Patents

Literature

4371 results about "Coated surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface coating is an economical method to achieve high performance characteristics on exposed surfaces, e.g. by welding overlays or by thermal spraying. A metal object can be surface coated on the exposed area to achieve high wear, corrosion resistance or thermal insulation. Surface coating can also be used to repair damaged parts.

Ballistic fabric laminates

InactiveUS6846758B2Improved ballistic protectionImprove protectionSynthetic resin layered productsPersonal protection gearElastomerYarn

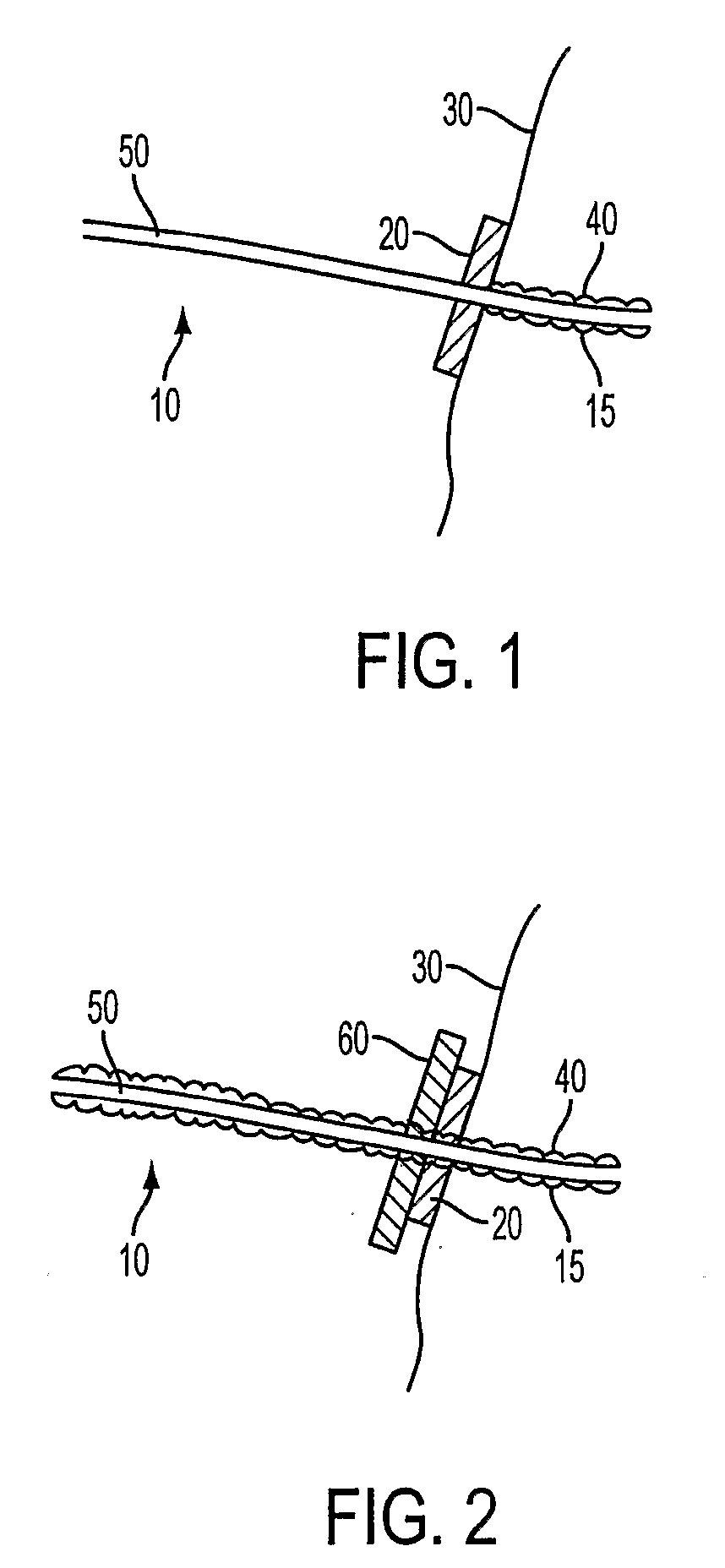

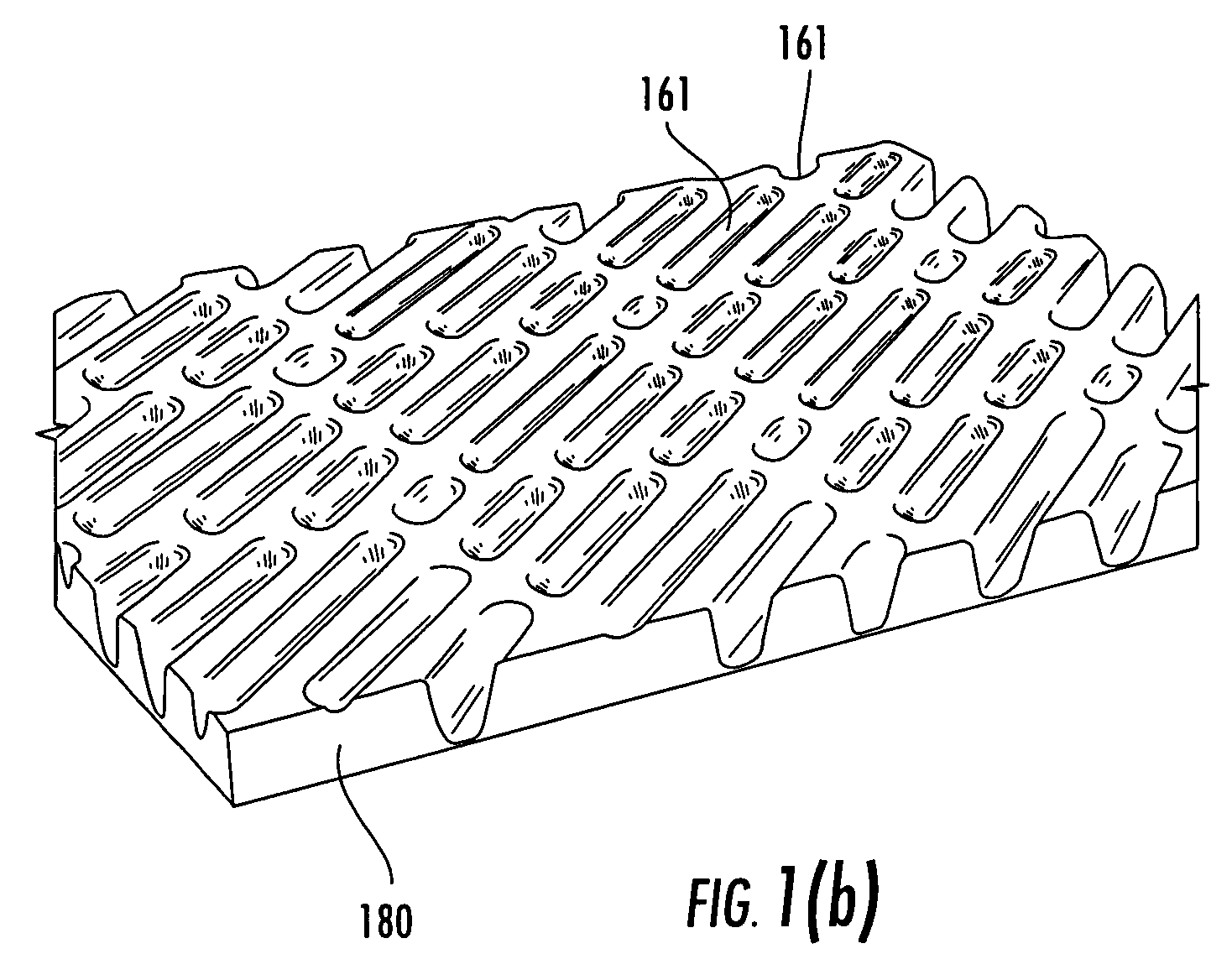

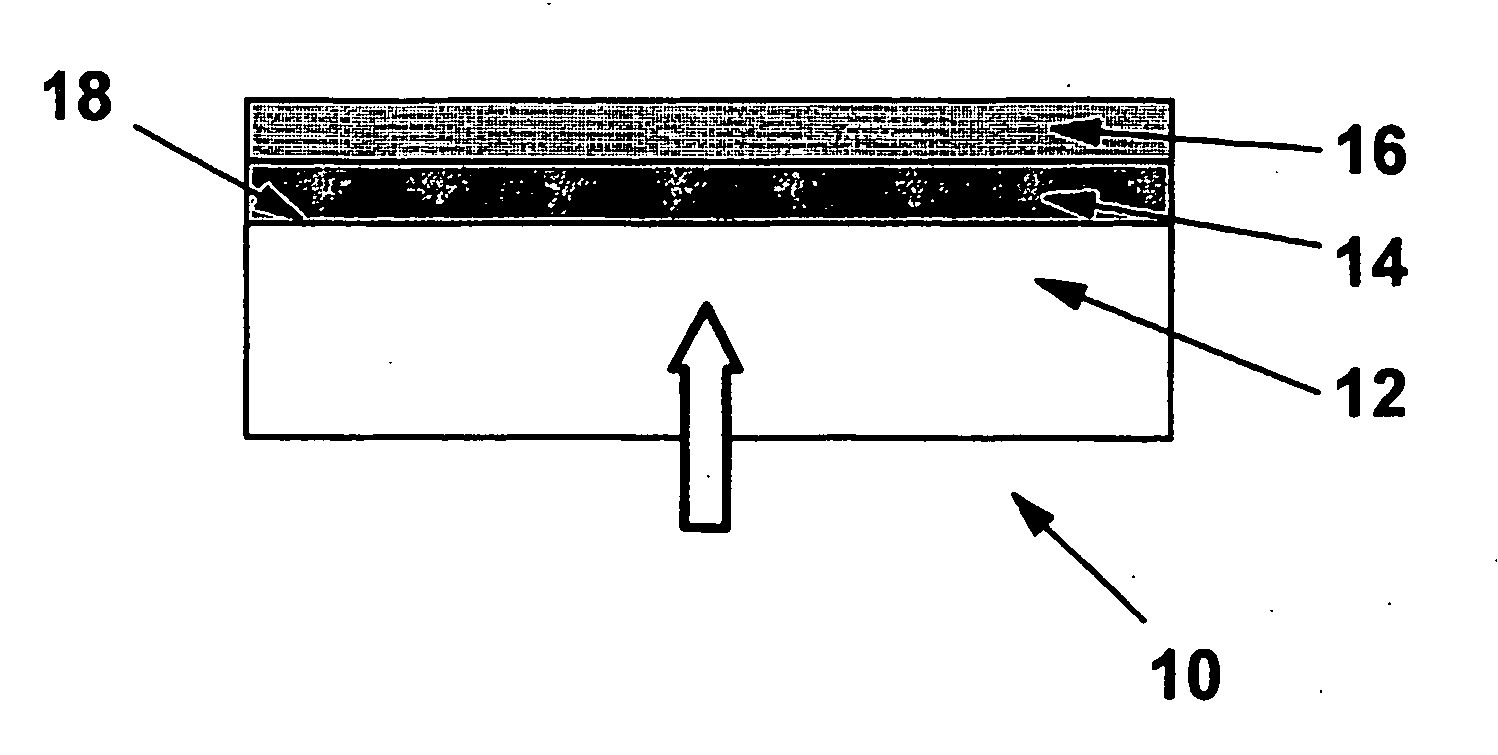

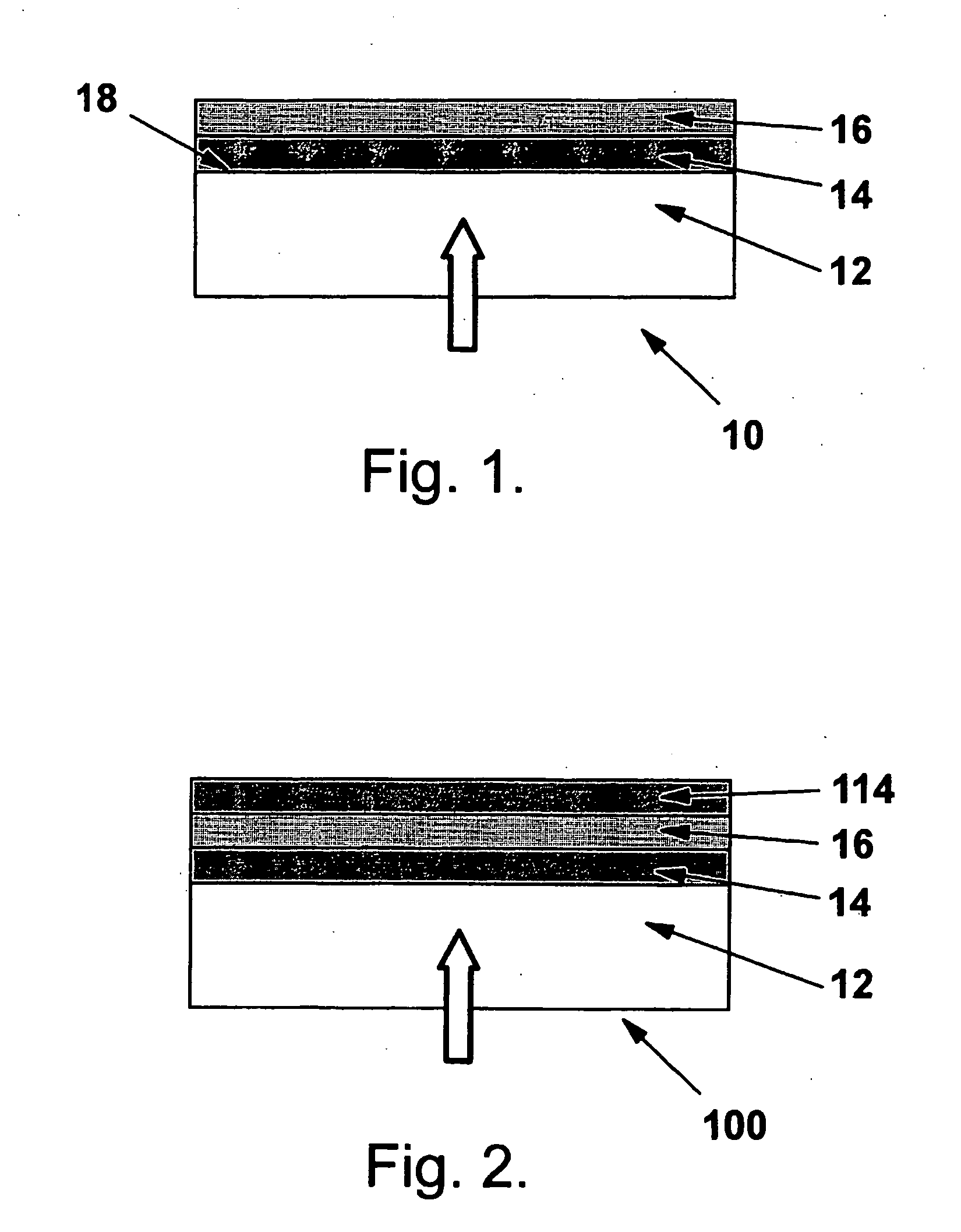

Woven fabric laminates having superior resistance to penetration by ballistic projectiles, assemblies thereof, and the method by which they are made. In one embodiment, among others, a laminate of the invention is comprised of a fabric woven from a high strength, high modulus yarn, a surface coating of a low modulus elastomer and a plastic film bonded to its elastomer-coated surface.

Owner:HONEYWELL INT INC

Coatings for enhancement of properties and performance of substrate articles and apparatus

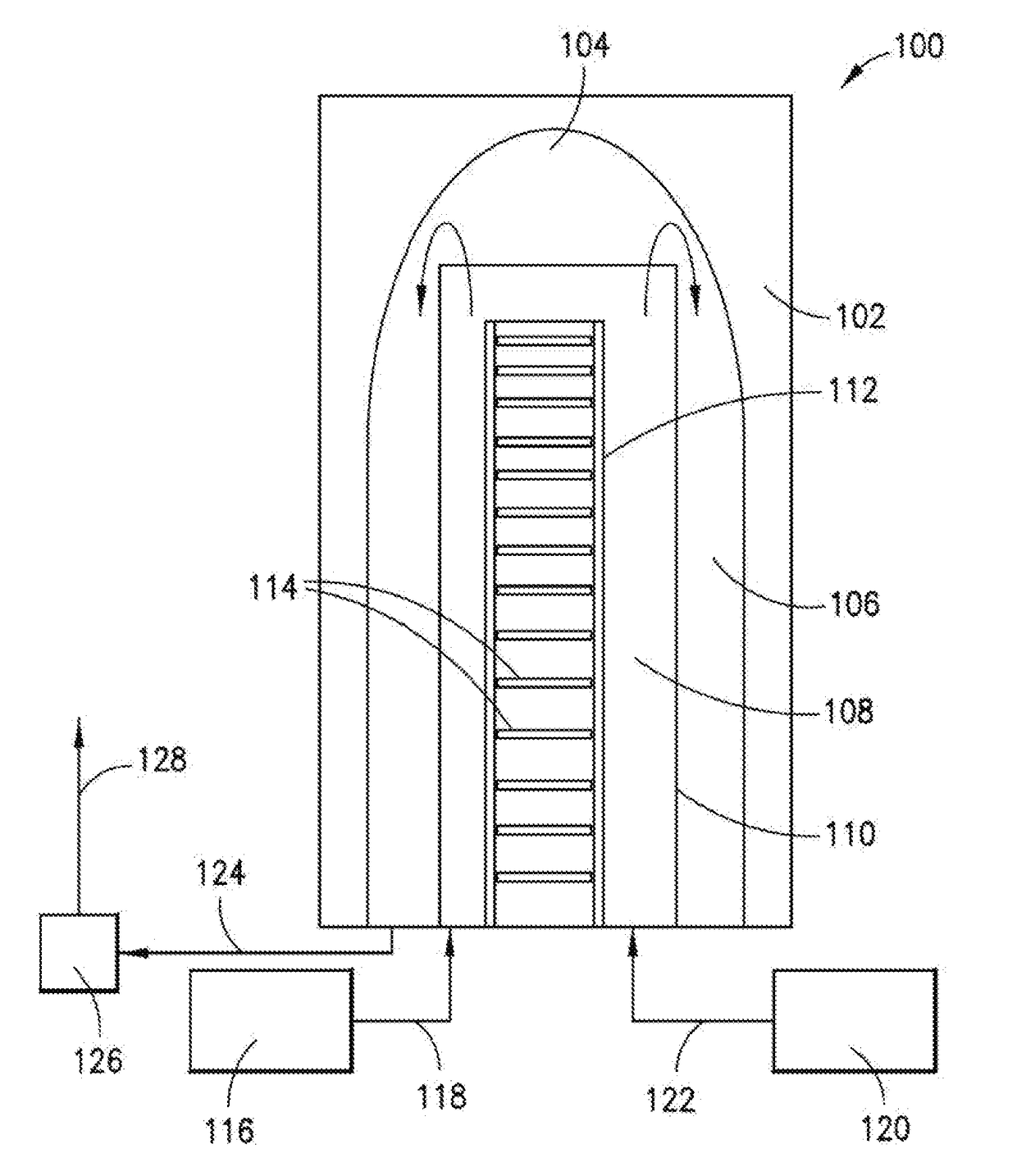

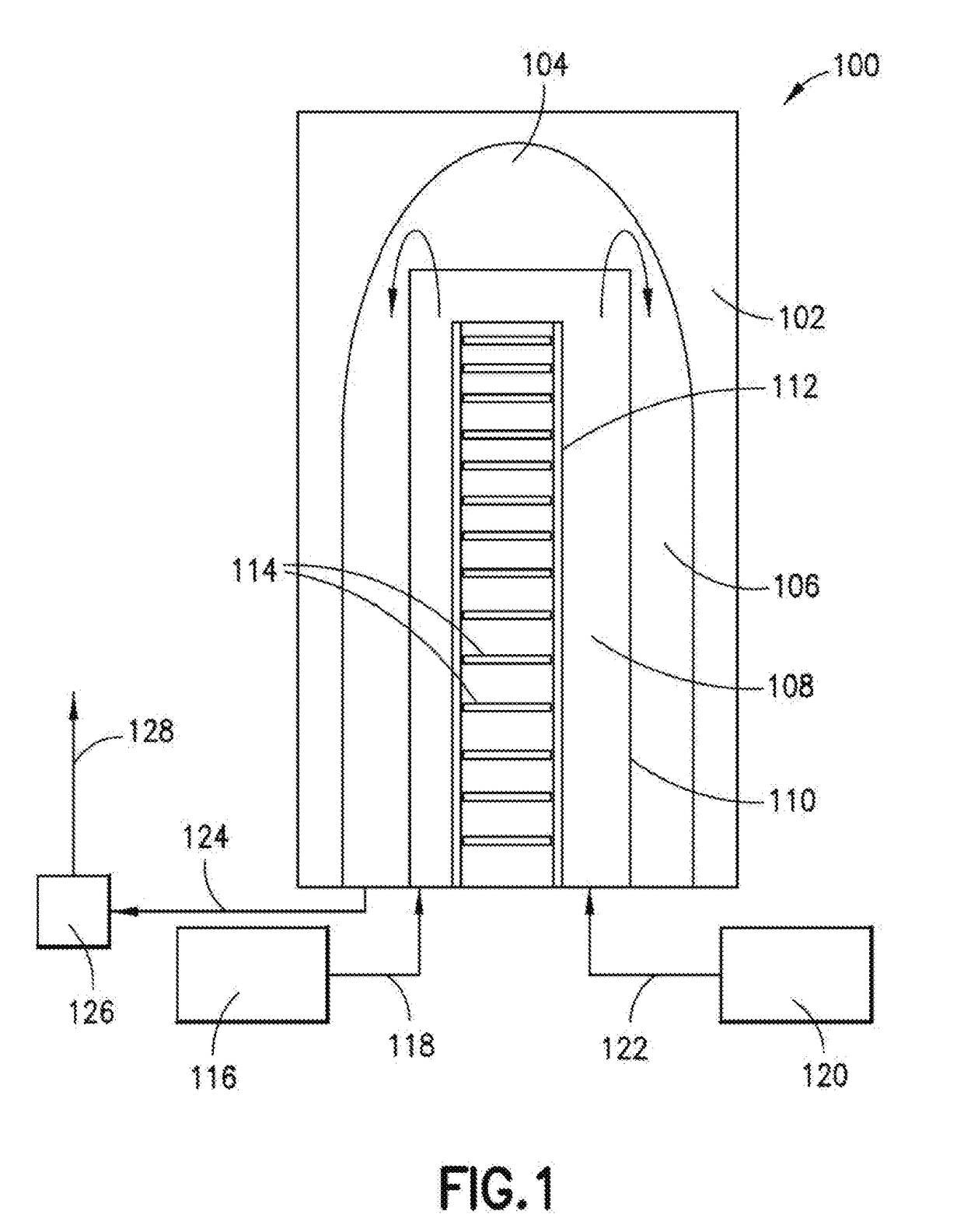

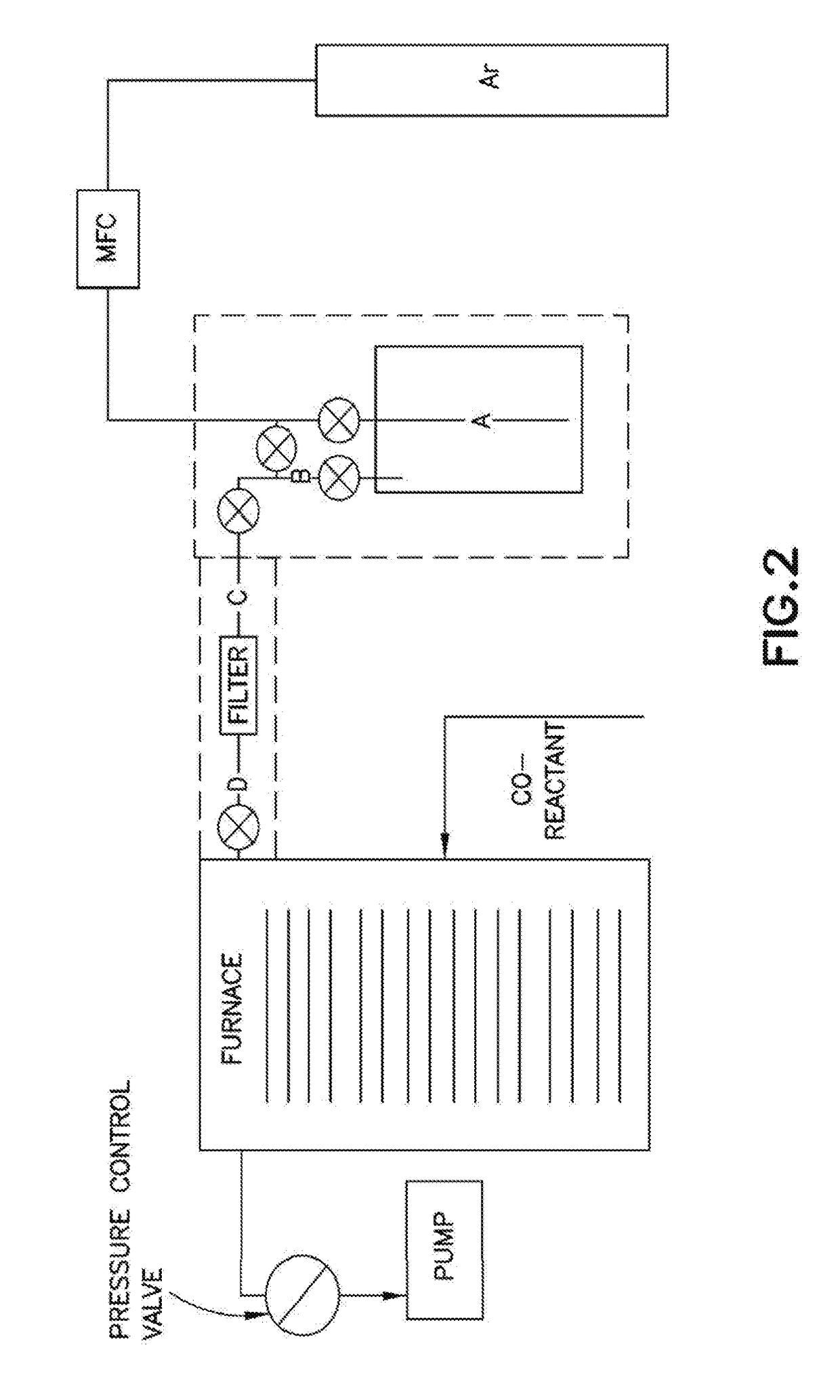

PendingUS20180044800A1Avoid reactionGood semiconductor performanceSemi-permeable membranesVacuum evaporation coatingCoated surfaceReactive gas

Coatings applicable to a variety of substrate articles, structures, materials, and equipment are described. In various applications, the substrate includes metal surface susceptible to formation of oxide, nitride, fluoride, or chloride of such metal thereon, wherein the metal surface is configured to be contacted in use with gas, solid, or liquid that is reactive therewith to form a reaction product that is deleterious to the substrate article, structure, material, or equipment. The metal surface is coated with a protective coating preventing reaction of the coated surface with the reactive gas, and / or otherwise improving the electrical, chemical, thermal, or structural properties of the substrate article or equipment. Various methods of coating the metal surface are described, and for selecting the coating material that is utilized.

Owner:ENTEGRIS INC

Antimicrobial Needle Coating For Extended Infusion

InactiveUS20070299409A1Convenient and smoothResisting reducing absorptionSurgeryMedical devicesCoated surfaceMedicine

The present invention relates to bioabsorbable polymeric coatings with antimicrobial agents that provide coated surfaces that resist protein absorption and infectious formation on coated surfaces of medical devices that are inserted or implanted in patients, and kits thereof with an antimicrobial disc.

Owner:ANGIOTECH BIOCOATINGS

Polymer coating for medical devices

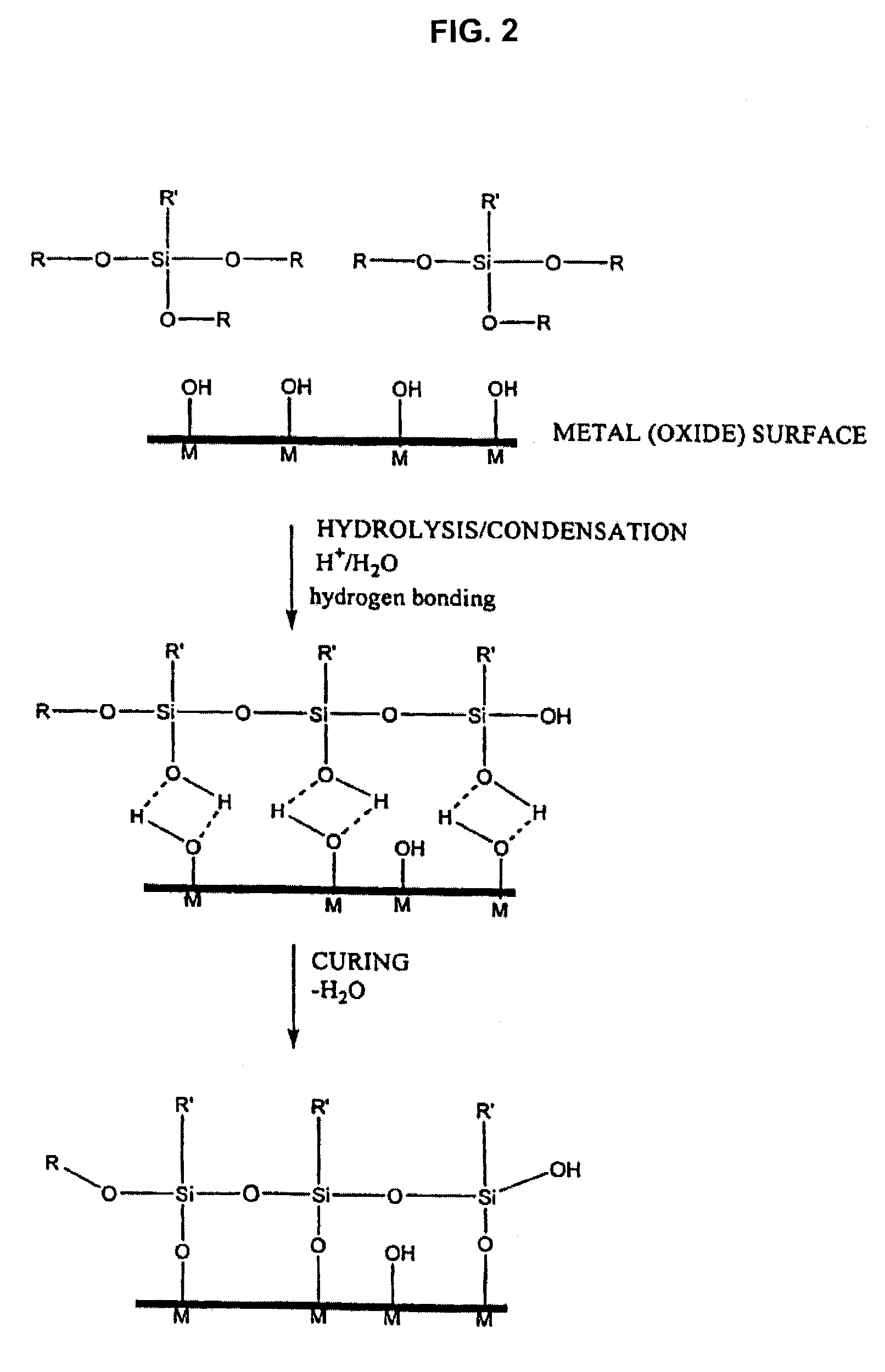

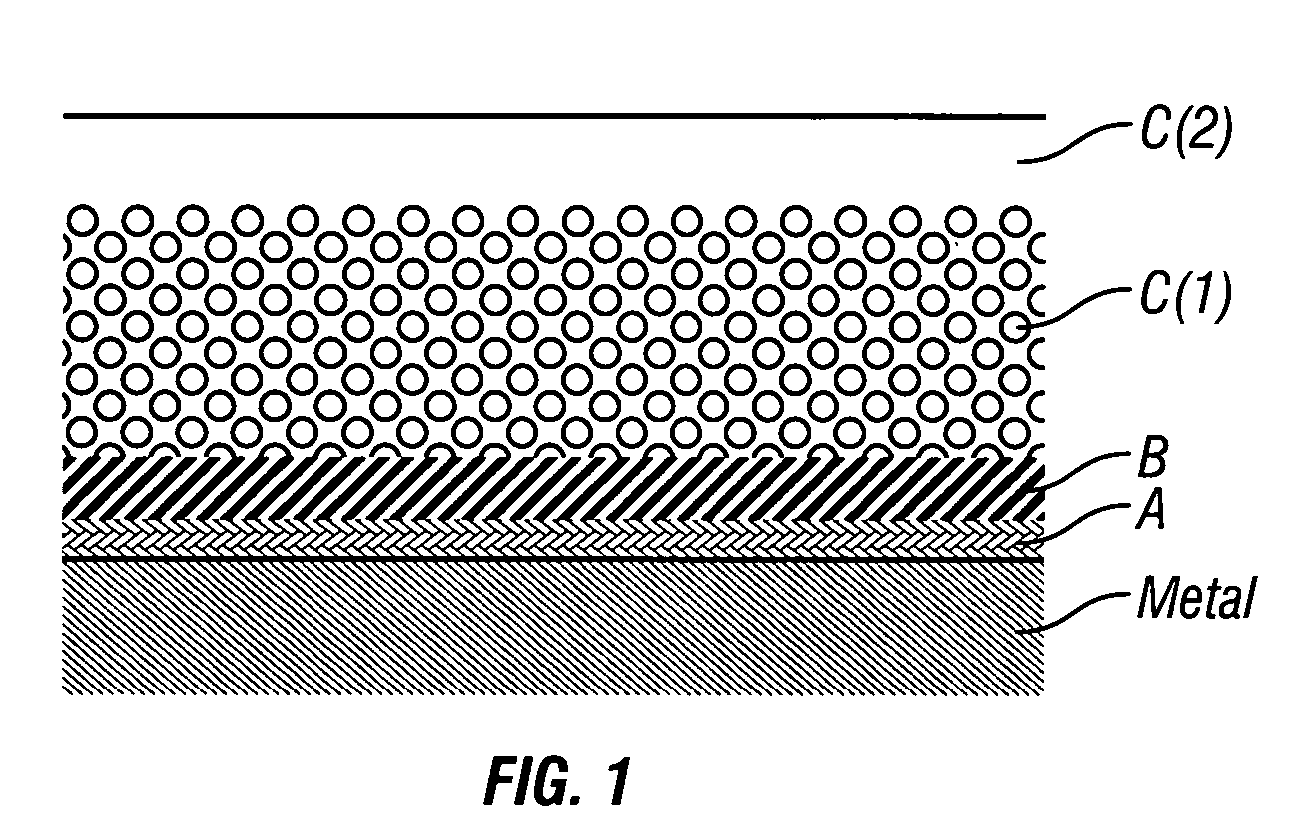

Coatings are provided in which surfaces may be activated by covalently bonding a silane derivative to the metal surface, covalently bonding a lactone polymer to the silane derivative by in situ ring opening polymerization, and depositing at least one layer of a polyester on the bonded lactone. Biologically active agents may be deposited with the polyester layers. Such coated surfaces may be useful in medical devices, in particular stents.

Owner:CV THERAPEUTICS INC

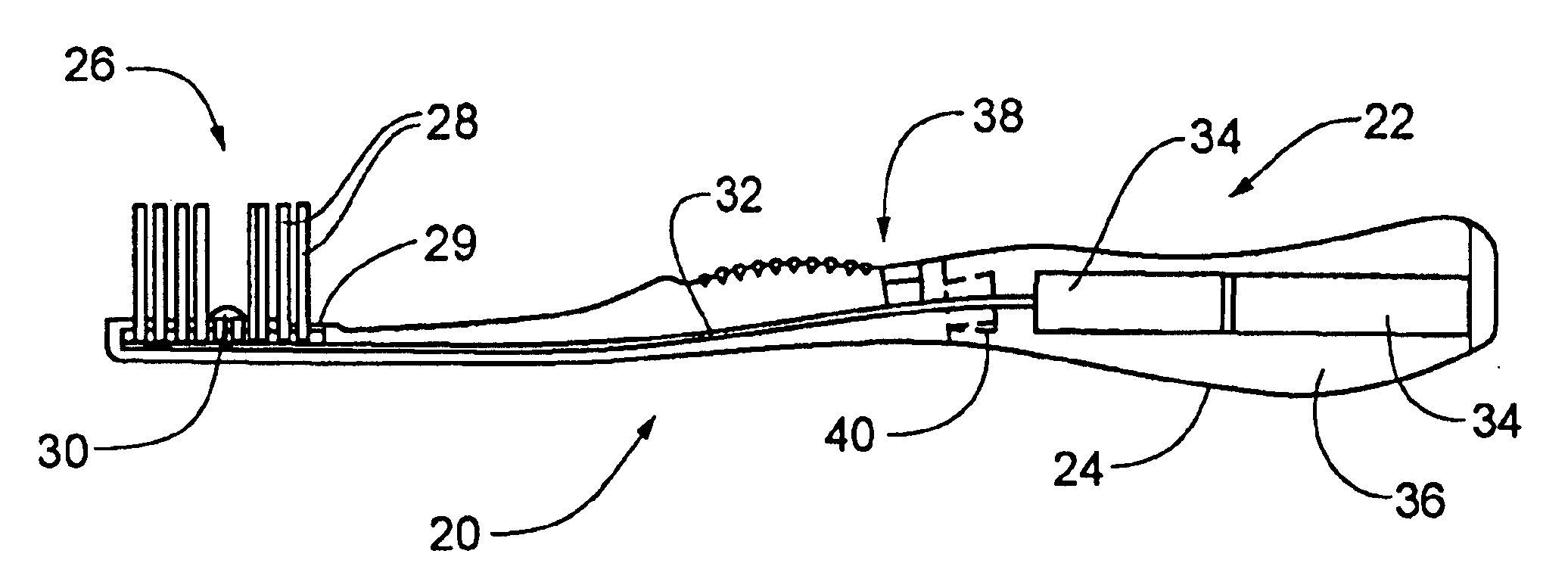

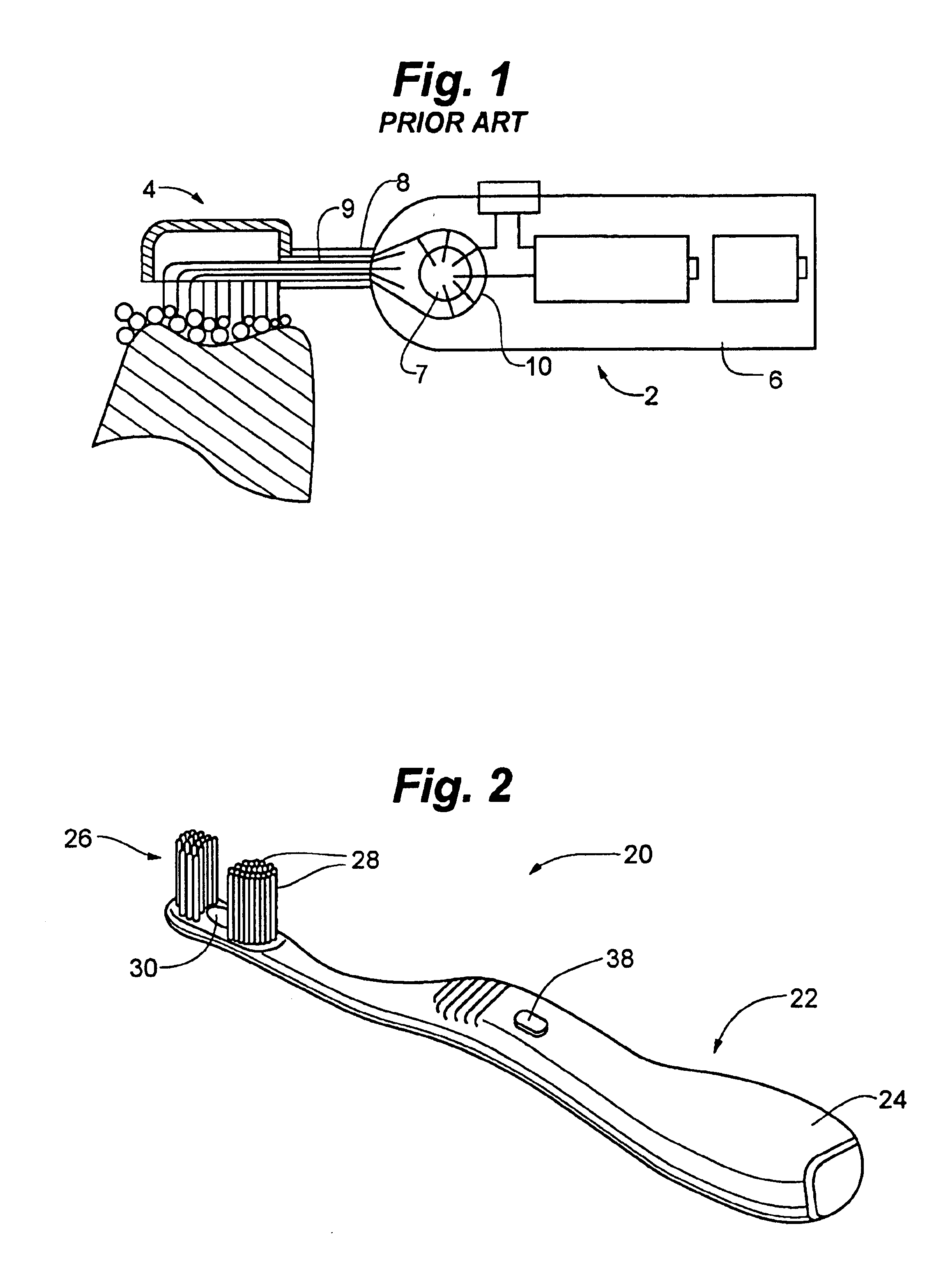

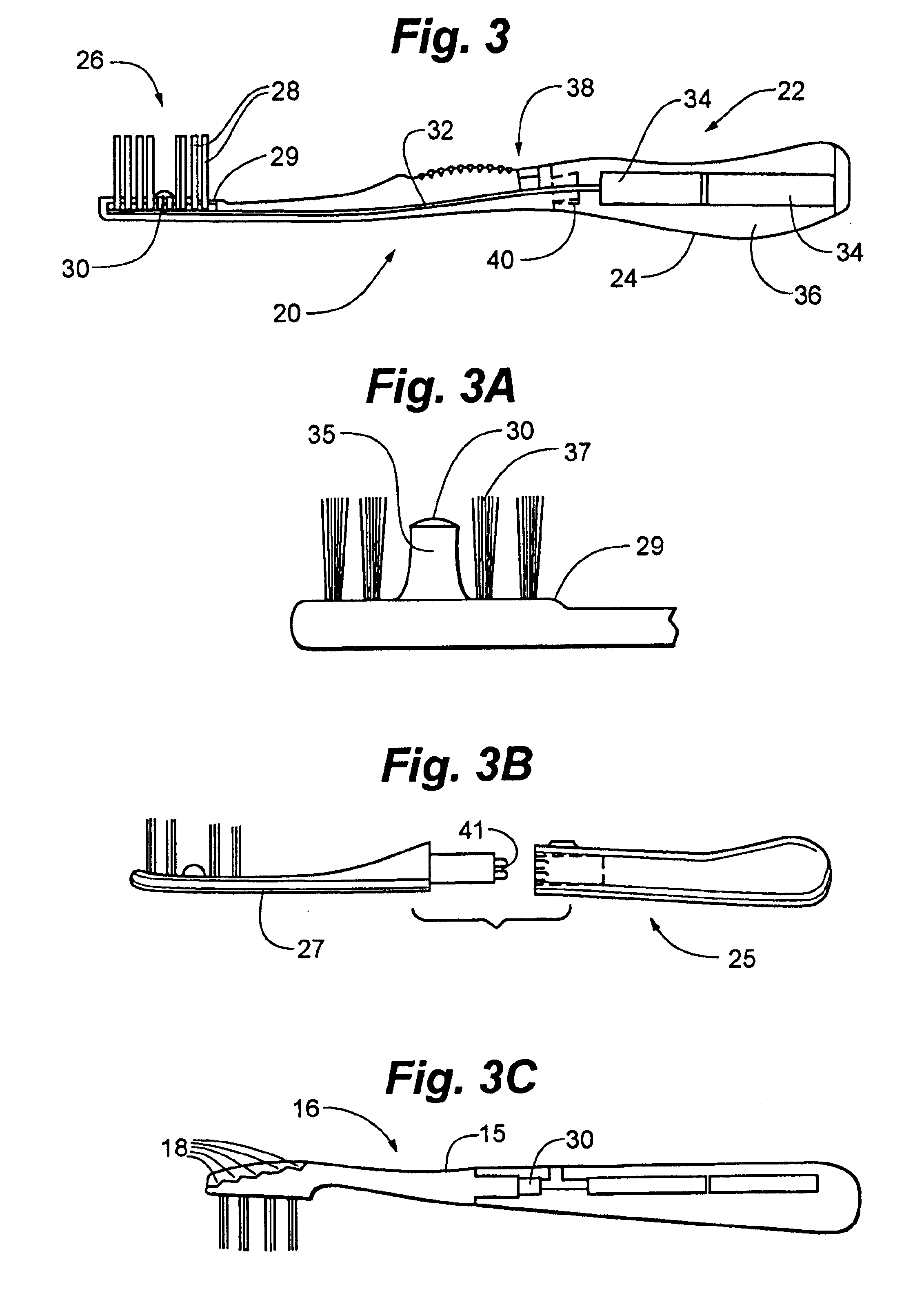

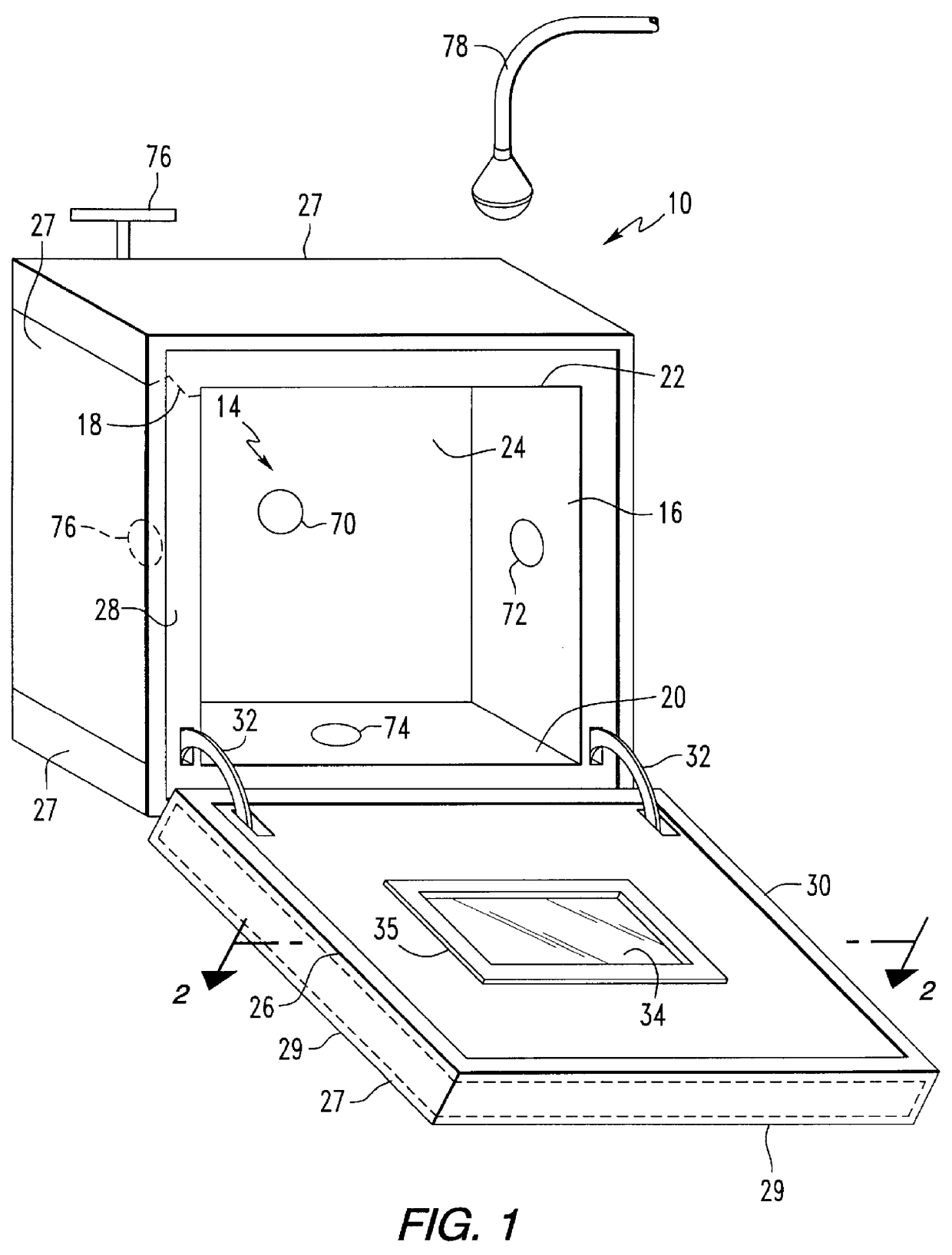

Enhanced dental hygiene system with direct UVA photoexcitation

A device and a method for delivering UVA light to the mouth in which a photocatalytic agent is distributed in the mouth and a UVA light source is located contiguously to the head of the device so that the photocatalytic agent distributed in the mouth is efficiently activated by UVA light produced by the device. The UVA light delivery device of the invention may be, inter alia, a toothbrush, a tongue scraper, an interdental toothbrush, a denture brush, a flossing device, a dental hand tool, or a wand adapted exclusively to applying UVA light to photocatalyst coated surfaces.

Owner:SUSR AMERICAS

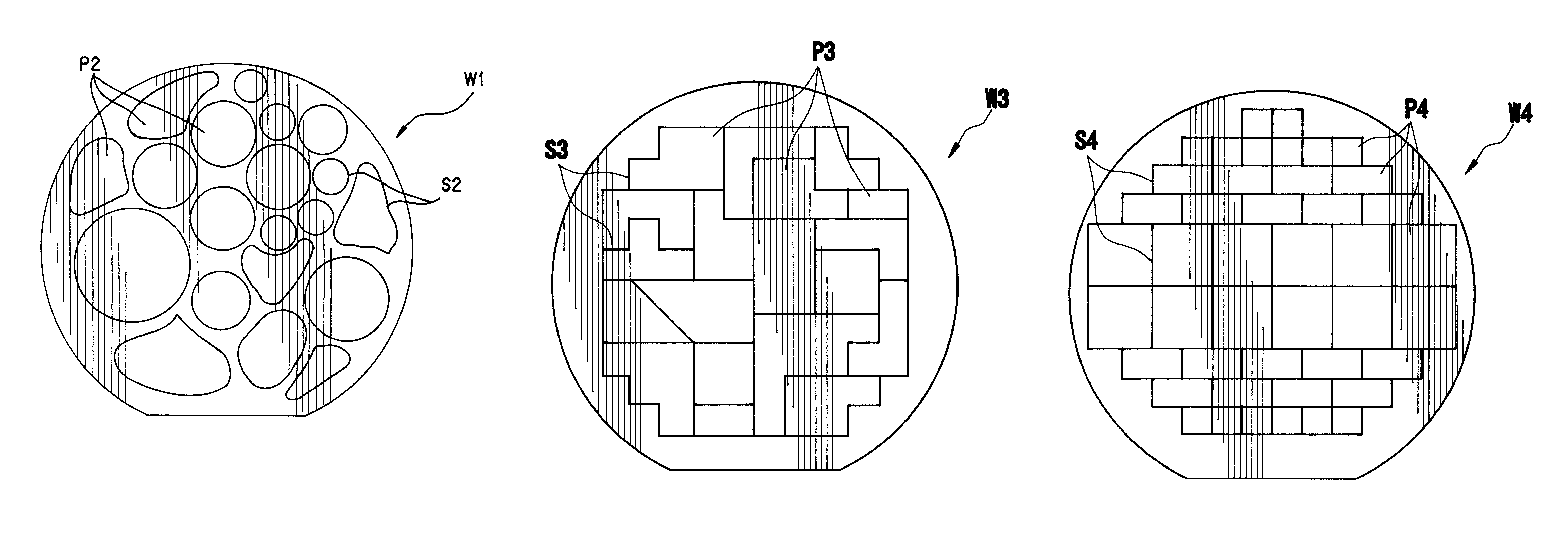

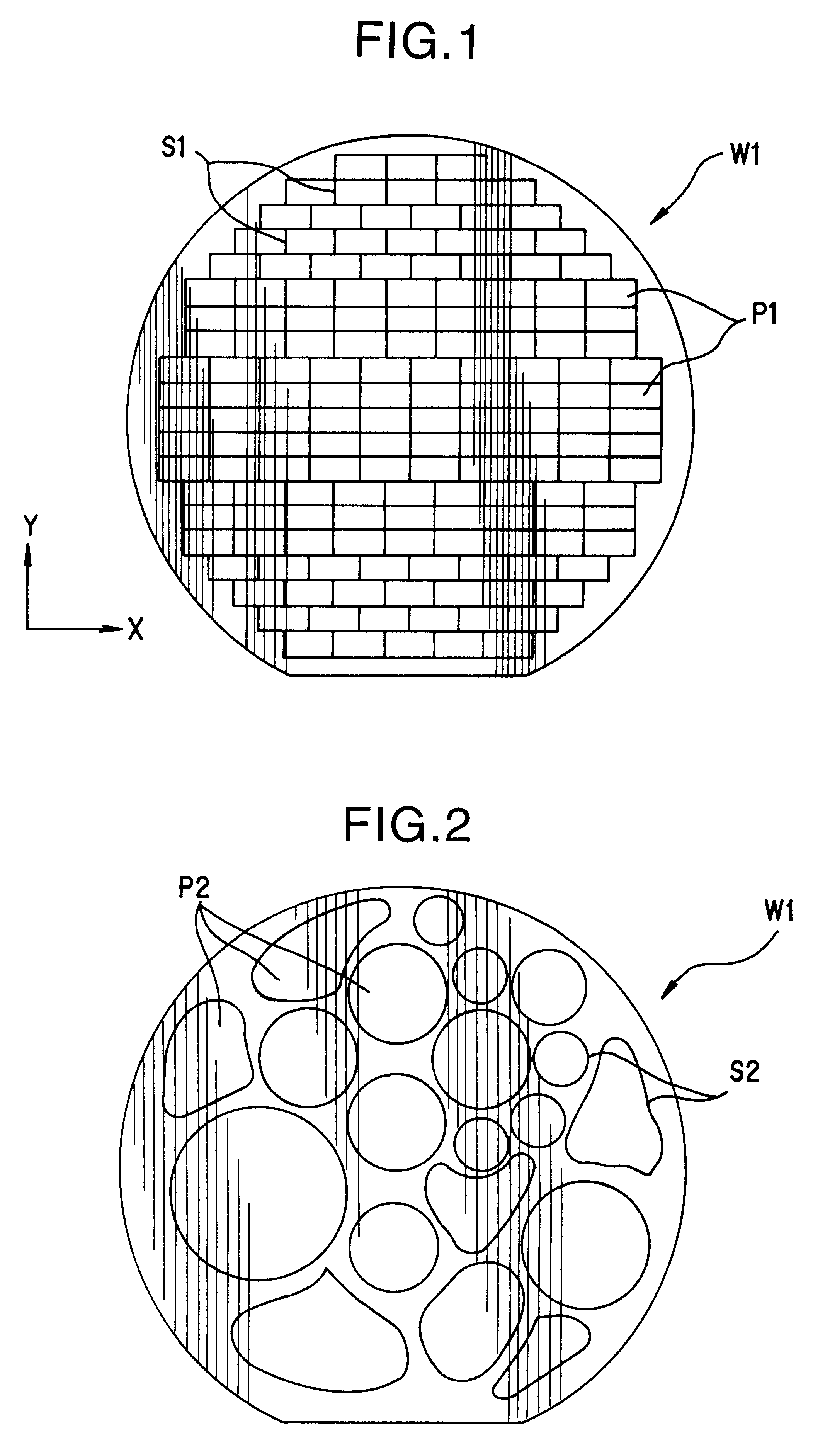

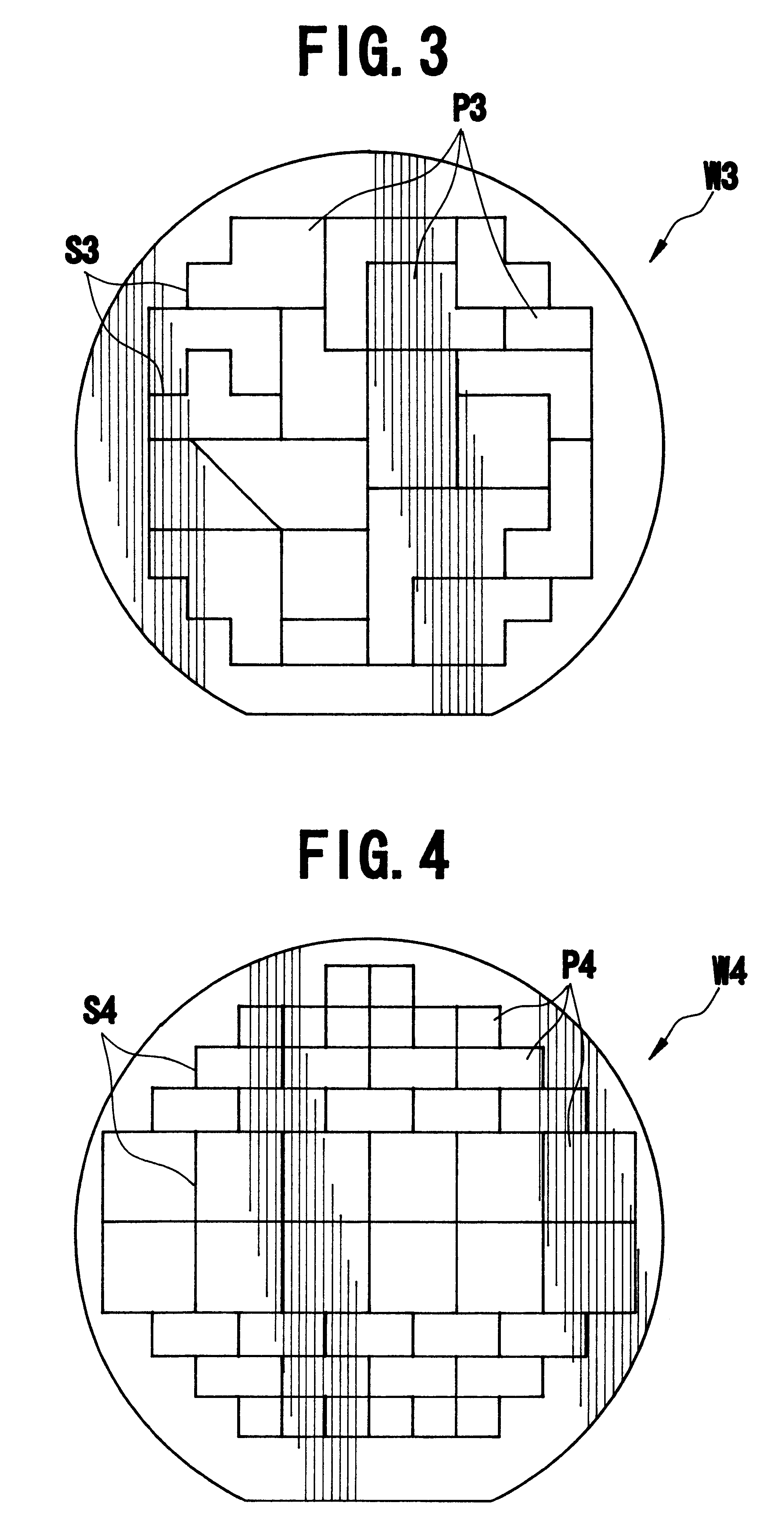

Semiconductor wafer having regular or irregular chip pattern and dicing method for the same

Disclosed is a semiconductor wafer whose pattern is composed of a plurality of chip areas delimited by a plurality of streets which at least one or more streets are not straight. Those chip areas may be rectangular ones of same or different sizes delimited by streets which are wholly or partly staggered, or ones of different shapes and / or sizes delimited by streets which are bent or curved so that they may separate adjacent chip areas. Such a semiconductor wafer can be separated into chips by: coating one of the opposite surfaces of each semiconductor wafer with a photo-resistive film; exposing the coated surface of the semiconductor wafer to the light to remove the coating area lying on the streets; subjecting the street-exposed wafer surface to chemical etching to make grooves in conformity with the streets; and separating the semiconductor wafer into chips. The separating step may include making grooves deep enough to reach the front side of the wafer by chemical etching or grinding the grooved wafer on its rear side to remove the remaining thickness of the grooved wafer.

Owner:DISCO CORP

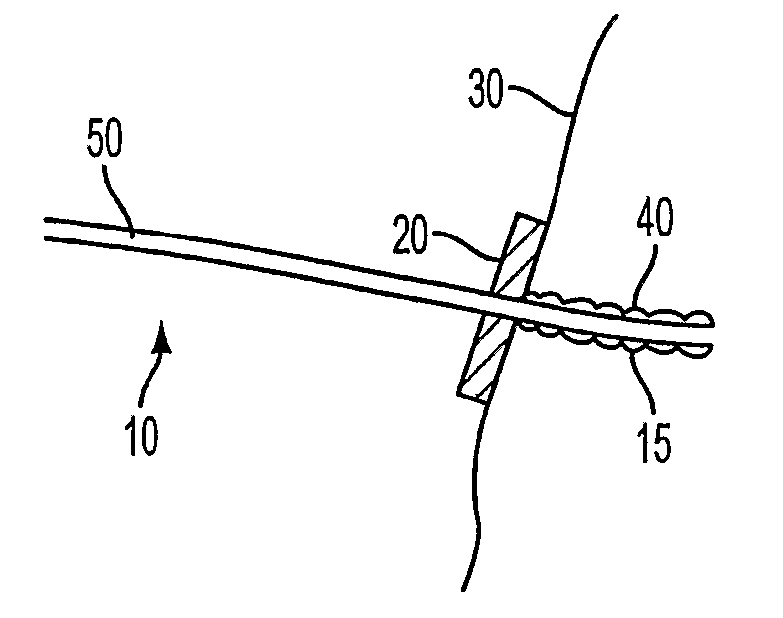

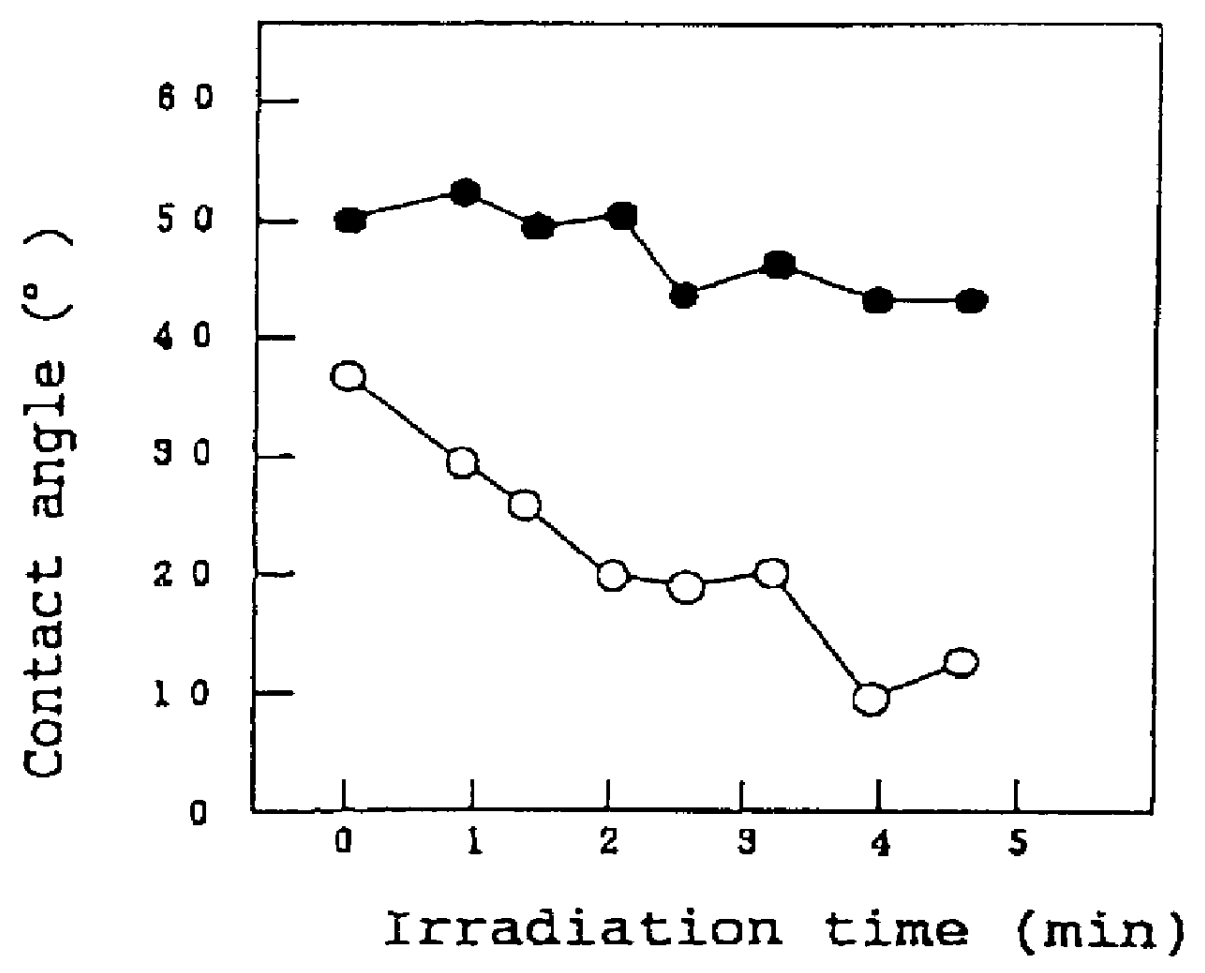

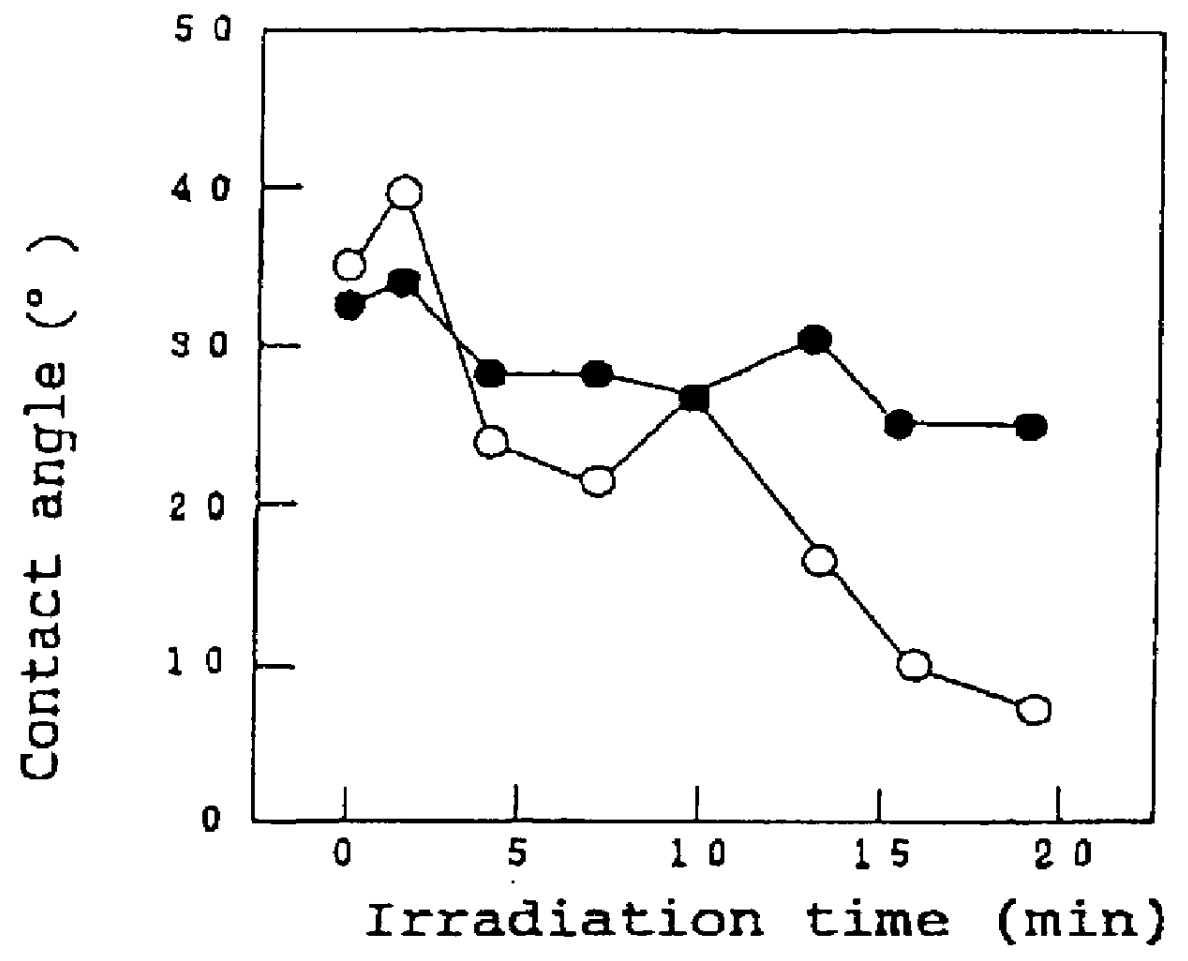

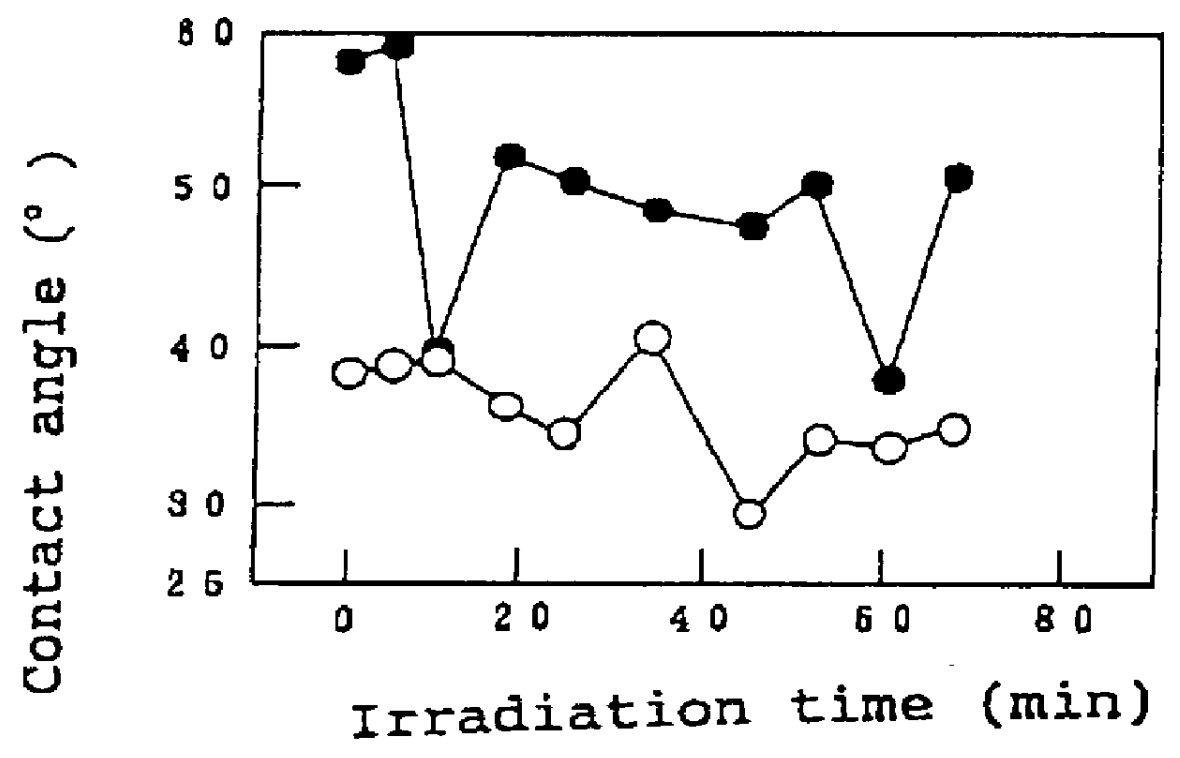

Method for photocatalytically hydrophilifying surface and composite material with photocatalytically hydrophilifiable surface

InactiveUS6090489AImproved oil repellencyEasy to disassembleOther chemical processesPretreated surfacesAtmospheric airSolid acid

A method for hydrophilifying the surface of a substrate by taking advantage of photocatalytic action. The substrate has a photocatalytic titania coating (10). The surface of the photocatalytic coating (10) bears the solid acid that increases a hydrogen bond component ( gamma Sh) in the surface energy in the solid / gas interface of the coating. Photoexcitation of the photocatalyst enhances the hydrogen bond component ( gamma Sh) in the surface energy of the photocatalytic coating (10), accelerating the physical adsorption of molecules of water in the atmosphere through a hydrogen bond (16) onto hydrogen atoms in a terminal OH group (12), bonded to a titanium atom, and a bridge OH group (14) on the surface of the coating. This results in the formation of a high density, physically adsorbed water layer (18) on the surface of the photocatalytic coating (10), thus permitting the surface of the substrate to be easily hydrophilified. The method is applicable to antifogging, antifouling, selfcleaning and cleaning of articles.

Owner:TOTO LTD

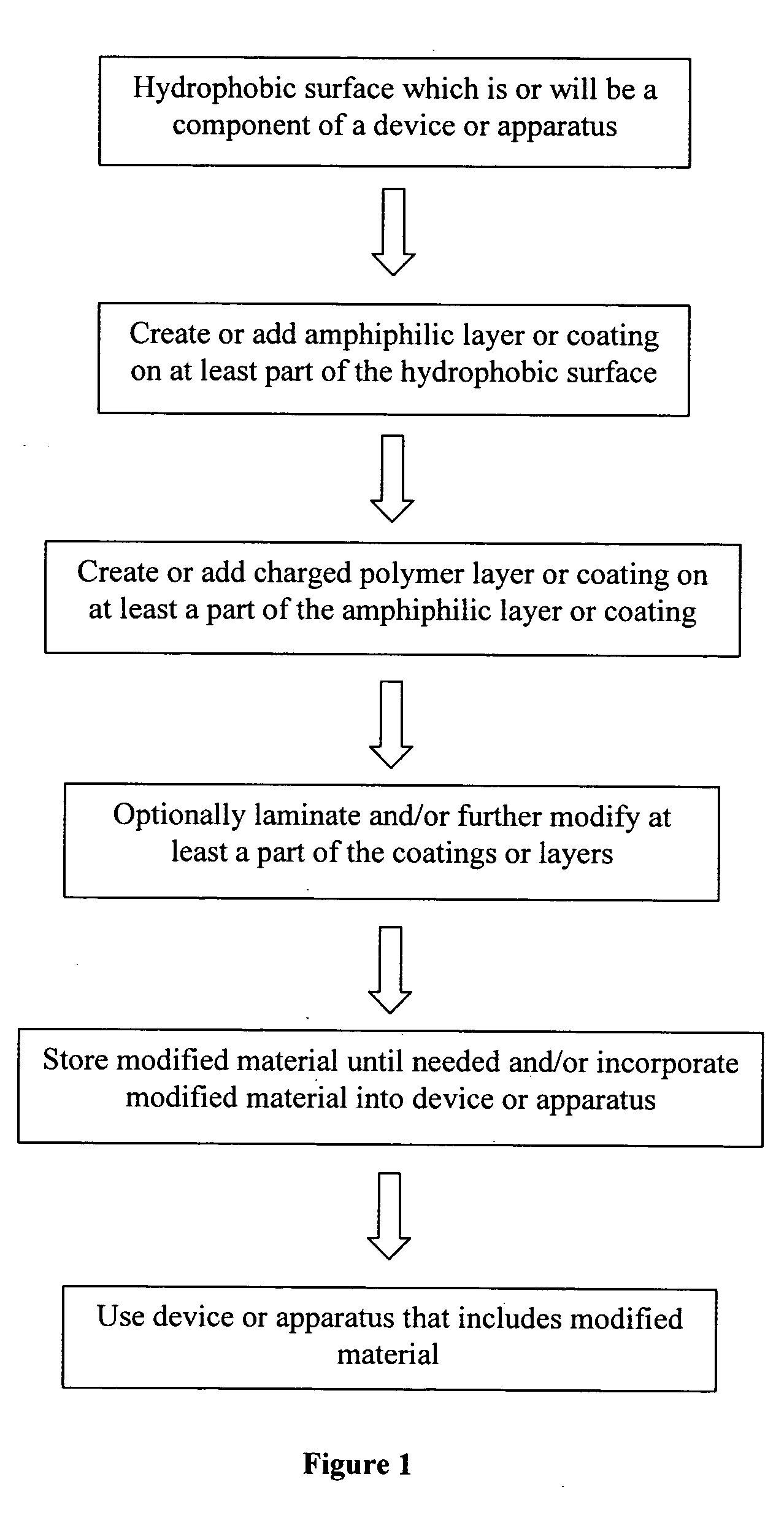

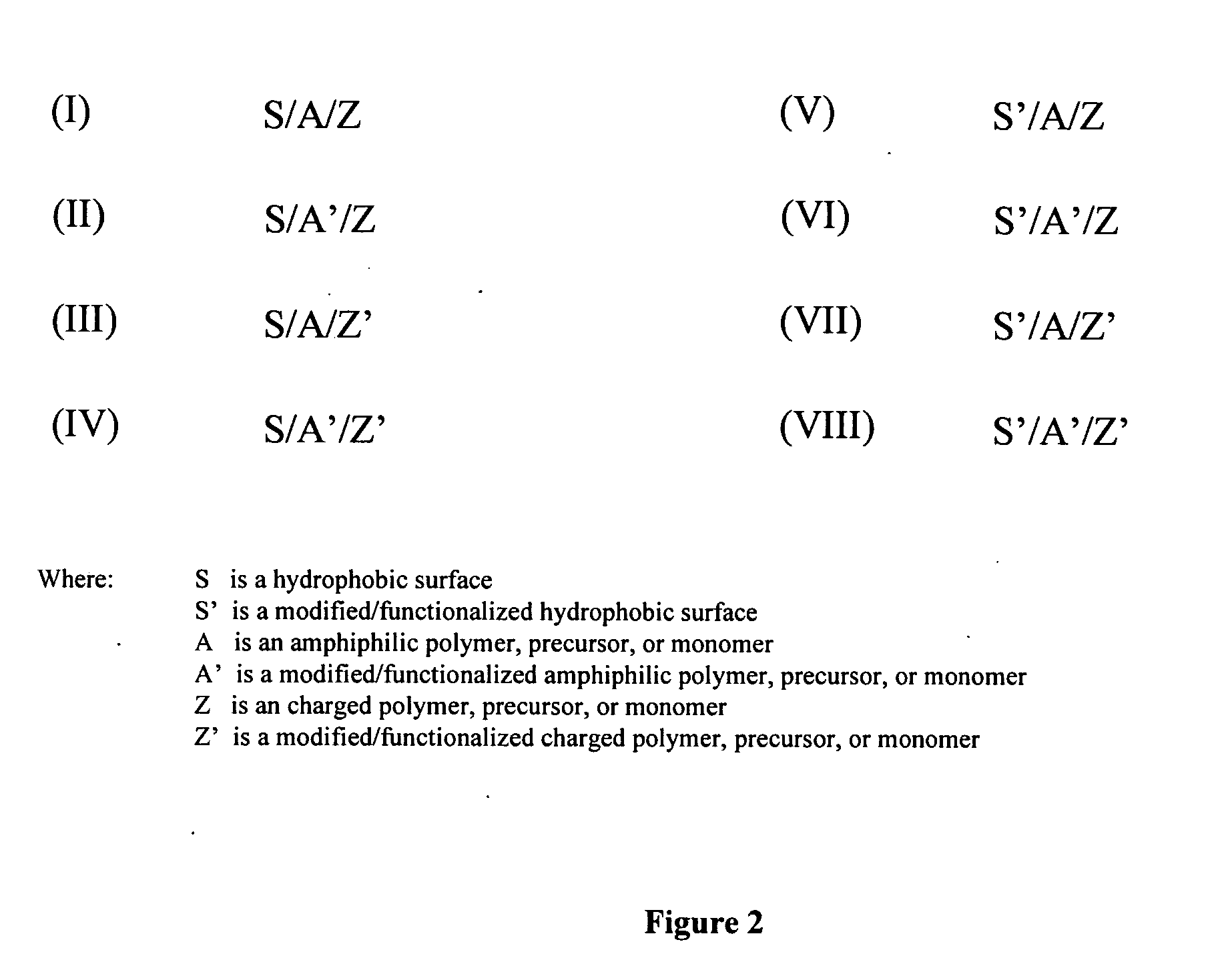

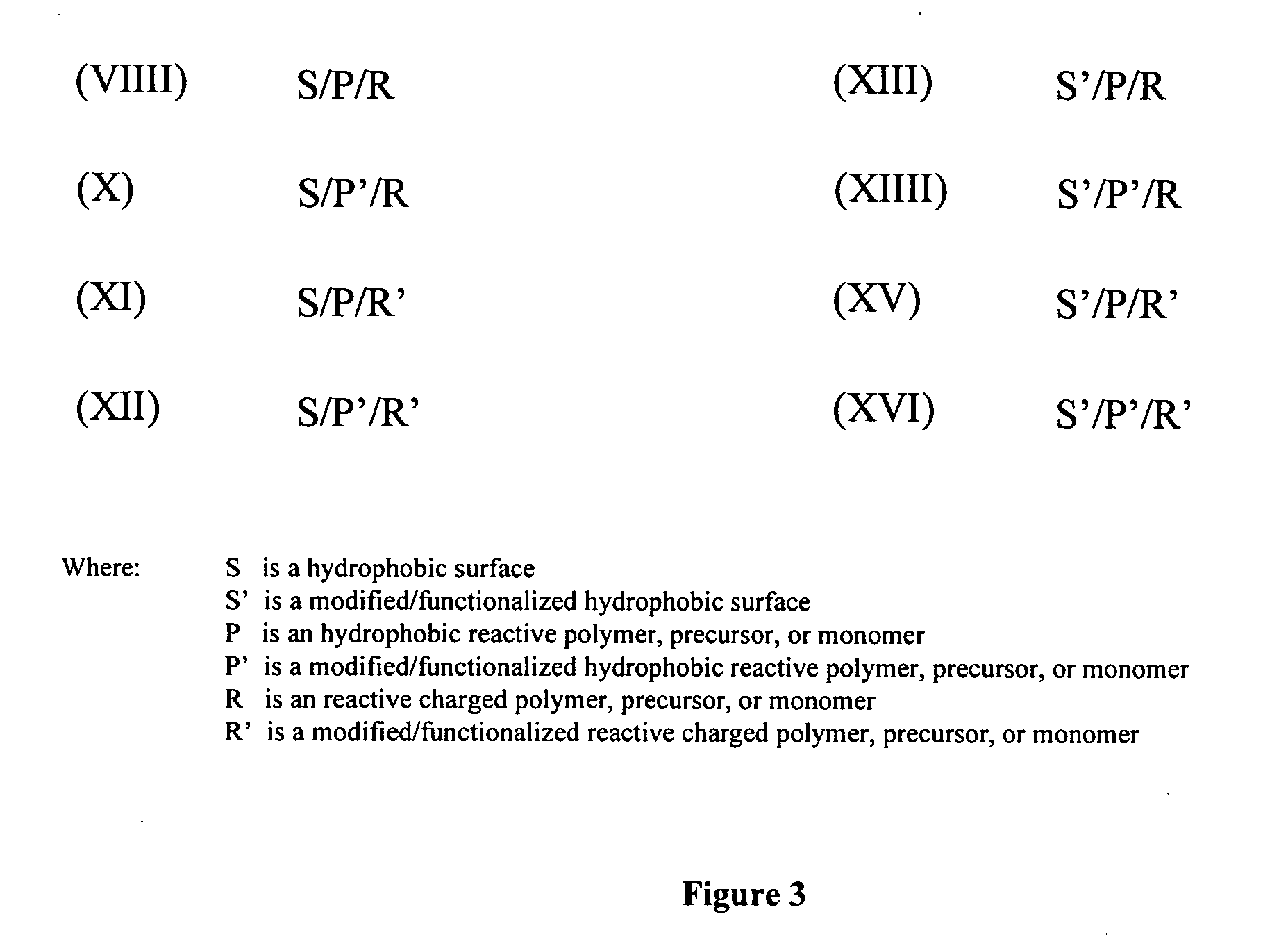

Methods, compositions and devices, including microfluidic devices, comprising coated hydrophobic surfaces

Methods are disclosed for coating at least a portion of a hydrophobic surface, including the surfaces of plastics or other polymers. Such methods include the use of a first coating layer and / or region that interacts with the hydrophobic surface, although the formation of a chemical bond between the first coating layer and the hydrophobic surface is not required. Subsequent layers may then interact chemically or non-chemically with at least a portion of the first coating layer and / or region. Such coated surfaces may be part of a device or apparatus, including microfluidic devices.

Owner:NORVIEL VERN

Head lamp assembly and accent lighting therefor

A head lamp assembly having a main functional head lamp and a UV LED light source configured to direct UV light through a decorative accent light pipe is provided. The light pipe extends at least partially about the functional head lamp, wherein the light pipe has a phosphor coated surface to convert the UV light traveling through the light pipe into visible, luminous light. The visible light is emitted from the light pipe to provide the desired decorative appearance about the functional head lamp.

Owner:REBO LIGHTING & ELECTRONICS LLC

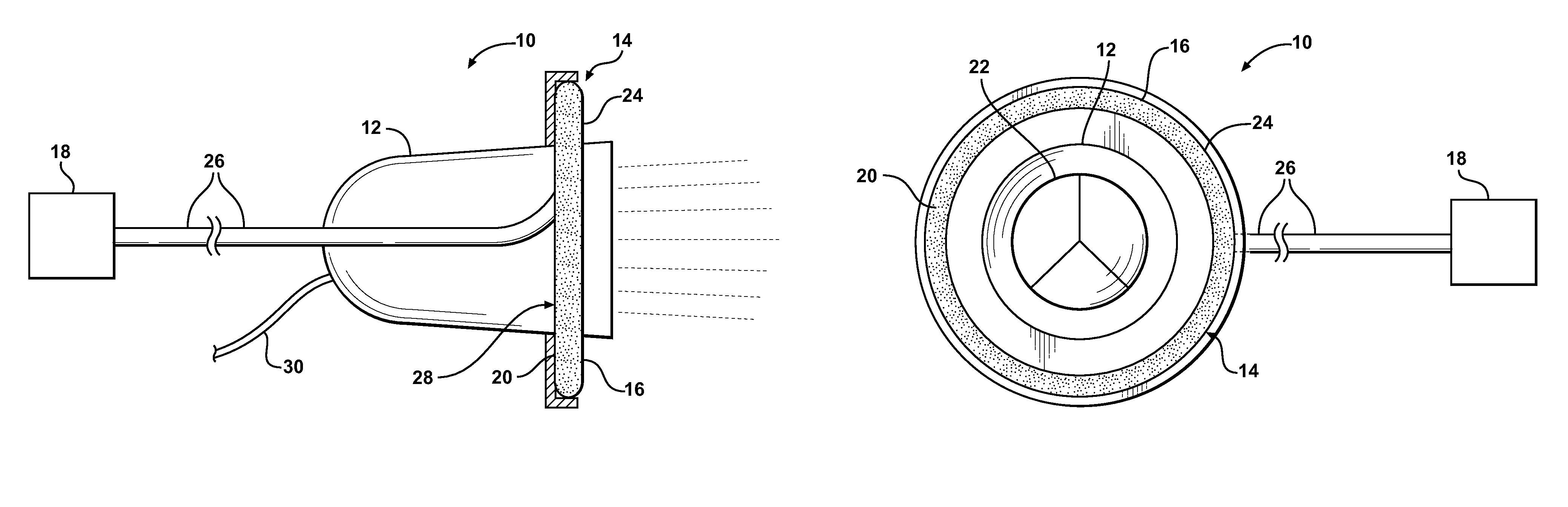

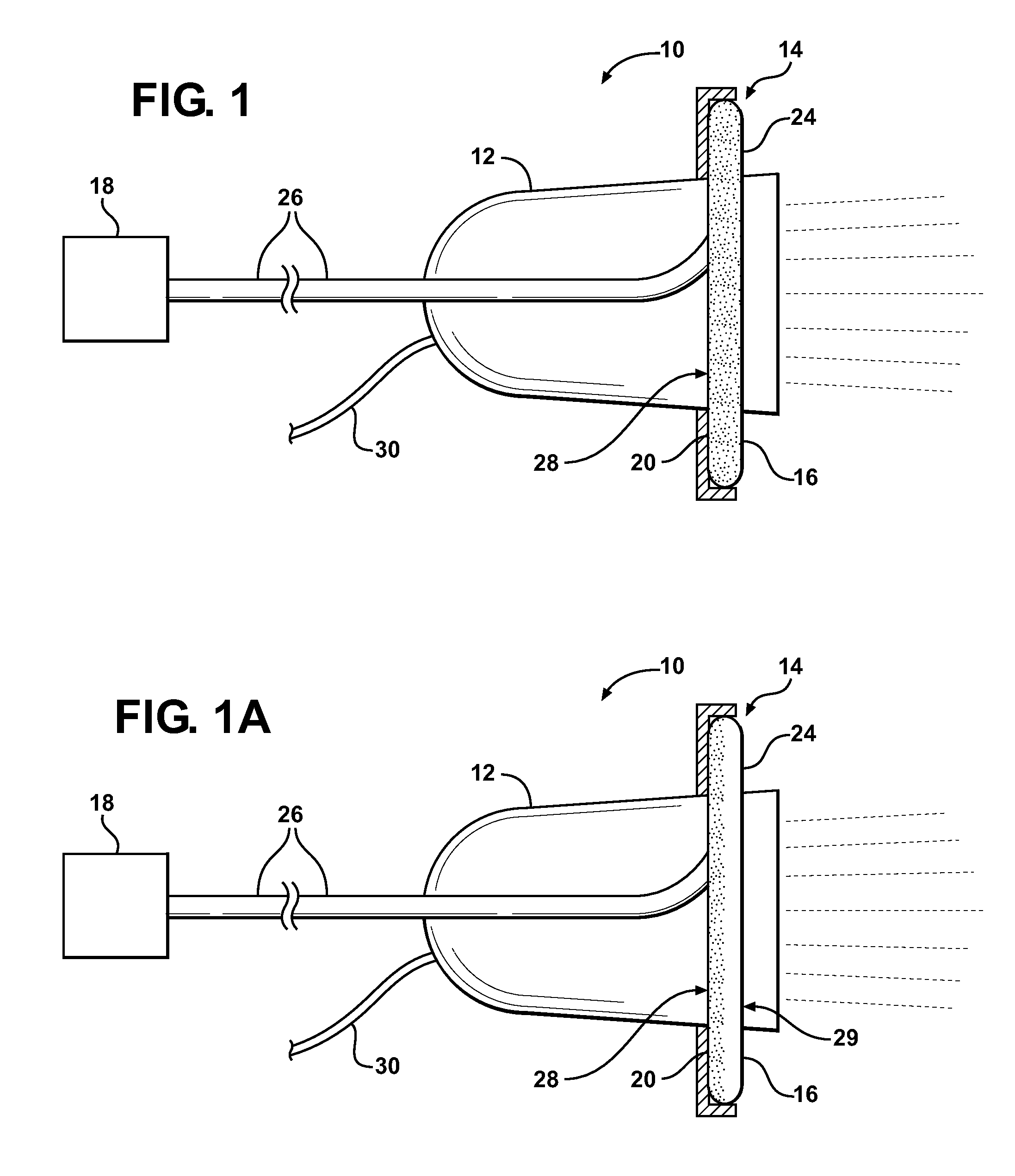

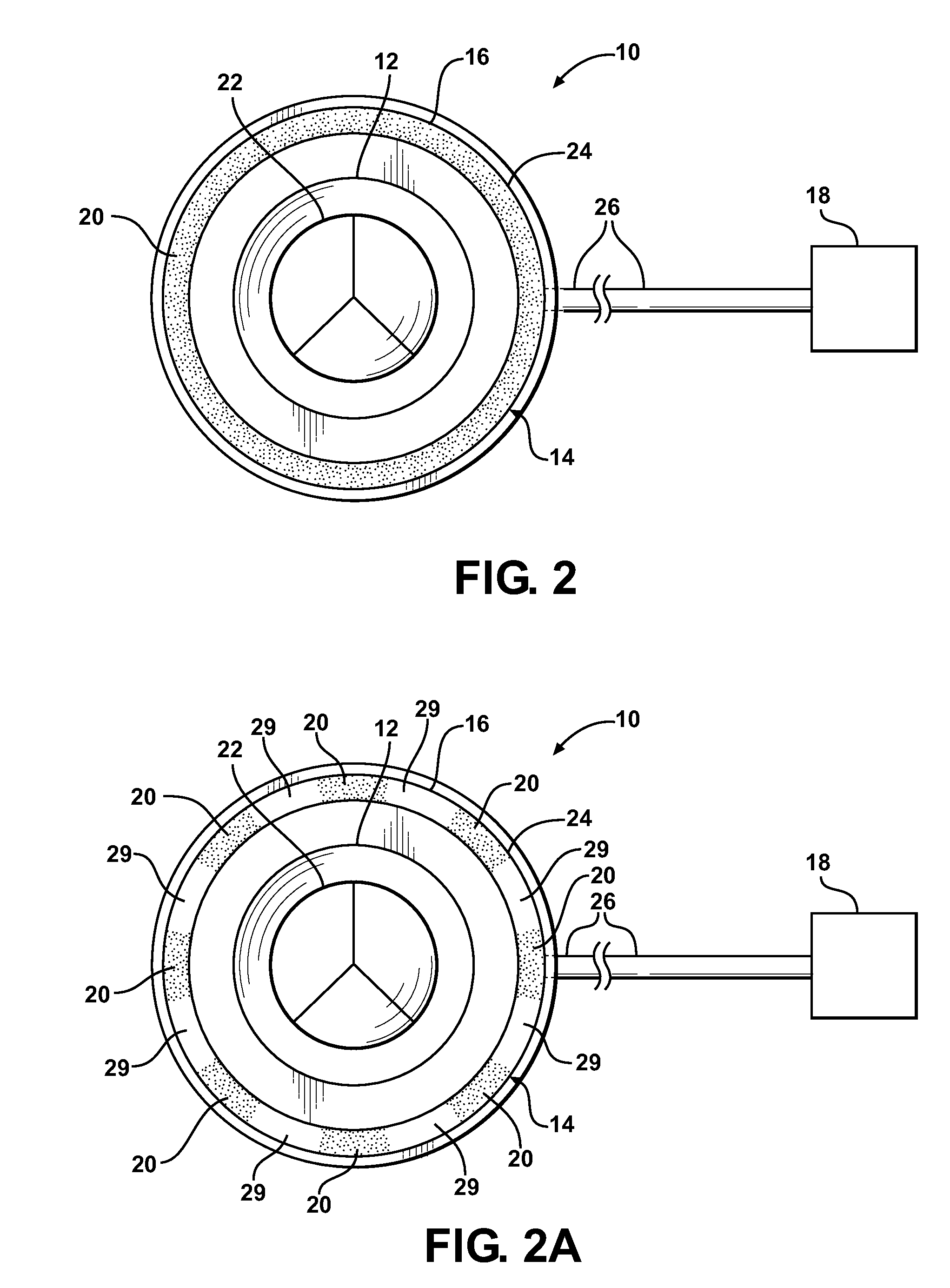

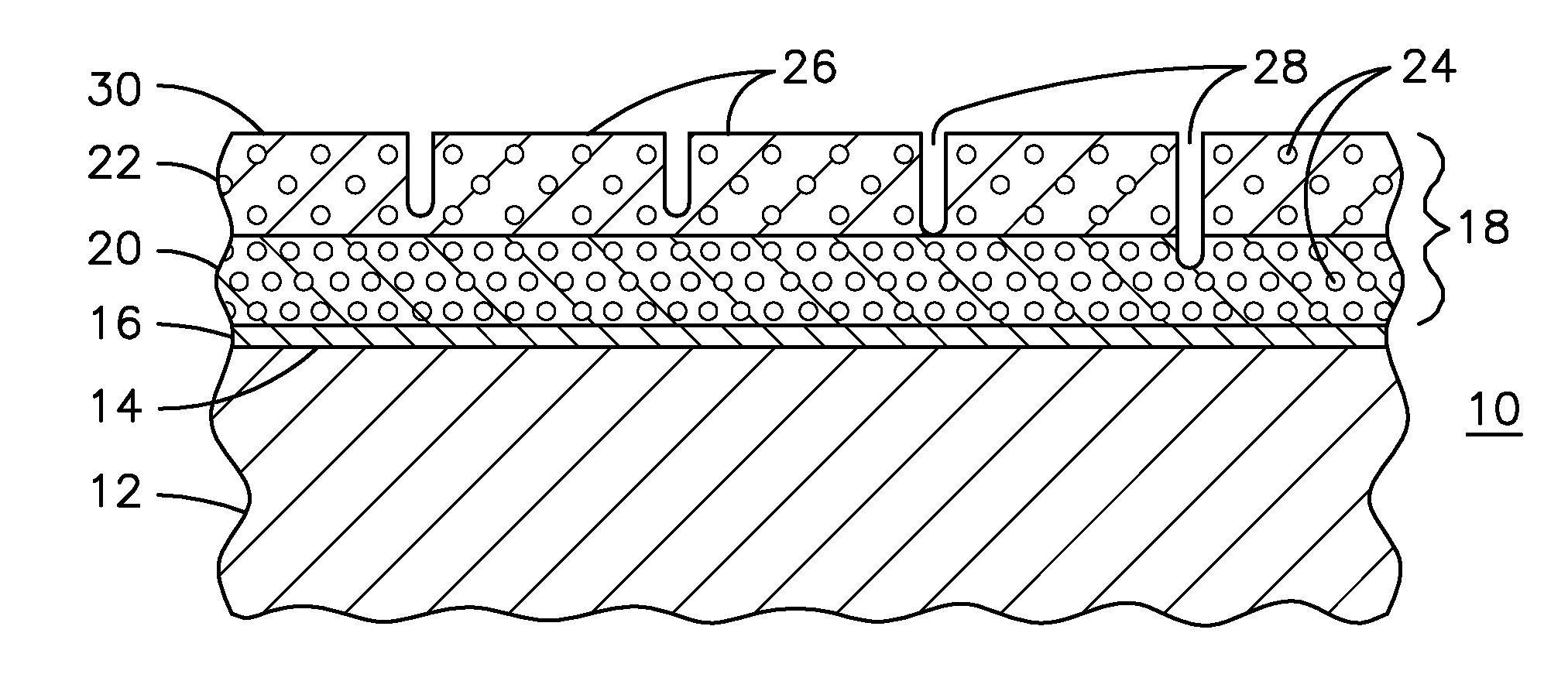

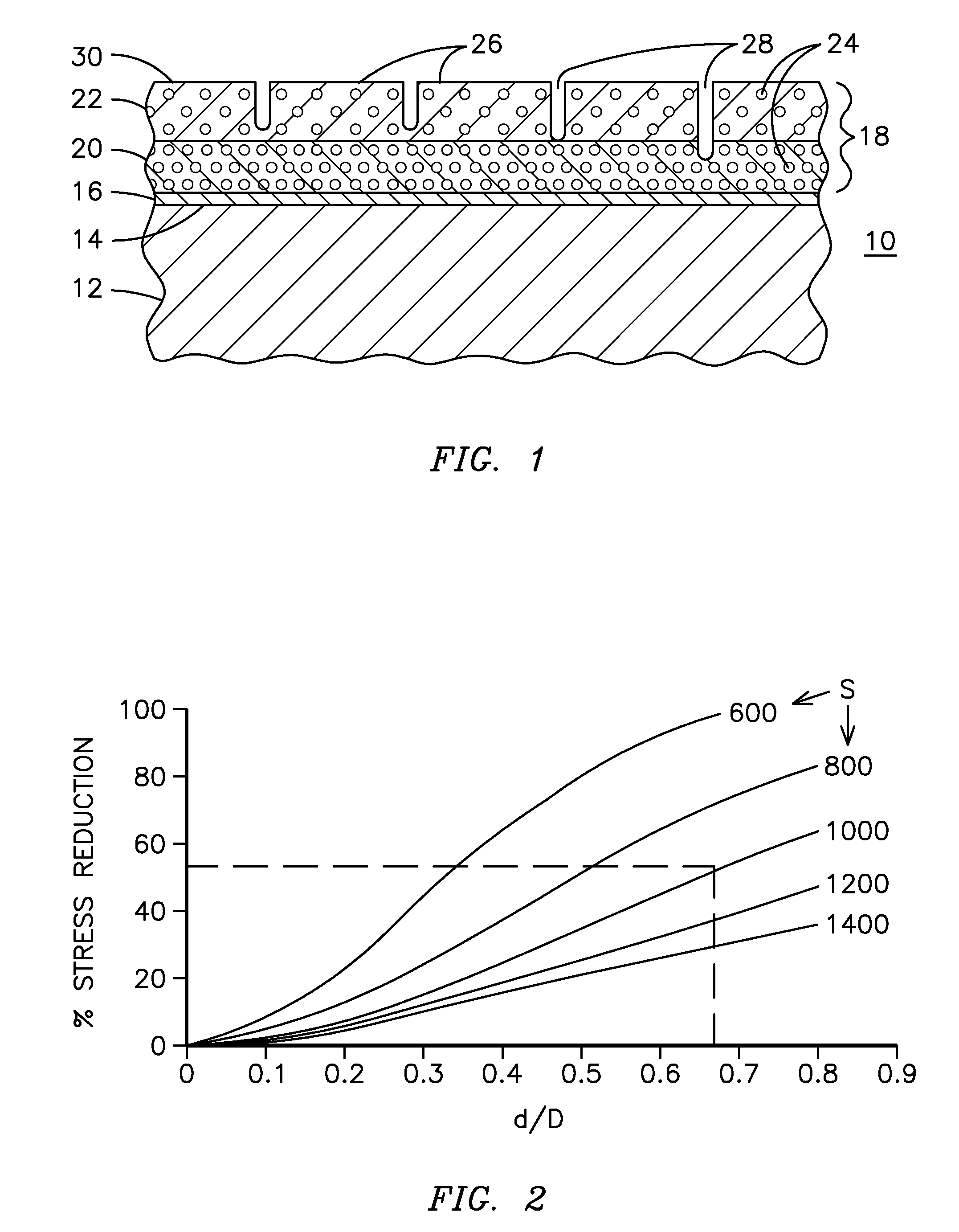

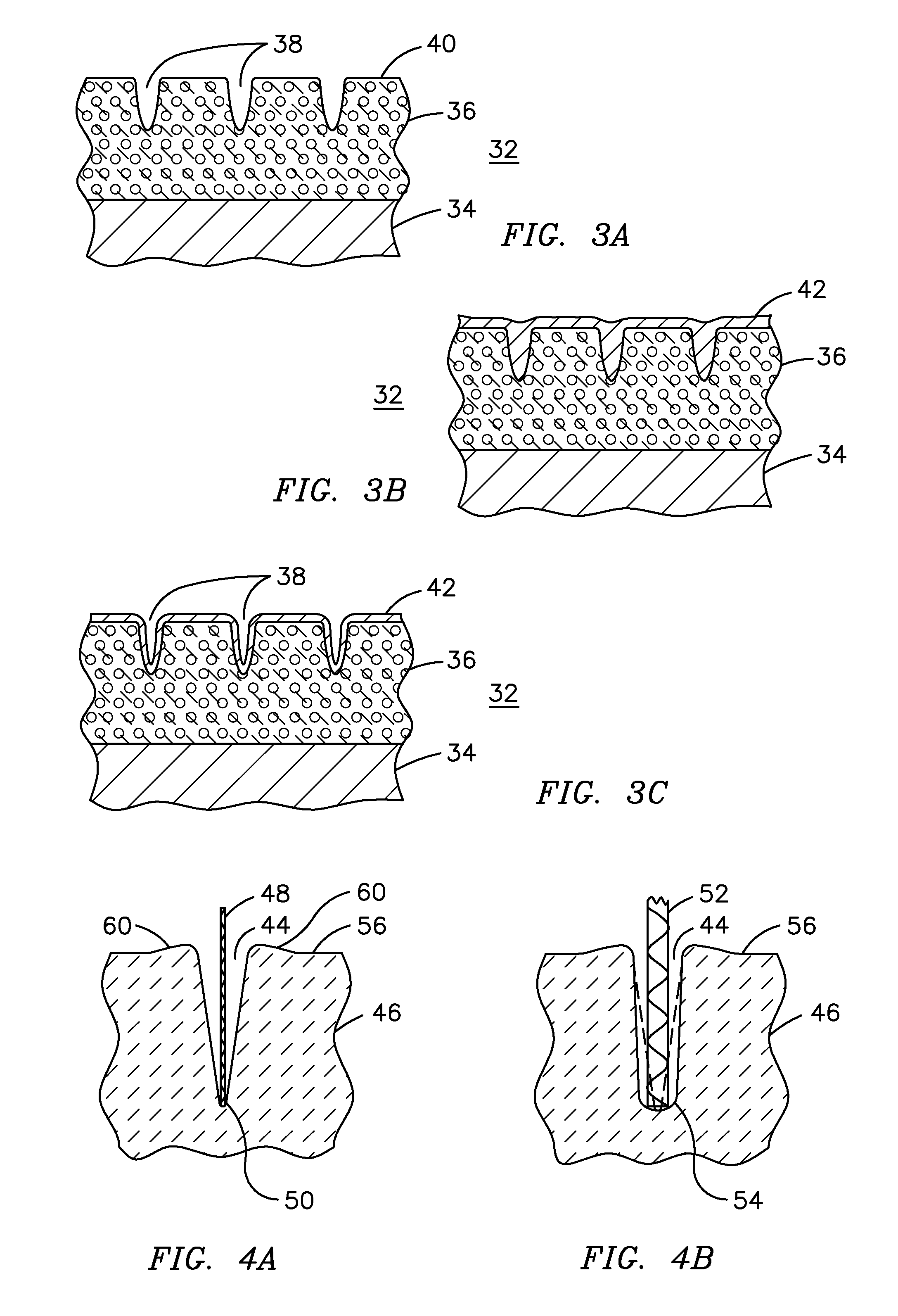

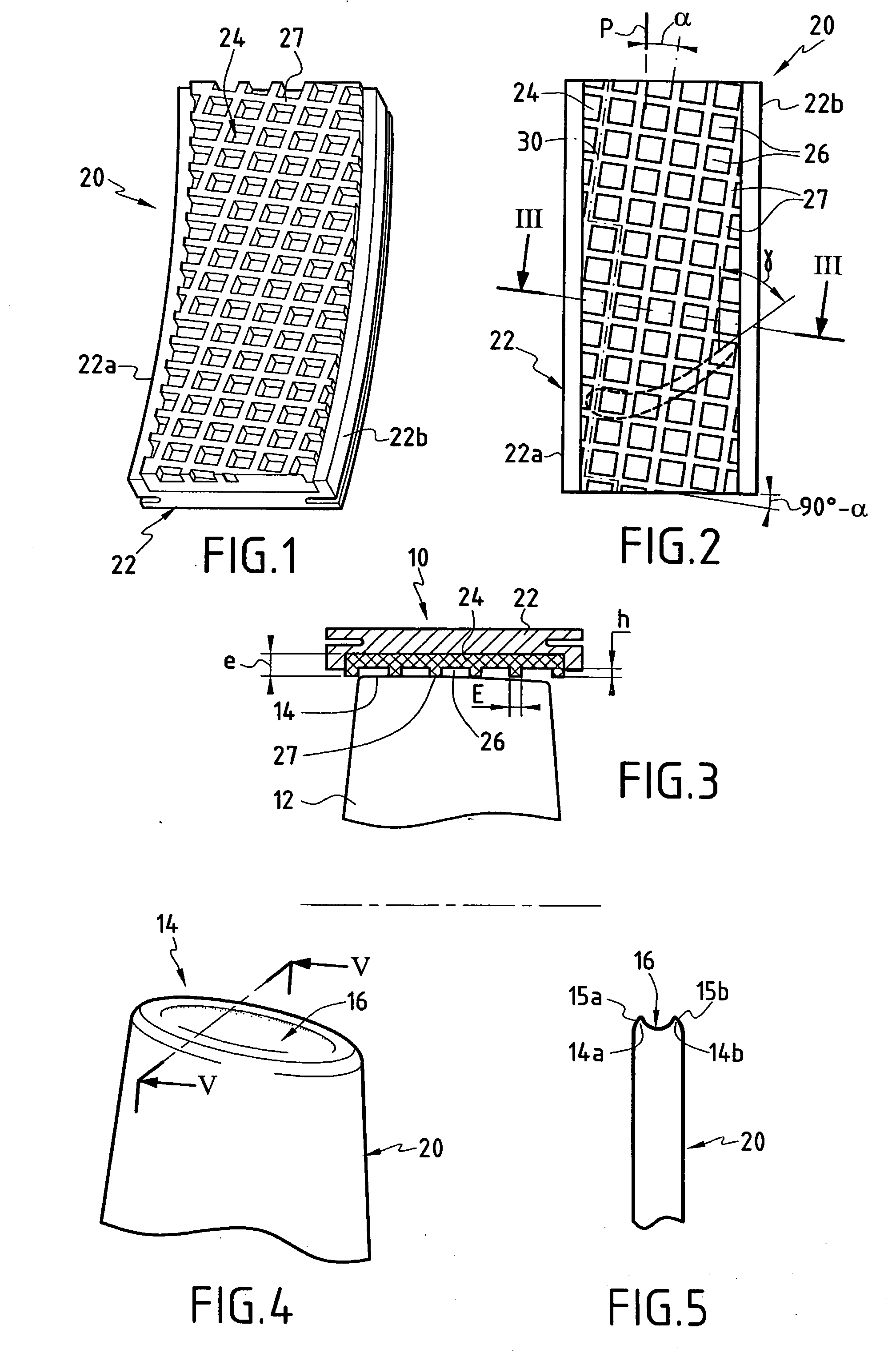

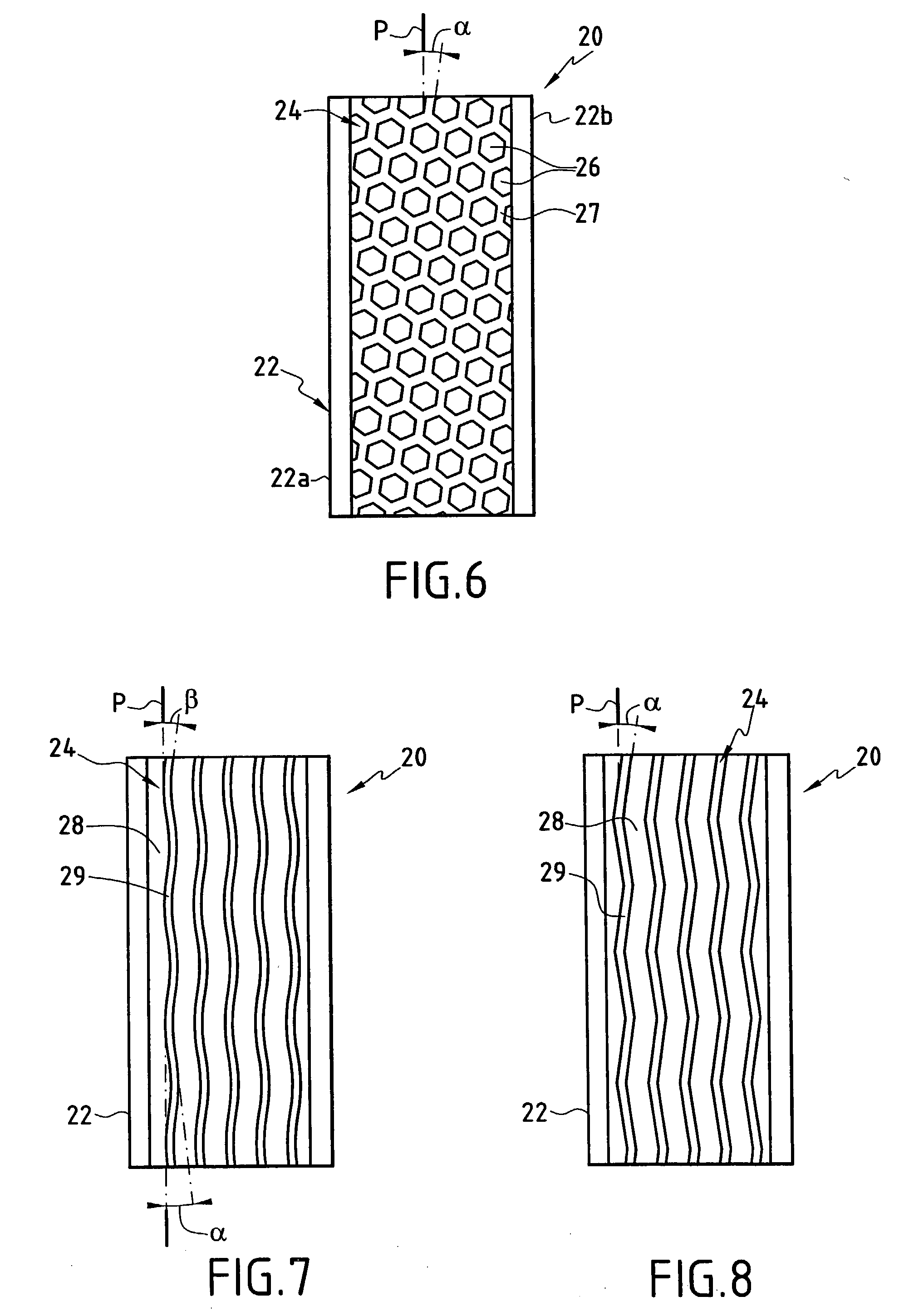

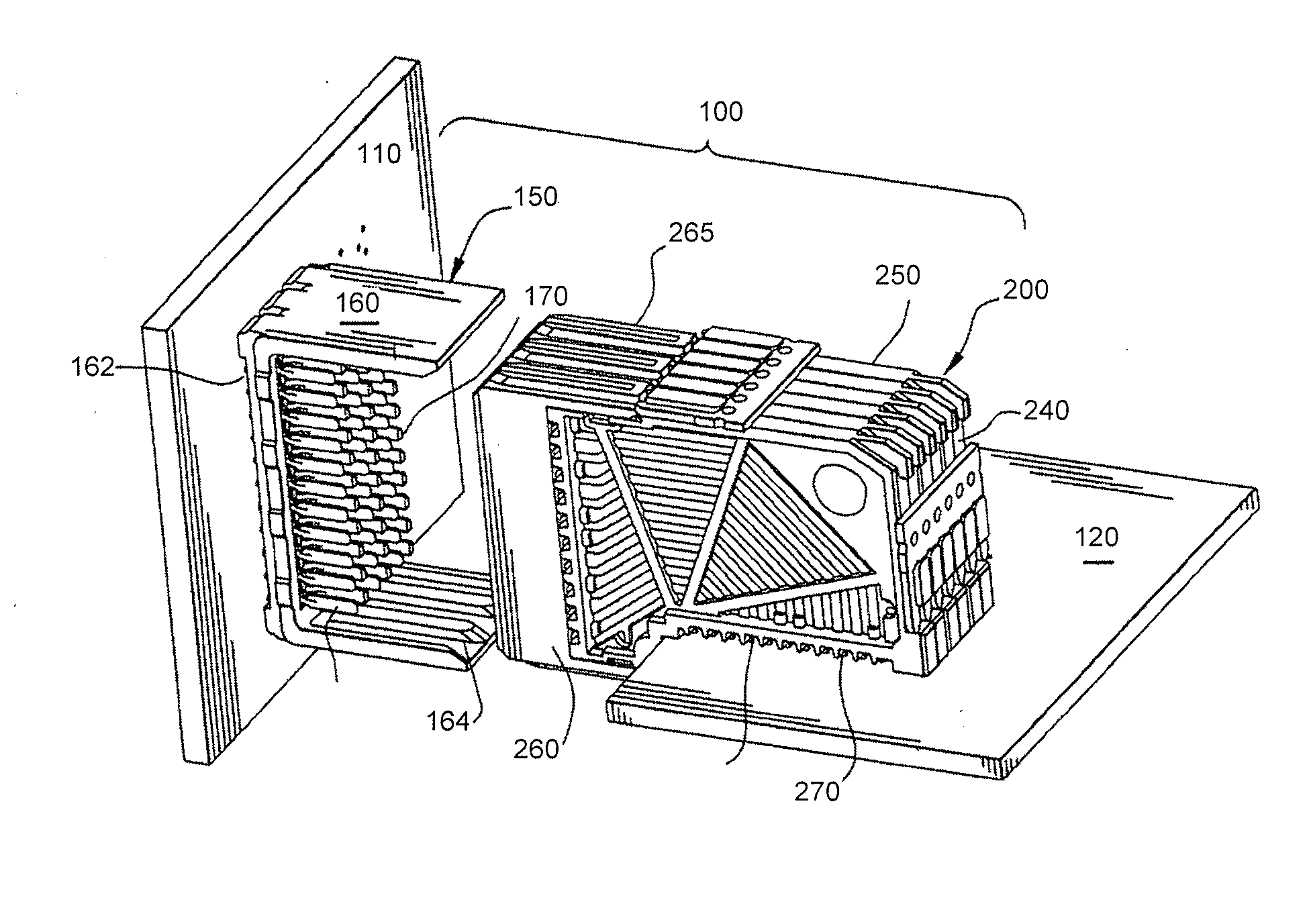

Segmented thermal barrier coating

A ceramic thermal barrier coating (TBC) (18) having first and second layers (20, 22), the second layer (22) having a lower thermal conductivity than the first layer for a given density. The second layer may be formed of a material with anisotropic crystal lattice structure. Voids (24) in at least the first layer (20) make the first layer less dense than the second layer. Grooves (28) are formed in the TBC (18) for thermal strain relief. The grooves may align with fluid streamlines over the TBC. Multiple layers (84, 86,88) may have respective sets of grooves (90), Preferred failure planes parallel to the coating surface (30) may be formed at different depths (A1, A2, A3) in the thickness of the TBC to stimulate generation of a fresh surface when a portion of the coating fails by spalling. A dense top layer (92) may provide environmental and erosion resistance.

Owner:SIEMENS ENERGY INC

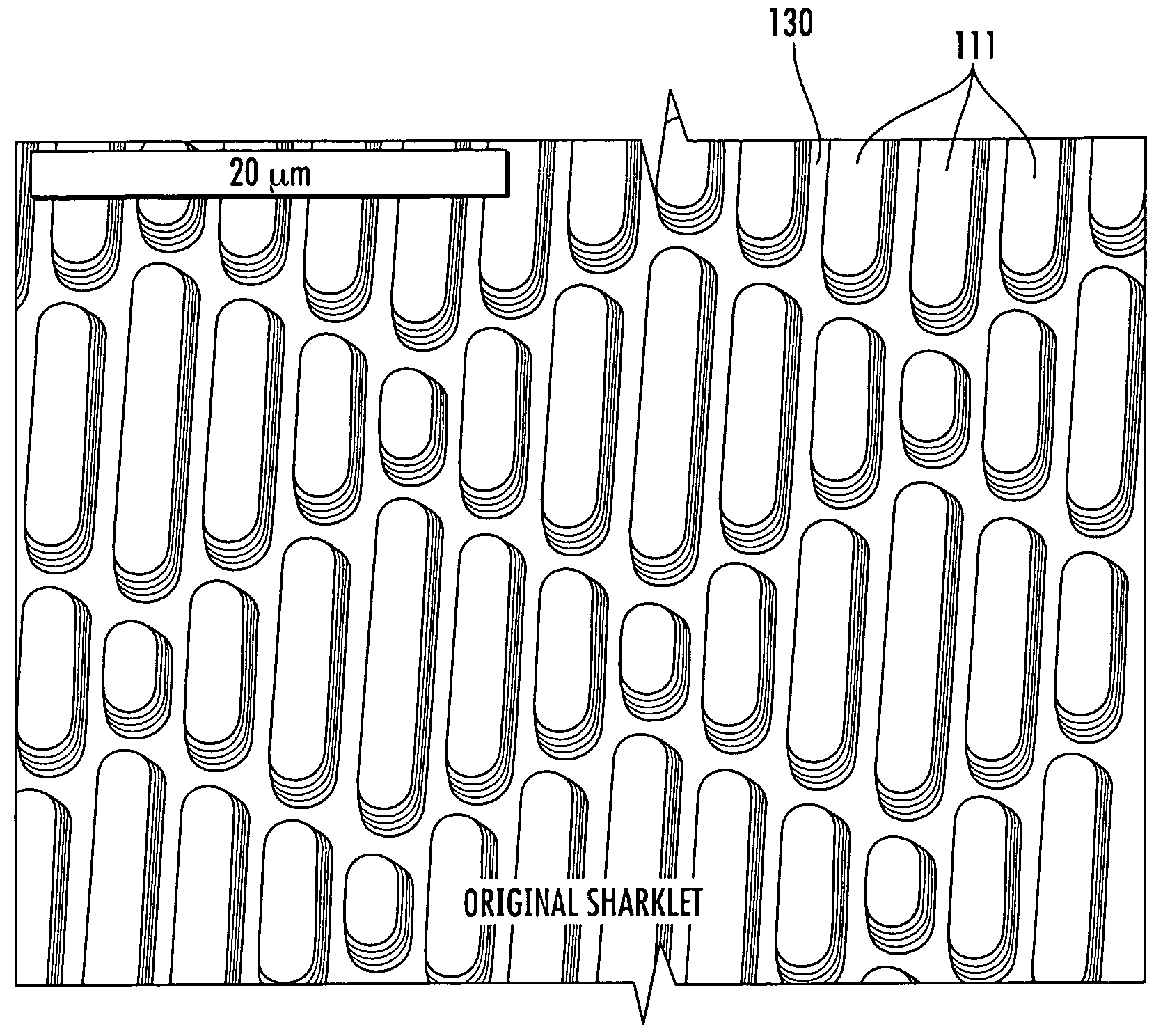

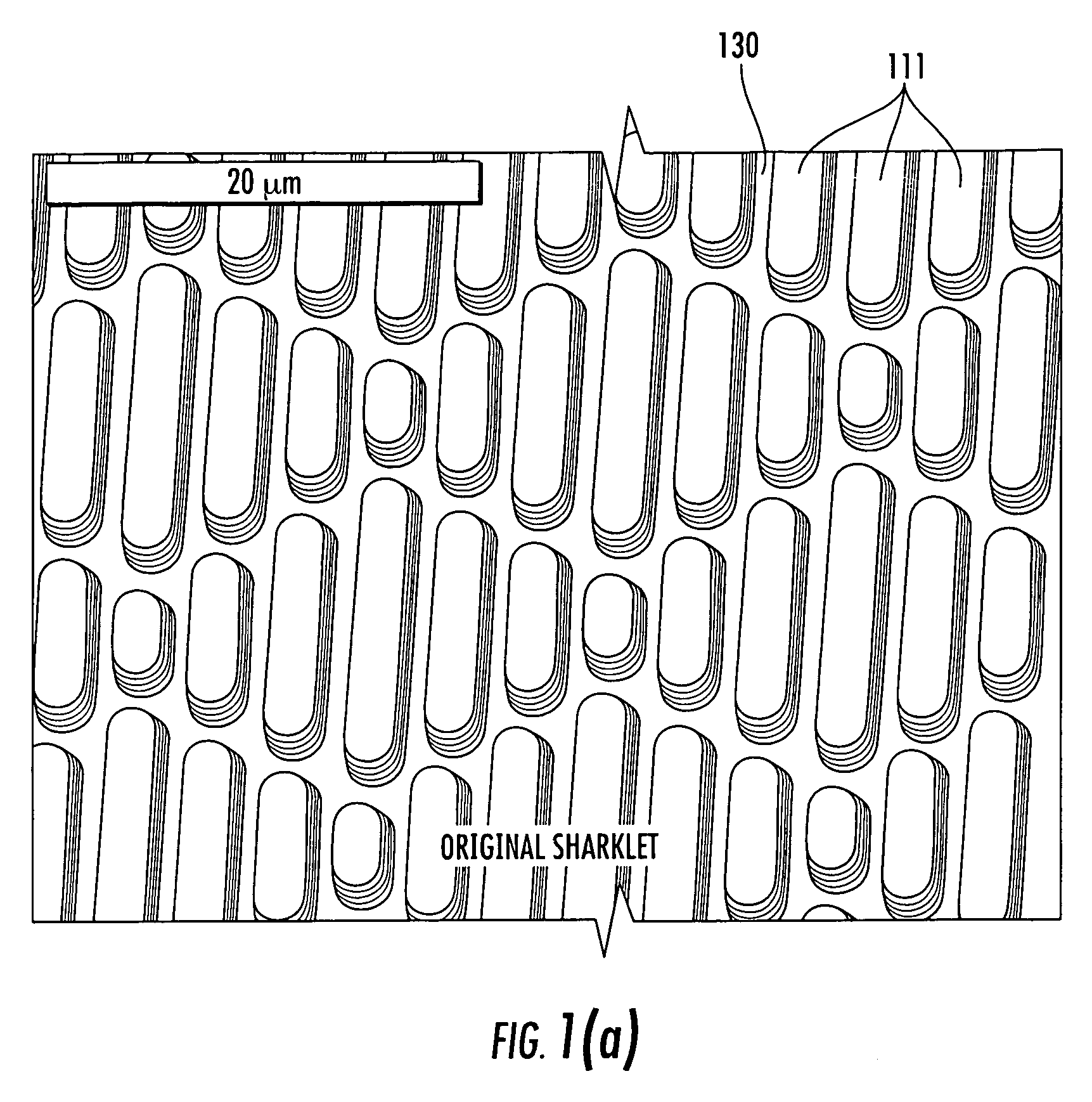

Surface topography for non-toxic bioadhesion control

A coated surface for resisting or enhancing bioadhesion includes at least one patterned polymer including coating layer having a plurality of features attached to or projected into a base surface. The features each have at least one microscale (<1 mm) dimension and have at least one neighboring feature having a substantially different geometry. The patterned coating layer preferably provides an average roughness factor (R) of from 4 to 50. The coating layer resists or enhances bioadhesion as compared to the base surface.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

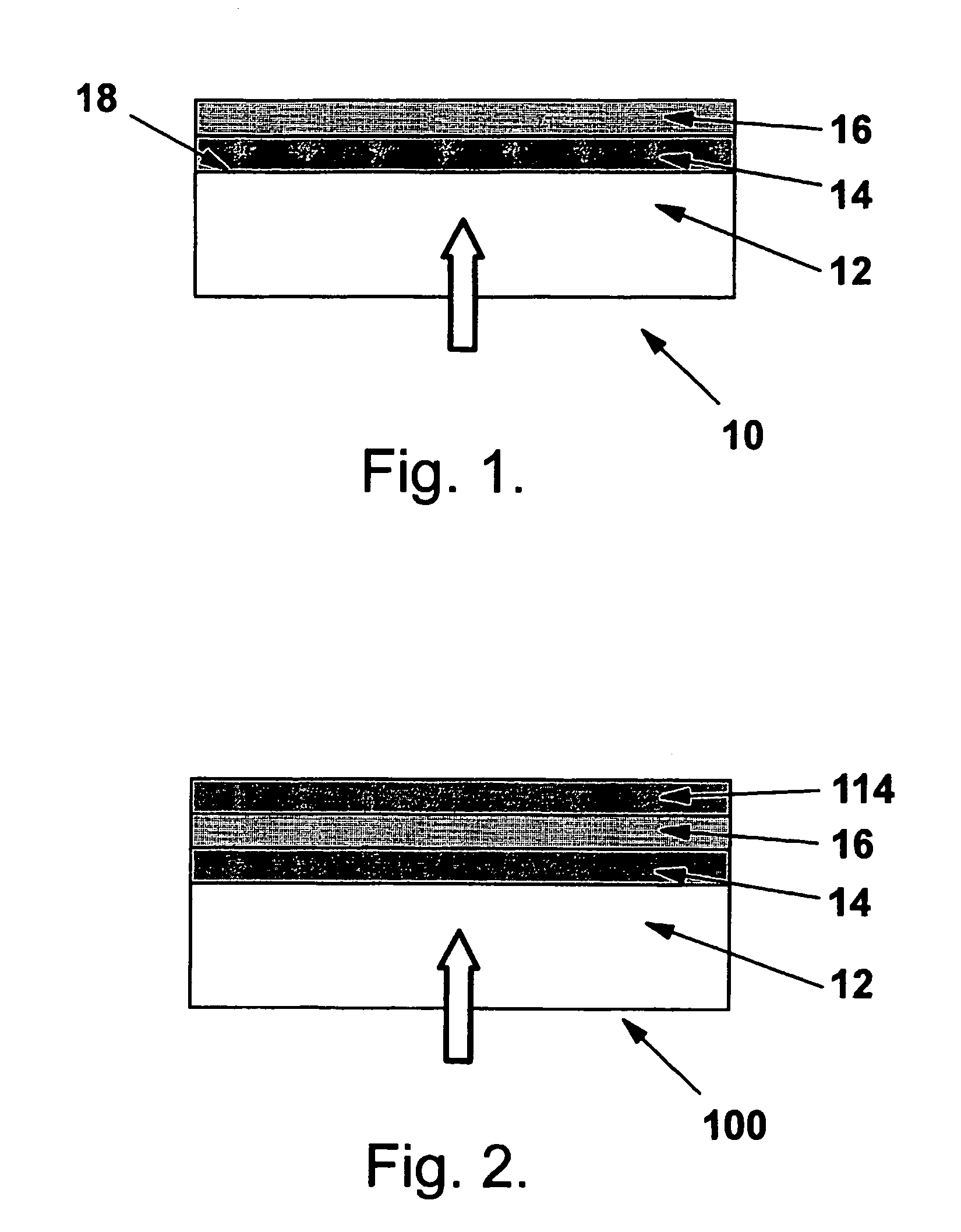

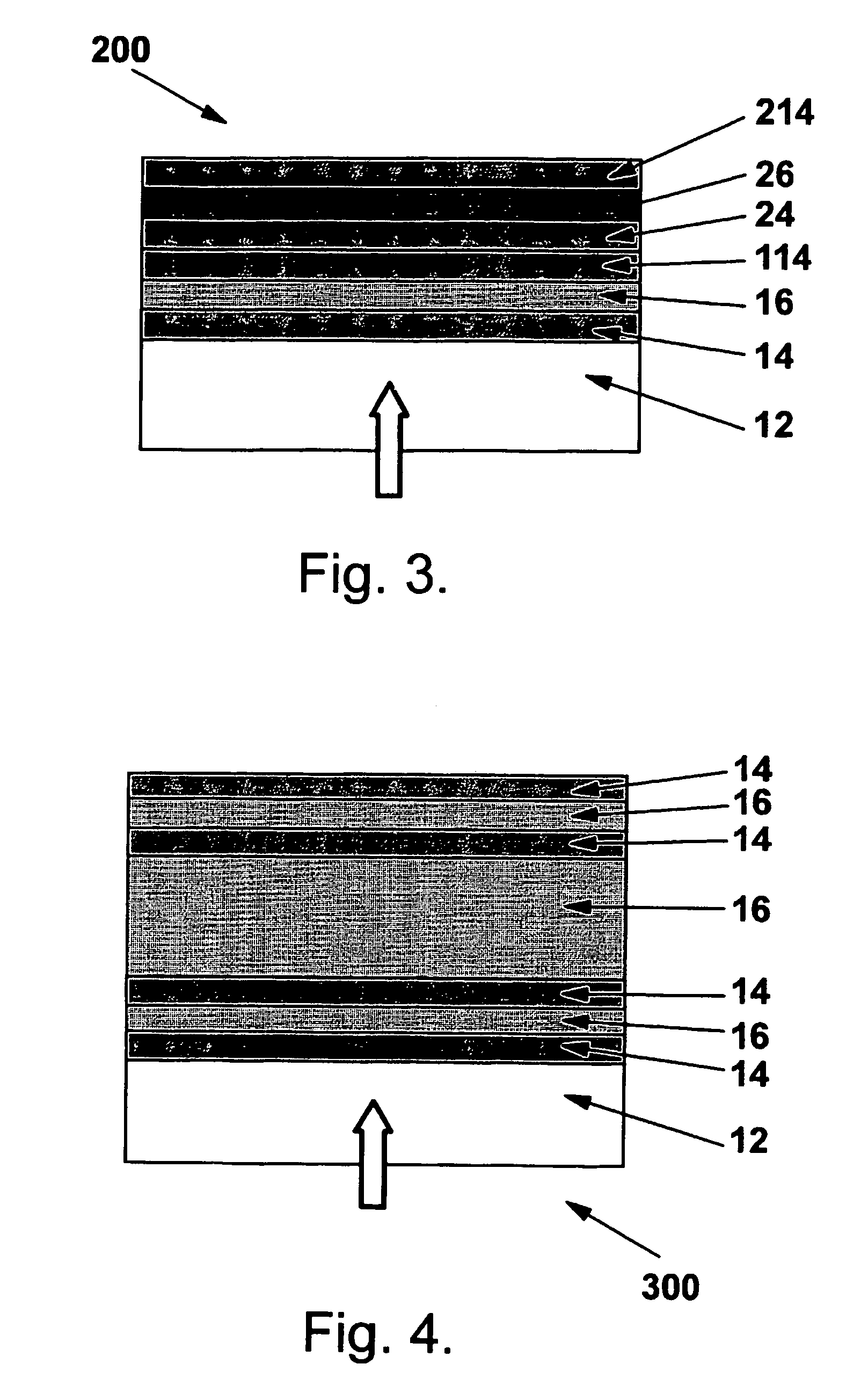

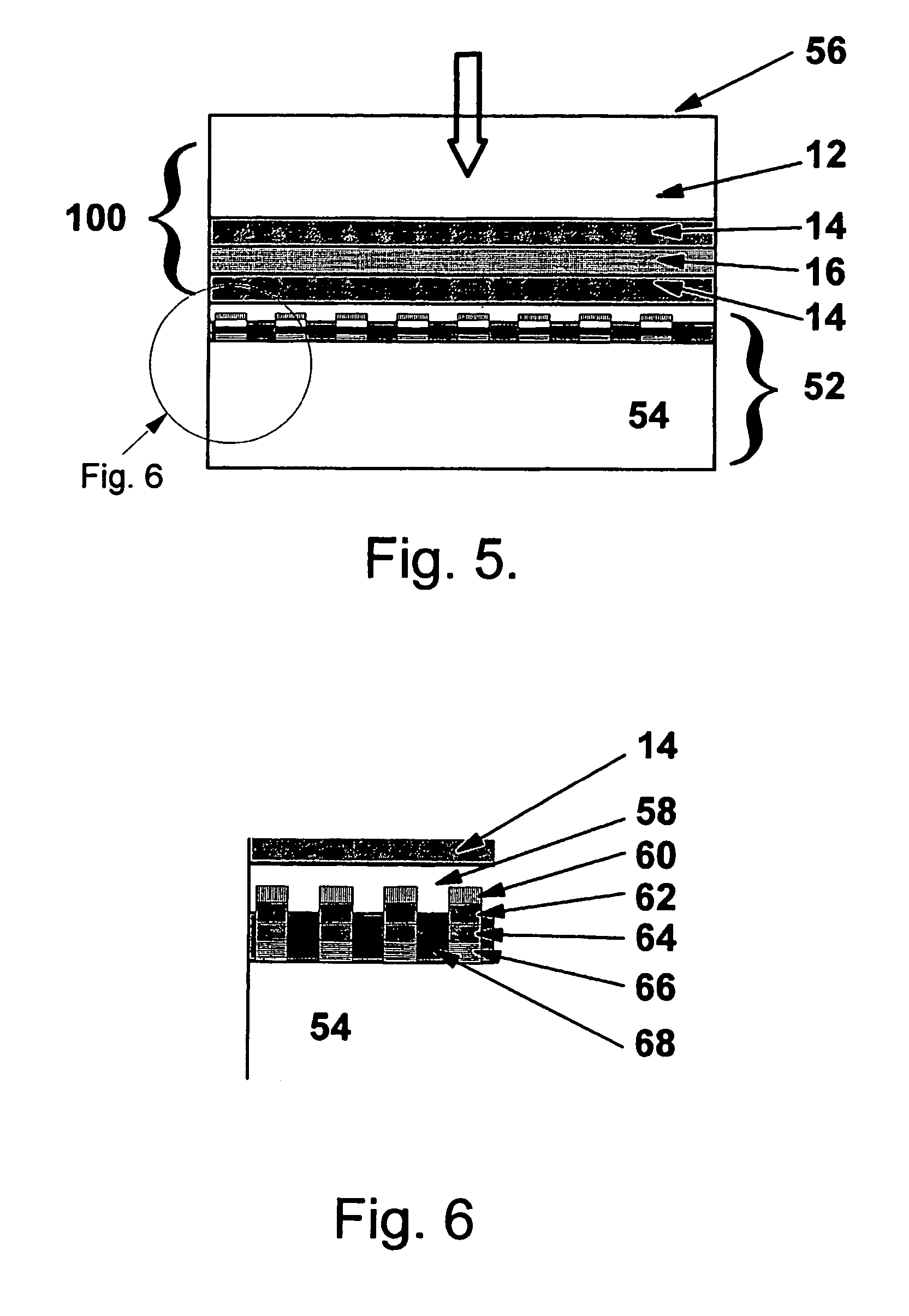

Coatings with low permeation of gases and vapors

A multilayer structure has barrier properties for gases and vapors, for example oxygen and water vapor; the structure comprises: an organic substrate layer, and a multilayer permeation barrier thereon; the barrier comprises: a) a first inorganic coating contacting a surface of the substrate layer, and b) a first organic coating contacting a surface of the inorganic coating; the structure may be employed in a variety of articles where barrier properties are important especially in electronic articles such as organic light emitting diode devices where superior barrier characteristics over the life of the device are required.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Polymer coating for medical devices

Coatings are provided in which surfaces may be activated by covalently bonding a silane derivative to the metal surface, covalently bonding a lactone polymer to the silane derivative by in situ ring opening polymerization, and depositing at least one layer of poly(lactide-co-caprolactone) copolymer on the bonded lactone. Biologically active agents may be disposed with the poly(lactide-co-caprolactone) copolymer layers. Such coated surfaces may be useful in medical devices, in particular stents.

Owner:CV THERAPEUTICS INC

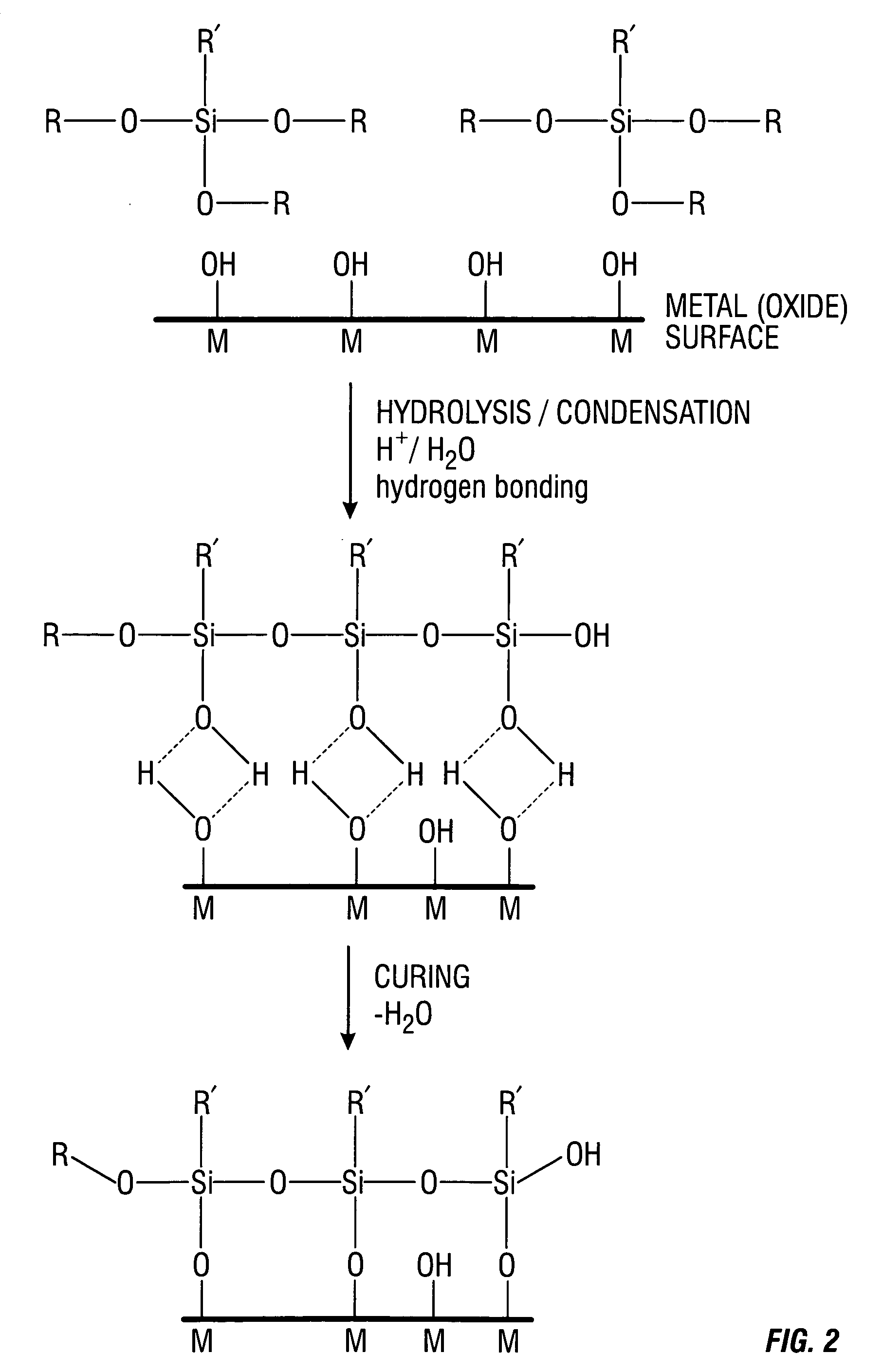

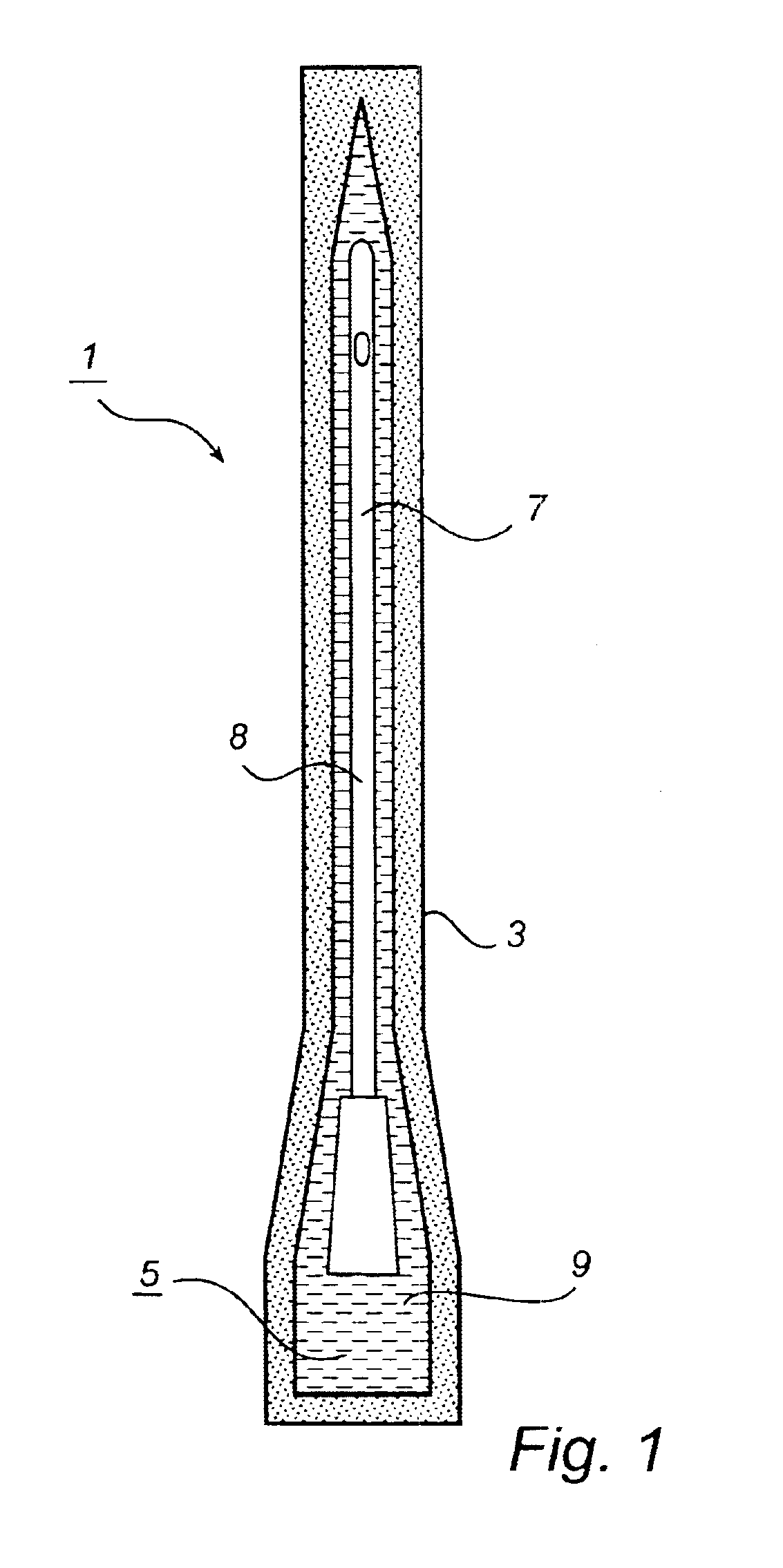

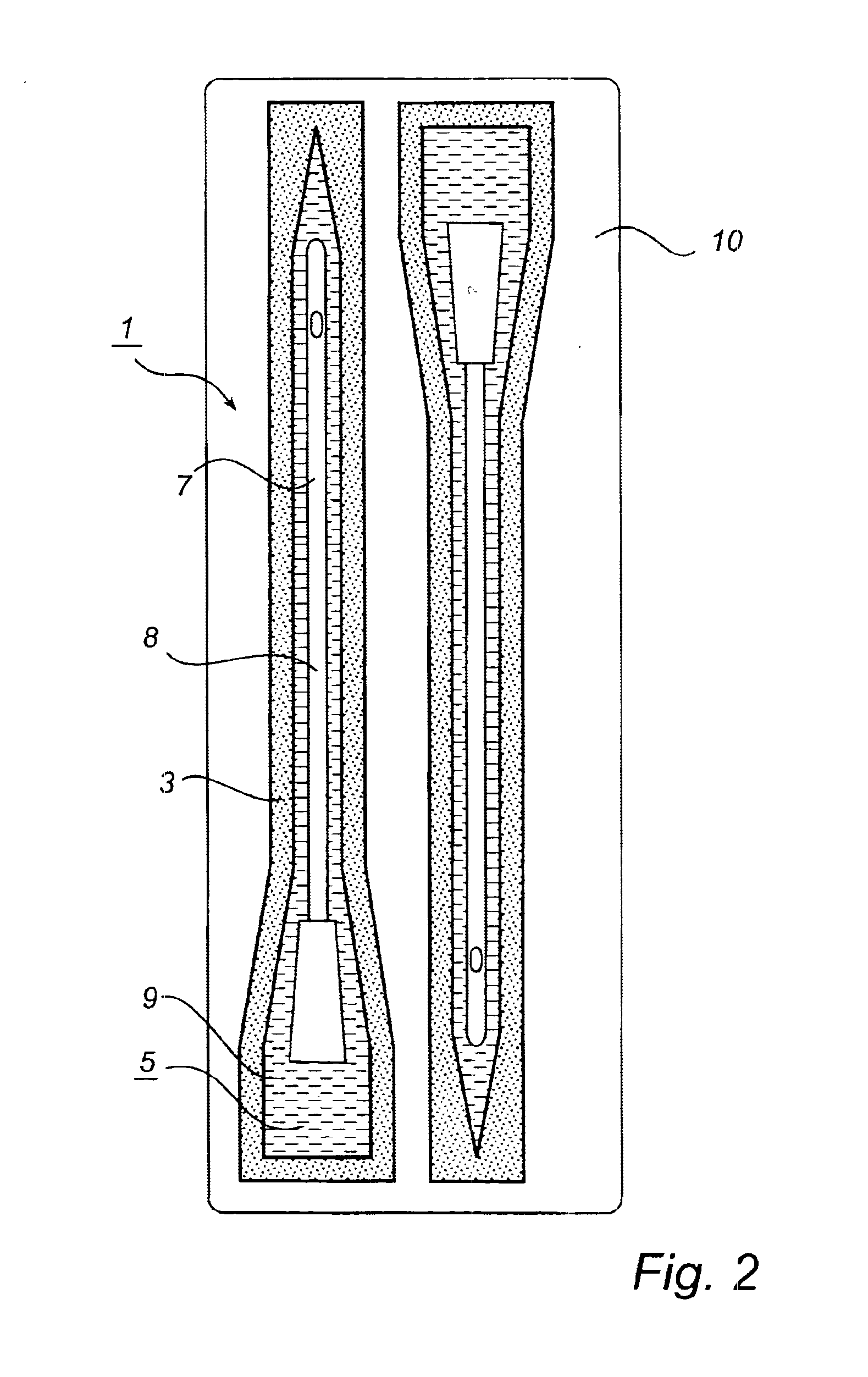

Storage package and a method for packaging

InactiveUS6848574B1Long shelf lifeExtended shelf lifeWrappersDispensing apparatusCoated surfaceUrethral catheter

A storage package (1) contains a medical device (7) having a coated surface (8 ) which exhibits a reduced friction when wetted with a wetting liquid and a supply of the wetting liquid (9). The package is adapted such that the coated surface of the medical device is maintained contact with the supply of wetting liquid during storage. A good shelf-life for the medical device is achieved an where the medical device is a urethral catheter the catheter is immediately “ready-for-use” after the package has been opened.

Owner:ASTRA TECH SE

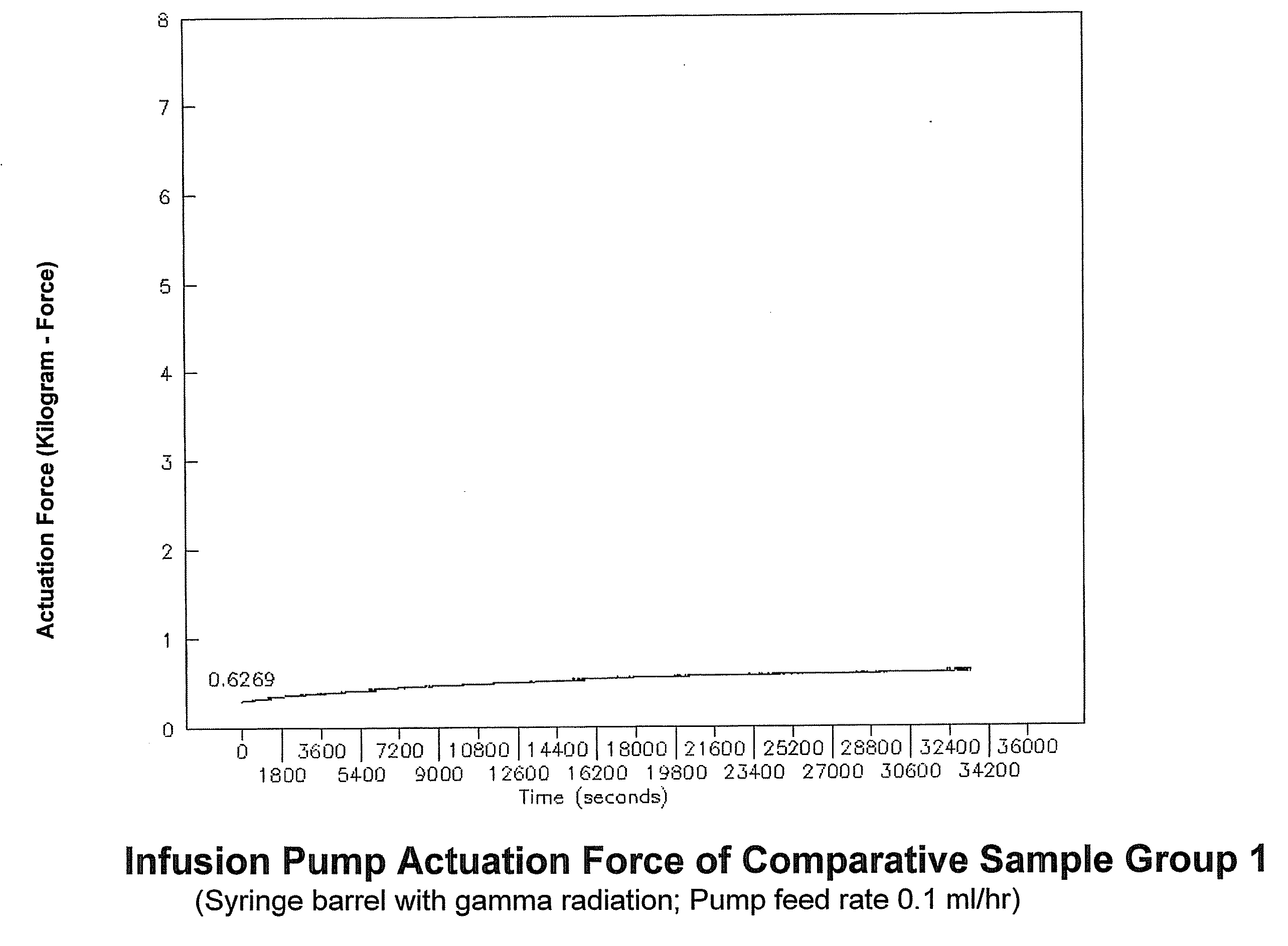

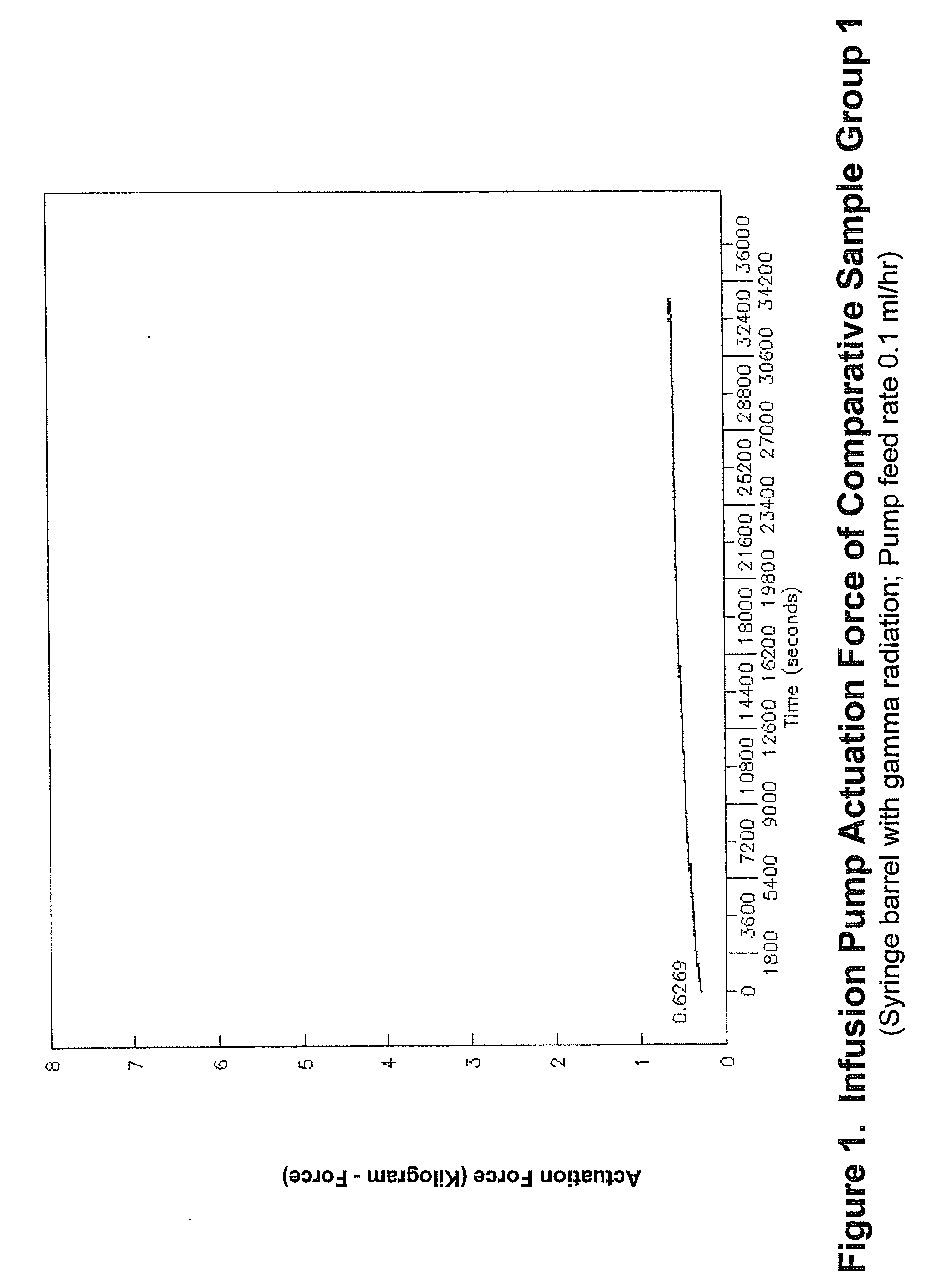

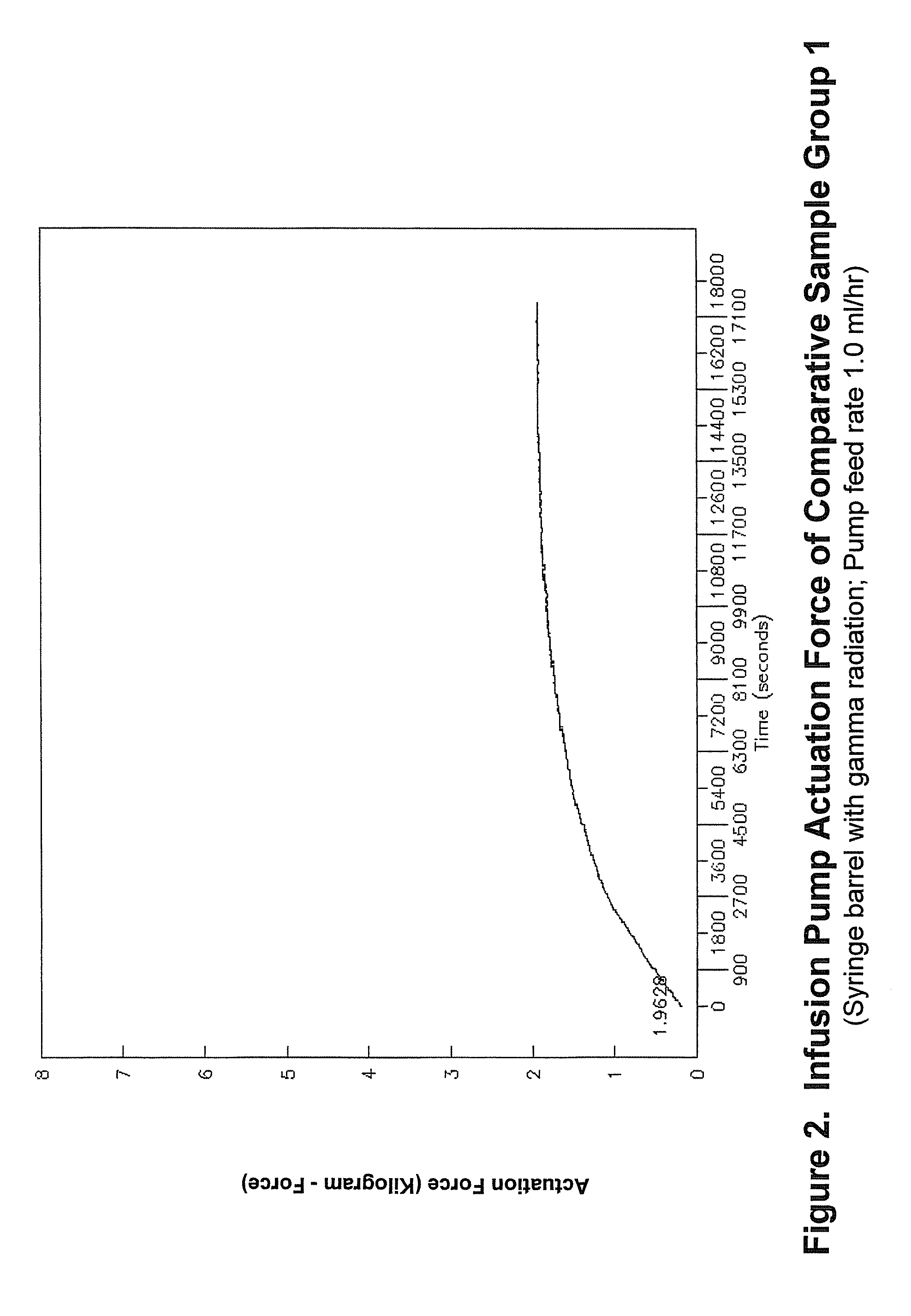

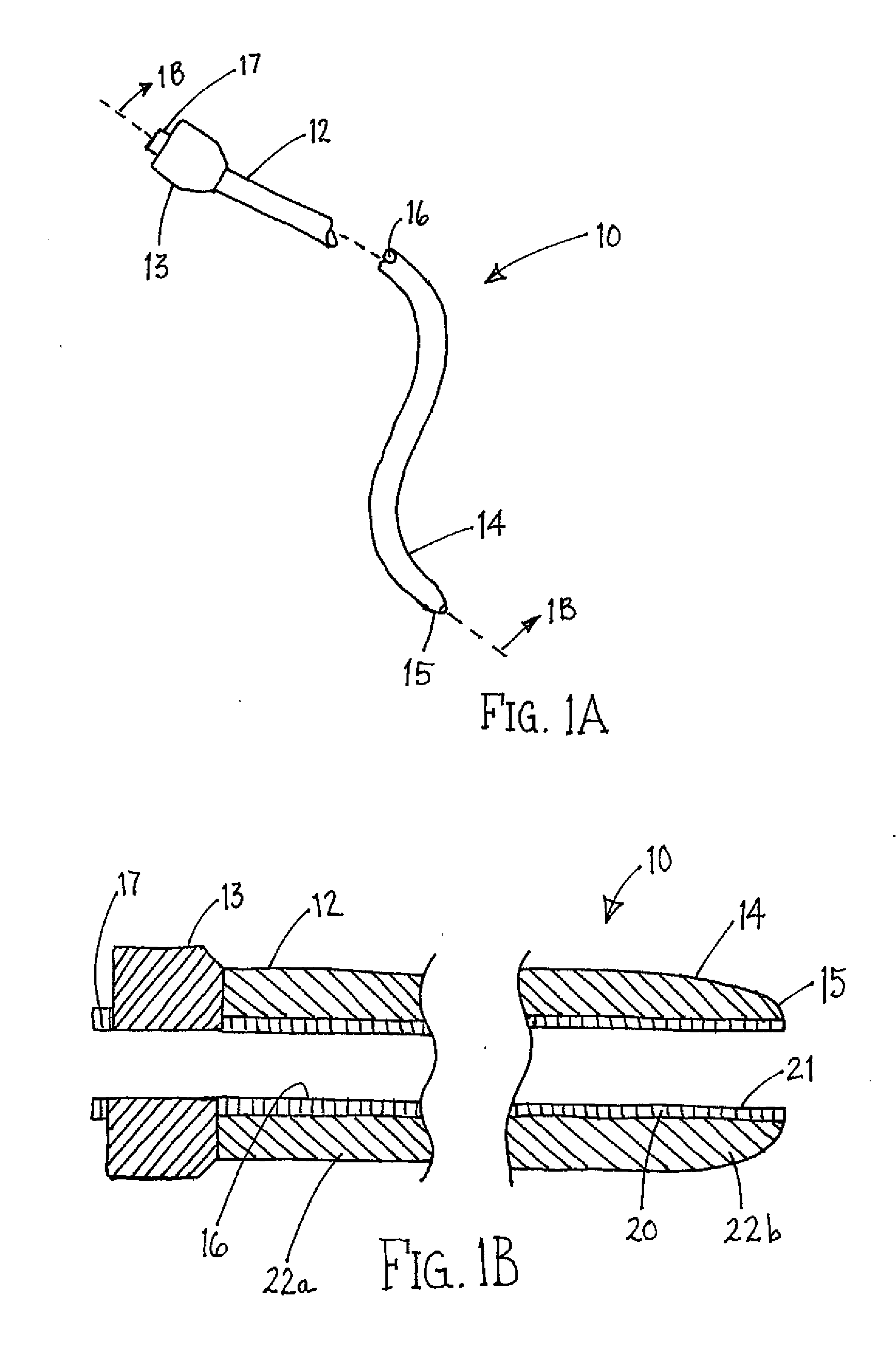

Medical Components Having Coated Surfaces Exhibiting Low Friction and Methods of Reducing Sticktion

This invention relates to components useful for medical articles, such as a syringe assembly, having sliding surface(s) coated with a composition including organopolysiloxane(s), the coating being adhered to the surface(s) of the component by crosslinking induced by oxidative treatment and irradiation with an isotope, electron beam or ultraviolet radiation or heat treatment; medical articles including the same; methods to reduce static and kinetic friction between slidable surfaces; and articles of low friction prepared thereby.

Owner:BECTON DICKINSON & CO

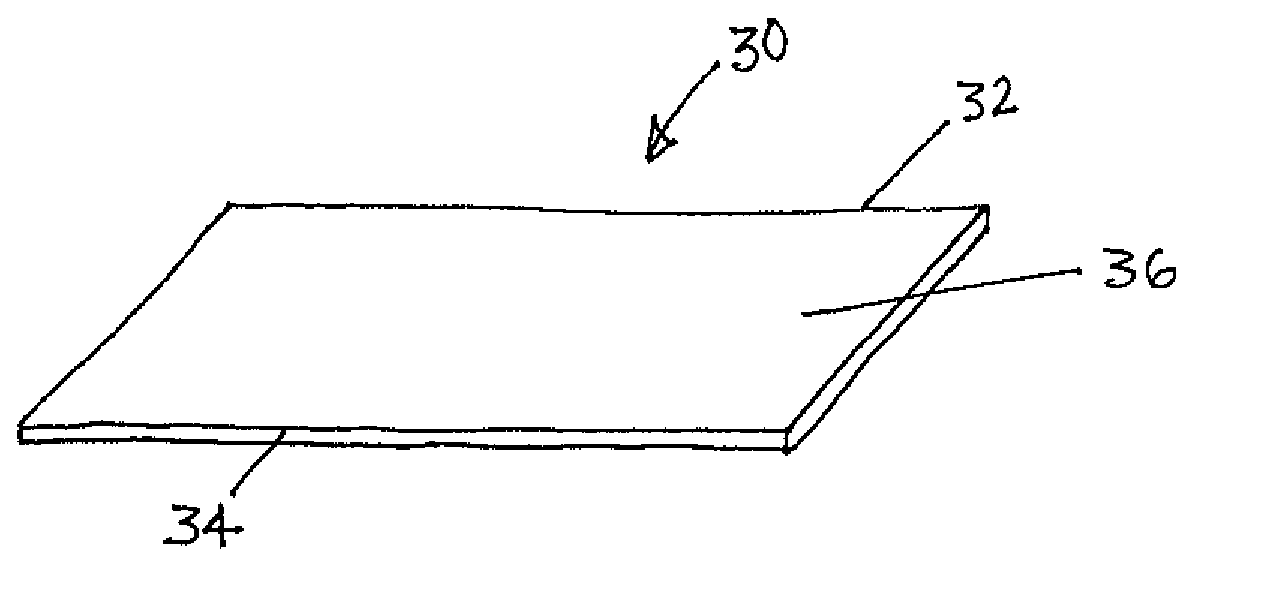

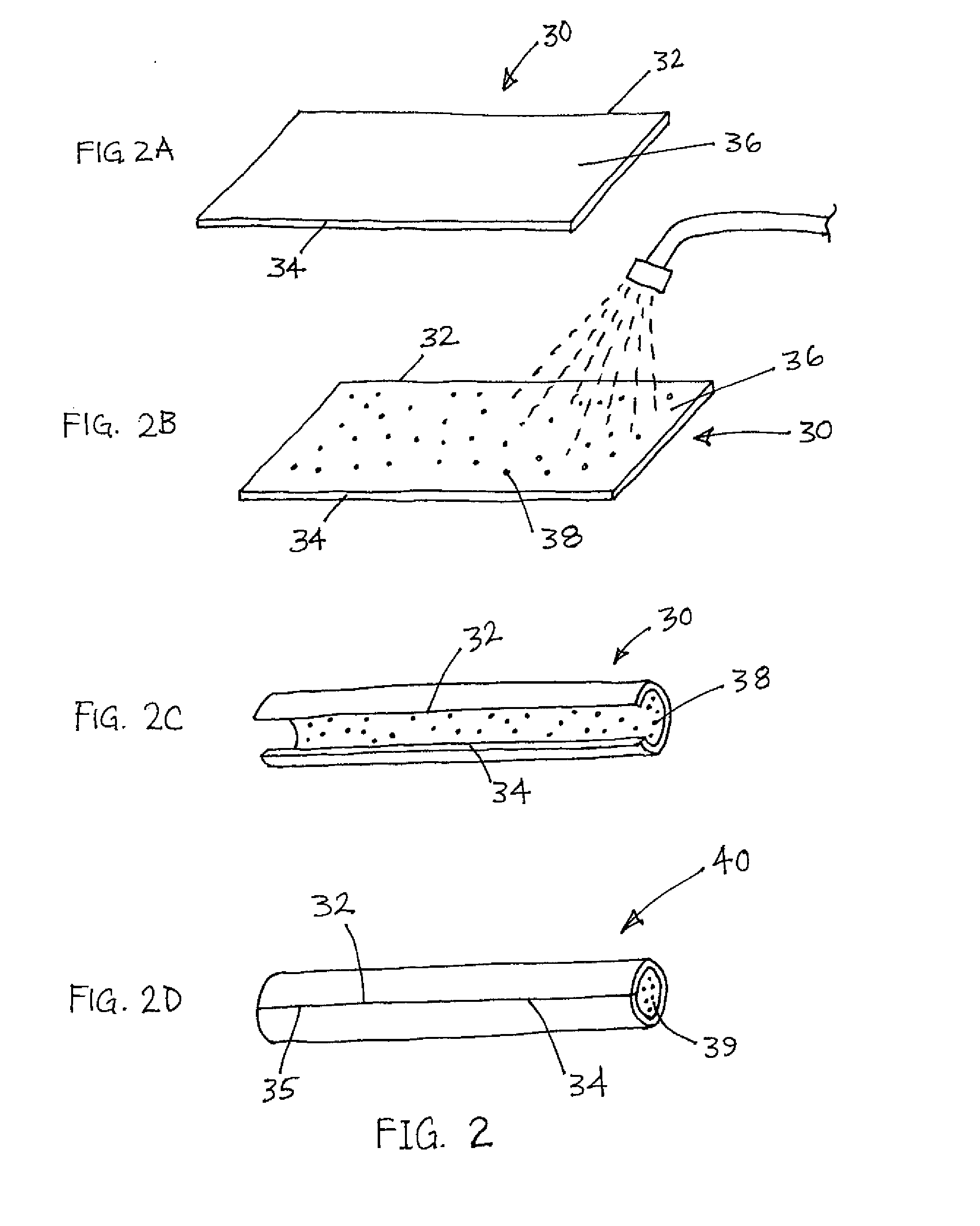

Catheters with lubricious linings and methods for making and using them

ActiveUS20090259202A1Improve cross linking and adhesionLamination ancillary operationsTransvascular endocardial electrodesCoated surfaceCatheter device

Apparatus and methods are provided for substantially continuously forming thin-walled sleeves that may be incorporated into tubular devices sized for introduction into a patient. In one embodiment, a pair of sheets including coated surfaces oriented towards one another are directed through a cutting apparatus to cut the sheets into multiple pairs of strips. The pairs of strips are bonded together to create a plurality of sleeves having lumens defined by the coated surfaces. In another embodiment, a sheet having a coated surface is fed through a cutting tool to separate the sheet into a plurality of strips, and the strips are formed into sleeves, e.g., by feeding the strips through a die or mandrel using a substantially continuous process. Optionally, the sleeves may be subsequently cut into individual tubular devices and / or further processed, e.g., by providing one or more layers around the sleeves to create catheters, sheaths, or other apparatus.

Owner:CLPH

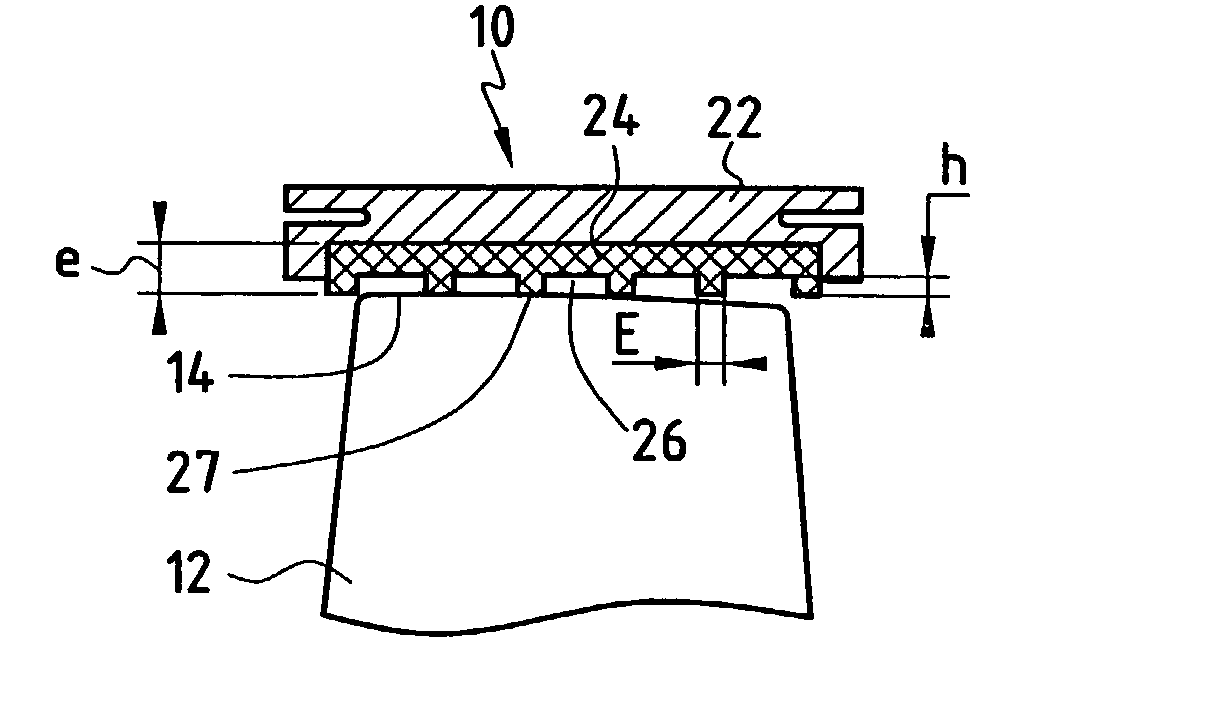

Abradable coating for gas turbine walls

InactiveUS20030175116A1Improve wear resistanceEffective thermal protectionPump componentsBlade accessoriesCoated surfaceEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

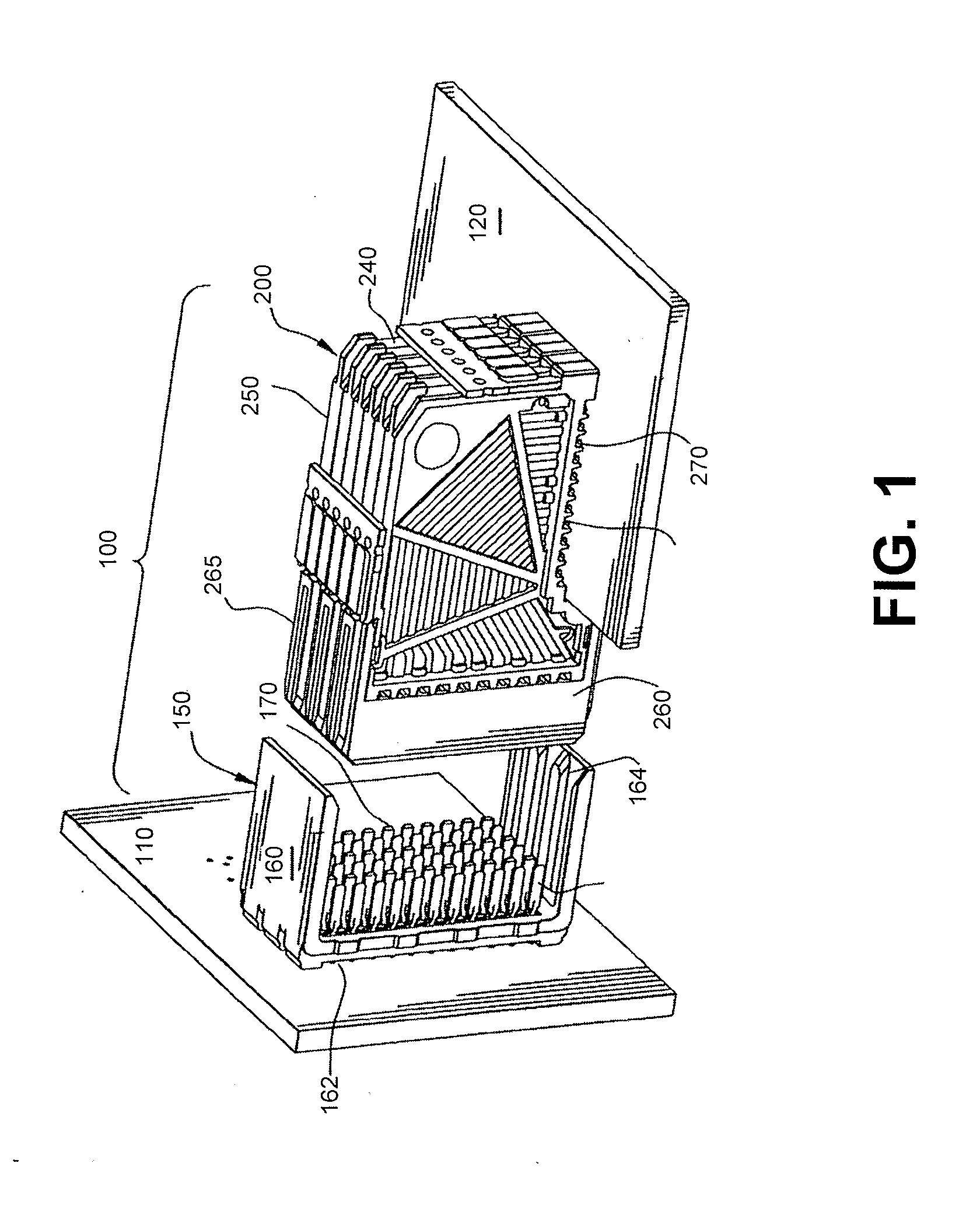

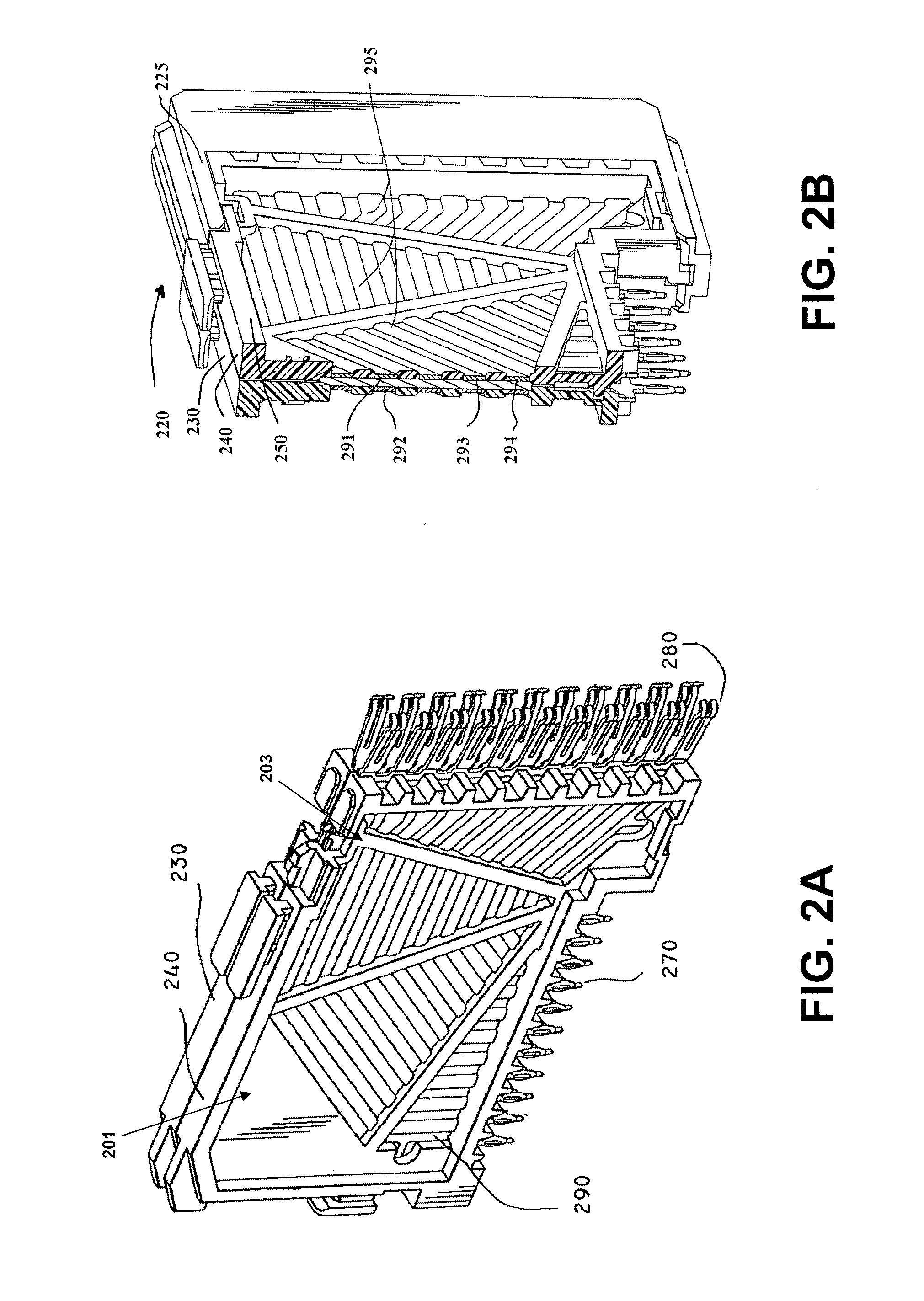

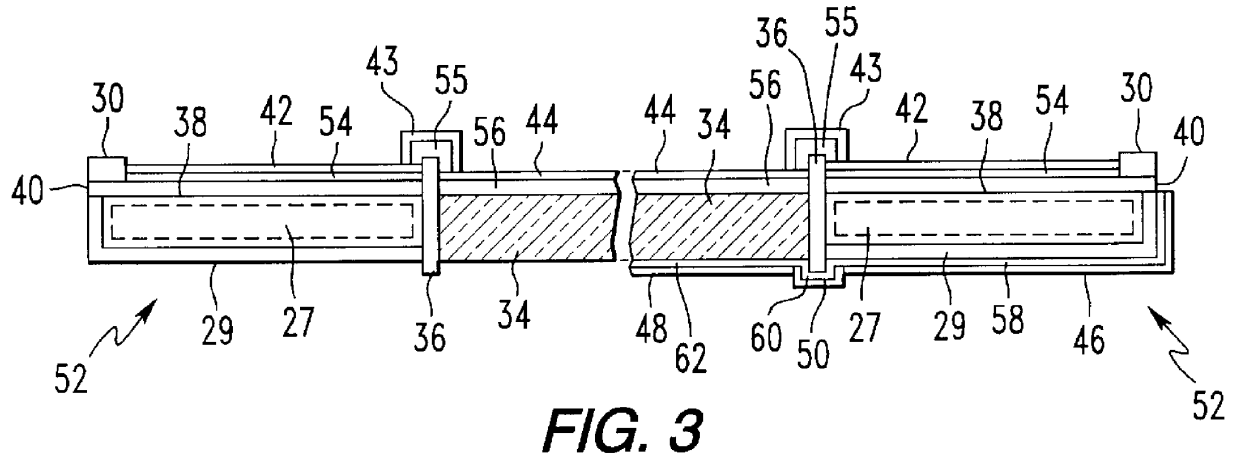

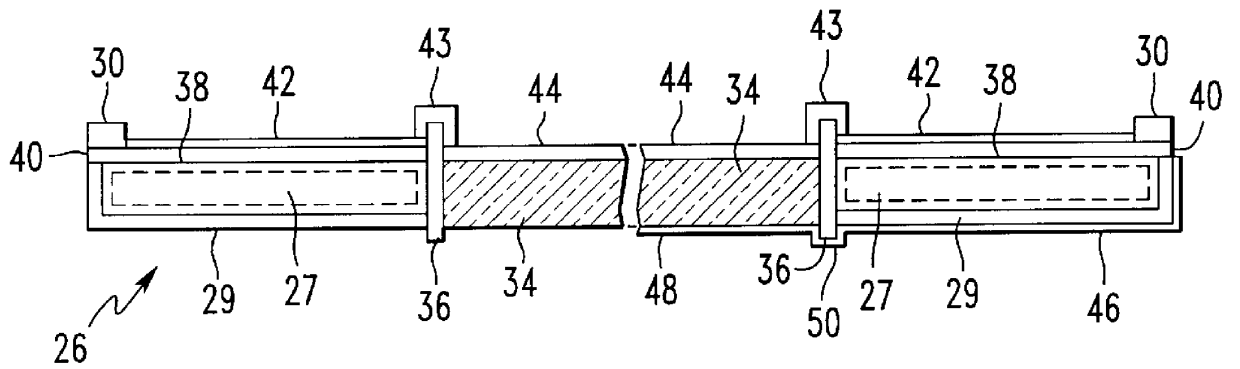

High frequency electrical connector

ActiveUS20110230095A1Reduce resonanceTwo-part coupling devicesCoupling protective earth/shielding arrangementsUltrasound attenuationCoated surface

Owner:AMPHENOL CORP

Magnetic tape

ActiveUS20180240492A1Avoid it happening againRecord information storageTape carriersCoated surfaceMagnetic tape

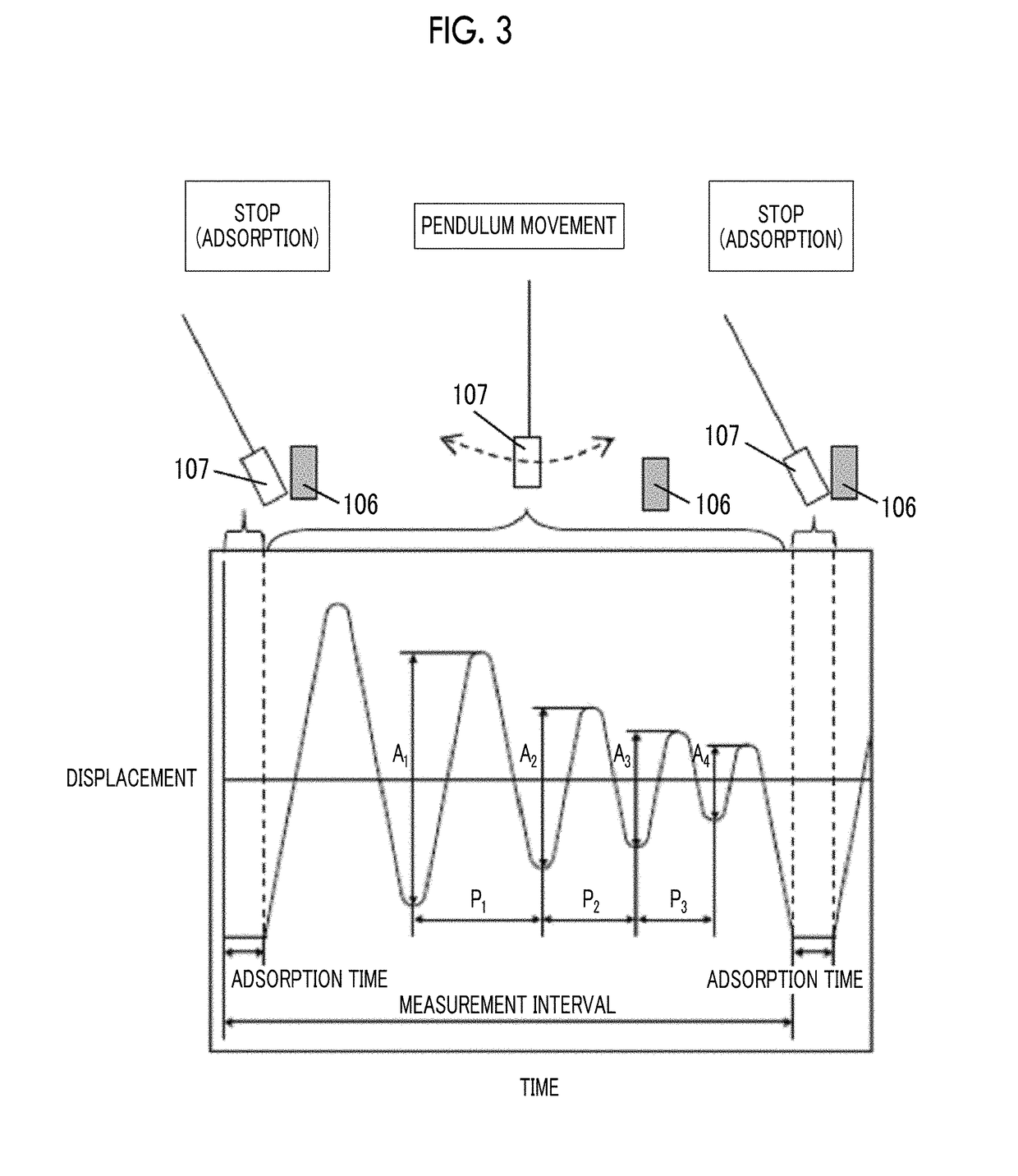

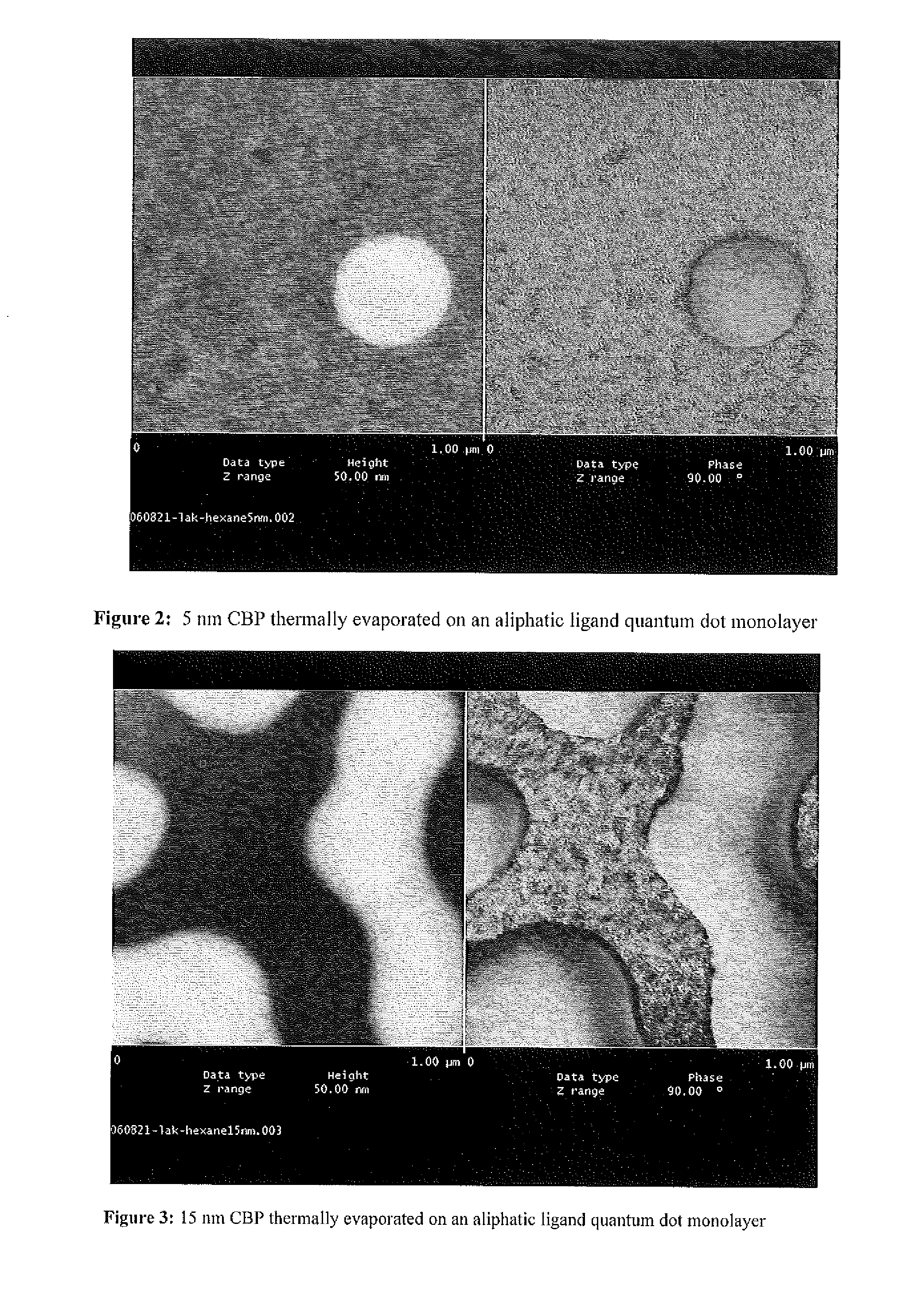

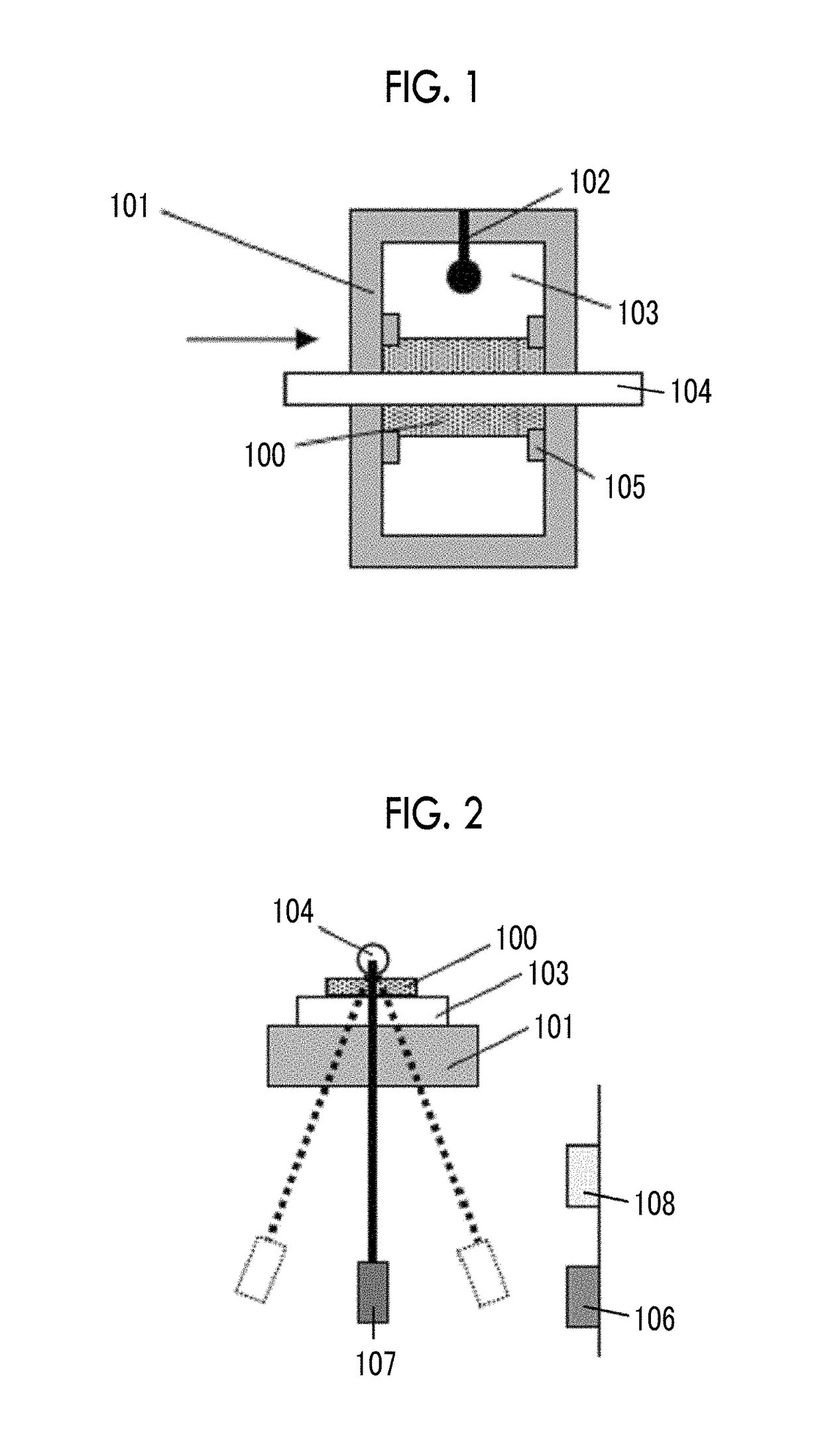

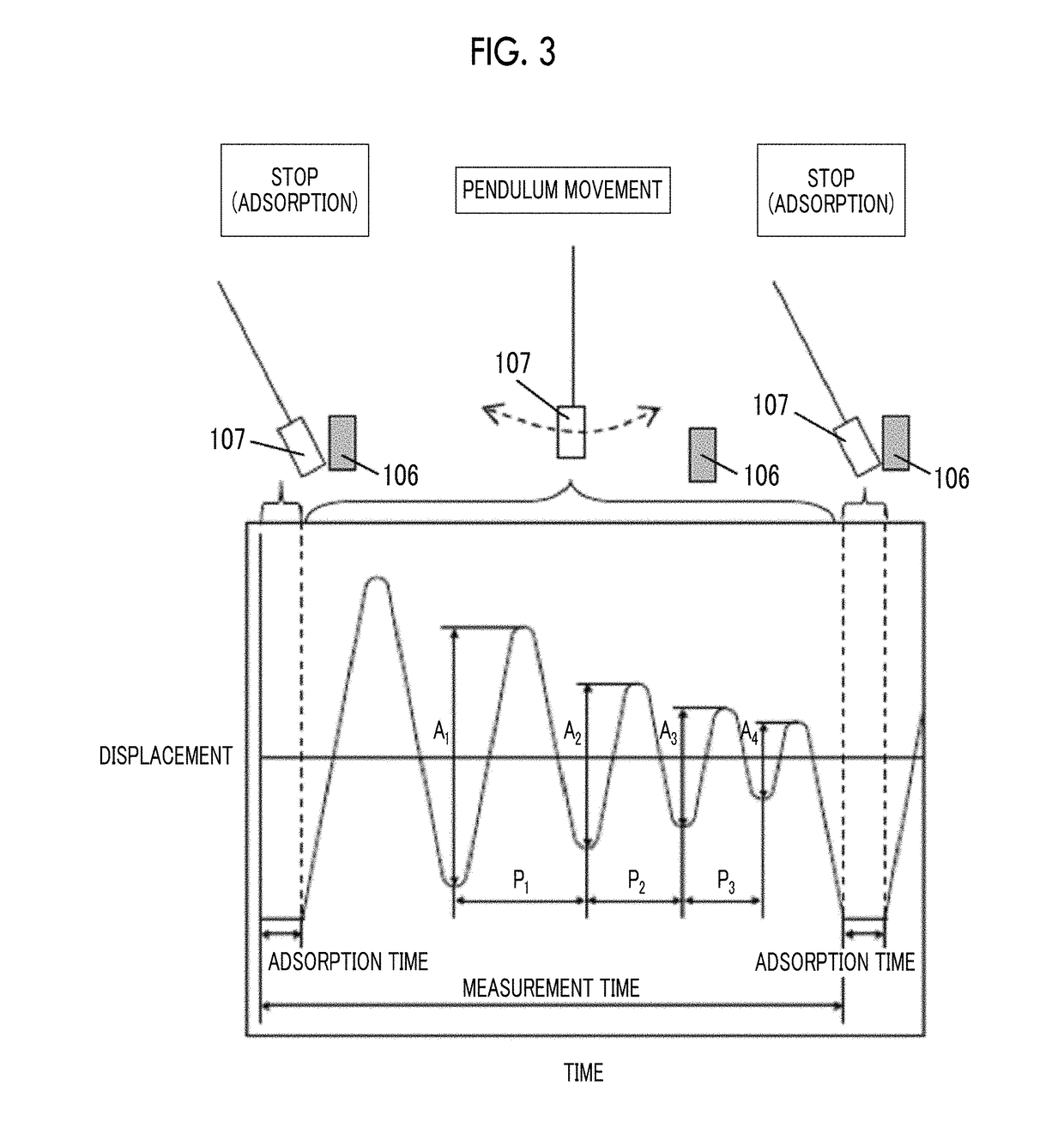

The magnetic tape includes a back coating layer having a thickness equal to or smaller than 0.30 μm and including fatty acid ester, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding a surface of the back coating layer is equal to or smaller than 0.060, a full width at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape is respectively greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between a spacing measured by optical interferometry regarding the surface of the back coating layer after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Coatings with low permeation of gases and vapors

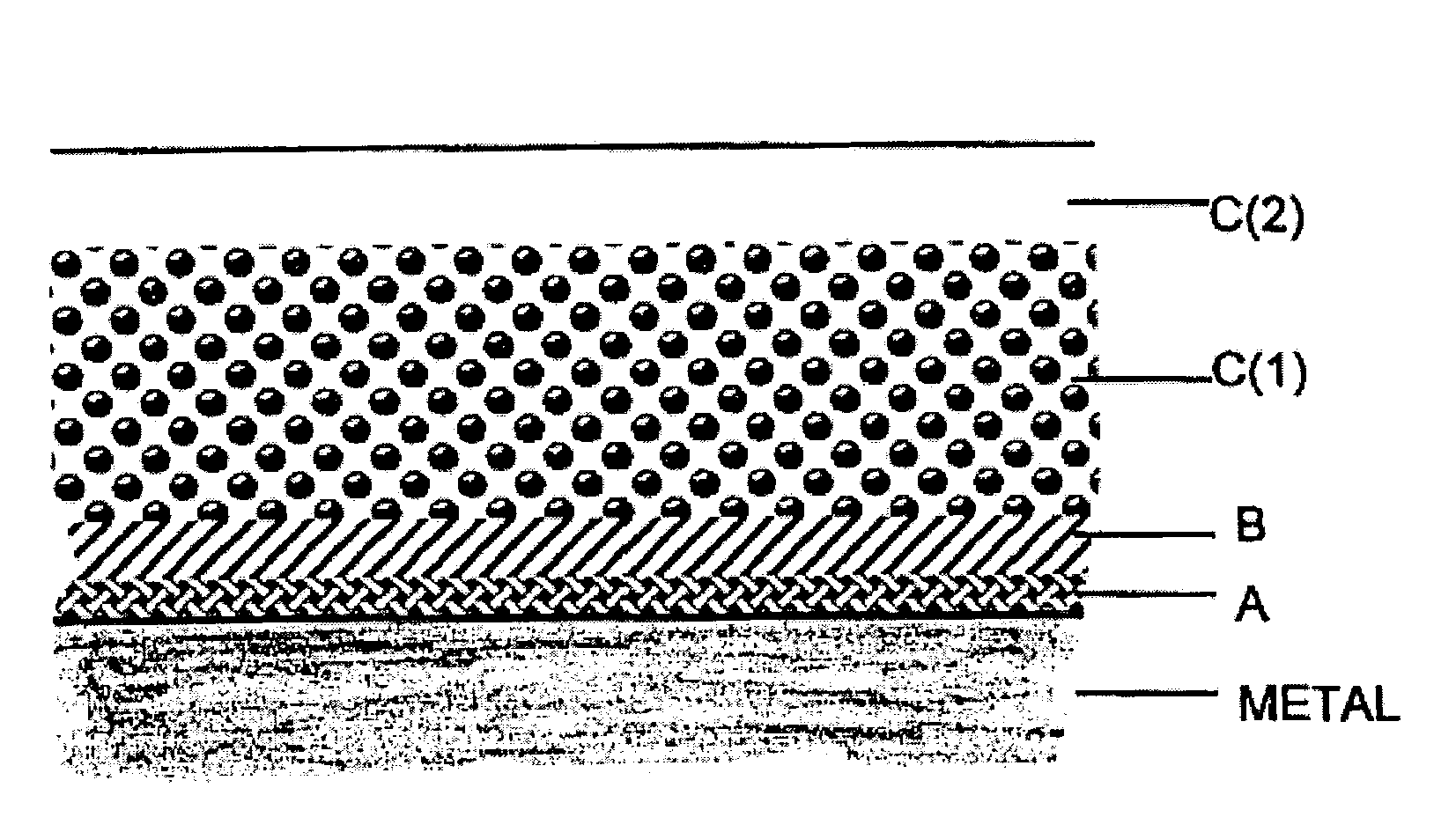

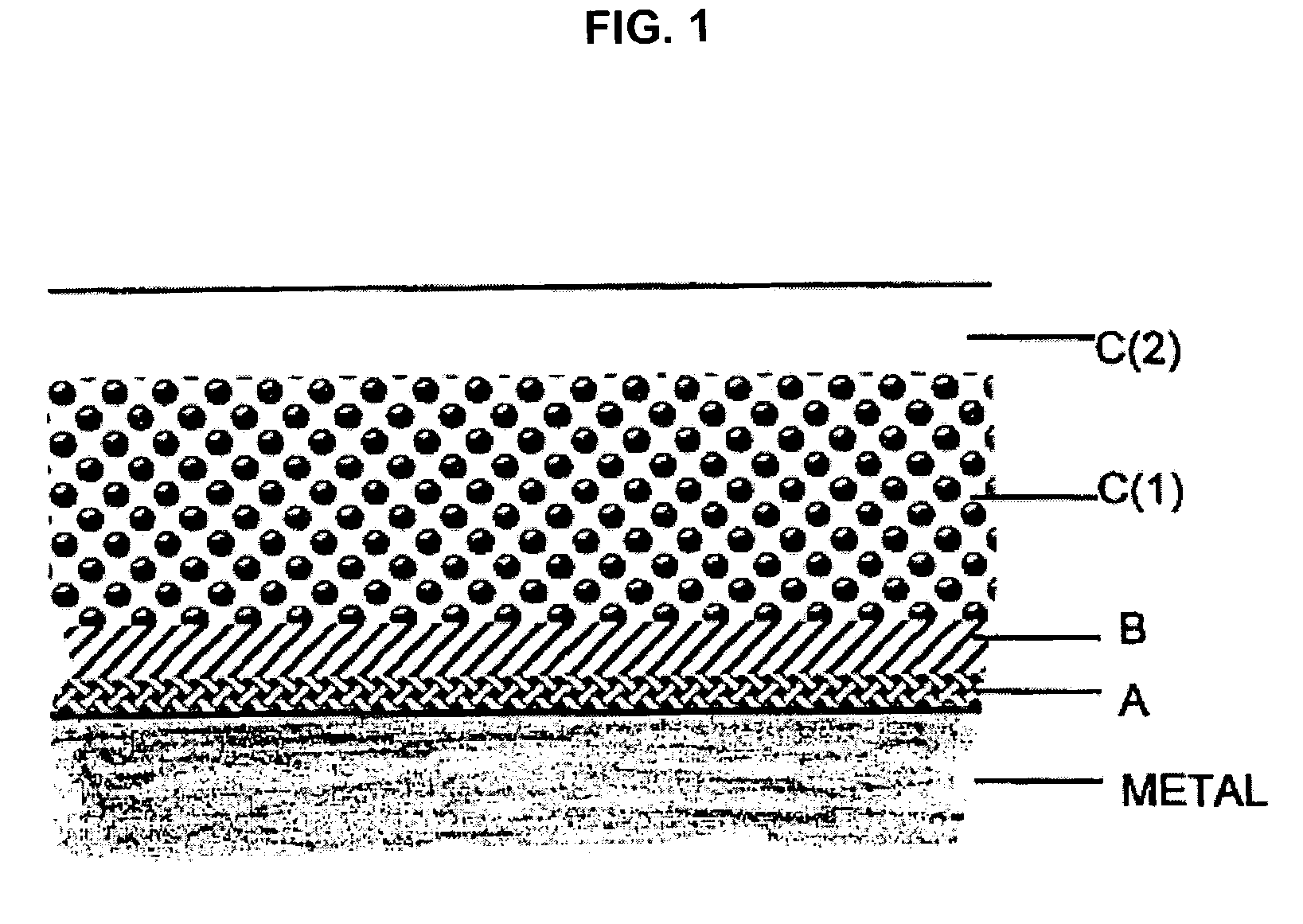

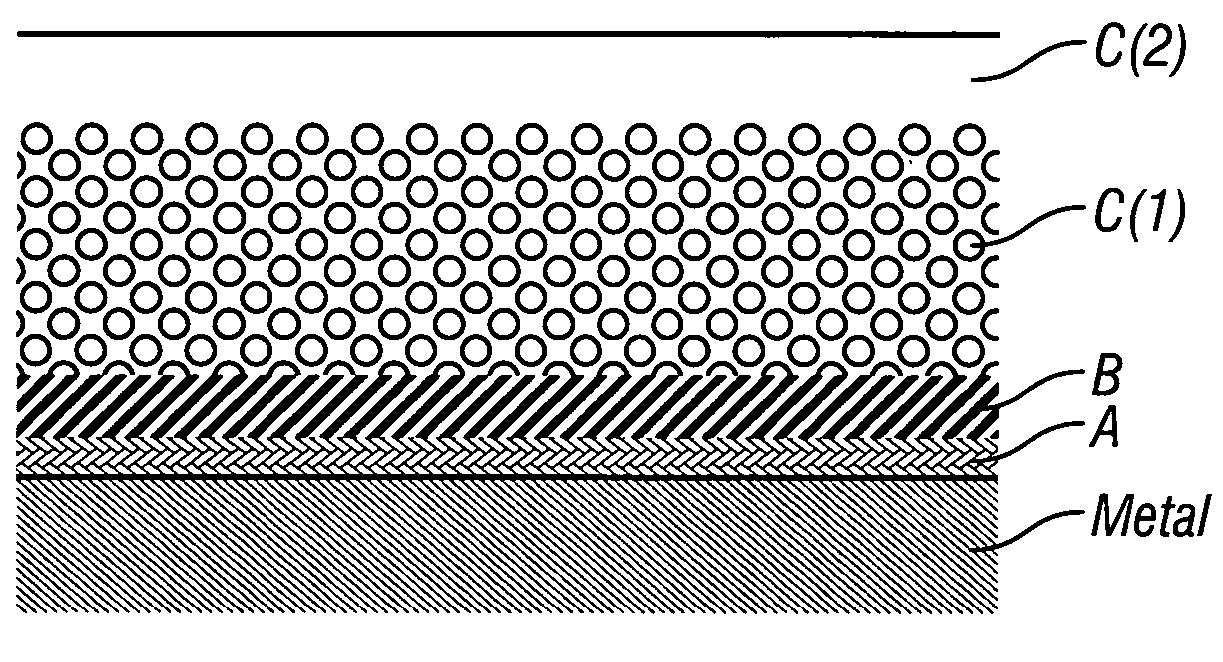

InactiveUS7074501B2Reduce permeationFinal product manufactureVacuum evaporation coatingCoated surfaceLight-emitting diode

A multilayer structure has barrier properties for gases and vapors, for example oxygen and water vapor; the structure comprises: an organic substrate layer, and a multilayer permeation barrier thereon; the barrier comprises: a) a first inorganic coating contacting a surface of the substrate layer, and b) a first organic coating contacting a surface of the inorganic coating; the structure may be employed in a variety of articles where barrier properties are important especially in electronic articles such as organic light emitting diode devices where superior barrier characteristics over the life of the device are required.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

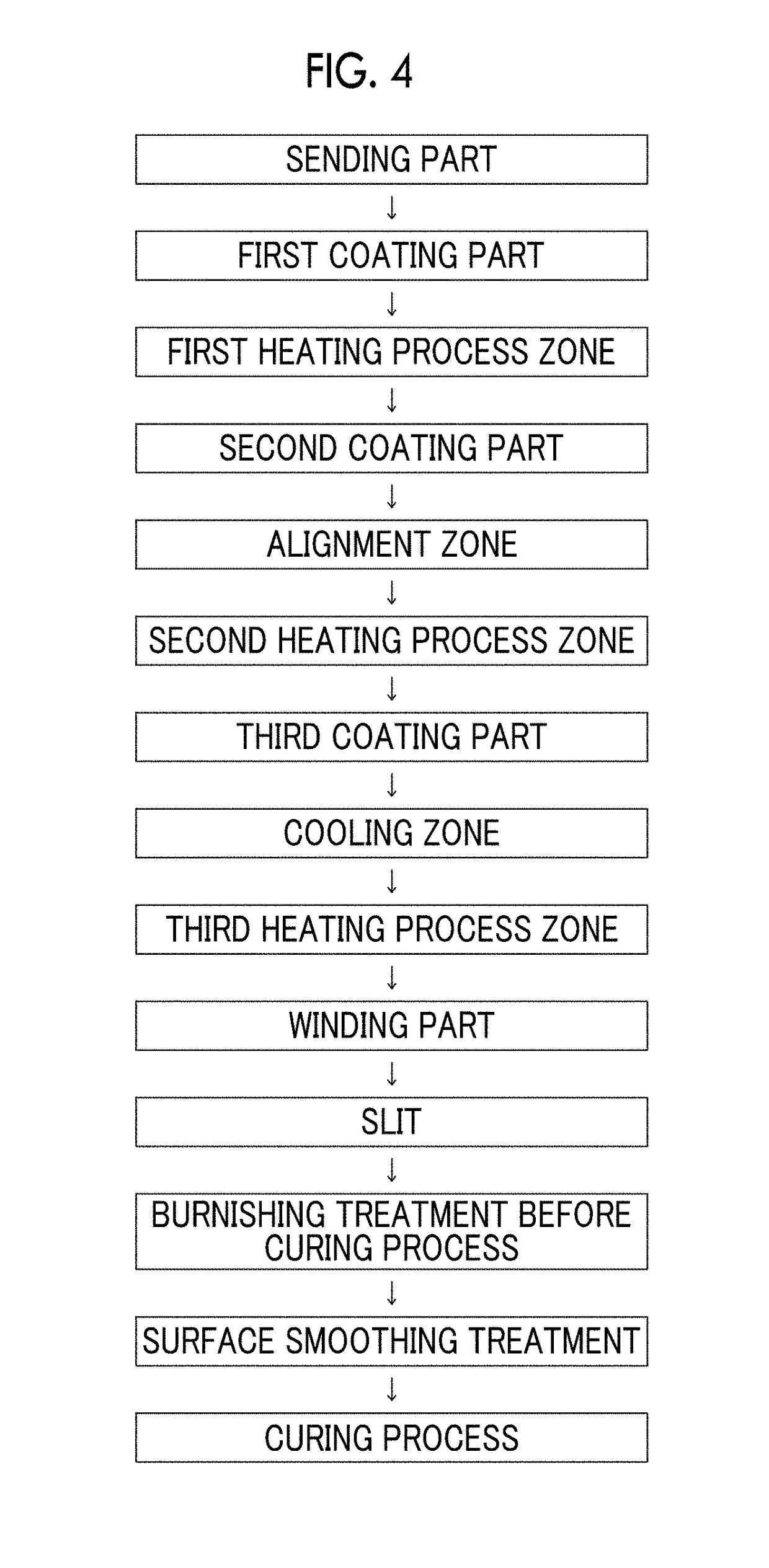

Magnetic tape

ActiveUS20190027181A1Improve surface smoothnessAvoid it happening againMagnetic materials for record carriersRecord information storageIn planeCoated surface

Provided is a magnetic tape in which an Ra measured regarding a surface of a magnetic layer is equal to or smaller than 1.8 nm, Int(110) / Int(114) of a hexagonal ferrite crystal structure obtained by an XRD analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic tape is 0.65 to 1.00, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between the spacings measured by optical interferometry regarding the surface of the back coating layer before and after performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

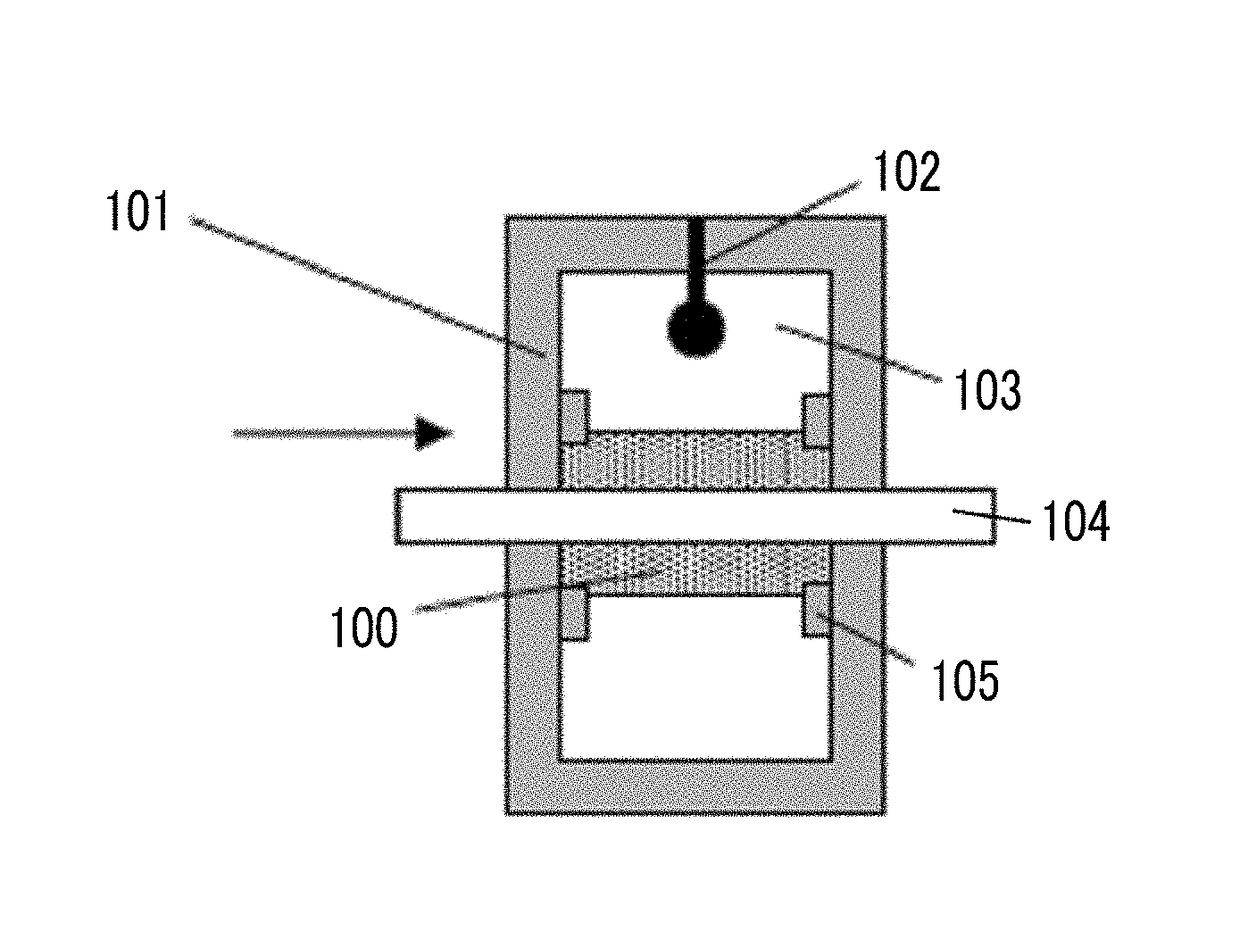

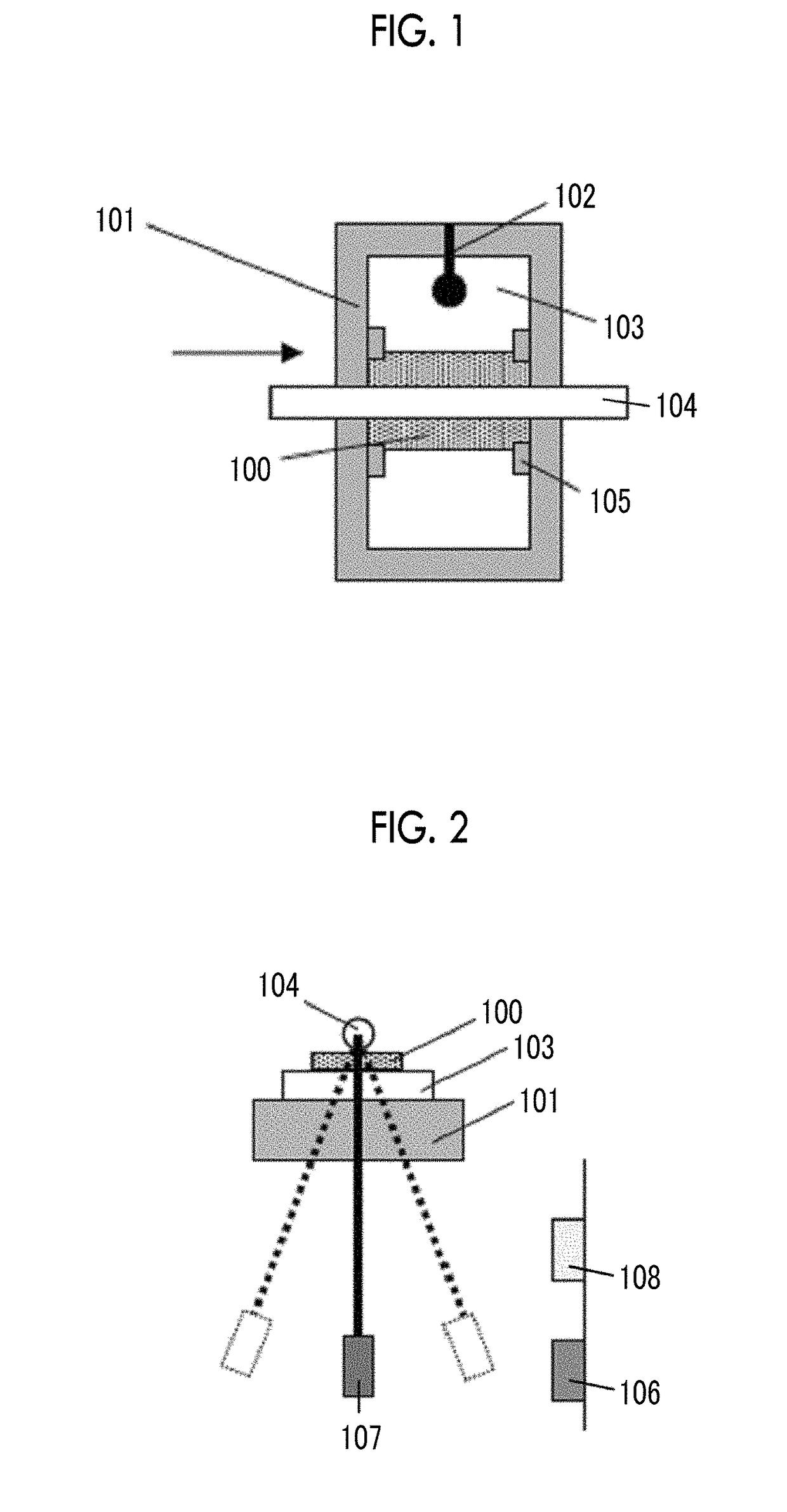

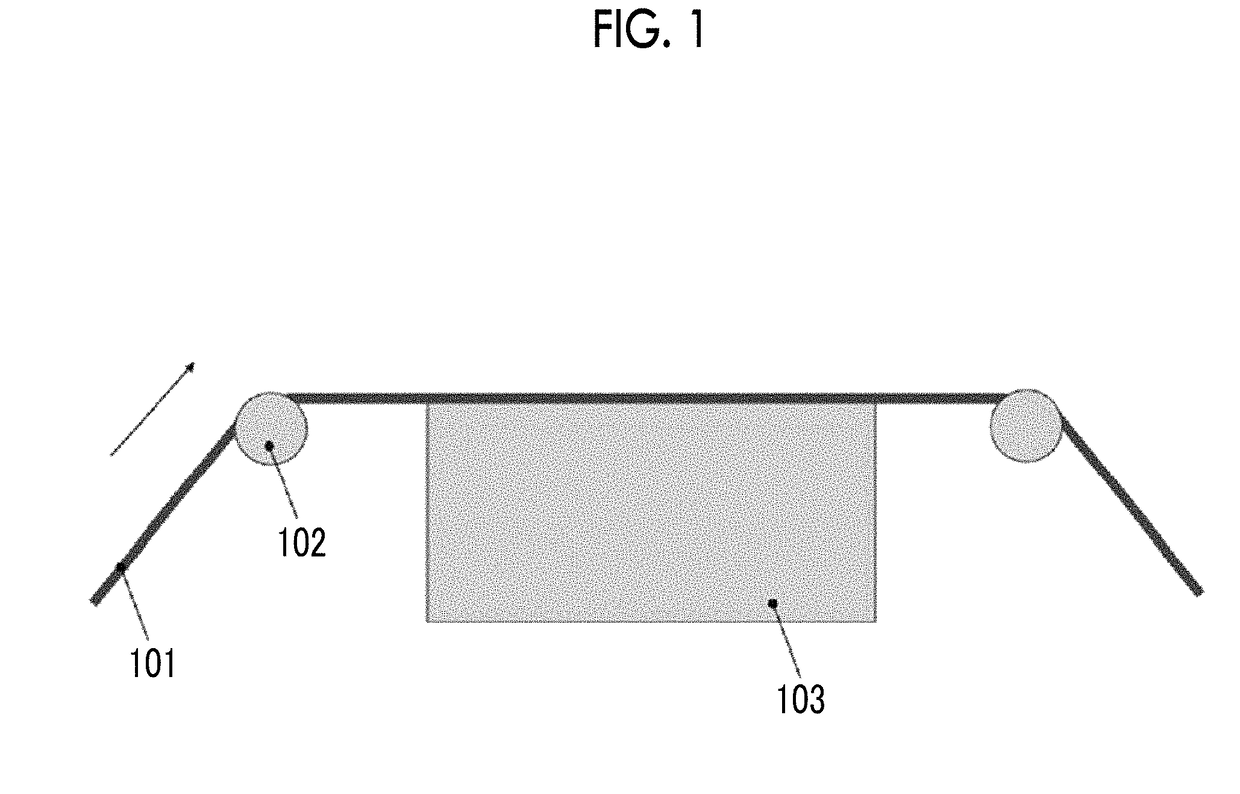

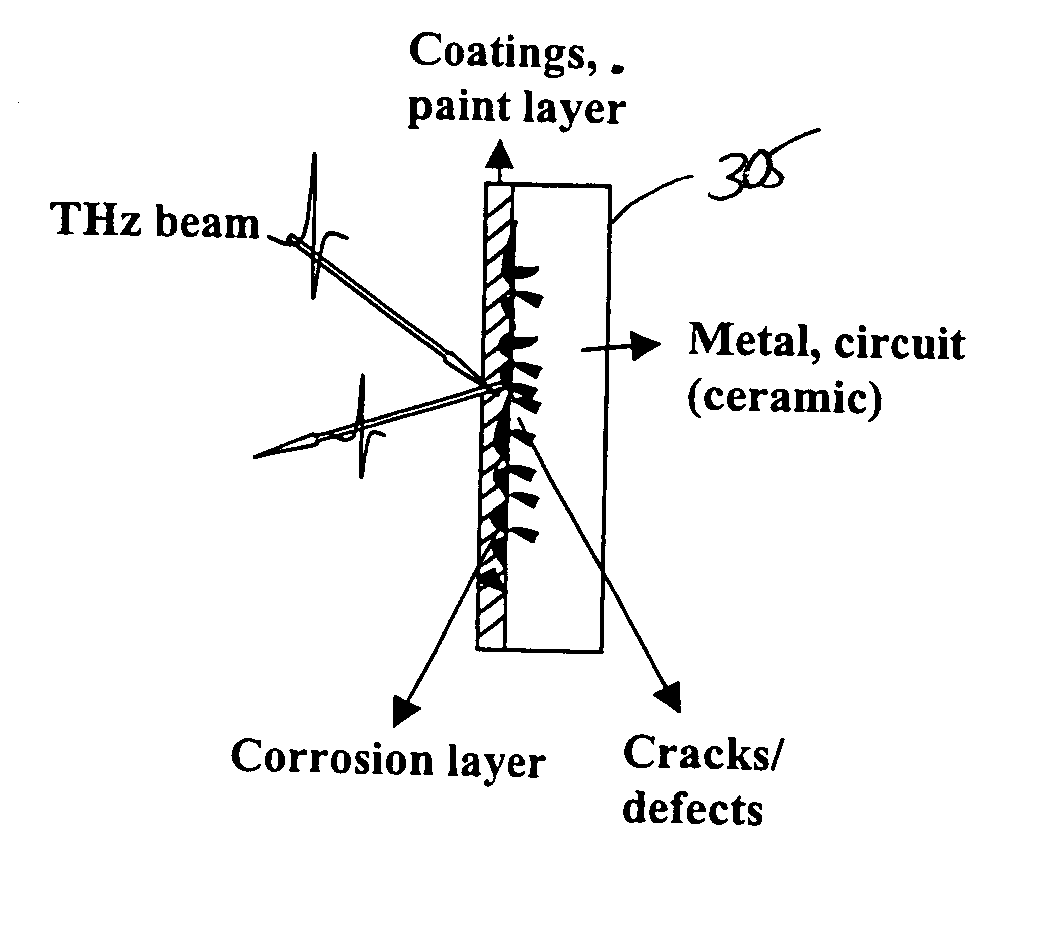

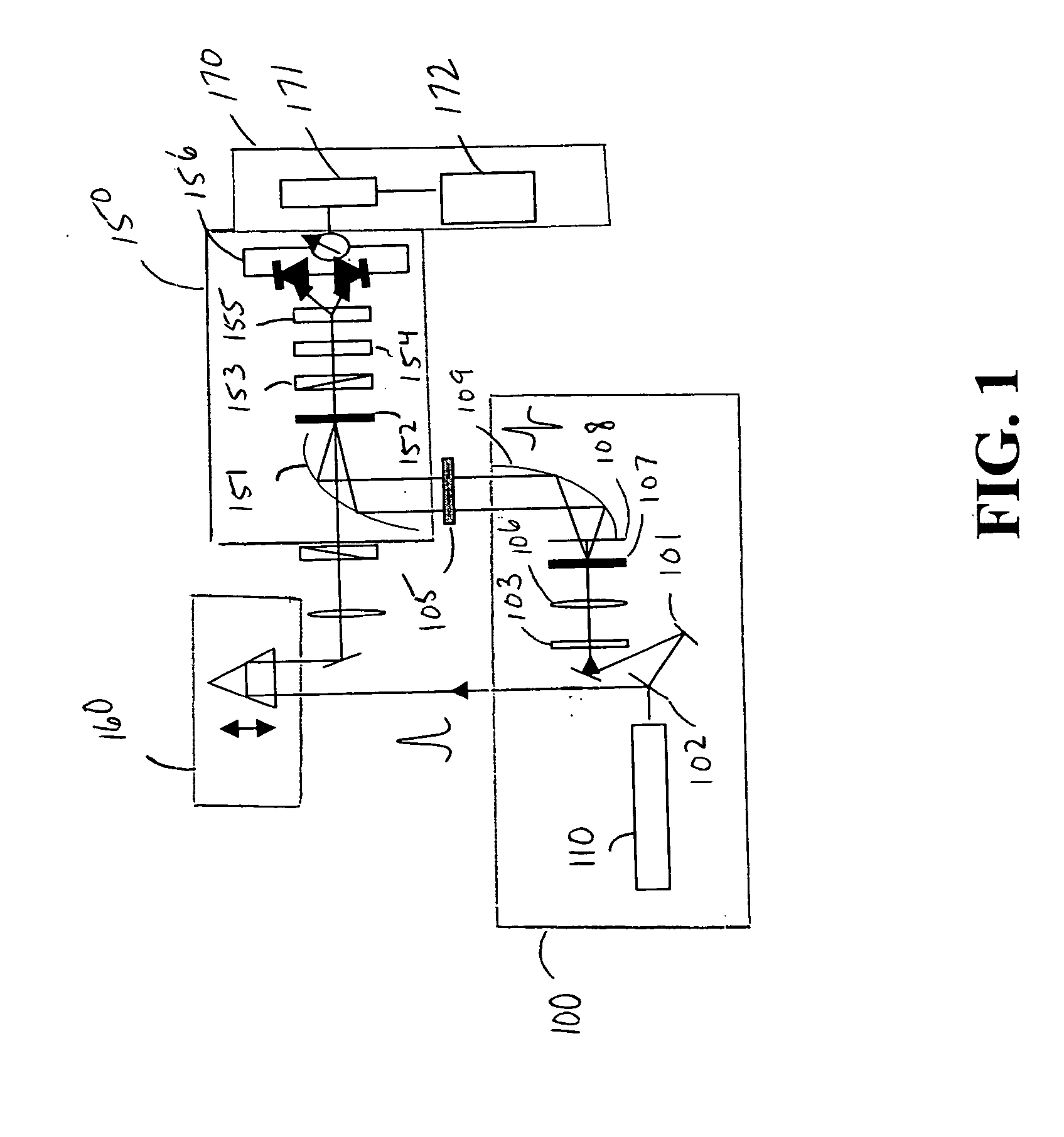

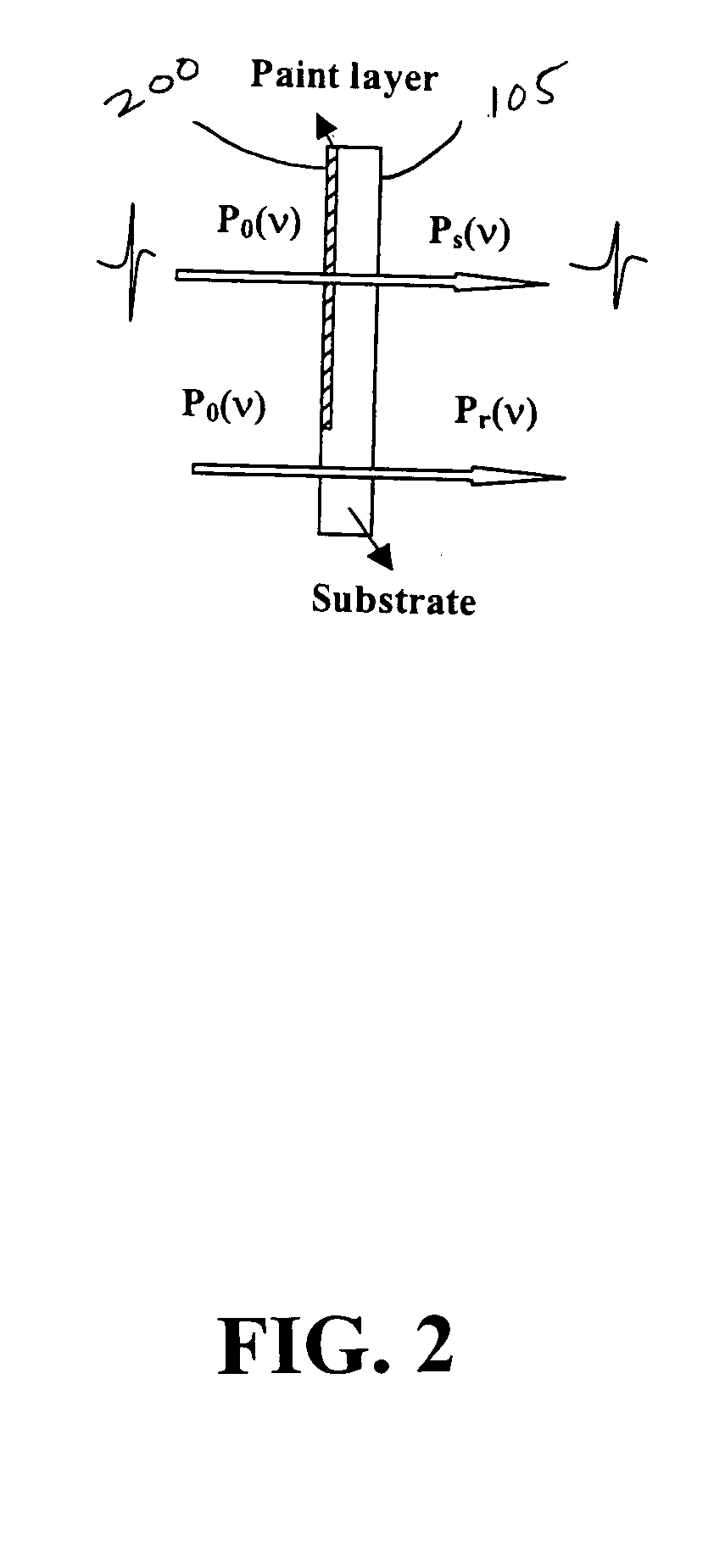

Systems and methods for non-destructively detecting material abnormalities beneath a coated surface

The present invention provides systems and methods for non-destructively detecting material abnormalities beneath a coated surface. A terahertz (THz) illumination unit illuminates an area of the coated surface. A detection unit detects light reflected from the illuminated area of the coated surface, and a processing unit images the illuminated area of the coated surface from optical characteristics received from the detection unit.

Owner:ALFANO ROBERT R +1

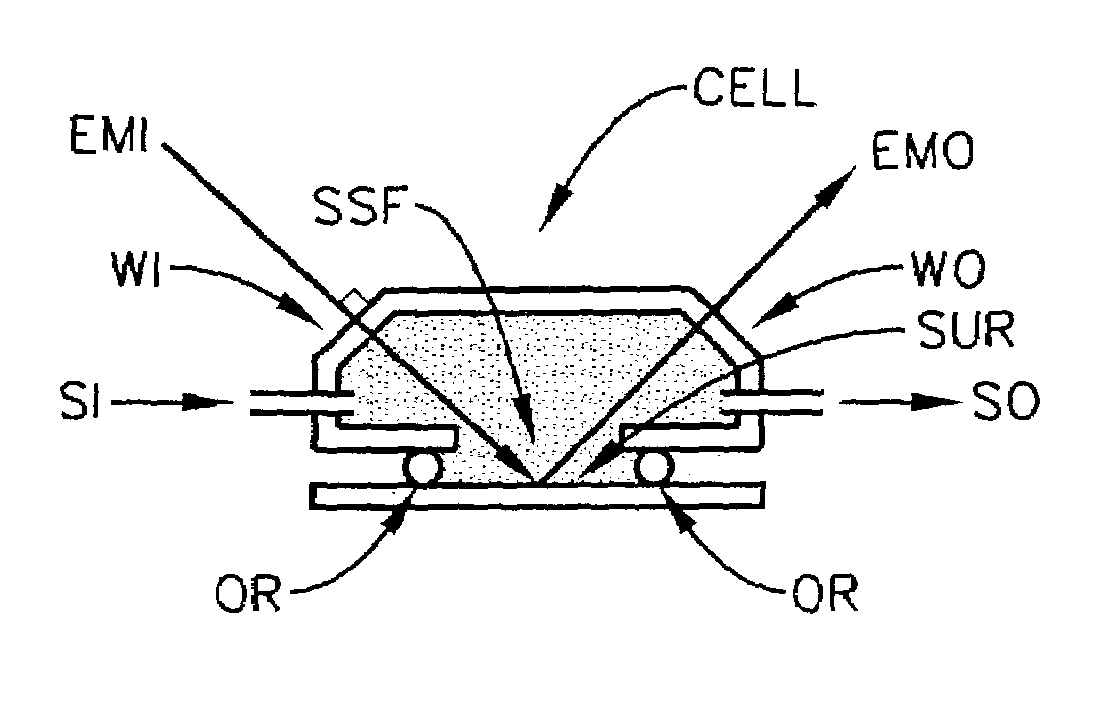

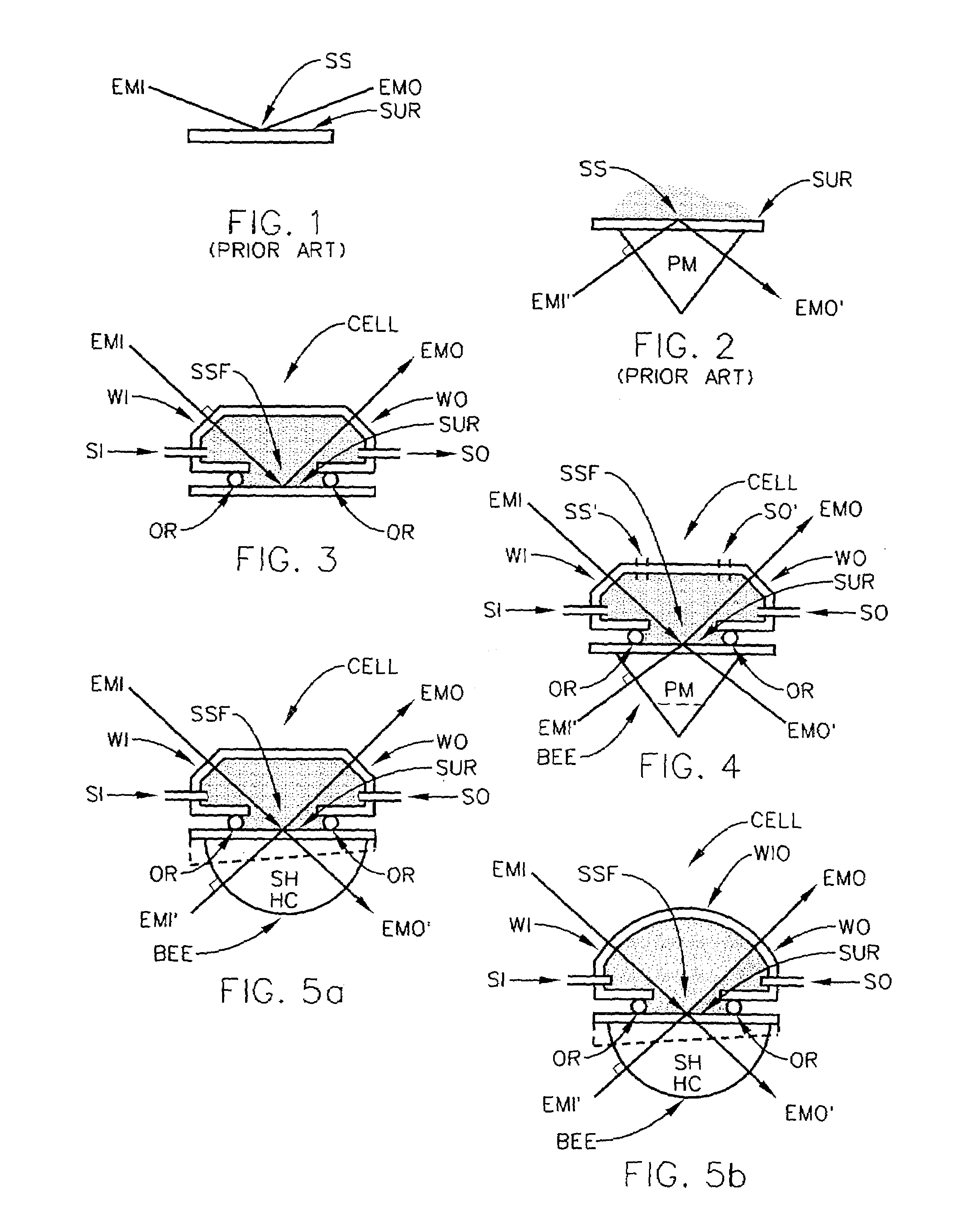

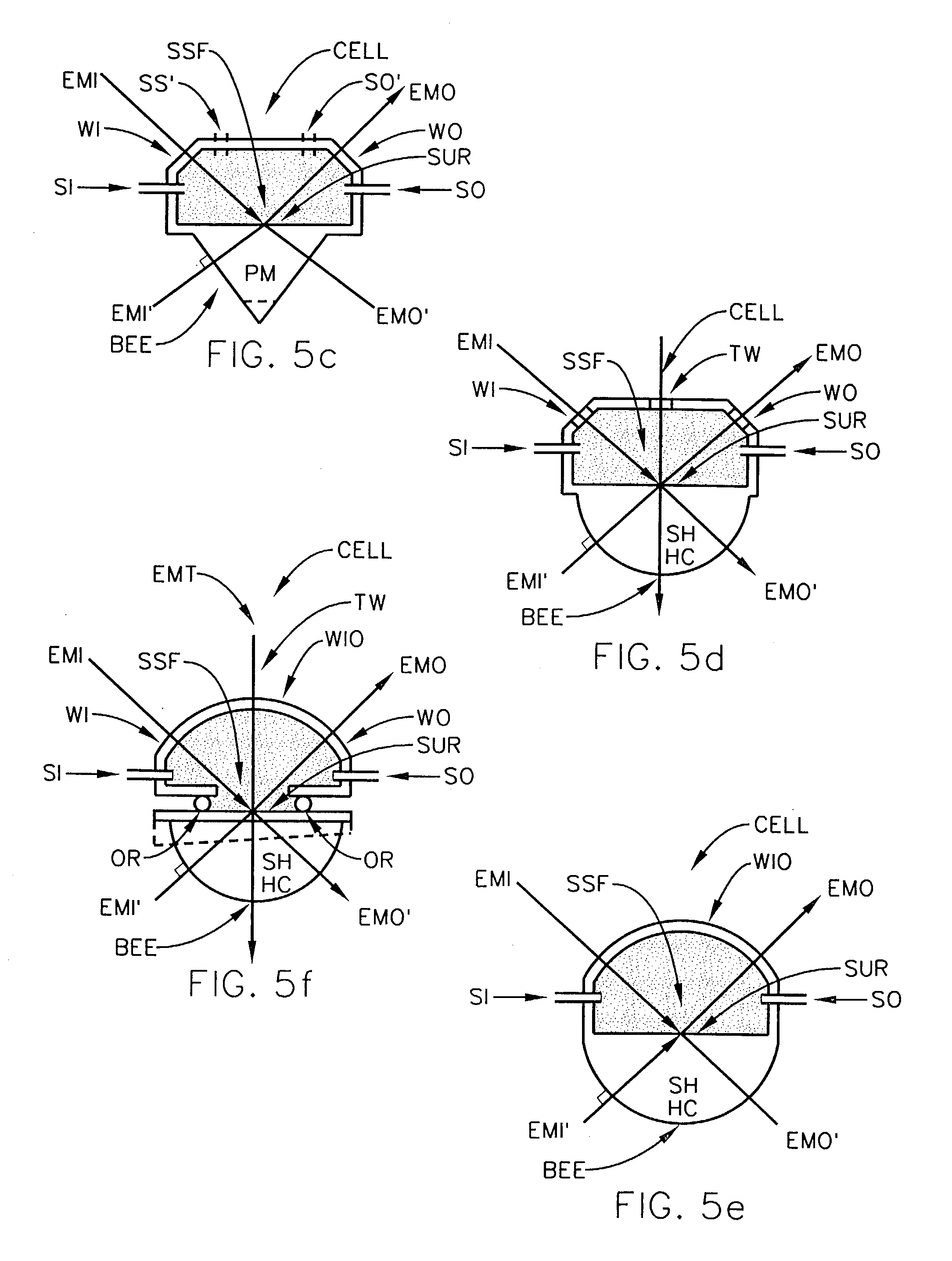

System and method enabling simultaneous investigation of sample with two beams of electromagnetic radiation

InactiveUS6937341B1Polarisation-affecting propertiesLight polarisation measurementCoated surfaceAngle of incidence

Disclosed are system and method for characterizing a system consisting of a fluid sample on a two sided stage, utilizing data obtained by applying, from both sides thereof, beams of electromagnetic radiation to a fluid coated surface in a containing cell volume. The beams can have the same or different wavelength content and / or polarization state, and can be applied at the same or different magnitude angles-of-incidence, and a third typically unpolarized beam can be applied at a normal angle-of-incidence.

Owner:J A WOOLLAM CO

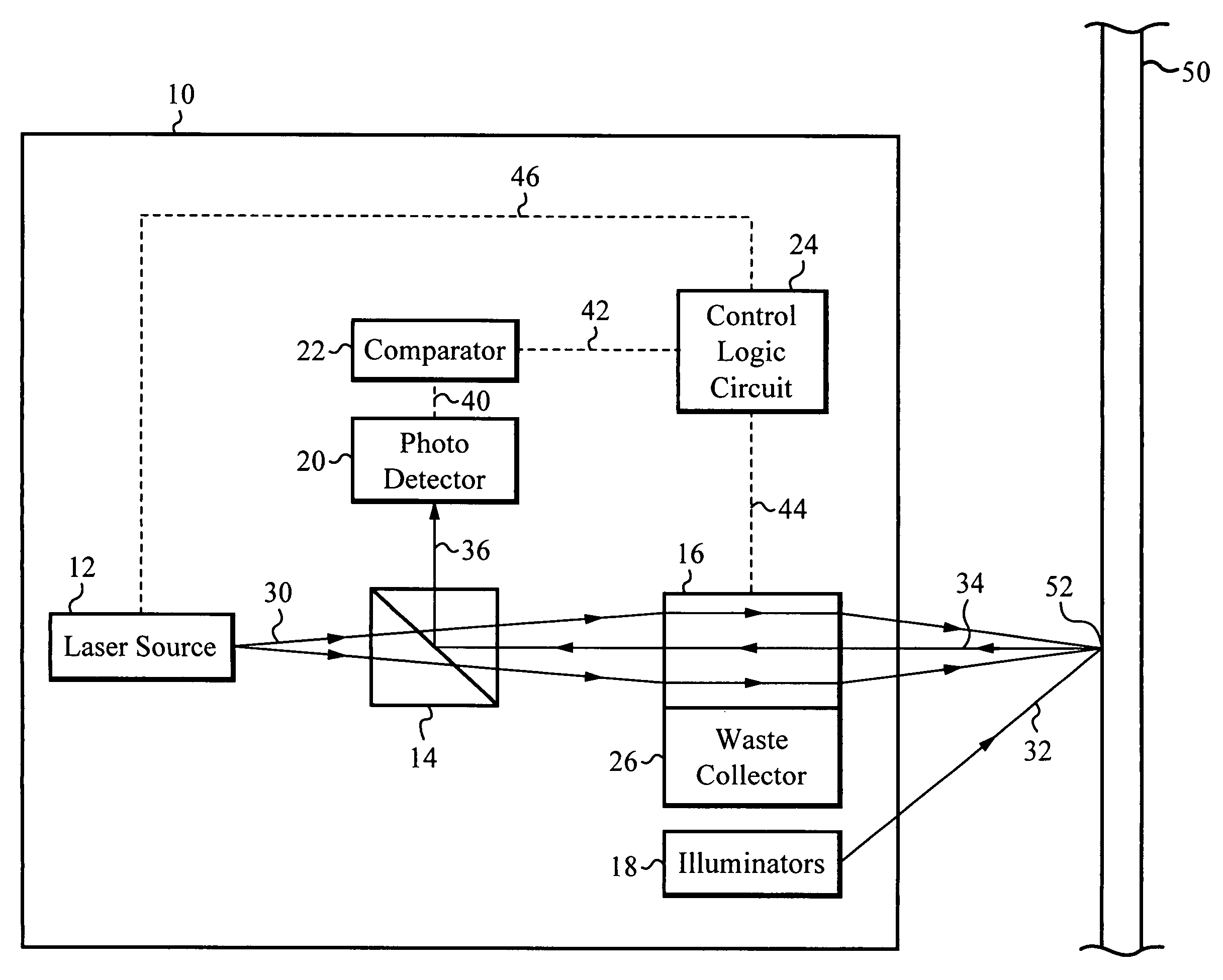

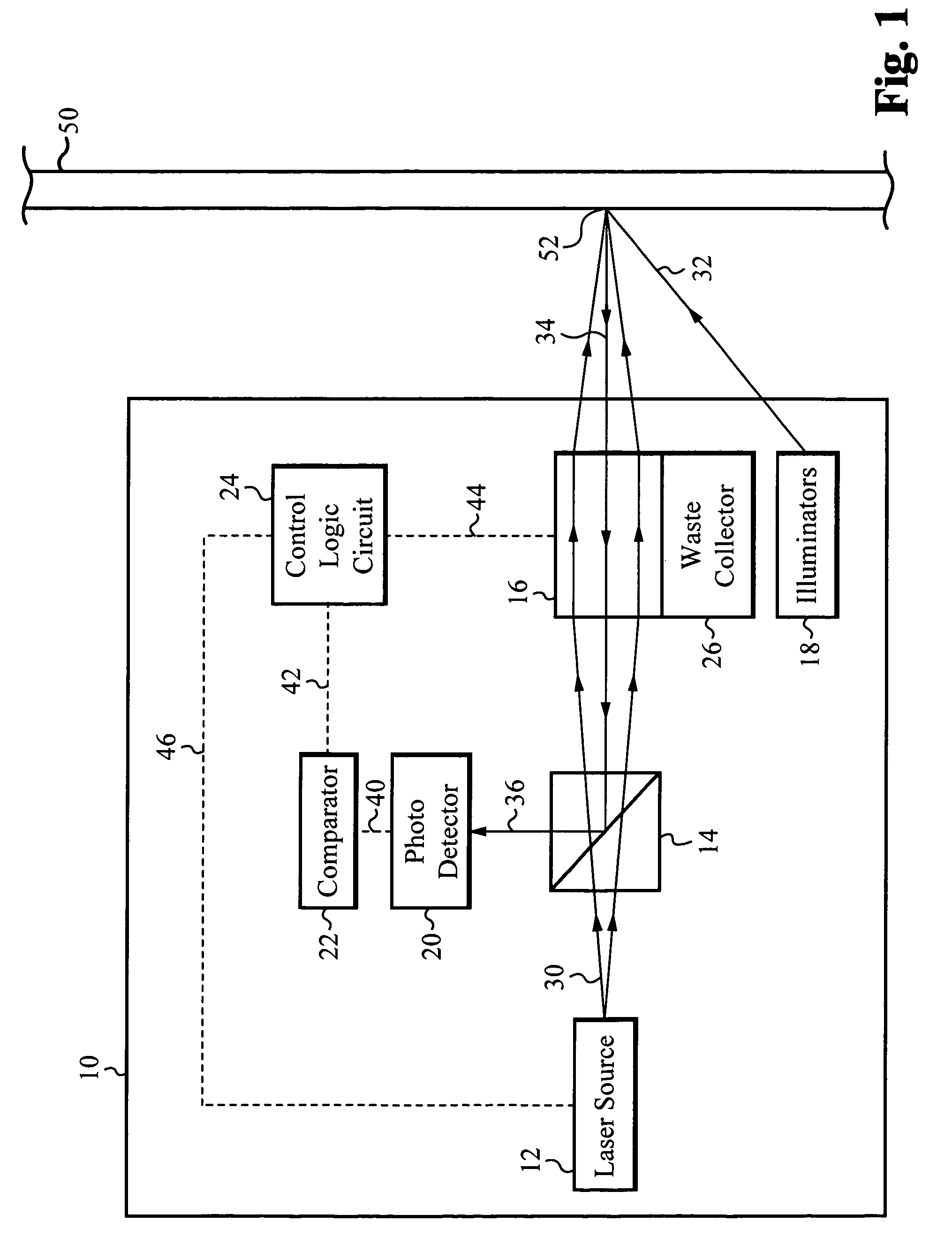

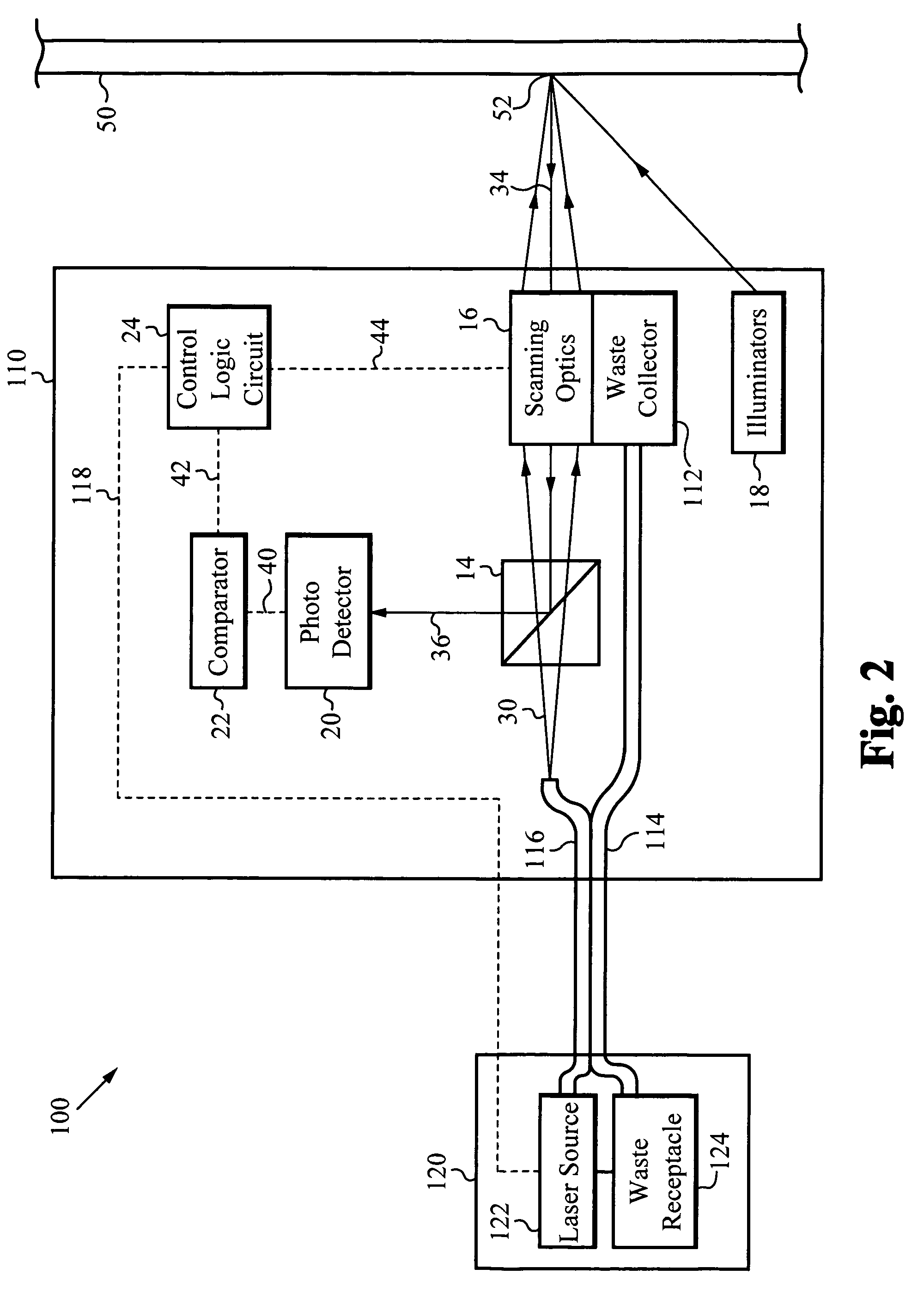

Color sensing for laser decoating

A coating removal apparatus utilizing a common optics path to provide laser pulses to a coated surface and to direct a light illumination reflected from the coated surface to a photosensitive detector and analyzer. The apparatus is an integrated device including a laser source, a beam splitter, scanning optics, a waste removal apparatus, one or more light illuminators, a photosensitive detector, a comparator, and a control logic circuit. Alternatively, the laser source is external to the integrated device and a fiber optic cable is used to connect the laser source to the integrated device.

Owner:GEN LASERTRONICS

Functionalized nanoparticles and method

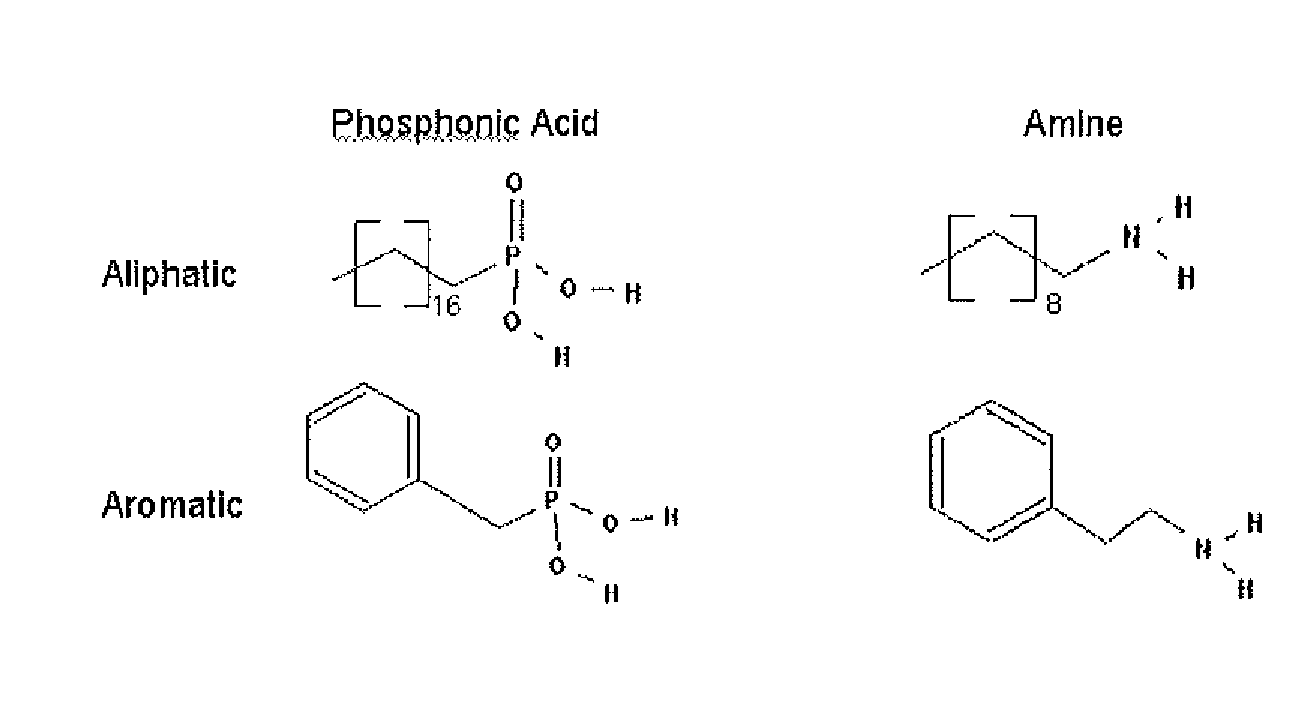

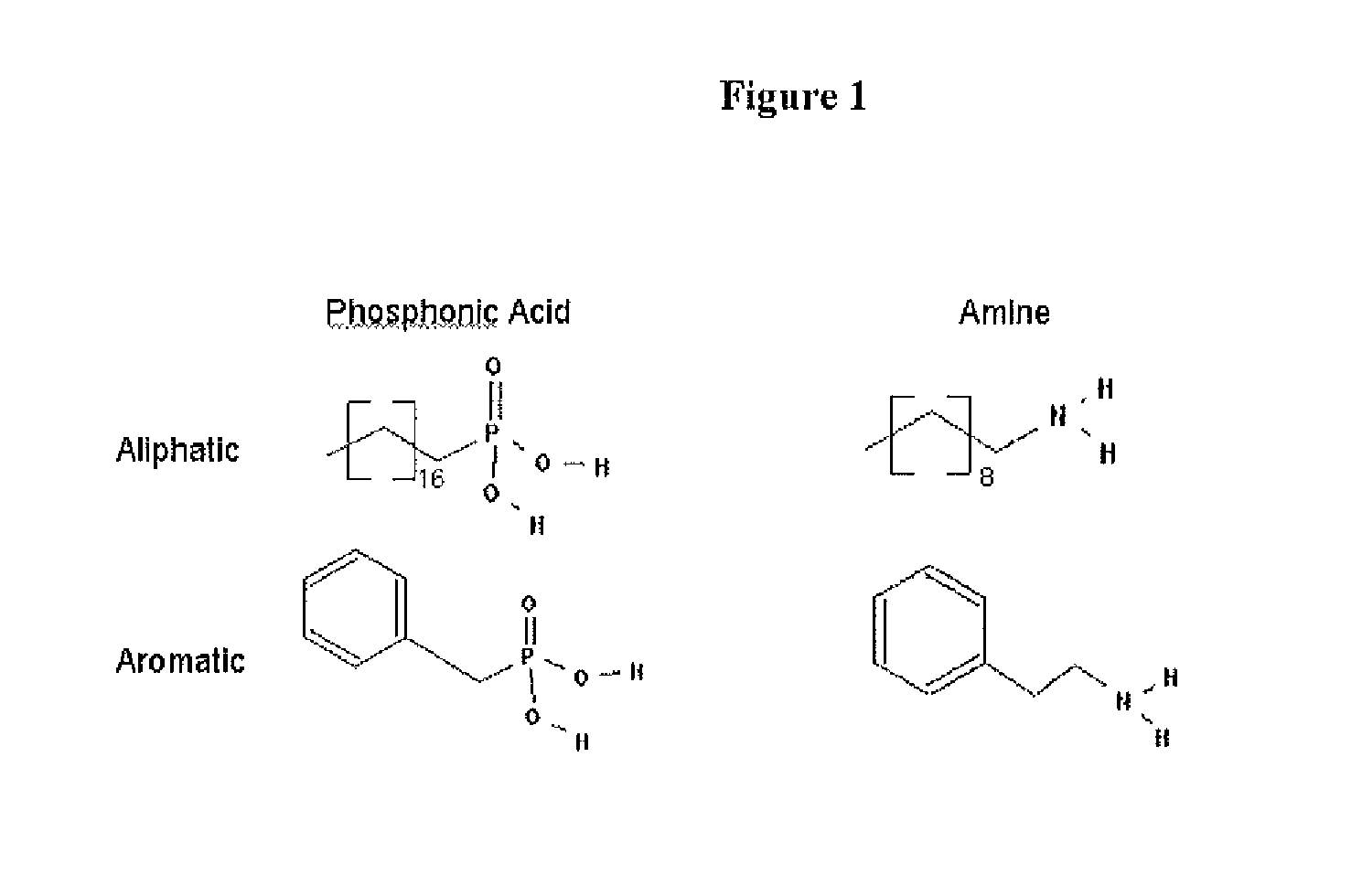

ActiveUS20100283014A1Material nanotechnologyPolycrystalline material growthSemiconductor materialsChemical reaction

A nanoparticle including an inorganic core comprising at least one metal and / or at least one semi-conductor compound comprising at least one metal includes a coating or shell disposed over at least a portion of a surface of the core. The coating can include one or more layers. Each layer of the coating can comprise a metal and / or at least one semiconductor compound. The nanoparticle further includes a ligand attached to a surface of the coating. The ligand is represented by the formula: X-Sp-Z, wherein X represents, e.g., a primary amine group, a secondary amine group, a urea, a thiourea, an imidizole group, an amide group, a phosphonic or arsonic acid group, a phosphinic or arsinic acid group, a phosphate or arsenate group, a phosphine or arsine oxide group; Sp represents a spacer group, such as a group capable of allowing a transfer of charge or an insulating group; and Z represents: (i) reactive group capable of communicating specific chemical properties to the nanocrystal as well as provide specific chemical reactivity to the surface of the nanocrystal, and / or (ii) a group that is cyclic, halogenated, or polar a-protic. In certain embodiments, at least two chemically distinct ligands are attached to an surface of the coating, wherein the at least two ligands (I and II) are represented by the formula: X-Sp-Z. In ligand (I) X represents a phosphonic, phosphinic, or phosphategroup and in ligand (II) X represents a primary or secondary amine, or an imidizole, or an amide; In both ligands (I) and (II) Sp, which can be the same or different in the two compounds, represents a spacer group, such as a group capable of allowing a transfer of charge or an insulating group; Z, which can be the same or different in the two compounds, is a group chosen from among groups capable of communicating specific chemical properties to the nanoparticle as well as provide specific chemical reactivity to the surface of the nanoparticle. In preferred embodiments, the nanoparticle includes a core comprising a semiconductor material.

Owner:SAMSUNG ELECTRONICS CO LTD

Magnetic tape

ActiveUS20190027175A1Improve surface smoothnessAvoid it happening againRecord information storageTape carriersIn planeX-ray

The magnetic tape includes a magnetic layer including ferromagnetic powder, non-magnetic powder, and a binding agent and a back coating layer including non-magnetic powder and a binding agent, in which the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, a center line average surface roughness measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, an intensity ratio of a peak intensity of a diffraction peak of a (110) plane with respect to a peak intensity of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic tape is 0.65 to 1.00, and a contact angle with respect to 1-bromonaphthalene measured regarding a surface of the back coating layer is 15.0° to 30.0°.

Owner:FUJIFILM CORP

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

Magnetic tape

ActiveUS20190027180A1Improve surface smoothnessAvoid it happening againMagnetic materials for record carriersRecord information storageIn planeX-ray

The magnetic tape includes a magnetic layer including ferromagnetic powder, non-magnetic powder, and a binding agent and a back coating layer including non-magnetic powder and a binding agent, in which the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, an intensity ratio of a peak intensity of a diffraction peak of a (110) plane with respect to a peak intensity of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic tape is 0.65 to 1.00, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding a surface of the hack coating layer is equal to or smaller than 0.060.

Owner:FUJIFILM CORP

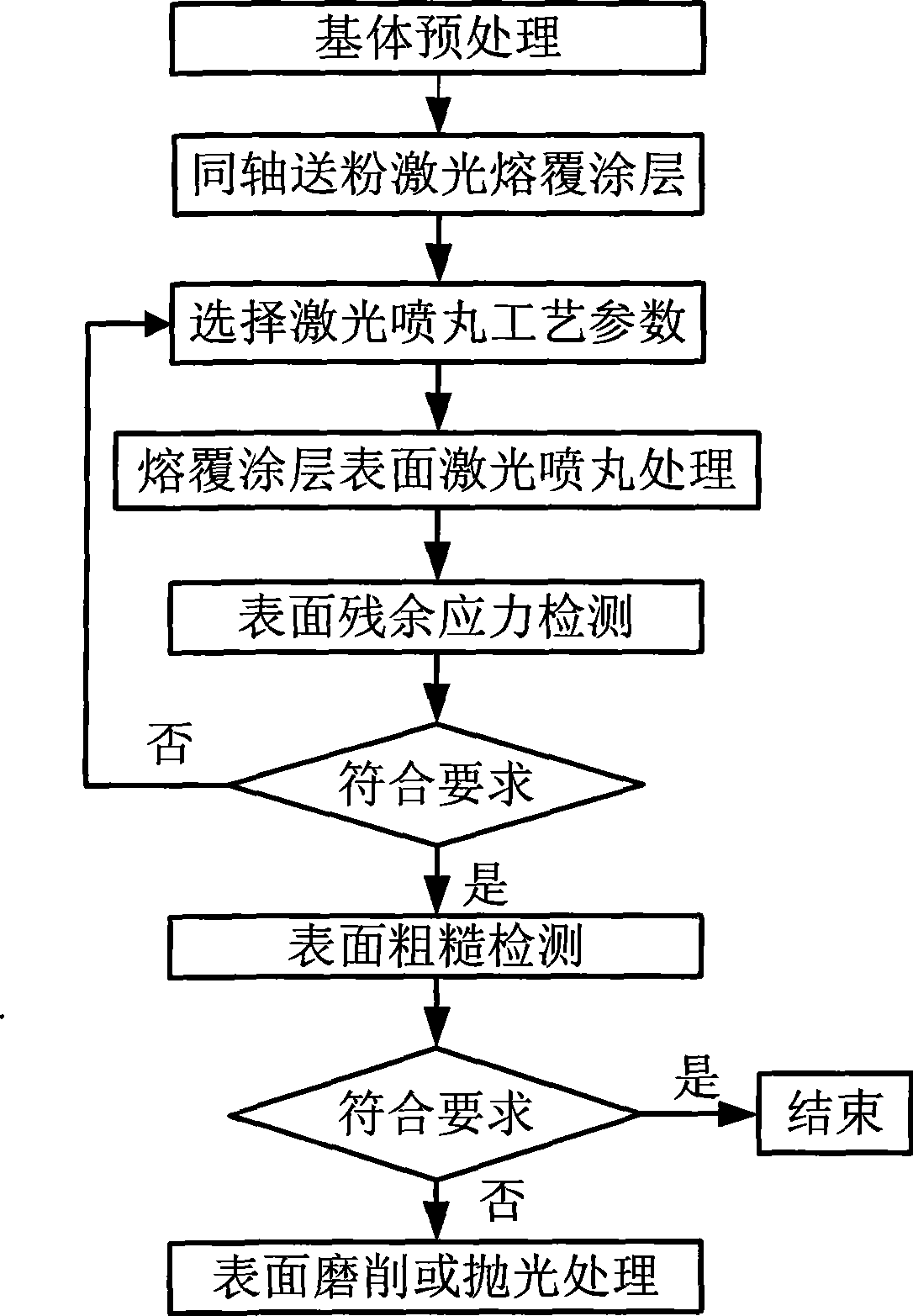

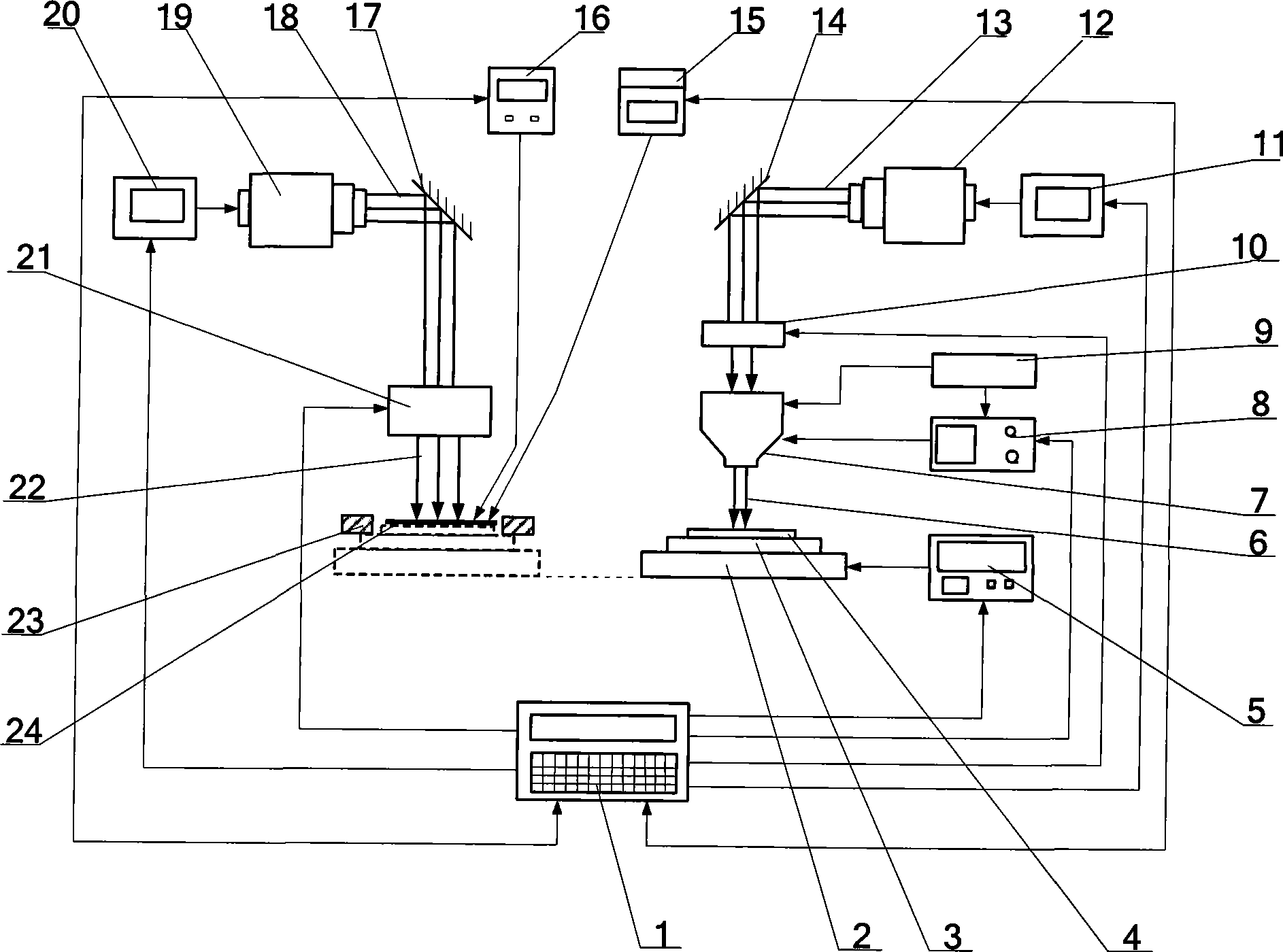

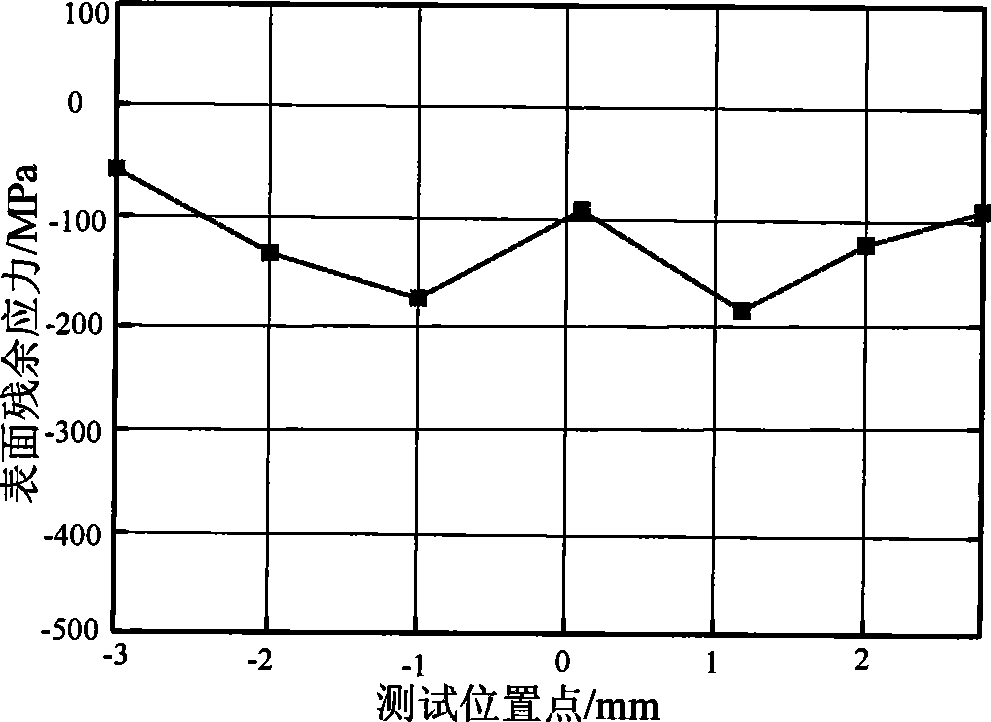

Method and device for strengthening surface modification by combination of laser cladding and laser peening

InactiveCN101392382AQuality improvementResidual stress distribution state changesMetallic material coating processesCoated surfaceSurface roughness

The invention provides a method for modifying a composite surface based on laser cladding and combining laser shock peening, and a device thereof. The method provided by the invention is characterized in that a coaxial and powder feeding type fast axial flow CO2 laser cladding unit clads a layer of coating on the surface of a substrate; then a neophane glass impulse laser shock peening unit is used for the shock peening on the surface of the cladded coating; a measurement feedback system is utilized to detect the surface roughness and the distribution state of residual stress of the cladded coating; the precise control over the surface roughness and the residual stress of the coating is realized by a central control and processing system so as to obtain a high quality surface-cladded coating with good performance. The device comprises the coaxial and powder feeding type laser cladding unit, the laser shock peening unit, a digital control working system, the measurement feedback system and the central control and processing system, and is under integrated control by a computer. The method and the device of the invention can reduce residual tensile stress and improve the quality of the cladded coating and prolong the service life thereof.

Owner:JIANGSU UNIV

Photocatalytically-activated self-cleaning appliances

InactiveUS6054227ASelf-cleaning stoves/rangesLiquid surface applicatorsCoated surfaceSufficient time

An appliance is rendered self-cleaning of accumulated organic contaminants on one or more surfaces of the appliance, by coating such surfaces of the appliance with a photocatalytically-activated self-cleaning coating. Upon exposing such coated surfaces to radiation of the appropriate wavelength, for a sufficient interval of time, at least a portion of the organic contaminants present on the photocatalytically-activated self-cleaning coating are removed. The coated surface is thereby cleaned without the need of manual effort or high temperatures. The radiation is generally actinic radiation, and more particularly includes ultraviolet radiation.

Owner:PPG IND OHIO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com