Patents

Literature

9642results about How to "Reduce porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

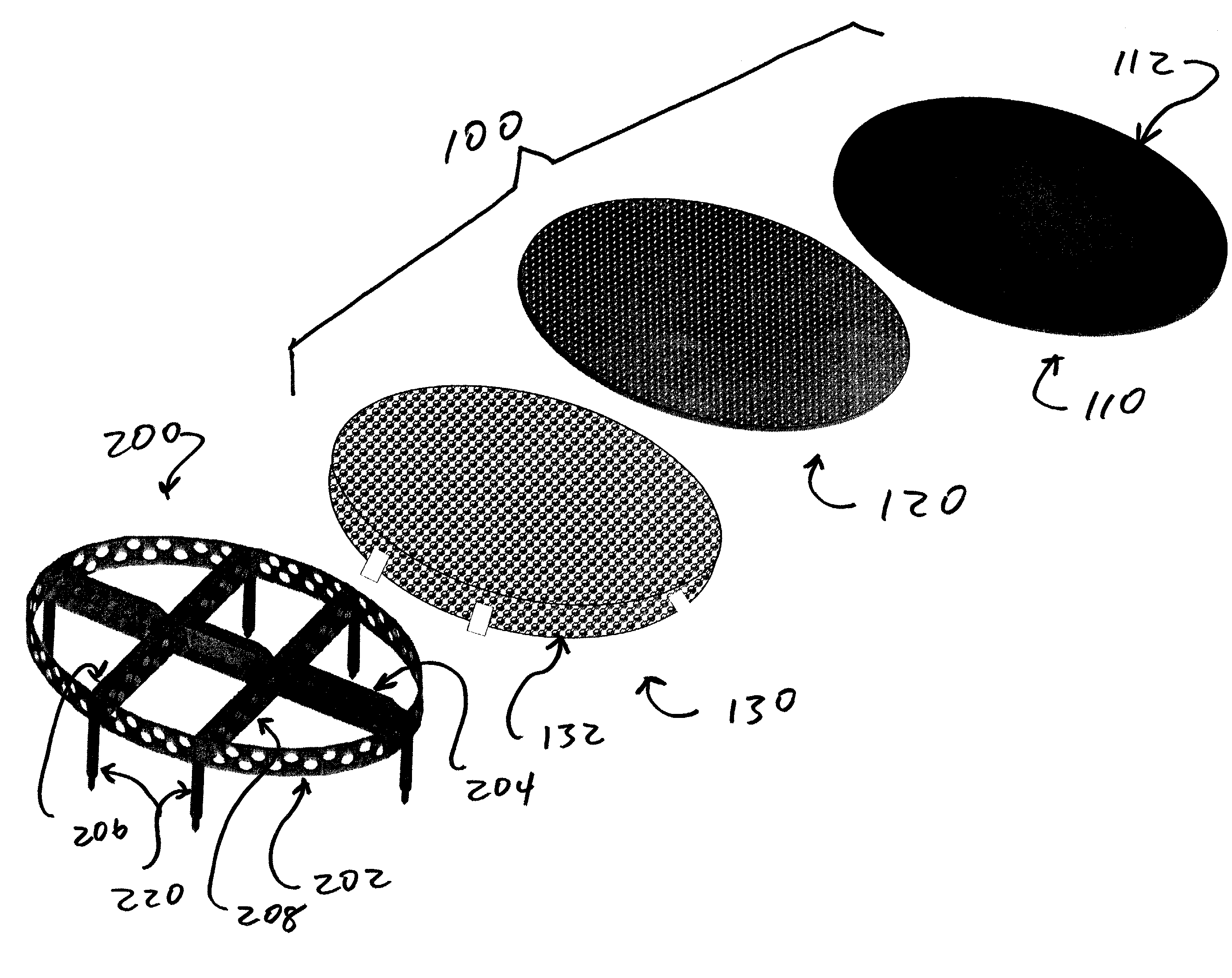

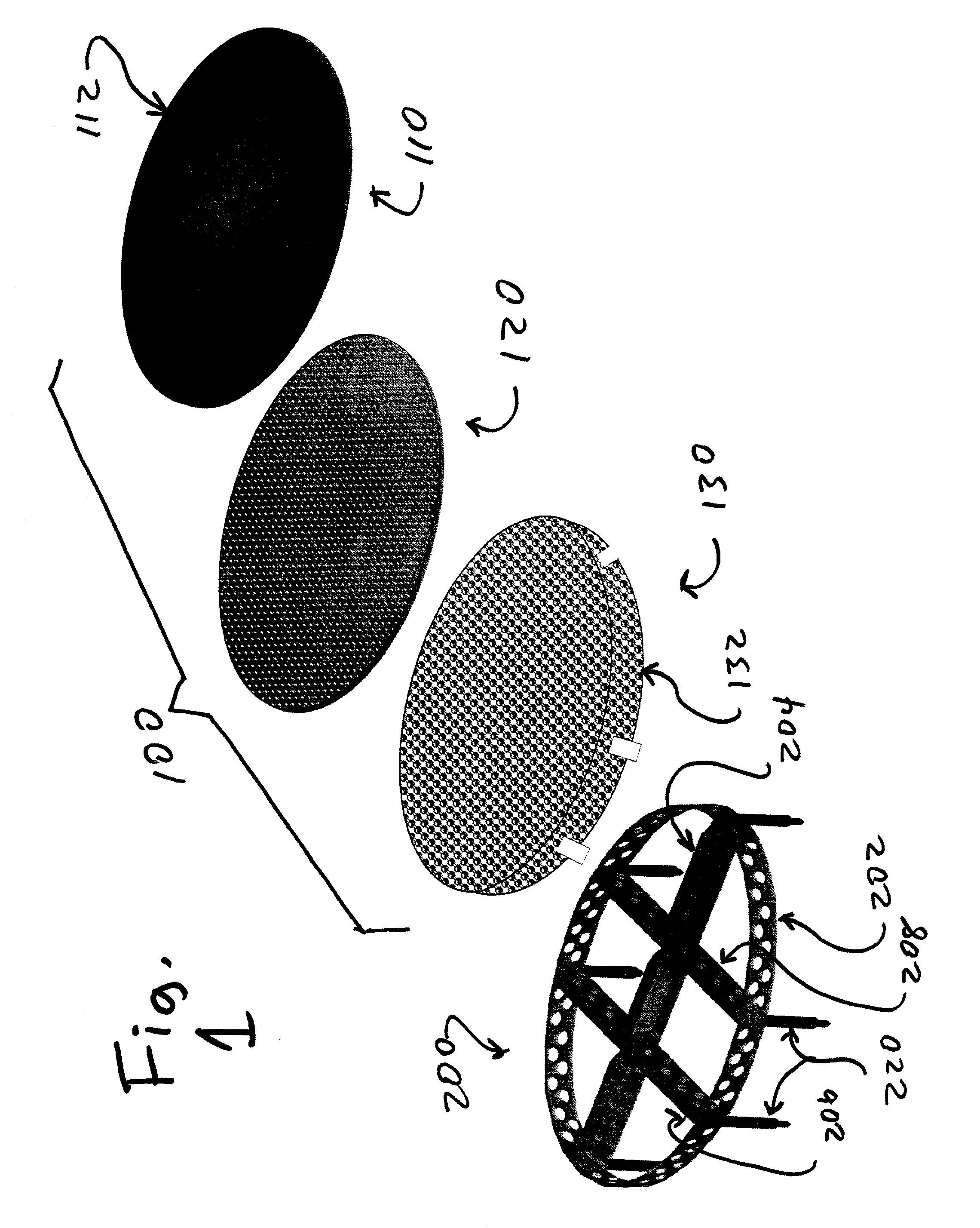

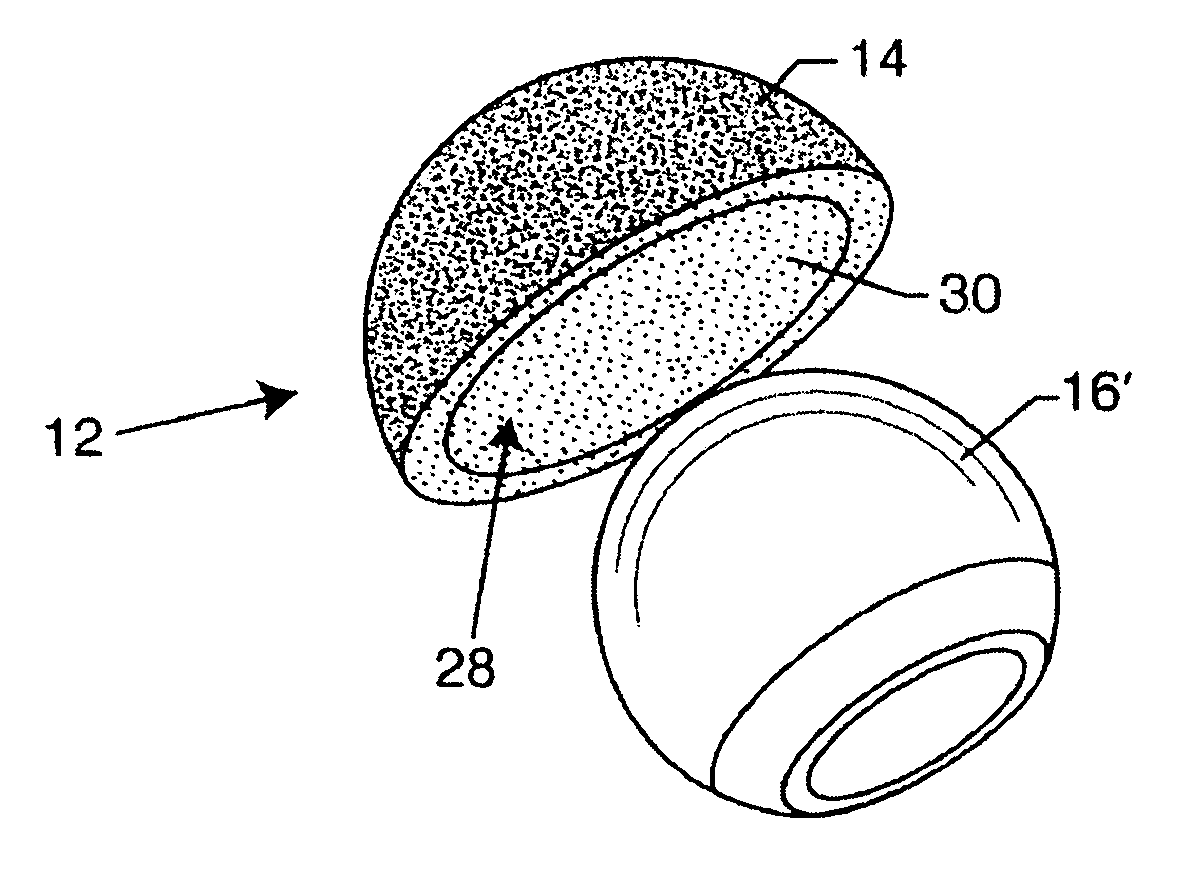

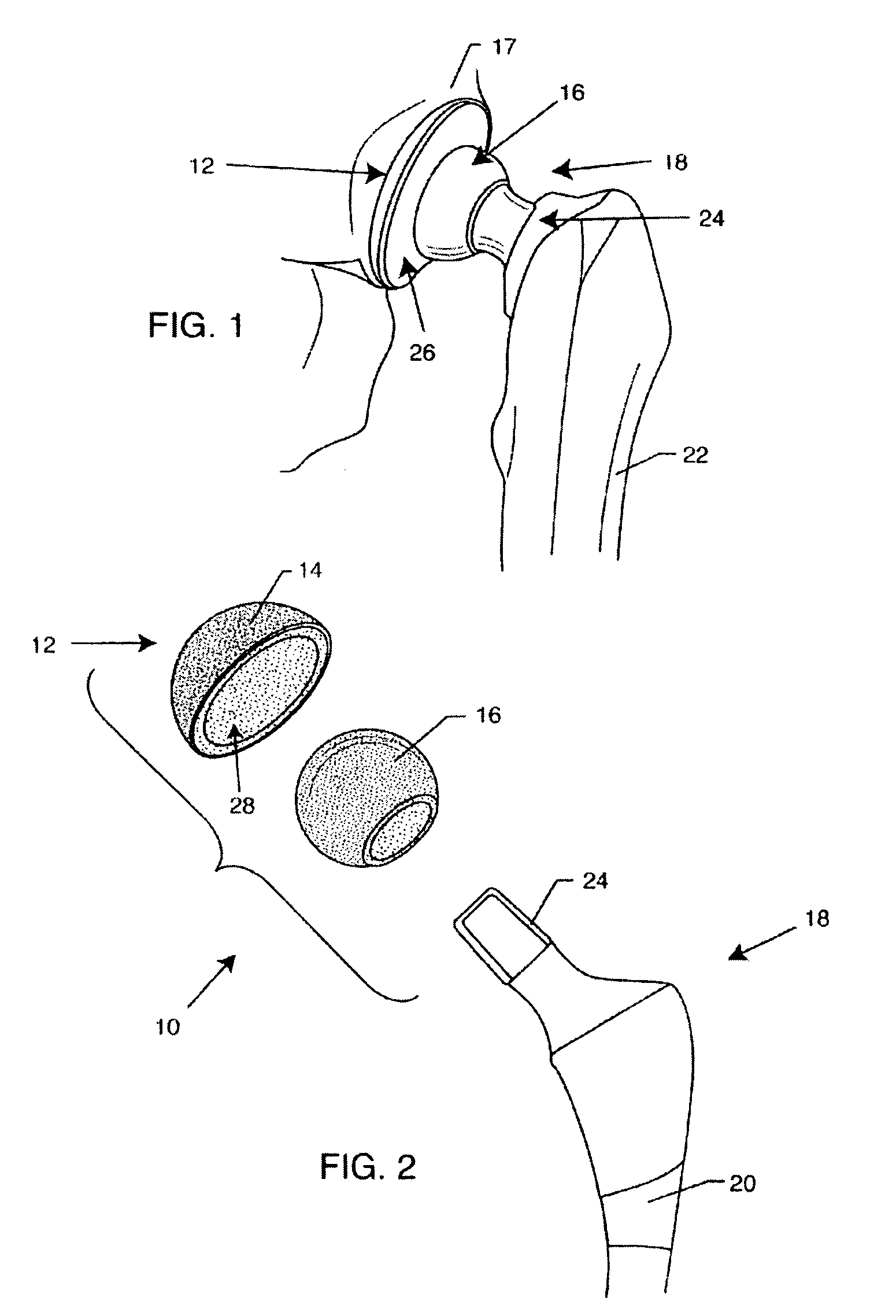

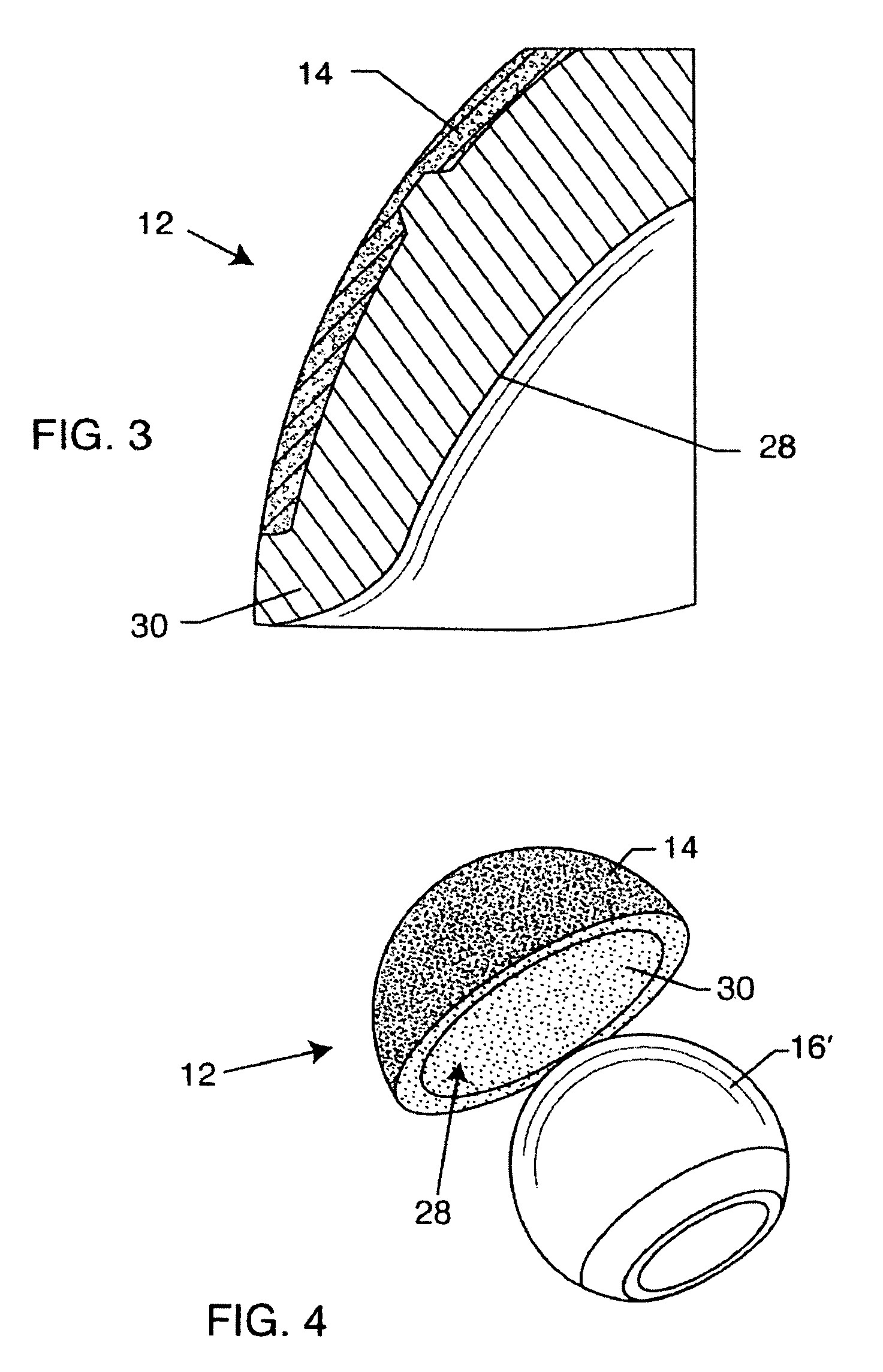

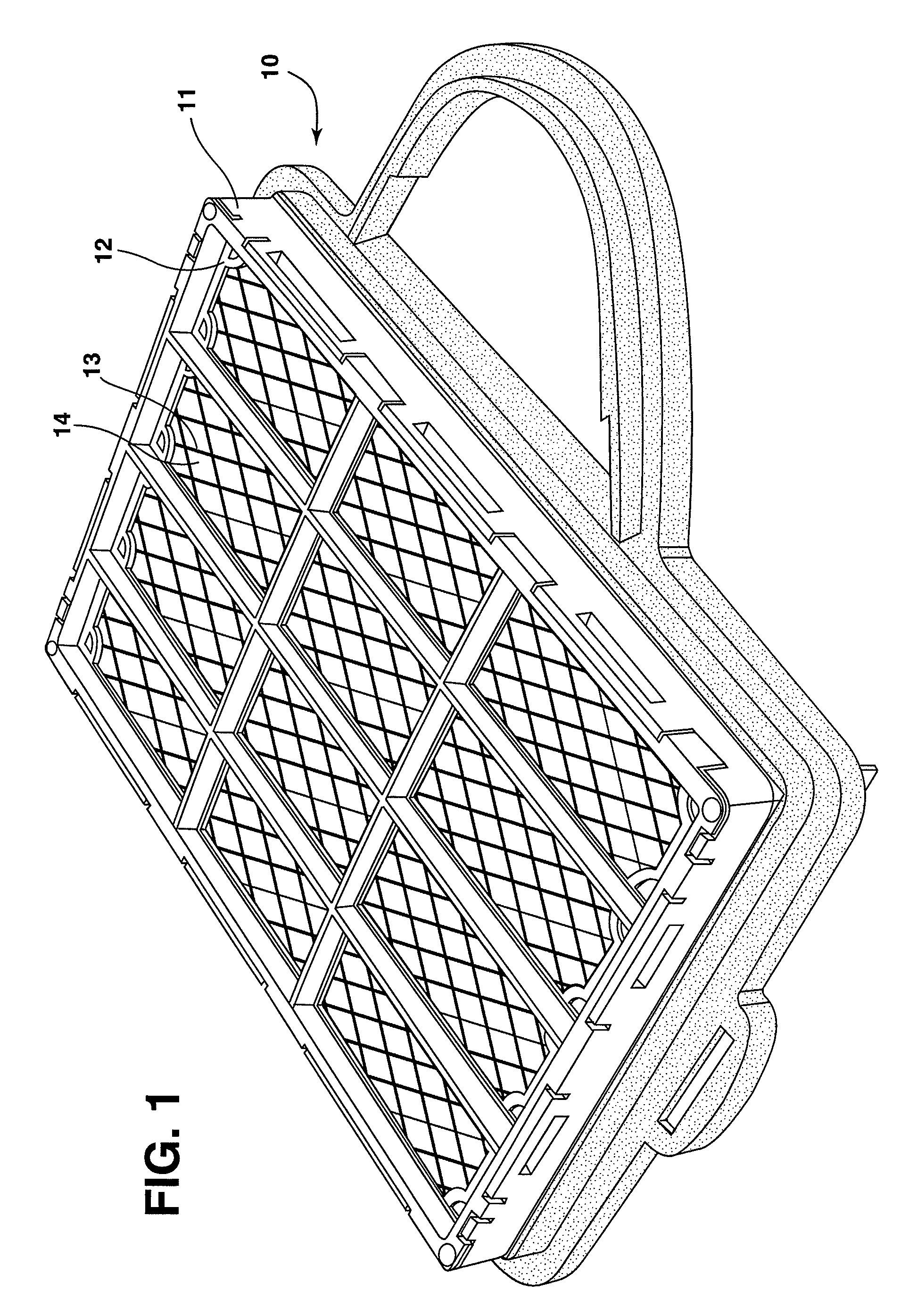

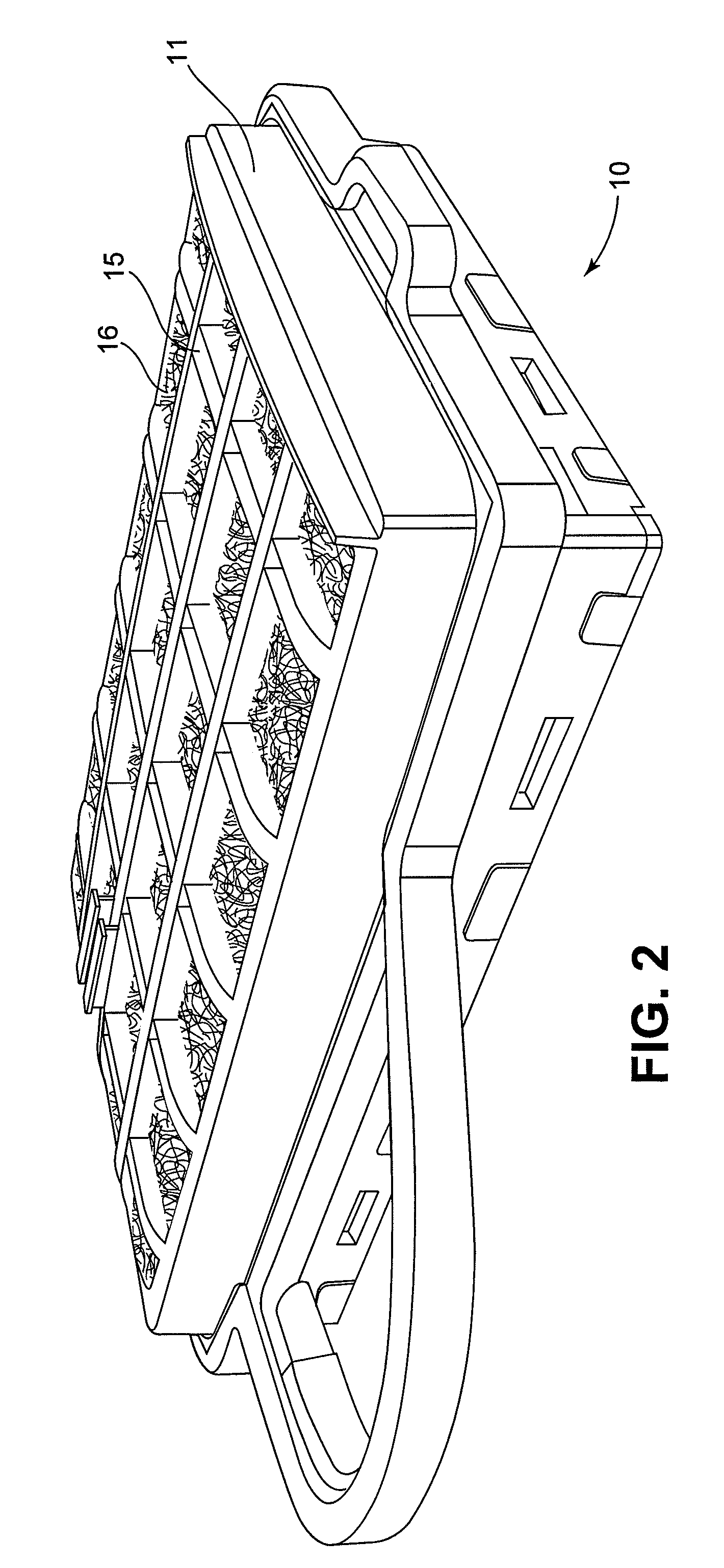

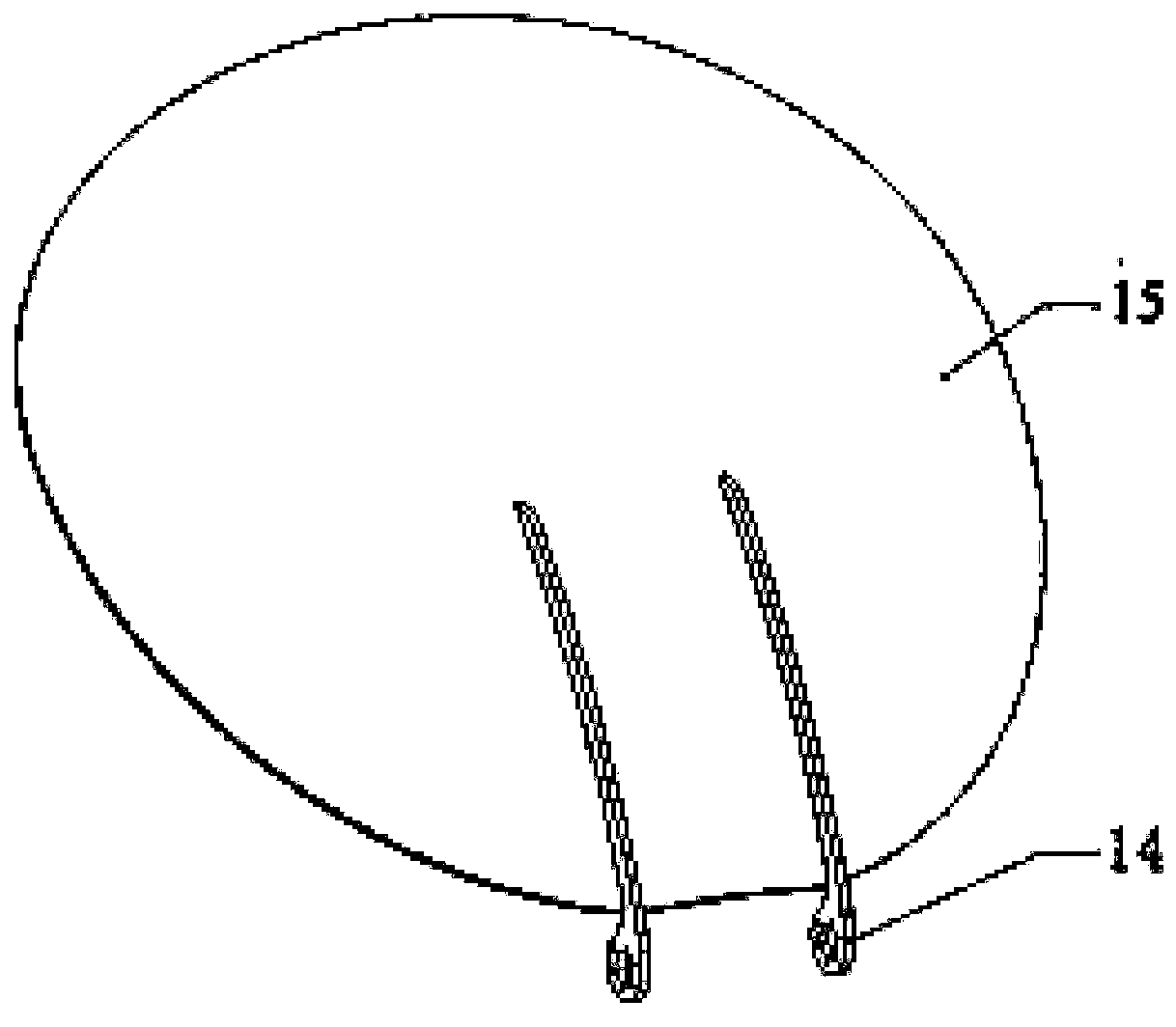

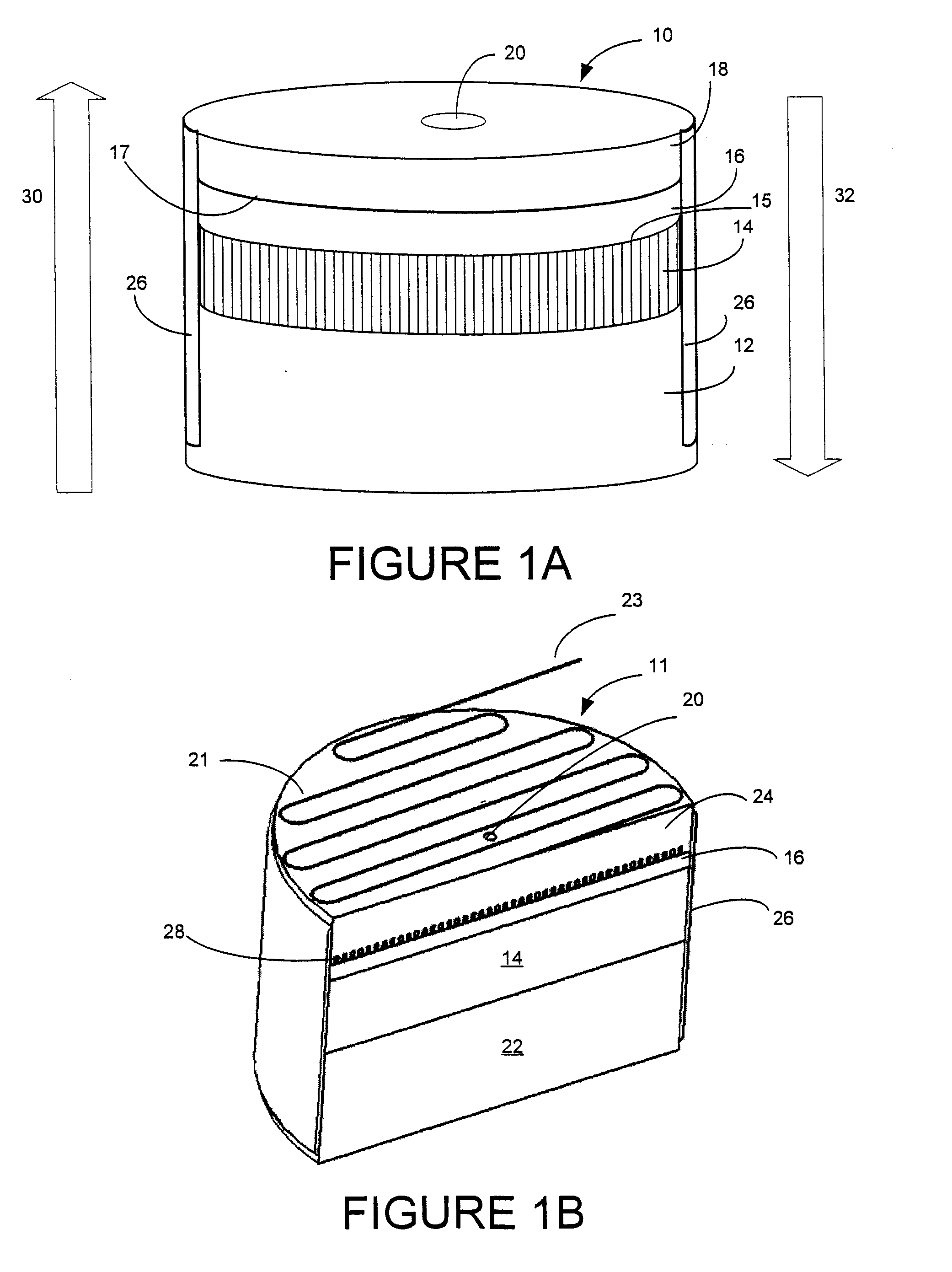

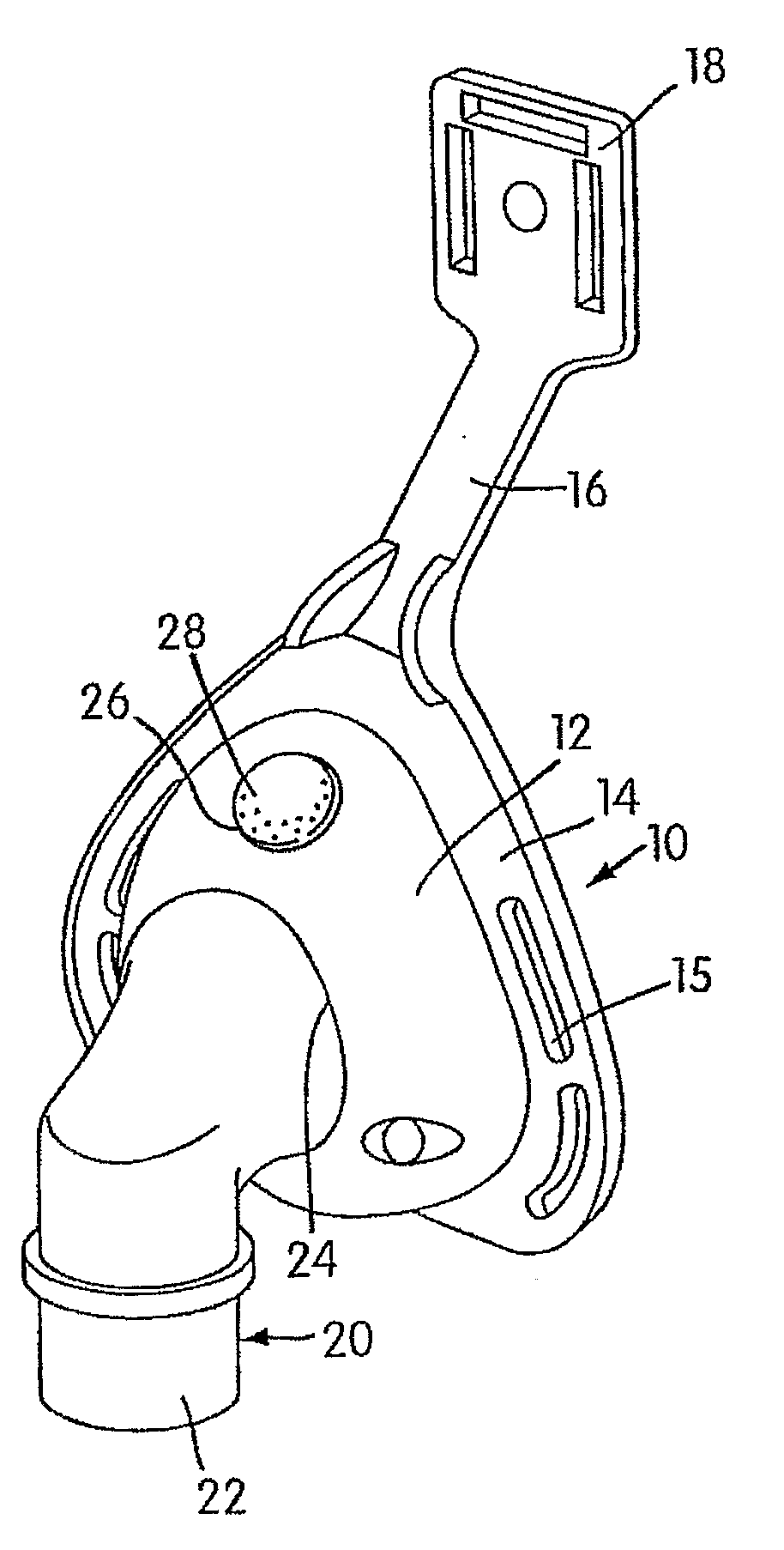

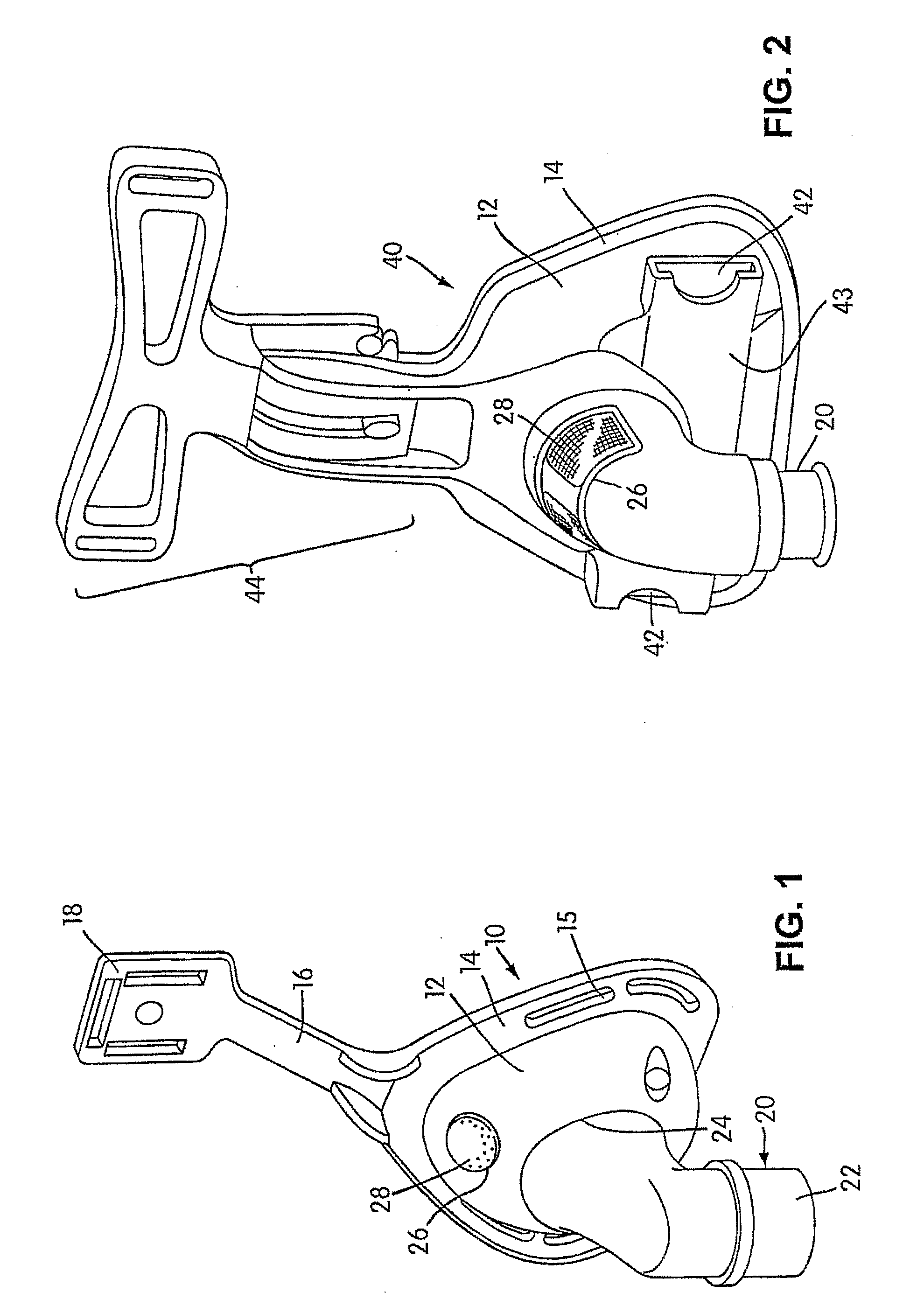

Cartilage repair implant with soft bearing surface and flexible anchoring device

InactiveUS9050192B2Strong and more permanent fixationSoft and bendableJoint implantsHip jointsCartilage repairSurgical implant

A surgical implant for replacing hyaline cartilage in a knee or other articulating synovial joint has an anchoring side on one side of the implant adapted for fixing the implant to one of the bones in the joint, and a bearing surface on the opposite side of the implant for lubricious rubbing and sliding contact with another bone in the joint. The anchoring side can be configured with an irregular surface for tissue ingrowth. The bearing side can include hydrogel. The implant can be rolled up from an original shape and surgically inserted by arthroscopic means, and opens into its original shape when released inside the joint.

Owner:FORMAE

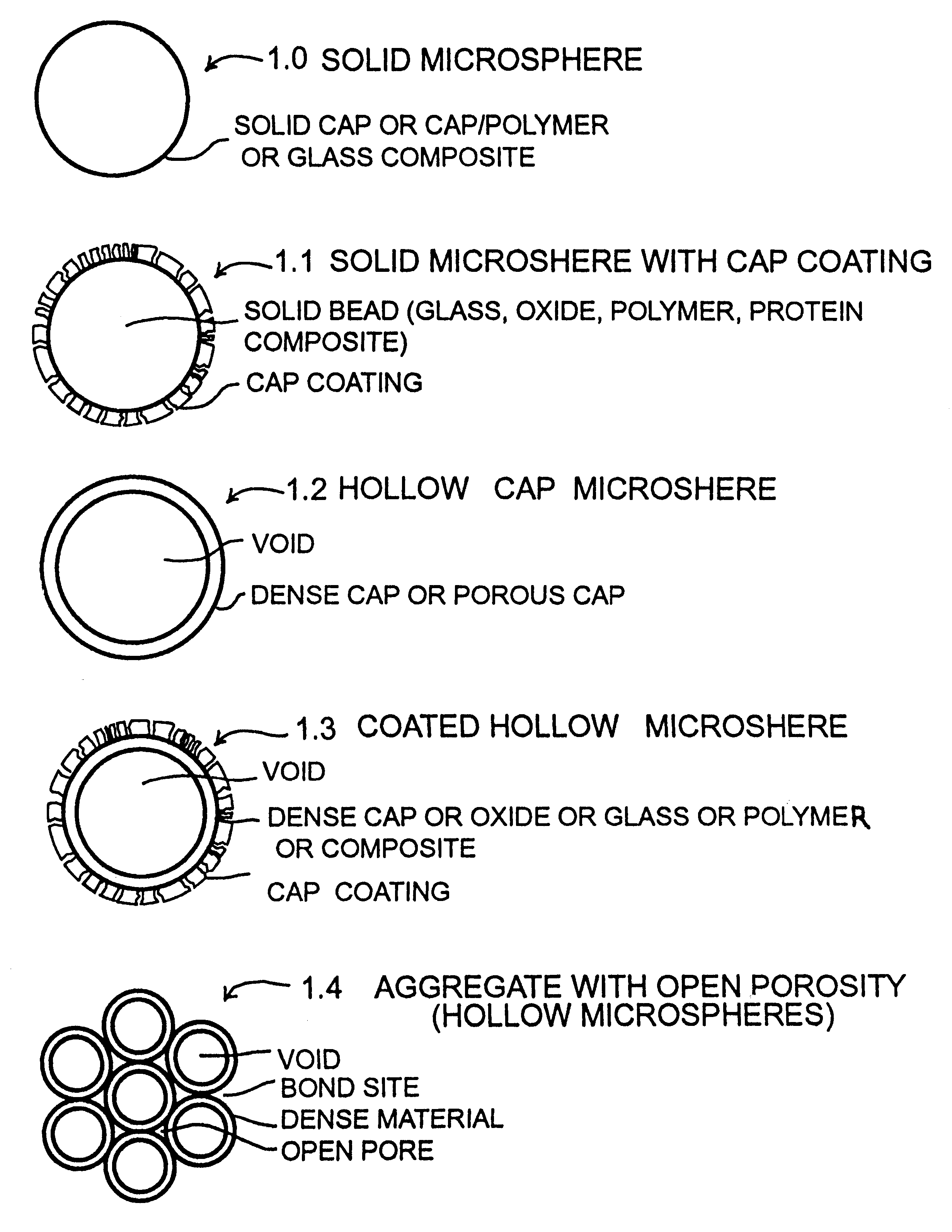

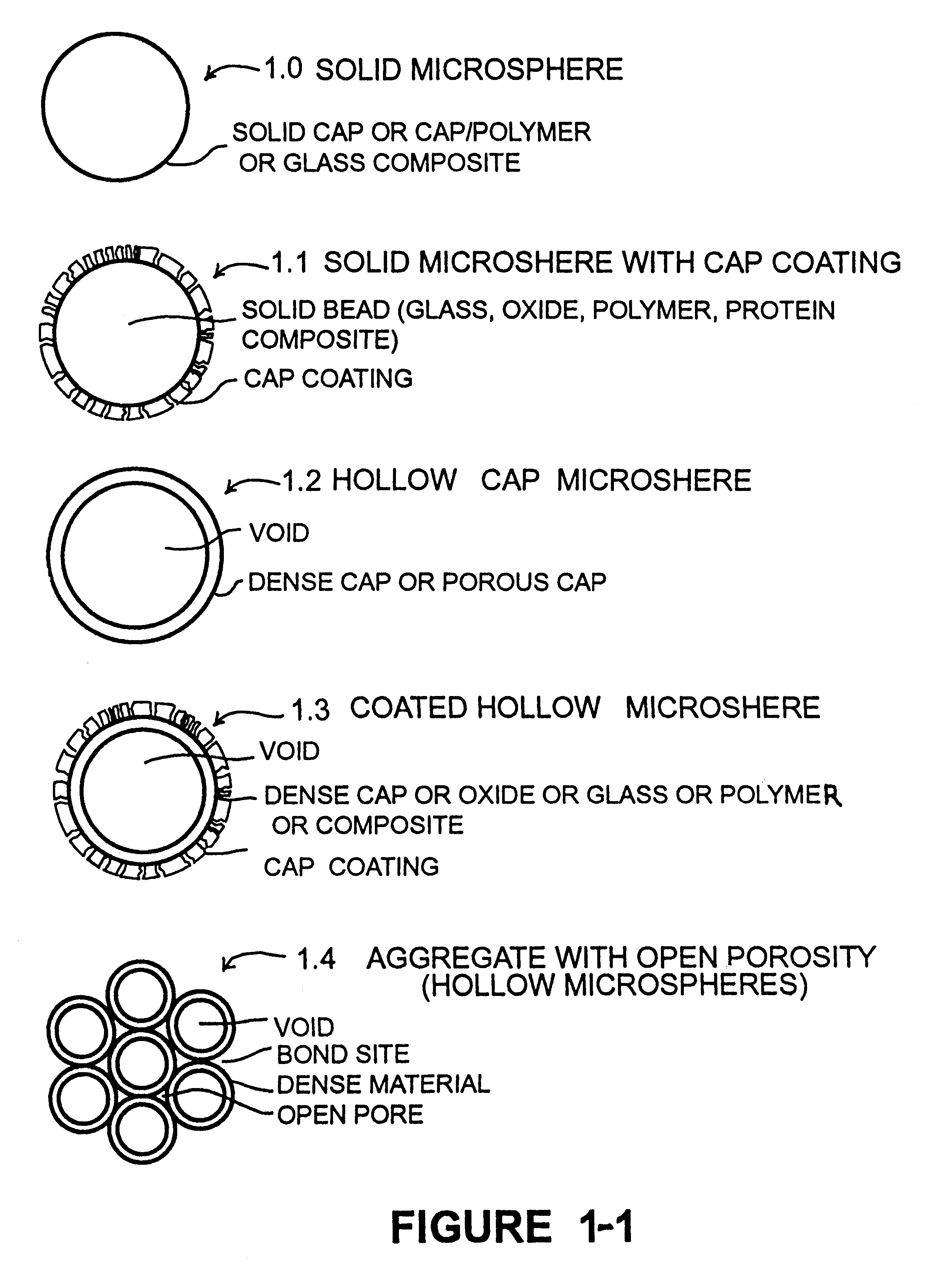

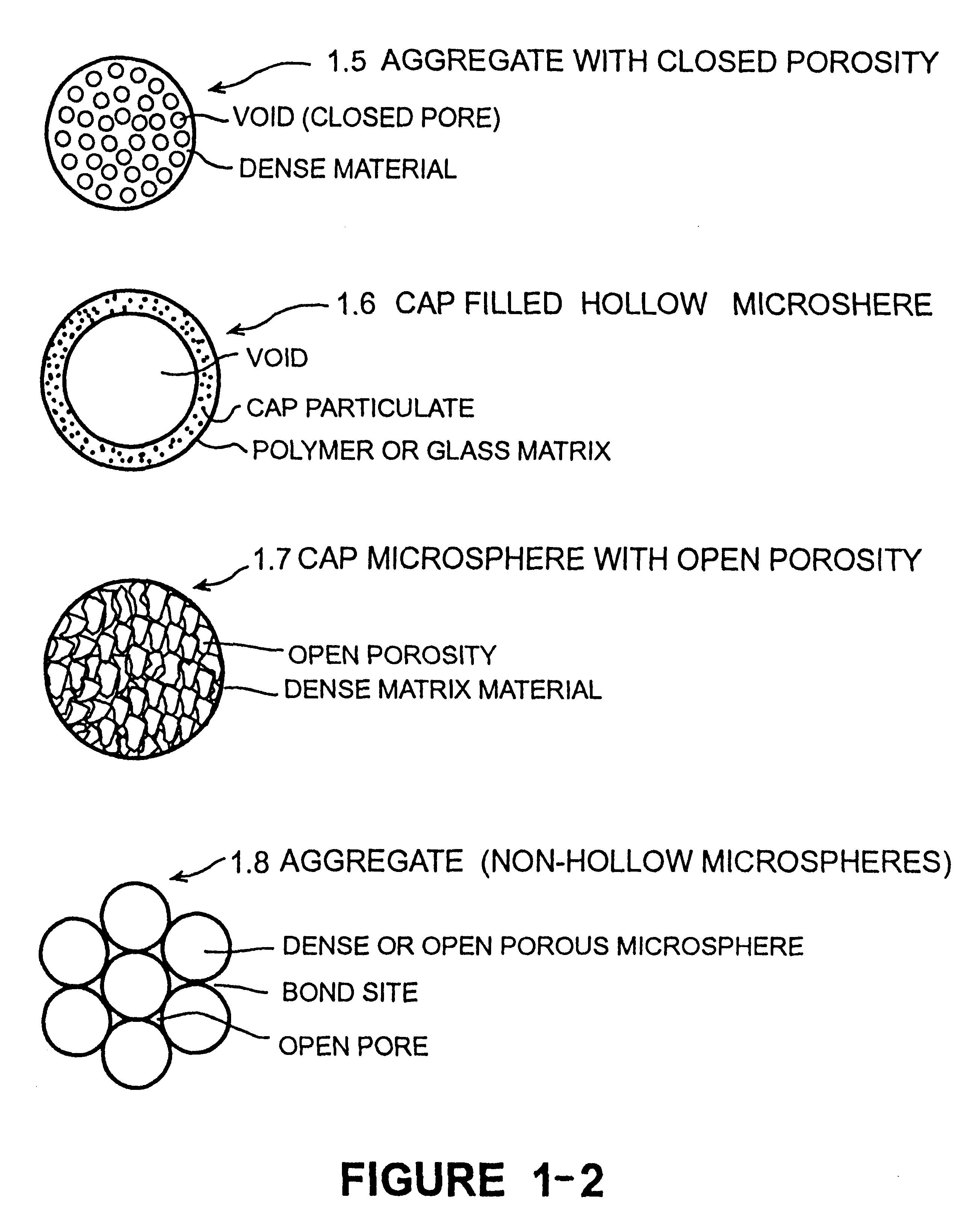

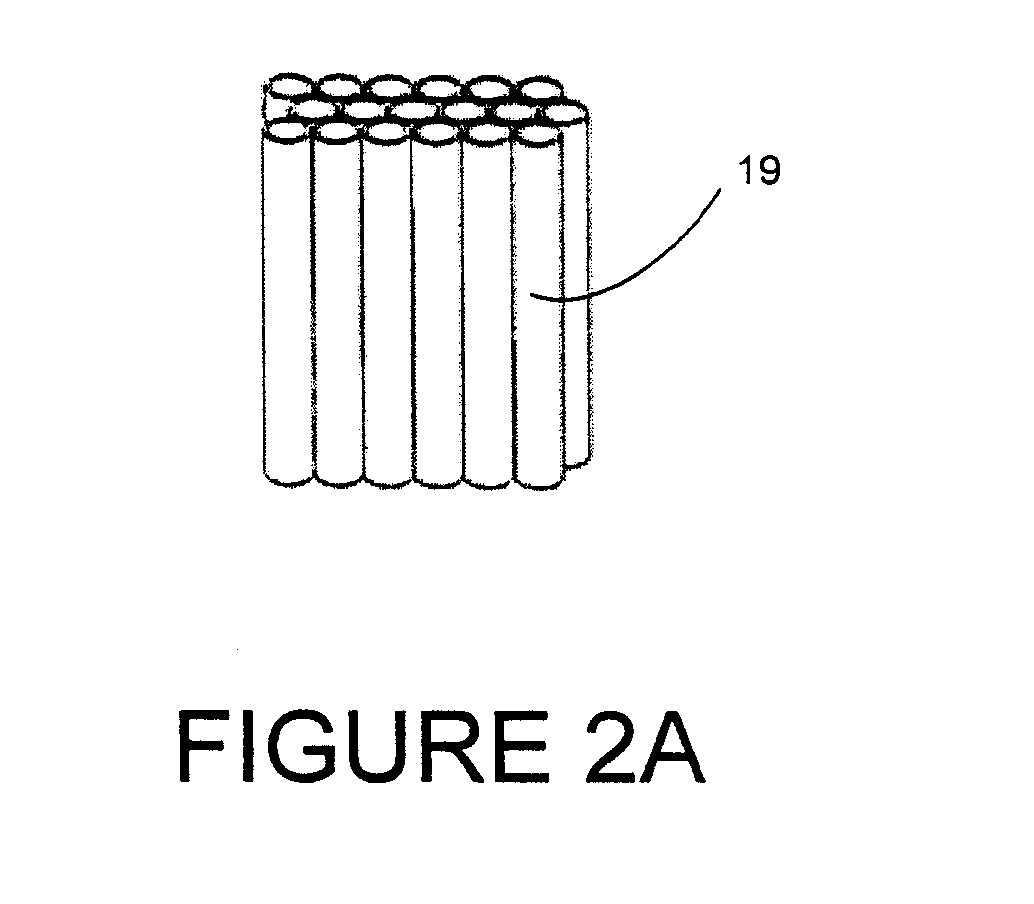

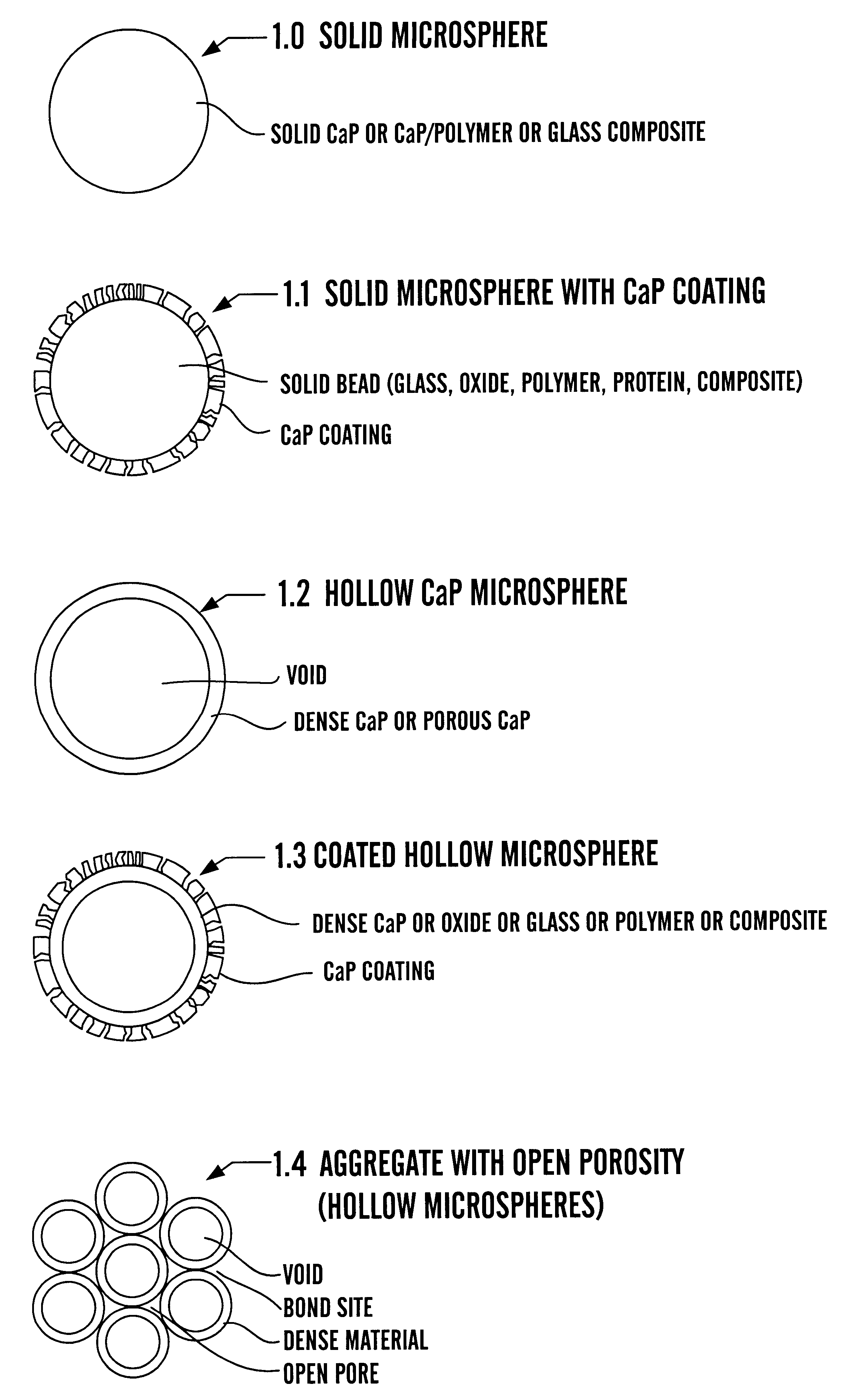

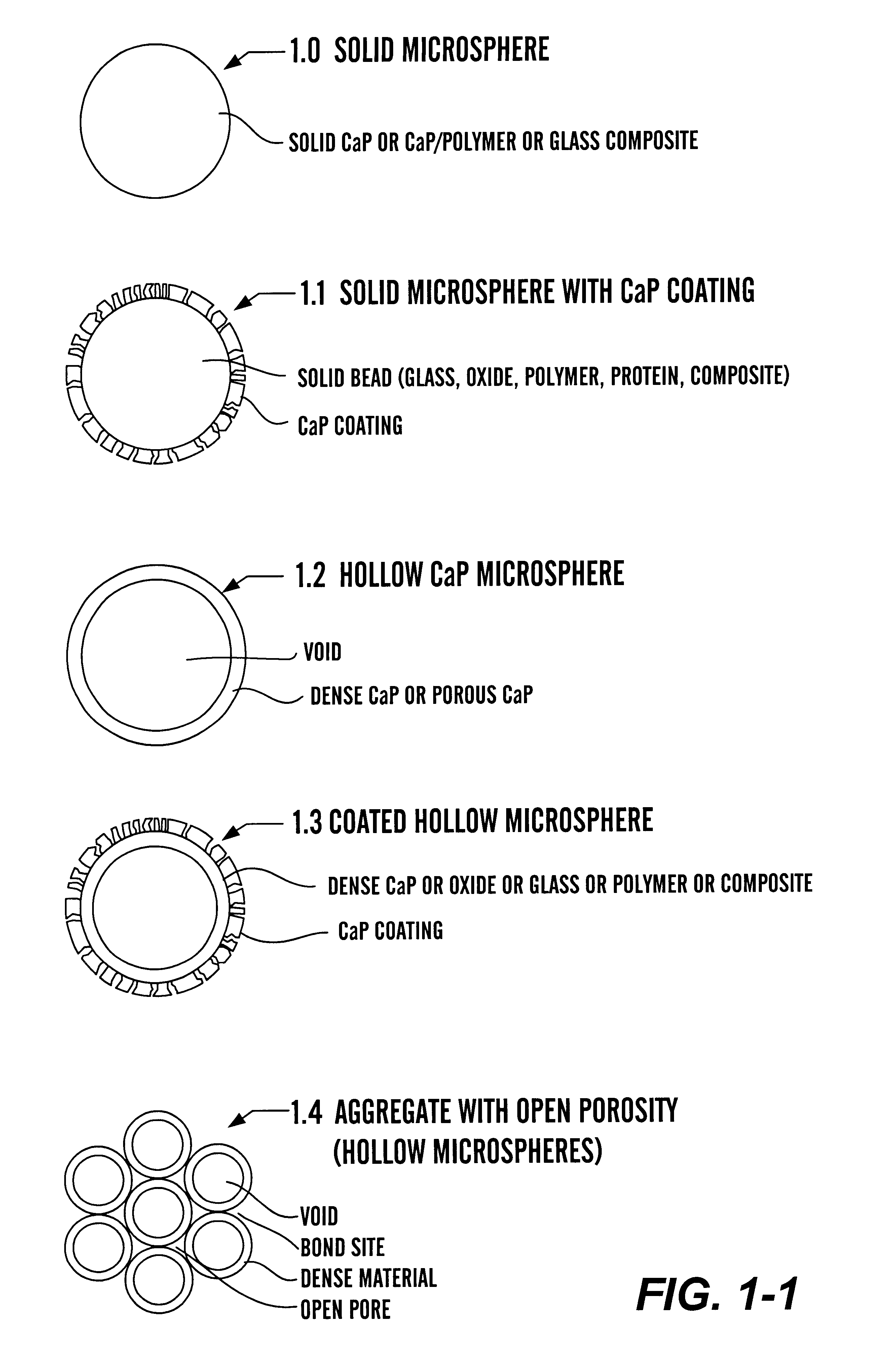

Calcium phosphate microcarriers and microspheres

InactiveUS6210715B1Increase resorbabilityCompressive strengthPowder deliveryBiocideChemistryCalcium biphosphate

The present invention provides calcium phosphate-based (CAP) microcarriers and microspheres and their use in cell culturing systems, chromatography and implantable biomedical materials.

Owner:CAP BIOTECH

Absorbent hygiene product

InactiveUS20050159720A1Surface area can be easilyUniform and stableLayered productsFibre treatmentAbsorbent materialPolymer chemistry

Owner:FREUDENBERG NONWOVENS LTD

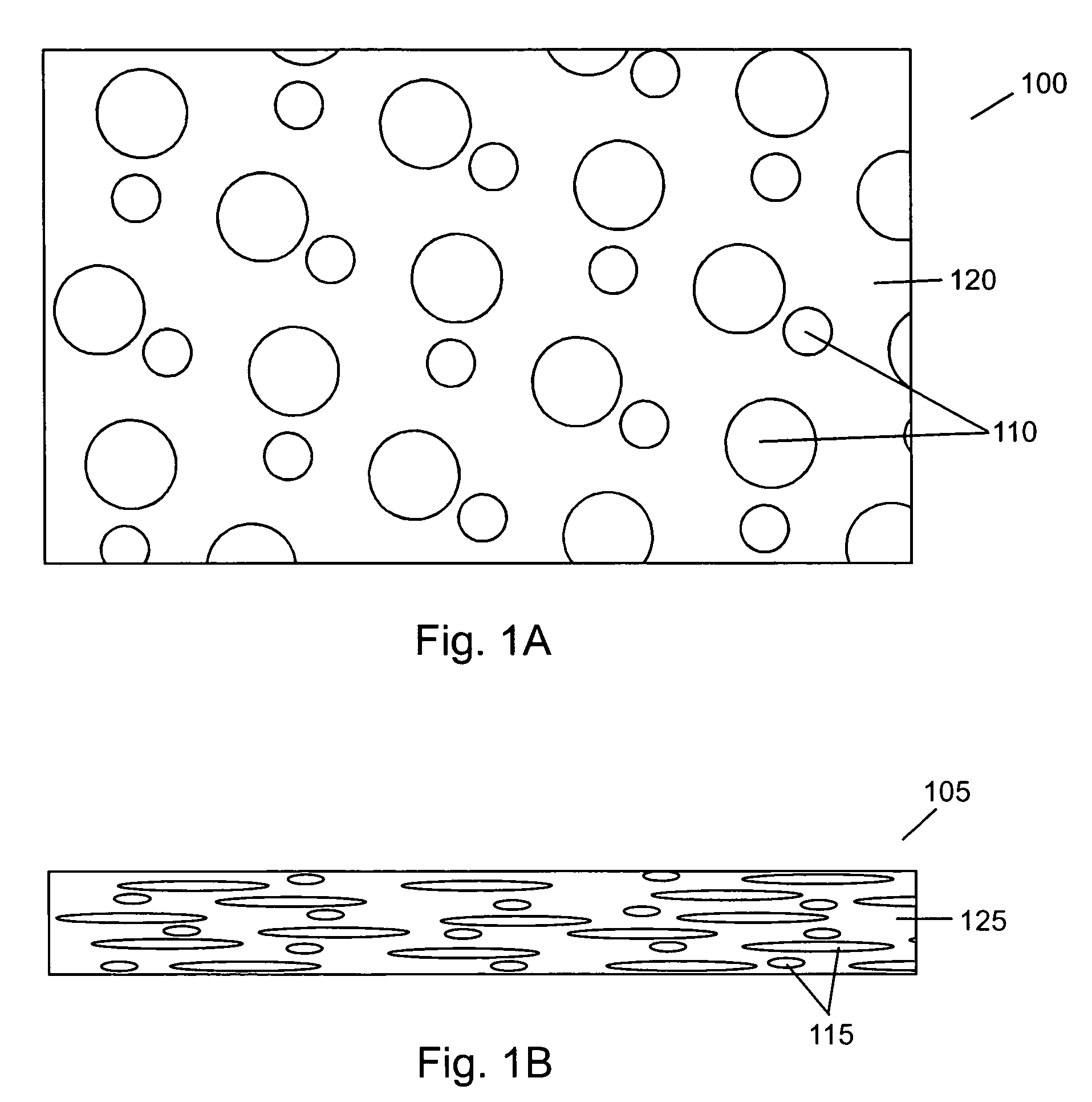

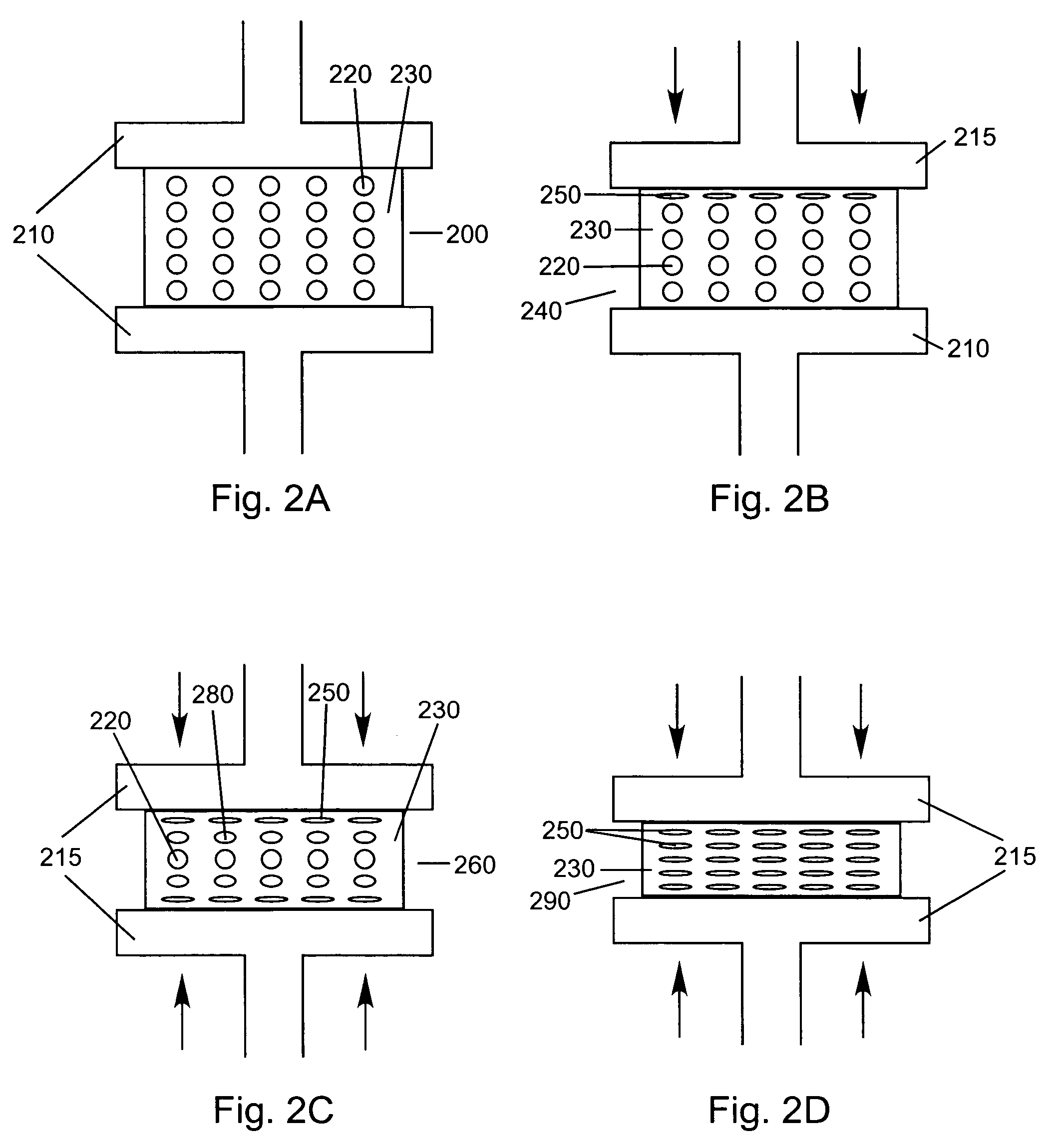

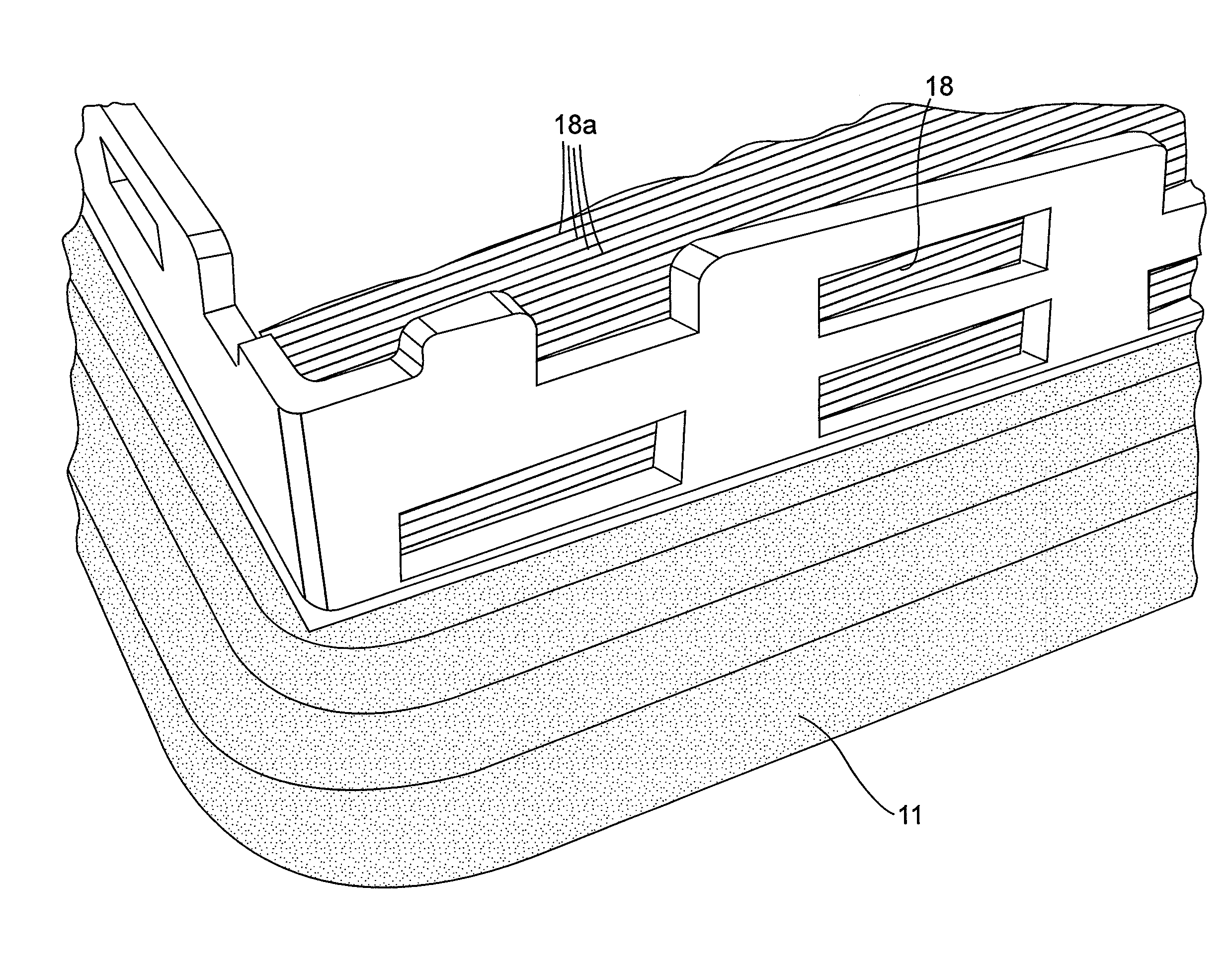

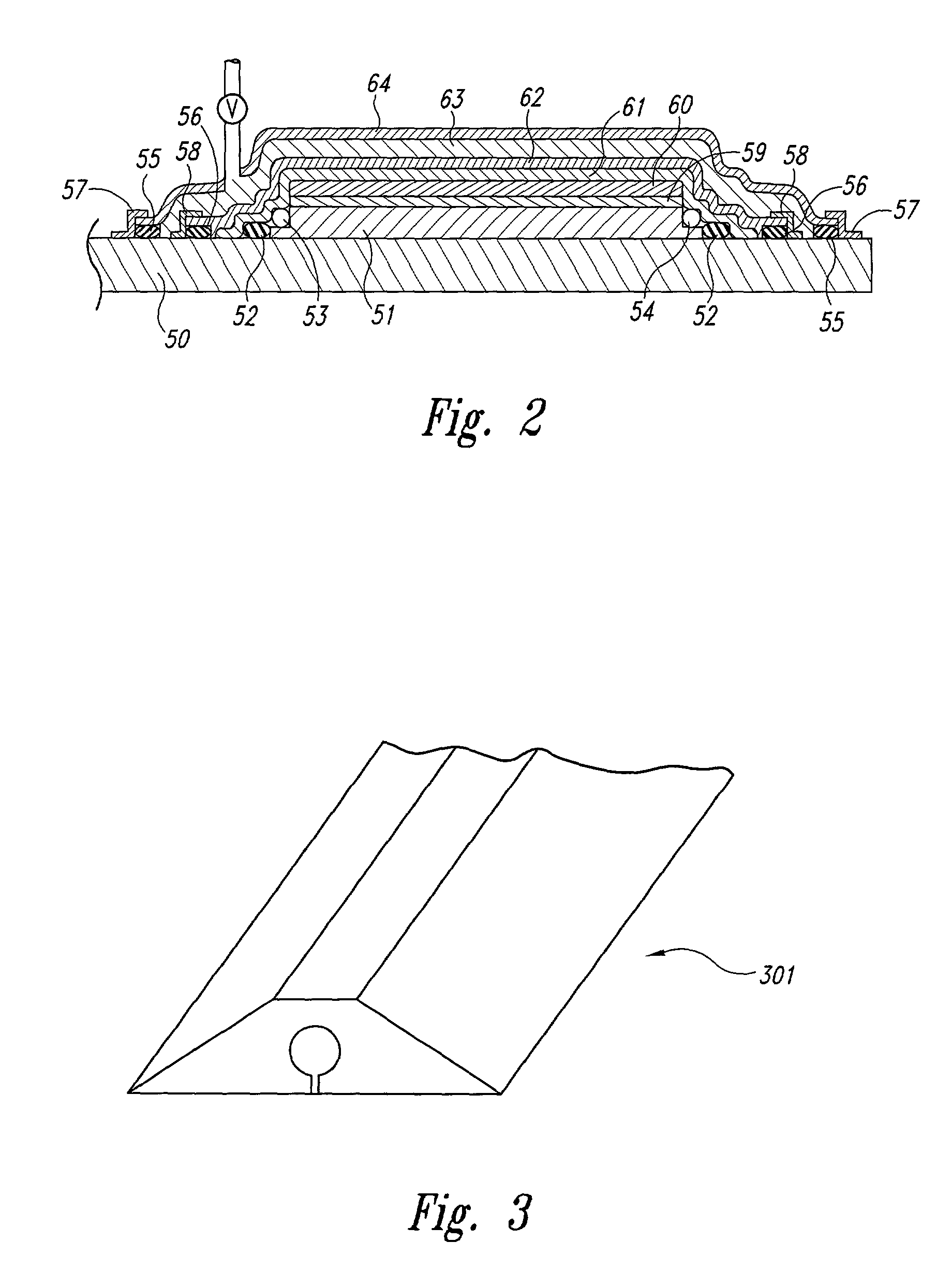

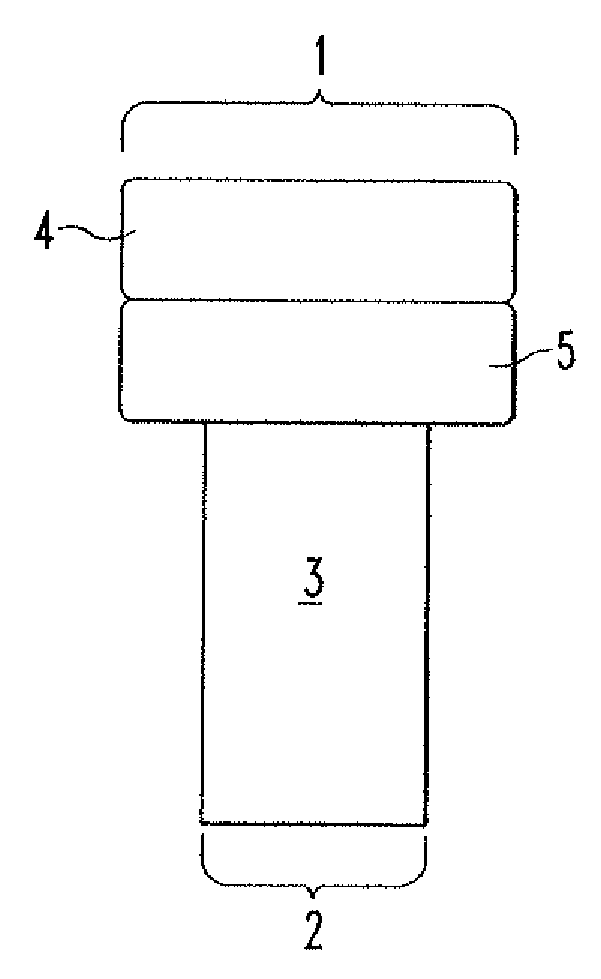

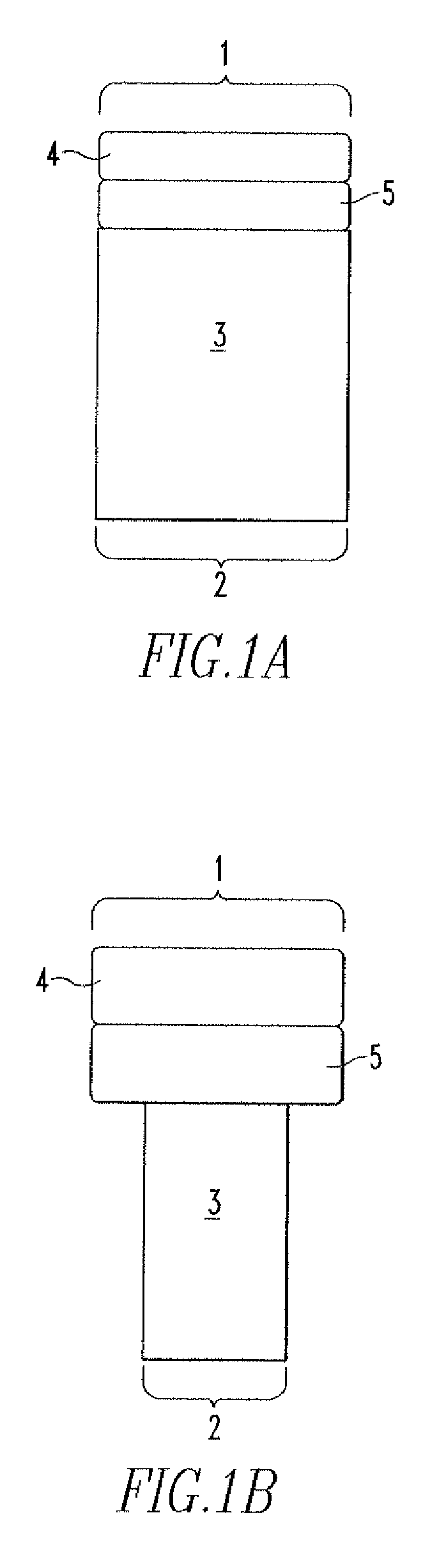

Compressed porous materials suitable for implant

ActiveUS7723395B2Increase surface areaReduce porosityInternal osteosythesisBone implantFluid migrationHigh intensity

A high strength porous polymeric material manufactured by a compression process is disclosed. The material results in a network of interconnected collapsed pores, which forces thin overlapping walls and passages to be created. The network provides permeable access for fluid migration throughout the material. The strength and / or permeability are advantageous for medical devices and implants.

Owner:DSM IP ASSETS BV

Hip prosthesis with monoblock ceramic acetabular cup

InactiveUS7695521B2High strengthImprove toughnessBone implantJoint implantsRight femoral headMetallic materials

An improved hip prosthesis includes an acetabular cup bearing component constructed from a relatively hard and high strength ceramic material for articulation with a ball-shaped femoral head component which may be constructed from a compatible ceramic or metal material. In one form, the acetabular cup further includes a ceramic porous bone ingrowth surface adhered thereto for secure ingrowth attachment to natural patient bone.

Owner:AMEDICA A DELAWARE

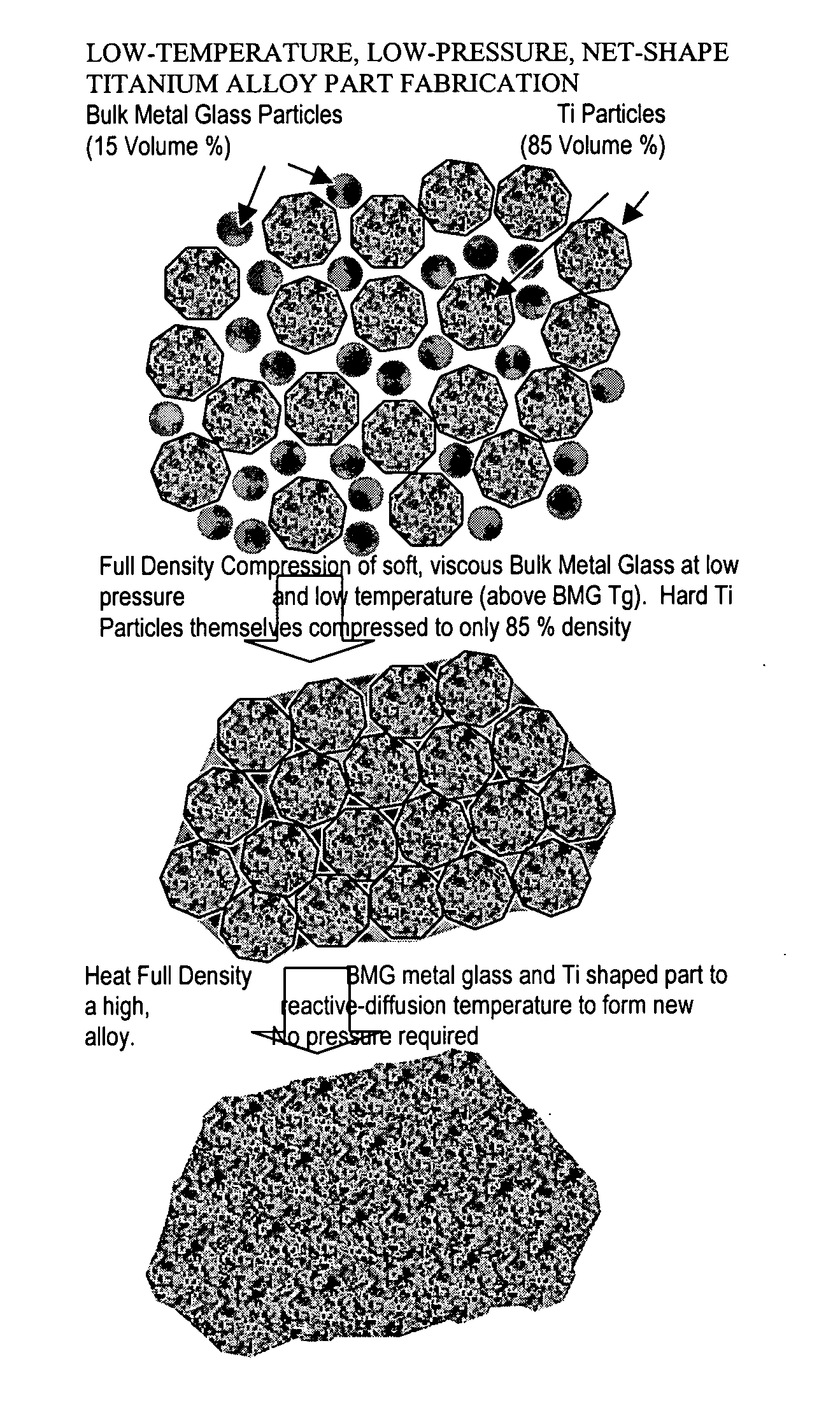

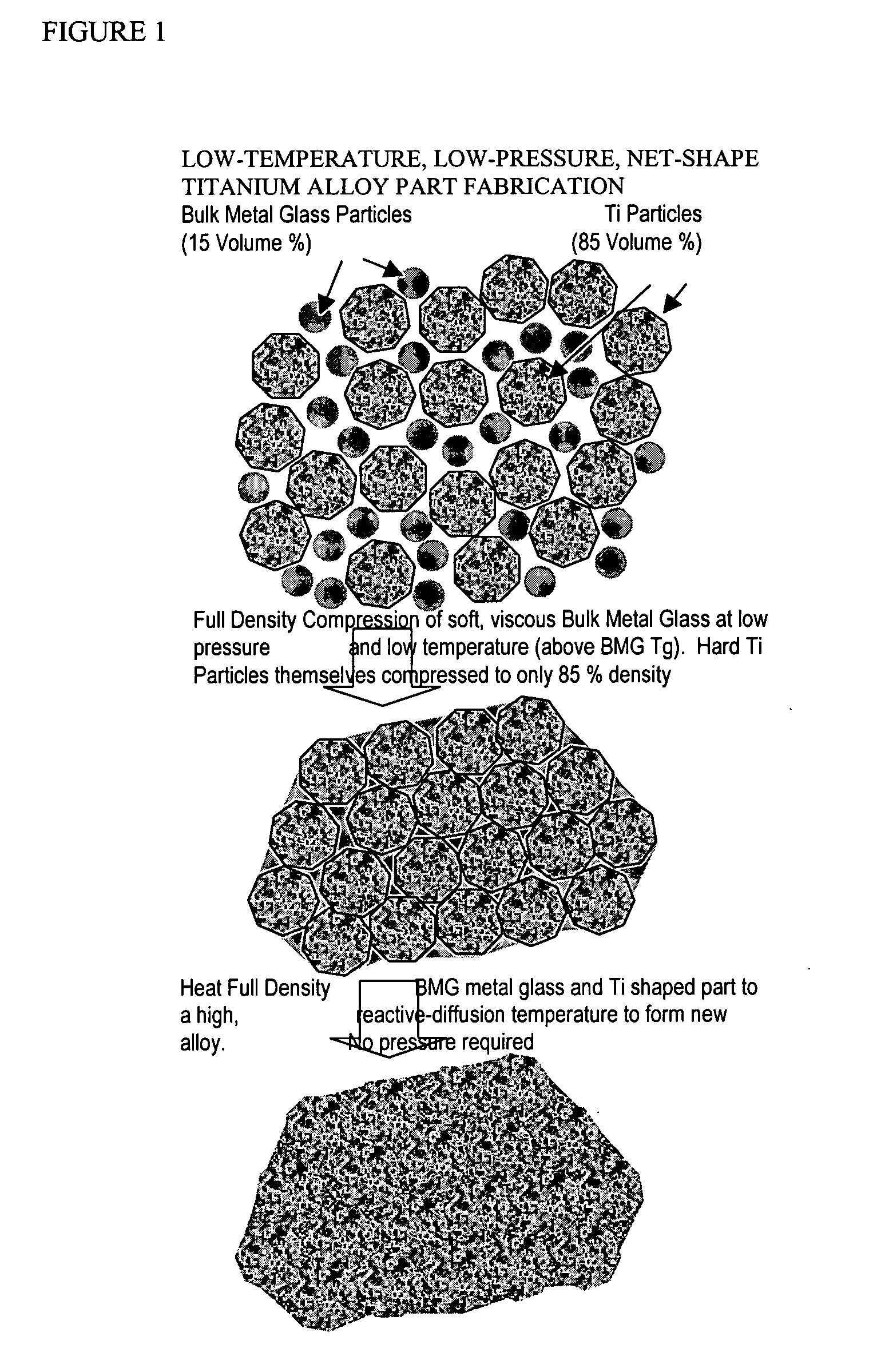

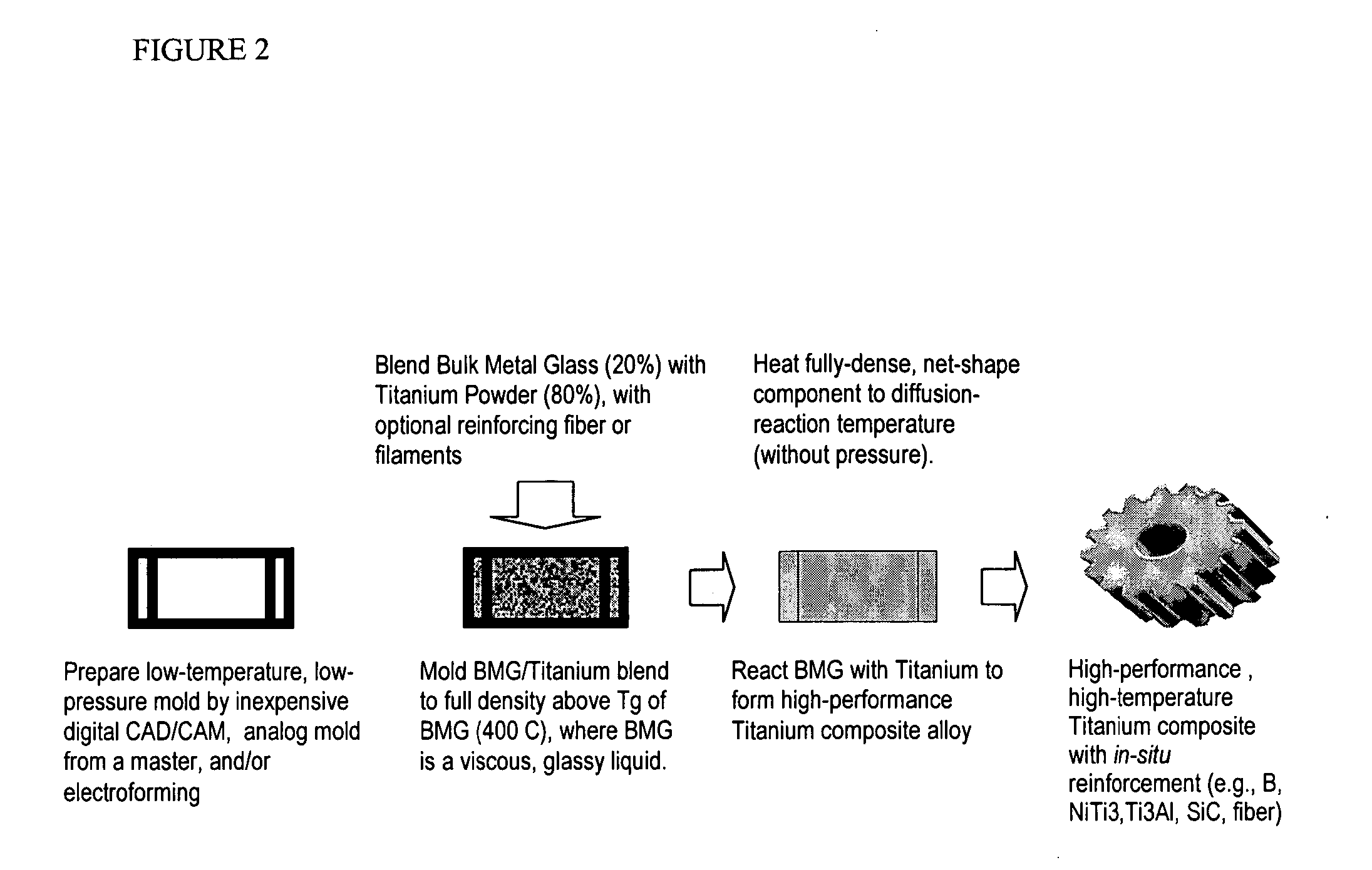

Titanium group powder metallurgy

InactiveUS20050084407A1Excellent cold formabilityImprove hardenabilityVitrificationVolumetric Mass Density

Methods and compositions relating to powder metallurgy in which an amorphous-titanium-based metal glass alloy is compressed above its glass transition temperature Tg with a titanium alloy powder which is a solid at the compression temperature, to produce a compact with a relative density of at least 98%.

Owner:MYRICK JAMES J

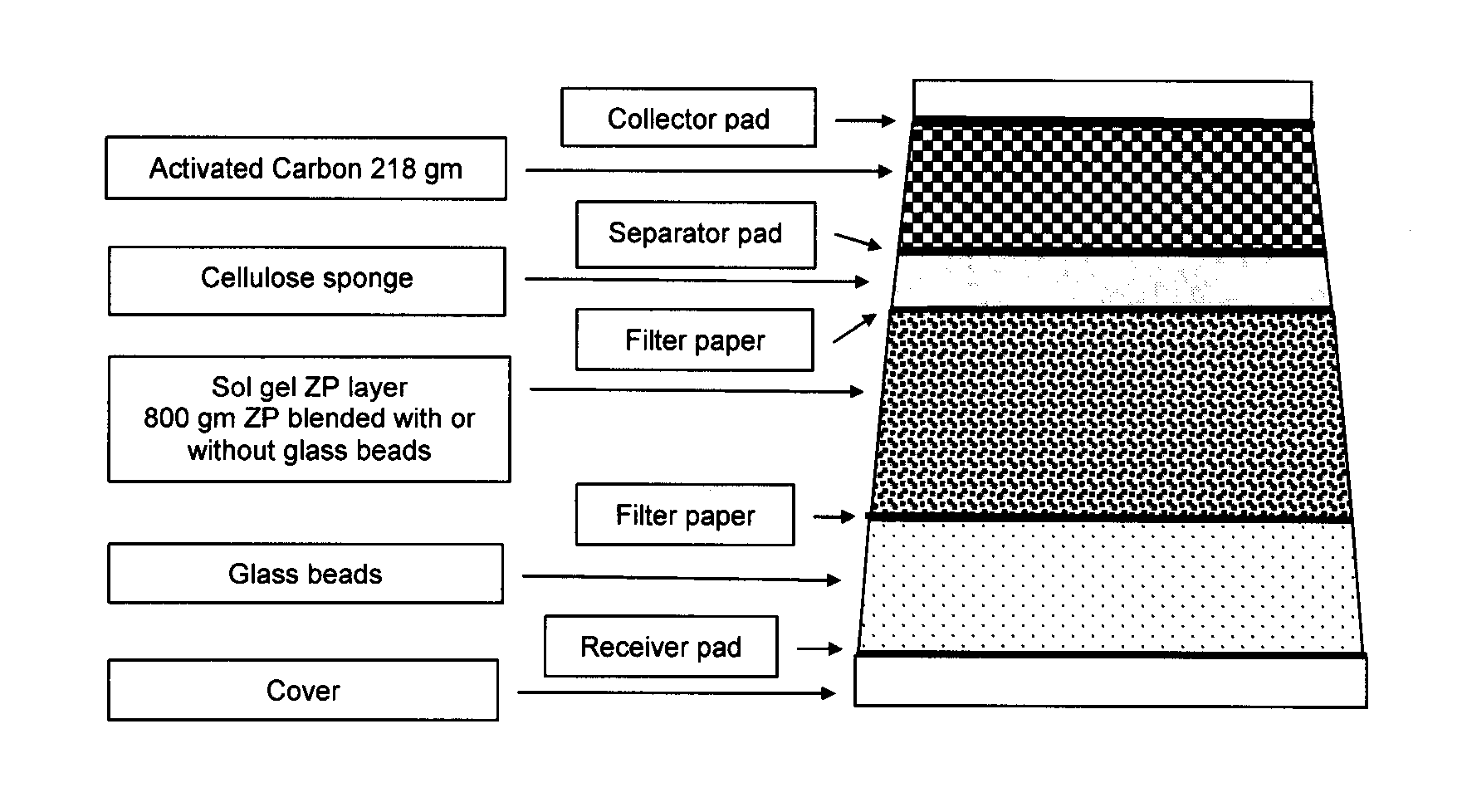

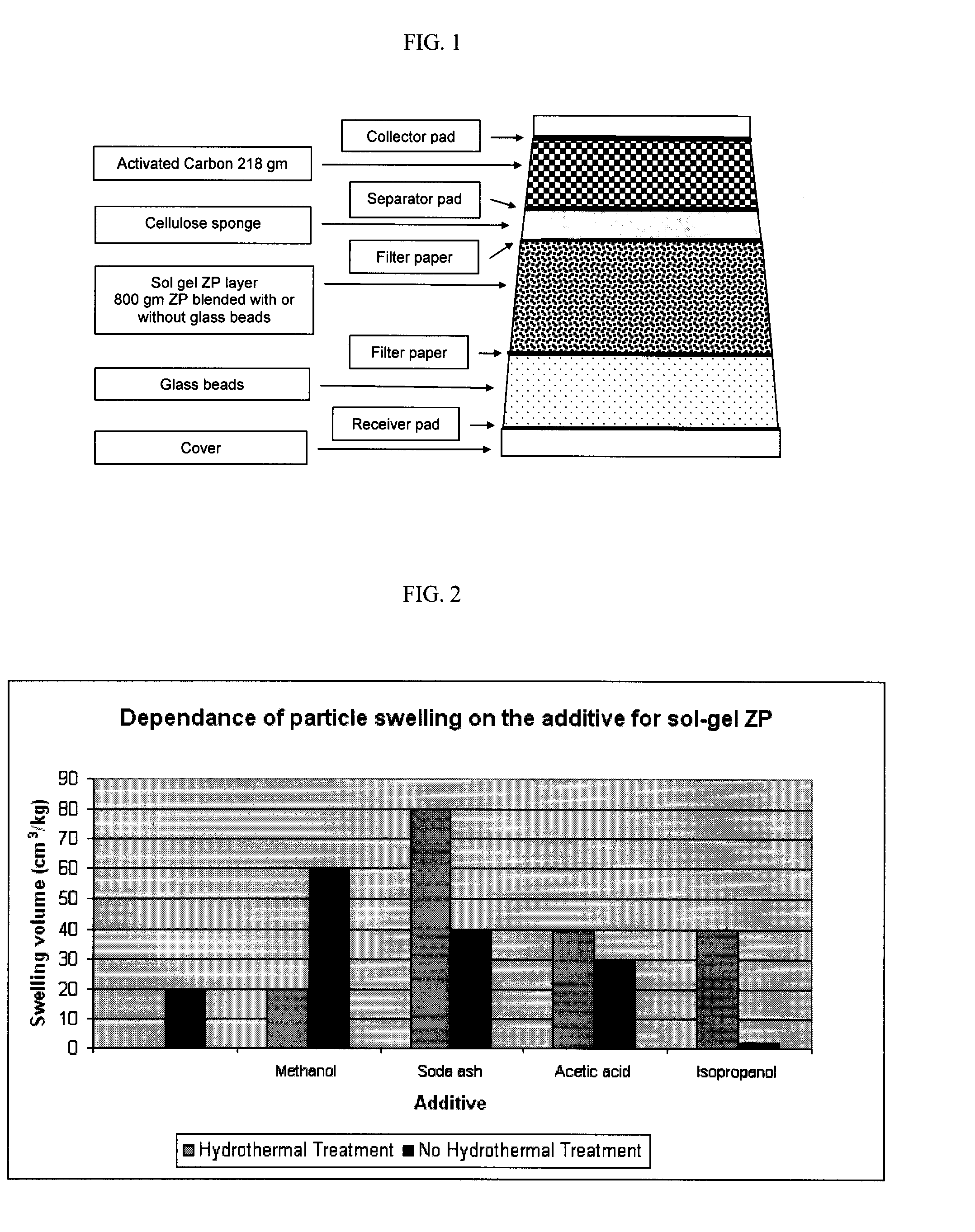

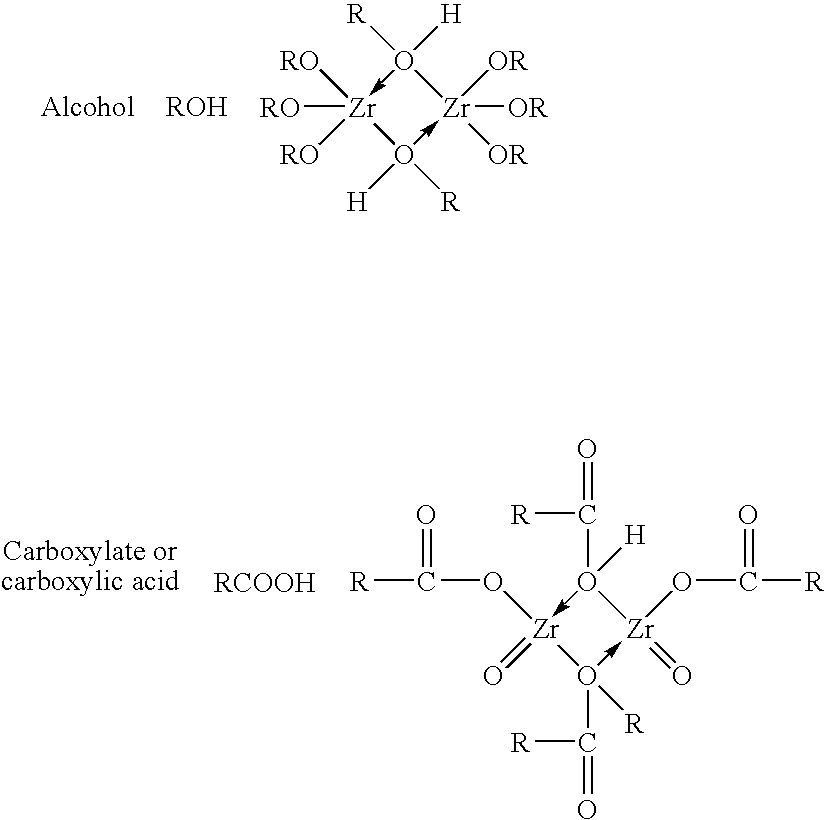

Zirconium Phosphate Particles Having Improved Adsorption Capacity and Method Of Synthesizing The Same

InactiveUS20100084330A1Avoid disadvantagesHigh porosityPhosphatesDialysis systemsPhosphoric acidOxygen

Zirconium phosphate particles are synthesized by providing a solution of zirconium oxychloride in an aqueous solvent, adding at least one low molecular weight, oxygen containing, monofunctional, organic additive to the solution, and combining this solution with heated phosphoric acid or a phosphoric acid salt to obtain zirconium phosphate particles by sol gel precipitation.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Implant scaffold combined with autologous or allogenic tissue

InactiveUS20050209705A1Reduce and prevent immune responseReducing and preventing inflammationBone implantJoint implantsComposite Tissue AllograftAutologous tissue

This invention provides implants comprising tissue having an intercellular matrix anchored to a biocompatible scaffold. The intercellular matrix of the tissue provides a natural medium to facilitate the healing and growth of damaged tissue in a patient. The present invention provides methods of treating damaged tissue in a patient by inserting such implants into the damaged tissue. The implants of the present invention include implants comprising allogenic and / or autologous tissue. The tissue may also be acellular.

Owner:OSTEOBIOLOGICS

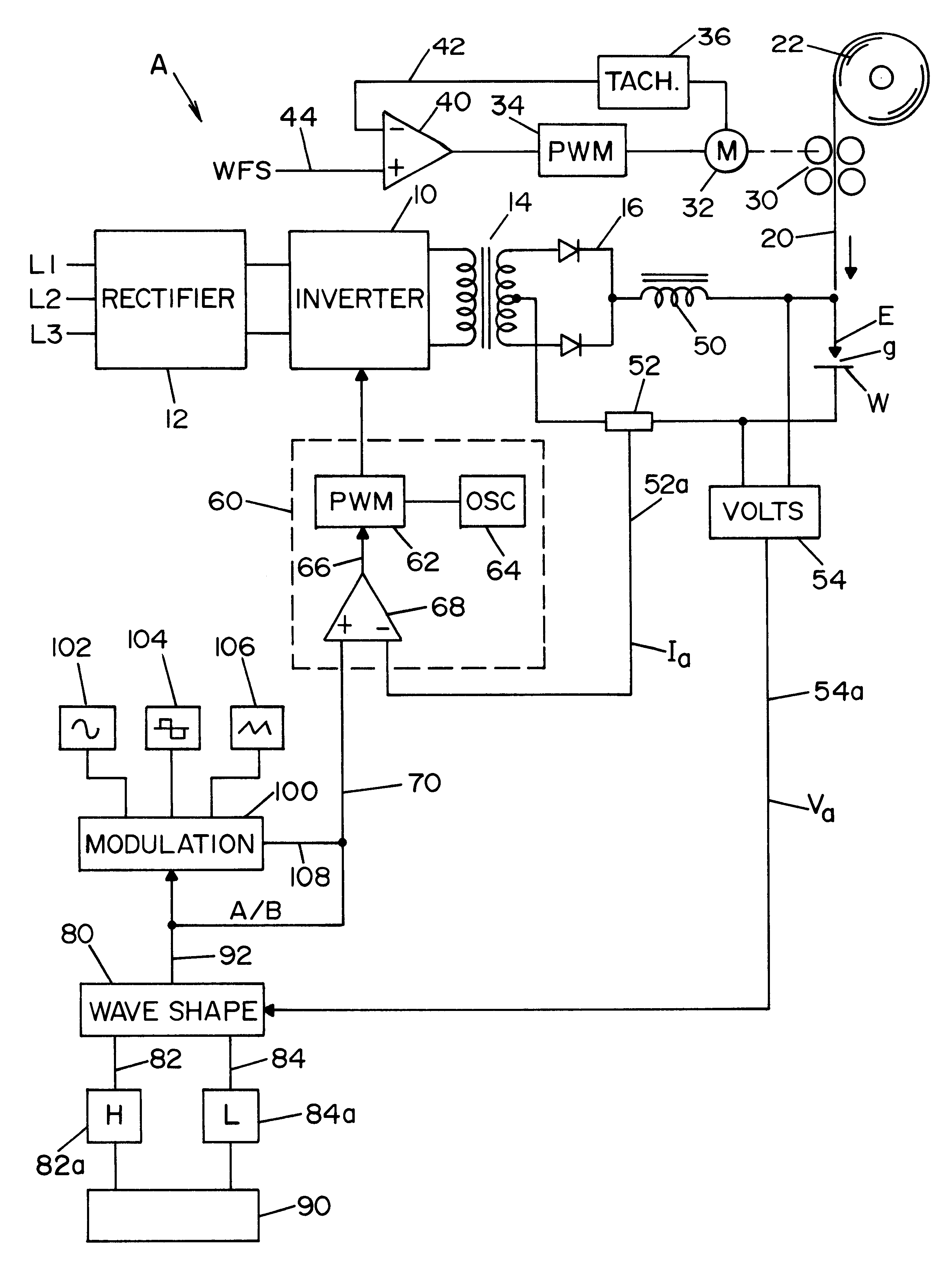

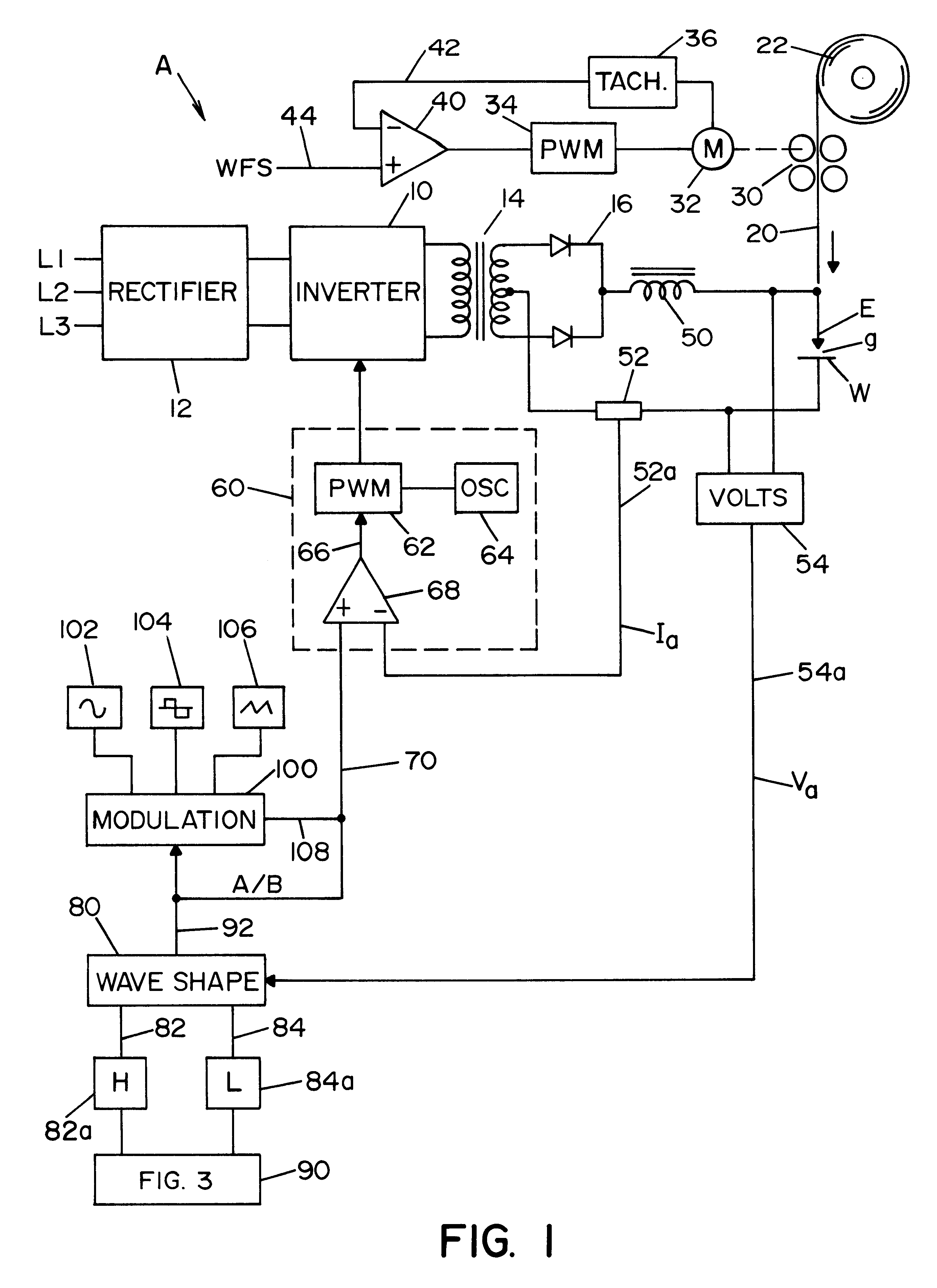

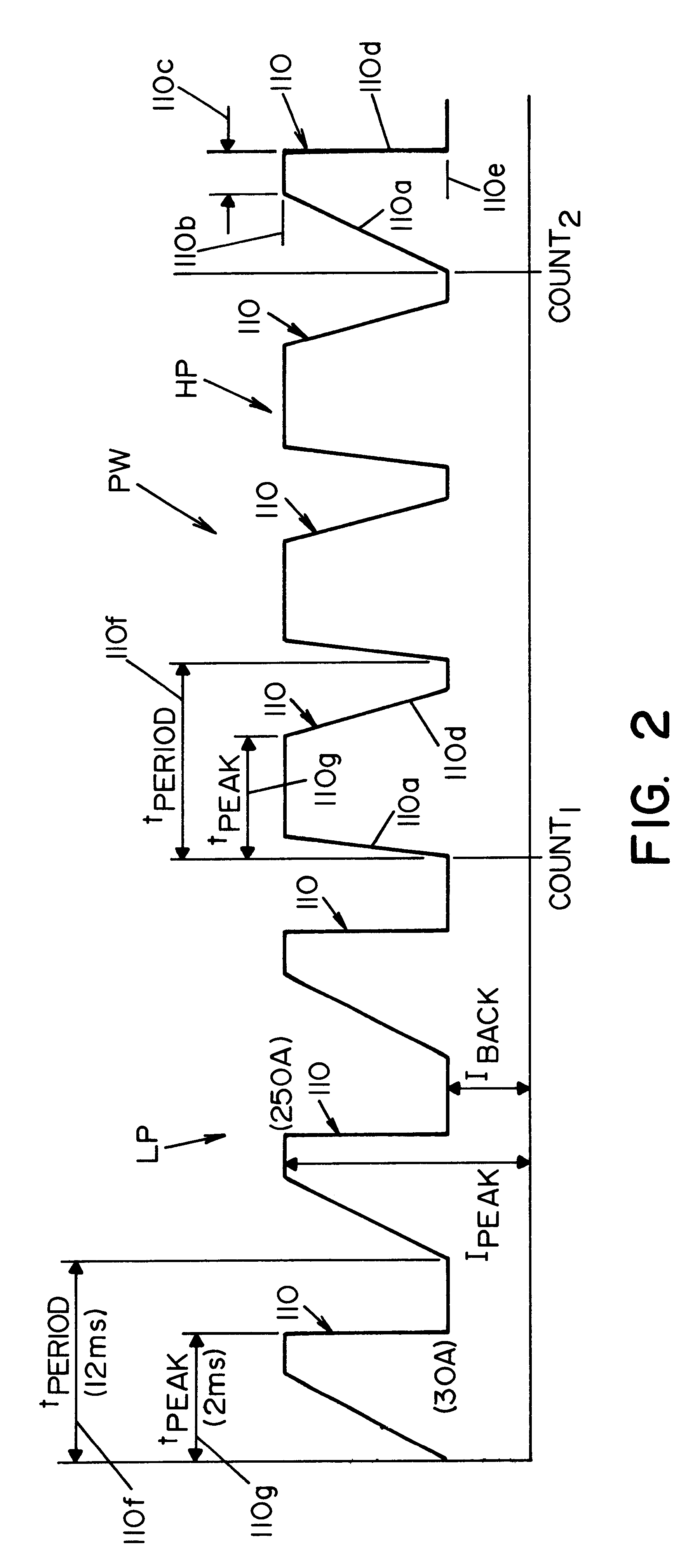

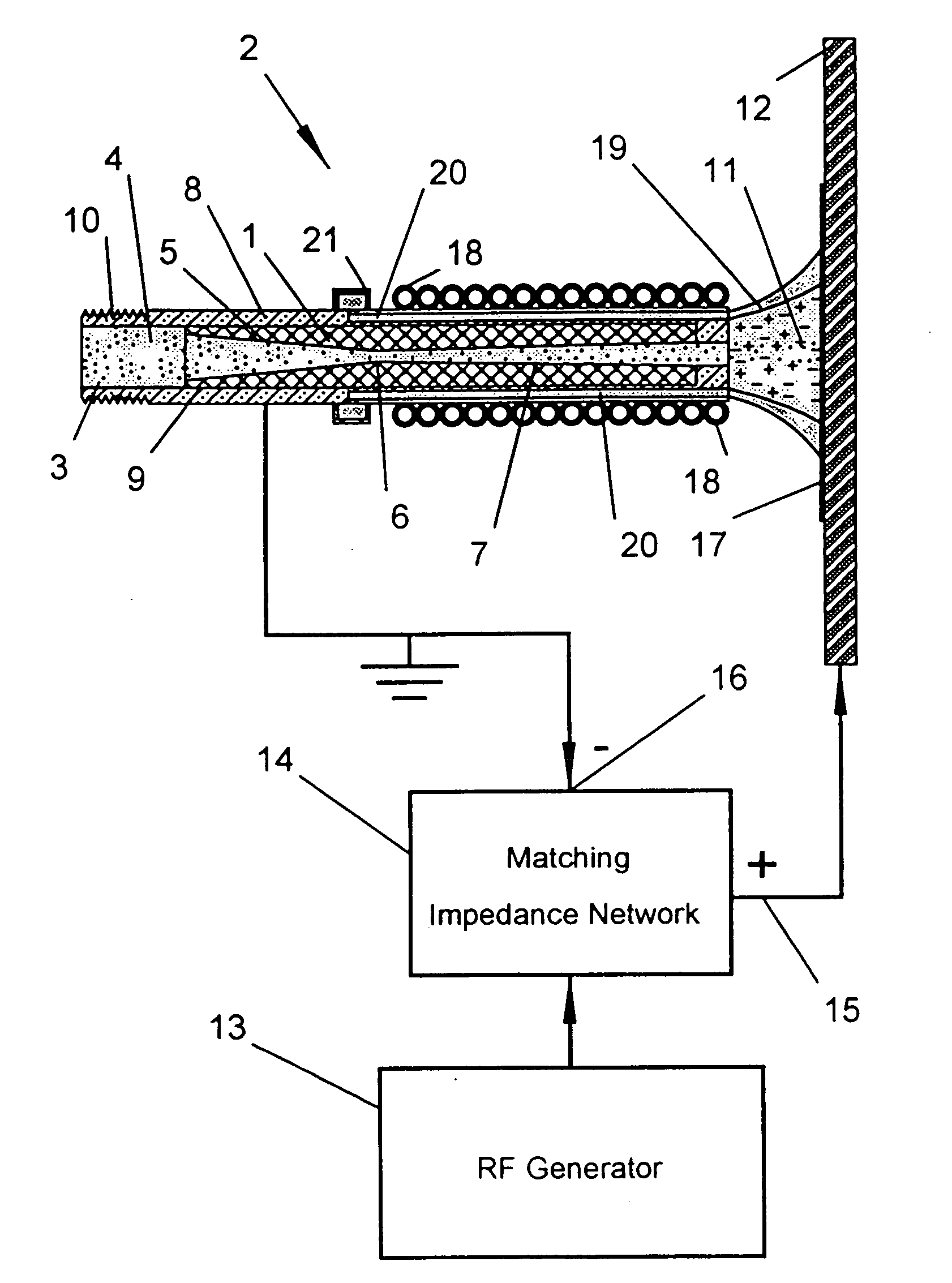

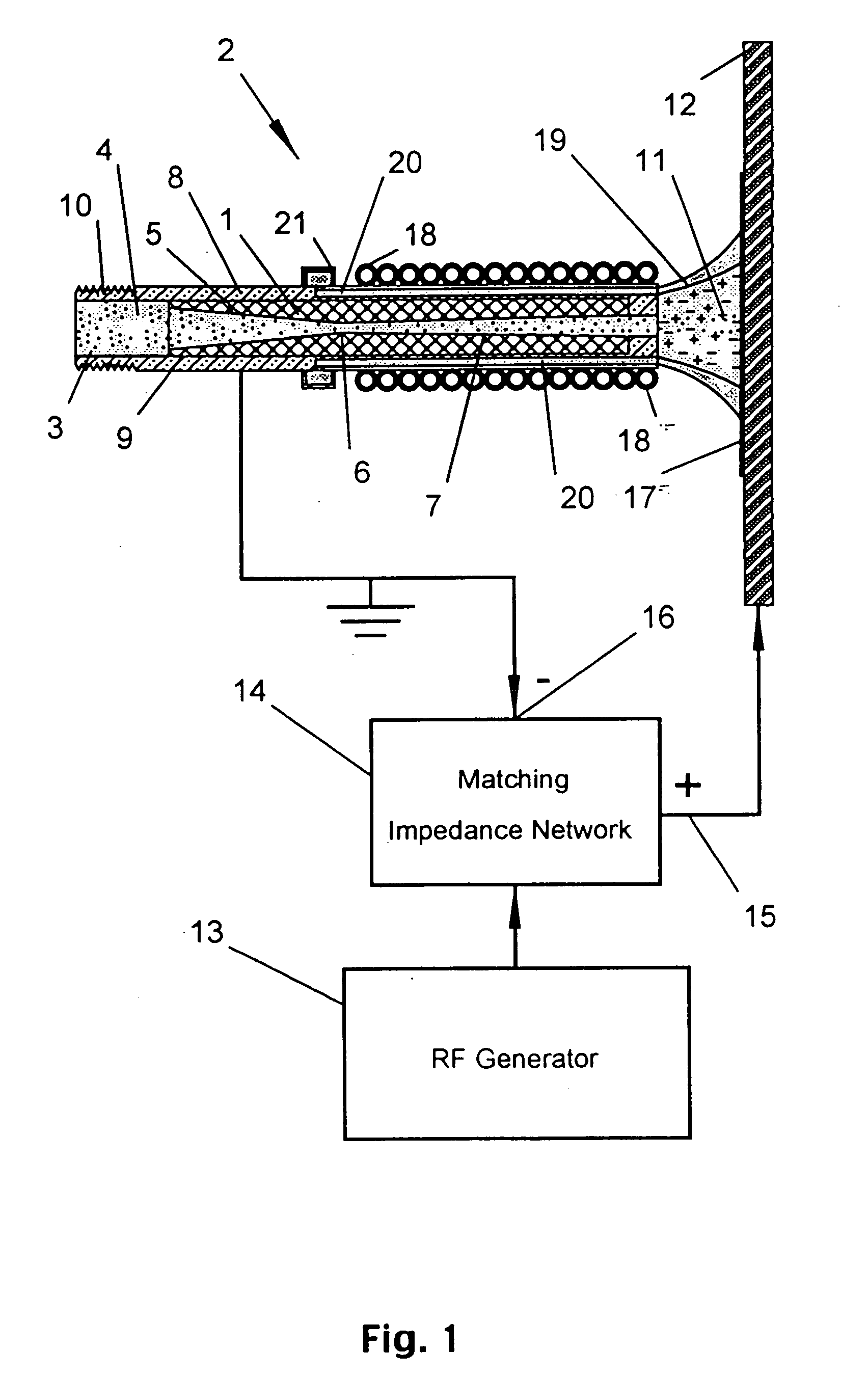

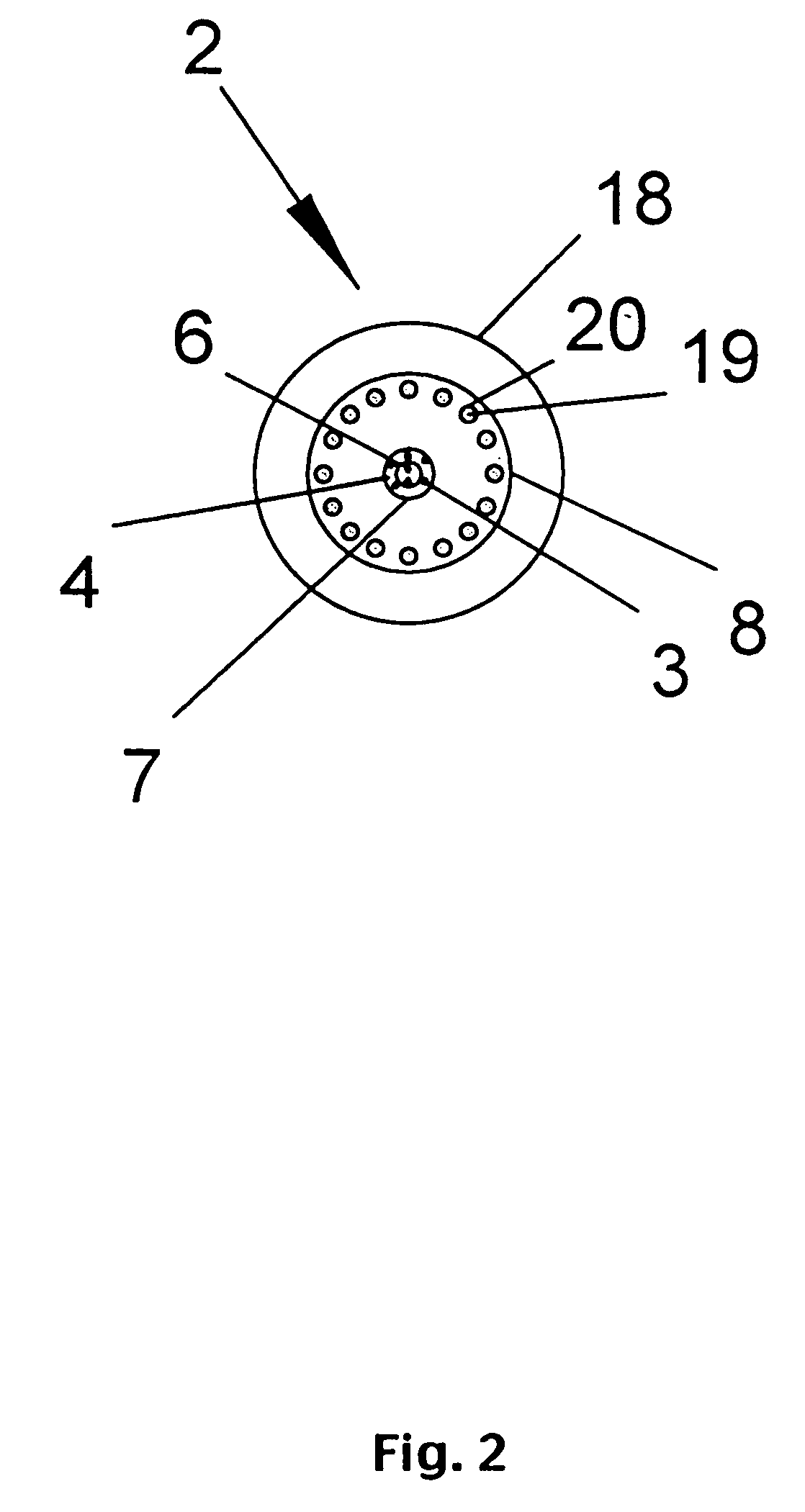

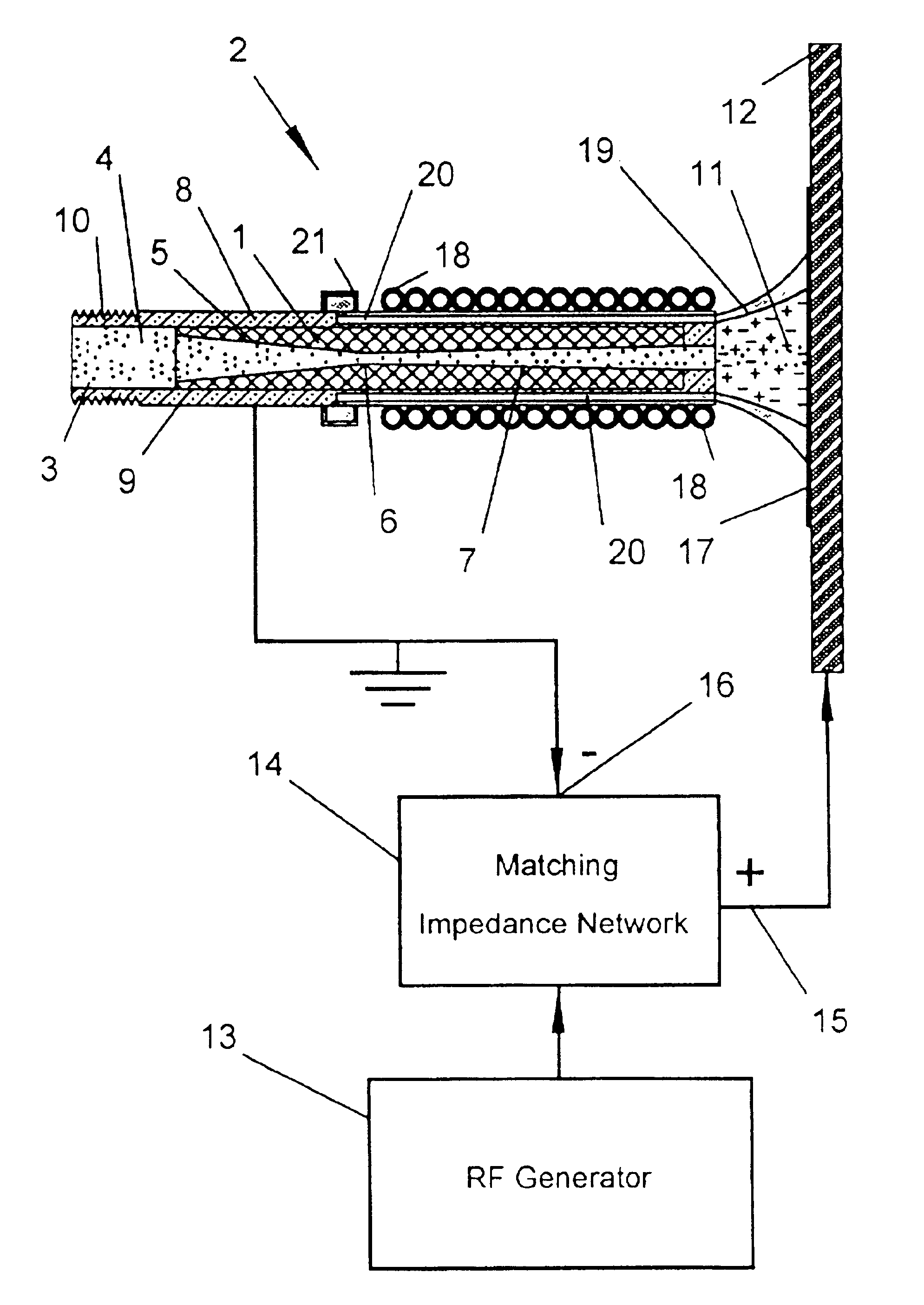

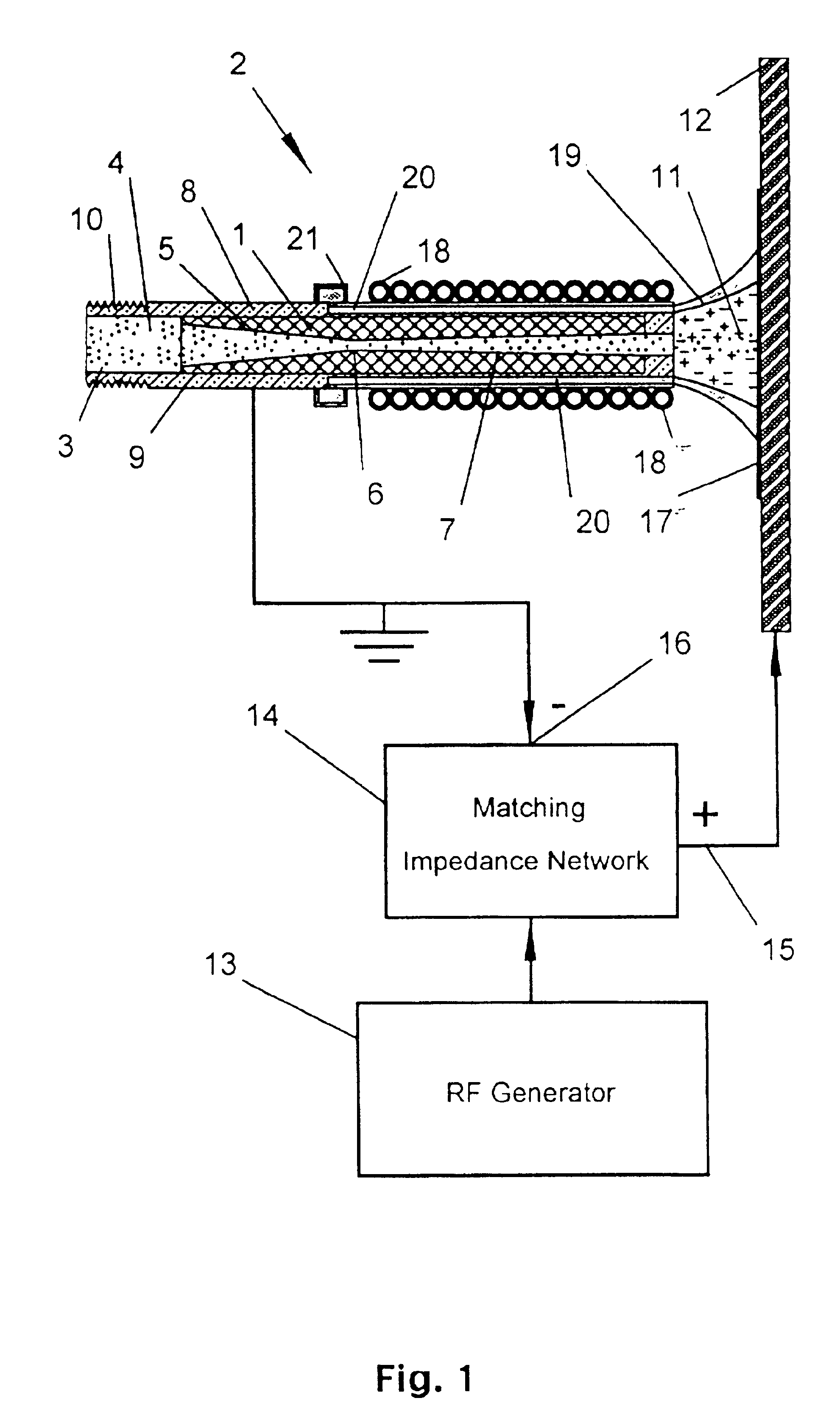

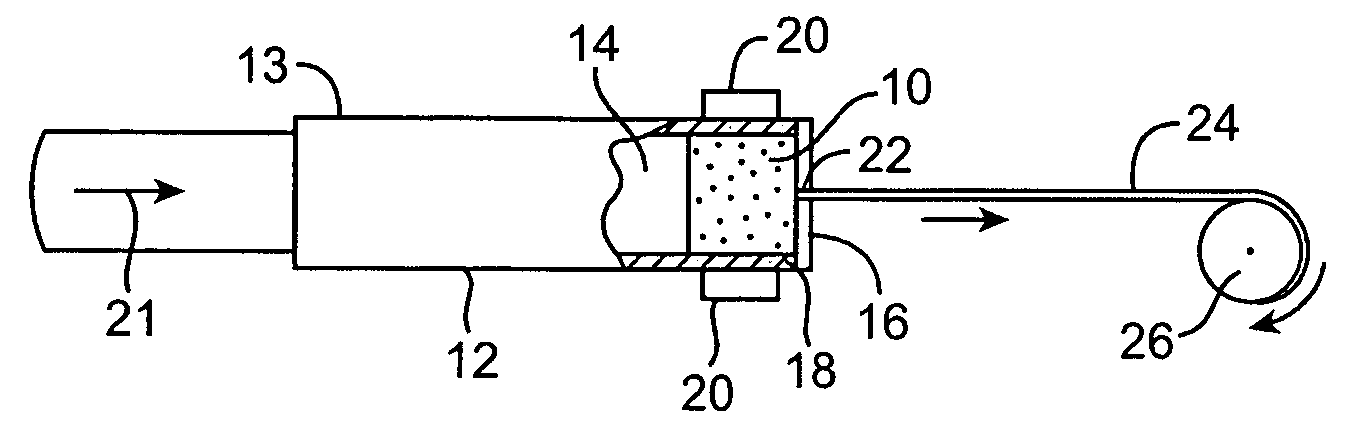

Electric arc welder using high frequency pulses

InactiveUS6515259B1Efficiently transferredMaximized efficiency and heatArc welding apparatusWave shapeElectric arc

An electric arc welder including a high speed switching power supply with a controller for creating high frequency current pulses through the gap between a workpiece and a welding wire advancing toward the workpiece, where the pulses and a background current defining a series of weld cycles. A wave shape generator defines the shape of the pulses and the background current including a controlled ramp up and / or ramp down in each of said cycles and a circuit to change the shapes of the pulses and / or background current in a repeating pattern in each of the weld cycles. The shape change in a cycle can be between first and second shapes or by a rhythmic AC modulation.

Owner:LINCOLN GLOBAL INC

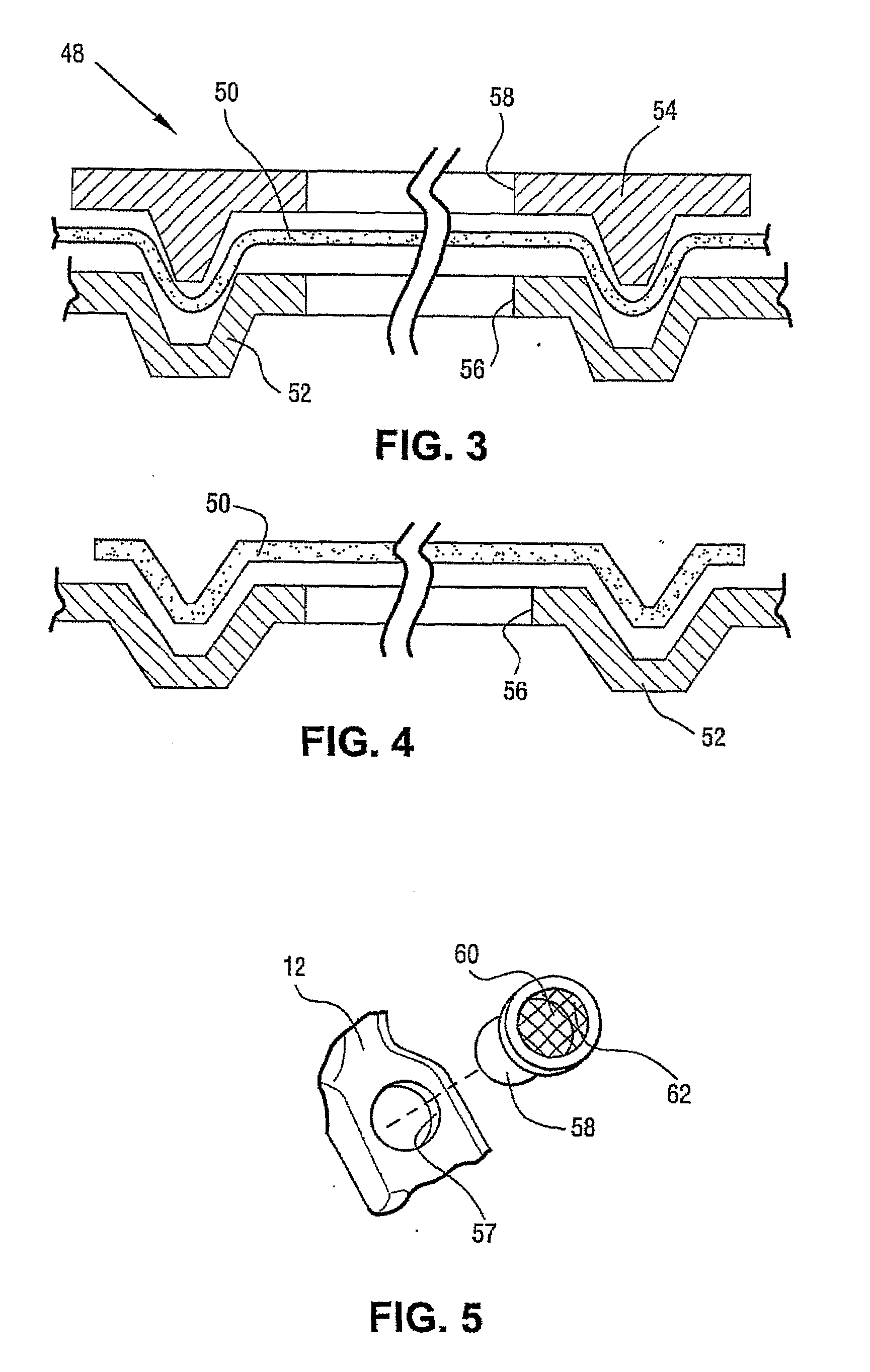

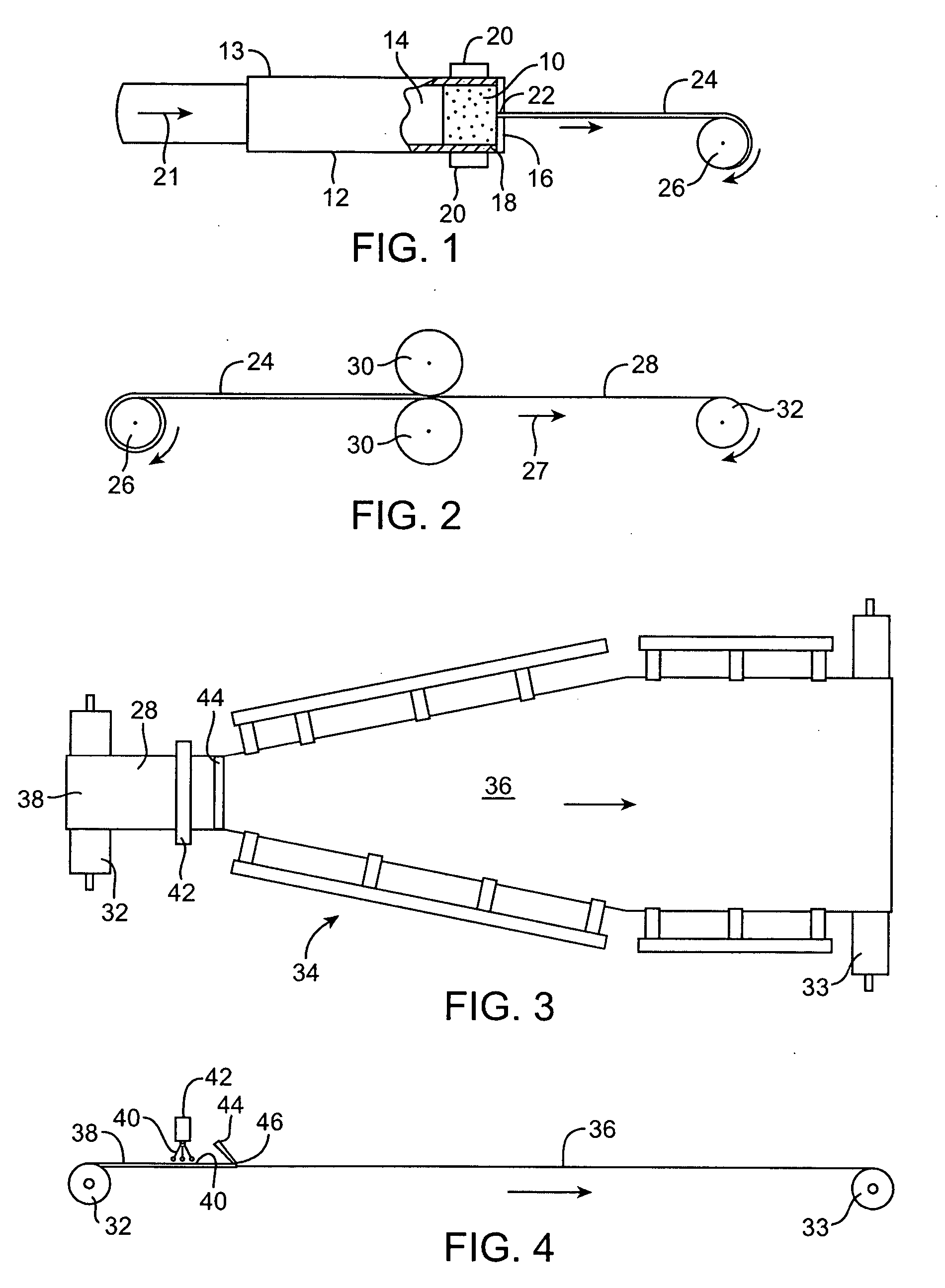

Filter element and method

InactiveUS20090044702A1Life of element can be lengthenedIncrease capacityCombination devicesNon-fibrous pulp additionMultiple formsParticulates

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

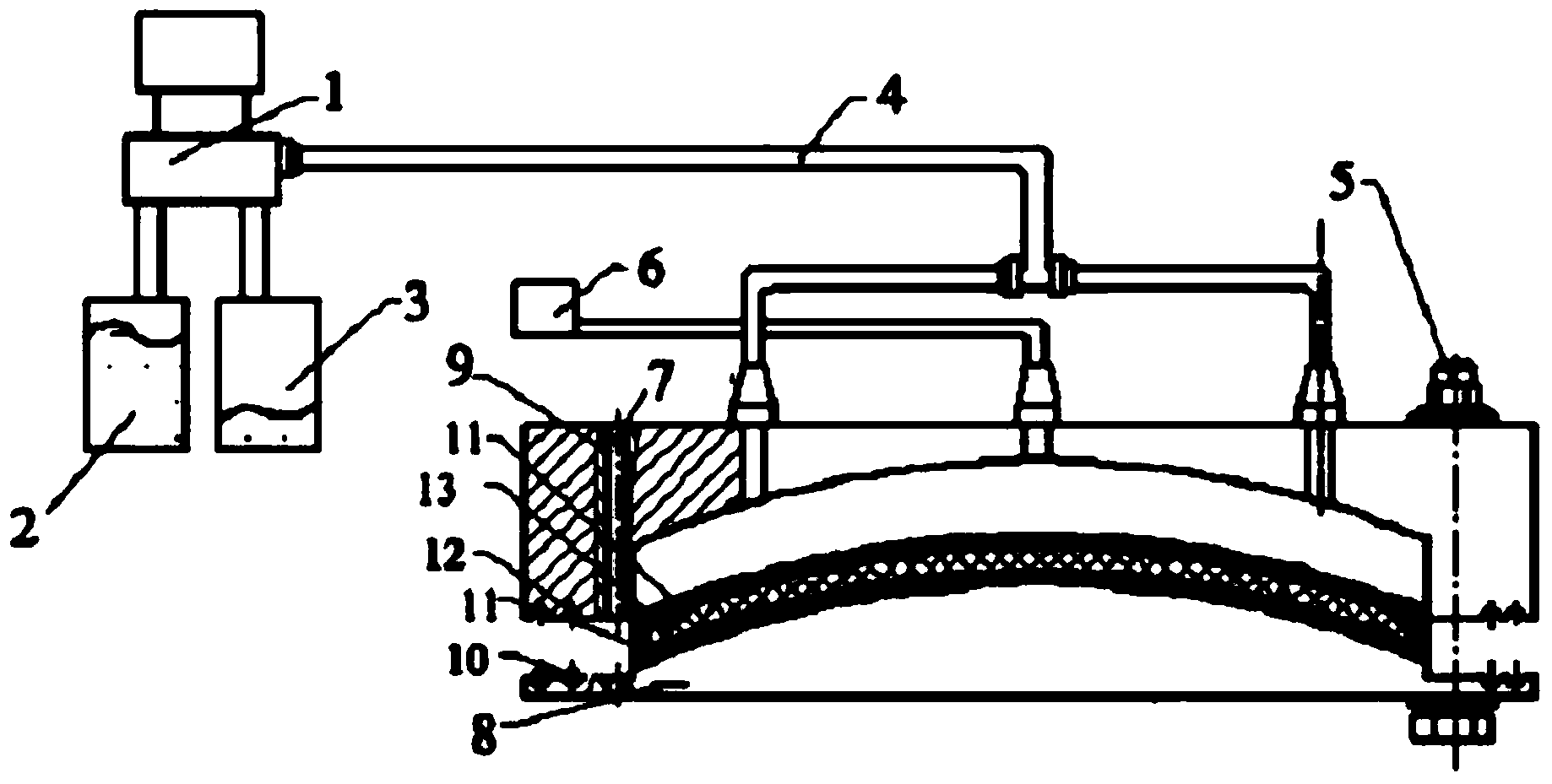

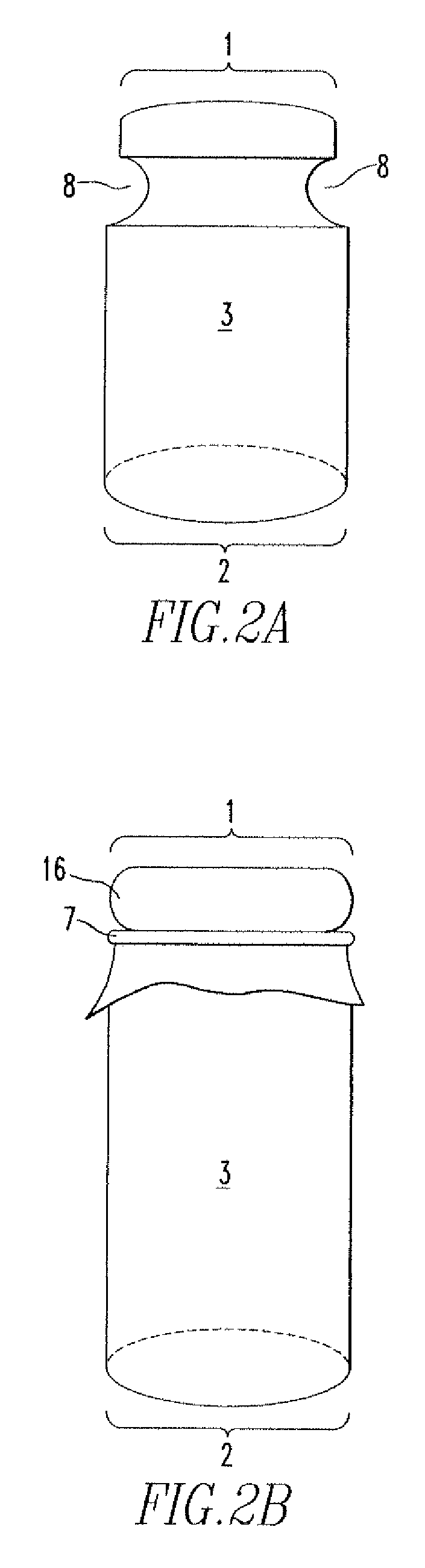

Manufacturing method for carbon fiber antenna surface

The invention relates to a manufacturing method for a carbon fiber antenna surface. The manufacturing method comprises the following steps of 1, prefabricating a die; 2, polishing the die; 3, chemically electroplating the die; 4, measuring the precision, and clearing away impurities; 5, coating a demolding agent; 6, paving carbon fiber cloth on a male die; 7, paving PVC foams on the surface of the male die; 8, paving carbon fiber cloth on the surface of the male die; 9, assembling the male die and a female die, and sealing and fastening the male die and the female die; 10, vacuumizing to enable the vacuum degree in the die to be smaller than -0.096MPa; 11, injecting epoxy resin and a solidifying agent from a material inlet of the female die; 12, sticking a layer of glass paper to the outer surface of a blank after the appearance gets through inspection and is qualified; 13, performing perforation and assembling; and 14, obtaining the carbon fiber antenna surface after the product is qualified through inspection. The carbon fiber antenna surface manufactured by the manufacturing method is smooth, and the precision can reach 0.1R.M.S; and due to normal-temperature solidification, energy is saved, and the cost is lowered.

Owner:XIAN TUOFEI COMPOSITE MATERIAL

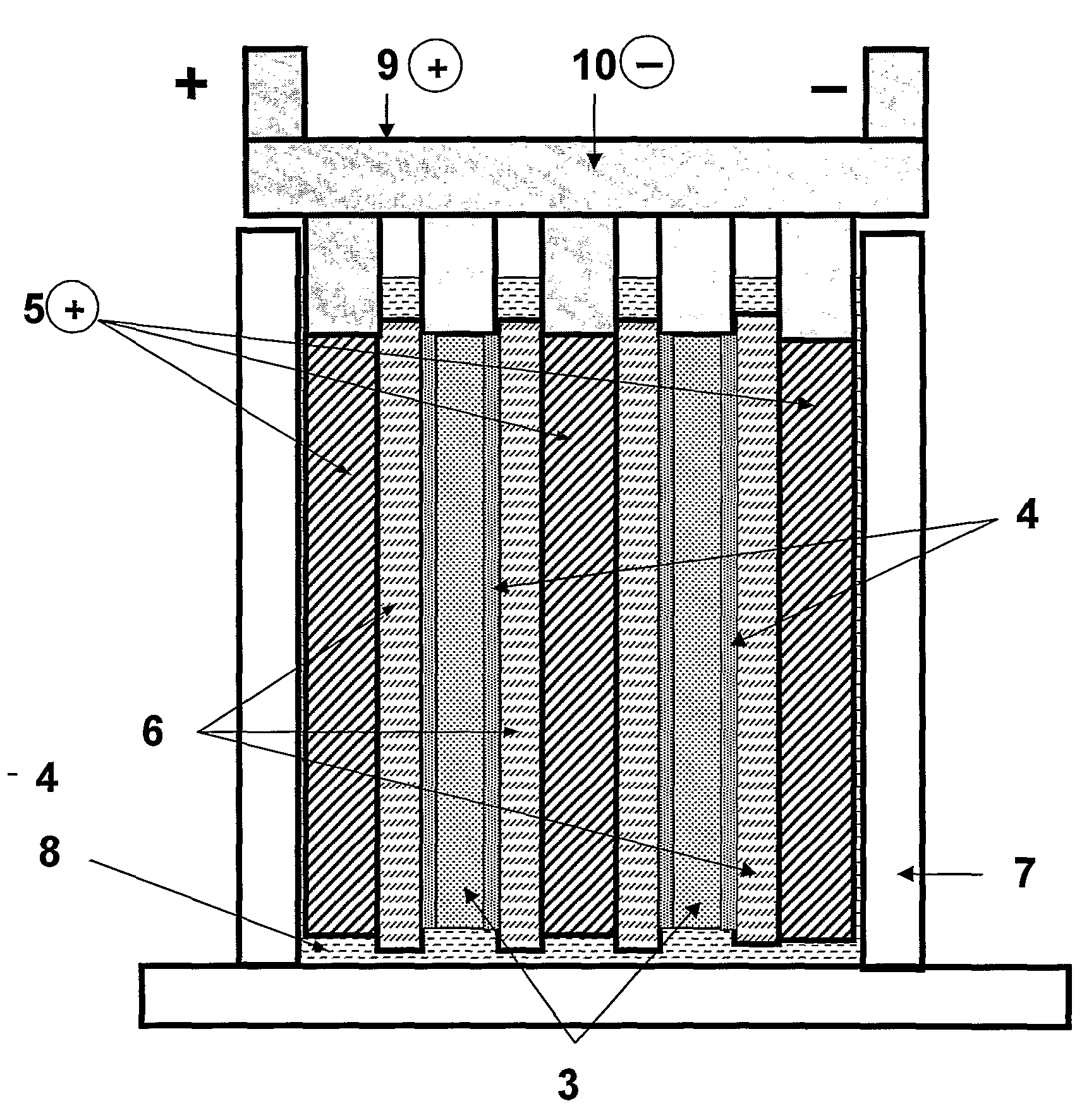

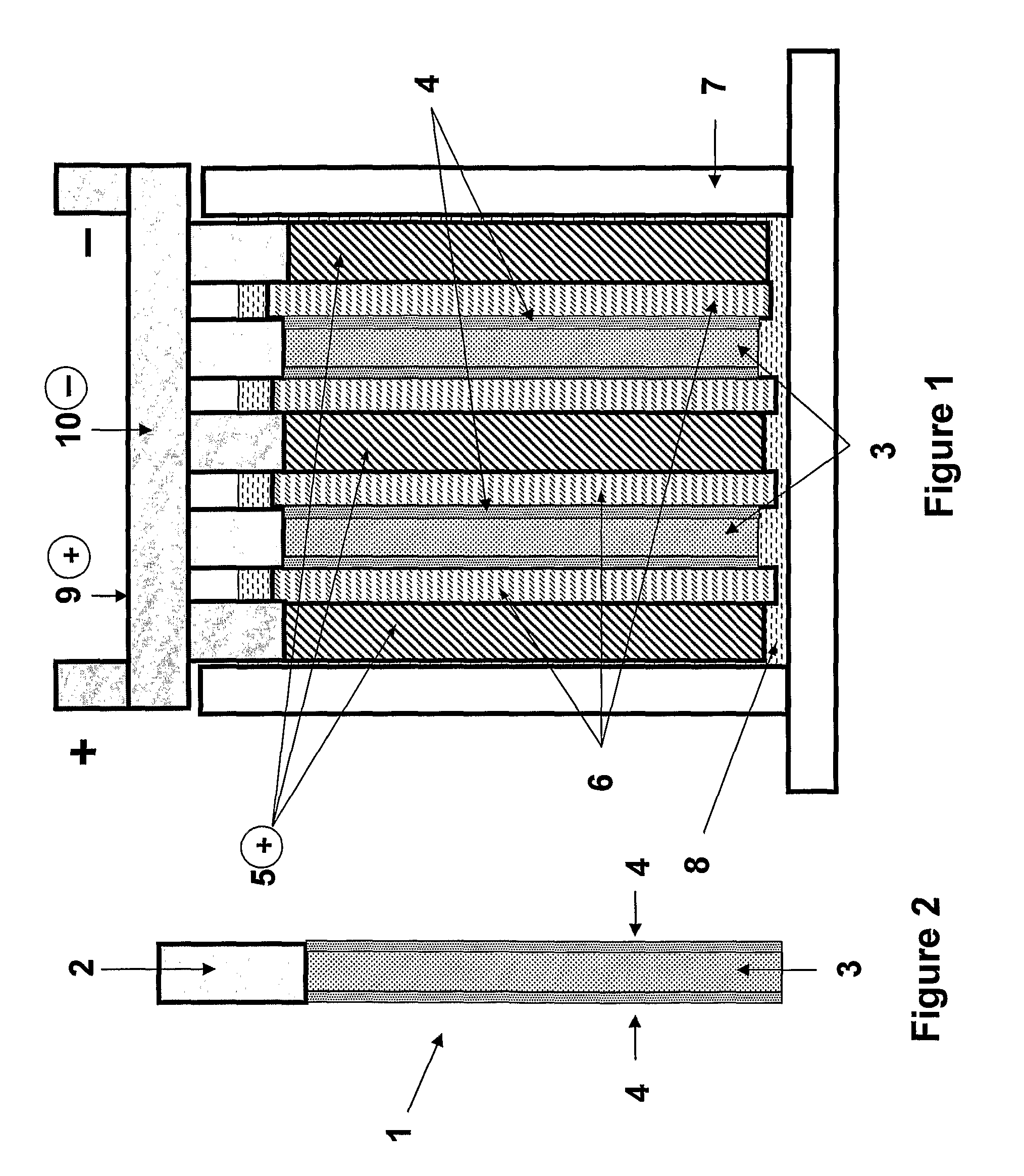

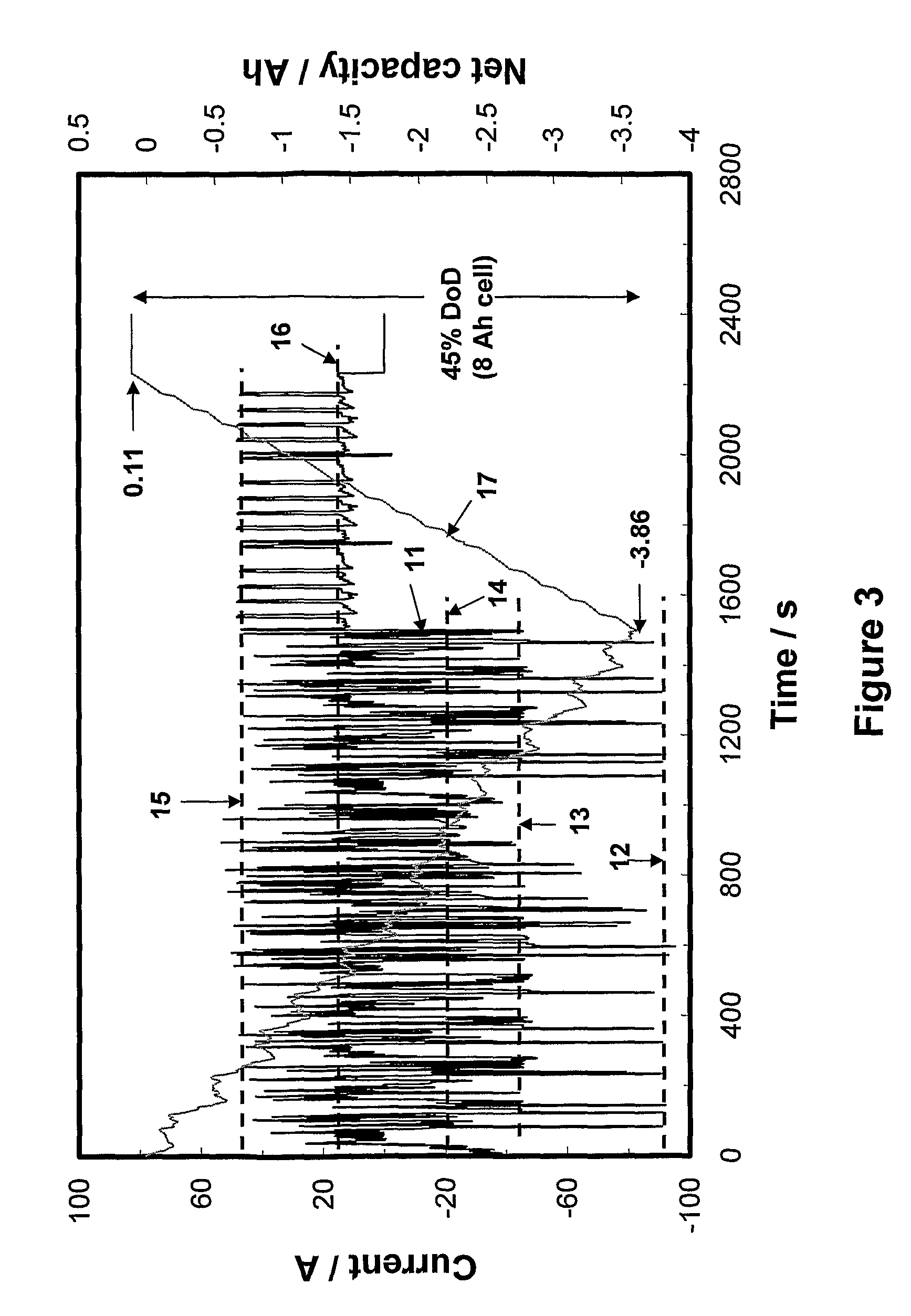

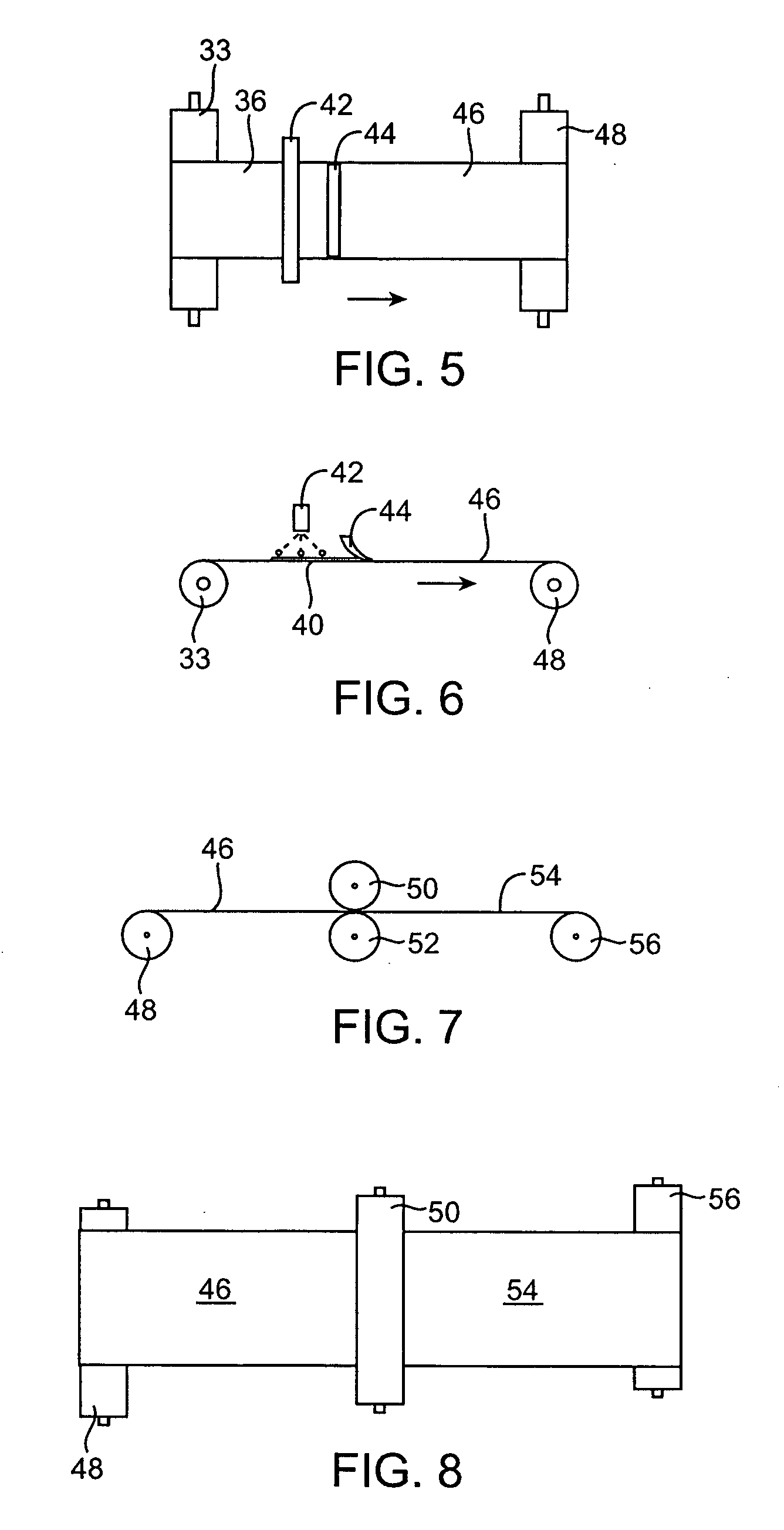

Energy storage device

ActiveUS20100203362A1Reduce heatImprove conductivityLead-acid accumulatorsCapacitor and primary/secondary cellsTin dioxideConductive materials

An energy storage device comprising at least one negative electrode, wherein each negative electrode is individually selected from (i) an electrode comprising negative battery electrode material; (ii) an electrode comprising capacitor electrode material; (iii) a mixed electrode comprising either—a mixture of battery and capacitor electrode material or—a region of battery electrode material and a region of capacitor electrode material, or—a combination thereof, and wherein the energy storage device either comprises at least one electrode of type (iii), or comprises at least one electrode of each of types (i) and (ii),—at least one positive electrode, wherein the positive electrode comprises positive battery electrode material and a charging ability-increasing additive, such as one or a mixture of: (a) carbon nanomaterial, vapour grown carbon fibre, fullerene, or a mixture thereof, and (b) tin dioxide conductive materials.

Owner:COMMONWEALTH SCI & IND RES ORG +1

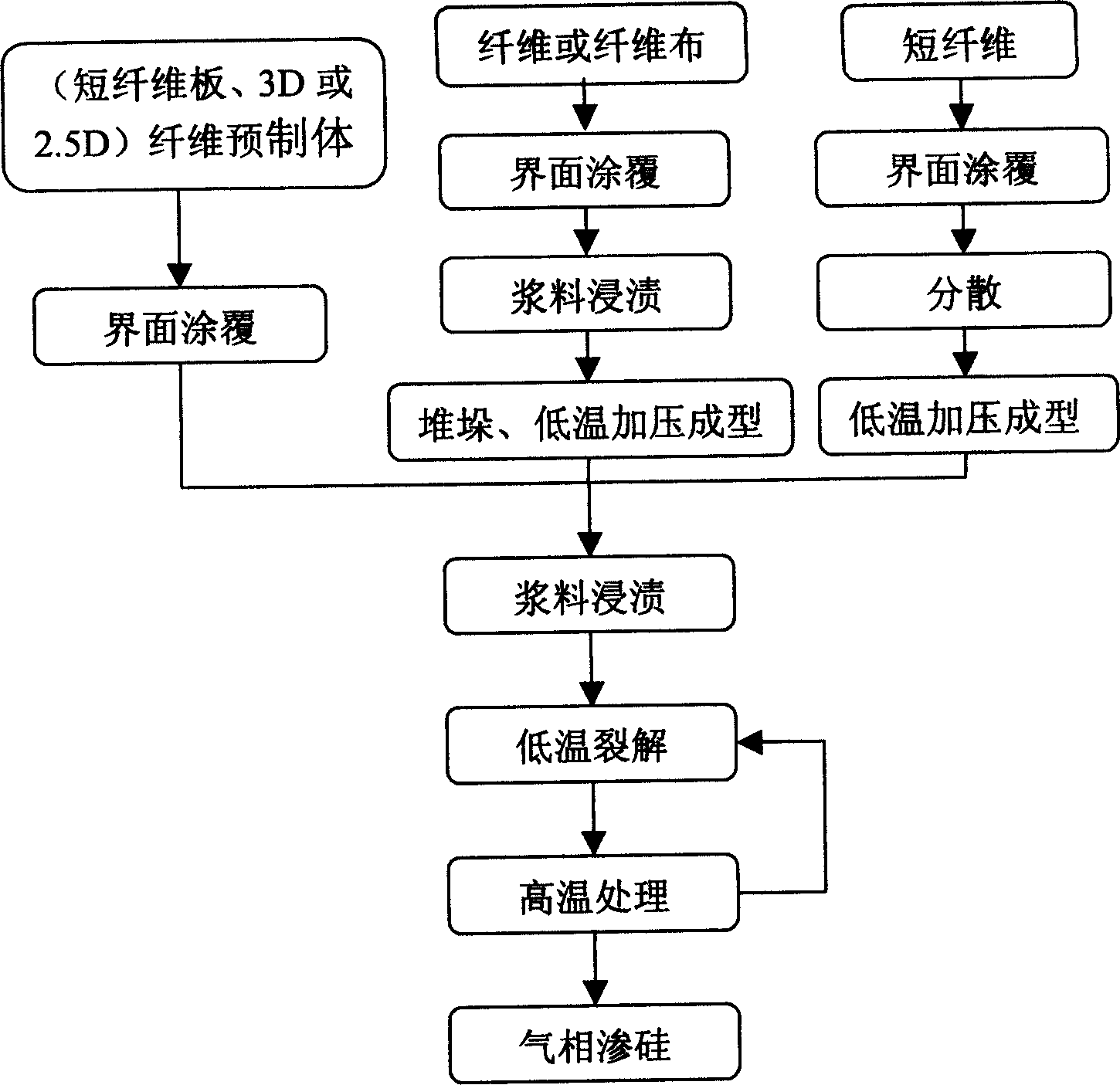

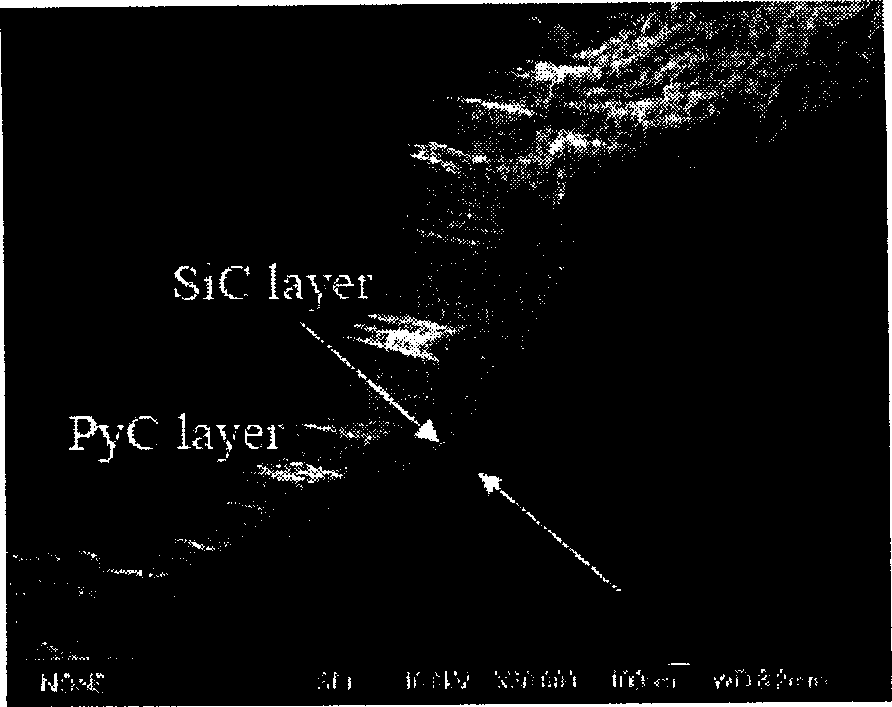

Method for preparing carbon-fiber reinforced silicon carbonate base composite by gas-phase siliconizing technology

This invention relates to preparation method gas phase siliconizing technique preparing high compact fiber reinforcement SiC group composite material. Protection layer interface is formed on fiber surface through gas phase or liquid phase, then they are dipped and cracked through nm SiC slime to make certain density precast body of fiber reinforcement SiC group. Carbon is added into the body through dipping and cracking way to form group body with certain pore, the group body penetrates inner part of the multi-hole body through gas phase silicon after it is high temperature treated, then it reacts with carbon and fills the pore to get compact basal body. The density of the material can reach 2.25-2.30g / cm3, open porosity is 3-6 percent; it is large more higher than traditional method of getting Cf / SiC material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Prepreg fabric and honeycomb sandwich panel

InactiveUS6429157B1Good self-adhesiveReduce porositySynthetic resin layered productsPaper/cardboard layered productsPorosityHoneycomb

A woven fabric prepreg comprising at least [A] a woven fabric as reinforcing fibers, [B] a thermosetting resin or thermosetting resin composition and [C] fine particles of a resin and having a cover factor of 95% or more, and a honeycomb sandwich panel, comprising skin panels fabricated by said woven fabric prepreg and [D] a honeycomb core can be obtained. The woven fabric prepreg little changes in tackiness with the lapse of time and has moderate drapability, being excellent in self adhesiveness to the honeycomb core when used as skin panels of a honeycomb sandwich panel. Furthermore, the honeycomb sandwich panel obtained has a small porosity in the skin panels fabricated by the cured prepreg and has excellent surface smoothness with few pits and depressions on the surfaces of the skin panels.

Owner:TORAY IND INC

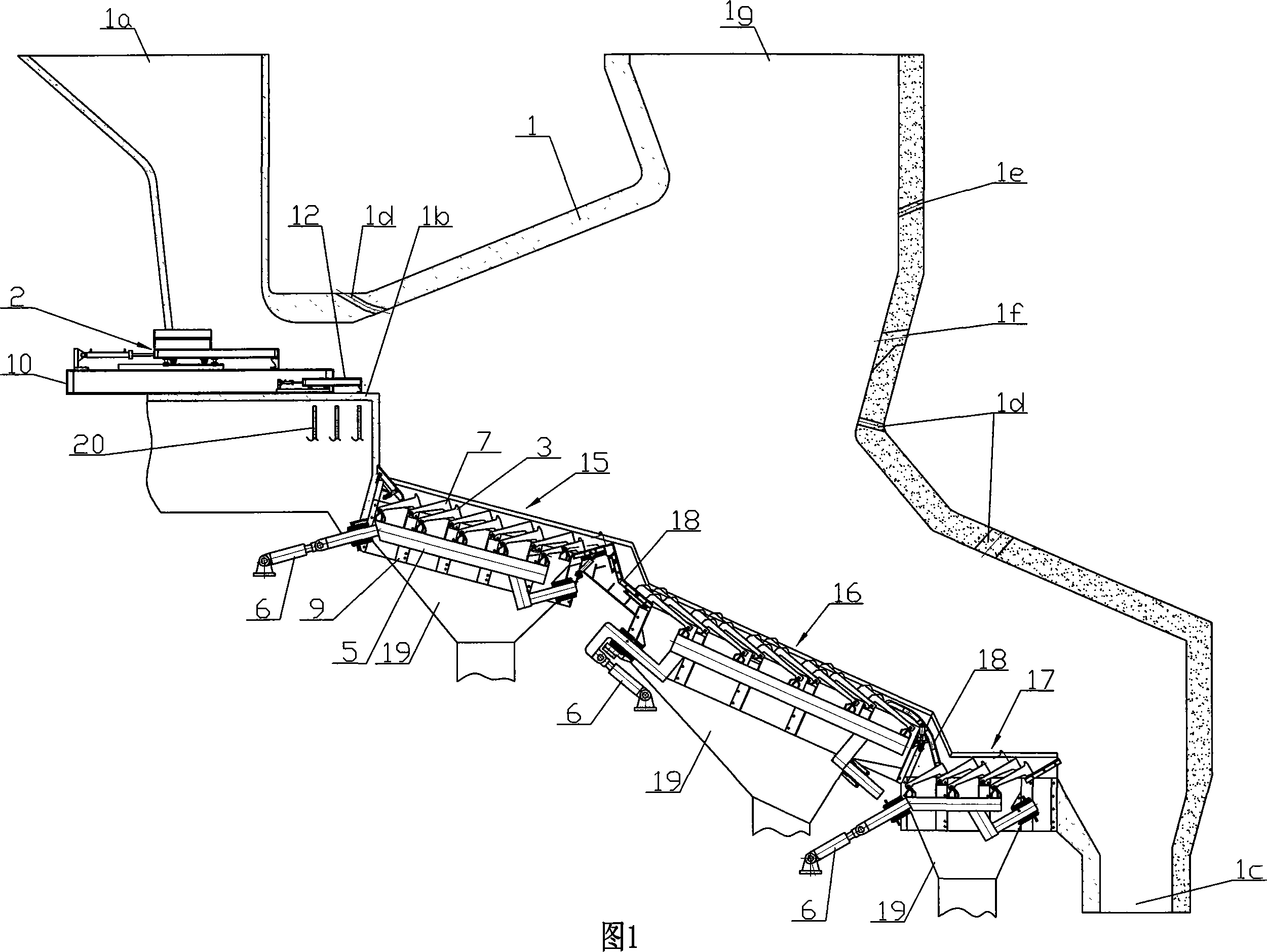

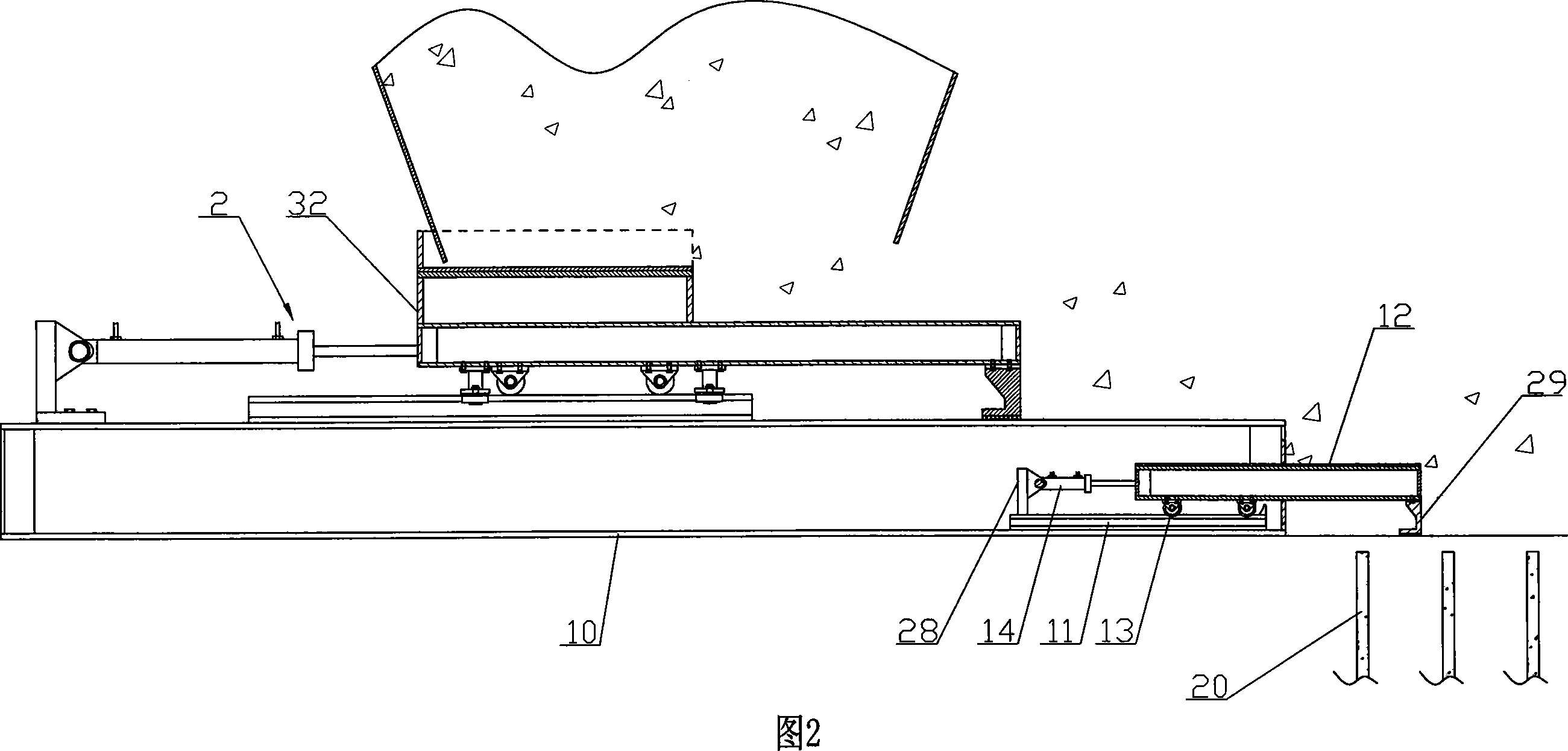

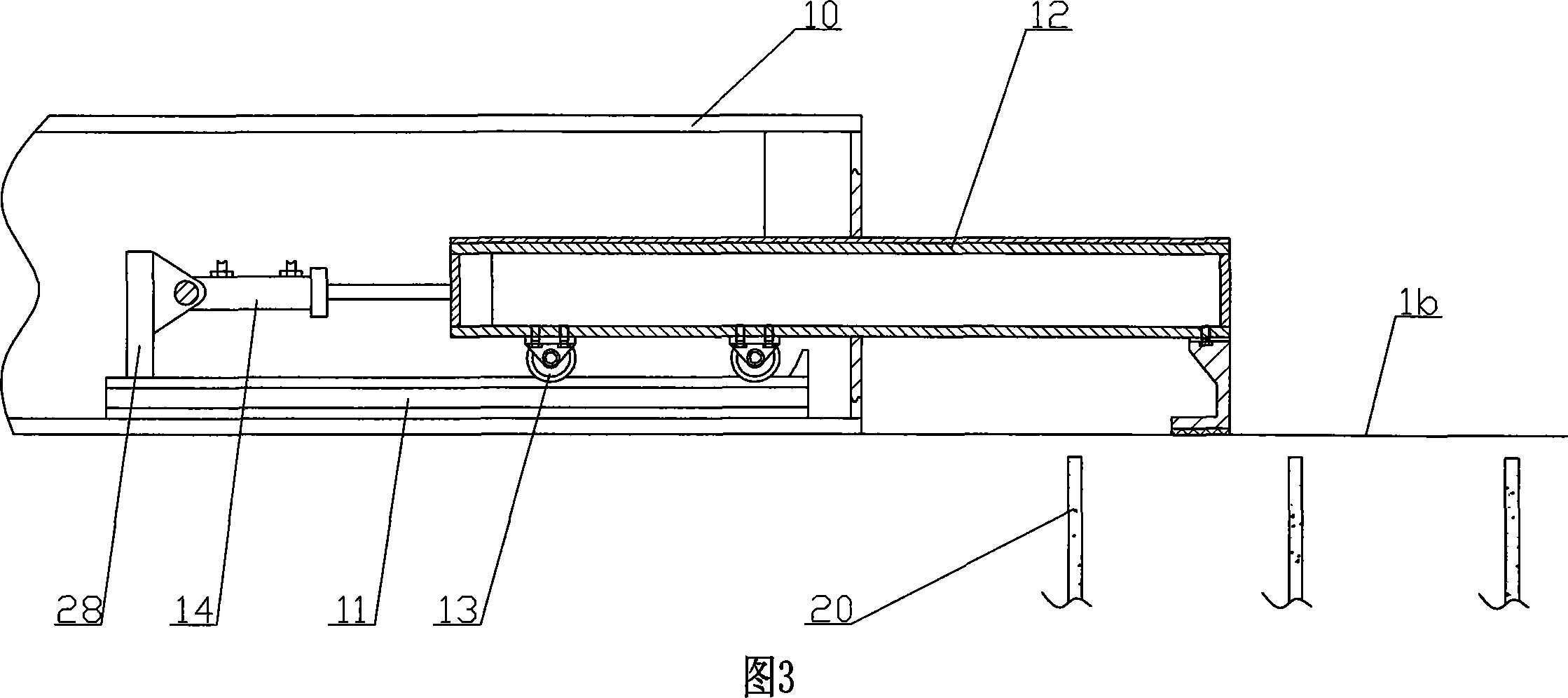

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

System and process for solid-state deposition and consolidation of high velocity powder particles using thermal plastic deformation

InactiveUS20050153069A1Reduced strengthEnhanced dynamic recovery of dislocation densityLiquid surface applicatorsMolten spray coatingFlow stressAcoustic wave

The invention relates to an apparatus and process for solid-state deposition and consolidation of powder particles entrained in a subsonic or sonic gas jet onto the surface of an object. Under high velocity impact and thermal plastic deformation, the powder particles adhesively bond to the substrate and cohesively bond together to form consolidated materials with metallurgical bonds. The powder particles and optionally the surface of the object are heated to a temperature that reduces yield strength and permits plastic deformation at low flow stress levels during high velocity impact, but which is not so high as to melt the powder particles.

Owner:INNOVATION TECH INC

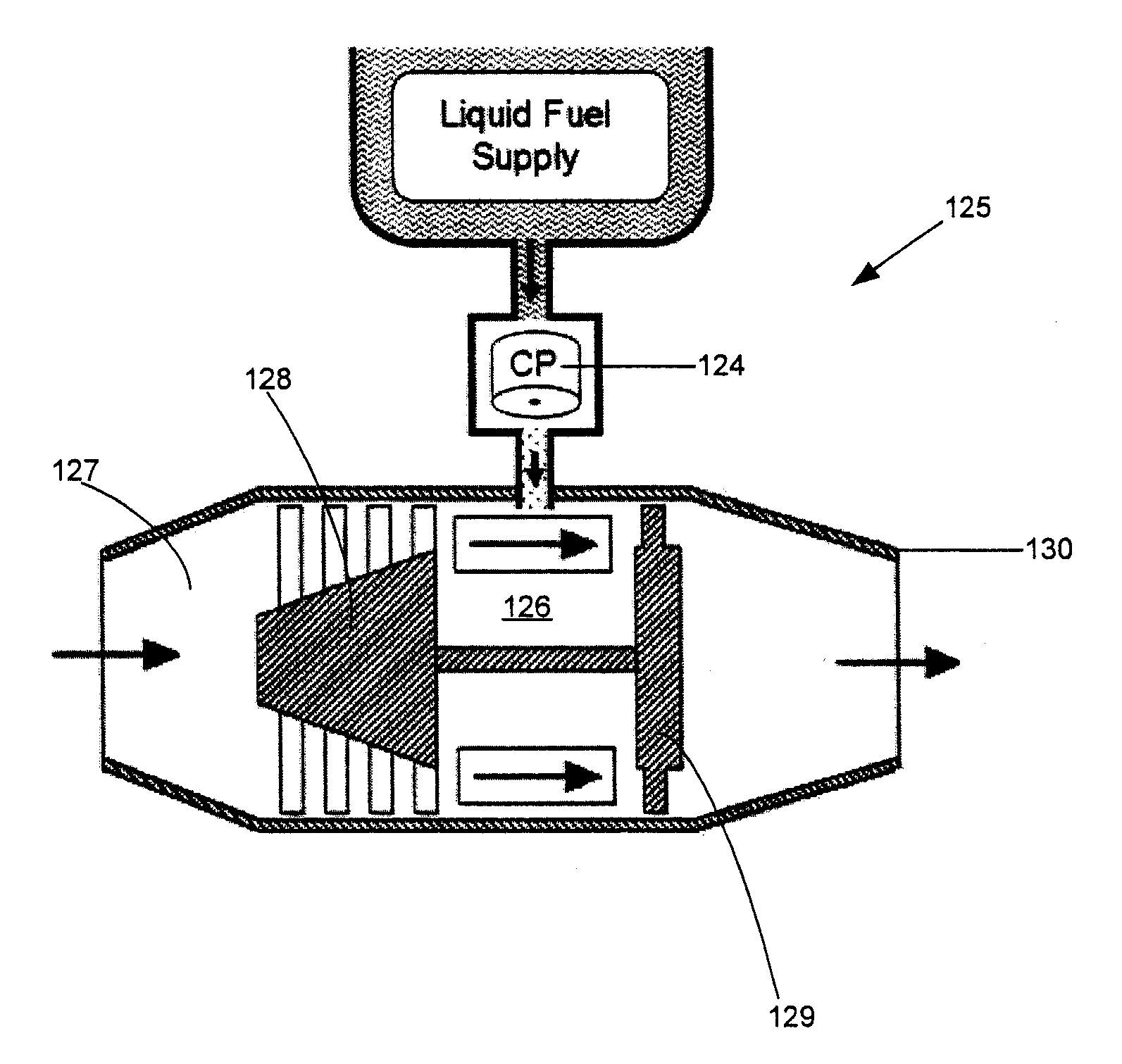

Capillary Pumps for Vaporization of Liquids

InactiveUS20090324206A1Improve permeabilityIncrease ratingsReactant parameters controlMixing methodsVaporizationEngineering

A capillary pump is provided for producing pressurized and unpressurized vapor emissions from liquid feed. In its simplest form, the capillary pump incorporates a liquid feed intake, a porous vaporization component, and a heat transfer component. Additional components, such as an insulator component, a feed pre-heat component, a liquid feed reservoir and / or delivery system, an integrated or associated heater component, a vapor collection chamber, a heat distribution component, an orifice component and / or vapor release component, may also be associated with or integrated in the improved capillary pumps. Capillary pump arrays are provided, and numerous applications for capillary pumps are disclosed.

Owner:VAPORE

Method and Apparatus for Managing Moisture Buildup In Pressurised Breathing Systems

ActiveUS20090044810A1Keep the flowImprove ventilationRespiratory masksBreathing masksPorosityRespiratory mask

A washout vent formed of or treated with hydrophobic or hydrophilic material, or a vent coated with hydrophobic or hydrophilic material, reduces noise and / or minimizes or precludes the formation of blockage in the vent pathway due to outflow of gas from a respiratory mask. One or the other or combinations of hydrophobic and hydrophilic materials may be used to repel or wick moisture away to minimize or preclude moisture buildup on vent surfaces and / or clogging of vent pathways, particularly when using humidified air. Sintered porous plastic hydrophobic or hydrophilic materials are utilized and the porosity may be varied integrally within the vent membrane or by forming the vent from layers of materials having different porosities.

Owner:RESMED LTD

System and process for solid-state deposition and consolidation of high velocity powder particles using thermal plastic deformation

InactiveUS6915964B2Modulus is reducedLower yield strengthMolten spray coatingSurface layering apparatusFlow stressAcoustic wave

The invention relates to an apparatus and process for solid-state deposition and consolidation of powder particles entrained in a subsonic or sonic gas jet onto the surface of an object. Under high velocity impact and thermal plastic deformation, the powder particles adhesively bond to the substrate and cohesively bond together to form consolidated materials with metallurgical bonds. The powder particles and optionally the surface of the object are heated to a temperature that reduces yield strength and permits plastic deformation at low flow stress levels during high velocity impact, but which is not so high as to melt the powder particles.

Owner:INNOVATION TECH INC

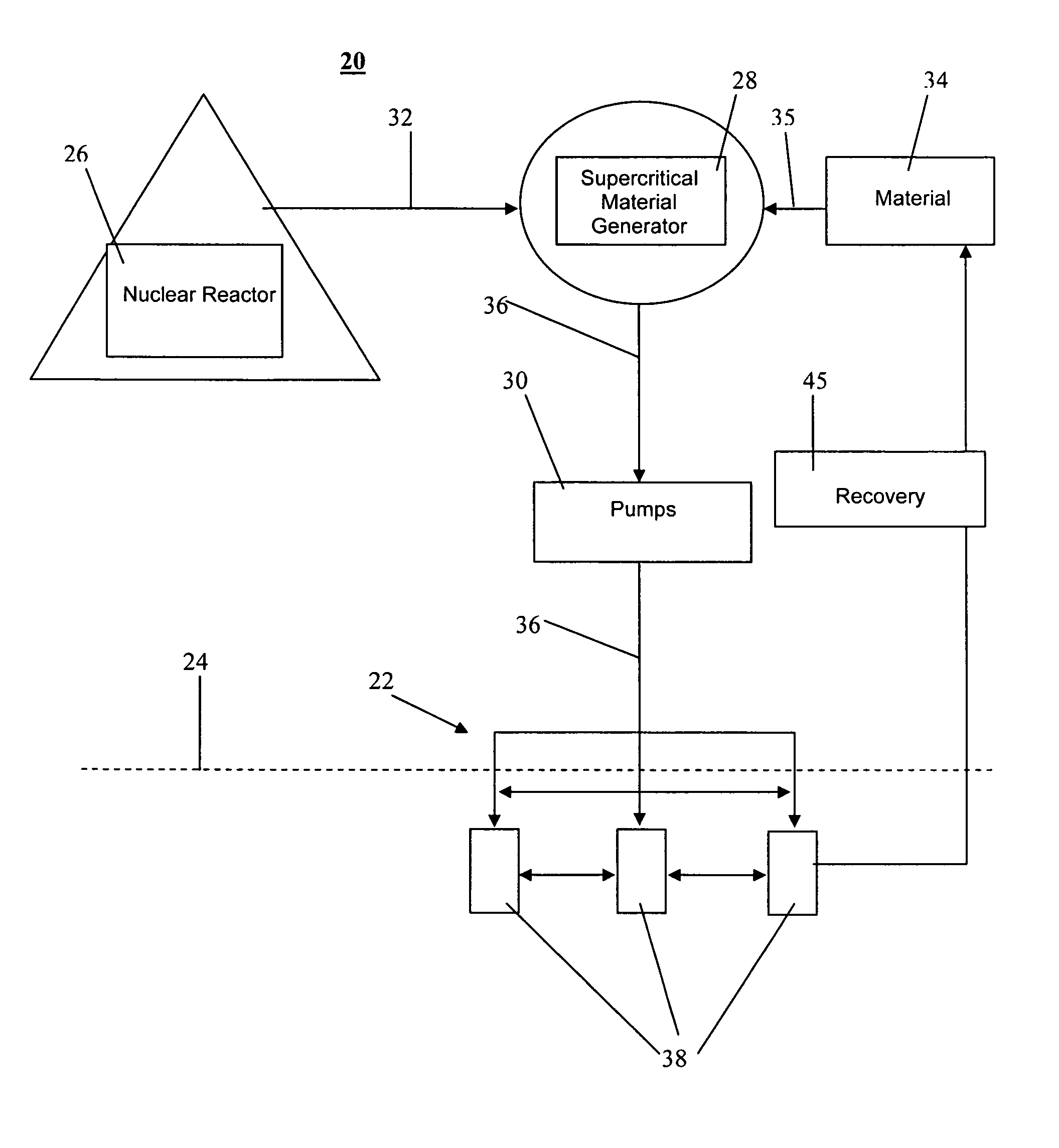

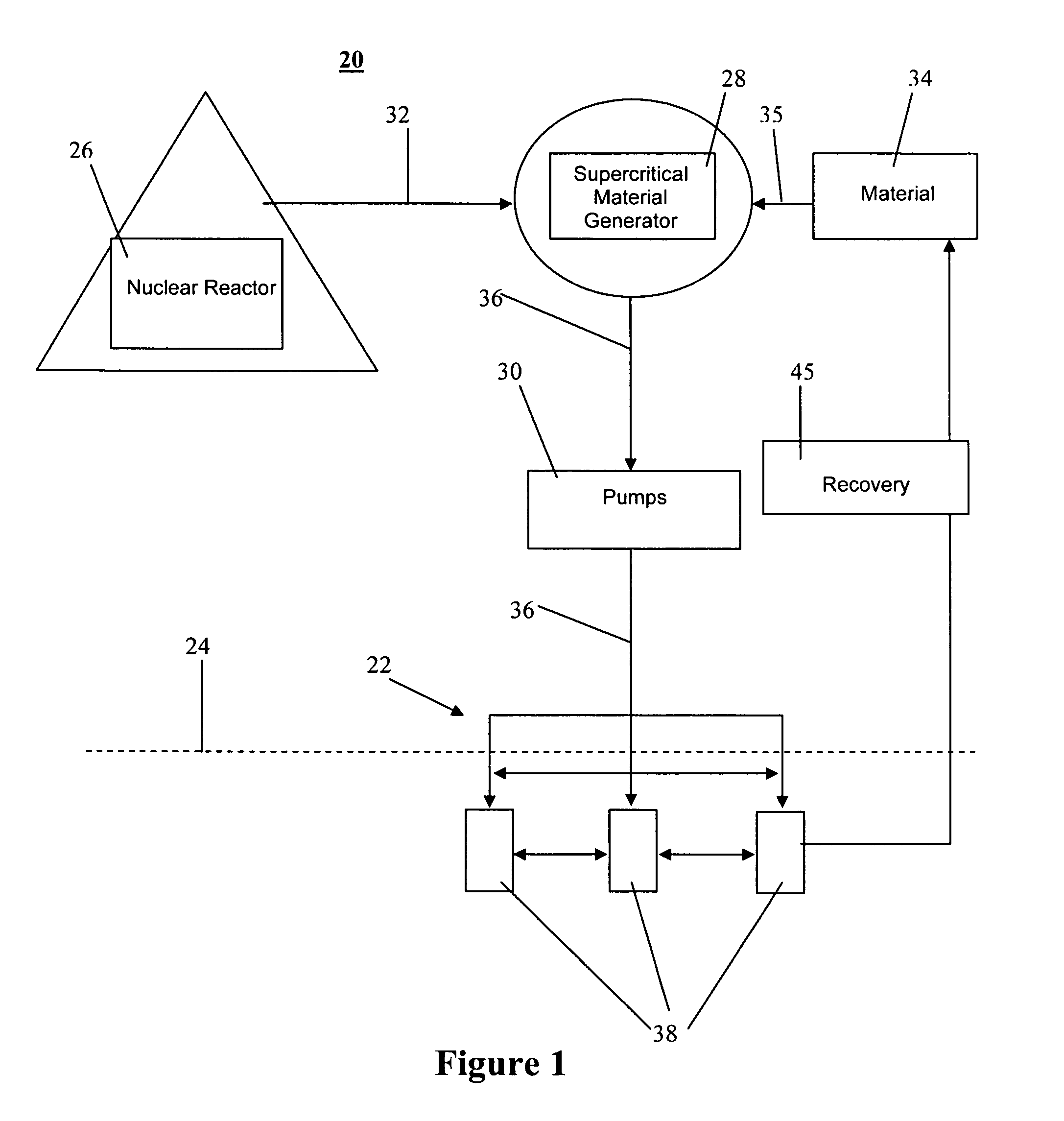

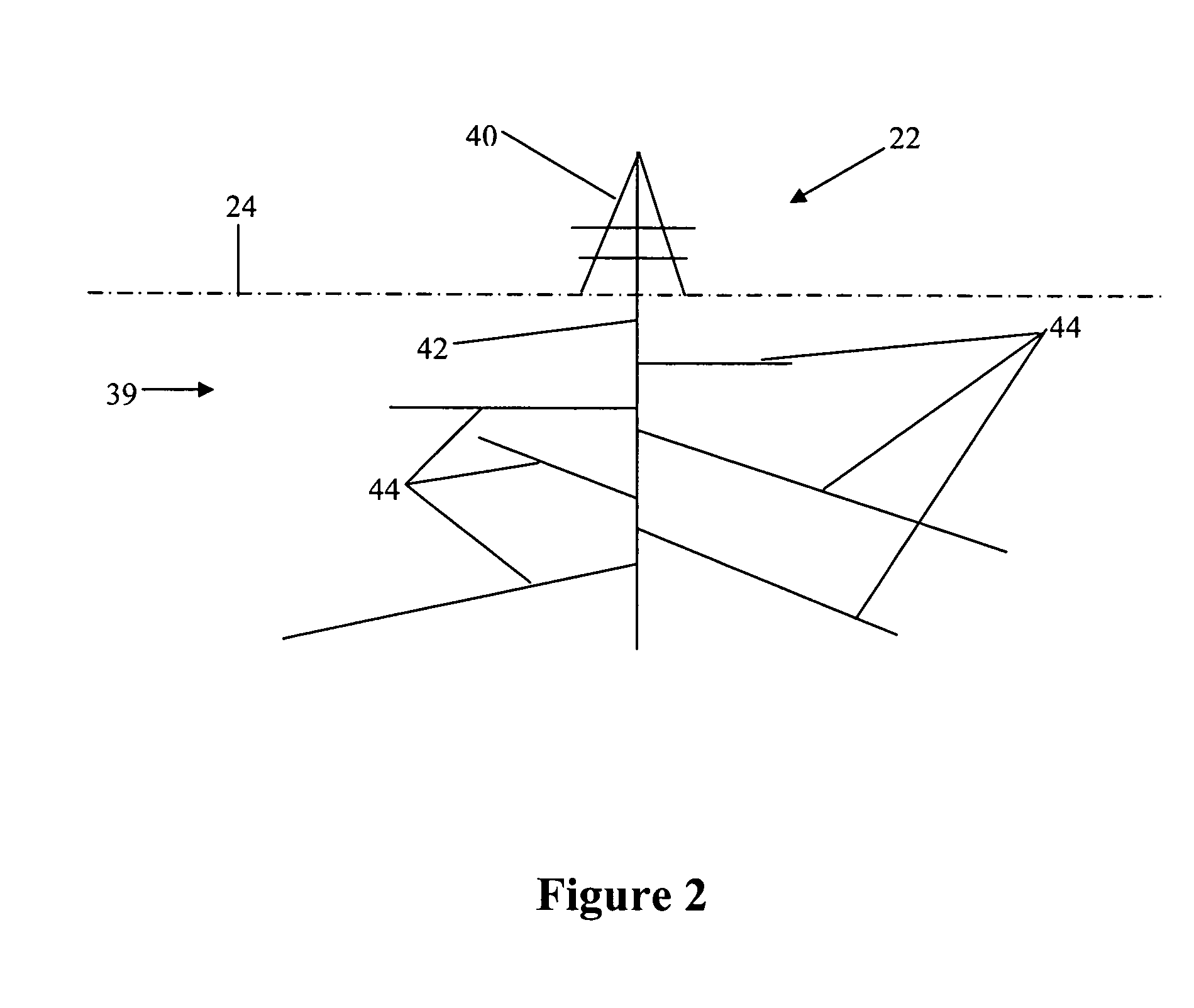

Method and system for extraction of hydrocarbons from oil shale

Owner:ULTRA SAFE NUCLEAR CORP

Calcium phosphate microcarriers and microspheres

The present invention provides calcium phosphate-based (CaP) microcarriers and their use, for example, in cell culturing systems, chromatography, and implantable biomedical materials.

Owner:CAP BIOTECH

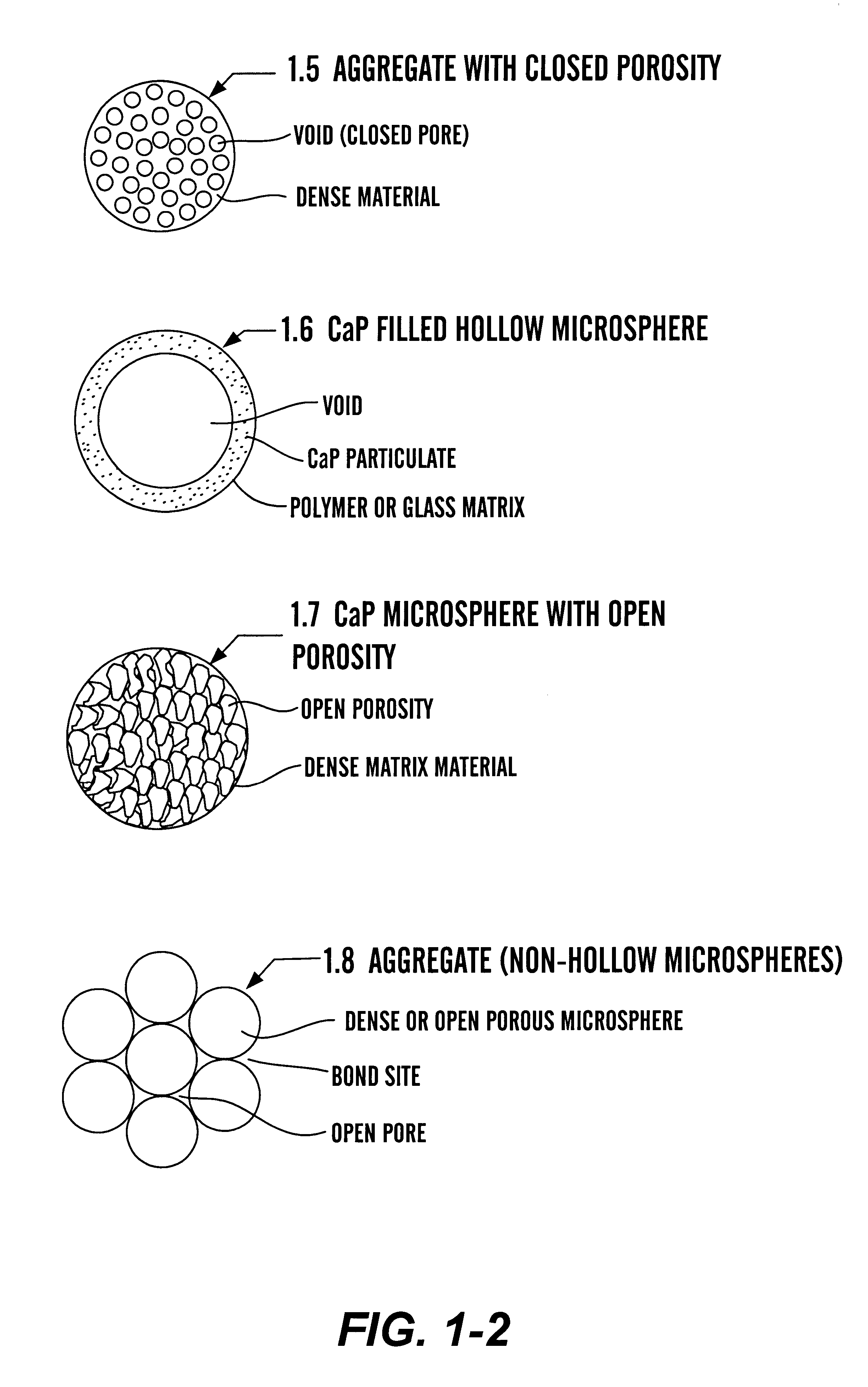

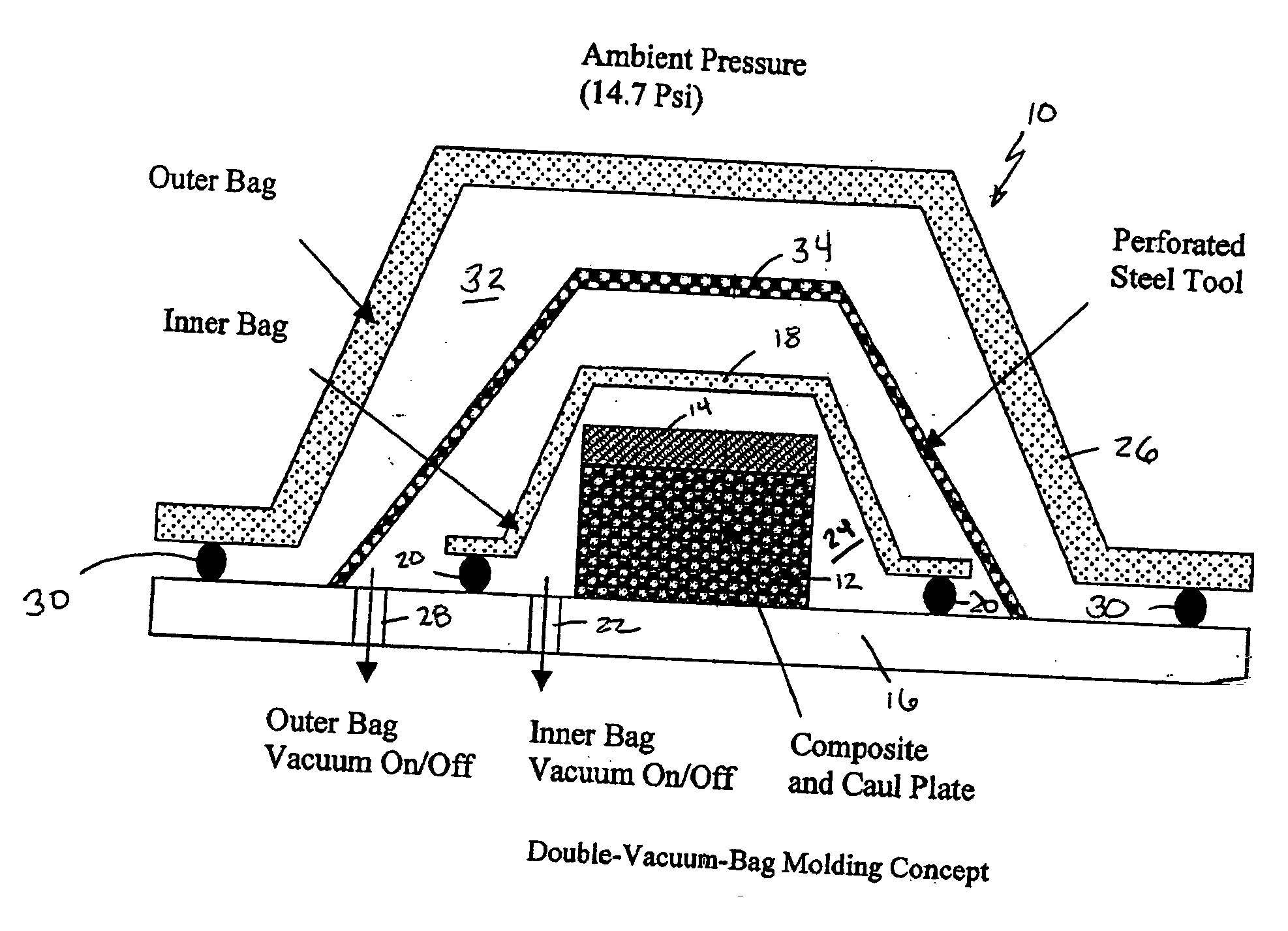

Double vacuum bag process for resin matrix composite manufacturing

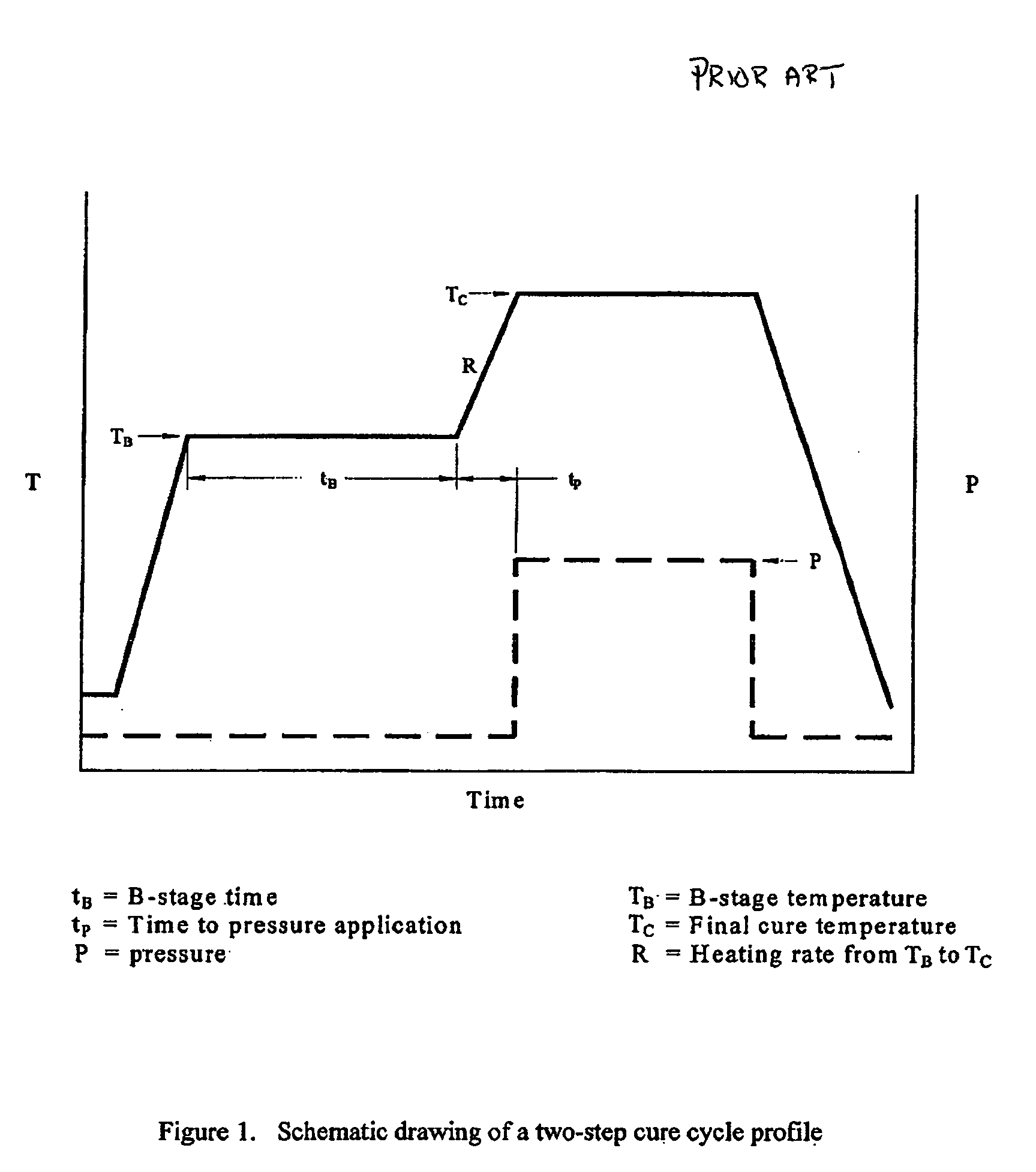

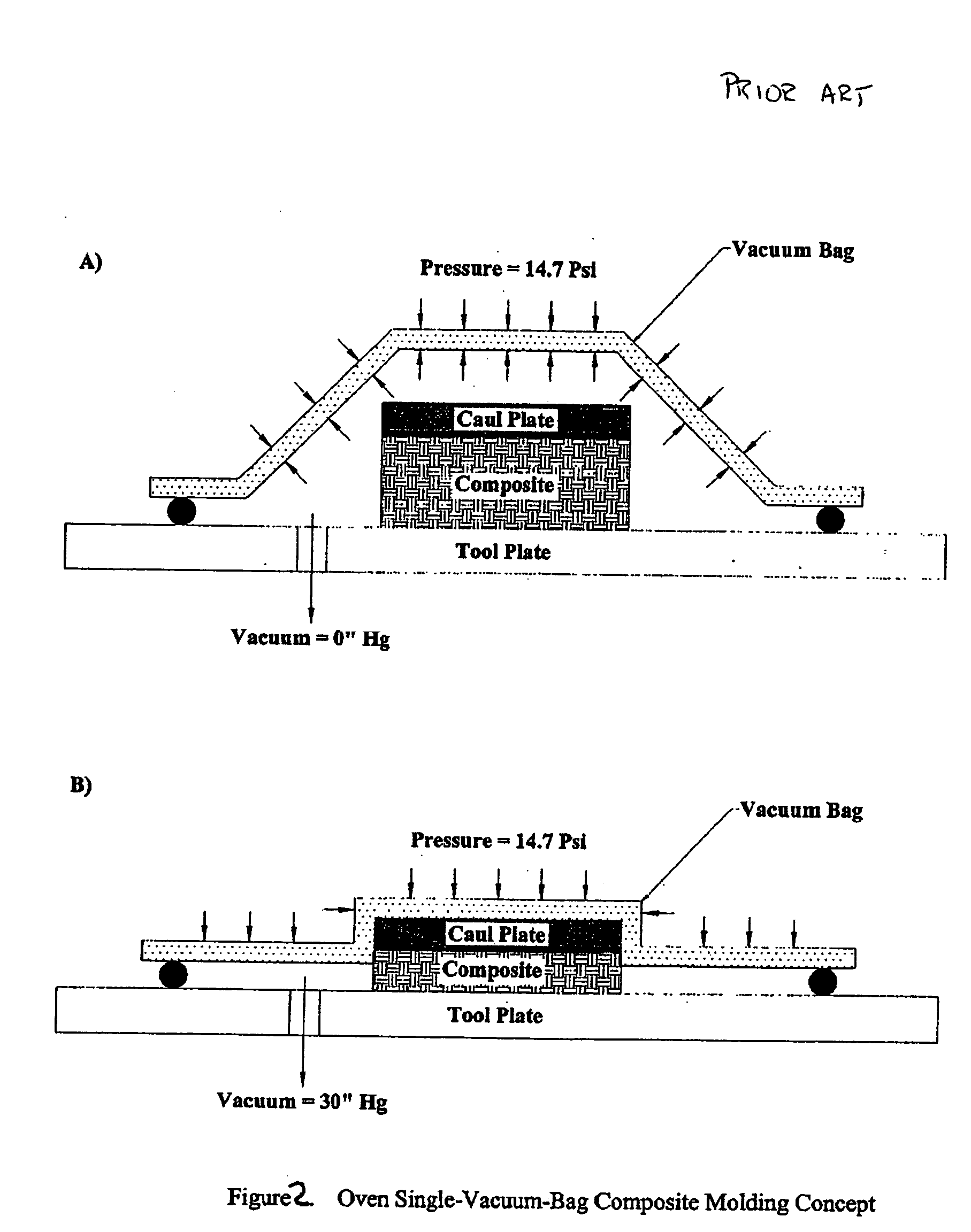

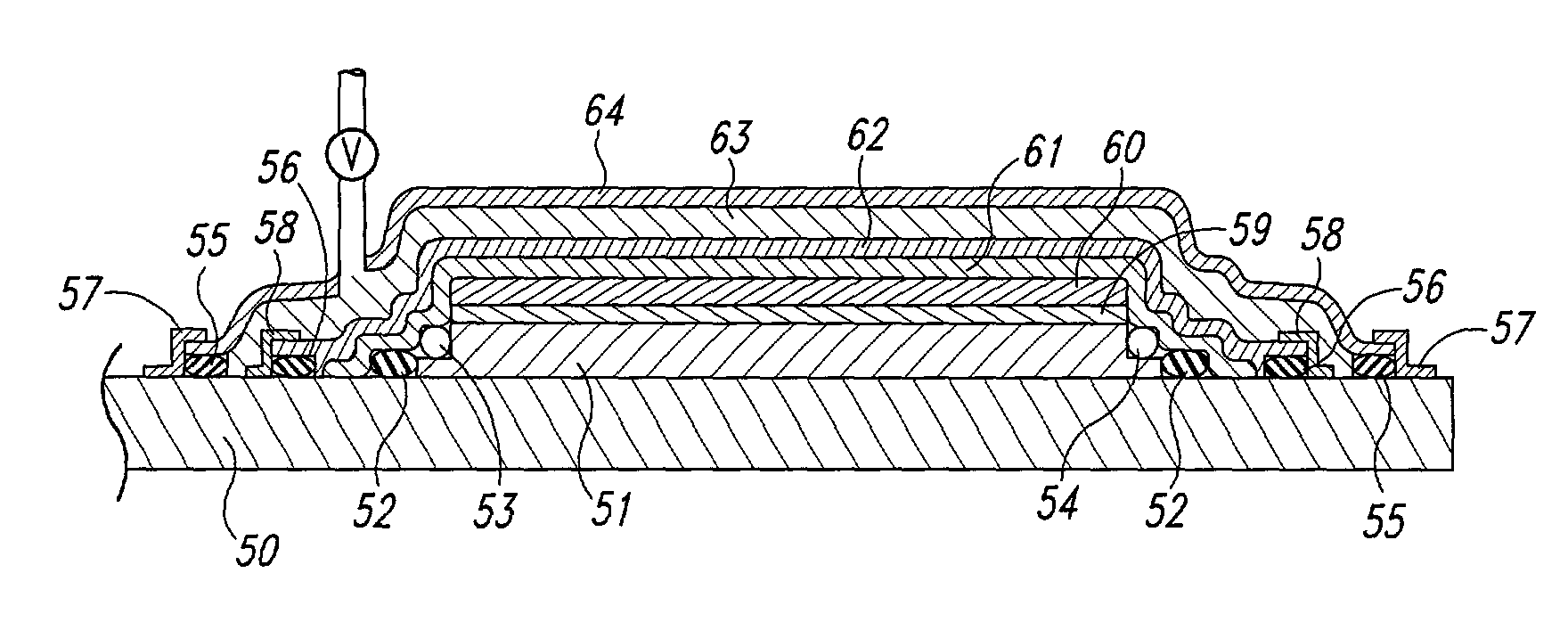

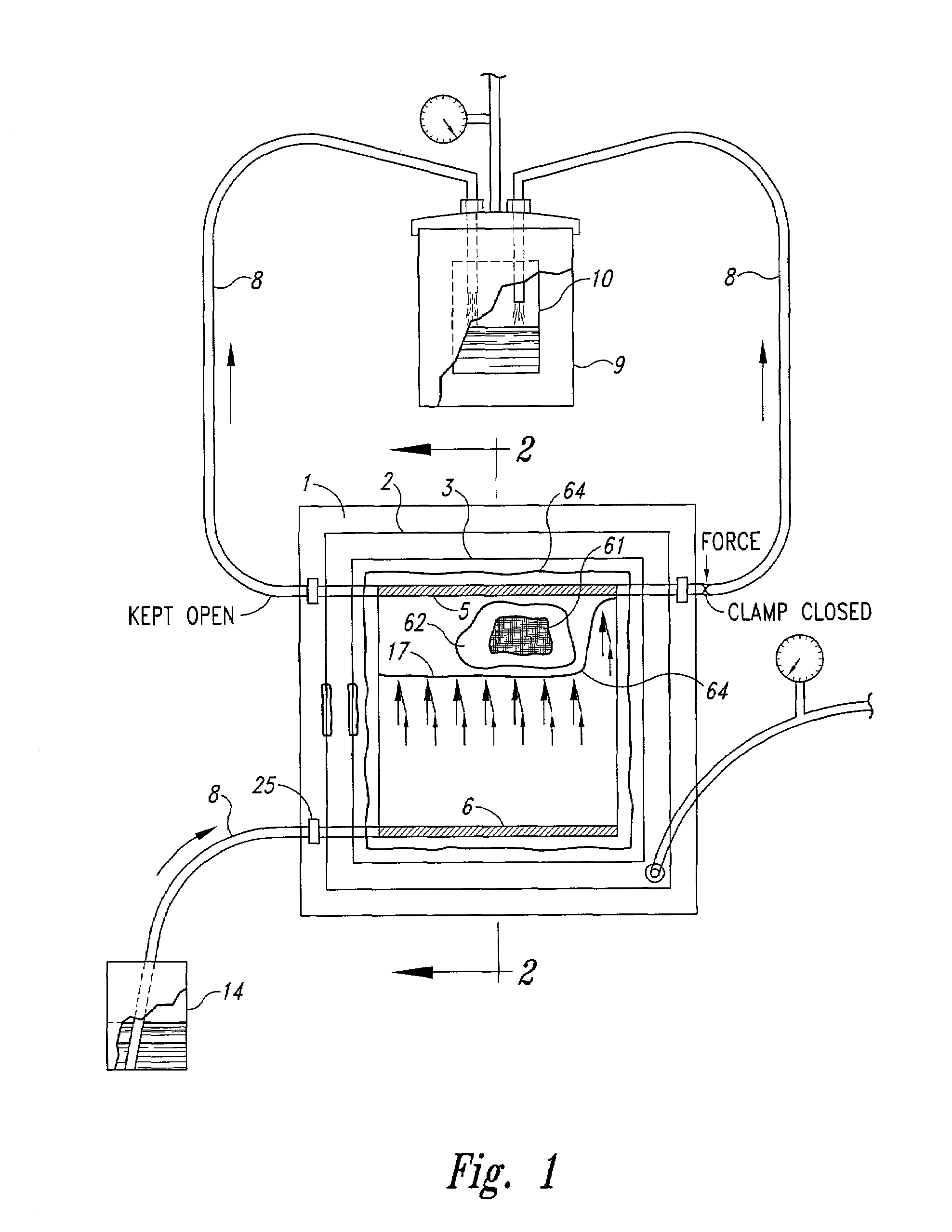

InactiveUS20050253309A1Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

Method of inducing new bone growth in porous bone sites

InactiveUS6599520B2High densityReduce porosityInternal osteosythesisSurgical adhesivesPorosityVolumetric Mass Density

A method of treating a condition in a vertebrate animal characterized by bone having increased porosity and / or decreased bone mineral density. The porous bone is injected with an effective amount of a flowable bone composition. Also provided is a kit for the treatment of porous bone wherein a flowable bone composition is contained within an injectable delivery system.

Owner:WARSAW ORTHOPEDIC INC

Porous sintered metal-containing materials

InactiveUS20060211802A1Adversely affecting the physical and/or chemical stabilityInhibit aggregationAdditive manufacturingTransportation and packagingSolvent freeMetallic materials

A process for manufacturing a porous metal-containing material is provided. For example, a composition is provided comprising particles dispersed in at least one solvent, the particles comprising at least one polymer material and at least one metal-based compound. The solvent can be substantially removed from the composition, and the polymer material can be substantially decomposed, thereby converting the solvent-free particles into a porous metal-containing material. In addition, metal-containing materials produced in accordance with the above process and their use in implantable medical devices can be provided.

Owner:CINVENTION AG

Double bag vacuum infusion process

InactiveUS7413694B2Reduce porosityMinimal surface porositySynthetic resin layered productsLaminationMedia controlsFiber

The double bag vacuum infusion process of the present invention provides a low cost method for producing complex composite assemblies without an autoclave. It also enables the production of highly innovative structures. The quality of the composites produced using such an infusion process are comparable to composites made using prepregs, hand layup or fiber placement, and autoclave curing. Double bagging provides vacuum integrity, controls bag relaxation while flow media controls the flow front to allow high quality aerospace-grade products.

Owner:THE BOEING CO

PTFE layers and methods of manufacturing

InactiveUS20060233991A1Reduce porosityHigh degreeStentsSynthetic resin layered productsPorosityFibril

Thin PTFE layers are described having little or no node and fibril microstructure and methods of manufacturing PTFE layers are disclosed that allow for controllable permeability and porosity of the layers. In some embodiments, the PTFE layers may act as a barrier layer in an endovascular graft or other medical device.

Owner:TRIVASCULAR2

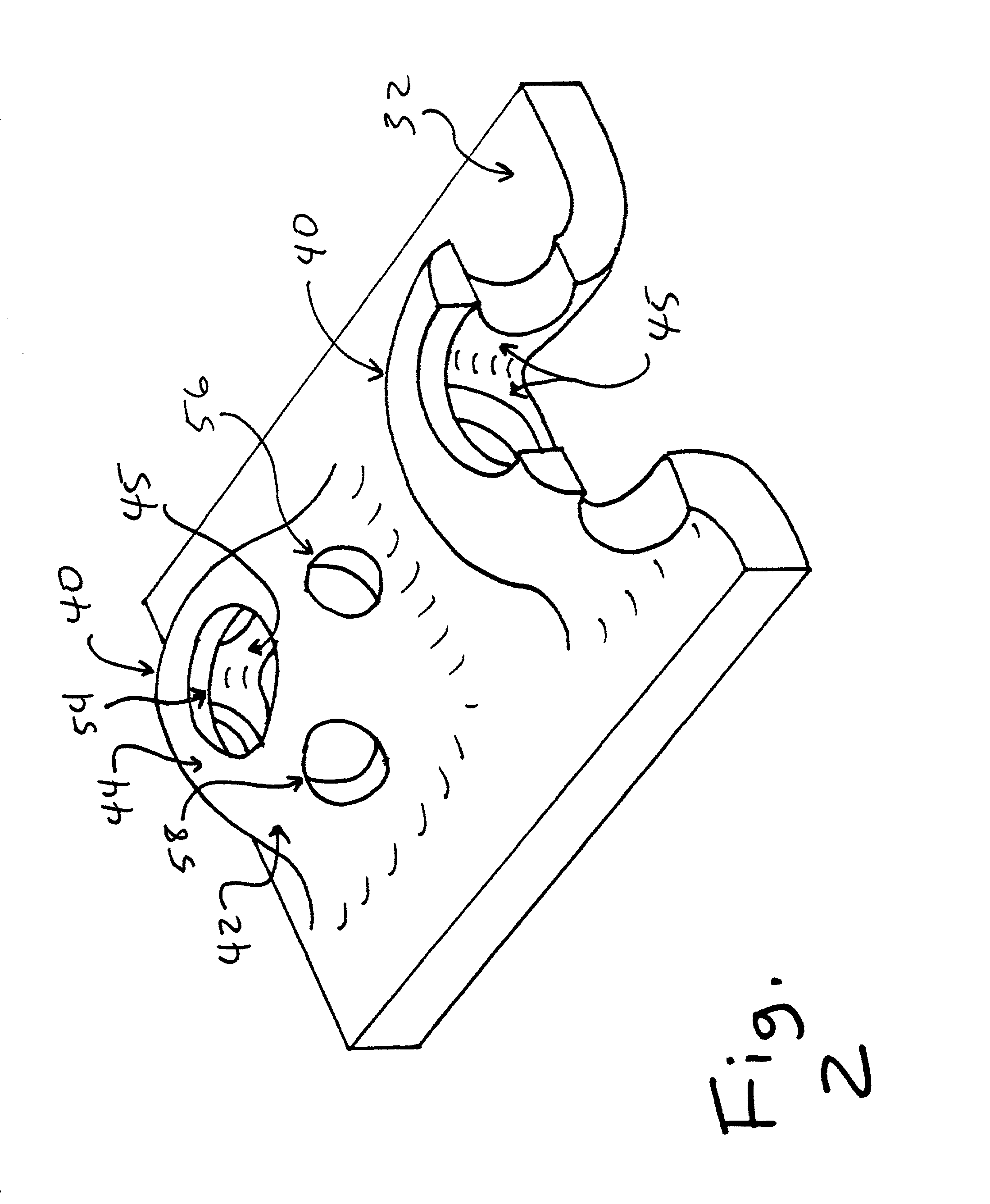

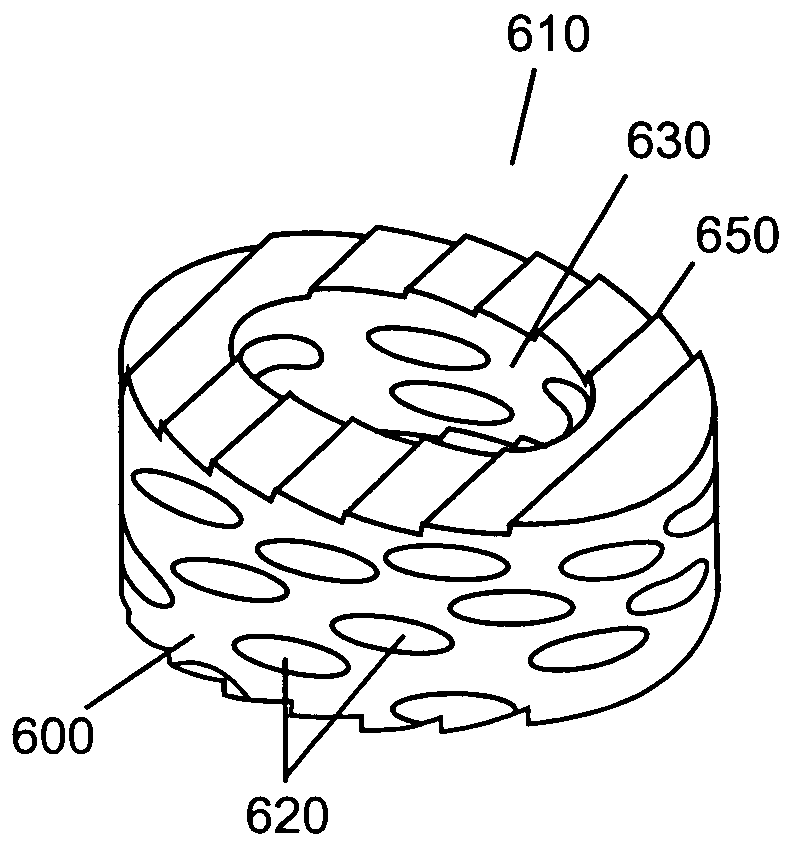

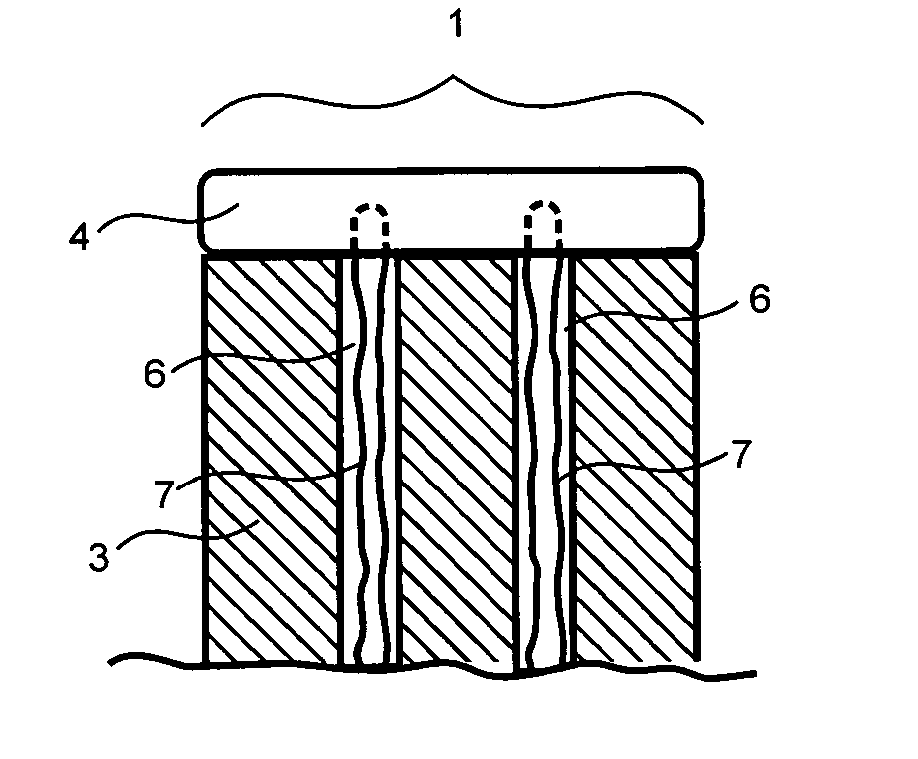

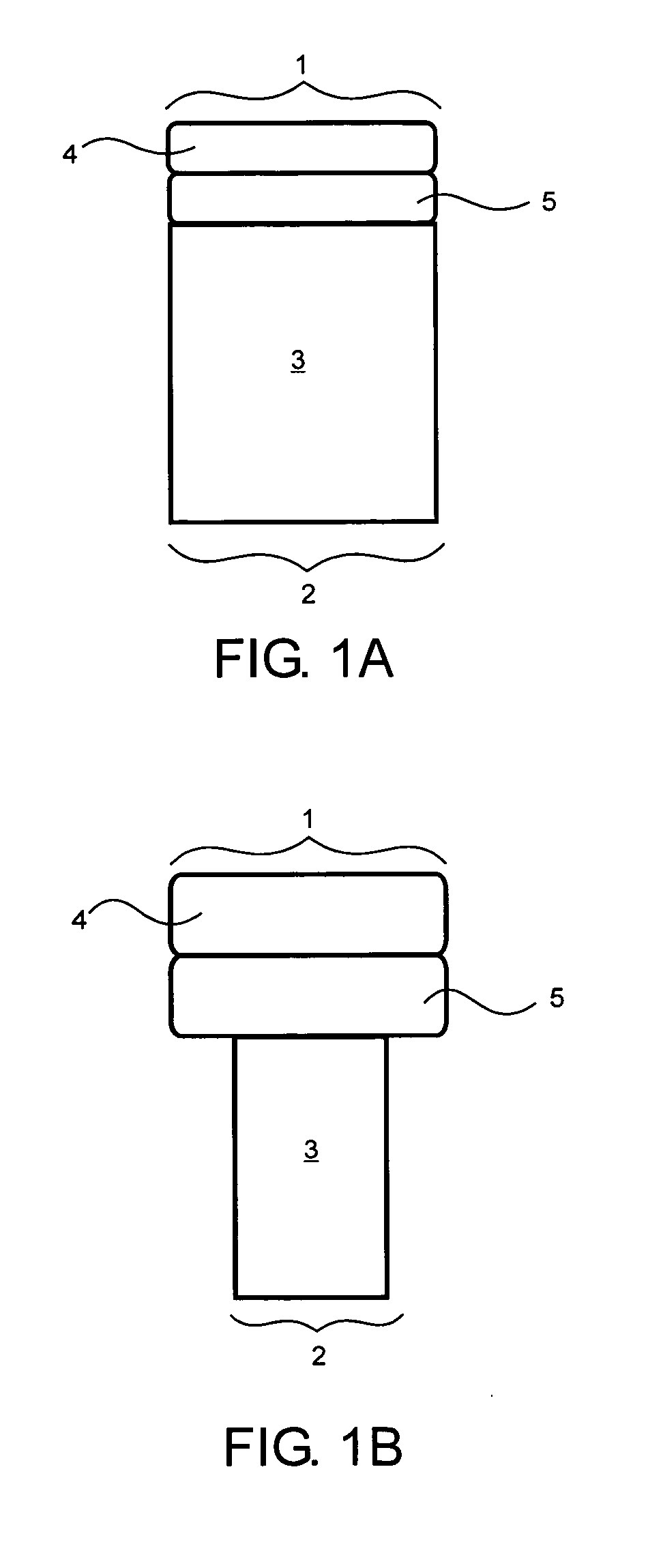

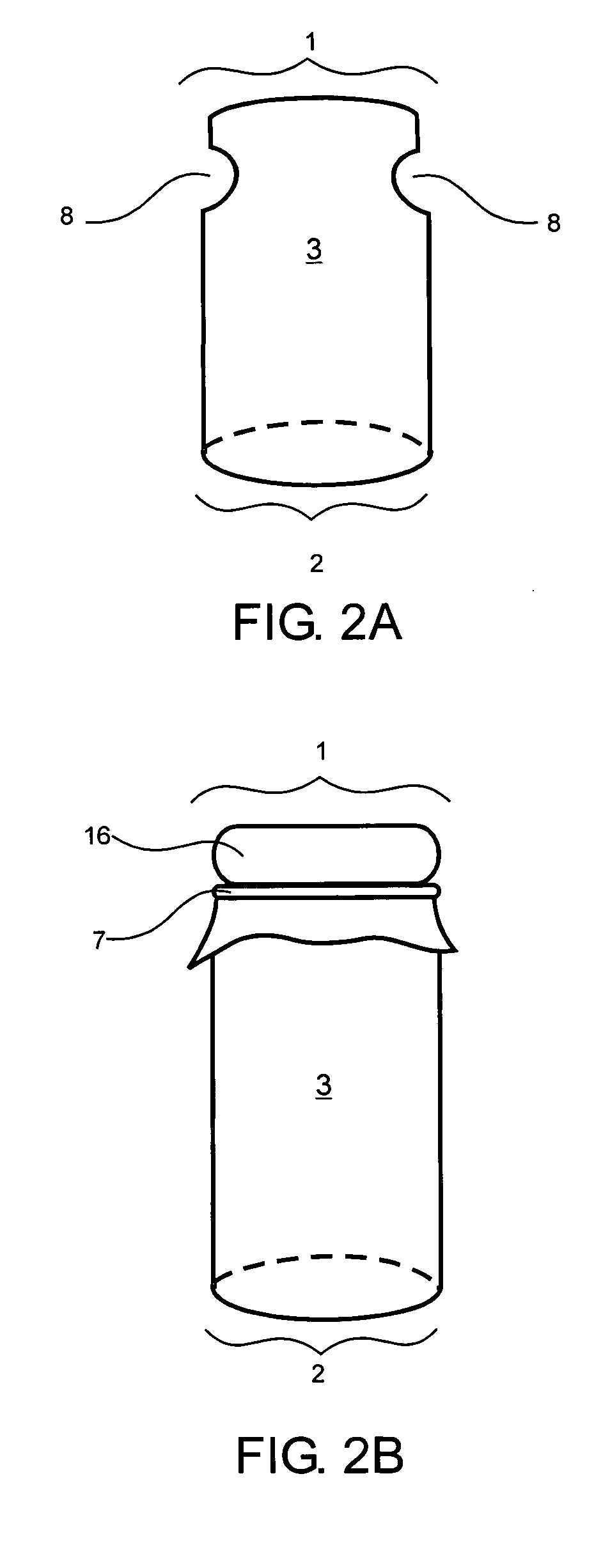

Implant Scaffold Combined With Autologous Tissue, Allogenic Tissue, Cultured Tissue, or combinations Thereof

InactiveUS20070185585A1Reduce and prevent immune responseReducing and preventing inflammationSuture equipmentsSkin implantsAutologous tissueTissue defect

The present disclosure relates to an implant for insertion into a tissue defect, such as a cartilage defect or a cartilage and bone defect. The implant includes a plug including a porous polymeric material having at least one channel therein, wherein the plug is sized to fit the tissue defect; and tissue. The tissue substantially fills the channel and is selected from a group including autologous tissue, allogenic tissue, cultured tissue, or combinations thereof. In an embodiment, the plug includes a plurality of porous polymeric phases. In another embodiment, the plug includes a plurality of channels wherein the channels are longitudinal and / or transverse. A method for repairing defective tissue is also disclosed.

Owner:BRACY BRAT +2

A method of manufacturing a carbon fiber antenna surface

The invention relates to a manufacturing method for a carbon fiber antenna surface. The manufacturing method comprises the following steps of 1, prefabricating a die; 2, polishing the die; 3, chemically electroplating the die; 4, measuring the precision, and clearing away impurities; 5, coating a demolding agent; 6, paving carbon fiber cloth on a male die; 7, paving PVC foams on the surface of the male die; 8, paving carbon fiber cloth on the surface of the male die; 9, assembling the male die and a female die, and sealing and fastening the male die and the female die; 10, vacuumizing to enable the vacuum degree in the die to be smaller than -0.096MPa; 11, injecting epoxy resin and a solidifying agent from a material inlet of the female die; 12, sticking a layer of glass paper to the outer surface of a blank after the appearance gets through inspection and is qualified; 13, performing perforation and assembling; and 14, obtaining the carbon fiber antenna surface after the product is qualified through inspection. The carbon fiber antenna surface manufactured by the manufacturing method is smooth, and the precision can reach 0.1R.M.S; and due to normal-temperature solidification, energy is saved, and the cost is lowered.

Owner:XIAN TUOFEI COMPOSITE MATERIAL

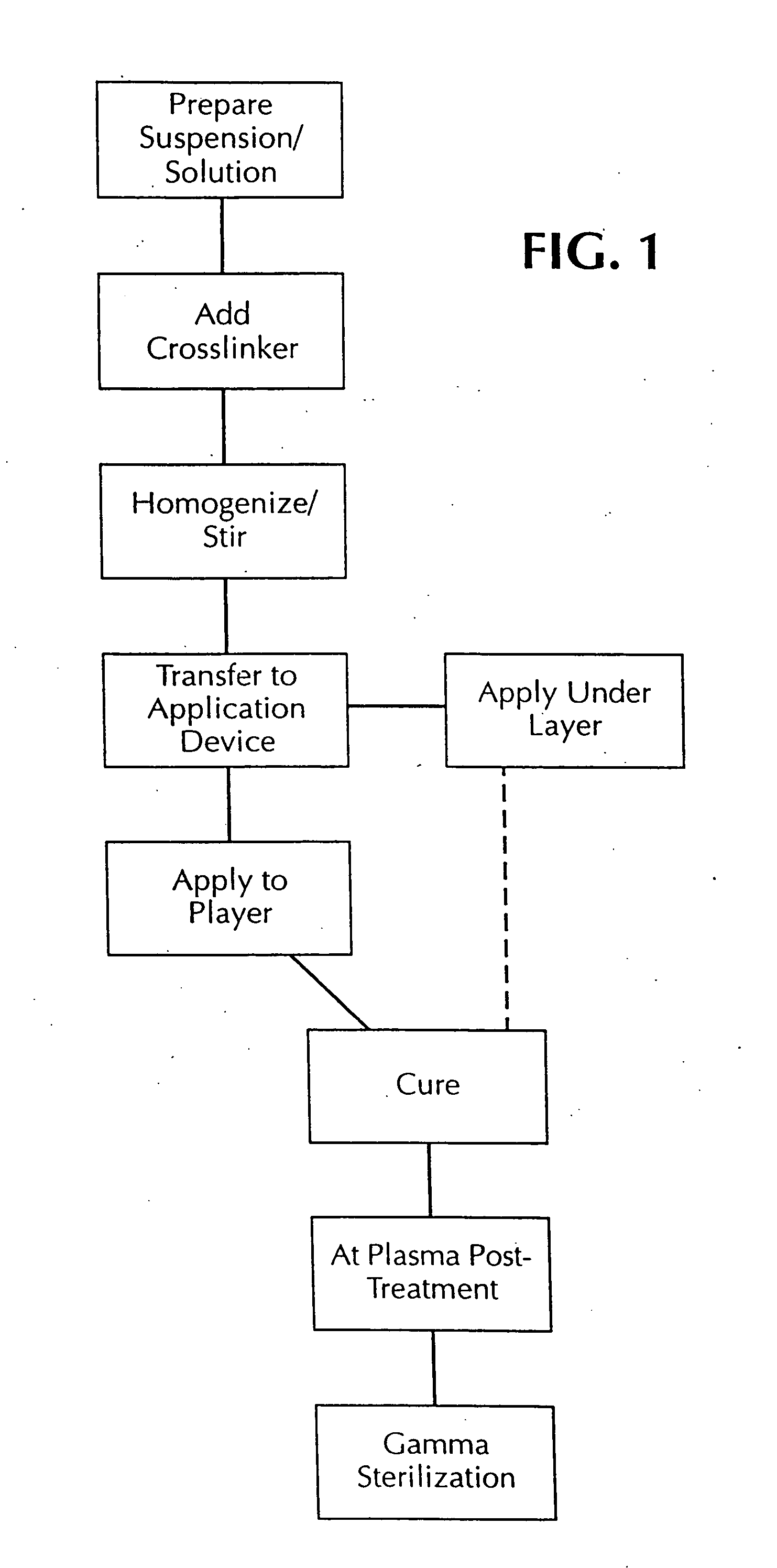

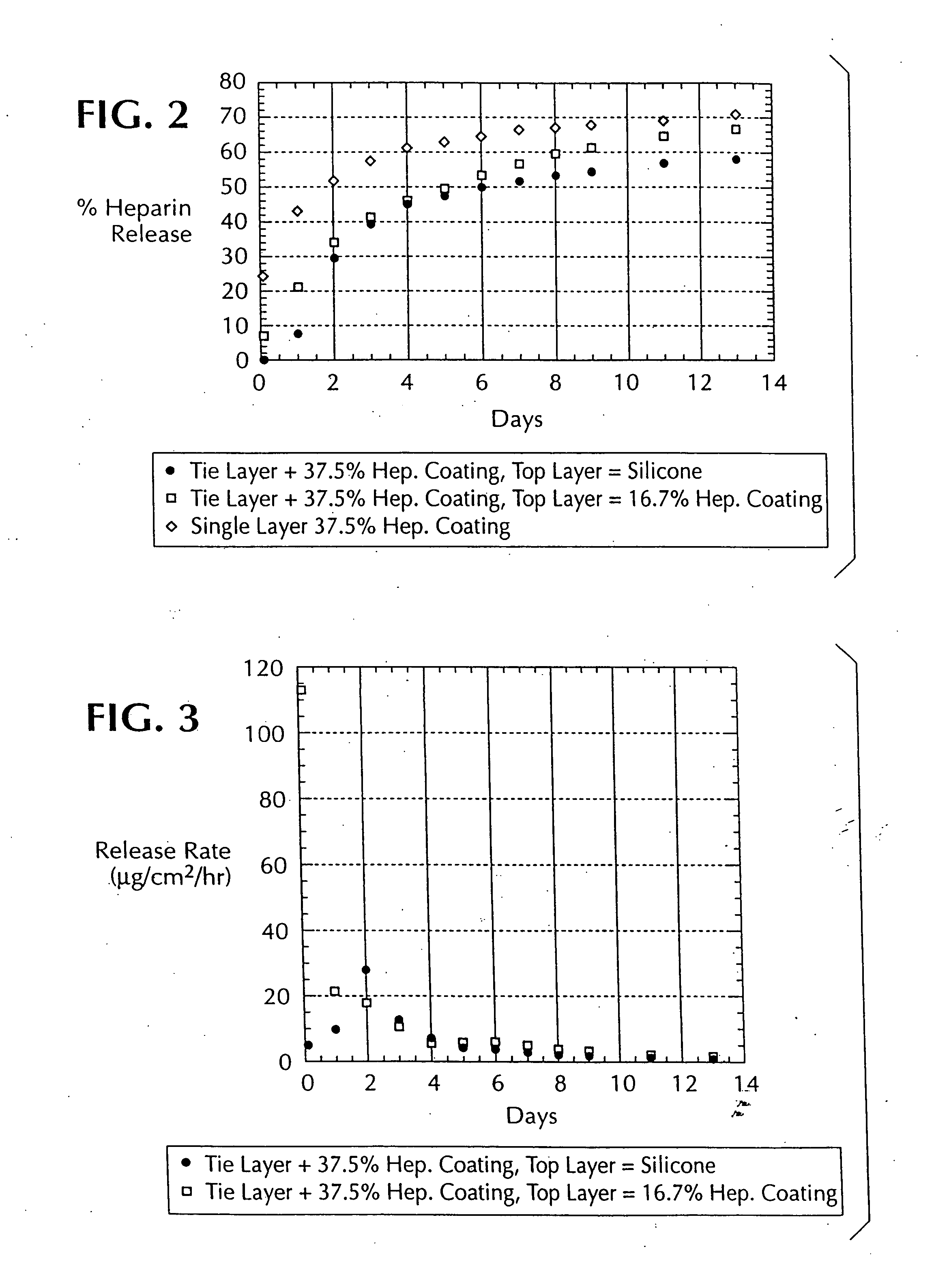

Medical device with drug

A method of coating implantable open lattice metallic stent prosthesis is disclosed which includes sequentially applying a plurality of relatively thin outer layers of a coating composition comprising a solvent mixture of uncured polymeric silicone material and crosslinker and finely divided biologically active species, possibly of controlled average particle size, to form a coating on each stent surface. The coatings are cured in situ and the coated, cured prosthesis are sterilized in a step that includes preferred pretreatment with argon gas plasma and exposure to gamma radiation electron beam, ethylene oxide, steam.

Owner:BOSTON SCI SCIMED INC

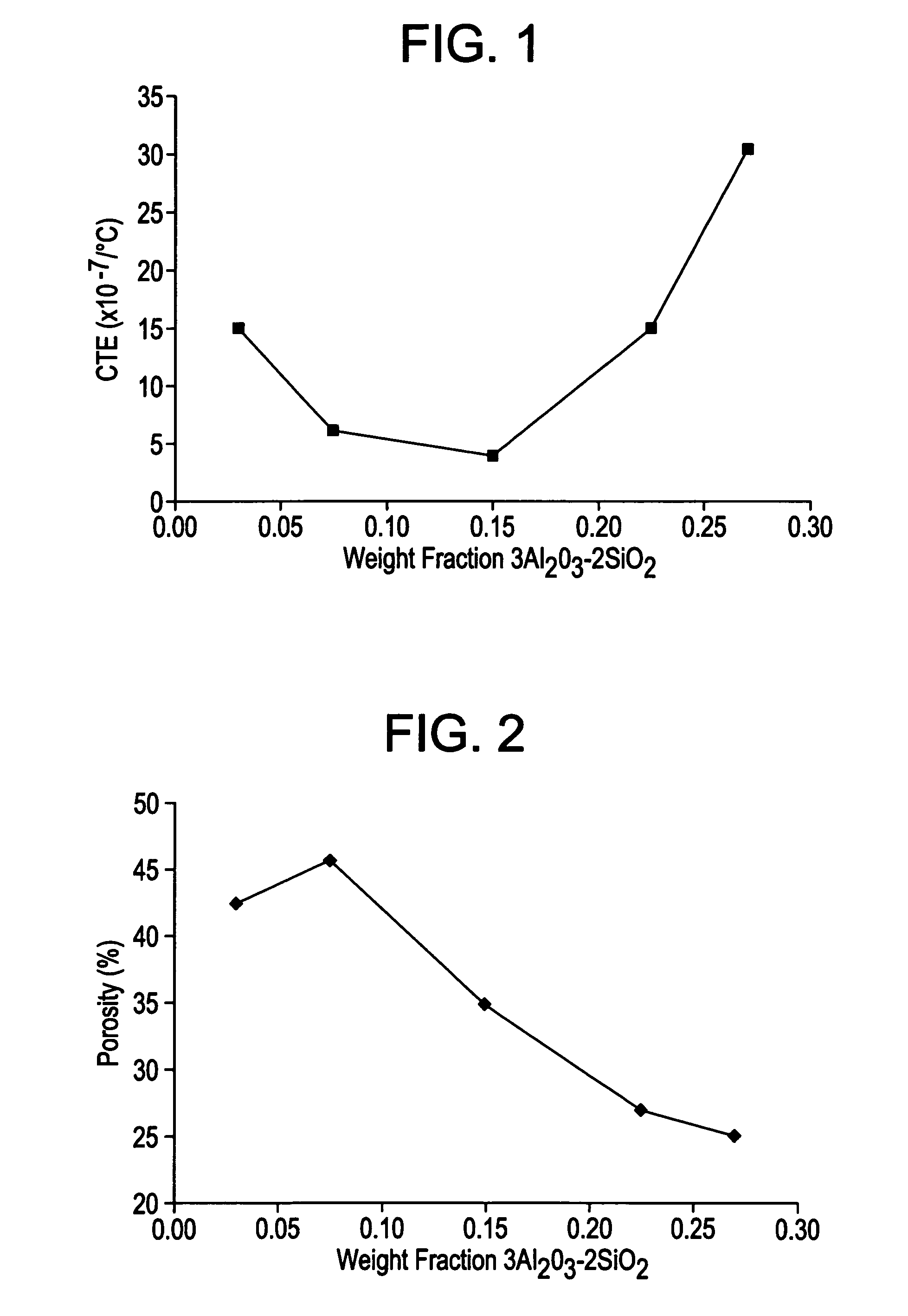

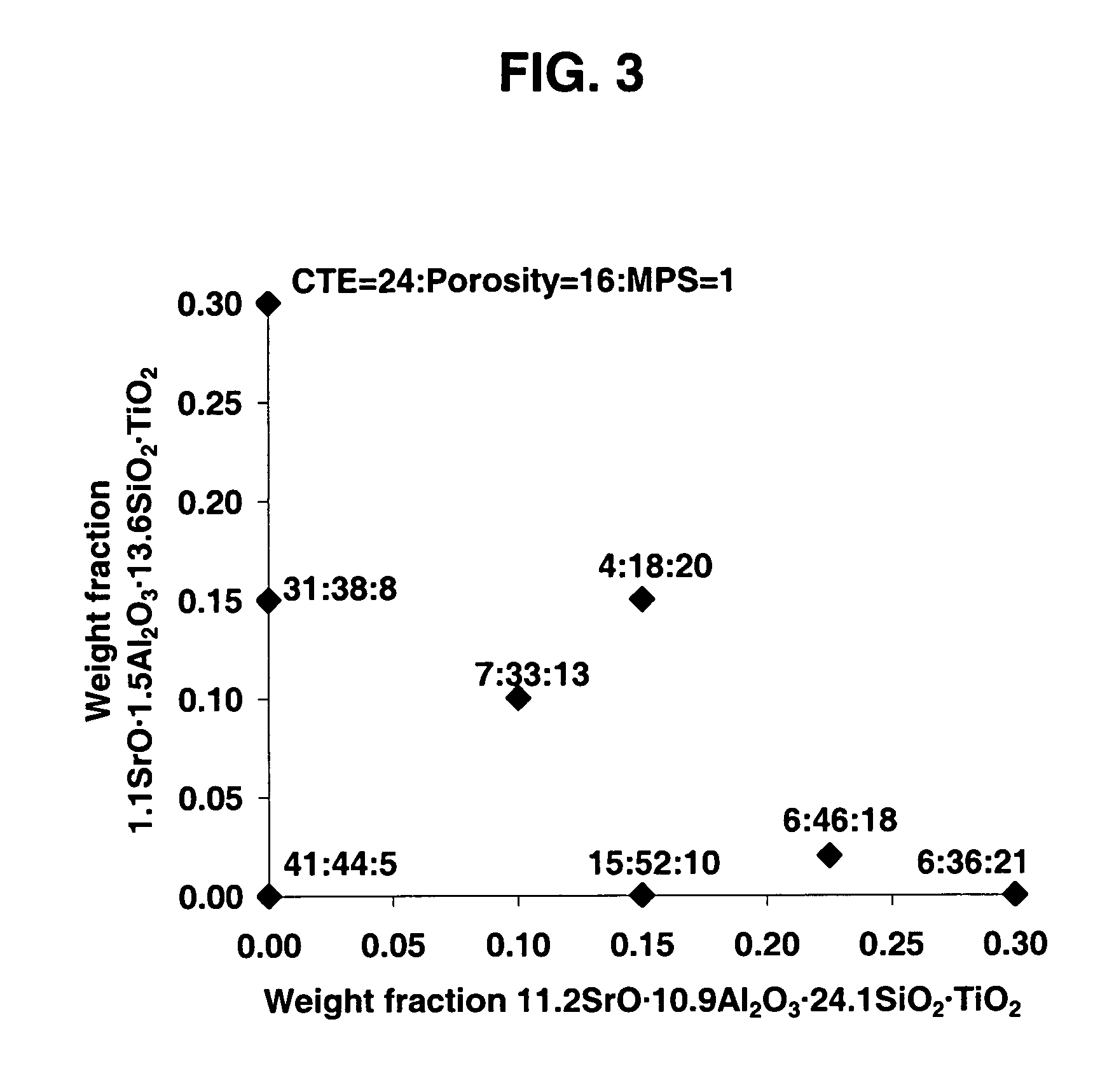

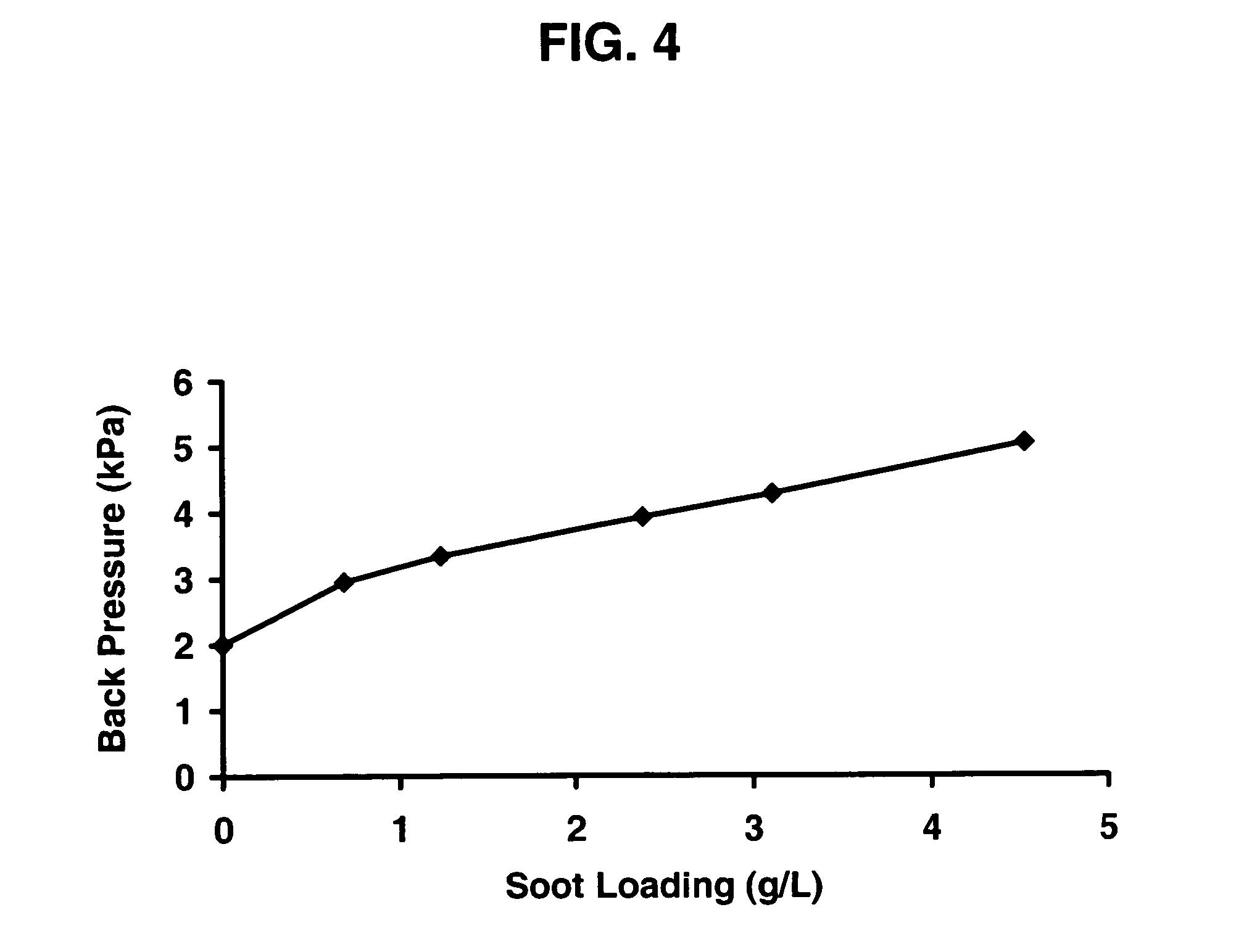

Aluminum titanate-based ceramic article

ActiveUS7001861B2Reduce manufacturing costHigh mechanical strengthDispersed particle filtrationExhaust apparatusFiltrationTitanate

An aluminum titanate-based ceramic article having a composition comprising u (Al2O3—TiO2)+v (R)+w (3Al2O3—2SiO2)+x (Al2O3)+y (SiO2)+z (1.1SrO-1.5Al2O3-13.6SiO2—TiO2)+a (Fe2O3—TiO2)+b (MgO-2TiO2), where, R is SrO—Al2O3-2SiO2 or 11.2SrO-10.9Al2O3-24.1SiO2—TiO2, where u, v, w, x, y, z, a and b are weight fractions of each component such that (u+v+w+x+y+z+a+b=1), and 0.5<u≦0.95, 0.01<v≦0.5, 0.01<w≦0.5, 0≦x≦0.5, 0≦y≦0.1, 0≦z≦0.5, 0<a≦0.3, and 0≦b≦0.3. A method of forming the ceramic article is provided. The ceramic article is useful in automotive emissions control systems, such as diesel exhaust filtration.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com