Method for synthesizing lithium ion battery positive electrode material

A lithium-ion battery and positive electrode material technology, applied in the field of materials, can solve the problems of uncontrollable thickness, unevenness, and high charging and discharging current of the battery, and achieve the effects of uniform and controllable thickness, reducing side reactions, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

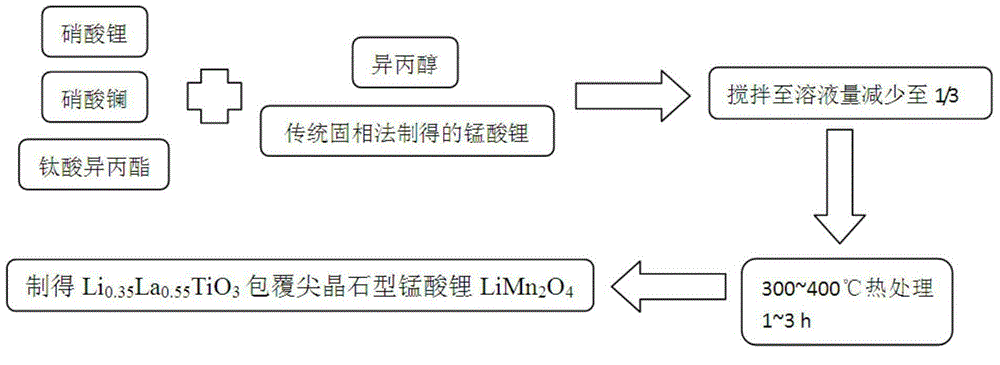

[0028] Such as figure 1 Shown in, the synthetic method of a kind of lithium ion battery cathode material of the embodiment of the present invention, concrete steps are:

[0029] Step 1, preparing spinel lithium manganese oxide LiMn 2 o 4 , in the embodiment of the present invention, spinel lithium manganese oxide LiMn 2 o 4 It can also be doped with one or more elements of other metal elements to form a doping compound LiM x mn 2-x o 4 . Here the doping element M includes the first and second main elements, transition metal elements and rare earth elements in the periodic table of elements, such as Na, K, Zn 2+ , Mg 2+ 、Al 3+ 、Cu 2+ 、Co 3+ 、Cr 3+ , Fe 3+ , V 4+ , La 3+ Wait.

[0030] Step 2, dissolving lithium nitrate, lanthanum nitrate and isopropyl titanate into 50mL of isopropanol according to the atomic ratio of 1:1:2 to prepare an isopropanol solution;

[0031] Step 3, then the LiMn obtained in the above step 1 2 o 4 Or single / multiple metal doped LiM ...

Embodiment 1

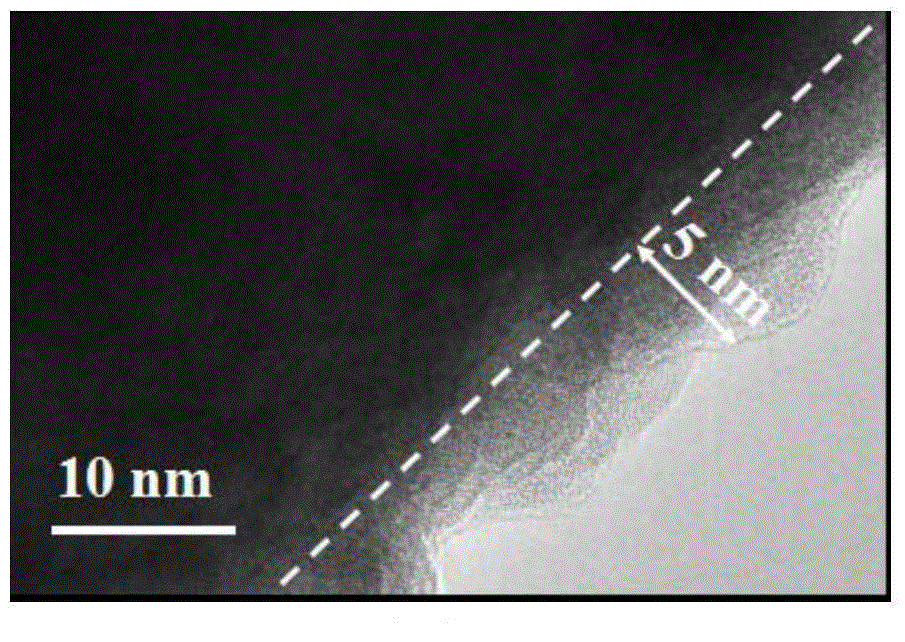

[0036] Such as figure 2 As shown in, the method of the present invention is used to synthesize the coating amount of 1wt.% Li 0.35 La 0.55 TiO 3 Coated spinel lithium manganese oxide LiMn 2 o 4 , it can be seen by transmission electron microscopy that the thickness of the cladding layer is 5nm. When charged and discharged at 1 / 2C, the initial capacity of the material is 105.0mAh / g, after 300 high-temperature cycles, the capacity is 76.1mAh / g, and the capacity retention rate is 72.5%.

Embodiment 2

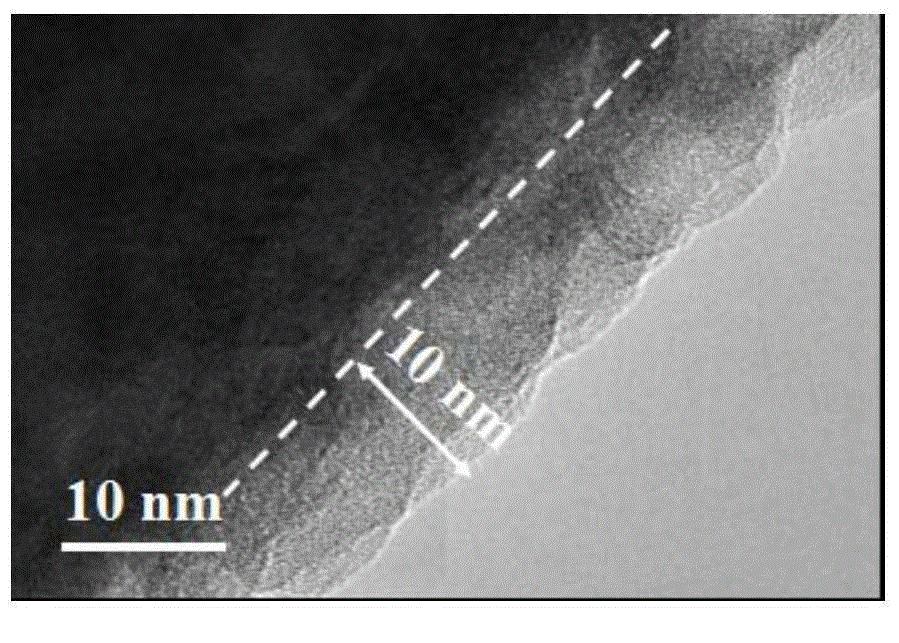

[0038] Such as image 3 As shown in, the method of the present invention is used to synthesize Li with a coating amount of 3wt% 0.35 La 0.55 TiO 3 Coated spinel lithium manganese oxide LiMn 2 o 4 , it can be seen by transmission electron microscopy that the thickness of the cladding layer is 10nm. When charged and discharged at 1 / 2C, the initial capacity of the material is 104.4mAh / g, after 300 high-temperature cycles, the capacity is 82.3mAh / g, and the capacity retention rate is 78.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com