Patents

Literature

9726 results about "Carbon steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon steel is a steel with carbon content up to 2.1% by weight. The term "carbon steel" may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels.

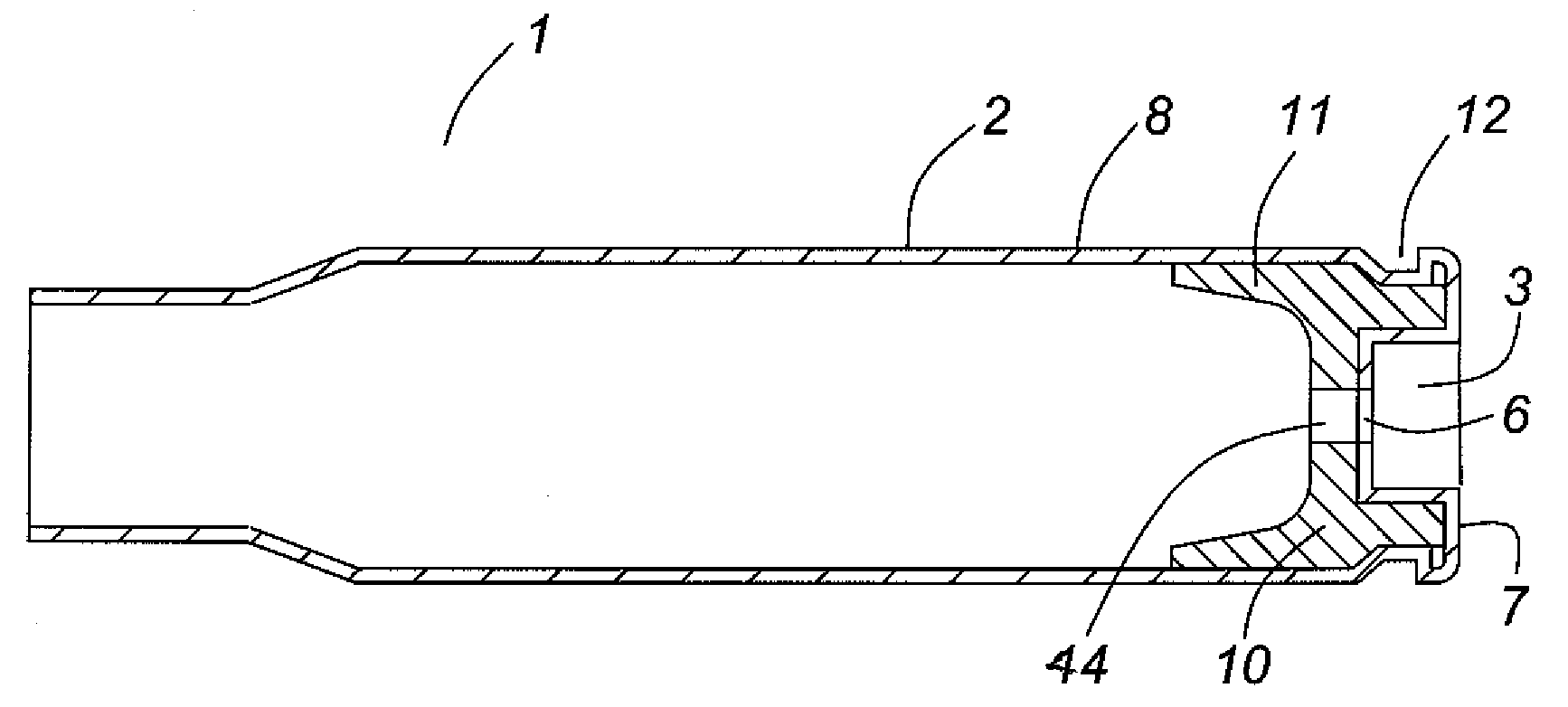

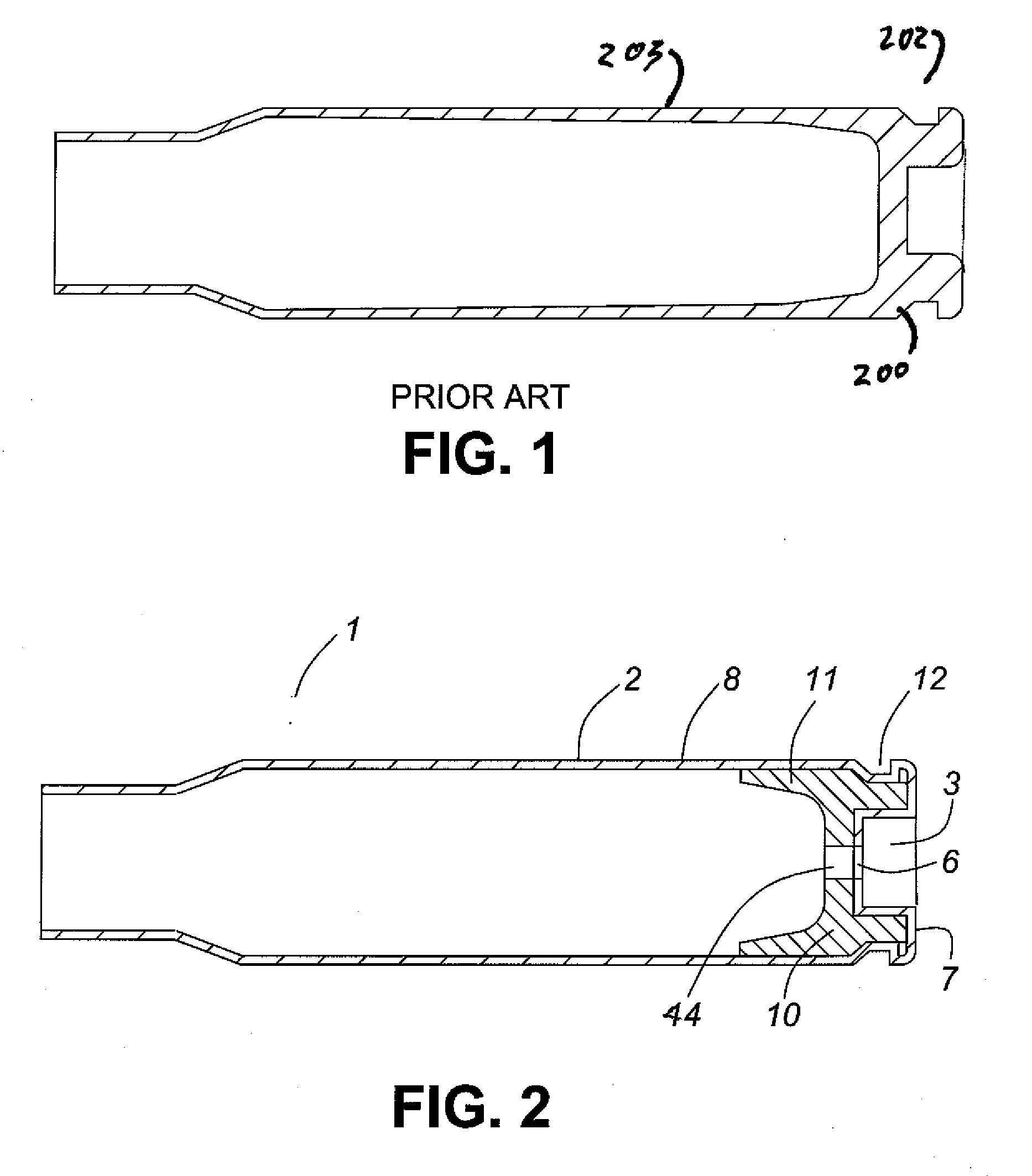

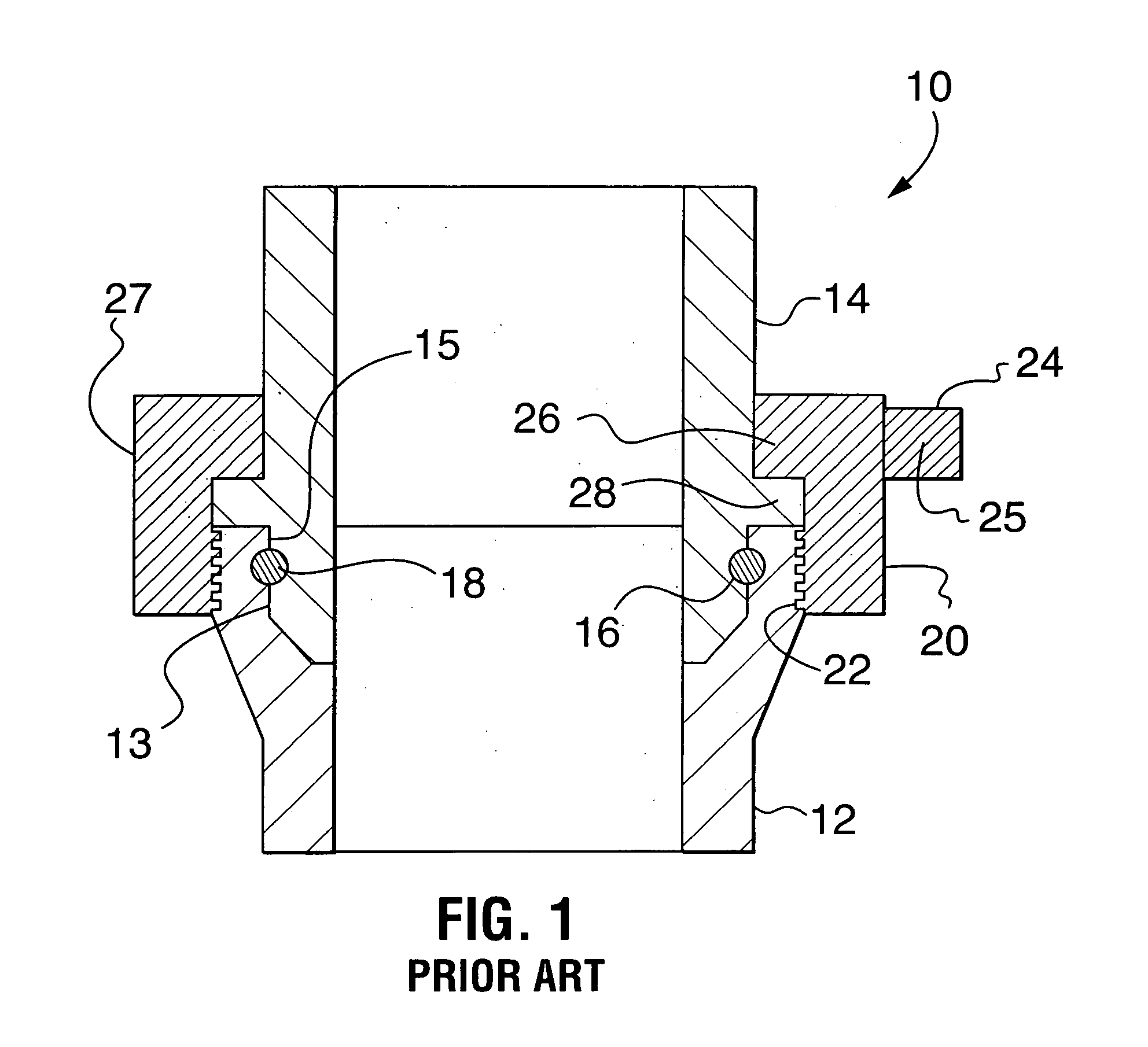

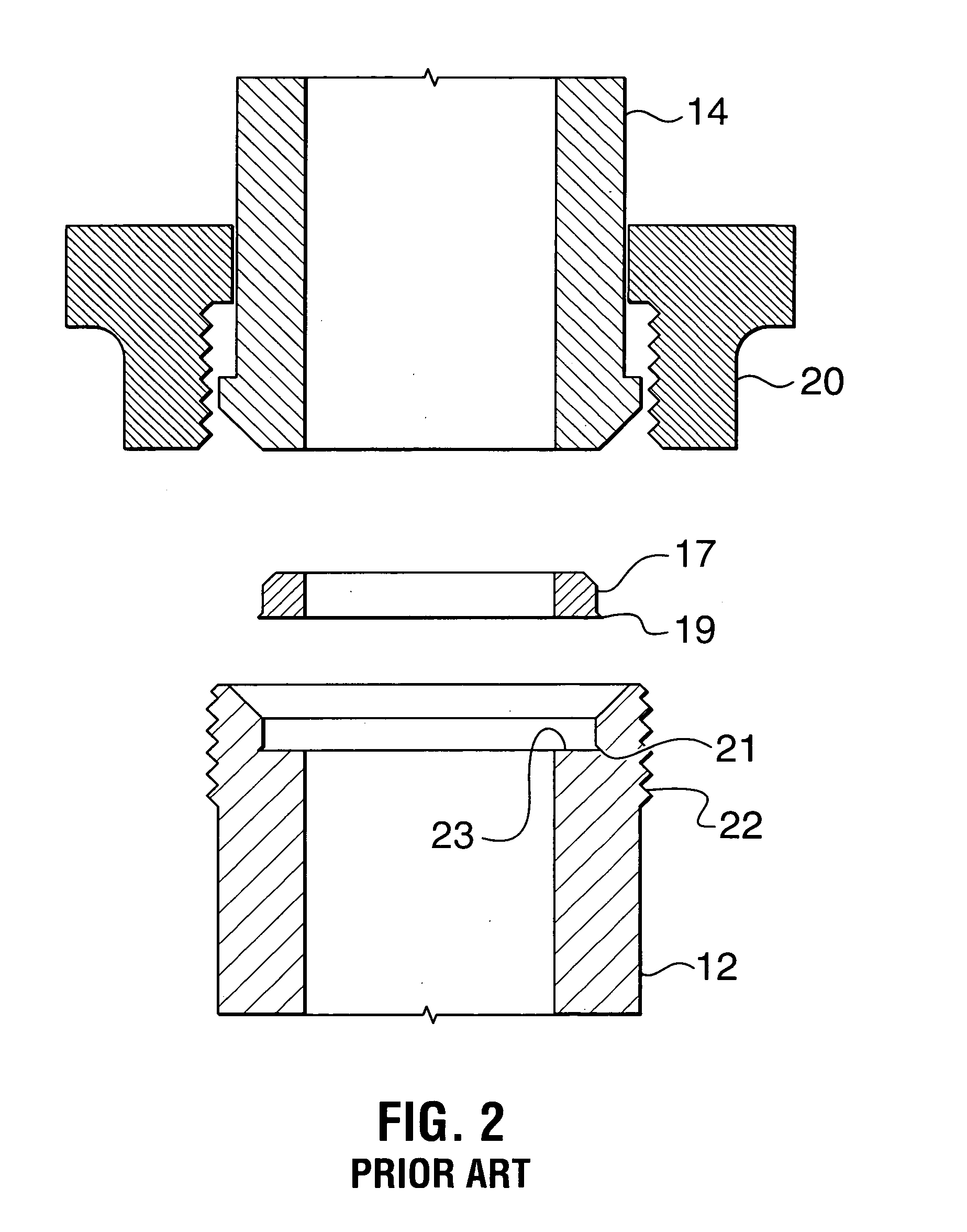

Thin walled, two component cartridge casing

A cartridge or ammunition casing is made of two components, one forming the outer casing sleeve and head end and the other comprising a plug seated within the head end to protect the outer casing material from propellant gases. The outer cylindrical sidewall and end panel of the casing may be made of a material selected from the group consisting of stainless steel, steel, pre-coated carbon steel, brass or brass-type alloys, aluminum, hardened aluminum alloys, and suitable polymeric plastic material such as nylon derivatives and VECTRA™. The inner plug may be made of a material selected from the group consisting of aluminum, brass, steel, stainless steel, and suitable polymeric materials.

Owner:TECH CORPORATION CO LTD

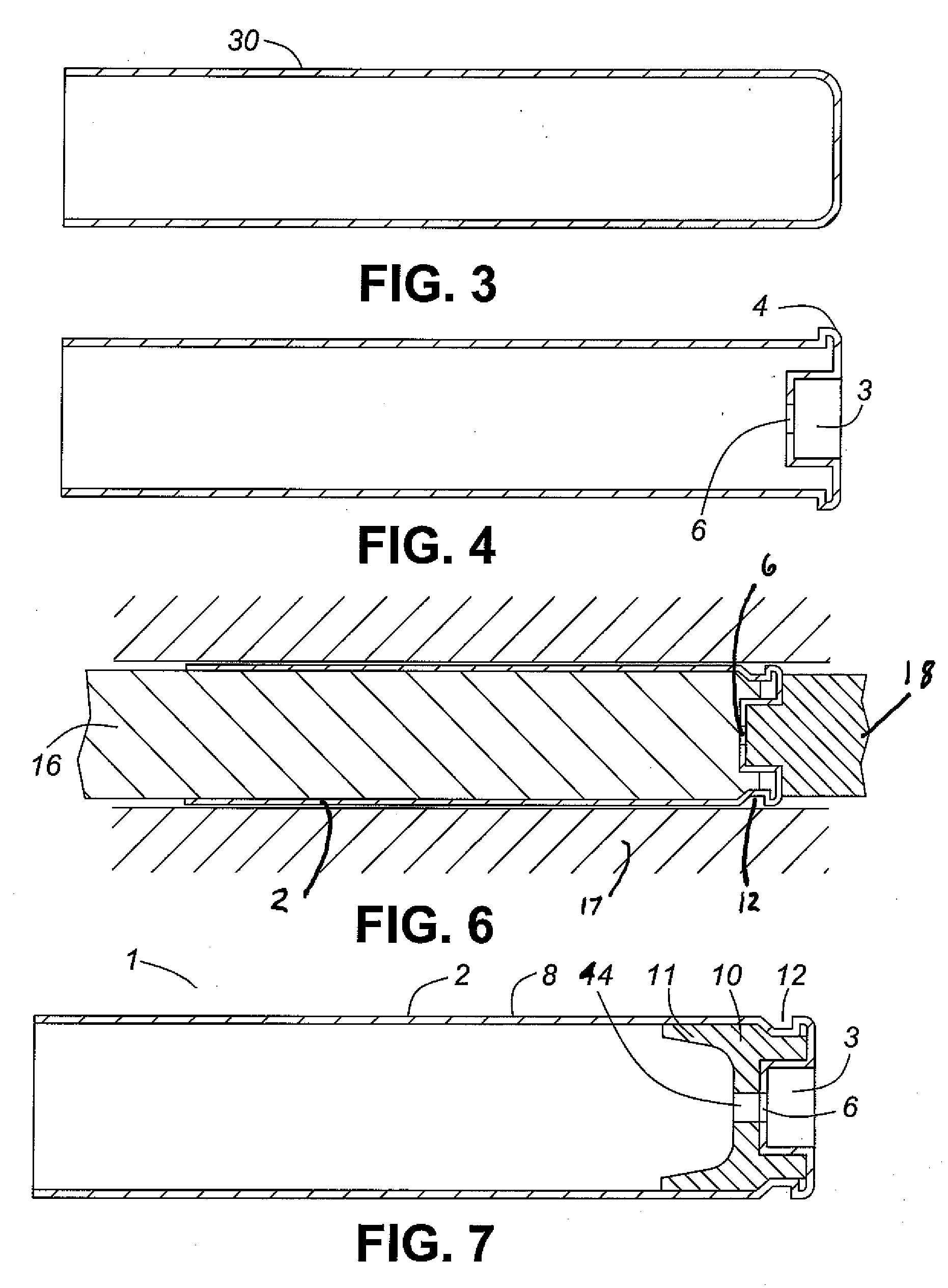

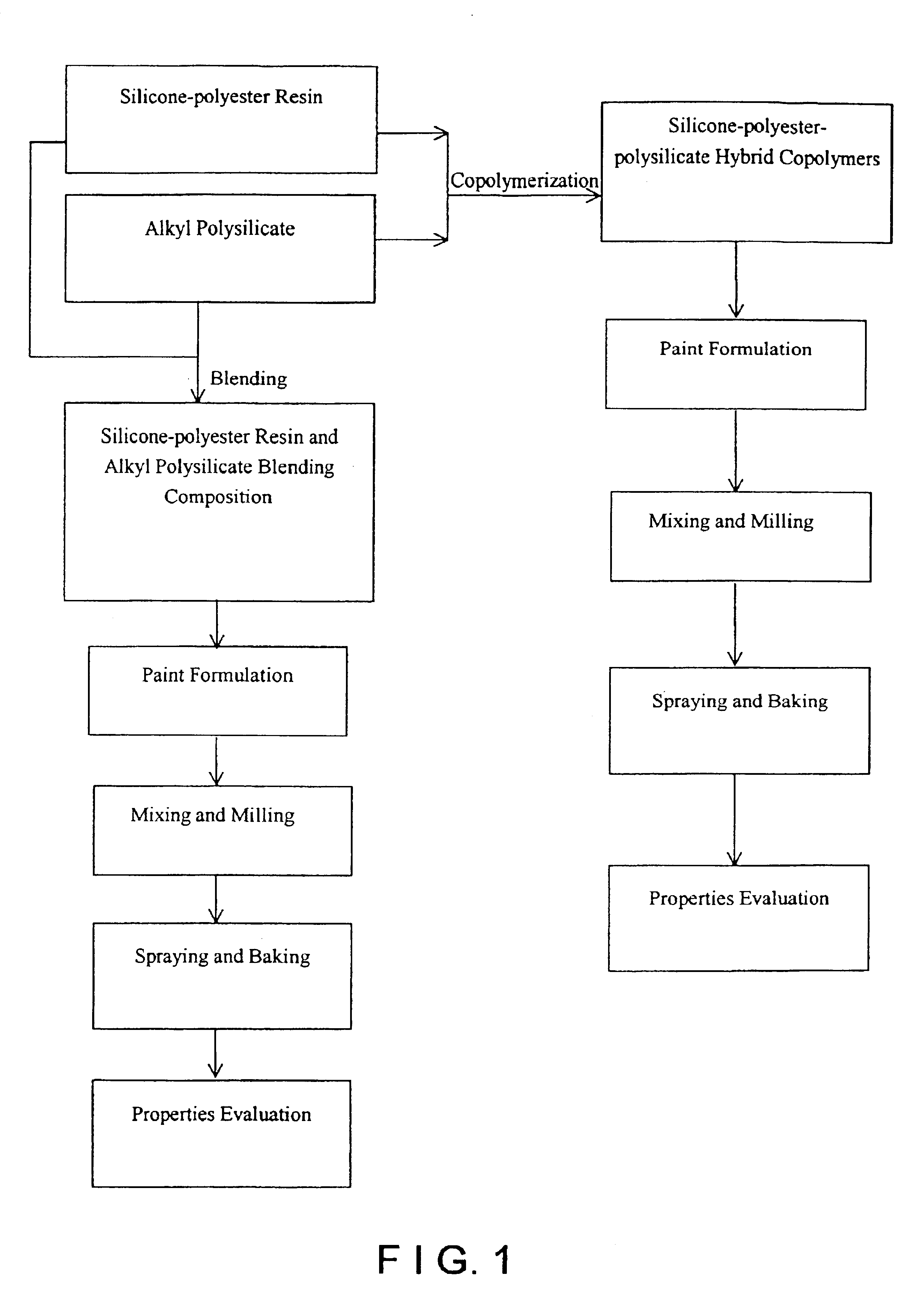

Silicone-polyester-polysilicate hybrid compositions for thermal resistance coating

InactiveUS6893724B2Improve heat resistanceExcellent adhesion to metalGlass/slag layered productsCoatingsCopolymerMaterials science

The present invention employs alkyl polysilicate to form silicone-polyester-polysilicate hybrid compositions with an appropriate proportion to modify silicone-polyester resin, or directly adds the alkyl polysilicate at an appropriate proportion into silicone-polyester resin to produce a hybrid composition. The composition in high baking temperature forms a hybrid structure having good thermal resistance, especially, hot-oil resistance and hot hardness, and good adhesion to metals such as carbon steel, stainless steel and aluminum. The present invention can be used in the field of the protective coating for heat-resistant metal such as frying pans and electric irons to be a kind of novel heat-resistant composition having hybrid structure. The composition in accordance with the present invention comprises (A)silicone-polyester; (B)alkyl polysilicate and the structure thereof comprises (RO)3—Si—O—(Si(OR)2—O)n—R, where n=0˜20 and R represents —CH3, —C2H5, —C3H7, or —C4H9. The composition mentioned above comprises the compounds of (A) and (B) or the copolymer comprised by (A) and (B).

Owner:GRAND TEK ADVANCE MATERIAL SCI

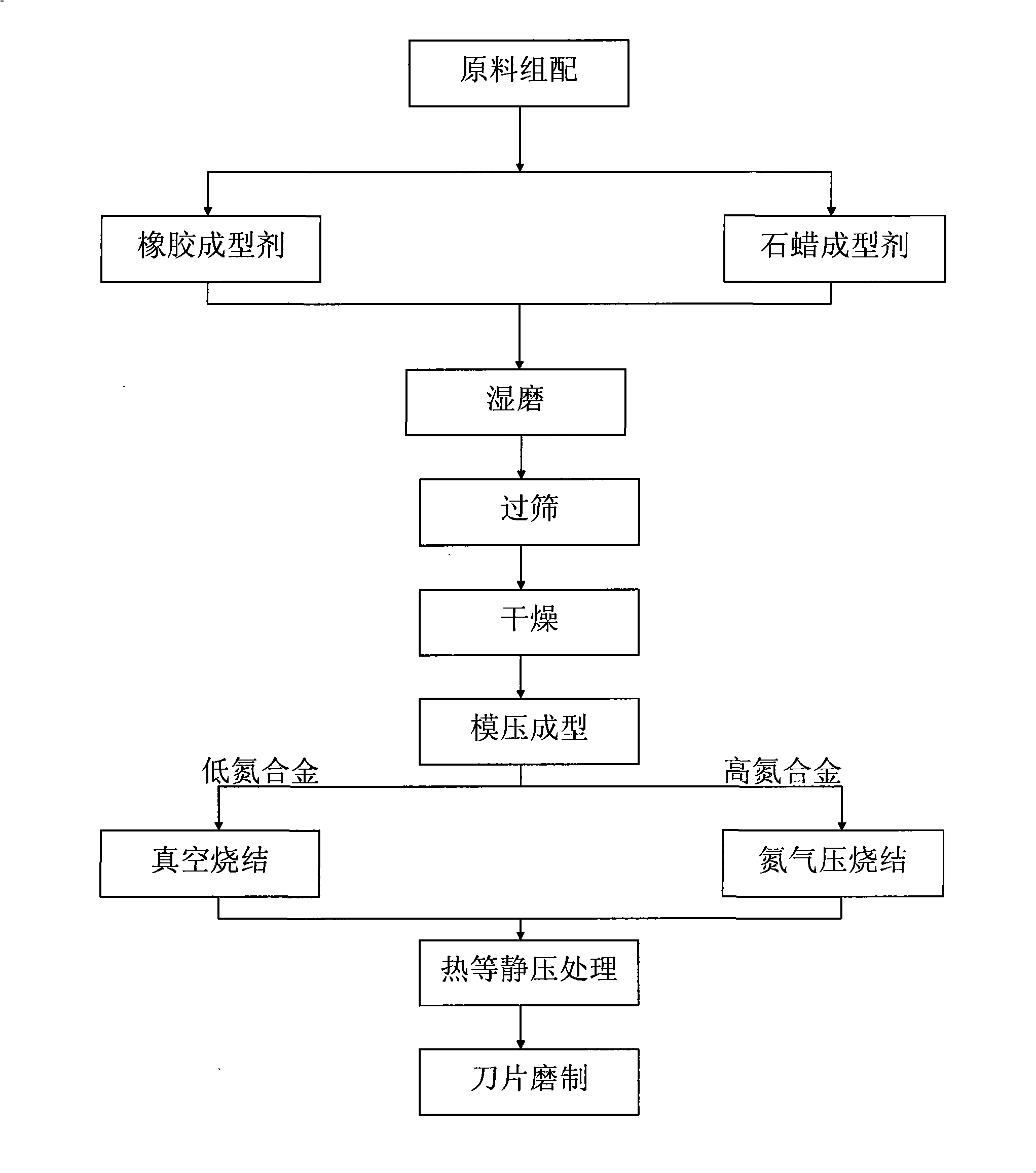

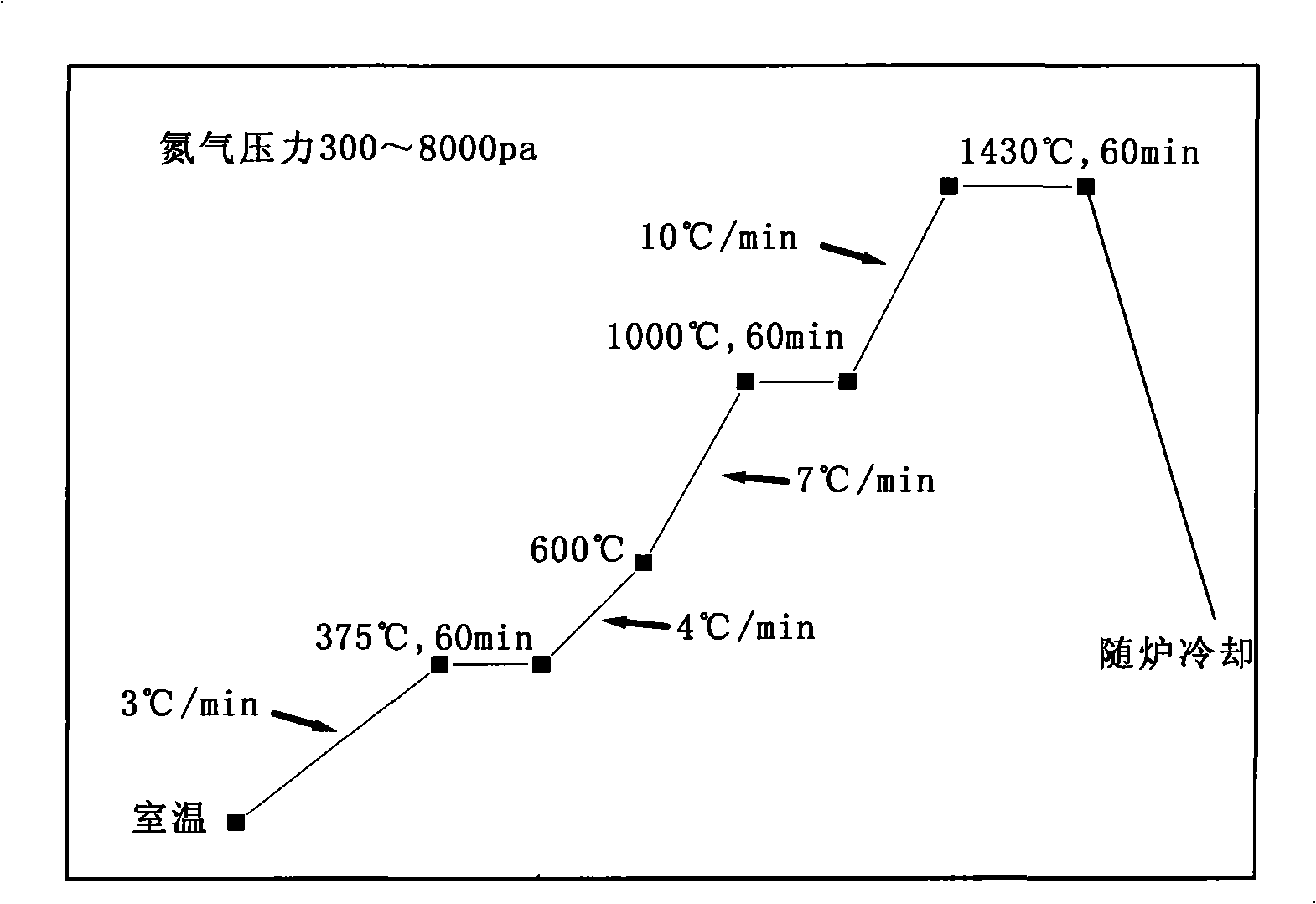

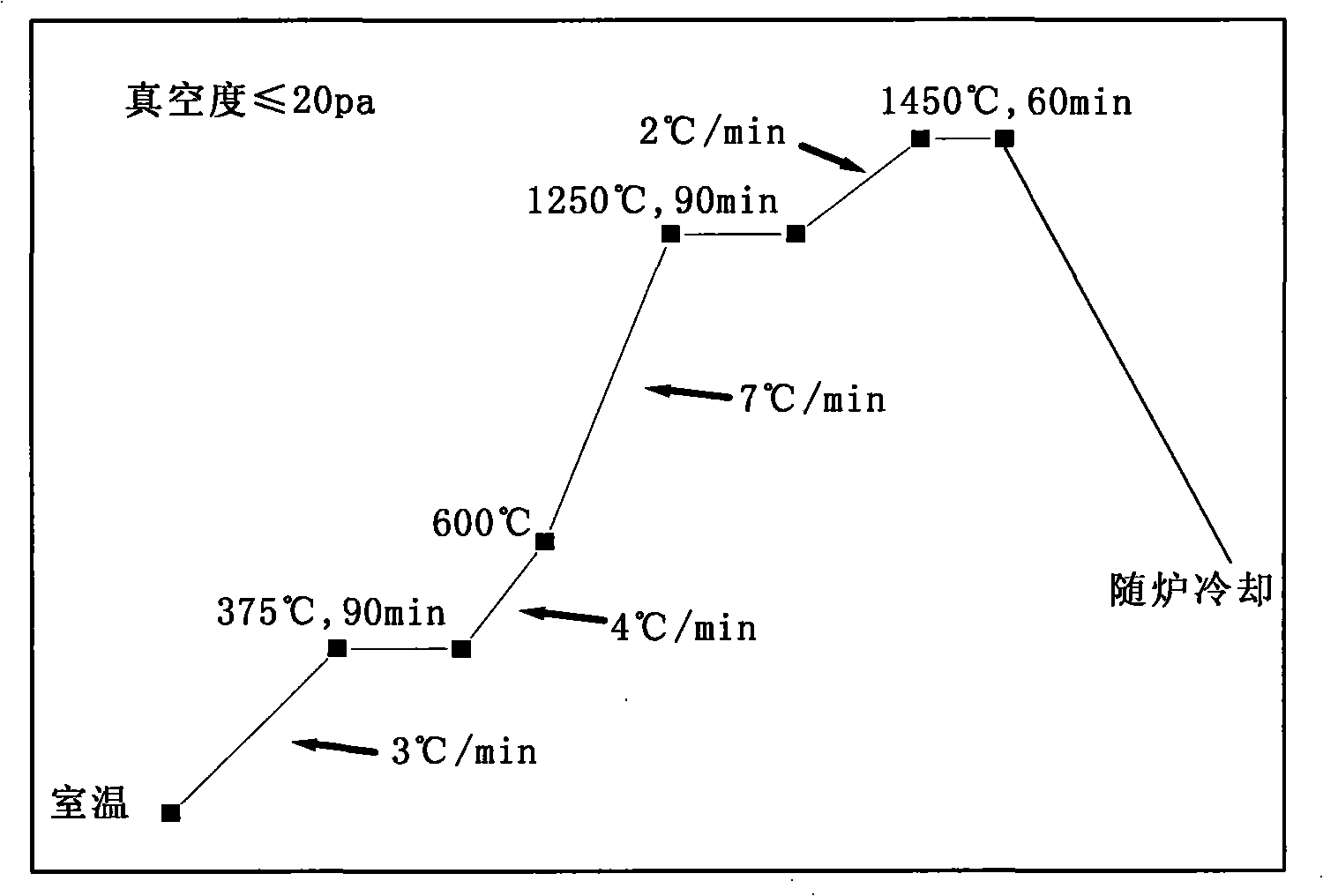

High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

InactiveCN101302595AReliable guarantee of high nitrogen-carbon ratioReliable Guarantee of HardnessLow nitrogenWear resistant

The invention provides a high-abrasion Ti(C, N) based metal ceramic tool and a preparation thereof. The Ti(C, N) based metal ceramic tool uses Ni and Co as a binder phase, is added with at least one carbonitride of Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x as a basic batch, and consists of at least one composition of WC, Mo2C, Co, Ni, ZrC, Cr3C2, VC, TaC and NbC, and the balance being Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x, wherein, an X value for adding the carbonitride of the Ti(C, N) based metal ceramic tool is as follows: X is less than or equal to 0.5 and more than or equal to 0.4, or the X is more than 0.5 and less than or equal to 0.7. The Ti(C, N) based metal ceramic tool is prepared according to the content of nitrogen by nitrogen pressure sintering or vacuum sintering combined with hot isostatic pressing treatment, thereby preventing nitrogen from escaping during the process of sintering high-nitrogen alloy, so that the high-nitrogen-carbon ratio in matrix and material hardness can be reliably guaranteed, and anti-oxidative abrasion property and anti-diffusive abrasion property of the material can be obviously increased through adding slight ZrC, Cr3C2, VC and other carbides into the basic batch; meanwhile, compactability and buckling strength of a low-nitrogen alloy structure can be obviously improved through optimally distributing each composition and content. The Ti(C, N) based metal ceramic tool is widely suitable for high-speed cutting tools of medium-low carbon steel and low alloy steel.

Owner:HUNAN UNIV OF SCI & TECH

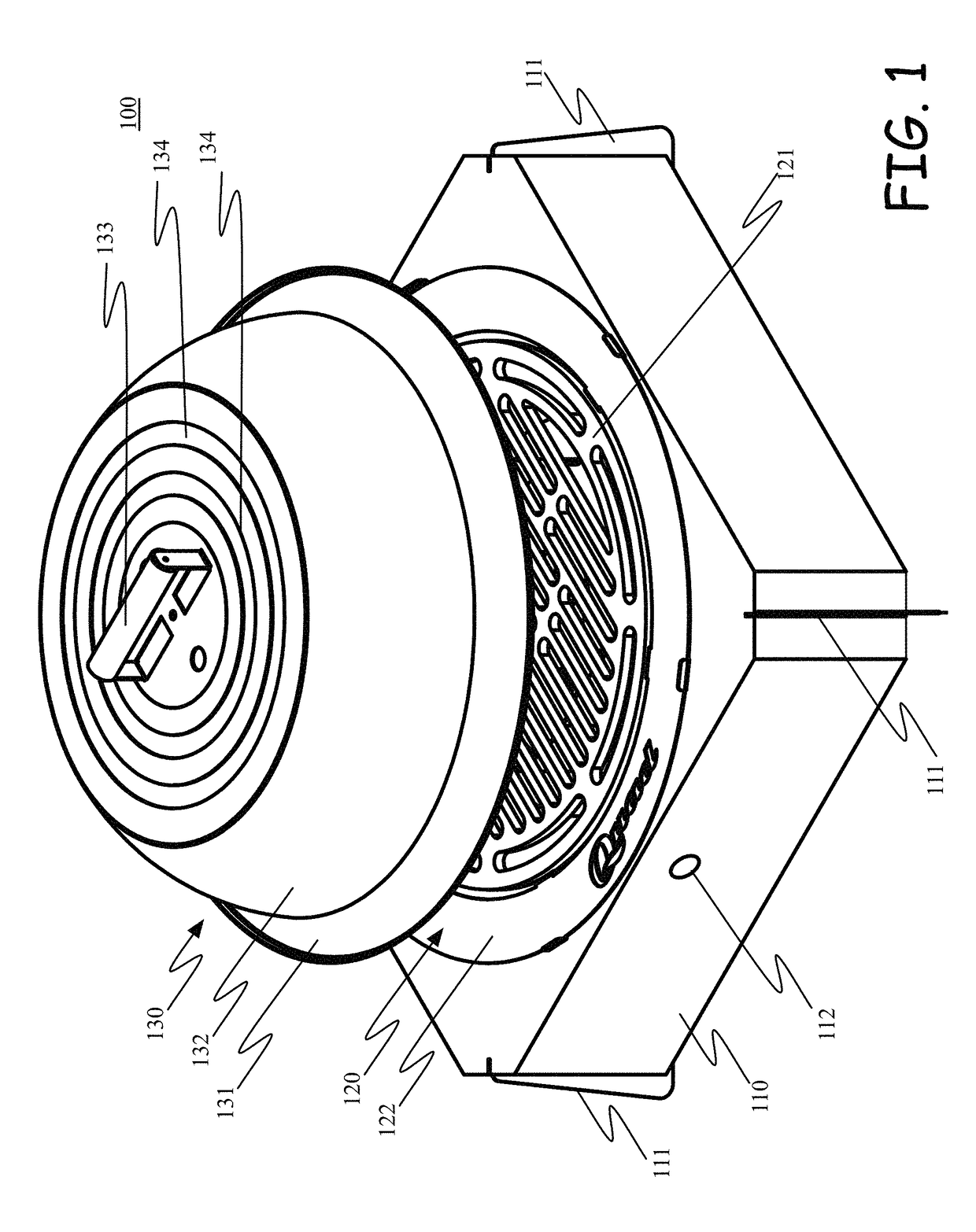

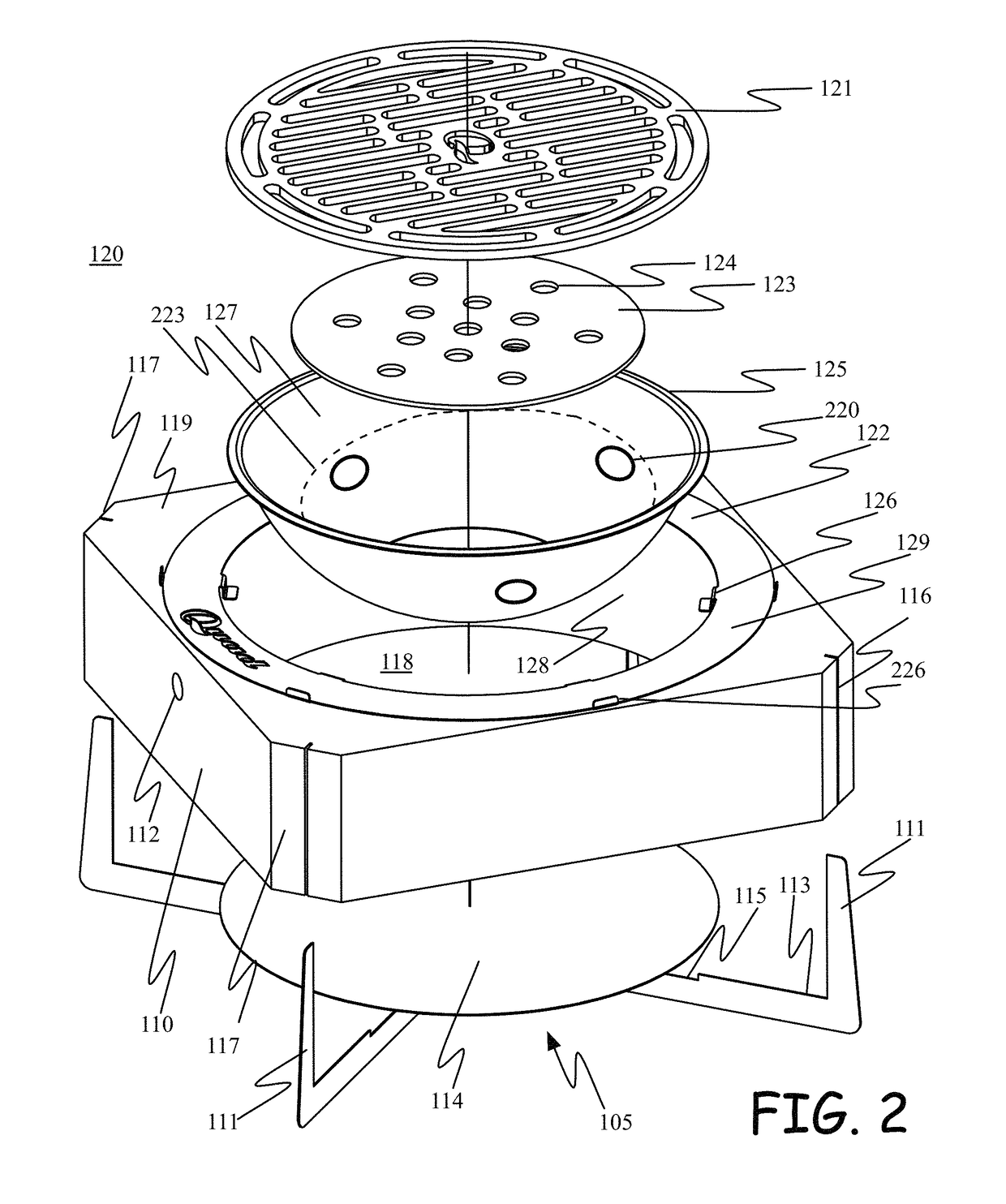

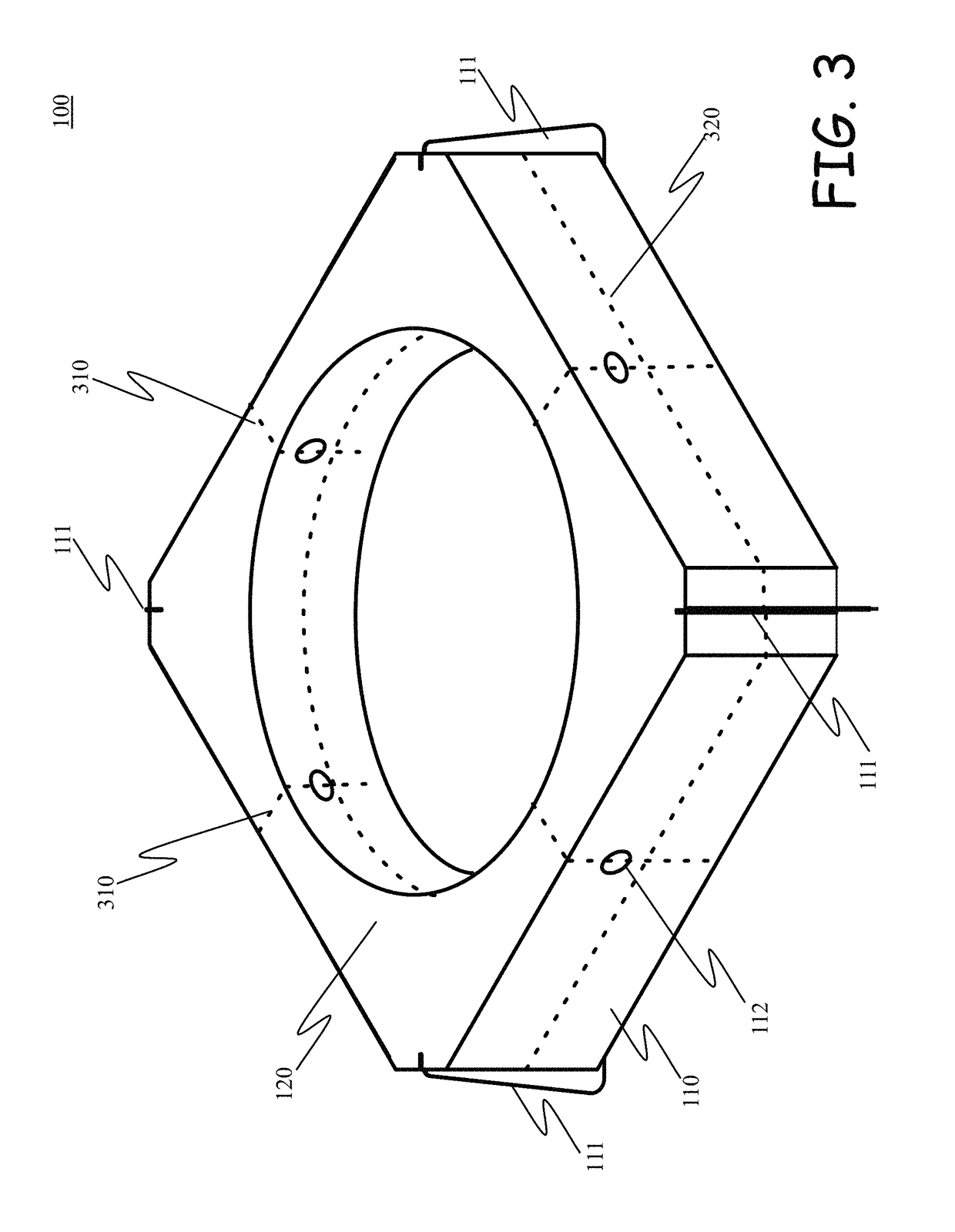

Versatile cooker

A versatile cooker that includes a crucible or base, a fire bowl with a cooking surface on top of it and, a cover / lid or dome that rests over the cooking surface. An exemplary embodiment of the cooker can be described as a naturally fired outdoor cooker constructed of a light weight, thermally insulated material such as Autoclaved Aerated Concrete (AAC) as the crucible, a stainless steel fire bowl and a dome lid. A grilling surface constructed out of carbon steel and ceramic disks are used as internal heat sinks.

Owner:COOKING WITH FIRE

High temperature common mild steel anti-oxidation coating and application thereof

InactiveCN101058684ADo not change the original performanceChange performanceLiquid surface applicatorsCoatingsMetallurgyReducer

The invention discloses a common low-carbon steel anti-oxidizing paint under high temperature, which comprises the following steps: grinding ore powder with Al2O3, SiO2, Fe2O3, metallurgical waste, reducer with carbon and inorganic binder to below 100 orders separately; blending evenly; stirring the powder with water evenly; adjusting the quantity of added water to the density of paint slurry to 1100-1500kg / m3; spraying the steel blank (below 1000 deg. c) before heat by rolling furnace directly; forming continuous protective layer to avoid oxidizing and damaging in the soaking course; saving the cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

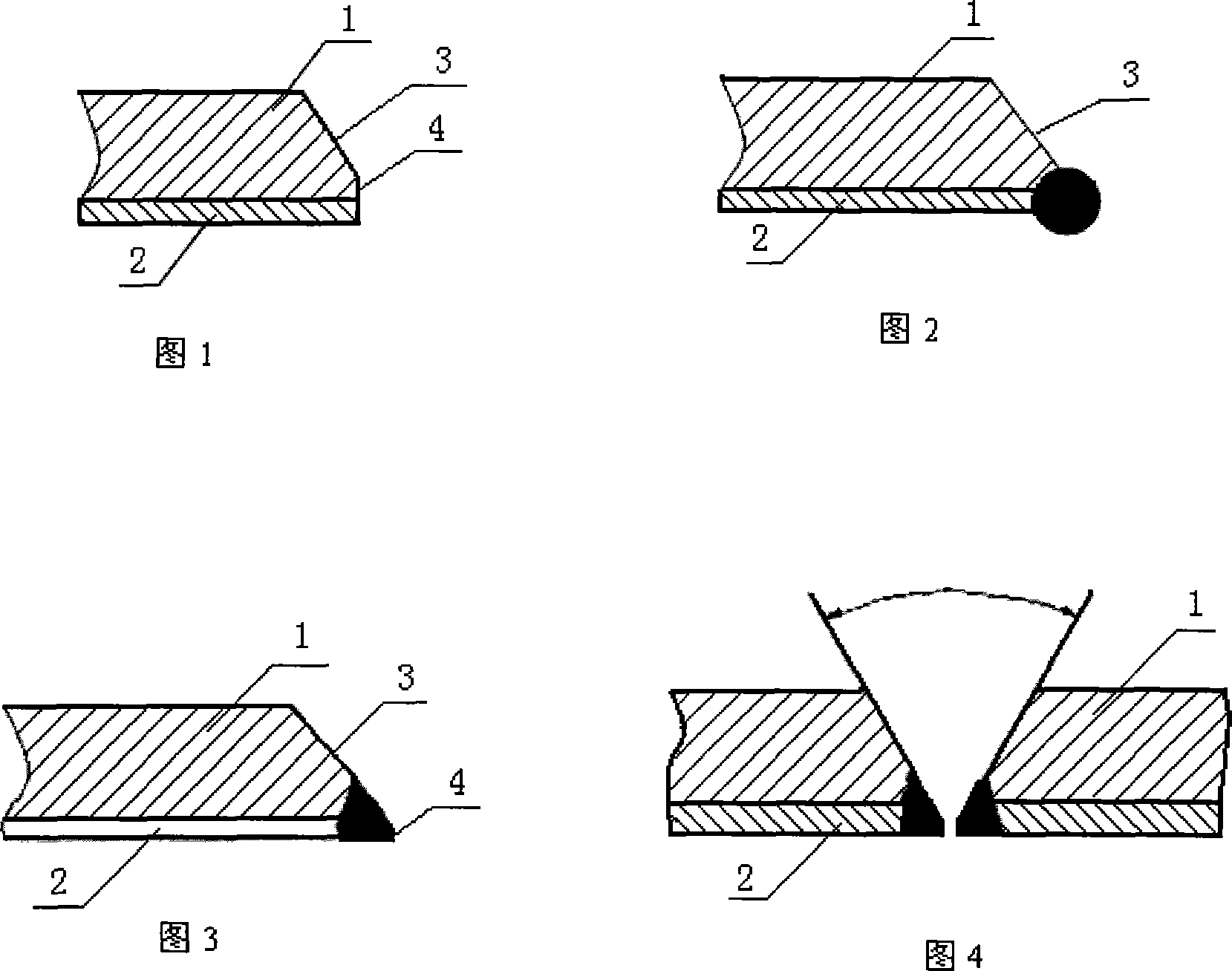

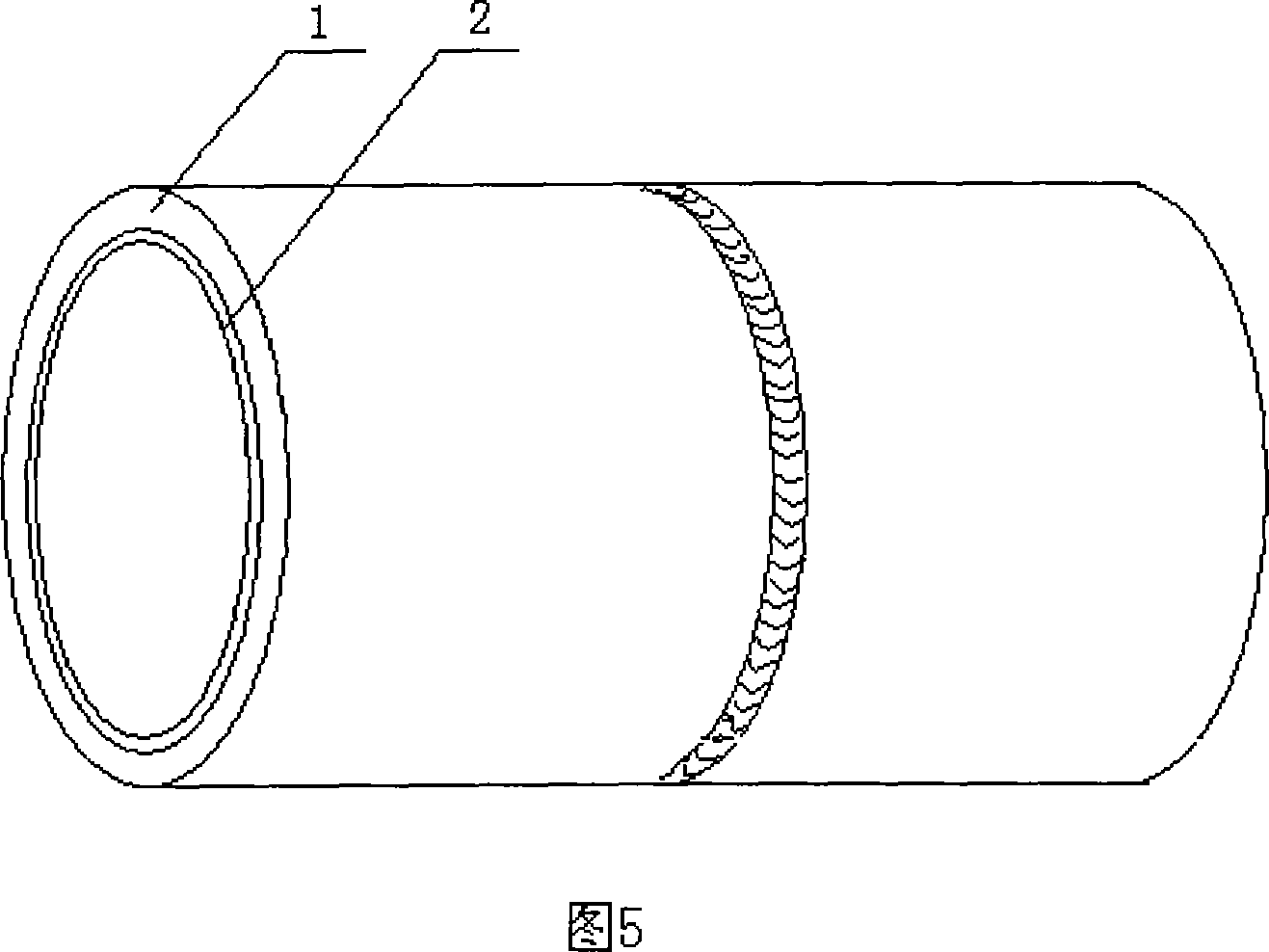

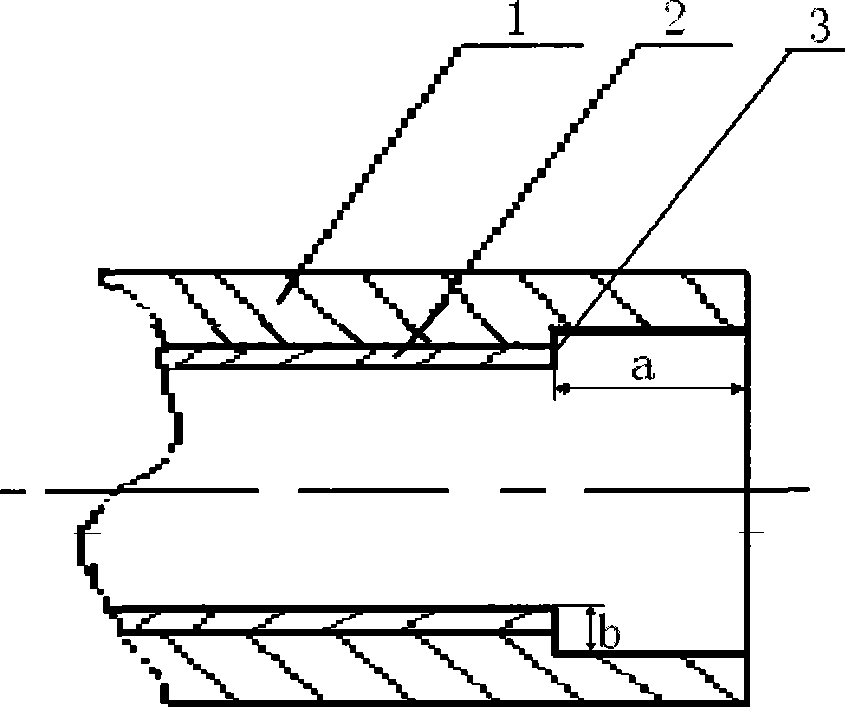

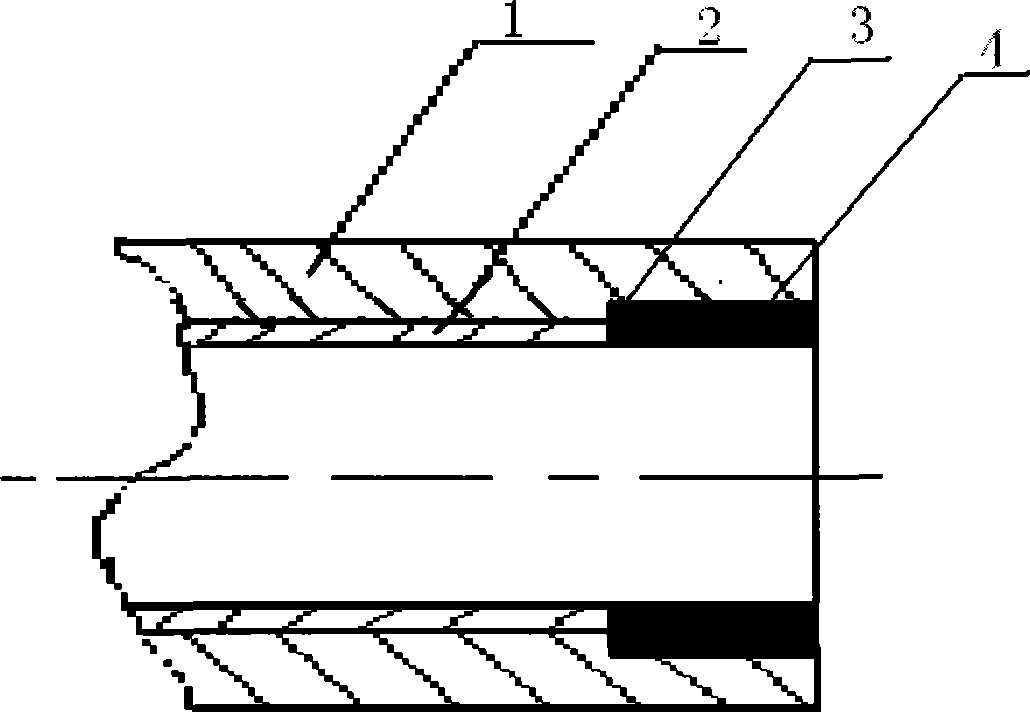

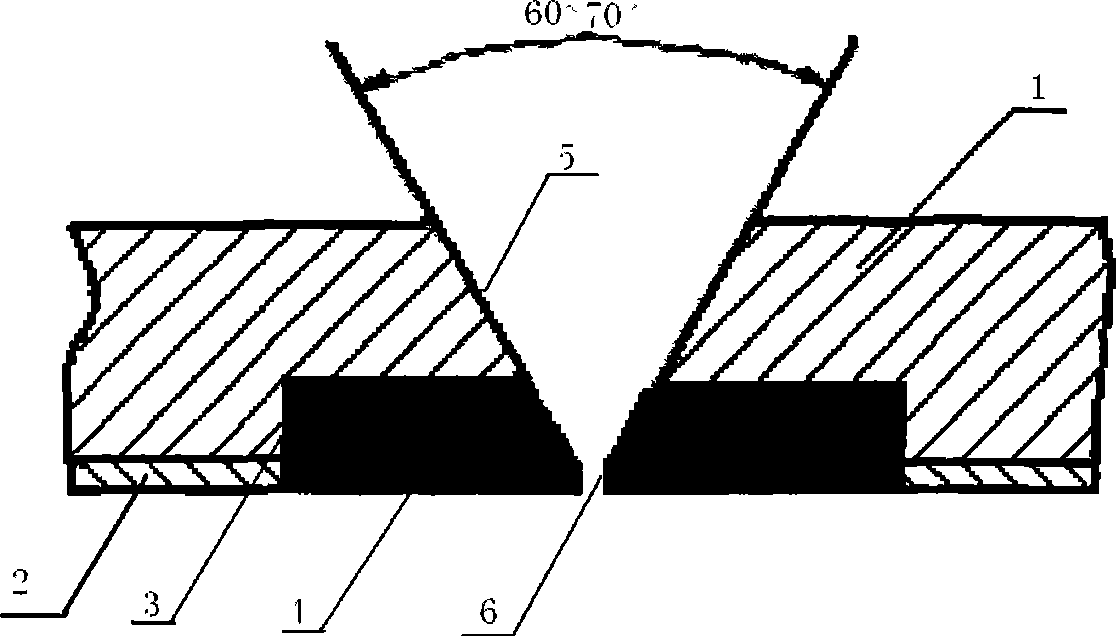

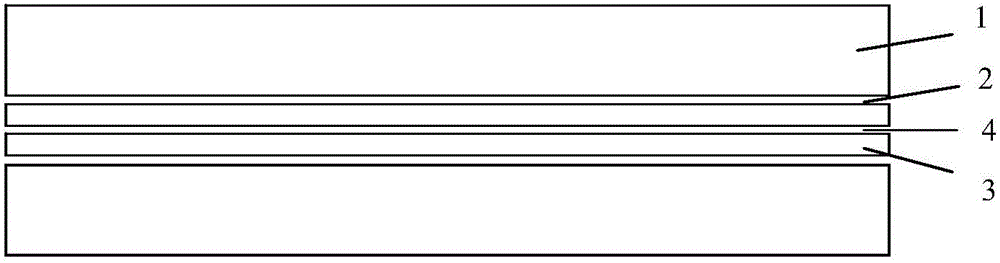

Thin-wall stainless steel double-layer and carbon steel base layer composite tube girth weld welding method

ActiveCN101100013AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsWeld seamMaterials science

The process of ring welding composite pipe comprising one thin stainless steel layer and one carbon steel base layer includes the following steps: 1. chamfering and eliminating oil stain; 2. bead welding and trimming chamfer; 3. pairing bimetal composite pipe chamfers; 4. argon shielded tungsten arc welding in the bottom; 5. welding the second layer to weld the base layers of two composite pipes; and 6. filling welding and finishing welding. During the welding process, stainless steel electrode and 309 or 309Mo welding material are adopted for reaching high strength and high toughness of the weld seam, and the chamfers have increased effective thickness of stainless steel layer for high welding quality and high corrosion resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for welding thin layer iron nickel base alloy carbon steel composite tube

ActiveCN101462193AIncrease the effective thicknessHigh strengthArc welding apparatusWelding/cutting media/materialsAlloyWeld seam

The invention relates to a method for welding a carbon steel composite pipe of a thin iron-nickel-based alloy. The method comprises: processing a step on the end part of the composite pipe; adopting the surfacing of argon arc welding on the surface of the step and trimming the surfacing layer; processing a groove; adopting tungsten electrode argon arc welding to carry out three-point positioning of spot welding evenly around a welding seam, and adopting the tungsten electrode argon arc welding to carry out back welding on the root; and adopting manual electric arc welding to carry out filling welding and overlay welding on the upper part of a second layer of back welding. The chemical compositions of a welding material by weight percentage: 0.02 to 0.1 percent of C, 0.2 to 1.0 percent of Si, 1.0 to 2.2 percent of Mn, 20.0 to 31.5 percent of Cr, 40.0 to 60.0 percent of Ni, 8.0 to 14.5 percent of Mo, 0.5 to 2.5 percent of Cu, 0 to 5.0 percent of Co, 0.3 to 4.2 percent of Nb, and the balance being Fe. The welding seam has the characteristics of no sensitivity to offset, favorable corrosion resistance, high strength and favorable plastic toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

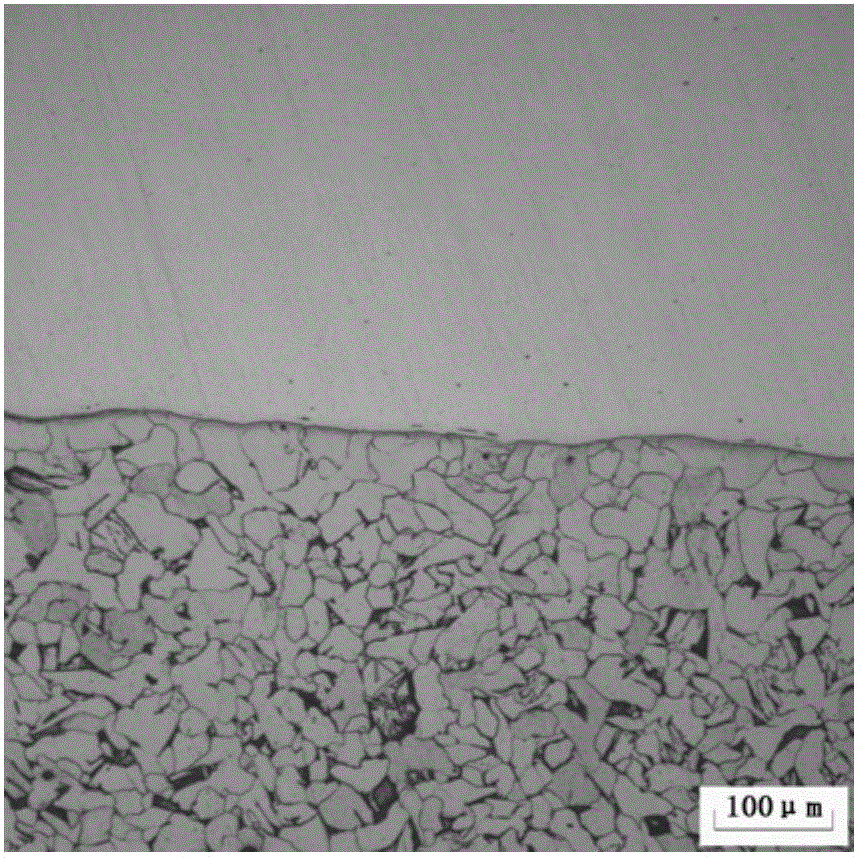

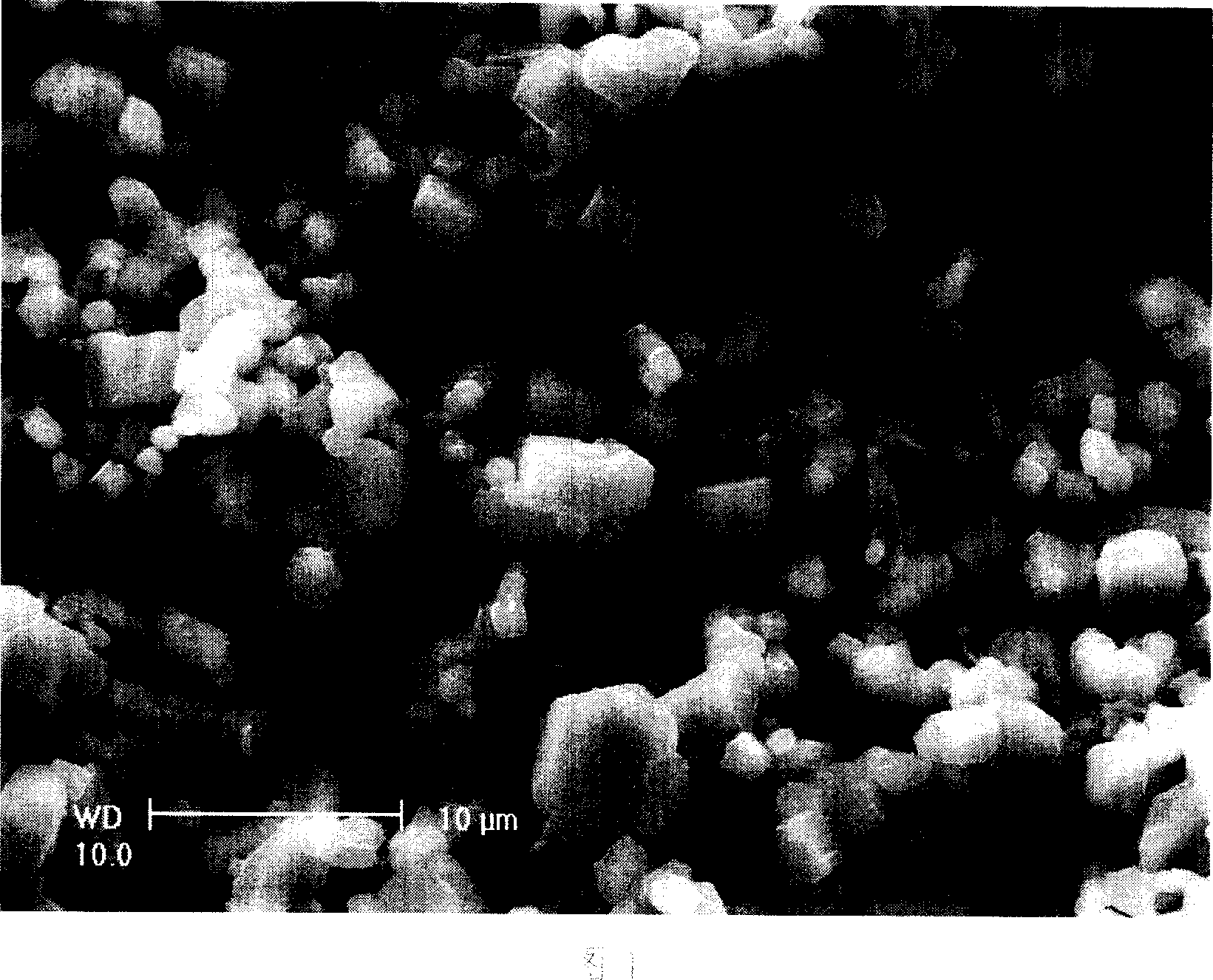

Low-carbon steels of superior mechanical and corrosion properties and process of making thereof

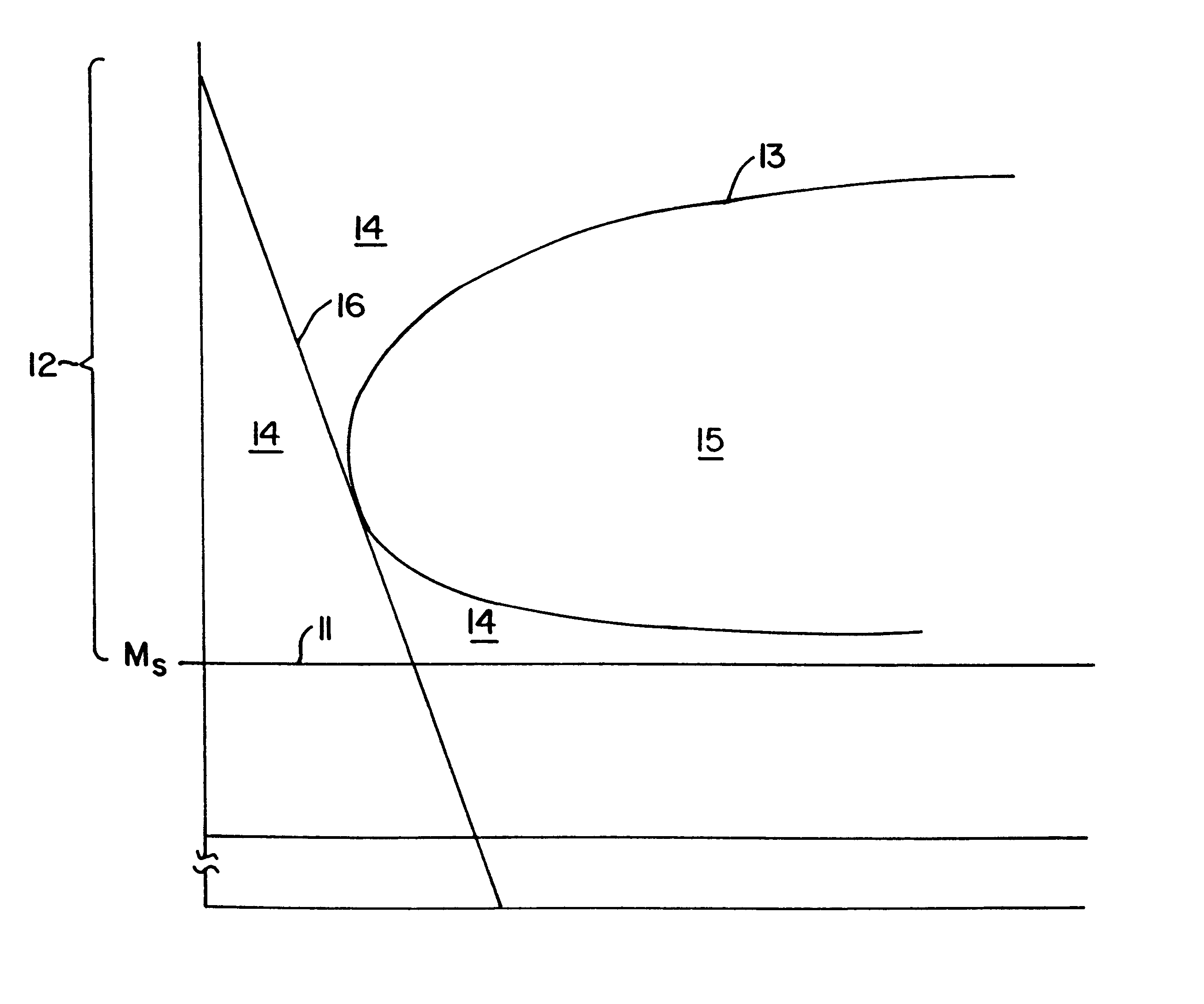

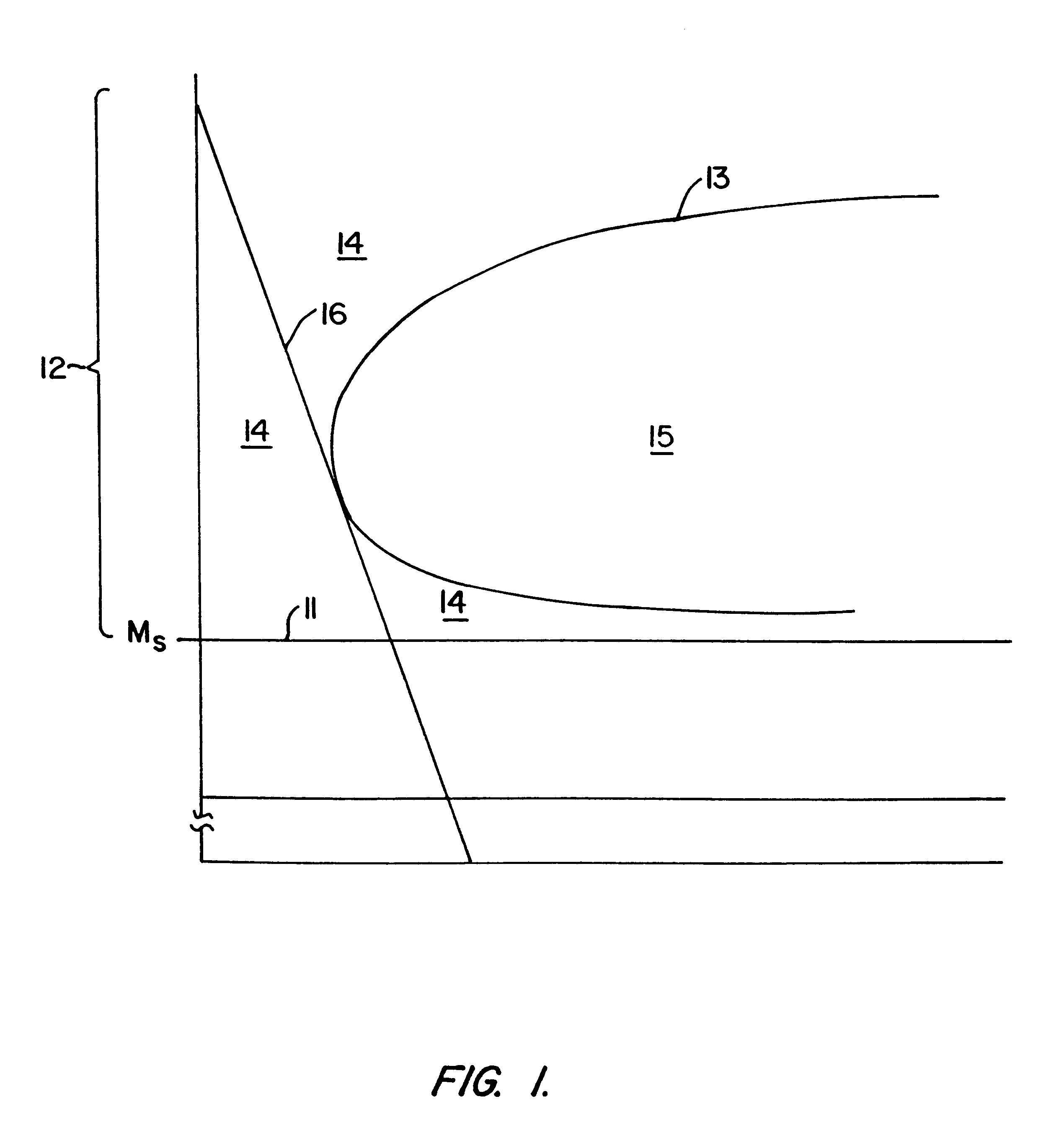

InactiveUS6273968B1Simple structureAccelerated corrosionFurnace typesHeat treatment furnacesCrystal twinningCarbide

Alloy steels that combine high strength and toughness with high corrosion resistance are achieved by a dislocated lath microstructure, in which dislocated martensite laths that are substantially free of twinning alternate with thin films of retained austenite, with an absence of autotempered carbides, nitrides and carbonitrides in both the dislocated martensite laths and the retained austenite films. This microstructure is achieved by selecting an alloy composition whose martensite start temperature is 350° C. or greater, and by selecting a cooling regime from the austenite phase through the martensite transition region that avoids regions in which autotempering occurs.

Owner:CMC STEEL FABTORS

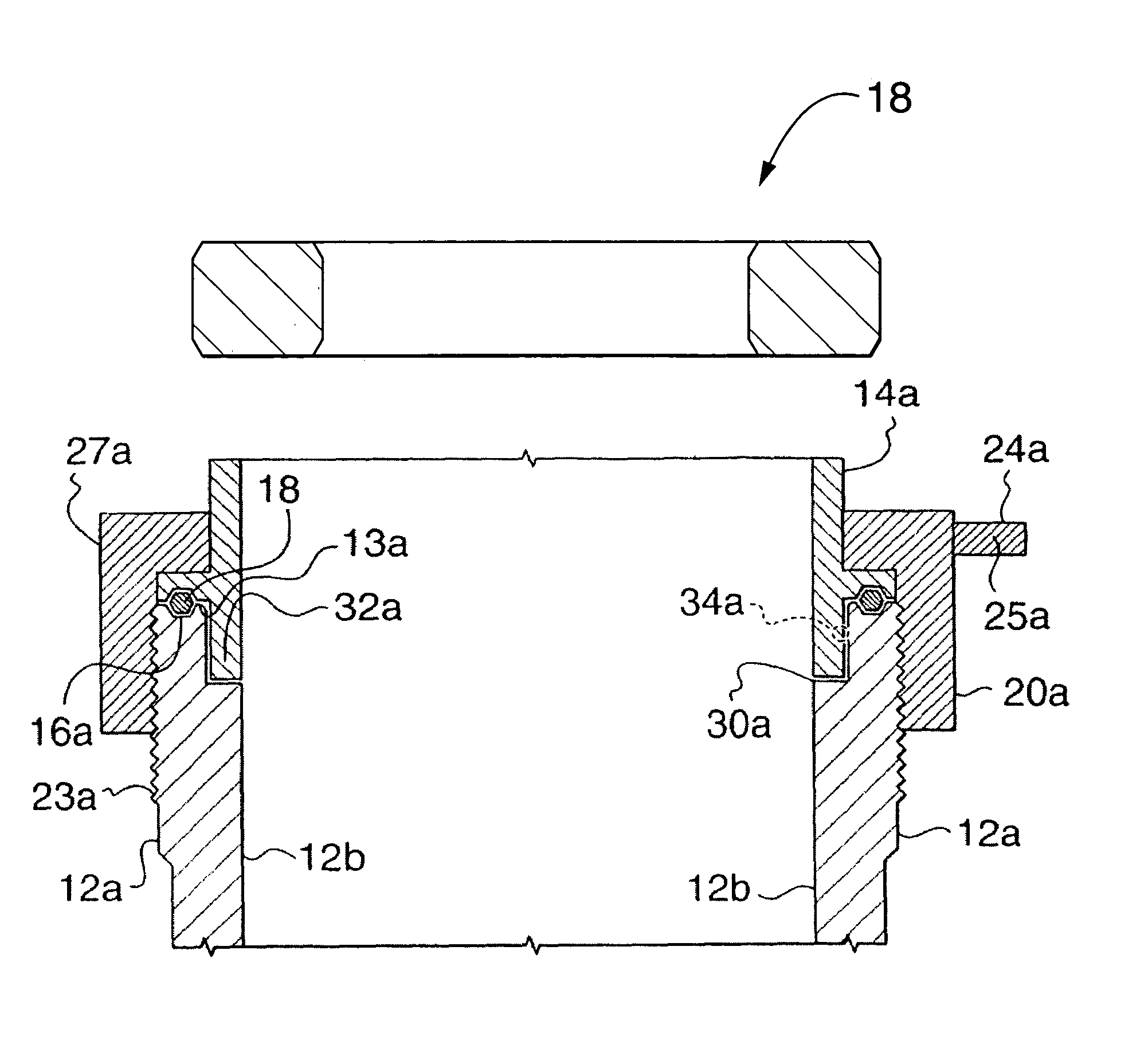

Metal ring gasket for a threaded union

InactiveUS7125055B2Improve sealingFlanged jointsFluid pressure sealed jointsHigh pressureScrew thread

A metal ring gasket for a threaded union provides a high-pressure, fluid-tight, metal-to-metal seal between subcomponents of a fluid conduit. The metal ring gasket is made of carbon steel or stainless steel depending on a composition of the fluid to be conveyed through the conduit. The metal ring gasket has beveled corners and is received in a beveled annular groove on mating surfaces of the subcomponents of the threaded union. When compressed in the annular groove between the subcomponents, the metal ring gasket creates an energized, high-pressure, fluid-tight seal that is highly resistant to pressure and is capable of maintaining a seal even at elevated temperatures resulting from direct exposure of the fluid conduit to fire.

Owner:OIL STATES ENERGY SERVICES +1

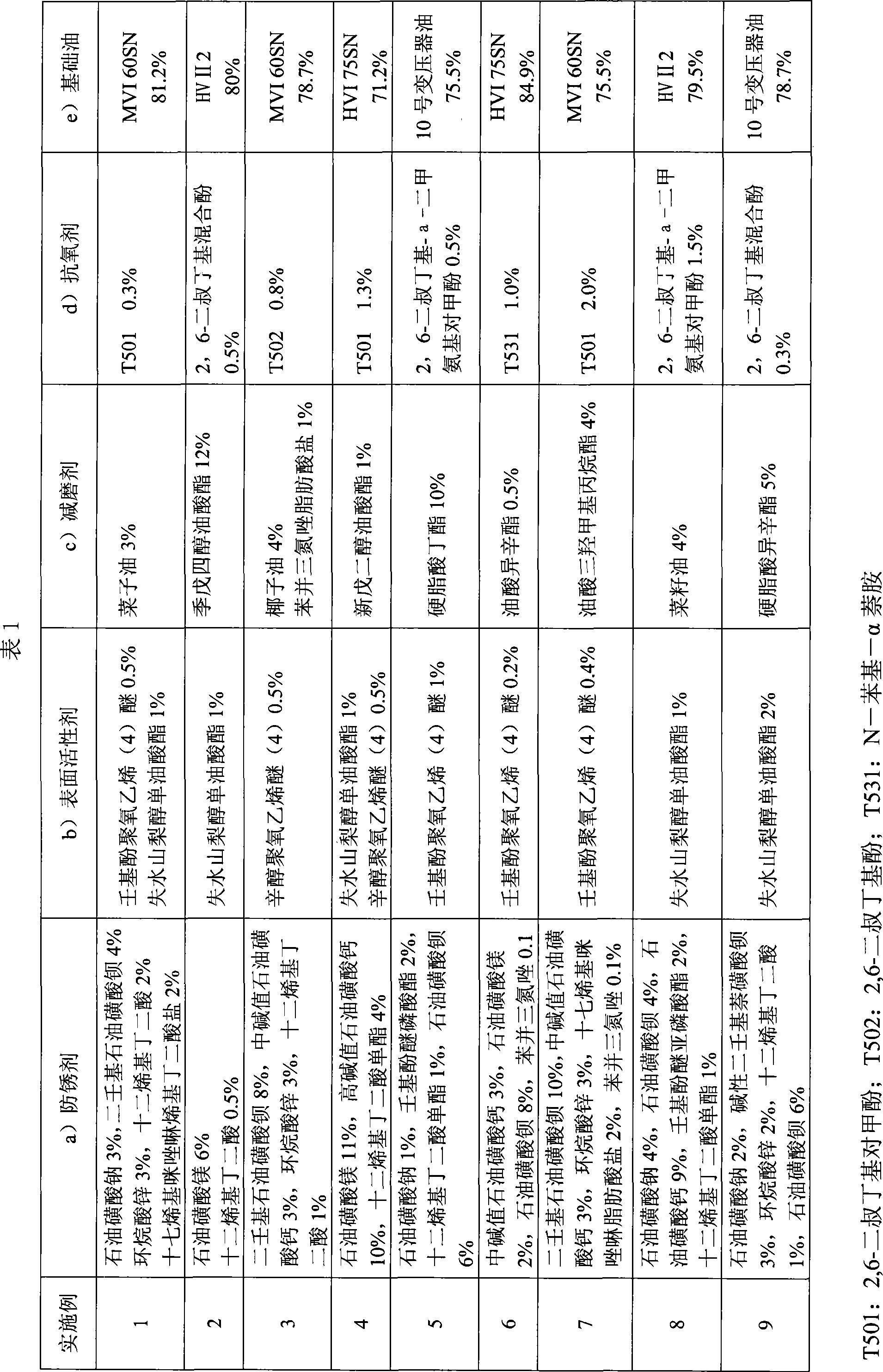

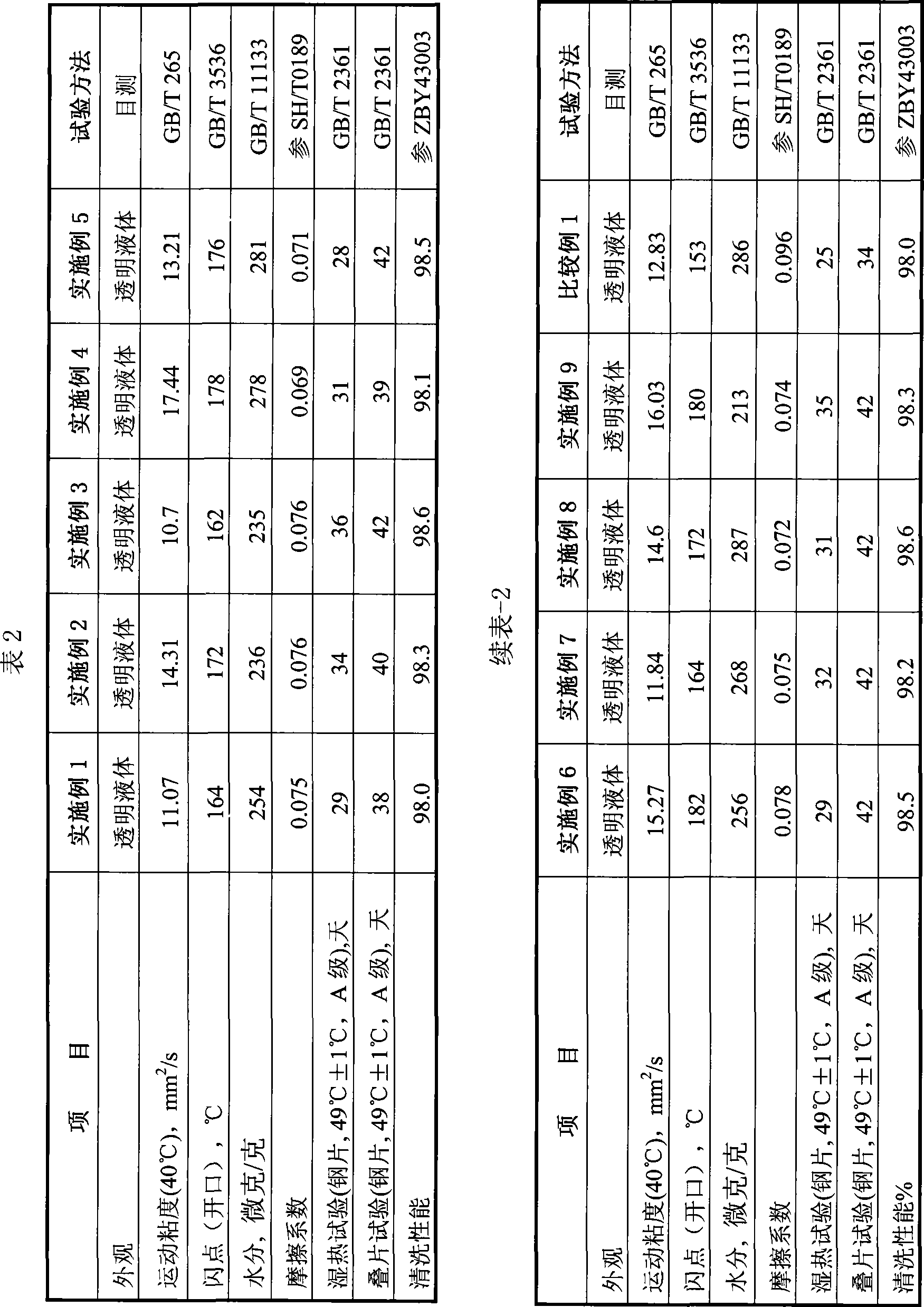

Electrostatic spraying antirust oil

The invention discloses an electrostatic painting antirust oil to solve the problem of plain carbon steel surface erosion, which is characterized by the following: this product is composed by 70.0-90.0 mass percent base oil, 5.0-29.0 mass percent antirust agent, 0.1-5.0 mass percent atomized property improver and 0.1-5.0 mass percent antioxidant. This invention possesses merits of low cost, high flash point, good washable and lower interfacial force.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Powdery alloy processing material in site by movable laser smelt-coating process

A movable field processing alloy powder material for the laser melting is to reinforce the nickel-base alloy using the below elements: Cr, W, Mo, Al, Ti, Co; also it can be added with the Co, C, N, Nb, Cu, B, Si and the minim rare-earth metal which can be the Ce, Y and the Hf. The invention has the high hardness, the strength and the low melting point, high wearing resistance. It has improved the cracking resistance, moldability, the stability and the uniformity of the laser melting layer. So it can repair the high temperature alloy, the carbon steel, the structural steel and the stainless steel by the laser melting.

Owner:SHENYANG DALU LASER TECH

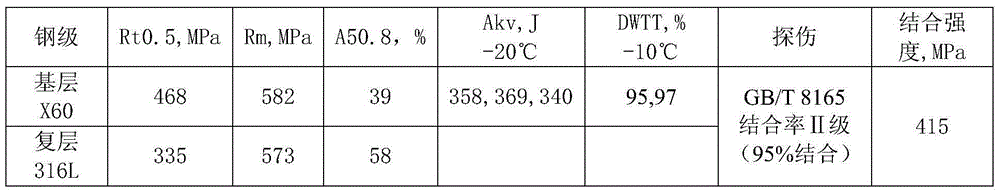

Carbon steel and stainless steel clad steel plate with toughness performance and production method

The invention discloses a carbon steel and stainless steel clad steel plate with toughness performance, and belongs to the technical field of production of metal clad plates. Carbon steel is a basal material, and satisfies the requirements of API5L "American Petroleum Pipeline Steel Specification"; 316L stainless steel is a multiple layer, and components satisfy the requirements of ASTM A240M-05 standard "Standard Specification of Chromium and Chromium Nickel Stainless Steel Plate, Sheet and Strip Steel for Pressure Vessels and General Purposes"; flux is BNi brazing filler metal; and solder resist is a mixture of magnesium oxide and aluminum oxide. The process comprises steel blank assembly, heating, rough rolling, finish rolling and heat treatment. The clad steel plate has excellent toughness performance and hydrogen induced cracking resistance, so that the use safety of crude oil conveying pipes is improved.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL

Aluminum oxide coated tool

InactiveUSRE41972E1Increase resistancePigmenting treatmentLiquid surface applicatorsHigh resistanceCarbon steel

There is provided a tool at least partly coated with at least two refractory layers of which one of the said layers is a fine-grained α-Al2O3-layer which is the top layer along the cutting edge-line and the other a TiCxNyOz- or a ZrCxNy-layer being the top layer on the clearance face. The coated tool exhibits excellent flank and crater wear and high resistance to flaking, particularly when used for machining of low carbon steel and stainless steel. Used cutting edges can easily be identified by the naked eye.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

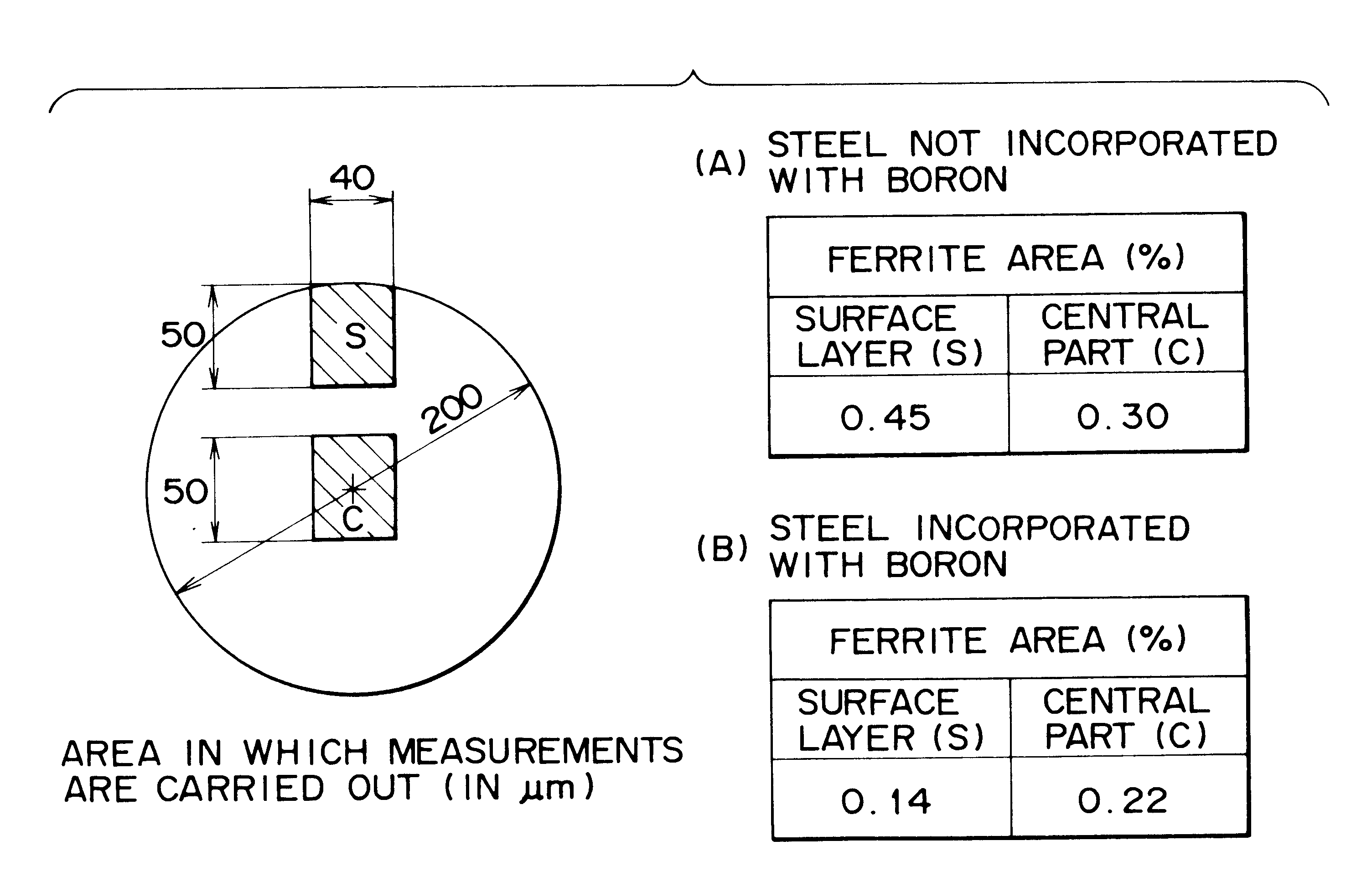

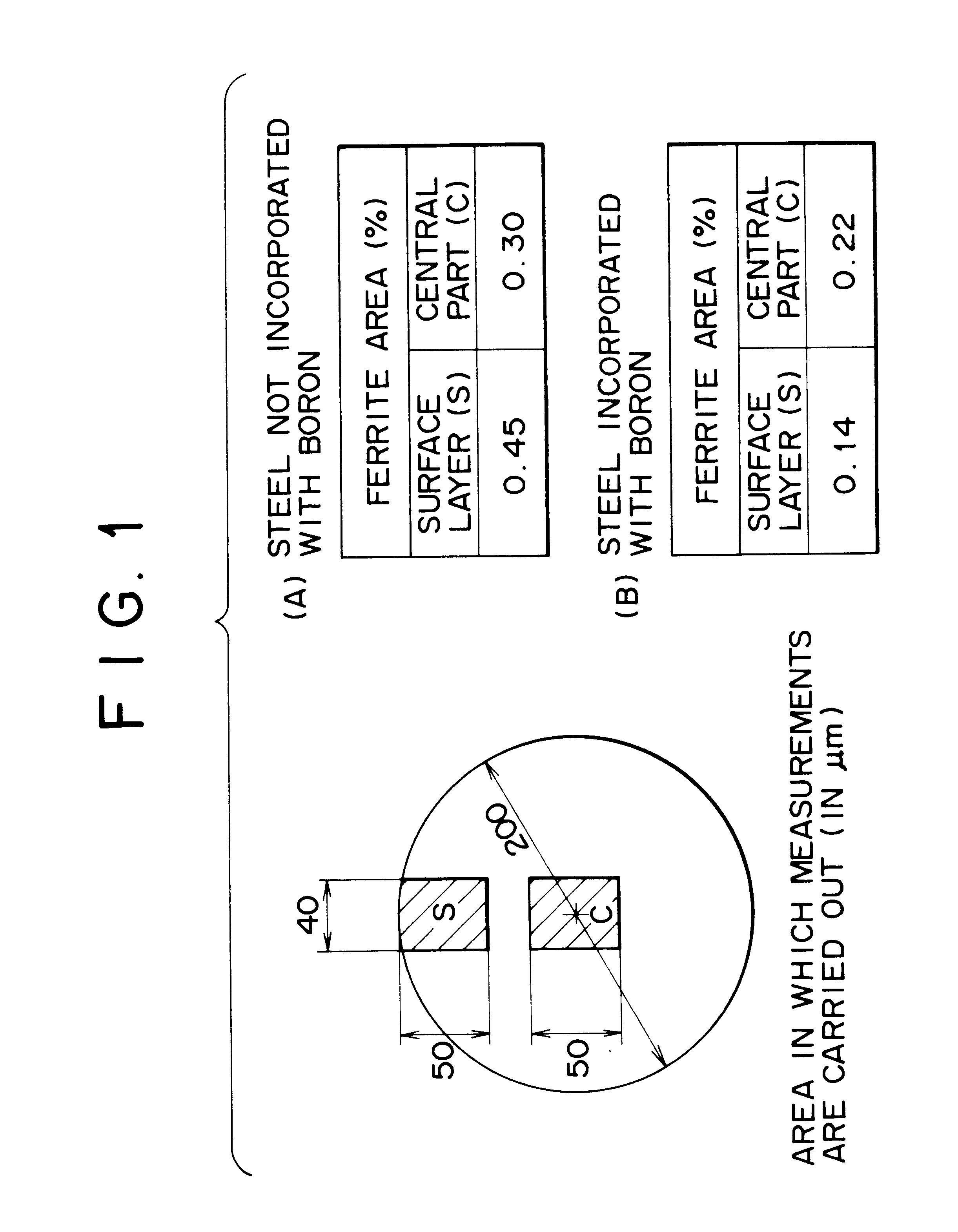

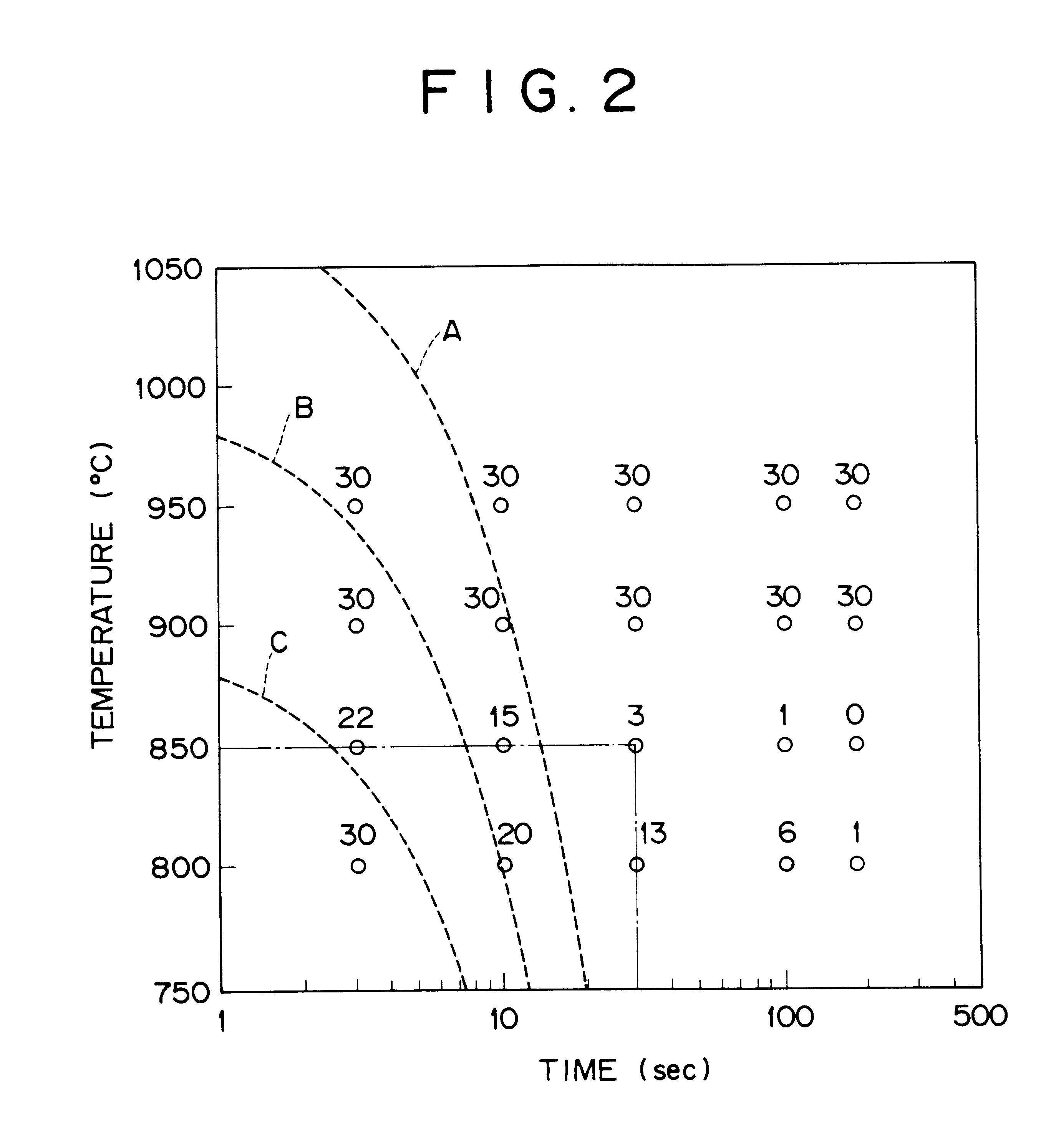

High-carbon steel wire superior in resistance to longitudinal cracking, steel product for the same, and process for production of the same

Disclosed herein are a high-carbon steel wire having high strength and superior in resistance to longitudinal cracking, a steel for said high-carbons steel wire, and a process for producing said steel. The high-carbon steel wire is characterized in that the essential components are C (0.65-1.2 wt %), Si (0.1-2.0 wt %), Mn (0.2-2.0 wt %), and Fe, the main phase is pearlite, and the ferrite area ratio is less than 0.40 % in the surface layer up to a depth of 50 mum from the surface. The high-carbon steel may further contain B (0.0003-0.0050 wt %), Ti (less than 0.030 wt %), and N (less than 0.0050 wt %), with the amount of B, Ti, and N satisfying the following equationThe resulting steel wire produced in the usual way contains ferrite in an amount less than 0.40 wt % in its surface layer. This low ferrite content is responsible for good resistance to longitudinal cracking because ferrite causes longitudinal cracking to start from it.

Owner:KOBE STEEL LTD

Steel-based copper alloy dual-metal sliding bearing and preparation method thereof

ActiveCN101649858ALow costImprove carrying capacityBearing componentsReflex reflectorsStearic acidLubrication

The invention discloses a dual-metal sliding bearing and a preparation method thereof. Carbon steel or stainless steel is taken as an outer layer material, and a powder metallurgy material taking a copper alloy as a basal body is taken as an inner layer material; the inner surface of the outer layer material is electroplated to form an electroplated copper layer with the thickness of 4-8 micrometres; the inner layer material comprises the following components by weight percent: 1%-20% of aluminum, 1%-8% of titanium, 1%-15% of stannum, 0.1%-5% of ferrum, 0.1%-2% of phosphorus, 0.1%-5% of nickel, at least one of 0.1%-2% of graphite and 0.1%-2% of molybdenum disulfide or 0.1%-2% of zinc stearate, and the balance of copper; and the bearing is impregnated with lubricating oil. The dual-metal sliding bearing has the advantages of low cost, high carrying capability, self-lubrication, excellent abrasion resisting capability, and the like, and can be widely applied to reciprocating swing positions of a swing arm, a bucket rod, a bucket, and the like of a large-tonnage and high-power excavator.

Owner:COB PRECISION PARTS

Production method of ultra low carbon steel

InactiveCN102719600AReduce the rate of oxygen blowing heating upReduce temperature dropManufacturing convertersSlagNitrogen

The invention provides a production method of an ultra low carbon steel. The method comprises the steps of: employing a blowing process for desulfurization and slag removal of molten iron, with control of oxygen blowing time and smelting cycle of a converter, argon bottom-blowing in the whole course, and control of S content in slag lime, [C] content at converter end point, and temperature and oxygen activity at the endpoint, adding lime in a tapping process, and modifying ladle top slag after tapping; employing natural decarburization to control carbon content in an RH, wherein Als in molten steel is less than 0.03% after deoxidation, carrying out vacuum-breaking, adding aluminum powder and top slag modifier into the top slag, blowing argon with stirring, vacuumizing again, and carrying out clean circulation for 2-10 min; and carrying out continuous casting with protective casting in the whole course, wherein a nitrogen increase amount in the molten steel is controlled at less than 2 ppm. The invention can effectively reduce temperature drop in a transmission process, reduce oxygen blowing heating rate in a subsequent RH refining treatment, save energy and shorten the time of refining. Besides, the method can effectively guarantee modification effect of the top slag, prevent nozzle clogging and realize sequence casting. Therefore, the method is particularly applicable to the production of high purity ultra low carbon steel.

Owner:ANGANG STEEL CO LTD

Method for smelting ultra-low carbon steel

ActiveCN102719593AHigh carbon contentReduce carbon contentManufacturing convertersProcess efficiency improvementHigh carbonSlag

The invention provides a method for melting ultra-low carbon steel. The method adopts a desulfuration of molten iron-converter-RH-continuous casting process, wherein a sulfur content in the molten iron is 0.002%-0.006% after desulphurization; converter smelting controls oxygen blowing time, an oxygen gun flow, a bottom-blowing intensity and a smelting period, adopts slag-stopping tapping, steel tapping with a content of C being 0.06%-0.08% and with a temperature of 1650-1680 DEG C, and an oxygen content in the molten iron is 0.03%-0.05%; an RH adopts forced decarburization with a highest vacuum degree of 67-100 MPa and decarburization time of 15-27 min, and a carbon content in the molten iron is 0.0010%-0.0020% and a dissolved oxygen content in the molten iron is 0.025%-0.040% after the decarburization; the molten iron is recycled for 3-5 min after deoxidation by adding aluminium and recycled for another 3-5 min after adding other alloys; a nitrogen content in the molten iron is 0.0015%-0.0035%, and the temperature is 1590-1640 DEG C; and killed steel treatment is carried out for 10-30 min. The method adopts converter tapping with a high carbon and low oxygen content, can use less or not use slag modified agents during the tapping process, accelerates the production rhythm, makes the molten steel cleaner, and reduces the production cost.

Owner:ANGANG STEEL CO LTD

Method for producing ultra-low-carbon steel

A method for producing ultra-low-carbon steel belongs to steel-making technology field. The process route is: molten iron desulfuration preprocess -converter smelting -RH vacuum process -slab continuous casting. The iron desulfuration preprocess applies blowing magnesium granules for desulfuration; the converter smelting terminal carbon content and oxygen activity of molten steel; applying slag dam operation when tapping without deoxidation; the ladle furnace proceeds operation of top slag modification and temperature controlling; RH vacuum processing to control the maximum vacuum; applying Al for deoxidation when the decarburization is finished, and alloying if the deoxidation is finished and assuring the deep vacuum processing time after the deoxidation; calming the molten steel when the vacuum is finished; applying non-carbon covering agent and non-carbon protection slag in the slab casting process; the continuous casting process uses full protection casting, and the casting process controls a reasonable pulling speed according to slab section. The advantages are: the invention resolves problem of nozzle clogging and improves castability of the ultra-low-carbon steel and implements multi-furnace continuous casting, and the components of carbon, phosphorus, sulphur and nitrogen of the completed product conforms smelting request of the ultra-low-carbon steel.

Owner:SHOUGANG CORPORATION

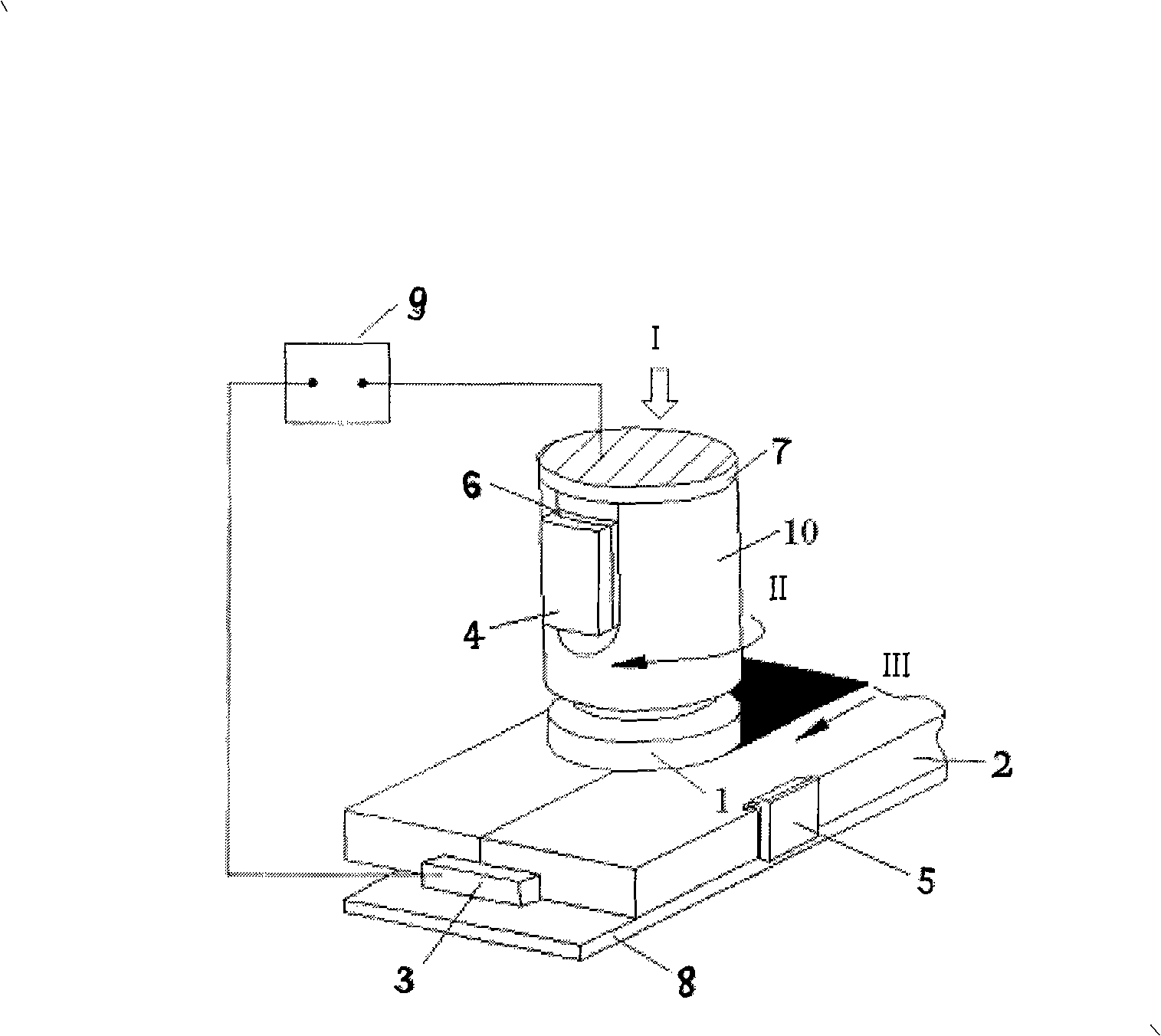

Electric conduction-stirring friction composite heat power supply welding method and equipment

ActiveCN101323054AOvercoming a lack of energy inputBreak through limitationsResistance welding apparatusNon-electric welding apparatusEngineeringWeld seam

The invention discloses a conducting-stirring friction hybrid heat source welding method and a piece of equipment, wherein, in stirring friction welding, a stir head and a workpiece are simultaneously insulated from the main body of a welding machine, the clamp of a fixed workpiece and a worktable, current is galvanized in the weld seam direction of the workpiece, the current and the weld seam through which the current flows produce resistance heat with the contact resistance of a friction stirring welding area, and the resistance heat together with stirring friction heat forms the hybrid heat source of the stirring friction welding. The method and the equipment of the invention have the following remarkable effects: 1. the limitation of the stirring friction welding on welding materials is broken through, leading the stirring friction welding to be used for welding such structural materials as black ferrous metals, superalloy, and the like; 2. the service life of the stir head can be improved; and 3. welding speed and welding quality can be further improved, thus improving the mechanical property of a welding joint. The method and the equipment of the invention can be used for the stirring friction welding, the preheating before welding, and the postweld heat treatment of such structural materials as carbon steel, stainless steel, and superalloy, etc.

Owner:罗键

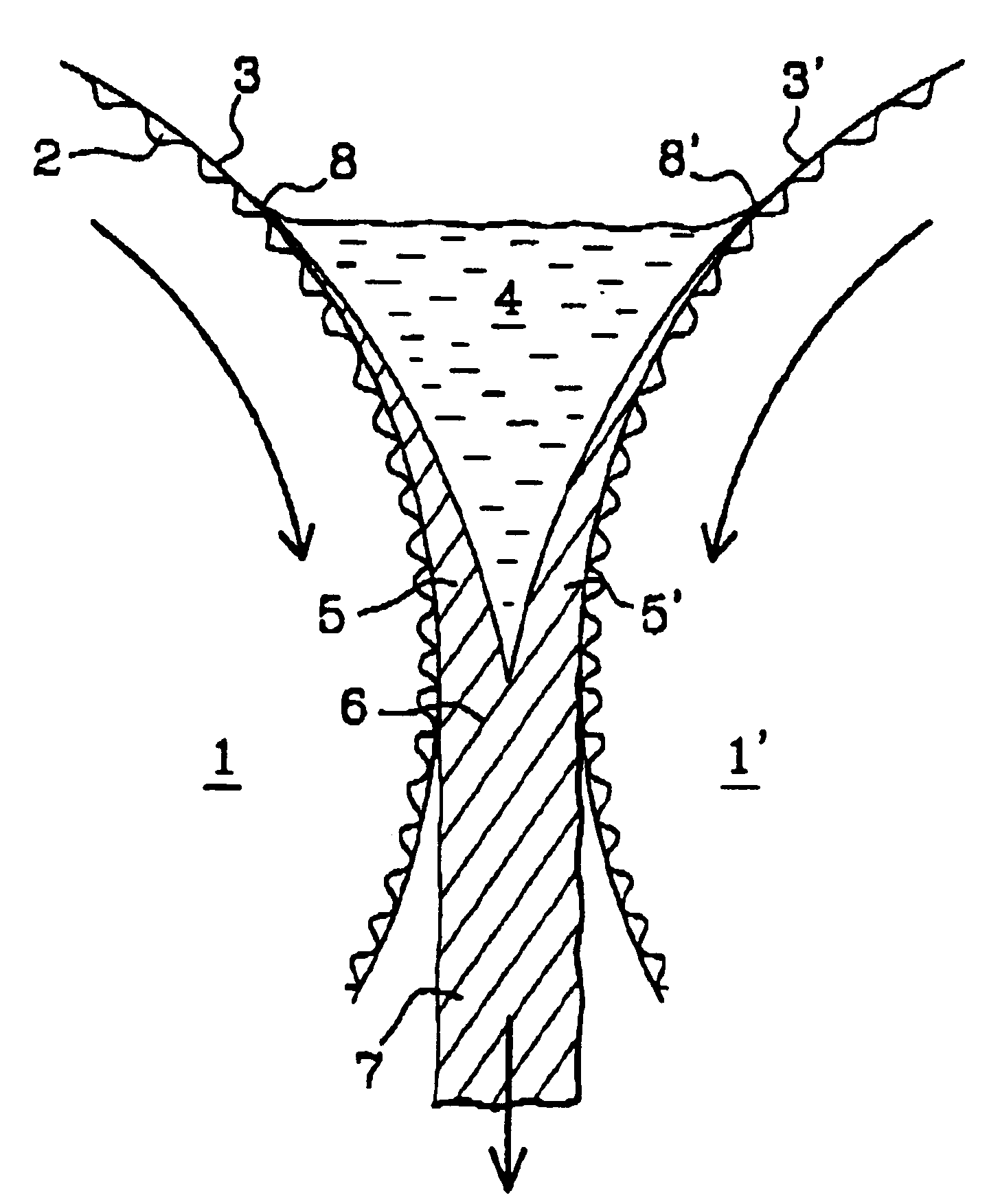

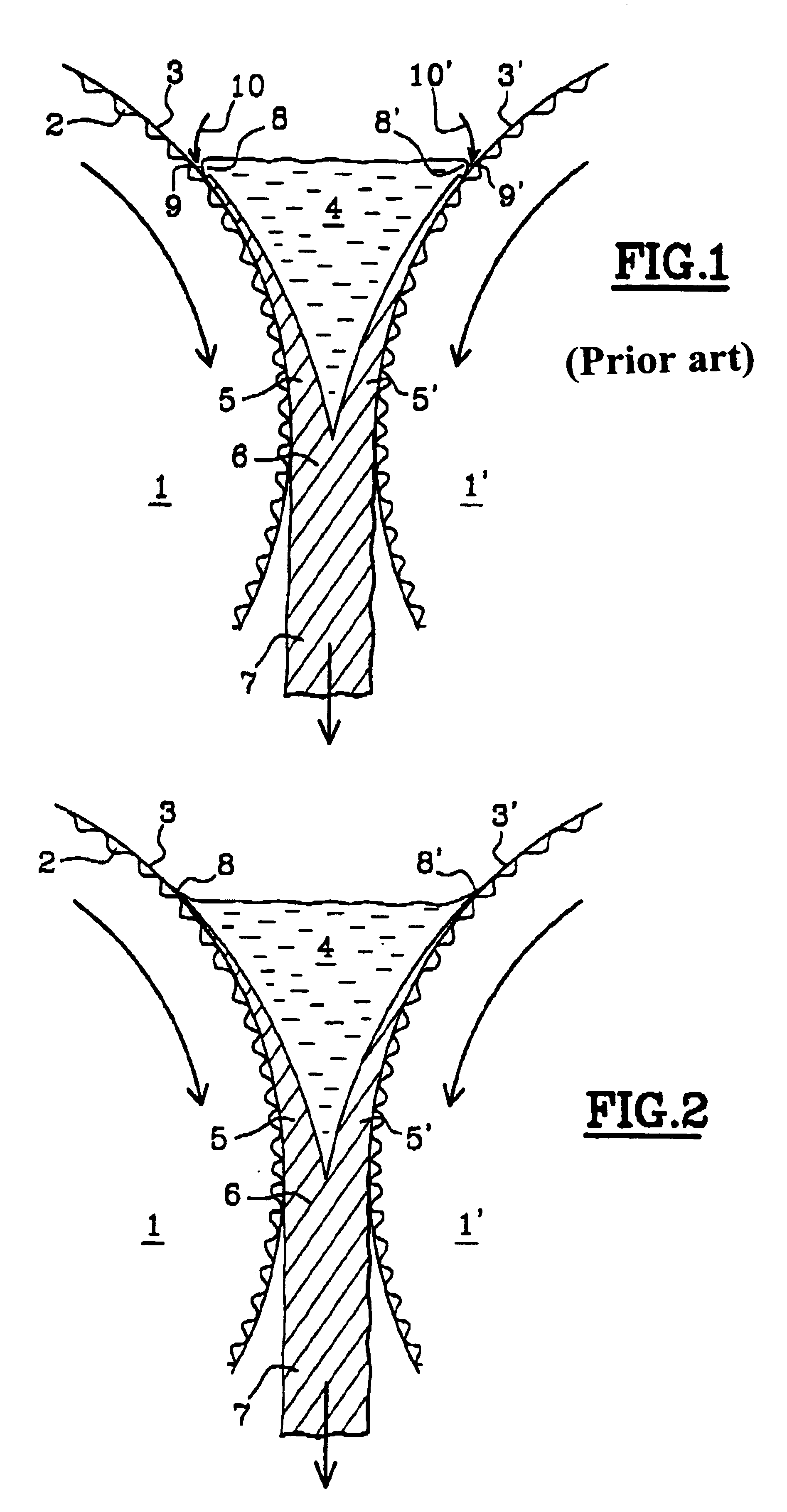

Process for manufacturing carbon-steel strip by twin-roll continuous casting, product produced and apparatus

A process for manufacturing carbon-steel strip having a thickness of less than or equal to 10 mm directly from liquid steel, by casting said liquid steel between the lateral surfaces, made of copper or copper alloy, of two internally cooled rotating horizontal rolls.

Owner:SOLLAC (SA)

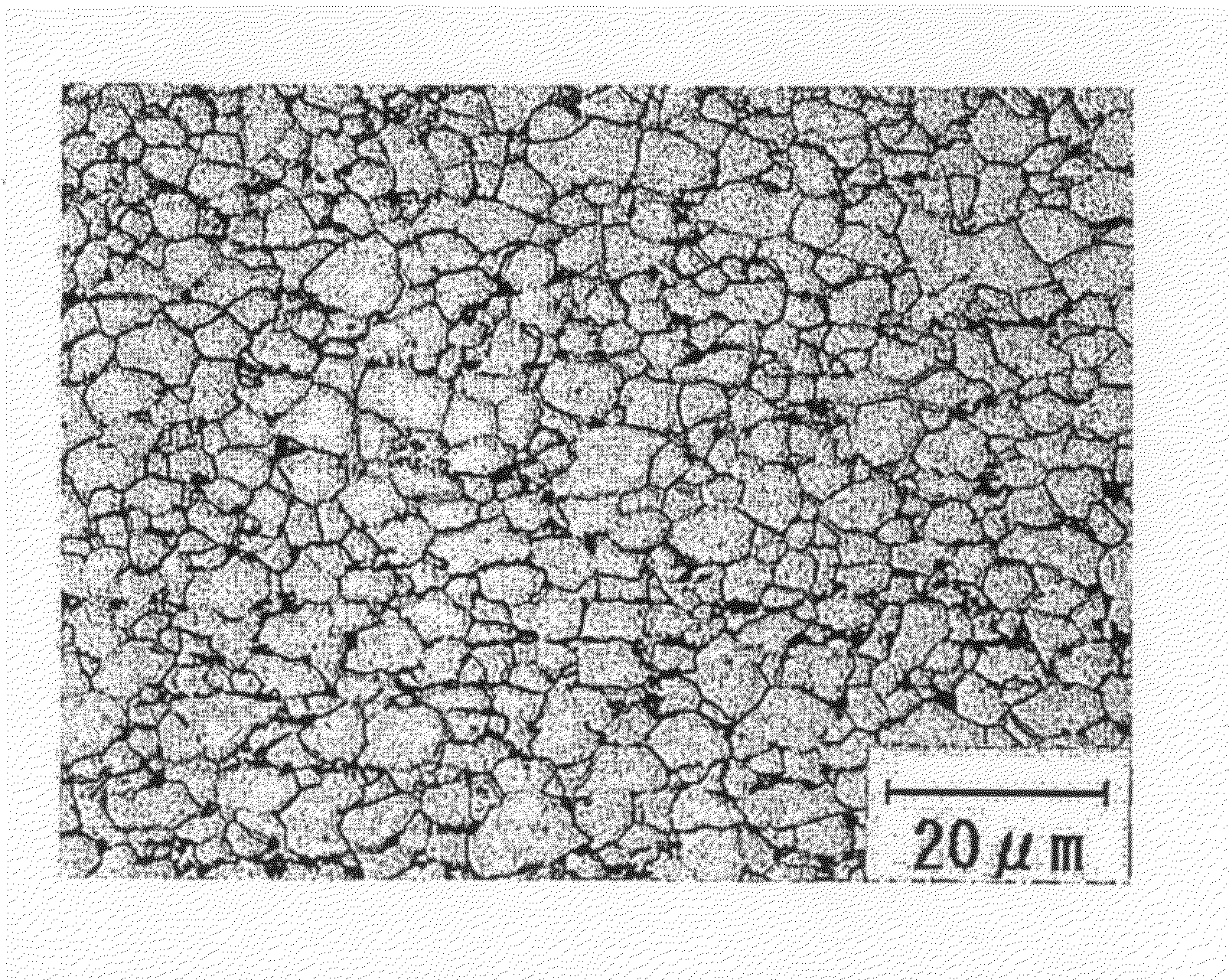

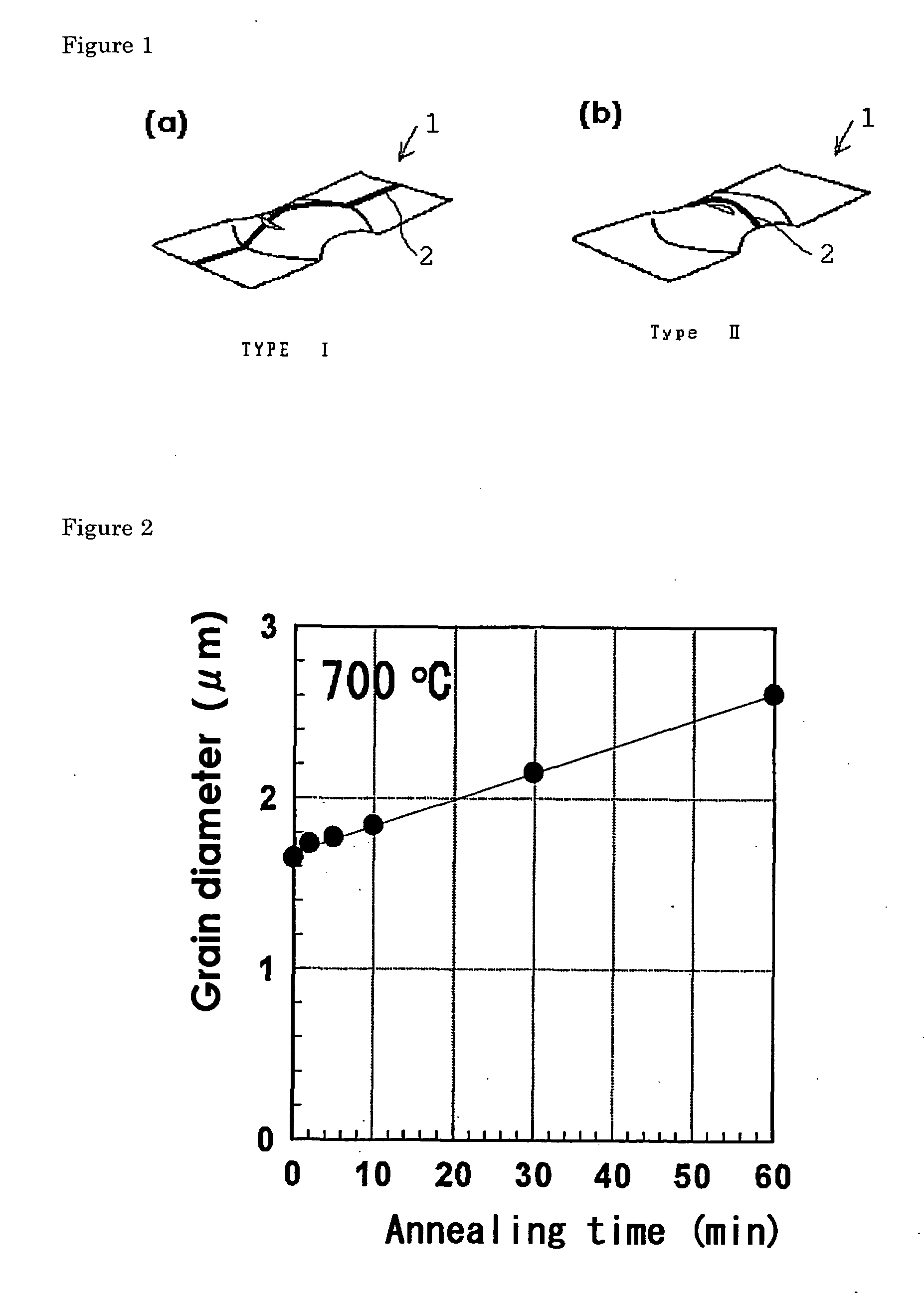

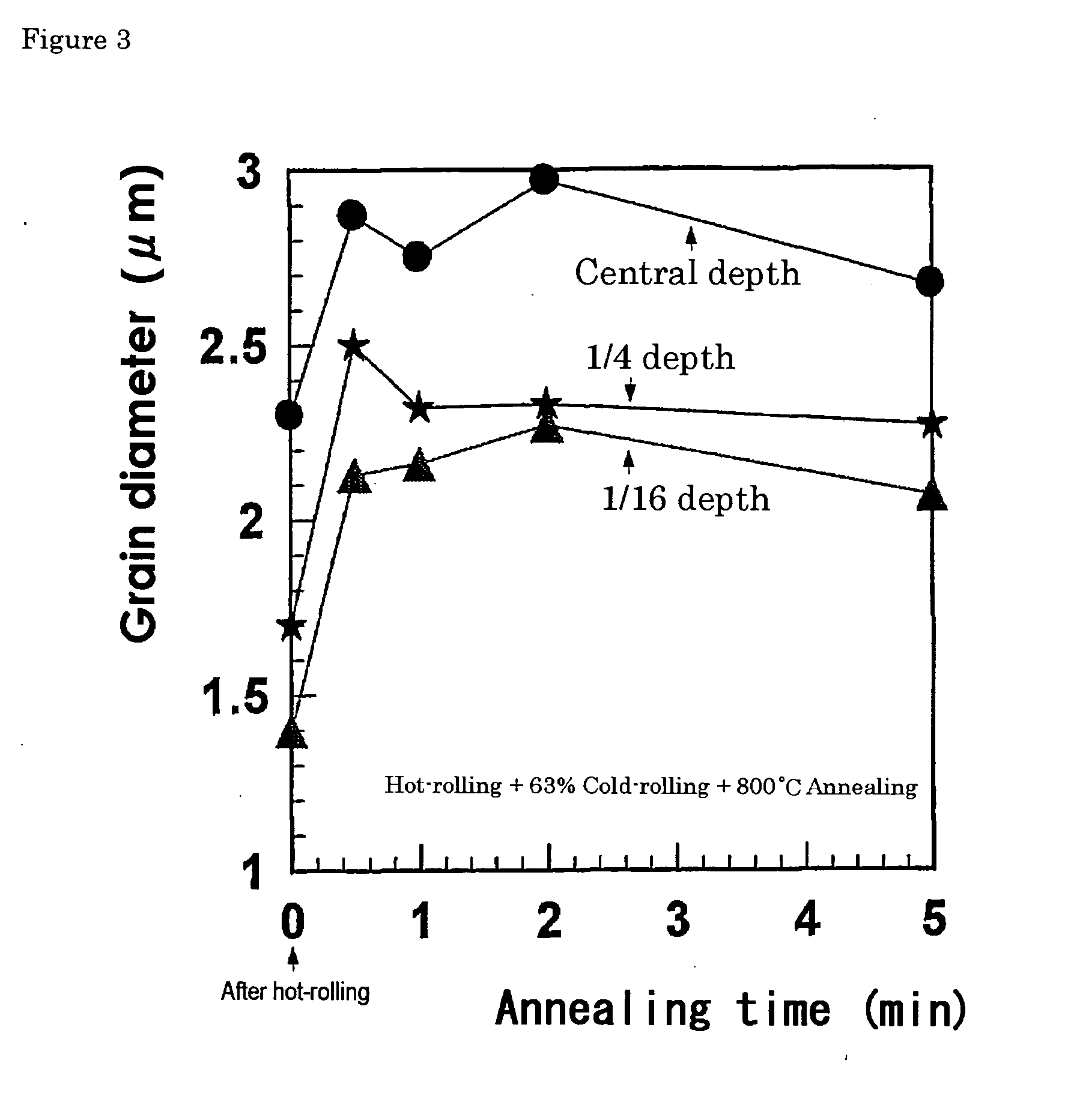

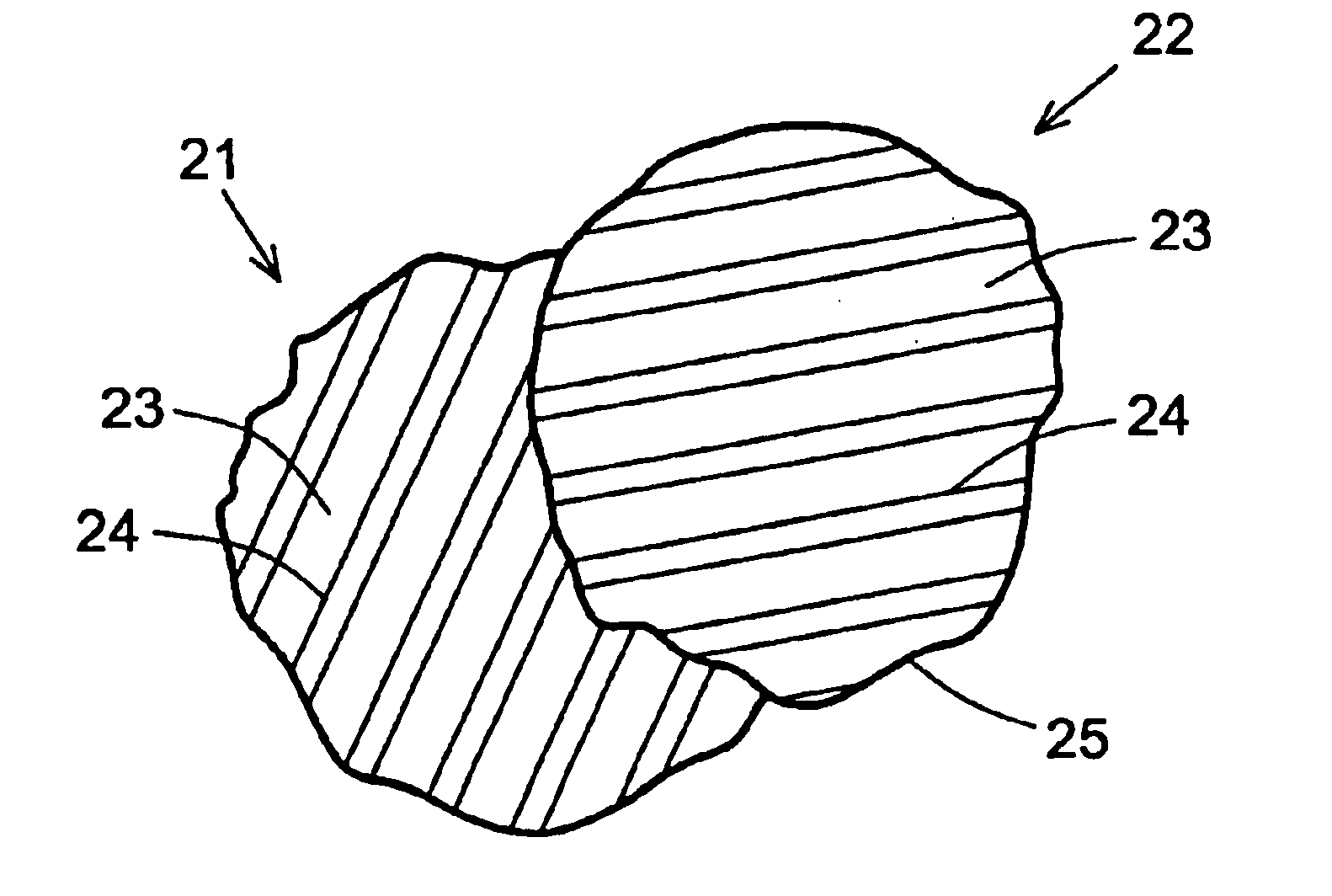

Hot-rolled steel sheet and cold-rolled steel sheet and manufacturing method thereof

InactiveUS20080202639A1Excellent mechanical propertiesLower transition temperatureHot-dipping/immersion processesFurnace typesMaterials scienceRaw material

A steel sheet excellent in mechanical strength, workability and thermal stability and suited for use as a raw material in such fields of manufacturing automobiles, household electric appliances and machine structures and of constructing buildings, and a manufacturing method thereof. are provided.The steel sheet is a hot-rolled steel sheet of carbon steel or low-alloy steel, the main phase of which is ferrite, and is characterized in that the average ferrite crystal grain diameter D (μm) at the depth of ¼ of the sheet thickness from the steel sheet surface satisfies the relations respectively defined by the formulas (1) and (2) given below and the increase rate X (μm / min) in average ferrite crystal grain diameter at 700° C. at the depth of ¼ of the sheet thickness from the steel sheet surface and said average crystal grain diameter D (μm) satisfy the relation defined by the formula (3) given below:1.2≦D≦7 formula (1)D≦2.7+5000 / (5+350·C+40·Mn)2 formula (2)D·X≦0.1 formula (3)wherein C and Mn represent the contents (in % by mass) of the respective elements in the steel.

Owner:NIPPON STEEL CORP

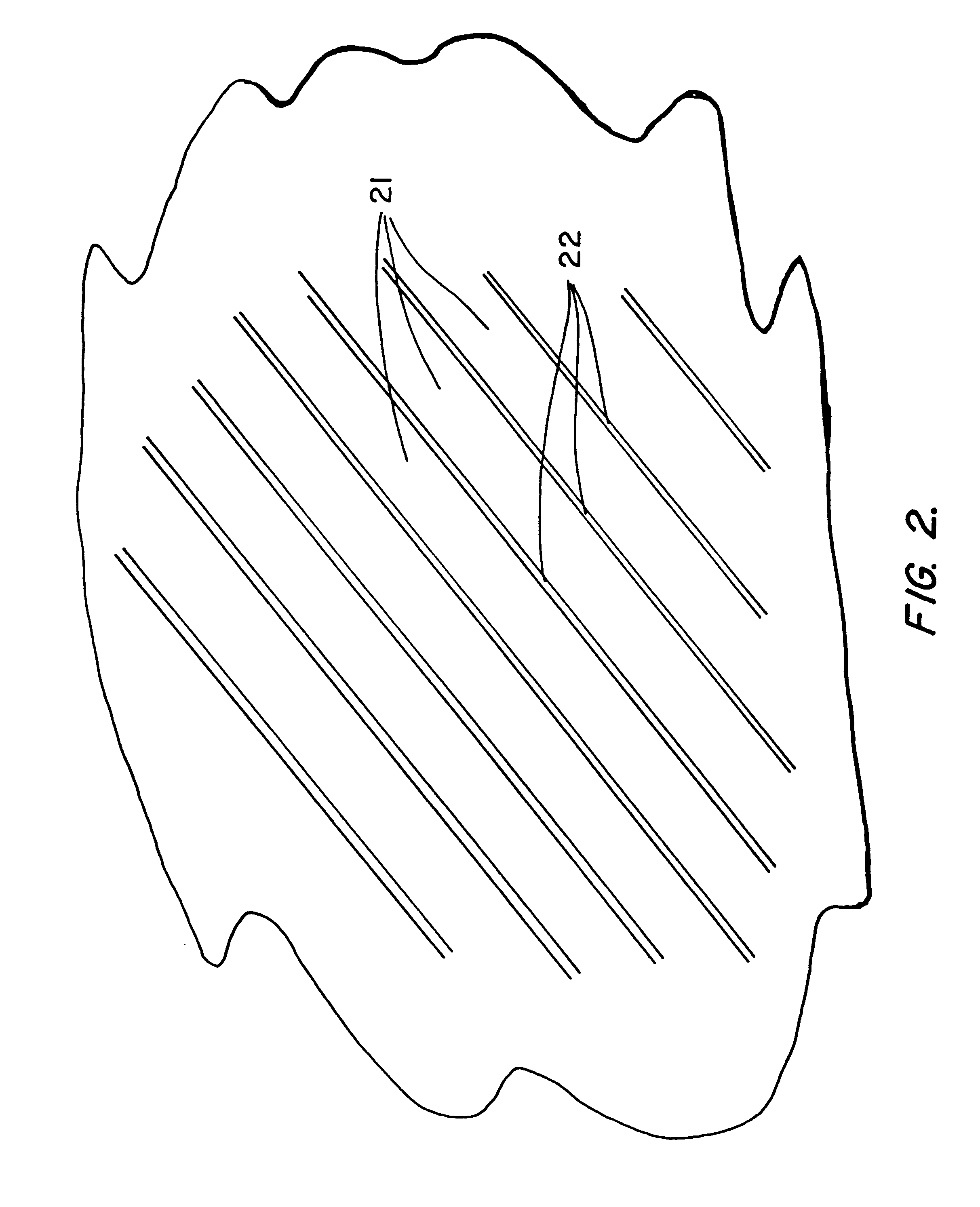

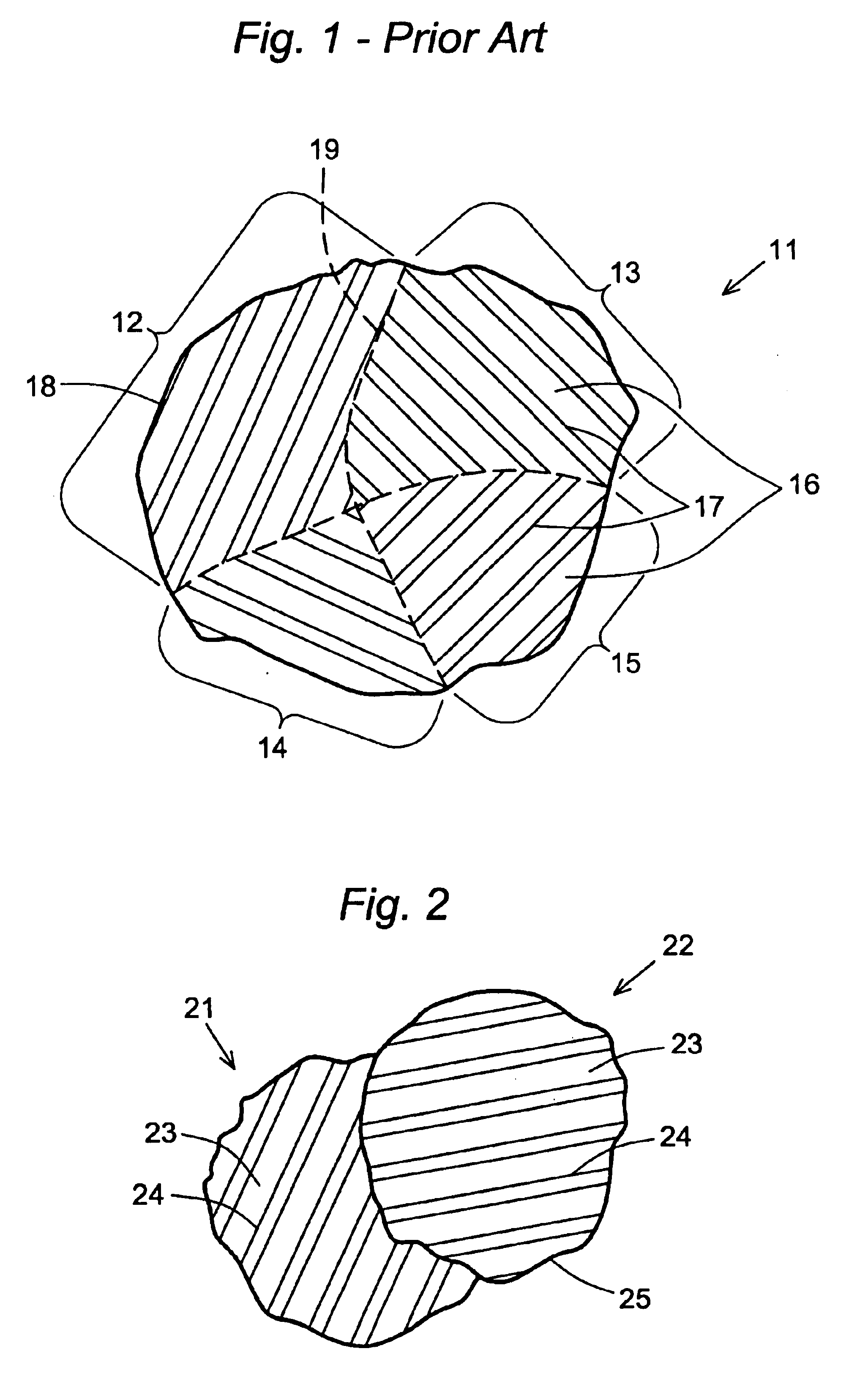

Nano-composite martensitic steels

Carbon steels of high performance are disclosed that contain dislocated lath structures in which laths of martensite alternate with thin films of austenite, but in which each grain of the dislocated lath structure is limited to a single microstructure variant by orienting all austenite thin films in the same direction. This is achieved by careful control of the grain size to less than ten microns. Further improvement in the performance of the steel is achieved by processing the steel in such a way that the formation of bainite, pearlite, and interphase precipitation is avoided.

Owner:MMFX STEEL CORP OF AMERICA +1

High hardness ferritic stainless steel wearable surfacing flux-cored wire

InactiveCN101224527AOvercome the disadvantage of poor wear resistanceHigh hardnessWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention provides a high hardness ferrite stainless steel wearable flux-cored wire, which takes a low carbon steel H08A cold rolling thin steel strip as an external wrapper; furthermore, the wrapper is internally provided with a powder core which is composed of graphite, metal and alloy powder; the weight percentages of all ingredients of the powder core are 50-75% of high carbon ferrochrome, 10-16% of ferrovanadium, 6-10% of ferrotitanium, 2-10% of tungsten carbide, 2-3% of nickel powder, 1.5-2.5% of silver graphite, 1-3.5% of boron carbide, 1-2% of aluminium magnesium powder, 0-10% of metallic chromium, and the residual quantity of reduced iron powder; the filling proportion of the powder core is 46-50%; the invention adopts the technical proposal that high-content ferrovanadium and adequate alloy powders such as tungsten carbide and boron carbide, etc. are added into the flux-cored wire, changes the microstructure of the existing ferrite stainless steel flux-cored wire surfacing alloy, overcomes the shortages of poor wearability and ductility, and can be applied to submerged arc bead weld manufacture or repair of the parts which has high requirement of abrasion and the corrosion resistance of the wearable grain.

Owner:XIANGTAN UNIV

Non-oxide composite low-carbon magnesia-carbon brick

A non-oxide compound magnesite-graphite brick containing carbon less than 6% belongs to a fire resisting material. The material contains magnesia of 75-94%, carbon of 1-5%, non-oxide such as nitride and boride of 0.4-20%, additive of 0-5%, and binder containg carbon. Such magnesite-graphite brick with low carbon has a low heat conductivity, a small acierating to the molten steel and less pollution to the low carbon steel compared to the common magnesite-graphite brick. The magnesite-graphite brick has a good slag resistance because the magnesia is the primary component. And it also has a good heat shock capacity because the carbon is one of the primary components. The carbon prevents said non-oxide from being oxidated. The brick maintains a good heat and shock resistance and slag resistance when reducing the proportion of the carbon because said non-oxide has a low heat expansion and a wet resistance to the slag.

Owner:江苏苏嘉集团新材料有限公司

Electrostatic painting anticorrosive oil and production method thereof

ActiveCN101486945ADoes not affect post-processing effectsPost-processing effect is reducedAdditivesAntioxidantBase oil

The invention relates to electrostatic spraying anti-rust oil and a production method thereof, which essentially solves the problems of the prior art that the lubricating property of the anti-rust oil is poor; and interlayer sliding is caused due to larger tension during the reeling process of the steel plate, resulting in steel plate scratch and having impact on the surface quality of the steel plate. The electrostatic spraying anti-rust oil commendably solves the problems by using the technical proposal comprising components of weight percentages as follows: a) 5 to 30 percent of anti-rust agent, b) 0.1 to 5 percent of surface activator, c) 0.1 to 15 percent of anti-friction composition, d) 0.1 to 5.0 percent of antioxidant and e) 50 to 90 percent of base oil, and can be used for the electrostatic spraying rust resistance of the cold-rolled carbon steel plate, galvanized plate and aluminized zinc silicon plate of the steel enterprises.

Owner:CHINA PETROLEUM & CHEM CORP

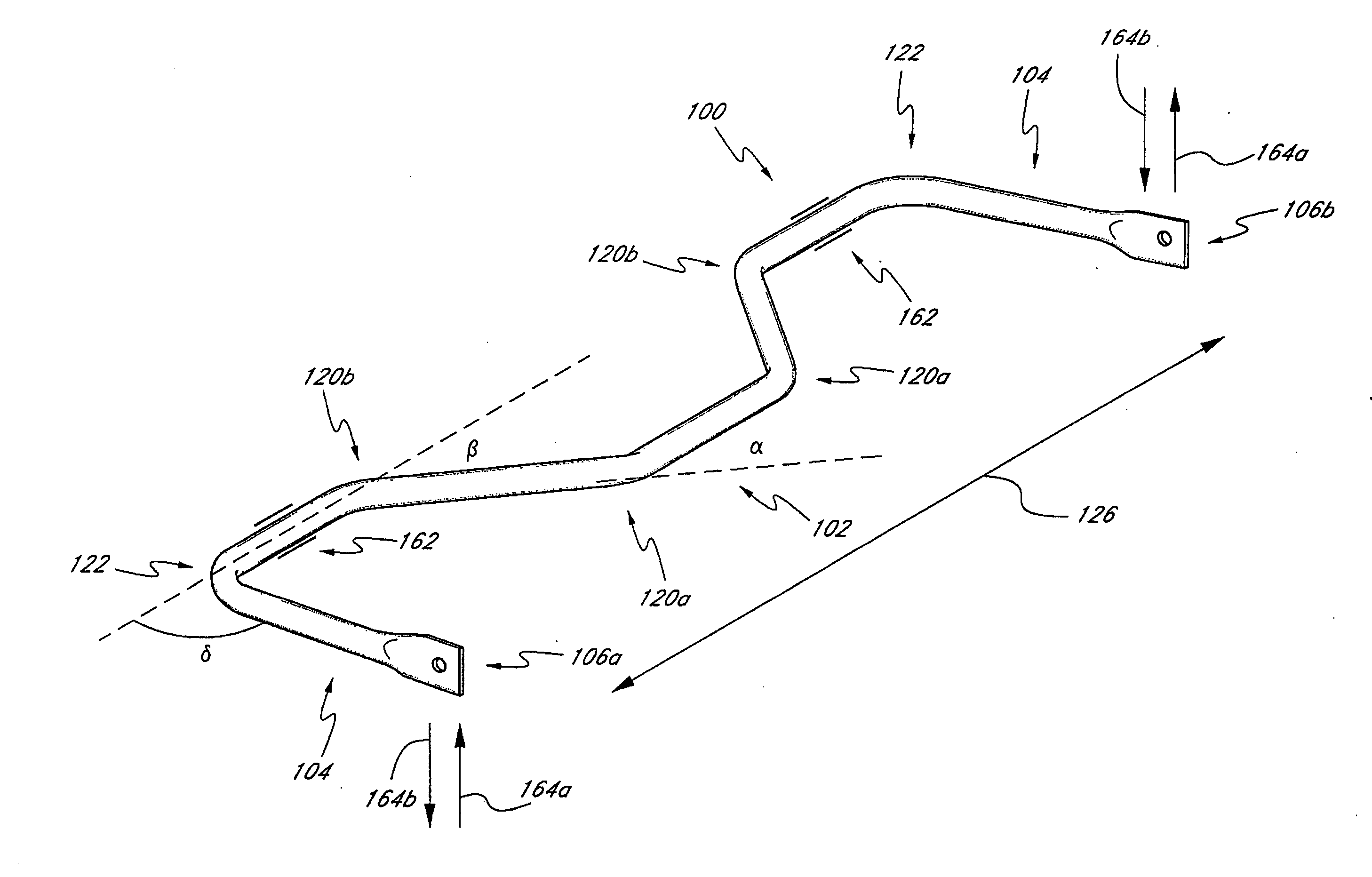

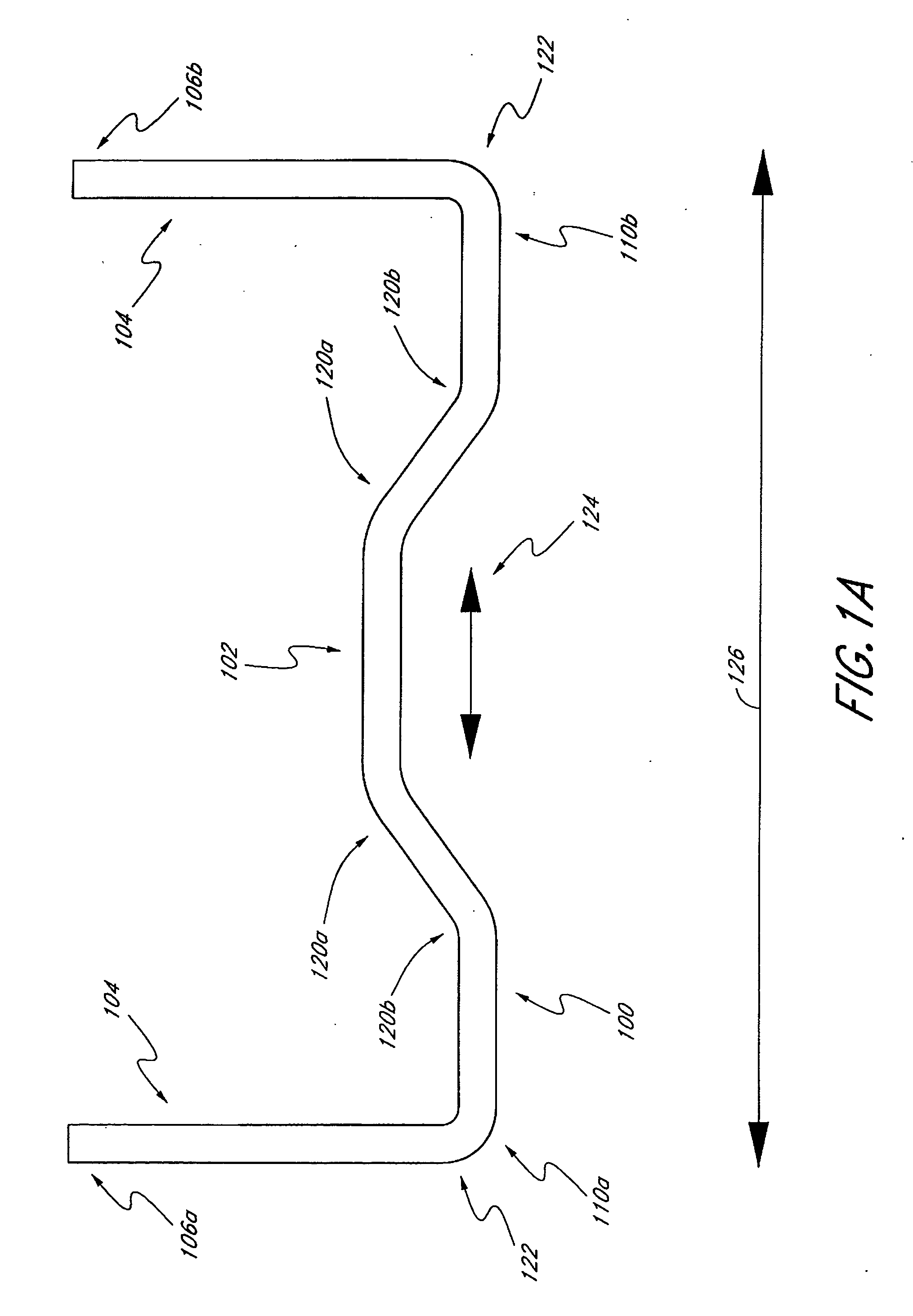

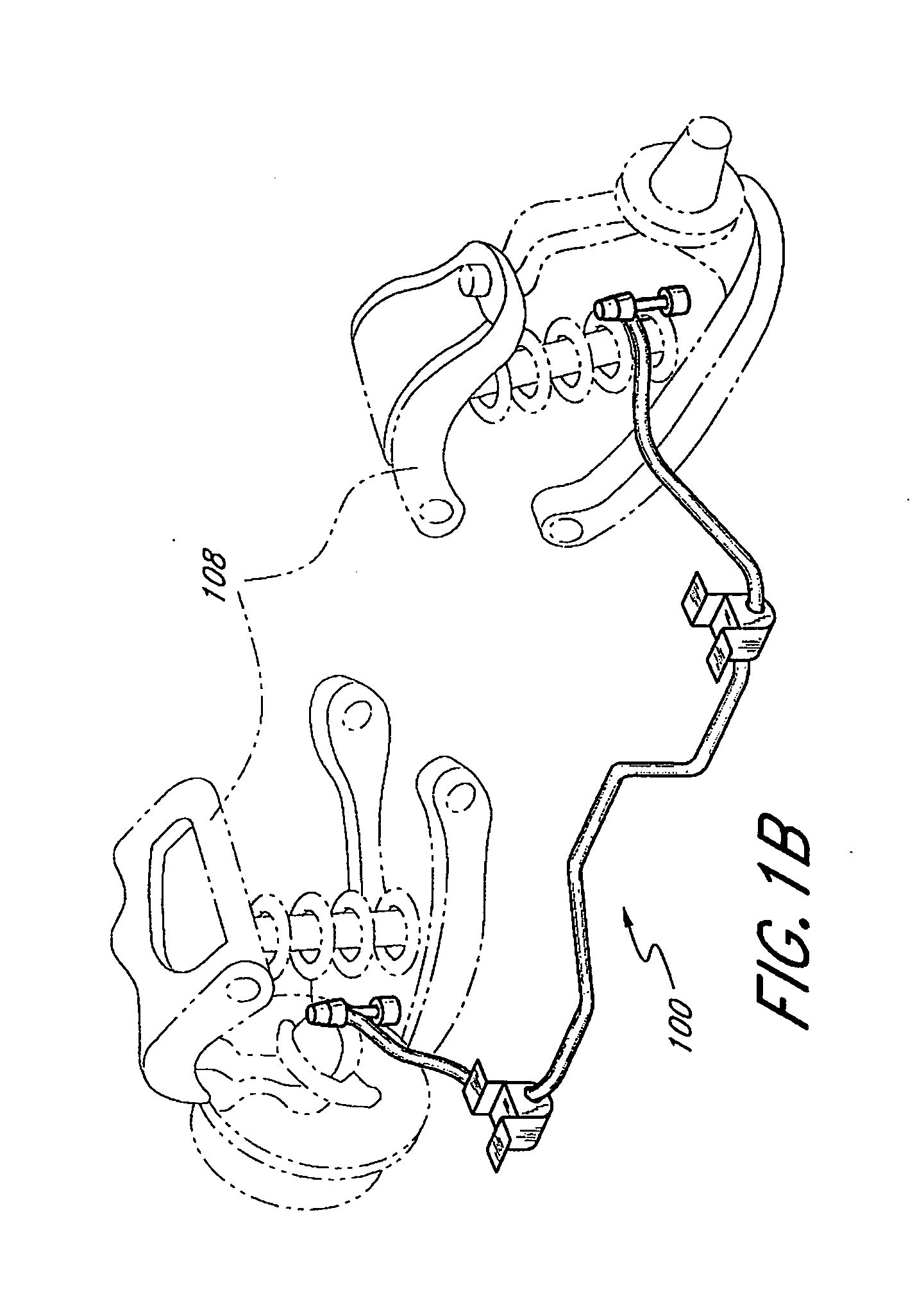

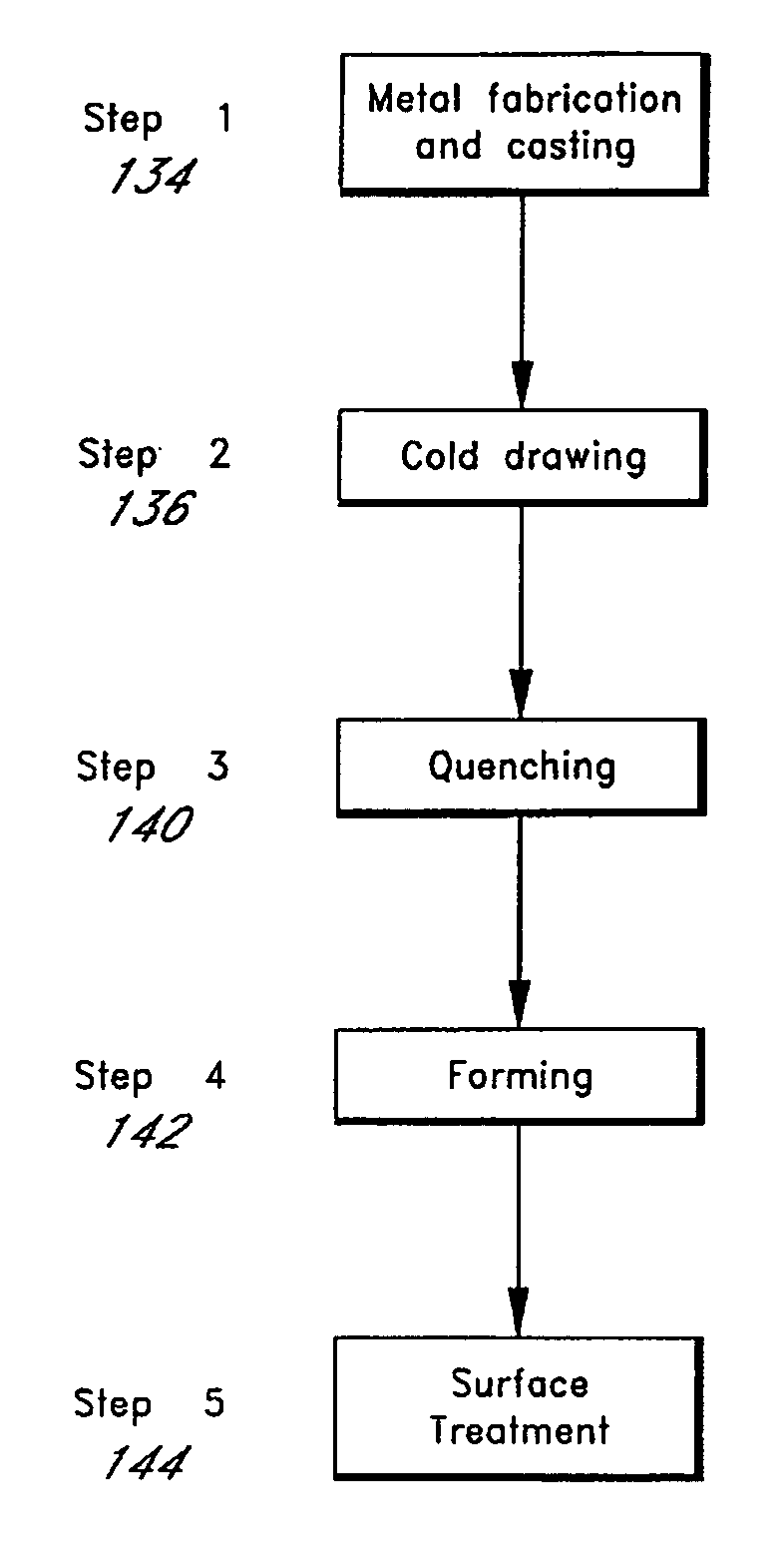

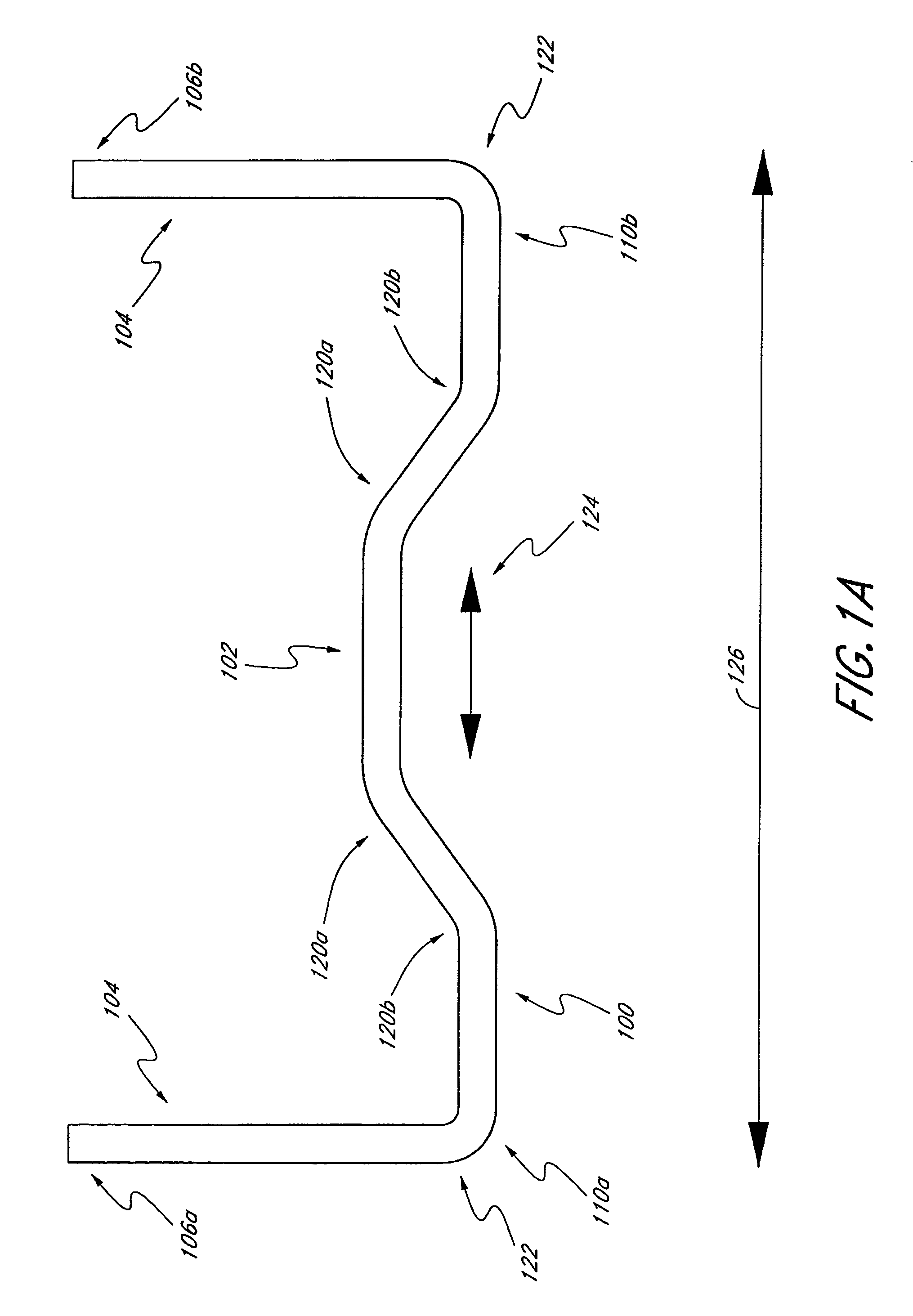

Methods of producing high-strength metal tubular bars possessing improved cold formability

ActiveUS20070216126A1Maintain mechanical propertiesOvercome problemsTorsion springsInduction heatingAlloyHigh intensity

A method for producing a tubular bar, more particularly a stabilizer bar, is provided. The method comprises providing a tubular bar of desired size having an outer and inner surface, heating the bar to an elevated temperature, quenching the bar by application of a cooling fluid to the surfaces of the bar, and forming the tube to a desired shape without annealing. The method further provides for the composition of a high-strength, high formability carbon steel alloy to be used in conjunction with the method. Advantageously, the bar is formable without thermal processing subsequent to quenching. In this fashion, metal tubular bars, such as stabilizer bars, may be formed at reduced cost.

Owner:TENARIS CONNECTIONS

Electrically-conducting paint based on TiB2 and its preparation method and application

InactiveCN101148549AExcellent physical and chemical propertiesHigh melting pointPolyurea/polyurethane coatingsEpoxy resin coatingsDiluentRoom temperature

The present invention relates to conducting paint, and is especially one kind of TiB2 powder based conducting paint powder and its preparation process and application. The TiB2 powder based conducting paint powder consists of film forming material, coupling agent, diluent, assistants and curing agent; and conducting assistant consists of TiB2 powder as main component, carbon black, graphite, acetylene black and other conducting powder in certain proportion. It is prepared through adding the assistants into the film forming material and dispersing in a dispersing machine, adding coupling agent and conducting powder through stirring, adding mixed diluent through stirring to obtain paint product. The conducting paint coating is formed through brushing, spraying or dipping, and cured at room temperature or through heating. The present invention has the advantages of high conducting property, high hardness, high wear resistance, excellent protecting performance, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Diamond/cubic boron nitride saw blade for cutting metal and fabricating method therefor

ActiveCN1669708ANo harmHuman and Environmental HazardsMetal sawing toolsSawing tools dressing arrangementsBoron carbideBoron nitride

This invention relates to a saw bit belonging to mechanical working field, which comprises metal base being alloy steel or carbon steel, with Phi8-Phi10mm radiating holes equispaced on its surface; Carcass including alumina, zircite, quartz, tungsten carbide, zirconium diboride, molybdenum disilicide; common abradant including brown fused alumina, carbofrax, green silicon carbide, cubic carbofrax, boron carbide; superhard abradant including diamond and cubic boron nitride. The produce process includes mixing carcass flour, working layered material batching-mixing process, welding layered material batching-mixing process, koldflo, thermal pressing-sintering formation, arc milling, welding, dressing and making edge. The invention has improved working efficiency, lowered product cost, and is suitable for cutting metal tube, plate such as this materials.

Owner:SF DIAMOND CO LTD

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

Methods of producing high-strength metal tubular bars possessing improved cold formability

ActiveUS7744708B2Maintain mechanical propertiesNo or minimal crackingInduction heatingFurnace typesAlloyHigh intensity

A method for producing a tubular bar, more particularly a stabilizer bar, is provided. The method comprises providing a tubular bar of desired size having an outer and inner surface, heating the bar to an elevated temperature, quenching the bar by application of a cooling fluid to the surfaces of the bar, and forming the tube to a desired shape without annealing. The method further provides for the composition of a high-strength, high formability carbon steel alloy to be used in conjunction with the method. Advantageously, the bar is formable without thermal processing subsequent to quenching. In this fashion, metal tubular bars, such as stabilizer bars, may be formed at reduced cost.

Owner:TENARIS CONNECTIONS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com