Patents

Literature

51583 results about "Yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yarn is a long continuous length of interlocked fibres, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery, or ropemaking. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework.

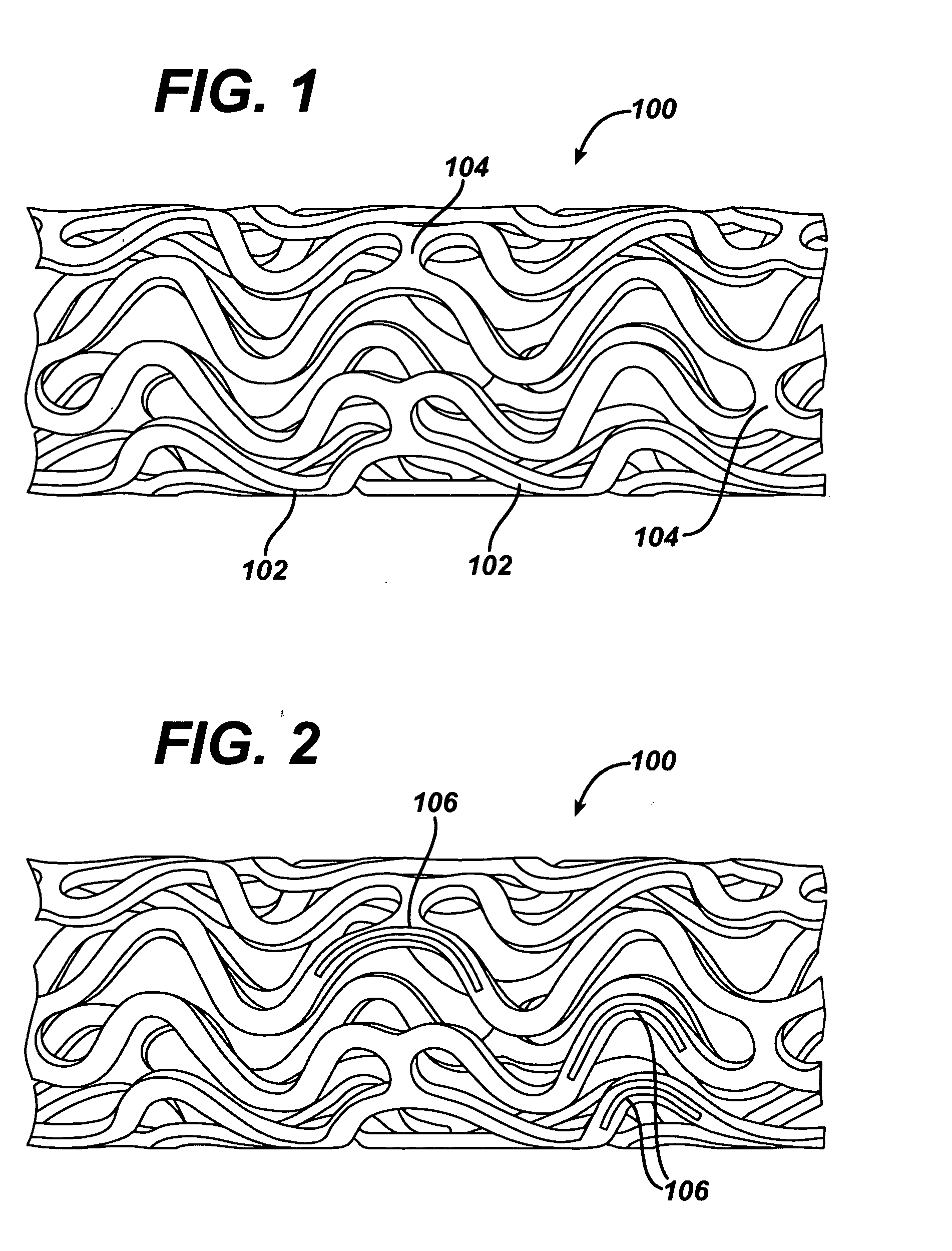

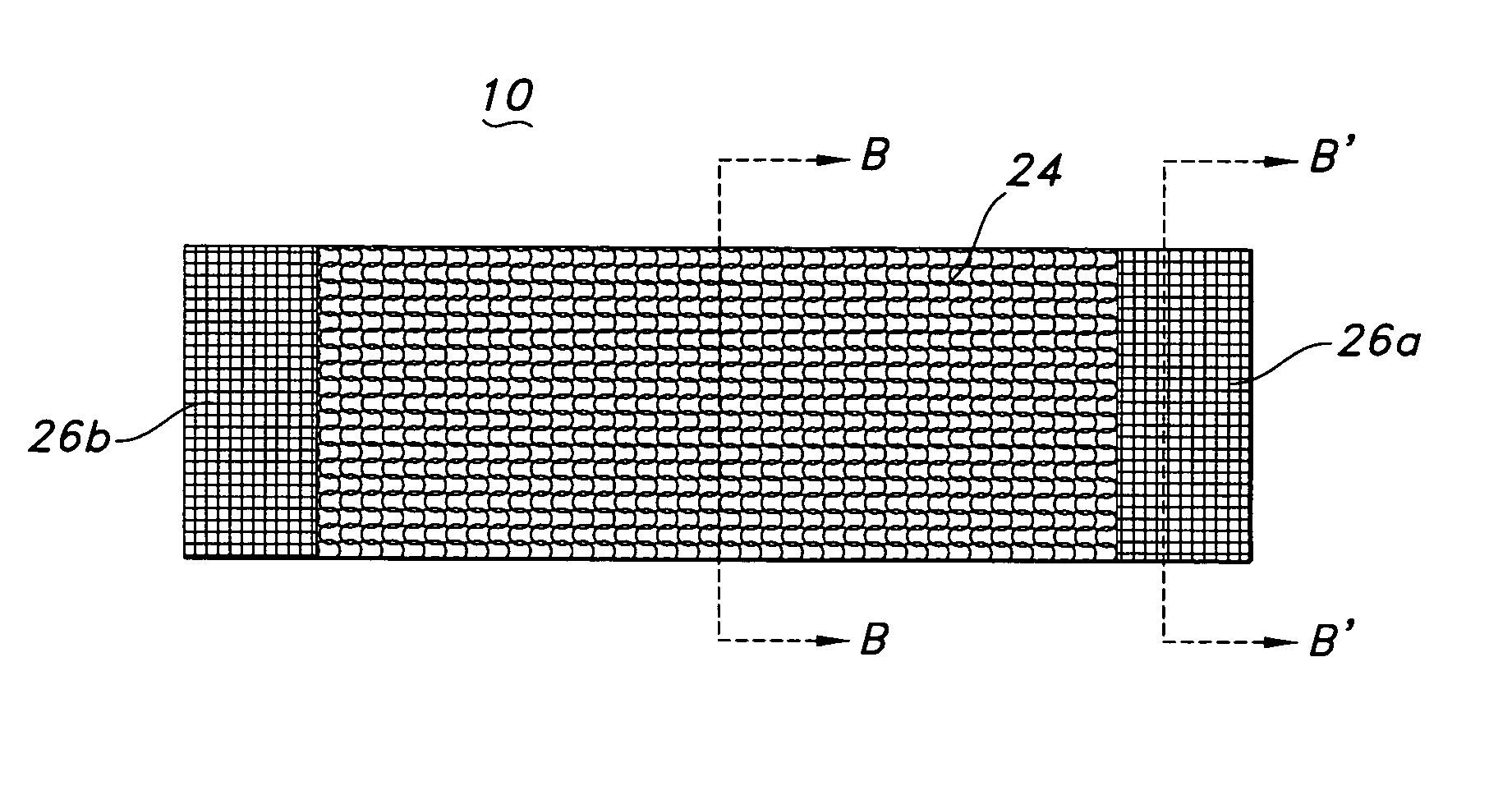

Surgical meshes

An implant includes a central portion composed of at least one yarn interconnected to form openings therein and a peripheral portion extending around the central portion. The peripheral portion includes at least one high strength yarn.

Owner:TYCO HEALTHCARE GRP LP

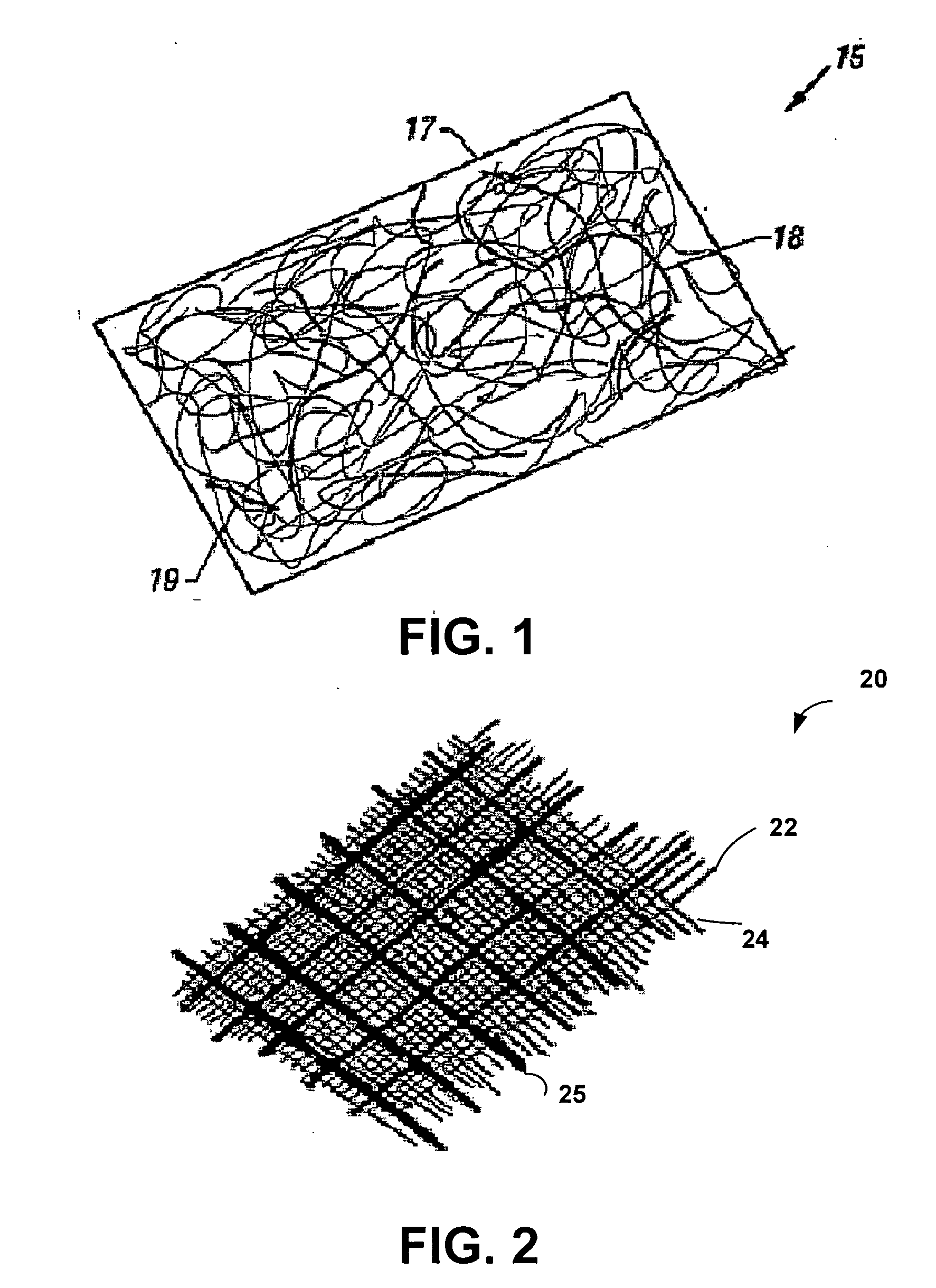

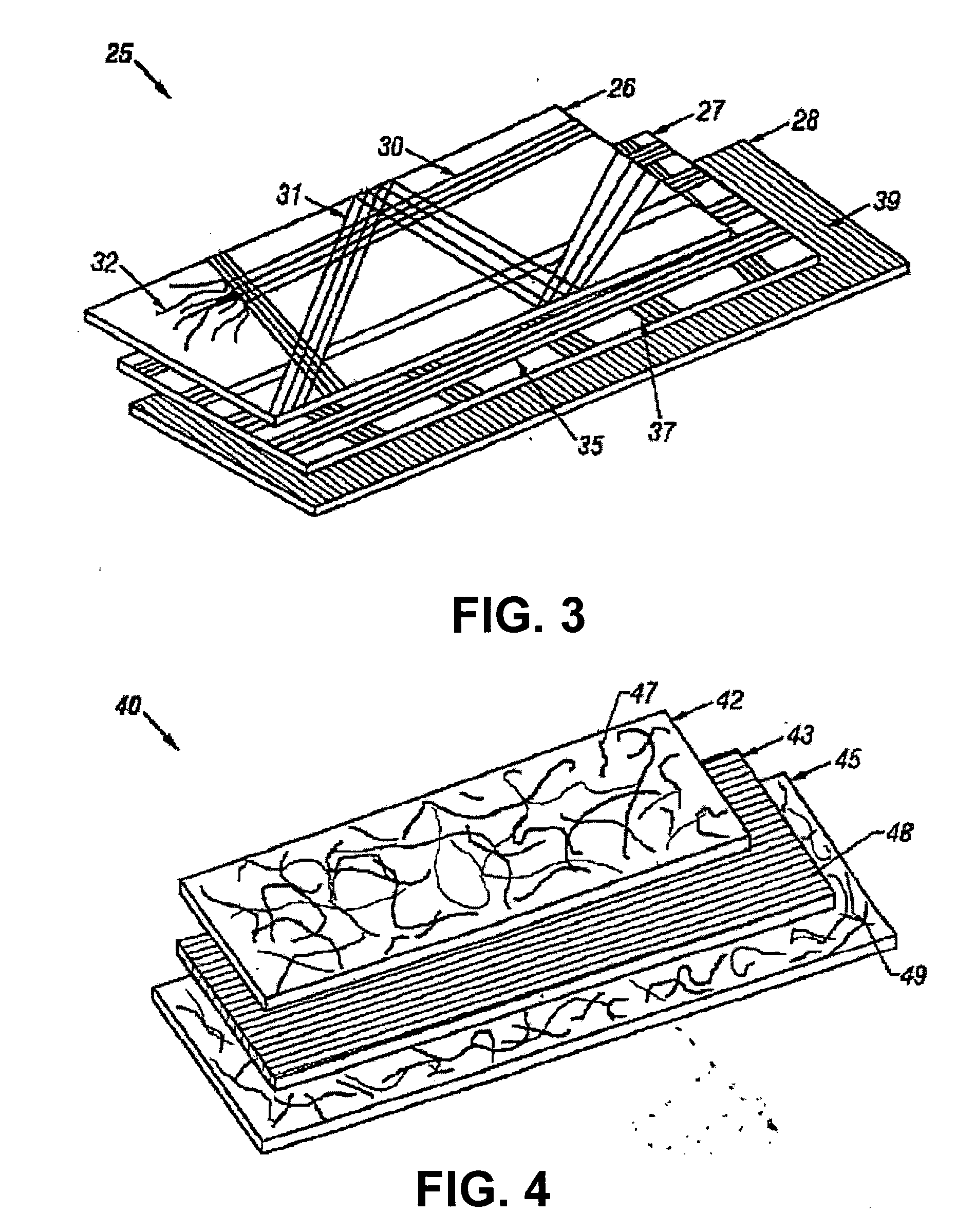

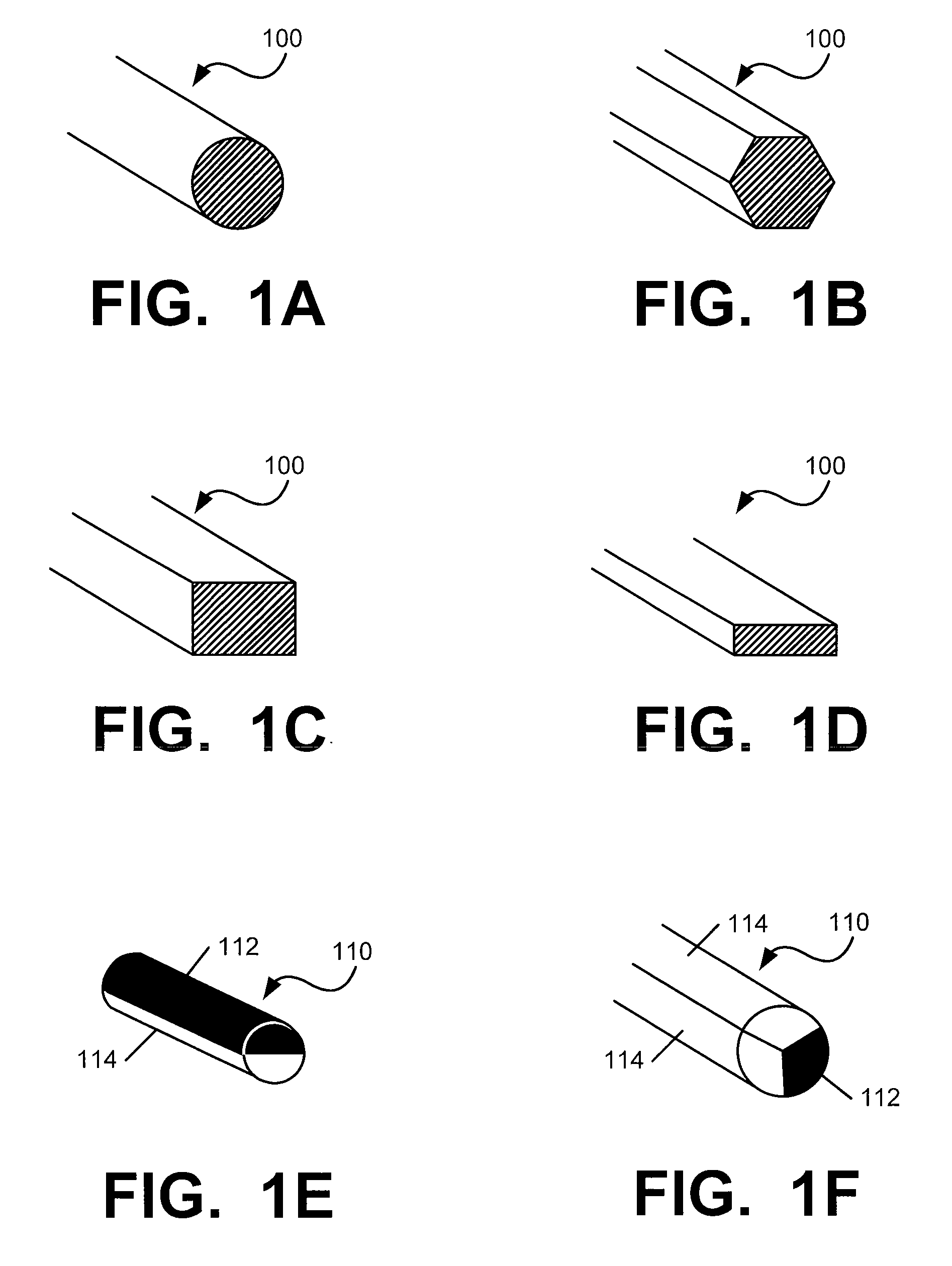

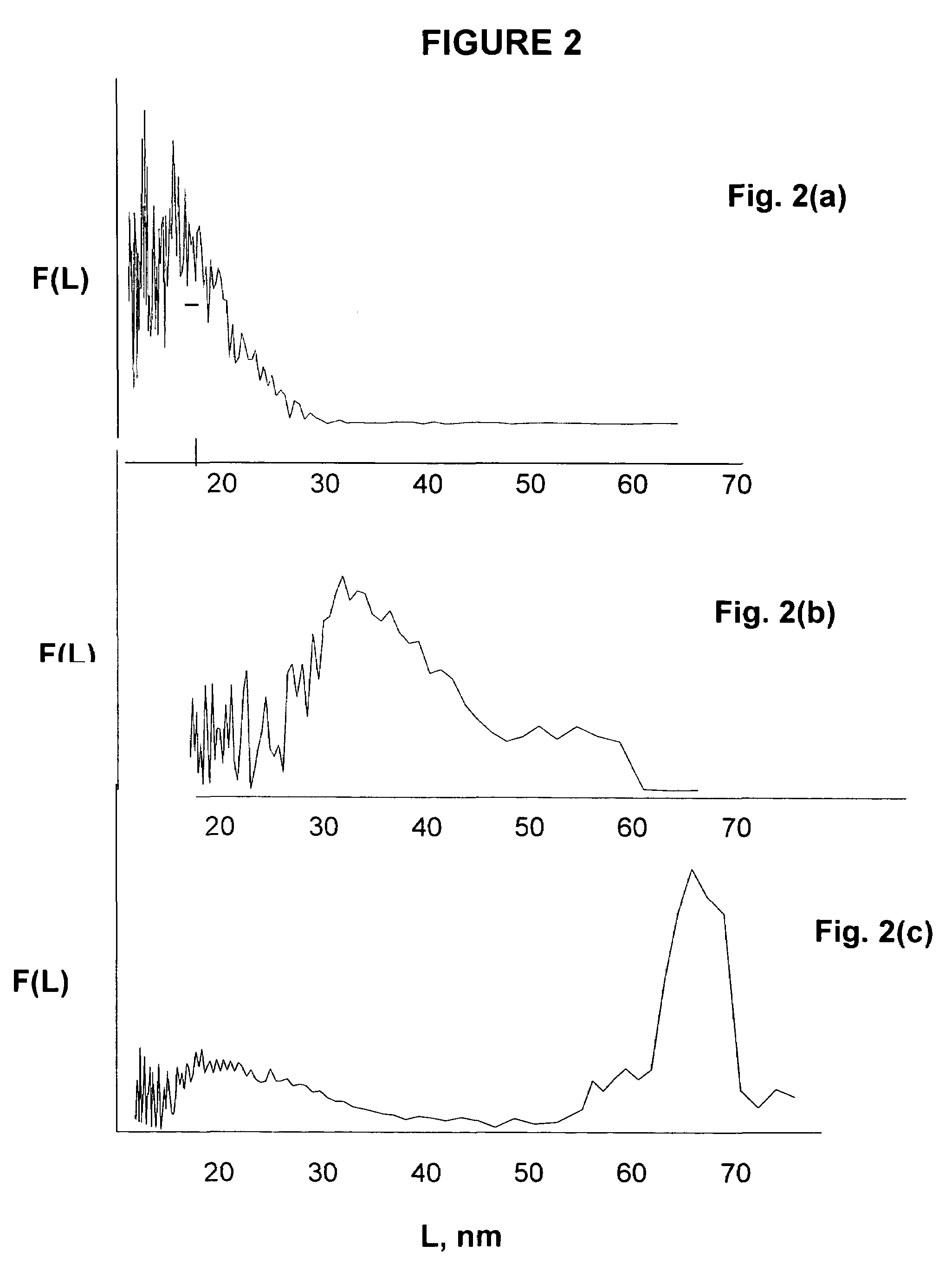

Selectively absorbable/biodegradable, fibrous composite constructs and applications thereof

A family of selectively absorbable / biodegradable, fibrous composite constructs includes different combinations of biostable and absorbable / biodegradable yarns assembled as initially interdependent, load-bearing components, transitioning to exhibit independent functional properties during in vivo end-use. The family of constructs consists of two groups, one group is made of fiber-reinforced composites of high compliance, absorbable matrices of segmented polyaxial copolyesters reinforced with multifilament yarn constructs, which are combinations of ultrahigh molecular weight polyethylene fibers and at least one absorbable / biodegradable fiber selected from silk fibers and multifilament yarns made from linear segmented, l-lactide copolyesters and poly (3-hydroxyalkanoates, are useful in orthopedic, maxillofacial, urological, vascular, hernial repair and tissue engineering applications. The second group is made of coated and uncoated, warp-knitted mesh constructs for use in hernial, vascular, and urological tissue repair and tissue engineering.

Owner:POLY MED

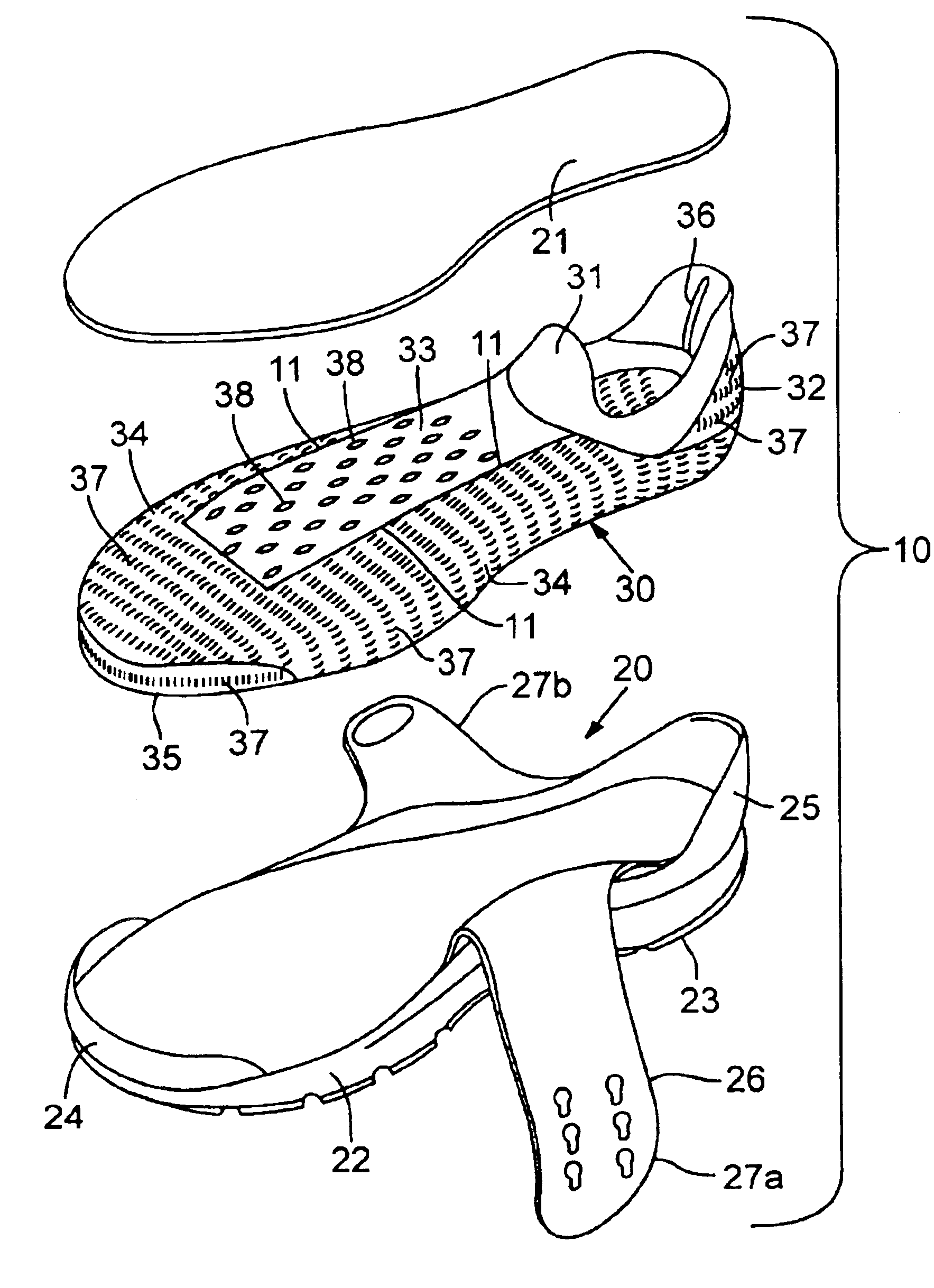

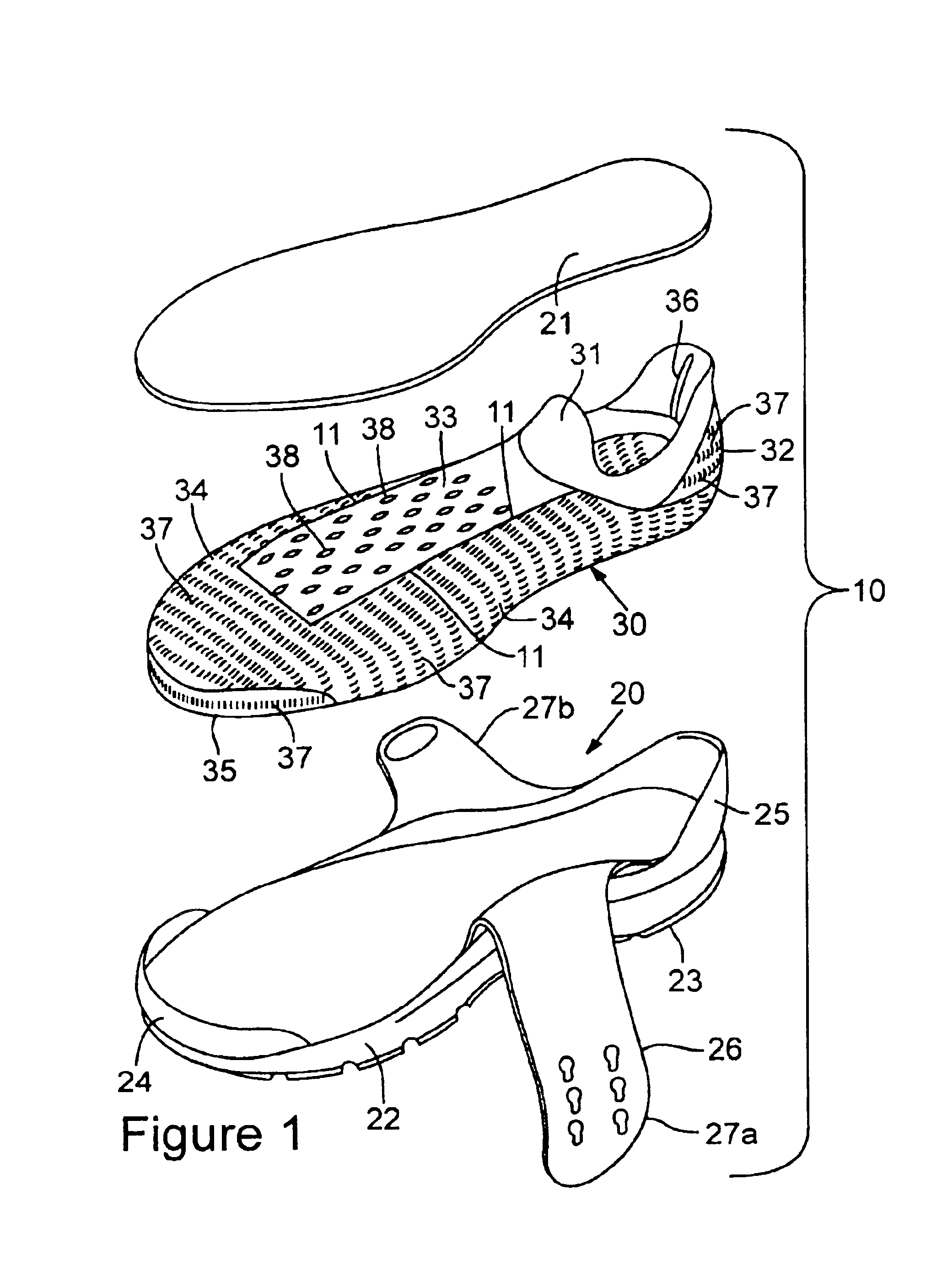

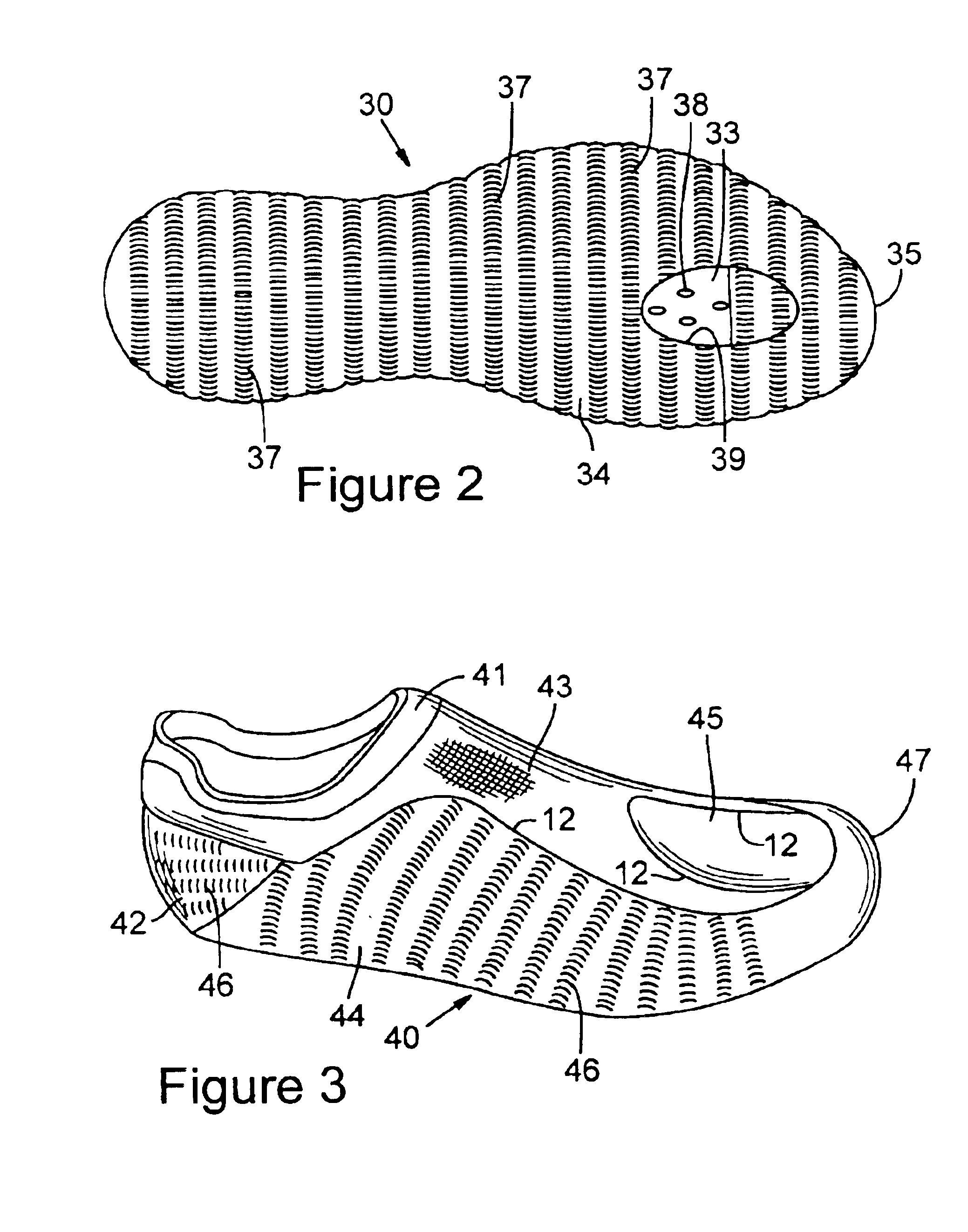

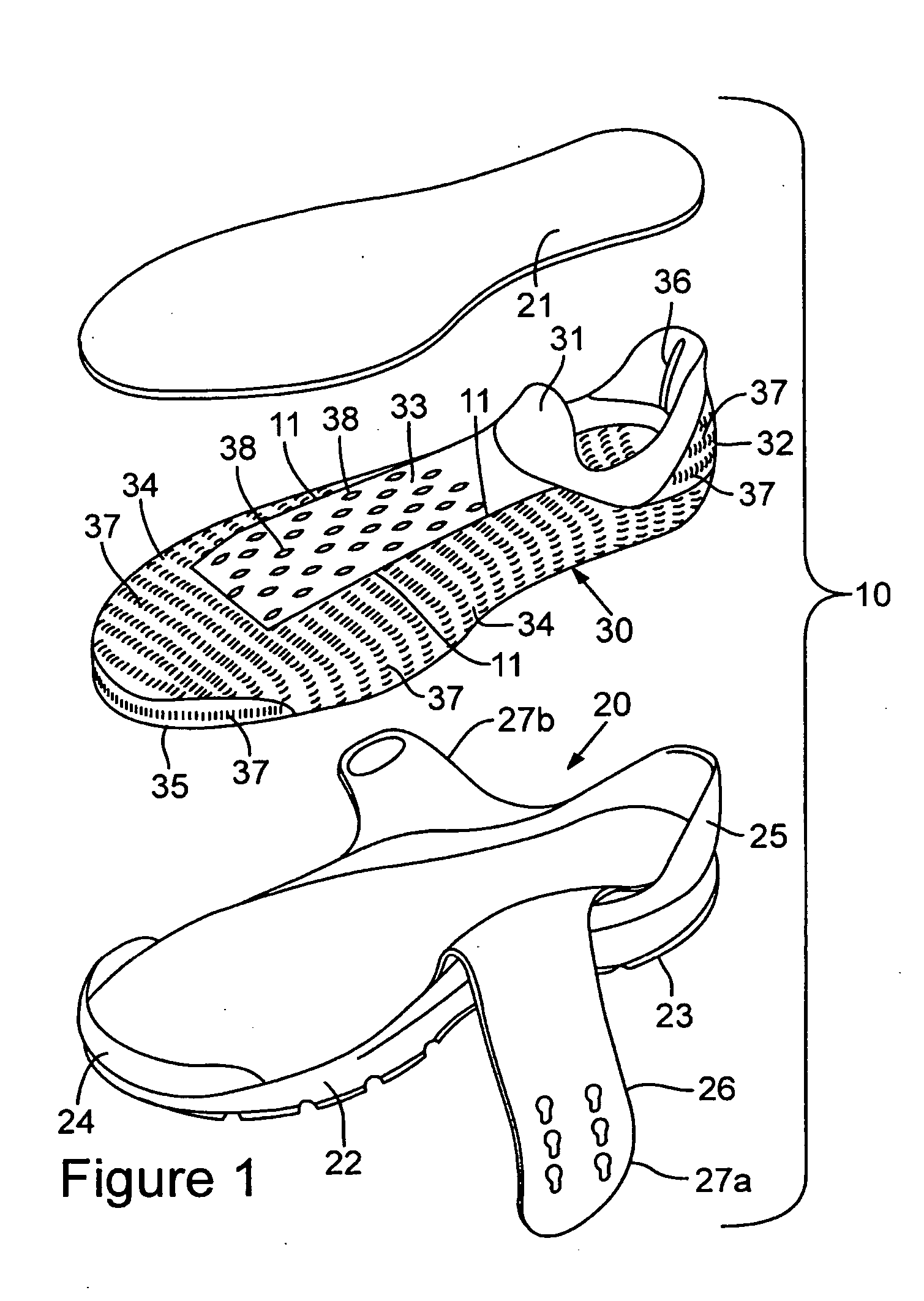

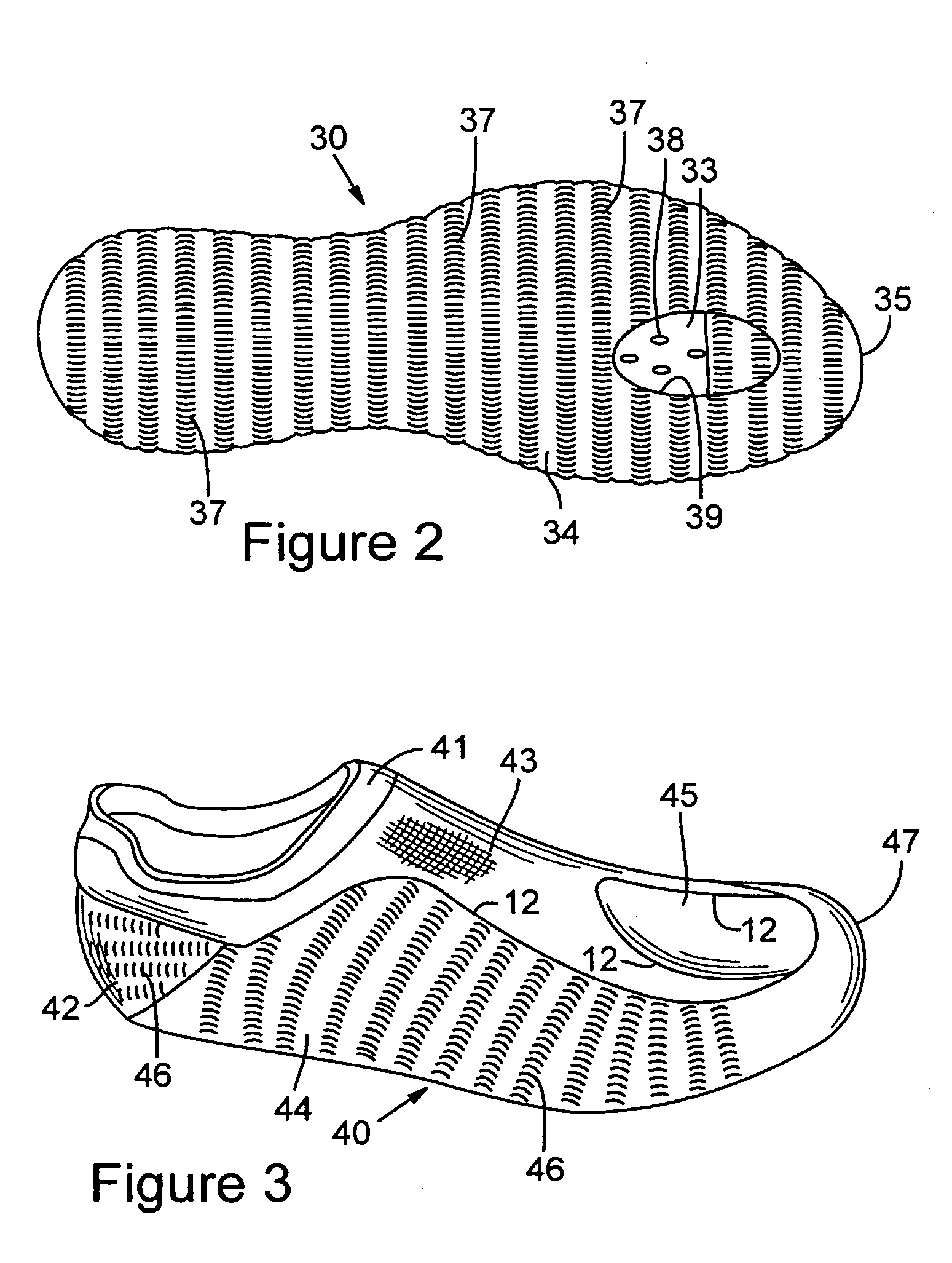

Footwear with knit upper and method of manufacturing the footwear

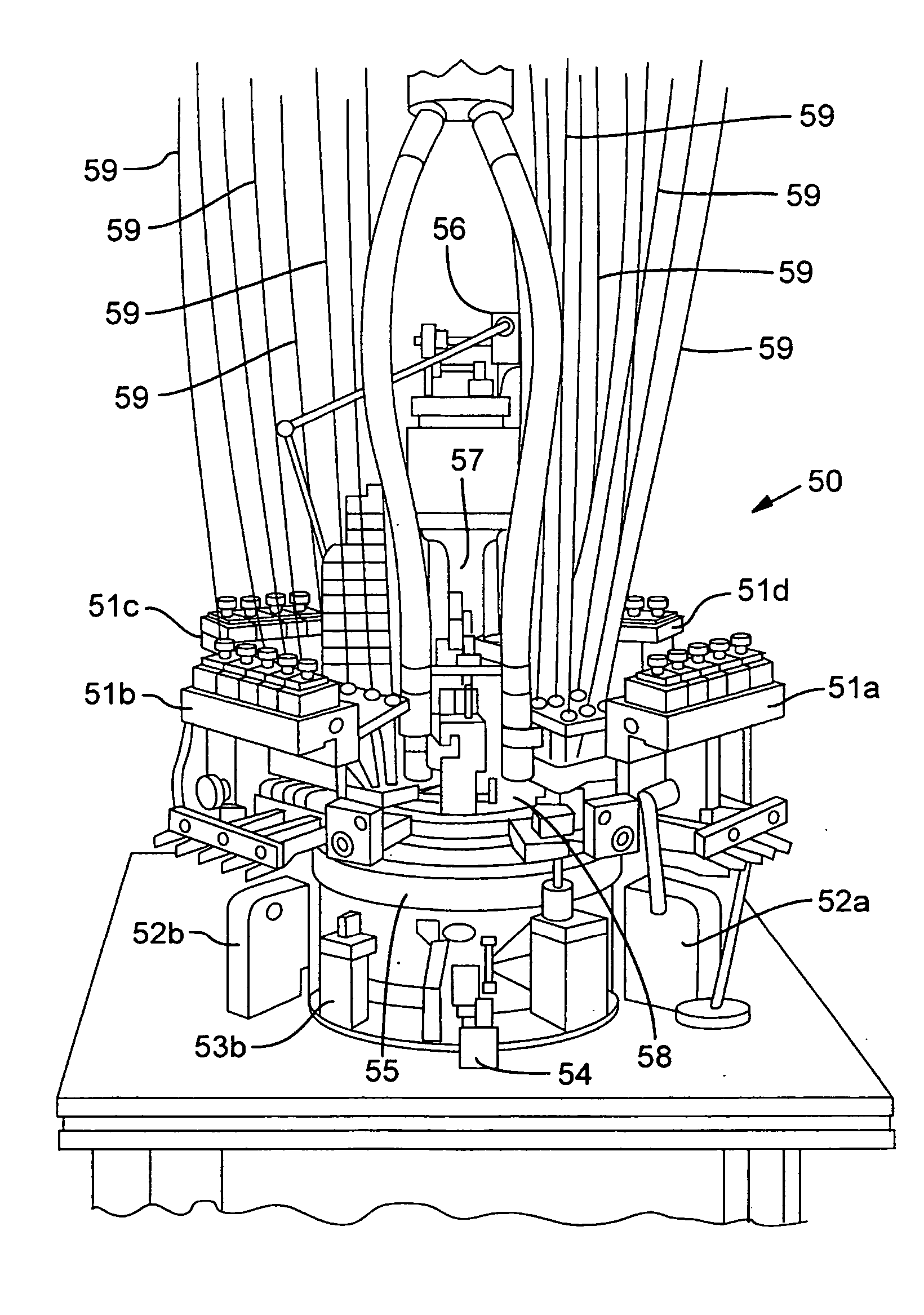

An article of footwear with a knit upper and a method of manufacturing the footwear are disclosed. The upper is formed through a knitting process to include a plurality of sections formed of different yarns and knits to provide the sections with different physical properties. In portions of the upper where sections formed of different yarns are in adjacent wales, a tuck stitch is utilized to join the sections. The method utilizes a circular knitting machine having multiple feeds that work together to knit the upper into a unitary, seamless structure. The multiple feeds, each of which provide multiple types of yarns, produce the sections to have varying physical properties.

Owner:NIKE INC

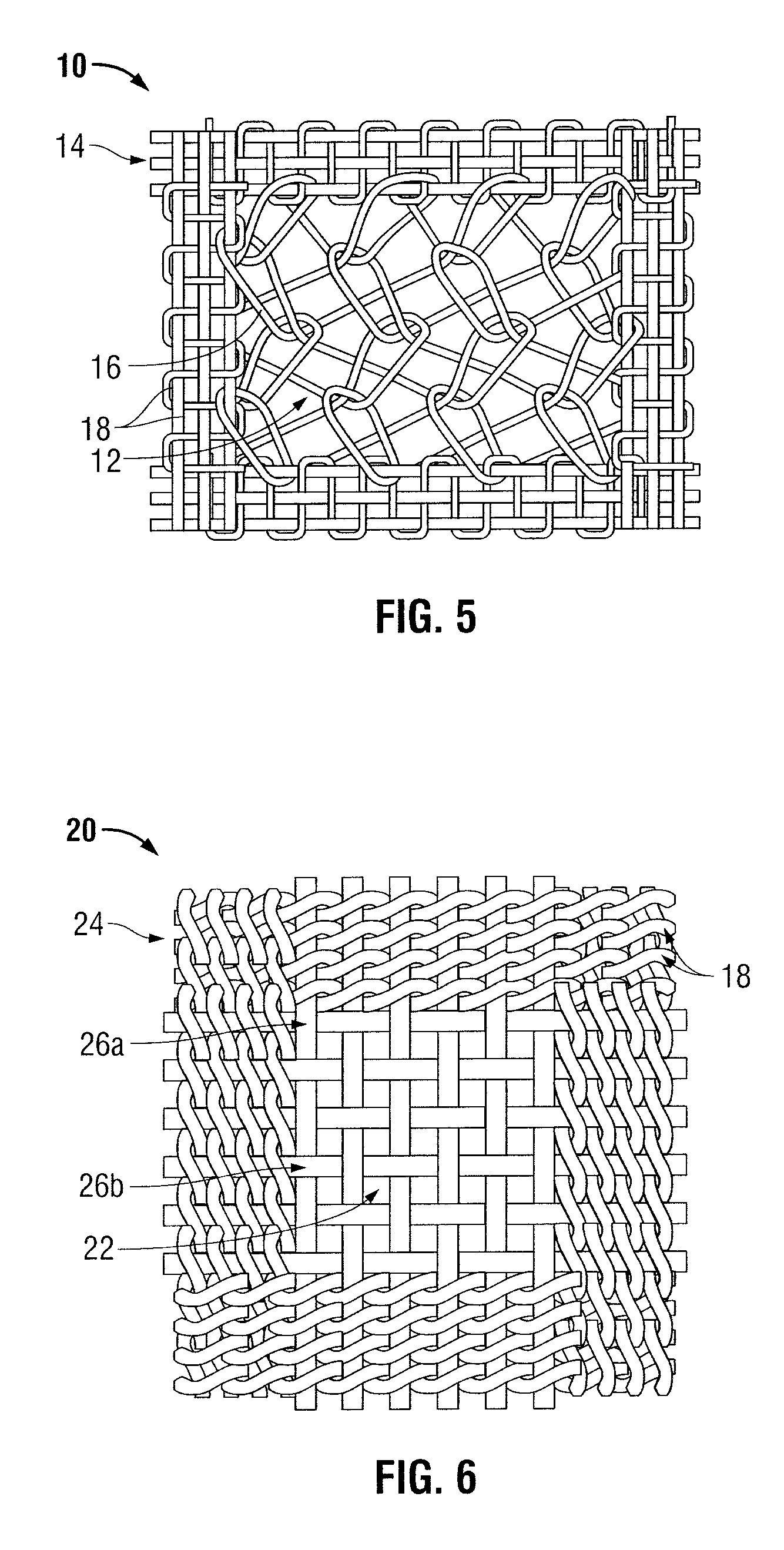

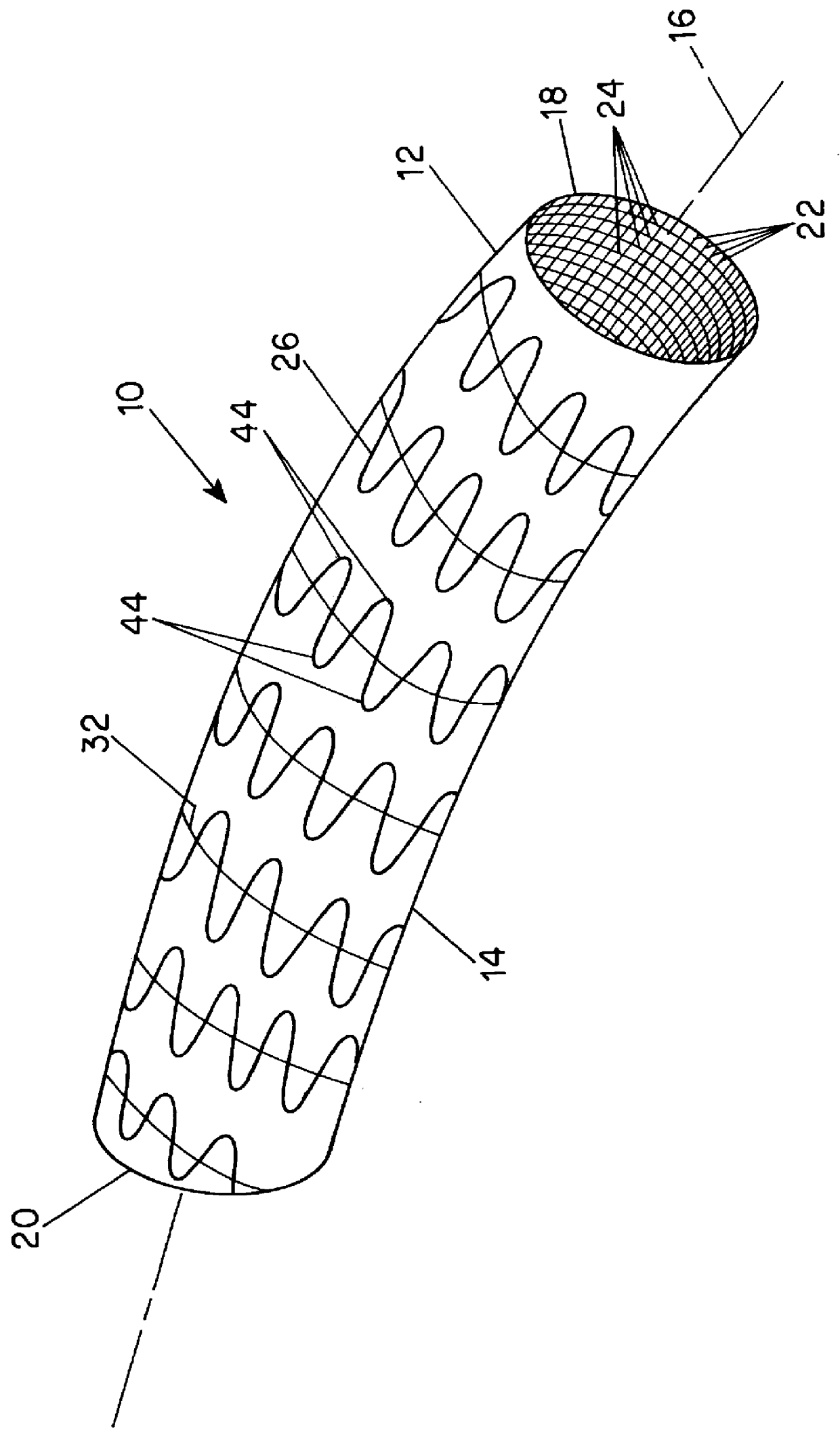

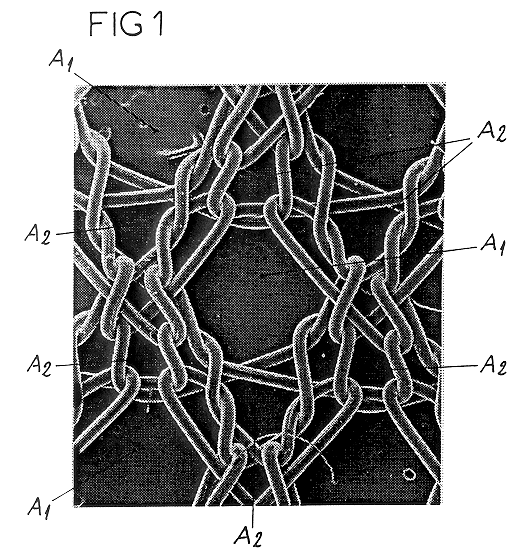

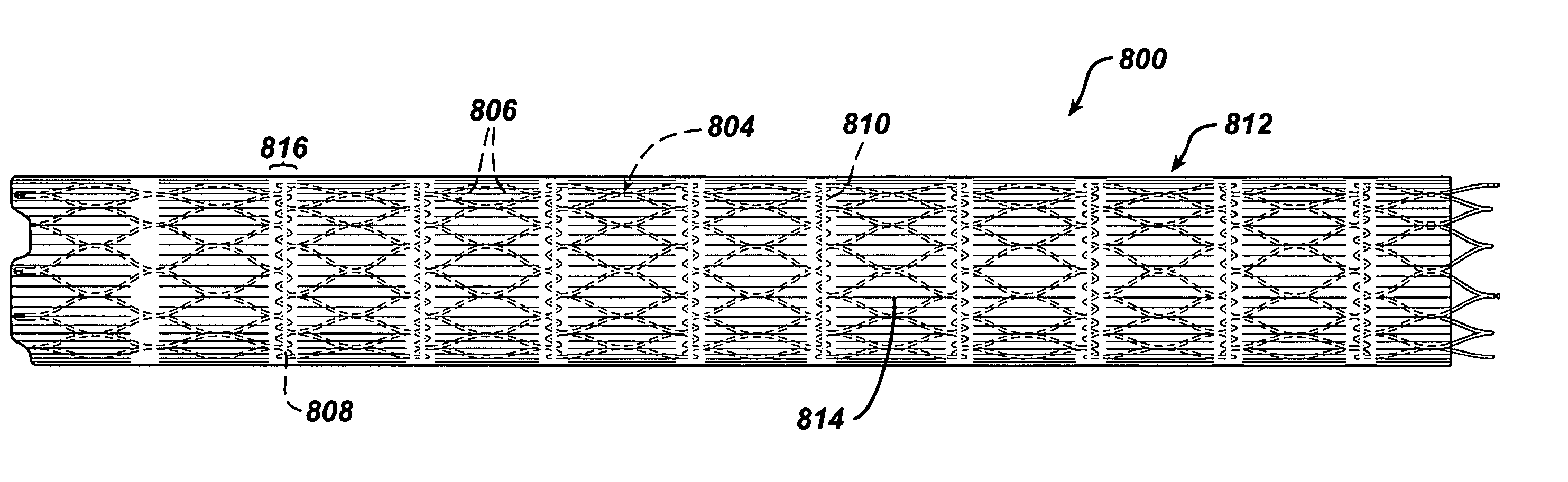

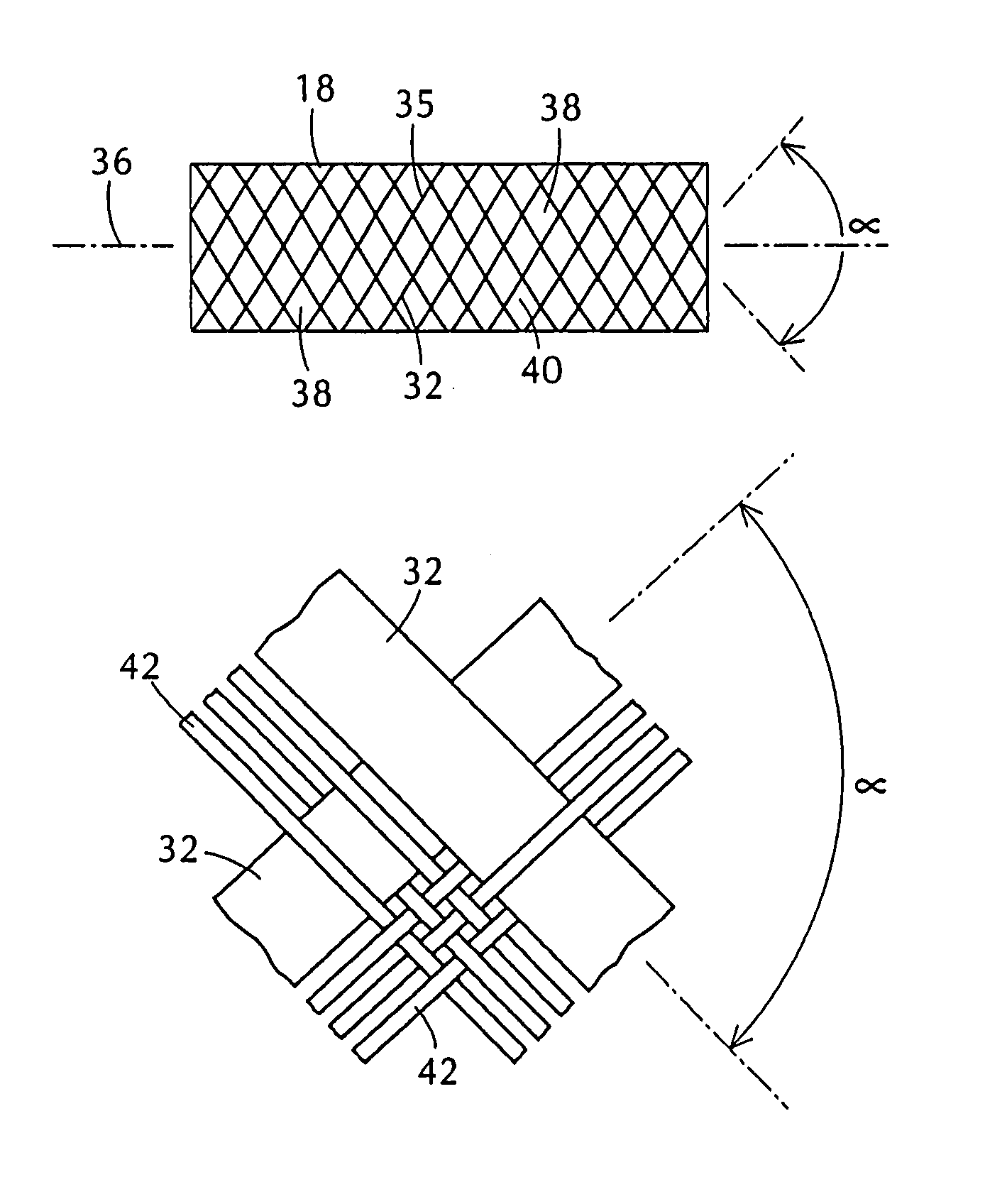

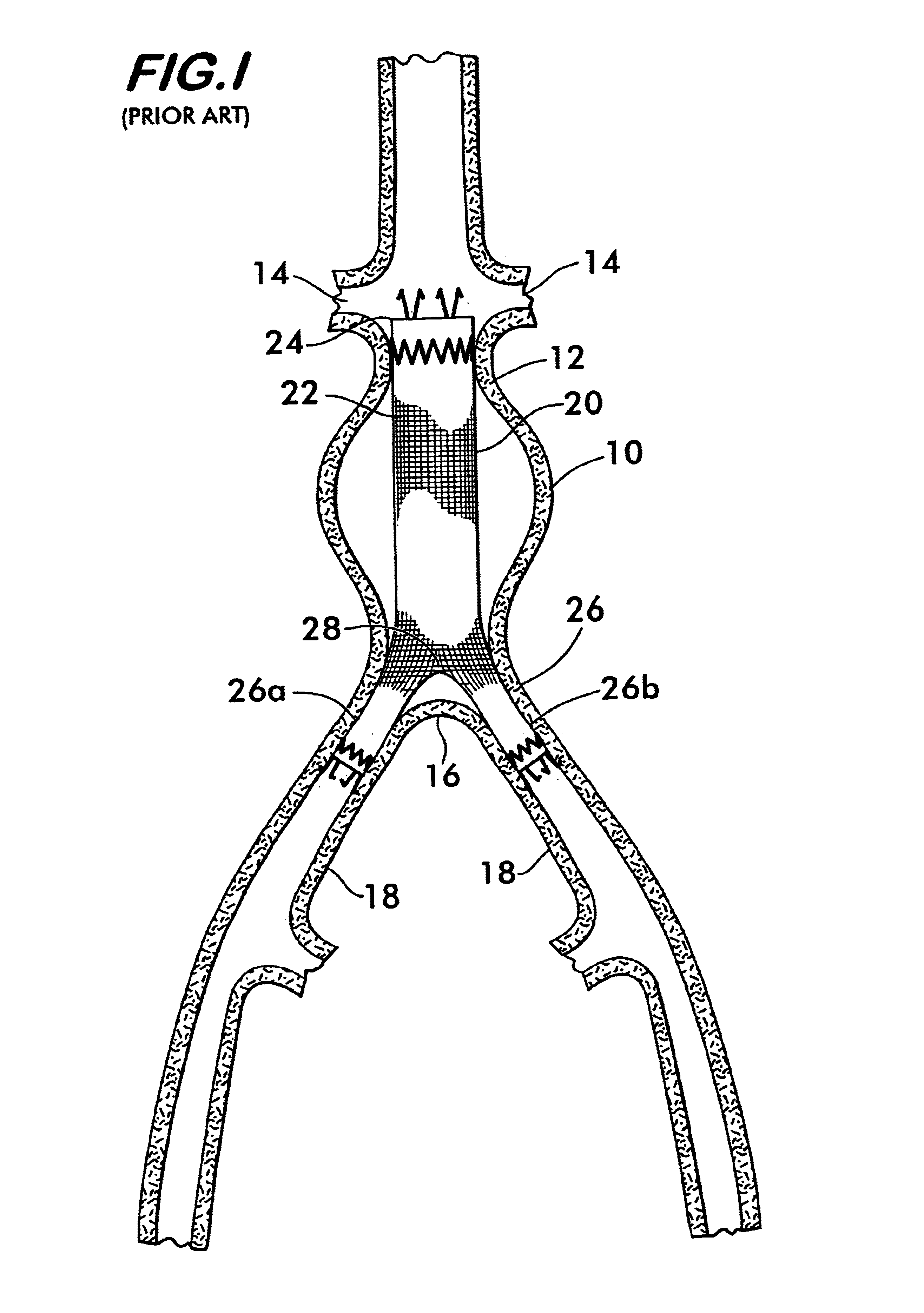

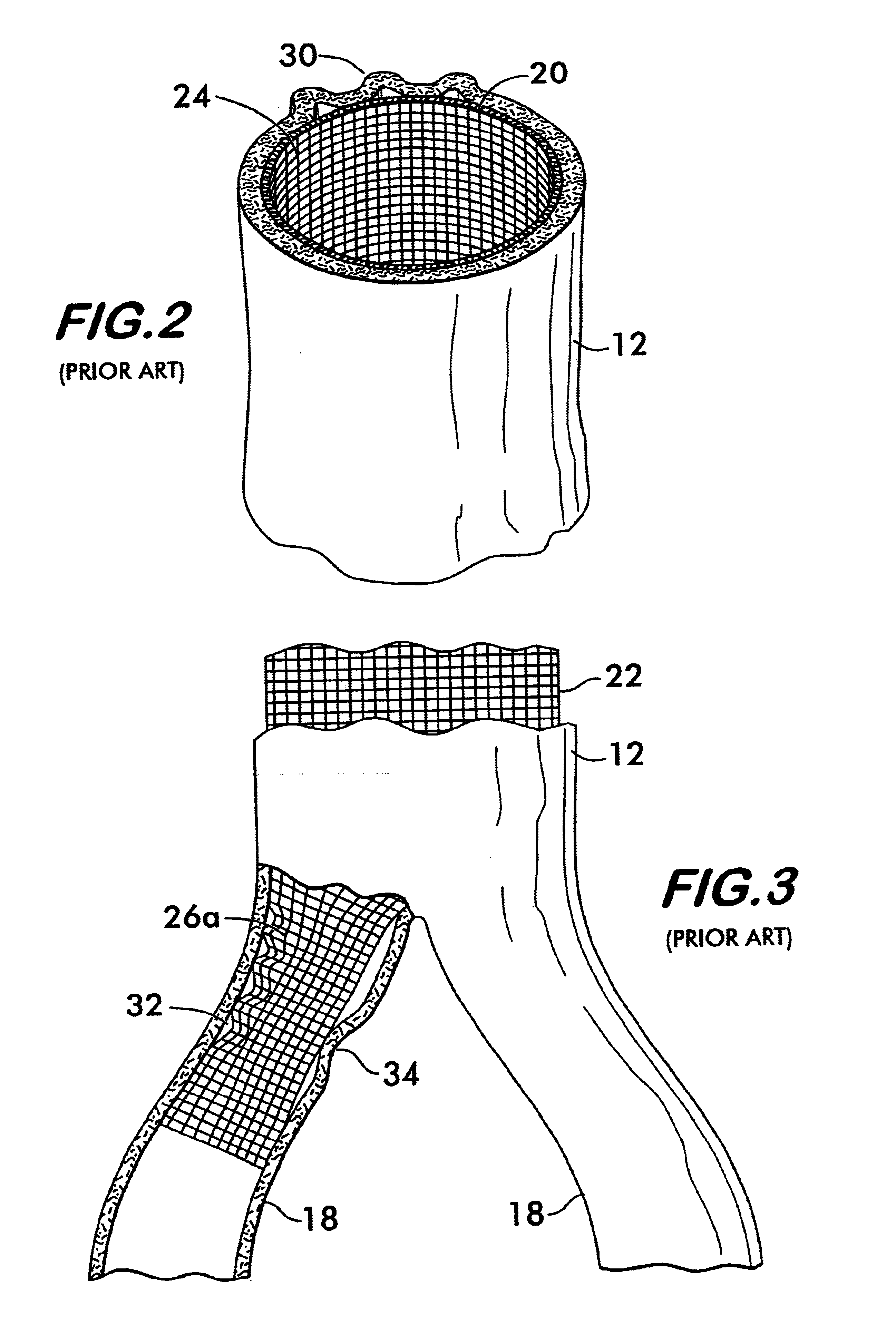

Woven stent/graft structure

A combined stent / graft structure for repair of a body tube in a living body. The structure includes a textile graft adapted to enhance fluid integrity of the body tube and a stent expandable between a first position permitting easy insertion of the stent into the body tube and a second position wherein the stent presses securely against the inside surface of the body tube. The stent includes a first elongate wire-shaped stent member with both a stent member global axis and a stent member local axis, and is integrally secured to the graft by at least one graft yarn of which the graft is formed. Substantial portions of the first stent member global axis form a non-orthogonal angle with the graft main portion axis when projected into a plane containing the graft main portion axis. A woven textile is also part of the invention as is a method of manufacturing such a woven textile, which can be used to produce stent / graft structures according to the invention.

Owner:SECANT MEDICAL

Footwear with knit upper and method of manufacturing the footwear

An article of footwear with a knit upper and a method of manufacturing the footwear are disclosed. The upper is formed through a knitting process to include a plurality of sections formed of different yarns and knits to provide the sections with different physical properties. In portions of the upper where sections formed of different yarns are in adjacent wales, a tuck stitch is utilized to join the sections. The method utilizes a circular knitting machine having multiple feeds that work together to knit the upper into a unitary, seamless structure. The multiple feeds, each of which provide multiple types of yarns, produce the sections to have varying physical properties.

Owner:NIKE INC

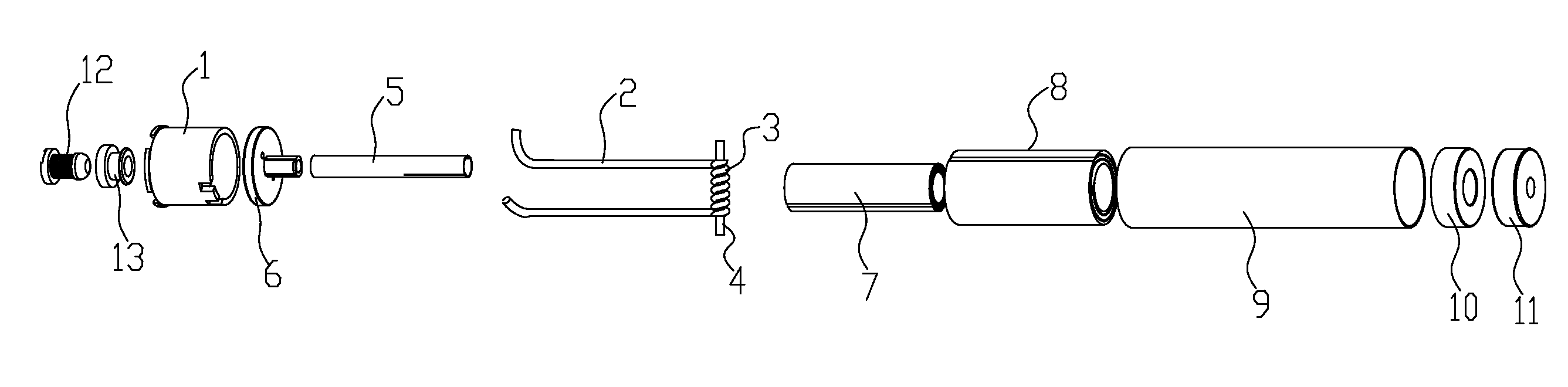

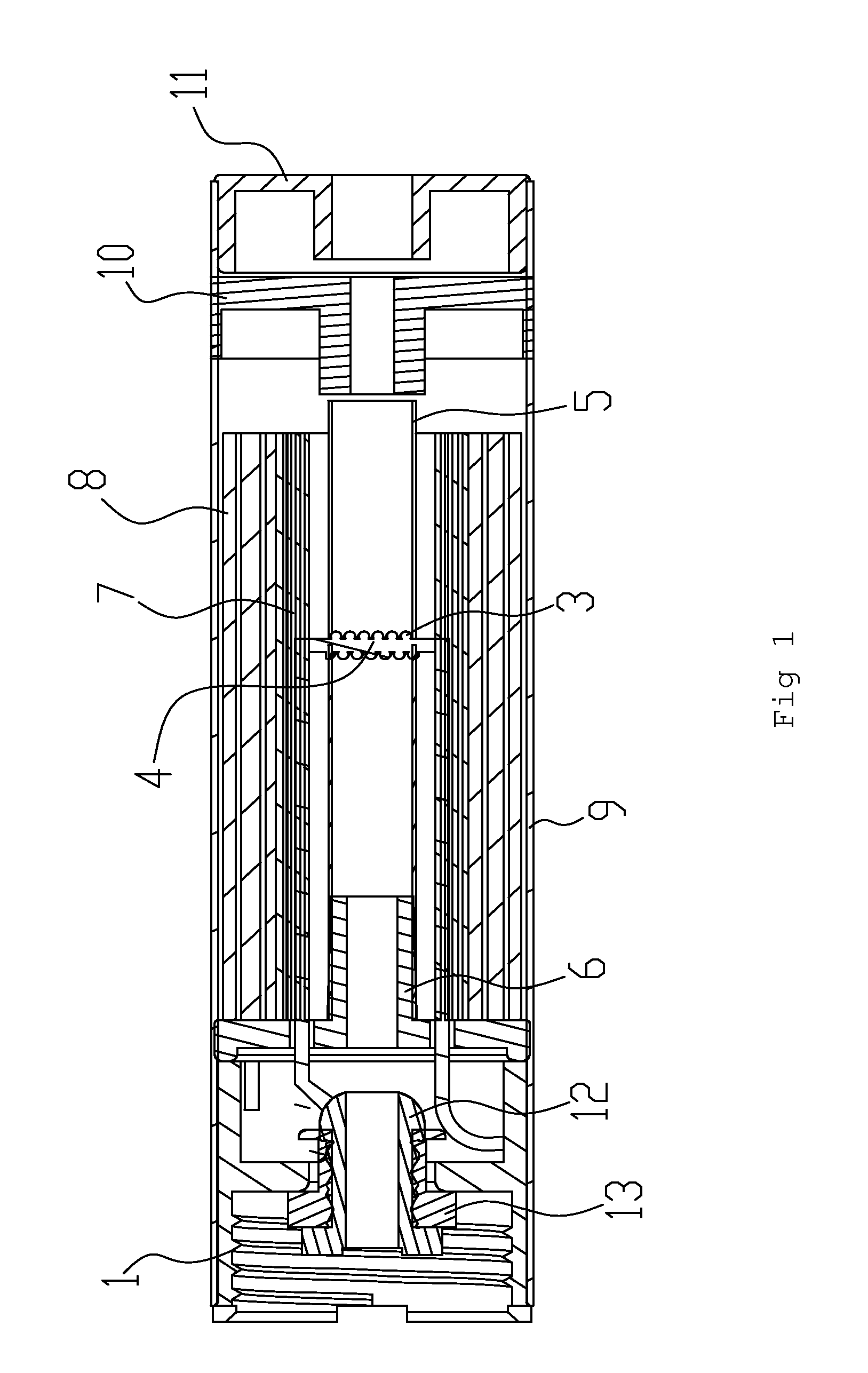

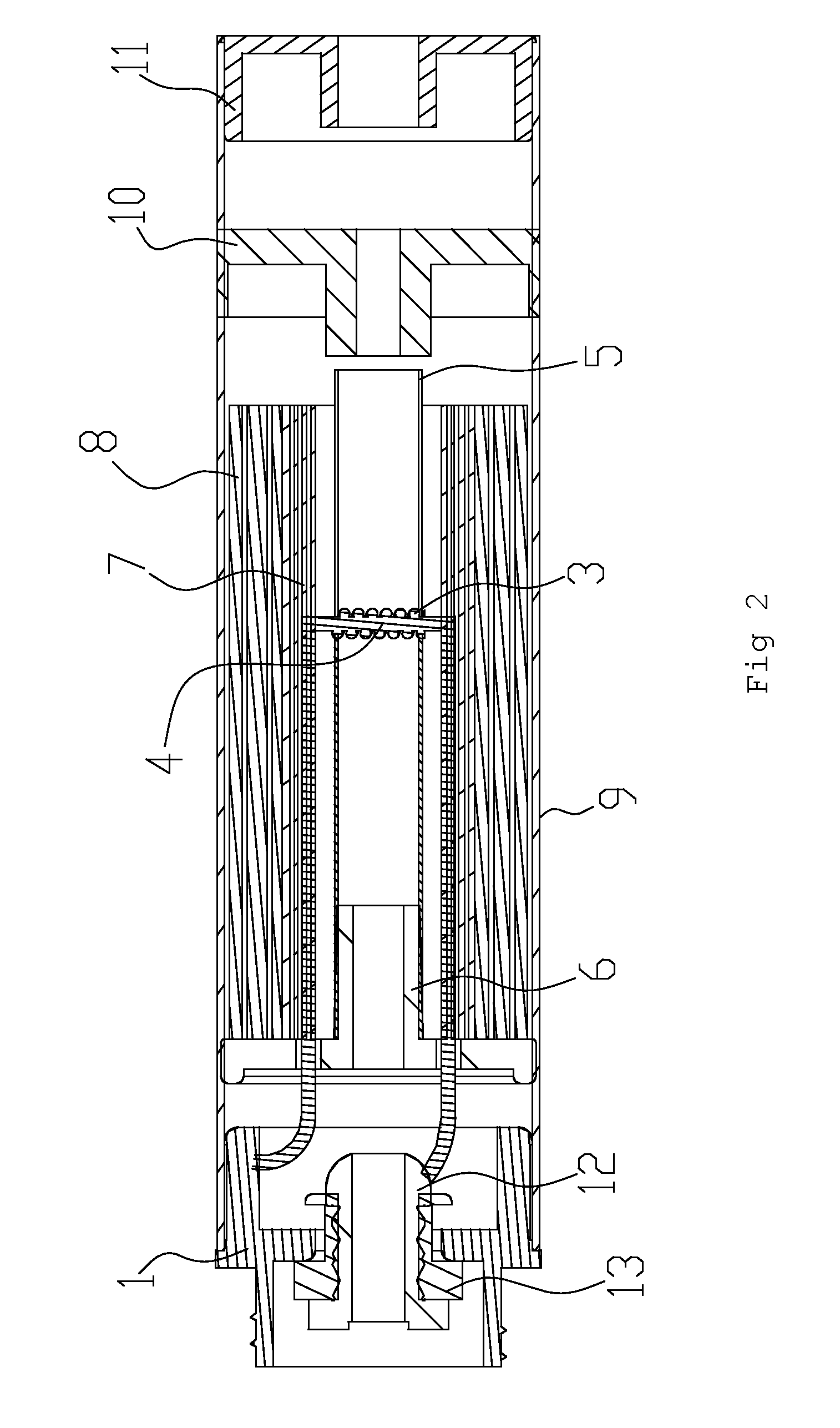

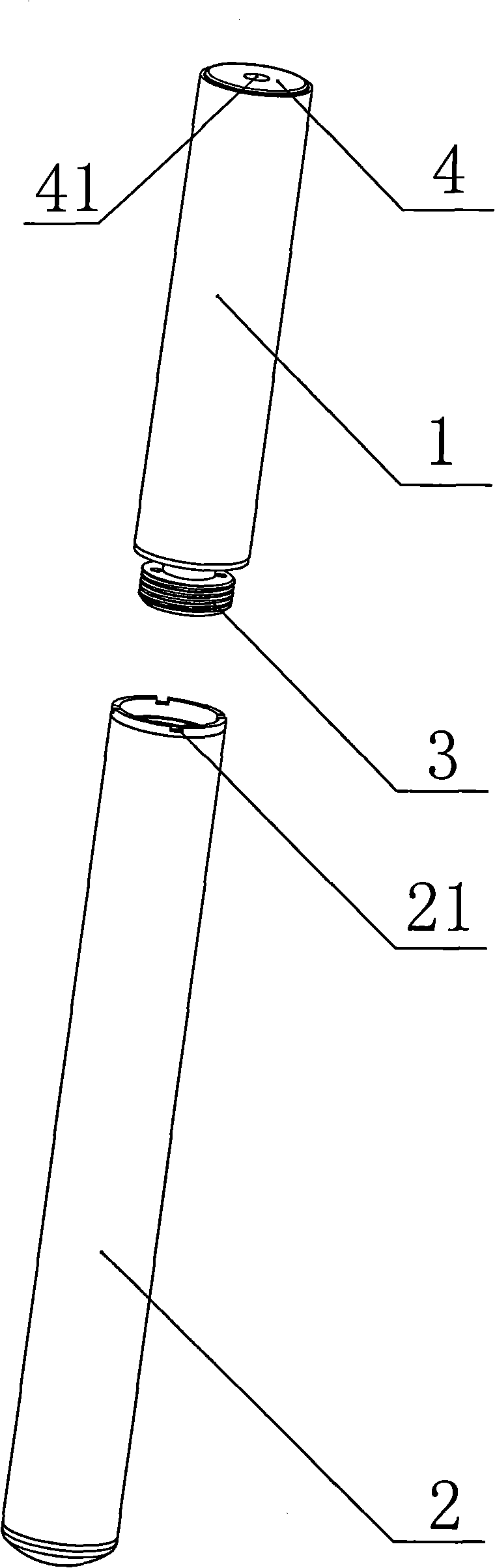

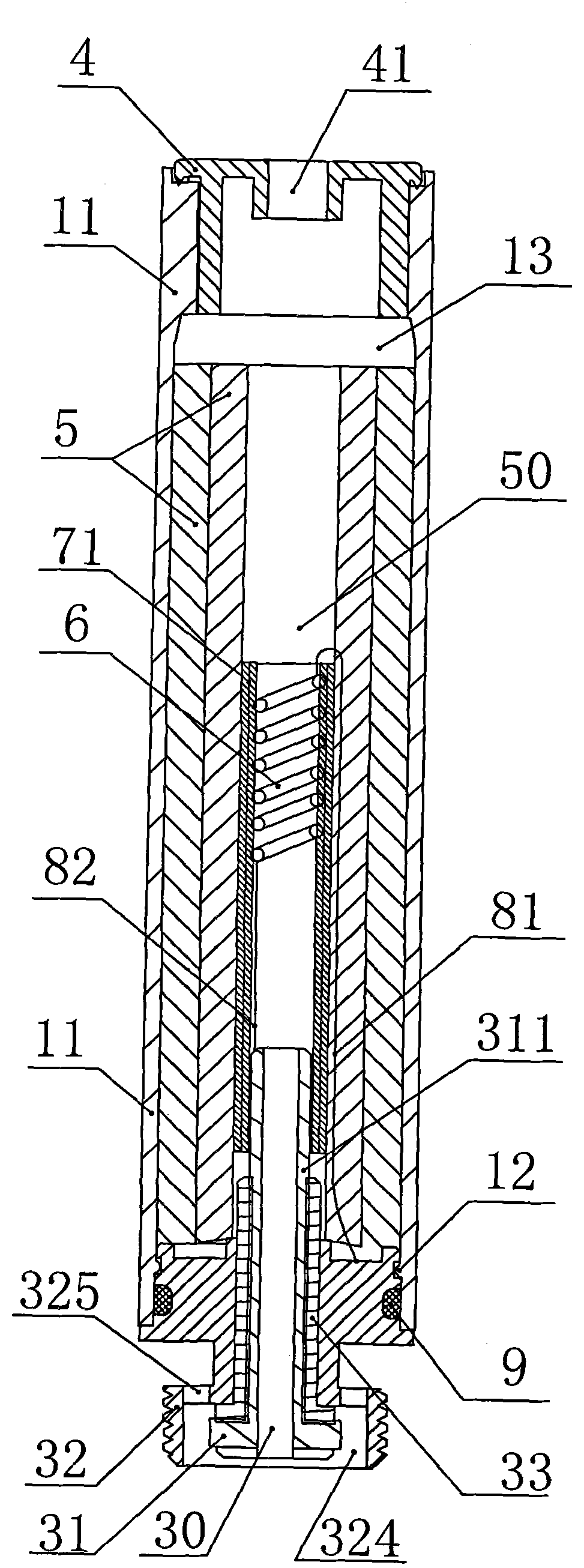

Tobacco Solution Atomizing Device For Electronic Cigarette

A tobacco solution atomizing device for electronic cigarette is disclosed the device comprises an atomizer installed in a fixing sleeve; a suction nozzle component and electrode connectors coupled on respective ends of the fixing sleeve, wherein the electrode connectors comprises a positive electrode connector and a negative electrode connector; the atomizer comprising a glass fiber tube, a glass fiber yarn, a heating coil, a cotton cloth layer and a synthetic fiber layer, wherein the glass fiber yarn is insert into the heating coil which is then located inside the glass fiber tube; the ends of the glass fiber silk and two wires which are used to electronically connect the heating coil to the positive and negative electrode connectors extends outward through the glass fiber tube; the cotton cloth layer enwraps the outside wall of the glass fiber tube and reveal ends of the glass fiber yarn are pressed tightly between the cotton cloth layer and the glass fiber tube; a synthetic fiber layer is filled within the annular shape space between the cotton cloth layer and the fixing sleeve for holding the tobacco solution.

Owner:LI YONGHAI +1

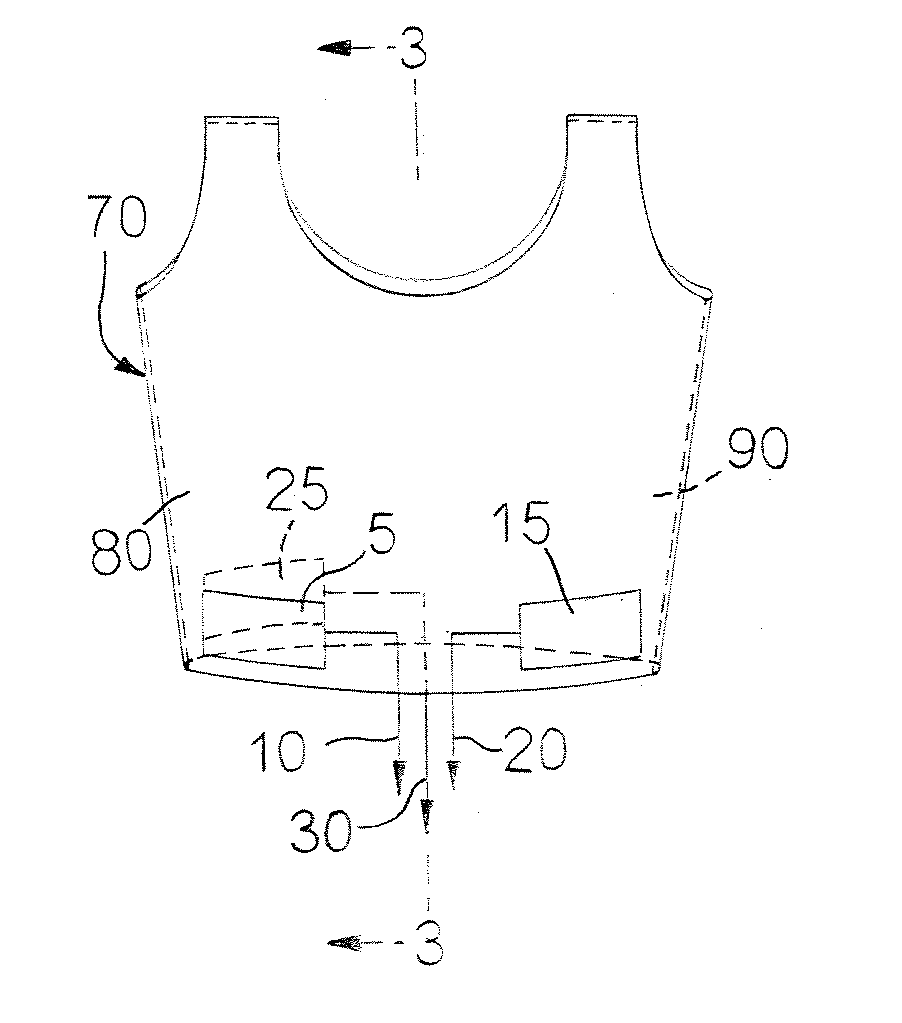

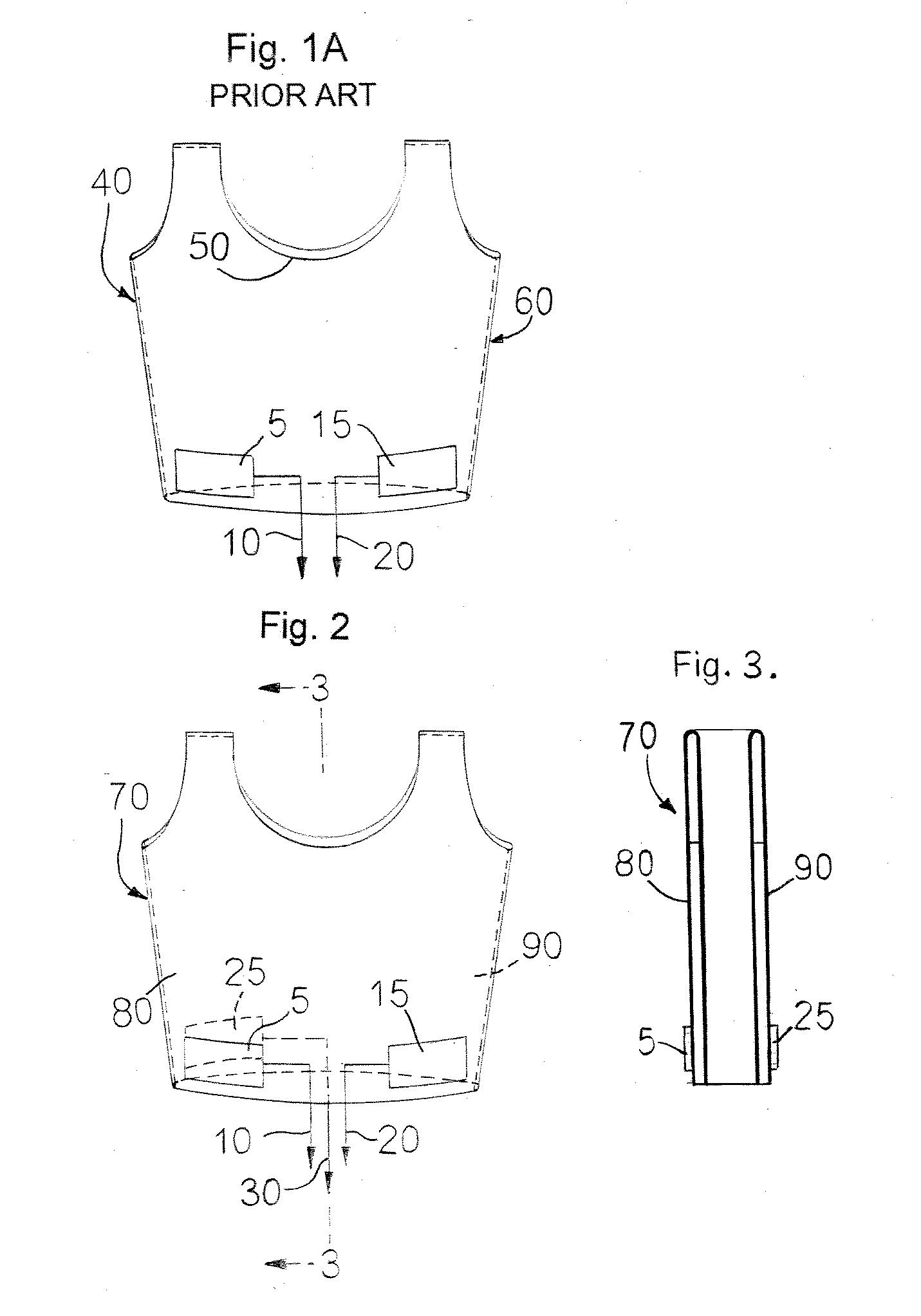

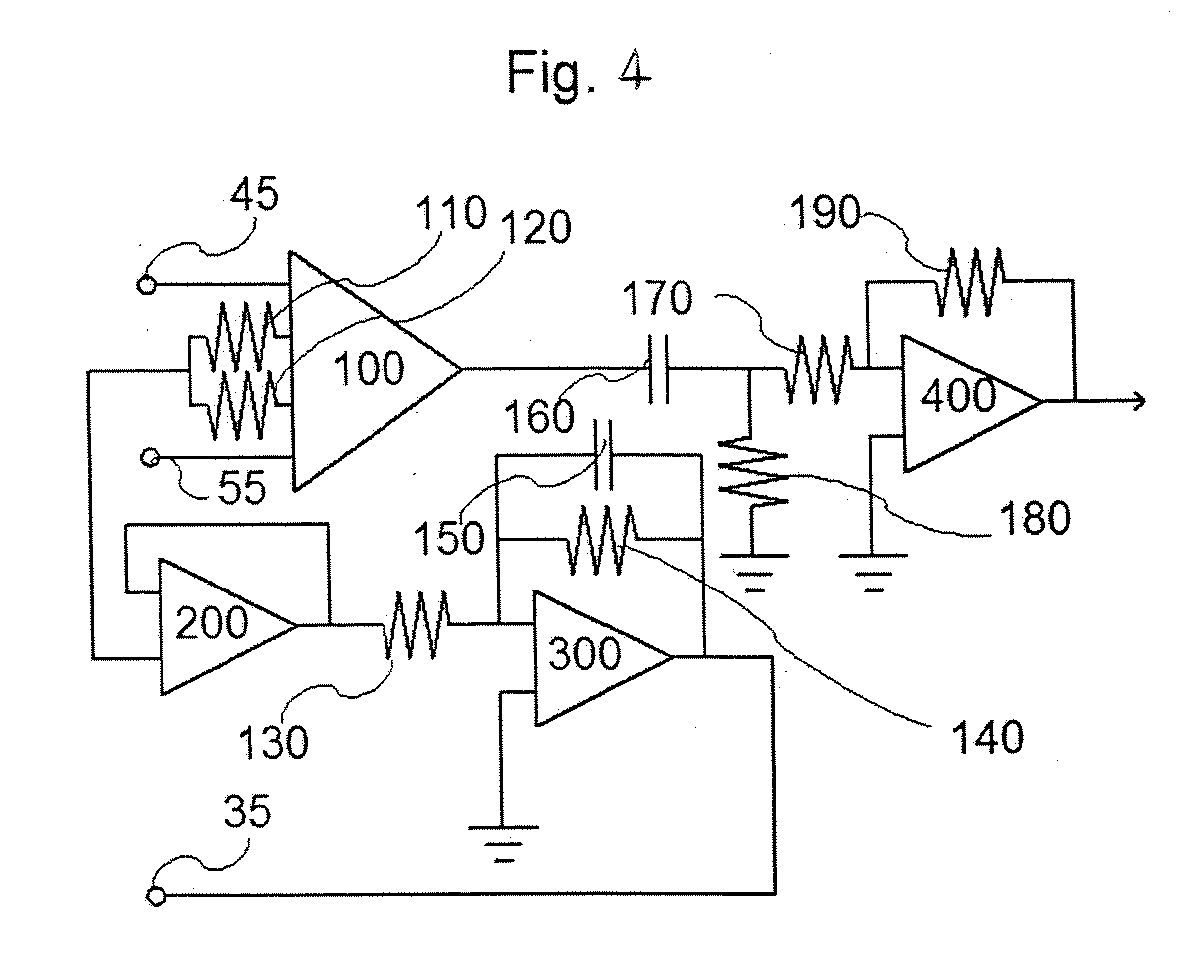

Physiological Monitoring Wearable Having Three Electrodes

A wearable system or garment comprises at least three conductive electrodes that may, for example, be made of stretch-recovery electrically conductive yarns integrated with non-conductive stretch-recovery yarns that make up the remaining portion of the wearable system or garment. The wearable or garment further comprises means for using three electrodes to monitor at least one physiological or biophysical event or characteristic of the wearer. One electrode is specifically used to feed back an inverted noise signal to the wearer to destructively interfere with the wearer generated noise. Specifically, the wearer's heart rate, ECG and associated electrical characteristics may be monitored in high resolution under dry electrode conditions.

Owner:TEXTRONICS

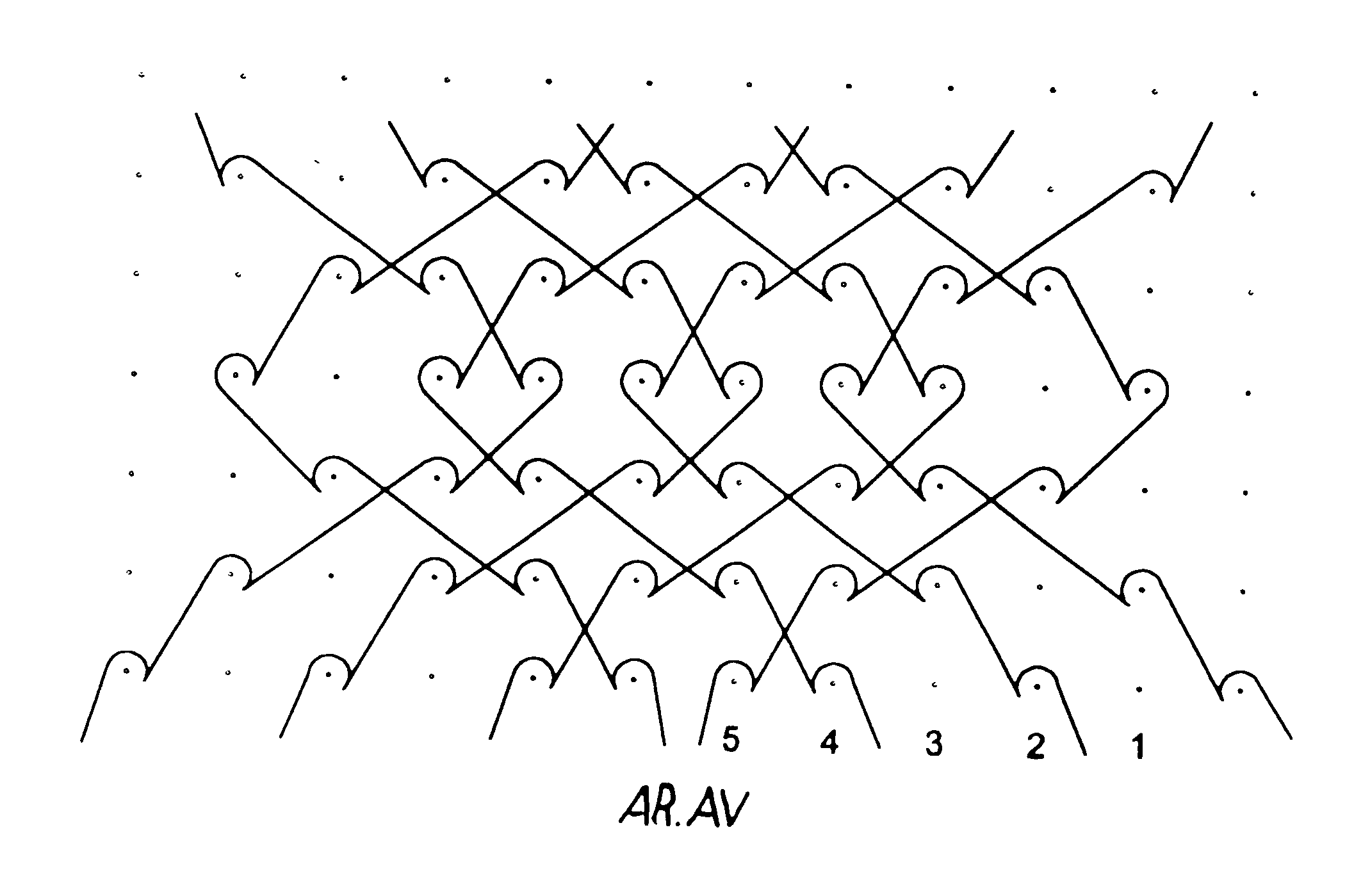

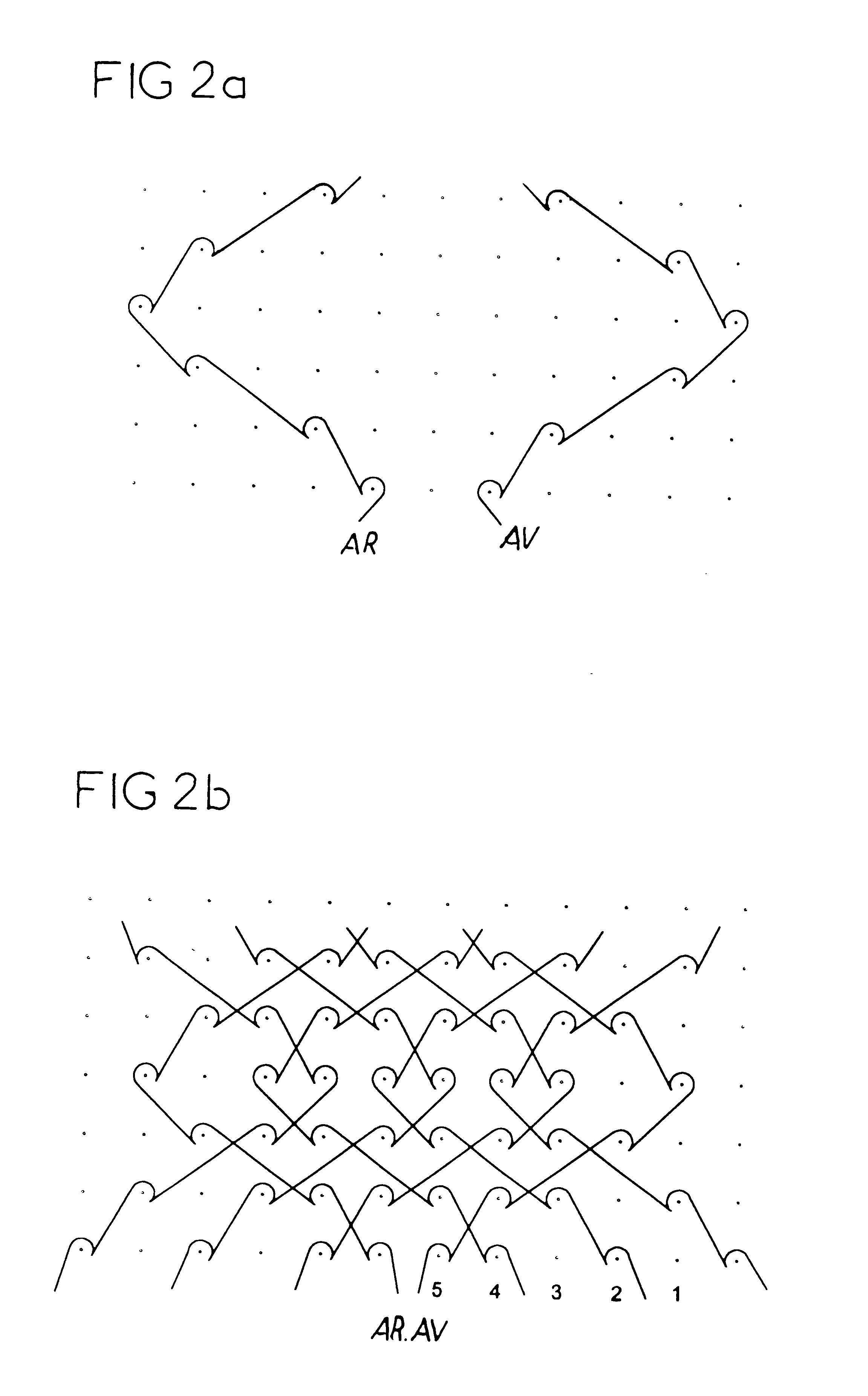

Isoelastic prosthetic filet stitch fabric

This knit is produced on the basis of a biocompatible polymer material monofilament, whose pattern is defined by a front lap and a rear lap of yarns knitted together and determines a plurality of cells each having a substantially polygonal shape. The pattern gives the knit a multidirectional tensile behavior such as obtained by a front lap capable of being obtained by knitting according to a scheme 5-4 / 4-3 / 2-1 / 0-1 / 1-2 / 3-4 and by a rear lap capable of being obtained by knitting according to a scheme 0-1 / 1-2 / 3-4 / 5-4 / 4-3 / 2-1.

Owner:SOFRADIM PROD SAS

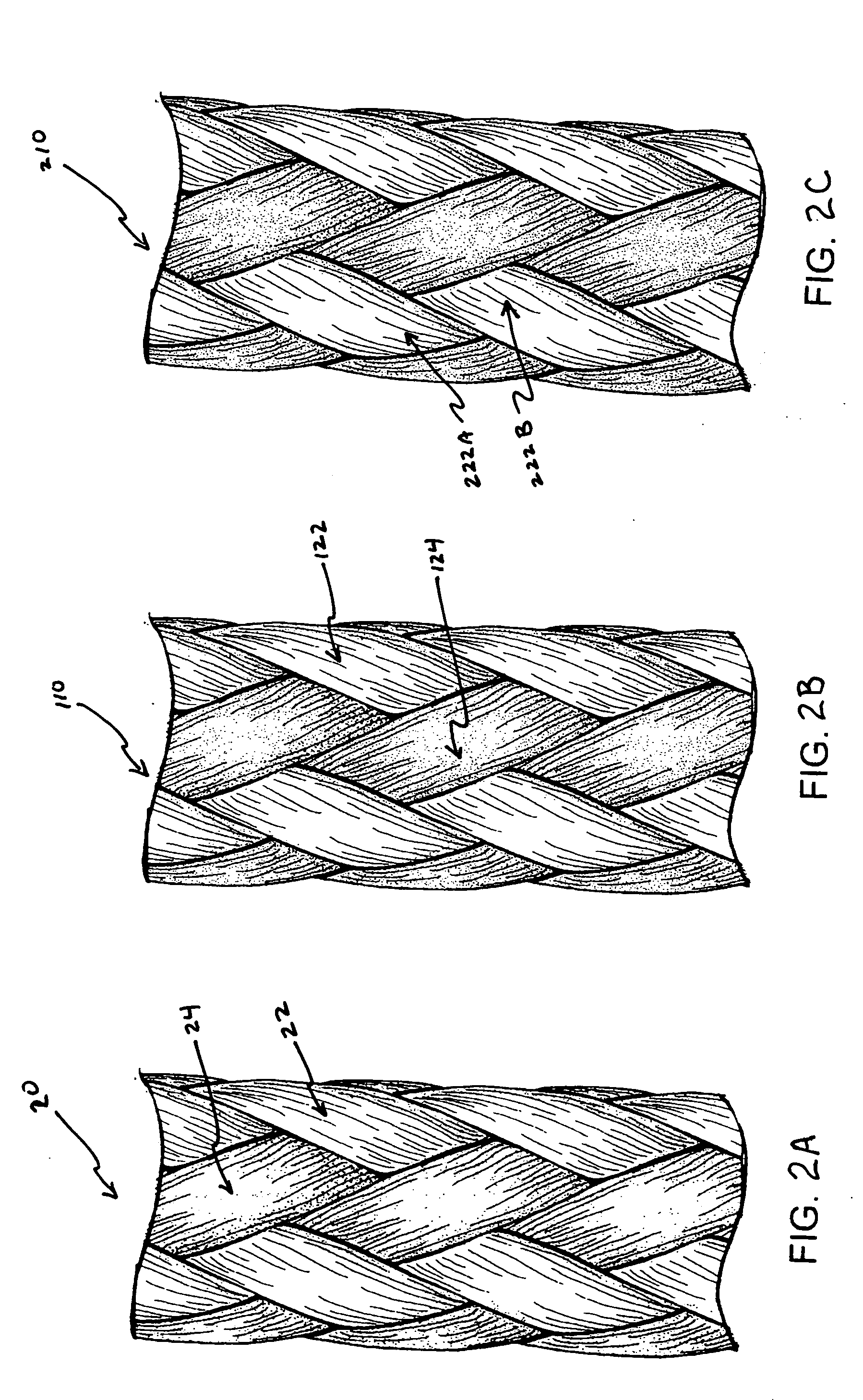

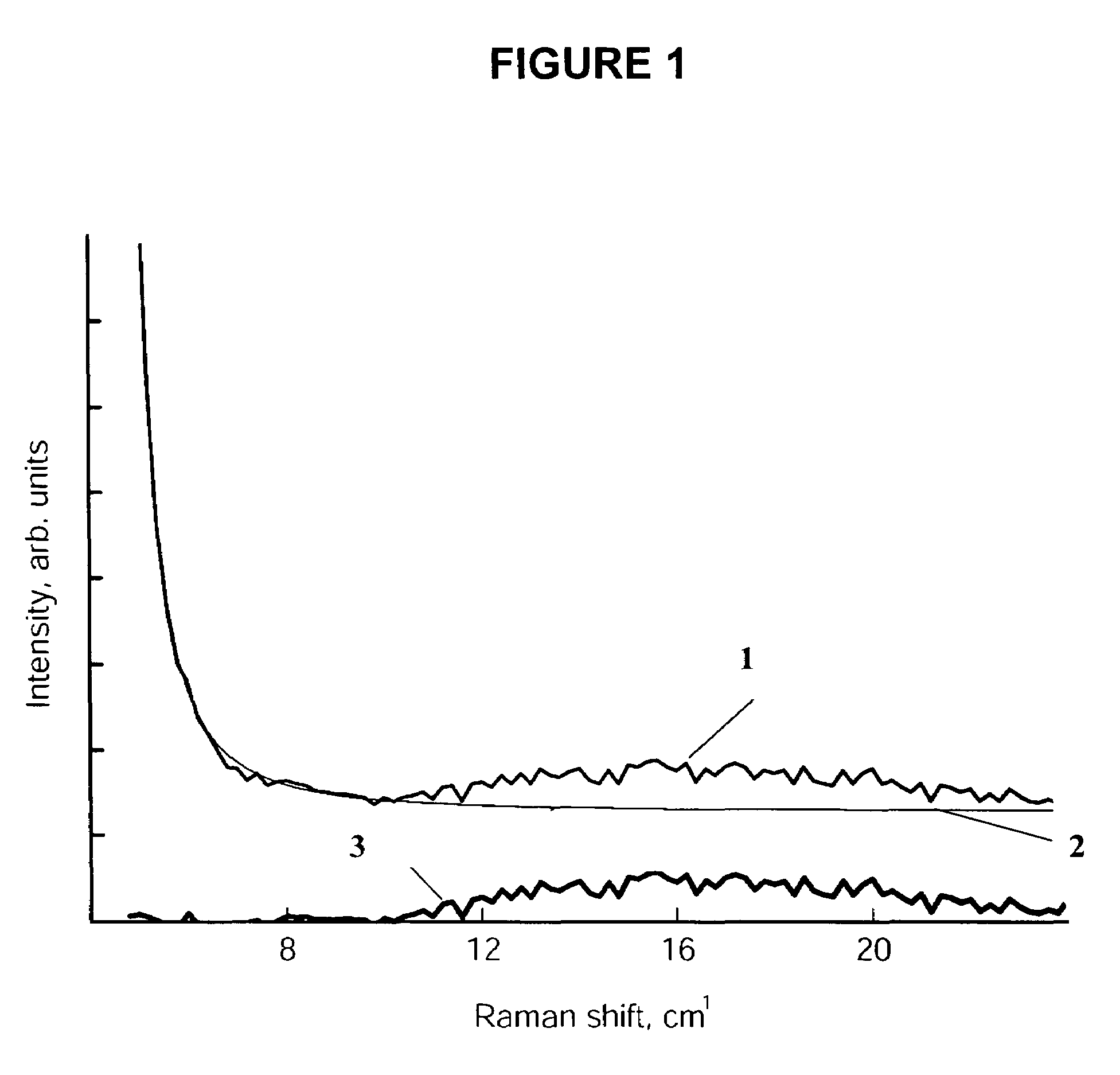

Carbon nanotube fabrics

The present invention provides fabrics that have unique chemical, electrical, and thermal properties. The fabrics comprise layers of yarns woven together wherein the yarns further comprise carbon nanotube fibers. These carbon nanotube fibers may be either single-walled or multi-walled carbon nanotubes. The use of carbon nanotube fibers allows the fabrics to insulate, semi-conduct or super-conduct electrical charges. Additionally, the thermal properties of carbon nanotubes allow thermal energy to flow efficiently between the fabric and a heat sink or source. Additional yarns of materials other than carbon nanotubes can be integrated or woven into the fabric to provide other unique properties for the fabric. These fabrics can be layered to form unique garments or structures.

Owner:LOCKHEED MARTIN CORP

Ballistic fabric laminates

InactiveUS6846758B2Improved ballistic protectionImprove protectionSynthetic resin layered productsPersonal protection gearElastomerYarn

Woven fabric laminates having superior resistance to penetration by ballistic projectiles, assemblies thereof, and the method by which they are made. In one embodiment, among others, a laminate of the invention is comprised of a fabric woven from a high strength, high modulus yarn, a surface coating of a low modulus elastomer and a plastic film bonded to its elastomer-coated surface.

Owner:HONEYWELL INT INC

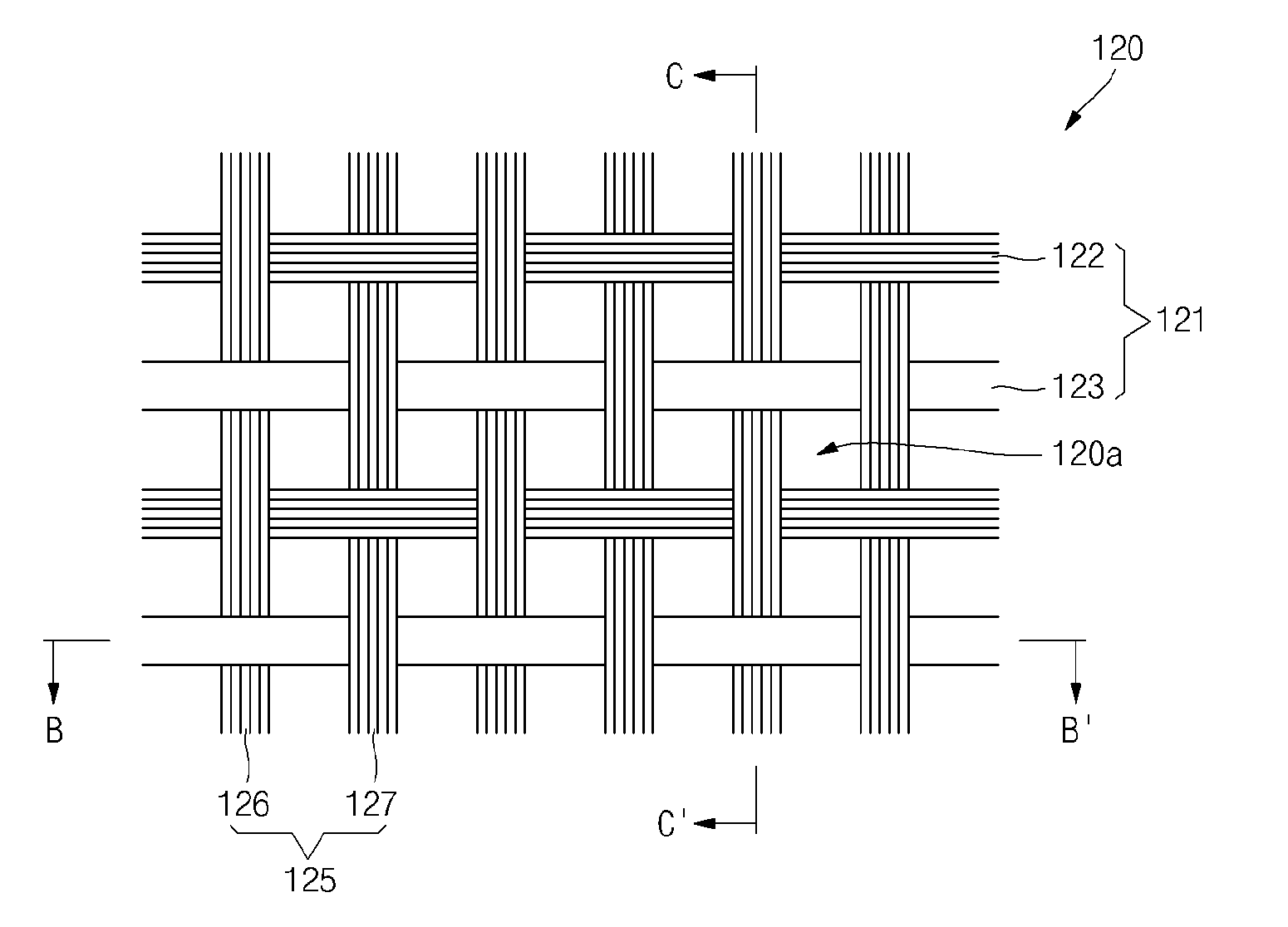

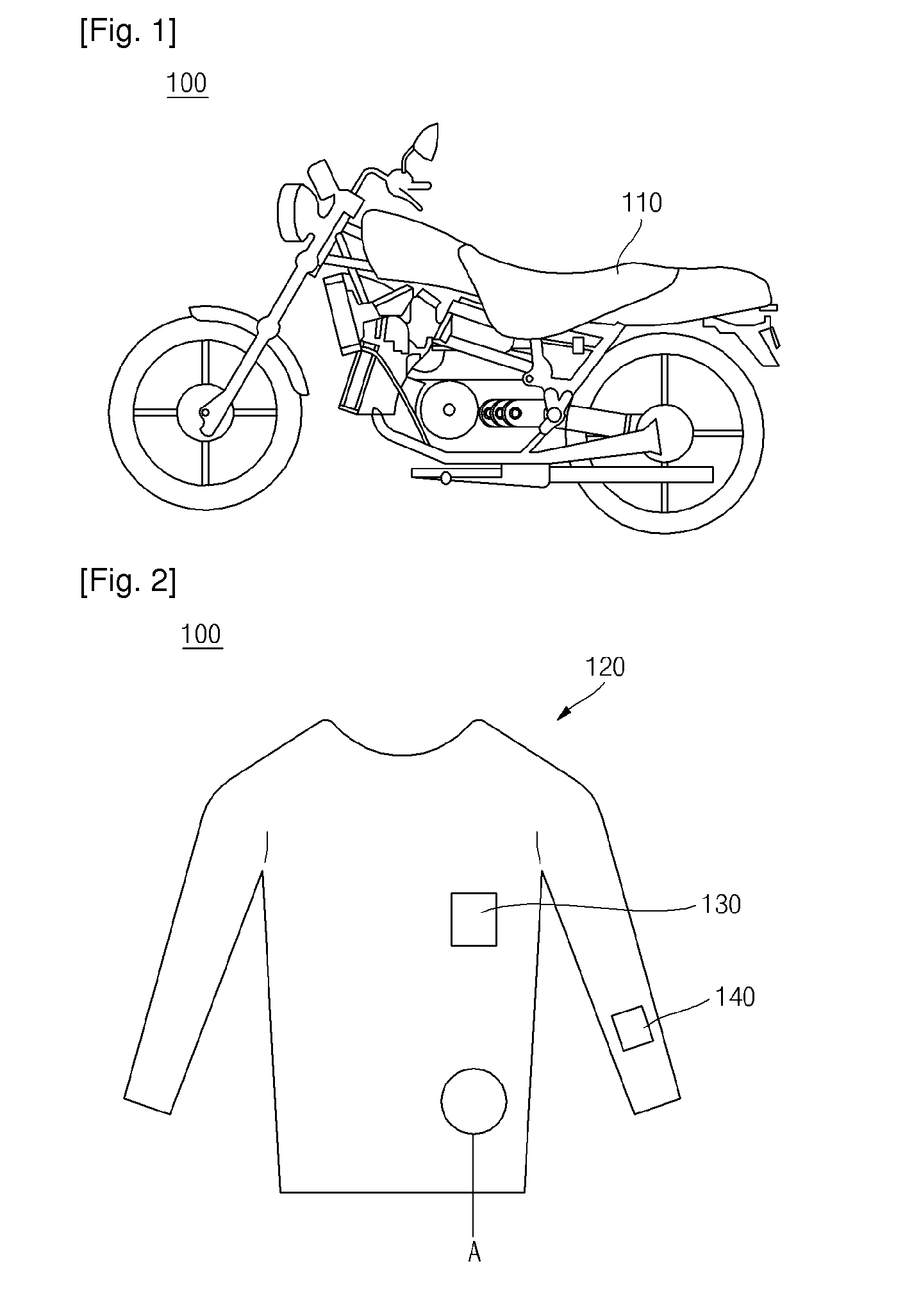

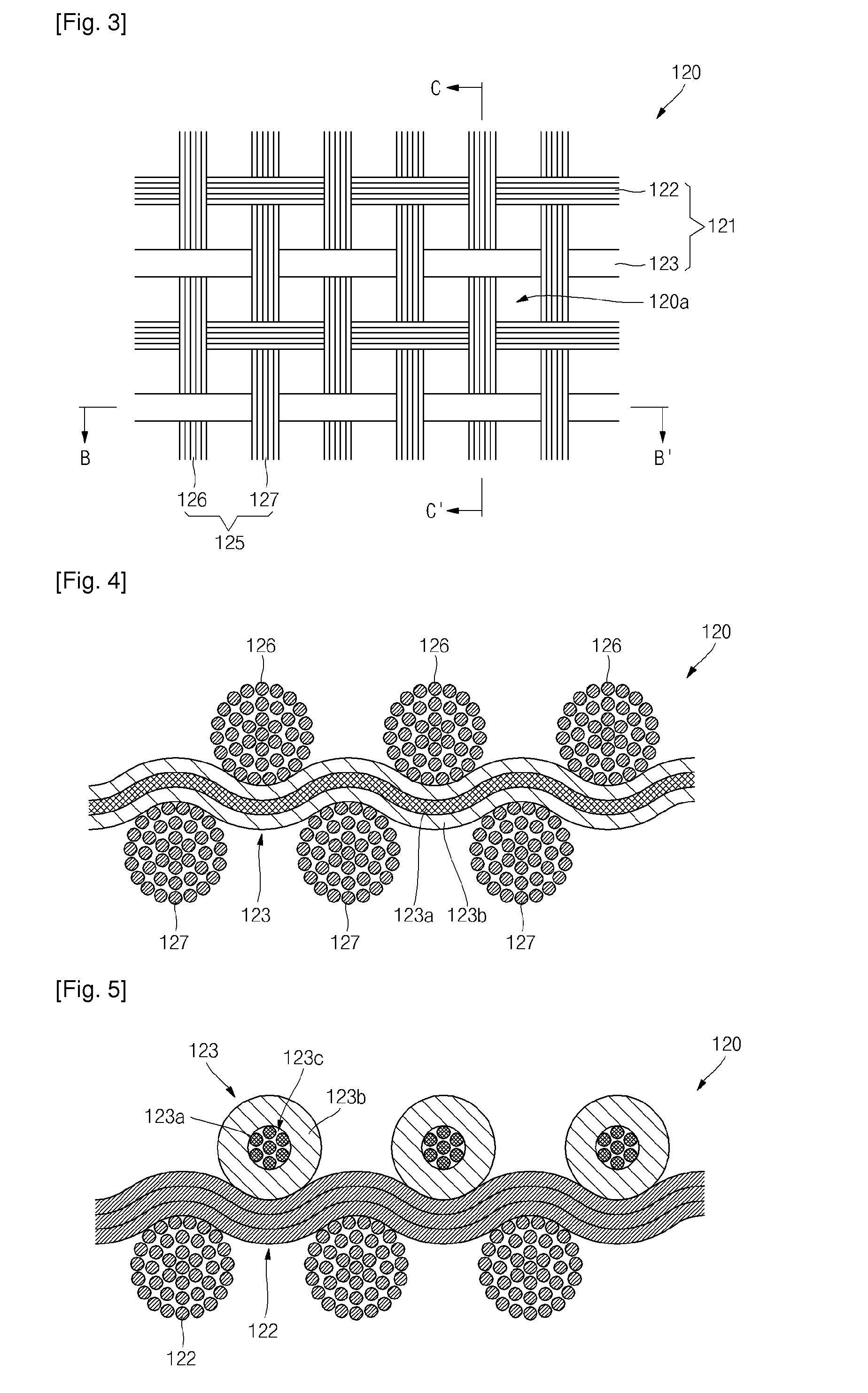

Contactlessly chargeable heater

ActiveUS20130032589A1Increasing user 's convenienceEasily transfers heatTransformersOhmic-resistance heatingYarnEngineering

The present invention relates to a contactlessly chargeable heater. In one example, the contactles sly chargeable heater includes: a charging patch emitting magnetic force by means of current applied to an inner coil; and a heating body, receiving the magnetic force from the charging patch to perform a contactless charging operation, and including a digital yarn for emitting heat via the power generated through the contactless charging operation. The digital yarn is woven together using threads within the heating body.

Owner:GAIA HEALTHCARE INC

Fabrics and Garments with Information Infrastructure

Fabrics, articles of apparel, and / or garment structures include infrastructure for transmitting information, such as signals produced by a wearer or from another source. Such fabrics may include: a textile formed through a knitting or weaving process, wherein at least one yarn used in the knitting or weaving process is electrically conductive to form sensor regions and / or other integrated electrically conductive infrastructure for transmitting electrical signals. Additional information is provided relating to methods for forming fabrics, articles of apparel, and / or garment structures of the types described above, as well as methods of using such products, e.g., for monitoring and / or displaying information regarding one or more physical and / or physiological parameters.

Owner:SENSATEX

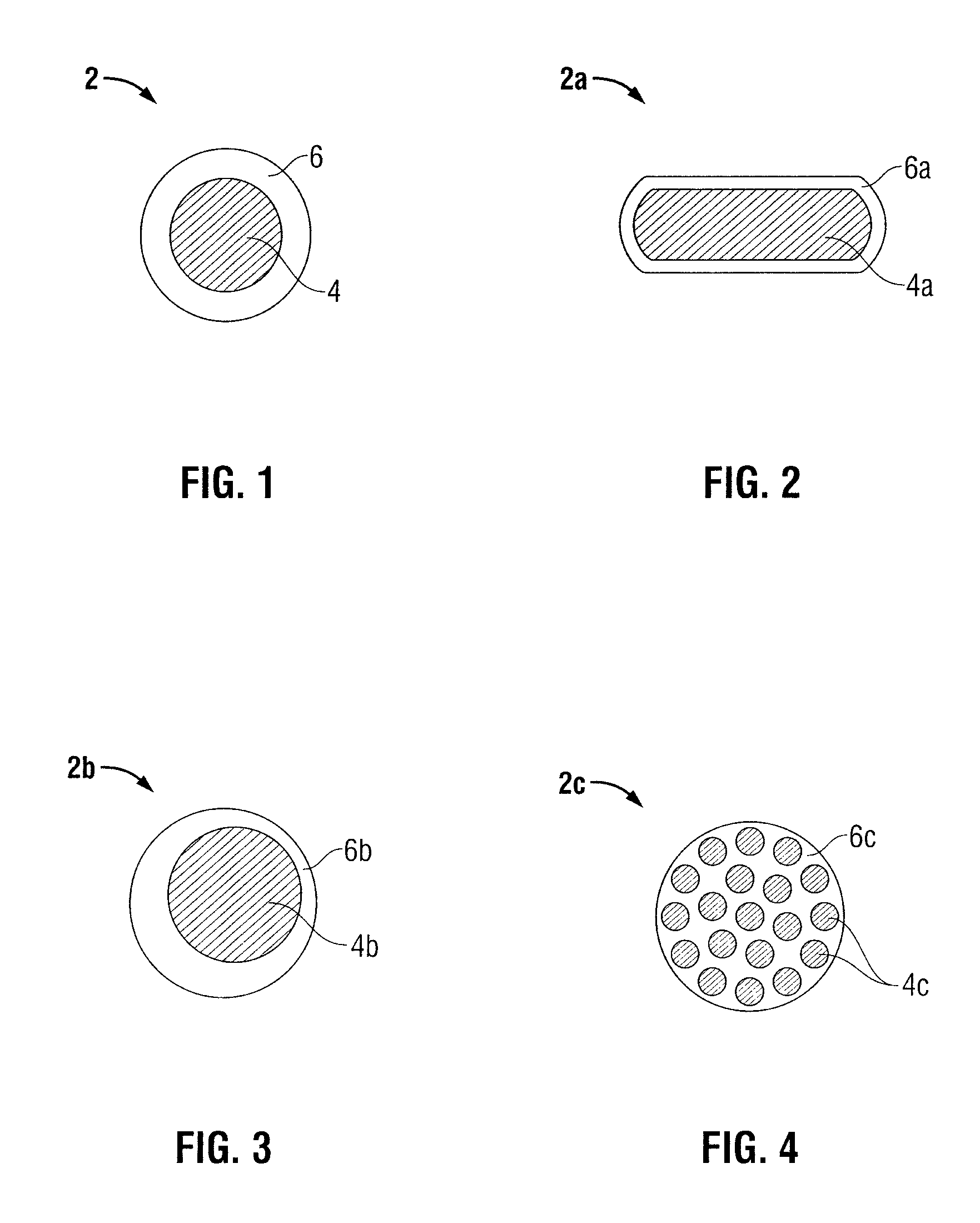

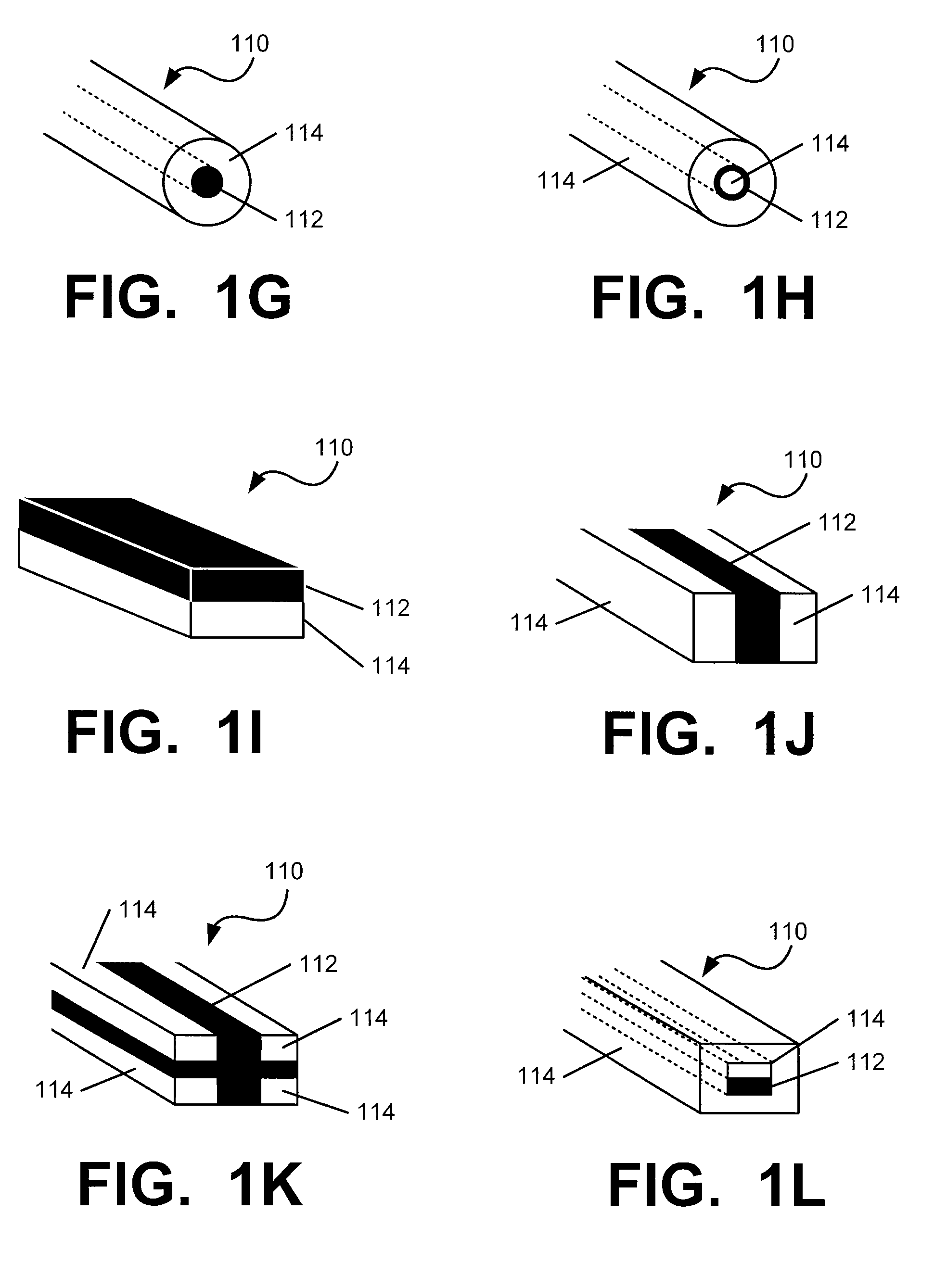

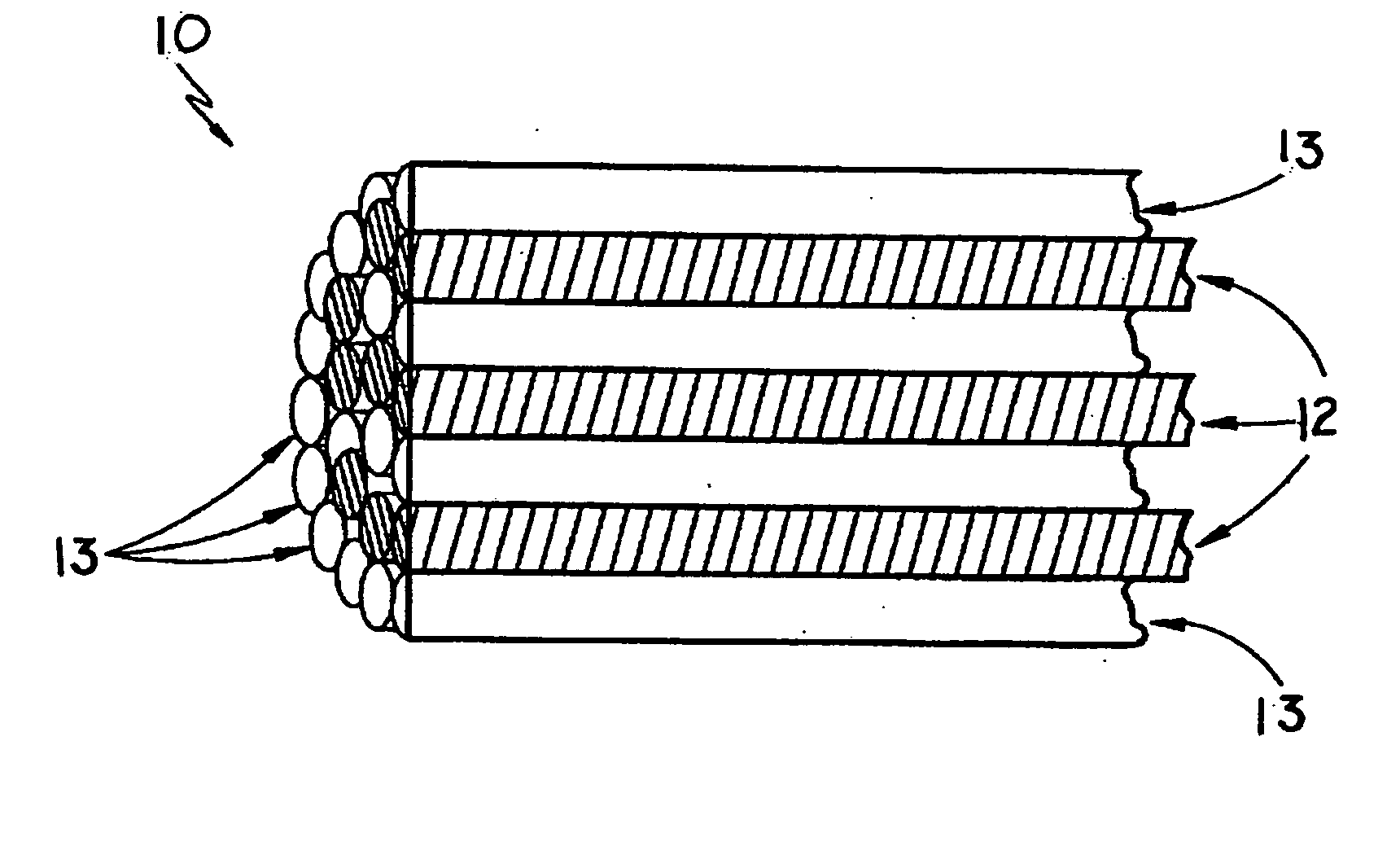

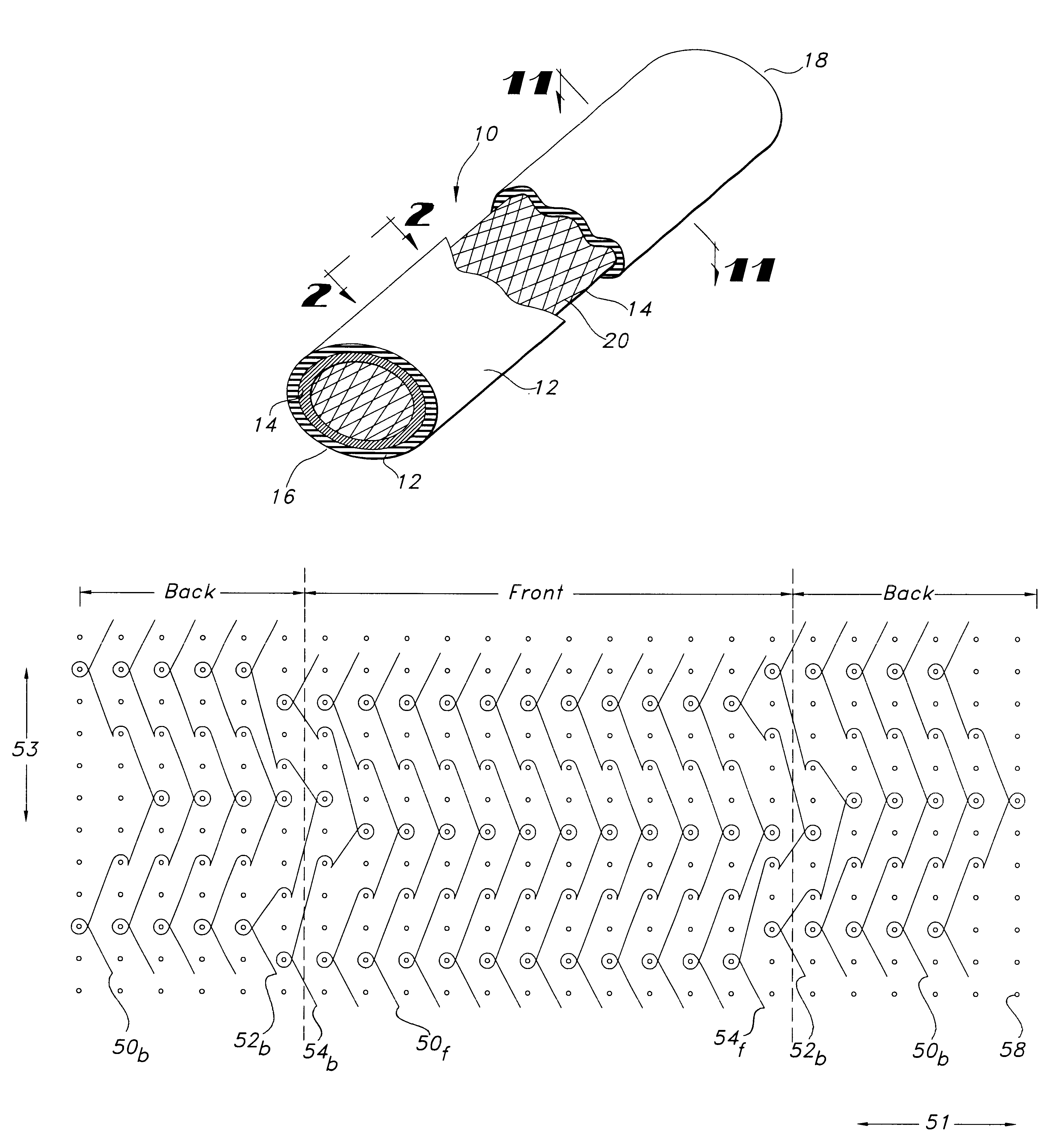

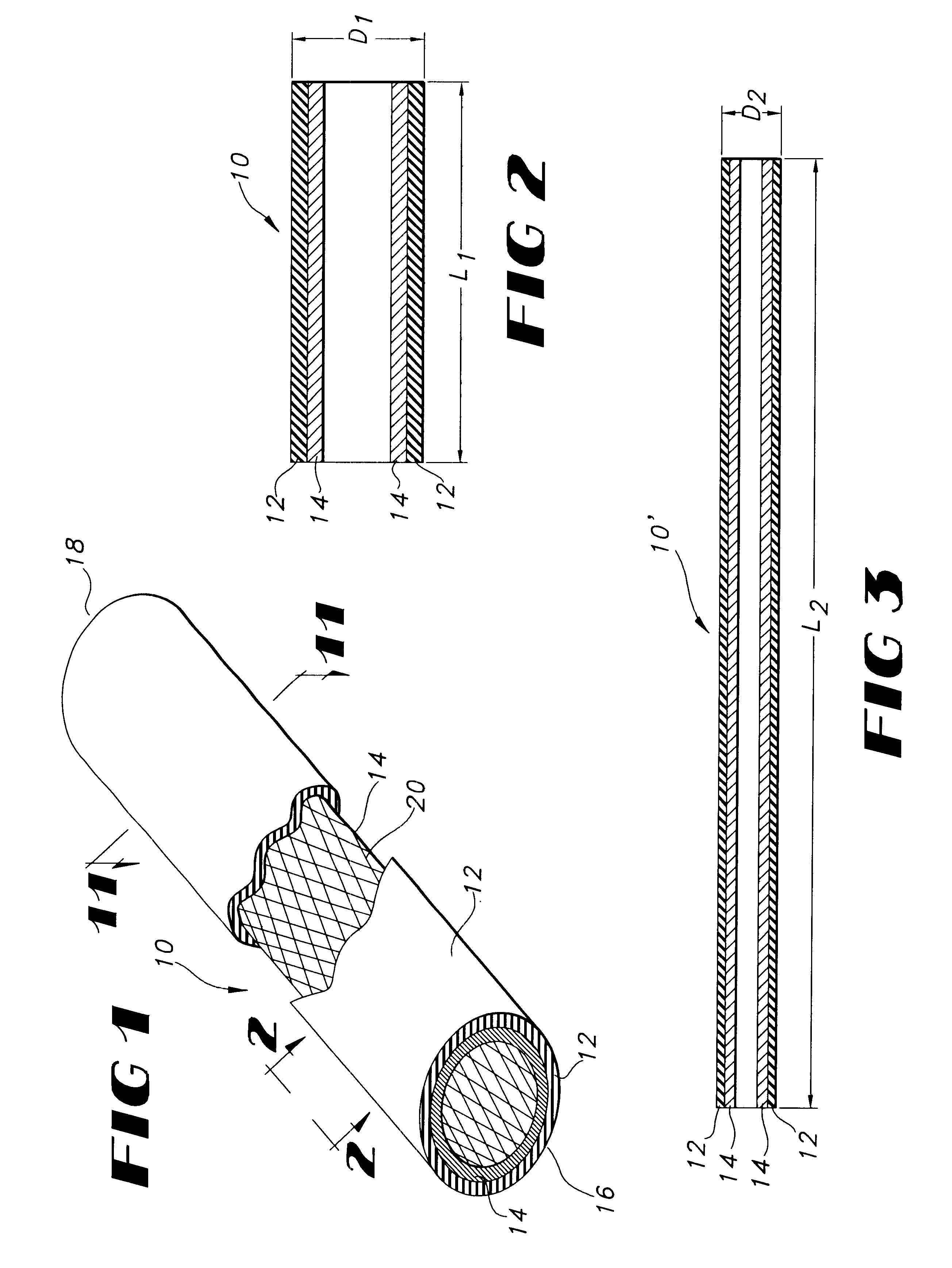

High strength suture with absorbable core and suture anchor combination

ActiveUS20050149118A1Improved absorption profileReducing knot profile of knotSuture equipmentsSurgical needlesYarnMedicine

A novel high tensile strength semi-absorbable composite suture with minimized non-absorbable mass. The suture has a core made from a bioabsorbable polymer. The core is covered by a braided sheath. The braided sheath is made from an absorbable yarn and a bioabsorbable yarn. The bioabsorbable yarn is made from a least one filament of a bioabsorbable polymer. The nonabsorbable yarn is made from at least one filament of ultra high molecular weight polyethylene.

Owner:DEPUY SYNTHES PROD INC

Water blocking electrical cable

ActiveUS7750244B1Light weightEasy to manufactureClimate change adaptationInsulated cablesYarnElectrical conductor

An electrical cable for shipboard use that can block water is disclosed. The electrical cable includes conductors, water swellable tapes, water swellable yarns, solid fillers, and a jacket. Each conductor is substantially wrapped with water swellable tape. The conductors are disposed adjacent to each other thereby forming interstitial voids between each of the conductors. Solid fillers and water swellable yarns are alternatively disposed in each interstitial void. Additional water swellable tape substantially envelopes the conductors, water swellable yarns, and solid fillers. The jacket is disposed on the outermost peripheral surface of the electrical cable.

Owner:GENERAL CABLE TECH CORP

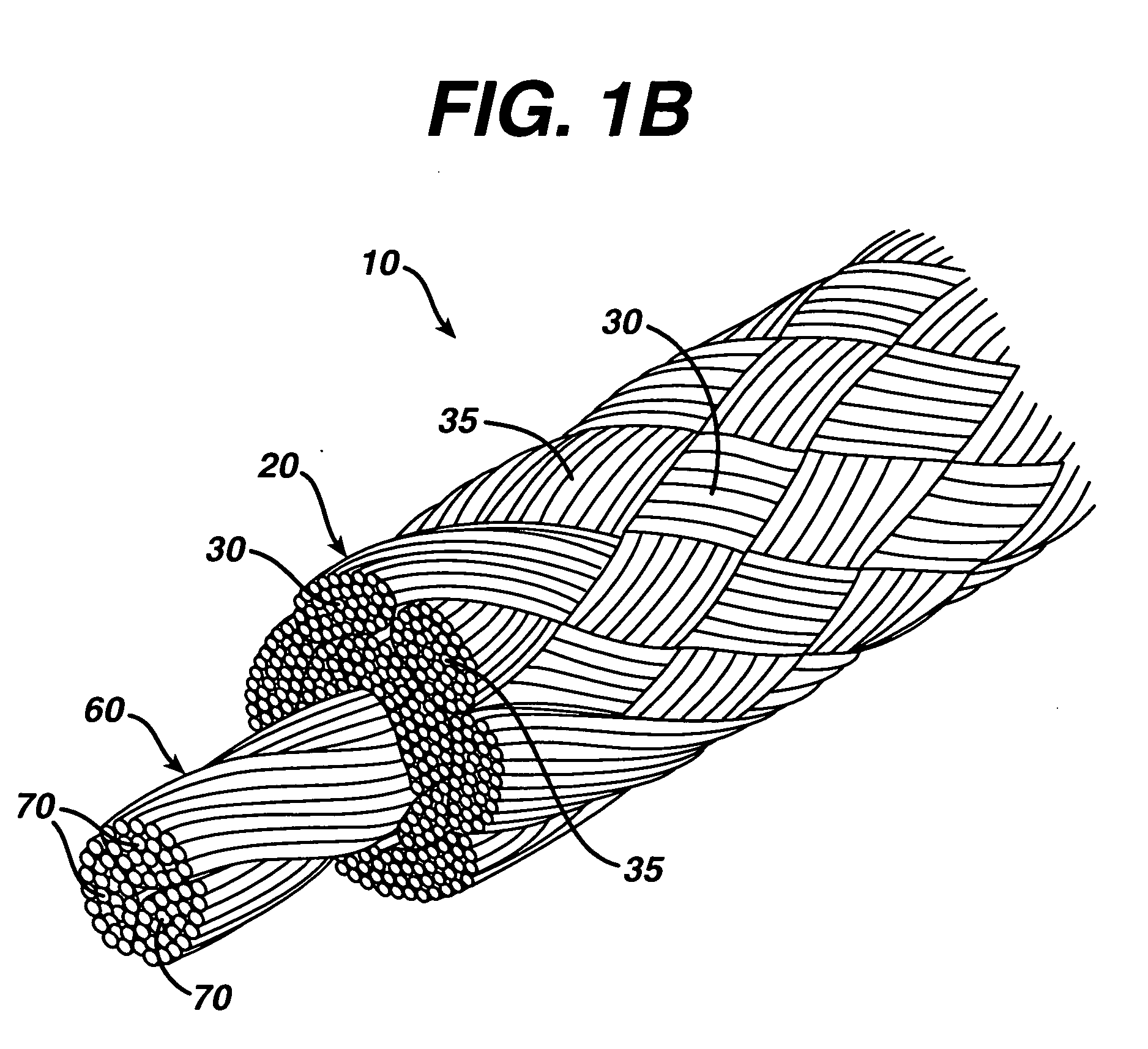

Yarns containing filaments made from shape memory alloys

Owner:TYCO HEALTHCARE GRP LP

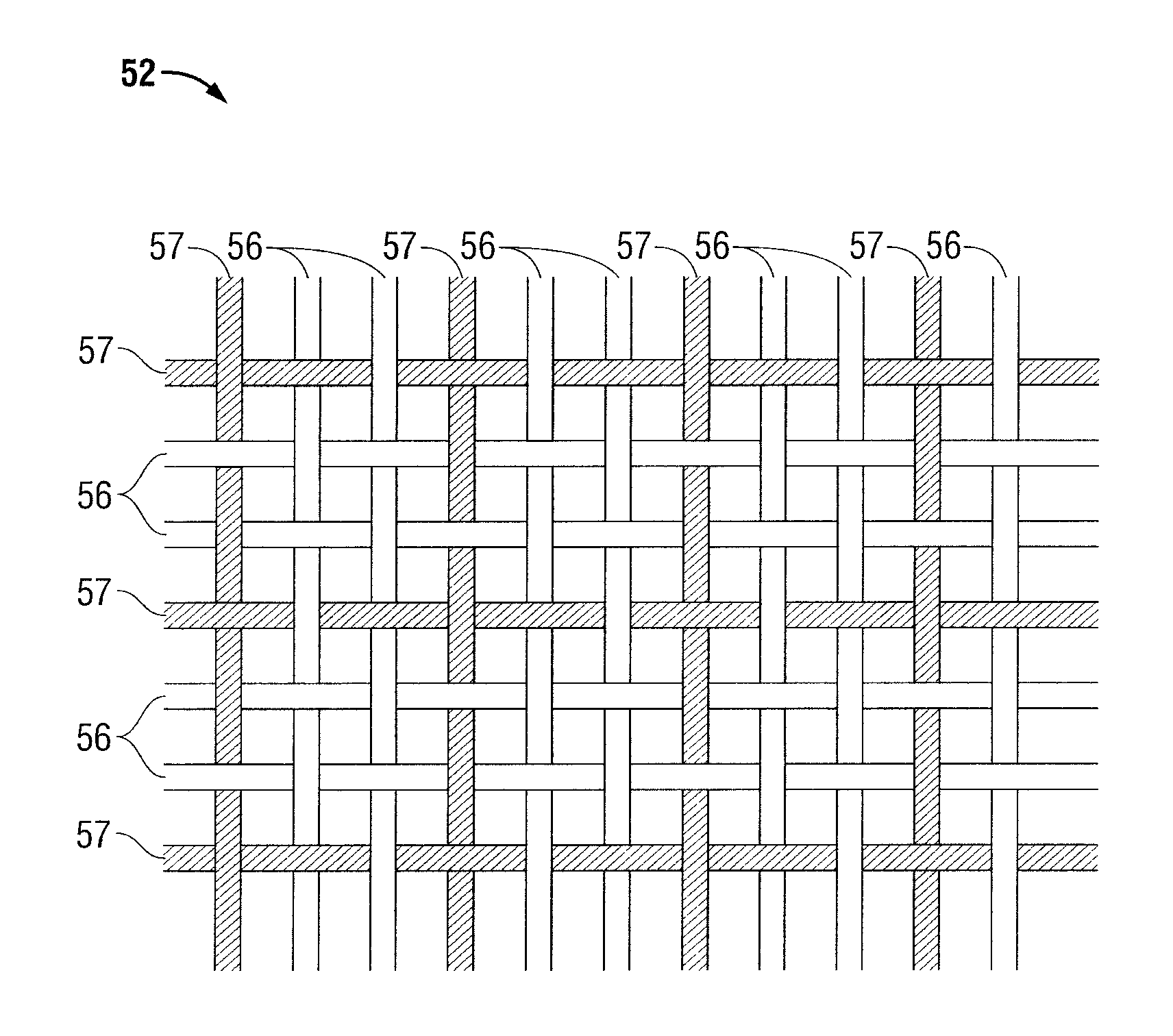

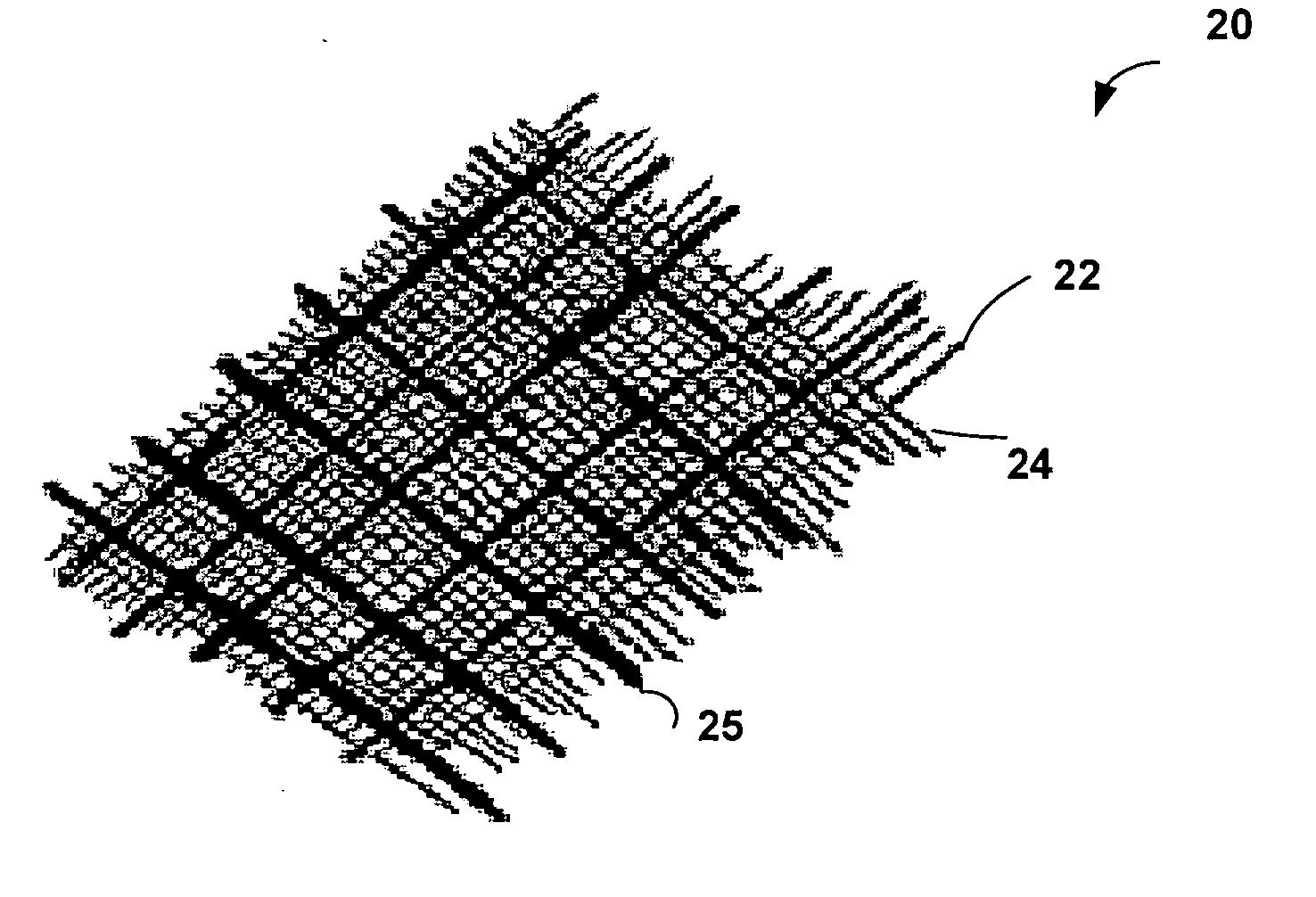

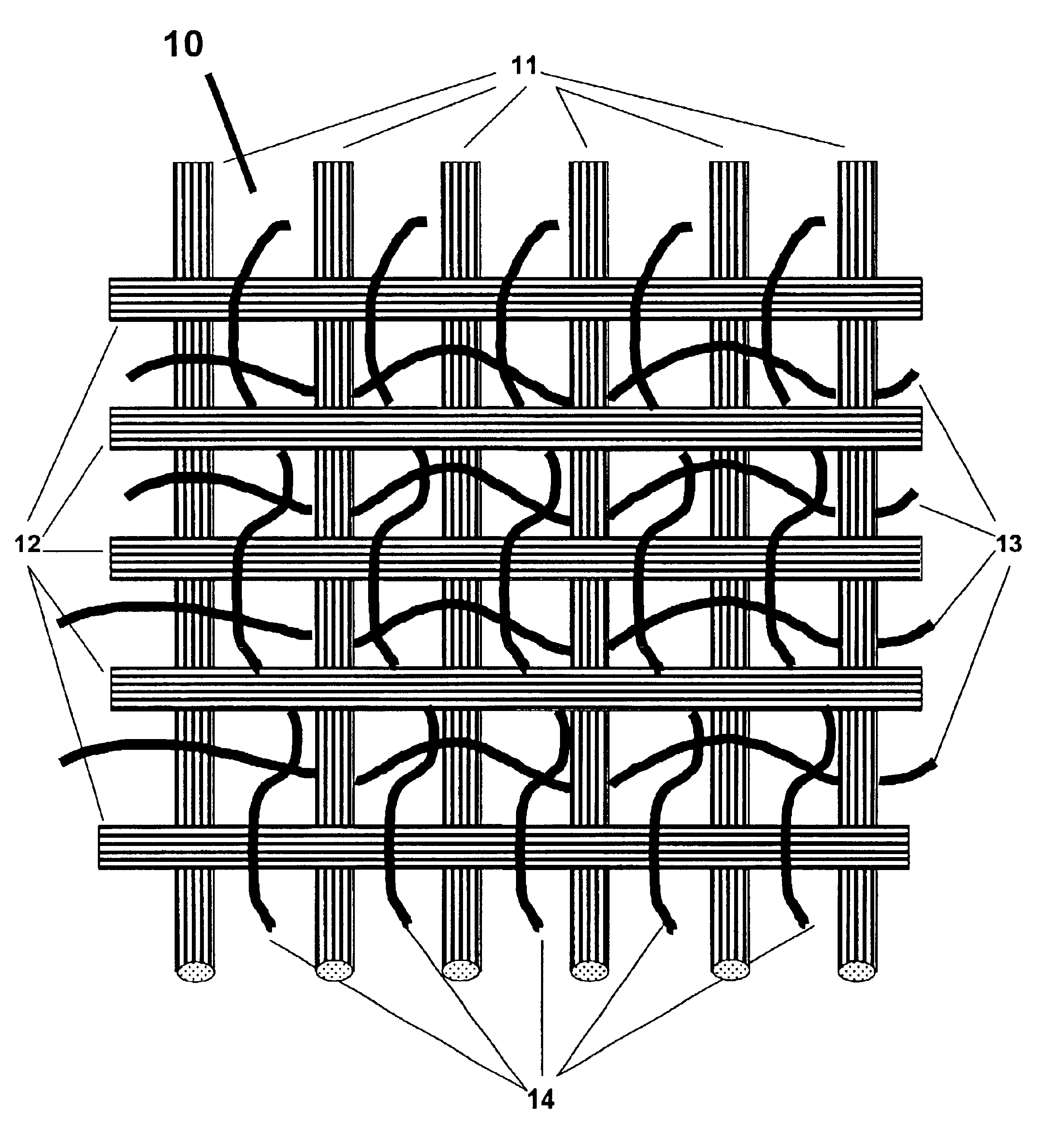

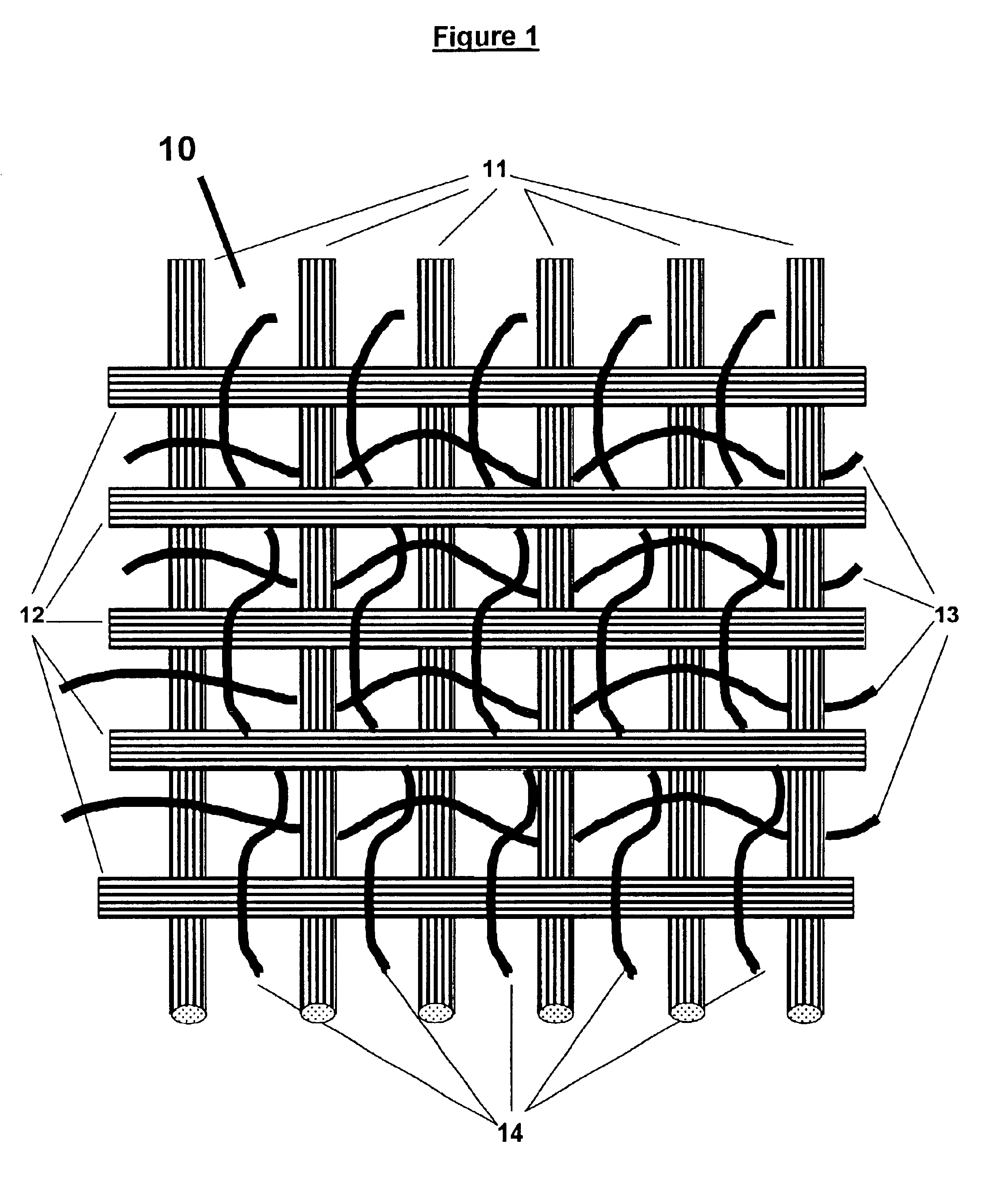

Bi-directional and multi-axial fabrics and fabric composites

InactiveUS6841492B2Increase resistanceImprove effectivenessOrnamental textile articlesProtective fabricsYarnEngineering

Bi-directional and multi-axial fabrics, fabric composites, ballistically resistant assemblies thereof, and the methods by which they are made. The fabrics are comprised of sets of strong, substantially parallel, unidirectional yarns lying in parallel planes, one above the other, with the direction of the yarns in a given plane rotated at an angle to the direction of the yarns in adjacent planes; and one or more sets of yarns having lower strength and higher elongation interleaved with the strong yarns. The fabrics of the invention provide superior ballistic effectiveness compared to ordinary woven and knitted fabrics but retain the ease of manufacture on conventional looms and knitting machines.

Owner:HONEYWELL INT INC

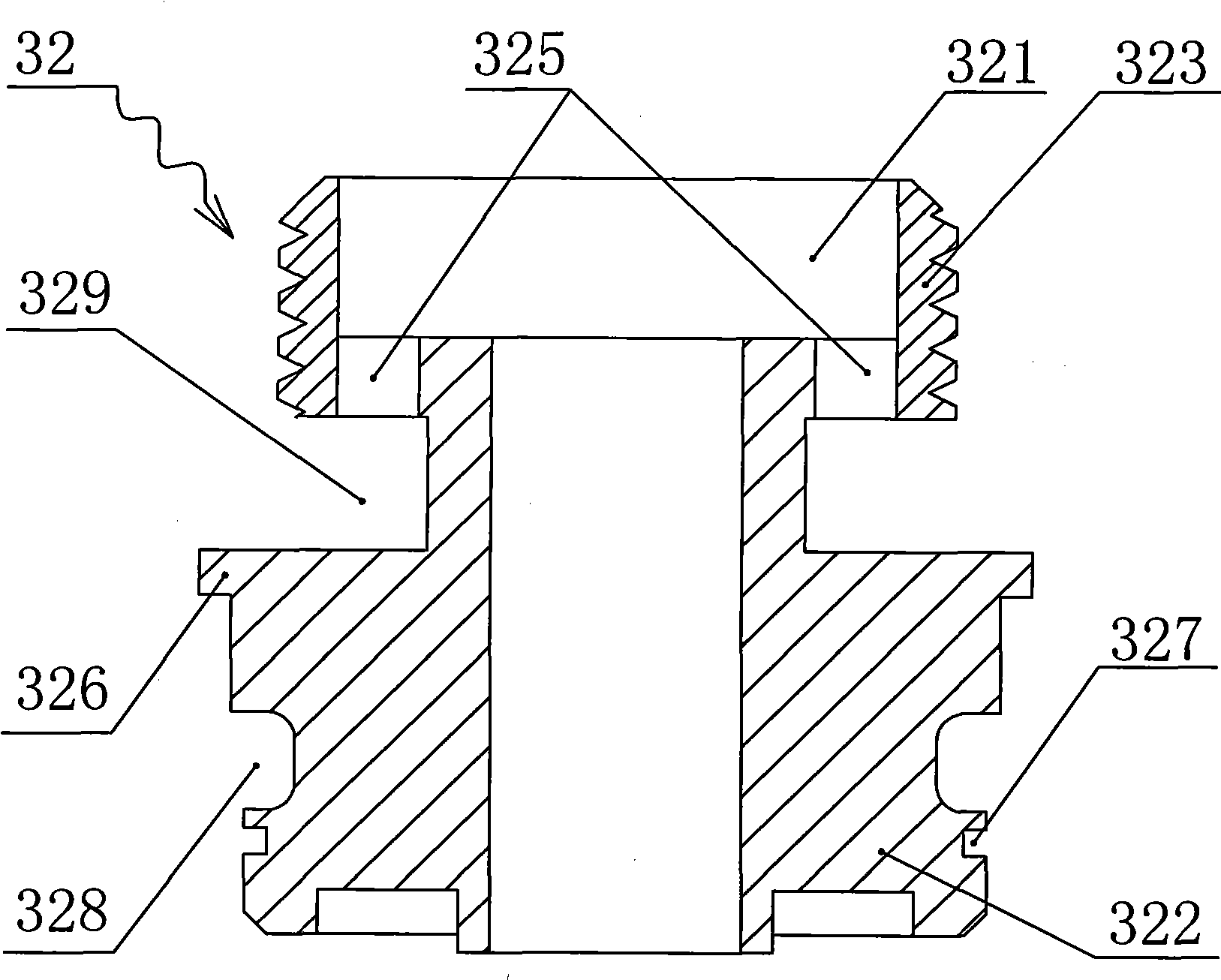

Suction nozzle of electronic atomizer

InactiveCN101843368AOvercome the defect of large air intake resistanceTobacco devicesMedical atomisersYarnFiber

The invention relates to a structural improvement on a suction nozzle of an electronic atomizer. The suction nozzle comprises a cylindrical outer shell, a front end cylindrical hole part of the outer shell is fixedly connected with a threaded electrode of the suction nozzle, a rear end cylindrical hole part of the outer shell is provided with a seal wall, a heater and fiber yarn are accommodated in an accommodating cavity of the outer shell, the fiber yarn can be used for storing atomized liquid, the heater is electrically connected with the threaded electrode of the suction nozzle, the threaded electrode of the suction nozzle is provided with an inner electrode and an outer electrode, the threaded electrode of the suction nozzle is provided with an air inlet, an air outlet is arranged in the seal wall, the fiber yarn is annularly distributed into the accommodating cavity, an axial central channel is formed in a middle position and is communicated with the air inlet and the air outlet, the heater is fixed in the central channel, the inner wall of the central channel is provided with a dispersion cloth layer of dispersion liquid, and at least one part of the central channel is fixedly connected with a hollow supporting pipe. Owing to the technical characteristics, the suction nozzle of the electronic atomizer can be applied to a device which can atomize odorant liquid for a user to suck.

Owner:陈志平

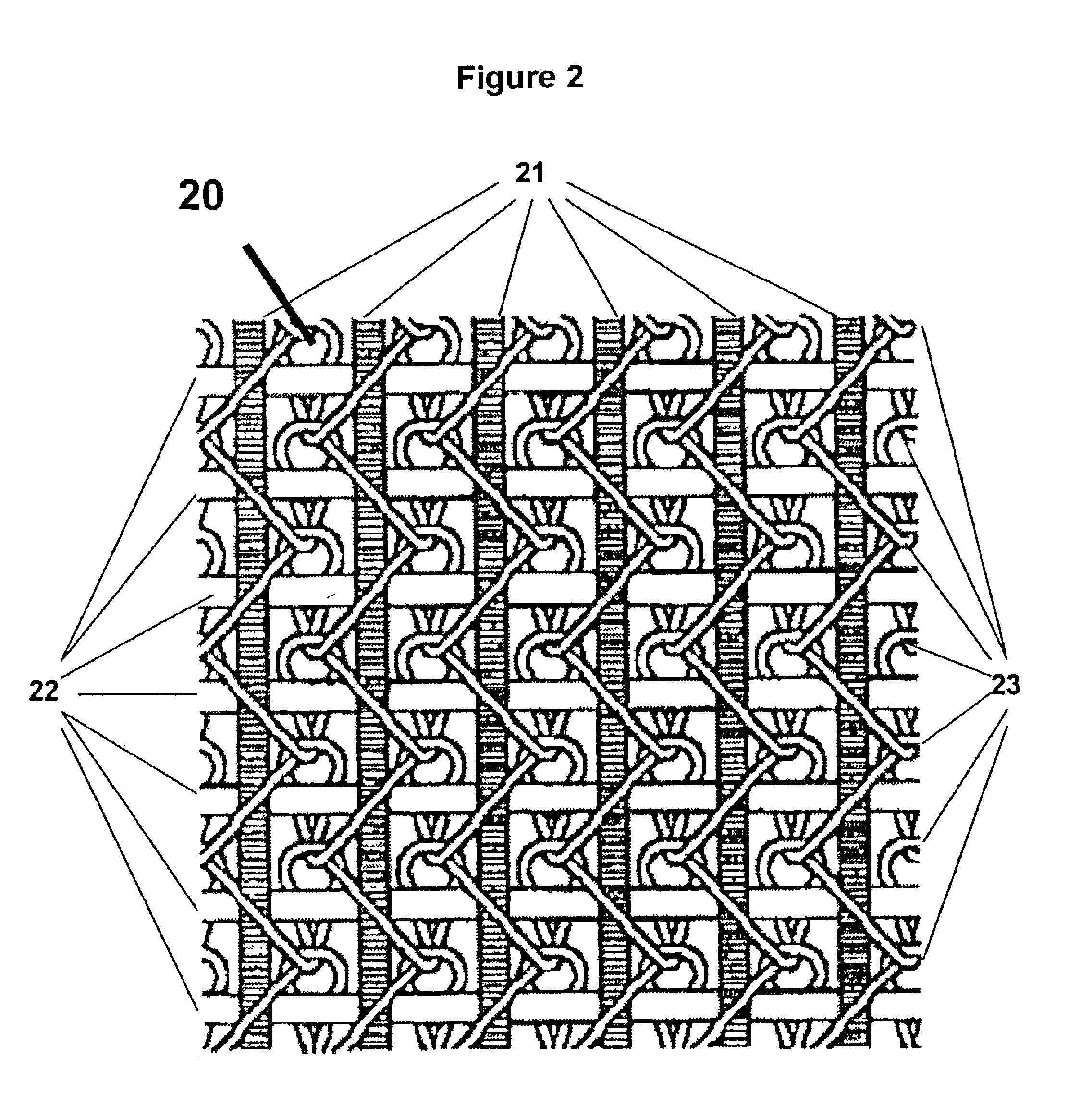

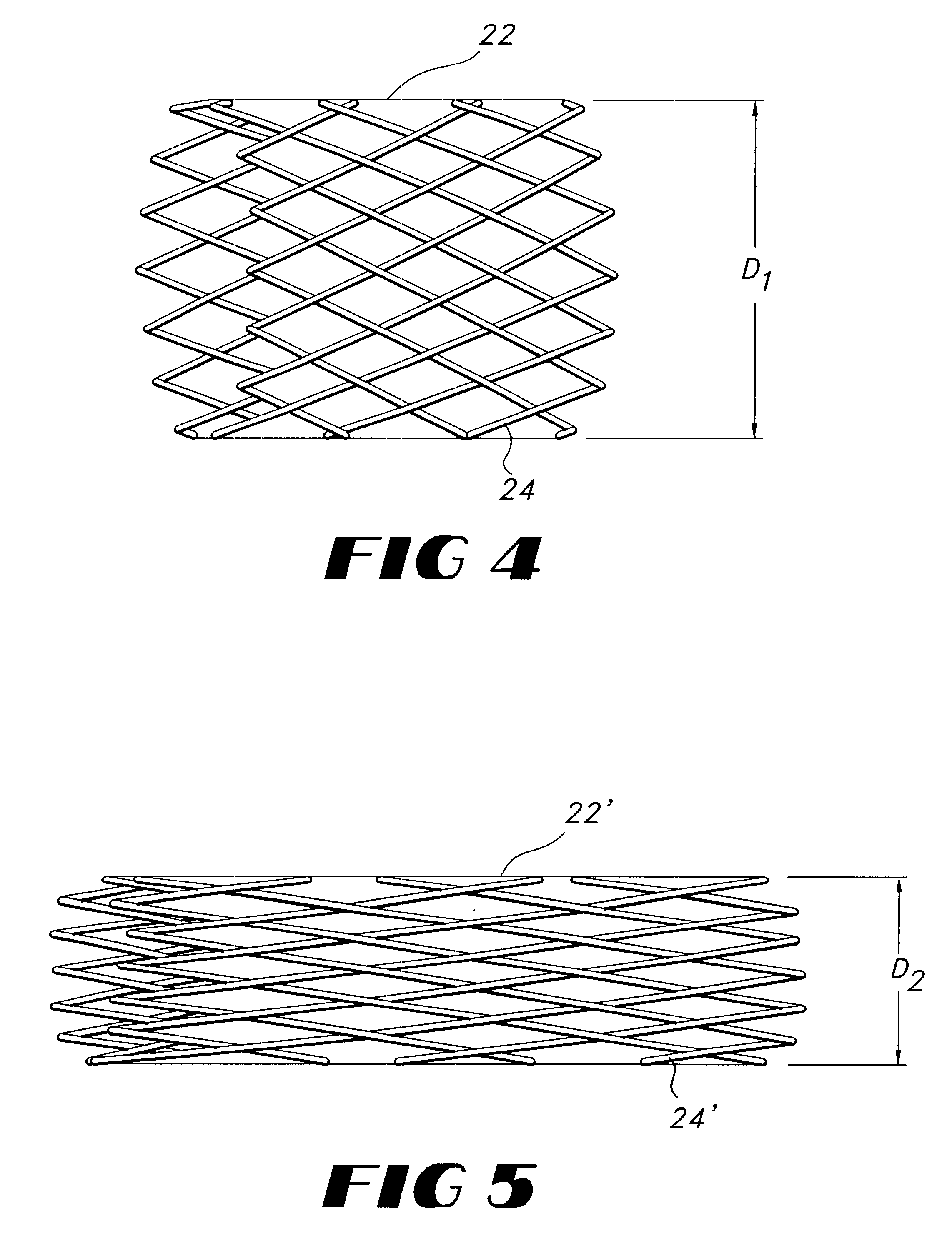

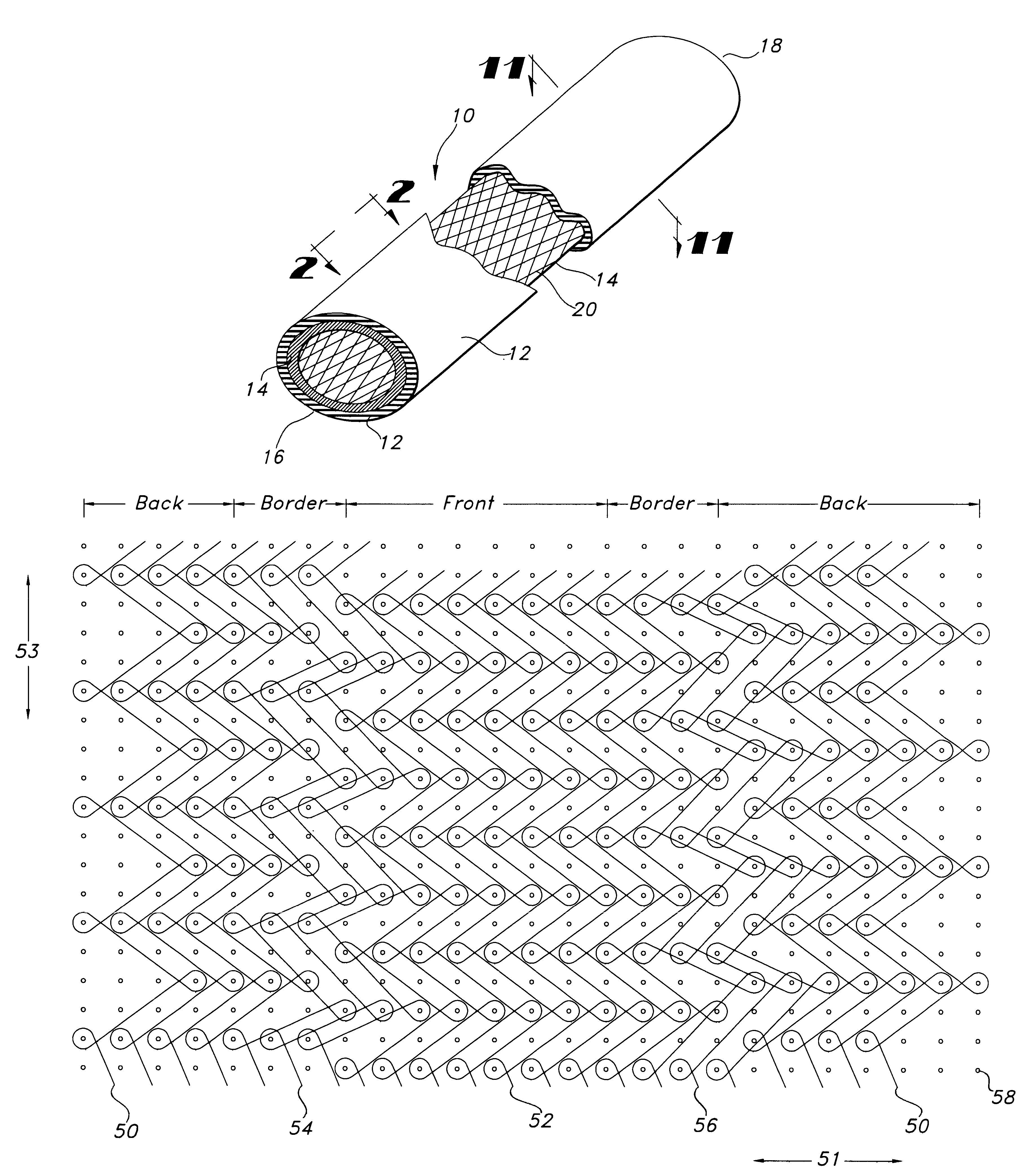

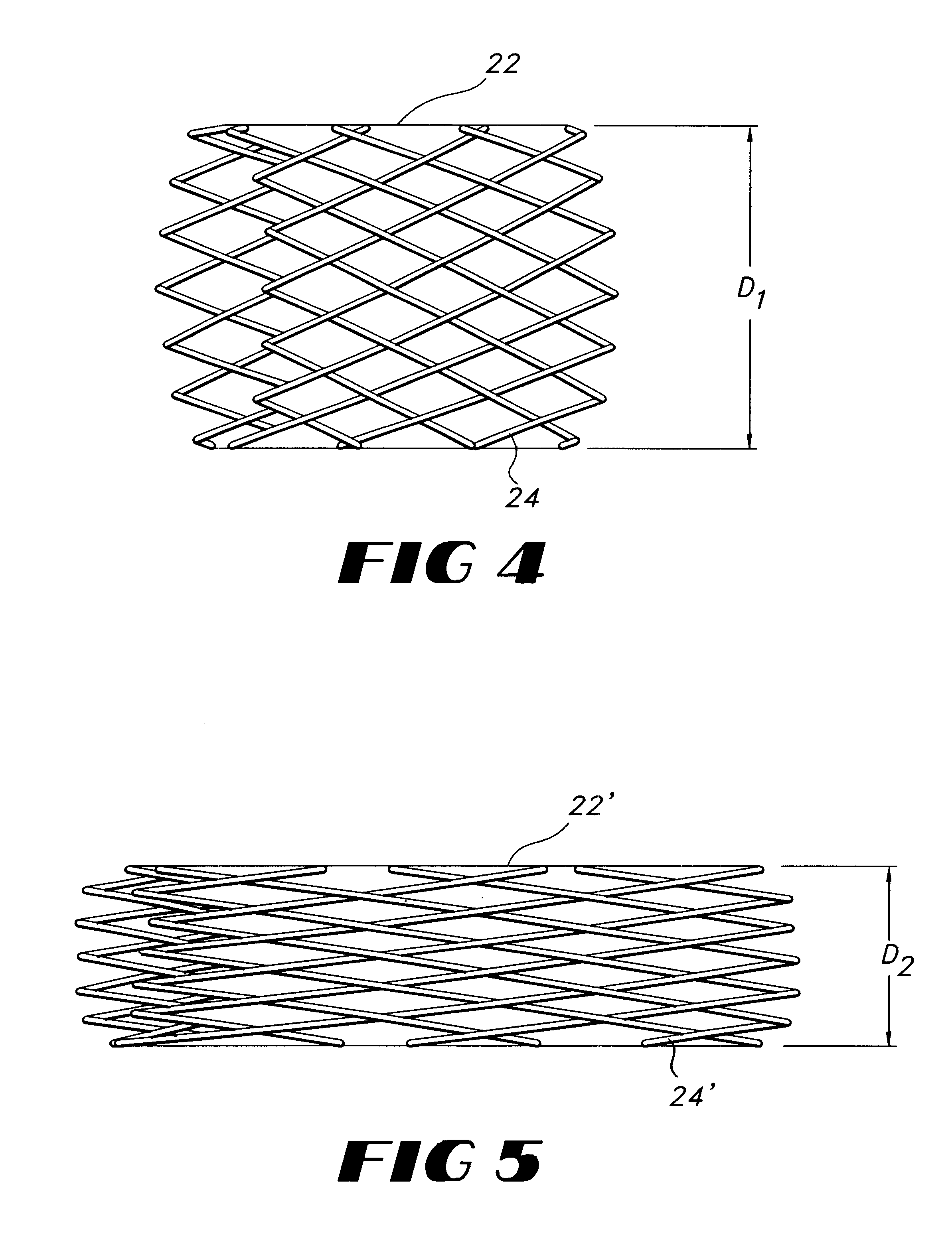

Low profile, high stretch knit prosthetic device

InactiveUS6540773B2High degree of flexibilityHigh degree of stretchabilityStentsWeft knittingYarnInsertion stent

A radially expandable stent-graft endoprosthesis is provided. The graft included in the stent-graft is a knitted tubular structure circumferentially disposed and securably attached to the stent. The knitted tubular structure has a knit pattern of interlacing yarns in an Atlas or a modified-Atlas pattern to provide greater than 150 percent longitudinal stretchability. A knitted tubular graft and a knitted medical fabric with greater than 150 percent longitudinal stretchability are also provided.

Owner:LIFESHIELD SCI

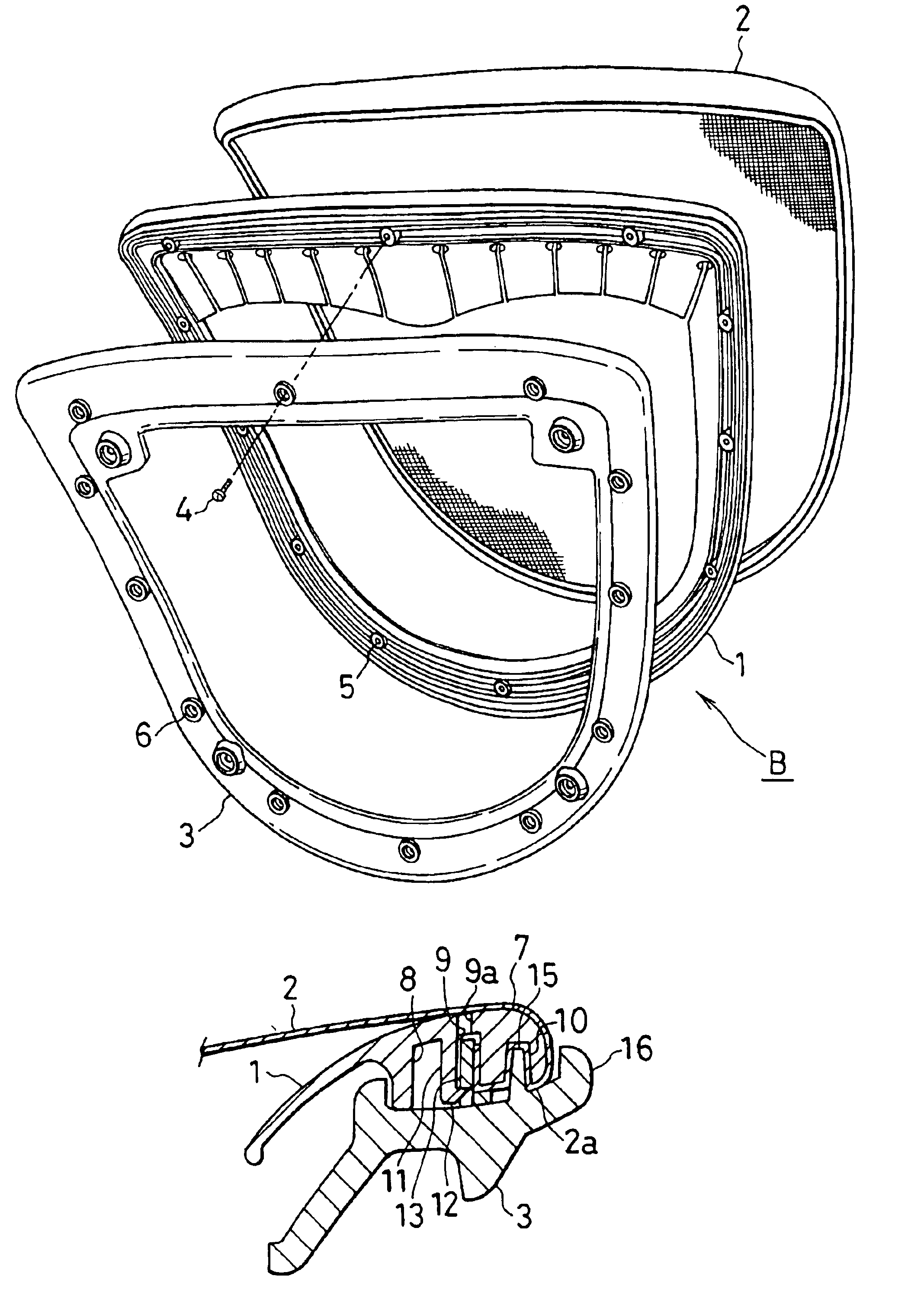

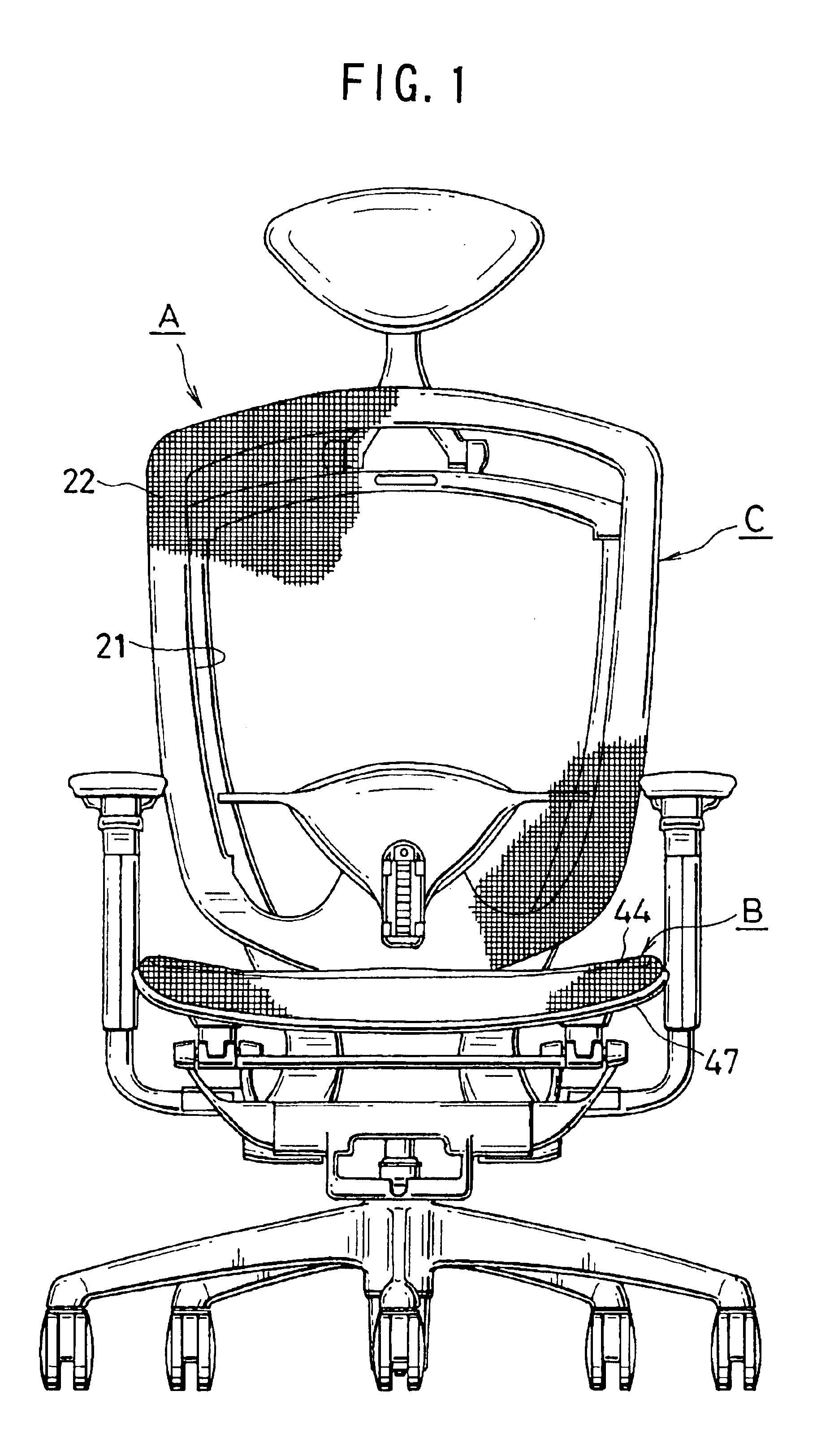

Structure for mounting a net member to a frame for a seat or backrest of a chair

InactiveUS6942300B2Simple low uniform tensile forceSuitable comfortStuffed mattressesSpring mattressesYarnEngineering

Owner:OKAMURA CORP

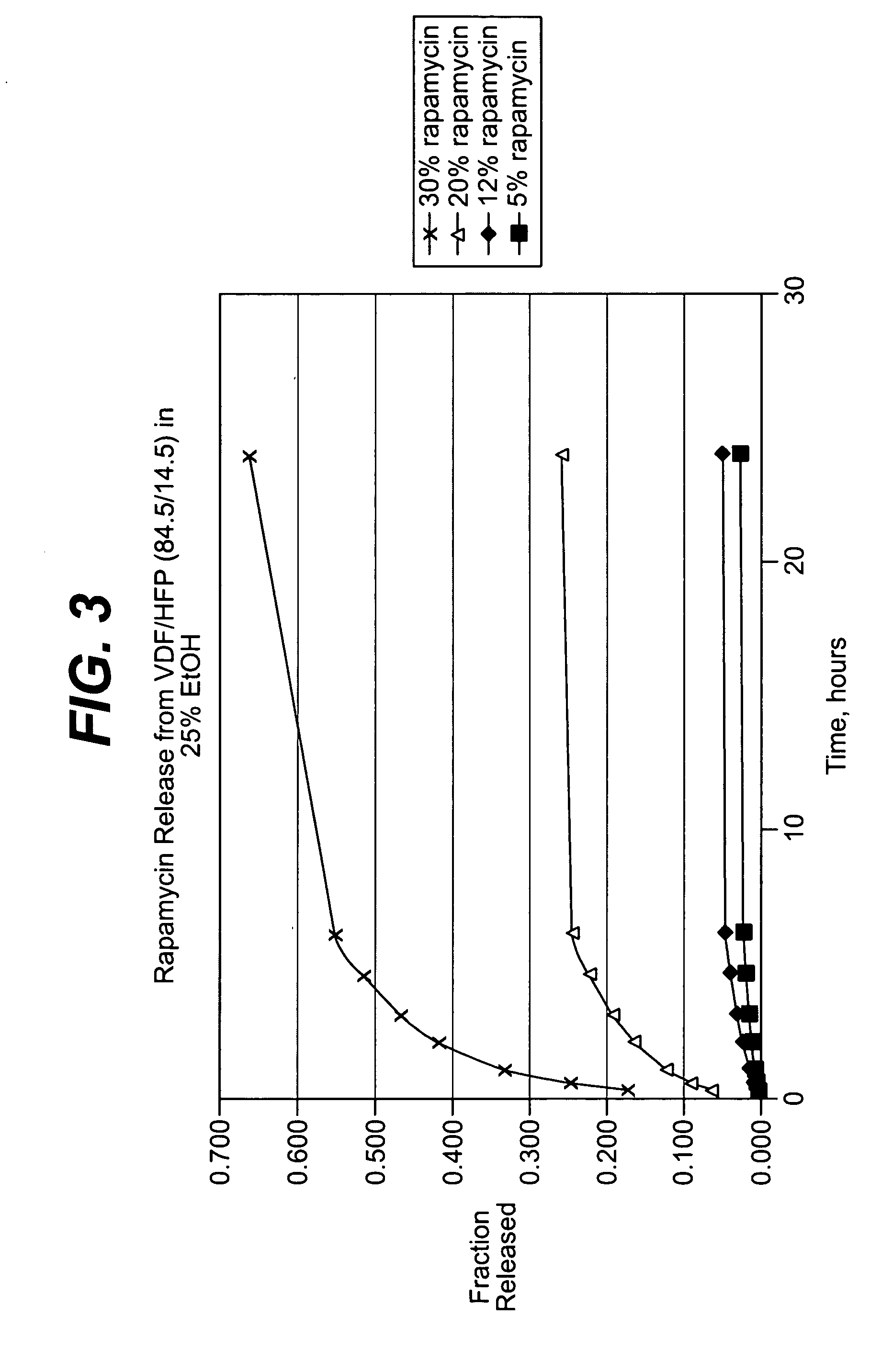

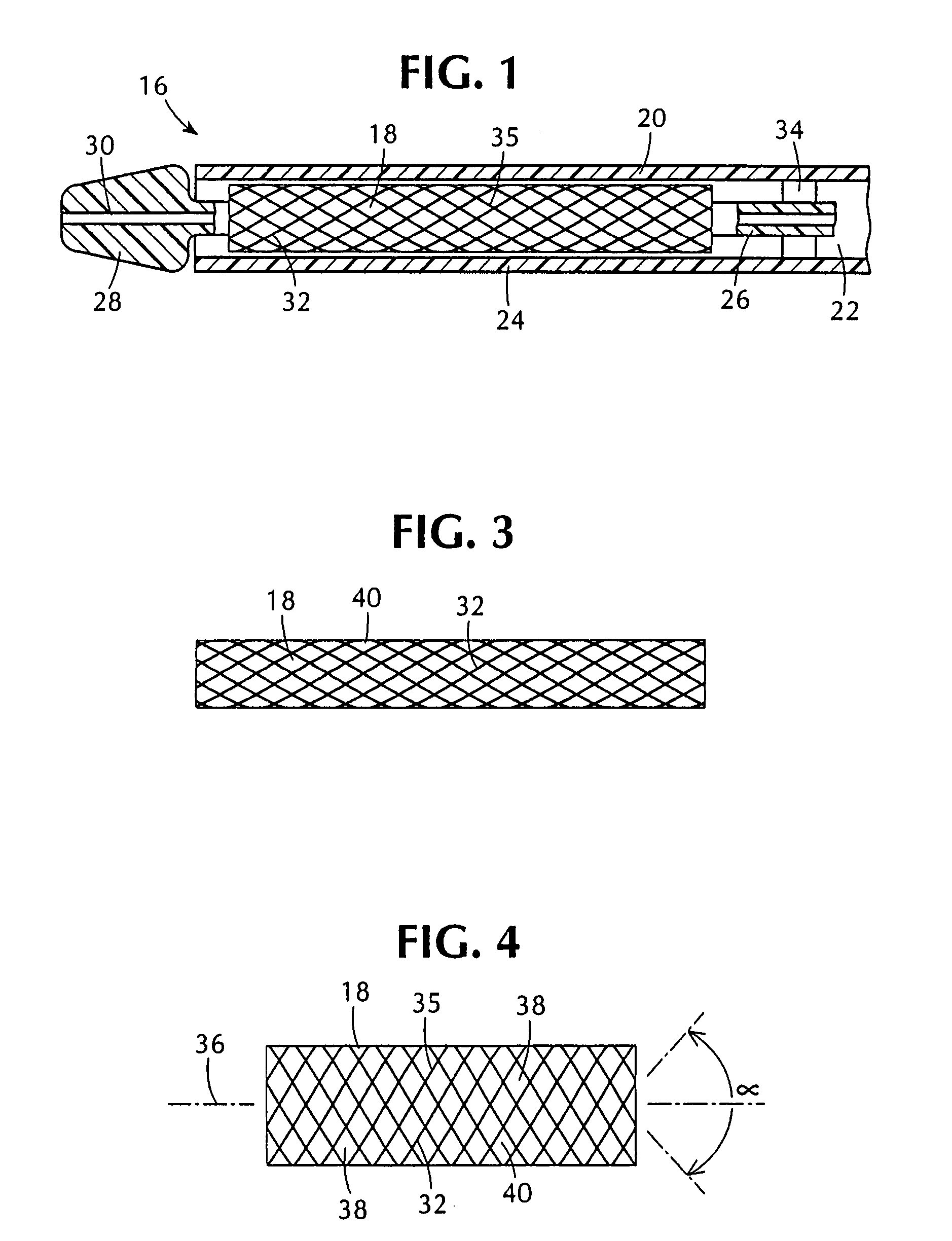

Endovascular graft with differentiable porosity along its length

Medical devices, and in particular implantable medical devices, may be coated to minimize or substantially eliminate a biological organism's reaction to the introduction of the medical device to the organism. The medical devices may be coated with any number of biocompatible materials. Therapeutic drugs, agents or compounds may be mixed with the biocompatible materials and affixed to at least a portion of the medical device such as a stent-graft. These therapeutic drugs, agents or compounds may also further reduce a biological organism's reaction to the introduction of the medical device to the organism. In addition, these therapeutic drugs, agents and / or compounds may be utilized to promote healing, including the formation of blood clots. A stent-graft fabricated from a thin-walled, high strength material provides for a more durable and lower profile endoprosthesis. The stent-graft comprises one or more stent segments covered with a fabric formed by the weaving, knitting or braiding of a biocompatible, high tensile strength, abrasion resistant, highly durable yarn such as ultra high molecular weight polyethylene. The one or more stent segments may be balloon expandable or self-expanding. The fabric may be attached to the stent segments utilizing any number of known materials and techniques. In addition, the pore size of the graft material may be varied.

Owner:CORDIS CORP

Drawn gel-spun polyethylene yarns and process for drawing

ActiveUS6969553B1Synthetic resin layered productsMonocomponent polyolefin artificial filamentYarnSports equipment

Owner:HONEYWELL INT INC

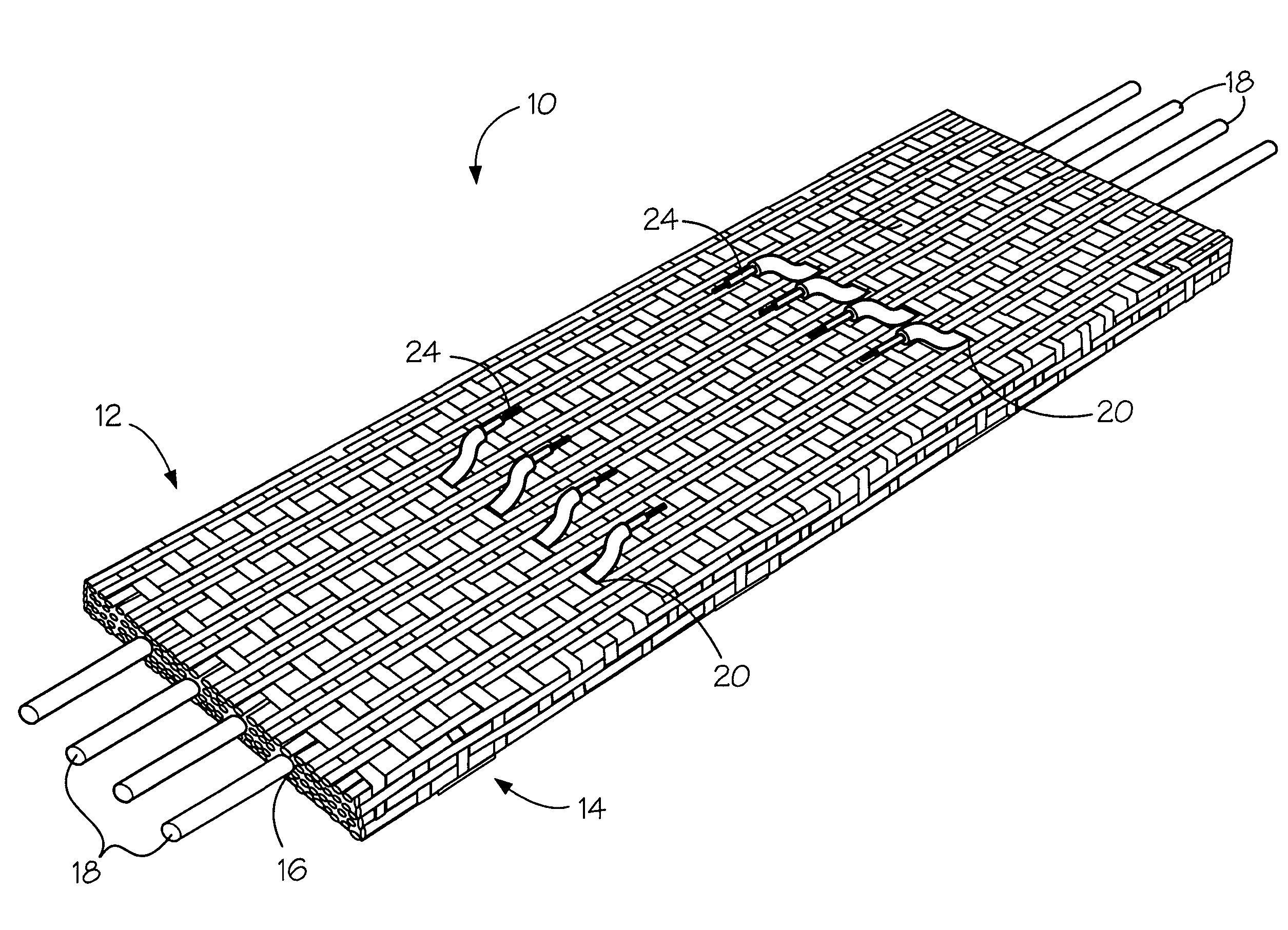

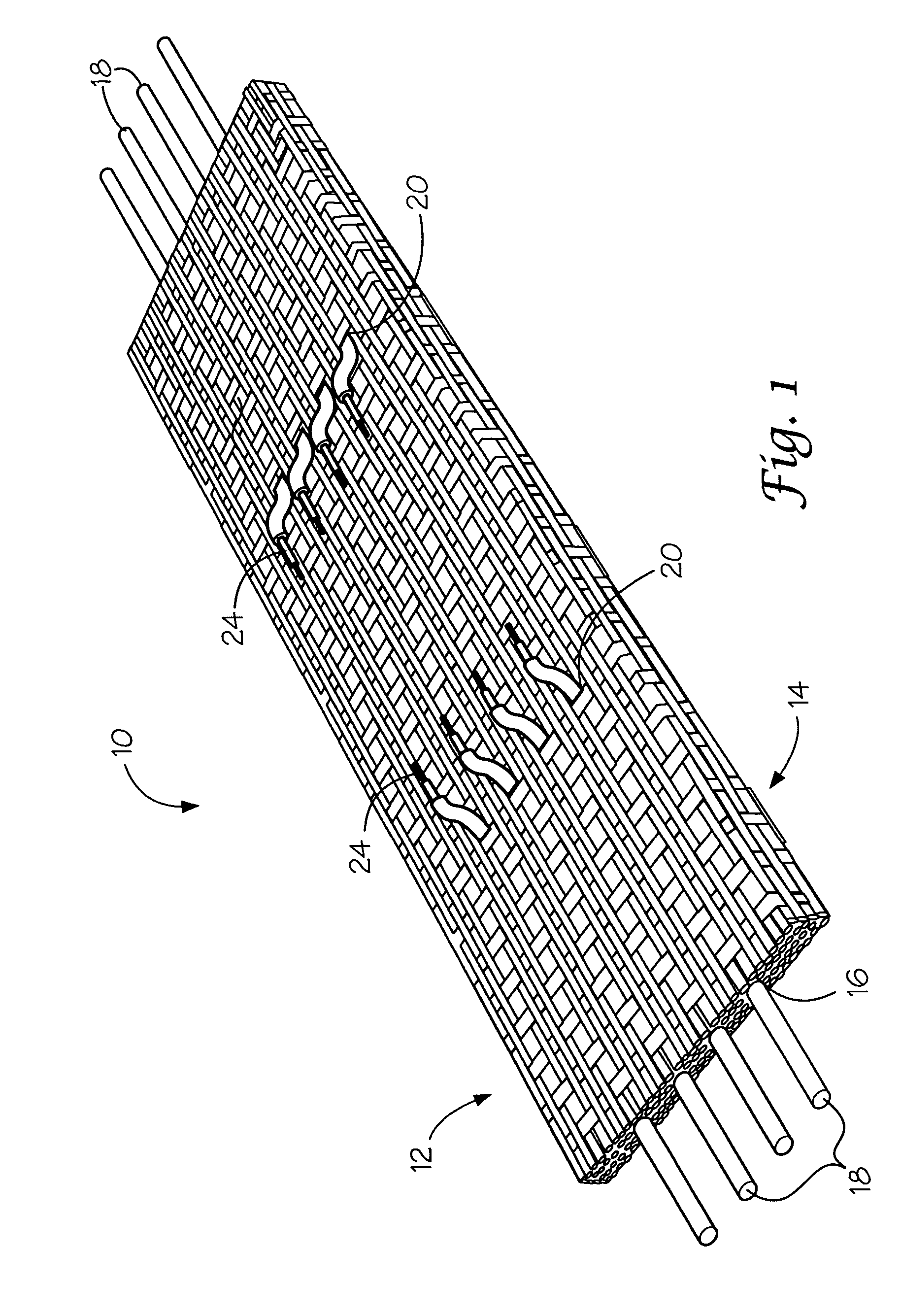

Elastic fabric with sinusoidally disposed wires

ActiveUS20060124193A1Reducing fabric lengthConductive stabilityCircuit bendability/stretchabilityGarmentsYarnEngineering

A fabric for use with a system for monitoring prescribed body functions comprising an elastic fabric, adapted to be carried by a torso, which is stretchable in its longitudinal direction so as to expand and contract in response to body movement and size. The carrier includes at least one conductive and inelastic yarn arranged longitudinally of and located between upper and lower surfaces. The conductive yarn is arranged in sinusoidal configurations longitudinally of the fabric. The conductive yarn forms a breakout through one of the outer surfaces, at selected locations along the length of the fabric, forming opposed exposed ends above the surface. A monitoring unit, which includes a connector and a sensor, is secured with the one surface at the breakout with the connector being united with the exposed ends of the conductive yarn. The fabric acts to maintain the monitoring unit in a desired stationary position allowing the sensor to sense signals emitted from the torso and transmit these senses signals.

Owner:WOVEN ELECTRONICS

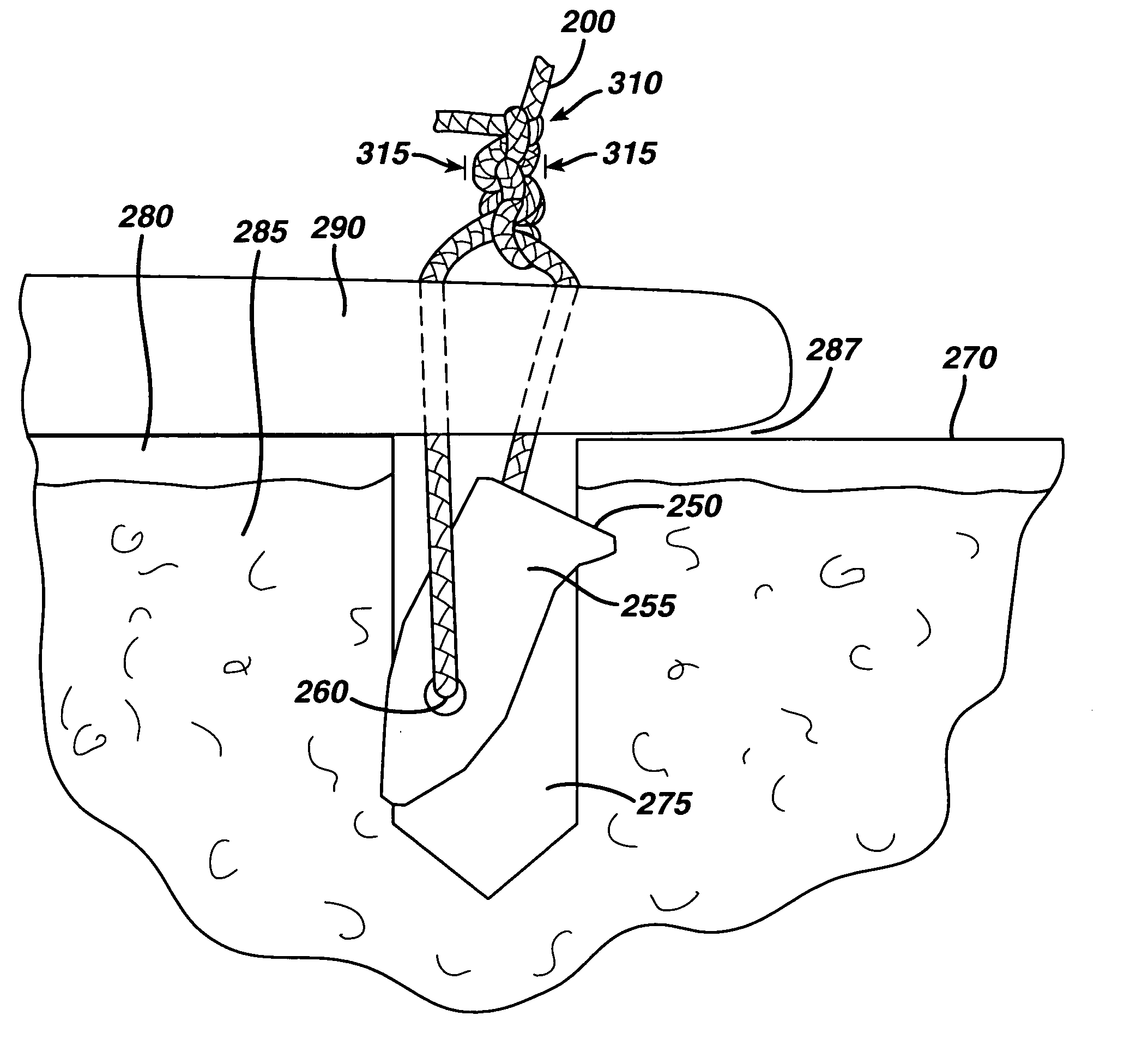

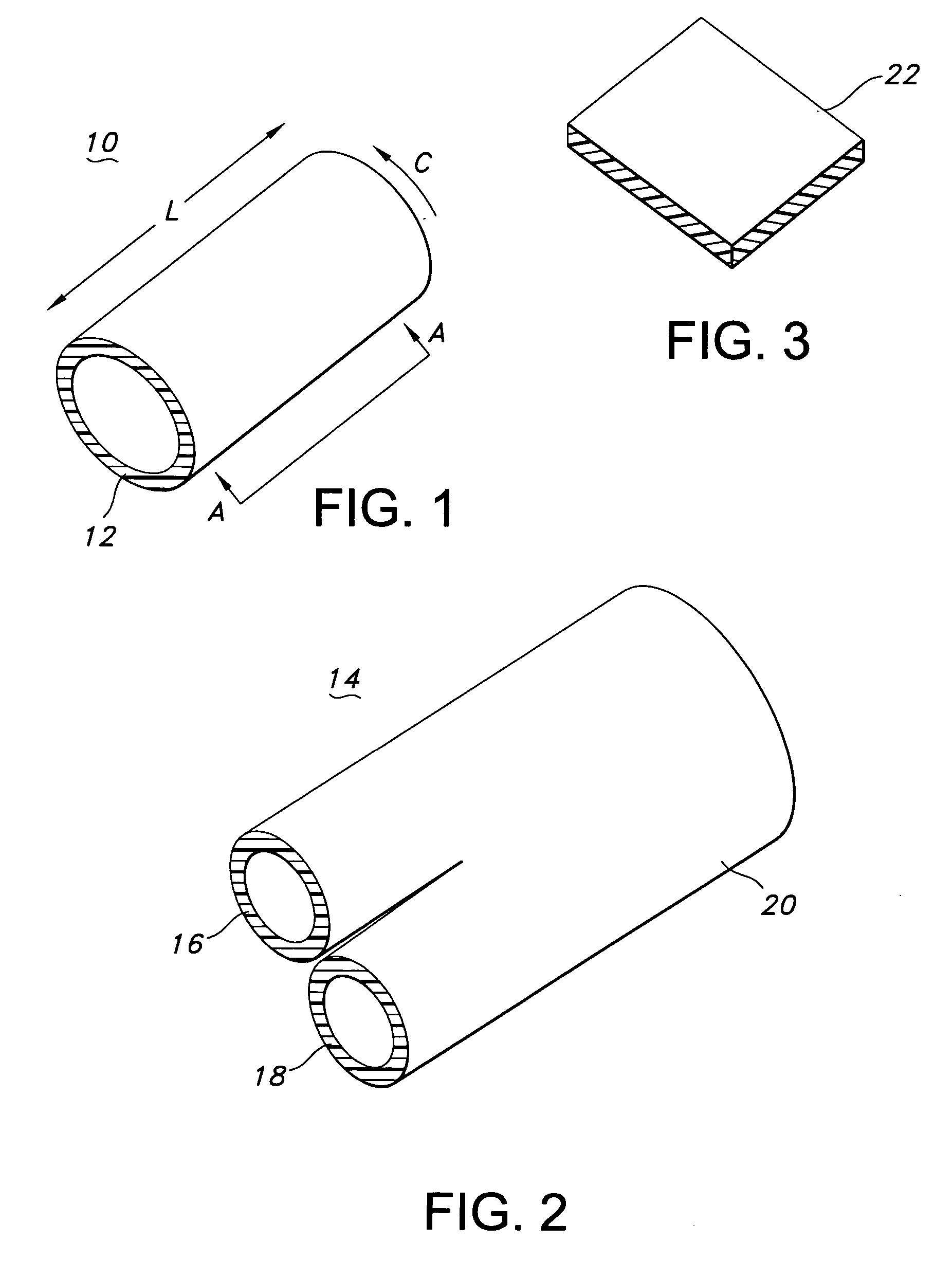

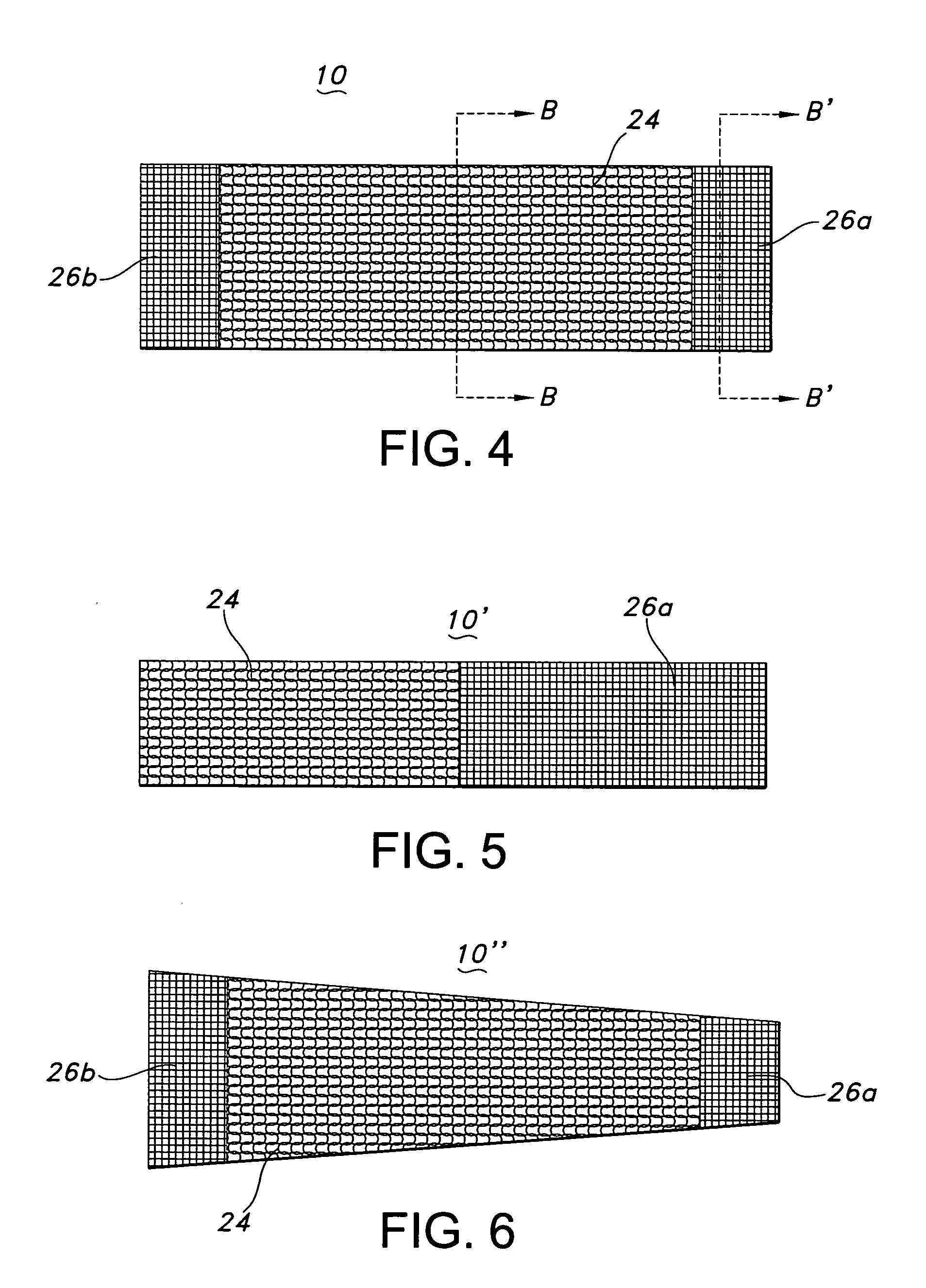

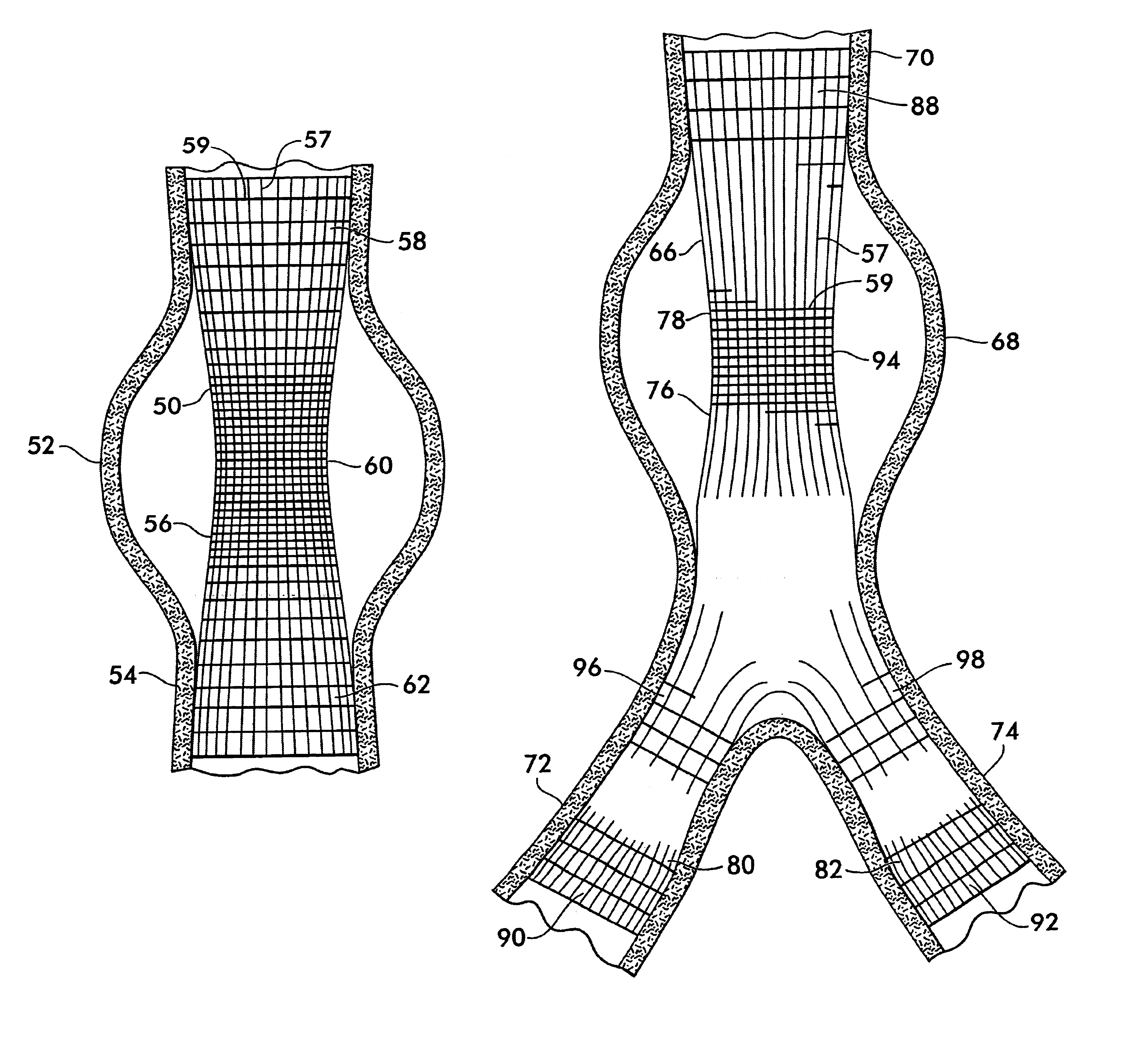

Composite medical textile material and implantable devices made therefrom

InactiveUS20050240261A1Improve complianceImprove the immunityStentsOrnamental textile articlesYarnImplanted device

An implantable composite medical device having a longitudinal length a woven textile portion having yarns interlaced in a woven pattern, a knitted textile portion having yarns interlooped in a knitted pattern. The woven and knitted portions are securably attached to one and the other to provide a composite woven and knitted textile surface along the longitudinal length of the device. The woven portion may have a permeability from about 30 to about 500 ml / min / cm2, and the knitted portion may have a permeability from about 30 to about 15,000 ml / min / cm2. Further, a crimped woven portion with a resiliently longitudinal stretchability from about 10 to about 100 linear percent over its quiescent longitudinal dimension or an uncrimped woven portion with a resiliently longitudinal stretchability of less than about 10 linear percent over its quiescent longitudinal dimension are useful. A knitted portion with a resiliently longitudinal stretchability from about 5 to about 200 linear percent over its quiescent longitudinal dimension is also useful.

Owner:LIFESHIELD SCI

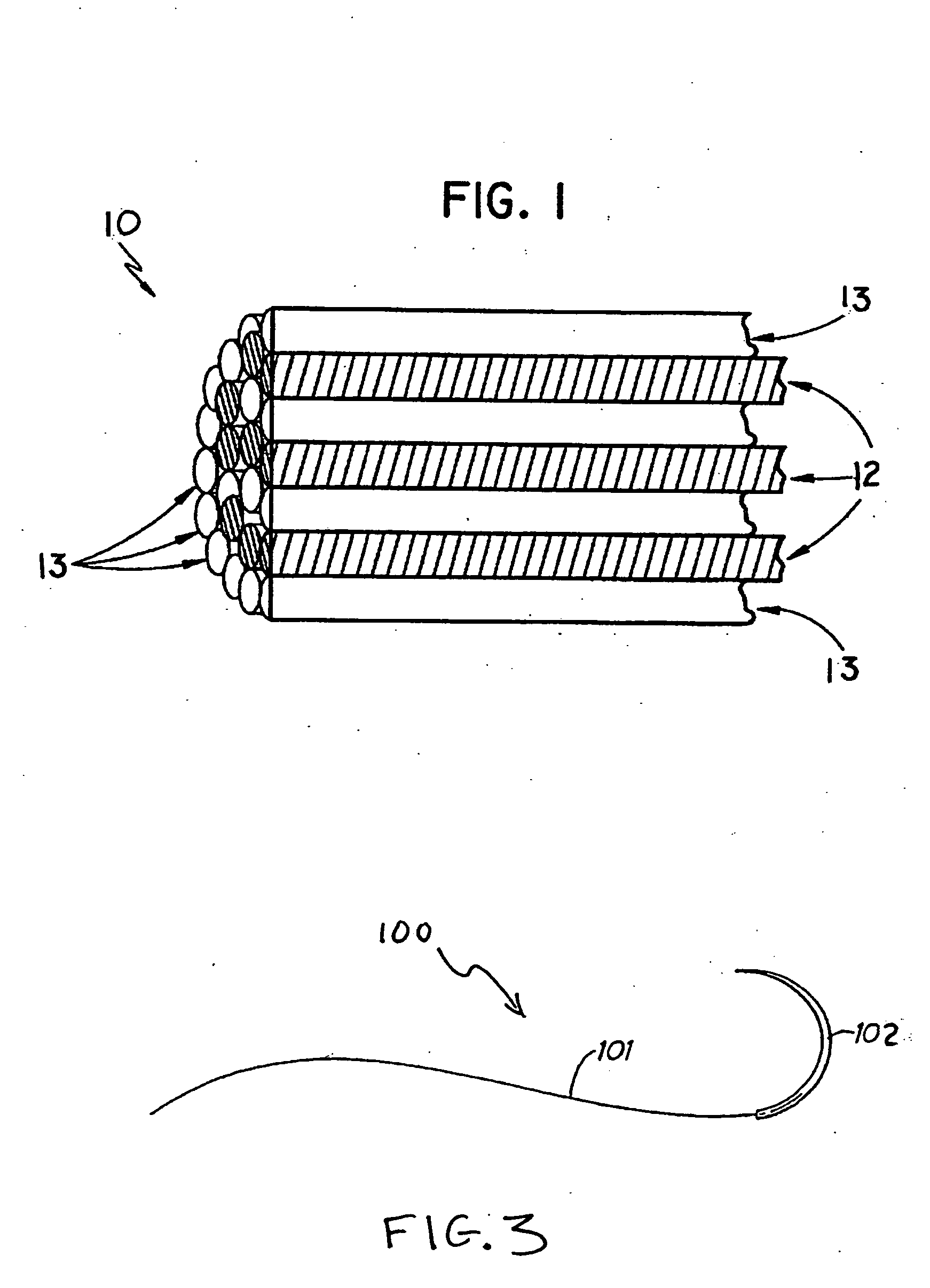

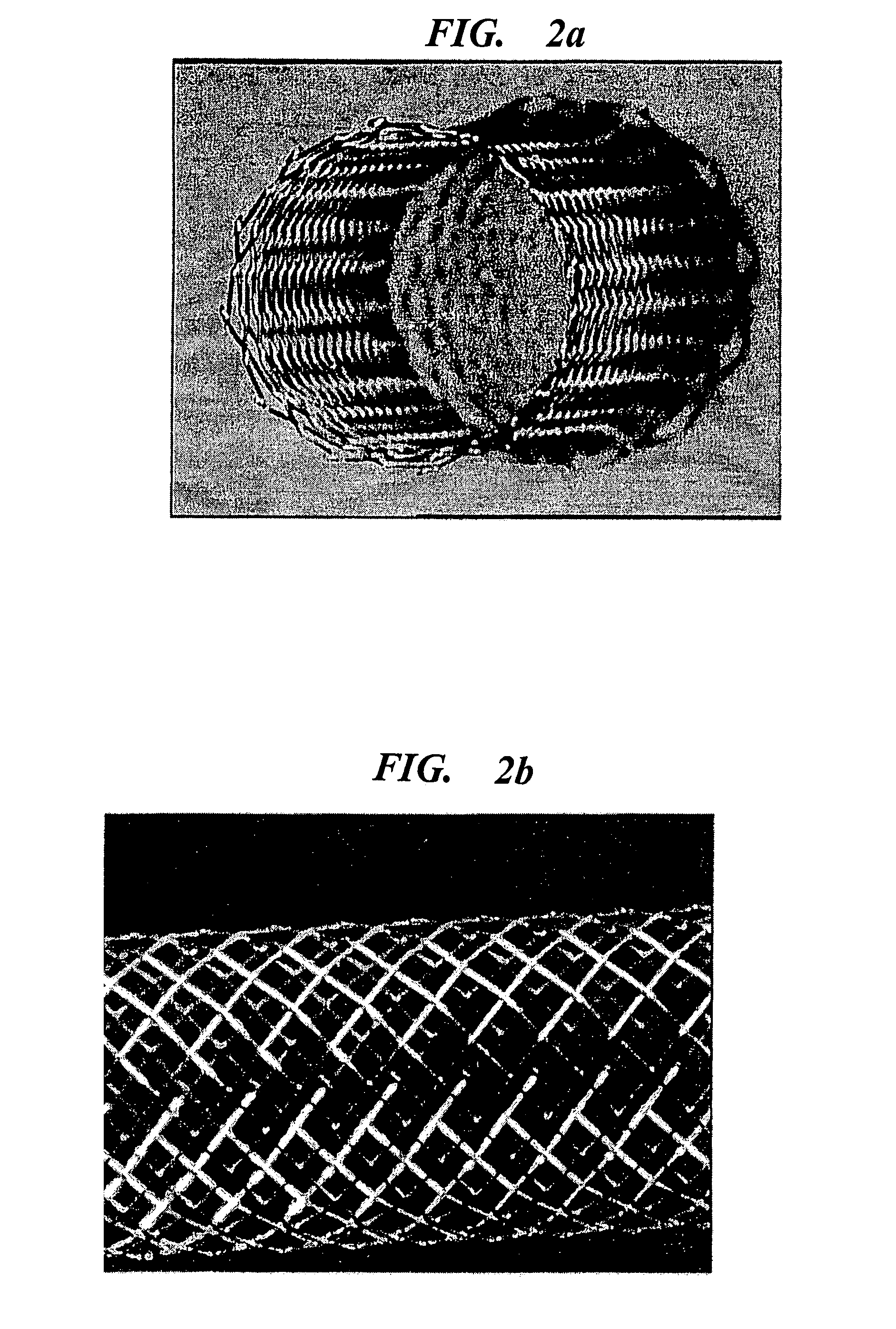

Braided composite prosthesis

A prosthesis for transluminal implantation consists of a flexible tubular interbraided structure of metal or polymeric monofilaments, and polymeric multifilament yarns. The prosthesis can be elastically deformed to reduce its diameter through axial elongation. The monofilaments and multifilament yarns are arranged in axially spaced apart helices, concentric on a common central axis of the prosthesis. The monofilaments are selectively shaped before their interbraiding with the multifilament yarns, either by an age-hardening or other heat-setting stage, or a cold-working stage that controllably plastically deforms the strands. The shaped structural strands cooperate to impart to the prosthesis its nominal shape and resilience. The textile strands cooperate to provide a sheeting that occupies interstices between adjacent structural strands, to reduce permeability and thereby enhance the utility of the prosthesis as a vascular graft. An alternative embodiment prosthesis includes elastically and plastically deformable structural strands, selectively plastically deformed by cold-working then interbraided to form the prosthesis.

Owner:LIFESHIELD SCI

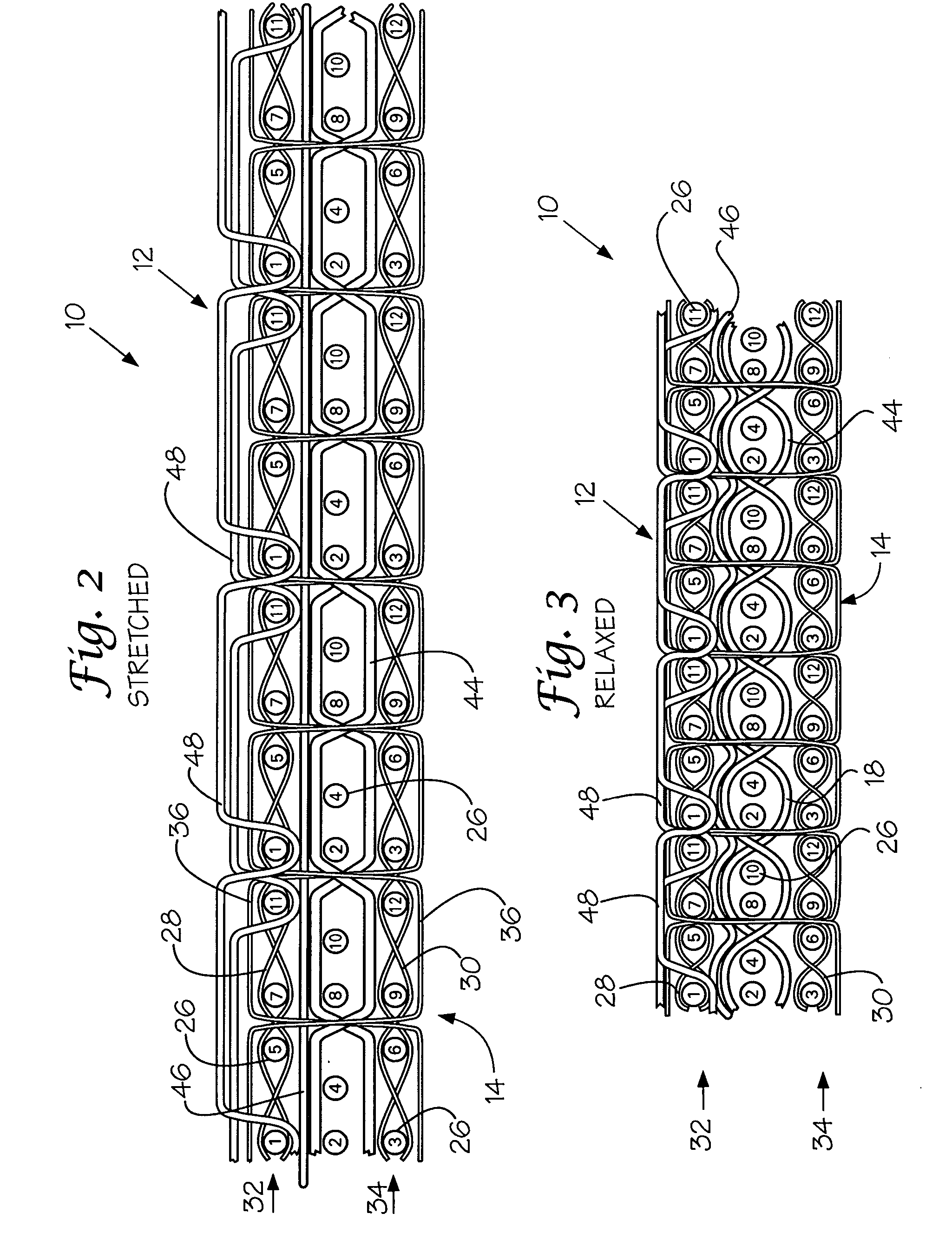

Low profile, high stretch, low dilation knit prosthetic device

A radially expandable stent-graft endoprosthesis is provided. The graft included in the stent-graft is a knitted tubular structure circumferentially disposed and securably attached to the stent. The knitted tubular structure has a warp knit pattern of interlacing yarns with at least a two-needle underlap to provide greater than 150 percent longitudinal stretchability while substantially inhabiting dilation. A knitted tubular graft and a knitted medical fabric with greater than 150 percent longitudinal stretchability are also provided.

Owner:LIFESHIELD SCI

Woven tubular graft with regions of varying flexibility

Owner:THE SECANT GRP

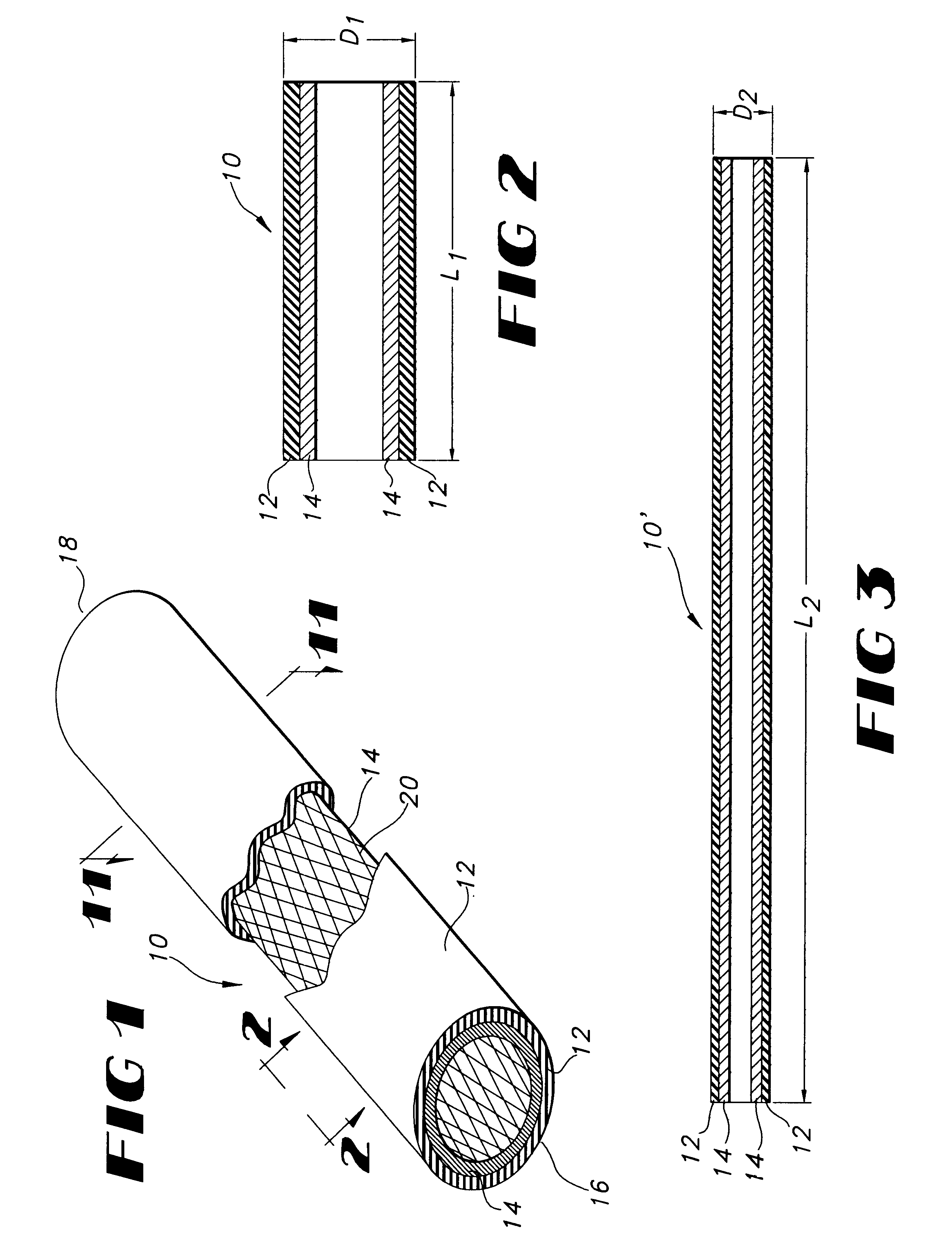

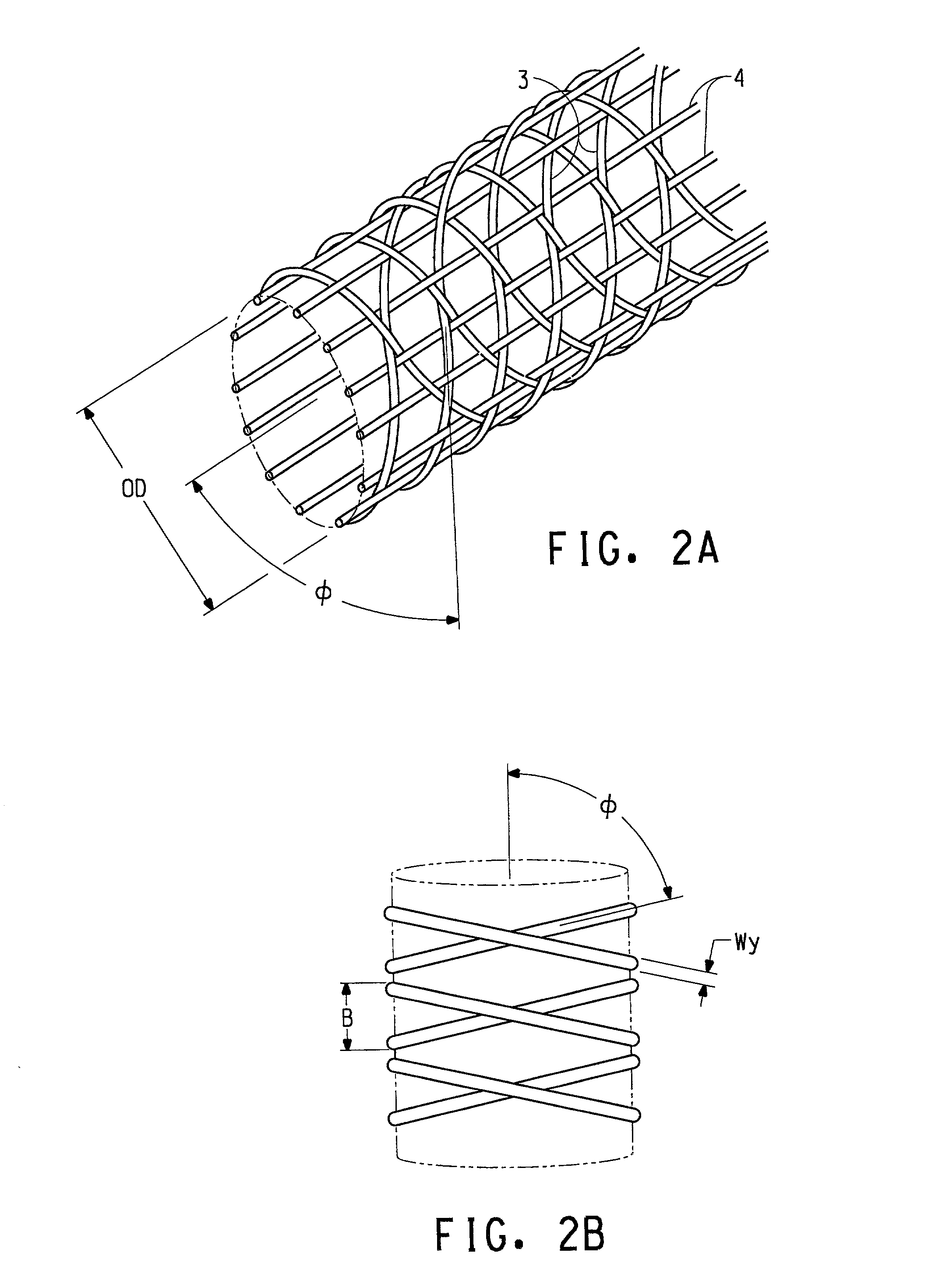

Elastomeric balloon support fabric

InactiveUS20020161388A1Promote recoveryHigh degree of stretchOrnamental textile articlesLayered productsYarnBalloon catheter

Balloon catheter covers are elastic fabric structures of interconnected yarns, the structure having a high degree of stretch and recovery in the circumferential direction with little change in dimension in the longitudinal direction during multiple pressurization cycles over full range of inflation and deflation of the balloon catheter. The covers have longitudinal yarns positioned at about zero degrees to the balloon axis and reversibly-stretchable, circumferential yarns positioned at a high angle Ø to the axis. A method for making the balloon catheter covers allowing nearly orthogonal placement of circumferential and longitudinal yarns involves triaxial braiding a minimum number of elastomeric braid yarns with multiple axial yarns to provide maximum convergence angle (approaching 90 degrees).

Owner:EI DU PONT DE NEMOURS & CO

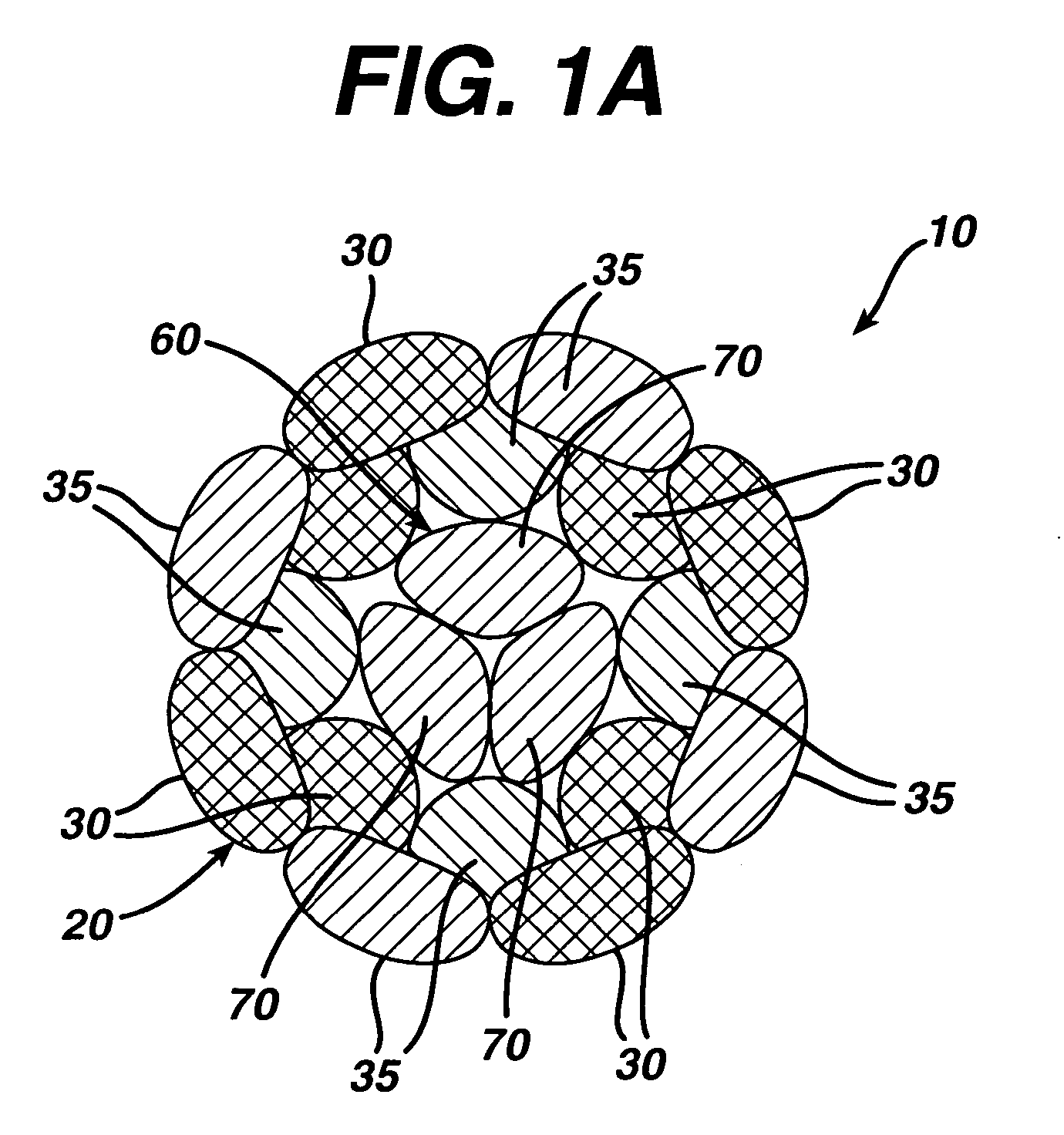

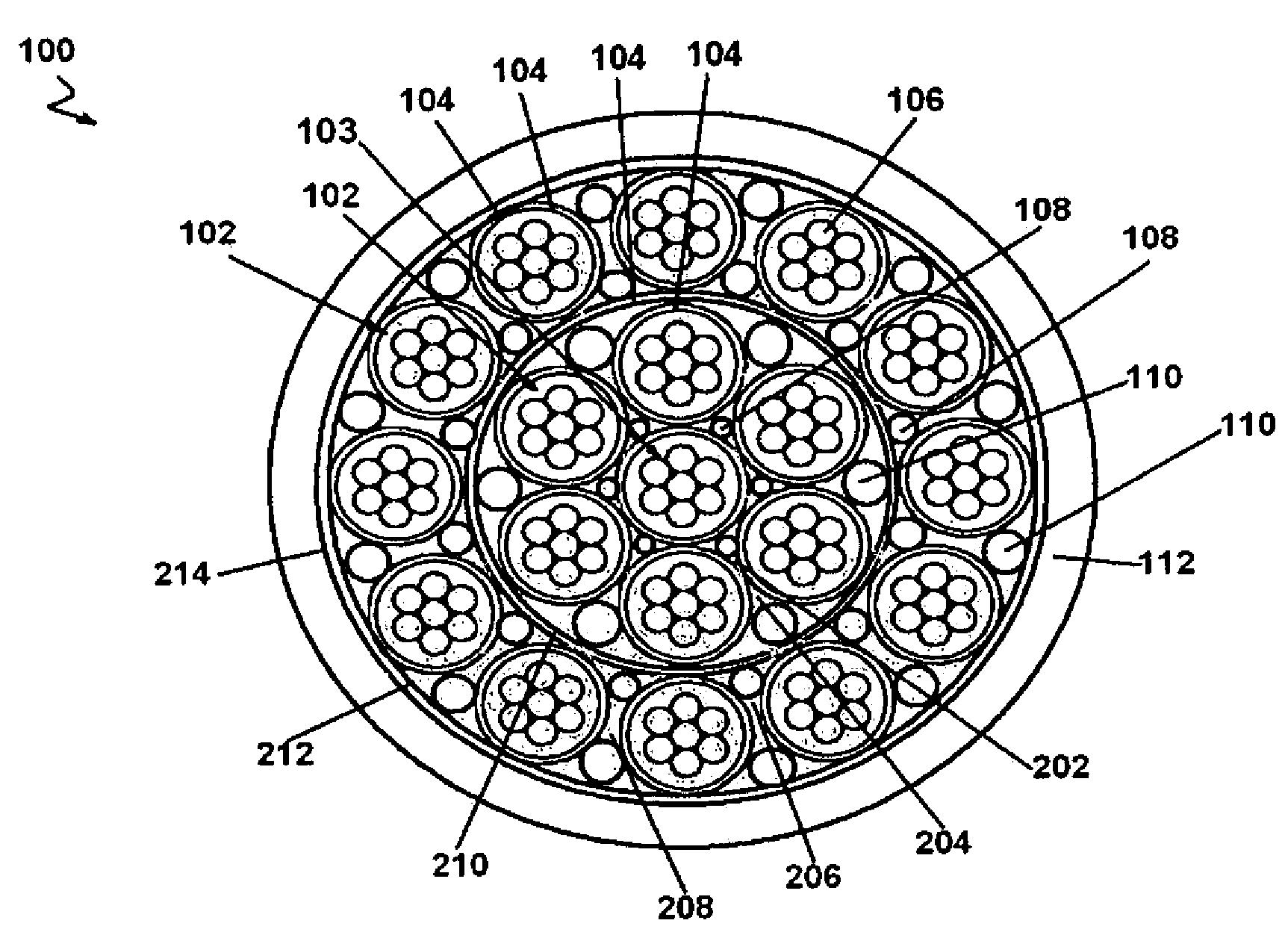

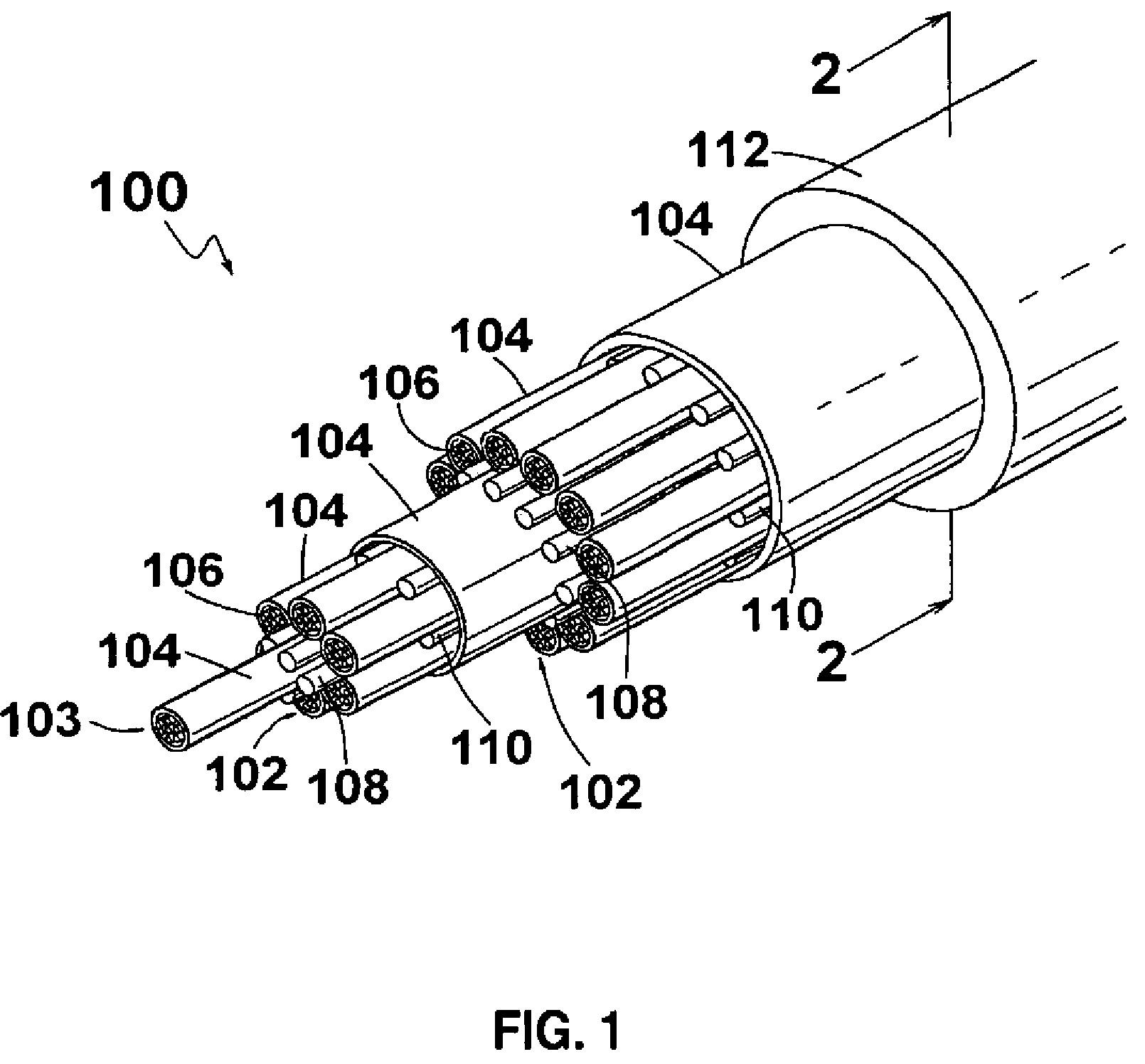

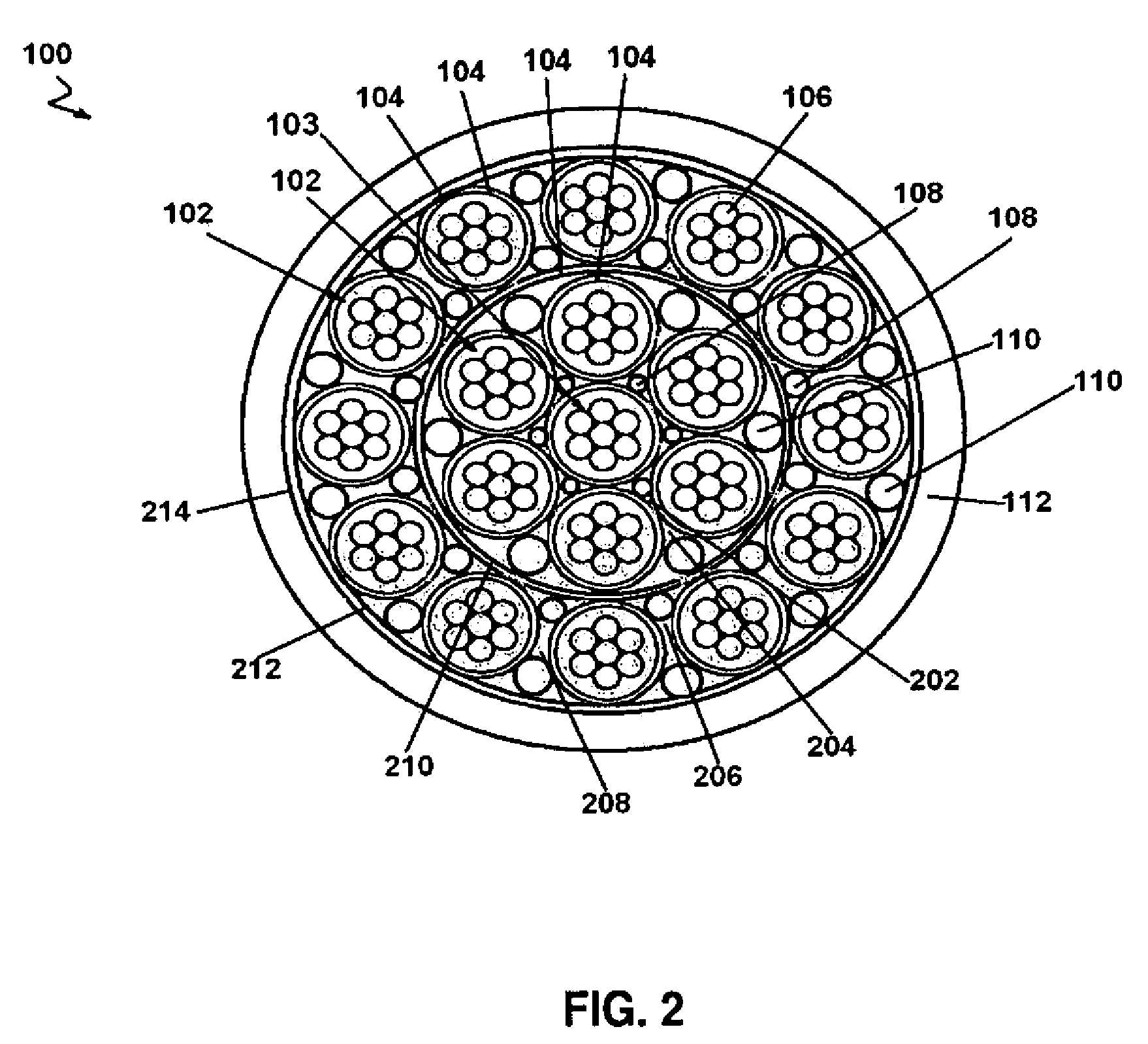

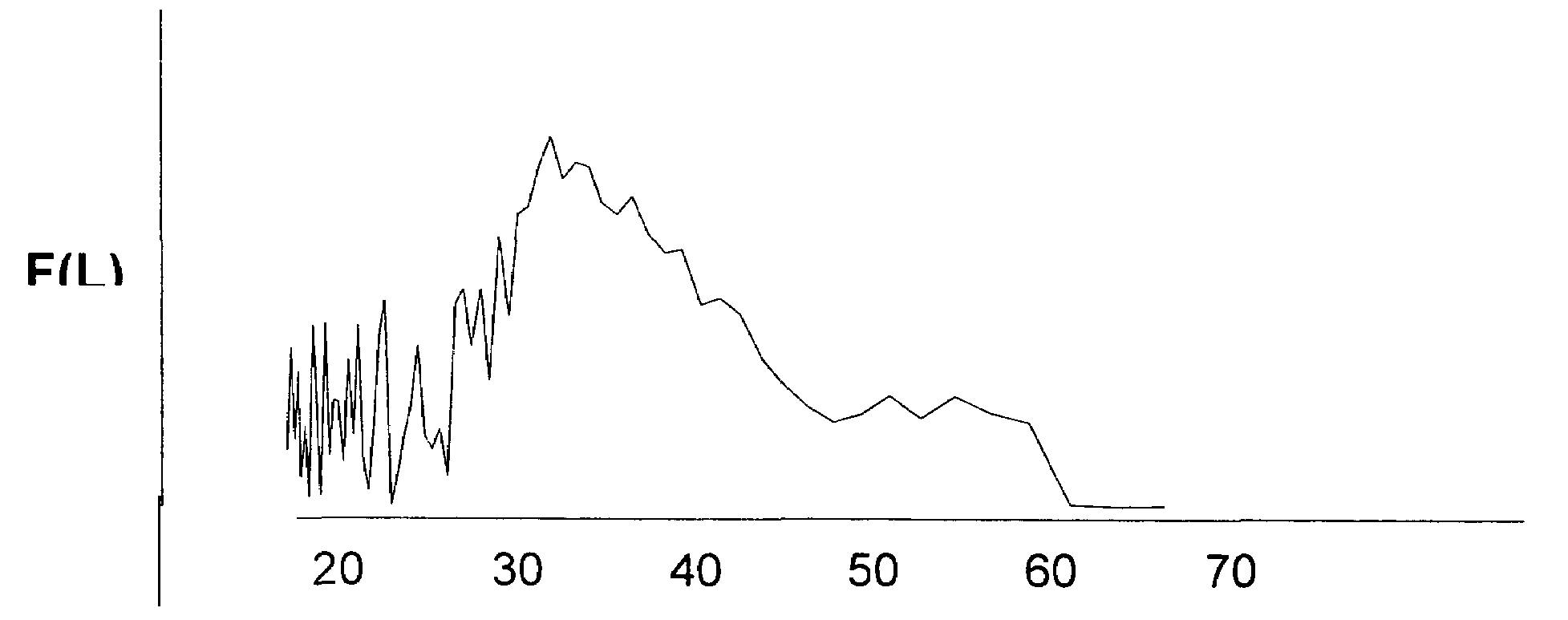

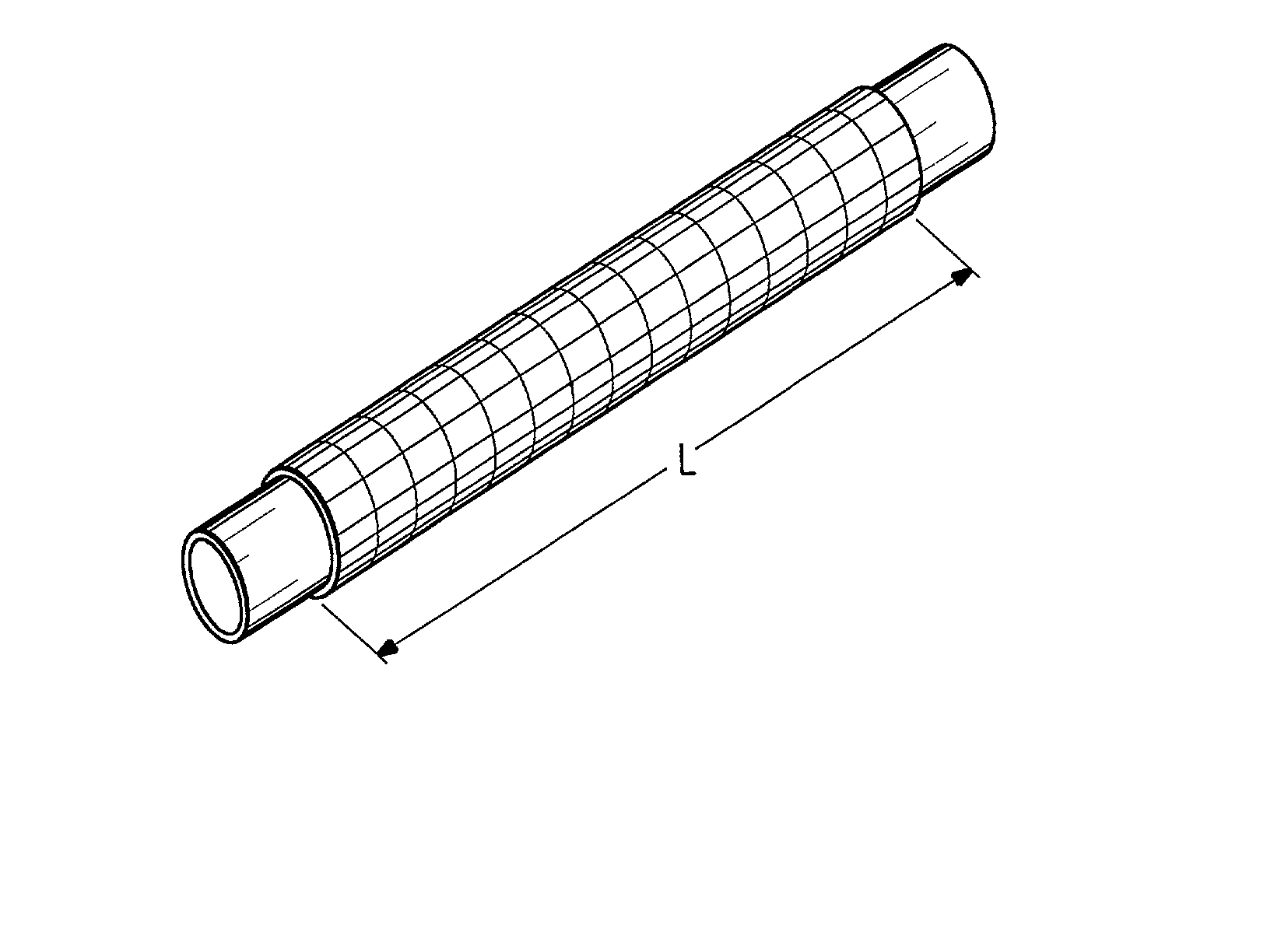

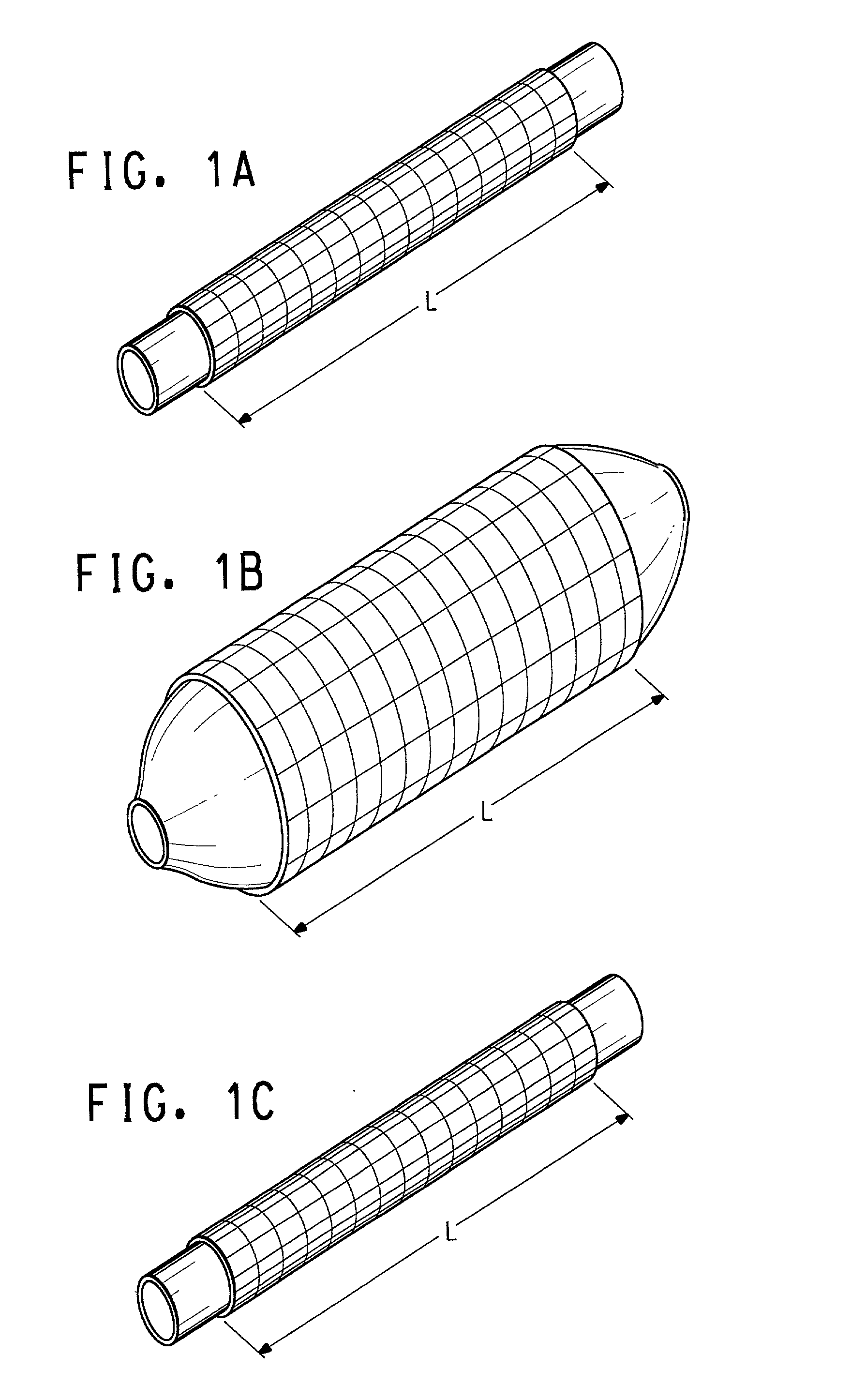

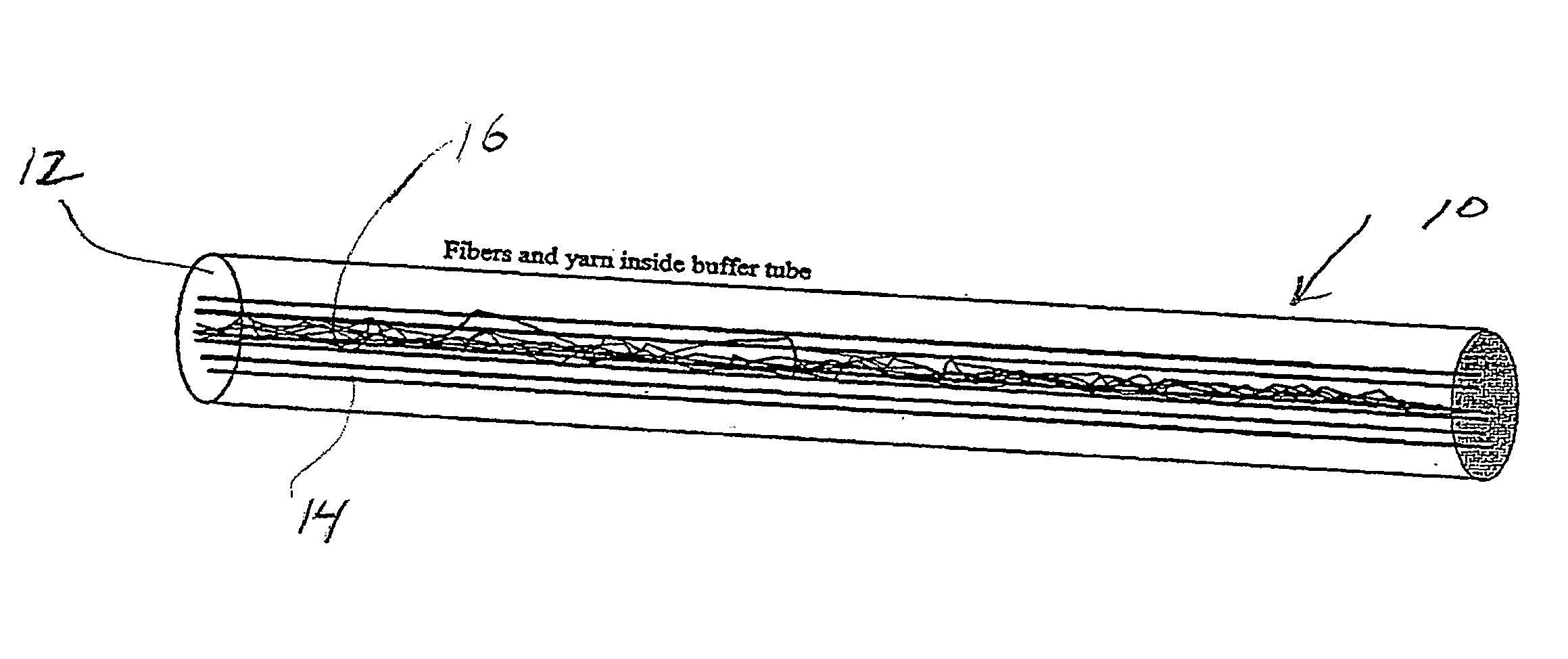

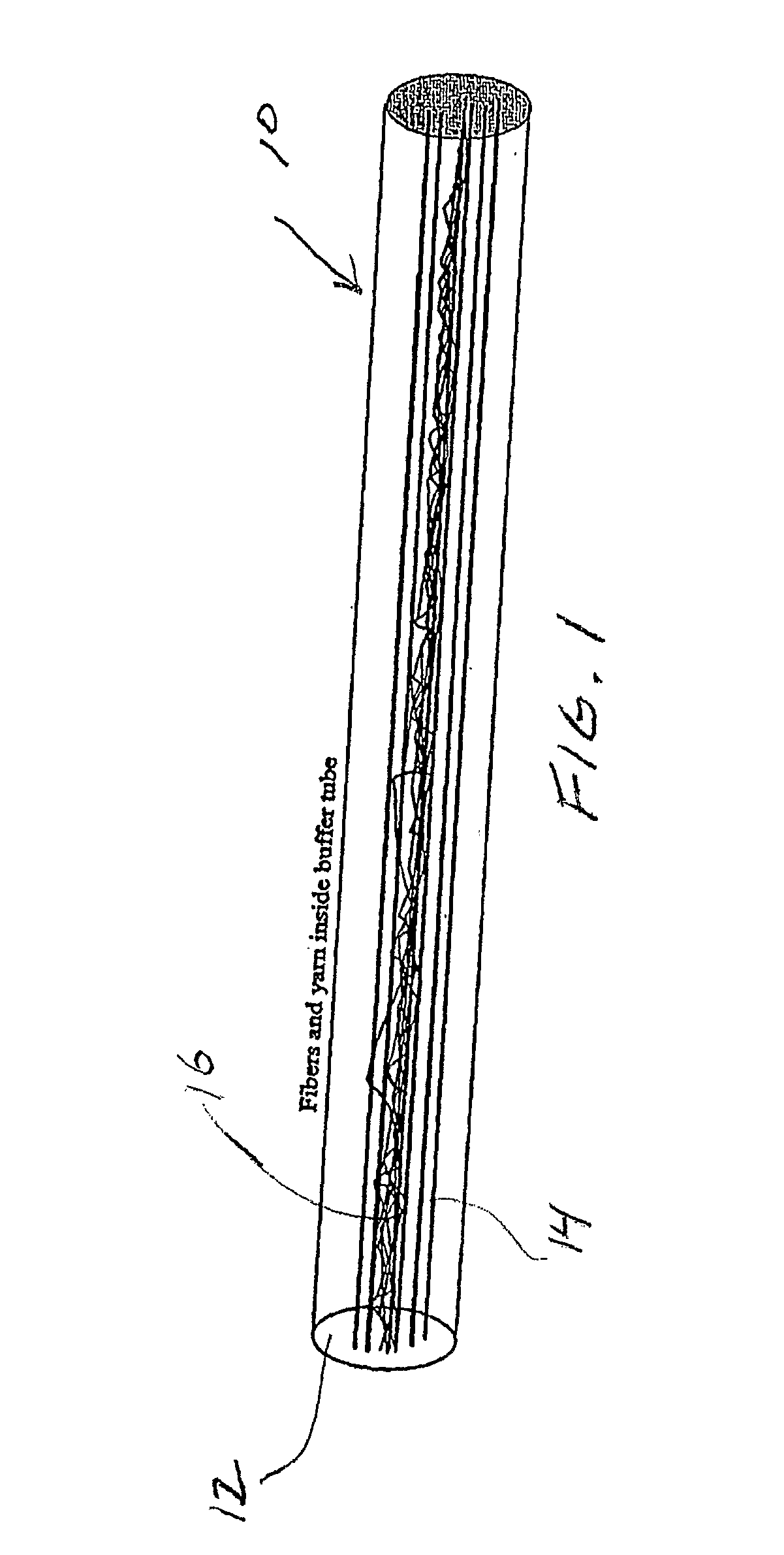

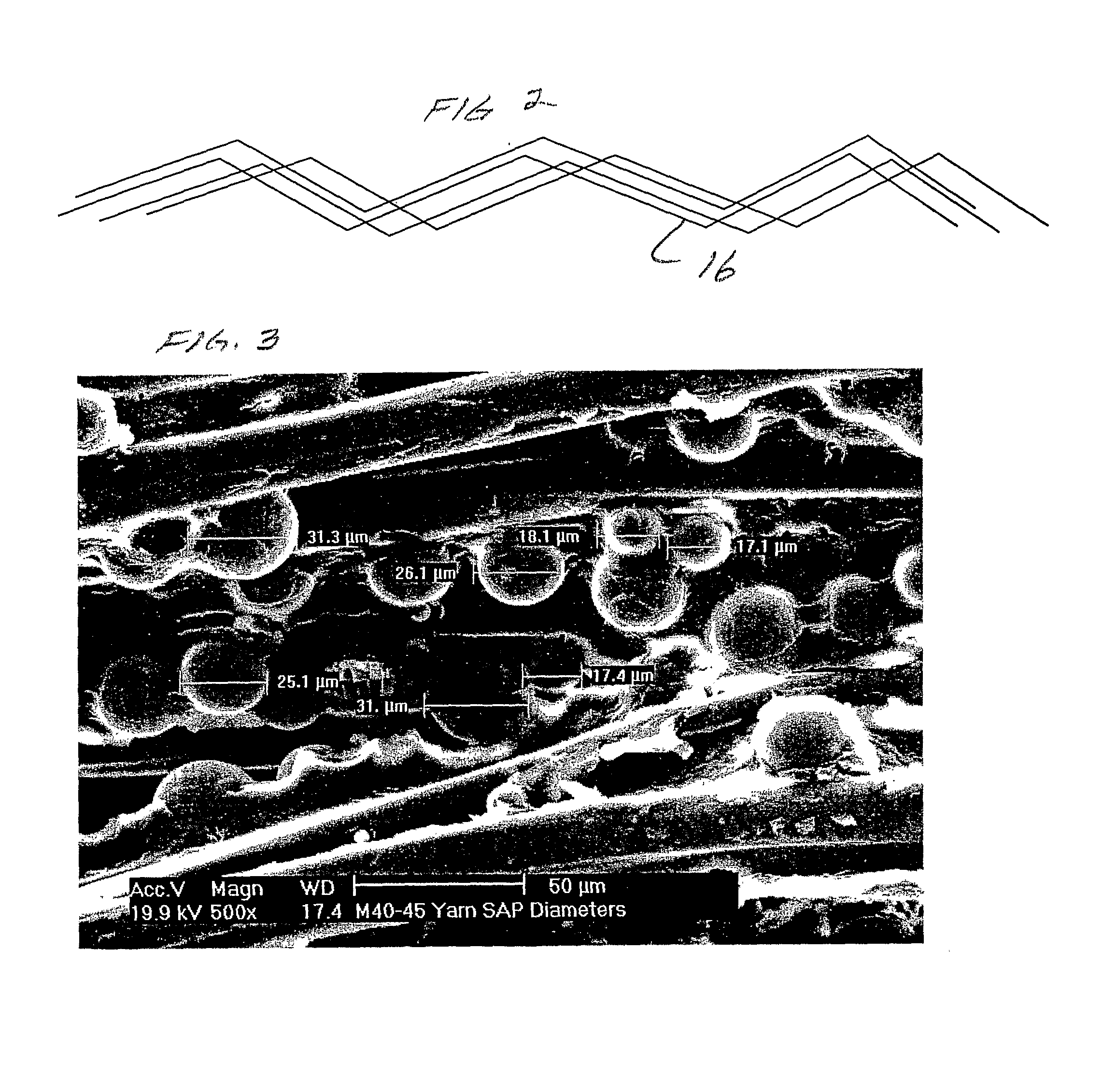

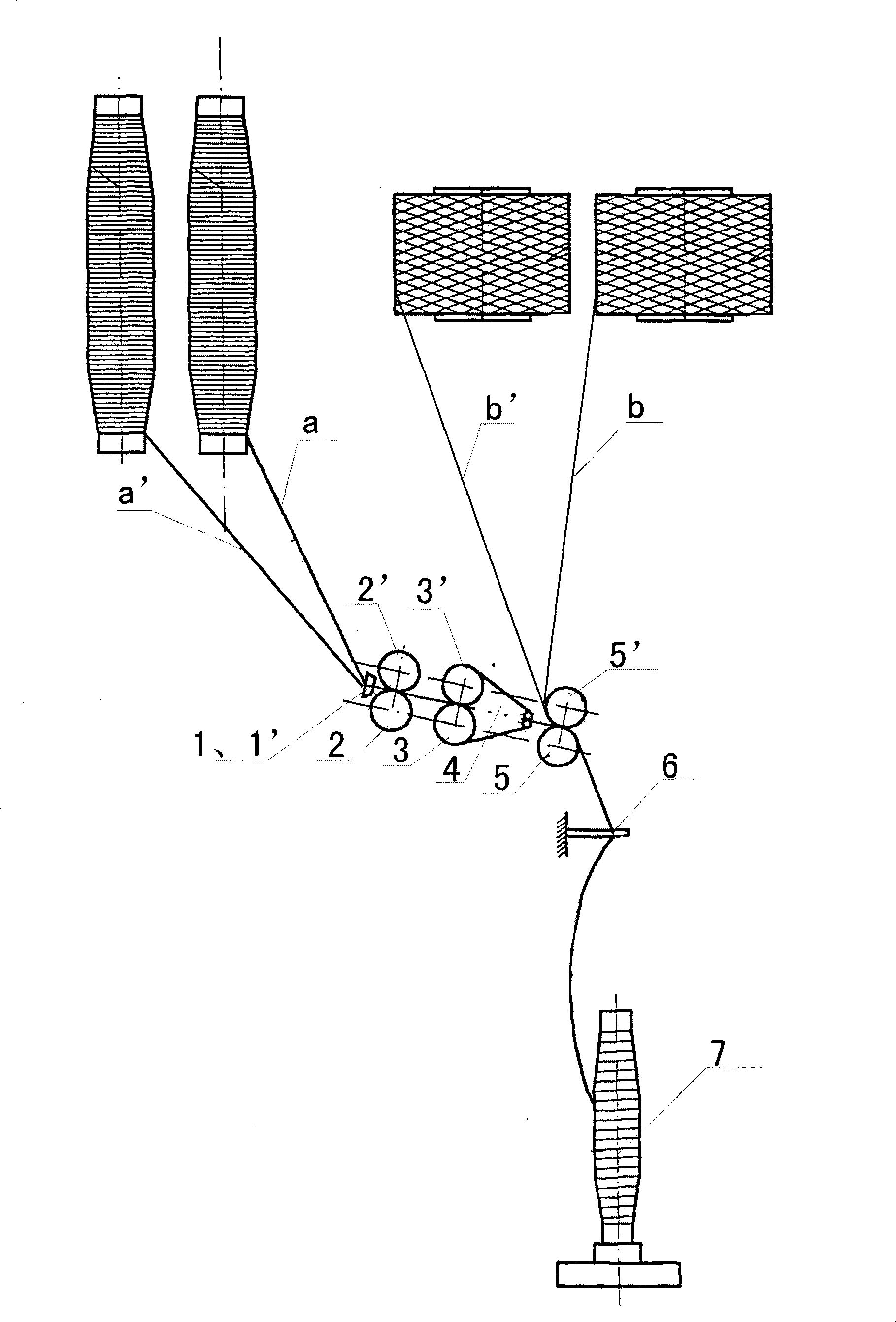

Grease-Free Buffer Optical Fiber Buffer Tube Construction Utilizing a Water-Swellable, Texturized Yarn

A buffered optical fiber arrangement that includes a buffer tube in which is provided optical fibers and a texturized yarn coated with a water-swellable material. The filament diameter of the yarn used in the present invention may be between about 5 microns and about 100 microns, more preferably between about 10 and about 60 microns, still more preferably between about 20 and about 40 microns. The linear density, or denier in grams per 9000 meters, of the base yarn may be between about 100 and 1000, more preferably between about 200 and 600, or still more preferably between about 250 and 350. The degree of decrease in length (the "degree of texturizing") between the perfectly straight filaments before texturizing and the texturized filament may be between 1 percent and 90 percent, more preferably between about 2 percent and 50 percent, or still more preferably between about 5 percent and 25 percent.

Owner:DRAKA COMTEQ BV

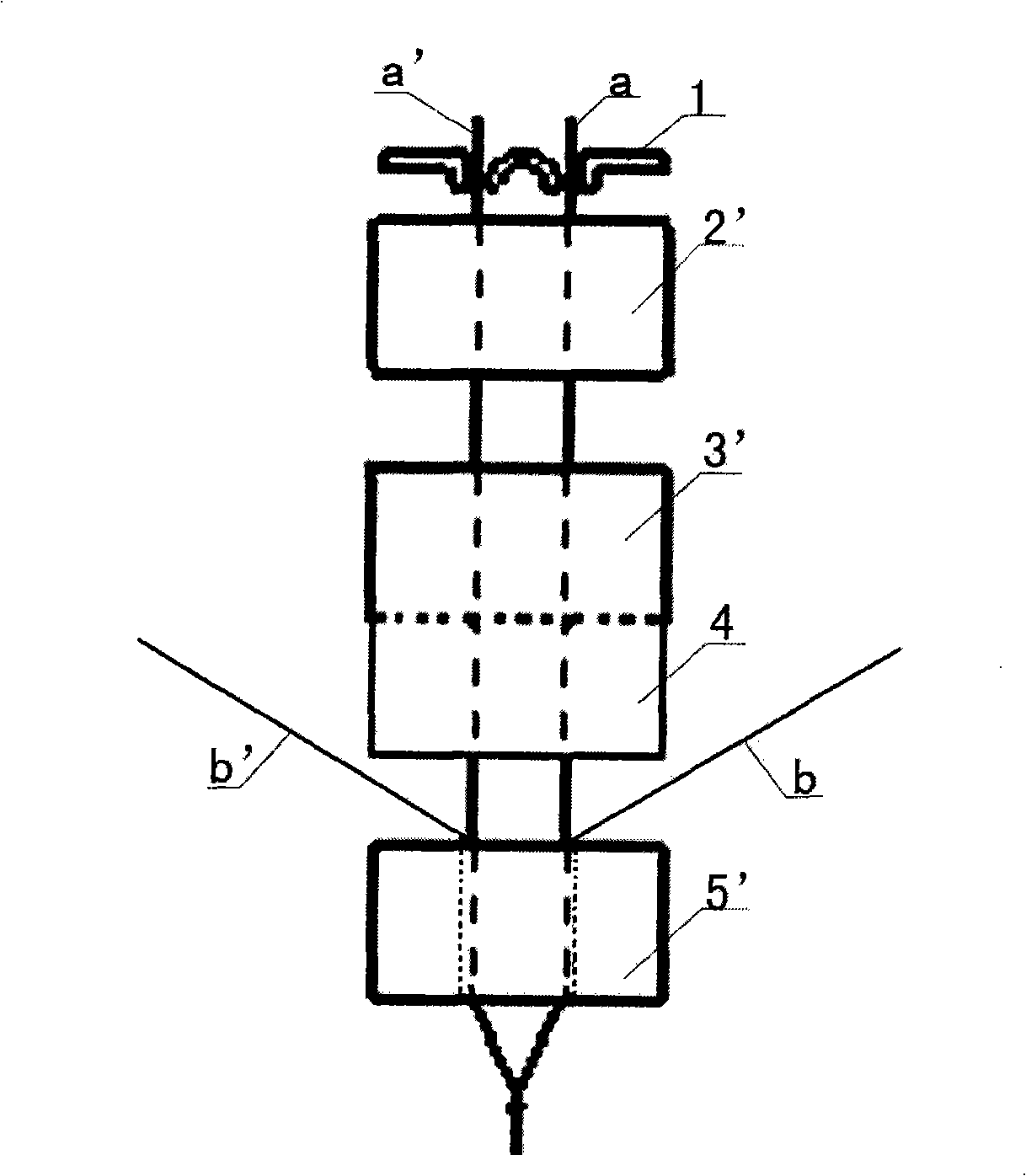

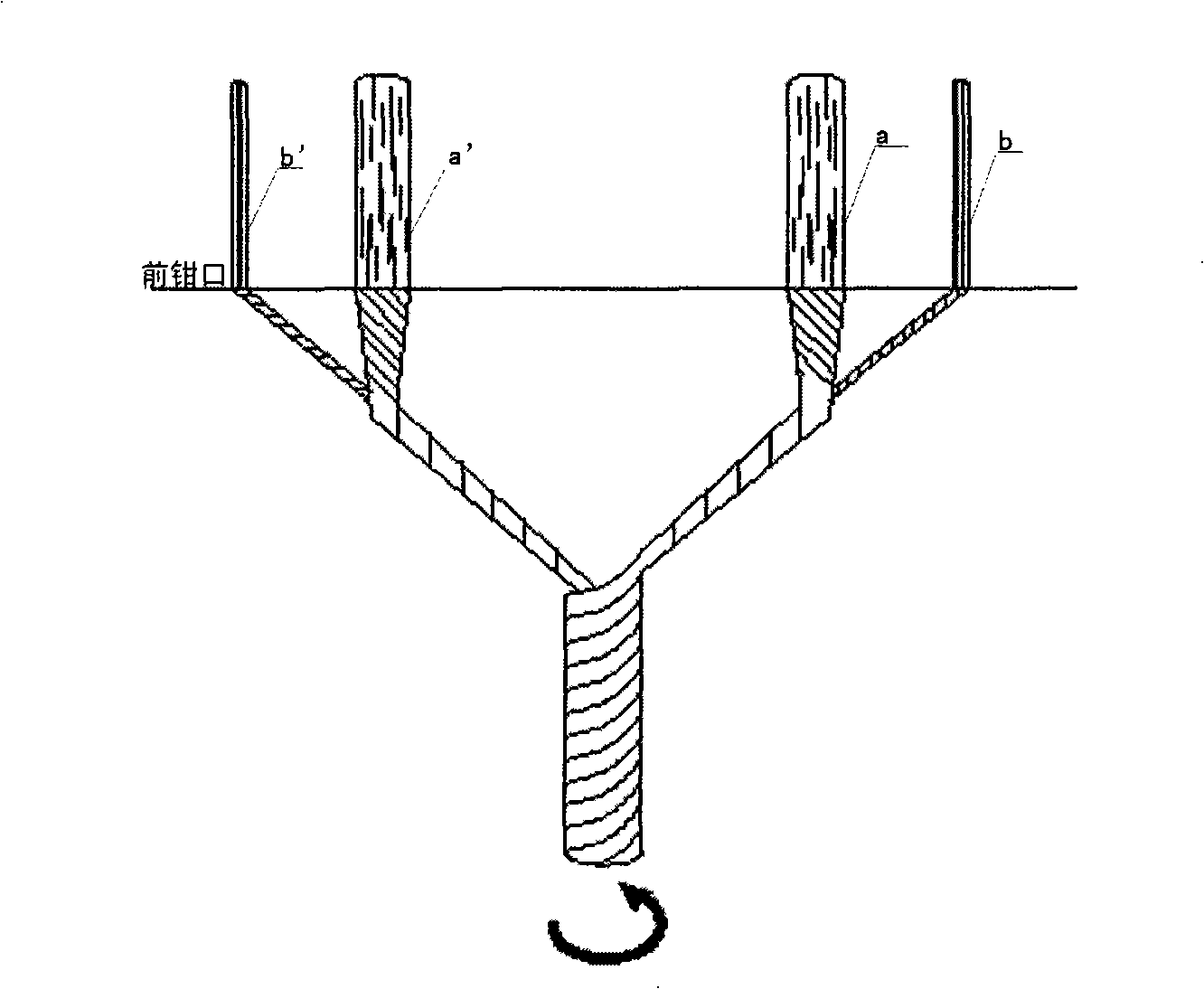

Positioning spinning method of embedded system

InactiveCN101492843ACompact structurePlay a reinforcing roleDrafting machinesContinuous wound-up machinesYarnFiber

Owner:WUHAN TEXTILE UNIV +2

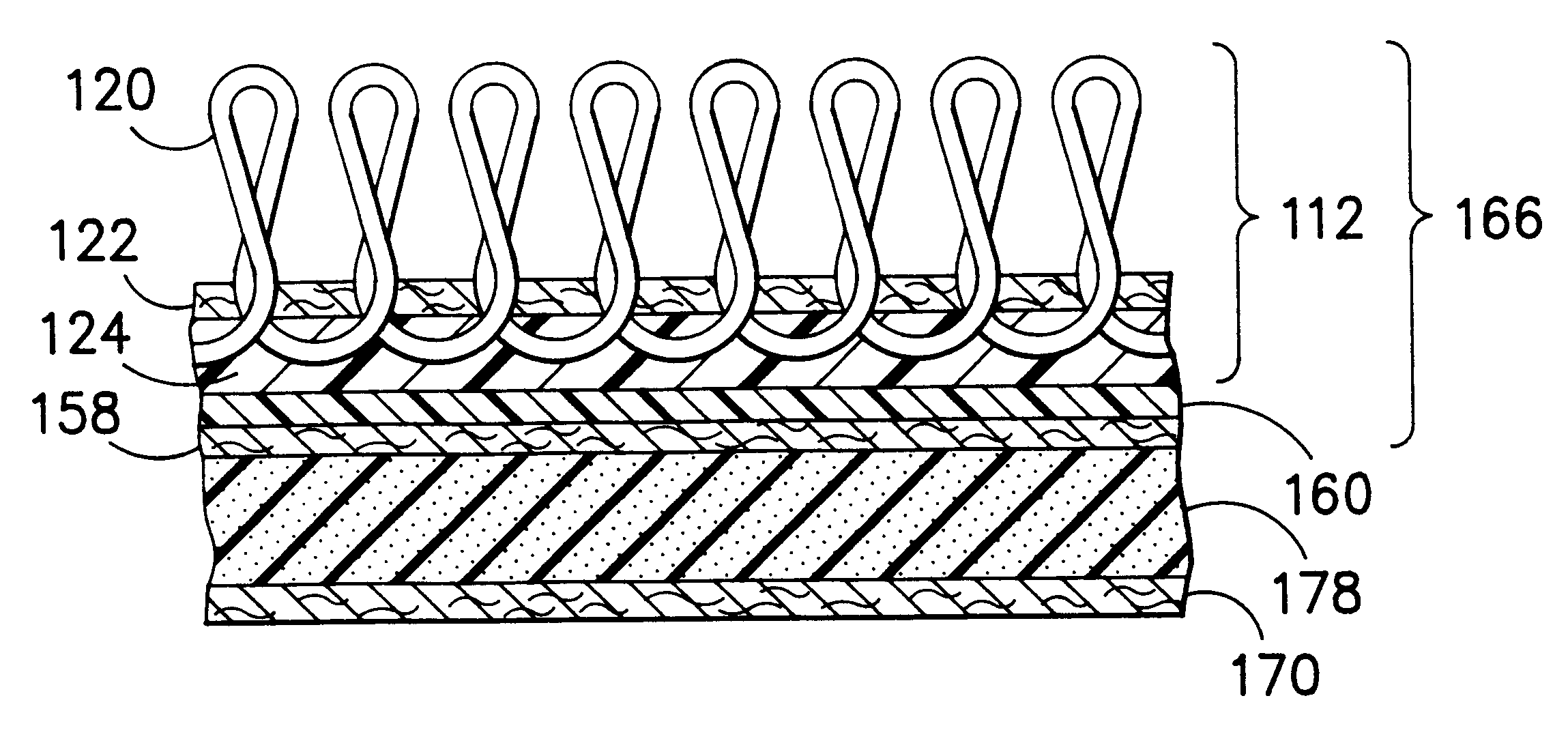

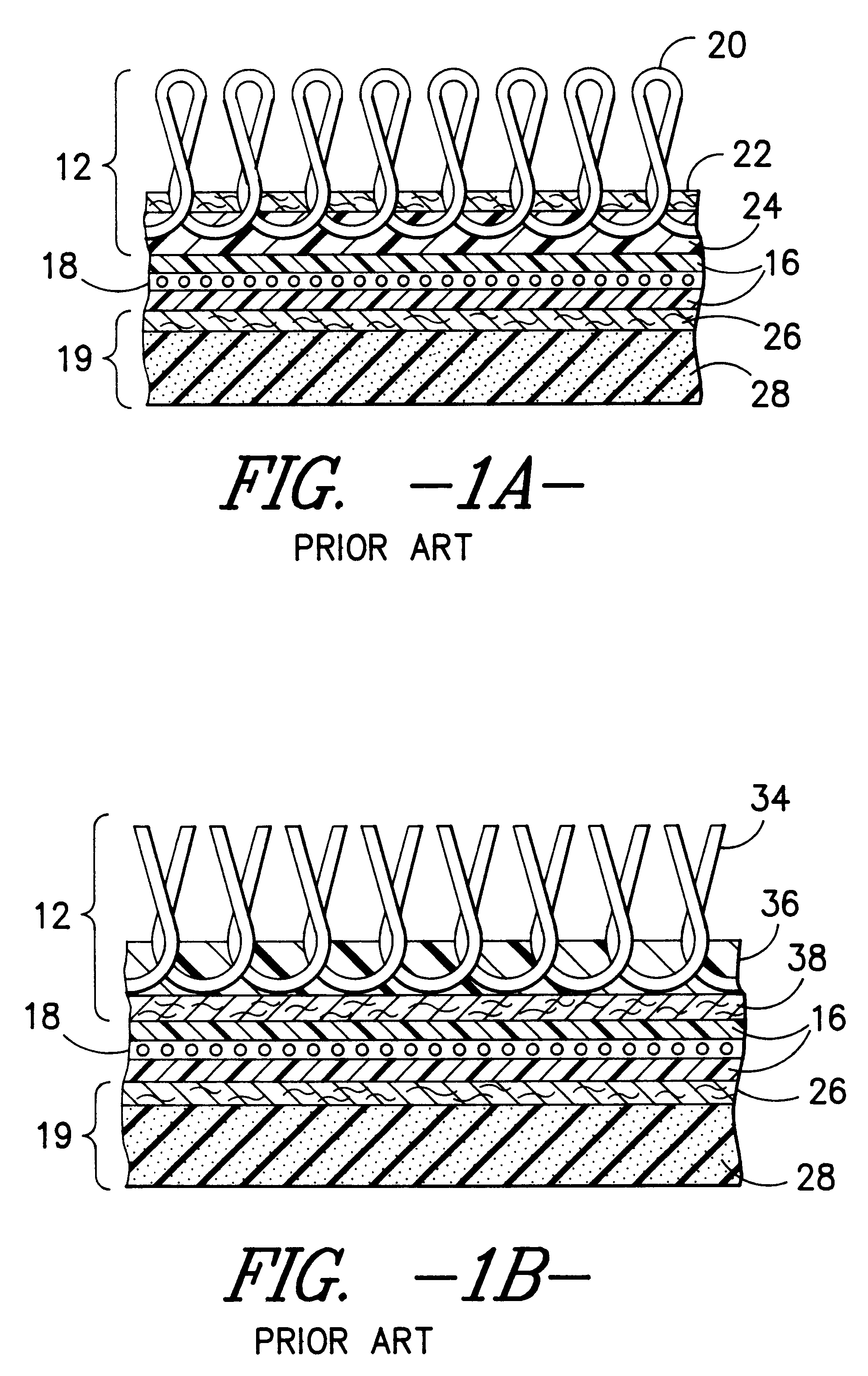

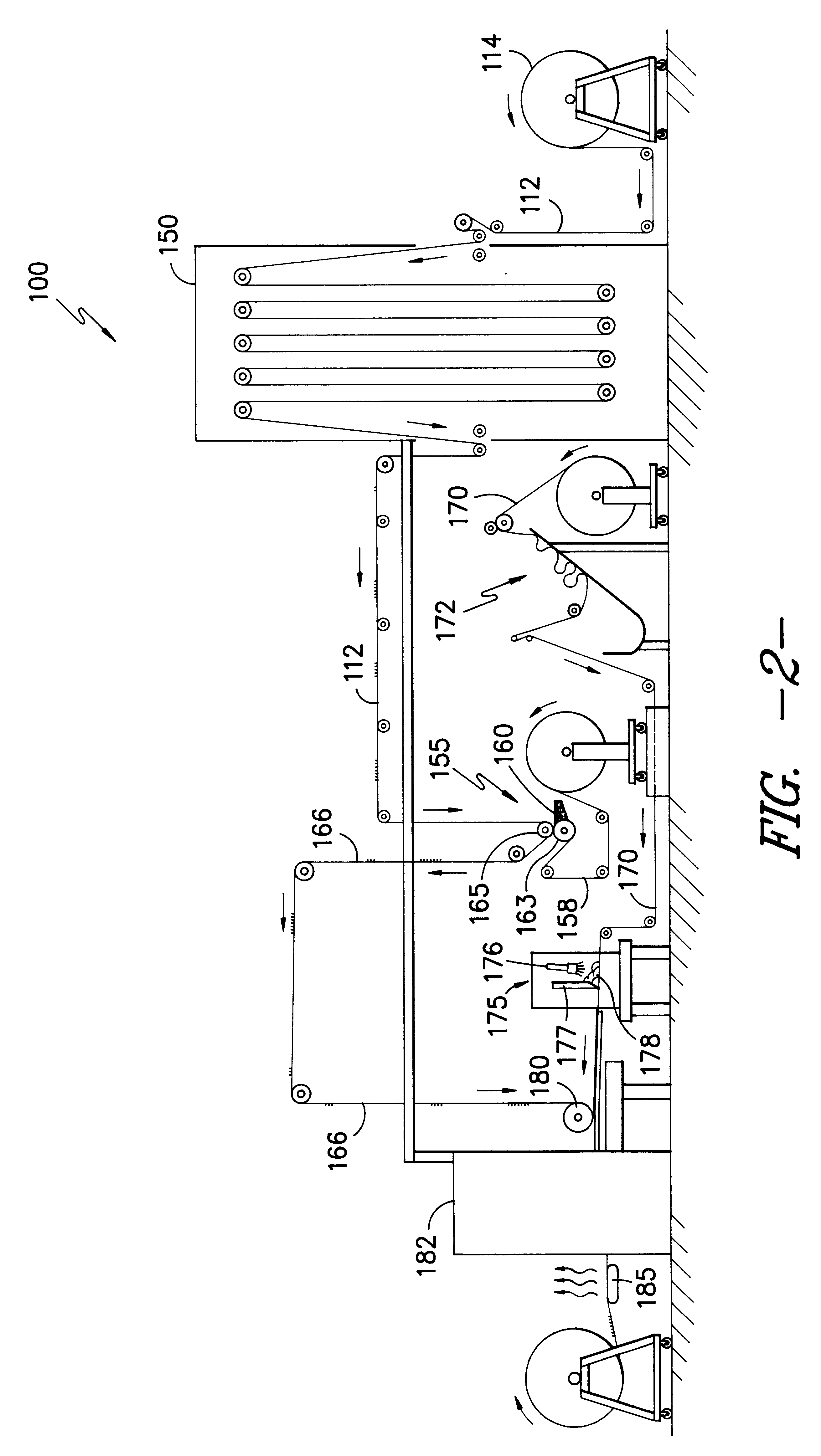

Cushion backed carpet

InactiveUS6203881B1Relieve pressureEasy to operateFibre treatmentSynthetic resin layered productsYarnAdhesive

An improved cushioned carpet fabric is provided. The cushioned carpet comprises a primary carpet having a primary base and a plurality of pile-forming yarns projecting outwardly from one side. A layer of reinforcement material is bonded to the primary base on the side opposite the pile forming yarns. The reinforcement layer is adjacent to and embedded in, a cushion layer of a polymer such as a polyurethane. There is preferably no additional adhesive between the cushion layer and the layer of reinforcement material since the primary carpet fabric is mated in-situ to the polyurethane-forming composition without preheating the polyurethane-forming composition. An apparatus and process for forming the cushioned carpet fabric of the present invention are also provided.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com