Patents

Literature

4145results about "Rotary drum furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

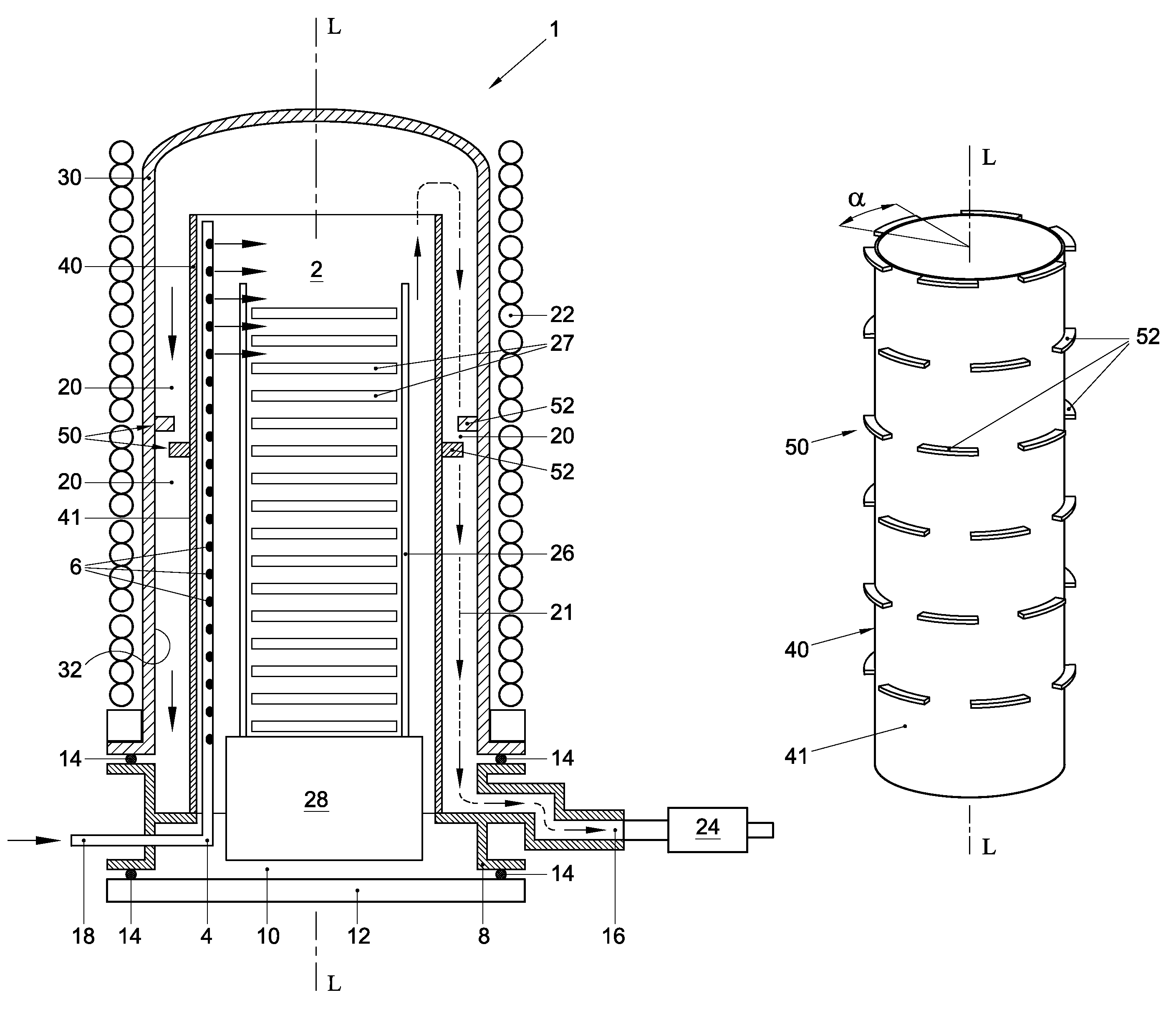

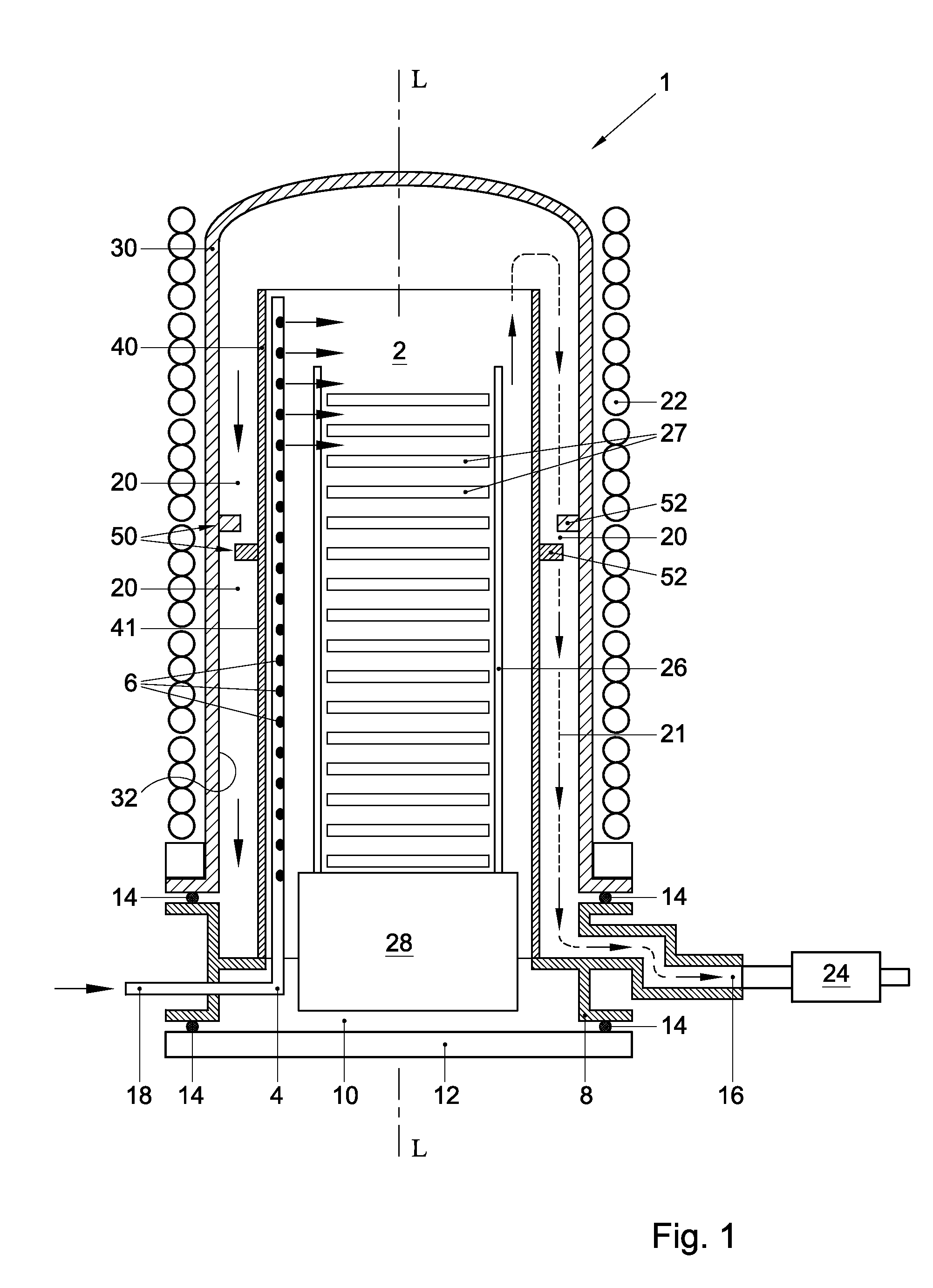

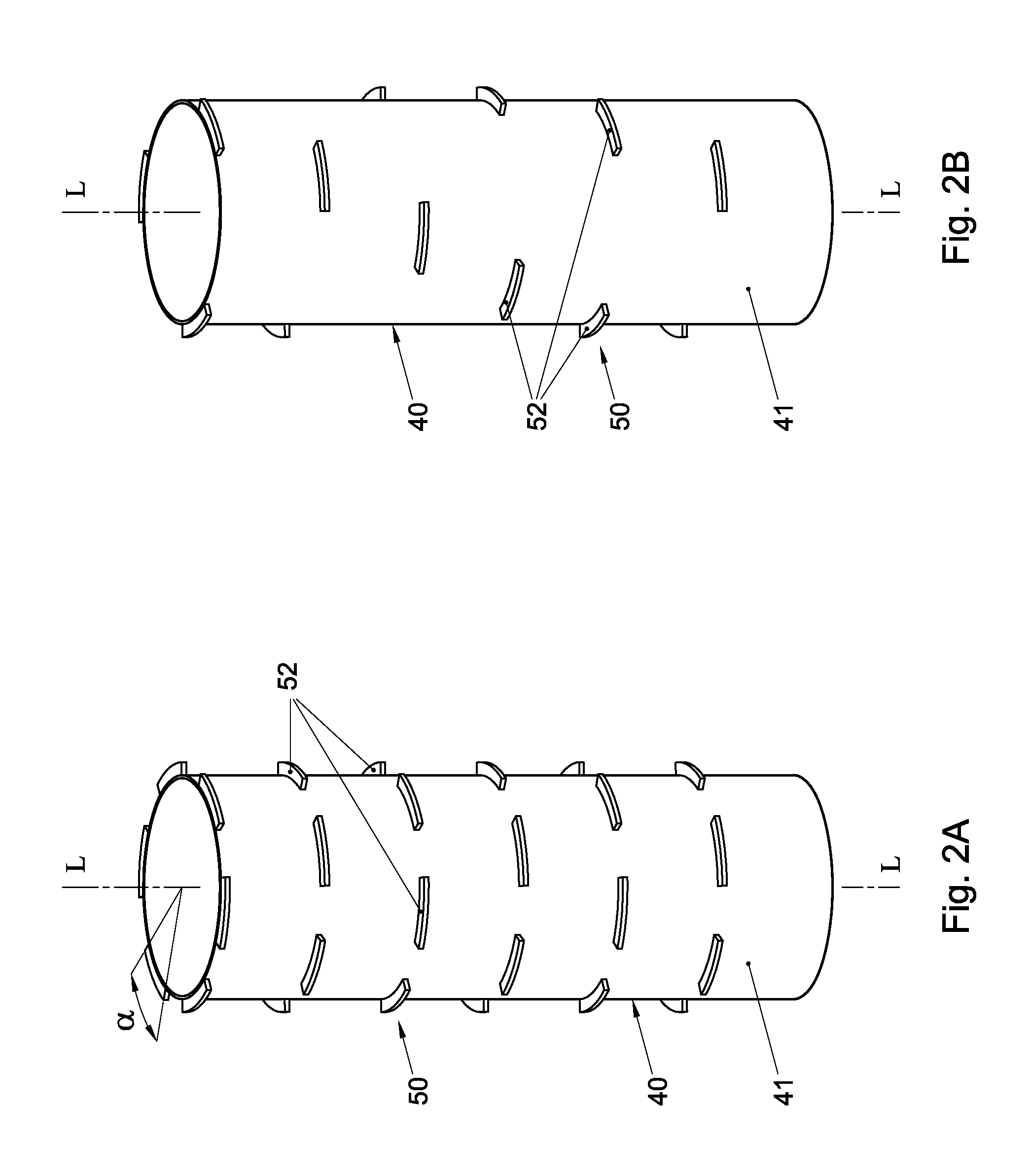

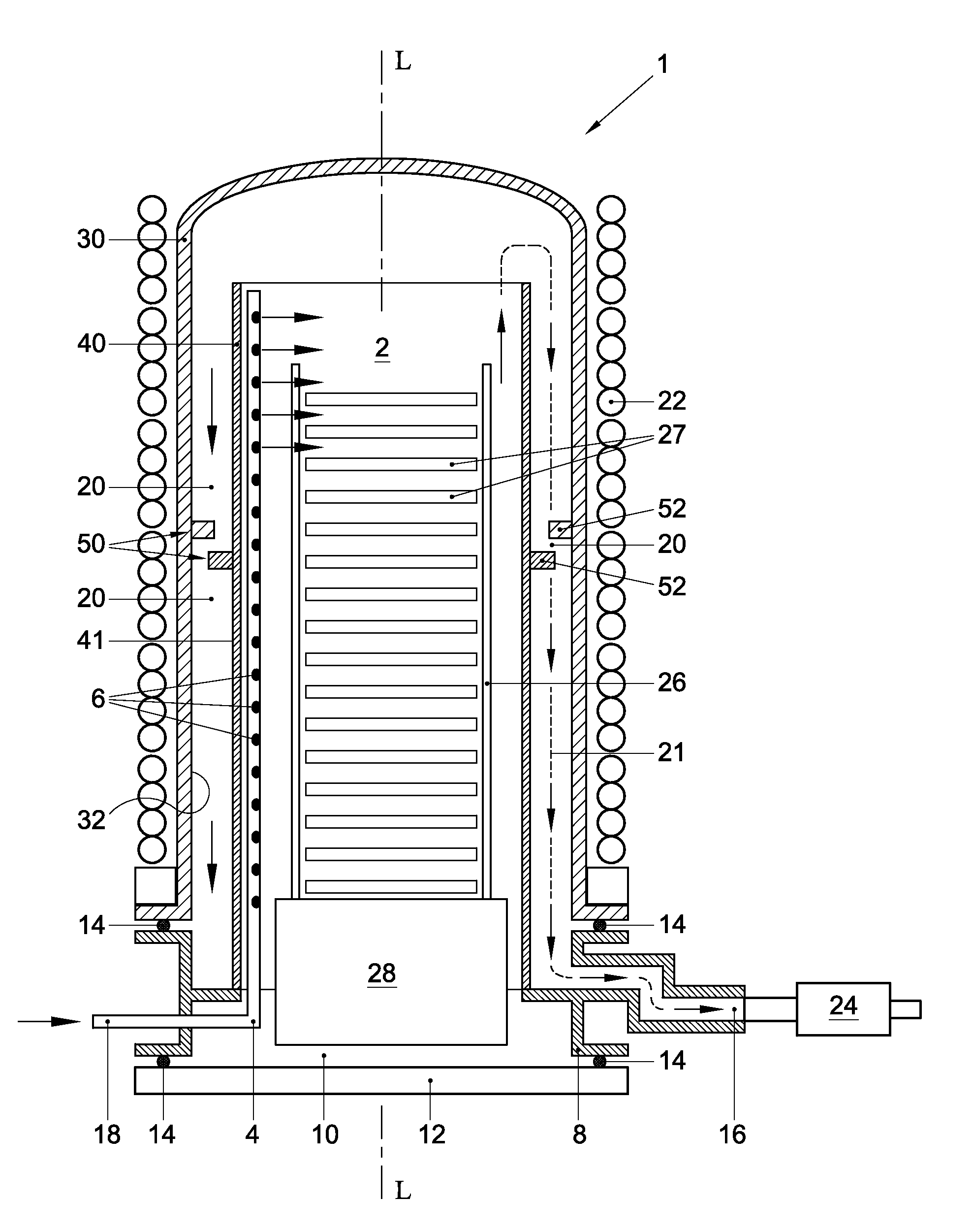

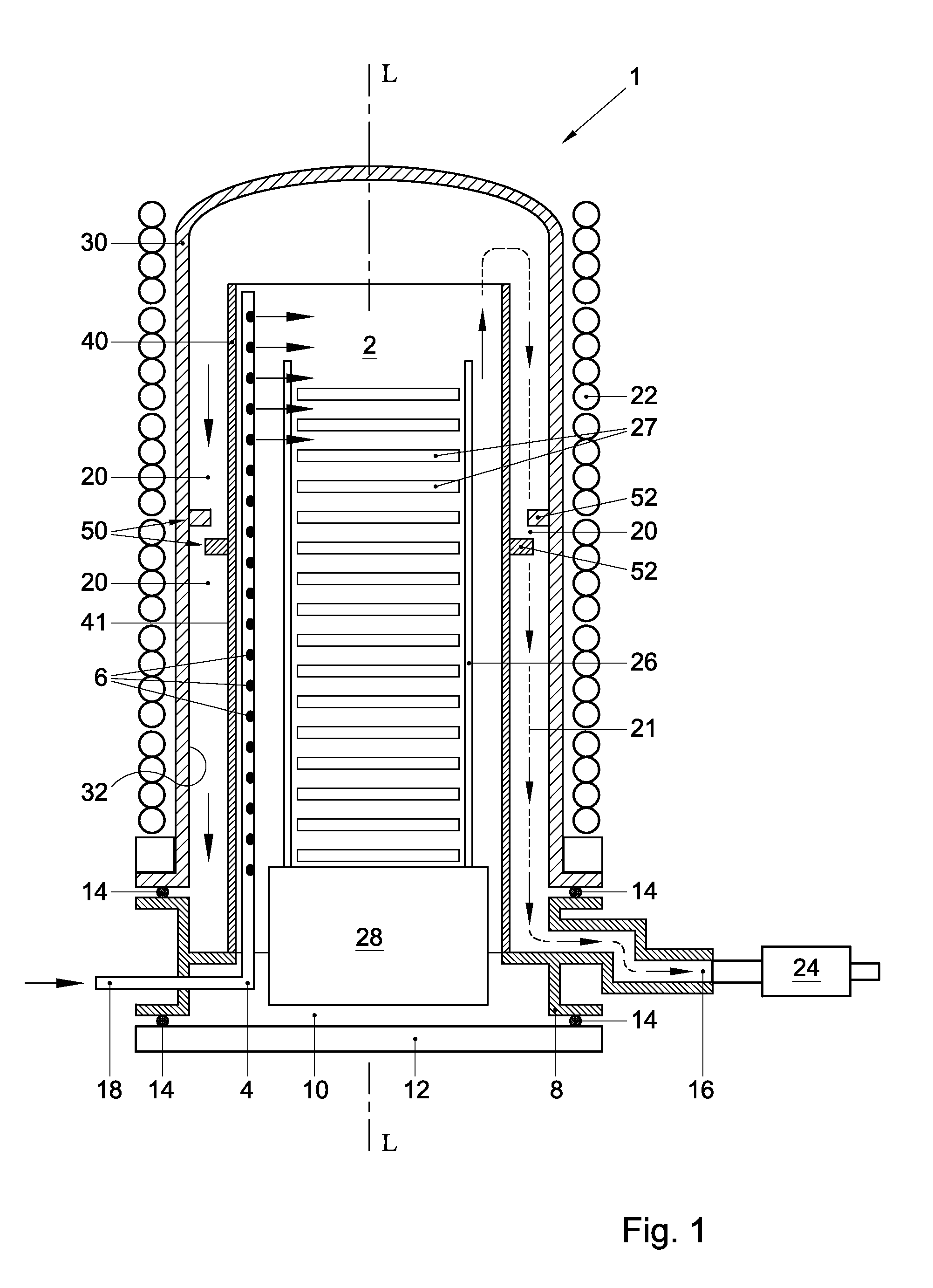

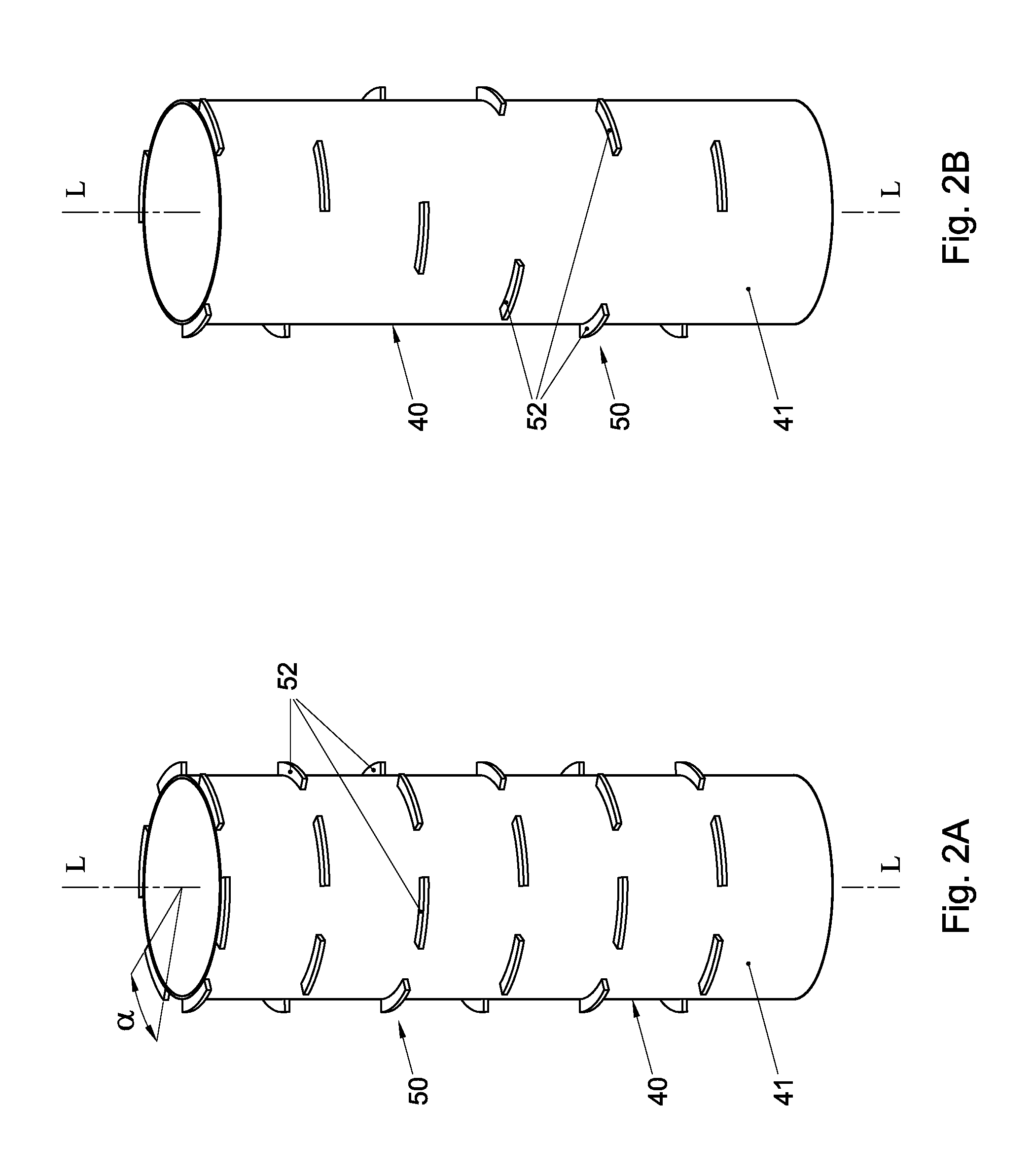

Thermal processing furnace and liner for the same

ActiveUS8398773B2Easy to transportMinimized in sizeDomestic stoves or rangesRotary drum furnacesEngineeringReaction tube

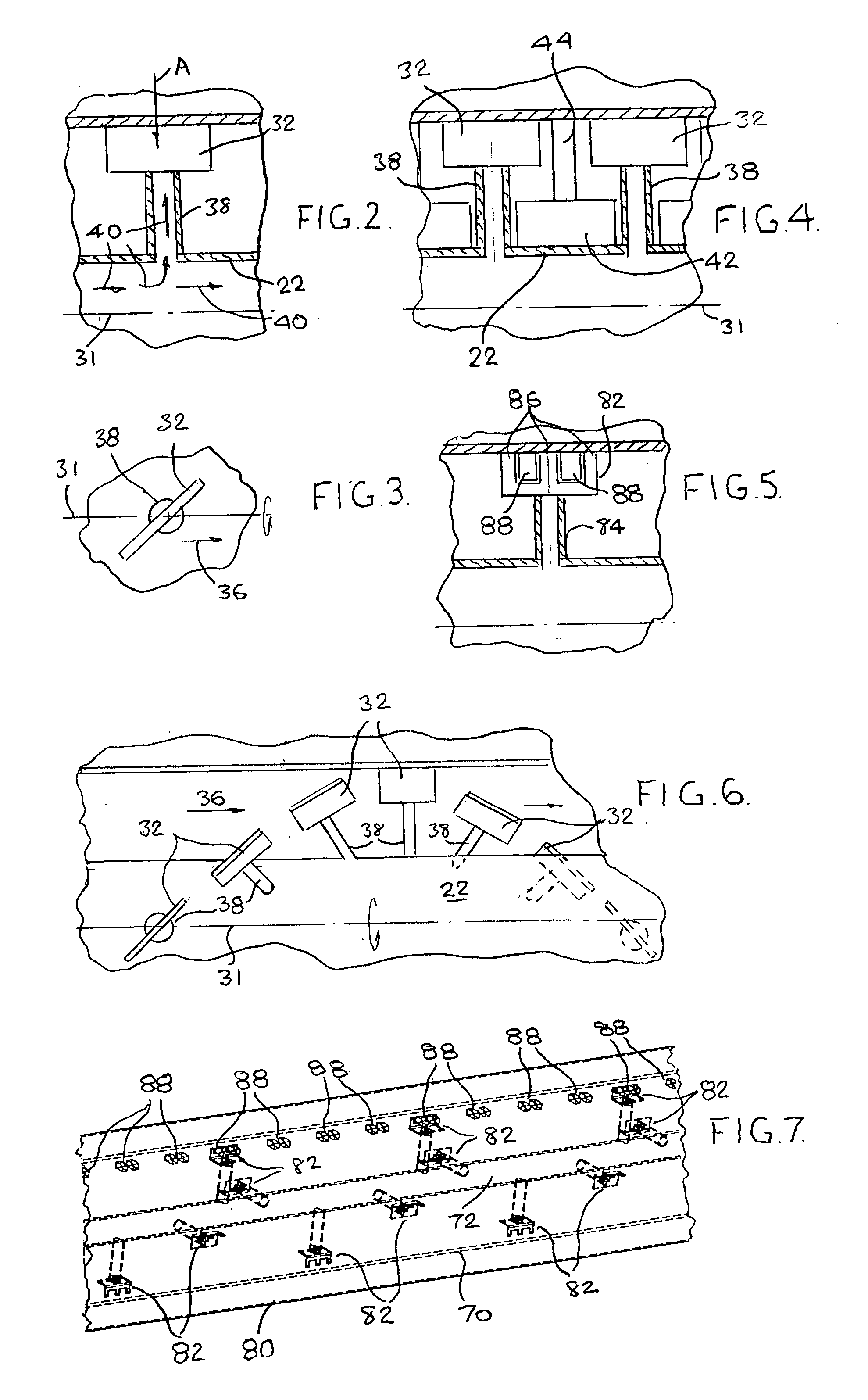

A thermal processing furnace, comprising:a generally bell jar-shaped outer reaction tube having a central axis; andan open-ended inner reaction tube for accommodating a wafer boat holding a plurality of substrates, which inner reaction tube is substantially coaxially disposed within the outer reaction tube, thereby defining a gas passage between an outer wall of the inner reaction tube and an inner wall of the outer reaction tube,wherein at least one of the outer wall of the inner reaction tube and the inner wall of the outer reaction tube is provided with a flow deflector that protrudes radially from the respective wall into the gas passage.

Owner:ASM INTERNATIONAL

Thermal processing furnace and liner for the same

ActiveUS20120186573A1Easy to transportReduce decreaseDomestic stoves or rangesRotary drum furnacesEngineeringBell jar

A thermal processing furnace, comprising:a generally bell jar-shaped outer reaction tube having a central axis; andan open-ended inner reaction tube for accommodating a wafer boat holding a plurality of substrates, which inner reaction tube is substantially coaxially disposed within the outer reaction tube, thereby defining a gas passage between an outer wall of the inner reaction tube and an inner wall of the outer reaction tube,wherein at least one of the outer wall of the inner reaction tube and the inner wall of the outer reaction tube is provided with a flow deflector that protrudes radially from the respective wall into the gas passage.

Owner:ASM INTERNATIONAL

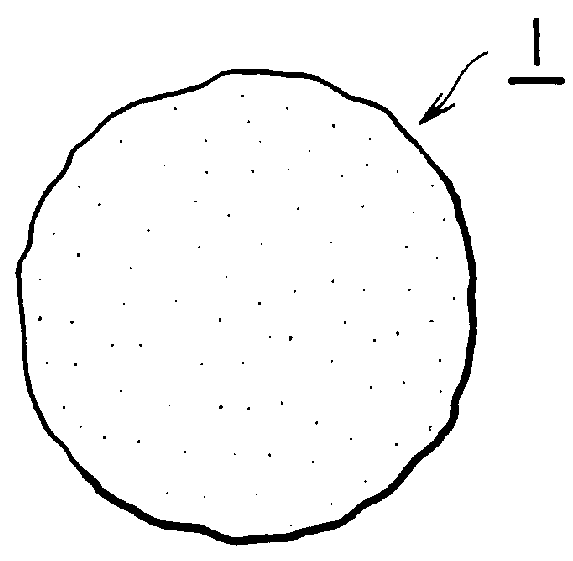

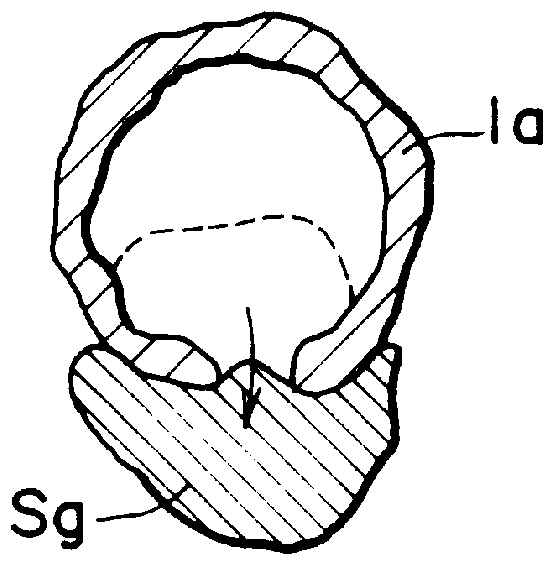

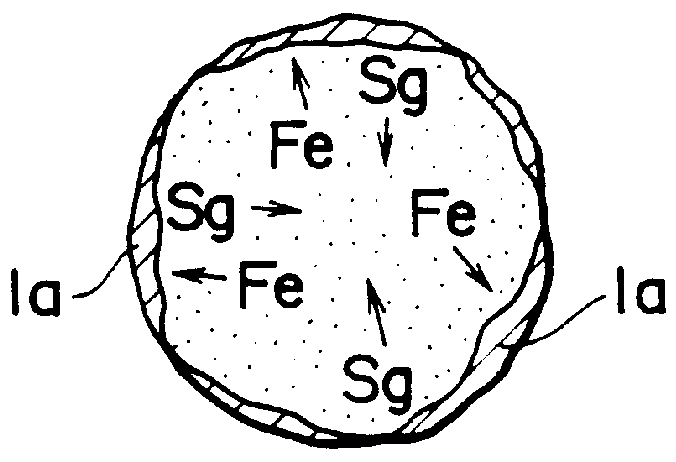

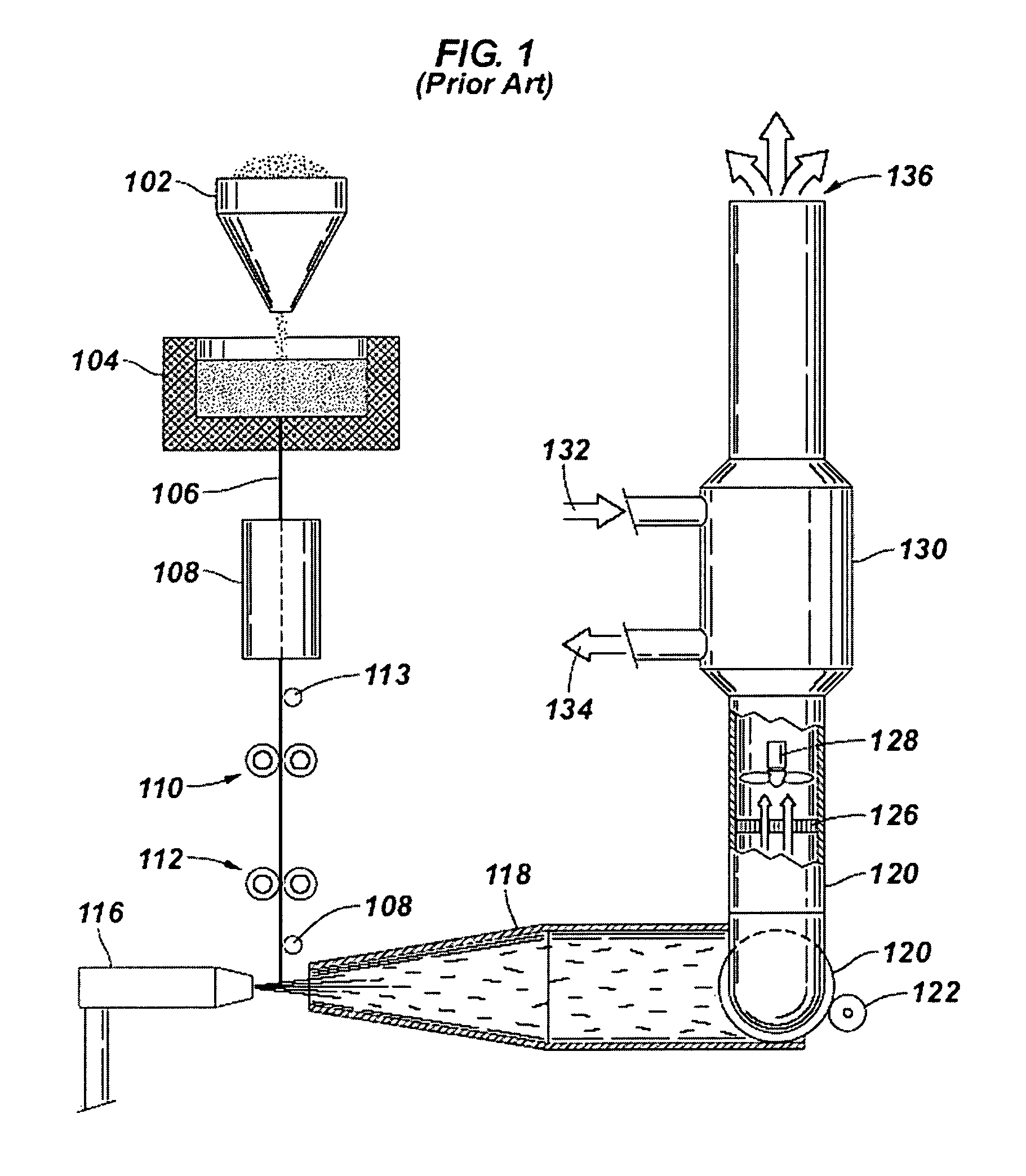

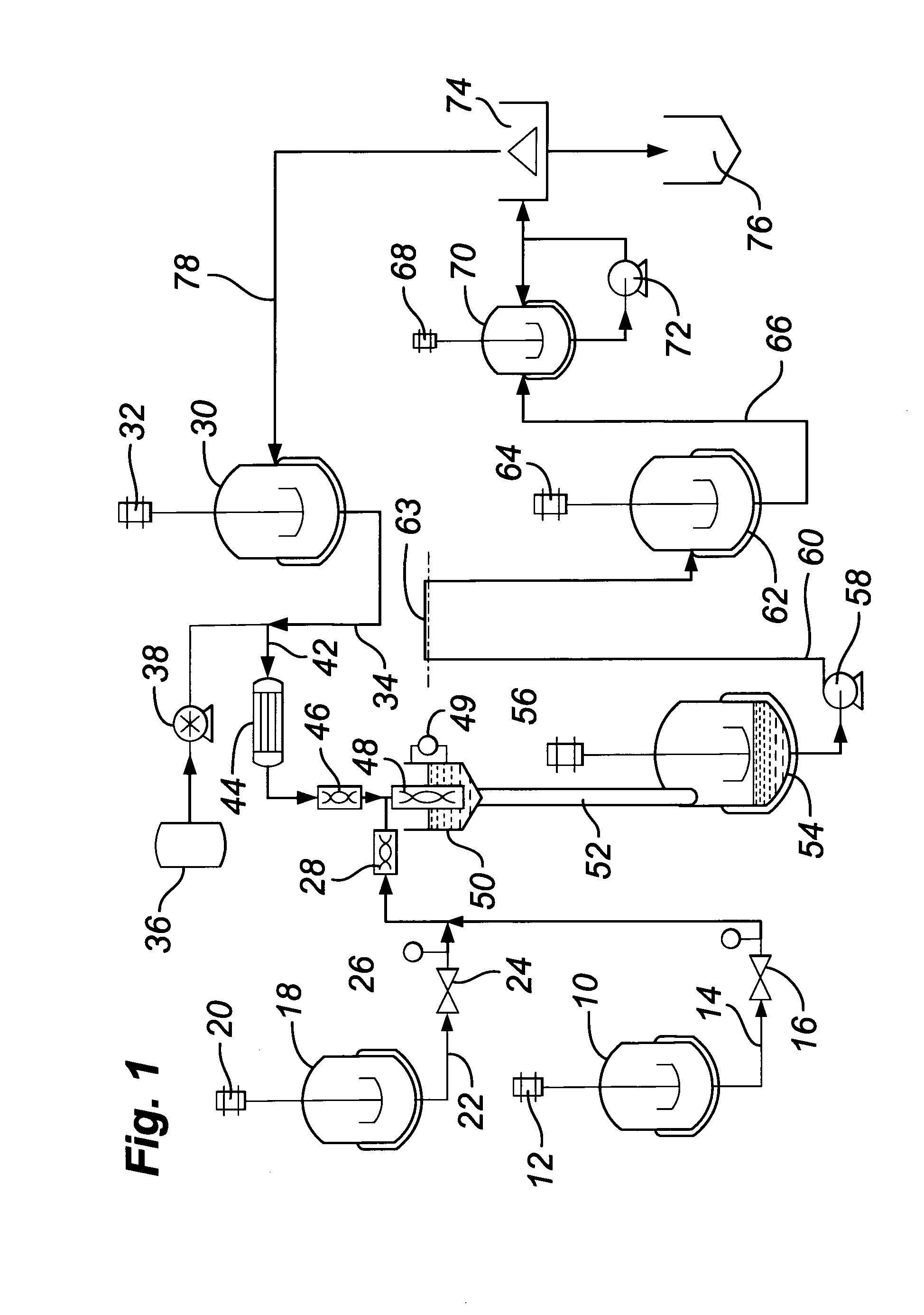

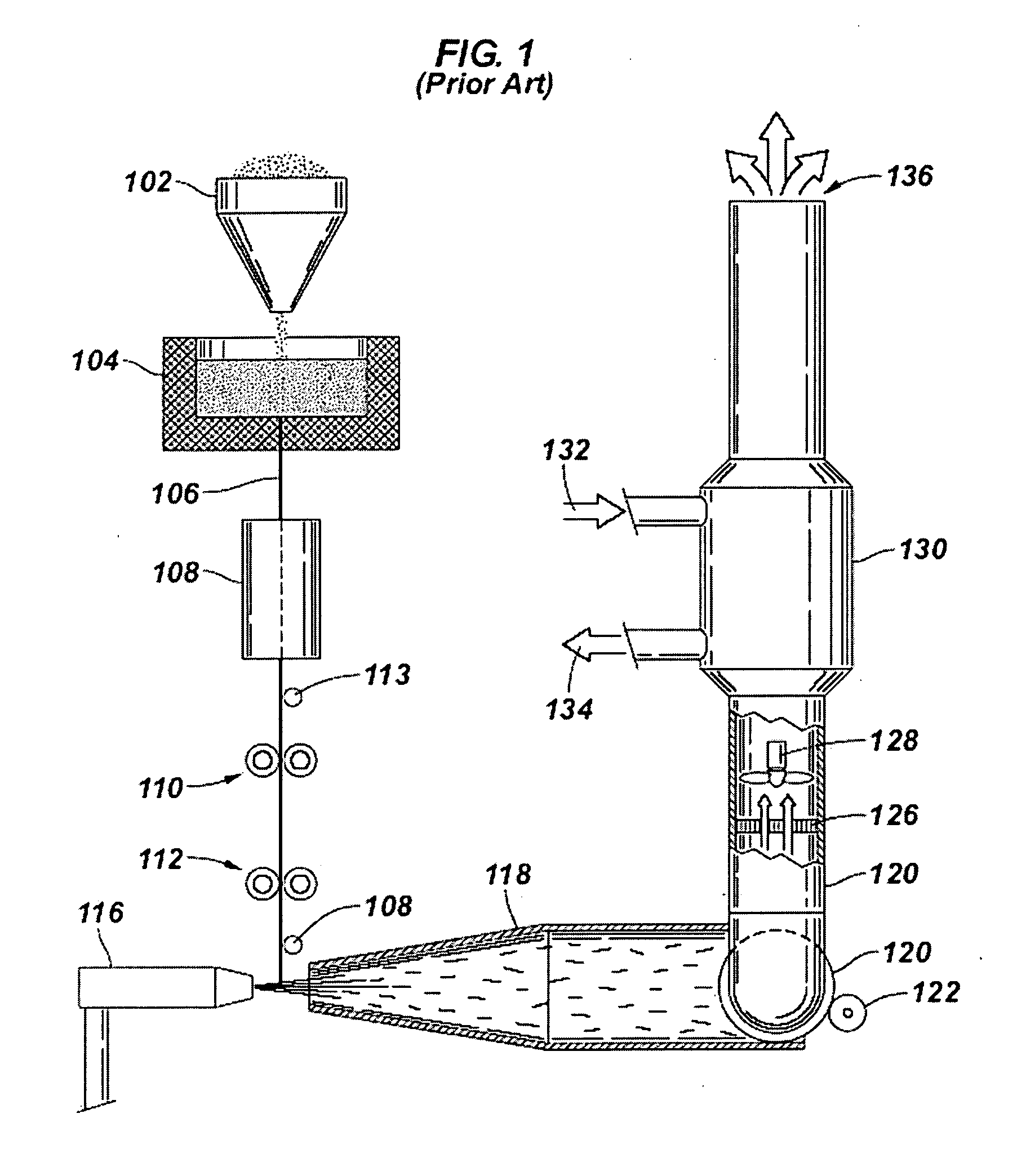

Method and apparatus for making metallic iron

InactiveUS6036744AHigh purityReadily and efficiently madeBlast furnace componentsRotary drum furnacesMolten slagCoal

A method of making metallic iron in which a compact, containing iron oxide such as iron ore or the like and a carbonaceous reductant such as coal or the like, is used as material, and the iron oxide is reduced through the application of heat, thereby making metallic iron. In the course of this reduction, a shell composed of metallic iron is generated and grown on the surface of the compact, and slag aggregates inside the shell. This reduction continues until substantially no iron oxide is present within the metallic iron shell. Subsequently, heating is further performed to melt the metallic iron and slag. Molten metallic iron and molten slag are separated one from the other, thereby obtaining metallic iron with a relatively high metallization ratio. Through the employment of an apparatus for making metallic iron of the present invention, the above-described method is efficiently carried out, and metallic iron having a high iron purity can be made continuously as well as productively not only from iron oxide having a high iron content but also from iron oxide having a relatively low iron content.

Owner:KOBE STEEL LTD

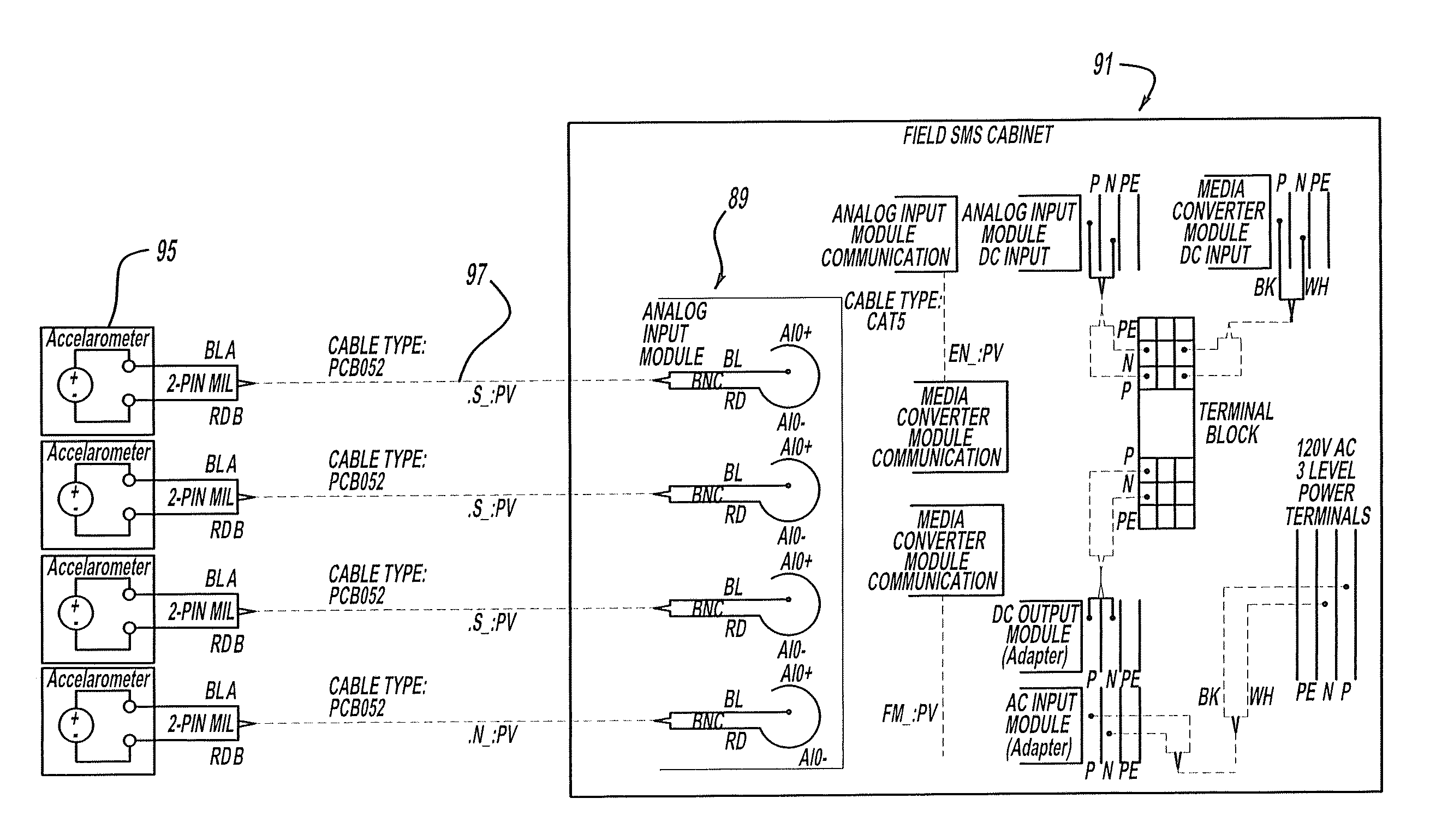

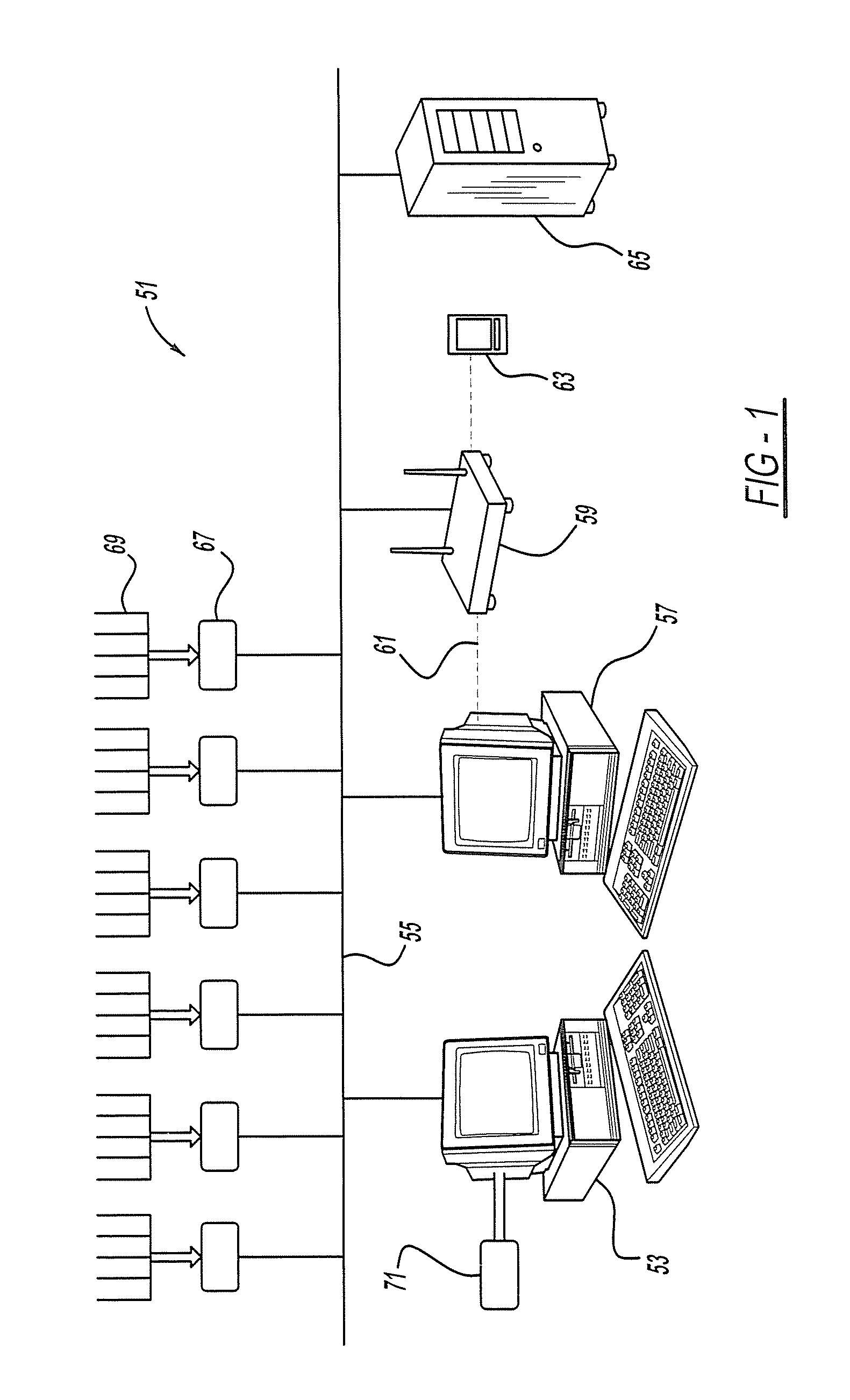

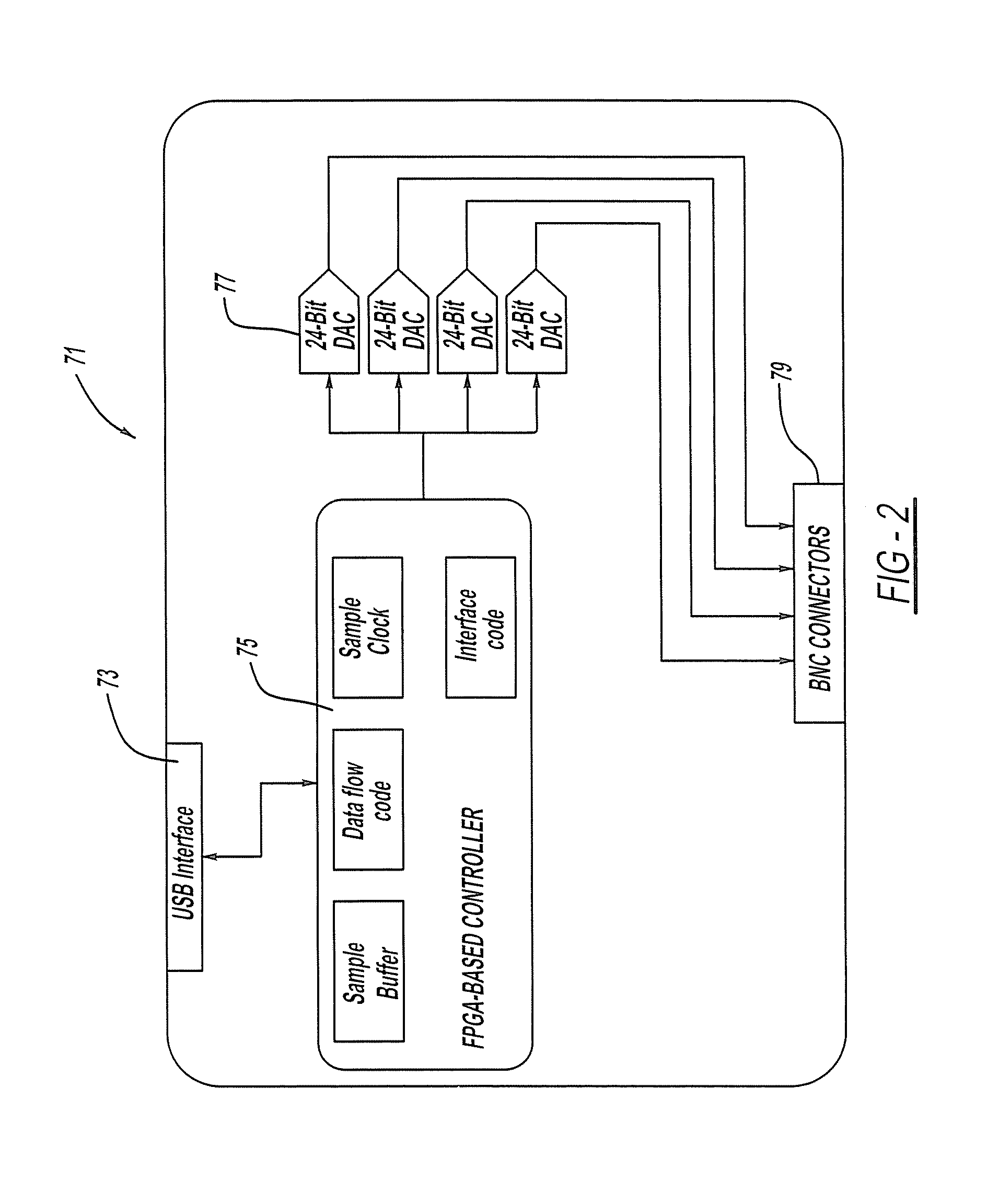

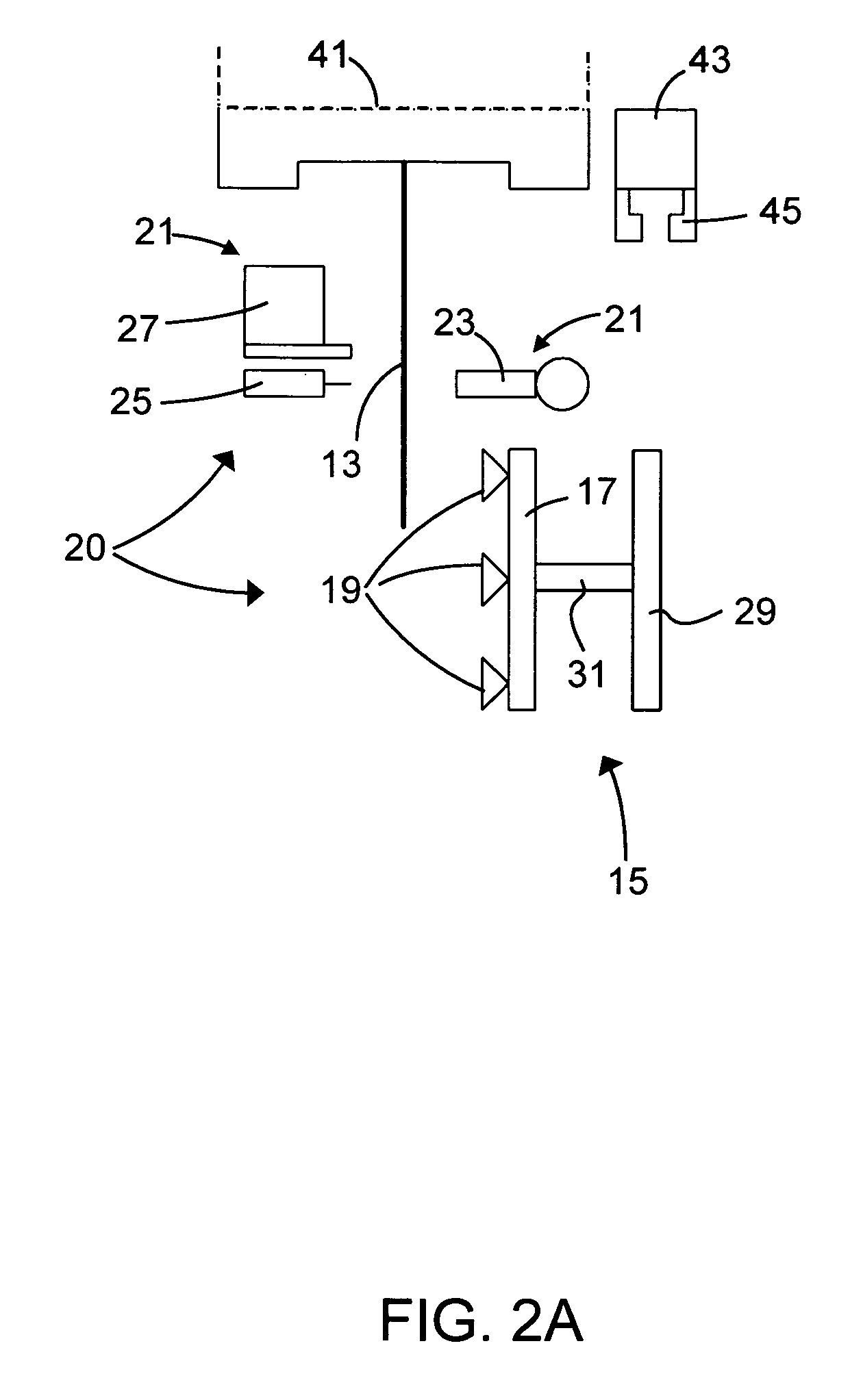

System for monitoring plant equipment

ActiveUS20110184547A1Improve sensed data analysisReduce hardware costsRotary drum furnacesRoads maintainenceCement manufacturingSoftware

A system for monitoring plant equipment is provided. Another aspect provides an automated analysis system wherein software instructions operably compare sensor data to predefined valves and determine mechanical problems in multiple machines. In another aspect, a cement manufacturing system includes sensors for sensing movement conditions of cement making machines. A further aspect provides a central computer connected to vibration sensors associated with cement making machines, where software instructions perform real-time comparisons and machine performance determinations, based at least in part on sensed signals.

Owner:HOLCIM US

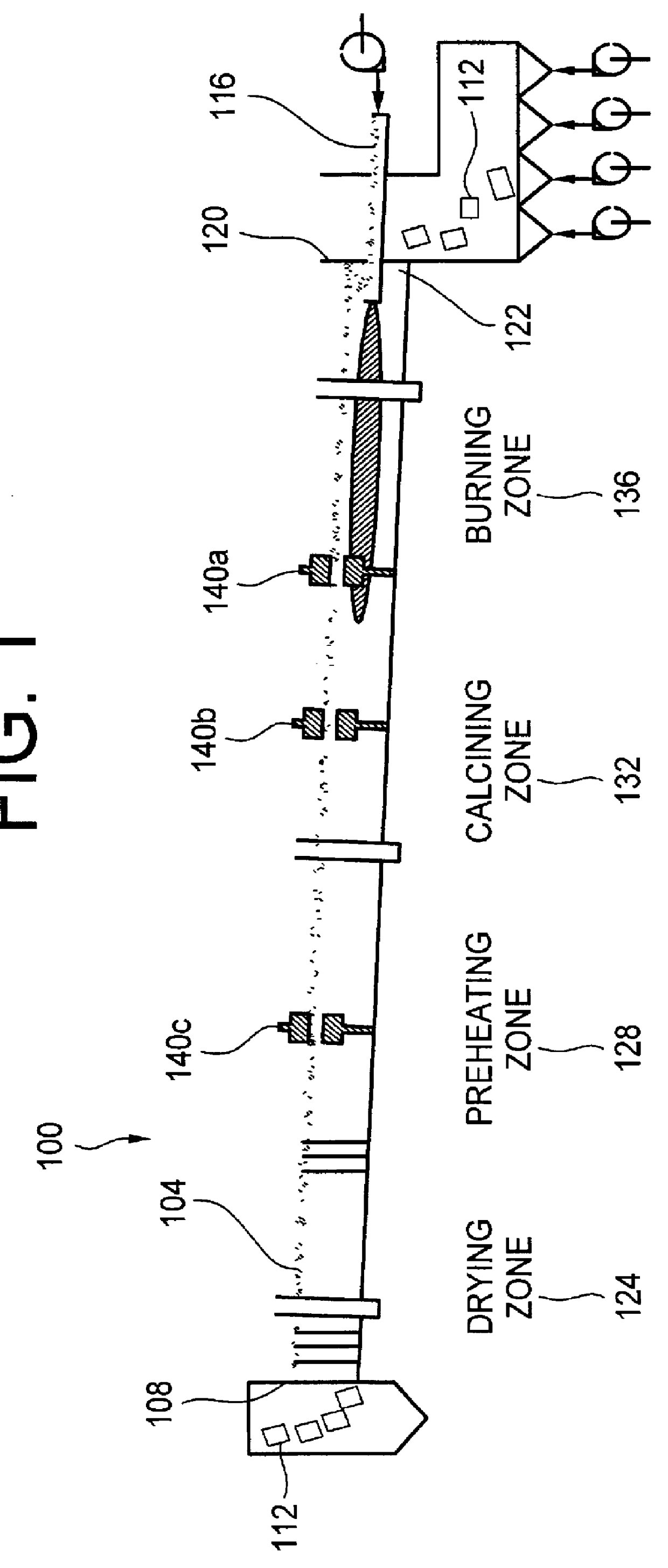

System and method for oxidant injection in rotary kilns

InactiveUS6116896AOperating means/releasing devices for valvesMuffle furnacesInjection portEngineering

A system and method for increasing the amount of oxygen in a kiln chamber is disclosed. The radial surface of a rotatable kiln is provided with at least one oxidant injection port extending through the radial surface into the kiln chamber. A cam is connected to the radial surface adjacent the oxidant injection port. A valve assembly including a valve chamber in fluid communication with an oxidant supply is mounted adjacent the kiln substantially in fixed spatial relation with the rotatable kiln body. The valve assembly includes a follower member adapted to contact a surface to the cam to actuate the valve assembly. Rotation of the kiln body brings the cam into contact with the follower member, thereby actuating the oxidant injection assembly, and injecting oxidant through the injection port into the kiln chamber.

Owner:LAIR LIQUIDE SOCITE ANONYME POUR LETUD & LEXPL DES PROCEDES GEORCLAUDE +1

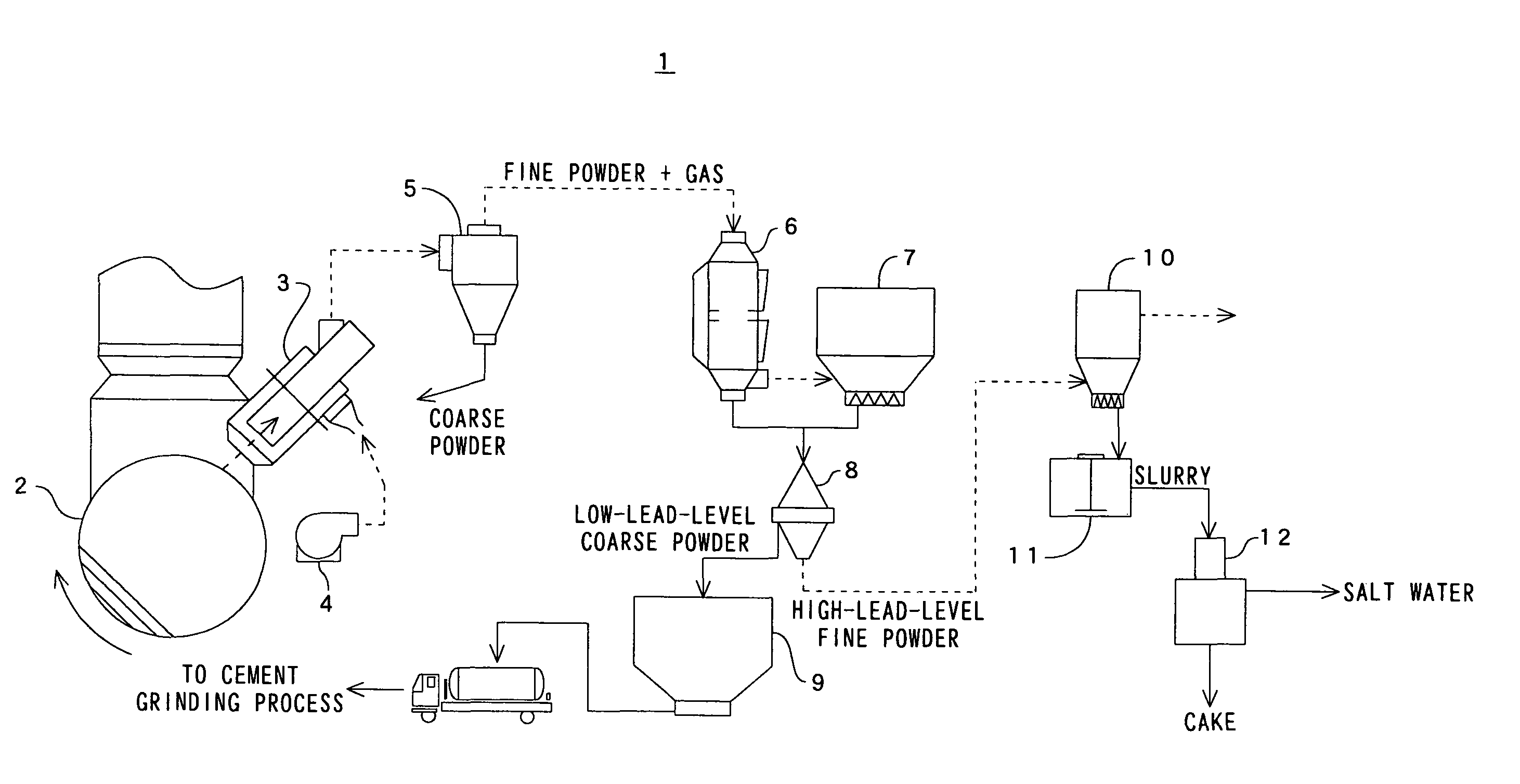

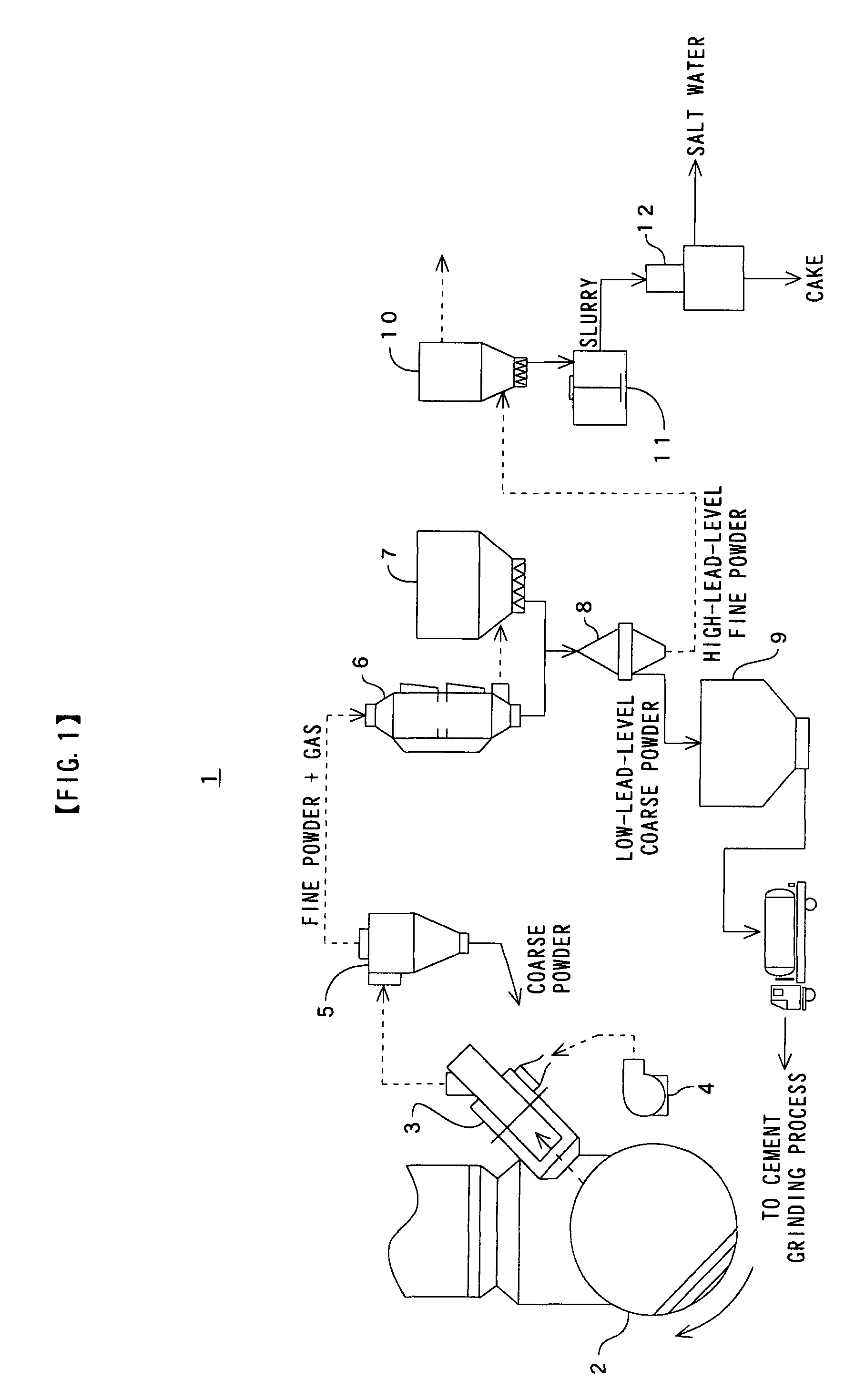

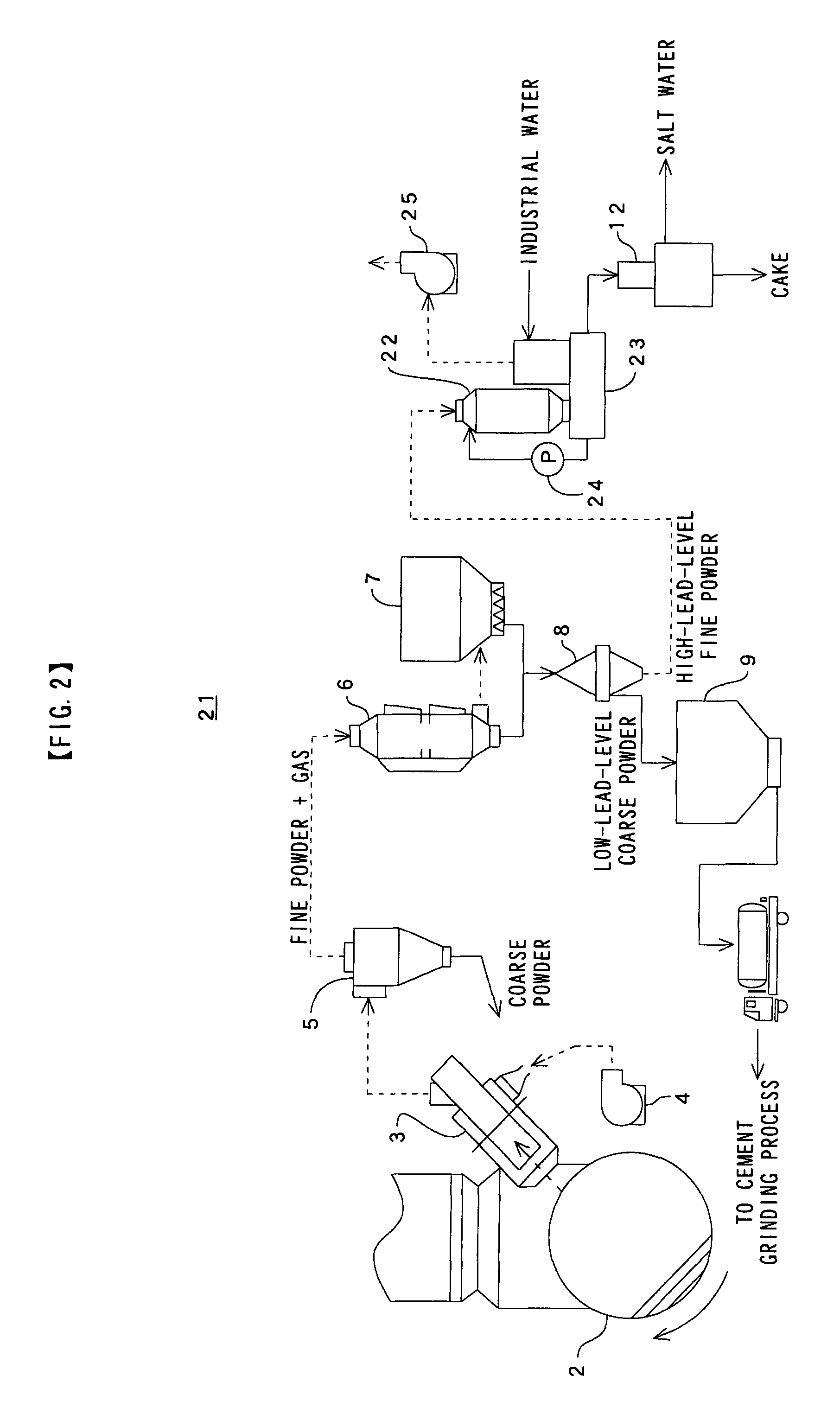

System and method for treating dust contained in extracted cement kiln combustion gas

ActiveUS7749311B2Effectively remove dustLow facility requirementsCombination devicesLiquid degasificationCycloneEngineering

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a first classifier 5 for separating coarse powder from dust contained in the combustion gas extracted; a dust collector 7 for collecting dust from the extracted gas containing fine powder discharged from the first classifier 5; and a second classifier 8 for dividing dust discharged from the dust collector 7 into fine powder and coarse powder, and others. Since more lead is distributed on the fine powder side classified by the second classifier 8, lead can efficiently be removed without using chemicals and the like. The fine powder classified by the classifier 8 may be desalted by washing; high-lead-level cake obtained after the washing can be recycled; or salt water can be added to a cement mill. The coarse powder may be added to a cement grinding process or returned to cement material grinding process after the desaltation through washing.

Owner:TAIHEIYO CEMENT CORP

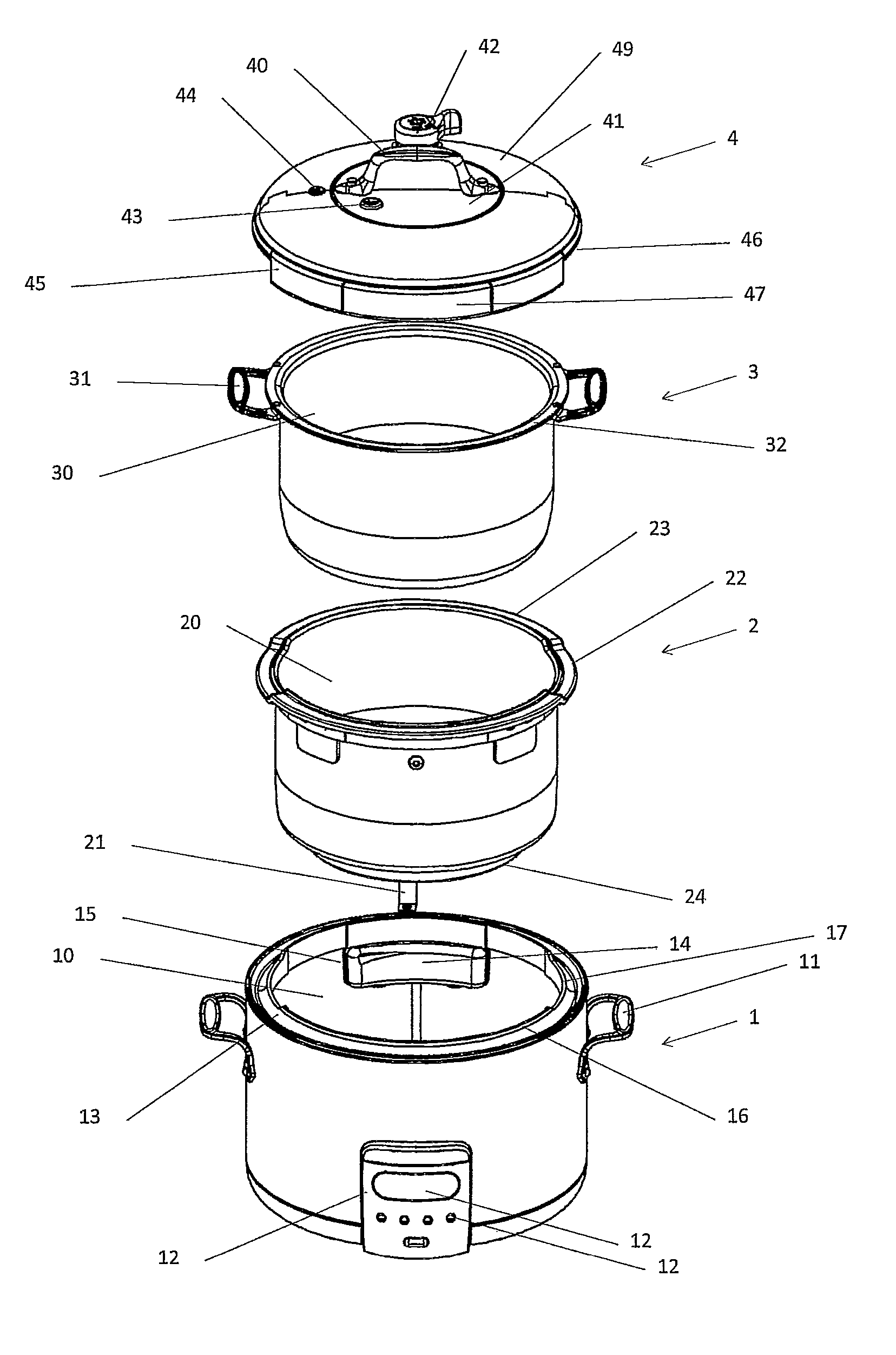

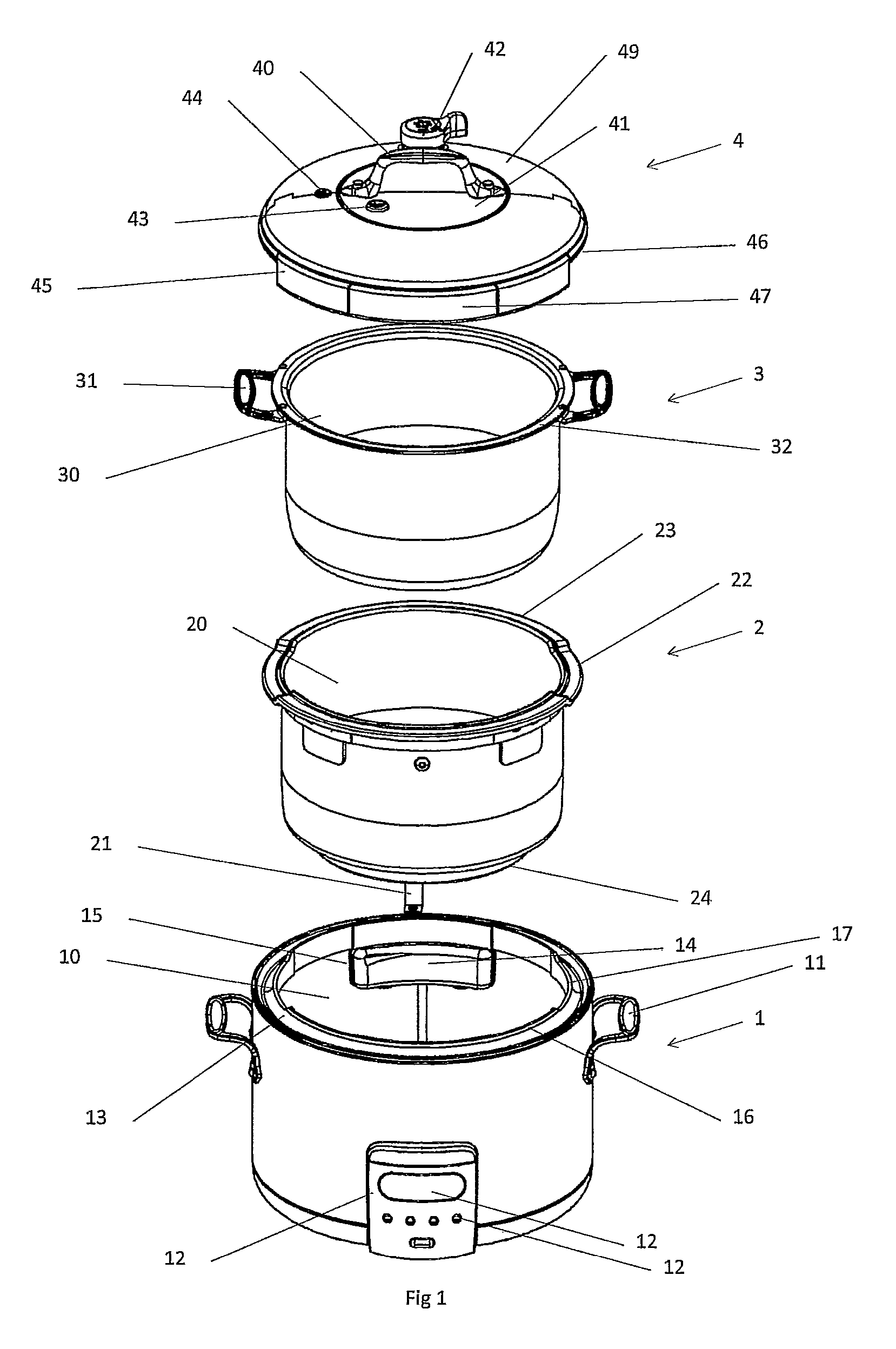

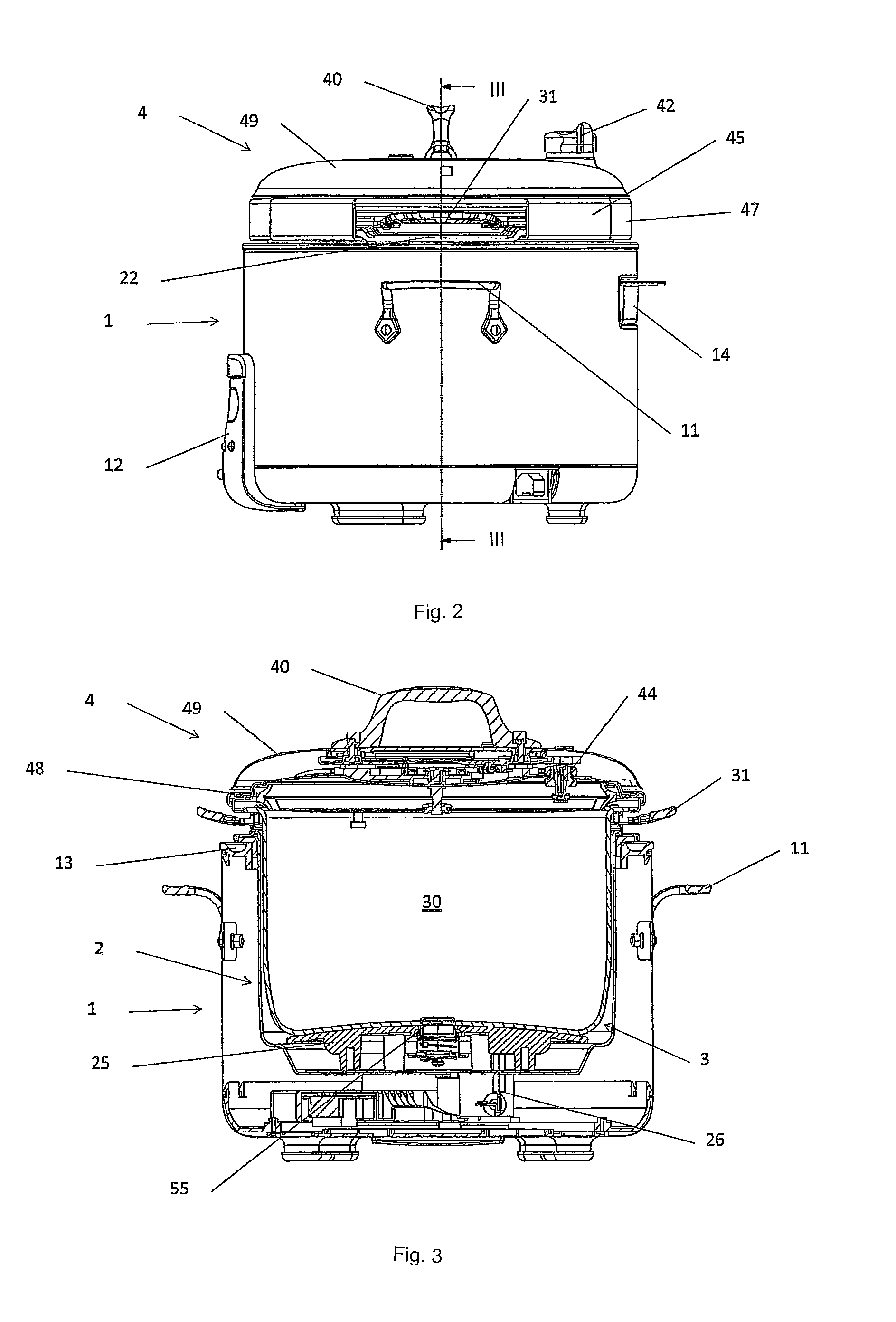

Electrical appliance for cooking food

InactiveUS8546731B2Easy and safe manipulationAvoid burnsRotary drum furnacesWater heating stoves/rangesEngineeringIngested food

An electric appliance for pressure cooking food includes a casing (1) and a lid (4) forming the outer jacket of the appliance, an outer vessel (2) forming the inner chamber of the appliance, a heating element (25) placed in the bottom of the outer vessel (2), a removable inner vessel (3) forming the container (30) for cooking food, wherein the inner vessel (3) includes at least one handhold (31) extending past the periphery of the casing (1).

Owner:SEB SA

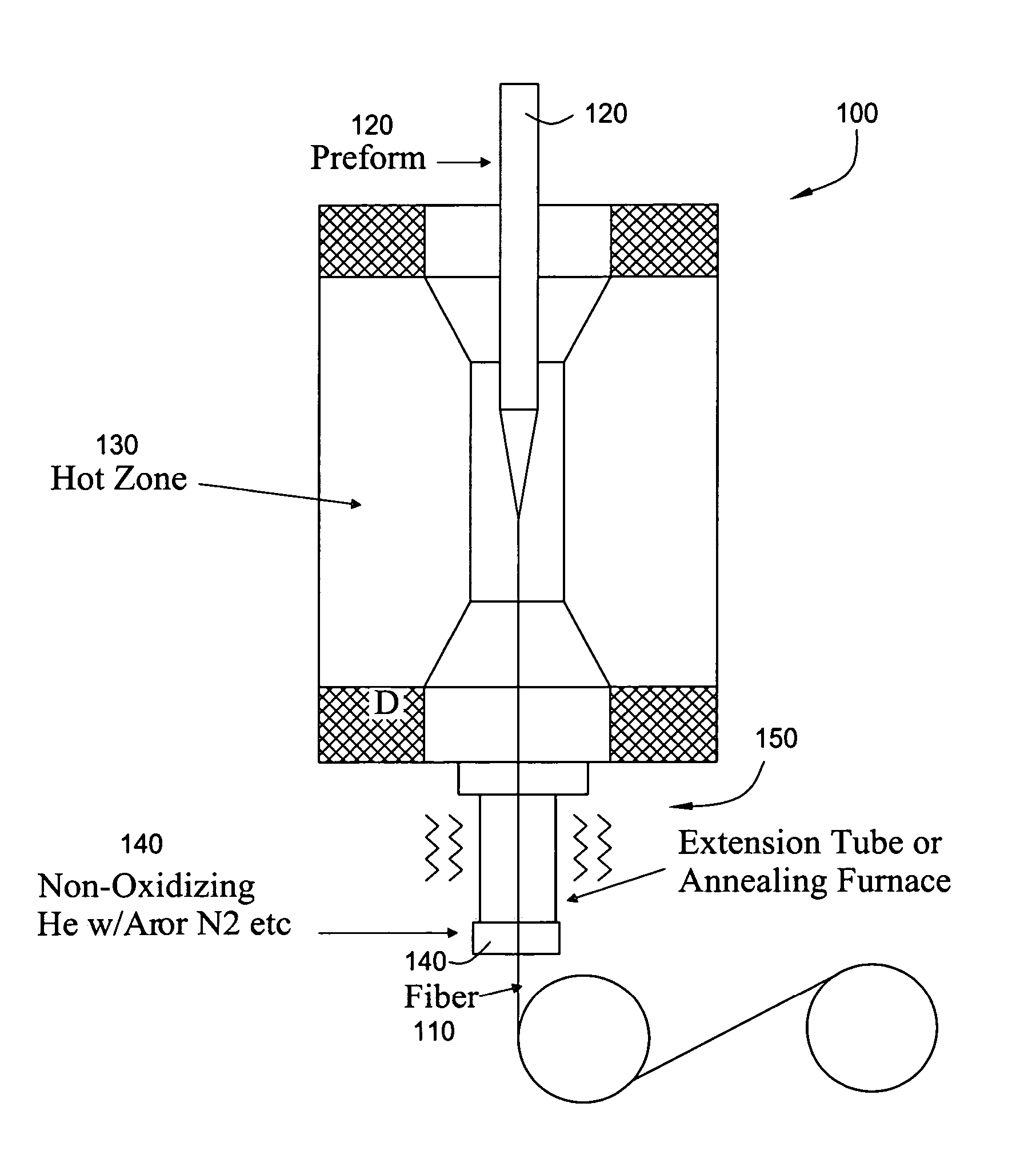

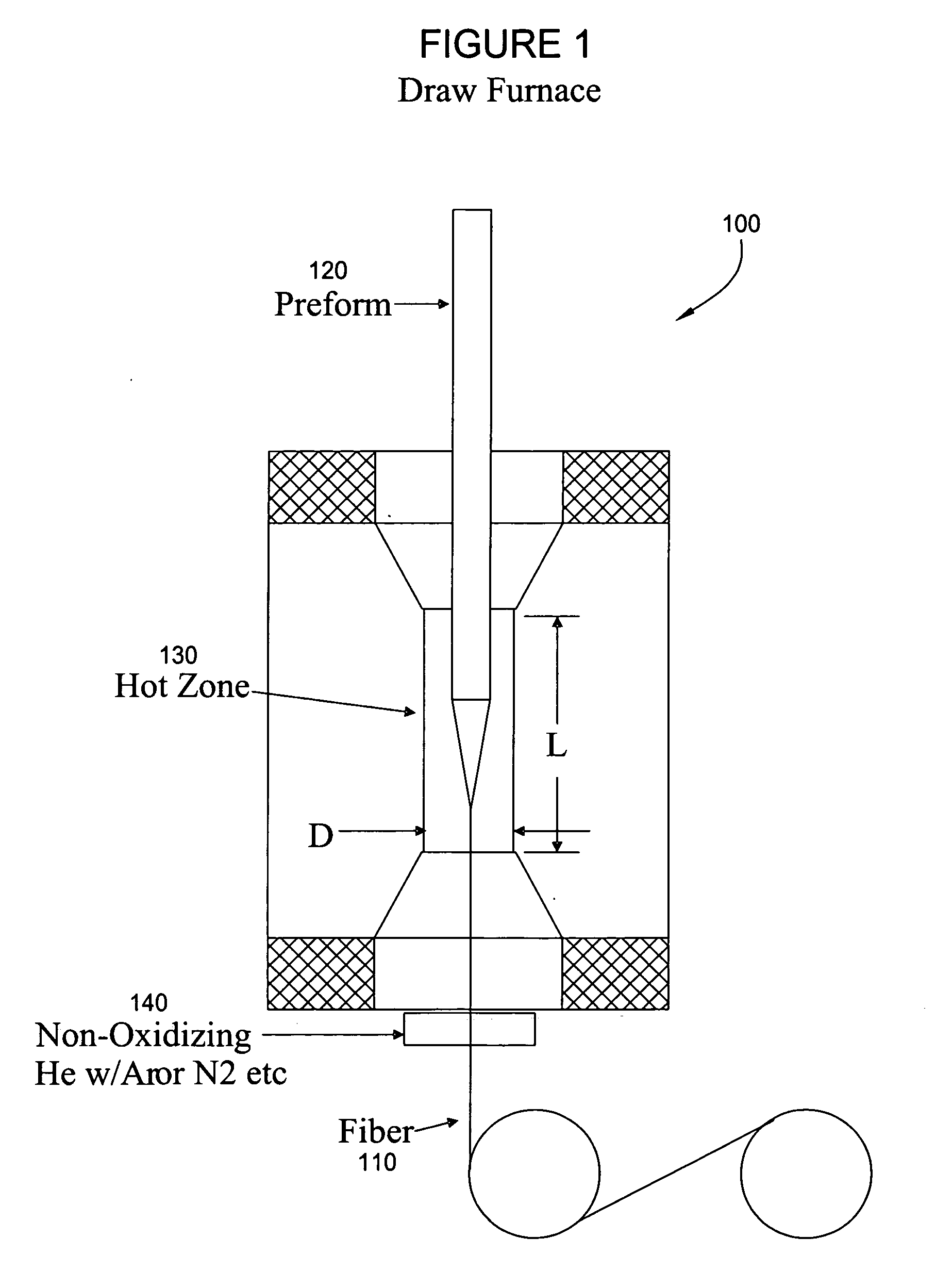

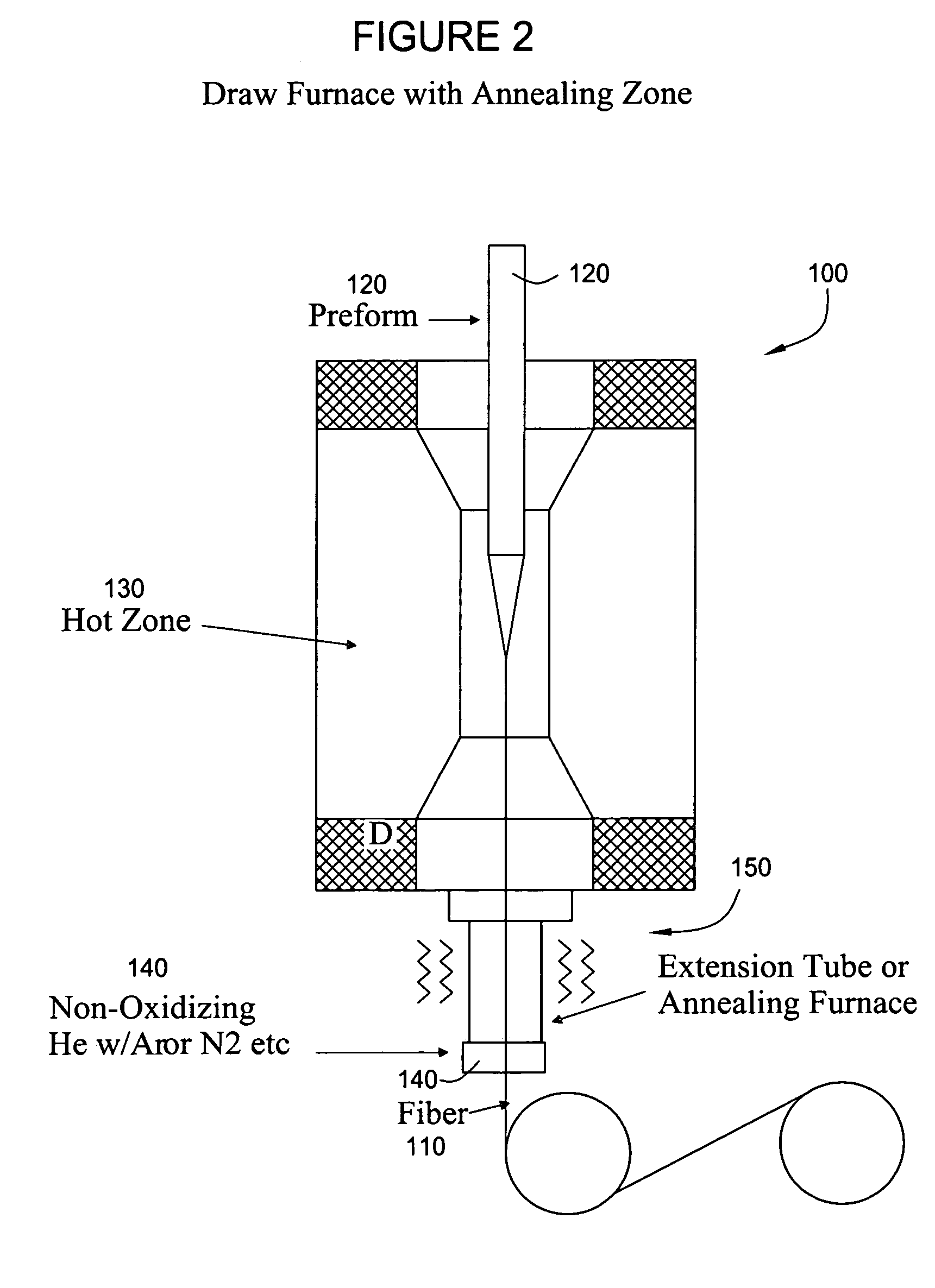

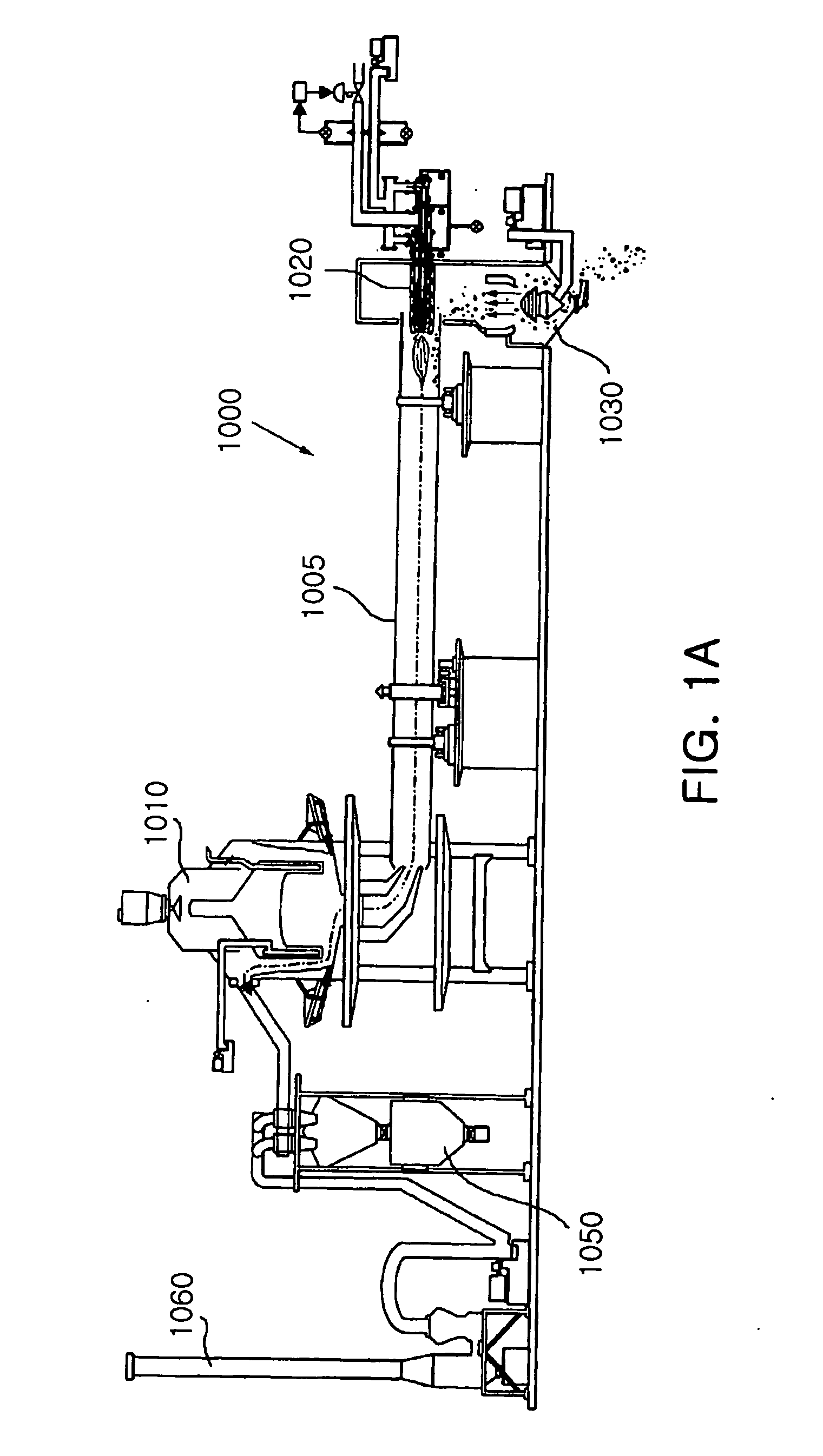

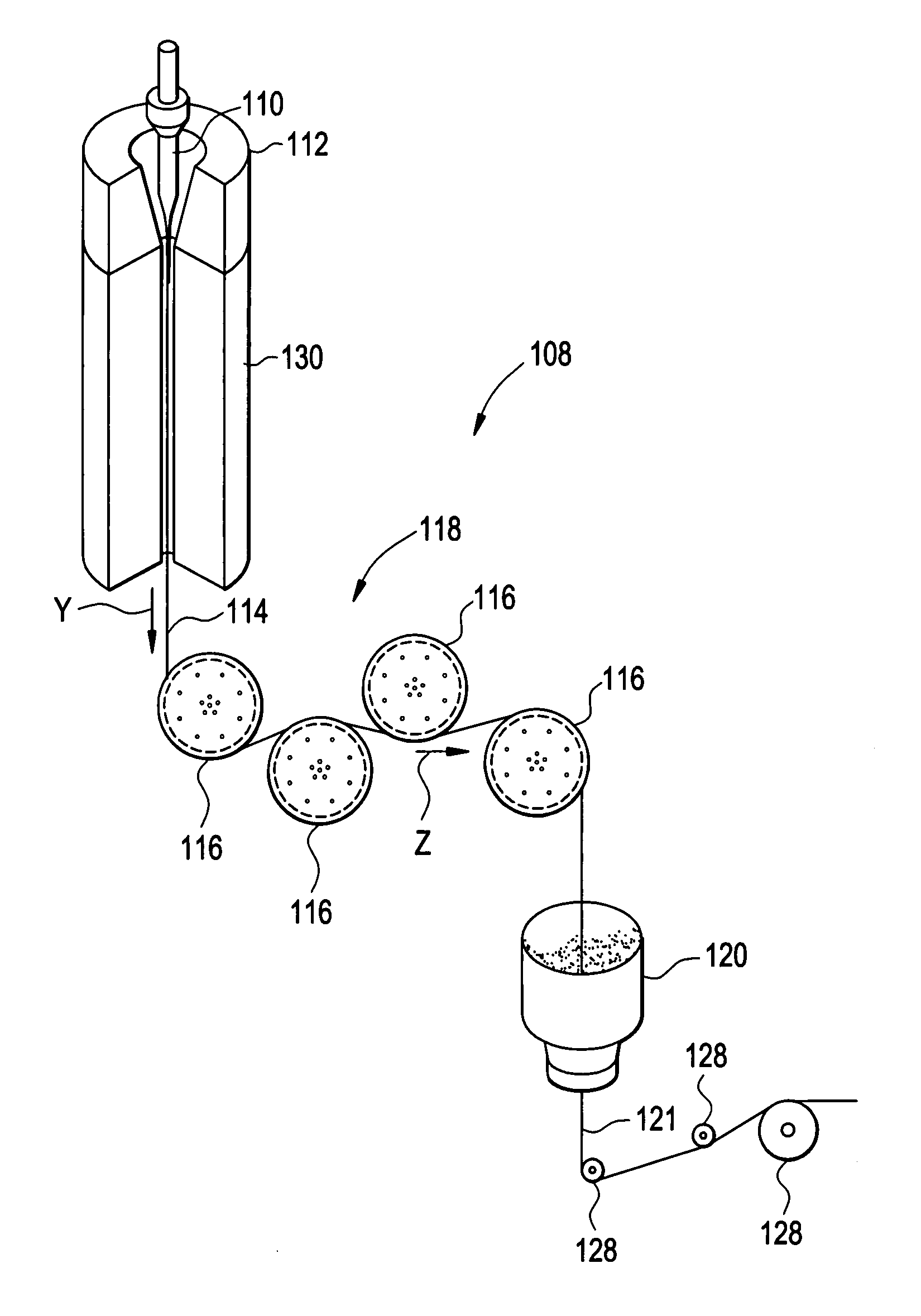

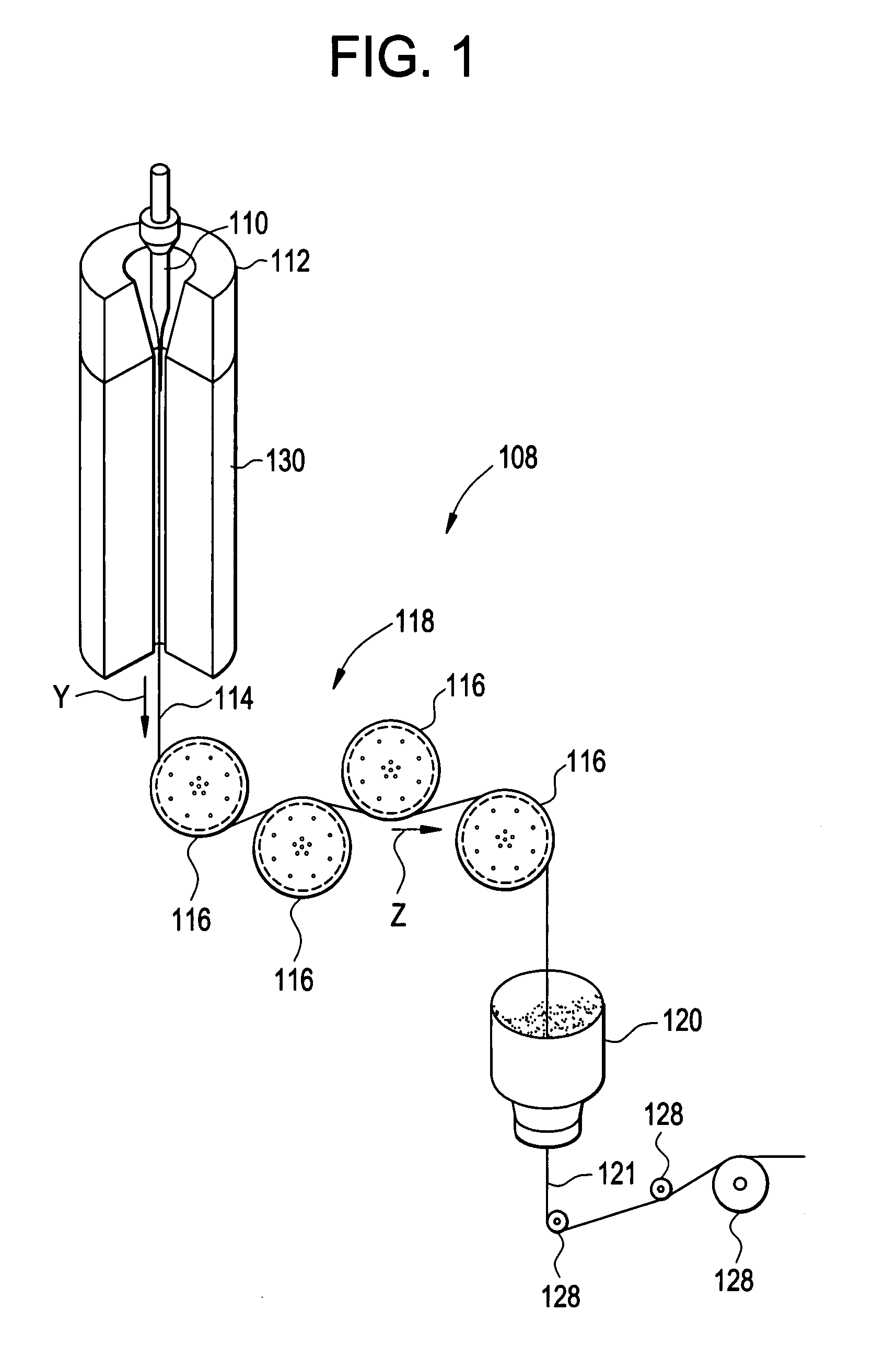

Furnace and process for drawing radiation resistant optical fiber

Apparatus and methods to fabricate a radiation hardened optical fiber from a preform are provided. Various parameters affecting the draw process are controlled to optimize the radiation resistance of the resulting fiber. An annealing zone may be provided to allow a drawn fiber exiting a primary hot zone to undergo an annealing process which may increase radiation resistance.

Owner:WEATHERFORDLAMB

Processes for making inorganic fibers

Inorganic fiber production processes and systems are disclosed. One process includes providing a molten inorganic fiberizable material, forming substantially vertical primary fibers from the molten material, and attenuating the primary fibers using an oxy-fuel fiberization burner. Other processes include forming a composition comprising combustion gases, aspirated air and inorganic fibers, and preheating a fuel stream and / or an oxidant stream prior to combustion in a fiberization burner using heat developed during the process. Flame temperature of fiberization burners may be controlled by monitoring various burner parameters.

Owner:JOHNS MANVILLE CORP

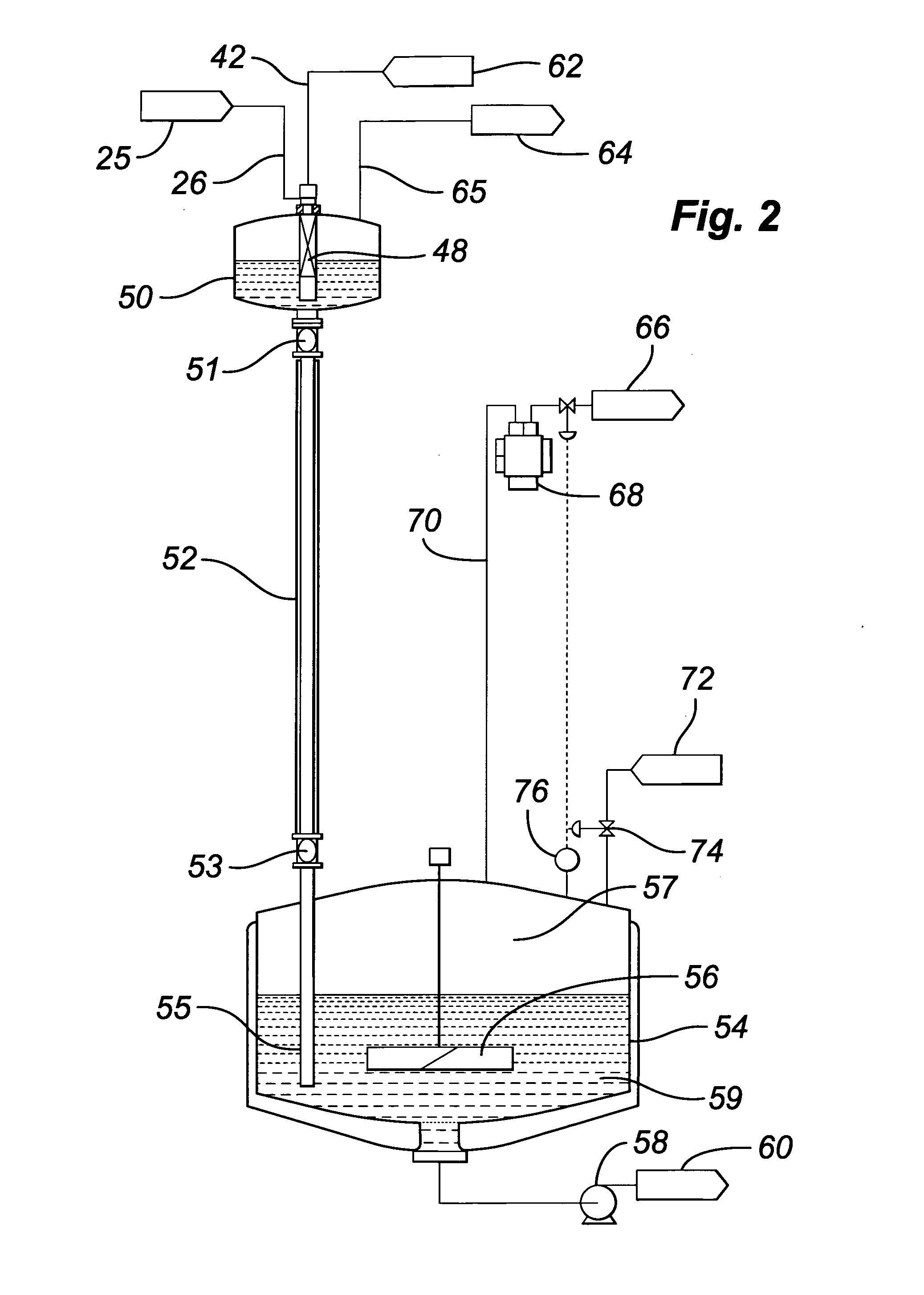

Carbonising and/or Activating Carbonaceous Material

A method is provided for carbonizing and activating carbonaceous material, which comprises supplying the material to an externally fired rotary kiln maintained at carbonizing and activating temperatures, the kiln having a downward slope to progress the material as it rotates, the kiln having an atmosphere substantially free of oxygen provided by a counter-current of steam or carbon dioxide, and annular weirs being provided at intervals along the kiln to control progress of the material. There may further be provided an externally fired rotary kiln for carbonizing and activating carbonaceous material having a hollow rotary body that has a downward slope towards a discharge end thereof, and which is provided at intervals along its length with annular weirs for controlling progress of the carbonaceous material. In embodiments, there is also provided a process is for producing discrete solid beads of polymeric material e.g. phenolic resin beads having a mesoporous structure, which may be useful as feedstock for the above mentioned carbonization / activation process or which may have other utility e.g. as ion exchange resins. The process may produce resin beads on an industrial scale without aggregates of resin building up speedily and interrupting production. The process comprises the steps of: (a) combining a stream of a polymerizable liquid precursor e.g. a novolac and hexamine as cross-linking agent dissolved in a first polar organic liquid e.g. ethylene glycol with a stream of a liquid suspension medium which is a second non-polar organic liquid with which the liquid precursor is substantially or completely immiscible e.g. transformer oil containing a drying oil; (b) mixing the combined stream to disperse the polymerizable liquid precursor as droplets in the suspension medium e.g. using an in-line static mixer; (c) allowing the droplets to polymerise in a laminar flow of the suspension medium so as to form discrete solid beads that cannot agglomerate; and (d) recovering the beads from the suspension medium. There is also provided apparatus for forming discrete solid beads of polymeric material, said apparatus comprising: a first line for conveying s stream of a polymerizable liquid precursor; a second line for conveying a stream of a dispersion medium with which the polymerizable liquid precursor is substantially or completely immiscible; an in-line mixer configured to receive a combined flow from the first and second lines and to disperse the polymerizable liquid precursor as droplets in the dispersion medium; a vertical polymerization column configured to receive the dispersion medium with the droplets dispersed therein and to permit the polymerizable liquid precursor polymerize while descending the column in a descending flow of polymerization medium; and a vessel at the base of the column for receiving the descending flow of dispersion medium and collecting polymerized solid beads.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

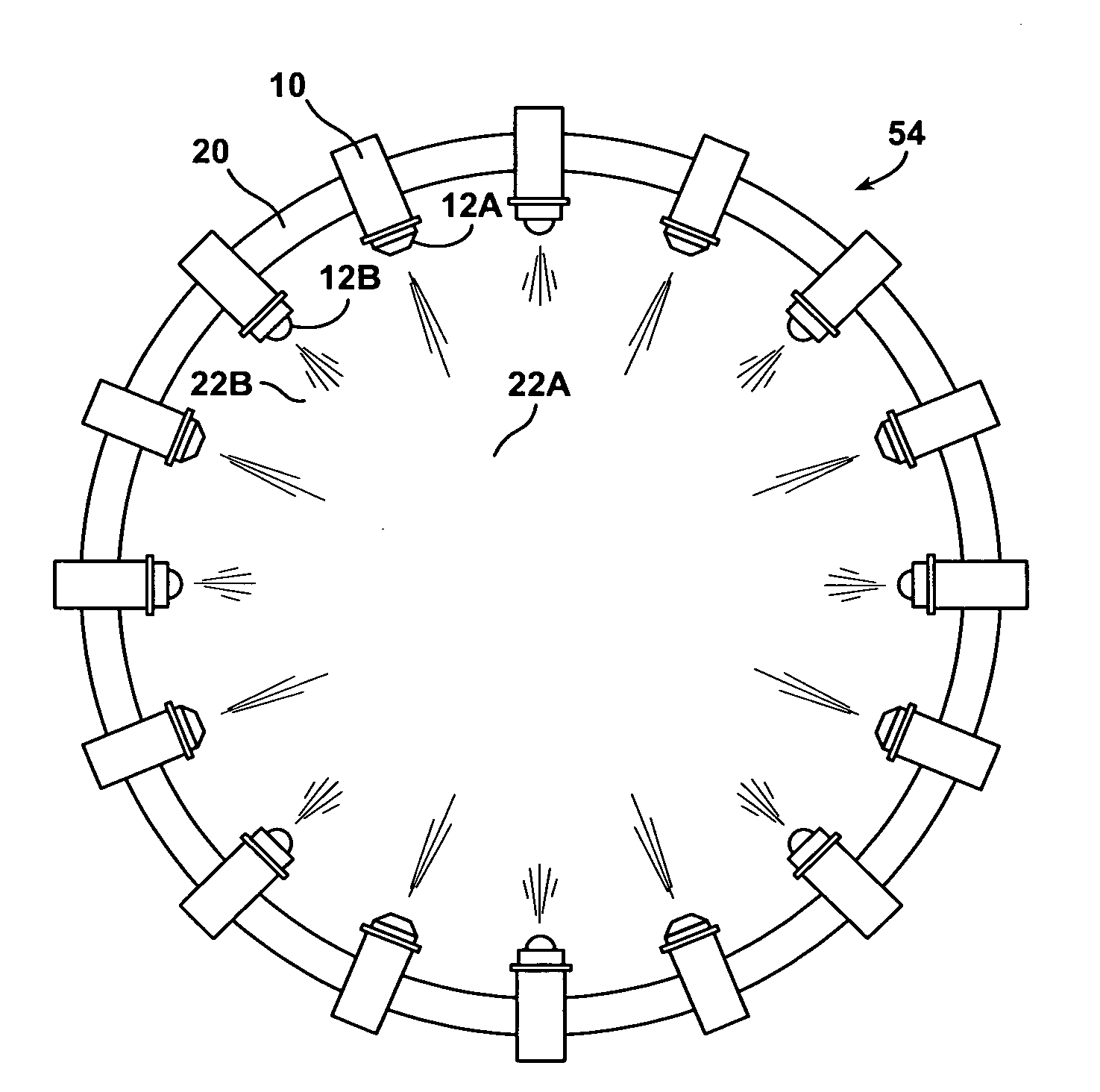

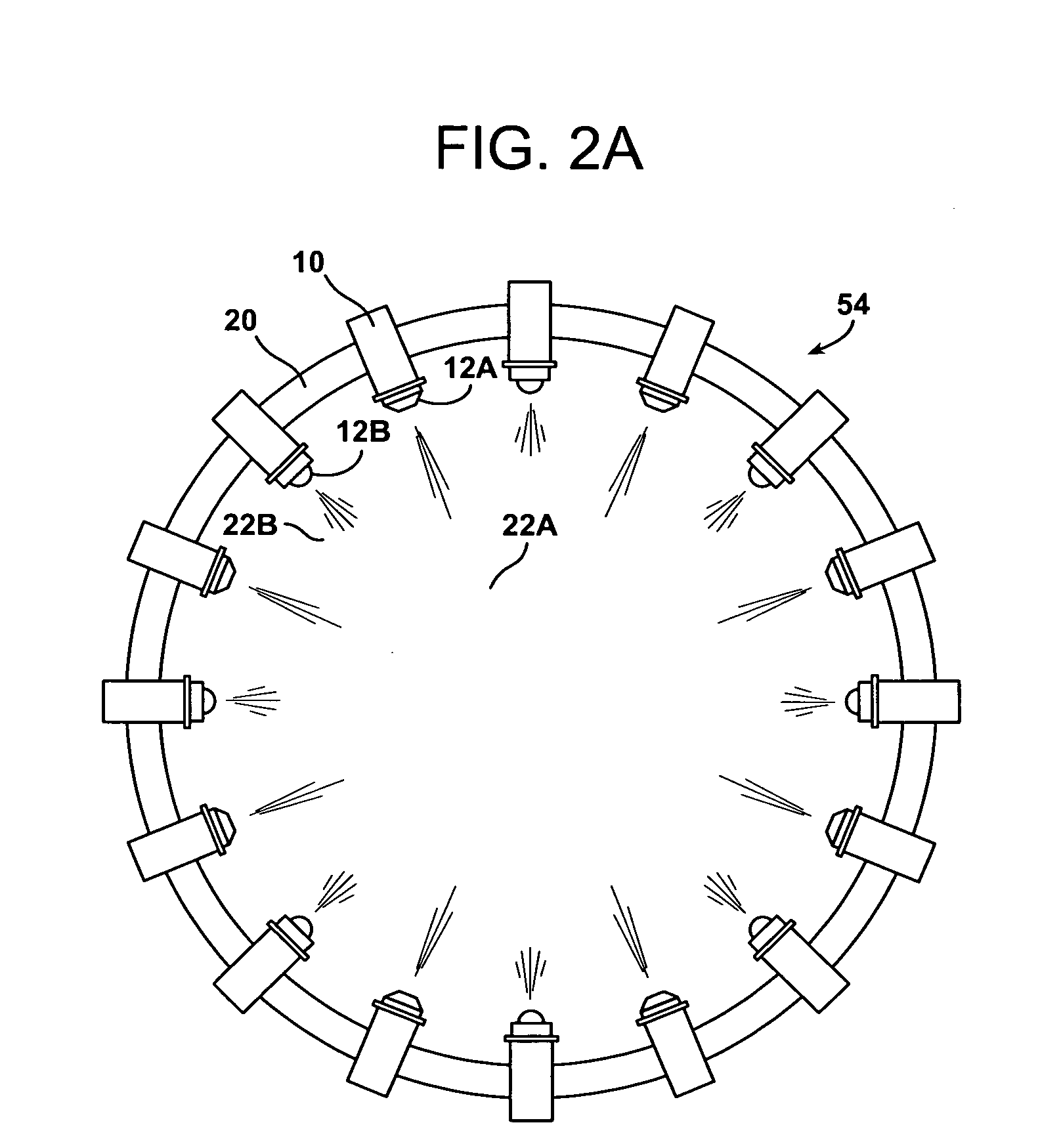

Cooling ring for use in manufacturing of fiberglass wool

InactiveUS20080156041A1Improve cooling effectImprove cooling efficiencyGlass furnace apparatusRotary drum furnacesGlass fiberFiber

The present invention provides improved cooling of a veil of glass fibers by using a combination of nozzle assemblies. The nozzle assemblies include air caps of differing configurations to control the penetration of the spray into the veil. One suitable spray configuration is a nozzle assembly having punch air cap that creates a narrow exit angle, high velocity flow of droplets to penetrate the veil to cool the fibers at the interior. Another suitable configuration is a nozzle assembly having a flat air cap that creates a wide exit angle, low velocity, dispersed spray pattern to cool the exterior of the veil. Preferably, the flat air cap creates a very fine particle size to increase the cooling efficiency of the spray. By using the cooling ring of the present invention, lower levels of binder to be applied to the fibers and environmental emissions from the plant may be reduced.

Owner:OWENS CORNING FIBERGLAS TECH INC

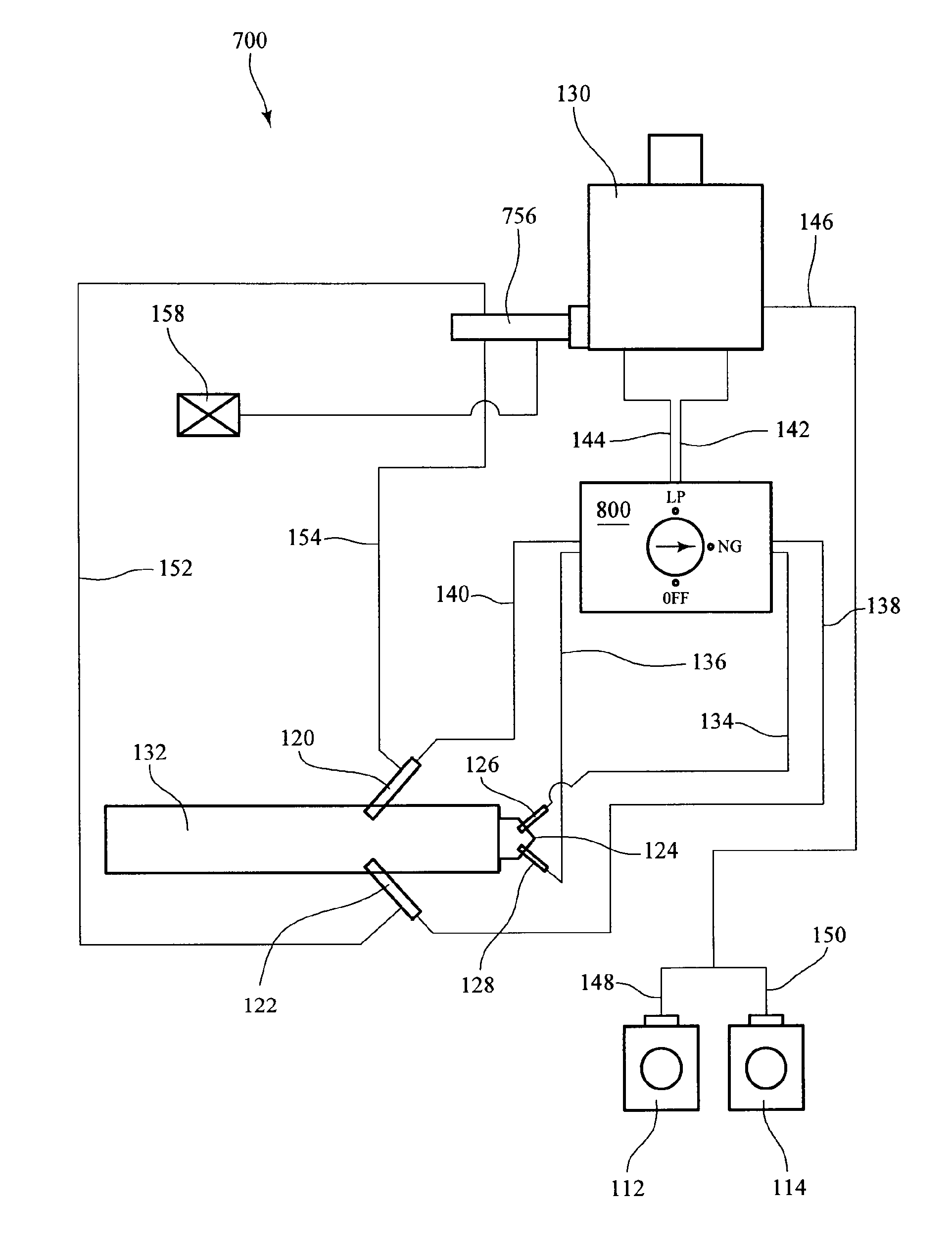

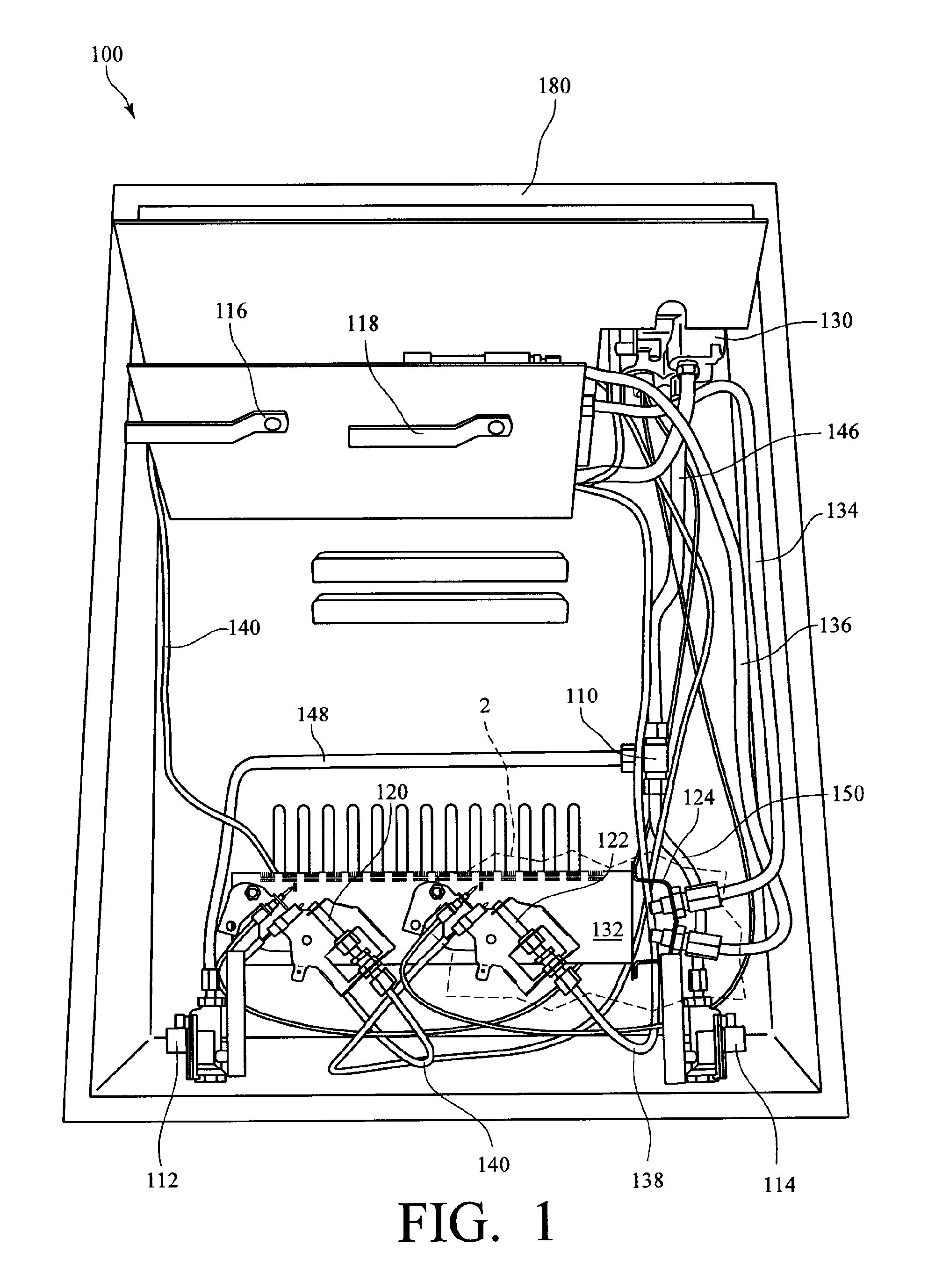

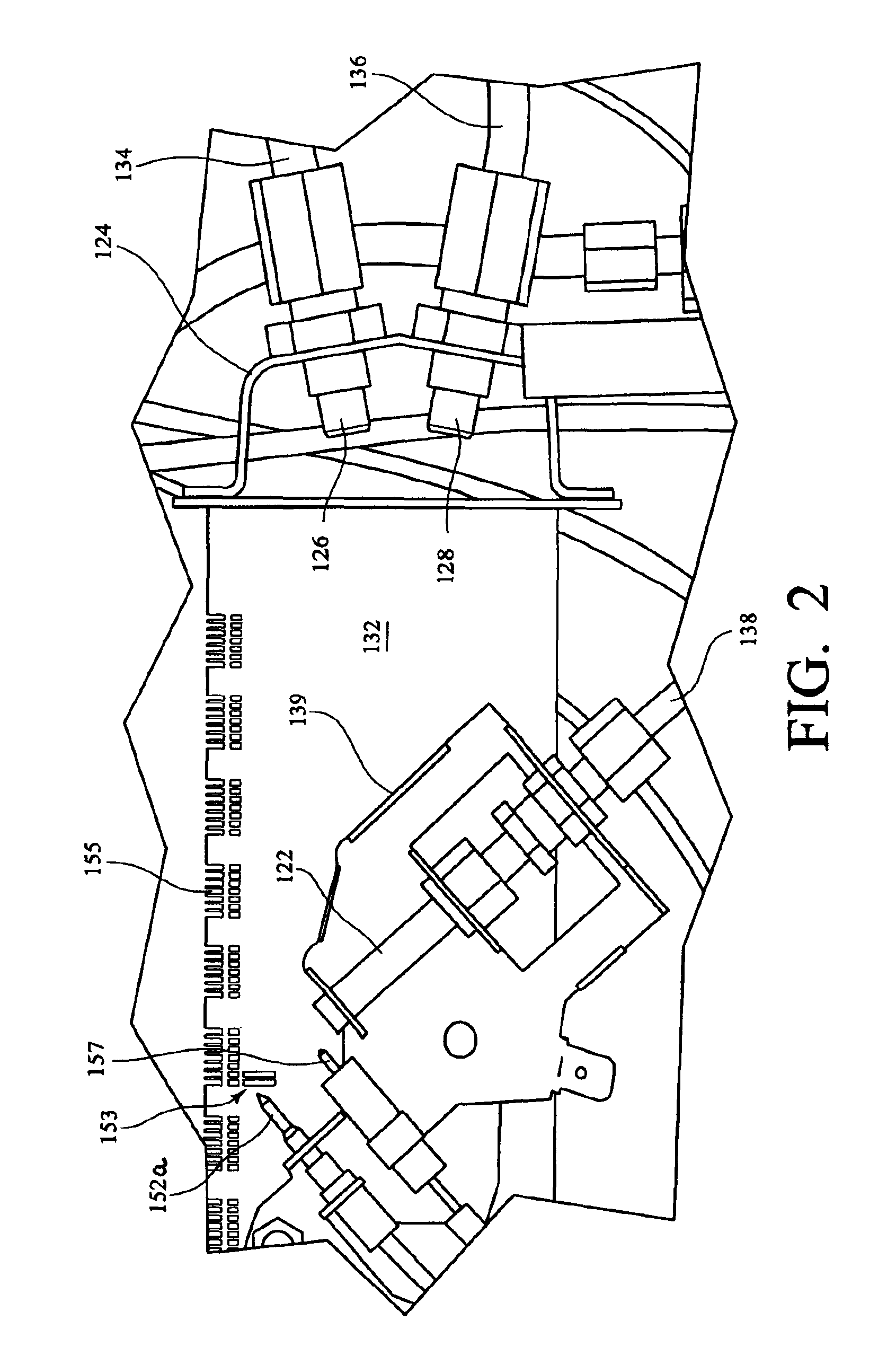

Dual fuel vent free gas heater

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports in an upper surface thereof. The gas outlet ports are in flow communication with at least one pilot flame burner. An adjustable fuel injector or at least two fuel injectors feed fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual fuel selection control valve, and / or temperature shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

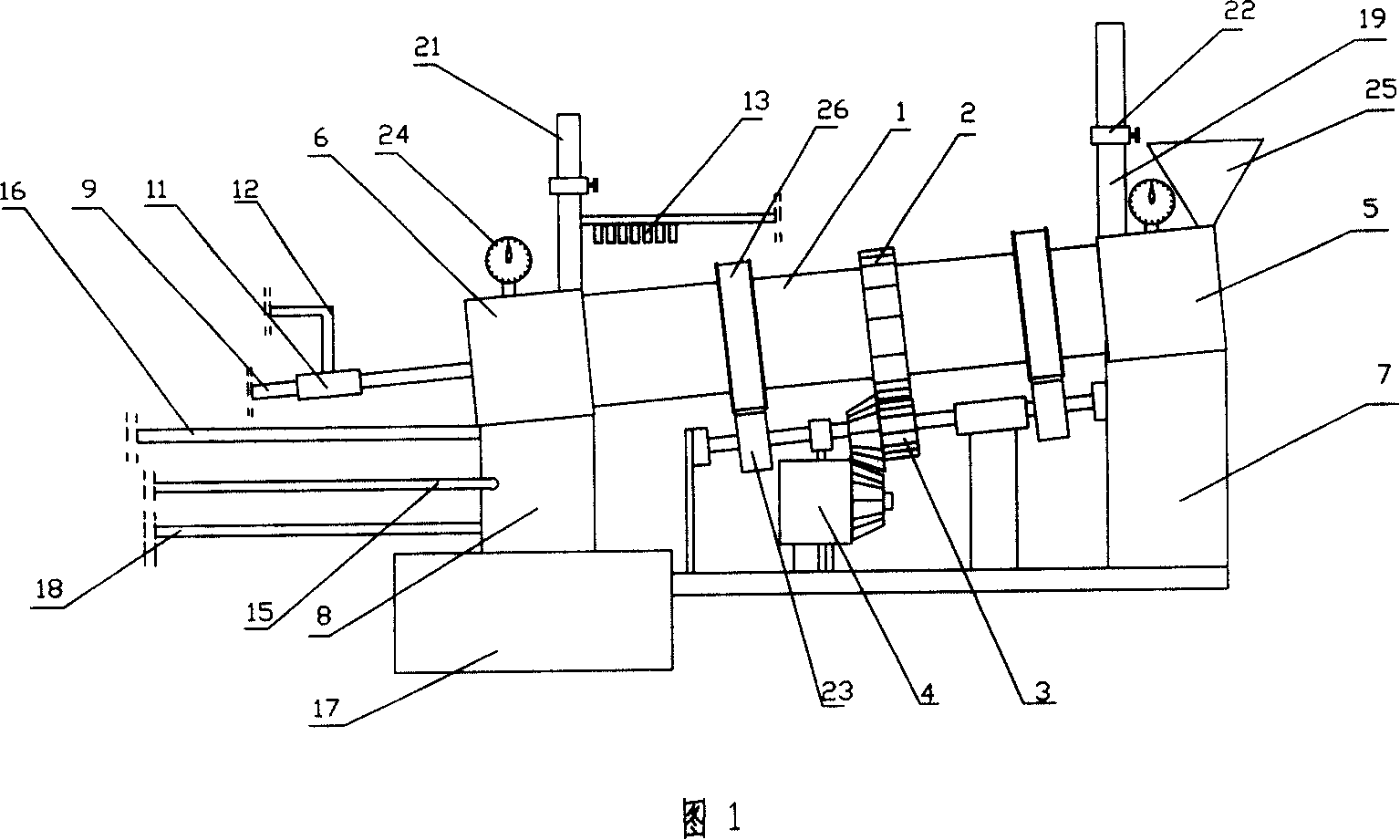

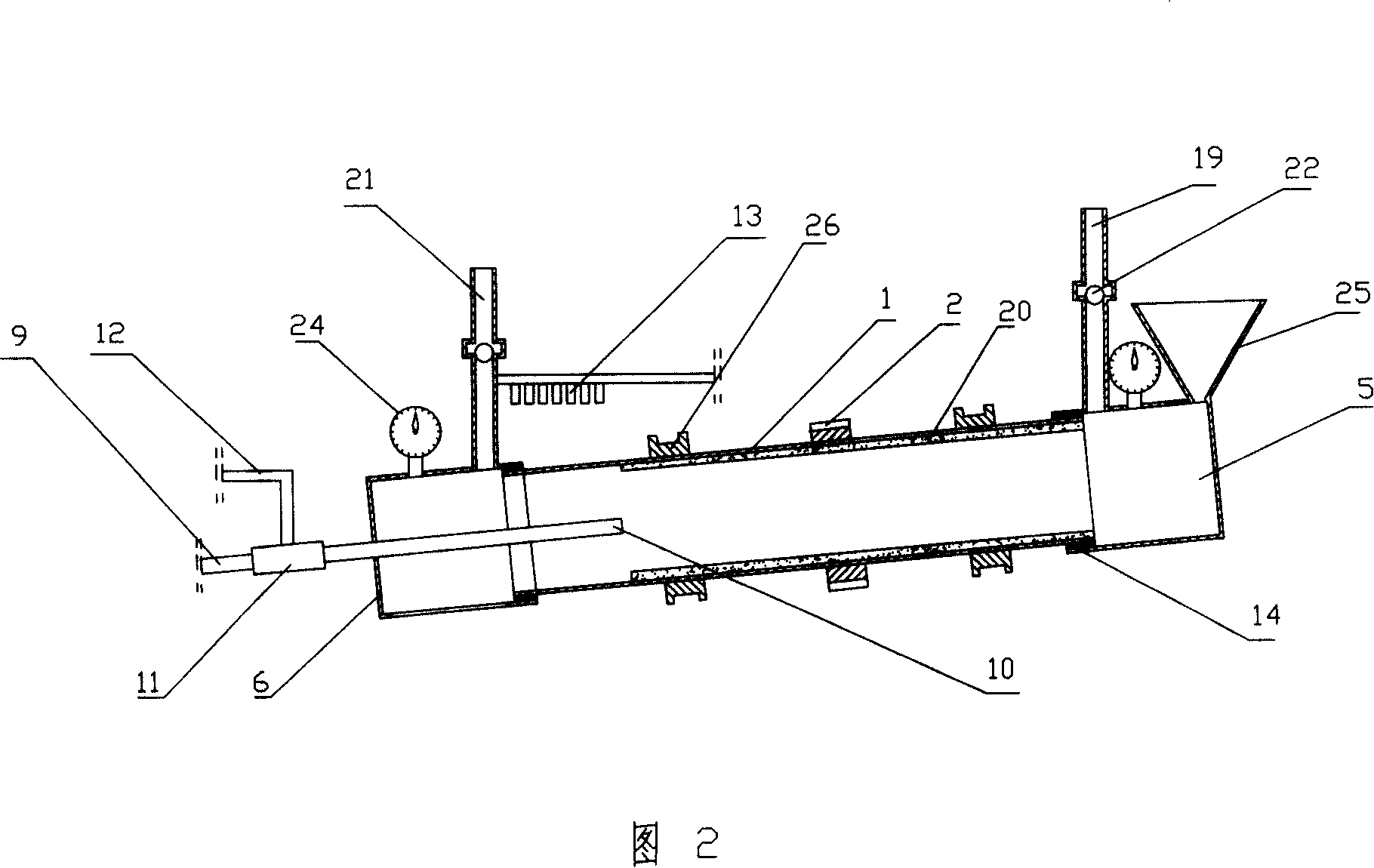

Graphite rotary tube furnace

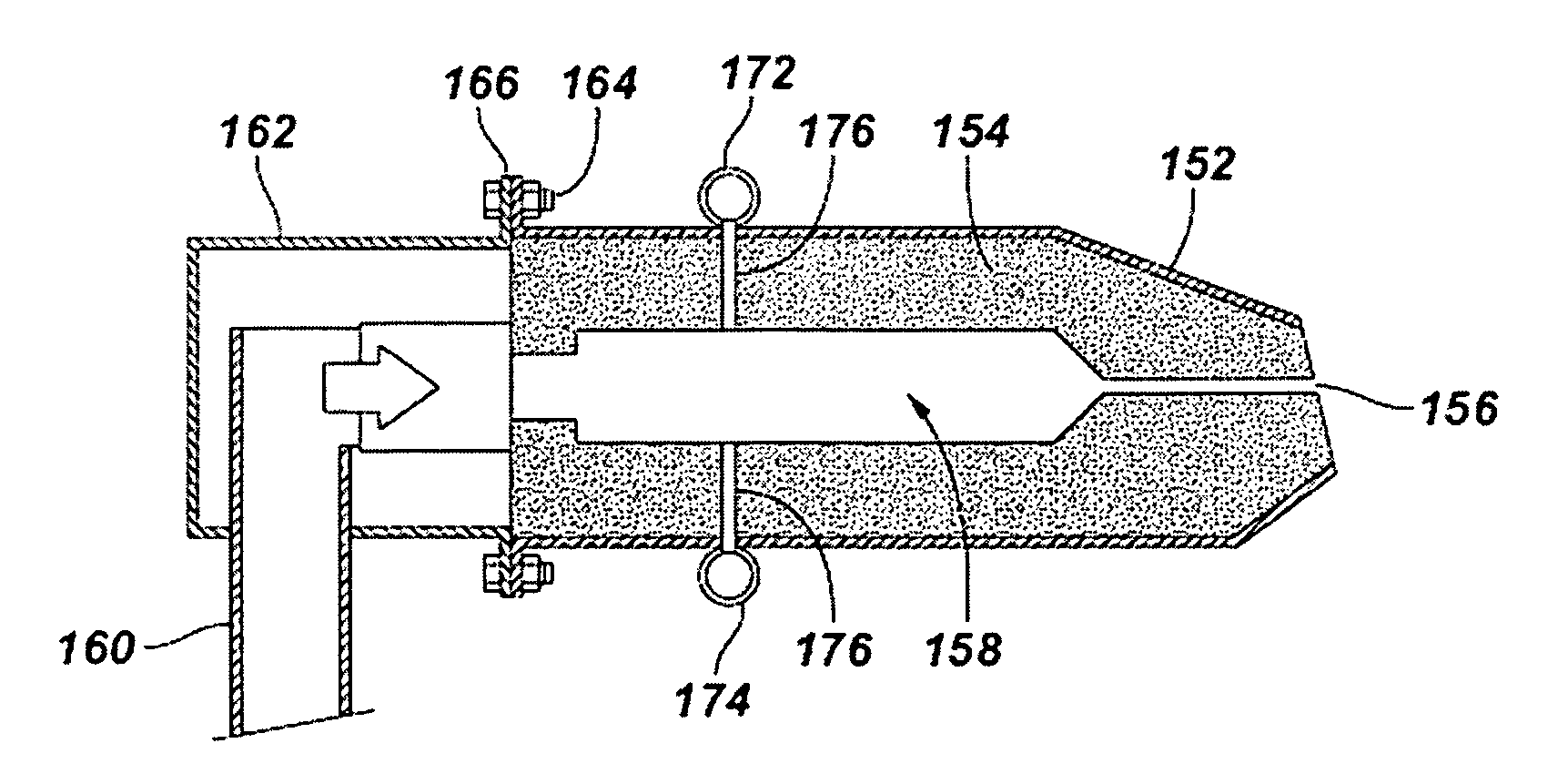

InactiveUS6042370AMinimizing radiation heat lossStable temperatureRotary drum furnacesCharge supportsRadiative heat lossRadiant heat

A rotary tube furnace suitable for operation in controlled atmospheres at temperatures in the range of 1500 DEG to 2800 DEG comprises a generally horizontal rotatable graphite tube slidably supported on water-cooled split ring graphite bearings. The graphite tube is rotated by means of a stainless steel drive plate and is contained within a flexible atmospheric sealing assembly and enclosure for the containment of a selected atmosphere around and within the tube and allows for the co-current or counter-current flow of gas during operation. Radiation baffles in the interior of the graphite tube inhibit radiant heat loss at the ends of the tube. The graphite tube may be constructed in two or more sections having threaded ends for ease of installation as well as removal or replacement for maintenance purposes. A heating section of the tube is heated by a plurality of graphite electrical heating elements contained within an insulated heating chamber.

Owner:HARPER INT CORP

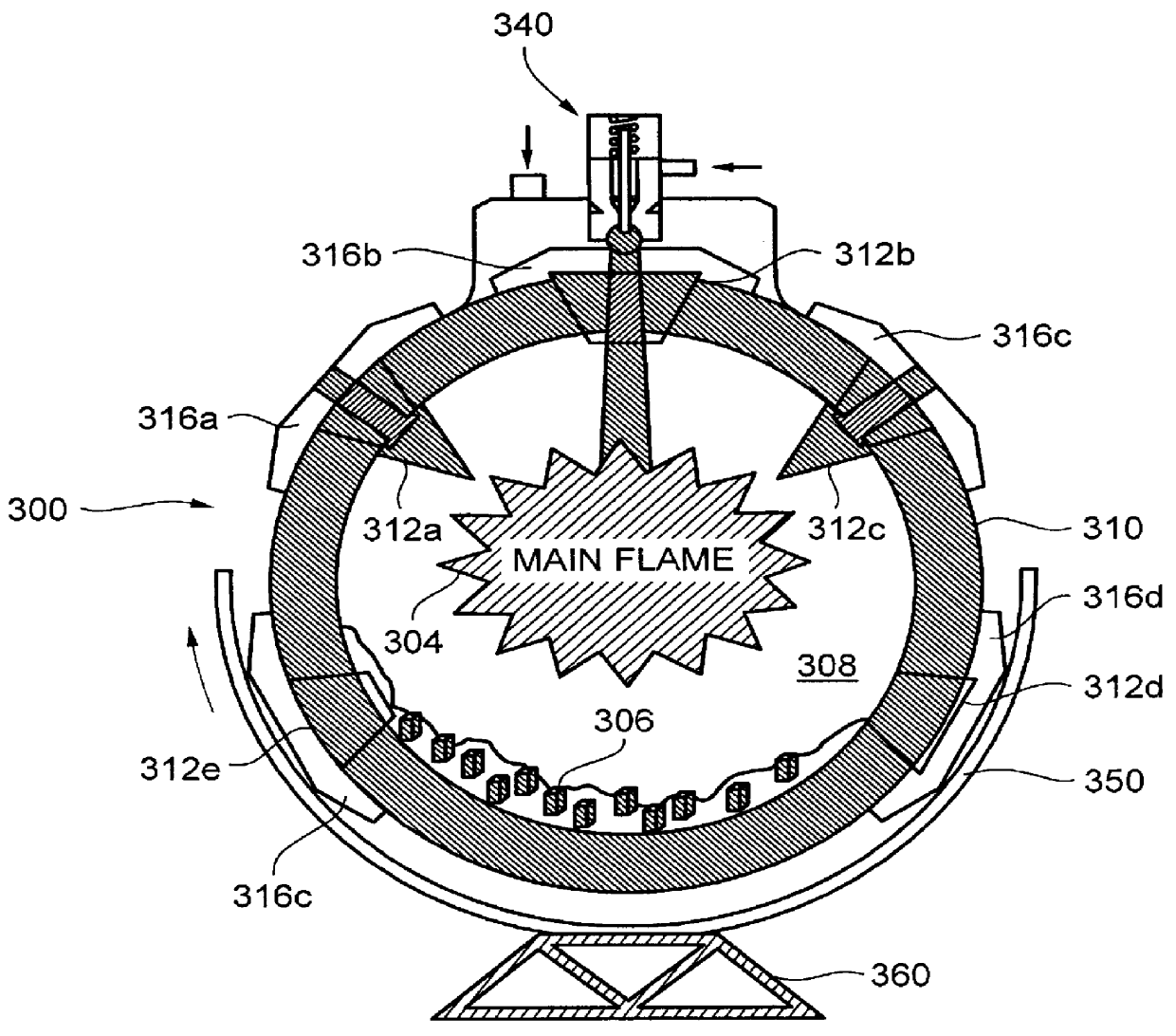

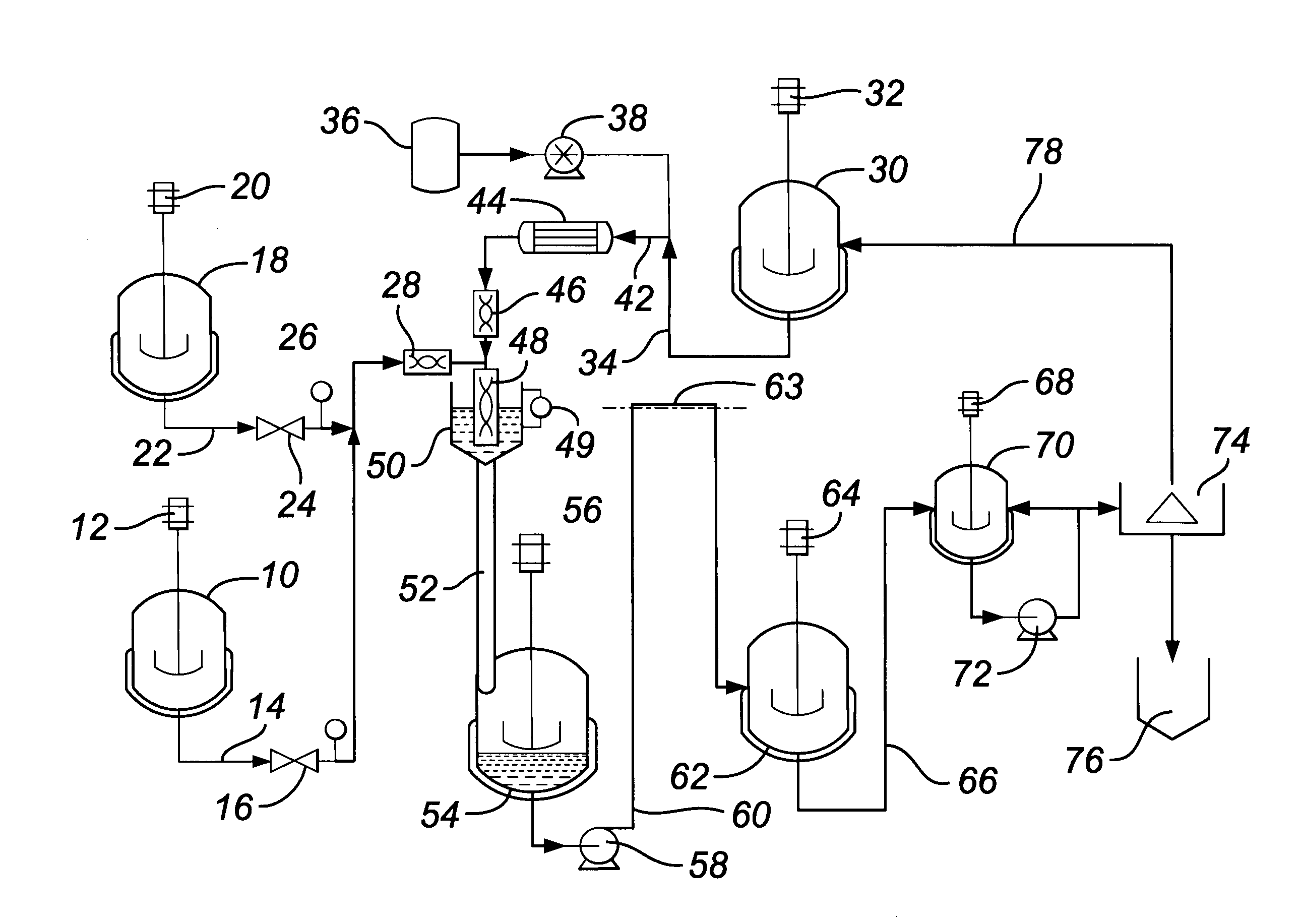

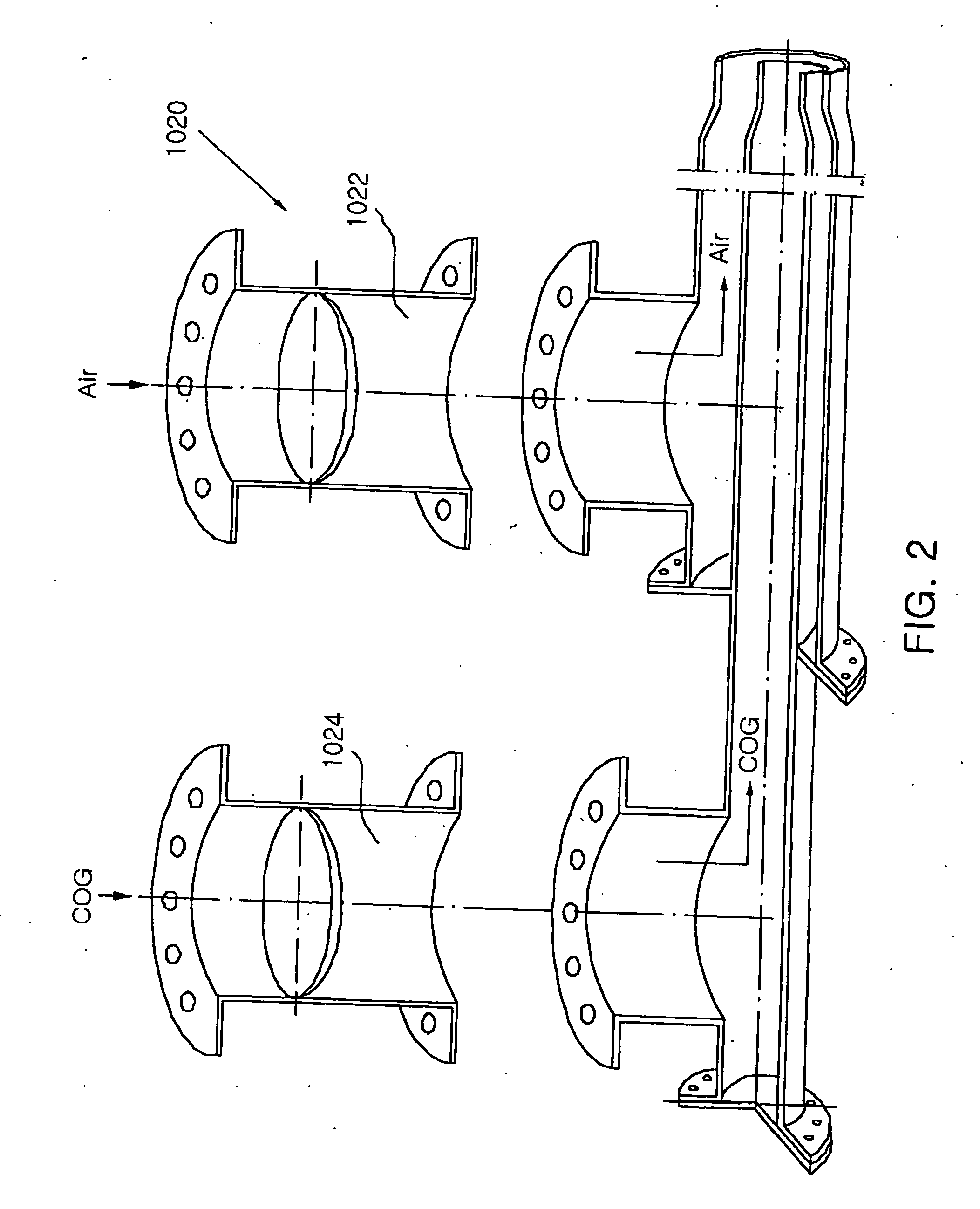

Method and burner apparatus for injecting a pulverized coal into rotary kilns, method and apparatus for producing cao using them

InactiveUS20060169181A1Reduce concentrationMinimize diameter variationPigmenting treatmentSolid fuel pretreatmentCombustorEngineering

The invention relates to a method and burner for injecting pulverized coal into a rotary kiln that uses pulverized coal as fuel in order to produce quick lime of excellent hydration level. The invention calcines lime stone charged into the rotary kiln, and uses pulverized coal as fuel of a heat source applied to the lime stone charged in the rotary kiln. The invention also provides a method and apparatus for producing quick lime by using the pulverized coal. The invention can use pulverized fossil fuel (hereinafter will be referred to as pulverized coal), which is created during coke manufacturing and cooling processes and collected by a dust collector, in order to produce quick lime of excellent hydration level while decreasing SOx (sulfide) and NOx (nitride) generation.

Owner:POHANG IRON & STEEL CO LTD

Sludge dryer

InactiveUS20050000108A1Avoid lostPrevent partial lossDrying solid materials without heatRotary drum furnacesSludgeEvaporation

Owner:RAGNARSSON ANDERS T

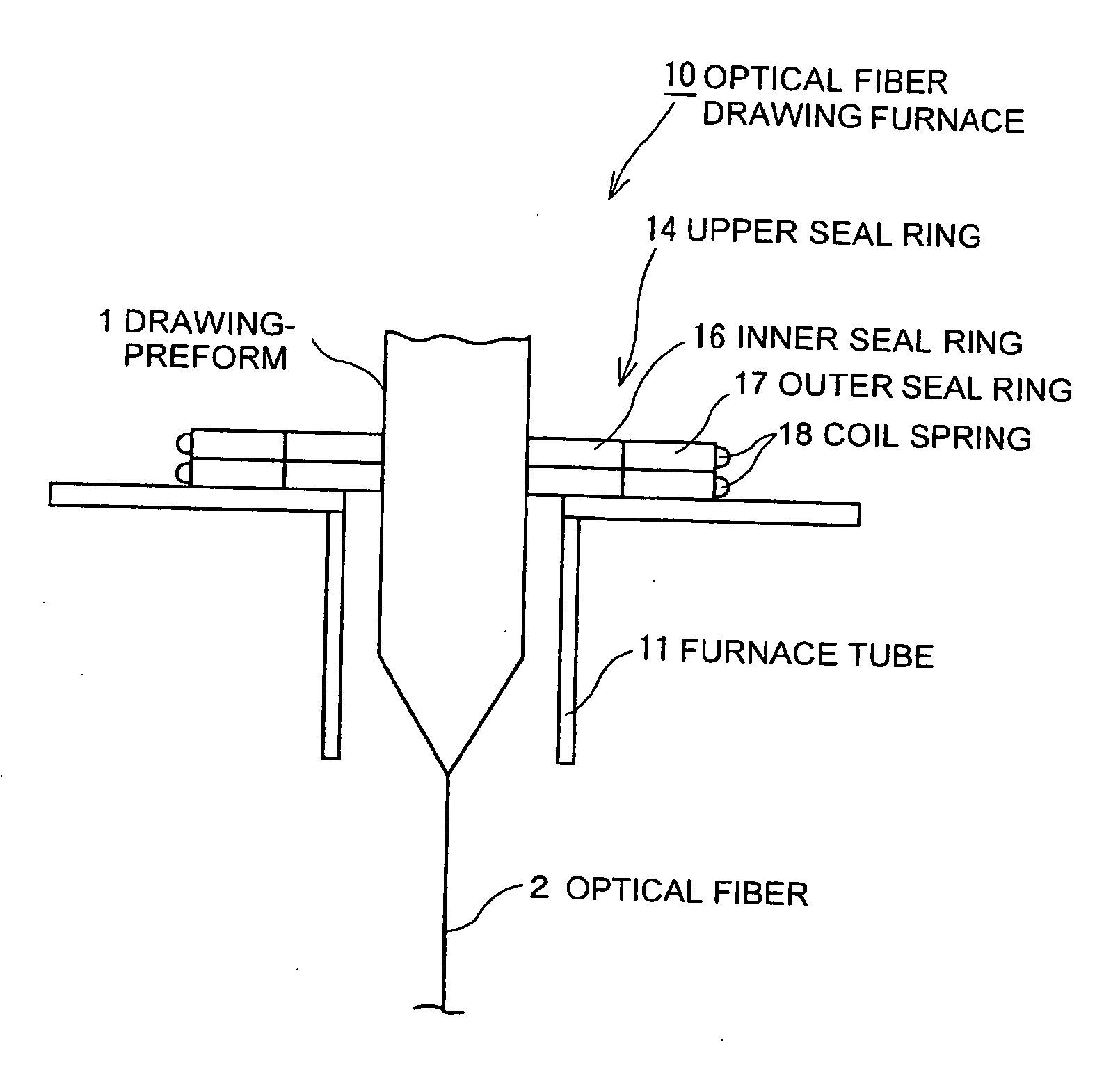

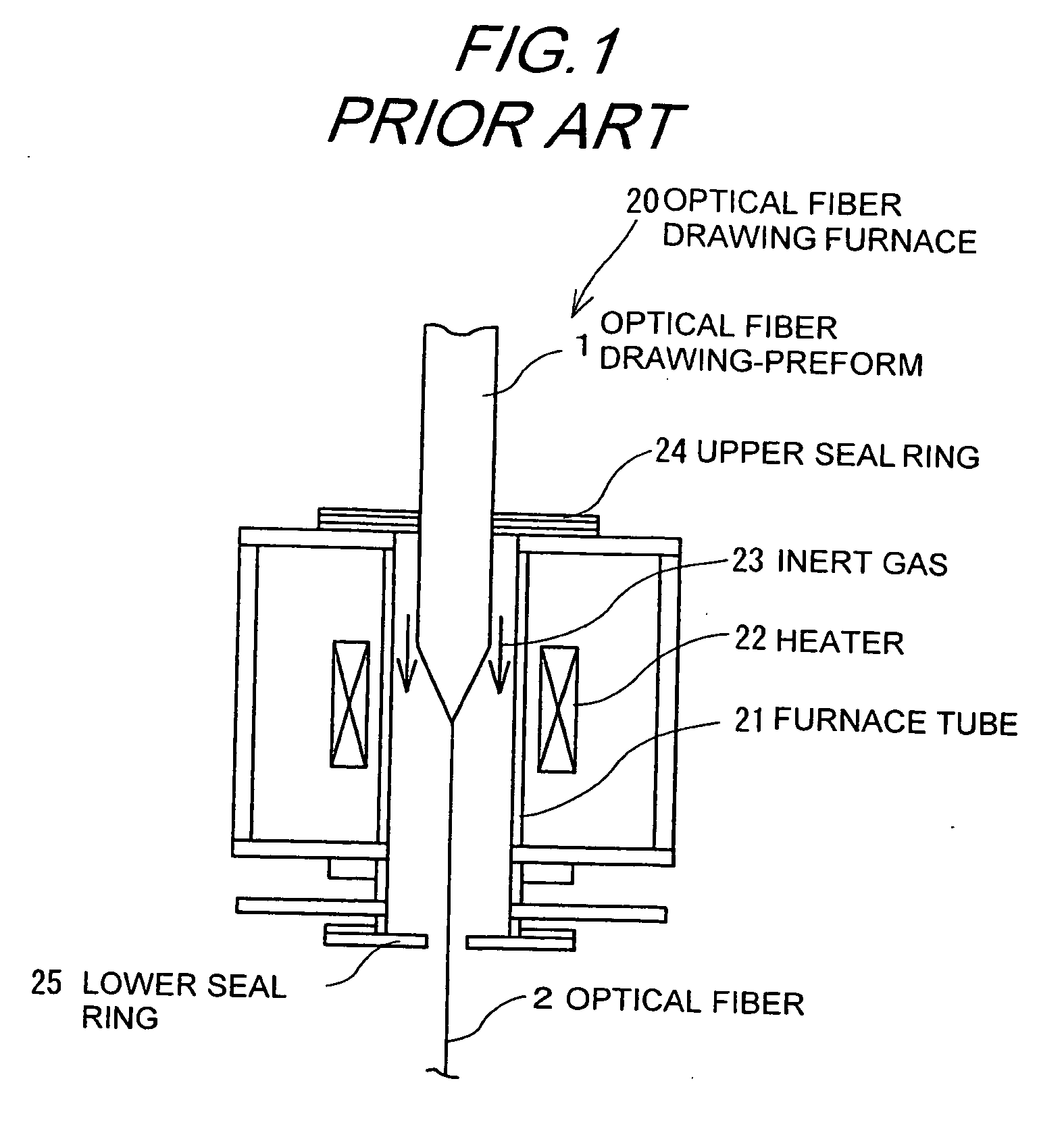

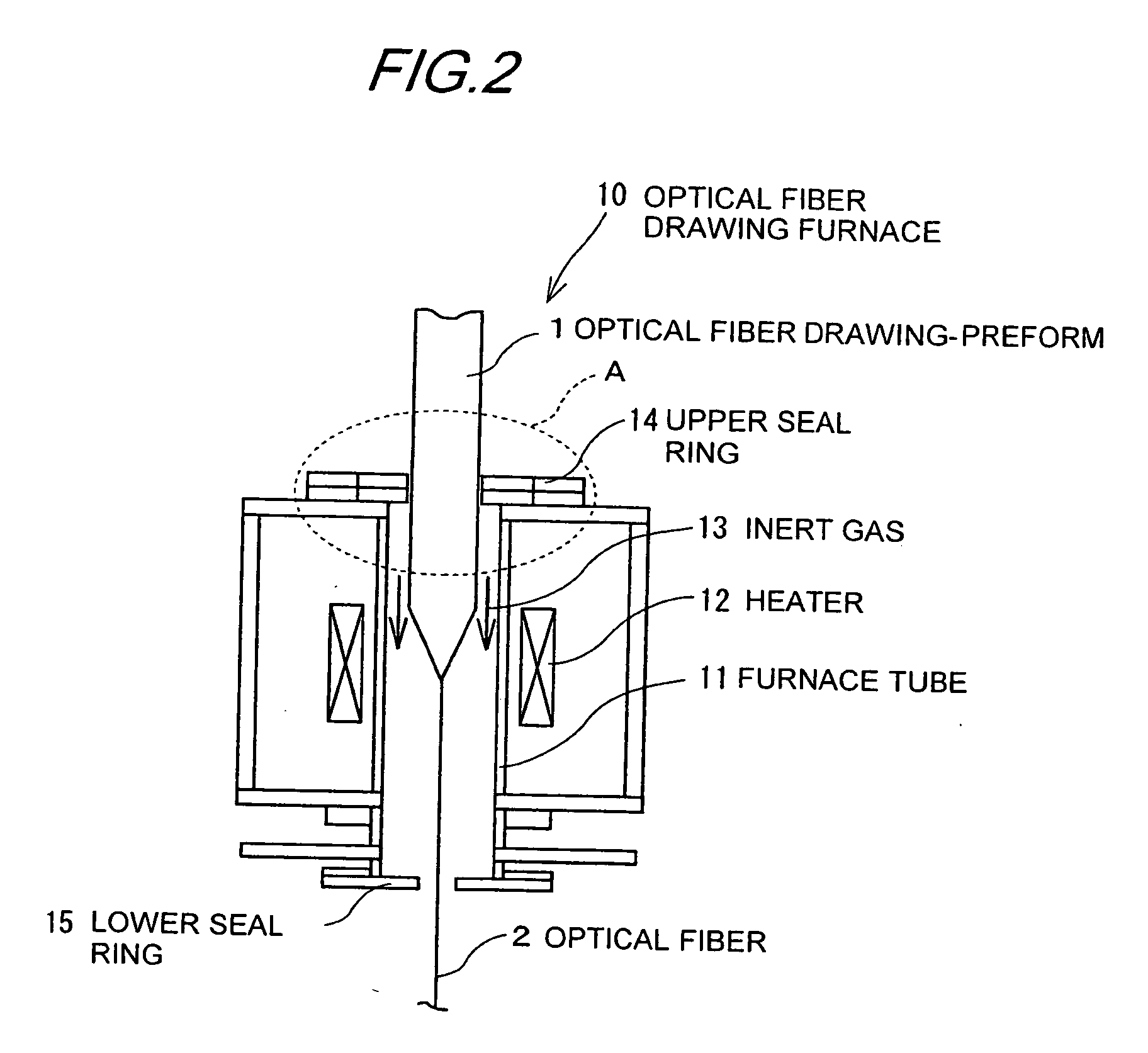

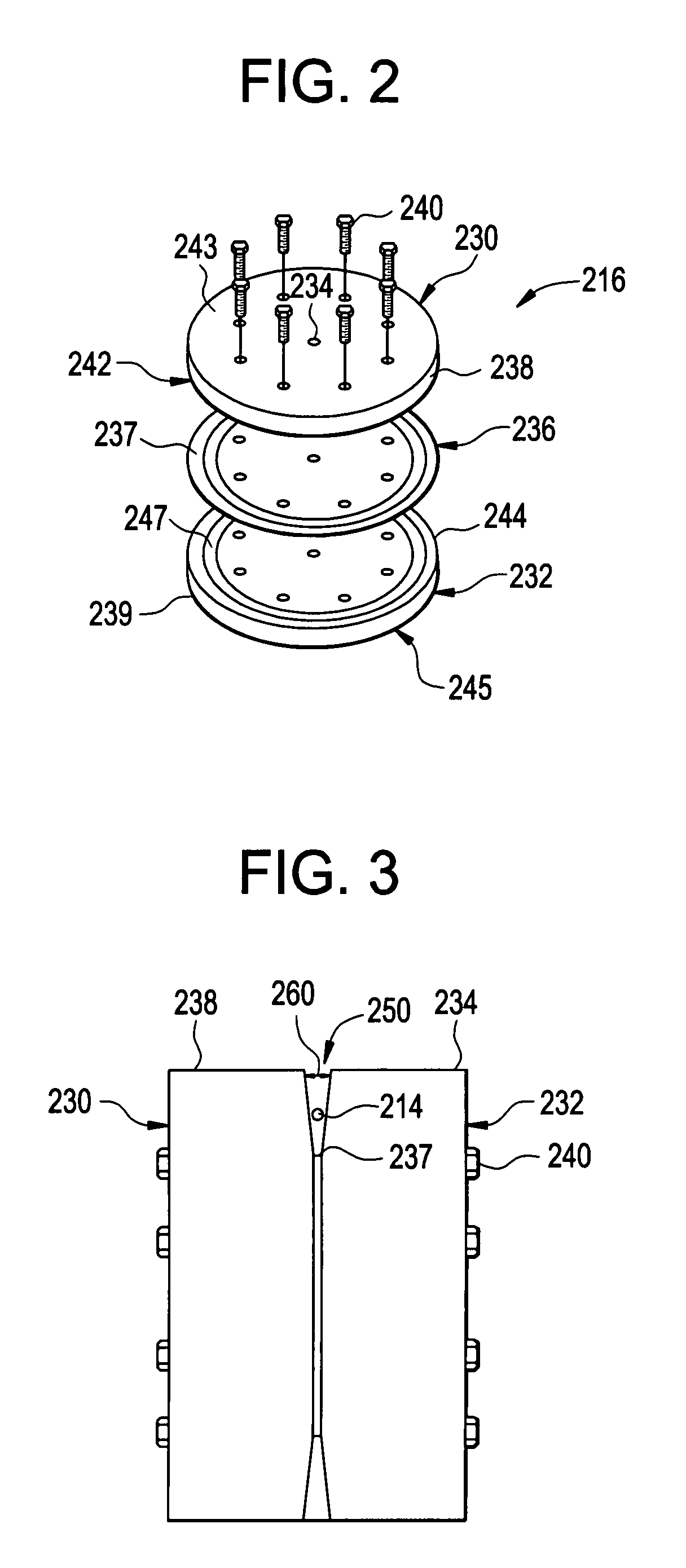

Optical fiber drawing apparatus, sealing mechanism for the same, and method for drawing an optical fiber

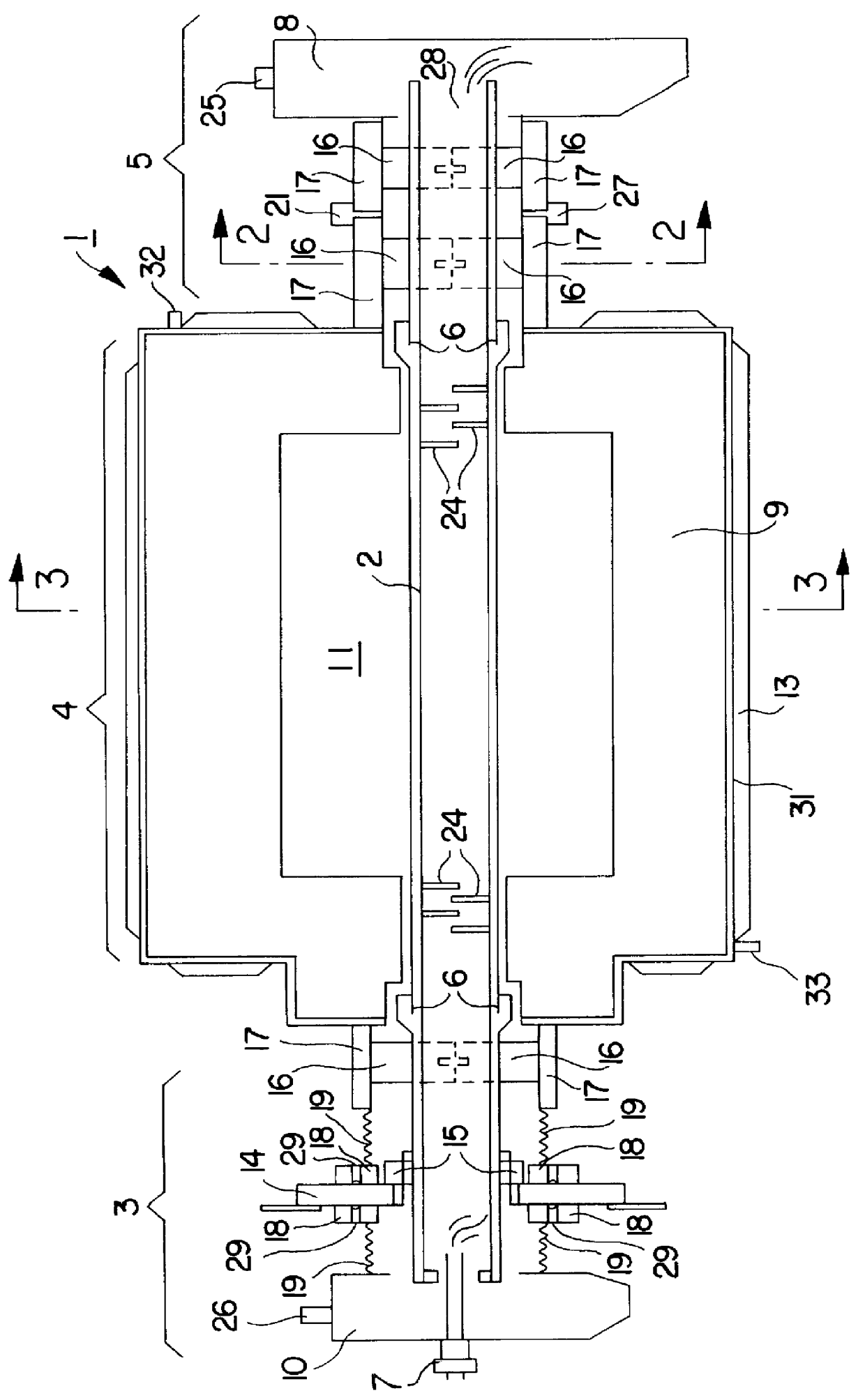

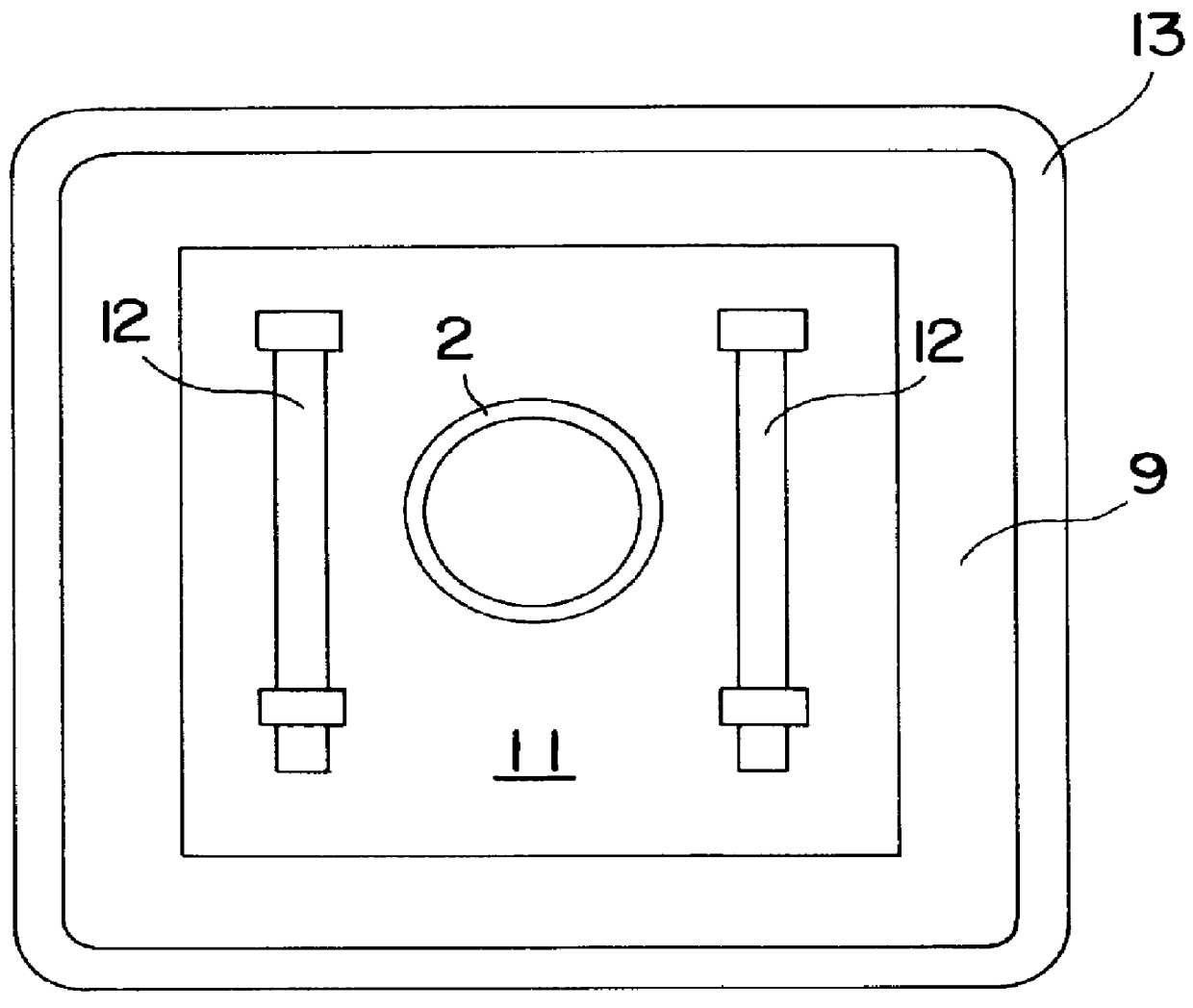

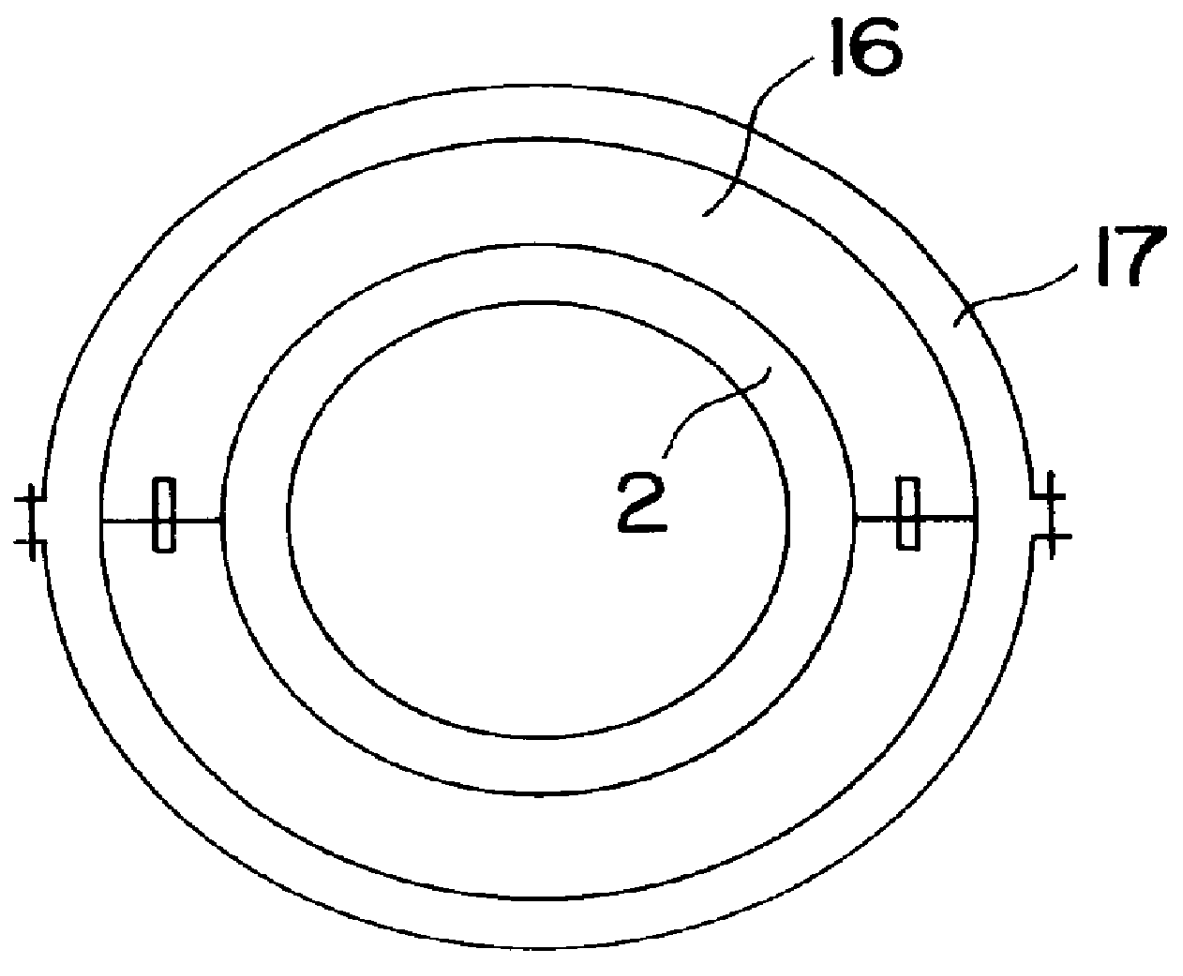

InactiveUS20060280578A1Simple structureKeep tightWashersGlass furnace apparatusCoil springEngineering

An inner seal ring 16 is composed by connecting a plurality of inner seal ring pieces 16A, an outer seal ring 17 is composed by connecting a plurality of outer seal ring pieces 17A provided at an outer periphery of the inner seal ring 16, and a coil spring 18 is arranged at an outer periphery of the outer seal ring 17. The inner seal ring 16 and the outer seal ring 17 are piled for two or more stages, respectively. A connecting part of the inner seal ring pieces 16A and a connecting part of the outer seal ring pieces 17 are arranged not to overlap each other. An inner diameter of the inner seal ring 16 is variable in accordance with an outer diameter in vertical direction of a drawing-preform 1 by using a coil spring 18.

Owner:HITACHI CABLE

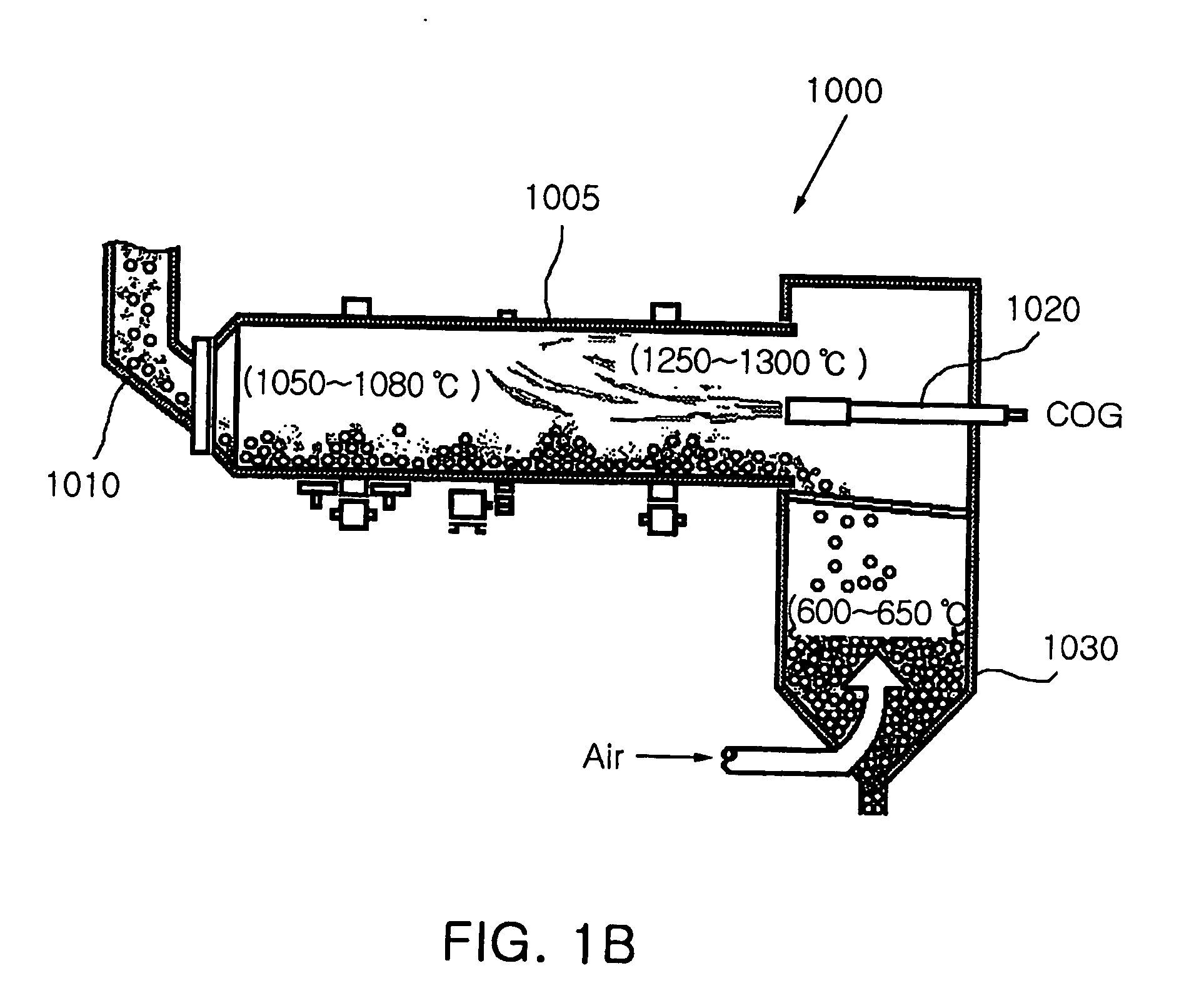

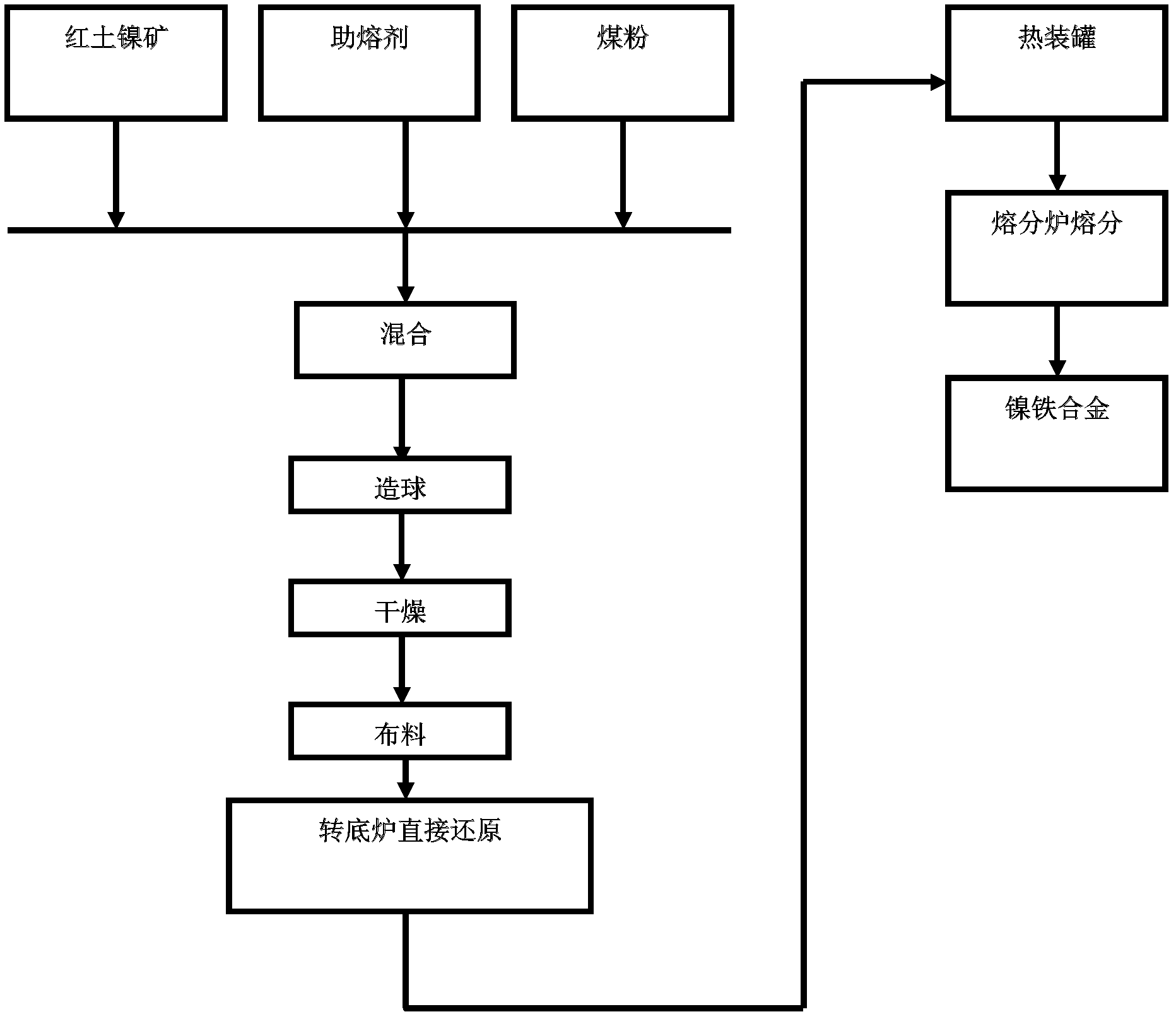

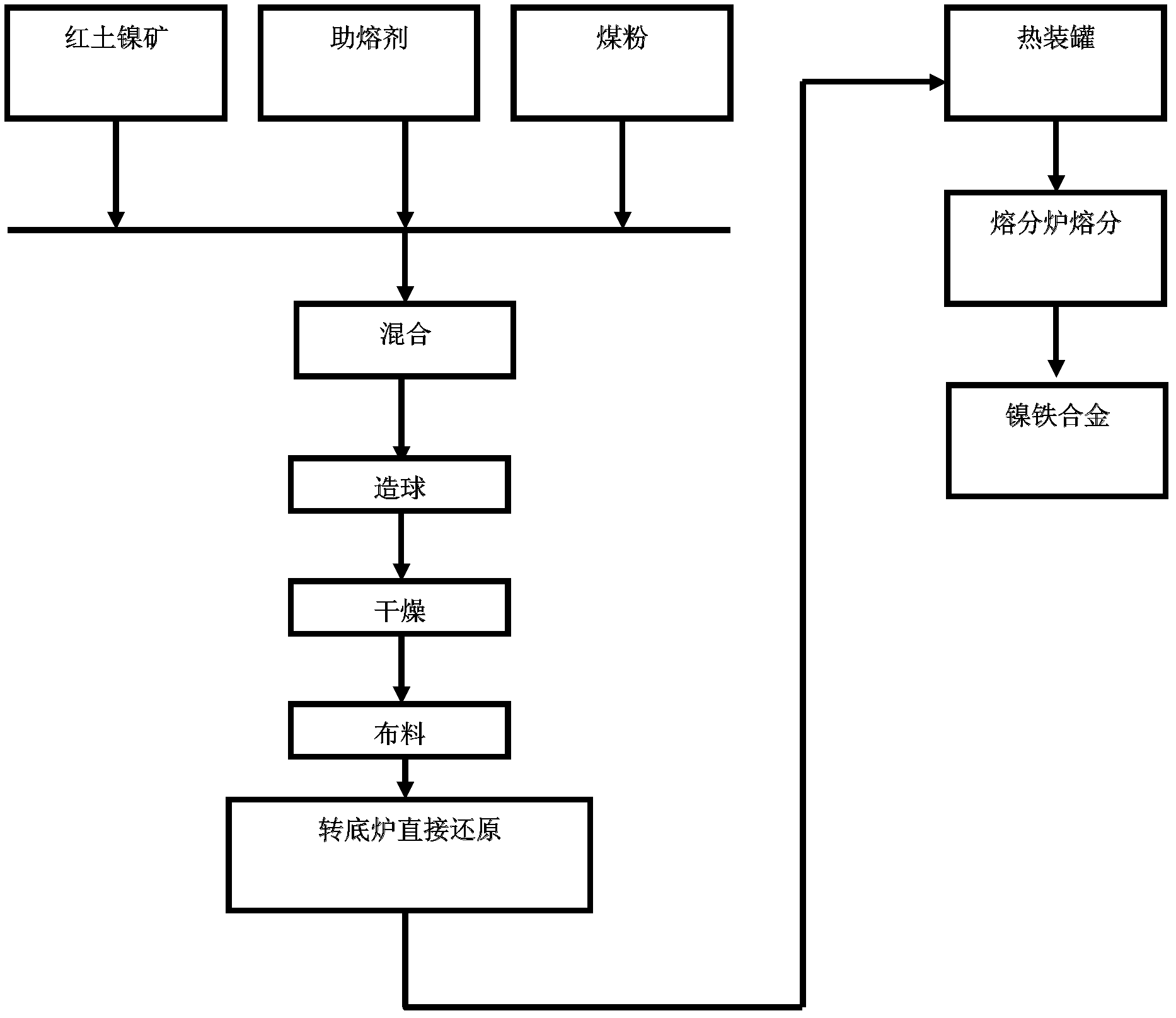

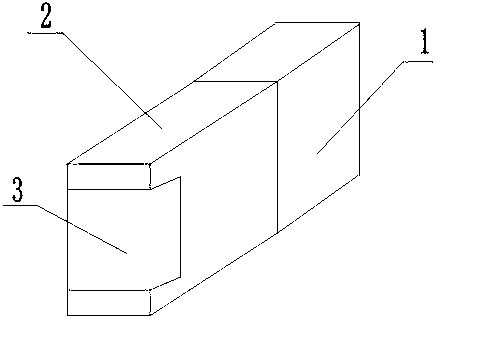

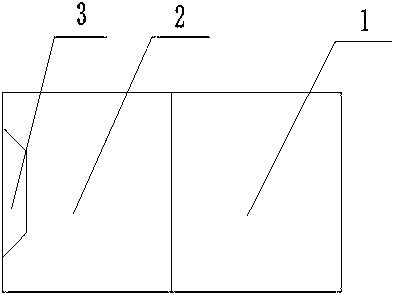

Iron-making method by performing coal-based direct reduction in rotary hearth furnace and melting in gas melting furnace on lateritic-nickel ore

The invention discloses an iron-making method by performing coal-based direct reduction in a rotary hearth furnace and melting in a gas melting furnace on lateritic-nickel ore. The method comprises the following steps: firstly mixing a certain quantity of coal, lateritic-nickel ore and a fluxing agent and then pelletizing, spreading green pellets in a rotary hearth furnace after the pellets are dried, and heating to the temperature of 1200-1300 DEG C and maintaining the temperature for 30-40 minutes to obtain high-temperature metallized pellets; hot-packing the high-temperature metallized pellets at 600-1100 DEG C from the rotary hearth furnace, and then transferring the packed pellets into a heat-accumulating gas melting furnace for melting at the temperature of 1420-1500 DEG C for 30 minutes, wherein the heat-accumulating gas melting furnace utilizes coal gas as fuel; and removing slag to finally obtain high-nickel ferronickel alloy. The iron-making method has the advantages of simple process, short flow, high efficiency, high nickel recovery rate and no need of coking coal and is applicable to the treatment of lateritic-nickel ore.

Owner:吴道洪 +1

Low-heat-conduction multi-layer mullite brick and preparation method thereof

ActiveCN103234346ALow thermal conductivityHigh strengthFurnace componentsRotary drum furnacesBrickMullite

Owner:郑州瑞泰耐火科技有限公司

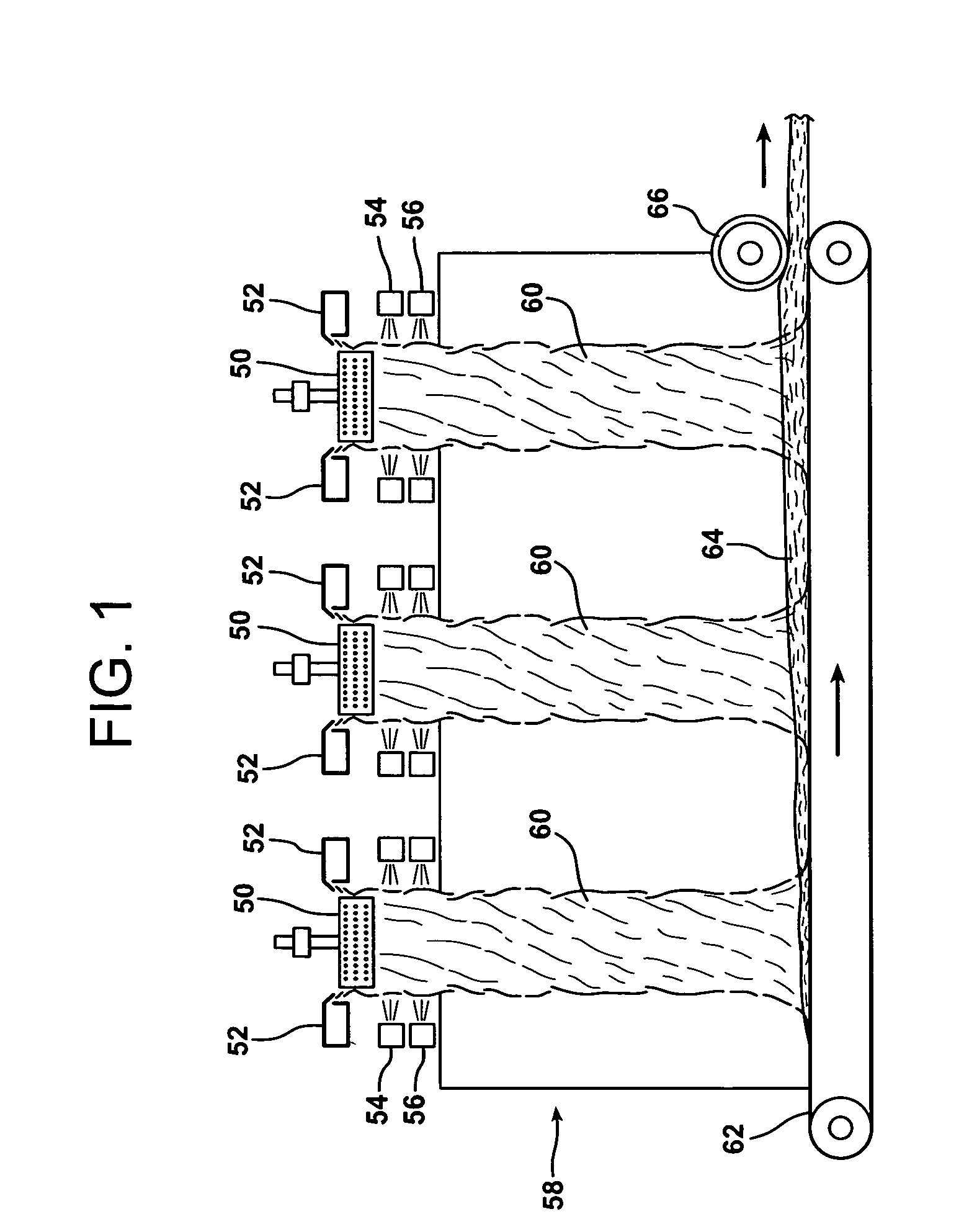

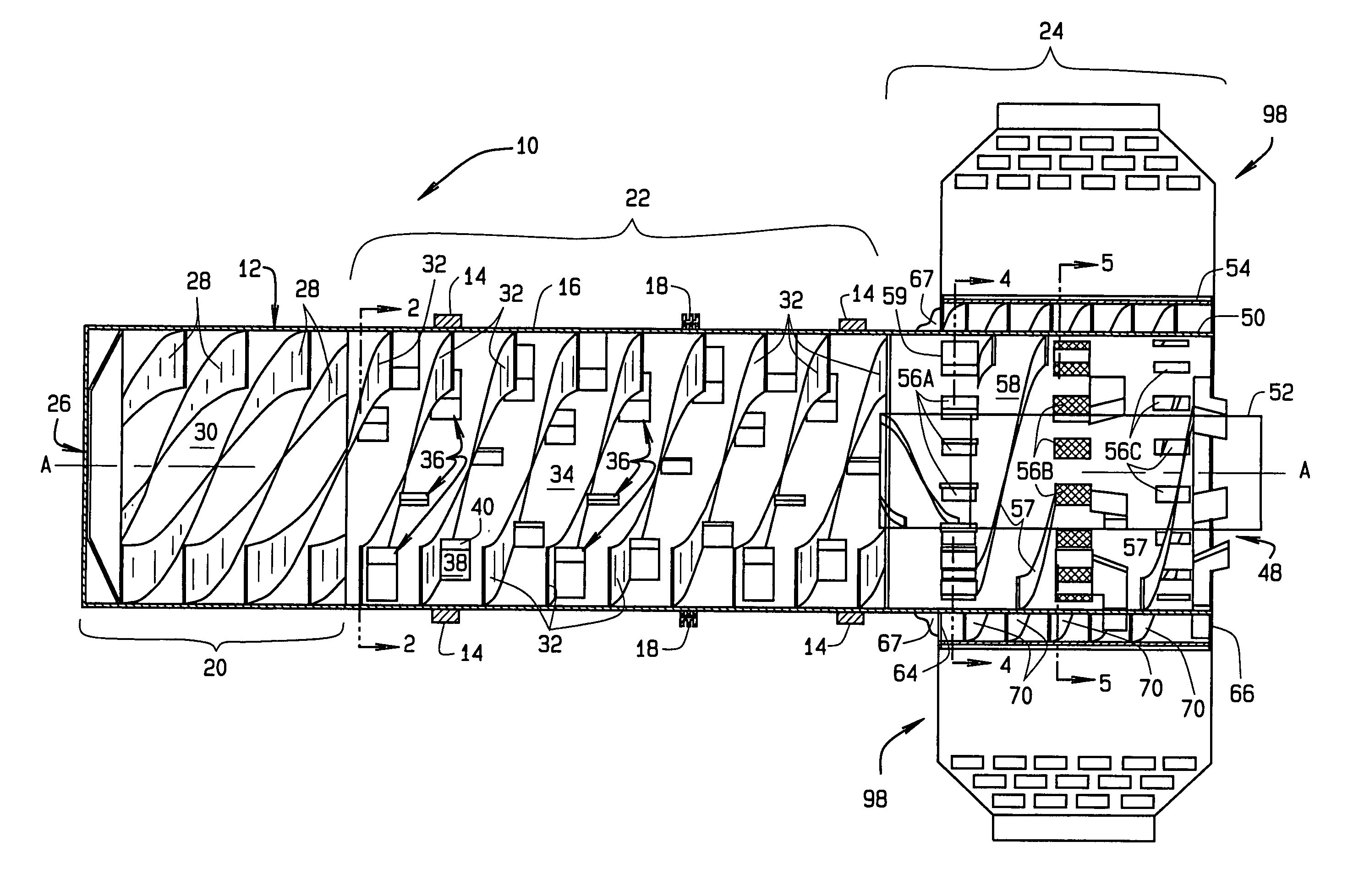

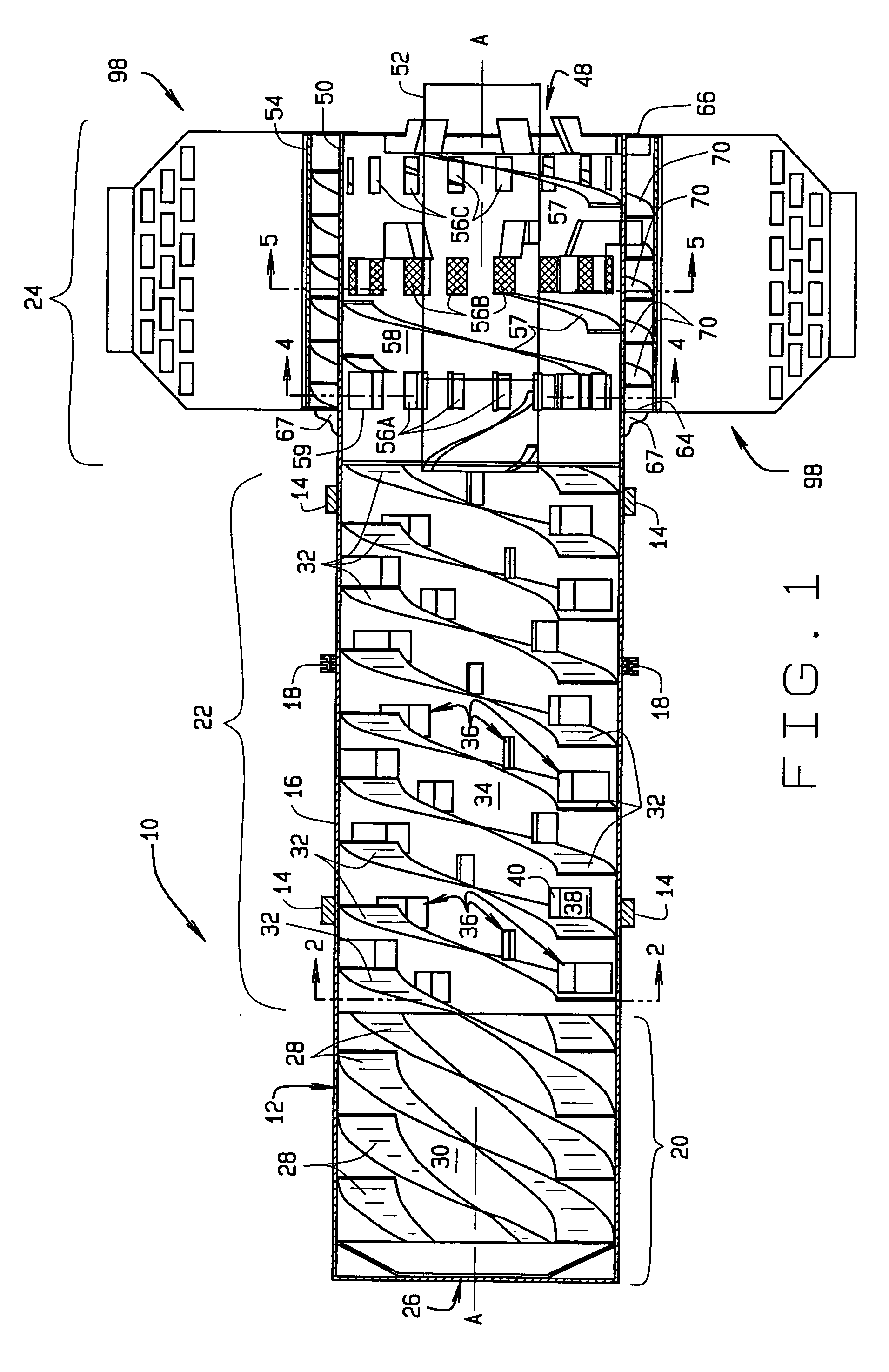

Processes and systems for making inorganic fibers

ActiveUS20070137259A1Quality improvementHigh strengthGlass making apparatusRotary drum furnacesFiberCombustor

Inorganic fiber production processes and systems are disclosed. One process includes providing a molten inorganic fiberizable material, forming substantially vertical primary fibers from the molten material, and attenuating the primary fibers using an oxy-fuel fiberization burner. Other processes include forming a composition comprising combustion gases, aspirated air and inorganic fibers, and preheating a fuel stream and / or an oxidant stream prior to combustion in a fiberization burner using heat developed during the process. Flame temperature of fiberization burners may be controlled by monitoring various burner parameters. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:JOHNS MANVILLE CORP

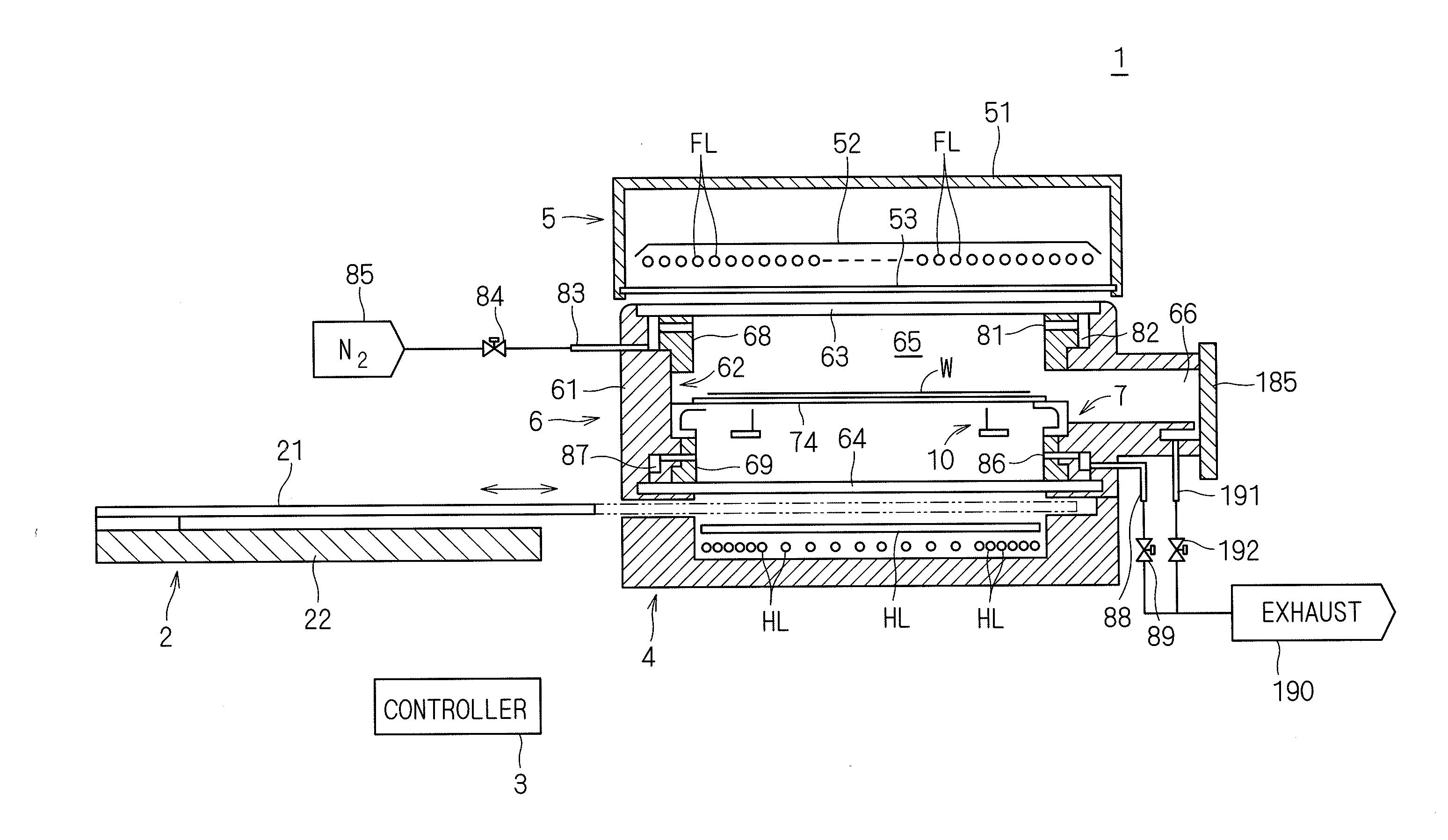

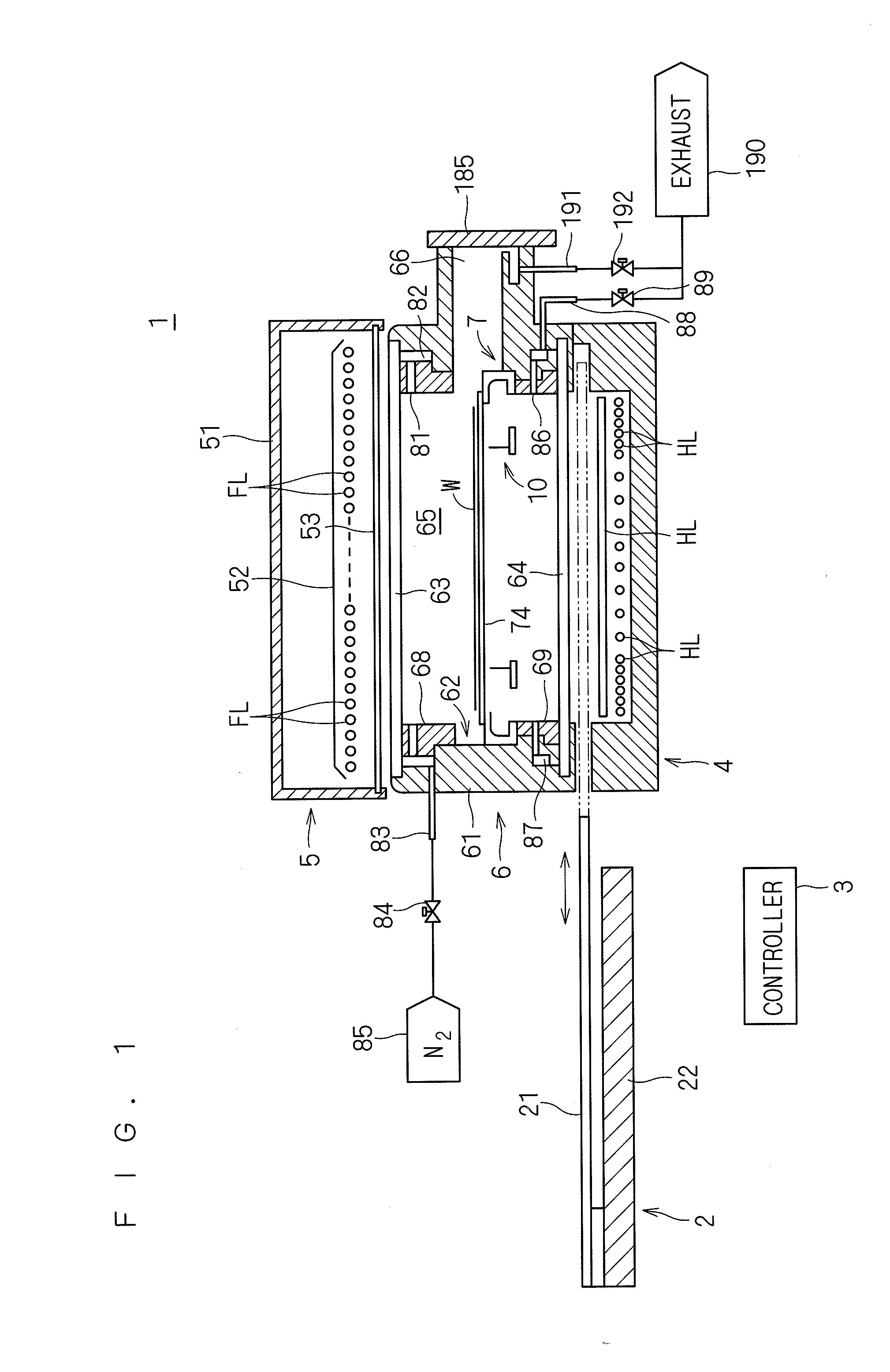

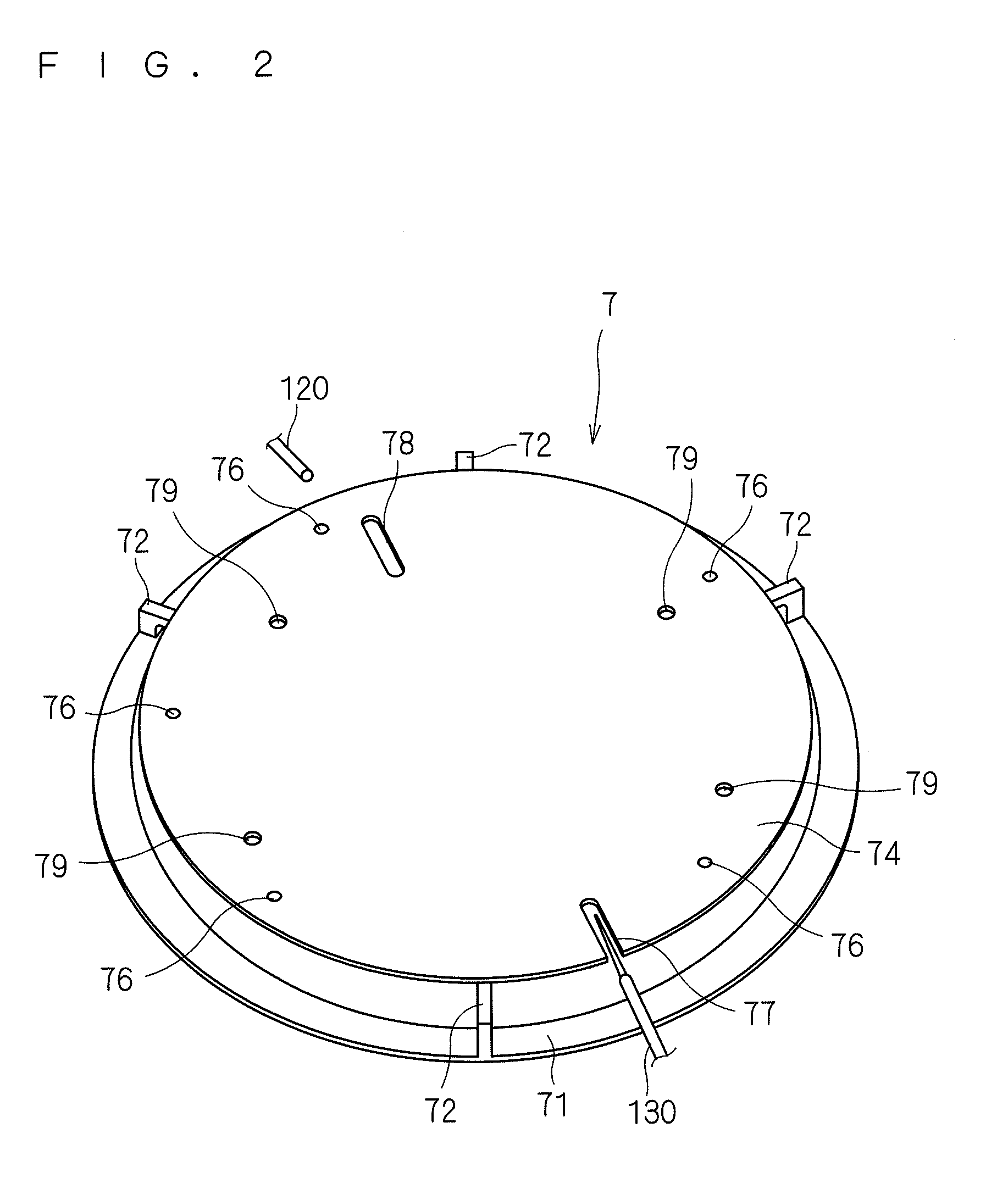

Heat treatment method and heat treatment apparatus for heating substrate by irradiating substrate with light

ActiveUS20120244725A1Avoid it happening againSuppress DiffuseRotary drum furnacesSemiconductor/solid-state device manufacturingEngineeringIrradiation

First irradiation which causes an emission output from a flash lamp to reach its maximum value over a time period in the range of 1 to 20 milliseconds is performed to increase the temperature of a front surface of a semiconductor wafer from a preheating temperature to a target temperature for a time period in the range of 1 to 20 milliseconds. This achieves the activation of the impurities. Subsequently, second irradiation which gradually decreases the emission output from the maximum value over a time period in the range of 3 to 50 milliseconds is performed to maintain the temperature of the front surface within a ±25° C. range around the target temperature for a time period in the range of 3 to 50 milliseconds. This prevents the occurrence of process-induced damage while suppressing the diffusion of the impurities.

Owner:DAINIPPON SCREEN MTG CO LTD

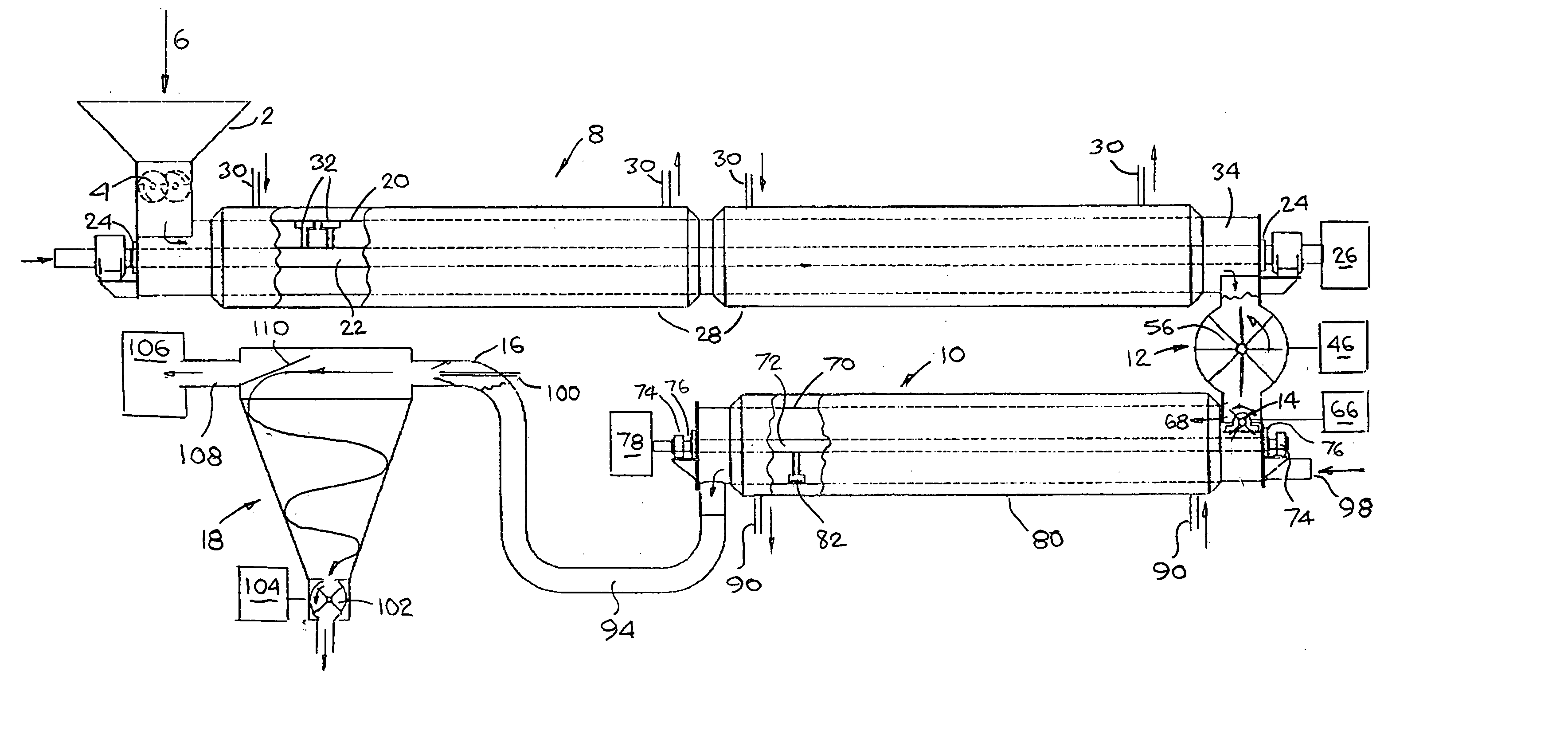

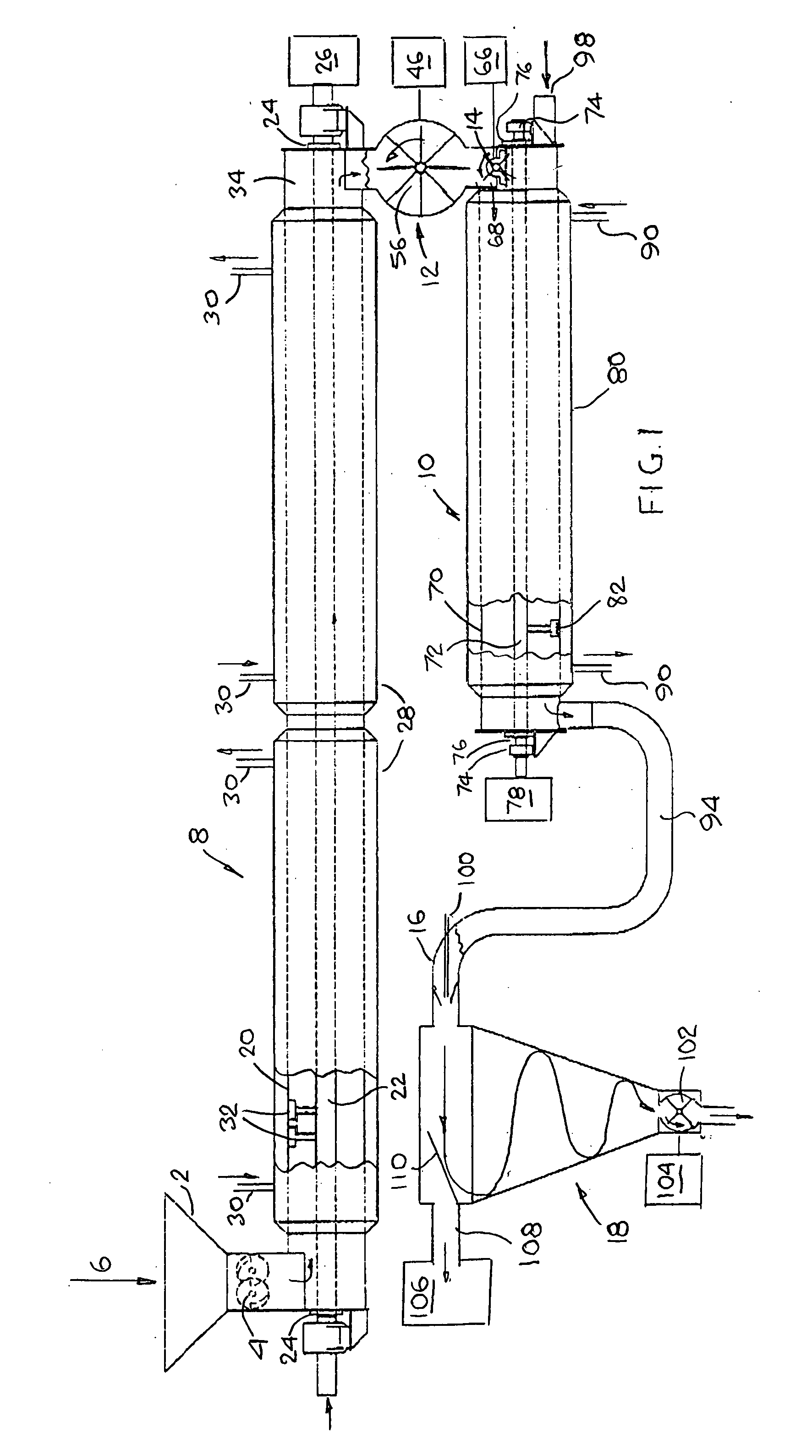

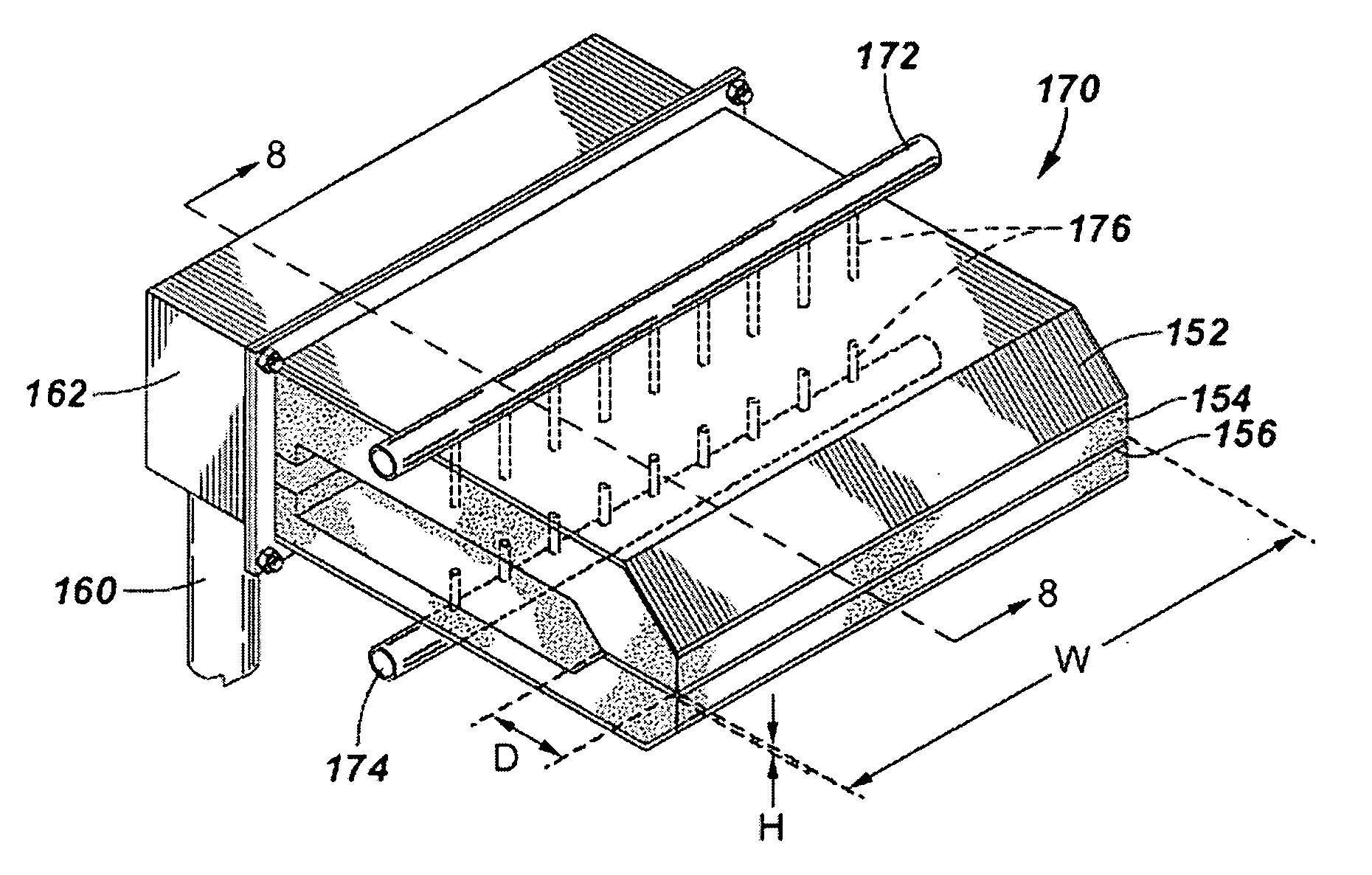

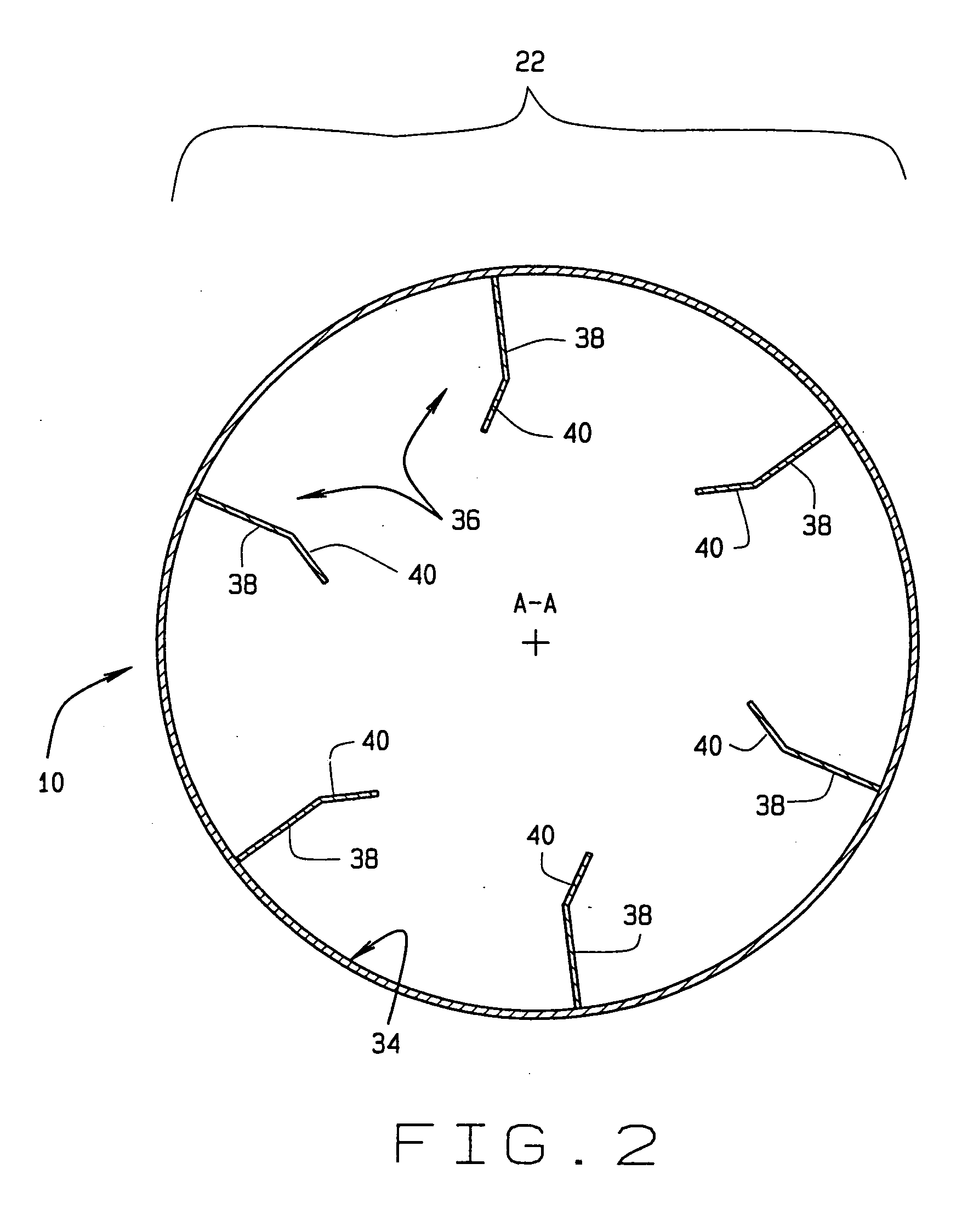

Granular and aggregate blending, cooling and screening rotary drum

InactiveUS20050236320A1Reliable constructionMinimal maintenanceRotating receptacle mixersRotary stirring mixersCounter flowCooling effect

A rotary drum configured for the efficient blending, cooling, and screening of granular products having an outer cylindrical shell, an intake end, and an exit or discharge end. The rotary drum is normally rotated at a predetermined speed by means of a conventional drive package. Disposed on an inner surface of the cylindrical shell is a plurality of compound helical flights and scoops or lifts, configured to blend granular product as it cascades from the intake end to the discharge or exit end of the rotary drum. A coaxially disposed cylindrical air passage adjacent the discharge end of the rotary drum, comprising an inner cylinder, that directs a counter flow of cooling air through the rotary drum towards the intake end, for cooling the cascading granular product as it approaches the screening segment of the rotary drum. The rotary drum having a plurality of discharge ports and grading screens just before its discharge end, provided in the surface of the outer cylindrical shell adjacent to the discharge end, to allow for the passage of air for attaining dust collection, while the counter flowing cooling air passes through the internally arranged inner cylinder to achieve the cooling effect within the rotary drum.

Owner:DIDION TECHNOLOGIES LLC

Fiber air turn for low attenuation fiber

A method for forming an optical fiber includes drawing the optical fiber from a glass supply and treating the fiber by maintaining the optical fiber in a treatment zone wherein the fiber is cooled at a specified cooling rate. The optical fiber treatment reduces the tendency of the optical fiber to increase in attenuation due to Rayleigh scattering, and / or over time following formation of the optical fiber due to heat aging. Methods for producing optical fibers along nonlinear paths incorporating fluid bearings are also provided thereby allowing for increased vertical space for the fiber treatment zone.

Owner:CORNING INC

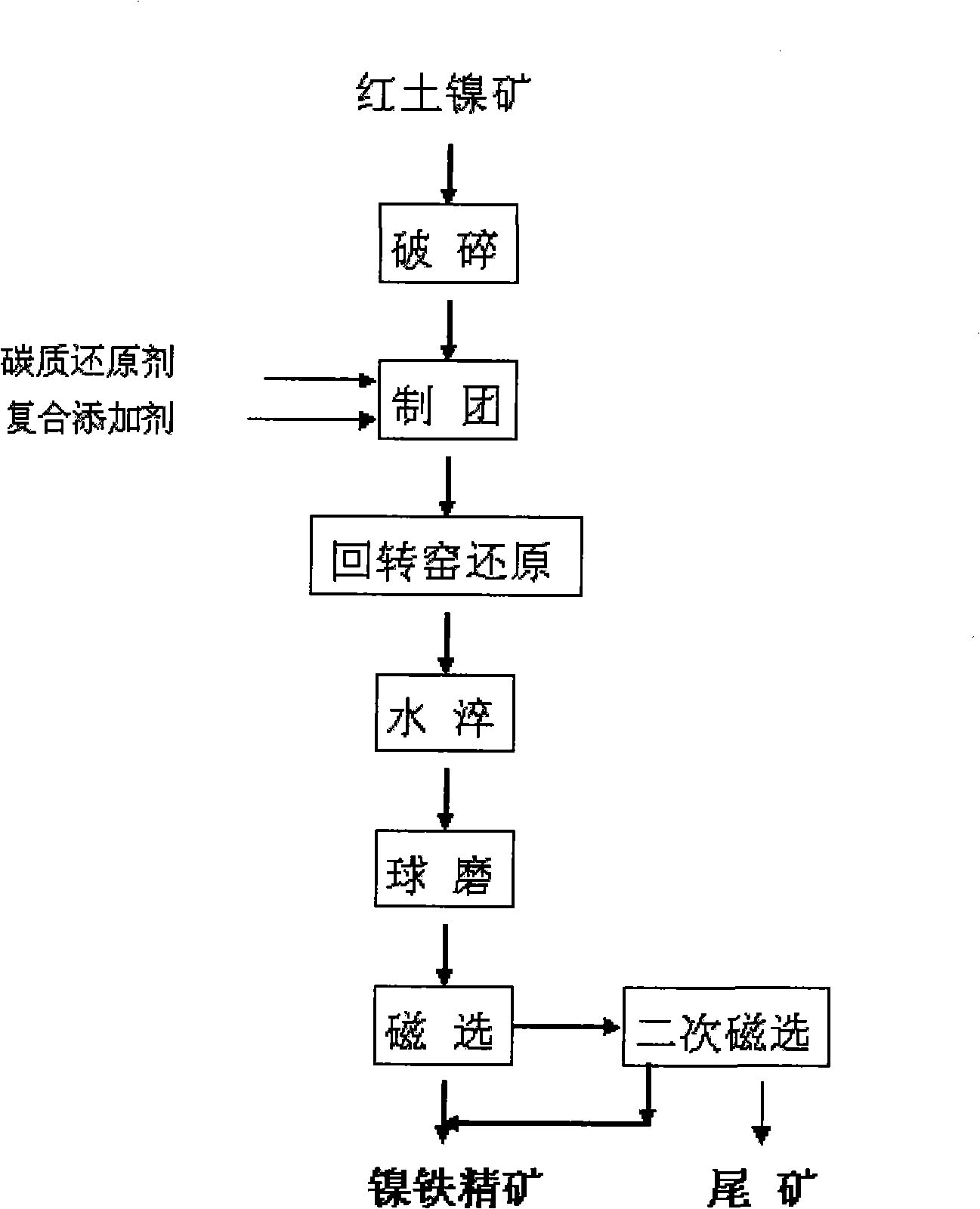

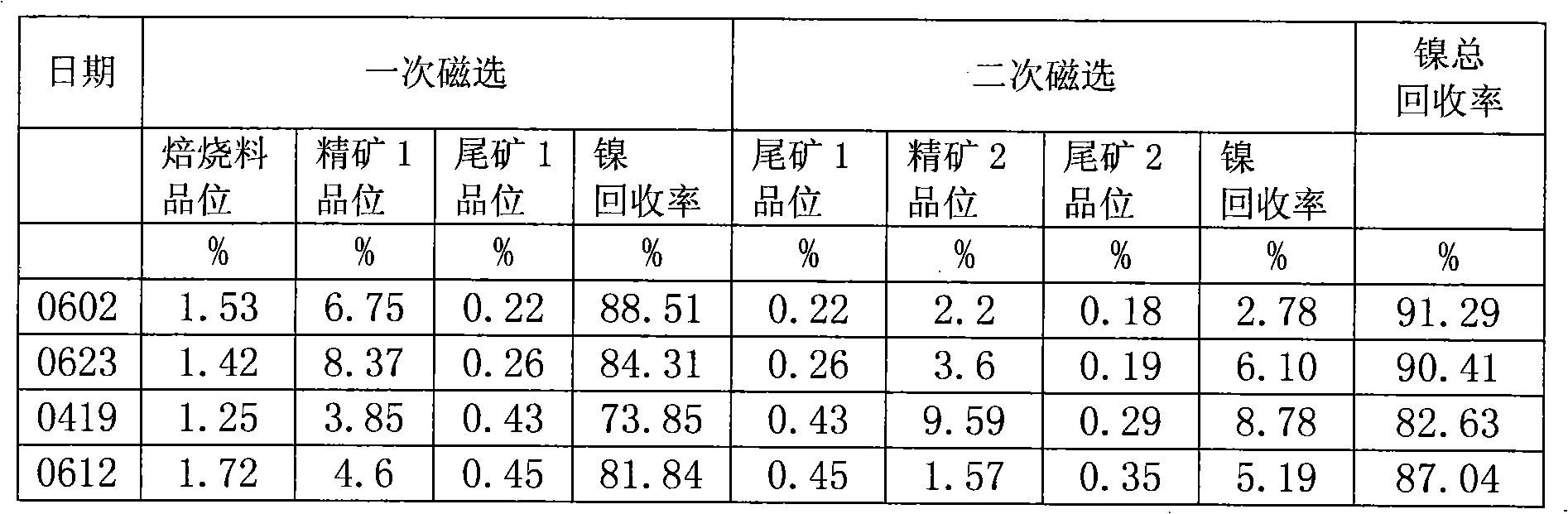

Method for enriching nickel iron ore concentrate from laterite type nickel ore by means of rotary kiln

InactiveCN101323904ANo pollution in the processSimple processRotary drum furnacesMagnetic separatorLaterite

The invention relates to a method for collecting ferronickel concentrate from lateritic nickel ores by a rotary kiln. The lateritic nickel ores are crushed, stirred and mixed with a carbonaceous reducing agent and a compound additive, made into pellets by a ball press or a marble machine and put into the rotary kiln for reducing and roasting; waste heat at the front part of the rotary kiln is used for carrying out the drying and preheating of the pellets; the high-temperature area of the rotary kiln is 9 to 10 meters away from a kiln outlet; the temperature of the high-temperature area is controlled to be 1000 to 1300 DEG C; roasting time is 0.5 to 2 hours; the dried pellets enter the high-temperature area of the rotary kiln for reducing and roasting; a magnetic separator with a magnetic field intensity of 3000 to 5000 gauss is adopted to sort roasted material obtained after water quenching and wet ball milling, thus obtaining high-content ferronickel concentrate; the method can realize the simultaneous recycling of nickel and iron and obtain the high-content ferronickel concentrate; the content of nickel is 5 to 13 percent and the recycling rate of nickel is 85 to 93 percent; the content of iron is 30 to 75 percent and the recycling rate of nickel is 60 to 85 percent; the reasonable utilization of the waste heat during process procedure achieves the purposes of saving energy and reducing discharge and greatly reduces pollution to the environment.

Owner:HONGHE HENGHAO MINING

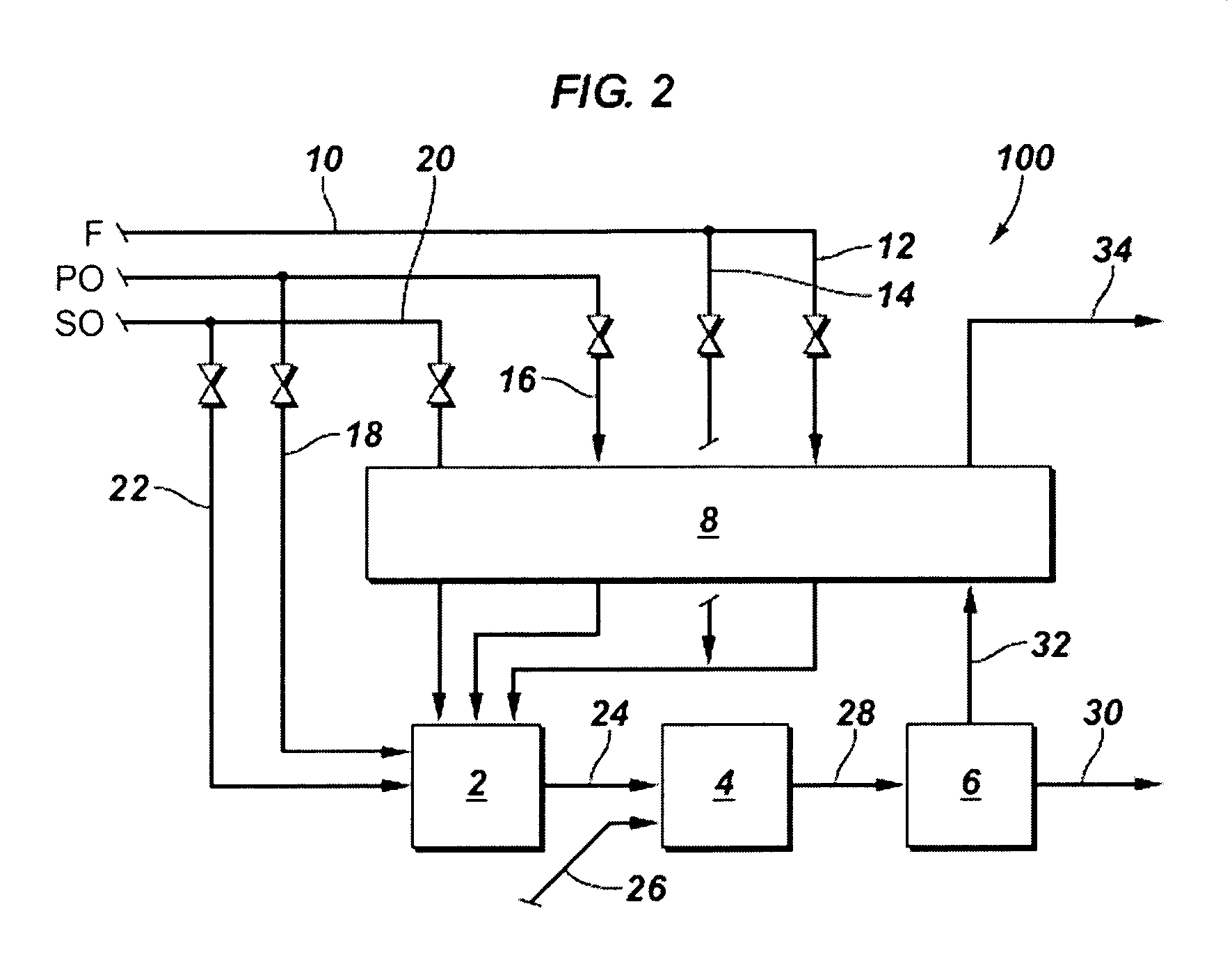

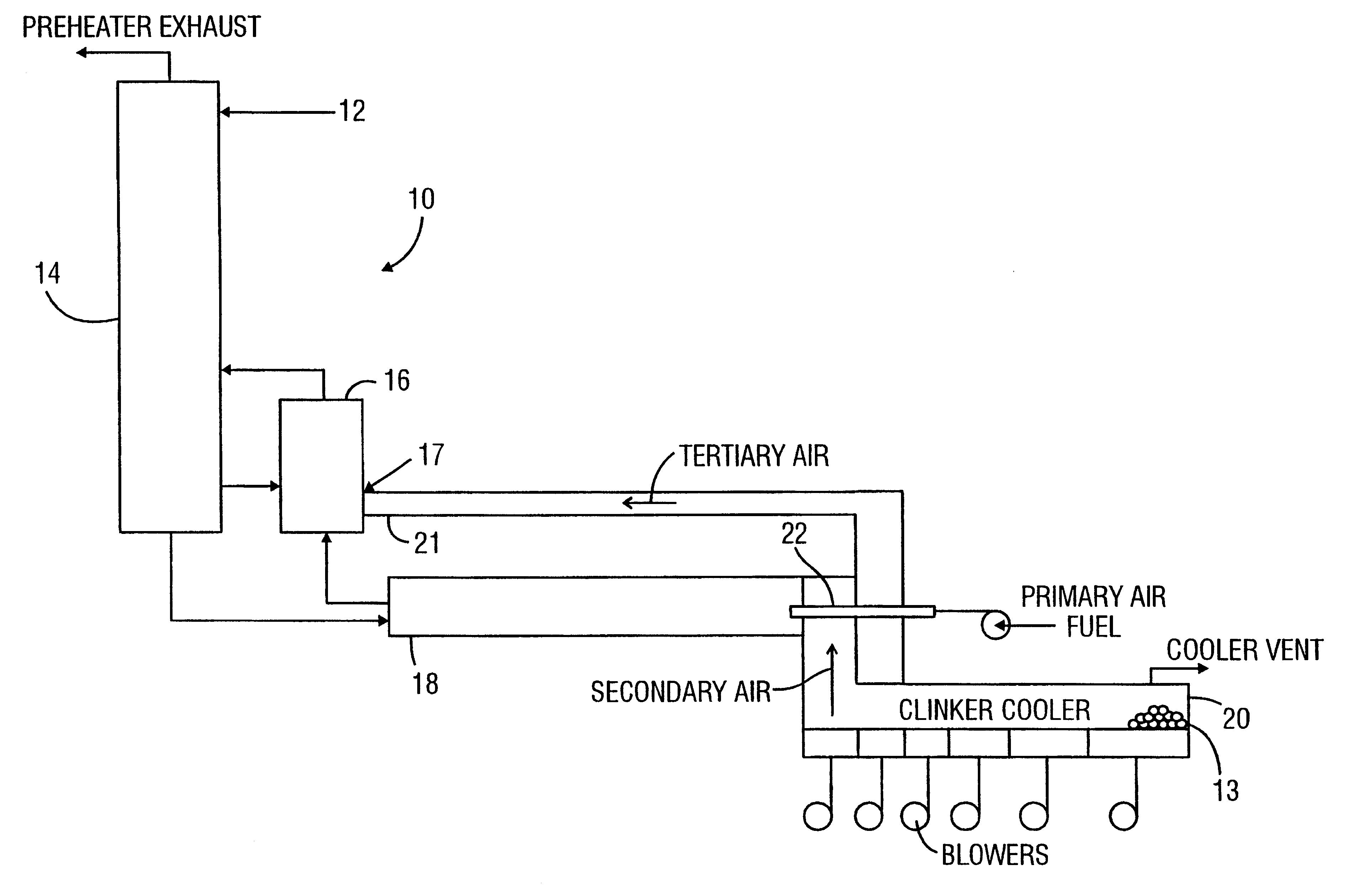

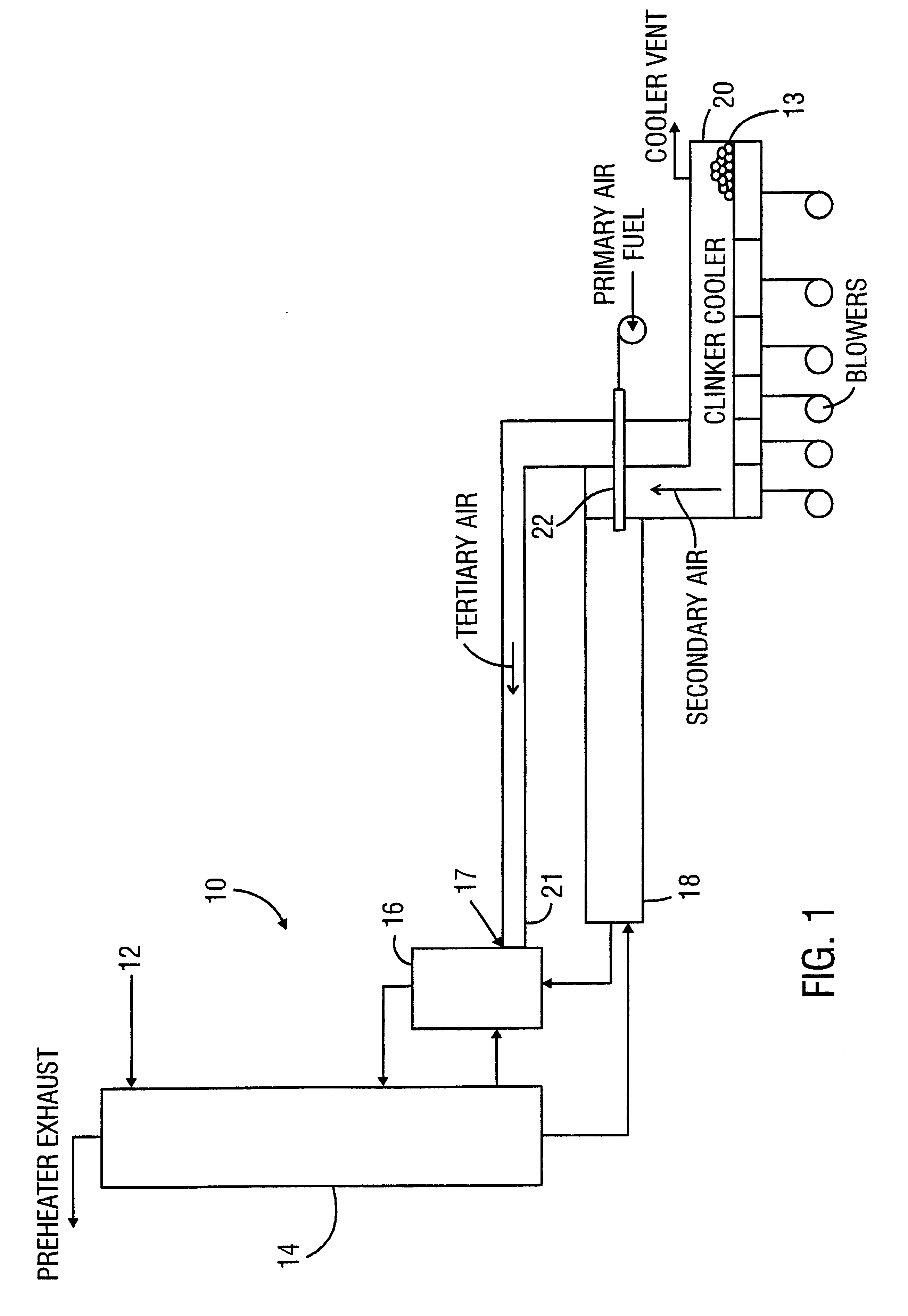

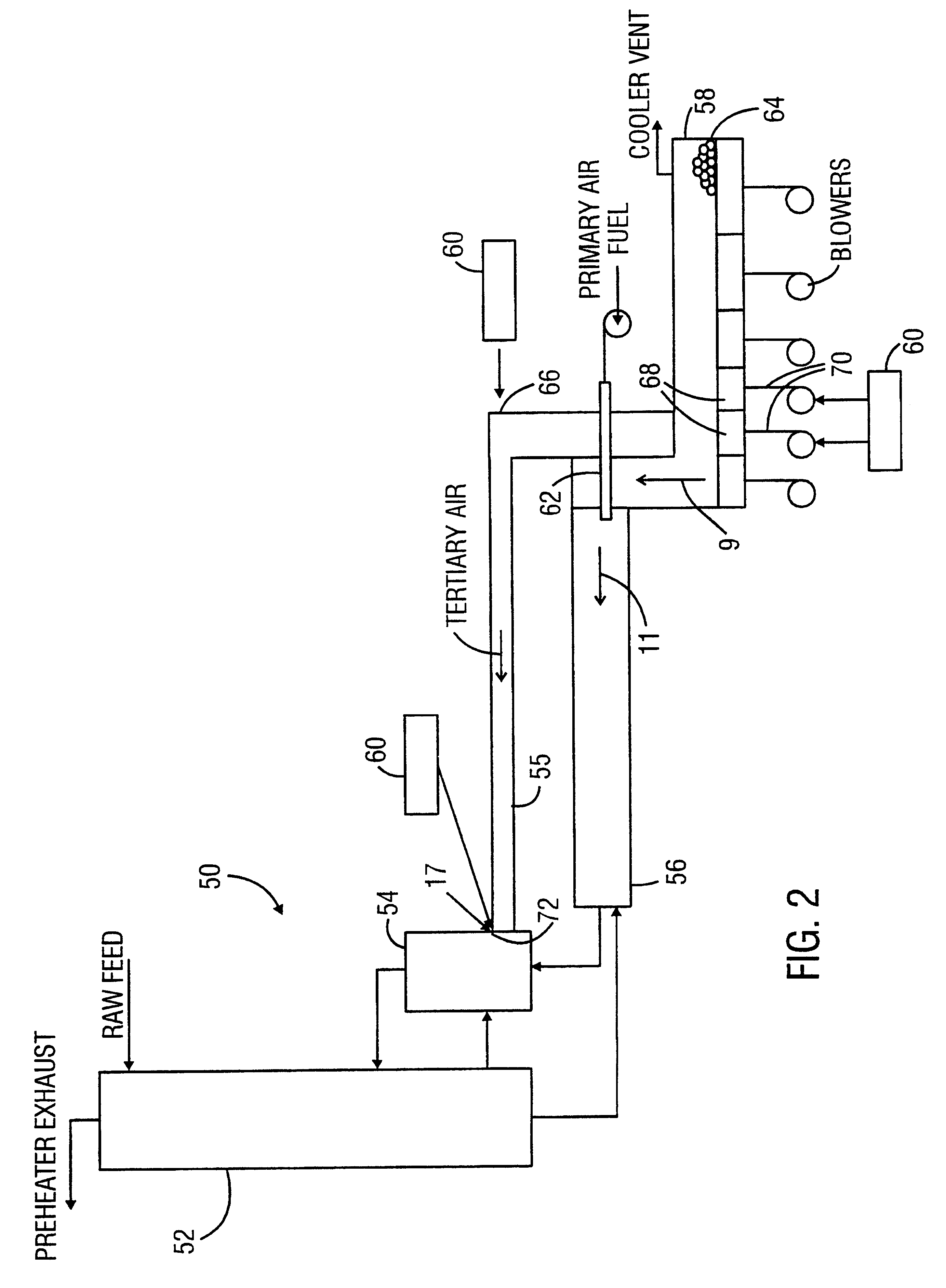

Oxygen enrichment of cement kiln system combustion

The invention in its various embodiments includes an apparatus and a method for improving combustion in a cement kiln system. The apparatus in one embodiment includes a precalciner and an oxygen source coupled to the precalciner. The method in one embodiment includes introducing oxygen into the precalciner of a cement kiln system.

Owner:CEMEX

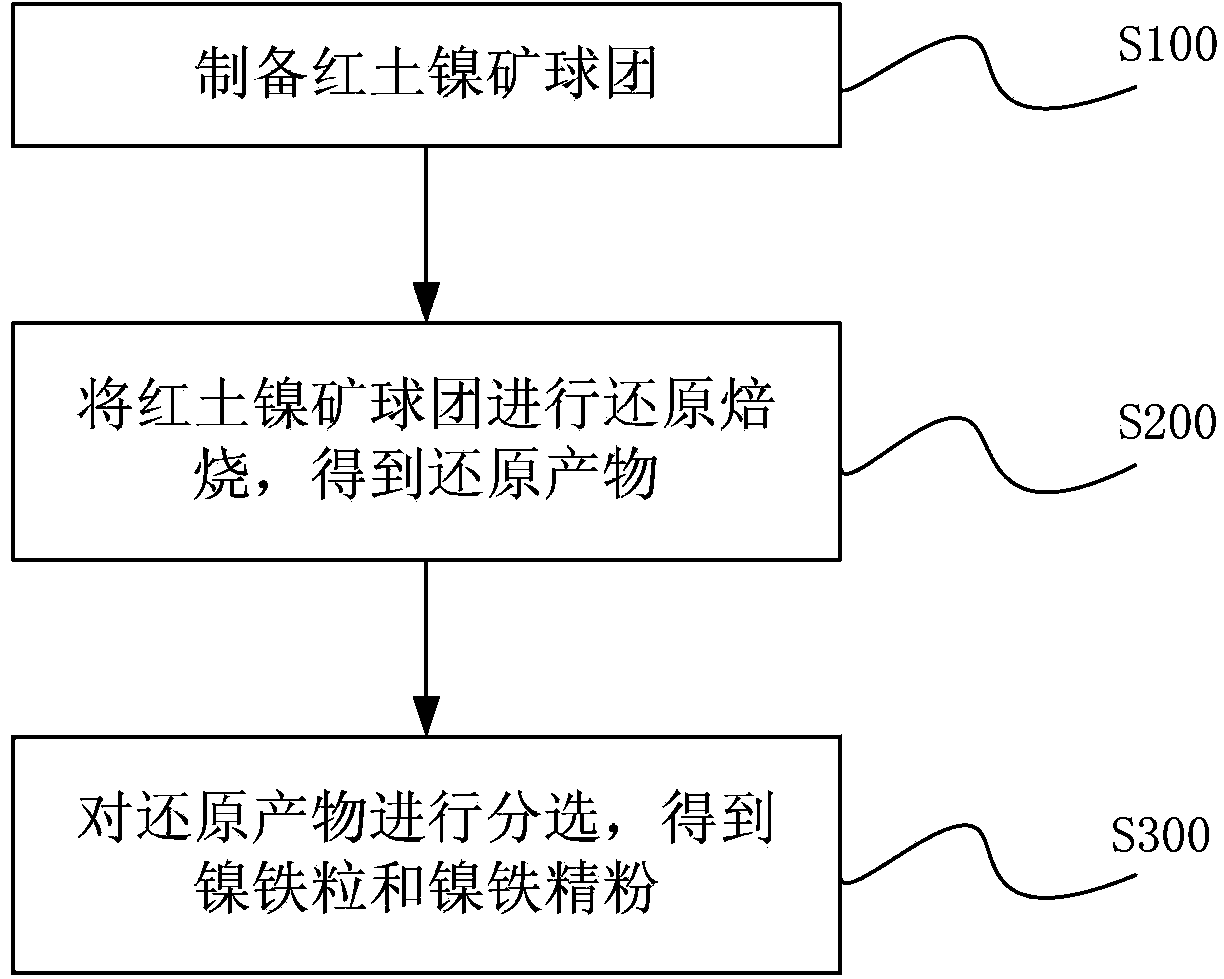

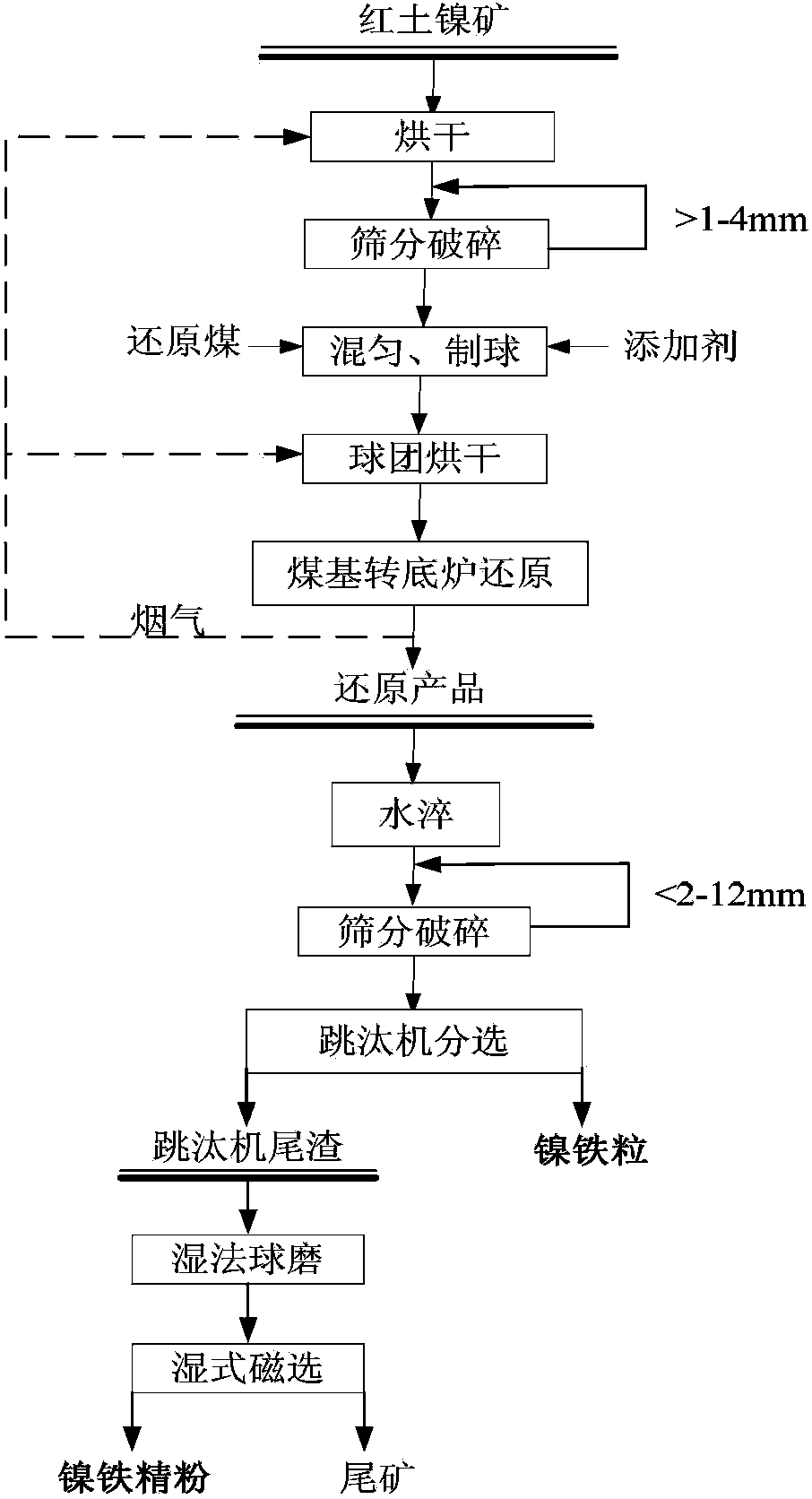

Treatment method of laterite-nickel ore

InactiveCN103667675AFully effective separationIncrease productionRotary drum furnacesWet separationReducerLaterite

The invention provides a treatment method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, a reducer and additives to obtain laterite-nickel ore pellets; carrying out reducing roasting on the laterite-nickel ore pellets in a rotary hearth furnace to obtain a reduction product; quenching the reduction product with water; crushing the quenched reduction product; carrying out separation on the crushed reduction product by using a jigging machine to obtain nickel iron granules and tailings; and carrying out wet ball milling and wet magnetic separation on the obtained tailings to obtain nickel iron refined powder and tailings. The method can be utilized to obviously enhance the yield and quality of the product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

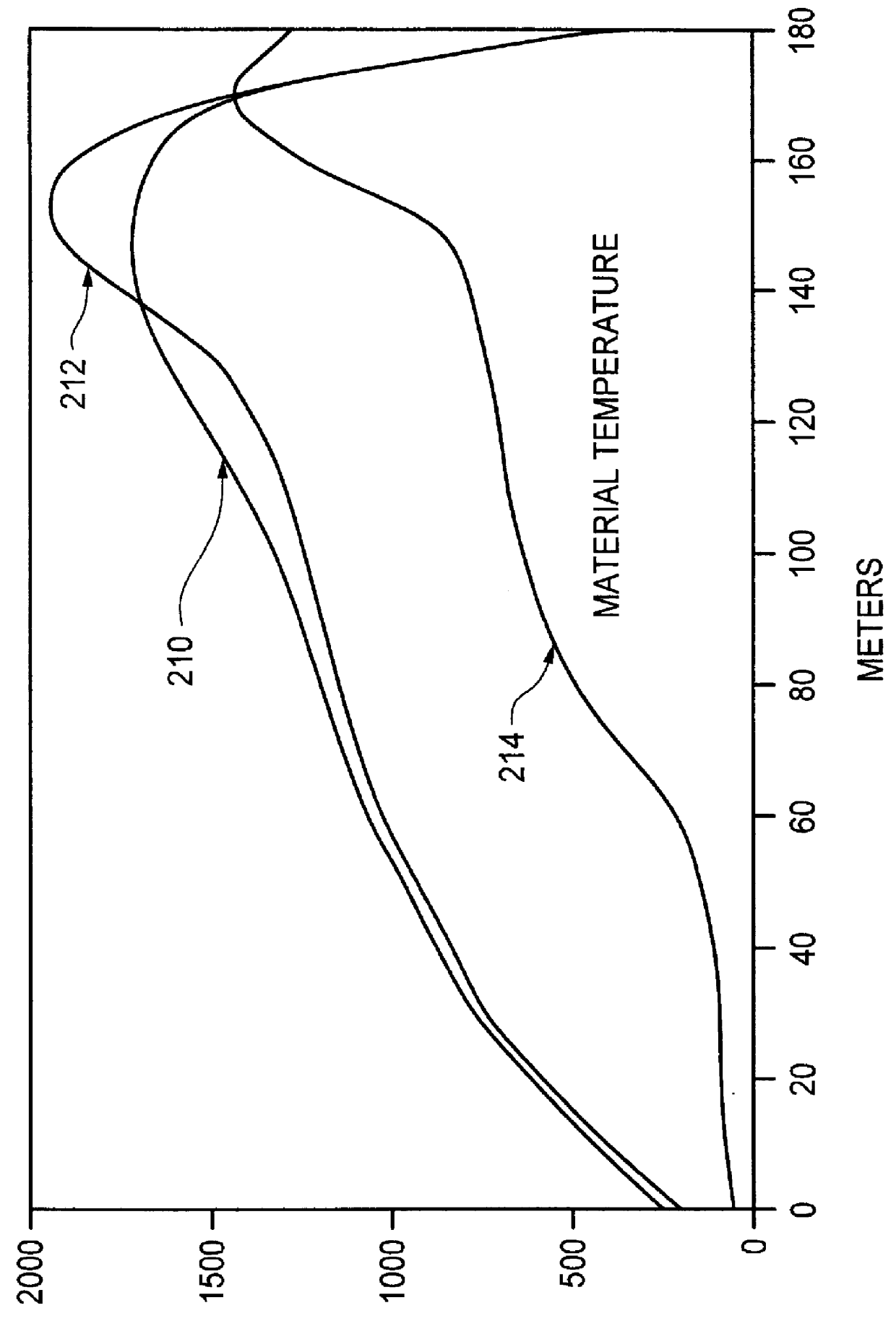

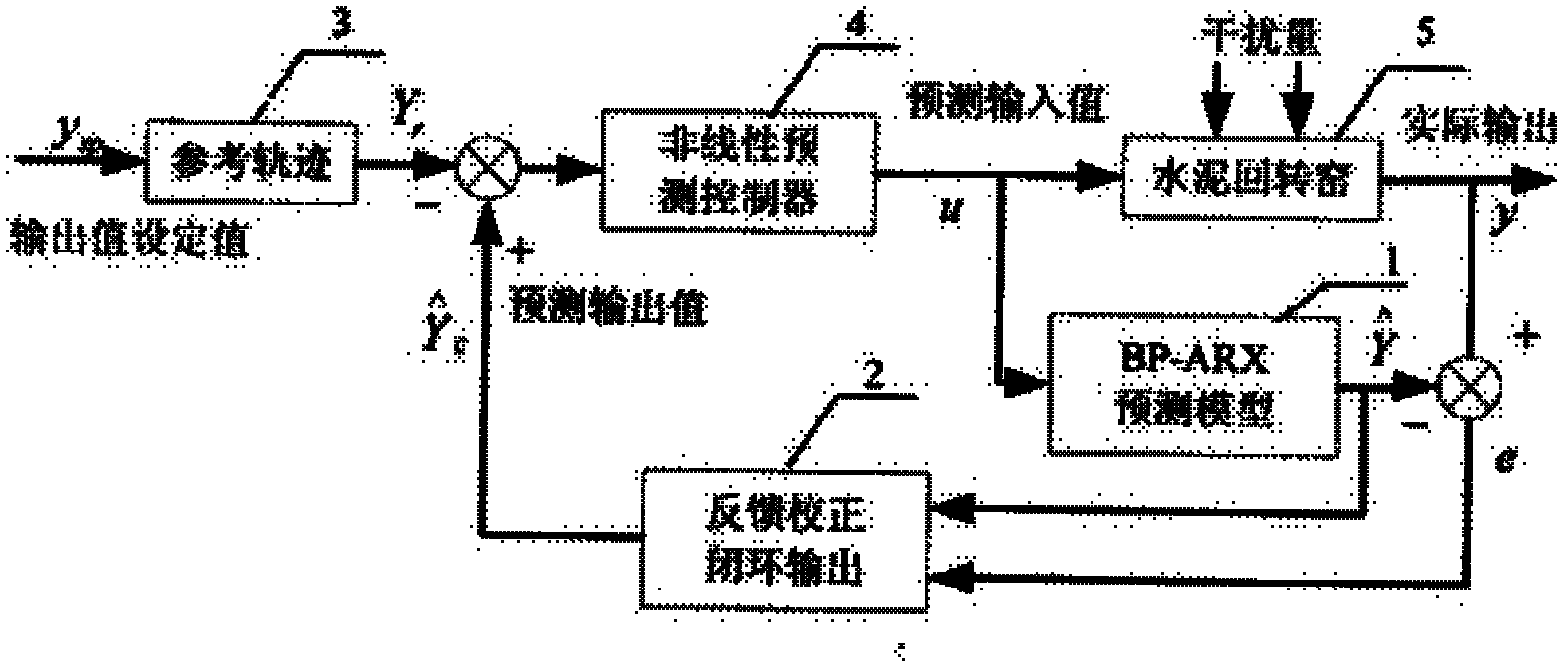

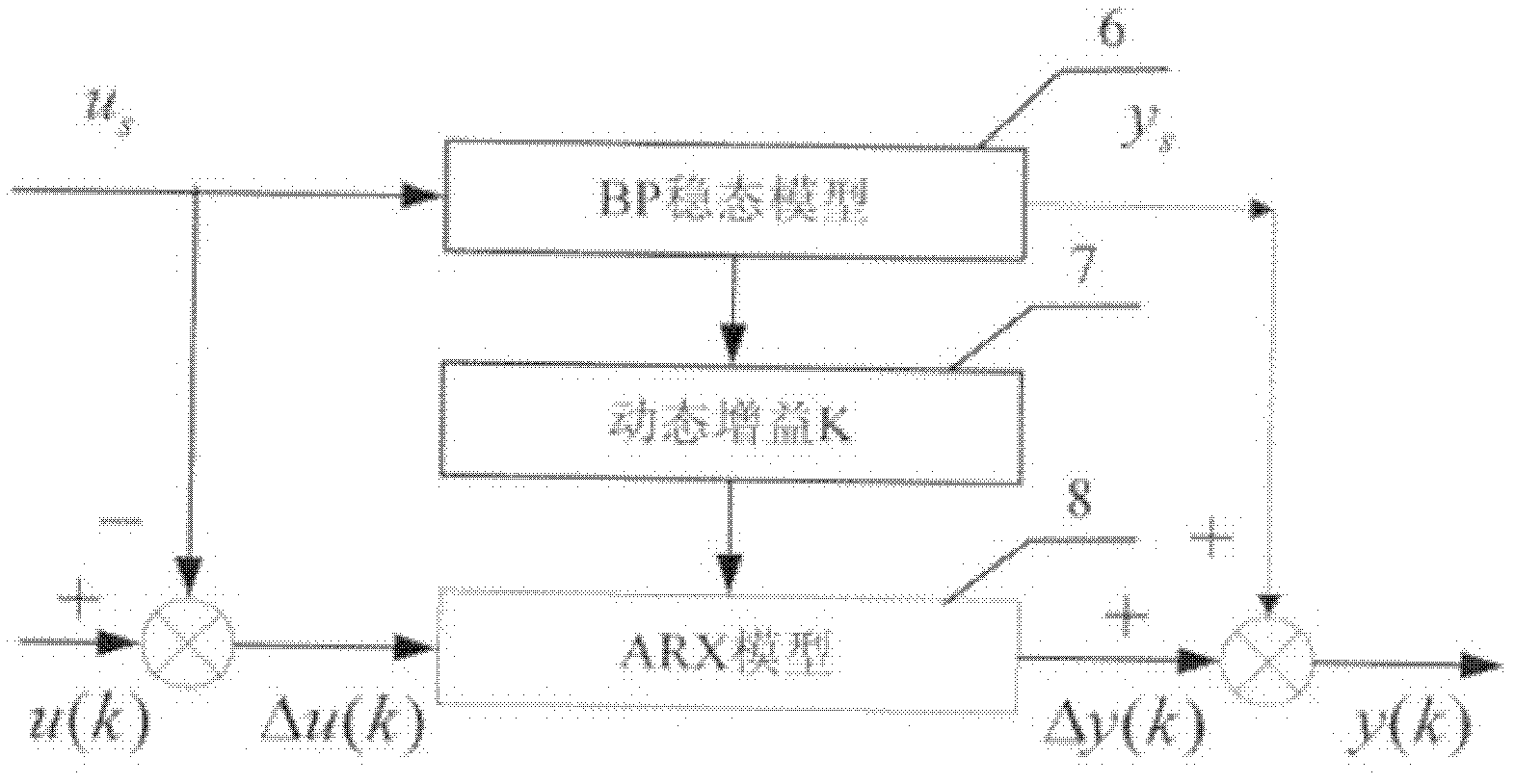

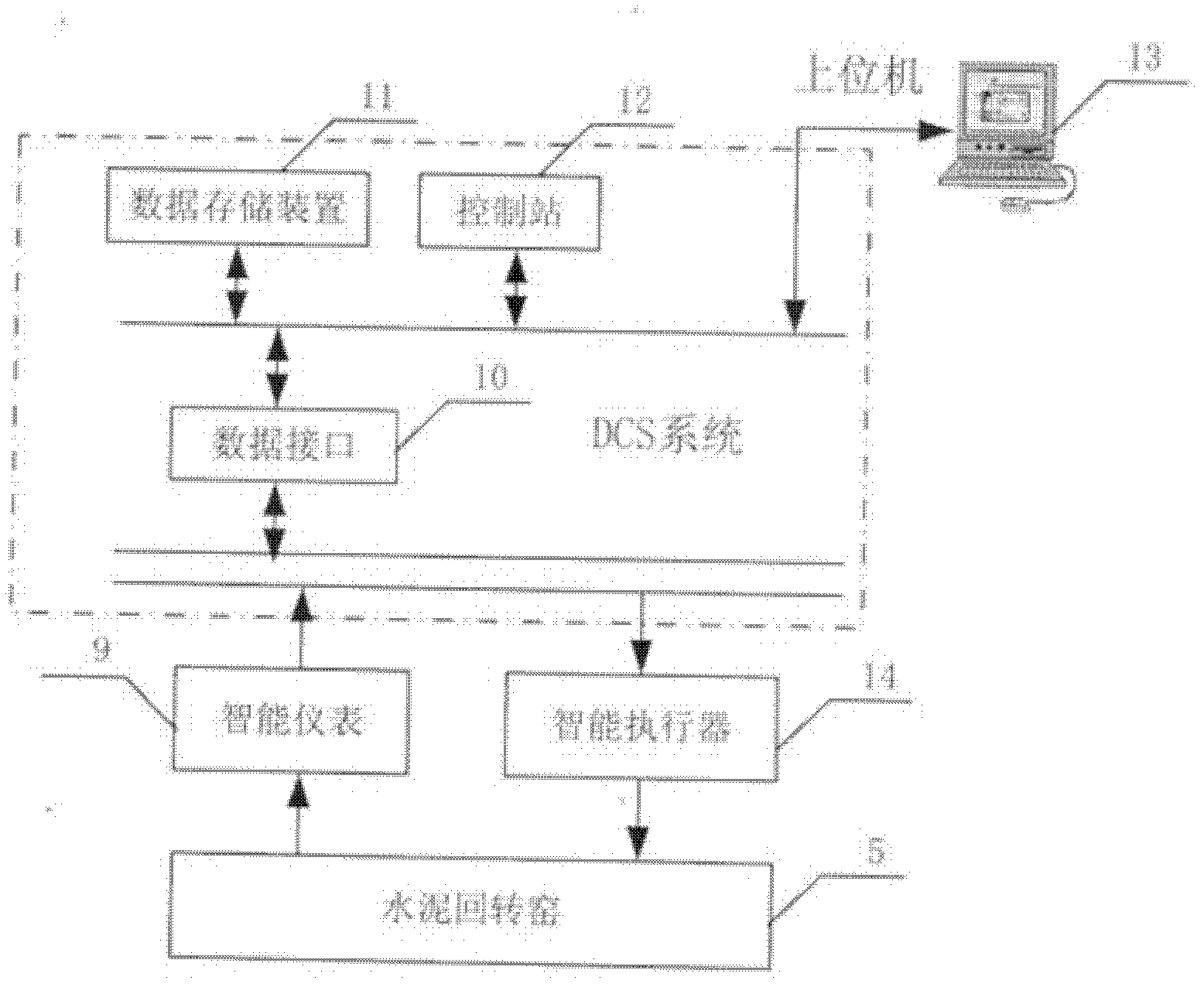

Calcination predictive control system and method for rotary cement kiln

InactiveCN102629104AStable temperatureTaking into account energy consumption per unit of productionRotary drum furnacesAdaptive controlData informationClosed loop

The invention relates to a calcination predictive control method and a calcination predictive control system for a rotary cement kiln. The method comprises the following steps of: (1) acquiring field data of the calcining process of the rotary cement kiln and classifying the field data; (2) respectively carrying out model identification on the data and organically combining the data to establish a prediction model; (3) carrying out prediction on historical and future data information on the calcining process by the prediction model to obtain an output of the calcining process and outputting error feedback correction by utilizing the model to obtain a closed-loop prediction output of the calcining process; and (4) according to the closed-loop prediction output and a reference output trace,constructing a non-linear target function and carrying out solution of a optimal solution on the target function by using a sequential quadratic programming method to obtain a predicted value of the calcination controlling quantity. The system comprises an intelligent detection instrument and an actuator which are connected with the rotary cement kiln, a data storage device and an upper computer,wherein a calcination predictive control algorithm is embedded in the upper computer. The calcination predictive control method and the calcination predictive control system for the rotary cement kiln can be suitable for the dynamism of the calcining process of the rotary cement kiln and the coupling, nonlinearity and obsoleteness between multiple variables, and obtain good control effect.

Owner:YANSHAN UNIV

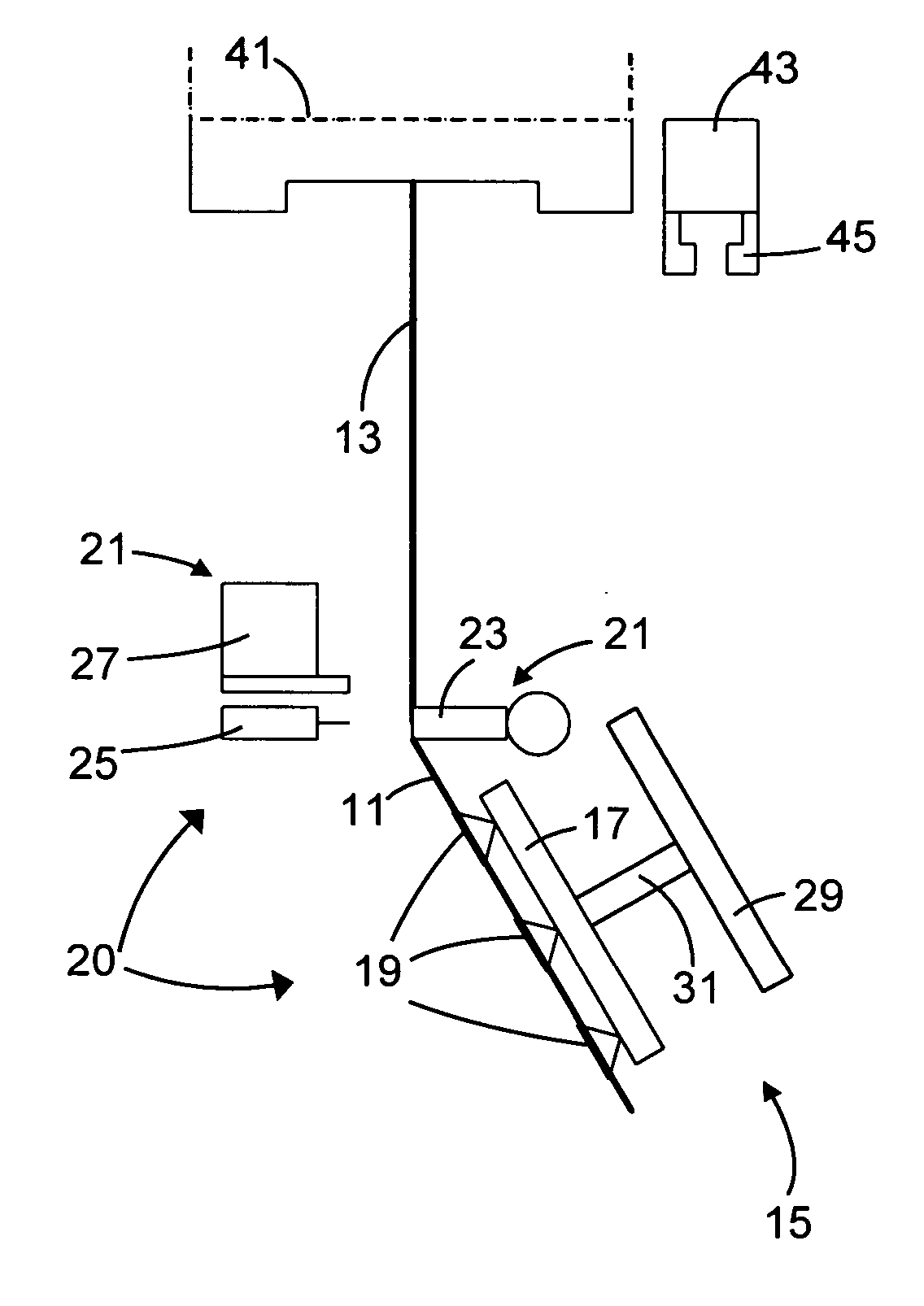

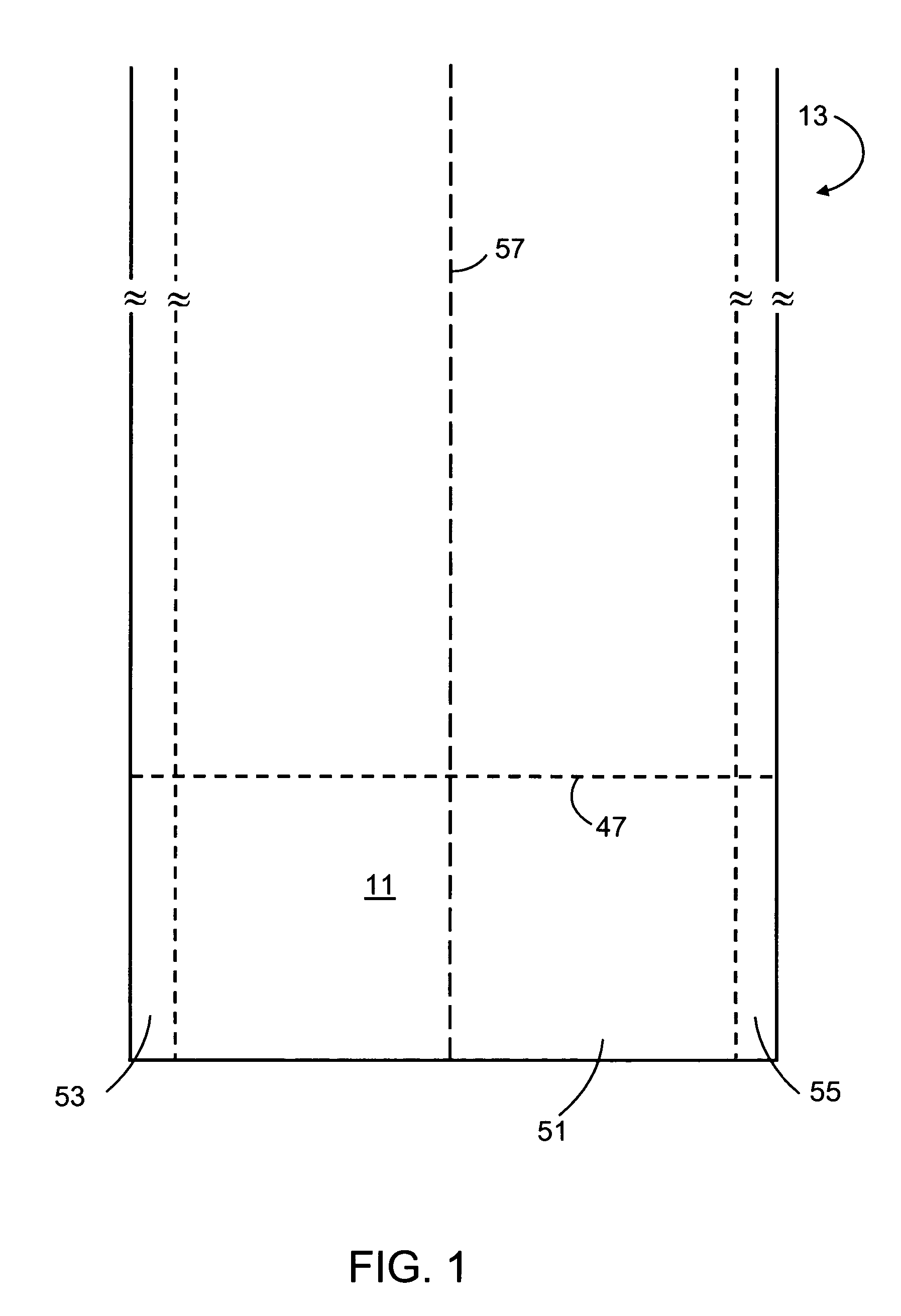

Methods and apparatus for reducing stress variations in glass sheets produced from a glass ribbon

InactiveUS20070095108A1Reduce exerciseStress variationRotary drum furnacesGlass transportation apparatusStress levelStress variation

Apparatus and methods are provided for reducing the variability of stress levels in glass sheets (11) cut from a moving glass ribbon (13). The reductions in variability are achieved by constraining the edge regions (53,55) of the ribbon (13) from movement in a horizontal plane at at least one location below the location where a separating assembly (20) forms a separation line (47) in the ribbon (13). Sets of vertically arranged wheels (35) which engage the edge regions (53,55) of the ribbon (13) can be used to provide the horizontal constraint without compromising the central, quality area (51) of the glass ribbon (13).

Owner:CORNING INC

Method for producing iron concentrate by brown hematite and siderite and reduction roaster

The present invention discloses a method for adopting the limonite and the siderite to produce iron powder and a reduction roaster. The material adopts the limonite and the siderite or the specularite, the hematite, and the sulphuric acid slag, the inclined rotary reduction roaster is used, the pressure of the furnace chamber is 250 to 350 Pa, under the deoxidizing atmosphere, the inert solid is rotated and moved to 650 to 900 DEG C from the low temperature, and is cooled and magnetized, and lastly become the iron powder through the dressing by magnetic separation. The present invention is adopted to produce the iron powder, the resources is rich and the production cost is low, and through the utilization of the powder metallurgy art, the iron content of the iron powder is controlled and the activation energy of the iron powder is reduced, and the chemical reaction ability is increased, thereby the output of iron powder is high, the quality is good, the iron powder is loose and porous, the specific surface is big, the apparent density is large, the manufacture cost of pellets sinter and steel smelting can be reduced greatly, and the iron powder can use directly to produce iron oxide red as well as H and N synthetic iron catalyst, or produce ultrapure iron powder.

Owner:郭元杰

Reduction and utilization method of dedusting ash of stainless steel

InactiveCN101705333AReduce pollutionHigh recovery rateRotary drum furnacesProcess efficiency improvementMixed materialsMolten steel

The invention relates to a reduction and utilization method of dedusting ash of stainless steel, comprising the following steps of: (1) preparing materials: uniformly stirring and mixing raw materials into a mixed material according to following proportions: 90-95 dedusting ash, 2-4 reducing agent and 3-6 bonding agent; (2) extrusion formation: pressing the mixed material into dedusting ash pressure balls; (3) maintaining: naturally drying and maintaining the dedusting ash pressure balls, wherein the measured intensity of the pressure balls is 2420N / each ball-2820N / each ball; (4) sintering: adding the dedusting ash pressure balls into a rotary kiln, sintering at 650+ / -50 DEG C for no less than 20 minutes, and discharging; (5) preparing materials for an electric furnace according to the following proportions: 70-80 stainless steel waste steel, 35-40 high-carbonferrochrome, 40-45 pig iron containing chromium and nickel, 3-5 dedusting ash pressure balls, 6-8 slag former and 0.3-0.5 reducing agent; and (6) melting: adding the prepared materials into the electric furnace for melting, and tapping when the temperature and the components of the molten steel meet the requirement. The reduction and utilization method of the dedusting ash of stainless steel has the advantages of low cost and little pollution to the environment.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

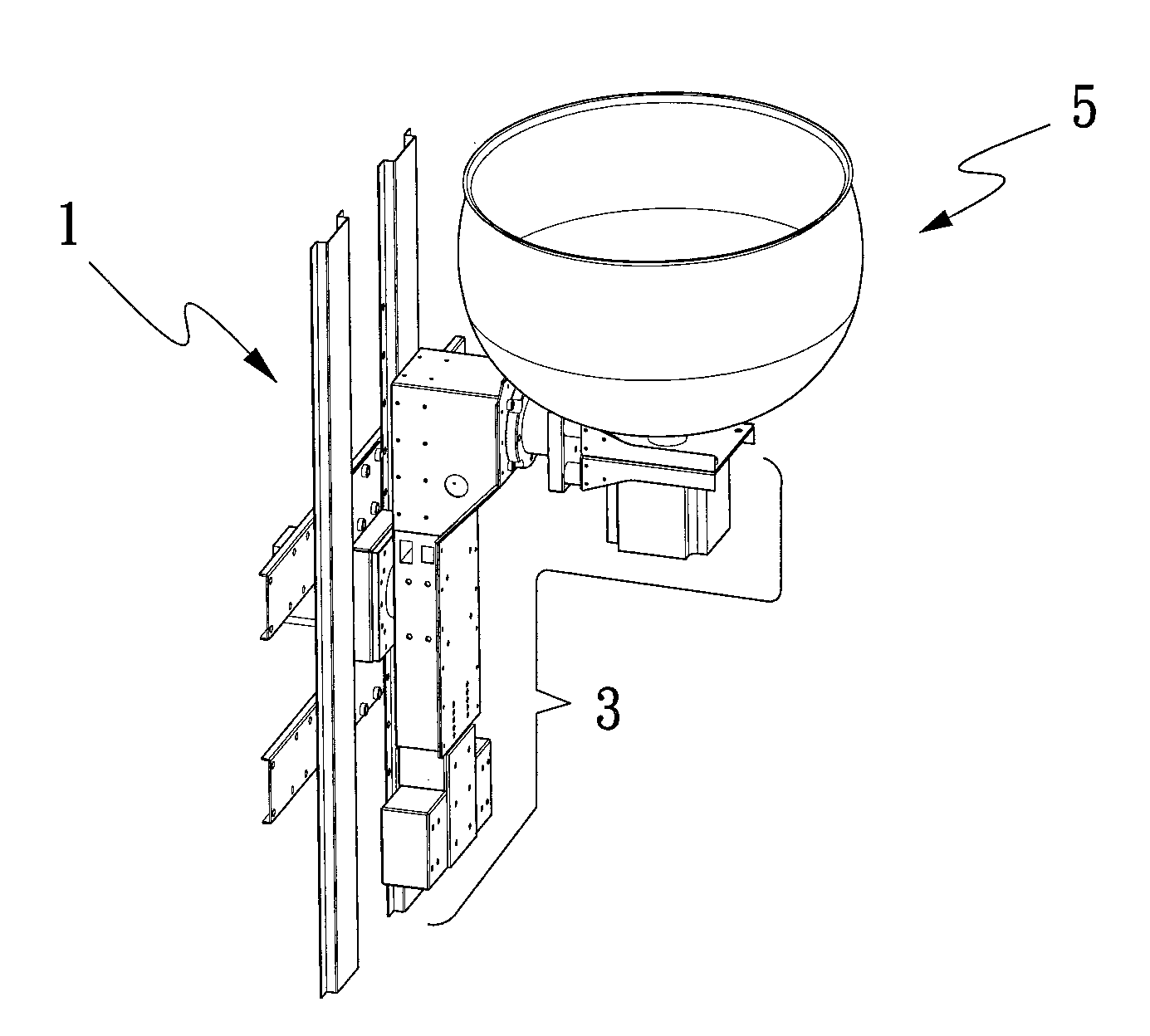

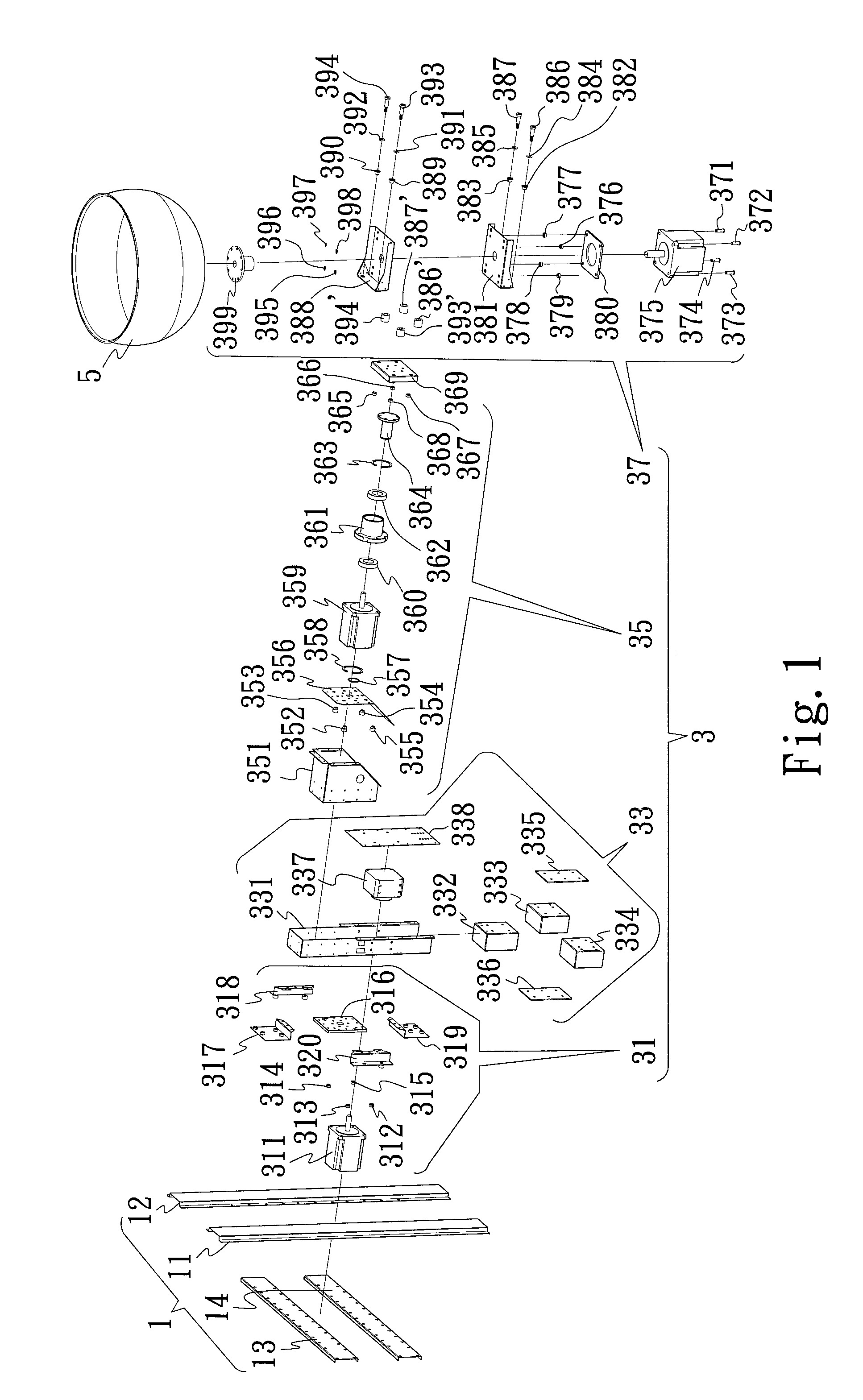

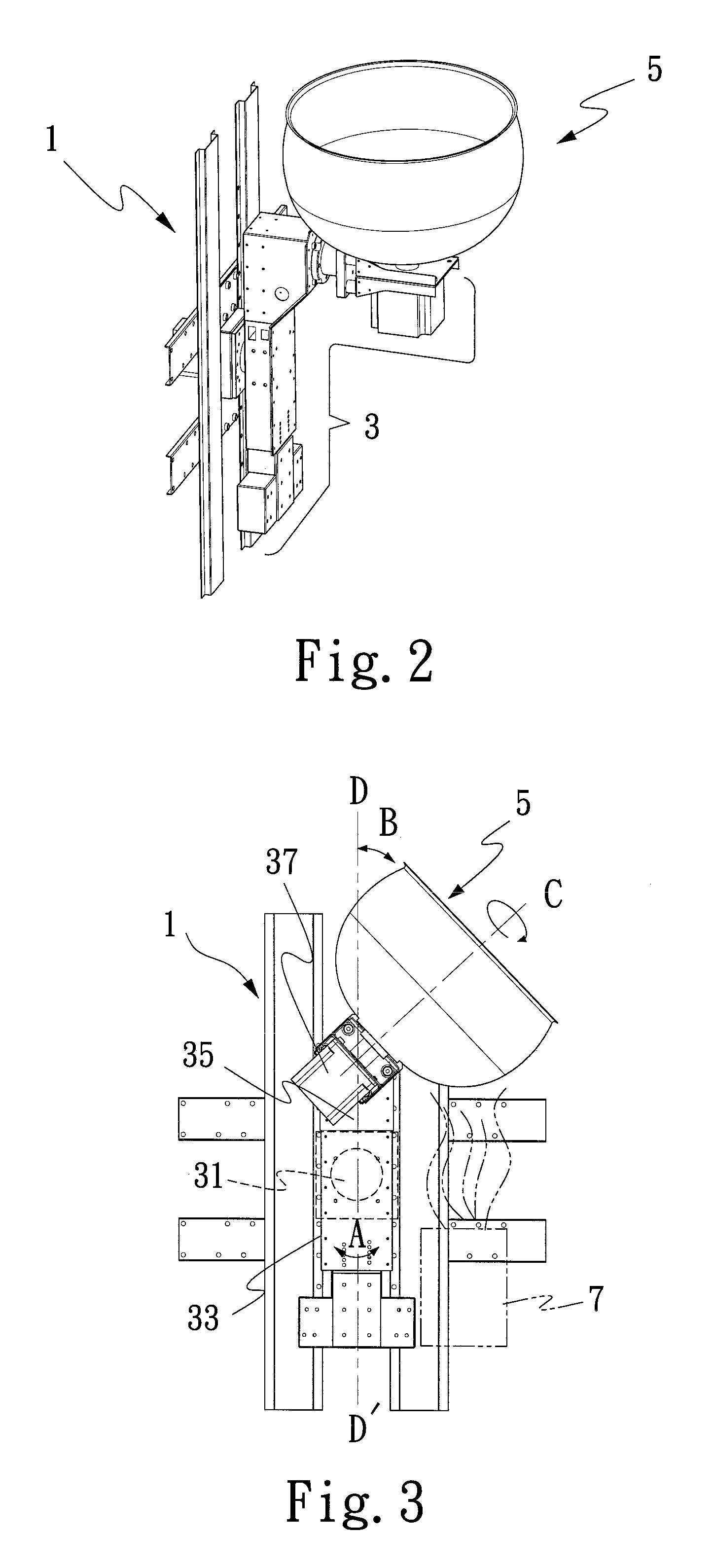

Automatic cooking device

ActiveUS7485830B2Easy to useCost effectiveDomestic stoves or rangesRotary drum furnacesFlavorEngineering

An automatic cooking device of the present invention comprises a rotating body and a cooking vessel that can regulate and control cooking processes. The rotating body is connected to a fixed structure, and the cooking vessel is attached on top of the rotating body. The automatic cooking device further utilizes integrated rotating devices, the cooking vessel and several driving motors to perform 3-dimensional movement including rotation, vibration, expanding and contracting motions, swinging or a combination of these motions. The automatic cooking device of the present invention is designed in such that it is simple to use and cost effective yet imparts meals cooked therein with the taste and flavor of food cooked traditionally. In other words, the automatic cooking device can cook various meals rapidly without impairing in quality of taste and flavor of the food. The automatic cooking device also can be used to prepare different meals.

Owner:VOLKS ROBOT TAIWAN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com