Patents

Literature

13907results about "Charge manipulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

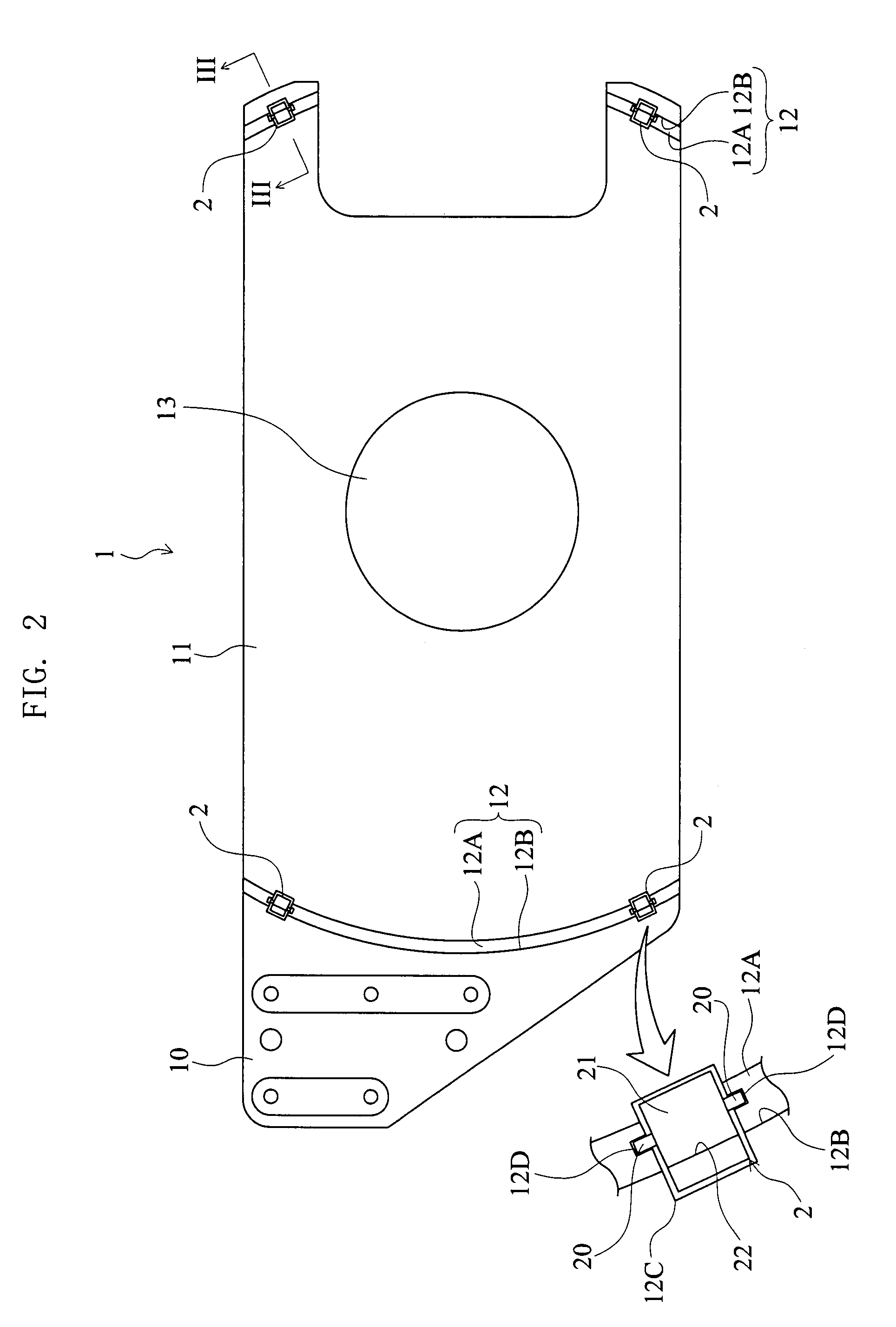

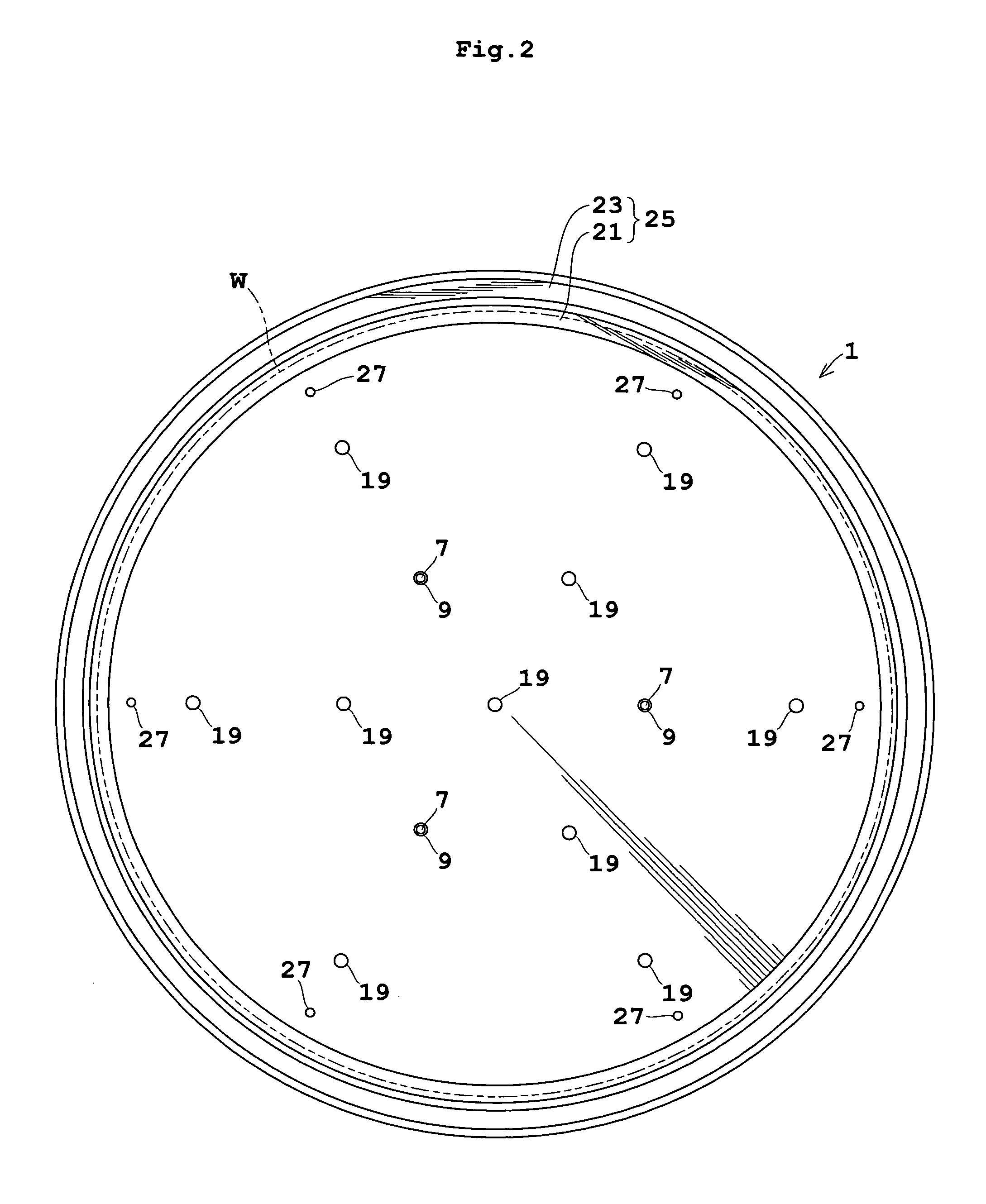

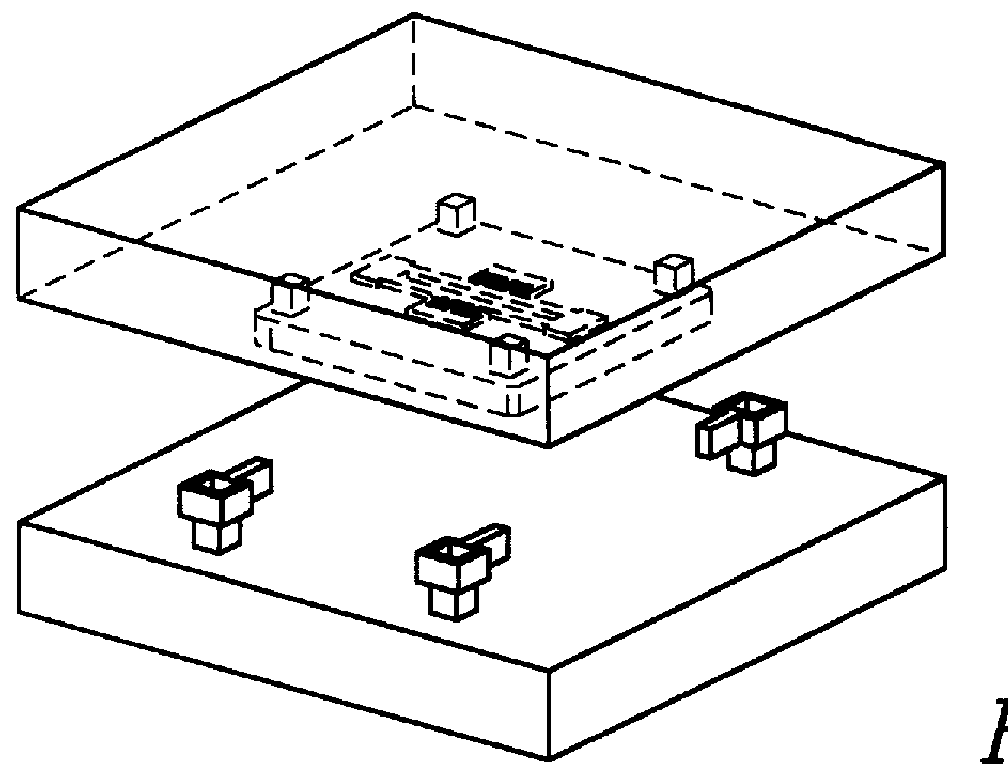

Heat treatment jig for semiconductor substrate

ActiveUS7329947B2Reduce stressSlips can be suppressed from occurringSemiconductor/solid-state device detailsCharge supportsSemiconductorSilicon

Owner:SUMITOMO MITSUBISHI SILICON CORP

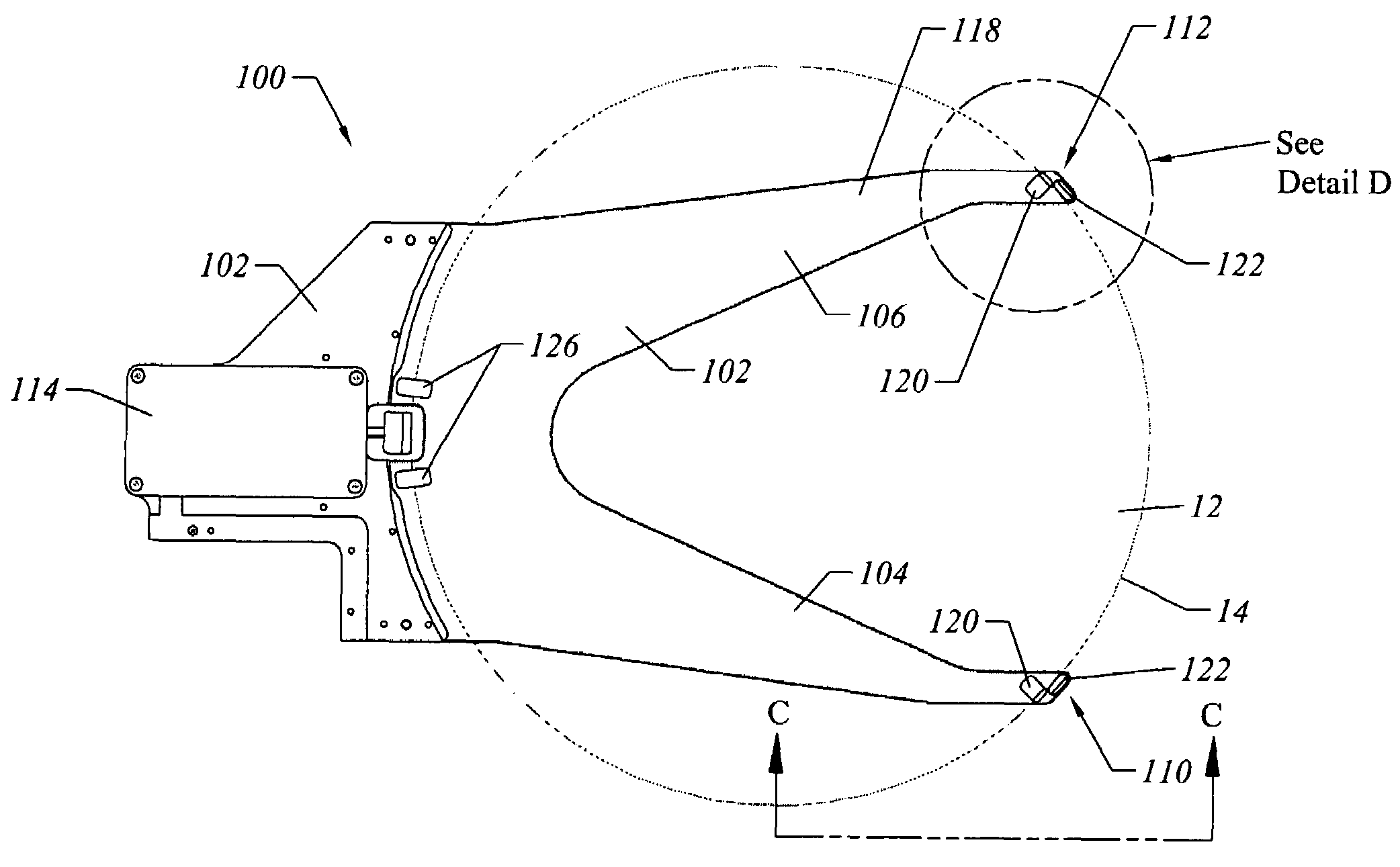

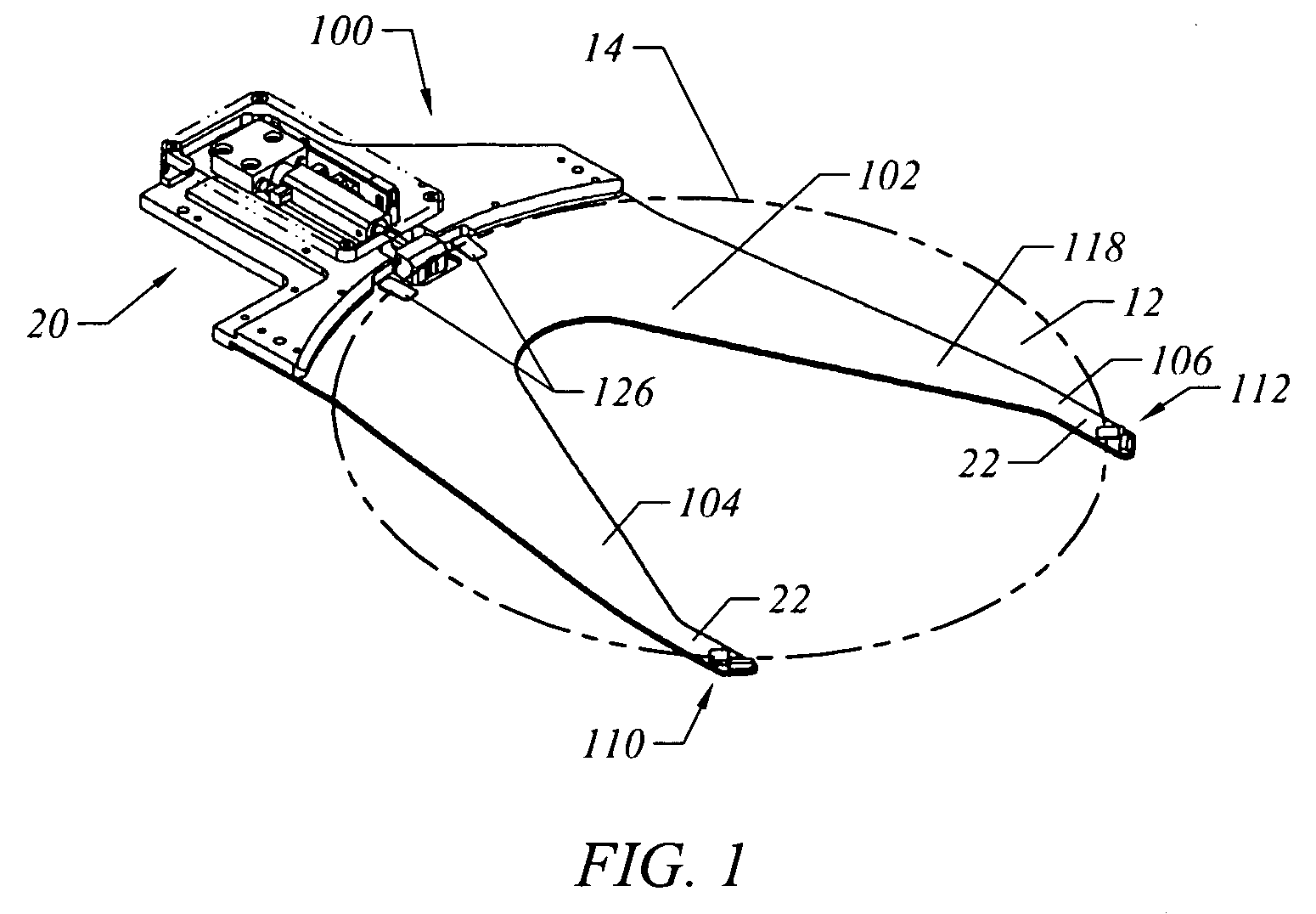

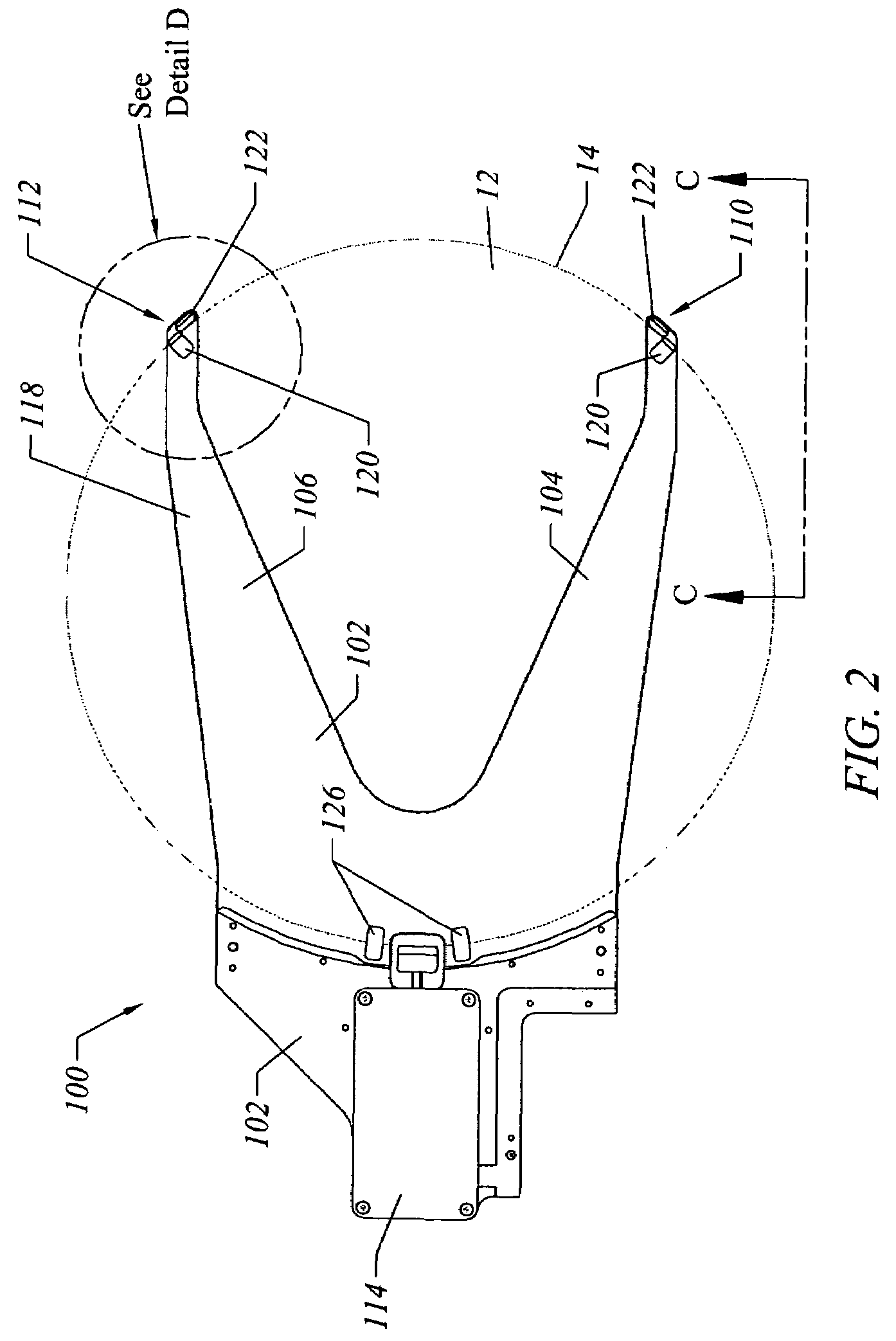

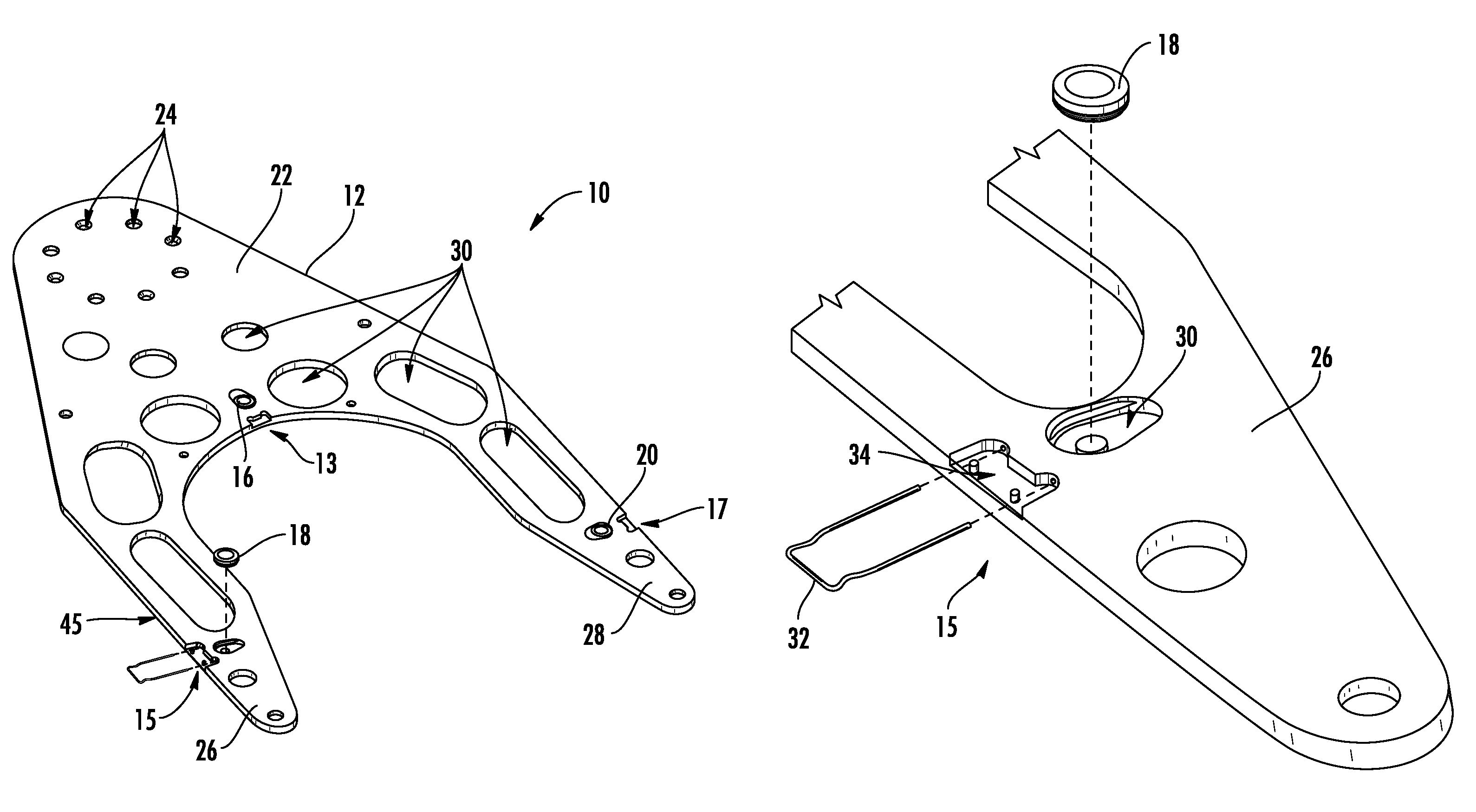

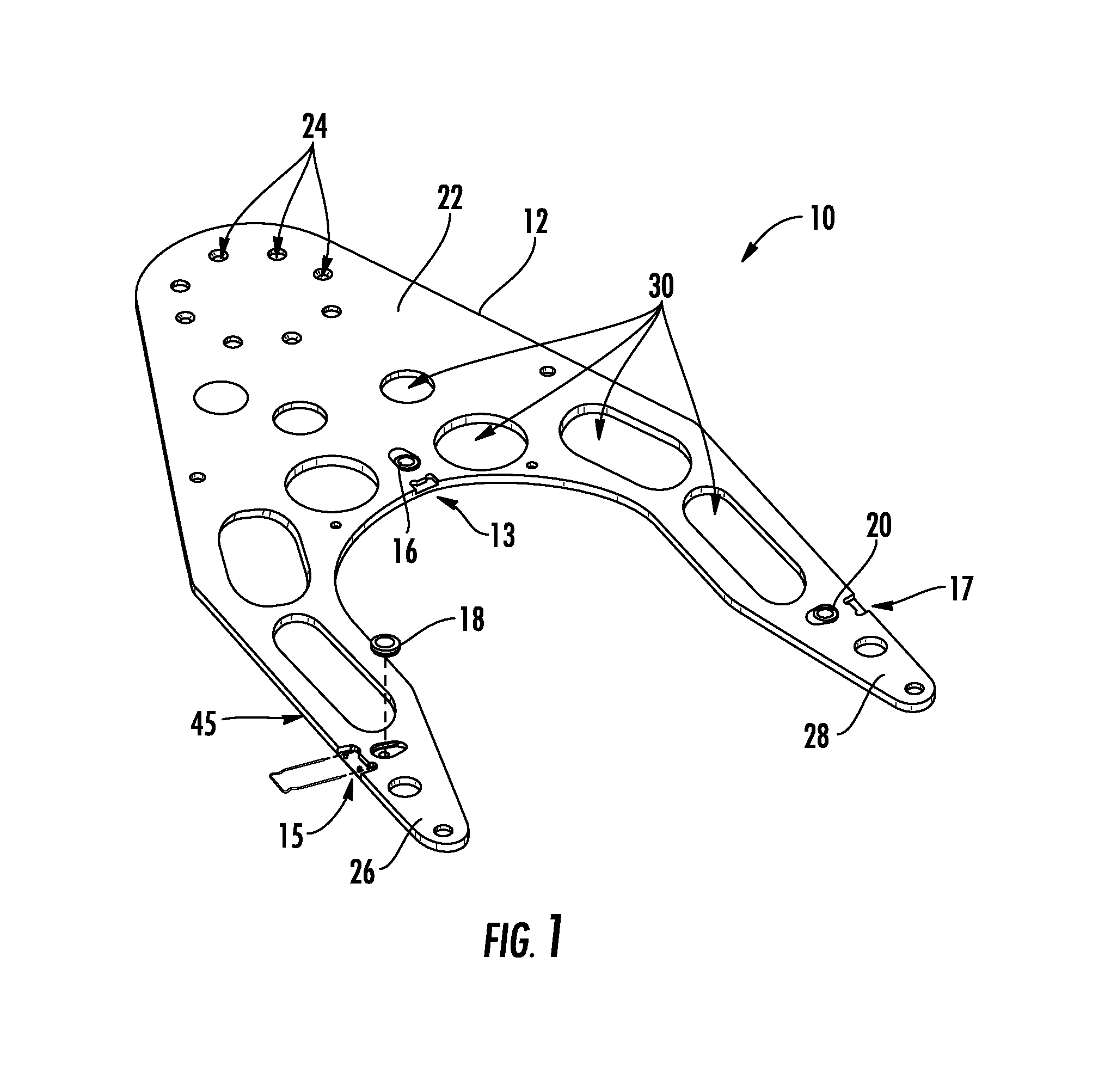

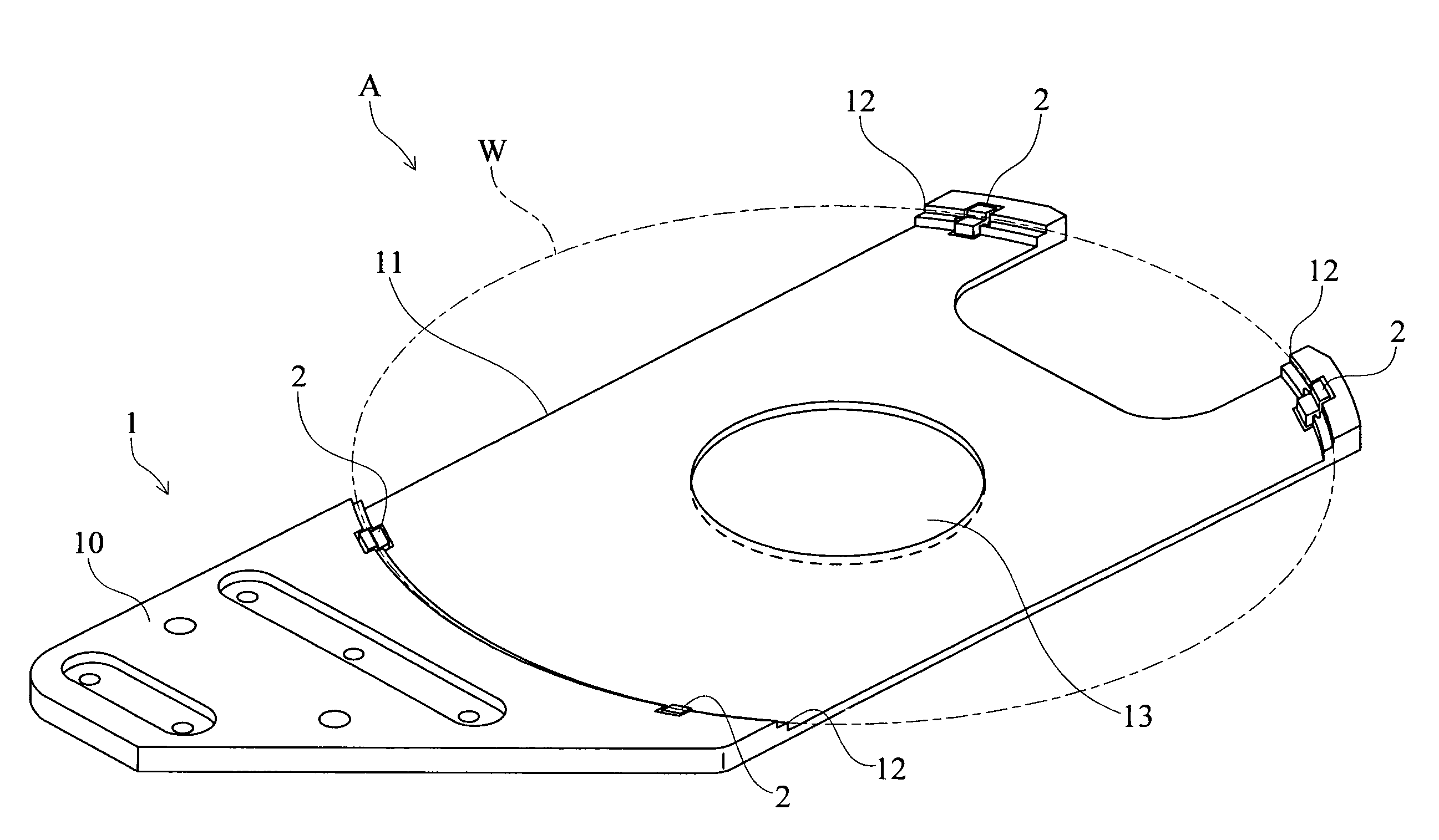

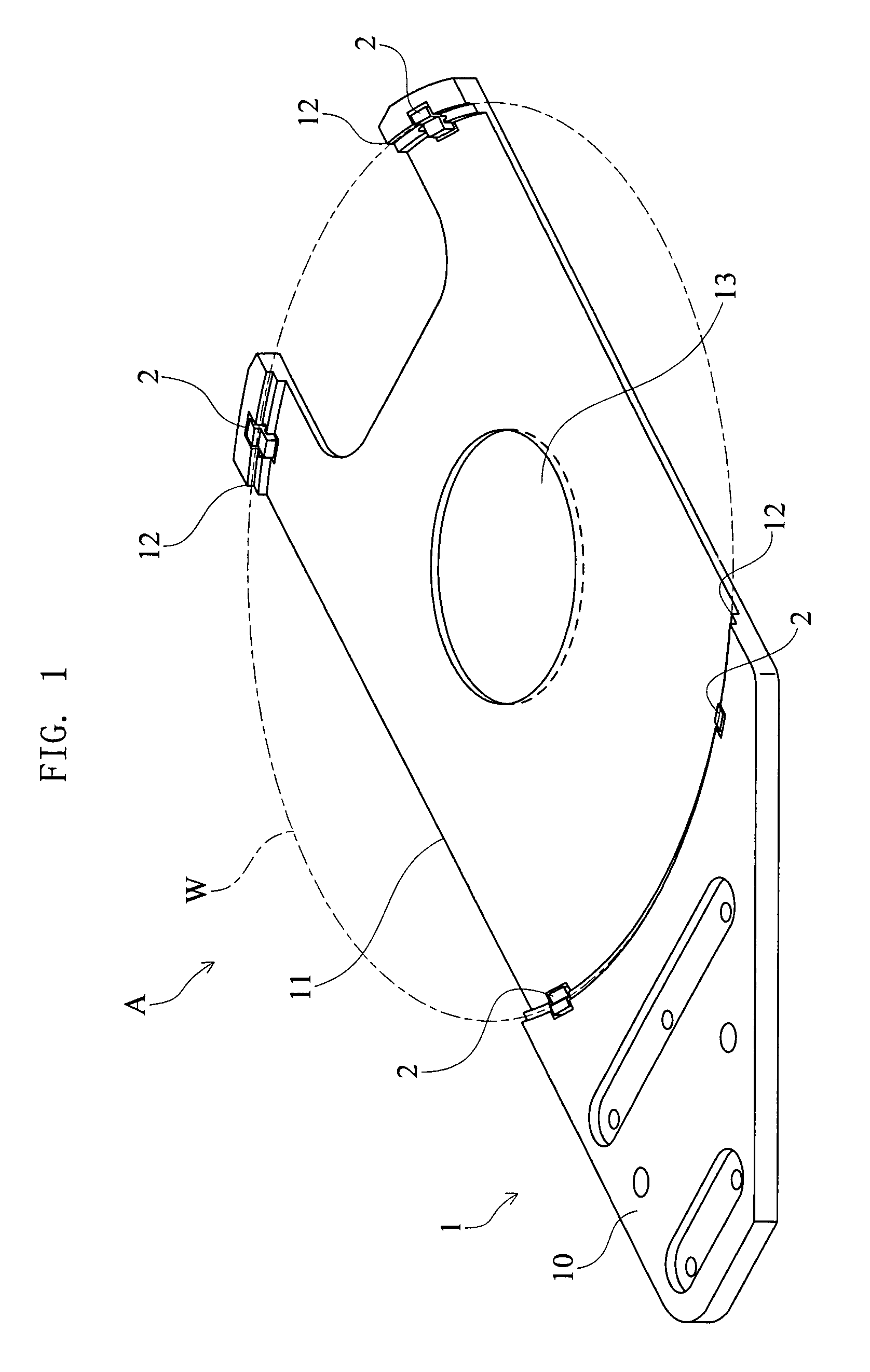

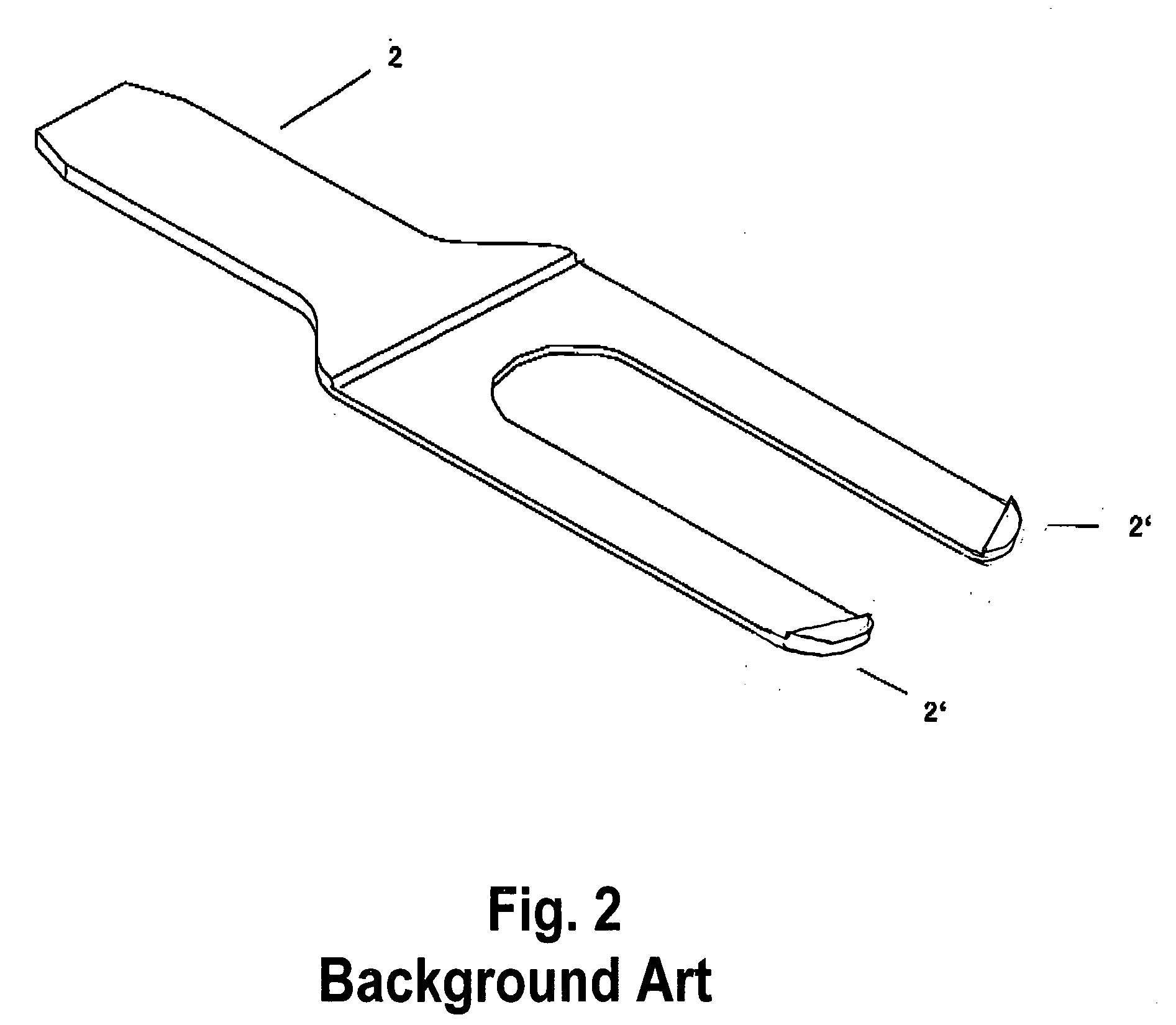

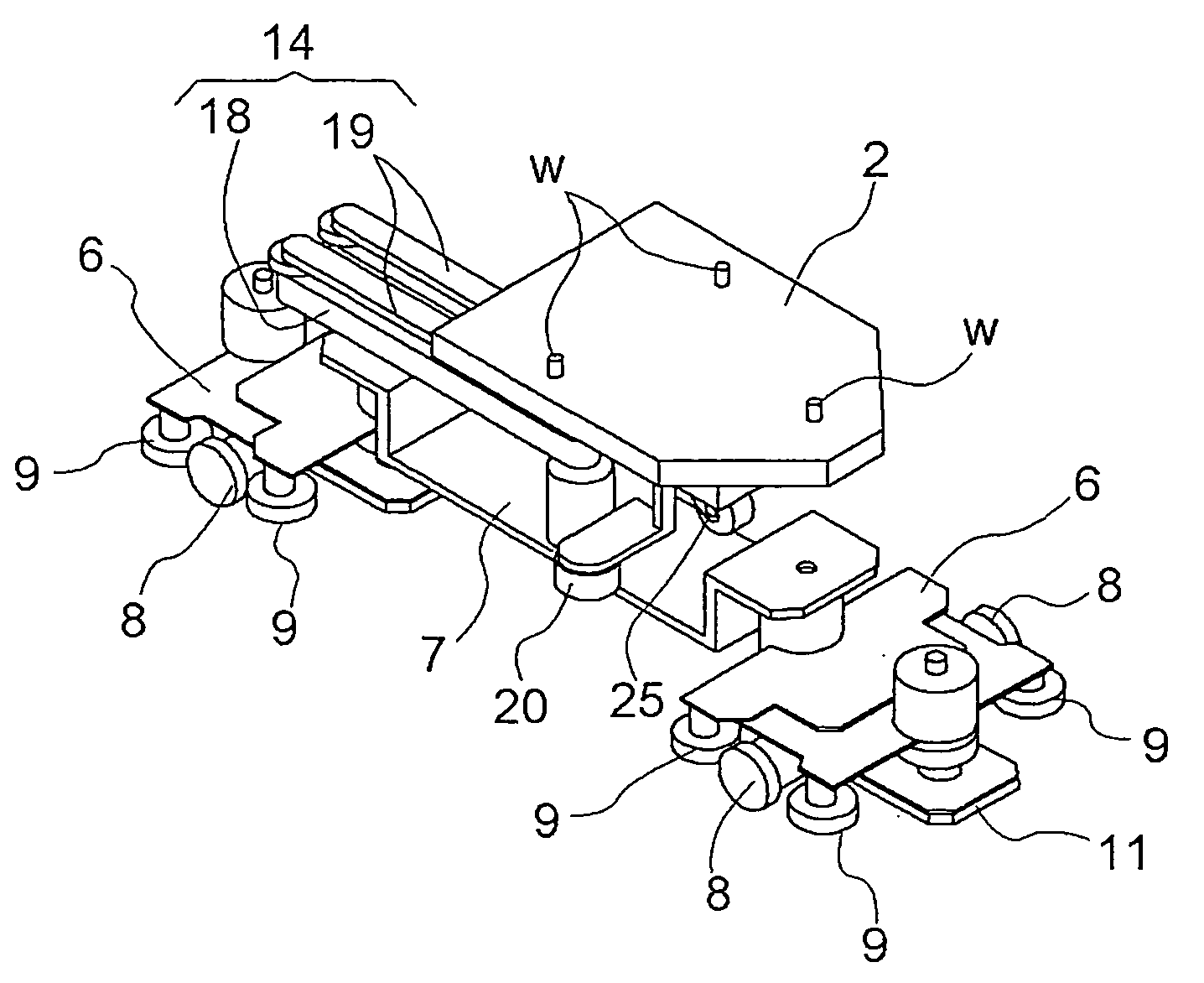

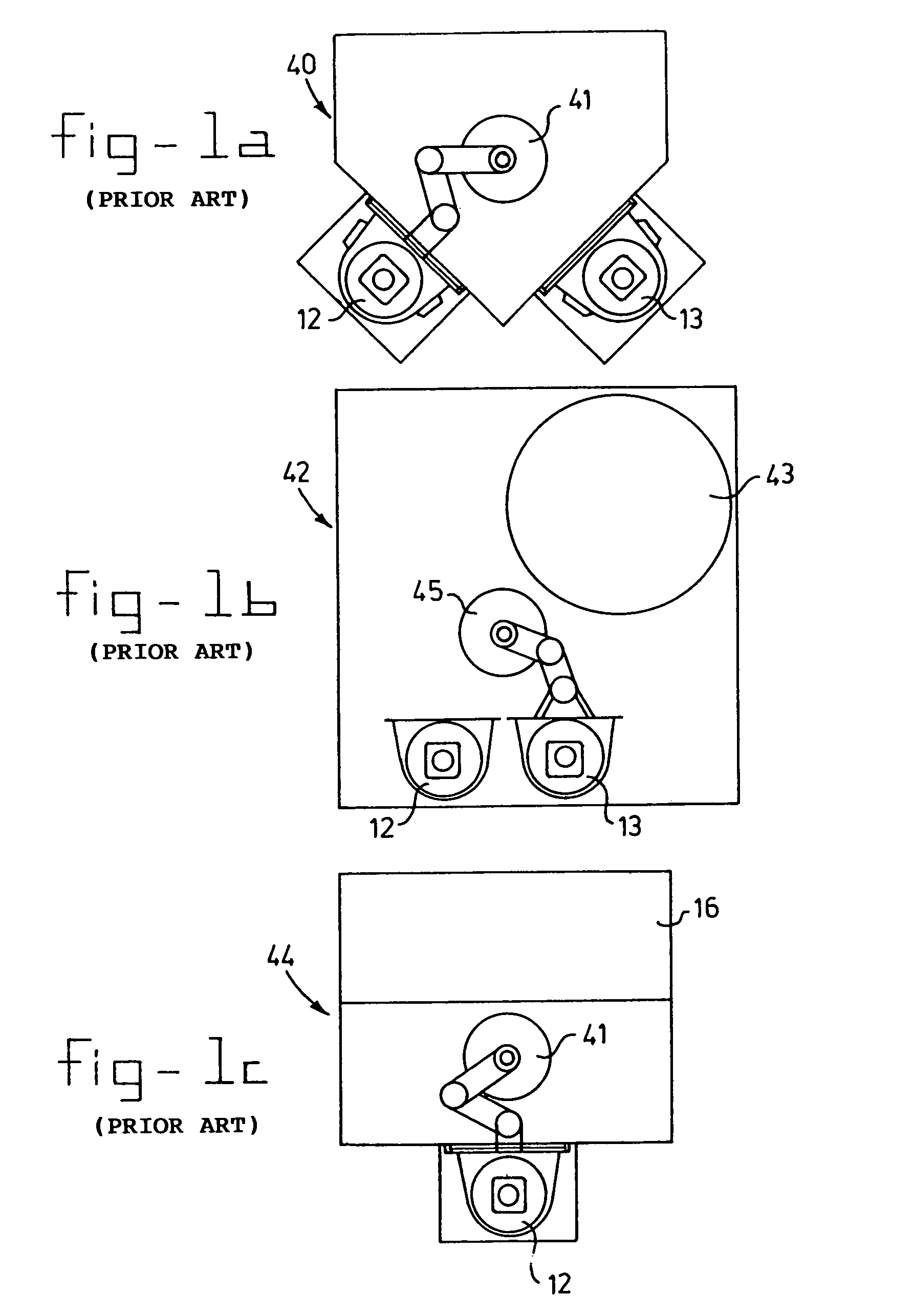

Active edge grip rest pad

ActiveUS7290813B2Precise and repeatable placementLow profileSemiconductor/solid-state device manufacturingLifting devicesActive edgeEngineering

The present invention comprises a distal rest pad for supporting a portion of a wafer seated on an end effector. In one embodiment, the rest pad includes a bottom support pad and an edge stop. Each element is mounted separately to the distal end of a support plate. The bottom support pad includes an inclined surface that transitions to a substantially horizontal surface at its distal end. The edge stop has a substantially vertical wafer contact surface that the peripheral edge of a wafer eventually contacts as the wafer is urged towards the distal rest pad. In another embodiment, the bottom support pad comprises an inclined surface. In yet another embodiment, the distal rest pad comprises a single structure. This distal rest pad includes a backstop portion and a bottom support separated by a particle collection groove. The bottom support may include an inclined lead-in surface that transitions into a flat contact surface or only comprise an inclined lead-in surface.

Owner:BOOKS AUTOMATION US LLC

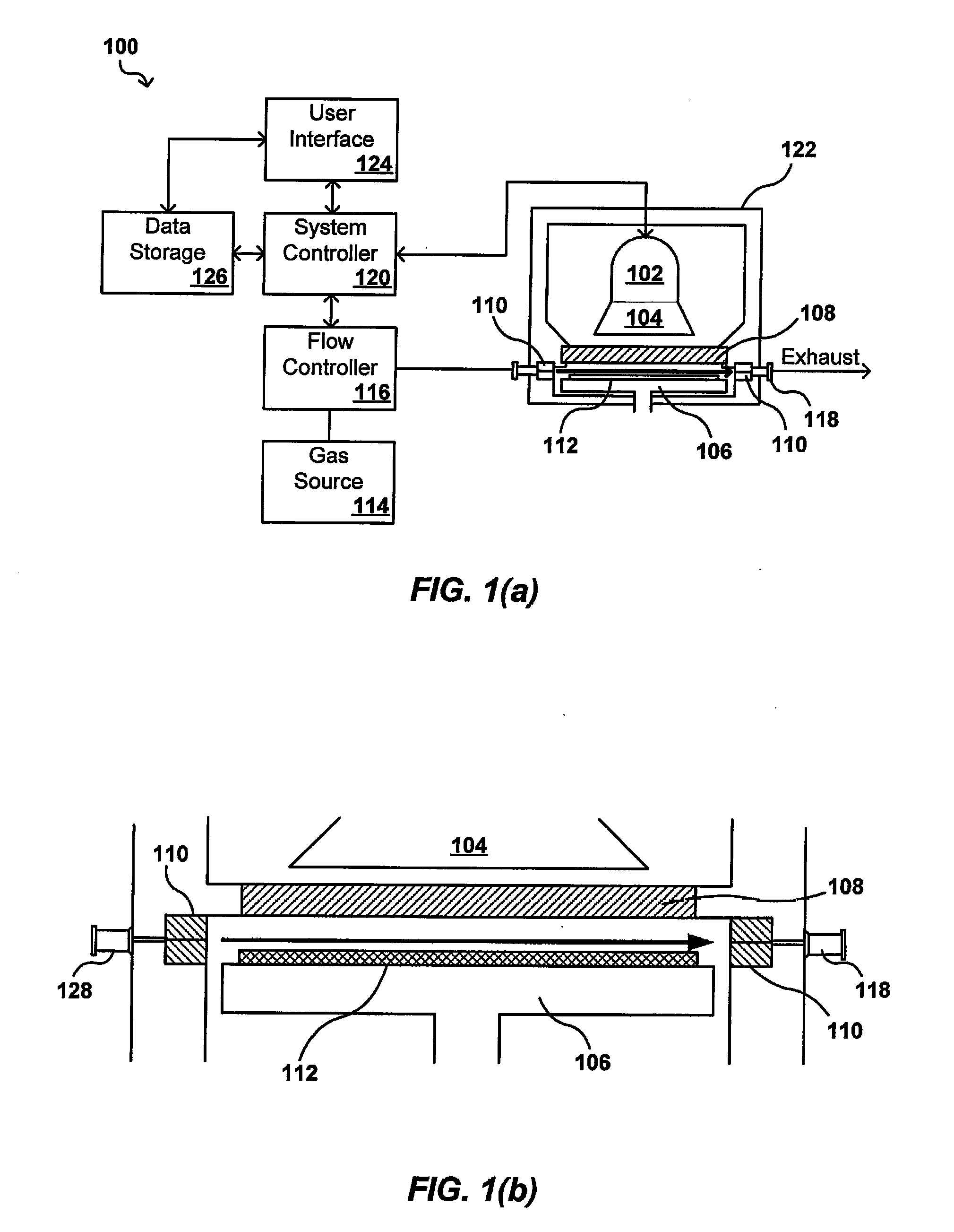

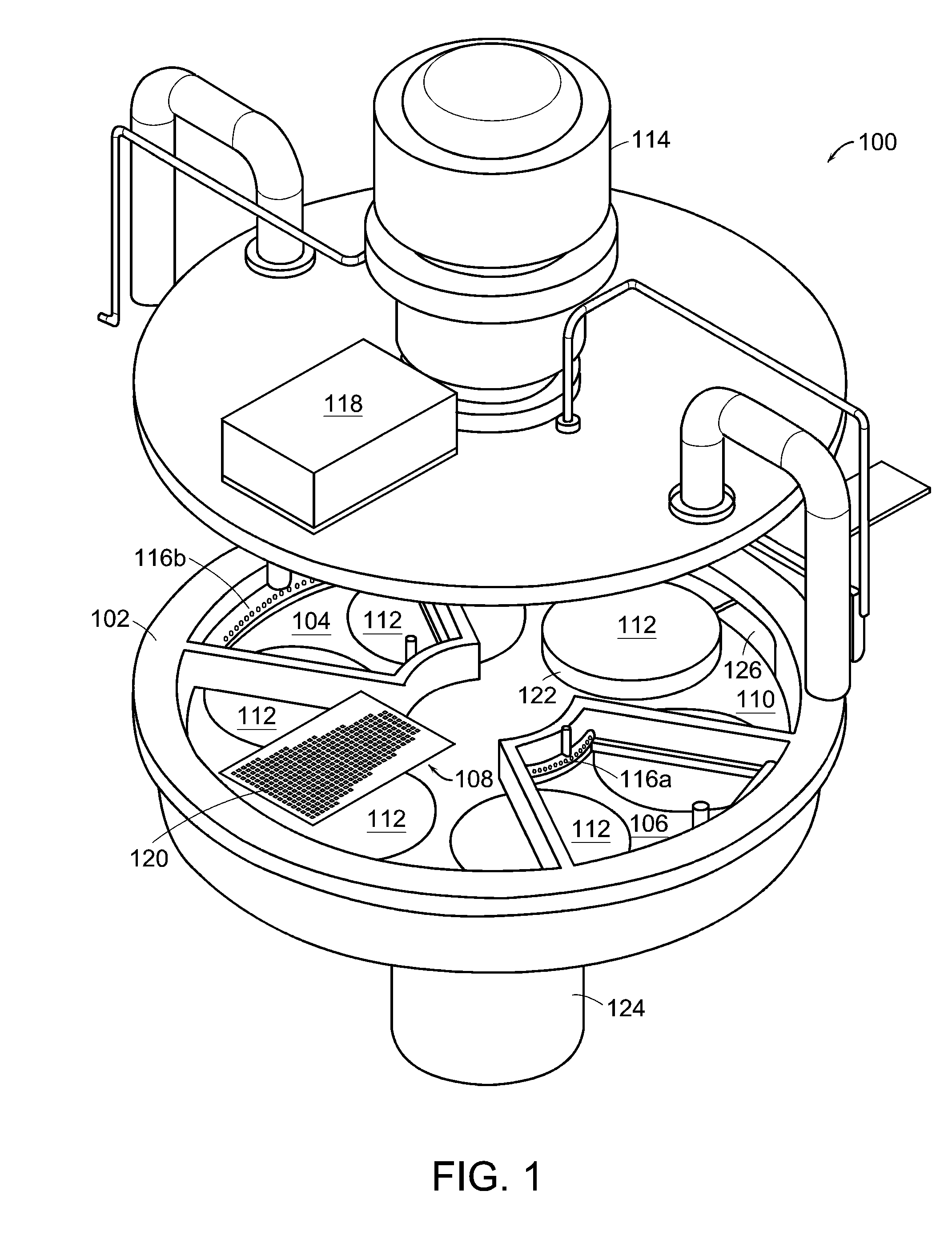

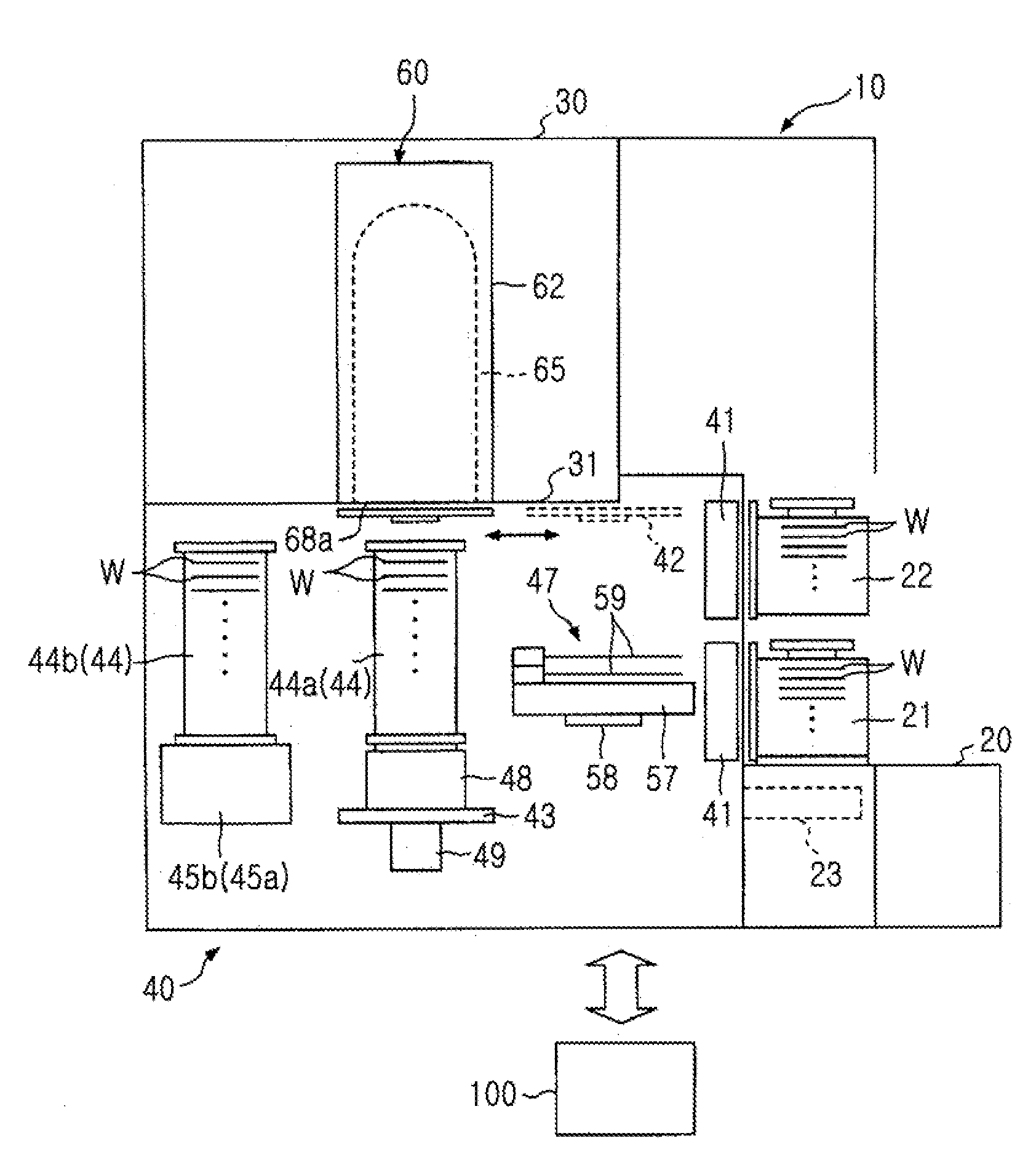

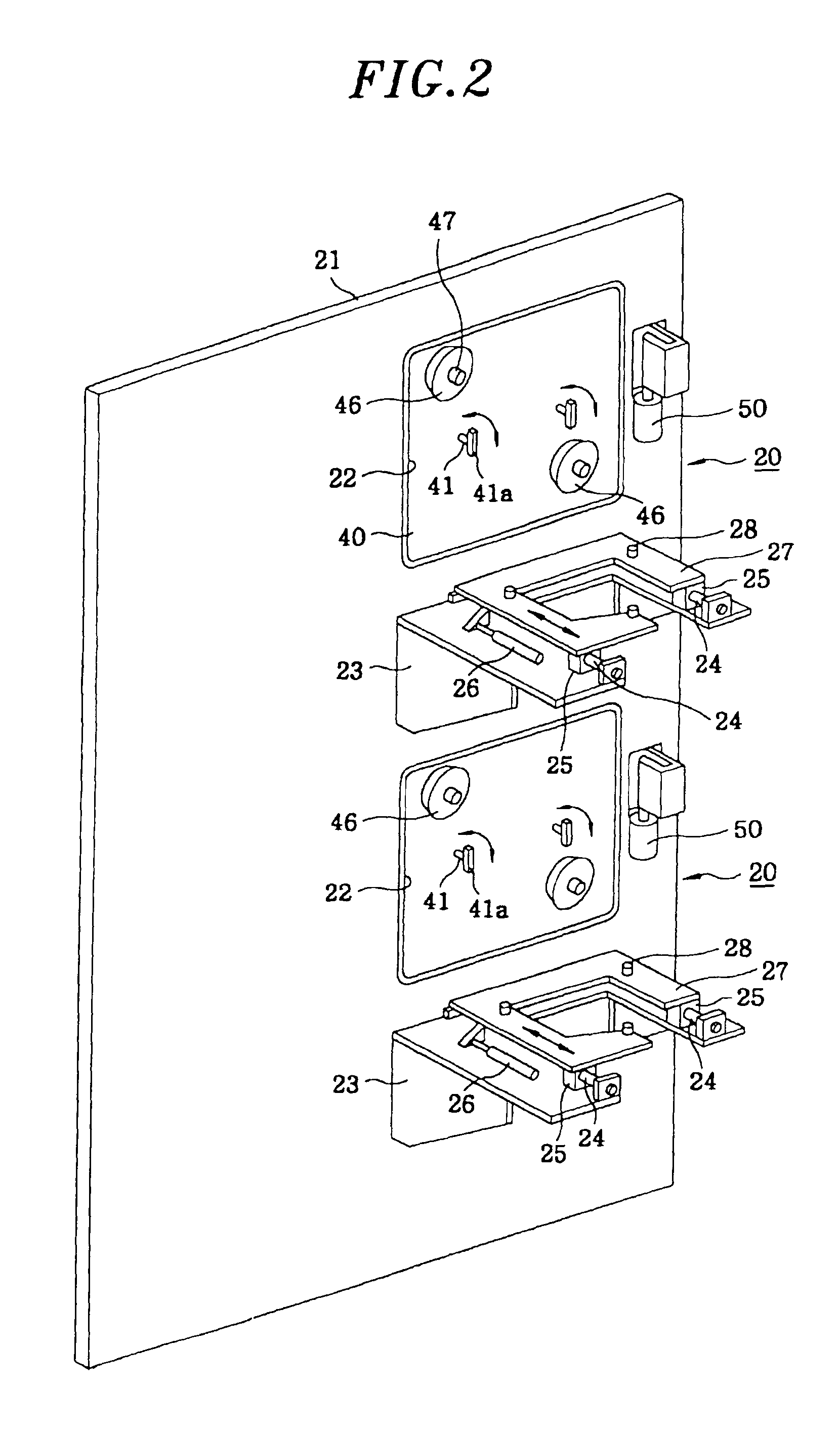

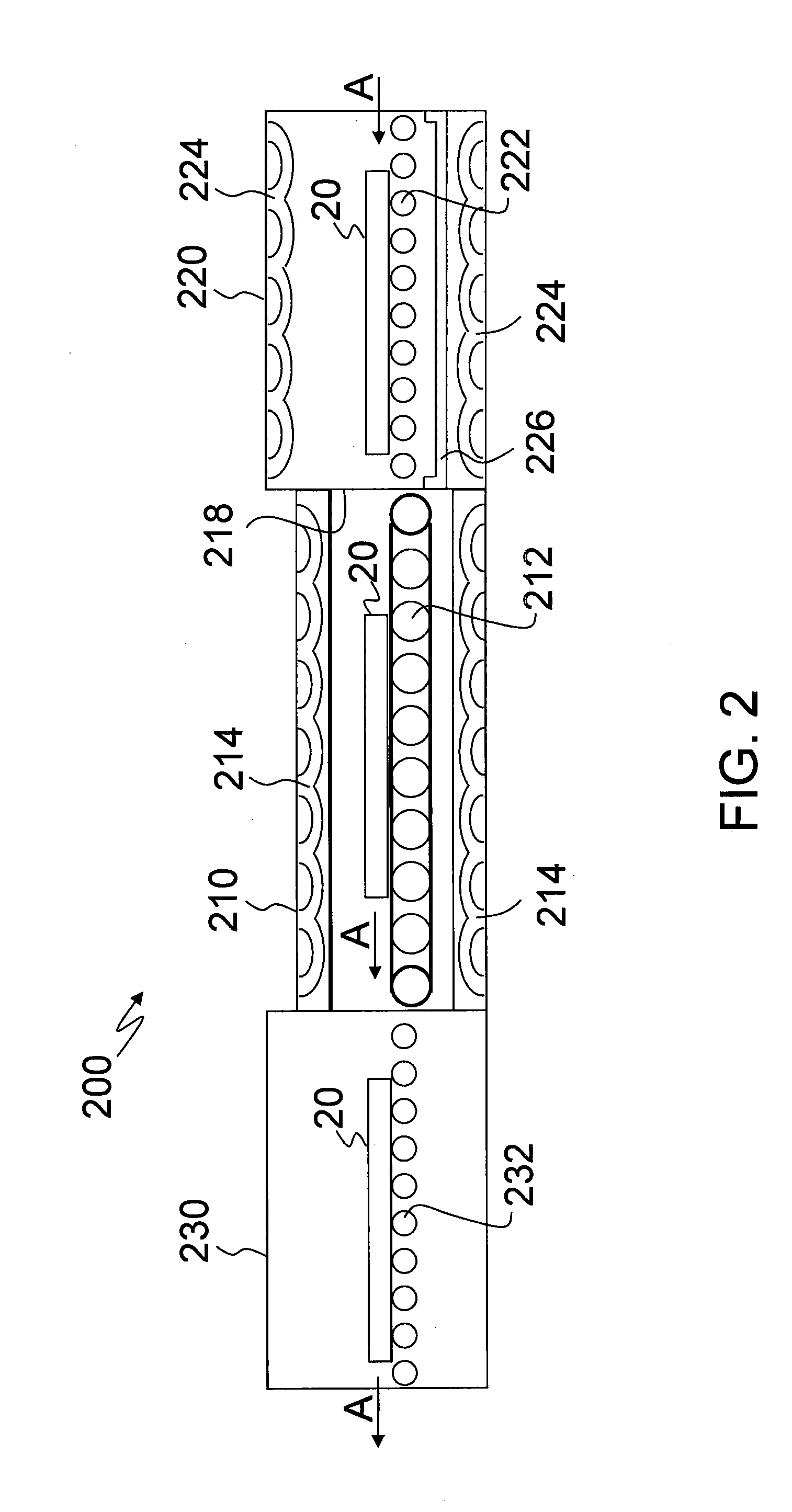

Semiconductor processing system

InactiveUS20070107845A1Easy to mergeSemiconductor/solid-state device manufacturingCharge manipulationAtmospheric pressureIntermediate structure

A semiconductor processing system includes an intermediate structure disposed between an atmospheric pressure entrance transfer chamber and a vacuum common transfer chamber. The intermediate structure includes a transfer passage for a target substrate to pass therein. The transfer passage includes a first buffer chamber a middle transfer chamber and a second buffer chamber detachably connected. An additional processing apparatus is detachably connected to the middle transfer chamber. The intermediate structure is selectively arranged in first or second state. In the first state, the additional processing apparatus performs a vacuum process, while the first buffer chamber is a load-lock chamber. In the second state, the additional processing apparatus performs an atmospheric pressure process, while the second buffer chamber is a load-lock chamber.

Owner:ISHIZAWA SHIGERU +6

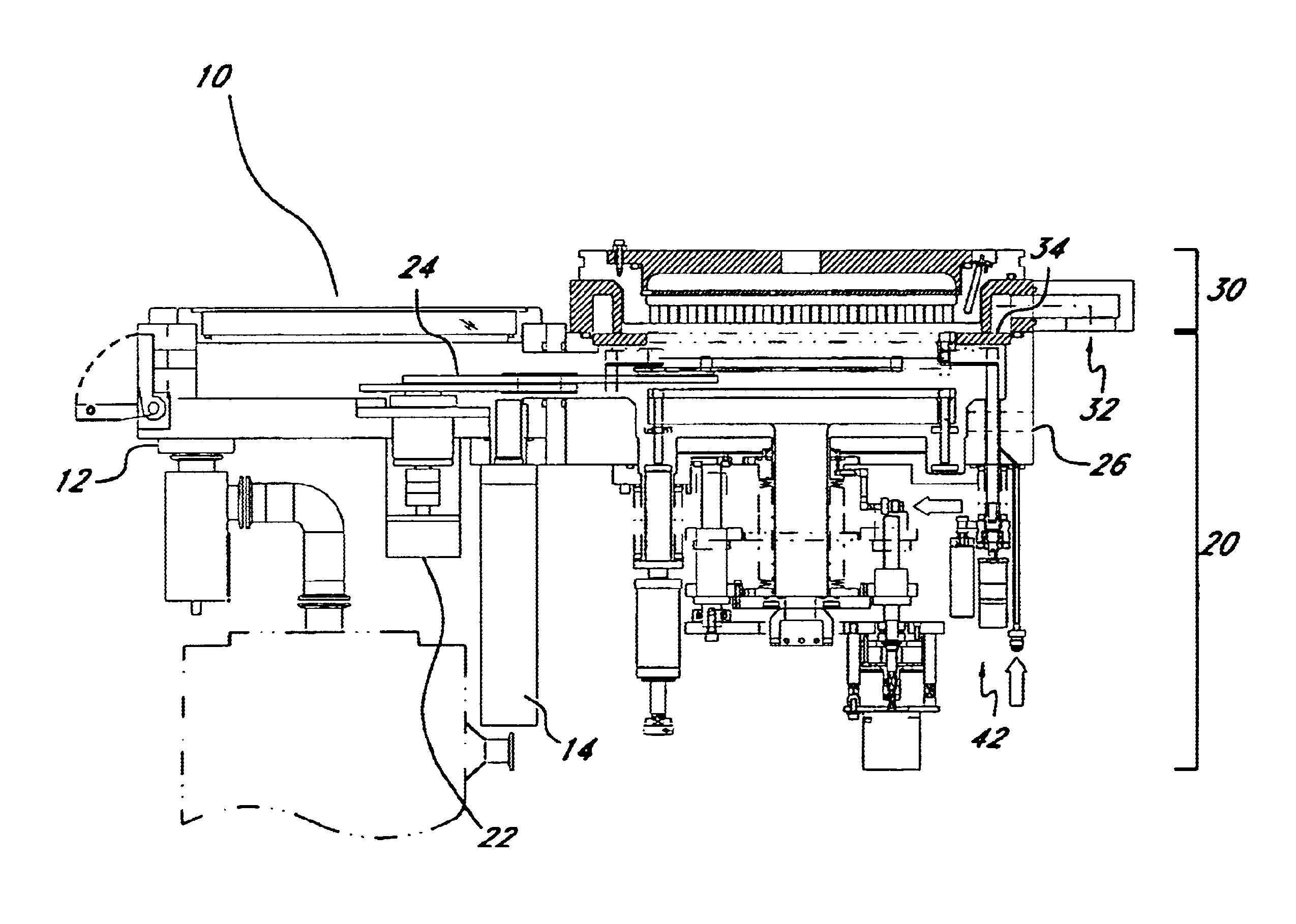

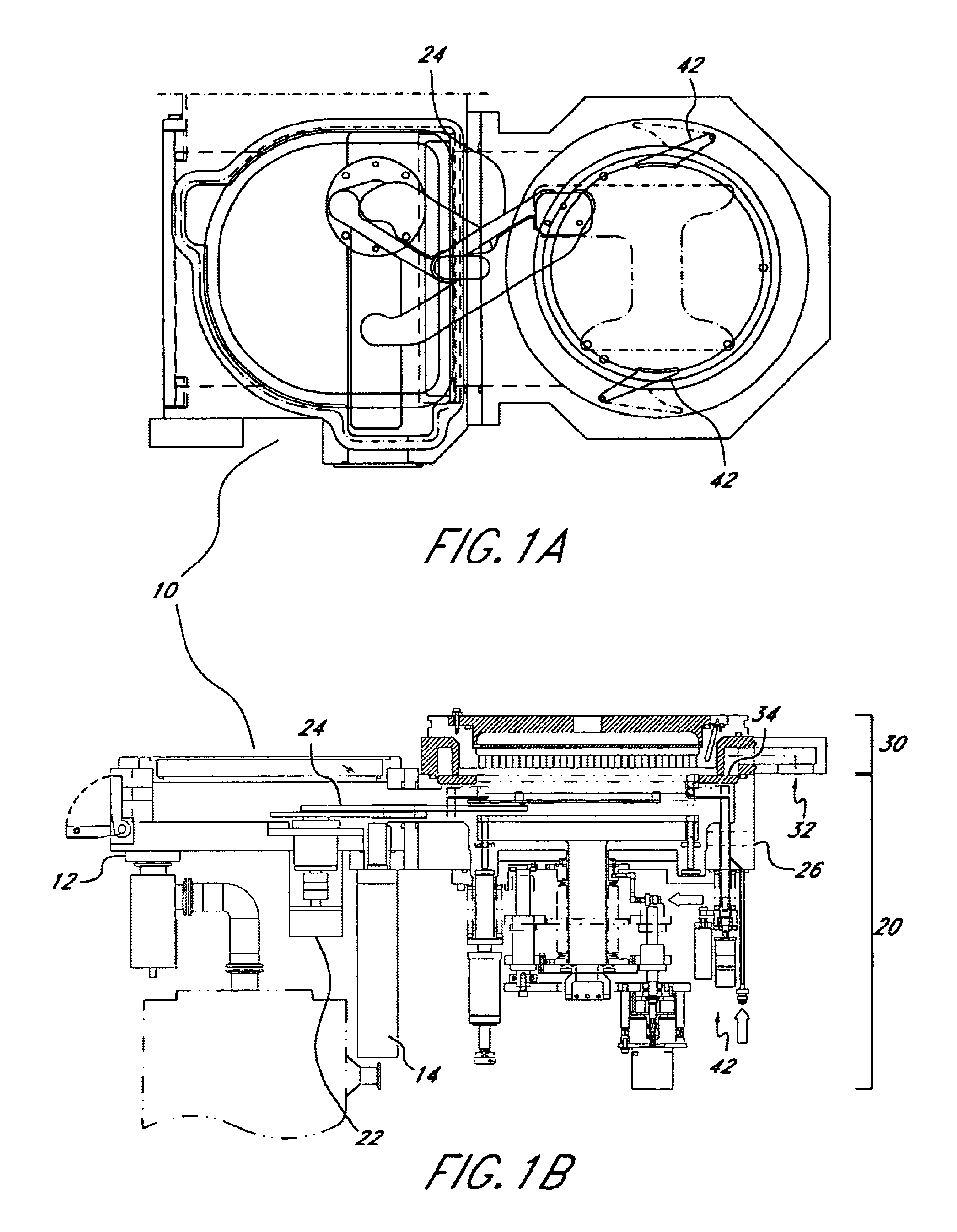

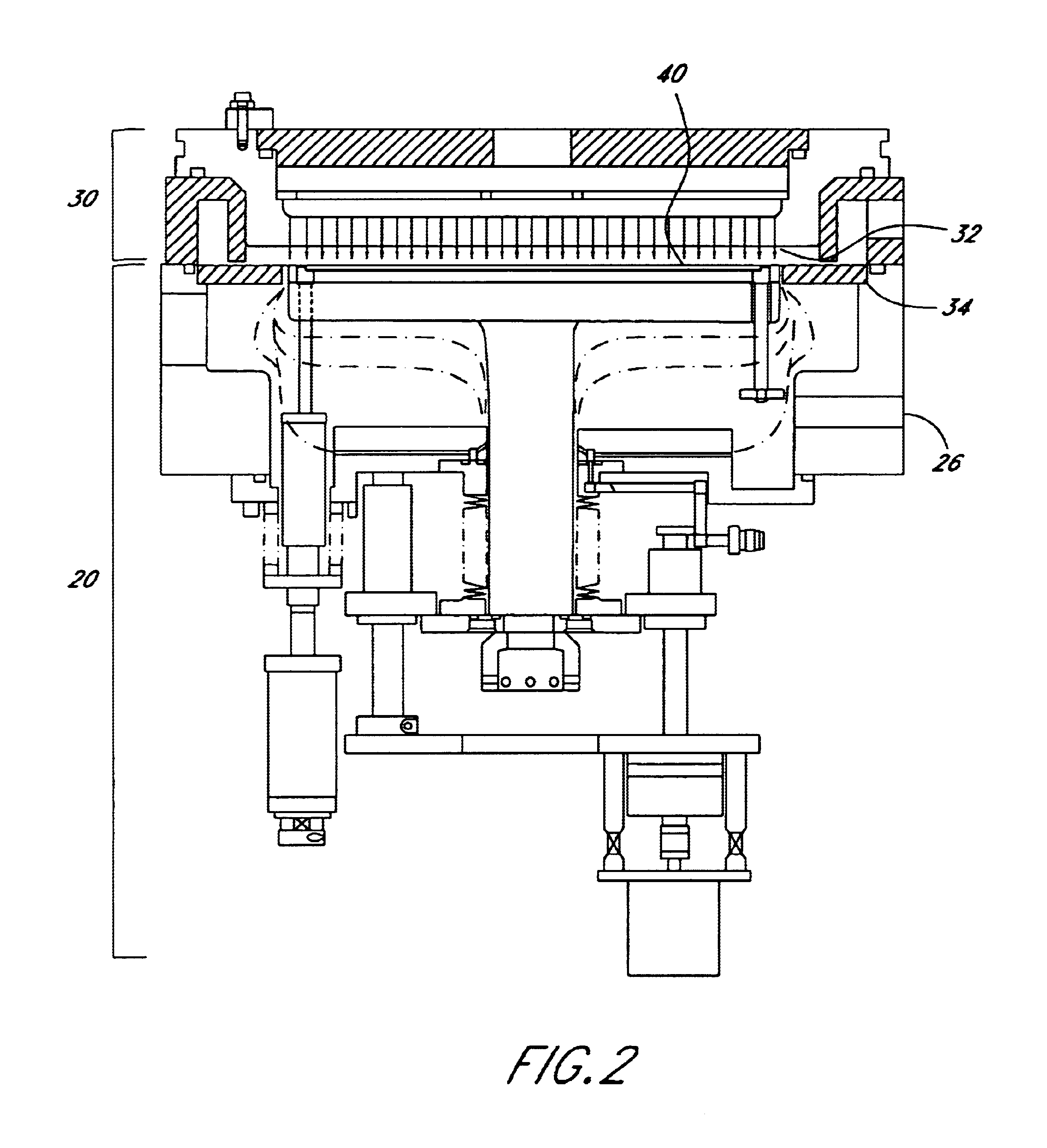

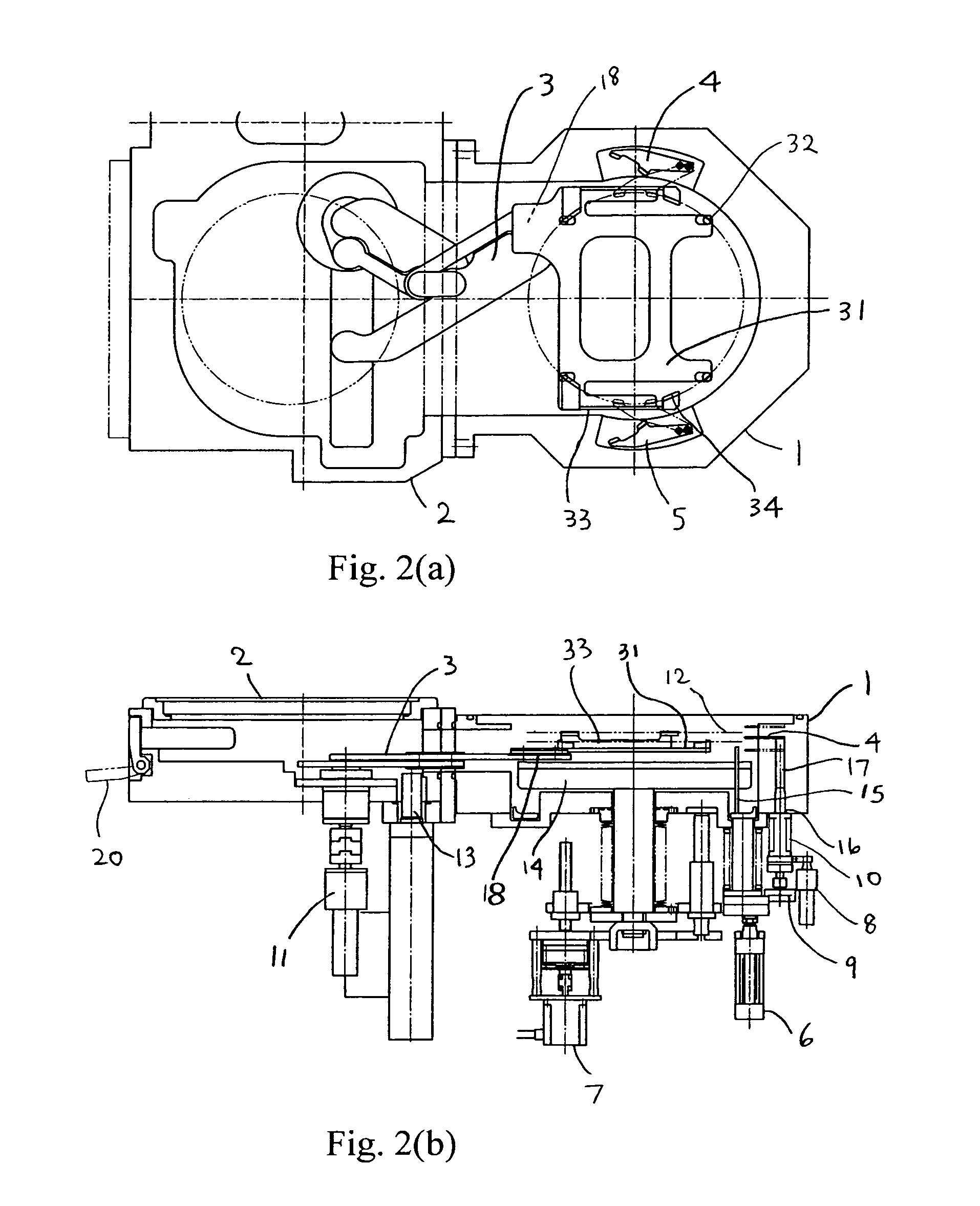

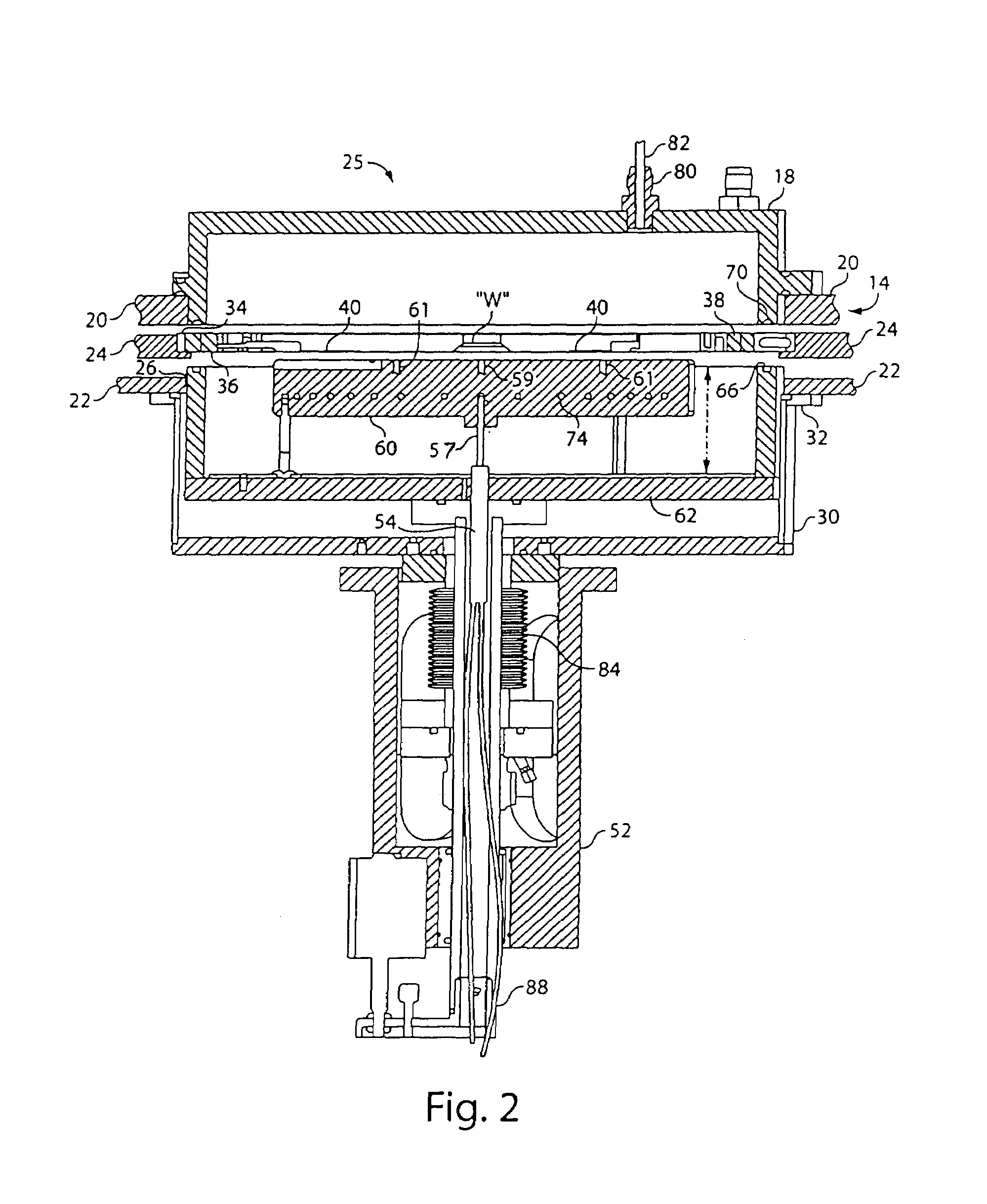

Semiconductor processing apparatus comprising chamber partitioned into reaction and transfer sections

InactiveUS6899507B2Reduce adhesionImprove efficiencySemiconductor/solid-state device manufacturingCharge manipulationEngineeringSemiconductor

Semiconductor processing equipment that has increased efficiency, throughput, and stability, as well as reduced operating cost, footprint, and faceprint is provided. Other than during deposition, the atmosphere of both the reaction chamber and the transfer chamber are evacuated using the transfer chamber exhaust port, which is located below the surface of the semiconductor wafer. This configuration prevents particles generated during wafer transfer or during deposition from adhering to the surface of the semiconductor wafer. Additionally, by introducing a purge gas into the transfer chamber during deposition, and by using an insulation separating plate 34, the atmospheres of the transfer and reaction chambers can be effectively isolated from each other, thereby preventing deposition on the walls and components of the transfer chamber. Finally, the configuration described herein permits a wafer buffer mechanism to be used with the semiconductor processing equipment, thereby further increasing throughput and efficiency.

Owner:ASM JAPAN

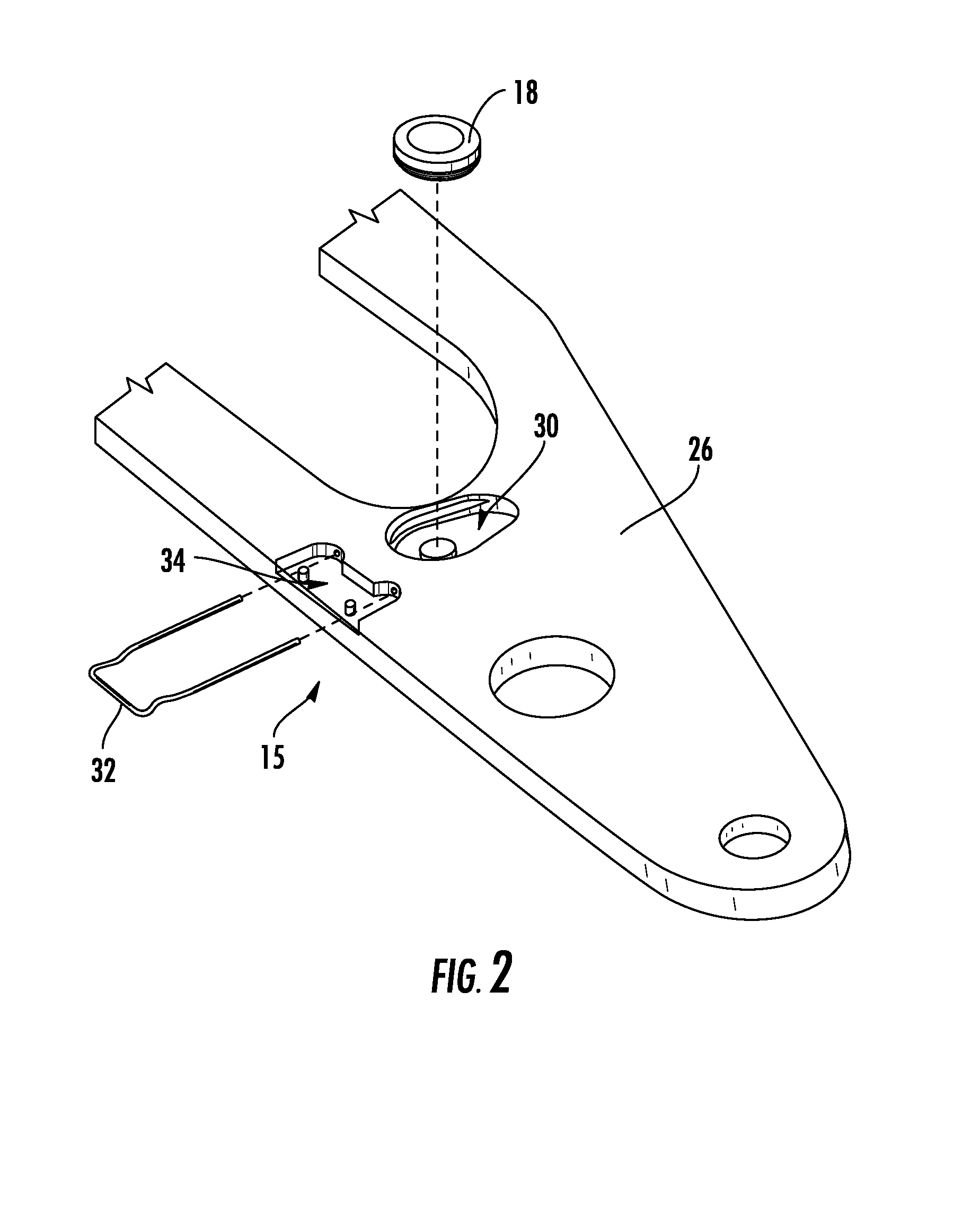

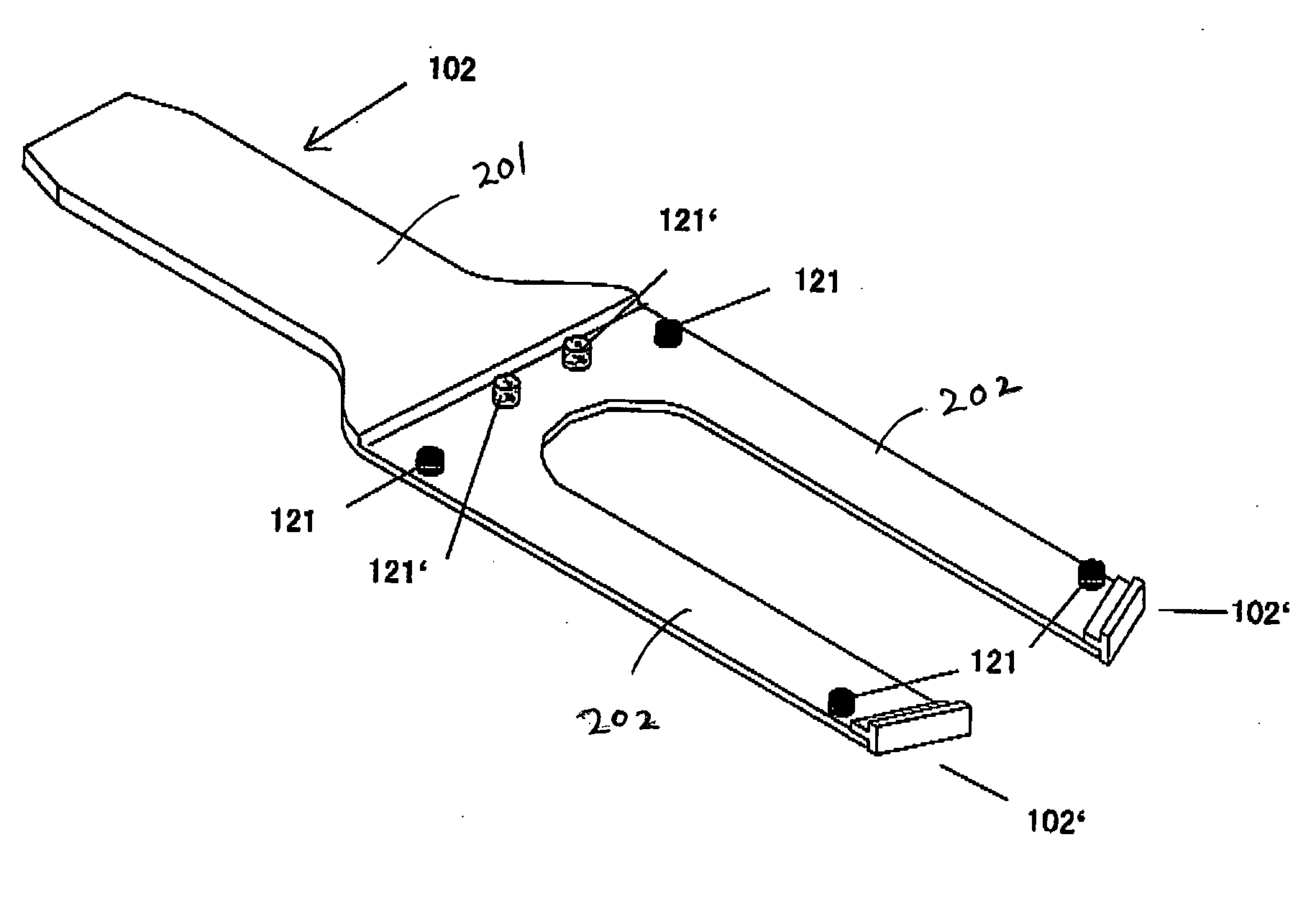

Spring retained end effector contact pad

ActiveUS8864202B1Reduce dispersionSecure attachmentGripping headsSemiconductor/solid-state device manufacturingContact padActuator

An end effector is disclosed for use in substrate processing. The end effector includes a effector body portion, a contact pad pocket formed in the end effector body, a spring retaining pocket formed in the end effector body adjacent the contact pad pocket and extending to an edge of the end effector body, and a pair of through-holes extending from the spring retaining pocket to the contact pad pocket. The end effector can include a contact pad seated within the contact pad pocket, the contact pad having at least one retaining channel formed therein, and a retaining spring having a pair of retaining arms extending from the retaining spring pocket through the through-holes and into the contact pad pocket. The retaining arms may extend at least partially into the at least one retaining channel of the contact pad and may thereby restrict movement of the contact pad.

Owner:VARIAN SEMICON EQUIP ASSOC INC

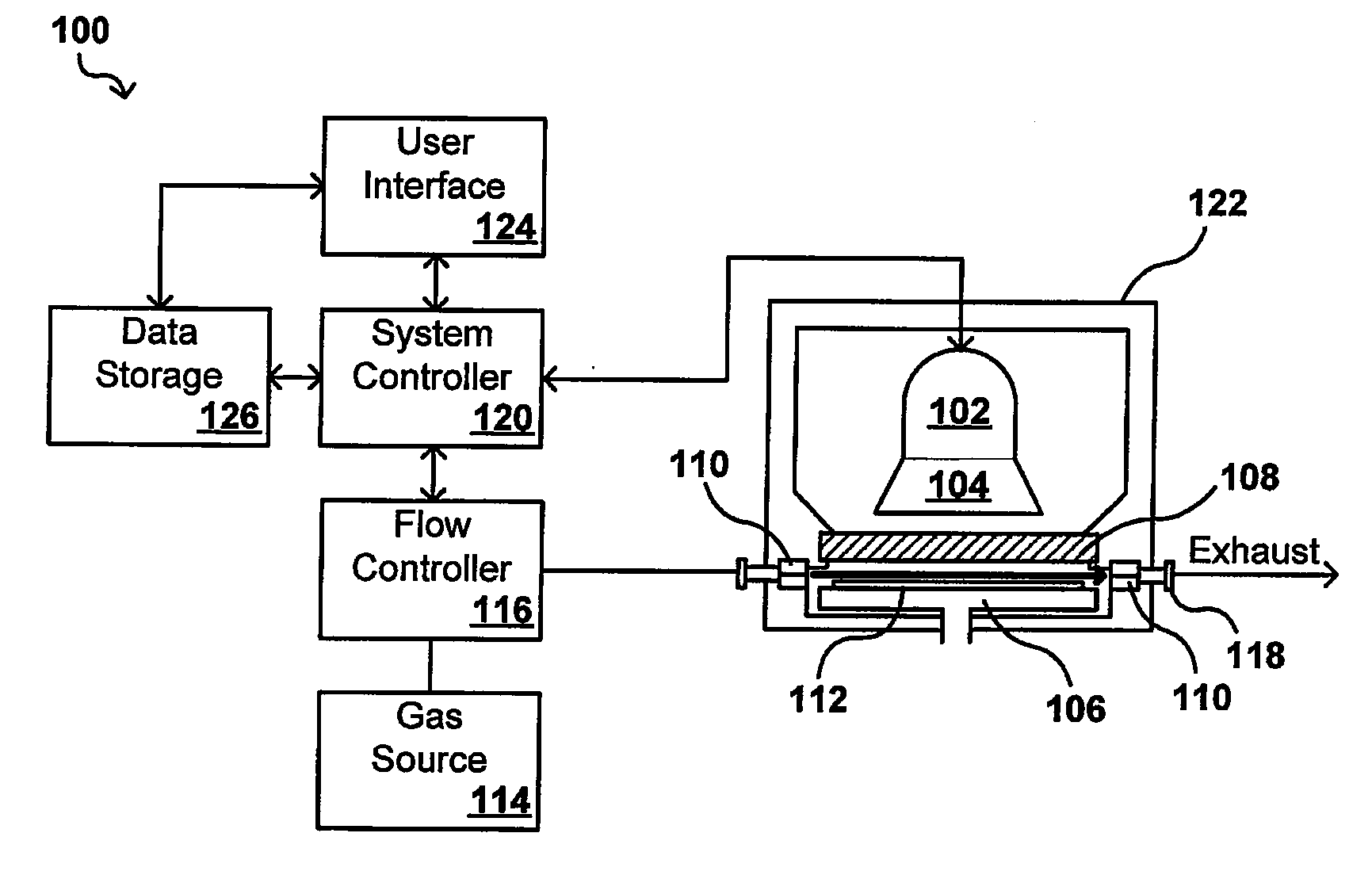

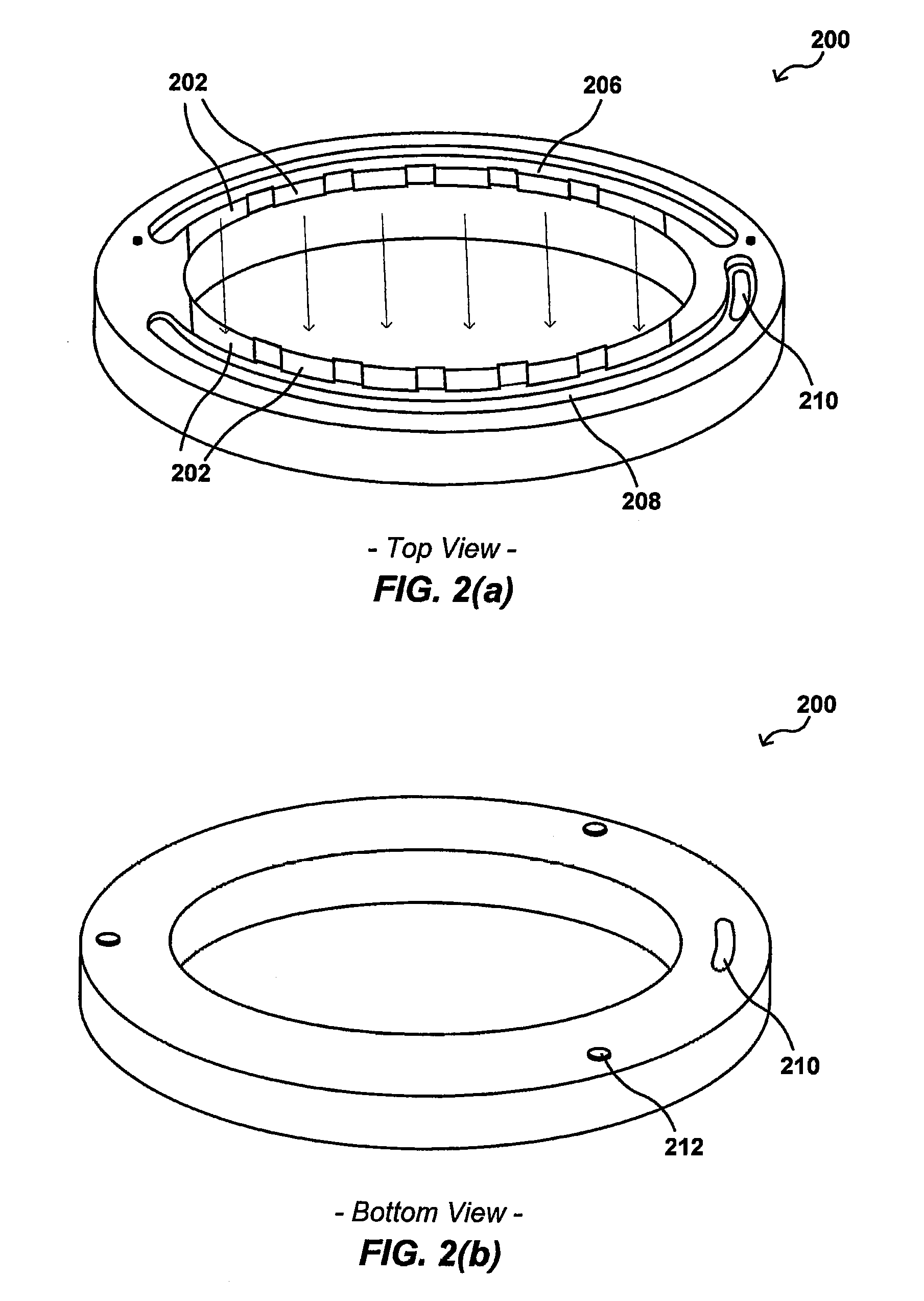

Increased tool utilization/reduction in mwbc for UV curing chamber

ActiveUS20070298362A1Avoid collectingHigh emissivitySemiconductor/solid-state device manufacturingCharge manipulationUV curingInjection port

A pump liner is used to direct a laminar flow of purge gas across a workpiece to remove contaminants or species outgassed or otherwise produced by the workpiece during processing. The pump liner can take the form of a ring having a plurality of injection ports, such as slits of a variety of shapes and / or sizes, opposite a plurality of receiving ports in order to provide the laminar flow. The flow of purge gas is sufficient to carry a contaminant or outgassed species from the processing chamber in order to prevent the collection of the contaminants on components of the chamber. The pump liner can be heated, via conduction and irradiation from a radiation source, for example, in order to prevent the condensation of species on the liner. The pump liner also can be anodized or otherwise processed in order to increase the emissivity of the liner.

Owner:APPLIED MATERIALS INC

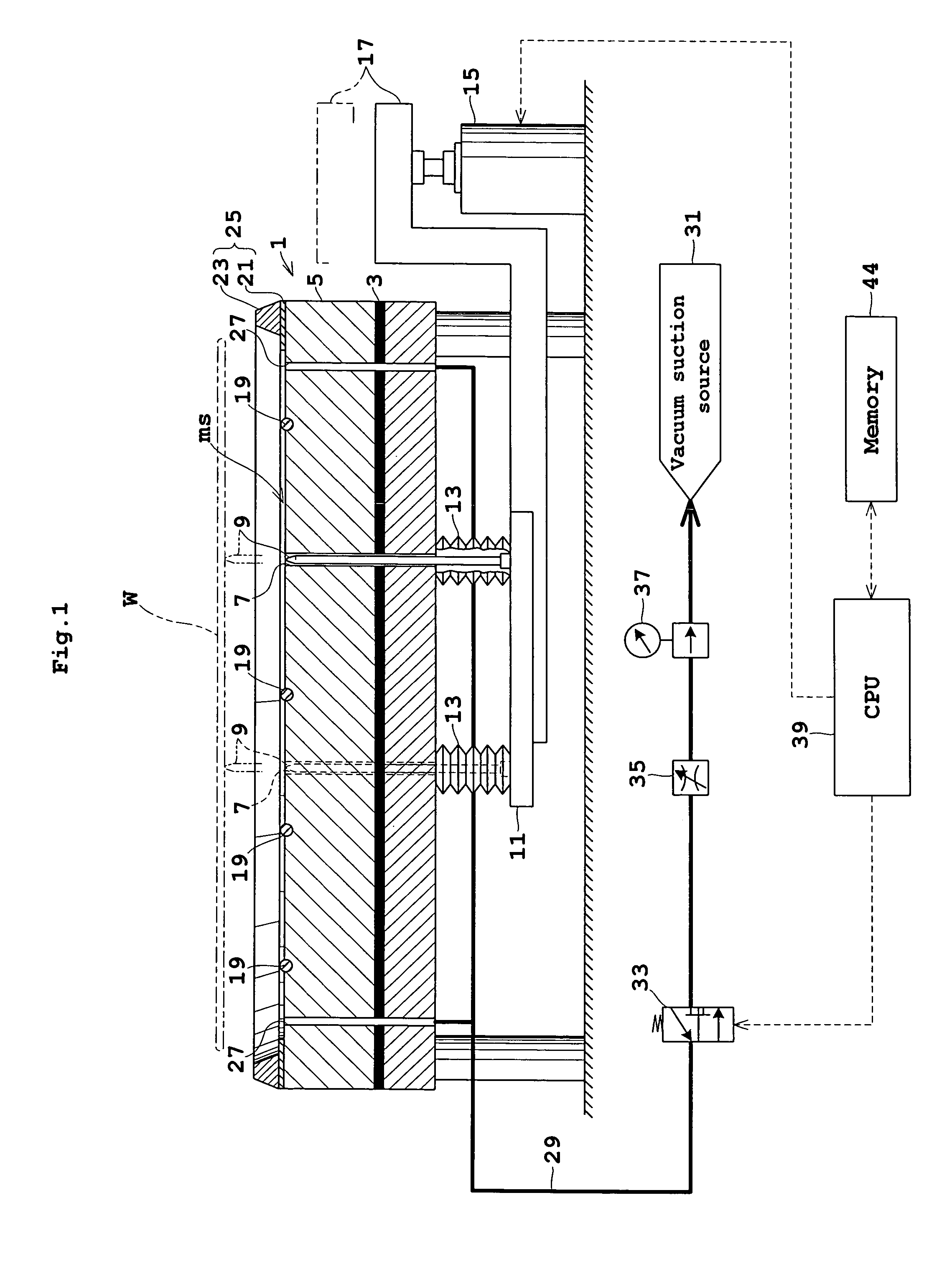

Work holding mechanism

ActiveUS7748760B2Improve shipping speedVacuum operationGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:DAIHEN CORP

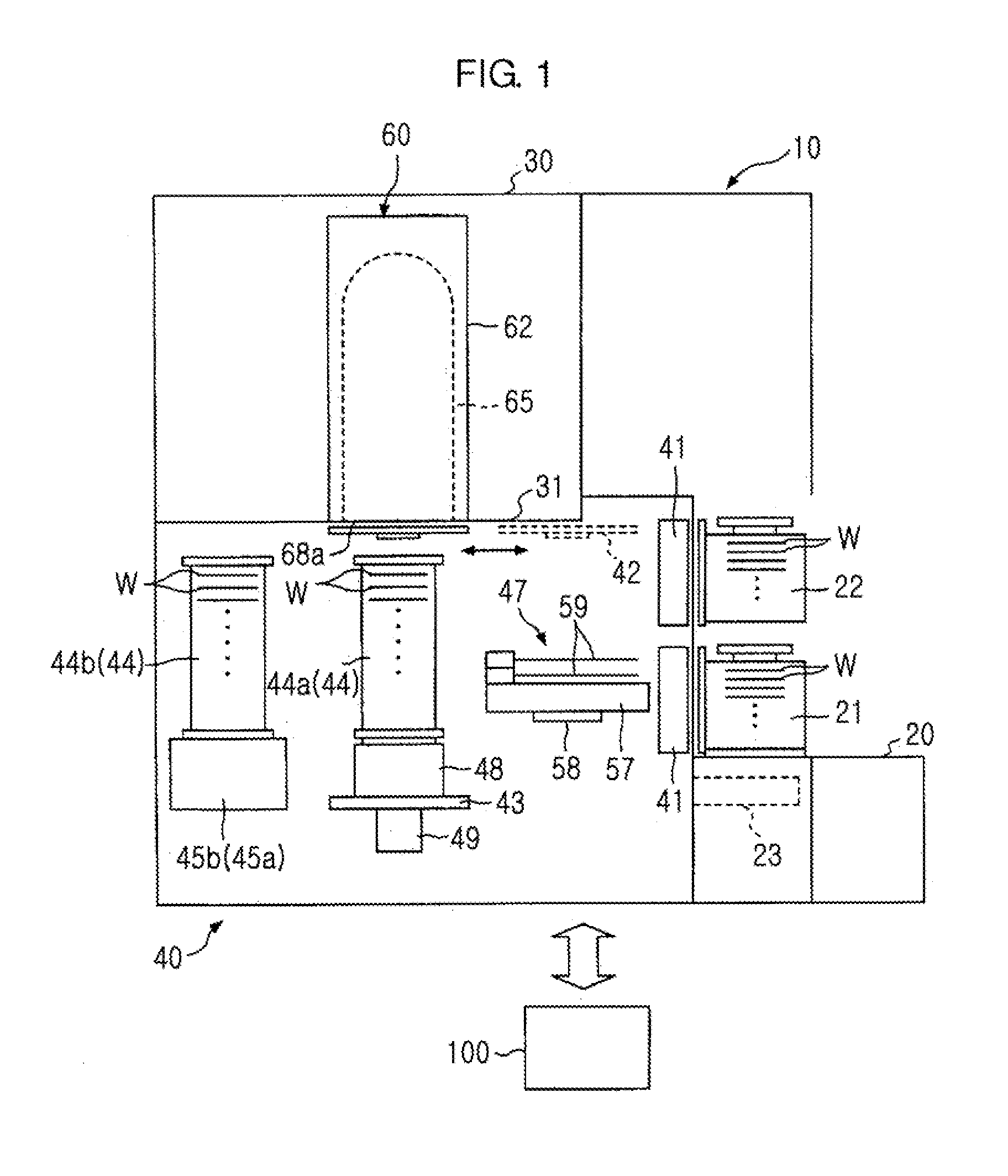

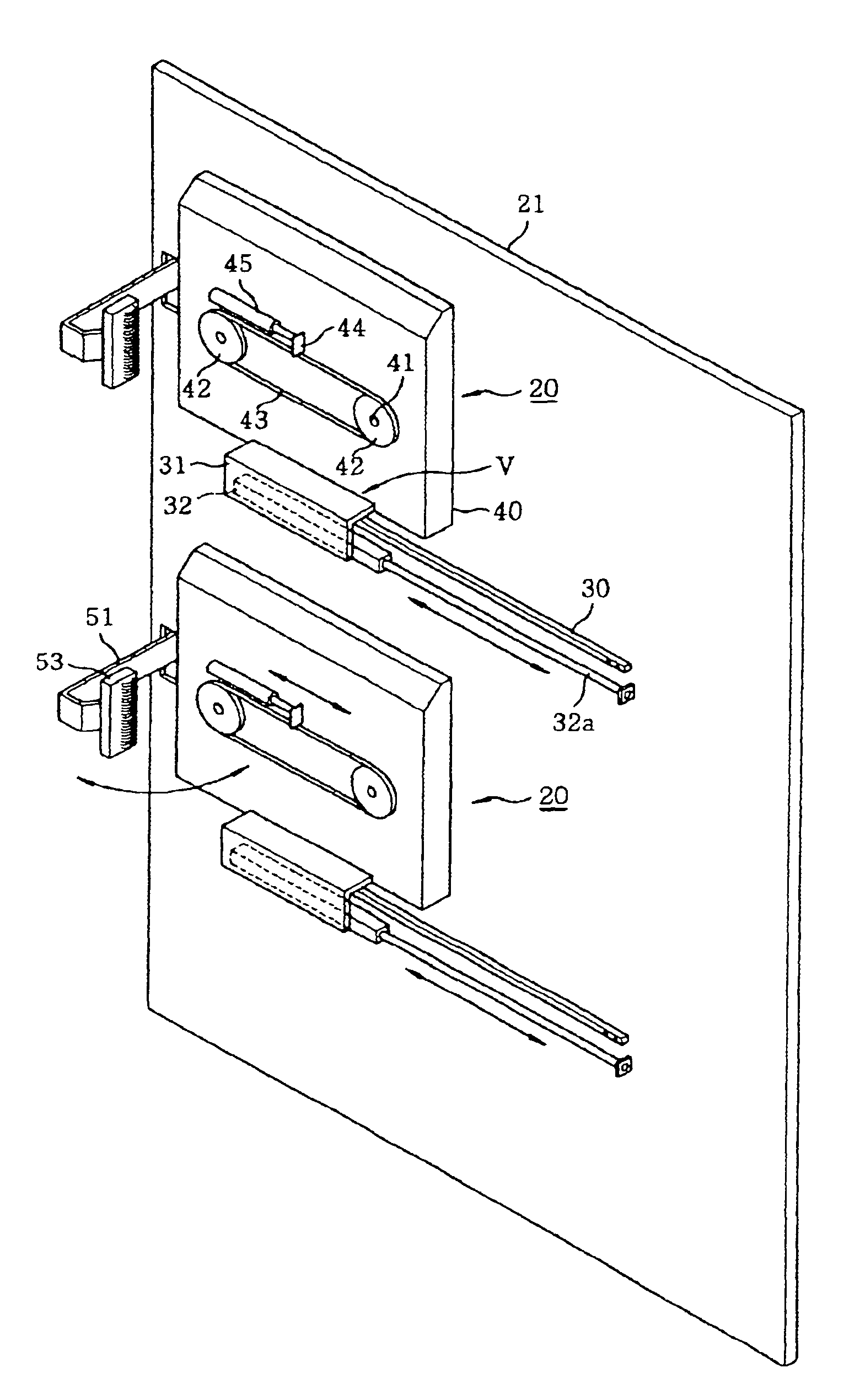

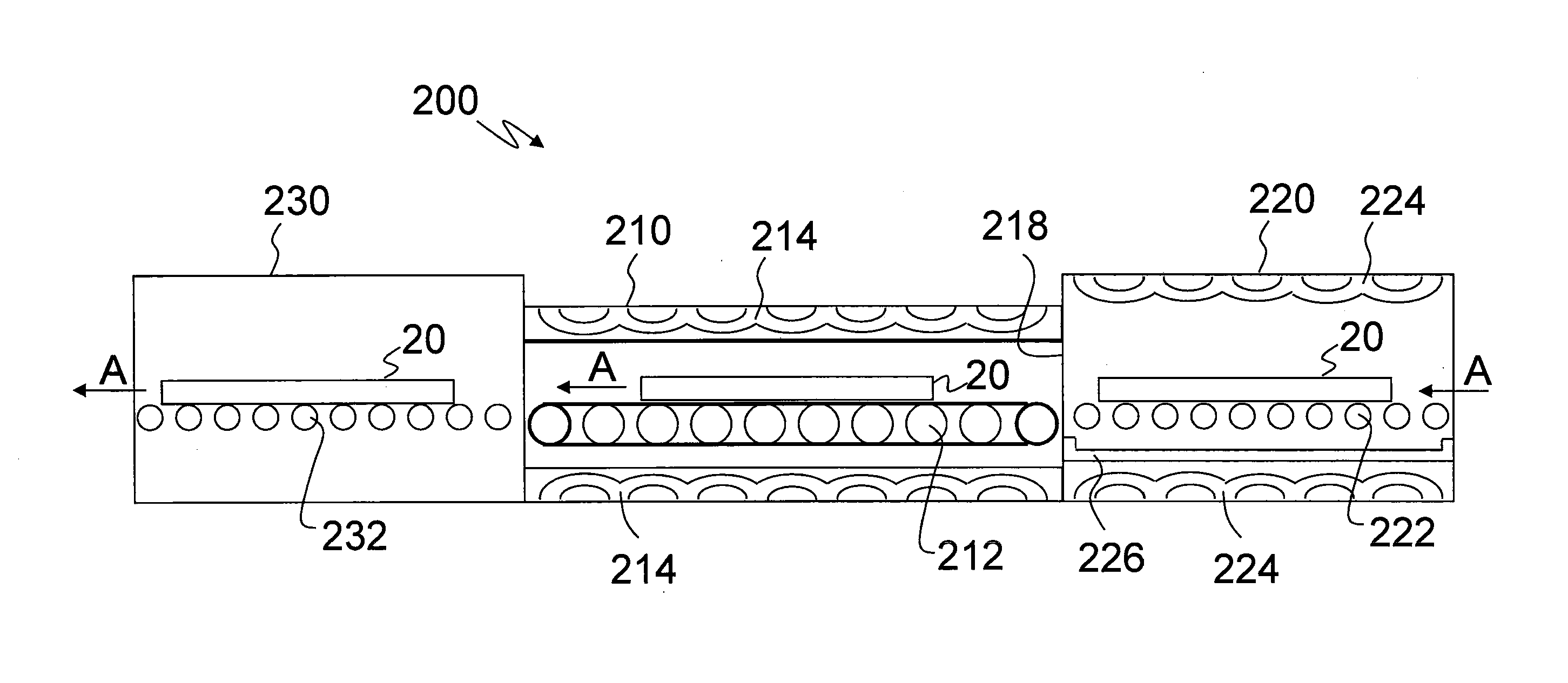

Substrate-processing apparatus with buffer mechanism and substrate-transferring apparatus

ActiveUS7690881B2Low costSmall footprintPliersSemiconductor/solid-state device manufacturingEngineeringActuator

A substrate transfer apparatus for loading and unloading substrates in a reaction chamber, includes: an arm having a distal end which is laterally movable in a straight line direction; and end-effectors for loading and unloading substrates in a reaction chamber, which include a lower end-effector and an upper end-effector. One of the lower end-effector or the upper end-effector is movably coupled to the arm at a distal end of the arm, and the other end-effector is fixed to the movably coupled end-effector. The fixed end-effector is fixed to the movably coupled end-effector.

Owner:ASM JAPAN

Wafer transfer mechanism

InactiveUS20060113806A1Easy to useEasy transferSemiconductor/solid-state device manufacturingCharge manipulationEngineeringTransfer mechanism

A transfer mechanism for transferring a workpiece includes an arm member including a tip projection provided at a tip end thereof for contacting a periphery of the workpiece and restricting movement of the workpiece. The arm member further includes multiple supporting projections protruding from a top surface thereof for contacting and supporting a back side of the workpiece.

Owner:ASM JAPAN

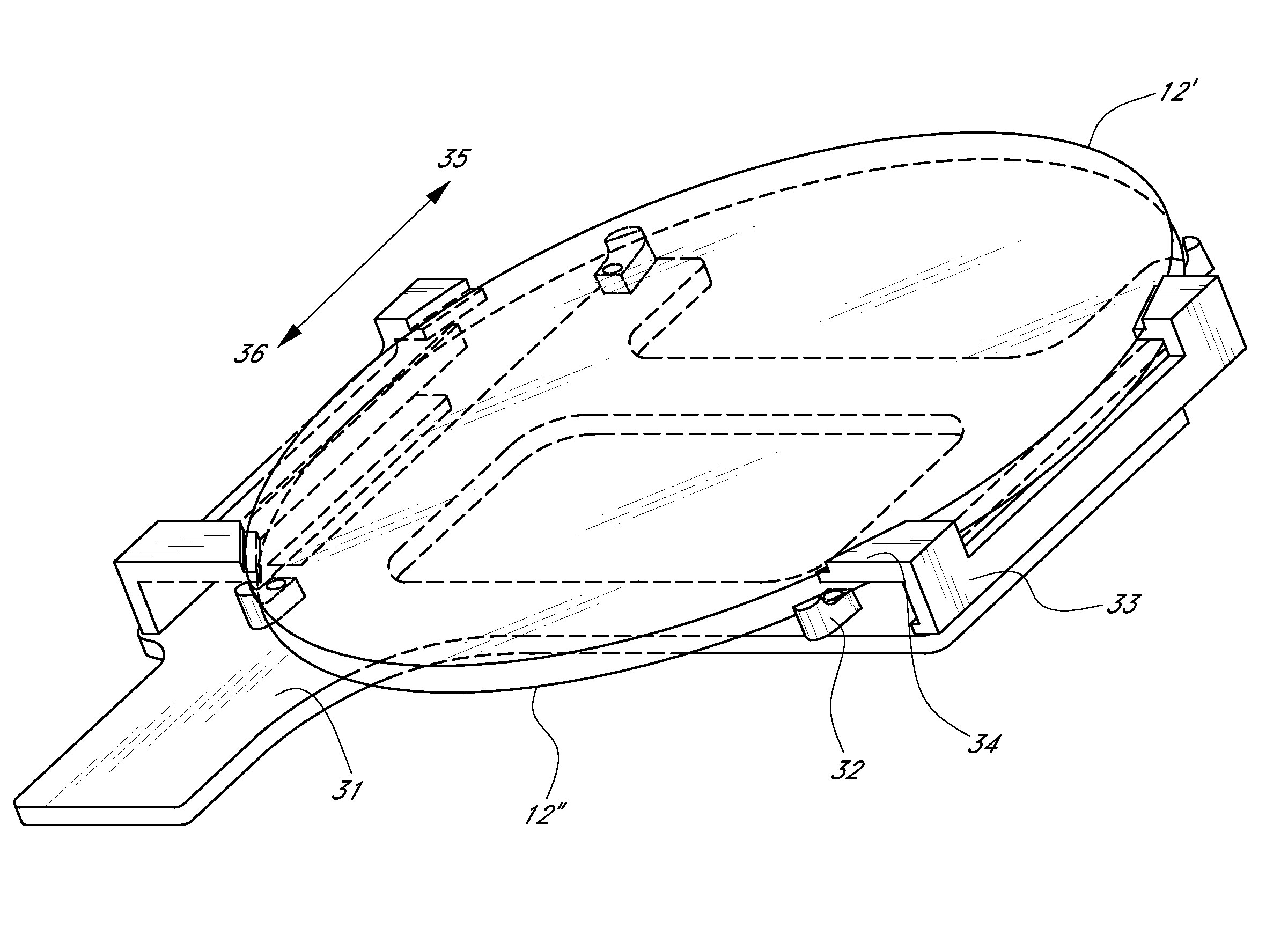

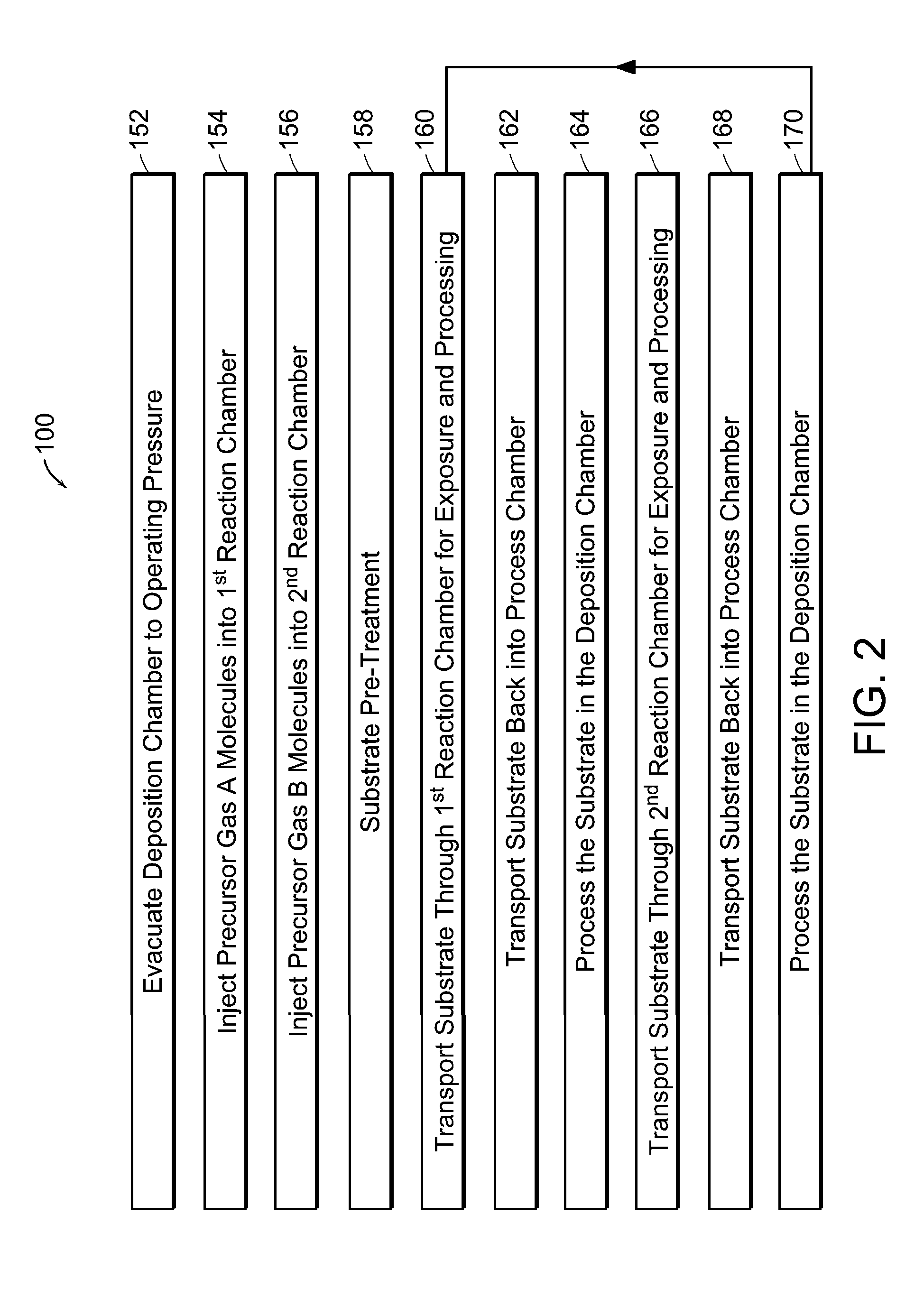

Continuous flow deposition system

An atomic layer deposition system is described that includes a deposition chamber. A first and second reaction chamber are positioned in the deposition chamber and contain a first and a second reactant species, respectively. A monolayer of the first reactant species is deposited on a substrate passing through the first reaction chamber. A monolayer of the second reactant species is deposited on a substrate passing through the second reaction chamber. A transport mechanism transports a substrate in a path through the first reaction chamber and through the second reaction chamber, thereby depositing a film on the substrate by atomic layer deposition. The shape of the first and the second reaction chambers are chosen to achieve a constant exposure of the substrate to reactant species when the transport mechanism transports the substrate in the path through the respective reaction chambers at the constant transport rate.

Owner:VEECON INSTR

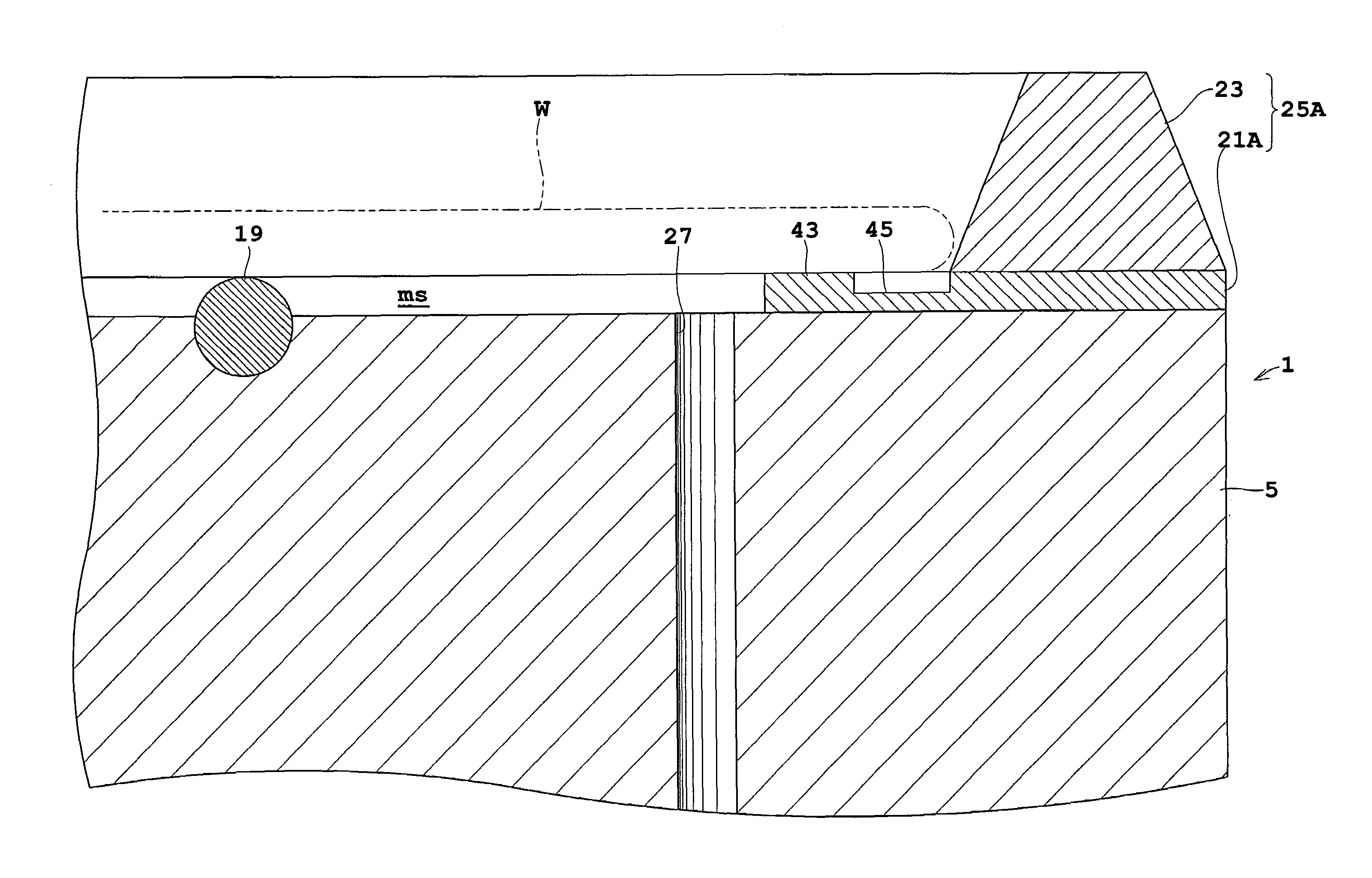

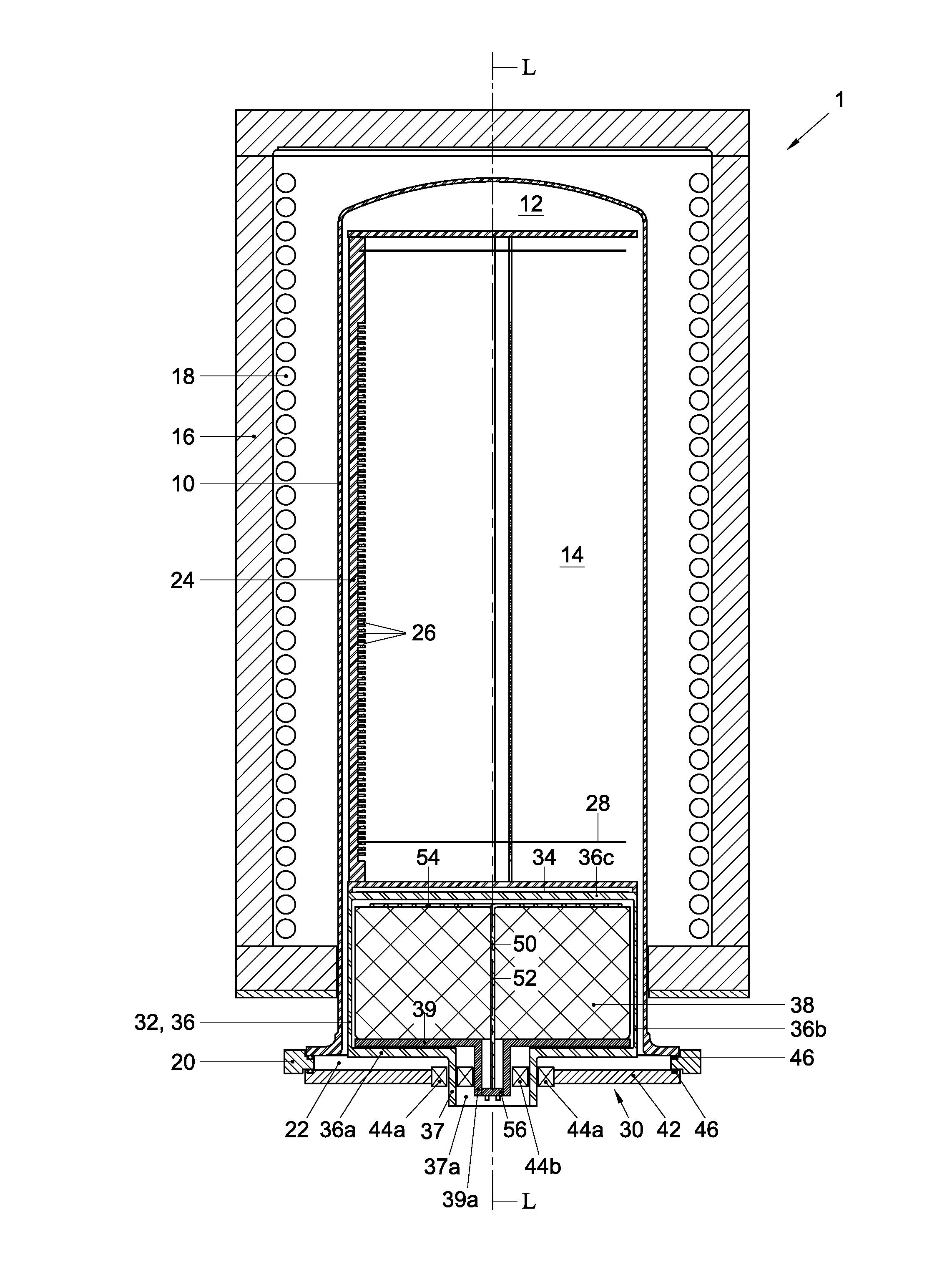

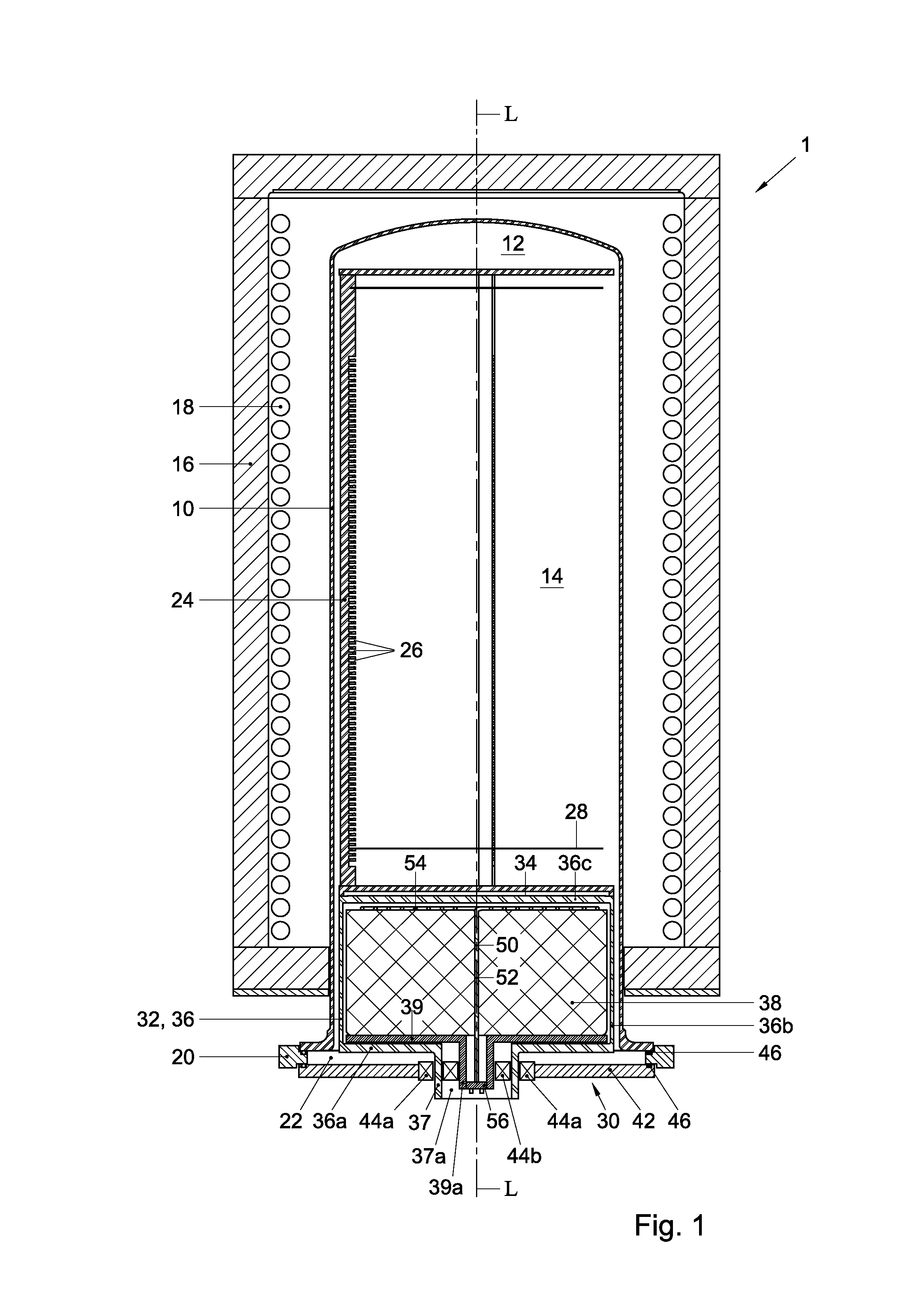

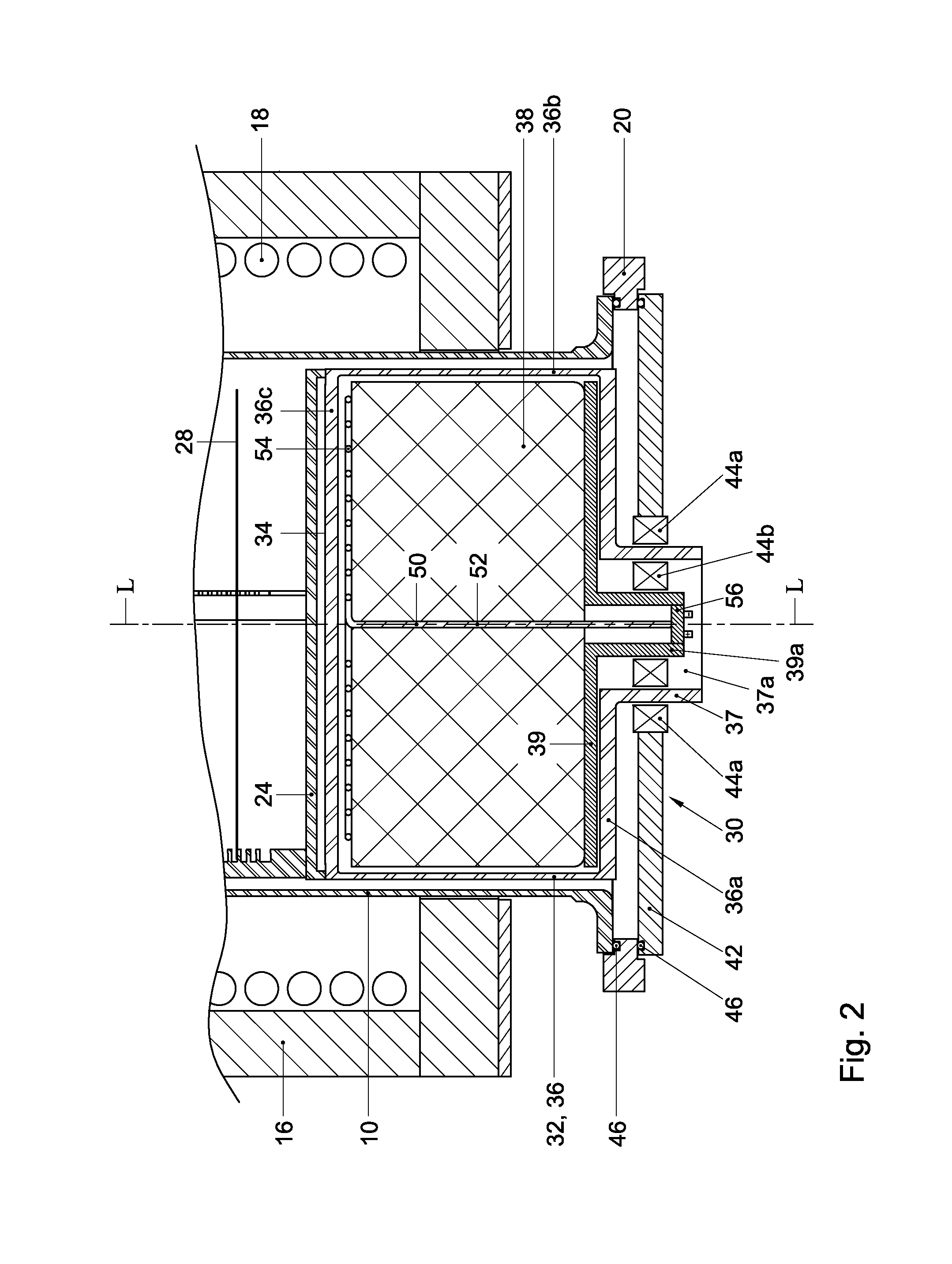

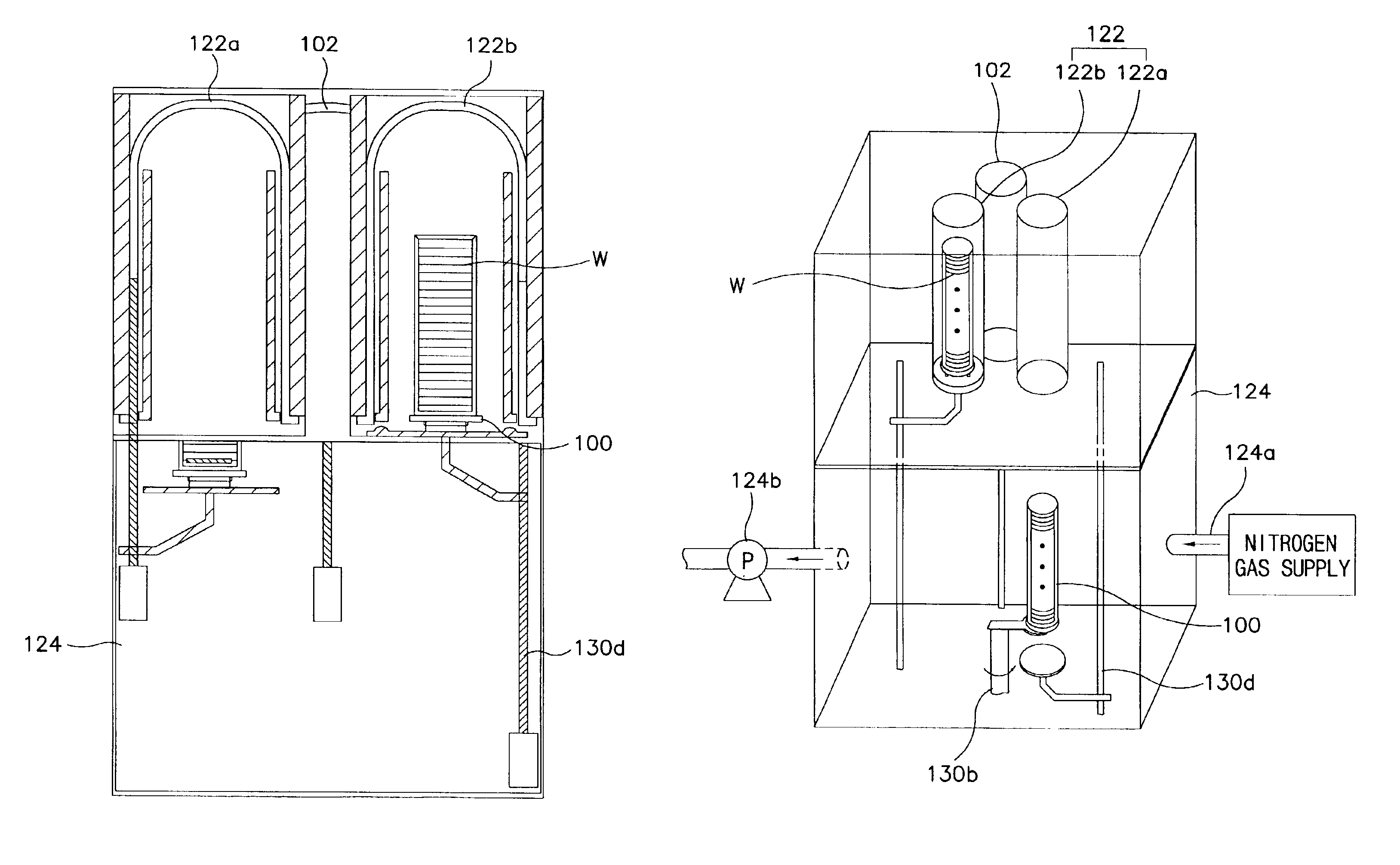

Substrate heat treatment apparatus

ActiveUS7432476B2Efficient actionEfficient use ofMuffle furnacesSemiconductor/solid-state device manufacturingMechanical engineeringHeat treated

Owner:DAINIPPON SCREEN MTG CO LTD

Wafer processing apparatus with heated, rotating substrate support

ActiveUS9018567B2Easy constructionEasy and economical to constructMuffle furnacesCharge supportsEngineeringSemiconductor

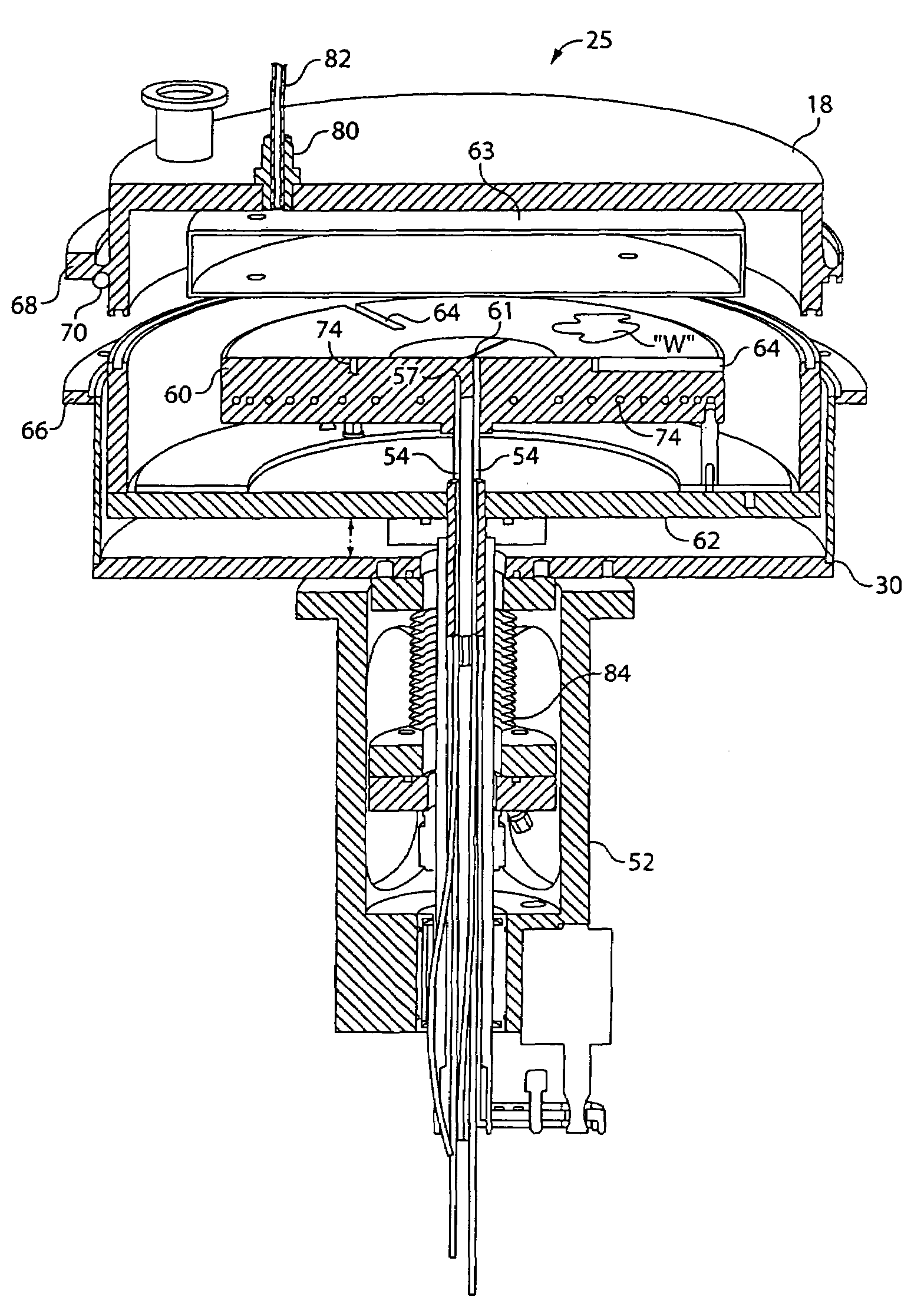

A semiconductor substrate processing apparatus (1), comprising a substrate support assembly (30), including a substrate support (32) defining an outer support surface (34) for supporting a substrate or substrate carrier (24) thereon, and a heater (50) comprising a heat dissipating portion (54) that is disposed within the substrate support (32) and that extends underneath and substantially parallel to the support surface (34), said substrate support (32) being rotatably mounted around a rotation axis (L) that extends through said support surface (34), such that the support surface (34) is rotatable relative to the heat dissipating portion (54) of the heater (50).

Owner:ASM IP HLDG BV

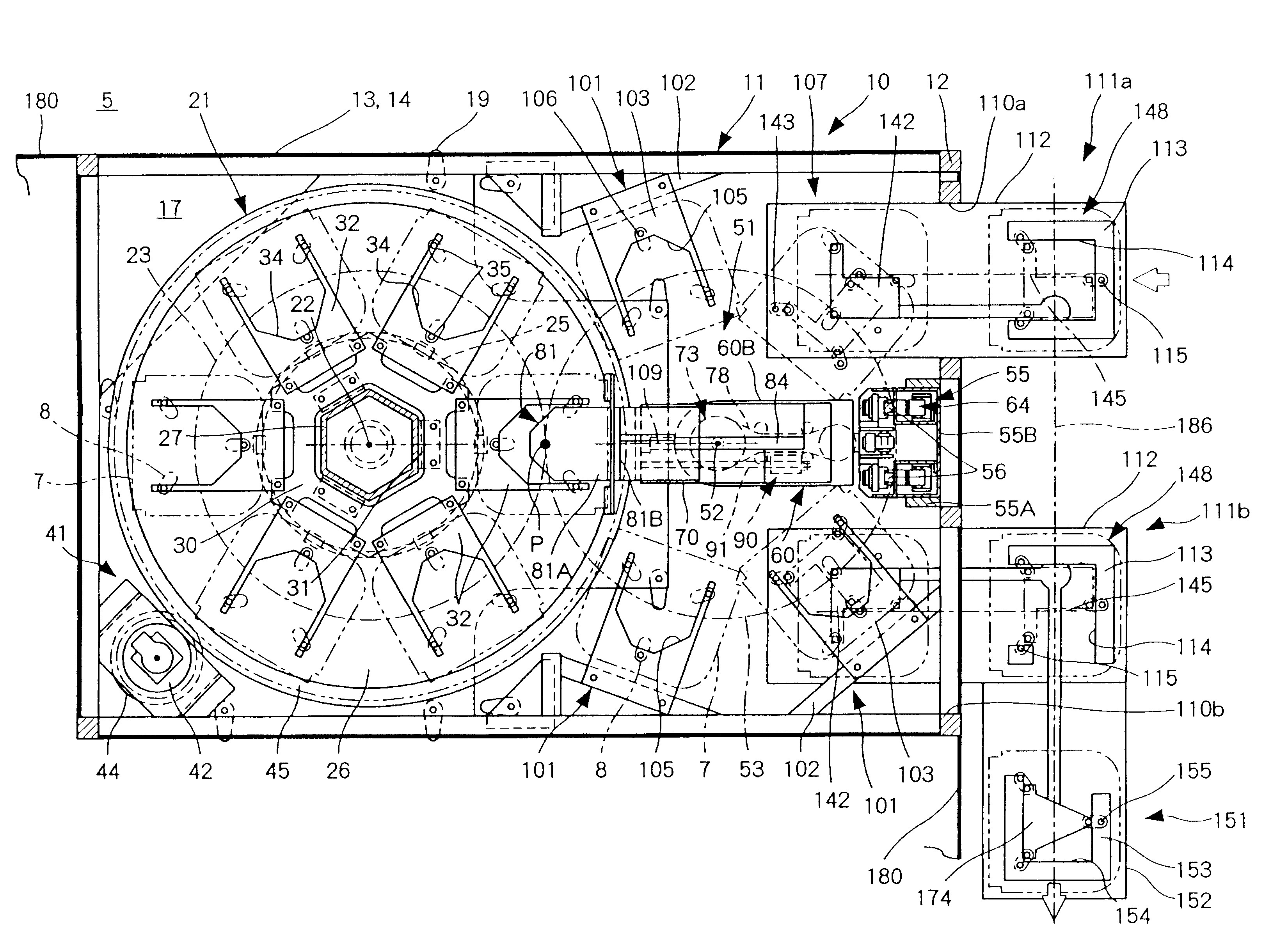

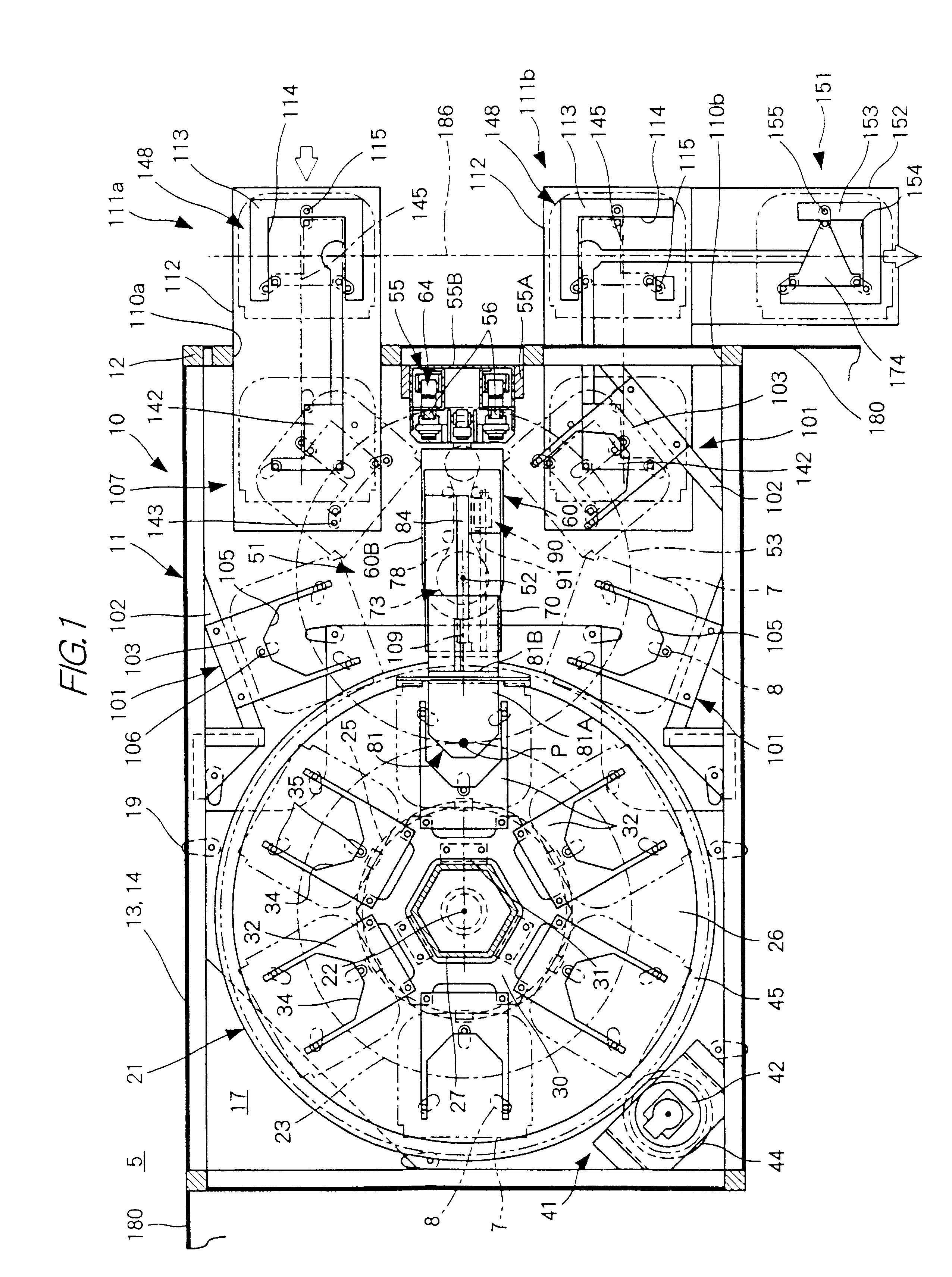

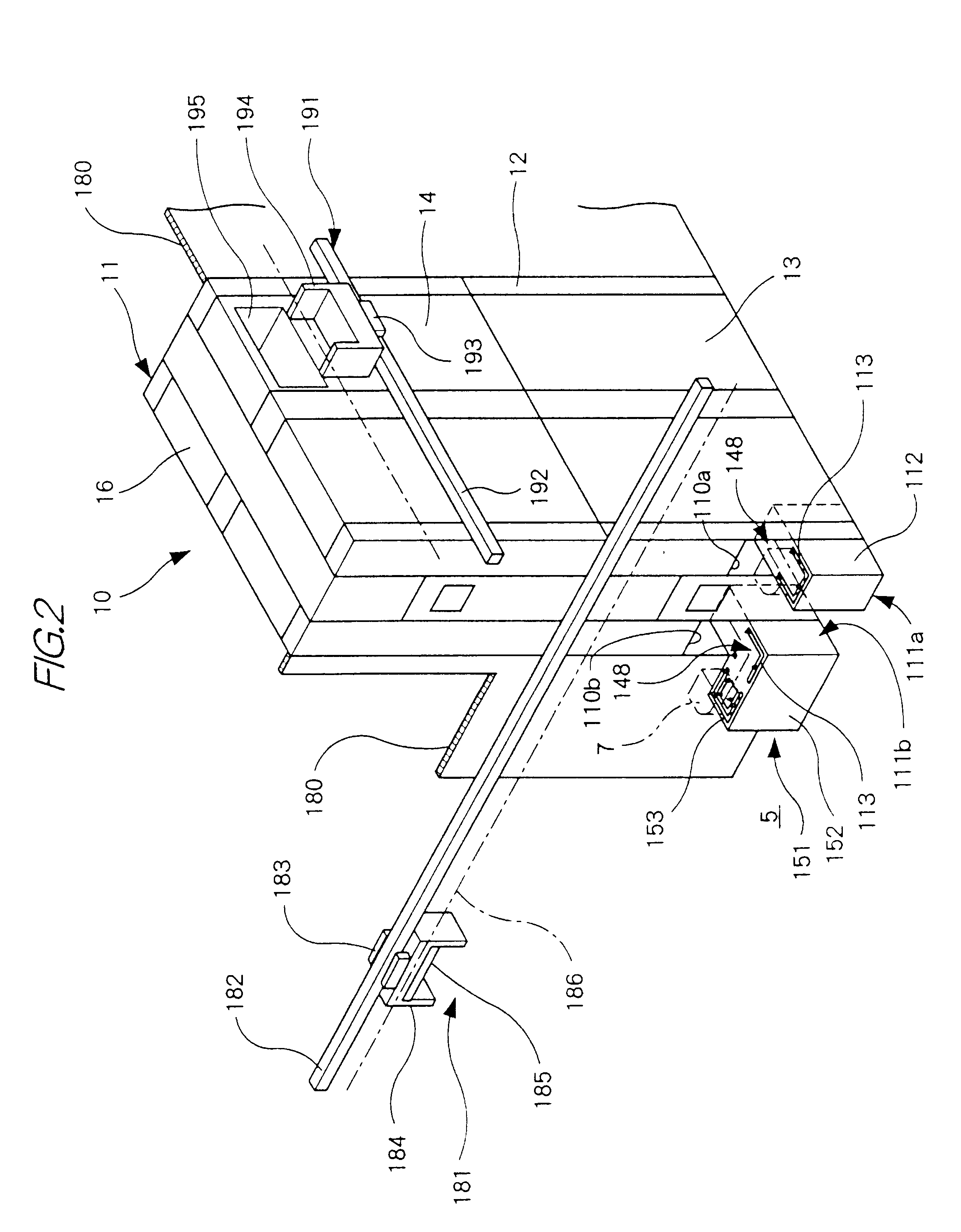

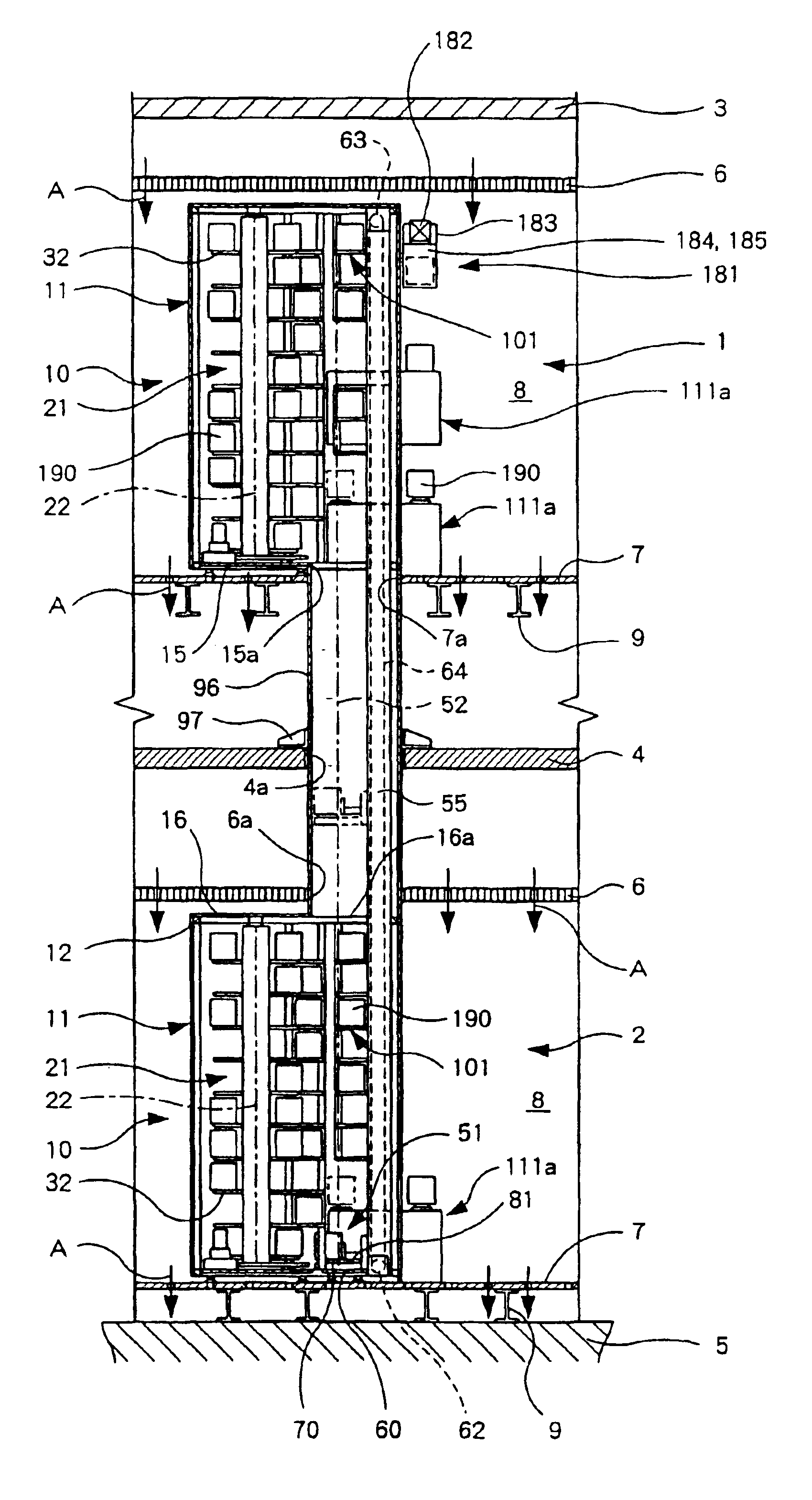

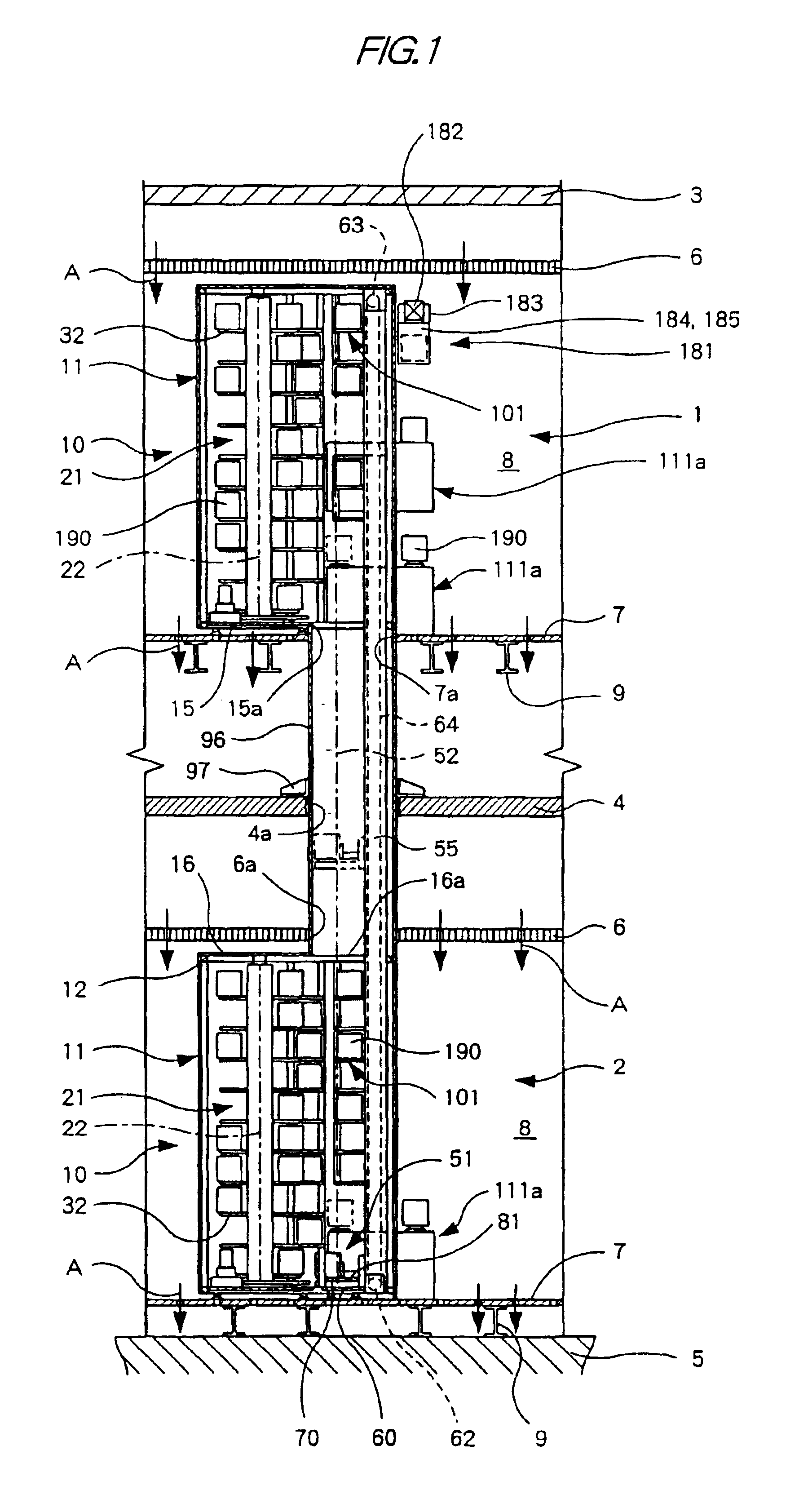

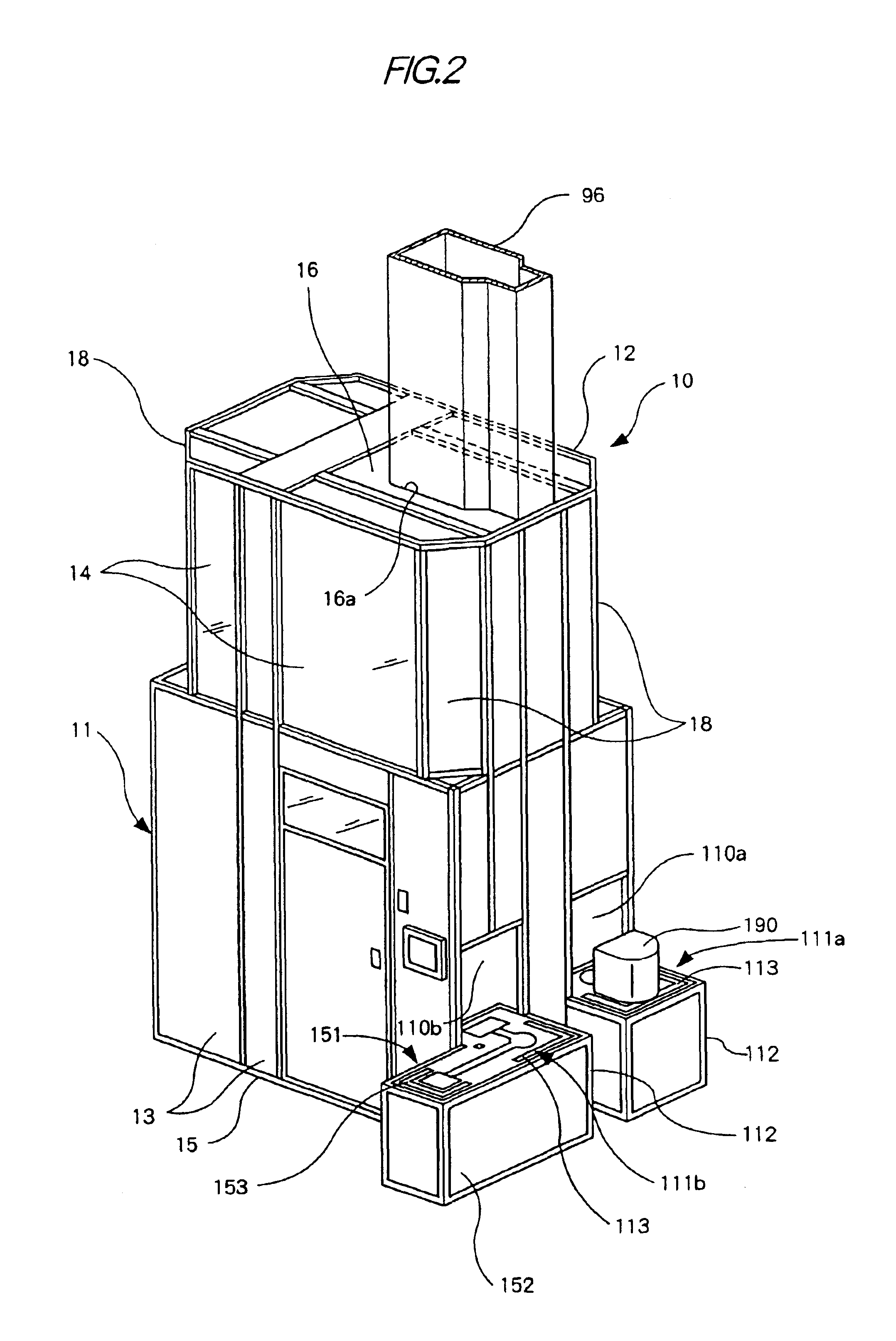

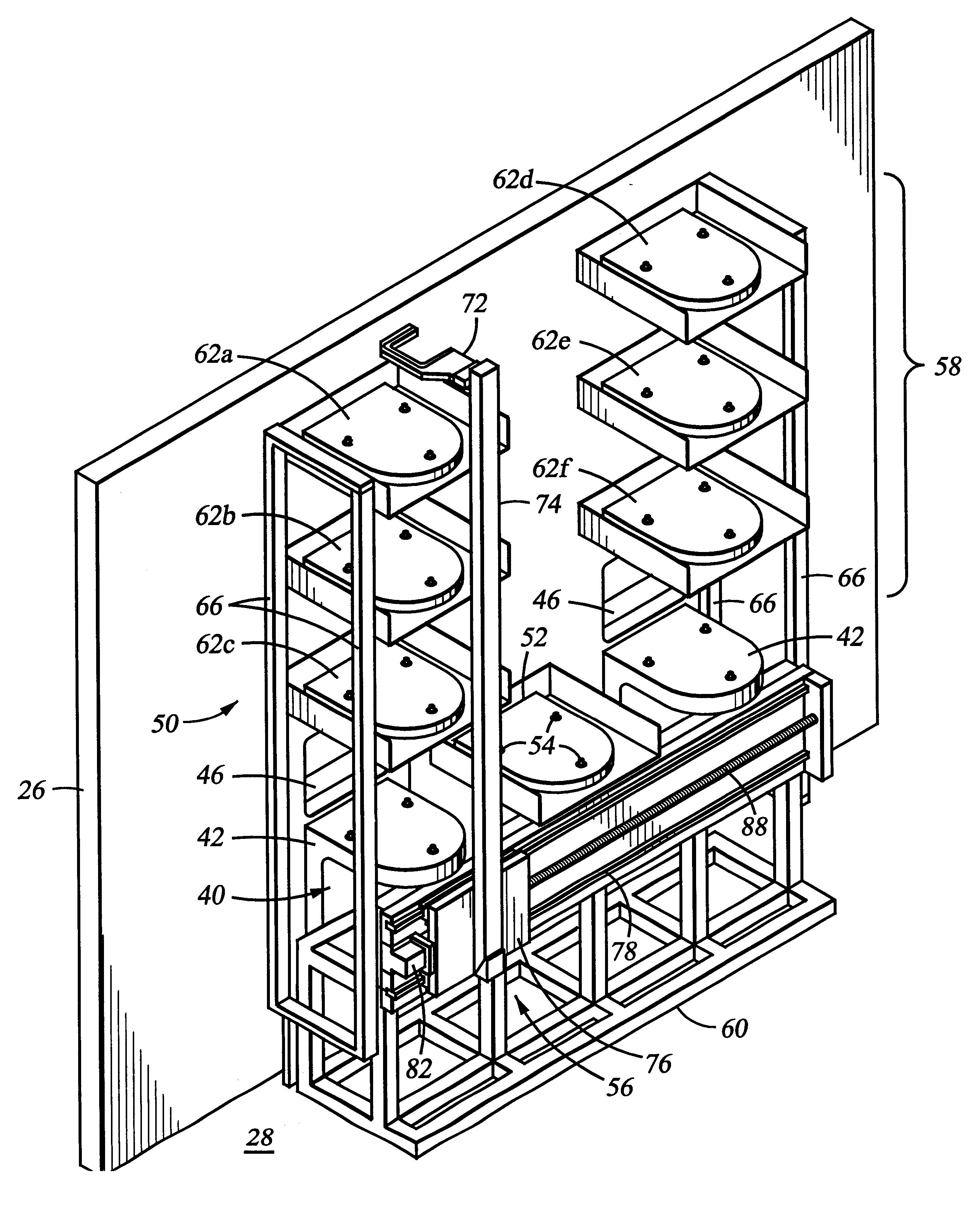

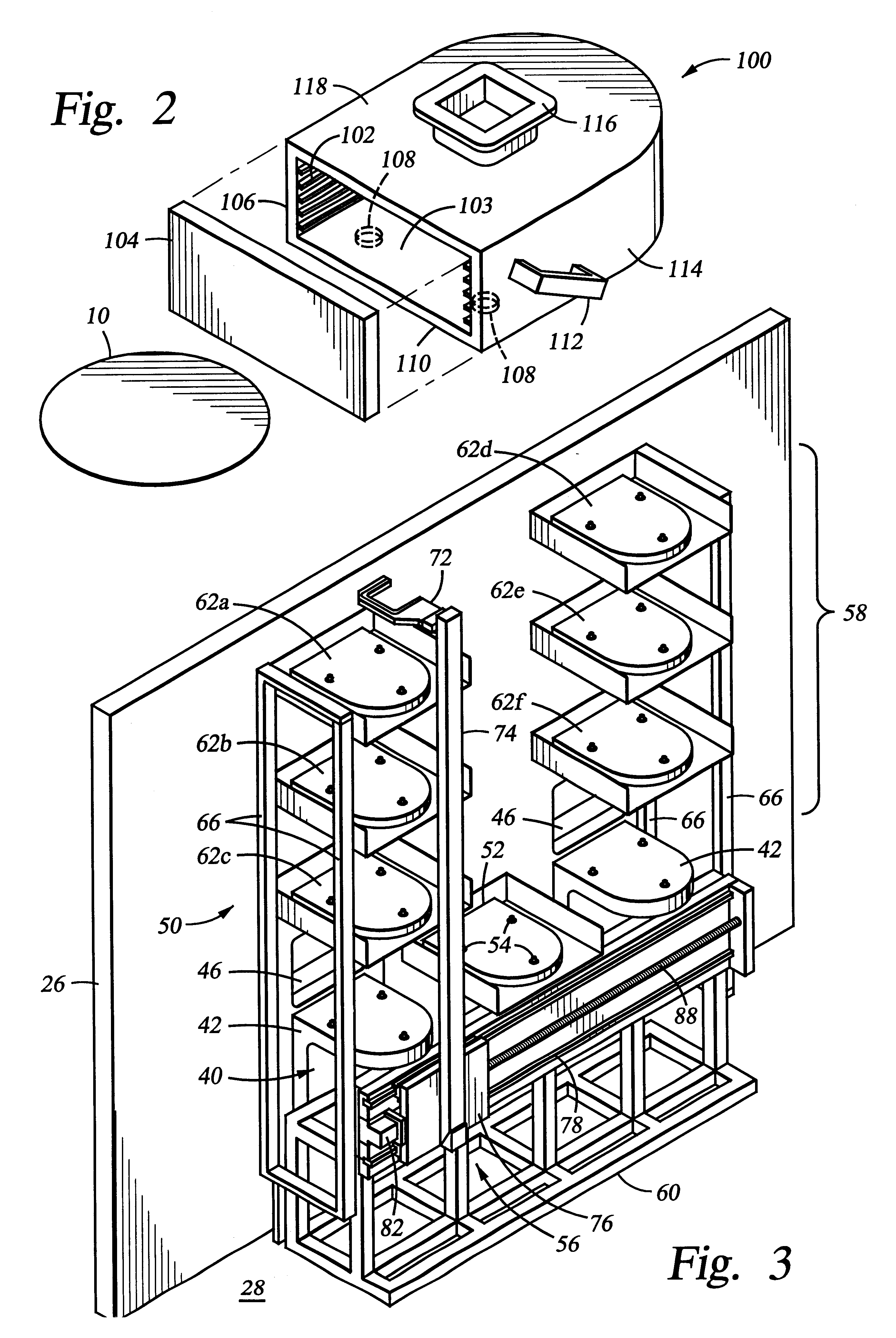

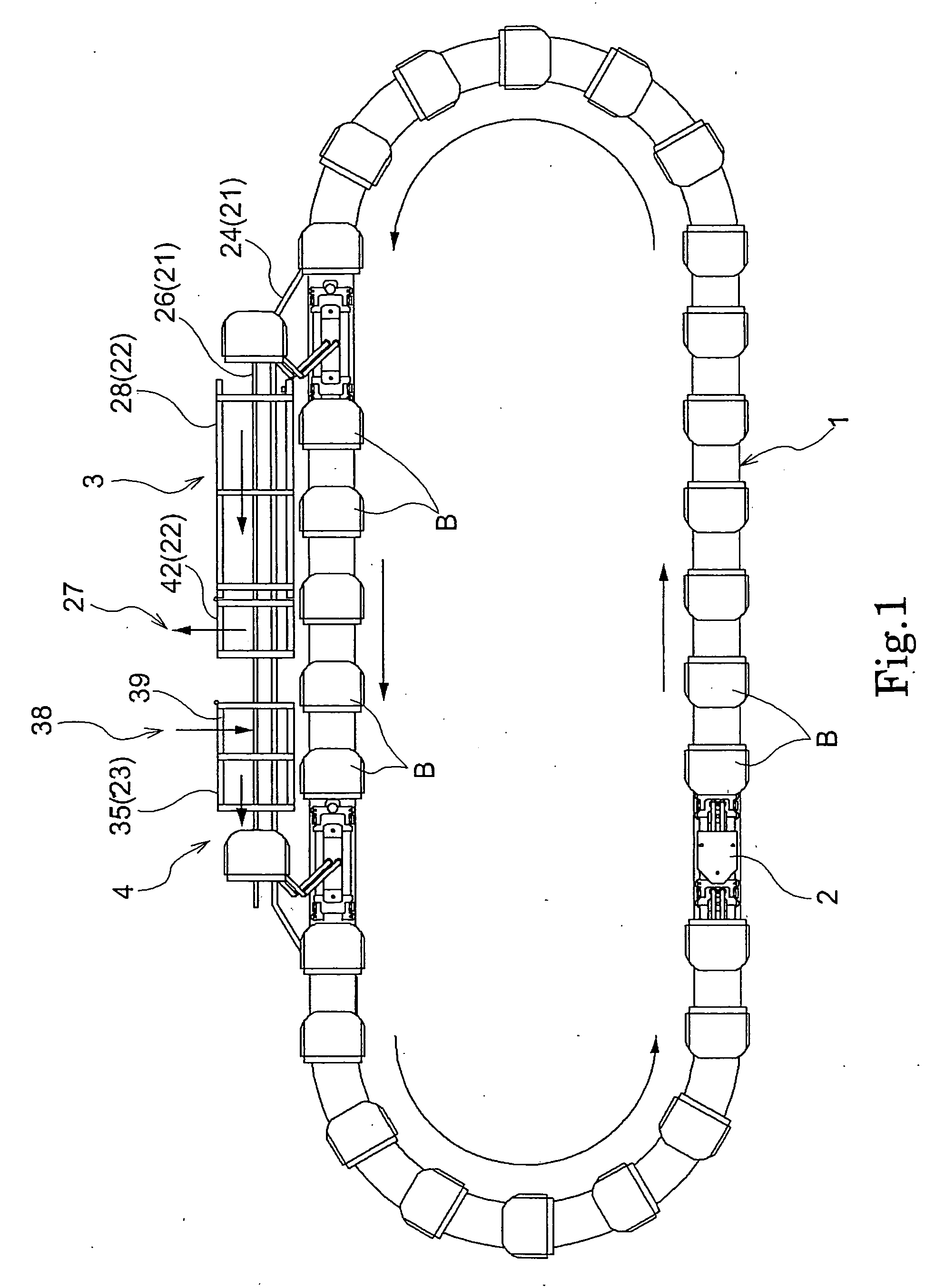

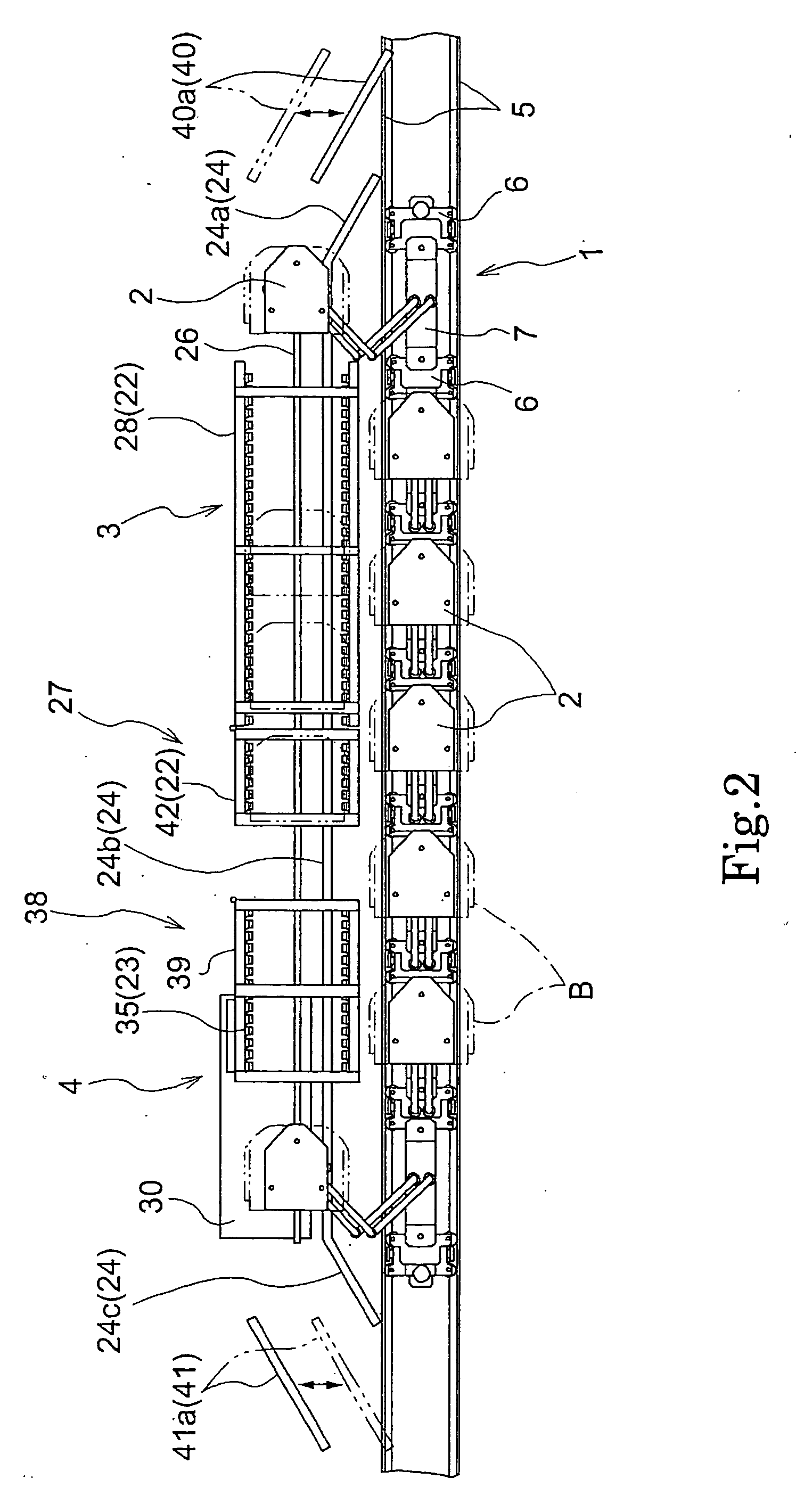

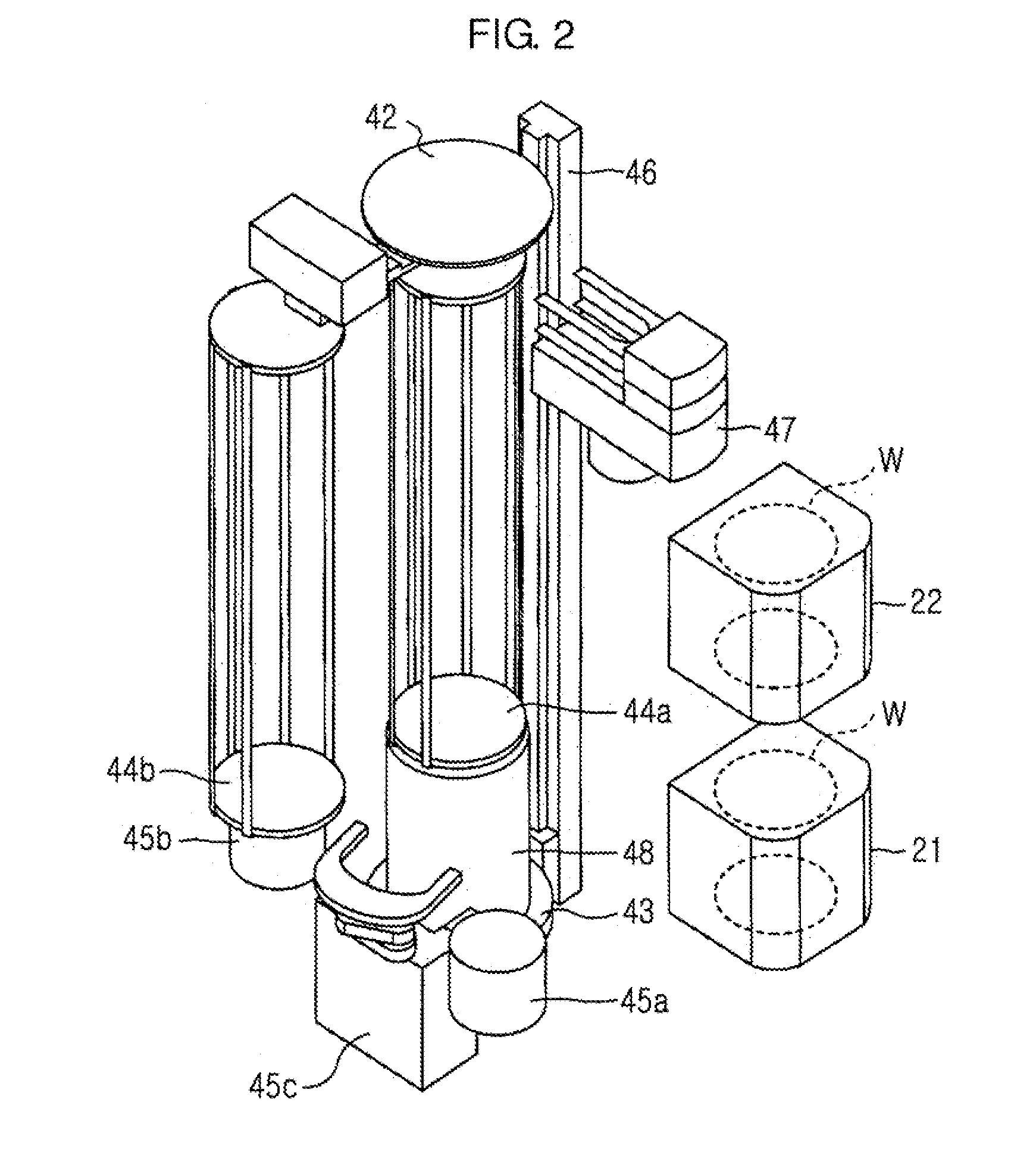

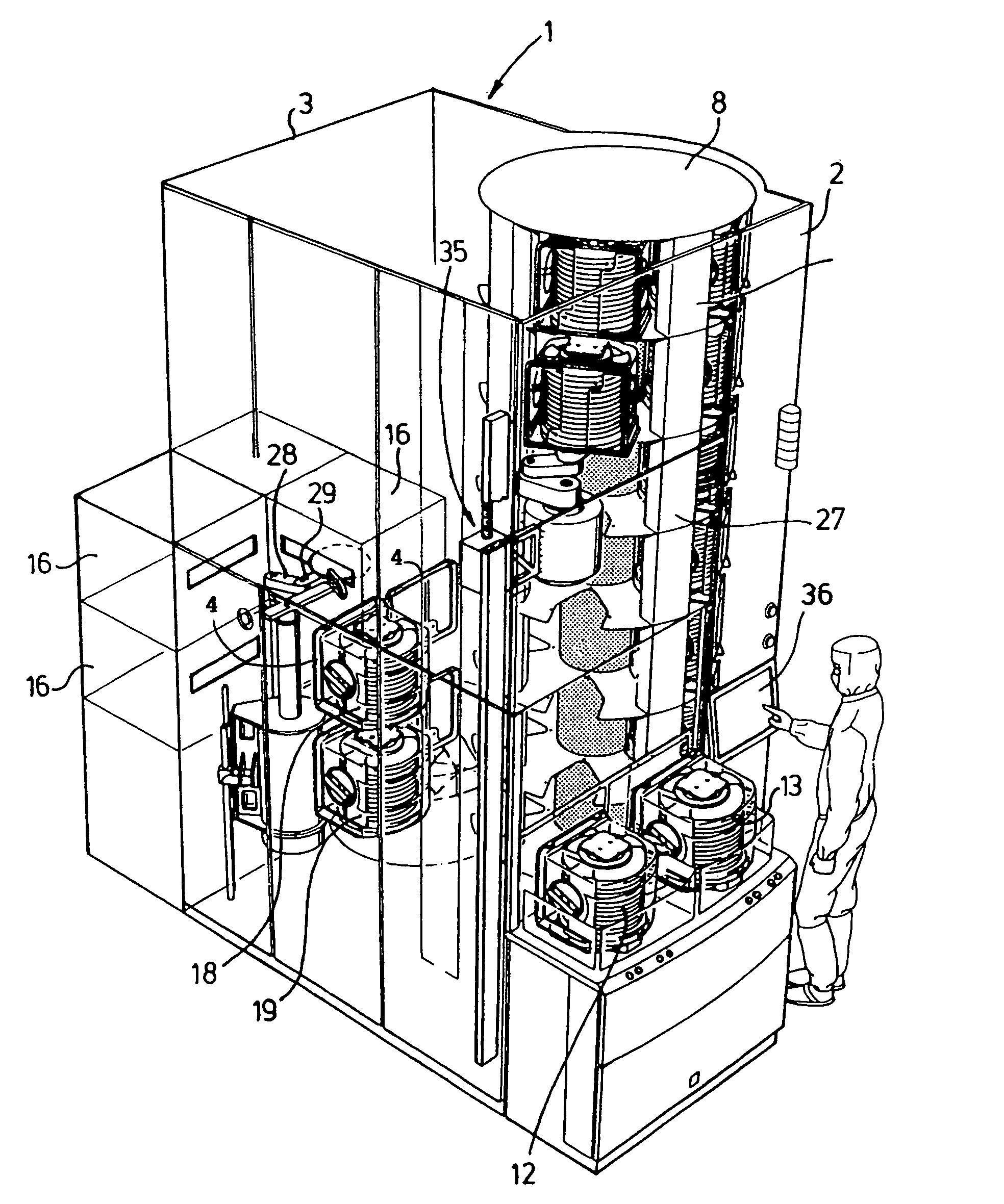

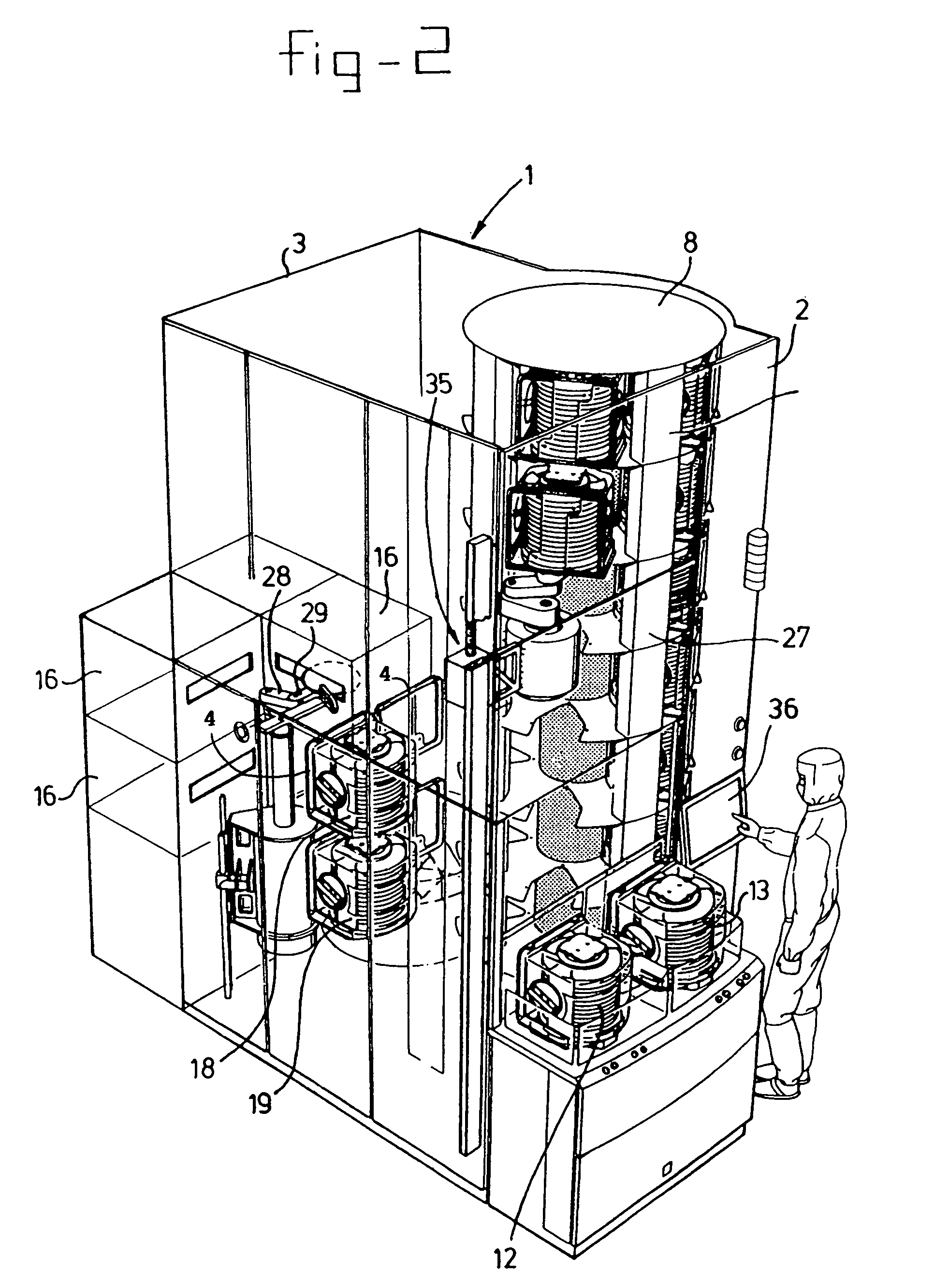

Load storage equipment

InactiveUS6722837B2Add supportEfficient storageCharge manipulationStorage devicesEngineeringVertical axis

There is provided compact load storage equipment that can store a large number of loads. The storage equipment comprises a rotary rack 21, a transferrer 51, one or more fixed racks 101, an inlet port 111a and an outlet port 111b. The rotary rack 21 is supported rotatably about a first vertical axis and includes a number of vertically arranged stages of turning load supports 32. The transferrer 51 adjoins the rotary rack 21 and includes a carrier 81, which can vertically move and rotate about a second vertical axis. The fixed racks 101 are positioned around the transferrer 51 and each includes a number of vertically arranged stages of fixed load supports 103. In plan view, the ports 111a and 111b each overlap with one of the rotary and fixed racks 21 and 101. The transferrer 51 can transfer loads between the carrier 81 and any one of the turning and fixed load supports 32 and 103, and between the carrier 81 and each of the ports 111a and 111b, by the turning and vertical movement of the carrier 81, or by the combination of the turning and vertical movement of the carrier 81 and the turning of the turning load supports 32.

Owner:DAIFUKU CO LTD

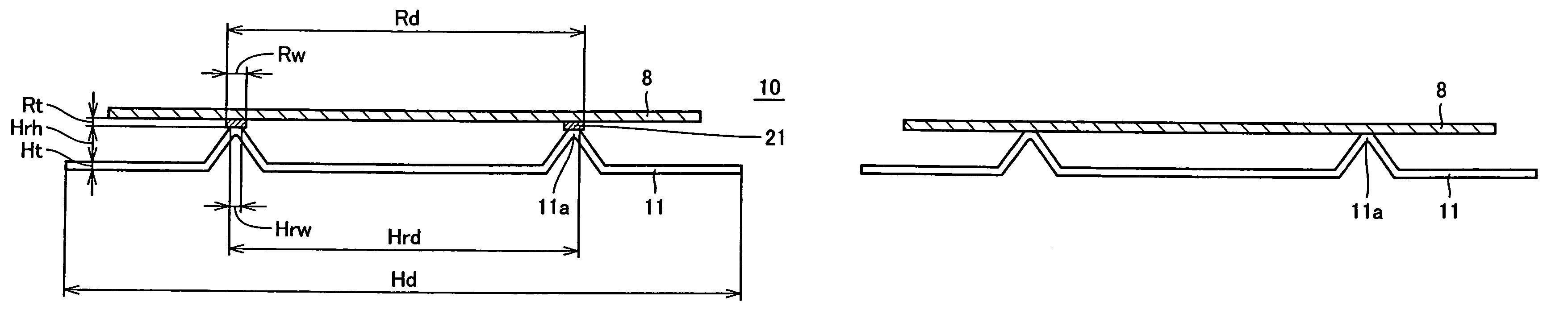

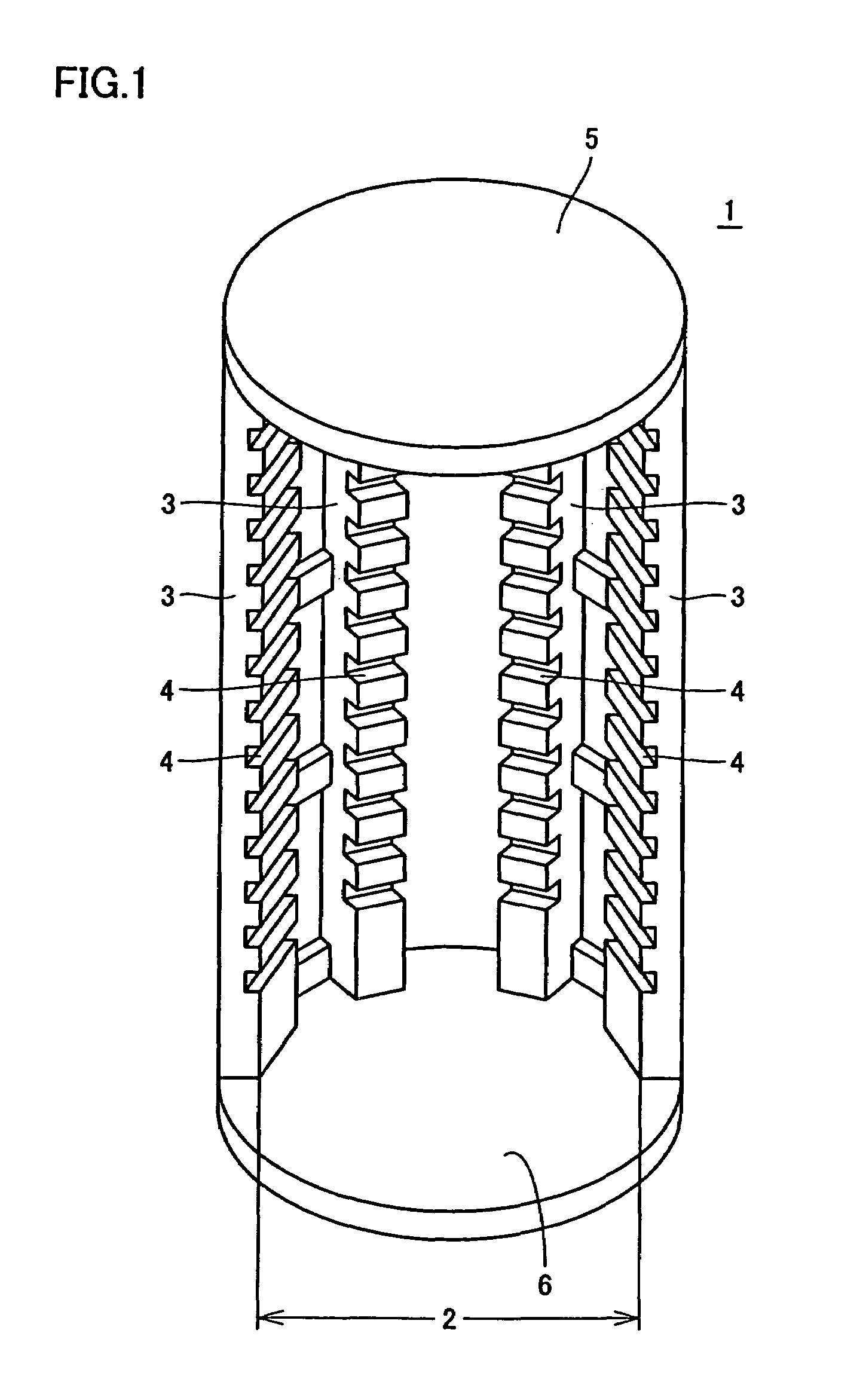

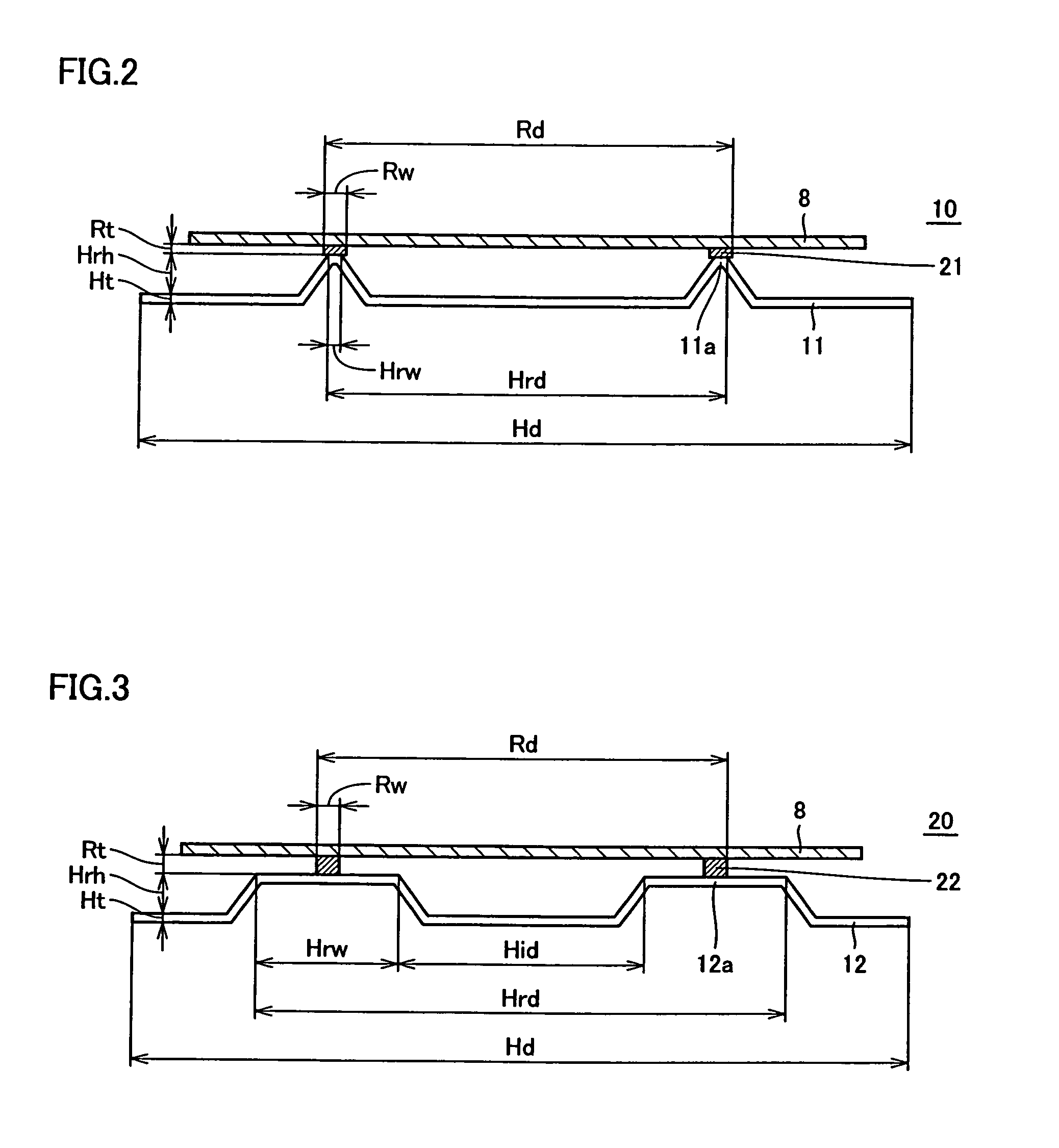

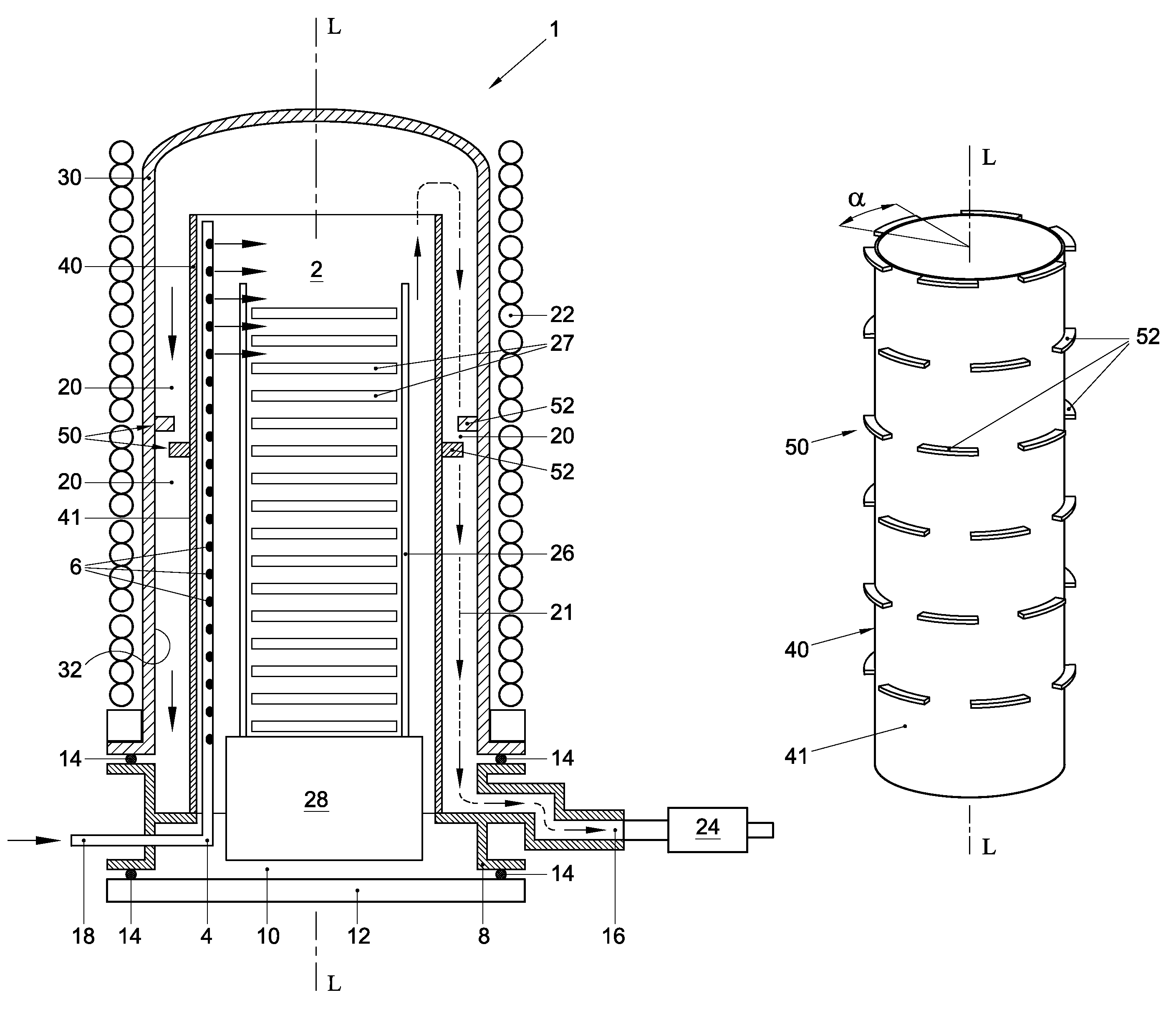

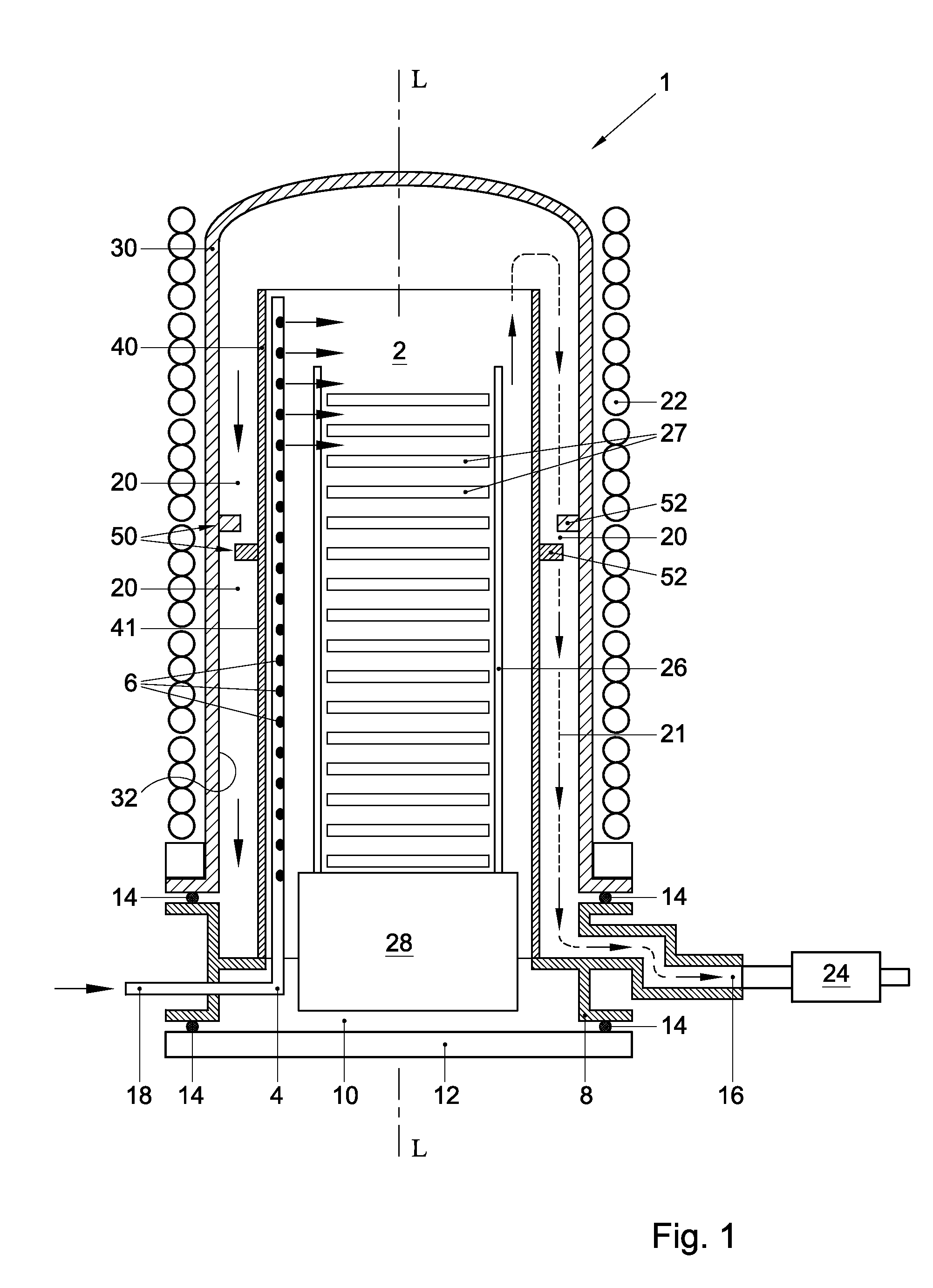

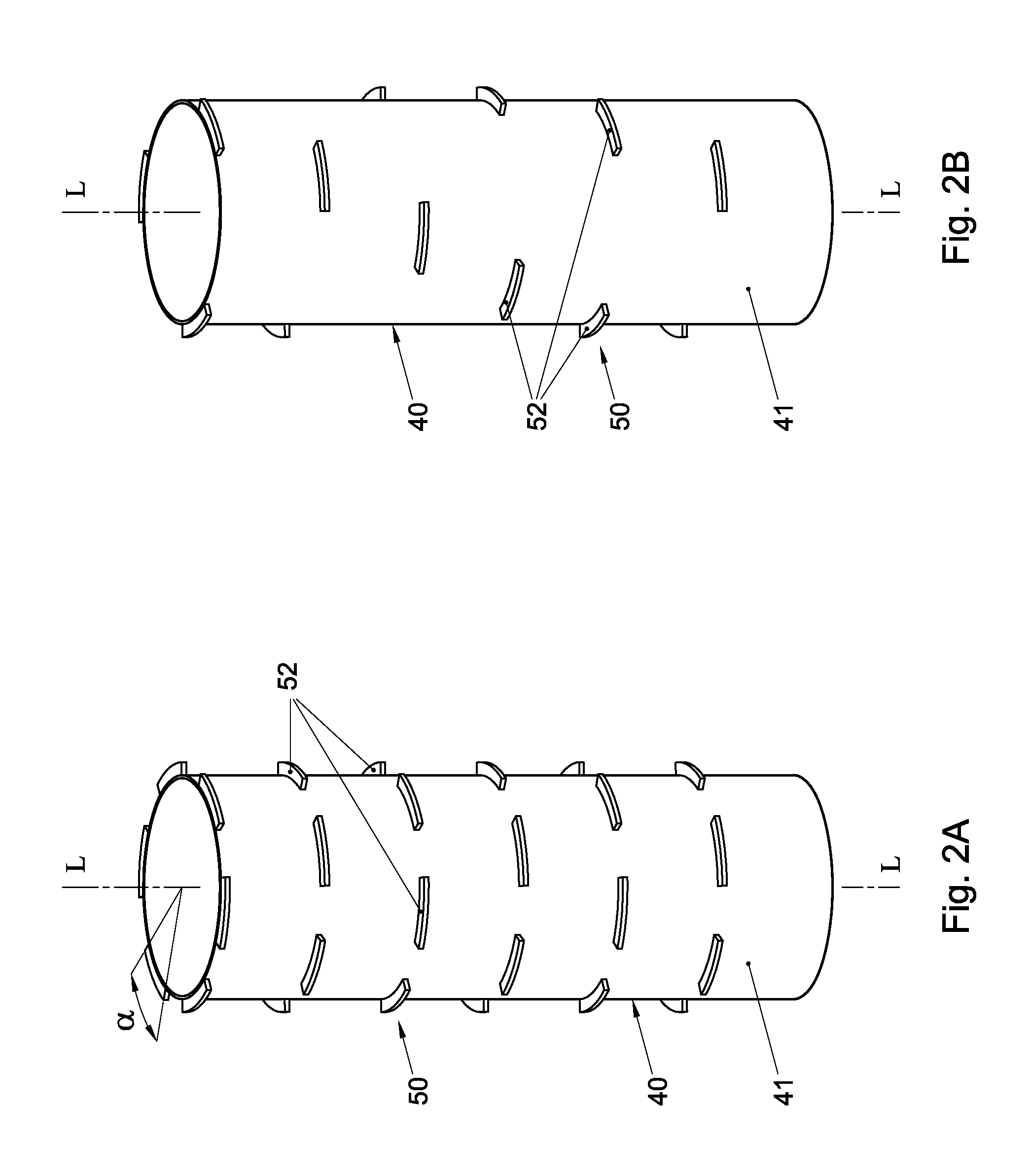

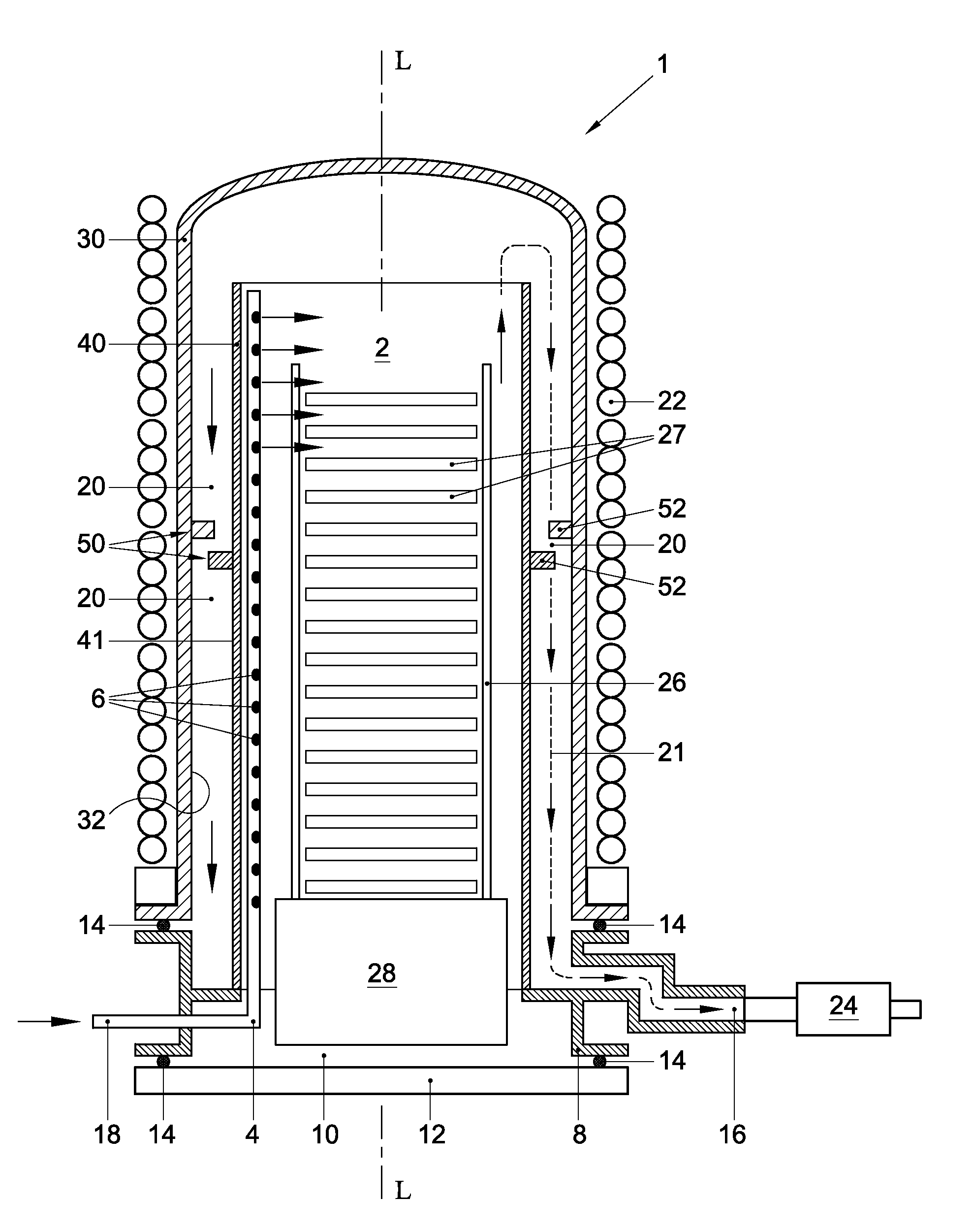

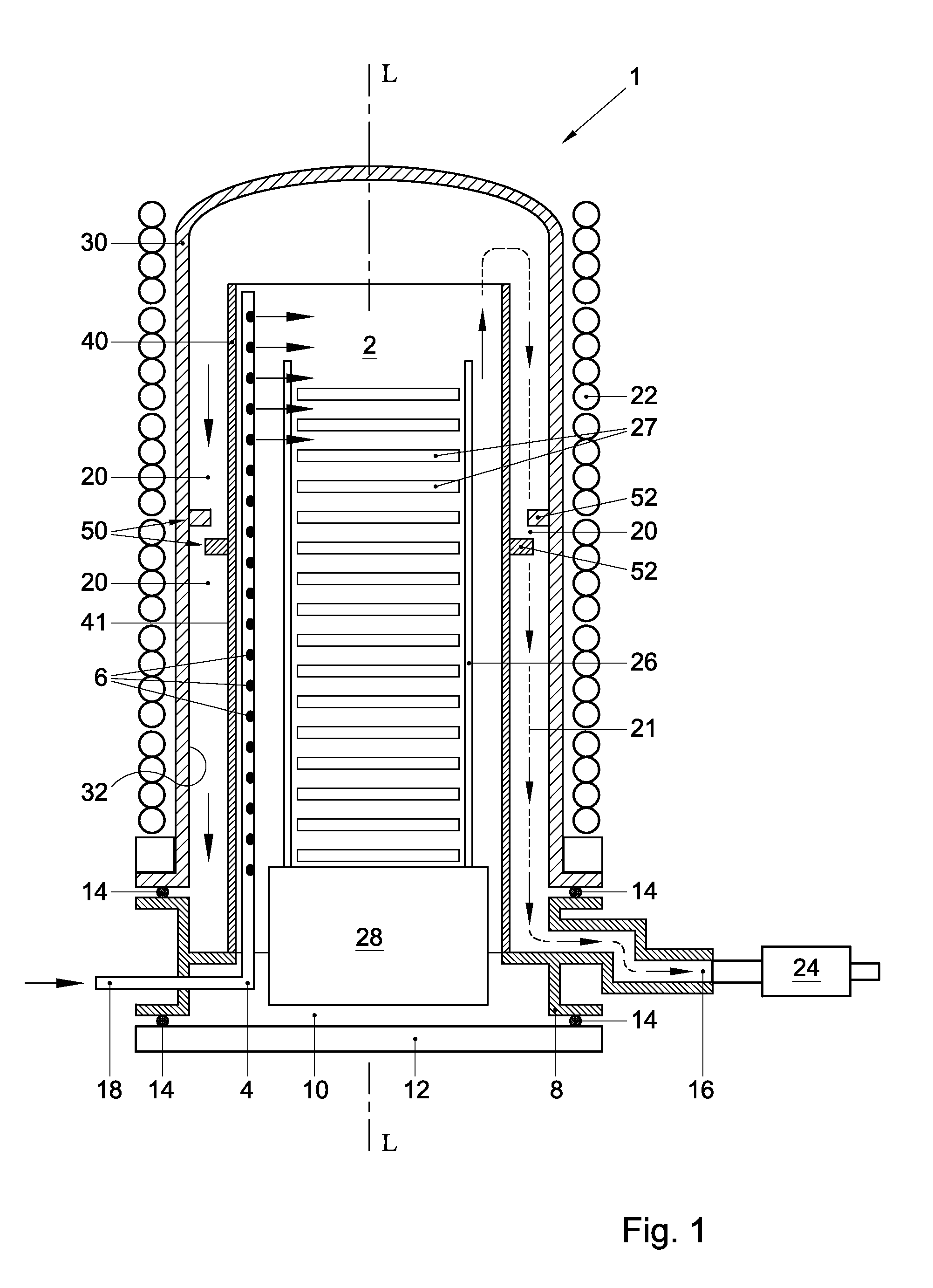

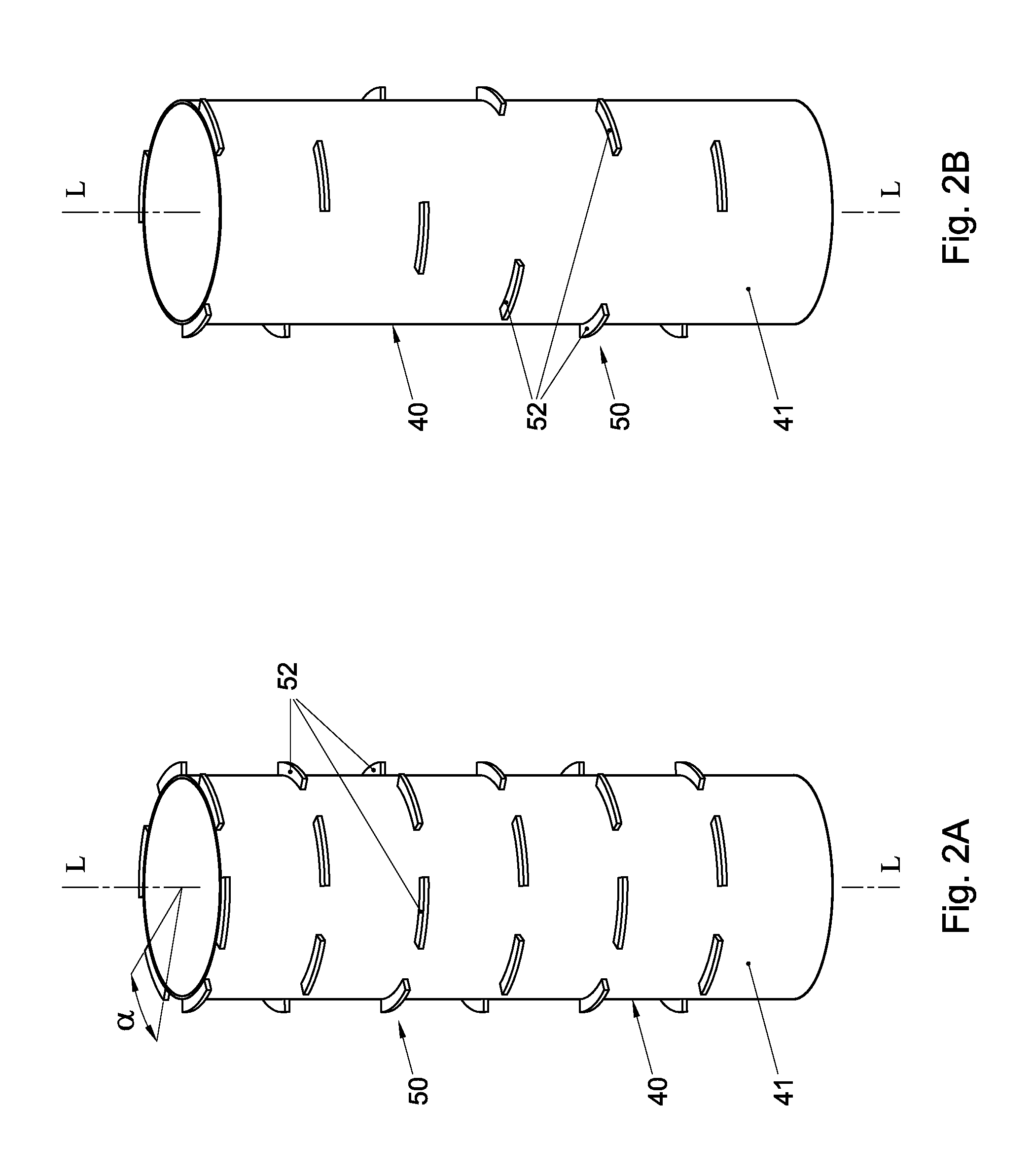

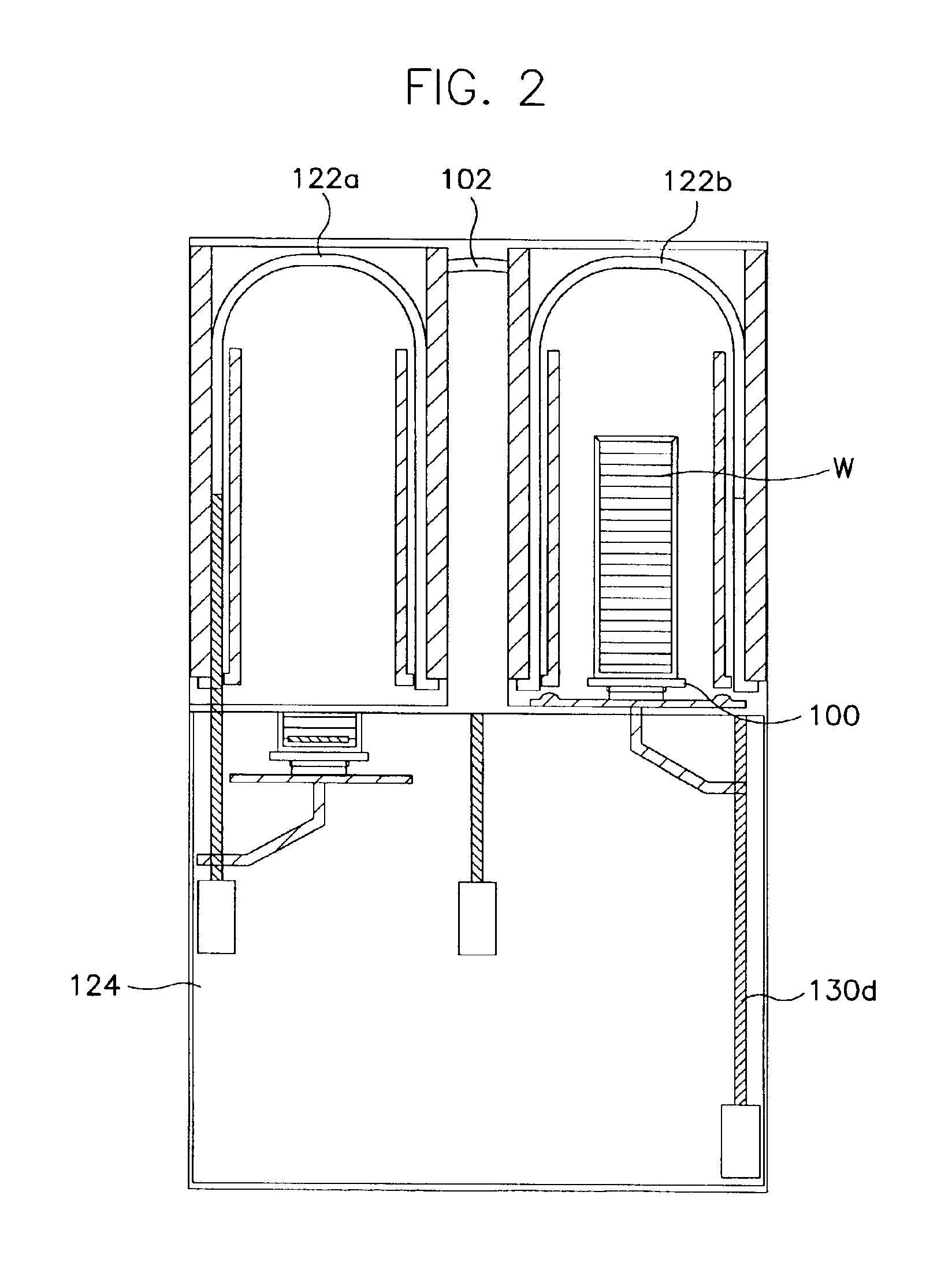

Thermal processing furnace and liner for the same

ActiveUS8398773B2Easy to transportMinimized in sizeDomestic stoves or rangesRotary drum furnacesEngineeringReaction tube

A thermal processing furnace, comprising:a generally bell jar-shaped outer reaction tube having a central axis; andan open-ended inner reaction tube for accommodating a wafer boat holding a plurality of substrates, which inner reaction tube is substantially coaxially disposed within the outer reaction tube, thereby defining a gas passage between an outer wall of the inner reaction tube and an inner wall of the outer reaction tube,wherein at least one of the outer wall of the inner reaction tube and the inner wall of the outer reaction tube is provided with a flow deflector that protrudes radially from the respective wall into the gas passage.

Owner:ASM INTERNATIONAL

Load storage equipment

InactiveUS6846146B2Easy constructionCharge manipulationStorage devicesVertical axisMechanical engineering

Load storage equipment according to the present invention includes rotary racks 21, each of which is supported independently on a story 1 or 2, and which may not extend vertically through the slab 4 between the stories 1 and 2. The storage equipment also includes a transferrer 51 common to the rotary racks 21. Each of the rotary racks 21 can turn on a vertical axis 22 and includes load supports 32 arranged circumferentially around the vertical axis 22 and vertically. The transferrer 51 extends vertically near the sides of the rotary racks 21 and through the slab 4. The transferrer 51 includes a carrier 81, which can vertically move to carry loads to and from the load supports 32.

Owner:DAIFUKU CO LTD

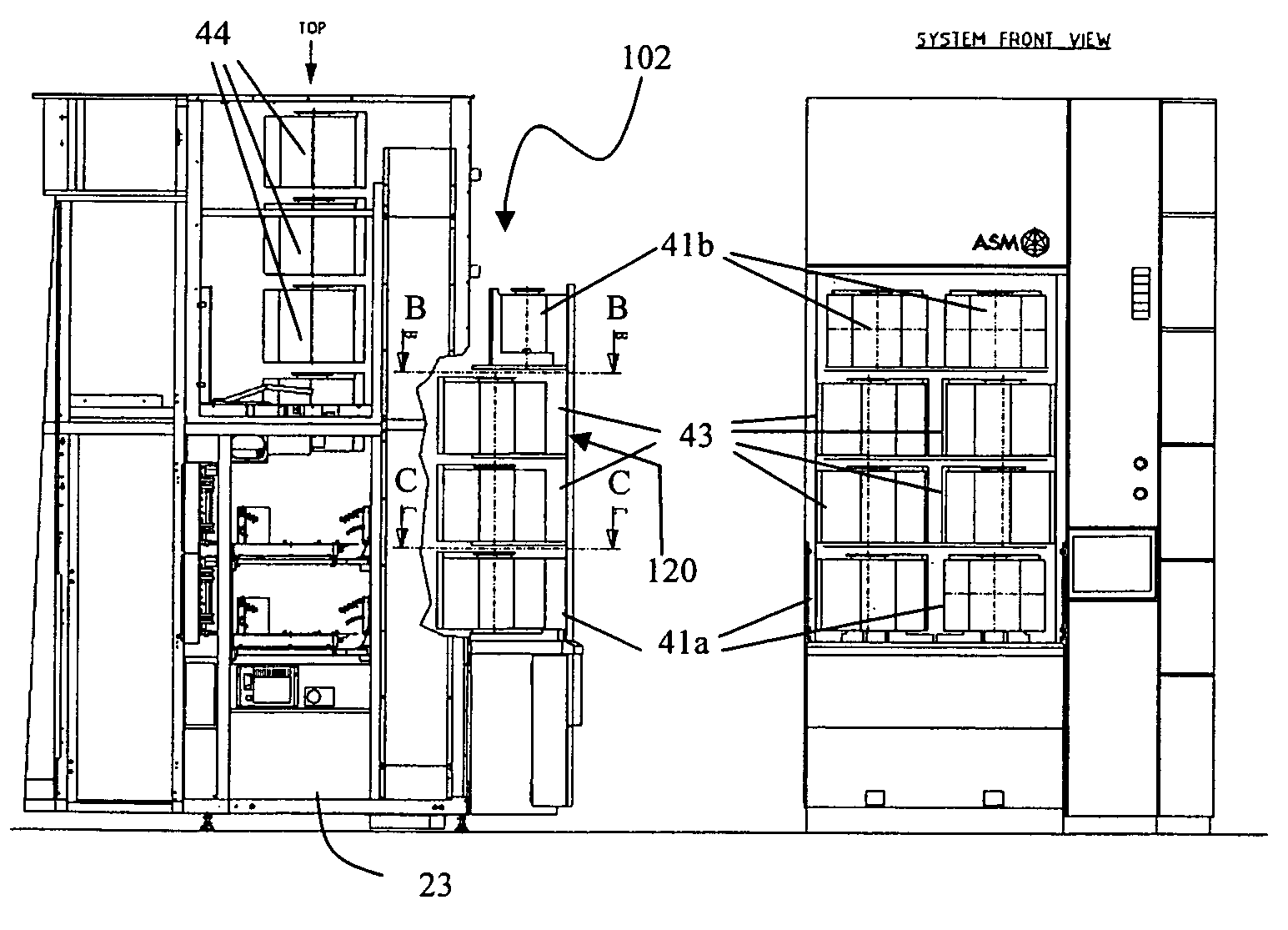

Processing system with increased cassette storage capacity

ActiveUS7740437B2Semiconductor/solid-state device manufacturingCharge manipulationMagnetic tapeEngineering

Owner:ASM IP HLDG BV

Apparatus for storing and moving a cassette

InactiveUS6283692B1Semiconductor/solid-state device manufacturingCharge manipulationDocking stationMagnetic tape

A cassette stocker includes a plurality of cassette storage shelves positioned adjacent a cleanroom wall above a cassette docking station, and a cassette mover to carry a cassette between the shelves and the docking station. An interstation transfer apparatus includes an overhead support beam and a transfer arm adapted to carry a cassette between processing stations.

Owner:APPLIED MATERIALS INC

Article transport device

InactiveUS20070034477A1Small and simpleSemiconductor/solid-state device manufacturingControl devices for conveyorsSolid of revolution

Owner:DAIFUKU CO LTD

Substrate processing apparatus

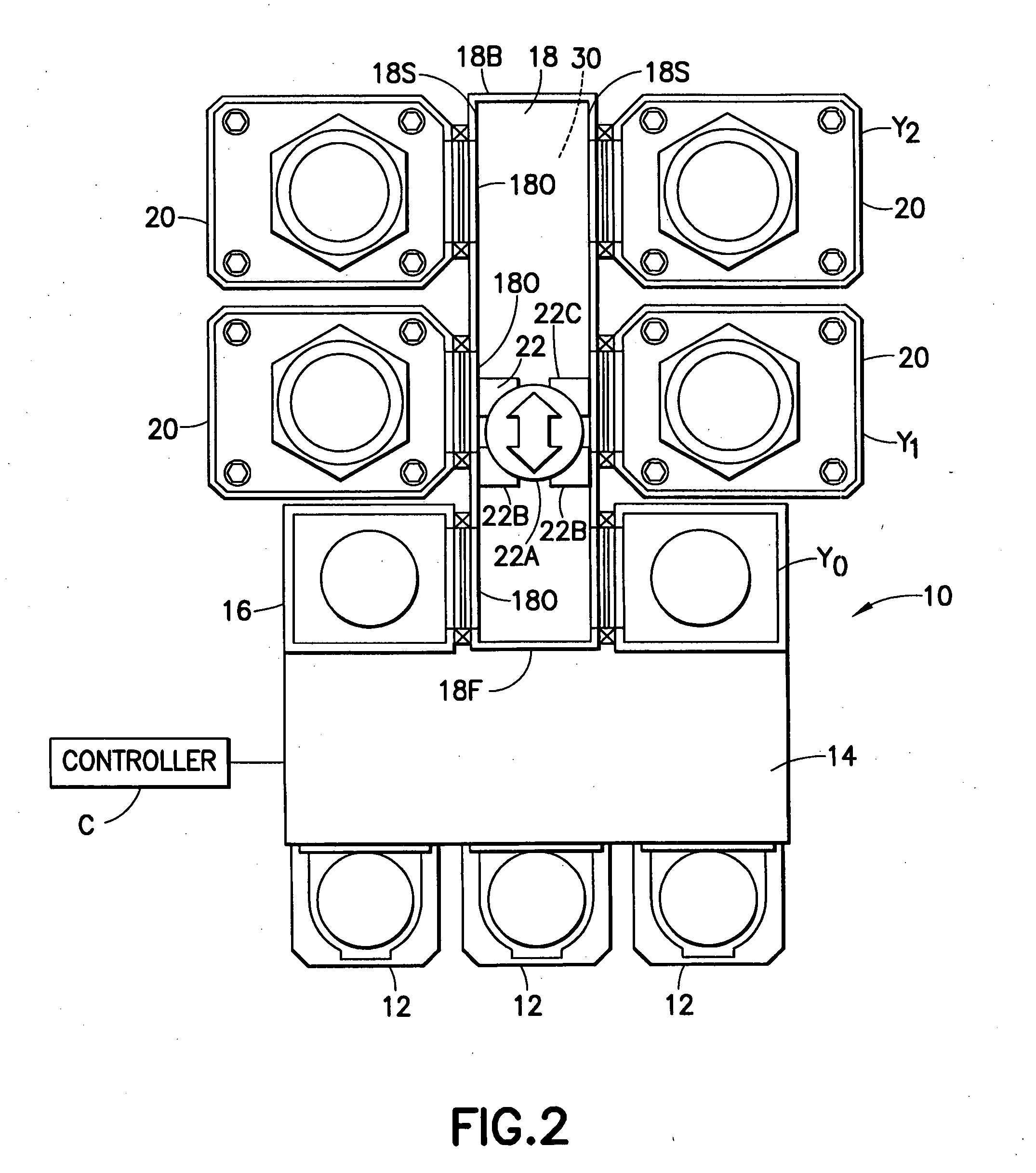

Substrate processing apparatus having a chamber, a generally linear array of process modules, a substrate transport, and a drive system. The chamber is capable of being isolated from the outside atmosphere. Each process module of the array is communicably connected to the chamber to allow a substrate to be transferred between the chamber and process module. The substrate transport is located in and is movably supported from the chamber. The transport is capable of moving along a linear path defined by the chamber for transporting the substrate between process modules. The drive system is connected to the chamber for driving and moving the transport along the linear path. The chamber comprises a selectable number of chamber modules serially abutted to defined the chamber. Each module has an integral portion of the drive system.

Owner:BOOKS AUTOMATION US LLC

Thermal treatment apparatus, temperature control system, thermal treatment method, temperature control method, and non-transitory computer readable medium embodied with program for executing the thermal treatment method or the temperature control method

InactiveUS20130065189A1Avoid it happening againIncrease power consumptionSemiconductor/solid-state device manufacturingCharge manipulationControl flowTemperature control

A thermal treatment apparatus includes a processing container, a substrate holding unit for holding a plurality of substrates at predetermined intervals in a direction inside the processing container, a heating unit for heating the processing container, a supply unit for supplying gas, a plurality of supply ports provided respectively at different locations in the direction, and a cooling unit for cooling the processing container by supplying the gas into the processing container by the supply unit via each of the supply ports, wherein the supply unit is provided in such a way that the supply unit independently controls flow rates of the gases supplied via each of the supply ports.

Owner:TOKYO ELECTRON LTD

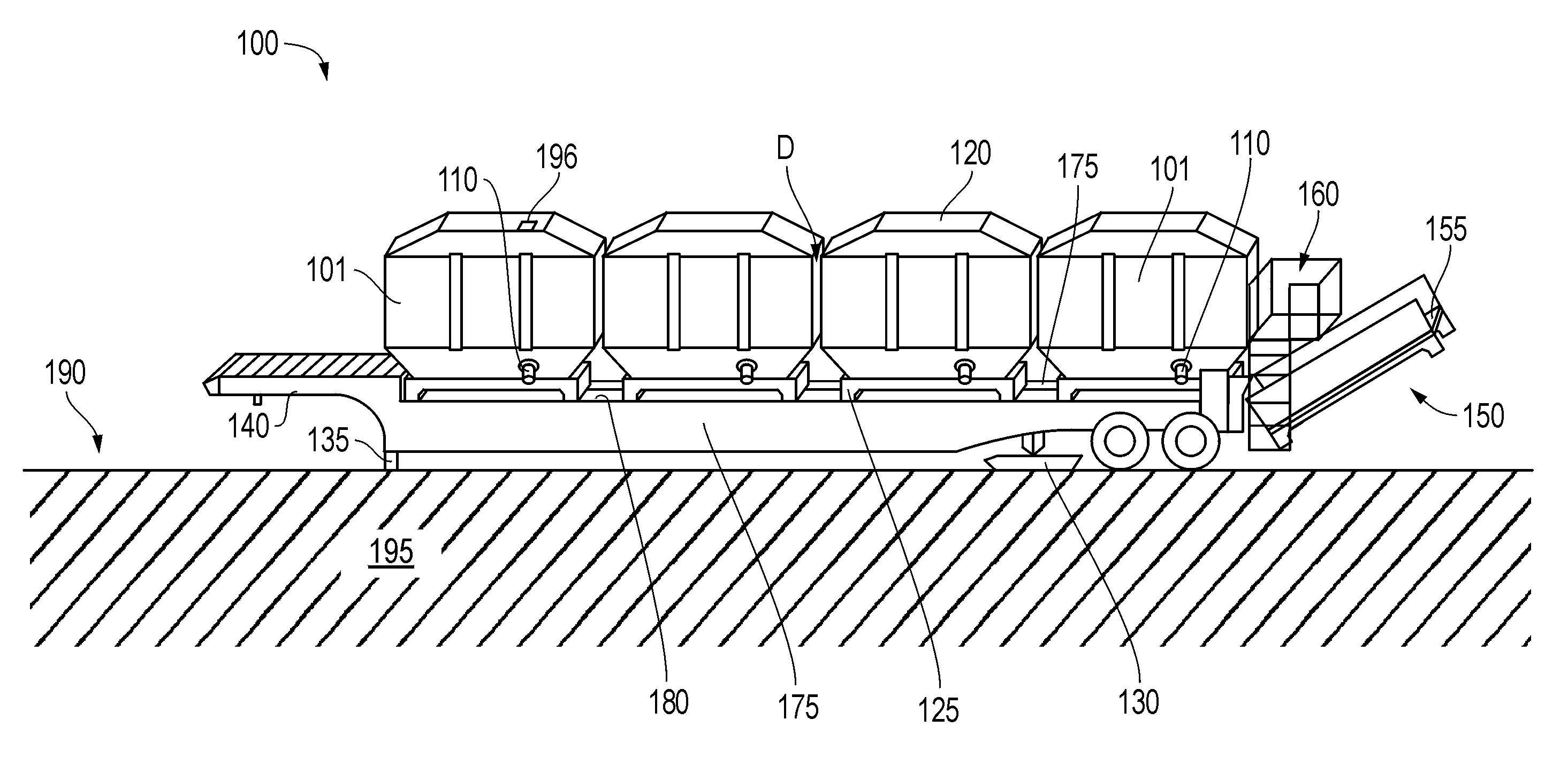

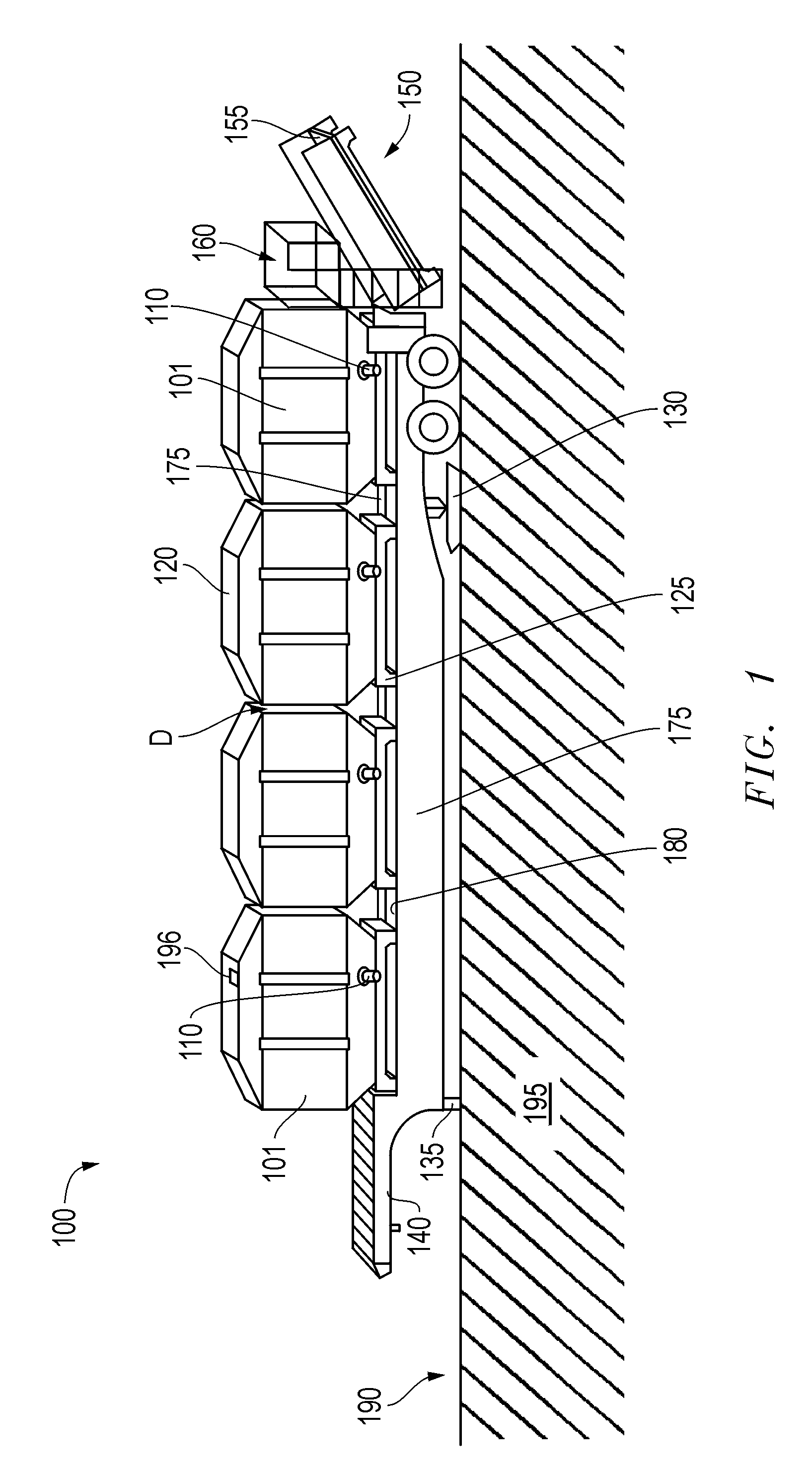

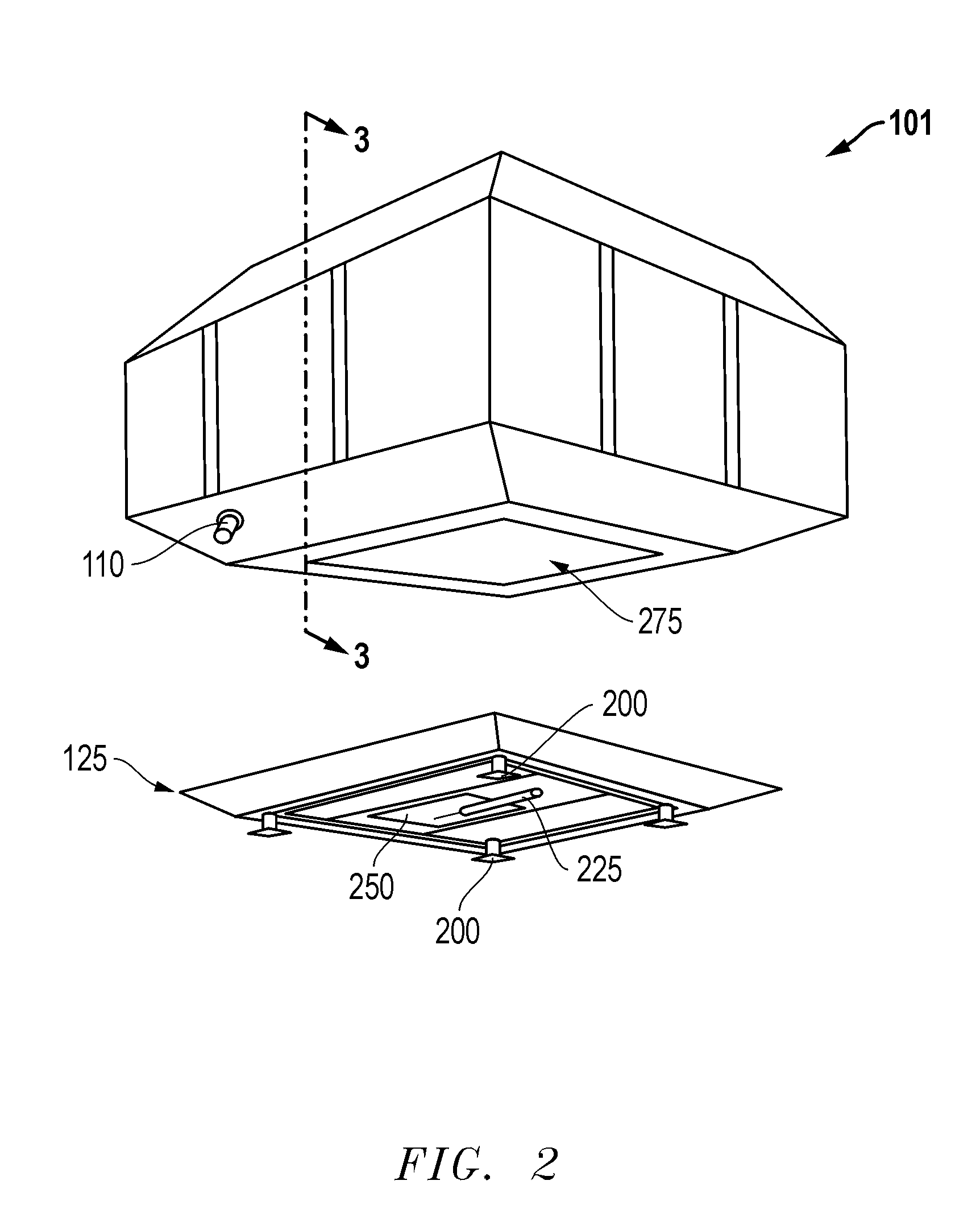

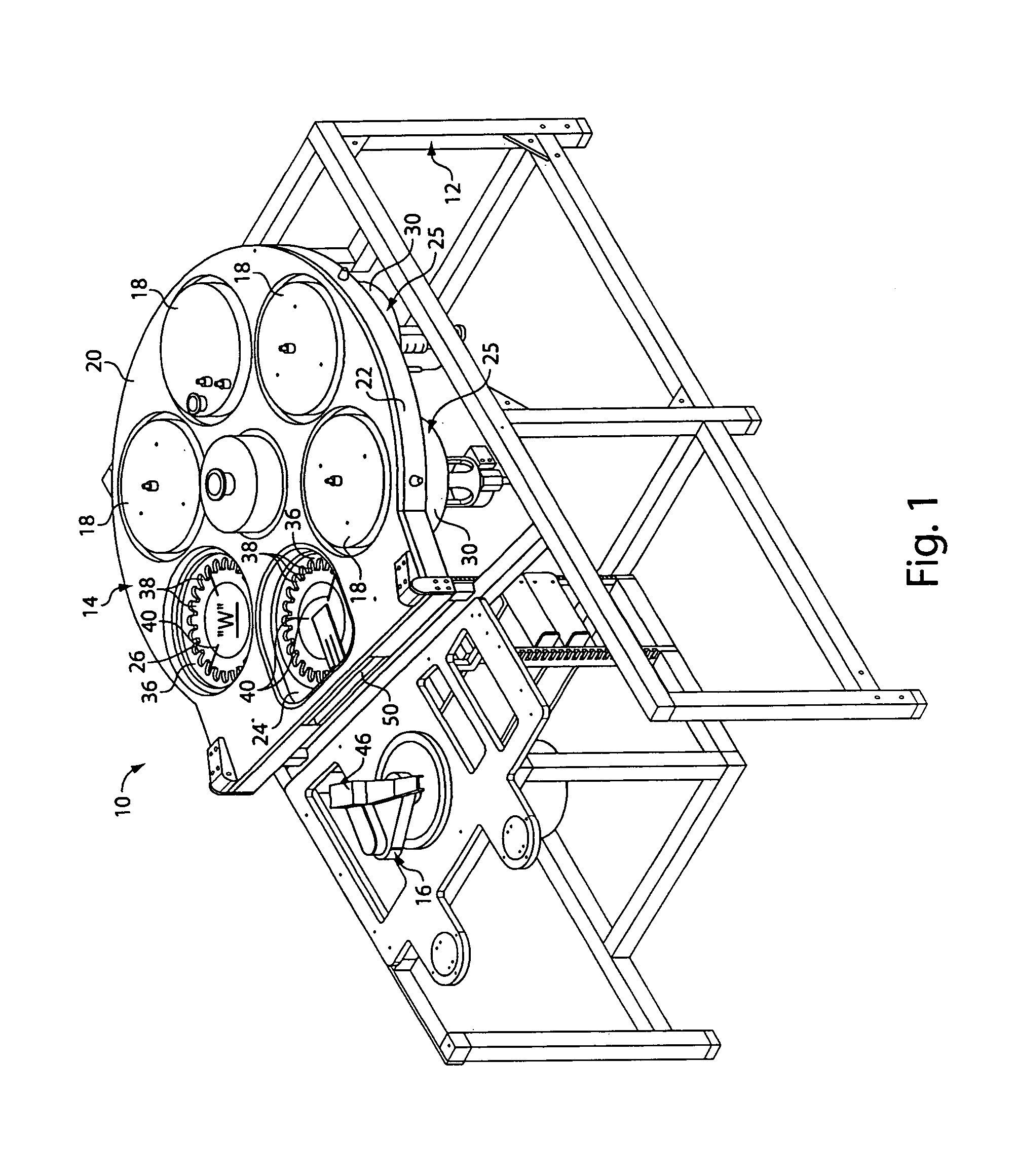

Aggregate Delivery Unit

A delivery unit for providing aggregate to a worksite, such as a wellsite location. The unit may include a mobile chassis for accommodating a plurality of modular containers which in turn house the aggregate. As such, a weight measurement device may be located between each container and the chassis so as to monitor aggregate levels within each container over time. The units may be particularly well suited for monitoring and controlling aggregate delivery during a fracturing operation at an oilfield. The modular containers may be of an interchangeable nature. Furthermore, a preferably wireless control device may be provided for monitoring and directing aggregate delivery from a relatively remote location.

Owner:SCHLUMBERGER TECH CORP

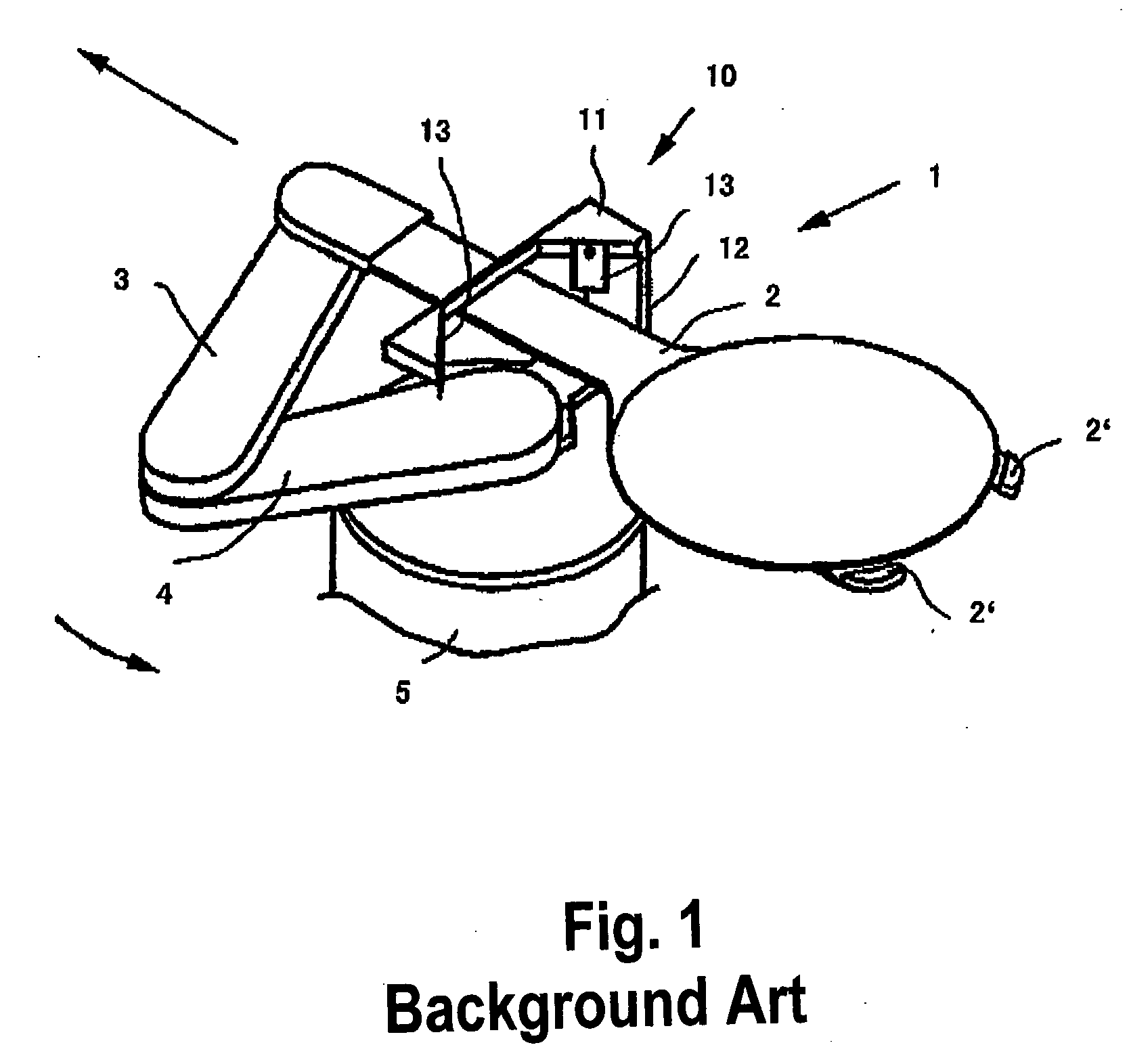

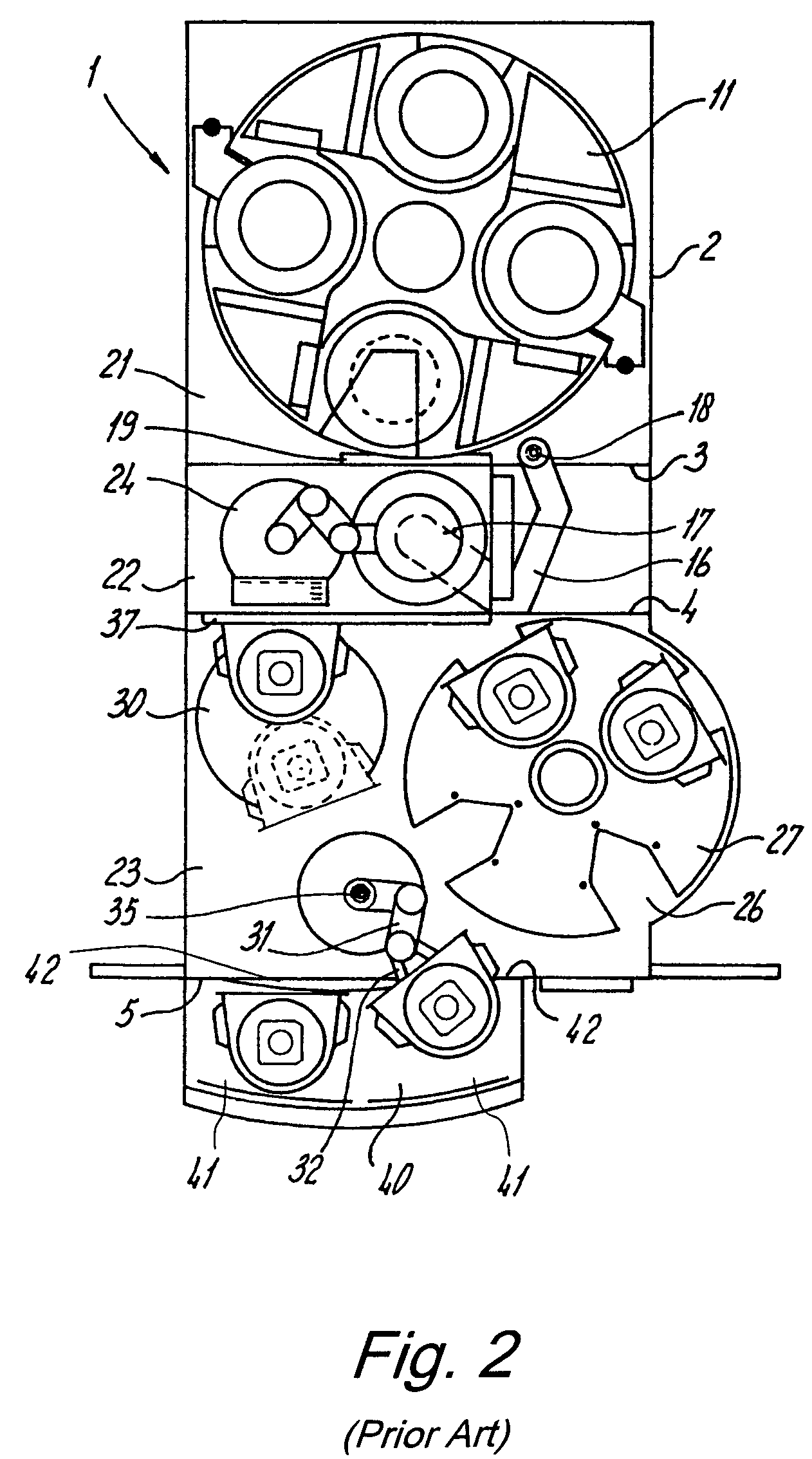

Isolation chamber arrangement for serial processing of semiconductor wafers for the electronic industry

InactiveUS7008879B2Simplifies loading and unloadingOptimization mechanismSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingBiochemical engineeringComputer module

An apparatus for the treatment of semiconductor wafers, comprising a supportive frame and a process table arranged on the supportive frame. The process table comprises a stationary upper platen and a stationary lower plate. An intermediate indexing plate is rotatively arranged between the upper platen and the lower plate. At least one wafer support pin is attached to the indexing plate for the support of a wafer by the indexing plate. An upper housing is arranged on the upper platen and an outer lower housing is arranged on the lower plate. A displacable lower isolation chamber is disposed within the outer lower housing, being displacable against the indexing plate to define a treatment module between the upper housing and the lower isolation chamber in which the wafer is treated. A wafer supporting treatment plate is arranged within the lower isolation chamber, for controlled rapid treatment of a wafer within the treatment module.

Owner:SEMLGEAR INC

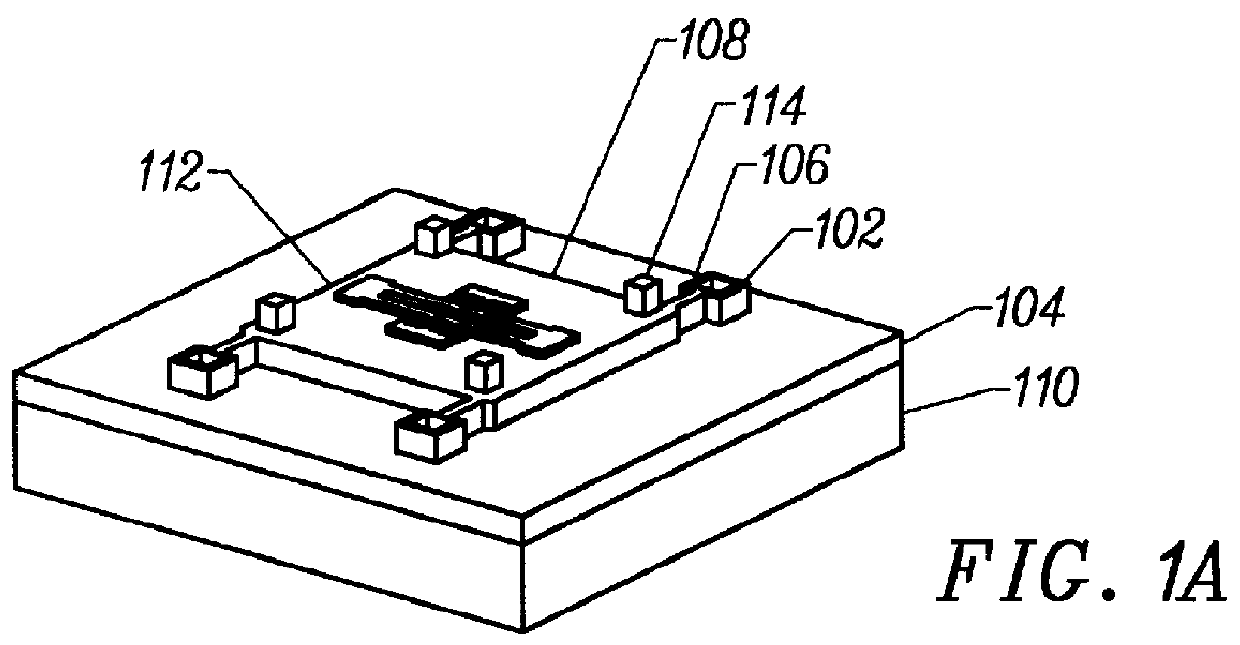

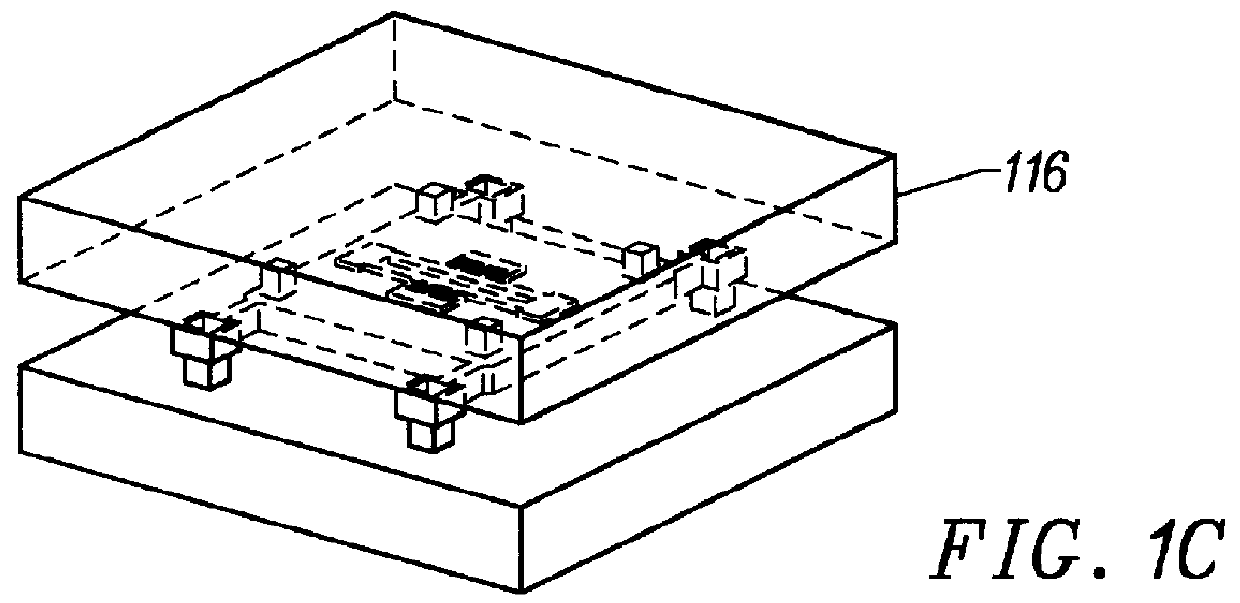

Wafer-to-wafer transfer of microstructures using break-away tethers

InactiveUS6142358AReduce tensionSemiconductor/solid-state device detailsWelding/cutting auxillary devicesOptoelectronicsMicrostructure

Break-away tethers to secure electronic, mechanical, optical, or other microstructures, during release from one substrate and transfer to another. Microstructures are fabricated with integrated tethers attaching them to a first substrate. The structures are undercut by etching and contacted and bonded to a second substrate. First and second substrates are separated, breaking the tethers.

Owner:RGT UNIV OF CALIFORNIA

Thermal processing furnace and liner for the same

ActiveUS20120186573A1Easy to transportReduce decreaseDomestic stoves or rangesRotary drum furnacesEngineeringBell jar

A thermal processing furnace, comprising:a generally bell jar-shaped outer reaction tube having a central axis; andan open-ended inner reaction tube for accommodating a wafer boat holding a plurality of substrates, which inner reaction tube is substantially coaxially disposed within the outer reaction tube, thereby defining a gas passage between an outer wall of the inner reaction tube and an inner wall of the outer reaction tube,wherein at least one of the outer wall of the inner reaction tube and the inner wall of the outer reaction tube is provided with a flow deflector that protrudes radially from the respective wall into the gas passage.

Owner:ASM INTERNATIONAL

Dual loading port semiconductor processing equipment

InactiveUSRE43023E1Improve throughputDrying gas arrangementsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate processing equipment comprises two pod supporting stages and two independently operable pod door openers. Each pod supporting stage is capable of placing thereon a pod for containing substrates therein. Each pod door openers having means for permitting access to the substrates inside the pod placed on a corresponding pod supporting stage.

Owner:KOKUSA ELECTRIC CO LTD

Sorting/storage device for wafers and method for handling thereof

InactiveUS7077614B1Easy and less-expensive to produceReducing throughout capacitySemiconductor/solid-state device manufacturingCharge manipulationMeasurement stationBiomedical engineering

Sorting / storage device for wafers. A sorting device is provided in which at least two cassettes containing wafers may be present and the wafers are moved from one cassette to the other cassette or vice versa. If appropriate, a measuring station may be present in the sorting device. In the immediate vicinity of the sorting device, the cassettes are stored in a magazine which is designed for this purpose and the cassettes are moved using a handling device for cassettes.

Owner:ASM INTERNATIONAL

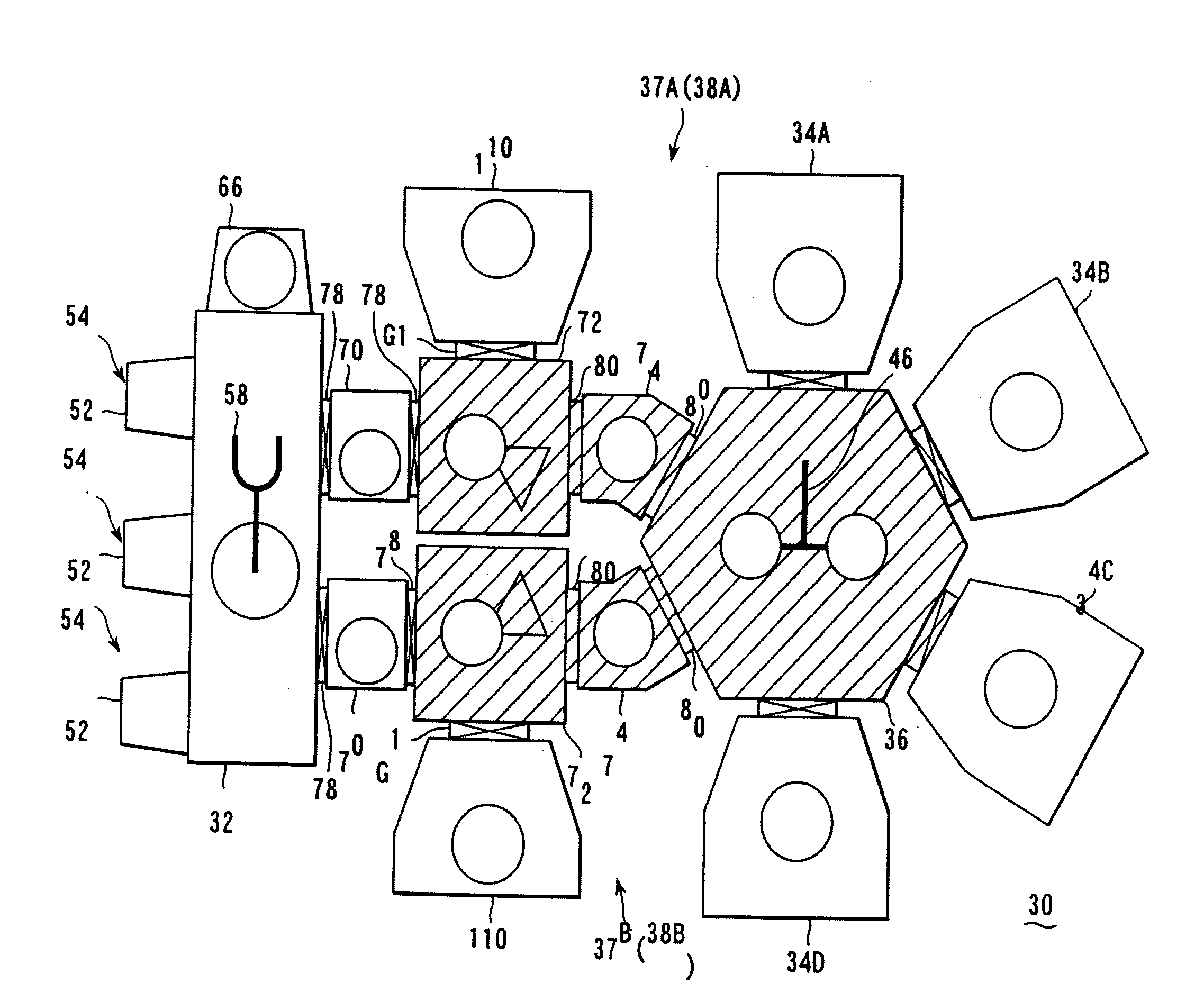

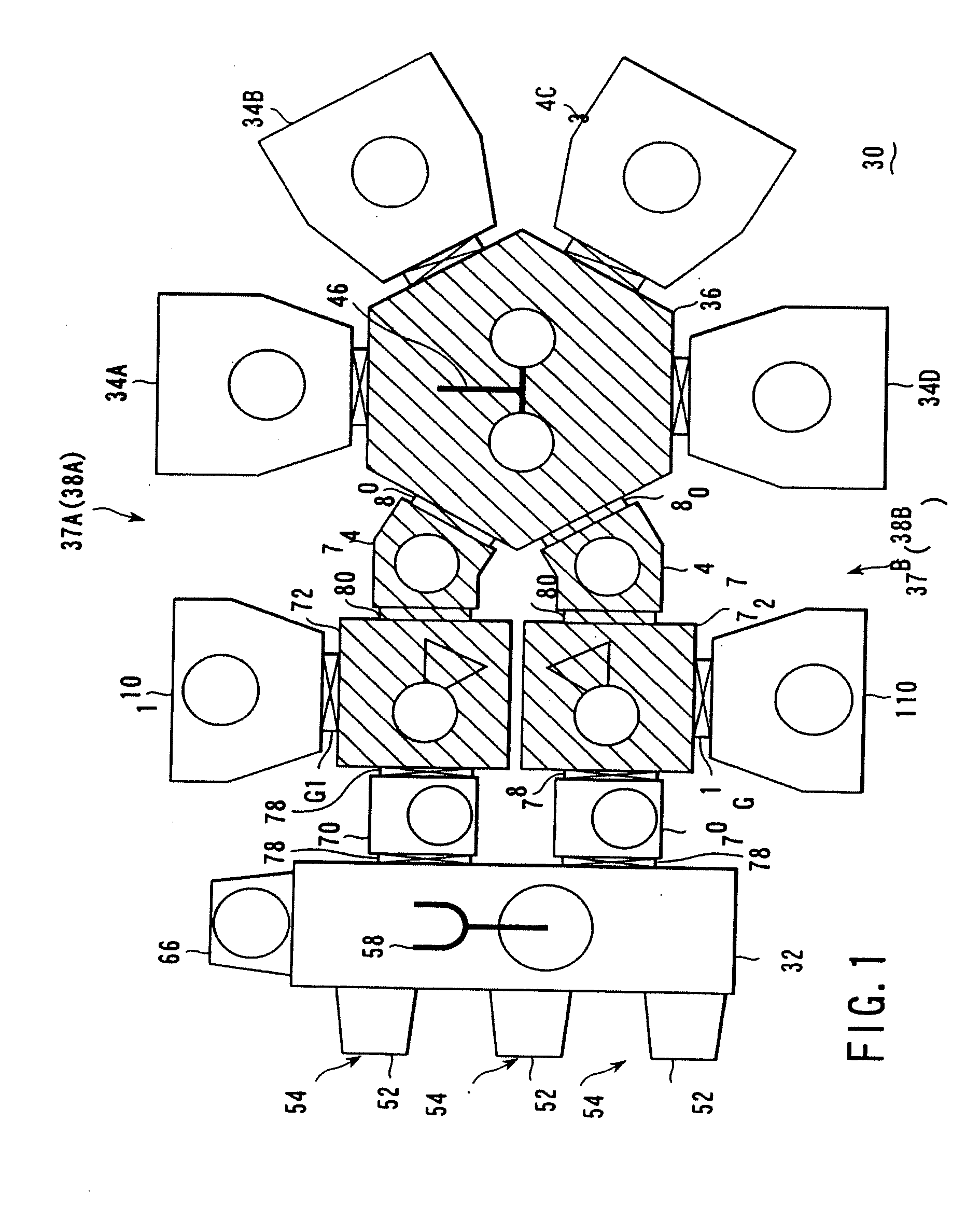

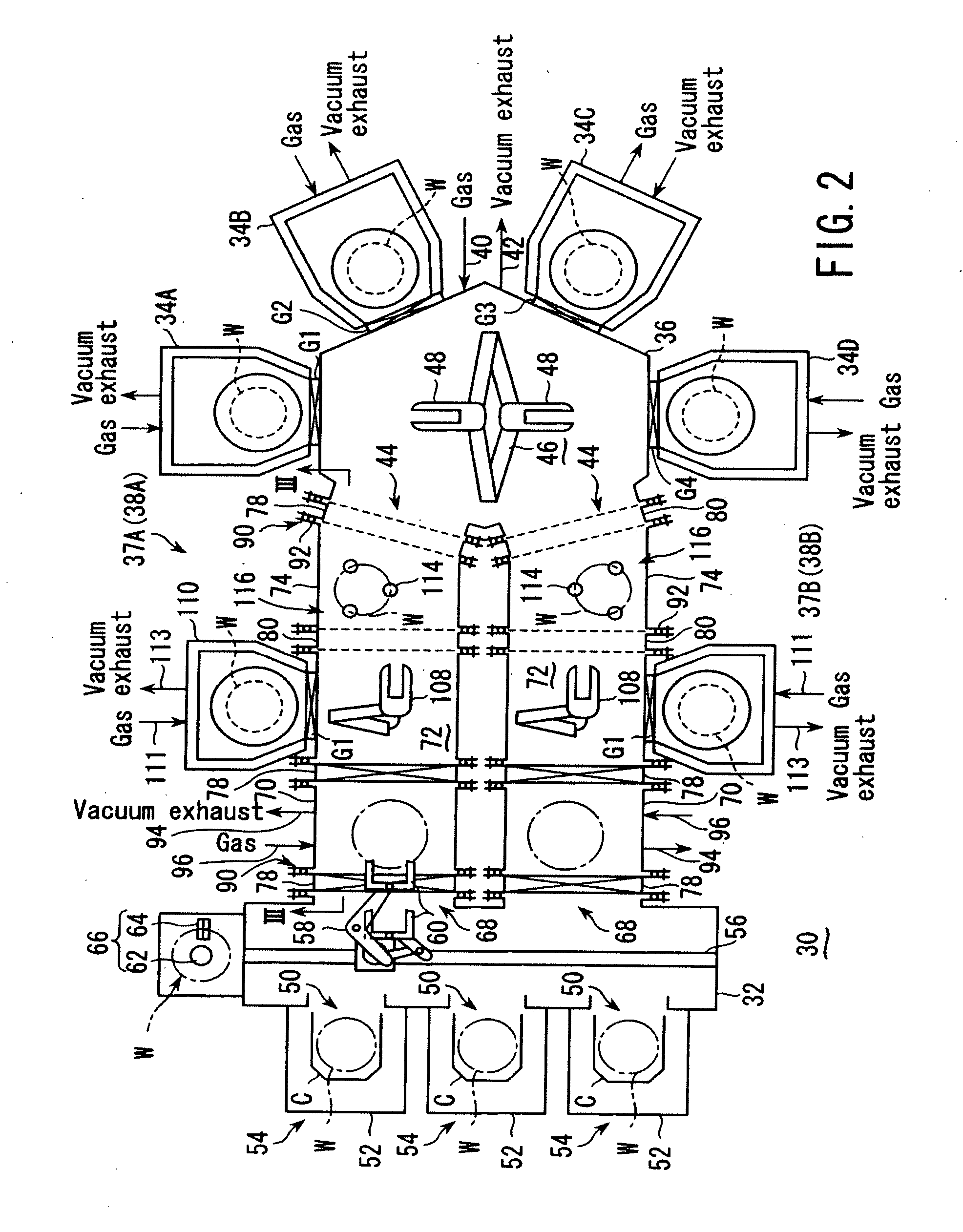

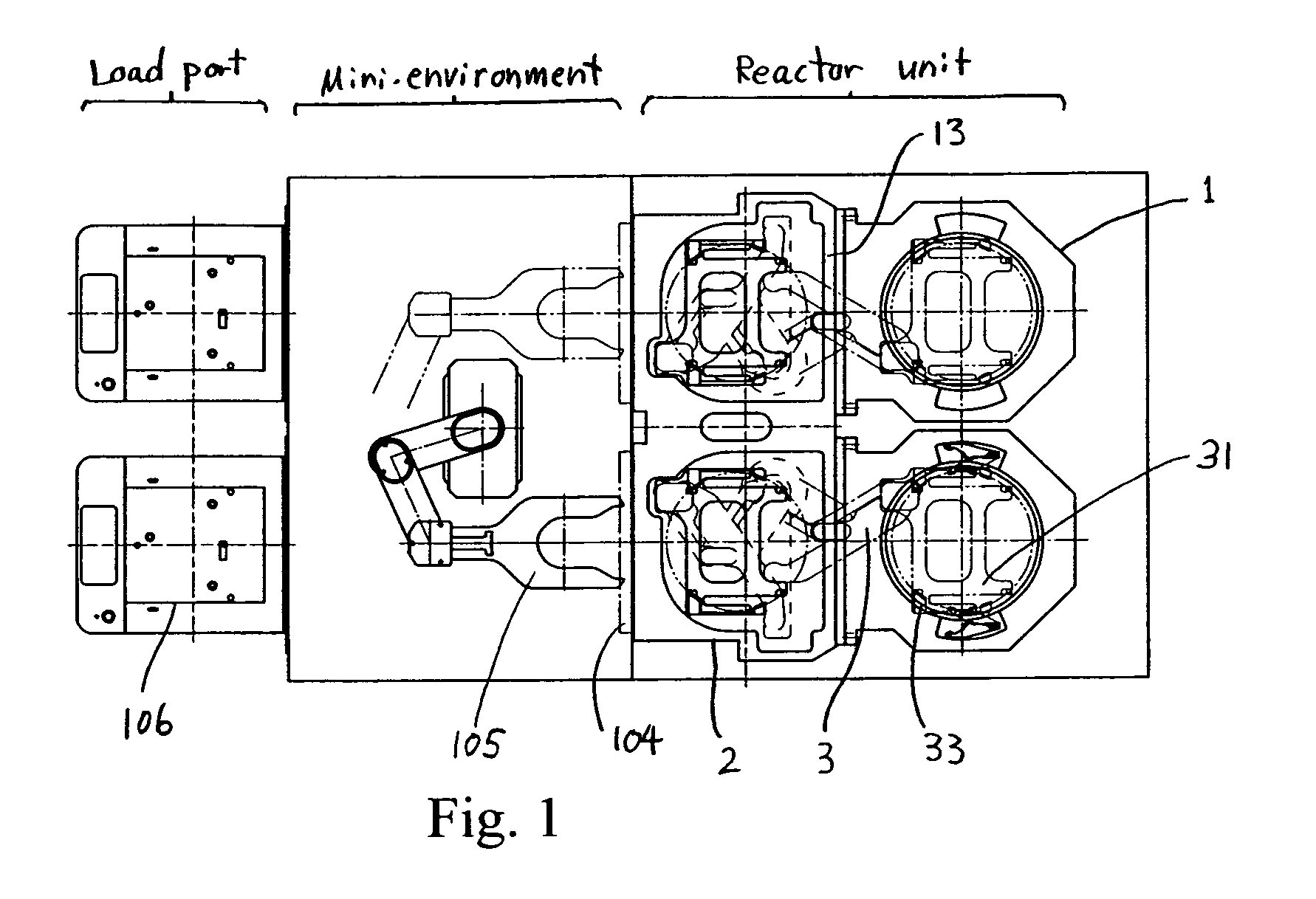

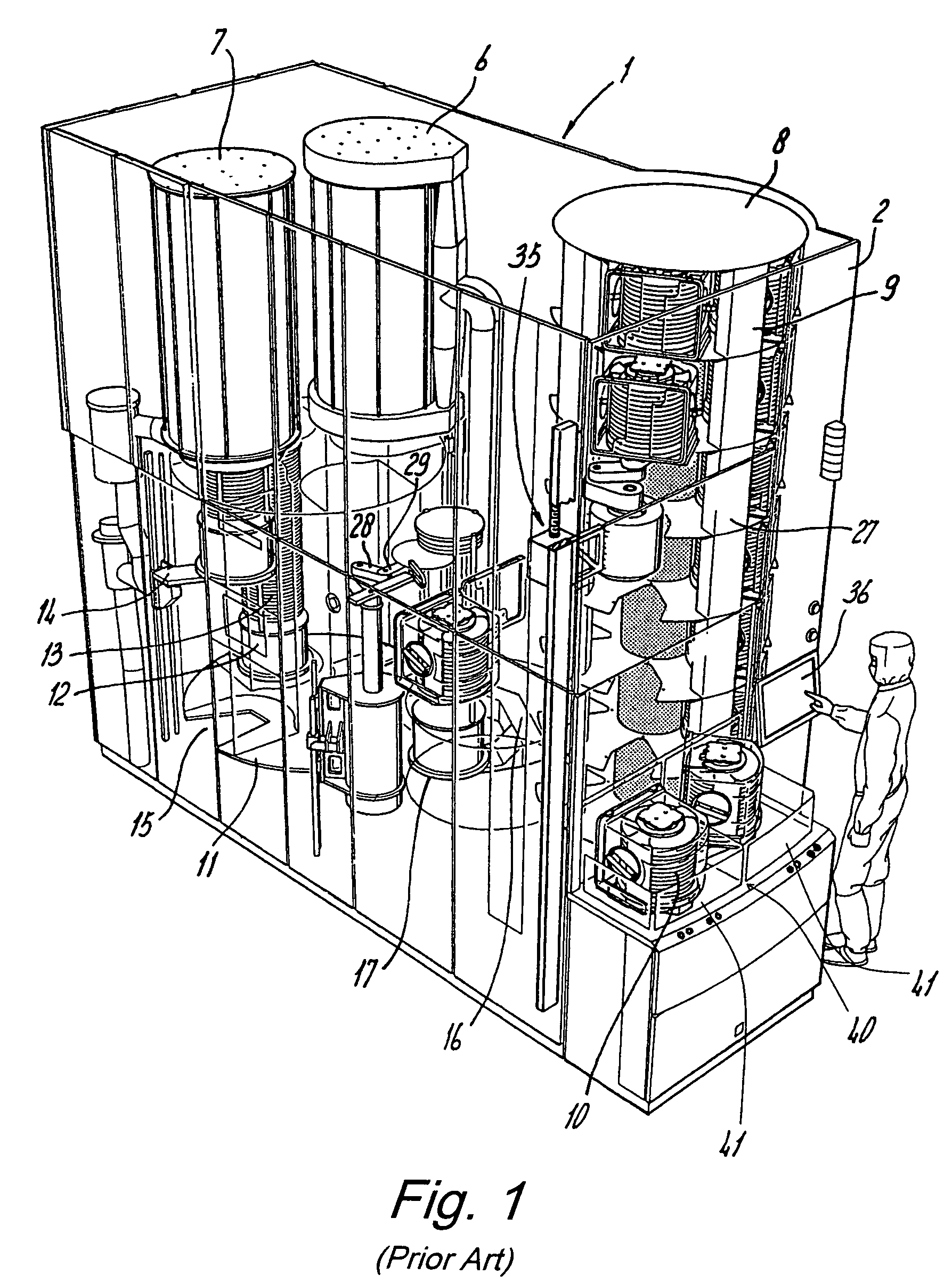

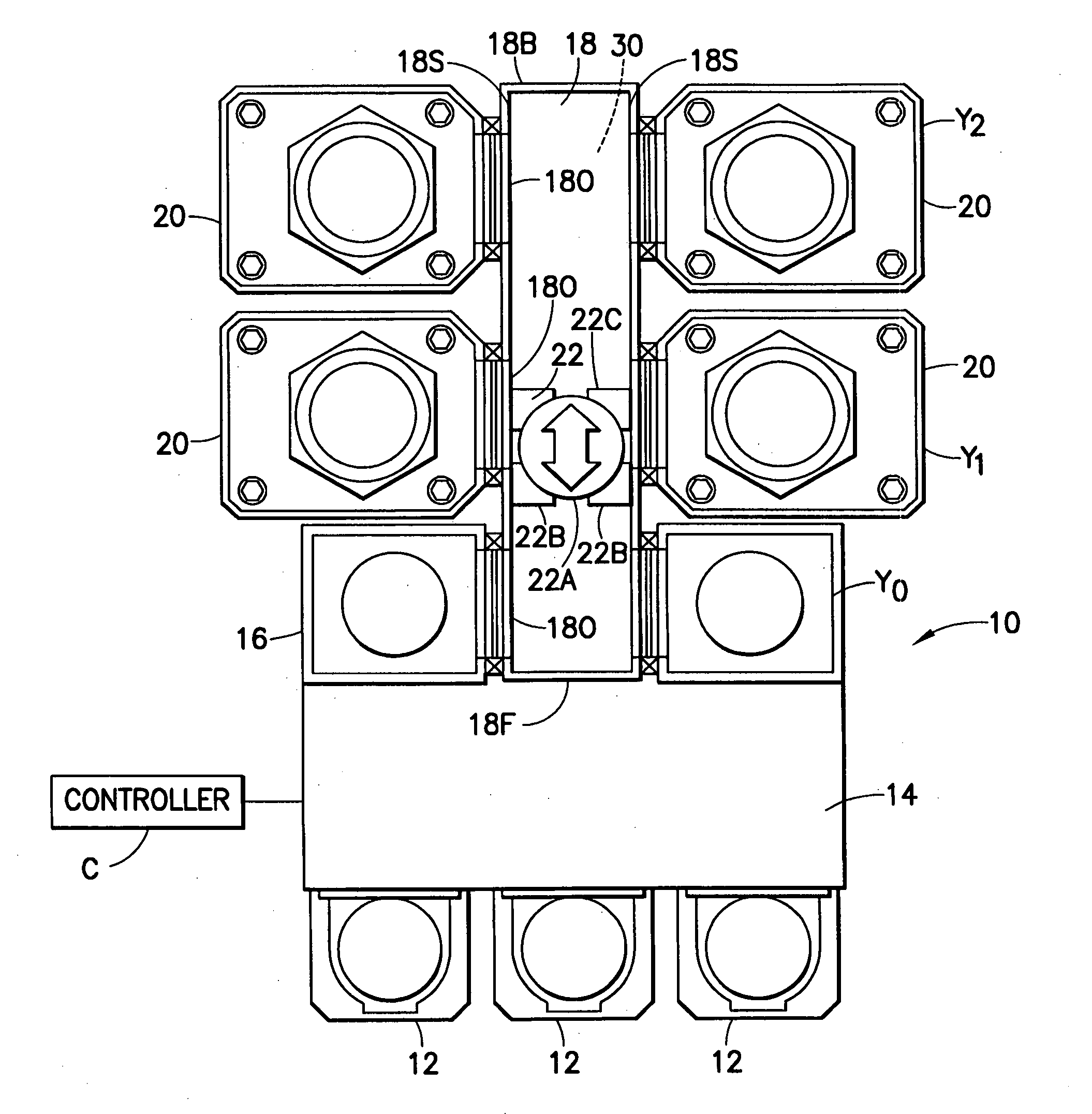

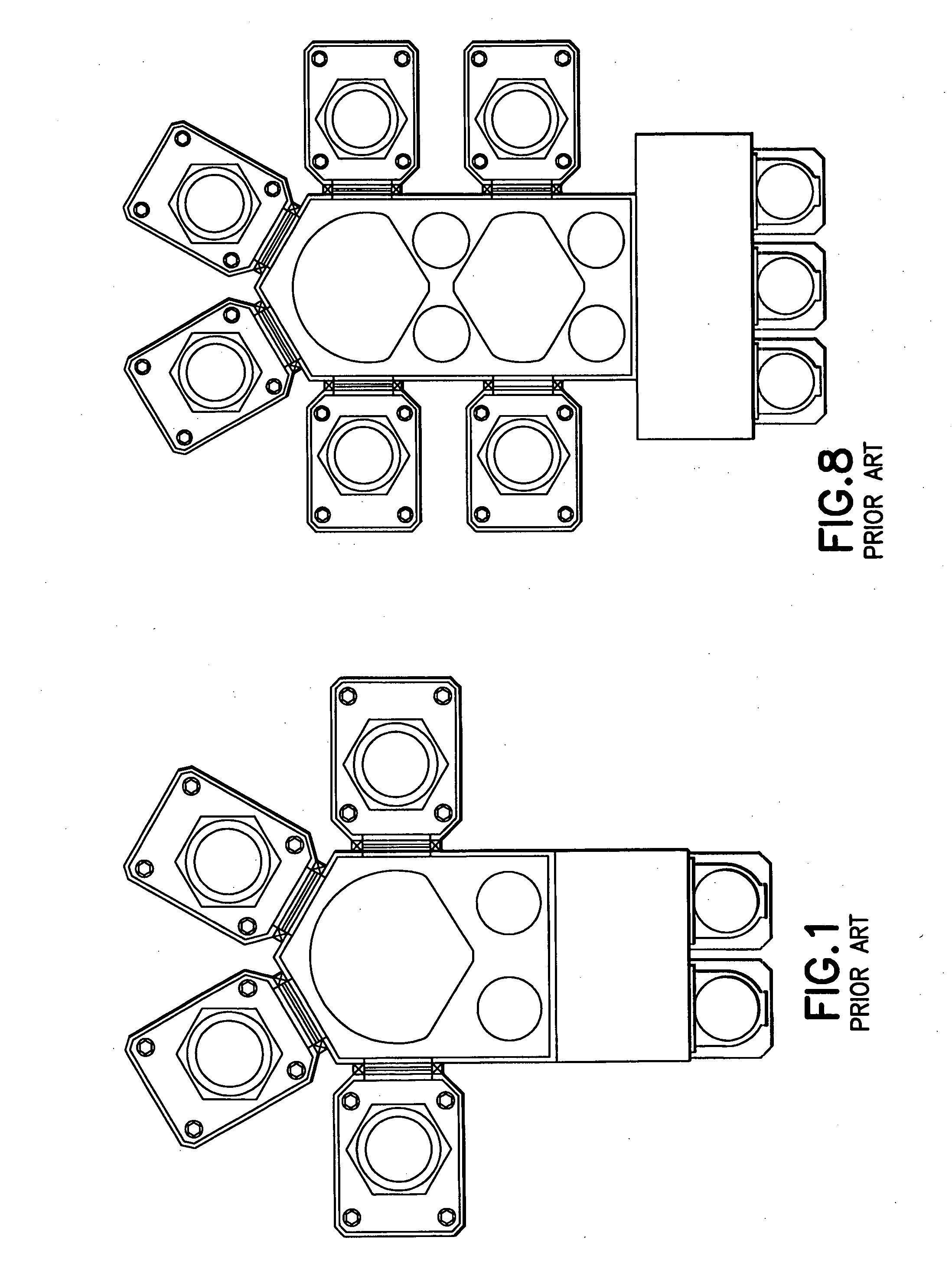

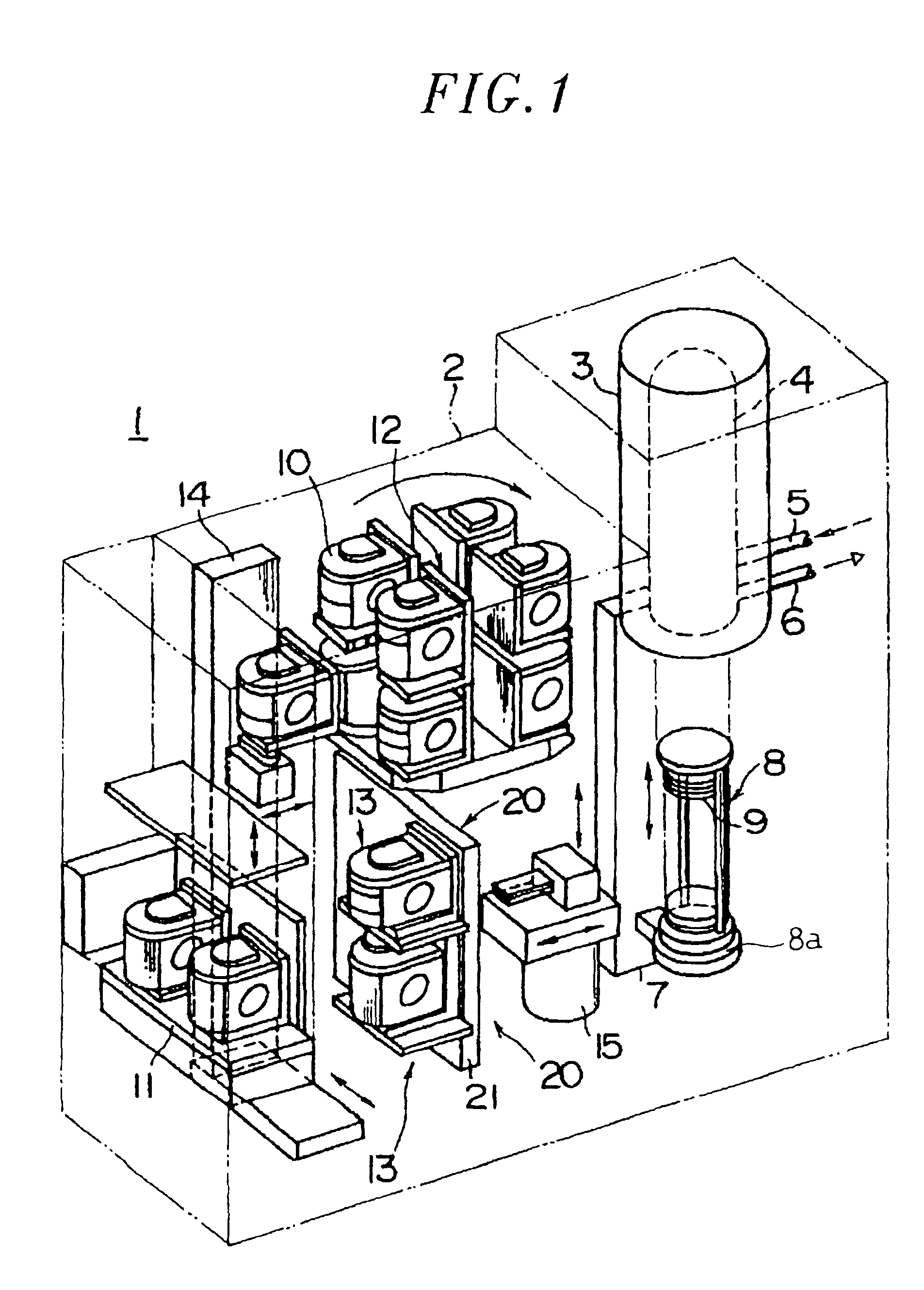

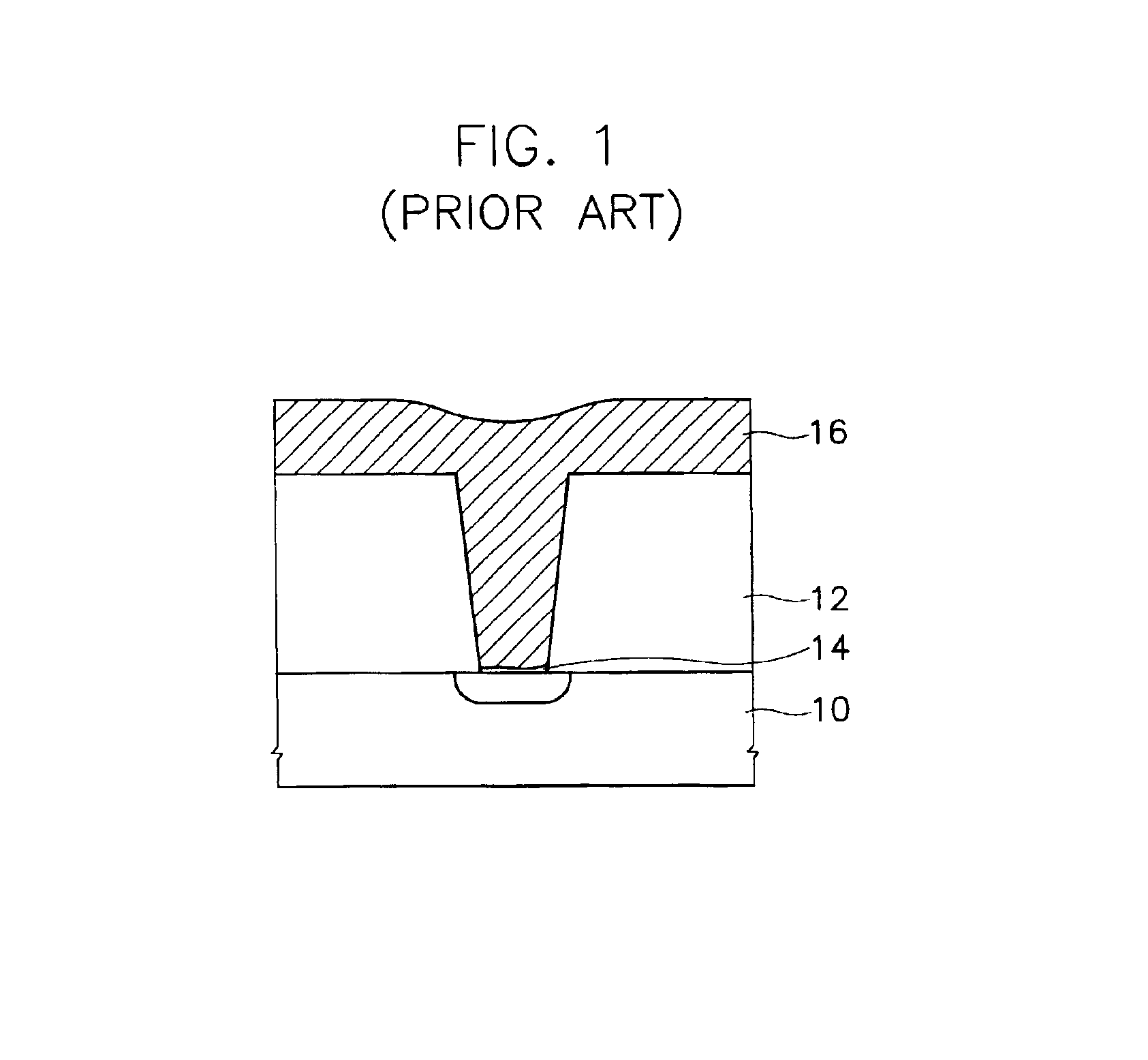

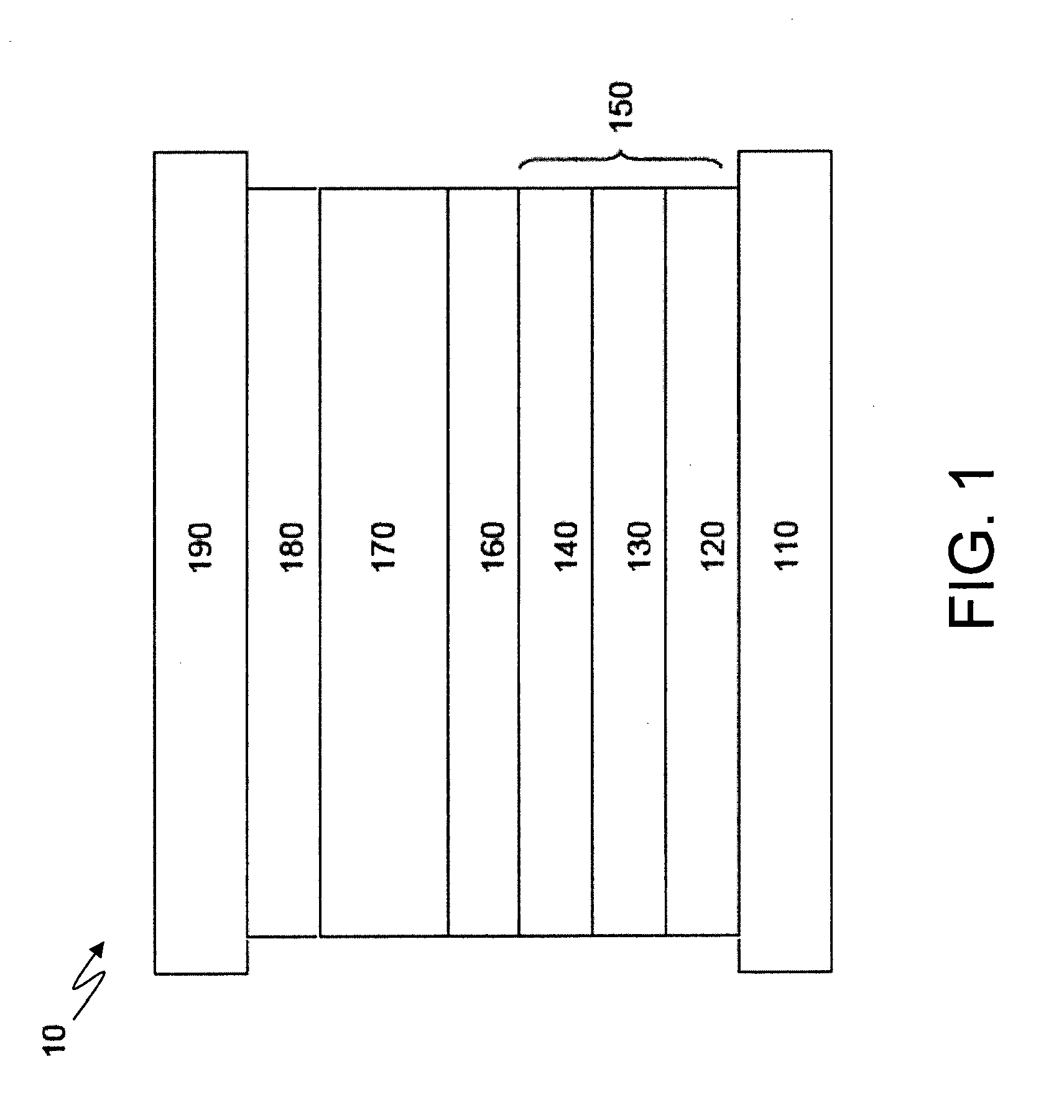

Method of and apparatus for performing sequential processes requiring different amounts of time in the manufacturing of semiconductor devices

InactiveUS6911112B2Without need for significant downtimeHigh productSemiconductor/solid-state device manufacturingCharge manipulationProduction rateDevice material

A method of manufacturing a semiconductor device includes first and second processes, the latter requiring more processing time. An apparatus for performing the semiconductor manufacturing process includes a first reactor, and a plurality of second reactors for each first reactor. A first group of wafers are subjected to the first process within the first reactor, and are then transferred into a second reactor as isolated from the outside air. The first group of wafers is subjected to the second process within the second reactor. At the same time, a second group of wafers are subjected to the first process within the first reactor. After the first process is completed, the second group of wafers is transferred into an unoccupied one of the second reactors as isolated from the outside air. There, the second group of wafers is subjected to the second process. Accordingly, process failures otherwise due to the exposure of the wafers are minimized, and productivity is high despite the difference in the processing times.

Owner:SAMSUNG ELECTRONICS CO LTD

Method and apparatus providing separate modules for processing a substrate

InactiveUS20130189635A1Semiconductor/solid-state device manufacturingCharge manipulationComputer moduleEngineering

A method and apparatus for heat treating a photovoltaic device. The apparatus includes a heating module, a processing module, and a cooling module in which the operating temperatures of the modules may be controlled separately. The heating module is configured to pre-heat a substrate and stabilize the substrate at the desired target temperature, the processing module is configured to thermally process the substrate, and the cooling module is configured for post-treatment cooling of the substrate.

Owner:JPMORGAN CHASE BANK NA

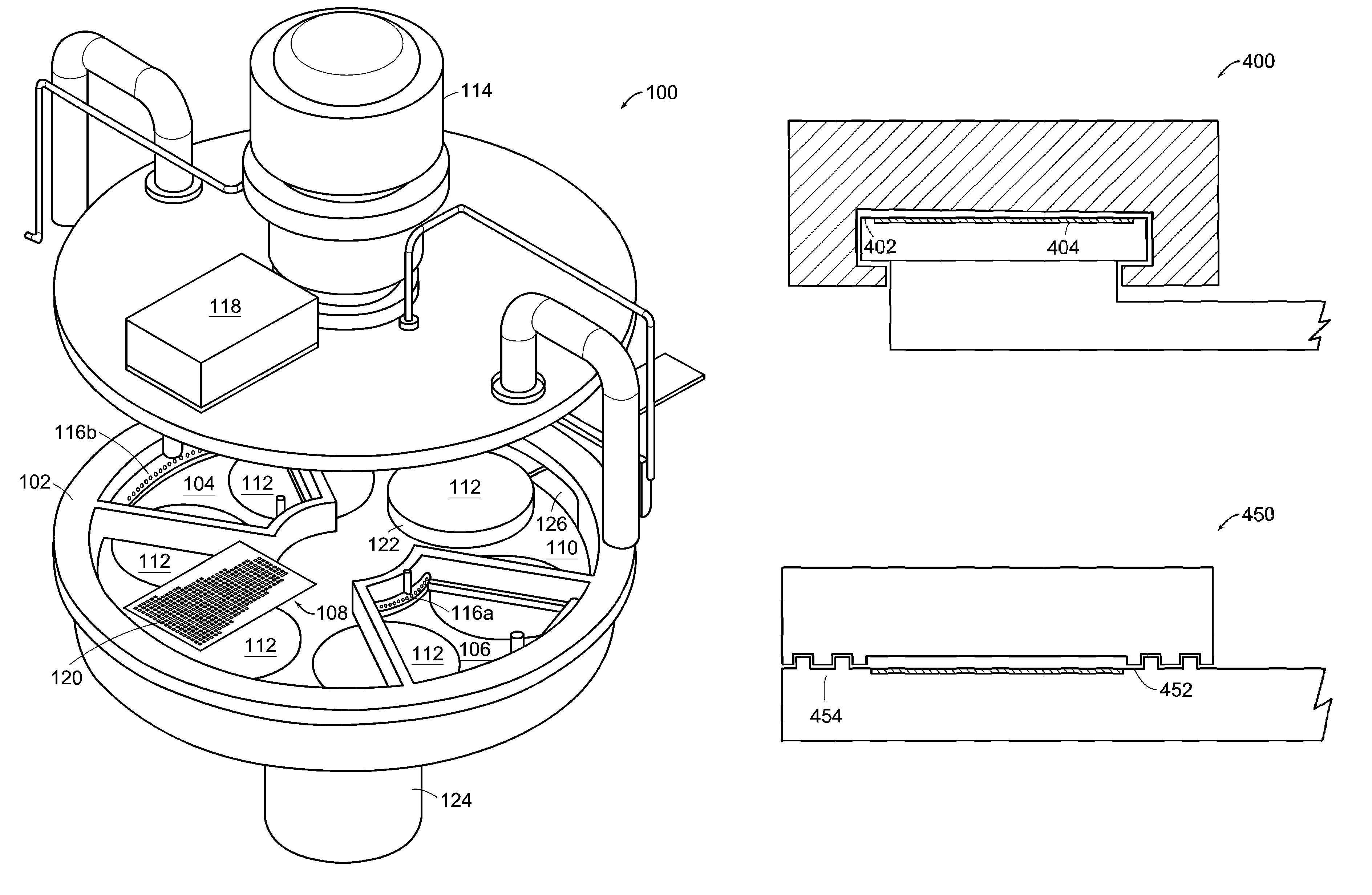

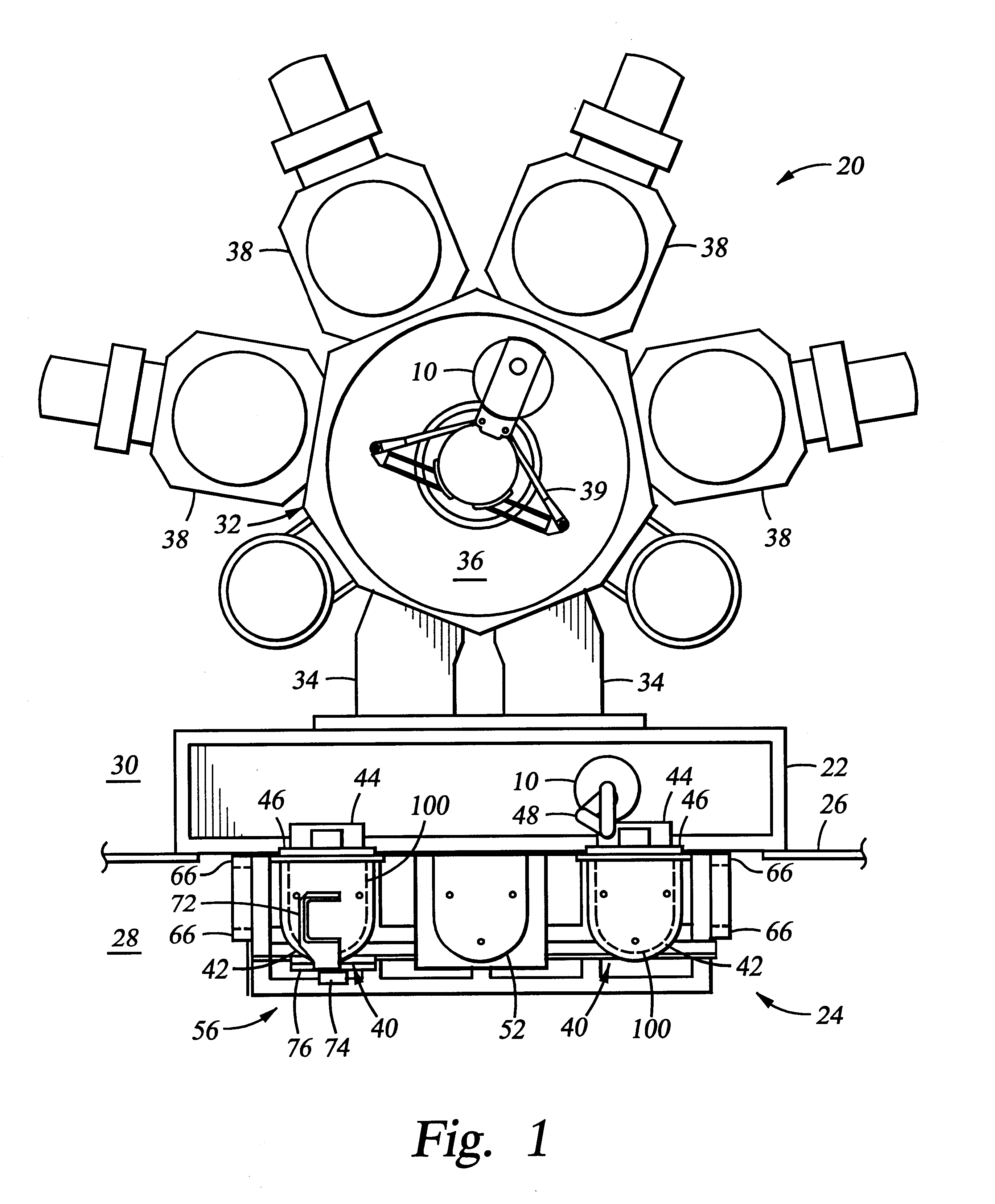

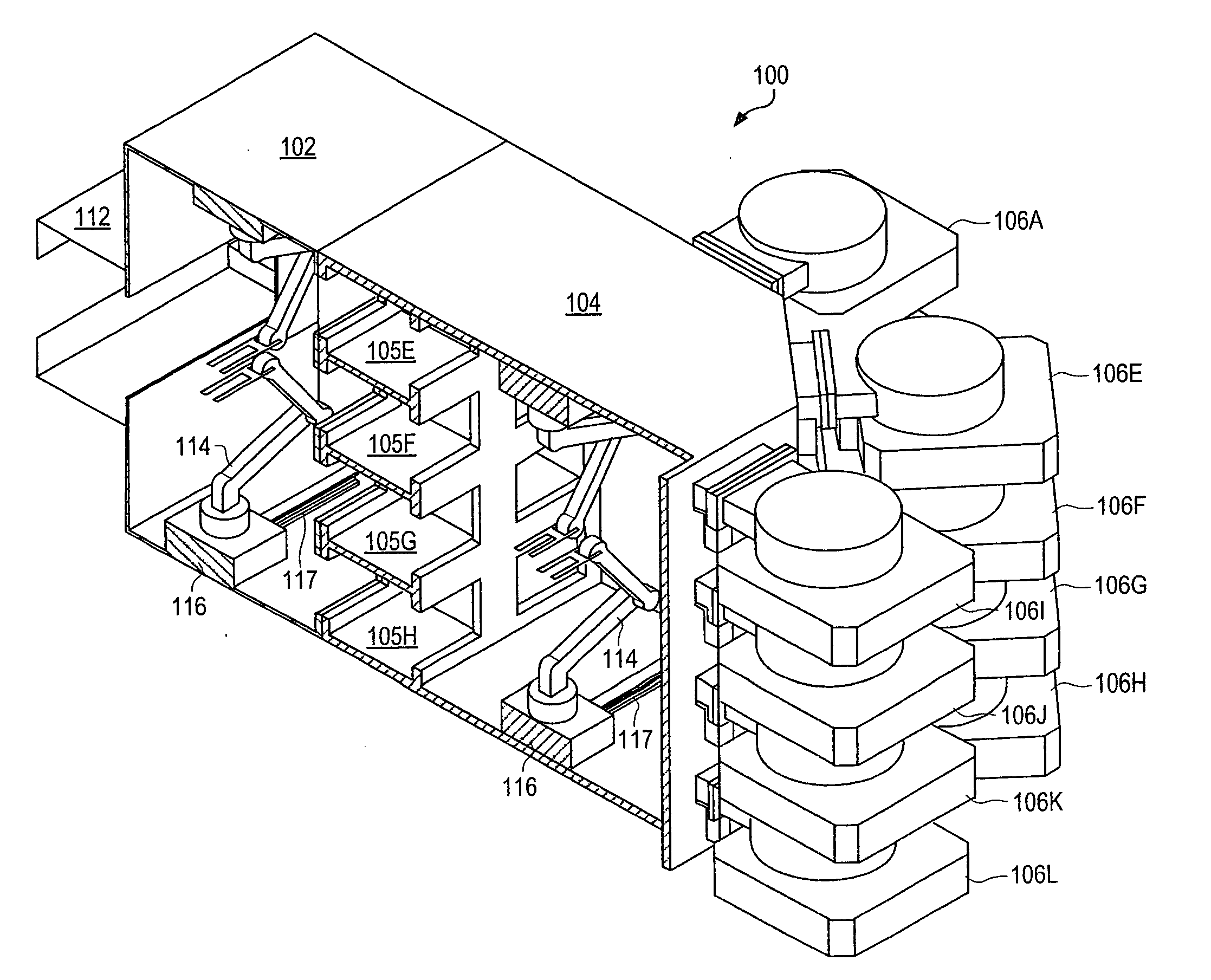

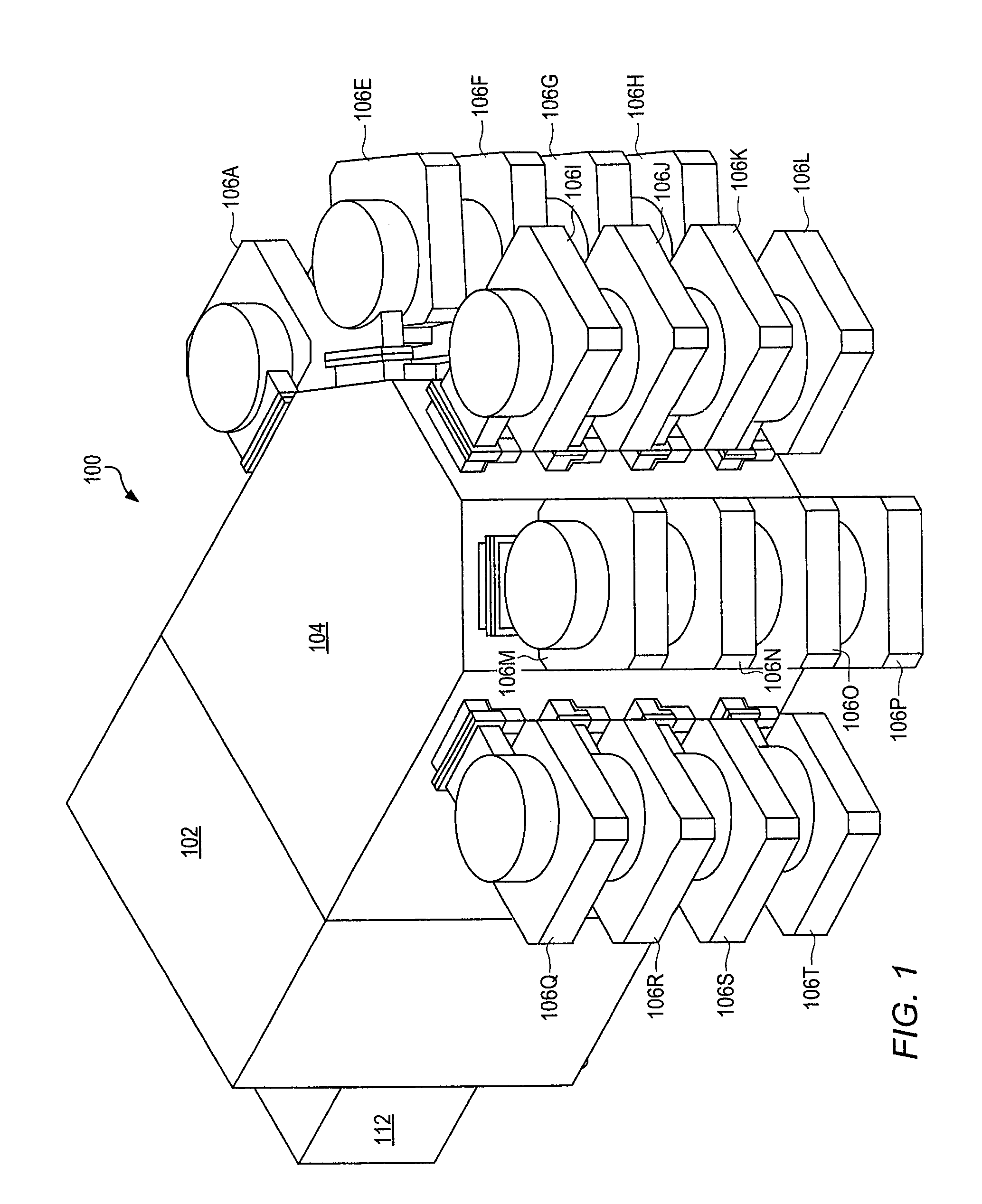

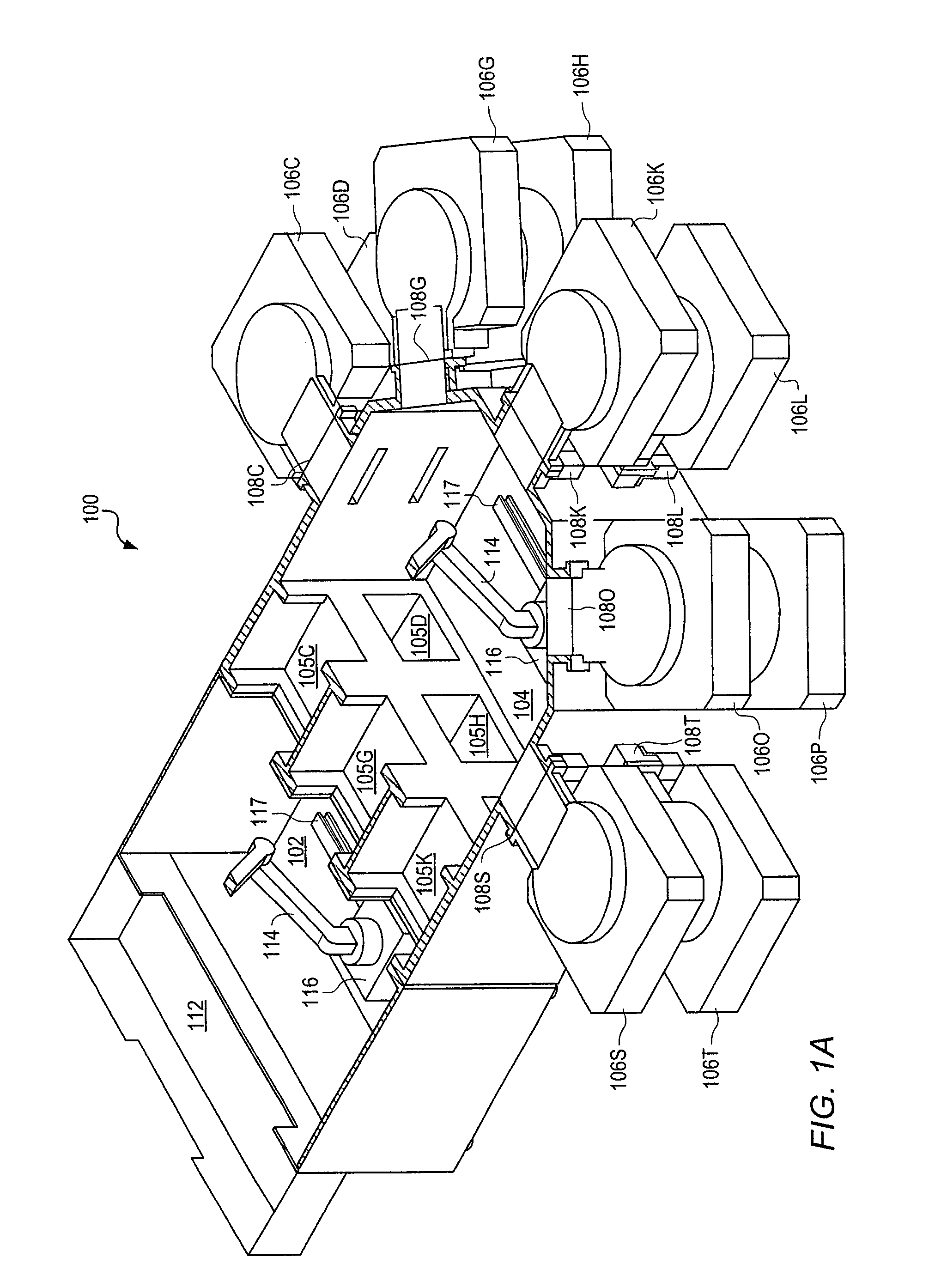

Stacked process chambers for substrate vacuum processing tool

InactiveUS20080202892A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingRobotic armSemiconductor

A substrate processing apparatus is described. The apparatus includes a substrate load lock chamber. A substrate transfer chamber is vacuum coupled to the substrate load lock chamber. A plurality of process chamber modules are vacuum coupled to the substrate transfer chamber. At least two of the process chamber modules are horizontally clustered around the substrate transfer chamber. In addition, at least two of the process chamber modules are vertically arranged with one process chamber module above the other process chamber module. The substrate transfer chamber includes one or more robotic arms for transferring semiconductor substrates between the substrate load lock chamber and the plurality of process chamber modules.

Owner:SMITH JOHN M +2

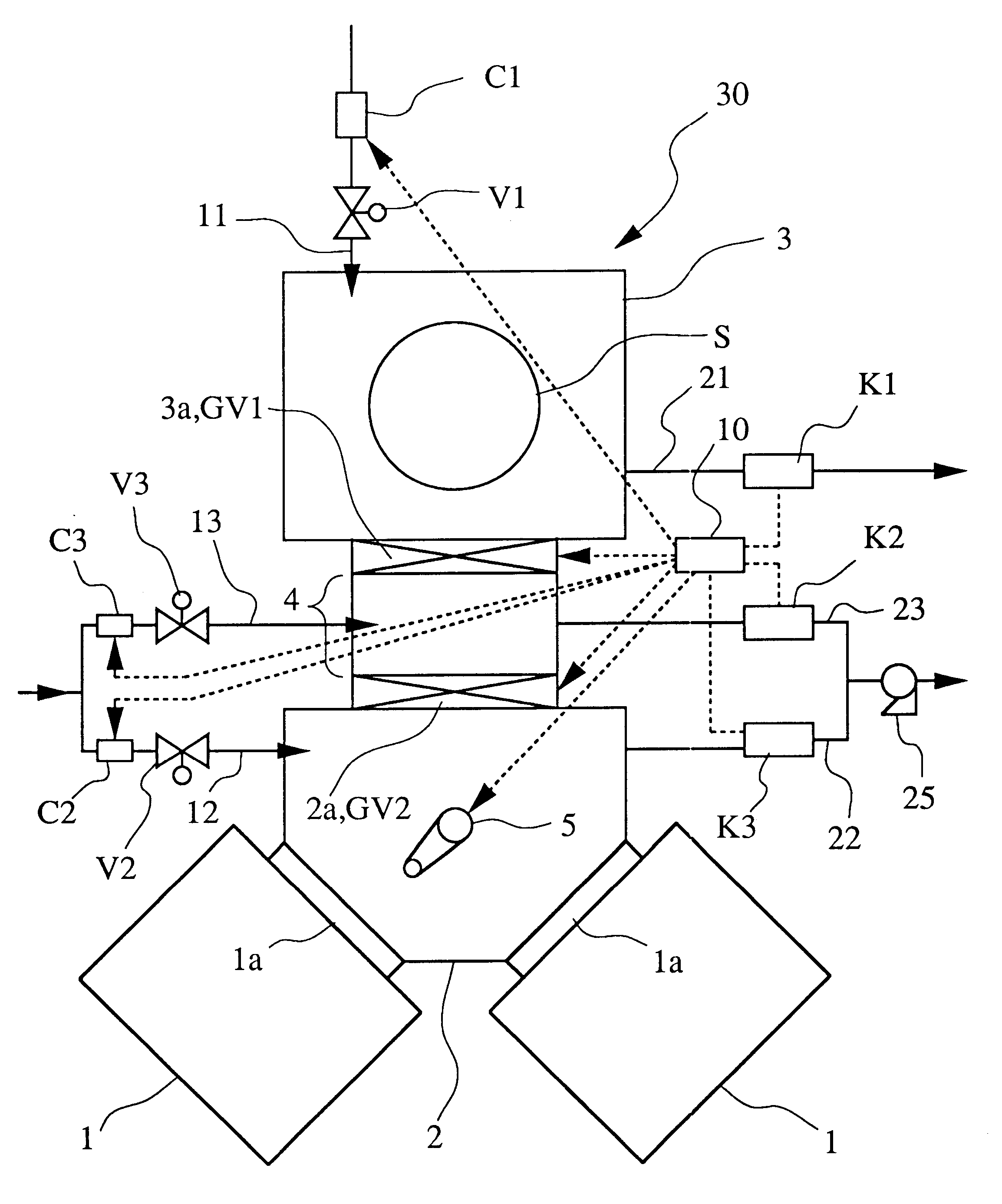

Transportation method for substrate wafers and transportation apparatus

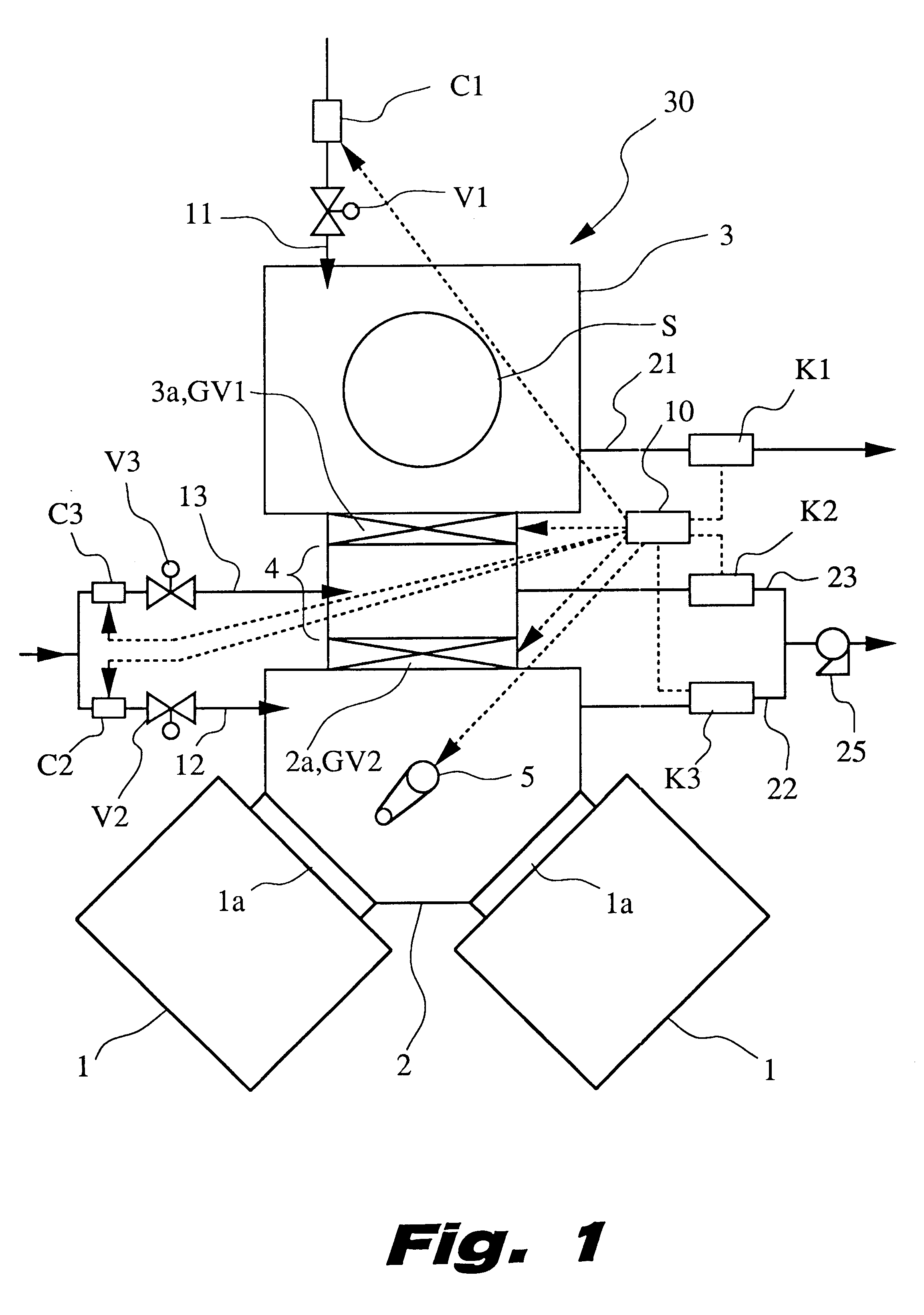

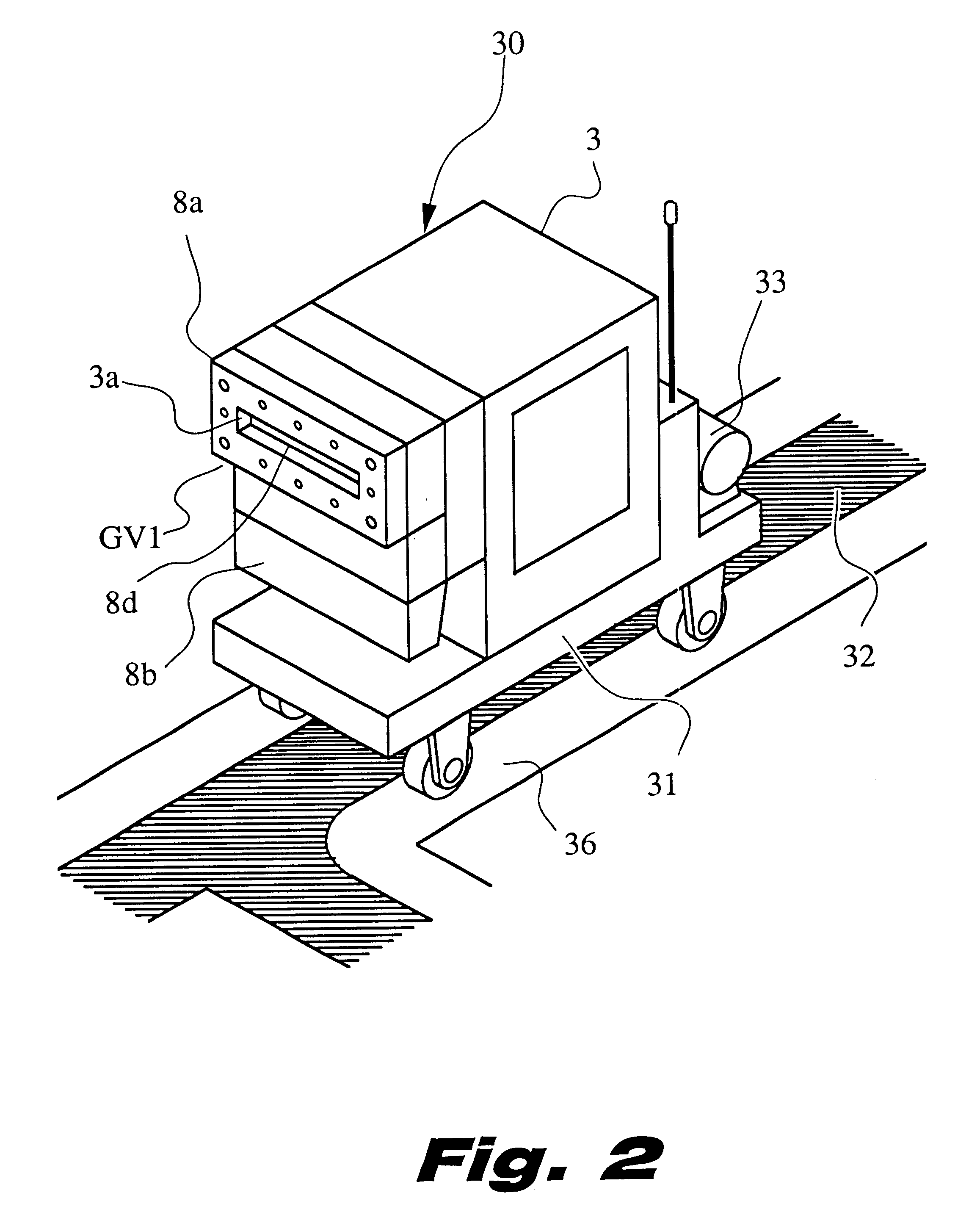

The present invention uses a transportation robot furnished with a storage chamber 3 that can store substrate wafers S under an inert gas atmosphere, and when transporting substrate wafers S between transportation chambers 2 installed on processing apparatus 1 and holding an inert gas atmosphere, connection chamber 4 is disposed between storage chamber 3 and transportation chamber 2 when placing and removing substrate wafers S between storage chamber 3 of transportation robot 30 and the transportation chamber 2 of processing apparatus 1, and after introducing inert gas into the connection chamber 4 at low pressure, opening the gate valves GV1 and GV2 between storage chamber 3 and transportation chamber 2.

Owner:NIPPON SANSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com