High-efficiency soft magnetic material and method for producing the same

A soft magnetic material and high-efficiency technology, applied in the fields of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of neglecting mechanical properties and electrical properties, components and processes and only pursuing magnetic permeability and eddy current loss. , to achieve the effects of good soft magnetic properties and electrical properties, high magnetic permeability, and improved magnetic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

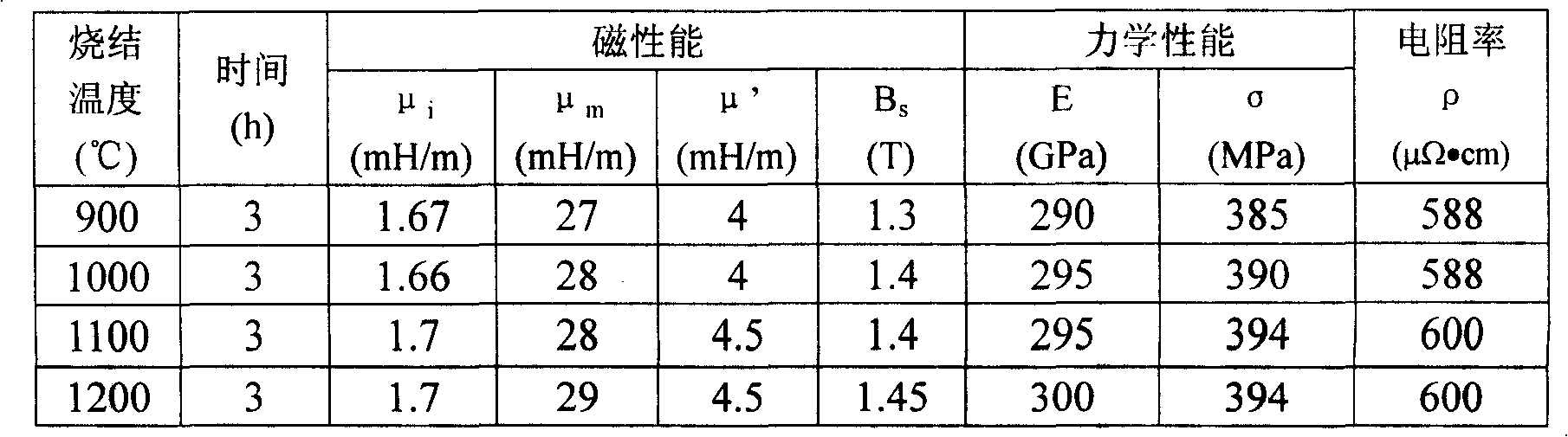

[0025] Composition is 90% Fe-Ni-Cu powder and 10% Mn-Zn ferrite (the composition of Fe-Ni-Cu is as follows: Ni50wt%, Fe46wt%, Cu 4wt%, the composition of Mn-Zn ferrite is as follows : MnO15at%, ZnO15at%, Fe 2 o 3 70at%), using the cold pressing and then sintering process, firstly, mix 90% Fe-Ni-Cu powder and 10% Mn-Zn ferrite powder evenly and press them on the press molding machine, during the cold pressing process The added pressure is 20MPa; and then sintered in the sintering furnace, vacuumize to 10 -3 Below Pa, fill with hydrogen of 122Pa, pre-fire at 450°C for 3h, then sinter at 900°C, 1000°C, 1100°C, 1200°C for 3h in a hydrogen atmosphere, then cool to 200°C with the furnace; then anneal When processing and annealing, first evacuate to 10 -3 Below Pa, fill with hydrogen at 100 Pa, anneal at 1100°C for 3 hours in a hydrogen atmosphere, and then chill to room temperature; finally test the soft magnetic properties, electrical properties and mechanical properties of the ...

no. 2 Embodiment

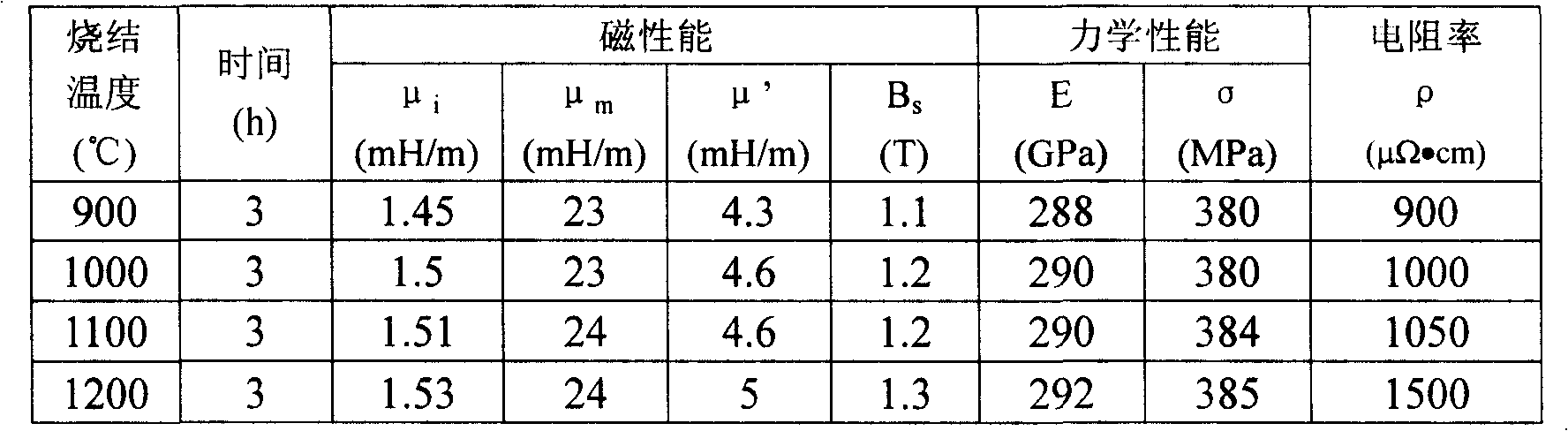

[0030] Composition is 80% Fe-Ni-Nb powder and 20% Ni-Zn ferrite (the composition of Fe-Ni-Nb is as follows: Ni49wt%, Fe49wt%, Nb2wt%, the composition of Ni-Zn ferrite is as follows: NiO30at%, ZnO20at%, Fe 2 o 3 50at%), using cold pressing and then sintering process, firstly, 80% Fe-Ni-Nb powder and 20% Ni-Zn ferrite powder are mixed evenly and then pressed on the press molding machine, during the cold pressing process The added pressure is 20MPa; and then sintered in the sintering furnace, vacuumize to 10 -3 Below Pa, fill with hydrogen of 122Pa, pre-fire at 450°C for 3h, then sinter at 900°C, 1000°C, 1100°C, 1200°C for 3h in a hydrogen atmosphere, then cool to 200°C with the furnace; then anneal When processing and annealing, first evacuate to 10 -3 Below Pa, fill with 100Pa hydrogen, anneal at 1100°C for 3 hours in a hydrogen atmosphere, and then chill to room temperature; finally test the soft magnetic properties, electrical properties and mechanical properties of the sa...

no. 3 Embodiment

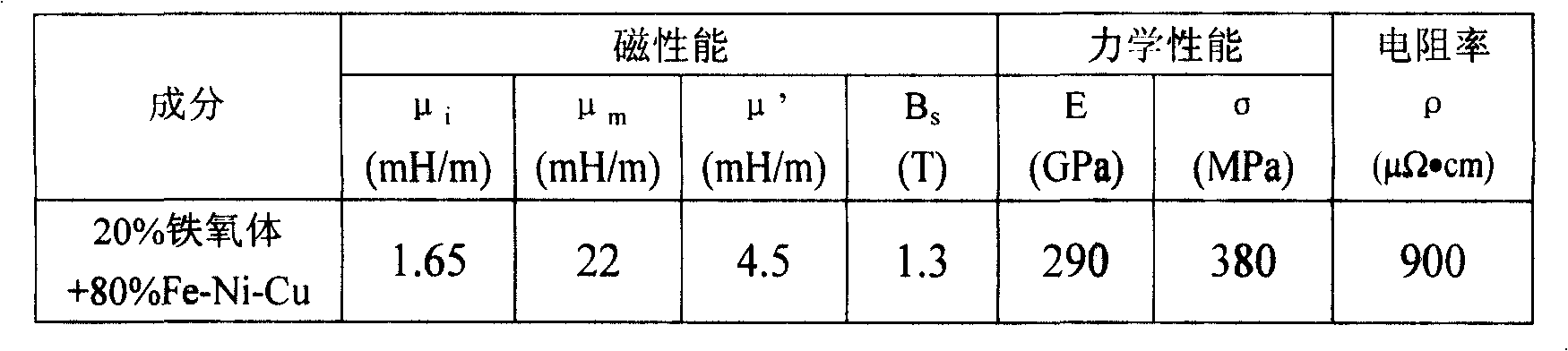

[0034] Fe-Ni-Cu powder of different proportions and Mn-Zn ferrite powder (the composition of Fe-Ni-Cu is as follows: Ni50wt%, Fe26wt%, Cu 4wt%, the composition of Mn-Zn ferrite is as follows: MnO15at% , ZnO15at%, Fe 2 o 3 70at%) is formed by hot-pressing process. First, hot-press the uniformly mixed soft magnetic composite magnetic powder at 930°C for 0.5h. During the hot-pressing process, the argon gas filled in is 100Pa, and the added pressure is 20MPa; then annealing is performed. , when annealing, first vacuum to 10 -3 Below Pa, fill with 100Pa hydrogen, anneal at 1100°C for 3 hours in a hydrogen atmosphere, and then chill to room temperature; finally test the soft magnetic properties, electrical properties and mechanical properties of the samples, and the results are shown in Table 3.

[0035] Table 3 Performance of different composition samples

[0036]

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com