Patents

Literature

1108results about How to "Excellent physical and chemical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

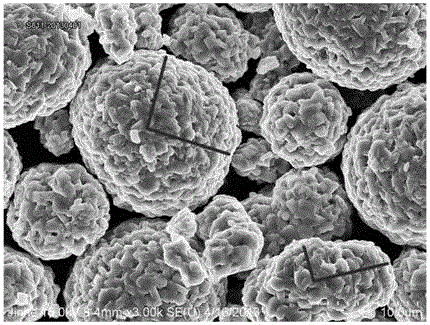

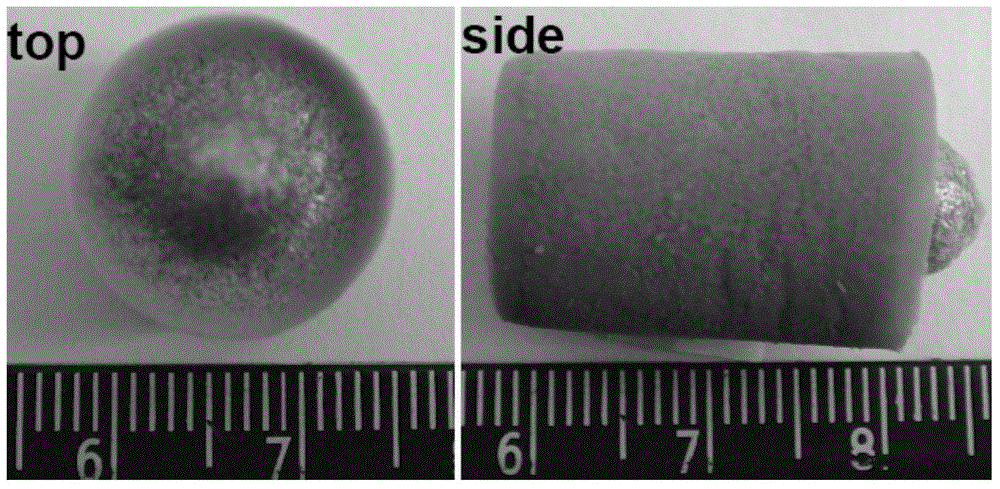

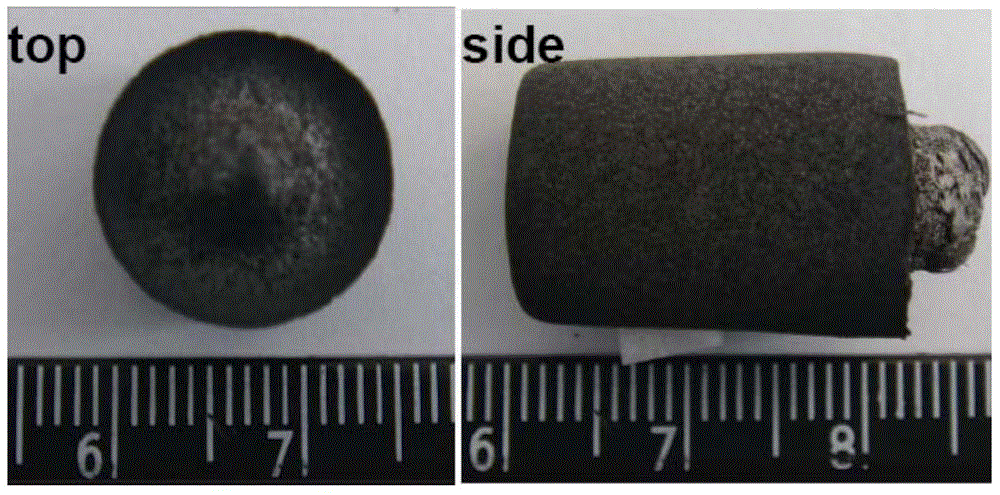

Boiling bed hydrogenation treatment catalyst and its preparing process

ActiveCN101240190AThe reaction equipment is simpleReduce operating costsRefining to eliminate hetero atomsLow speedSpherical shaped

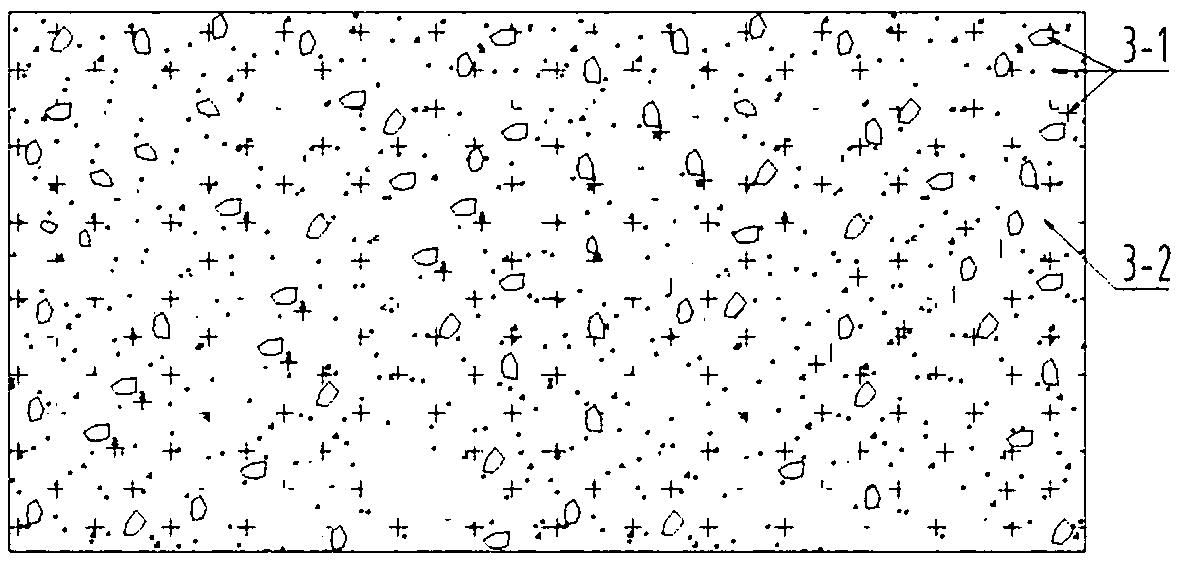

The invention relates to a boiling bed hydrogenation catalyst and a preparation method. The boiling bed hydrogenation catalyst of the invention is spherical shape which diameter is 0.1mm to 0.8mm, and has appropriate amount of additives and hydrogenation of metal components, and has reasonable hole distribution. The catalyst preparation method of the invention is spherical carrier impregnation, the process of spherical carrier preparation is following: making catalyst carrier raw material which is in appropriate temperature into appropriate size grain, then spheroidizing the grain, heating the conglobation and making them into spherical catalyst carrier. The process for making the catalyst carrier raw material into the appropriate size grain is that wet stock passes screen stencil by mechanical action and generates grain. Between the processes of the making grain and nodularization, granular material primely is placed for a period of time or operates in low-speed in nodularization device for a period of time. The catalyst of the invention appropriately conducts the boiling bed hydrogenation for heavy oil, residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

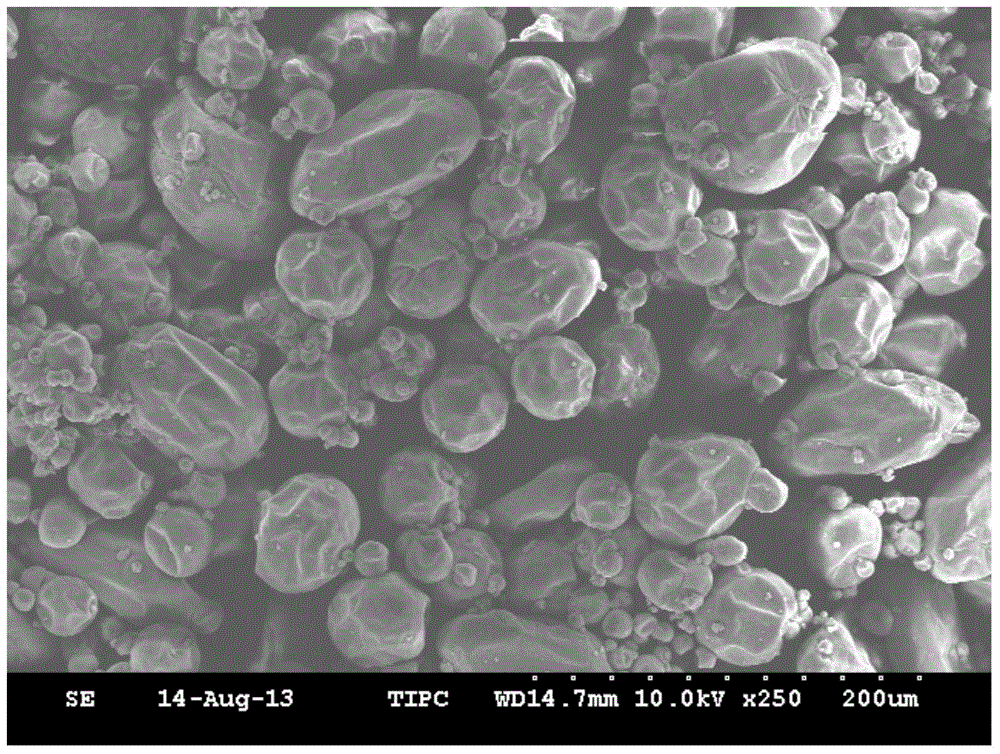

High-molecular composite powder material for SLS and preparation method therefor

ActiveCN103709737AExcellent physical and chemical propertiesImprove mechanical propertiesErbium lasersMacromolecule

The invention discloses a high-molecular composite powder material for SLS. The composite powder material comprises the following ingredients, by weight, 85%-99% of high-molecular powder, 0.1%-10% of laser absorbents, 0.1%-3% of flow promoters and 0.1%-2% of anti-oxidants. The preparation method for the composite powder material is advantaged by simple technology, environmental protection and easy implementation, and a high-molecular composite powder material with excellent molding performances can be obtained. The composite powder material can perform SLS molding through a fiber laser, the product precision is improved effectively, and application of the SLS technology in many fields is promoted.

Owner:ZRAPID TECH CO LTD

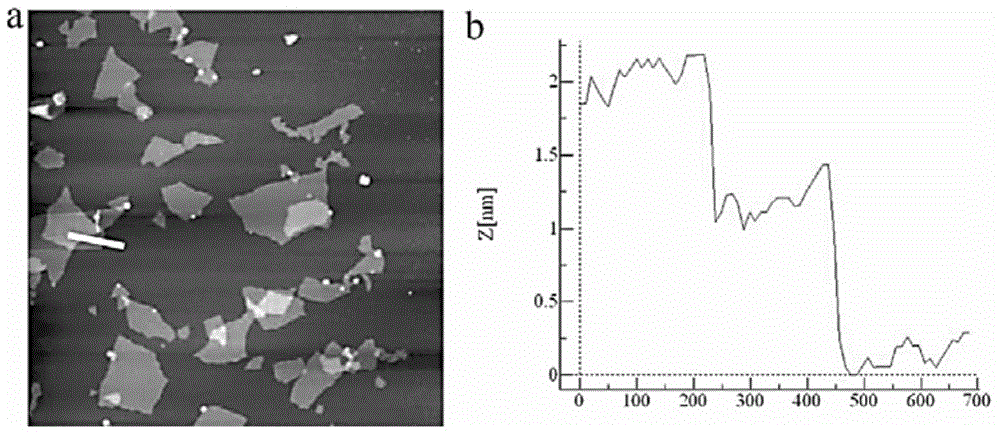

Method for preparing graphene crosslinked type organic aerogel and carbon aerogel by normal-pressure drying

InactiveCN102774824AHigh strengthNot easy to shrinkCarbon preparation/purificationSupercritical dryingCross-link

The invention relates to a method for preparing graphene crosslinked type organic aerogel and carbon aerogel by normal-pressure drying, which takes phenols (P), amines, aldehydes, catalyst and solvent as a reaction system and graphene substances containing active functional groups as a cross-linking agent. The method comprises the steps of: curing to obtain organogel, and then carrying out normal-pressure drying to obtain the organic aerogel; and carrying out pyrolysis on the organic aerogel in the inert atmosphere at the temperature of 500-1600 DEG C to obtain the graphene crosslinked type carbon aerogel. The preparation method of the organic aerogel and the carbon aerogel is simple and rapid in technology; the conventional supercritical drying technology is avoided, and the prepared novel organic aerogel and carbon aerogel materials taking graphene as framework have new performances and wide application prospect; and the industrial production of the carbon aerogel can be expected to be realized.

Owner:BEIJING UNIV OF CHEM TECH

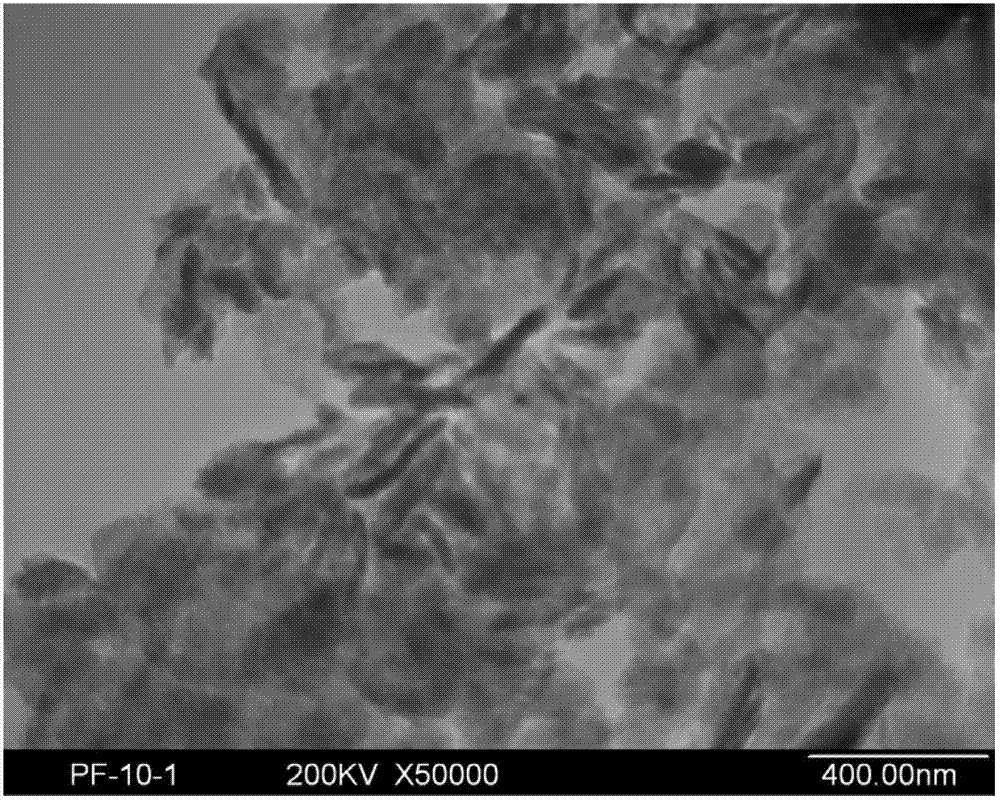

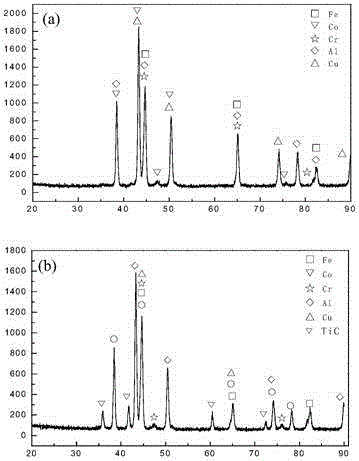

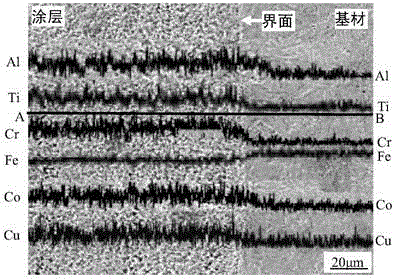

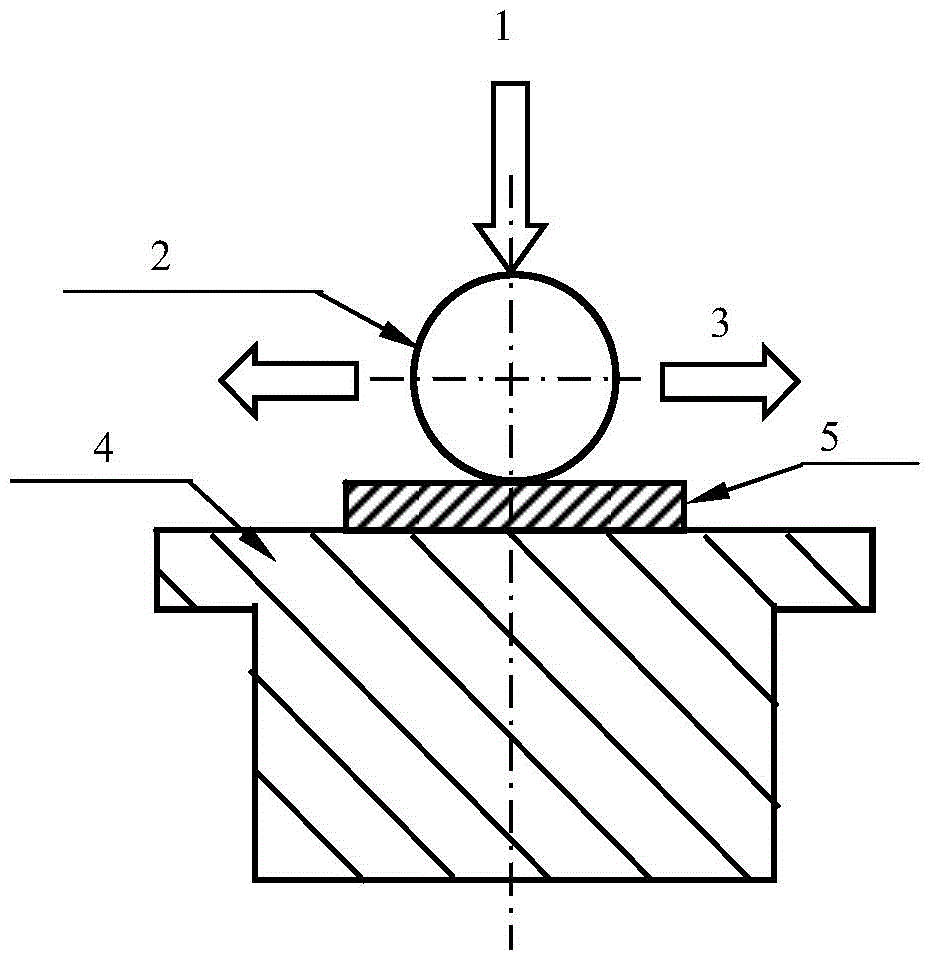

Powder for high-entropy alloy-based composite material modified layer prepared on ferrous alloy surface

ActiveCN104651828AImprove performanceExcellent physical and chemical propertiesMetallic material coating processesHigh entropy alloysAlloy surface

The invention discloses a powder for a high-entropy alloy-based composite material modified layer synthesized on the surface of an iron single element alloy by a laser reaction and a preparation technology and belongs to the field of a surface engineering technology. The invention provides more excellent properties for the high-entropy alloy modified layer. The powder for the high-entropy alloy-based composite material is composed of 50-99 wt% of a high-entropy alloy powder and 1-50 wt% of a reinforced phase powder. By a laser irradiation alloying method, a high-entropy alloy-based composite material modified layer which has a uniformly distributed microstructure, is crack-free and has better performance than an original high-entropy alloy coating can be prepared.

Owner:SHENYANG POLYTECHNIC UNIV

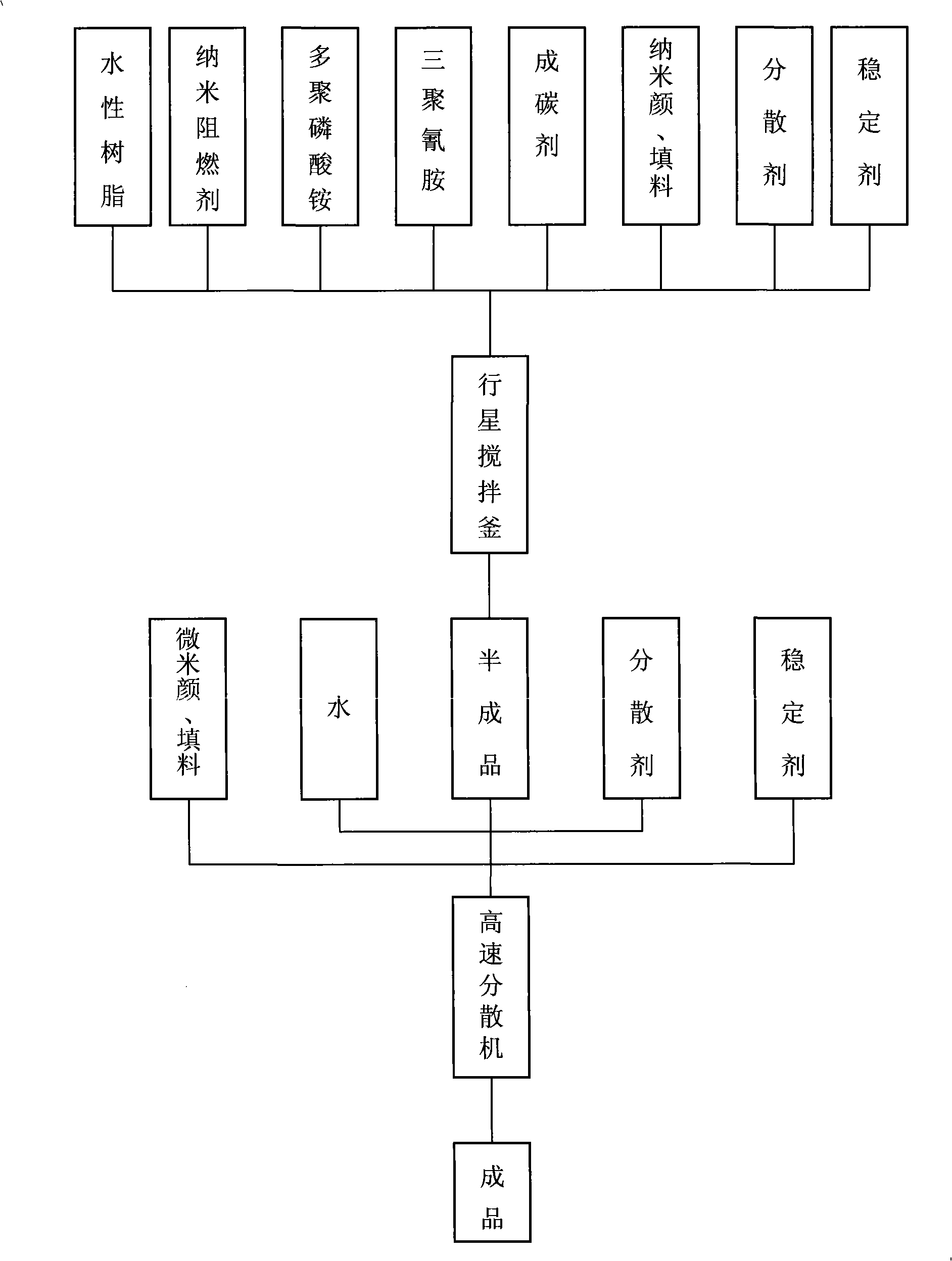

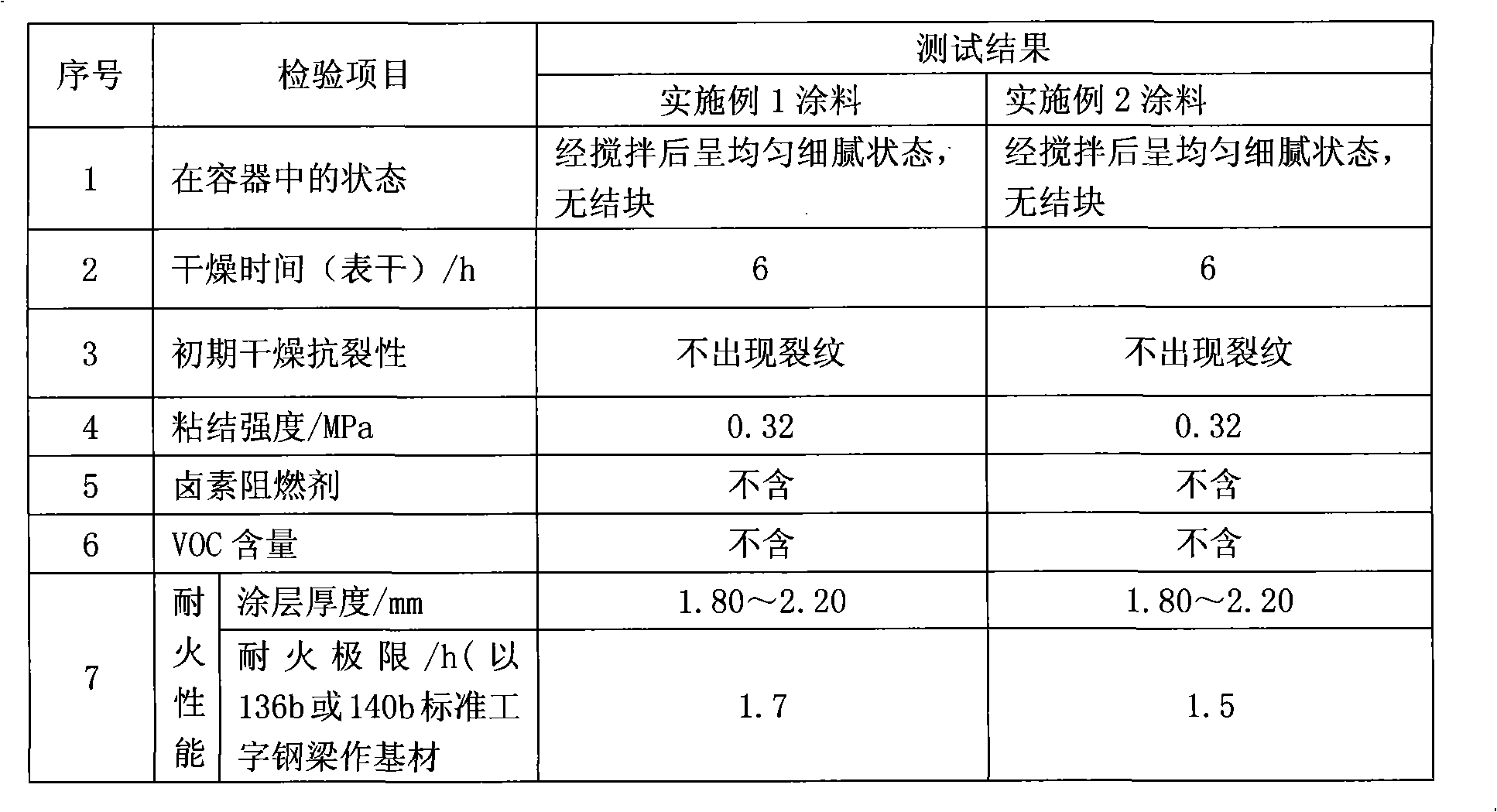

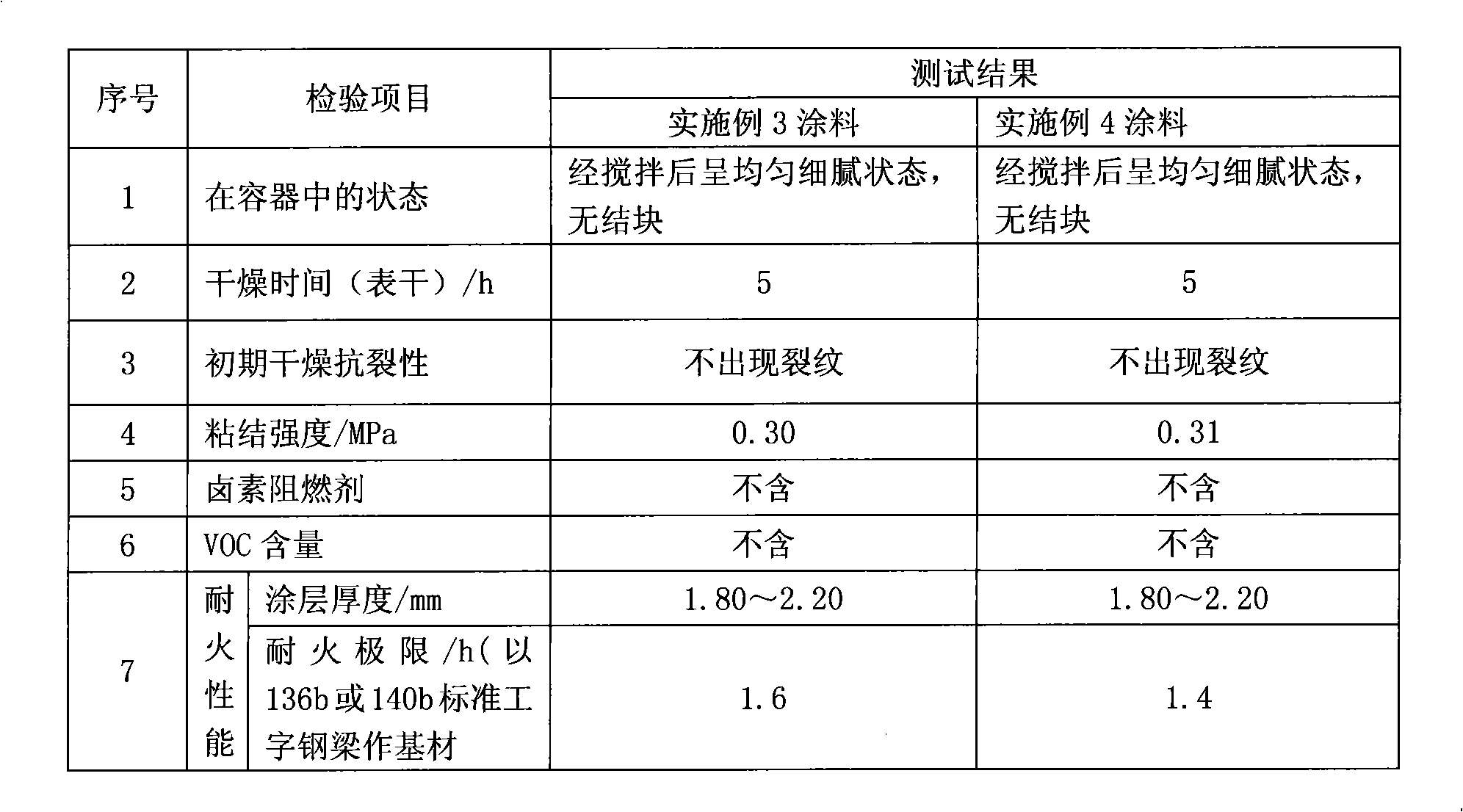

Environment-friendly aqueous nanometer fireproof flame-retardant coating and preparation thereof

InactiveCN101280142AImprove fire performanceLow VOC contentFireproof paintsEmulsion paintsPolymerStabilizing Agents

The invention is environmental-friendly waterborne nanometer fireproof flame-retardant coating and the preparation method, which belong to the fireproof flame-retardant coating manufacturing industry. The flame-retardant coating is obtained through the compounding of two types of flame-retardant agents, waterborne resin, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and filler, micrometer pigment and filler and other auxiliary agent; the flame-retardant coating contains no organic agent and halogen flame retardant, low VOC content, good fireproof property, good physical and chemical properties; the composition of the flame-retardant coating is as follows: the content of waterborne resin is 10-90%; the content of phyllo-silicate nanometer flame retardant which contains phosphor, nitrogen organic intercalation is 1-50%; the content of nanometer magnesium hydroxide flame retardant wrapped by polymer is 1-50%; the content of ammonium polyphosphate is 1-30%; the content of melamine is 1-20%; the content of carbon-forming agent is 1-30%; the content of nanometer pigment and filler is 0.1 to 30%; the content of micrometer filler is 0.1 to 60%; the content of dispersant is 0.1 to 10%; the content of stabilizer is 0.1 to 10%; the content of water is 0.1 to 50%; the content of micrometer pigment is proper; firstly, waterborne resin, nanometer flame retardant, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and fillers, dispersant and stabilizer are put into a planet stirring reactor for stirring and even dispersion; micrometer pigment and filler, water, dispersant and stabilizer are added to the discharged mixture and then put into a high-speed dispersion machine for even dispersion so that the product is obtained.

Owner:中山市孙大化工科技有限公司

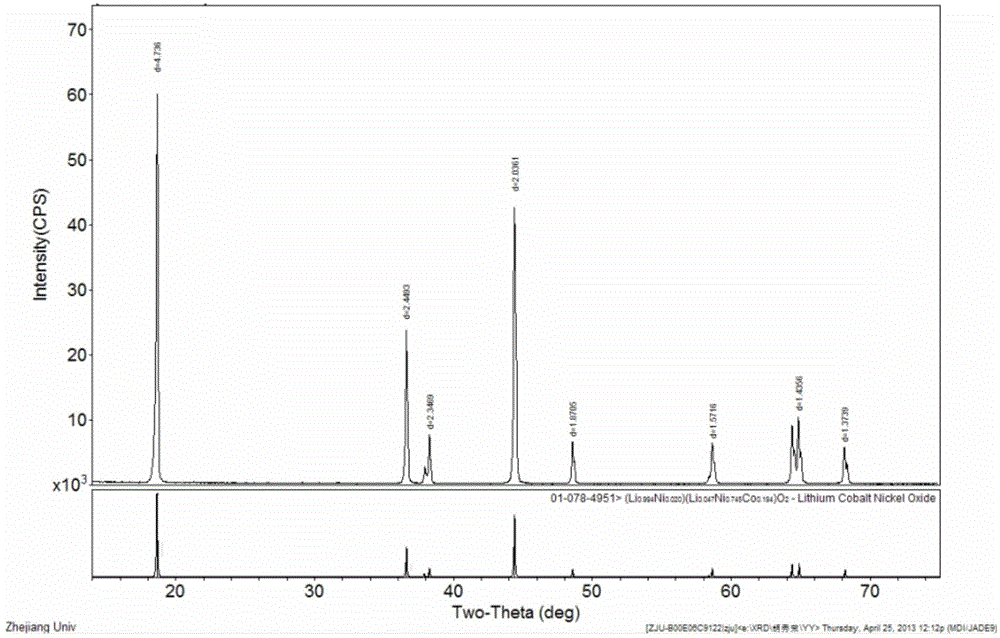

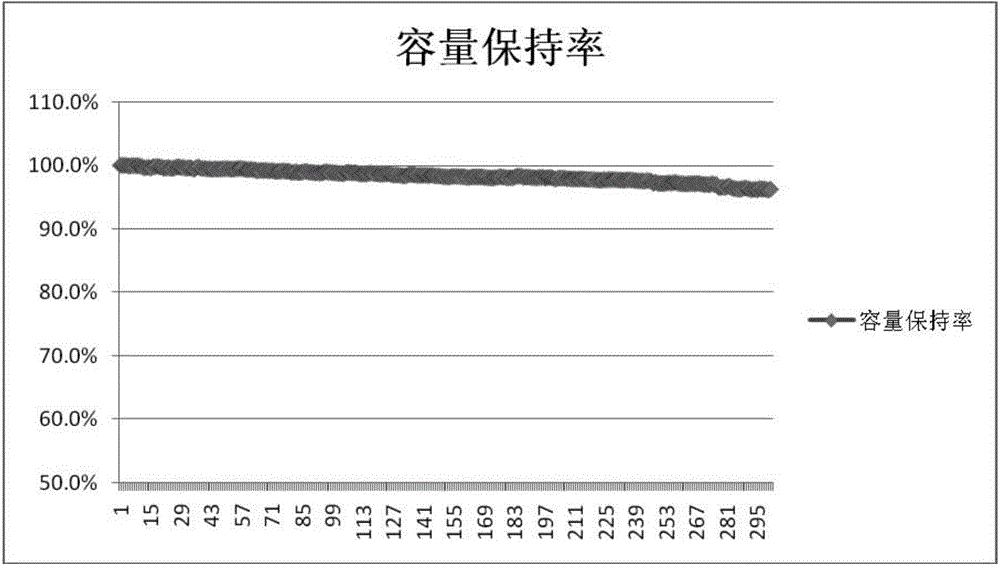

Nickelic cathode material rich in lithium and preparation method thereof

Owner:GUIZHOU RONGBAI LITHIUM BATTERY MATERIAL CO LTD

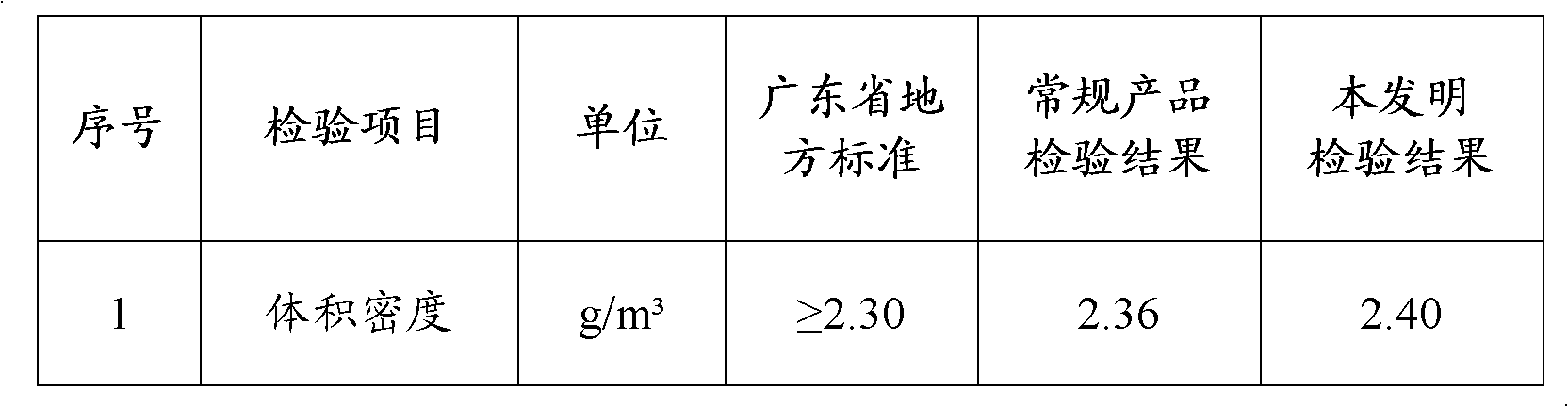

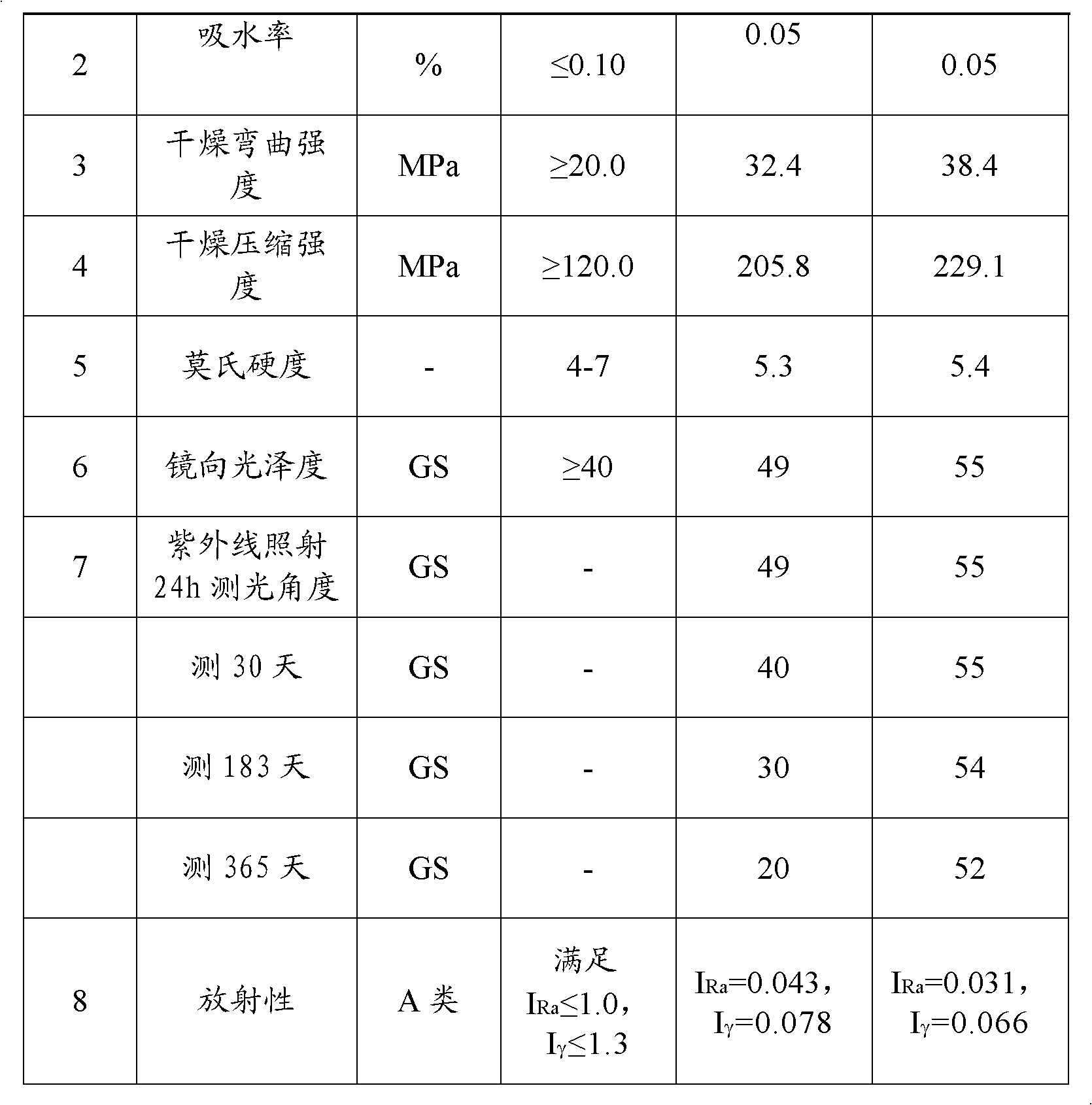

Quartzite material, artificial quartzite plate and manufacturing process thereof

ActiveCN102030497AExcellent physical and chemical propertiesGood anti-light aging performanceArtificial stonePolyresin

The invention discloses an artificial quartzite plate material which comprises the following components in percentage by total mass of quartzite plate: 60-63 percent of quartz sand with the grain size of 5-100 meshes and inorganic silicon materials of waste glass granules, and the like, 28-32 percent of quartzite powder with 320-3000 meshes, 7-9 percent of unsaturated resin and 0.4-0.6 percent ofpigment and a coupling agent as well as other components in percentage by mass of resin: 0.5-1 percent of ultraviolet absorber, 0.5-1 percent of disintegrant and 0.8-1 percent of curing agent. The invention also discloses the quartzite plate prepared from the raw materials and a manufacturing process thereof. In the invention, the quartzite plate is produced by the steps of vibrating and pressurizing the quartz sand, the quartzite powder, the inorganic silicon materials of waste glass granules, and the like and the unsaturated resin under the vacuum state and curing and synthesizing under theintermediate temperature. The quartzite plate overcomes the problem that the traditional artificial stone is aged under strong lights after long-term use outdoors and has favorable physical and chemical properties.

Owner:新云石业(云浮)有限公司

Optical glass for high-refractivity low dispersion precision die mould

ActiveCN1935717AExcellent physical and chemical propertiesGood chemical stabilityRefractive indexOptical glass

The invention provides a high-refractivity, low-dispersivity, fine moulding optical glass, comprising SiO2:1-8wt%, B2O3:16-30wt%, La2O3:15-40wt%, Gd2O3:0-20wt%, ZnO:8-30wt%, Nb2O5:0.5-14.5wt%, WO3:0-12.5wt%, TiO2:0-9wt%, Li2O:0.5-4wt%, ZrO2:1-10 wt%, Y2O3:0-5 wt%, Yb2O3:0-5 wt%, Lu2O3:0-5 wt%, Na2O: 0-3 wt%, K2O:0-2 wt%, Al2O3:0-2 wt%, BaO:0-3 wt%, CaO:0-3 wt%, SrO:0- 3 wt%, MgO:0-3 wt%, Sb2O3:0-0.5 wt%, and SnO2:0-0.5 wt%. And the invention adopts a B2O3-SiO2-La2O3(Gd2O3)-ZnO system, and uses Nb2O5, WO3 and TiO2 in the reasonable proportion to make glass have the required optical constants and good physicochemical properties of fine moulding. And its transformation temperature (Tg) is lower than 560 deg.C. And it has no high-price Ta2O5 but has good chemical stability, able to be produced in batches and stably by single pot or continous smelting furnace, or other equipment, and suitable for low-cost and fine moulding nonspherical lenses and other optical components.

Owner:CDGM OPTICAL GLASS

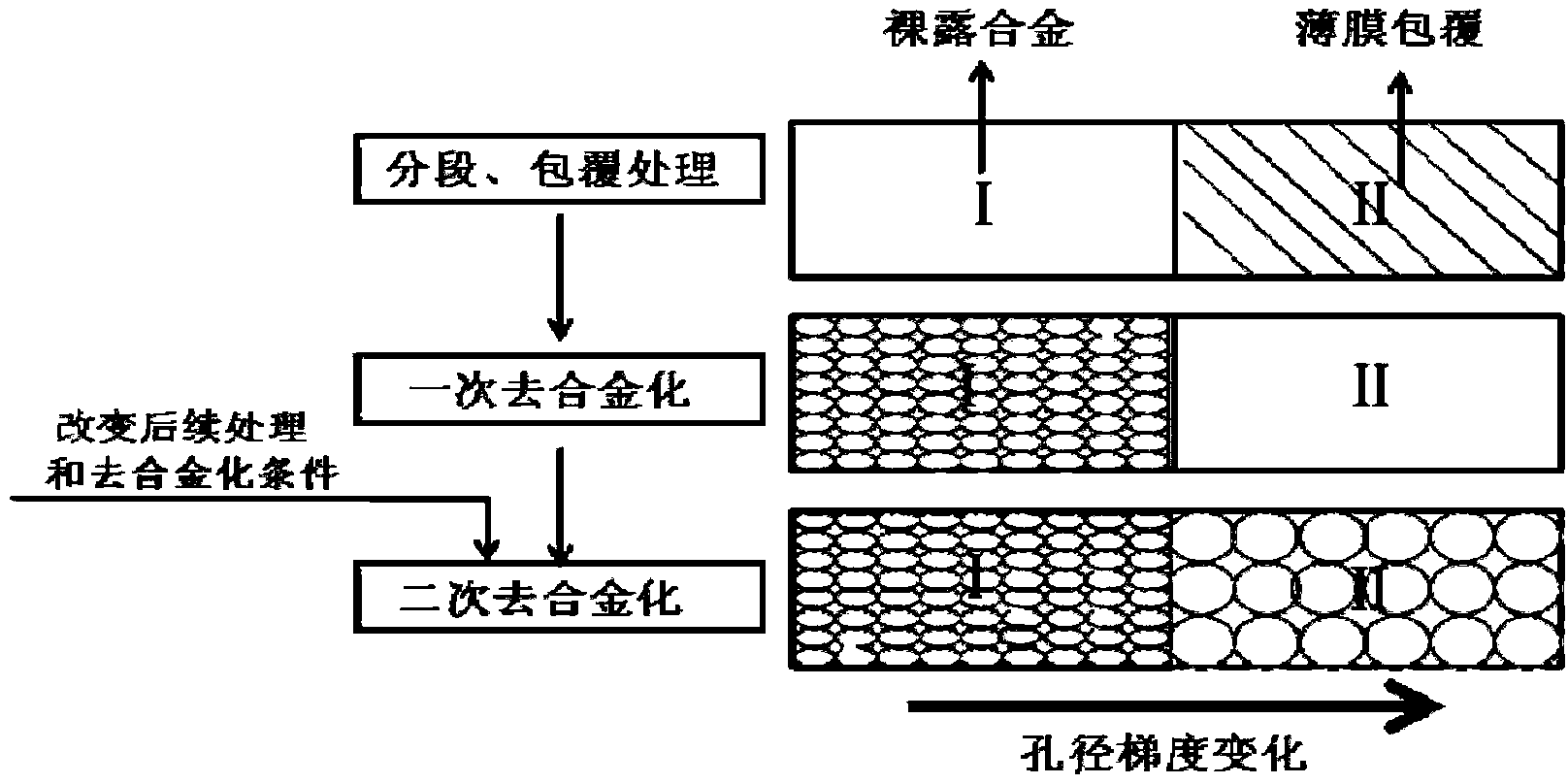

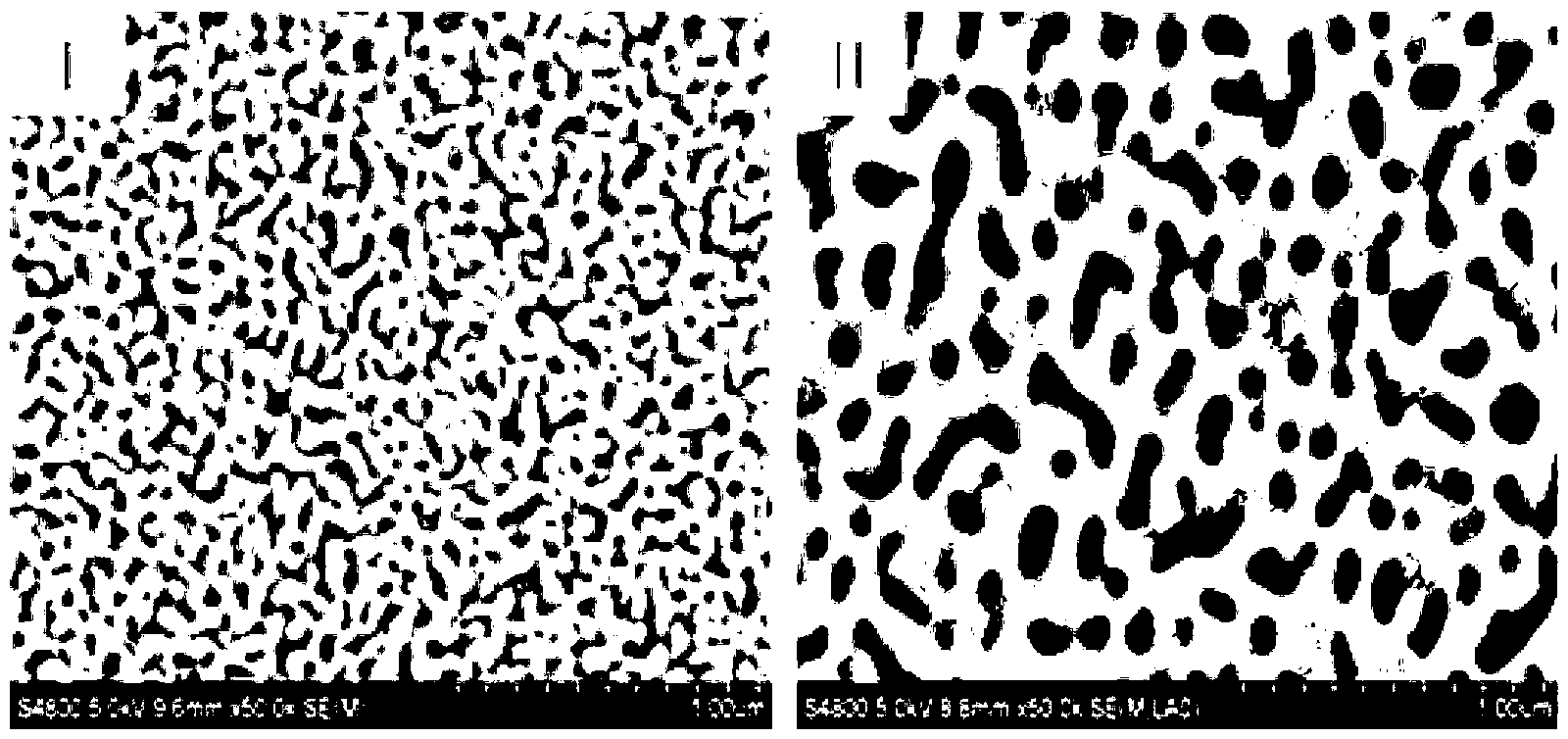

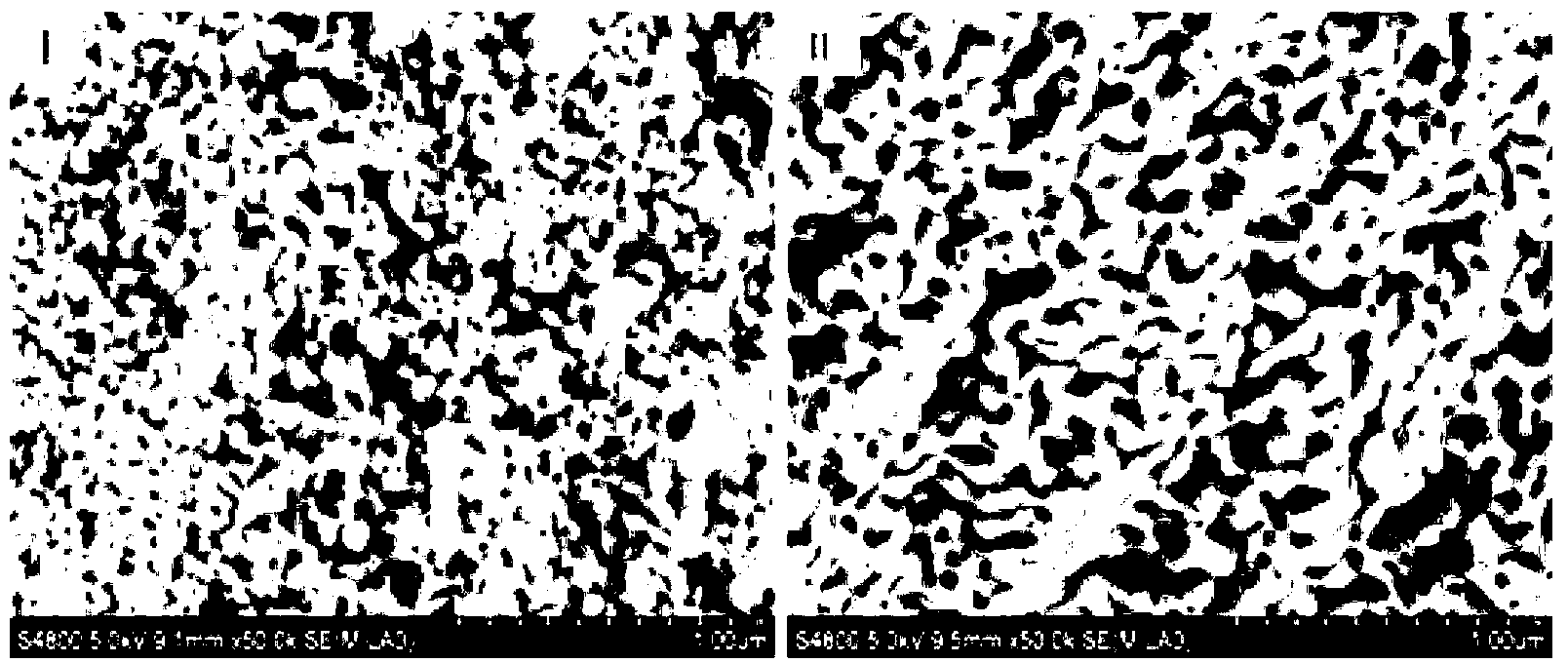

Nano-porous metal material with gradient changes in aperture and preparation method thereof

ActiveCN103290247AExcellent physical and chemical propertiesRealize NanoizationMetallic materialsAlloy

The invention belongs to the field of nano-metal functional materials and provides a nano-porous metal material. The aperture of the nano-porous metal material changes in a gradient manner along the length direction or the radial direction of the metal material, so that the nano-porous metal material has broad application prospects in electrochemical porous electrodes, catalyst carriers, biomedical filter parts, composite material products and the like. A preparation method of the nano-porous metal material comprises the following steps of: (1) preparing a precursor alloy containing an active metal and an inert metal; (2) coating the precursor alloy in segments or in parts; and (3) performing dealloying treatment by adopting different dealloying conditions in segments or in parts.

Owner:四川省新材料工业设计研究院股份有限公司

Wood-plastic composite material and preparation method thereof

The invention relates to the technical field of polymer processing, in particular to a wood plastic composite material and a preparation method thereof. The invention discloses the wood plastic composite material which is prepared from the following raw materials in weight percentage: 30 to 60 percent of wood fibre, 30 to 60 percent of waste plastics, 1 to 4 percent of stearic acid, 1 to 4 percent of industrial white oil, 1 to 3 percent of a coupling agent and 4 to 6 percent of a lubricant. The invention also discloses the method for preparing the wood plastic composite material and wood plastic products which are prepared from the wood plastic composite material. The wood plastic products produced by using the wood plastic composite material as a raw material are superior to similar products in the appearance quality and the physiochemical performance.

Owner:SHANGHAI BESTON PLASTICS

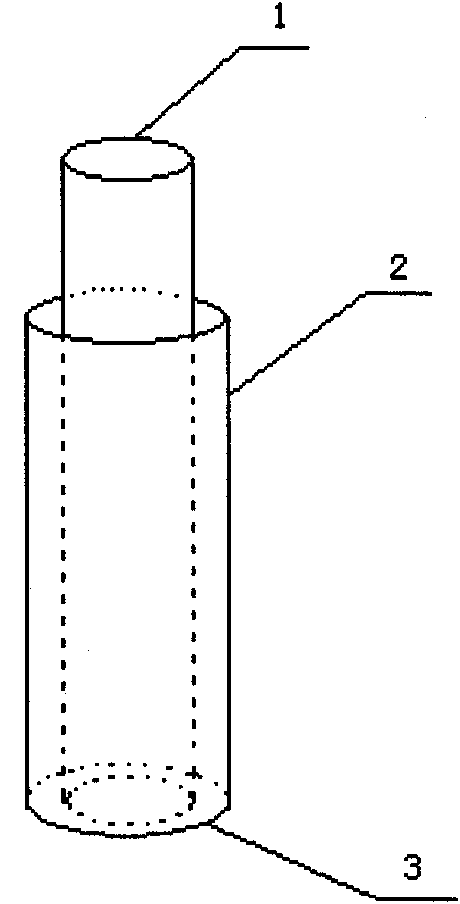

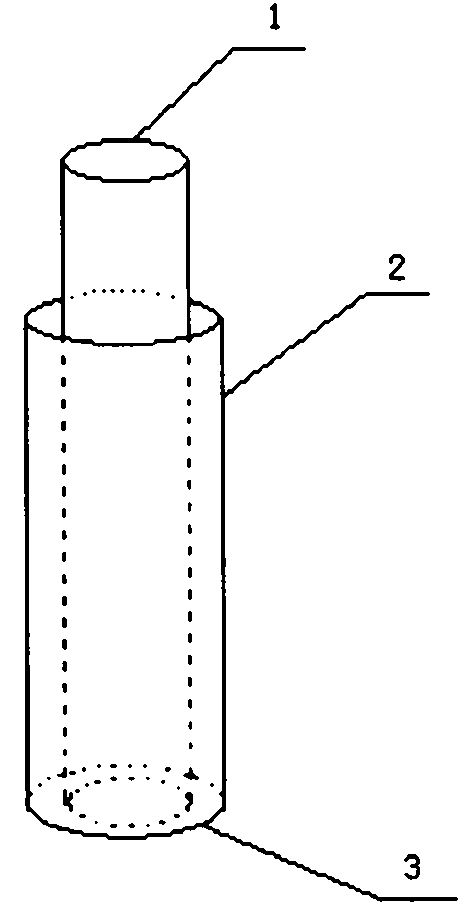

Small-caliber silk fibroin tubular material and preparation method thereof

InactiveCN101879330AExcellent physical and chemical propertiesGood biological propertiesMonocomponent protein artificial filamentPharmaceutical containersRepair tissueBiocompatibility Testing

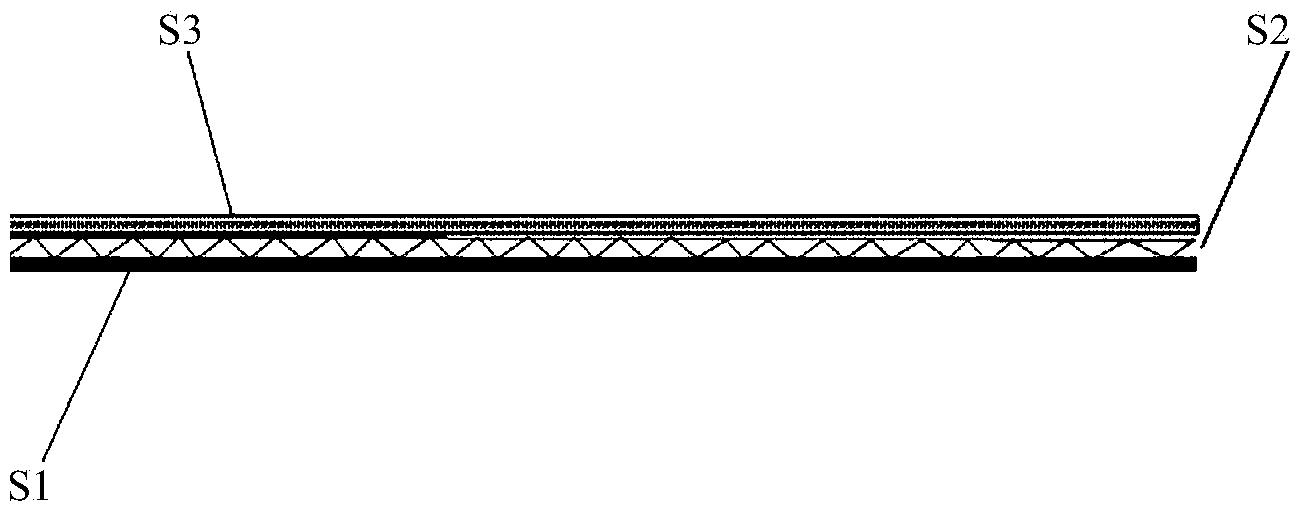

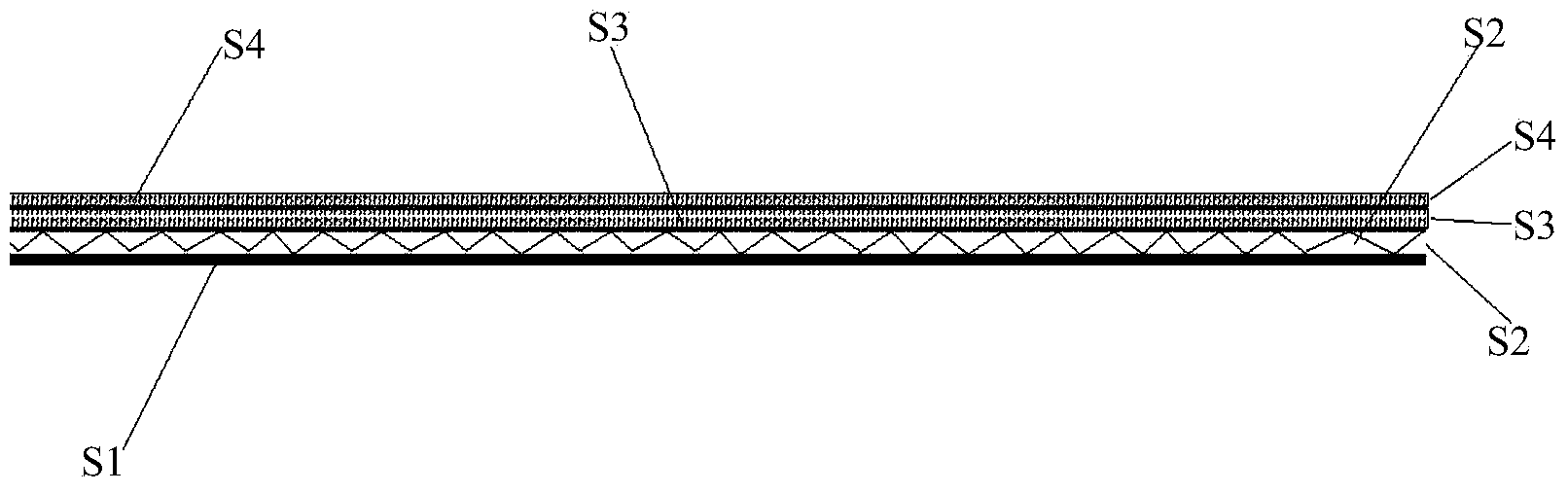

The invention discloses a small-caliber silk fibroin tubular material and a preparation method thereof and belongs to the field of biomedical materials. The tubular material consists of three layers of materials which are firmly jointed, wherein an outer layer is a tubular electrostatic spinning silk net; a middle layer is a netlike pipe formed by weaving bright silk prepared from degummed silk; and an inner layer is a silk porous material. After the processes of soaking, drying, curing and the like in silk solution, the three layers of the material are firmly jointed, and the inner layer is treated by using anti-coagulation medicaments such as heparin and the like so that the material has coagulation resistance; and the tubular material obtained by using a forming die consisting of a cylindrical intermediate (1), a hollow cylinder (2) and a round base (3) has the inner diameter of between 1 and 8 millimeters, the thickness of between 0.2 and 2 millimeters, high mechanical property, biocompatibility, coagulation resistance and capability of repairing tissues such as blood vessels, nerves and the like.

Owner:SUZHOU UNIV

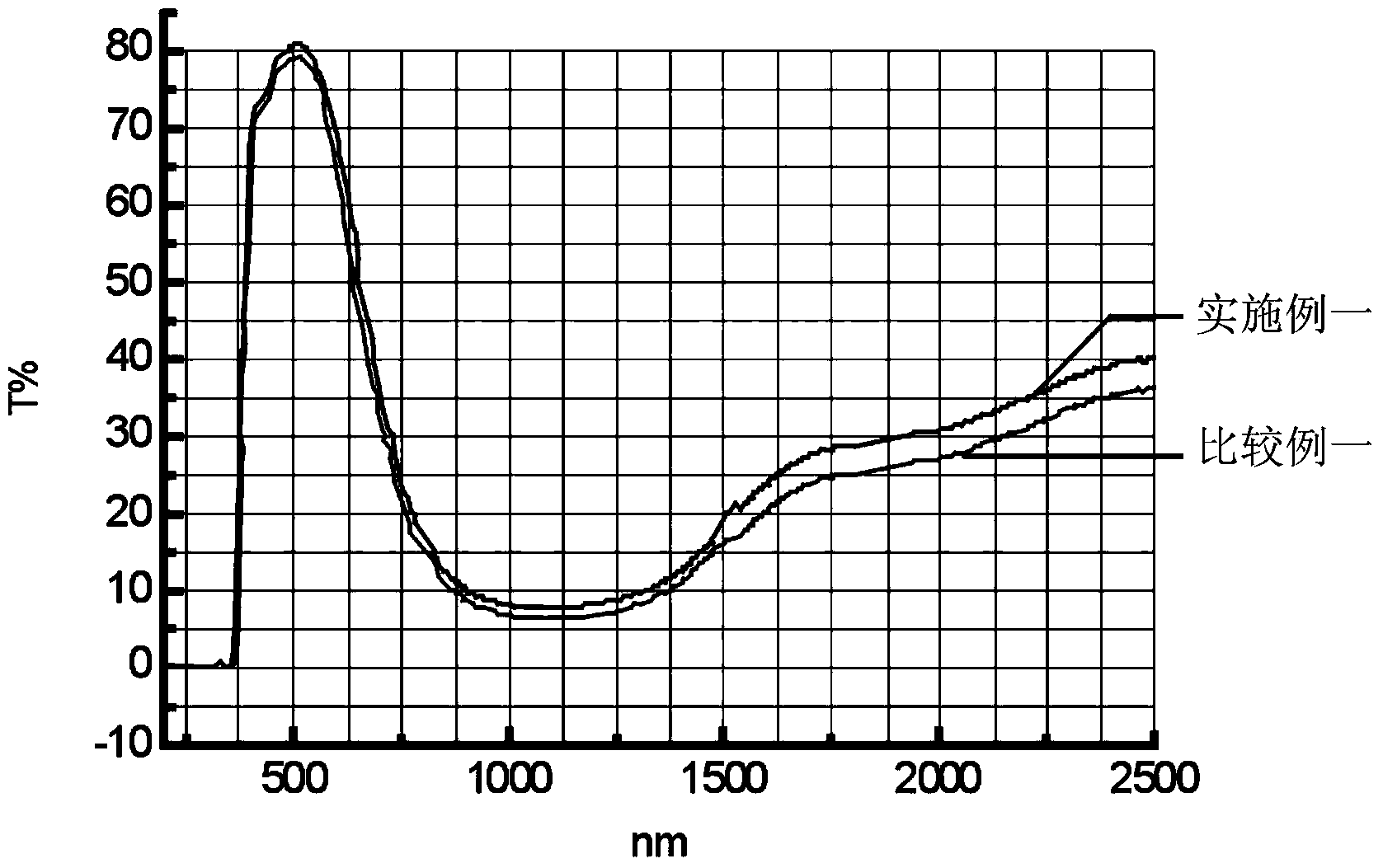

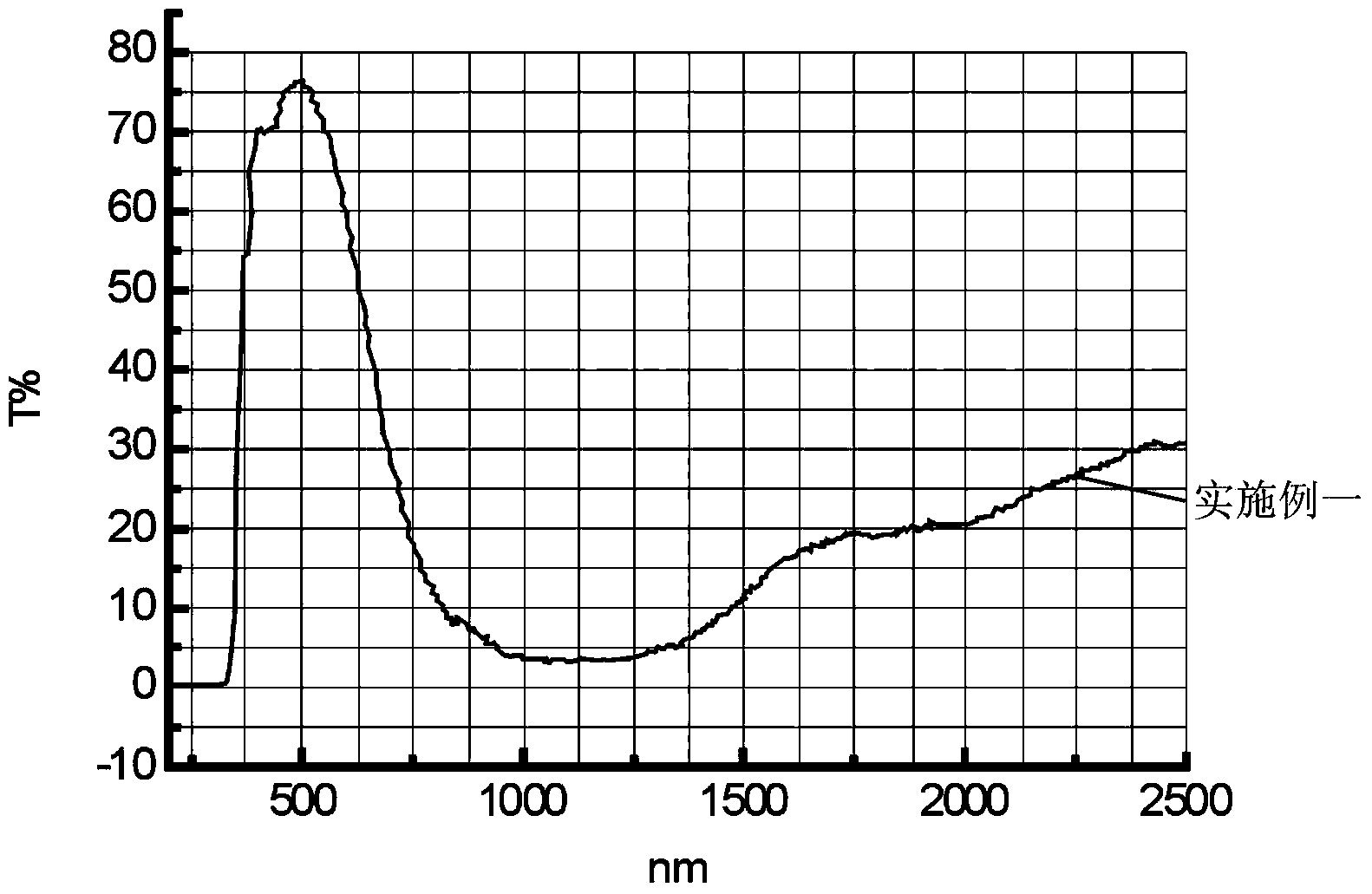

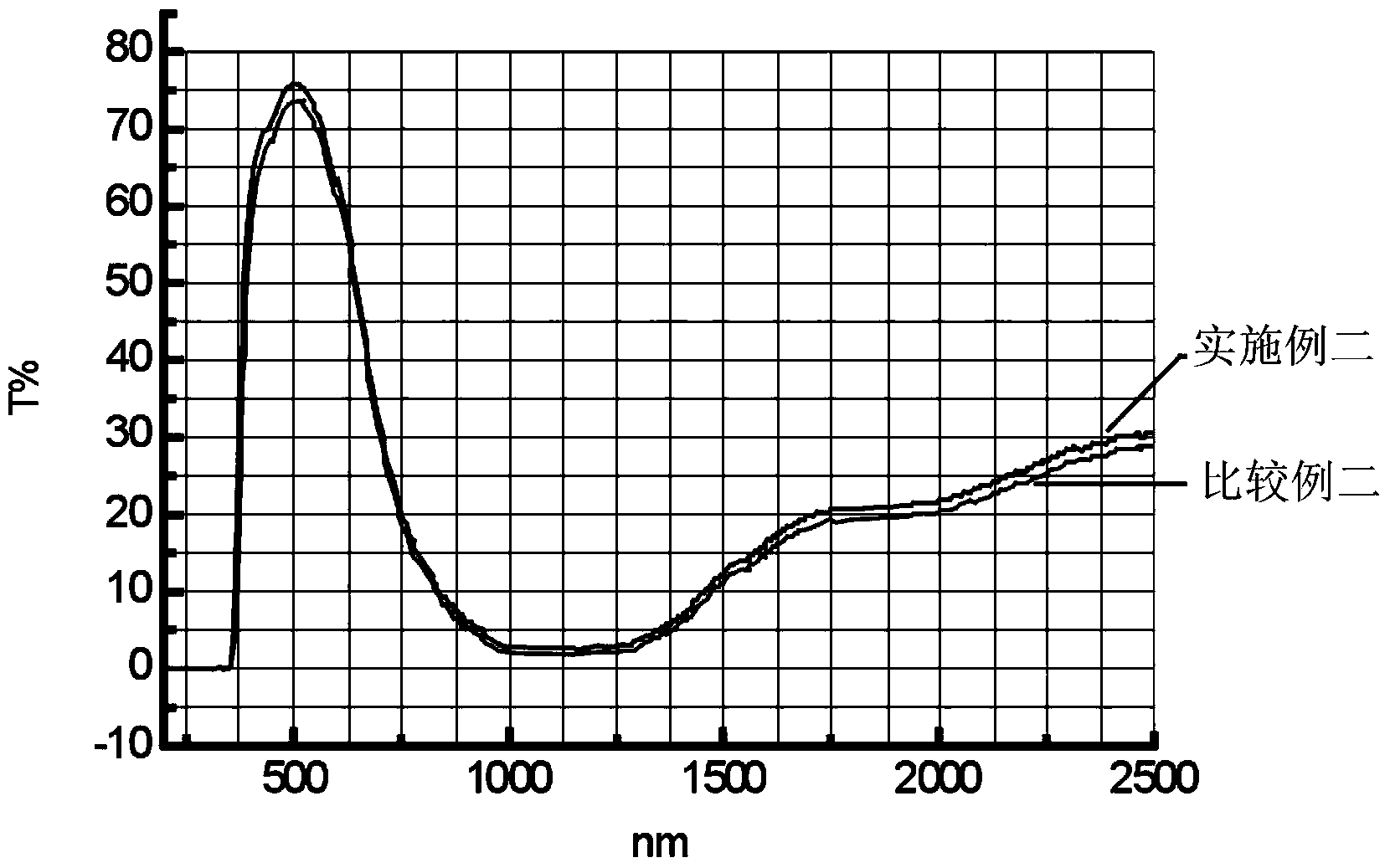

Glass composition for absorbing ultraviolet ray and infrared ray and its application

ActiveCN103641309AImprove transmittanceReduce the temperatureWindowsWindscreensInfraredChemical oxygen demand

The invention relates to a glass composition for absorbing ultraviolet ray and infrared ray, which comprises a glass basic composition (weight ratio): 60-75% of SiO2, 8-20% of Na2O, 3-12% of CaO, 0.1-5% of Al2O3, 2-5% of MgO; 0.02-7% of K2O, 0.1-5% of BaO and 0.01-0.4% of SO3; and a glass body coloring coordination part for absorbing ultraviolet ray and infrared ray: 0.22-1.35% of Fe2O3, 0.001-0.8% of ZrO2+HfO2, 0-0.5% of Cl, 0-2% of B2O3, 0.01-0.8% of TiO2, 0.001-0.06% of CuO; 0-2.0% of Br, 0-0.02% of MnO, 0-2.0% of F, 0.001-0.5% of Sr and 0.005-2.2% of CeO2. The redox ratio of Fe2O3 in the glass composition is 0.4-0.8. Rare metals and rare earth metal compound with a certain amount can be added in the glass composition, limitation of the current heat insulation glass can be breakthrough, chemical oxygen demand of the raw materials and the redox ratio can be controlled in a reasonable mode, obstruction to ultraviolet ray, infrared ray and total energy can be effectively realized, visible light transmittance is simultaneously increased, so that heat insulation glass capable of strongly absorbing the ultraviolet ray and near infrared can be obtained.

Owner:何开生

Novel foam high-polymer composite and production method thereof

InactiveCN102643491AReduce temperature sensitivityExcellent physical and chemical propertiesThermoplasticPolymer science

The invention belongs to the field of construction materials and particularly relates to novel foam high-polymer composite and a production method. The novel foam high-polymer composite comprises 10-90 parts of thermoplastic plastics, 0.5-3 parts of plasticizer, 0.5-3 parts of flexibilizer, 0.5-3 parts of tackifier, 0.3-2 parts of internal and external lubricant, 0.5-3 parts of stabilizer, 0.5-5 parts of crosslinking modifier, 0.5-12 parts of regulator, 0.5-5 parts of foaming agent, 0.5-3 parts of filler, 0-20 parts of flame retardant, 10-90 parts of inorganic powder and pigment in proper quantity. The novel foam high-polymer composite in the technical scheme is energy-saving, emission-reducing, acid-resistant and alkali-resistant, weak in temperature sensitivity and excellent in physical and chemical performance.

Owner:刘海福 +1

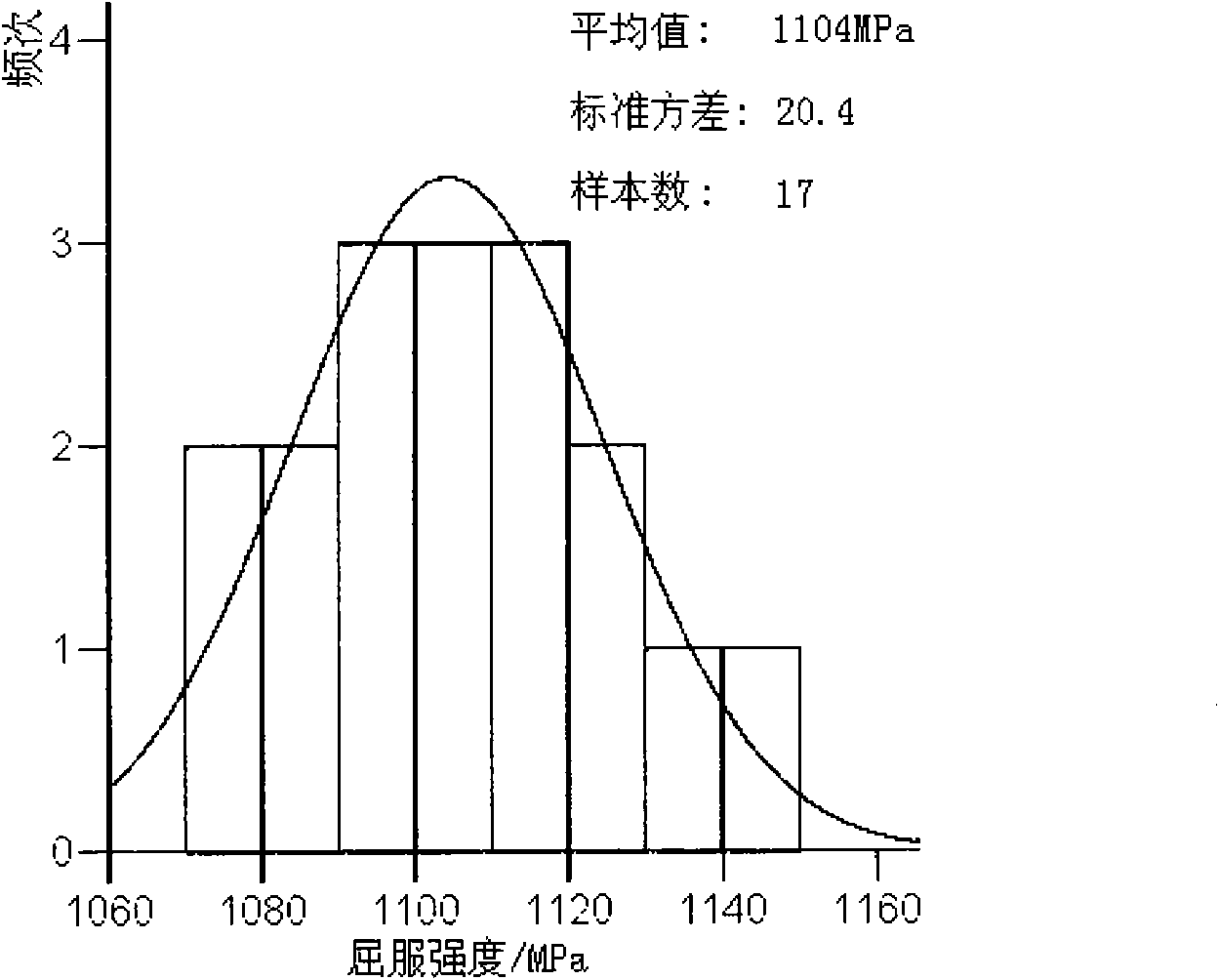

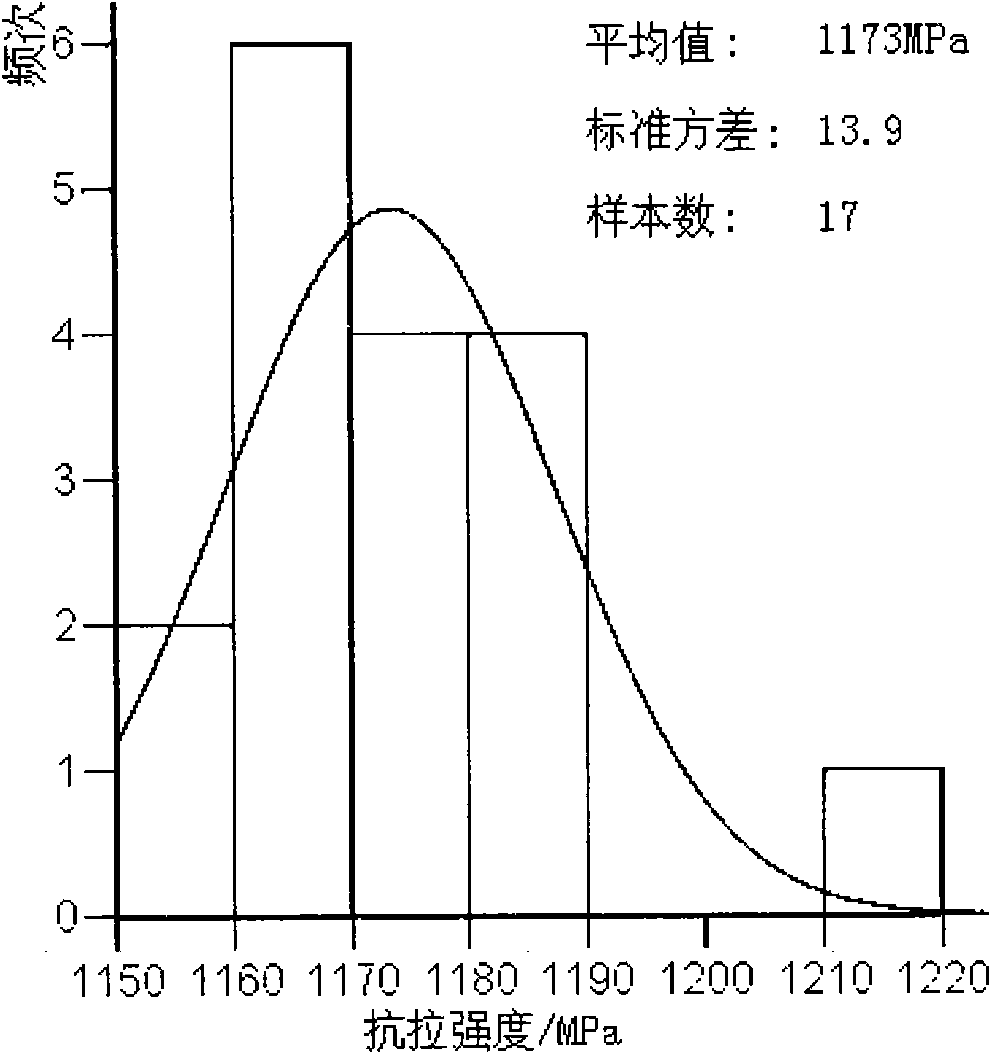

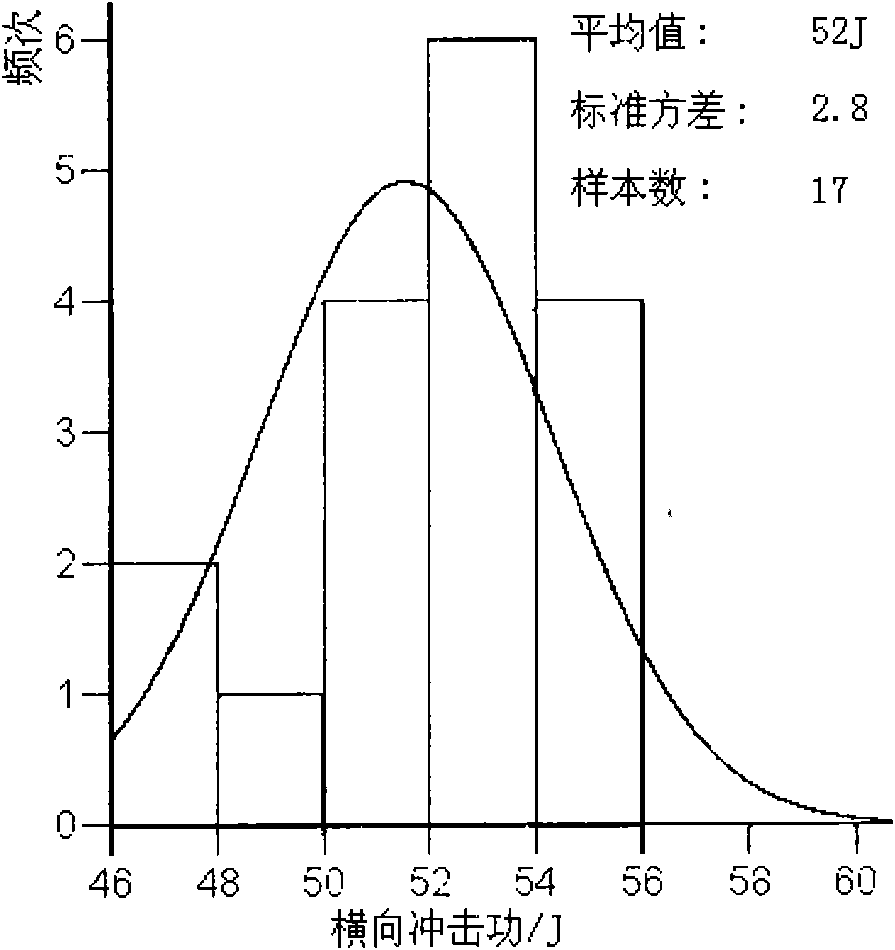

Steel pipe for borehole operation of 150ksi steel grade high toughness oil and gas well and production method thereof

ActiveCN101613829AImprove the level of toughnessExcellent physical and chemical propertiesElectric furnaceProcess efficiency improvementElectric arc furnaceHigh density

The invention provides a steel pipe for borehole operation of 150ksi steel grade high toughness oil and gas well and a production method thereof. The components of the steel pipe are as follows by weight percentage: 0.22%-0.26% of C, 0.15%-0.35% of Si, 0.40%-0.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.90%-1.10% of Cr, 0.70%-0.80% of Mo, 0.10%-0.15% of V, and the balance being Fe. The production method of the invention utilizes scrap steel and sponge iron or molten iron as steelmaking raw materials, after going through electric arc furnace smelting, external refining and vacuum degassing, continuous casting is carried out on the raw materials to mold round billets, and then high-precision hot rolling is carried out on the round billets to mold seamless steel pipes for quenching and heat treatment, finally the hollow plain end seamless steel pipes are obtained. The product has the beneficial effects that the steel pipe features good physical and chemical properties, can be applied to borehole testing of the oil and gas well with high density of rock and increasing production operations such as perforation, fracturing and the like, and 150ksi grade steel pipe strength and toughness matched thereof ensures the security of the whole borehole operation system in the situation.

Owner:TIANJIN STEEL PIPE MFG CO LTD

Sewing-free hot melt adhesive TPU-PU leather and preparation method thereof

ActiveCN103437195AExcellent physical and chemical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolymer science

The invention provides a piece of novel sewing-free hot melt adhesive TPU-PU leather, and a preparation method thereof. The TPU-PU leather comprises release paper, a hot melt adhesive film, a TPU film and a dry-type PU film, wherein the release paper comprises a paper bottom layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material is composed of polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; a TPU raw material is composed of polymer polybasic alcohol, 1,4-cyclohexane-diisocyanate, a chain extender and a plurality of functional additives; a PU raw material is composed of polyester dibasic alcohol, straight chain diol, isocyanate, TDI trimer, dimethyl formamide, butanone, black sand, and a plurality of functional addictives. Through the adoption of the preparation method, innovations are conducted on the raw material components of the release paper, the hot melt adhesive, the TPU film and the PU film; the manufactured sewing-free TPU-PU leather has the technical advantages of firmness in adhesion, durability, environment-friendly materials, no invisible harm to a human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Water-thinned isocyanate adhesive with corn starch as main material and its prepn process

The present invention belongs to the field of adhesive technology, and features that the present invention is double component no-aldehyde waterproof timber adhesive comprising main adhesive component, which is prepared with corn starch and through esterification to form emulsion and copolymerization with grafting stabilizer under certain pH condition, and curing agent, which is prepared with polyisocyanate through closing the isocyanate radical. The present invention has the features of unique composition, no environmental pollution, low cost, etc. and is used in various timber products.

Owner:时君友

Concrete pavement material for heavy traffic roads and preparation method thereof

ActiveCN104193221AElastic modulus controllableHigh modulus of elasticitySolid waste managementMass ratioWaste rubber

The invention relates to a concrete pavement material for heavy traffic roads and a preparation method thereof. The material is composed of a component A, a component B and a component C in a mass ratio of 1:(0.2-0.6):(4-8). The component A comprises the following components in parts by mass: 40-80 parts of epoxy resin, 0-20 parts of epoxy reactive diluent, 10-50 parts of elastic modifier, 0.2 part of defoaming agent and 0.2 part of dispersing agent. The component B comprises the following components in parts by mass: 100 parts of curing agent, 0-10 parts of curing accelerator and 1 part of coupling agent. The component C comprises the following components in parts by volume: 100 parts of fine stone, 30-300 parts of fine sand, 130-800 parts of waste rubber particle, 50-100 parts of waste rubber powder and 10-20 parts of crystal whisker. Compared with the prior art, the concrete pavement material for heavy traffic roads has the advantages of high strength, favorable durability, favorable roadability, energy saving, environment friendliness and the like, and is convenient for construction.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

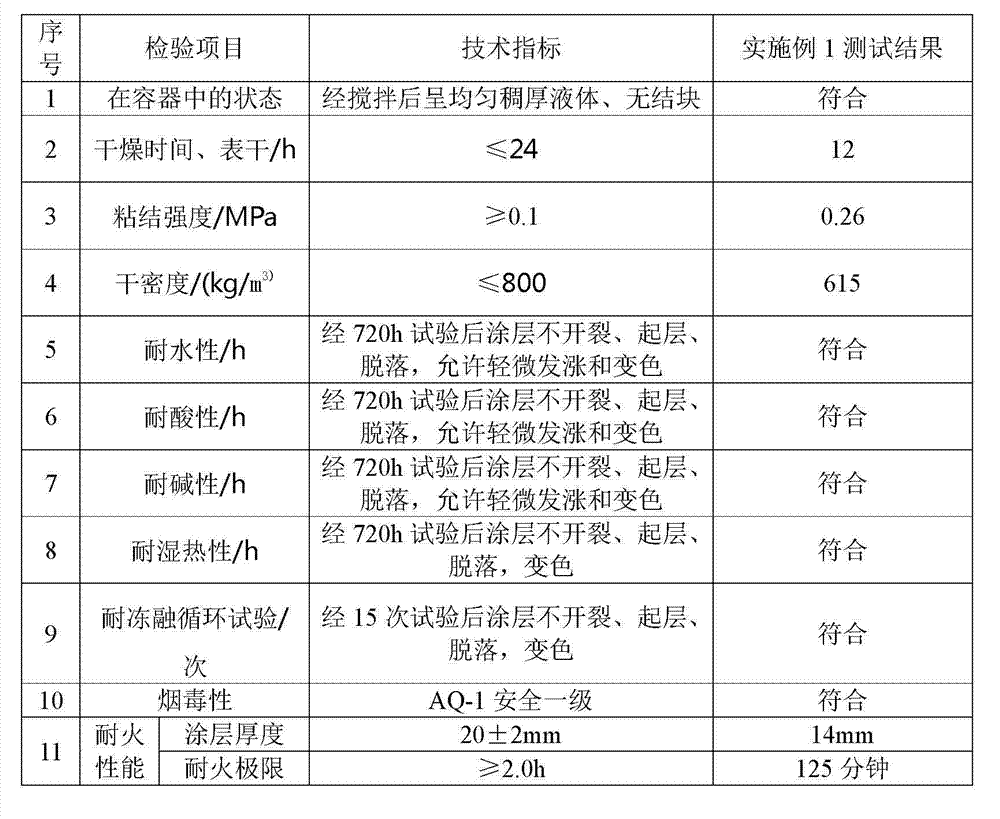

Thin fire-resistant/flame-retardant paint for tunnel and preparation method thereof

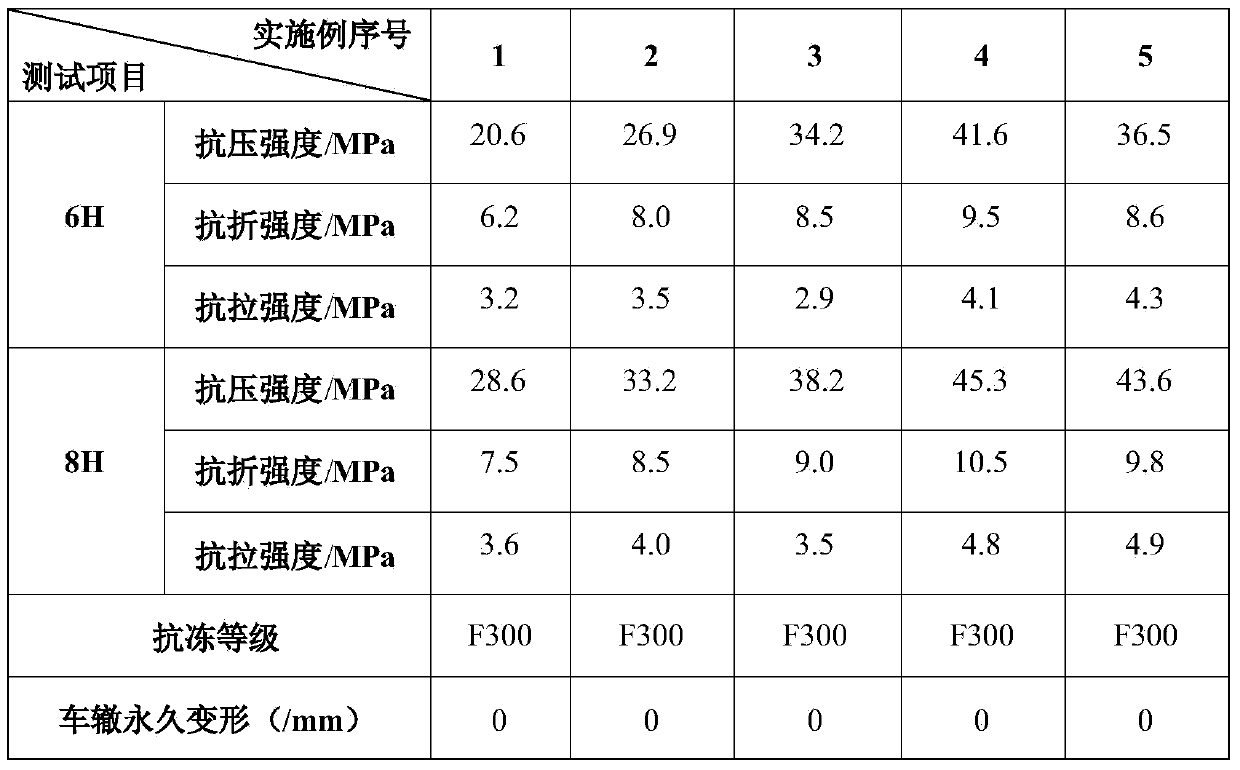

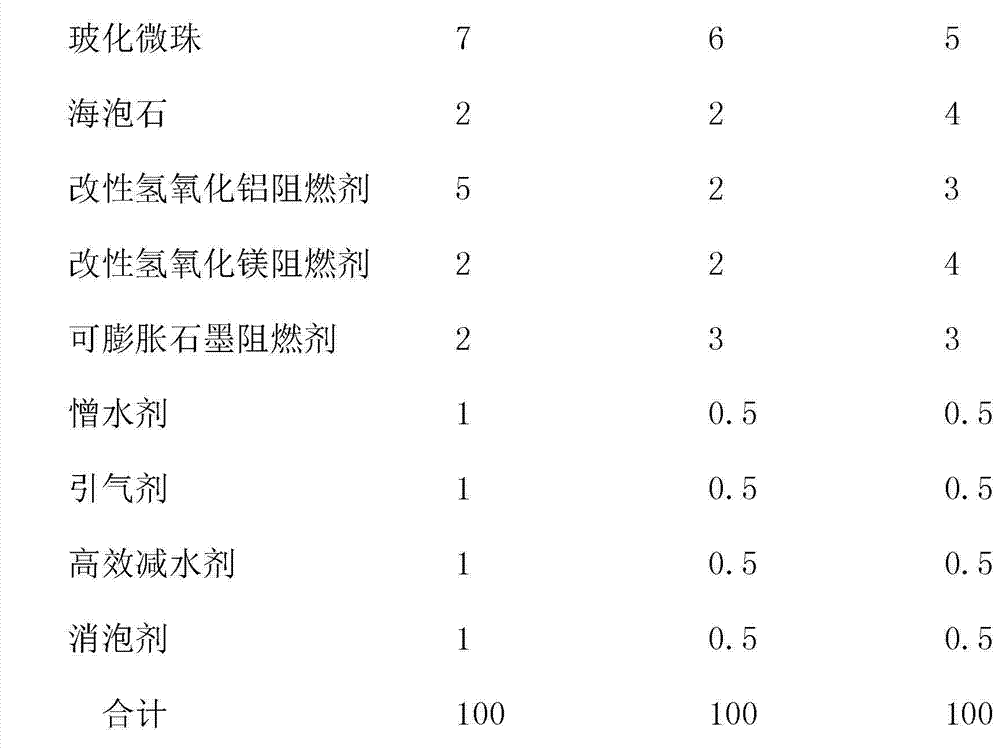

The invention relates to thin fire-resistant / flame-retardant paint for a tunnel and a preparation method thereof. The paint is prepared from the following raw materials in percentage by weight: 40-50% of silicate cement, 5-10% of high-alumina cement, 1-5% of fly ash, 1-5% of redispersible rubber powder, 1-5% of aluminum silicate fiber, 5-10% of expanded perlite, 5-10% of vermiculite, 5-10% of hollow glass microsphere, 5-10% of vitrified microsphere, 1-5% of sepiolite, 1-5% of modified aluminum hydroxide flame retardant, 1-5% of modified magnesium hydroxide flame retardant, 1-5% of expandable graphite flame retardant, 0.5-1% of air entraining agent, 0.5-1% of water reducing agent, 0.5-1% of water repelling agent and 0.5-1% of defoaming agent. The paint provided by the invention has excellent bonding strength, high fire resistance, low heat conductivity and remarkable sound absorption and noise reduction effect, further has favorable moisture resistance, water resistance and durability, and effectively reduces the coating thickness, saves the resources and lowers the construction difficulty on the premise of meeting Chinese standards and related specifications.

Owner:BAOJI TIEJUN CHEM ENG ANTI CORROSION INSTALLATION

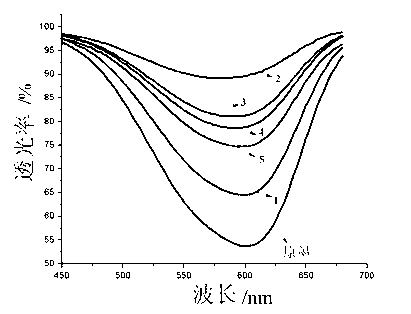

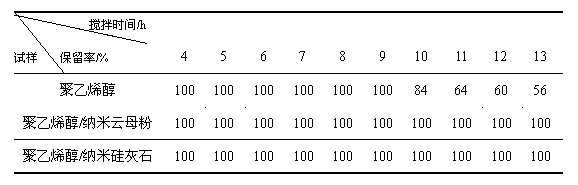

Polyvinyl alcohol/ inorganic nanocomposite hydrogel and preparation method thereof

The invention discloses polyvinyl alcohol / inorganic nanocomposite hydrogel, which is characterized by being formed by the following components: 30-90 parts by weight of polyvinyl alcohol and 0.1-20 parts by weight of inorganic nanocomposite particles through a chemical crosslinking gel method, wherein the inorganic nanocomposite particles comprise nano clay, nano mica powder, a nano molecular sieve, nano wollastonite, nano graphite, nanosilicon dioxide or a carbon nano tube. With the adoption of the polyvinyl alcohol / inorganic nanocomposite hydrogel, the mechanical strength of polyvinyl alcohol hydrogel is enhanced on the basis of not influencing the moisture of the hydrogel, the service life is prolonged, the permeability of the polyvinyl alcohol hydrogel is improved, and a channel is reserved for transmission of matters. As the selection of the materials, the production cost is controlled, and the better economic benefit is brought. The invention also discloses a preparation method of the polyvinyl alcohol / inorganic nanocomposite hydrogel. The preparation method is simple and feasible to operate and good in mechanical strength, and can be produced industrially.

Owner:CHINA PETROCHEMICAL CORP +2

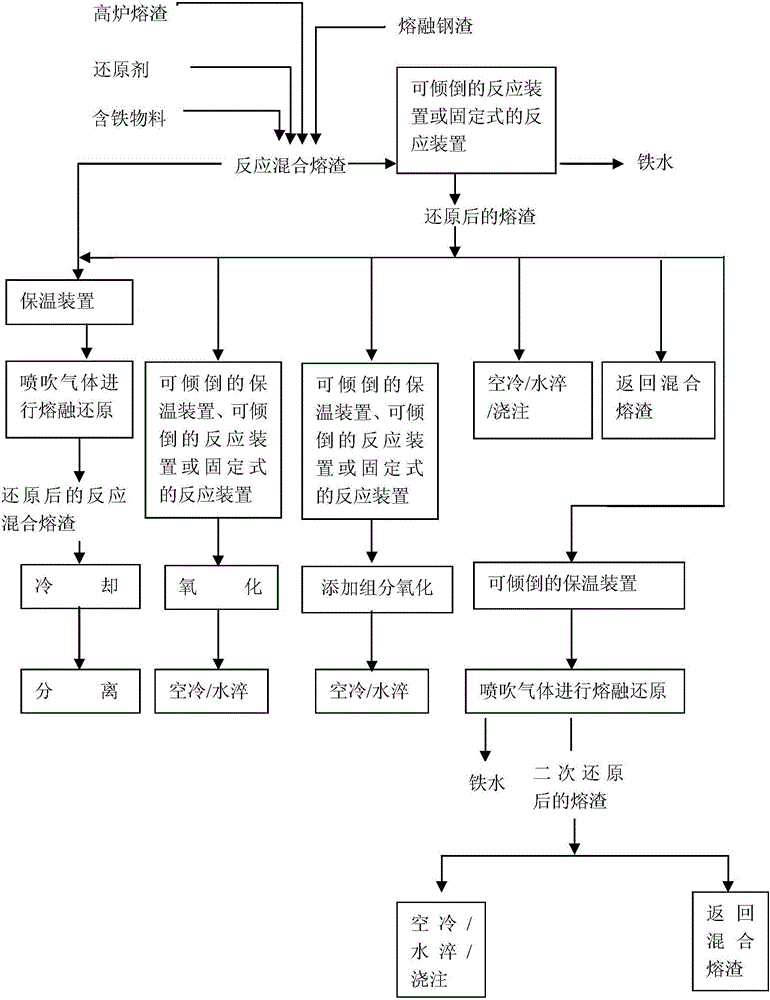

Mixed slag smelting reduction production and thermal refining method

ActiveCN106191344AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementMolten stateReducing agent

The invention discloses a mixed slag smelting reduction production and thermal refining method, and belongs to the field of non-blast furnace iron smelting and comprehensive utilization of resources. The method comprises the following steps: 1) an iron-contained material and a reducing agent are added in mixed slag of blast furnace slag and molten steel slag for heating to reach a molten state; and oxide gas is sprayed for iron smelting by smelting reduction to treat most iron-contained material; and 2) an iron component, a calcium silicon component and a phosphorus component in the mixed slag are separated and recovered according to a reaction device. After smelting reduction, the reduced slag can serve as a cement additive, a cement regulator, a cement clinker or a cement clinker with high production additional value, so that the method realizes efficient comprehensive utilization of the resources, and is a new smelting reduction iron making method. The method uses smelting reduction of the mixed slag for production of pig iron or steel and phosphorus-enriched phases and thermal refining, is short in reaction time, high in metal recovery rate, low in production cost, high in raw material adaptability, high in handling quantity, environment-friendly and high in economic benefit, and can effectively achieve the goal of efficient recycling of metallurgic resources and heat energy.

Owner:NORTHEASTERN UNIV

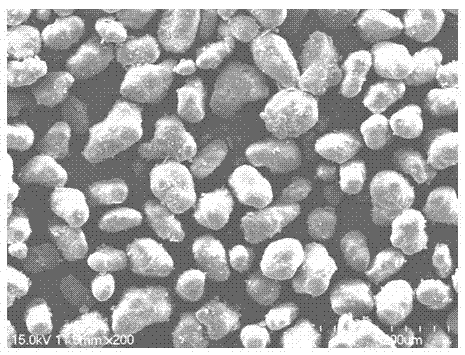

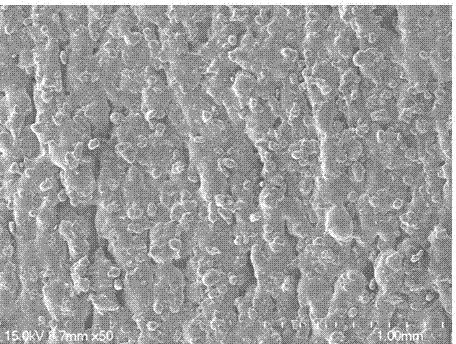

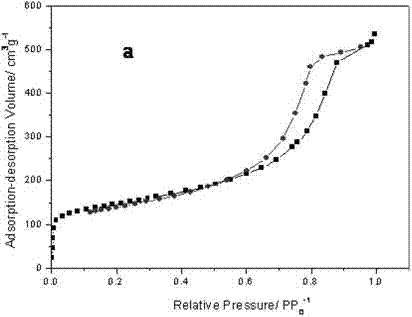

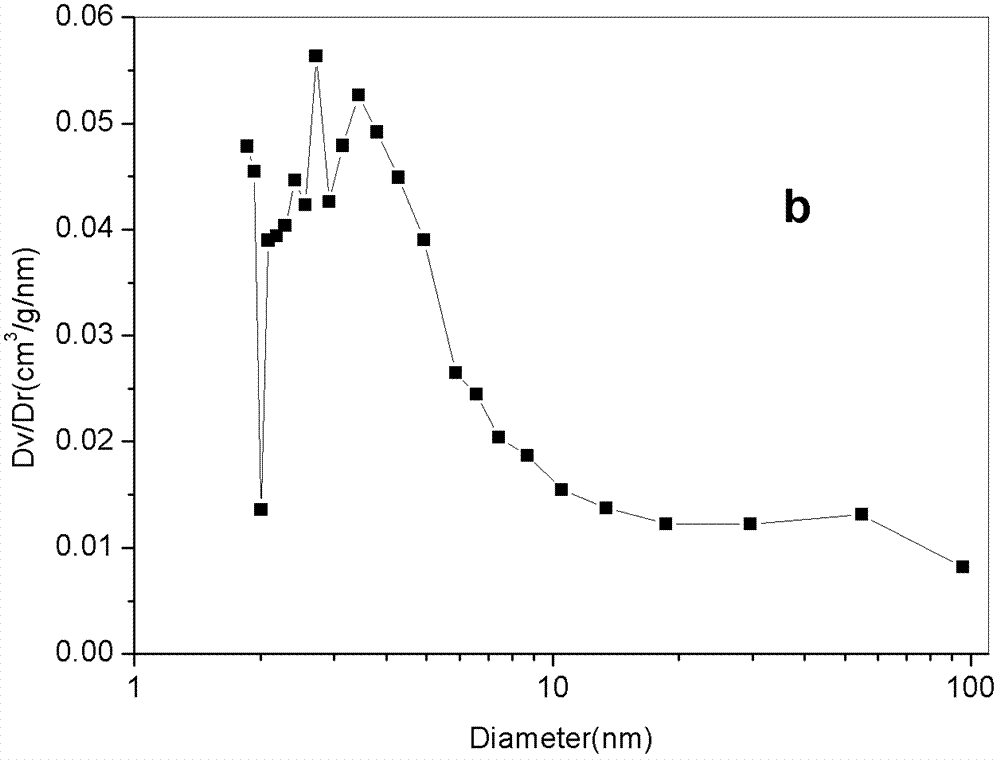

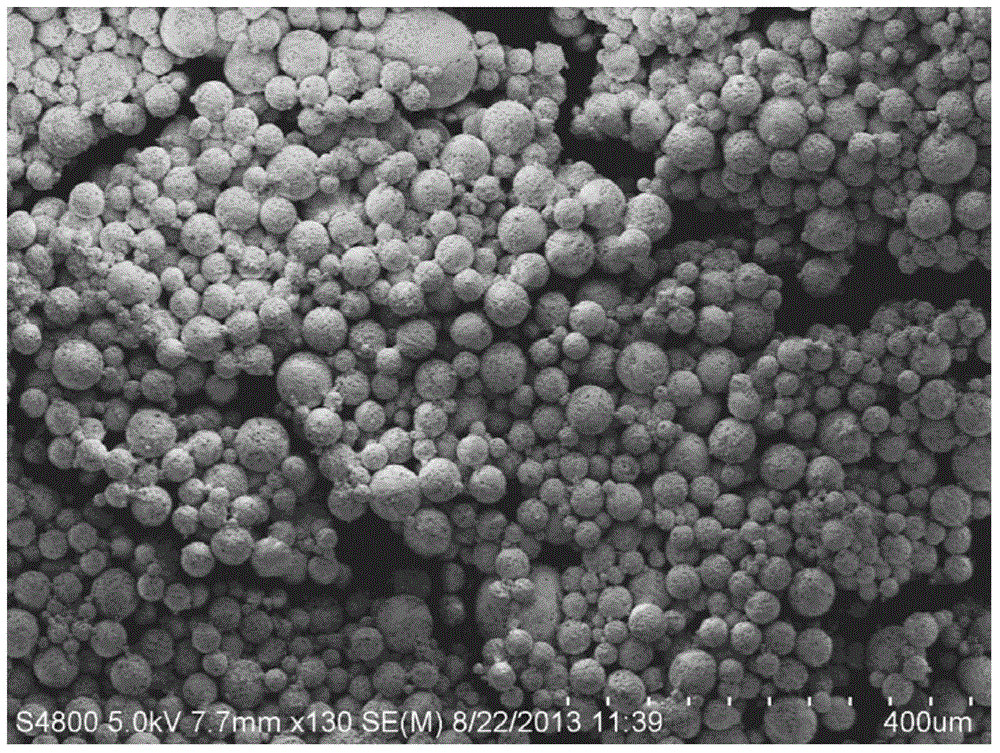

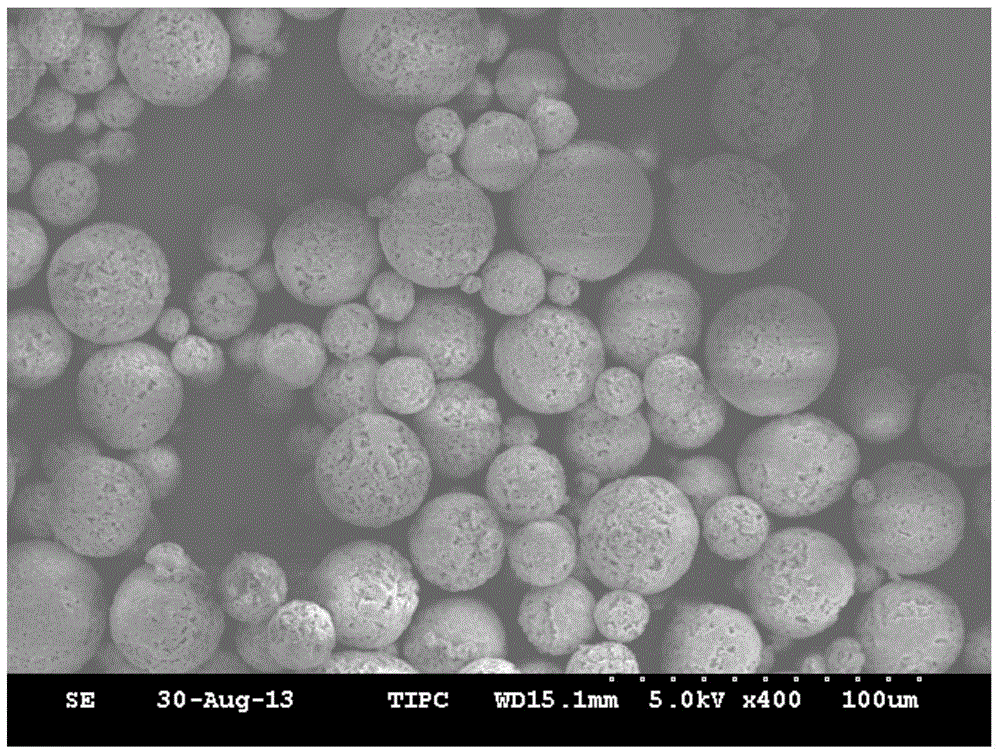

Preparation method of nylon micro powder for selective laser sintering

The present invention discloses a preparation method of nylon micro powder for selective laser sintering, the method is as follows: in the manner of dissolution-precipitation, first a dispersant is introduced into a polymer good solvent system, a poor solvent is added for precipitating of a polymer, and by use of the interaction of the dispersant and polymer chains in the system and particle stability protective effect, well dispersed polymer microspheres can be obtained. A used solvent and the used dispersant both can be recycled, compared with the prior art, no high-temperature high-pressure equipment is used, the process is simple, and the preparation method is cost-effective, environmentally-friendly and easy to implement. According to the method, the nylon powder for selective laser sintering with excellent physical and chemical properties can be obtained, the nylon powder has good particle shape and liquidity, larger sintering window, and better heat resistance and thermal stability, and can meet the needs of SLS parts in the aerospace, automotive, medical equipment, electronic equipment, machinery mold, art work and other fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Lamellar corneal stroma bracket as well as preparation method and application thereof

The invention discloses a lamellar corneal stroma bracket as well as a preparation method and application thereof. The method comprises the following steps: carrying out low-permeability swelling, repetitive freeze-thawing, enzyme digesting, drying and sterilizing treatment on a corneal stroma sheet of a fresh animal eyeball cut down under a sterile condition, wherein the enzyme digesting adopts buffer liquor containing DNA (deoxyribonucleic acid) enzyme and RNA (ribonucleic acid) enzyme to treat, ultrasonic treatment is carried out after the enzyme digestion treatment, and then drying and sterilizing treatment is carried out. The invention further provides application of the lamellar corneal stroma bracket as a corneal stroma substrate. The method disclosed by the invention can be used for reducing damages on a corneal stroma collagen structure to the greatest extent; collagenous fiber arrangement is orderly, holes are uniform and regular, cell residues are avoided, the lamellar structure is kept complete, and the biocompatibility of the bracket material is improved.

Owner:QINGDAO CHUNGHAO TISSUE ENG

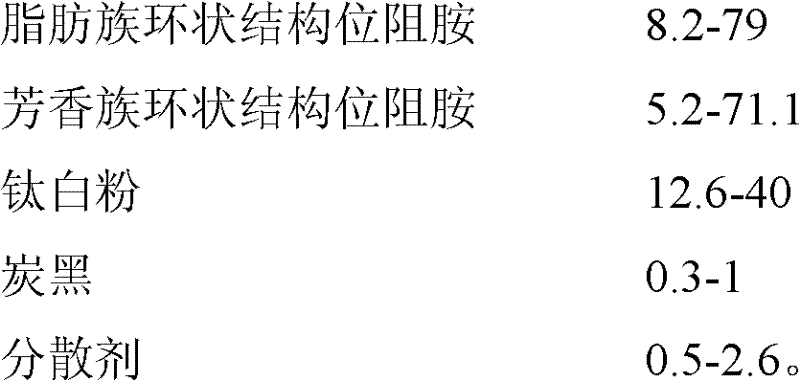

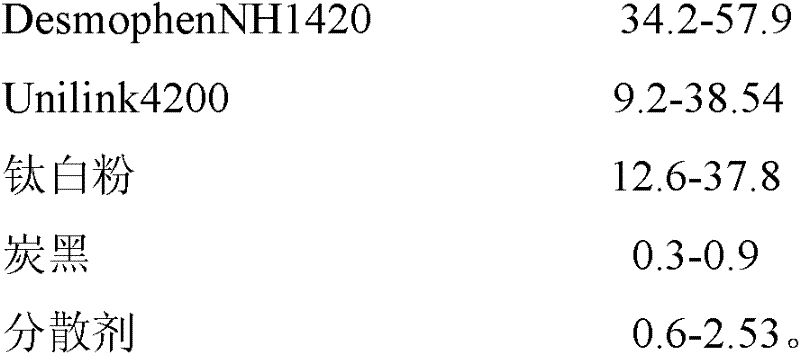

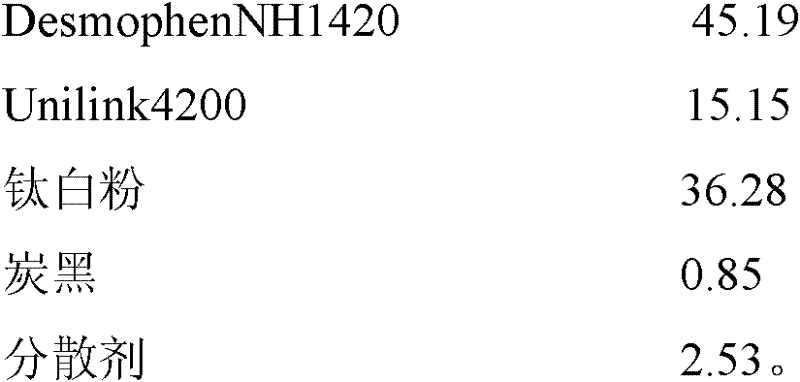

Bi-component slow-reaction polyurea and preparation method thereof

ActiveCN102675583AStrong Coating CompatibilityStrong adhesionPolyurea/polyurethane coatingsPolymer scienceShock resistance

The invention discloses a bi-component slow-reaction polyurea and a preparation method thereof. Isocyanate prepolymer and annular sterically hindered amine are used for preparing the bi-component slow-reaction polyurea, a component A is preferably made of TDI (toluene 2,4-diisocyanate) and N-220, chain extender in a component B is made of annular sterically hindered amine mixture and filler, and the annular sterically hindered amine is mainly prepared by combining aliphatics and aromatics. The bi-component slow-reaction polyurea is excellent in tensile strength, tear strength, breaking elongation, low-temperature bendability, shock resistance, flexibility and bonding strength and peel strength with base materials, and further has the advantages of fine operable time and coating performance. Further, the bi-component slow-reaction polyurea is fine in infiltration performance, low in internal stress of coatings, high in adhesive force, accordant with the environment protection requirements, suitable for small-field construction and low in cost, can be used as a lapping material, and can be also used for repairing spray polyurea coatings.

Owner:北京市大禹王防水工程集团有限公司

Method for preparing microcrystalline glass by utilization of red mud-fly ash-titanium slag

The invention discloses a method for preparing microcrystalline glass by the utilization of red mud-fly ash-titanium slag, comprising the following steps: burdening 25-70 wt% of red mud, 23-70 wt% of fly ash, 1-10 wt% of titanium slag and 0-10 wt% of a cosolvent, mixing, melting, moulding, carrying out nucleation amd crystallization, and carrying out cold working. Main components of the product contain, by weight, 12-39.8% of Al2O3, 13.6-50% of SiO2, 0.8-5.2% of TiO2, 6.5-19% of CaO, 0.5-7.1% of Fe2O3, 0.64-2% of MgO and 1.5-8.2% of Na2O+K2O. the technology is simple; utilization rate of waste residues is high, and amount of admixture reaches more than 90%; costs of raw materials are effectively reduced; and performance of the product reaches the microcrystalline glass architectural decoration quality standard ''JCT872-2000'', and the product can be used in preparation of various tubes and sheet materials.

Owner:GUIZHOU UNIV

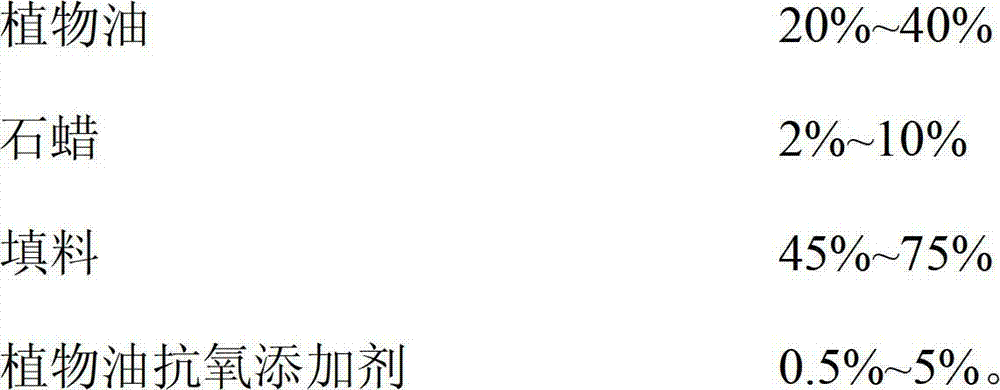

Stuffing for capacitor and preparation method thereof

ActiveCN103035405AWell mixedGood natureThin/thick film capacitorFixed capacitor housing/encapsulationVegetable oilParaffin oils

The invention relates to a stuffing for a capacitor. The stuffing for the capacitor, according to the quality percentage, comprises 20% to 40% of vegetable oil, 2% to10% of paraffin, 45% to75% of stuffing, and 0.5% to 5% of vegetable oil antioxidant additives. The preparation method of the stuffing for the capacitor includes the following procedures: the vegetable oil is heated up to 80 DEG C to 120 DEG C, is under vacuum treatment at least 8 hours, then breaking the vacuum, is added into vegetable oil antioxidant additives, and is under vacuum treatment again at least 8 hours with the temperature keeping in the range of 80 DEG C to 120 DEG C. The paraffin is heated up to 70 DEG C to 120 DEG C to melt. The stuffing for the capacitor can be obtained through mixing the vegetable oil after the heat treatment, melted paraffin and the stuffing together. The stuffing for the capacitor has electrical performance and physics and chemistry performance.

Owner:ANHUI MASCOTOP ELECTRONICS

Preparation method of graphene aerogel and graphene-carbon nanotube aerogel

The invention relates to a preparation method of graphene aerogel and graphene-carbon nanotube aerogel. According to the method, graphene oxide or a mixture of graphene oxide and carbon nanotube is subjected to drying treatment; graphene oxide is reduced through a magnesium thermal reaction; the material is soaked in an acidic water solution; and impurities are removed, and the material is dried, such that graphene aerogel or graphene-carbon nanotube aerogel is obtained. Compared with prior arts, the method provided by the invention has the advantages of simple process, and is green and environment-friendly. Magnesium powder is adopted as a reducing agent. Compared to reducing agents such as hydrazine hydrate, sodium borohydride, formaldehyde, carbohydrate compounds, ascorbic acid and hydroiodic acid, magnesium powder has higher reducibility, such that the graphene aerogel or graphene-carbon nanotube aerogel with high carbon-oxygen ratio can be prepared. The electrical conductivity of the graphene aerogel or graphene-carbon nanotube aerogel can reach 10<4>s / cm. The graphene aerogel or graphene-carbon nanotube aerogel has large specific surface area, and is non-toxic and harmless. The graphene aerogel or graphene-carbon nanotube aerogel can be widely applied.

Owner:TONGJI UNIV

Waterborne epoxy resin modified emulsified asphalt and preparation and application thereof

InactiveCN102618045AGood emulsificationImprove hydrophilicityPaving detailsBuilding insulationsEpoxyRoad surface

The invention discloses waterborne epoxy resin modified emulsified asphalt, which contains emulsified asphalt and self-emulsifying waterborne epoxy resin, wherein the volume ratio of the emulsified asphalt to the self-emulsifying waterborne epoxy resin is 1: (0.2-0.8); the emulsified asphalt is nonionic emulsified asphalt, anionic emulsified asphalt or cationic emulsified asphalt, and the solid content of the emulsified asphalt is 20 to 60 percent; and the self-emulsifying waterborne epoxy resin contains waterborne epoxy resin curing agent, water and liquid epoxy resin in a mass ratio of 1: (0.8-2): (2-5). The invention also discloses a preparation method for the waterborne epoxy resin modified emulsified asphalt and application in preparation of an asphalt type waterproof coating. After the common commercial emulsified asphalt is modified by the waterborne epoxy resin, the break elongation of the emulsified asphalt can be improved, and the modified emulsified asphalt has high adhesive strength with a base plane, certain strength and high waterproof property and ageing resistance; and the modified emulsified asphalt can be used for making the asphalt type waterproof coating, and can also be used for repairing road pavements.

Owner:重庆融极环保工程有限公司

Formulation of environment-friendly ceramic polymer composite material and preparation thereof

ActiveCN101580615AReduce temperature sensitivityExcellent physical and chemical propertiesSolid waste managementThermoplasticCross-link

The invention belongs to the field of building materials, an in particular relates to a formulation of an environment-friendly ceramic polymer composite material and a preparation thereof. The technical proposal is that the environment-friendly ceramic polymer composite material comprises thermoplastic plastics, bamboo powder, plasticizers, internal and external lubricants, cross-linking modifiers, bulking agents, fire retardants, pigments, and gray materials. The technical proposal is energy conservation and emission reduction and has the advantages that the materials are acid resistant and alkali resistant, the temperature sensitivity is low and the physical and chemical properties are superior. Various sectional materials prepared from the environment-friendly ceramic polymer composite material have the advantages of stable physical and chemical properties, high strength, no toxicity, tastelessness, acid and alkali resistance, and high and low temperature resistance; and after surface treatment, the sectional materials can generate woody feelings, and have high imitative degree and secondary processing properties of sawing, nailing, cutting or bolt fixing.

Owner:SHANDONG HUAZHIYE NEW MATERIAL TECH CO LTD

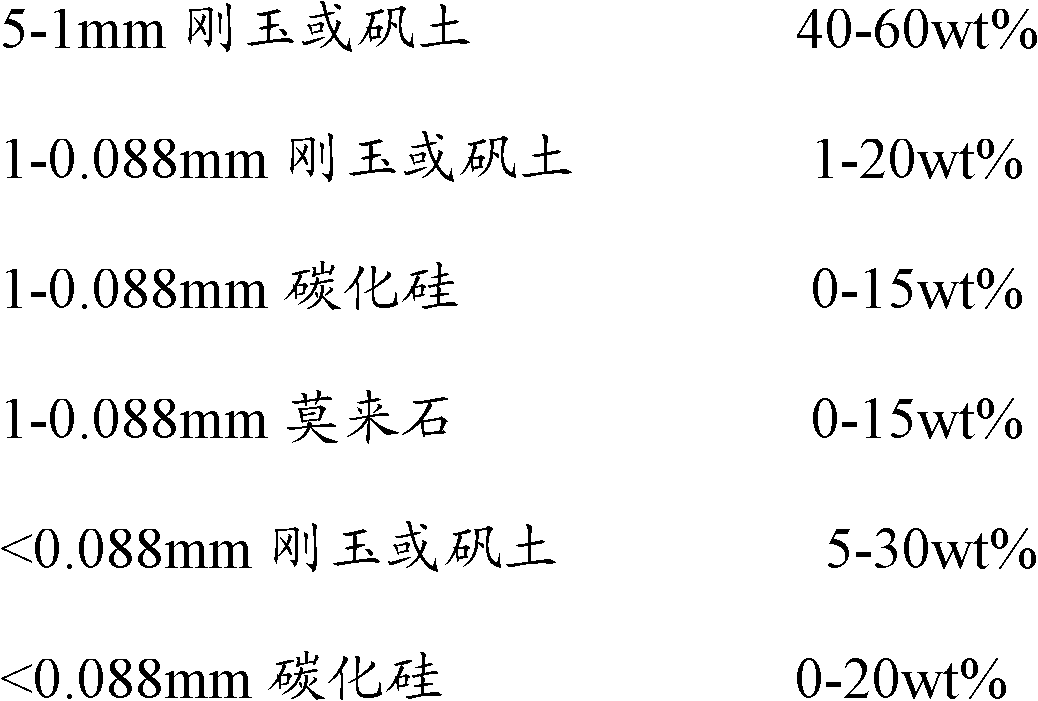

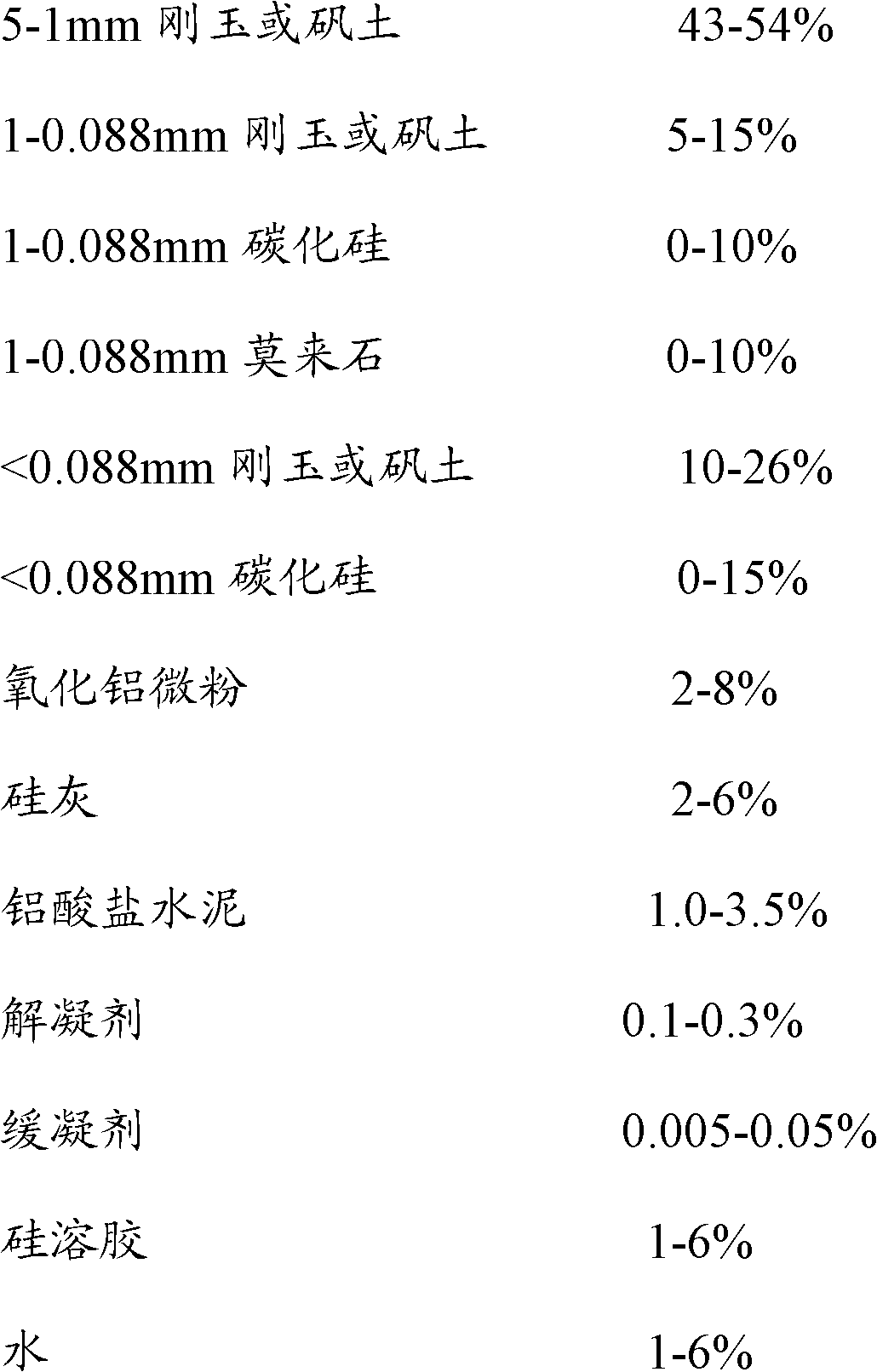

Composite castable refractory

The invention relates to a composite castable refractory. The composite castable refractory comprises adamantine spar or / and alumina, mullite and silicon carbide which serve as granules, cement, alumina micro powder and wollastonite which serve as matrixes, a phosphate deflocculant, an organic acid retarder, diluted silica sol and water. A preparation method comprises the following steps of: weighing solid raw materials according to the amount of a formula, blending, and pouring the mixture into a stirrer; adding the silica sol and the water according to the amount of the formula; and stirring, dumping, conveying, pouring, vibrating, demolding, conserving and baking to prepare the composite castable refractory. The composite castable refractory is normal in coagulation and quick in hardening, has the excellent performance of high purity, high-temperature resistance, low air holes and erosion resistance, and is suitable for linings at the positions with the requirements of high-temperature resistance, erosion resistance or high-temperature abrasion resistance in high-temperature kiln furnaces.

Owner:ANHUI RUITAI NEW MATERIALS TECH

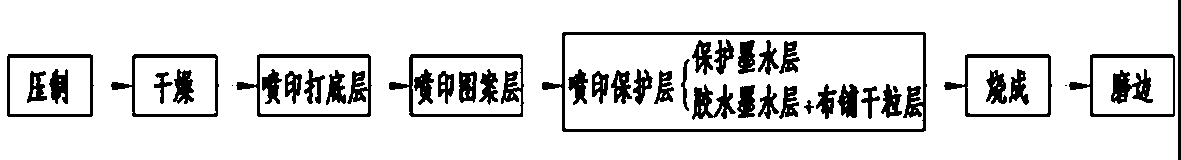

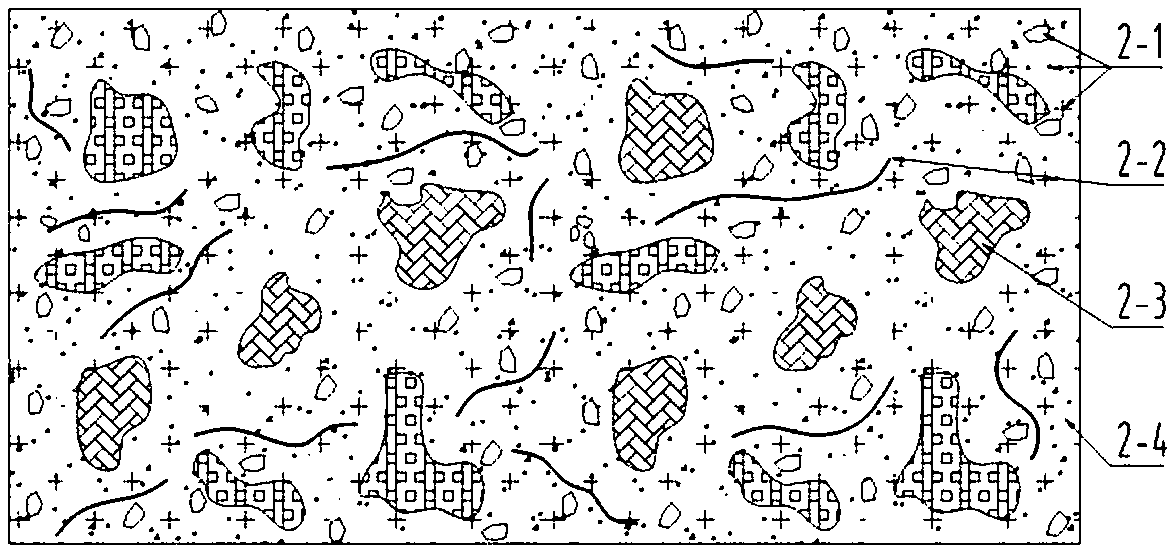

Ceramic large plate of anhydrous glaze line all-digital jet printing process and manufacturing method thereof

InactiveCN108394008AHigh transparencyLabor savingSpecial ornamental structuresCeramic shaping apparatusSurface patternEngineering

The invention discloses a ceramic large plate of an anhydrous glaze line all-digital jet printing process. The large plate comprises a bottom blank layer and a surface pattern layer; the surface pattern layer consists of a jet printing bottoming layer, a jet printing pattern layer, a jet printing protection layer / or a jet printing glue layer bonded with a dry particle layer in sequence from bottomto top; and the bottoming layer, the pattern layer, the protection layer / or the glue layer are formed by digital jet printing through a ceramic ink jet printer. The ceramic large plate and a manufacturing method thereof on a glaze line hardly need manual operation in the whole process for all-digital jet printing of the ceramic large plate and a sheet thereof; the texture is rich; the yield is increased; and anhydrous scene production environment is more accordant with modern green and intelligent manufacturing.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com