Patents

Literature

44results about How to "High-temperature performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

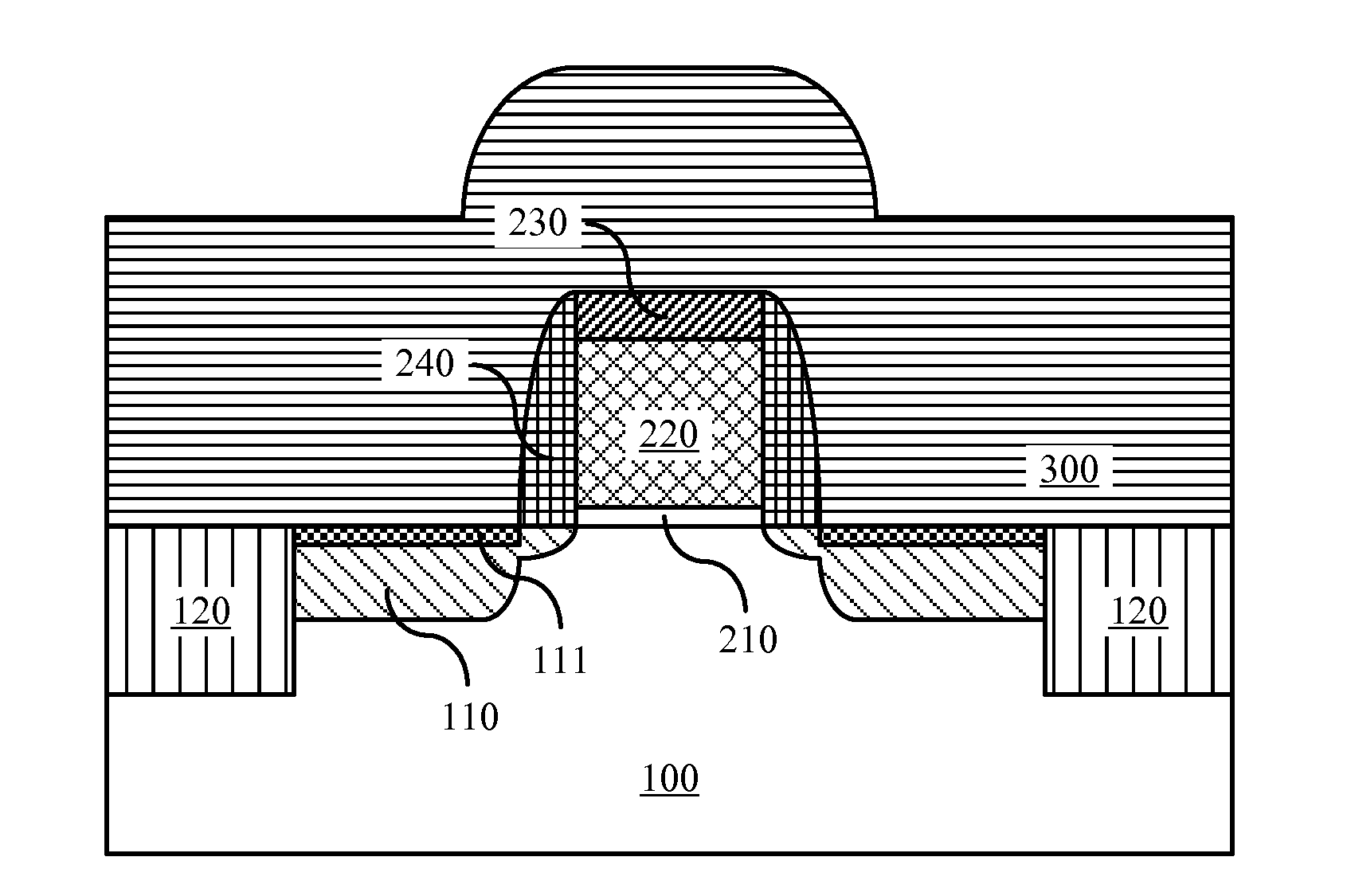

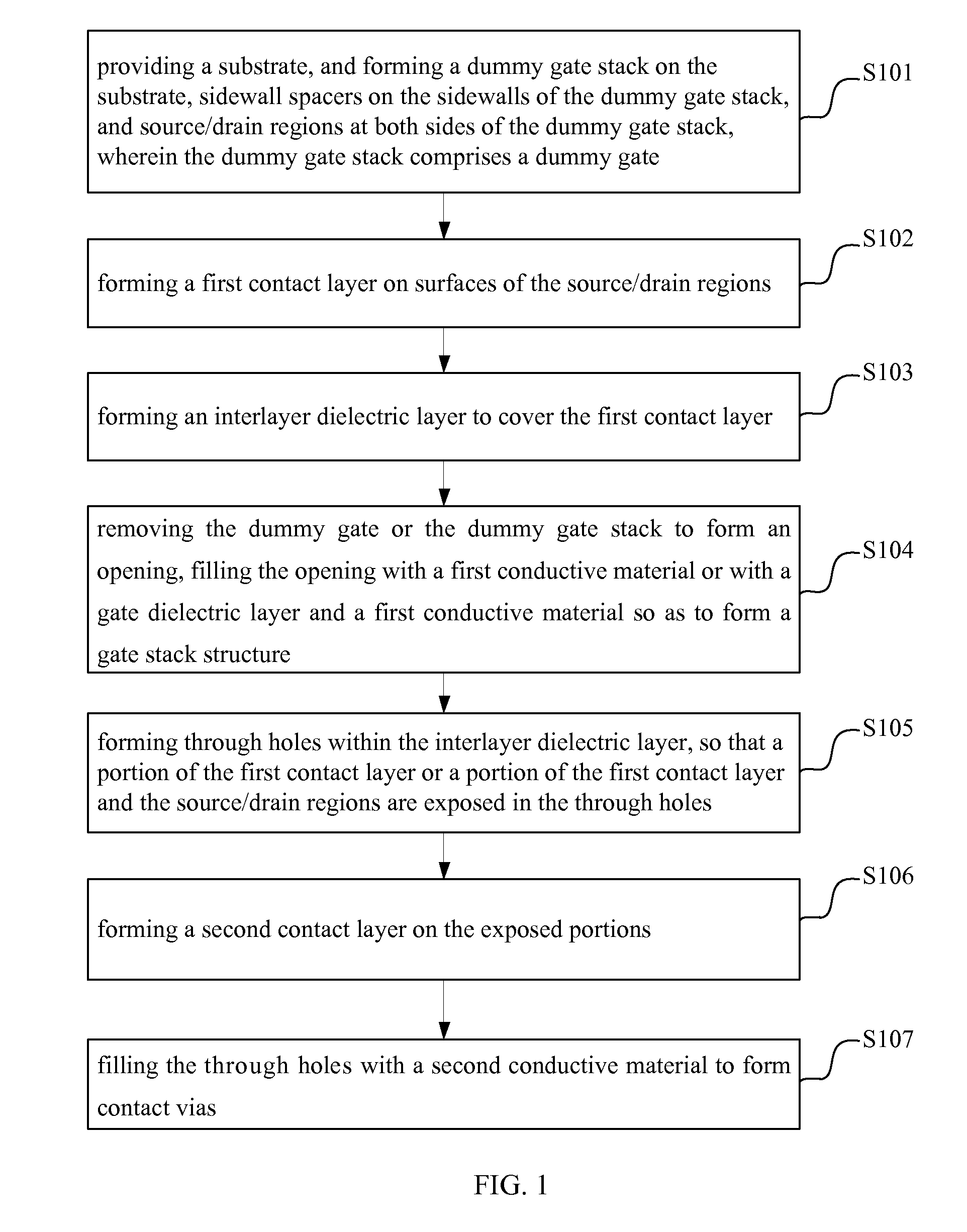

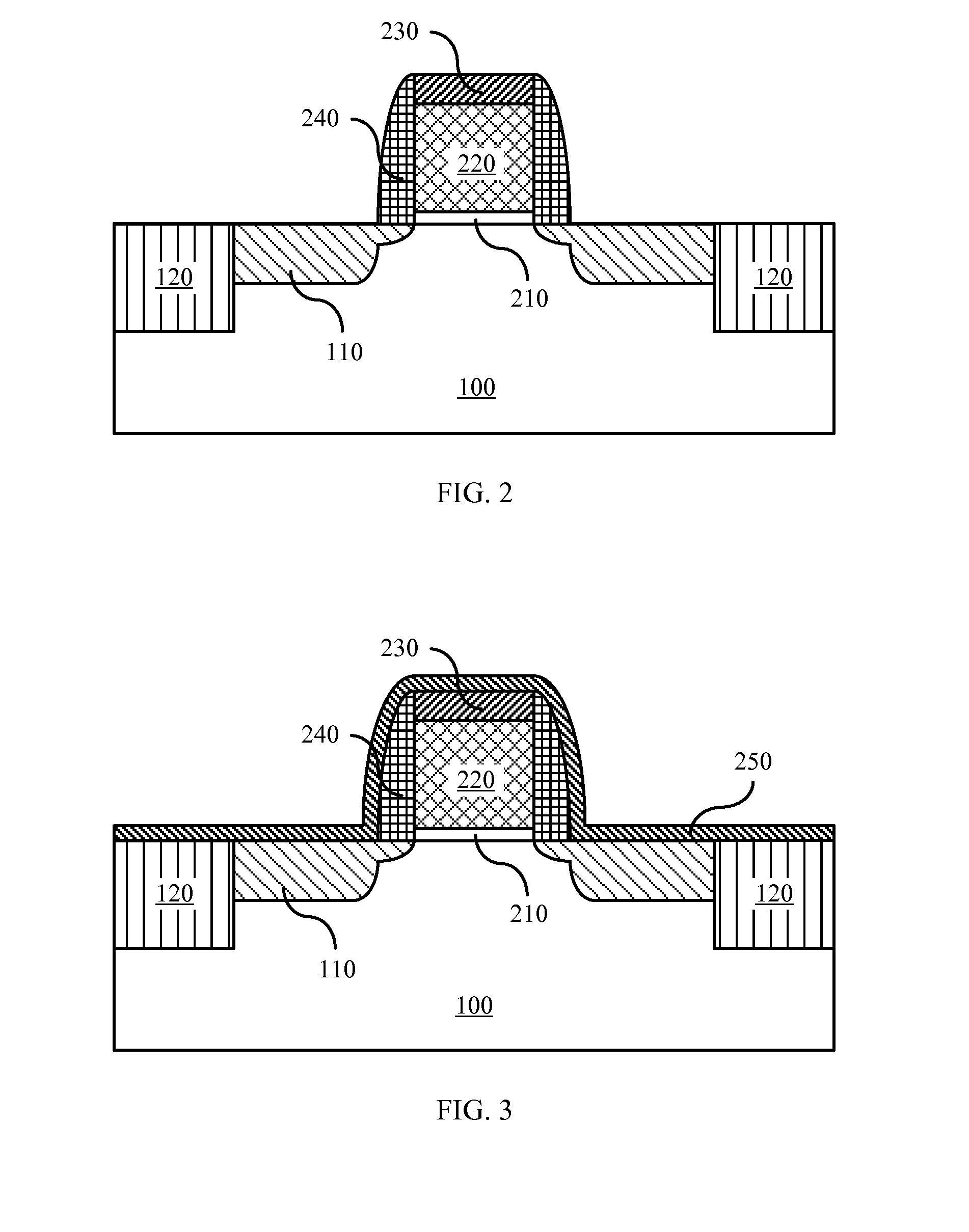

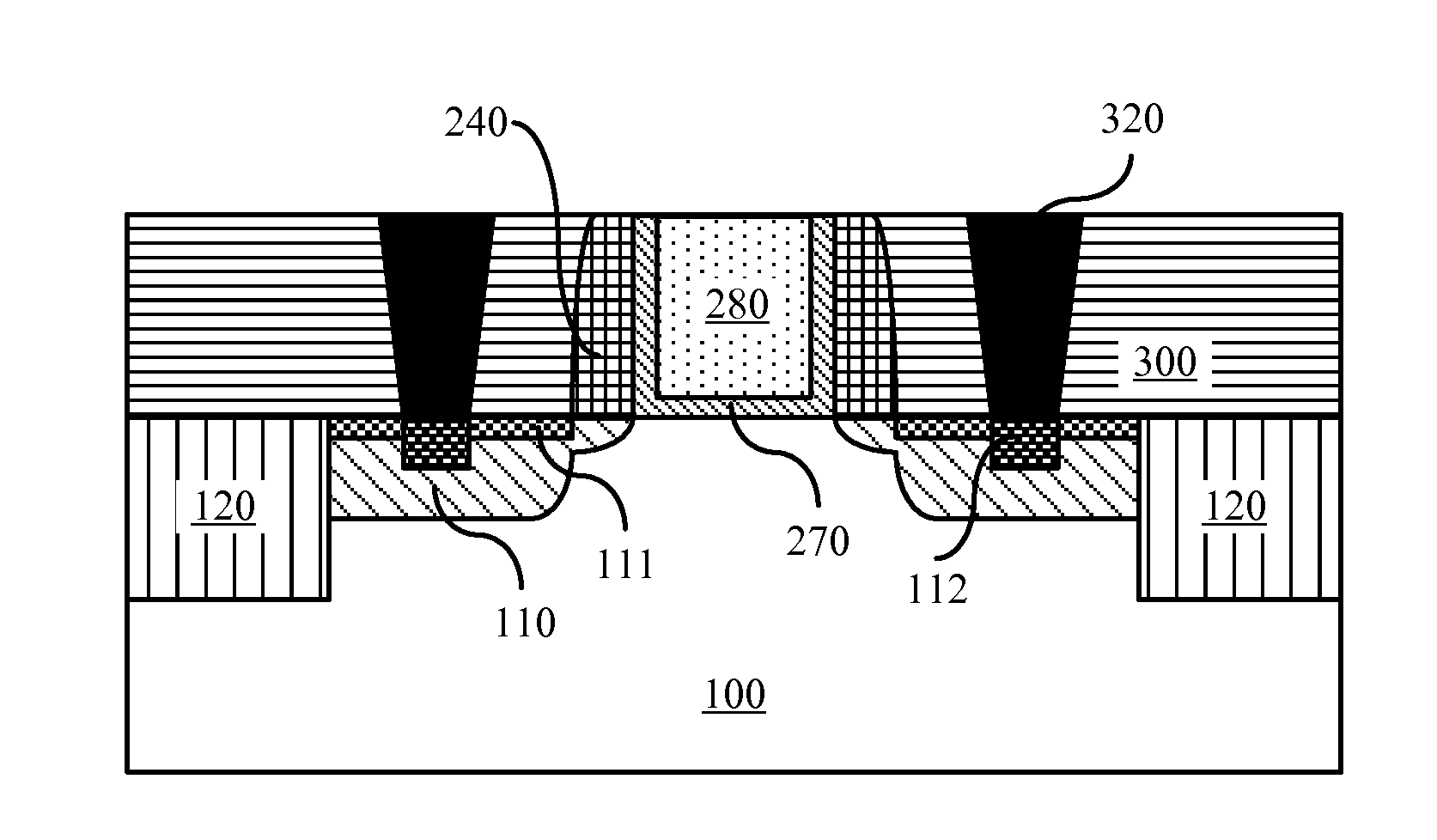

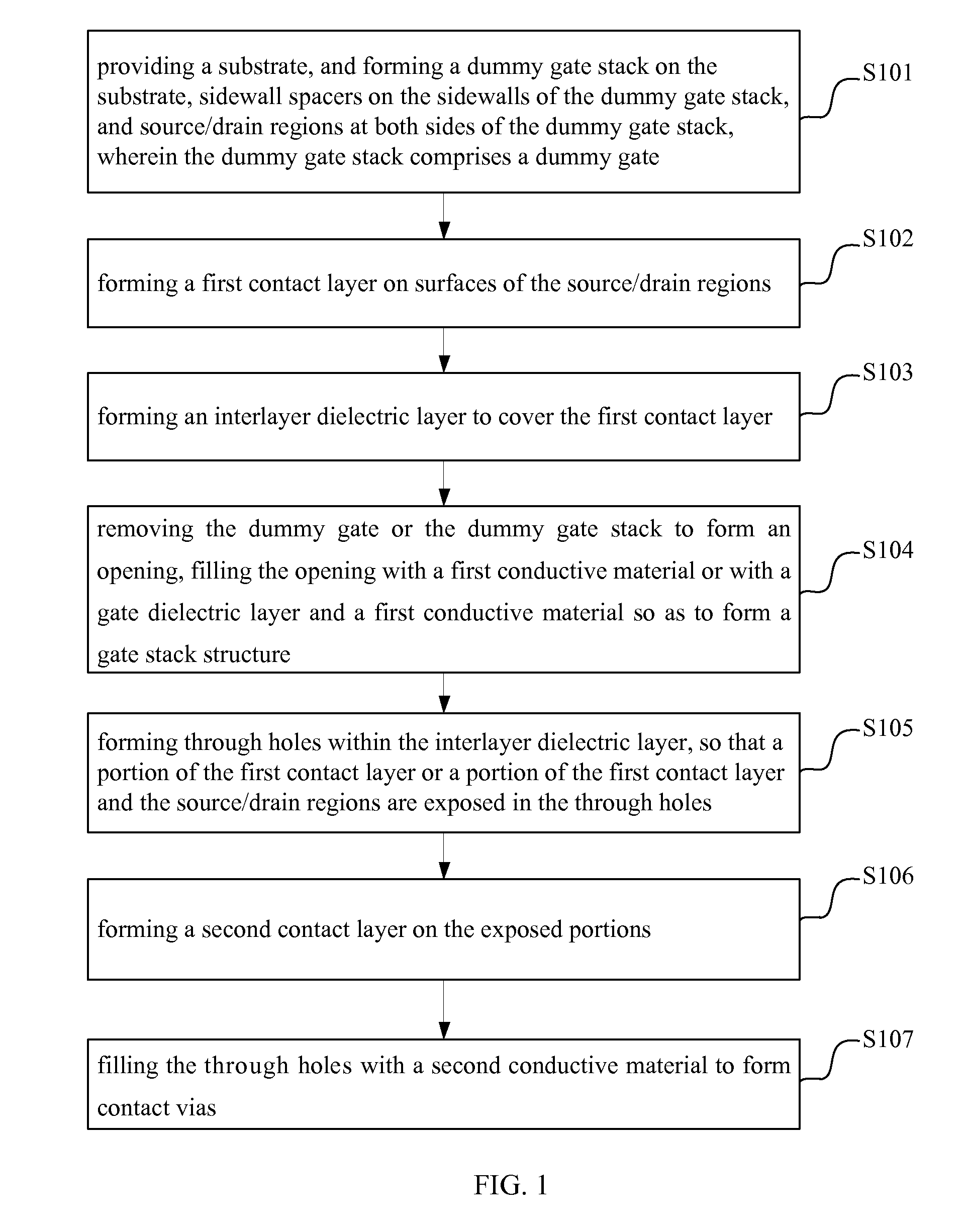

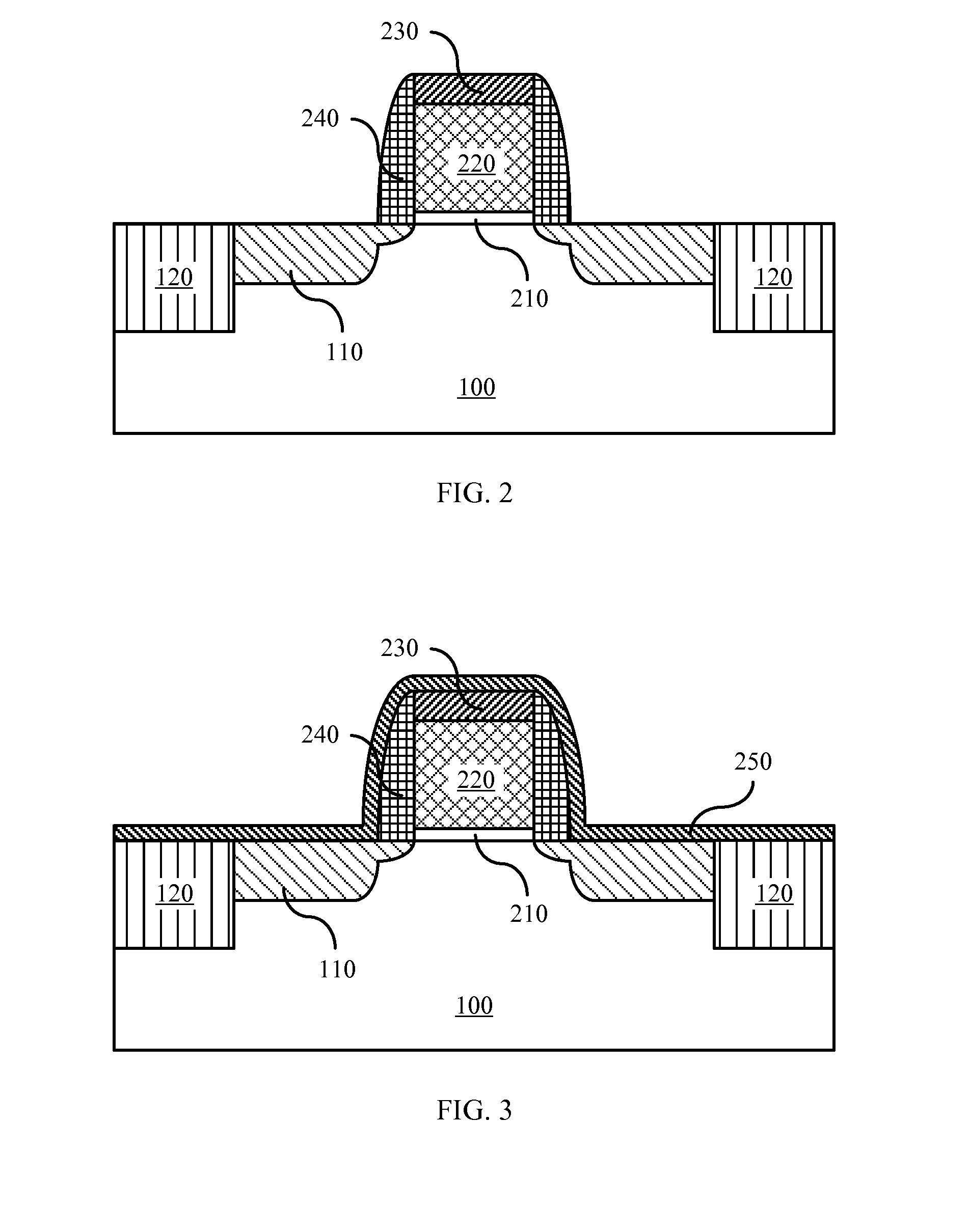

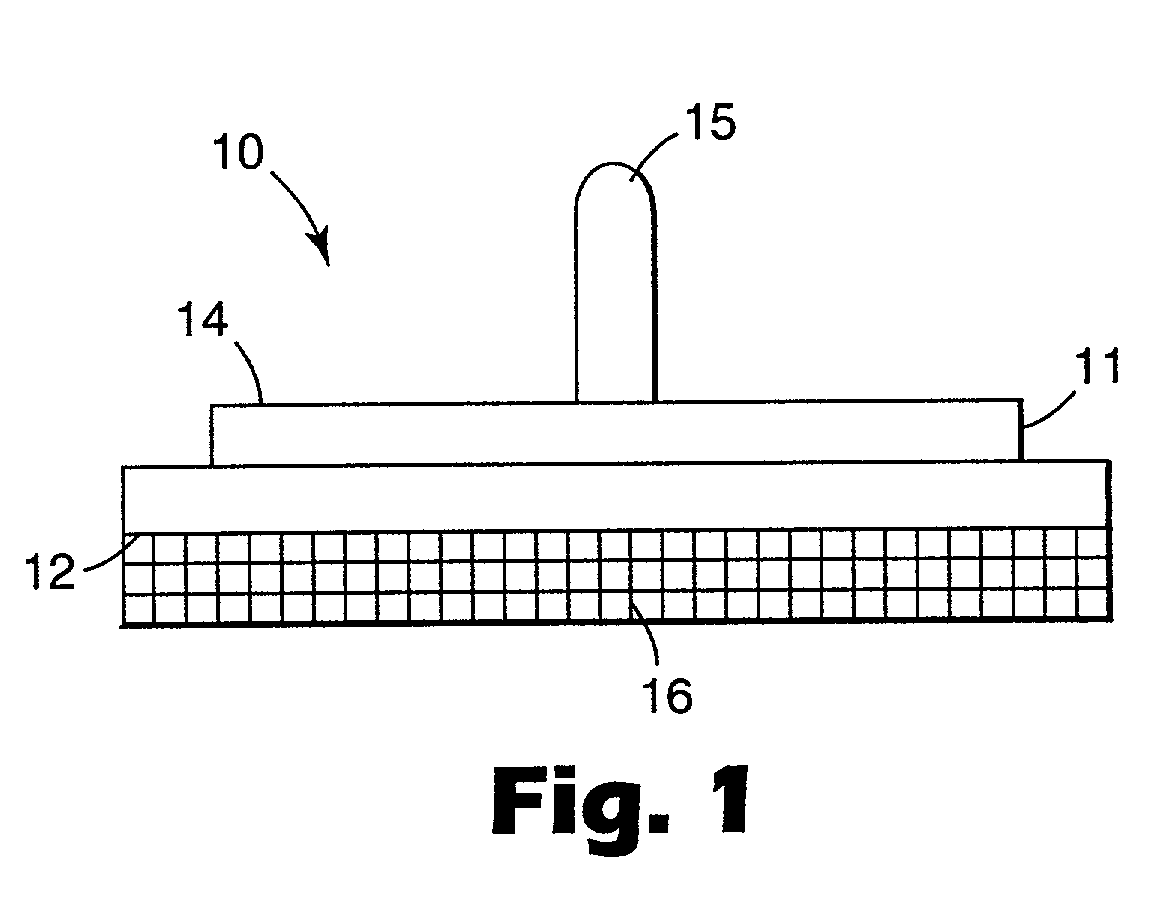

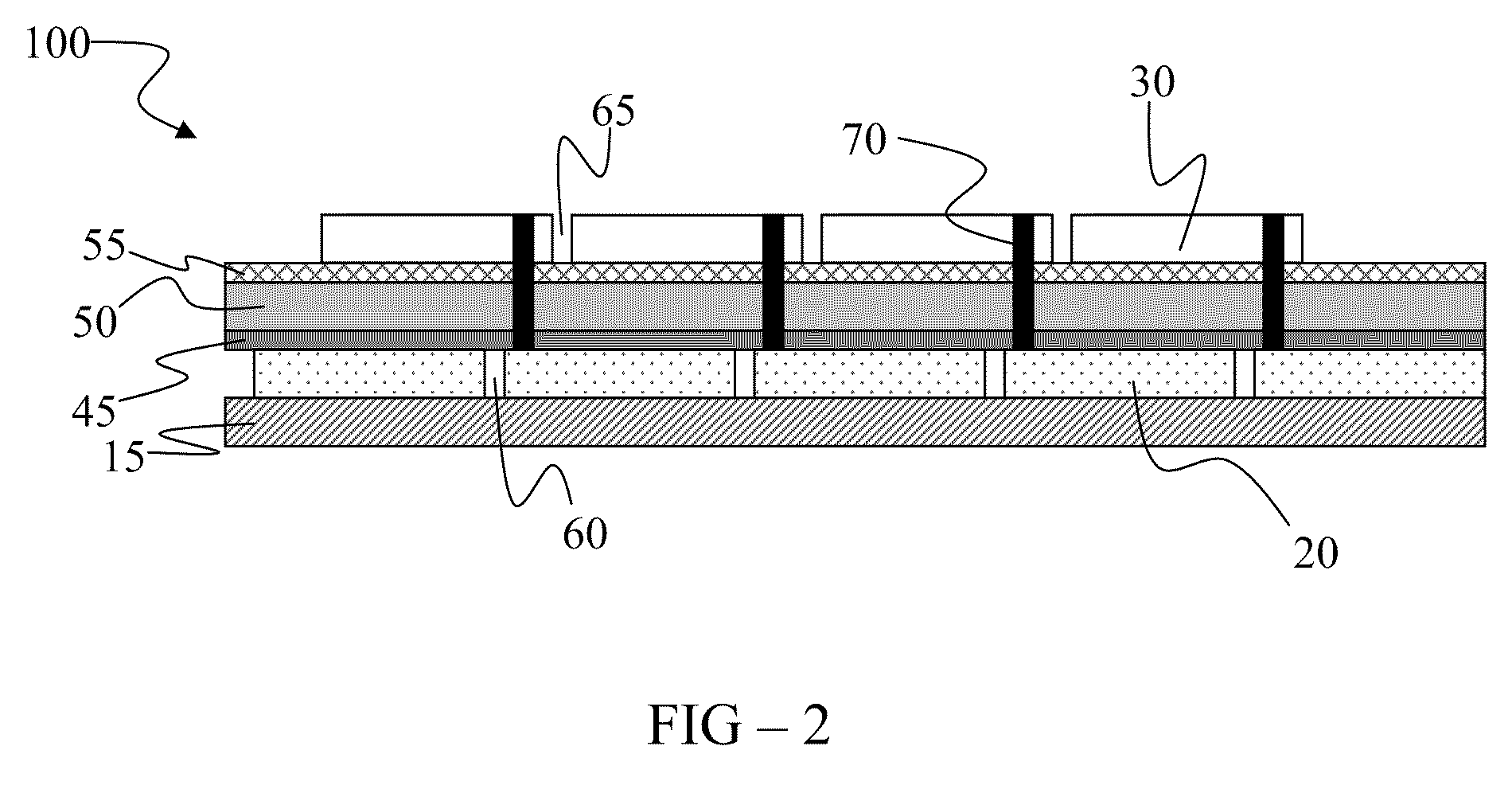

Semiconductor Structure and Method for Manufacturing the Same

ActiveUS20120205728A1Reduce contact resistanceIncrease the areaSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricSemiconductor structure

The present invention provides a method for manufacturing a semiconductor structure, comprising: providing a substrate, and forming a dummy gate stack on the substrate, sidewall spacers on sidewalls of the dummy gate stack, and source / drain regions at both sides of the dummy gate stack, wherein the dummy gate stack comprising a dummy gate; forming a first contact layer on surfaces of the source / drain regions; forming an interlayer dielectric layer to cover the first contact layer; removing the dummy gate or the dummy gate stack material to form an opening, filling the opening with a first conductive material or with a gate dielectric layer and a first conductive material to form a gate stack structure; forming through holes within the interlayer dielectric layer, so that a portion of the first contact layer or a portion of the first contact layer and the source / drain regions are exposed in the through holes; forming a second contact layer on the exposed portions of the regions; filling the through holes with a second conductive material to form contact vias. Besides, the present invention further provides a semiconductor structure, which is favorable for reducing the contact resistance.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

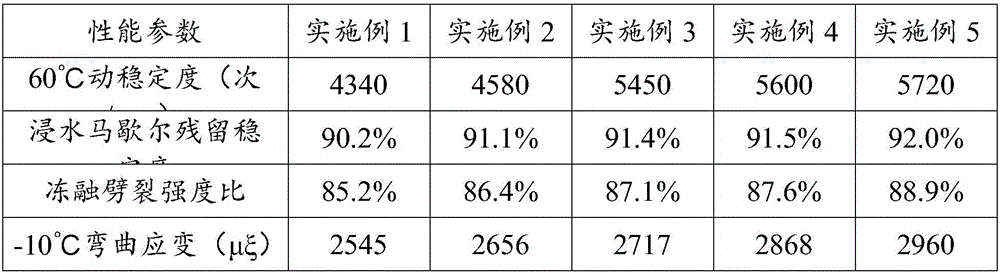

Cold mixing color asphalt mixture and preparation method

The invention discloses a cold mixing color asphalt mixture and a preparation method. The preparation method comprises the following steps: selecting aromatic hydrocarbon oil, rubber oil, petroleum resin, epoxy resin, a modifier, a plasticizer, a diluent, diatomite, a pigment and stabilizers, and mixing the materials according to the mass proportion, thus obtaining color asphalt cement; selecting an emulsifier, the stabilizers and a defoamer, and mixing the three materials with the color asphalt cement in proportion, thus obtaining emulsified color asphalt cement; and selecting an aggregate, a filler, cement, a waterborne curing agent, an expansive agent and the emulsified color asphalt cement, and mixing the materials in proportion, thus obtaining the cold mixing color asphalt mixture.

Owner:SHENZHEN TRAFFIC CONSTR ENG TEST & DETECTION CENT

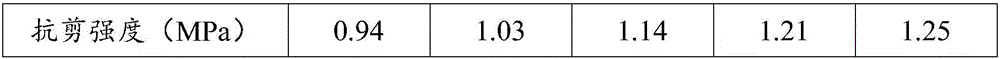

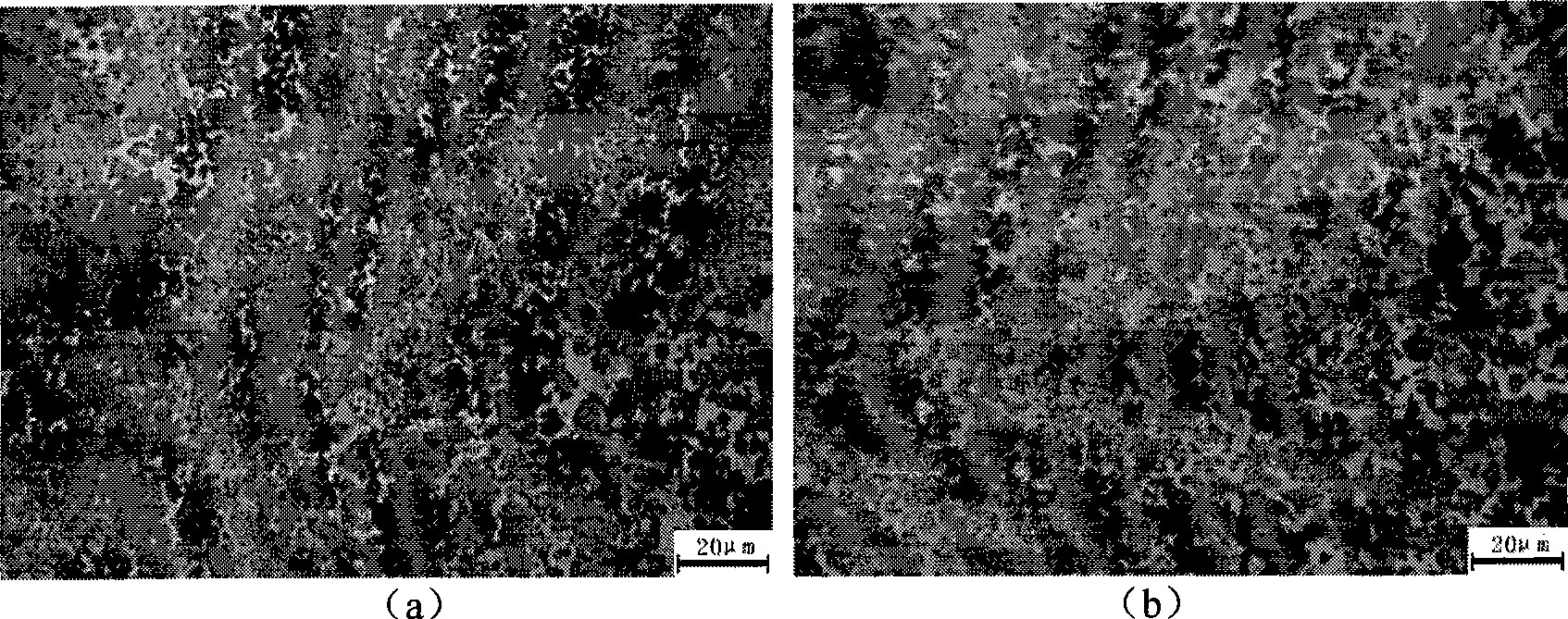

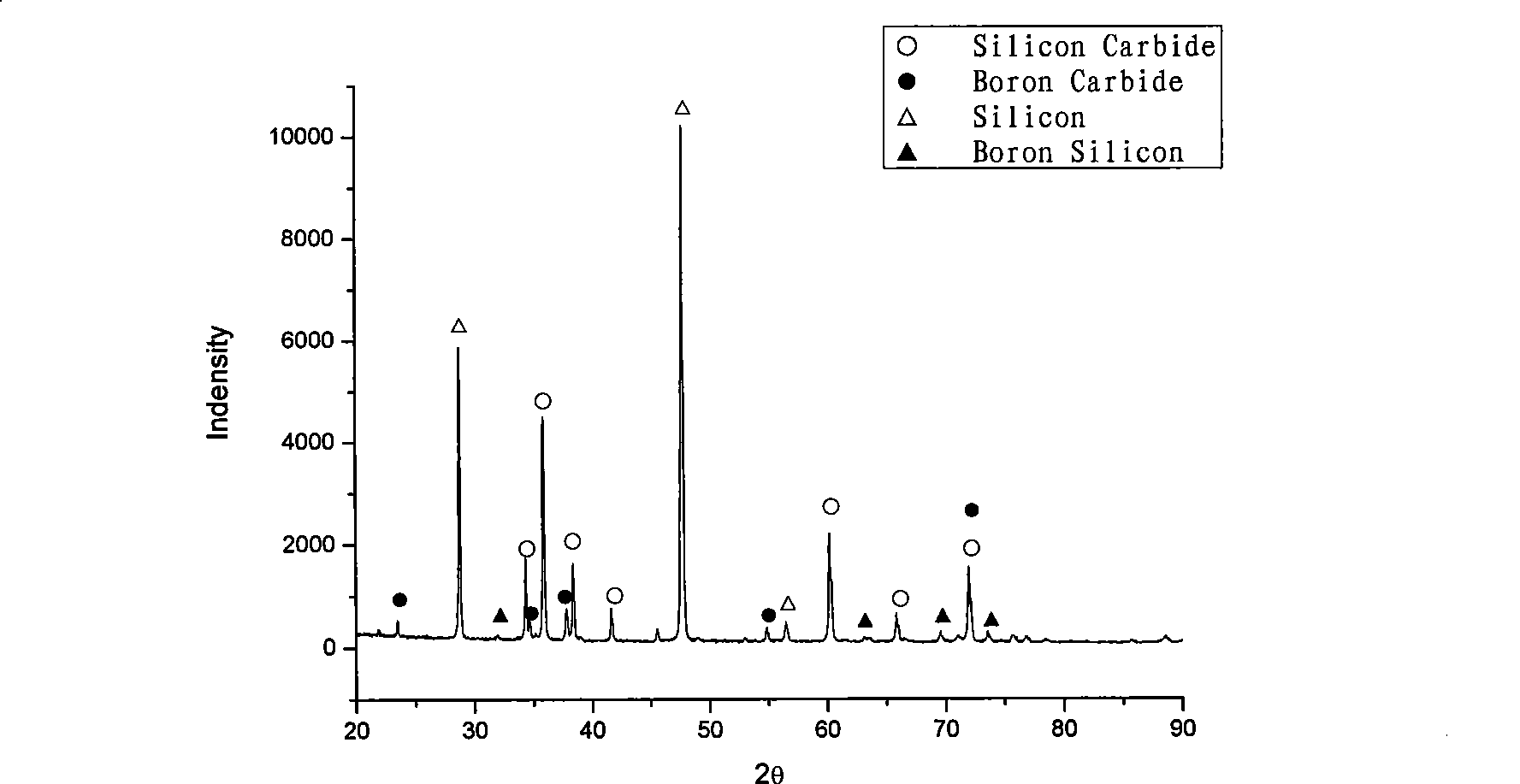

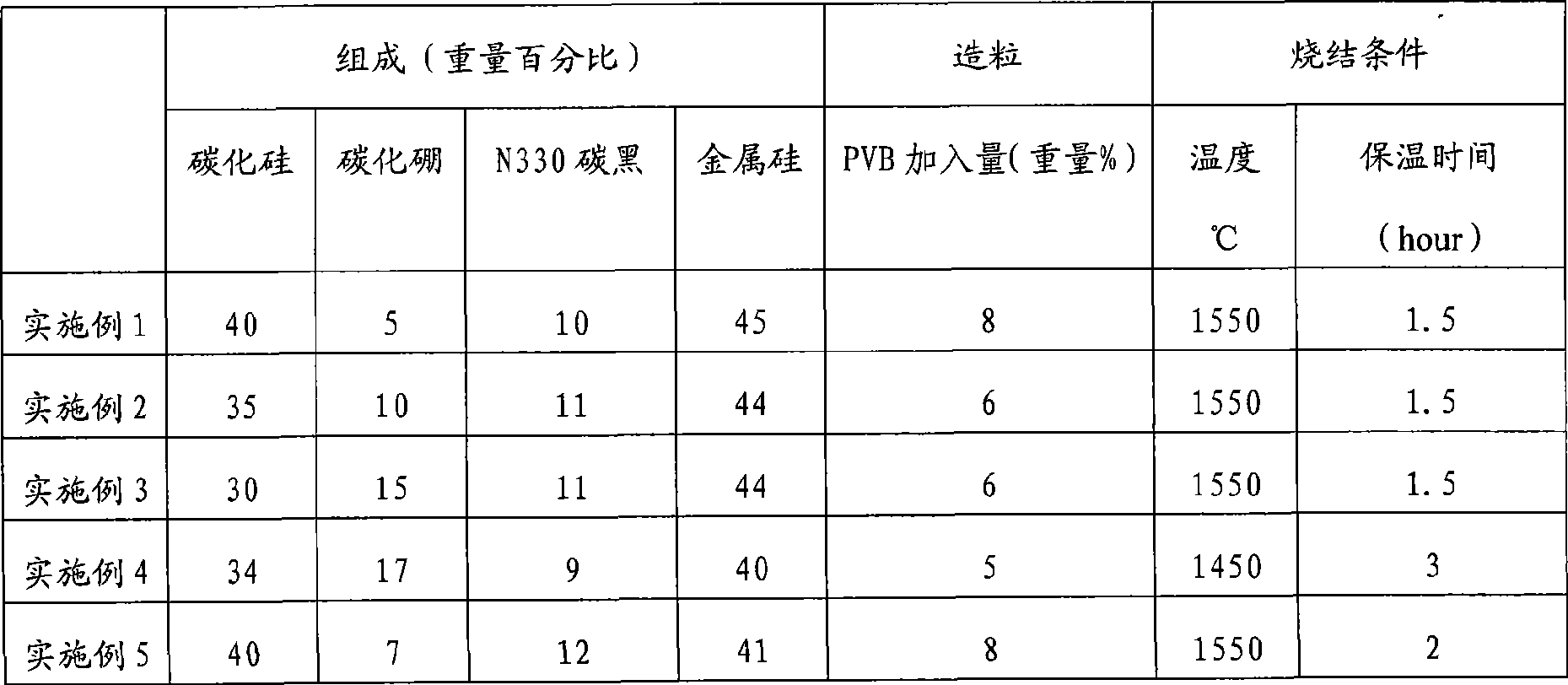

Silicon carbide based reinforced composite ceramic and preparation

The invention discloses a reinforced silicon carbide-based composite ceramic and a preparation method thereof. The composite ceramic is characterized by comprising the following components based on weight percentages: 30%-40% of silicon carbide powder, 5%-17% of boron carbide powder, 9%-12% of nano carbon black and 40%-50% of silicon metal. The method comprises the following steps: firstly, ball milling and wet mixing are performed on the silicon carbide powder, the carbon black and the boron carbide powder to obtain mixed powder, and a bonding agent PVB is added for granulation, die pressing is performed for forming; then the formed green compact is dried and put in an air furnace for binder removal; and finally, the obtained green compact is put into a graphite crucible with silicon powder, and siliconizing and sintering are completed after 1-3h heat preservation at 1450-1550 DEG C under a vacuum environment, thus obtaining a sintering body. The boron carbide particle reinforced reaction sintered silicon carbide composite ceramic prepared by the method can be widely used as a structural material under high-temperature atmosphere and corrosive atmosphere, a frictional wear material and the like; and as the composite ceramic has better obdurability and hardness, the ceramic can be used as a substitute material of the traditional reaction sintered silicon carbide.

Owner:珠海亿特立新材料有限公司

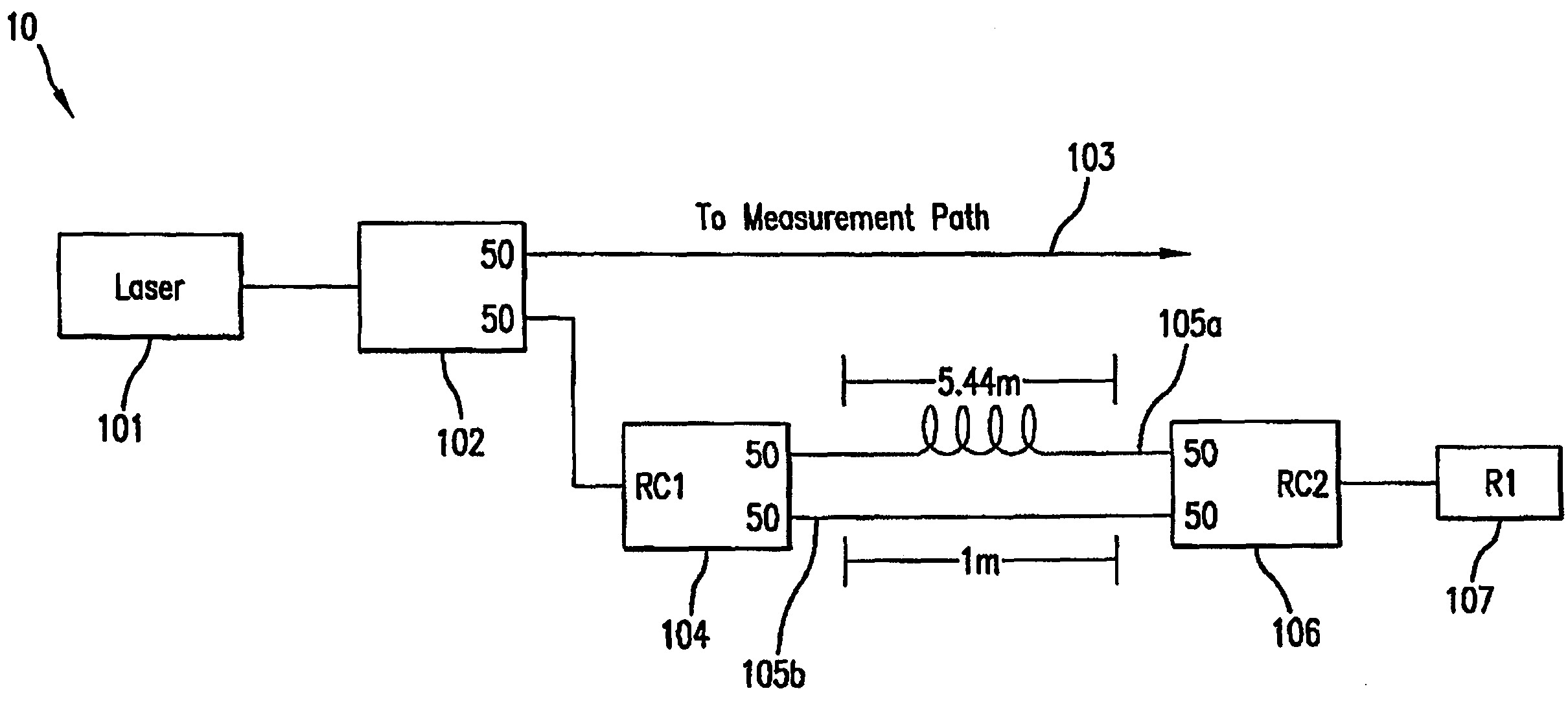

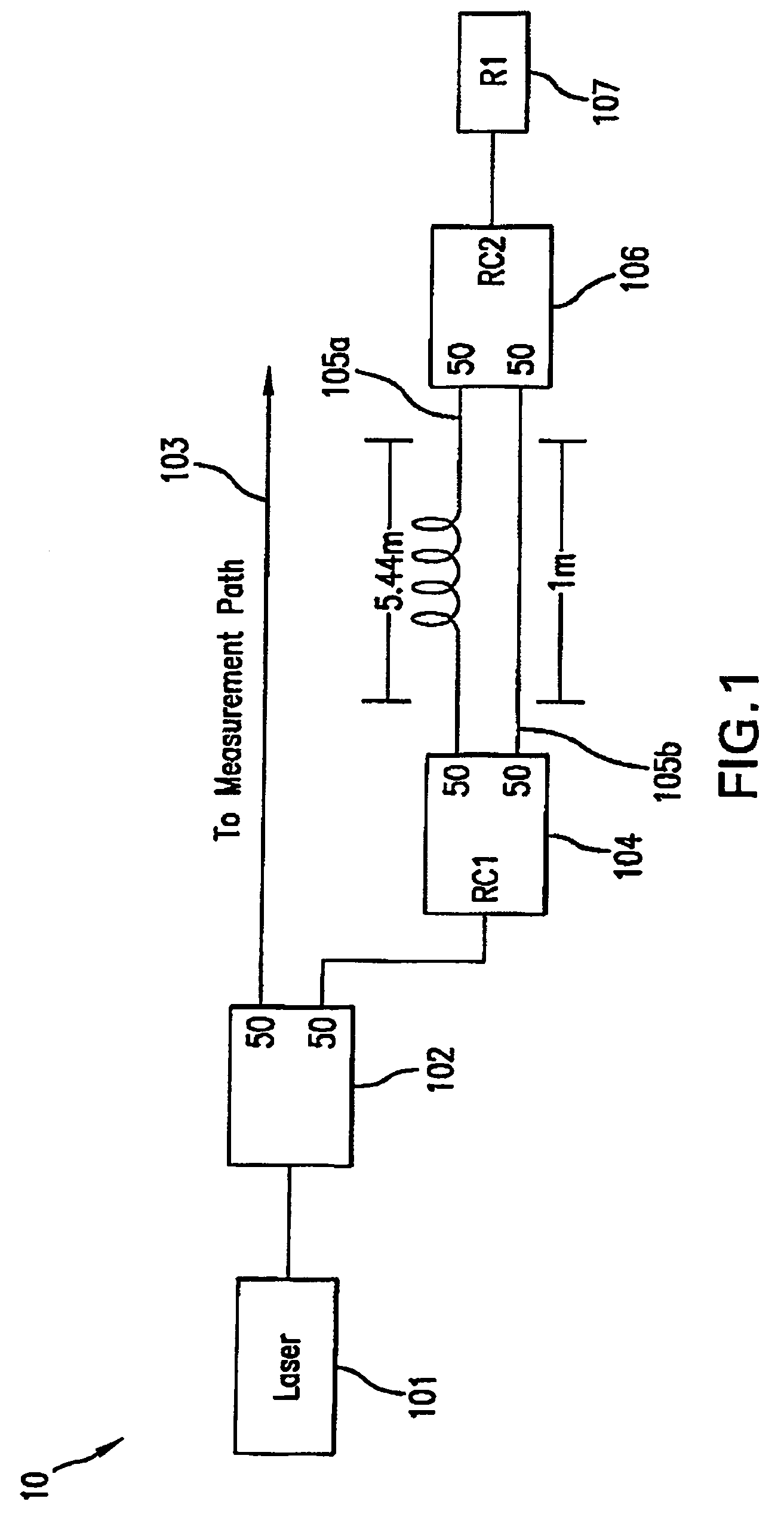

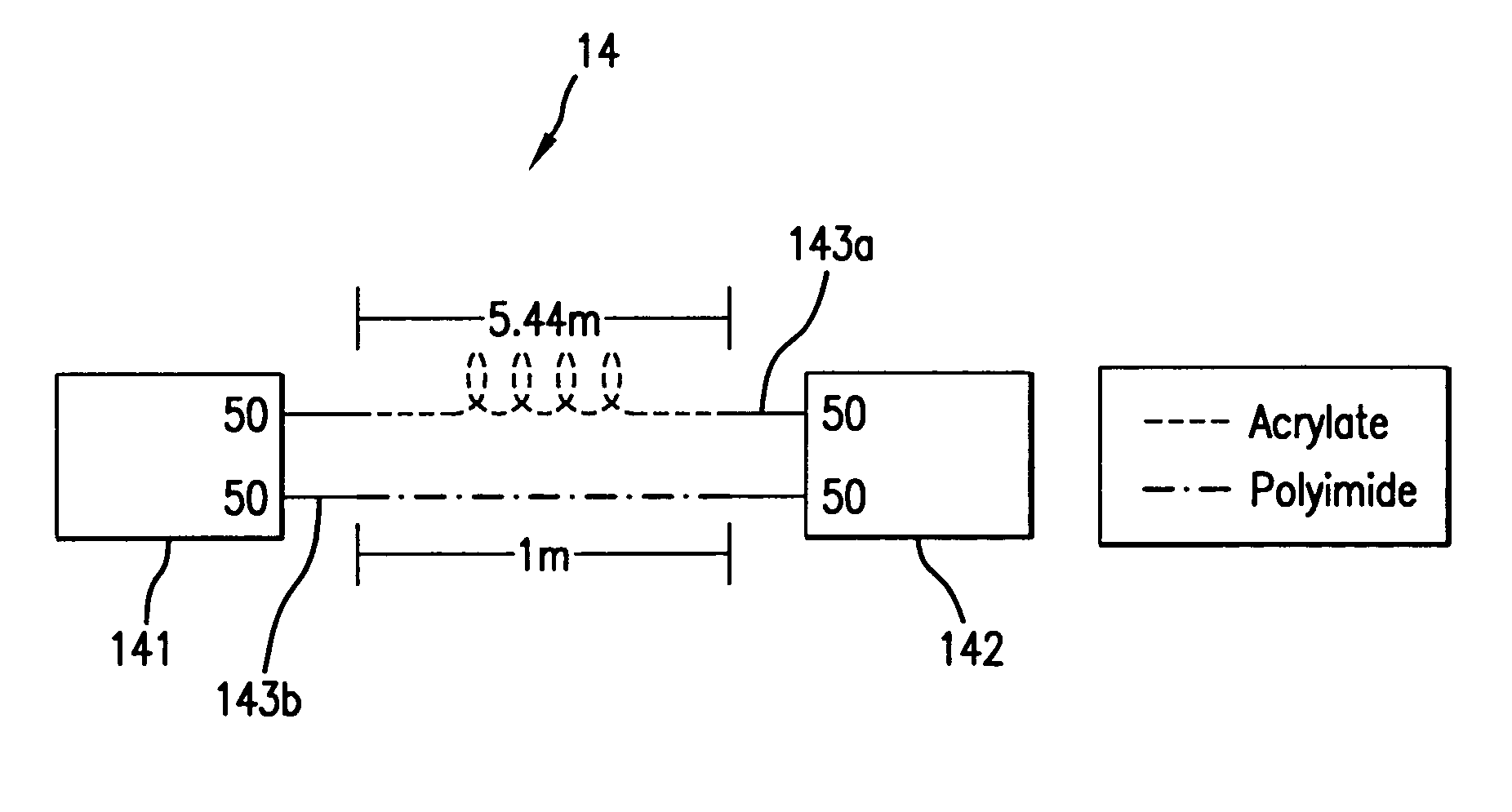

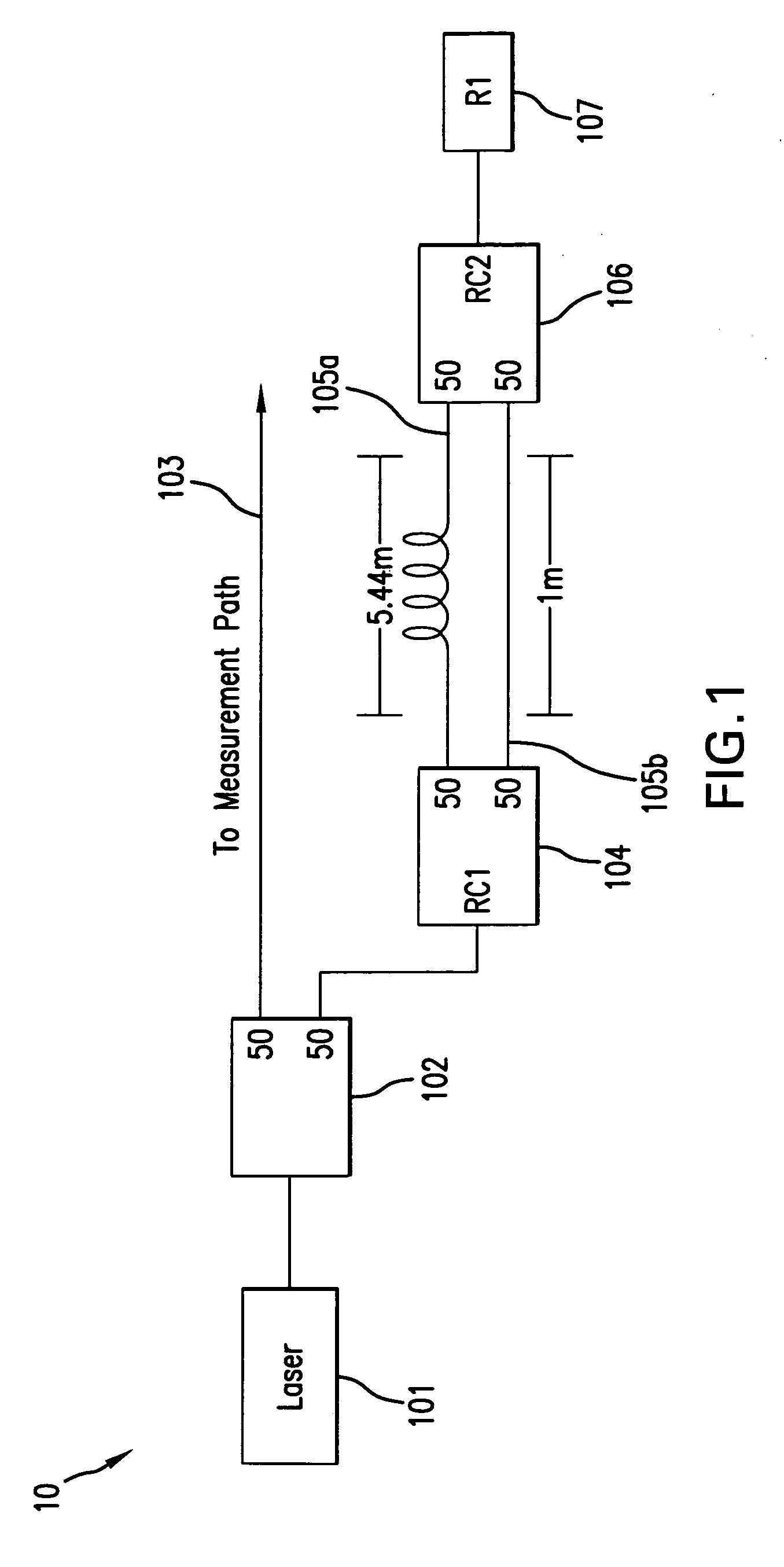

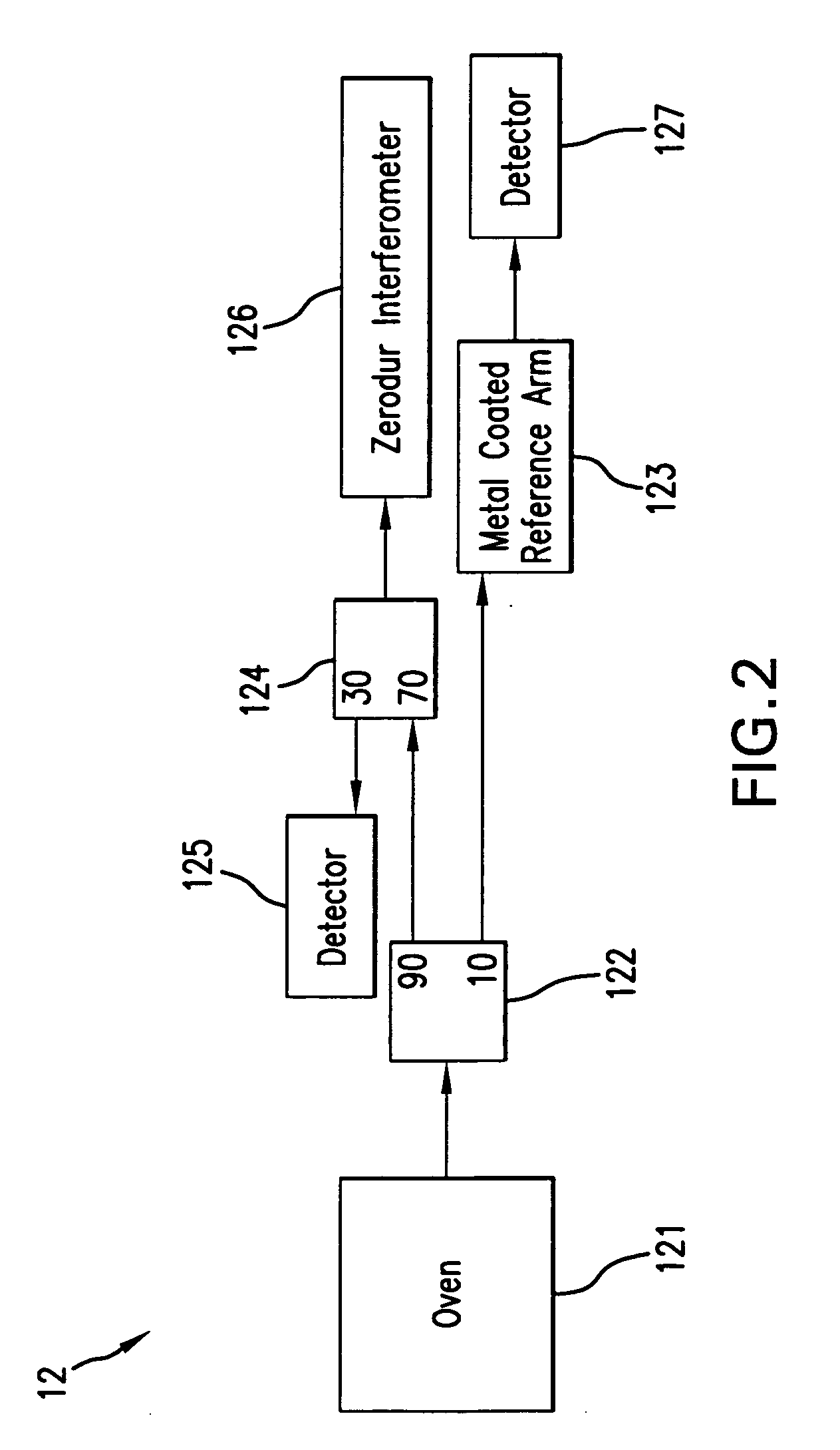

Precision length standard for coherent laser radar

ActiveUS7925134B2Slow changeHigh-temperature performanceWave based measurement systemsOptical fibre with multilayer core/claddingFiberEnvironmental effect

Owner:NIKON METROLOGY

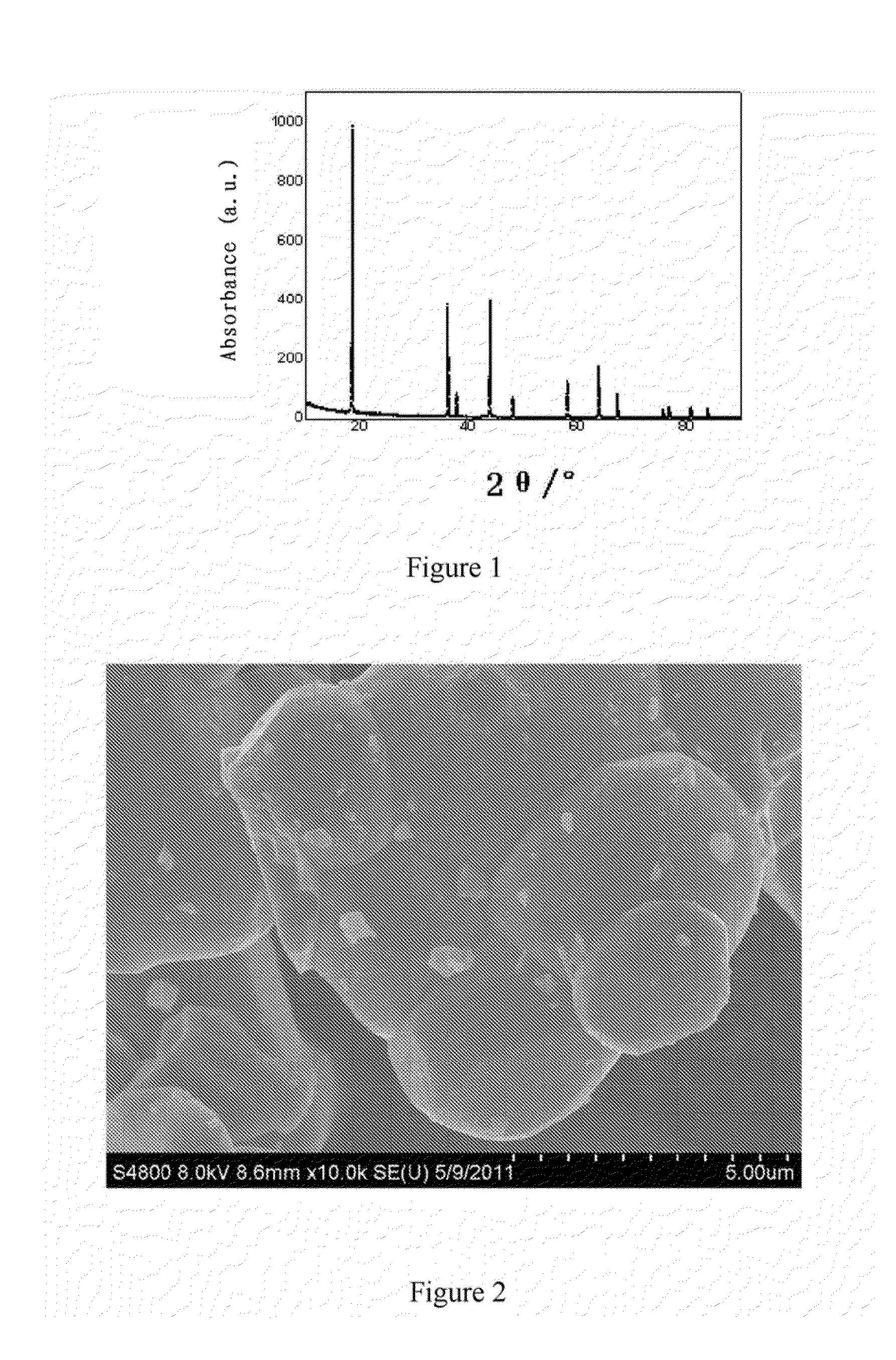

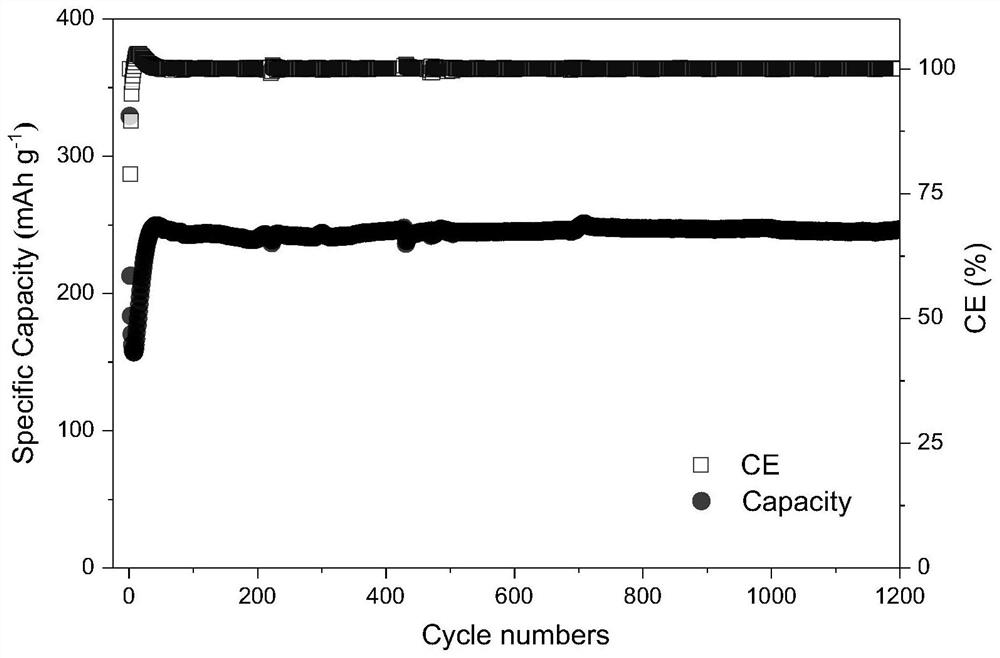

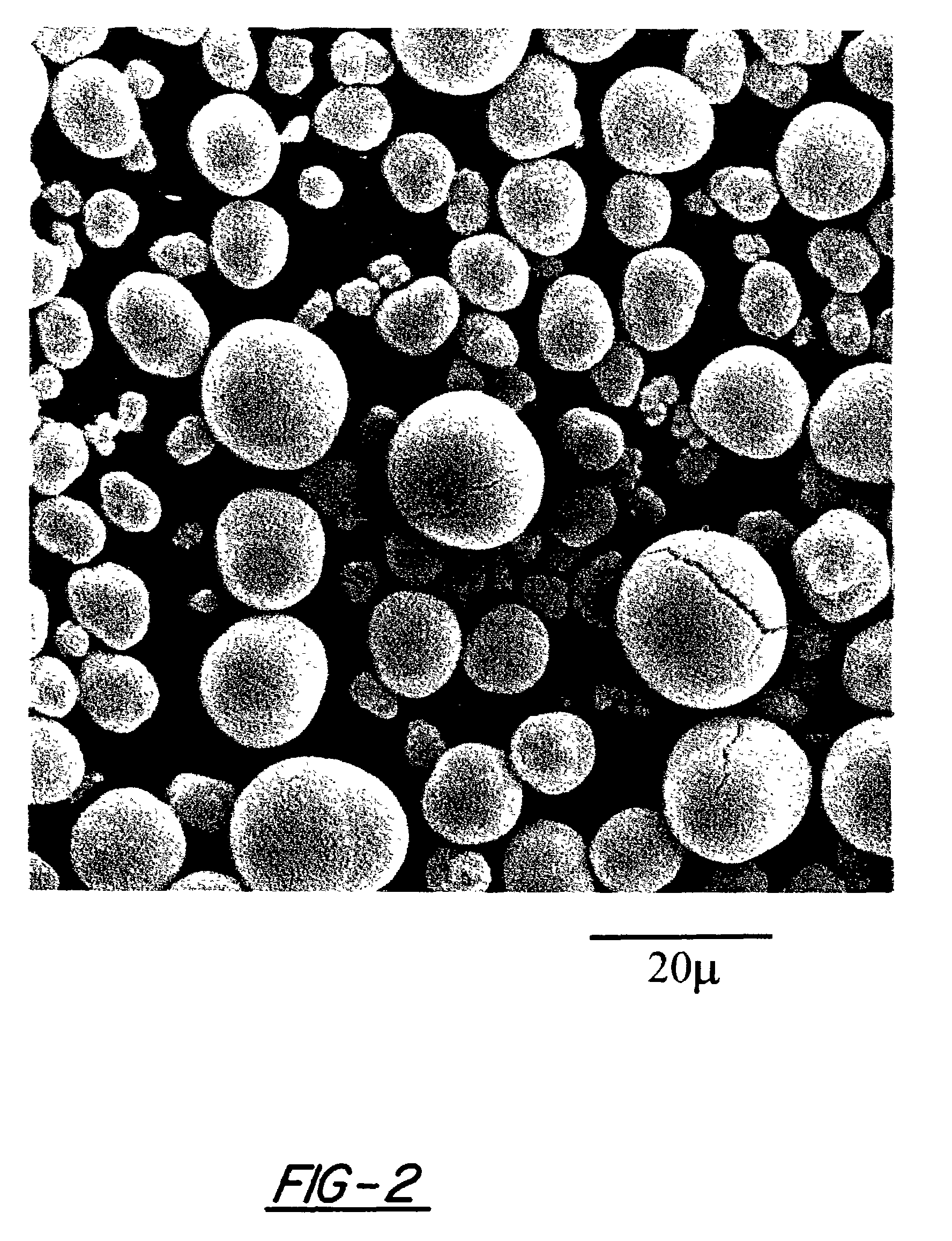

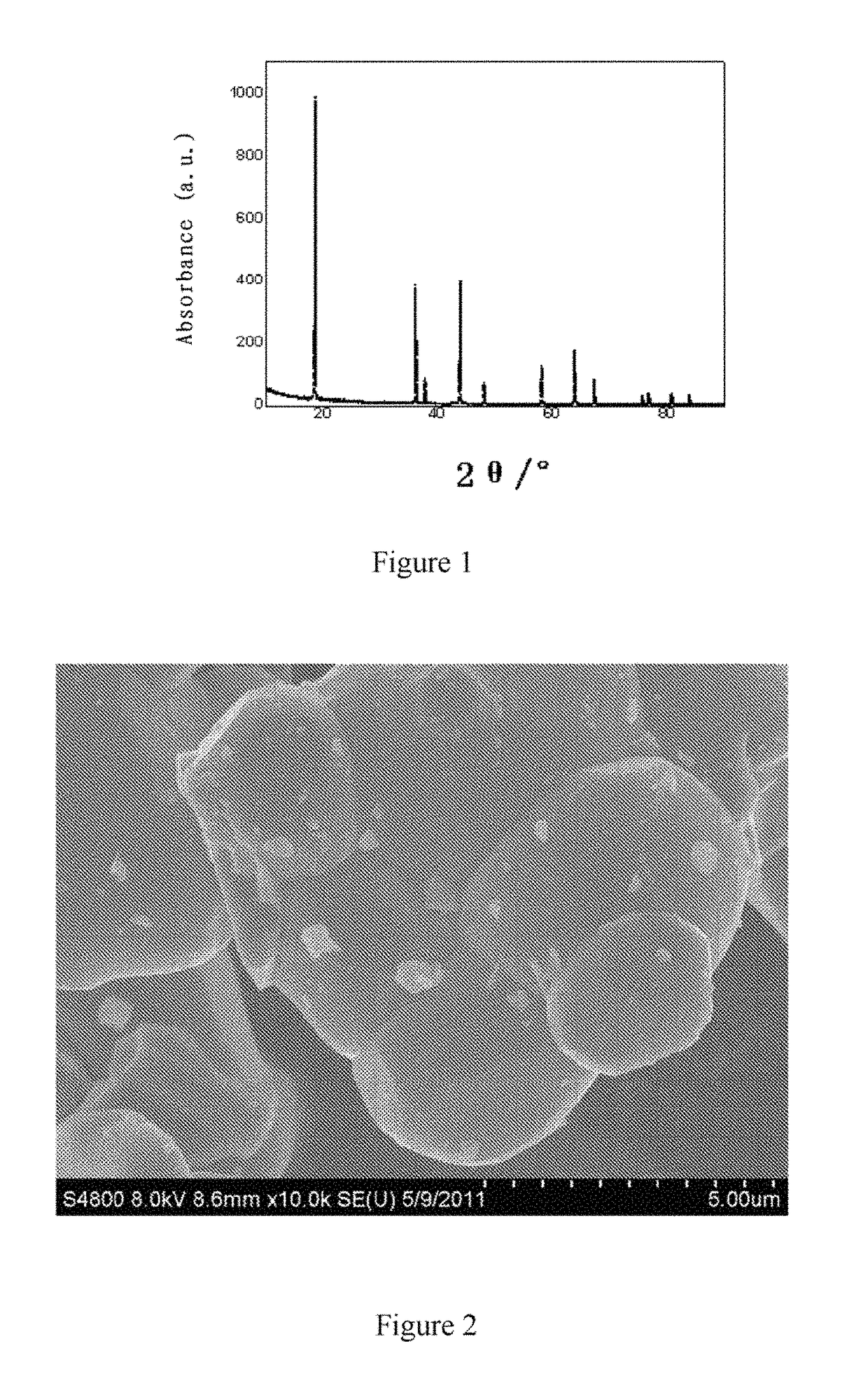

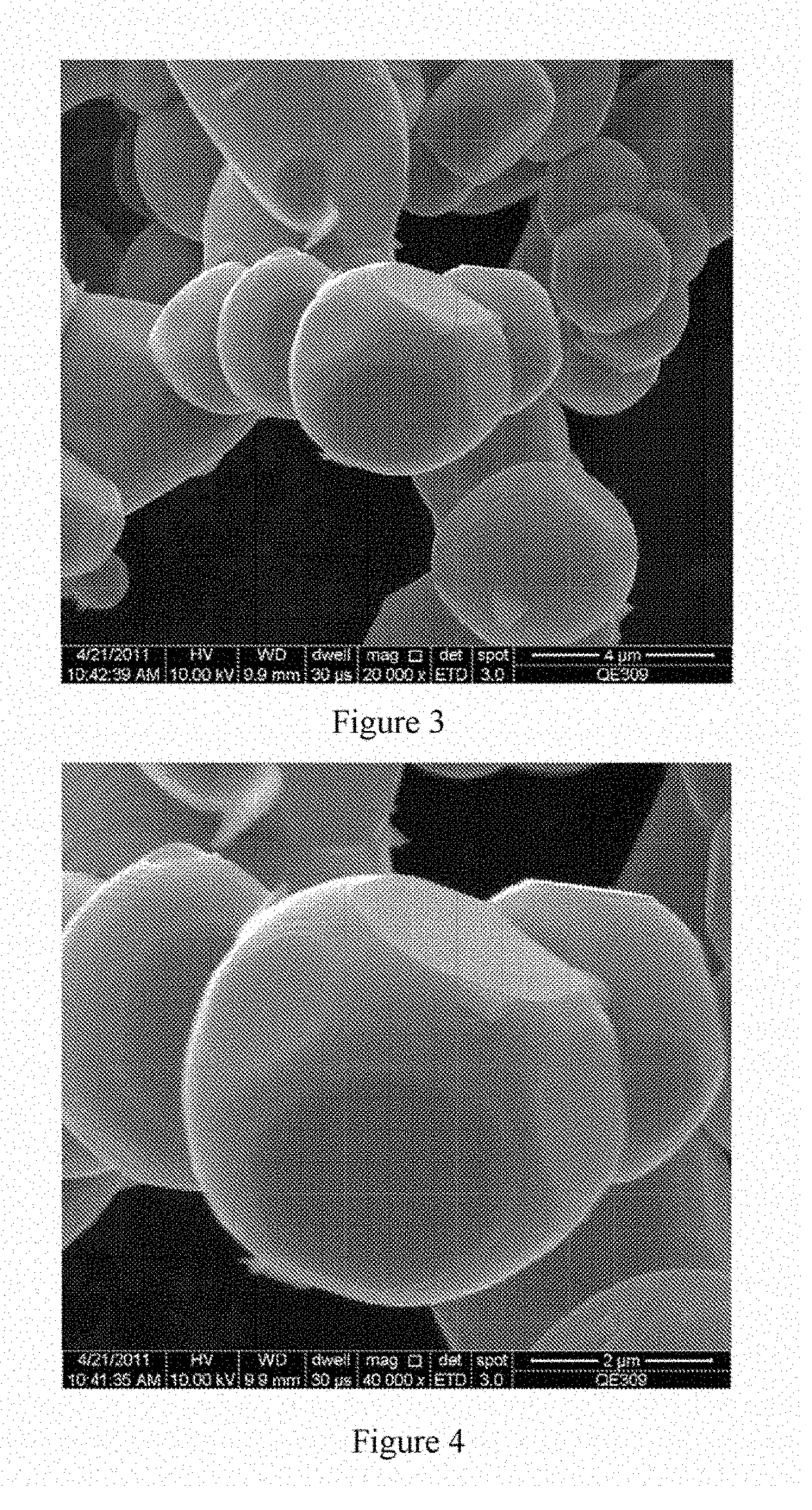

Positive electrode material for lithium battery, preparing method thereof and lithium battery

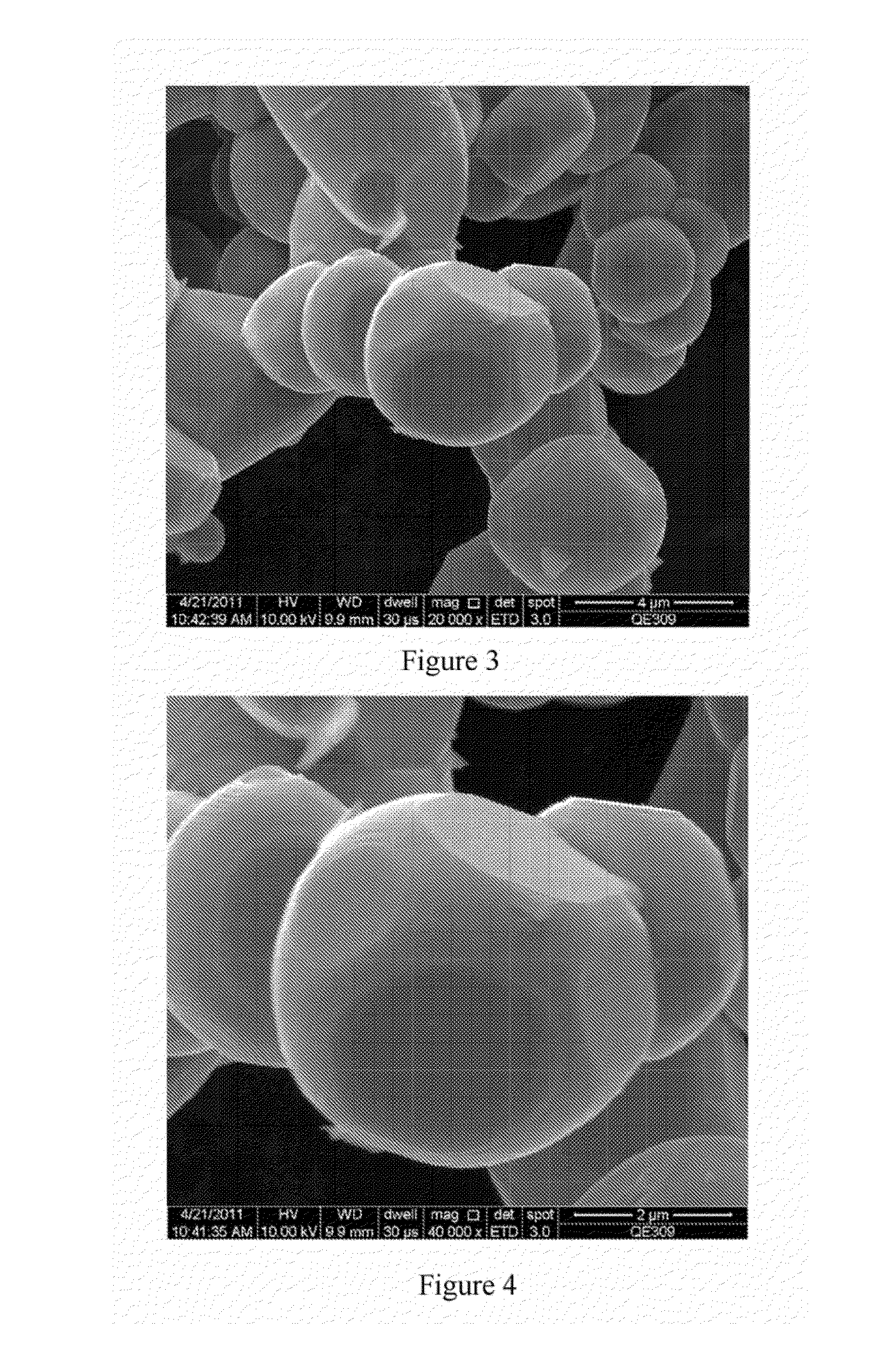

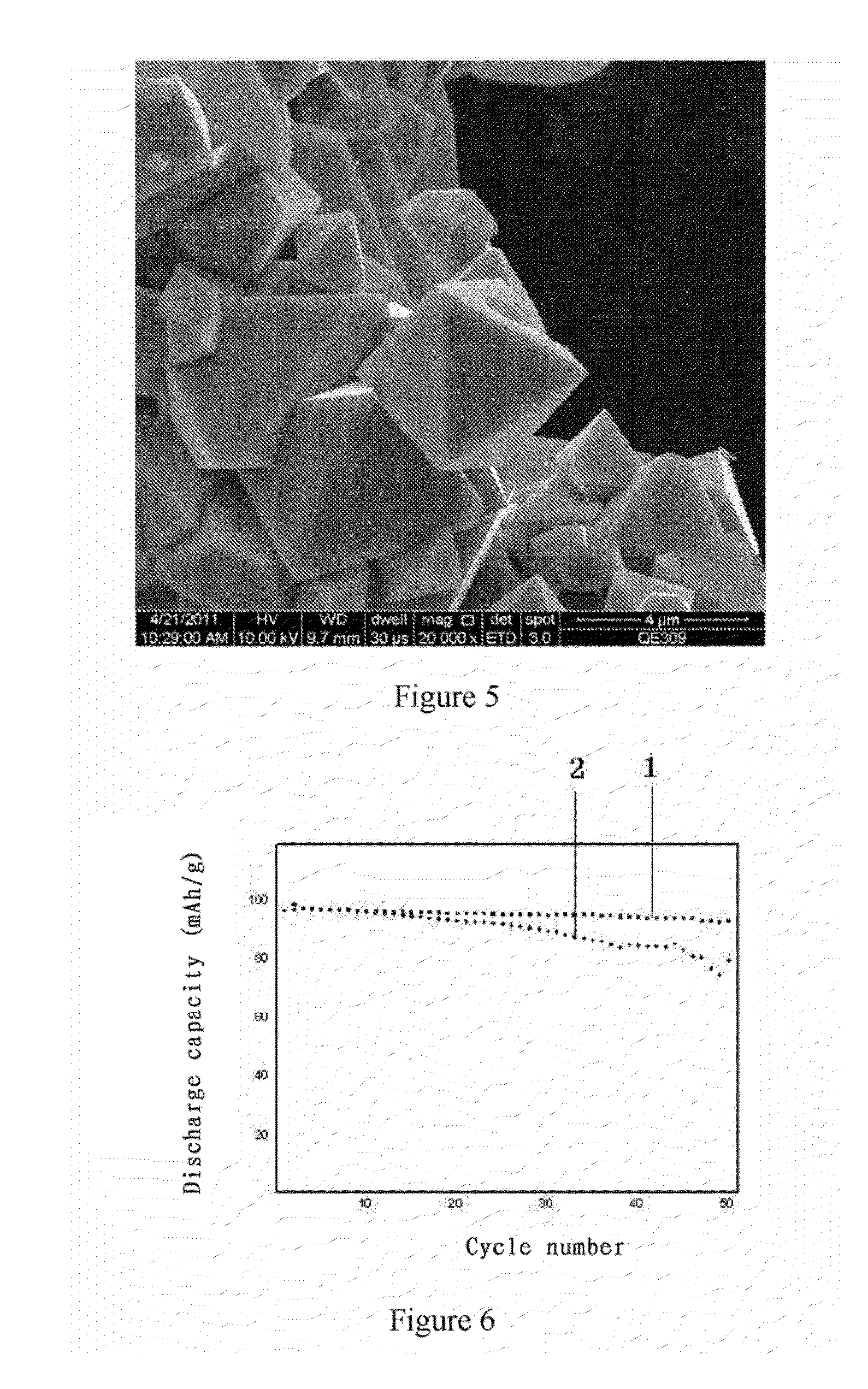

ActiveUS20140170492A1Good filling capability and high-temperature cycling performanceHigh-temperature performanceSilver accumulatorsAlkaline accumulator electrodesLithium-ion batteryMaterials science

Provided is a positive electrode material for a lithium battery with an atomic ratio expressed by the formula (I) Lia(MxMn2-x)(O4-yZy) for 0.8≦a≦1.2, 0≦x≦1 and 0≦y≦1 in which M is one or more of Li, Na, K, Ca, Mg, Al, Ti, Sc, Ge, V, Cr, Zr, Co, Ni, Zn, Cu, La, Ce, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, Pb and Si and Z is one or more of OH, halogens, N, P, S and O, and the primary particles of the positive electrode material have a spheroidal topography. The adjacent (111) family planes of the primary particles are connected by curved surfaces without obvious edges. A preparing method of a positive electrode material for a lithium battery and a lithium battery are also provided. The positive electrode material of the present invention provides a good high-temperature cycling performance and filling capability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Semiconductor structure and method for manufacturing the same

ActiveUS8642471B2Reduce contact resistanceReduce exposureSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceSemiconductor structure

The present invention provides a method for manufacturing a semiconductor structure. The method can effectively reduce the contact resistance between source / drain regions and a contact layer by forming two contact layers of different thickness on the surfaces of the source / drain regions. Further, the present invention provides a semiconductor structure, which has reduced the contact resistance.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

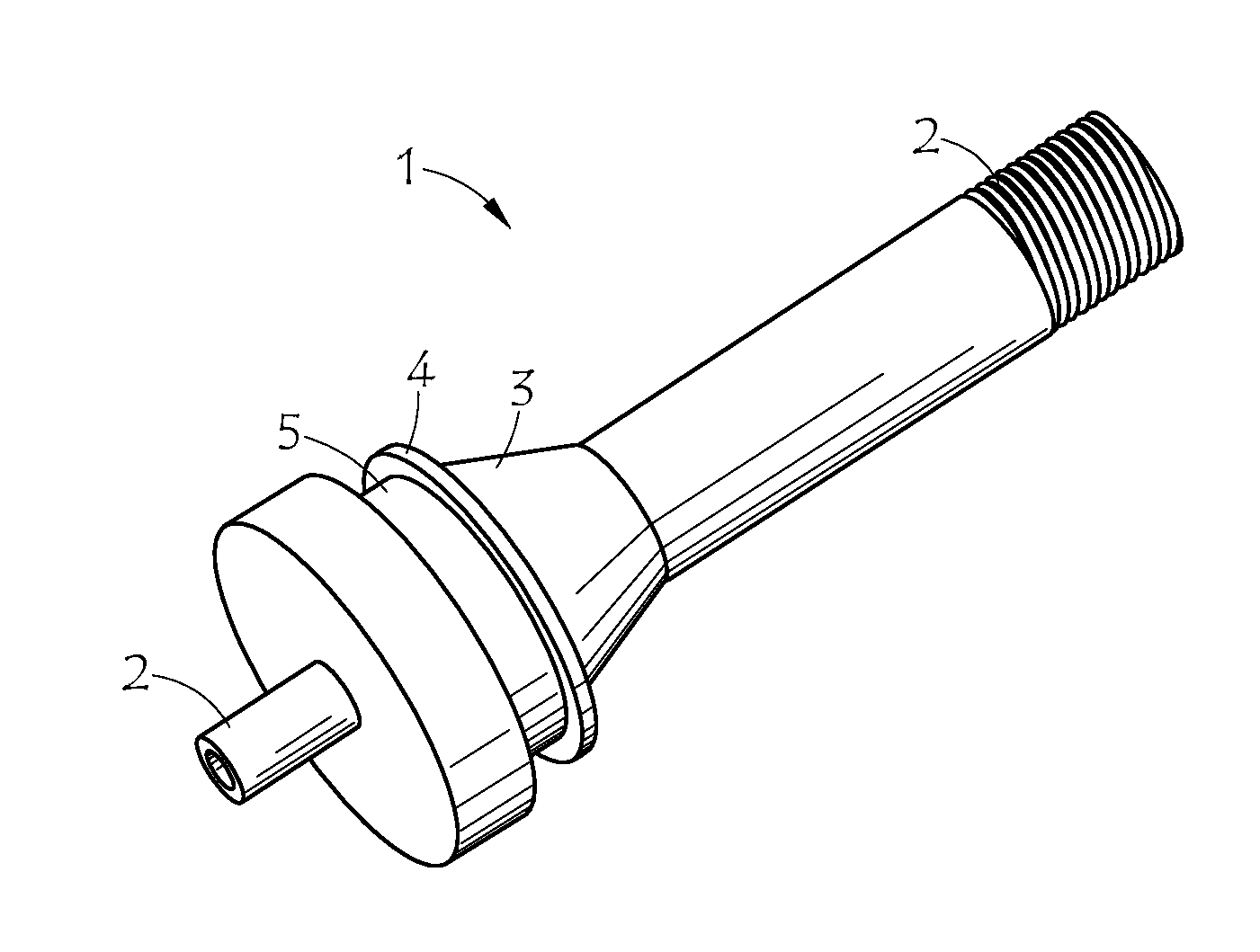

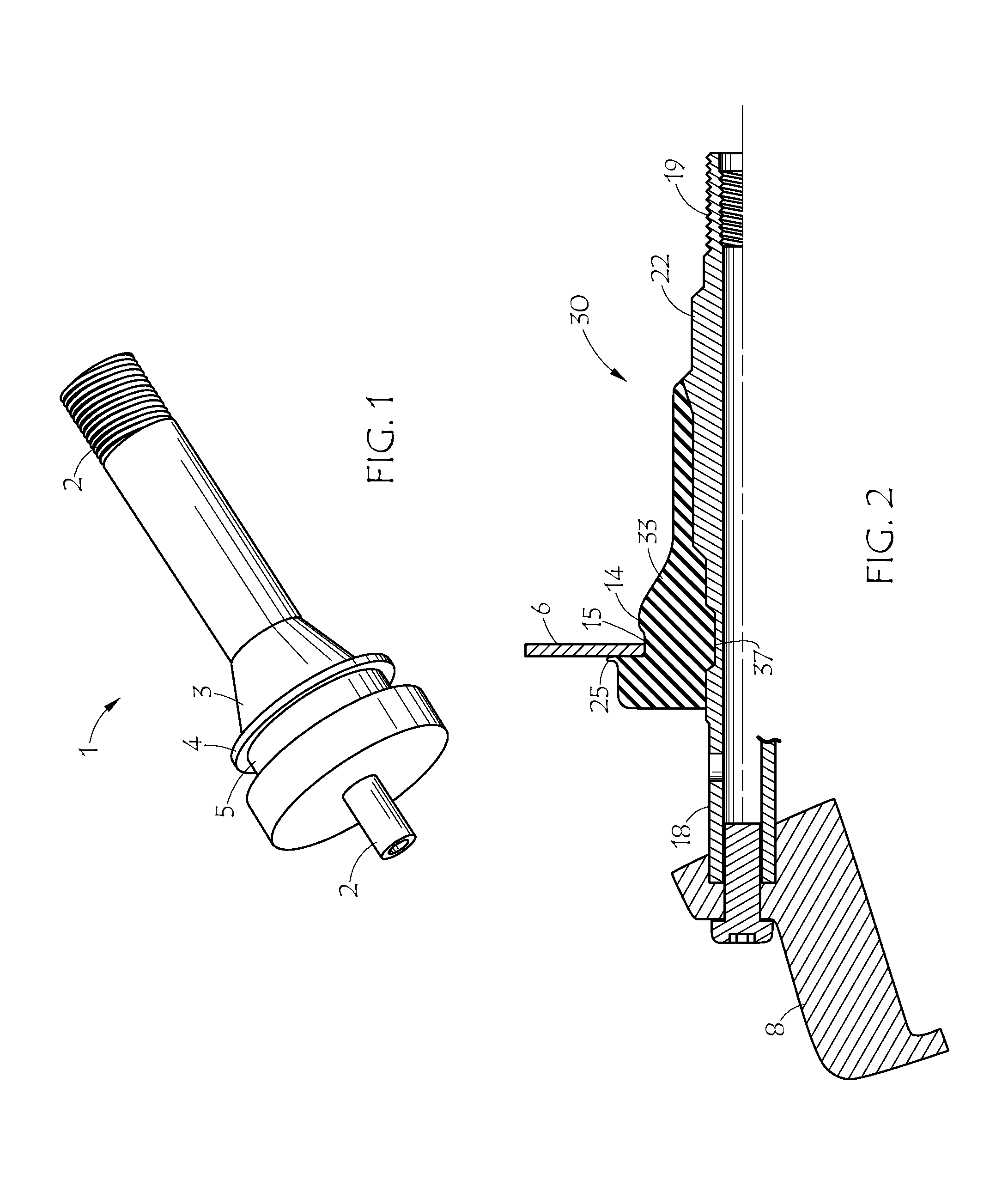

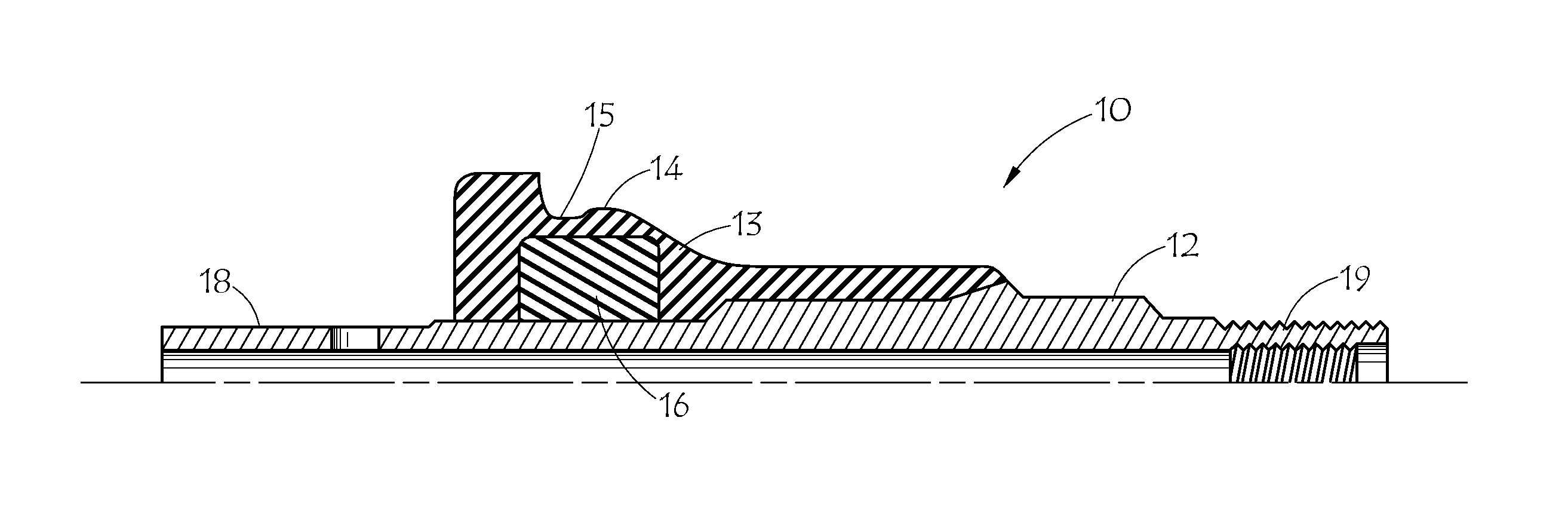

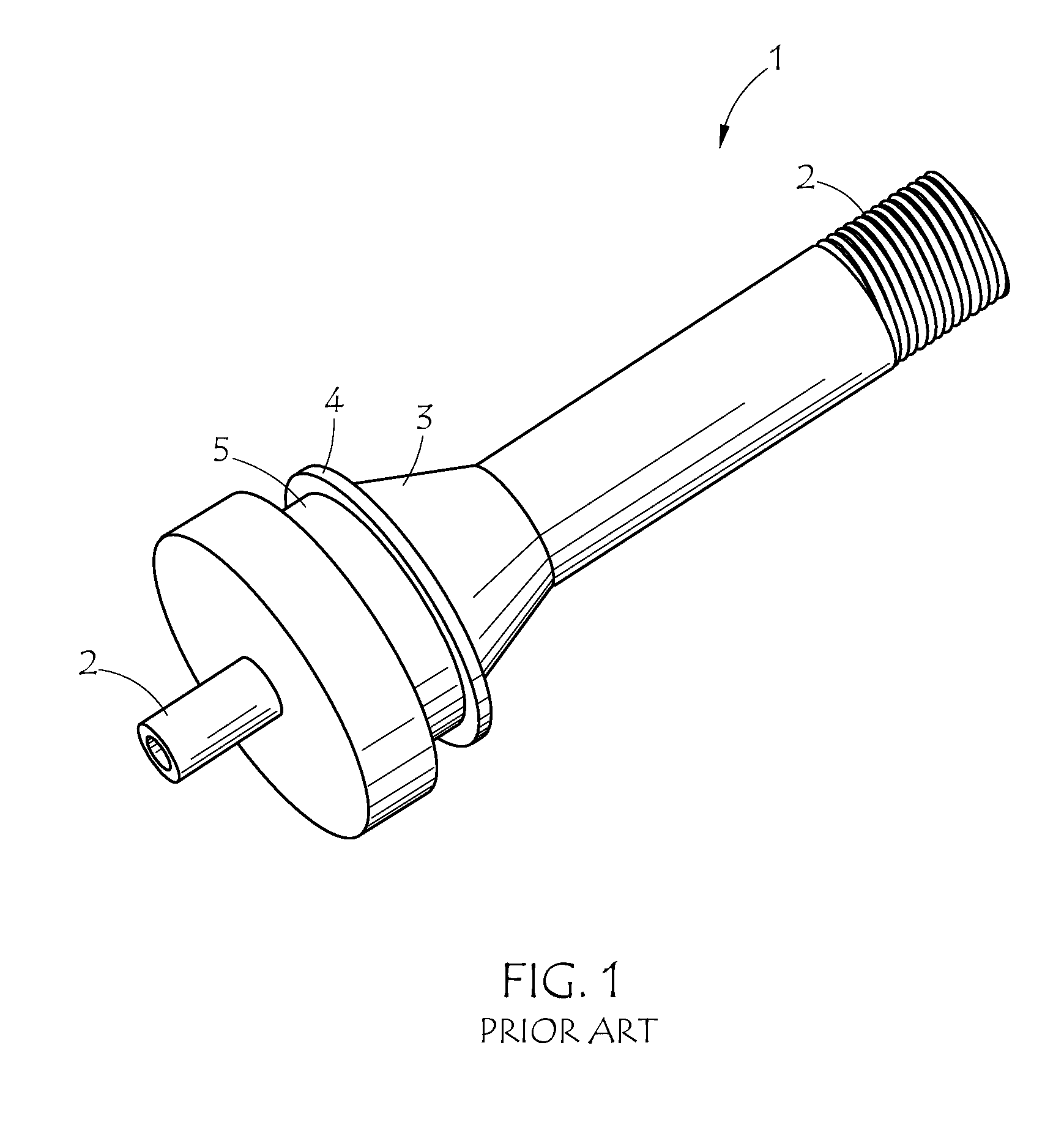

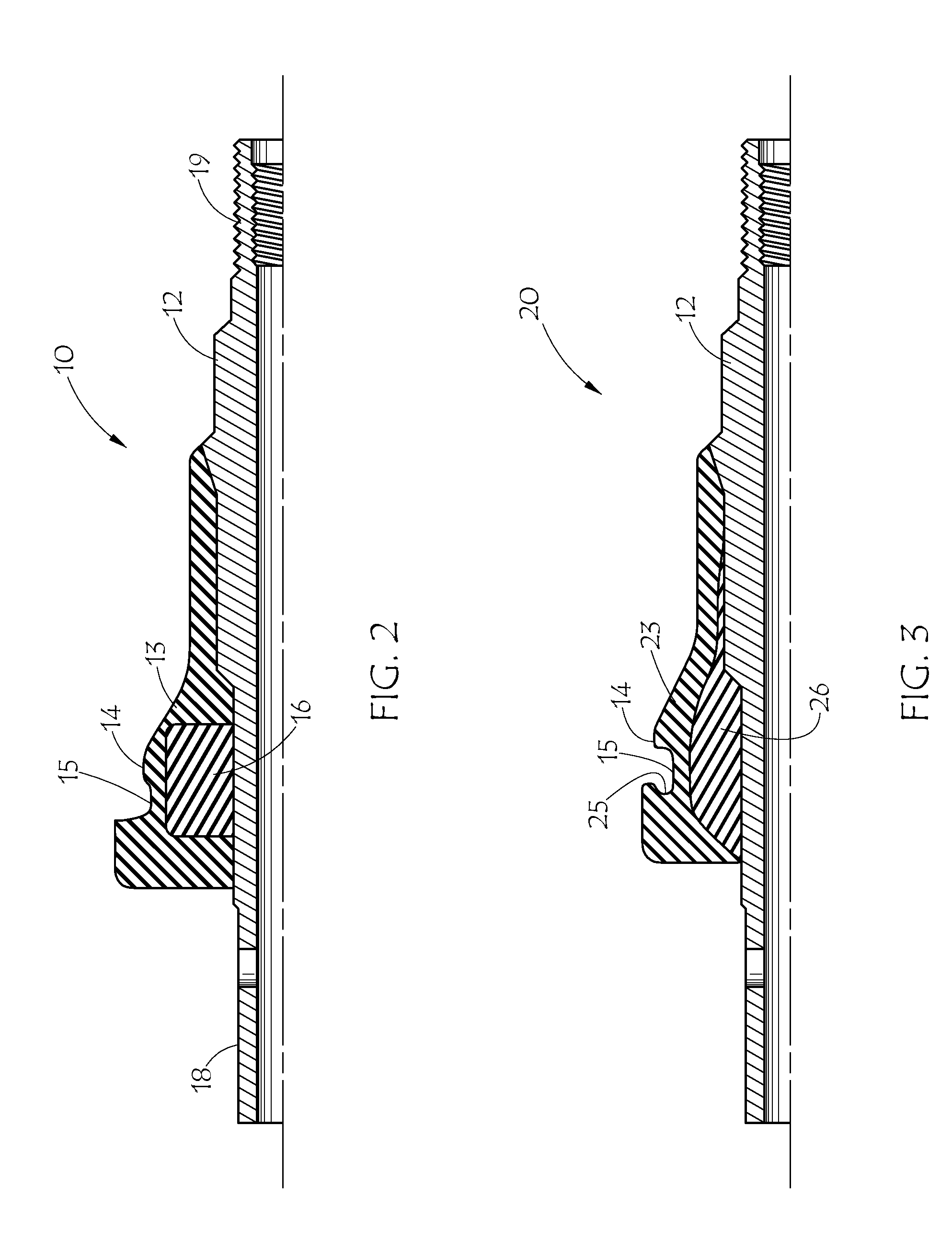

Rubber composition for tire valve and tire valve

InactiveUS20130333817A1Improve high speed and high temperature performanceIncrease speedLamination ancillary operationsSpecial tyresCarbon blackMechanical engineering

A tire valve for snap-in mounting in a valve hole in a wheel rim, having a resilient member surrounding and bonded to at least a portion of the valve body, wherein the resilient member is a vulcanized rubber composition comprising ethylene alpha-olefin elastomer, carbon black, high-density inert filler, and an efficient vulcanization cure system.

Owner:THE GATES CORP

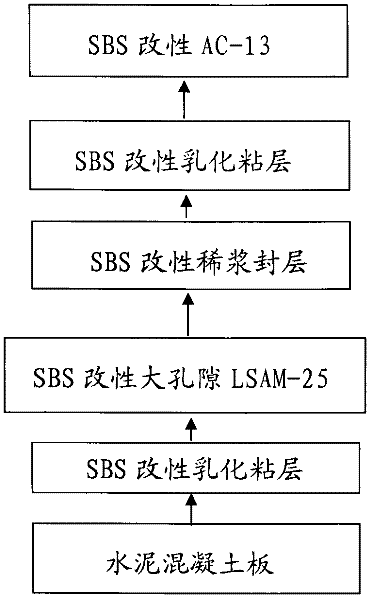

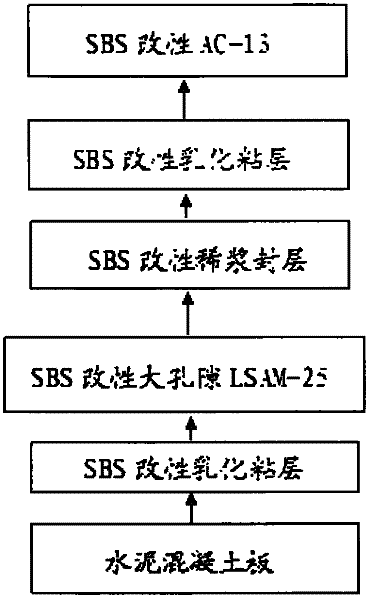

Thin-layer asphalt pavement overlaid with old cement concrete suitable for heavy-duty coal transportation traffic

The invention relates to a thin-layer asphalt pavement overlaid with old cement concrete suitable for heavy-duty coal transportation. The cement concrete slab is provided with a rubber mastic high elastic stress absorption belt and a rubber mastic high elastic stress absorption belt. SBS modified macroporous LSAM-25 with a thickness of 6-8 mm is arranged on the top, and a SBS modified slurry seal layer with a thickness of 1 cm is arranged on the top of the SBS modified macroporous LSAM-25, and the top of the SBS modified slurry seal layer SBS modified AC-13 with a thickness of 4cm is set, and SBS is passed between SBS modified AC-13 and SBS modified slurry seal layer, SBS modified macroporous LSAM-25 and rubber mastic high elastic stress absorption belt The porosity of the modified emulsified adhesive layer connected with SBS modified macroporous LSAM-25 ranges from 18% to 22%. The pavement has excellent bearing capacity and high temperature stability, good anti-reflective cracking effect, long service life of the pavement, and can meet the needs of heavy-duty traffic such as coal transportation.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Hot melt adhesive composition for bonding a locator pin to glass

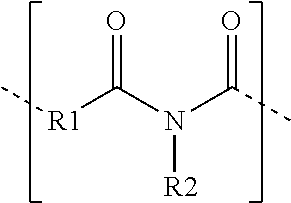

InactiveUS20010025079A1High temperature performanceEquipment employPolyureas/polyurethane adhesivesSpecial tyresChemistryTan delta

The present invention provides an adhesive composition comprising a uniform mixture of components, the components comprising a first and a second thermoplastic polyurethane, the first thermoplastic polyurethane being a thermoplastic polyurethane of which the shear tan delta versus temperature curve approaches infinity at a temperature above 150° C. and that has a glass transition temperature of not more than 10° C., the second thermoplastic polyurethane having a softening point of not more than 80° C. and the adhesive composition being solid at a temperature of 20° C. and being capable of bonding to glass or a ceramic frit layer provided on glass at a temperature between 100° C. and 160° C. The present invention further provides a method for bonding a locator pin to a window glass using the adhesive composition and further a locator pin having the adhesive composition.

Owner:3M INNOVATIVE PROPERTIES CO

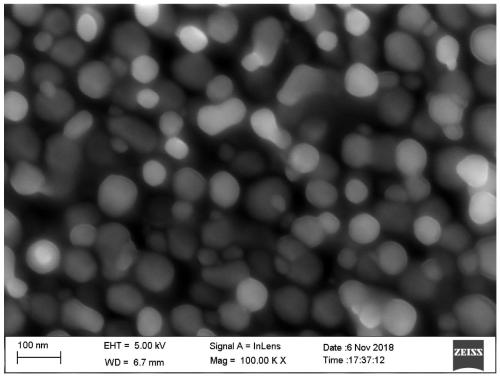

Soft magnetic powder

ActiveUS20100038580A1Large specific resistanceLow core lossMetal-working apparatusInorganic material magnetismVolumetric Mass DensityMaterials science

A powder magnetic core is provided for operating at high frequencies that is obtained by pressure forming an iron-based magnetic powder covered with an insulation film, which has a specific resistance less than 1000, preferably less than 2000, and most preferably less than 3000 μm, and a saturation magnetic flux density B above 1.5, preferably above 1.7, and most preferably above 1.9 (T). A method for the preparation of such cores as well as a powder which is suitable for the preparation also are provided.

Owner:HOGANAS AB

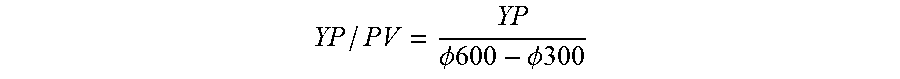

Copolymer of dimer acid-organic amine and shear strength improving agent of water in oil emulsion drilling fluid and drilling fluid

The present subject matter relates to a dimer acid-organic amine copolymer, comprising structural units from a dimer acid, structural units from an alkyl amine, and structural units from an aromatic amine, wherein, the dimer acid is a dimer of oleic acid and linoleic acid, the alkyl amine is one or more of C10-C20 alkyl primary amines, and the aromatic amine is one or more of aniline and aniline with one or more sites on the benzene ring substituted by C1-C3 alkyl. The present subject matter provides a shearing strength improving agent for water in oil emulsion drilling fluids and a drilling fluid containing the shearing strength improving agent. The shearing strength improving agent provided in the present invention can be used to significantly improve the yield point, ratio of yield point to plastic viscosity, gel strength of water in oil emulsion drilling fluids even in a small concentration, and is applicable to water in oil emulsion drilling fluids that contain or don't contain organic clay.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Deformation high-temperature alloy capable of forming composite corrosion-resistant layer and preparation process of deformation high-temperature alloy

The invention discloses a deformation high-temperature alloy capable of forming a composite corrosion-resistant layer and a preparation process of the deformation high-temperature alloy. The deformation high-temperature alloy is prepared from the components in percentage by mass: 16-19% of Cr, 10-15% of Co, 0.5-1.5% of Ti, 3.5-4.5% of Al, less than or equal to 0.5% of W, less than or equal to 5.0%of Mo, less than or equal to 0.5% of Si, less than or equal to 0.5% of Mn, 0.5-1.0% of Nb, 0.04-0.07% of C and the balance of Ni. The preparation process comprises the steps of homogenization treatment after smelting; hot rolling; and final heat treatment. The room temperature and 850 DEG C tensile yield strengths of the alloy are higher than 820 MPa and 520 MPa correspondingly, meanwhile, the deformation high-temperature alloy has excellent processing performance and tissue stability, no harmful phase is separated out during heat exposure of 850 DEG C, and the room temperature and 850 DEG Ctensile yield strengths after heat exposure for 1350 h under the temperature are higher than 630 MPa and 370 MPa correspondingly.

Owner:CHINA HUANENG GRP CO LTD +1

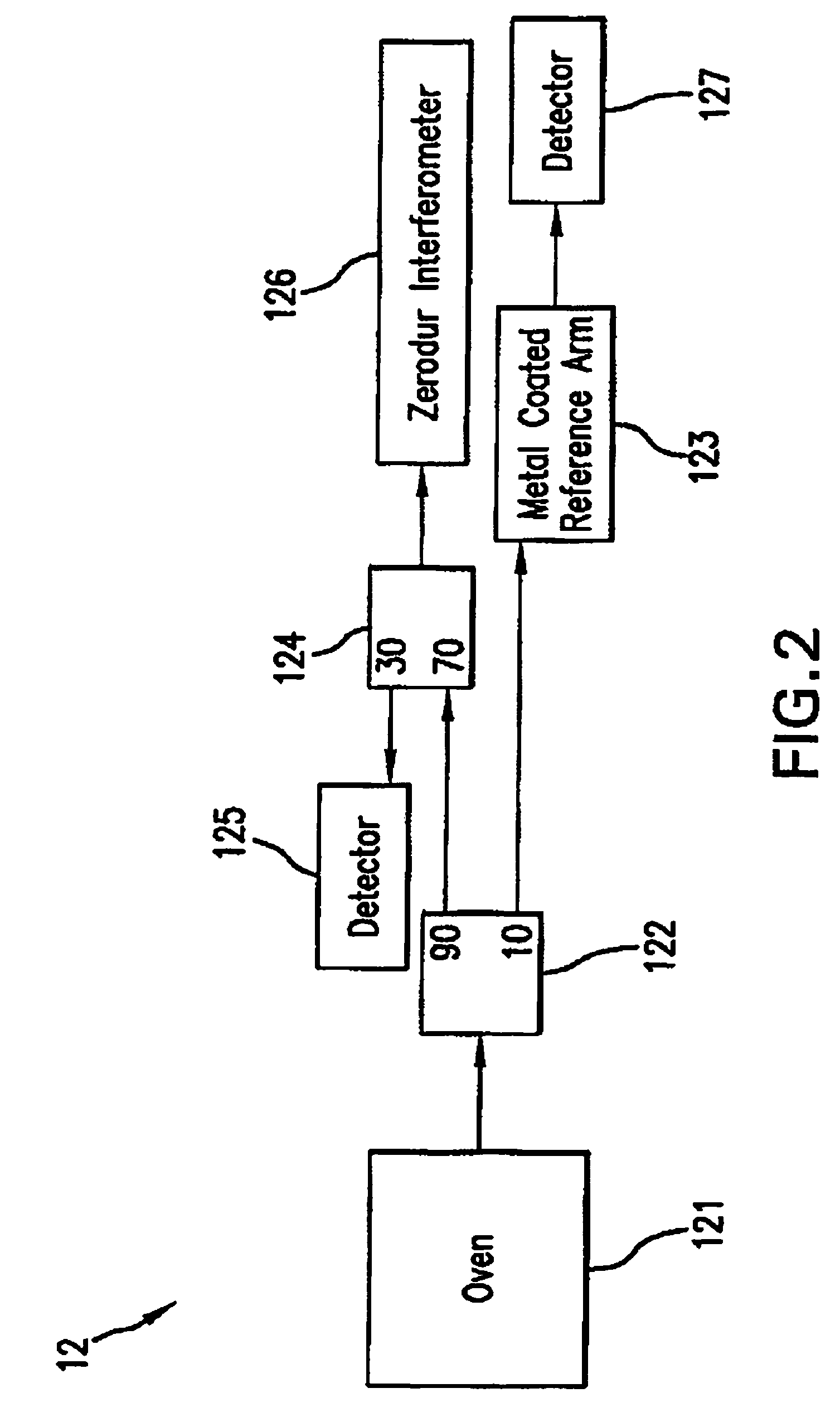

Precision length standard for coherent laser radar

InactiveUS20060280415A1Limit desirabilityCompromise long term reliabilityWave based measurement systemsOptical fibre with multilayer core/claddingPhysicsEnvironmental effect

This disclosure presents a version of a coherent laser radar system that is immune to environmental effects on Mach-Zehnder-configured interferometers and reference length standards comprising such systems. The present disclosure also describes methods and materials which alleviate interferometer drift due to vapor absorption using a polyimide coated polarization maintaining fiber to reduce the change in the length of a reference arm.

Owner:METRIS USA

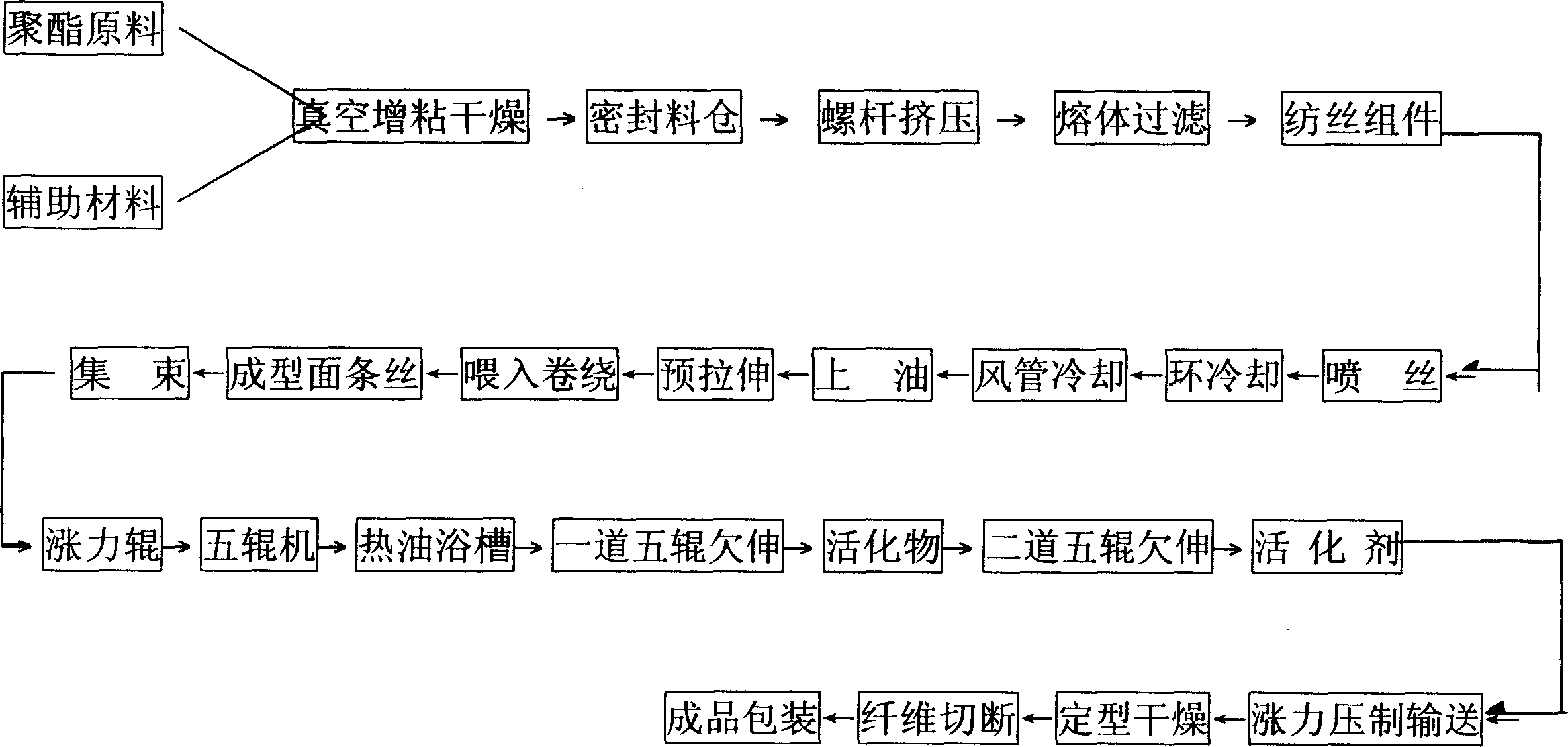

Production process of engineering fibre for polyester road

InactiveCN1467315ATangledExtend your lifeBuilding insulationsMonocomponent polyesters artificial filamentPolyesterFiber

A process for preparing the polyester fibres used for road engineering includes such steps as pretreating the polyester as raw material, fusing and extruding by screw extruder, jet spinning, cooling, prestretching, winding, collecting to 6-7 hundred thousands dens, tension mixing, stretching in oil bath, stretching, adding hot activator, stretching, adding hot activator, overheat stretching, extension, compression, drying and cutting short.

Owner:陈成泗 +2

Method for connecting aluminum matrix composite with titanium alloy

InactiveCN103862161APerformance does not deteriorateImprove performanceNon-electric welding apparatusTitanium alloyCeramic matrix composite

The invention provides a method for connecting an aluminum matrix composite with a titanium alloy and relates to method for connecting a composite with an alloy. The method is used for solving the problems in the prior art that the advantages of high temperature and high-temperature use performance are completely lost, no liquid phase is generated between powder, the reaction is weaker, meanwhile a lot of unreacted particles remain in a joint, and the performance is lower. The method comprises the following steps: 1, preparing mixed powder; 2, preparing a middle laminated blank; 3, connecting, thereby finishing the connection of the aluminum matrix composite and the titanium alloy. According to the method, a liquid phase is generated and Al-Ti exothermic reaction is induced, so that connection can be realized at a low temperature, powder of a middle layer does not react fully, no residual particle exists, a joint is uniform in tissue and stable in performance and has certain high-temperature performance and good quality. The invention provides the method for connecting the aluminum matrix composite with the titanium alloy.

Owner:HARBIN INST OF TECH

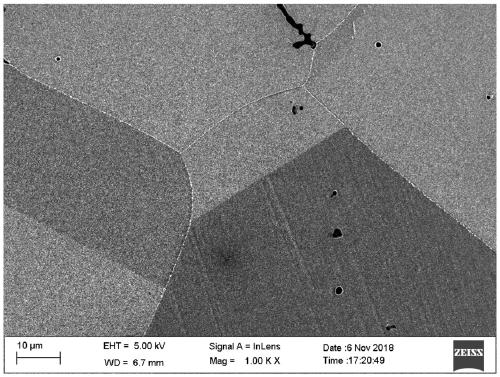

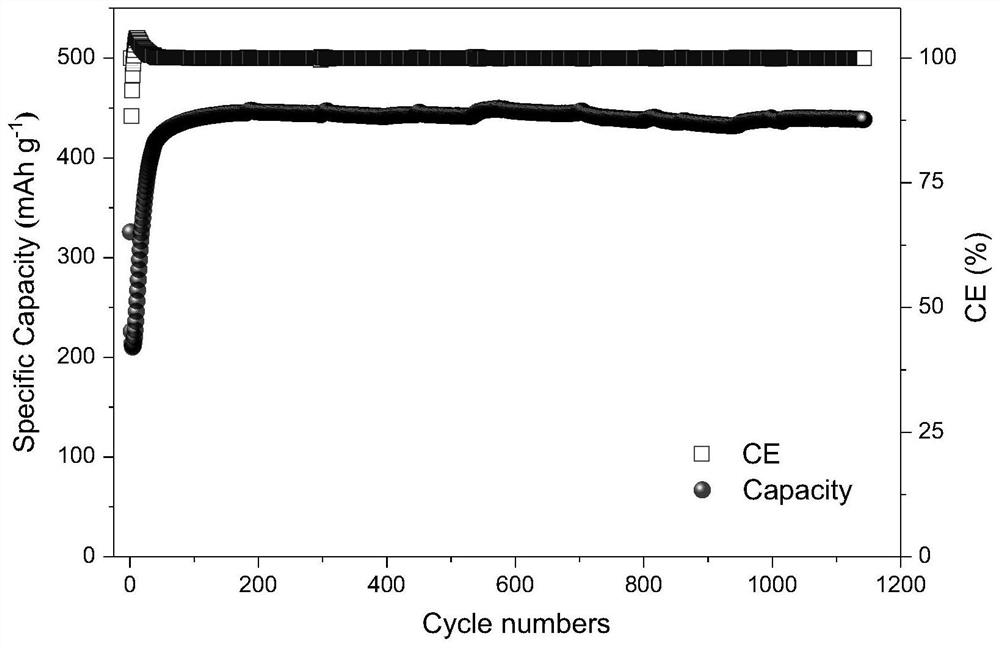

Metal oxide and method for preparing the same

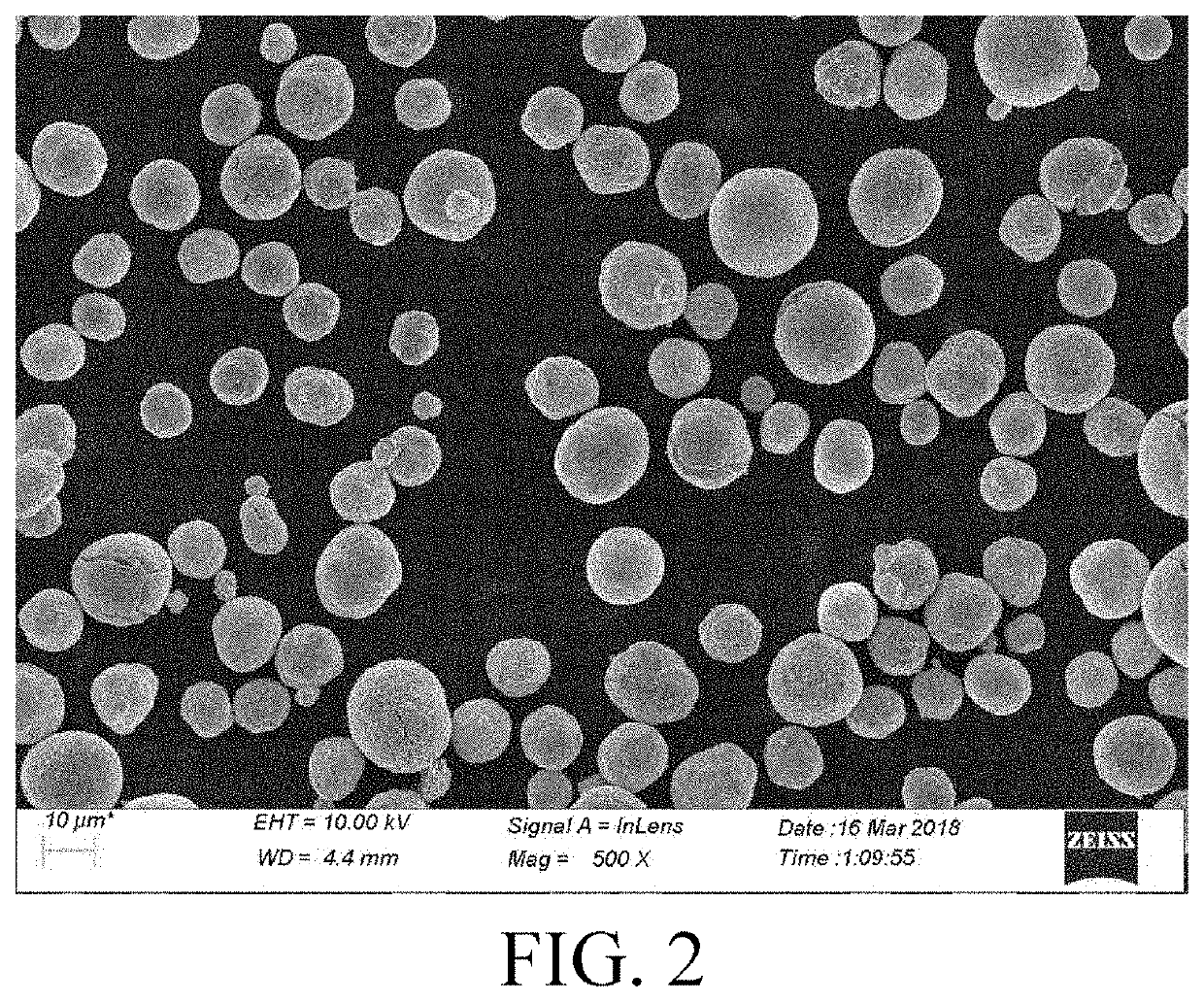

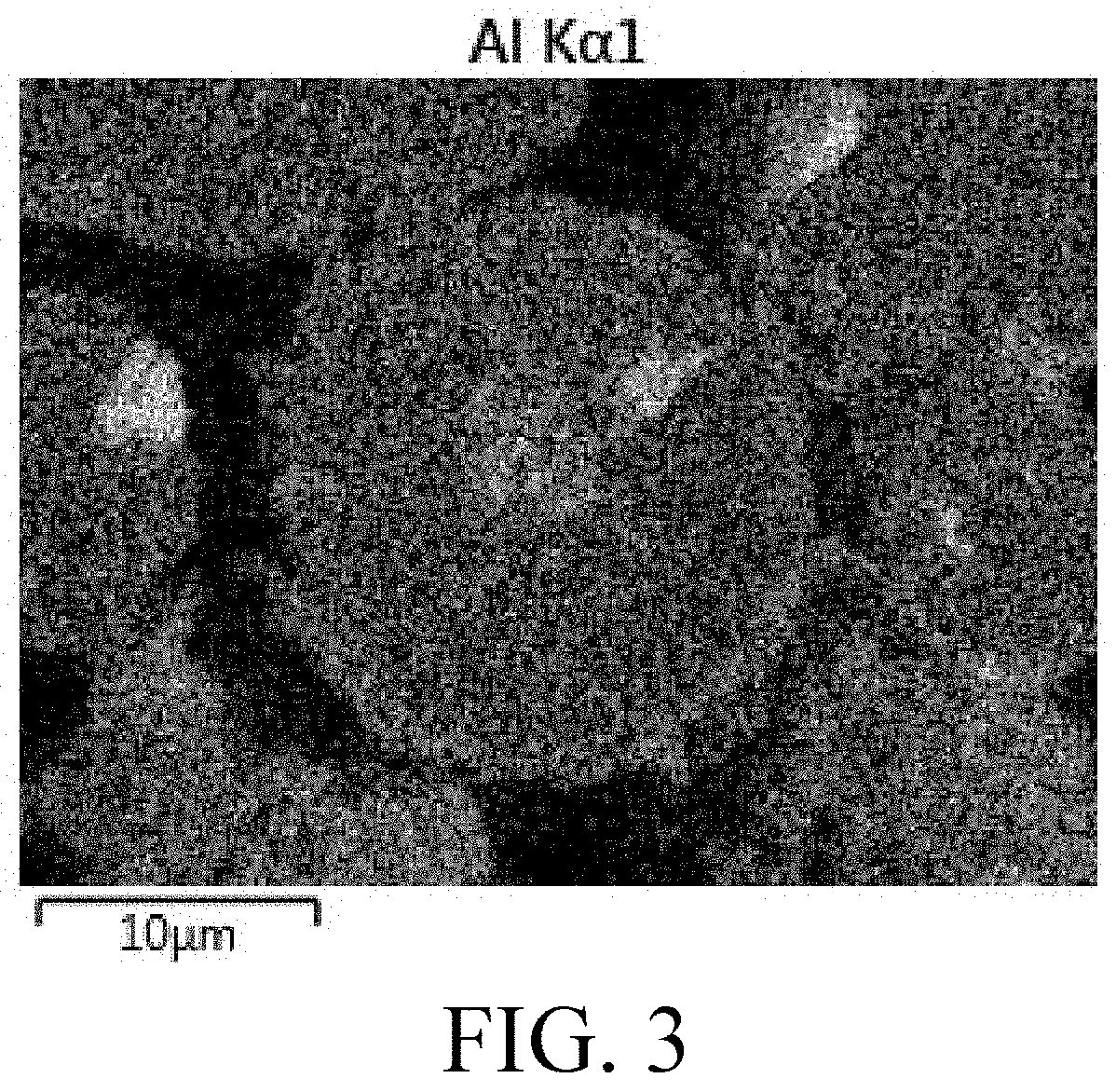

ActiveUS20200035991A1Improve structural stabilityHigh-temperature performanceSecondary cellsPositive electrodesOptical spectrometerScanning electron microscope

This application relates to a metal oxide and a method for preparing the same. Specifically, Co3O4 is selected as a precursor of lithium cobalt oxide, and one or more metal elements M are doped in the particles of Co3O4 to obtain a doped lithium cobalt oxide precursor Co3−xMxO4, where 0<x≤0.3. The difference value, measured by a spectrometer of a scanning electron microscope, of the weight percentage of one of M in two identical area regions is E, wherein 0<E≤1% (wt. %). A lithium ion battery with lithium cobalt oxide prepared from the precursor as a cathode material shows great cycle stability, high-temperature energy storage performance and safety performance in a high-voltage (equal to or greater than 4.45 V) charging and discharging environment.

Owner:NINGDE AMPEREX TECH

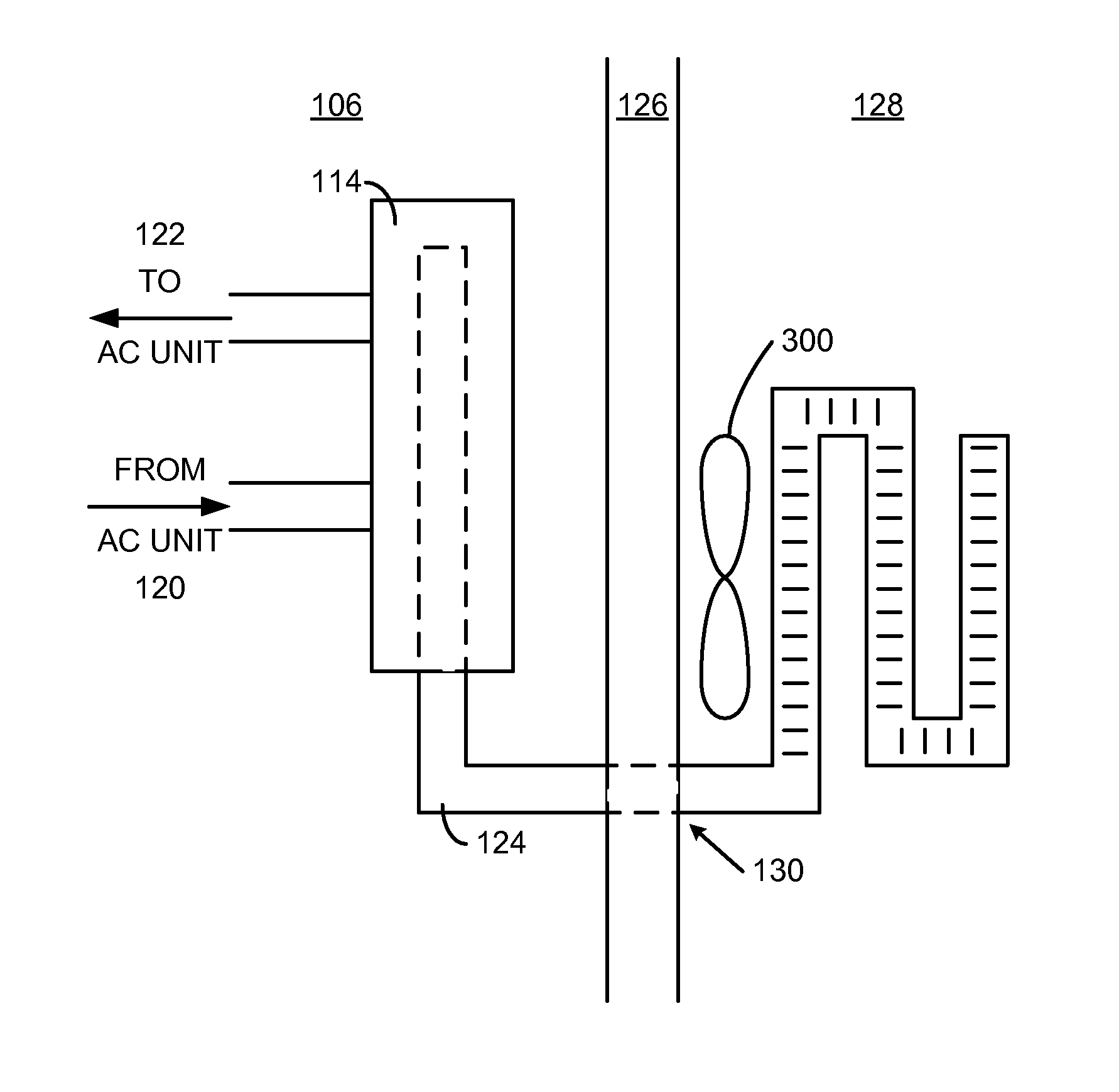

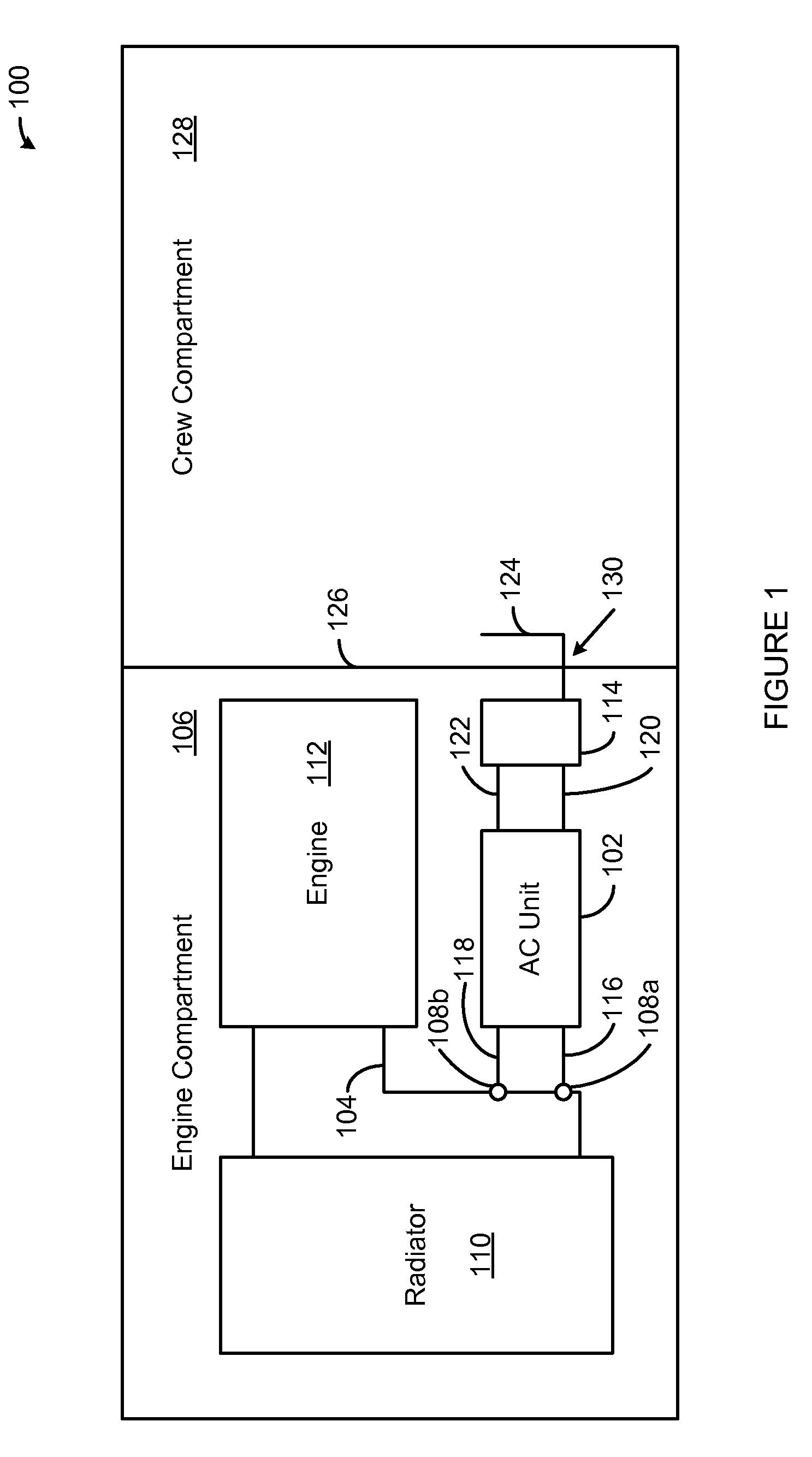

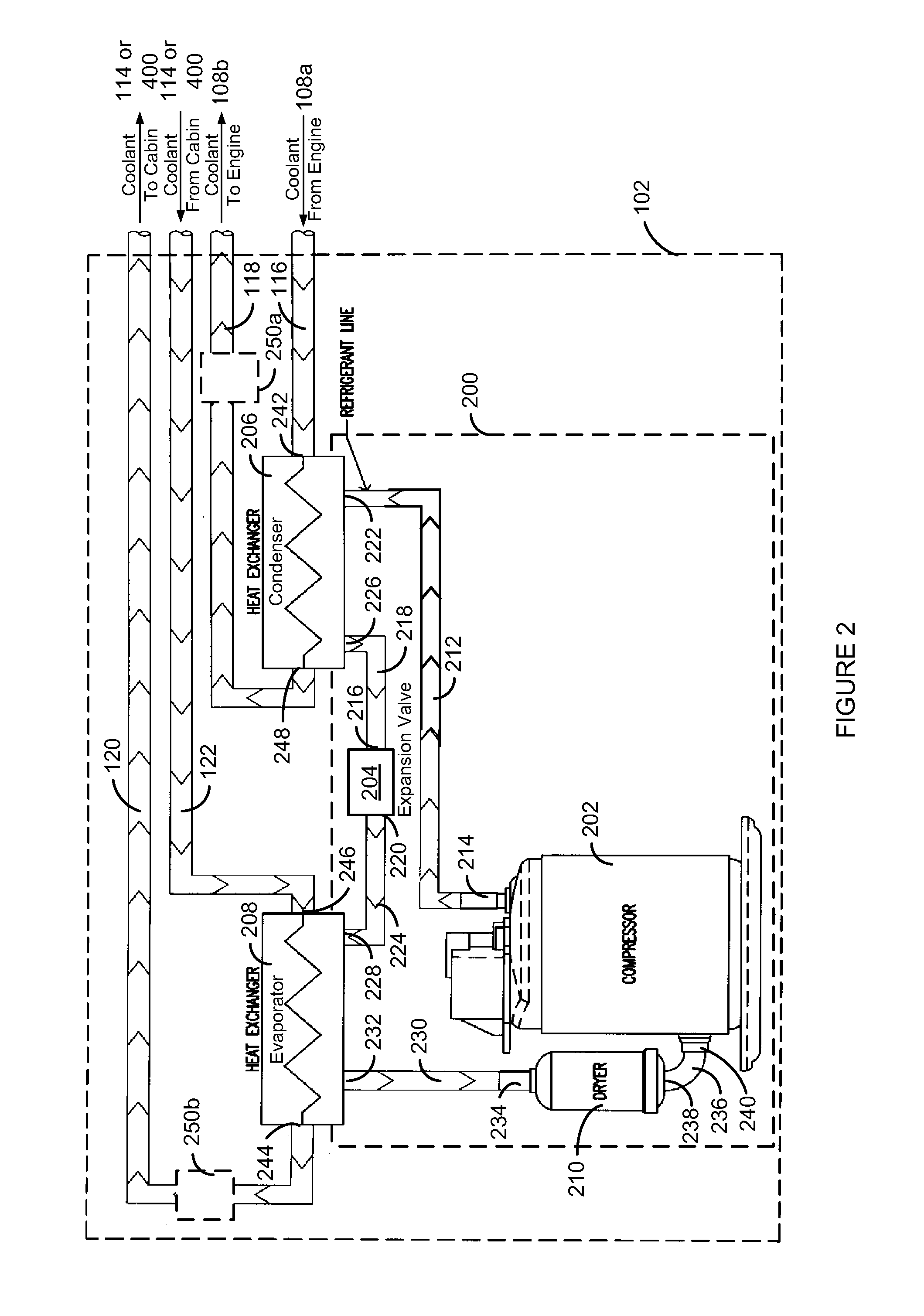

Vehicle air conditioner

InactiveUS8544292B2Easy to installEasy to removeAir-treating devicesRailway heating/coolingEngineeringRefrigerant

The present invention provides an air conditioner for a vehicle that includes a closed refrigeration loop. The closed refrigeration loop includes a compressor, a refrigerant-to-coolant heat exchanger, a coolant-to-refrigerant heat exchanger and a refrigerant dryer in series fluid connection with one another. An engine coolant outlet connector is connected to the coolant-to-refrigerant exchanger. A compartment inlet connector connected to the coolant-to-refrigerant heat exchanger. A compartment outlet connector connected to the refrigerant-to-coolant heat exchanger. An engine coolant inlet connector connected to the refrigerant-to-coolant heat exchanger.

Owner:OMNITHERM +1

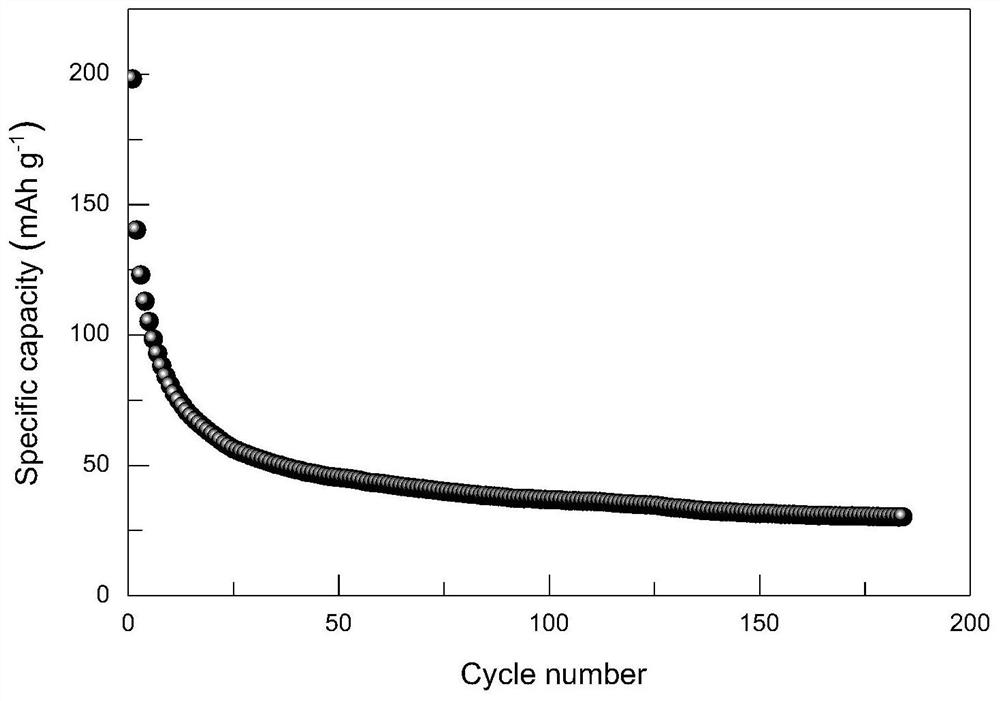

Preparation method of hydrogel electrolyte for aqueous zinc ion energy storage battery

PendingCN113782844AMild reaction conditionsEasy to operateFinal product manufactureSecondary cellsPolyacrylamideElectrochemistry

The invention discloses a preparation method of a hydrogel electrolyte for an aqueous zinc ion energy storage battery, which comprises the steps of S1, adding polyacrylamide into a zinc salt aqueous solution, and stirring until the polyacrylamide is dissolved to obtain a solution A; S2, sequentially adding a cross-linking agent and an initiator into the solution A, fully stirring, and heating and forming to obtain hydrogel B; and S3, soaking the hydrogel B in a zinc salt aqueous solution to obtain the hydrogel electrolyte. The zinc salt aqueous solution is a zinc perchlorate aqueous solution, a zinc sulfate aqueous solution or a mixture thereof. The zinc salt hydrogel electrolyte prepared by the preparation method disclosed by the invention not only has relatively good mechanical properties such as stretching and bending, and relatively good temperature-resistant use performance, but also has obviously improved electrochemical properties such as specific capacity and rapid charge and discharge, and can be applied to high-performance zinc ion energy storage batteries.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Thermoplastic elastomer compositions, methods for making the same, and articles made therefrom

Provided are thermoplastic elastomer compositions composed of a thermoplastic component, an elastomeric component, and at least one particulate composition. Particulate compositions are composed of a particulate material and a carrier medium. Exemplary particulate materials include minerals, mineral compounds, including mineral oxides, clays, carbon, nanotubes, and combinations thereof. Typical carrier mediums are one or more polar polymers, apolar polymers, one or more oils, poly α-olefins, or combinations thereof. The at least one particulate composition is dispersed within the thermoplastic component and / or the elastomeric component. Particulate compositions include clay grease compositions wherein a clay, e.g., an exfoliated clay, is utilized as a thickener.

Owner:CELANESE INT CORP

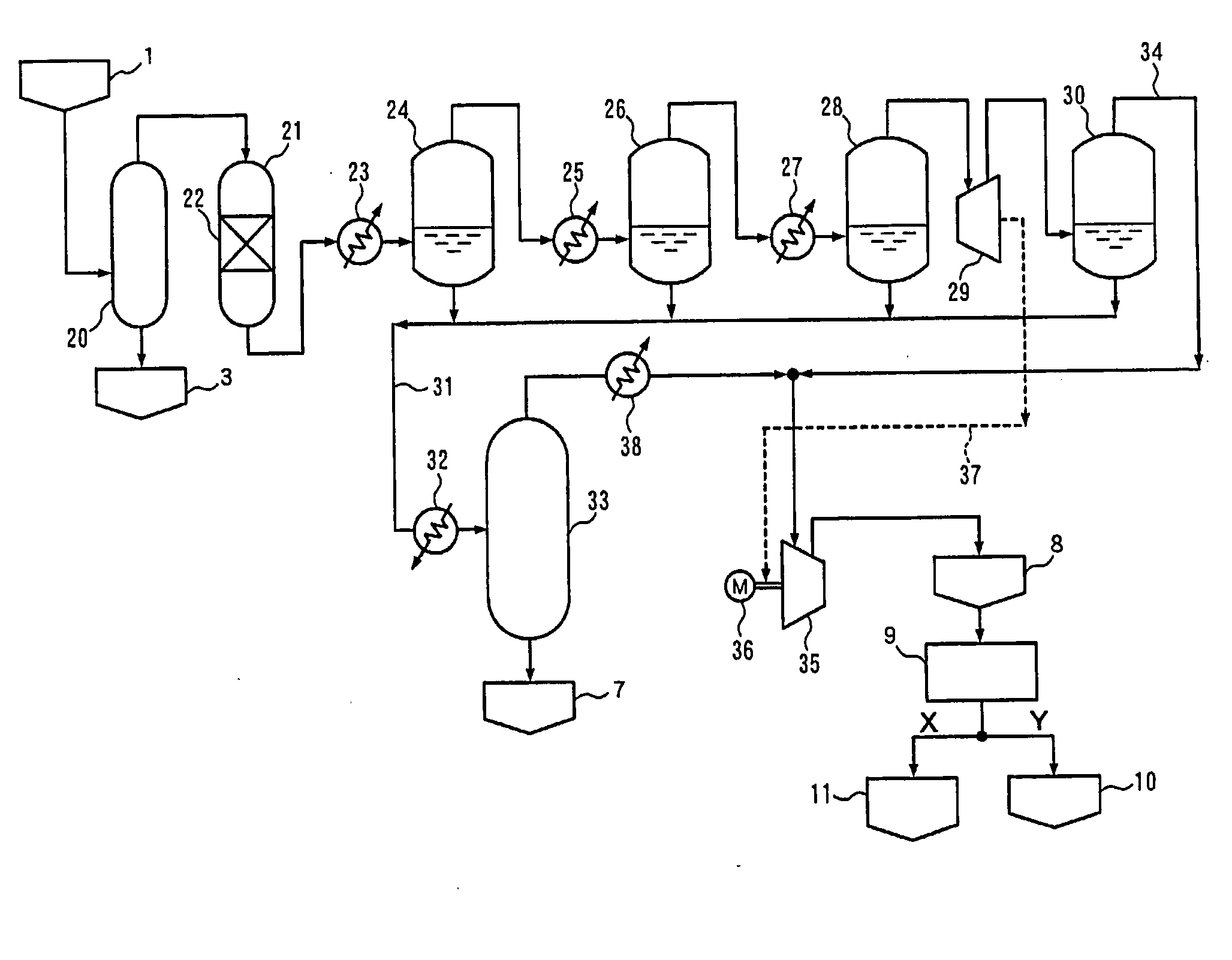

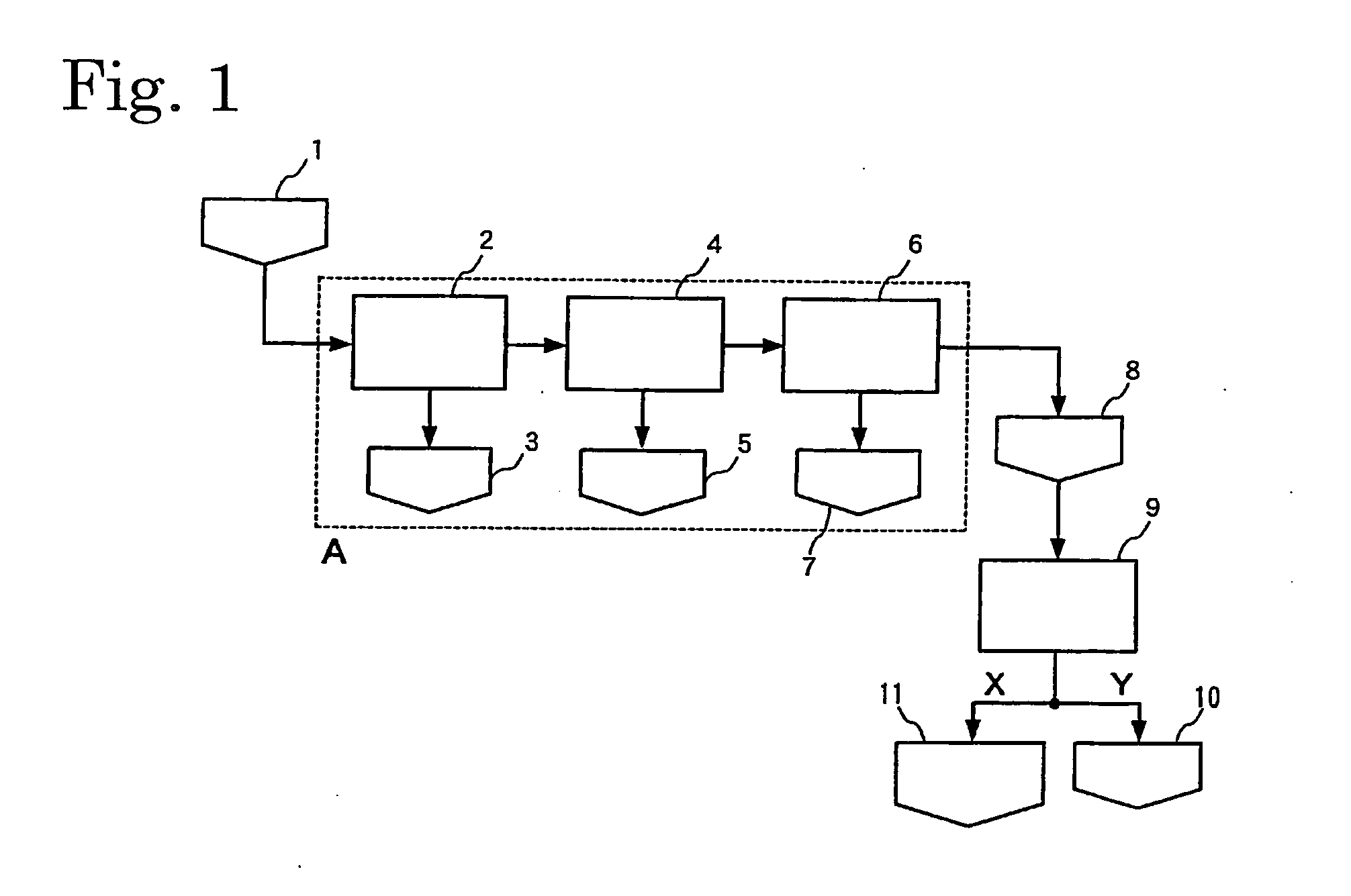

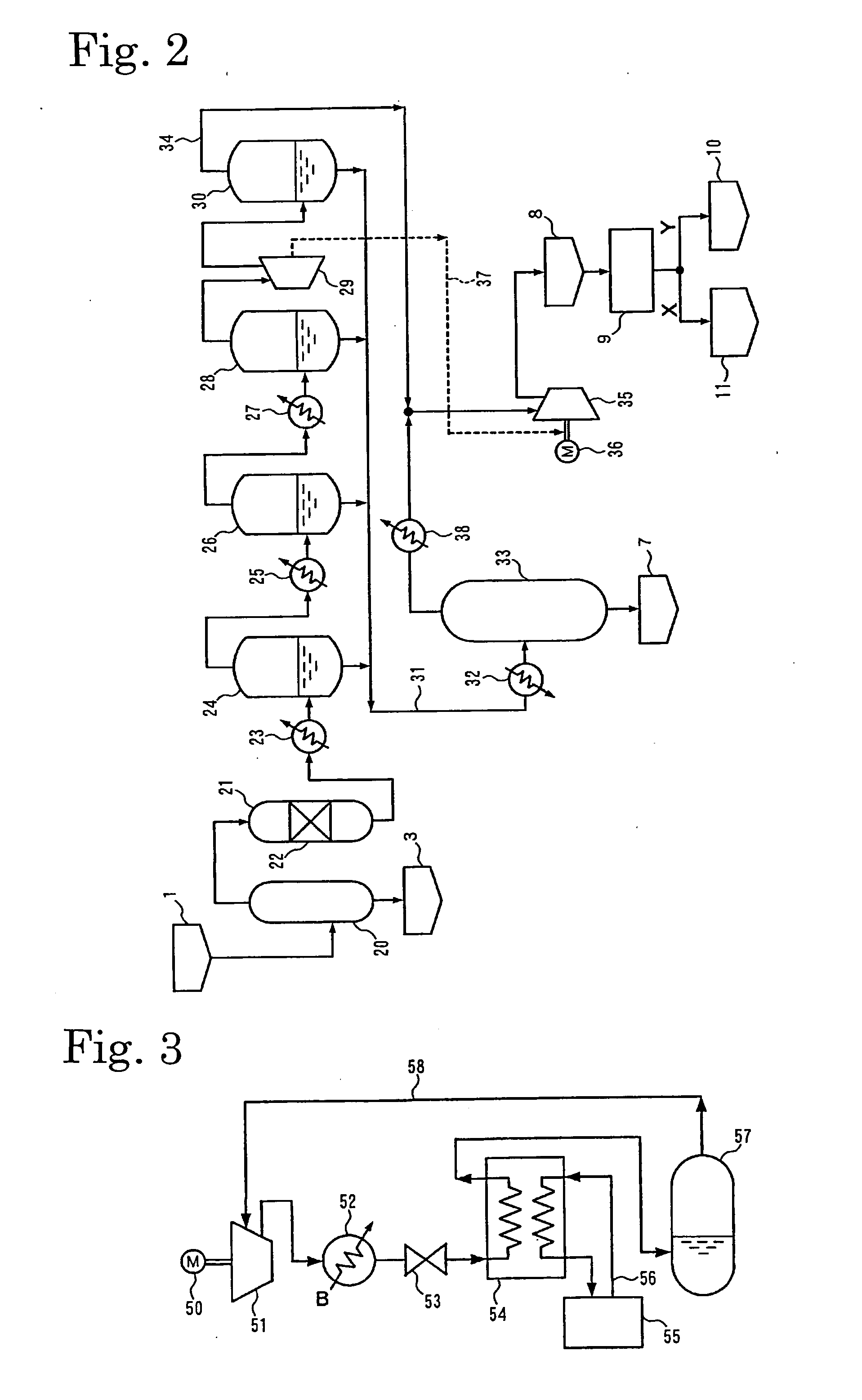

Method of producing gas hydrate

InactiveUS20100000254A1Low costHigh-temperature performanceSolidificationHydrogenProduct gasFuel gas

Provided is a method of producing gas hydrate at a low cost. An acid gas 3 is removed from a natural gas 1, and after dehydration 5 of accompanying water, part of heavy components which do not produce gas hydrate 10 are separated and removed under a relatively high temperature. Moreover, the rest of the heavy components are taken out in a gas hydrate production step 9 together with an excessive portion of light components not contributing to production of the gas hydrate 10, as a fuel gas 11 which is used as a cooling source or a power source for a cooling system in the gas hydrate production step 9.

Owner:MITSUI ENG & SHIPBUILD CO LTD

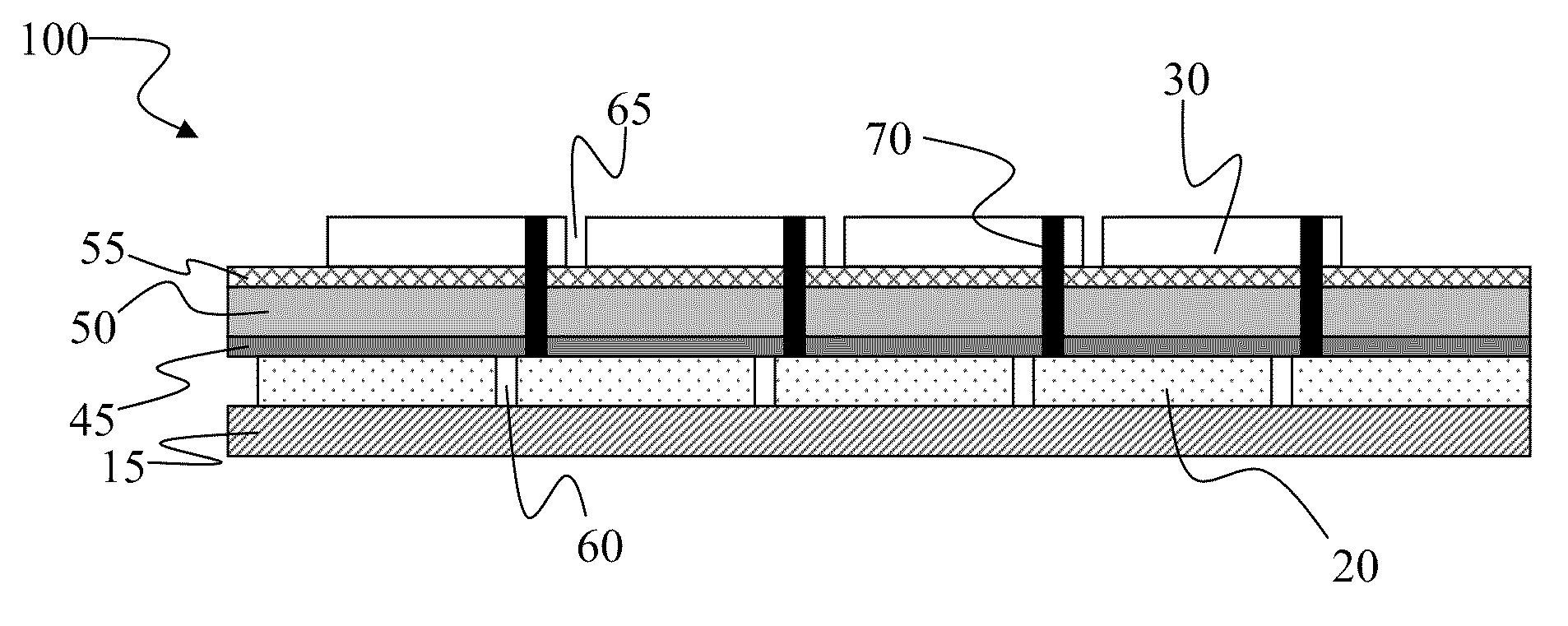

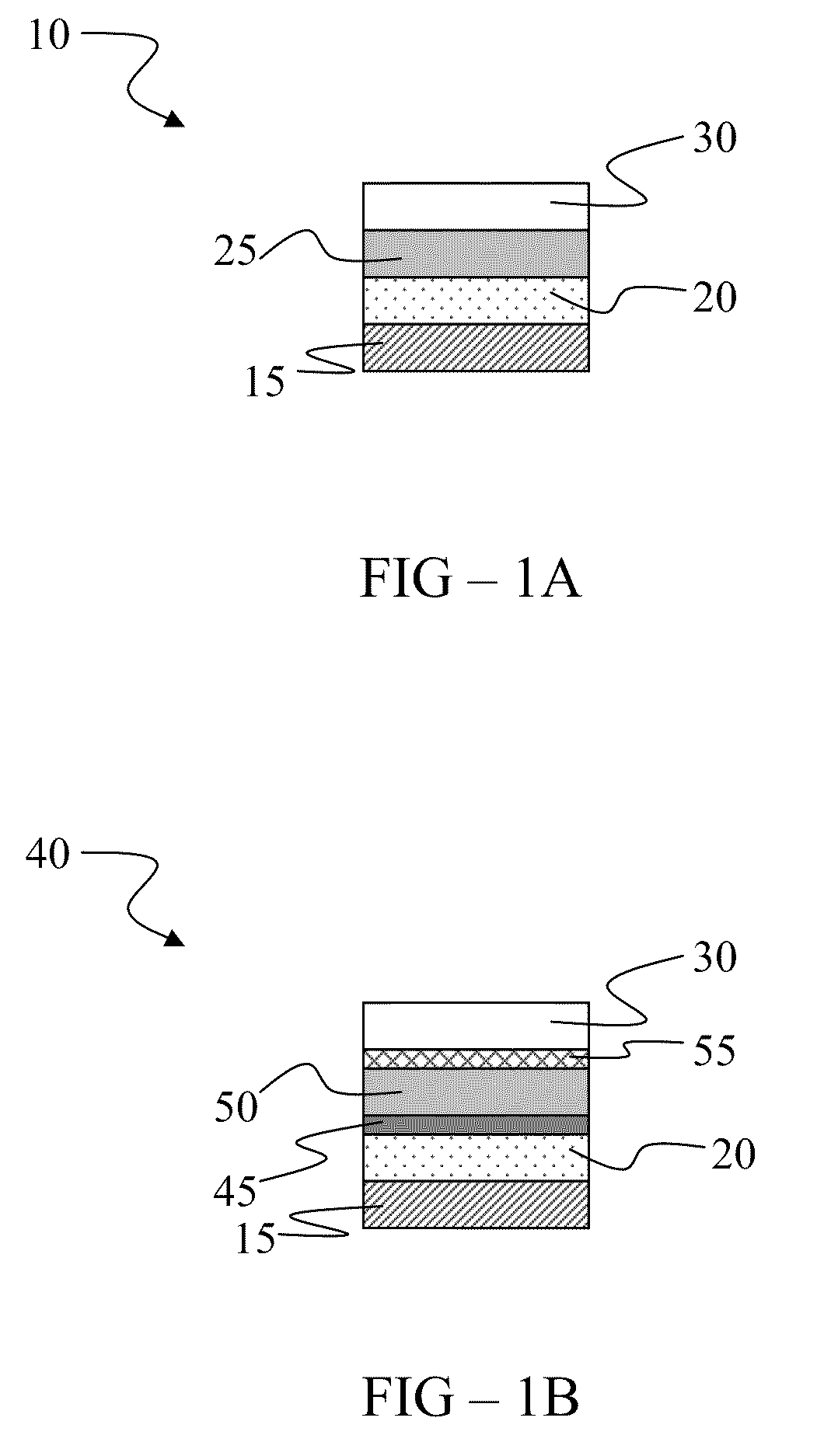

Monolithic Integration of Photovoltaic Cells

InactiveUS20110083724A1Improve conductivityHigh bonding strengthPV power plantsFinal product manufactureThermal stabilityMicrocrystalline silicon

A photovoltaic device and method of forming a photovoltaic device. The photovoltaic device includes a fluorine-containing photovoltaic material and a transparent electrode. Inclusion of fluorine in the photovoltaic material increases its thermal stability. The effect is particularly pronounced in photovoltaic materials based on disordered forms of silicon, including amorphous, nanocrystalline, or microcrystalline silicon. The higher thermal stability permits deposition or annealing of the transparent electrode at high temperature. As a result, high conductivity is achieved for the transparent electrode without degrading the photovoltaic material. The higher conductivity of the transparent electrode facilitates series integration of individual devices to form a module. The method includes forming a photovoltaic material from a fluorinated precursor or treating a photovoltaic material in a fluorine-containing ambient.

Owner:OVSHINSKY TECH

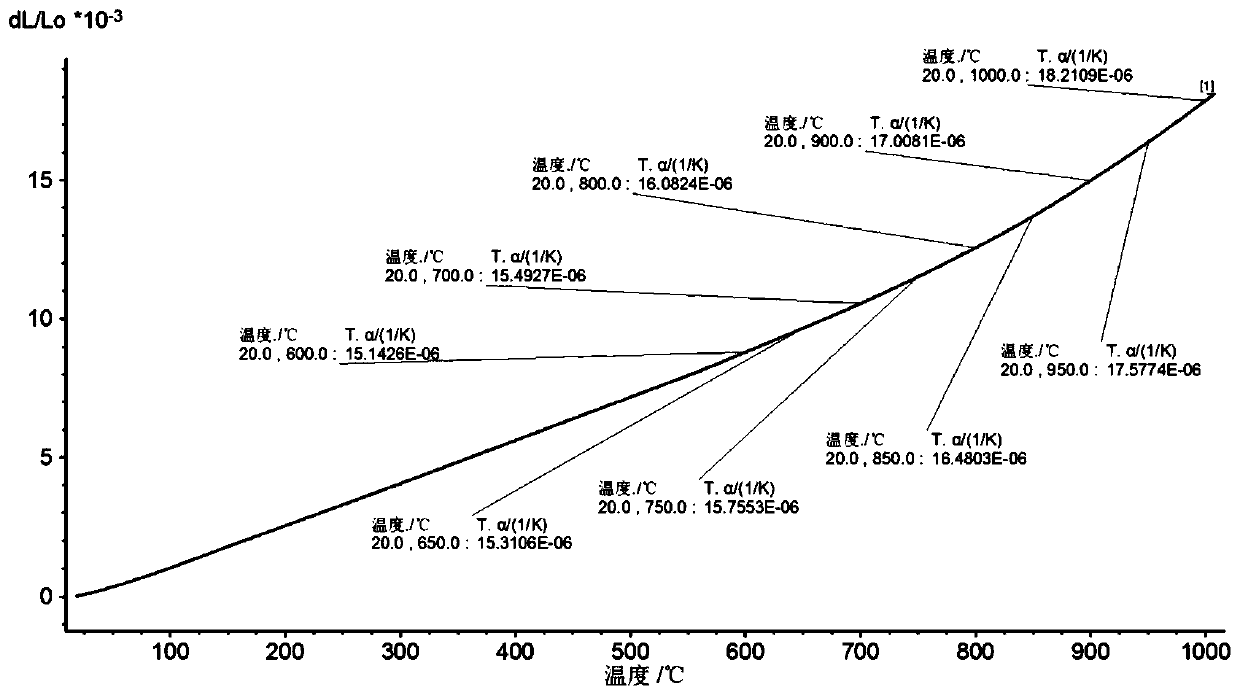

Ferritic steel for turbochargers

PendingUS20190153557A1High-temperature performanceHigh-temperature creep resistanceGas turbine plantsTurbochargerAlloy

Owner:BORGWARNER INC

Lithium-ion battery

ActiveUS20190305365A1Improve responseCatalyzed reactionCell electrodesSecondary cellsPhosphateFluoride

A lithium-ion battery, comprising a cathode, an anode, and a non-aqueous electrolyte; the cathode comprises a cathode active material and a metal oxide and / or metal fluoride coating which covers the surface of the cathode active material; the cathode active material is at least one of materials illustrated in general formula I or II: formula I: LixNiyM1-yO2, wherein 0.5≤x≤1.2, 0.5≤y≤1, and M is selected from at least one of Co, Mn, Al, Ti, Fe, Zn, Zr, Cr, and formula II: LikCozL1-zO2, wherein 0.5≤k≤1.2, 0.5<z≤1, and L is selected from at least one of Ni, Mn, Al, Ti, Fe, Zn, Zr, Cr. According to the lithium-ion battery, the charge cut-off voltage of the lithium-ion battery reaches 4.3 V or more by means of a synergistic effect of the unsaturated phosphate compounds and the coating at the surface of the cathode active material.

Owner:SHENZHEN CAPCHEM TECH

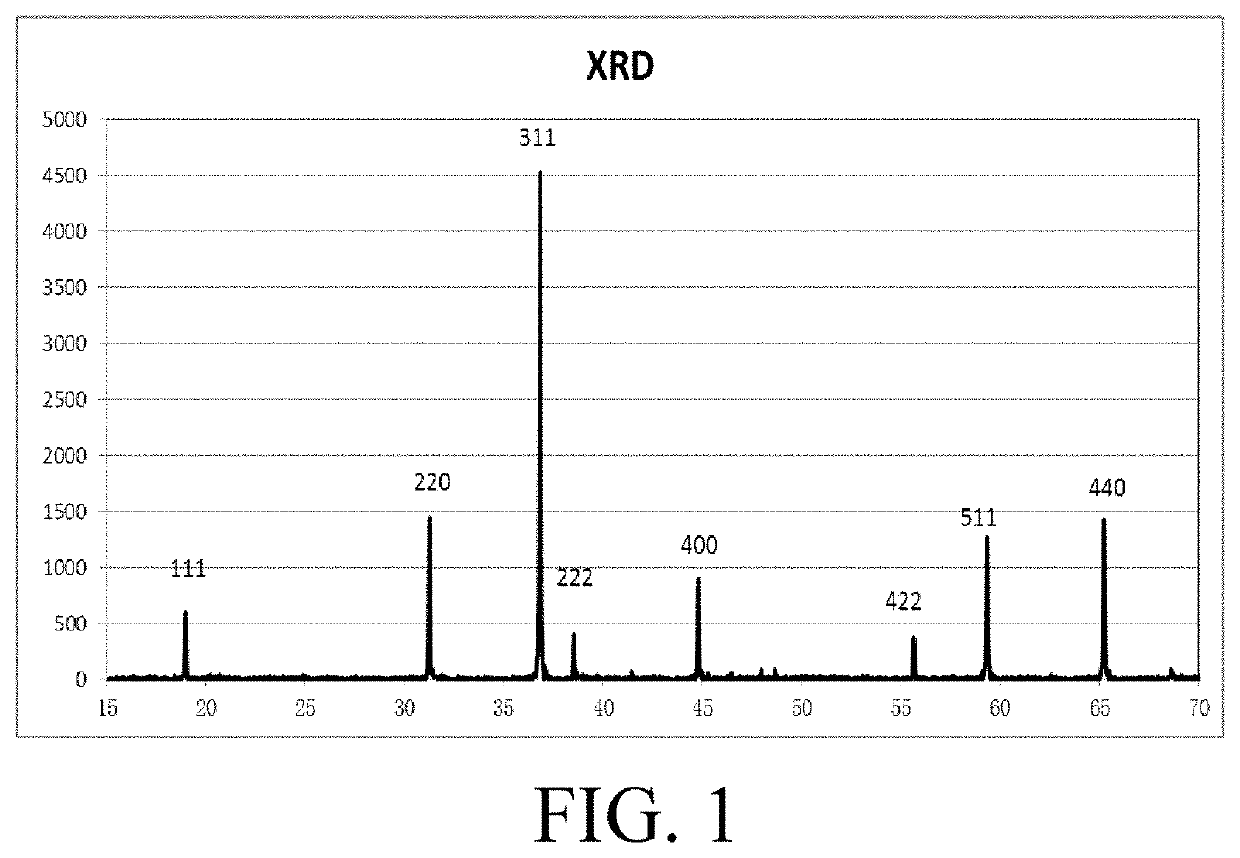

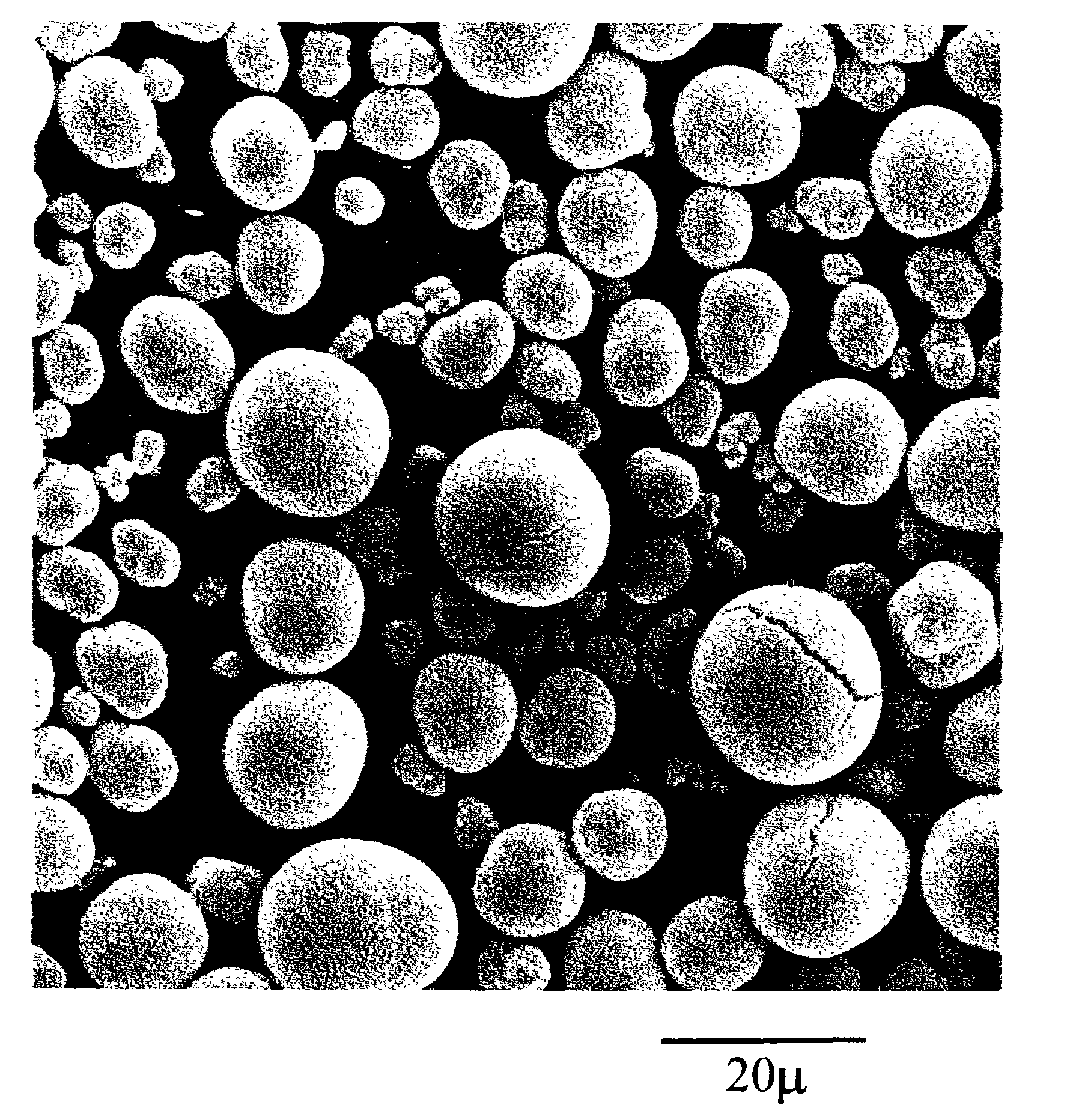

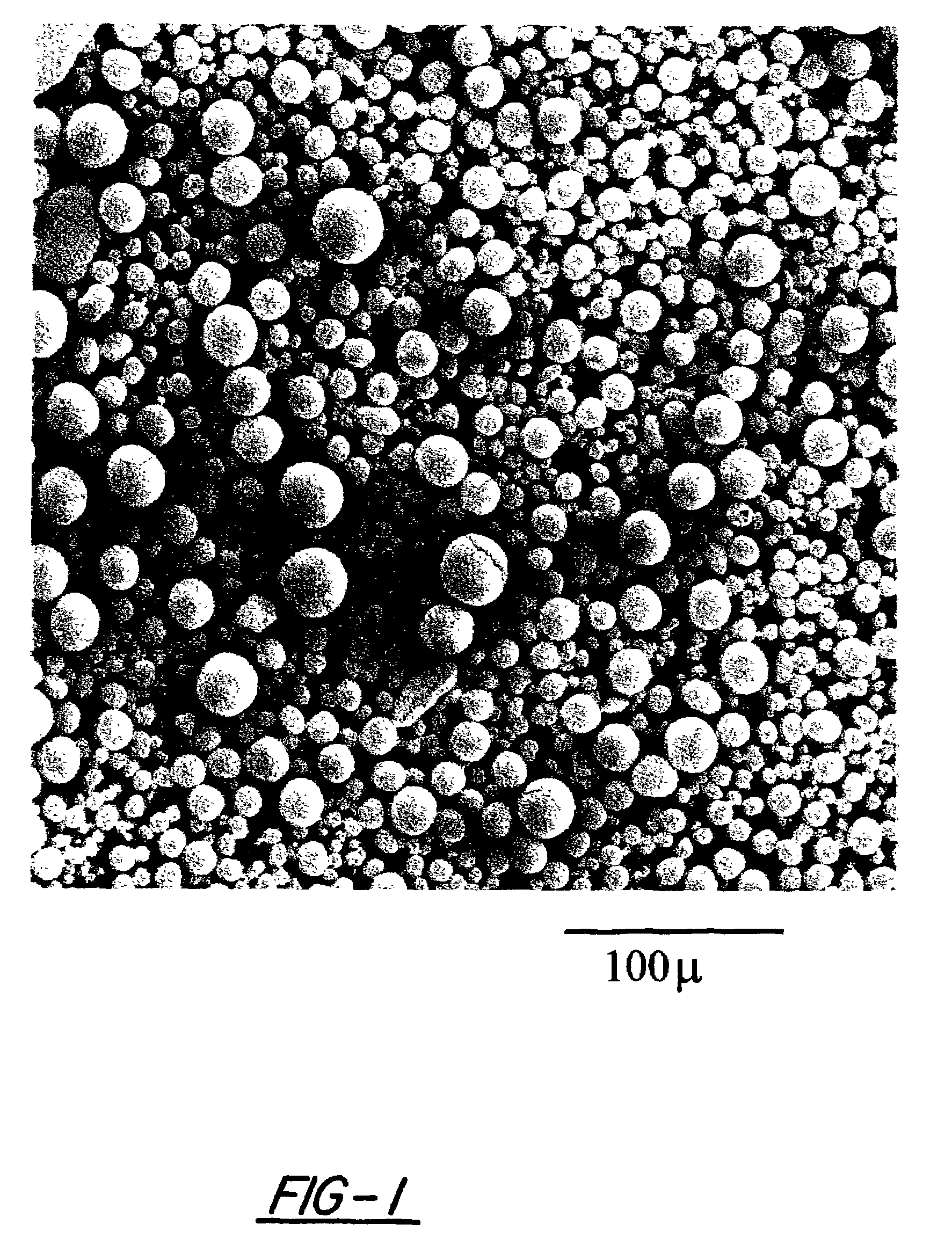

Nickel Hydroxide electrode material with improved microstructure and method for making the same

InactiveUS7294434B2Improve rendering capabilitiesIncrease capacityOxygen/ozone/oxide/hydroxideActive material electrodesNickel oxide hydroxideX-ray

Nickel hydroxide material comprising particles with a microstructure including crystallites of less than 103 Å as measured in the 101 direction by x-ray diffraction.A method of making positive electrode material for use in an alkaline rechargeable electrochemical cell comprising forming a metal ion solution and increasing the pH to precipitate positive electrode material with a crystallite structure of 120 Å or less in the 101 direction.

Owner:CHEVRON TECH VENTURES

Positive electrode material for lithium battery, preparing method thereof and lithium battery

ActiveUS9954225B2Good filling capability and high-temperature cycling performanceHigh-temperature performanceCell electrodesLithium oxides/hydroxidesLithium-ion batteryMaterials science

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

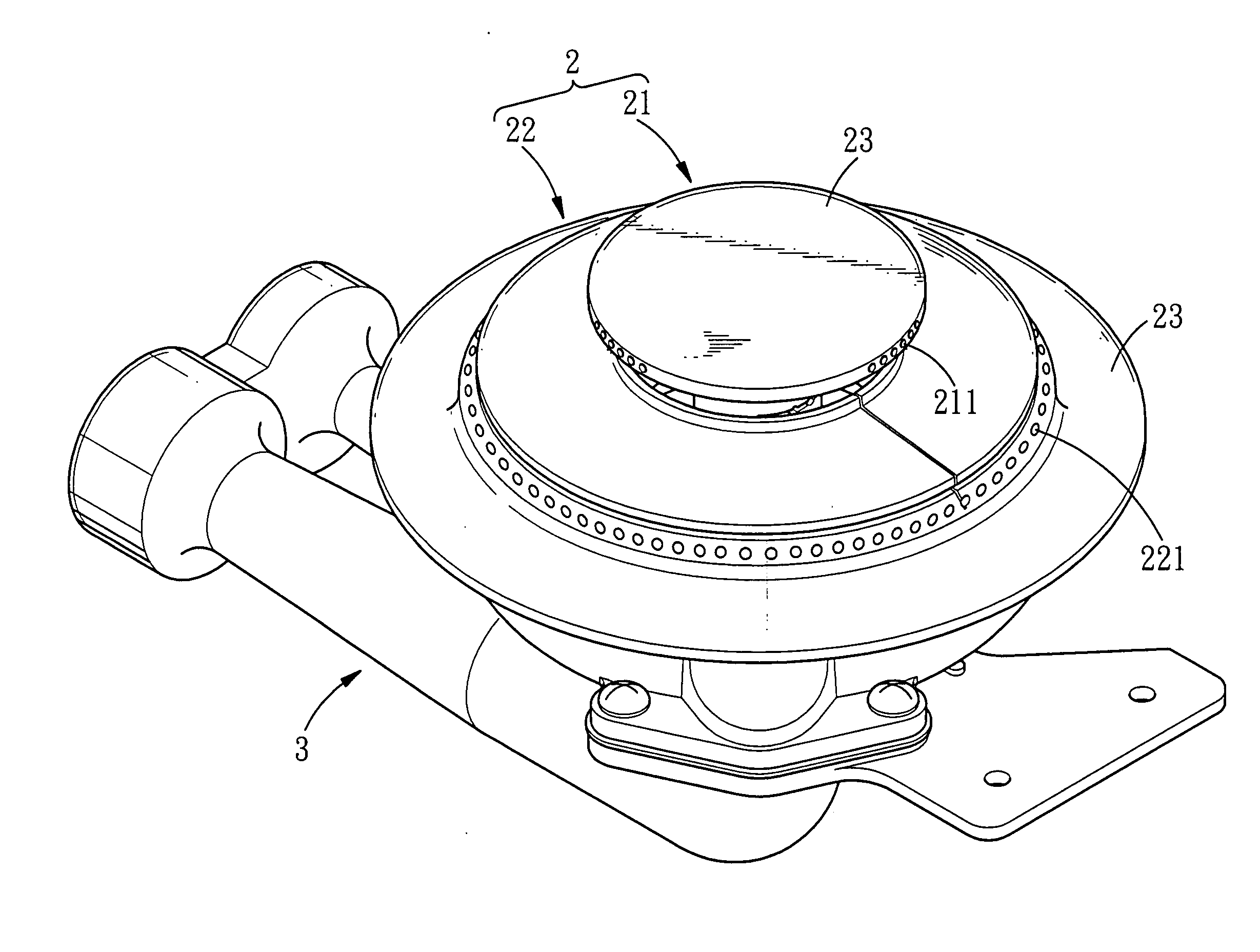

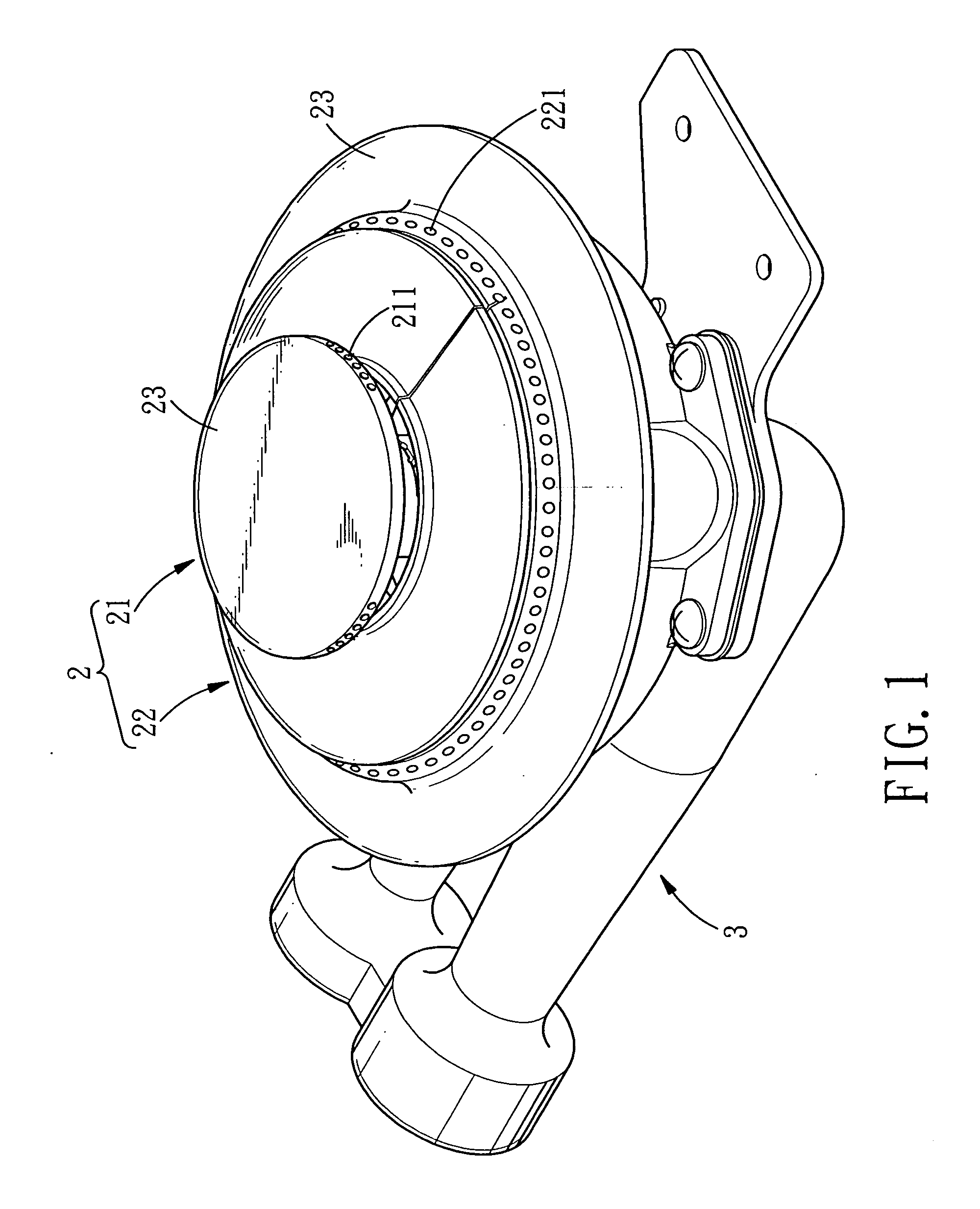

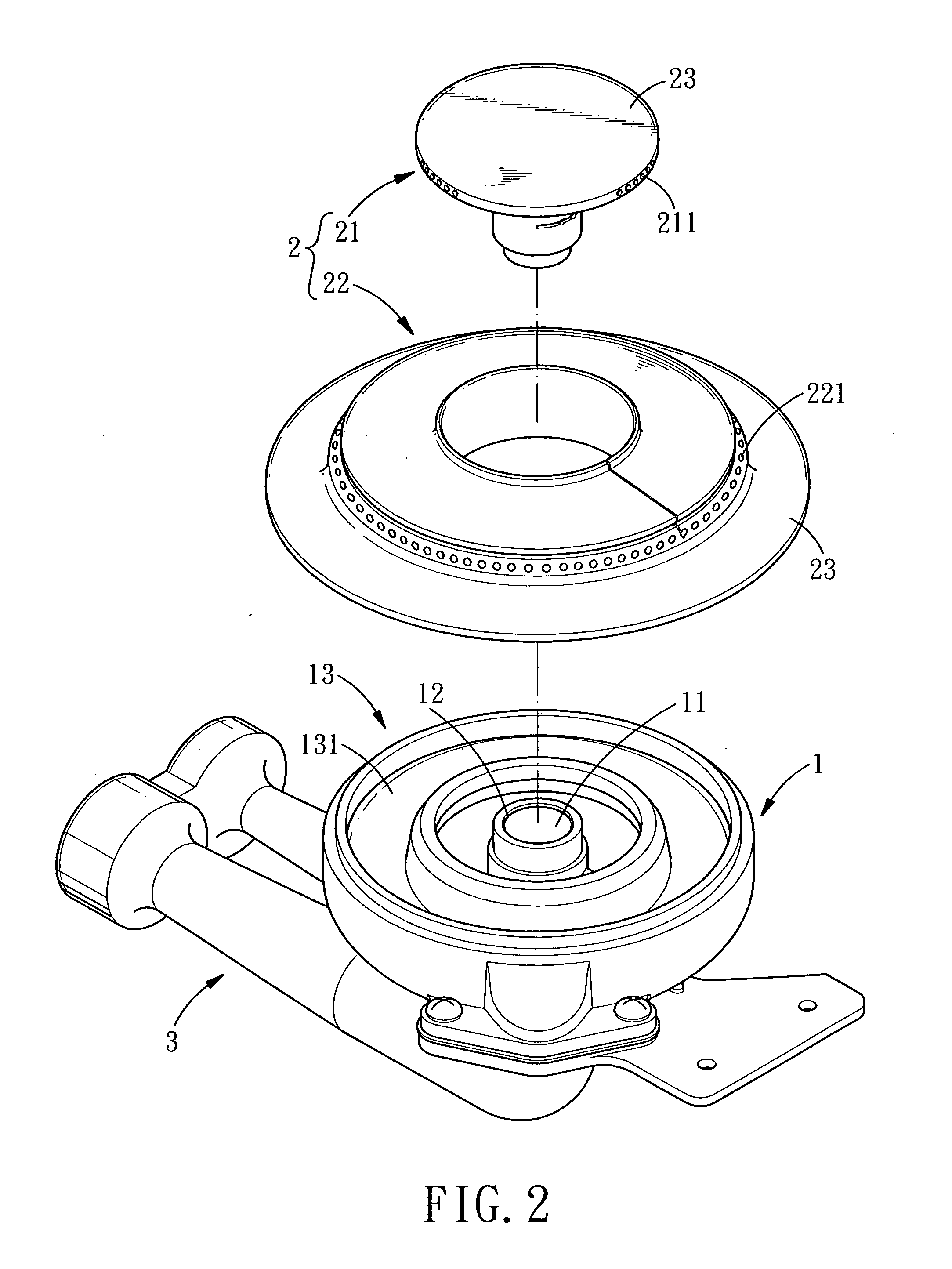

Head for a precision ceramic gas cooker

InactiveUS20080054102A1High temperature performanceSolve the real problemDomestic stoves or rangesCooking fumes removalMetallurgyCooker

A head for a precision ceramic gas cooker comprises a seat, a cover assembly and a mixing tube. The seat, the cover assembly and the mixing tube are made of precision ceramic which has the high temperature resisting property, and are coated with enamel on the surfaces thereof so as to provide variety of colors and patterns of the head, thus solving the conventional problem of unable to change the colors and patterns of the metal materials.

Owner:CHANG YUAN FU

Woven fabric with a modified ester resin for use as a wet friction liner

InactiveUS6875473B2Improve adhesionHigh glass transition temperatureLiquid surface applicatorsSynthetic resin layered productsYarnOligomer

Woven fabric of continuous, untwisted carbon yarn is impregnated with a modified cyanate ester resin or oligomer, preferably at least about 10% by weight of the combined weight of the cured resin and fabric. The cured fabric may be employed as a wet friction material suitable for use in transmission fluid couplings, and the like. The cured composite sheet can be backed with an adhesive film or liquid bonding paste for ease of bonding to one side of the metal portion of the transmission or clutch. Where thicker material is required, two or more cured composite sheets can be bonded together for applications such as transmissions.

Owner:J D LINCOLN

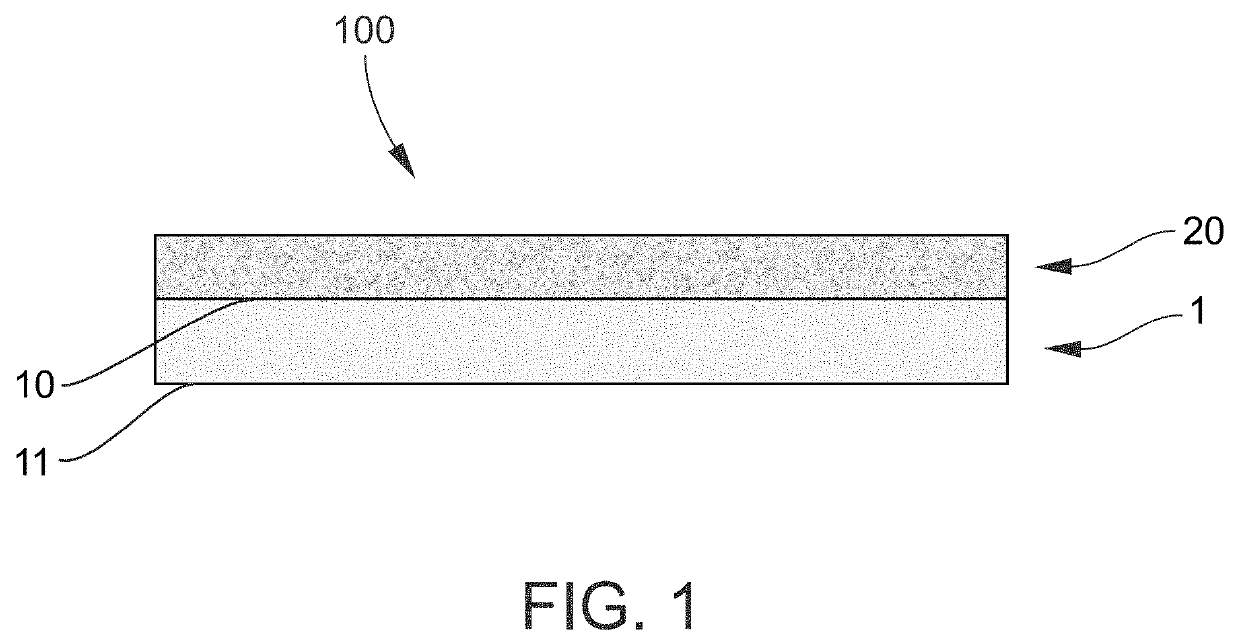

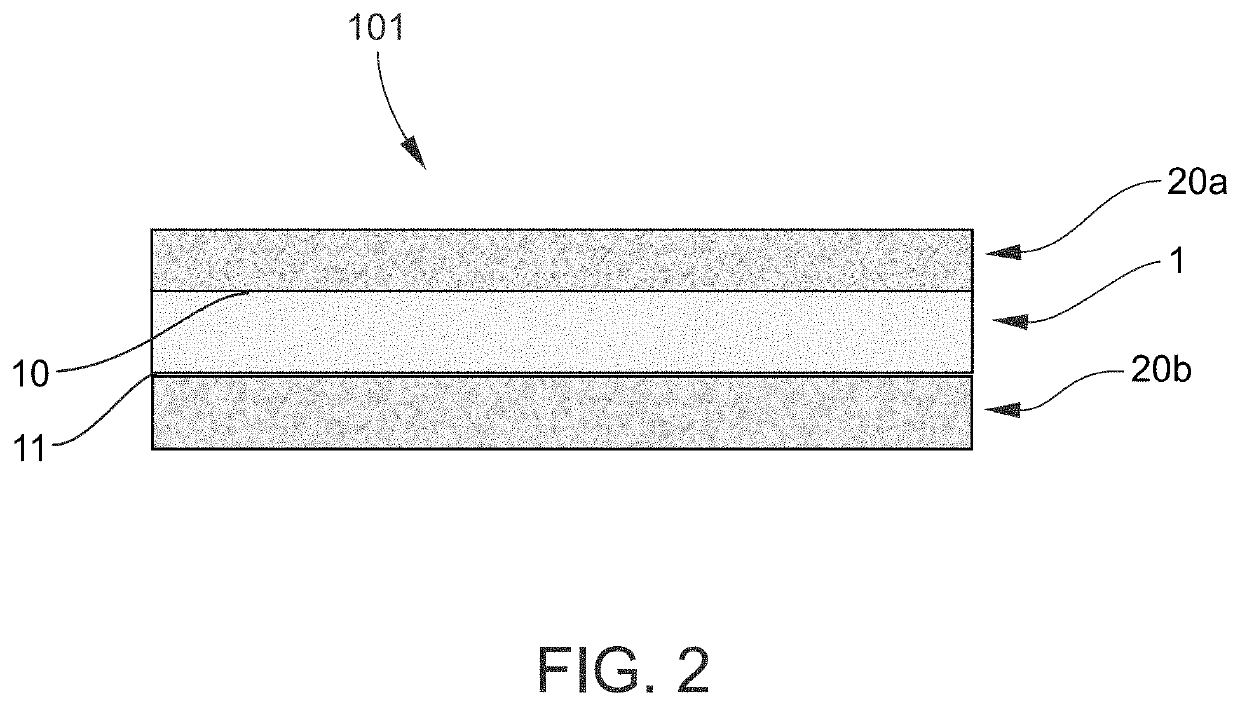

Polyimide coated separators, porous polyimide coatings, lithium batteries, and related methods

PendingUS20220094017A1Improve mechanical stabilityReduce Shrinkage ProblemsHybrid capacitor separatorsFinal product manufactureCoated membraneElectrical battery

The instant disclosure or invention is preferably directed to a polyimide coated membrane, separator membrane, or separator for a lithium battery such as a high energy or high voltage rechargeable lithium battery and the corresponding battery. The separator preferably includes a porous or microporous polyimide coating or layer on at least one side of a polymeric microporous layer, membrane or film. The polyimide coating or layer may include other polymers, additives, fillers, or the like. The polyimide coating may be adapted, for example, to provide oxidation resistance, to block dendrite growth, to add dimensional and / or mechanical stability, to reduce shrinkage, to add high temperature performance (HTMI function), to prevent electronic shorting at temperatures above 200 deg C., and / or the like. The microporous polymeric base layer may be adapted, at least, to hold liquid, gel, or polymer electrolyte, to conduct ions, and / or to block ionic flow between the anode and the cathode in the event of thermal runaway (shutdown function). The polyimide coated separator may be adapted, for example, to keep the electrodes apart at high temperatures, to provide oxidation resistance, to block dendrite growth, to add dimensional stability, to reduce shrinkage, to add high temperature performance (HTMI function), to prevent electronic shorting at temperatures above 200 deg C., to increase puncture strength, and / or to block ionic flow between the anode and the cathode in the event of thermal runaway (shutdown function). Although secondary lithium battery usage may be preferred, the instant polyimide coated membrane may be used in a battery, cell, primary battery, capacitor, fuel cell, textile, filter, and / or composite, and / or as a layer or component in other applications, devices, and / or the like.

Owner:CELGARD LLC

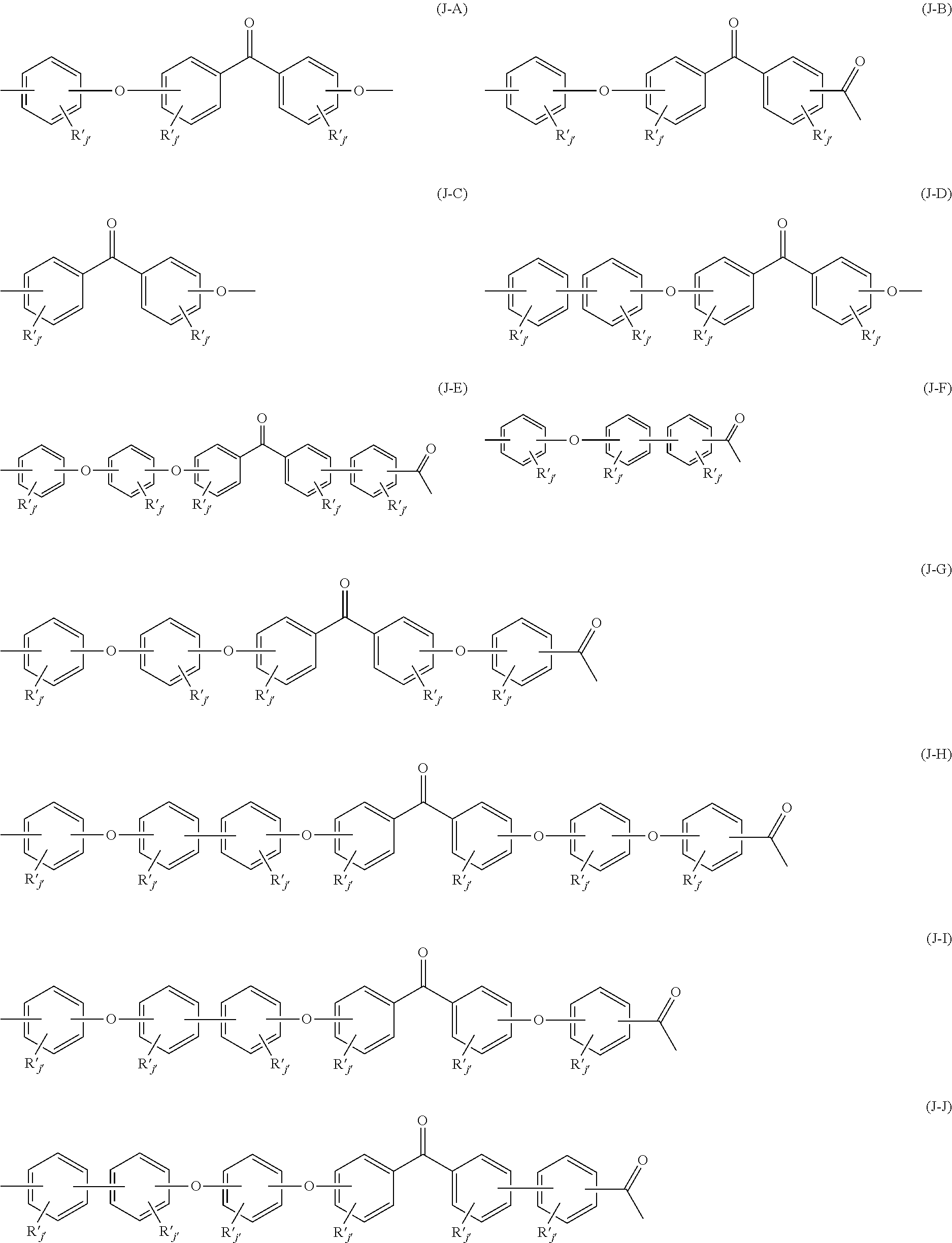

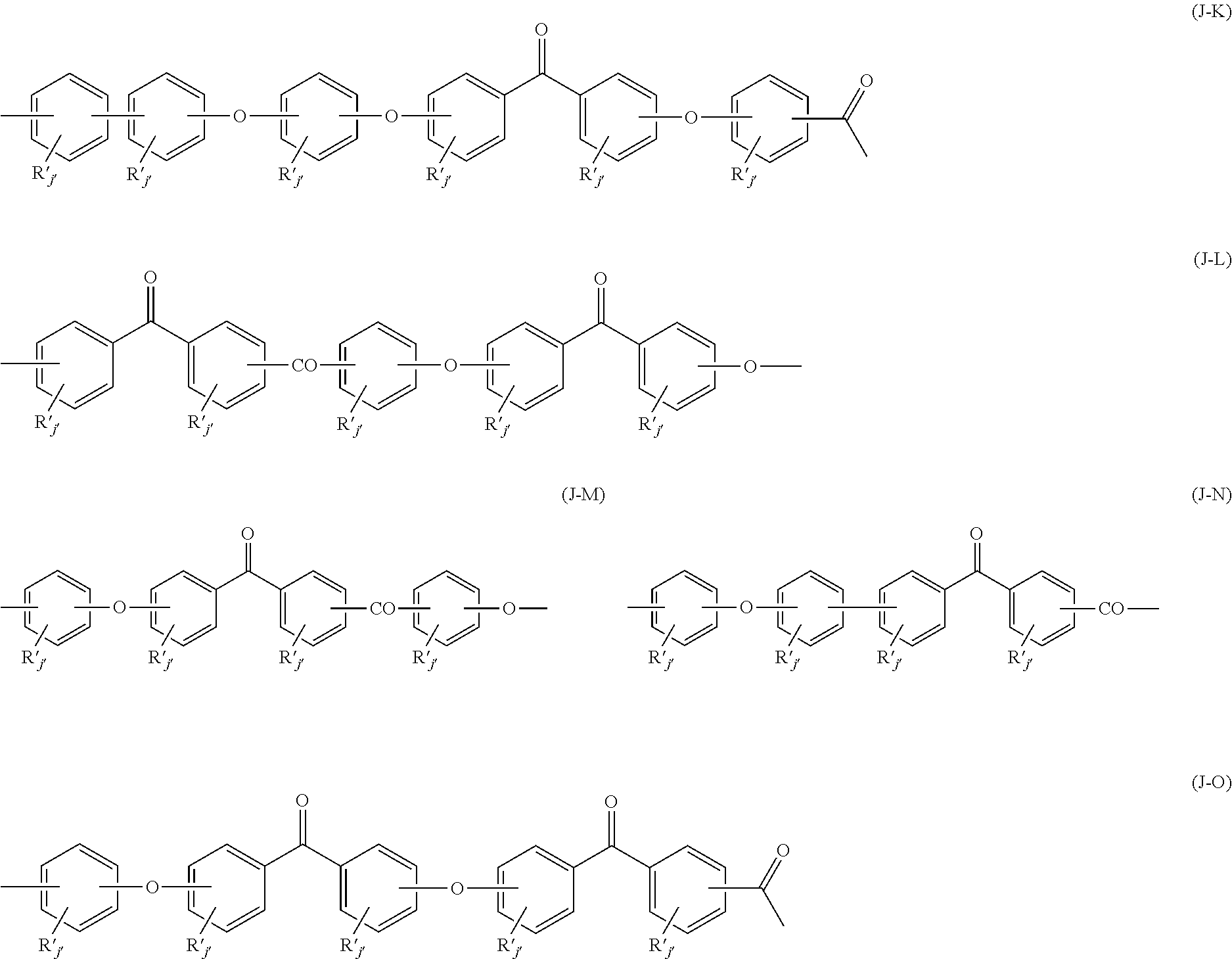

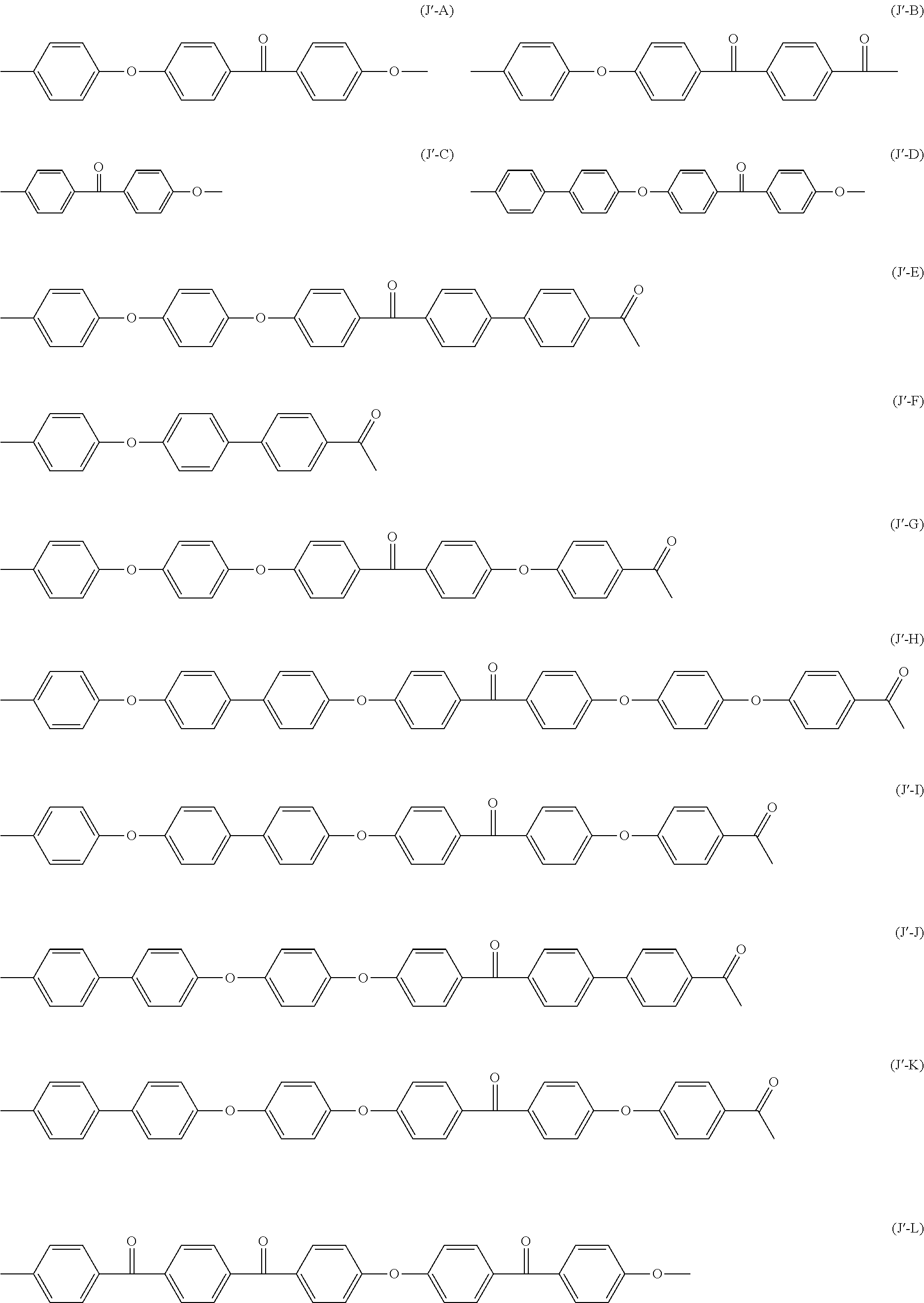

High Melt Flow PEAK Compositions

ActiveUS20150203712A1Increase frictionHigh wear capacityWood working apparatusCeramic shaping apparatusArylTetrafluoroethylene

A composition [composition (C)] comprising: from 0.1 to 99.8% by weight (wt. %) of at least one poly(aryl ether ketone) polymer having a melt flow rate (MFR) equal to or higher than 8 g / 10 min at 400° C. and under a load of 2.16 kg, as measured in accordance with ASTM method D1238 [(PAEKHMF) polymer], from 0.1 to 30 wt. % of at least one poly(tetrafluoroethylene)polymer having a D50 particle size equal to or below 10 μm, and having a melting temperature equal to or below 324° C. [(PTFE) polymer], and from 0.1 to 30% wt. % of at least one carbon fiber, and wherein all % are based on the total weight of the composition (C).

Owner:SOLVAY SPECIALTY POLYMERS USA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com