Patents

Literature

101results about How to "Realize Nanoization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

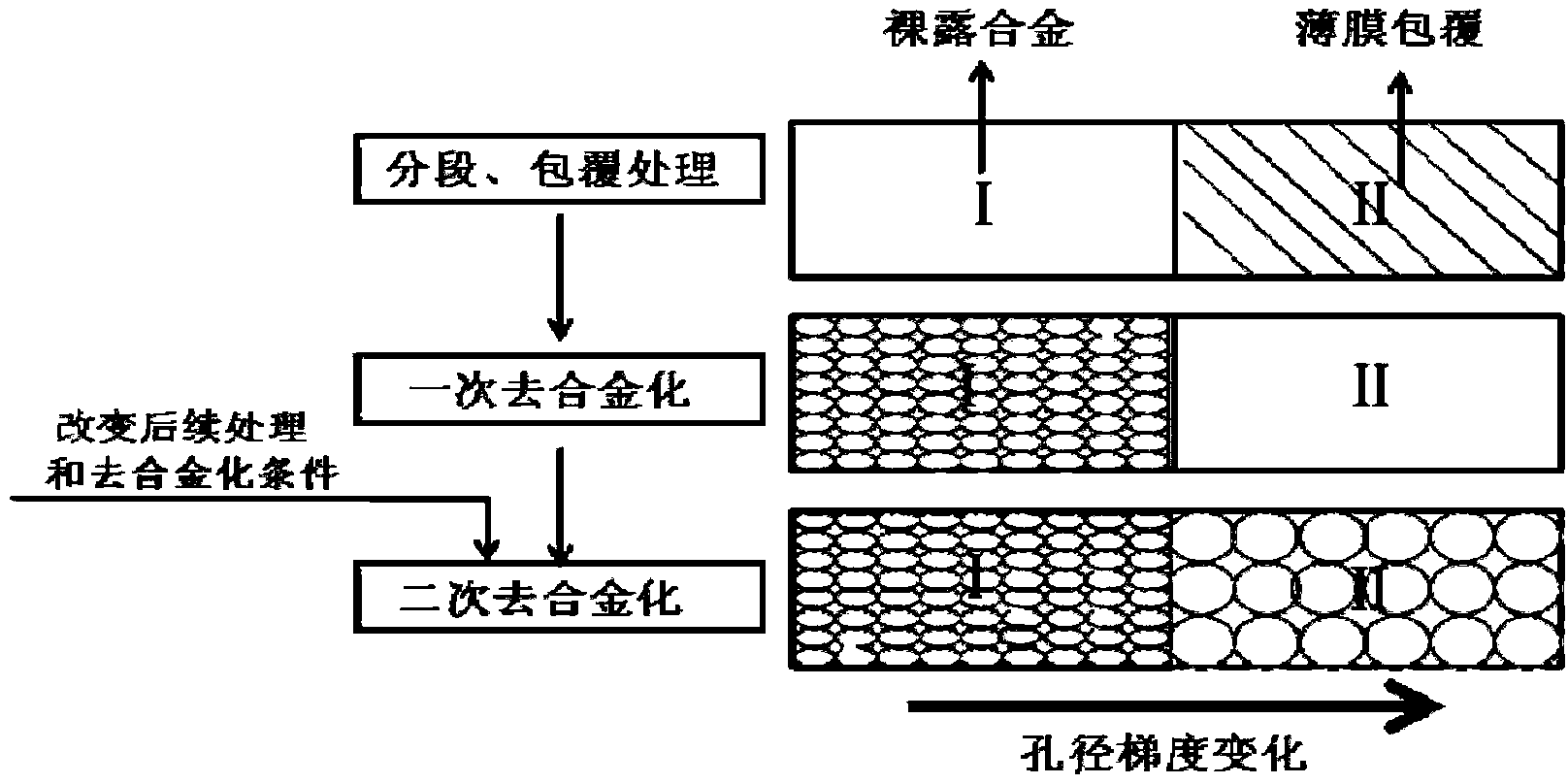

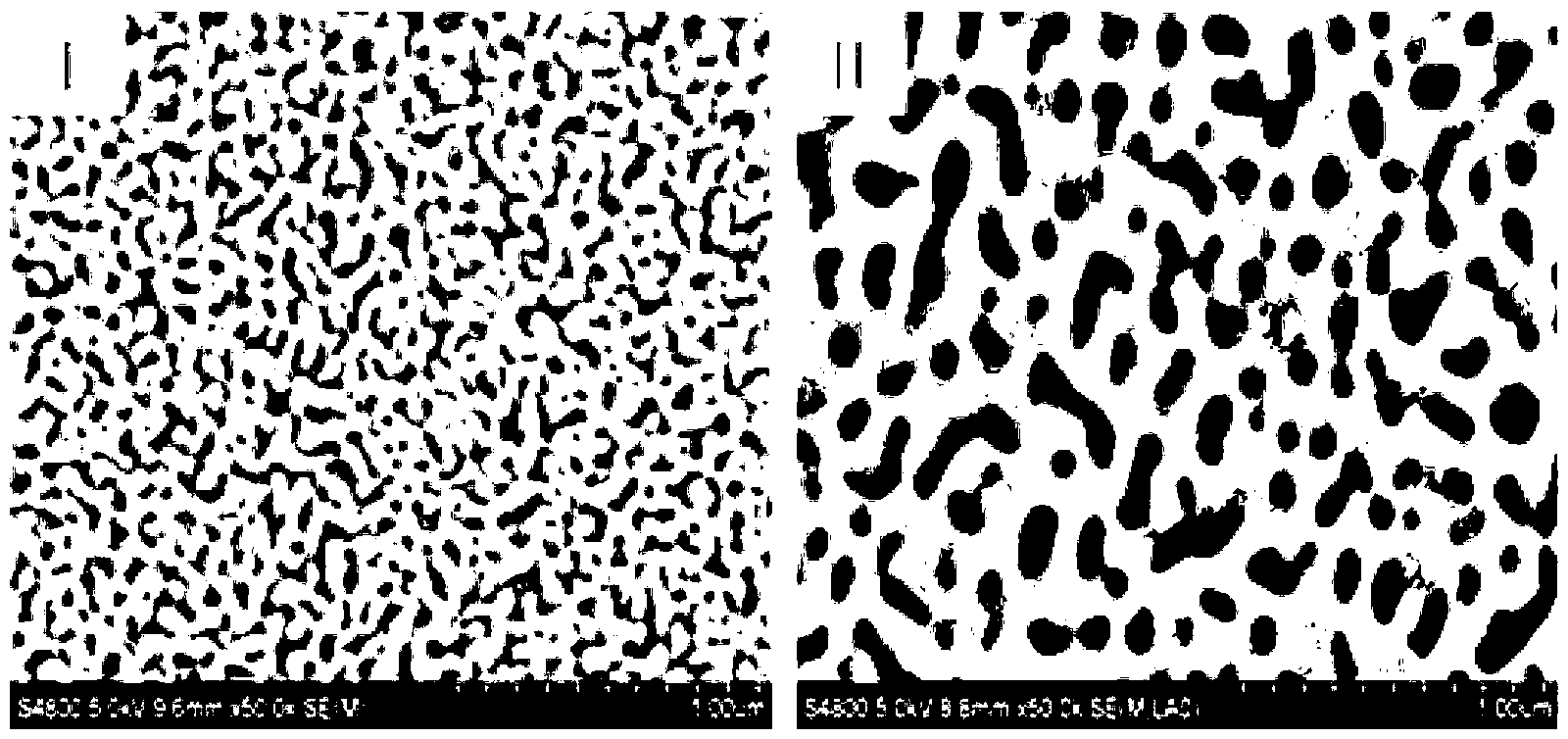

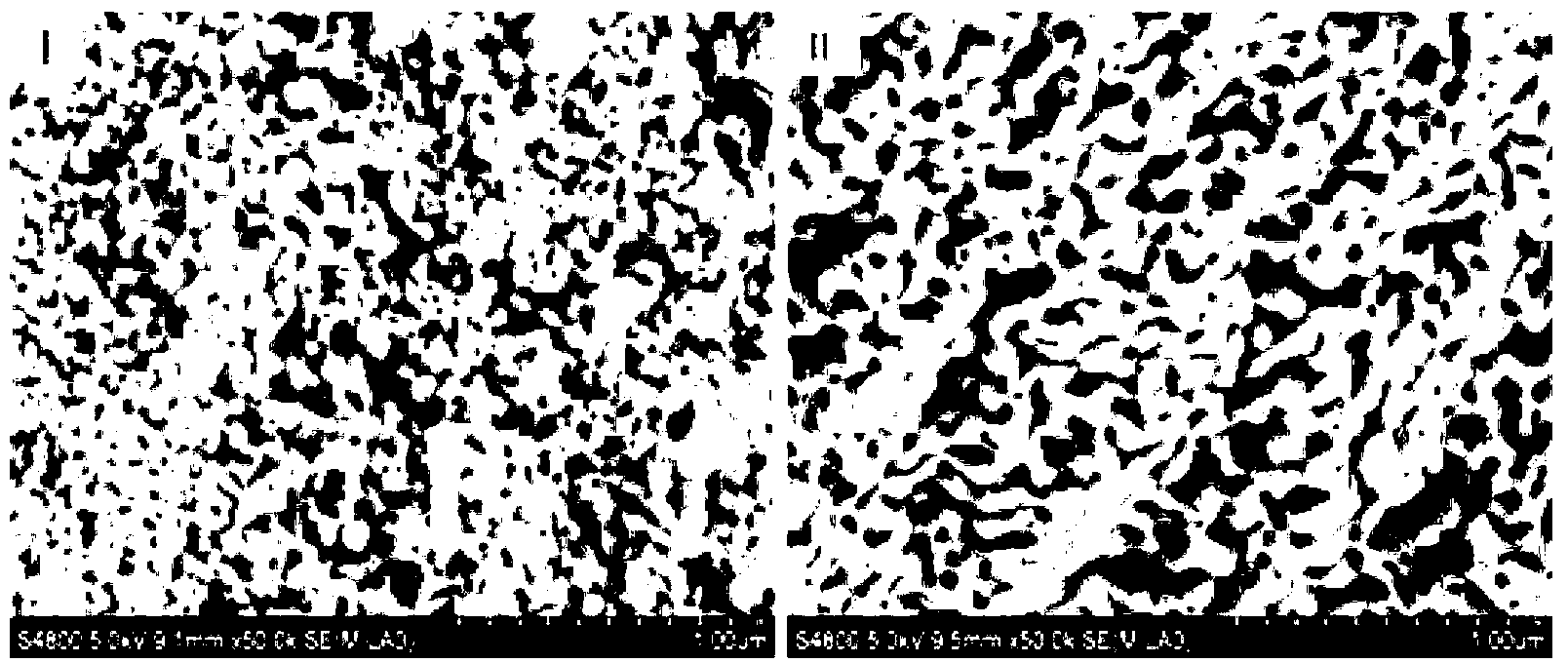

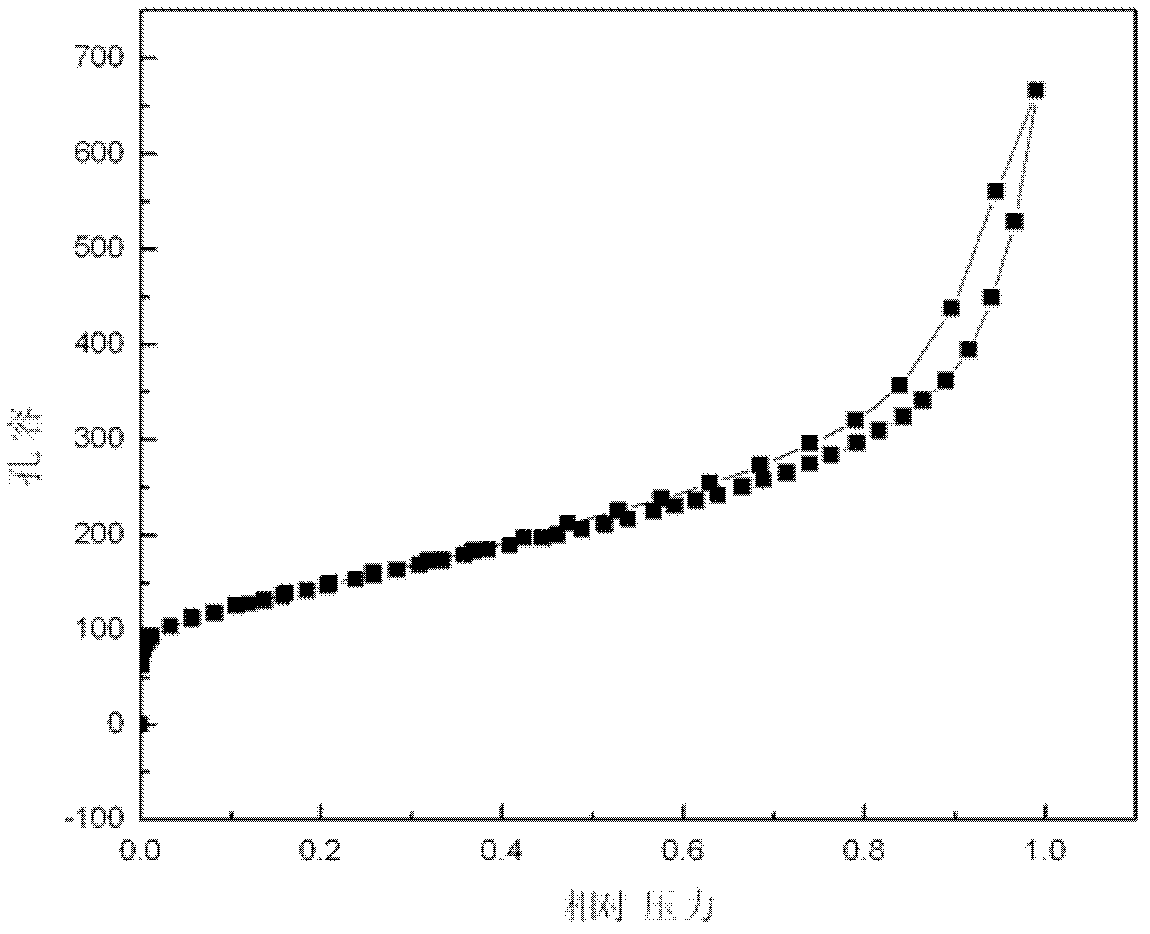

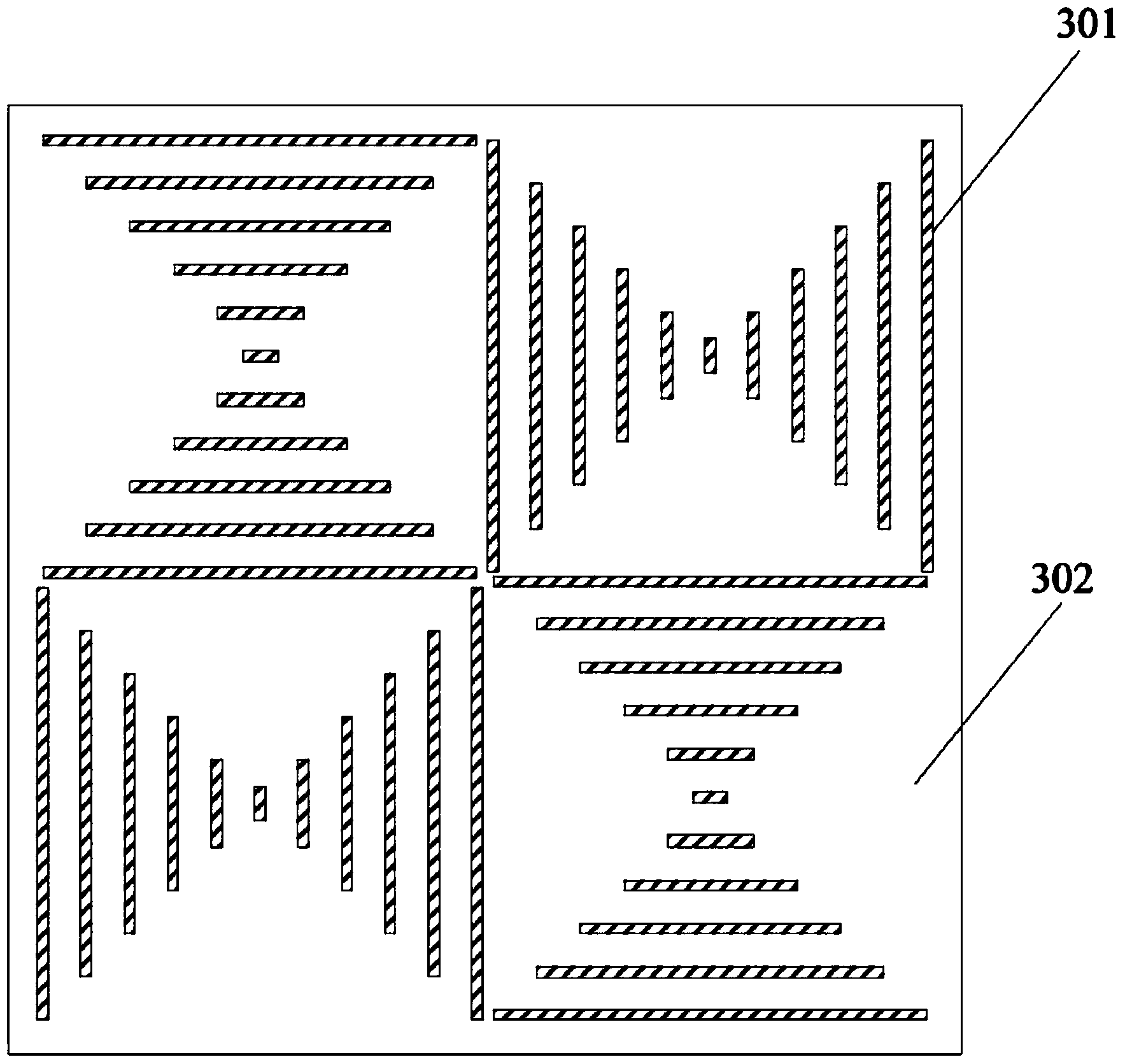

Nano-porous metal material with gradient changes in aperture and preparation method thereof

ActiveCN103290247AExcellent physical and chemical propertiesRealize NanoizationMetallic materialsAlloy

The invention belongs to the field of nano-metal functional materials and provides a nano-porous metal material. The aperture of the nano-porous metal material changes in a gradient manner along the length direction or the radial direction of the metal material, so that the nano-porous metal material has broad application prospects in electrochemical porous electrodes, catalyst carriers, biomedical filter parts, composite material products and the like. A preparation method of the nano-porous metal material comprises the following steps of: (1) preparing a precursor alloy containing an active metal and an inert metal; (2) coating the precursor alloy in segments or in parts; and (3) performing dealloying treatment by adopting different dealloying conditions in segments or in parts.

Owner:四川省新材料工业设计研究院股份有限公司

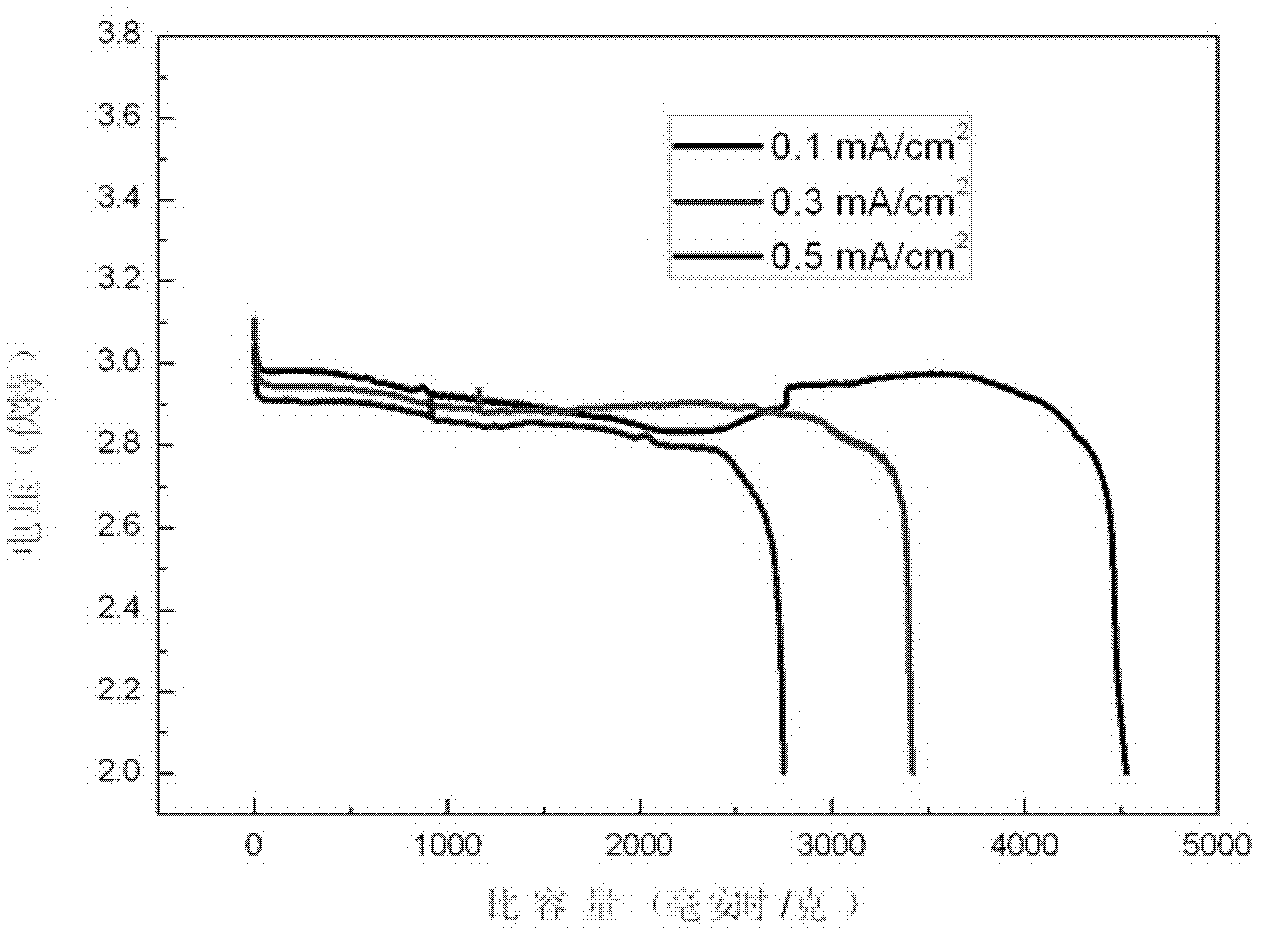

Micro-nano-structure anode material for Li-air battery and preparation method of micro-nano-structure anode material

The invention relates to a micro-nano-structure anode material for a Li-air battery and a preparation method of the micro-nano-structure anode material. The preparation method comprises the following steps of: preparation of hollow composite precursor fibers through electrostatic spinning by blending a metal nitride catalyst precursor with a high-carbon polymer in an organic solvent, preprocessing of the precursor fiber material, nitridation of complex fibers, and pore-forming and pore-expansion through activation. The preparation method is simple in technique and convenient to operate and is easy to realize the uniform distribution of nanoscale catalyst particles in hollow carbon fibers. A prepared anode material tube is hollow internally, a plurality of holes are formed on the wall of the tube, and metal nitride catalysts are uniformly distributed in the three-dimensional holes of the wall of the tube, so that high specific surface area provides a sufficient place for the reaction of the battery, and the hollow pore passage in the tube can ensure an oxygen diffusion channel to be smooth and has good ion transport capacity and electrical conductivity. According to the invention, the charge-discharge capacity of the Li-air battery can be improved effectively, the power multiplying performance and the power density of the Li-air battery can be improved, the internal resistance of the battery can be reduced, and the charge-discharge polarization can be lessened through the uniform distribution of the nanoscale metal nitride, therefore, the micro-nano-structure anode material has good industrialization prospect.

Owner:CENT SOUTH UNIV

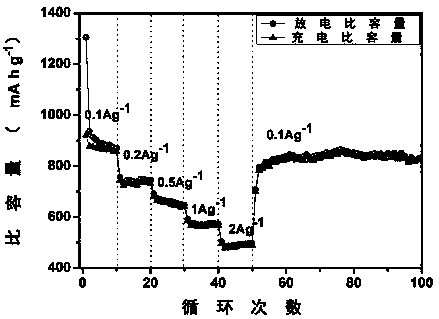

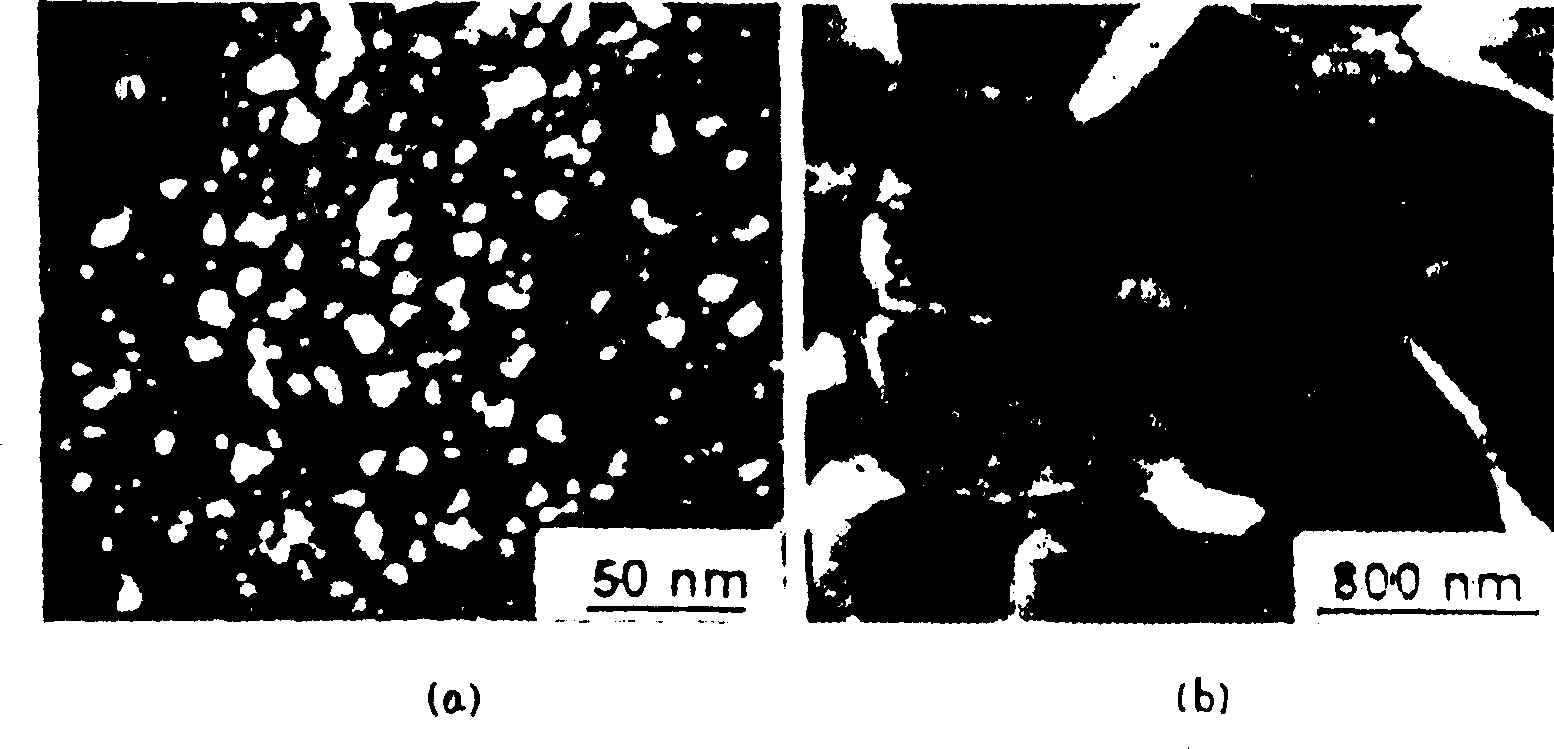

Lithium ion battery negative electrode material and preparation method thereof

InactiveCN108321358AImproved magnification performanceImprove electrochemical performanceCell electrodesCarbon compositesHigh rate

The invention provides a tin-based alloy / carbon composite material for a lithium ion battery negative electrode material and a preparation method thereof. Metal salt and organic ligands are stirred and dissolved in a solvent according to a certain proportion; normal temperature or solvent heat reaction is performed for preparing a porous MOF (metal-organic framework); tin salt is added into the MOF, so that the tin salt is fully adsorbed; MOF precursor powder containing the tin salt is calcined in air; carbonization is performed in inert gas to obtain a nanometer tin cobalt alloy / carbon composite material. The appearance of the prepared nanometer tin cobalt alloy / carbon composite material is a regular polyhedral spherical shape; the nanometer tin alloy size is smaller than 10nm; the material is uniformly dispersed in a porous polyhedral carbon base body. When the material is used for a lithium ion battery negative electrode, high reversible capacity, good cycling stability and high-rate performance are realized.

Owner:BEIJING UNIV OF CHEM TECH

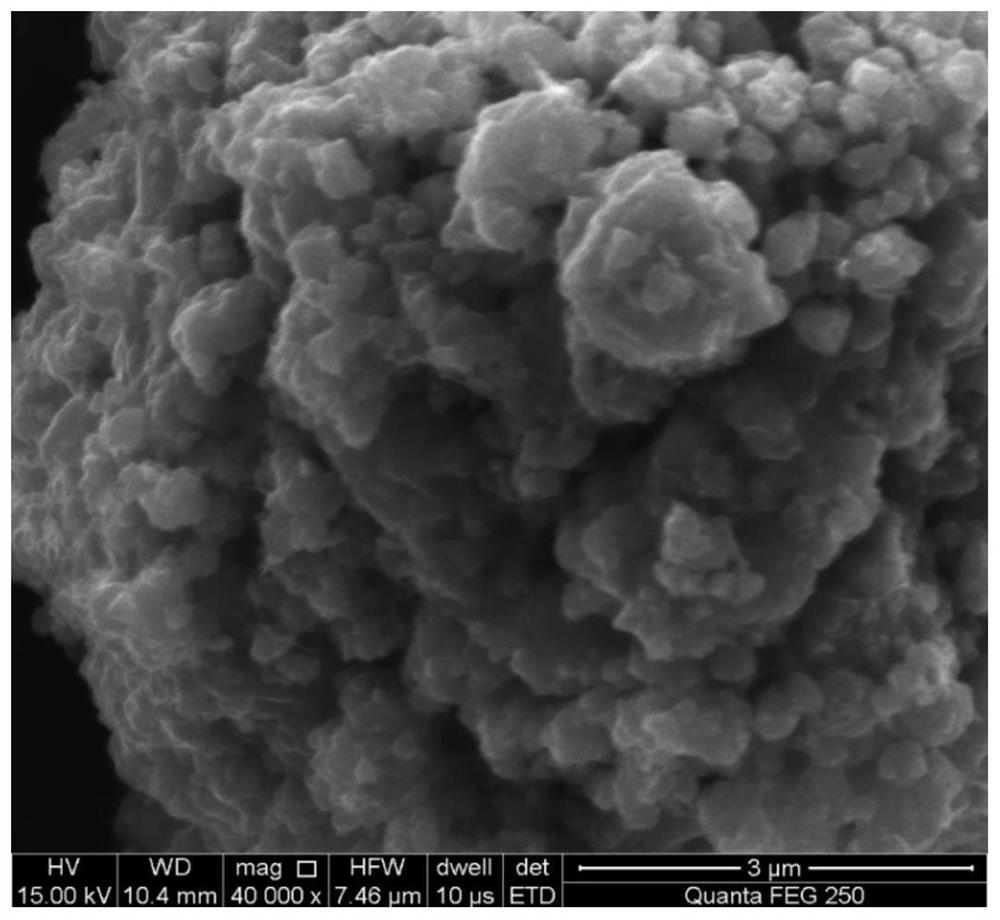

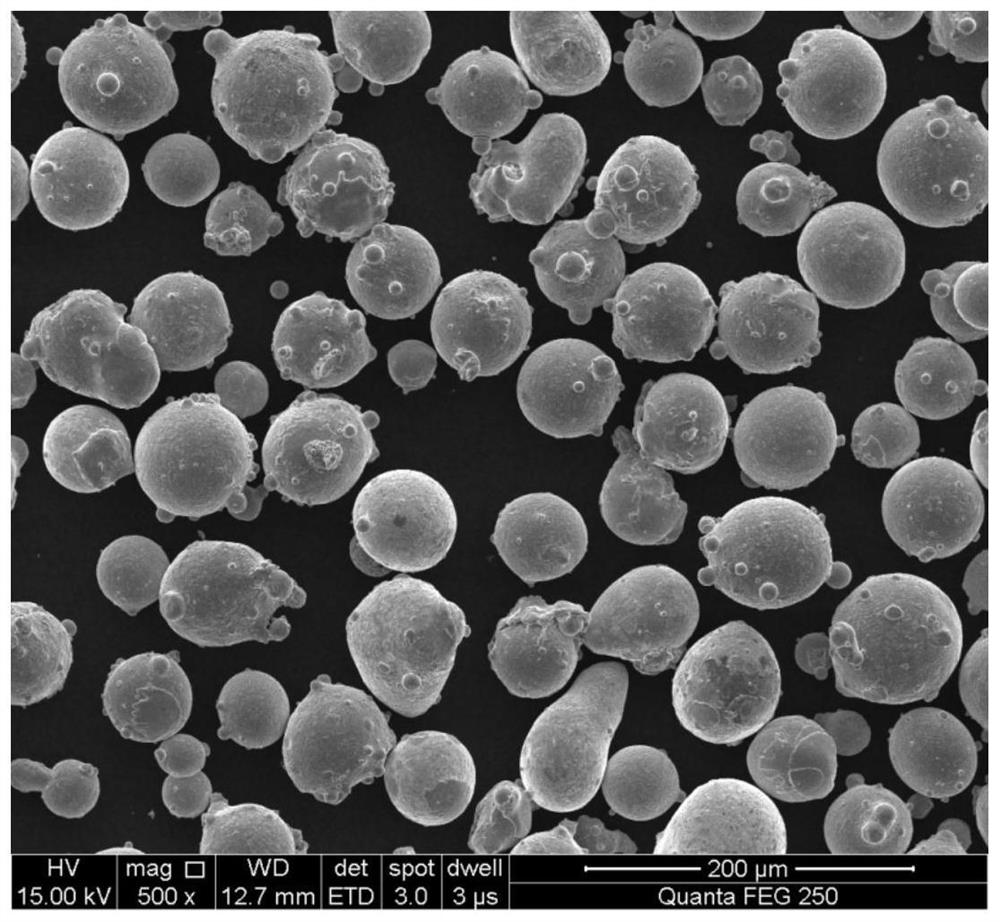

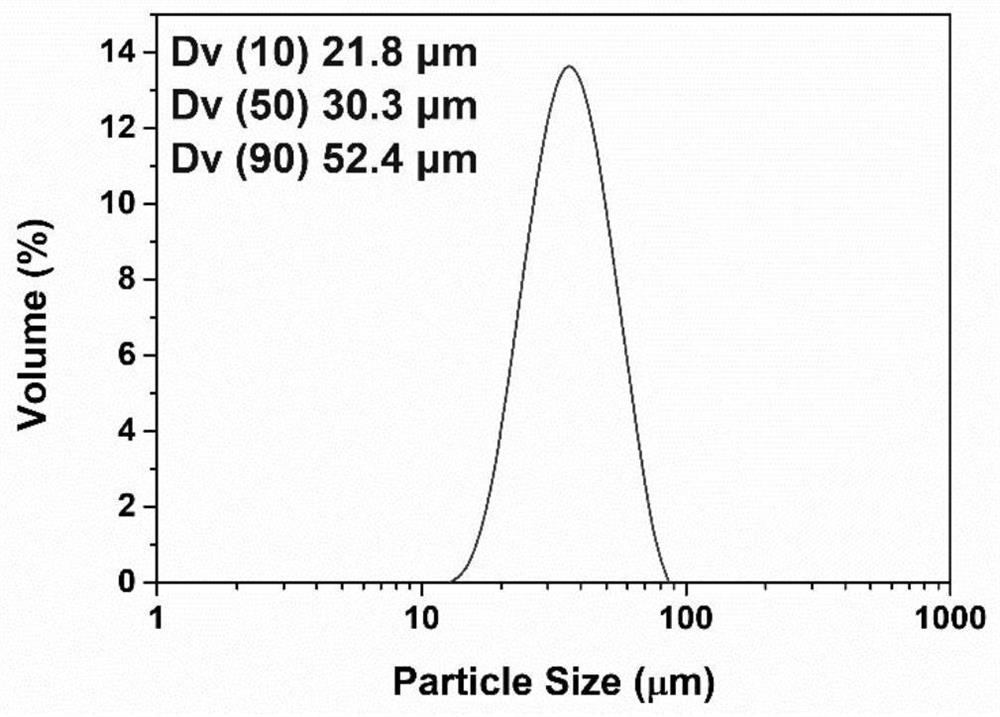

Nano ceramic metal composite powder for 3D printing and application

ActiveCN111940723AHigh sphericityGood liquidityAdditive manufacturing apparatusTransportation and packagingCeramic particleCeramic metal

The invention provides nano ceramic metal composite powder for 3D printing and application. A metal material is used as a matrix, and ceramic particles are used as a reinforcing phase. One or more ceramic particles of micron-sized TiC, TiB2, WC, SiC, CrC, Al2O3, Y2O3 and TiO2 are used as raw materials, the mass percent of the added ceramic particles is 0.5-10.0%, through a specific ball milling process, plasma spheroidization, airflow classification and screening, the metal composite powder with high sphericity, good fluidity, narrow particle size range and uniformly distributed nano-ceramicsis obtained, and the high requirement of a 3D printing technology for powder is met; and a nano-ceramic reinforced metal composite material is prepared through the 3D printing technology. According tothe prepared metal composite material, nano ceramic phases are uniformly distributed, and the metal composite material has excellent mechanical properties. Micron-sized ceramic particles are adopted,uniform dispersion is achieved through nanocrystallization, and the cost is low; and parts in any complex shape can be integrally formed and prepared, and the material utilization rate is increased.

Owner:CENT SOUTH UNIV

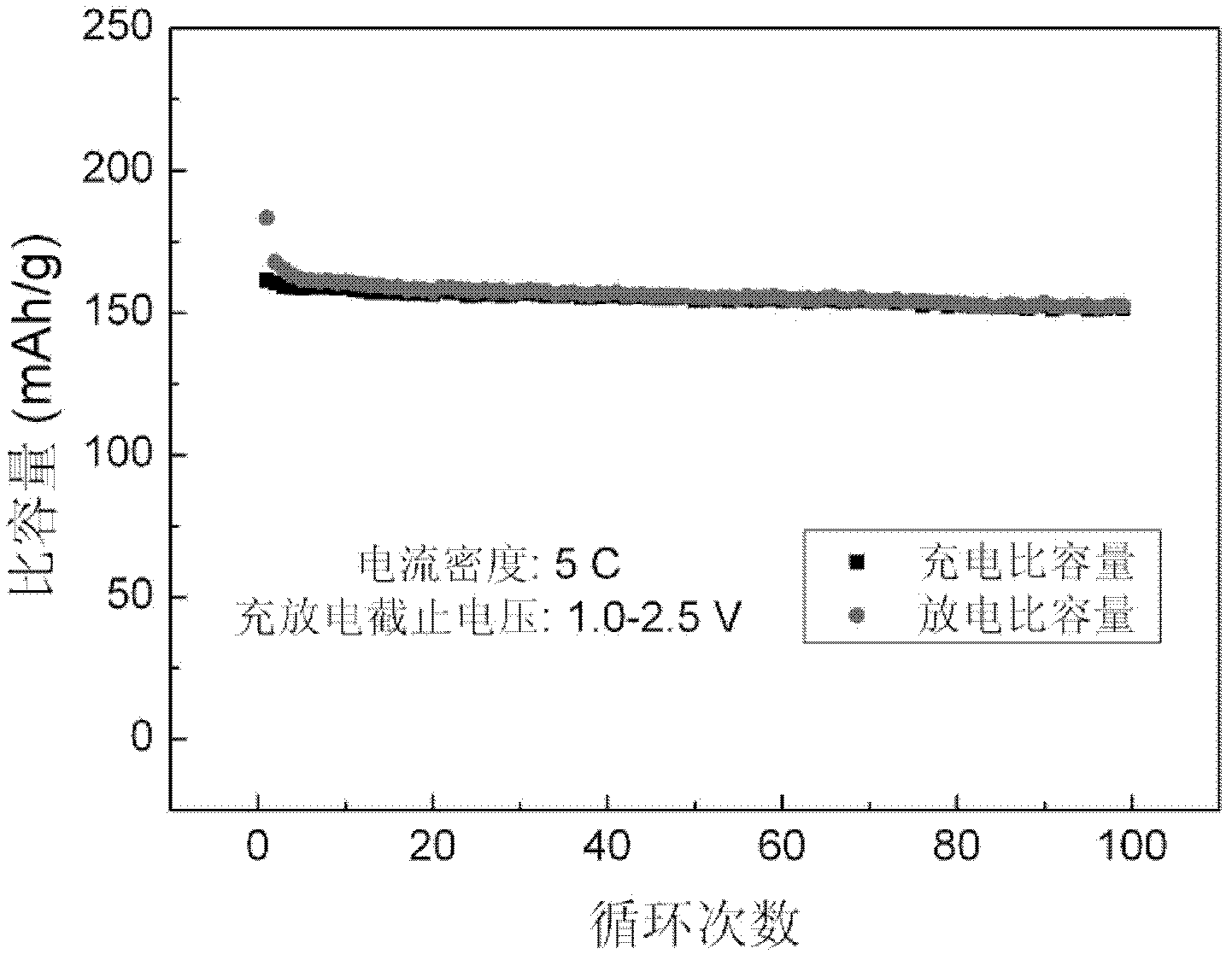

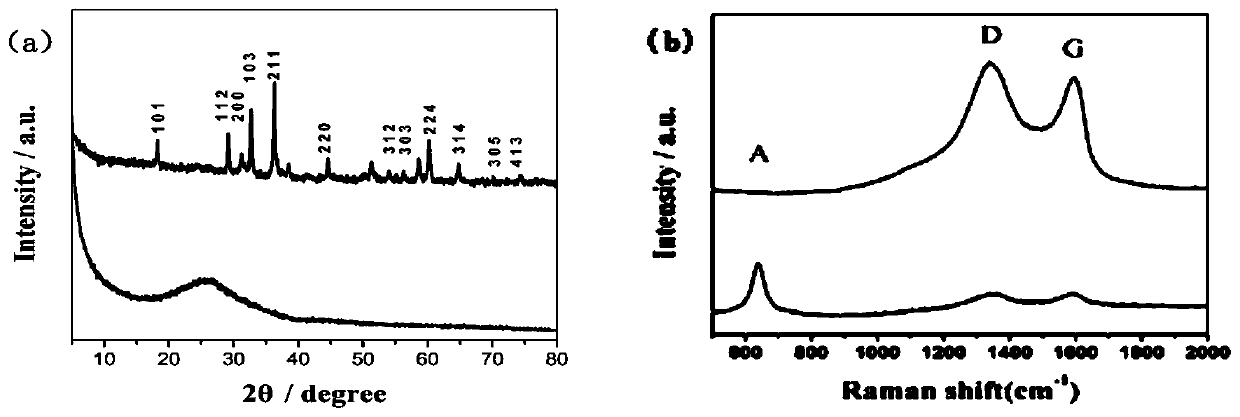

Preparation method for lithium ion battery composite cathode material

The invention discloses a preparation method for a lithium ion battery composite cathode material, and belongs to the field of new materials and electrochemistry, and aims to provide a compound electrode material capable of charging and discharging at a high magnification and an economical and feasible preparation process. The preparation method comprises the following steps of: preparing Li4Ti5O12-TiO2 nano particles by using lithium acetate and tetrabutyl titanate as raw materials and ammonia water as a pH value regulator, and adopting a solvent thermal bonding treatment method; then uniformly coating a carbon source on the surface of the Li4Ti5O12-TiO2 composite particles through a rotary evaporation process; and performing high-temperature pyrolysis to prepare a Li4Ti5O12-TiO2 / C composite material. The Li4Ti5O12-TiO2 / C composite material prepared by the method is fine in particle and uniform in particle size and composition distribution, has high magnification property and cyclical stability, can bring advantages of Li4Ti5O12, TiO2 and C into play, is an ideal high-magnification lithium ion battery composite cathode material, and can be widely used in the fields of portable electronic equipment, electric vehicles, aerospace and the like.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of powder hot spray nano-material coating

InactiveCN1413774AImprove adsorption capacityHigh bonding strengthLiquid surface applicatorsCoatingsThermal sprayingCermet

A hot spray process for preparing the coated layer of nano-class powder includes such steps as cleaning the surface of substrate, activating, nano-class roughening, and hot spray of nano-class powder by large-diameter spray gun. The resultant coated layer features high mechanical properties, simple process, high deposition rate of powder and high spray efficiency.

Owner:金科

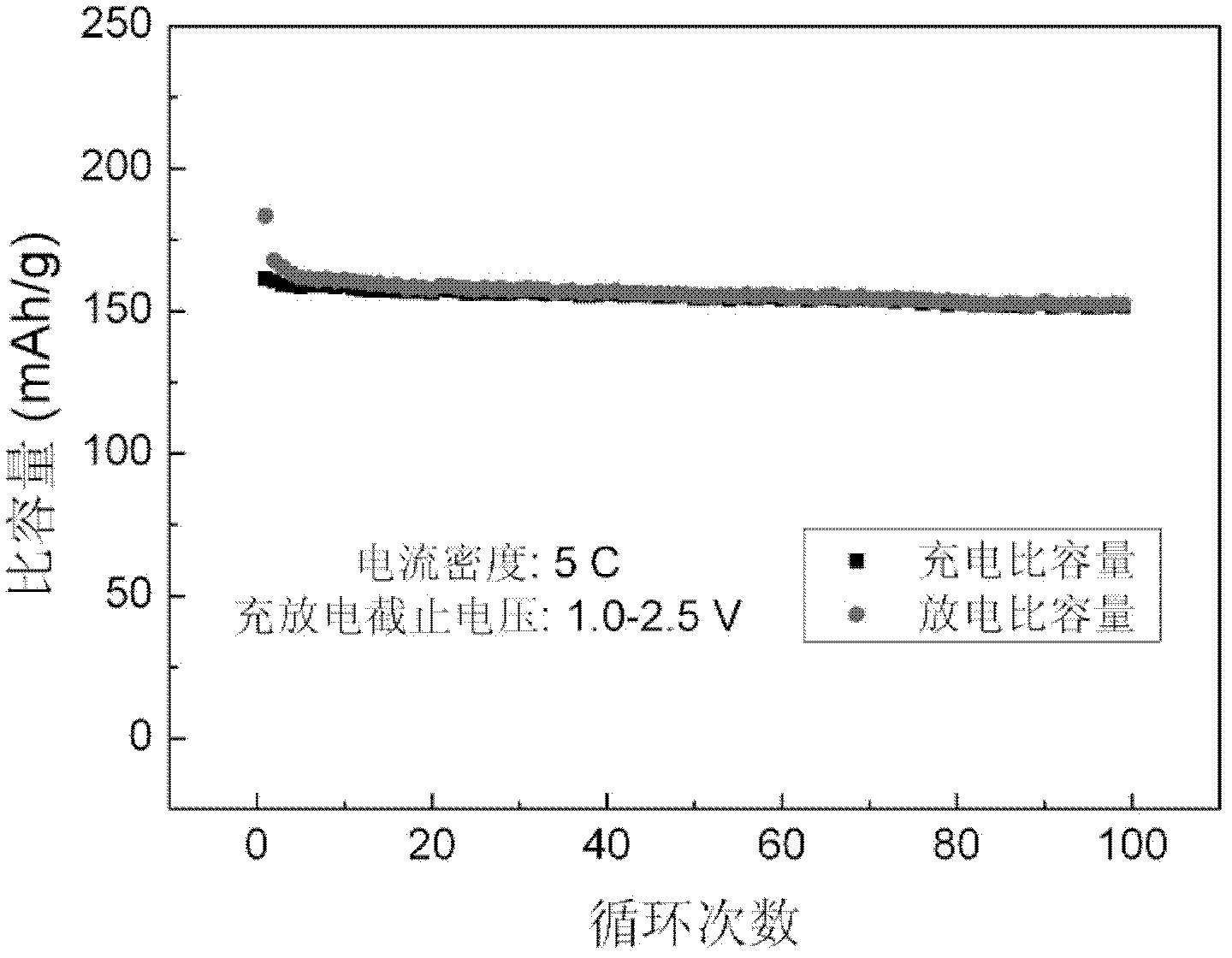

Preparation method of lithium manganese iron phosphate positive electrode material

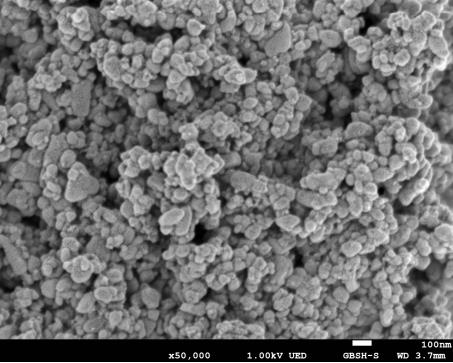

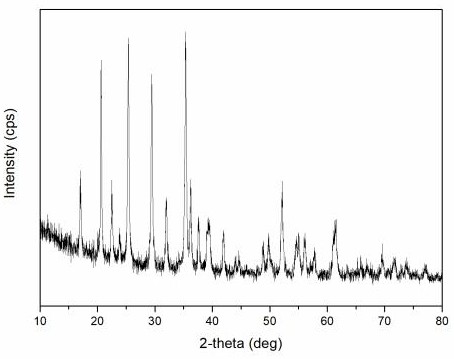

PendingCN113929073ARealize NanoizationAchieve primary particle sizeSecondary cellsPositive electrodesLithium iron phosphatePhysical chemistry

The invention discloses a method for preparing lithium manganese iron phosphate by a solid phase method. The preparation method comprises the following steps: weighing a certain amount of a manganese source and an iron source according to a molar ratio of 7:3, weighing a lithium source, a phosphorus source, a carbon source and a dopant according to a certain stoichiometric ratio, adding pure water, carrying out ball milling and sanding, controlling the sanding particle size D50 to be less than or equal to 300 nm, and carrying out spray drying to obtain brown precursor powder; and sintering the precursor under the protection of a nitrogen atmosphere, controlling the sintering temperature to be 600-700 DEG C, then performing crushing and screening, and removing iron to obtain the lithium manganese iron phosphate positive electrode material. The lithium manganese iron phosphate prepared by the method is simple in process and easy to control in process, compared with existing lithium iron phosphate and ternary materials, the lithium manganese iron phosphate is lower in cost and higher in voltage platform, and meanwhile, the obtained lithium manganese iron phosphate has good electrical performance and cycle performance.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

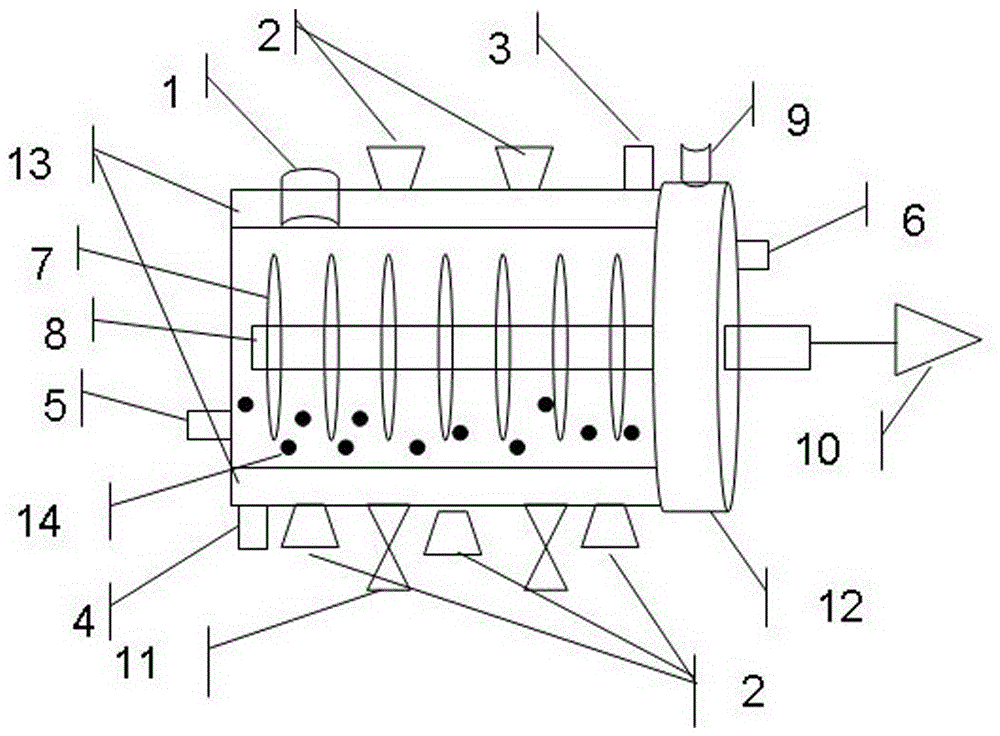

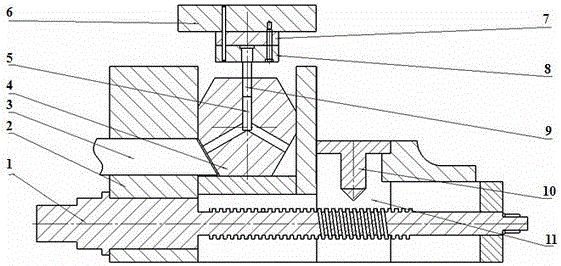

Multifunctional ball-milling device capable of manufacturing nanopowder or slurry efficiently and manufacturing process of multifunctional ball-milling device

InactiveCN105921222ANanoization speed increasedImprove particle size distributionGrain treatmentsMicrowaveHigh energy

The invention discloses a multifunctional ball-milling device capable of manufacturing nanopowder or slurry efficiently and a manufacturing process of the multifunctional ball-milling device. The high-energy ball-milling device comprises a motor, a grinding cylinder, functional auxiliary assemblies, a circulating cooling device, a protecting atmosphere assembly and a support. The grinding cylinder comprises a stirring rod, grinding discs, a material and grinding medium feeding opening, a filtering and separating device and a discharging opening. The circulating cooling device is arranged on the grinding cylinder and comprises a circulating cooling jacket, a cooling liquid inlet and a cooling liquid outlet. The functional auxiliary assemblies are at least one of a microwave generation device, an ultrasonic generator, a discharging device and a magnetic field generation device. The protecting atmosphere assembly is arranged on the grinding cylinder and comprises a protecting gas inlet, a protecting gas outlet and vacuumizing equipment. The functional auxiliary assemblies have the functions and beneficial effects of microwaves, ultrasound, discharging, magnetic fields, temperature fields and the like, so that the device meets the requirements on different conditions, and the operability of the device is improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

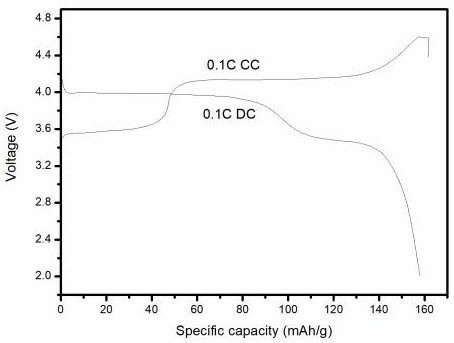

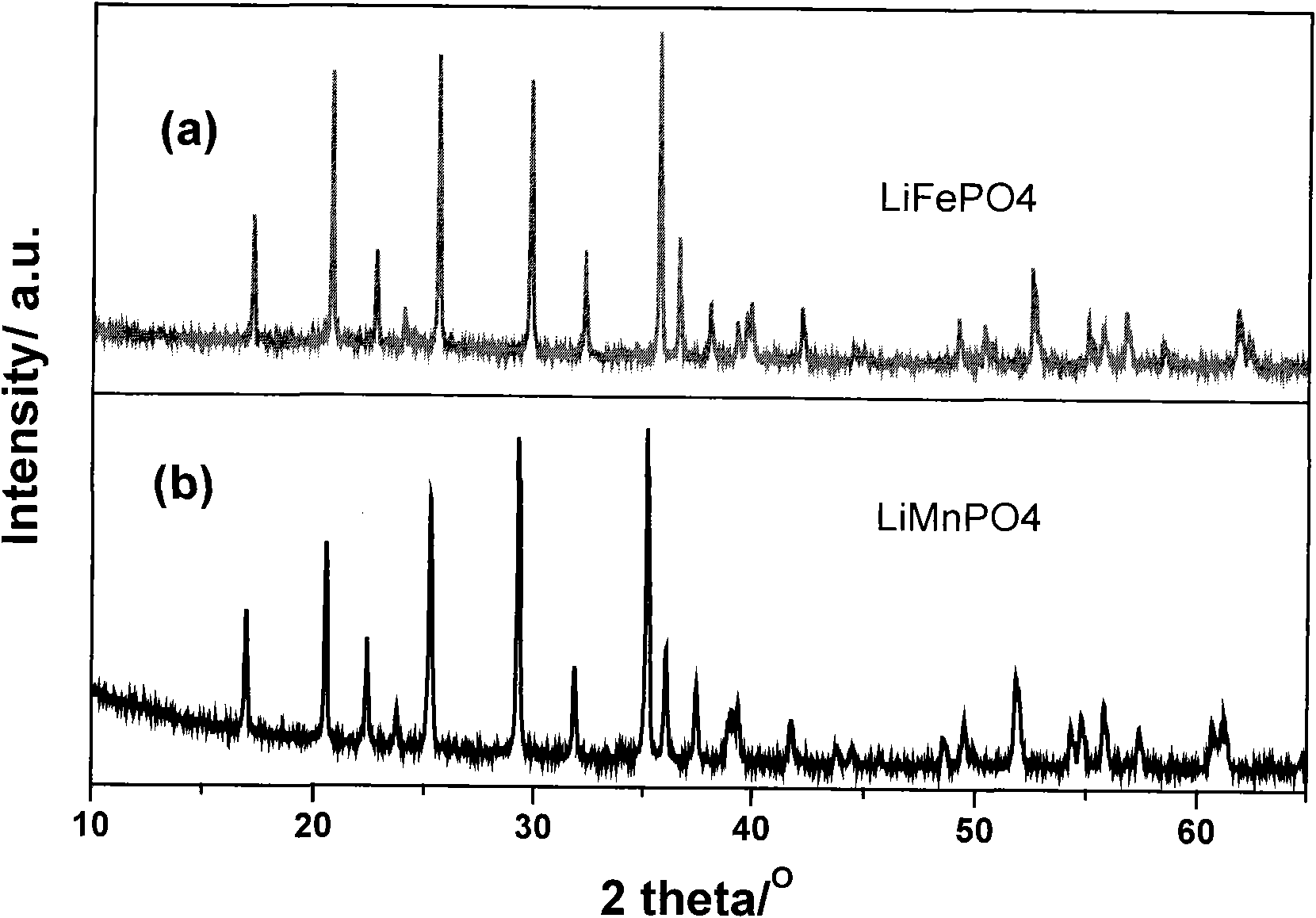

Nano-modified polyanionic cathode active material, preparation method thereof, and lithium ion secondary battery

ActiveCN102315444ARealize NanoizationImprove conductivityCell electrodesSecondary cellsLithiumPhysical chemistry

The invention relates to a nano-modified polyanionic cathode active material, a preparation method and a cathode-active-material-based lithium ion secondary battery. The cathode active material is the polyanionic cathode active material with high nanocrystallization degree obtained by uniformly mixing various metal ion source-containing precursors, polyanion-containing precursors and a lithium-containing precursor in a certain ratio in a solid phase or liquid phase mode, drying the mixture, and controlling the crystal growth by means of heat treatment; the molecular formula of the polyanionic material is LimMnXpOq, wherein m, n, p and q are any positive integers less than 10; M is one or a plurality of metals; and X is one or more of P, Si, S, As, Mo, W and the like. The preparation method of the invention is simple and convenient to operate, and is easy for large-scale production. The cathode-active-material-based lithium ion secondary battery has the advantages of high volume, high multiplying performance, high cyclical stability and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

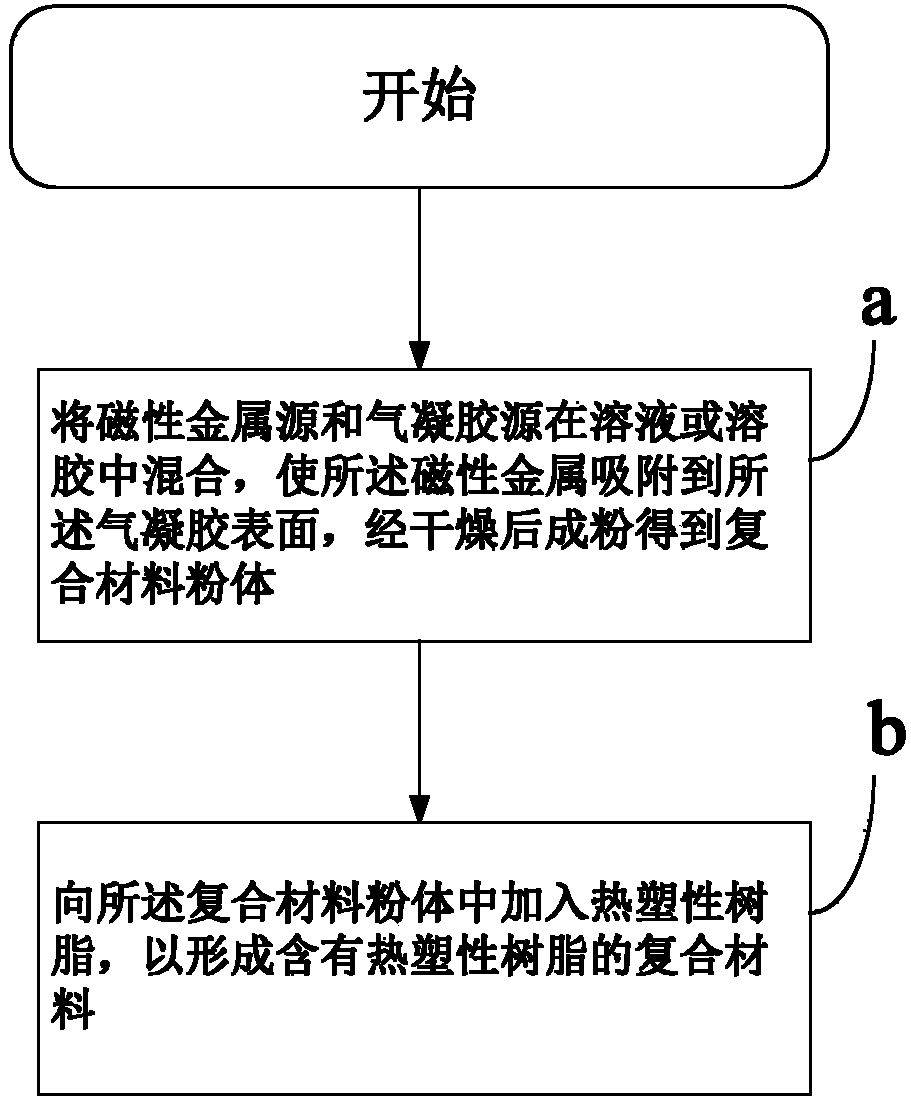

Microwave absorbing material and preparation method thereof

The invention discloses a microwave absorbing material. The microwave absorbing material comprises, by volume, 0.1-90% of aerogel, 0.1-50% of a magnetic metal and 5-90% of a thermoplastic resin. The preparation method of the microwave absorbing material comprises the following steps of a, coating the surface of aerogel with the magnetic metal by adsorption to obtain composite material powder, and b, adding the thermoplastic resin into the composite material powder to obtain the thermoplastic resin-containing composite material. The microwave absorbing material has the advantages of high resistivity, small density and good microwave-absorbing performances.

Owner:KUANG CHI INST OF ADVANCED TECH

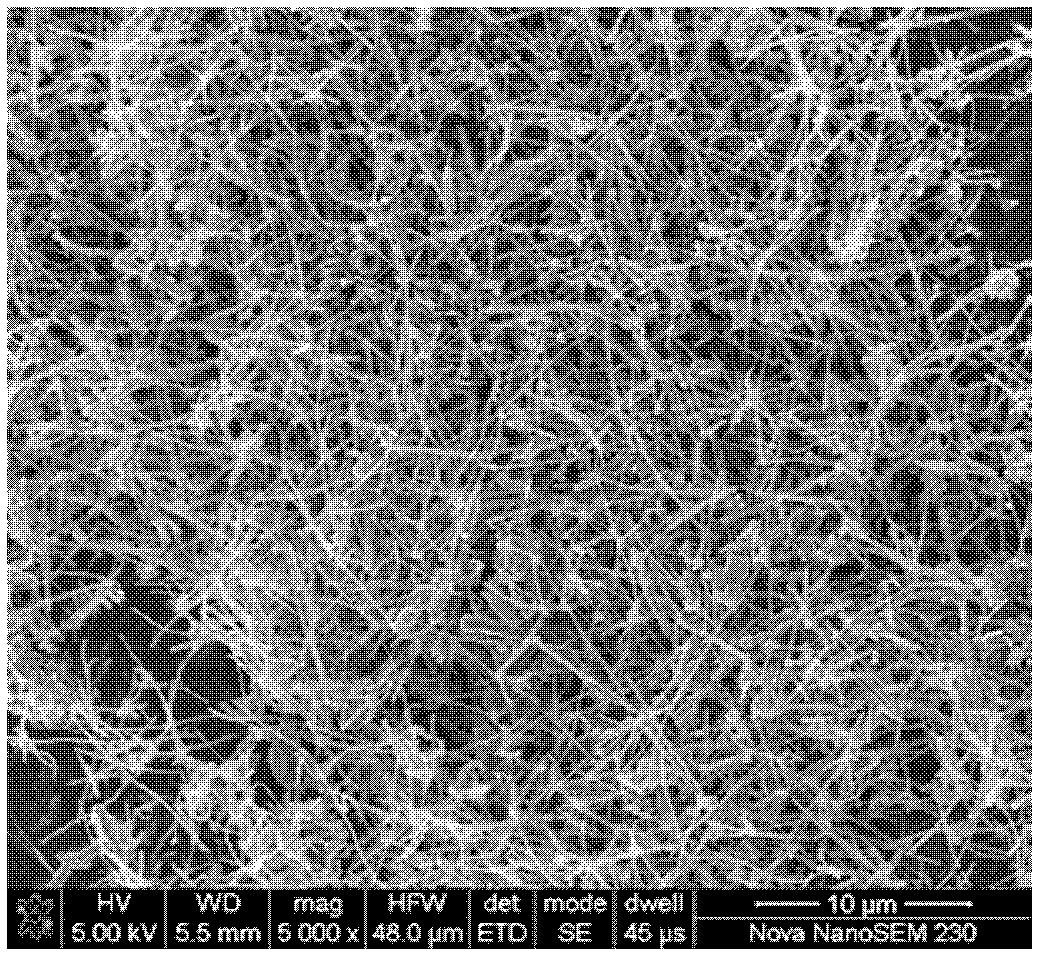

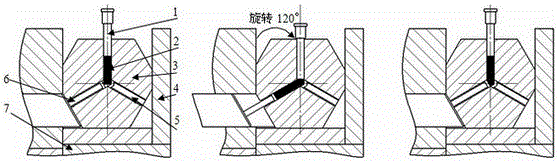

Method for preparing titanium alloy nano materials through warm extrusion of herringbone channel mold

The invention discloses a method for preparing titanium alloy nano materials through warm extrusion of a herringbone channel mold. The method is characterized in that through the herringbone central axis, the herringbone channel mold is rotated by 120 degrees, and then subsequent-pass extrusion is carried out; repeated plastic deformation of the titanium alloy nano materials can be achieved, and finally, large deformation is accumulated; the nano titanium alloy materials are obtained; in each pass extrusion process, the rotating direction of the herringbone mold is changed, and uniform severe plastic deformation of the titanium alloy can be achieved; and the grain size is uniform, and refined nano grains are equiaxed grains with large grain boundary angles, and the mechanical property of the blocky nano titanium alloy is further improved, and on the premise that the high density is ensured, the high strength and the good toughness are high.

Owner:福建省诺希科技园发展有限公司

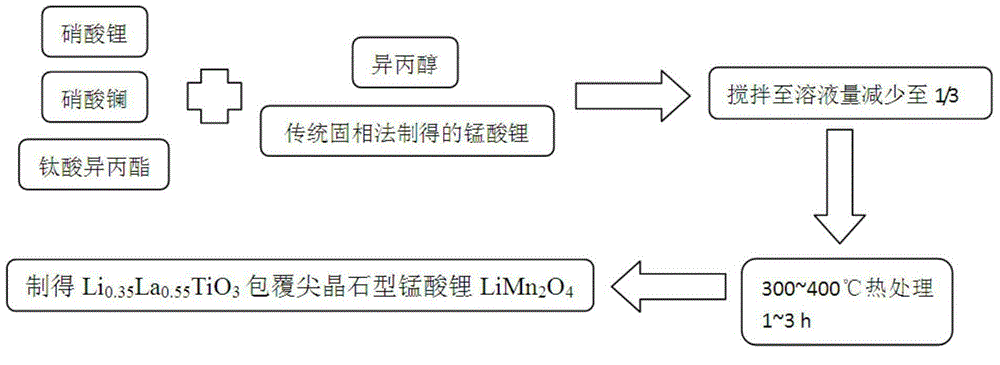

Method for synthesizing lithium ion battery positive electrode material

InactiveCN105206821AUniform and controllable thicknessReduce exposureMaterial nanotechnologyCell electrodesLanthanum nitrateLithium electrode

The invention discloses a method for synthesizing a lithium ion battery positive electrode material. The method comprises the following steps: dissolving lithium nitrate, lanthanum nitrate and titanium tetraisopropanolate in isopropyl alcohol to prepare an isopropyl alcohol solution; adding spinel-type lithium manganate into the isopropyl alcohol solution for stirring, and carrying out 1-3 hours' heat treatment at 300-400 DEG C to prepare Li0.35La0.55TiO3 coated spinel-type lithium manganate. According to the technical scheme, the method has the advantages that nanocrystallization of a coating layer can be effectively realized, and the coating thickness is uniform and controllable; through the coating layer with a nano-sized surface, the contact between LiMn2O4 and an electrolyte can be effectively reduced, side reactions triggered in a charge-discharge process of a lithium ion battery can be reduced, the stability of the lithium ion battery can be improved, and the high-temperature cycle life of the lithium ion battery can be prolonged.

Owner:SHANGHAI ELECTRICGROUP CORP +1

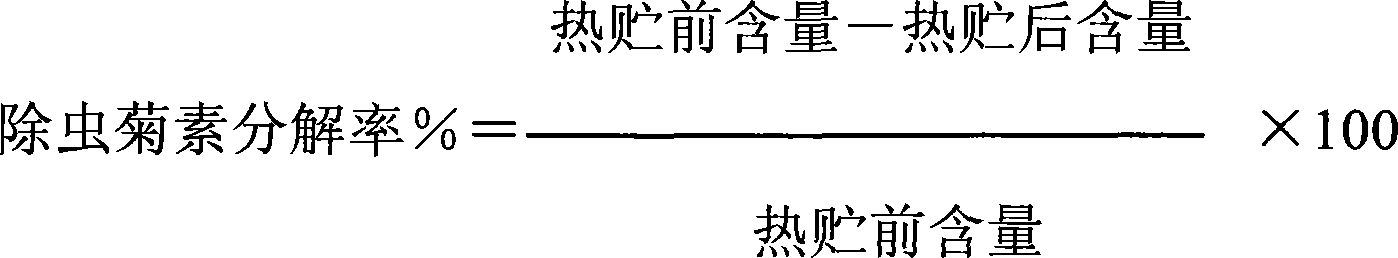

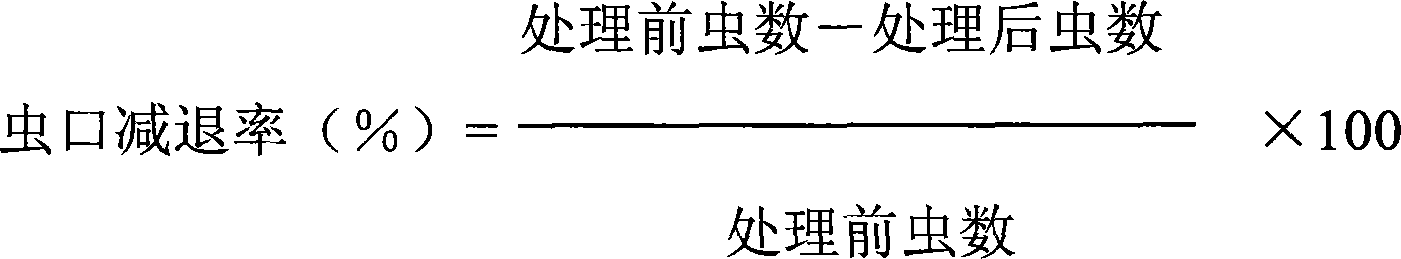

Insecticide of water micellar emulsion of natural pyrethrum element and preparation method

InactiveCN101049105ASave resourcesReduce manufacturing costBiocideAnimal repellantsEmulsionMicroemulsion

A natural pyrethrin microemulsion as an insecticide for preventing and killing the most of agricultural and vegetable pests is prepared from natural pyrethrin, natural assistant, chemical assistant, and water.

Owner:西双版纳创森实业有限公司

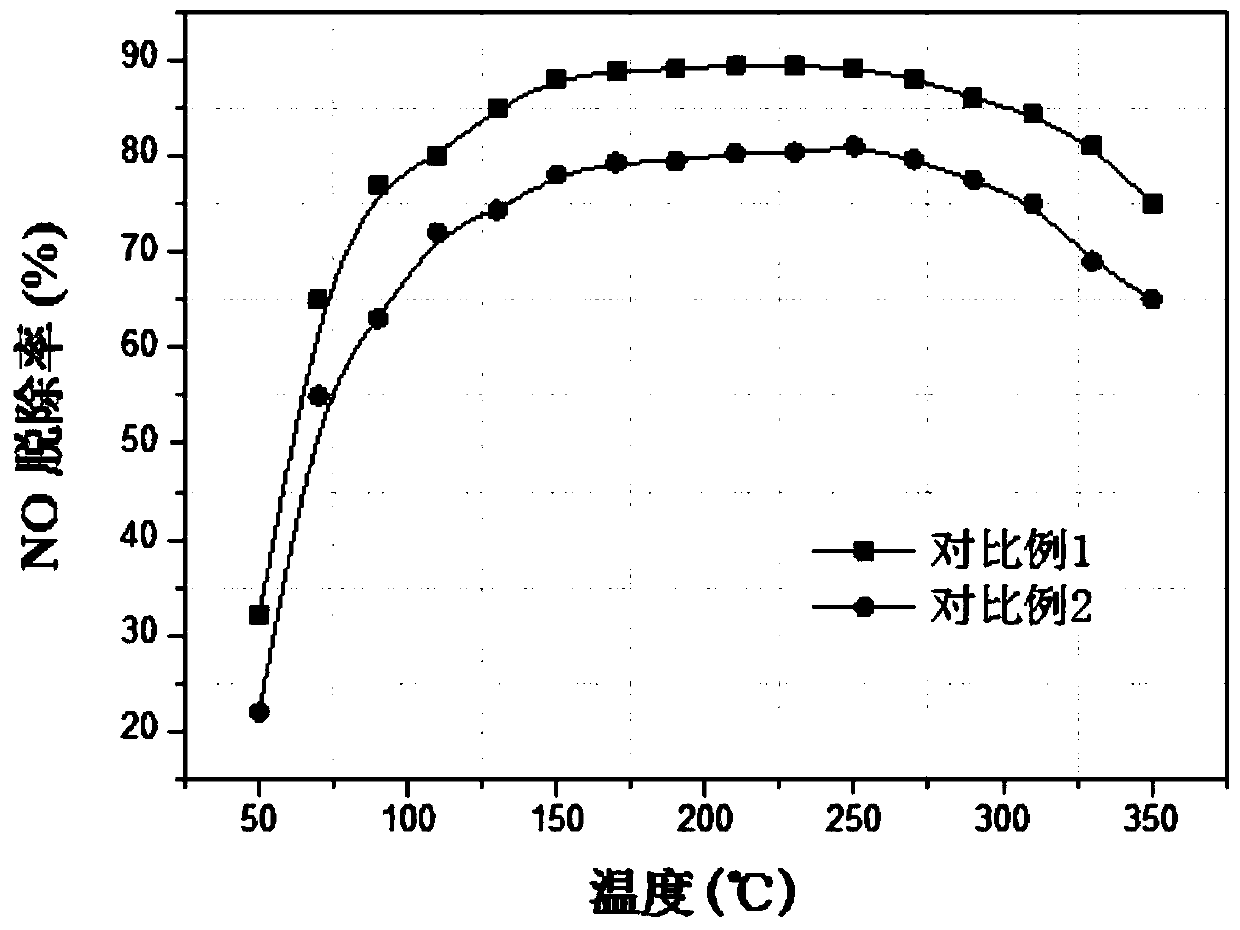

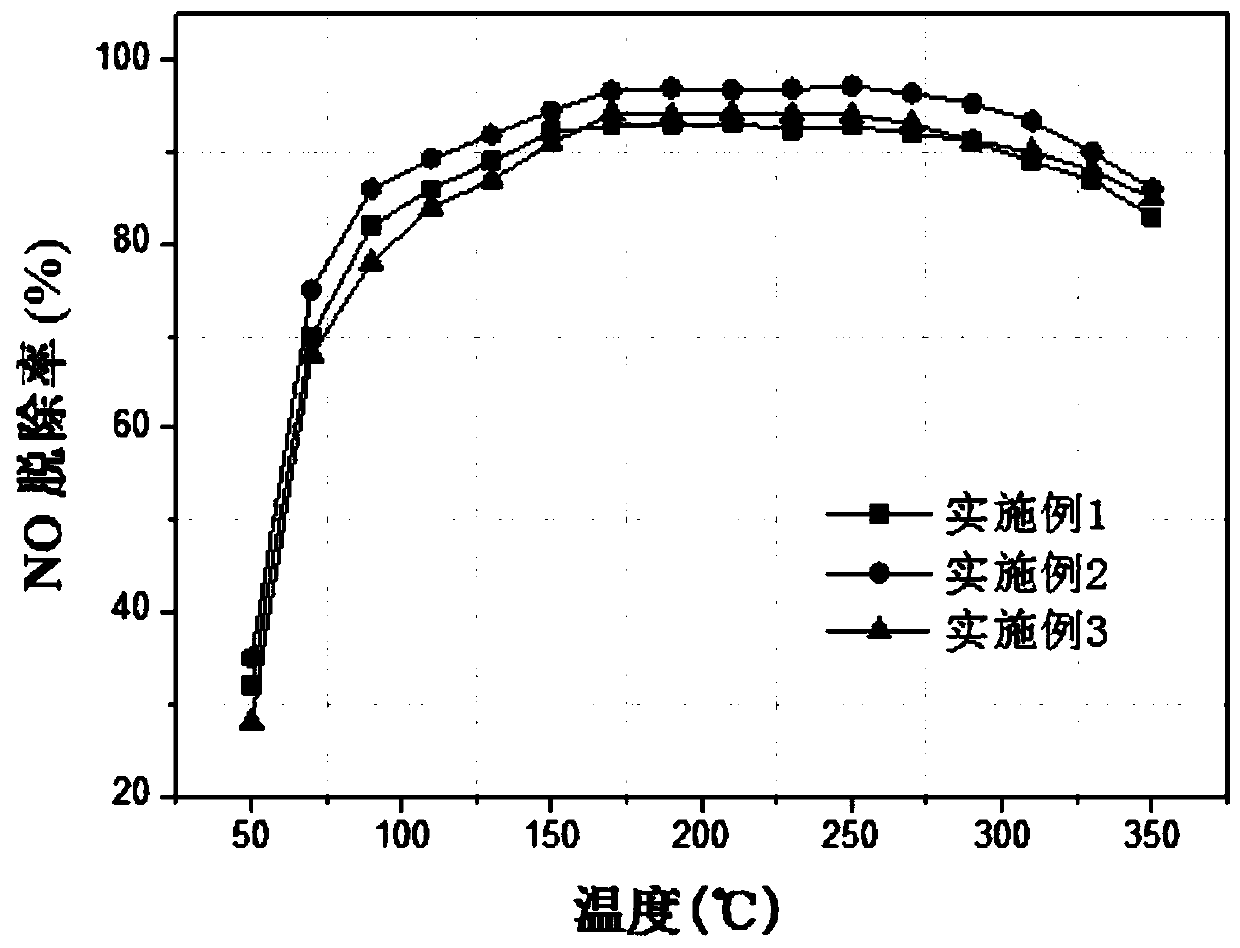

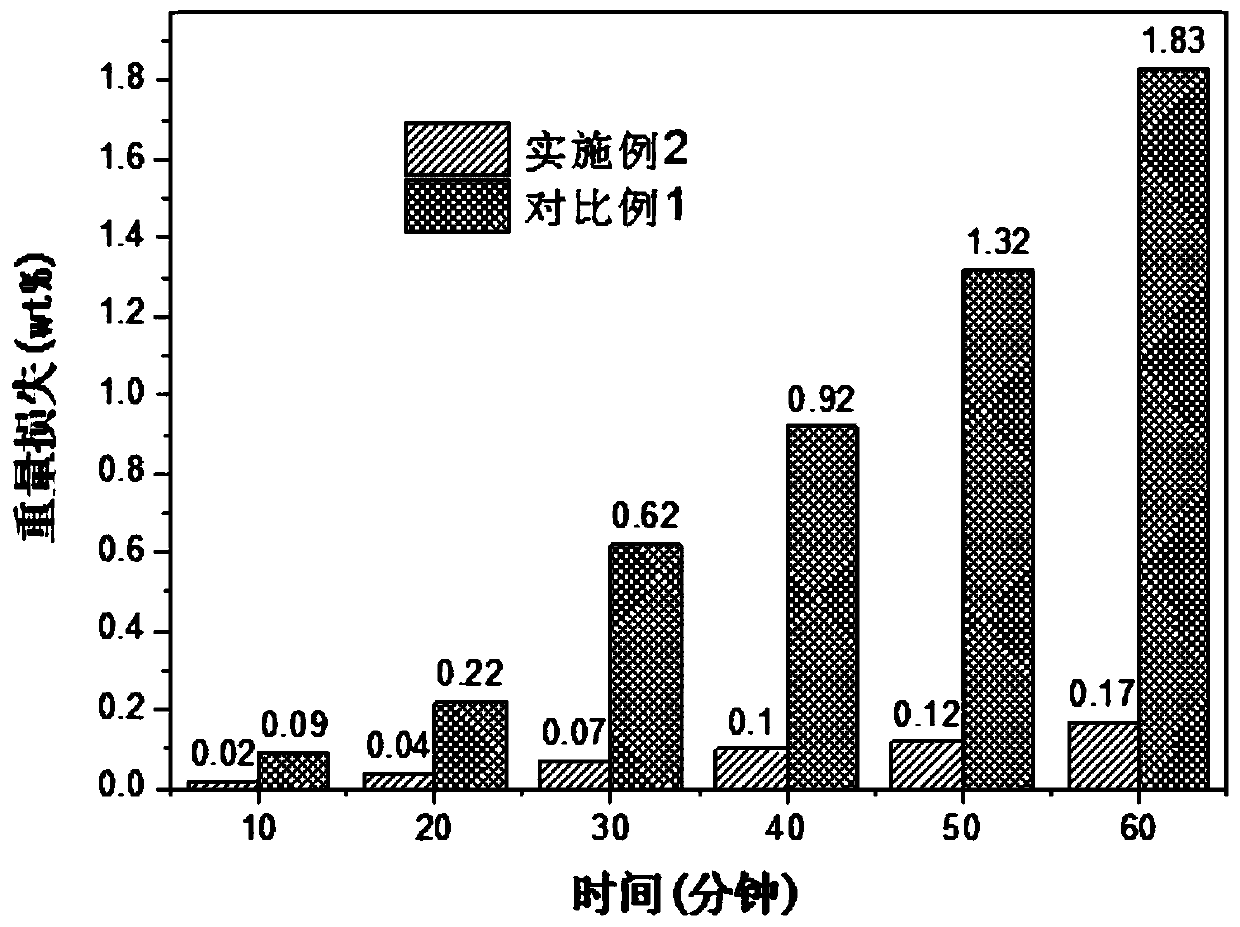

Preparation method of wire mesh denitration catalyst for SCR and catalyst prepared by preparation method

ActiveCN110368934AImprove adhesion strengthImprove bindingGas treatmentDispersed particle separationActive componentMetallic materials

The invention discloses a preparation method of a wire mesh denitration catalyst for selective catalytic reduction (SCR), and relates to the technical field of environmentally-friendly catalytic materials. The method is proposed based on the problem that an active component in a current denitration catalyst is not easily supported on the surface of a metal material carrier; and the method comprises the following steps: (1) performing etching on a carrier; and (2) performing impregnation on the carrier, performing drying, and performing calcination. The invention also provides the wire mesh denitration catalyst for the SCR prepared by the above preparation method. The method provided by the invention has the beneficial effects that the wire mesh denitration catalyst for the SCR prepared bythe method has good denitration performance under the temperature condition of 70-120 DEG C, and the activity at 80 DEG C reaches 80% or more.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

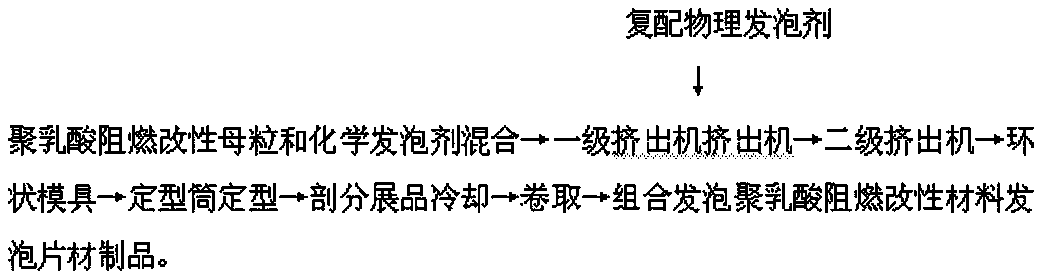

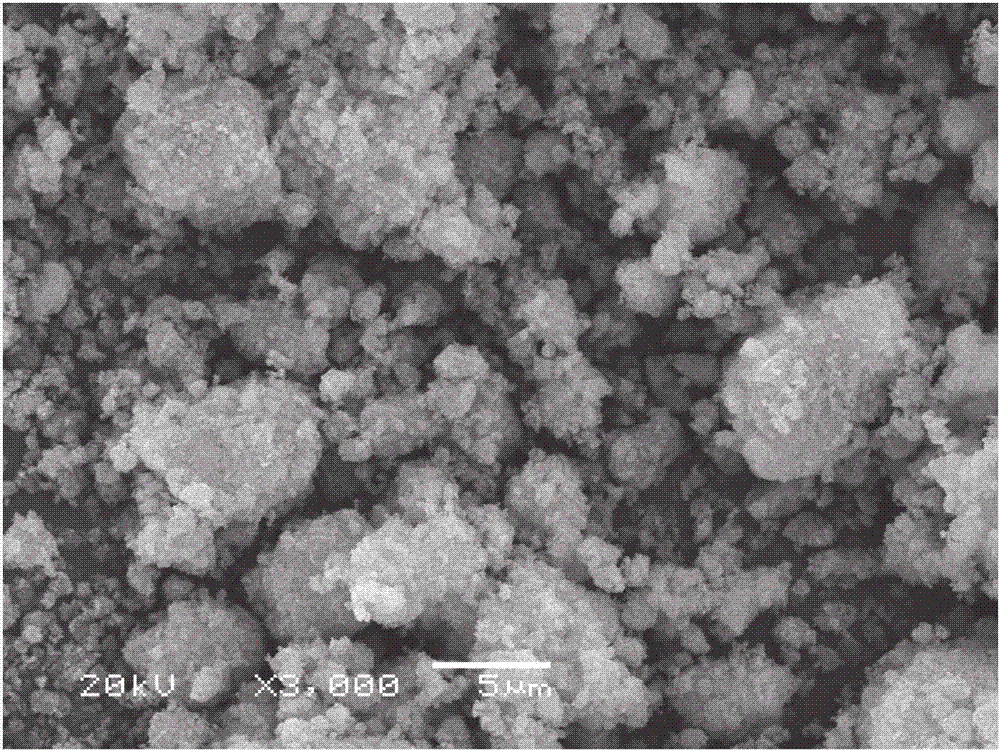

Combined foaming polylactic acid heat-resistant flame-retardant modified material and preparation method of product

The invention relates to a combined foaming polylactic acid heat-resistant flame-retardant modified material and a preparation method of a product, and belongs to the technical field of biodegradablefoaming materials. The preparation method comprises the following steps: weighing a flame retardant, a chain extender, a peroxide, a fatty acid amide compound refined from natural vegetable oil, a modifier, a degradable auxiliary material, polylactic resin and a nucleating agent in parts by weight; mixing the raw materials in a mixer according to the formula; melting, reacting and extruding the mixture in a twin-screw extruder at 160-210 DEG C to obtain polylactic acid flame-retardant modified masterbatch. The obtained polylactic acid flame-retardant modified masterbatch and a compound chemical foaming agent can be further mixed through various plastic processing modes, then a compound physical foaming agent is injected, and in cooperation with a supercritical fluid foaming agent conveyingdevice, the mixture is processed into the product in a large-scale mode. According to the technology, the foaming rate can be increased, the comprehensive performance of the foaming material is effectively improved, and the prepared foaming material and product have low apparent density and are widely applied to the fields of heat insulation, buffering and packaging.

Owner:广州绿徽新材料研究院有限公司

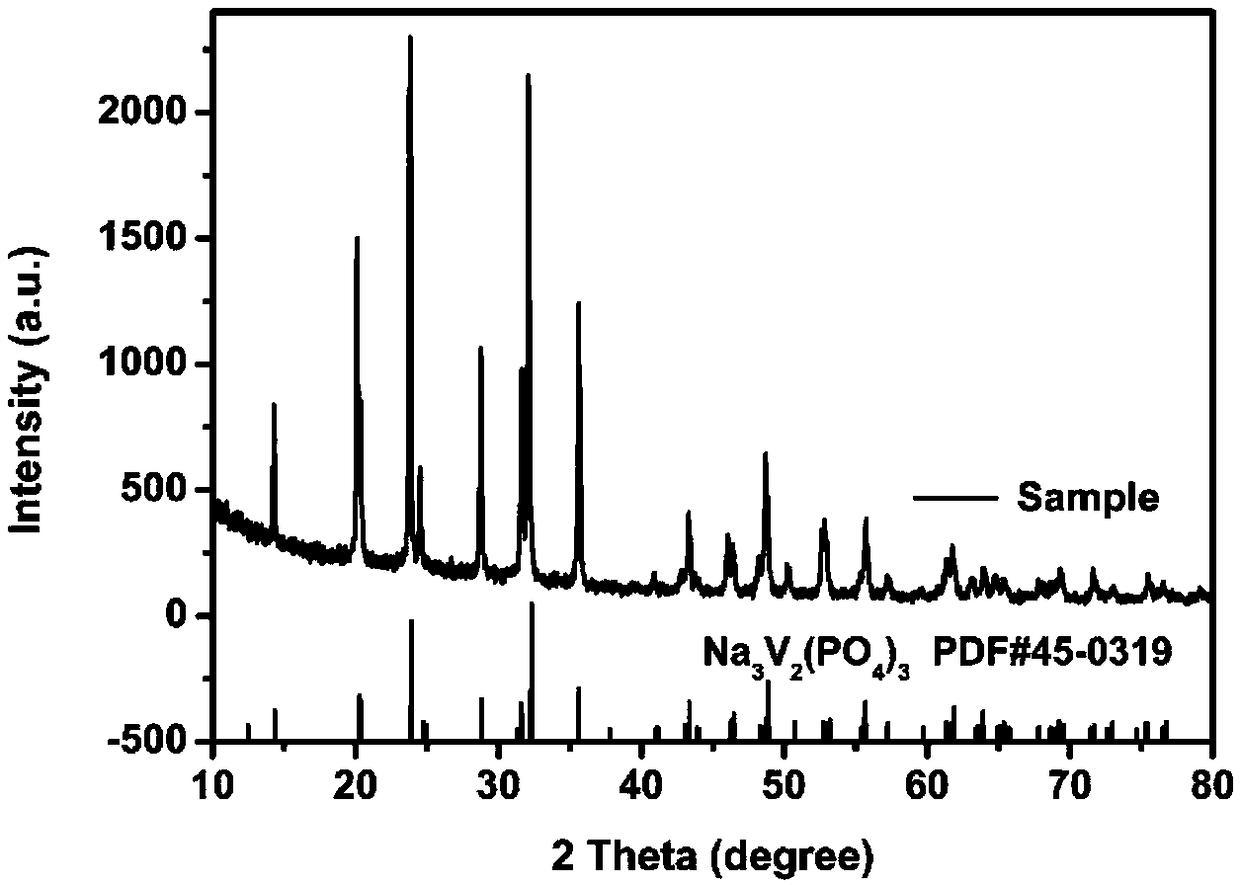

Sodium vanadium pyrophosphate/carbon composite positive electrode material, and preparation and application thereof

InactiveCN107017398ASolve the shortcomings of poor conductivityGood electrical propertiesMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention discloses a preparation method for a porous sodium vanadium pyrophosphate positive electrode material of a sodium-ion battery. According to the method, nitrogen-doped carbon-coated porous sodium vanadium pyrophosphate particles with uniform particle sizes are prepared by using a hydrothermal method. The preparation method comprises the following steps: subjecting vanadium-source monomers and nitrogen-containing carbon-source monomers to a hydro-thermal reaction so as to allow a corresponding conductive polymer to grow on vanadium oxide particles in situ; subjecting a hydro-thermal product, a sodium source and a phosphorus source to ball milling so as to obtain a precursor; and successively carrying out calcining, washing and drying so as to obtain the nitrogen-doped carbon-coated porous sodium vanadium pyrophosphate particles with uniform particle sizes. Moreover, the invention also discloses the positive electrode material of the sodium-ion battery prepared by using the preparation method. The preparation method provided by the invention is simple in process and low in cost for raw materials. The prepared material is nitrogen-doped carbon-coated porous sodium vanadium pyrophosphate. The hydrothermal method is employed for in-situ generation of the conductive polymer on the surface of the vanadium source to adjust the morphology of the material and uniformity of a carbon layer; and the material is used for the sodium-ion battery and shows excellent electrochemical performance.

Owner:CENT SOUTH UNIV

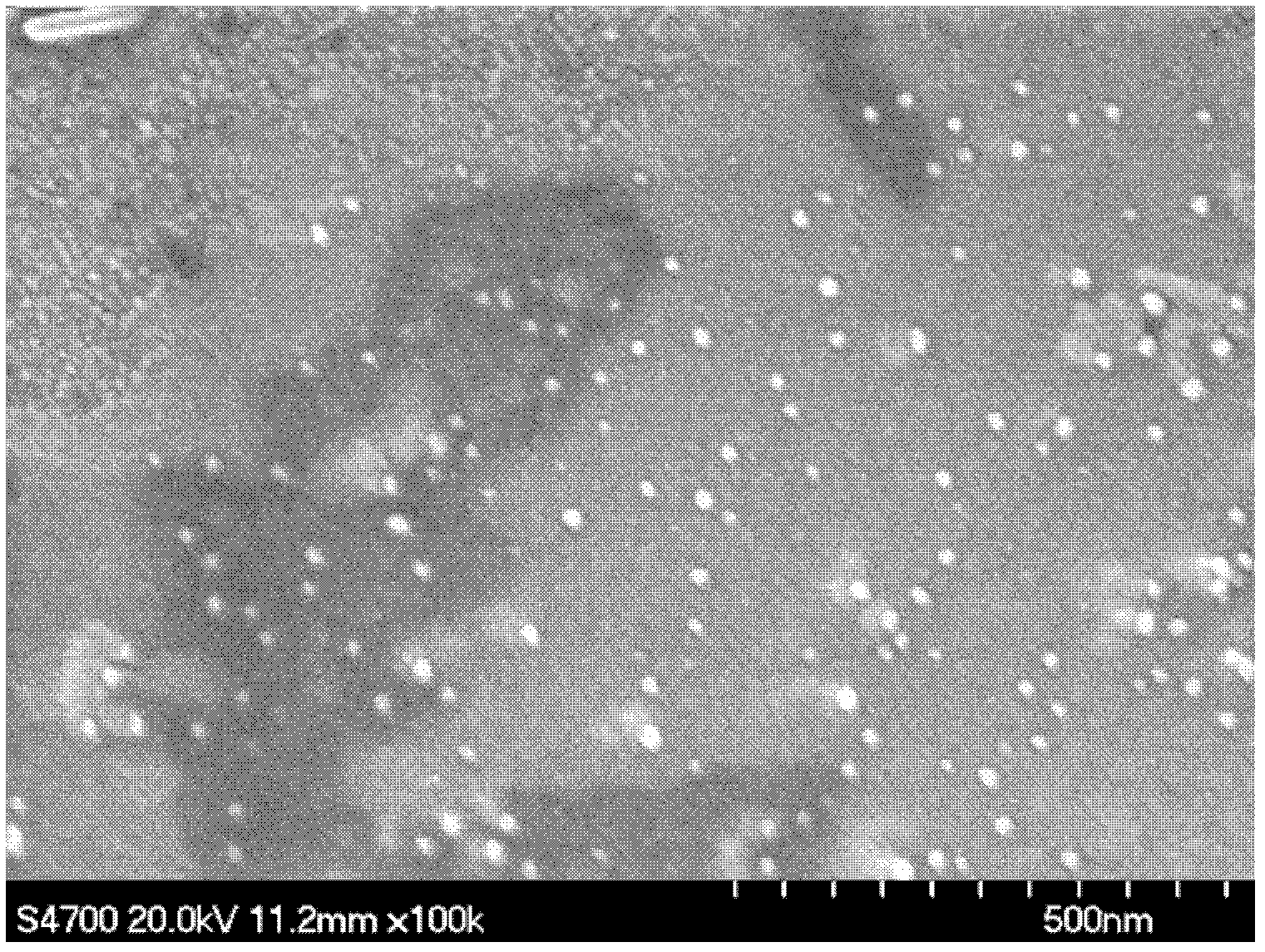

Method for preparing nano-phase reinforced nickel-based superalloy by adopting micron ceramic particles

ActiveCN112011702AFine grainGood mechanical propertiesMaterial nanotechnologyAdditive manufacturing apparatusMicron scaleNanoceramic

The invention provides a method for preparing a nano-phase reinforced nickel-based superalloy by adopting micron ceramic particles. In the nano-phase reinforced nickel-based superalloy, a nickel-basedsuperalloy is taken as a matrix, and one or more of TiC, TiB2, WC and Al2O3 are taken as a reinforcing phase. The particle size of a ceramic particle raw material as the reinforcing phase is 1-5 [mu]m; the adding amount of the ceramic particle raw material is 1 to 5 percent by weight; nickel-based superalloy composite powder with uniformly distributed nano-ceramics is prepared through a specificball milling process; the nano-ceramic phase reinforced nickel-based superalloy is prepared through a 3D printing technology; and the prepared material is uniform in nano-ceramic phase distribution and has excellent mechanical properties. Micron-sized ceramic particles are adopted, so that the cost is low; and parts in any complex shape can be integrally formed and prepared, so that the material utilization rate is increased.

Owner:CENT SOUTH UNIV

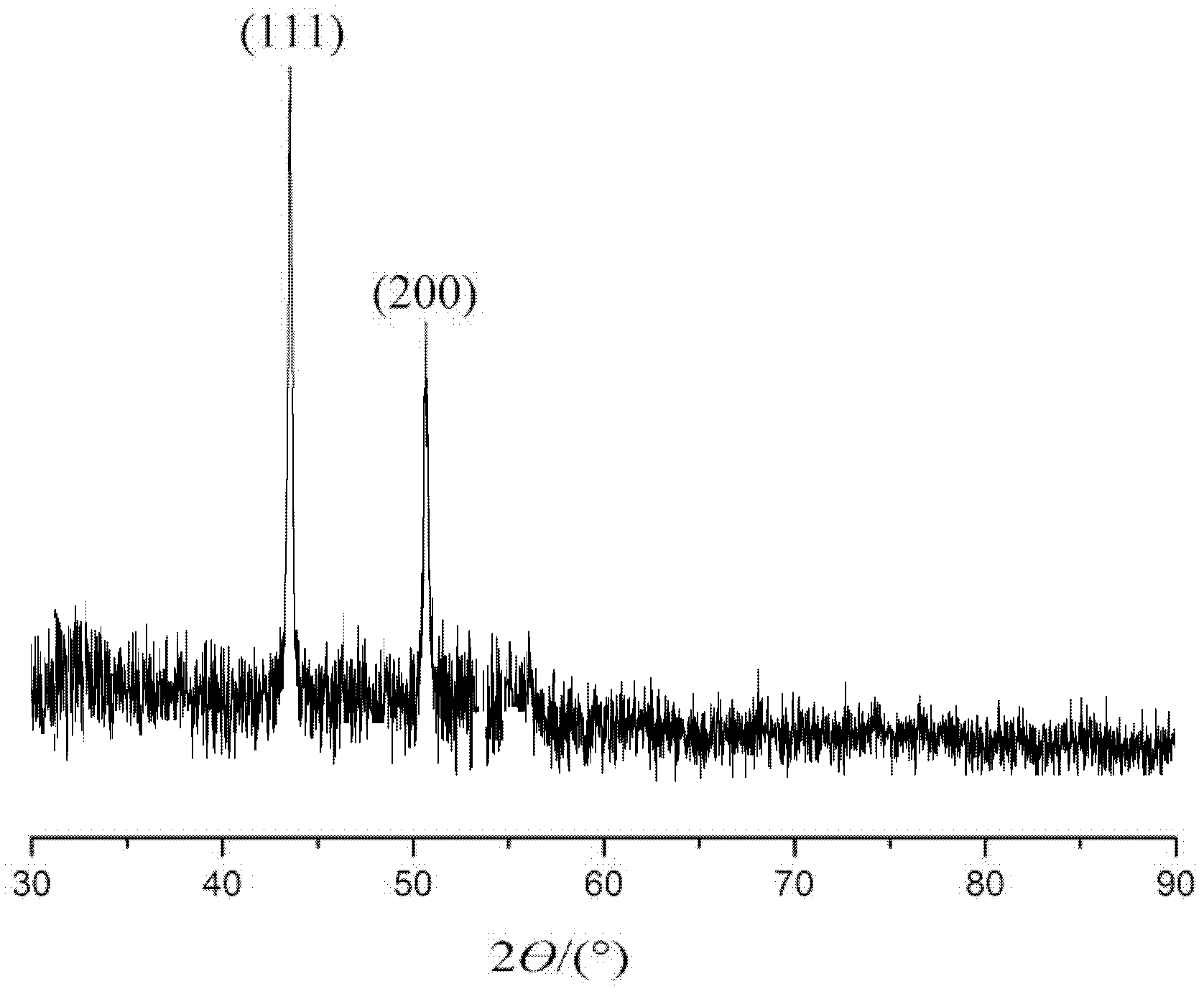

Photoinduced copper ion metal nanocrystallization method

The invention discloses a photoinduced copper ion metal nanocrystallization method. Under a photophobic condition, copper salt, photoinitiator and additive are fully dissolved by solvent and mixed uniformly to prepare a reaction solution system; and then the reaction solution system is injected into a light transmission container, radiated by a light source with the absorption wavelength being corresponding to that of the photoinitiator to generate metal copper nano particles. A preparation process is simple, the material cost is low, high-purity and non-impurity metal copper nano particles can be obtained, the stability of the reaction system is high when the reaction system is photophobic, the immediate starting and immediate stopping of the reaction are realized by controlling the on and the off of the light source, and the sizes of the particles are controlled by adjusting the reaction time.

Owner:BEIJING UNIV OF CHEM TECH

Internal stress self explosion auxiliary crushing method

InactiveCN1943865ARetain biological activityNano crushing is easy to handlePowder deliveryGrain treatmentsWater immersionThermal expansion

The present invention relates to crushing technology for mineralized biomass and is internal stress explosion aided crushing method. Based on the differences between the organic matter and inorganic matter inside the mineralized biomass in thermal expansion coefficient and water immersion capacity, the mineralized biomass is applied with thermal shock and water soaking, so as produce great internal stress and thus spontaneous explosion and cracking. The present invention may be used in the pre-treatment of superfine crushing mineralized biomass, such as pearl, and has the advantages of simple operation, no pollution, low cost and other advantages.

Owner:TSINGHUA UNIV

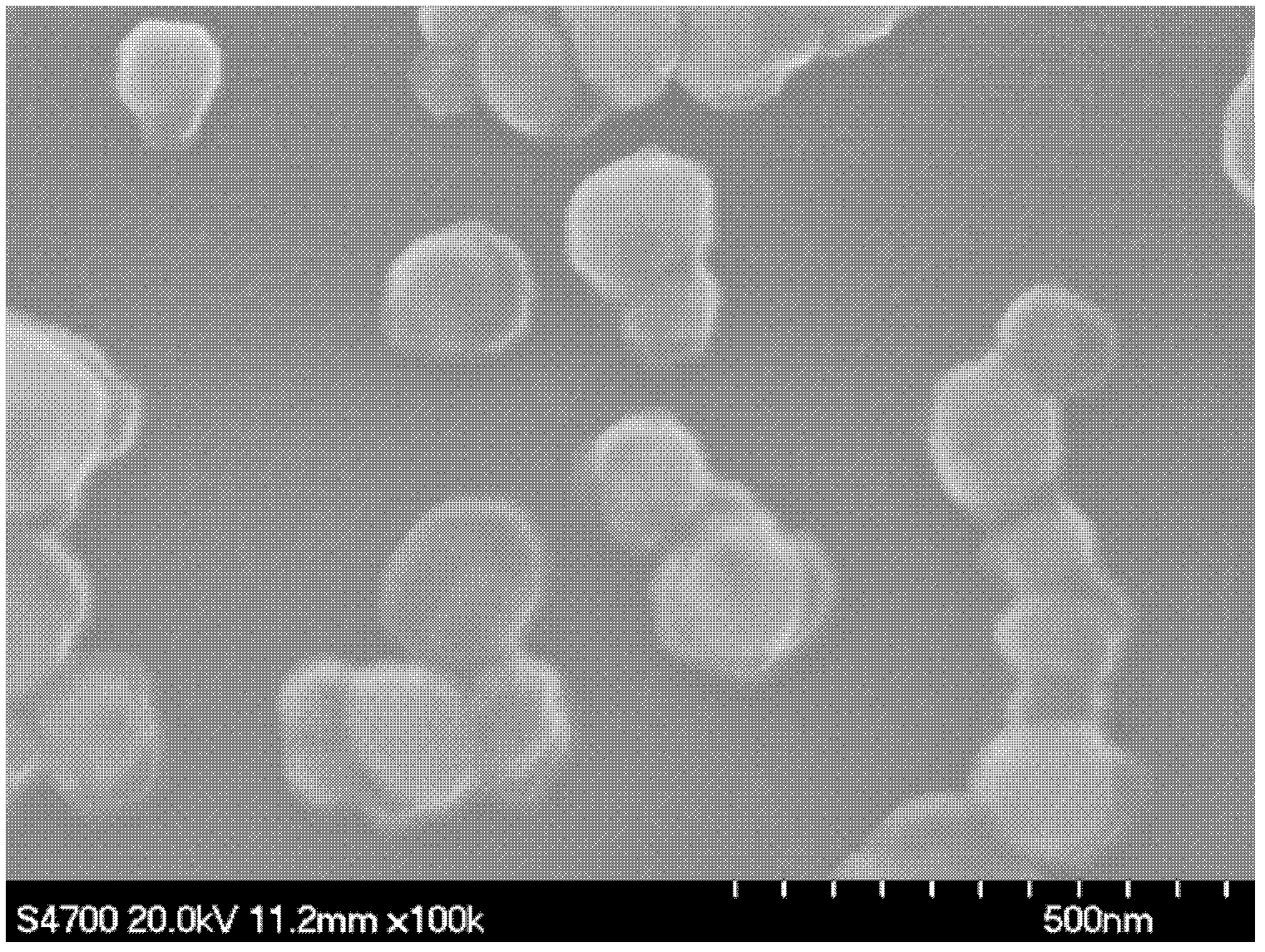

Metal-catechin composite nano-material as well as preparation method and application thereof

ActiveCN113045528AImprove stabilityLowered coordination numberOrganic active ingredientsOrganic chemistryAnti-inflammatoryChemistry

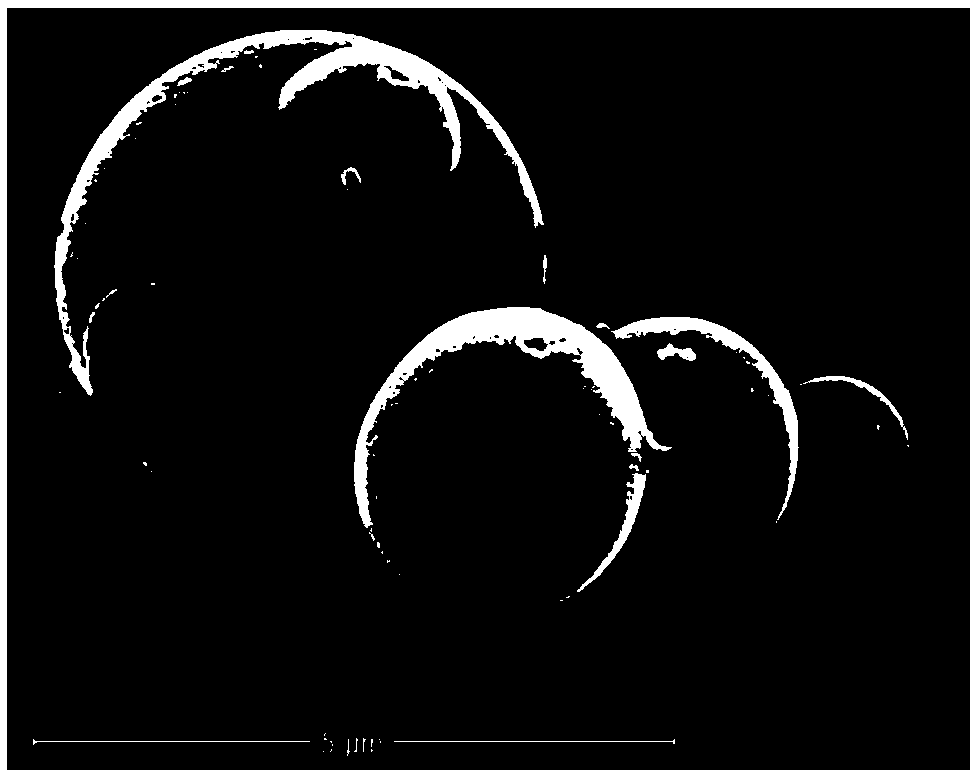

The invention relates to a metal-catechin composite nano-material as well as a preparation method and application thereof. The metal-catechin composite nano-material is spherical nano-particles formed by coordination binding of metal ions and catechin, and the diameter of the metal-catechin composite nano-material is 5-500 nm. According to the principle of metal-organic coordination, a metal salt solution and a catechin solution are mixed and stirred at 20-80 DEG C to prepare the metal-catechin composite nano-material. The stability of the prepared metal-catechin composite nano-material is remarkably improved, meanwhile, the metal-catechin composite nano-material can be easily endocytosed by cells with uptake capacity such as stem cells, immune cells and tumor cells, catechin molecules can be efficiently released, the metal-catechin composite nano-material participates in the intracellular process, and the metal-catechin composite nano-material further has good degradability. Meanwhile, the nano-material has high bone formation promoting and fat formation inhibiting efficiency, can be used for bone defect repair based on bone tissue engineering of stem cells, can also be used as an anti-fat-forming agent to inhibit inflammatory response of macrophages, can be used for anti-inflammatory treatment of inflammatory diseases, and can also be used for bone tissue repair assisted by the macrophages.

Owner:SHANDONG UNIV

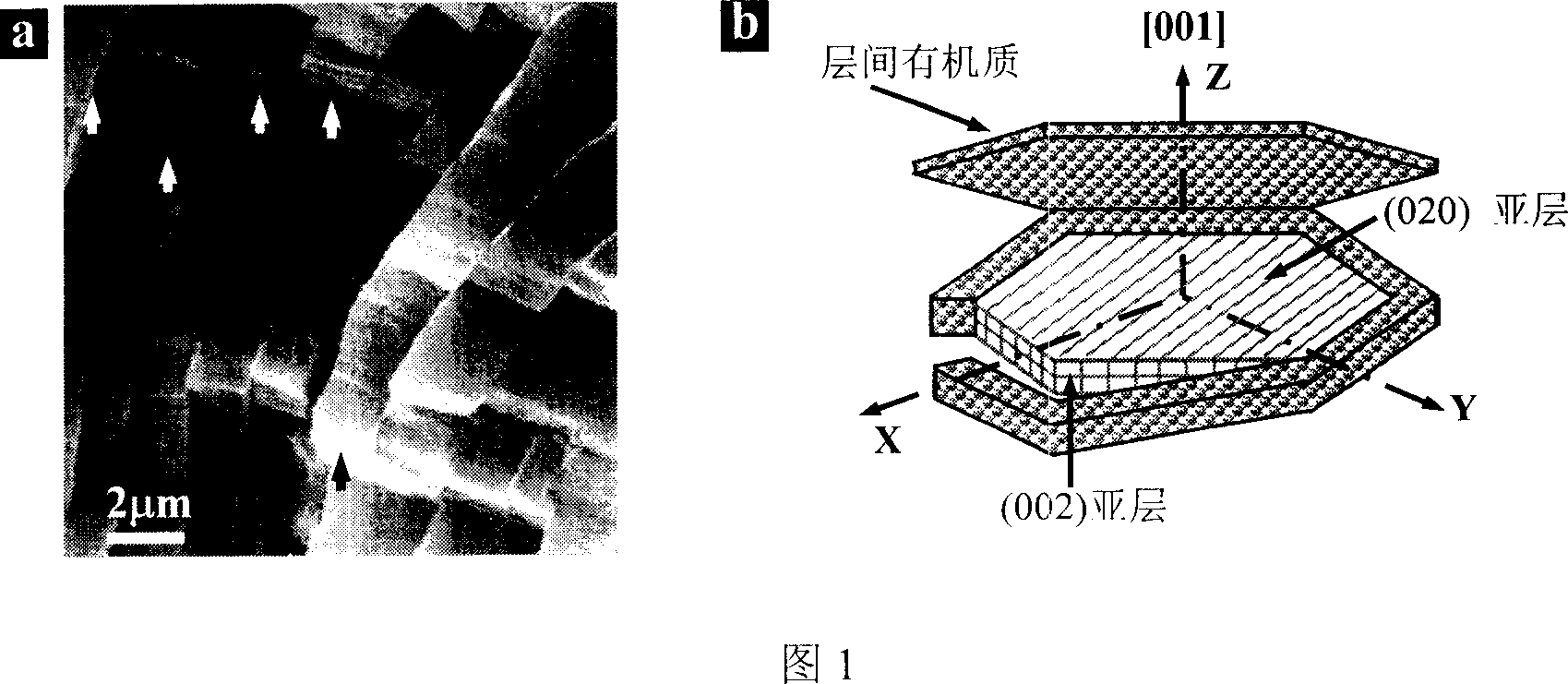

Nanostructure-containing polycrystalline diamond, polycrystalline diamond composite sheet and preparation method thereof

InactiveCN110227822AOvercoming difficulties in the preparation processOvercome cleavage brittle fractureTransportation and packagingMetal-working apparatusNanometrePolycrystalline diamond

The invention relates to a nanostructure-containing polycrystalline diamond for cutting tools, grinding tools, drill tools and wear parts, a polycrystalline diamond composite sheet and a preparationmethod thereof. The polycrystalline diamond layer in the polycrystalline diamond or the polycrystalline diamond composite sheet is composed of continuous and bonded diamond components and a catalyticmaterial located in the gaps thereof, wherein the diamond component comprises a nanostructured polycrystal (polycrystalline) diamond particles, which are micron-sized and Carbonado-type nanostructuredpolycrystalline diamond particle raw materials prepared by an explosion method. The catalytic material located in the gaps may be partially or completely removed to enhance the thermal stability of the polycrystalline diamond or polycrystalline diamond composite sheet. The preparation method comprises sintering the diamond particles under the conditions of high temperature and high pressure withthe help of the catalytic material, wherein the diamond particles comprise the Carbonado-type nanostructured polycrystalline diamond particles.

Owner:姜文辉

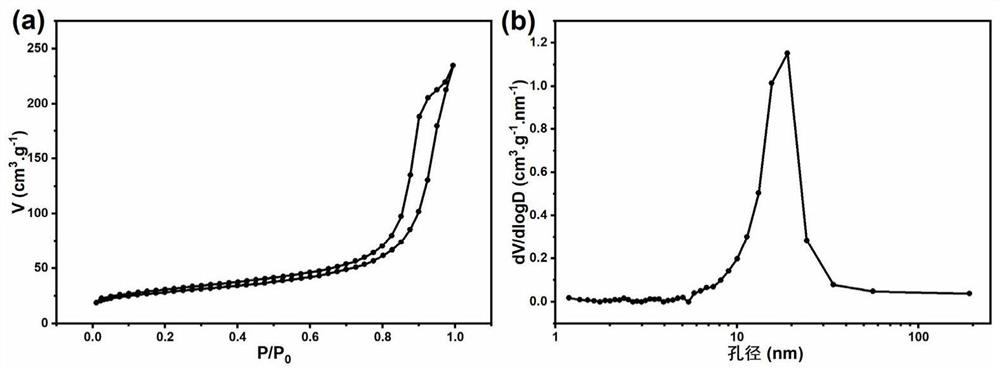

Method for preparing multi-stage spherical sodium vanadium phosphate composite positive electrode material

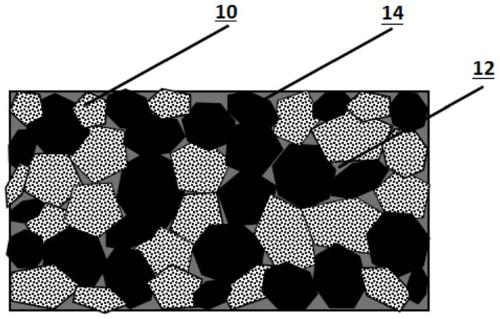

InactiveCN108807899AWell-developed grainsSmall granularityCell electrodesSecondary cellsMicrosphereSodium-ion battery

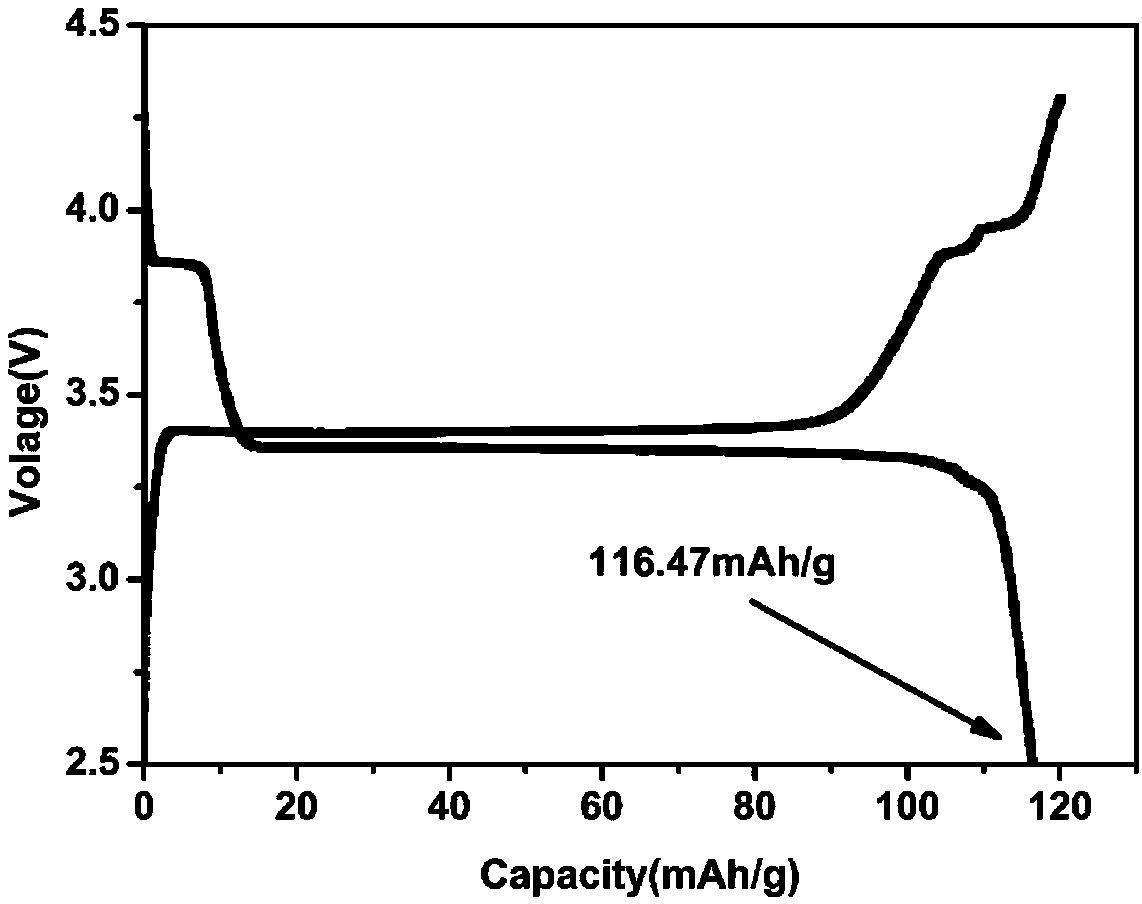

The invention relates to a method for preparing a multi-stage spherical sodium vanadium phosphate composite positive electrode material. The method comprises the following steps: using oxalic acid, avanadium source, a sodium source and a phosphorus source as main raw materials, and using urea as a pelletizing agent and a carbon source, forming a spherical sodium vanadium phosphate precursor by ahydrothermal method, drying the precursor and subjecting to two-step heat treatment in a nitrogen atmosphere to obtain the multi-stage spherical sodium vanadium phosphate composite positive electrodematerial. The sodium vanadium phosphate composite positive electrode material obtained by the invention has multi-stage spherical morphology, and the microsphere particles have a diameter of 1 to 5 mum. The positive electrode material can be used for a sodium ion battery. In a working voltage range of 2.5 V to 4.3 V, under the 0.1C rate, the first-round discharge specific capacity can reach 116.47 mAh / g; under the 10C rate, the first-round discharge specific capacity is 95 mAh / g, and the capacity retention rate is 98% or above after 100 times of complete charging and discharging process withcertain current. Compared with the prior art, the method not only improves the electrochemical performance of the positive electrode material, but also the method for synthesizing the spherical morphology is simple and effective.

Owner:WUHAN UNIV OF TECH

High heat value fuel and preparation method thereof

The invention provides a high heat value fuel and a preparation method thereof. According to the present invention, methanol is used as a main material, and is supplemented with polyethylene glycol 400, an organic nano-modified nickel-aluminum-molybdenum alloy is introduced, and a gelled structure is formed through a photopolymerization reaction, wherein the organic nano-modified nickel-aluminum-molybdenum alloy is chemically bonded to the pores of the gelled structure, has a stable structure, and has a heat value synergistic effect on methanol and polyethylene glycol 400, and the gelled structure can increase the contact area between oxygen and fuel, promote the complete combustion of sufficient fuel, reduce the combustion cost, and greatly increase the heat value of the product.

Owner:重庆品坊新能源技术开发有限公司

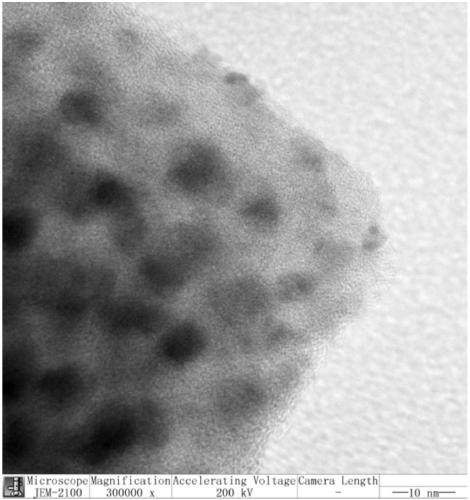

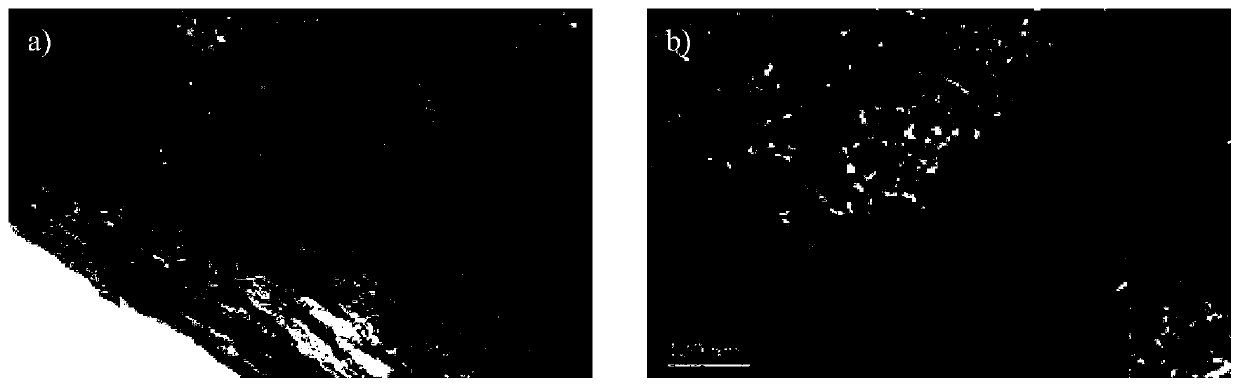

Molybdenum carbide/carbon nano hydrogen production catalyst synthesized by utilizing ink

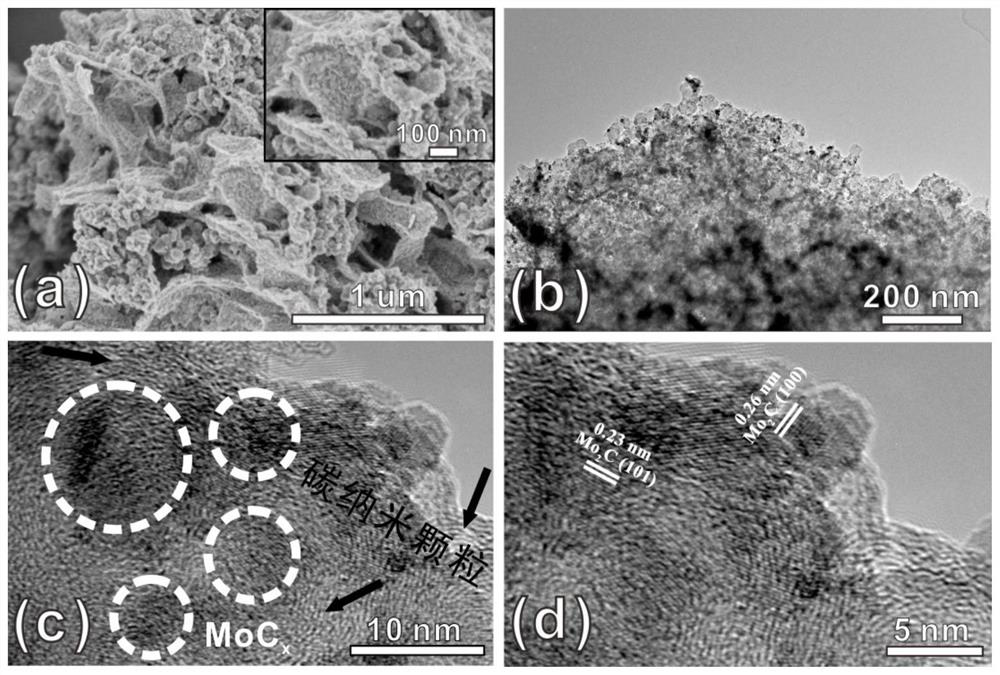

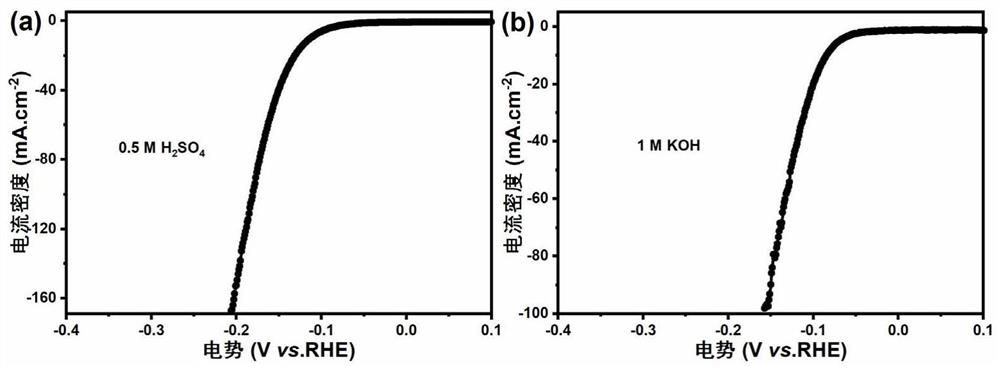

ActiveCN111905783ARaw materials are easy to getLow priceCatalyst activation/preparationElectrodesPtru catalystElectrolysis

The invention discloses an ink-assisted synthesized molybdenum carbide / carbon nano electro-catalytic hydrogen production catalyst with a 3D hierarchical porous structure, which is characterized by comprising molybdenum carbide nano-particles and carbon nano-particles, wherein the molybdenum carbide nano-particles and the carbon nano-particles are crossed, and the molybdenum carbide nano-particlesare located in the active center of the catalyst. The carbon nanoparticles are derived from ink, have a graphitization-like structure, carry negative charges and have a three-dimensional hierarchicalporous structure, and the catalyst electrolyzes water to produce hydrogen under acidic or alkaline conditions. The 3D hierarchical porous structure in the electrocatalyst can effectively promote transmission of electrolyte and diffusion of generated hydrogen bubbles, and under the synergistic effect of rich double-pore structures, highly-dispersed active nanoparticles and excellent electrocatalytic conductivity brought by adjustable free carbon content, the overpotential in the water electrolysis hydrogen production process is greatly reduced, and excellent electrocatalytic hydrogen productionactivity and stability are obtained.

Owner:FUDAN UNIV

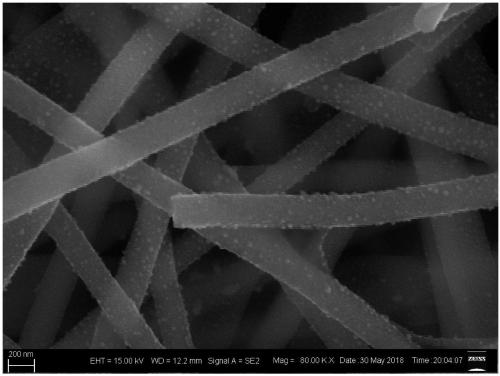

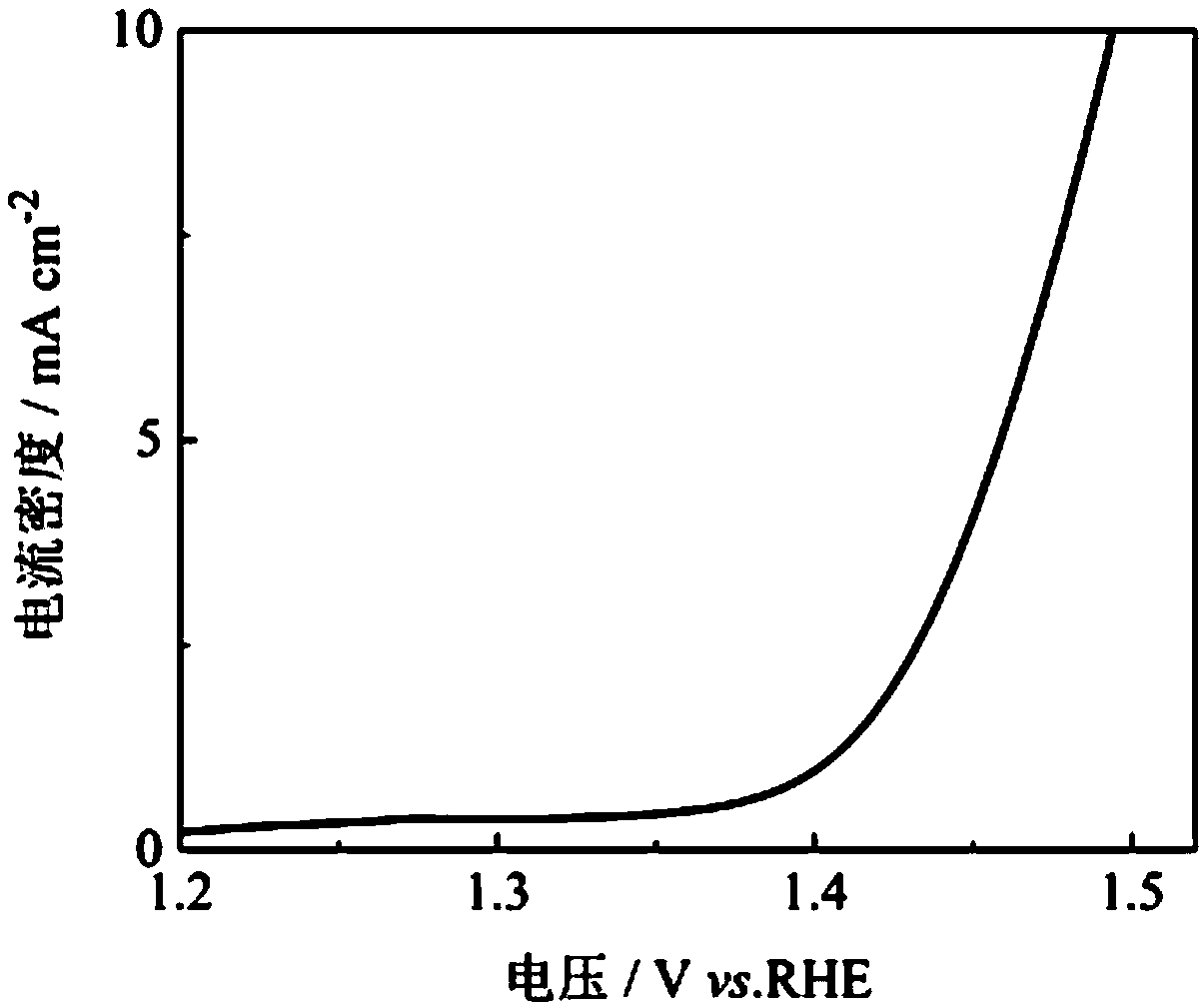

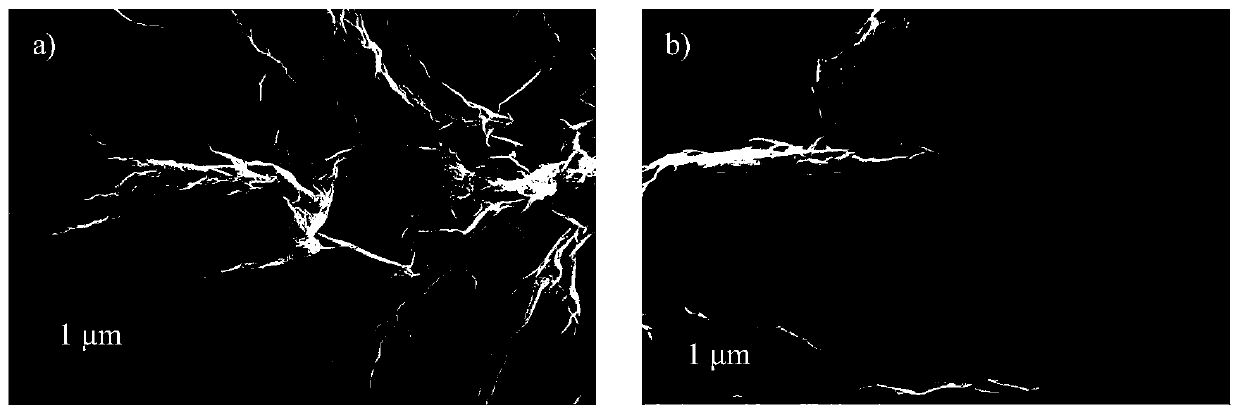

Nitrogen and sulfur in situ co-doped nickel cobalt based carbon fiber electrolytic water catalyst and preparation method thereof

ActiveCN109046426ASimple and effective preparation methodImprove activity and stabilityPhysical/chemical process catalystsElectrodesFiber matrixElectrospinning

The invention discloses a nitrogen and sulfur in situ co-doped nickel cobalt based carbon fiber electrolytic water catalyst and a preparation method thereof, and relates to a nickel cobalt based carbon fiber electrolytic water catalyst and a preparation method thereof. The invention aims at solving the problems of low electrolytic efficiency and poor stability of a used catalyst in the existing preparation of hydrogen. The catalyst is prepared from a carbon fiber matrix and nanoparticles, wherein the nanoparticles are loaded at the inner part and on the surface of the carbon fiber matrix. Thepreparation method comprises the following steps: weighing nickel nitrate, cobalt nitrate and a thioamide compound according to the molar ratio of all elements in molecular formulae NixCoyNz and NiaCobSxc, and then adding polyvinyl pyrrolidone to obtain a precursor solution; carrying out electrostatic spinning and finally carrying out high temperature sintering. The nitrogen and sulfur in situ co-doped nickel cobalt based carbon fiber electrolytic water catalyst material, disclosed by the invention, has the advantages of better catalyst activity and stability and double function catalysis of hydrogen precipitation and oxygen precipitation; the electrolytic efficiency reaches as high as 95 percent. The preparation method disclosed by the invention is suitable for preparing an electrolytic water catalyst.

Owner:HARBIN INST OF TECH

Manufacturing method of graphene/manganese dioxide super-capacitor electrode

ActiveCN110534355ALarge specific surface areaStrong mechanical strengthMaterial nanotechnologyCarbon compoundsCvd grapheneCapacitance

A manufacturing method of a graphene / manganese dioxide super-capacitor electrode belongs to the functional carbon material manufacturing field. The manufacturing method comprises the following steps of manufacturing a graphene / manganese dioxide compound without a template and other surfactants, wherein the graphene / manganese dioxide compound is composed of the graphene and manganese dioxide nanoparticles uniformly loaded between graphene layers, and a diameter of the manganese dioxide nanoparticles is 10-20 nm; and then manufacturing the graphene / manganese dioxide compound into a super-capacitor electrode. The graphene / manganese dioxide supercapacitor electrode manufactured in the method is placed in a 1mol / L NaSO4 electrolyte. A capacitance of a super capacitor measured under a 1.6 V potential window is 380-540F / g, and the capacitance is 85-90% of an initial value after 1000 cycles under 100mV / s.

Owner:王习宇

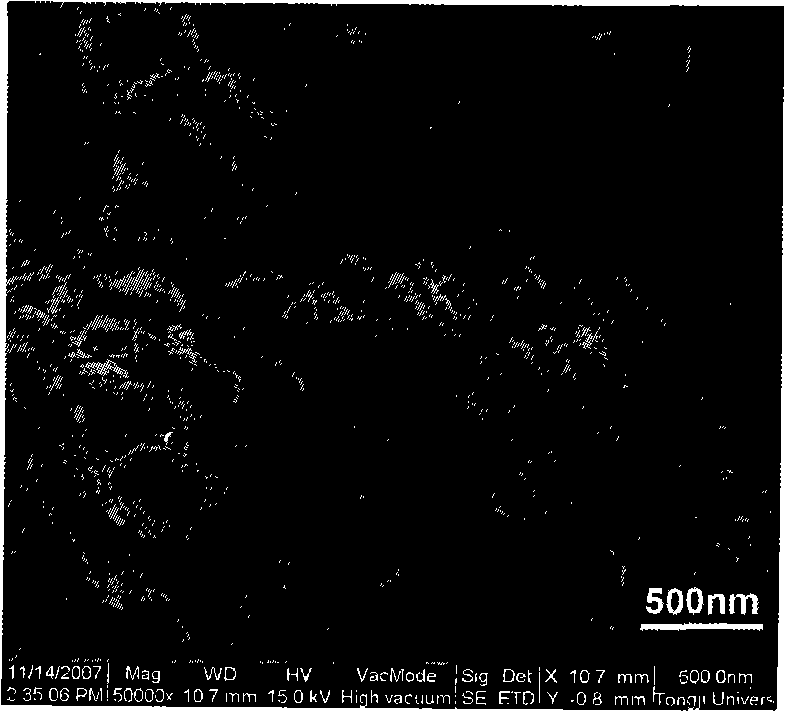

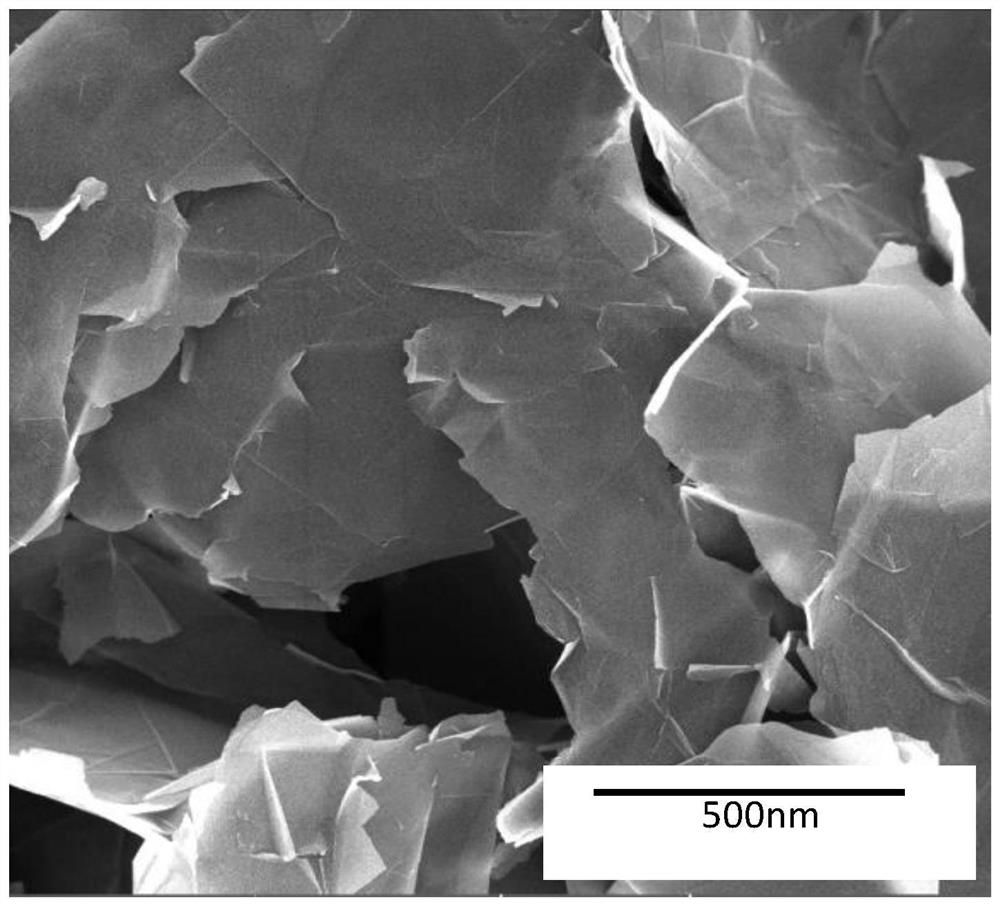

Method for preparing nano-stage naphthylamine sulfonate and aniline copolymer

The invention discloses a method for preparing nano sulfonic acid naphthylamine and aniline copolymer. The method is characterized in that: the neutral aqueous solution in sodium sulfonate naphthylamine is added in aniline aqueous solution and fully dissolved; then, oxidizing agent is added; when the reaction is finished, filtration, collection, precipitation, cleaning and drying are carried out to complete the preparation.

Owner:TONGJI UNIV

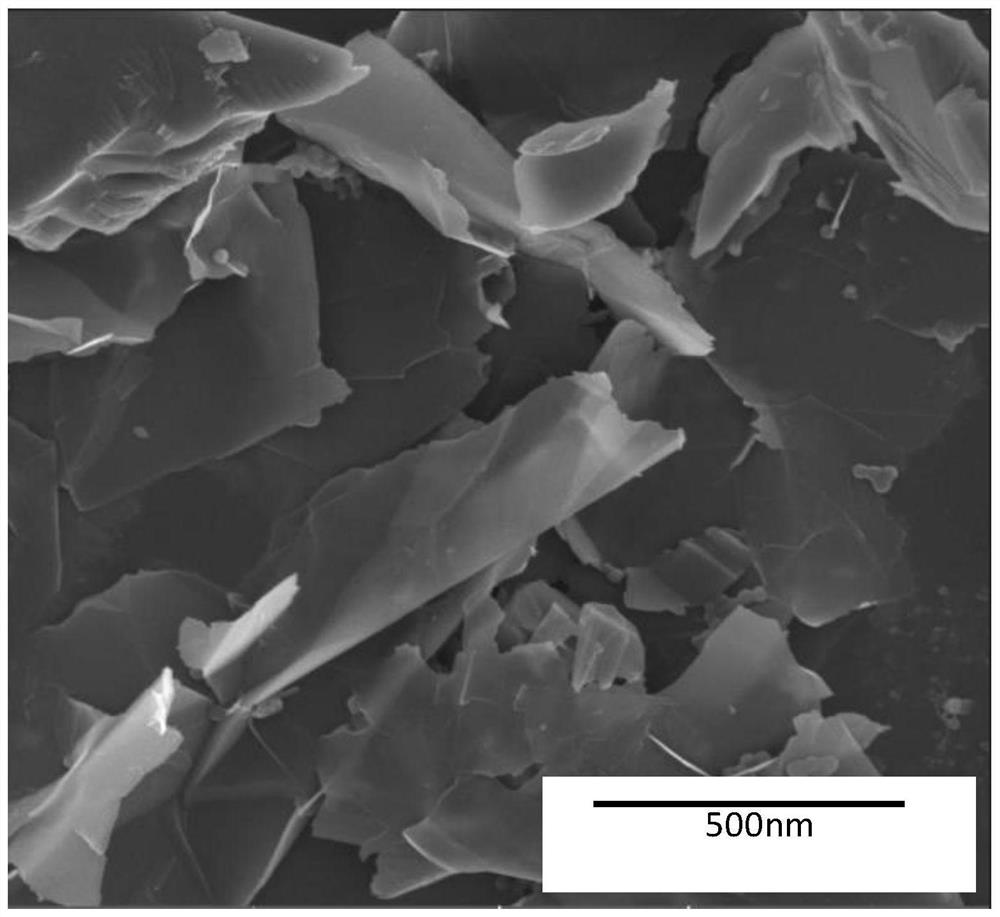

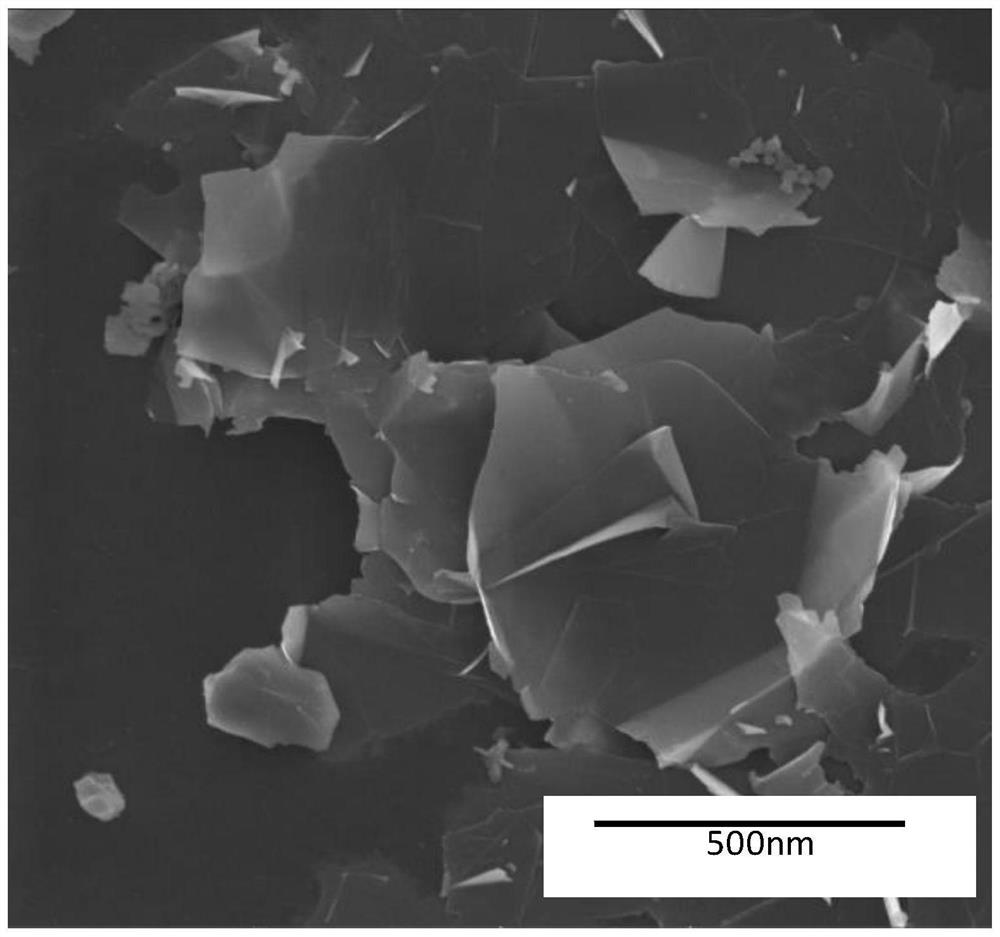

Small-sheet-diameter graphene powder, graphene conductive paste, preparation method of graphene conductive paste, and application

PendingCN112978722AGood dispersionEvenly dispersedCell electrodesGrapheneConductive pasteFluid phase

The invention provides graphene powder. The graphene powder is obtained by conducting slit spraying stripping on graphite through a supercritical fluid. According to the invention, graphene with relatively thin thickness and relatively small sheet diameter can be prepared under the conditions of low cost and no pollution through a supercritical liquid phase narrow hole stripping technology, so that the graphene can be uniformly dispersed in an oil phase or a water phase subsequently, and the small-sheet-diameter graphene conductive paste for a lithium ion battery is prepared. According to the small-sheet-diameter graphene conductive paste provided by the invention, graphene nanocrystallization can be realized, electronic conductance can be improved as far as possible, ion resistance can be reduced, and on the premise of ensuring battery performance, the dosage of a conductive agent can be reduced as far as possible, the dosage of active substances can be improved, and the energy density of a battery can be increased as far as possible. The preparation method is low in cost, mild and pollution-free in condition, easy to control and more suitable for industrial popularization and application.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

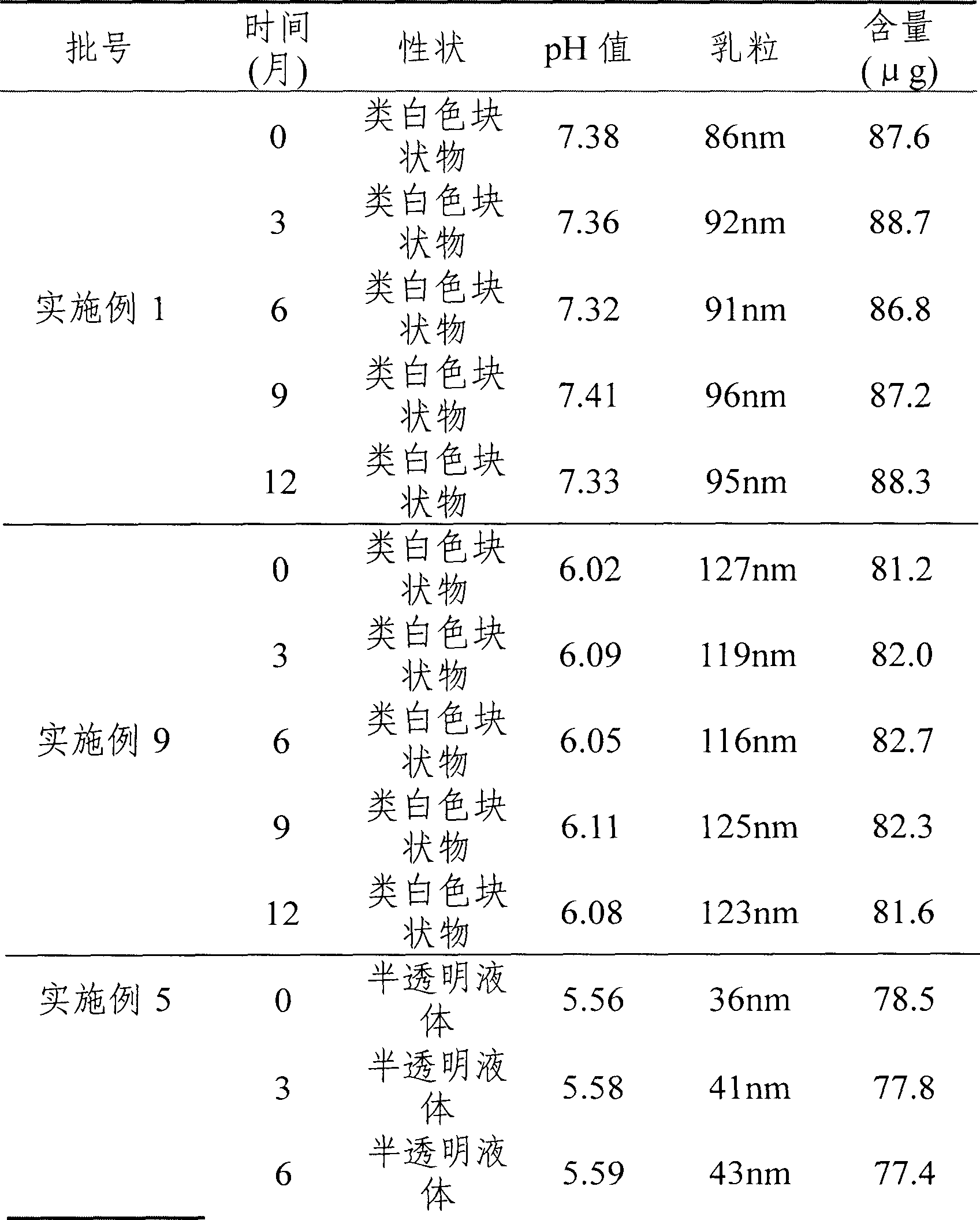

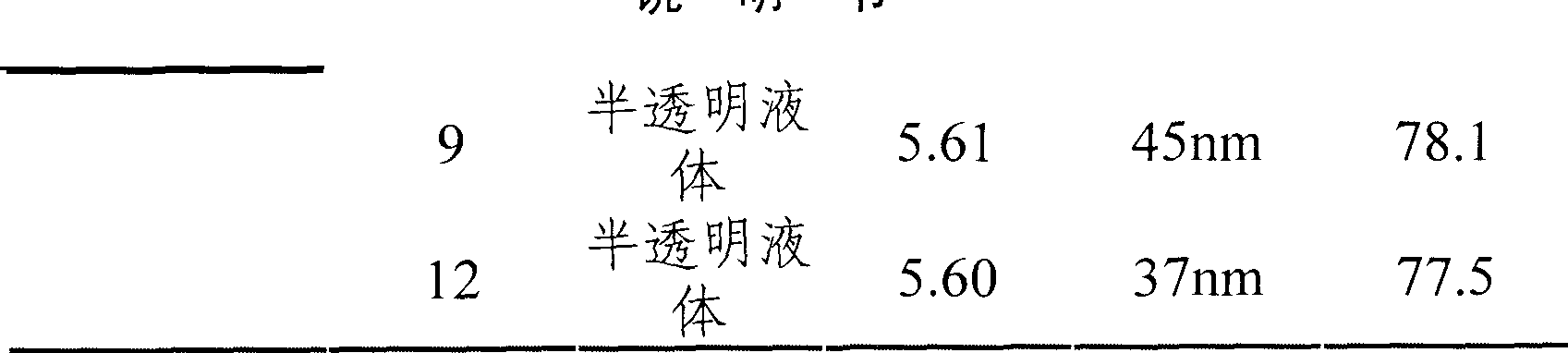

Cucurbitacin nano preparation comprising protein, preparation method and use thereof

InactiveCN1919339BRealize NanoizationQuality improvementOrganic active ingredientsPeptide/protein ingredientsWhite blood cellCurative effect

The invention discloses a cucurbitacin nanometer agent with protein, which can be liquid agent or solid agent. The protein nanometer particle can be reserved under indoor temperature, which improves drug quality and effect. the liquid agent contains0.05-10% (W / V) protein quantity and 0.001-1% (W / V) cucurbitacin and the solid agent consists of 50-99.9% (W / V) protein and 0.001-50% (W / V) cucurbitacin.

Owner:SHENYANG PHARMA UNIVERSITY

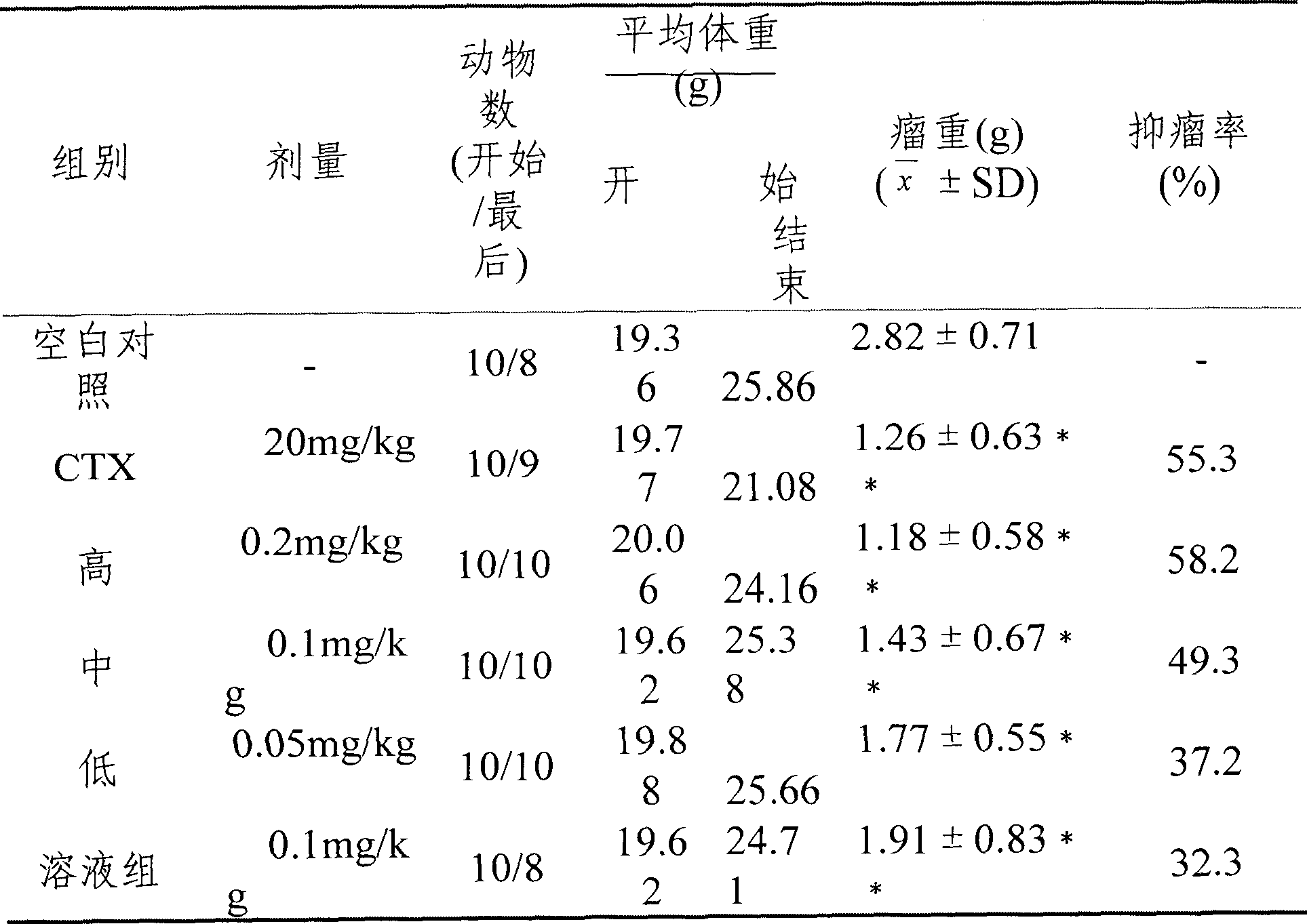

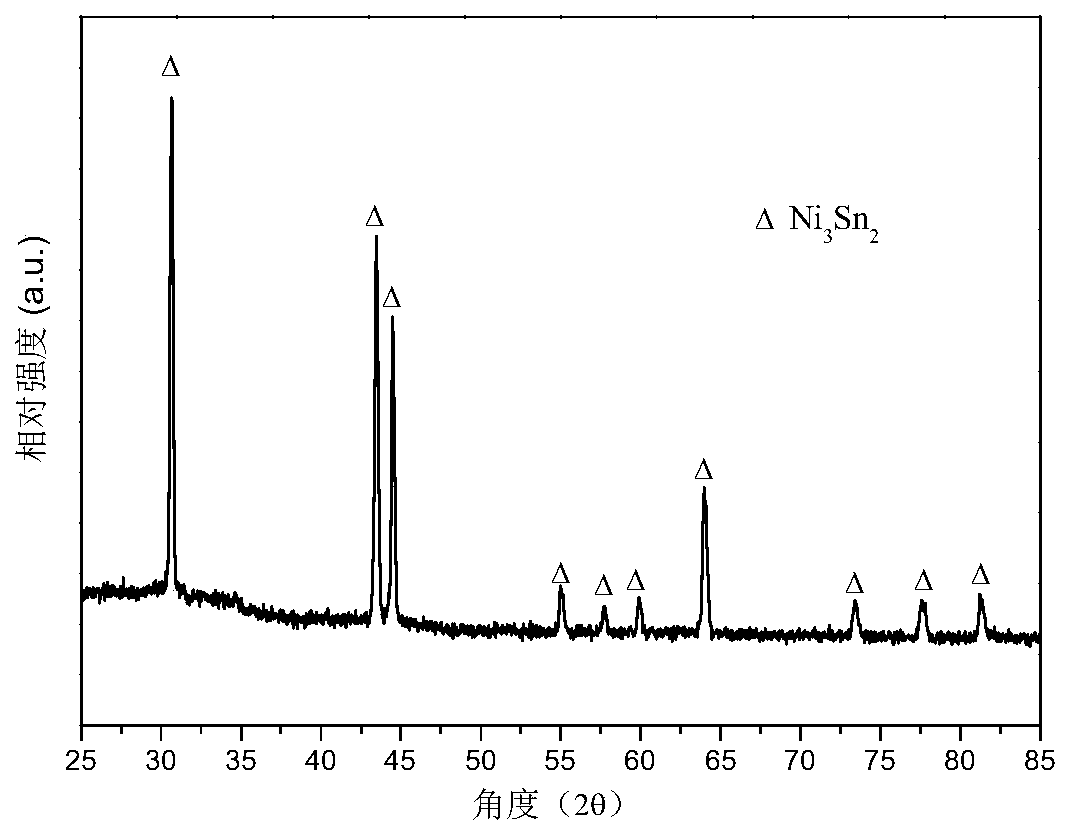

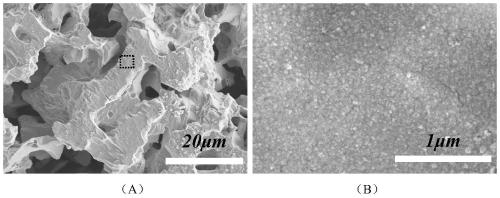

Nickel-tin alloy-based three-dimensional tin oxide nanoparticle-micron porous nickel-tin compound lithium ion battery anode and preparation method thereof

ActiveCN111193006ALarge specific surface areaSmall volume changeMaterial nanotechnologySecondary cellsNanoparticlePhysical chemistry

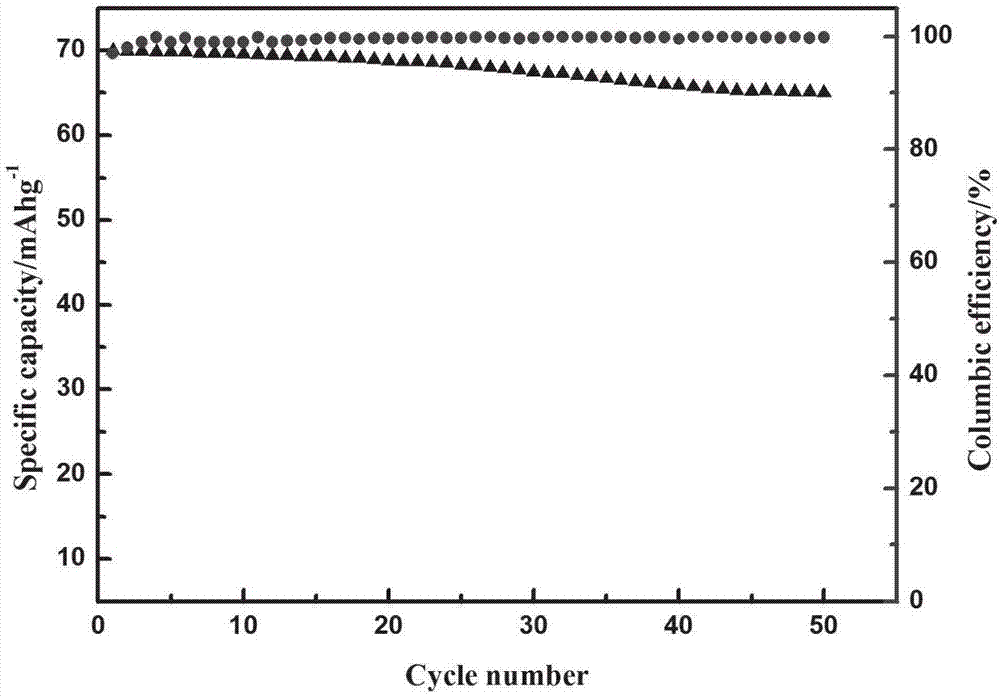

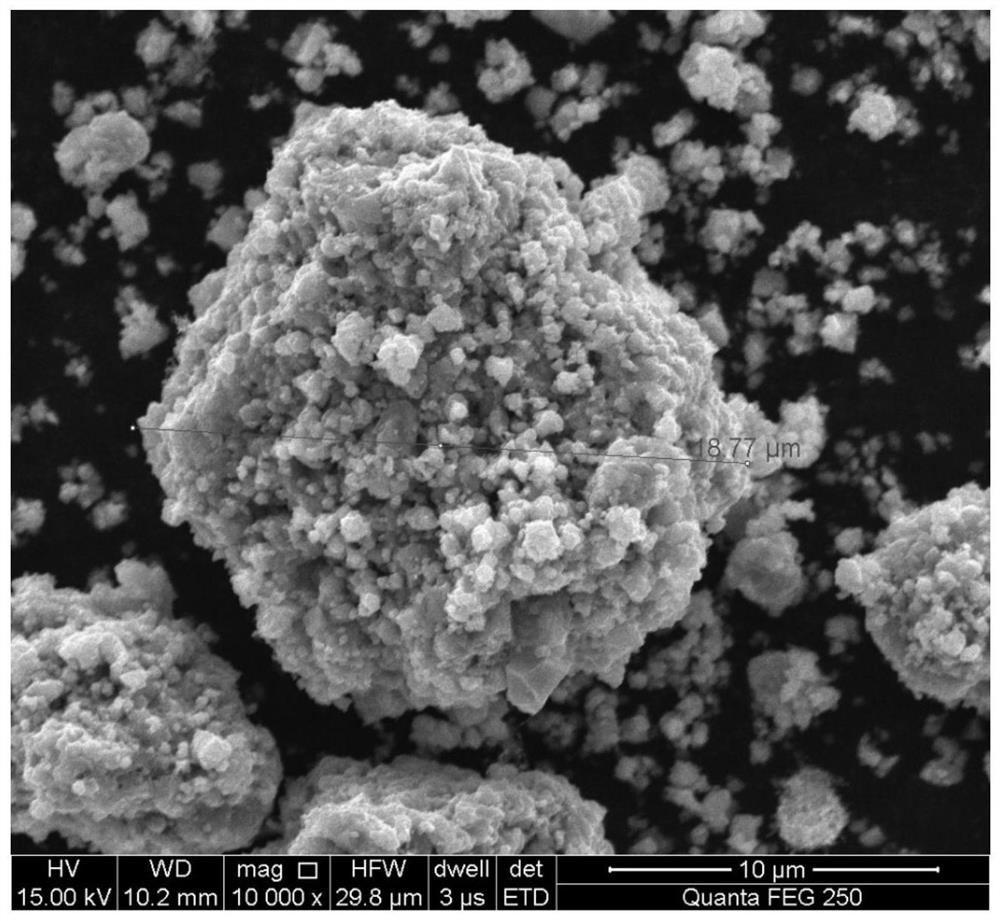

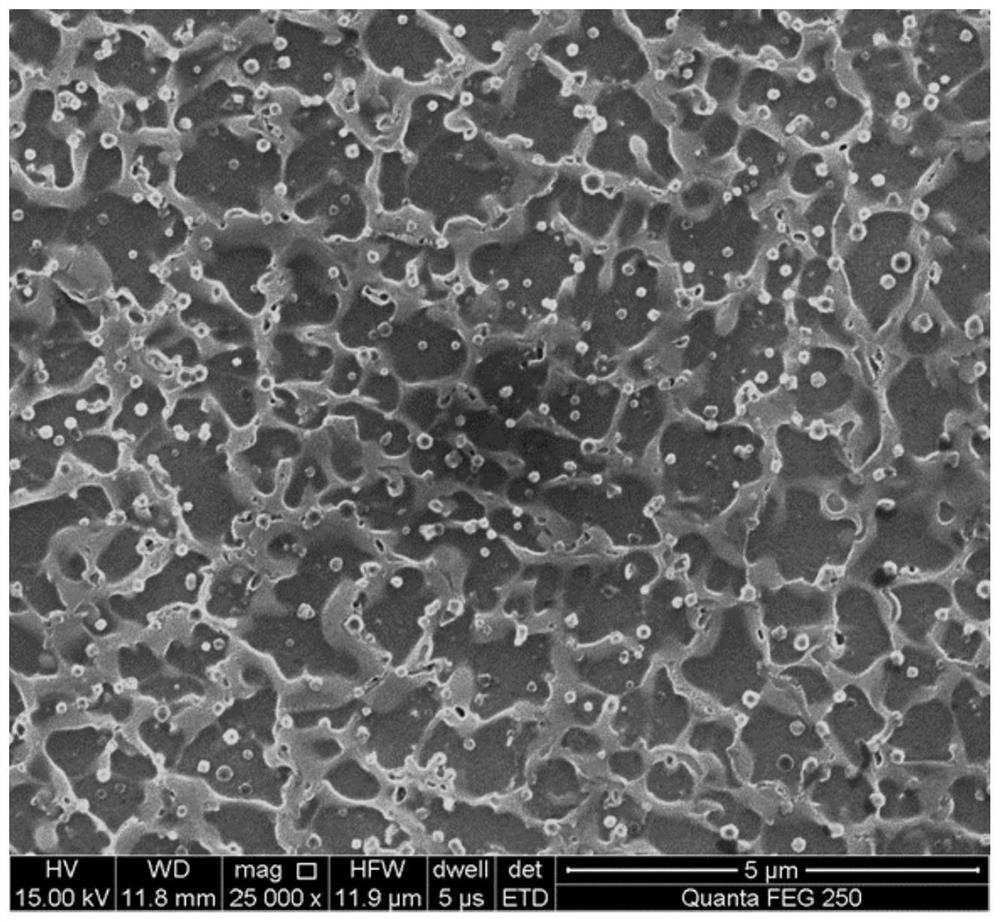

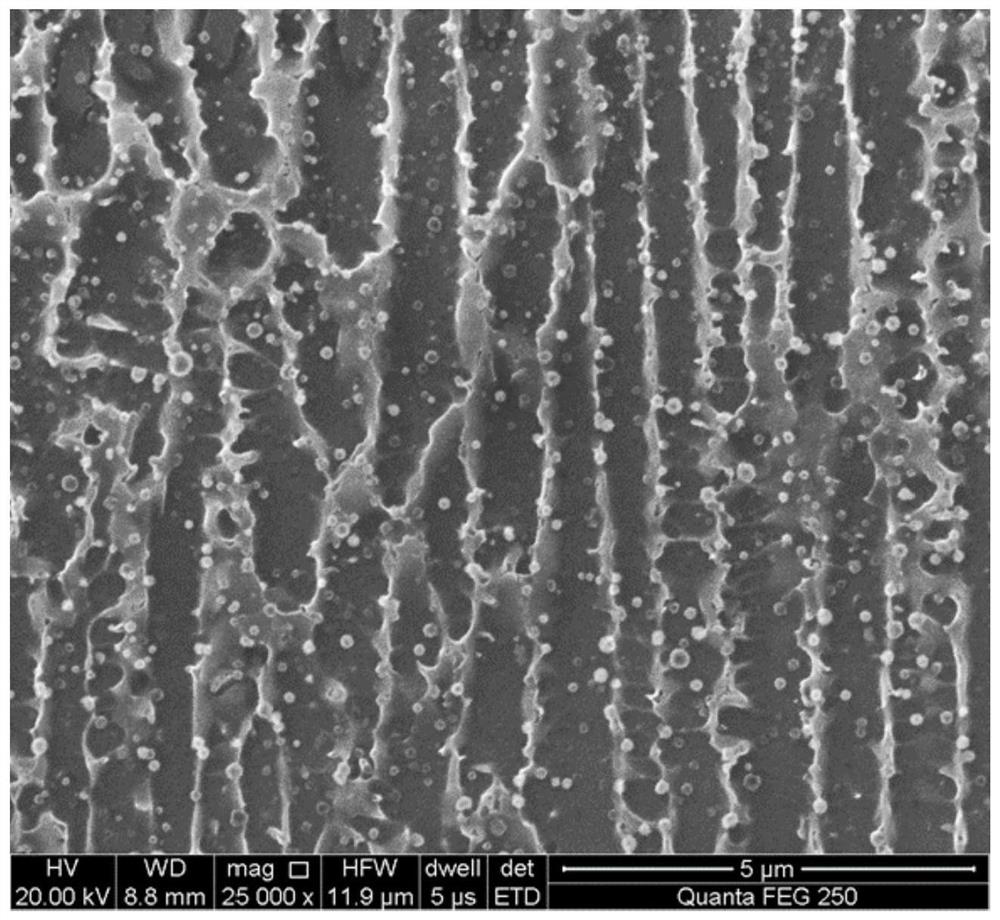

The invention provides a nickel-tin alloy-based three-dimensional tin oxide nanoparticle-micron porous nickel-tin compound lithium ion battery anode, which is composed of a three-dimensional micron porous nickel-tin compound skeleton and tin oxide nanoparticles, the nickel-tin compound is Ni3Sn2, and the tin oxide is SnO2 and SnO; the tin oxide nanoparticles are formed in situ by partially oxidizing tin in a three-dimensional micron porous nickel-tin compound skeleton; the tin oxide nanoparticles are dispersed and distributed on the surface of the three-dimensional micron porous nickel-tin compound skeleton or are uniformly distributed on the surface of the three-dimensional micron porous nickel-tin compound skeleton to form a tin oxide nanoparticle layer; when the tin oxide nanoparticlesare assembled to form the tin oxide nanoparticle layer, the lithium ion battery anode has a double-connected micron-nano composite pore structure. The invention also provides a preparation method of the lithium ion battery anode. The lithium ion battery anode has relatively high specific capacity and excellent cycle performance.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com