Patents

Literature

102164results about How to "Small footprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

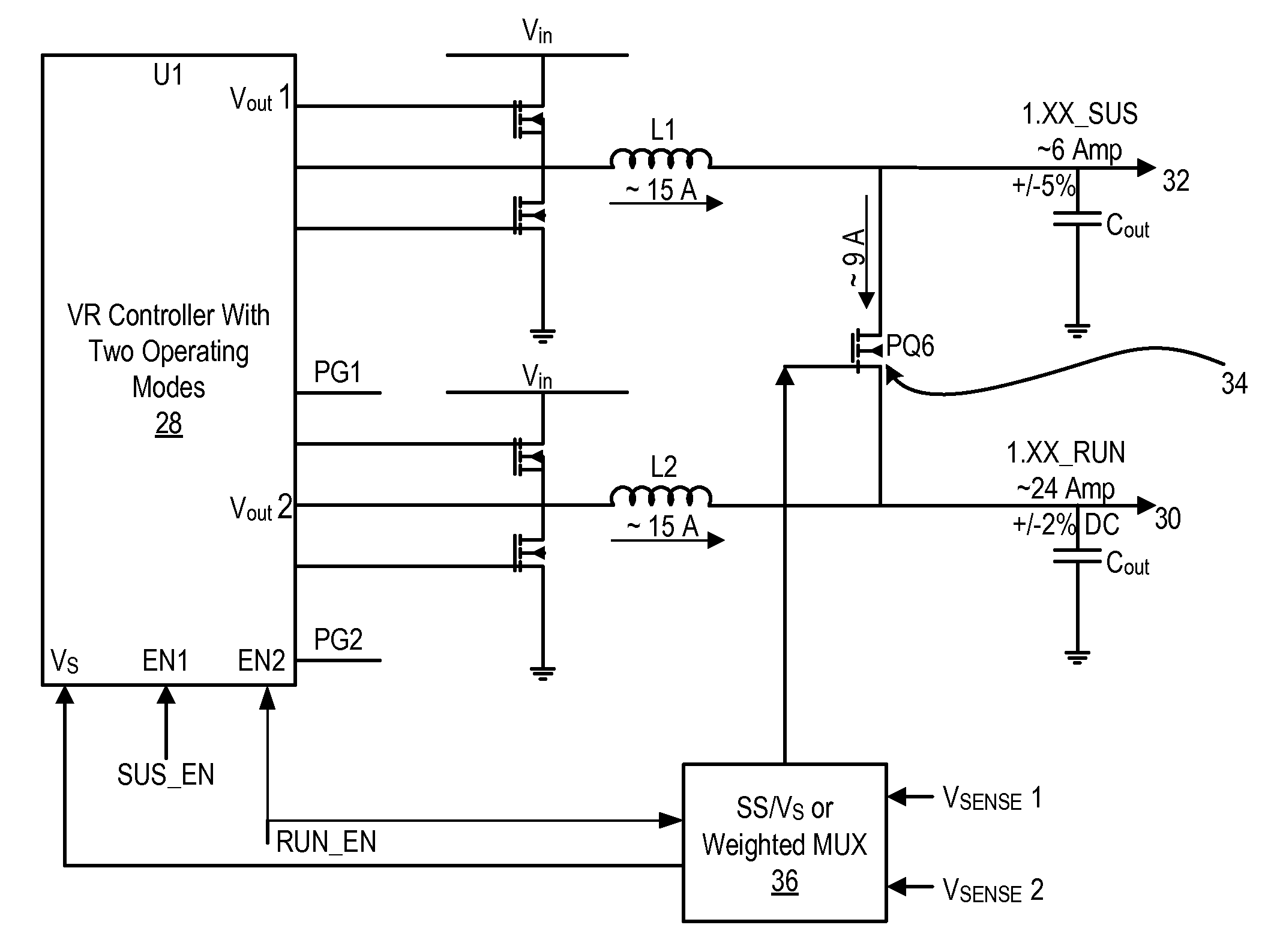

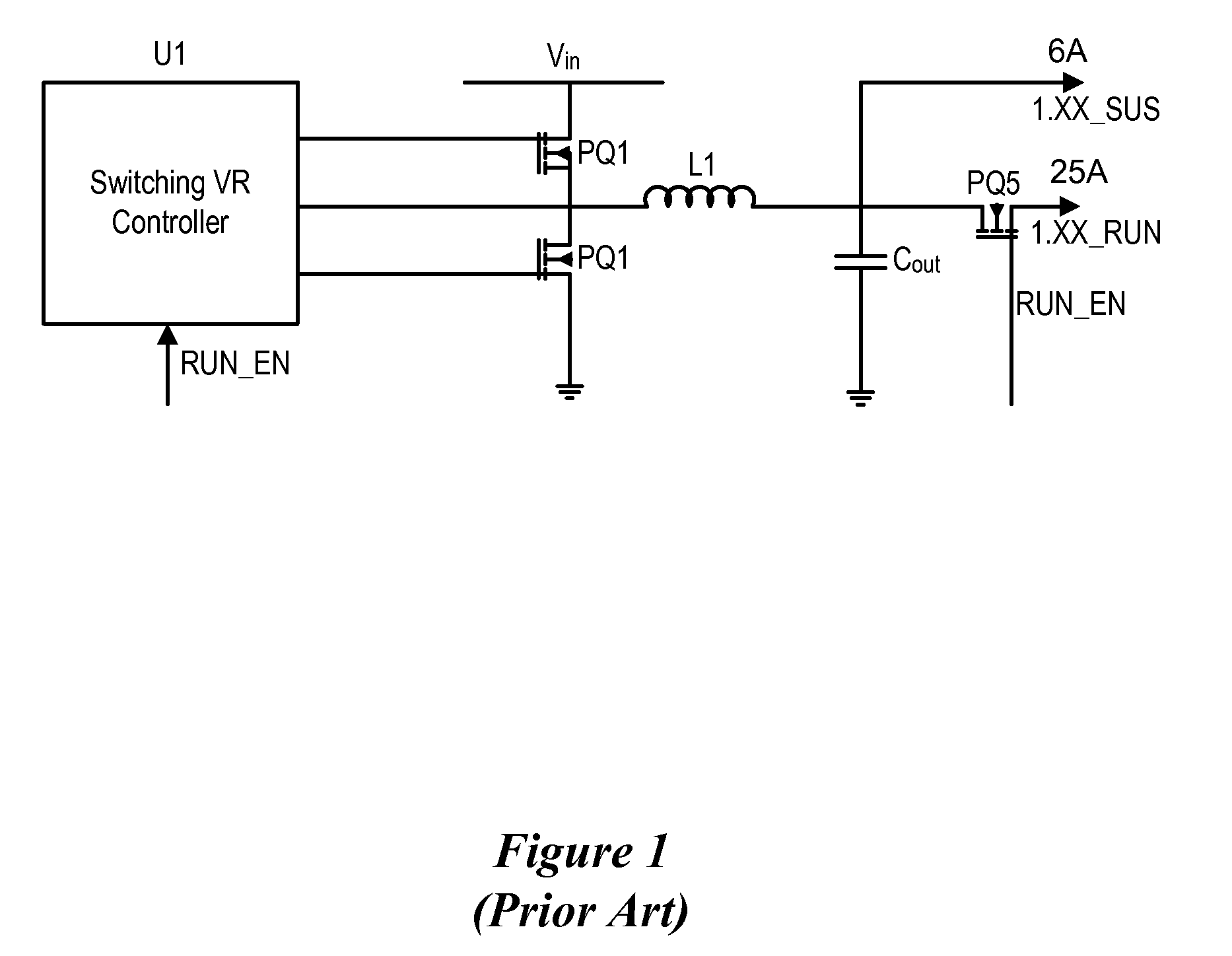

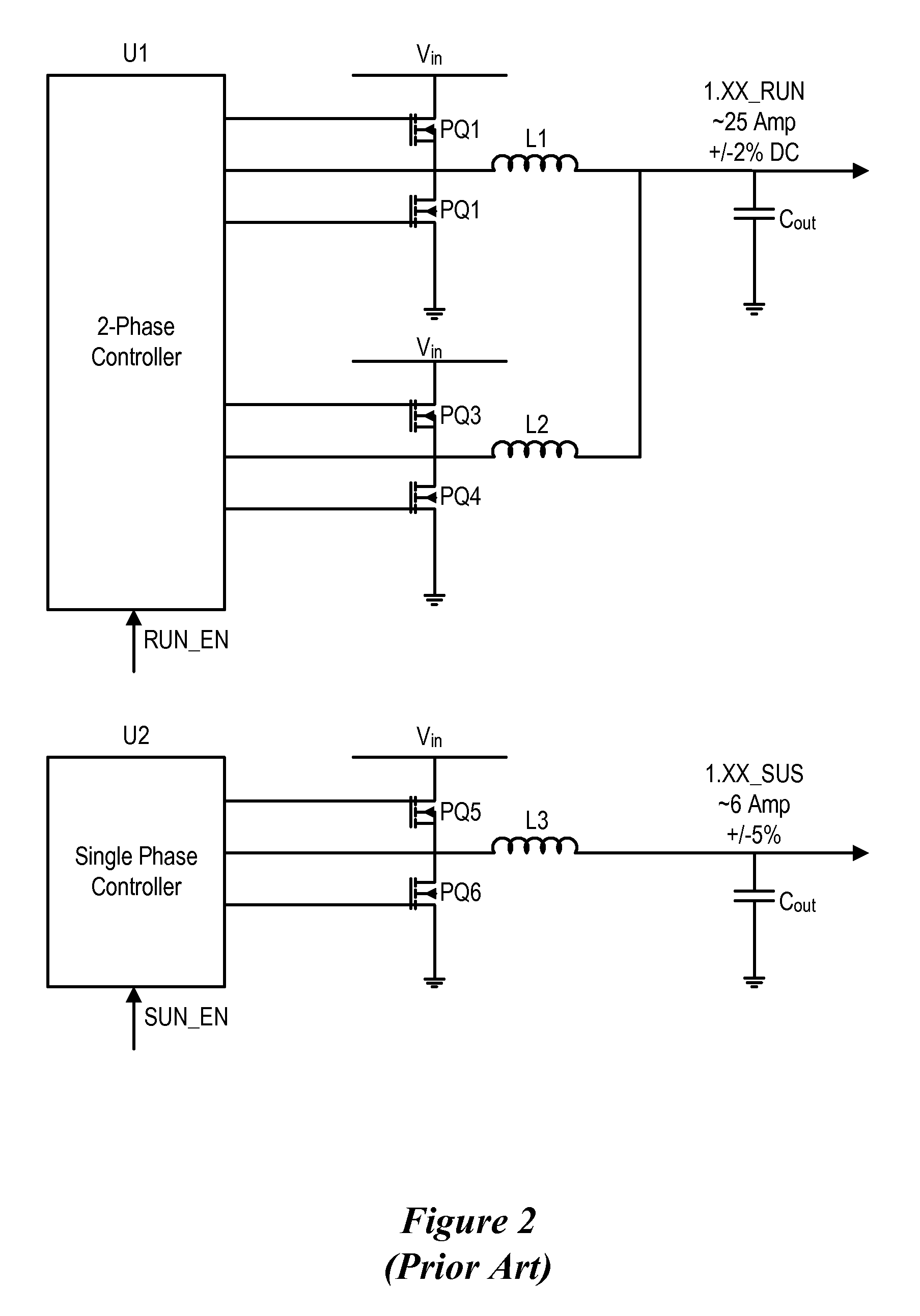

System and method for powering an information handling system in multiple power states

ActiveUS8063619B2Reduce disadvantagesReduce problemsElectric signal transmission systemsDc network circuit arrangementsMOSFETVoltage regulation

Power is supplied to an information handling system chipset with a single voltage regulator having dual phases. A first phase of the voltage regulator provides power to a low power state power rail in an independent mode to support a low power state, such as a suspend or hibernate state. A second phase of the voltage regulator provides power to a run power state power rail in combination with the first phase by activation of a switch, such as a MOSFET load switch, that connects the low power state power rail and the run power state power rail. Voltage sensed from both power rails is applied to control voltage output so that the run power state power rail is maintained within more precise constraints than the low power state power rail.

Owner:DELL PROD LP

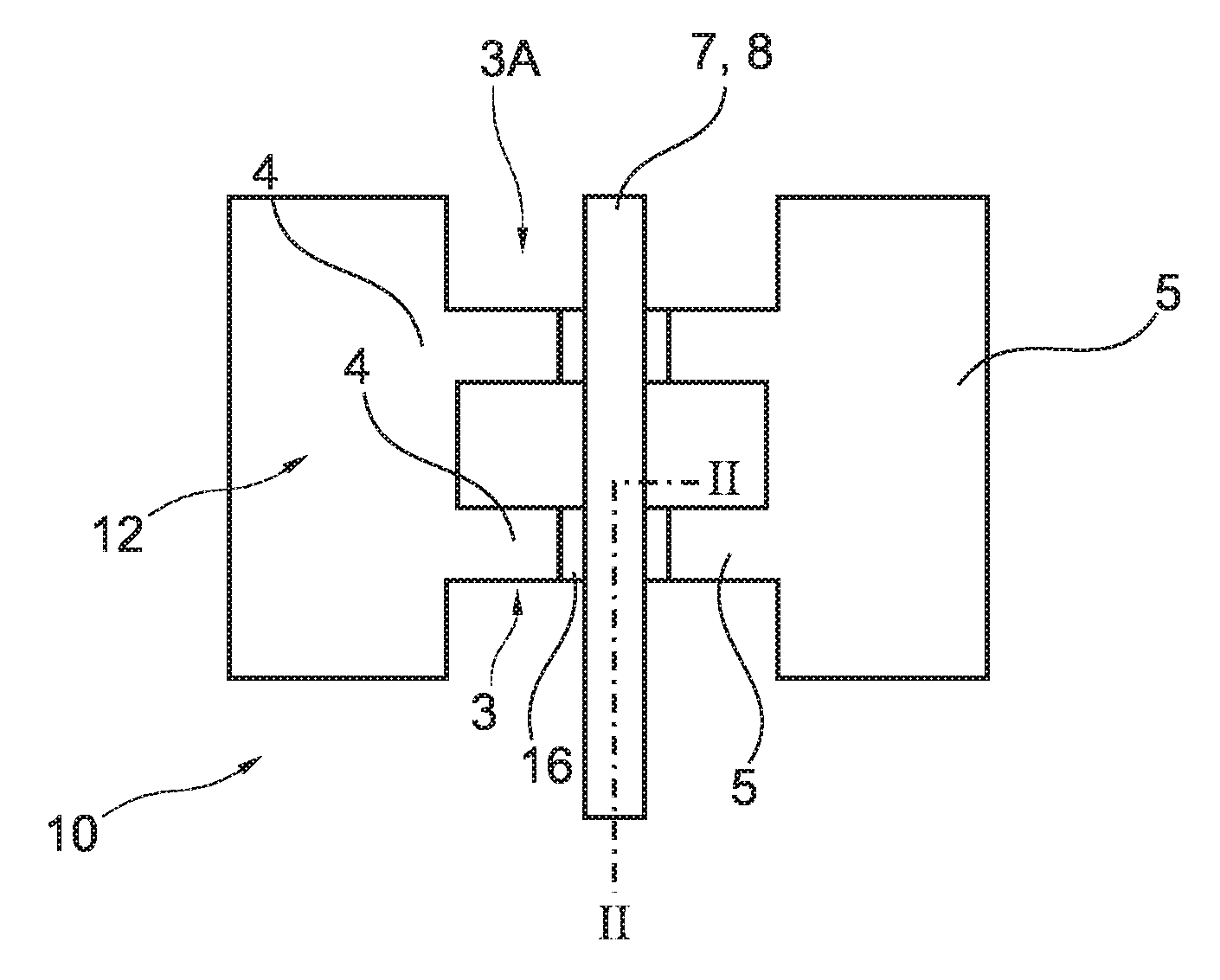

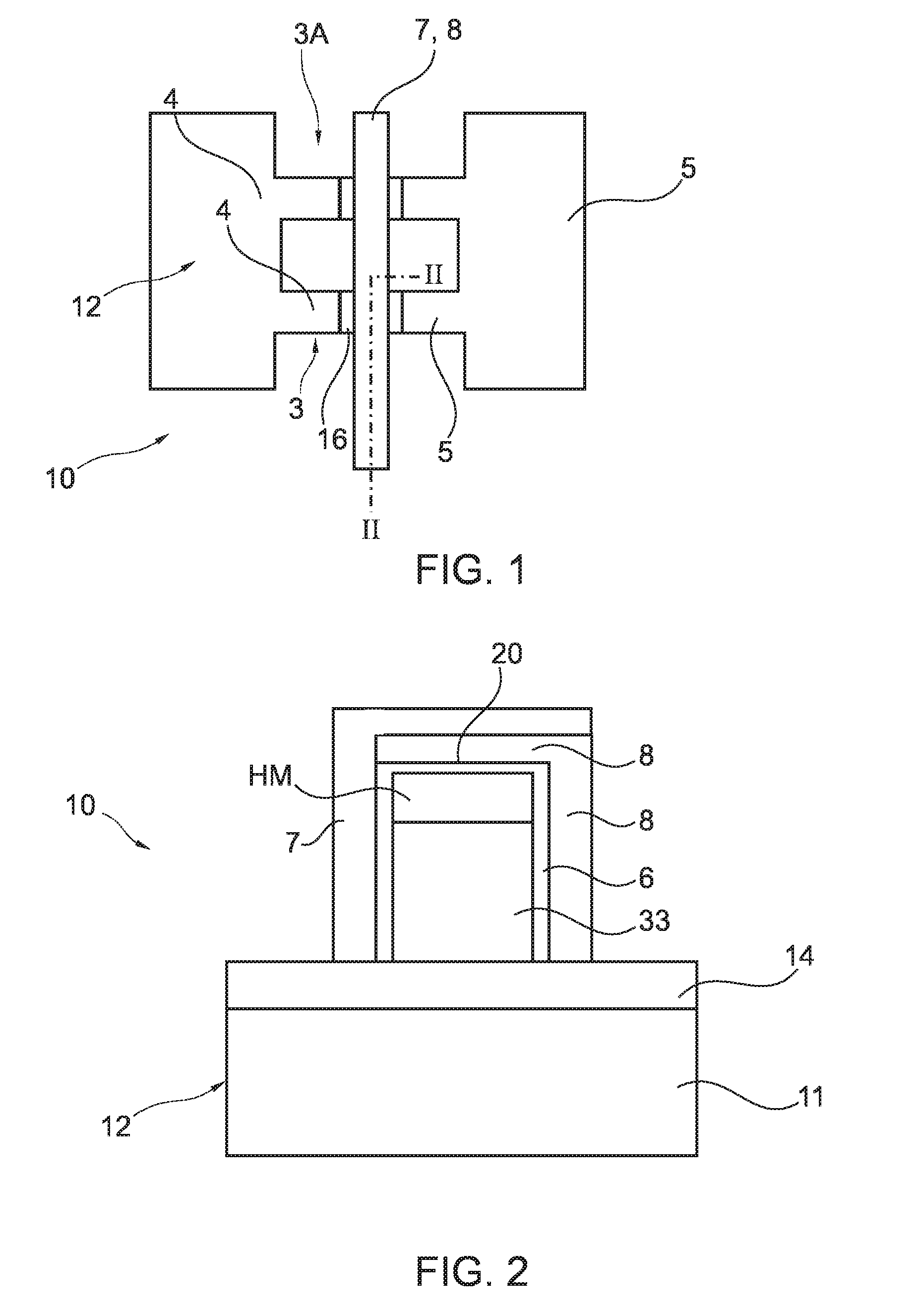

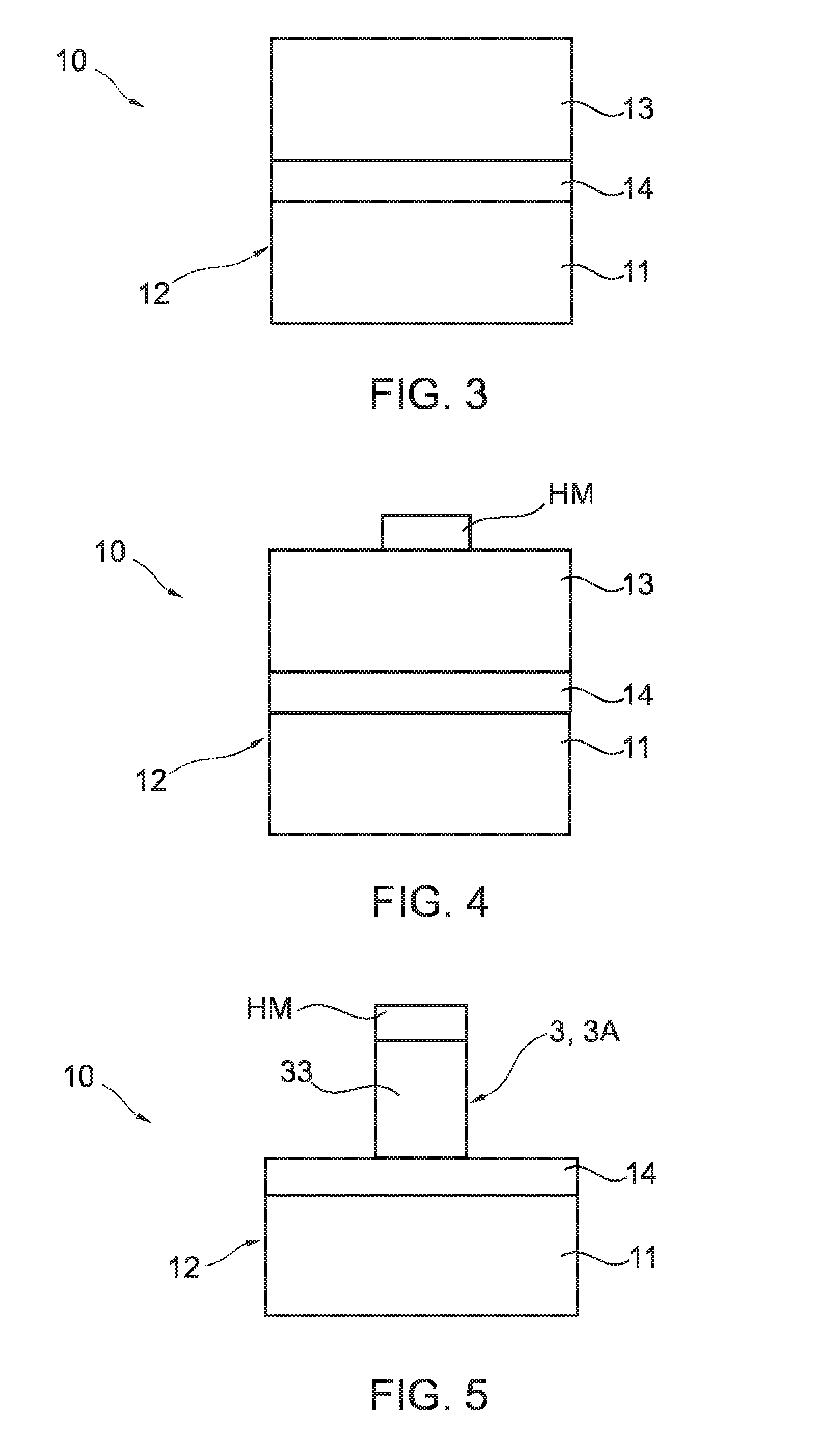

Transistor device and method of manufacturing such a transistor device

ActiveUS20100025766A1Suitable for high-scale integrationImprove device performanceSolid-state devicesSemiconductor/solid-state device manufacturingGate insulatorEngineering

A transistor device (10), the transistor device (10) comprising a substrate (11, 14), a fin (3, 3A) aligned along a horizontal direction on the substrate (11, 14), a first source / drain region (4) of a first type of conductivity in the fin (3, 3A), a second source / drain region (5) of a second type of conductivity in the fin (3, 3A), wherein the first type of conductivity differs from the second type of conductivity, a channel region (33) in the fin (3, 3A) between the first source / drain region (4) and the second source / drain region (5), a gate insulator (6) on the channel region (33), and a gate structure (7, 8) on the gate insulator (6), wherein the sequence of the first source / drain region (4), the channel region (33) and the second source / drain region (5) is aligned along the horizontal direction.

Owner:UNITED MICROELECTRONICS CORP

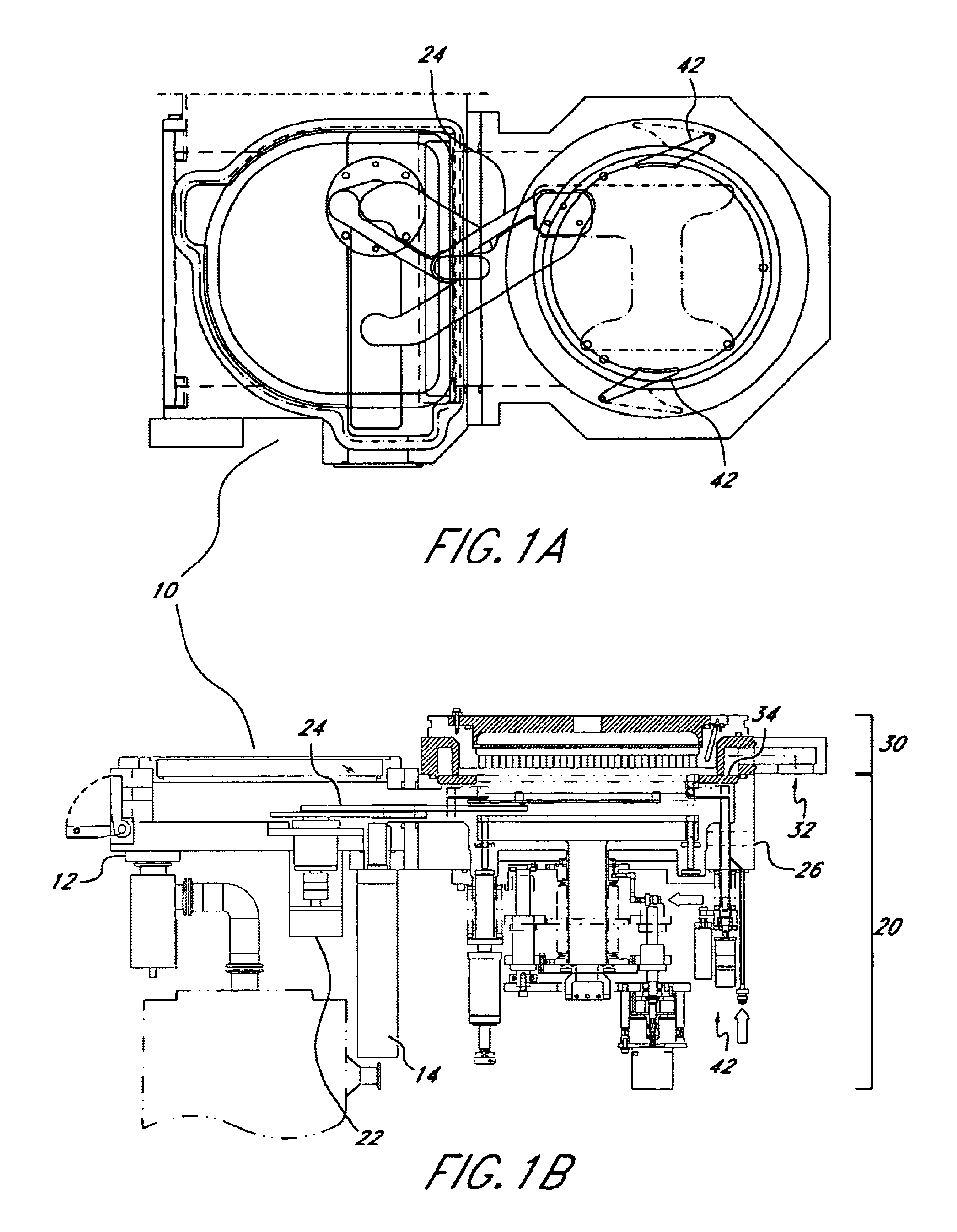

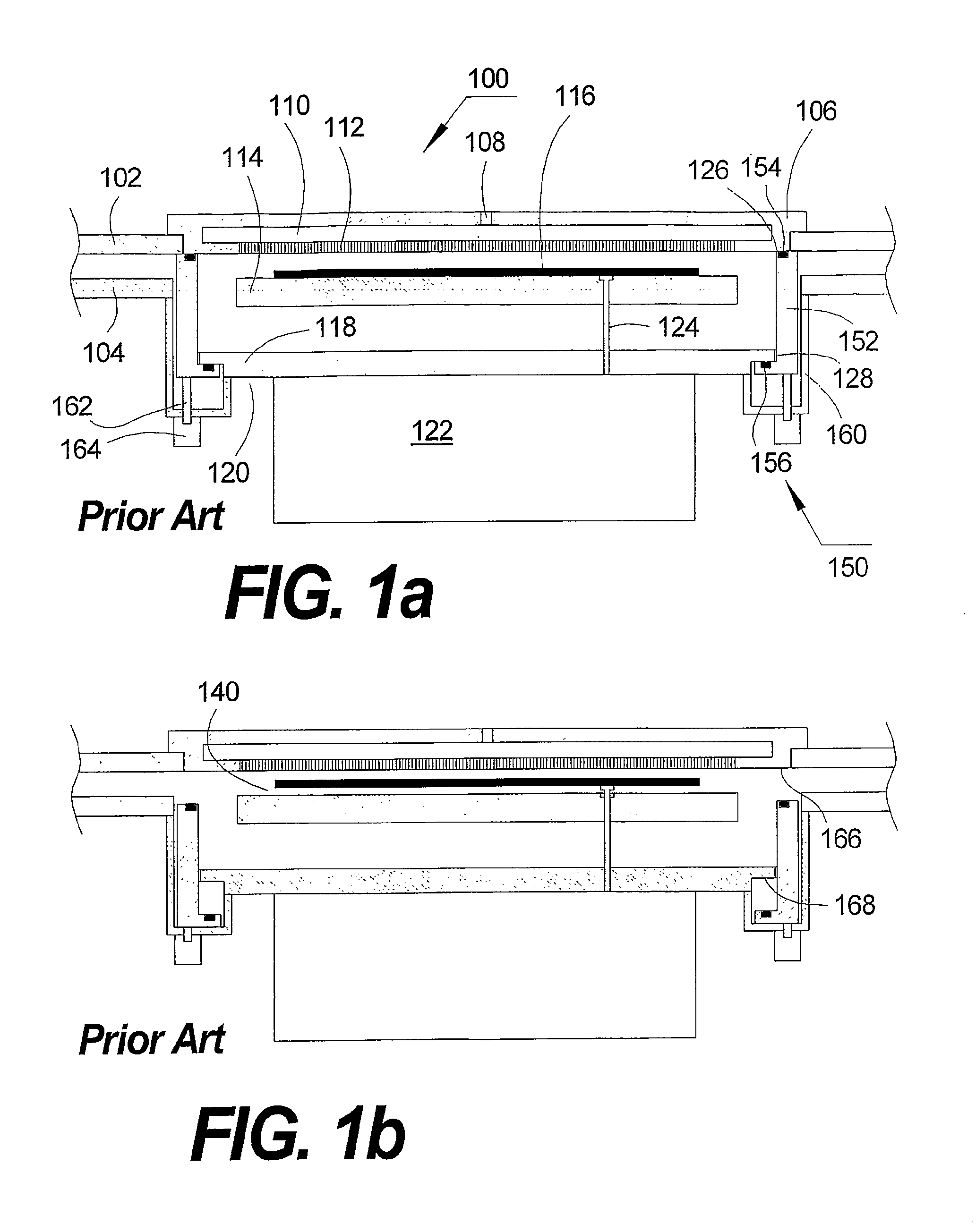

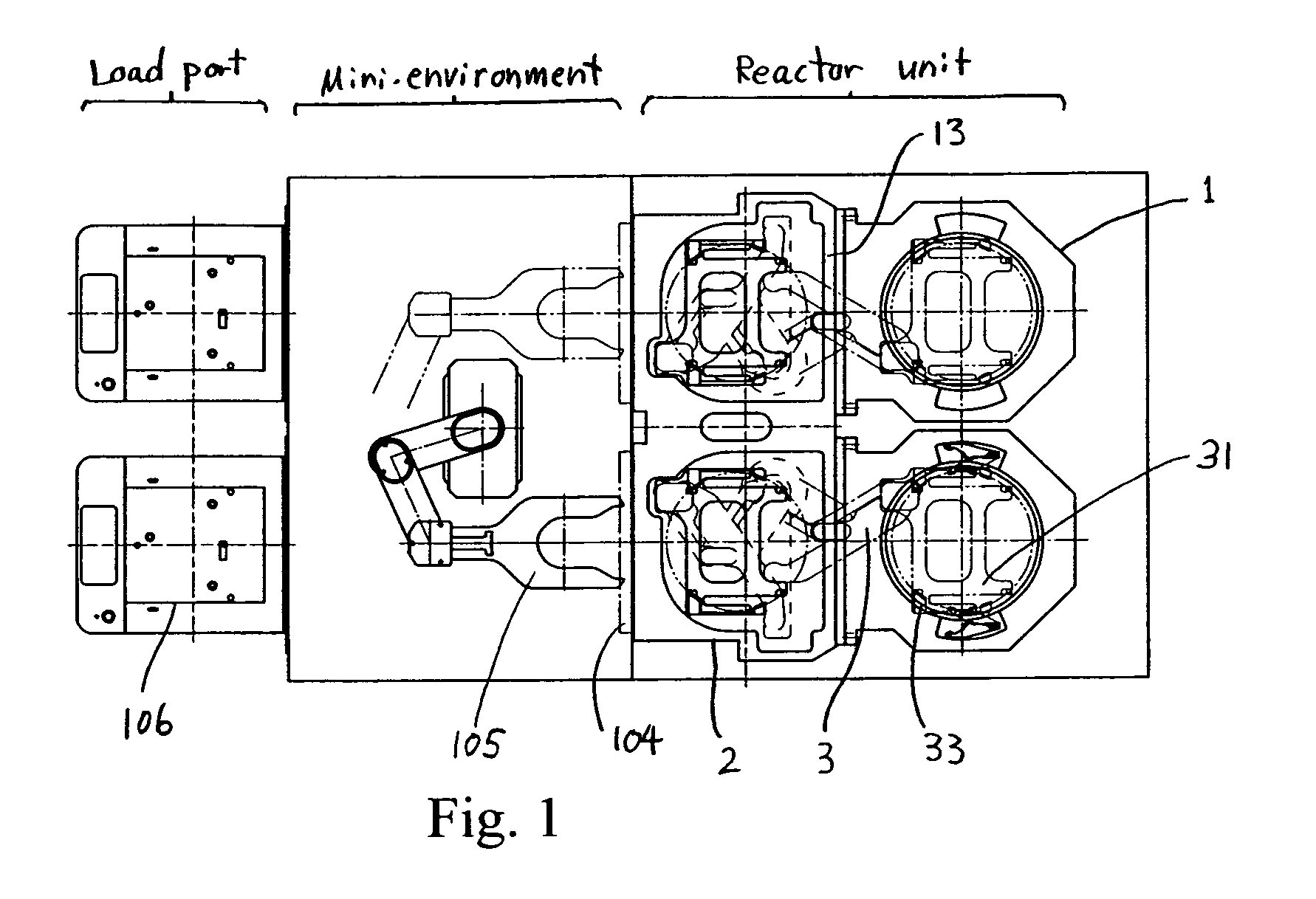

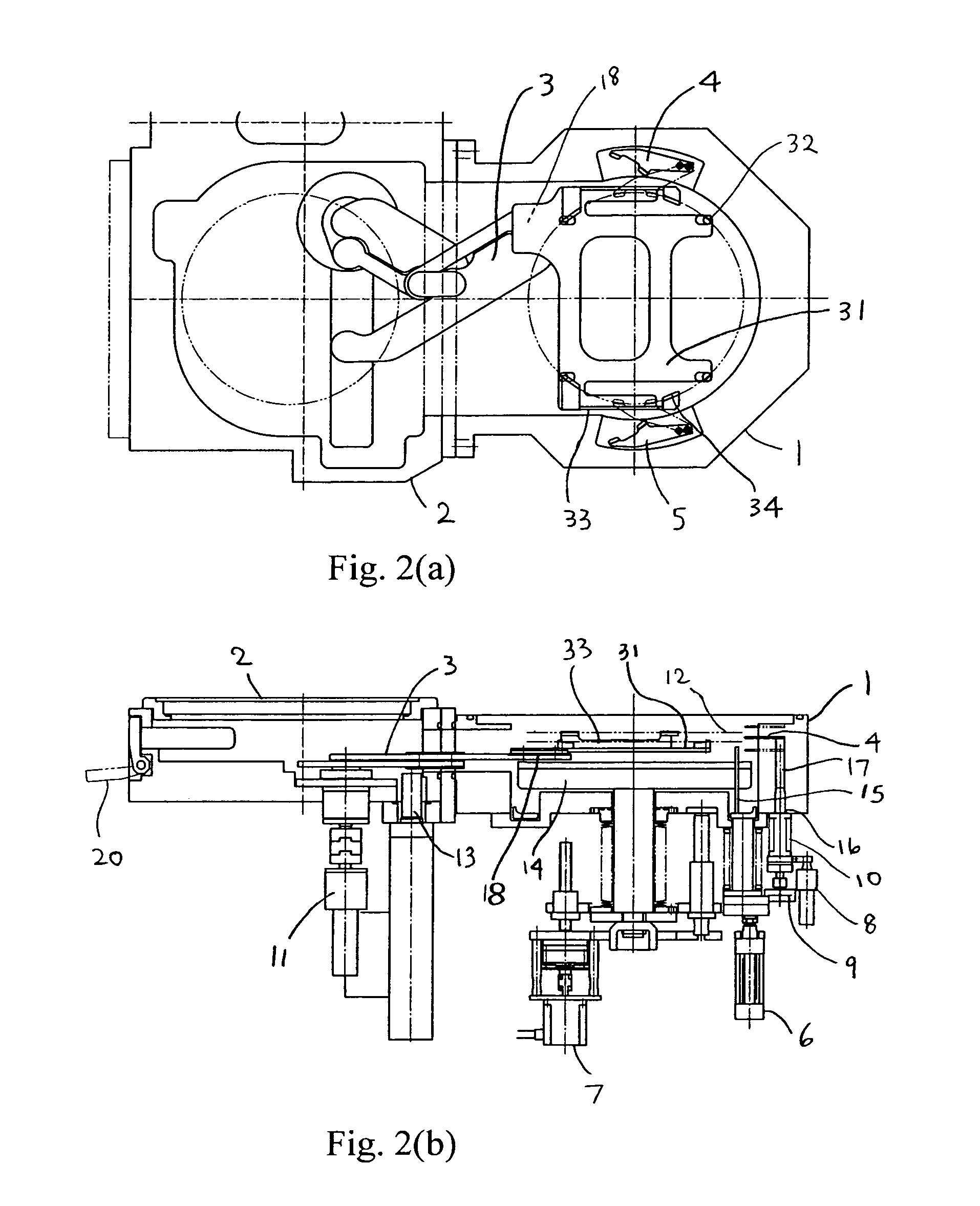

Semiconductor processing apparatus comprising chamber partitioned into reaction and transfer sections

InactiveUS6899507B2Reduce adhesionImprove efficiencySemiconductor/solid-state device manufacturingCharge manipulationEngineeringSemiconductor

Semiconductor processing equipment that has increased efficiency, throughput, and stability, as well as reduced operating cost, footprint, and faceprint is provided. Other than during deposition, the atmosphere of both the reaction chamber and the transfer chamber are evacuated using the transfer chamber exhaust port, which is located below the surface of the semiconductor wafer. This configuration prevents particles generated during wafer transfer or during deposition from adhering to the surface of the semiconductor wafer. Additionally, by introducing a purge gas into the transfer chamber during deposition, and by using an insulation separating plate 34, the atmospheres of the transfer and reaction chambers can be effectively isolated from each other, thereby preventing deposition on the walls and components of the transfer chamber. Finally, the configuration described herein permits a wafer buffer mechanism to be used with the semiconductor processing equipment, thereby further increasing throughput and efficiency.

Owner:ASM JAPAN

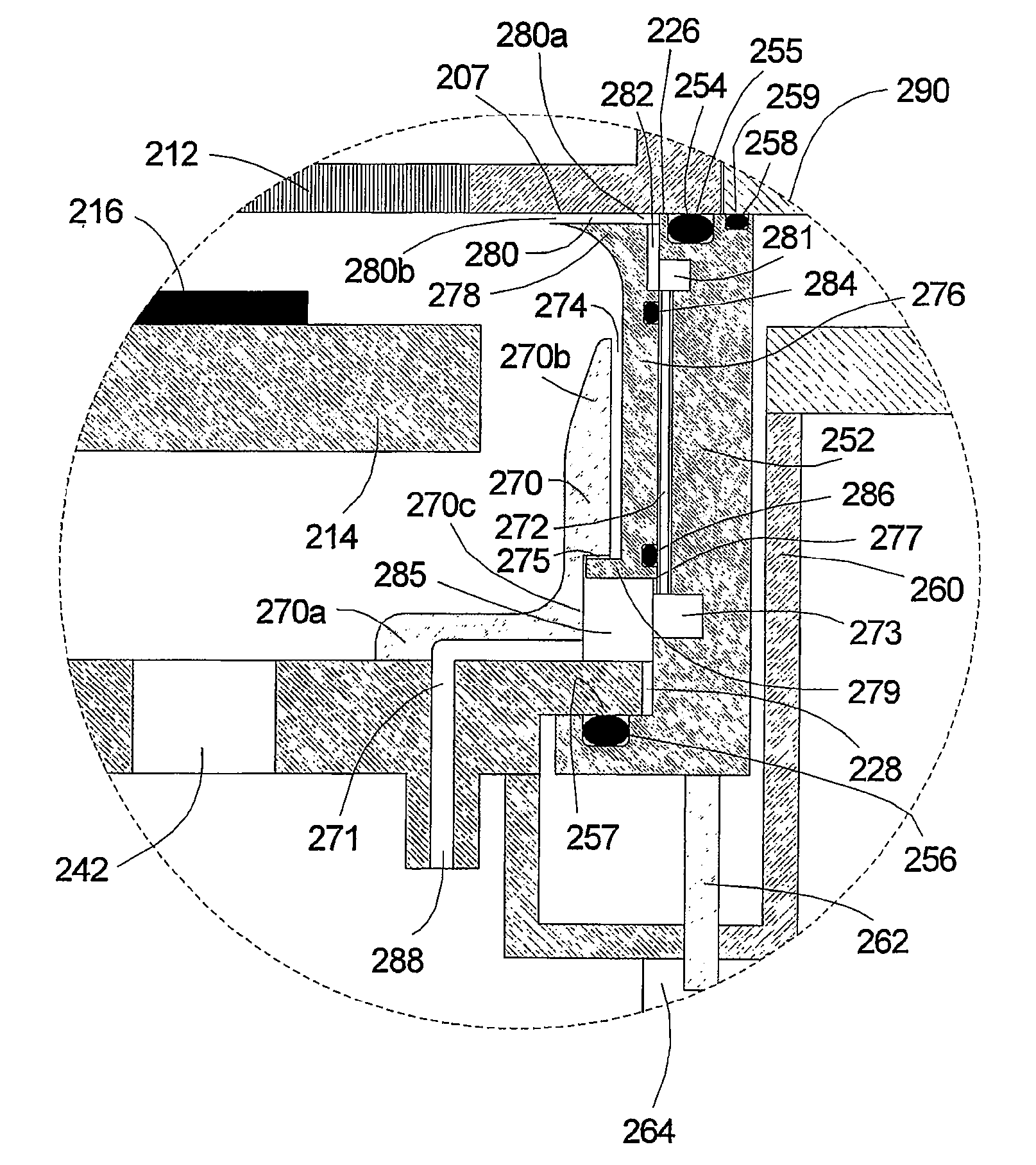

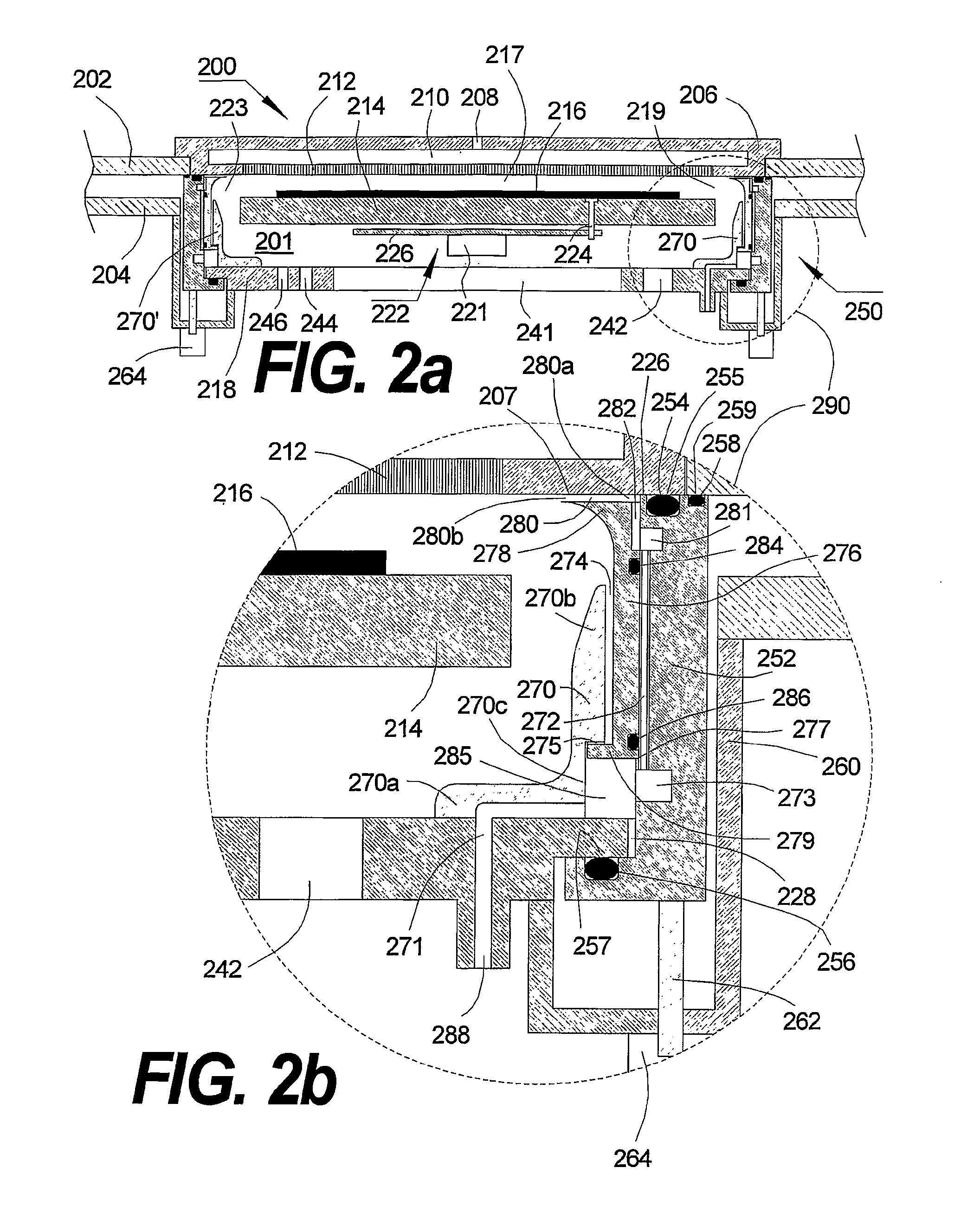

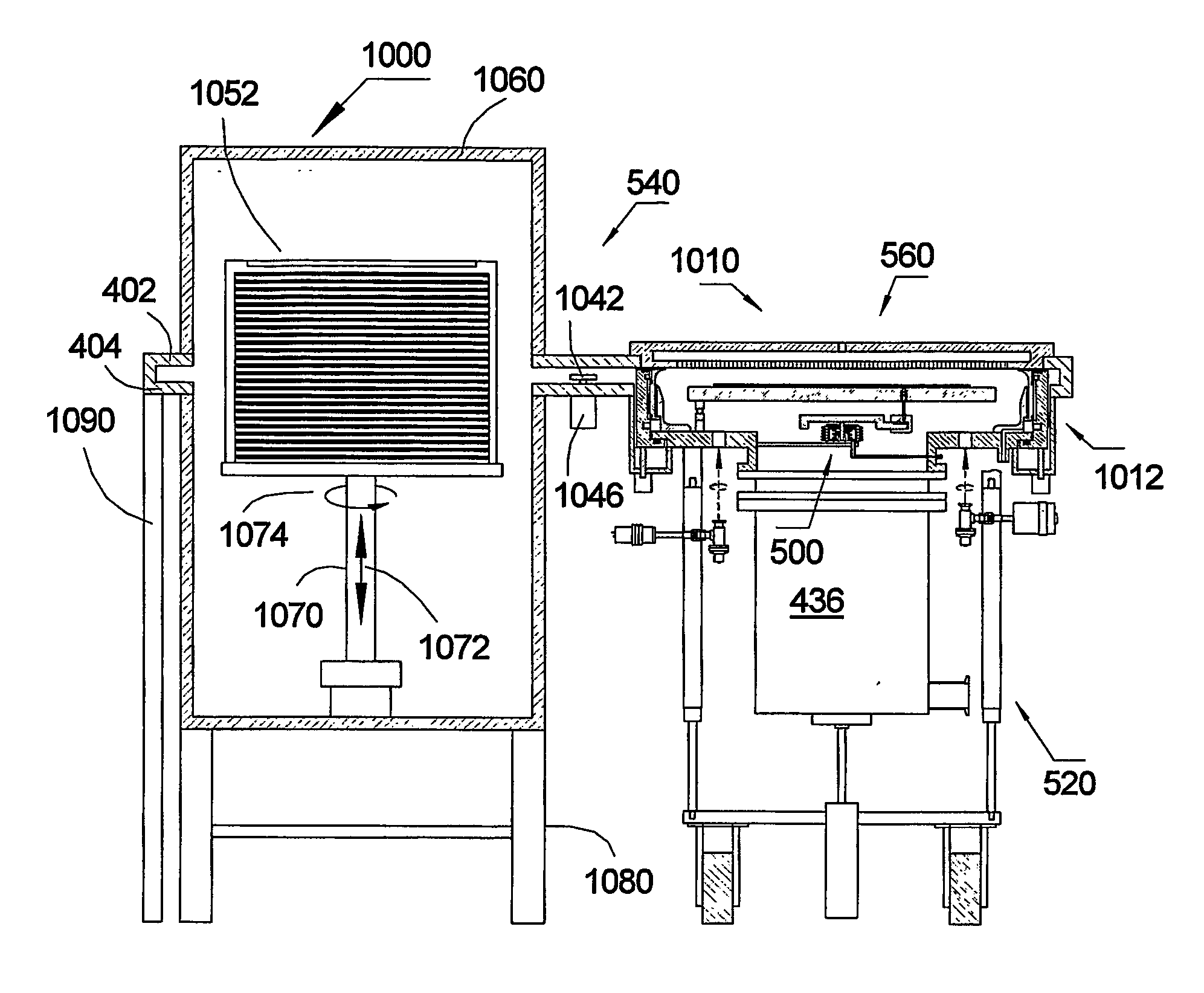

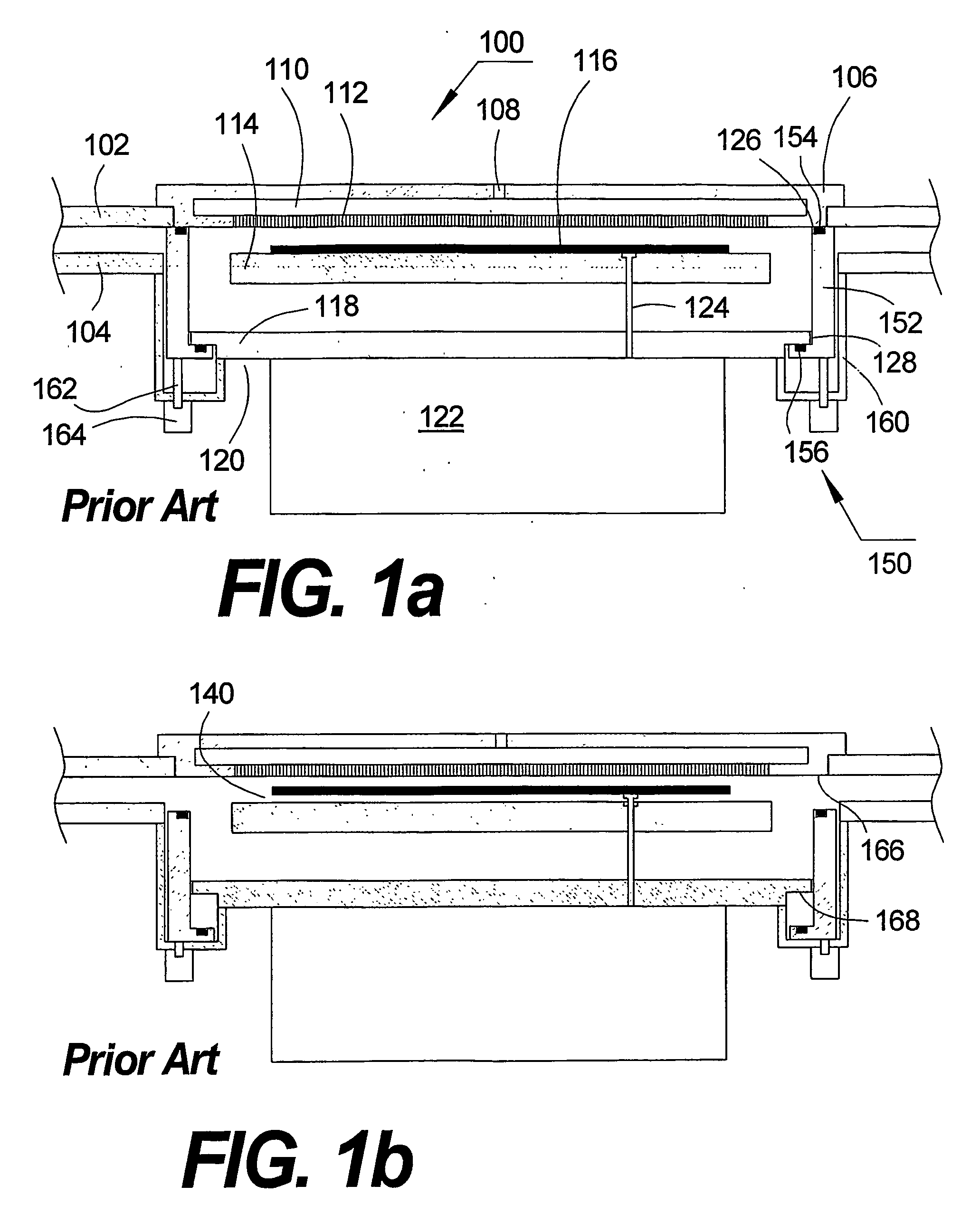

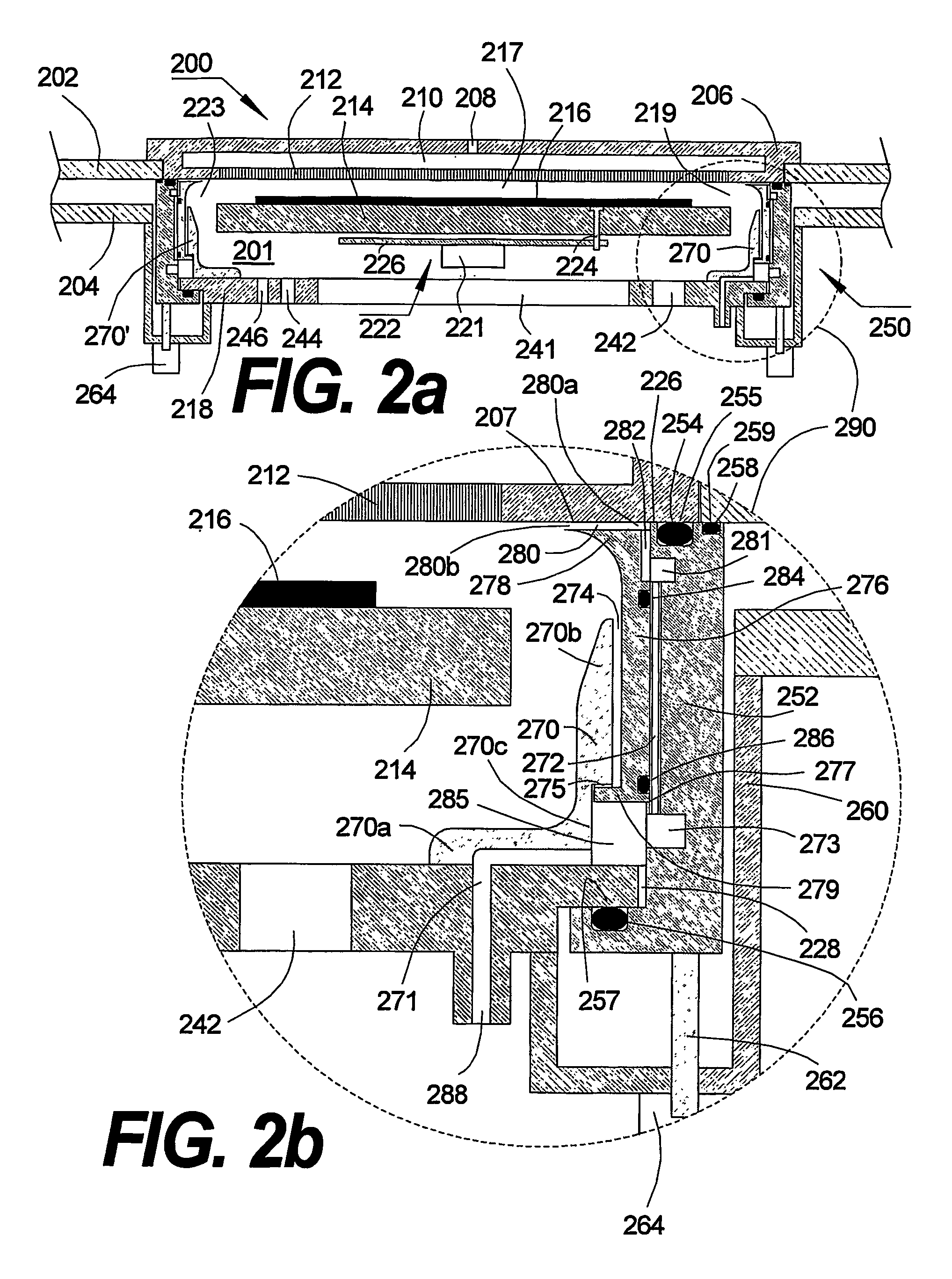

Perimeter partition-valve with protected seals and associated small size process chambers and multiple chamber systems

ActiveUS7682454B2Improve performanceSmall sizeVacuum evaporation coatingSputtering coatingModularityHandling system

Owner:SUNDEW TECH

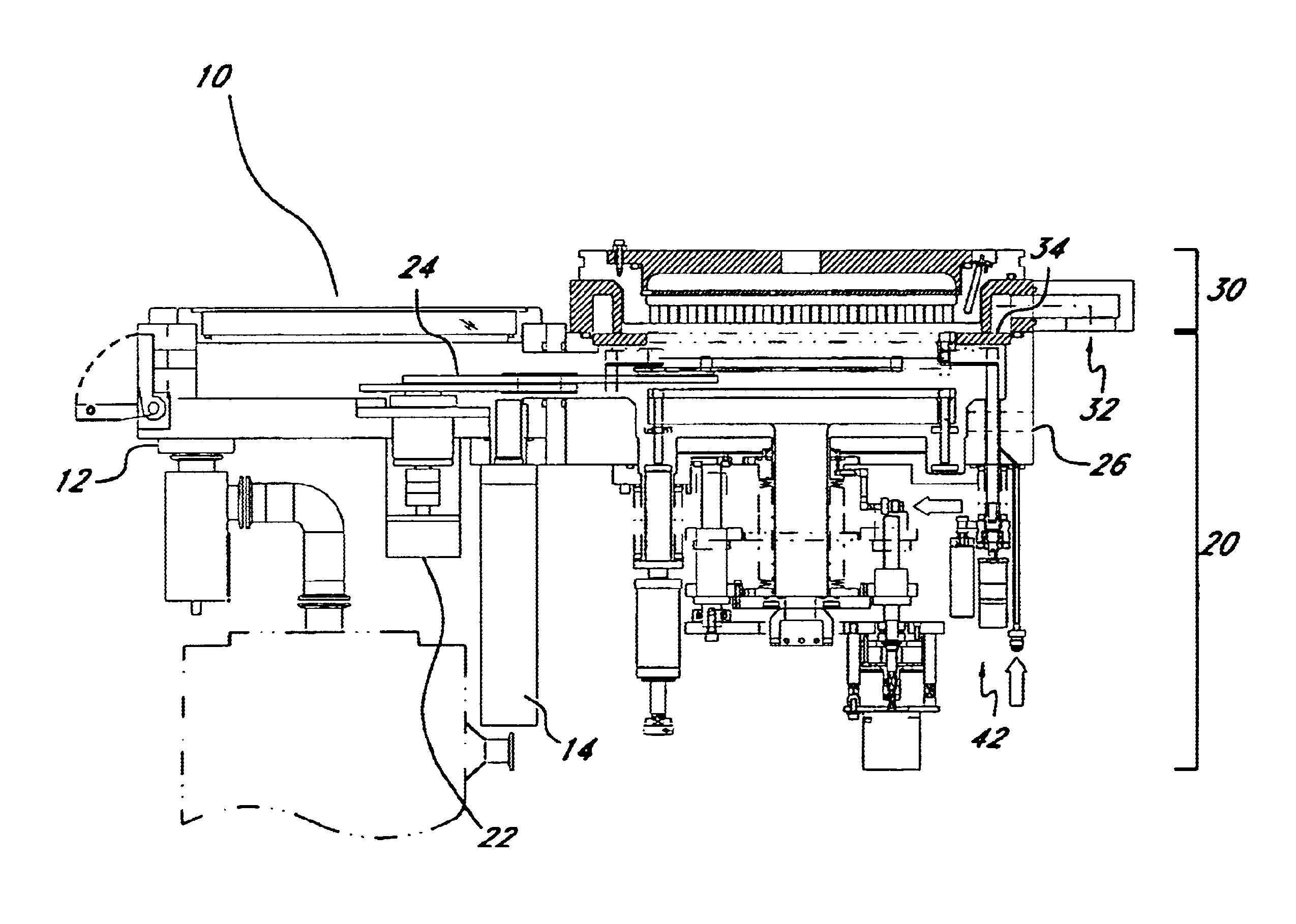

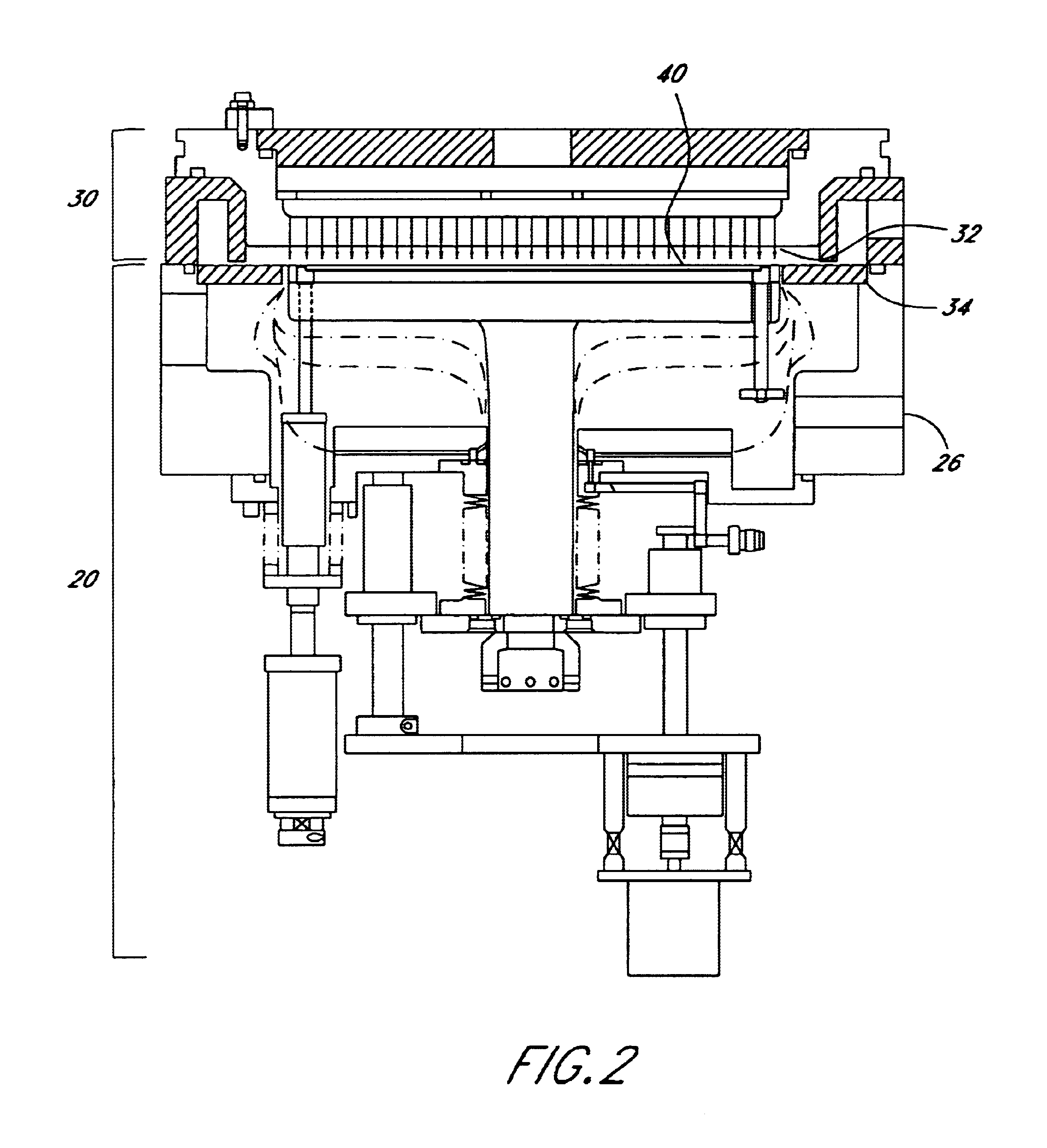

Substrate-processing apparatus with buffer mechanism and substrate-transferring apparatus

ActiveUS7690881B2Low costSmall footprintPliersSemiconductor/solid-state device manufacturingEngineeringActuator

A substrate transfer apparatus for loading and unloading substrates in a reaction chamber, includes: an arm having a distal end which is laterally movable in a straight line direction; and end-effectors for loading and unloading substrates in a reaction chamber, which include a lower end-effector and an upper end-effector. One of the lower end-effector or the upper end-effector is movably coupled to the arm at a distal end of the arm, and the other end-effector is fixed to the movably coupled end-effector. The fixed end-effector is fixed to the movably coupled end-effector.

Owner:ASM JAPAN

Perimeter partition-valve with protected seals and associated small size process chambers and multiple chamber systems

ActiveUS20070051312A1Improve securityImprove performanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingModularityHandling system

A seal-protected perimeter partition valve apparatus (450) defines a vacuum and pressure sealed space (401) within a larger space (540) confining a substrate processing chamber with optimized geometry, minimized footprint and 360° substrate accessibility. A compact perimeter partitioned assembly (520) with seal protected perimeter partition valve (450) and internally contained substrate placement member (480) further provides processing system modularity and substantially minimized system footprint.

Owner:SUNDEW TECH

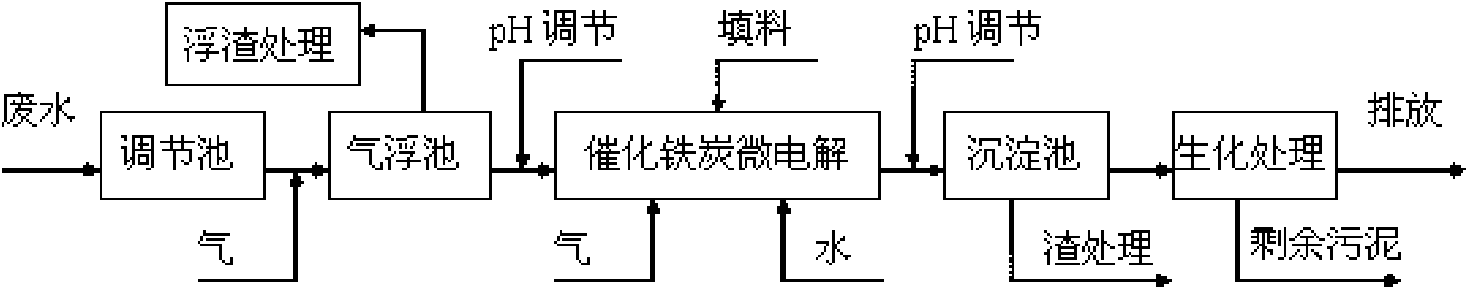

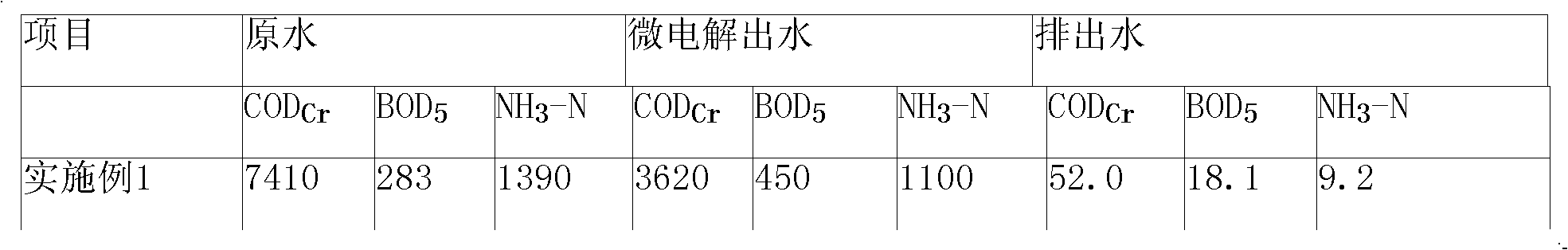

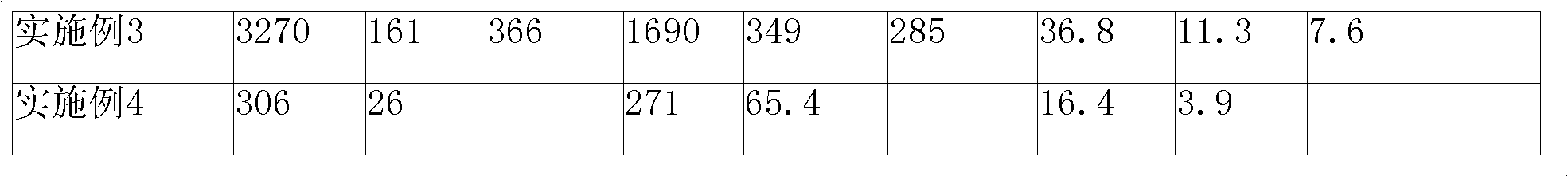

Catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater

InactiveCN101665311AReduce processing loadEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention relates to a catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater; the organic wastewater is collected to an adjusting tank and enters an air floatation tank for air floatation treatment to remove part of the organic matters after the adjustment of water volume and water quality; the scruff is collected or recovered; the wastewatergoes through Ph adjustment and then enters a catalytic iron-carbon and micro-electrolysis unit to improve the biochemical quality; the effluent goes through Ph adjustment and then enters a sedimentation tank; the effluent of the sedimentation tank adopts anoxic-aerobic biochemistry treatment to remove the organic matters and ammonia nitrogen and then is emitted after reaching the standard; and the filler of the catalytic iron-carbon and micro-electrolysis unit comprises iron, carbon and a catalyst, wherein the mass ratio of the iron, carbon and catalyst is 1: (0.3-1.5): (0.01-0.5). The invention can effectively improve the micro-electrolysis electrochemical reaction efficiency and the degrading capability to the organic matters, and reduce the wastewater treatment cost with convenient technological operation.

Owner:CENT SOUTH UNIV

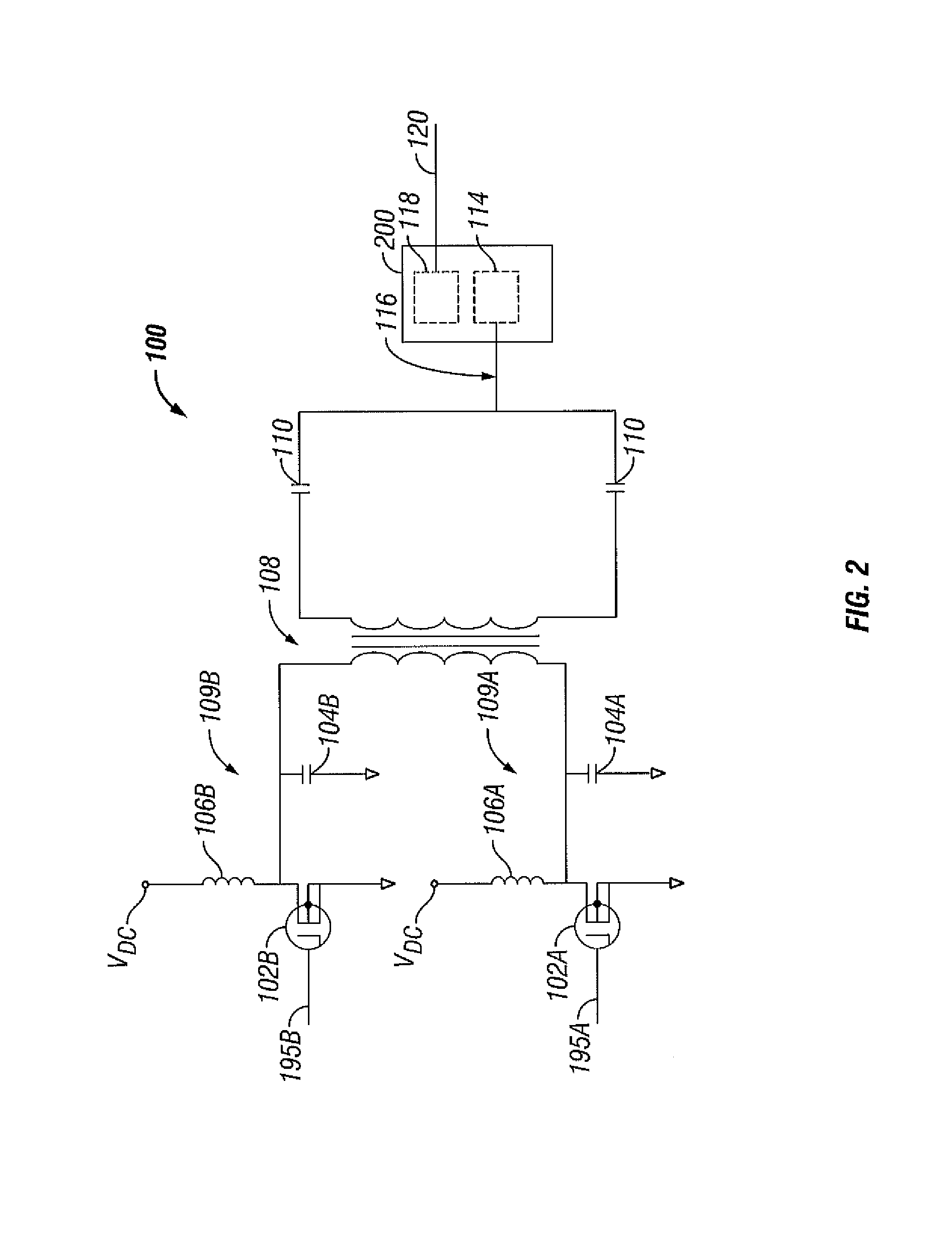

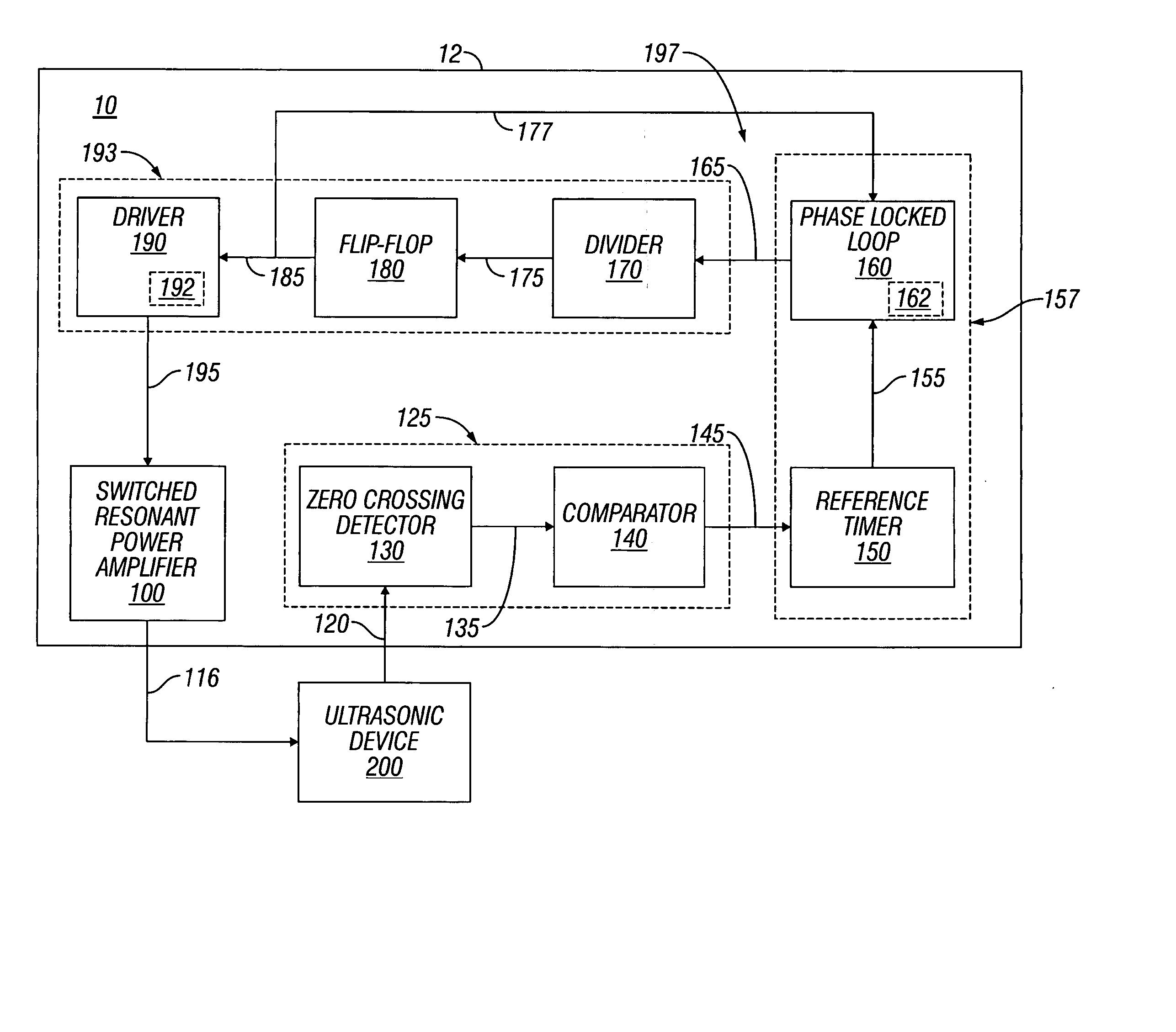

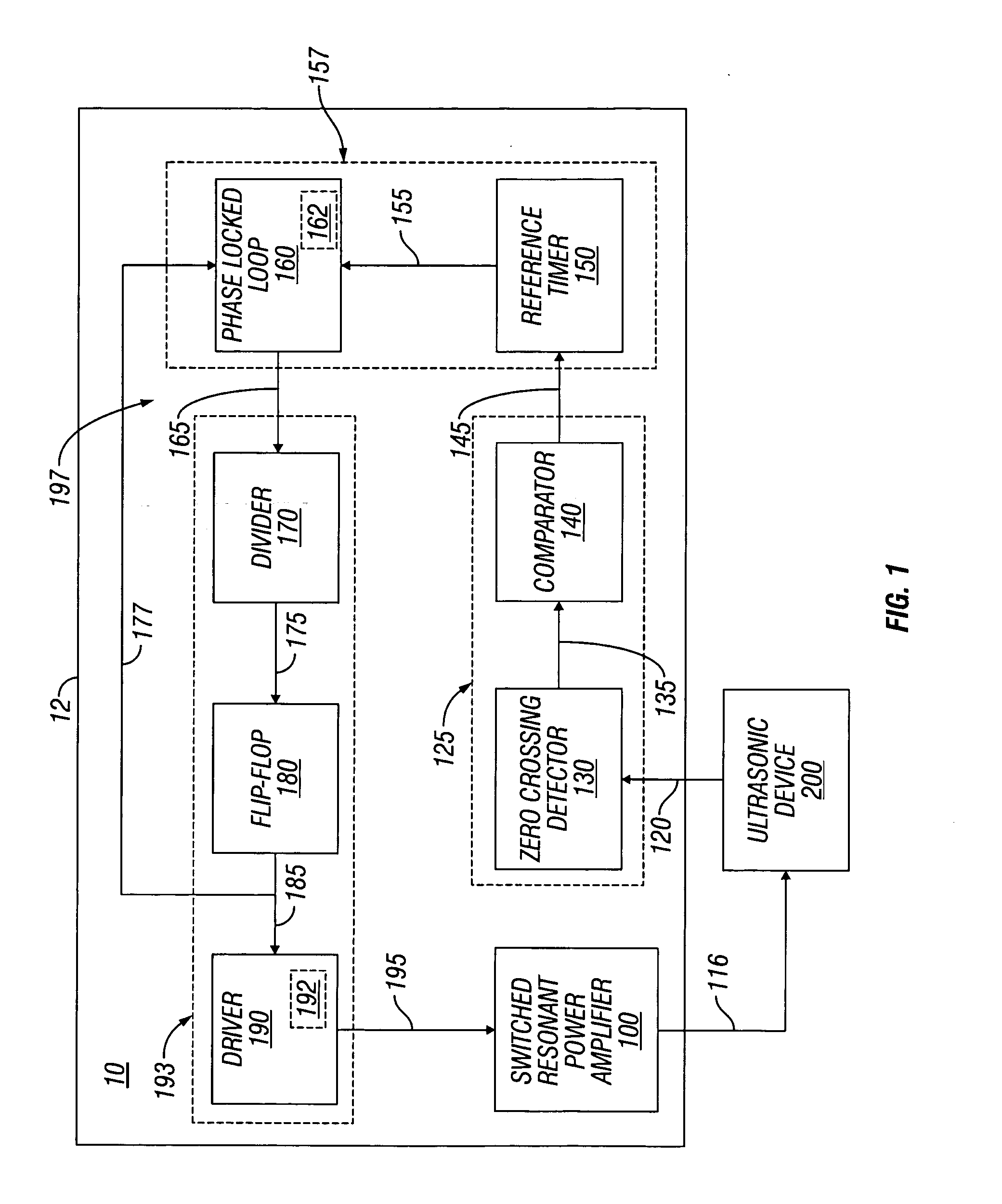

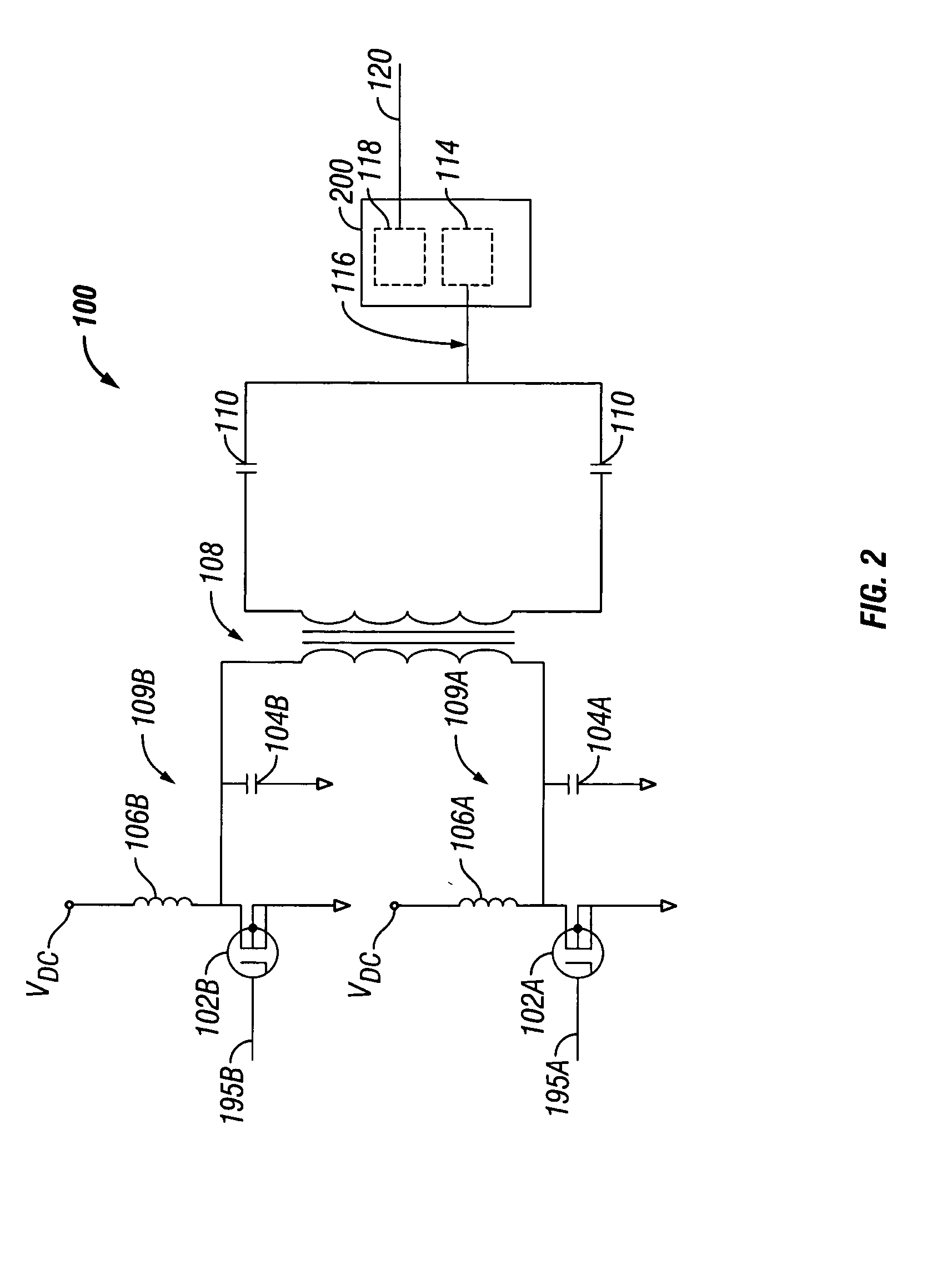

Switched resonant ultrasonic power amplifier system

ActiveUS7396336B2Operation efficiency can be improvedSmall footprintUltrasound therapyAmplifier modifications to raise efficiencyHemt circuitsControl ultrasound

Owner:COVIDIEN AG

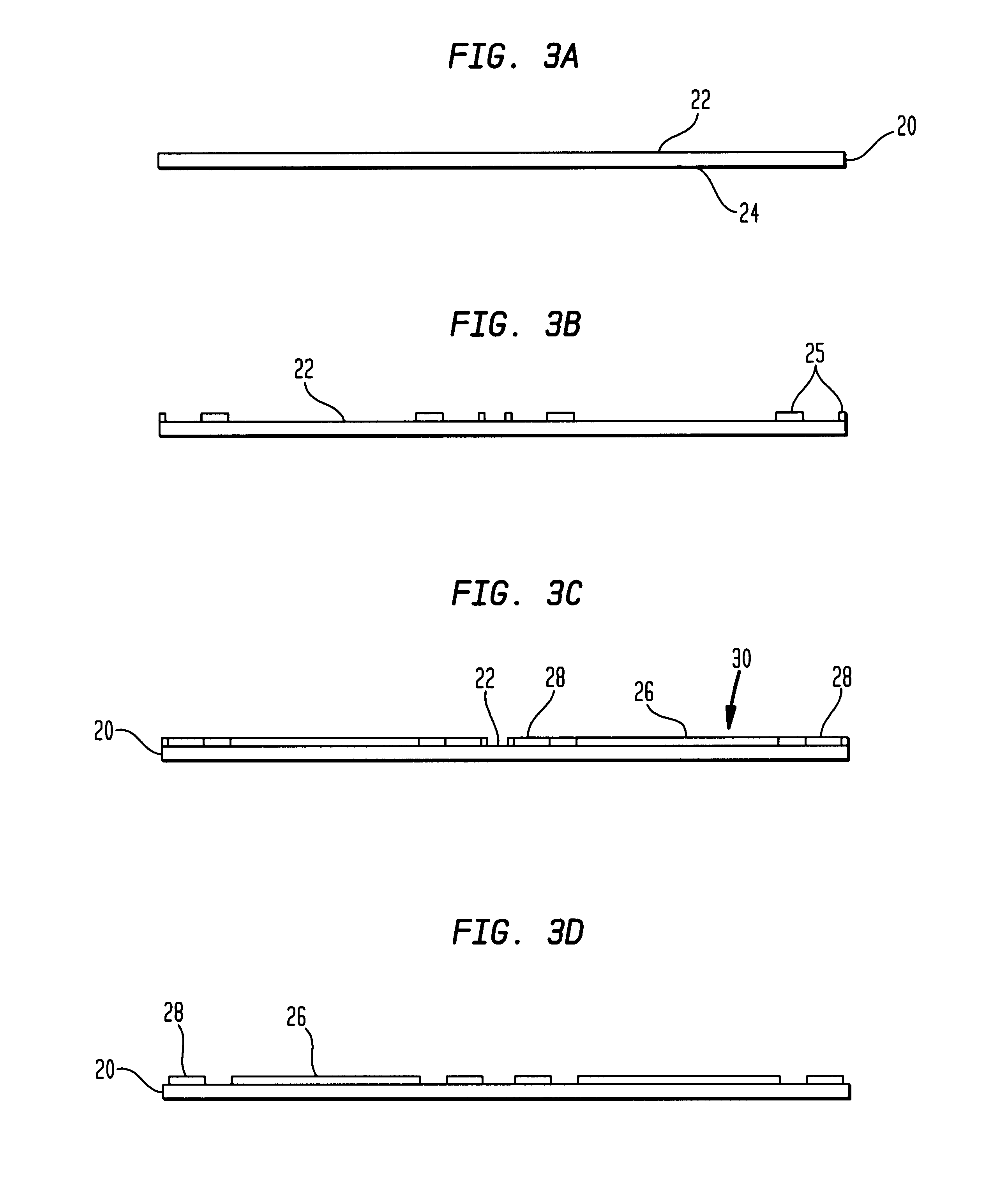

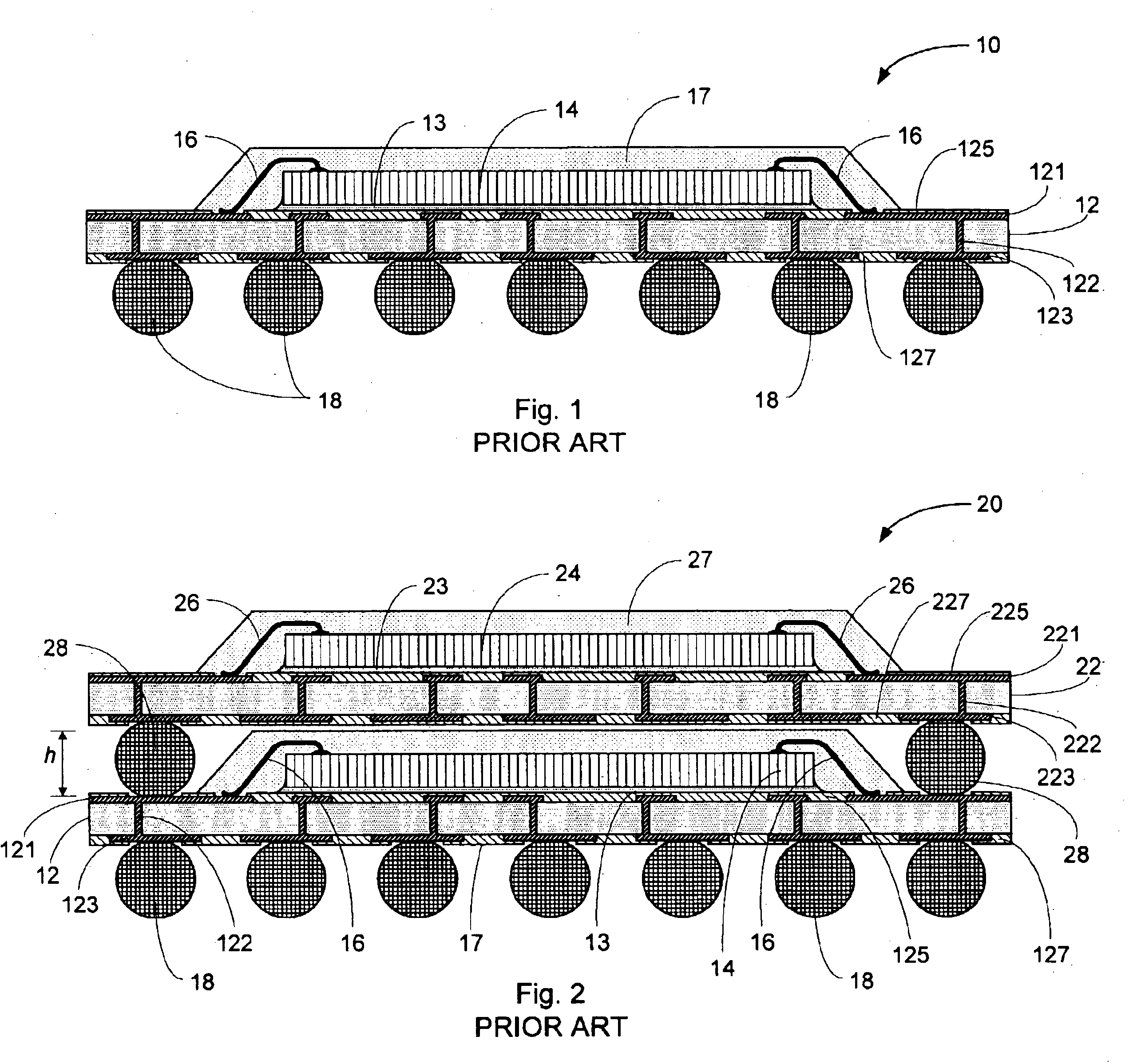

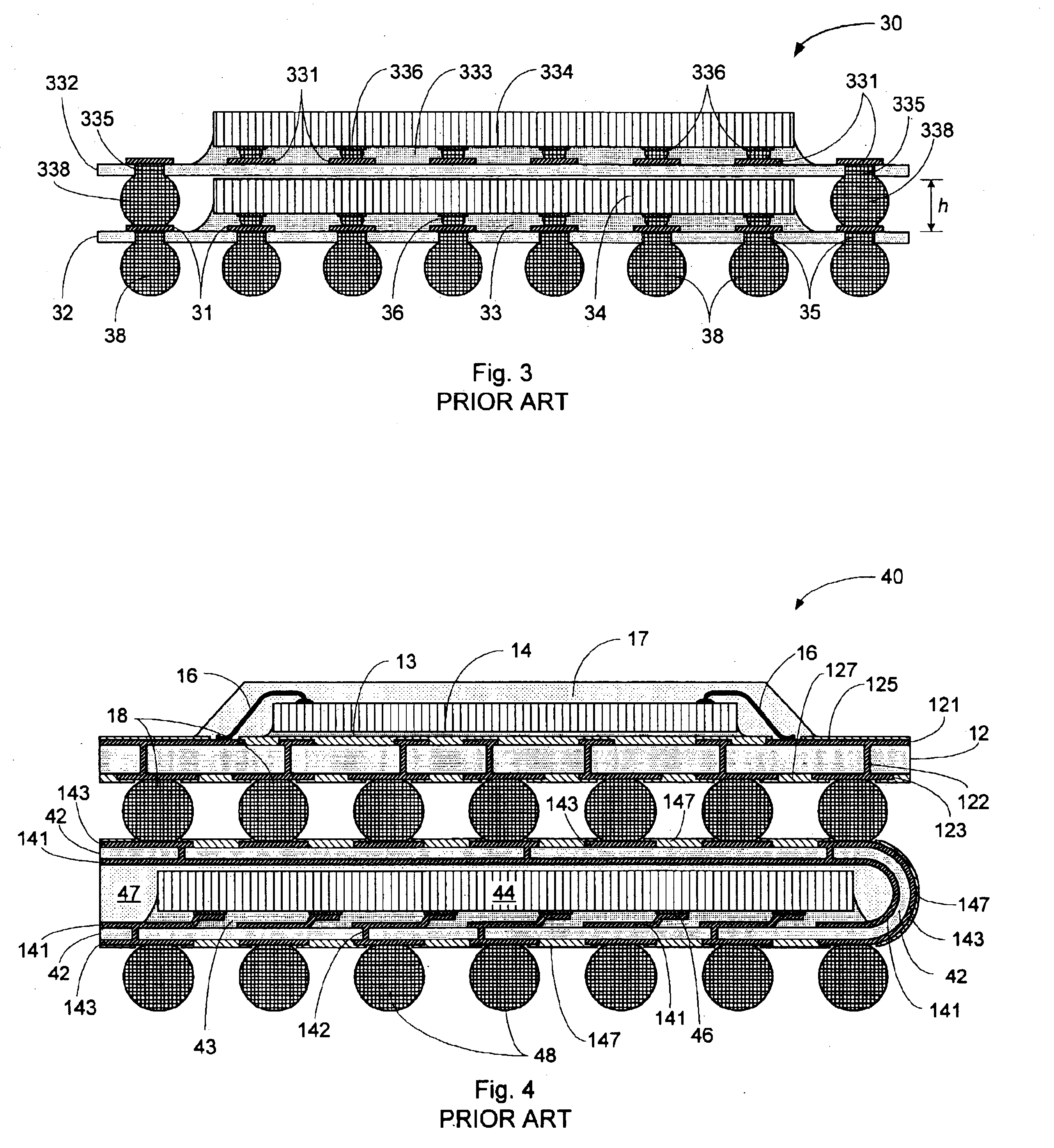

Semiconductor packages having light-sensitive chips

InactiveUS6583444B2Readily flexEasy to moveSemiconductor/solid-state device detailsSolid-state devicesProgrammable read-only memorySemiconductor package

A method of making a microelectronic package includes providing a sacrificial layer having a first surface and providing an optoelectronic element having a front face including one or more contacts and a rear surface and securing the rear surface of the optoelectronic element over the first surface of the sacrificial layer. The one or more contacts are then electrically interconnected with one or more conductive pads on the sacrificial layer and a curable and at least partially transparent encapsulant is provided over the first surface of the sacrificial layer so as to encapsulate the optoelectronic element and the conductive pads. The encapsulant is then cured the sacrificial layer is at least partially removed so as to leave said one or more conductive pads on a bottom surface of the encapsulant, the bottom surface of the encapsulant defining the bottom of the package. The optoelectronic element may include a light sensitive chip such as an ultraviolet-erasable programmable read-only memory (UV EPROM) or a light emitting chip, such as a light emitting diode (LED).

Owner:TESSERA INC

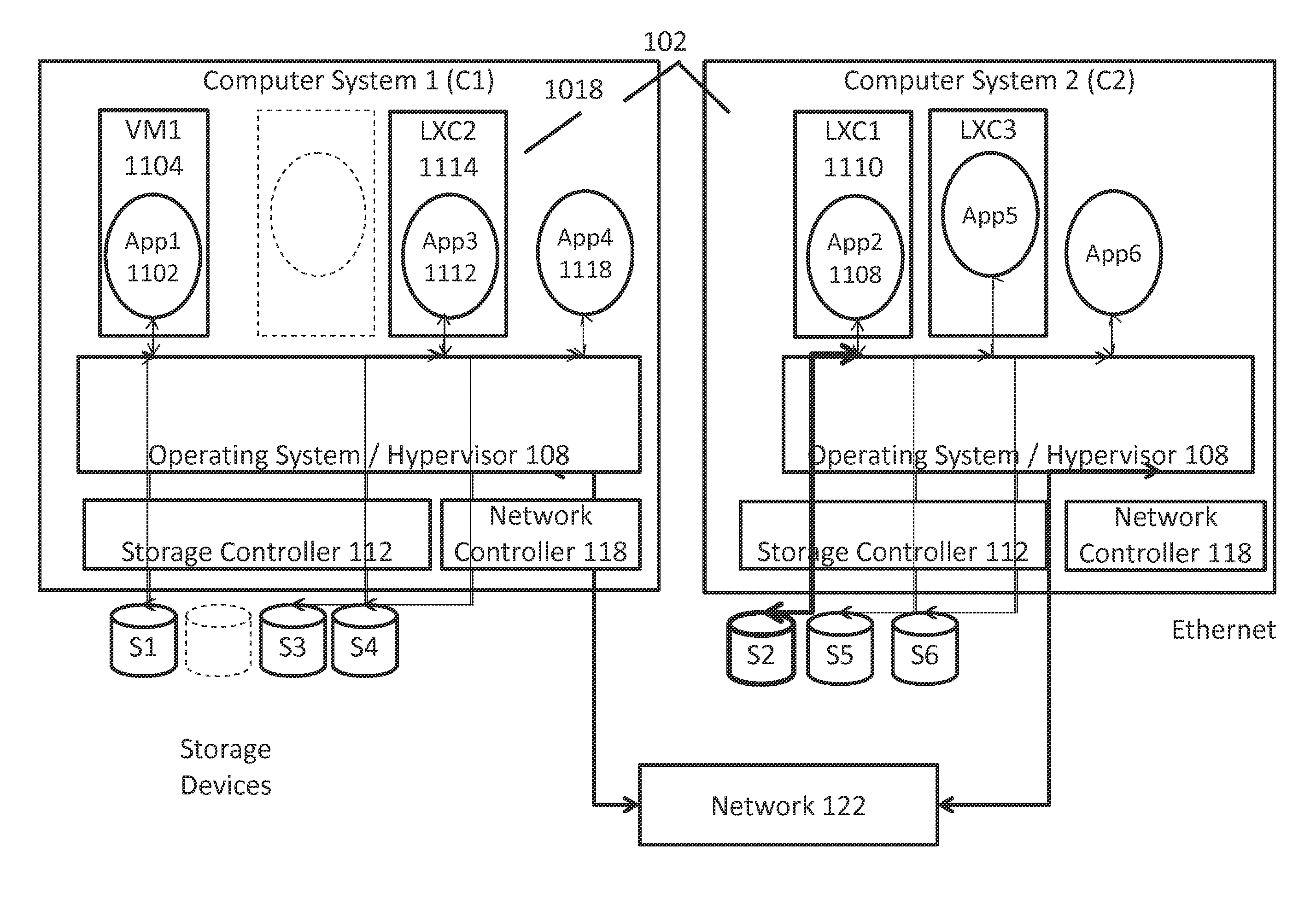

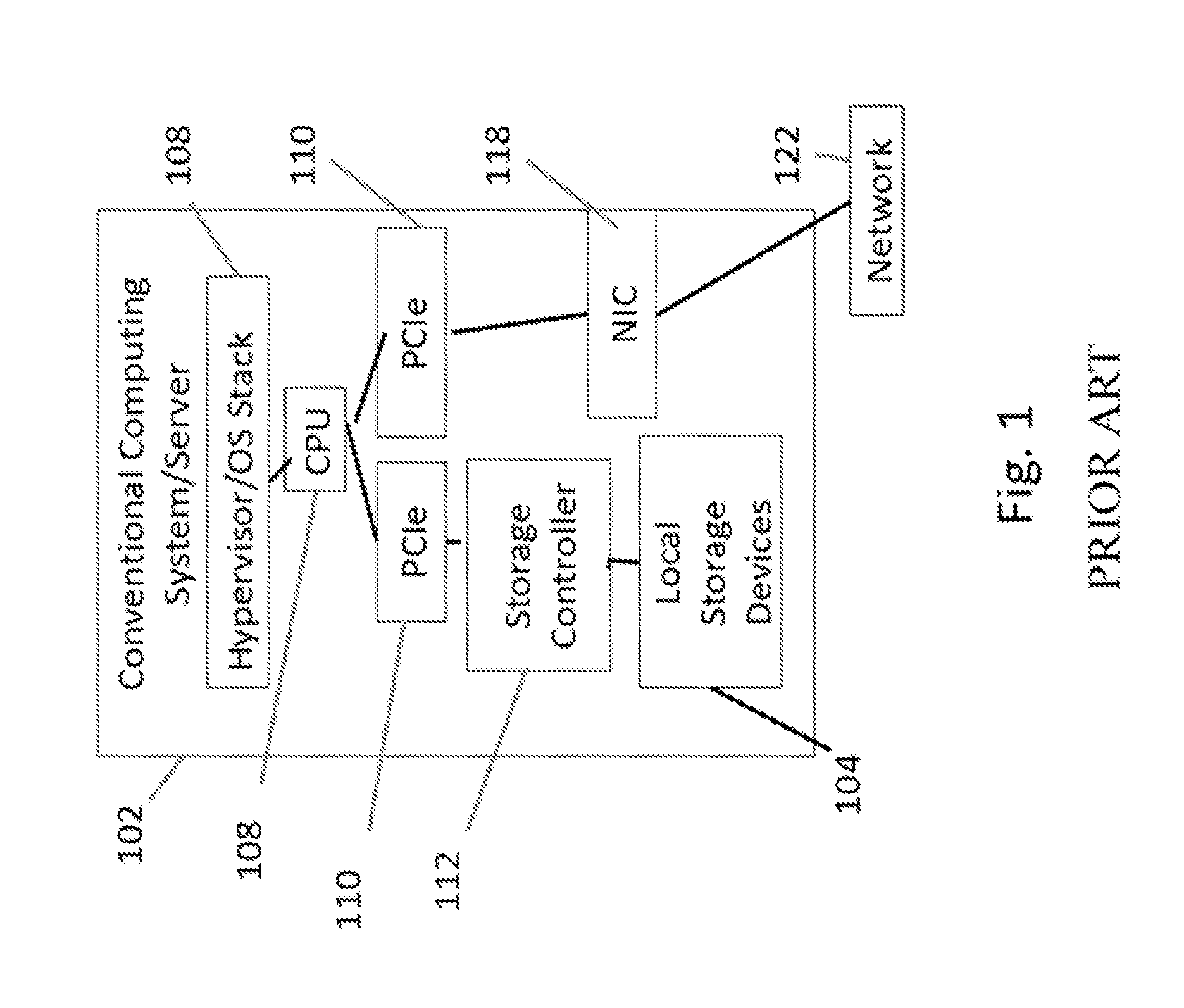

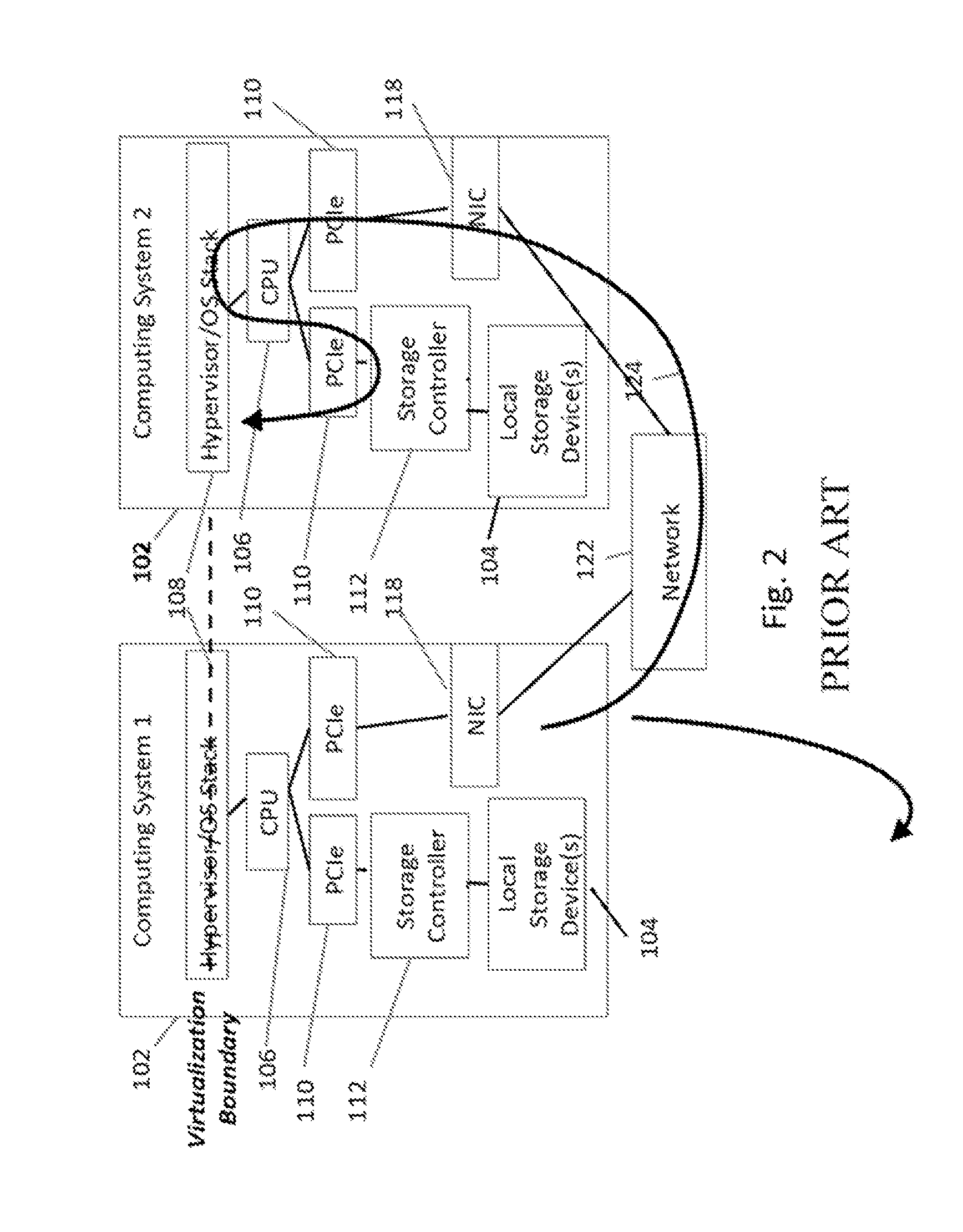

Methods and systems for converged networking and storage

InactiveUS20150254088A1Easy programmingImprove performanceResource allocationDigital computer detailsTraffic capacityNetwork interface controller

A device includes a converged input / output controller that includes a physical target storage media controller, a physical network interface controller and a gateway between the storage media controller and the network interface controller, wherein gateway provides a direct connection for storage traffic and network traffic between the storage media controller and the network interface controller.

Owner:DIAMANTI INC

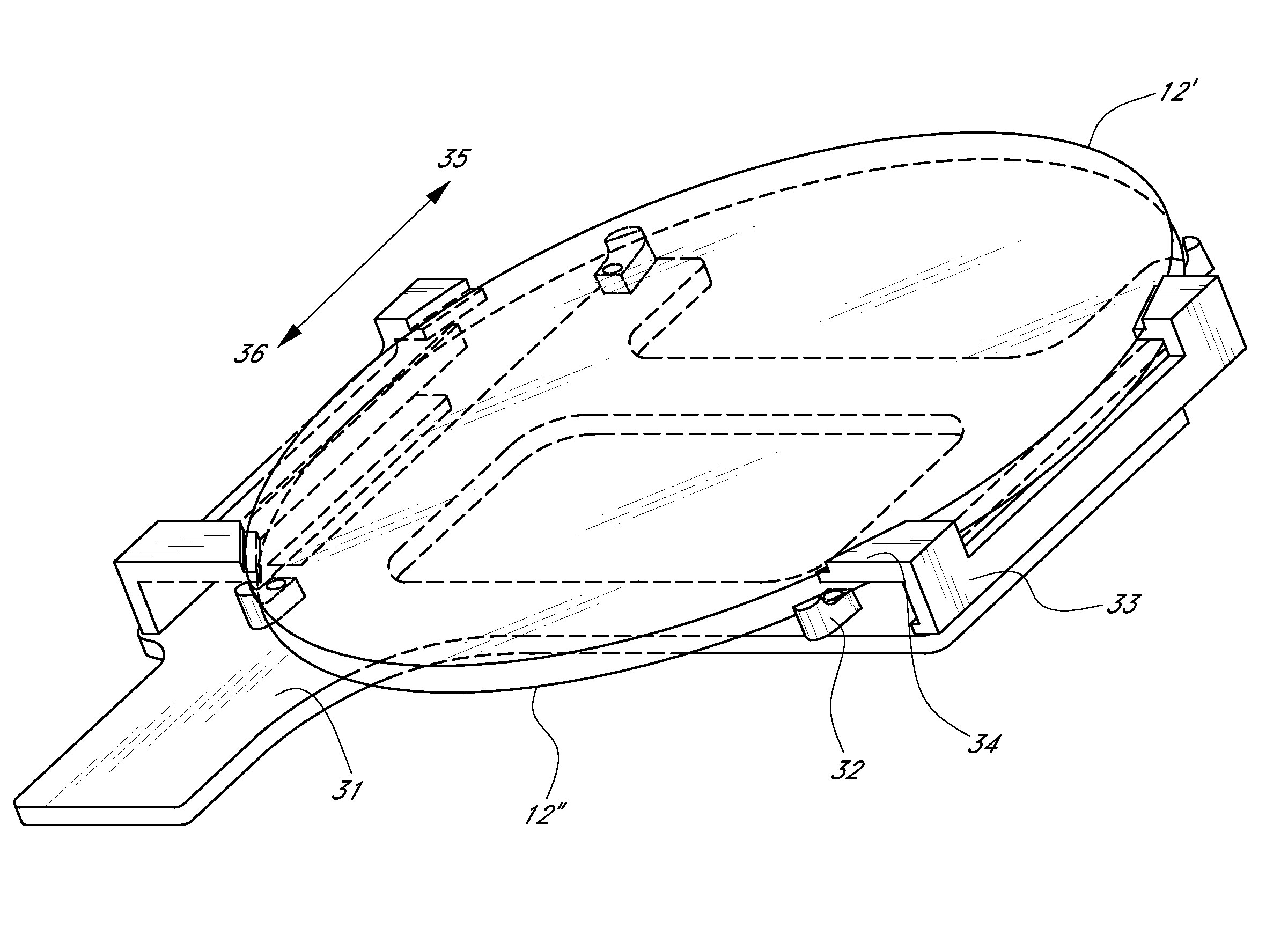

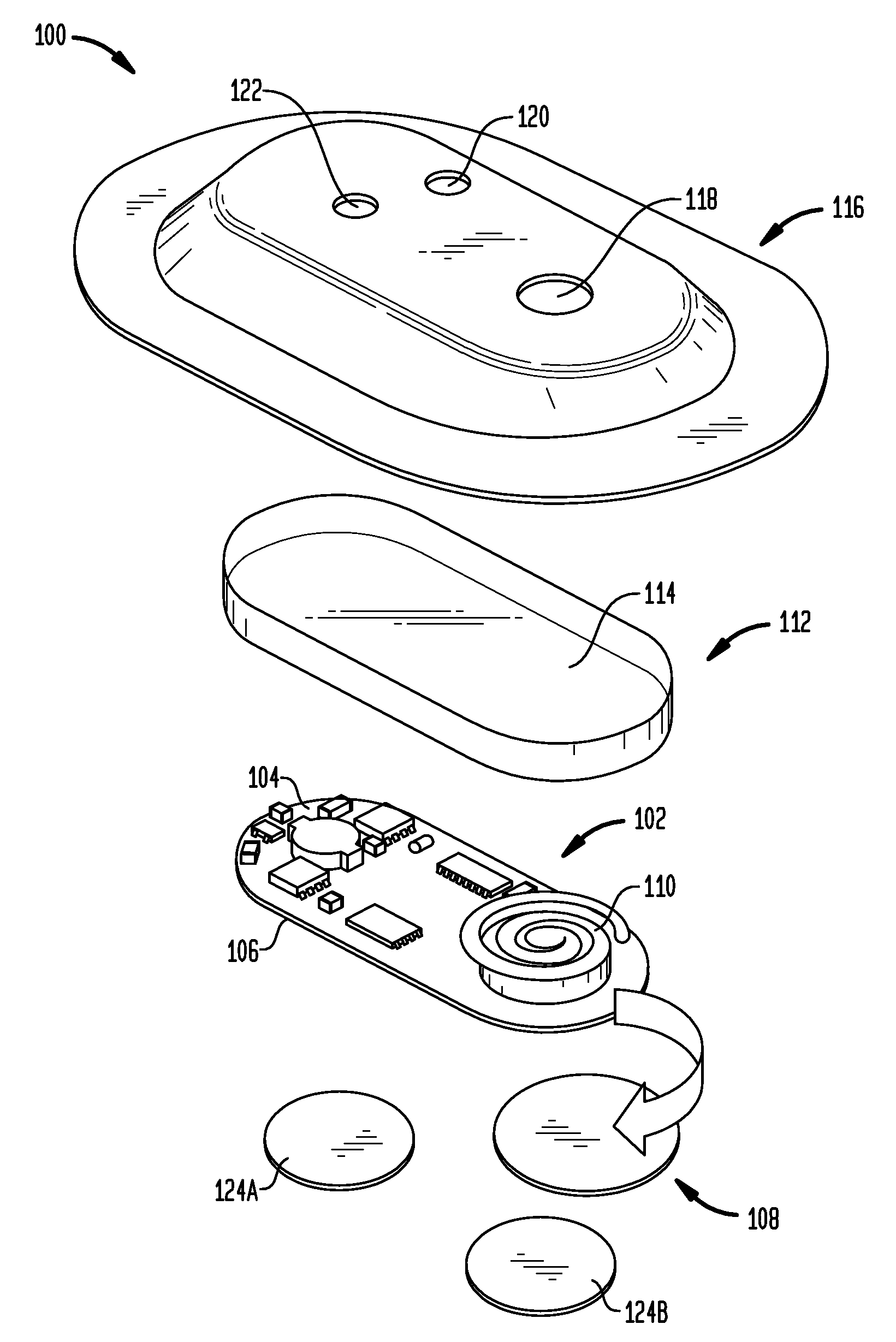

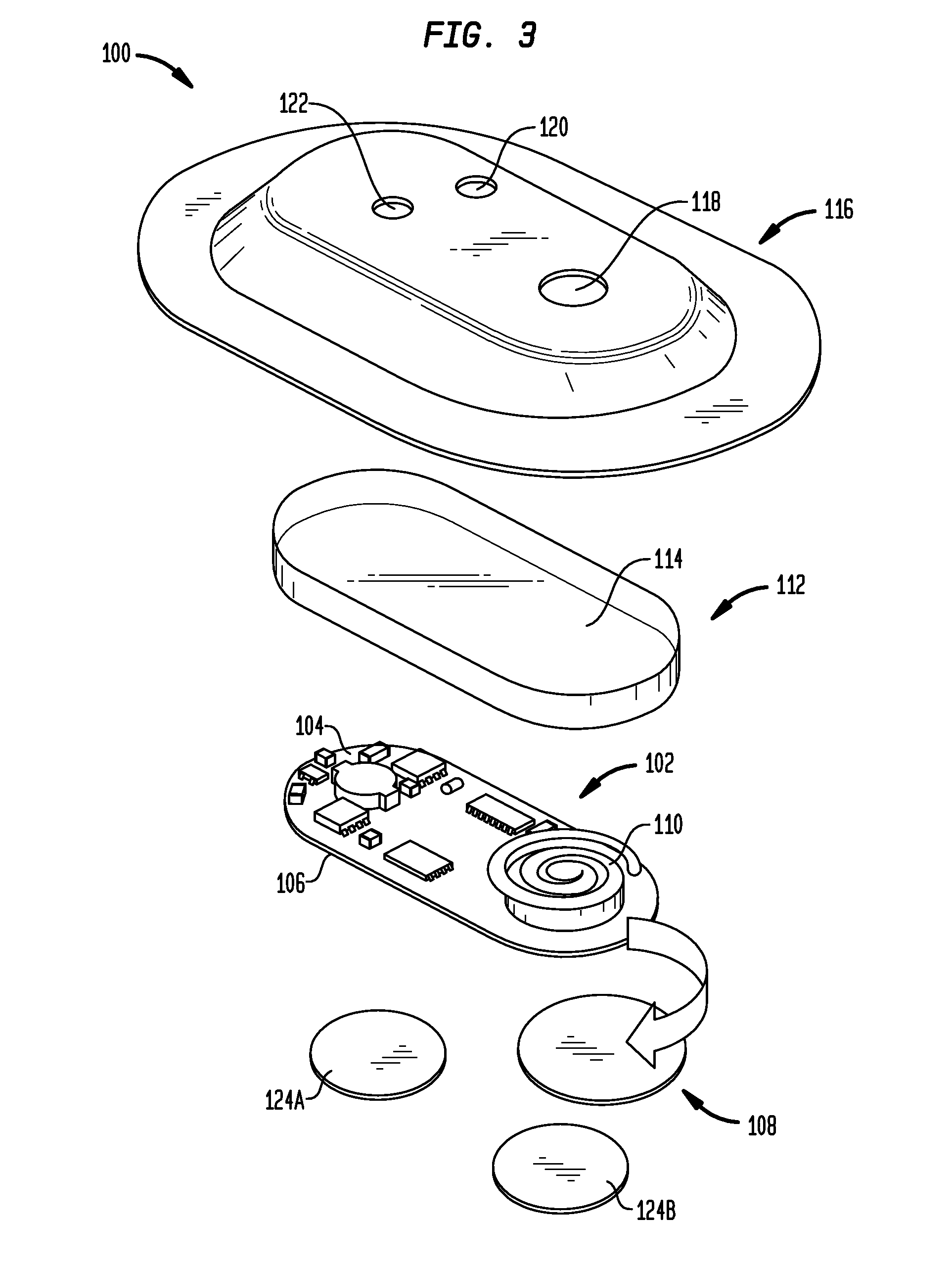

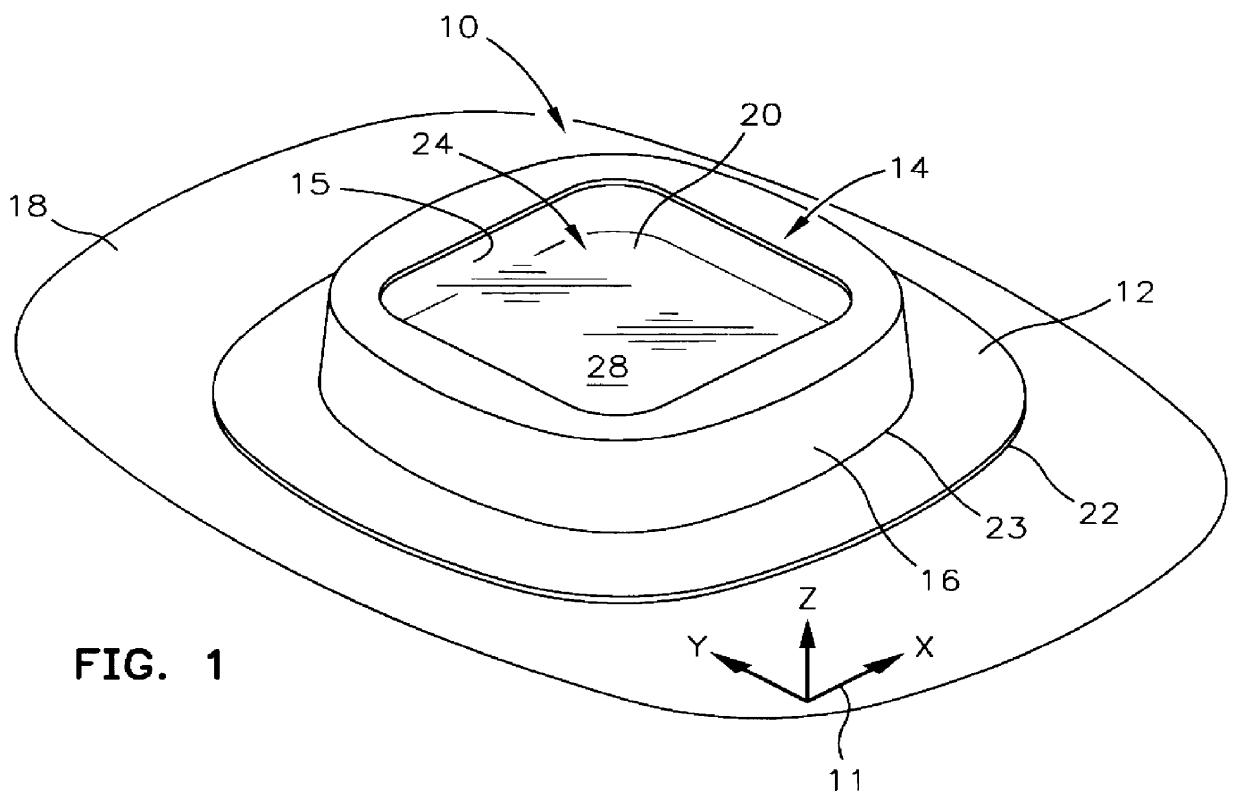

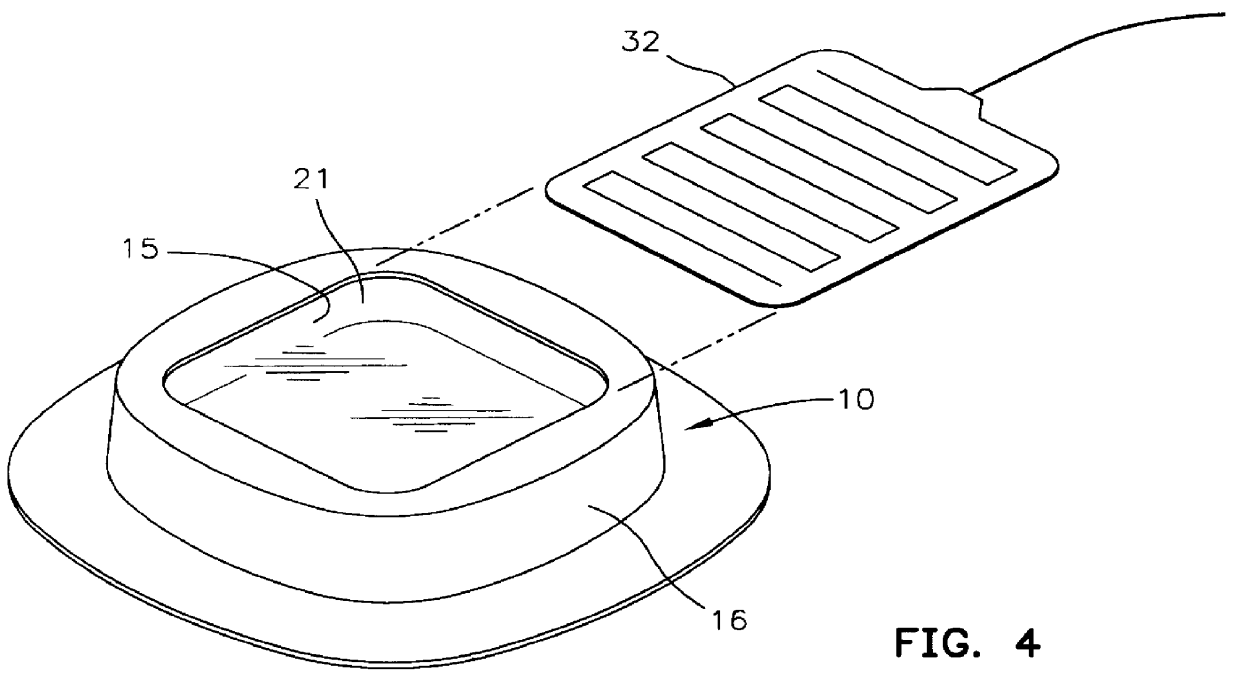

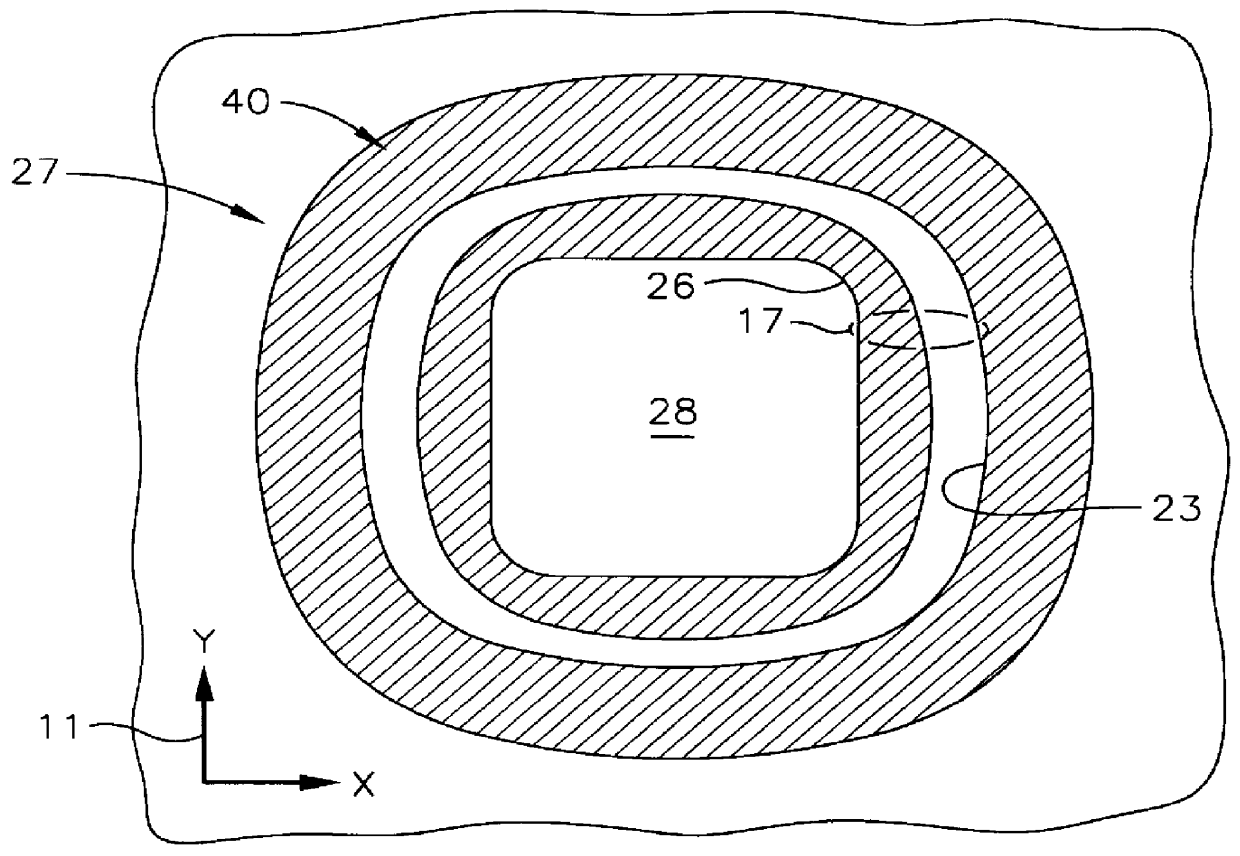

Nerve Stimulation Patches And Methods For Stimulating Selected Nerves

ActiveUS20090132018A1Improve efficiencyLess battery powerPrinted circuit aspectsPrinted circuit manufacturePulse envelopeCarrier signal

A selective nerve stimulation patch includes a substrate having a top surface and a bottom surface, integrated components overlying the top surface of the substrate and being electrically interconnected with one another for generating at least one nerve stimulating signal, electrodes integrated into the substrate and exposed at the bottom surface thereof for applying the at least one nerve stimulating signal to a target nerve, a waterproof, breathable cover overlying the substrate and the integrated components, and a support flange surrounding the substrate and coupling the cover and the substrate together. The support flange has a top surface that slopes downwardly toward an outer perimeter thereof, and at least a portion of the cover conforms to the sloping top surface of the support flange. In one embodiment, the patch generates a high frequency waveform with properties such as amplitude, frequency and the like chosen so as to overcome tissue impedance and the stimulation threshold of the target nerve. The modulated waveform is the waveform obtained by modulating the carrier waveform by a pulse envelope.

Owner:ETHICON INC

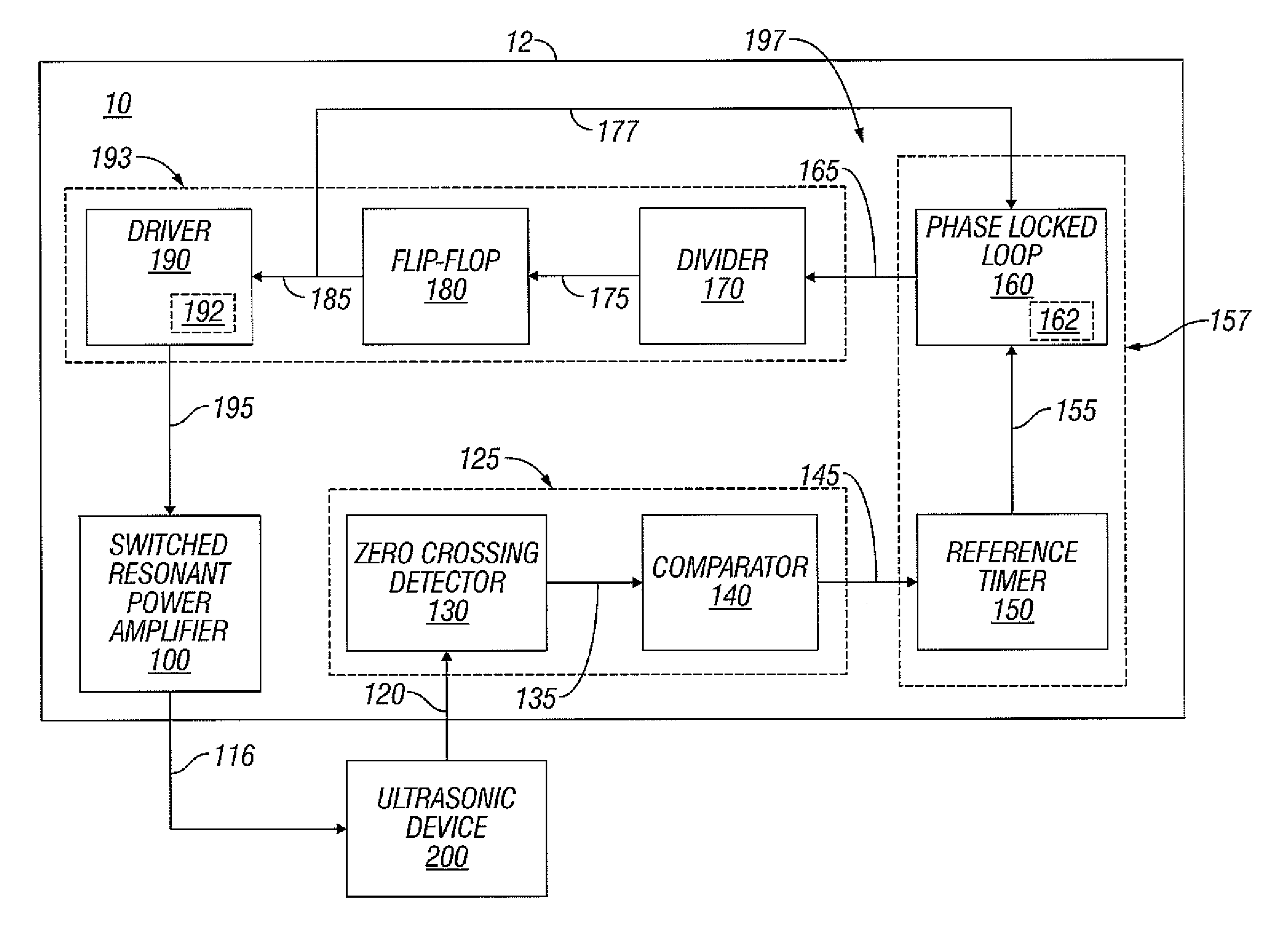

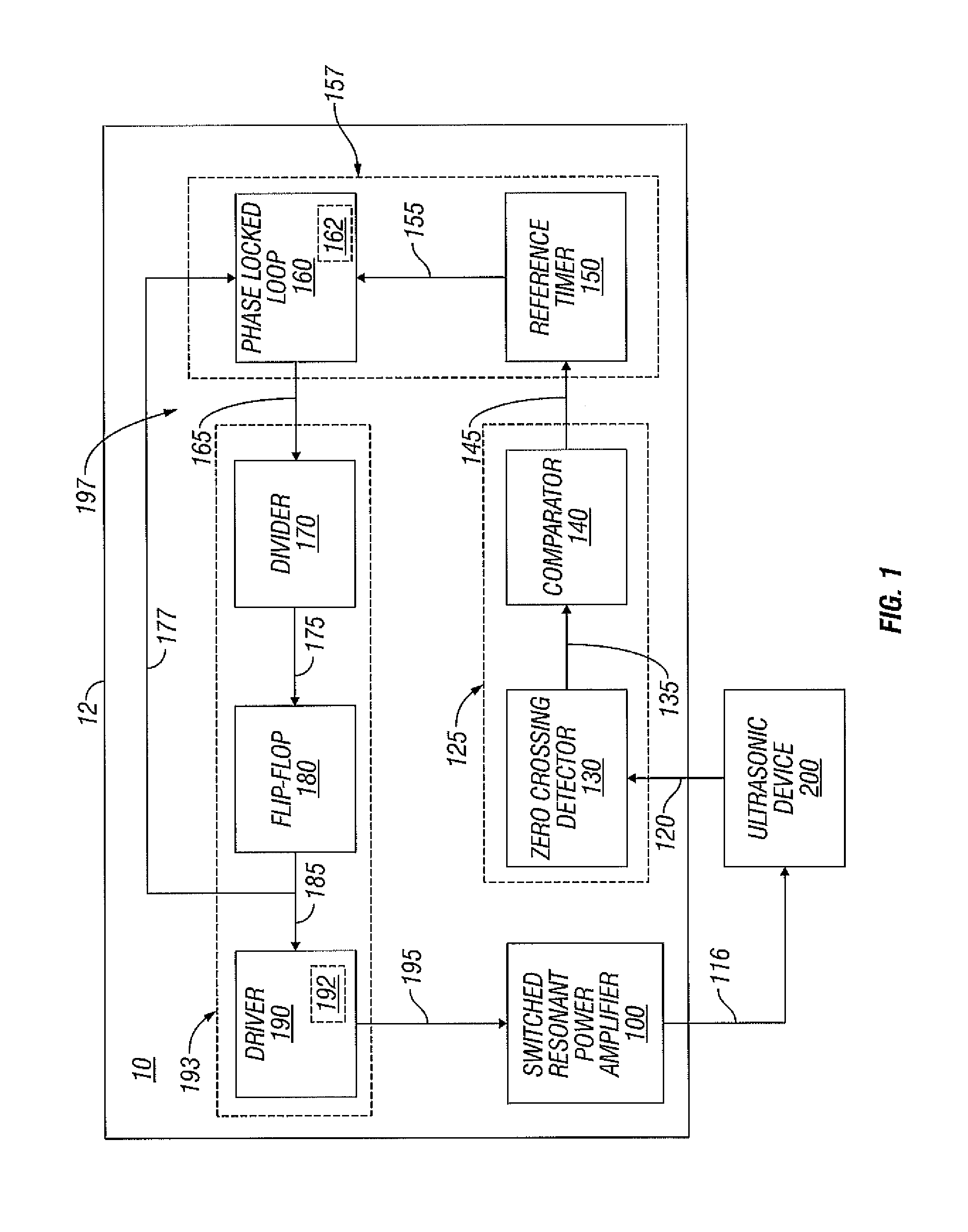

Switched resonant ultrasonic power amplifier system

ActiveUS20050149151A1Reduce frequencyControl outputUltrasound therapyAmplifier modifications to raise efficiencySonificationAudio power amplifier

A switched resonant power amplifier system for ultrasonic transducers is disclosed. The system includes an amplifier that receives and processes a driver output signal for generating a drive signal that is provided to an ultrasonic device for controlling output of the ultrasonic device. An output control circuit receives and processes a signal related to a feedback signal generated by the ultrasonic device and a divider reference signal, and generates a compensated clock signal that is adjusted for at least one of phase and frequency differences between the received feedback signal and the divider reference signal. A compensated drive circuit receives and processes the compensated clock signal for generating the divider reference signal, and for generating the driver output signal.

Owner:COVIDIEN AG

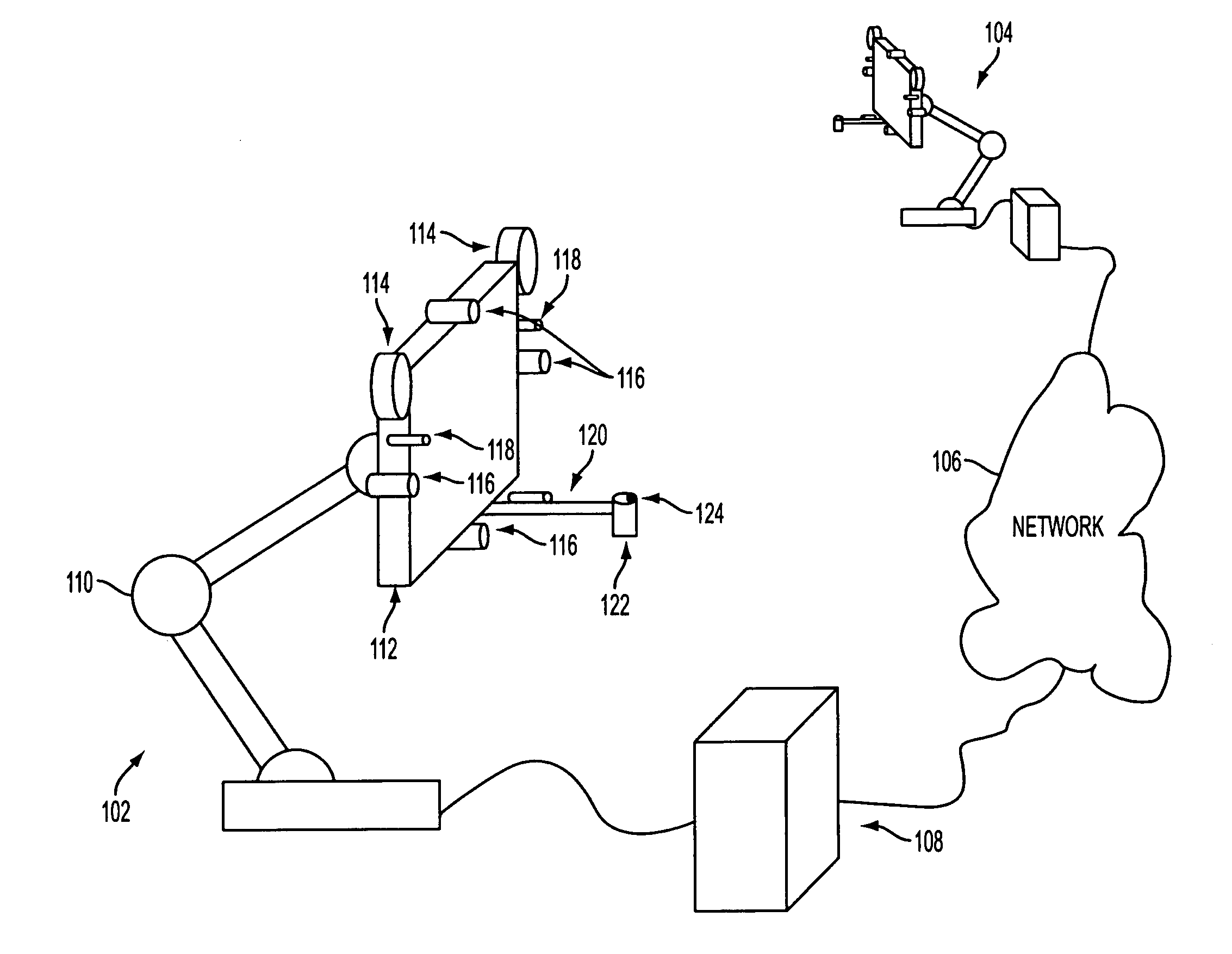

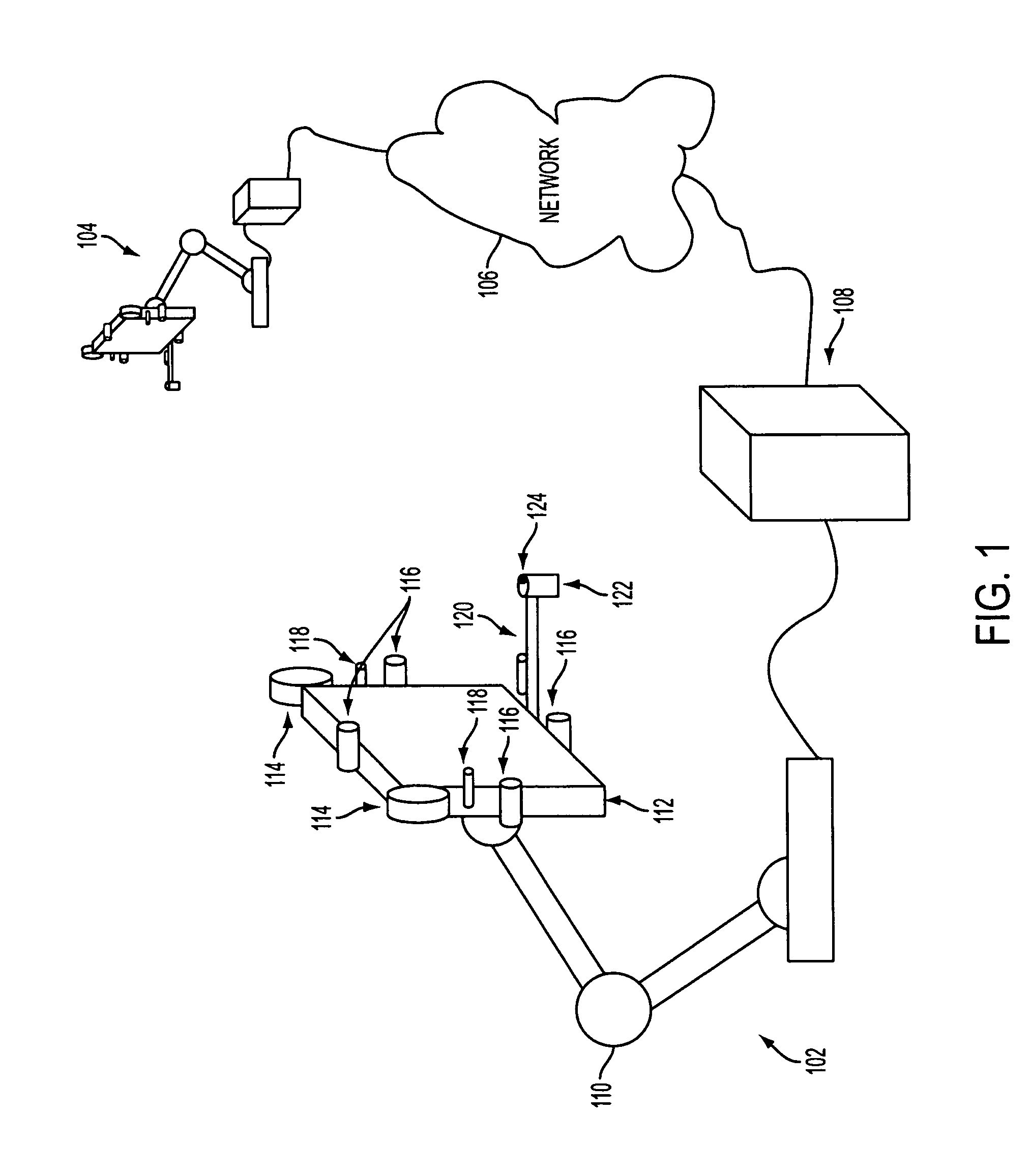

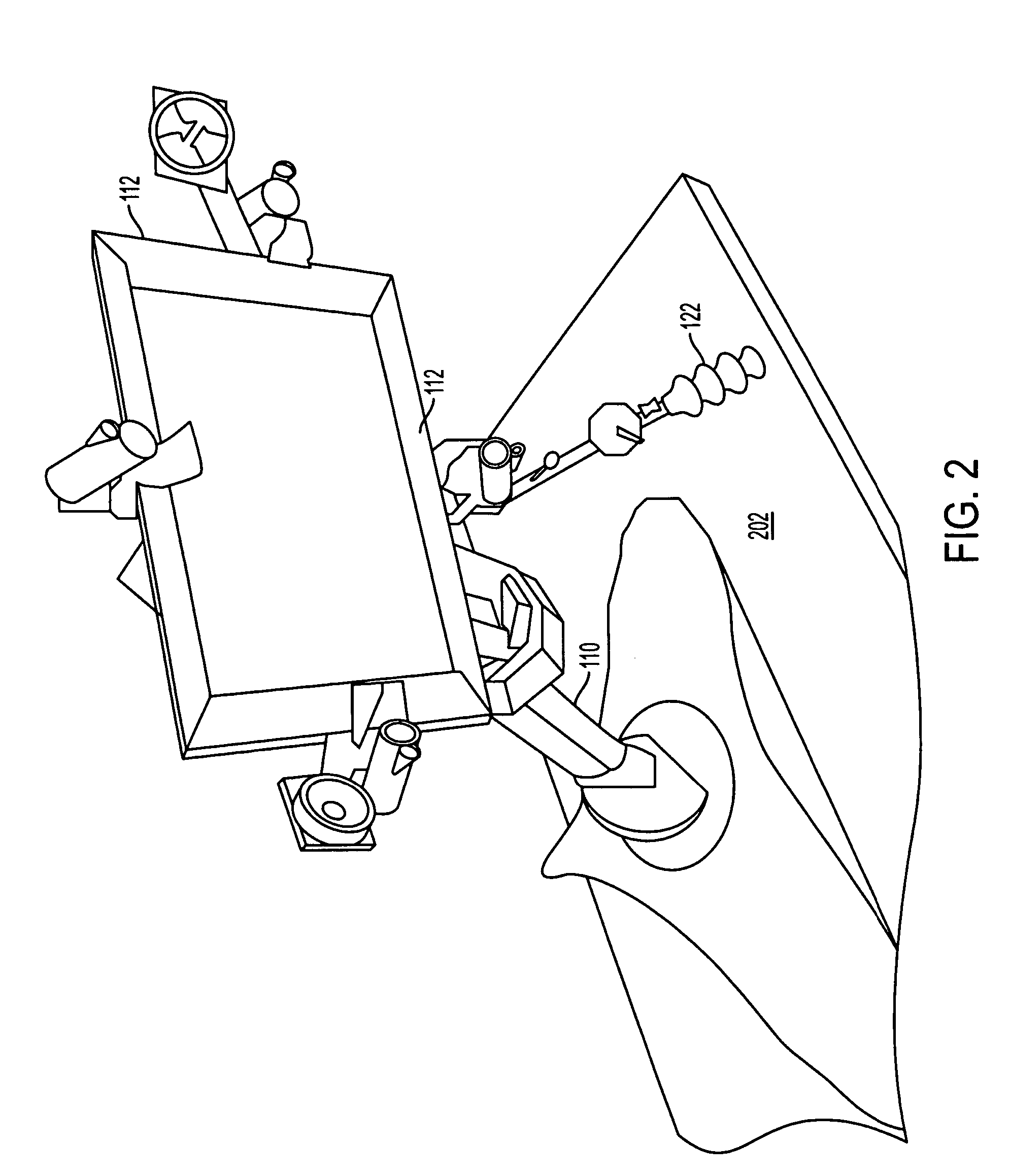

Movable audio/video communication interface system

InactiveUS7626569B2Easily integrated with other mode of workingReduce componentsCathode-ray tube indicatorsTwo-way working systemsHead movementsSensor array

A system that includes a desk top assembly of a display and sensors mounted on a robotic arm. The arm moves the assembly so that it remains within position and orientation tolerances relative to the user's head as the user looks around. Near-field speaker arrays supply audio and a microphone array senses a user's voice. Filters are applied to head motion to reduce latency for arm's tracking of the head. The system is full duplex with other systems allowing immersive collaboration. Lighting and sound generation take place close to the user's head. A haptic interface device allows the user to grab the display / sensor array and move it about. Motion acts as a planar selection device for 3D data. Planar force feedback allows a user to “feel” the data. Users see not only each other through display windows, but can also see the positions and orientations of each others' planar selections of shared 3D models or data.

Owner:MORGAN STANLEY +1

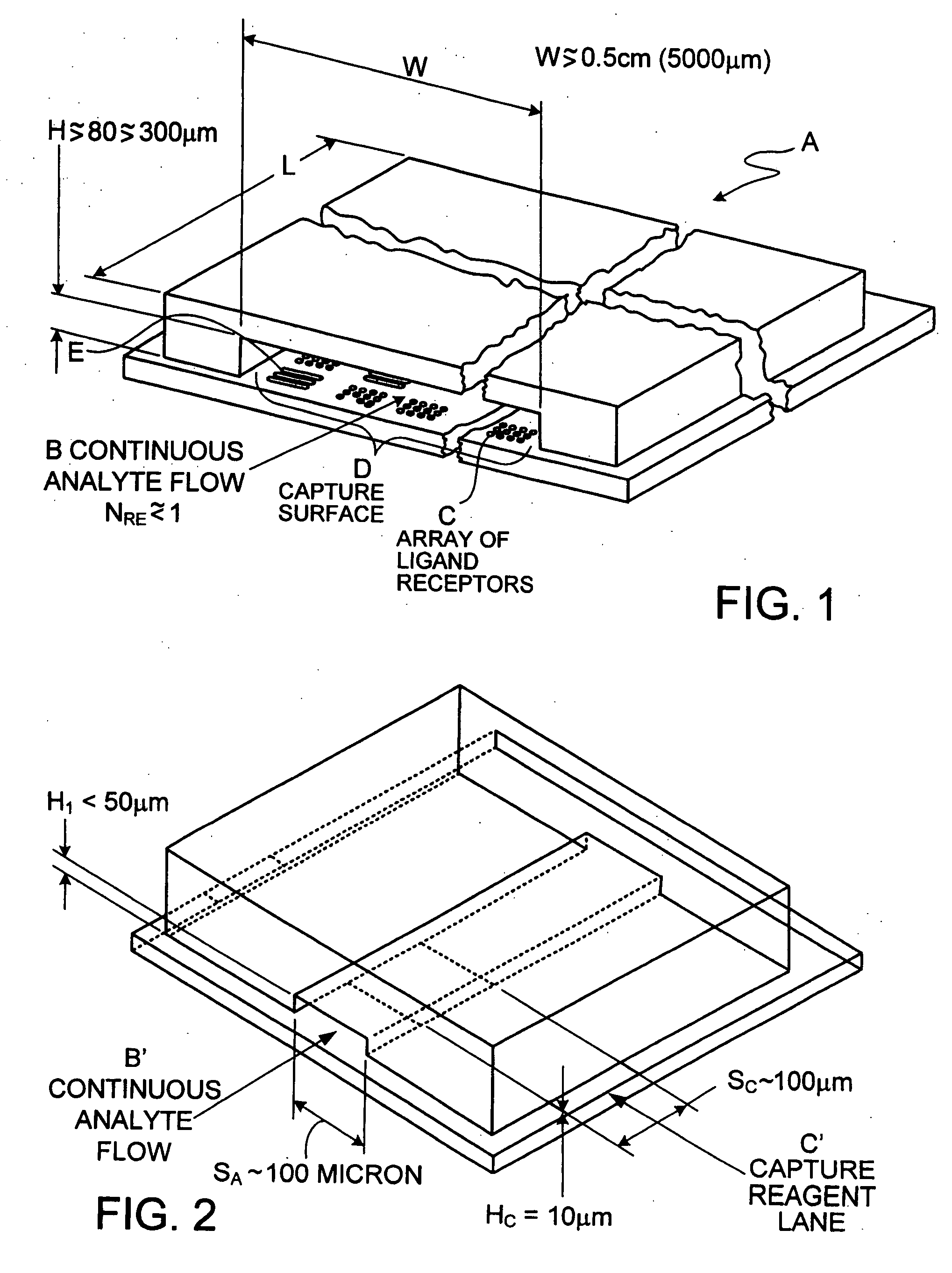

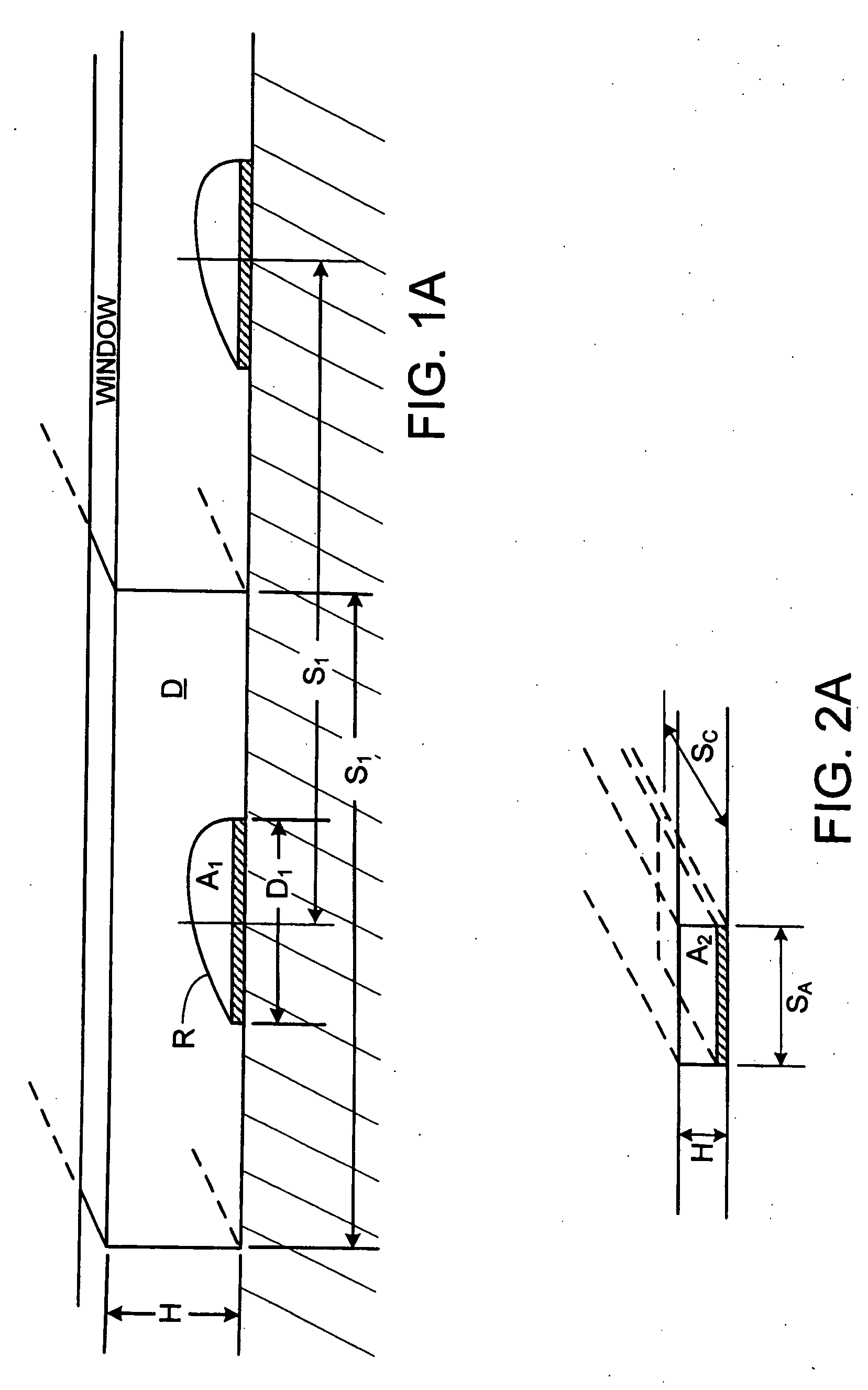

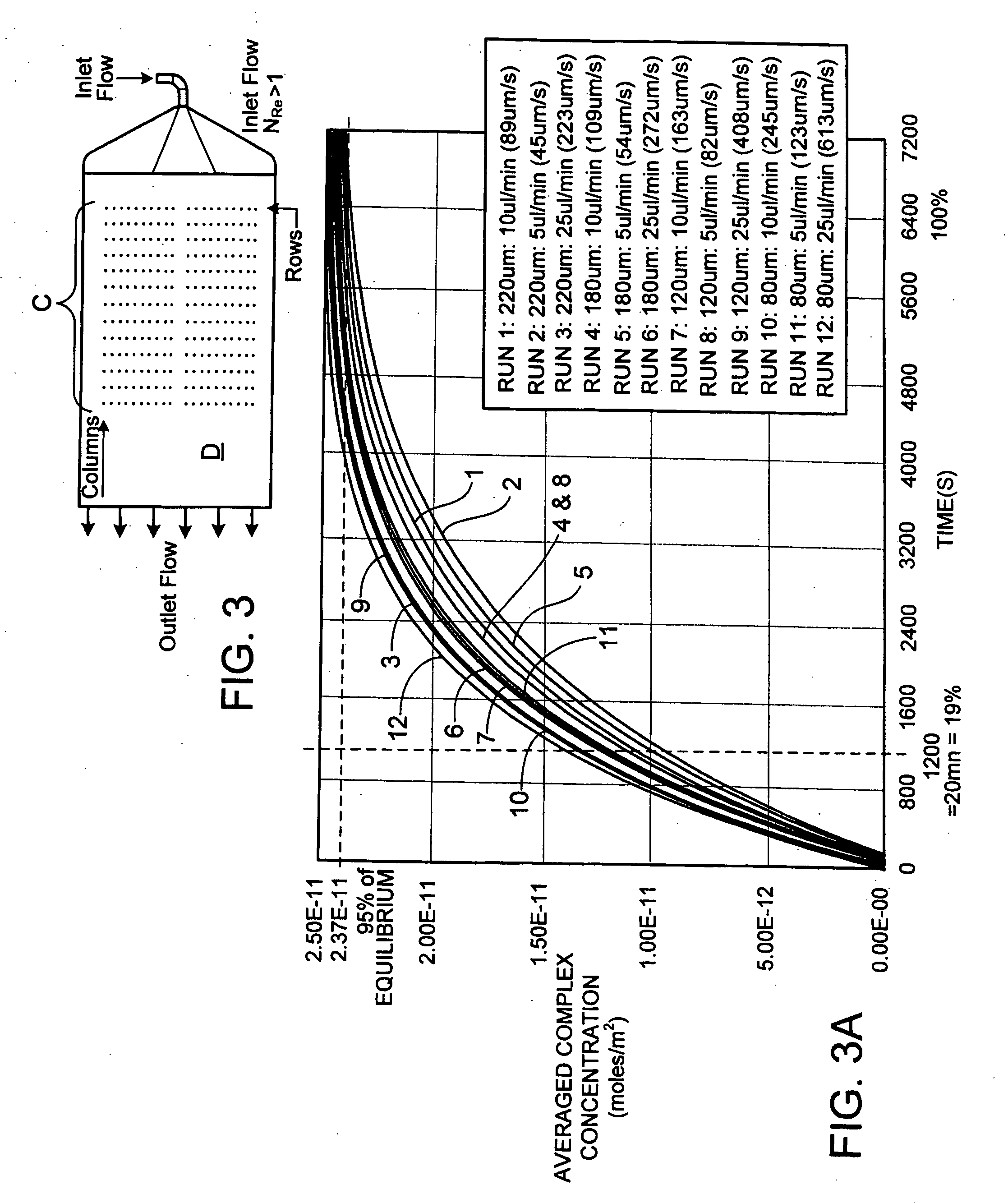

Assays based on liquid flow over arrays

InactiveUS20060275852A1Highly credible resultLow coefficient of variationBioreactor/fermenter combinationsBiological substance pretreatmentsAssayAnalyte

Cassette (50) performs assays, e.g. multiplexed protein biomarker assays. Wide, bubble-free, slow flows are produced from liquids stored on cassette (50), flowing over wide array (20) of ligand receptors on a capture surface. Flows of Reynolds Number less than about 1, preferably 1×10−1 to 5×10−3, are heated in region (34) preceding and including bubble removal system (128). Analyte is introduced through compressed septum (32). External actuations of displacement pumps (30, 37) and valves (137 A, B, and C) produce flows in response to flow-front optical sensors (150, 152). Elastic sheet provides pump and valve diaphragms and resilient expansion of mixing volume (131). Break-away cover portions are pistons. Heating is by conduction through cassette from external contact heater. Planar cassette body, when tilted from horizontal, enables upward flow from pumped storage (134, 135) to reaction (133) to waste (139), with buoyancy bubble removal before reaction. Reading of fluorescence is by external reader, employing calibration, control and reference features on capture surface. Extensive set of calibration features of differing intensities enables self-calibration.

Owner:AVANTRA BIOSCI CORP

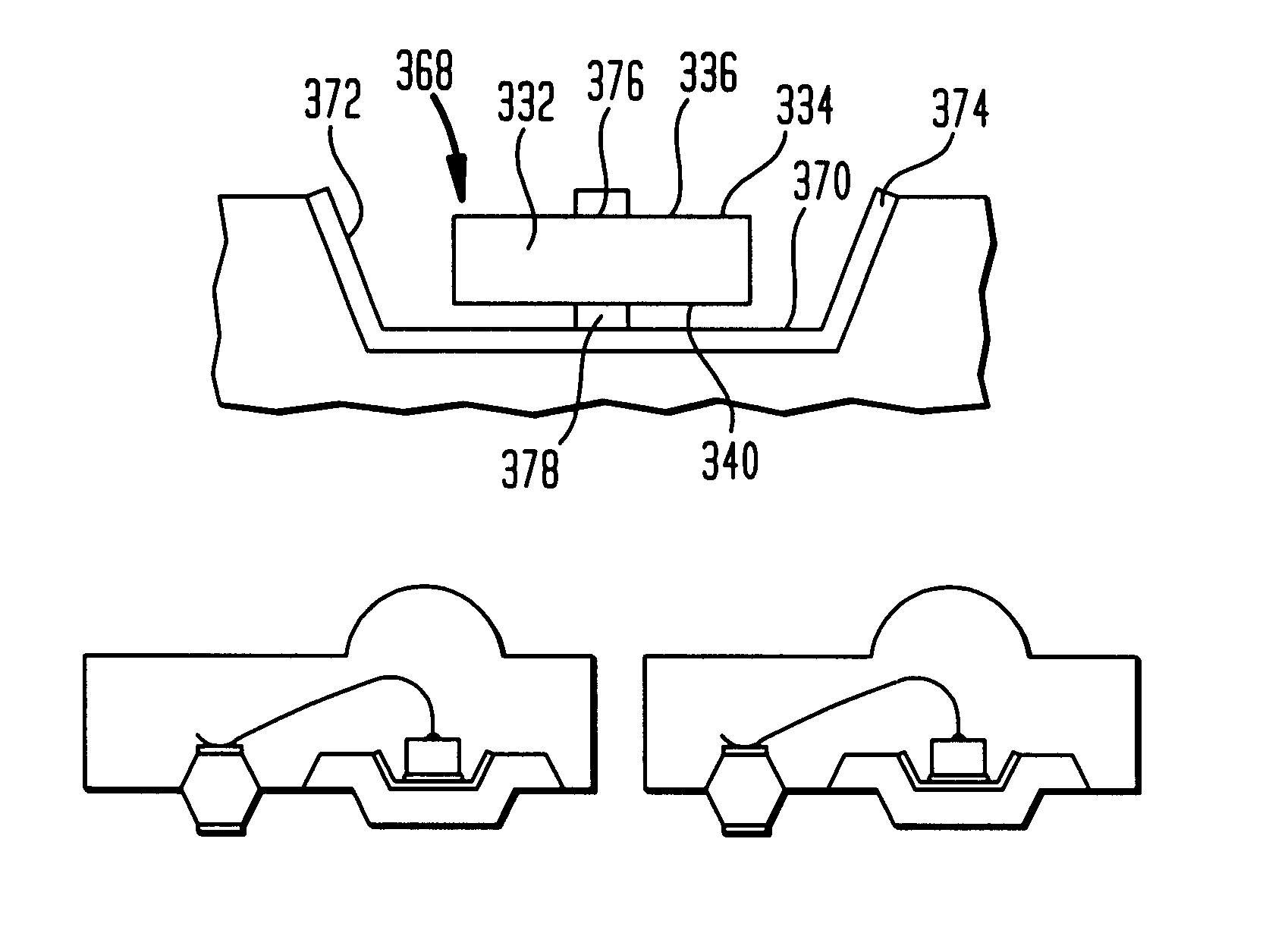

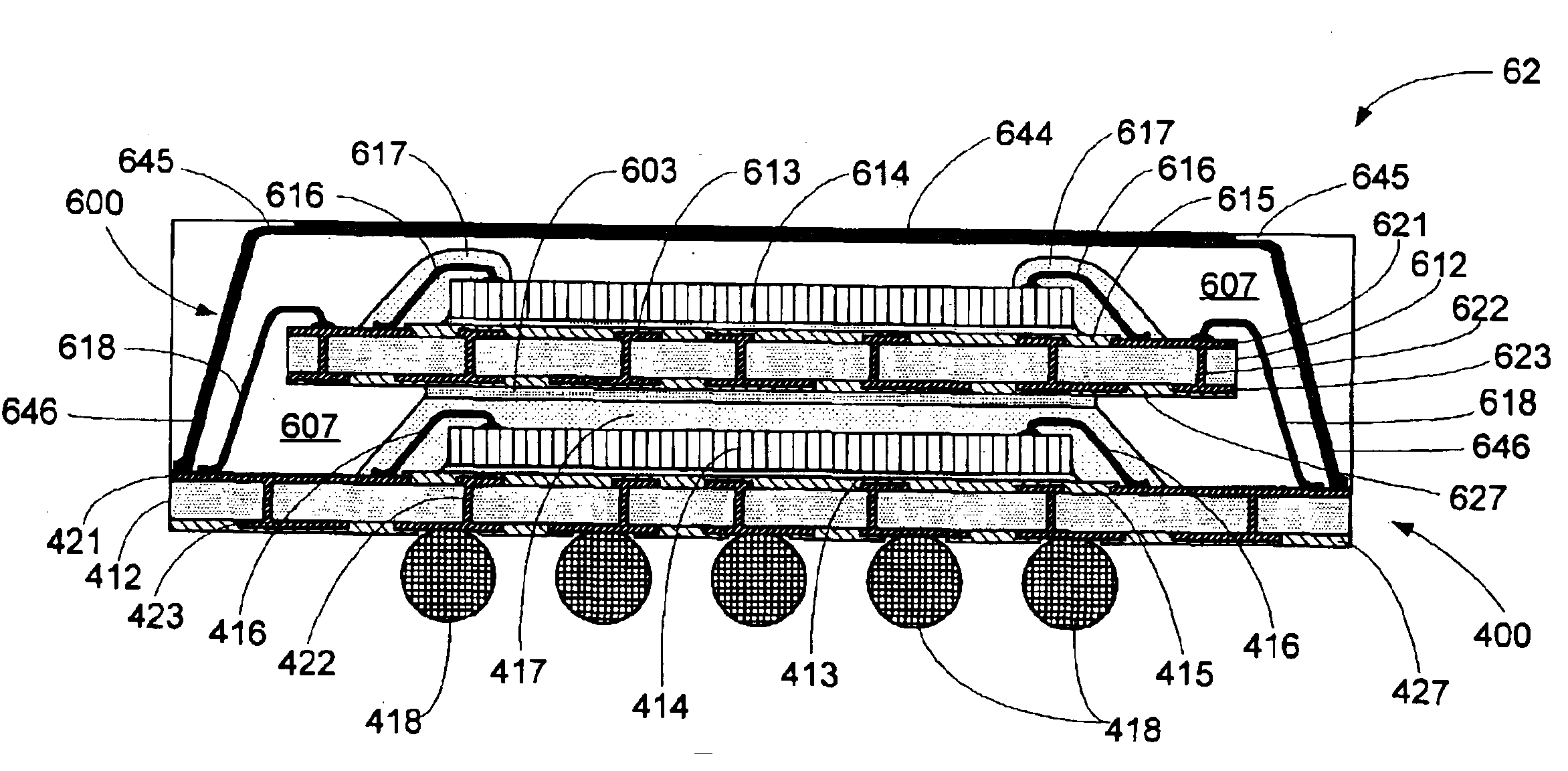

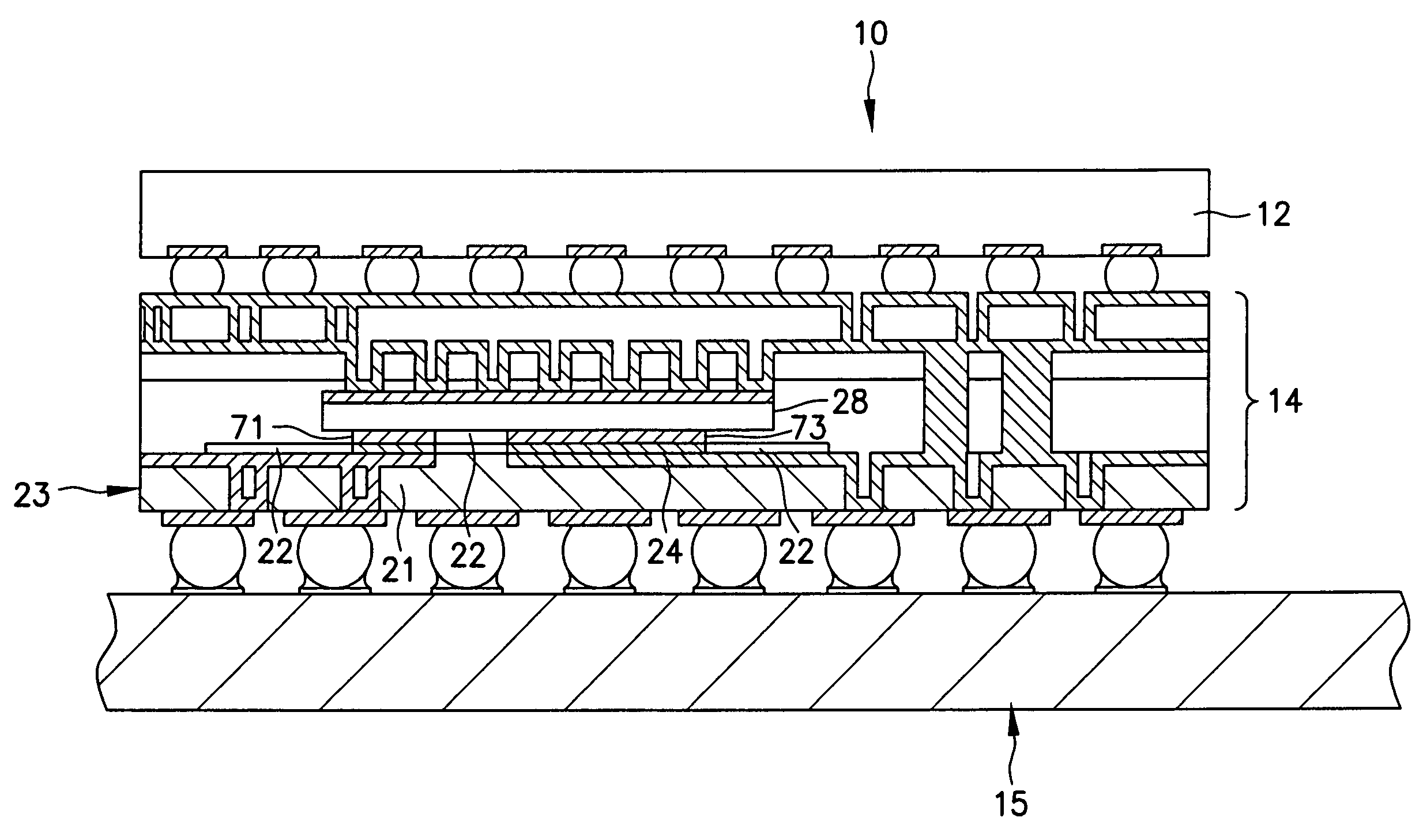

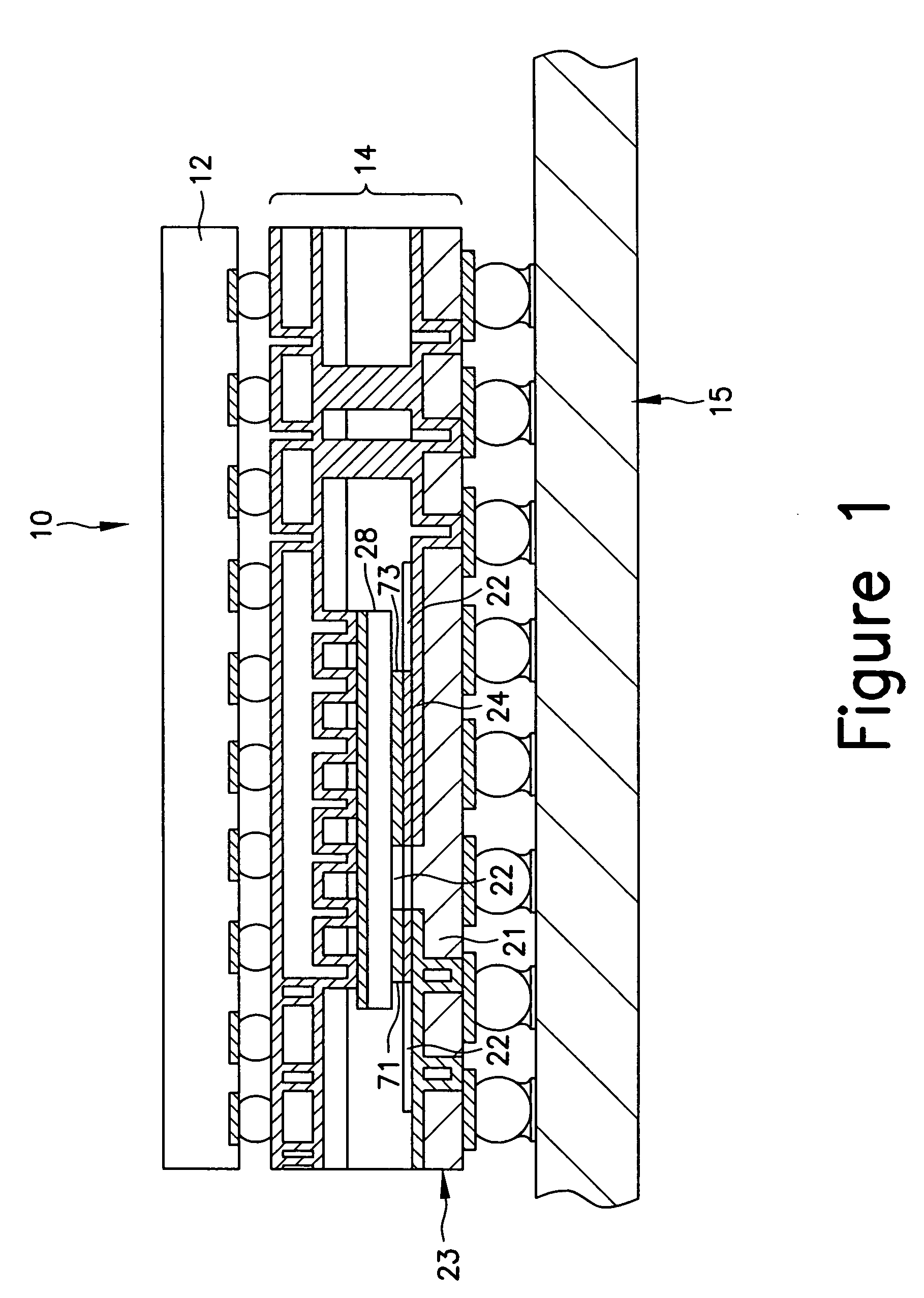

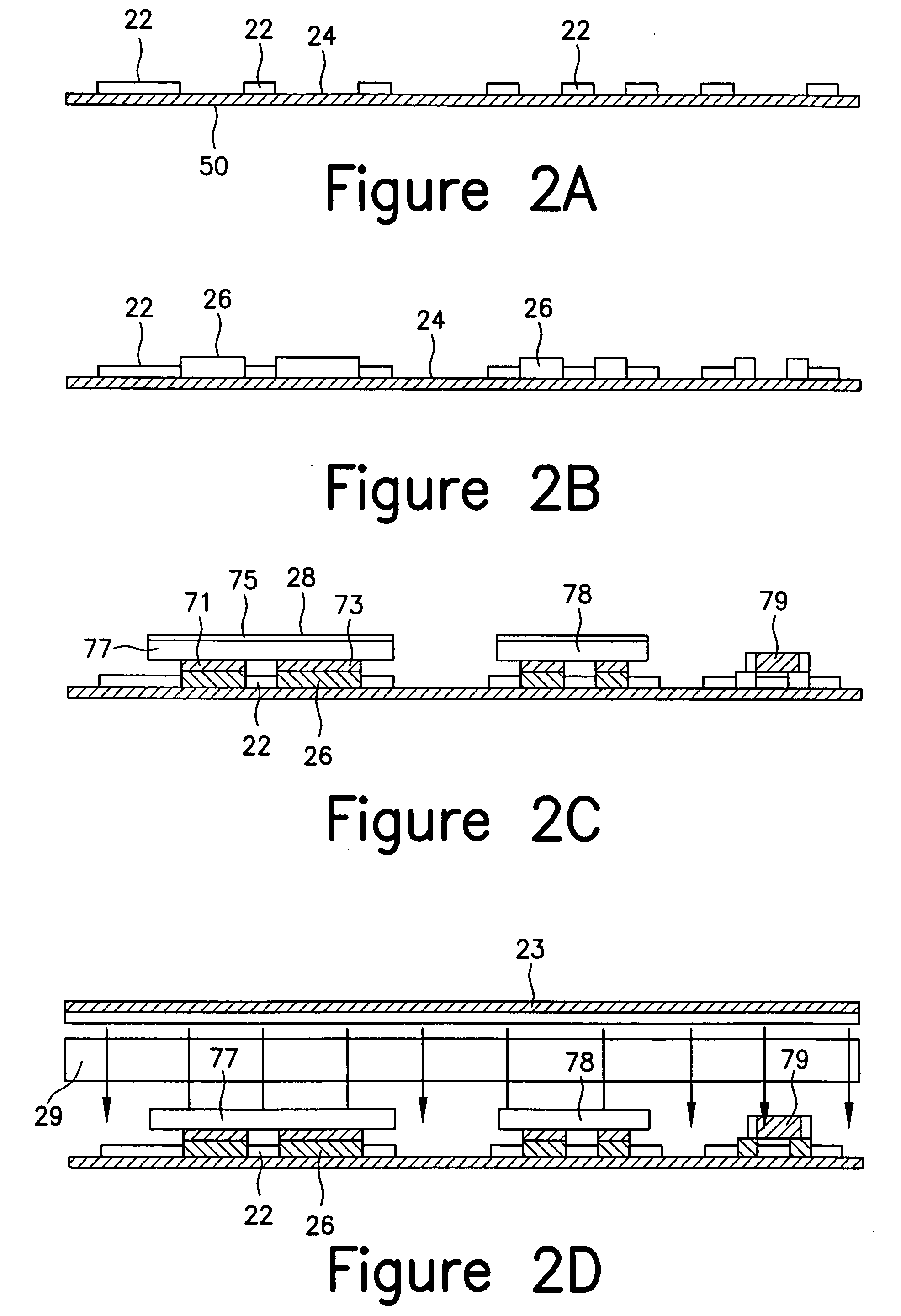

Semiconductor multi-package module having wire bond interconnect between stacked packages and having electrical shield

ActiveUS6838761B2Low production costOverall design flexibilitySemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

A semiconductor multi-package module having stacked lower and upper packages, each package including a die attached to a substrate, in which the upper and lower substrates are interconnected by wire bonding. Also, a method for making a semiconductor multi-package module, by providing a lower molded package including a lower substrate and a die, affixing an upper molded package including an upper substrate onto the upper surface of the lower package, and forming wire bond z-interconnects between the upper and lower substrates.

Owner:STATS CHIPPAC LTD

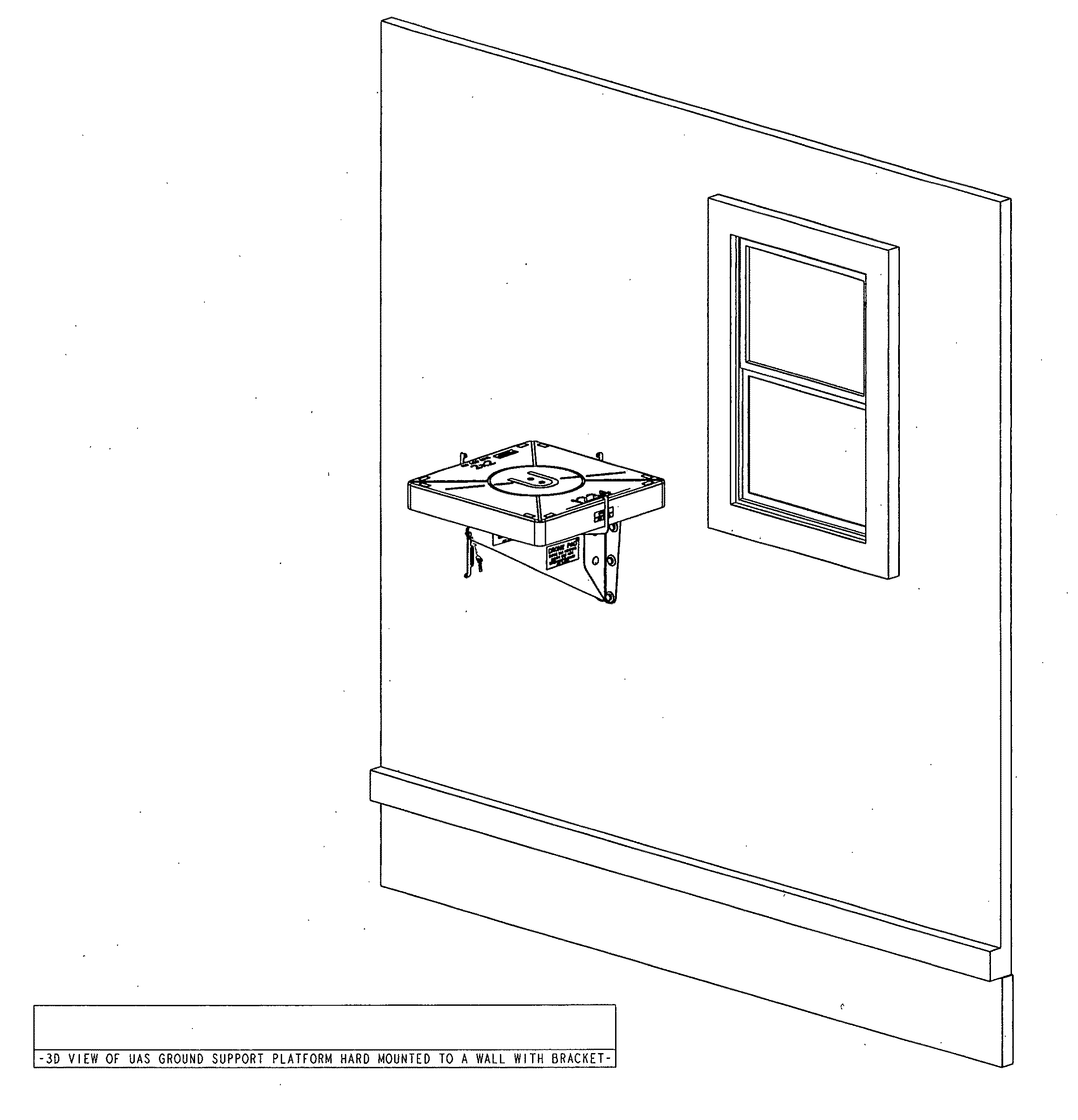

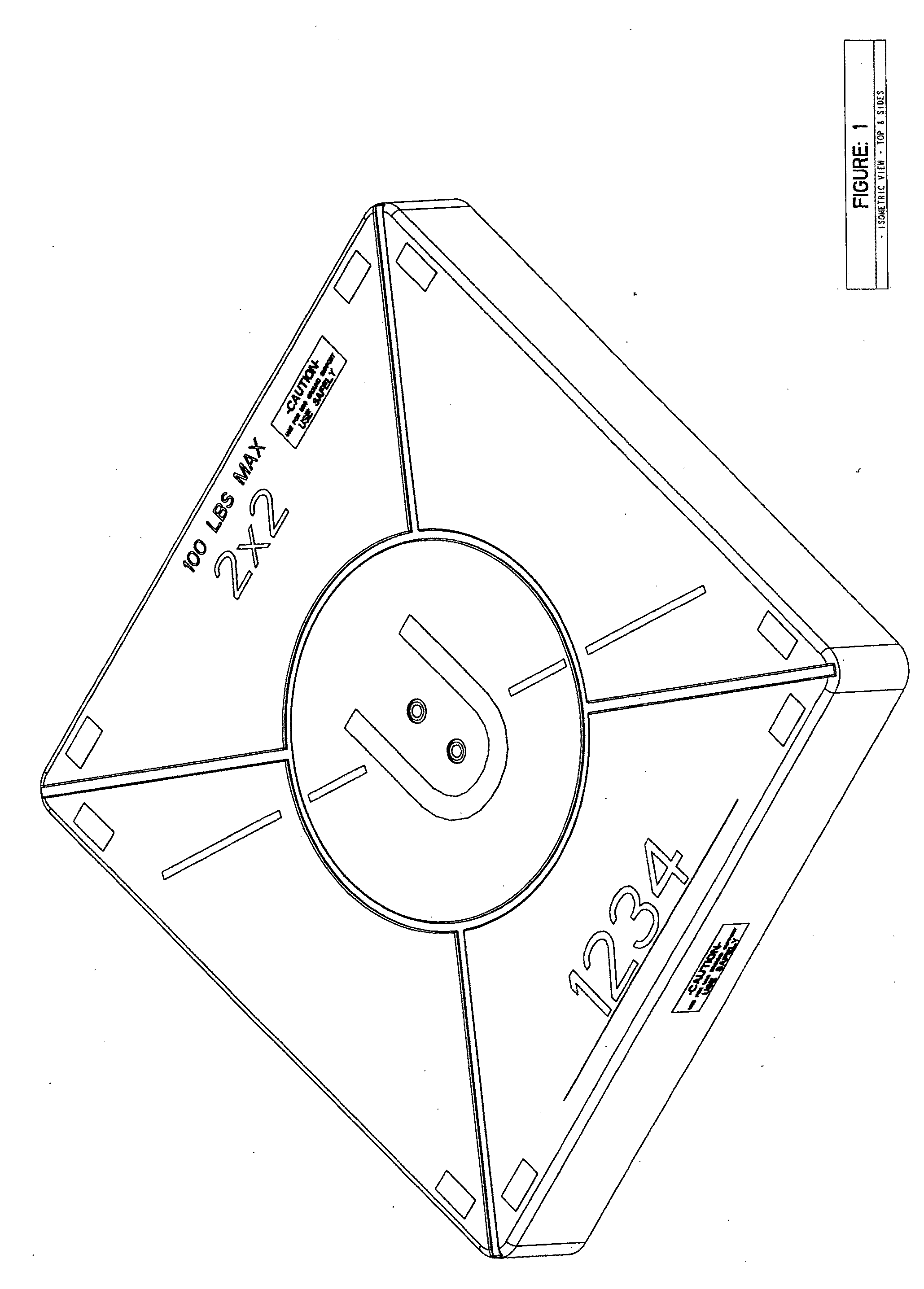

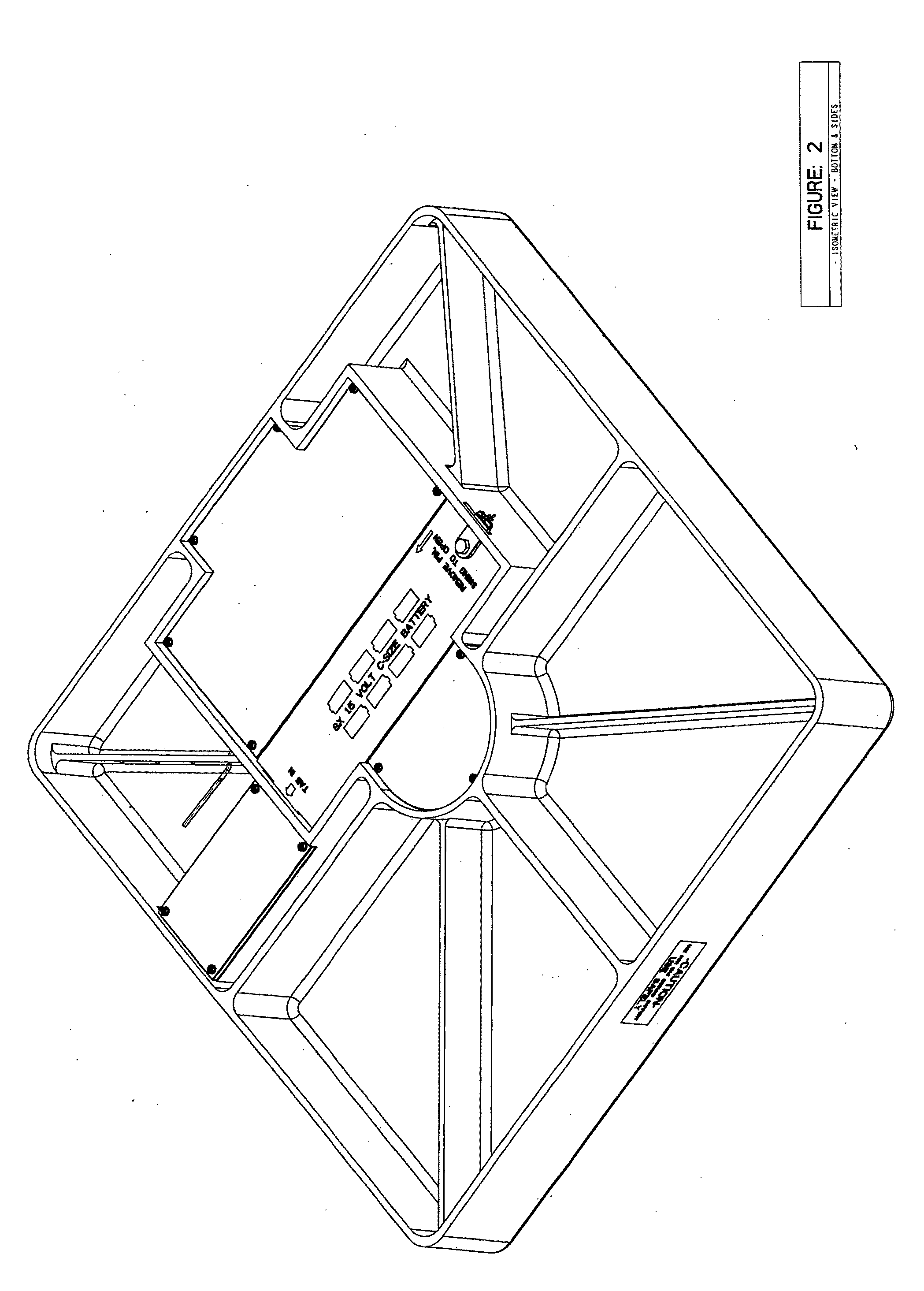

Unmanned Aircraft Systems Ground Support Platform

InactiveUS20160068277A1Small footprintPromotes personal safetyHelicopter landing platformRemote controlled aircraftUncrewed vehicleAirplane

The Unmanned Aircraft Systems ground support platform is a portable, multifunctional apparatus to accommodate UAS (Drone, UAV) landings, takeoffs, idle time, maintenance, retail merchandise product display and package delivery support within the UAS recreational and business industry. The Unmanned Aircraft Systems ground support platform will provide stability and cleanliness of a Unmanned Aerial Vehicle. Ownership identification is intergraded into the base platform.

Owner:MANITTA SALVATORE

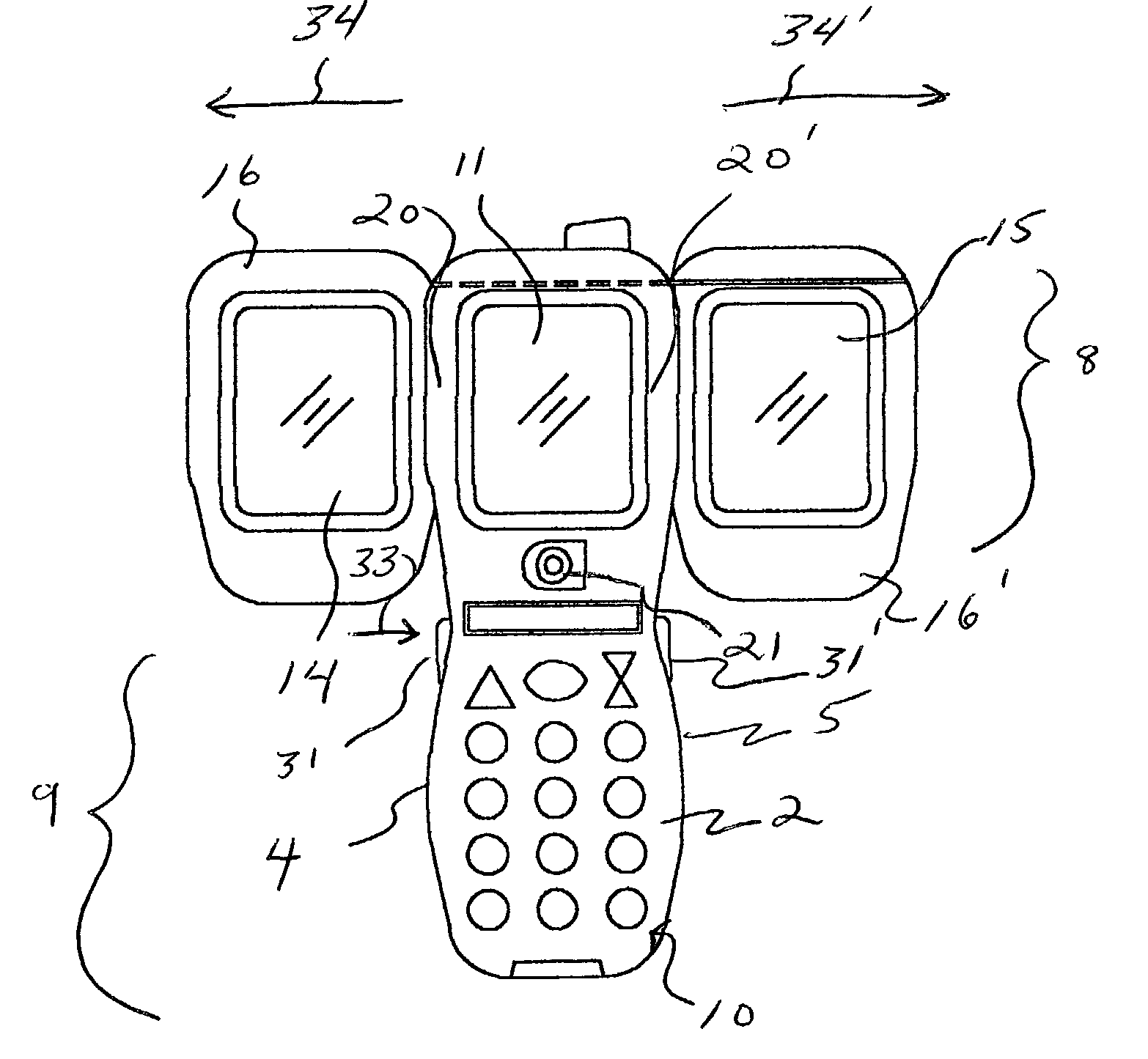

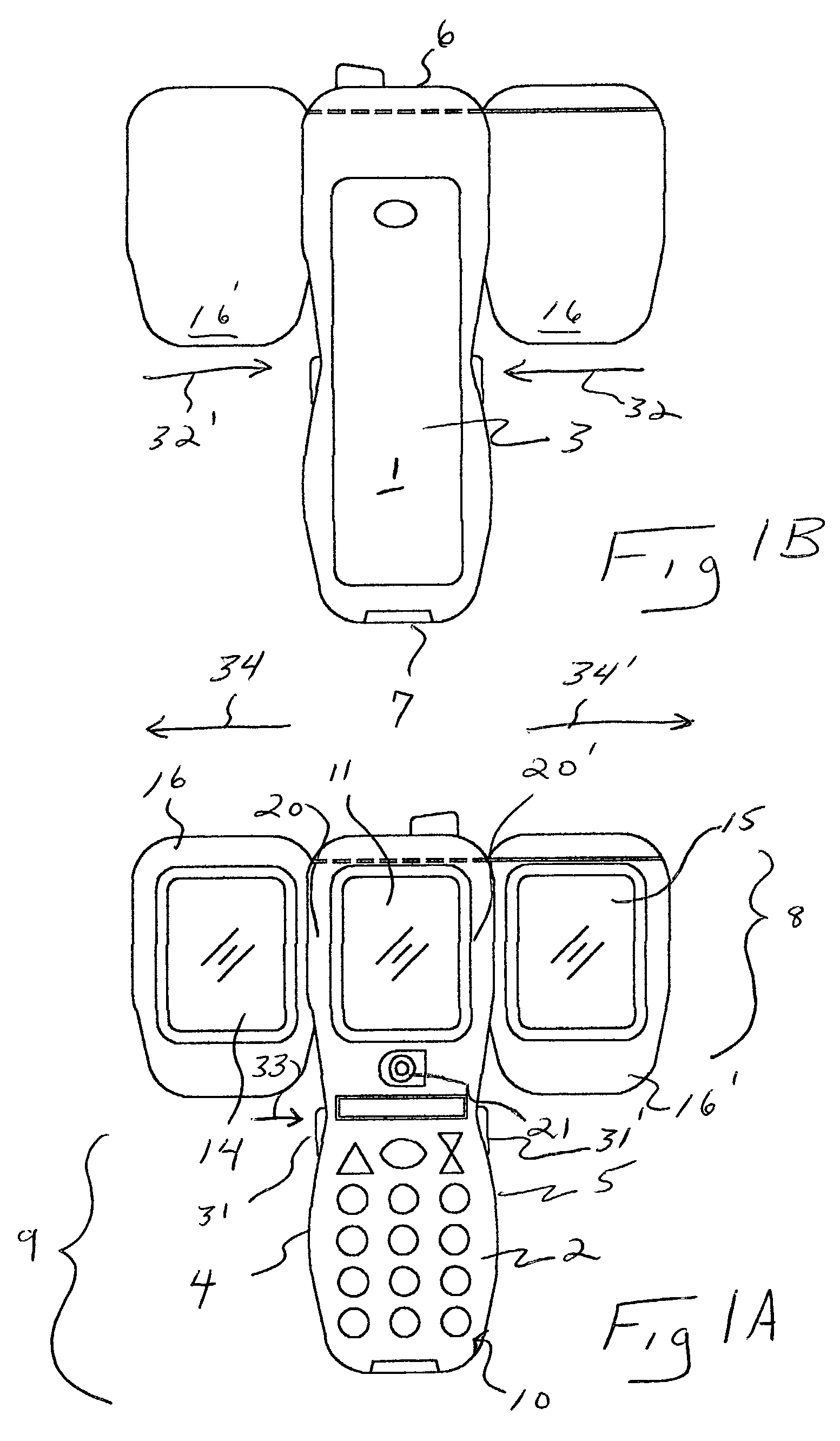

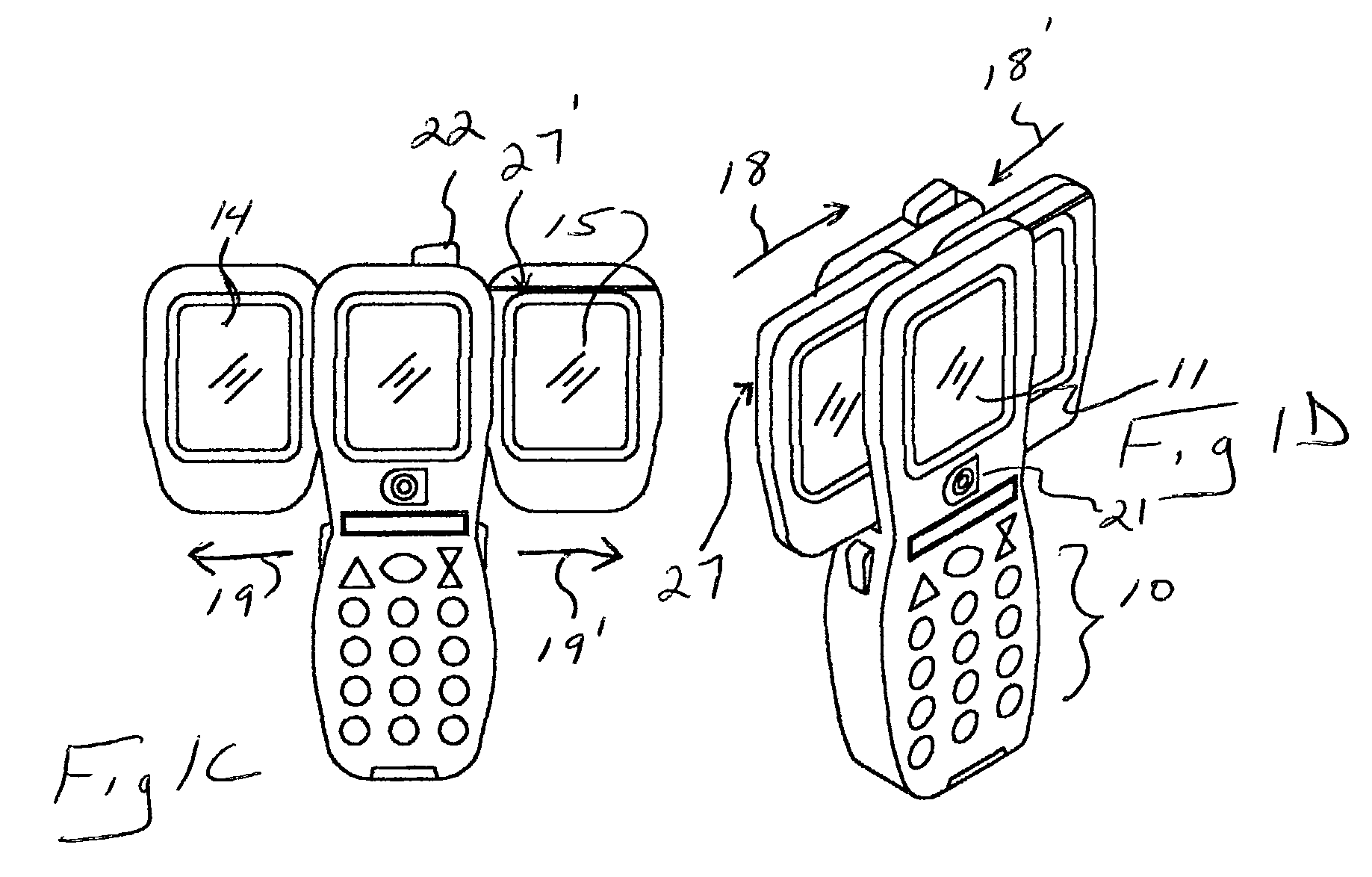

Wireless mobile device

InactiveUS20040204126A1Small footprintOvercome limitationsInterconnection arrangementsDevices with multiple display unitsData informationWireless mobile devices

A wireless Mobile Executive Assistant (MEA) in the form of a PDA / Phone having multiple, independently oriented screens configured to provide data, video independently or in combined fashion. Formed in the opposing first and second edges adjacent to a body having main display screen formed thereon are first and second slots, respectively, the first and second slots formed to receive first and second, slidingly engaging ancillary display screens. Each of the first and second display screens provide independent video or data information from the MEA, or video or other data transmission via the MEA, and can accordingly be used to conference simultaneously with three independent parties on three separate screens. The first and second screens each slidingly engage from a stored position fully with their respective first and second slots, wherein the screens are not discernable to the observer, and the MEA has the appearance of an ordinary cellular-type phone; alternatively, the first and second screens may emanate so that the phone has a first screen emanating from one side, and a second screen emanating generally from the opposite side of the unit, with the main screen situated therebetween. In addition to independent transmissions, all three screens can be deployed to form a single wide screen transmission.

Owner:MICROSITE TECH

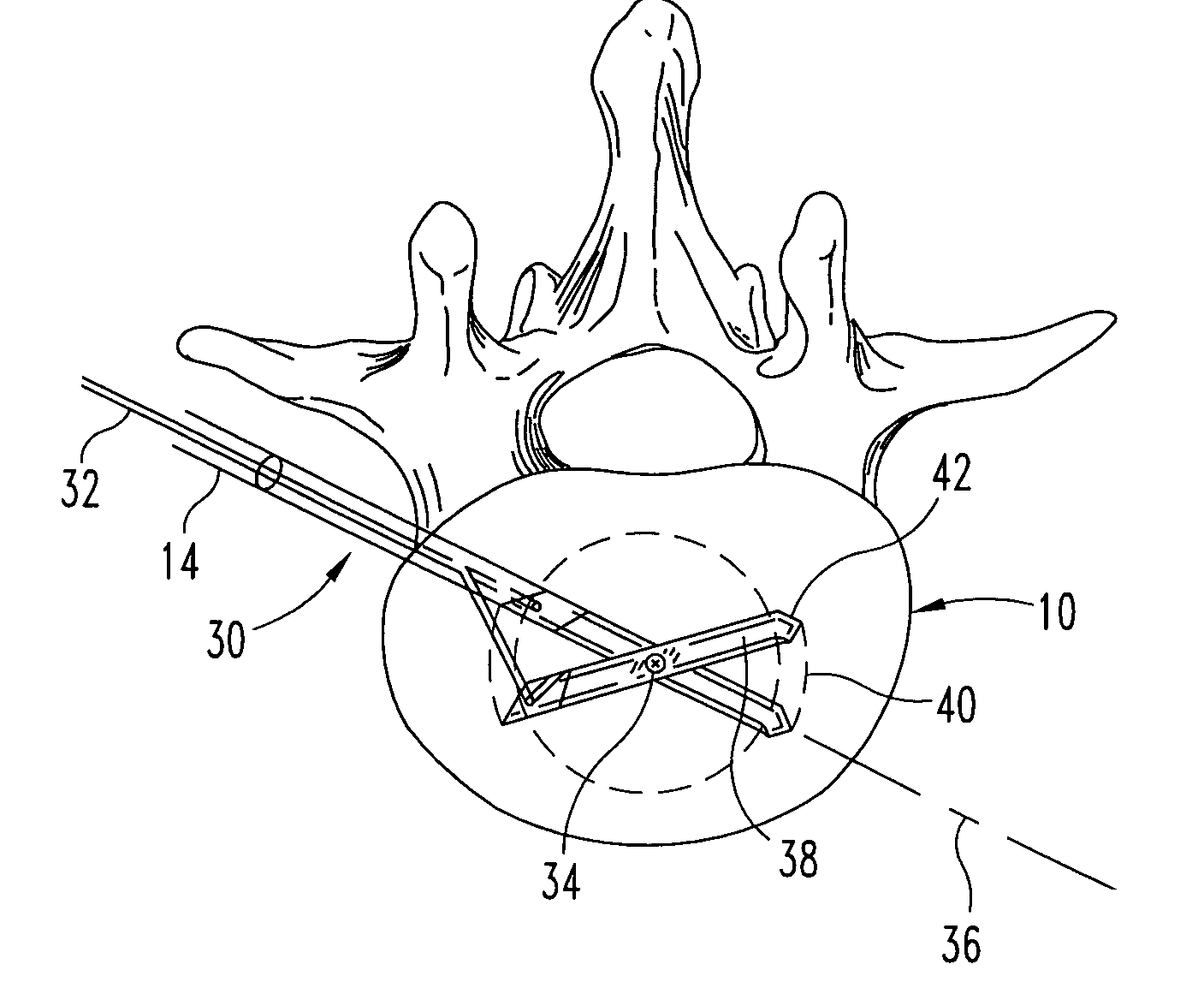

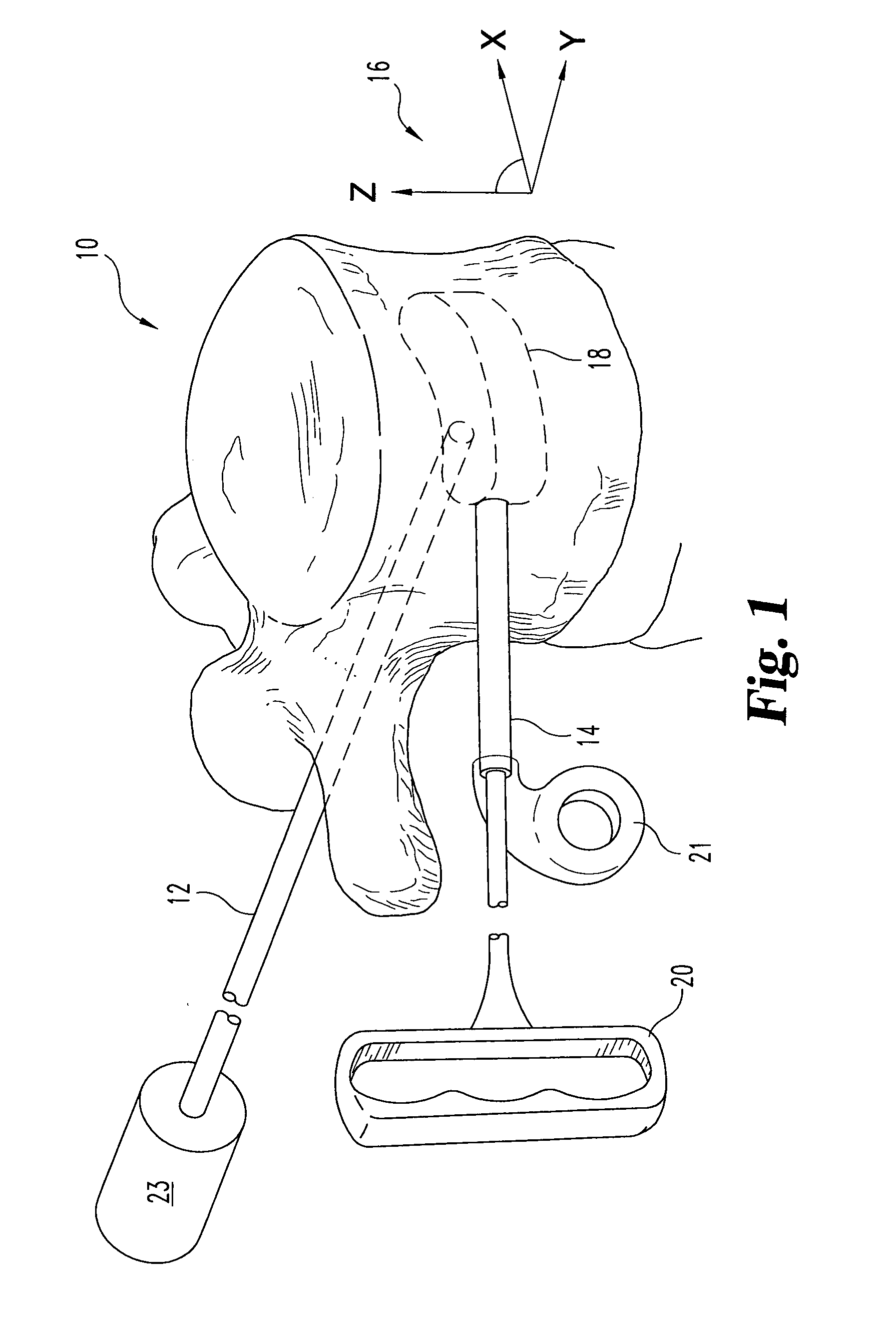

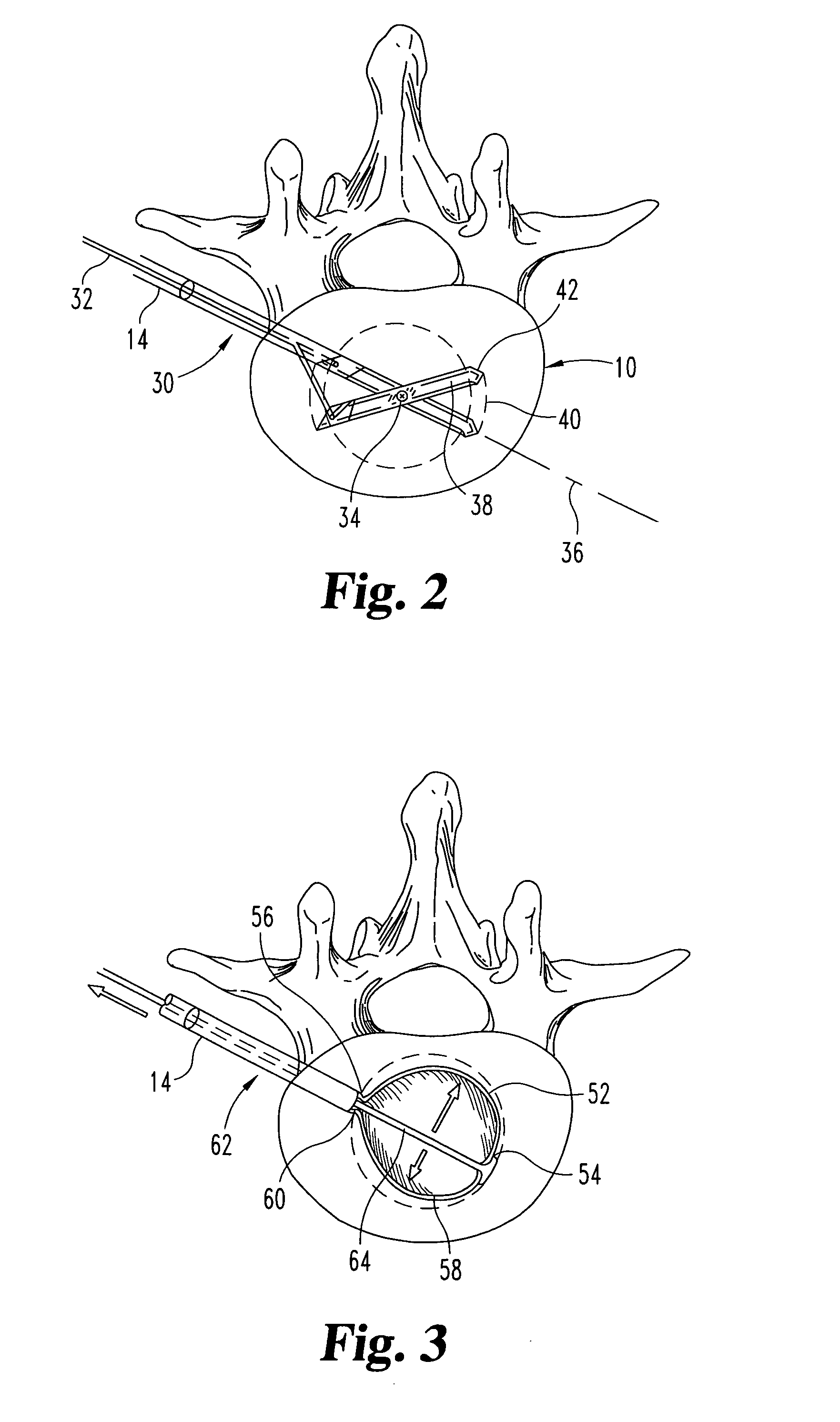

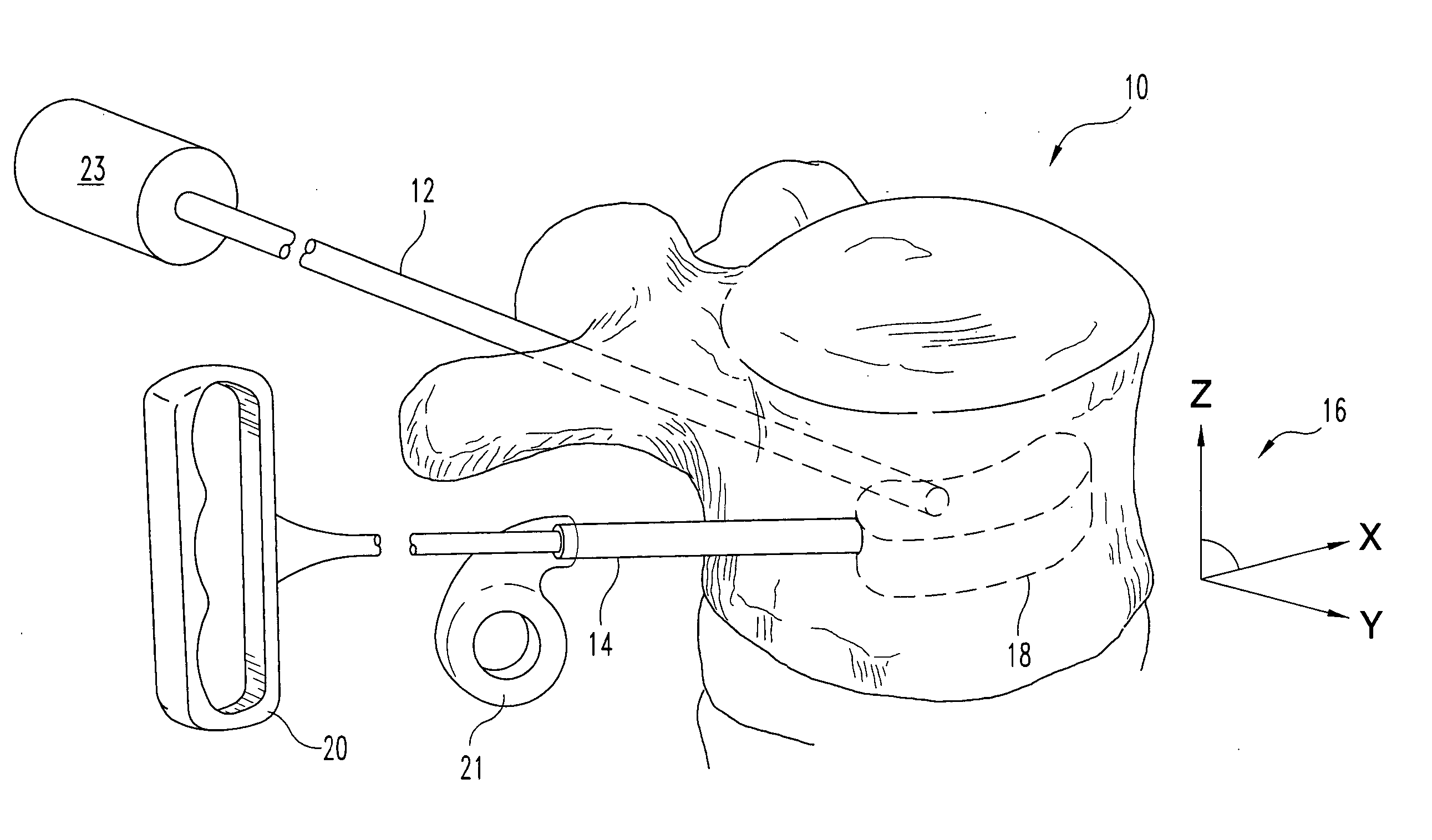

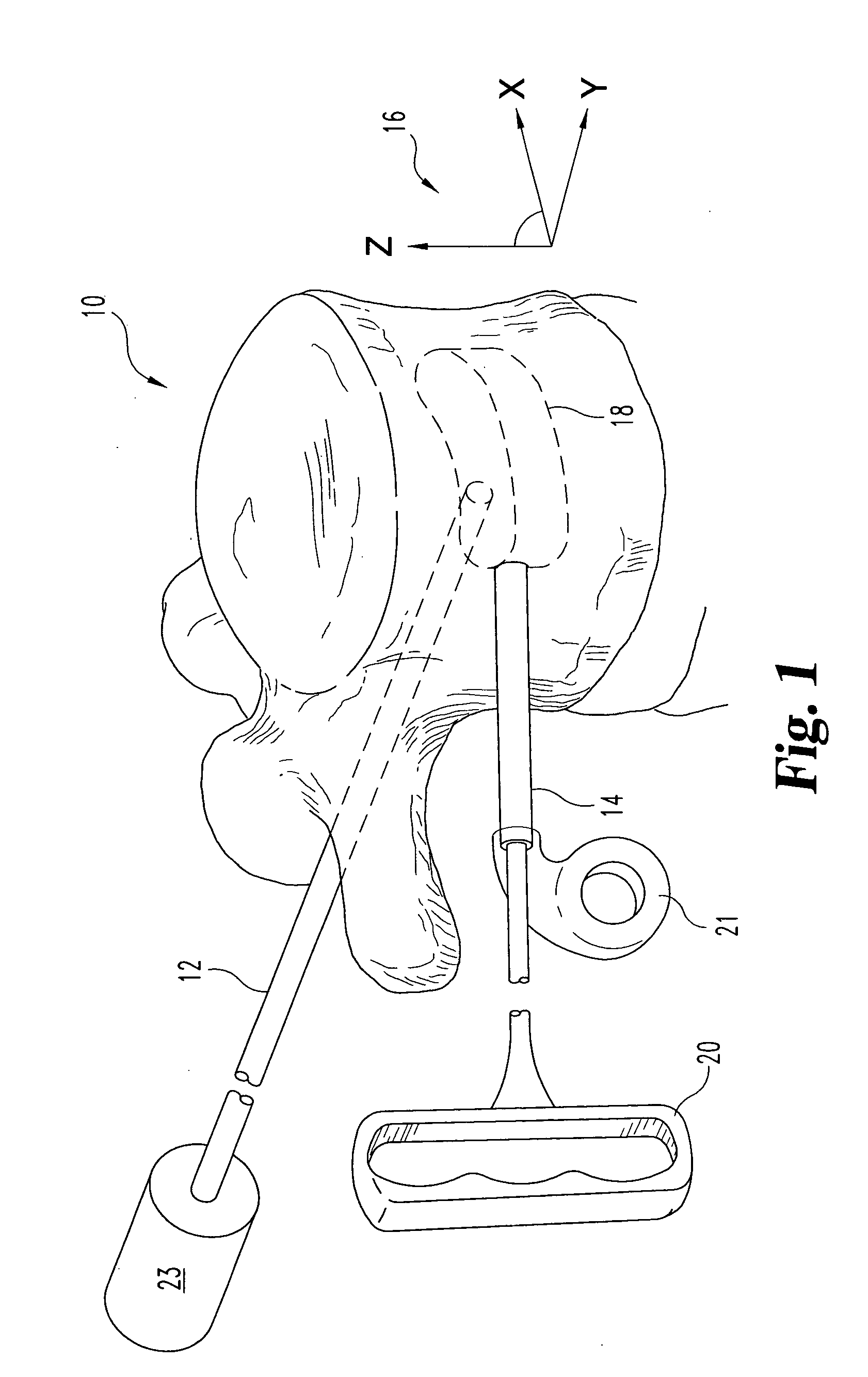

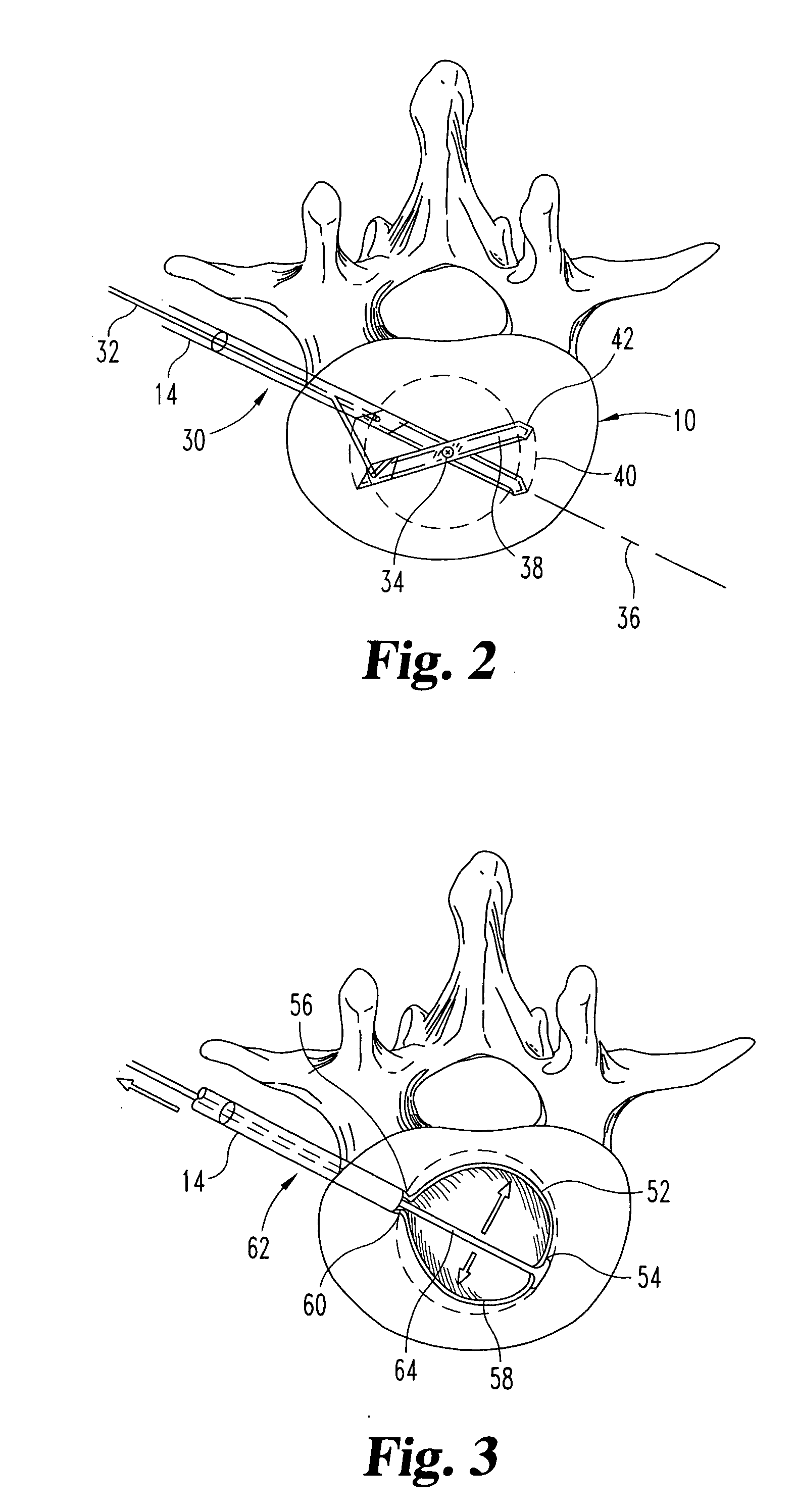

Transverse cavity device and method

InactiveUS7114501B2Small footprintForce is smallInternal osteosythesisRestraining devicesSurgical departmentGeneral surgery

The invention teaches the use of a surgical instrument for creating and preparing a cavity in a bony intervertebral body. Asymmetrical cutting structures selectively open a cavity which has a relatively large surface area in the vertical direction.

Owner:SPINEWAVE

Flexible non-contact wound treatment device with a single joint

A non-contact wound treatment device suitable for releasable attachment to a patient's skin surface over a selected wound area in a non-contact position relative to the selected wound area, the wound treatment device comprising an attachment portion suitable for releasable attachment with the patient's skin surface, having an inner perimeter for defining the selected wound area, a wound treatment portion with a wound cover and a support member supporting the wound cover, and a transition portion with a joint connecting the wound treatment portion to the attachment portion.

Owner:GEN ELECTRIC CAPITAL

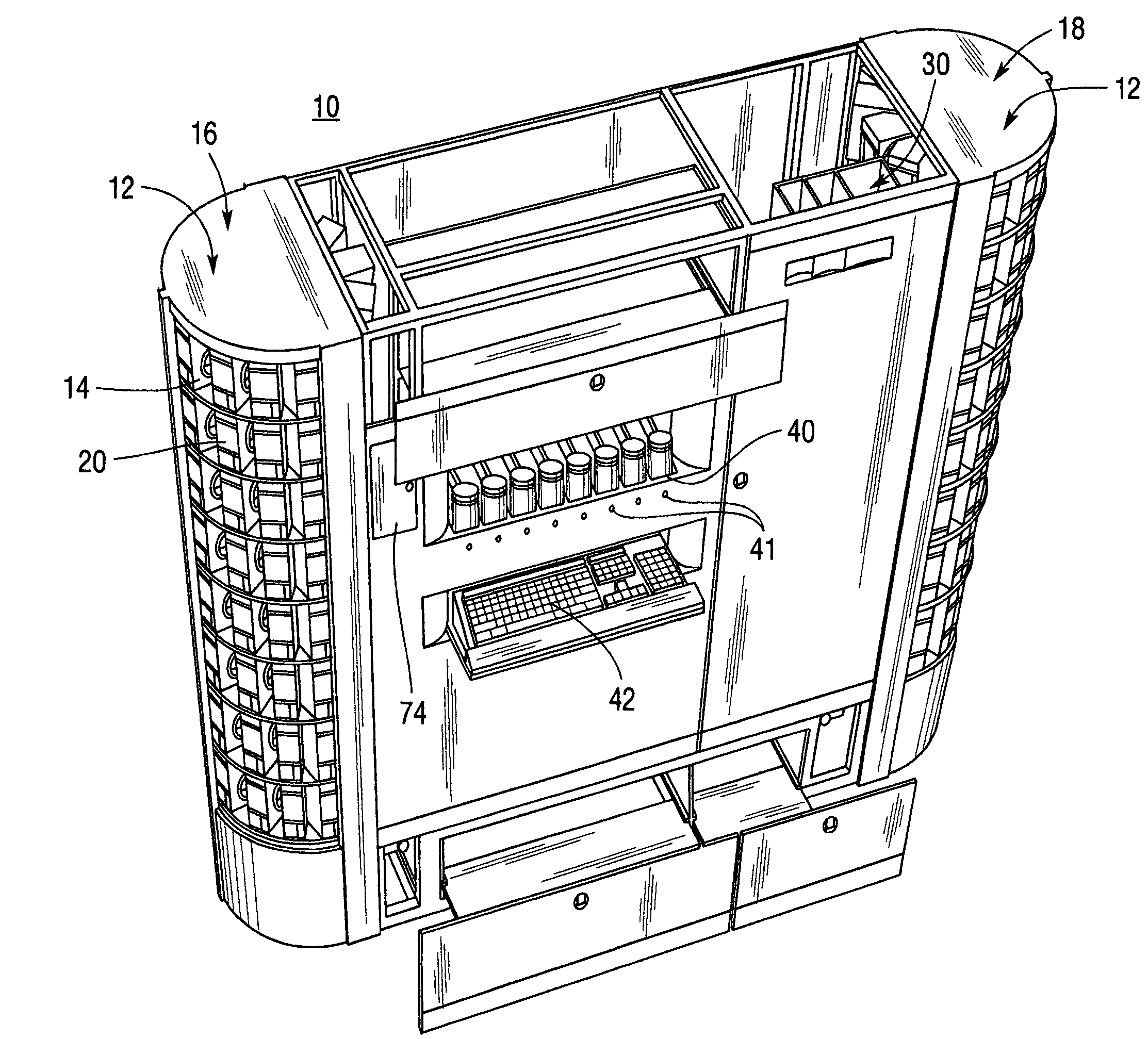

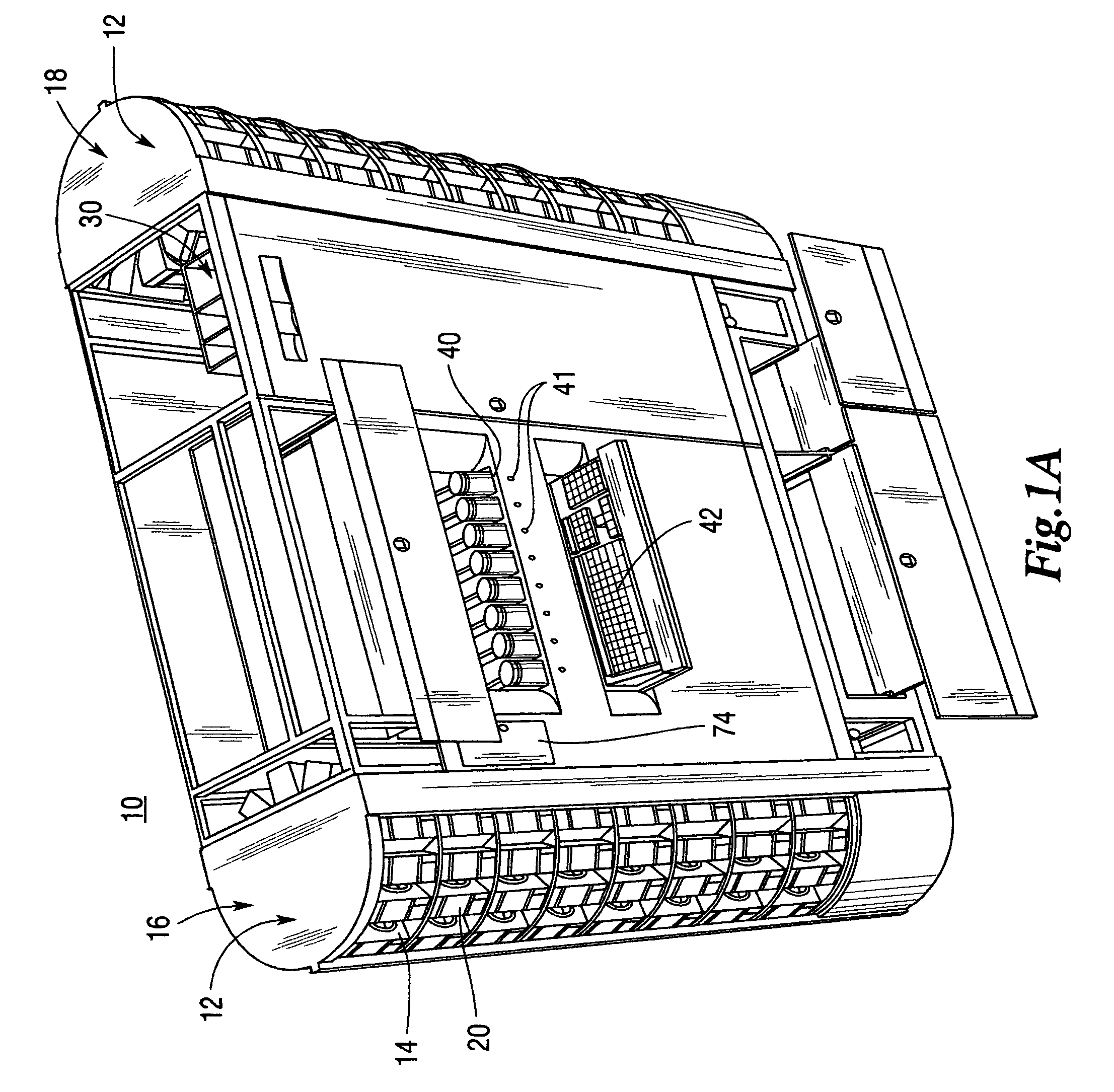

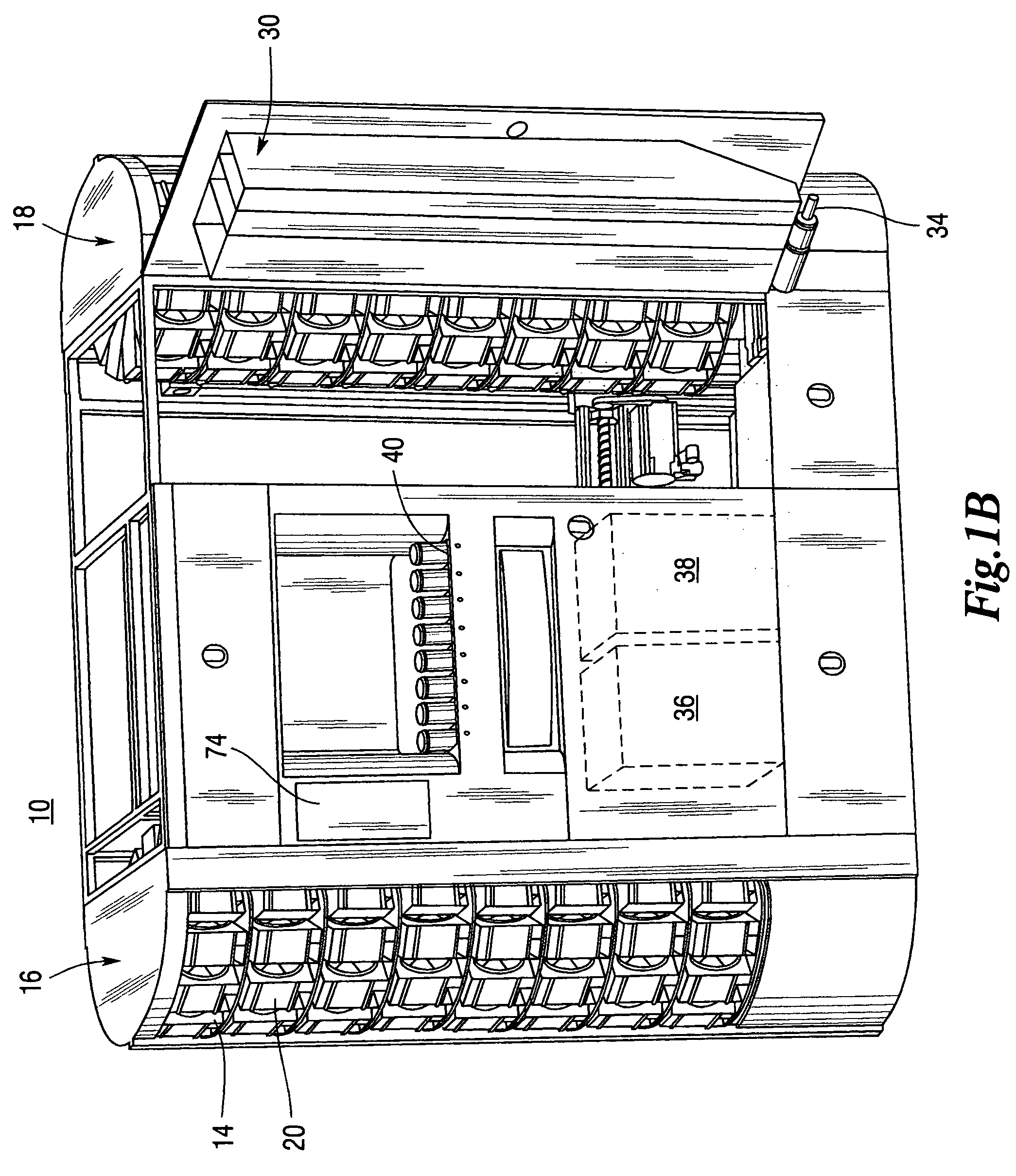

Prescription filling apparatus implementing a pick and place method

ActiveUS7228198B2Easy to scaleSmall footprintDigital data processing detailsSolid materialComputer control systemOutput device

An apparatus for filling vials comprises a shelving unit defining an array of storage locations. The shelving unit may be an array in an XY plane or one or more carousels. A plurality of storage containers are provided, each removably carried by one of the storage locations. A counting and dispensing unit, a source of vials, a label printer and application unit or units, and an output device are also provided. The output device may take a variety of forms such as an output chute, which is preferably used when a capping unit is provided, an output conveyor, a plurality of output lanes, and an output carousel, which may be a dedicated carousel or a portion of the carousel providing the plurality of storage locations. A computer controlled engagement device provides motion in a Z direction. The engagement device may be comprised of a first stage for engaging the storage containers and a second stage for engaging the vials. A computer controlled system carries the engagement device and moves the engagement device in XY directions among the plurality of storage locations, counting and dispensing unit, source of vials, label printer and application unit, and output device. Methods of operating and refilling the vial filling apparatus are also disclosed.

Owner:MCKESSON AUTOMATION SYST

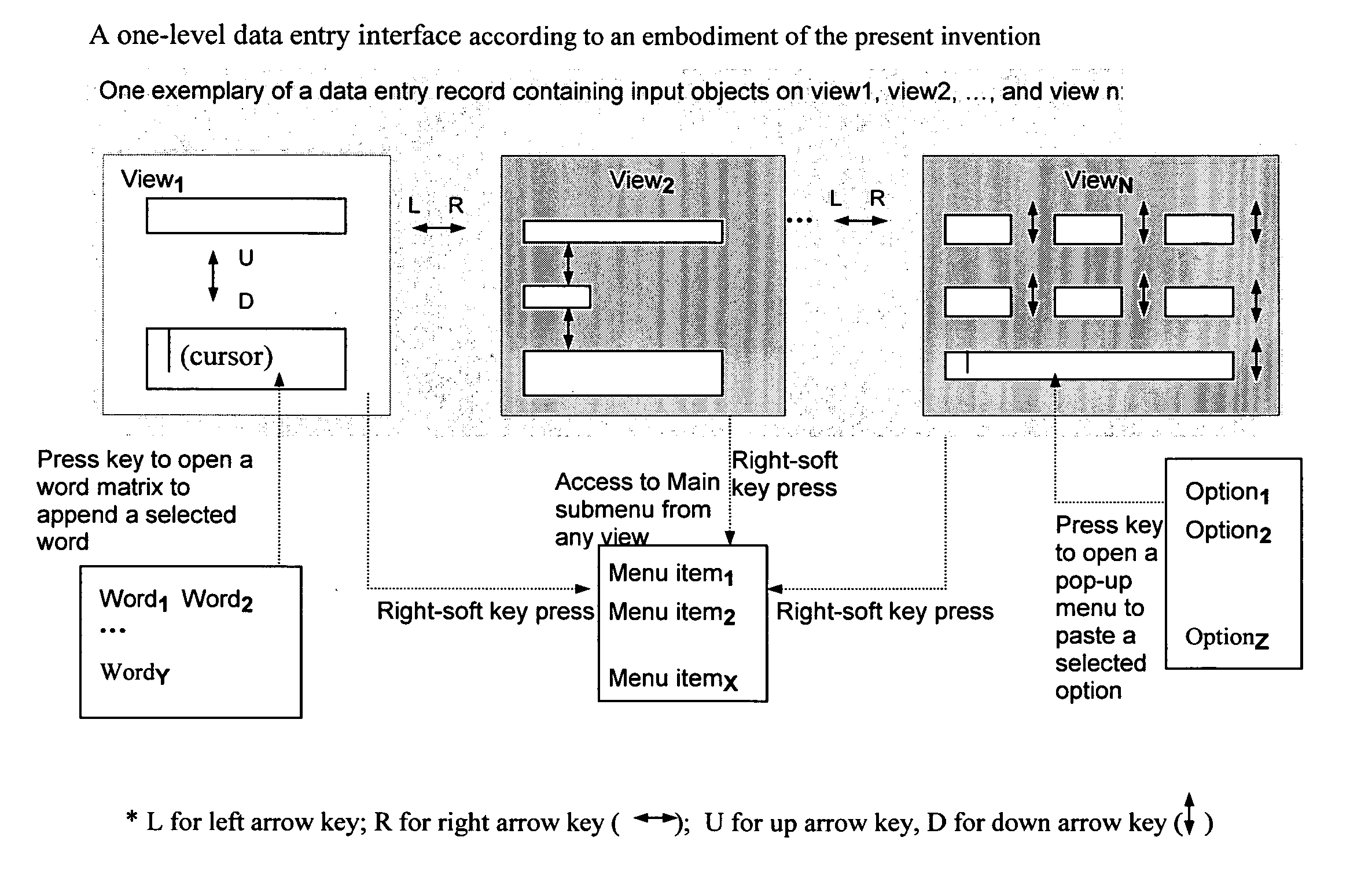

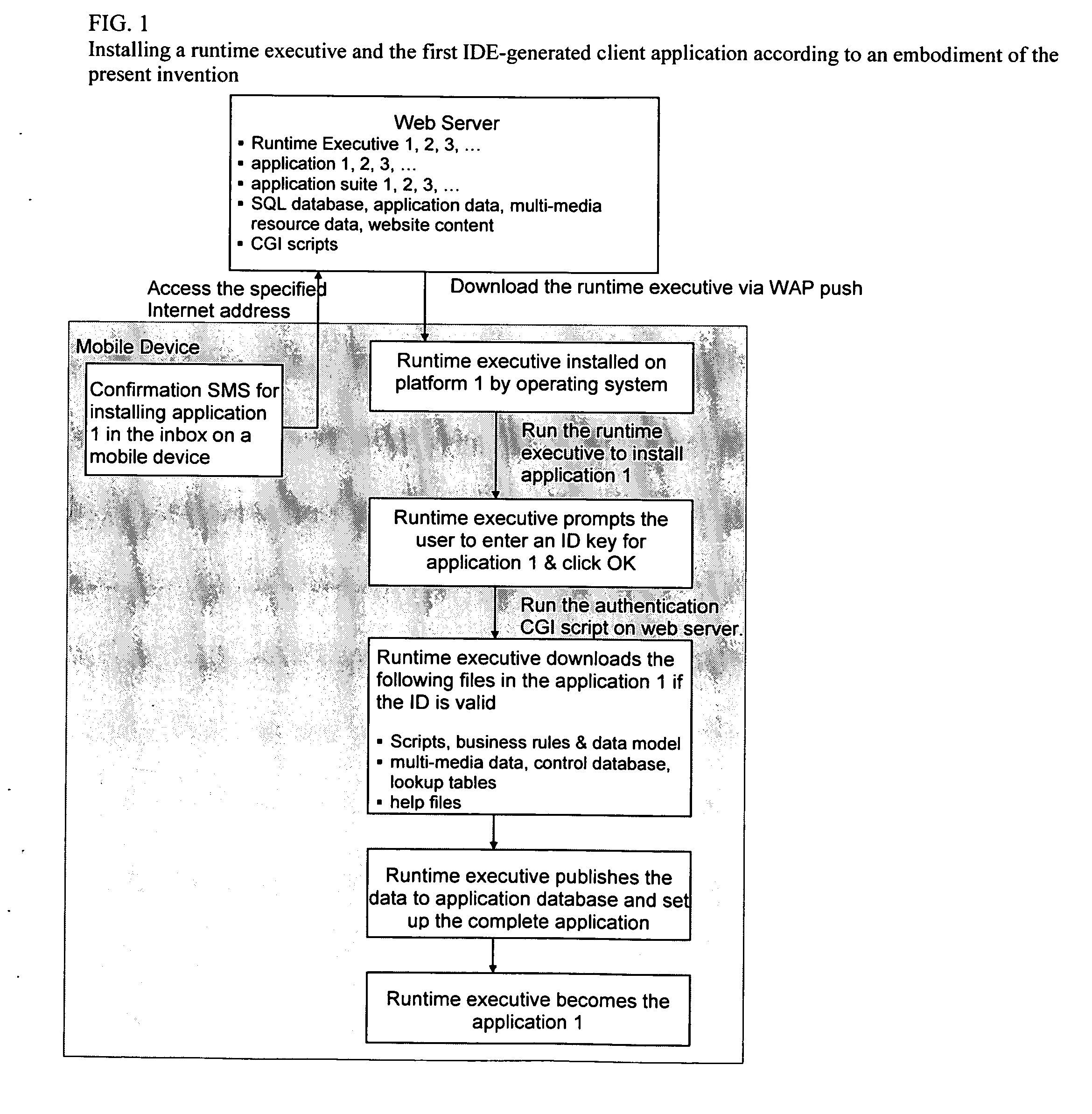

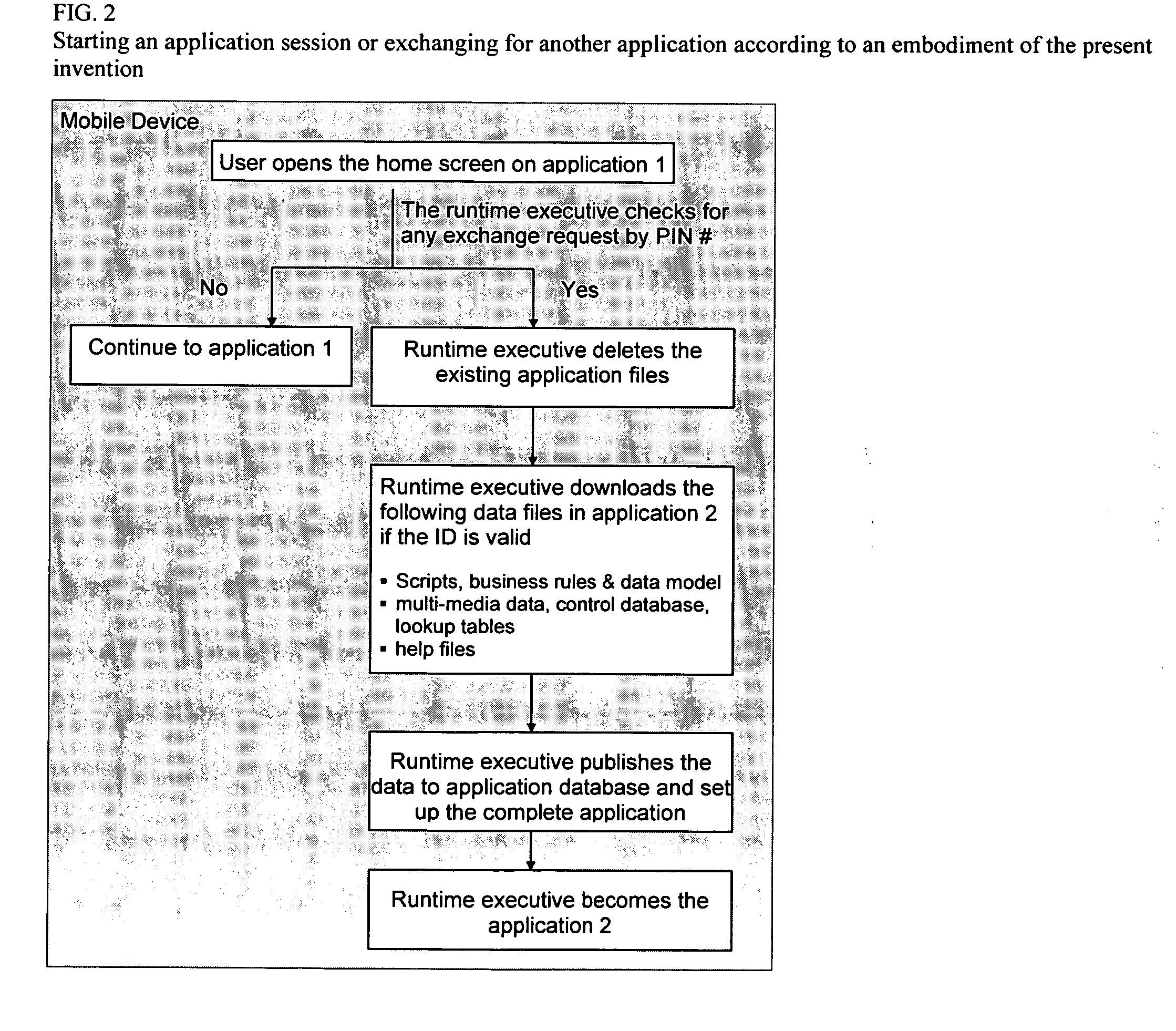

Method and system for designing, implementing, and managing client applications on mobile devices

InactiveUS20080046557A1Easy accessEasy to navigateSoftware engineeringMultiple digital computer combinationsTypingData file

A system that designs, implements, and manages client applications on mobile devices using runtime executives and an IDE. In one aspect, the runtime executive delivers consistent GUI and application behavior within and across mobile development platforms. In another aspect, the runtime executive can set up data files of an IDE-generated client application on mobile devices and then become that application itself while supporting a pay-per-download subscription service. The runtime executive delivers multimedia content in presentation format via a one-level browsing interface, enables data entries across tabbed views with minimal typing and drilidowns via a one-level data entry interface, and precisely processes scripts and commands, including calls to COM libraries. The IDE allows non-programmers to design the GUI and the scripts for mobile device applications and compile them into application data files for multiple development platforms, which are then loaded and executed by runtime executives.

Owner:CHENG JOSEPH C

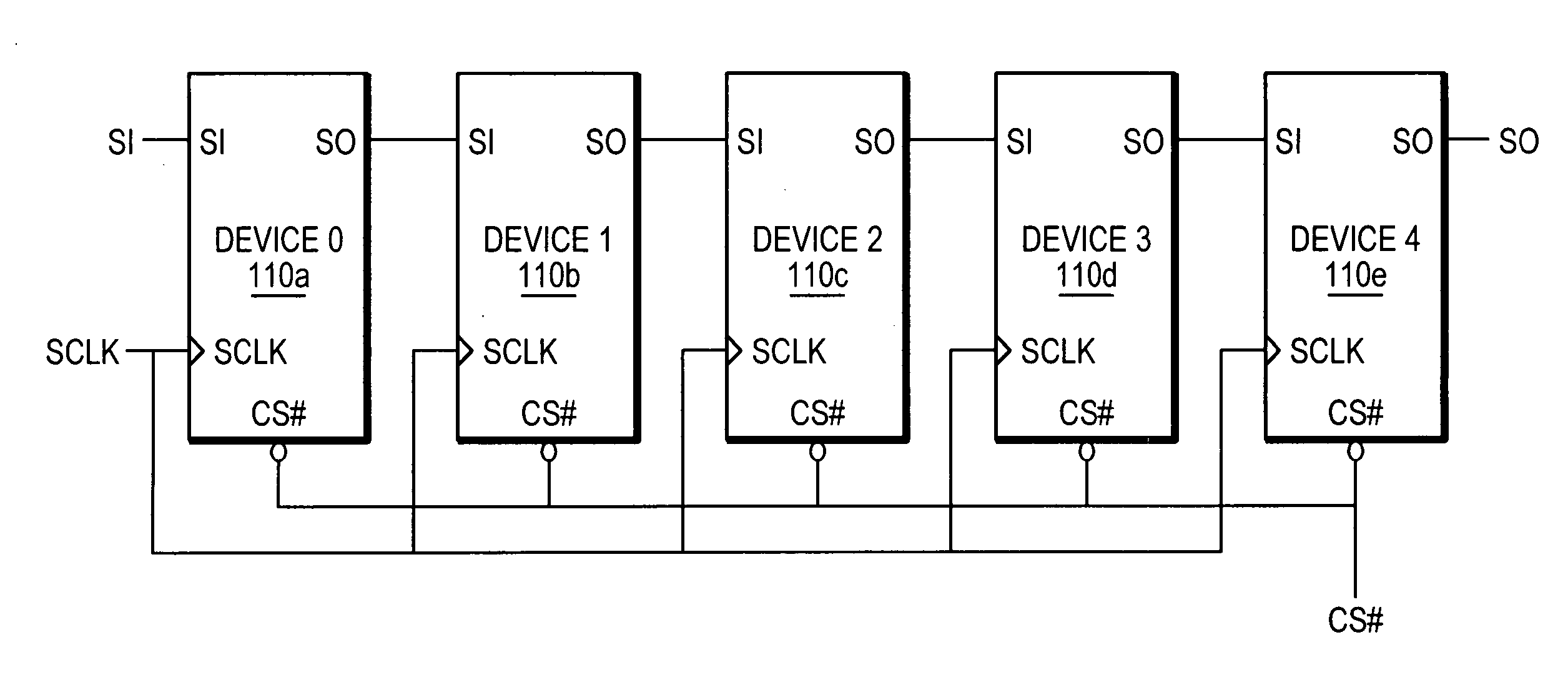

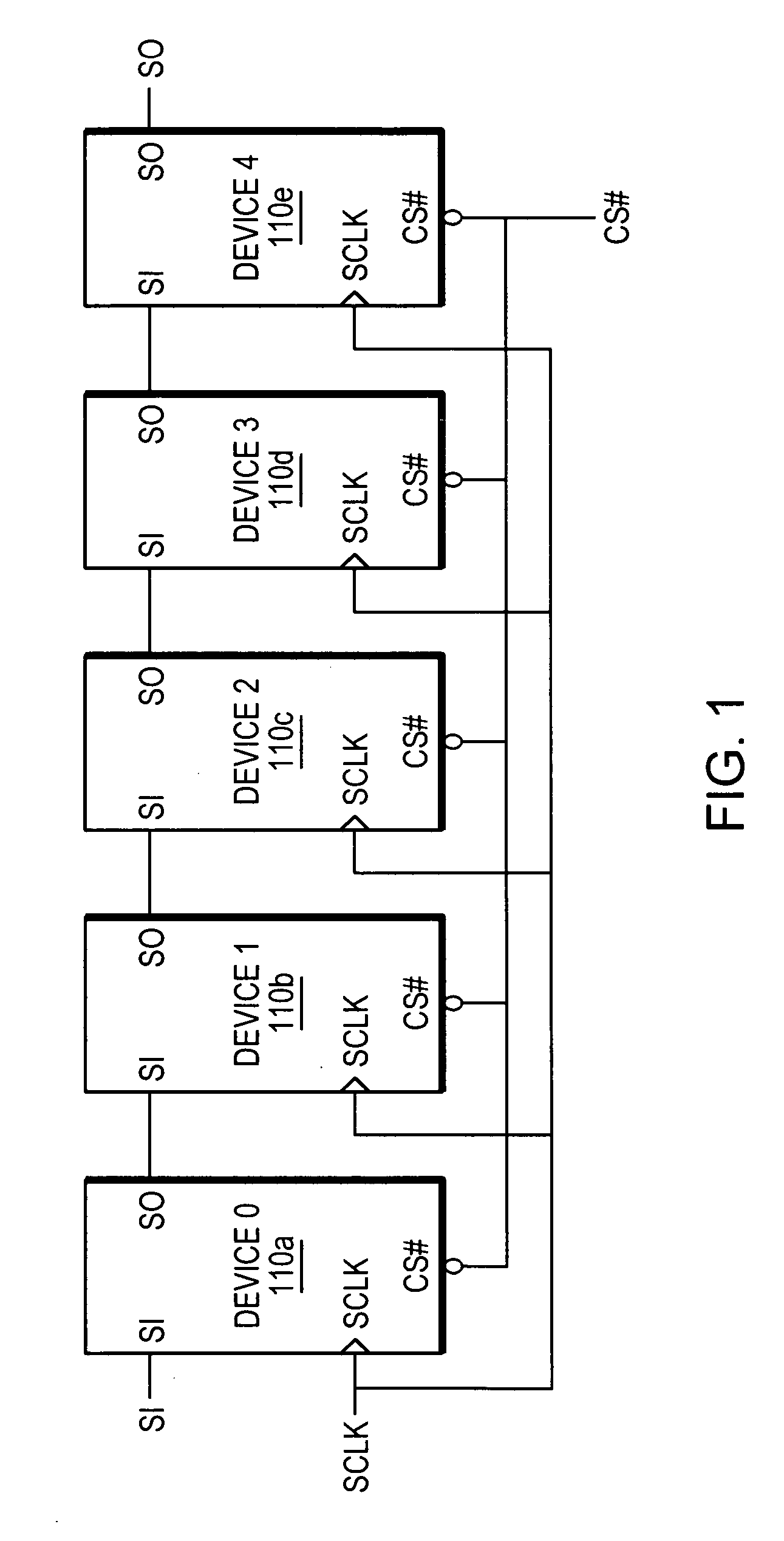

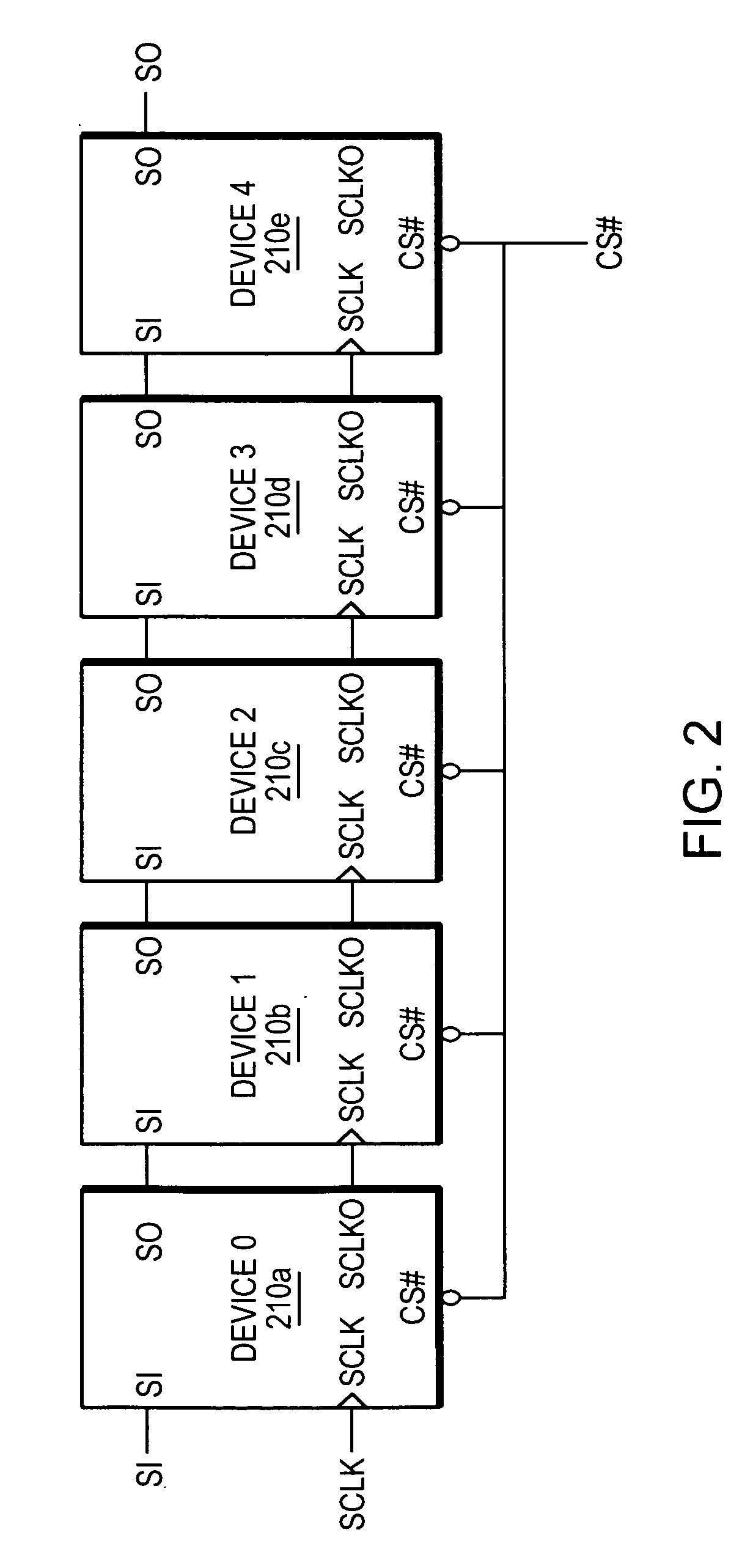

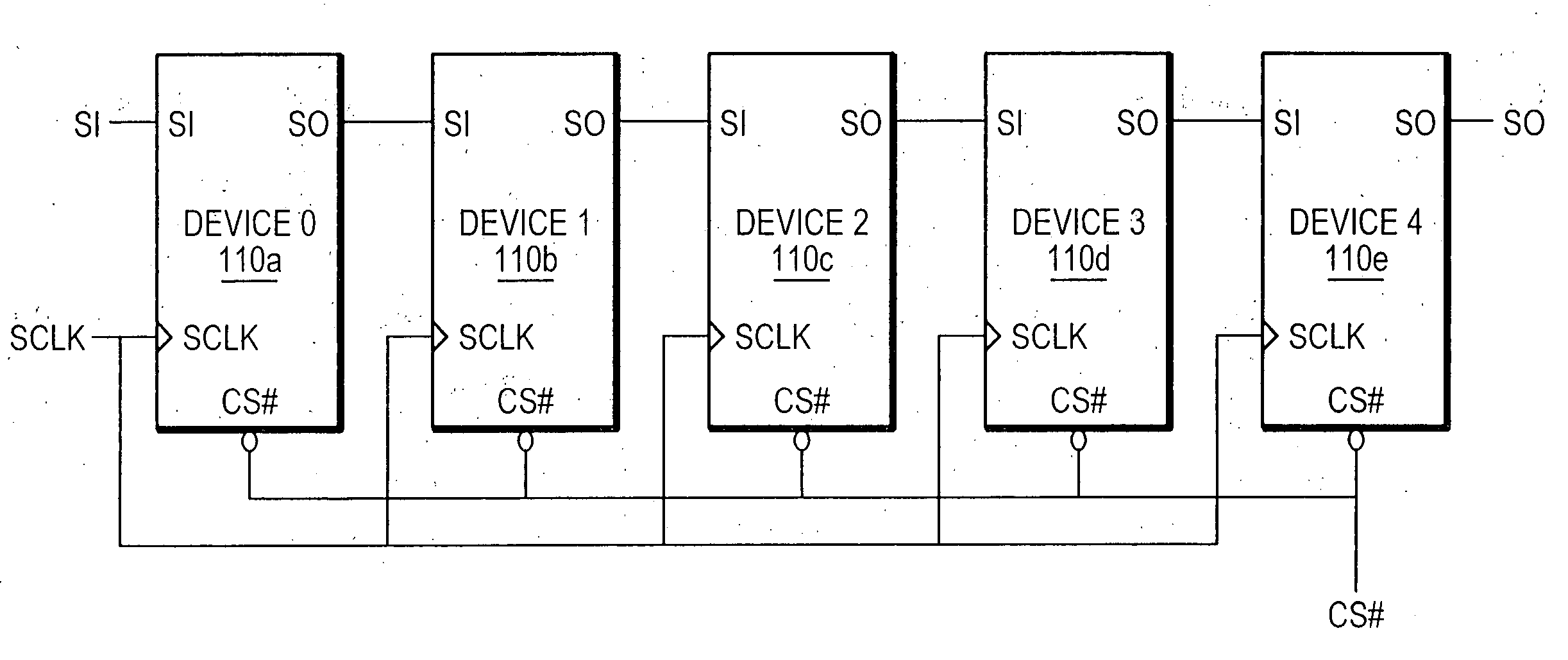

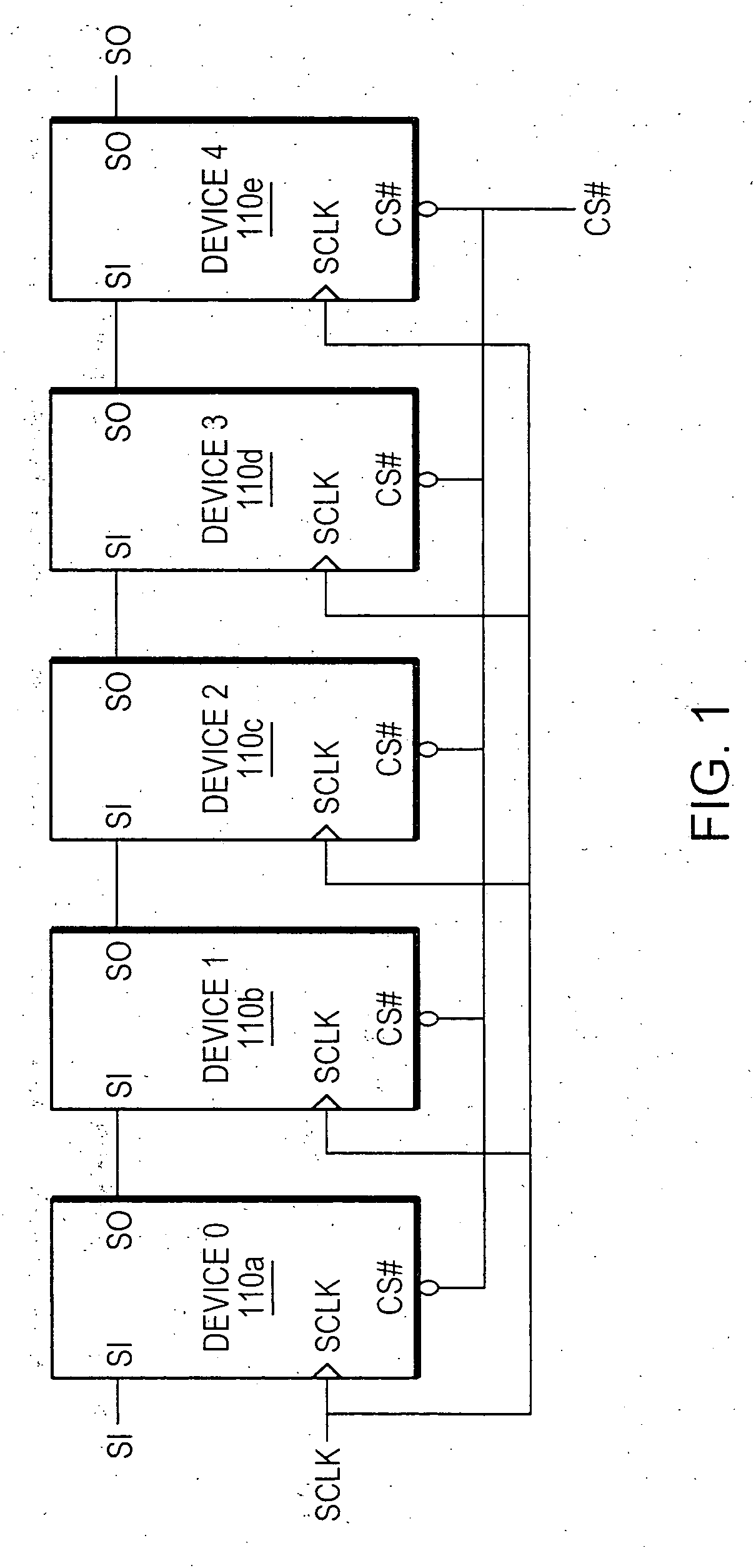

Daisy chain cascading devices

InactiveUS20070076502A1Few and short connectionIncrease speedRead-only memoriesDigital storageComputer hardwareControl signal

A technique for serially coupling devices in a daisy chain cascading arrangement. Devices are coupled in a daisy chain cascade arrangement such that outputs of a first device are coupled to inputs of a second device later in the daisy chain to accommodate the transfer of information, such as data, address and command information, and control signals to the second device from the first device. The devices coupled in the daisy chain comprise a serial input (SI) and a serial output (SO). Information is input to a device via the SI. The information is output from the device via the SO. The SO of an earlier device in the daisy chain cascade is coupled to the SI of a device later in the daisy chain cascade. Information input to the earlier device via the device's SI is passed through the device and output from the device via the device's SO. The information is then transferred to the later device's SI via the connection from the earlier device's SO and the later device's SI.

Owner:CONVERSANT INTPROP MANAGEMENT INC

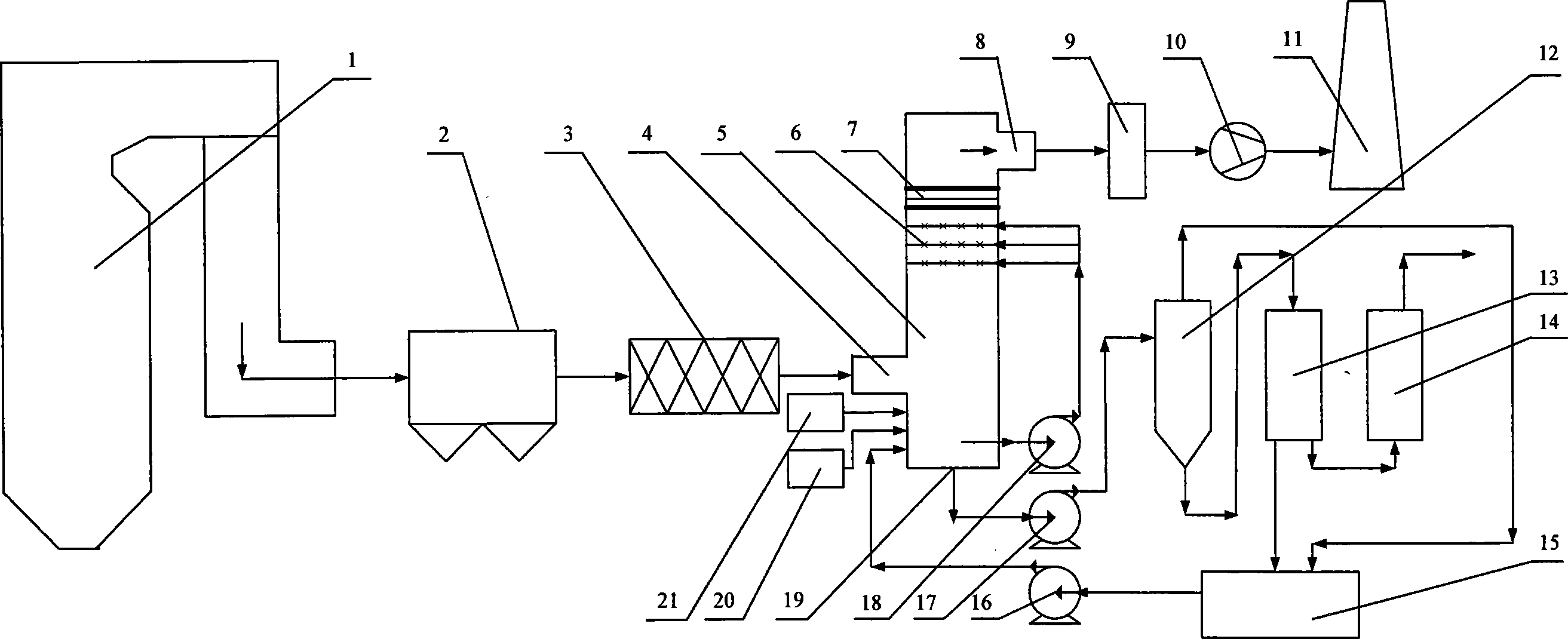

Simultaneously desulfurization and denitration wet ammonia flue gas cleaning technology and system thereof

InactiveCN101053747ASimple processSmall footprintDispersed particle separationFertilizerNitric oxide

A wet ammonium flue gas cleaning process for desulfurizing and denitrifying and a system thereof are disclosed. The process oxidates NO in the flue gas to be NO2, makes SO2 and NO2 in the flue gas react with ammonium to product ammonium sulfite, ammonium nitrate and ammonium nitrite, then oxidates ammonium sulfite and ammonium nitrite therein to product the byproduct that is ammiaonia sulfate and ammonium nitrate, and lastly gets the clear flue gas after demisting to the desulfurizing and denitrifying flue gas. The system comprises a dust pre-collector, a hydrogen peroxide or ozone sprayer, and a desulfurizing and denitrifying tower, which are connected in turns, wherein ammonia replenishment system and an air feeding device are mounted at the bottom of the desulfurizing and denitrifying tower, sprinkling layer which can cycle sprinkle is mounted at the middle, and a demister is mounted at the upper. The invention has a simple process, a simplified system, a low investment and operation cost. The invention not only has a high efficiency in desulfurizing and denitrifying, but also a high utilance of desulfurizing and denitrifying absorbent, and byproduct of desulfurization and denitration can be utilized as chemical fertilizer of ammiaonia sulfate and ammonium nitrate.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

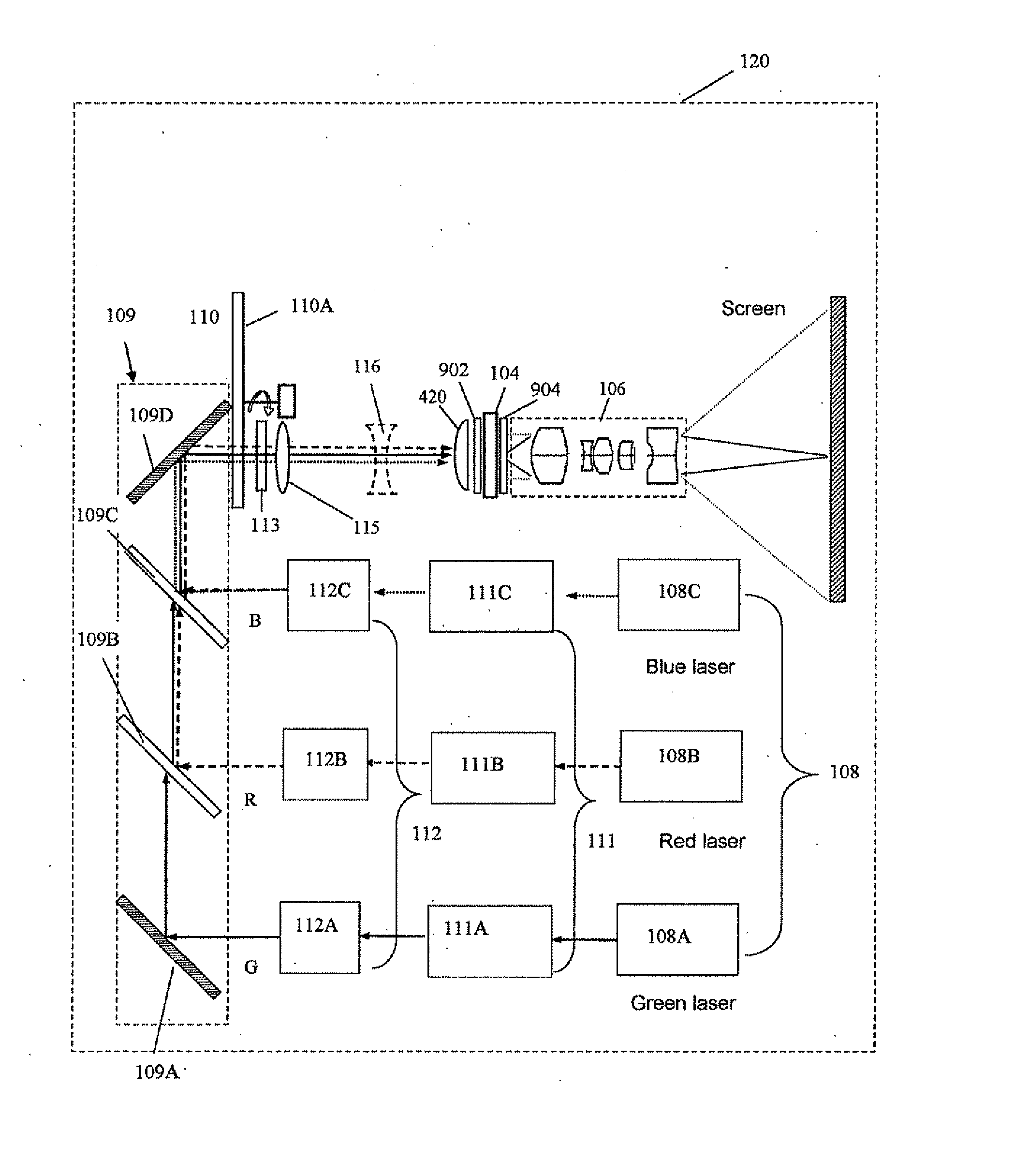

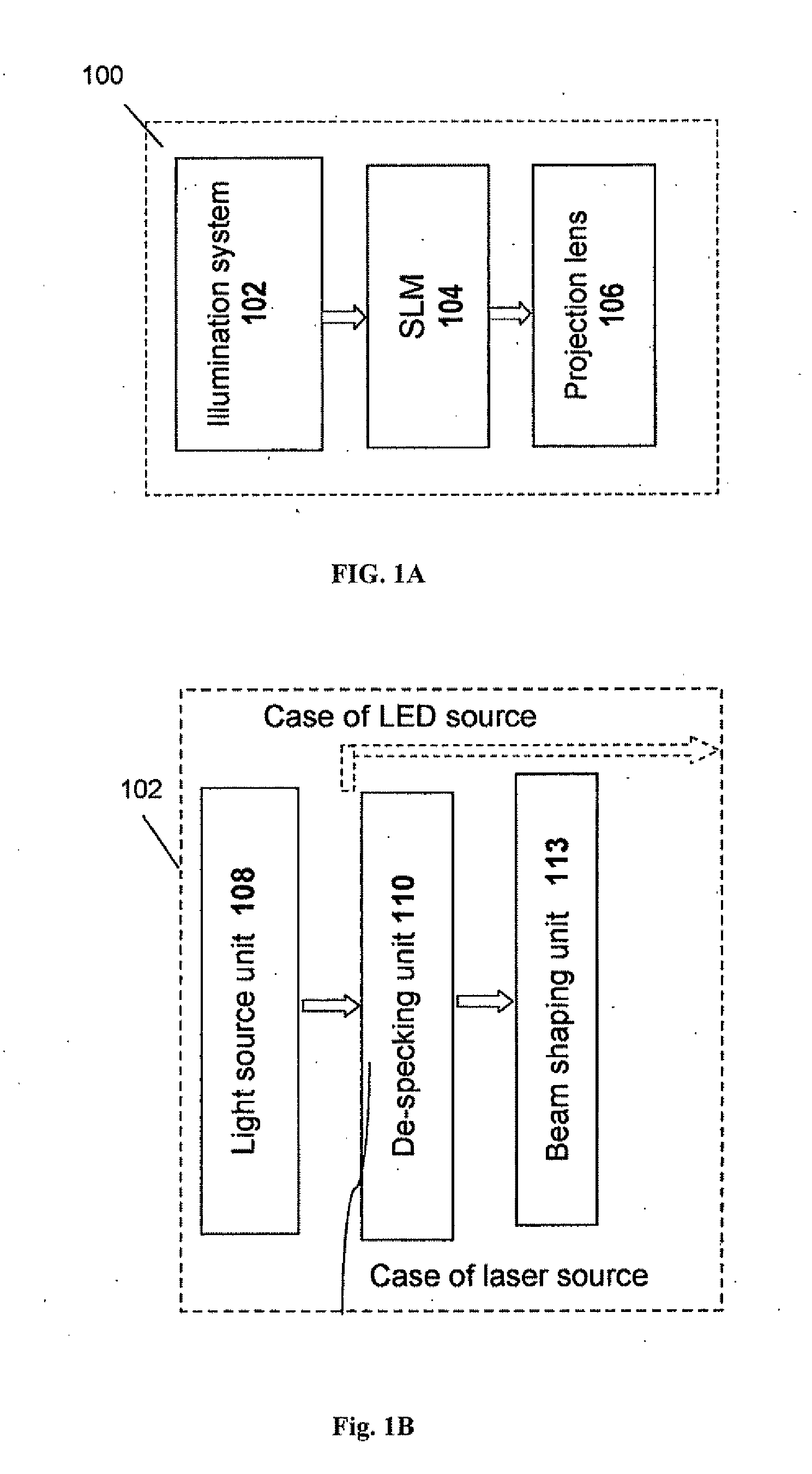

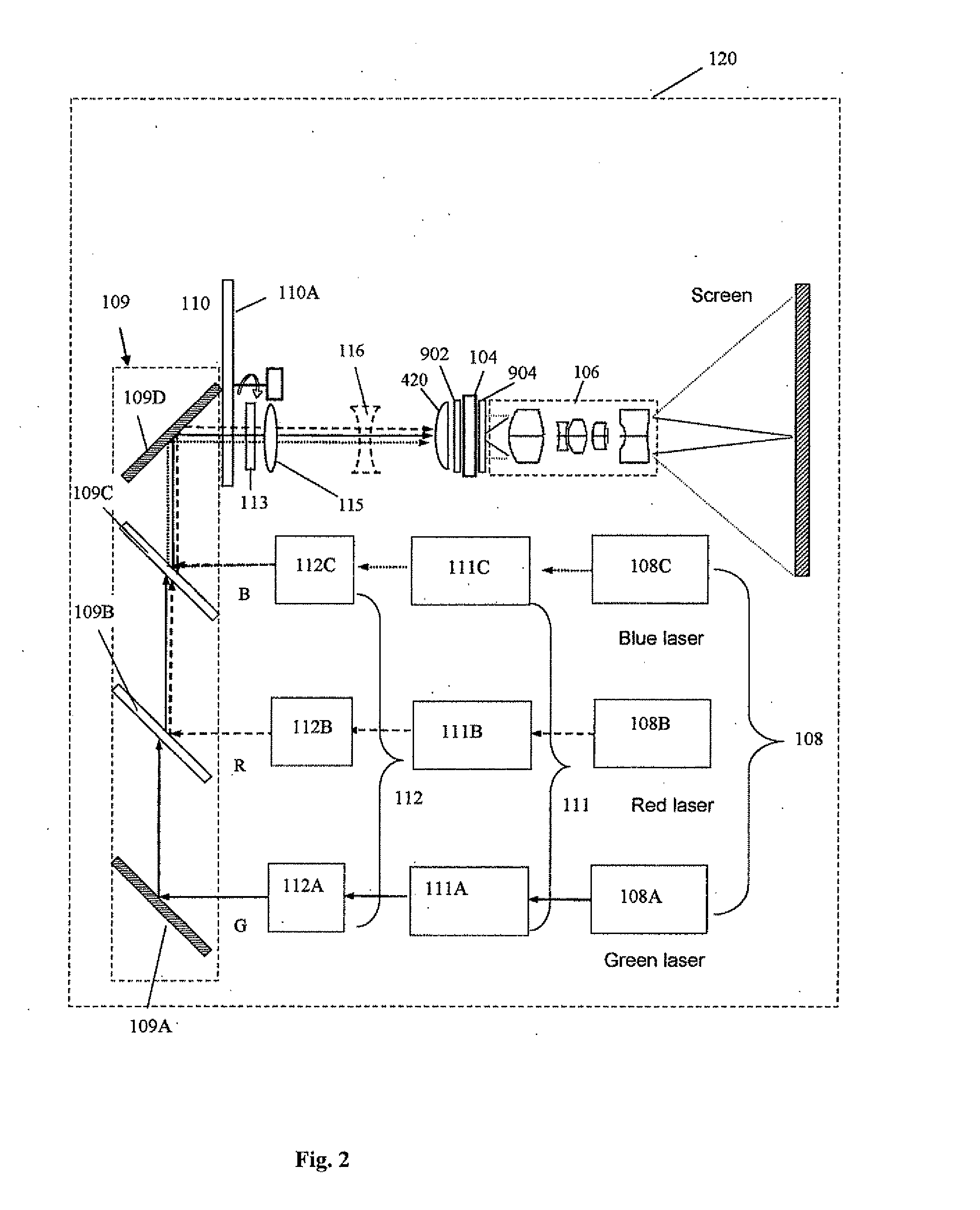

Micro-projector

InactiveUS20110037953A1Increase brightnessQuality improvementTelevision system detailsPrismsDisplay deviceLaser source

The present invention provides a projection display comprising an illumination system comprising at least one laser source unit and configured and operable for producing one or more light beams; a spatial light modulating (SLM) system accommodated at output of the illumination system and comprising one or more SLM units for modulating light incident thereon in accordance with image data; and a light projection optics for imaging modulated light onto a projection surface. The illumination system comprises at least one beam shaping unit comprising a Dual Micro-lens Array (DMLA) arrangement formed by front and rear micro-lens arrays (MLA) located in front and rear parallel planes spaced-apart along an optical path of light propagating towards the SLM unit, the DMLA arrangement being configured such that each lenslet of the DMLA directs light incident thereon onto the entire active surface of the SLM unit, each lenslet having a geometrical aspect ratio corresponding to an aspect ratio of said active surface of the SLM unit.

Owner:EXPLAY

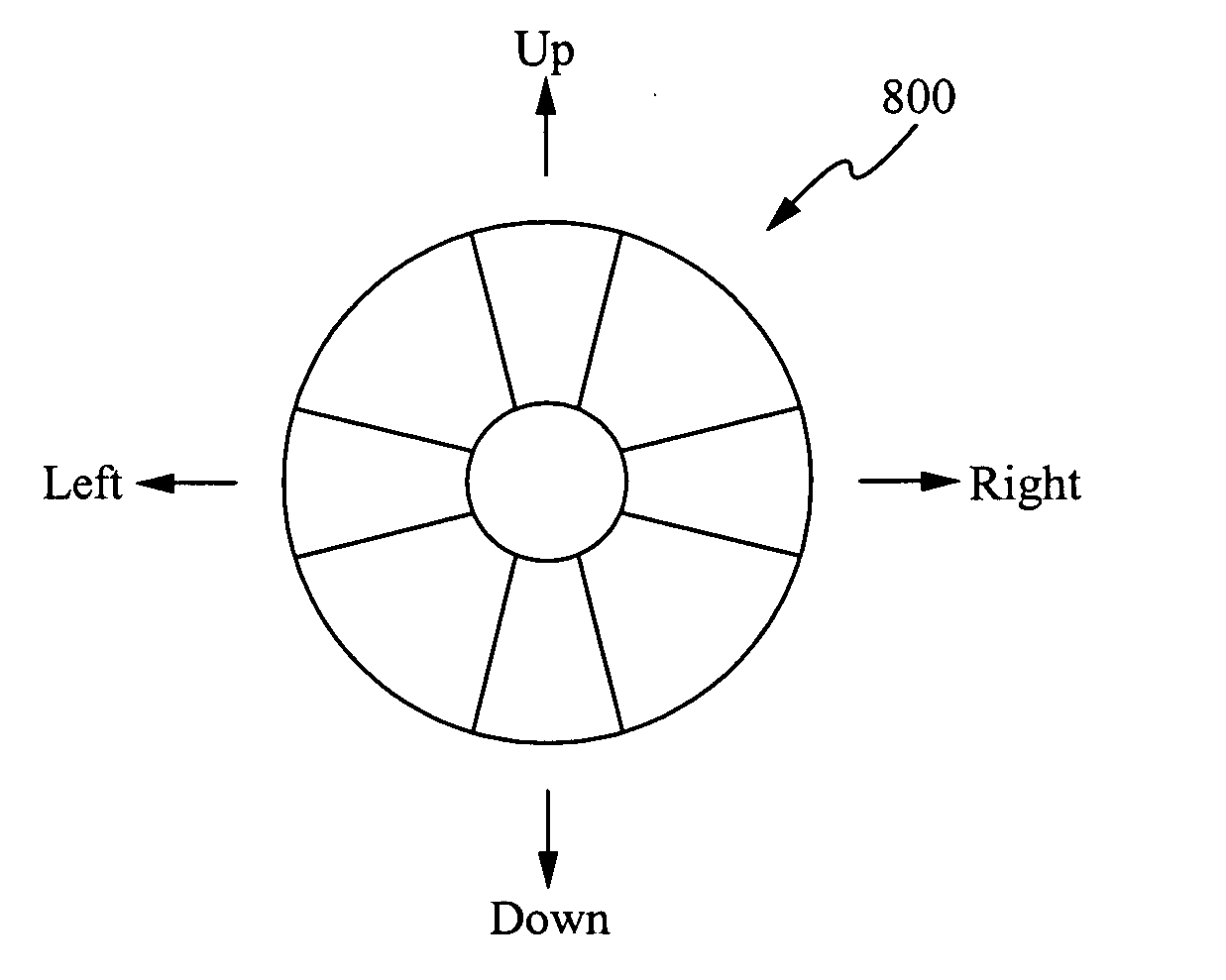

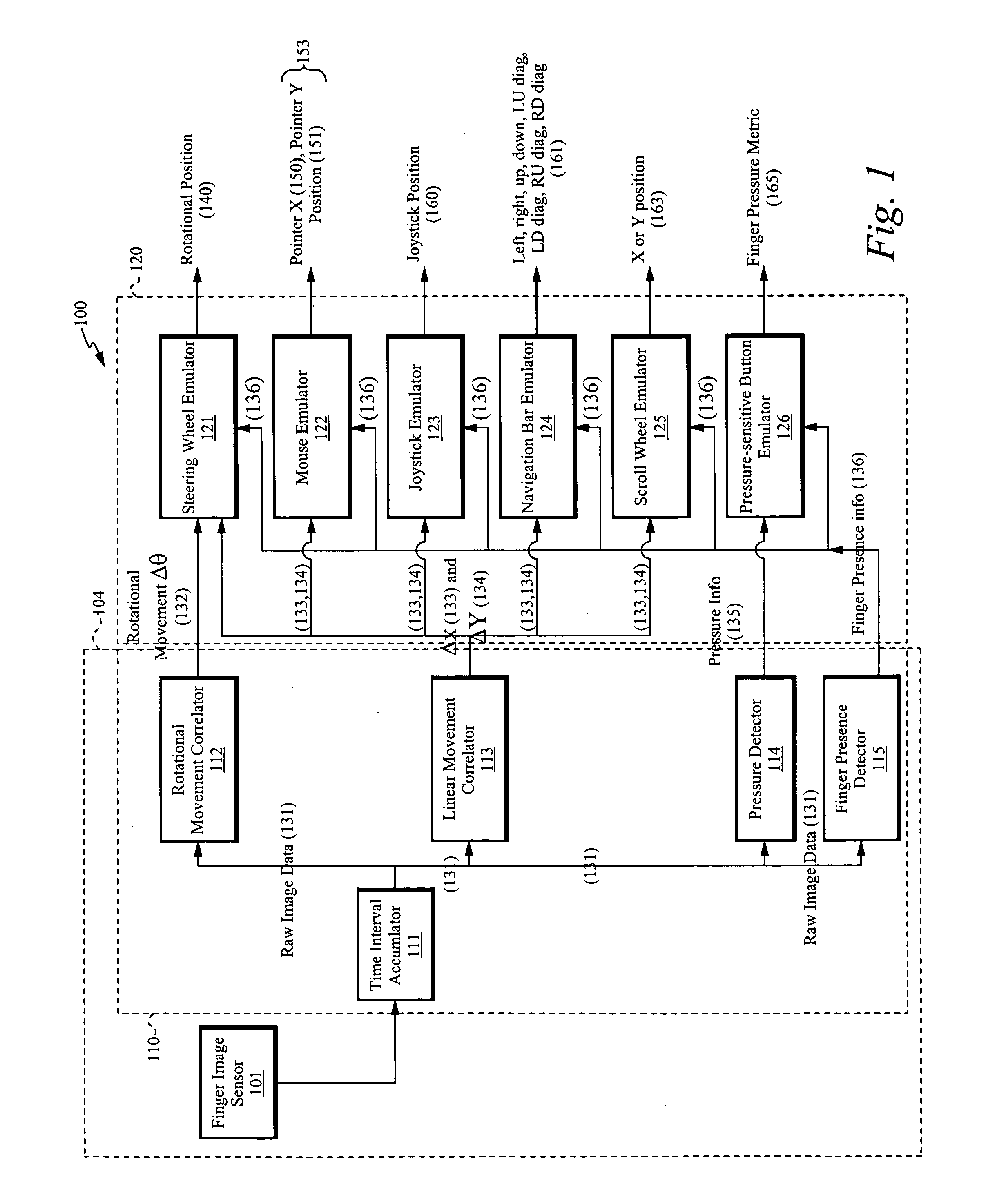

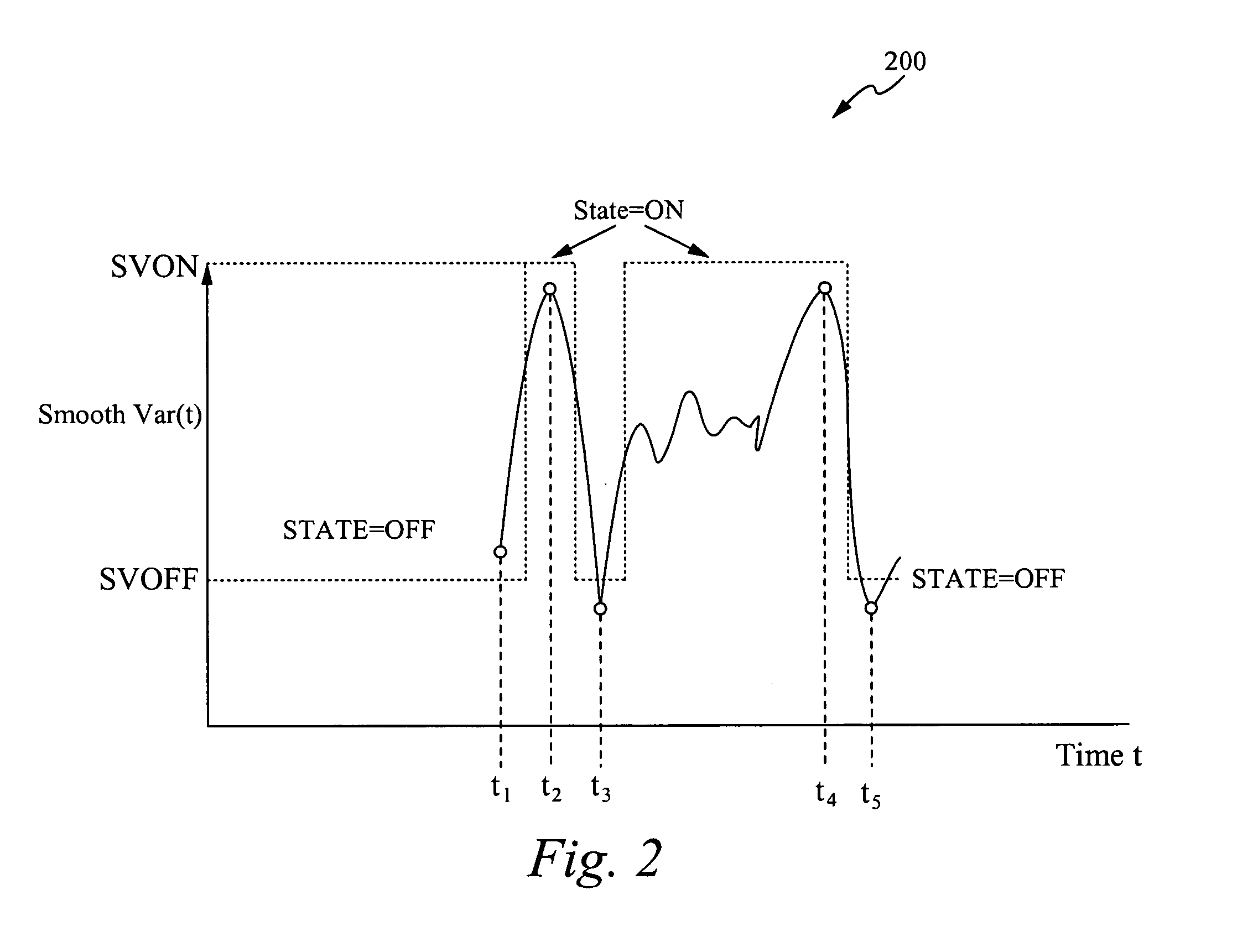

System and method for a miniature user input device

ActiveUS20050012714A1Small footprintNot easy to wearCharacter and pattern recognitionCathode-ray tube indicatorsJoystickSteering wheel

A system and method of the present invention emulates electronic input devices such as a steering wheel, a mouse, a joystick, a navigation bar, a scroll wheel, and a pressure-sensitive button. The method comprises swiping a finger on a swipe sensor, calculating a difference between a first position of the finger on the swipe sensor and a second position on the swipe sensor, and translating the difference into a plurality of sets of signals. Each set of signals is used to emulate the signals generated by one of the electronic input devices. The method thus uses a single swipe sensor to emulate multiple electronic input devices. In a preferred embodiment, the system is used to control a display on a portable electronic device is coupled to or forms part of the portable electronic device.

Owner:APPLE INC

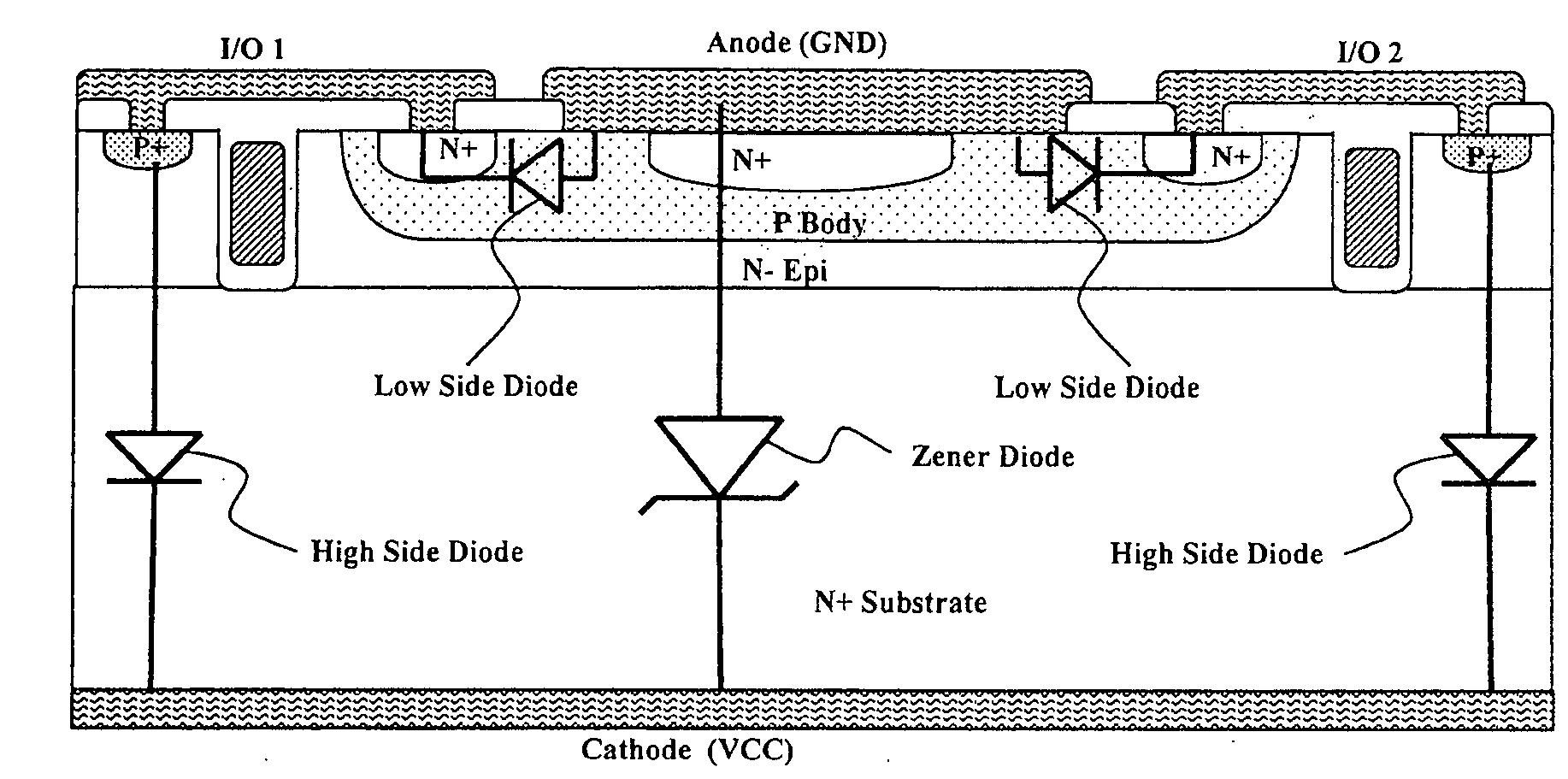

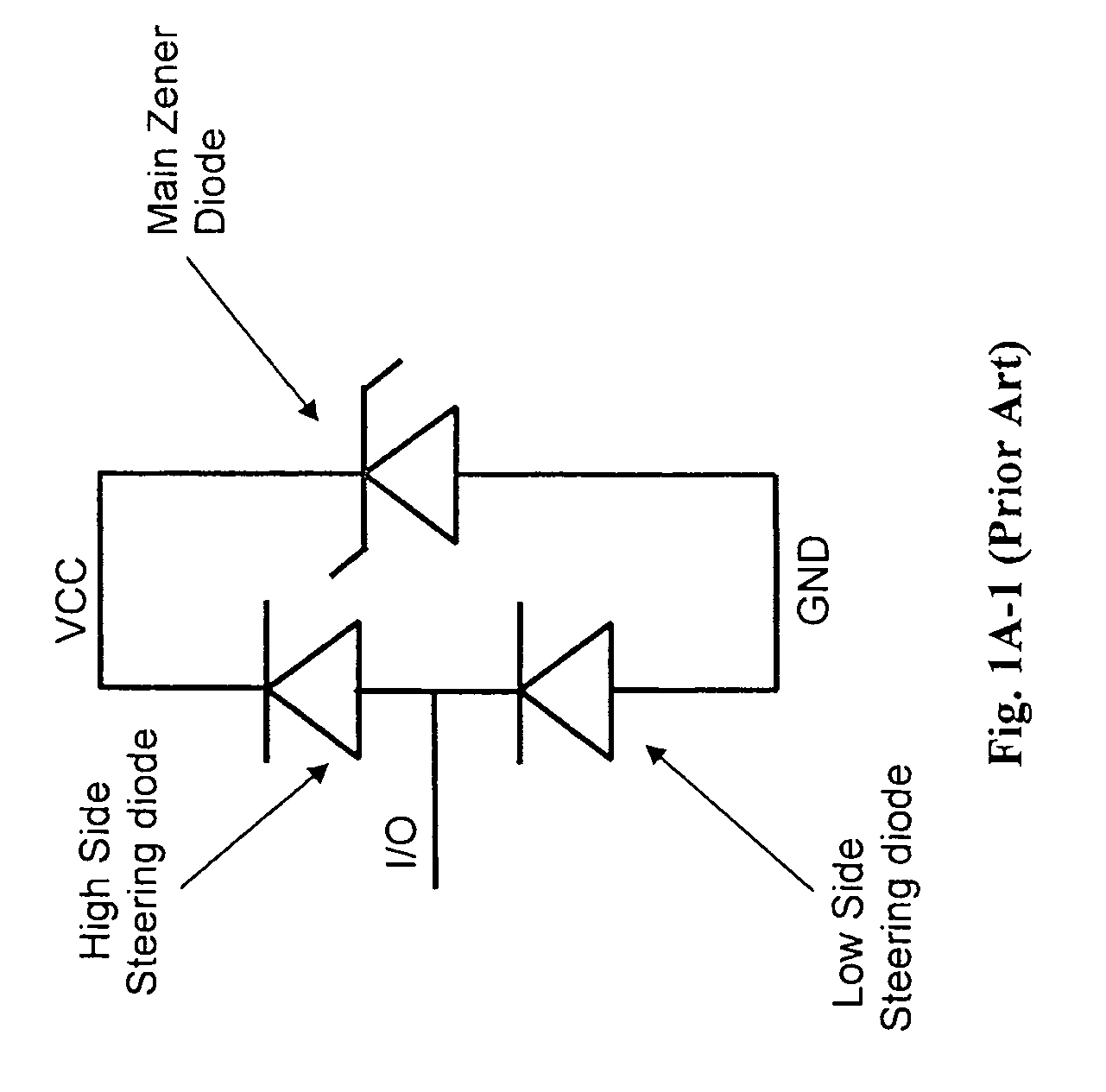

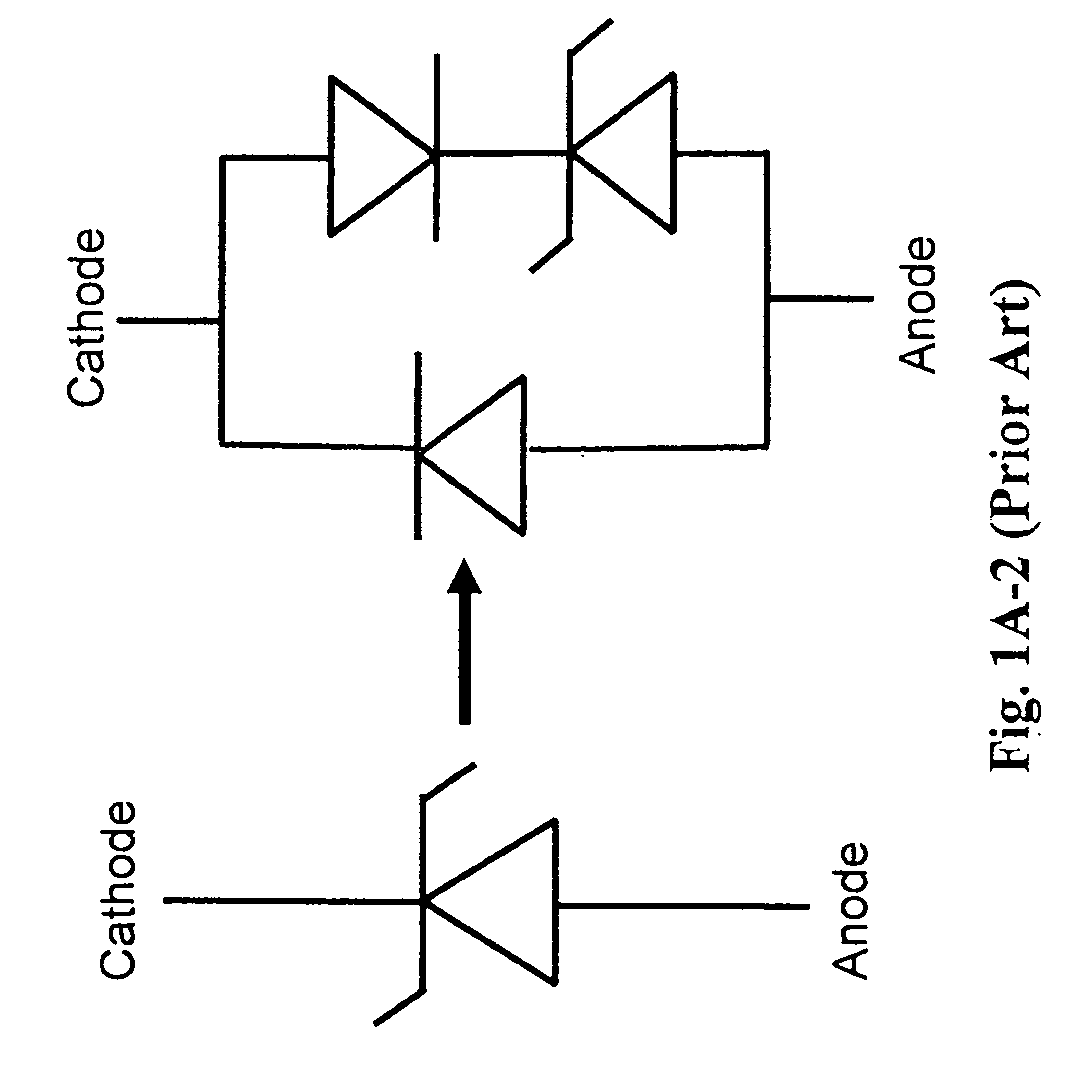

Optimized configurations to integrate steering diodes in low capacitance transient voltage suppressor (TVS)

ActiveUS20090045457A1Reduced lateral areaReduce areaSemiconductor/solid-state device detailsSolid-state devicesCapacitanceZener diode

A transient-voltage suppressing (TVS) device disposed on a semiconductor substrate including a low-side steering diode, a high-side steering diode integrated with a main Zener diode for suppressing a transient voltage. The low-side steering diode and the high-side steering diode integrated with the Zener diode are disposed in the semiconductor substrate and each constituting a vertical PN junction as vertical diodes in the semiconductor substrate whereby reducing a lateral area occupied by the TVS device. In an exemplary embodiment, the high-side steering diode and the Zener diode are vertically overlapped with each other for further reducing lateral areas occupied by the TVS device.

Owner:ALPHA & OMEGA SEMICON INC

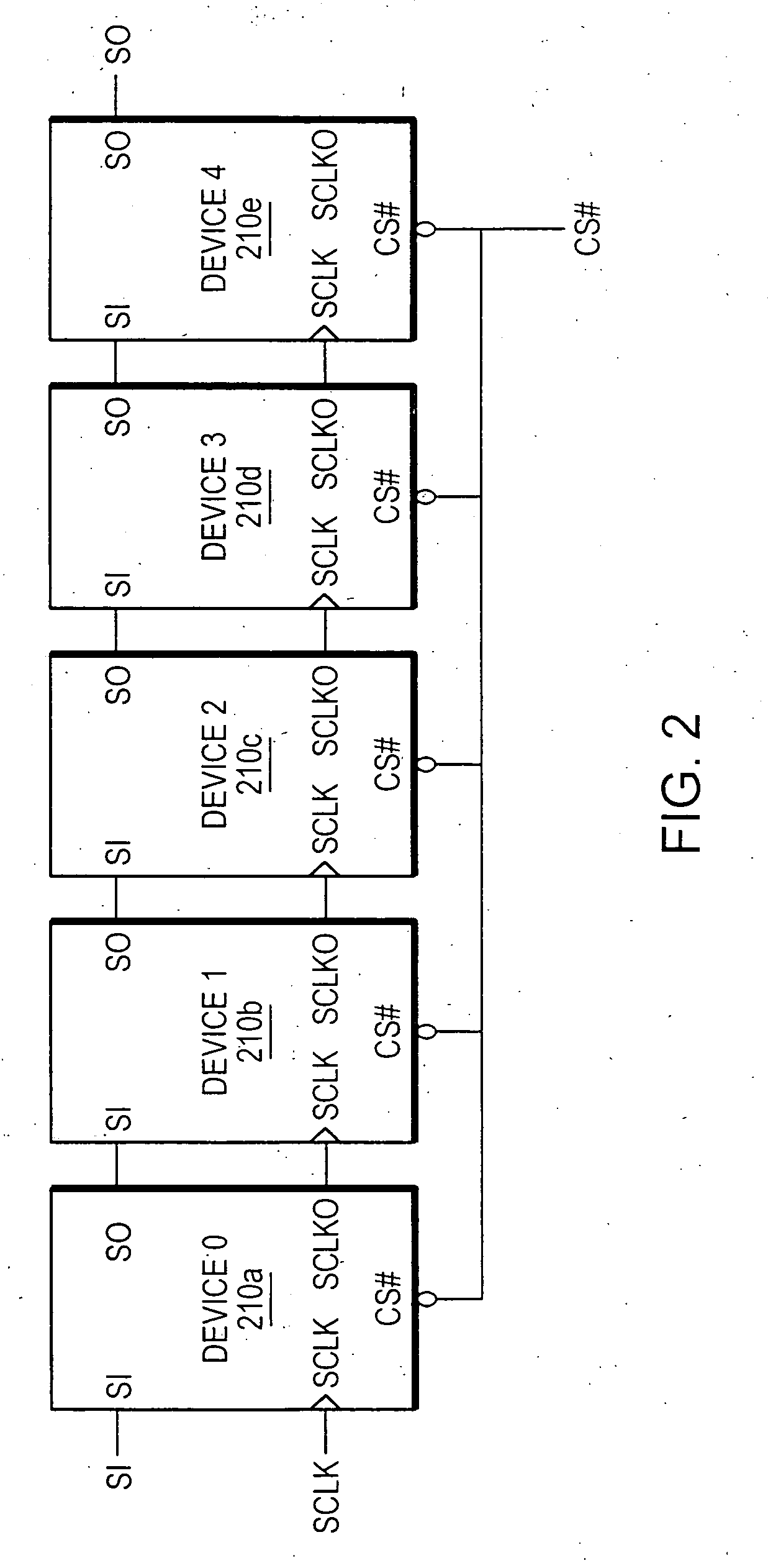

Daisy chain cascading devices

ActiveUS20070109833A1Few and short connectionIncrease speedRead-only memoriesDigital storageComputer hardwareControl signal

A technique for serially coupling devices in a daisy chain cascading arrangement. Devices are coupled in a daisy chain cascade arrangement such that outputs of a first device are coupled to inputs of a second device later in the daisy chain to accommodate the transfer of information, such as data, address and command information, and control signals to the second device from the first device. The devices coupled in the daisy chain comprise a serial input (SI) and a serial output (SO). Information is input to a device via the SI. The information is output from the device via the SO. The SO of an earlier device in the daisy chain cascade is coupled to the SI of a device later in the daisy chain cascade. Information input to the earlier device via the device's SI is passed through the device and output from the device via the device's SO. The information is then transferred to the later device's SI via the connection from the earlier device's SO and the later device's SI.

Owner:MOSAID TECH

Transverse cavity device and method

InactiveUS20050182412A1Strong interferenceSmall footprintEndoscopic cutting instrumentsOsteosynthesis devicesSurgical deviceSurgical instrument

A surgical instrument for creating and preparing a cavity in a bony intervertebral body is provided with asymmetrical cutting structures. These asymmetrical cutting structures selectively open a cavity which has a relatively large surface area in the vertical direction. In one embodiment, the cutting structure includes a shearing element that sweeps out a cutting arc that is larger than the instrument delivery area.

Owner:JOHNSON WESLEY +4

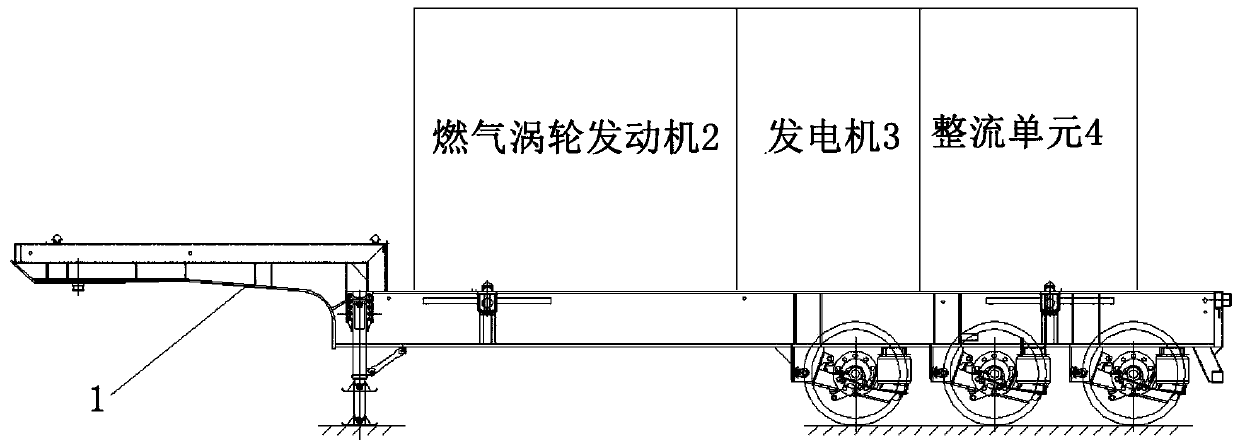

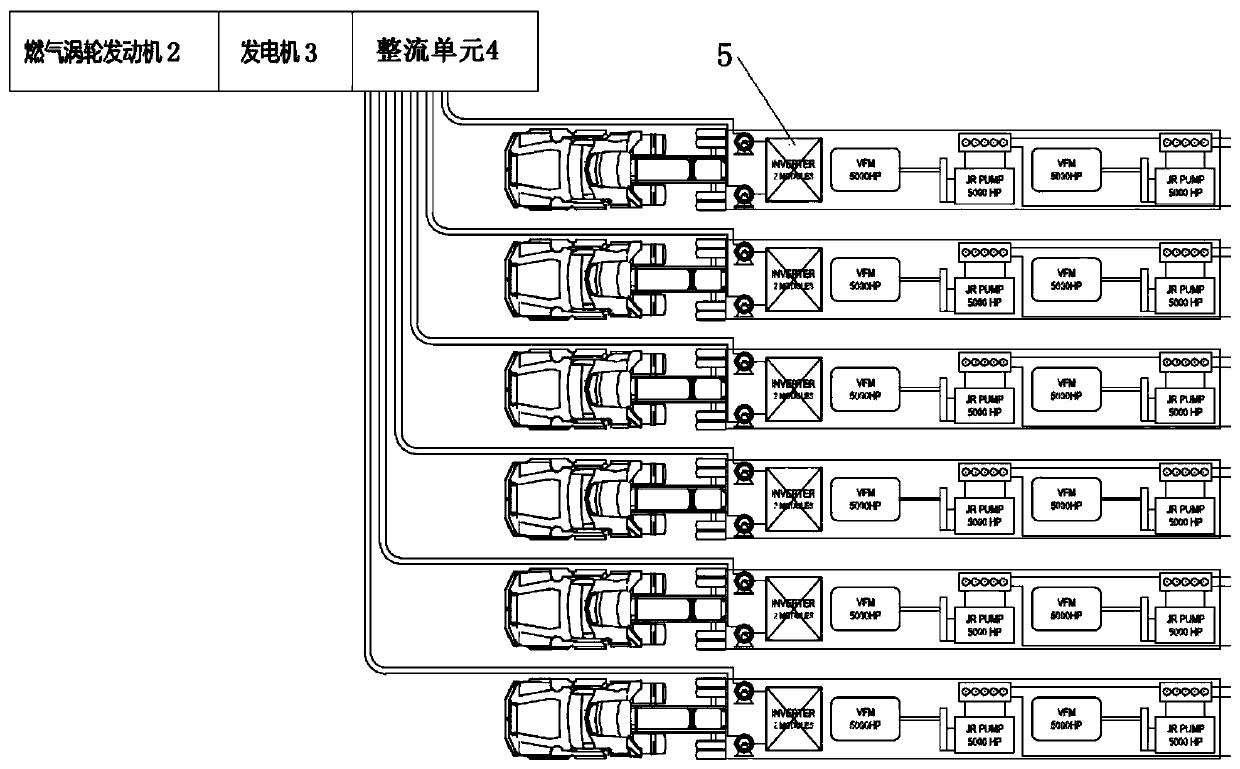

Power supply semi-trailer of electric drive fracturing equipment

PendingCN110118127AReduce wiringOptimize space layoutAssociation with control/drive circuitsGas turbine plantsElectricityTransformer

The invention discloses a power supply semi-trailer of electric drive fracturing equipment. The combination manner of a gas turbine engine, a power generator and a rectification unit is adopted, the power generator directly transmits the winding form and voltages needed by a rectification unit, conventional rectification transformer equipment is omitted, the rectification unit is connected with inversion units through common direct current buses, the common direct current buses can drive the multiple inversion units separately, and wiring of power supply circuits is reduced. The high-voltage inversion units are arranged on a gooseneck of the electric drive semi-trailer, and the space arrangement of the equipment is optimized. The whole power supply equipment is more compact in structure, small in occupied area and simple in wiring.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Embedded power management control circuit

InactiveUS20050207133A1Save spaceImprove cooling effectPrinted circuit assemblingDigital data processing detailsElectricityElectronic systems

A peripheral electronic system for an electronic device including a motherboard having multiple individual electrically connected vertically stacked modules, at least one of which is a circuit board assembly including active and / or passive electronic components embedded therein with the components being electrically connected by conductive traces to provide desired operating function. The peripheral electronic system further includes an electrical connector array on an exposed surface of the composite structure to provide electrical connections between the peripheral electronic system and the motherboard.

Owner:INTERNATIONAL RECTIFIER COEP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com