Patents

Literature

6457 results about "Digital control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital control is a branch of control theory that uses digital computers to act as system controllers. Depending on the requirements, a digital control system can take the form of a microcontroller to an ASIC to a standard desktop computer. Since a digital computer is a discrete system, the Laplace transform is replaced with the Z-transform. Also since a digital computer has finite precision (See quantization), extra care is needed to ensure the error in coefficients, A/D conversion, D/A conversion, etc. are not producing undesired or unplanned effects.

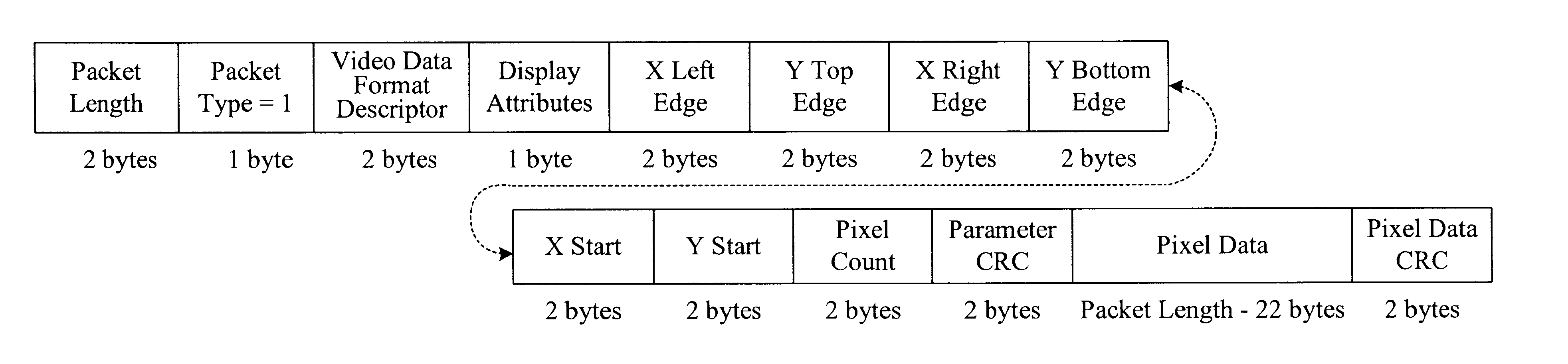

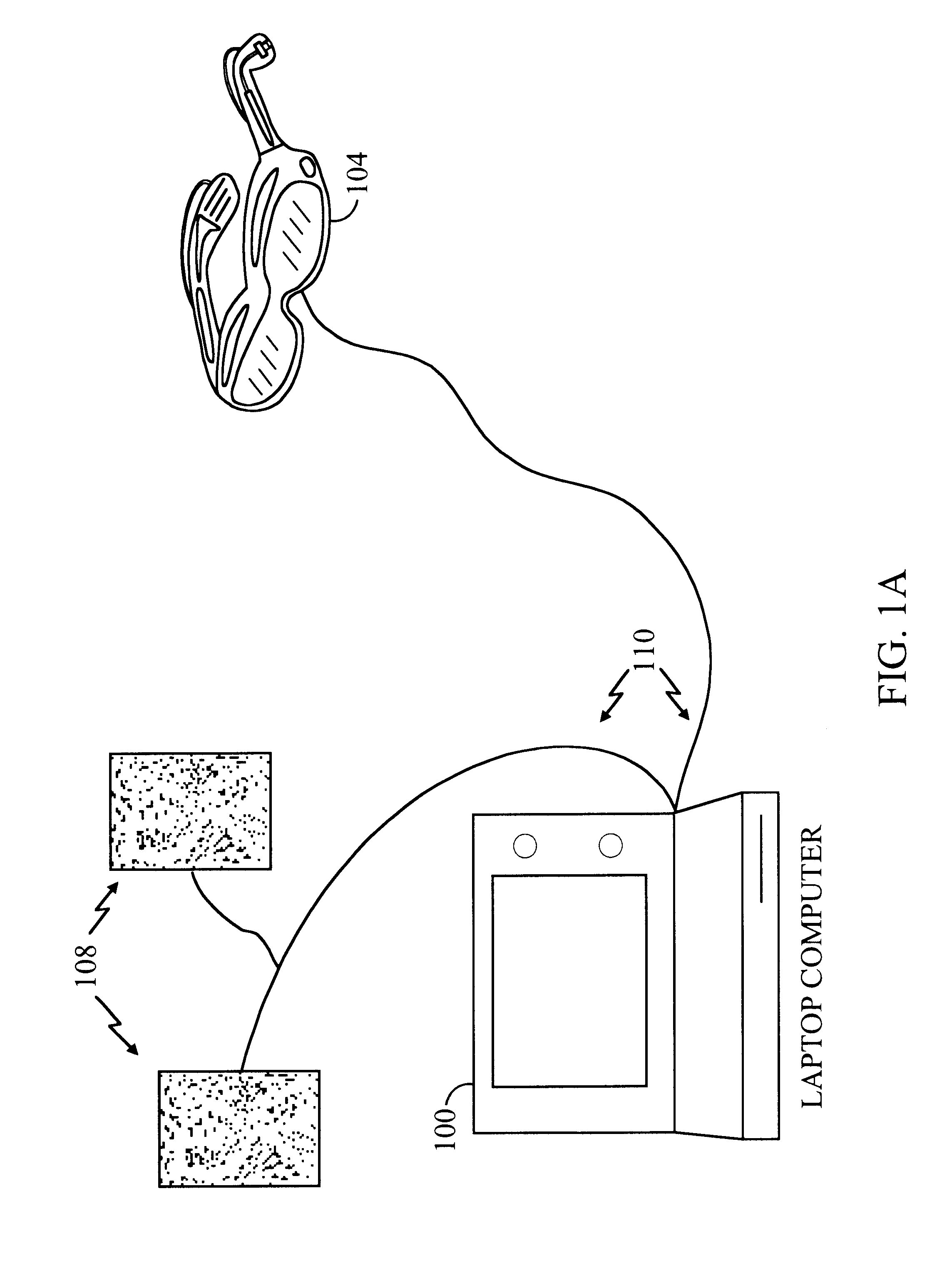

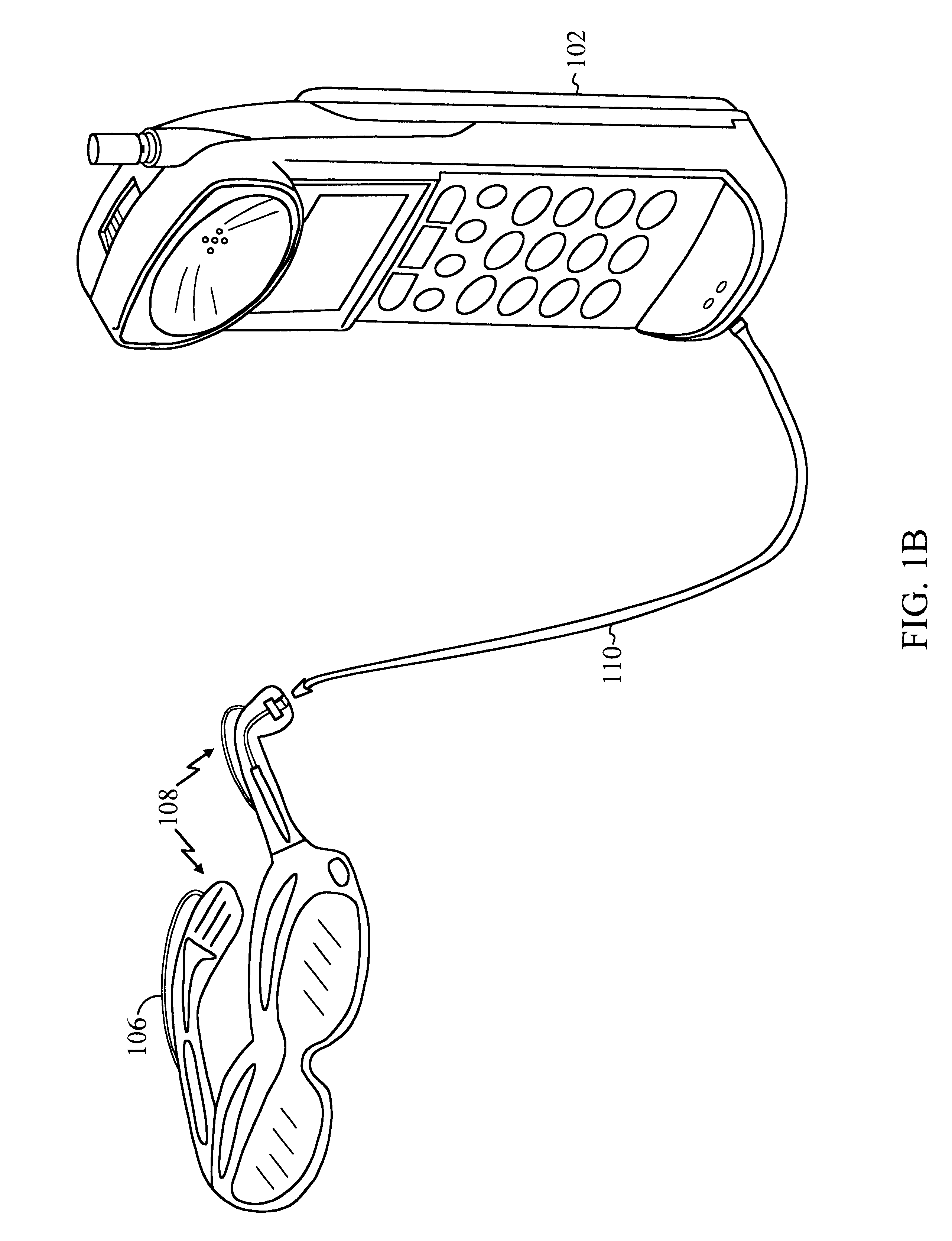

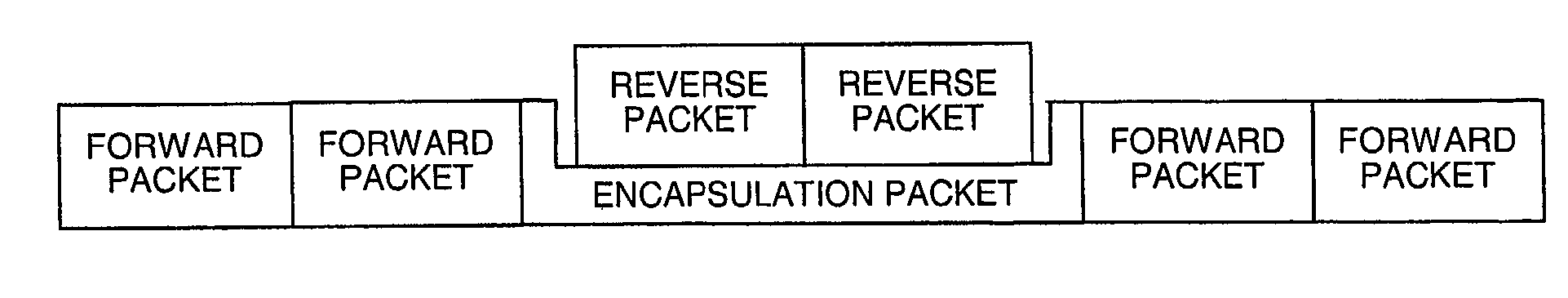

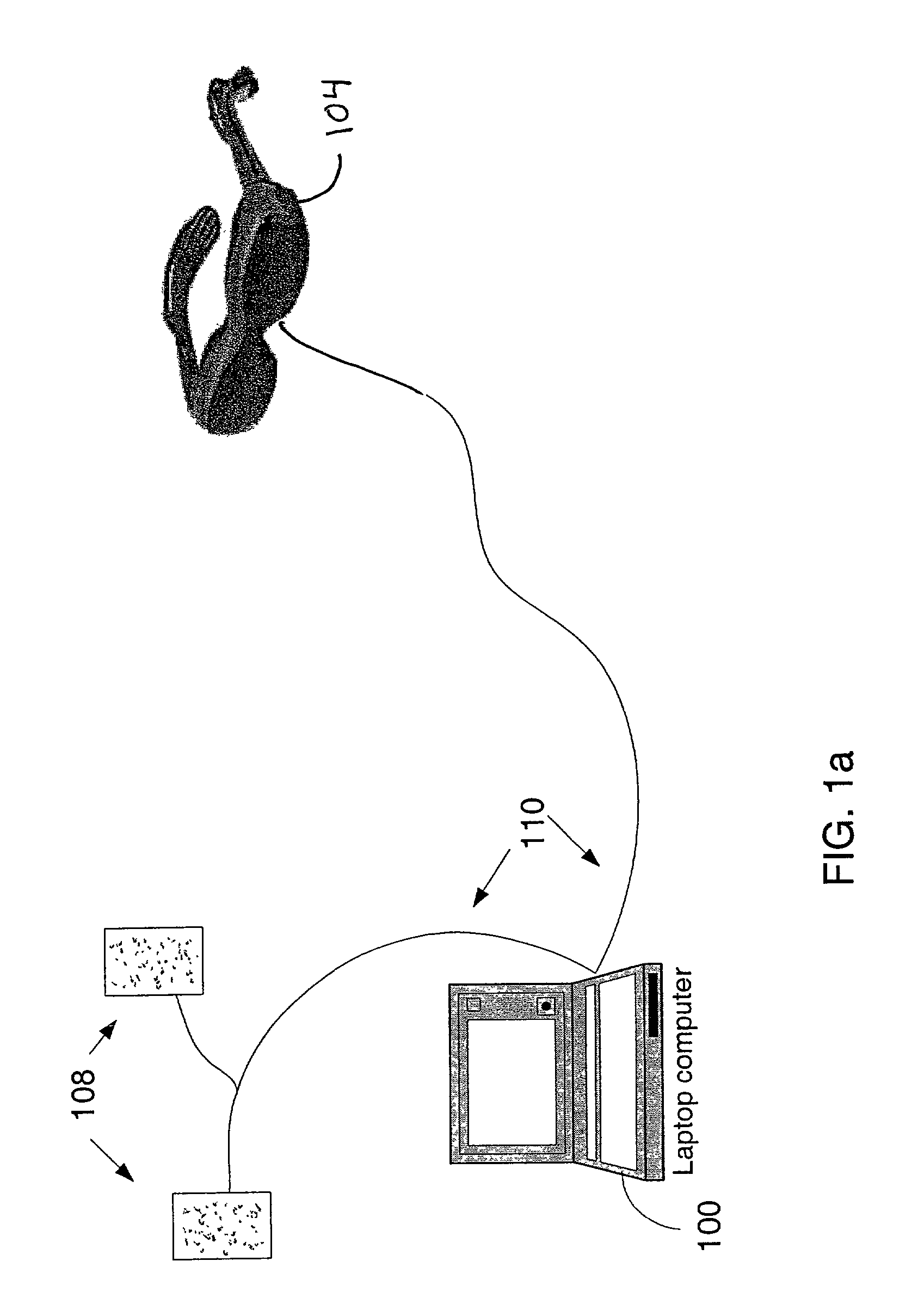

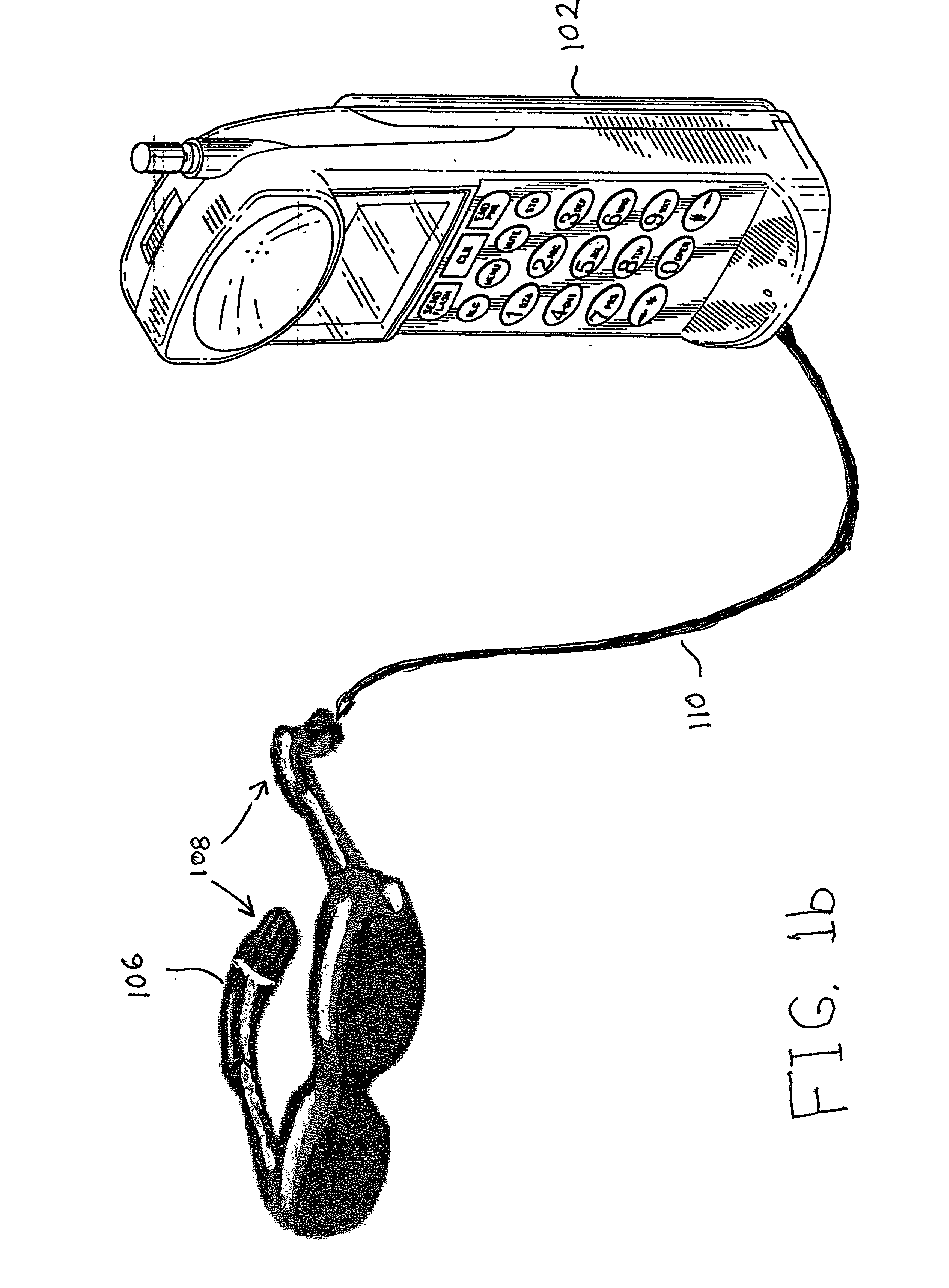

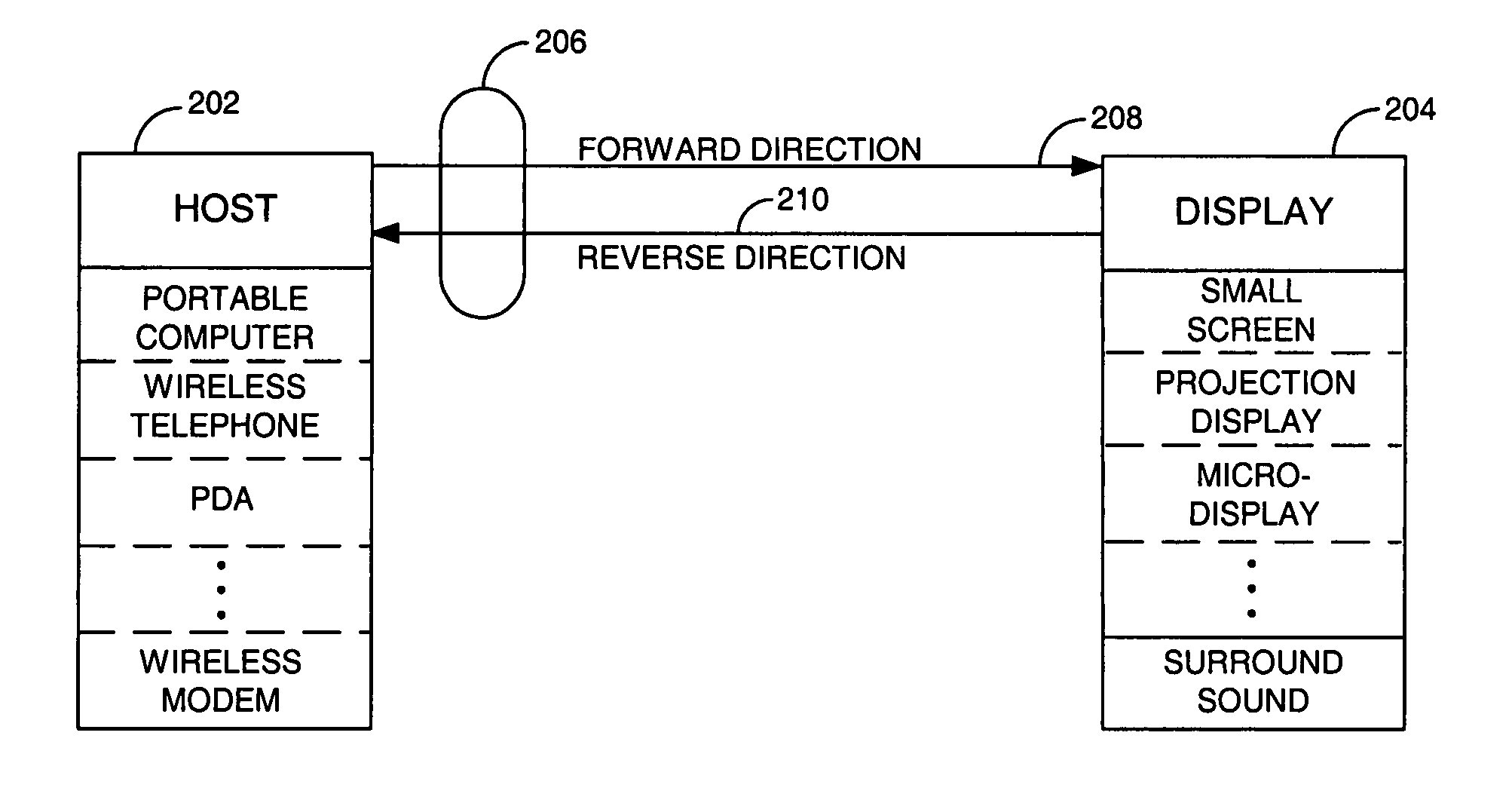

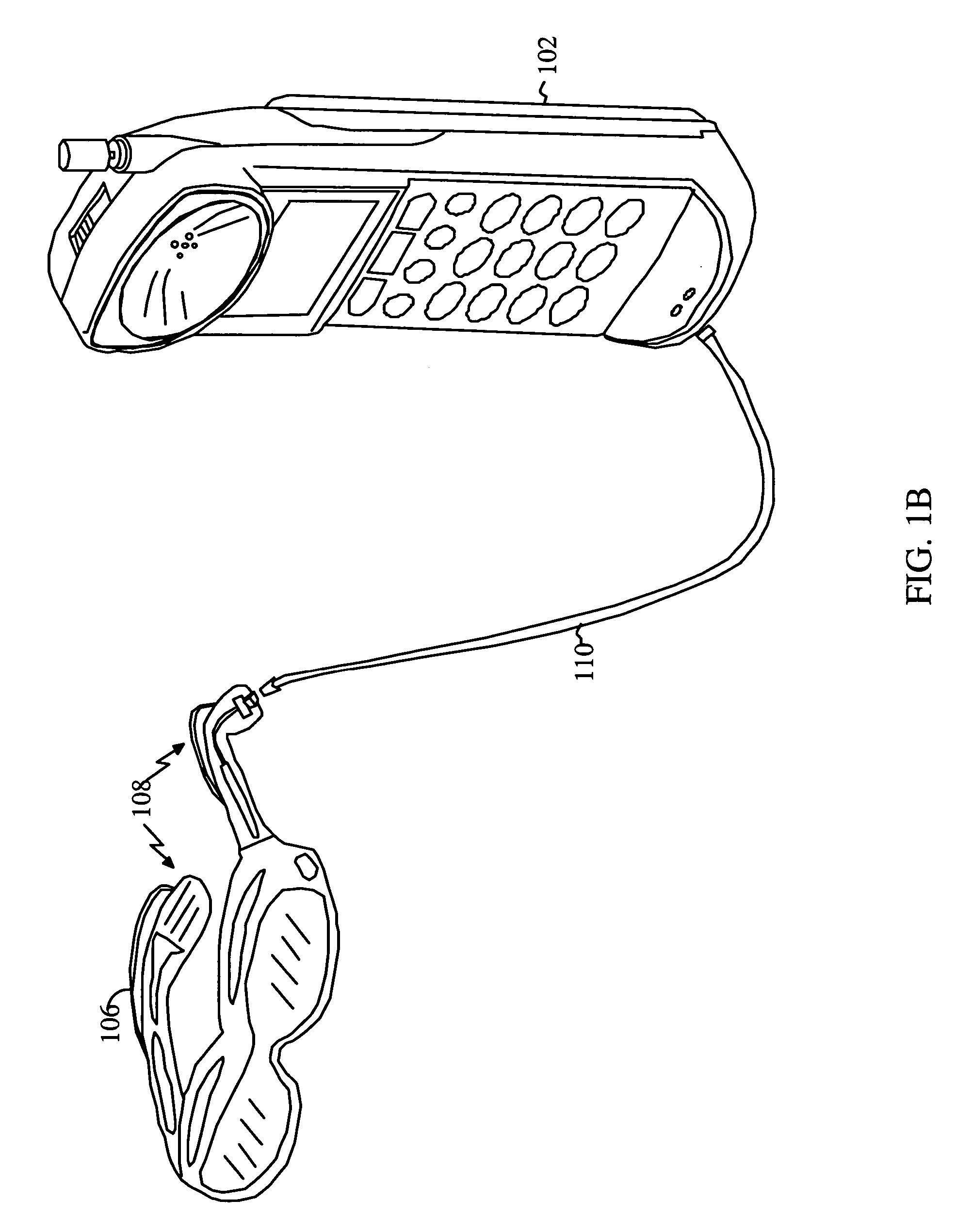

Generating and implementing a communication protocol and interface for high data rate signal transfer

A data Interface for transferring digital data between a host and a client over a communication path using packet structures linked together to form a communication protocol for communicating a pre-selected set of digital control and presentation data. The signal protocol is used by link controllers configured to generate, transmit, and receive packets forming the communications protocol, and to form digital data into one or more types of data packets, with at least one residing in the host device and being coupled to the client through the communications path. The interface provides a cost-effective, low power, bi-directional, high-speed data transfer mechanism over a short-range "serial" type data link, which lends itself to implementation with miniature connectors and thin flexible cables which are especially useful in connecting display elements such as wearable micro-displays to portable computers and wireless communication devices.

Owner:QUALCOMM INC

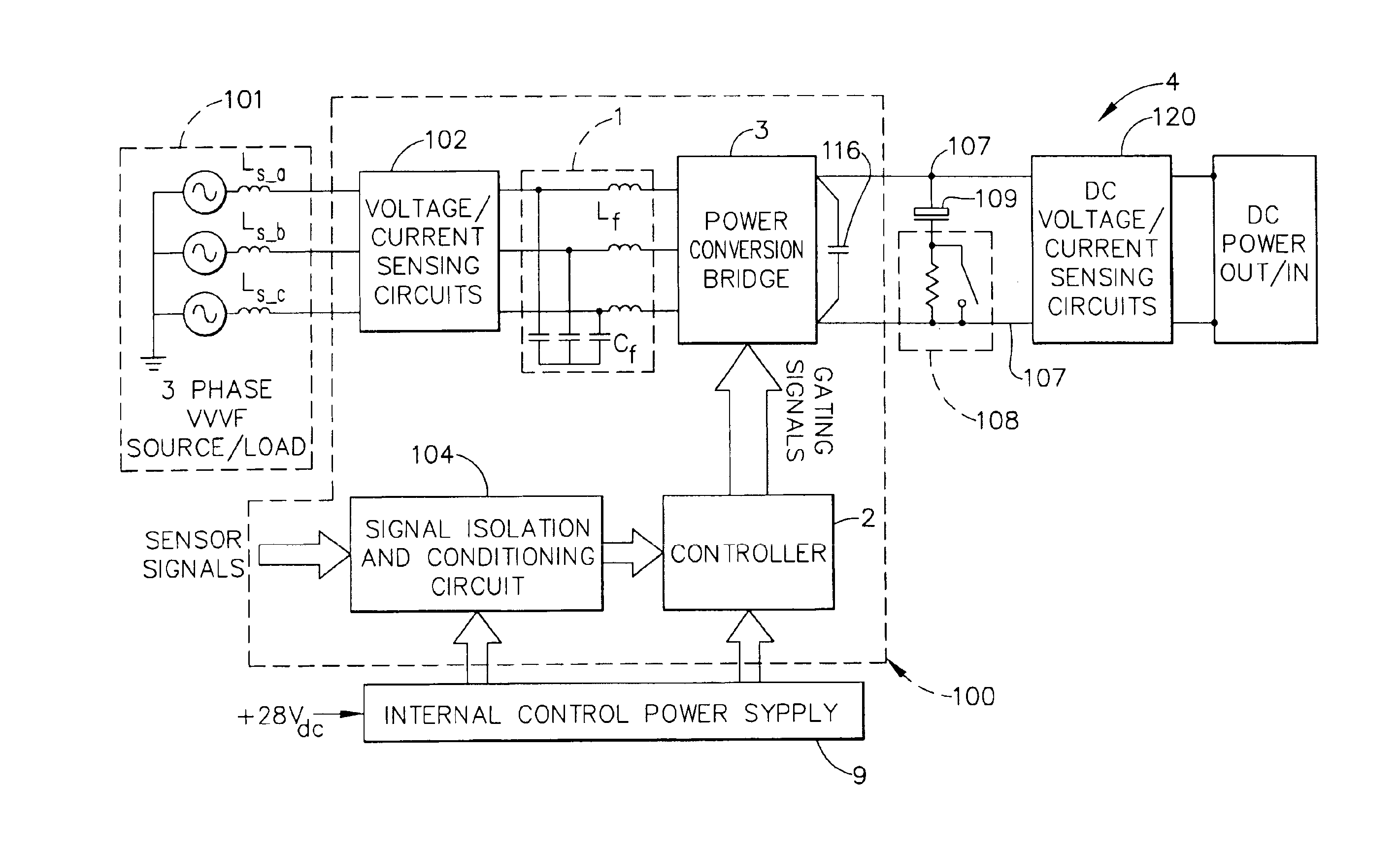

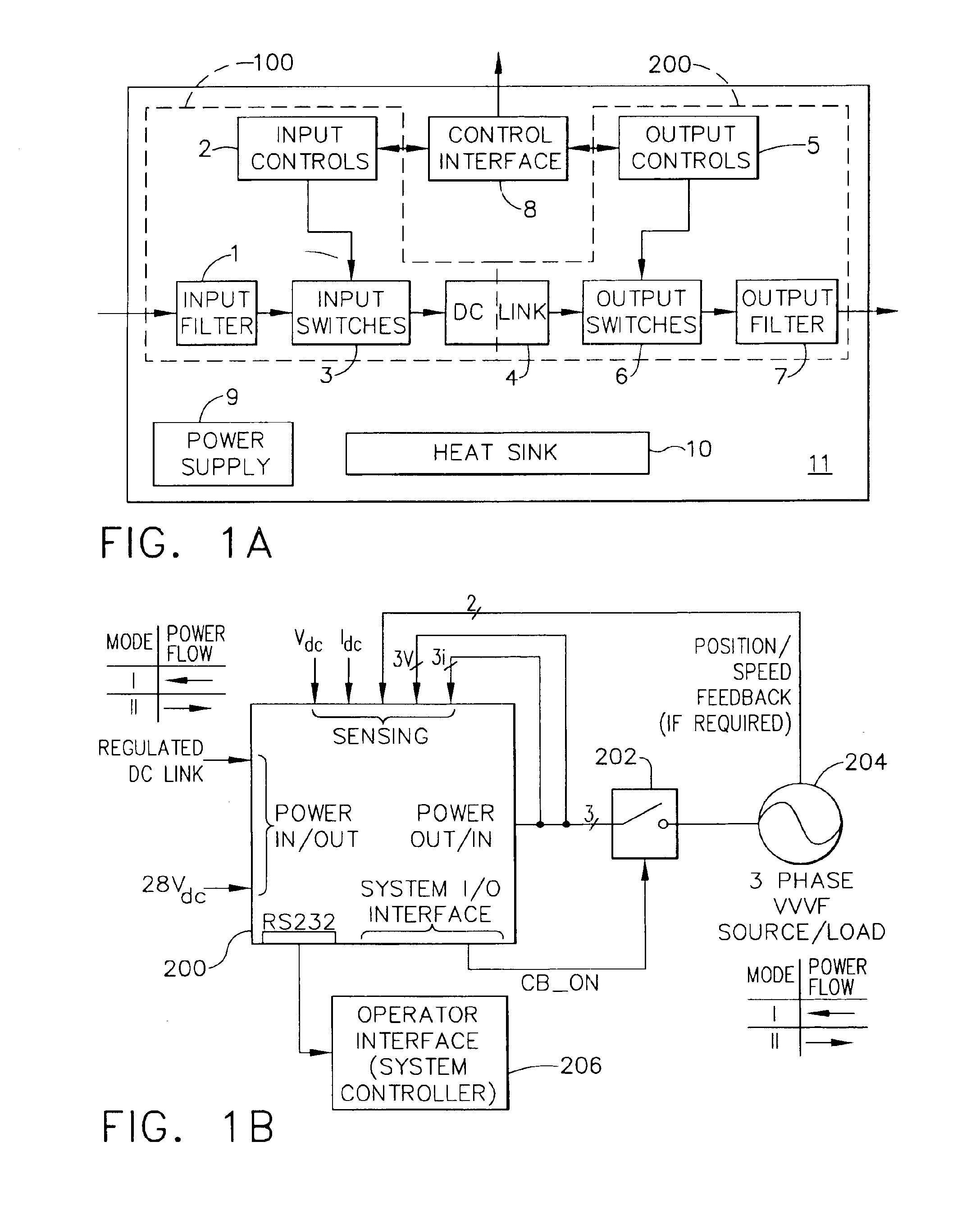

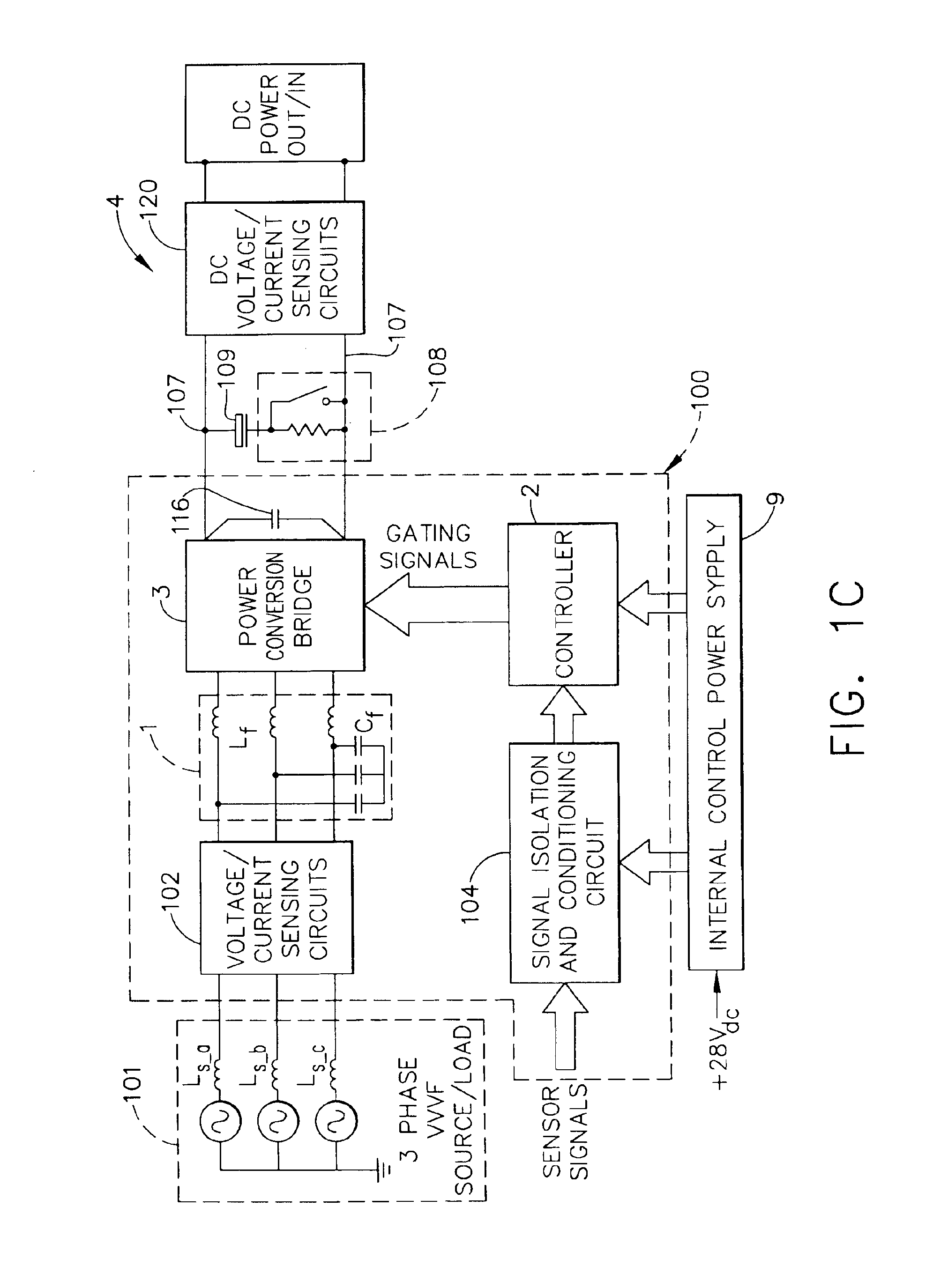

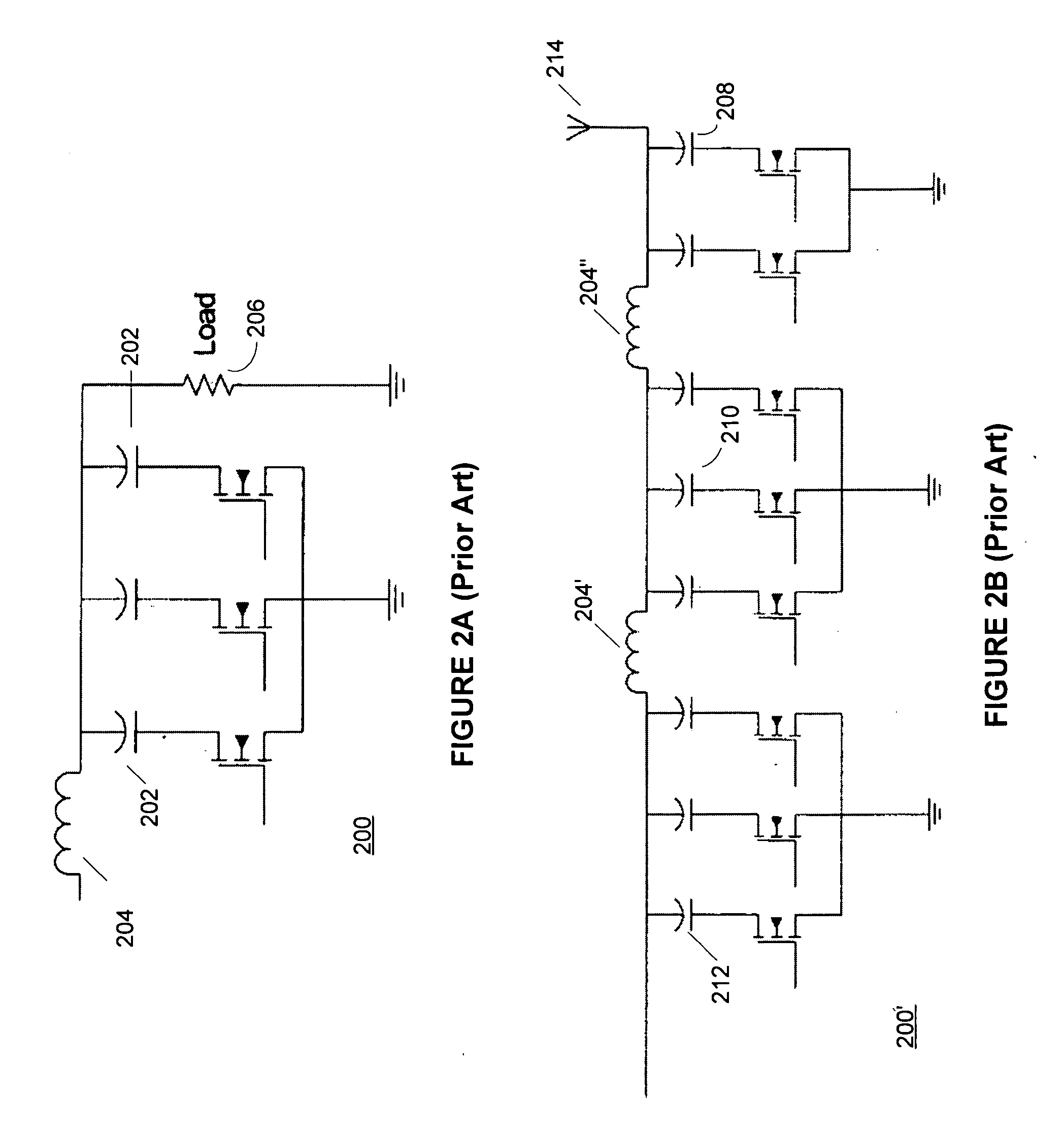

Synchronous and bi-directional variable frequency power conversion systems

InactiveUS6850426B2Facilitate easeLow costAc-dc conversion without reversalDc-dc conversionDigital controlAC power

A synchronous bi-directional active power conditioning system (11) suitable for wide variable frequency systems or active loads such as adjustable speed drives which require variable voltage variable frequency power management systems is disclosed. Common power electronics building blocks (100, 200) (both hardware and software modular blocks) are presented which can be used for AC-DC, DC-AC individually or cascaded together for AC-DC-AC power conversion suitable for variable voltage and / or wide variable frequency power management systems. A common control software building block (2, 5) includes a digital control strategy / algorithm and digital phase lock loop method and apparatus which are developed and implemented in a digital environment to provide gating patterns for the switching elements (3, 6) of the common power-pass modular power electronics building blocks (100, 200).

Owner:HONEYWELL INT INC

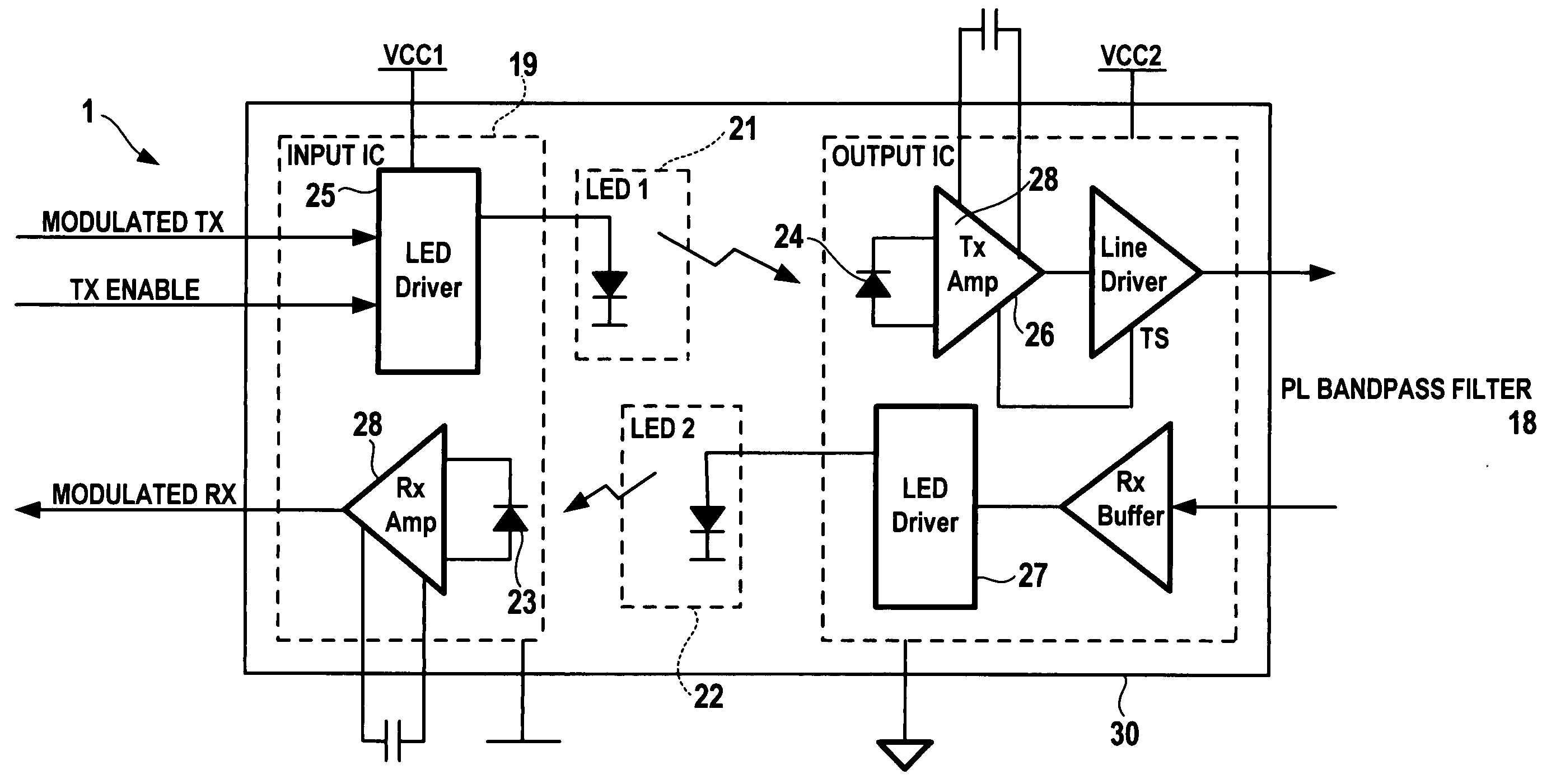

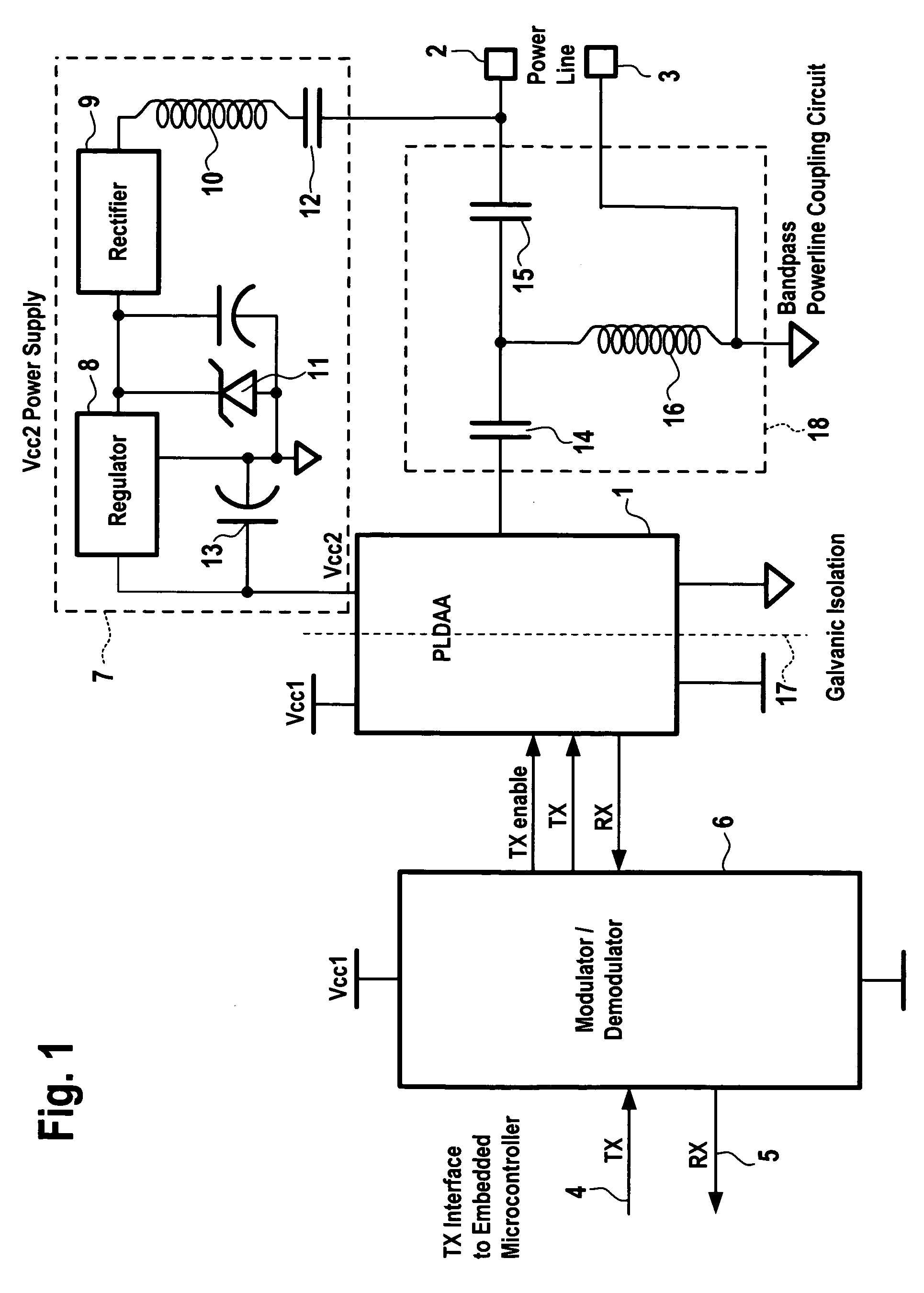

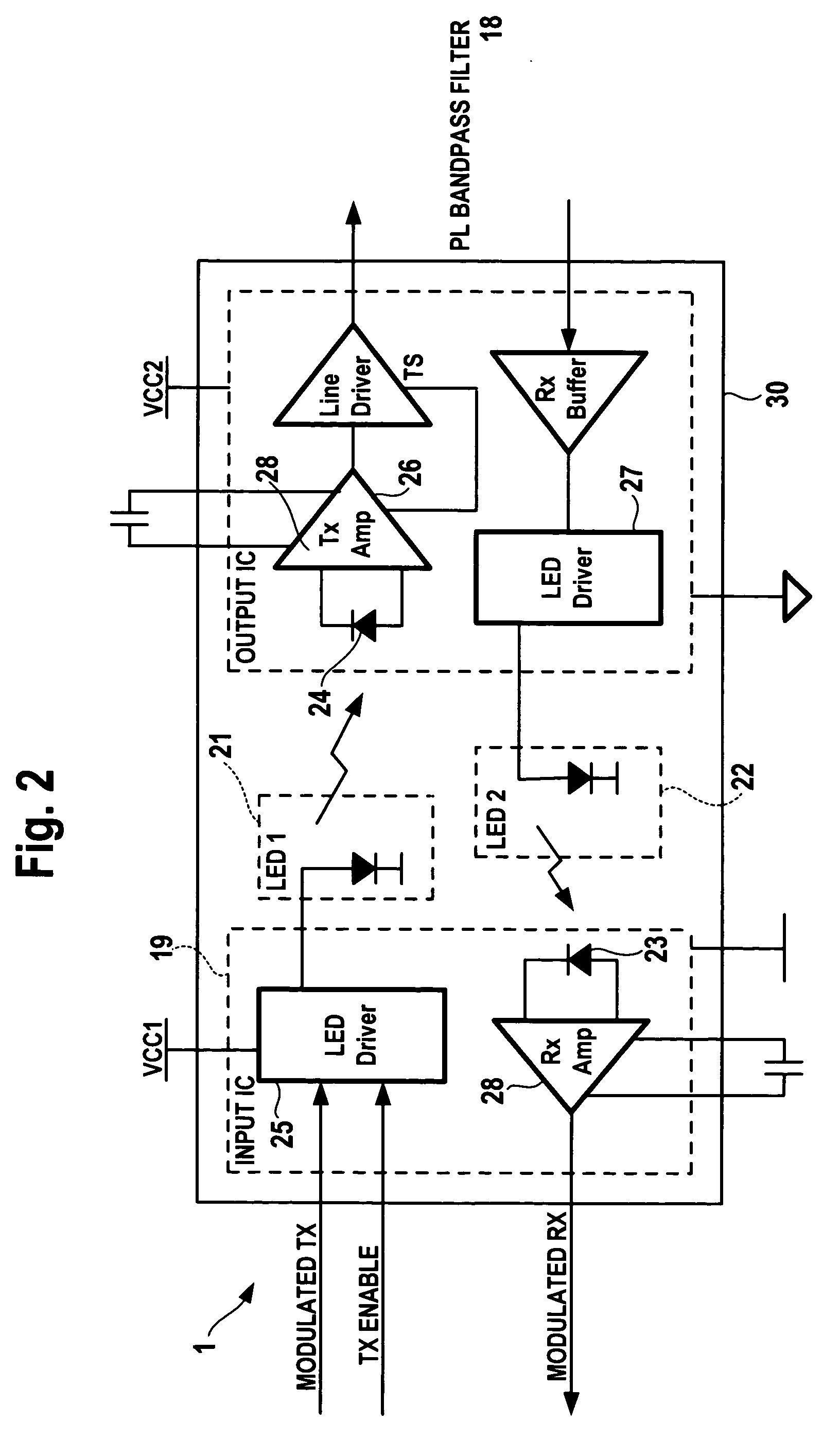

Coupling circuit arrangement for data communication over power lines

InactiveUS20050069321A1Effective preventionSave design spaceElectric signal transmission systemsFrequency-division multiplex detailsControl signalData signal

A coupling circuit arrangement for data communication over a power line comprises a modulator / demodulator circuit for modulating data signals for transmission over the power line, and for demodulating signals which have been transmitted over the power line into data signals, a power supply circuit, and isolation means for providing galvanic isolation from the power line. The isolation means comprises light emitting elements and light detecting elements, which are arranged between the modulator / demodulator circuit and the power line. The isolation means may also be used to transmit a digital control signal which indicates the status of the power supply circuit or an over-temperature condition, or which is a transmit enable signal. The digital control signal may be encoded in the analog data signal by a digital shift in the DC bias level or by a complete removal of the DC biasing signal.

Owner:AVAGO TECH INT SALES PTE LTD

Generating and implementing a communication protocol and interface for high data rate signal transfer

A data Interface for transferring digital data between a host and a client over a communication path using packet structures linked together to form a communication protocol for communicating a pre-selected set of digital control and presentation data. The signal protocol is used by link controllers configured to generate, transmit, and receive packets forming the communications protocol, and to form digital data into one or more types of data packets, with at least one residing in the host device and being coupled to the client through the communications path. The interface provides a cost-effective, low power, bi-directional, high-speed data transfer mechanism over a short-range "serial" type data link, which lends itself to implementation with miniature connectors and thin flexible cables which are especially useful in connecting display elements such as wearable micro-displays to portable computers and wireless communication devices.

Owner:QUALCOMM INC

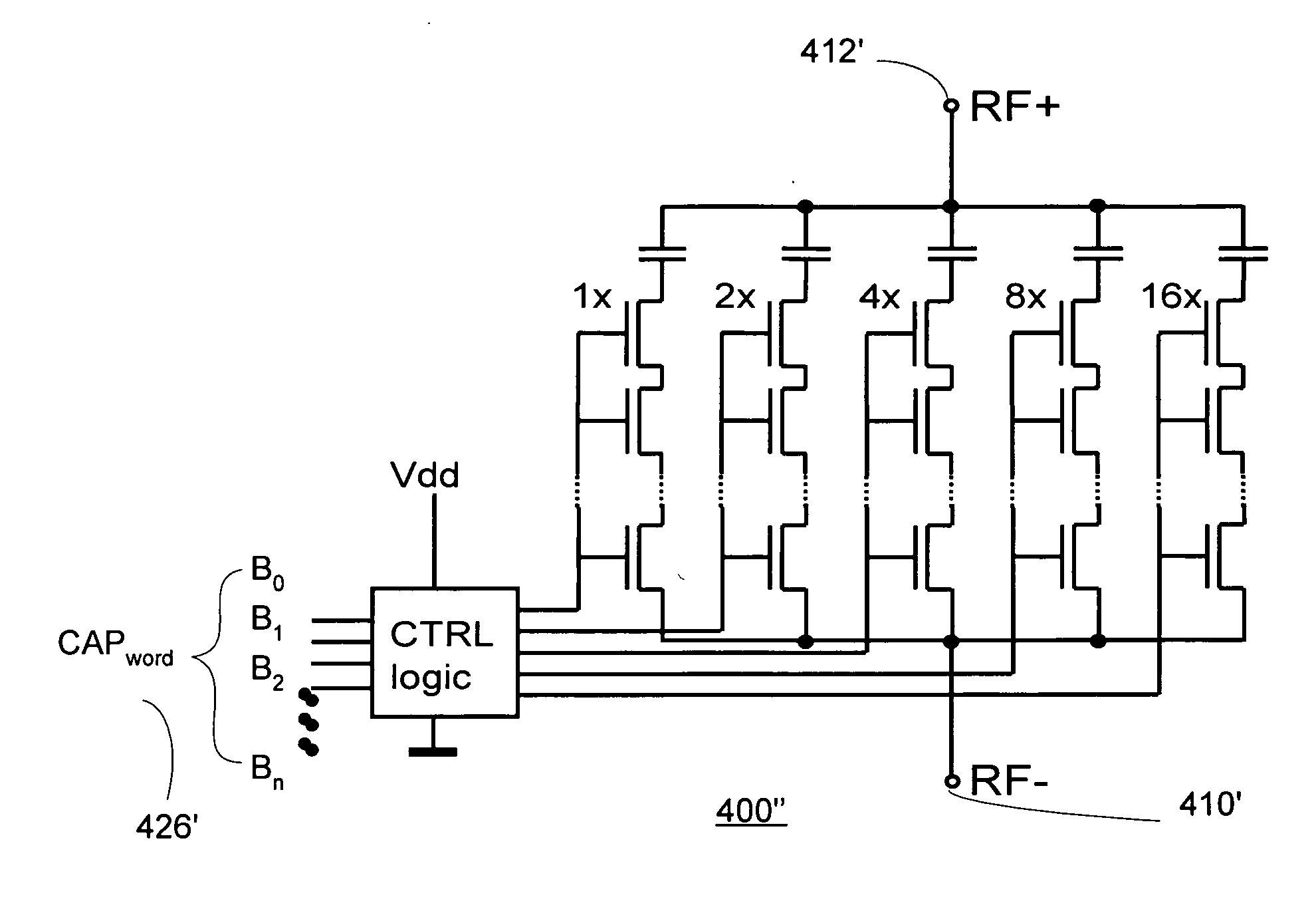

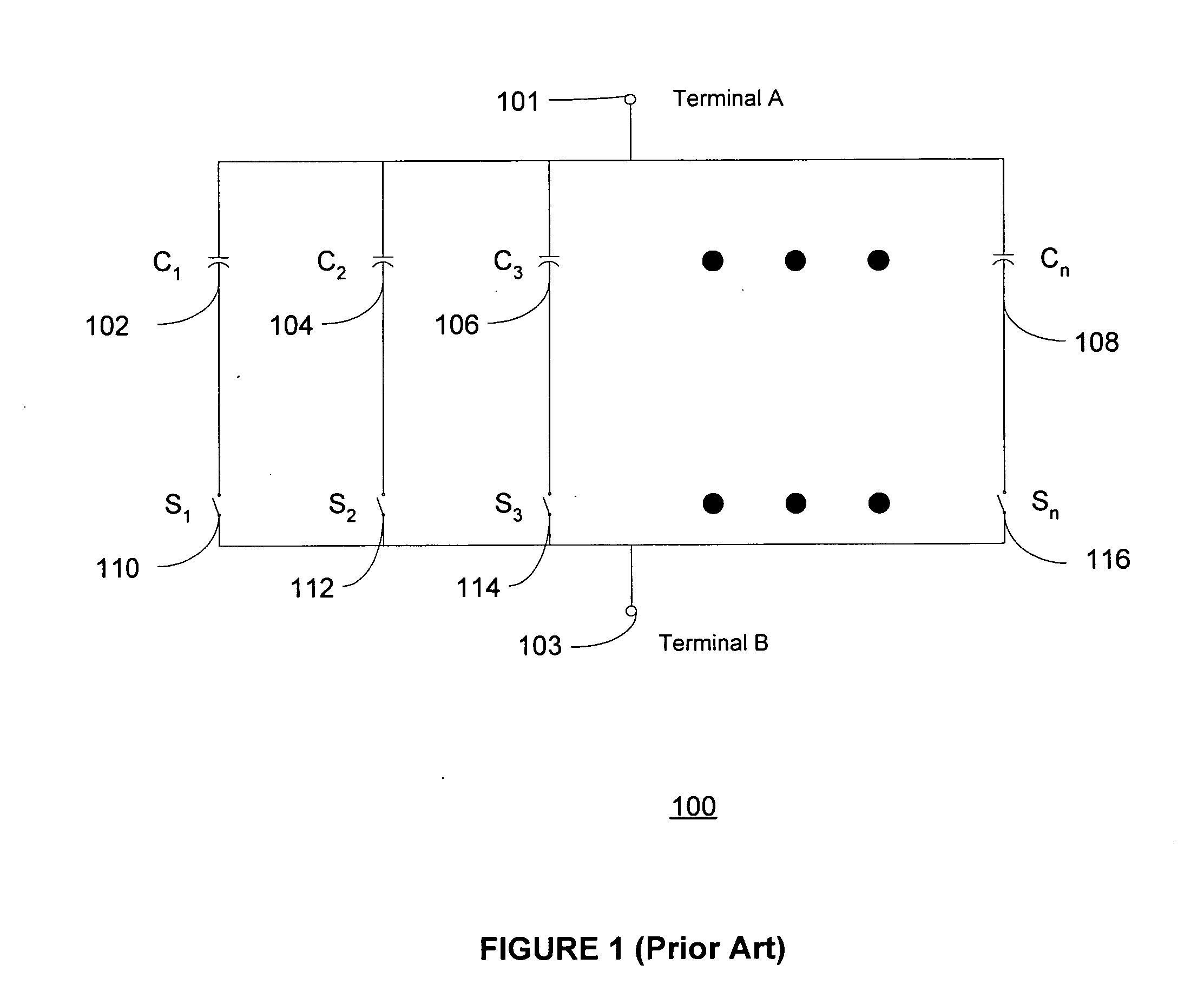

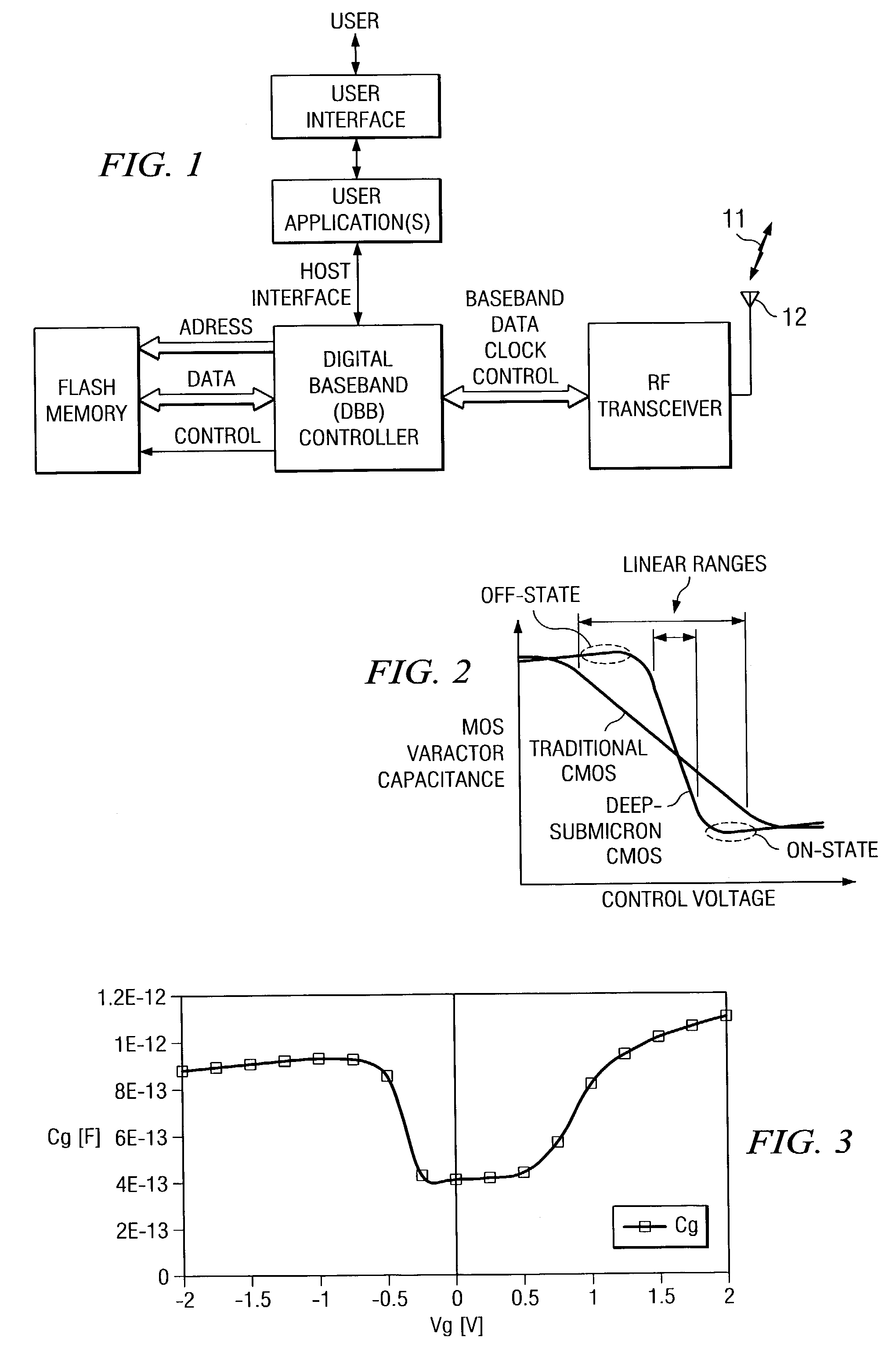

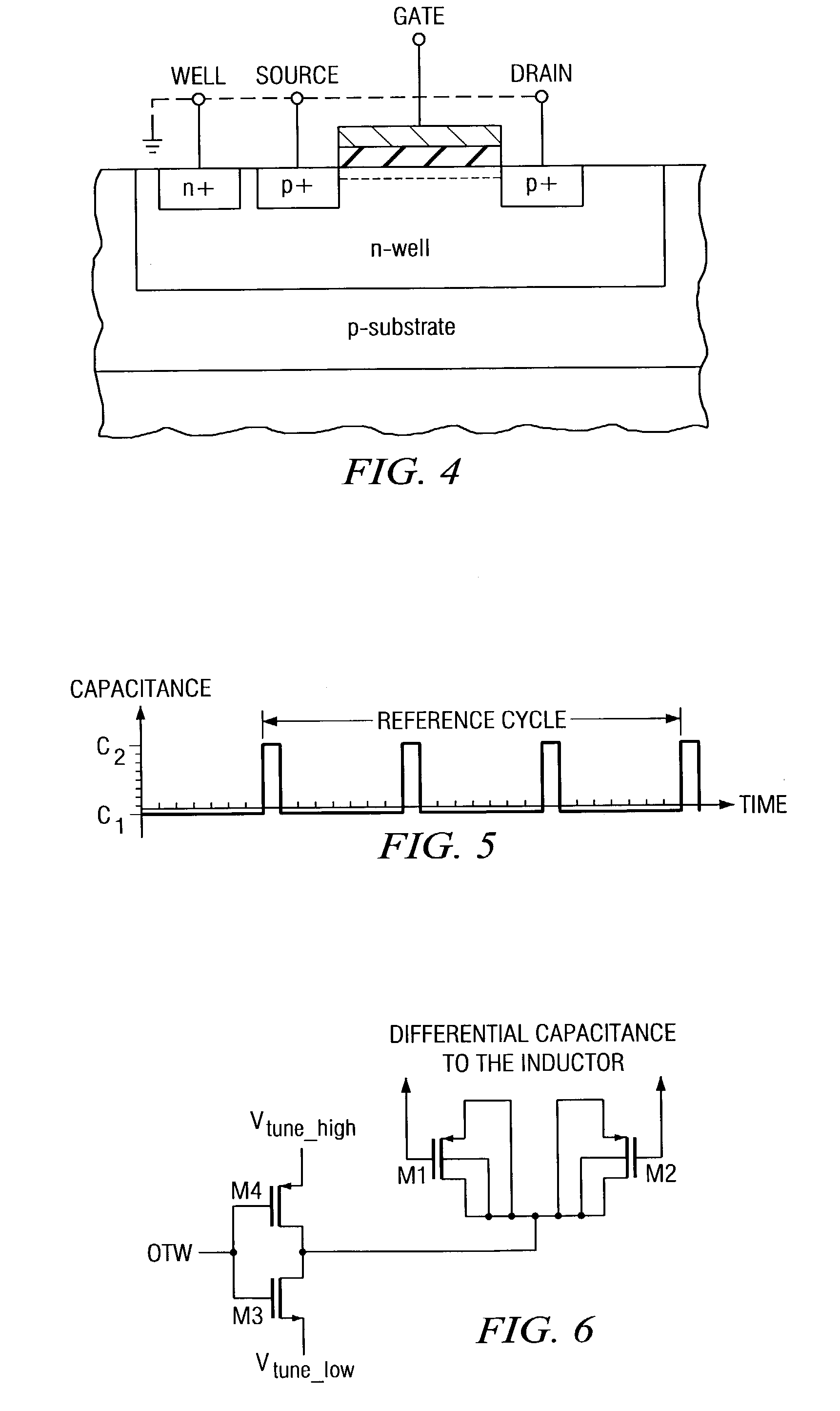

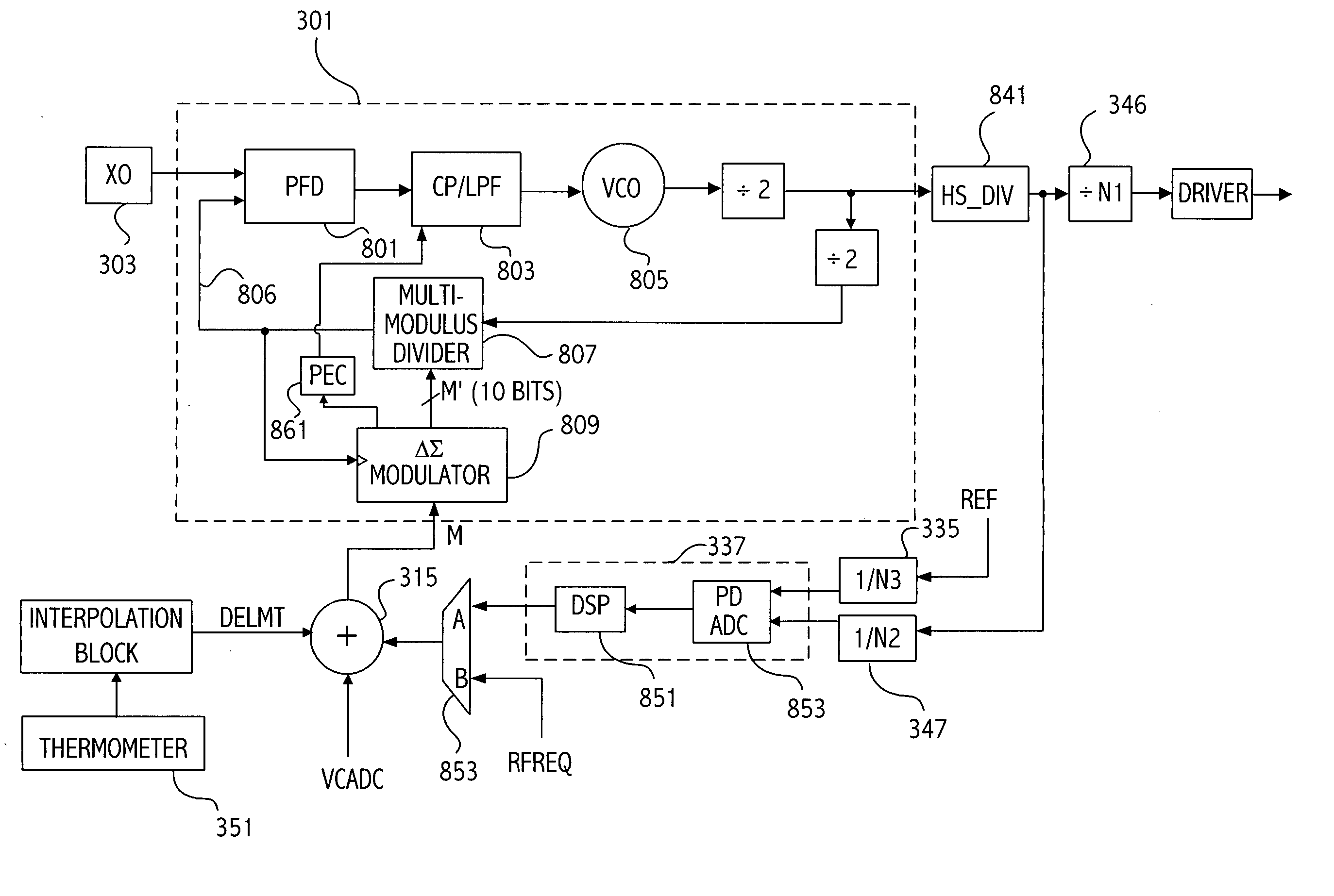

Method and apparatus for use in digitally tuning a capacitor in an integrated circuit device

ActiveUS20110002080A1Easy to controlHigh Power Handling CapabilityAnalogue/digital conversionImpedence matching networksCapacitanceLeast significant bit

A method and apparatus for use in a digitally tuning a capacitor in an integrated circuit device is described. A Digitally Tuned Capacitor DTC is described which facilitates digitally controlling capacitance applied between a first and second terminal. In some embodiments, the first terminal comprises an FW+ terminal and the second terminal comprises an RF terminal. In accordance with some embodiments, the DTCs comprises a plurality of sub-circuits ordered in significance from least significant bit (LSB) to most significant bit (MSB) sub-circuits, wherein the plurality of significant bit sub-circuits are coupled together in parallel, and wherein each sub-circuit has a first node coupled to the first RF terminal, and a second node coupled to the second FW terminal. The DTCs further include an input means for receiving a digital control word, wherein the digital control word comprises bits that are similarly ordered in significance from an LSB to an MSB.

Owner:PSEMI CORP

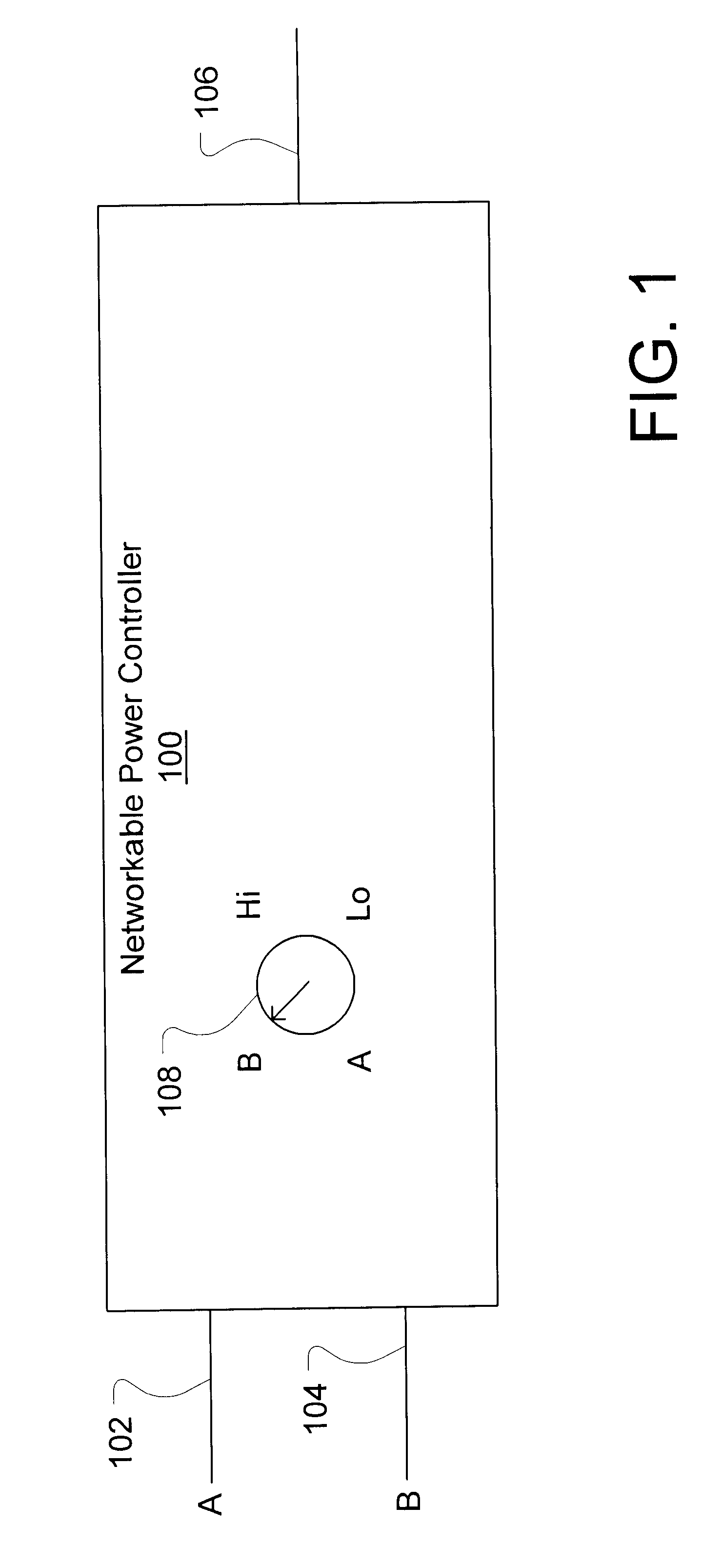

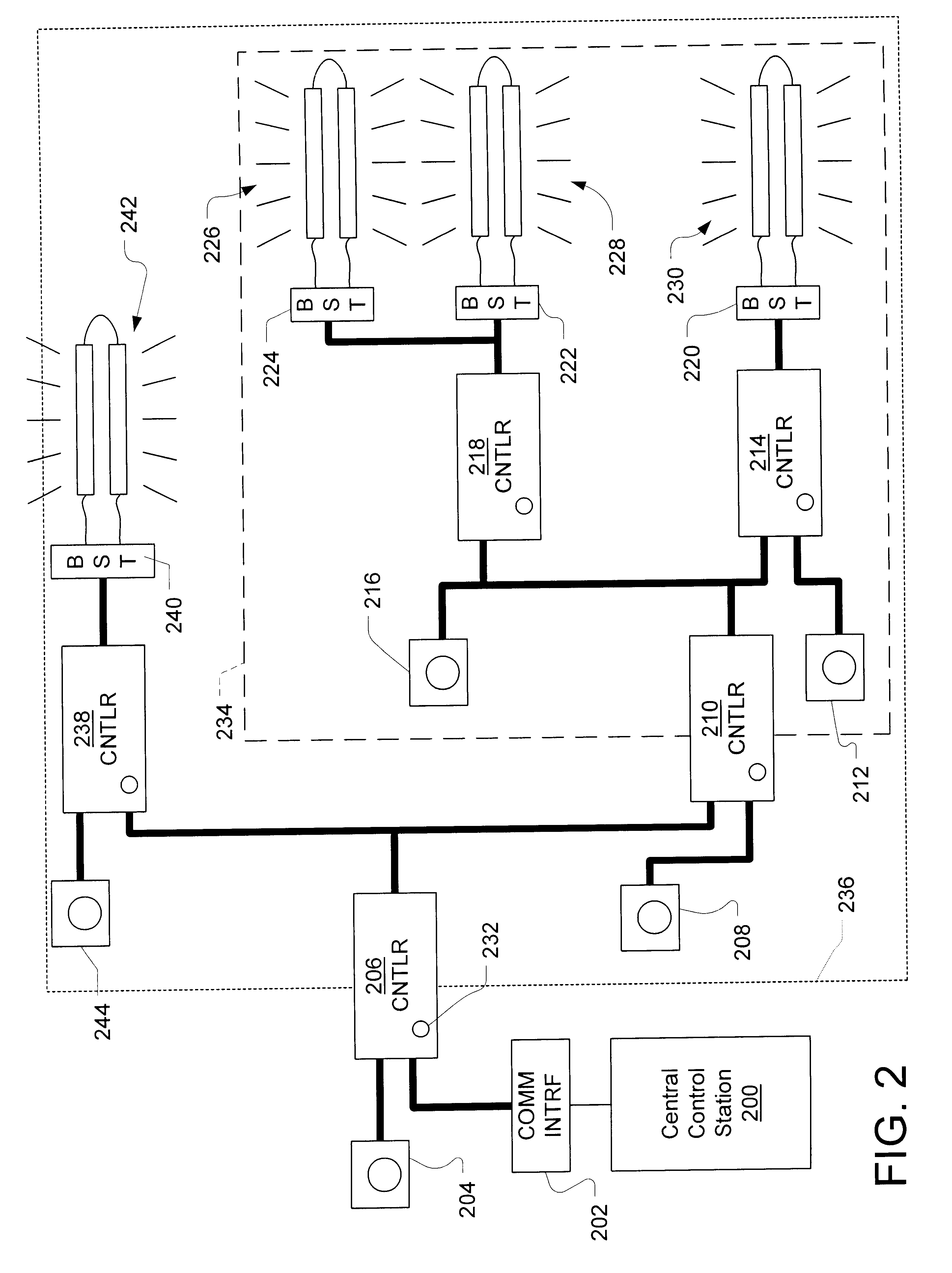

Networkable power controller

InactiveUS6400103B1Telemetry/telecontrol selection arrangementsSpace heating and ventilation safety systemsDigital controlBuilding automation

A networkable power controller includes a mode selector for selectively conducting of a plurality of input signals to an output of the networkable power controller, where the input signals and the output signals satisfy the same signaling protocol. The networkable power controller may be networked with other networkable power controllers, lighting ballasts and other building automation control devices, and user-controlled voltage selectors to provide a lighting control network. A power controller may include a mode selector that may be used in combination with other control devices or components, including a rotary dimmer control, a digital slide dimmer control, a demand load shedder component, a photometer component, and a communications interface. The communications interface allows digital control of the networkable power controller.

Owner:POWER CIRCUIT INNOVATIONS

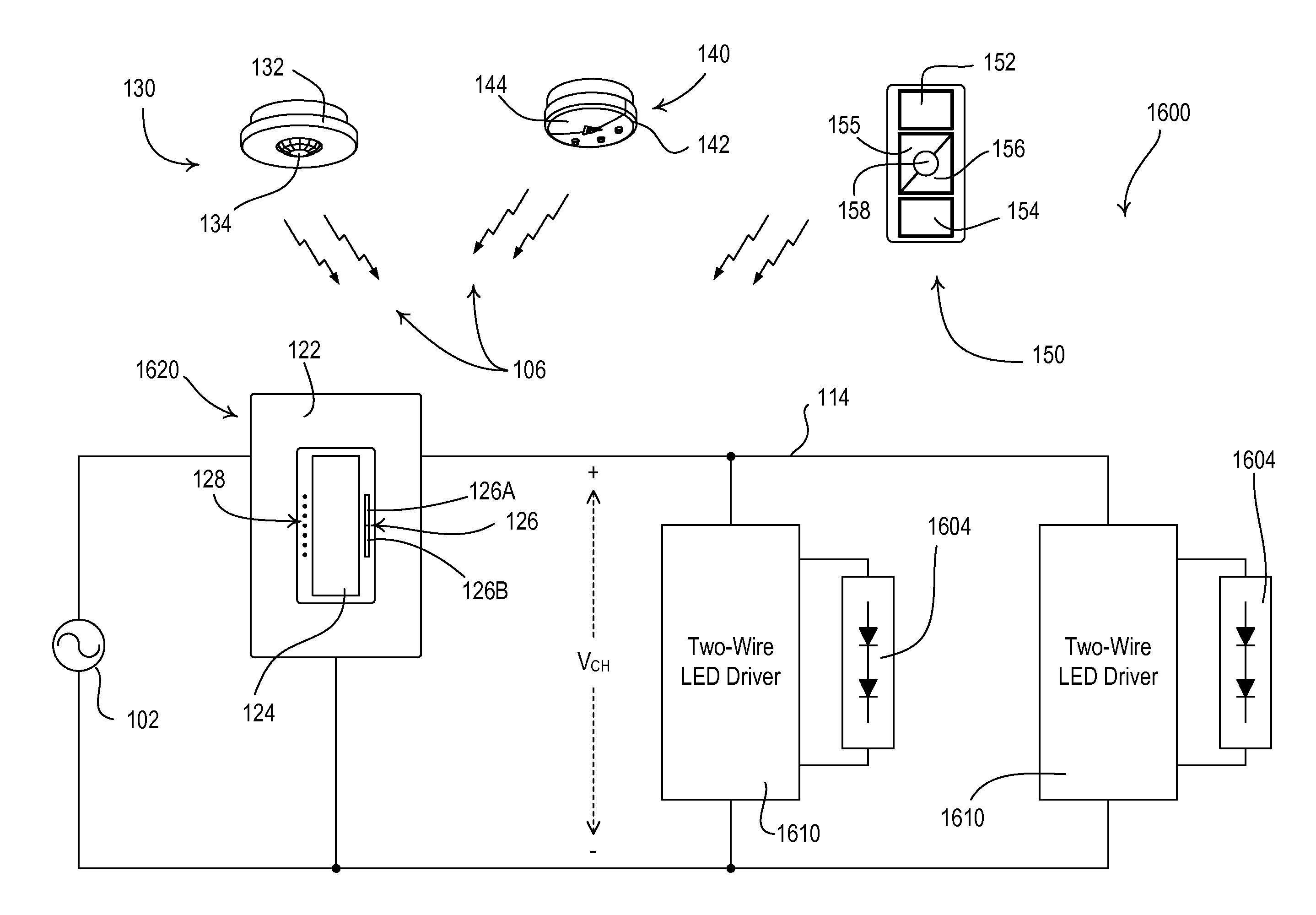

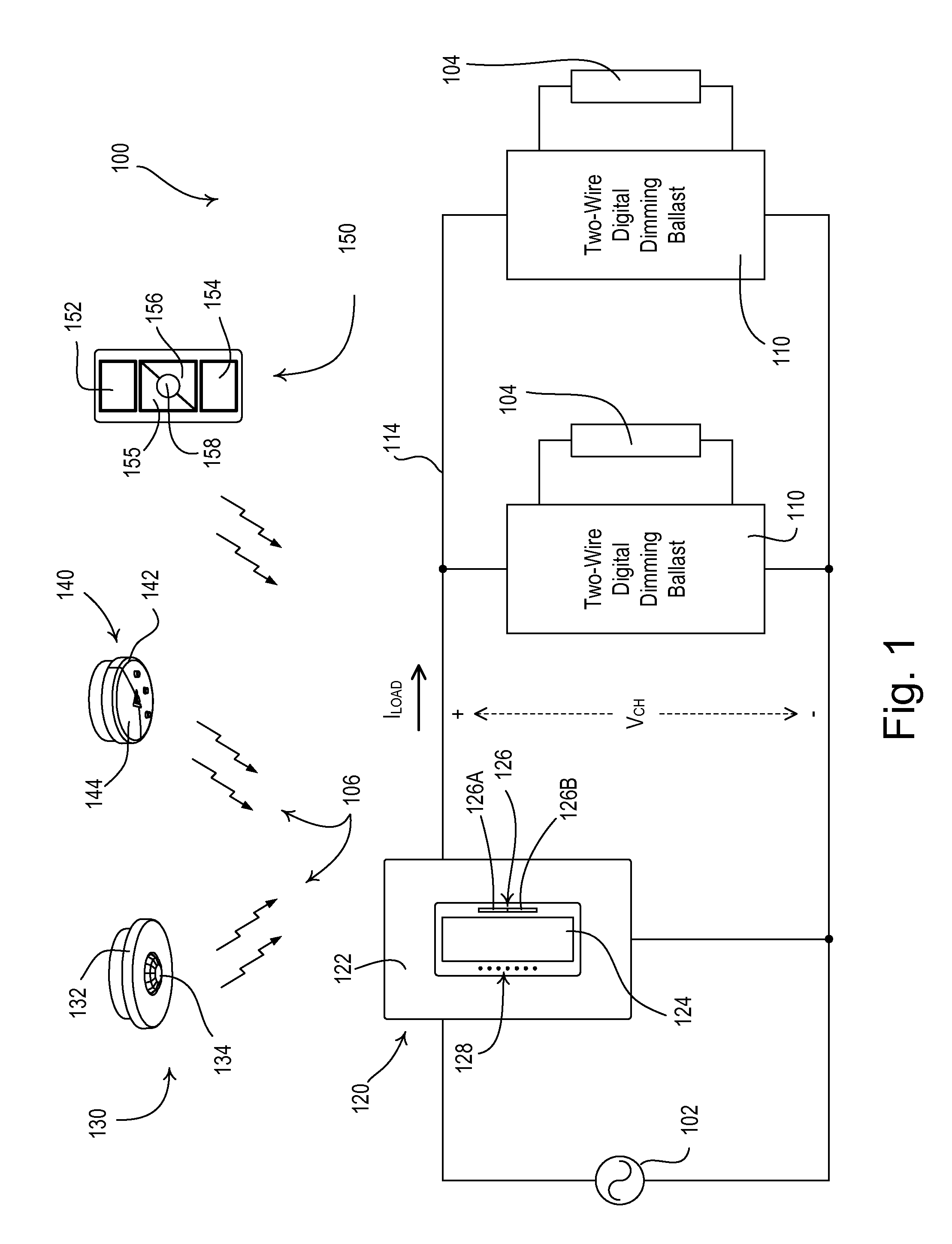

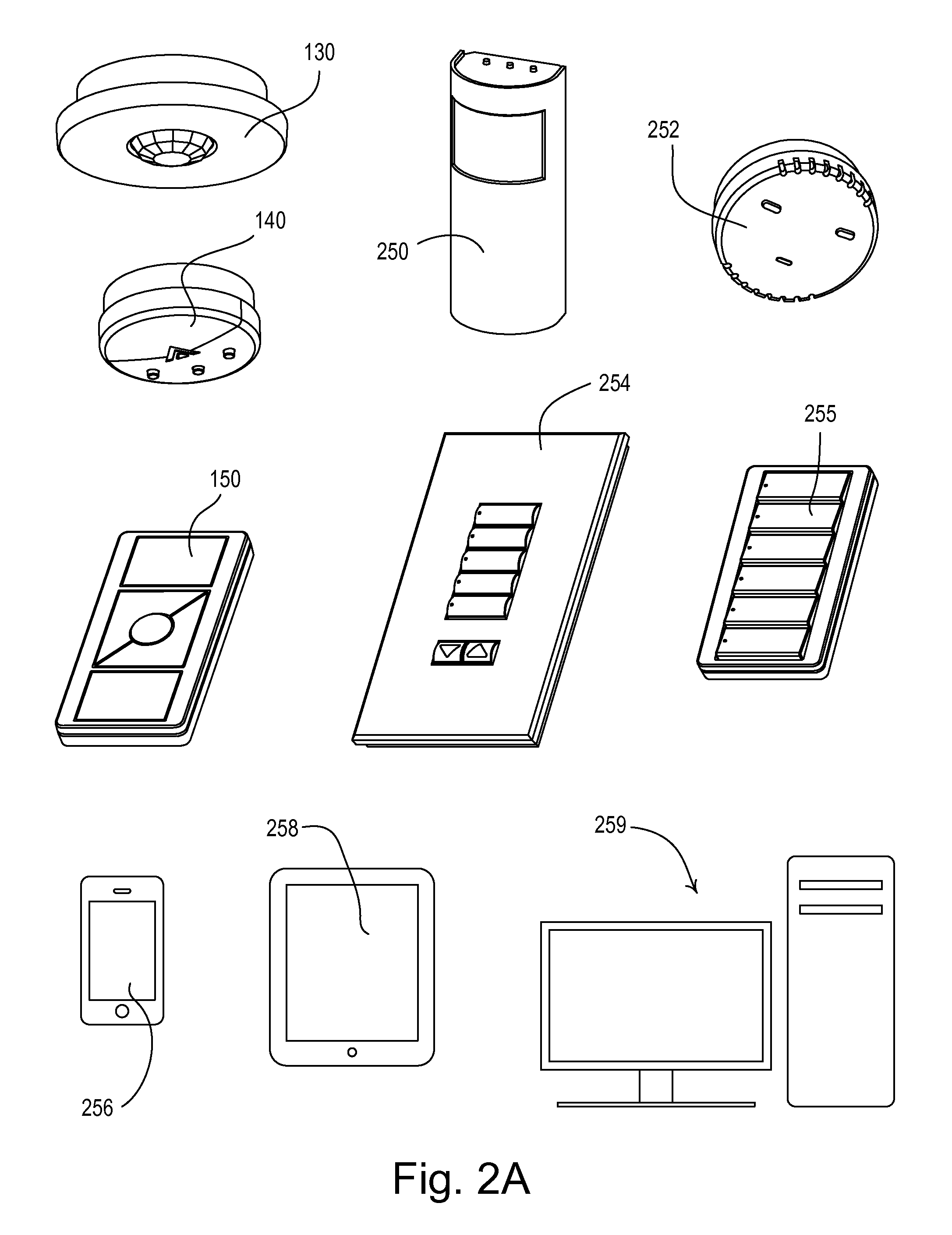

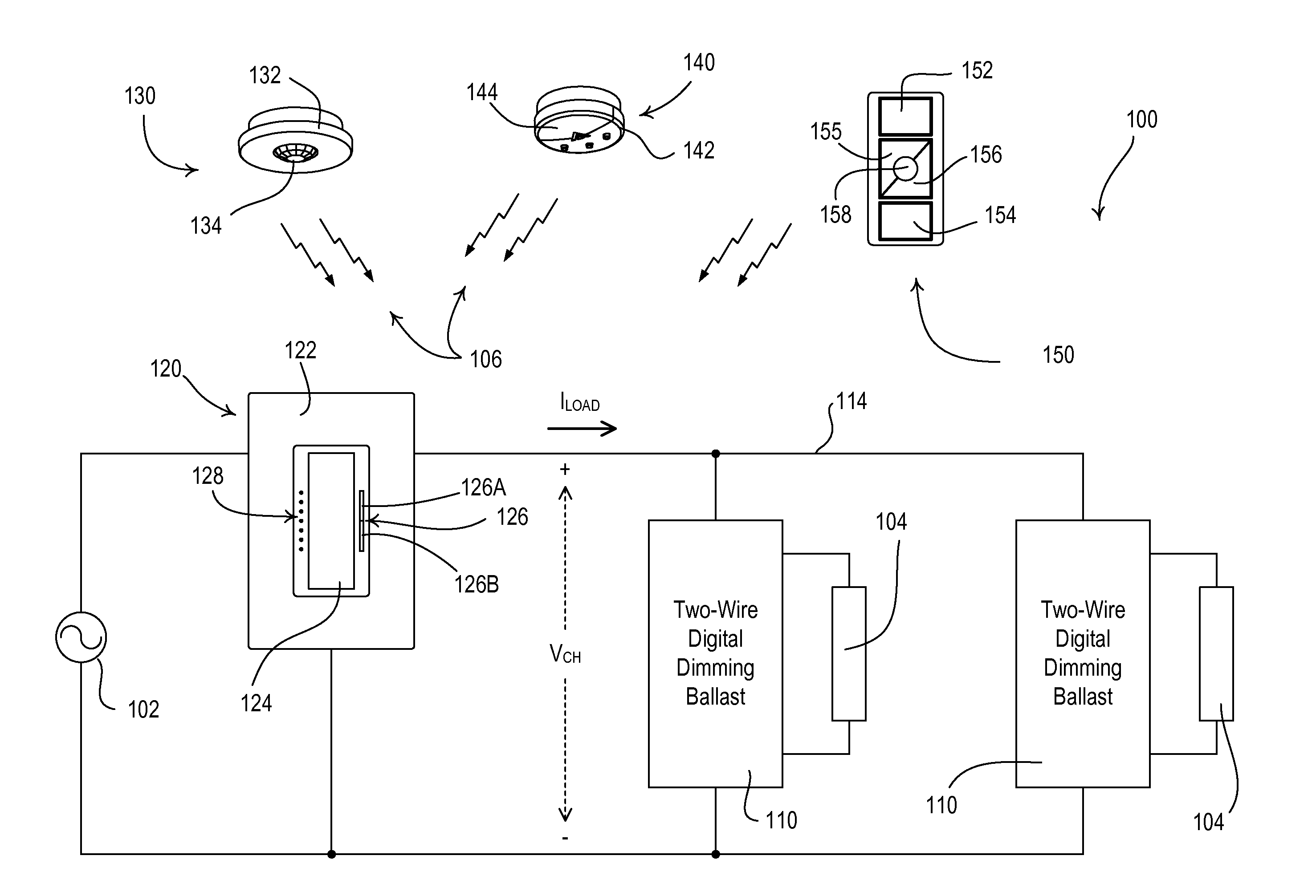

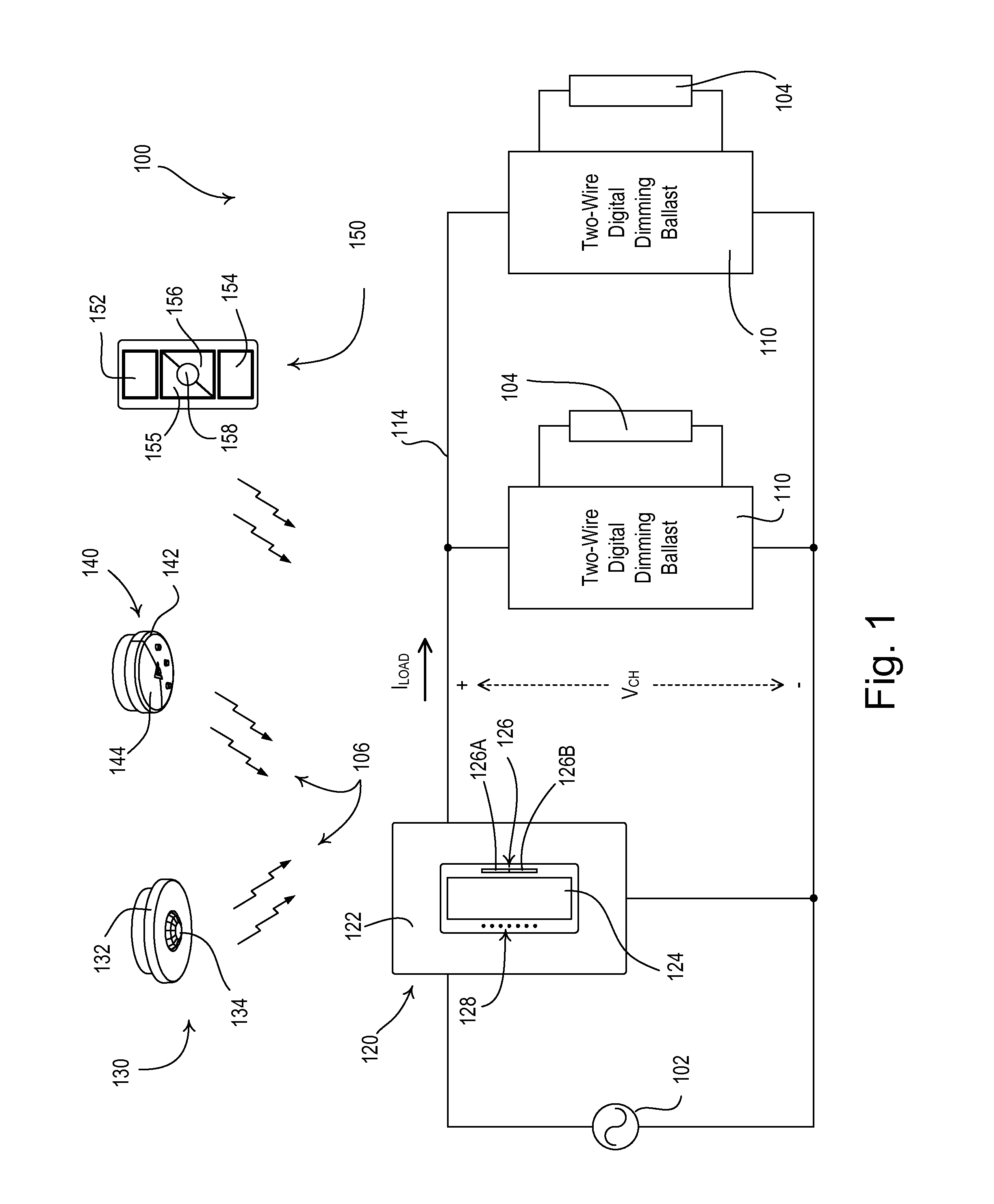

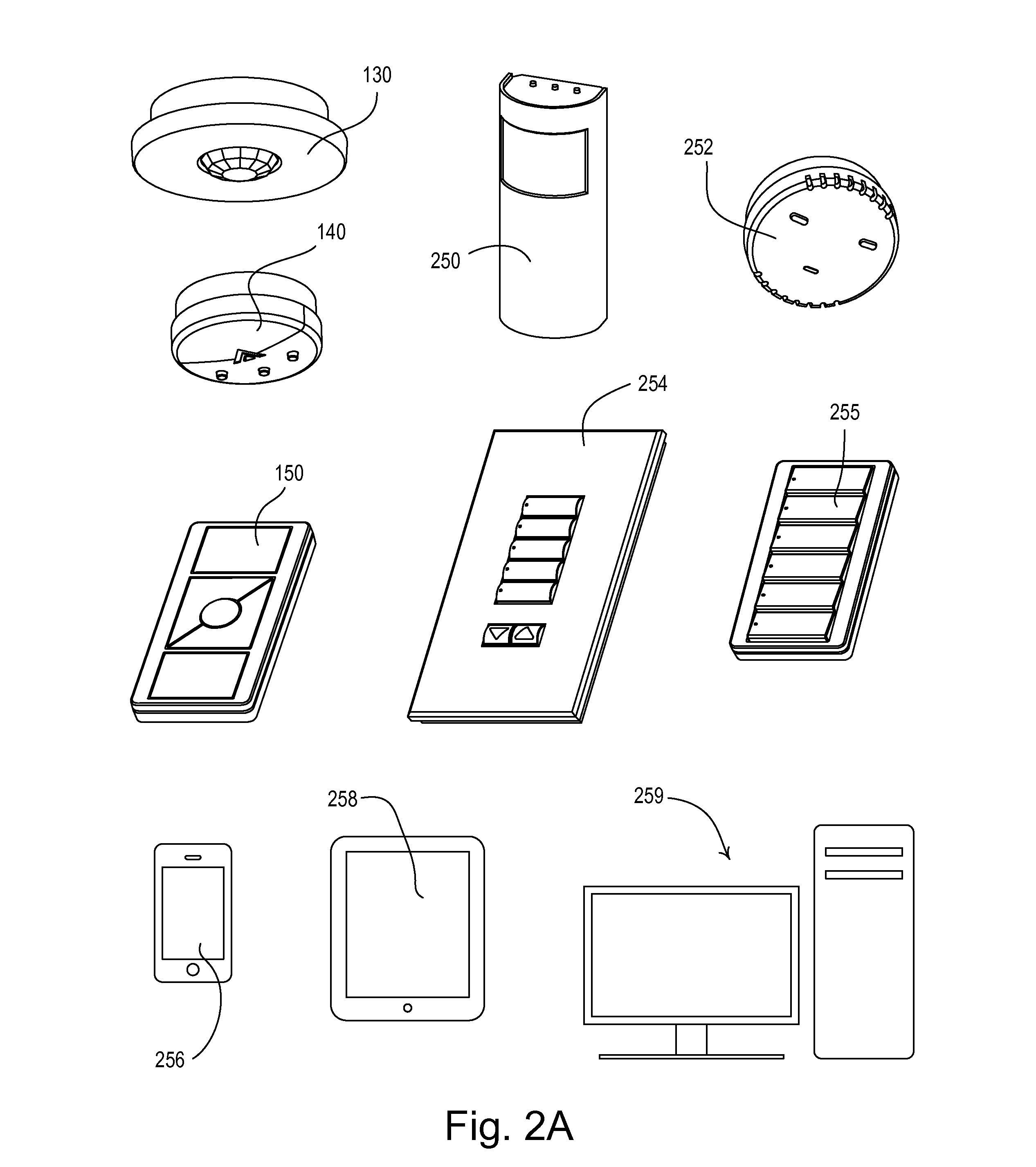

Digital load control system providing power and communication via existing power wiring

ActiveUS20130181630A1Reliable detectionPower distribution line transmissionElectroluminescent light sourcesControl systemPhase control

A load control system comprises a load control device for controlling an electrical load receiving power from an AC power source, and a controller adapted to be coupled in series between the source and the load control device. The load control system may be installed without requiring any additional wires to be run, and is easily configured without the need for a computer or an advanced commissioning procedure. The load control device receives both power and communication over two wires, and the controller generates a phase-control voltage that has at least one timing edge in each half-cycle, and transmits digital messages by modulating a timing edge of the phase-control voltage relative to a reference edge. The controller may be operable to receive inputs from a plurality of different input devices, and the load control device may be operable to control a plurality of different loads.

Owner:LUTRON TECH CO LLC

Digital load control system providing power and communication via existing power wiring

ActiveUS20140265880A1Reliable detectionQuality improvementElectrical apparatusElectroluminescent light sourcesControl systemPhase control

A two-way load control system comprises a power device, such as a load control device for controlling an electrical load receiving power from an AC power source, and a controller adapted to be coupled in series between the source and the power device. The load control system may be installed without requiring any additional wires to be run, and is easily configured without the need for a computer or an advanced commissioning procedure. The power device receives both power and communication over two wires. The controller generates a phase-control voltage and transmits a forward digital message to the power device by encoding digital information in timing edges of the phase-control voltage. The power device transmits a reverse digital message to the controller via the power wiring.

Owner:LUTRON TECH CO LLC

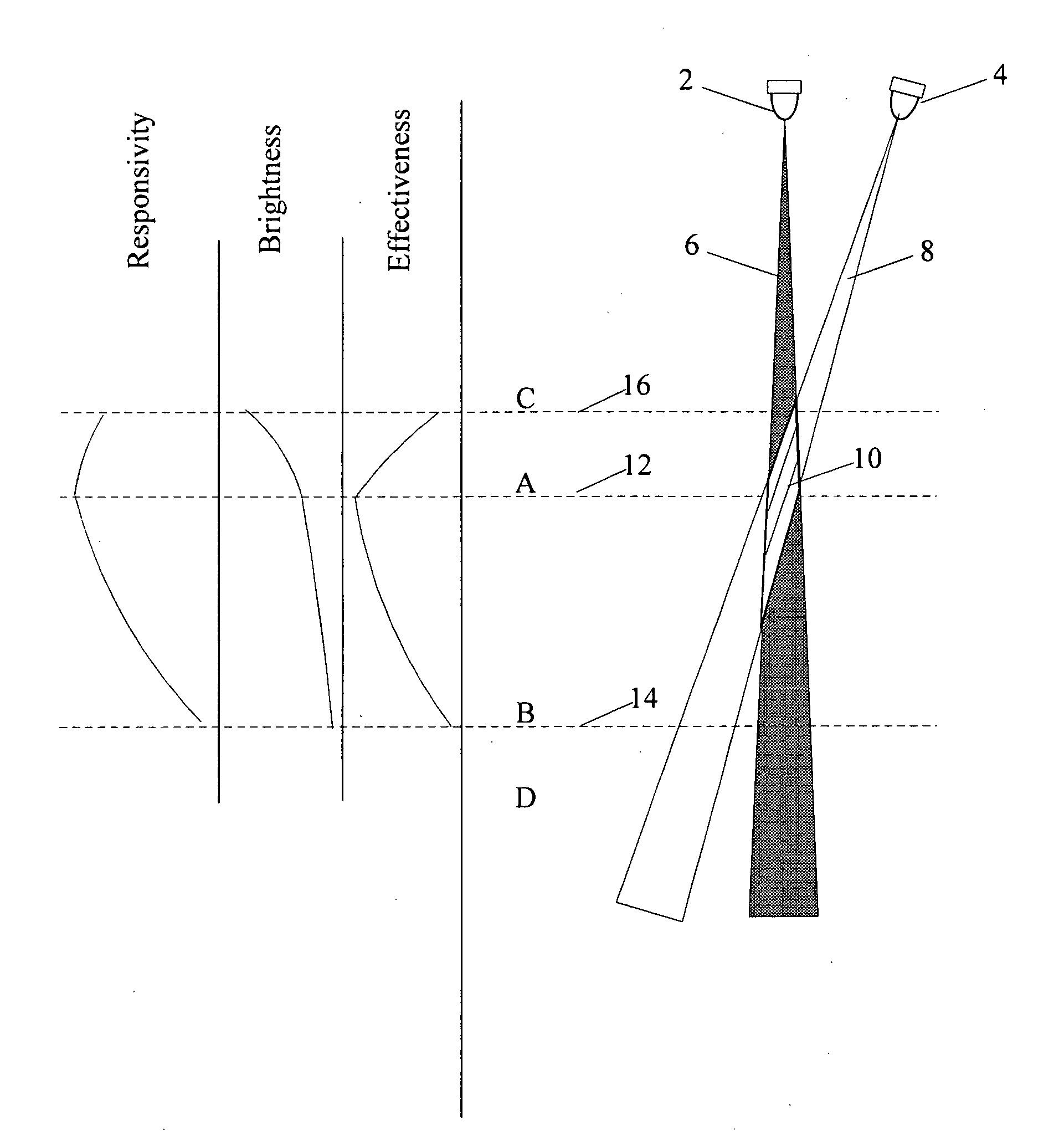

Apparatus and method for the precision application of cosmetics

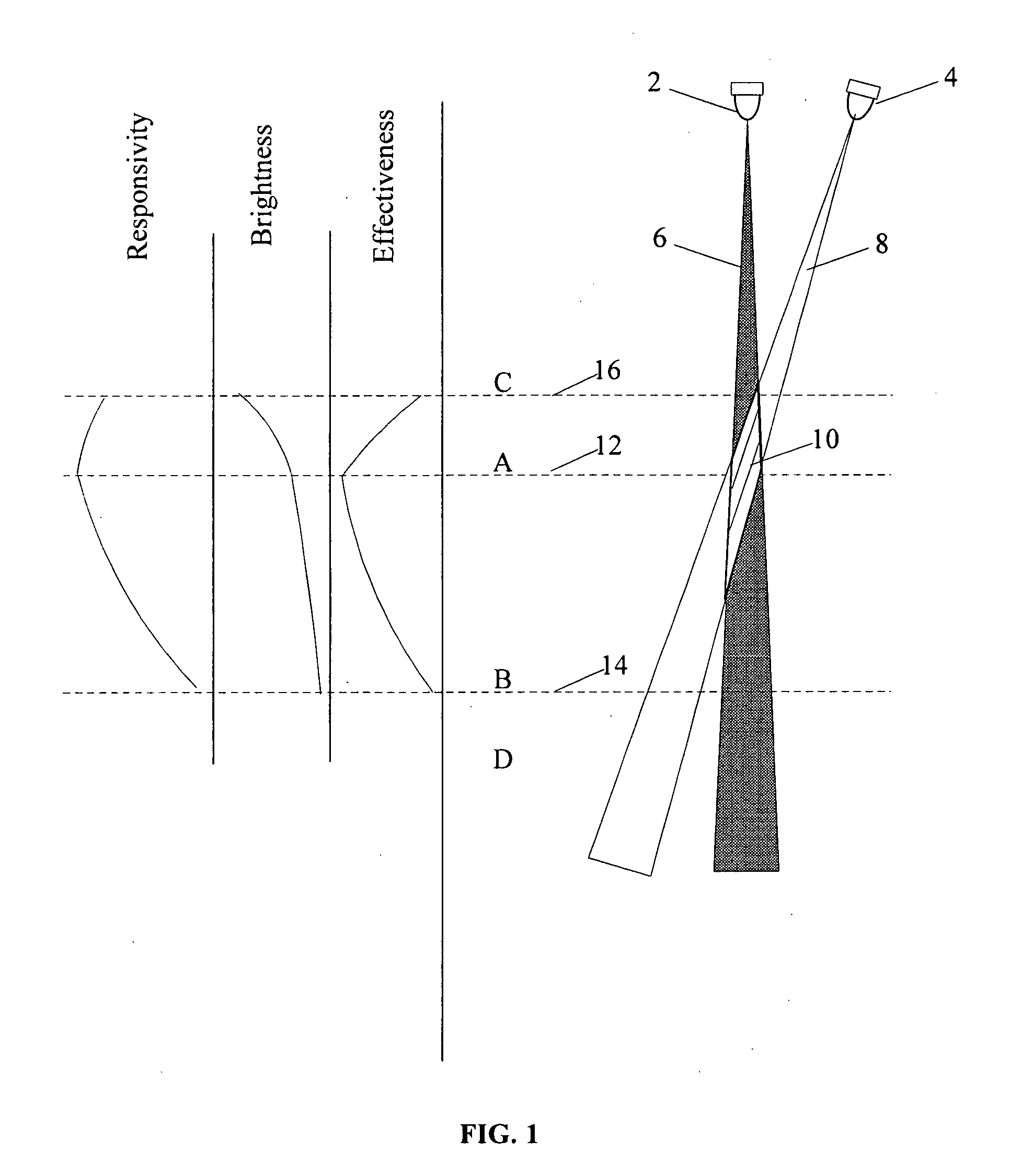

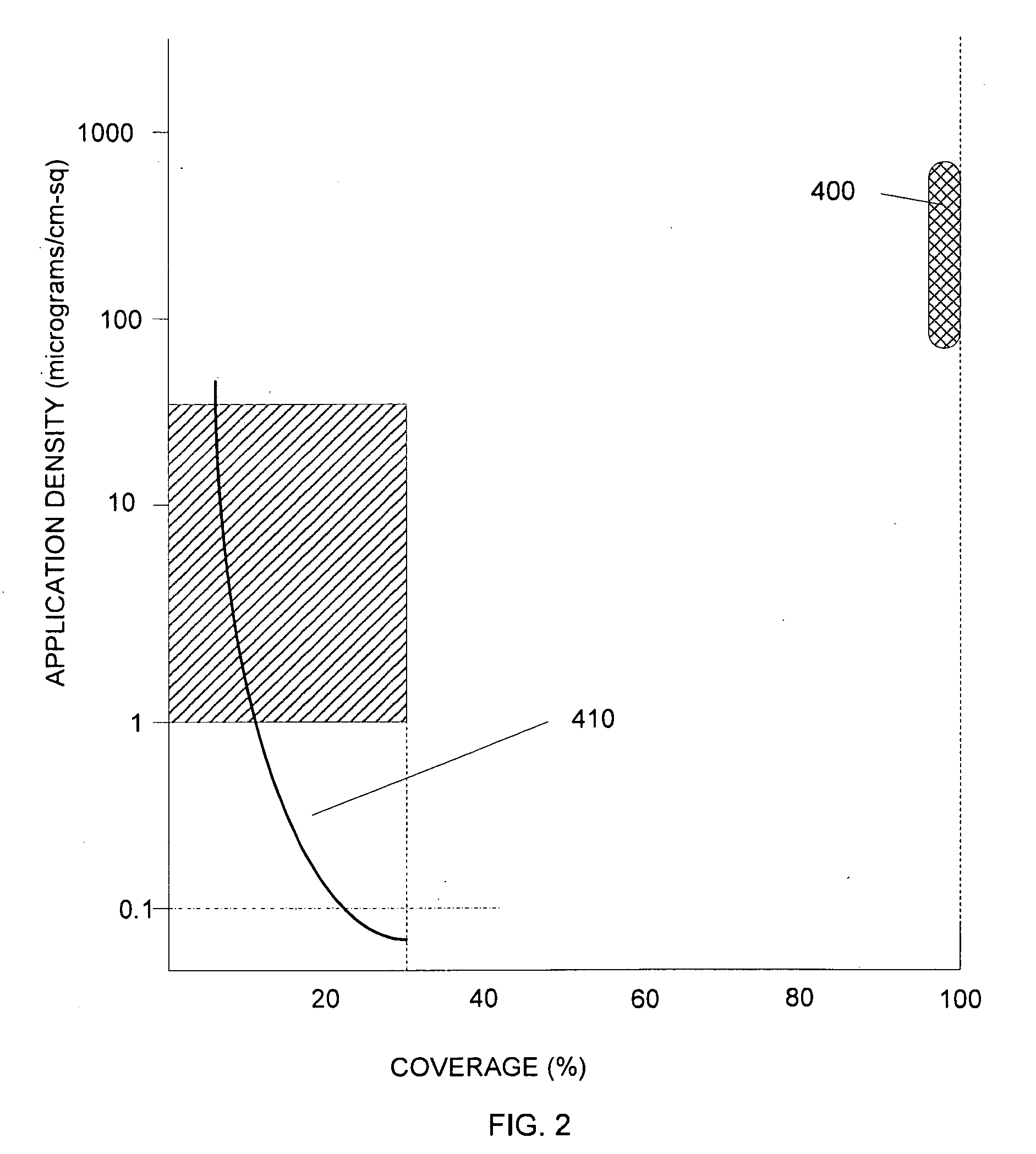

ActiveUS20090025747A1Easy to moveArea coveredTypewritersPackaging toiletriesCamera imageVolumetric Mass Density

One or more reflectance modifying agent (RMA) such as a pigmented cosmetic agent is applied selectively and precisely with a controlled spray to human skin according to local skin reflectance or texture attributes. One embodiment uses digital control based on the analysis of a camera images. Another embodiment, utilizes a calibrated scanning device comprising a plurality of LEDs and photodiode sensors to correct reflectance readings to compensate for device distance and orientation relative to the skin. Ranges of desired RMA application parameters of high luminance RMA, selectively applied to middle spatial frequency features, at low opacity or application density are each be significantly different from conventional cosmetic practice. The ranges are complementary and the use of all three techniques in combination provides a surprisingly effective result which preserves natural beauty while applying a minimum amount of cosmetic agent.

Owner:TCMS TRANSPARENT BEAUTY LLC

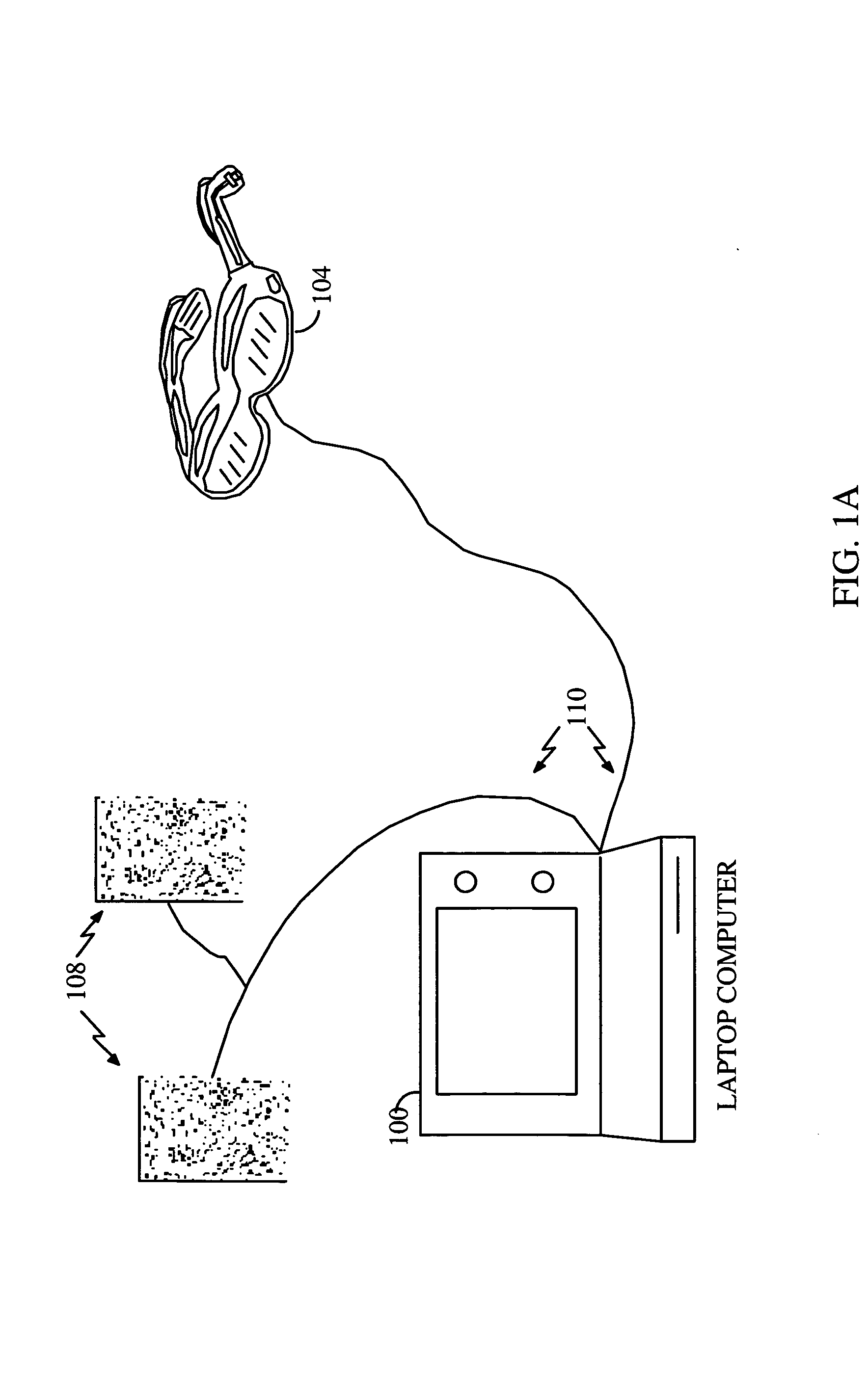

Generating and implementing a signal protocol and interface for higher data rates

ActiveUS20050021885A1Increase data rateEnergy efficient ICTPulse modulation television signal transmissionDigital dataDisplay device

A data Interface for transferring digital data between a host and a client over a communication path using packet structures linked together to form a communication protocol for communicating a pre-selected set of digital control and presentation data. The signal protocol is used by link controllers configured to generate, transmit, and receive packets forming the communications protocol, and to form digital data into one or more types of data packets, with at least one residing in the host device and being coupled to the client through the communications path. The interface provides a cost-effective, low power, bi-directional, high-speed data transfer mechanism over a short-range “serial” type data link, which lends itself to implementation with miniature connectors and thin flexible cables which are especially useful in connecting display elements such as wearable micro-displays to portable computers and wireless communication devices.

Owner:QUALCOMM INC

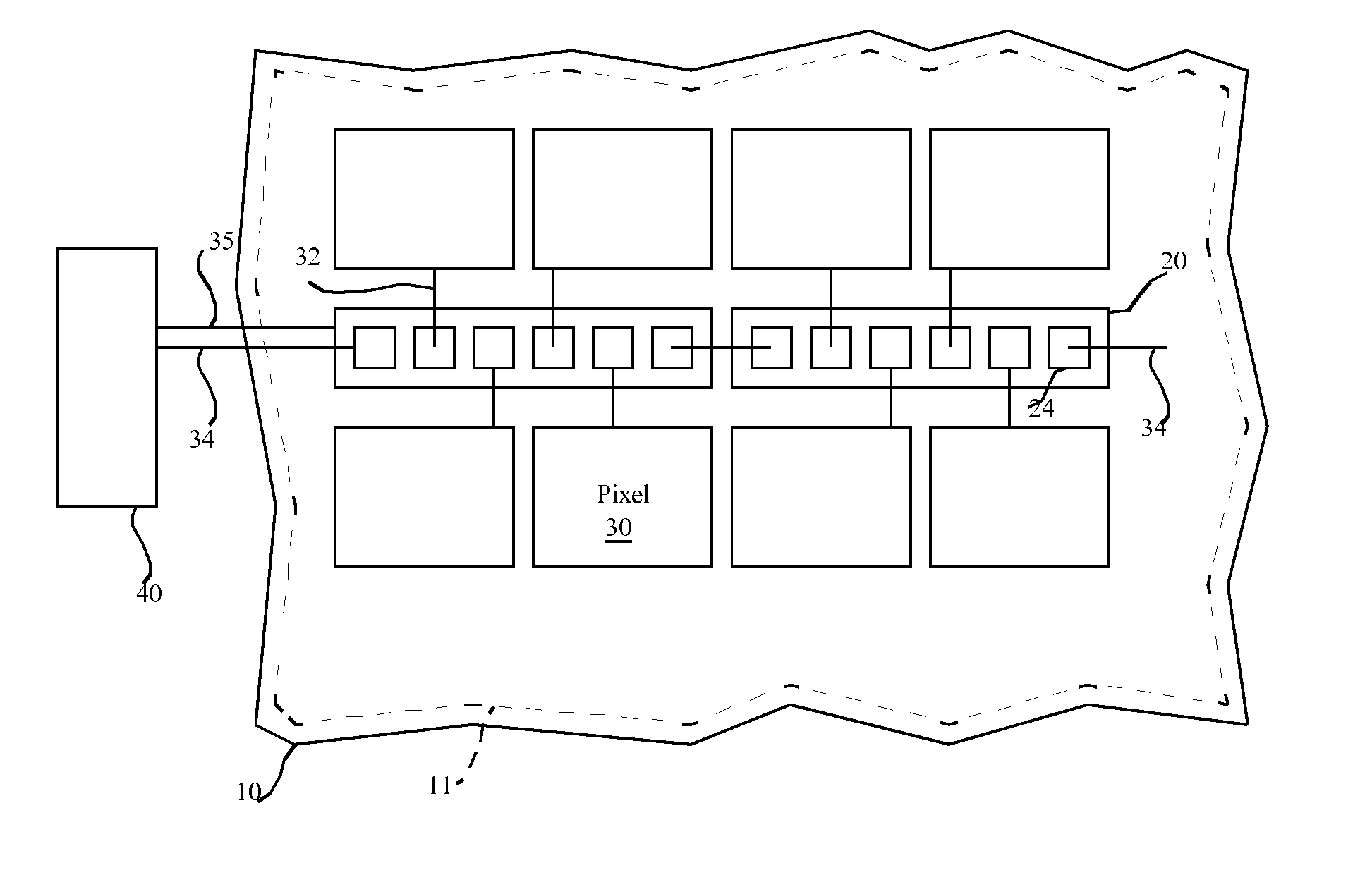

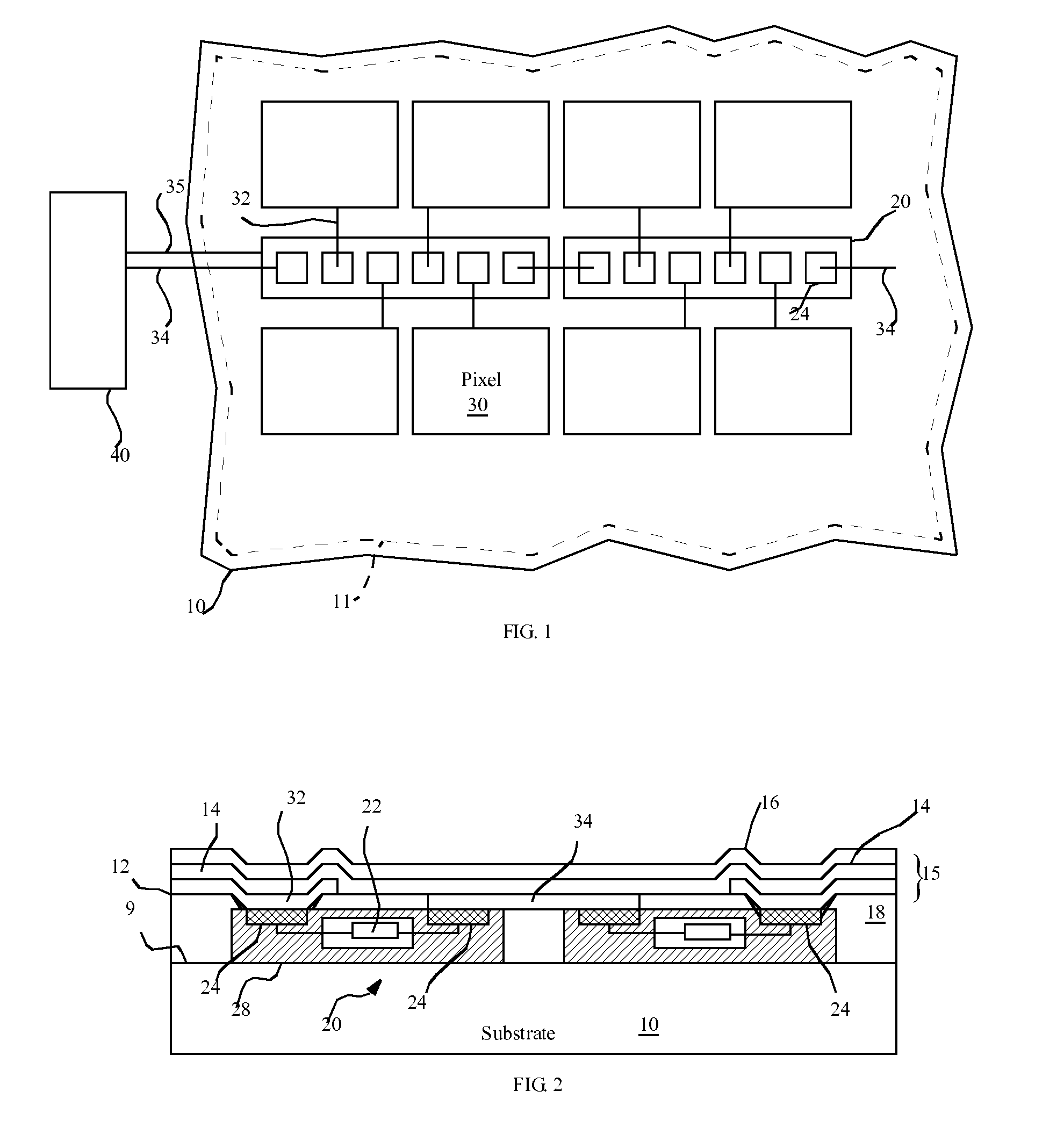

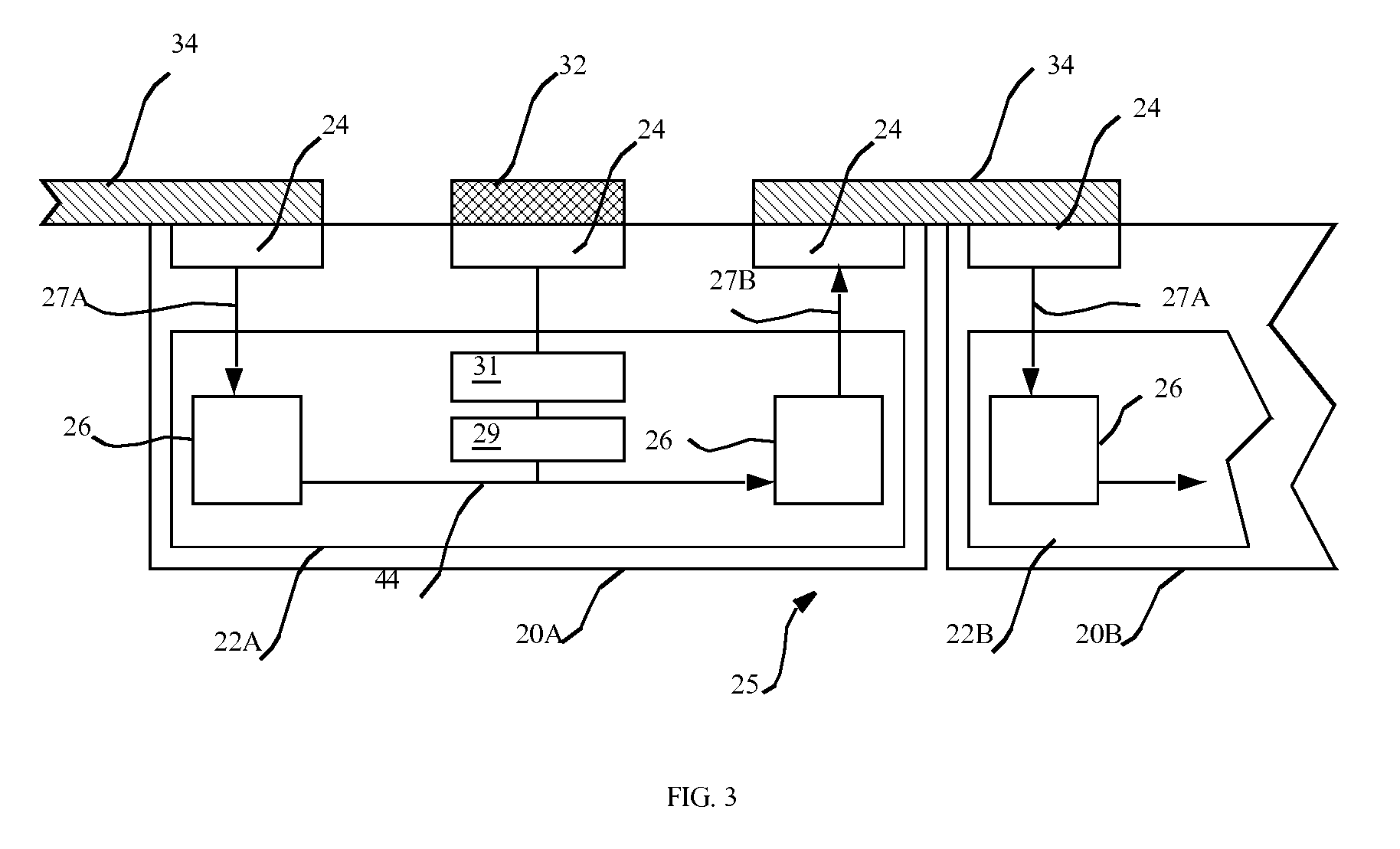

Chiplet display device with serial control

ActiveUS8803857B2Higher-performance pixel circuit and image quality and digital controlElectrical apparatusElectroluminescent light sourcesImaging qualityDisplay device

Owner:GLOBAL OLED TECH

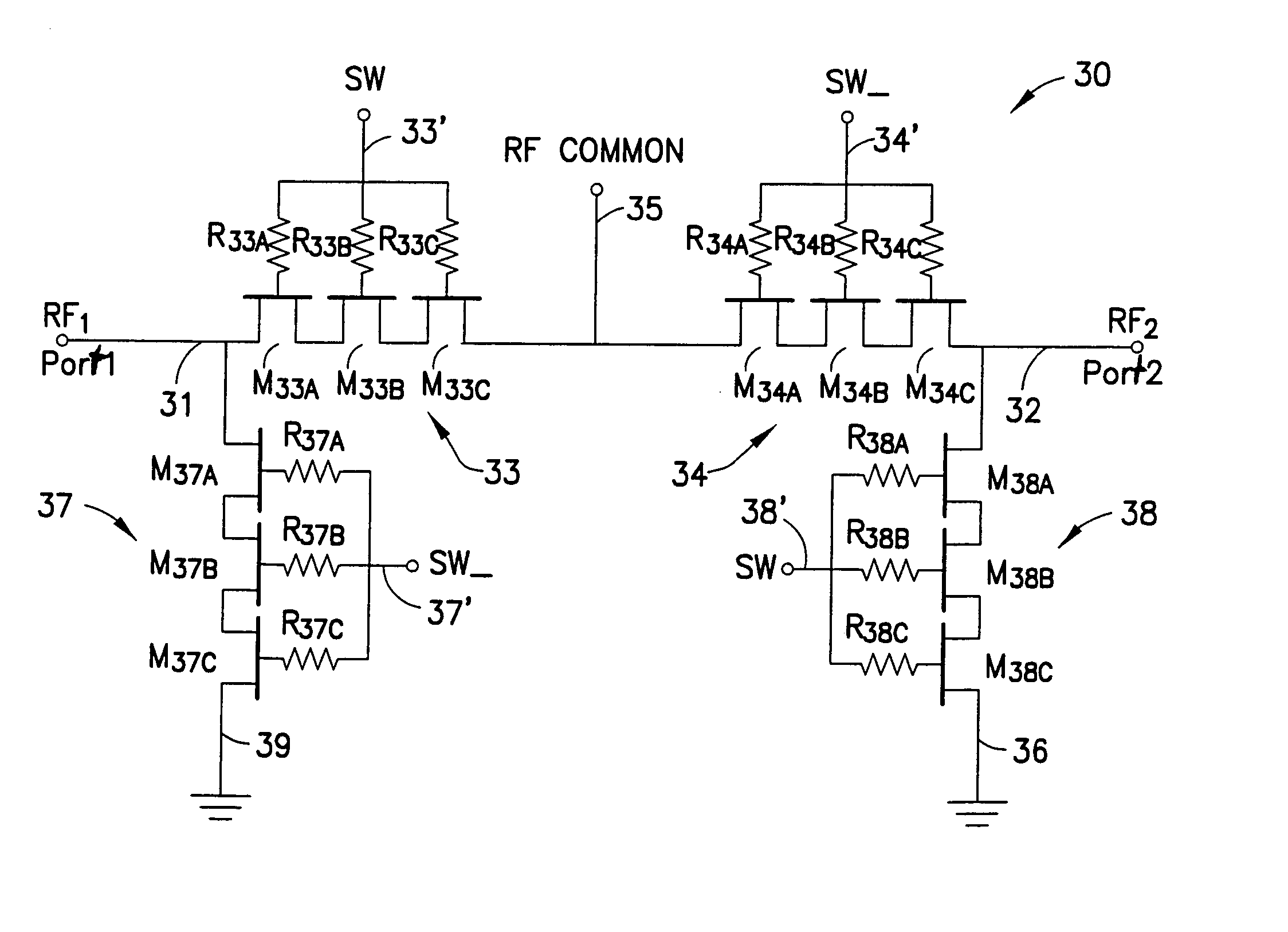

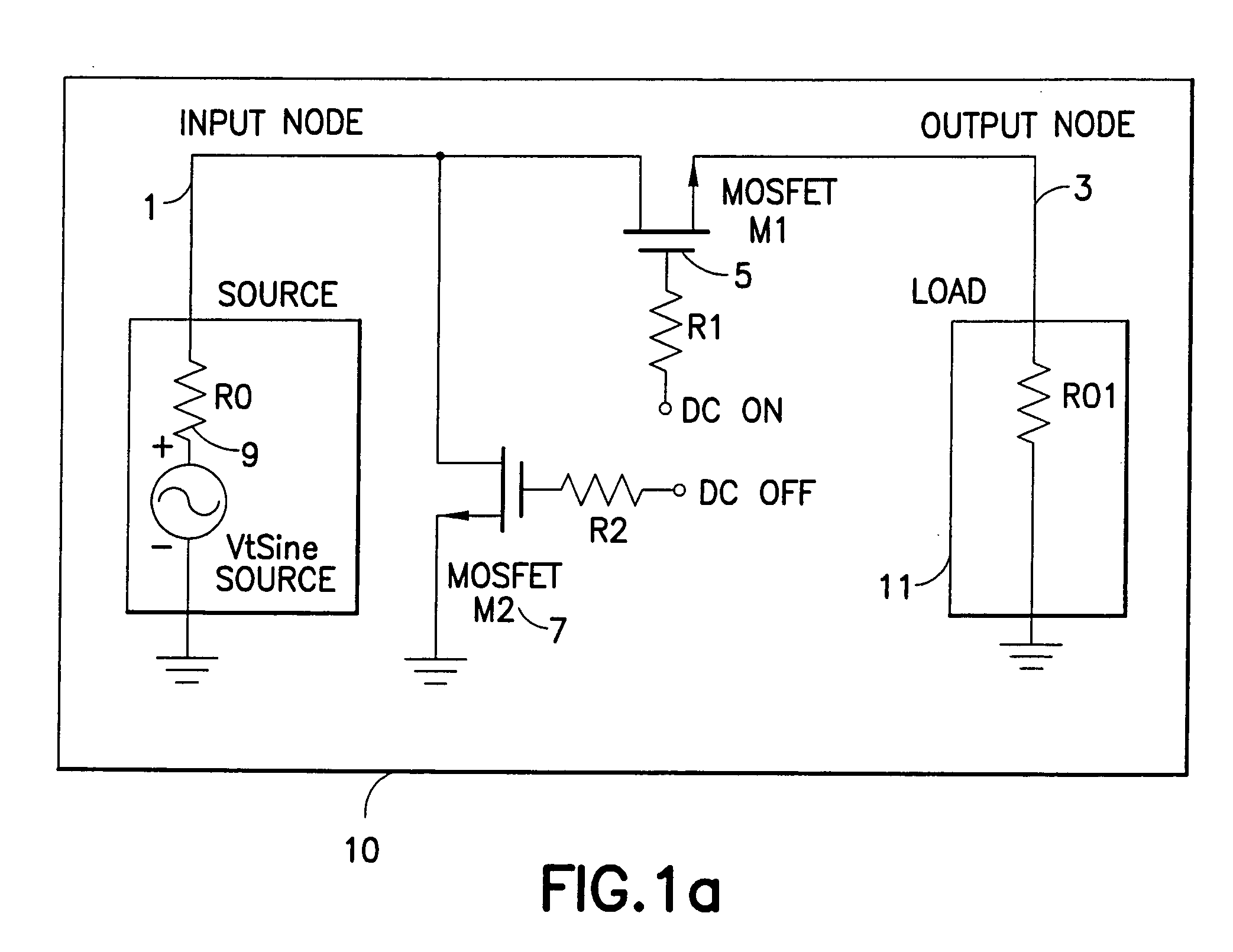

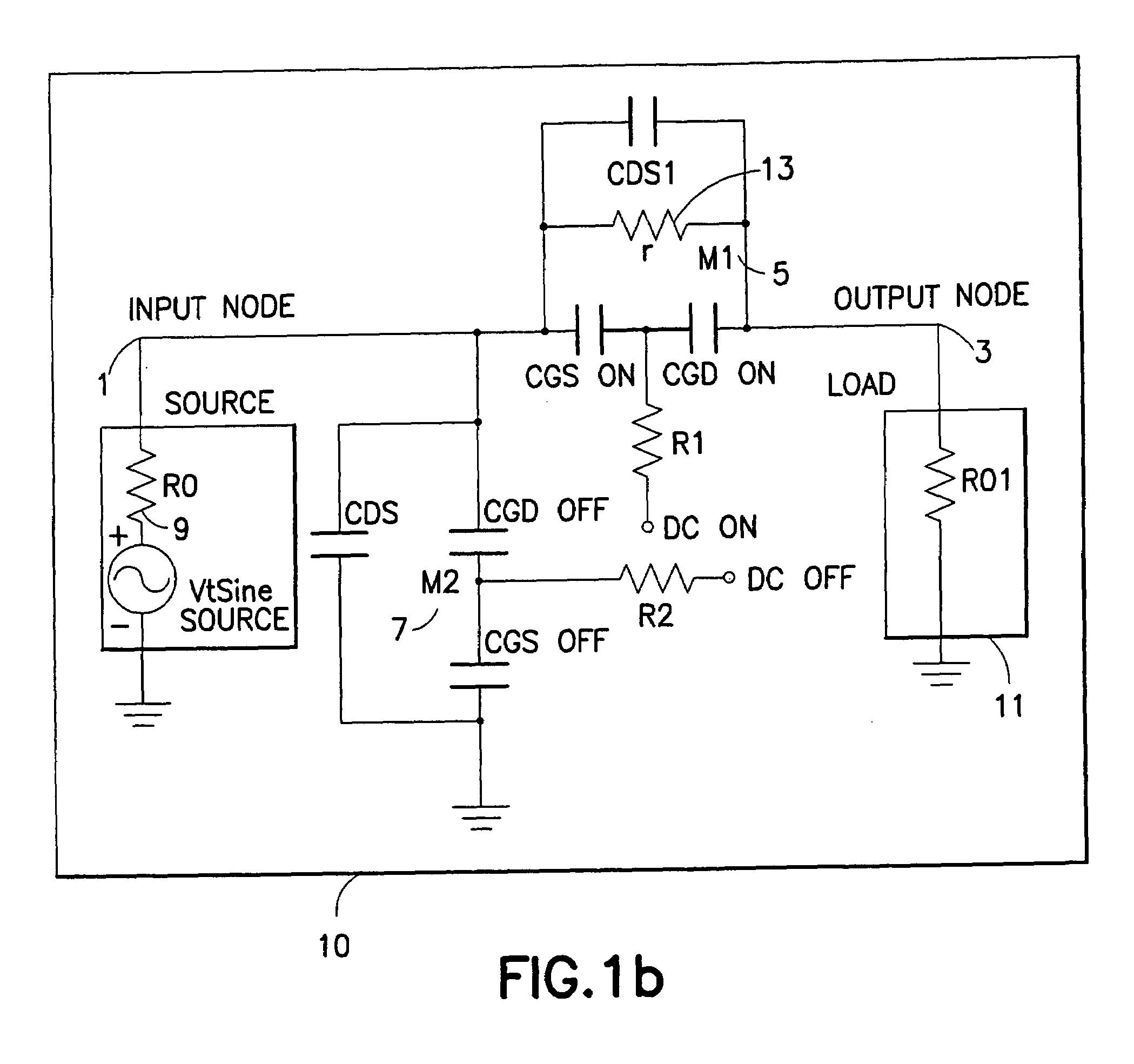

Switch circuit and method of switching radio frequency signals

InactiveUS7123898B2Easy to switchImprove reliabilityTransistorSolid-state devicesMOSFETDigital control

A novel RF buffer circuit adapted for use with an RF switch circuit and method for switching RF signals is described. The RF switch circuit is fabricated in a silicon-on-insulator (SOI) technology. The RF switch includes pairs of switching and shunting transistor groupings used to alternatively couple RF input signals to a common RF node. The switching and shunting transistor grouping pairs are controlled by a switching control voltage (SW) and its inverse (SW_). The switching and shunting transistor groupings comprise one or more MOSFET transistors connected together in a “stacked” or serial configuration. The stacking of transistor grouping devices, and associated gate resistors, increase the breakdown voltage across the series connected switch transistors and operate to improve RF switch compression. A fully integrated RF switch is described including digital control logic and a negative voltage generator integrated together with the RF switch elements. In one embodiment, the fully integrated RF switch includes a built-in oscillator, a charge pump circuit, CMOS logic circuitry, level-shifting and voltage divider circuits, and an RF buffer circuit. Several embodiments of the charge pump, level shifting, voltage divider, and RF buffer circuits are described. The inventive RF switch provides improvements in insertion loss, switch isolation, and switch compression.

Owner:PSEMI CORP

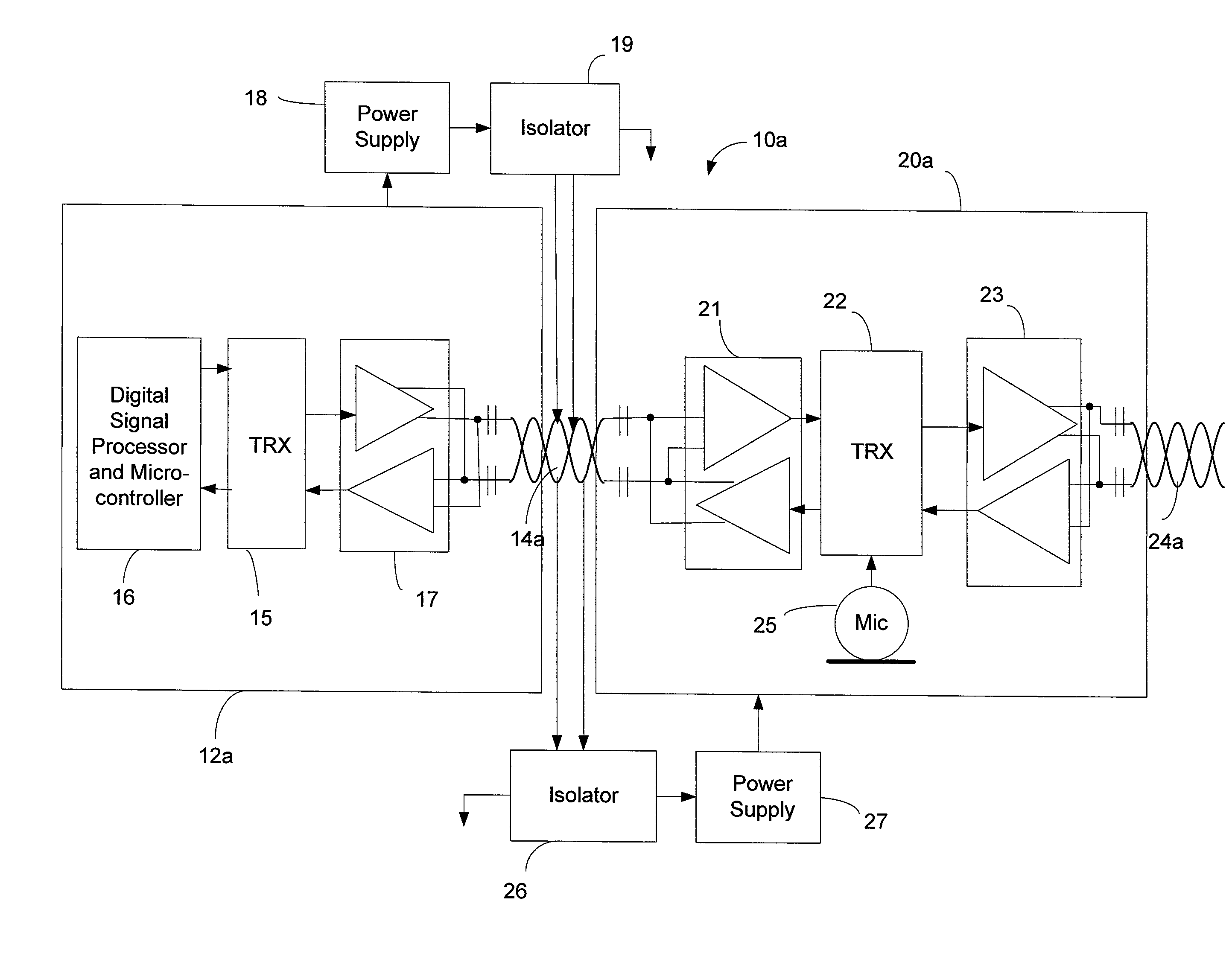

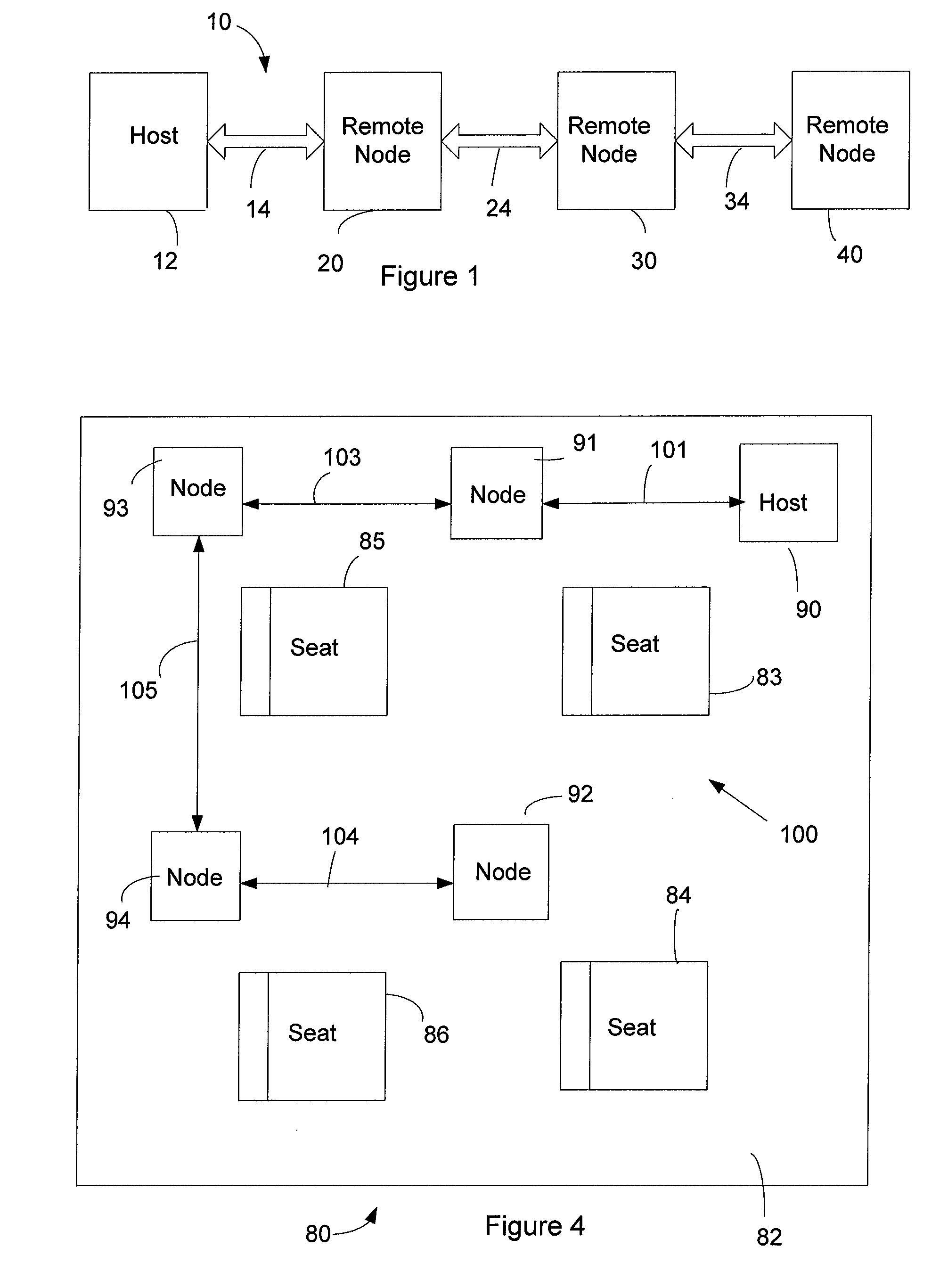

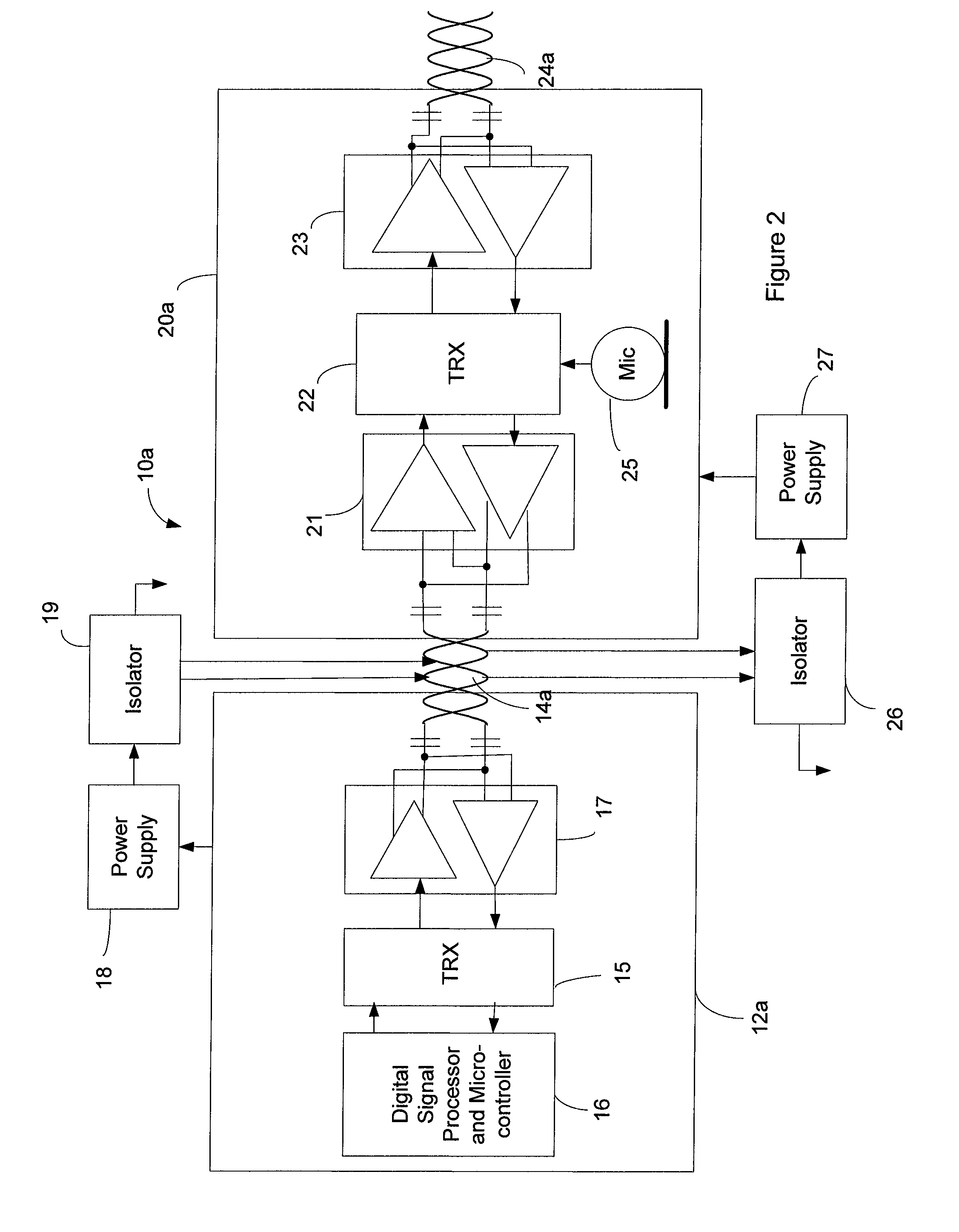

System for accomplishing bi-directional audio data and control communications

ActiveUS8615091B2Synchronisation information channelsAudio data retrievalTransceiverControl communications

A system for accomplishing bi-directional digital audio data and control communications. There is a host end that includes a host transceiver, a host digital signal processor that outputs a master clock signal and audio data, and a source of low-voltage power for the host components. There are a number of remote nodes connected together serially. Each remote node includes a transceiver and a low-voltage power supply that provides power to the other remote node components. A shielded two-wire communication network connects the host node to one of the remote nodes, and connects each remote node to either one or two other remote nodes in a daisy-chain configuration. The host end is enabled to transmit and receive over the communication network digital audio data and digital control signals. The remote nodes are each enabled to receive over the communication network digital audio data and digital control signals, and are each enabled to transmit over the communication network digital control signals. The source of low-voltage power at the host end is coupled to the communication network. The remote power supplies each have an input coupled to the communication network to derive the power for the remote nodes from the power coupled to the network by the host end.

Owner:BOSE CORP

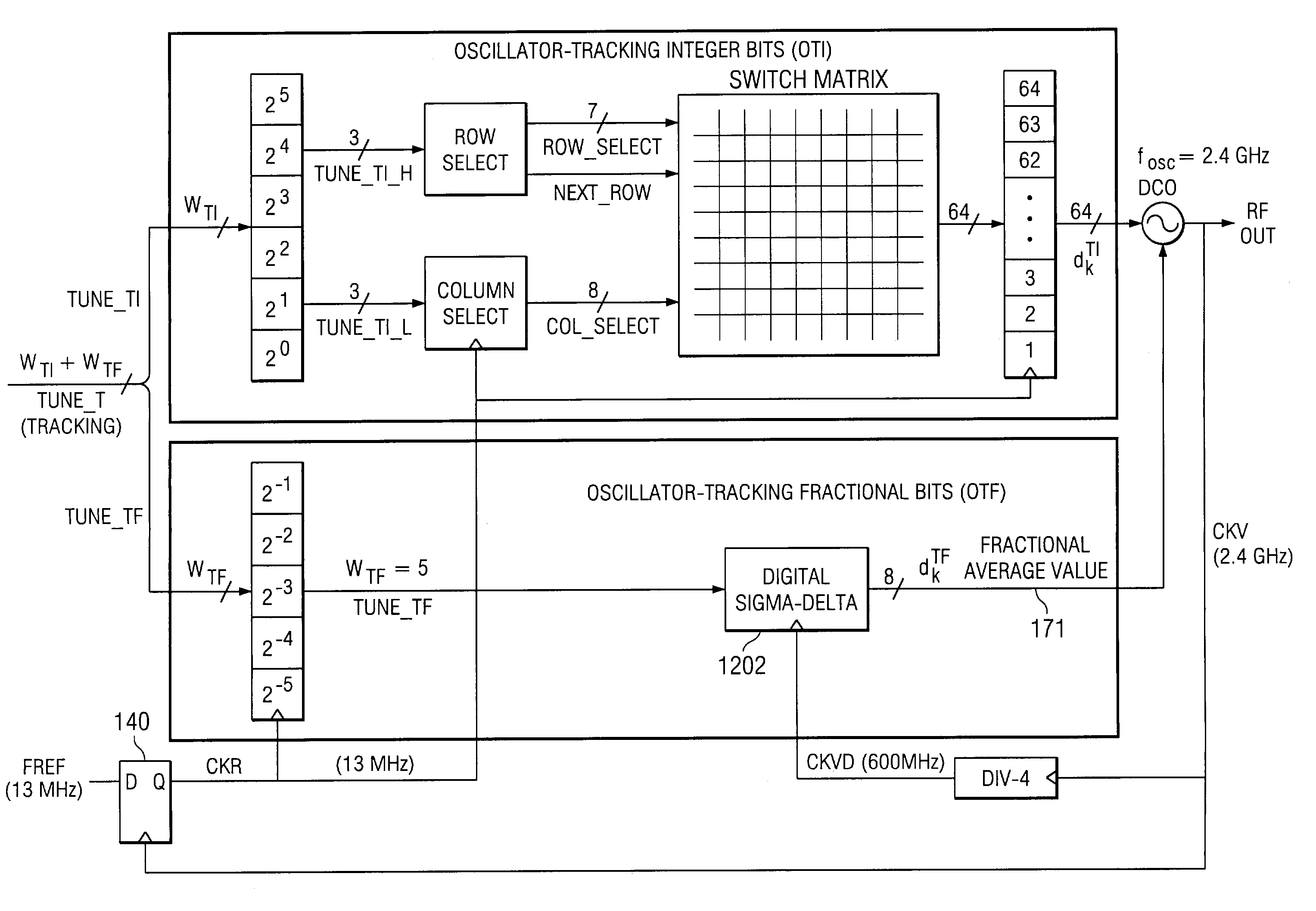

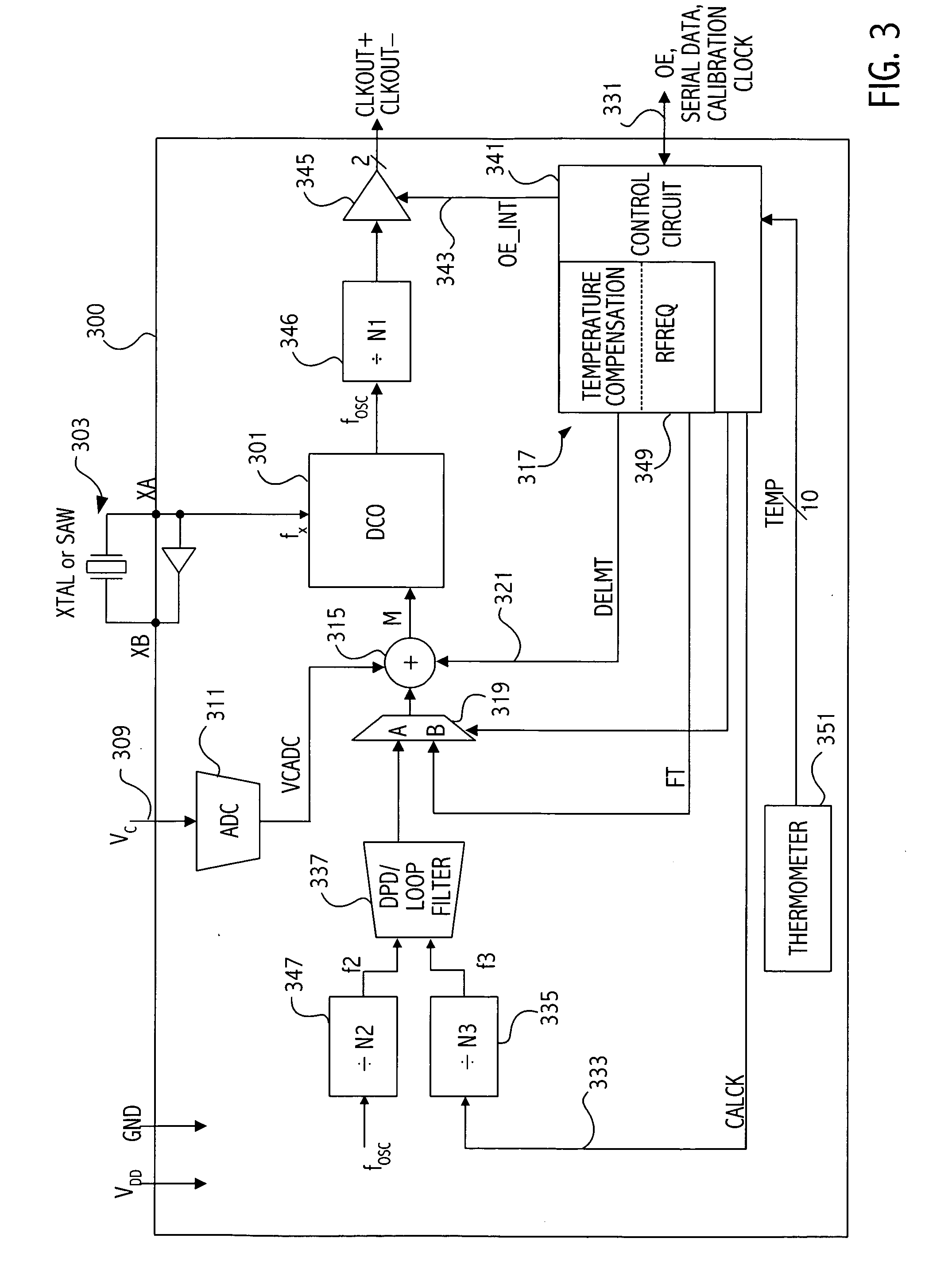

All-digital frequency synthesis with capacitive re-introduction of dithered tuning information

An all-digital frequency synthesizer architecture is built around a digitally controlled oscillator (DCO) that is tuned in response to a digital tuning word (OTW). In exemplary embodiments: (1) a gain characteristic (KDCO) of the digitally controlled oscillator can be determined by observing a digital control word before and after a known change (Δfmax) in the oscillating frequency; and (2) a portion (TUNE_TF) of the tuning word can be dithered (1202), and the resultant dithered portion(dkTF)can then be applied to a control input of switchable devices within the digitally controlled oscillator.

Owner:TEXAS INSTR INC

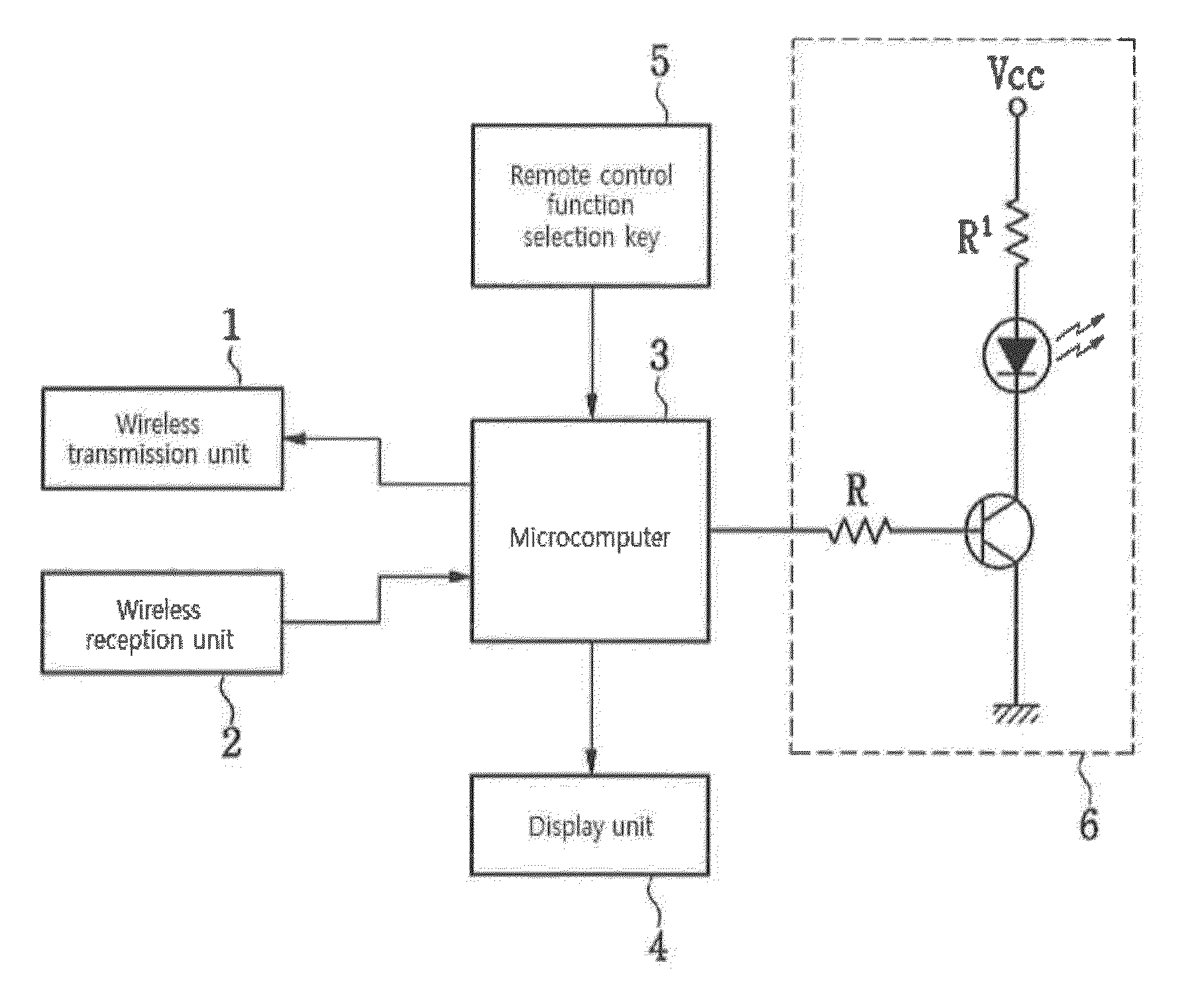

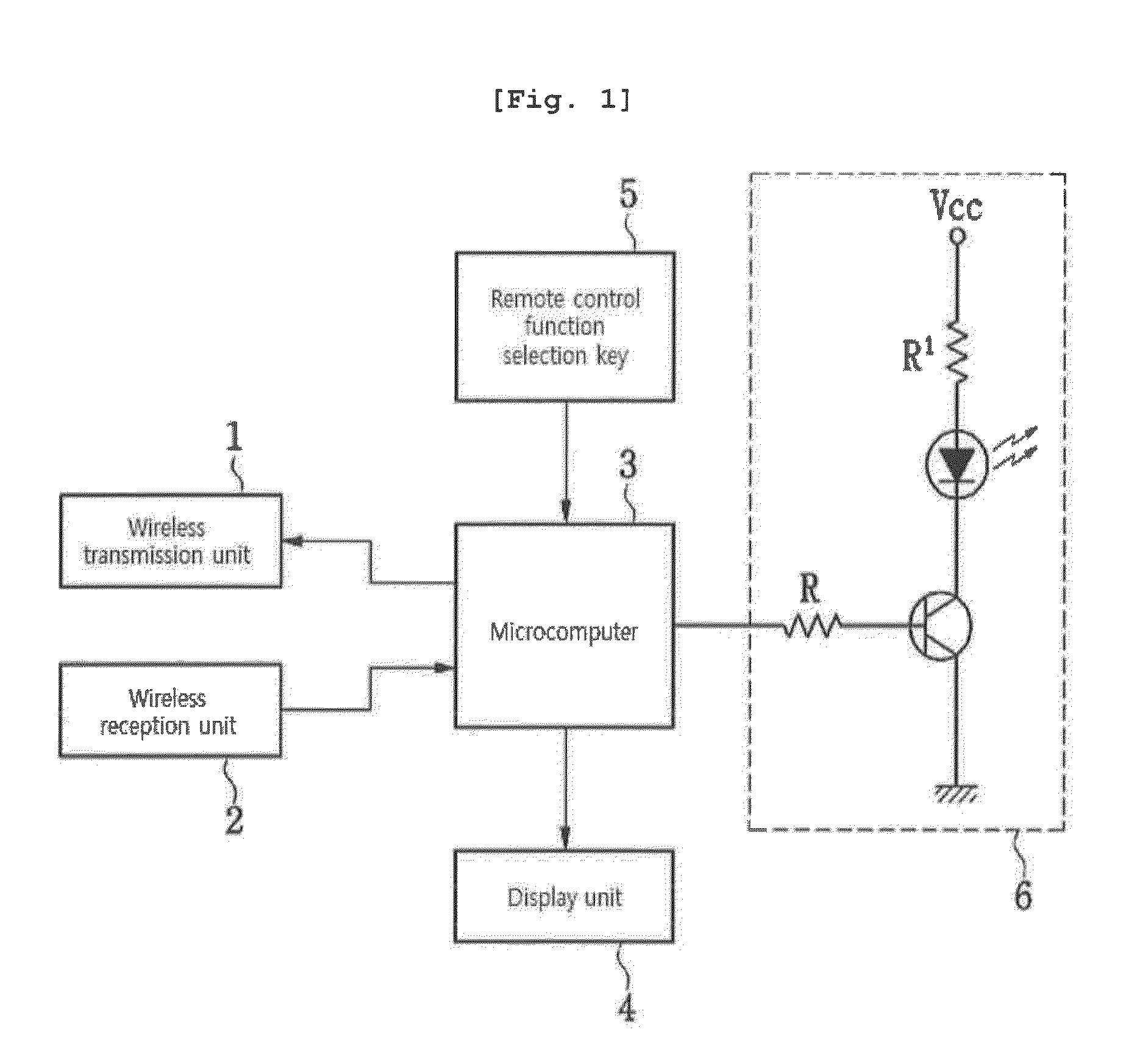

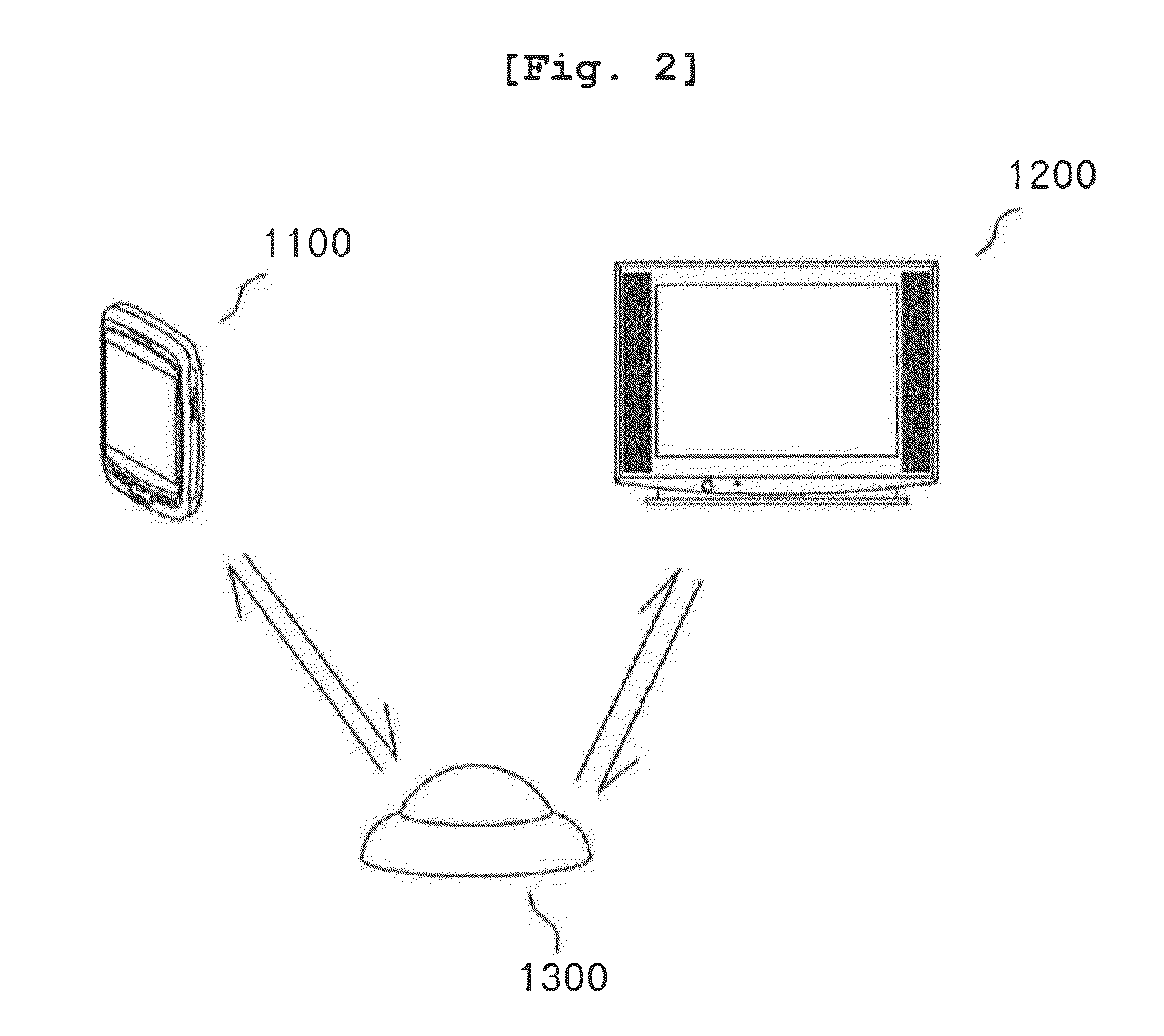

Digital device control system using smart phone

InactiveUS20130171981A1Low costEasy to downloadEnergy efficient ICTNon-electrical signal transmission systemsFar distanceEngineering

There is provided a digital device control system using a smart phone, including a smart phone having an application of a remote control function, a digital device of which on / off of a power supply, channel or volume is controlled according to a signal received from the smart phone, and an IR repeater functioning as a central control unit connected to the smart phone through Bluetooth or Wi-Fi communication and connected to the digital device through a plurality of infrared ray communications in order to remotely control the digital device, and therefore, the digital device can be controlled using the smart phone instead of a remote controller. In addition, since a plurality of LEDs capable of performing infrared ray communication is included in the IR repeater so as to transmit and receive an infrared signal of a wide range, a digital device desired to be controlled can be remotely controlled even when the digital device is placed at a far distance or at a blind spot in a room, and a plurality of digital devices can be controlled simultaneously.

Owner:DIGIENCE +1

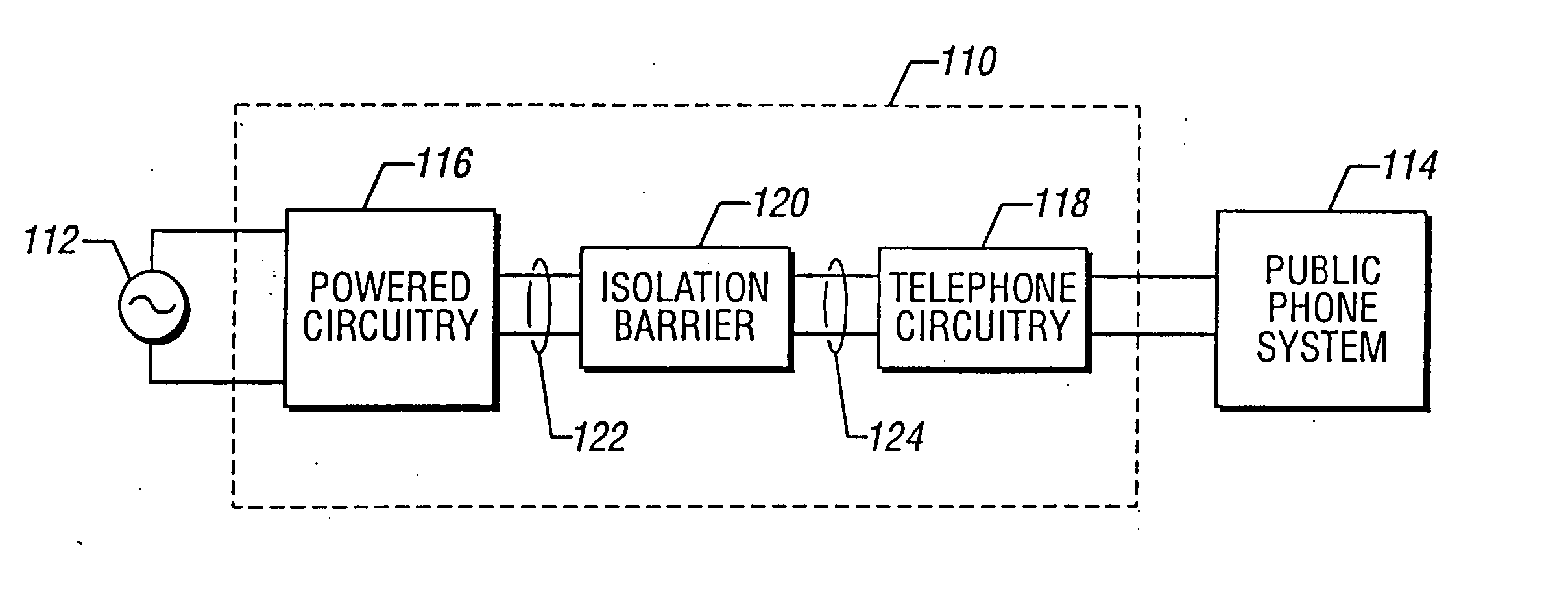

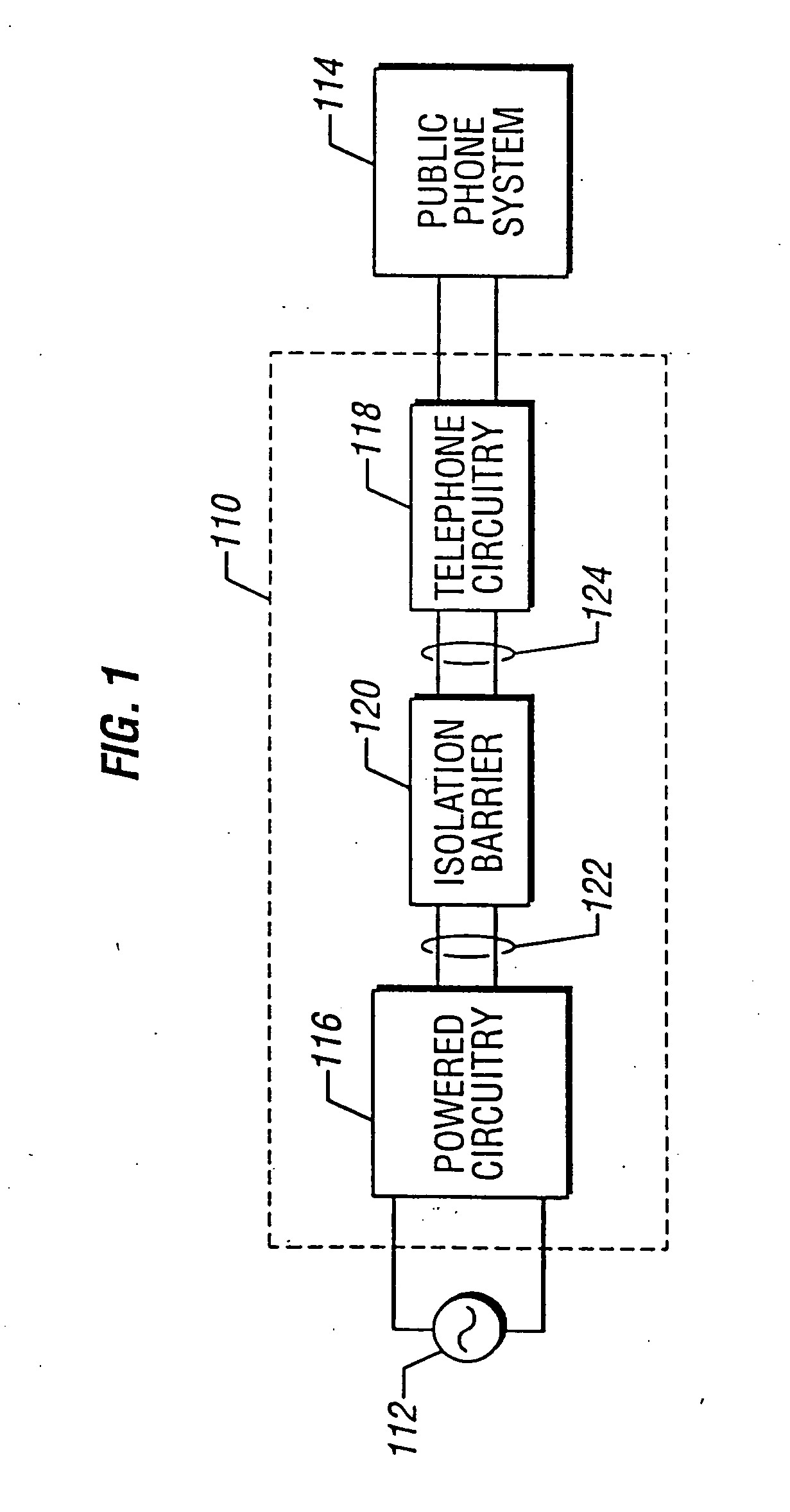

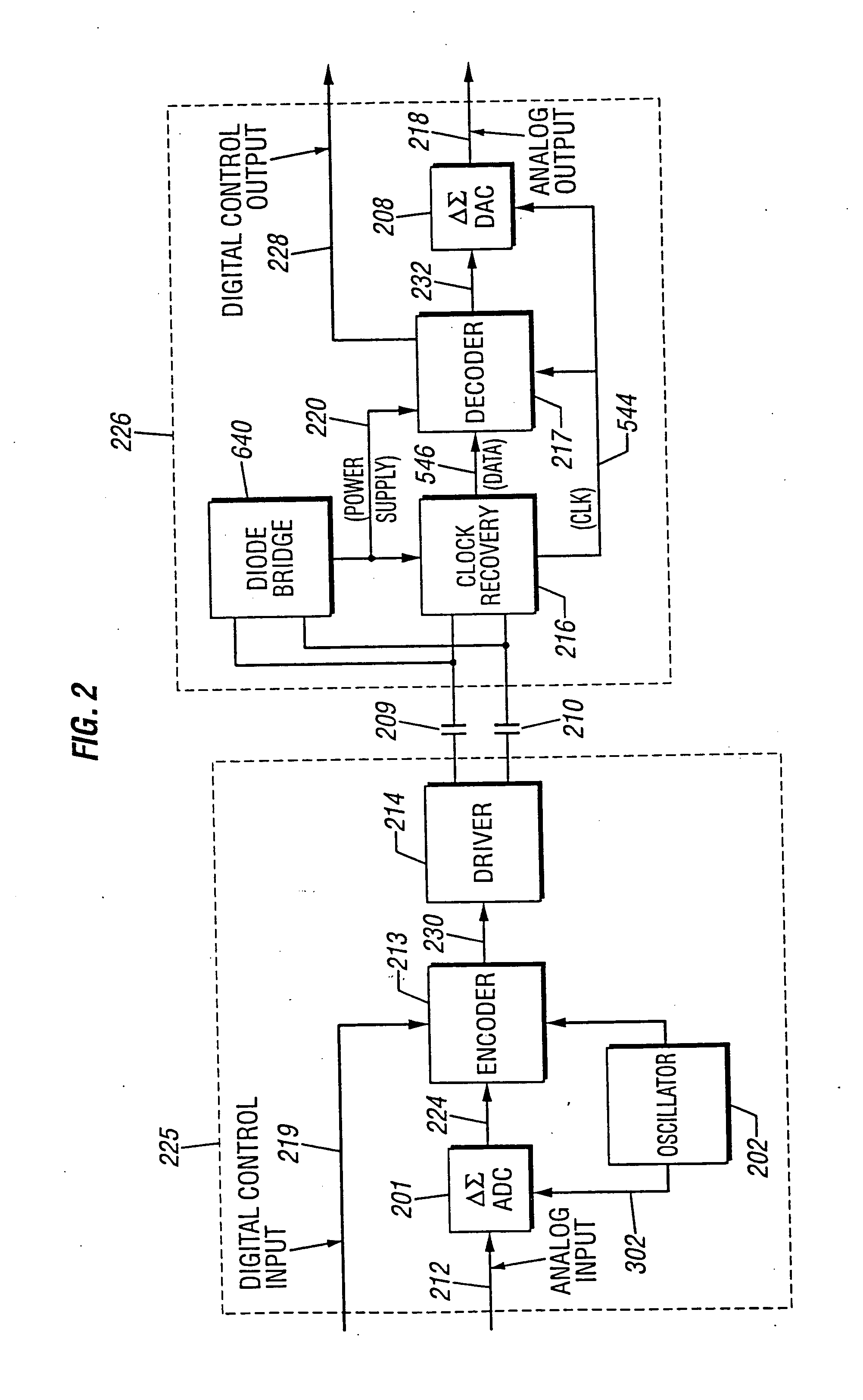

Direct digital access arrangement circuitry and method for connecting DSL circuitry to phone lines

InactiveUS20050036604A1Exact reproductionInterconnection arrangementsDc level restoring means or bias distort correctionCapacitanceDigital data

An isolation system is provided that is suitable for use in telephony, medical instrumentation, industrial process control and other applications. Preferred embodiments of the invention comprise a capacitive isolation barrier across which a digital signal is communicated. The system provides a means of communication across the isolation barrier that is highly immune to amplitude and phase noise interference. Clock recovery circuitry may be employed on one side of the isolation barrier to extract timing information from the digital signal communicated across the barrier, and to filter the effects of phase noise introduced at the barrier. Delta-sigma converters may be disposed on both sides of the isolation barrier to convert signals between analog and digital domains. An isolated power supply may also be provided on the isolated side of the barrier, whereby direct current is generated in response to the digital data received across the isolation barrier. A bidirectional isolation system is provided whereby bidirectional communication of digital signals is accomplished using a single pair of isolation capacitors. In preferred embodiments, the digital data communicated across the barrier consists of digital delta-sigma data signals multiplexed in time with other digital control, signaling and framing information. Finally, the isolation system may include a pulse transformer to accommodate ADSL circuitry, whereby power is transmitted through the pulse transformer.

Owner:SILICON LAB INC

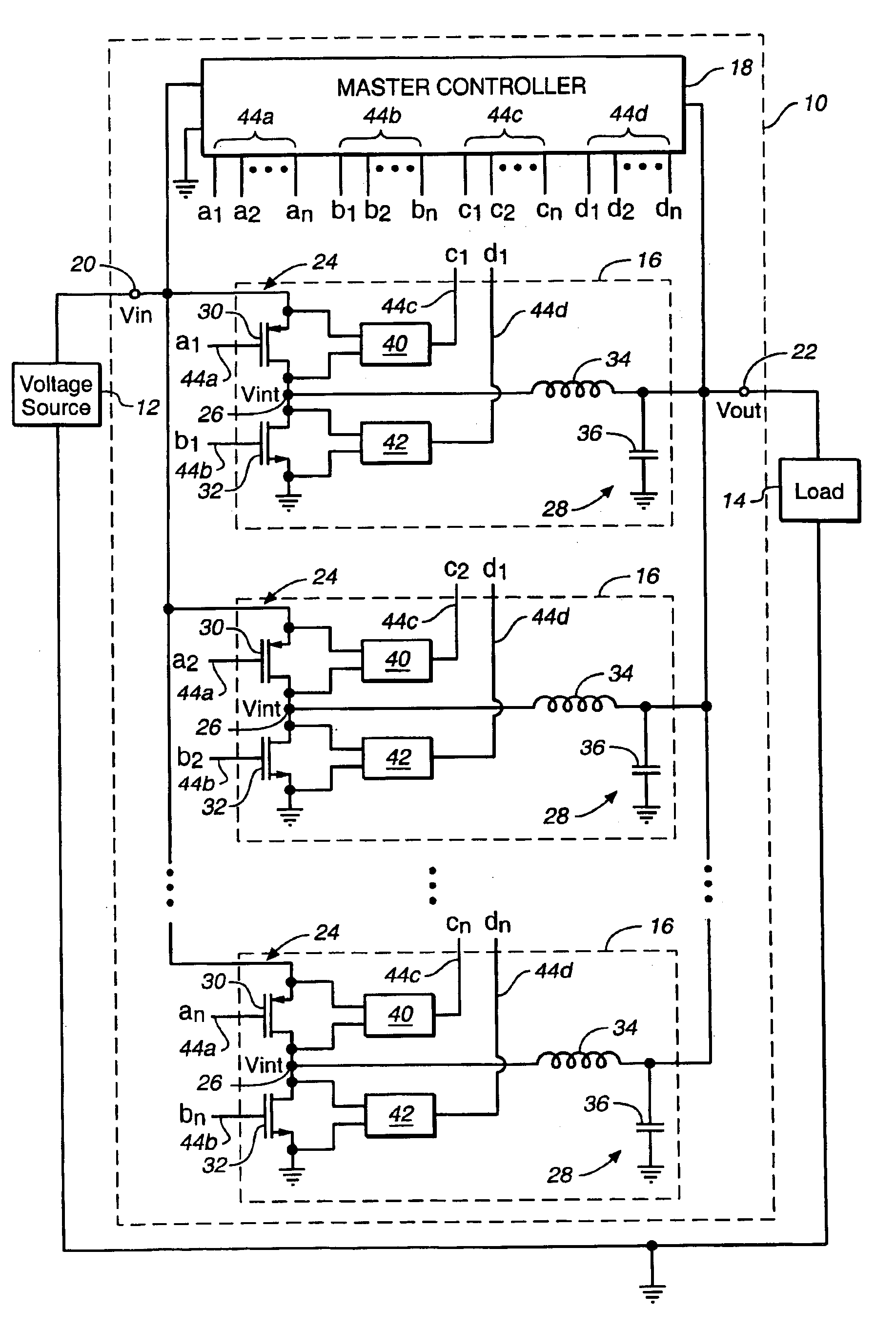

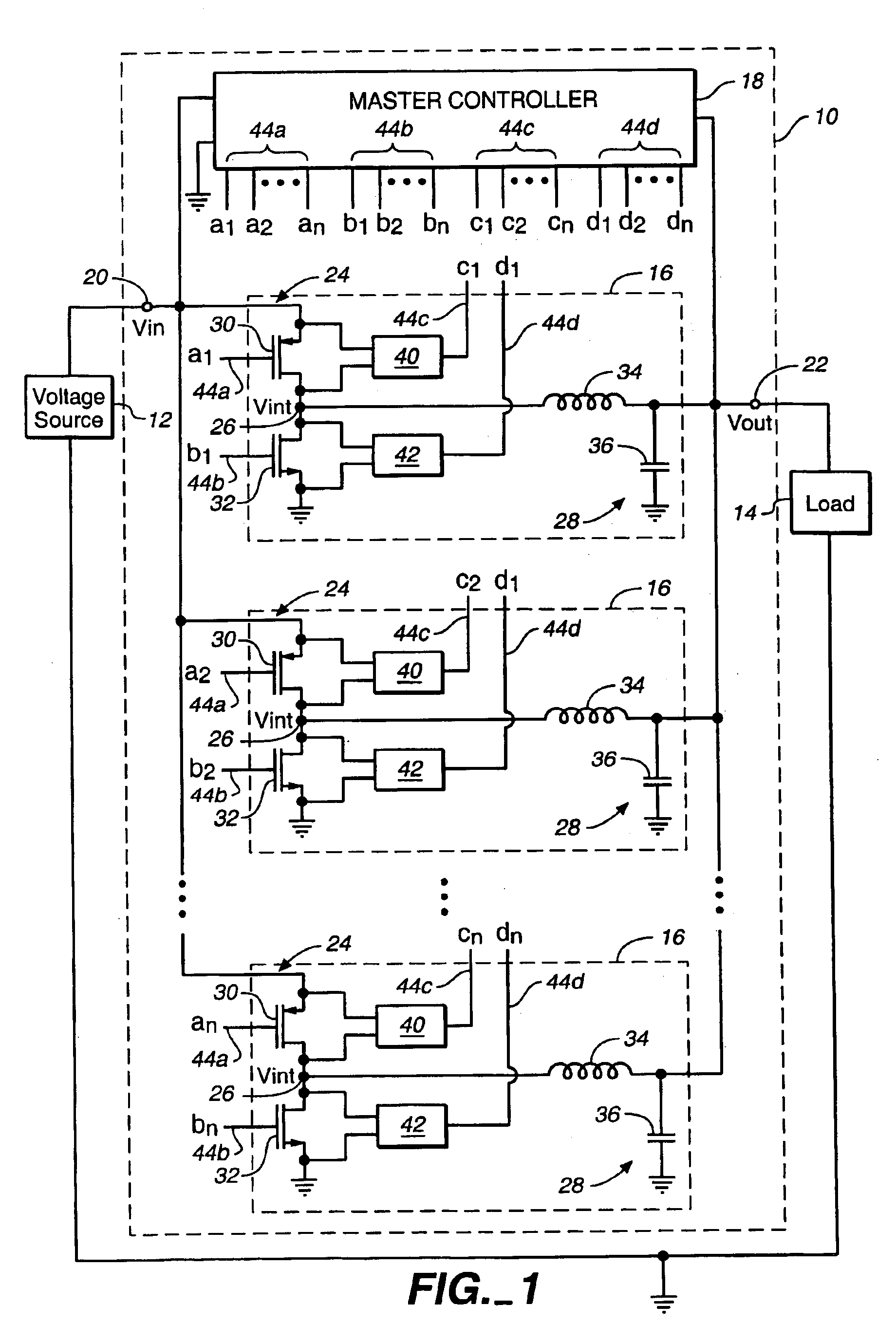

Digital voltage regulator using current control

InactiveUS6853169B2Reduce current rippleReduce in quantityApparatus without intermediate ac conversionDc source parallel operationDigital feedbackControl signal

A digitally implemented voltage regulator having including a plurality of slaves coupled in parallel. Each slave includes a switching circuit that intermittently couples an input terminal and an output terminal of the voltage regulator in response to a digital control signal for the corresponding slave. A current sensor in each slave generates a digital first feedback signal derived from the current passing through the corresponding switching circuit. A digital controller receives and uses the digital feedback signals from the plurality of slaves to generate a digital control signal for each slave. The digital controller operates active slaves of the plurality of slaves at determined phase offsets to minimize voltage ripple and maintain the output voltage at the output terminal at a substantially constant level.

Owner:VOLTERRA SEMICONDUCTOR

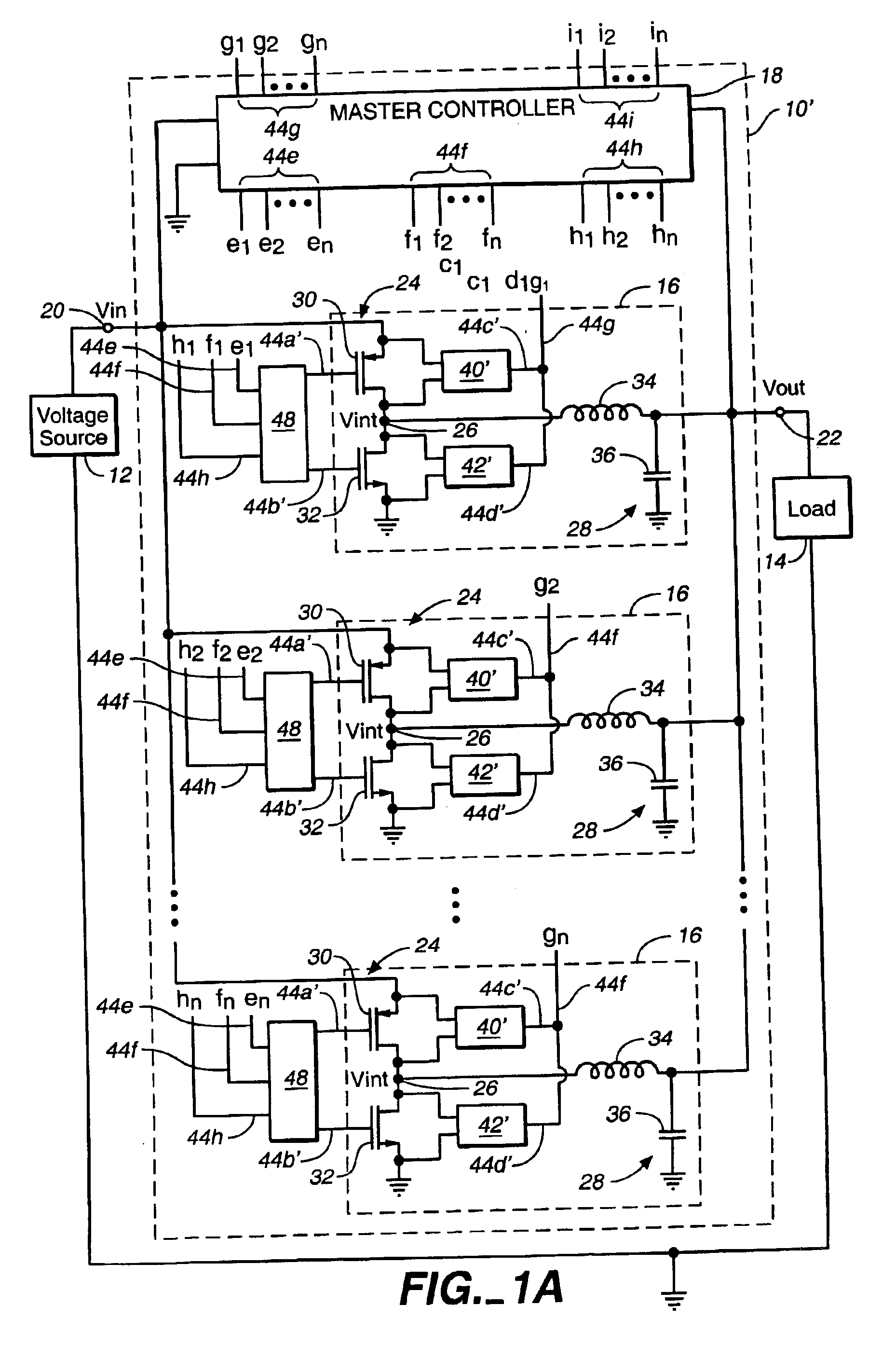

Dual loop architecture useful for a programmable clock source and clock multiplier applications

InactiveUS20040232995A1Pulse automatic controlGenerator stabilizationFrequency multiplierDigital control

A first phase-locked loop (PLL) circuit includes an input for receiving a timing reference signal from an oscillator, a controllable oscillator circuit supplying an oscillator output signal, and a multi-modulus feedback divider circuit. A second control loop circuit is selectably coupled through a select circuit to supply a digital control value (M) to the multi-modulus feedback divider circuit of the first loop circuit to thereby control the oscillator output signal. While the second control loop is coupled to supply the control value to the feedback divider circuit, the control value is determined according to a detected difference between the oscillator output signal and a reference signal coupled to the second control loop circuit at a divider circuit. While the second control loop circuit is not coupled to control the first PLL circuit, the first PLL circuit receives a digital control value to control a divide ratio of the feedback divider, the digital control value is determined at least in part according to a stored control value stored in nonvolatile storage, the stored control value corresponding to a desired frequency of the oscillator output signal.

Owner:SKYWORKS SOLUTIONS INC

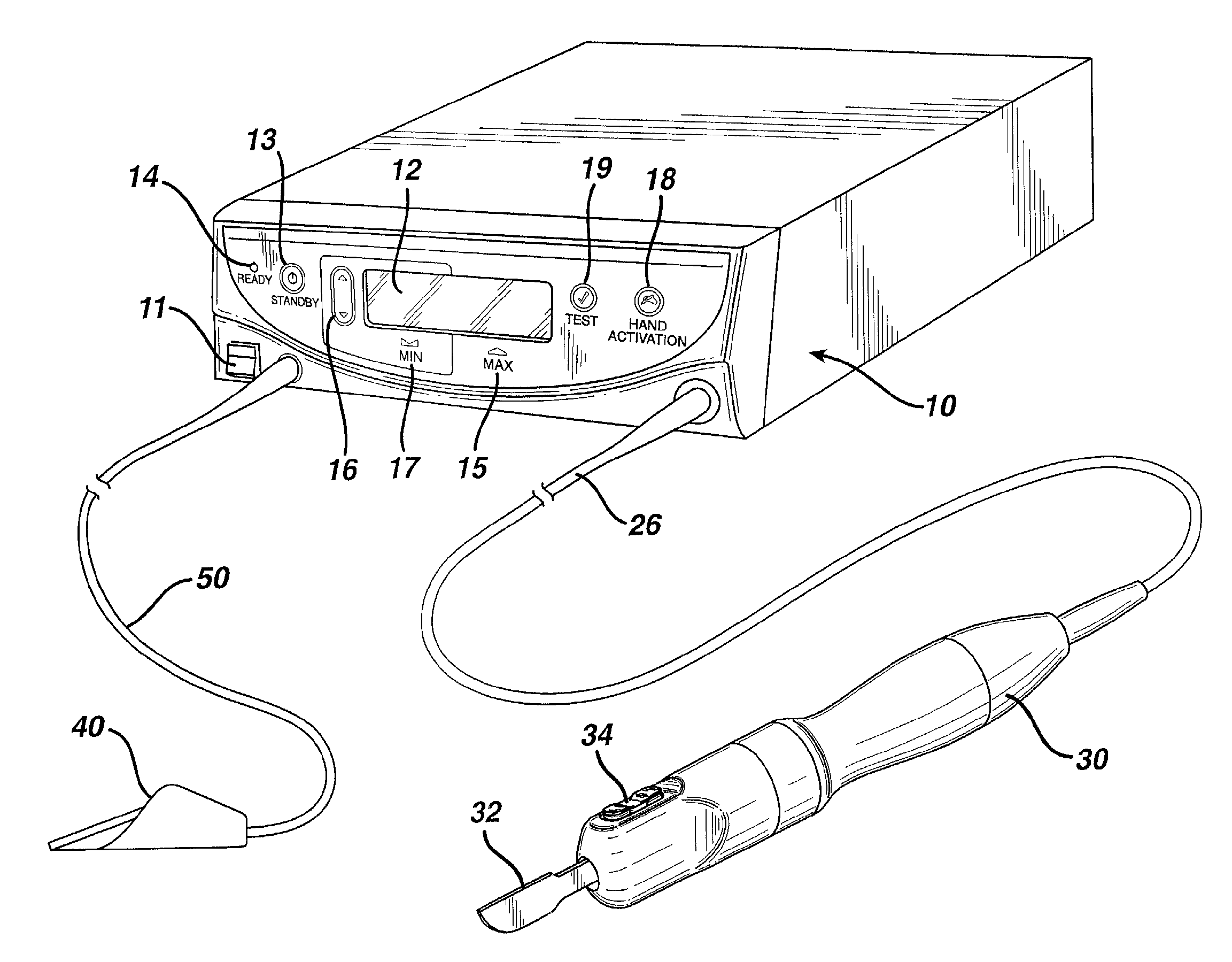

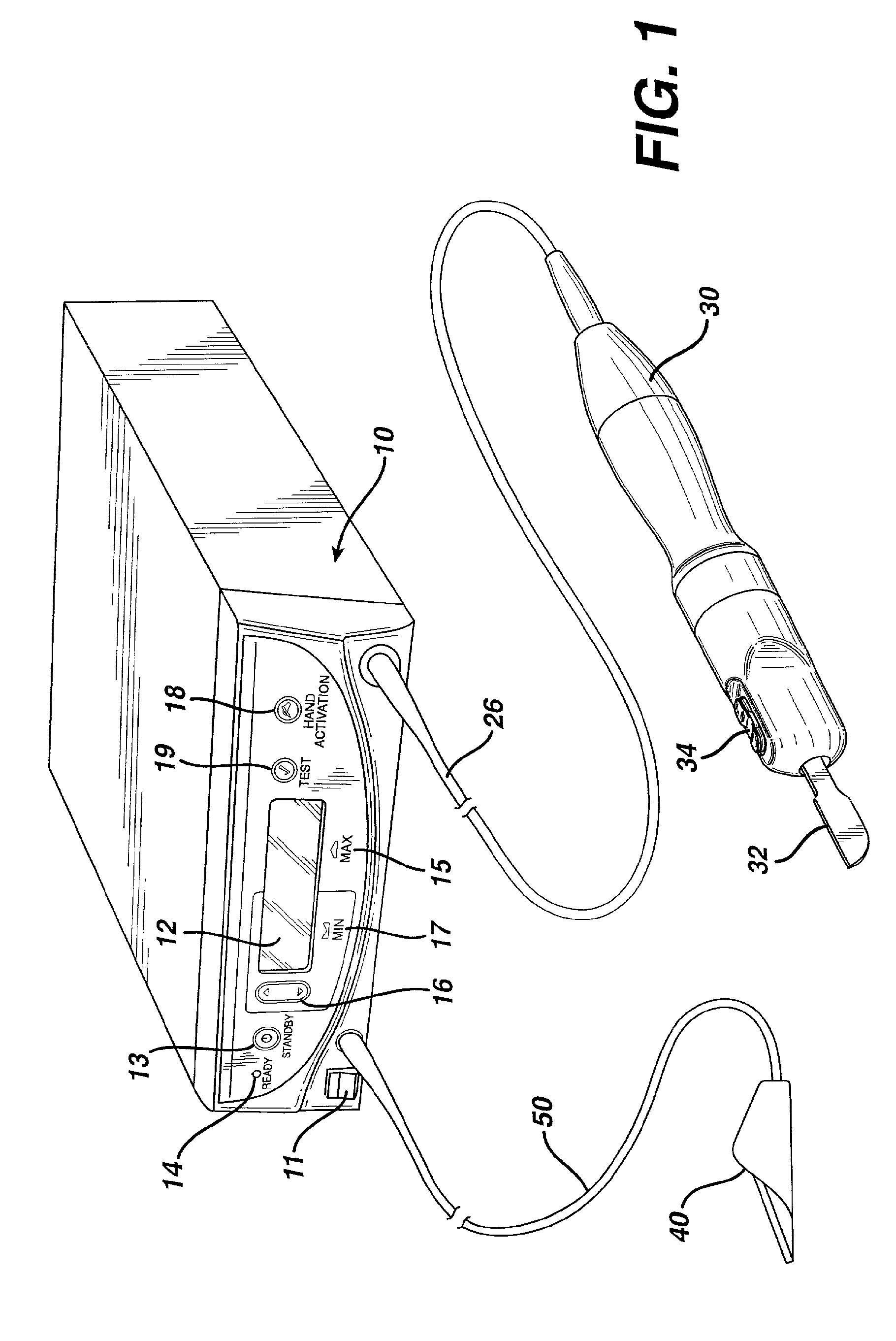

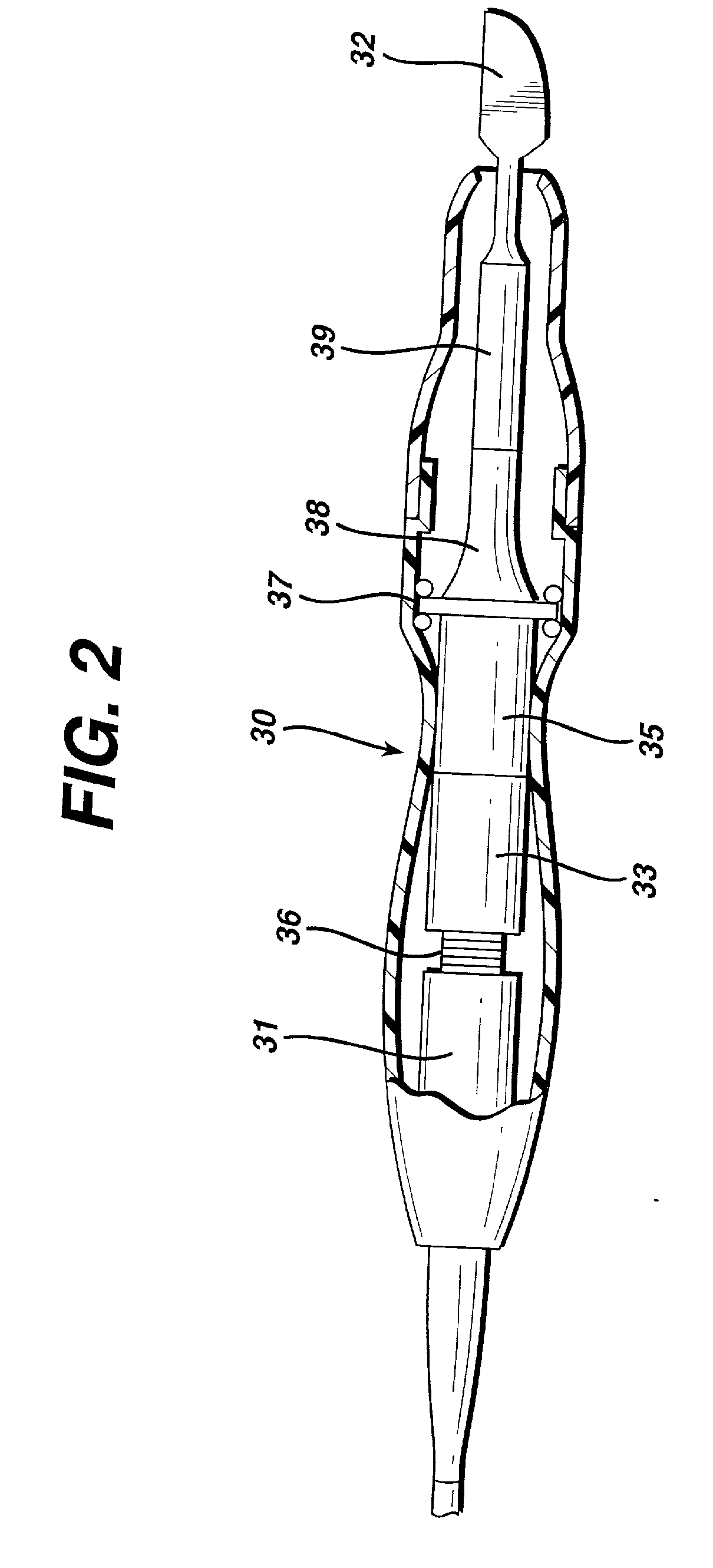

Ultrasonic surgical system

InactiveUS20100125292A1Inconsistent performanceLower capability requirementsSurgerySurgical operationDigital signal processing

An ultrasonic surgical system utilizes a digital control system to generate ultrasonic drive current for transducers that are located in a hand piece and are attached to a surgical scalpel or blade in the hand piece so as to vibrate the blade in response to the current. The digital control includes a digital signal processor (DSP) or microprocessor; a direct digital synthesis (DDS) device; a phase detection logic scheme, a control algorithm for seeking and maintaining resonance frequency; and design scheme that allows to regulate current, voltage, and power delivered to an ultrasonic thereby a device. Such system allows the power versus load output curve to be tailored to a specific hand piece, which improves efficiency and reduces heat. Further, the components of the digital system are much less sensitive to temperature variations, thereby allowing it to operate with narrow as needed frequency range around the desired resonance in order to avoid excitation of other resonances. Also, the digital system provides increased flexibility in locating the resonance frequency of the blade and running diagnostic tests. The start of a user initiated diagnostic test that requires movement of the blade is caused by operating two of the system switches, which guards against accidental operation of the blade which could be harmful if in contact with tissue and also generate false diagnostic results. In addition, the system has interlock with an Electrosurgical unit so that it is not effected by the electromagnetic interference generated by that unit.

Owner:WIENER EITAN T +1

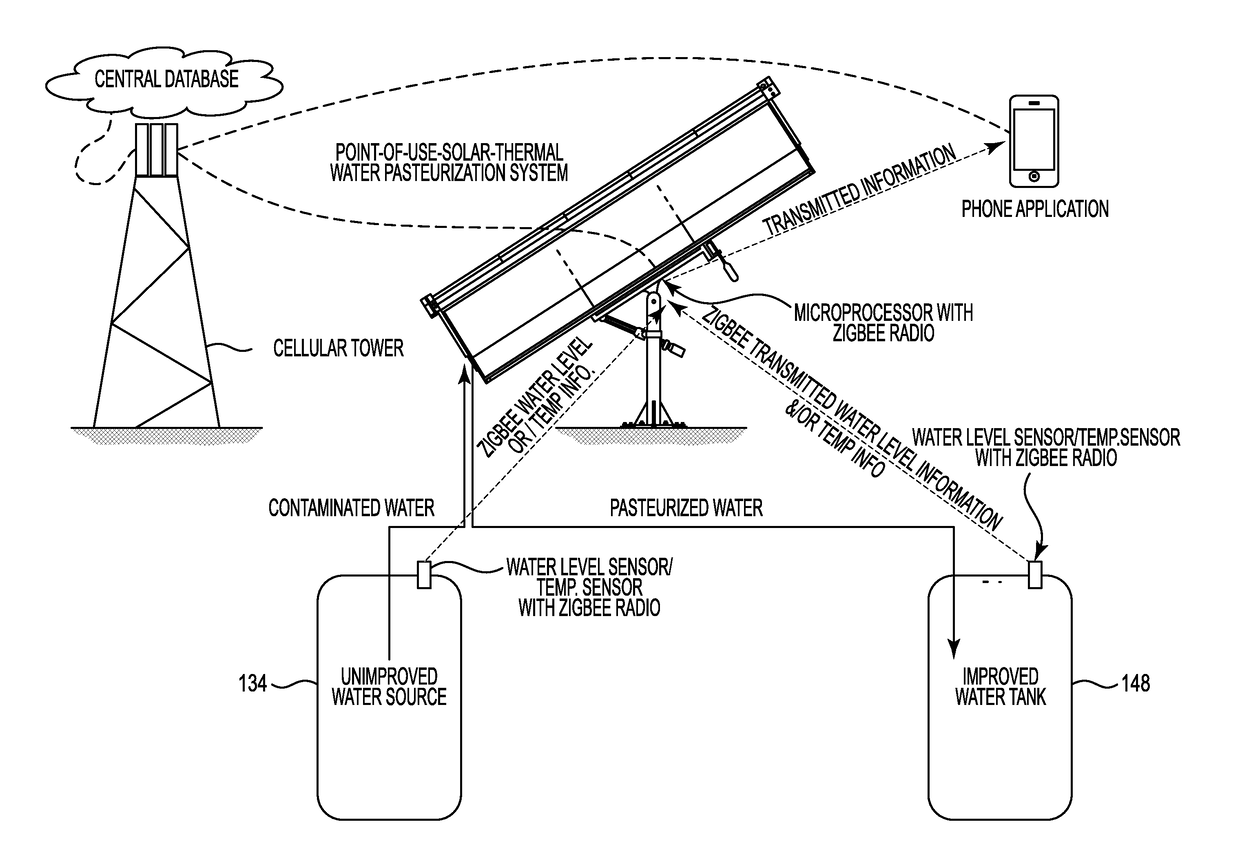

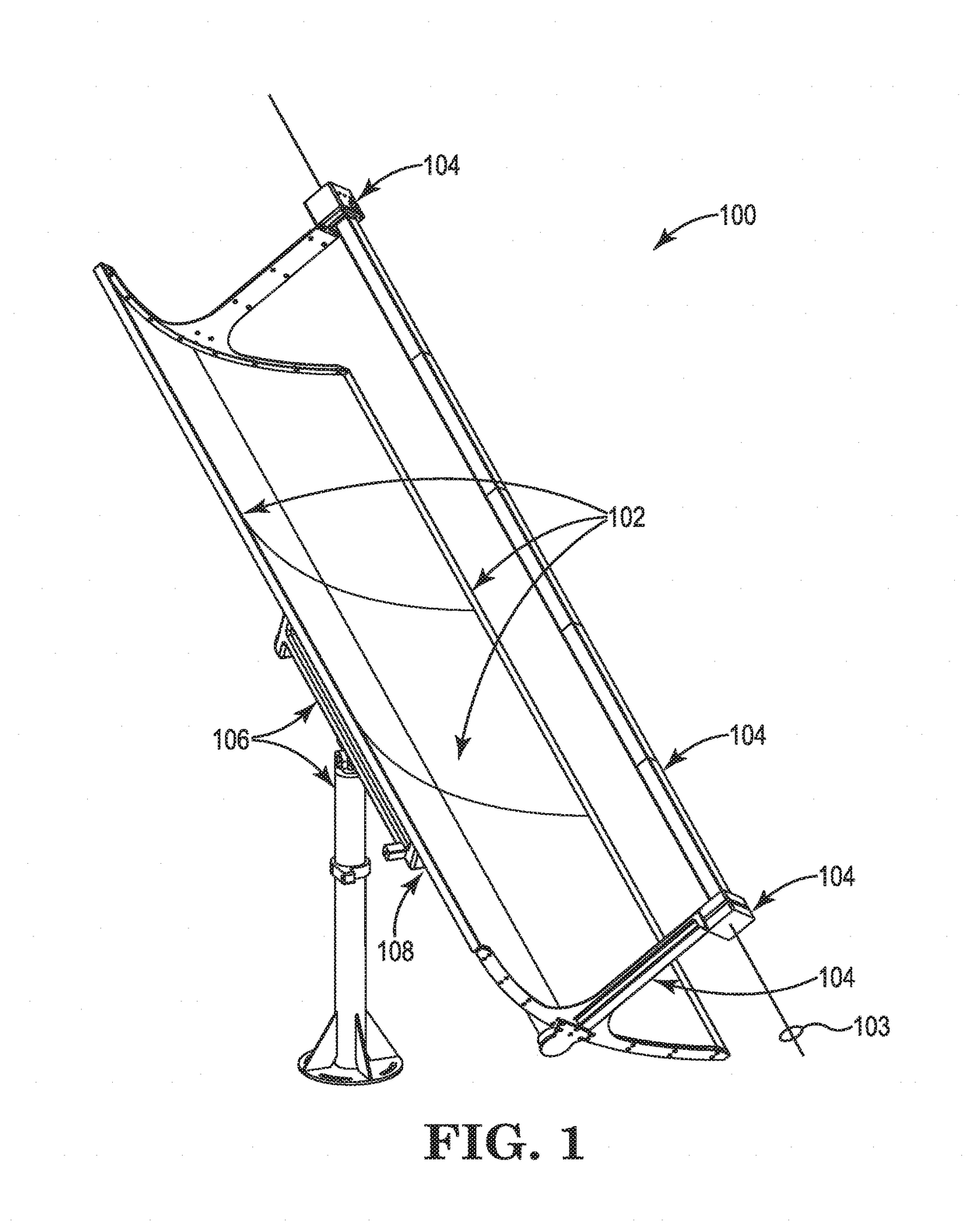

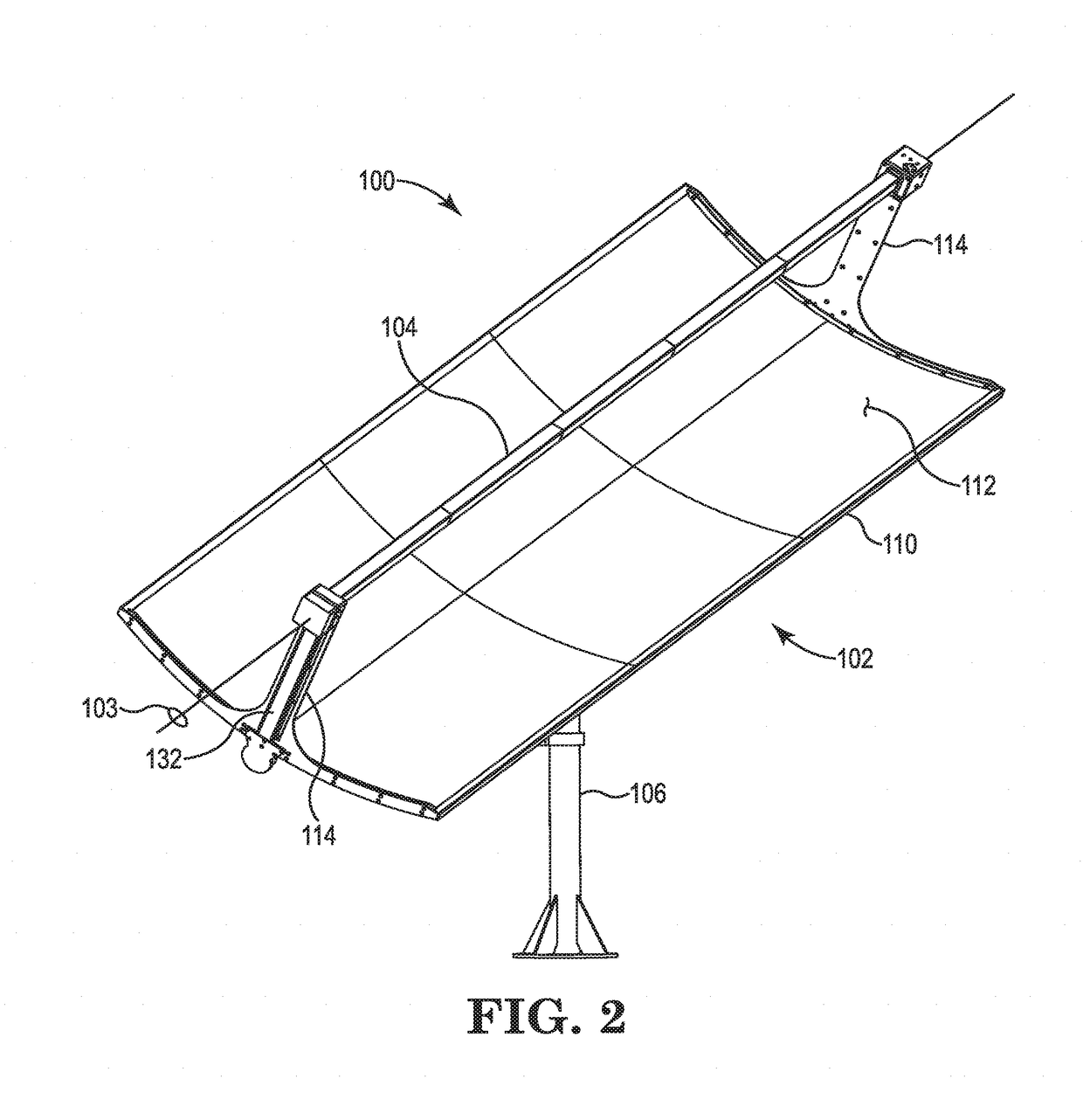

Digital fluid heating system

ActiveUS20180142905A1Solar heating energyGeneral water supply conservationAutomatic controlCommunications system

A digital fluid heating system may include a solar collection system configured for focusing sunlight on a focal axis, an elongated flow element arranged and configured for transporting fluid along the solar collection system at the focal axis, and a flow-control assembly comprising a digitally controlled valve configured to control the flow of the fluid in the elongated flow element such that pathogens present in the fluid are substantially inactivated before the fluid exits the fluid heating system and at a maximized flow rate under the given energy providing conditions. The system may also include one or more digital controls and communication systems for remote and / or automatic control.

Owner:WTS

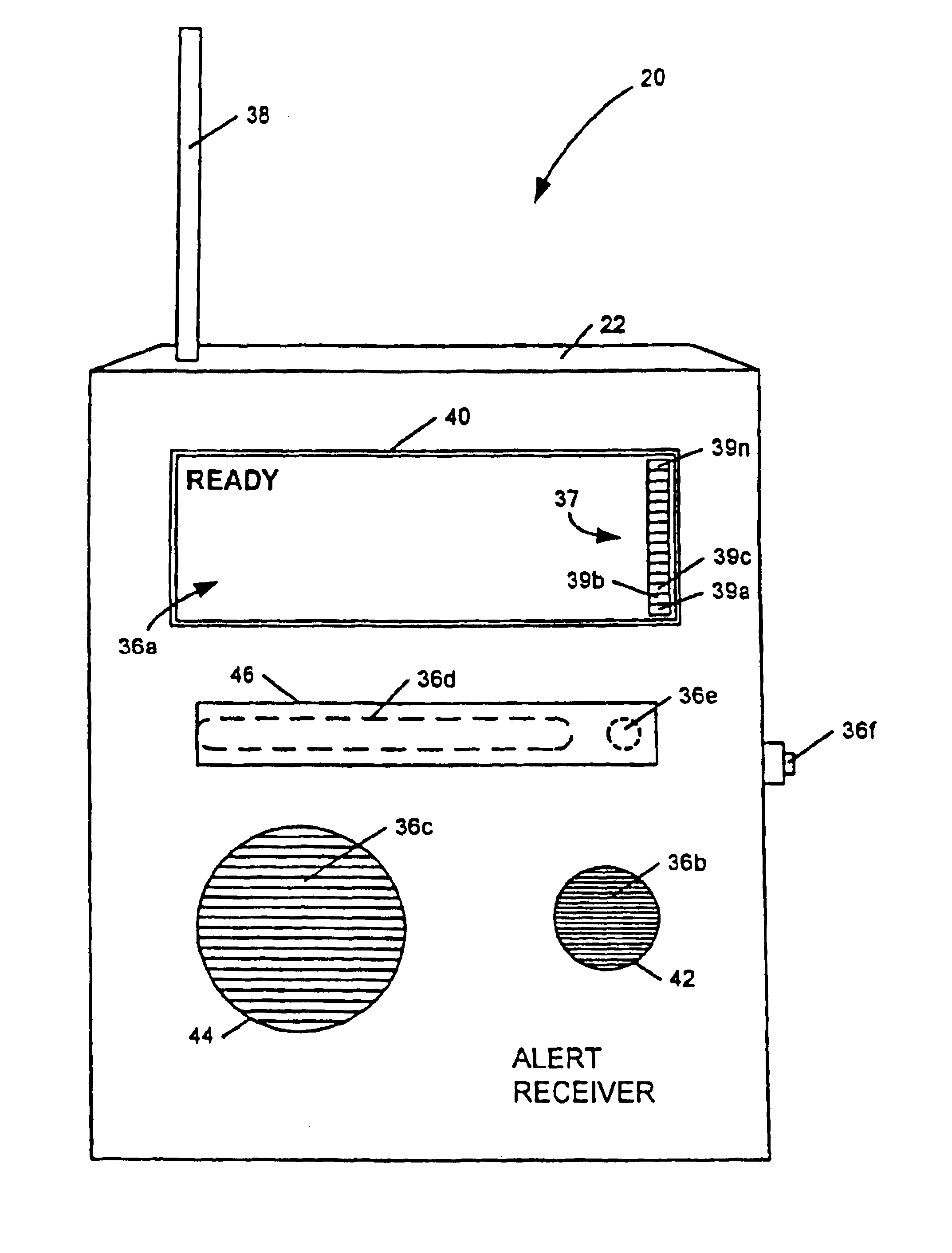

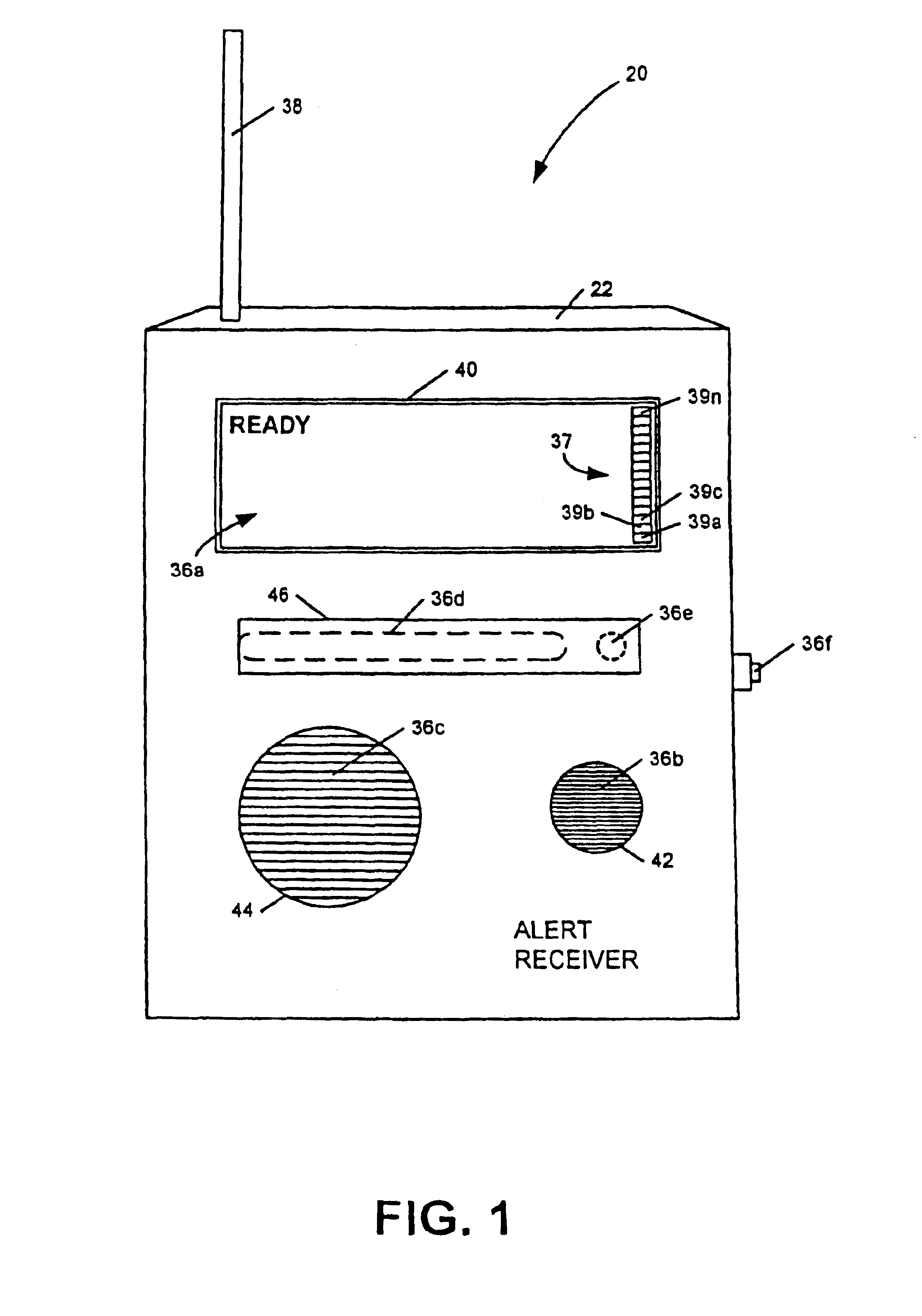

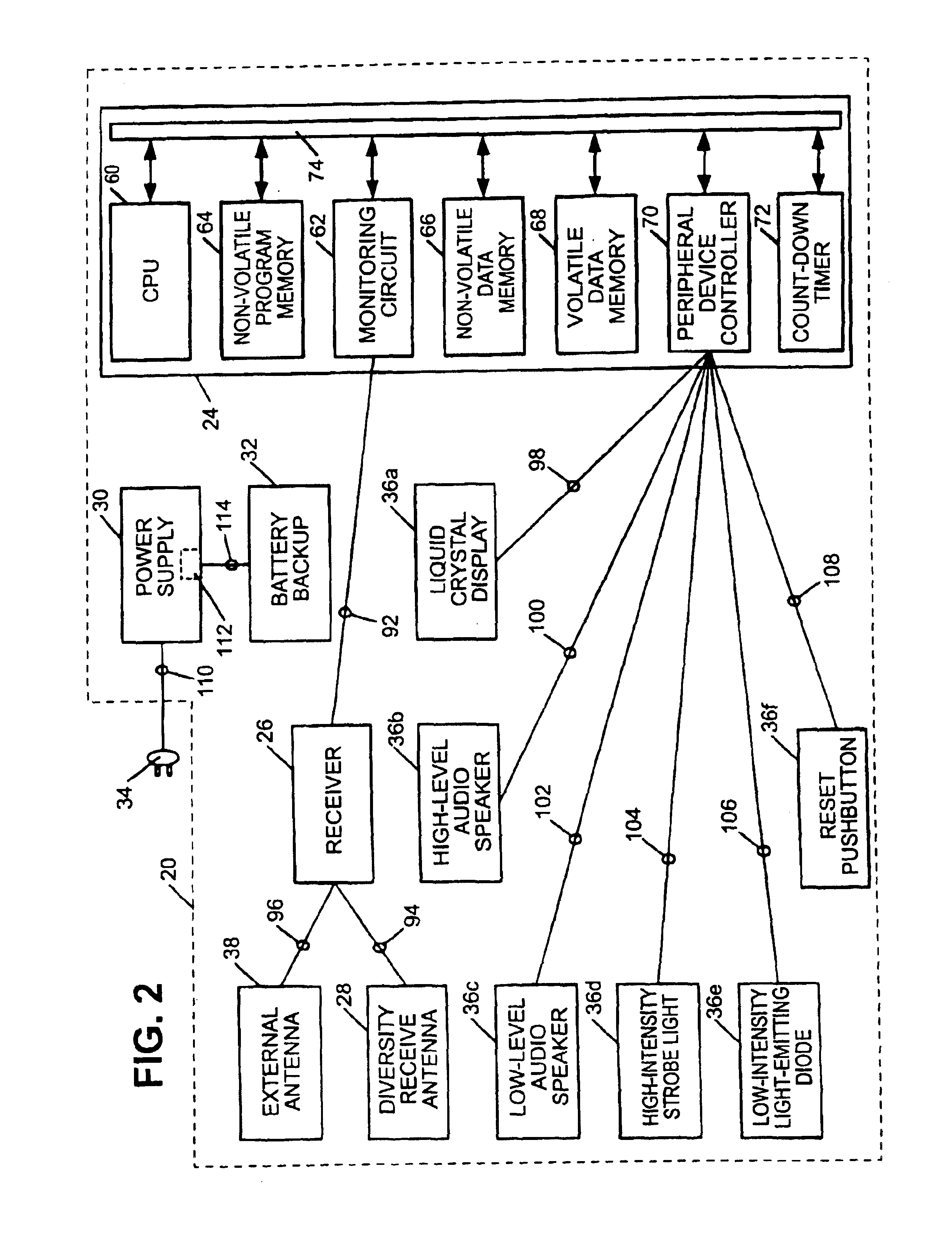

Apparatus and method for providing weather and other alerts

InactiveUS6867688B2Increase signal strengthPrecise functionFrequency-division multiplex detailsTime-division multiplexMicrocomputerTelecommunications network

An apparatus, including an alert device having a receiver, and method are provided for receiving alert information broadcast via particular telecommunication transmitters operating within a cellular, PCS, or other wireless telecommunications network, thereby allowing delivery of a message. The alert device includes a receiver for receiving digital messages in the form of broadcast messages on a digital control channel, a microcomputer having a monitoring circuit that monitors received digital messages for the presence of an alert code associated with alert messages regarding an alert condition, and a plurality of peripheral devices which produce various tones and flashing lights in response to the alert device's reception of an appropriate alert message. The alert device can be provisioned over the air to respond to particular preferred system providers and controlled user groups. The alert device can also control and external device to provide a warning to the user.

Owner:SAFETY THROUGH CELLULAR +1

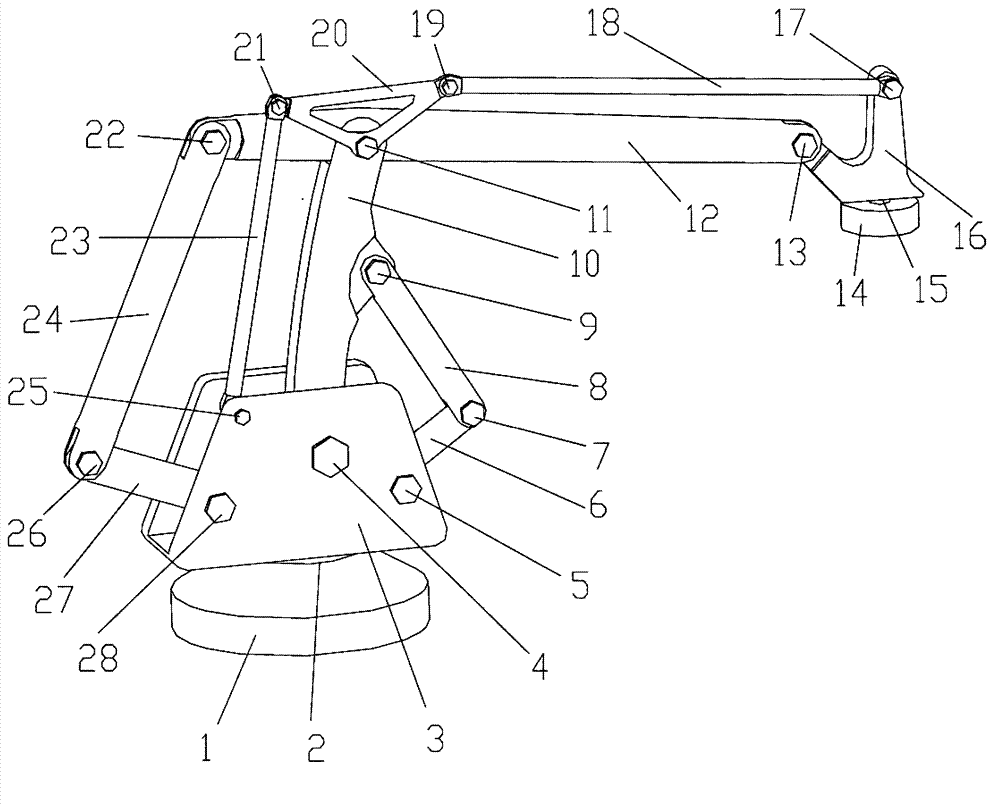

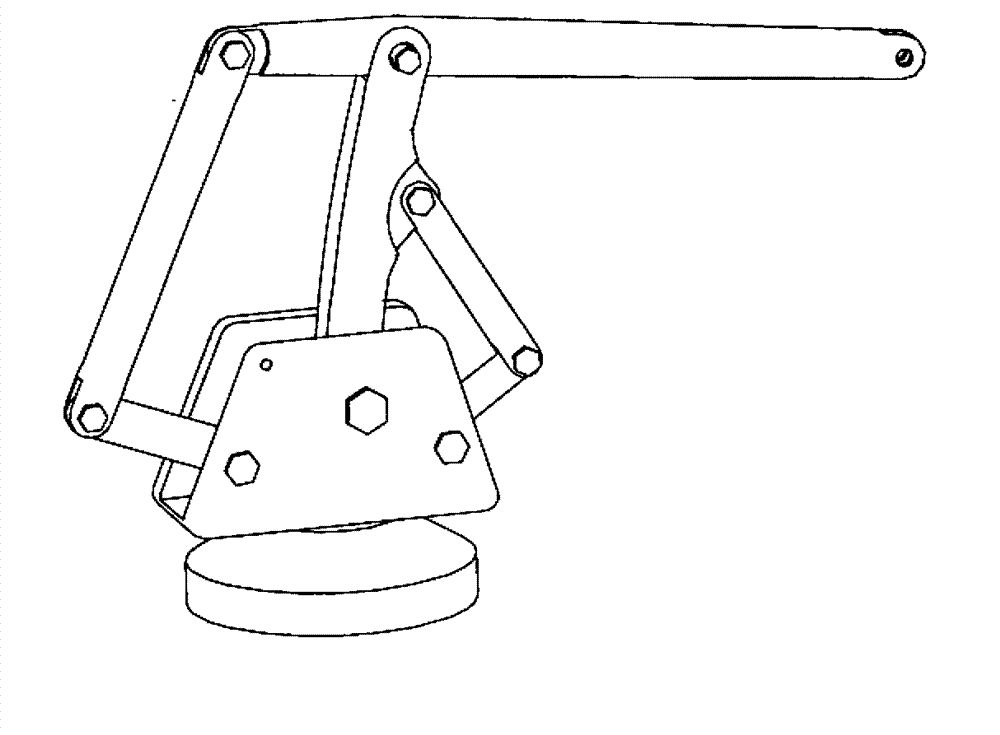

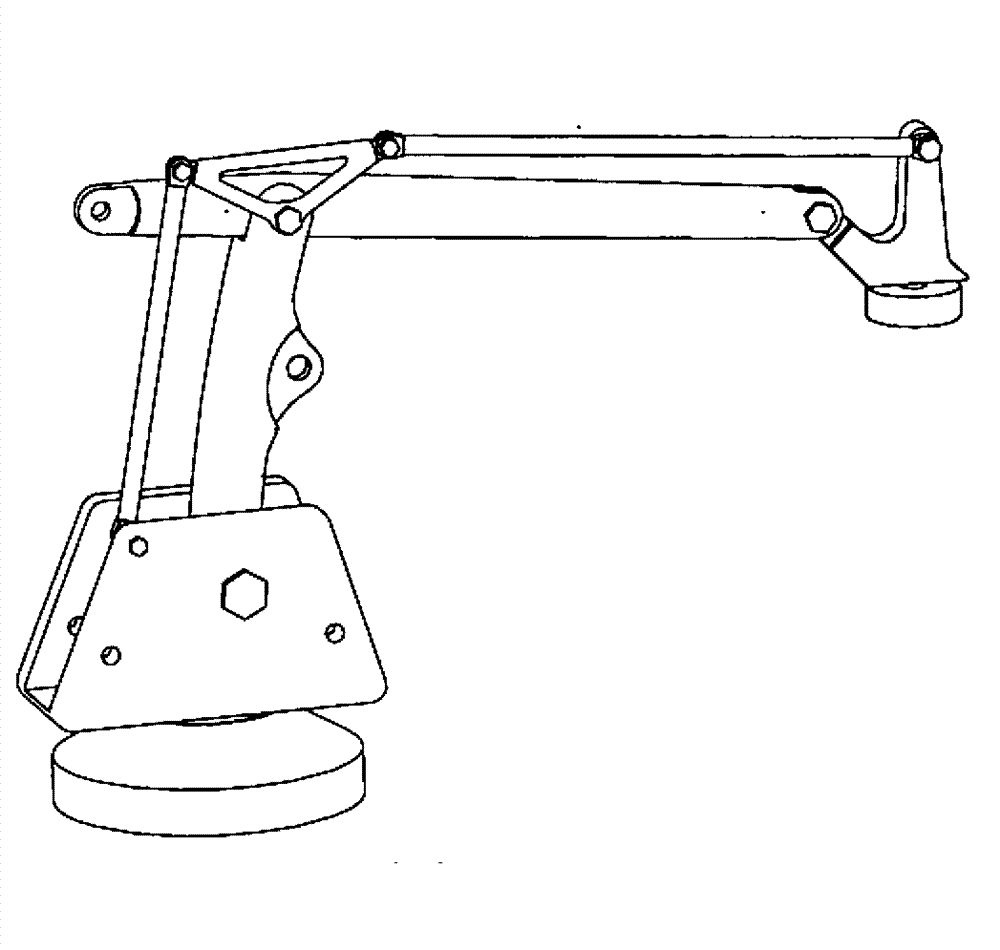

Multi-degree-of-freedom controllable mechanism type stacking robot

InactiveCN103029124AFlexible operationImprove flexibilityProgramme-controlled manipulatorGripping headsEngineeringMulti degree of freedom

The invention discloses a multi-degree-of-freedom controllable mechanism type stacking robot, which comprises a pedestal, a rotary rack, an arm lifting mechanism, an end effector translation retaining mechanism and a flange, wherein the rotary rack is connected to the pedestal through a rotary pair; the arm lifting mechanism comprises a large arm, a small arm, a first driving rod, a first connecting rod, a second driving rod and a second connecting rod; all the rods are connected through hinges; the end effector translation retaining mechanism comprises a parallelogram mechanism consisting of the large arm, a first auxiliary connecting rod, a triangular auxiliary rack and the rotary rack and a parallelogram mechanism consisting of the small arm, a second auxiliary connecting rod, a triangular auxiliary rack and an end effector translation retainer; all the rods are connected through hinges; the flange is connected to the end effector translation retainer through the rotary pair; and different end effectors can be arranged according to actual requirements. The multi-degree-of-freedom controllable mechanism type stacking robot has the advantages of simple structure, high bearing capacity, large working space, flexibility in operation, capabilities of driving through a servo motor for control, realizing intelligence and digital control and meeting handling and stacking requirements of high speed, heavy load, precision and the like and extremely broad application prospect.

Owner:GUANGXI UNIV

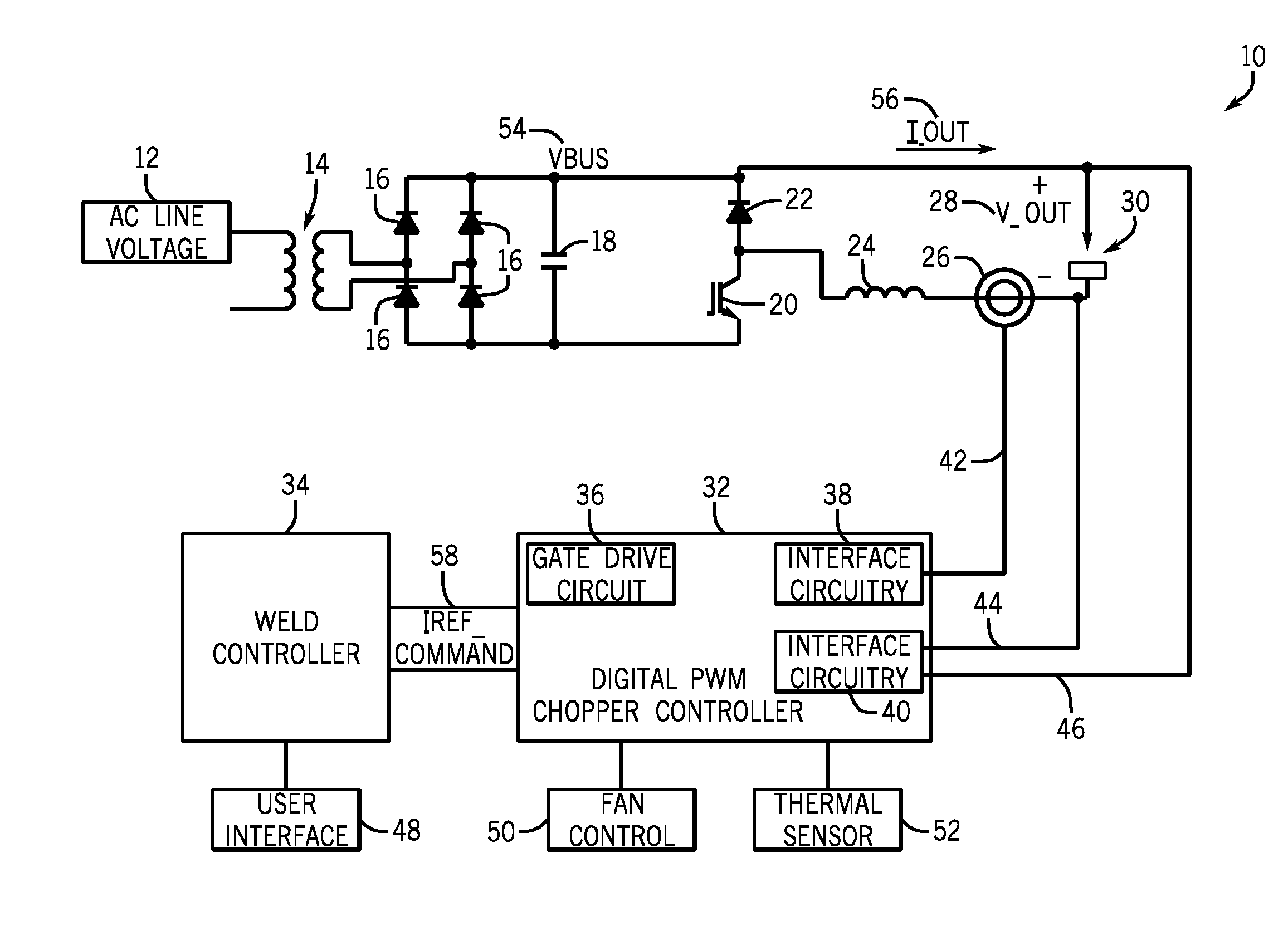

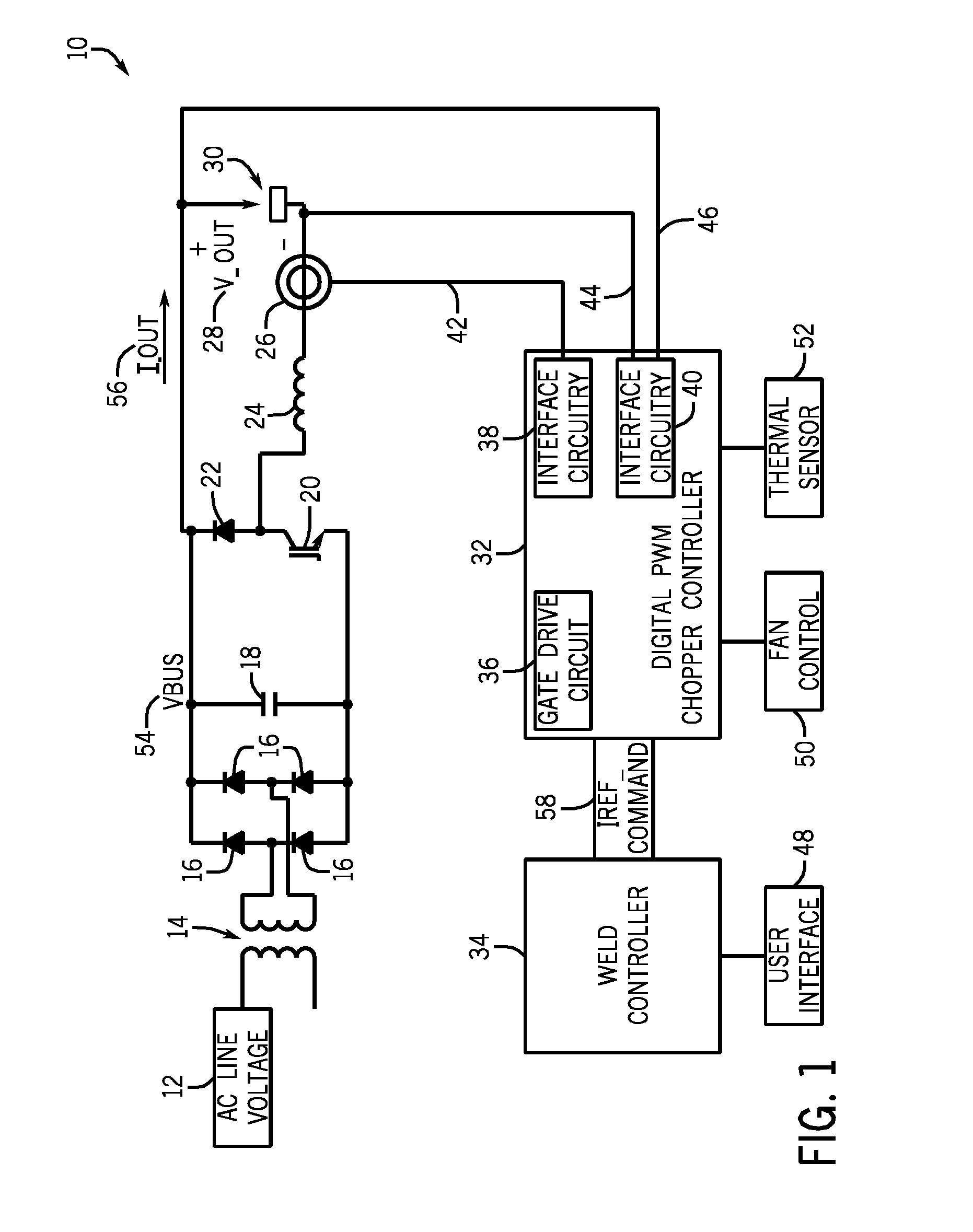

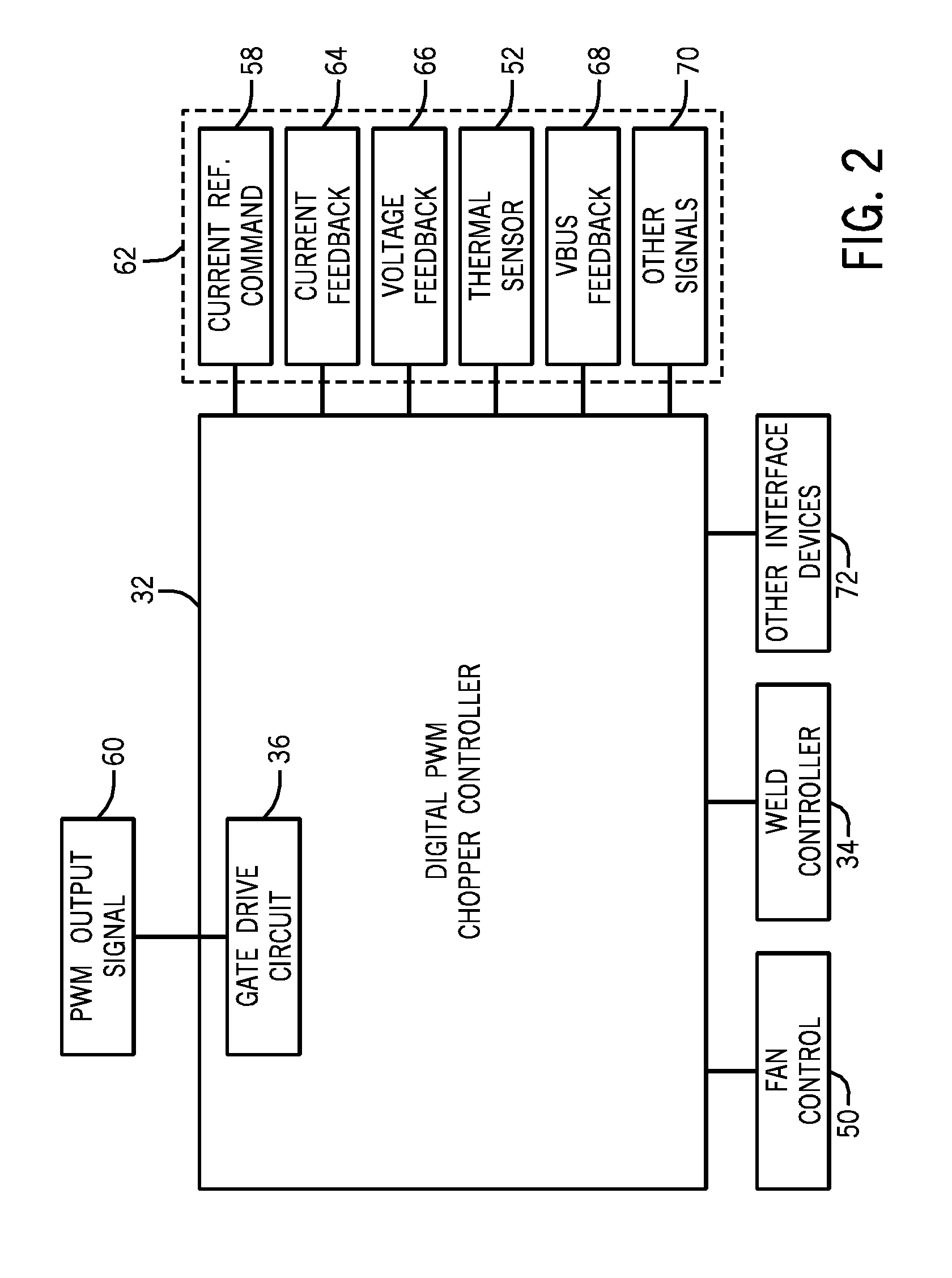

Welding power supply with digital control of duty cycle

A welding power supply including power conversion circuitry adapted to receive a primary source of power, to utilize one or more power semiconductor switches to chop the primary source of power, and to convert the chopped power to a welding output is provided. The provided welding power supply includes a pulse width modulated (PWM) digital controller including gate drive circuitry that generates a PWM output signal that controls the switching of the one or more power semiconductor switches. The PWM output signal includes a duty cycle term corrected for one or more sources of error in the welding system.

Owner:ILLINOIS TOOL WORKS INC

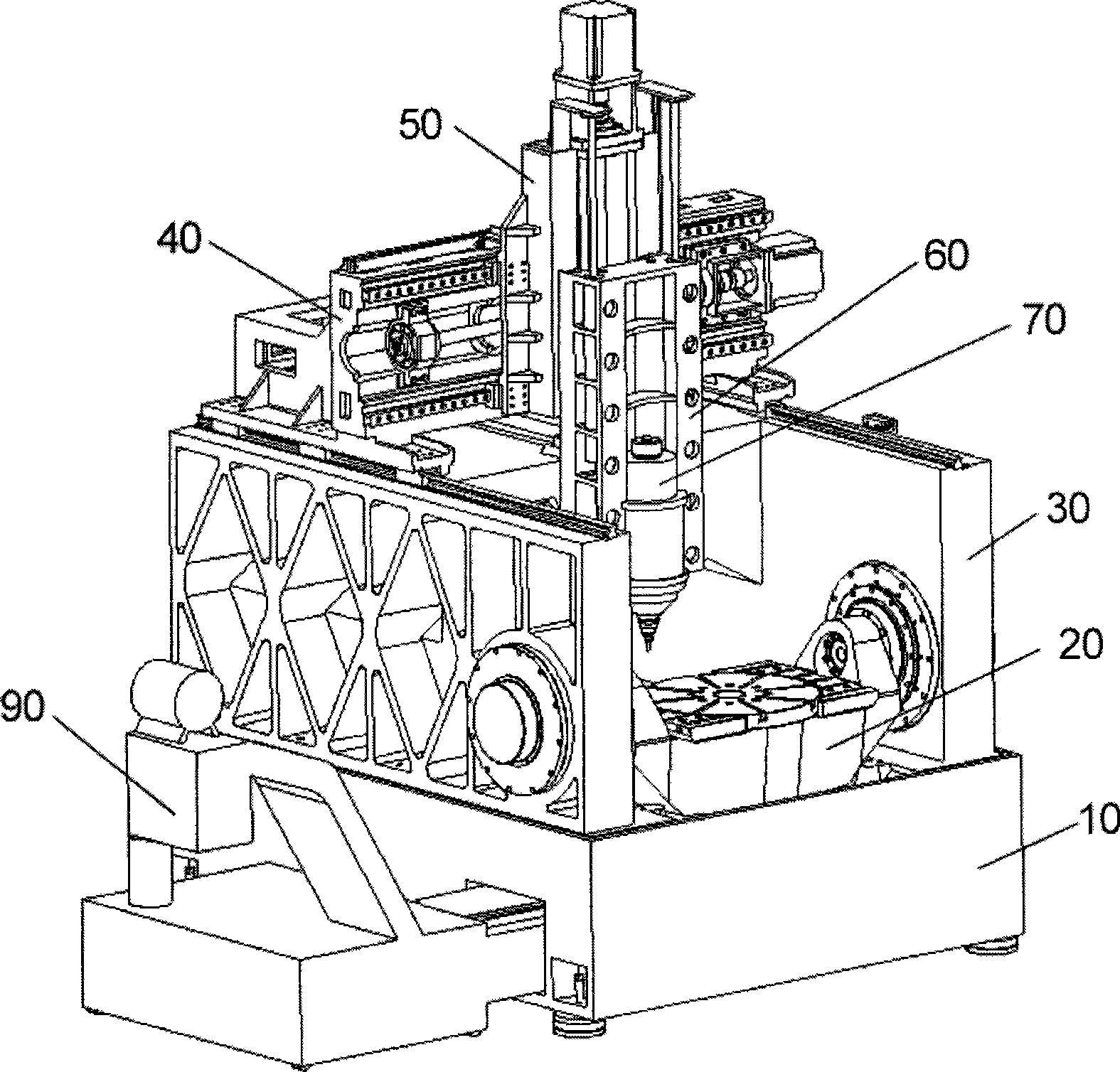

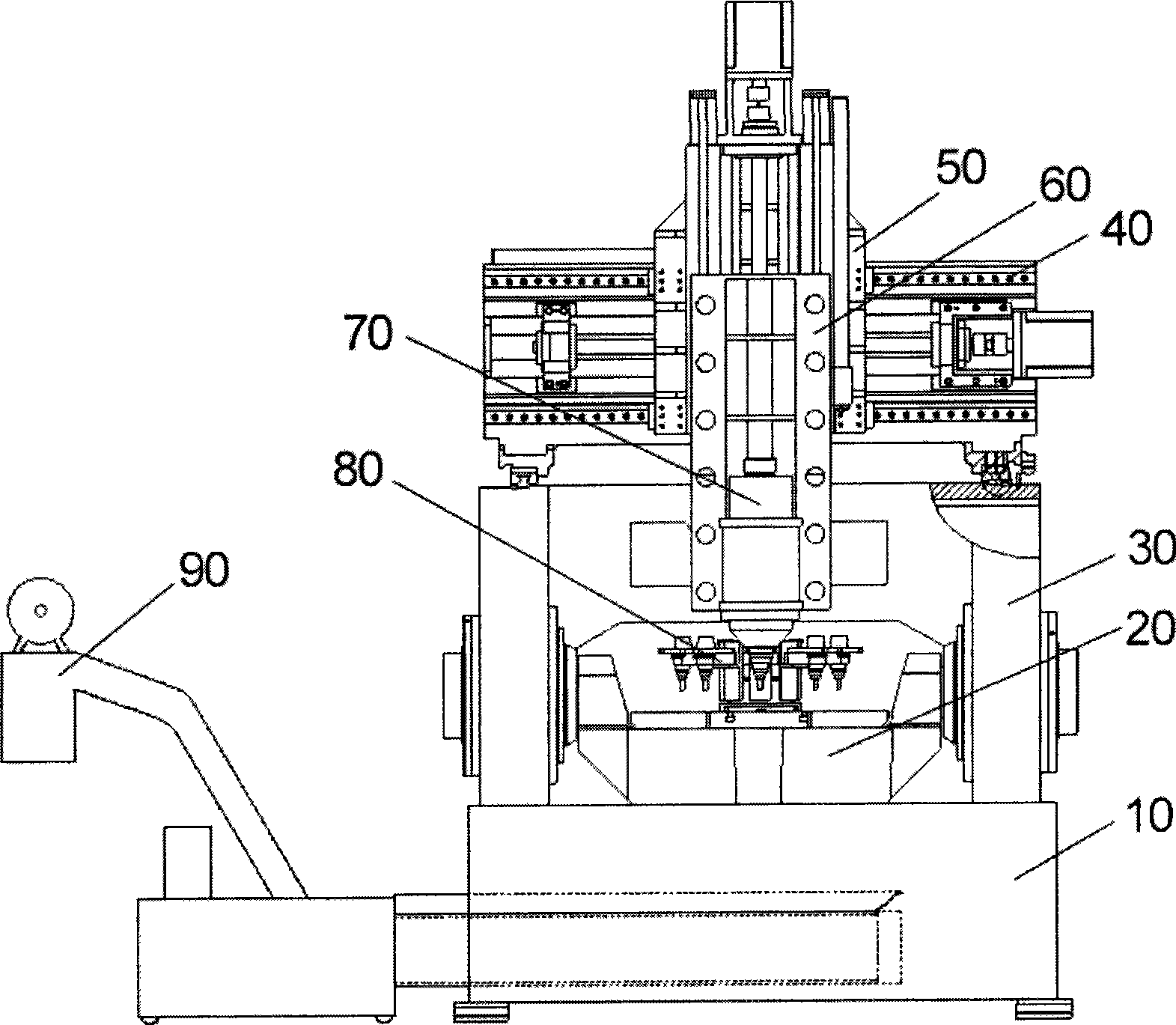

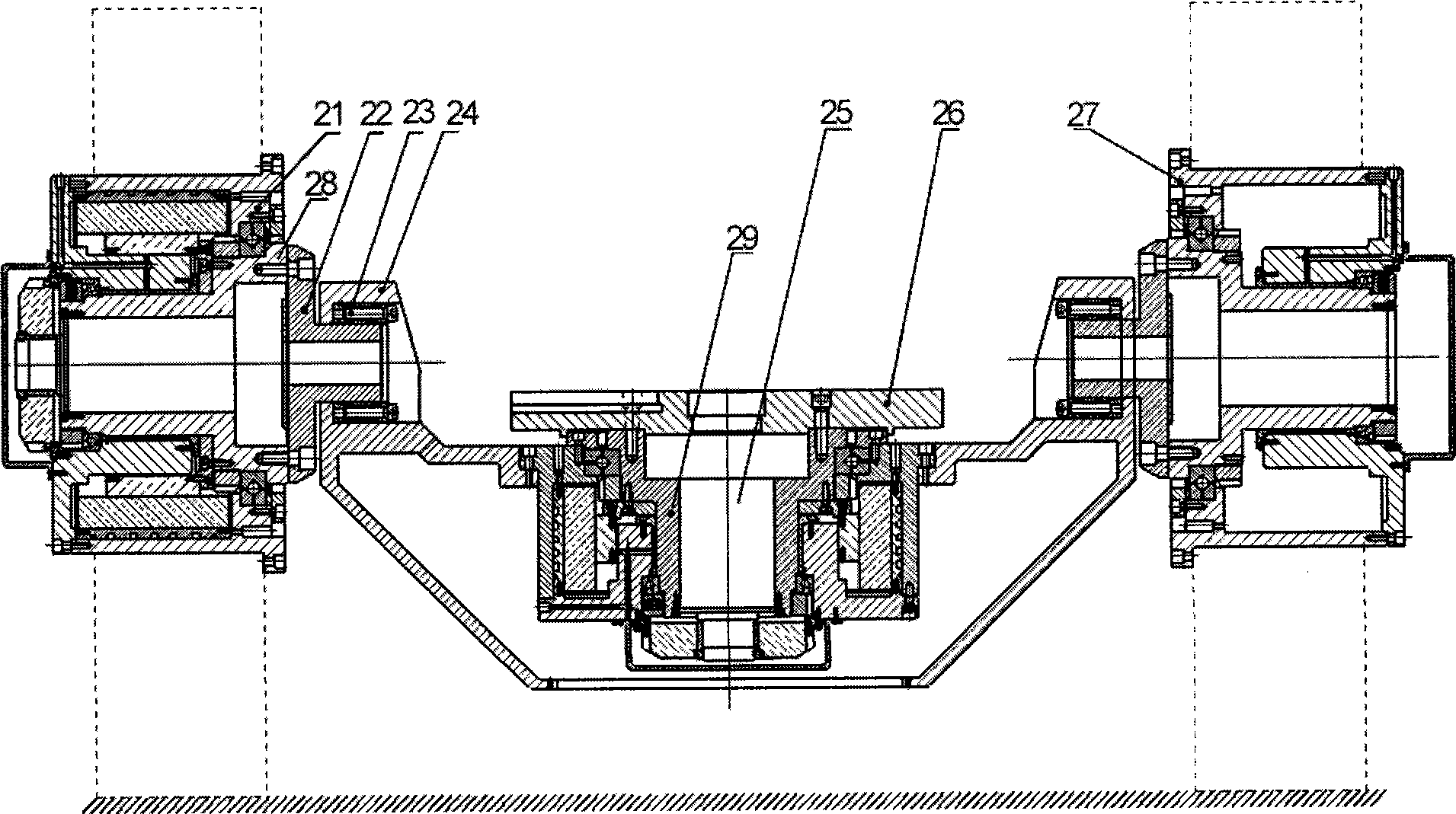

Five-shaft linkage numerical control machining center

InactiveCN101480777ANovel structureSmall footprintLarge fixed membersPositioning apparatusNumerical controlPortal frame

The invention discloses a five-axle linkage digital-control processing centre which comprises a lathe bed (10) and a portal frame (30), wherein the portal frame (30) comprises a left portal upright post (32), a right portal upright post (32) and a fixing portal crossbeam (35), and the front part of each portal upright post (32) is provided with a direct driving type double-shaft precise rotating table (20) which enables a working table (26) to simultaneously rotate round an A shaft and a C shaft. Furthermore, the portal frame (30) is provided with a crossbeam (40) which can move along the Y direction, the front part of the crossbeam (40) is provided with a slide carriage (50) which can move along the X direction, the front part of the slide carriage (50) is provided with a main shaft box (60) which can move along the Z direction, the main shaft box (60) is provided with a main shaft installing hole (66) used for installing a main shaft (70), and a tool magazine (80) is arranged in a cavity positioned between the lathe bed (10) and the portal frame (30). The invention has novel structure, small occupied area, space saving, low cost and stable operation and property. Besides, a motion shaft of a machine tool has high dynamic property, regulating property, positioning precision and repeated positioning precision.

Owner:三六零安全科技股份有限公司 +2

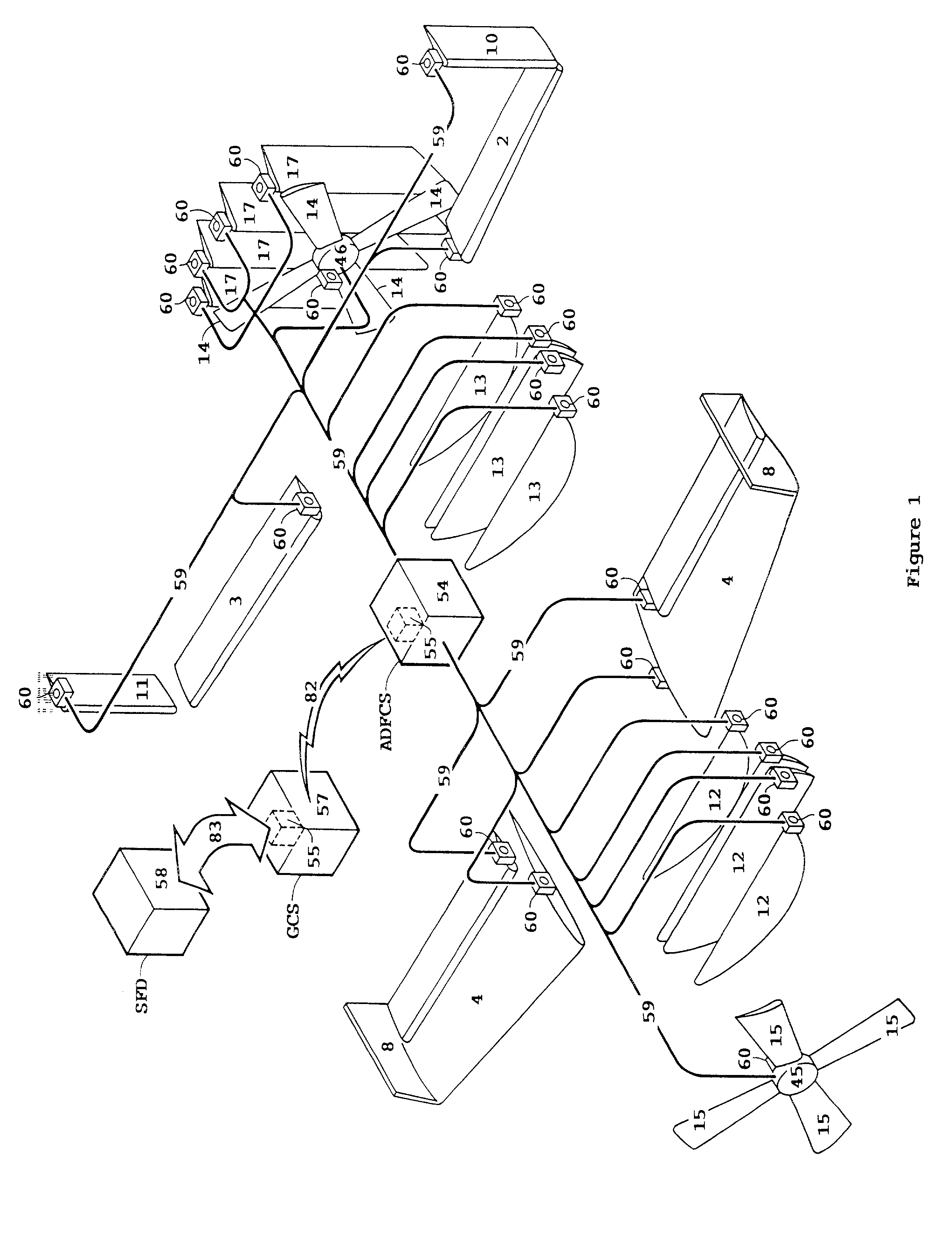

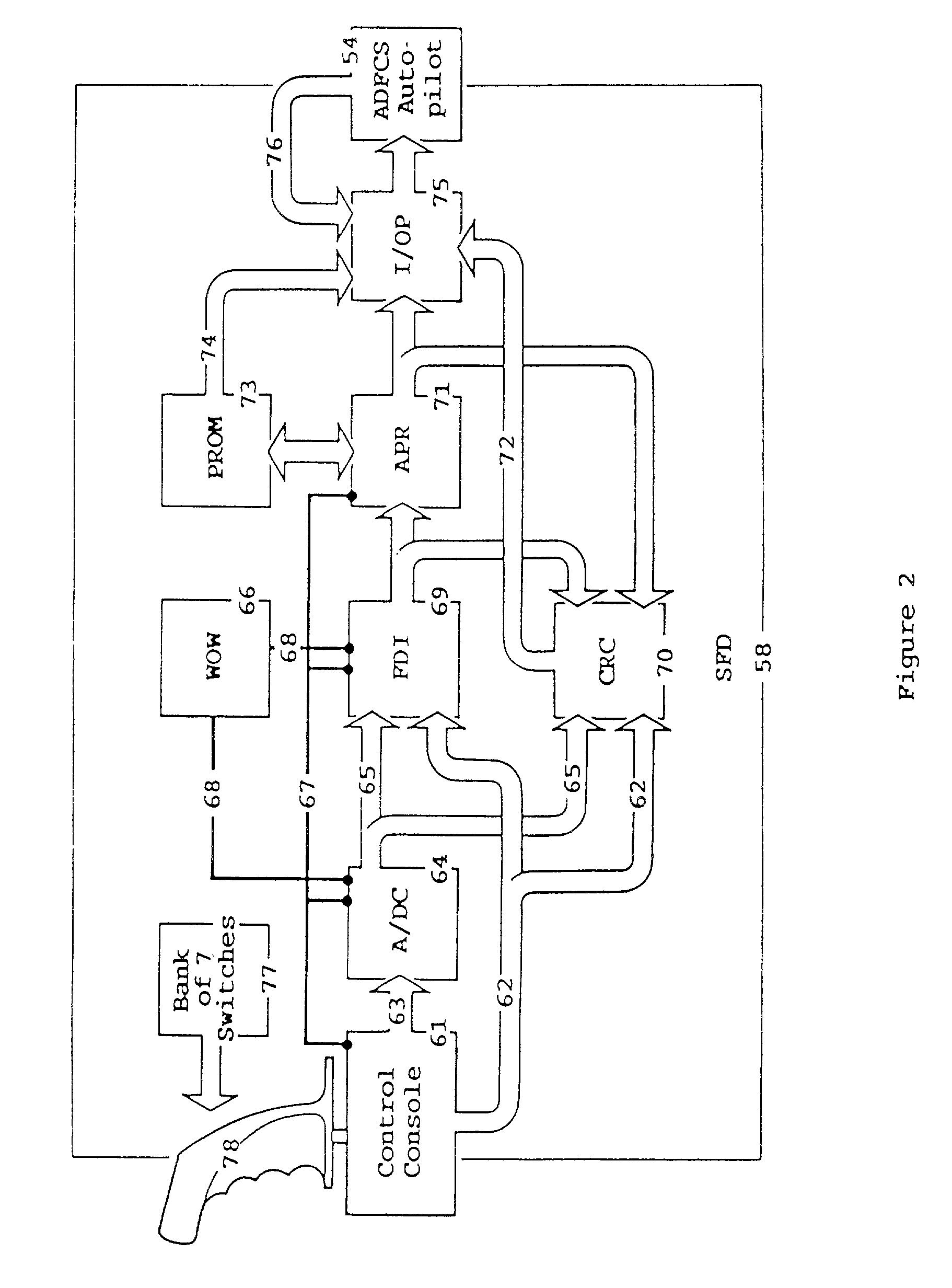

Semiautonomous flight director

InactiveUS20020030142A1Reduce a skilled pilots' workloadUnmanned aerial vehiclesActuated automaticallyWorkloadDigital control

A device for programming industry standard autopilots by unskilled pilots. The effect of the invention is such that when the invention is employed in a flying body comprising an industry standard autopilot with a digital flight control system, the invention provides for the safe operation of any aircraft by an unskilled pilot. The device additionally affords skilled pilots a more rapid and simplified means of programming autopilots while in flight thus reducing a skilled pilot's cockpit workload for all aircraft flight and directional steering, way points, and aircraft flight functions reducing the possibility of pilot error so as to effect safer flight operations of an aircraft by affording a skilled pilot to direct aircraft steering and function while under continuous autopilot control.

Owner:JAMES TERRY JACK

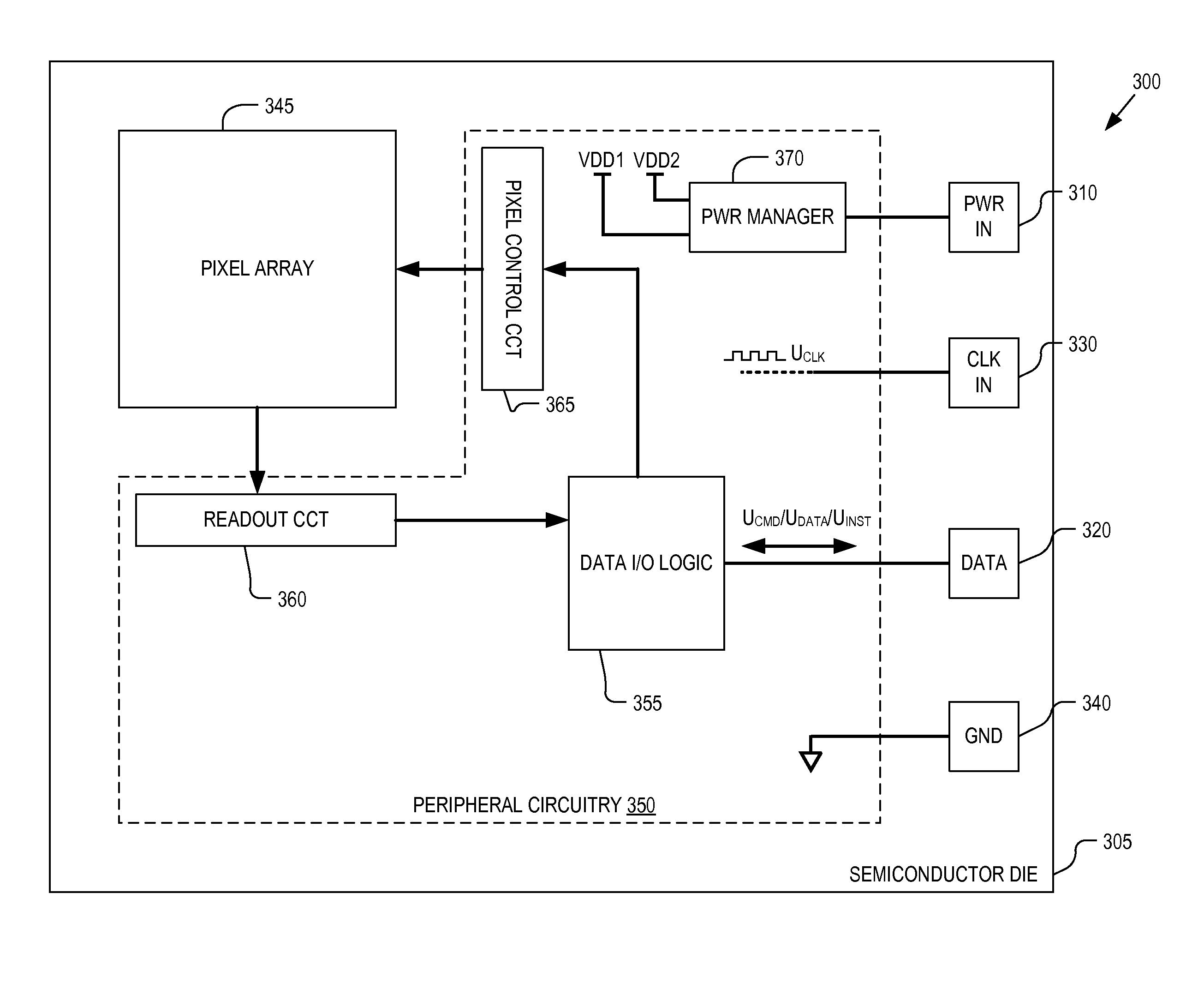

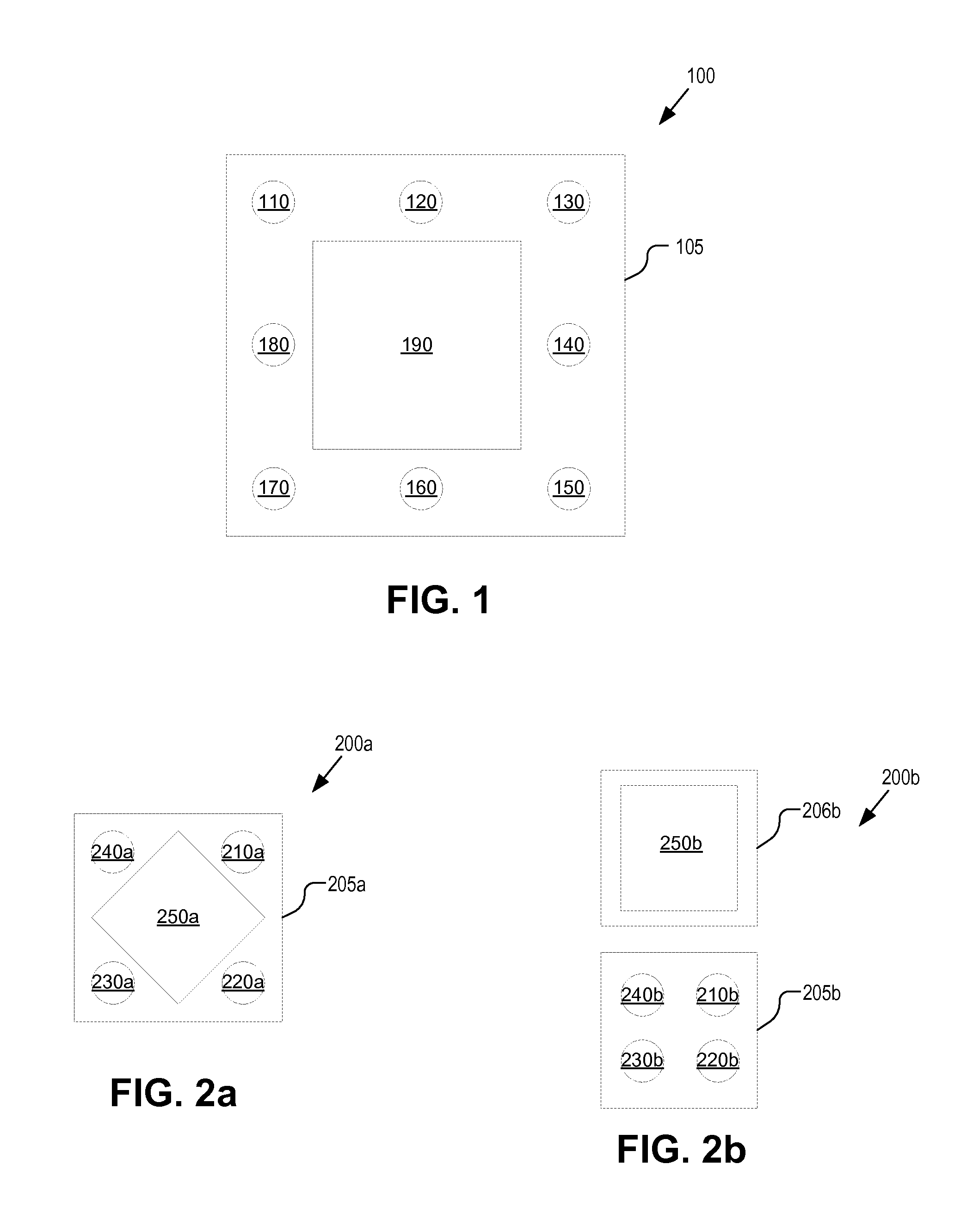

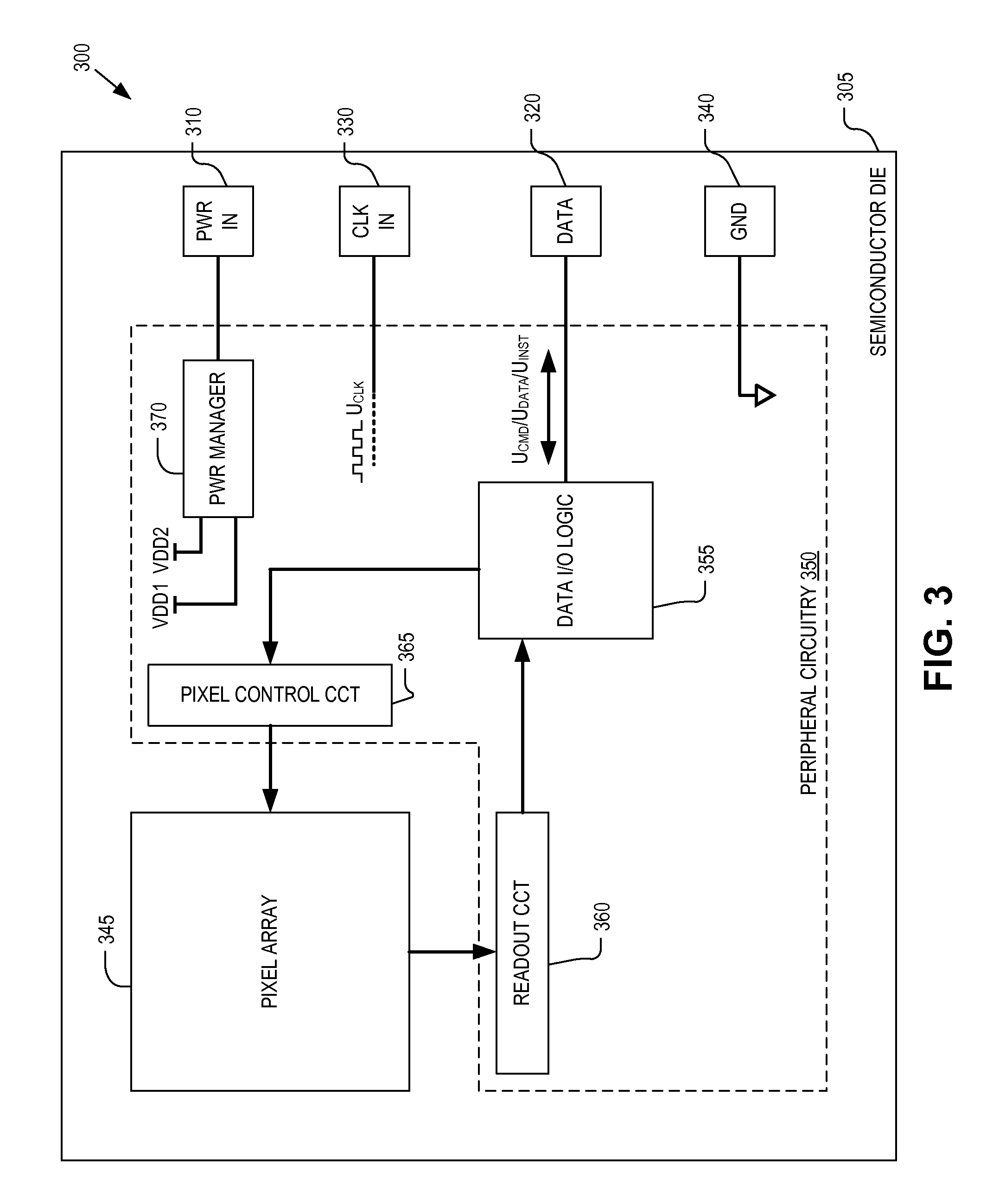

Shared terminal of an image sensor system for transferring image data and control signals

An example image sensor system includes an image sensor having a first terminal and a host controller coupled to the first terminal. Logic is included in the image sensor system, that when executed transfers analog image data from the image sensor to the host controller through the first terminal of the image sensor and also transfers one or more digital control signals between the image sensor and the host controller through the same first terminal.

Owner:OMNIVISION TECH INC

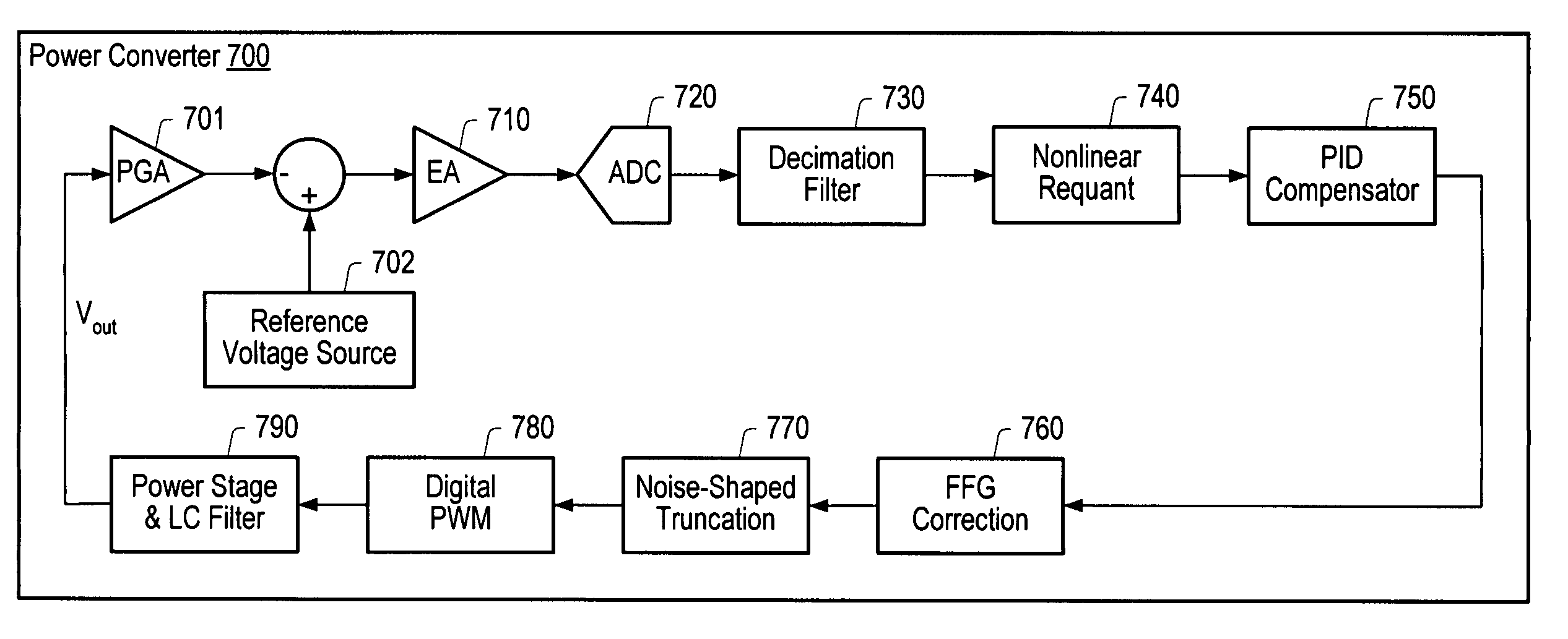

Hardware efficient digital control loop architecture for a power converter

ActiveUS7239257B1Reduce in quantityElectric signal transmission systemsConversion with intermediate conversion to dcImage resolutionNoise shaping

A power converter including a hardware efficient control loop architecture. Error detection circuitry may generate an error signal based on the difference between a power converter output voltage and a reference voltage. An oversampling ADC may digitize the error signal. The transfer function associated with the ADC may include quantization levels spaced at non-uniform intervals away from a center code. A digital filter may calculate the average of the digitized error signal. A nonlinear requantizer may reduce the number of codes corresponding to the output of the digital filter. A proportional integral derivative (PID) unit may multiply the output of the nonlinear requantizer by PID coefficients to generate a PID duty cycle command, and a gain compensation unit may dynamically adjust the PID coefficients to maintain a constant control loop gain. A noise-shaped truncation unit including a multi-level error-feedback delta sigma modulator may reduce the resolution of the PID duty cycle command.

Owner:INTERSIL INC

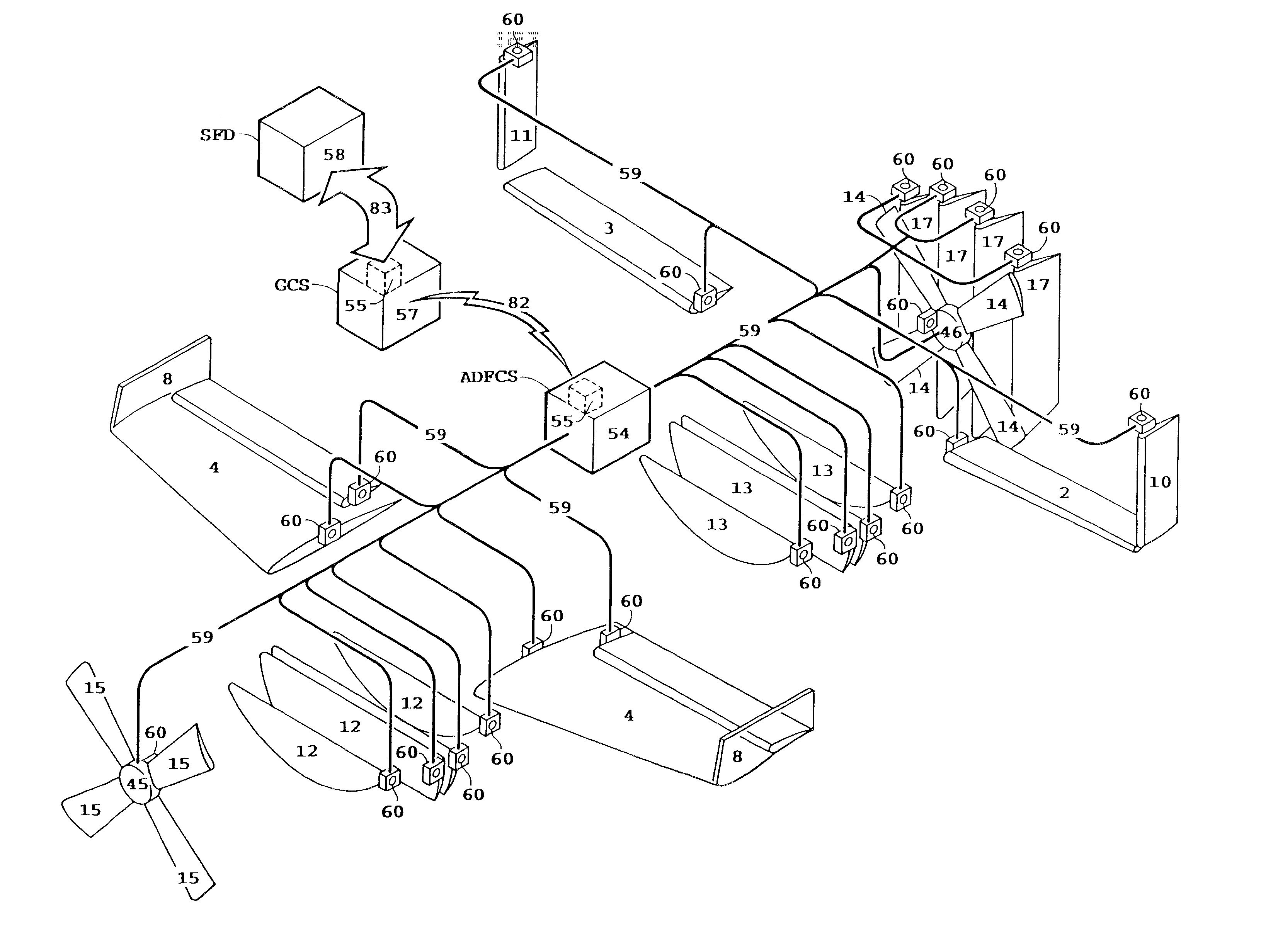

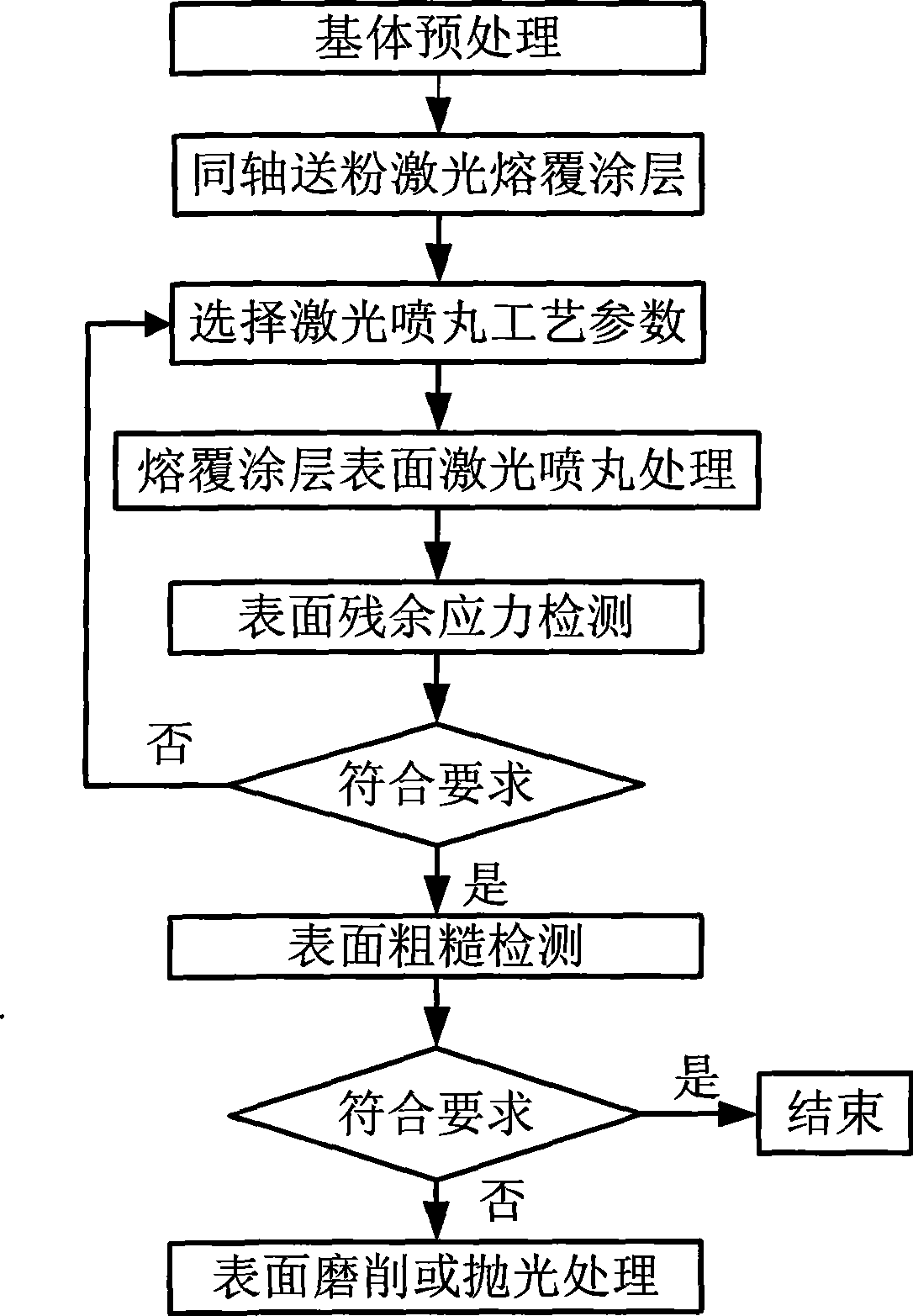

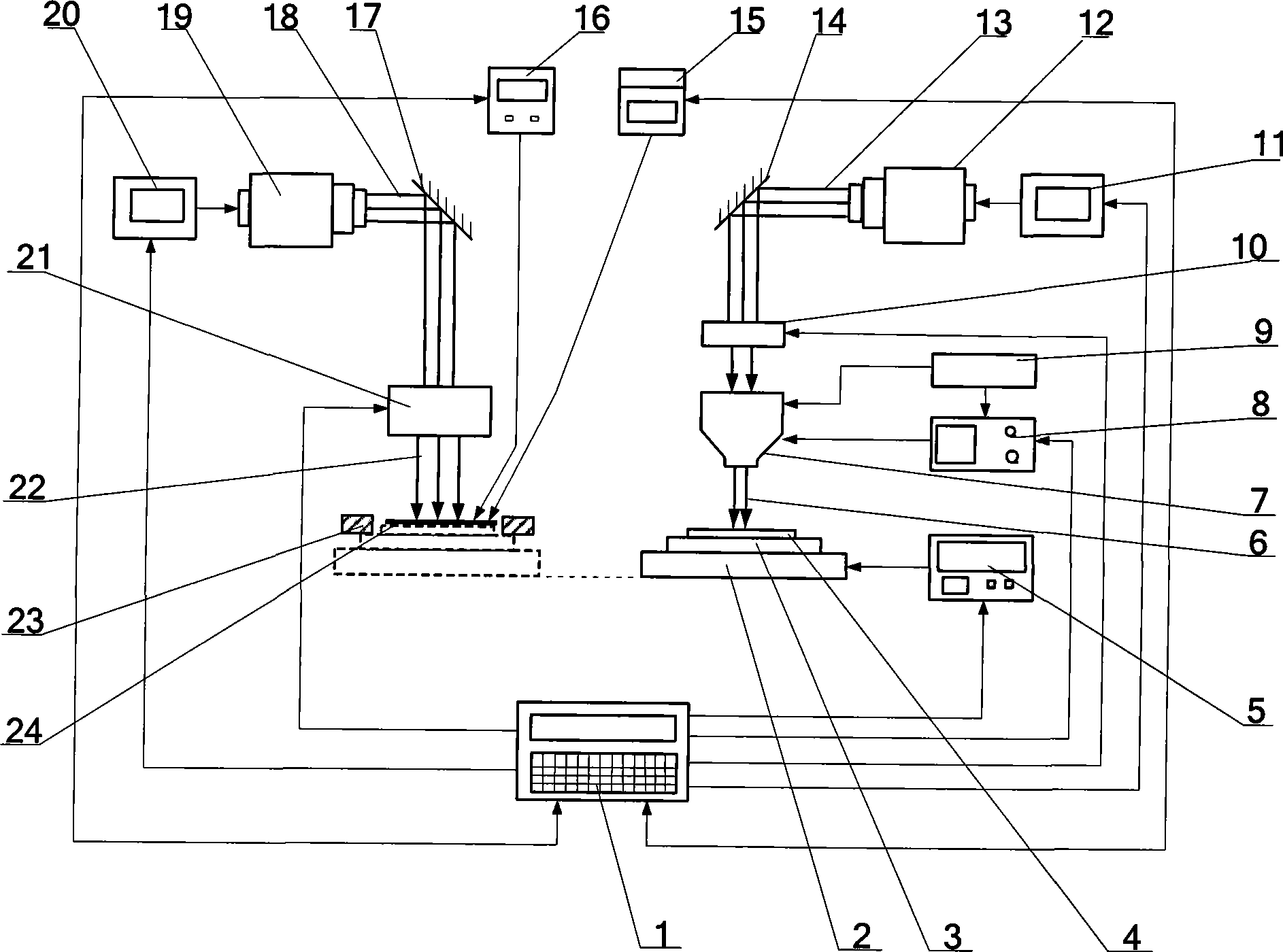

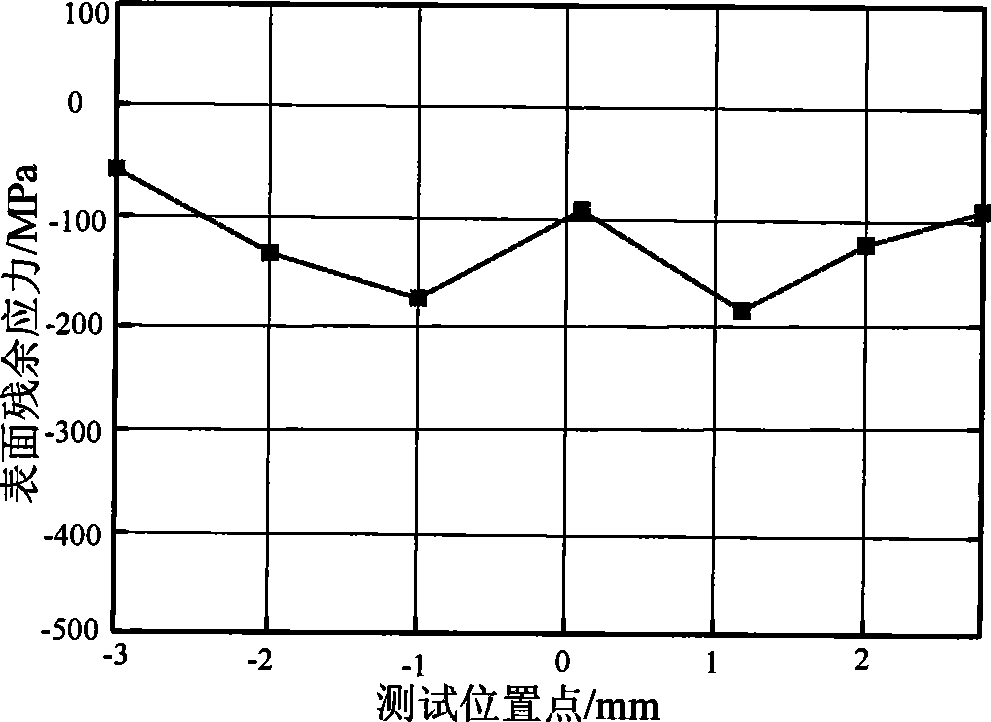

Method and device for strengthening surface modification by combination of laser cladding and laser peening

InactiveCN101392382AQuality improvementResidual stress distribution state changesMetallic material coating processesCoated surfaceSurface roughness

The invention provides a method for modifying a composite surface based on laser cladding and combining laser shock peening, and a device thereof. The method provided by the invention is characterized in that a coaxial and powder feeding type fast axial flow CO2 laser cladding unit clads a layer of coating on the surface of a substrate; then a neophane glass impulse laser shock peening unit is used for the shock peening on the surface of the cladded coating; a measurement feedback system is utilized to detect the surface roughness and the distribution state of residual stress of the cladded coating; the precise control over the surface roughness and the residual stress of the coating is realized by a central control and processing system so as to obtain a high quality surface-cladded coating with good performance. The device comprises the coaxial and powder feeding type laser cladding unit, the laser shock peening unit, a digital control working system, the measurement feedback system and the central control and processing system, and is under integrated control by a computer. The method and the device of the invention can reduce residual tensile stress and improve the quality of the cladded coating and prolong the service life thereof.

Owner:JIANGSU UNIV

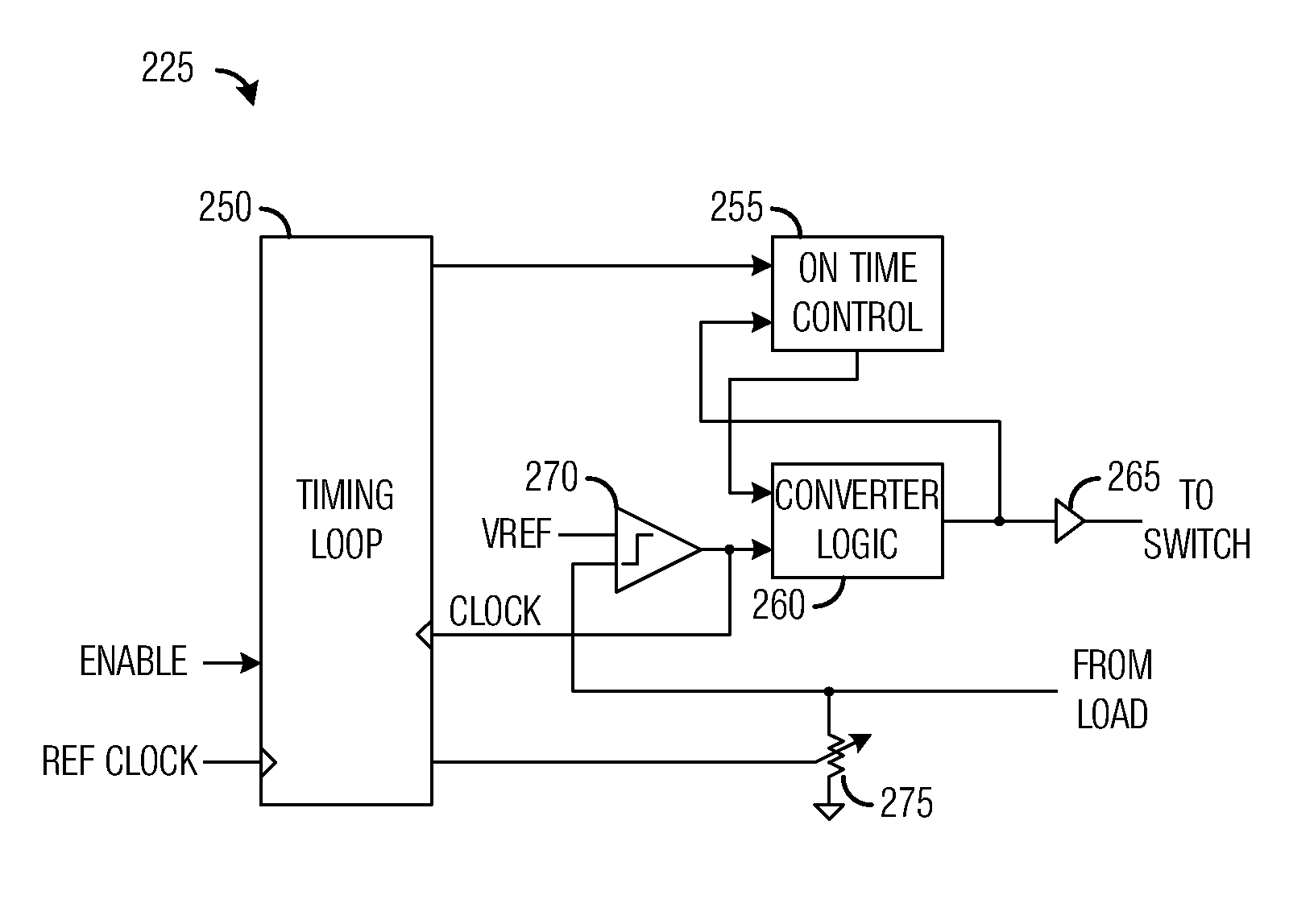

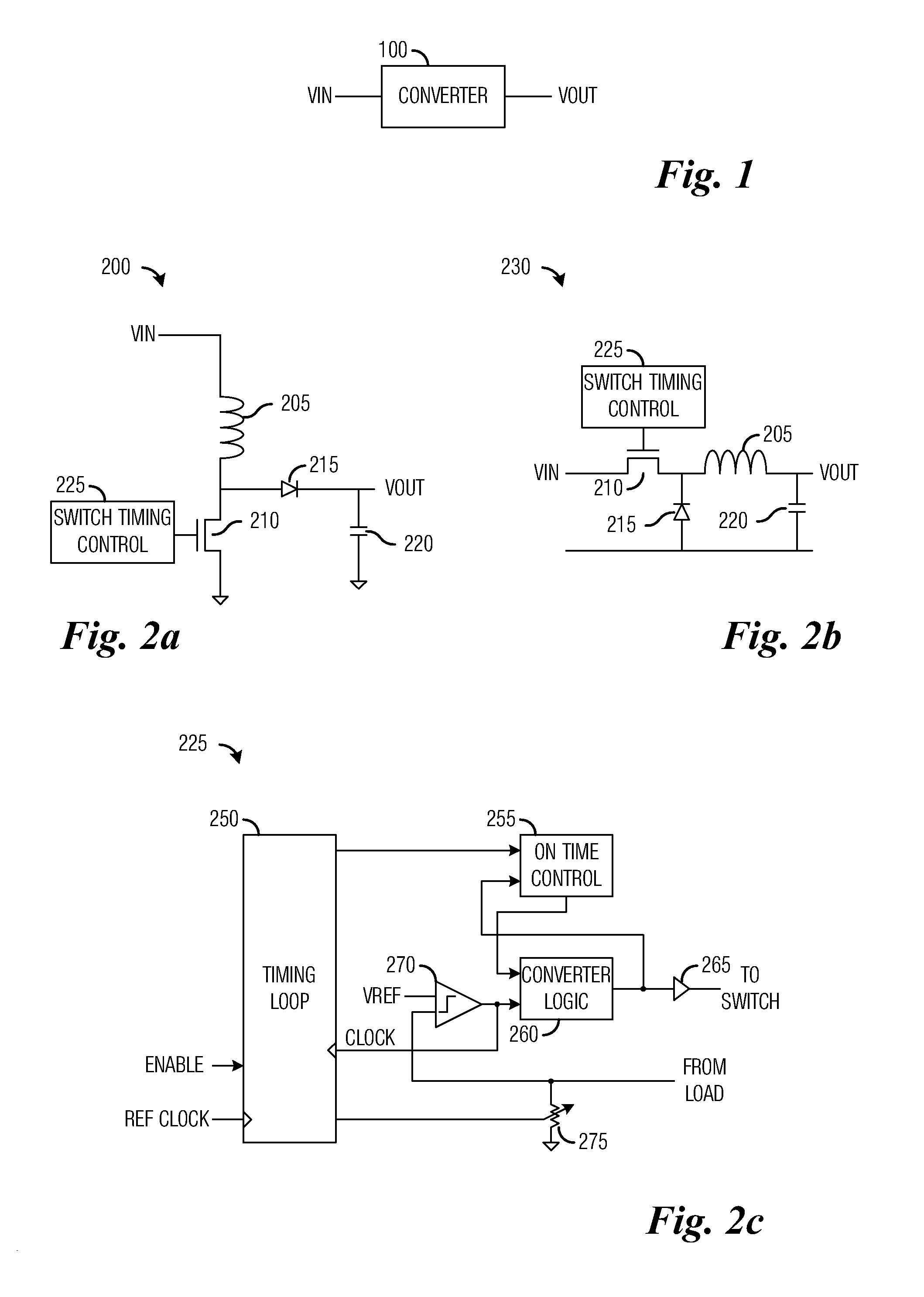

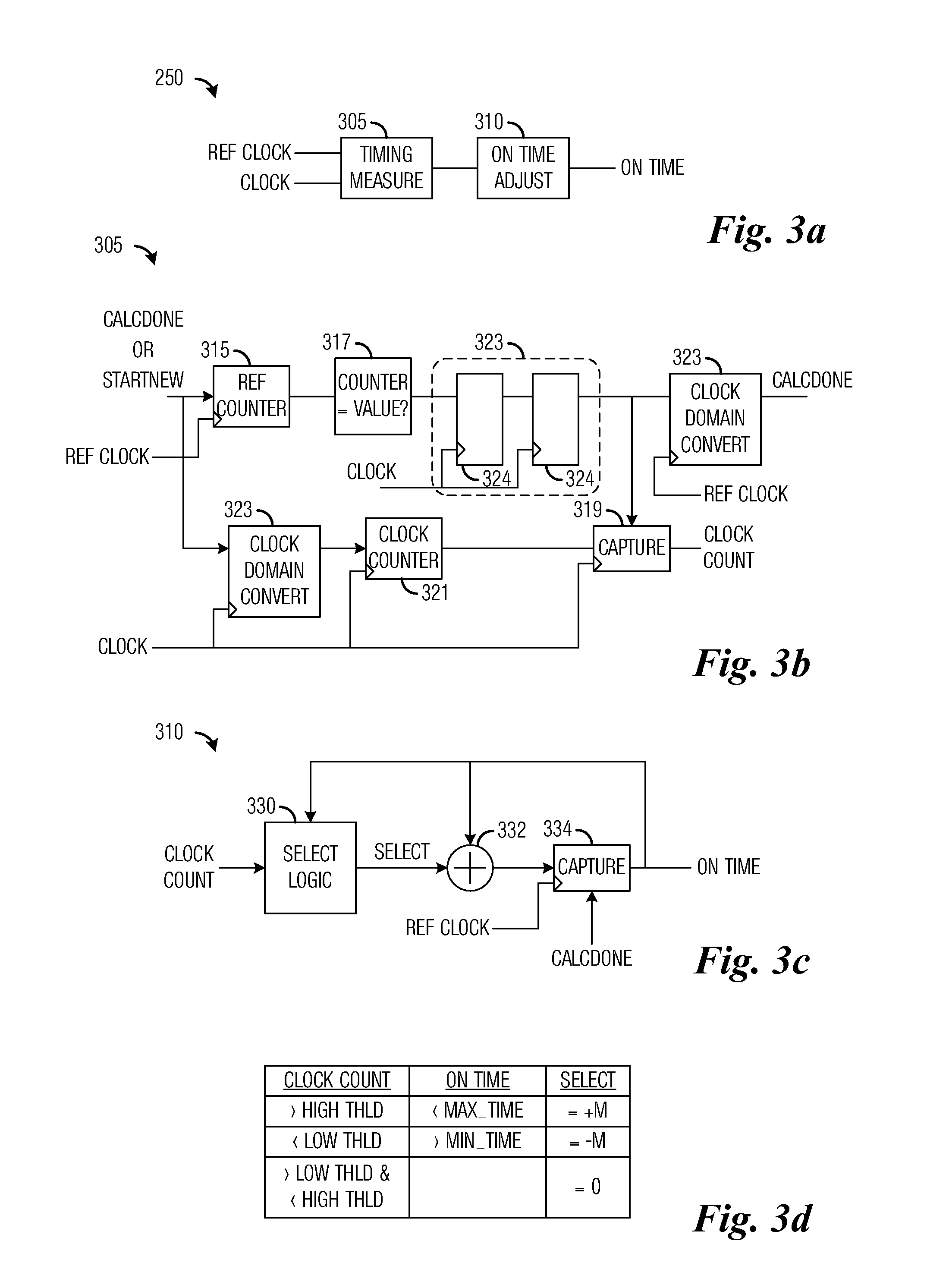

System and Method for Controlling a Hysteretic Mode Converter

ActiveUS20080252278A1Independent controlDc-dc conversionElectric variable regulationVoltage converterEngineering

A system and method for controlling a conversion frequency of a hysteretic mode voltage converter. A digital control loop comprises a timing measure unit having a first input coupled to a reference clock and a second input coupled to a clock based on a switching of the switching of the converter, and an on time adjust unit coupled to the timing measure unit. The timing measure unit counts a number of clock ticks of a clock signal provided by the clock occurring during a period of time specified by a number of clock ticks of a reference clock signal provided by the reference clock. The on time adjust unit adjusts an on time control signal based on the count of the number of clock ticks of the clock signal to alter a frequency of the switching.

Owner:TEXAS INSTR INC

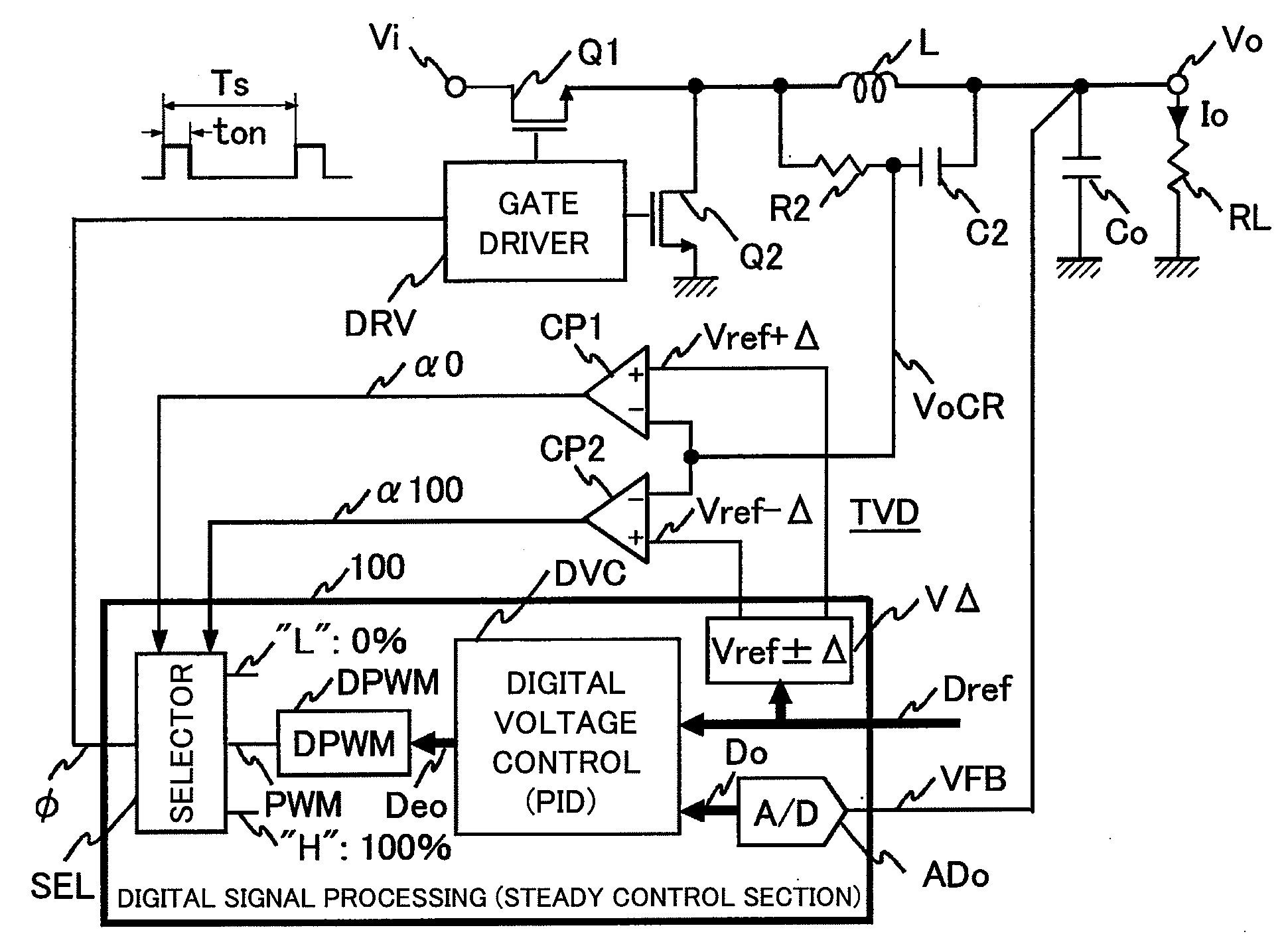

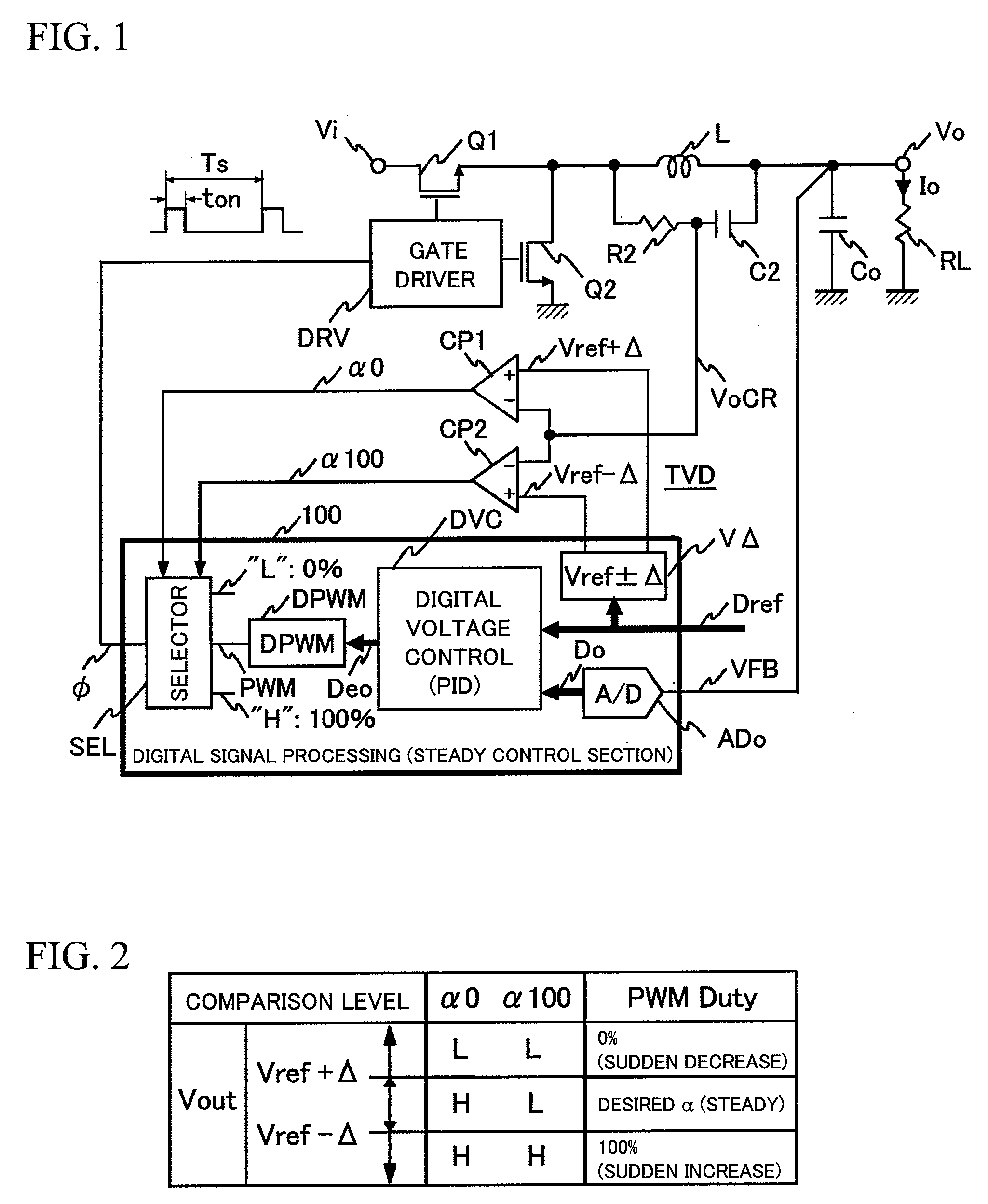

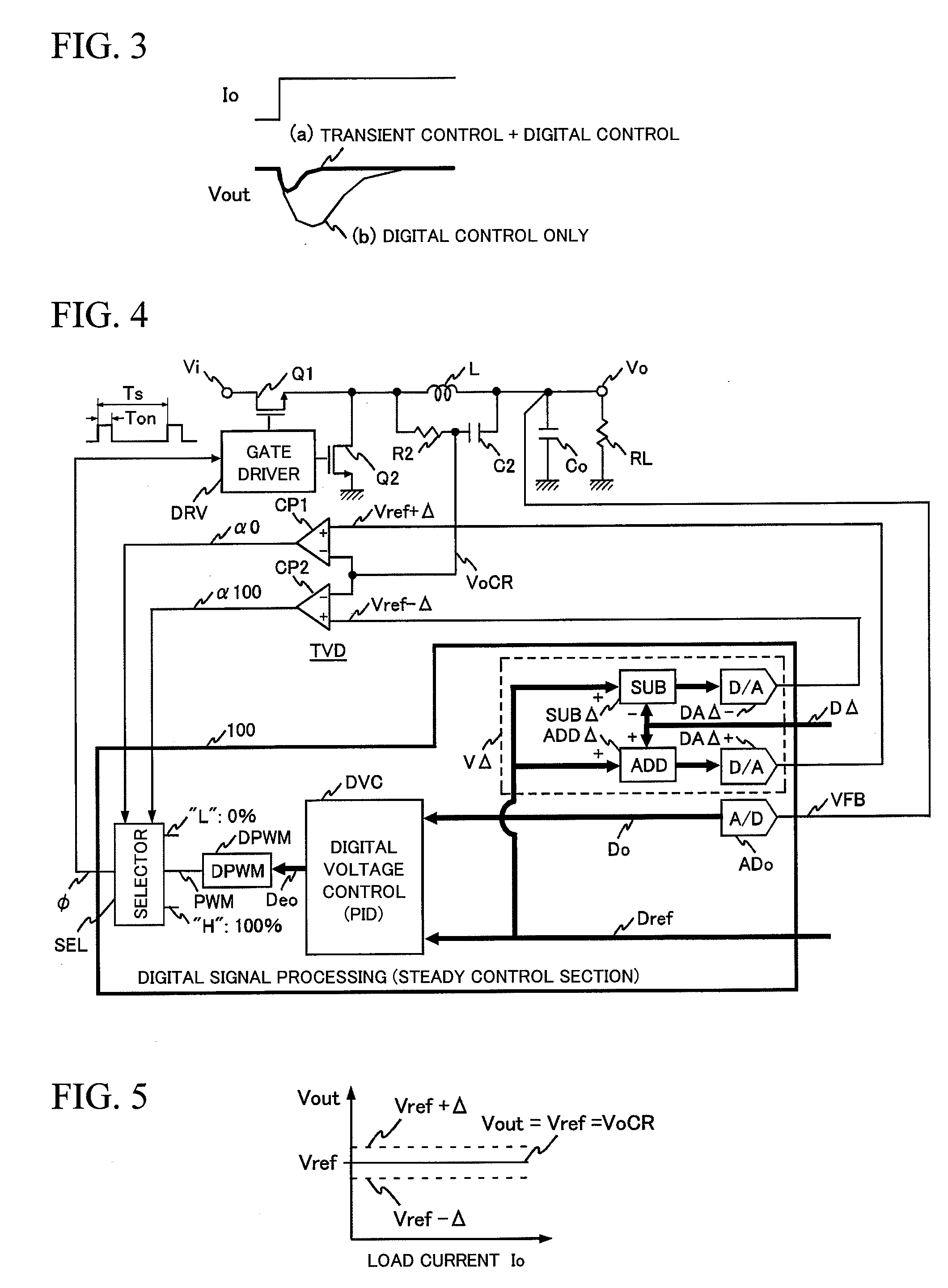

Digital control switching power-supply device and information processing equipment

ActiveUS20080252277A1Large capacitanceLow costDc-dc conversionElectric variable regulationDigital signal processingInformation processing

To provide a digital control switching power-supply device capable of suitably achieving fast transient response at the time of a sudden load change. In parallel with normal digital signal processing means that outputs a PWM pulse signal having a desired duty, transient variation detection means composed of a CR filter provided across an output inductor and a window comparator is provided in preparation for a sudden load change. If a sudden decrease in load is detected, a PWM pulse signal having a duty of 0% is forcedly output, and if a sudden increase in load is detected, a PWM pulse signal having a duty of 100% is forcedly output.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com