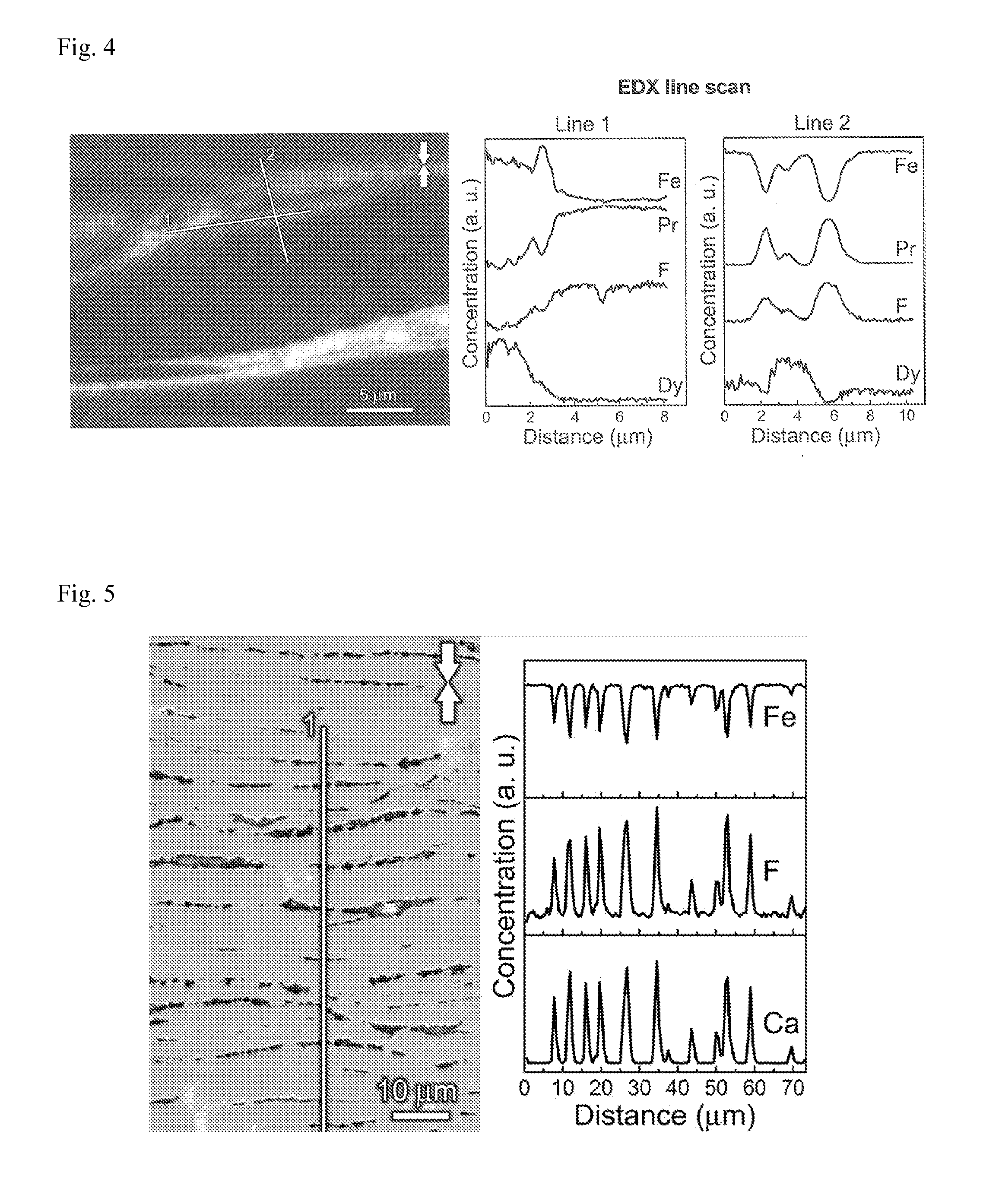

Rare Earth Composite Magnets with Increased Resistivity

InactiveUS20150132174A1High resistivityReduce eddy current lossTransportation and packagingMetal-working apparatusDielectricHigh resistivity

Owner:ELECTRON ENERGY CORP

Composite magnetic core structure and magnetic element

ActiveCN102956344AHigh application frequencyImprove consistencyTransformers/inductances coils/windings/connectionsInorganic material magnetismMagnetic fluxMagnetic core

The embodiment of the invention discloses a composite magnetic core structure and a magnetic element, which are used for reducing magnetic core loss and increasing the frequency of application. In the embodiment of the invention, the composite magnetic core structure consists of a first magnetic core part and a second magnetic core part, the first magnetic core part is made of low-magnetic permeability soft magnetic material, the second magnetic core part is made of high-magnetic permeability soft magnetic material, and the first magnetic core part and the second magnetic core part are combined and formed into a magnetic flux loop.

Owner:XFUSION DIGITAL TECH CO LTD

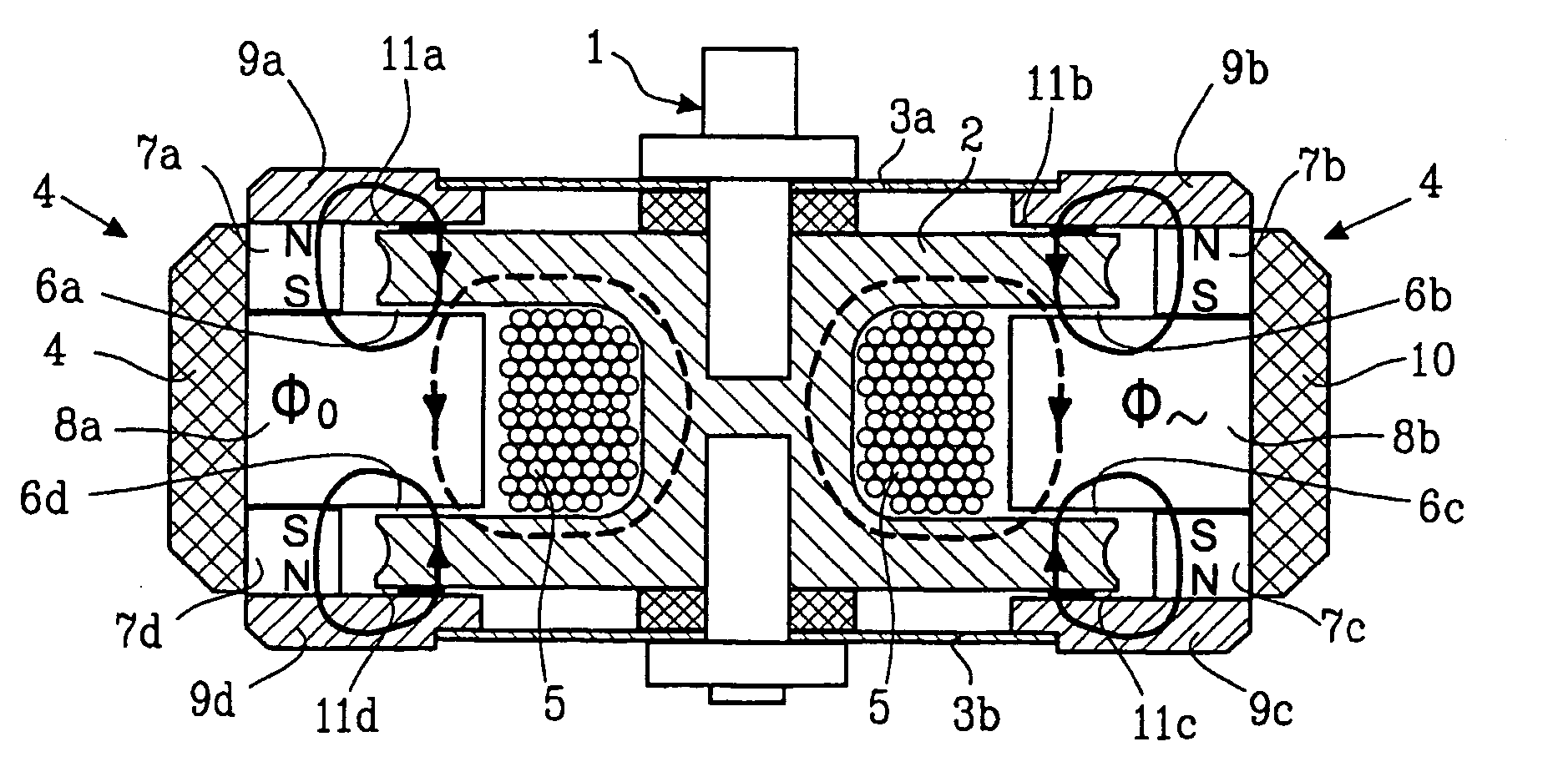

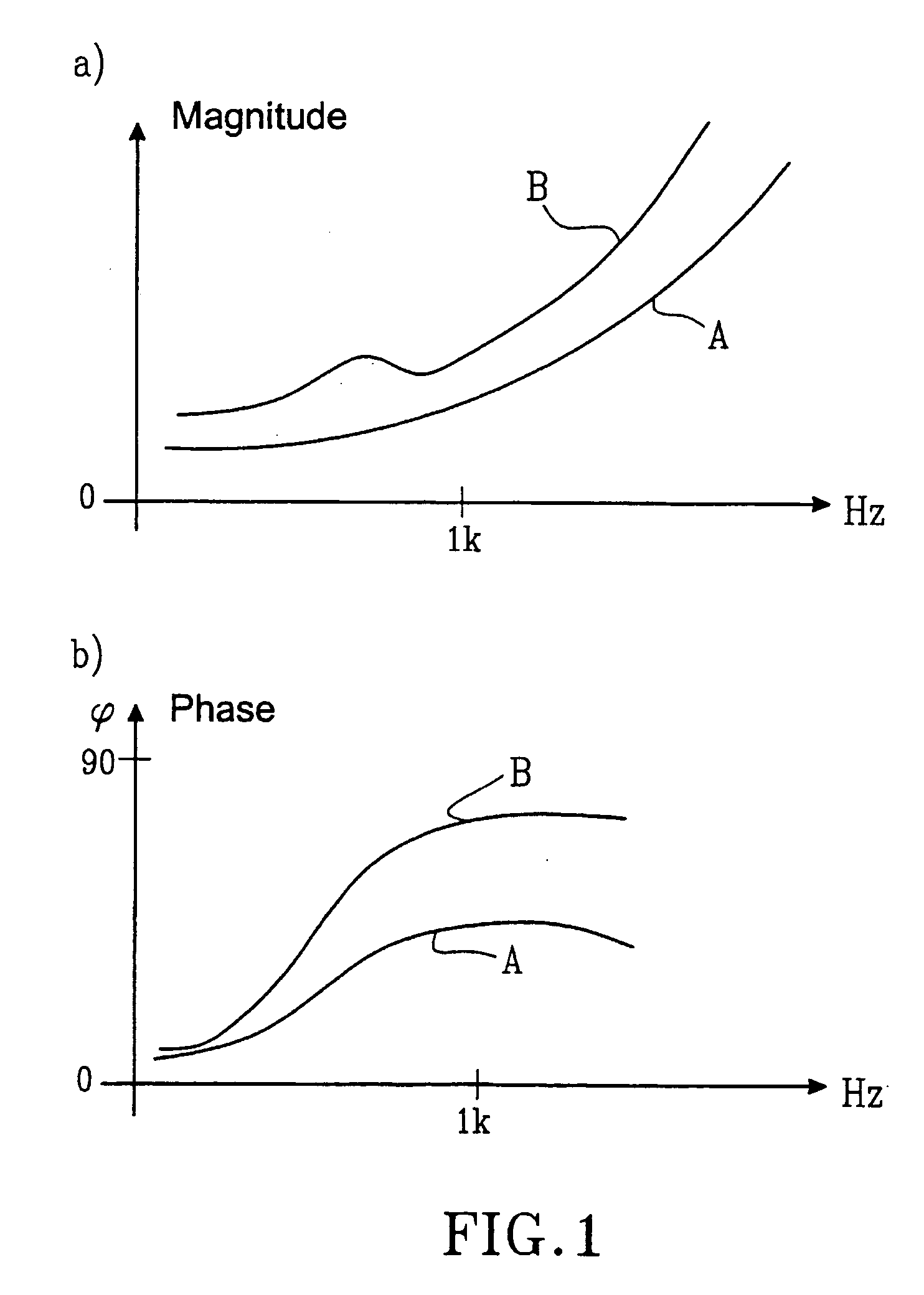

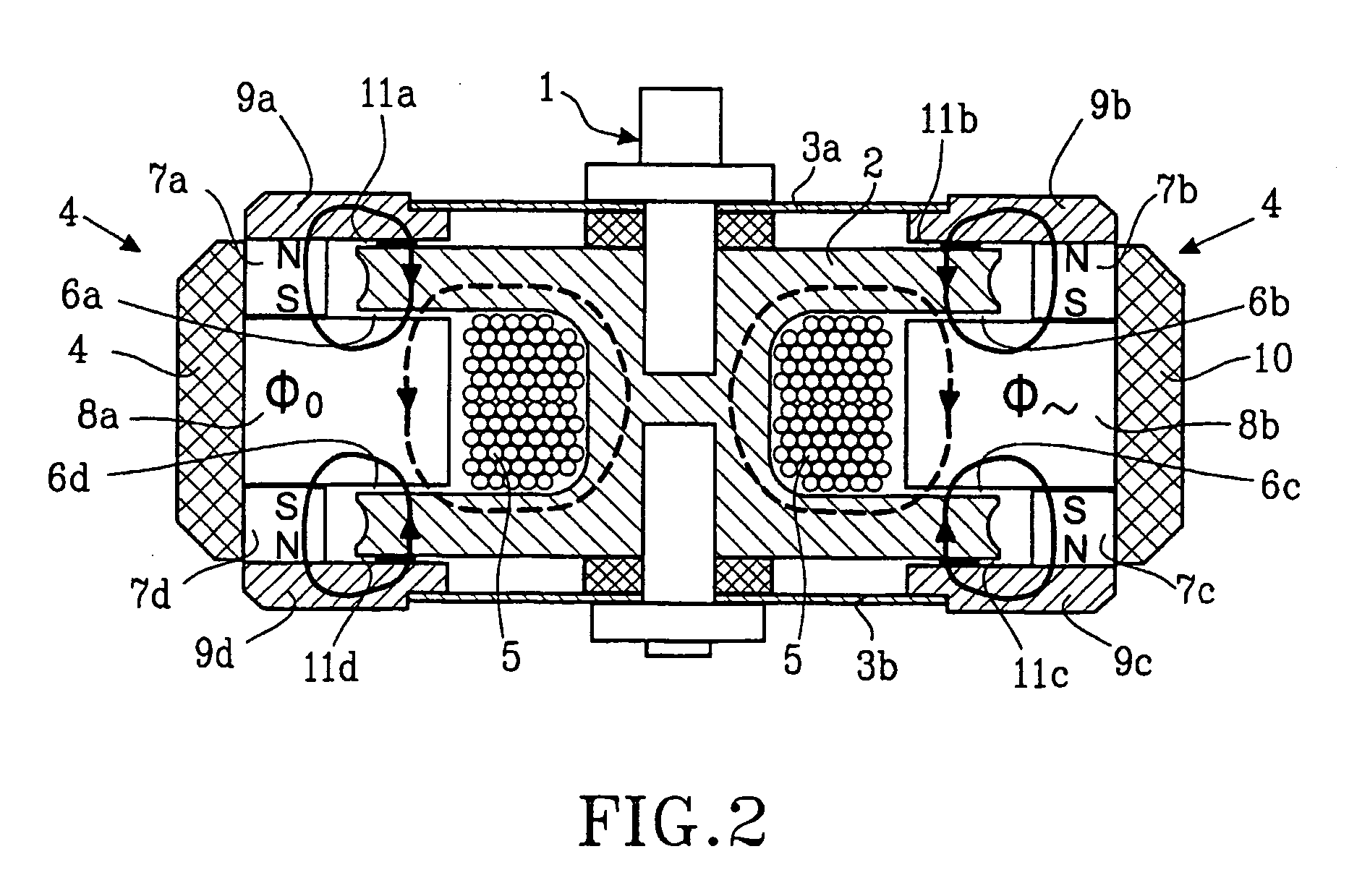

Means at electromagnetic vibrator

InactiveUS20050135651A1Improve magnetic propertiesIncrease inductanceTransducer detailsBone conduction transducer hearing devicesMagnetic signalElectromagnetic vibration

The present invention relates to an electromagnetic vibrator of variable reluctance type, according to a new principle which provides higher efficiency, smaller dimension, and higher reliability compared to known technology. This has been obtained by that the magnetic signal flux generated by the coil is closed through a bobbin body and one or more yokes, and wherein the bobbin body and the yokes are made of laminated metal sheets having good magnetic properties.

Owner:OSSEOFON

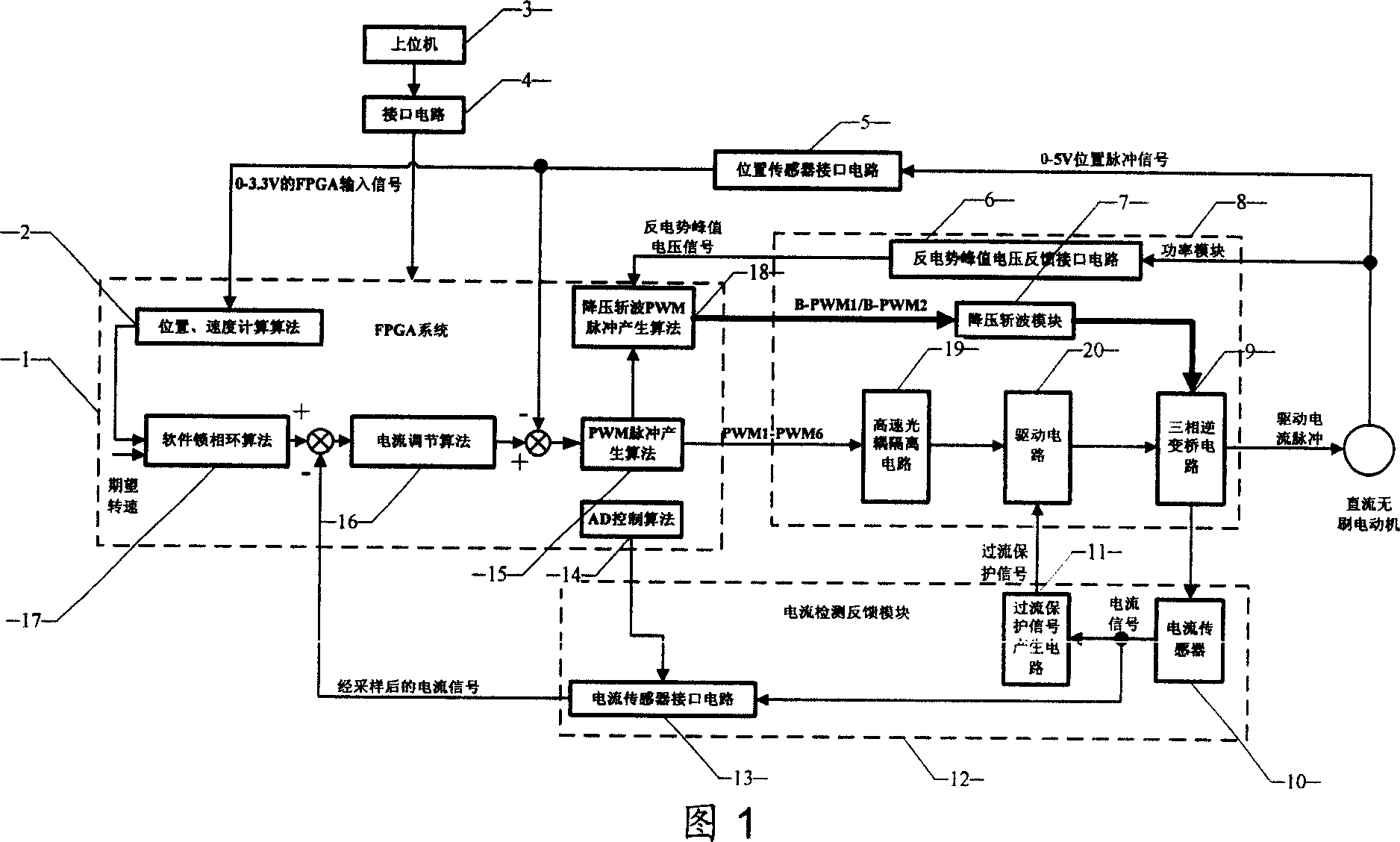

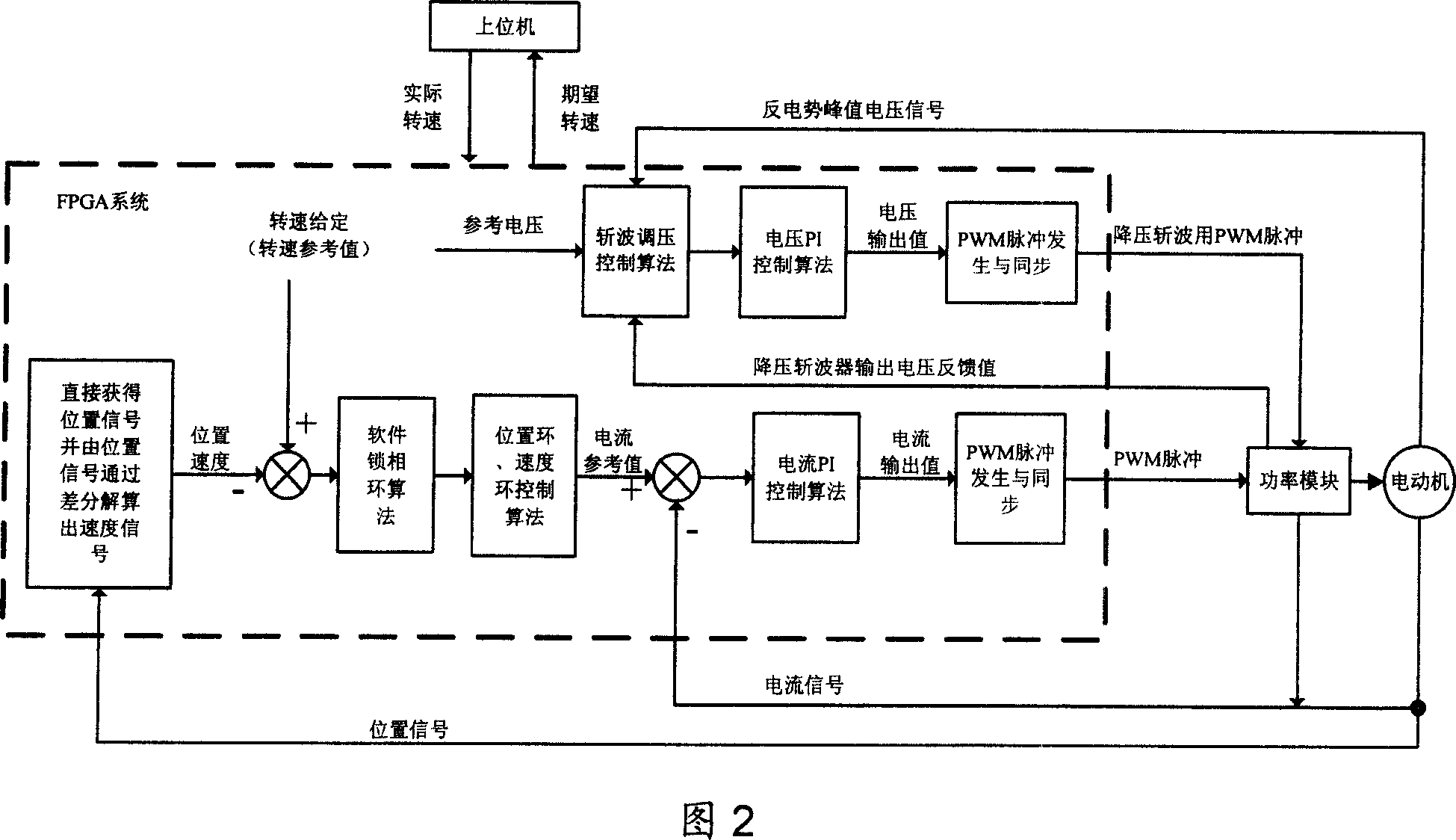

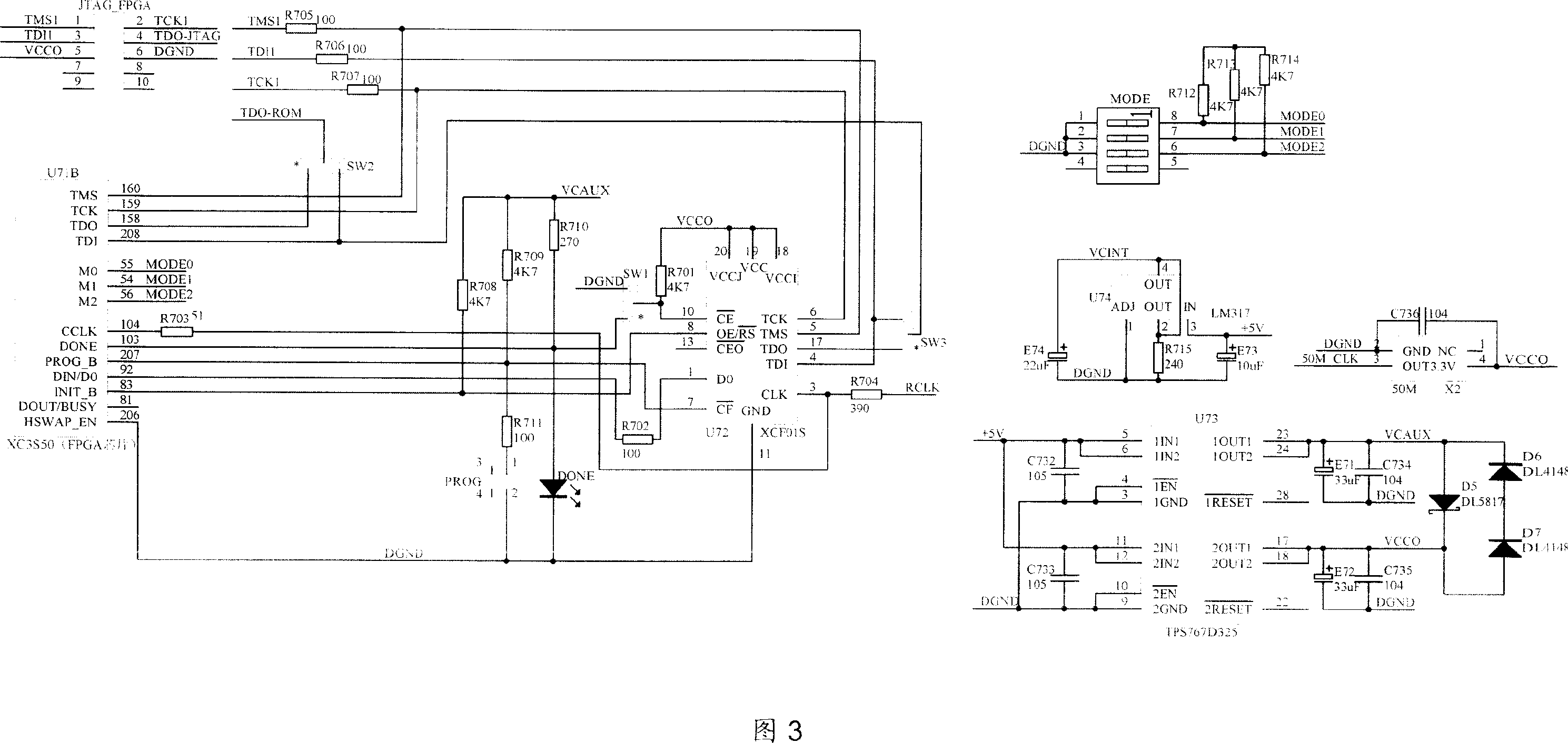

A low-loss, high reliability integration magnetic levitation flywheel DC brushless motor control system

InactiveCN1968003AHigh control precisionHighly integratedField or armature current controlElectronic commutatorsBrushless motorsFpga implementations

The invention relates to a magnetic suspension flywheel direct-current non-brush motor controlling system, wherein it comprises FPGA system, direct-current detecting feedback module, positioning sensor interface circuit, and power module; the FPGA module obtains request rotation speed from super machine, via sensor interface circuit and feedback module to obtain position signal and current signal, and the control algorism of FPGA, to calculate out the control value, and process reduction chopper PWM modulation, and amplify via amplifying module to generate the needed control current, and realize control accurately. The invention has low power consumption and high reliability.

Owner:BEIHANG UNIV

Fe-Si-Al magnetic core preparation method and inorganic composite insulation coating material for magnetic core

ActiveCN105304308AEasy to processGood temperature characteristicsInductances/transformers/magnets manufactureMagnetic materialsHeat treatingSurface coating

The invention discloses a Fe-Si-Al magnetic core preparation method and an inorganic composite insulation coating material for a magnetic core, belonging to the field of Fe-Si-Al magnetic material and used for solving the high eddy-current loss problem of existing magnetic cores and such problems caused by the fact that the existing magnetic cores usually use organic coating materials as stress is difficult to eliminate in a forming process, the insulation property of the material is poor, and the volatilization quantity of organics is large in heating processes such as heat treatment. The Fe-Si-Al magnetic core preparation method disclosed by the invention comprises the following steps: cast ingot smelting, powder making, surface phosphorization, insulation coating, compression moulding, annealing treatment and surface coating; the prepared Fe-Si-Al magnetic core has the advantages of low eddy-current loss, small magnetic conductivity temperature coefficient, good temperature stability, high direct current superposition characteristic, high saturation flux density and good high-frequency characteristic and meets the requirements for high frequency, small size, high power and electromagnetic interference resistance of electronic devices.

Owner:临沂银凤新材料技术服务有限公司

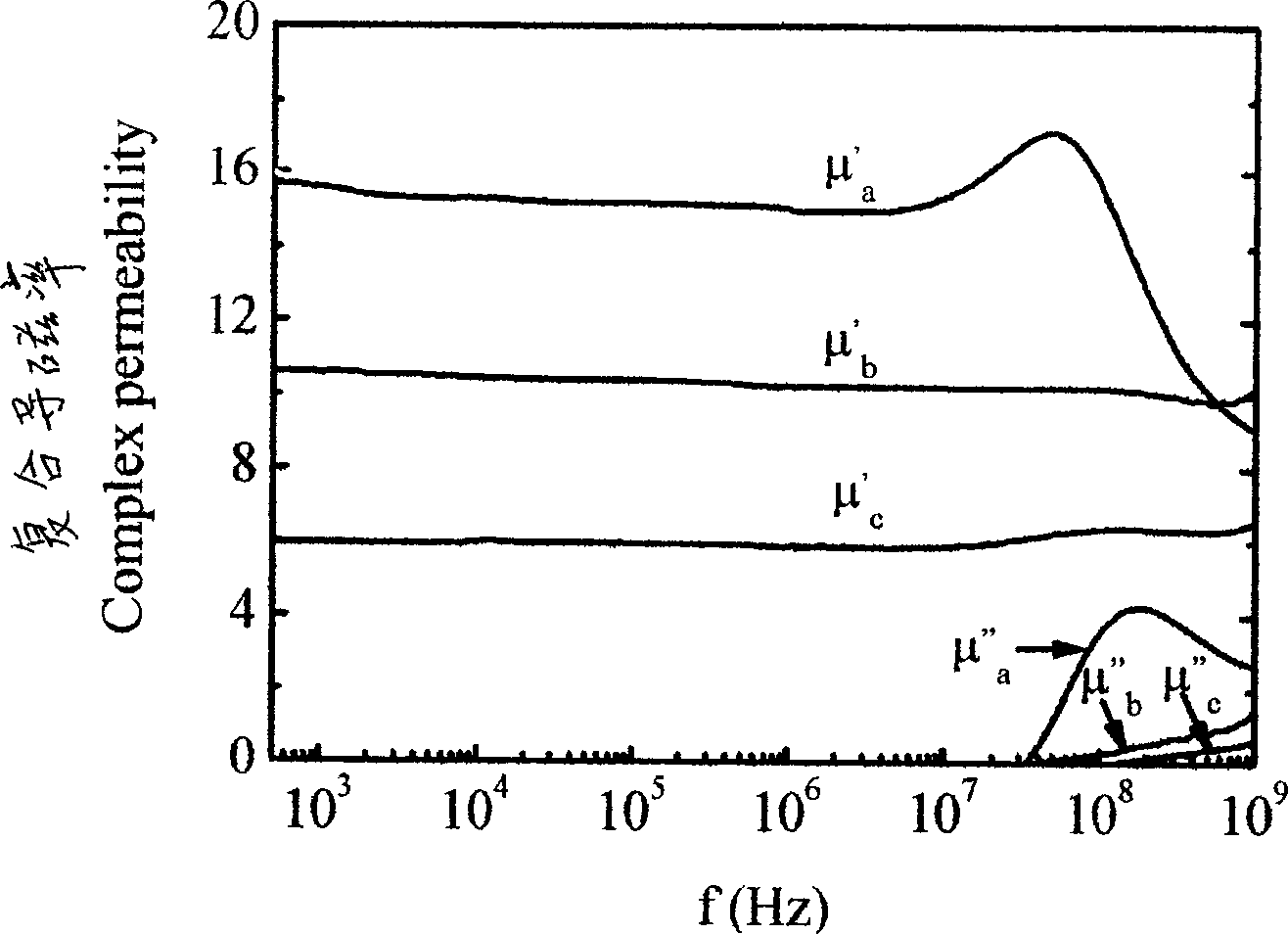

Magnetic material for high frequency wave, and method for production thereof

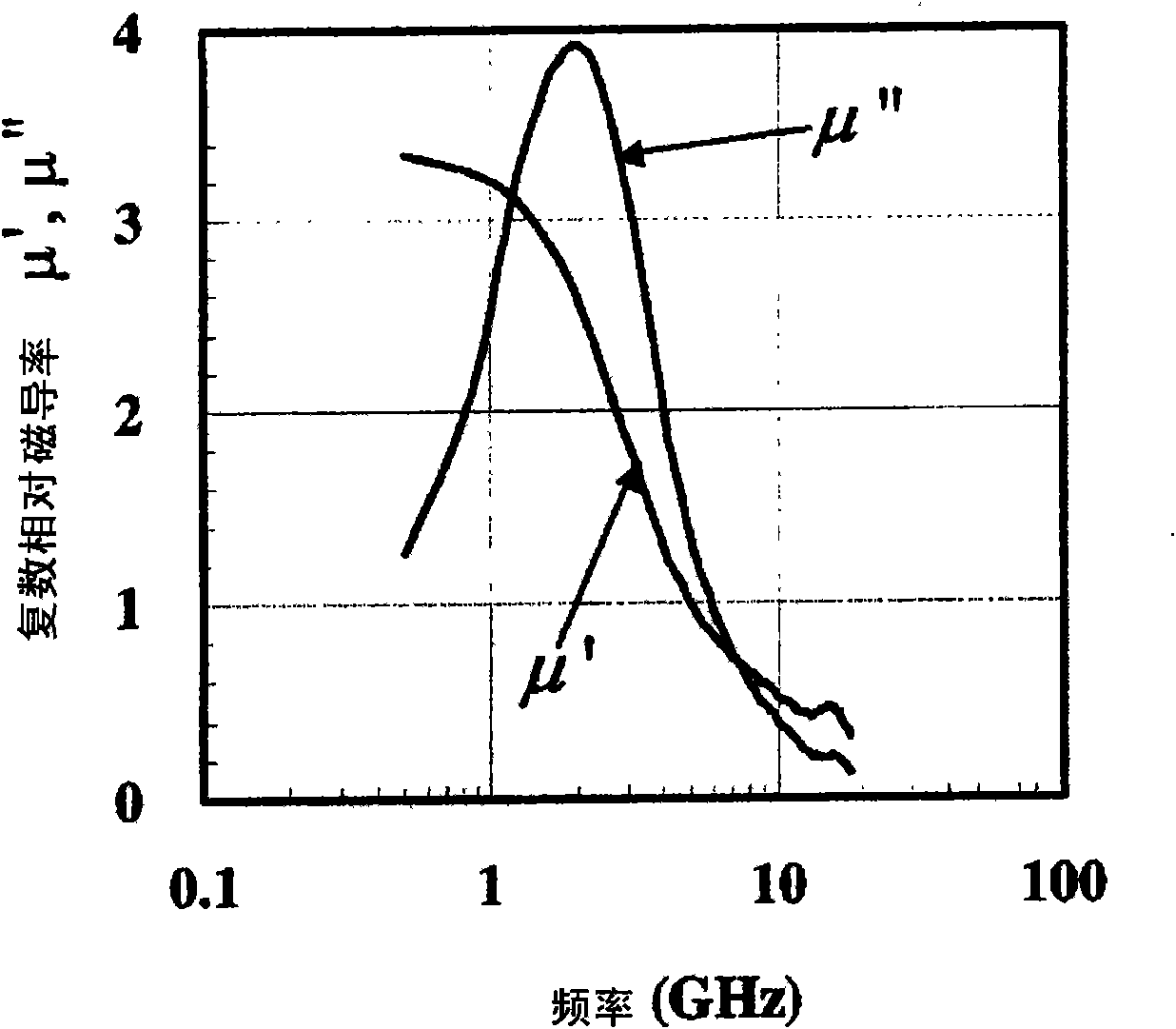

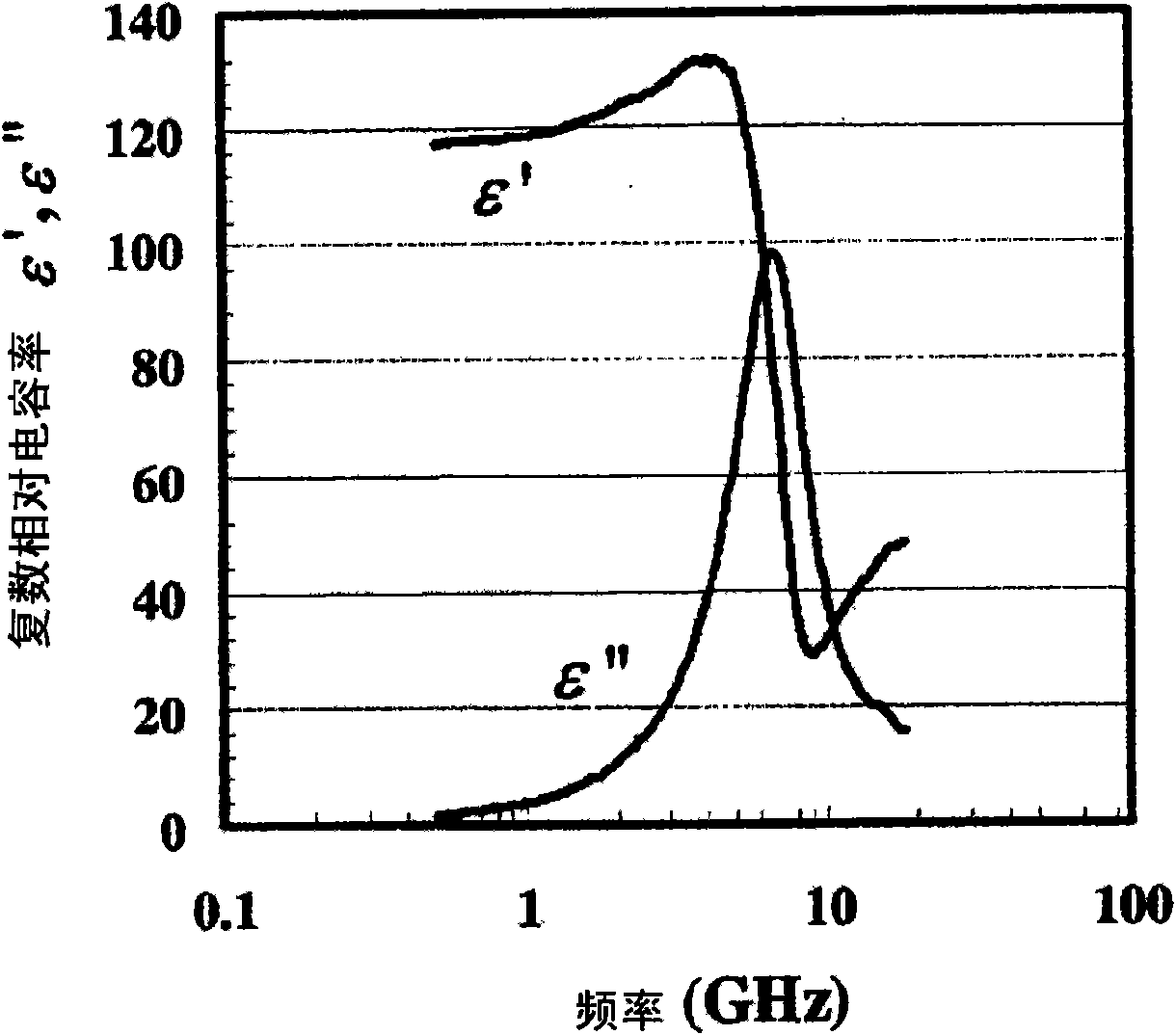

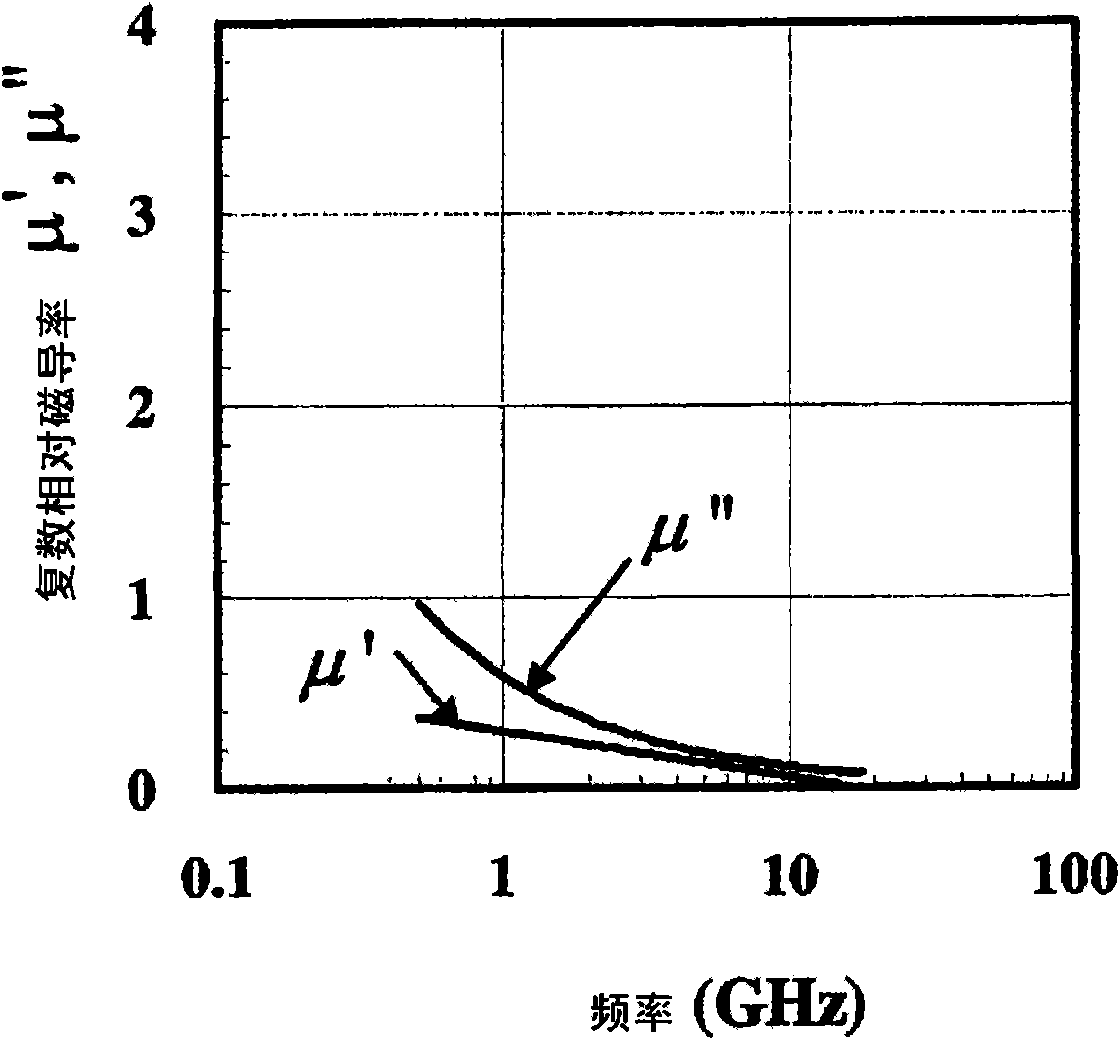

InactiveCN101669180AImprove permeabilityReduce eddy current lossInorganic material magnetismIron compoundsRare-earth elementEddy current

Disclosed is a magnetic material for a high frequency wave which has high magnetic permeability and small eddy-current loss, particularly a magnetic material for a high frequency wave which can be used suitably in an information device which works in a high frequency field of 1 GHz or higher. Specifically disclosed is a composite magnetic material for a high frequency wave, which comprises a (rareearth element)-(iron)-(nitrogen)-based magnetic material and a (rare earth element)-(iron)-(nitrogen)-based magnetic material whose surface is coated with a ferrite magnetic material.

Owner:TOKYO INST OF TECH

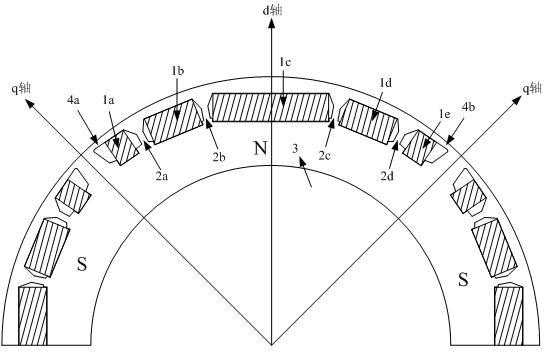

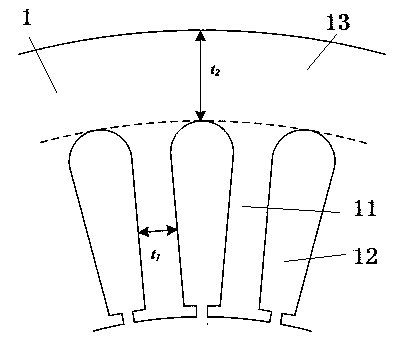

Rotor of built-in permanent magnet motor and magnetic steel structural parameter determining method thereof

InactiveCN102157998AHigh mechanical strengthIncrease stiffnessMagnetic circuit rotating partsElectric machinePermanent magnet motor

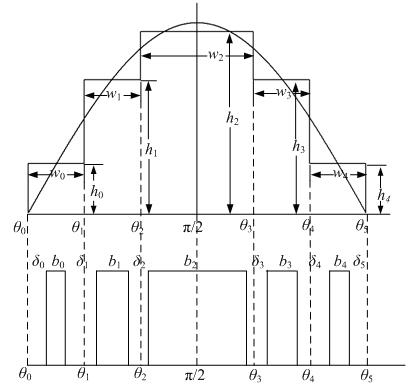

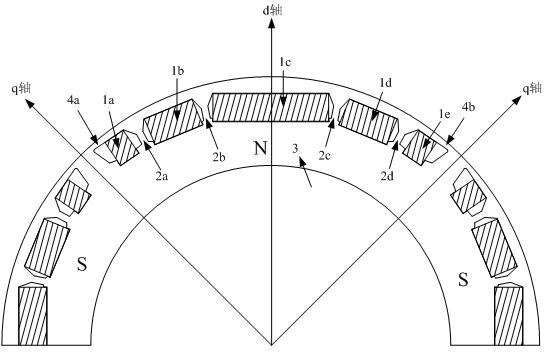

The invention relates to a rotor of a high-quality and high-speed built-in permanent magnet motor and a magnetic steel structural parameter determining method thereof. In the invention, the whole section magnetic steel of each electrode of the rotor of a conventional built-in permanent magnet motor is divided into multiple sections of magnetic steel which have the same polarity and different widths; the multiple sections of the magnetic steel are respectively arranged in a rotor core; and reinforcing ribs with the function of magnetic isolation are arranged among the multiple sections of the magnetic steel. By reasonably modulating and determining the width and distribution of each section of the magnetic steel, the air gap magnetic density waveform approaches sine distribution; harmonic components are reduced to the greatest extent; the eddy current loss of the magnetic steel and the torque pulsation of the motor are simultaneously reduced; and the electromagnetic performance of the motor is enhanced. Furthermore, the multiple sections of the magnetic steel are arranged in the circumference along the rotor; the highest rotating speed of the safe operation of the rotor is greatly enhanced on machinery; the radial thickness which is needed by the magnetic circuit of the rotor is obviously reduced on the structure; the rotational inertia and weight of the rotor are reduced; the dynamic response of the motor is improved; and the requirements of a high-speed driving system on the performance of the motor are met.

Owner:SHANGHAI UNIV

Preparing method for fine sheet metal magnetically soft alloy powder

ActiveCN104858441AImprove permeabilityHigh strengthInorganic material magnetismMicrometerGranularity

The invention relates to a preparing method for fine sheet metal magnetically soft alloy powder and belongs to the technical field of metal and alloy powder preparation. The method comprises the steps that two or three of Fe, Si, Al, Ni and Mo are selected as raw materials to carry out alloy distributing; a medium-frequency induction furnace is adopted for carrying out alloy smelting; a two-flow atomization method is adopted for carrying out atomizing on a melt, and alloy powder approximately spherical is prepared; by means of mechanical milling, flattening is carried out on the alloy powder; annealing treatment is carried out on the obtained sheet powder, and by means of an ultrasonic vibrating sieve, the fine sheet metal magnetically soft alloy powder is prepared. The powder prepared through the method, the granularity ranges from 10 micrometers to 100 micrometers, the average thickness ranges from 0.1 micrometer to 5 micrometer, the radial thickness ratio ranges from 50 to 500, and the powder flattening rate reaches 90%. According to the method, the powder preparing process is simple, the production efficiency is high, the production cost is low, the quality of the magnetically soft powder core can be effectively improved, and the manufacturing cost is reduced.

Owner:有研增材技术有限公司

High-efficiency soft magnetic material and method for producing the same

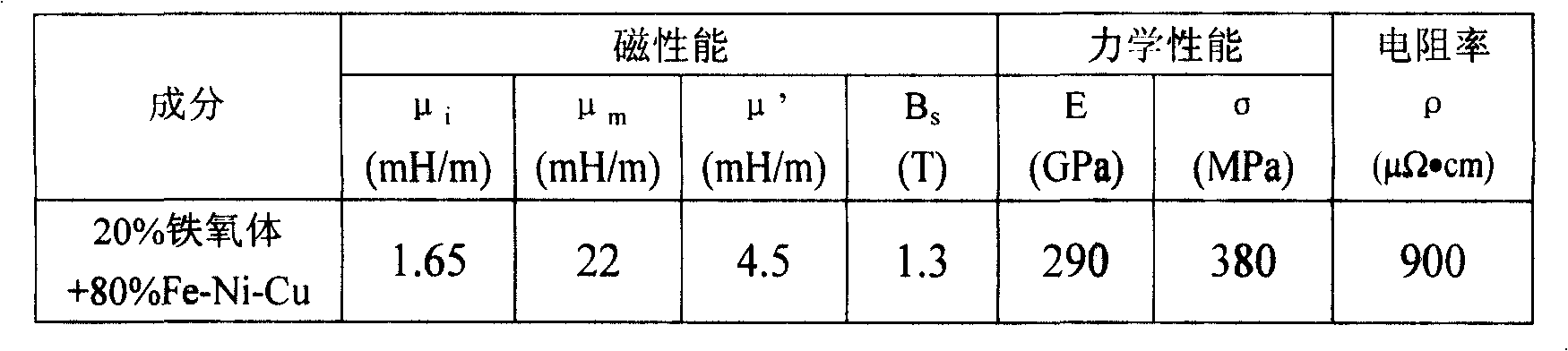

InactiveCN101246773AGuaranteed mechanical propertiesExcellent soft magnetic propertiesInorganic material magnetismInductances/transformers/magnets manufactureMetalMagnet

The invention relates to a highly efficient soft magnetic material and the preparing method thereof. The soft magnetic material is composed of metal soft magnetic material and soft magnetic ferrite, the metal soft magnetic material is composed of at least one selected from Fe-Ni-Me system (Me is one or more than two selected form Cu, Cr, Nb, V, W, Si, Pd, Zn, Al, Ti and Mn), Fe-Co system, Fe-Co-V system, Fe-Al system and Fe-Al-Me system (Me is one or more than two selected form Co, Cr and Mo), the soft magnetic ferrite is composed of at least one selected form Mn-Zn system, Ni-Zn system, Li-Zn system, Cu-Zn system and Mg-Zn system soft magnetic ferrites. The preparing method of the soft magnetic material comprises the steps of: cold pressing, and sintering, hot pressing or spark plasma sintering. The soft magnetic material does not have the drawbacks of low resistivity of the metal soft magnetic and low magnetic strength of the ferrite, as well as keeps the superior properties of the metal soft magnetic and low magnetic strength of the ferrite.

Owner:GRIREM ADVANCED MATERIALS CO LTD

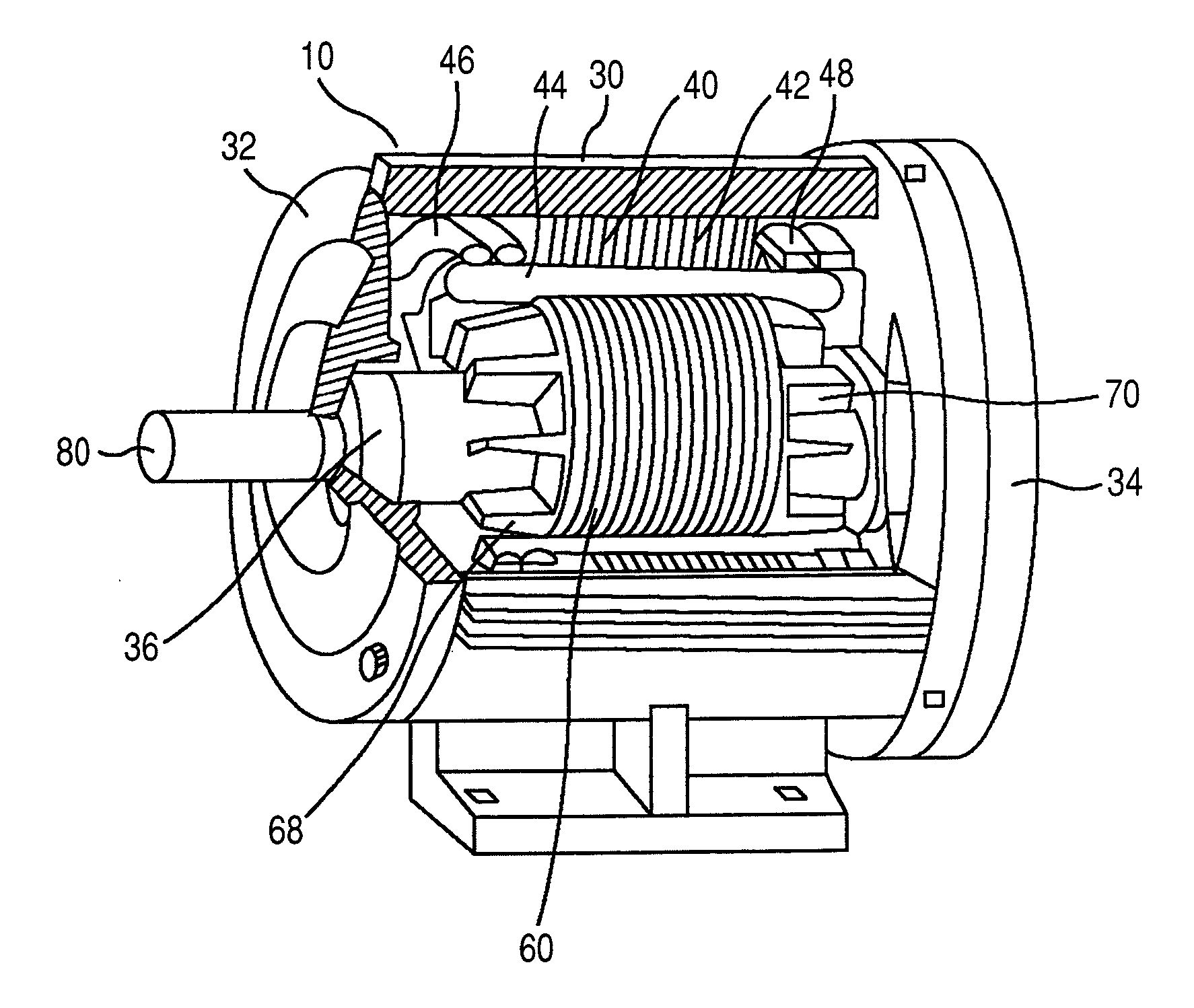

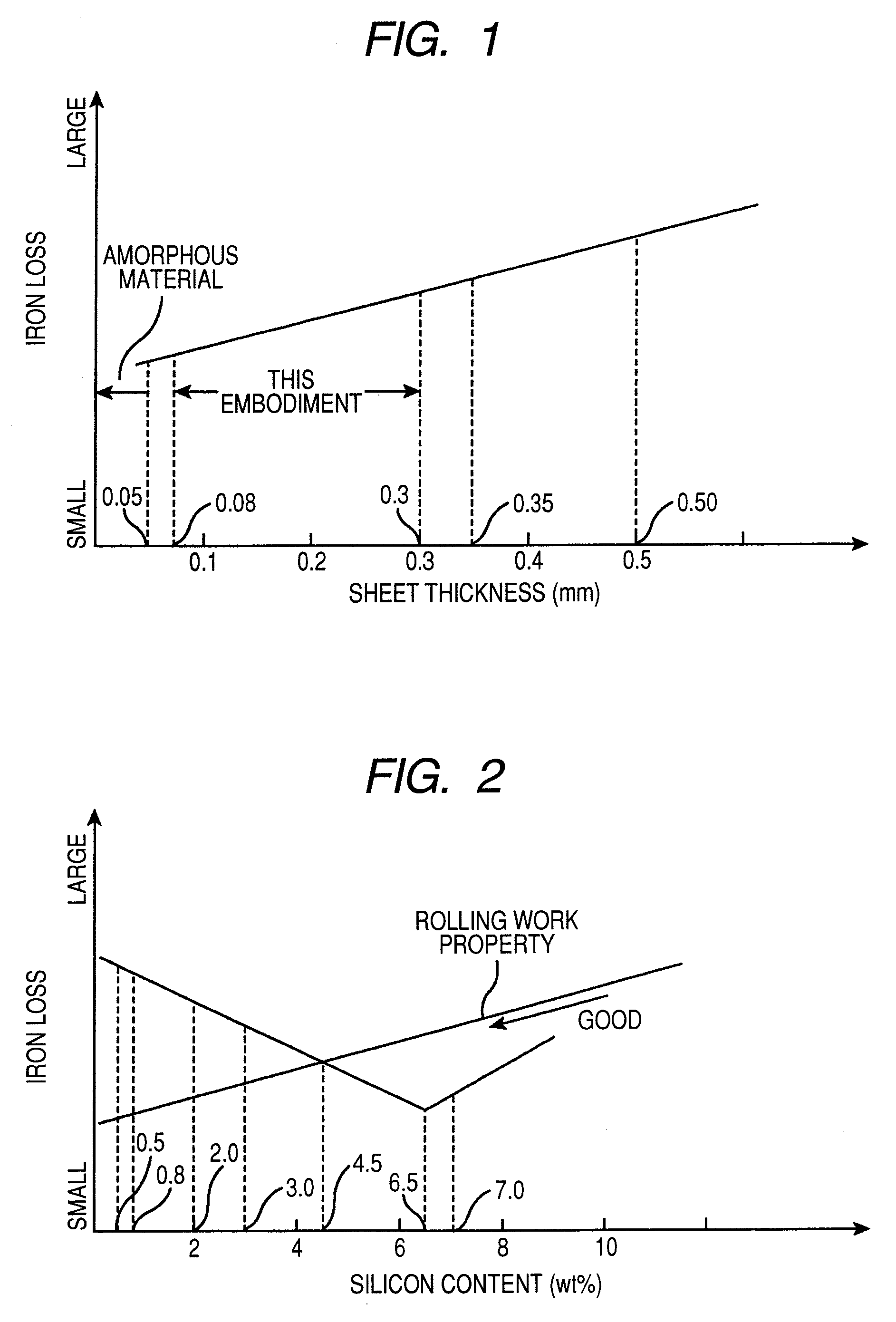

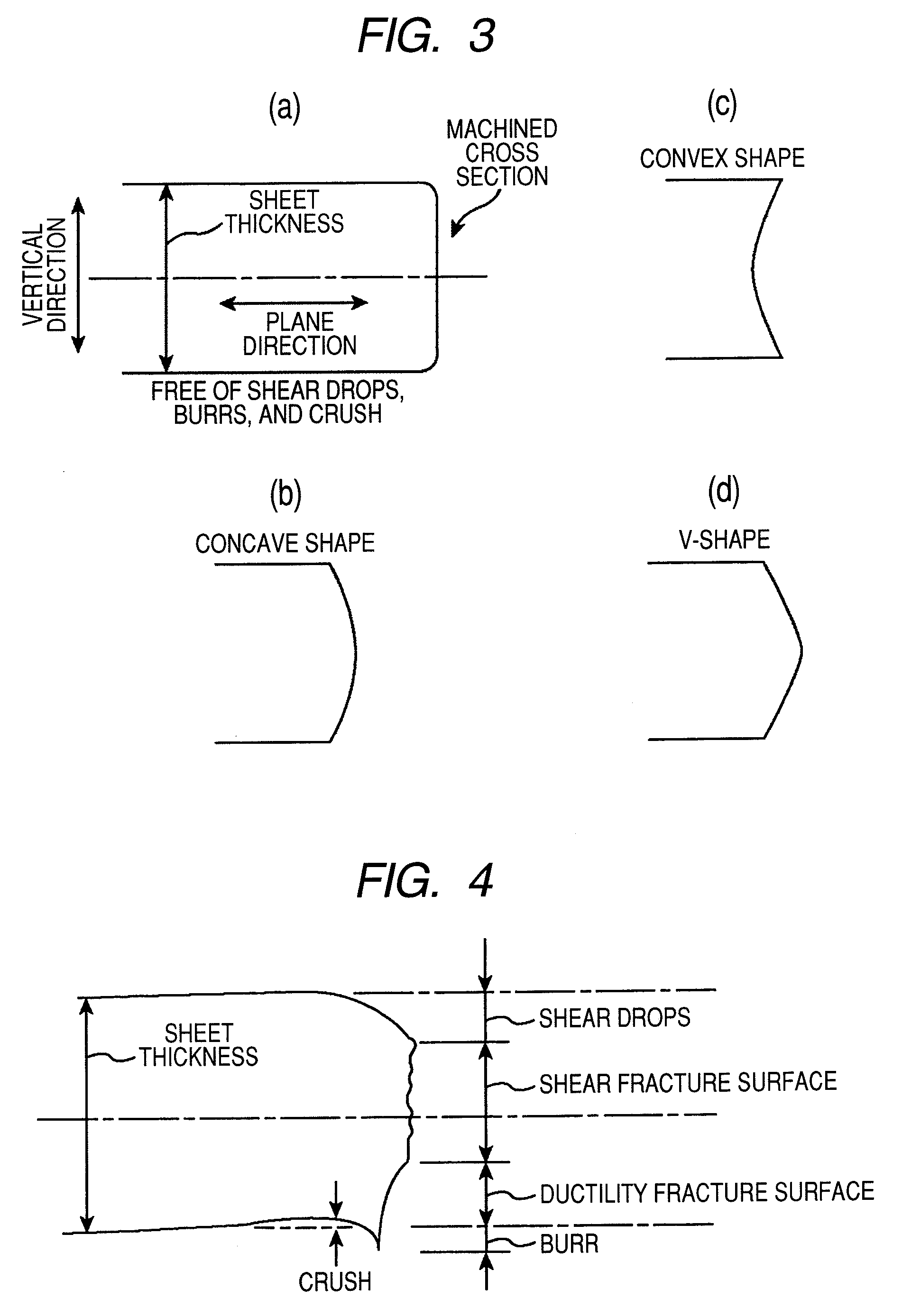

Rotating electrical machine

InactiveUS20080012445A1Reduce iron lossReduce eddy-current lossMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineConductor Coil

A rotating electrical machine comprises a stator and a rotor; the stator comprising a stator core having teeth and slots, and stator windings disposed in the slots, wherein the stator core is made of laminated steel sheets, teeth and slots of the steel sheet are made by etching, and the thickness of the steel sheet is between 0.05 mm and 0.30 mm. Specifically, it is preferable that the steel sheet used herein be a silicon steel sheet containing crystalline particles.

Owner:HITACHI LTD

Short-circuit fault-tolerant vector control method for embedded hybrid magnetic material fault-tolerant cylindrical linear motor

InactiveCN105245156ASimple structureImprove reliabilityElectronic commutation motor controlAC motor controlVoltage source inverterCompensation strategy

The invention discloses a short-circuit fault-tolerant vector control method for an embedded hybrid magnetic material fault-tolerant cylindrical linear motor. The short-circuit fault-tolerant vector control method comprises the following steps: building a five-phase embedded hybrid magnetic material fault-tolerant cylindrical linear motor model; compensating normal thrust missing caused by a short-circuit fault phase and suppressing a thrust ripple caused by phase short-circuit current with non-fault phase current of the motor; and obtaining expected phase voltage by adopting a series of coordinate conversion and voltage feed-forward compensation strategies, and achieving a fault-tolerant vector control after the phase short-circuit fault of the motor by a zero-sequence voltage harmonic injection-based CPWM modulation mode. According to the short-circuit fault-tolerant vector control method, the motor can suppress the thrust ripple of the motor under the condition of a phase short-circuit fault-tolerant operation; more importantly, the dynamic property, the steady-state performance and the properties in a normal state are consistent; the switching frequency of a voltage source inverter is constant; a CPU is low in overhead; and a natural coordinate system only needs to counterclockwise rotate a certain angle in any phase short-circuit fault, so that the motor fault-tolerant operation can be achieved.

Owner:JIANGSU UNIV

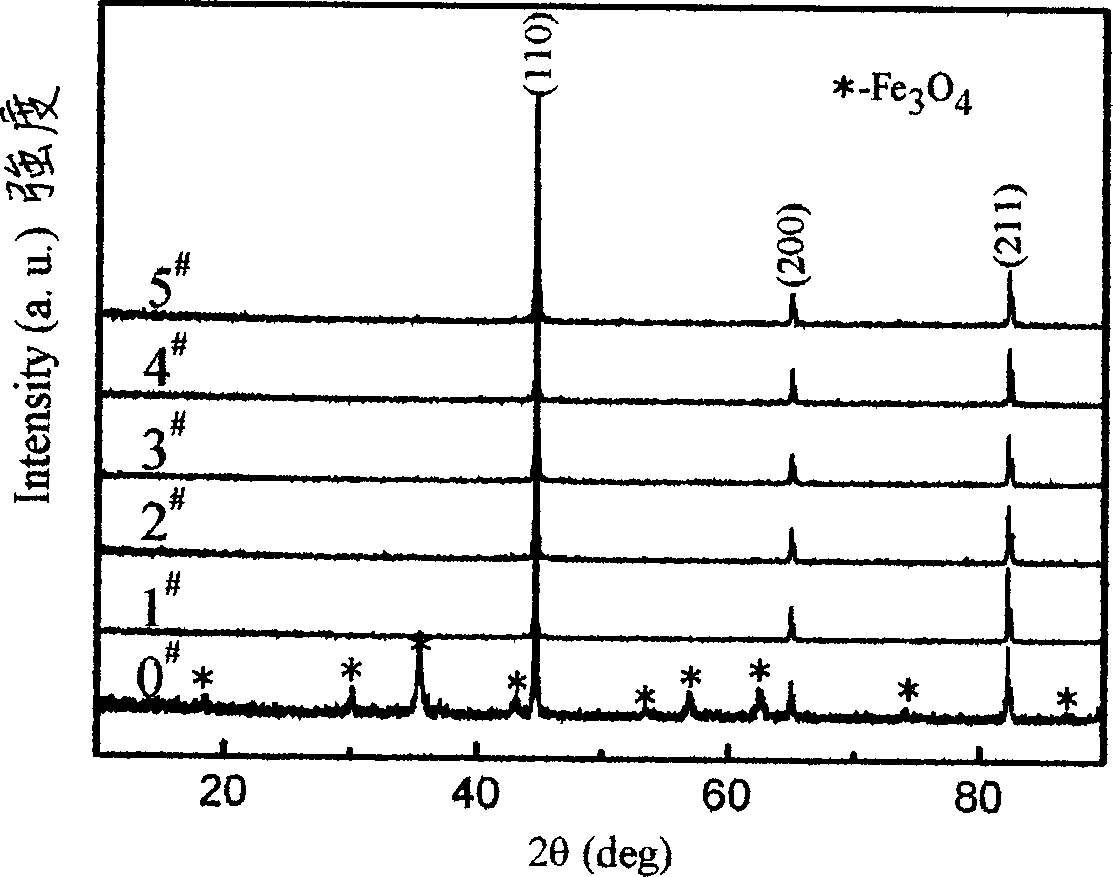

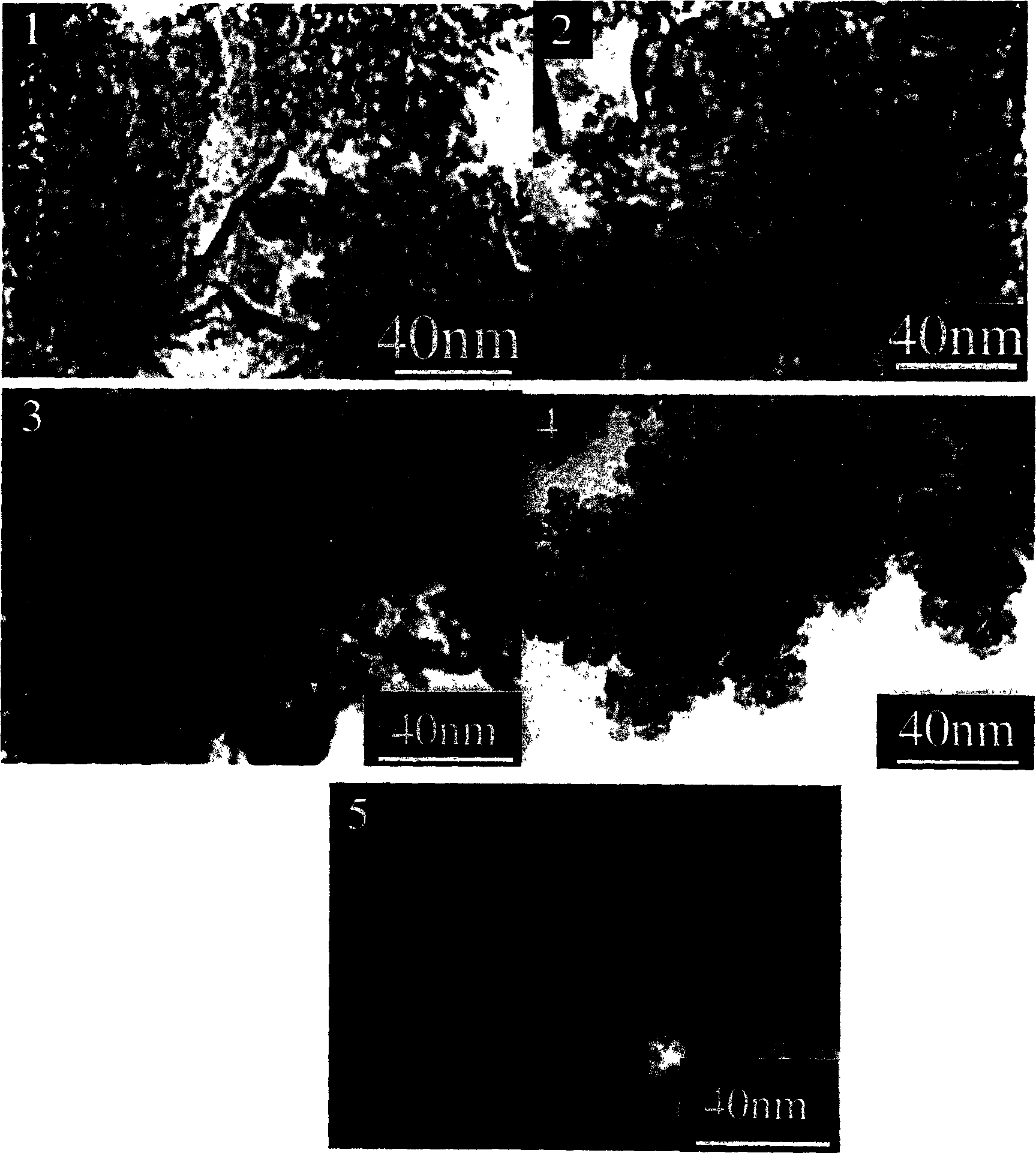

Core/shell structure containing Fe/SiO2 composite nano particles with high stability and method for making same

InactiveCN1594450ASimple preparation processEasy to controlInorganic pigment treatmentSilicic acidComposite nanoparticles

The invention discloses a core / shell-structure-containing Fe / SiO2 composite nano particles with high stability and its preparing process which comprises, using ferric salt as raw material, organic acid as complexing agent, absolute ethyl alcohol or isopropyl alcohol as dissolvent so as to form uniform non-aqueous gel, charging silicic acid ethyl acetate, evaporating and dehydrating to form gel, preparatory roasting in air to remove the organics, deacidizing at different temperature in H2 atmosphere.

Owner:NANJING UNIV

Iron-based soft magnetic composite magnetic powder core and preparation method thereof

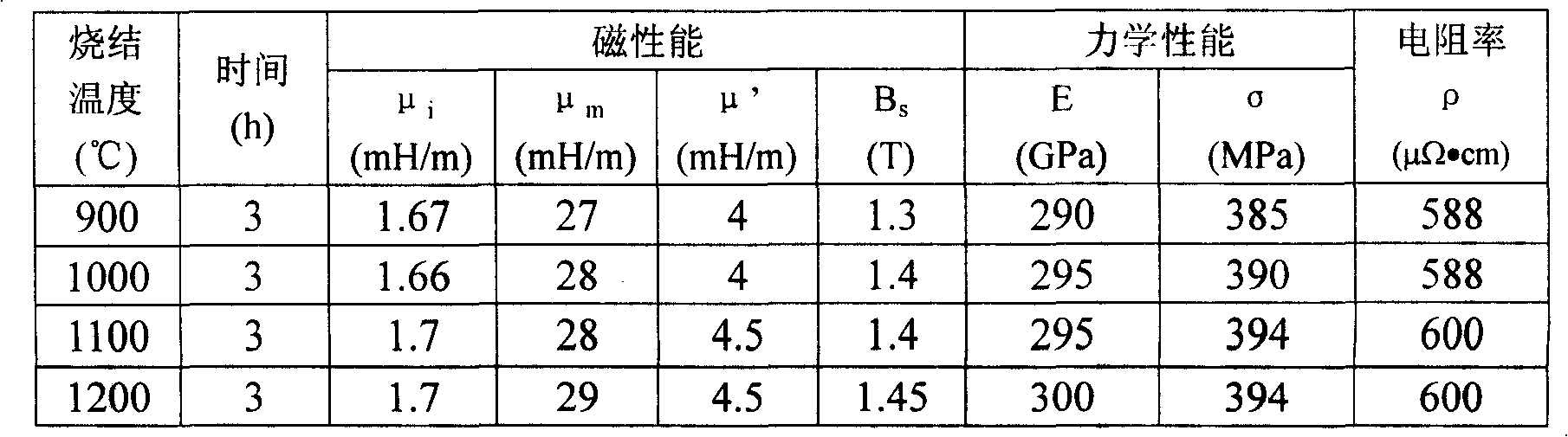

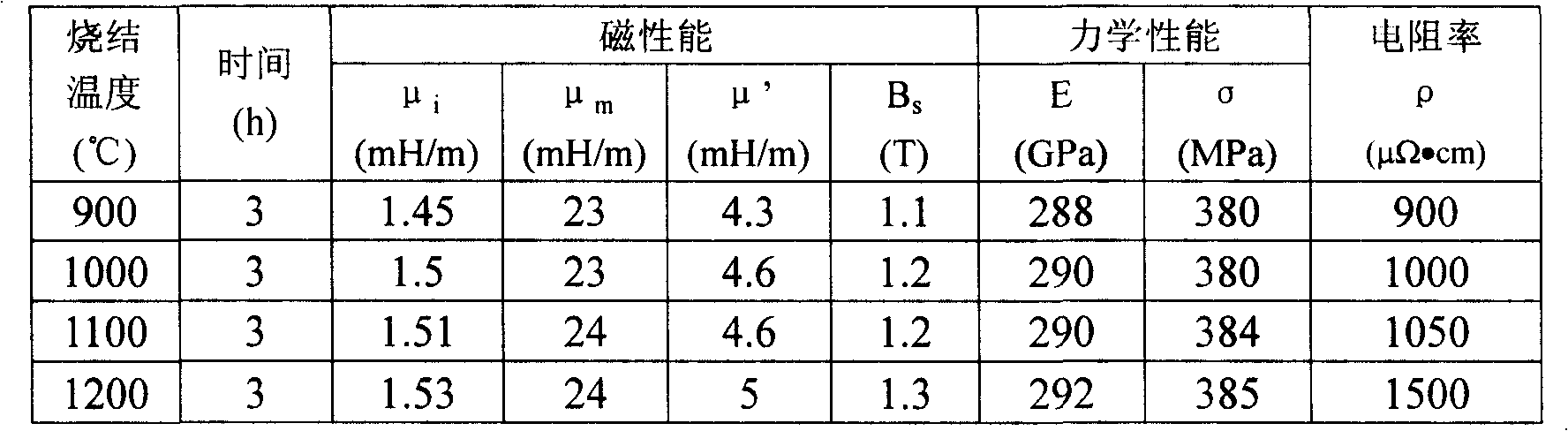

ActiveCN104078182AThickness controllable and adjustableGuaranteed uniformityInorganic material magnetismAlcoholHeat stability

The invention relates to an iron-based soft magnetic composite magnetic powder core and a preparation method thereof. The invention adopts the technical scheme as follows: sequentially adding iron-based alloy powder, absolute ethyl alcohol, a silane coupling agent and distilled water into a reaction vessel according to the mass ratio of 1:(6-10):(0.04-0.10):(0.2-0.4), and stirring; adding tetraethyl orthosilicate or methyl silicate, then adding ammonia water, stirring continuously, washing, filtering and drying; placing the obtained composite powder with a core-shell heterostructure into an annealing furnace, performing heat preservation for 1-3 h under the condition of 600-800 DEG C, performing furnace cooling and performing compression moulding; sintering for 1-10 h under the condition of 900-1350 DEG C, so that the iron-based soft magnetic composite magnetic powder core is obtained after furnace cooling. The prepared iron-based soft magnetic composite magnetic powder core has the characteristics that the insulating property is good, the iron loss is low, high magnetic strength is achieved, the heat stability is good and the service life is prolonged when the iron-based soft magnetic composite magnetic powder core is used at a higher environment temperature.

Owner:WUHAN UNIV OF SCI & TECH

Core structure of skew-pole rotor of permanent magnet motor and laminating method thereof

InactiveCN103779993AReduce eddy current lossReduce Flux LeakageMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet motorMagnetism

The invention discloses a core structure of a skew-pole rotor of a permanent magnet motor and a laminating method of the core structure. The core structure comprises a shaft and rotor cores, wherein the rotor cores are provided with a first locating hole, a second locating hole, a third locating hole and a fourth locating hole respectively. According to the laminating method, the first locating hole of the first rotor core, the second locating hole of the second rotor core, the third locating hole of the third rotor core and the fourth locating hole of the fourth rotor core are located at the same circumferential position through a locating pin, a spiral staggered structure is formed by magnetic steel bonding faces on the rotor cores, and then the skew pole effect of the rotor can be achieved. The core structure of the skew-pole rotor of the permanent magnet motor and the laminating method of the core structure have the advantages that eddy-current loss of the motor can be reduced by the adoption of the laminated structure of the rotor cores, magnetic leakage between adjacent pieces of magnetic steel can be reduced by the arrangement of magnetism isolation grooves, the performance of the motor is improved, the structure is simple, and the machining and manufacturing process is convenient to carry out.

Owner:王必生

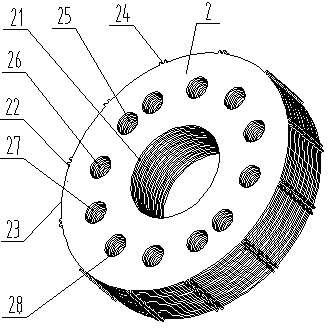

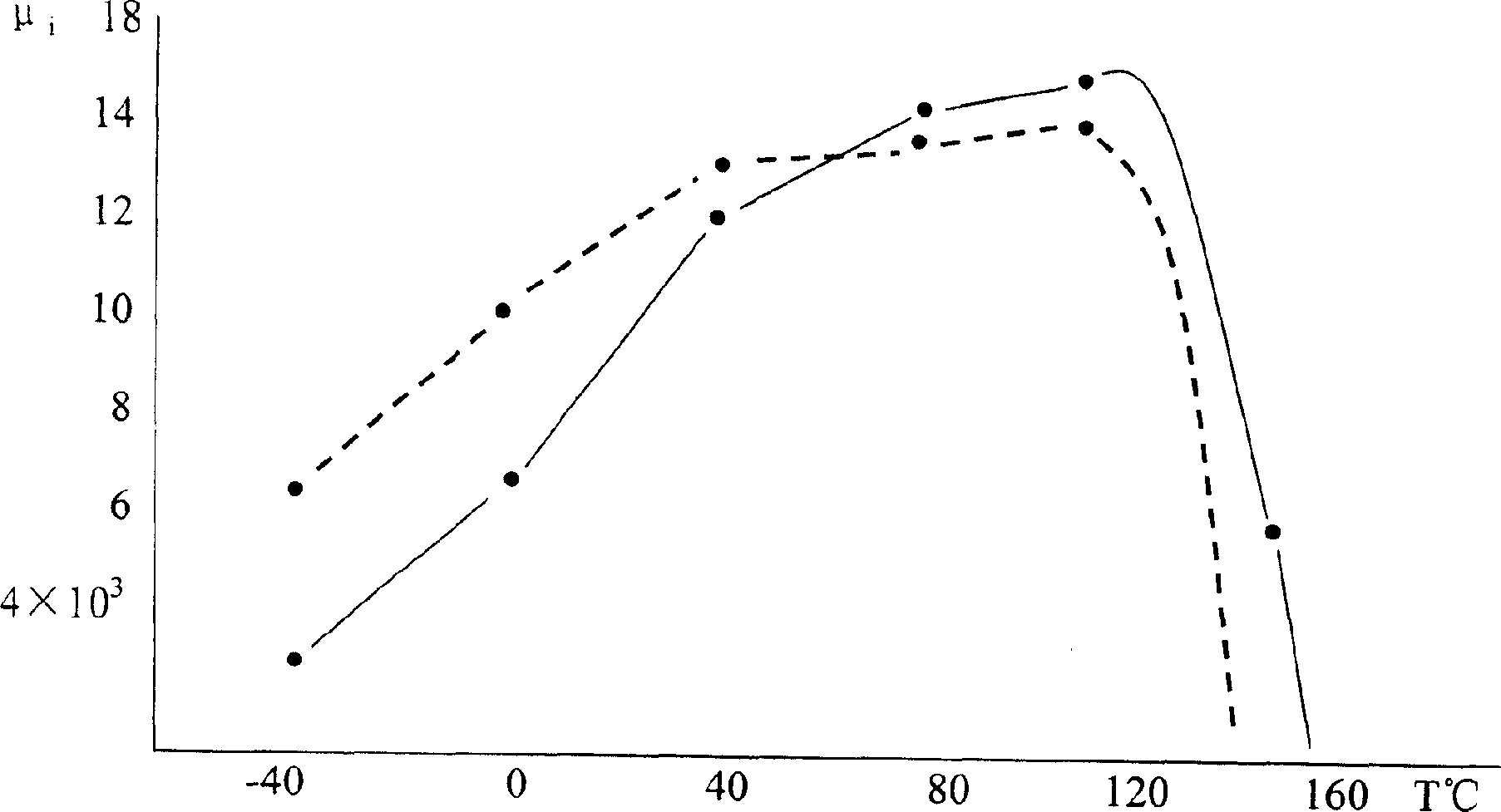

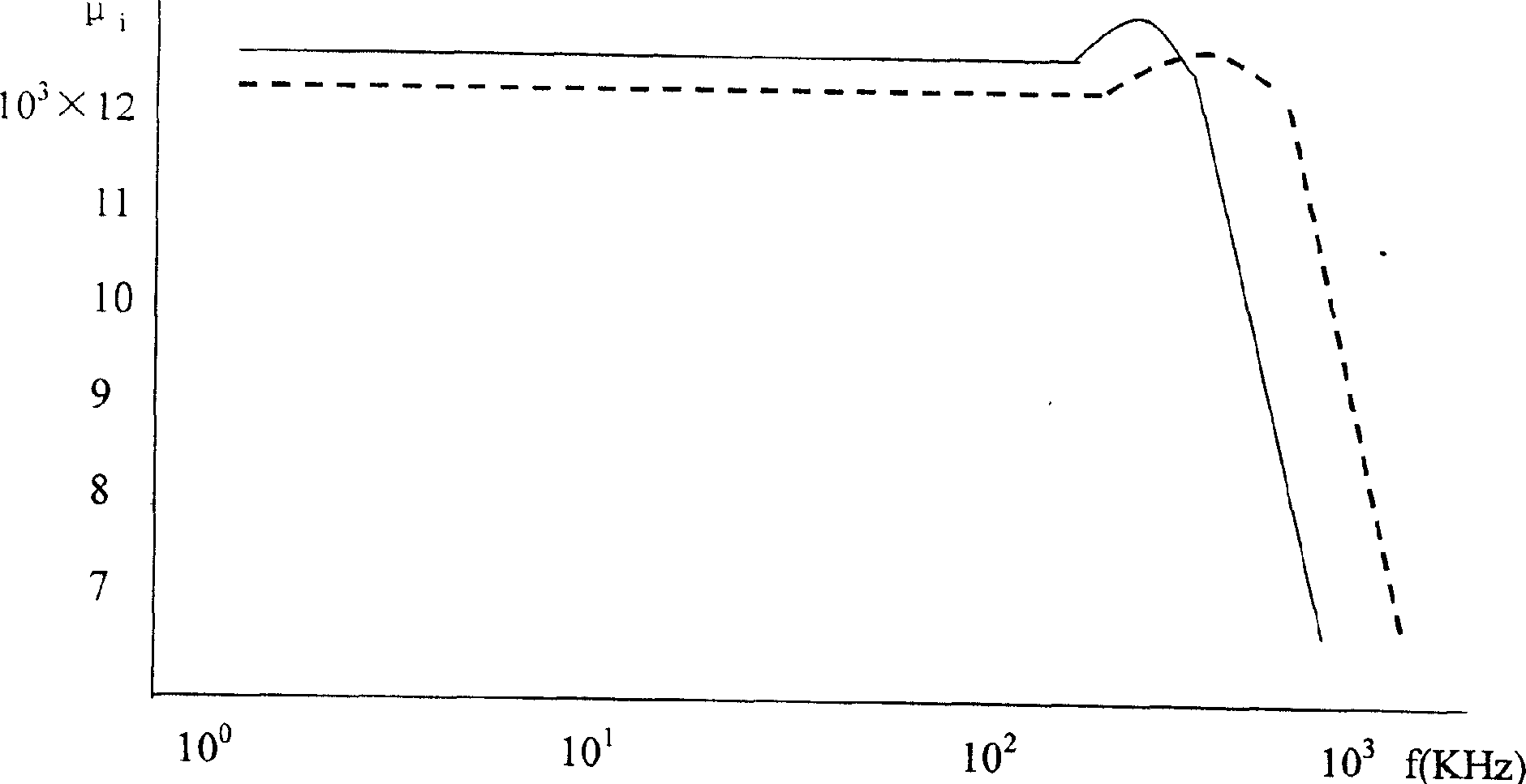

Ferrite magnet material of manganese-zinc, and Method for preparing high conductive ferrite of manganese-zinc from material

ActiveCN1697094AIncrease temperatureImprove performanceInorganic material magnetismManganese oxideTitanium oxide

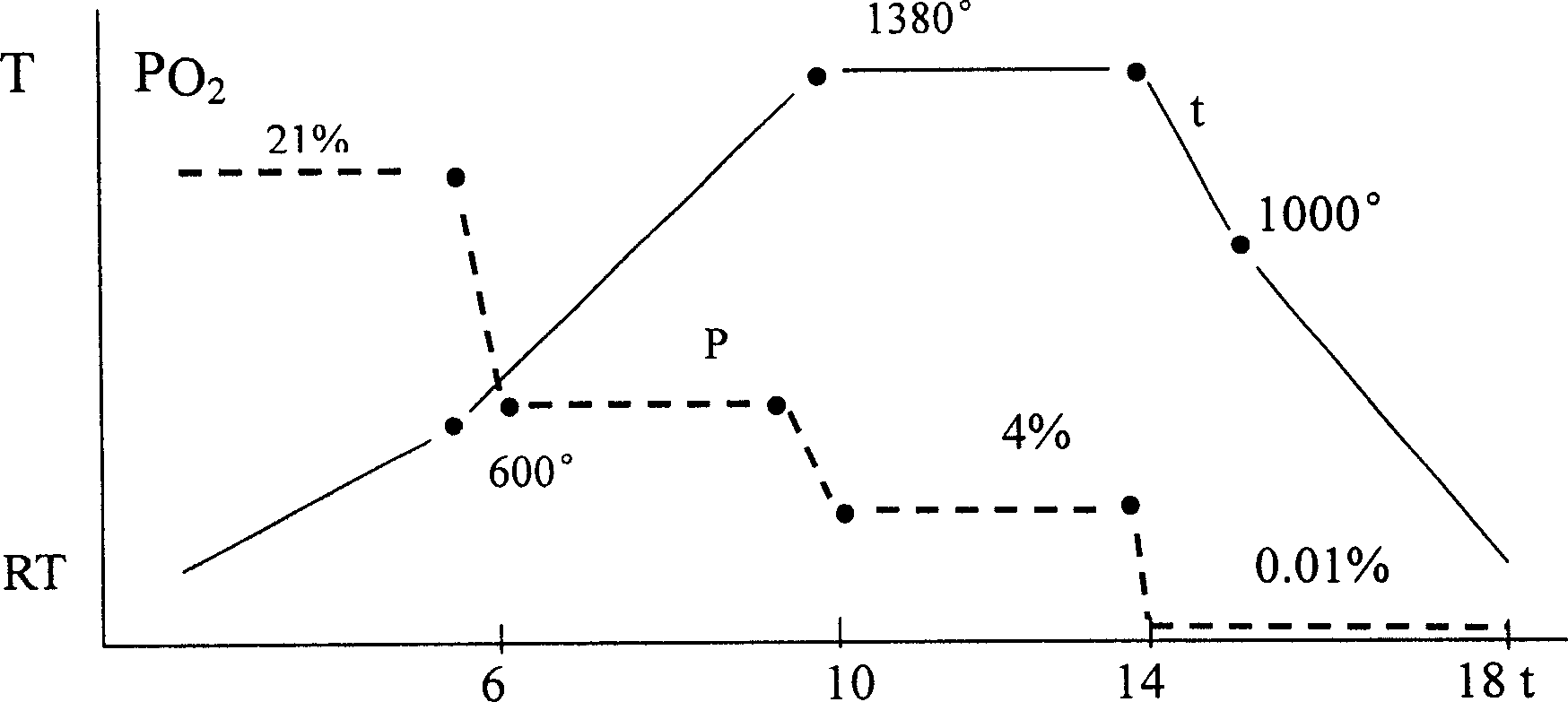

Mixed main material including 51.5-52.8 mol% ferric oxide, 23.3-26.0 mol% manganese oxide, and 22.5-24.0 mol% zinc oxide is processed through shake grinding and pre-burning procedures. Next, auxiliary materials including 500-1000ppm calcium oxide, 300-1500ppm titanium oxide and 100-400ppm bismuth oxide are added to the said processed main material. Then, procedures including sand mill, granulation, body blank and burning are carried out in sequence to produce products. Advantages are: reasonable compounding ratio between main and auxiliary materials provides precondition for producing the disclosed product in high magnetic permeability and low coefficient of specific loss; optimized curve of agglomeration technology prevents oxidation of products, and improves temperature and even atmosphere in kiln. The product shows preferred initial permeability, coefficient of specific loss and coefficient of specific temperature.

Owner:SUZHOU GUANDA MAGNET

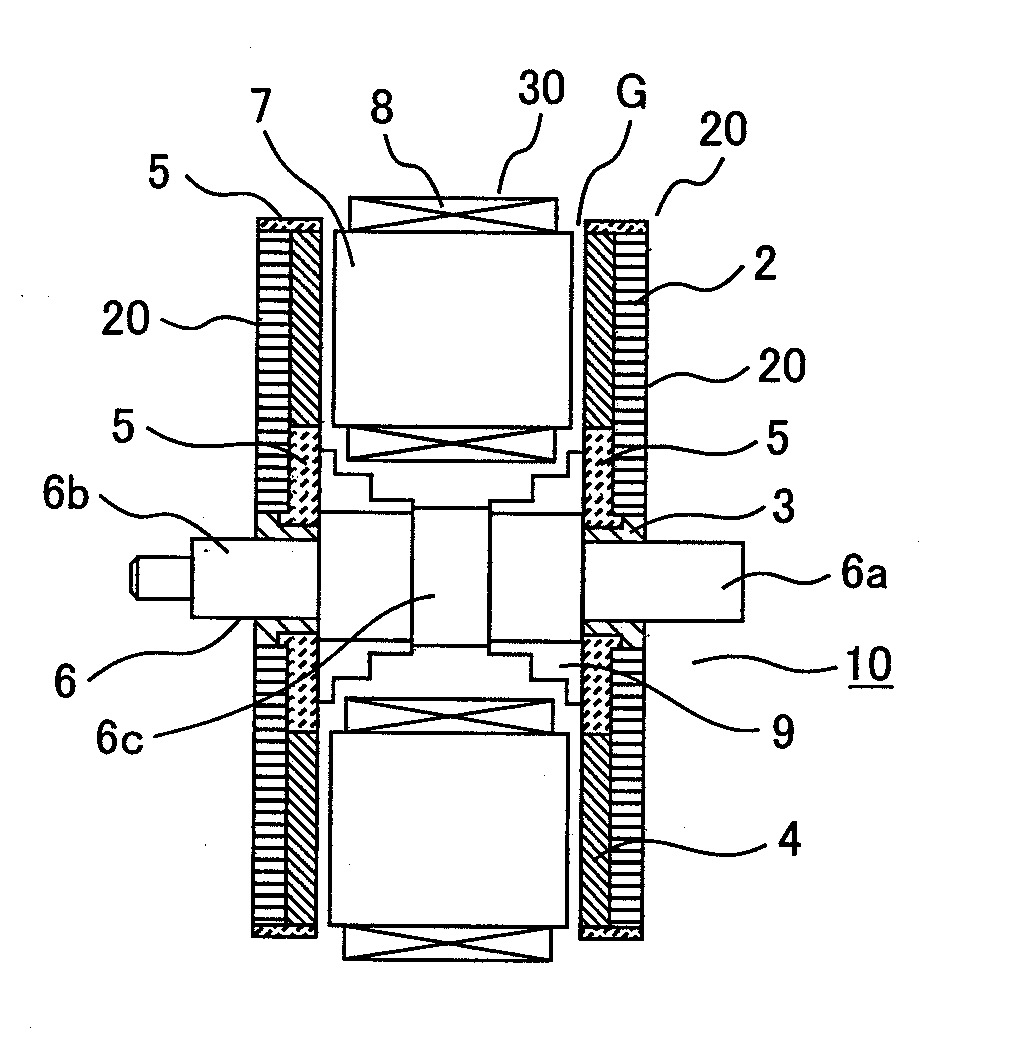

Vertical type magnetic suspension flywheel energy storage system

InactiveCN105591492AReduce manufacturing difficultyReduce manufacturing costMechanical energy handlingBearingsSupporting systemFlywheel energy storage

The invention belongs to the field of electrotechnics, discloses a vertical type magnetic suspension flywheel energy storage system, and provides a vertical type magnetic suspension flywheel energy storage system advantaged in high rotating speed, low standby loss and low cost, mainly for the purpose of solving the structural defect existing in a conventional flywheel energy storage system in the prior art. The vertical type magnetic suspension flywheel energy storage system is mainly characterized in that a rotating shaft connecting a motor with a flywheel is omitted, the motor is designed to be of an external rotor structure and an external rotor of the motor is arranged on the inner wall of the cylindrical flywheel. A sufficient centripetal force is provided for the motor rotor rotating at a high speed by use of the feature that the flywheel itself is high in structural strength such that the design requirement for high rotating speed of the flywheel energy storage system is satisfied. A radial suspension portion in a support system employs a design of a permanent magnetic suspension bearing so that the design requirements for low cost and low standby loss are met; and the vertical type magnetic suspension flywheel energy storage system can be widely applied to such occasions as power grid peak adjustment and frequency modulation, an uninterrupted power supply, aerospace and the like.

Owner:张瑞彬

Magnetic isolation material and preparation method and application thereof

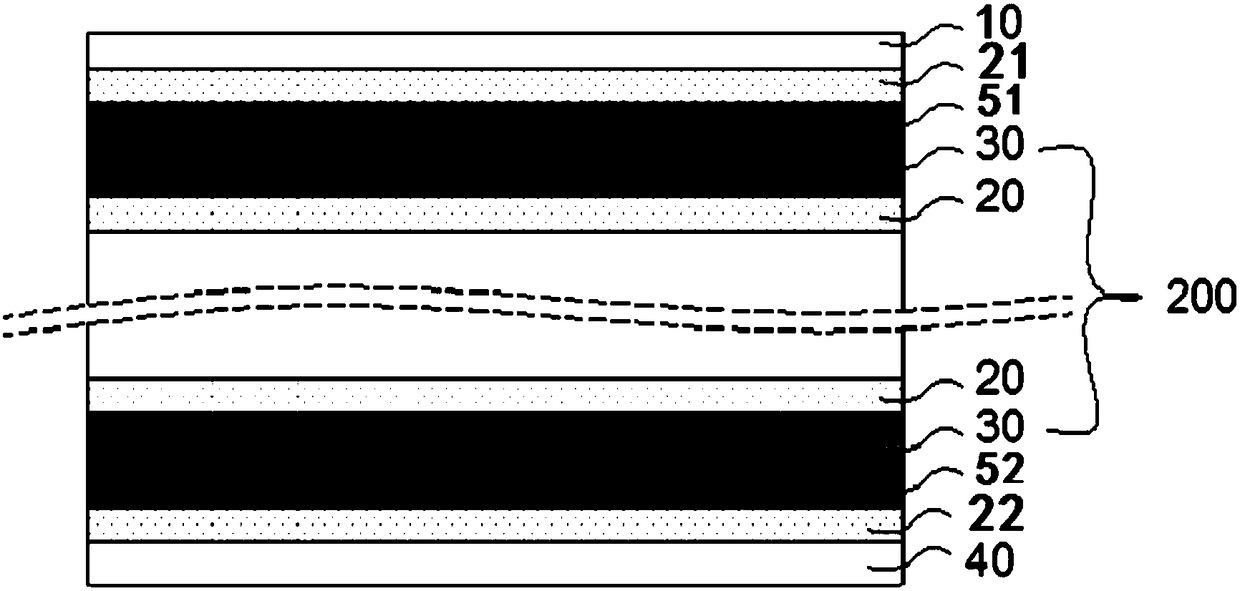

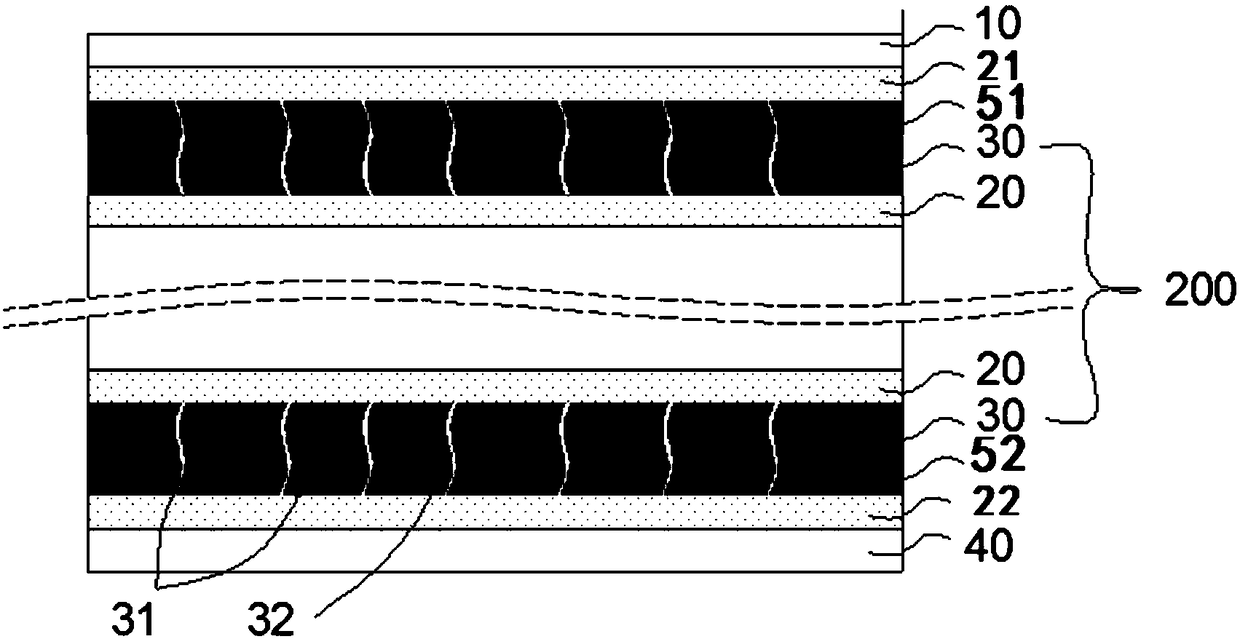

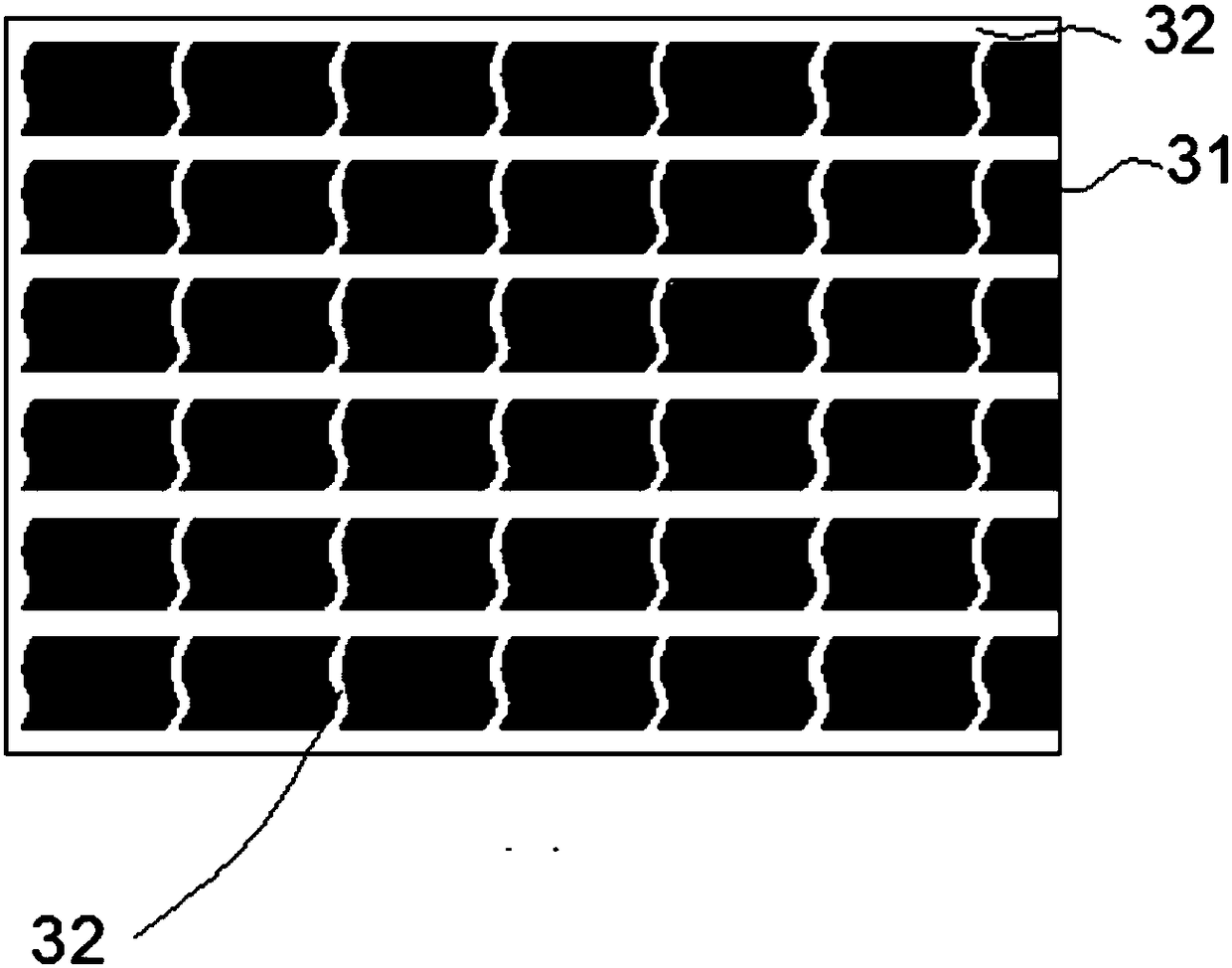

ActiveCN108430204AImprove shielding effectImprove thermal conductivityMagnetic/electric field screeningCircuit arrangementsTectorial membraneMagnetic isolation

The invention relates to the field of magnetic isolation material, and discloses a magnetic isolation material and a preparation method and application thereof. The magnetic isolation material comprises a magnetic layer and protective films and an off-type films arranged on different sides of the magnetic layer, wherein the magnetic layer comprises at least one magnetic material sheet layer. The magnetic material sheet layer comprises a plurality of magnetic material chips and the gap between the magnetic material chips are at least partially filled with air; a first glue layer is arranged between the protective film and the magnetic layer and a second glue layer is arranged between the off-type film and the magnetic layer. The preparation method overcomes the problems of complex preparation process of the magnetic isolation material in the prior art, and the prepared magnetic isolation material is with better performance.

Owner:苏州格优微磁磁材有限公司

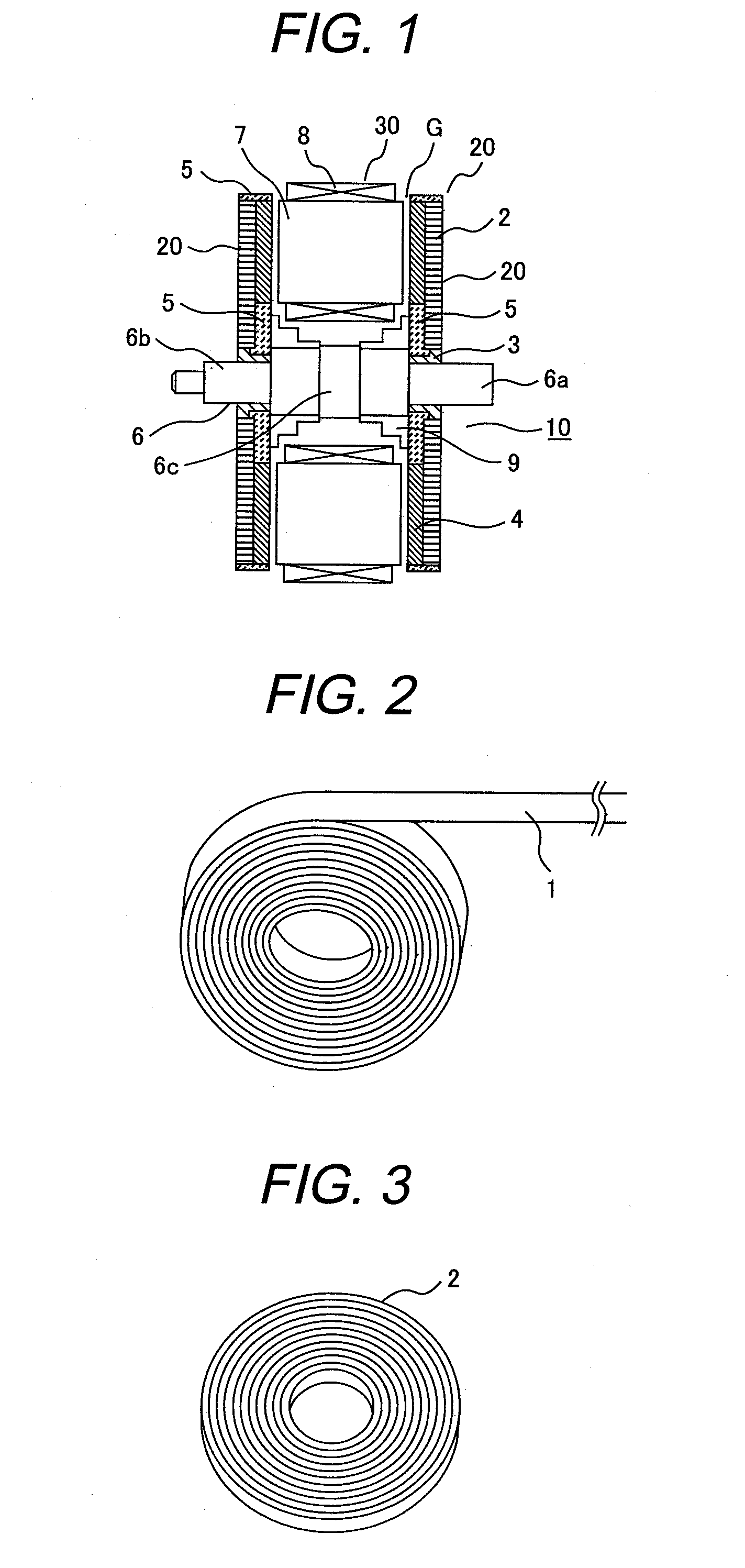

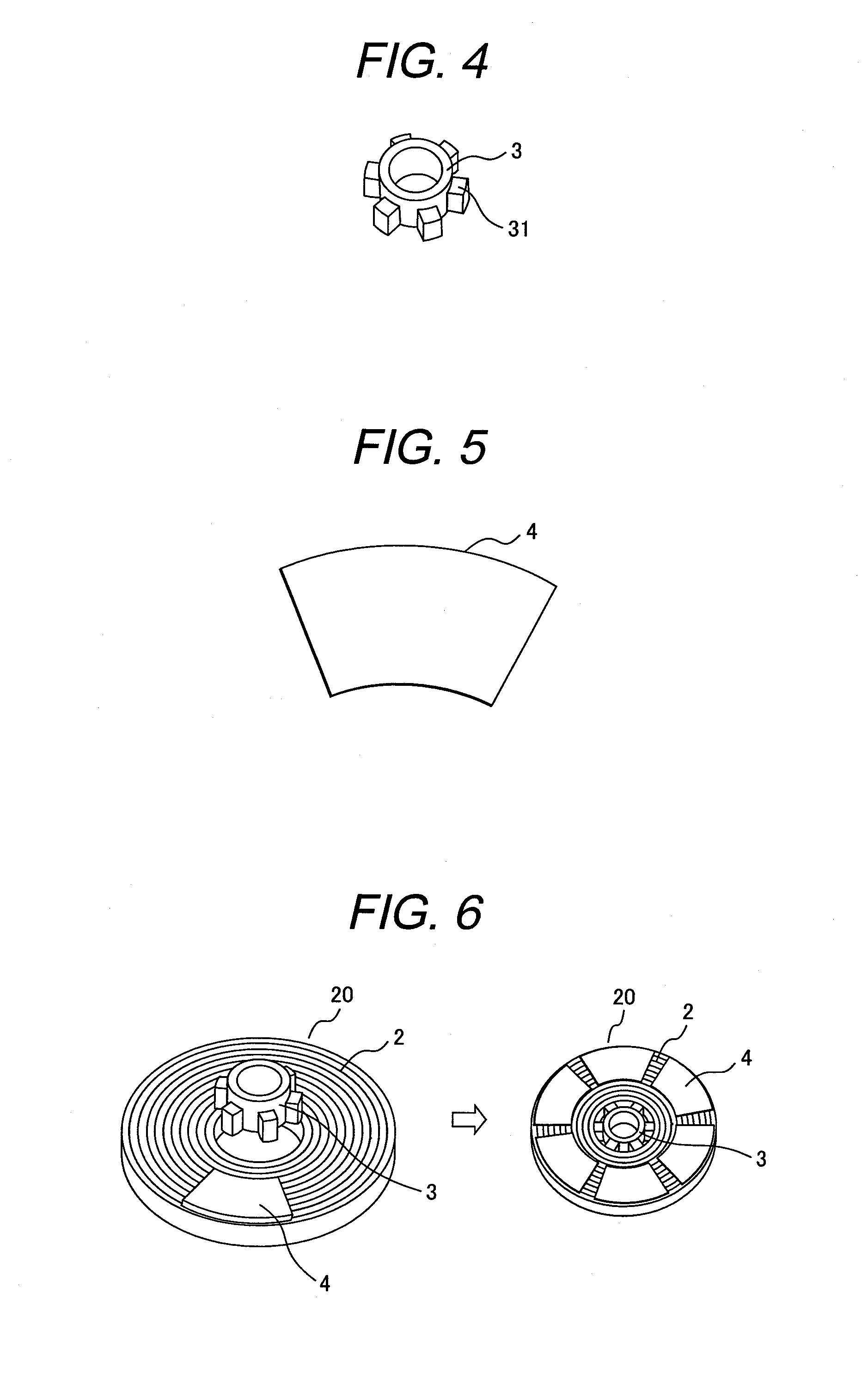

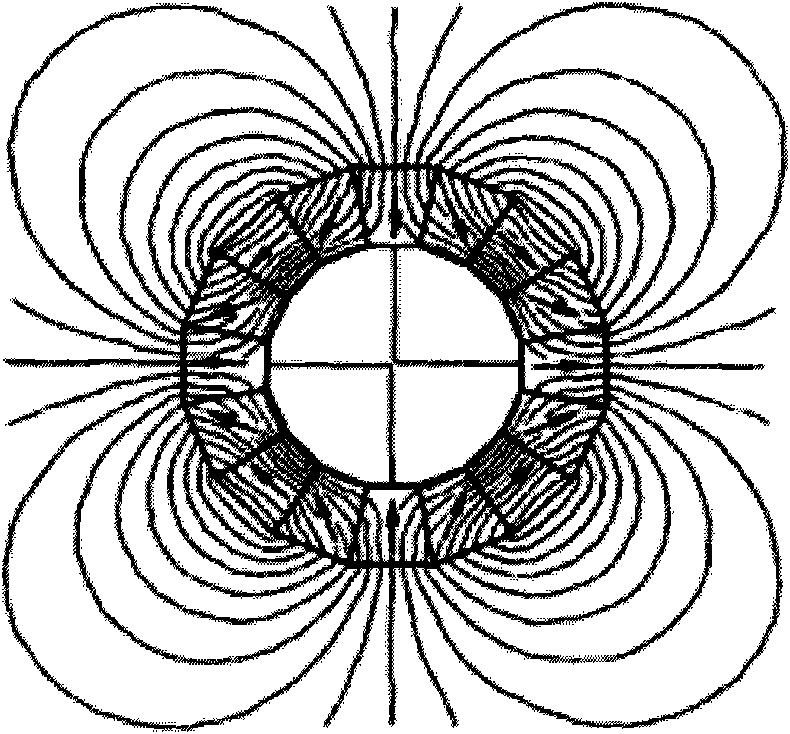

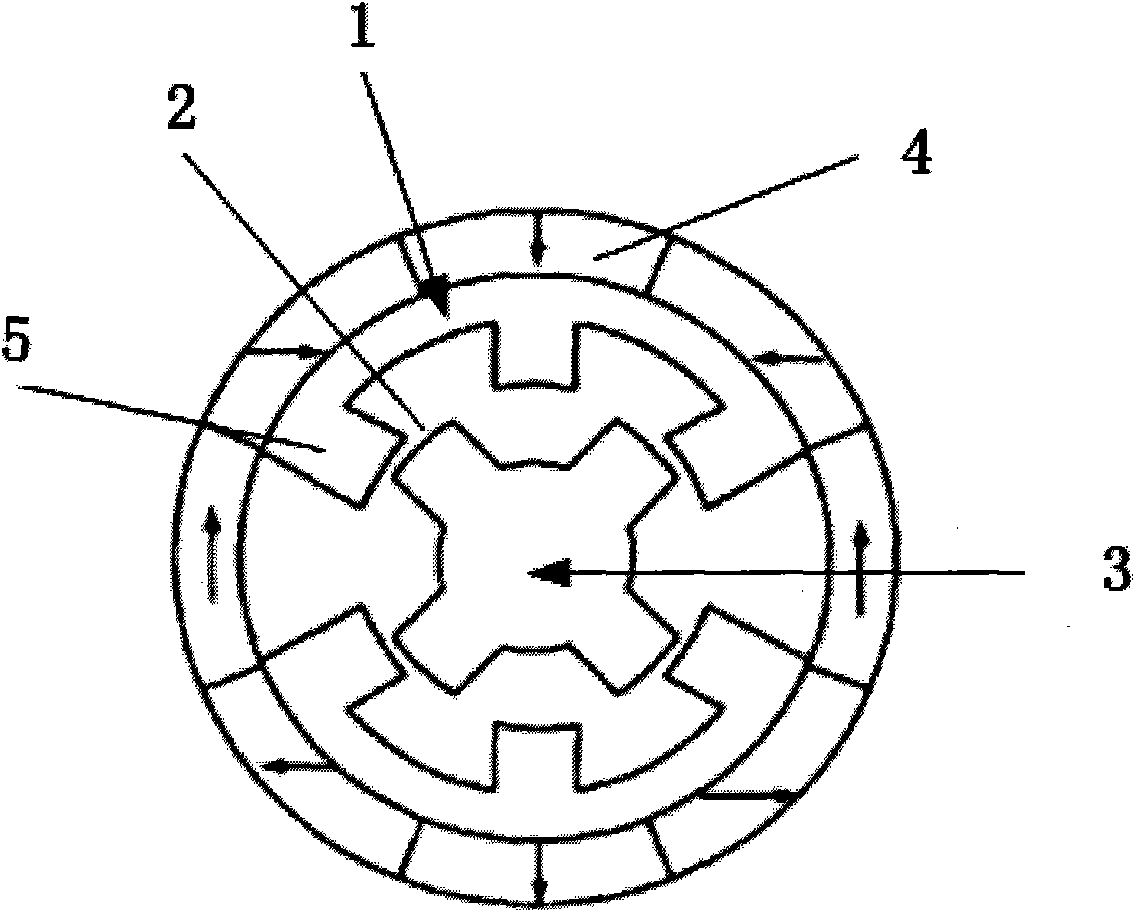

Axial gap rotating electrical machine and rotor used therefor

ActiveUS20110156519A1Reduce eddy current lossSimple manufacturing processMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineEngineering

In the axial gap rotating electrical machine, the rotor includes a rotor yoke that is formed by wrapping amorphous ribbon wound toroidal core, which is obtained by winding an amorphous magnetic metal ribbon into a toroidal core. Magnets having plural poles are circumferentially disposed on a stator-facing surface of the amorphous ribbon wound toroidal core.

Owner:HITACHI METALS LTD

Soft magnetism composite powder and preparation method thereof

InactiveCN103177838ACoated evenlyImprove antioxidant capacityInorganic material magnetismSelf-healingPolyethylene glycol

The invention discloses soft magnetism composite powder and a preparation method of the soft magnetism composite powder. The soft magnetism composite powder is the composite powder which has two layers of inorganic insulation coating structures, the inner core of the composite powder is magnetic particles of FeSiAl or FeSi, SiO2 in a network state is coated on the outer layer of the magnetic particles, and nanocrystalline B2O3 is coated outside the SiO2. The preparation method of the soft magnetism composite powder comprises the following steps: (1) preparing magnetism SiO2 core-shell structural powder; (2) uniformly mixing the magnetism SiO2 core-shell structural powder prepared in the step (1), borate N-butyl, absolute ethanol, polyethylene glycol and deionized water, dropwise adding acetic acid, adjusting the potential hydrogen (pH) value of the mixed solution to be 5-6, stirring the mixed solution for 1-5 hours at the temperature of 40 DEG C-80 DEG C till a complete reaction is achieved, and drying the mixed solution at the temperature 40 DEG C-100 DEG C till the weight is constant; and (3) calcining the dried powder at the temperature of 400 DEG C-500 DEG C for 1-2 hours under the protective atmosphere. The soft magnetism composite powder prepared through the method has a good physical performance and a good magnetic performance. Due to the fact that a B2O3 film is coated outside the SiO2 shell layer, the magnetic powder is enabled to have a crack self-healing capability under the condition of high temperature, the electrical resistivity of a magnetic powder core is improved, and the eddy-current loss of materials is reduced.

Owner:CENT SOUTH UNIV

Method for performing insulating treatment on metal magnetic powder and preparing metal magnetic powder

ActiveCN104759619AImprove insulation performanceHigh resistivityInorganic material magnetismPhosphatePhosphoric acid

The invention discloses a method for performing insulating treatment on metal magnetic powder and preparing metal magnetic powder. The method comprises the following steps: reacting phosphoric acid and boric acid on the surface of metal magnetic powder, generating and absorbing a layer of phosphate and borate on the surface of the metal magnetic powder to obtain required B and P diffusion sources; under a vacuum atmosphere, performing diffusion reaction, diffusing B and P elements on the surface of the metal magnetic powder to inner part of the metal, and forming a metal gap compound containing B or P below a metal magnetic powder phosphate and borate coating layer after penetrating B and P on the surface of the metal magnetic powder. The metal gap compound and the boric acid left outside the magnetic powder have low melting point, are changed to be liquid at a high temperature to achieve the effects of an inorganic binder. The method has the beneficial effects of improving the insulation of the metal magnetic powder surface, and improving the resistance of the metal magnetic powder particles and the contact resistance of the magnetic powder; inorganic binding coater is adopted to directly form, so that the cost is reduced, the magnetic core strength is improved, and the atmospheric pollution is avoided.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

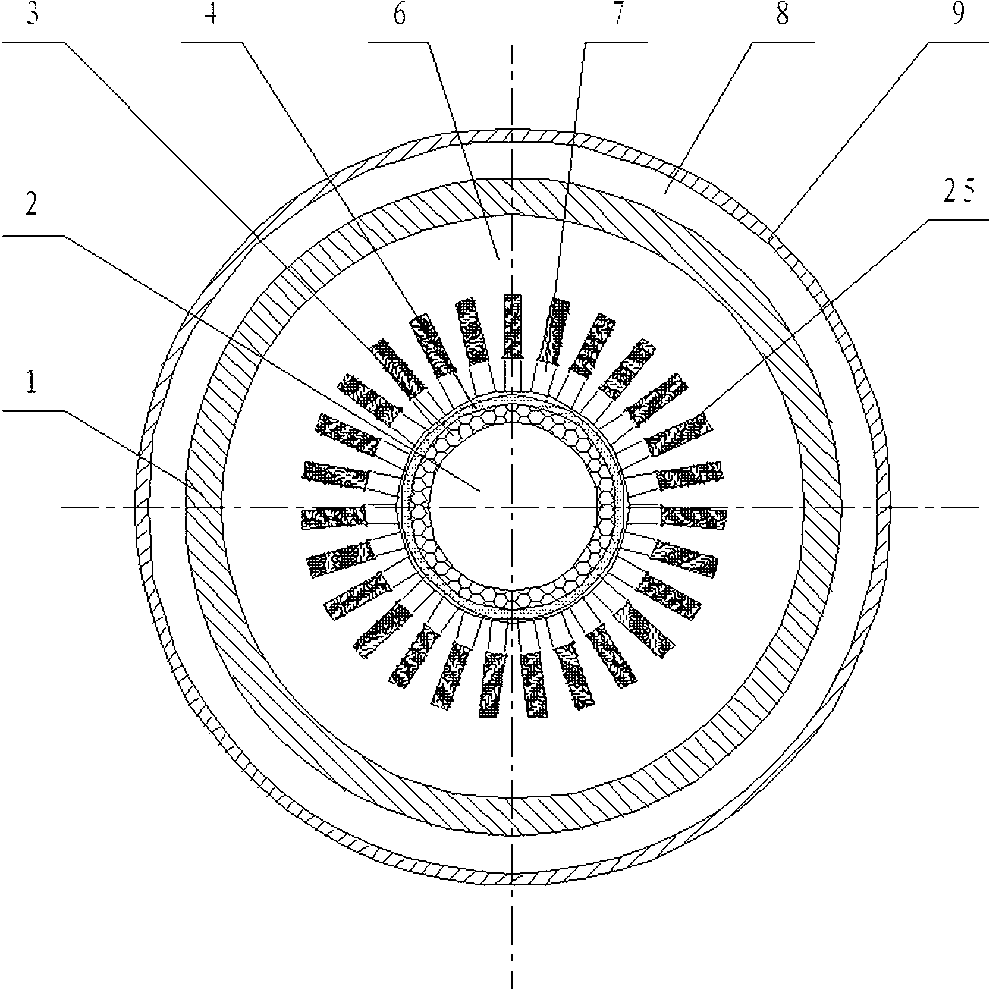

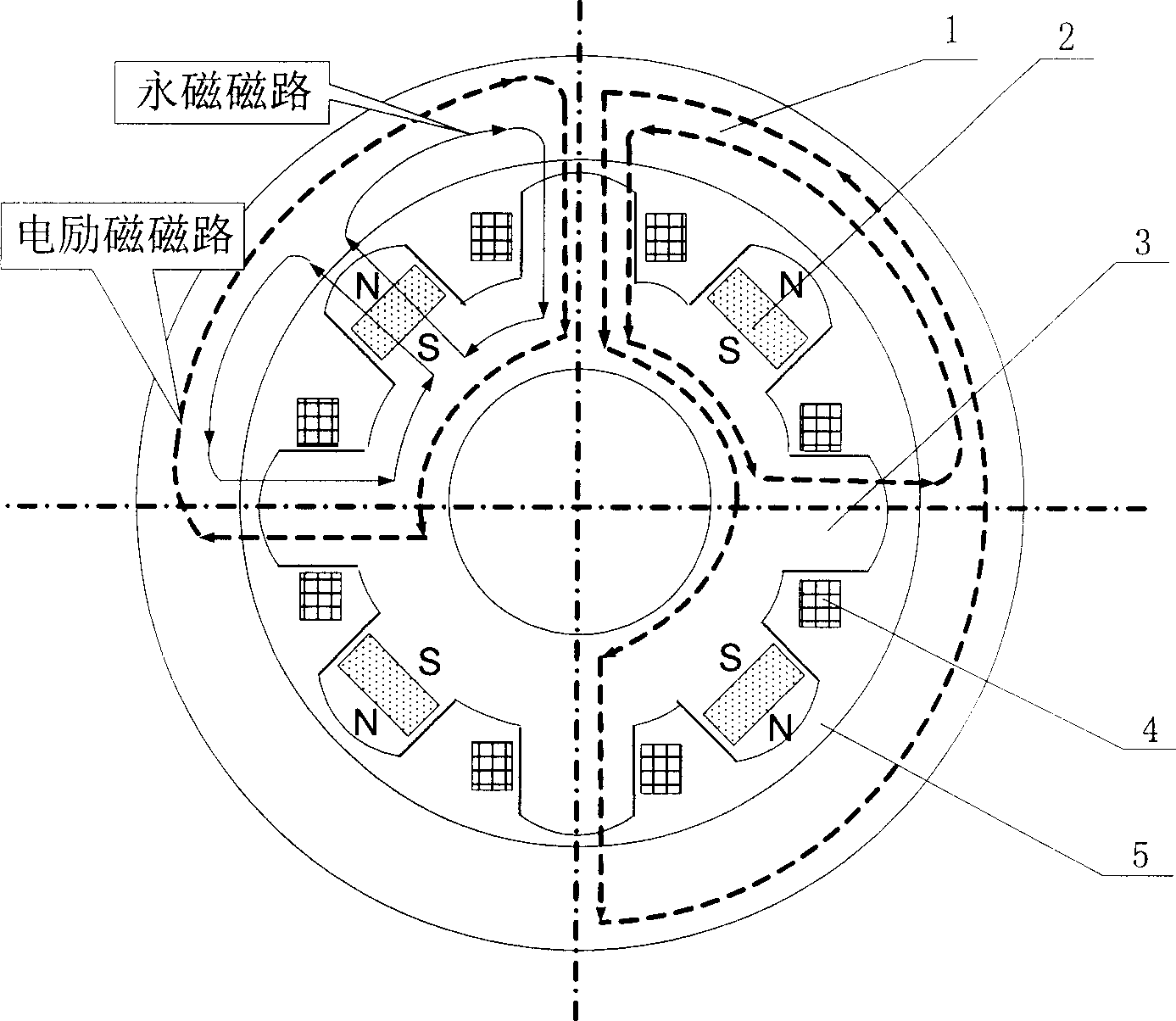

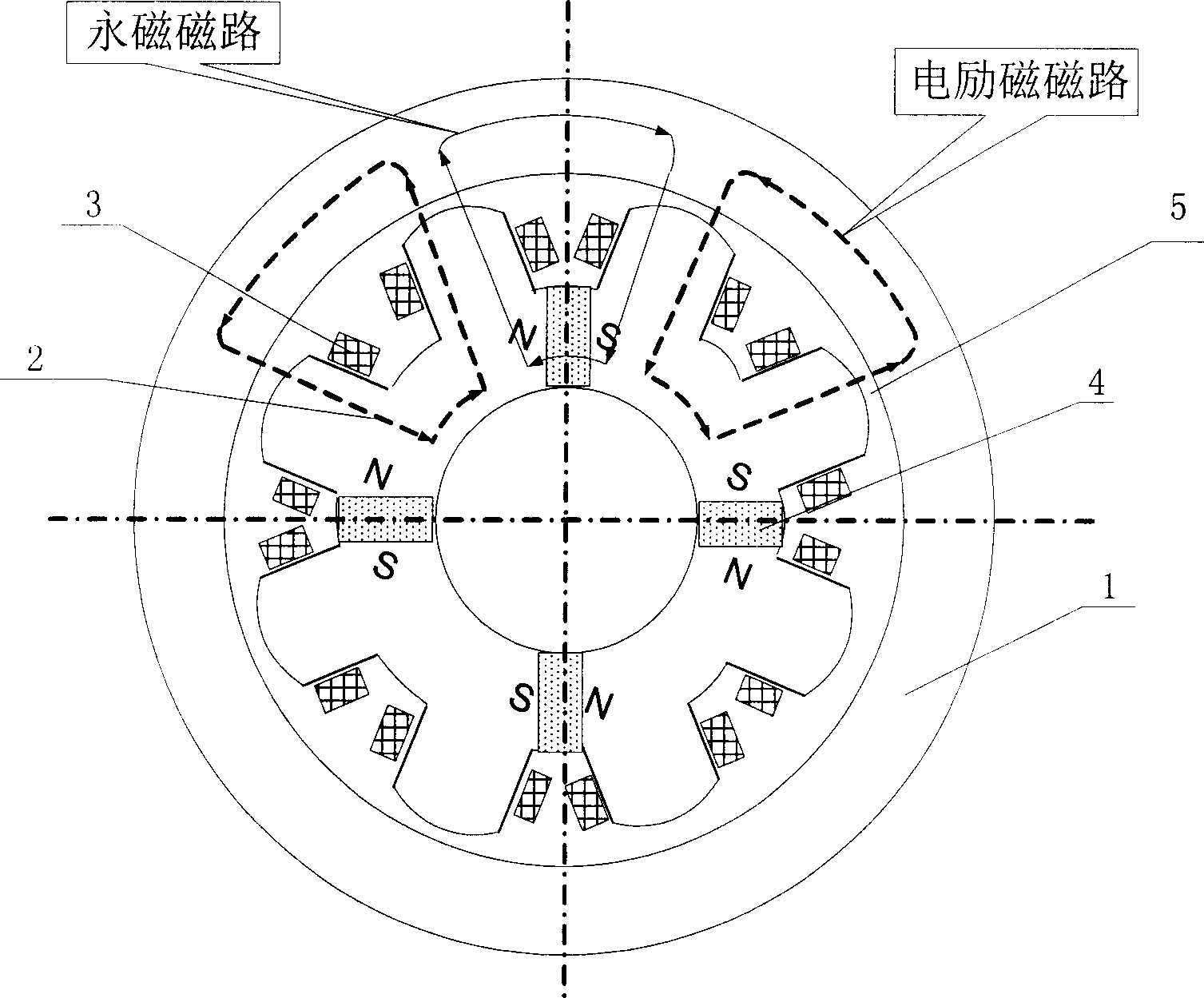

Halbach array parallel rotor composite excitation brushless synchronous motor

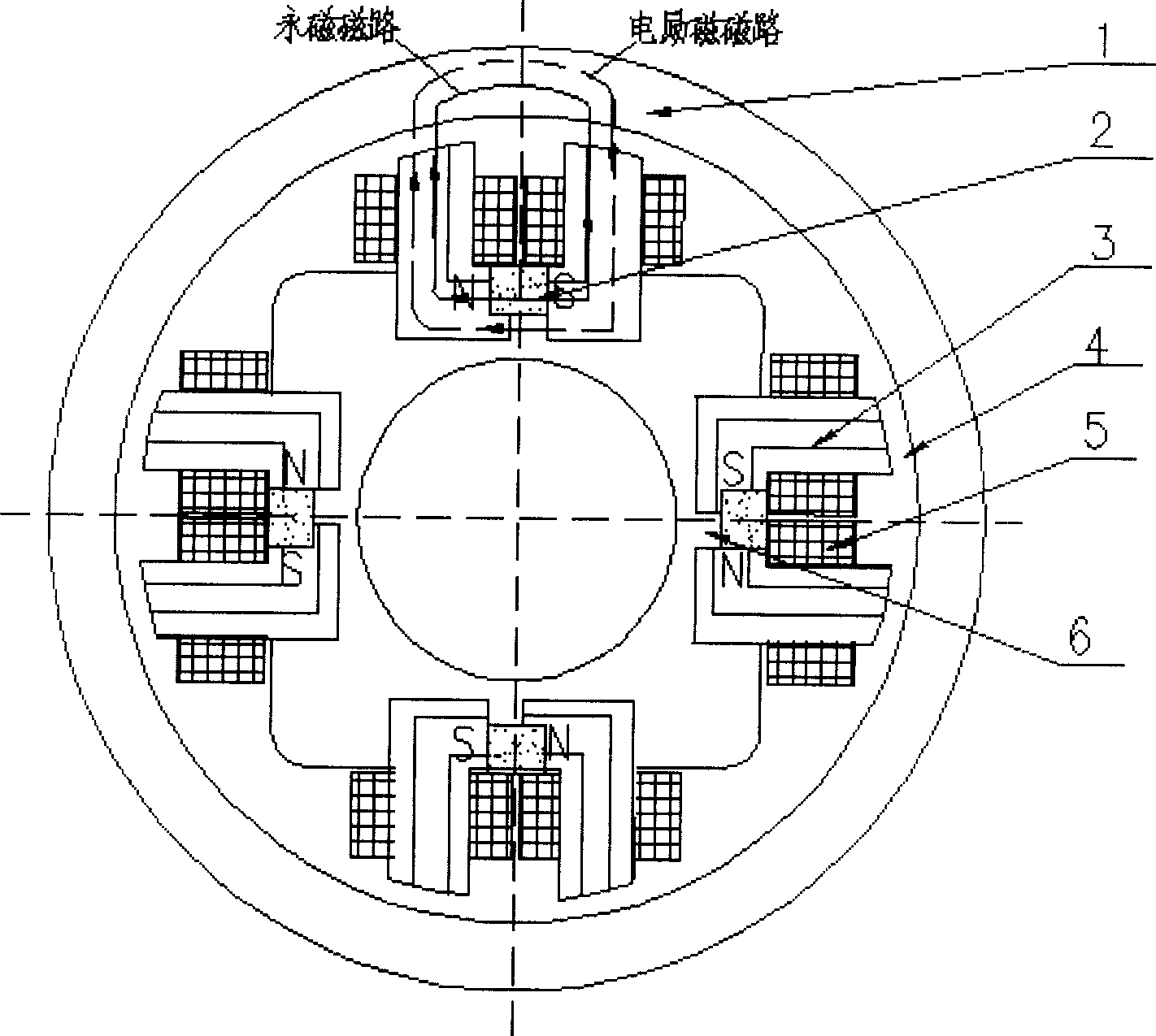

InactiveCN101572464AImprove reliabilityLarge adjustment rangeDynamo-electric machinesSynchronous motorElectric machine

The invention relates to a Halbach array parallel rotor composite excitation brushless synchronous motor, which comprises a rotor and a stator for accommodating the rotor, wherein the stator comprises a magnetic groove sleeve, an annular exciting winding and the like; the magnetic groove sleeve is fixed on a motor end cover through bolts and is not contacted with the rotor; and the annular exciting winding is fixed at the groove of the magnetic groove sleeve. The rotor consists of a rotating shaft and a Halbach rotor and an electric excitation rotor which are arranged on the rotating shaft in parallel, and the Halbach rotor comprises a non-magnetic rotor supported by the rotating shaft and a Halbach array permanent magnet arranged on the surface of the non-magnetic rotor; the electric excitation rotor comprises a claw pole structure connected with the rotating shaft; and the Halbach rotor is separated from the electric excitation rotor by a separating magnetic ring formed by air gaps. The brushless synchronous motor can reduce the eddy current loss of the rotor, enlarge the adjustable range of a magnetic field and improve the power density of the motor, and has the advantages of high reliability and good energy-saving effect.

Owner:SHANGHAI DIANJI UNIV

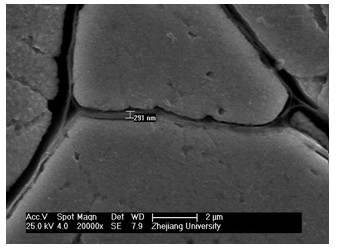

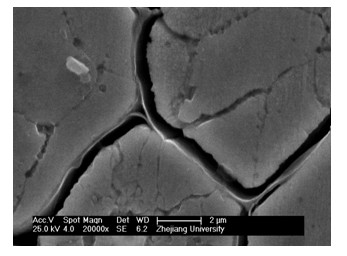

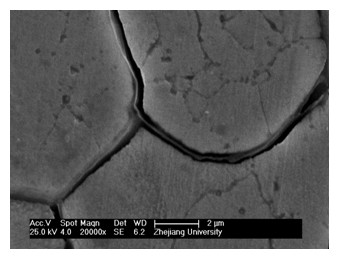

Preparation method of high-frequency high-magnetic-permeability low-loss iron nickel molybdenum metal magnetic powder core

ActiveCN102436894AReduce lossImproved high frequency magnetic performanceInorganic material magnetismInductances/transformers/magnets manufactureEpoxyStearic acid

The invention discloses a preparation method of a high-frequency high-magnetic-permeability low-loss iron nickel molybdenum metal magnetic powder core. According to the traditional method, during magnetic powder insulated costing, the quantity of on-magnetic substances is more, and the high density and high magnetic permeability of the iron nickel molybdenum magnetic powder core can not be realized. The preparation method provided by the invention comprises the following steps: firstly screening selected iron nickel molybdenum magnetic powder subjected to water atomization or iron nickel molybdenum magnetic powder subjected to gas atomization; secondly reacting the iron nickel molybdenum magnetic powder in a chromic acid aqueous solution, thus generating an insulation film on the surface of the magnetic powder; drying for two hours, and solidifying and stabilizing the insulation film on the surface of the magnetic powder; then adding zinc stearate serving as a lubricating agent into the iron nickel molybdenum magnetic powder, mixing and pressing the magnetic powder to obtain the iron nickel molybdenum magnetic powder core and carrying out annealing heat treatment under N2 atmosphere; and finally spraying epoxy paint on the iron nickel molybdenum magnetic powder core. The preparation method provided by the invention can be used for uniformly and firmly generating hundreds of nanometers of the insulation film on the surface of the iron nickel molybdenum magnetic powder, the insulated coating effect is good, the consumption of the non-magnetic insulants is reduced, and the purpose of improving the density and magnetic permeability of the magnetic core is achieved.

Owner:ZHEJIANG UNIV +1

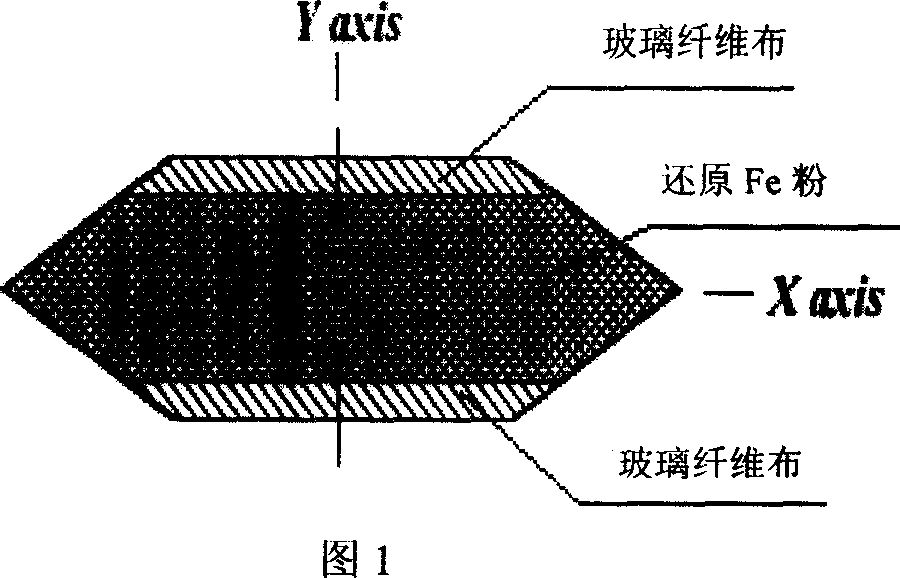

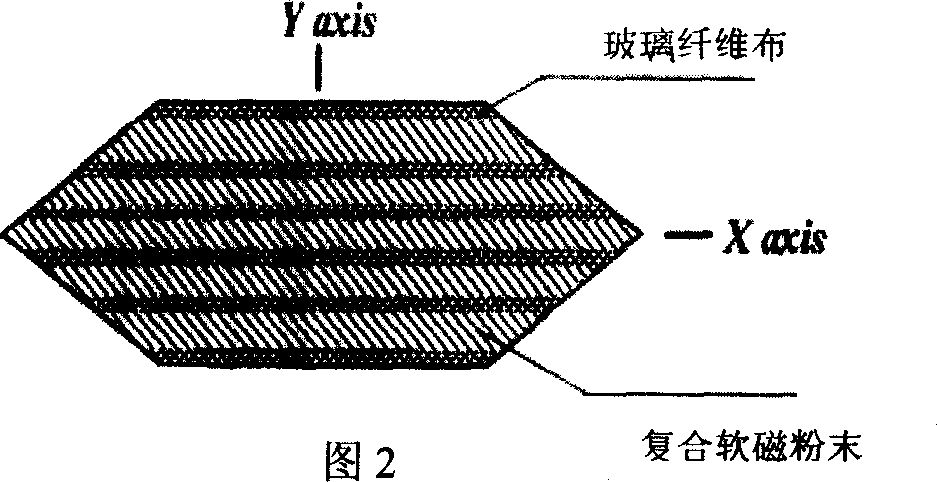

Composite soft magnetic powder magnetic conducting material for slot wedge of electric machine and preparation thereof

InactiveCN1949406AHas a relative magnetic permeabilityImprove insulation performanceWindingsInorganic material magnetismHigh resistivityLoad loss

The invention relates to a dynamo using slot wedge using compound soft magnetic powder magnetic conductance material. The powder is the compound soft magnetic powder compounded from MnZn ferrite powder and reduced iron powder or carbonyl iron dust. The radio is 10-90wt% high resistivity magnetic powder, and 10-90wt% high magnetic permeability magnetic powder. Adding certain quantity glass fiber into compounded magnetic powder layer, separating structure would be formed. The invention could decrease supplementary load loss of dynamo, as well as eddy current loss, and improve efficiency of dynamo.

Owner:SICHUAN UNIV

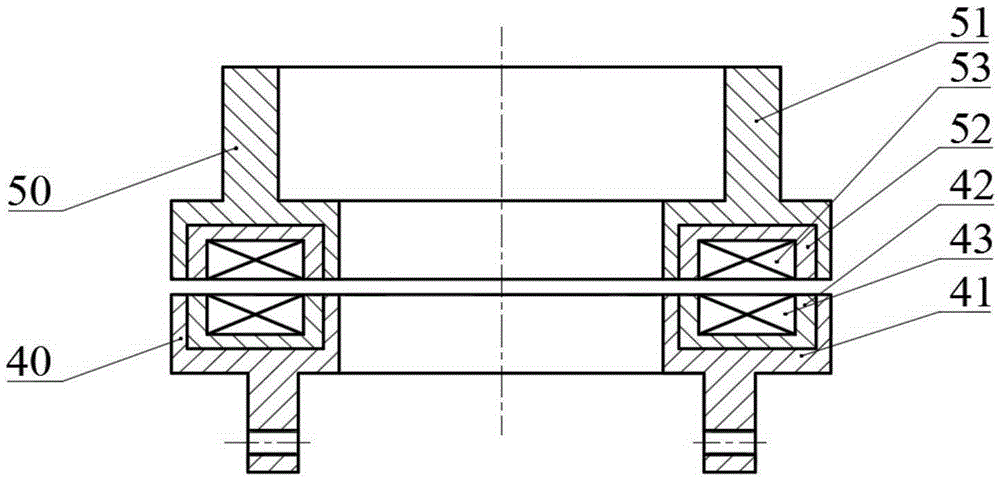

Low watt consumption permanent magnet offset external rotor hybrid radial magnetic bearing

InactiveCN1752471AReduce volumeReduce eddy current lossShaftsRotary machine partsMagnetic bearingMagnetic poles

The permanent-magnet offset outer rotor mixed radial magnetic bearing with low power consumption is composed of rotor iron core. Permanent-magnets, stator iron cores and excitation coils. Said invention also provides ther arrangement mode, between outer surface of stator iron core and inner surface of rotor iron core a certain gap is remained to form air gap, between two stator iron cores and permanent magnet a second air gap is formed. The permanent magnet utilizes stator iron core magnet poles to form offset magnetic field on X and Y directions.

Owner:BEIHANG UNIV

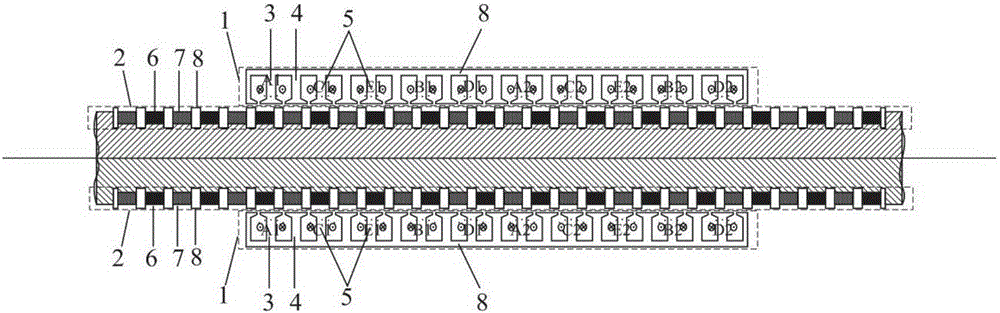

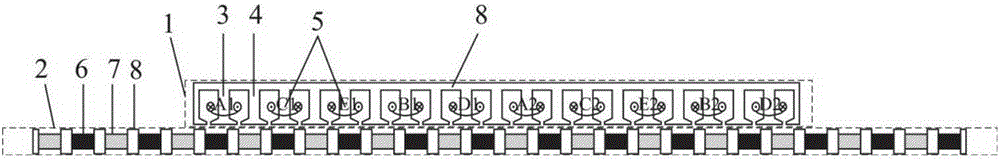

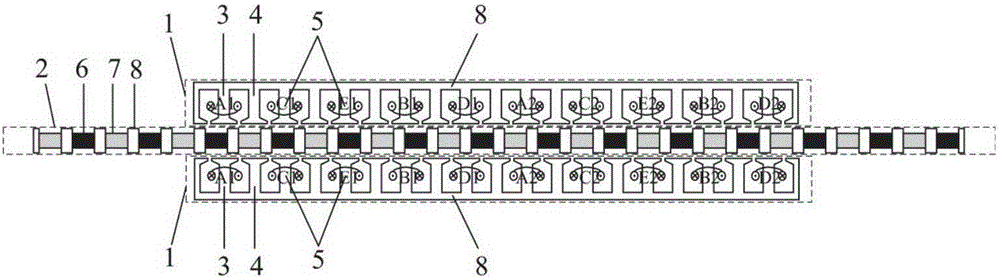

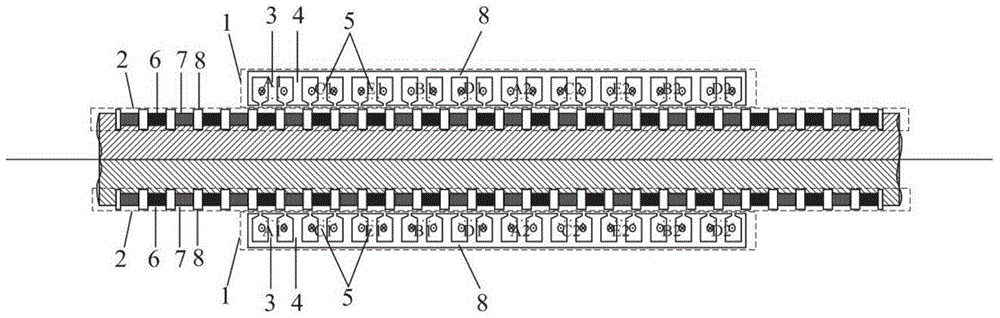

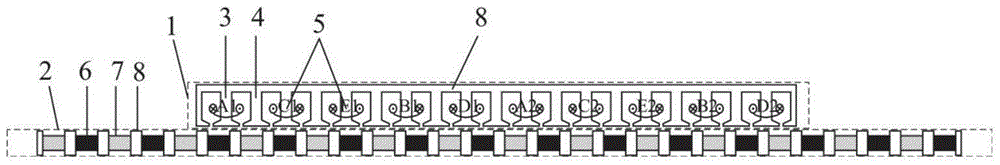

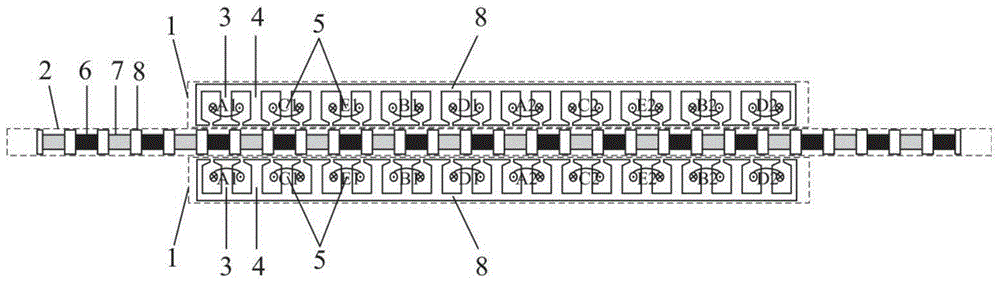

Embedded type mixing magnetic material fault-tolerant cylindrical linear motor

The invention discloses an embedded type mixing magnetic material fault-tolerant cylindrical linear motor which comprises primary bodies and secondary bodies. The length of each primary body is smaller than that of each secondary body. An air gap is reserved between each primary body and the corresponding secondary body. Each primary body comprises armature teeth, fault-tolerant teeth and a coil winding. The 2*m armature teeth and the 2*m fault-tolerant teeth are uniformly distributed on each primary body, wherein m is the phase number of the motor and is larger than or equal to three; the armature teeth and the fault-tolerant teeth are arranged at intervals in a staggered mode. Only one set of disc-shaped coil windings are placed into an armature tooth groove of each primary body. No windings are arranged on the fault-tolerant teeth. The secondary bodies of the motor are made of mixing magnetic materials, a part of ferrite is used for replacing a part of rare earth permanent magnets to form four different mixing magnetic material structures, on one hand, the quantity of the adopted rare earth permanent magnets is greatly reduced, and the cost of the motor is reduced; on the other hand, as the magnetic energy product of the permanent magnets is reduced, the eddy-current loss of the motor is reduced greatly, and efficiency of the motor is improved.

Owner:JIANGSU UNIV

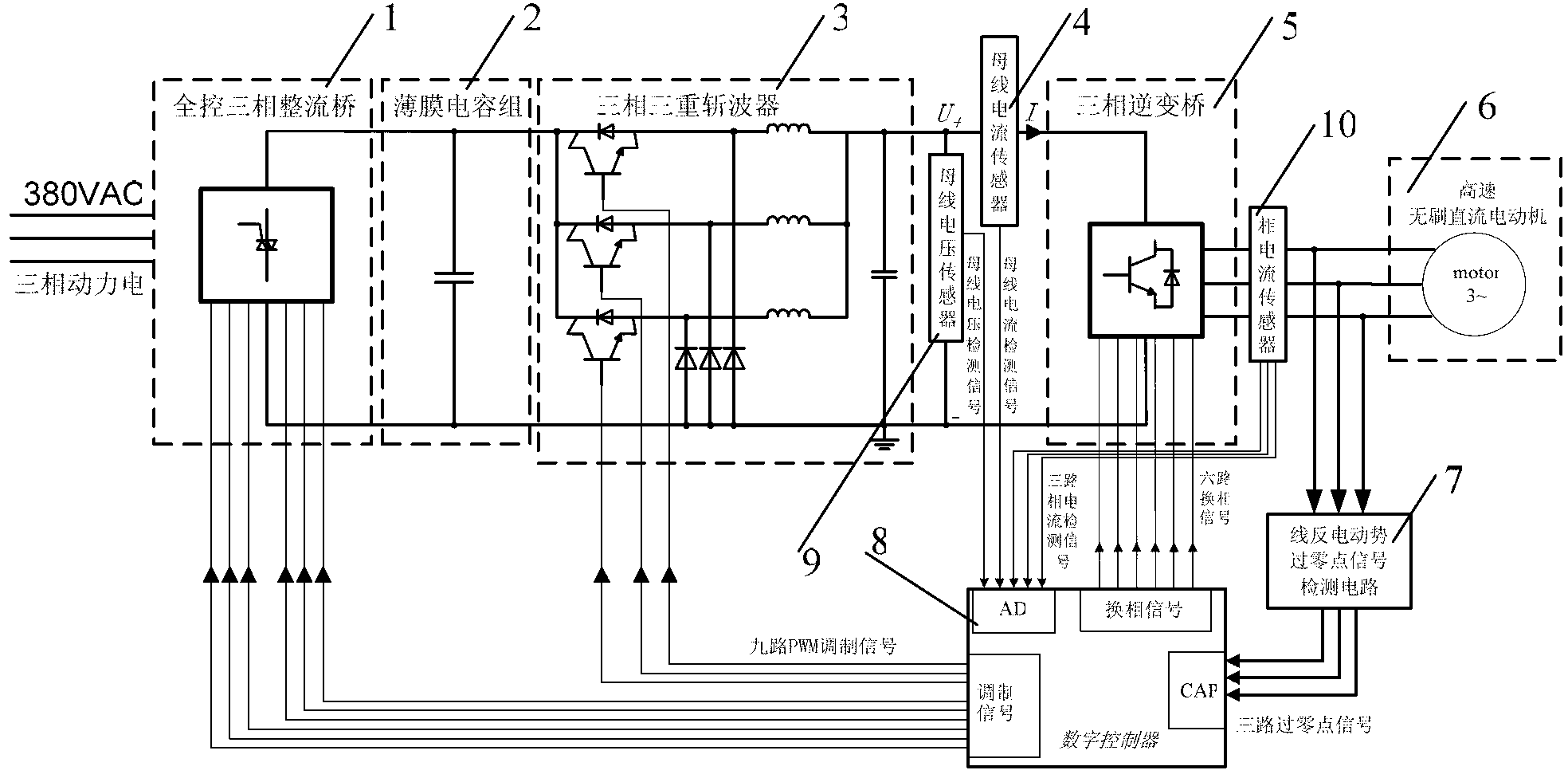

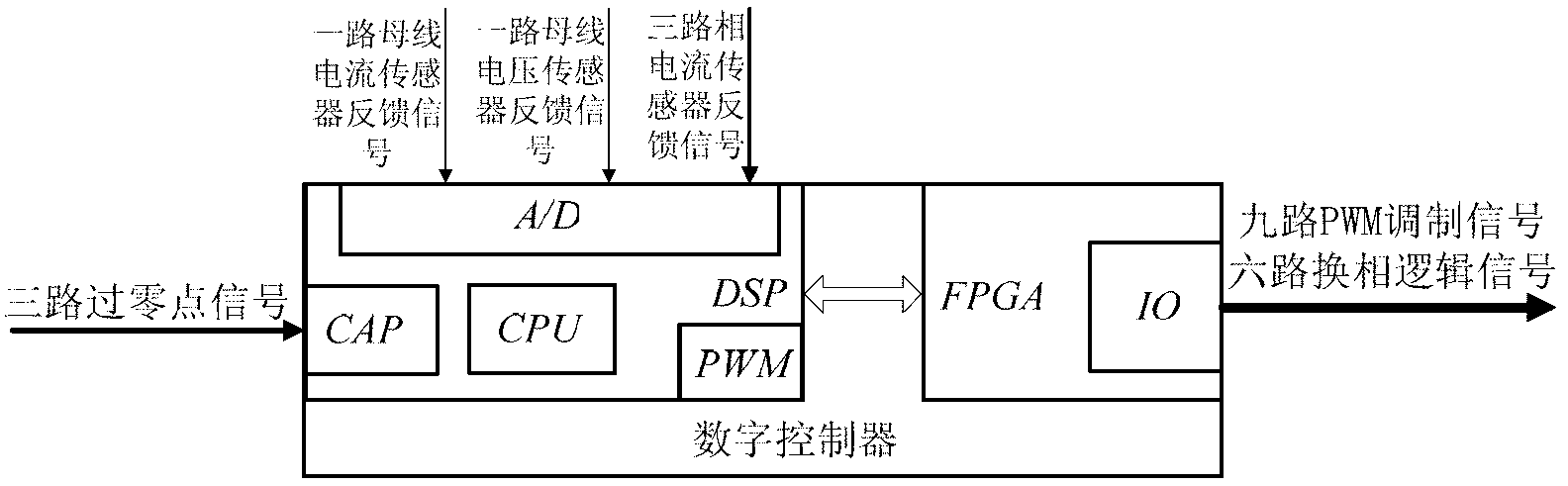

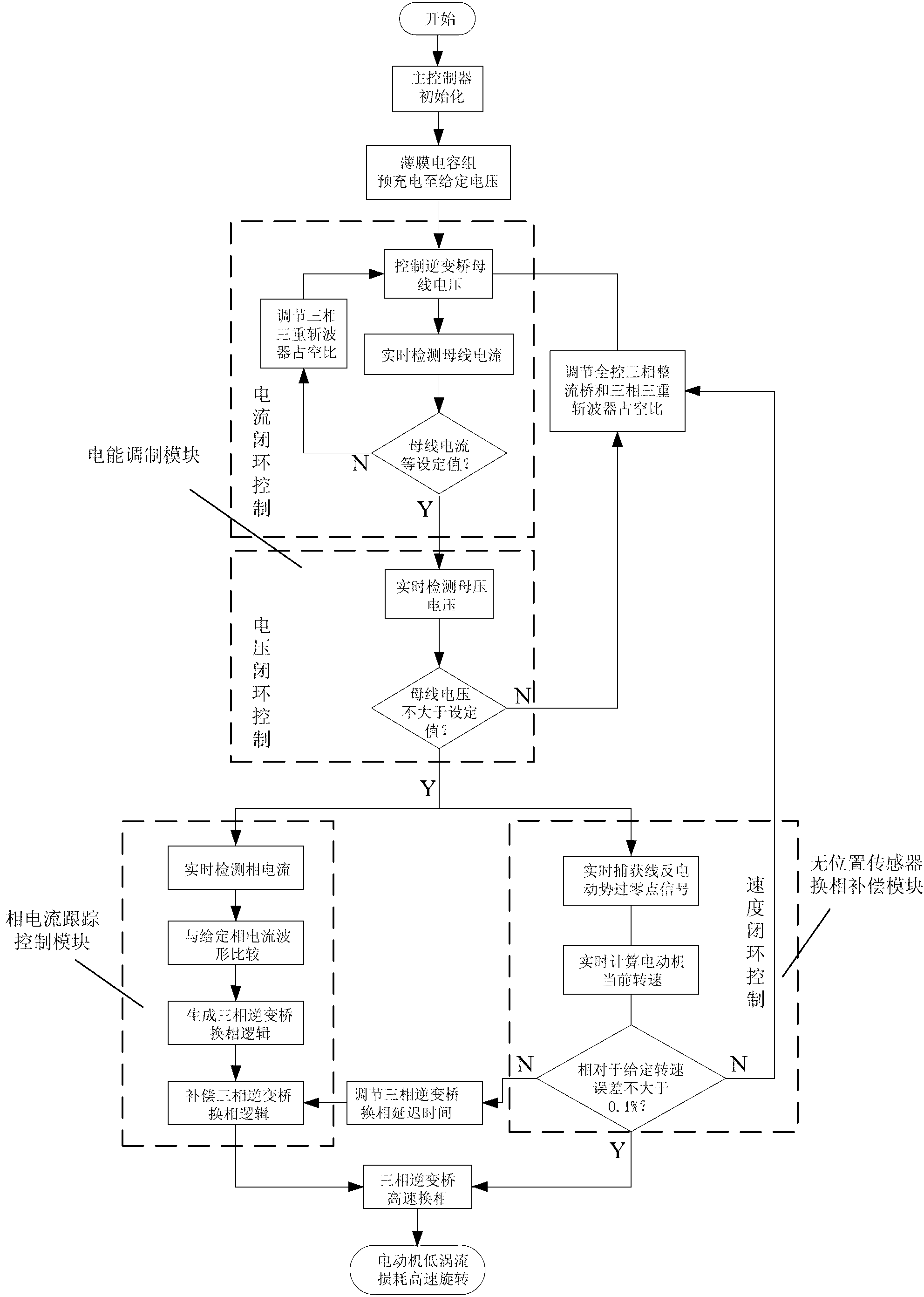

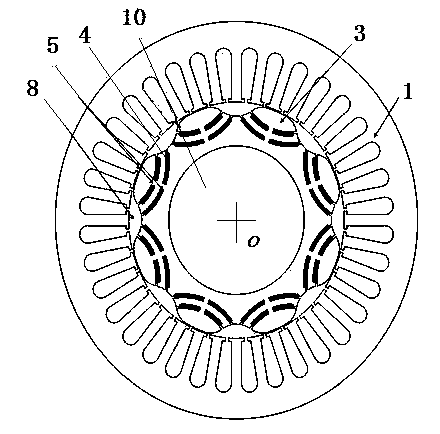

Position-free sensor control system of high speed brushless direct current motor

InactiveCN103248291AGuaranteed power modulation requirementsImprove operational efficiencySingle motor speed/torque controlElectronic commutatorsPhase currentsControl system

A position-free sensor control system of a high speed brushless direct current motor is mainly formed by a digital controller, a full control three phase rectifying bridge, a three phase trebling chopper, a three phase inverter bridge, the high speed brushless direct current motor, a phase current sensor and other parts. Aiming at the problem of large loss of a large-current high-frequency modulating vortex of the high speed brushless direct current motor, the position-free sensor control system disclosed by the invention adopts the full control three phase rectifying bridge and the three phase trebling chopper to perform dual-level electric energy modulating so as to conduct tracking control on the phase current outputted by the three phase inverter bridge. The digital controller adjusts the duty ratio of nine paths of PWM (pulse-width modulation) modulating signals according to tracking error of the phase current, and compensates six paths of phase changing logic signals in real time, thus realizing the high speed rotating of the high-speed brushless direct motor under low vortex loss. The position-free sensor control system of the high speed brushless direct current motor effectivley solves the problem of large vortex loss during the high-speed rotatation of the high speed brushless direct current motor and has important applying value in the control and research of the position-free sensor of the high-speed brushless direct current motor.

Owner:BEIHANG UNIV

Direct-axis magnetic field enhanced type wide-range speed control permanent magnet brushless motor for electric automobile

ActiveCN104253499AMeet high torque performance requirementsImprove driving abilityMagnetic circuit rotating partsElectric machinesMagnetic barrierBrushless motors

The invention discloses a direct-axis magnetic field enhanced type wide-range speed control permanent magnet brushless motor for an electric automobile. A magnetic barrier fills each slot of a rotor, and the magnetic barriers are symmetrical relative to a centerline, i.e., a quadrature axis, of slot parts of the rotor; four sections of arc-shaped permanent magnet steel are fixedly embedded on each tooth part of the rotor, the four sections of arc-shaped permanent magnet steel are divided into an inner layer and an outer layer, two sections are arranged on each layer, the two sections of permanent magnet steel on each layer are the same in structure and are symmetrical relative to a centerline, i.e., a direct axis of the tooth parts of the rotor, the two sections of permanent magnet steel on the same layer do not run through each other and are not connected with each other, and an arc-shaped magnetic bridge is formed between the two sections of permanent magnet steel; a circle center of each section of permanent magnet steel is located on the diameter of the rotor; the direct-axis inductance of the motor is larger than the quadrature-axis inductance, so that the motor can adopt a control method with zero direct-axis current and can also adopt a direct-axis magnetic field enhanced control method during low-speed operation or startup, and can adopt a coordinated control method of direct-axis magnetic field enhancement and slight direct-axis magnetic field weakening during high-speed operation, and the speed control range is wider.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com